Patents

Literature

128results about How to "Deposition stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

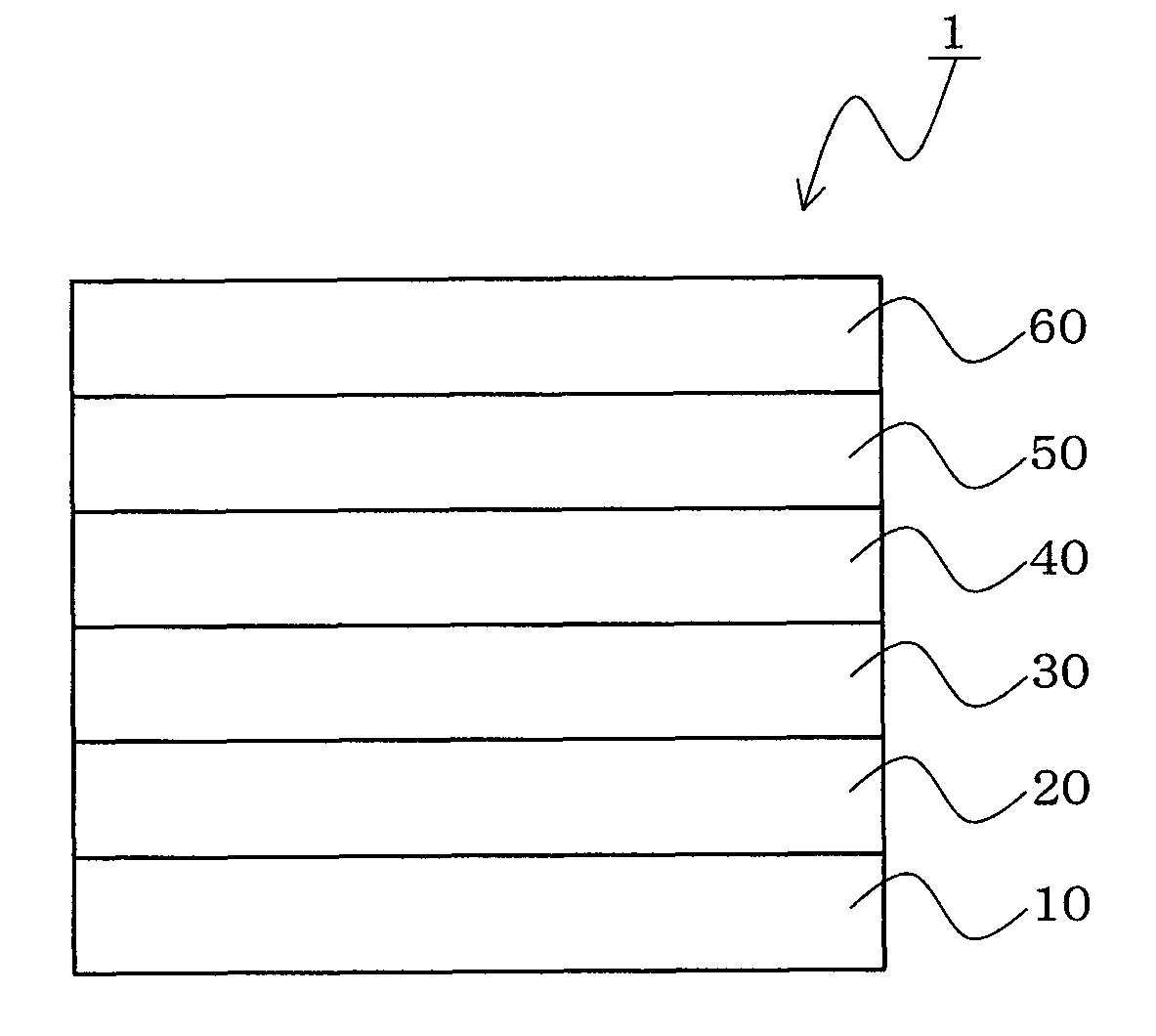

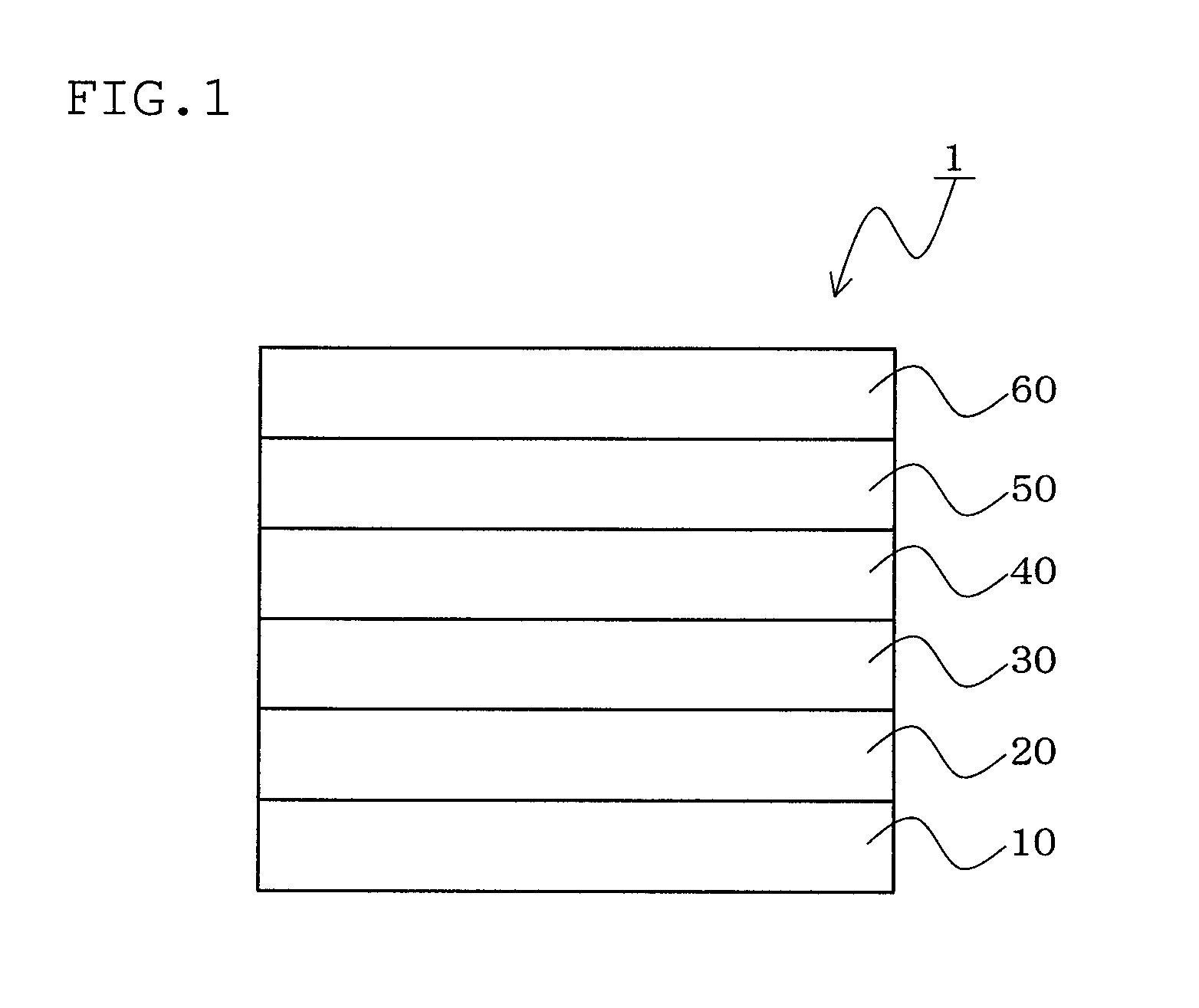

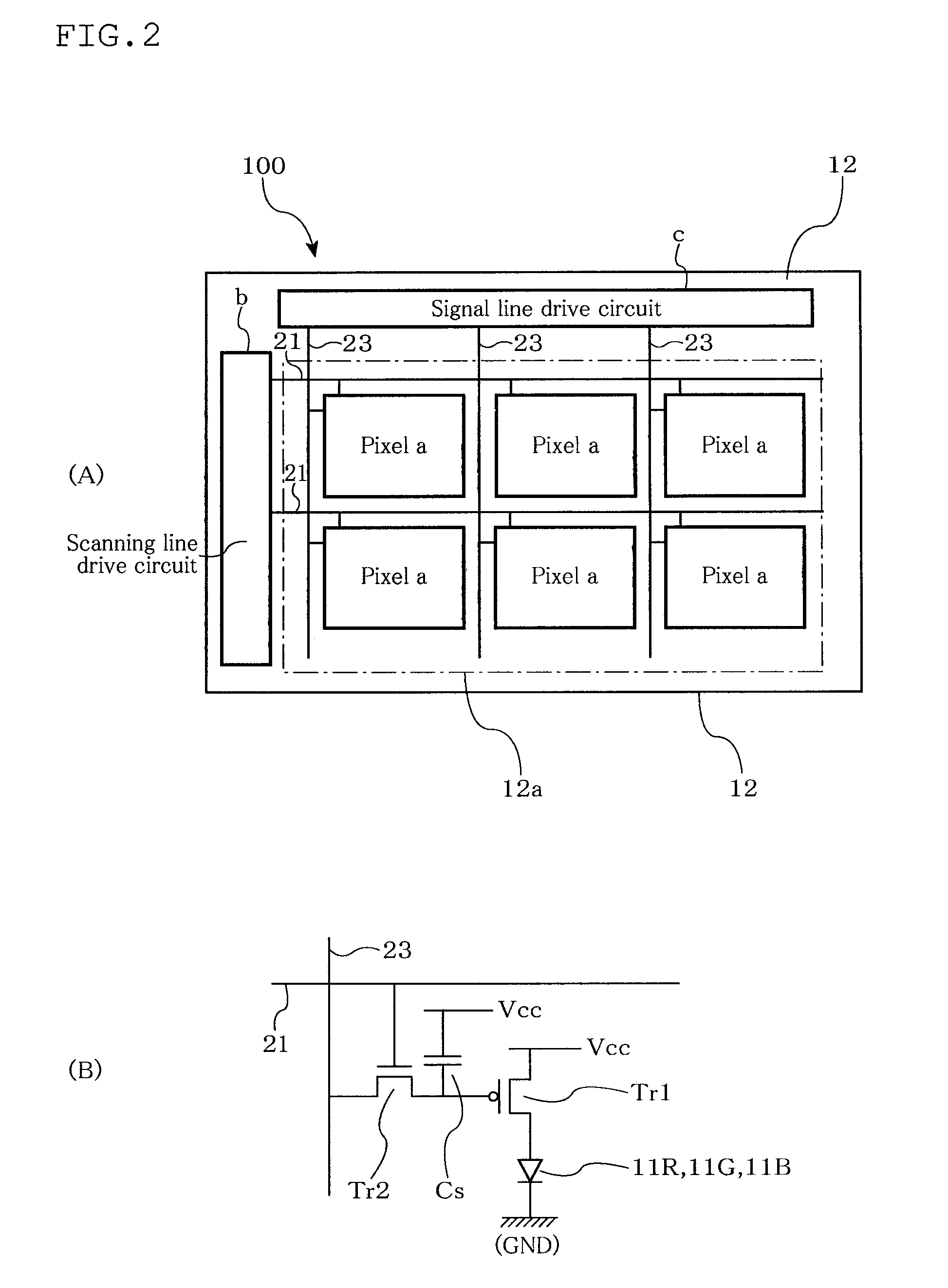

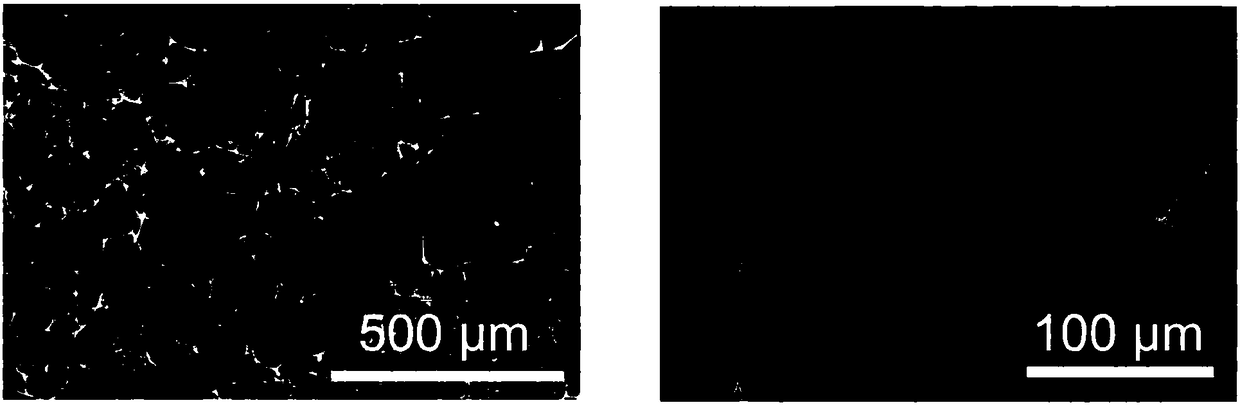

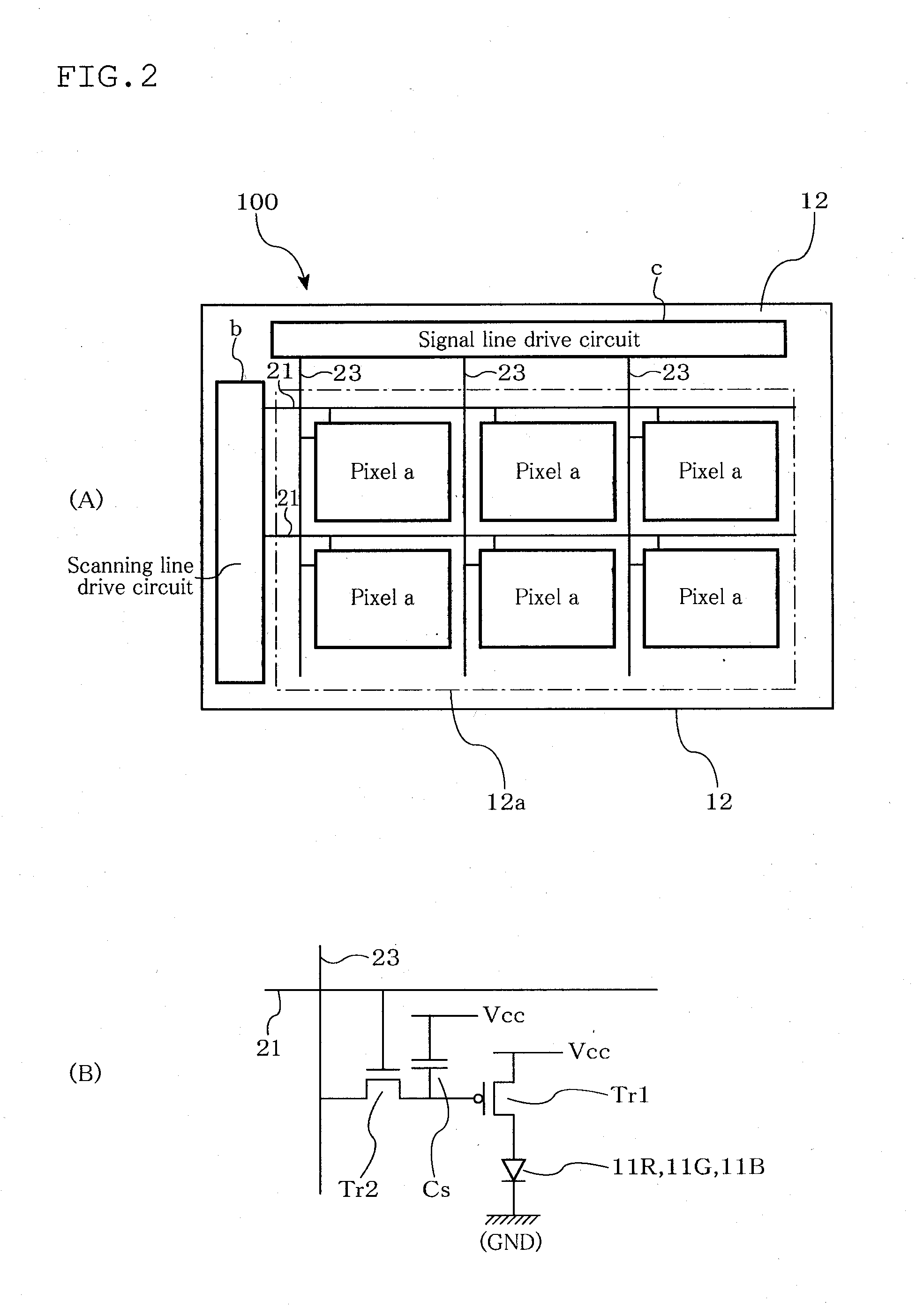

Material for organic electroluminescent device, organic electroluminescent device, and organic electroluminescent display

ActiveUS8044390B2Improve heat resistanceDeposition stabilityOrganic chemistryElectroluminescent light sourcesHalogenHydrogen

A material for an organic electroluminescent device including an imine derivative represented by the following formula (Ia) or (Ib),wherein Y1 to Y4 are independently a carbon atom or a nitrogen atom; R1 to R4 are independently hydrogen, an alkyl group, an aryl group, a heterocycle, a halogen atom, a fluoroalkyl group or a cyano group; and R1 and R2, or R3 and R4 may be bonded together to form a ring.

