Patents

Literature

42391results about How to "Improve heat resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Material for organic electroluminescent element and organic electroluminescent element employing the same

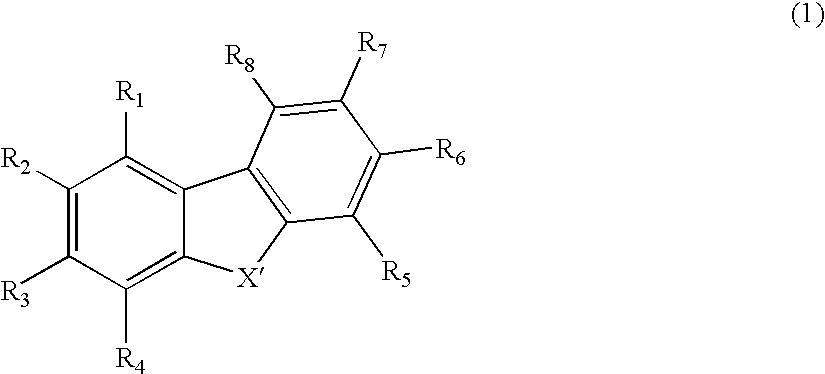

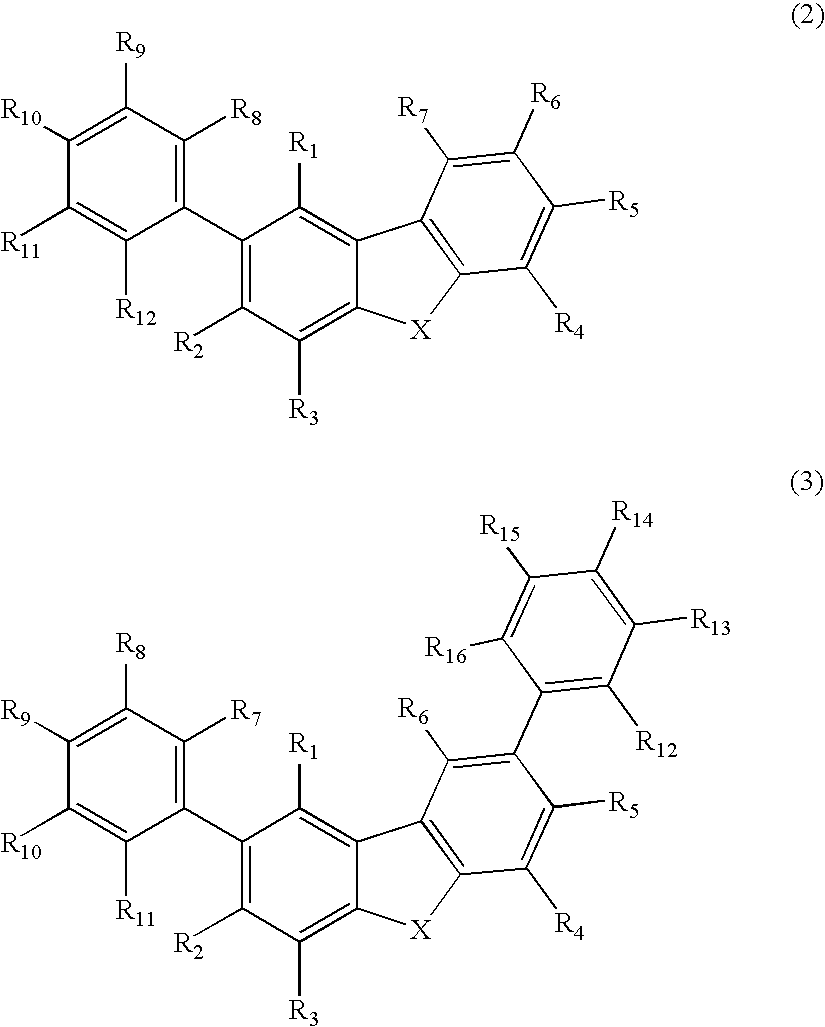

ActiveUS20090030202A1Improve efficiencyImprove heat resistanceOrganic chemistryDischarge tube luminescnet screensHeat resistanceHost material

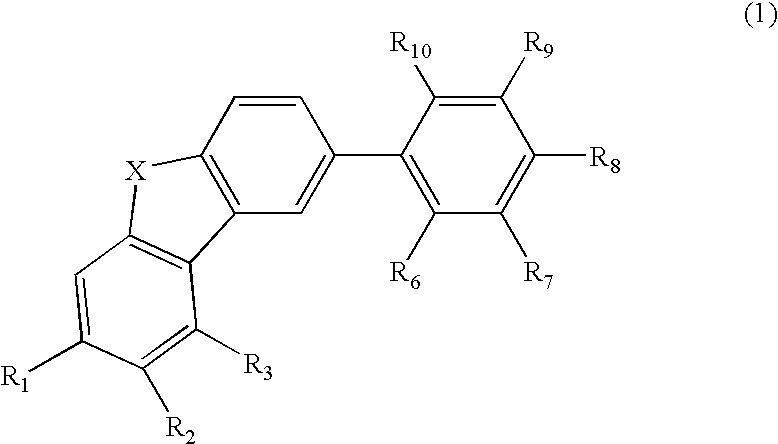

A material for organic electroluminescence devices for use as a host material in combination with at least one phosphorescent metal complex, which comprises a compound having a specific heterocyclic structure, is described. Also described is an organic electroluminescence device having an anode, a cathode and an organic thin film layer having one or more layers. The organic thin film layer is interposed between the anode and cathode and has a light emitting layer containing a host material in combination with at least one phosphorescent metal complex. At least one layer of the organic thin film layer contains the material for organic electroluminescence devices. The material for organic electroluminescence devices provides an organic electroluminescence device which has a high emitting efficiency, causes little pixel defects, is excellent in heat resistance, and show a long lifetime.

Owner:IDEMITSU KOSAN CO LTD

Material for organic electroluminescence device and organic electroluminescence device utilizing the same

ActiveUS20090017330A1High efficiencyHigh heat resistanceOrganic chemistryElectroluminescent light sourcesOrganic electroluminescenceChemistry

A material for organic electroluminescence devices of the invention which is for use in combination with at least one phosphorescent metal complex has a specific heterocyclic structure. The material for organic electroluminescence devices is used as a host material or a hole transporting material. An organic electroluminescence device having an anode, a cathode and an organic thin film layer having one or more layers which is interposed between the anode and cathode, in which at least one layer of the organic thin film layer contains the material for organic electroluminescence devices, has a high emitting efficiency, causes little pixel defects, is excellent in heat resistance, and shows a long lifetime.

Owner:IDEMITSU KOSAN CO LTD

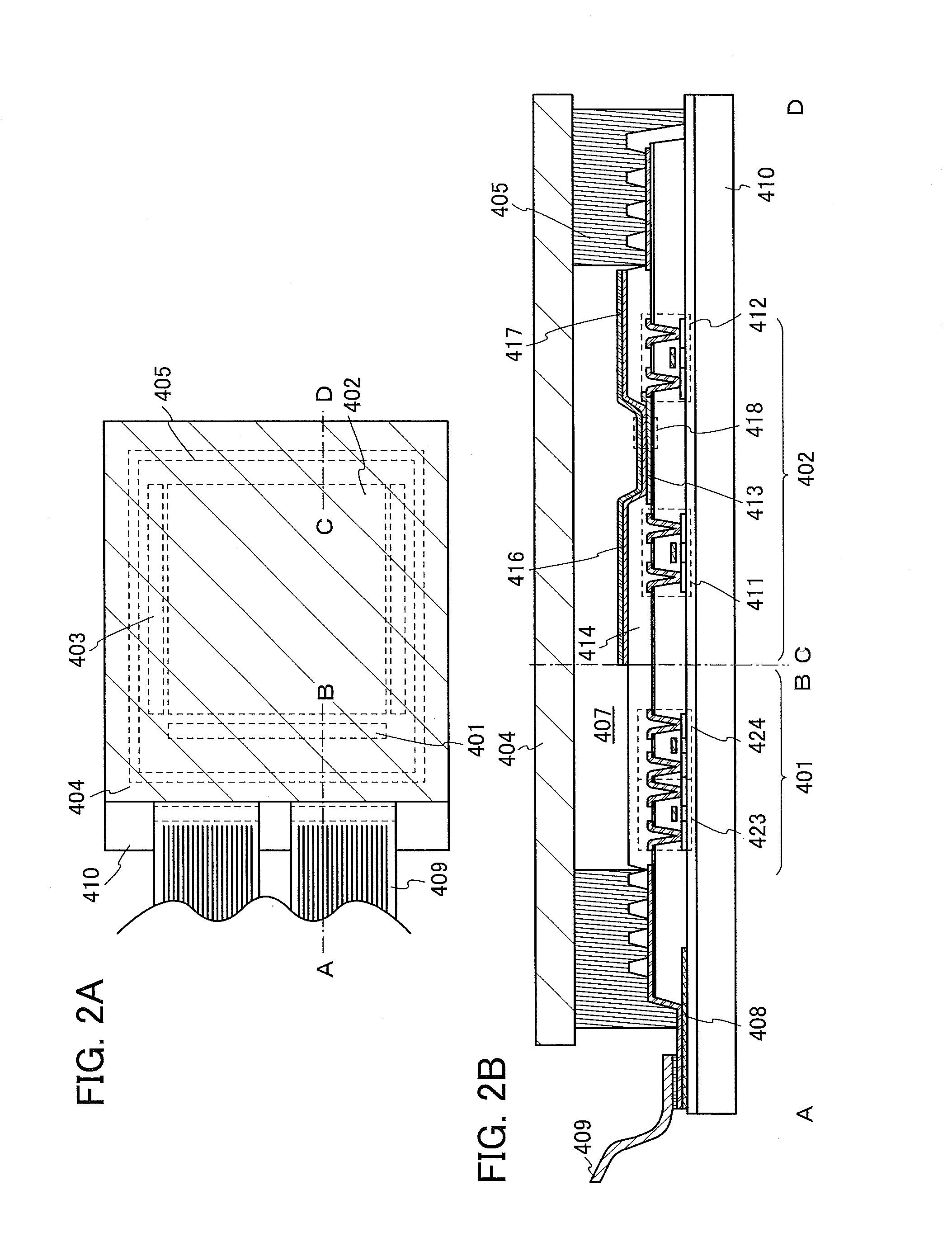

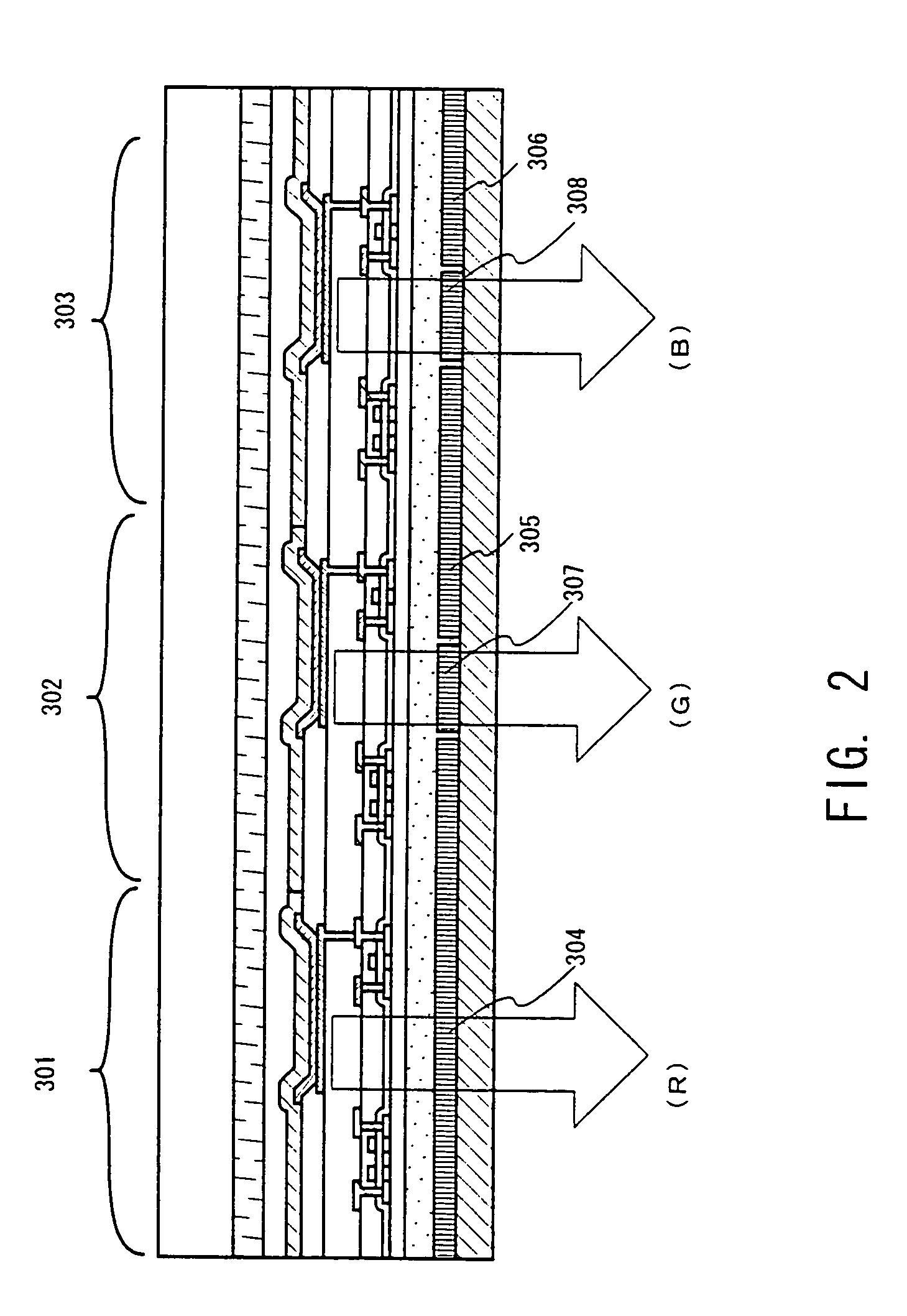

Light-Emitting Element, Light-Emitting Device, Electronic Appliance, and Lighting Device

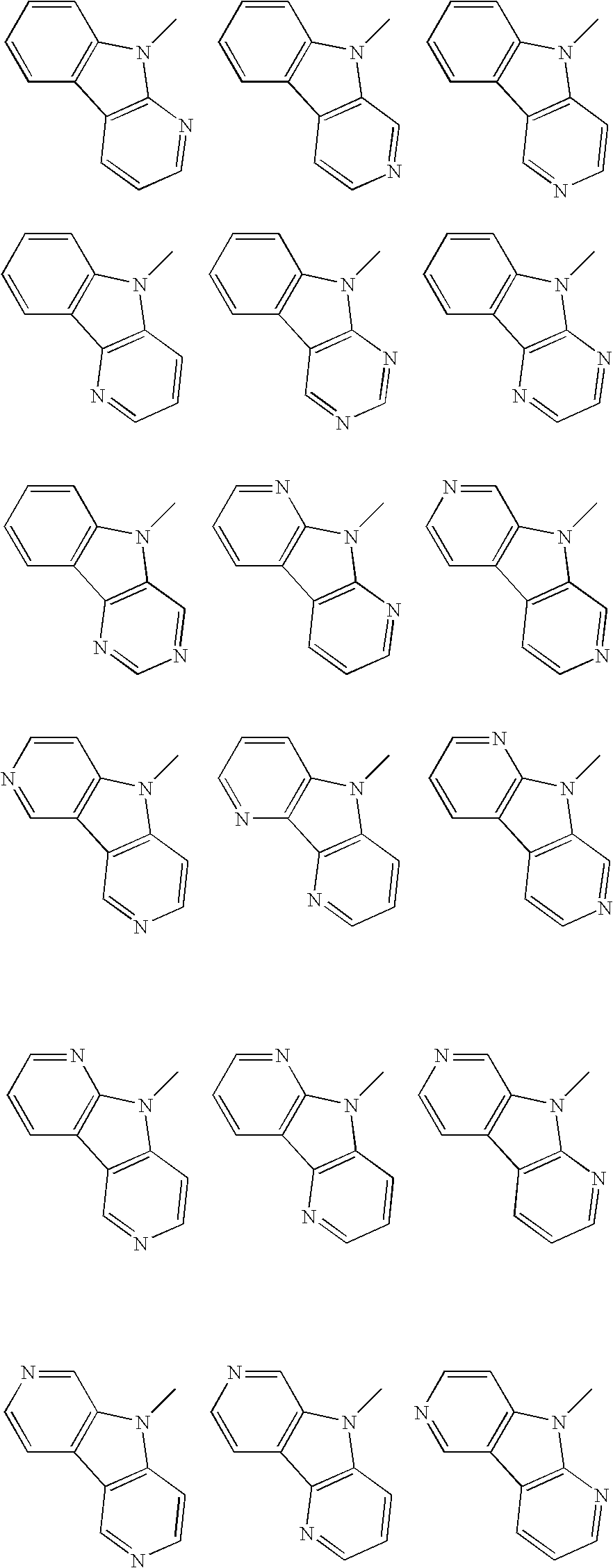

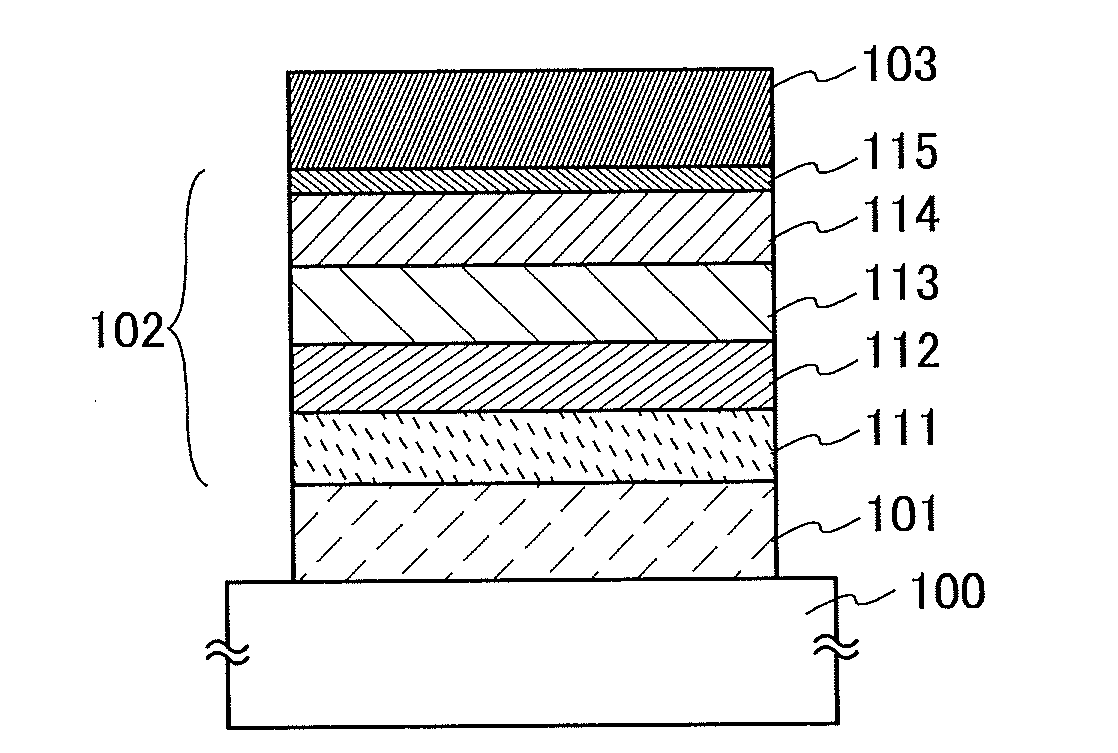

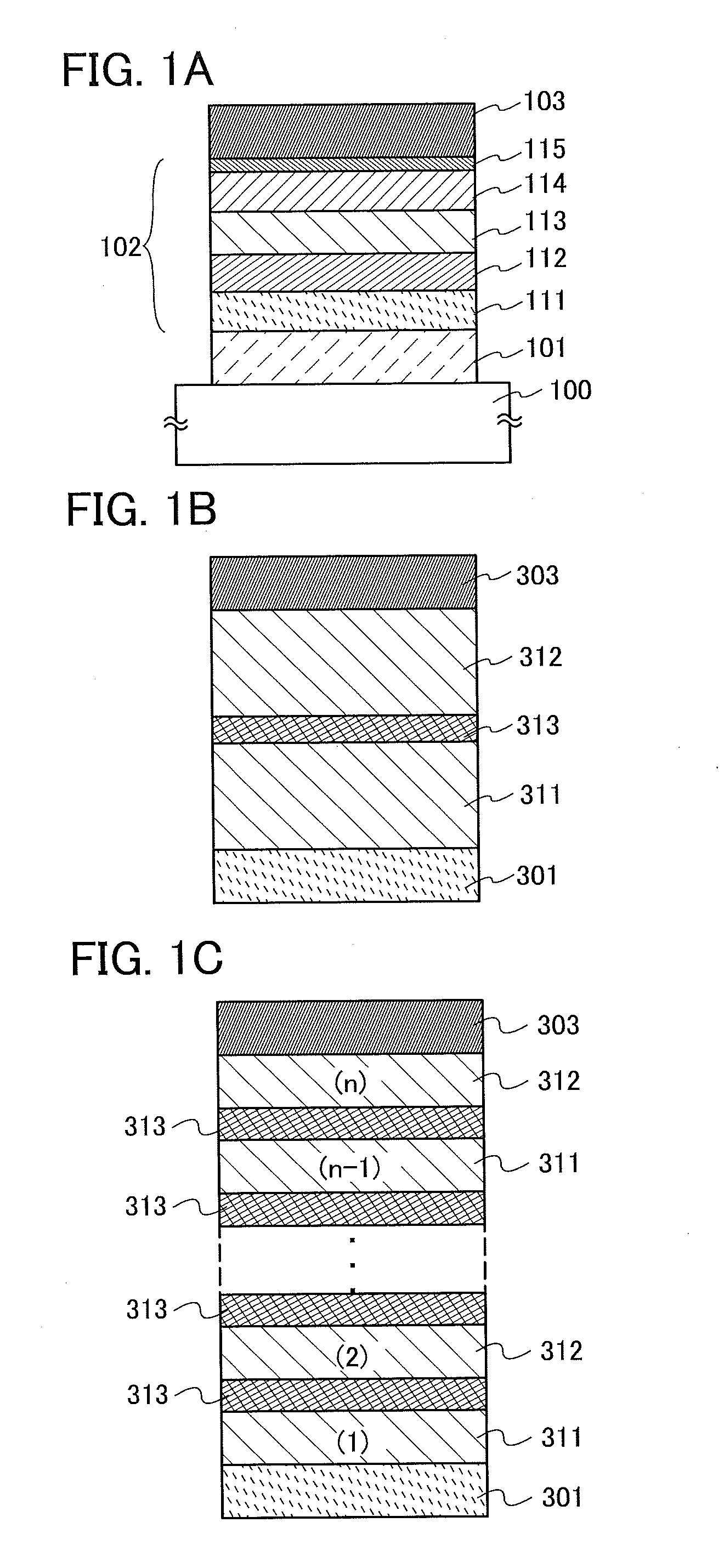

InactiveUS20140183503A1Reduce the driving voltageImprove current efficiencyOrganic chemistrySolid-state devicesLow voltageQuinoline

Disclosed is a light-emitting element having high emission efficiency, capable of driving at low voltage, and showing a long lifetime. The light-emitting element contains a compound between a pair of electrodes, and the compound is configured to give a first peak of m / z around 202 and a second peak of m / z around 227 in a mass spectrum. The first and second peaks are product ions of the compound and possess compositions of C16H9 and C17H10N, respectively, which are derived from a dibenzo[f,h]quinoline unit.