Owner:IDEMITSU KOSAN CO LTD +1

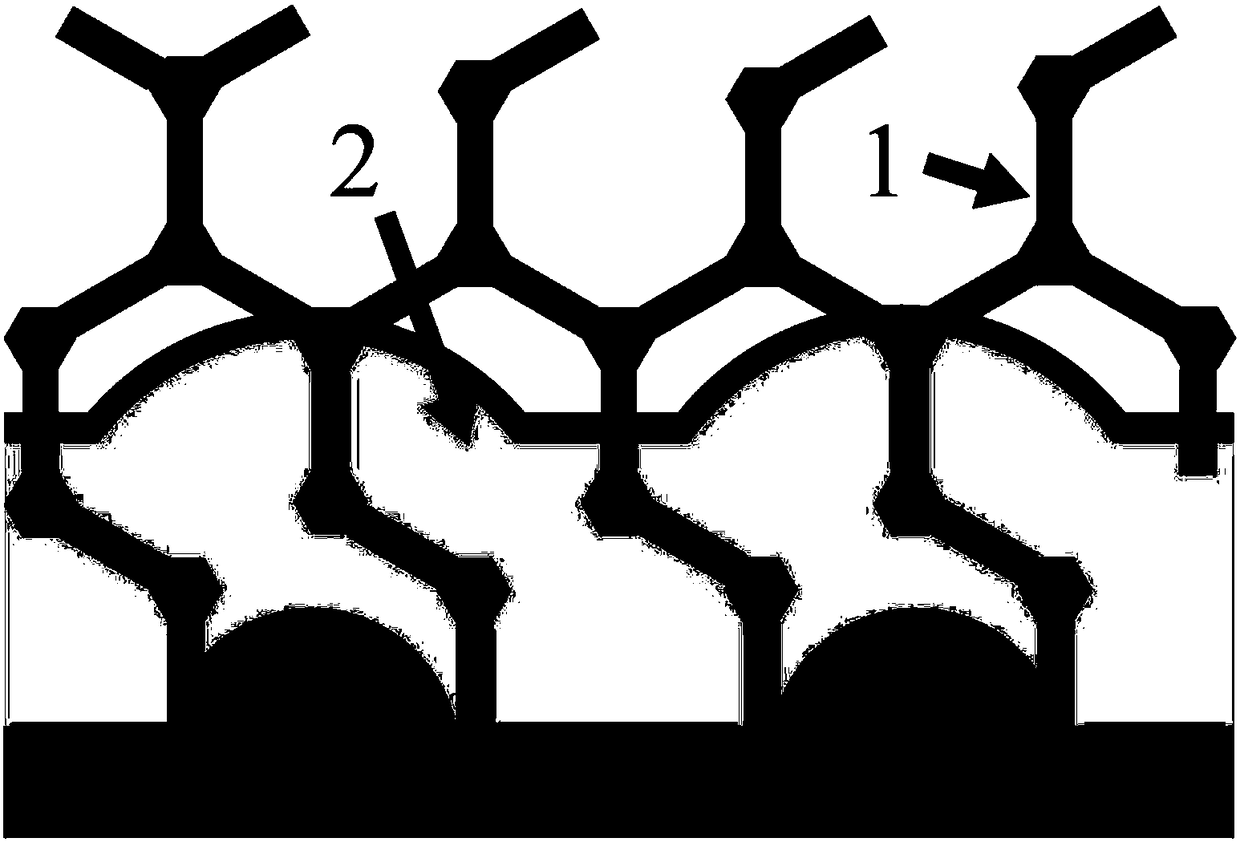

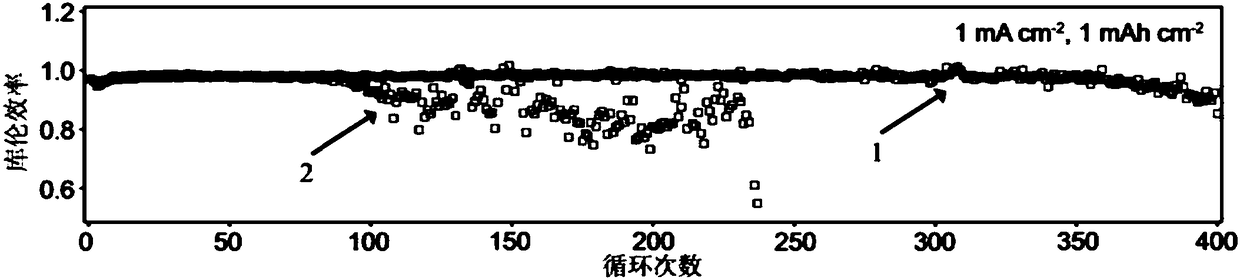

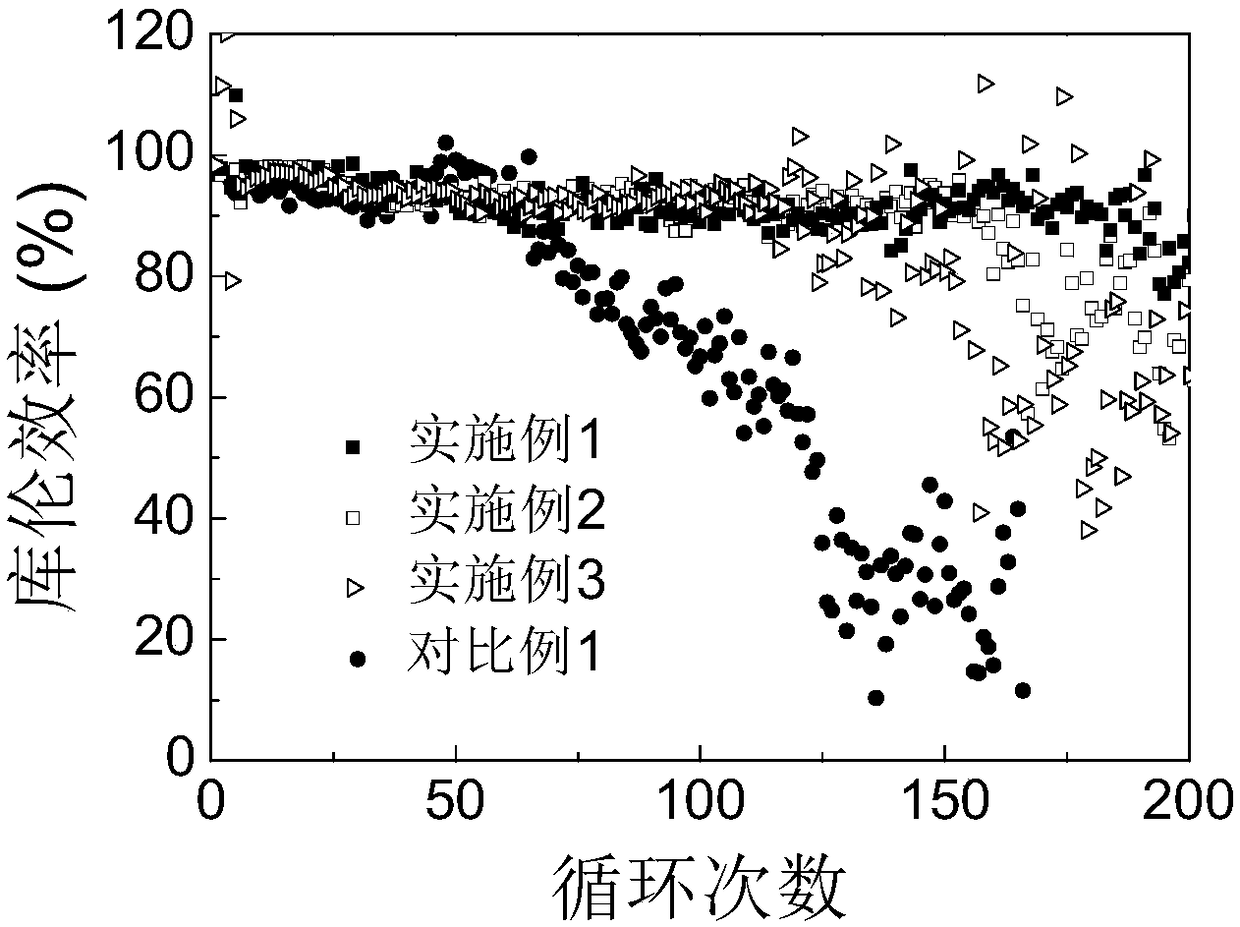

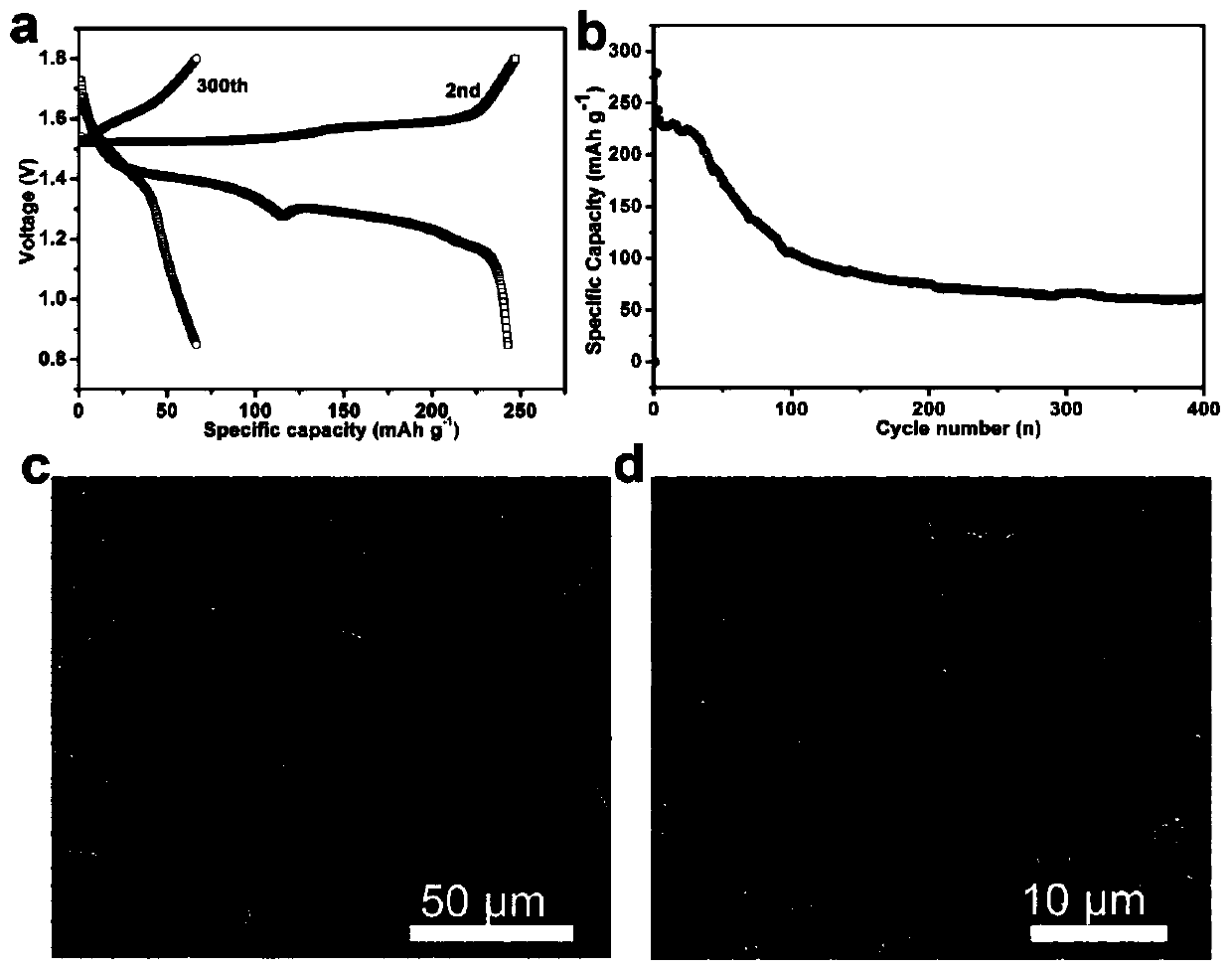

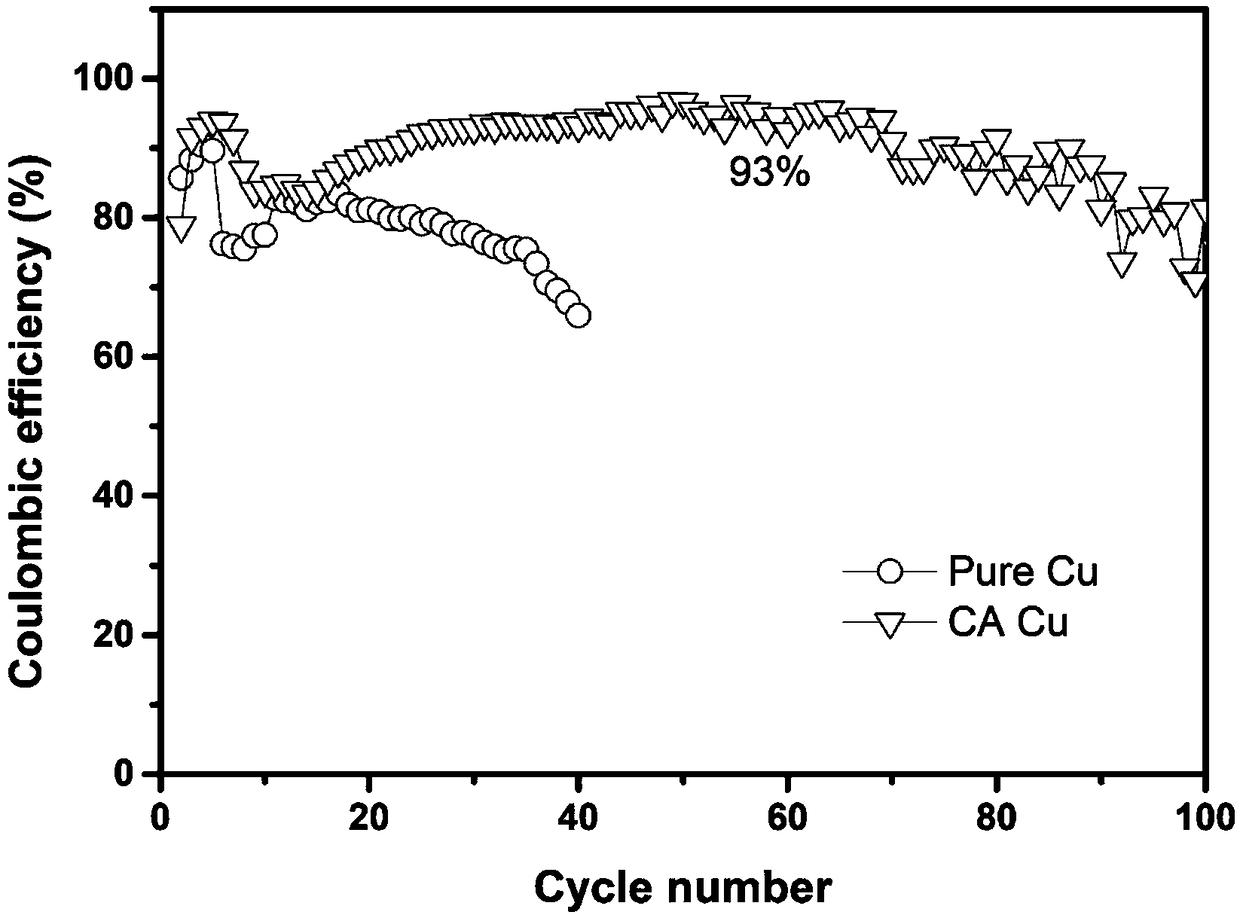

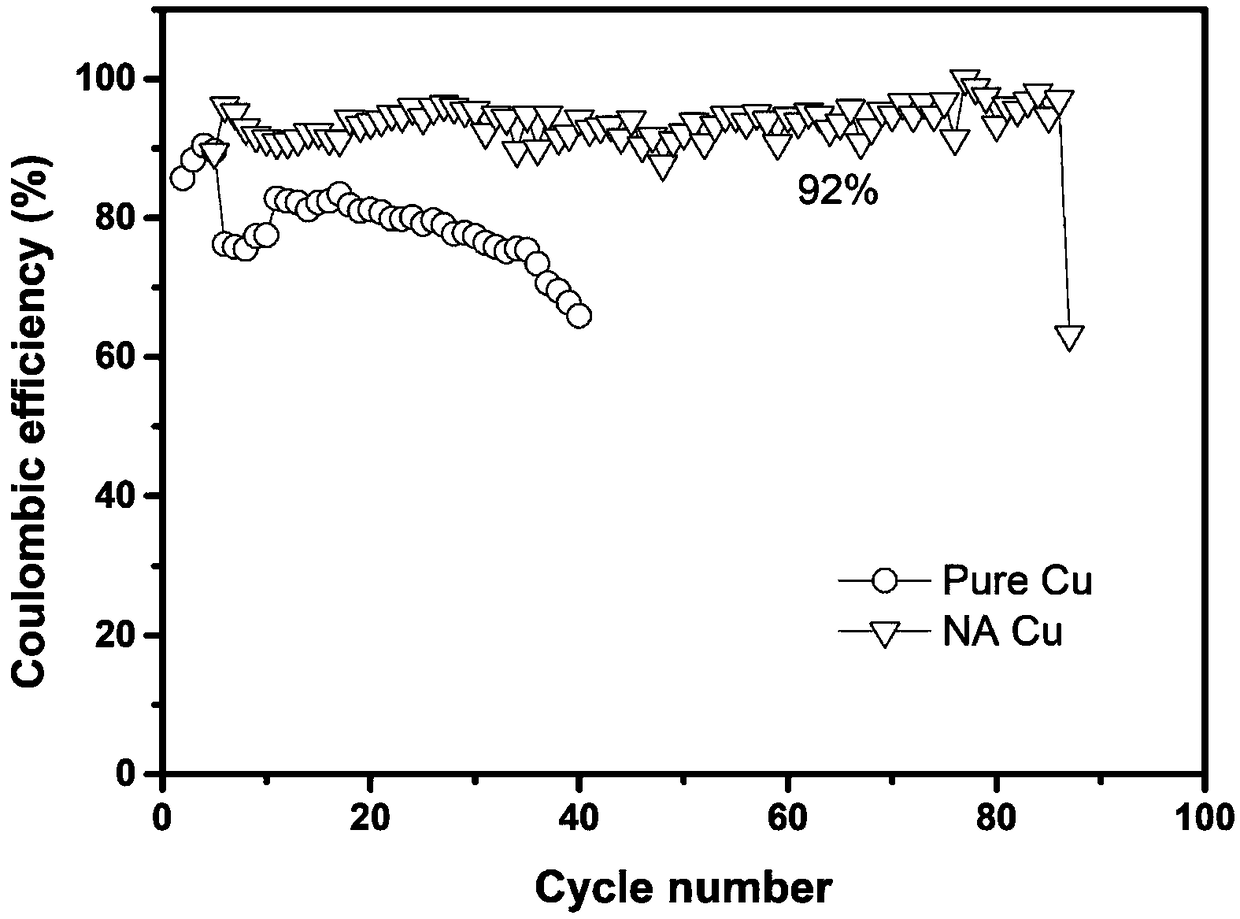

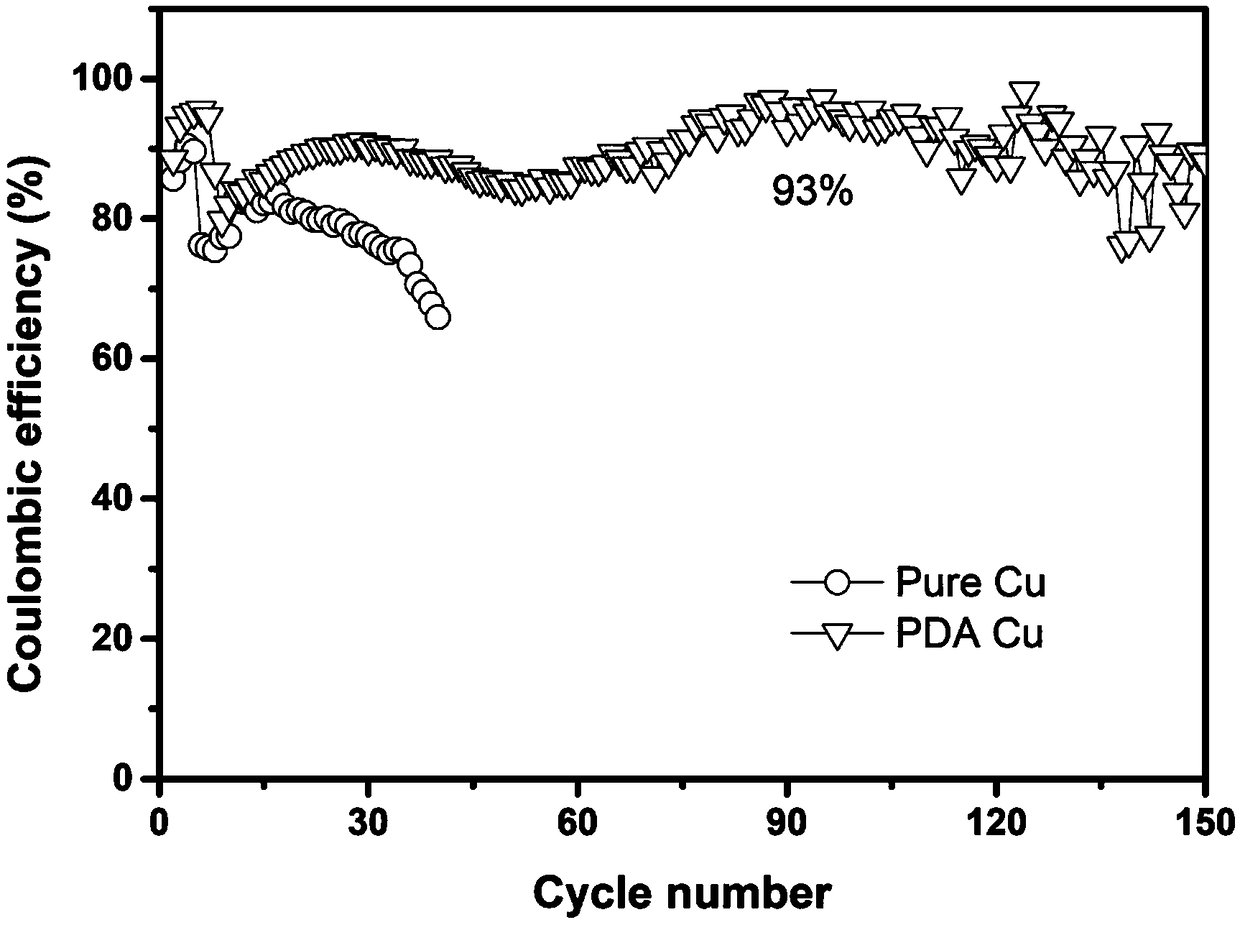

Anode material for lithium metal battery as well as preparation method and application of anode material

PendingCN108232117AImprove Coulombic efficiencyImprove securityCell electrodesLi-accumulatorsPolyvinylidene difluoridePolyvinylidene fluoride

The invention discloses an anode material for a lithium metal battery. The anode material comprises a current collector and a carrier which is in tight fit with the current collector, wherein the carrier has a three-dimensional framework structure; a gap of the three-dimensional framework structure is filled with lithium metal; the carrier is selected from at least one of polymelamine, polyacrylonitrile, polyaniline, polyimide, polyvinylidene fluoride and polytetrafluoroethylene. The anode material disclosed by the invention has the advantages that a nonconductive polymer with the three-dimensional framework structure is used as the carrier, and stable deposition of lithium ions is realized by using interaction of functional groups contained in the carrier and the lithium ions; meanwhile,volumetric expansion is inhibited, internal stress of the battery is relieved, and thereby the aim of inhibiting growth of lithium dendrites is achieved. The coulombic efficiency, the safety of the lithium ion battery obtained by assembling the anode material prepared disclosed by the invention is remarkably improved and cycle life is obviously prolonged.

Owner:ZHEJIANG UNIV

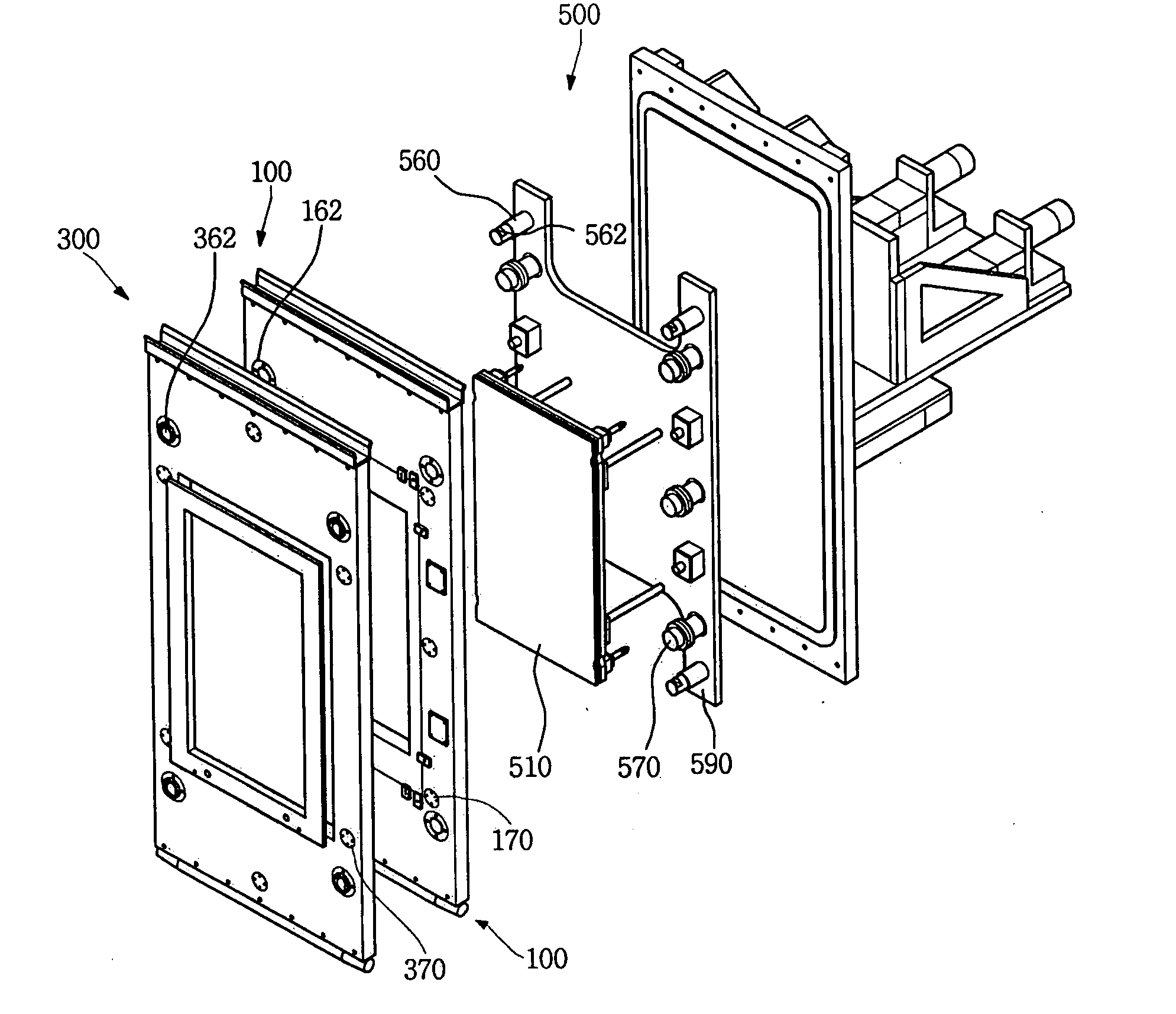

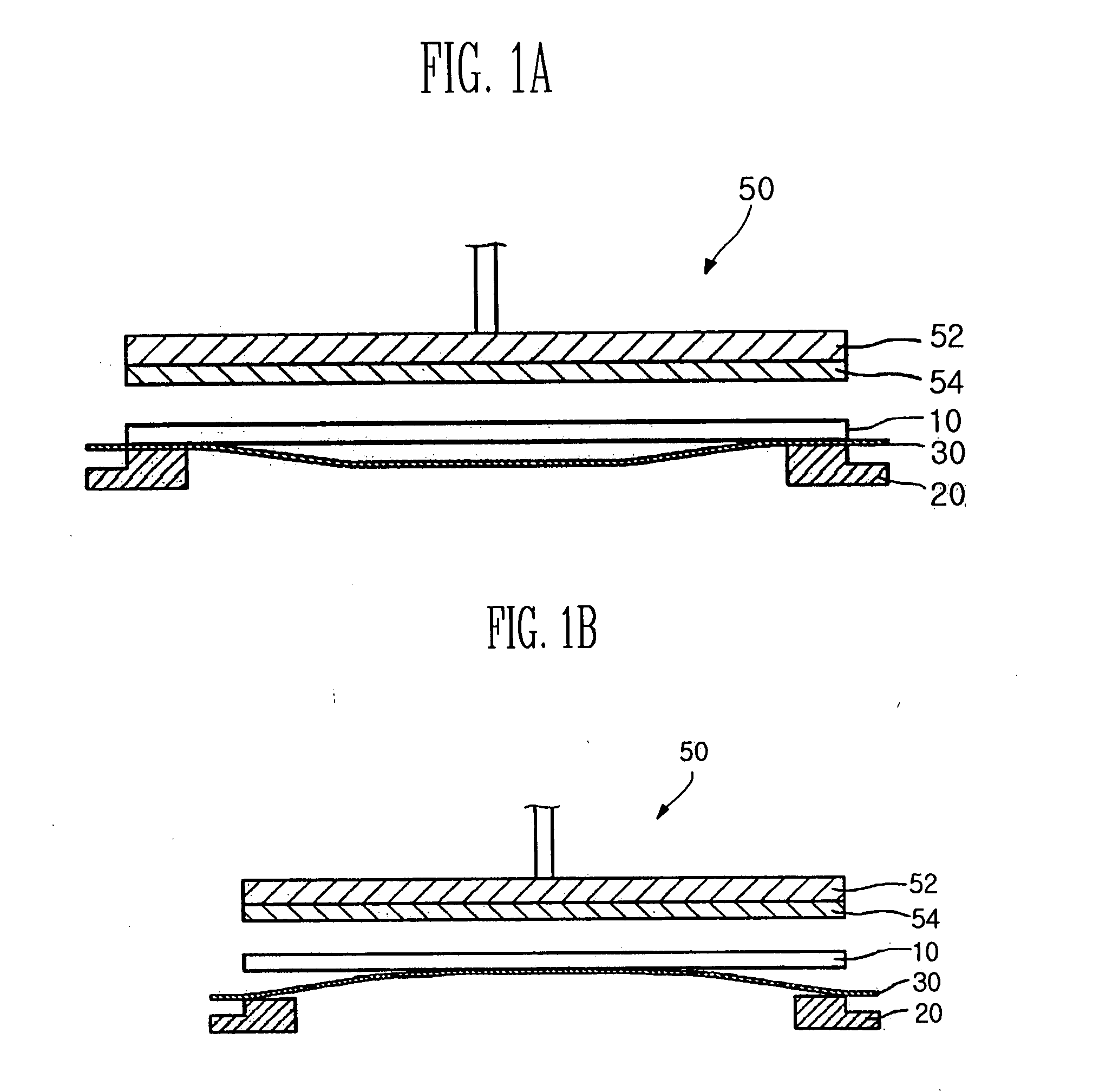

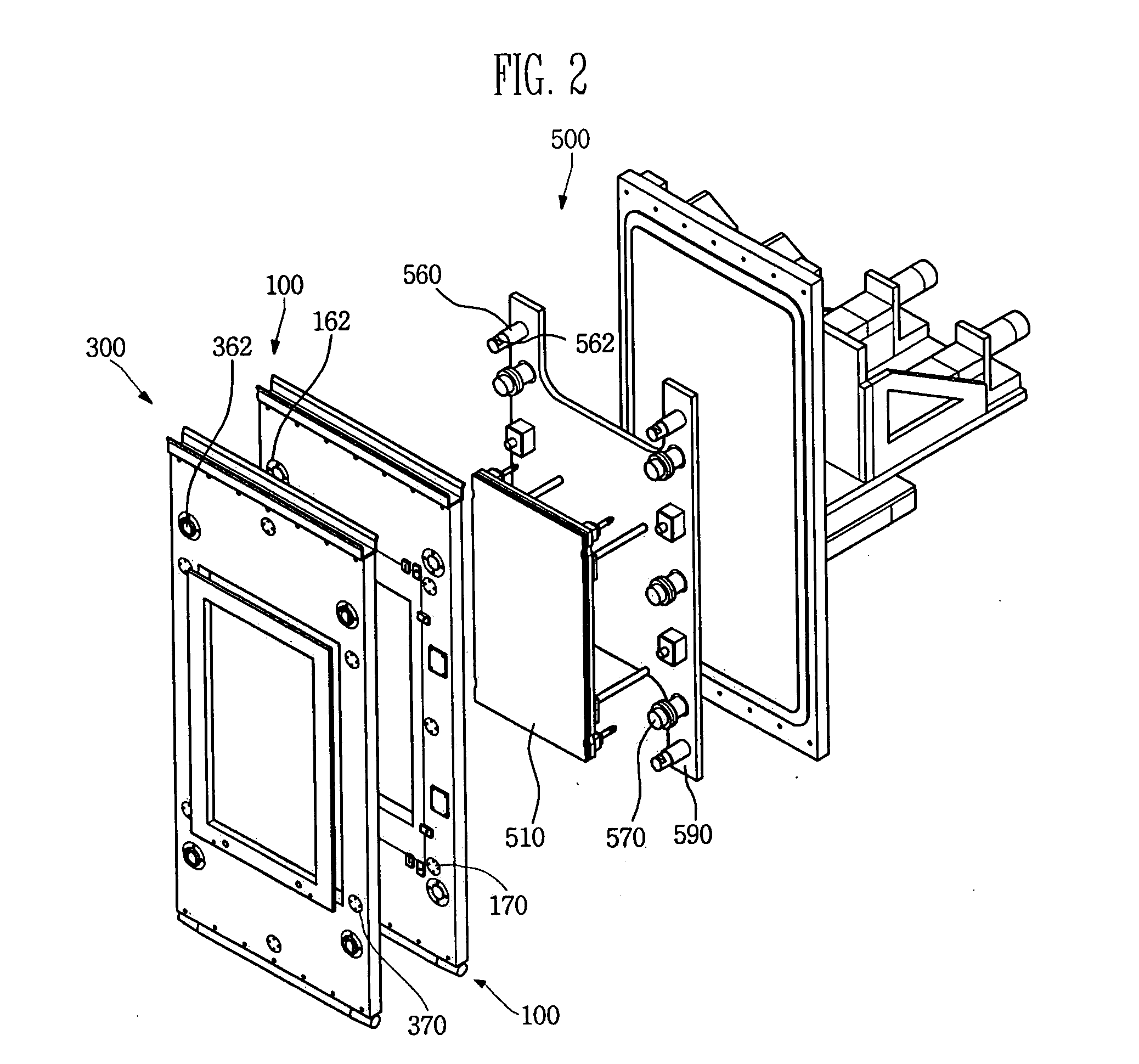

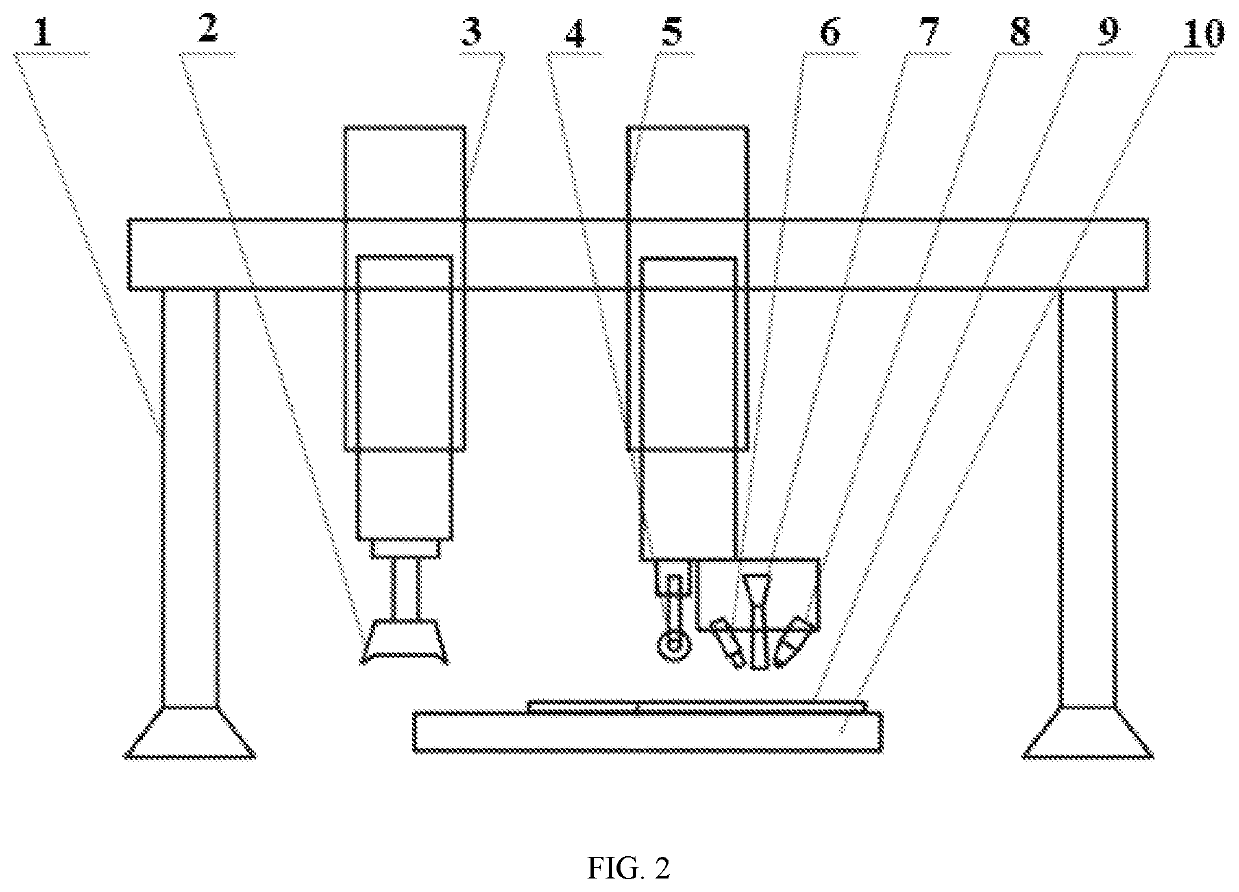

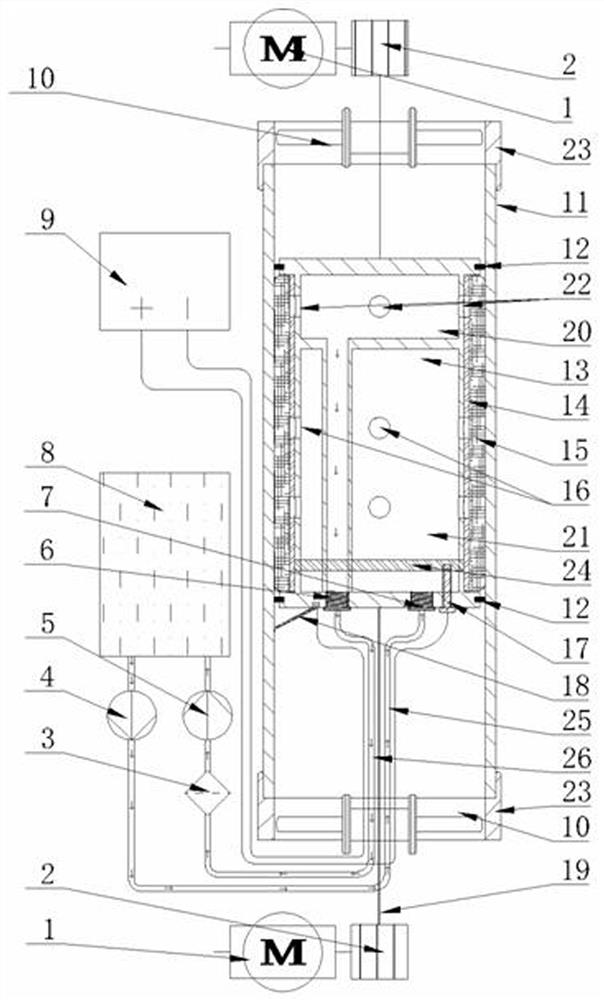

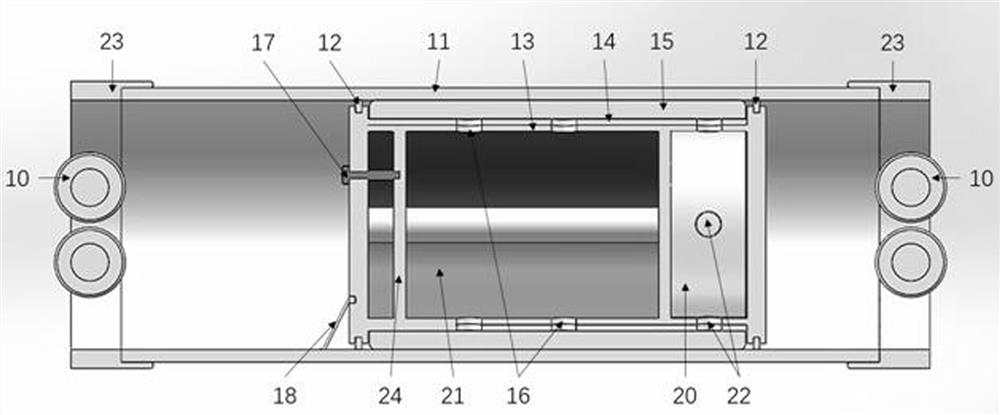

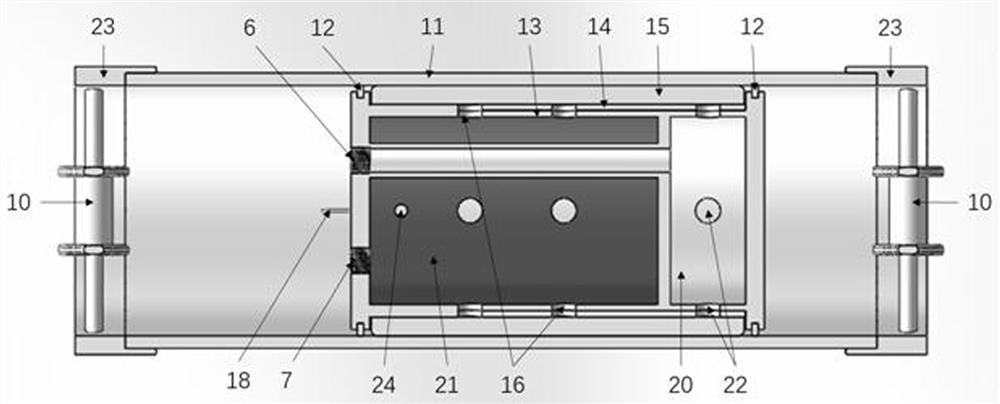

Alignment system, vertical tray transporting assembly, and deposition apparatus with the same