Owner:SEMICON ENERGY LAB CO LTD

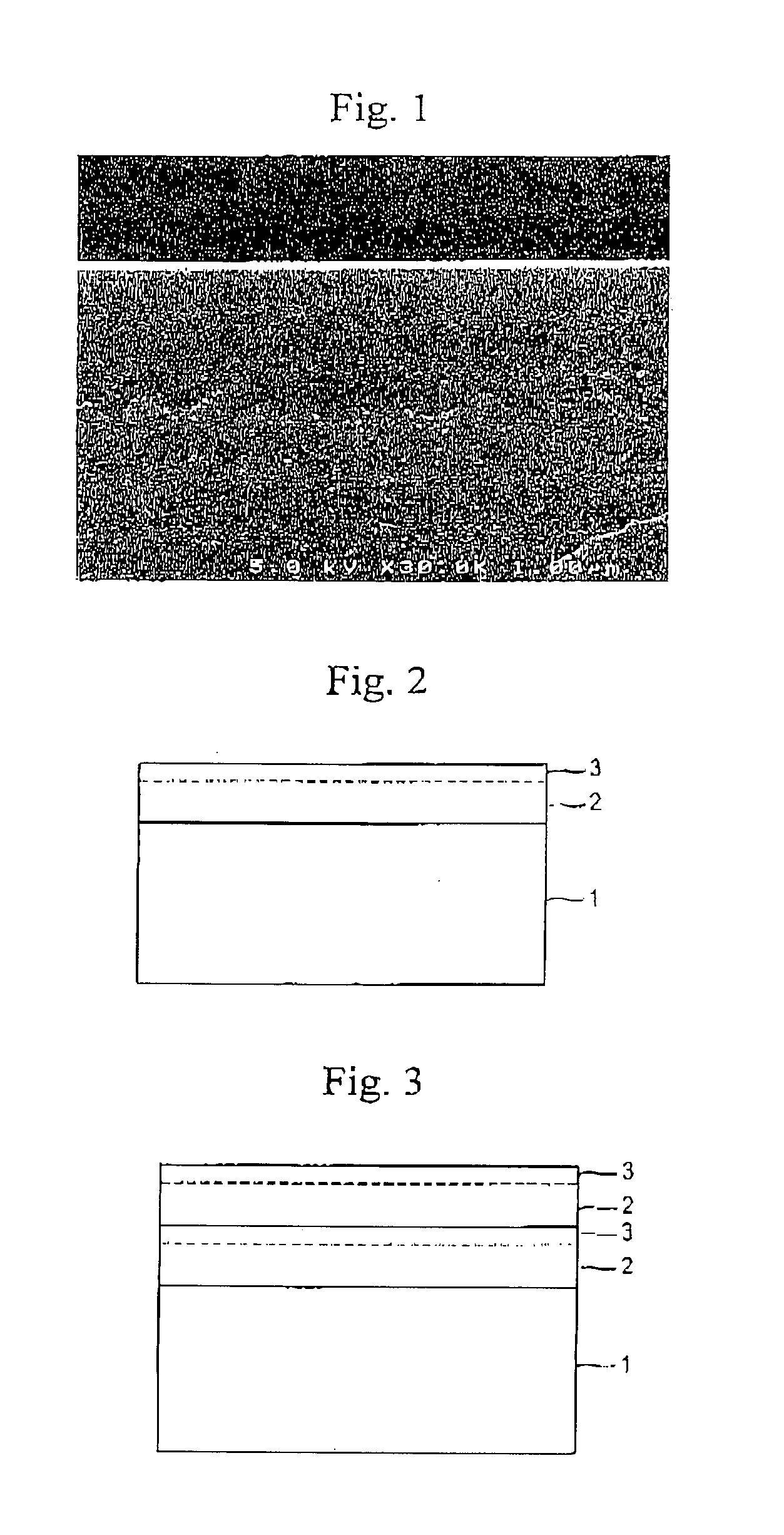

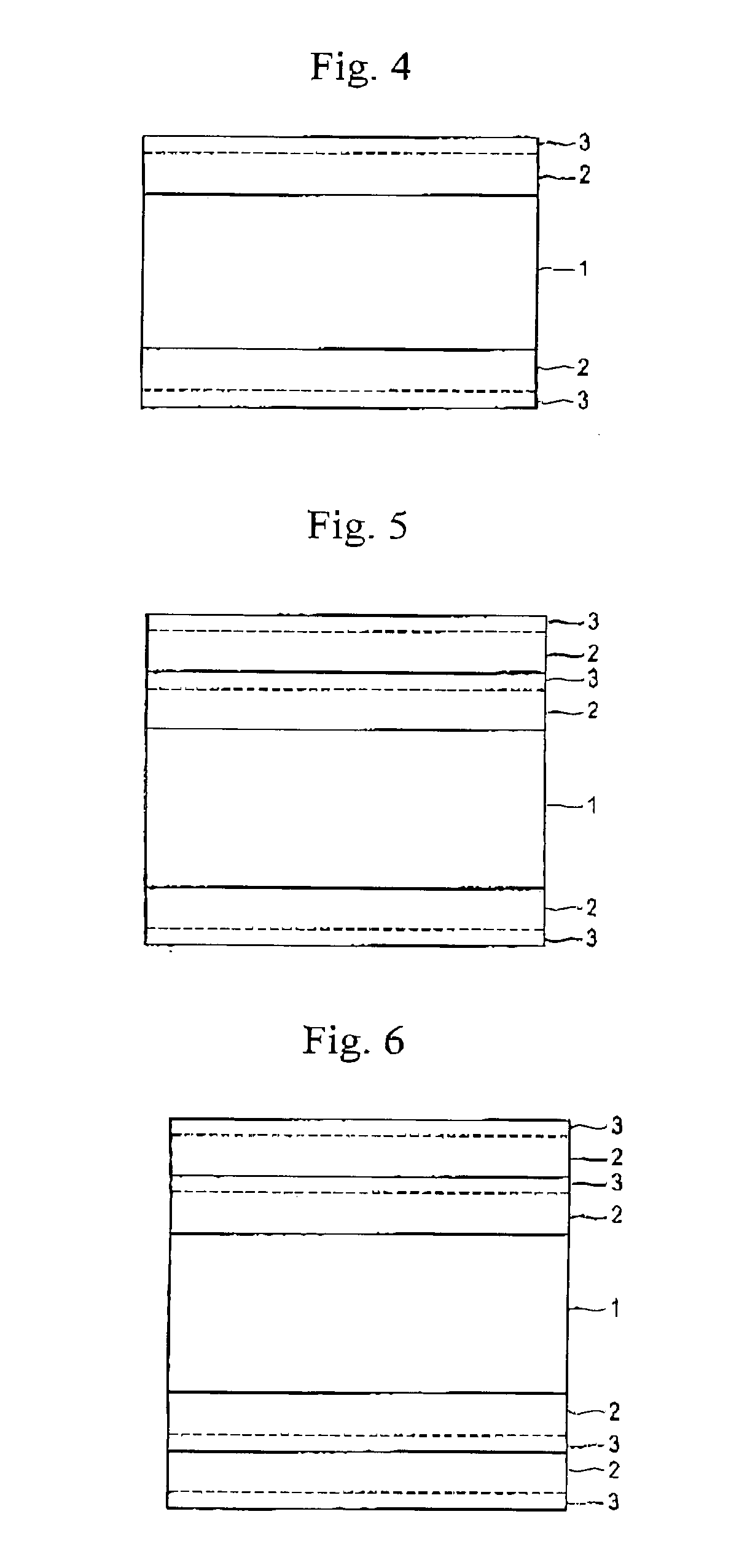

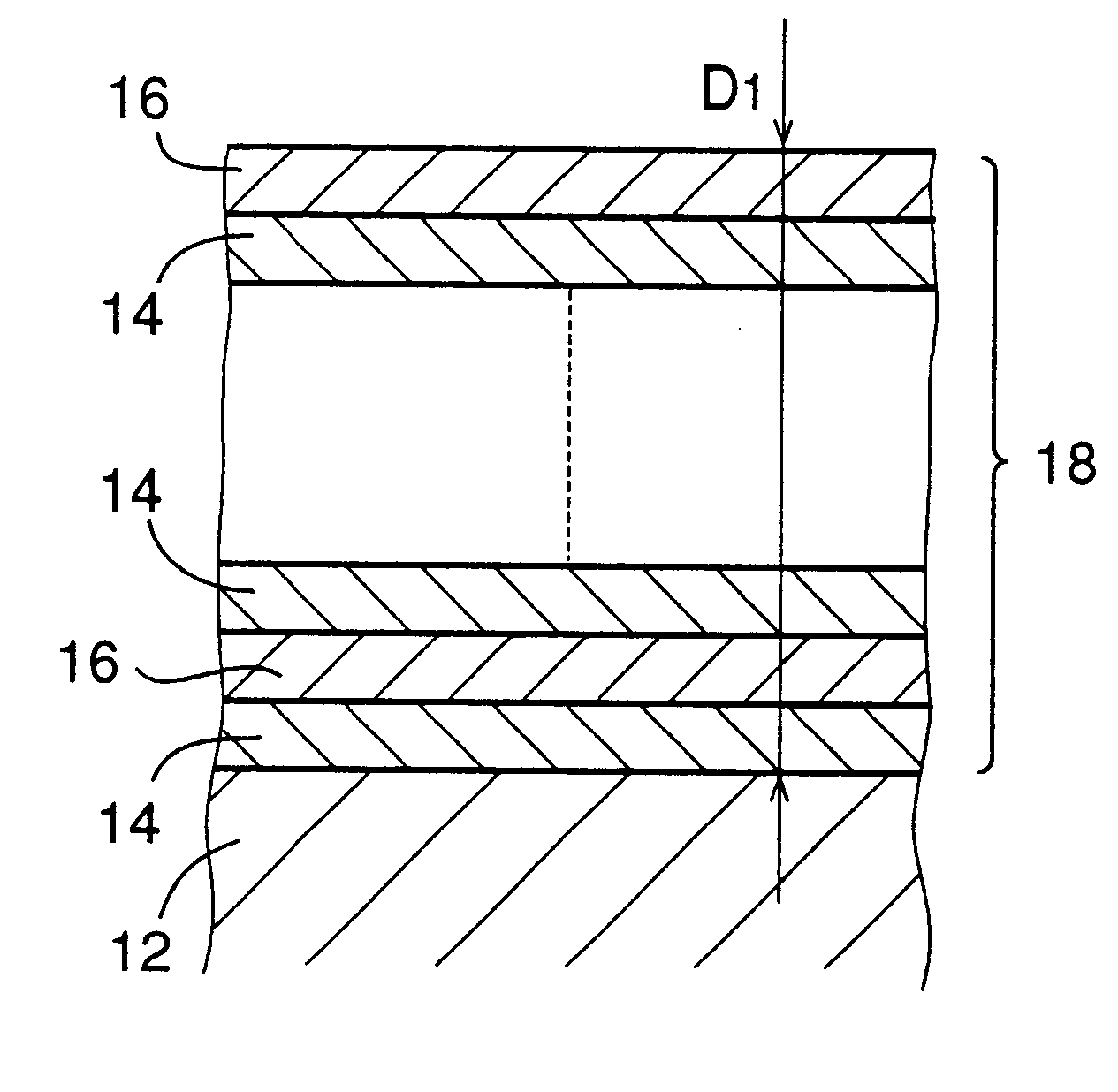

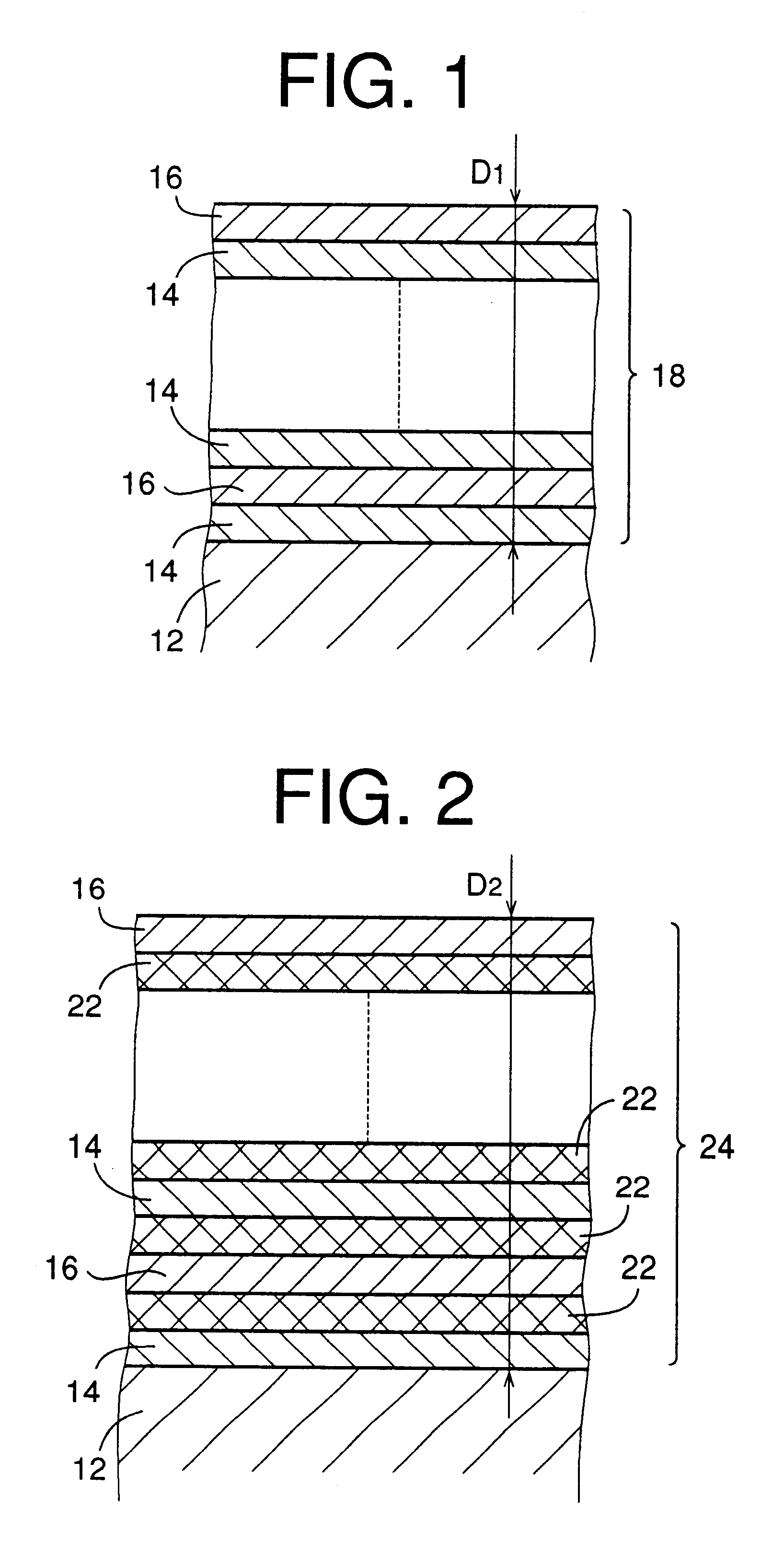

Method for fabrication of transparent gas barrier film using plasma surface treatment and transparent gas barrier film fabricated thereby

InactiveUS20100285319A1Excellent gas barrier performanceEconomical and simple methodSynthetic resin layered productsPretreated surfacesOptoelectronicsInorganic layer

The present invention relates to a method of fabricating a transparent gas barrier film by using plasma surface treatment and a transparent gas barrier film fabricated according to such method which has an organic / inorganic gradient interface structure at the interface between an organic / inorganic hybrid layer and an inorganic layer. Since the method of the present invention is capable of fabricating a gas barrier film by plasma surface treatment instead of deposition under high vacuum, it can mass-produce a transparent gas barrier film with excellent gas barrier properties in an economical and simple manner. Further, since the transparent gas barrier film fabricated according to the method of the present invention shows excellent gas barrier properties and is free of crack formation and layer-peeling phenomenon, it can be effectively used in the manufacture of a variety of display panels.

Owner:KOREA INST OF SCI & TECH

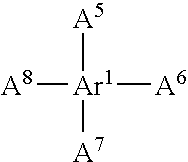

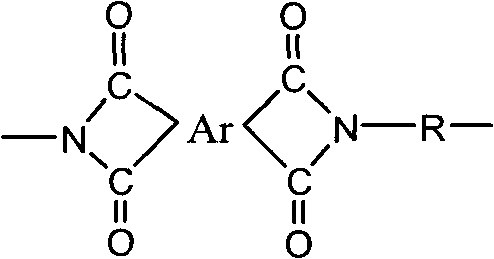

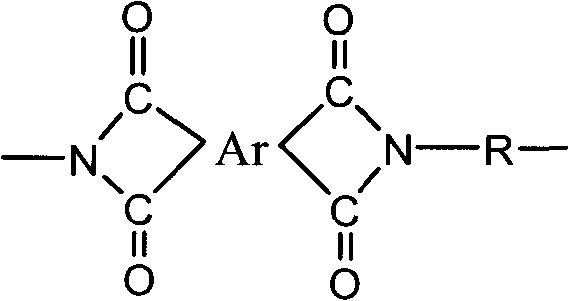

Material for organic electroluminescent device, organic electroluminescent device, and organic electroluminescent display

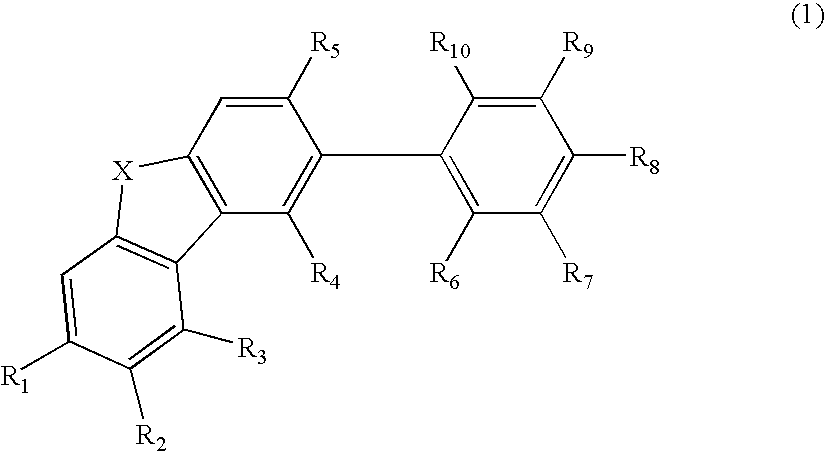

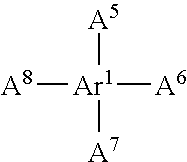

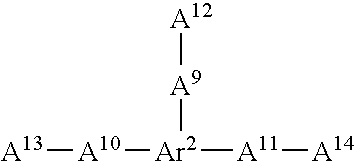

ActiveUS8044390B2Improve heat resistanceDeposition stabilityOrganic chemistryElectroluminescent light sourcesHalogenHydrogen

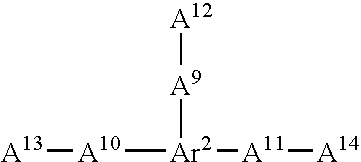

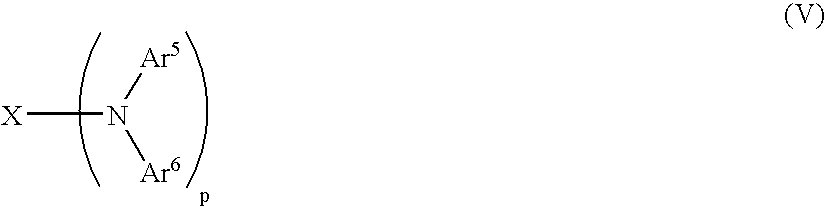

A material for an organic electroluminescent device including an imine derivative represented by the following formula (Ia) or (Ib),wherein Y1 to Y4 are independently a carbon atom or a nitrogen atom; R1 to R4 are independently hydrogen, an alkyl group, an aryl group, a heterocycle, a halogen atom, a fluoroalkyl group or a cyano group; and R1 and R2, or R3 and R4 may be bonded together to form a ring.

Owner:IDEMITSU KOSAN CO LTD +1

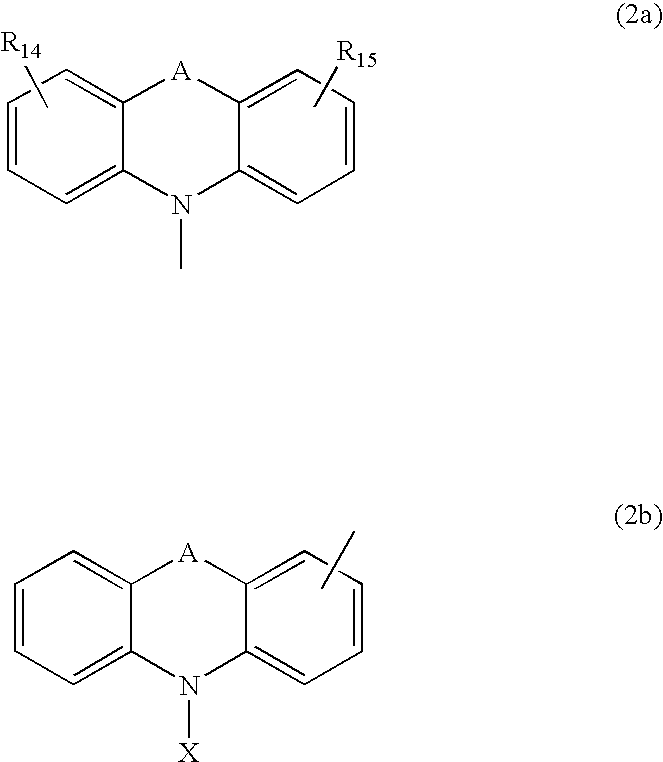

Organic electroluminescence device and organic light emitting medium

ActiveUS20050064233A1High color purityImprove heat resistanceMaterial nanotechnologyOrganic chemistryAnthraceneHeat resistance

An organic electroluminescence device having a layer of an organic light emitting medium which comprises (A) a specific arylamine compound and (B) at least one compound selected from specific anthracene derivatives, spirofluorene derivatives, compounds having condensed rings and metal complex compounds and is disposed between a pair of electrodes and an organic light emitting medium comprising the above components (A) and (B) are provided. The organic electroluminescence device exhibits a high purity of color, has excellent heat resistance and a long life and efficiently emits bluish to yellowish light. The organic light emitting medium can be advantageously used for the organic electroluminescence device.

Owner:IDEMITSU KOSAN CO LTD

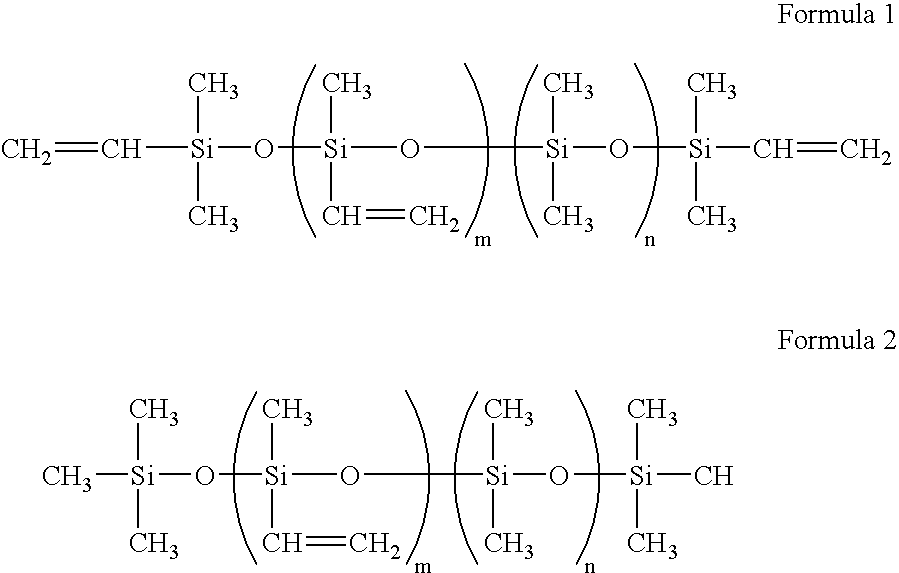

Light emitting device with silicone resin layer formed by screen printing

ActiveUS7745818B2Improve heat resistanceConvenient lightingDischarge tube luminescnet screensLamp detailsScreen printingPolystyrene