InactiveUS20060150910A1Minimize impactEnsuring sufficient uniformityVacuum evaporation coatingSputtering coatingEngineeringDeposition process

An alignment system, a vertical tray transporting assembly and a deposition apparatus having the same allow alignment of high precision, and perform a stable deposition process in a short period of time, minimize the effect of fine particles during transportation, and secure a sufficient uniformity of a mask by fixing and supporting a vertically disposed substrate using a fixing holder member and an auxiliary attaching member in a tray of a vertical in-line deposition alignment system.

Owner:SAMSUNG DISPLAY CO LTD

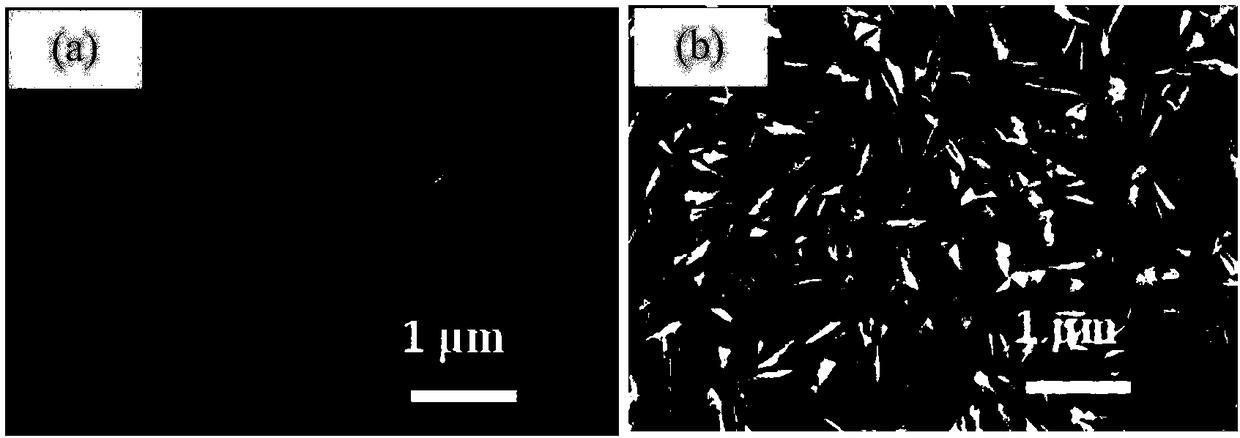

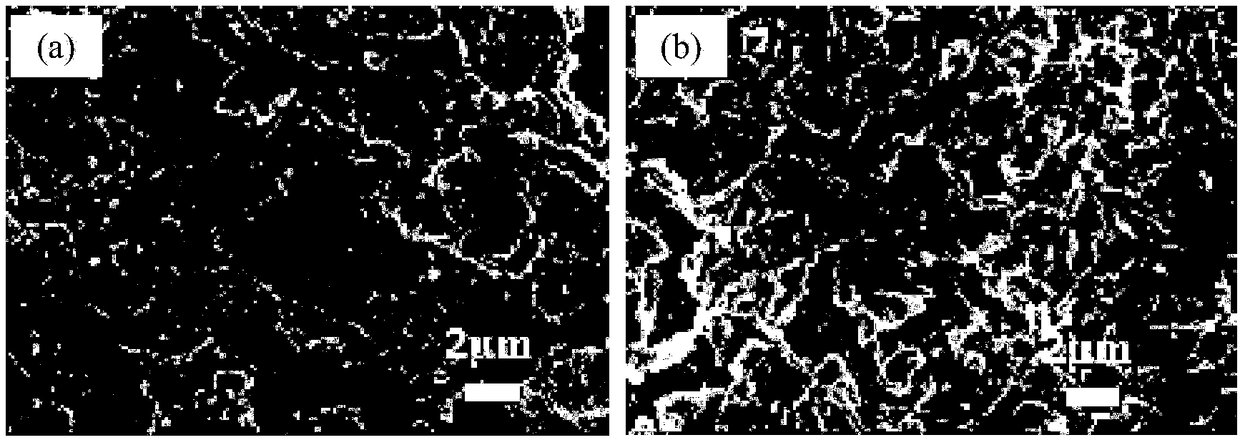

Stable lithium metal negative electrode

InactiveCN108428858AFacilitates ion transportAchieve even distributionElectrode carriers/collectorsNon-aqueous electrolyte accumulator electrodesLithium dendriteCurrent collector

The invention belongs to the technical field of a battery and particularly relates to a stable lithium metal negative electrode. The stable lithium metal negative electrode comprises a negative electrode current collector and a negative active material layer loaded on the surface of the current collector; the negative active material layer is a lithium metal layer; the negative electrode current collector comprises a current collector body and a lithium-philic nanometer array growing on the current collector body in situ; the thickness of the lithium-philic nanometer array is 0.8 <mu>m to 20 <mu>m. Compared with the prior art, the stable lithium metal negative electrode has the following advantages: the lithium-philic nanosheet array is arranged on the current collector body, so that ion transmission is facilitated, uniform distribution of lithium ions can be realized, the affinity of the stable lithium metal negative electrode and the lithium metal can be improved, a lithium-philic nucleation site is provided, and uniform nucleation and stable deposition of the lithium metal in the deposition process are realized. The array structure growing in situ can guarantee to be in tight contact with a copper current collector and reduce the effective current density of the electrode, so that uniform deposition of the lithium metal is realized; the lithium-philic current collector can inhibit the growth of lithium dendrites.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

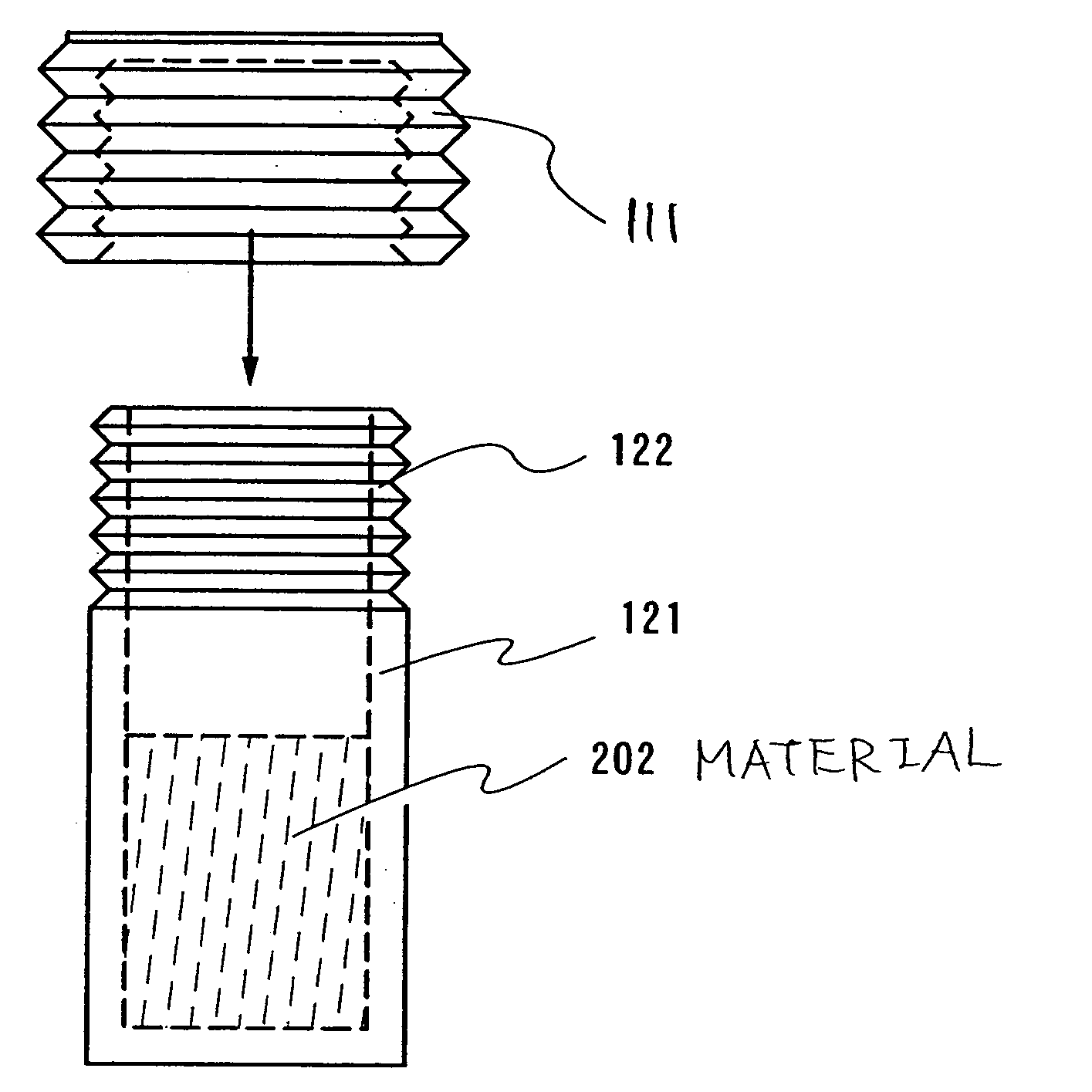

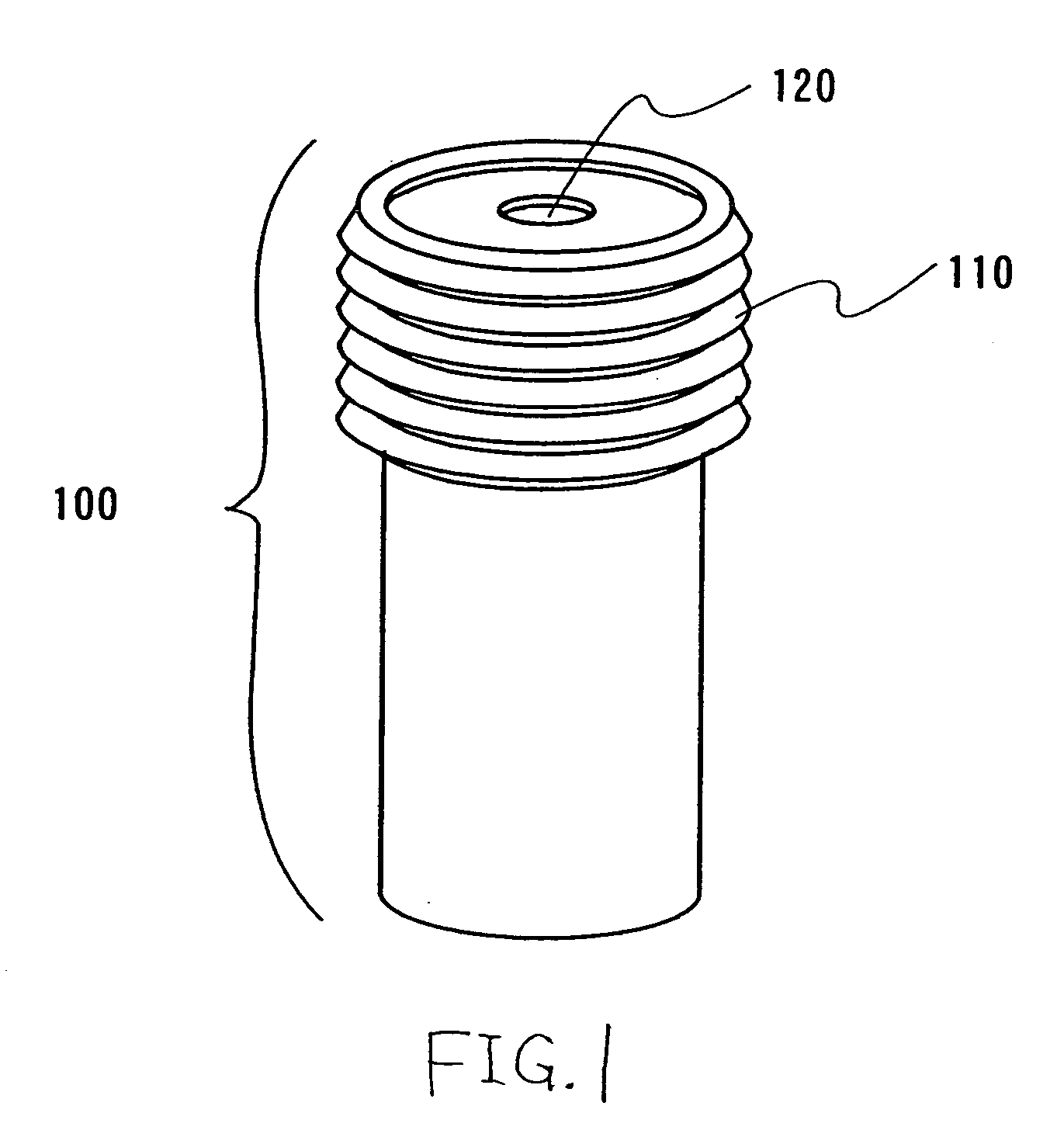

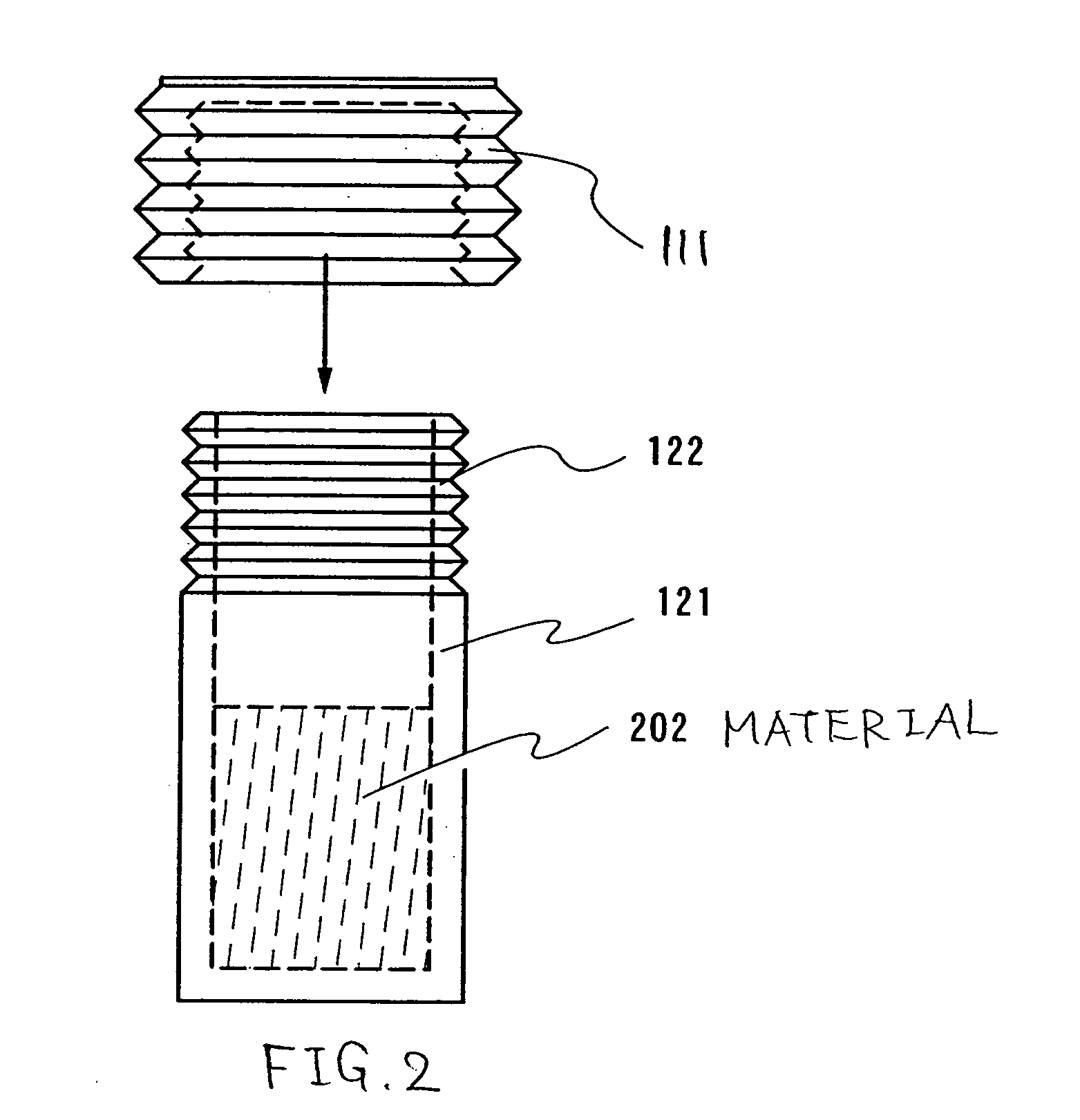

Evaporation container and vapor deposition apparatus

InactiveUS20050022743A1Improve throughputAvoid cloggingSolid-state devicesVacuum evaporation coatingProduction rateGas phase

To provide an evaporation container and a vapor deposition apparatus in which vapor deposition can be performed stably with use of an evaporation container formed of an inexpensive material being easily processed without clogging the material. The side surface of a lid for the evaporation container is provided with an accordion-shaped structure. The lid of the evaporation container is made larger than an opening of an evaporation source such that the lid is directly contacted to a heating portion. According to the structure, the periphery of the opening for the lid is not easily cooled down; and therefore the variation in temperature between the body and the lid of the container is hardly generated. Consequently, an evaporated material hardly clog at the opening, vapor deposition can be stably performed for a long time, thereby increasing productivity.

Owner:SEMICON ENERGY LAB CO LTD

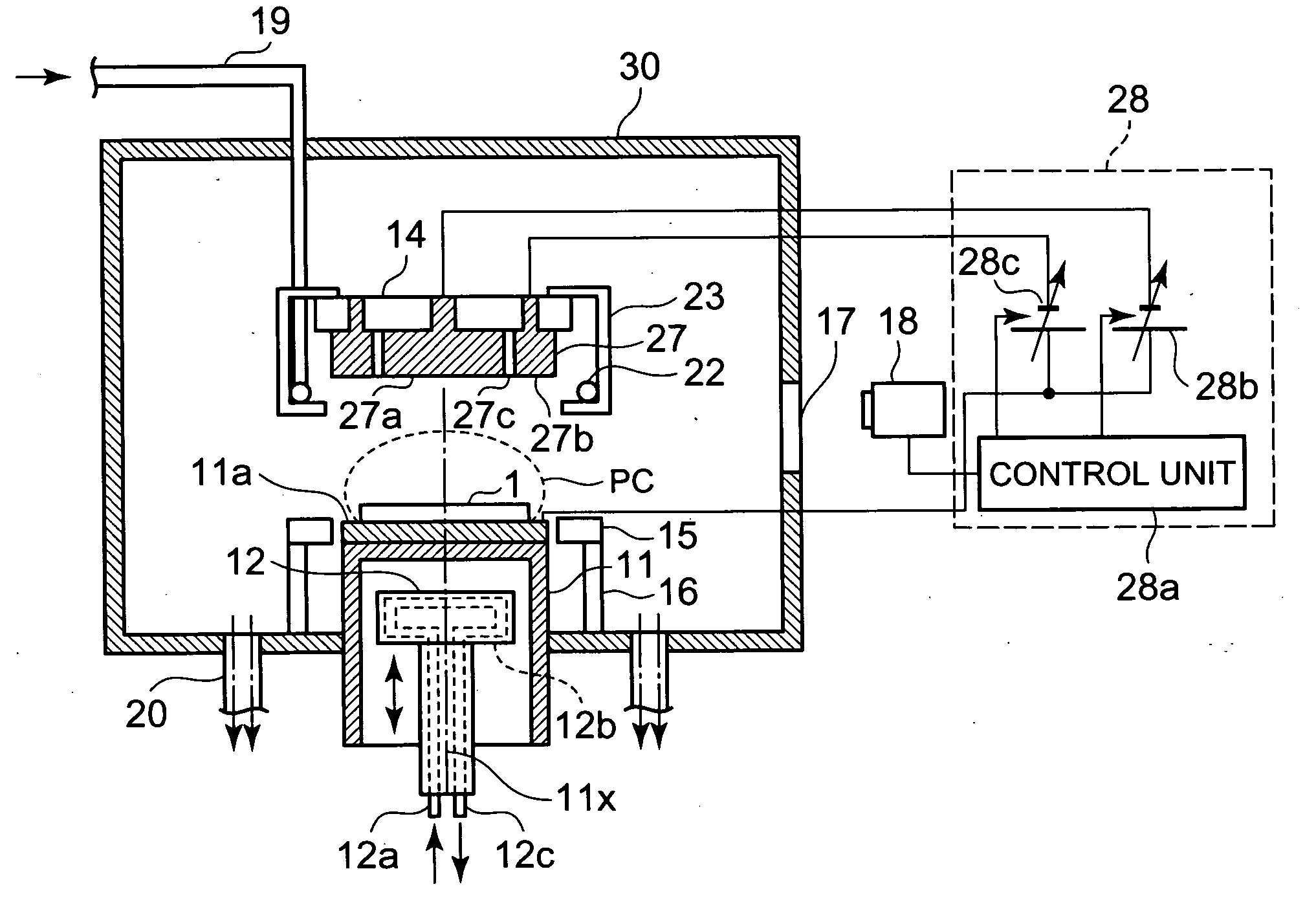

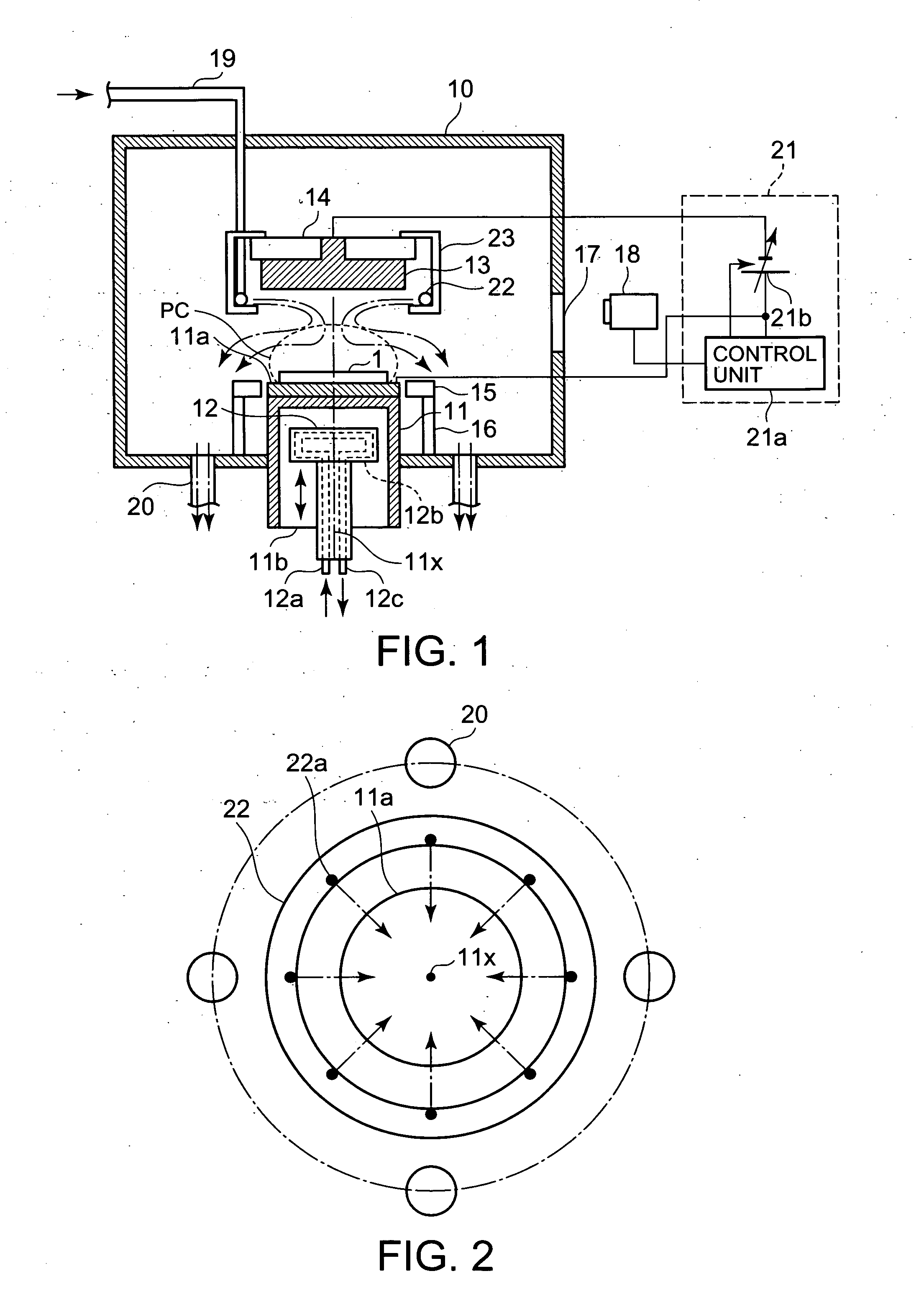

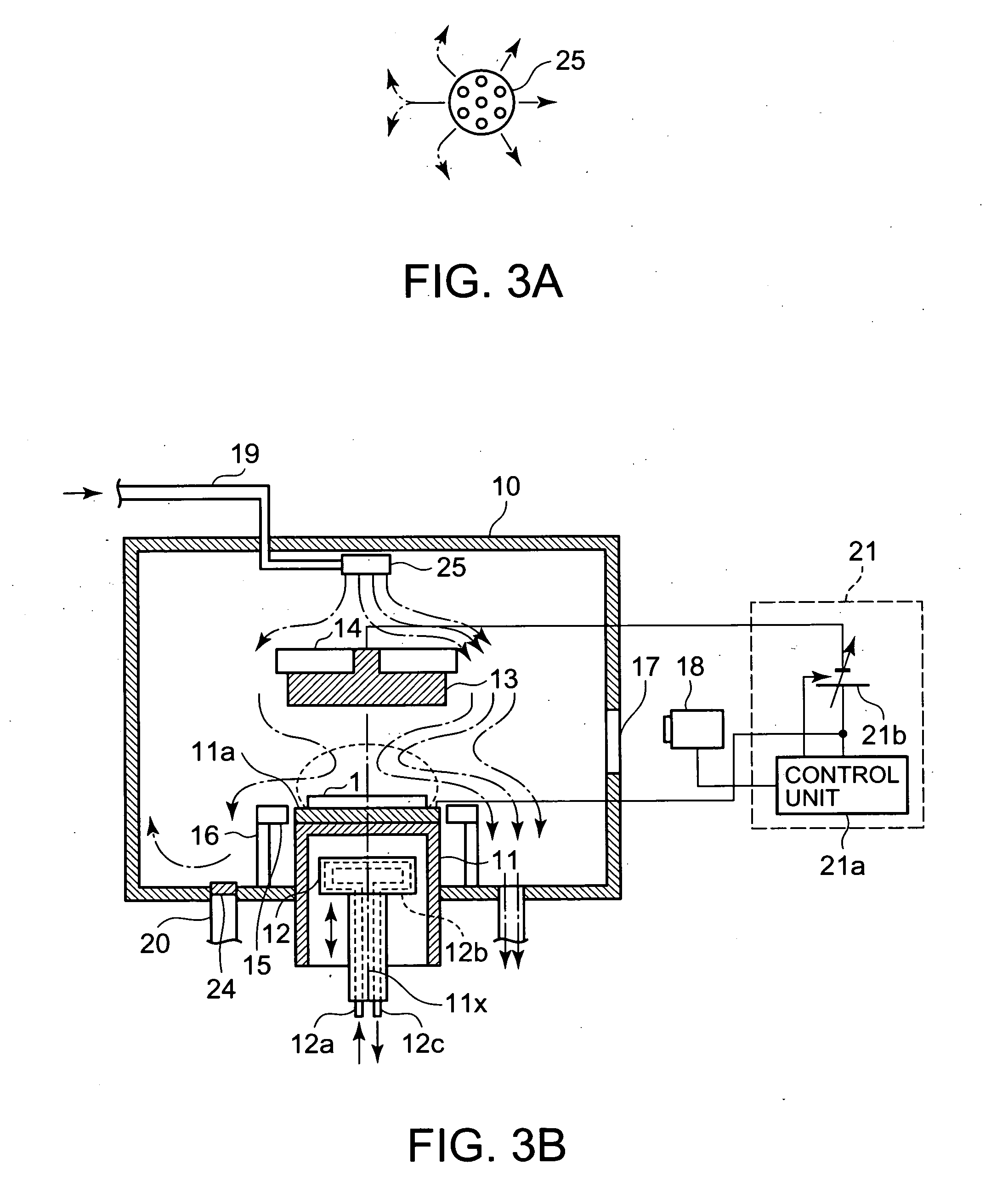

Plasma CVD apparatus and film deposition method

InactiveUS20080226838A1Deposition stabilityUniform supplyElectric discharge tubesChemical vapor deposition coatingEngineeringGas supply