Owner:NICHIA CORP

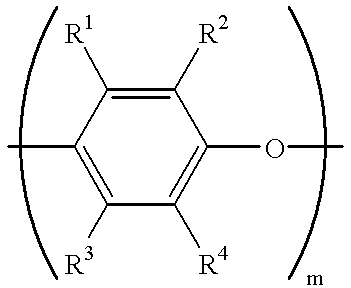

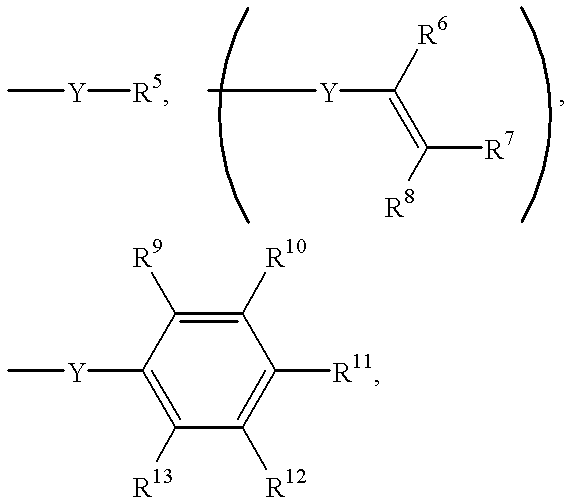

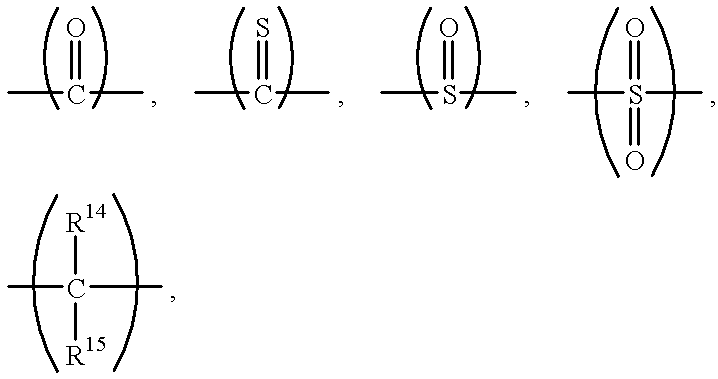

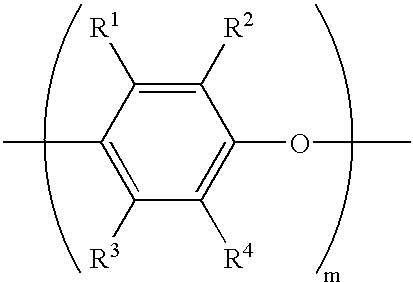

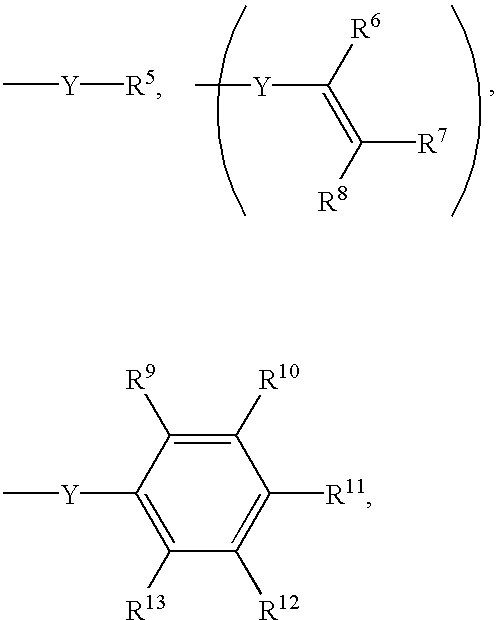

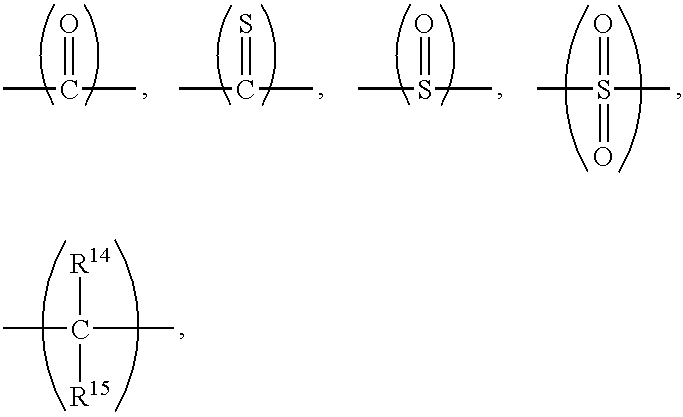

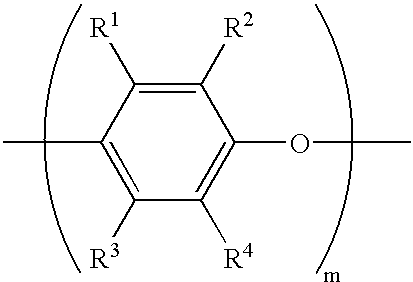

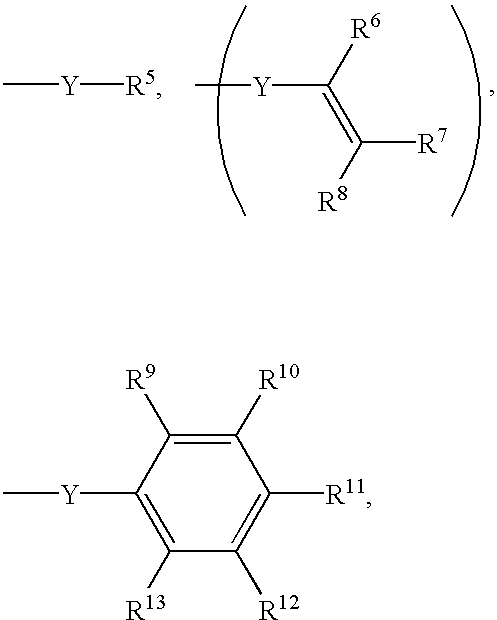

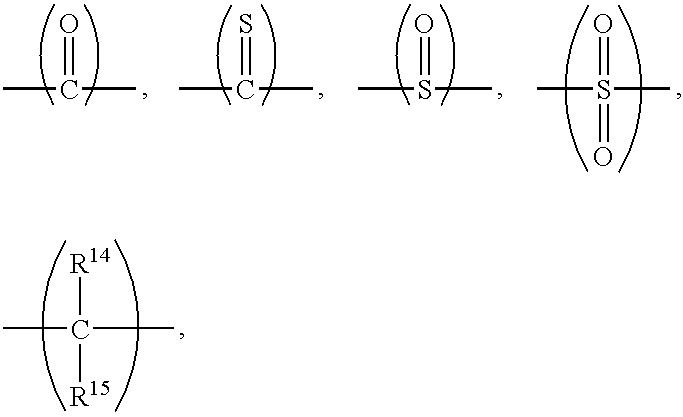

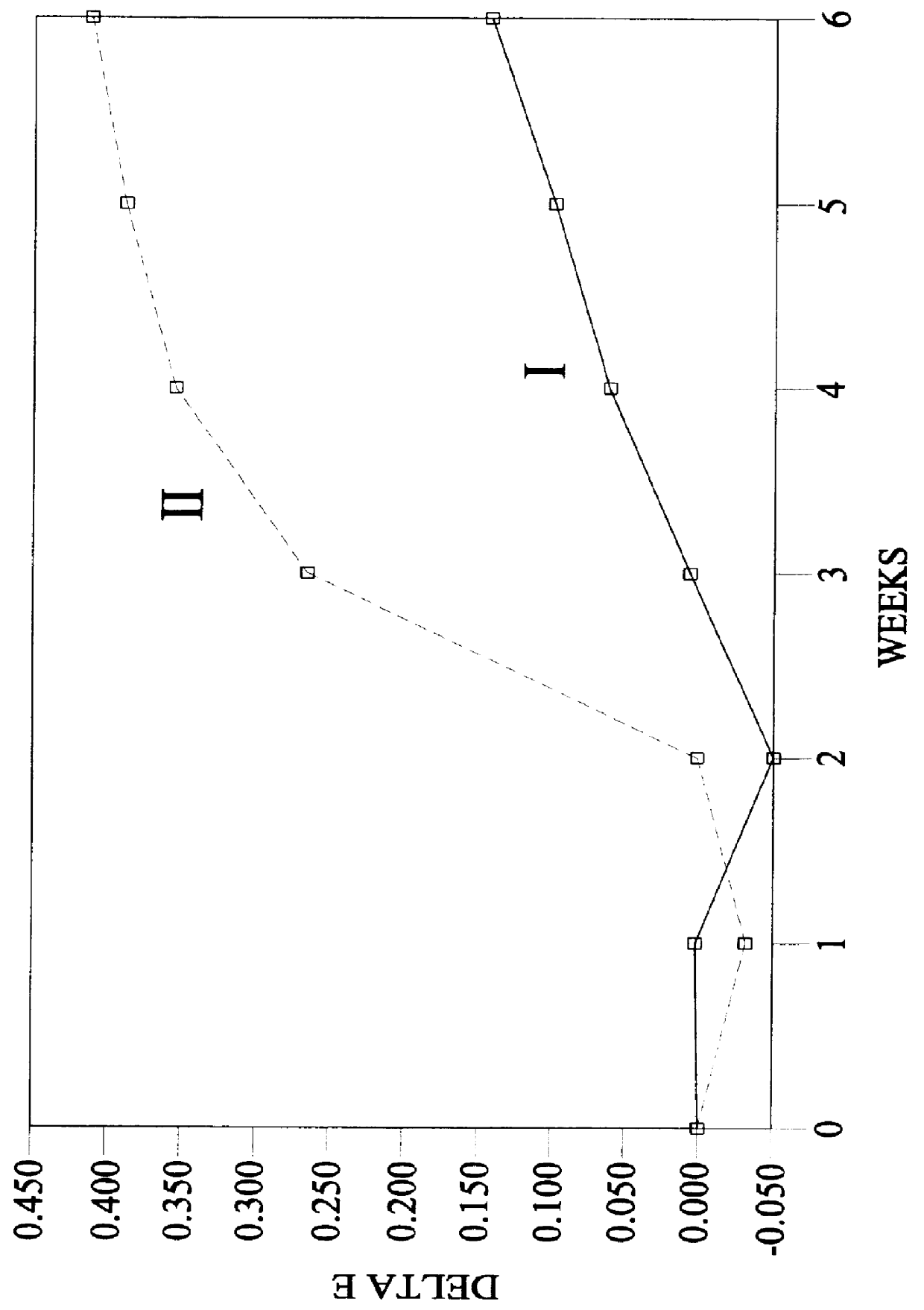

Poly(arylene ether)-containing thermoset composition, method for the preparation thereof, and articles derived therefrom

InactiveUS6627704B2Fast curingReduce sensitivitySynthetic resin layered productsPolyether coatingsHeat resistanceEther

Owner:SABIC INNOVATIVE PLASTICS IP BV

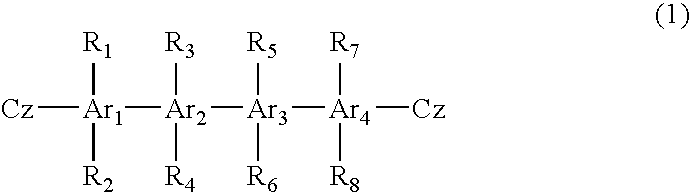

Material for organic electroluminescence device and organic electroluminescence device using the same

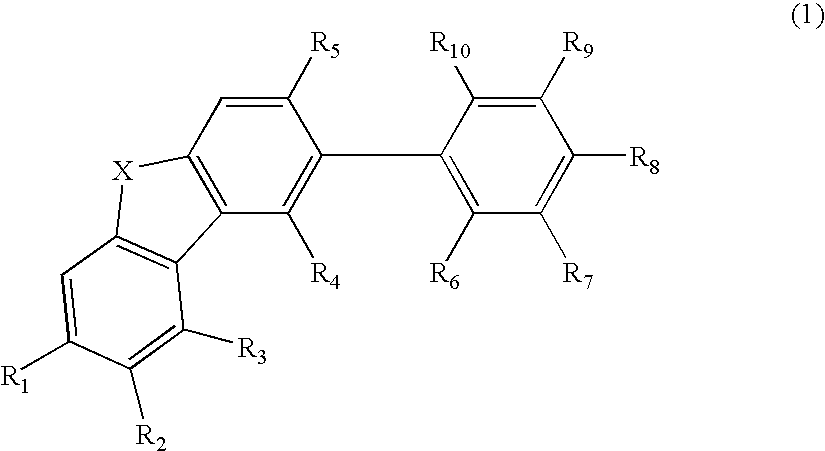

InactiveUS20070224446A1Improve current efficiencyImprove heat resistanceSilicon organic compoundsDischarge tube luminescnet screensHeat resistanceOrganic electroluminescence

A material for organic electroluminescence device with specific structure. An an organic electroluminescence device comprising a cathode, an anode and an organic thin film layer which is sandwiched between the cathode and the anode and comprises at least one layer, wherein at least one layer in the organic thin film layer contains a material for the organic electroluminescence device described above. An organic electroluminescence device with excellent efficiency of light emission, without pixel defects, which is superior in heat resistance and prolonged lifetime is obtained.

Owner:IDEMITSU KOSAN CO LTD

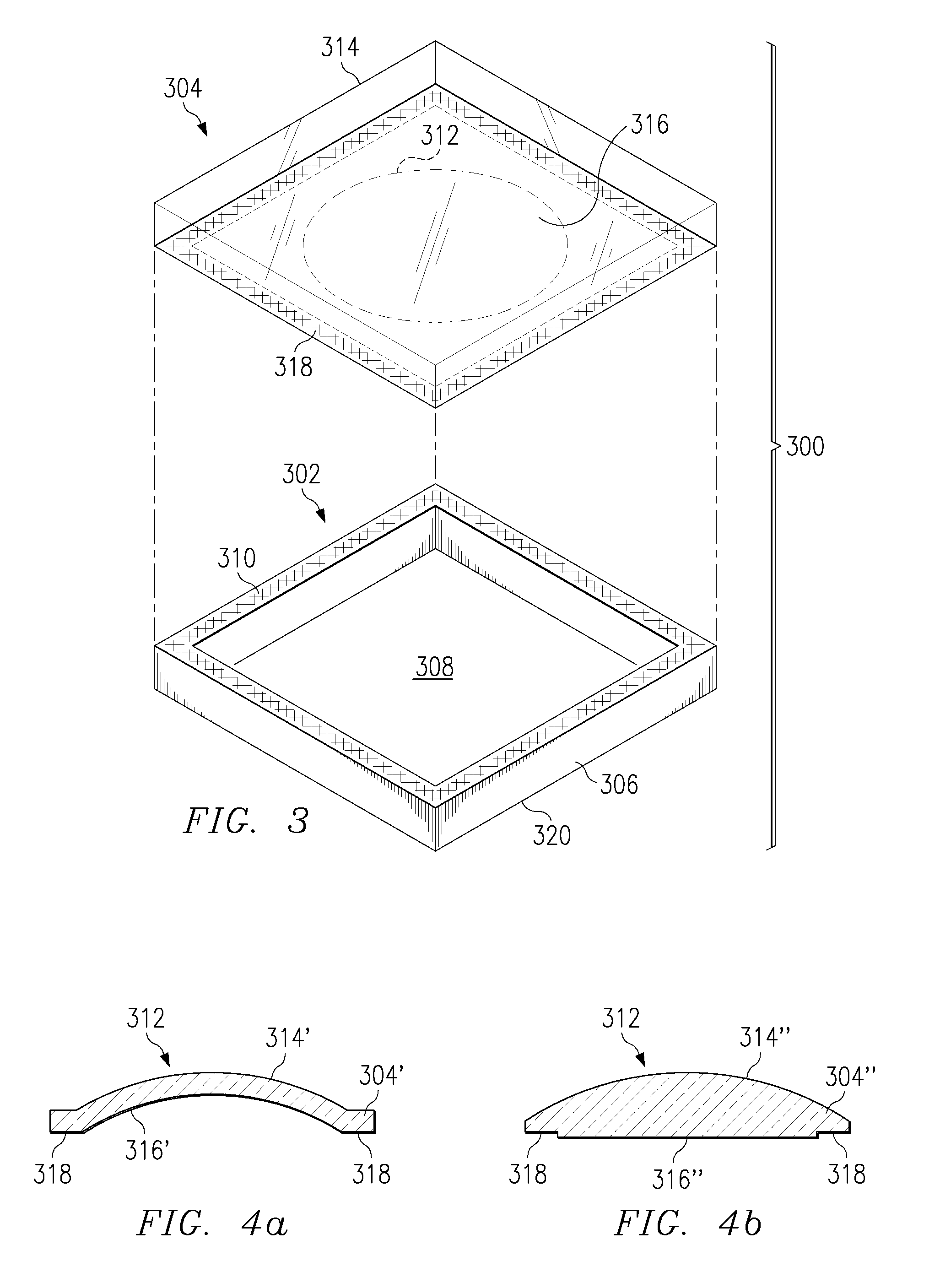

Insulated glazing units

InactiveUS20060187608A1Improve heat resistanceReduce weight and depthDoors/windowsSemiconductor/solid-state device detailsInsulated glazingEngineering

A hermetically sealed multi-pane window assembly comprises first and second windowpane sheets formed of transparent materials. A first sealing member has an inner edge and an outer edge, the inner edge being hermetically attached around the periphery of the first windowpane sheet by diffusion bonding. A second sealing member has an inner edge and an outer edge, the inner edge being hermetically attached around the periphery of the second windowpane sheet by diffusion bonding and the outer edge being hermetically attached to the outer edge of the first sealing member. A spacer assembly is disposed between the first and the second windowpane sheets for maintaining a gap therebetween, whereby a hermetically sealed cavity is defined between the first and the second windowpanes.

Owner:ASTRAVAC GLASS INC

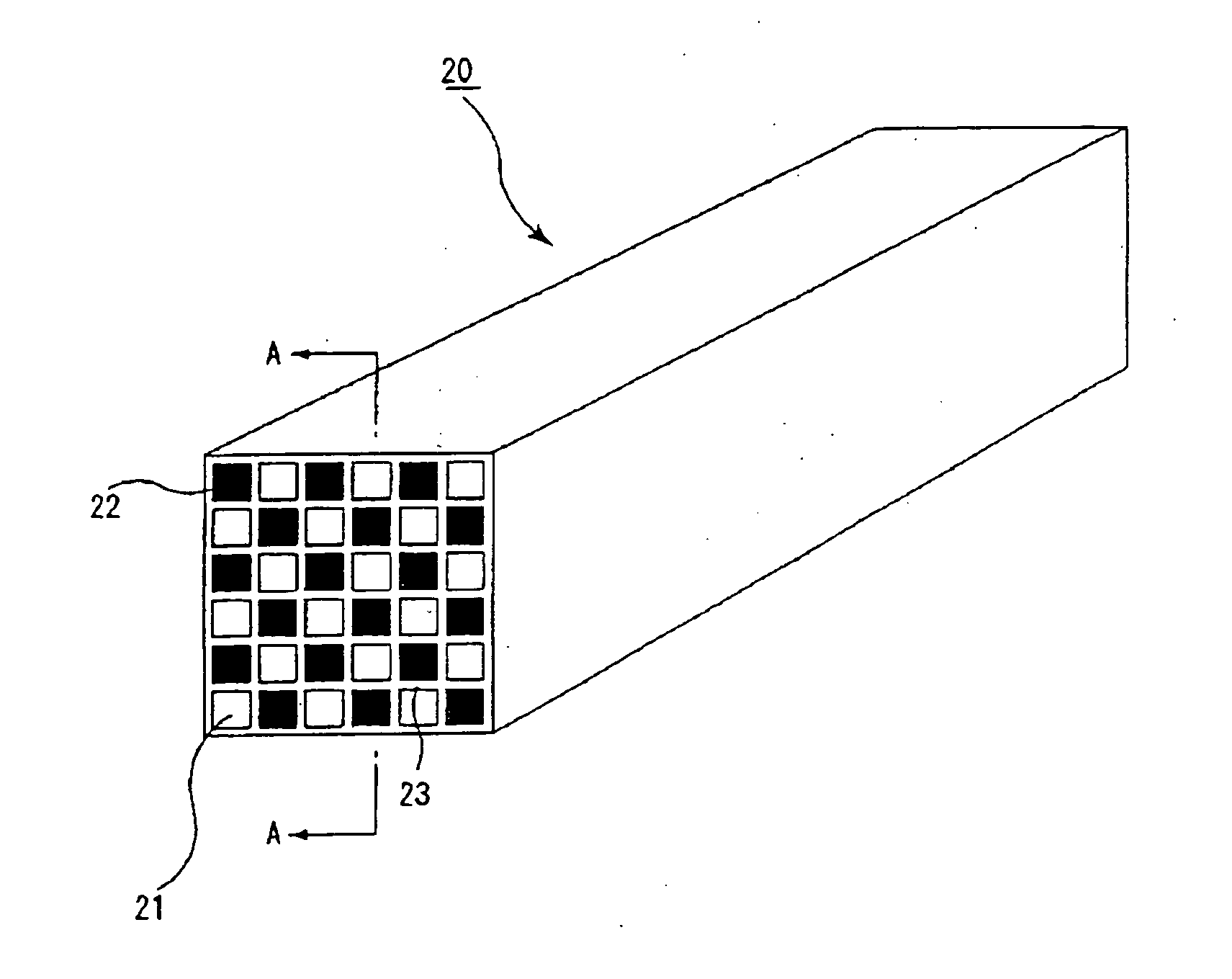

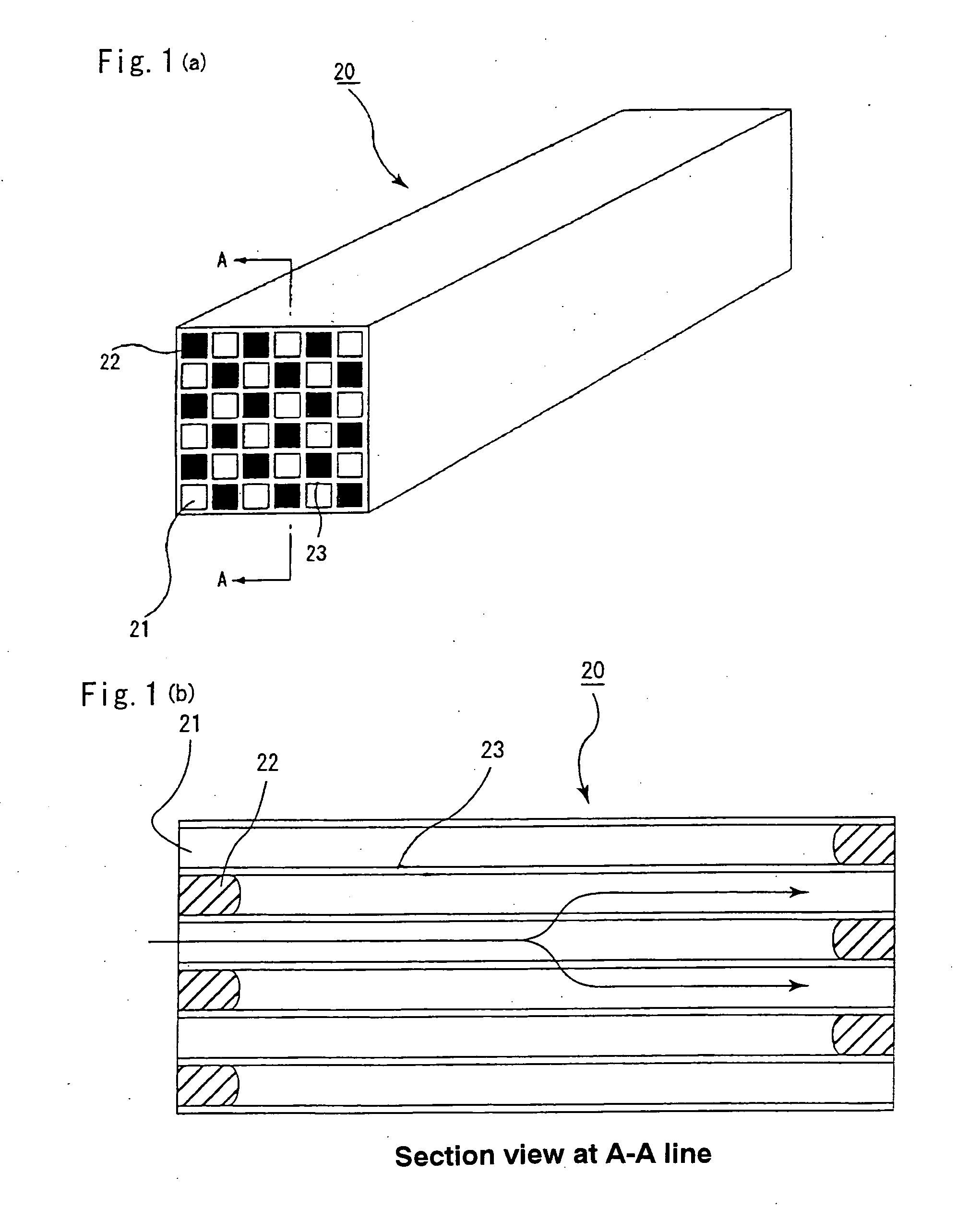

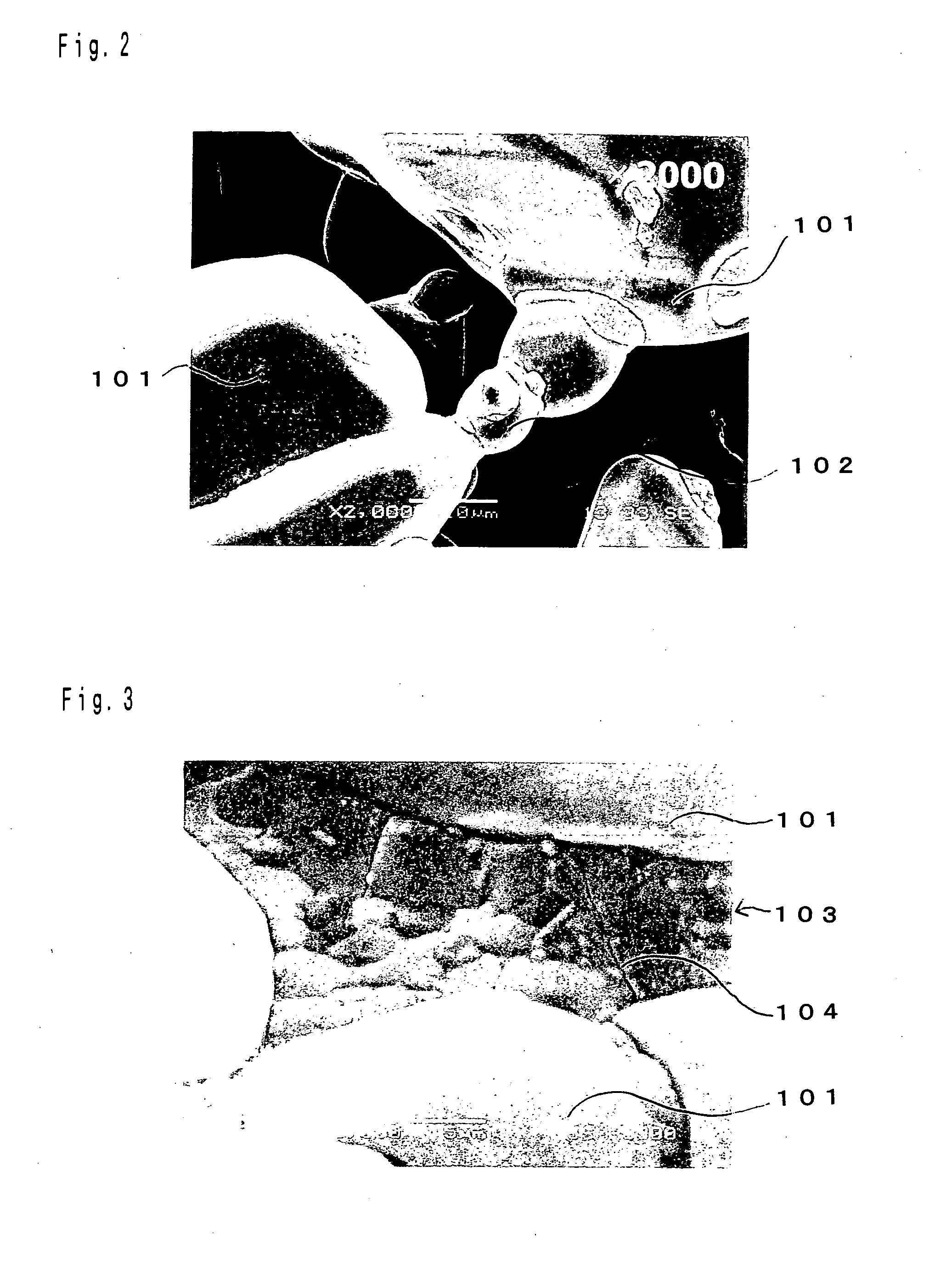

Sintered ceramic compact and ceramic filter

InactiveUS20060051556A1Shock mitigationAvoid micro cracksDispersed particle filtrationExhaust apparatusCeramic sinteringMetallurgy

The present invention provides for a ceramic sintered body and a ceramic filter having a long-term stability which can prevent cracks from occurring due to the breakage of ceramic particles when thermal stress is applied in regeneration process and the like, and can prevent catalyst carried from deteriorating when regeneration treatment is conducted repeatedly. The invention is a ceramic sintered body comprising ceramic coarse particles and porous bonding layers existing between the ceramic coarse particles to connect the particles and comprising ceramic fine particles having an average particle size smaller than that of the ceramic coarse particles and / or the aggregates thereof, and a ceramic filter prepared by using the ceramic sintered body.

Owner:IBIDEN CO LTD

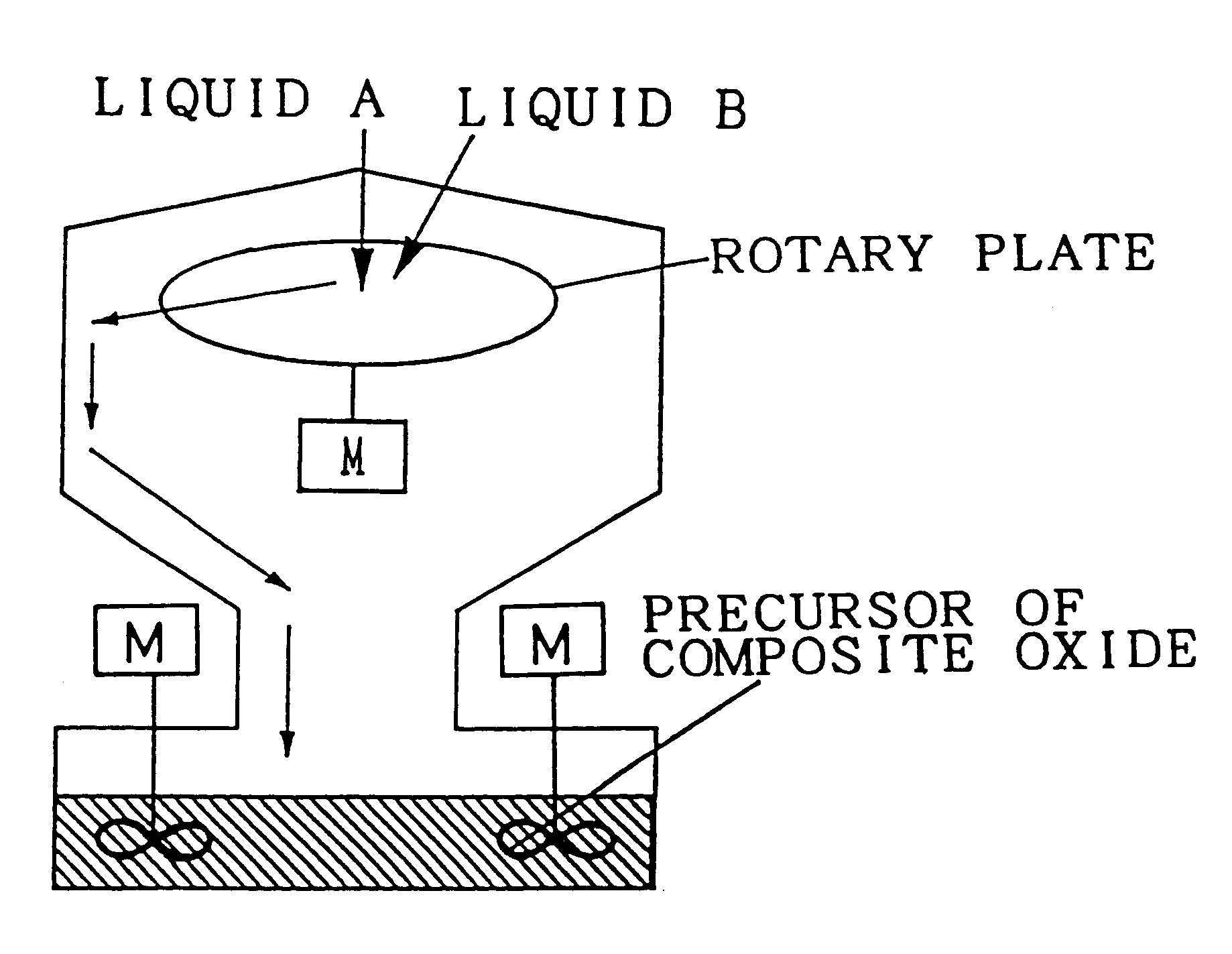

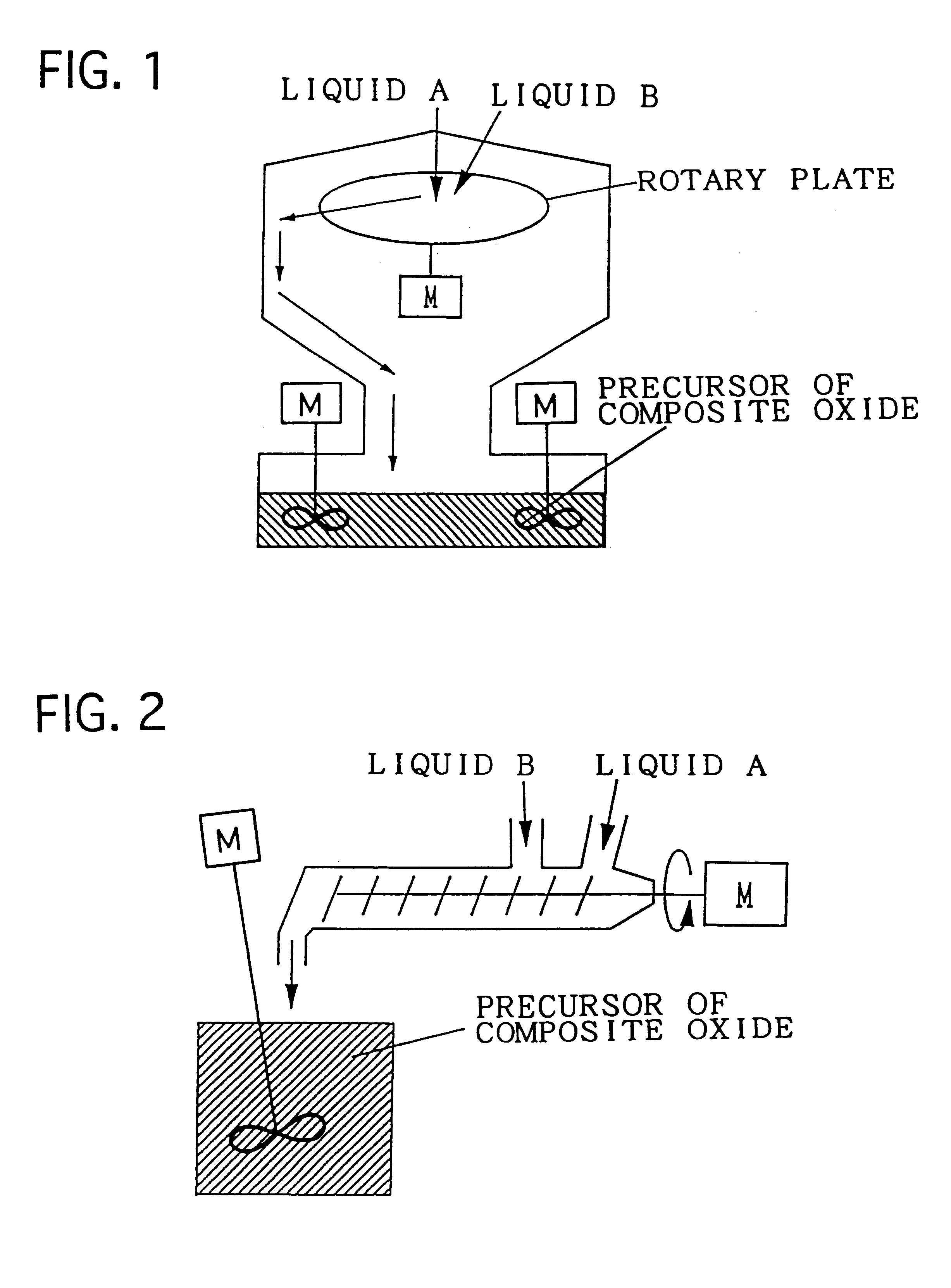

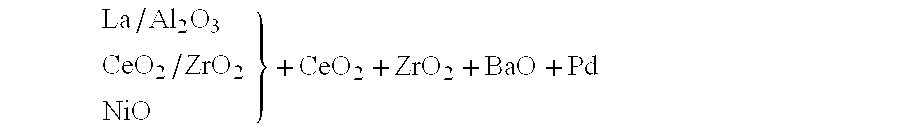

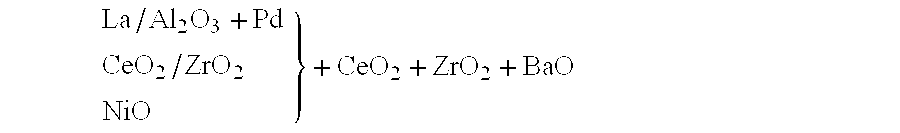

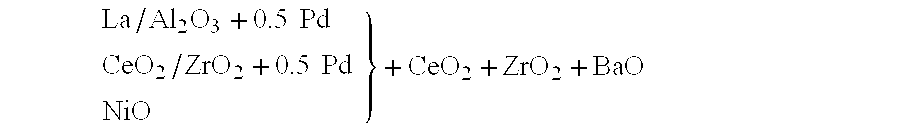

Composite oxide, composite oxide carrier and catalyst

InactiveUS6306794B1Improve heat resistanceImprove homogeneityInternal combustion piston enginesDispersed particle separationHeat resistanceCerium

The composite oxide and the composite oxide carrier are manufactured by the precursor forming step and firing step. The composite oxide catalyst is obtained by preparing a composite of catalytic components simultaneously with the formation of the precursor of composite oxide in the step of forming the precursor of composite oxide. The composite oxide and the composite oxide carrier are composed of a composite oxide in which at least one of cerium and zirconium, and aluminium disperse with extremely high homogeneity. With this structure, the heat resistance of the carrier is improved and consequently, enlargement of particles of the composite oxide defining the carrier, and sintering of adjacent particles of the composite oxide can be restrained, whereby the catalyst using the composite oxide carrier in accordance with the present invention is excellent in heat resistance.