A plasma CVD apparatus includes a first electrode which is disposed in a reacting furnace and on which a substrate is mounted, a second electrode that is disposed above and opposite the first electrode and generates plasma with the first electrode, and a first gas supply nozzle that is disposed at a height between a height of the first electrode in the reacting furnace and a height of the second electrode, and has a plurality of ejection ports formed and arranged in such a way as to surround an area between the first electrode and the second electrode where plasma is generated.

Owner:KOICHI IND PROMOTION CENT +1

Preparation method of nano-silver antibacterial real silk

InactiveCN102936835ALong-lasting antibacterial functionGood washabilityAnimal fibresLong actingFibroin

The invention discloses a preparation method of nano-silver antibacterial real silk. The method comprises the following steps of: placing the un-degummed real silk thread or product in neutral silk proteinate mixed liquid to remove sericin, soaking the product in a silver nitrate aqueous solution, performing padding treatment in plant leaf extract dispersion liquid, taking out the product, and washing, drying or airing to obtain the antibacterial real silk or product with in-situ formation of nano-silver. According to the technical scheme of the invention, the fibril structure of fibroin fiber is partially separated or puffed and then subjected to two-step impregnation to sequentially realize adsorptive fixation, in-situ growth and reduction of silver ions on the real silk surface and in the fiber; the generated nano-silver is permeated and diffused inside and on the surface of the real silk fiber / textile; and the obtained nano-silver antibacterial real silk product has a long-acting antibacterial function and good washing resistance.

Owner:SUZHOU UNIV

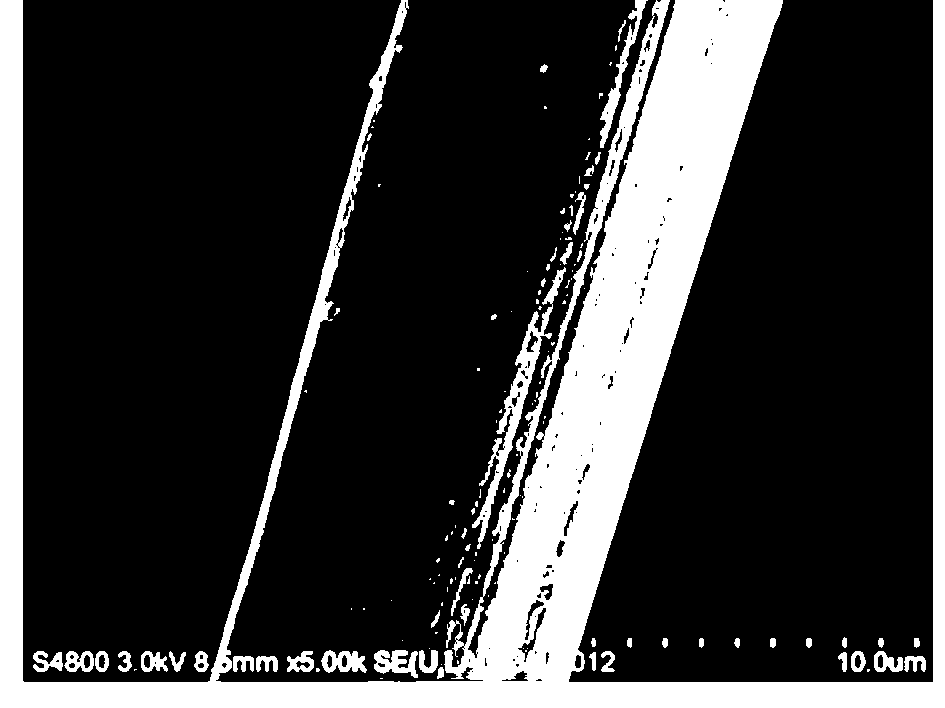

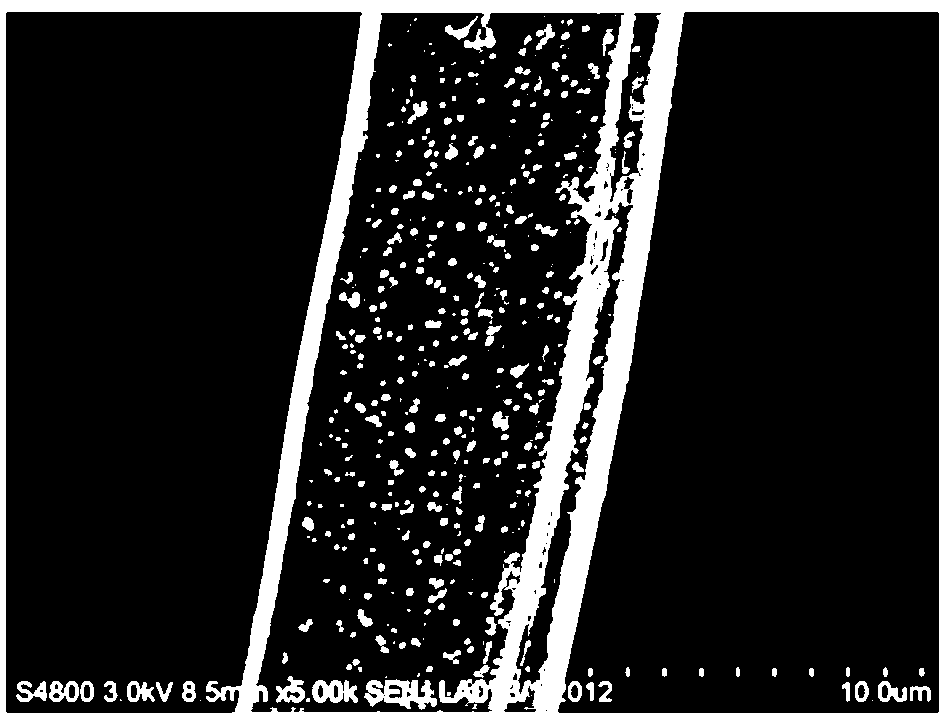

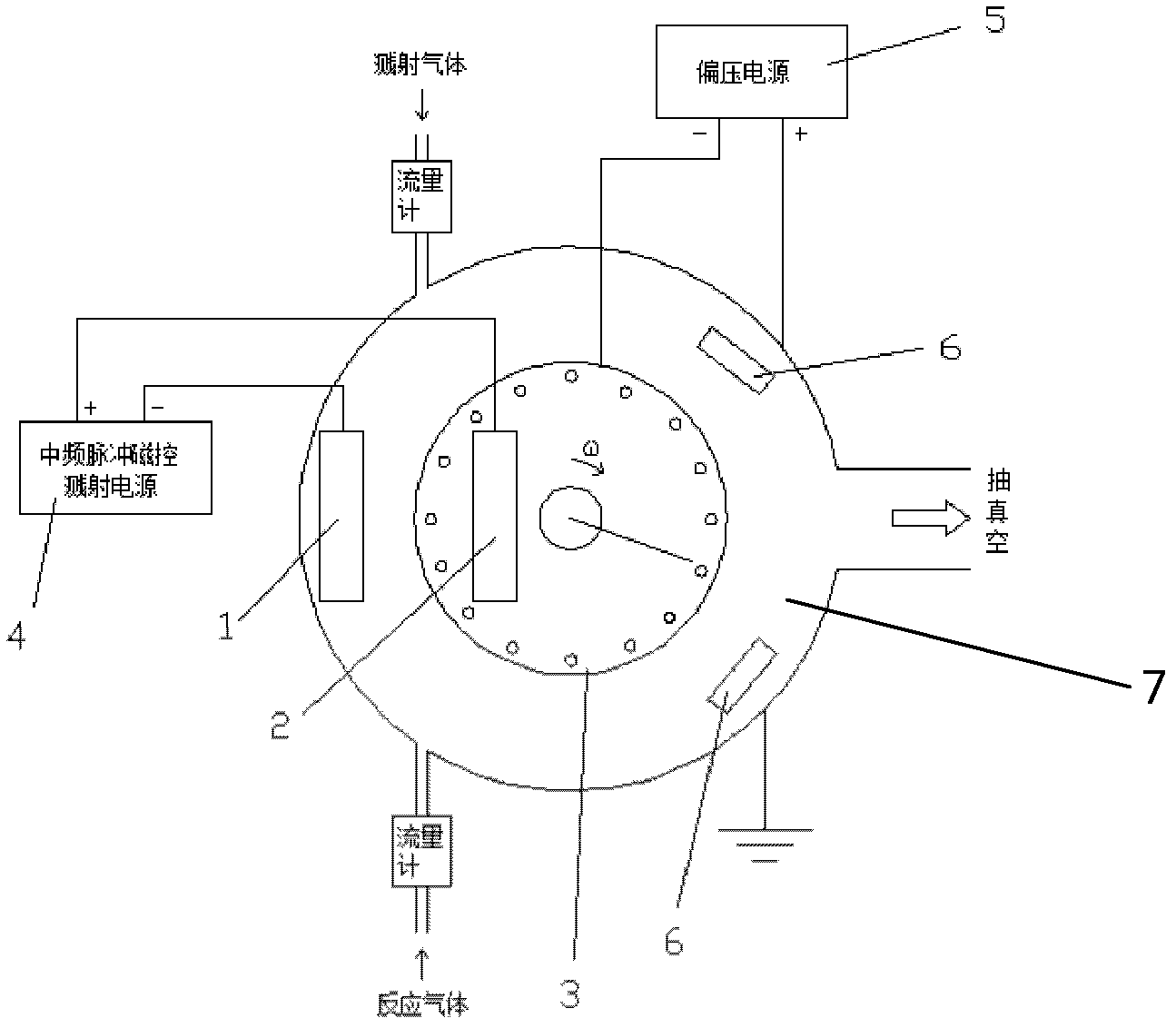

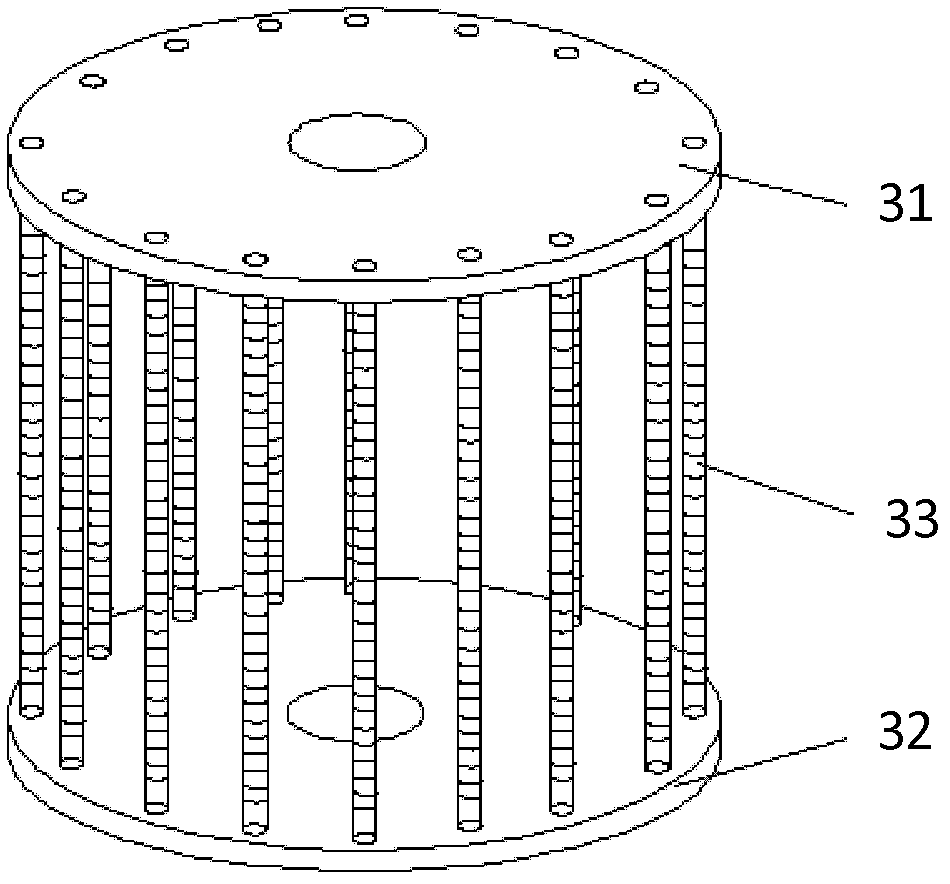

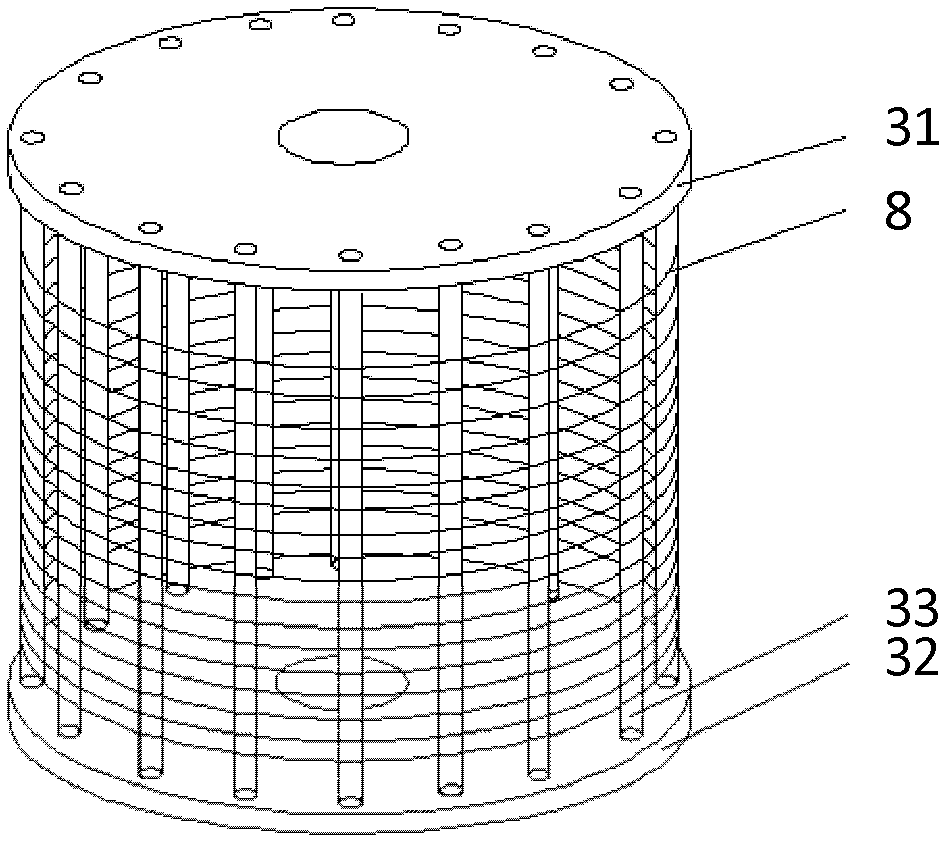

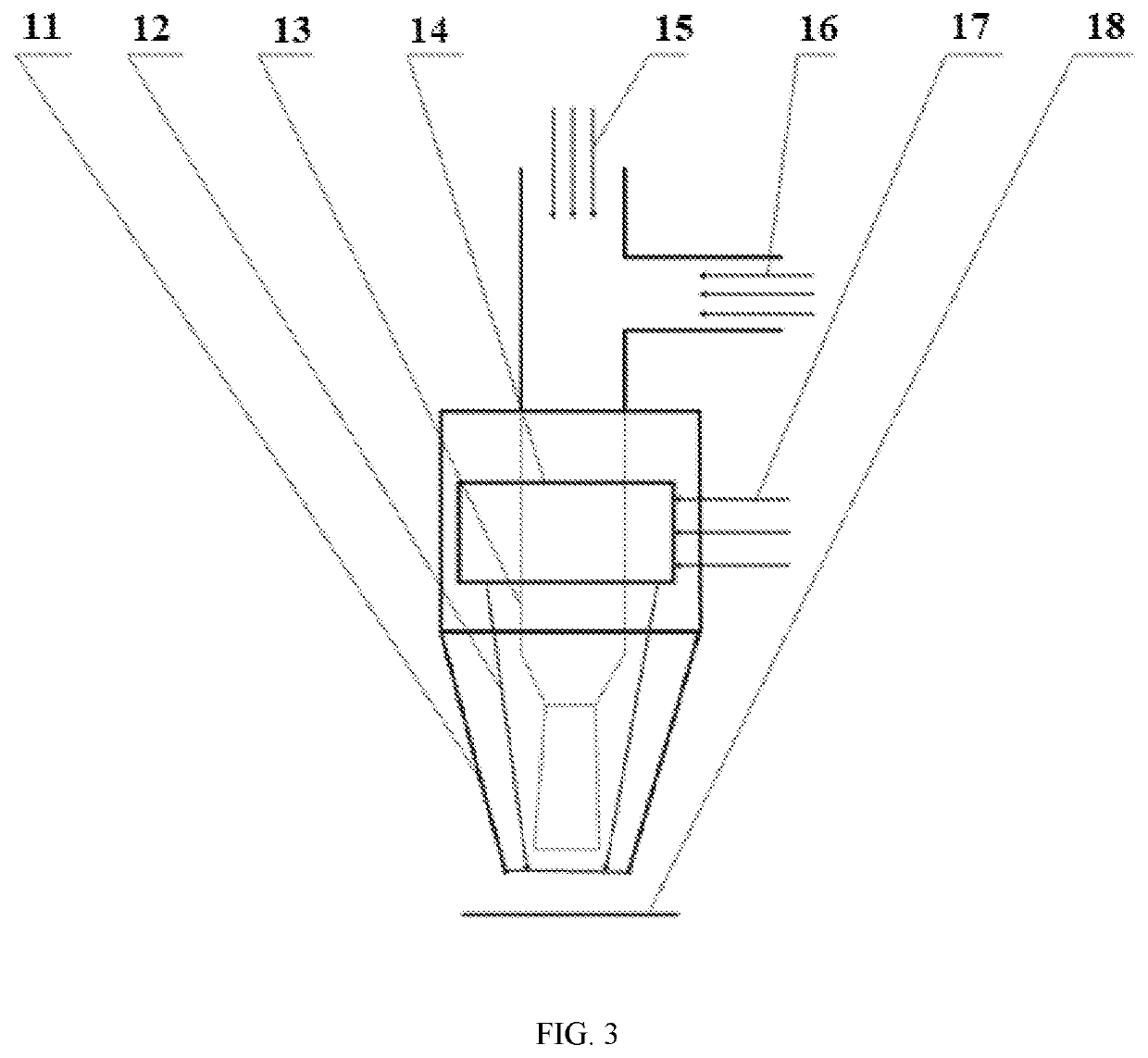

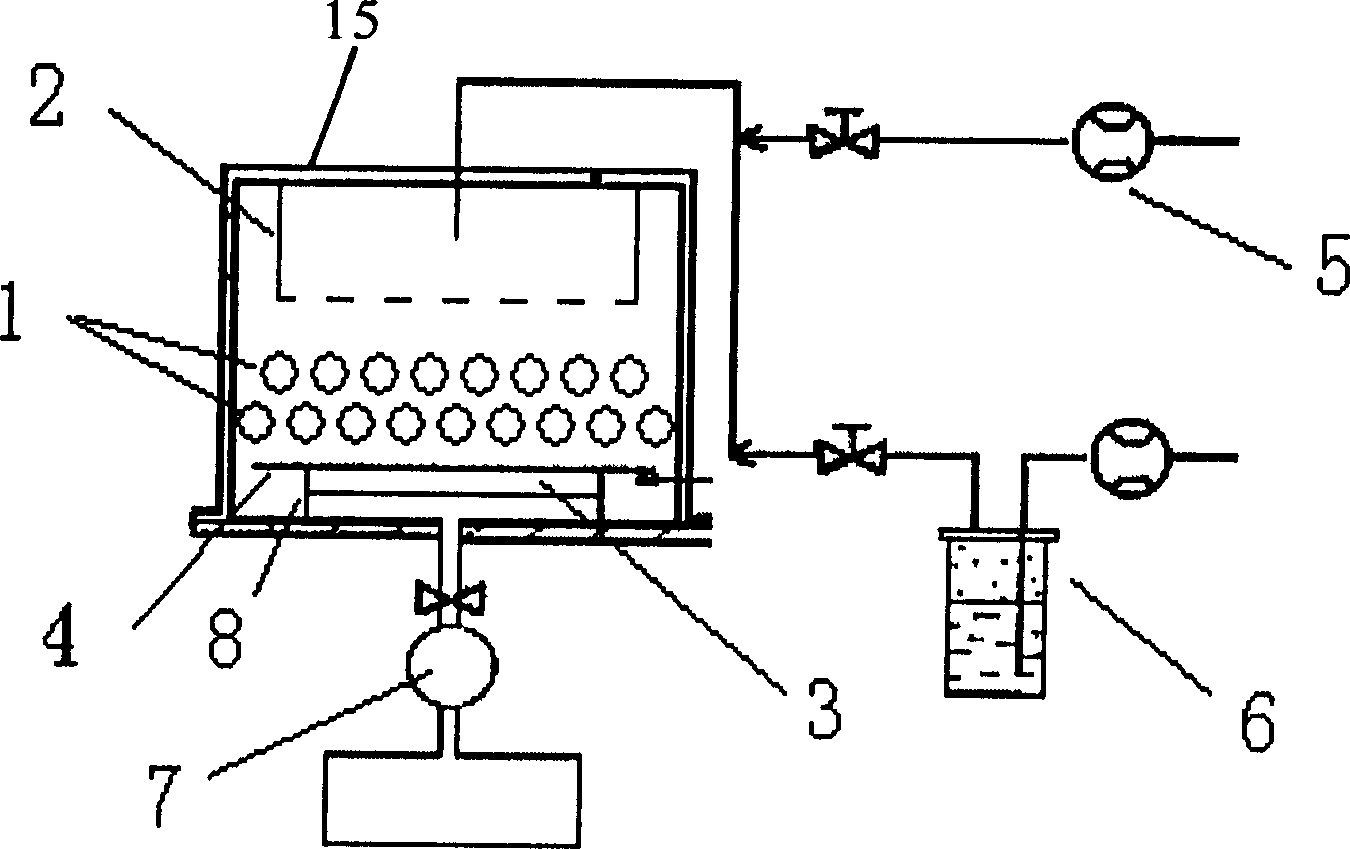

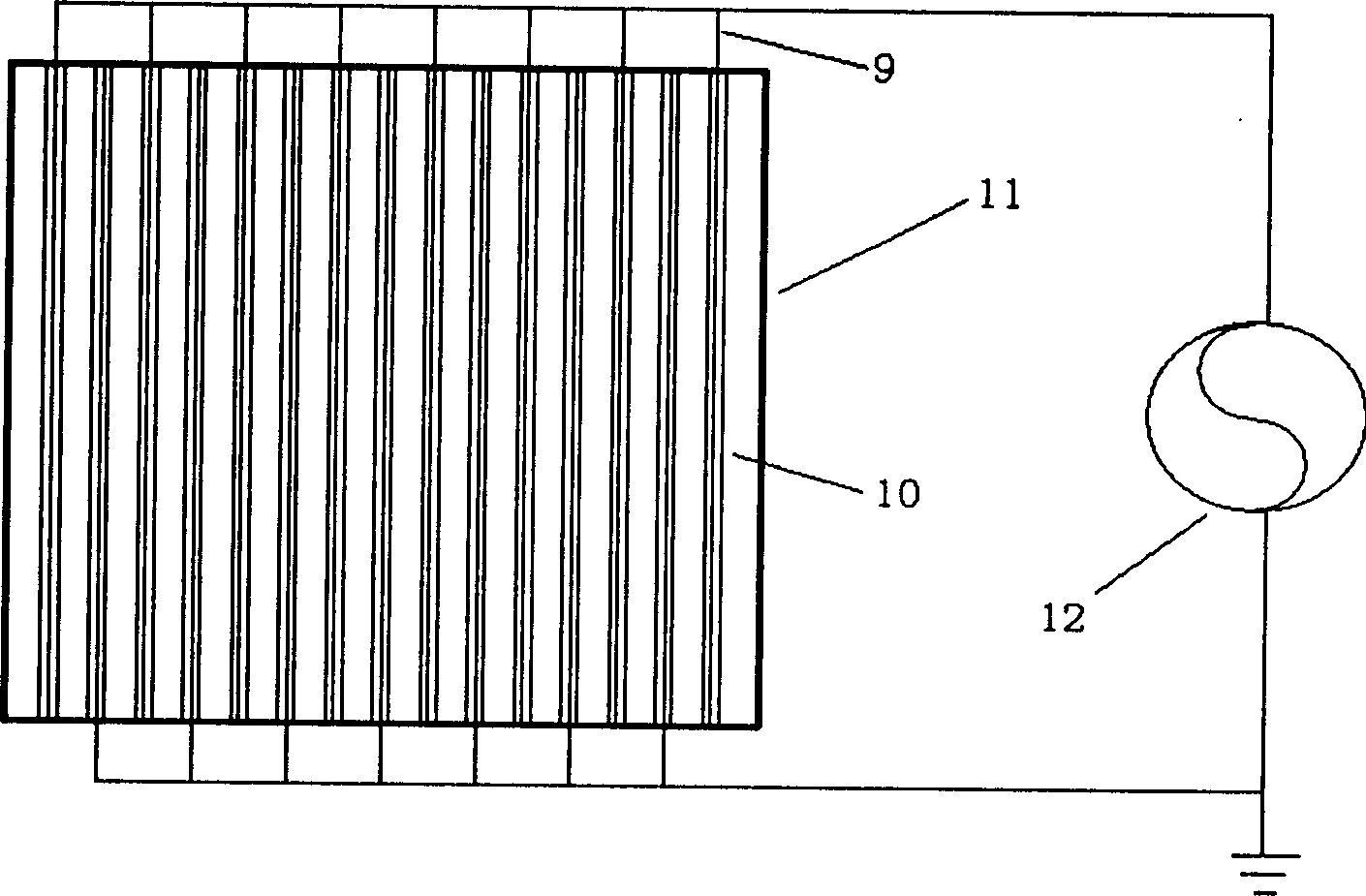

Device and method for depositing film on SiC fiber surface

InactiveCN102251224AUniform thicknessPrevent escapeVacuum evaporation coatingSputtering coatingIntermediate frequencySputter deposition