Owner:TOYOTA CENT RES & DEV LAB INC

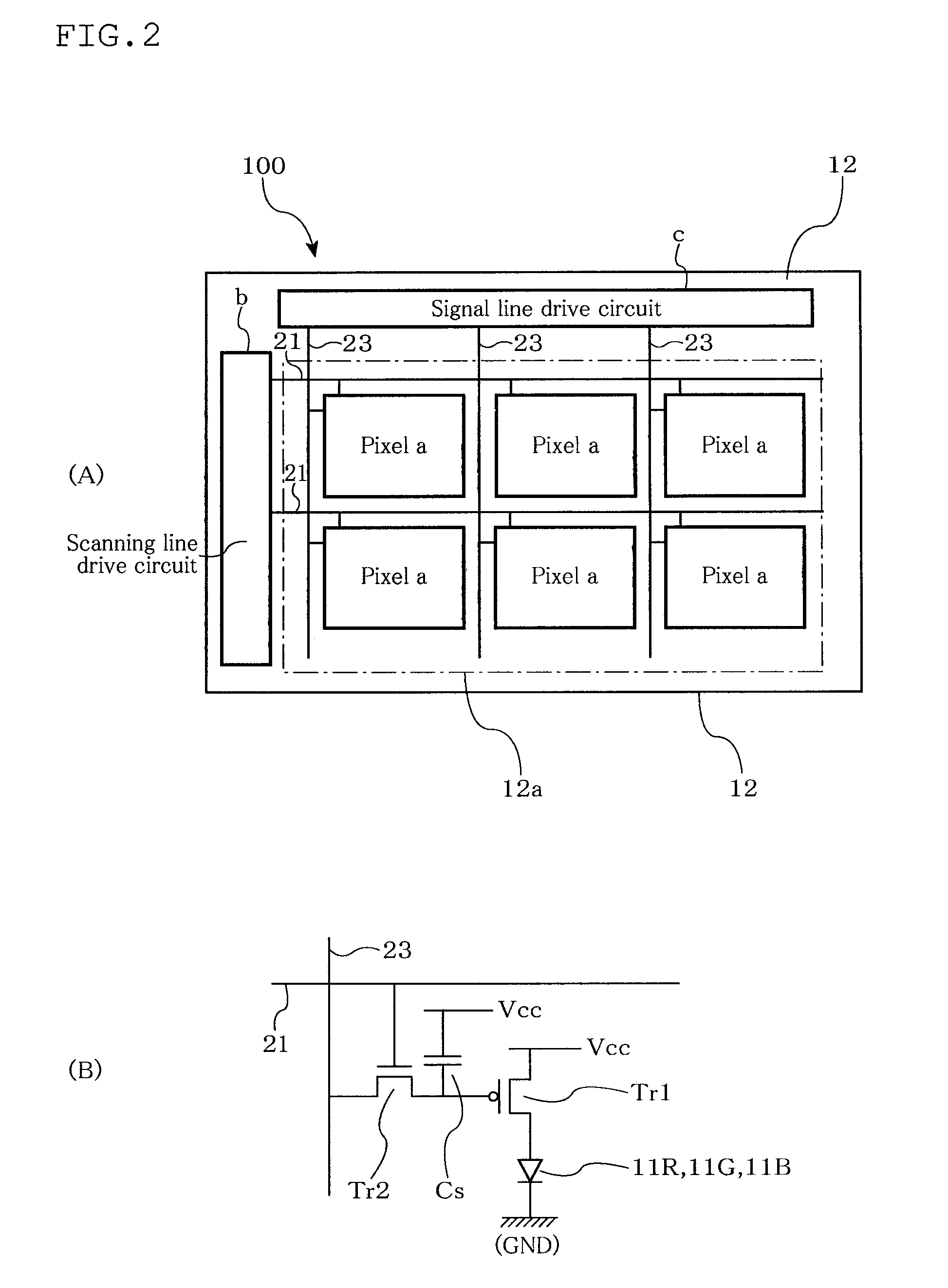

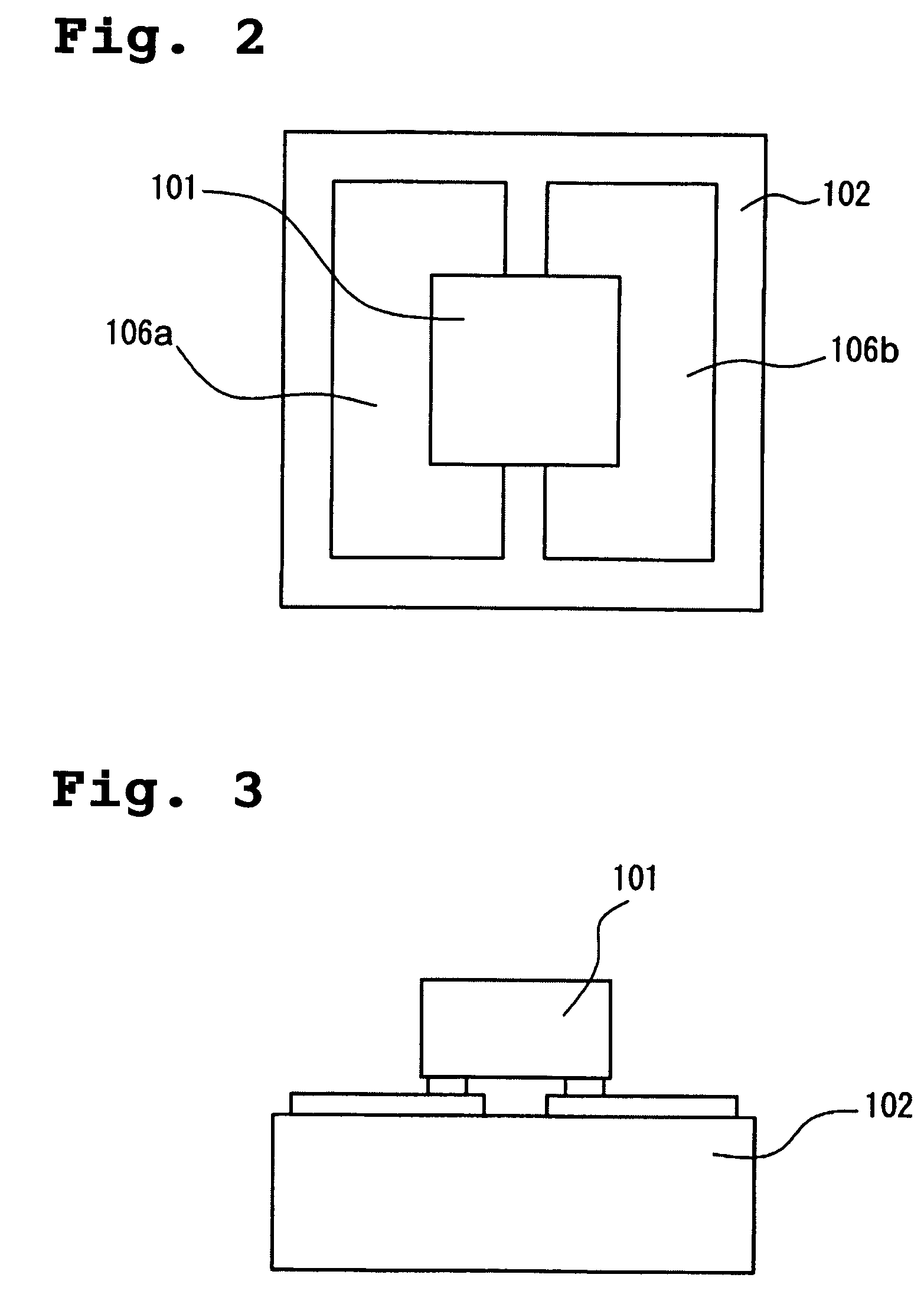

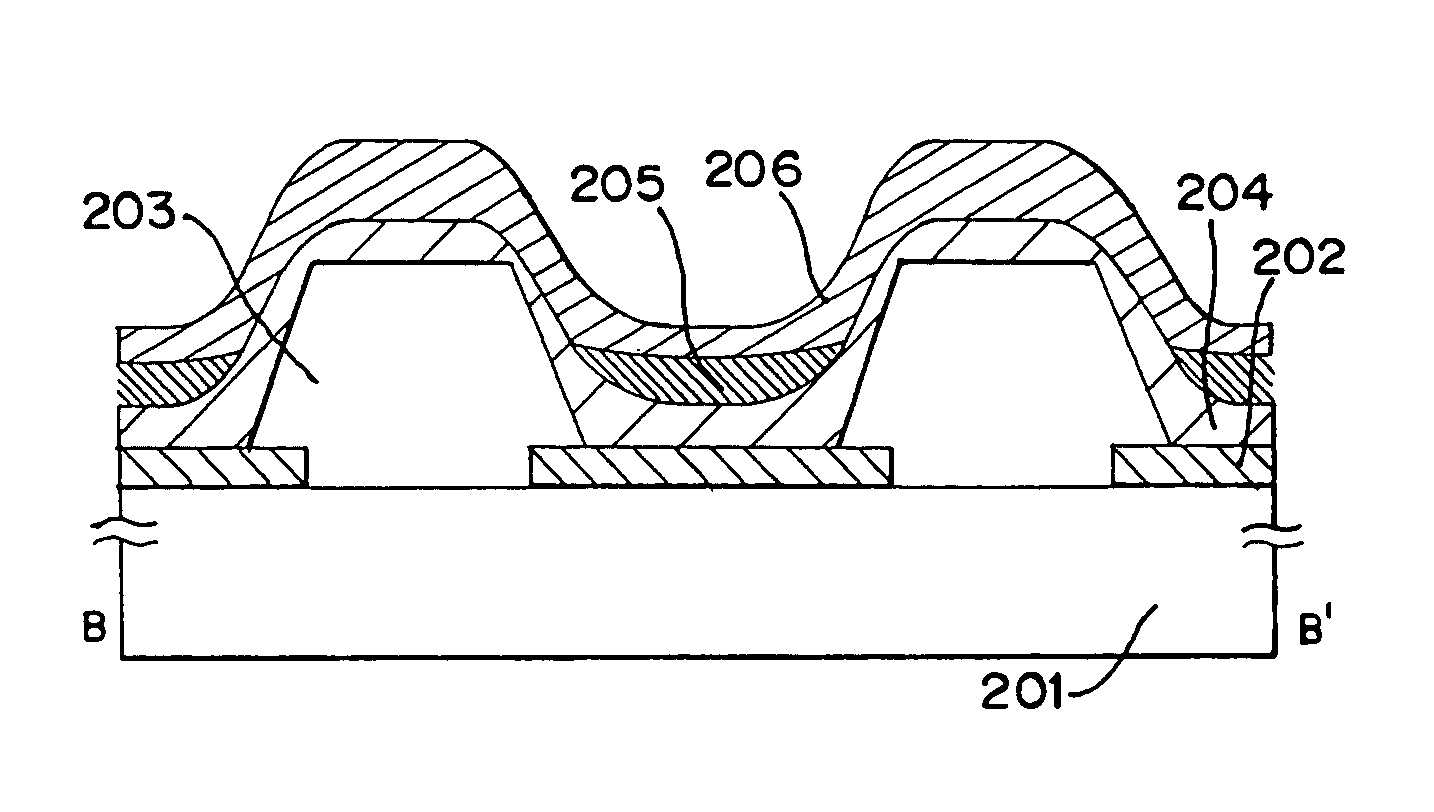

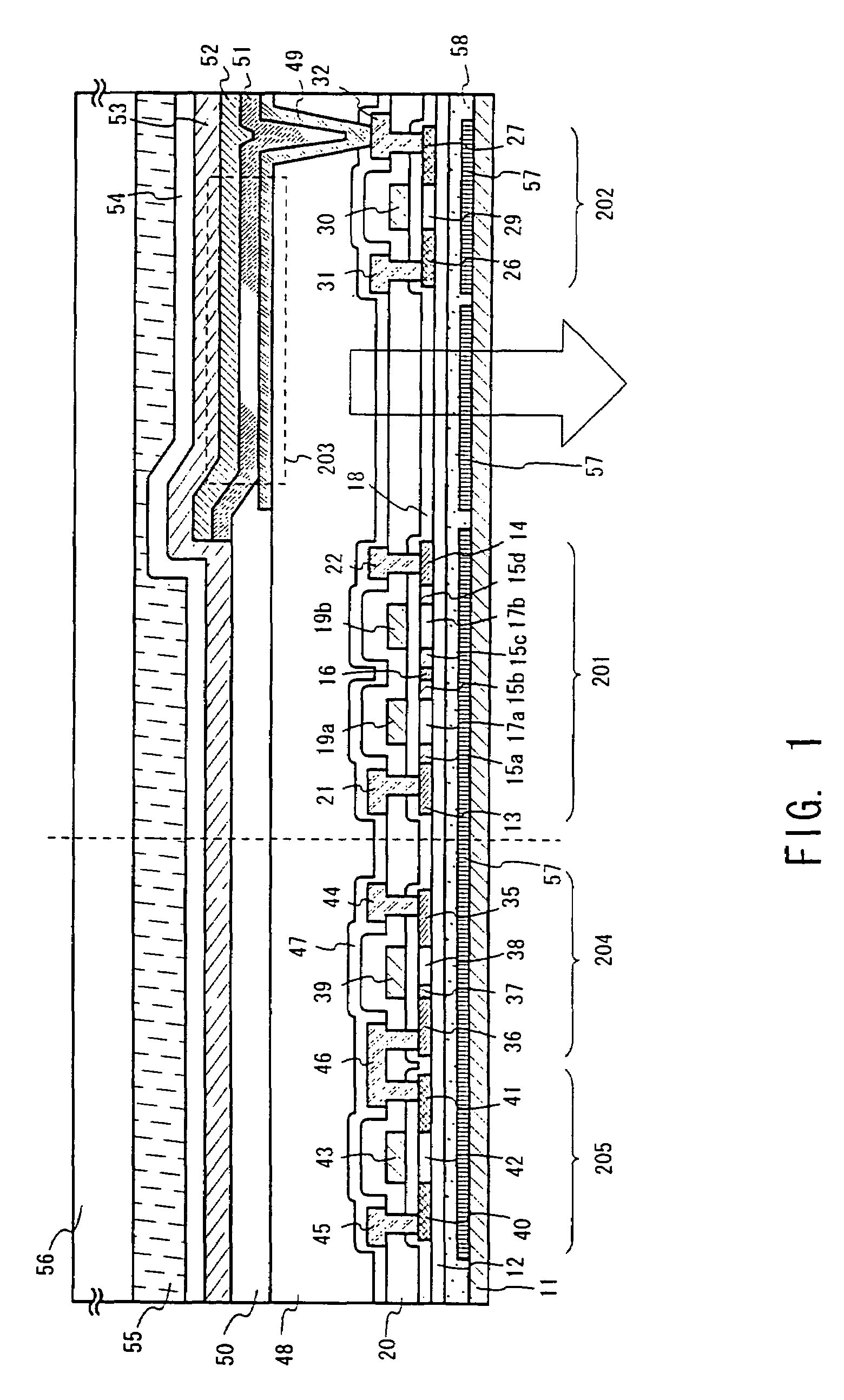

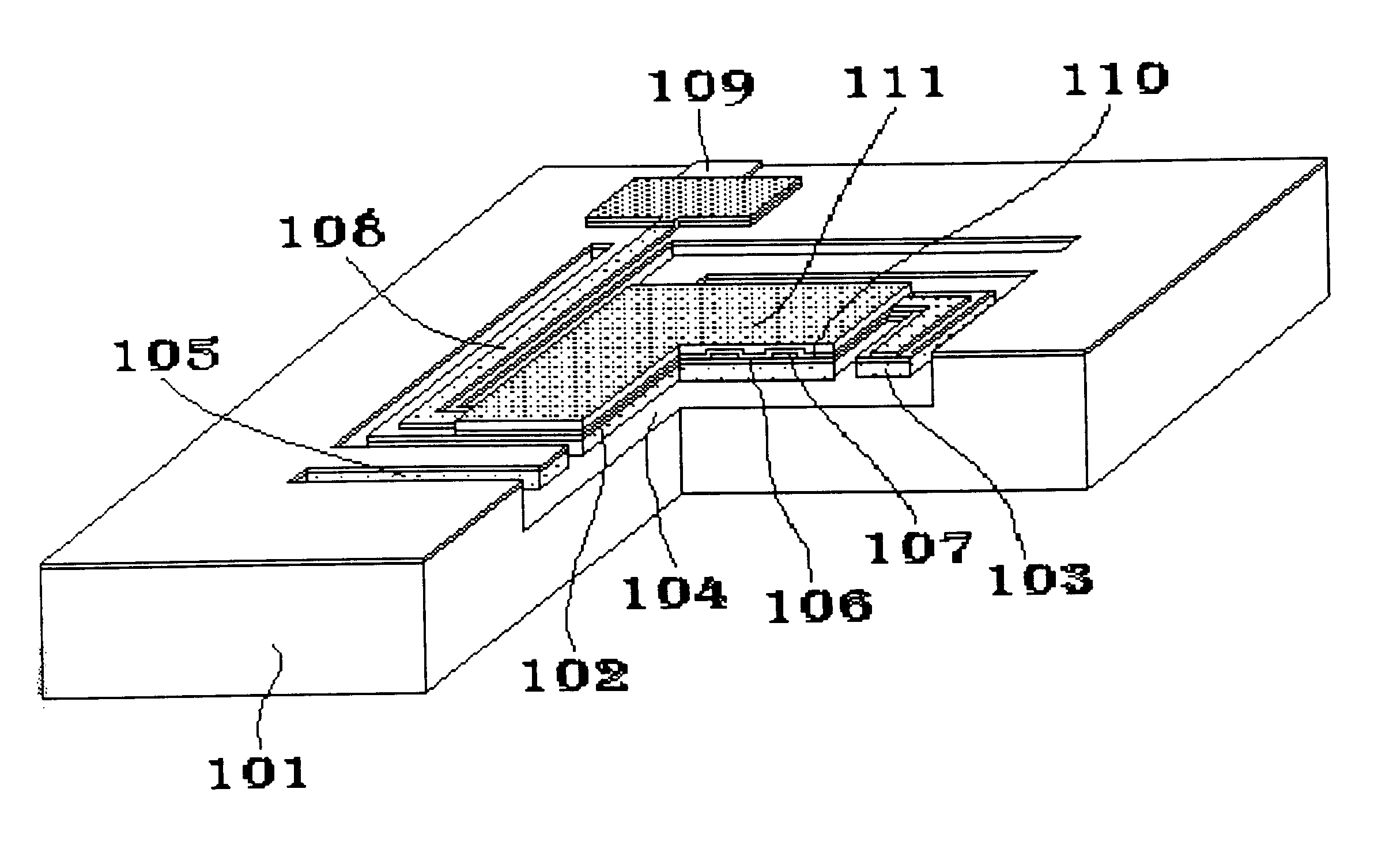

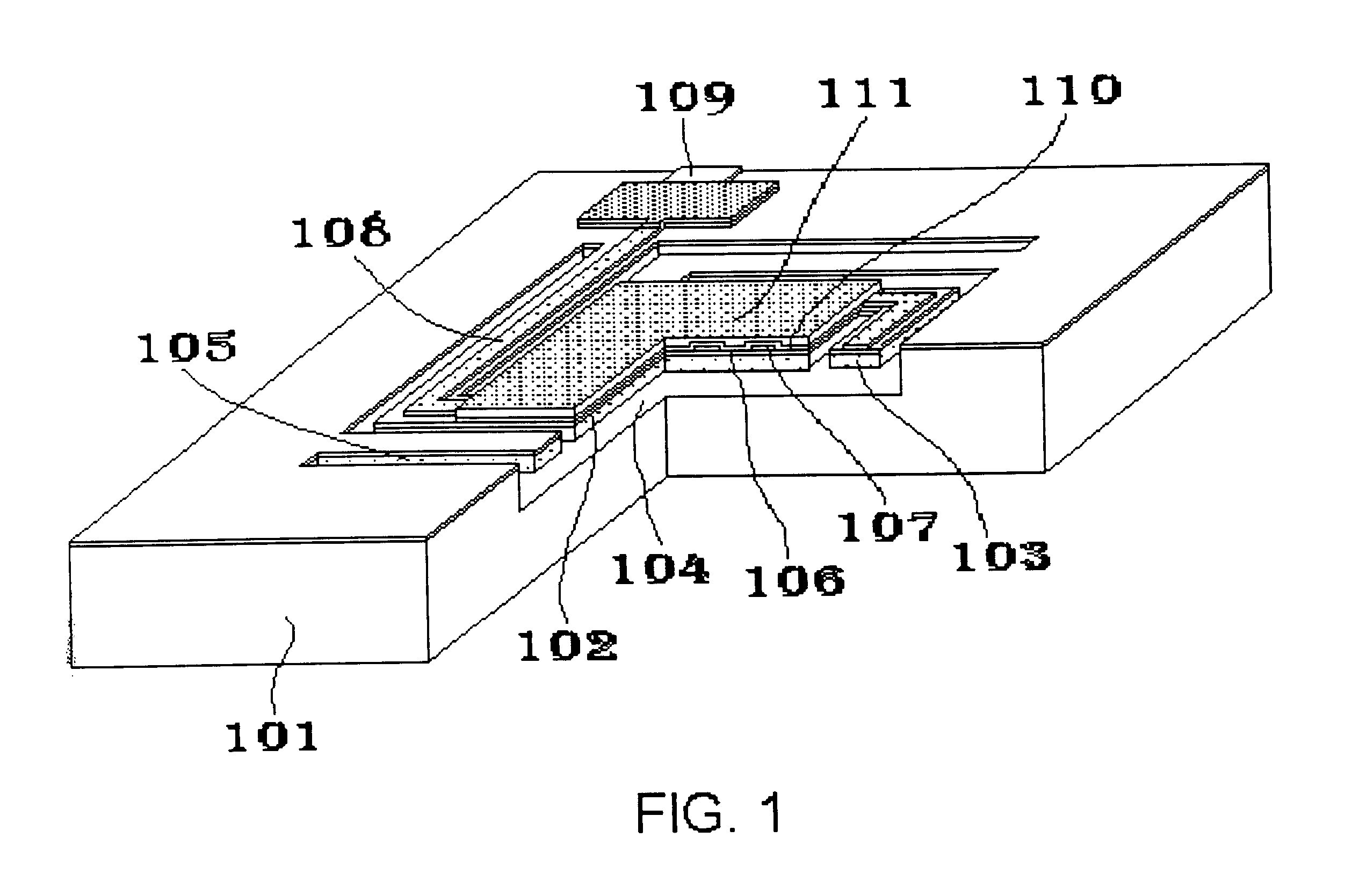

Display device and method for manufacturing thereof

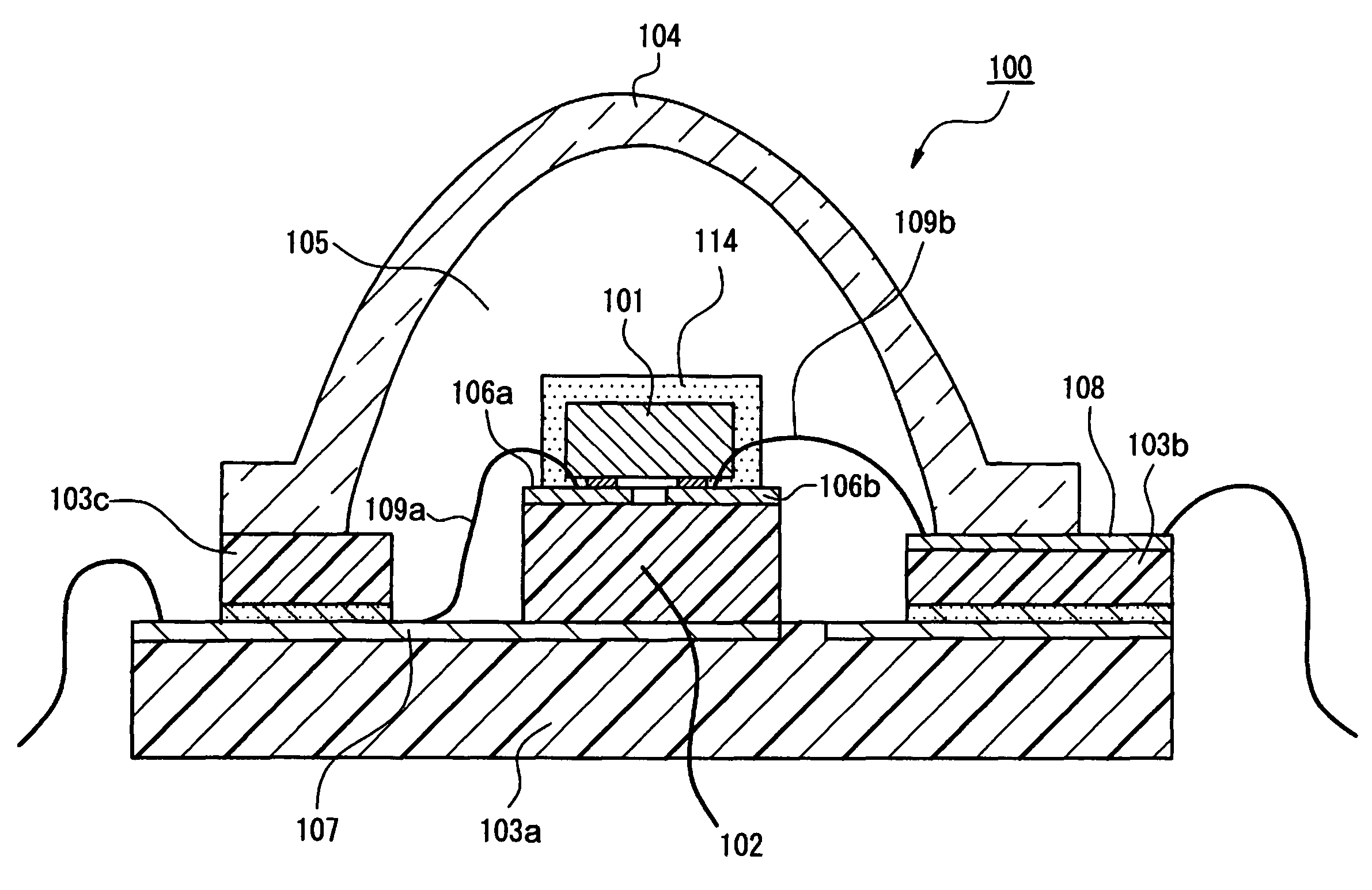

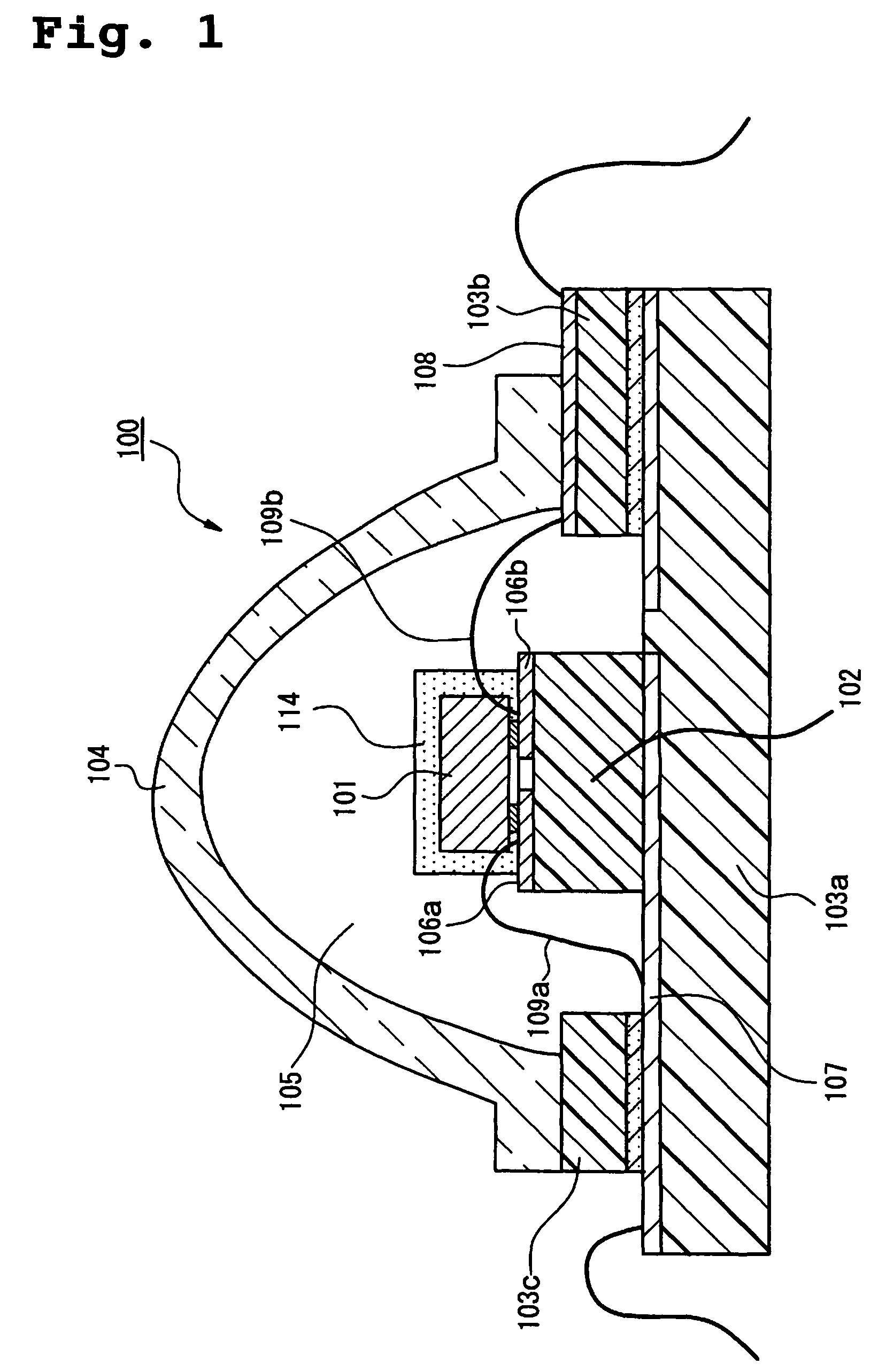

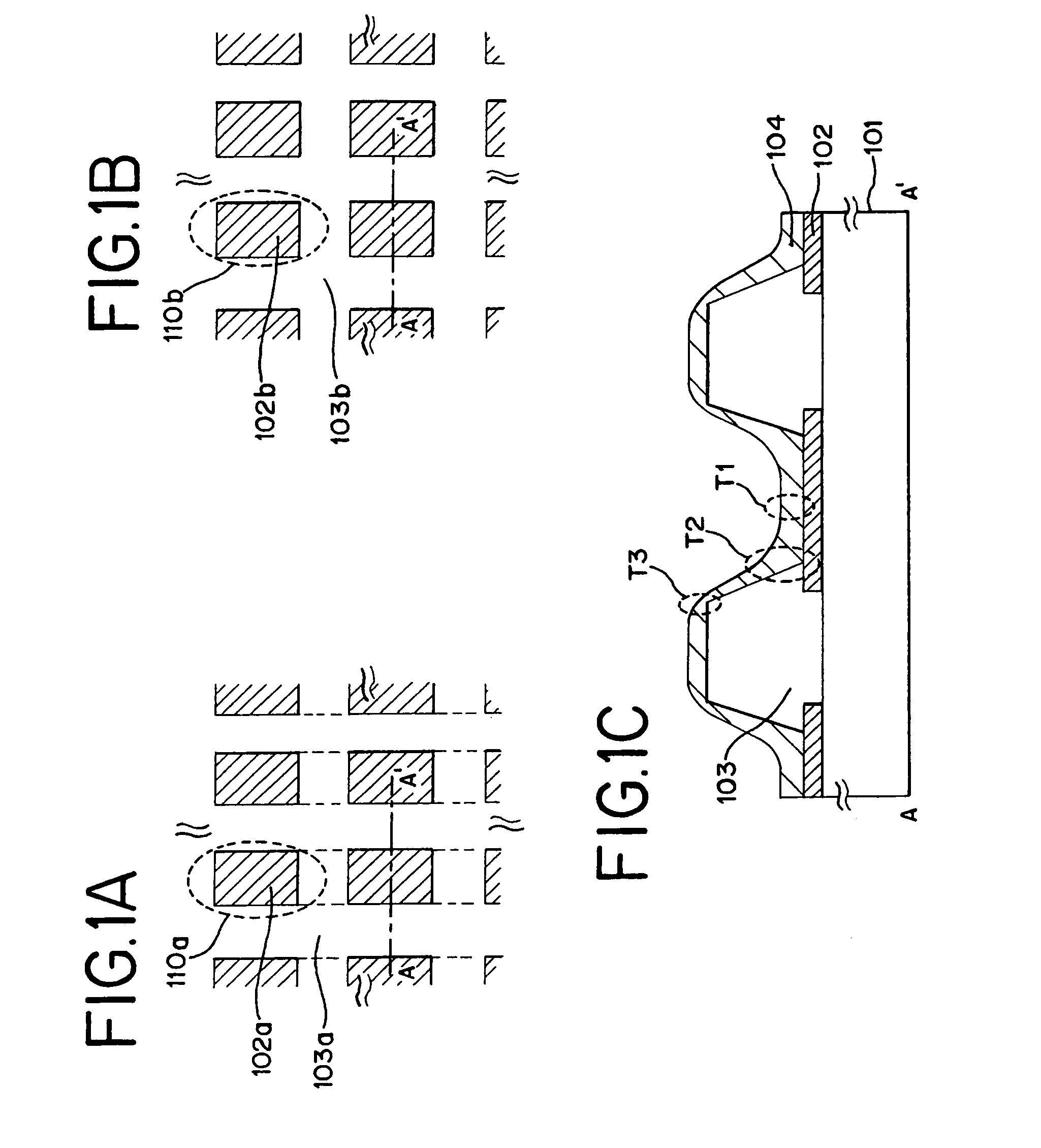

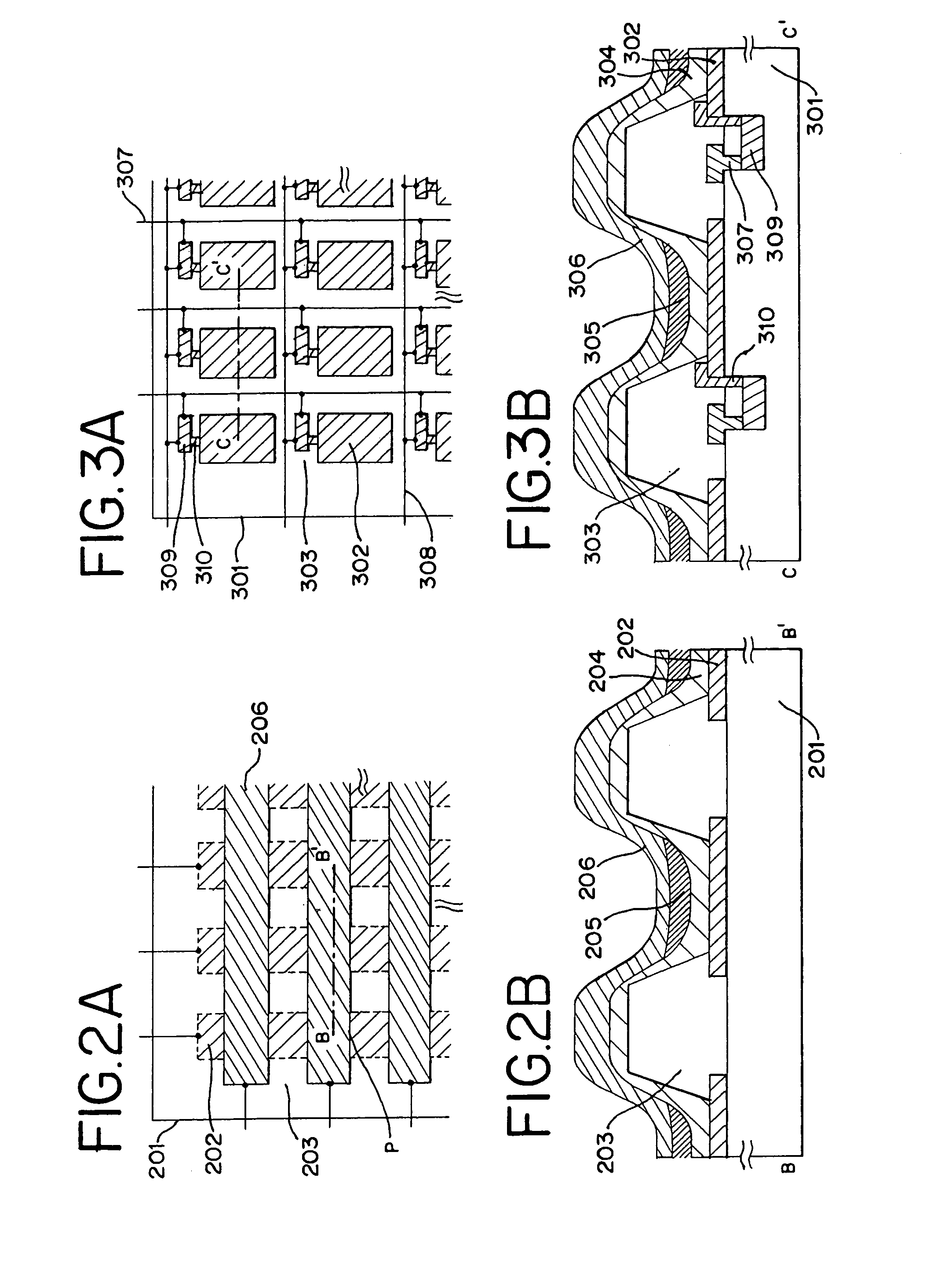

InactiveUS7199516B2Reduce the driving voltageImprove heat resistanceDischarge tube luminescnet screensElectroluminescent light sourcesConductive polymerDisplay device

It is a problem to provide an electric apparatus less in consumption power and long in life by the manufacture using the display device.An insulating bank 103a is provided in a form surrounding the pixel portions 110a on first electrodes 102a over a substrate. The entire surface is applied, by a wet scheme(method), with an organic conductive film 104. The organic conductive film 104 has a thickness form of T2>T1>T3 under the influence of the insulating bank 103. Accordingly, the portion T3 has an increased resistance in a lateral direction, making possible to prevent against crosstalk. Due to a conductive polymer as a buffer layer 104, a display device can be provided which is low in drive voltage. Furthermore, because the portion T2 is increased in thickness, the electric-field concentration is relaxed at and around the pixel portion. This makes it possible to prevent the organic light-emitting element from deteriorating at around the pixel.

Owner:SEMICON ENERGY LAB CO LTD

Organic electroluminescence device and organic light emitting medium

InactiveUS20060033421A1High color purityImprove heat resistanceMaterial nanotechnologyOrganic chemistryAnthraceneOrganic electroluminescence

An organic electroluminescence device having a layer of an organic light emitting medium which comprises (A) a specific arylamine compound and (B) at least one compound selected from specific anthracene derivatives, spirofluorene derivatives, compounds having condensed rings and metal complex compounds and is disposed between a pair of electrodes and an organic light emitting medium comprising the above components (A) and (B) are provided. The organic electroluminescence device exhibits a high purity of color, has excellent heat resistance and a long life and efficiently emits bluish to yellowish light. The organic light emitting medium can be advantageously used for the organic electroluminescence device.

Owner:IDEMITSU KOSAN CO LTD

Heat-expandable microcapsules, process for producing the same, and method of utilizing the same

InactiveUS6235394B1High TgHigh heat-resistanceSynthetic resin layered productsCellulosic plastic layered productsPolymer scienceHeat resistance

A heat-expandable microcapsule comprising a polymer shell formed by polymerizing (I) acrylonitrile, a main monomer component, (II) a monomer having carboxyl and (III) a monomer having groups reactive with the carboxyl of the monomer (II) and of a liquid having a boiling point lower than the softening point of the polymer and being encapsulated in the polymer shell. The heat-expandable microcapsules expand within high temperature range, 240° C. or above, and have heat-resistance.

Owner:MATSUMOTO YUSHI SEIYAKU

Poly(arylene ether)-containing thermoset composition, method for the preparation thereof, and articles derived therefrom

InactiveUS20010053820A1Fast curingReduce sensitivitySynthetic resin layered productsThin material handlingHeat resistanceEther

A thermosetting composition comprises a capped poly(arylene ether), an alkenyl aromatic monomer, and an acryloyl monomer. The composition provides good flow properties and fast curing rates. After curing, the composition exhibits good stiffness, toughness, heat resistance, and dielectric properties.