The invention relates to vacuum coating magnetron sputtering deposition technology, and particularly a device and a method for depositing a film on a SiC fiber surface; on one hand, a film with a uniform thickness is deposited on a continuous SiC fiber surface; on the other hand, the problem of target material poisoning of compound film deposition is solved, and the continuity and stability of the deposition process is realized. The device is provided with a target material I, a target material II, a workpiece rotating shelf, an intermediate-frequency pulsed magnetron sputtering power supply, a magnetron sputtering vacuum chamber; the workpiece rotating shelf is disposed in the magnetron sputtering vacuum chamber; the target material I and the target material II are facingly disposed inside and outside the workpiece rotating shelf in the magnetron sputtering vacuum chamber; a cathode of the intermediate-frequency pulsed magnetron sputtering power supply is connected to the target material I; and an anode of the intermediate-frequency pulsed magnetron sputtering power supply is connected to the target material II. According to the invention, the gas flow, the reaction gas types, the sputtering time and the like in the vacuum chamber of the magnetron sputtering device are adjusted so as to realize the deposition of metals or compound films with different types and different thicknesses on a continuous SiC fiber surface, and to realize the surface modification of the SiC fiber.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

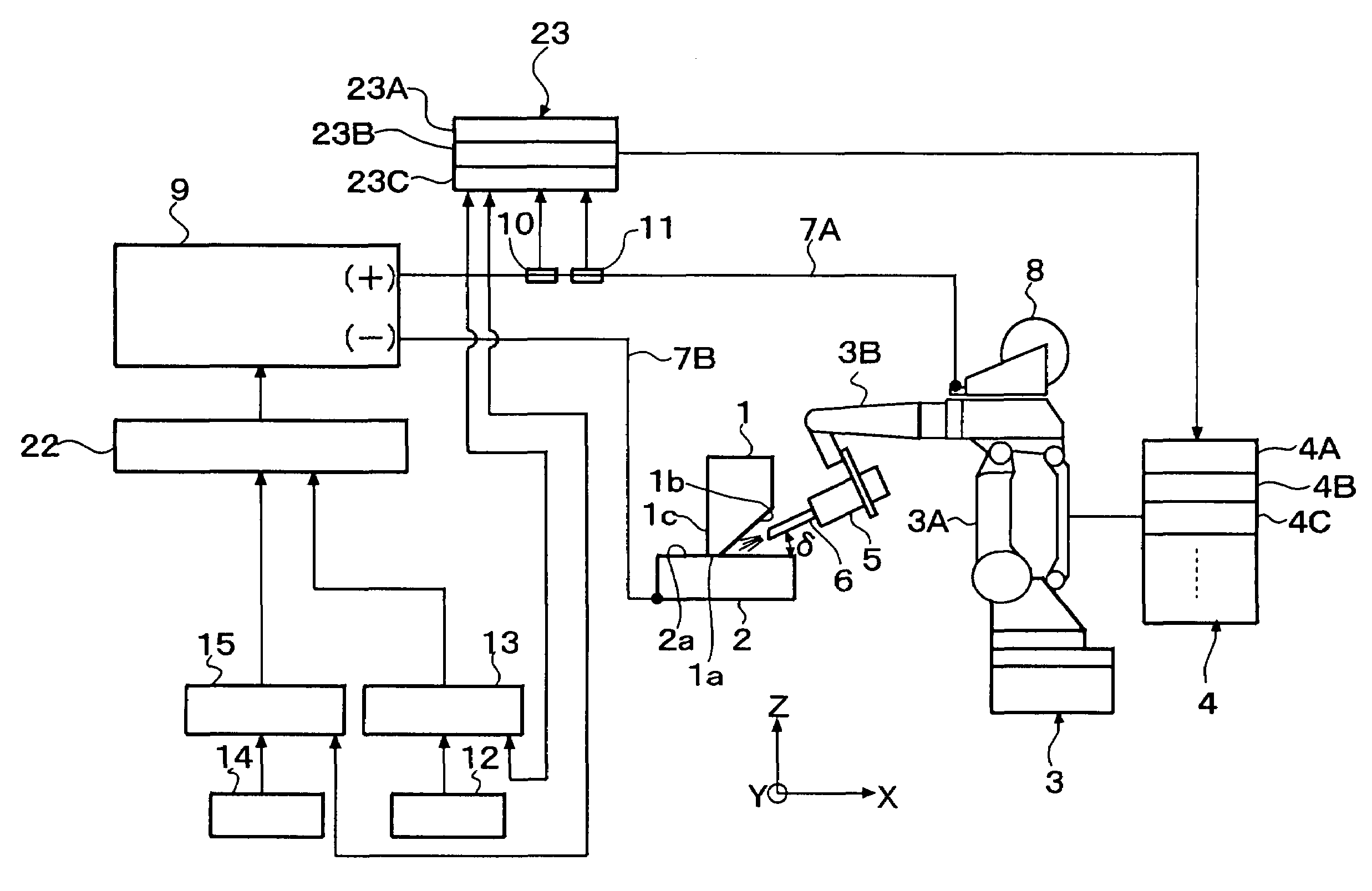

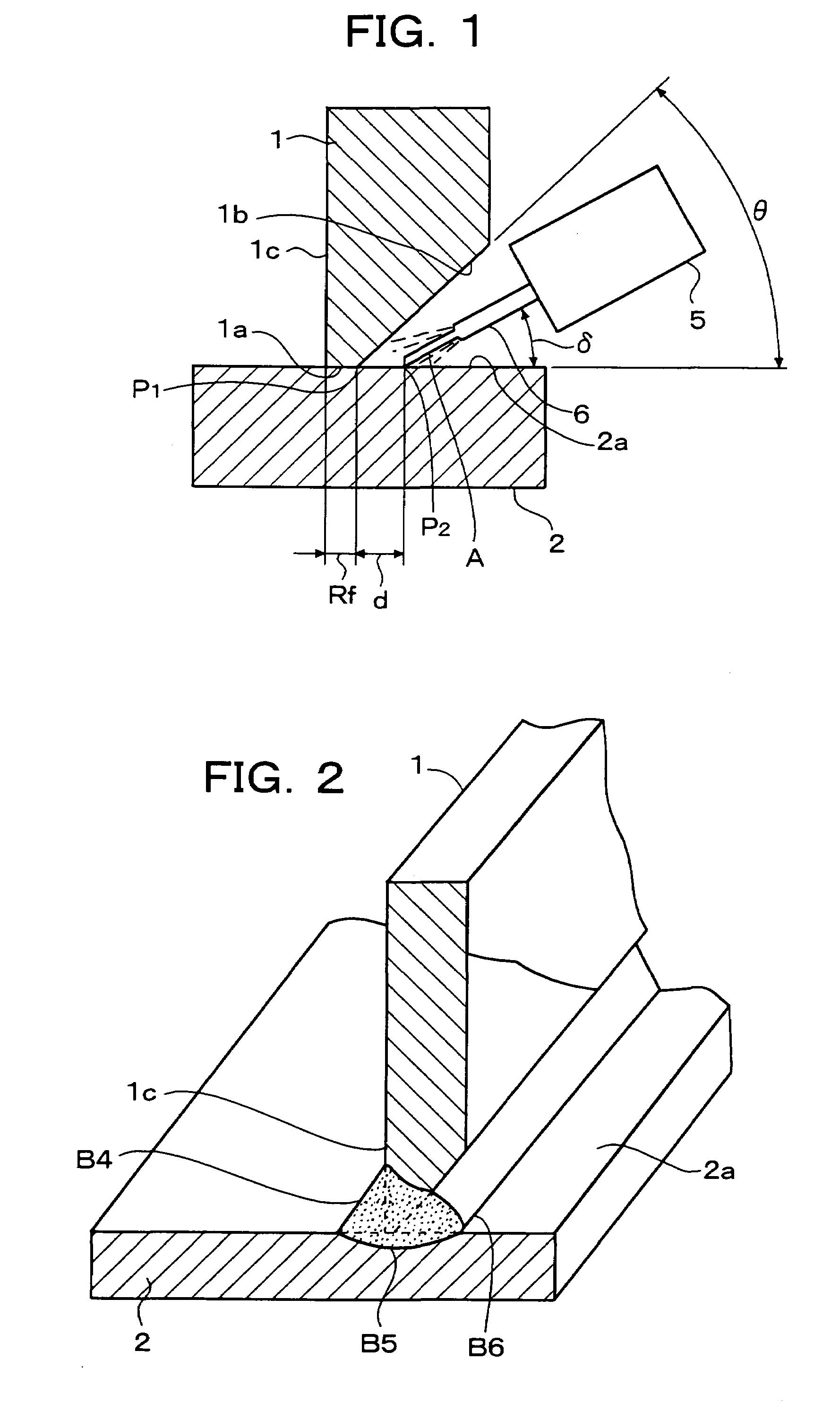

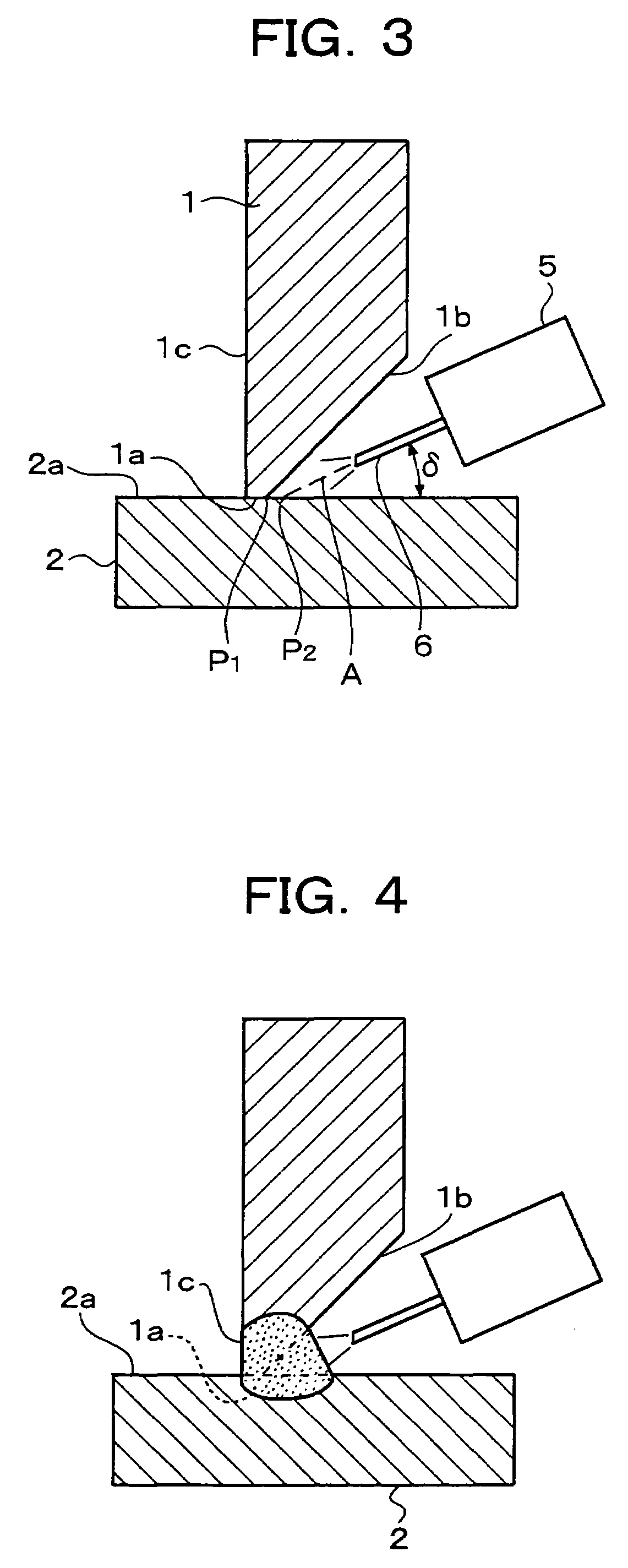

Welding method, welding device, welded joint, and welded structure

InactiveUS7005607B2Accurately force outExcellent welding workabilityArc welding apparatusWelding/cutting media/materialsFillet weldButt welding

A welding method is disclosed for butt welding a first base material 1 and a second base material 2 with each other. To also permit stable and efficient formation of a bead in the form of a fillet weld on a back side of a groove by conducting arc welding from the side of the groove without arranging a bead beforehand on the back side of the groove, the first member 1, on which a root face 1a and a single groove face 1b have been formed, is brought at its root face 1a into contact with a flat surface 2a of the second base material 2. A welding wire 6 is arranged facing on the groove formed by the contact between the first base material 1 and the second base material 2. The first base material 1 and the second material 2 are caused to fuse at an area of contact between them by an arc from the welding wire 6. A melt, which has been formed by the fusion at the area of contact and the like, is forced out to the back side of the groove to form a bead B4 in the form of a fillet weld on the back side of the groove.

Owner:NIHON KENKI CO LTD

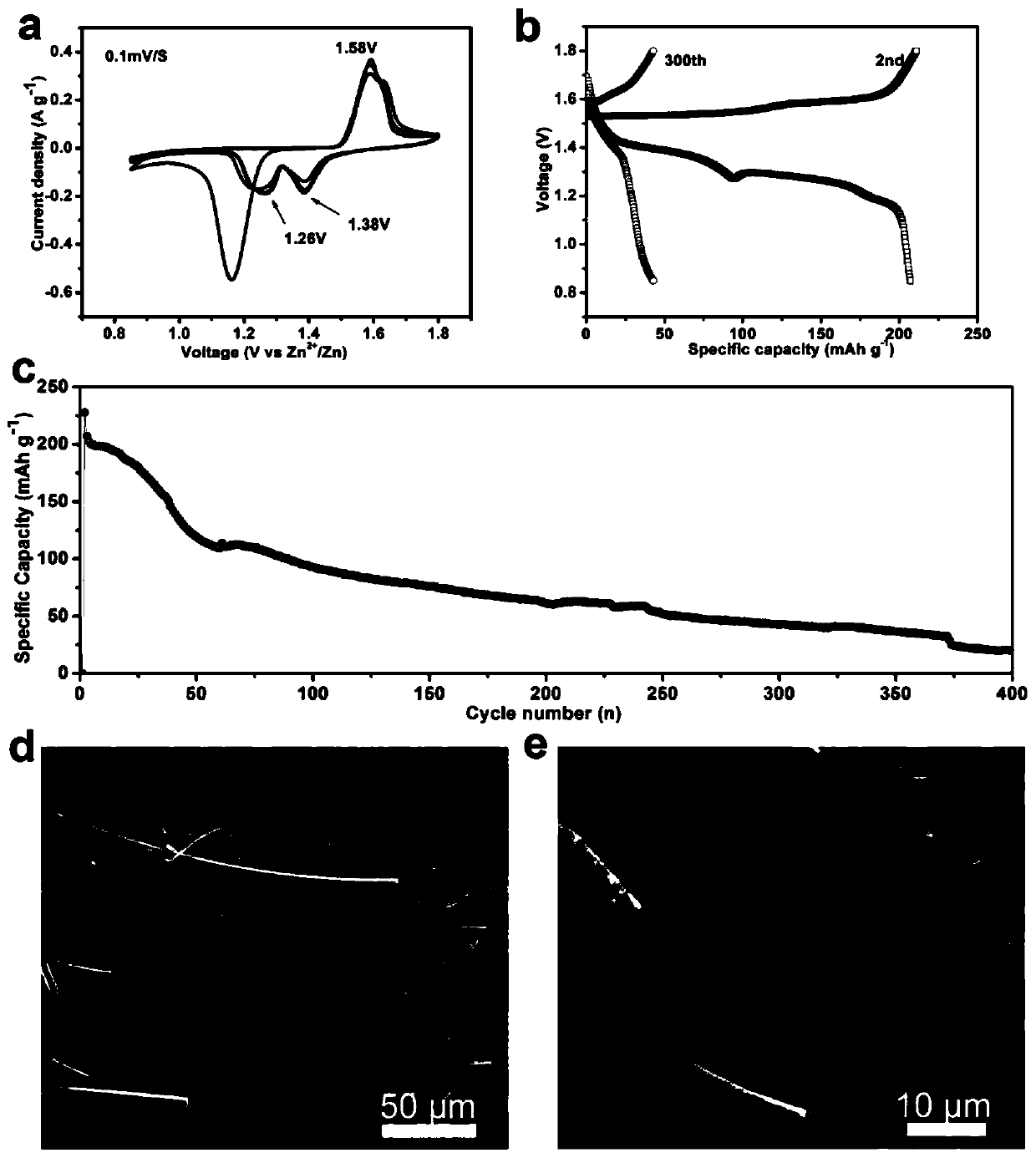

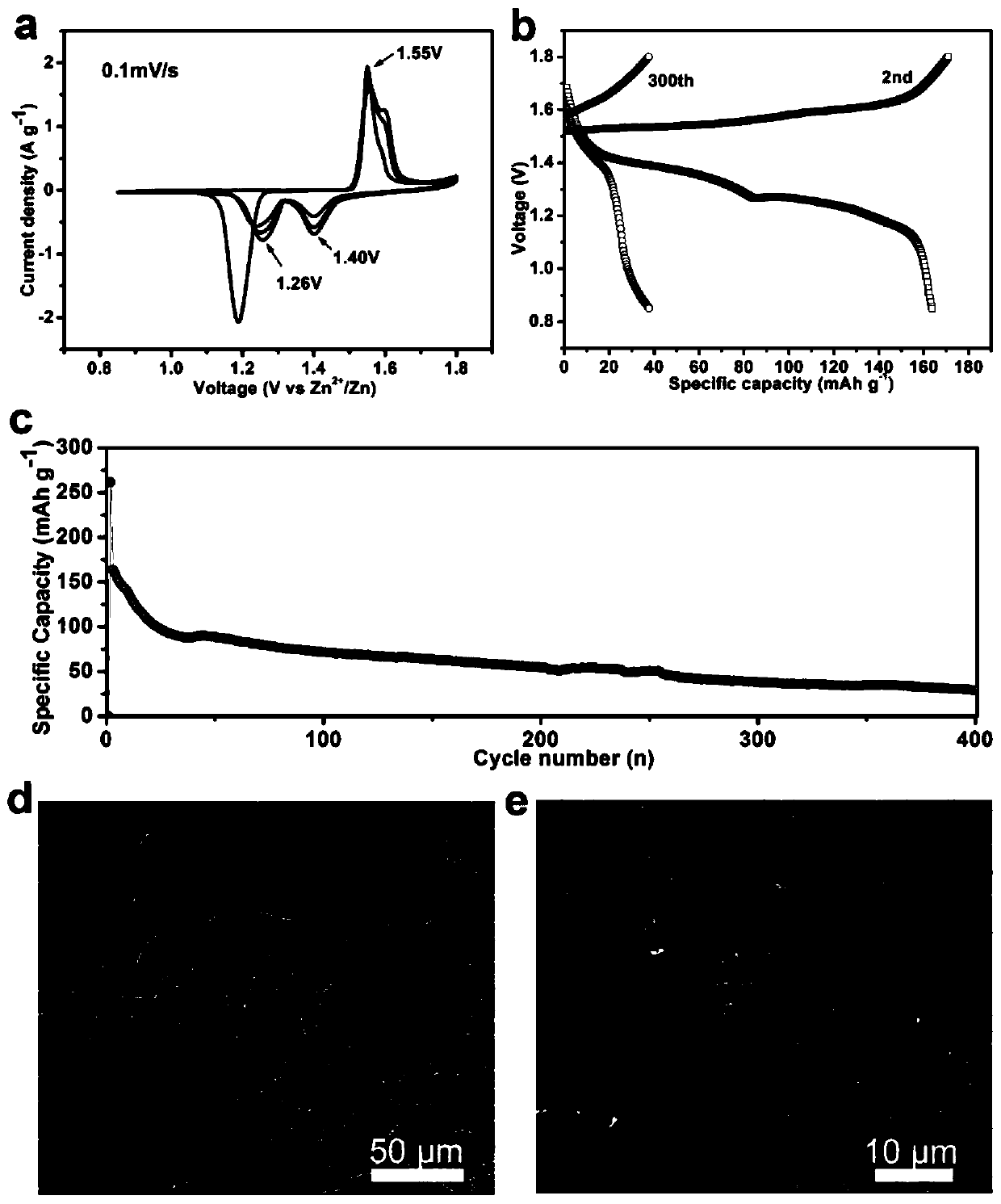

Metal zinc negative electrode with uniform mesoporous structure coating and preparation method and application thereof

ActiveCN110416549AReduce short circuitAlleviate volume expansionElectrode manufacturing processesNegative electrodesPorositySlurry

The invention discloses a metal zinc negative electrode with a uniform mesoporous structure coating and a preparation method and application thereof, belonging to the technical field of aqueous zinc ion batteries. The metal zinc negative electrode comprises a zinc negative electrode and a clay slurry layer, and is prepared by pre-embedding zinc. The raw material powder of the clay slurry includes1-20wt% of polyvinylidene fluoride and 80-90wt% of clay material. The aqueous zinc ion battery negative electrode coating presented in the invention can play a role of a protective layer, isolate thedirect contact between the zinc negative electrode and the electrolyte to a certain extent, reduce the side reaction between the electrode and the electrolyte and improve the cycle stability. The layered porosity of the material itself can prevent dendrites from being generated and penetrating a diaphragm in the cycle process, alleviate the volume expansion of the negative electrode, reduce the occurrence of short circuit of the battery and improve the safety performance.

Owner:CENT SOUTH UNIV

Composite material negative electrode, battery and preparation method thereof

ActiveCN110690420ADeposition stabilityDeposition planarizationFinal product manufactureCell electrodesMetallic materialsDielectric layer

The invention provides a composite material negative electrode, a battery and a preparation method thereof. The composite material negative electrode comprises a three-dimensional skeleton and activemetal. The three-dimensional skeleton comprises a non-conductive porous dielectric layer prepared from the raw material of a polymer material or an inorganic oxide and a porous conductive layer prepared from the raw material of a carbon material or a metal material, wherein the porous dielectric layer and the porous conductive layer are periodically assembled together to form the three-dimensionalskeleton with alternating conductive / dielectric periods, and the active metal is embedded in the three-dimensional skeleton to form the composite material negative electrode. The periodic conductiveskeleton controls the electron transmission path and the ion concentration distribution so that the composite material negative electrode can effectively improve the stability of the metal negative electrode in the cycle process, inhibit dendrite growth and improve the safety of the metal negative electrode.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