Owner:SABIC INNOVATIVE PLASTICS IP BV

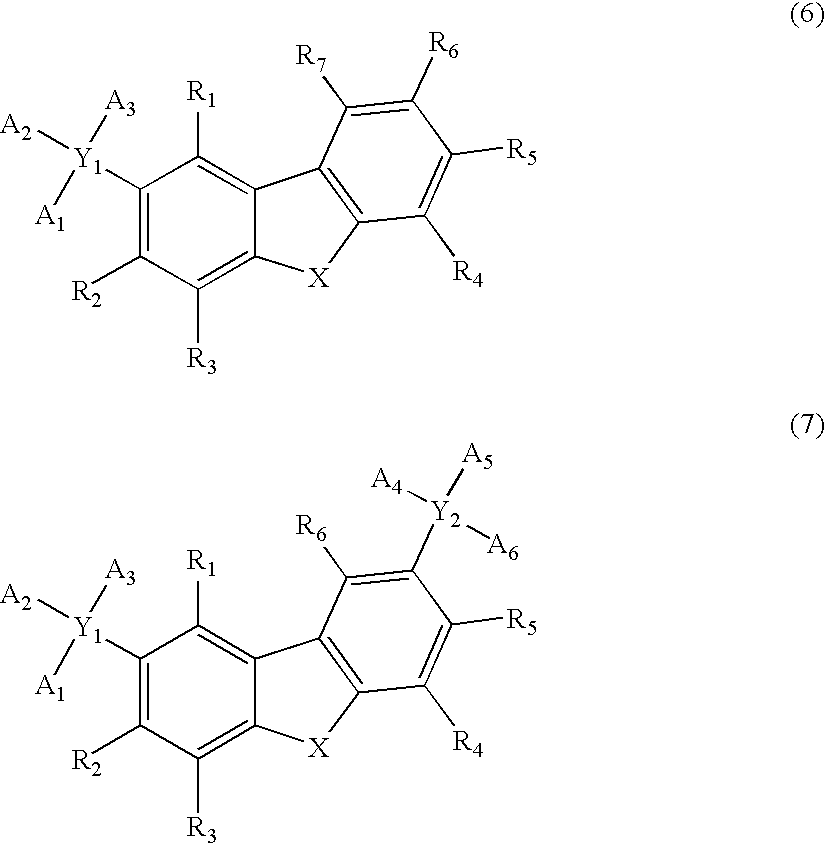

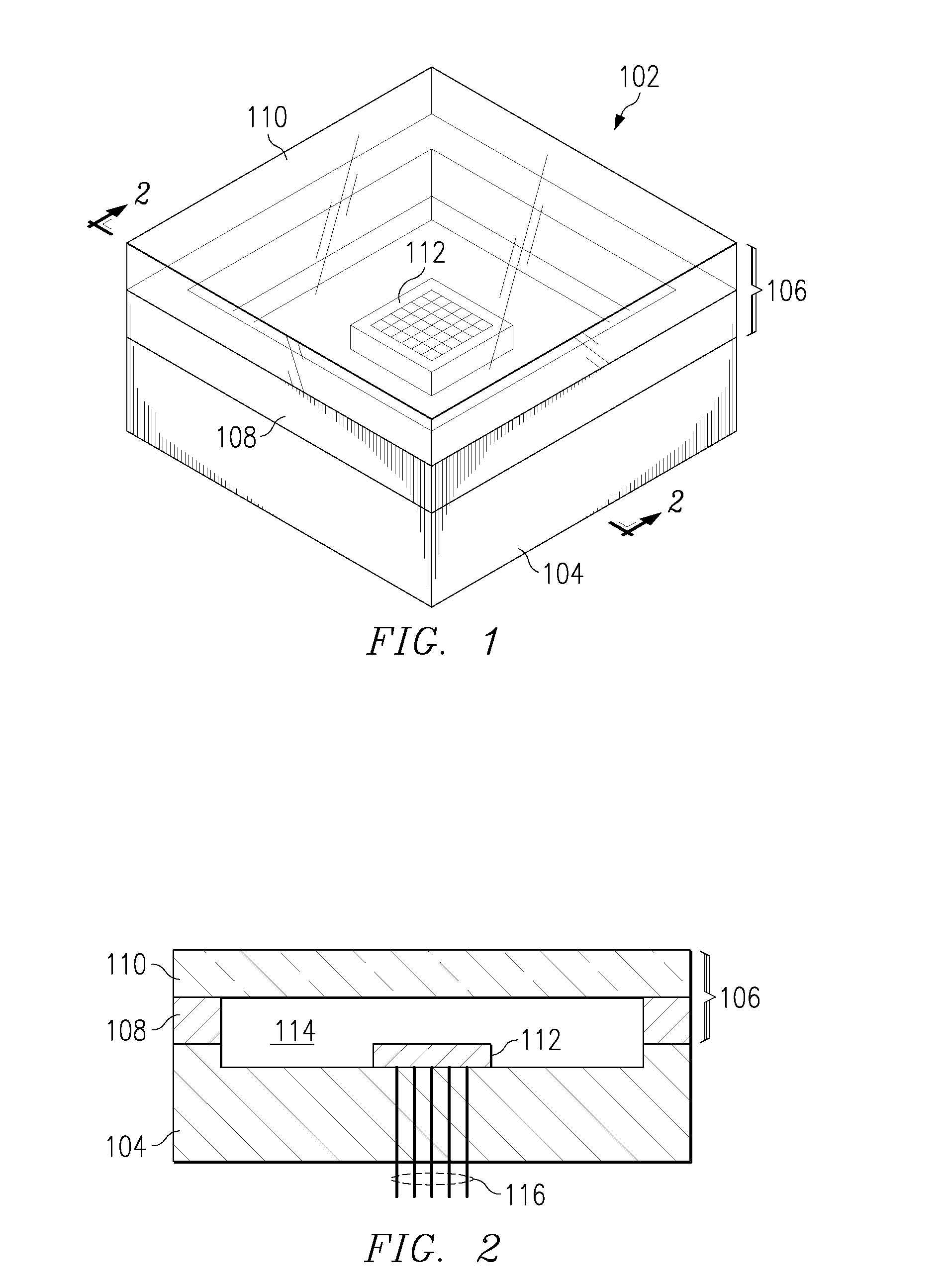

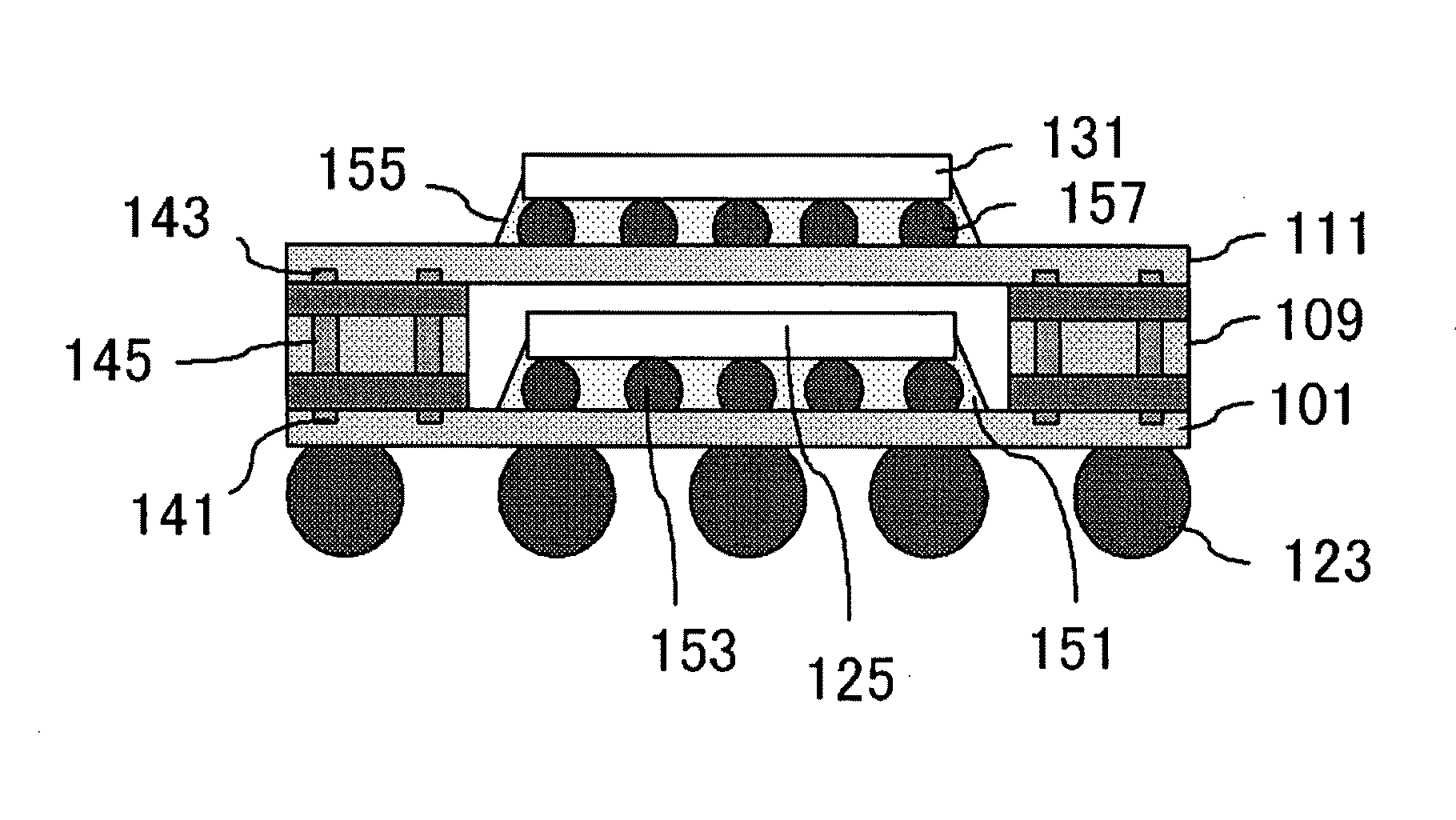

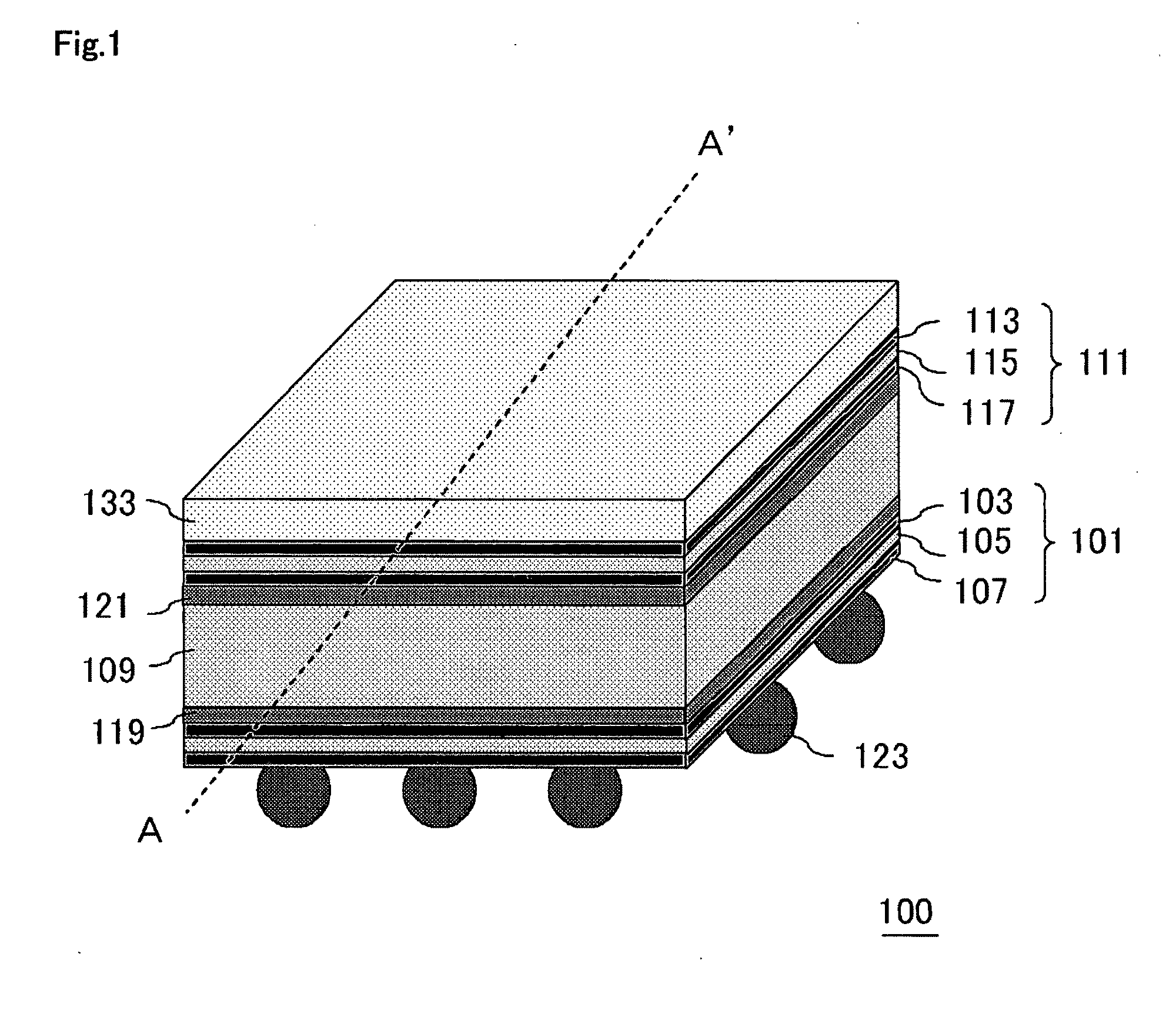

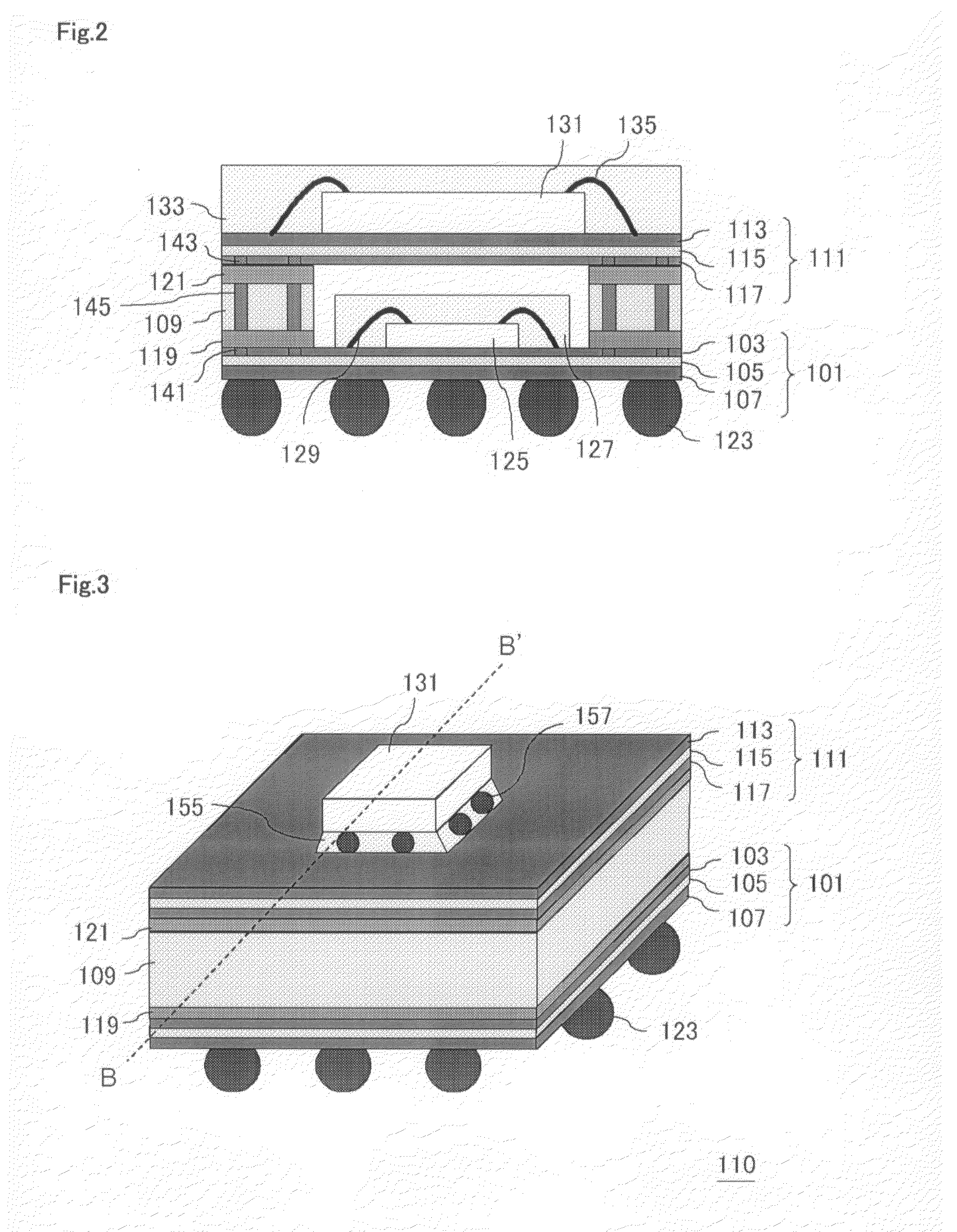

Semiconductor Device and Method for Manufacturing Semiconductor Device

InactiveUS20090243065A1Improve joint reliabilityLower elastic modulusSemiconductor/solid-state device detailsSolid-state devicesSurface mountingSemiconductor chip

A semiconductor device (100) comprises a first resin substrate (101) on which a first semiconductor chip (125) is mounted a surface thereof; a second resin substrate (111) on which a second semiconductor chip (131) is mounted on a surface thereof; and a resin base material (109), joined to a front surface of the first resin substrate (101) and to a back surface of the second resin substrate (111), so that these surfaces are electrically connected. The resin base material (109) is disposed in a circumference of the first resin substrate (101) in the surface of the first resin substrate (101). Further, the first semiconductor chip (125) is disposed in a space section provided among the first resin substrate (101), the second resin substrate (111) and the resin base material (109) in the surface of the first resin substrate (101).

Owner:SUMITOMO BAKELITE CO LTD

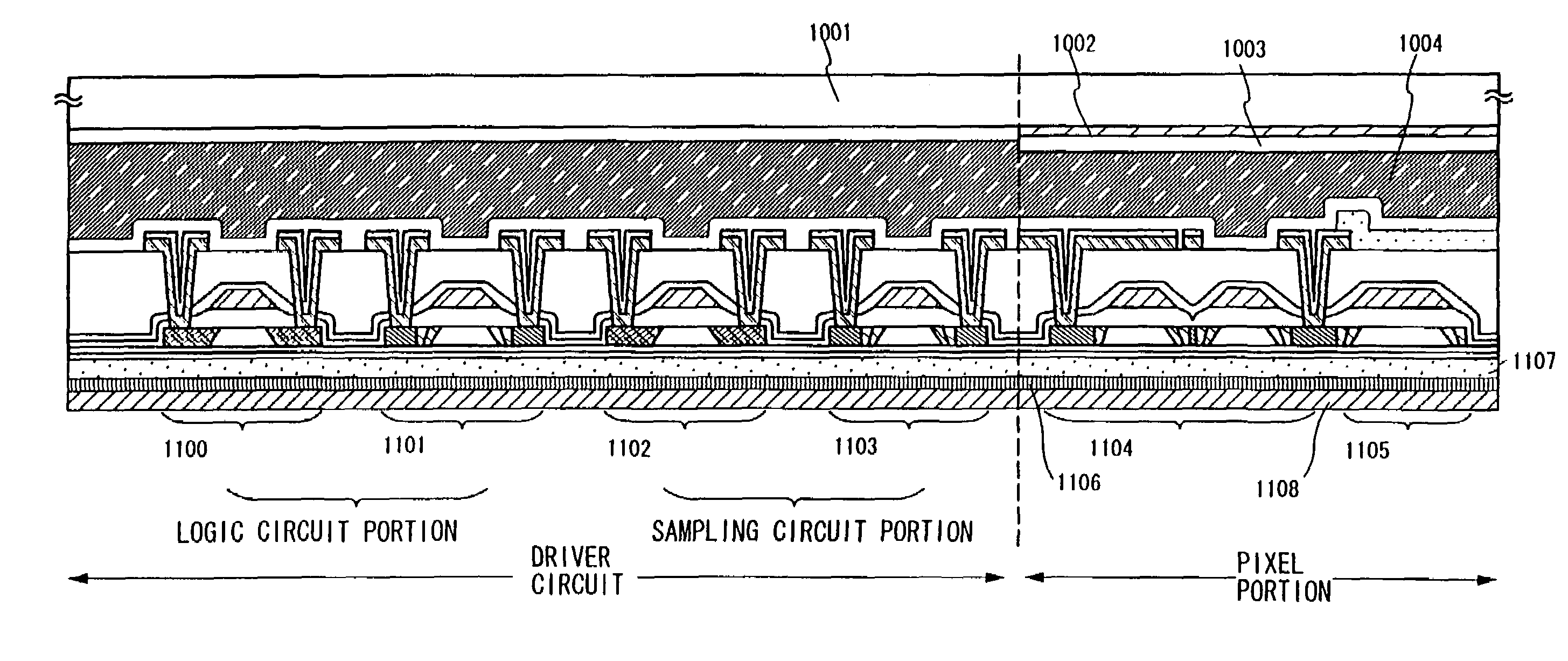

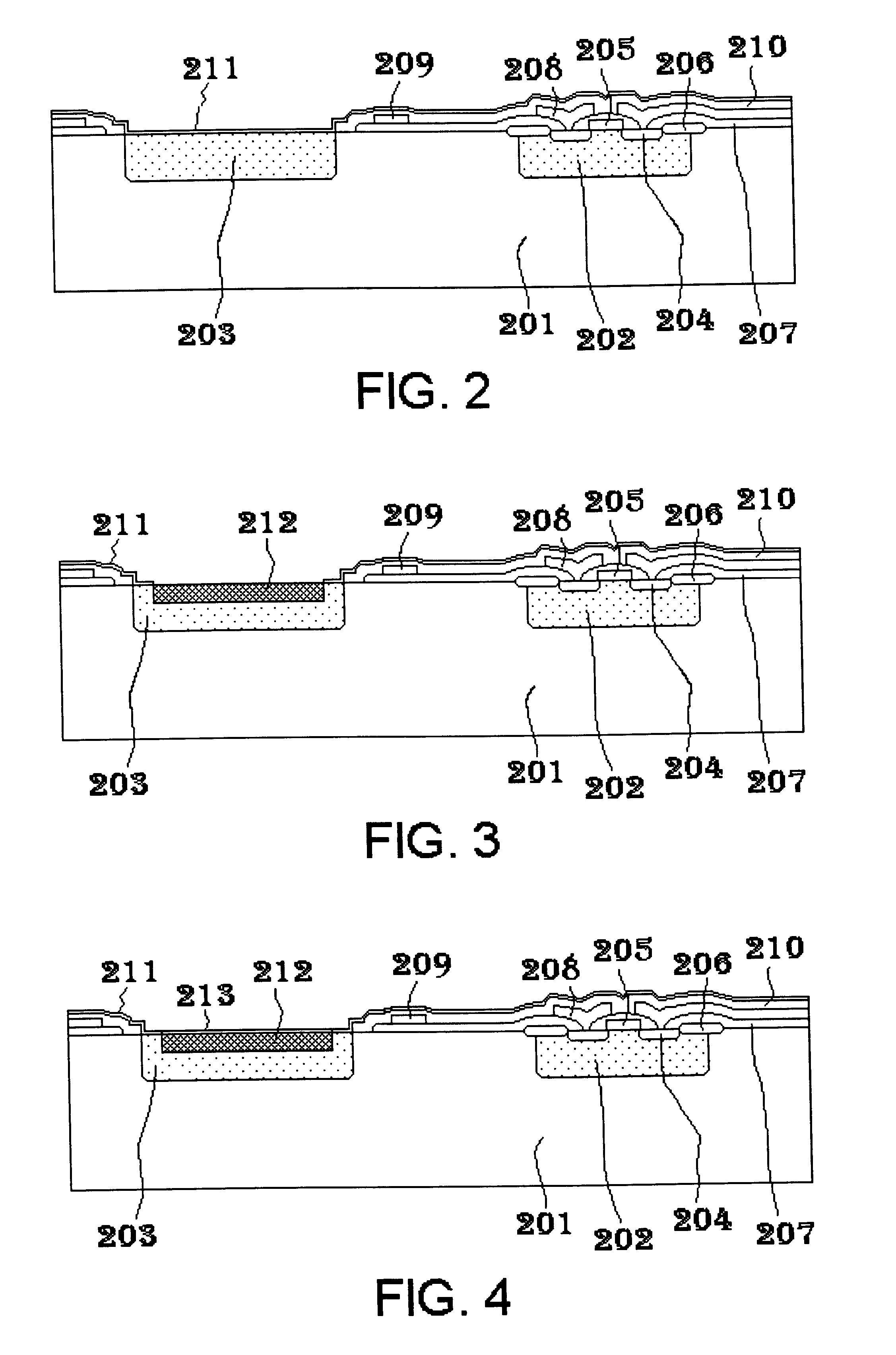

Semiconductor device and manufacturing method thereof

InactiveUS7119364B2Improve heat resistanceExcellent electrical propertiesFinal product manufactureElectroluminescent light sourcesHeat resistanceColor film

A high performance electric device which uses an adhesive layer over a substrate. A color filter is over a substrate, and an adhesive layer is also located over the substrate and color film. An insulating layer is over the adhesive layer, and thin film transistors cover the insulating film and the color filters. Light emitting elements cover the thin film transistors and emit light through the substrate that is through the adhesive layer and color filter. The substrate may be plastic, thus increasing the heat resistance.

Owner:SEMICON ENERGY LAB CO LTD

Exhaust gas treatment catalyst for internal combustion engines with two catalytically active layers on a carrier structure

InactiveUS6348430B1Improve heat resistanceHigh activityInorganic chemistryInternal combustion piston enginesParticulatesPartial oxidation

A catalyst for treating the exhaust gas from internal combustion engines is provided, wherein the catalyst contains two catalytically active layers supported on a support. The first catalytically active layer contains a platinum group metal in close contact with all of the constituents of the first catalytically active layer, wherein the constituents of the first catalytically active layer include particulate aluminum oxide; particulate oxygen storage material, such as cerium oxide, cerium / zirconium and zirconium / cerium mixed oxides, and alkaline earth metal oxides. The second catalytically active layer, which is in direct contact with the exhaust gas, contains particulate aluminum oxide and at least one particulate oxygen storage material, such as cerium oxide, cerium / zirconium and zirconium / cerium mixed oxides. Rhodium is supported on part of the aluminum oxides in the second catalytically active layer or on the particulate oxygen storage material in the second catalytically active layer. By providing the platinum group metal in close contact with all of the constituents of the first catalytically active layer, improved conversion efficiency of the impurities in the exhaust gas can be achieved.

Owner:UMICORE AG & CO KG +1

Poly(arylene ether)-containing thermoset composition, method for the preparation thereof, and articles derived therefrom

InactiveUS6812276B2Fast curingReduce sensitivitySynthetic resin layered productsSpecial tyresEndcappingHeat resistance

Owner:SABIC GLOBAL TECH BV

Poly (arylene ether)-containing thermoset composition, method for the preparation thereof, and articles derived therefrom

InactiveUS20030096123A1Fast curingReduced curing rate oxygen sensitivitySynthetic resin layered productsSpecial tyresHeat resistanceEther

Owner:SABIC GLOBAL TECH BV

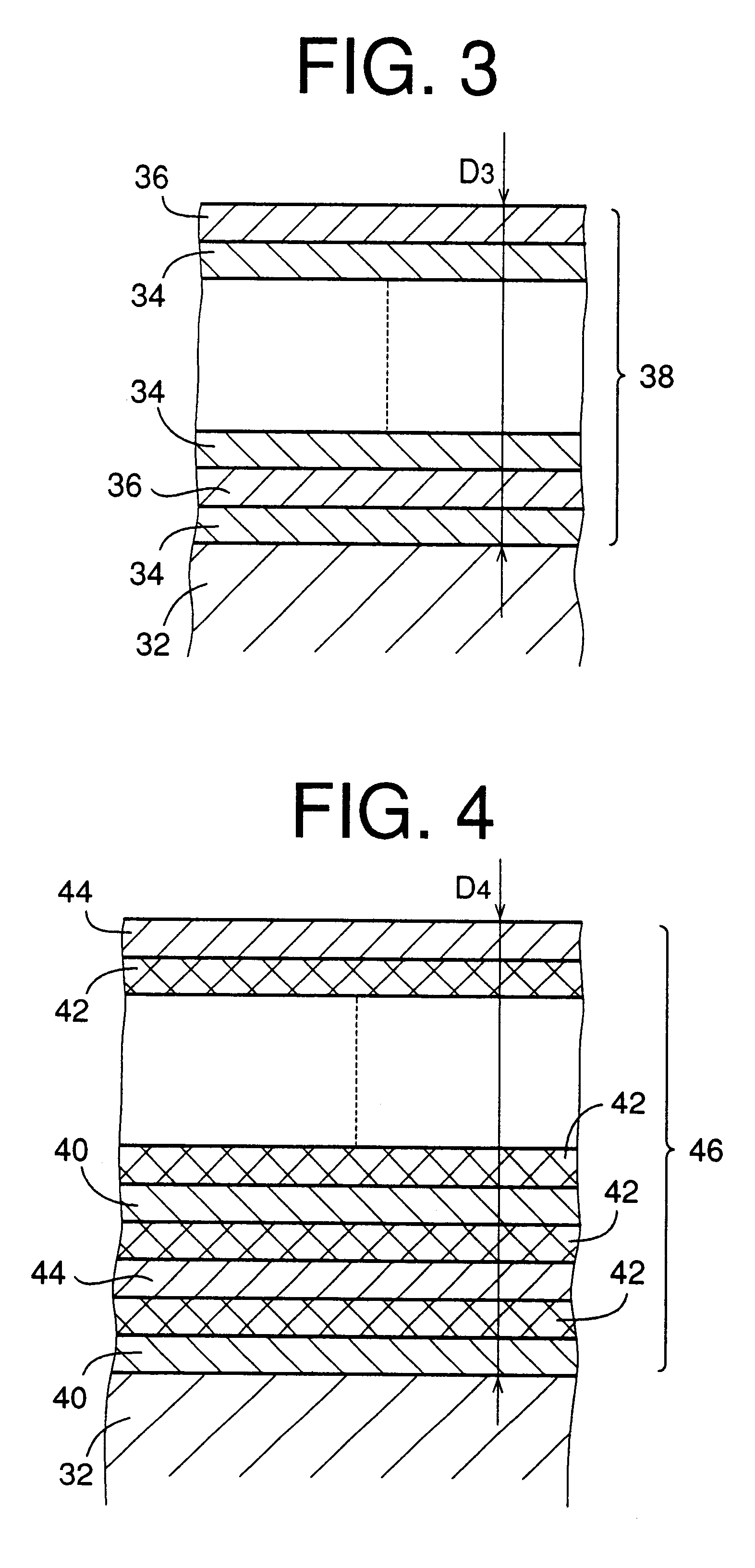

Hard multilayer coated tool having increased toughness

InactiveUS6309738B1Improve toughnessLower resistancePigmenting treatmentVacuum evaporation coatingTitaniumToughness

A hard multilayer coated tool including: (a) a substrate; and (b) a multilayer coating covering the substrate, the multilayer coating comprising first and second coating layers which are alternately laminated on the substrate, each of the first coating layers having and average thickness of 0.10-0.50 mum and containing titanium therein, each of the second coating layers having and average thickness of 0.10-0.50 mum and containing aluminum therein, the multilayer coating having and average thickness of 0.50-10.0 mum.

Owner:OSG

Radiation-curable liquid resin composition for coating optical fibers

InactiveUS6136880AConvenient coatingLow viscositySynthetic resin layered productsYarnPhotoinitiatorChemistry

Owner:DSM IP ASSETS BV

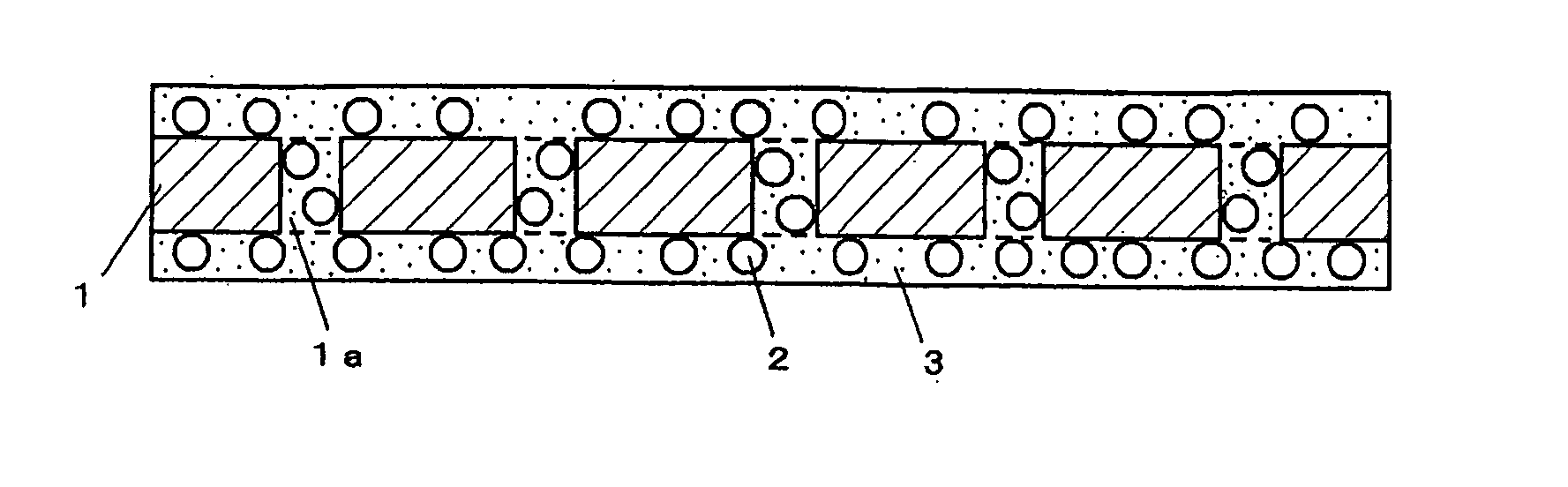

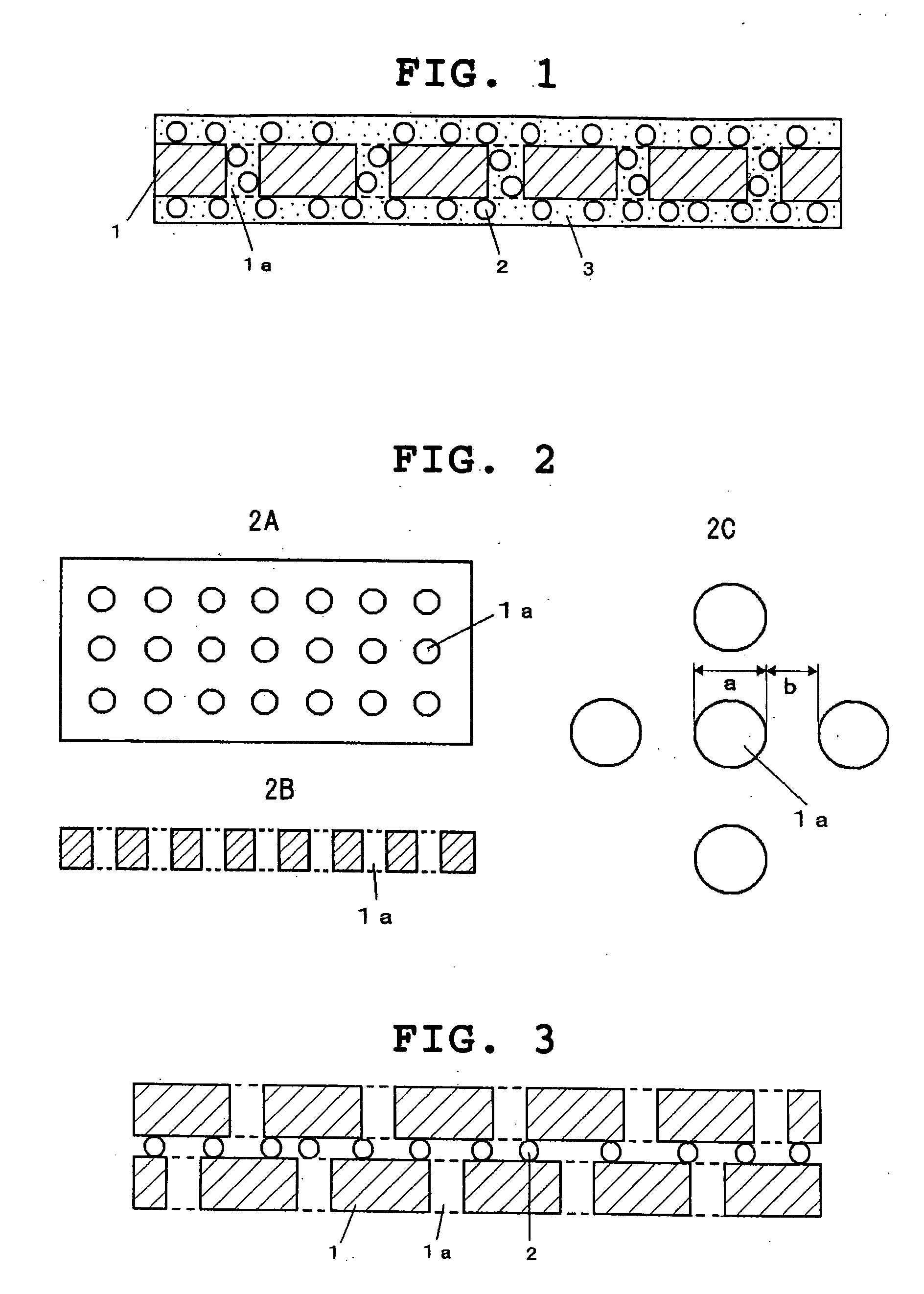

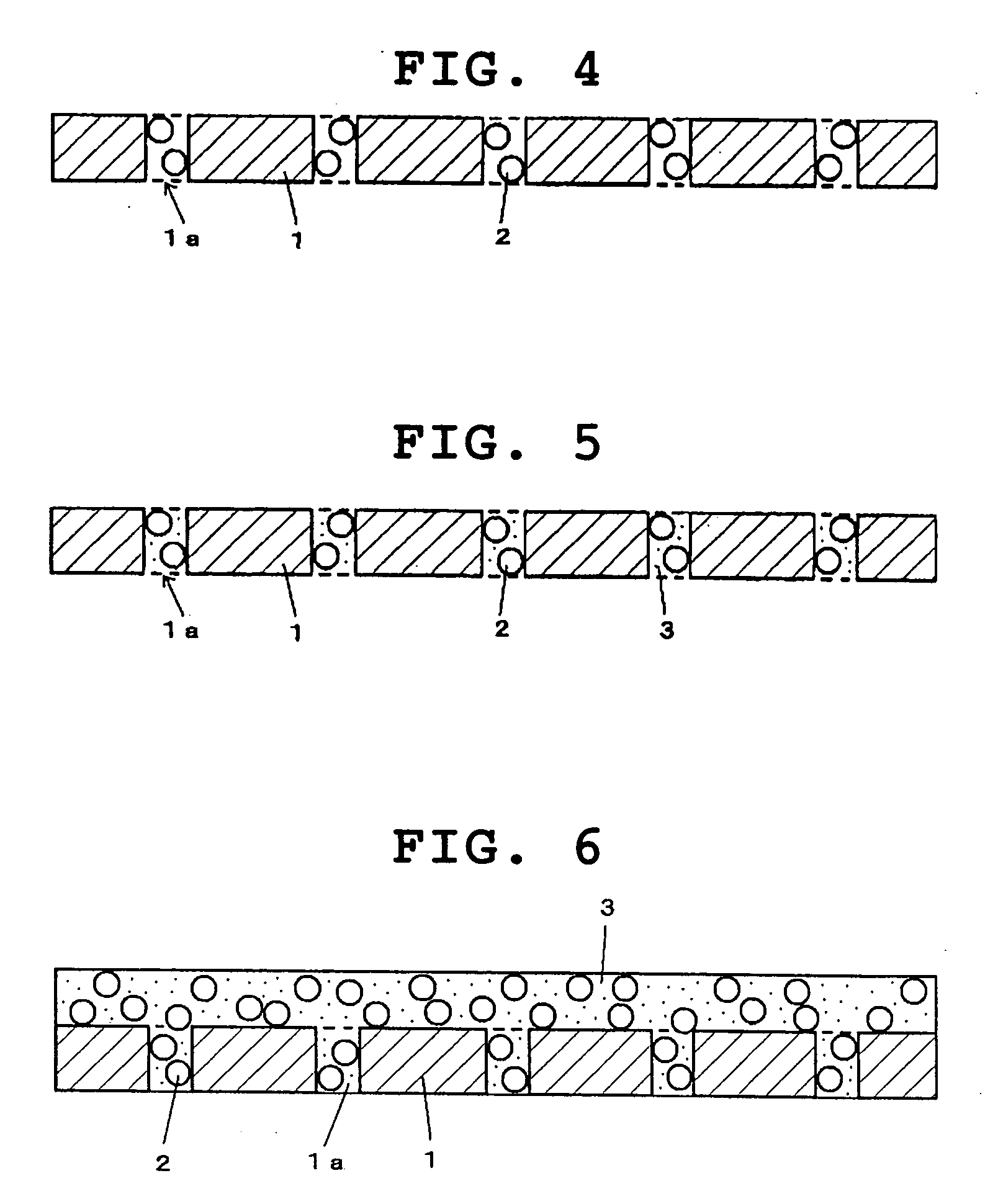

Separator for nonaqueous electrolyte batteries, nonaqueous electrolyte battery using it, and method for manufacturing separator for nonaqueous electrolyte batteries

InactiveUS6511774B1High tear strengthEnhanced penetration strengthNon-aqueous electrolyte accumulatorsCell seperators/membranes/diaphragms/spacersHigh energyEngineering

The present invention provides a separator for non-aqueous electrolyte batteries which neither breaks nor slips off at the time of fabrication of battery, gives excellent battery fabricability, causes no internal short-circuit caused by contact between electrodes even if the electrodes are externally short-circuited, can inhibit ignition of battery and produces high energy density and excellent cycle life, and further provides a non-aqueous electrolyte battery using the separator and a method for manufacturing the separator. That is, the present invention relates to a separator for non-aqueous electrolyte batteries which comprises a porous base containing at least one member selected from a porous film, a woven fabric or nonwoven fabric containing an organic fiber and a paper and an organometallic compound applied to the porous base; a method for the manufacture of the separator for non-aqueous electrolyte batteries which comprises allowing said porous base to contact with a solution of organometallic compound by impregnation, coating or spraying, followed by drying or curing with heating to apply the organometallic compound to the porous base; and a non-aqueous electrolyte battery using the separator.

Owner:MITSUBISHI PAPER MILLS LTD

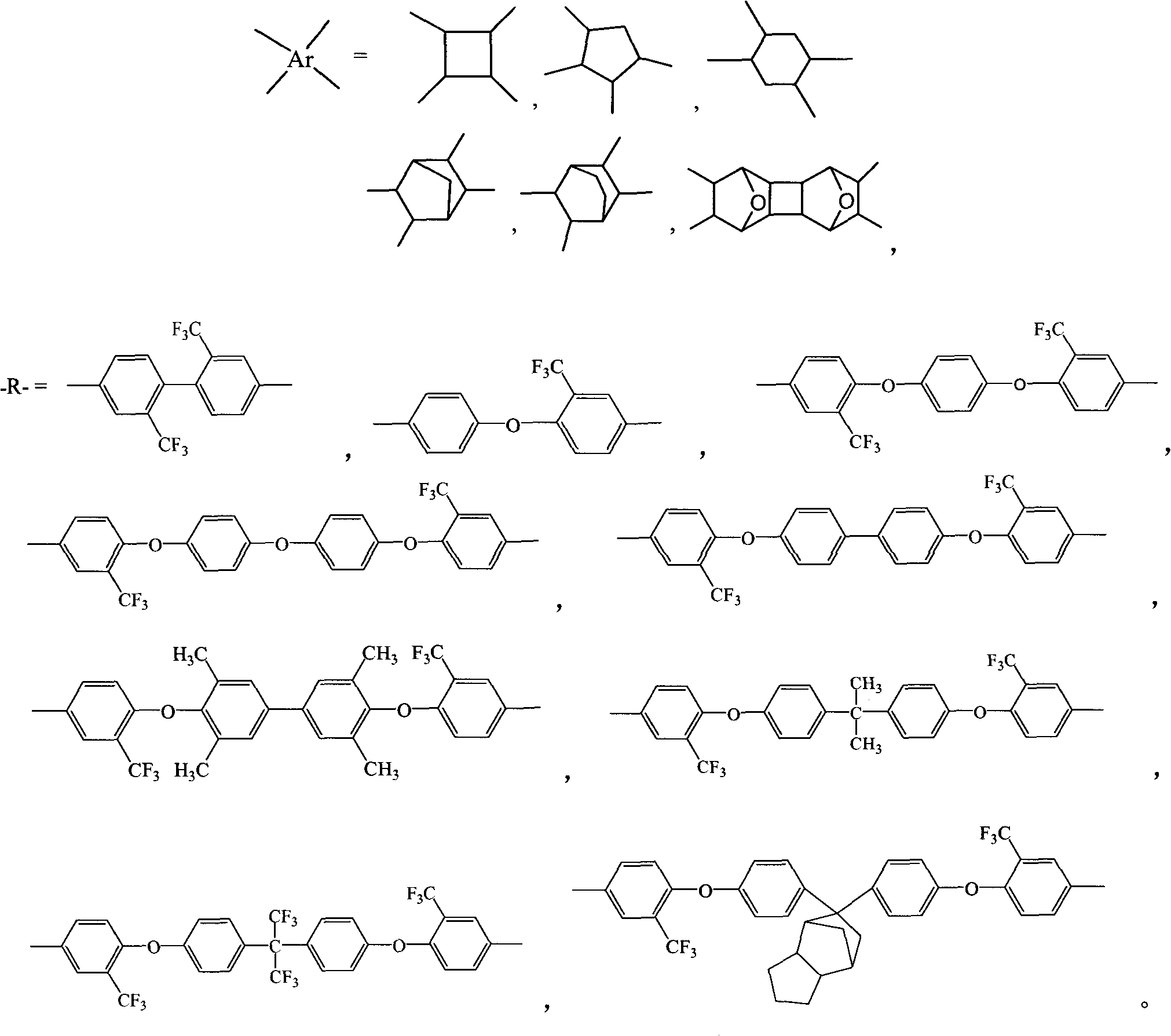

Colorless and transparent polyimide nano-composite material membrane and preparation method thereof

The invention relates to a colorless and transparent polyimide nano-composite material membrane and a preparation method thereof. The polyimide nano-composite material membrane is prepared by a method of compounding alicyclic dianhydride and fluorinated diamine serving as monomers with a certain amount of inorganic nano-particles by using nano-composite technology and performing thermal imidization with gradient temperature increase. The amount of added nano-particles is controlled between 0.01 and 5.00 weight percent to obtain the colorless and transparent polyimide nano-composite material membrane with high heat resistance. The membrane has a glass transition temperature of over 250 DEG C, a light transmittance of over 90 percent at 450 nanometers and an ultraviolet wavelength of about 300 nanometers, and can be used as a substrate material for a photoelectric device, a semiconductor material, an optical waveguide material and the like.