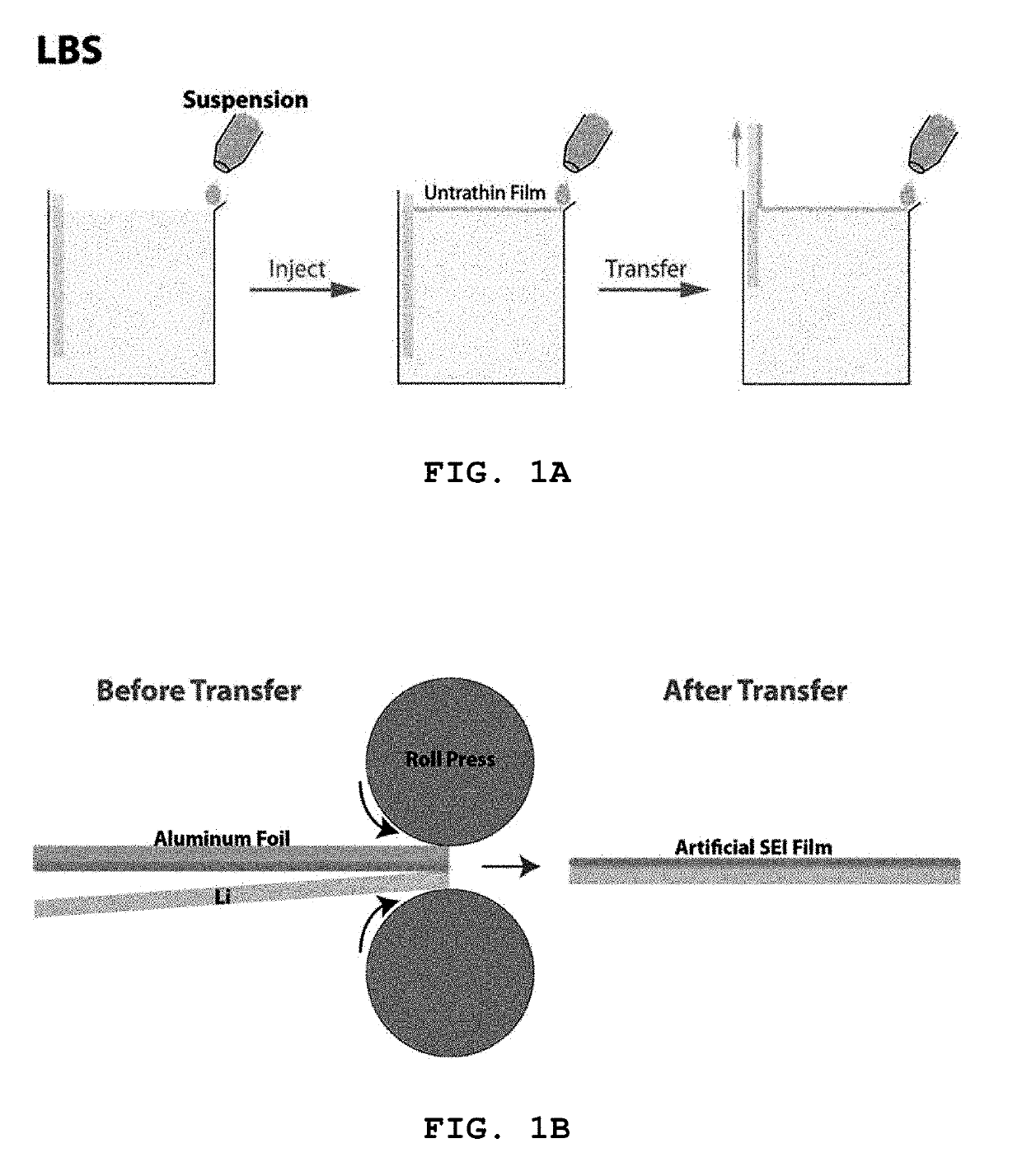

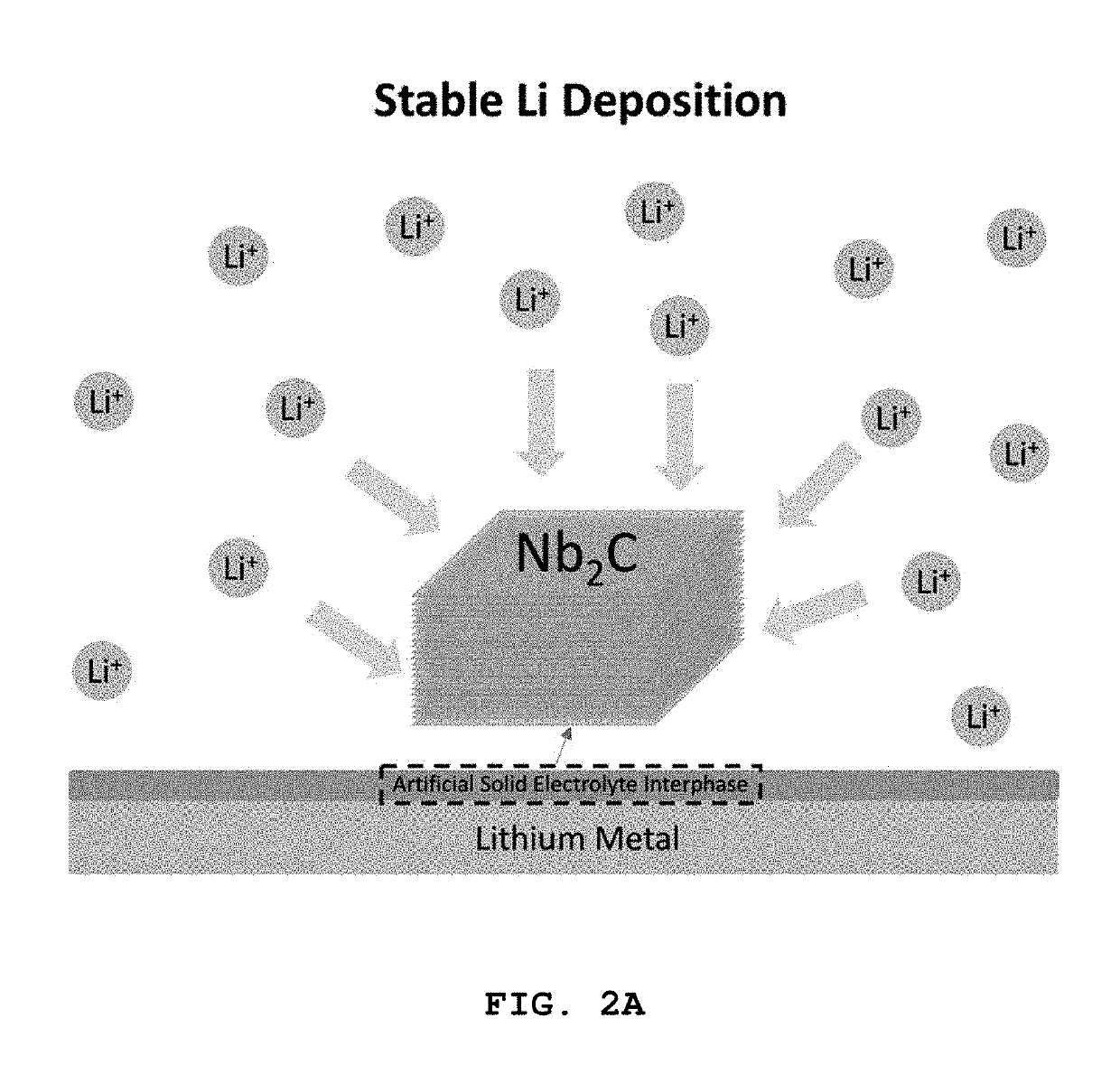

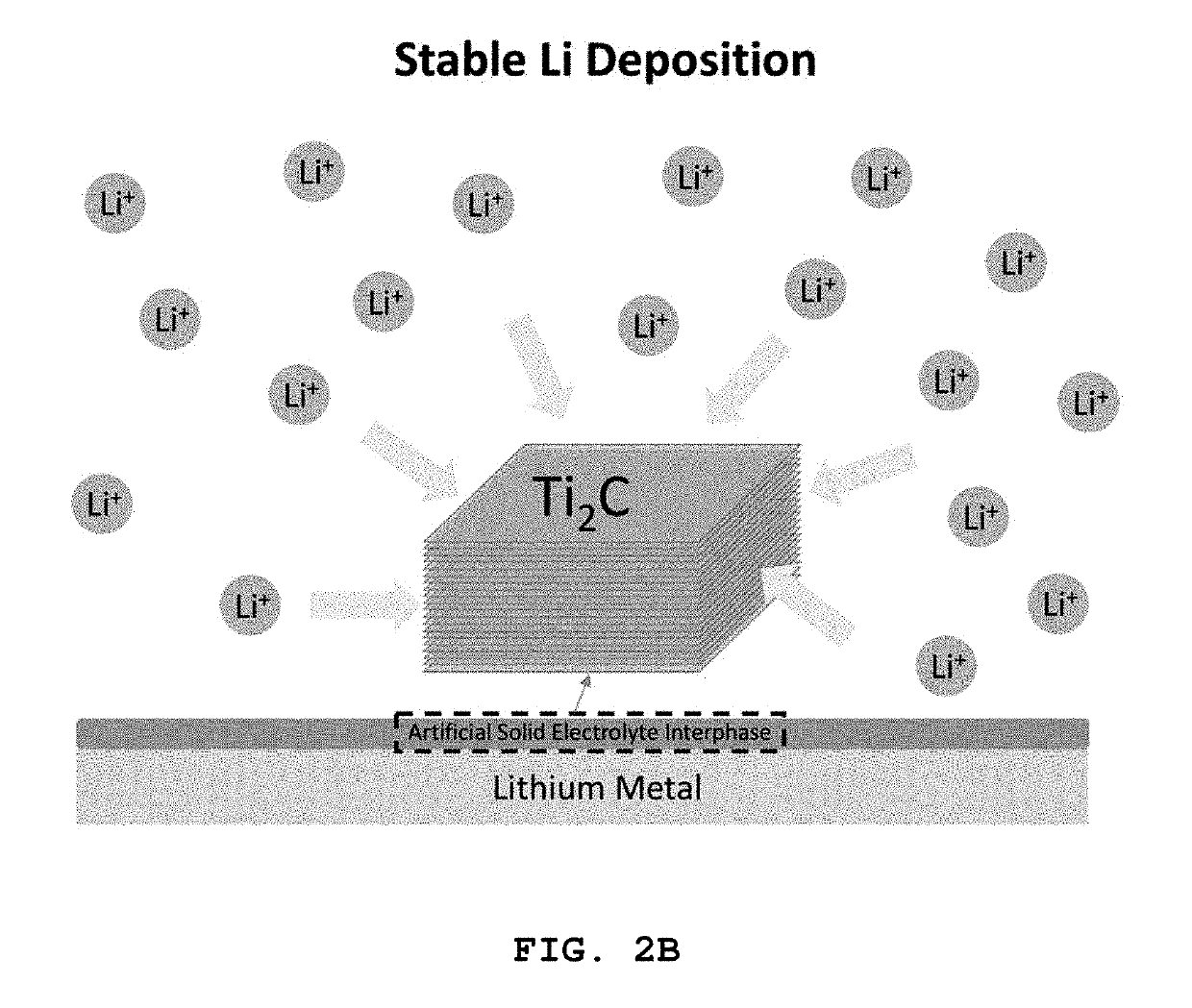

Anode for lithium metal secondary battery including mxene thin film, method for producing the anode and lithium metal secondary battery including the anode

ActiveUS20190267630A1Good stabilityHigh coulombic efficiencyElectrode manufacturing processesFuel and secondary cellsPower gridElectrochemistry

The aim of the present invention is to provide an electrolyte system for prolonging the life of lithium metal anode-based secondary batteries while maintaining the energy density of the batteries. The ultimate aim of the present invention is to use lithium metal in combination with cathodes, such as transition metal oxide, sulfur, and air electrodes, that are currently used in lithium ion batteries for future unmanned electric vehicles and grid energy storage systems as well as in lithium metal secondary batteries with high energy density. The use of lithium metal is also expected to contribute to the development of newly emerging unmanned aircrafts such as drones. The present invention is expected to be globally competitive in the secondary battery and electrochemical capacitor industries. Research on the safety of high density energy materials, particularly when handled, is attracting a great deal of researchers' attention because high energy density is achieved at the sacrifice of safety in the commercialization of products. Due to the social and technological criticism associated with the recent explosion of smartphones, it is particularly necessary to ensure safety of batteries with high energy density. Particularly, next-generation batteries have energy densities at least substantially two times to a maximum of eight times higher than existing lithium ion batteries. For this reason, next-generation batteries and systems using next-generation batteries should be necessarily investigated and verified for safety. Therefore, the present invention provides a method for forming a Mxene thin film as a stable SEI film that can stabilize a lithium metal anode of a lithium metal secondary battery that may catch fire or explode and can suppress the formation and diffusion of lithium dendrites to prevent the occurrence of an internal short circuit.

Owner:KOREA INST OF SCI & TECH

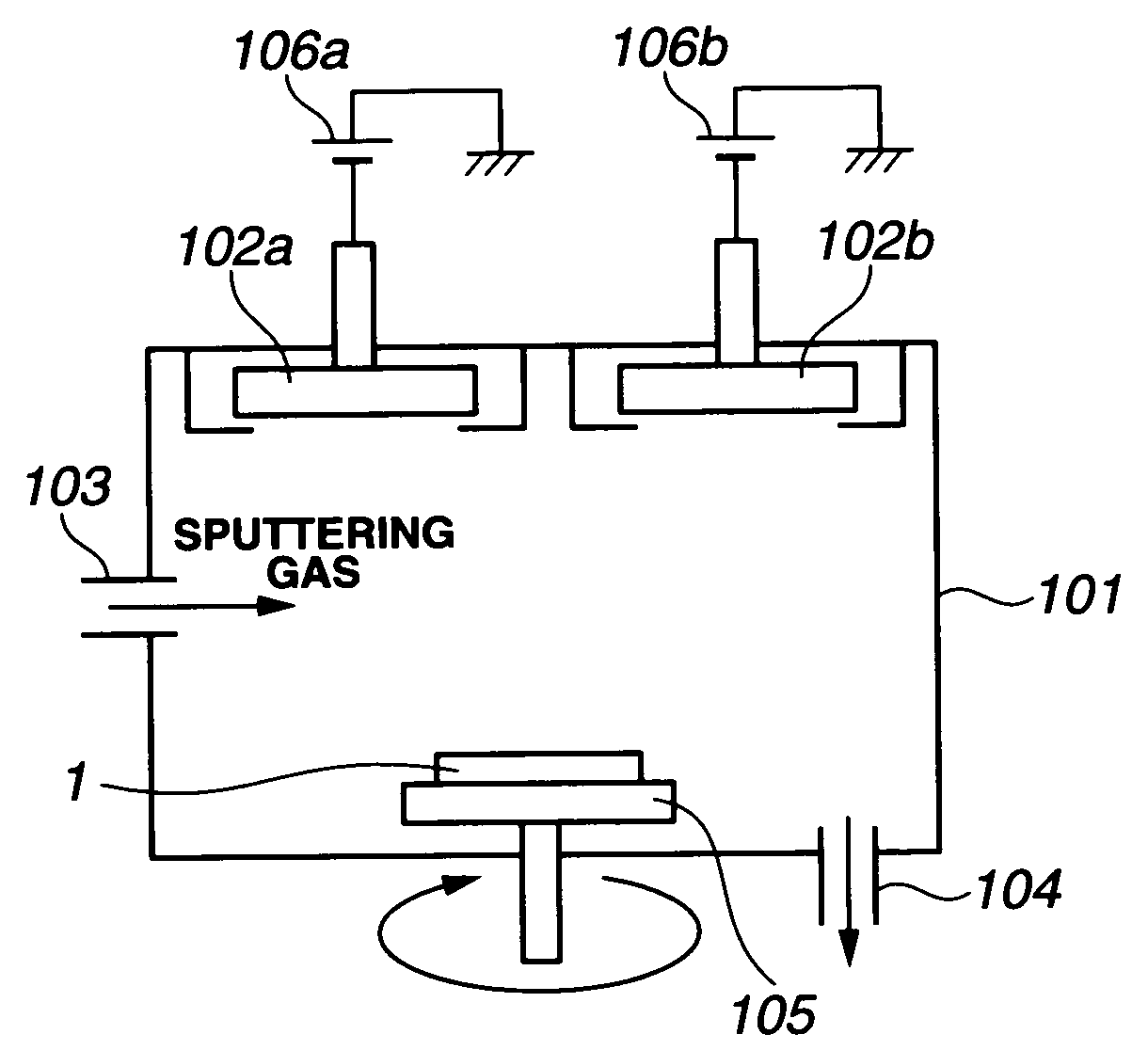

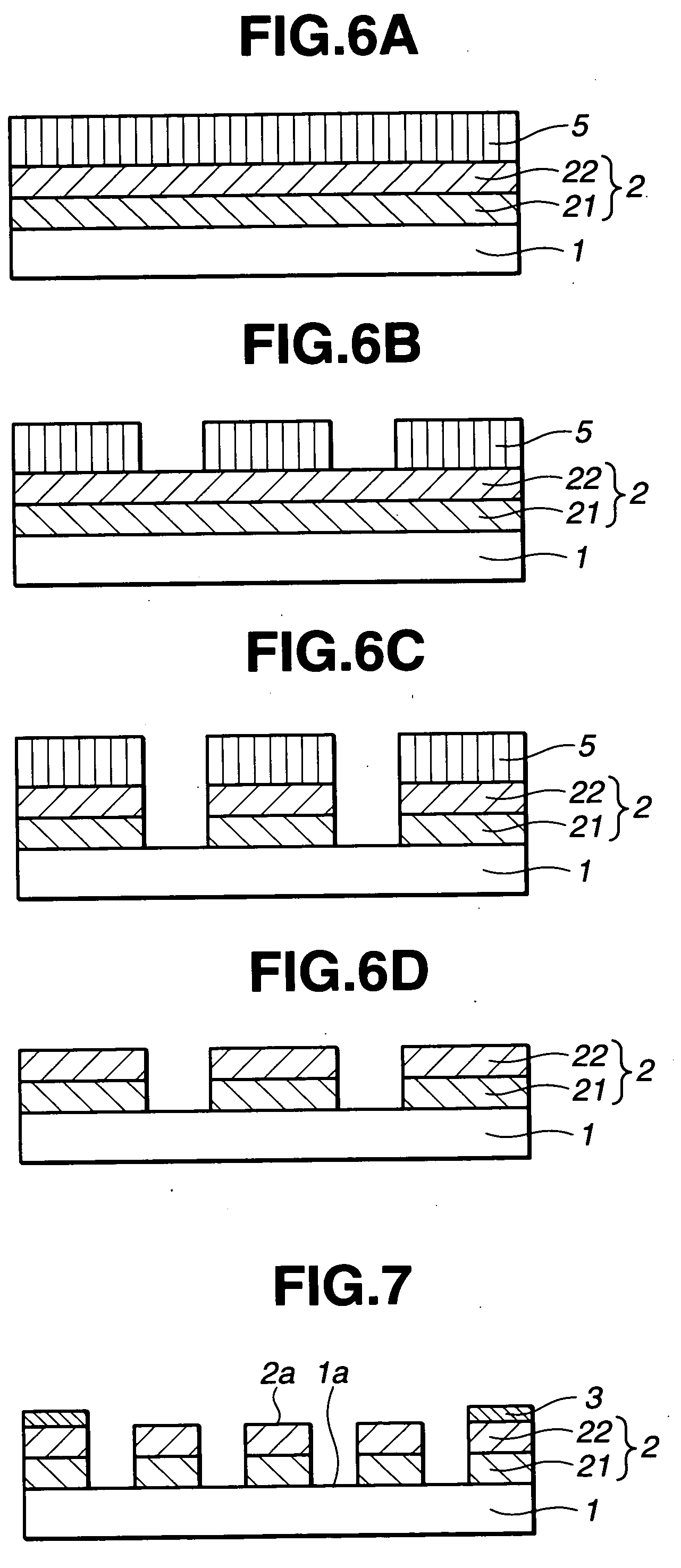

Preparation of halftone phase shift mask blank

ActiveUS20050186485A1Minimize variationLess defectVacuum evaporation coatingPhotomechanical apparatusPhase shiftedMetal

In preparing a halftone phase shift mask blank, a metal and silicon-containing compound film serving as a halftone phase shift film is formed on a transparent substrate by a co-sputtering process including the steps of disposing a metal-containing target and a silicon target in a chamber, feeding sputtering gases into the chamber, and applying electric powers across both the targets at the same time. The sputtered region area of the metal-containing target is smaller than the sputtered region area of the silicon target.

Owner:SHIN ETSU CHEM CO LTD

Gallium Oxide/Zinc Oxide Sputtering Target, Method of Forming Transparent Conductive Film and Transparent Conductive Film

ActiveUS20090250669A1High densityLow bulk resistanceCellsConductive materialHigh densityVolumetric Mass Density

Provided is a high-density gallium oxide / zinc oxide sintered sputtering target containing 20 massppm or greater of each zirconium oxide and aluminum oxide, wherein the total content thereof is less than 250 ppm. This gallium oxide (Ga2O3) / zinc oxide (ZnO) sputtering target (GZO target) improves the conductivity and bulk density of the target by adding trace amounts of specific elements. In other words, it is possible to obtain a target capable of increasing the sintered density, inhibiting the formation of nodules, and preventing the generation of abnormal electrical discharge and particles by improving the component composition. Further, provided are a method of forming a transparent conductive film with the use of the target, and a transparent conductive film formed thereby.

Owner:JX NIPPON MINING& METALS CORP

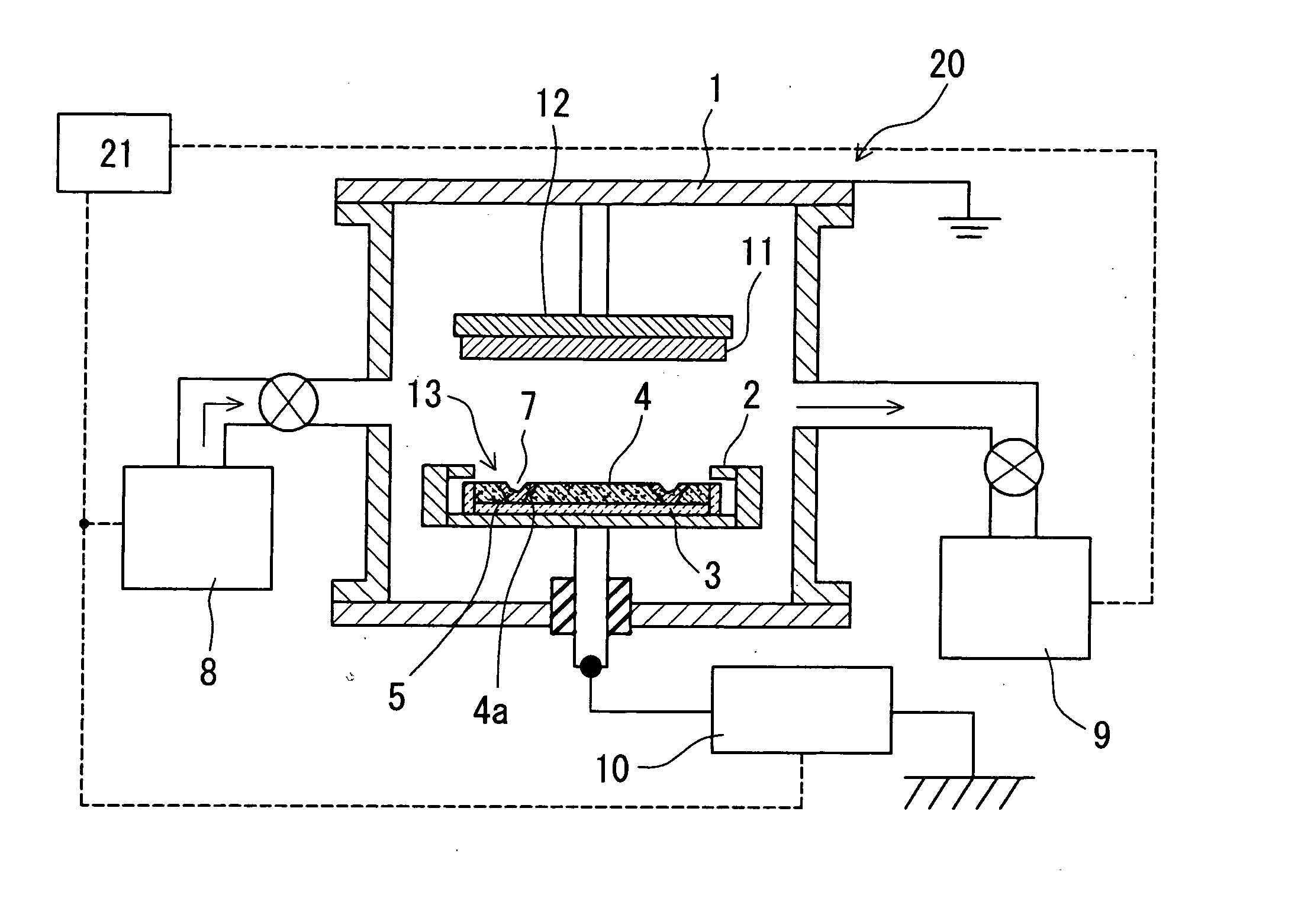

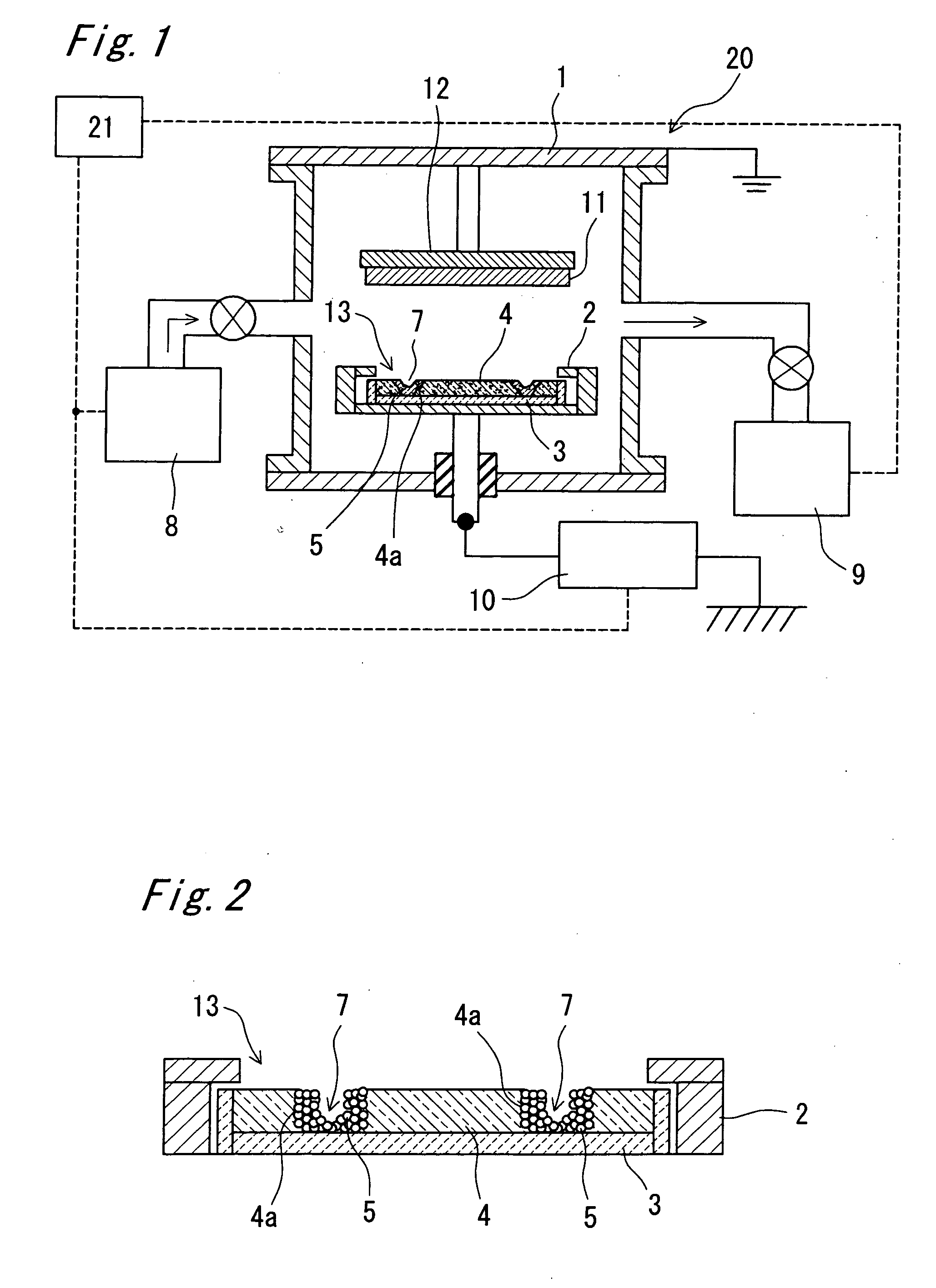

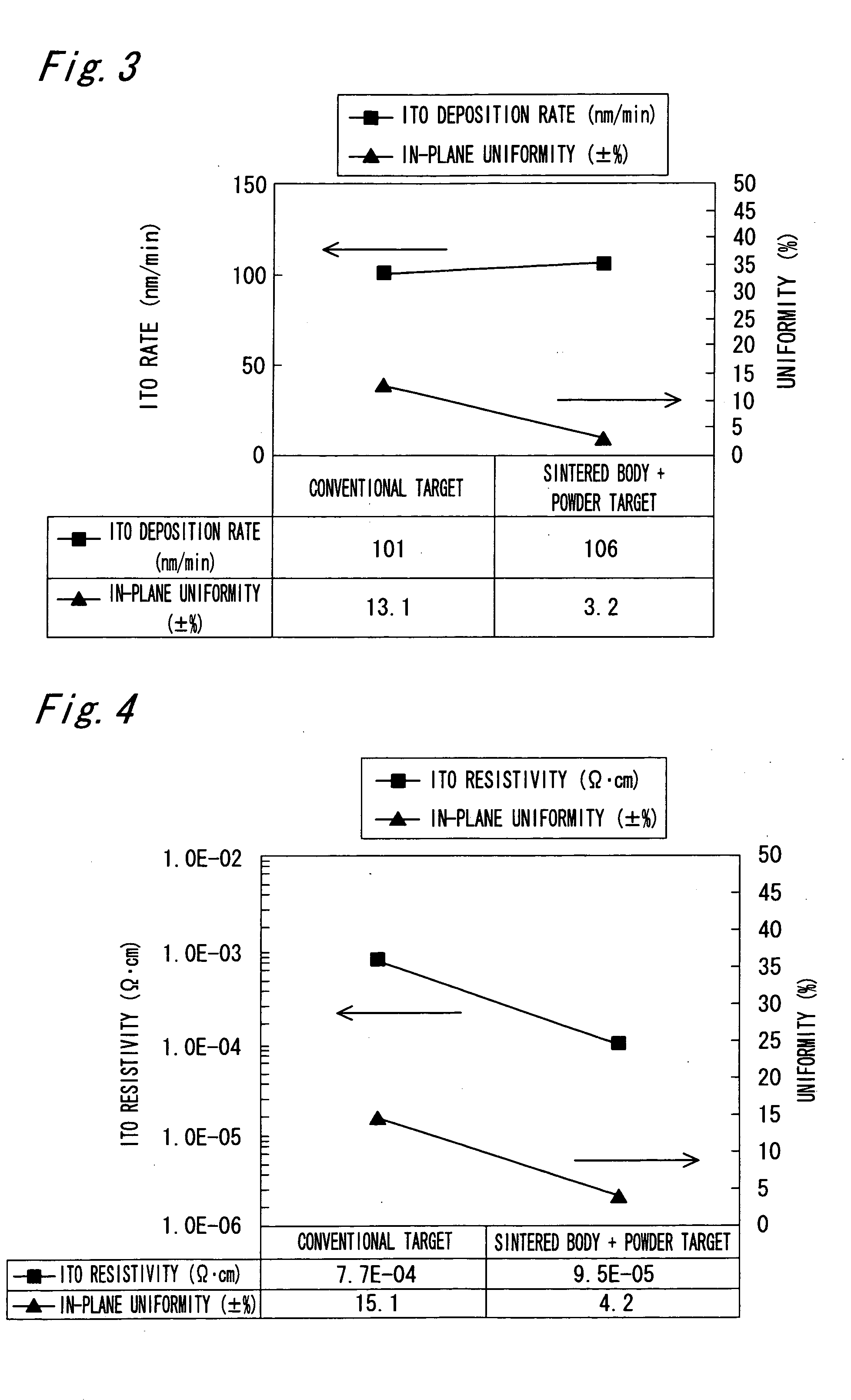

Deposition method by physical vapor deposition and target for deposition processing by physical vapor deposition

InactiveUS20060272936A1Increase deposition rateImprove in-plane uniformityCellsElectric discharge tubesIn planeGas phase

A deposition apparatus includes a processing chamber internally having a reduced-pressure space for deposition process to be carried out therein, a base material holding member for holding a base material to be subjected to the deposition process, a target support member for supporting a target thereon, and a power supply unit for applying electric power to the target support member to generate a plasma in the reduced-pressure space. In the deposition apparatus, deposition process is carried out by using the target, which has a recess portion in its surface and in which a powder target formed of a powder material is placed in an inner surface of the recess portion. Thus, the in-plane uniformity of deposition rate is improved and a stable film deposition is fulfilled.