Owner:UNIV OF SCI & TECH LIAONING

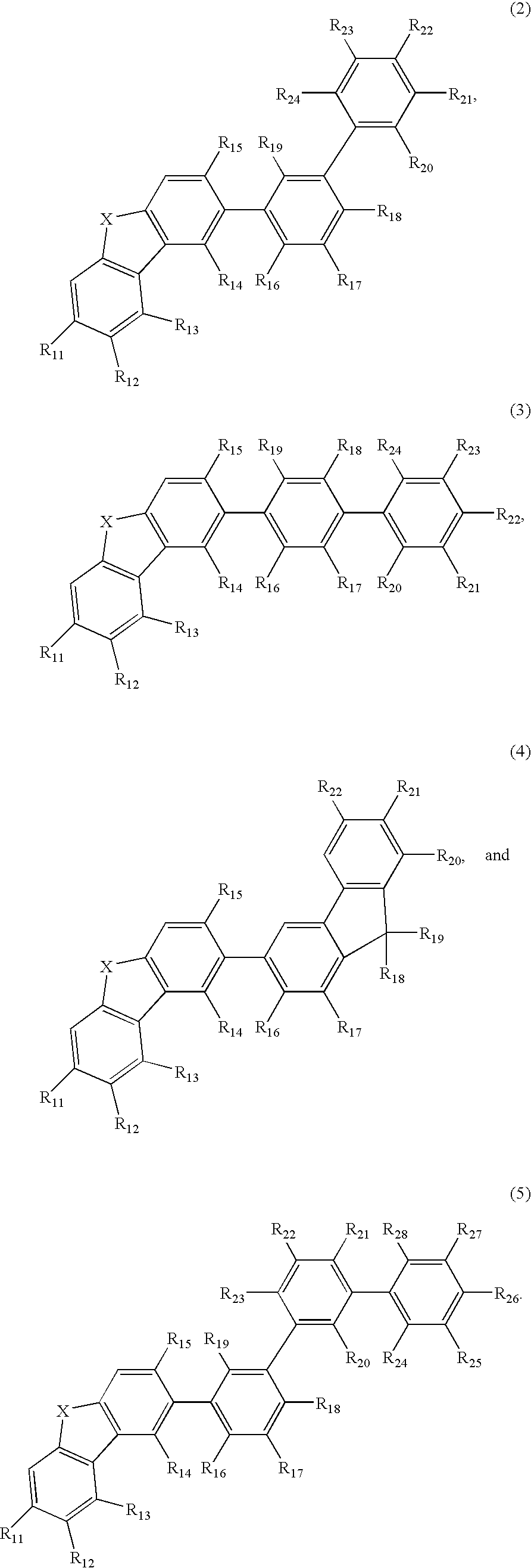

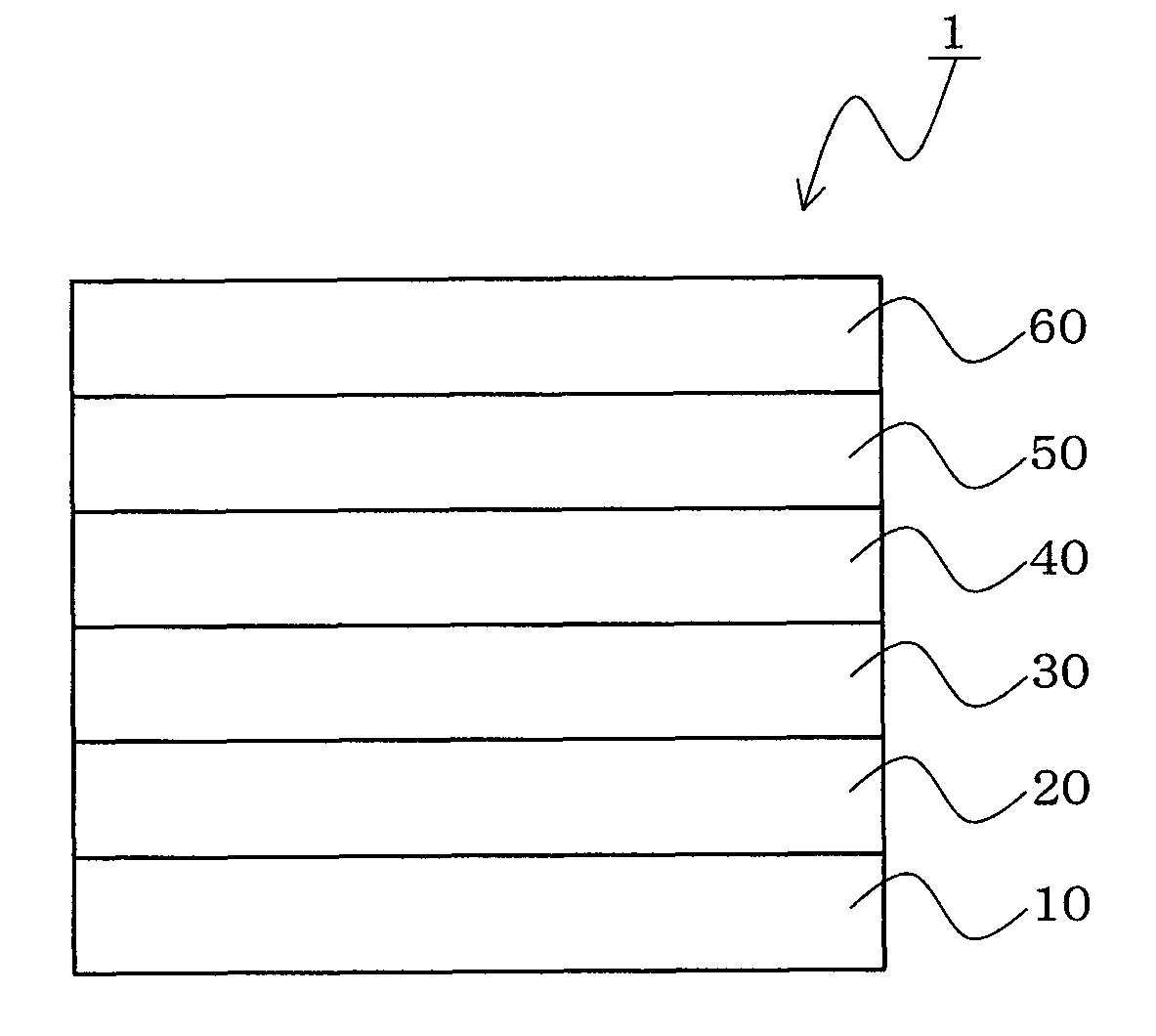

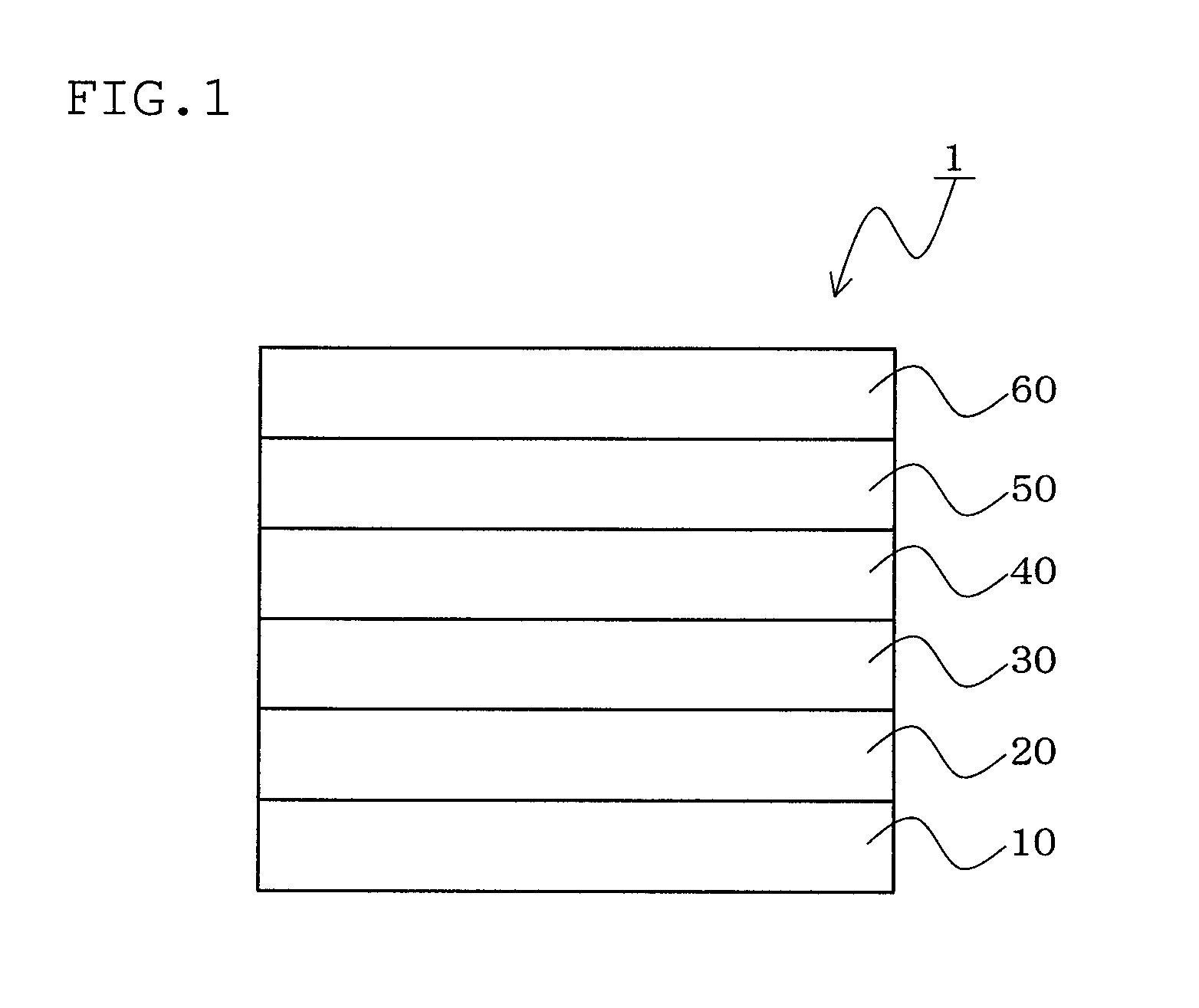

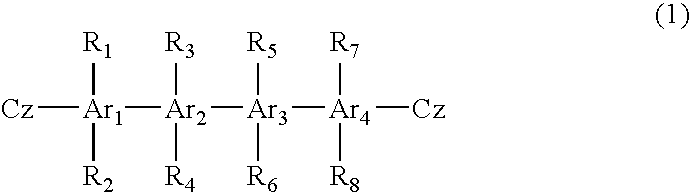

Material for organic electroluminescent device and organic electroluminescent device using same

ActiveUS20070128467A1Solve low luminous efficiencyImprove heat resistanceGroup 4/14 element organic compoundsDischarge tube luminescnet screensOrganic filmThin membrane

Provided is a material for an organic electroluminescence device, which is composed of a compound having a specific structure; and is capable of providing an organic electroluminescence device having a high luminous efficiency, excellent heat resistance, and a long lifetime while having no pixel defects, and an organic electroluminescence device using the same. The organic electroluminescence device comprises an organic thin film layer composed of one or more layers including at least a light-emitting layer and sandwiched between a cathode and an anode. In the organic electroluminescence device, at least one layer of the organic thin film layer comprises the material for an organic electroluminescence device.

Owner:IDEMITSU KOSAN CO LTD

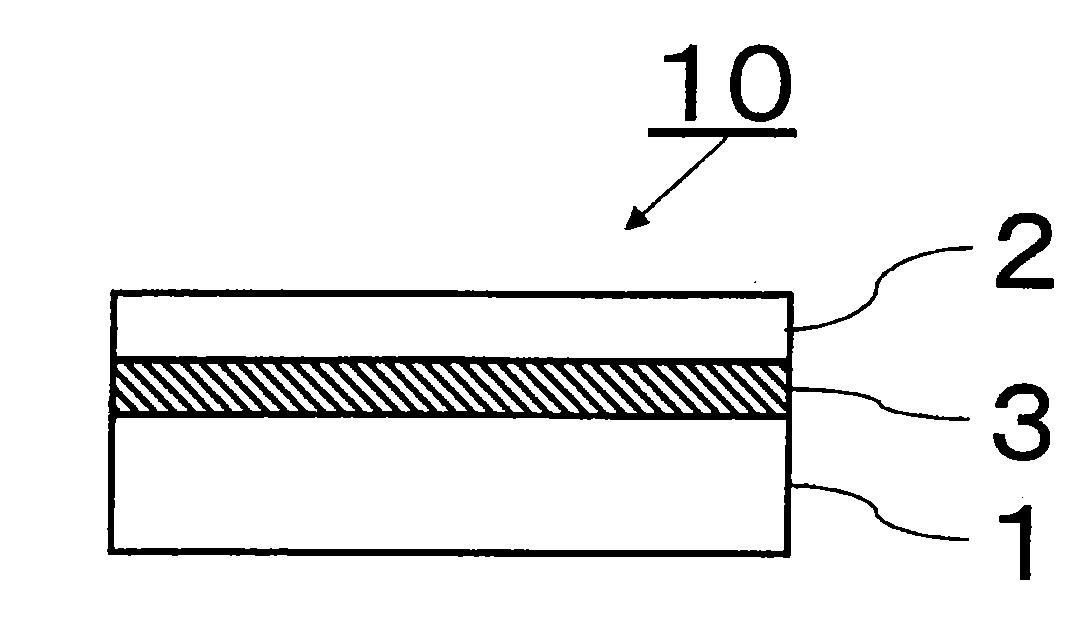

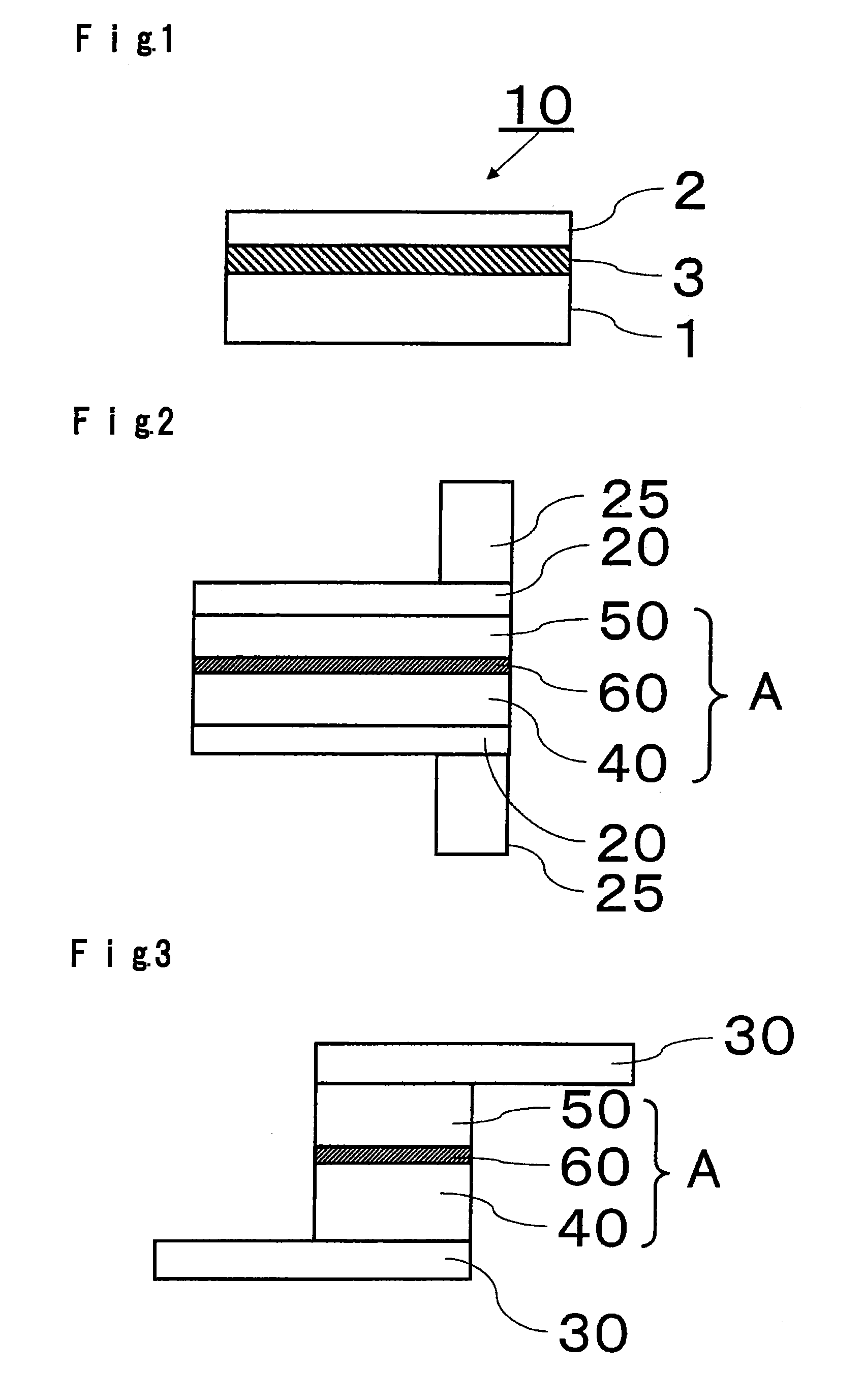

Thin plate glass laminate and process for producing display device using thin plate glass laminate

ActiveUS20080135175A1Easy to removeExcellent adhesive propertyLiquid crystal compositionsSynthetic resin layered productsSilicone resinForeign matter

To provide a thin plate glass laminate of a thin plate glass substrate and a support glass substrate, which suppresses inclusion of bubbles and occurrence of convex defects due to foreign matters, from which the thin plate glass substrate and the support glass substrate are easily separated, and which is excellent in heat resistance, a process for producing a display device using such a thin plate glass laminate, and a silicone for release paper for such a thin plate glass laminate.A thin plate glass laminate formed by laminating a thin plate glass substrate and a support glass substrate, wherein the thin plate glass substrate and the support glass substrate are laminated by means of a silicone resin layer having releasability and non-adhesive properties.

Owner:ASAHI GLASS CO LTD

Electronic component separator and method for producing the same

InactiveUS20050208383A1Improve reliabilityImprove machinabilityHybrid capacitor separatorsCell seperators/membranes/diaphragms/spacersLithiumElectronic component

The present invention provides a separator that, when used in a lithium ion secondary battery, polymer lithium secondary battery, aluminum electrolytic capacitor or electric double-layer capacitor, offers desired levels of various practical characteristics, undergoes minimal heat shrinkage even when overheated, and exhibits high reliability and excellent workability. The electronic component separator proposed by the present invention comprises a porous base made of a substance having a melting point of 180° C. or above, and a resin structure provided on at least one side of and / or inside the porous base, and the porous base and / or resin structure contains filler grains.

Owner:TOMOEGAWA PAPER CO LTD

Microbolometer infrared sensors

InactiveUS6359276B1High mechanical strengthReduce residual stressSolid-state devicesMaterial analysis by optical meansThermal isolationMicrobolometer

A microbolometer infrared sensor utilizes a porous silicon bridge as its thermal isolating and mechanical supporting structure. Porous silicon formed from single crystal silicon on lightly doped p-type silicon has a thermal conductivity lower than silicon dioxide and silicon nitride, and, therefore, when used as a mechanical supporting structure, can offer better thermal isolation performance. The porous silicon layer can be fabricated much thicker than silicon dioxide and silicon nitride membranes since there is almost no residual stress therein. A thicker porous silicon bridge has higher mechanical support strength. The porous silicon process is a low temperature process. It facilitates a fabrication strategy of microelectronics first and micromechanics last.

Owner:TU XIANG ZHENG

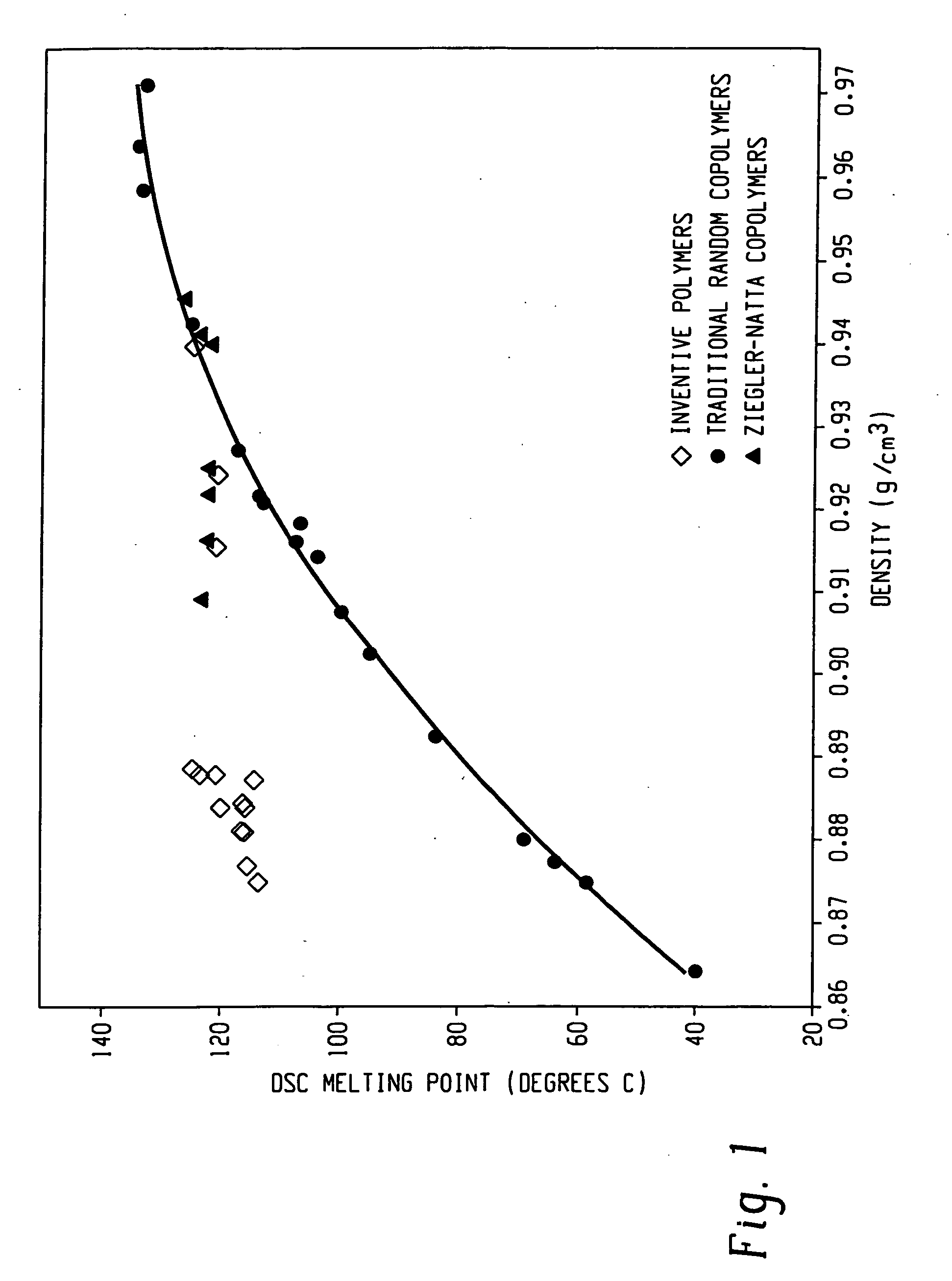

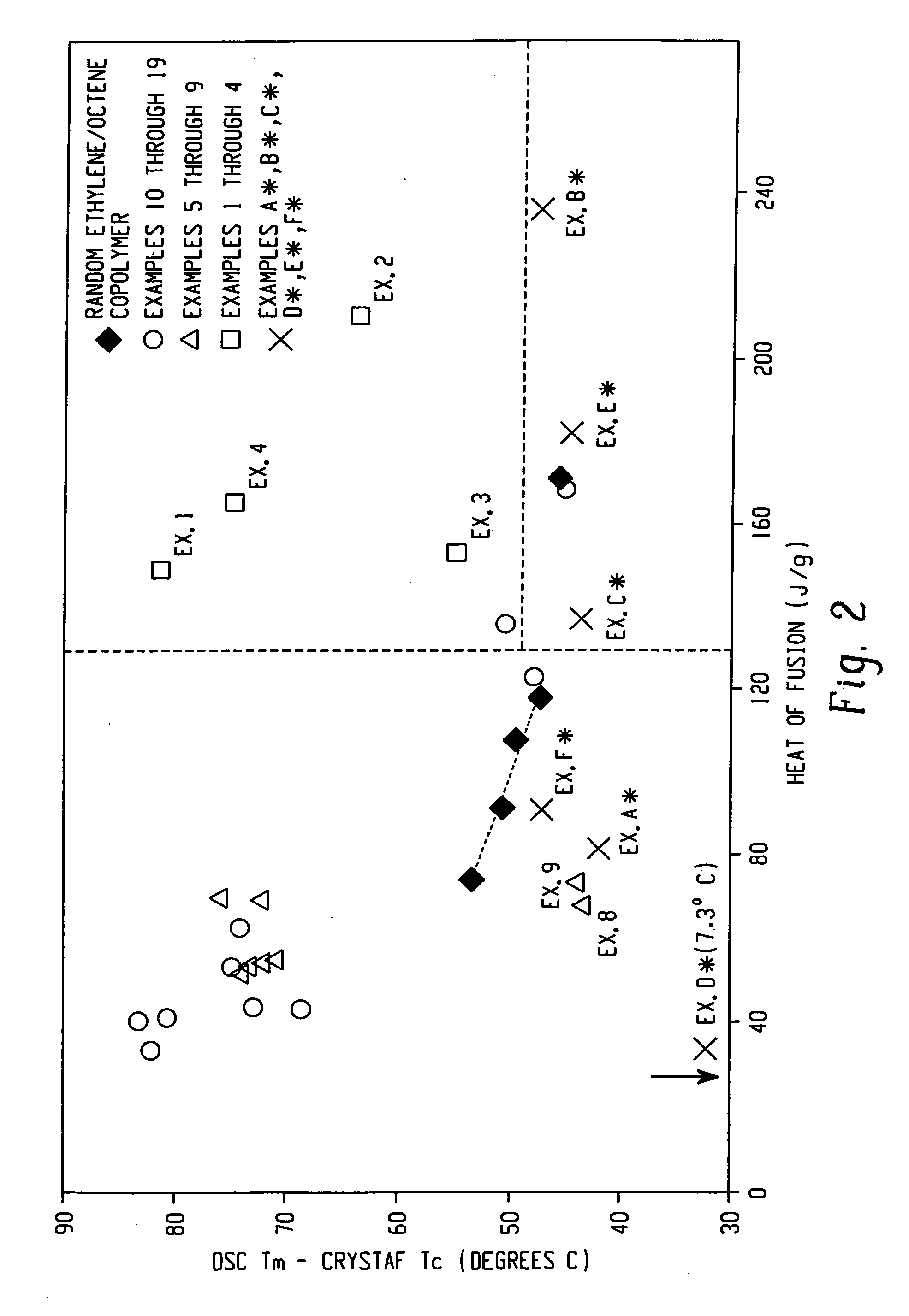

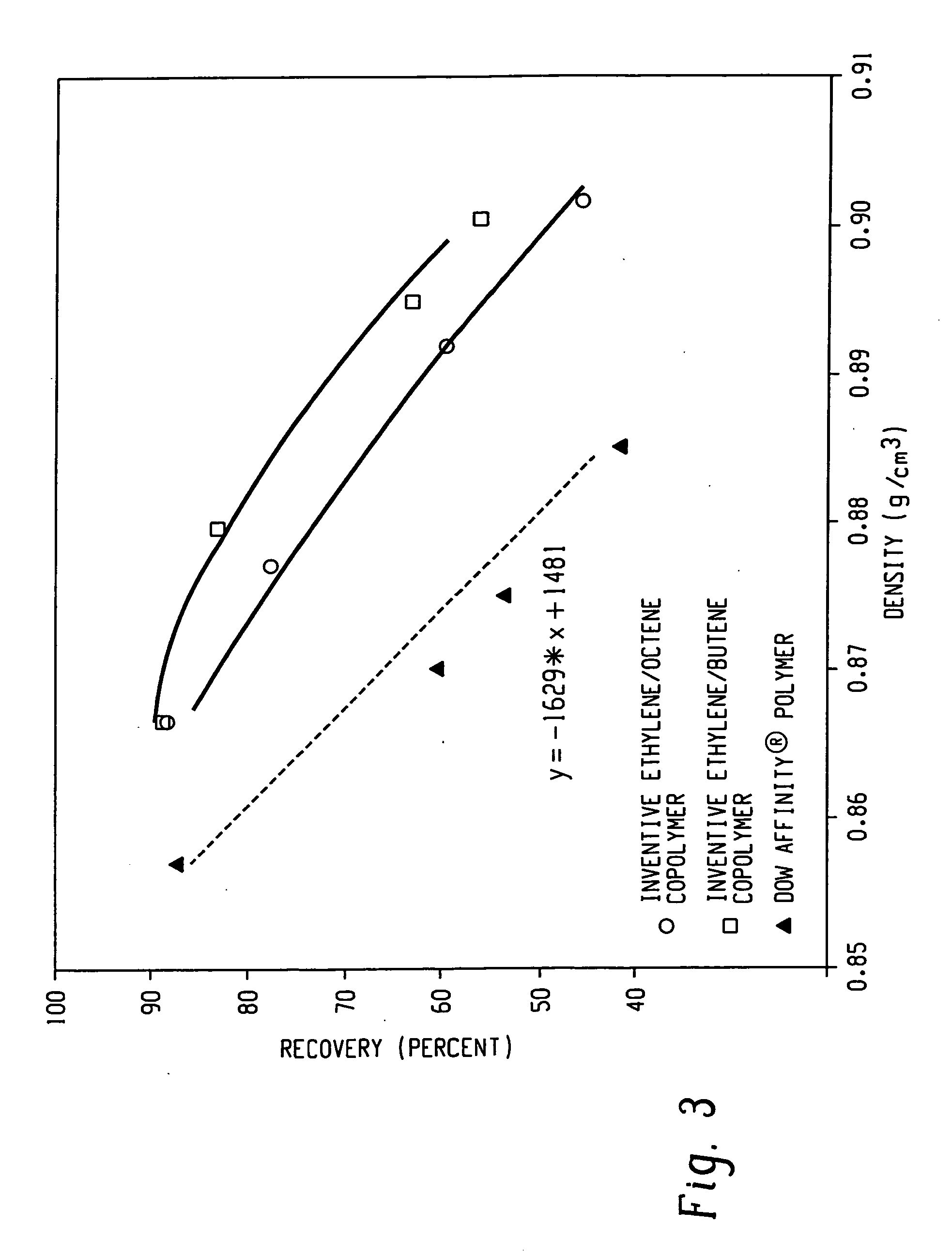

Compositions of ethylene/alpha-olefin multi-block interpolymer for elastic films and laminates

ActiveUS20070078222A1Easy to processHigh tensile strengthPersonal careSynthetic resin layered productsPolyolefinHigh pressure

This invention relates to polyolefin compositions. In particular, the invention pertains to elastic polymer compositions that can be more easily processed on cast film lines, extrusion lamination or coating lines. The compositions of the present invention preferably comprise an elastomeric polyolefin resin and a high pressure low density type resin.

Owner:DOW GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com