Owner:PANASONIC CORP

Copper current collector for lithium metal secondary battery, preparation method thereof and lithium metal secondary battery

InactiveCN108649232AImprove mechanical propertiesHigh ion transfer numberElectrode carriers/collectorsLi-accumulatorsCopper foilLithium-ion battery

The invention provides a copper current collector for a lithium metal secondary battery, comprising a copper foil and a polymer layer introduced on the surface of the copper foil, wherein the polymerlayer is a functional polymer with one or several groups of cyan, hydroxyl, amino, aldehyde group and carboxyl; inorganic nanoparticles are dispersed in the polymer layer; the inorganic nanoparticlesare one or several of alkylated alumina nanoparticles, nano silica, nano calcium carbonate, nano calcium phosphate, and iron oxide nanoparticles; and the inorganic nanoparticles have a mass fraction in the polymer layer of 0-5 percent. The invention introduces a functional polymer layer on the surface of the copper current collector, and the polymer layer may change the current density and stabilize the deposition of the metal lithium, thereby inhibiting the generation of lithium dendrites, stabilizing the SEI film, and improving the efficiency and safety of the lithium metal battery. The invention also provides a method for preparing a copper current collector for a lithium metal secondary battery and the lithium metal secondary battery.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

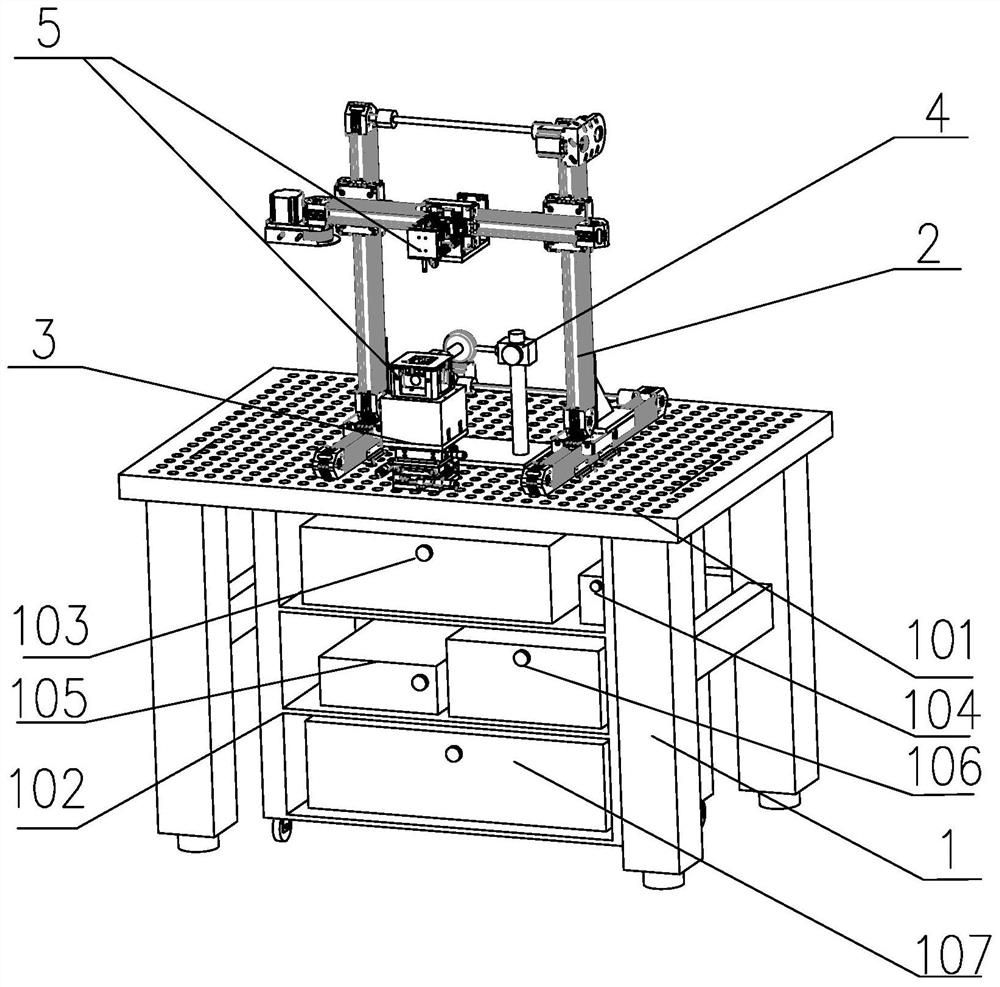

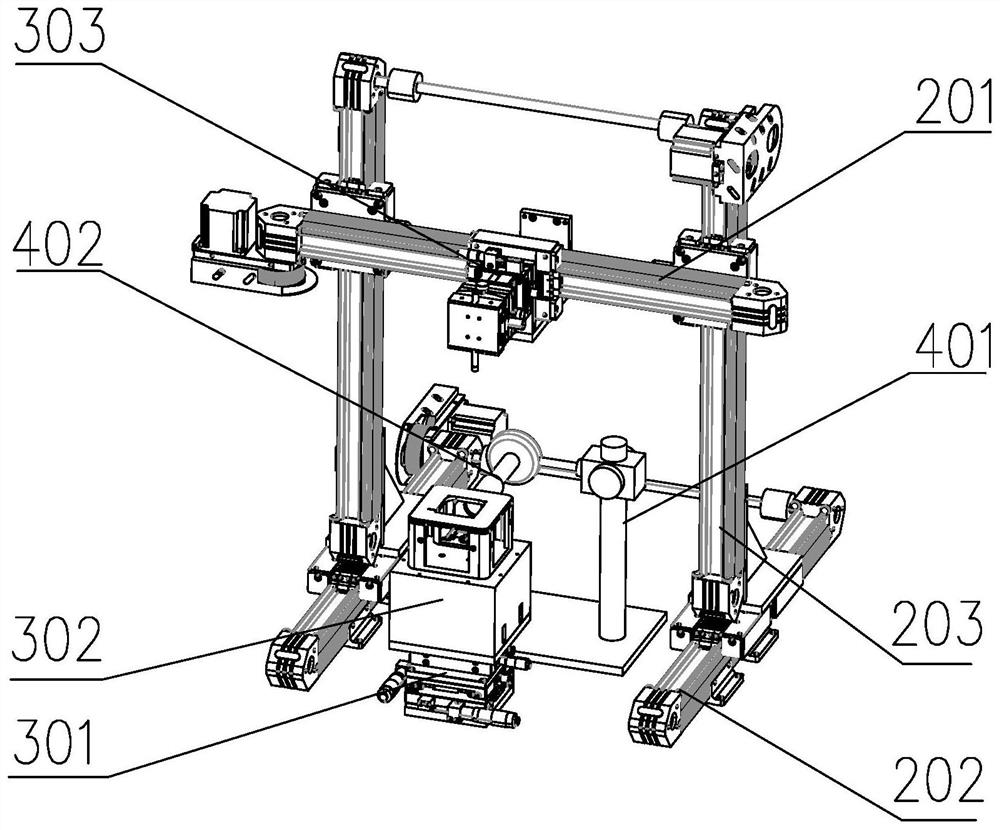

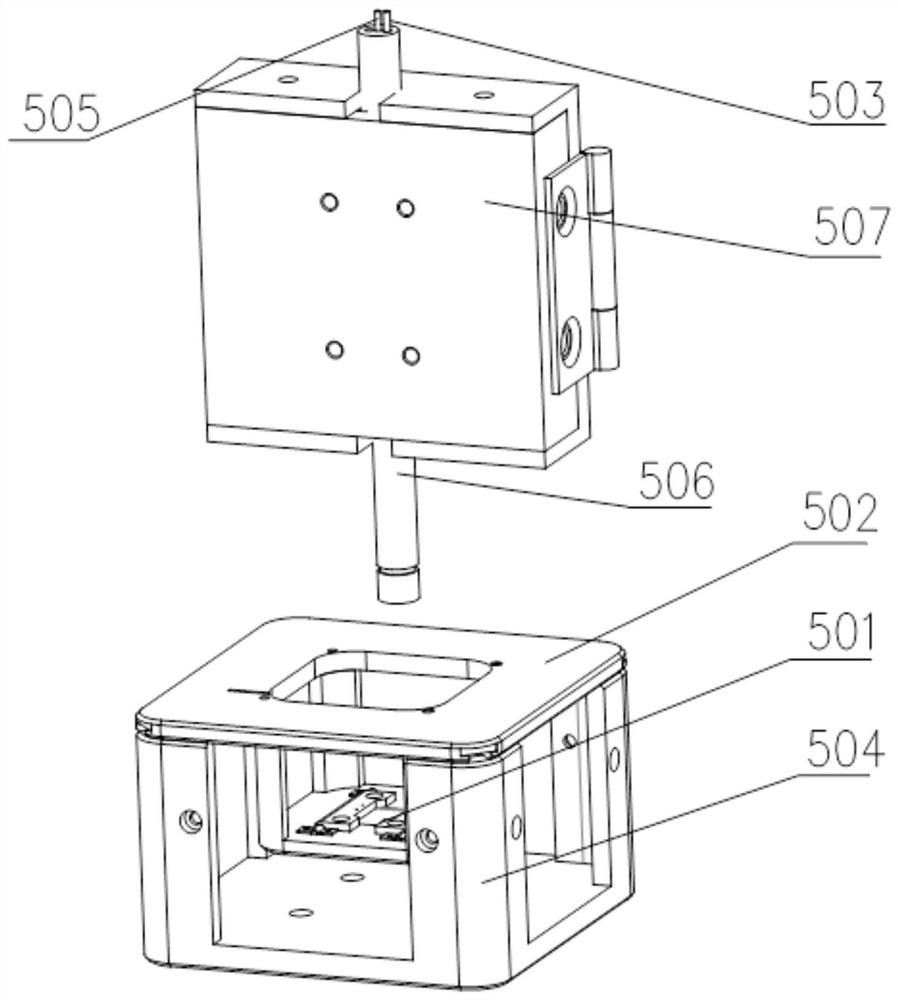

Additive manufacturing method and device for ceramic and composite thereof

PendingUS20200398457A1Shorten speedImprove plasticityAdditive manufacturing apparatusCeramic shaping apparatusNumerical controlComputer-aided

Additive manufacturing (AM) methods and devices for high-melting-point materials are disclosed. In an embodiment, an additive manufacturing method includes the following steps. (S1) Slicing a three-dimensional computer-aided design model of a workpiece into multiple layers according to shape, thickness, and size accuracy requirements, and obtaining data of the multiple layers. (S2) Planning a forming path according to the data of the multiple layers and generating computer numerical control (CNC) codes for forming the multiple layers. (S3) Obtaining a formed part by preheating a substrate, performing a layer-by-layer spraying deposition by a cold spraying method, and heating a spray area to a temperature until the spraying deposition of all sliced layers is completed. (S4) Subjecting the formed part to a surface modification treatment by a laser shock peening method.

Owner:HUAZHONG UNIV OF SCI & TECH

Photocatalytic auto-cleaning process of stains

InactiveUS20060137708A1Avoid complex processSimple and efficientLighting and heating apparatusElectrostatic cleaningPhoto catalyticFluorescence

The present invention provides a process for photocatalytically treating stains of chilly and turmeric caused on kitchen tiles and platforms by coating a thin film of photocatalyst made of a semiconductor such as titanium dioxide uniformly dispersed in dilute silica sol thereon and using a light source such as a fluorescent lamp to irradiate and photoexcite the photo catalytic thin film by the small amount of UV radiation included in the fluorescent light, resulting in photo decomposition and auto-cleaning of the stains.

Owner:COUNCIL OF SCI & IND RES

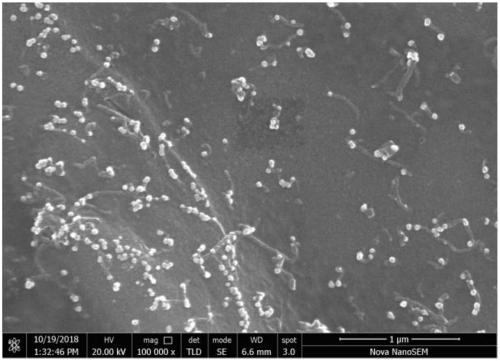

Method for preparing Pt-based catalyst by pulse electrodeposition under ultrasonic conditions

InactiveCN109331820AEvenly dispersedUniform and firm loadCell electrodesCatalyst activation/preparationPulse power supplyControllability

The invention discloses a method for preparing a Pt-based catalyst by pulse electrodeposition under ultrasonic conditions, and belongs to the technical field of electrodeposition. The method combinesadvantages of both pulse electrodeposition and ultrasonic conditions, and electrodeposits to prepare the Pt-based catalyst by separately preparing a desired salt solution as an electroplating solutionin an aqueous solution, an organic solvent or an ionic liquid, and using a carbon material as a carrier, and using a pulse power supply to set different pulse electrodeposition current densities, current on-off time ratios (ton / toff), temperatures and other process parameters. According to the invention, the method for preparing the Pt-based catalyst by combining the pulse electrodeposition withthe ultrasonic conditions is simple in process operation, environmentally-friendly and strong in condition controllability; and the prepared Pt-based catalyst is small in average particle size, largein specific surface area and firm to bond with the carrier.

Owner:DALIAN UNIV OF TECH

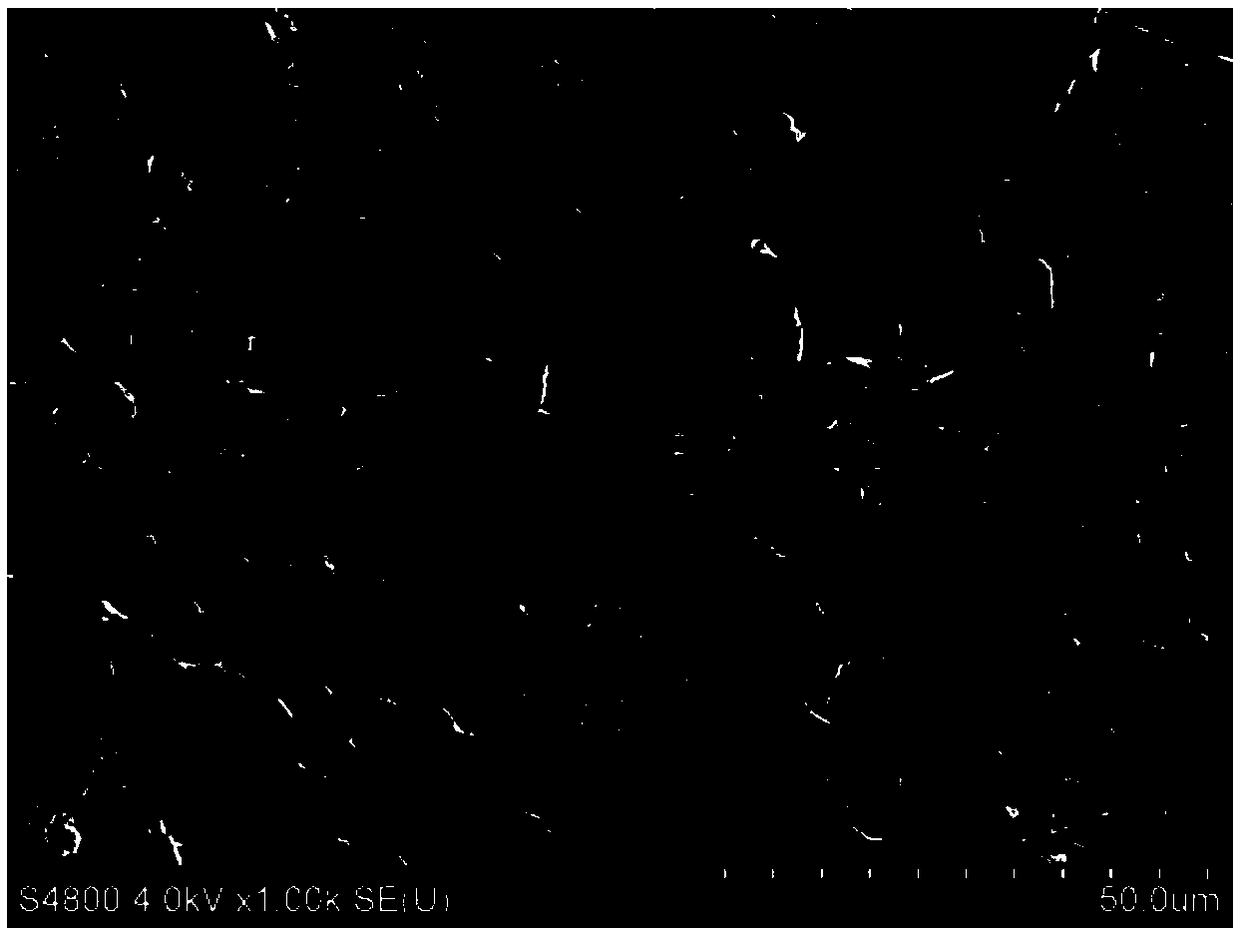

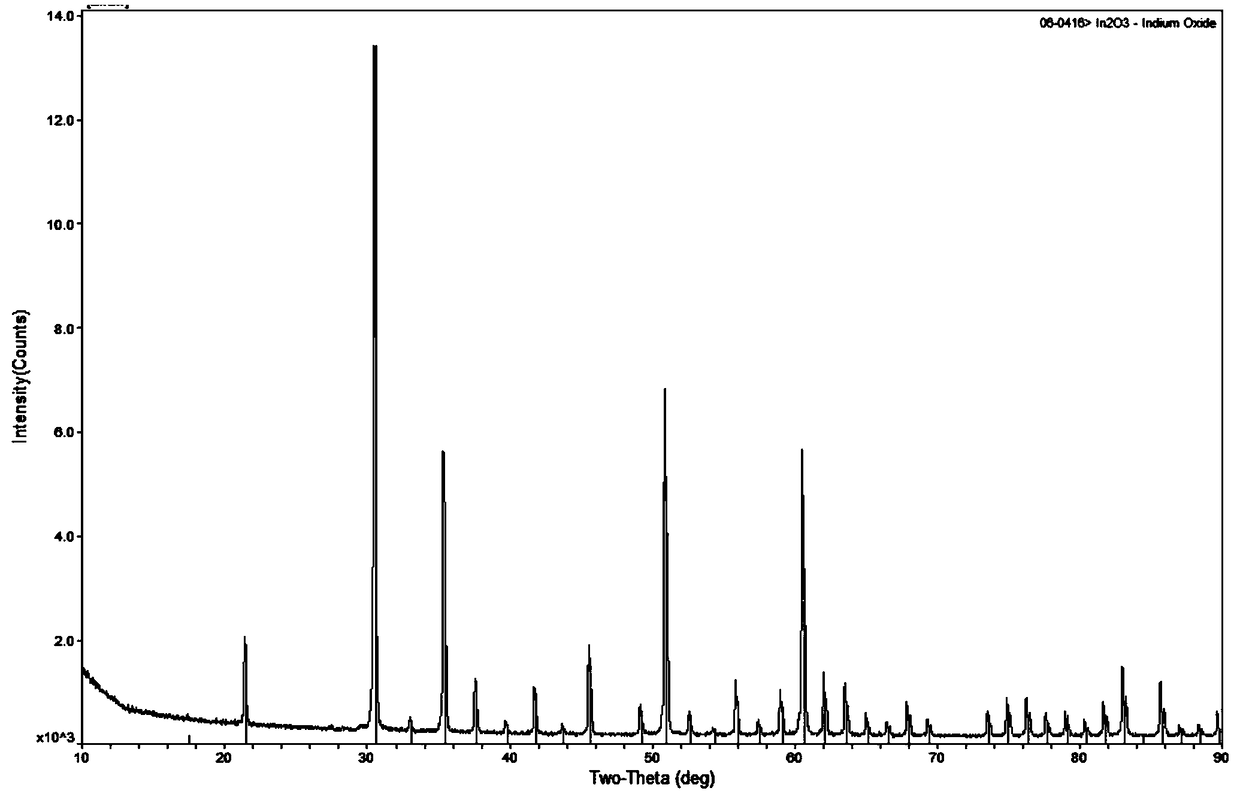

Preparation method of indium tin oxide (ITO) ceramic target material

The invention discloses a preparation method of an indium tin oxide (ITO) ceramic target material. The method includes steps of: 1) during molding process of a ceramic green body, performing pressuremaintenance to a mold and temperature maintenance at 150-220 DEG C for 10-50 min, so that a microcell hydrothermal reaction among the particles in the green body is carried out, and achieving objectsof material transfer and round and smooth granules; 2) heating the mold to 270-400 DEG C, and maintaining the pressure and temperature at the temperature for 10-50 min to achieve supercritical treatment of water among the particles, so that the inorganic substances dissolved in water are uniformly separated out at crystal boundary, thus finally achieving intercrystalline welding effect and furthereffectively increasing the compactness of the green body, which is beneficial to reduction of the compactness and sintering temperature of the ITO target material. The method achieves compact sintering at lower than 1500 DEG C. The ITO target material is 5-10 [mu]m in grain size and is higher than 99.5% in relative density. The internal structures are all a cubic phase structure of indium oxide in the material without generation of any secondary phase substances.

Owner:宁波纳诺特新材料科技有限公司

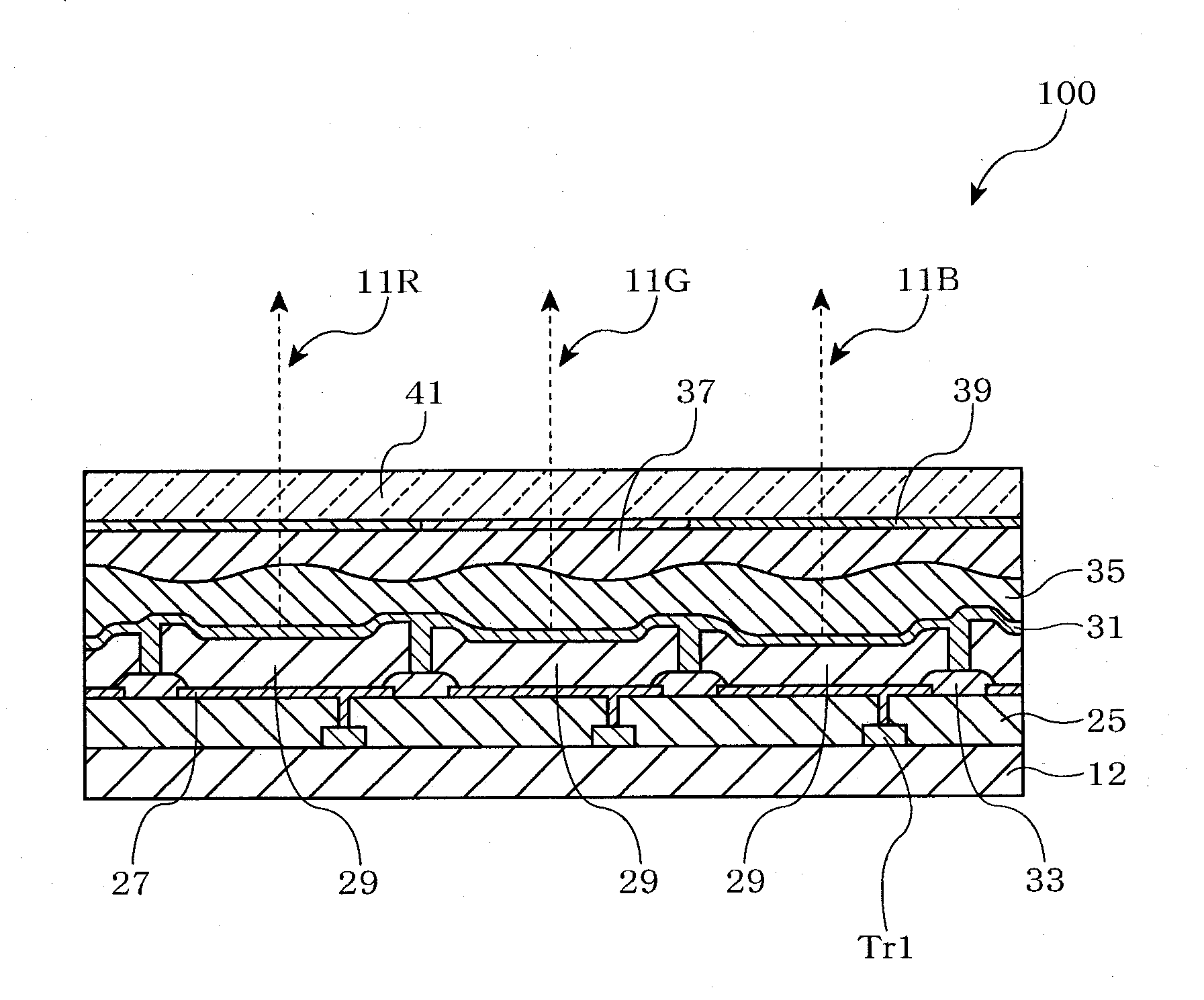

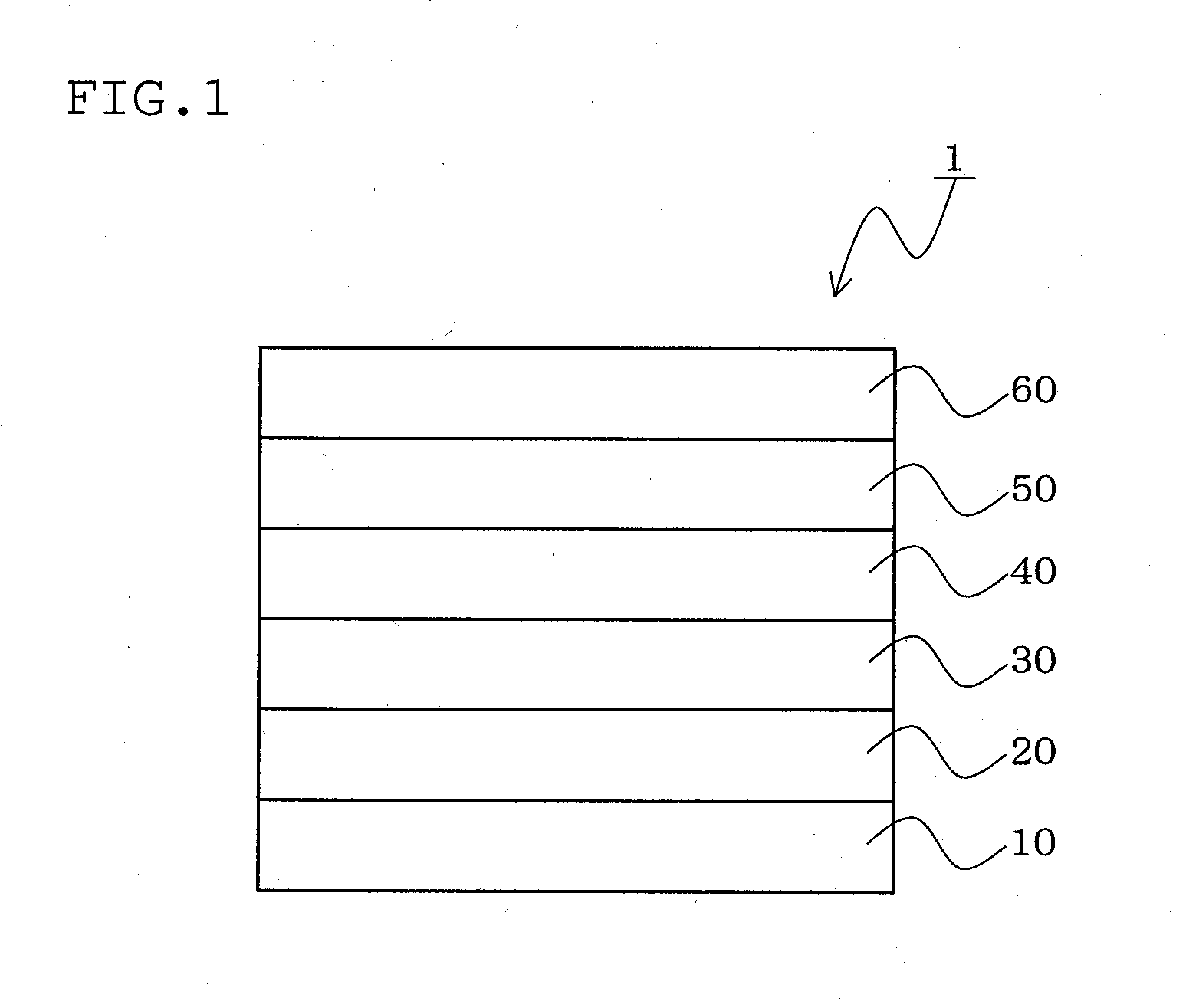

Material for organic electroluminescent device, organic electroluminescent device, and organic electroluminescent display

ActiveUS20100181555A1Reduce voltageImprove heat resistanceOrganic chemistryElectroluminescent light sourcesArylHalogen

A material for an organic electroluminescent device including an imine derivative represented by the following formula (Ia) or (Ib),wherein Y1 to Y4 are independently a carbon atom or a nitrogen atom; R1 to R4 are independently hydrogen, an alkyl group, an aryl group, a heterocycle, a halogen atom, a fluoroalkyl group or a cyano group; and R1 and R2, or R3 and R4 may be bonded together to form a ring.

Owner:IDEMITSU KOSAN CO LTD +1

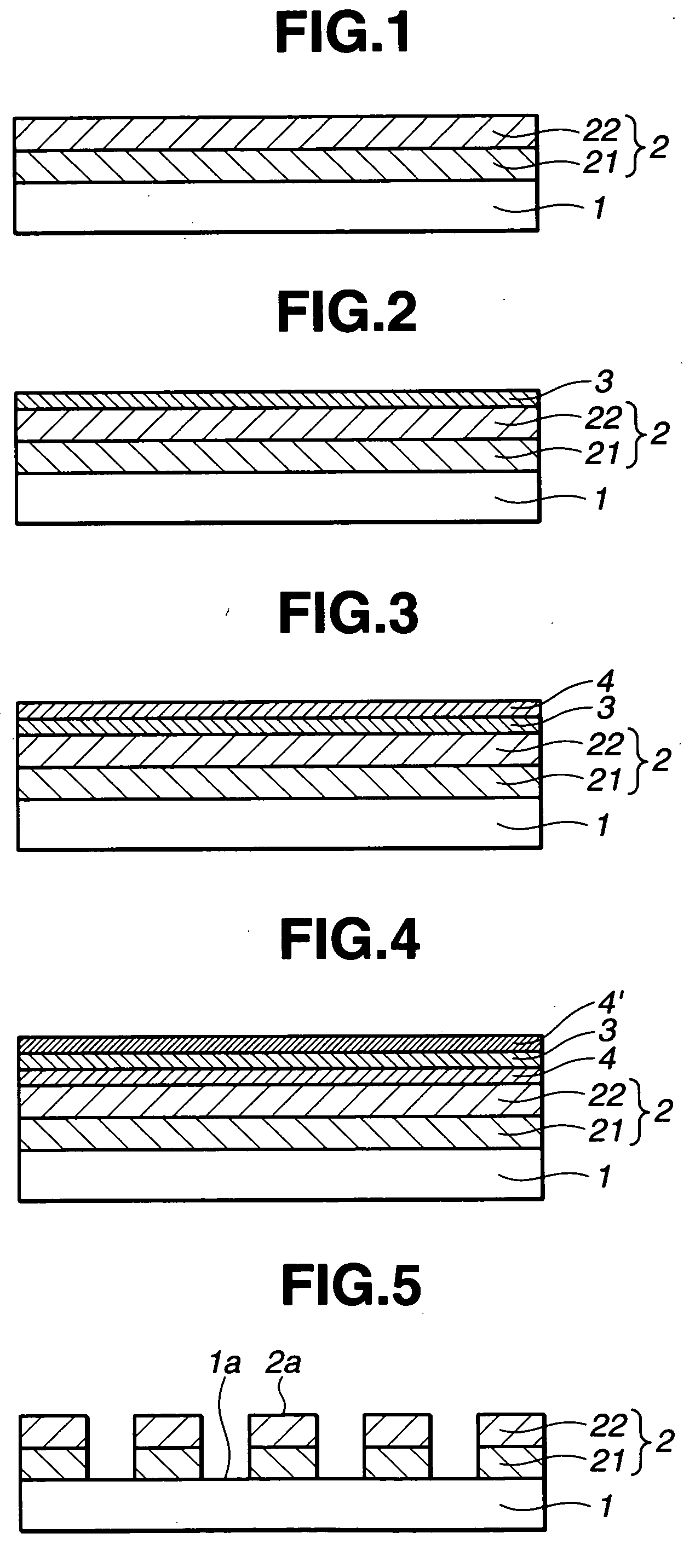

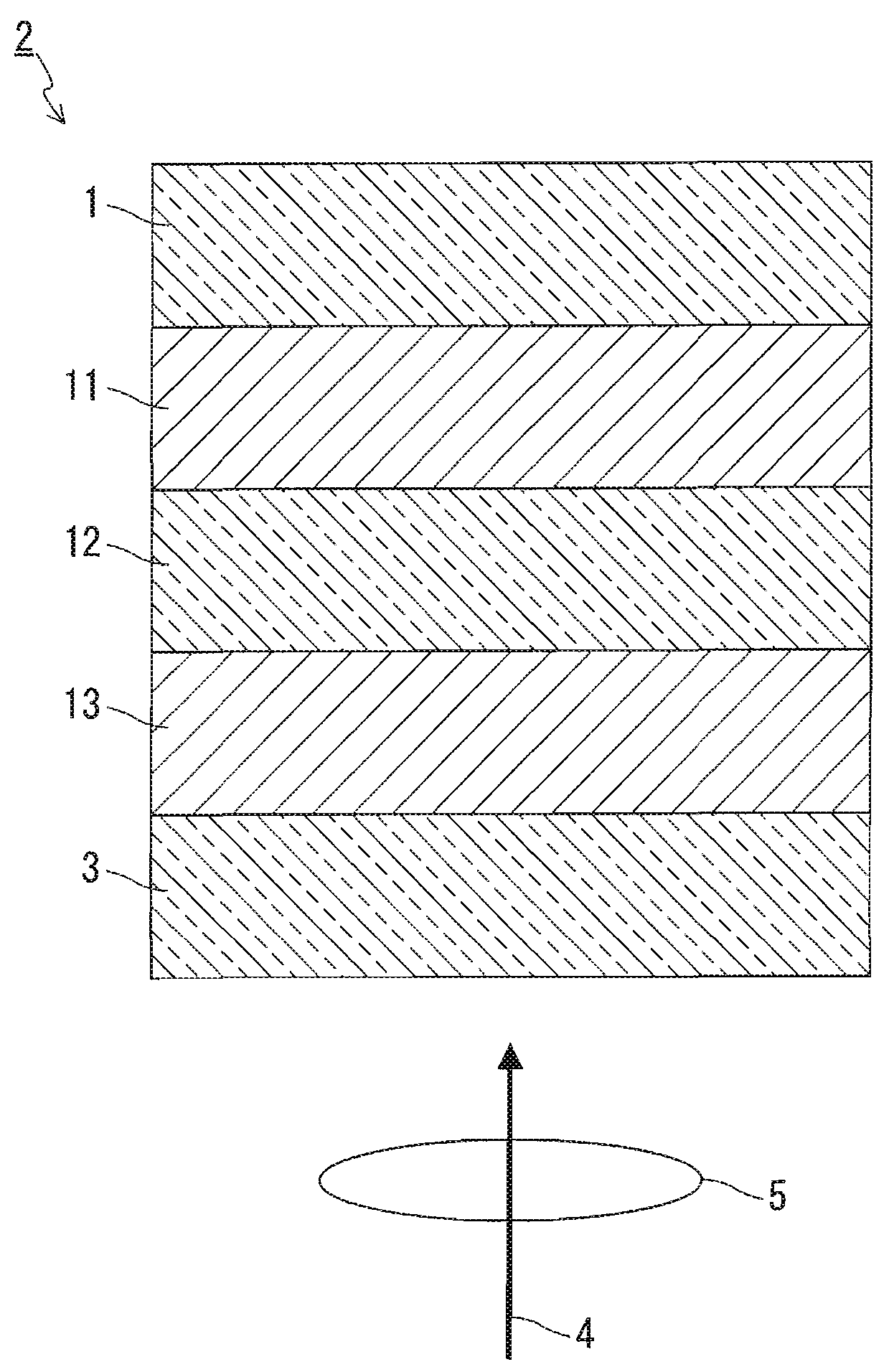

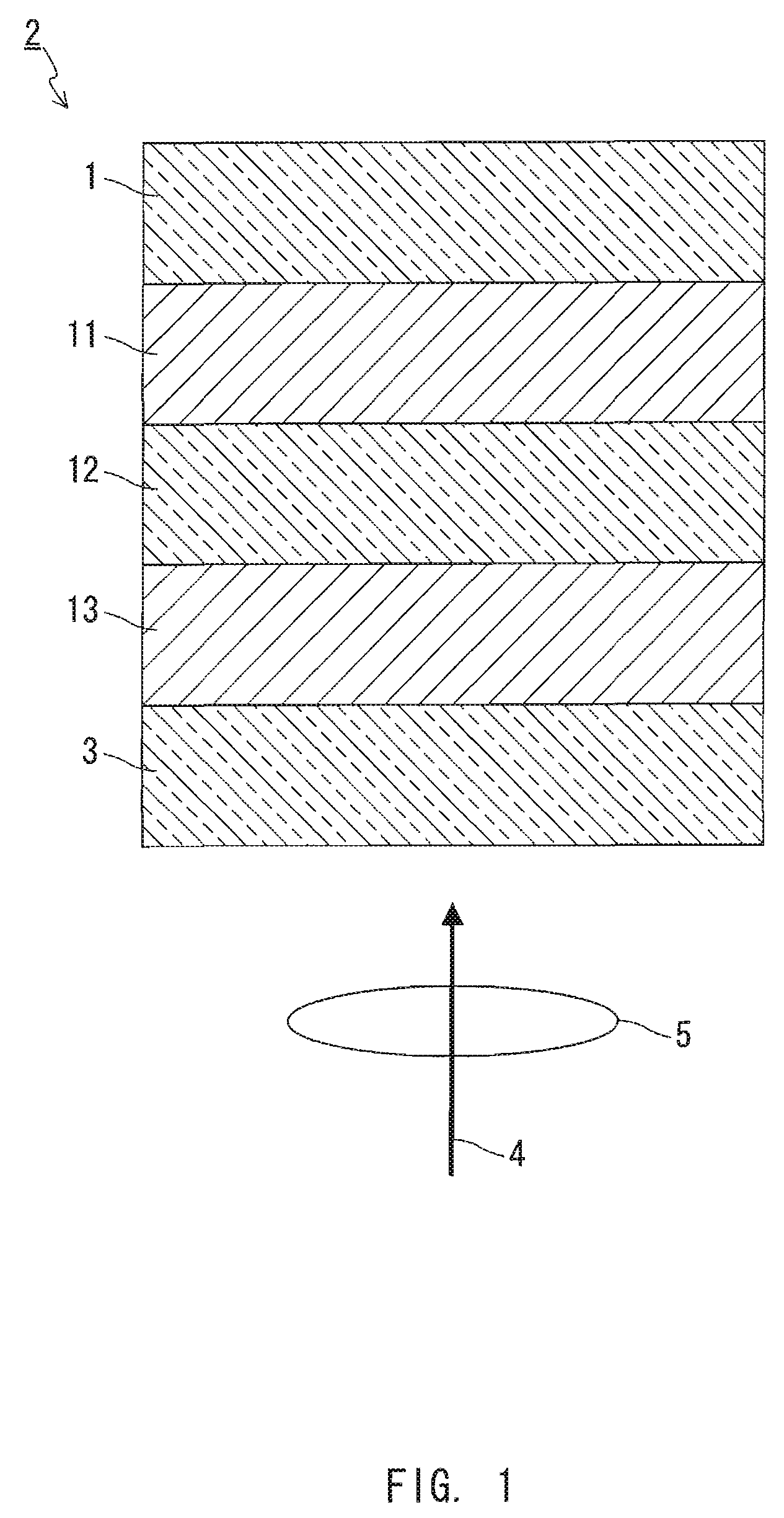

Information recording medium and method for manufacturing same

InactiveUS20090086608A1High transmittanceGood characteristicLayered productsPhotomechanical apparatusPhysicsTransmittance

An information recording medium of the present invention includes N information layers on a substrate (1), where N is an integer of 2 or more. Information is recorded / reproduced by irradiating each of the information layers (11, 12) with a laser beam (4). When the N information layers are referred to as a first information layer to an N-th information layer sequentially from the opposite side to a laser beam incident side, the L-th information layer included in the N information layers includes at least a recording layer (135) capable of undergoing a phase change through laser beam irradiation, a reflective layer (132), and a transmittance adjusting layer (131) in this order from the laser beam incident side, where L is an integer satisfying 2≦L≦N. The transmittance adjusting layer (131) contains Nb, oxygen (O), and at least one element M selected from Ti, Zr, Hf, Y, Cr, Zn, Ga, Co, Bi, In, Ta, and Ce. In the transmittance adjusting layer (131), the content of Nb is at least 2.9 atom %.

Owner:PANASONIC CORP

Method of atmospheric pressure plane discharge chemical gaseous phase depositing nano-particular film and its device

InactiveCN1786262ARealize the structureDeposition stabilityChemical vapor deposition coatingGas phaseEngineering

The invention relates to an atmosphere pressure plane discharging chemical vapor deposition nanometer membrane granulose method and equipment. Its features are setting airflow divider in the reactor to make airflow uniformly flow through the discharging area and form film; setting different plane discharging unit in the reactor, increasing and reducing the cross distance to adjust deposited film component, and form crystalline state film; applying static high-voltage field to adjust forming predecessor and spatial configuration to adjust and control the film growth appearance.

Owner:DONGHUA UNIV

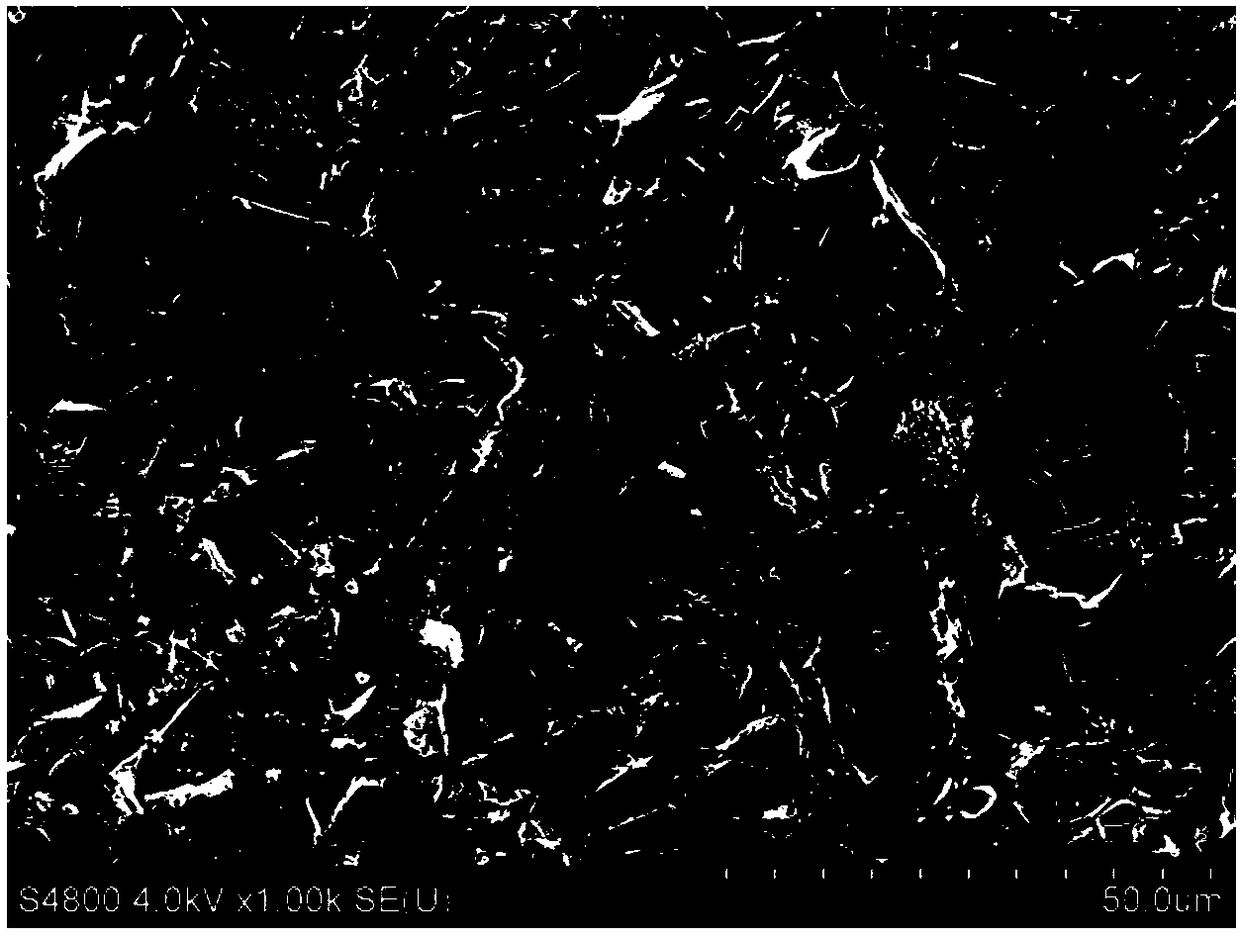

Preparation method of lithium-philic carbon nanotube paper and preparation method of composite metal lithium negative electrode

PendingCN112176772AStable lithium depositionInhibition of lithium dendrite growthMaterial nanotechnologySpecial paperMetallic lithiumPapermaking

The invention provides a preparation method of lithium-philic carbon nanotube paper. The preparation method specifically comprises the following steps: uniformly mixing carbon nanotube powder and lithium-philic nano material powder, and carrying out papermaking to form a film by using a wet papermaking process. In order to improve the film strength under low thickness, nanocellulose can be added,then the film is heated in an inert gas environment to enable the lithium-philic nano material and the carbon nano tube to be tightly combined, and the nanocellulose is carbonized to form the carbon nano fiber with the lithium-philic surface. According to the prepared lithium-philic carbon nanotube paper, better chemical contact exists between the lithium-philic nano material and the carbon nanotubes, and the lithium-philic nano material in the carbon nanotubes is wide in dispersion and stable in deposition; the lithium metal negative electrode prepared by the method has the effects of inhibiting lithium dendritic crystal growth and modifying solid electrolyte interface film components, and also has the effects of providing space for lithium metal deposition, reducing the nucleation barrier of lithium deposition, remarkably improving the cycle stability of the lithium metal negative electrode and prolonging the cycle life of the lithium metal negative electrode.

Owner:柔电(武汉)科技有限公司 +1

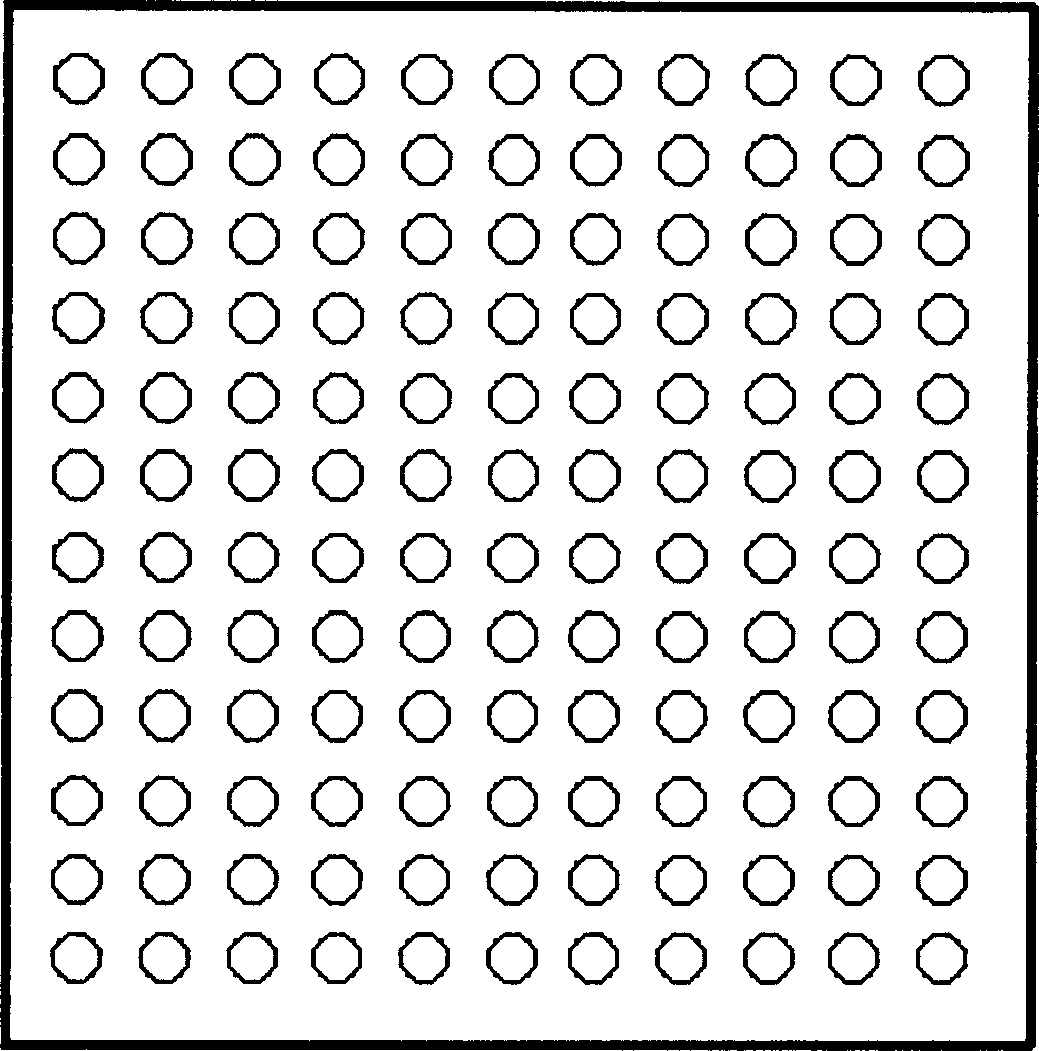

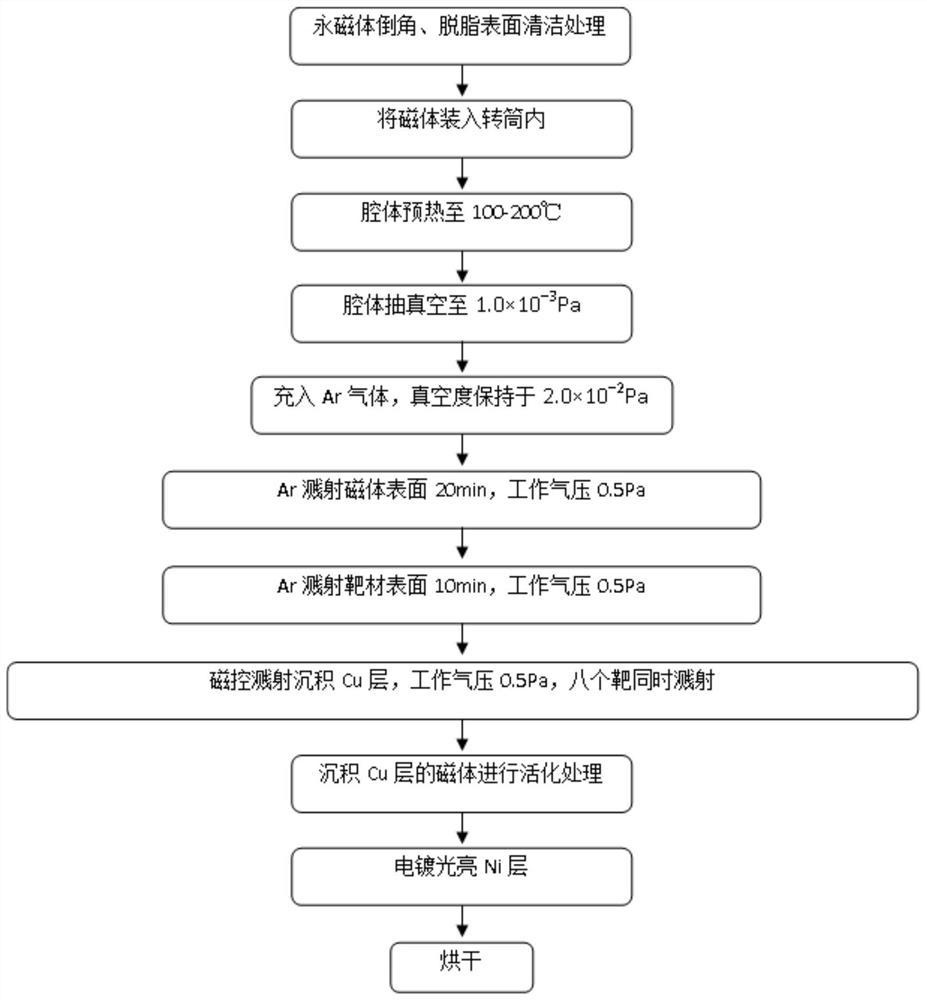

Preparation method of ultrathin neodymium-iron-boron permanent magnet surface protective coating

ActiveCN112725751ASolve the problem of magnetic performance degradationMagnetic does not affectVacuum evaporation coatingSputtering coatingSurface cleaningCopper

The invention discloses a preparation method of an ultrathin neodymium-iron-boron permanent magnet surface protective coating. The method comprises the steps that direct current magnetron sputtering coating is performed on a neodymium-iron-boron magnet subjected to surface cleaning treatment to obtain a neodymium-iron-boron magnet with a copper gradient coating deposited on the surface; surface pretreatment is performed on the obtained neodymium-iron-boron magnet with the copper layer deposited on the surface, and then a nickel-based coating is applied to obtain the neodymium-iron-boron magnet with the Cu-Ni combined coating deposited on the surface; in the sputtering process, power supplies of a Cu-Sn target and a Cu target are turned on, and the Cu-Sn target and the Cu target are sputtered at the same time; the initial power of the Cu-Sn target is 120 W and is gradually reduced according to the speed of 3-5 W / min in the sputtering process until the Cu-Sn target is turned off; and the power of the Cu target is 150 W and is always kept unchanged, and the time is 1.5-3.0 hours. The ultrathin permanent magnet combines the advantages that a prepared film layer is deposited firmly and is compact and resistant to corrosion due to the fact that acid pickling pretreatment is not required in a magnetron sputtering technology, and the problem that the magnetic performance is reduced due to the fact that an acid pickling solution and an electroplating solution erode a matrix structure in the surface treatment process of the permanent magnet is solved.

Owner:TAIYUAN UNIV OF TECH

Pulse-assisted electrochemical deposition metal pipeline inner wall coating device and preparation method

The invention relates to the technical field of non-traditional machining, in particular to a pulse-assisted electrochemical deposition metal pipeline inner wall coating device and a preparation method. The device comprises a servo motor, a cable winder, a cable, a liquid storage tank, a plating bin, a sealing rubber ring, an anode pipe sleeve, a liquid absorption cotton felt, an anode conductive bolt, a cathode conductive probe, a pulse power supply and a pipe orifice cable guide anti-abrasion roller sleeve. The liquid absorption cotton felt outside the plating bin clings to the inner wall of the pipeline for plating, the electrolyte storage and supply circulating filtration system supplies electrolyte to the plating bin, and the pulsed power supply generates an electric field at the contact part of the inner wall of the pipeline and the plating bin through the anode conductive bolt and the cathode conductive probe, so that positive ions in the electrolyte are deposited on the surface of the inner wall of the pipeline to form a plating layer. And by adjusting the feeding speed, the current density, the electrolyte circulating speed, the pH value, the temperature and the like, the pipeline inner wall coating which is good in uniformity, compact in structure and good in film-substrate binding force is prepared.

Owner:HENAN INST OF SCI & TECH

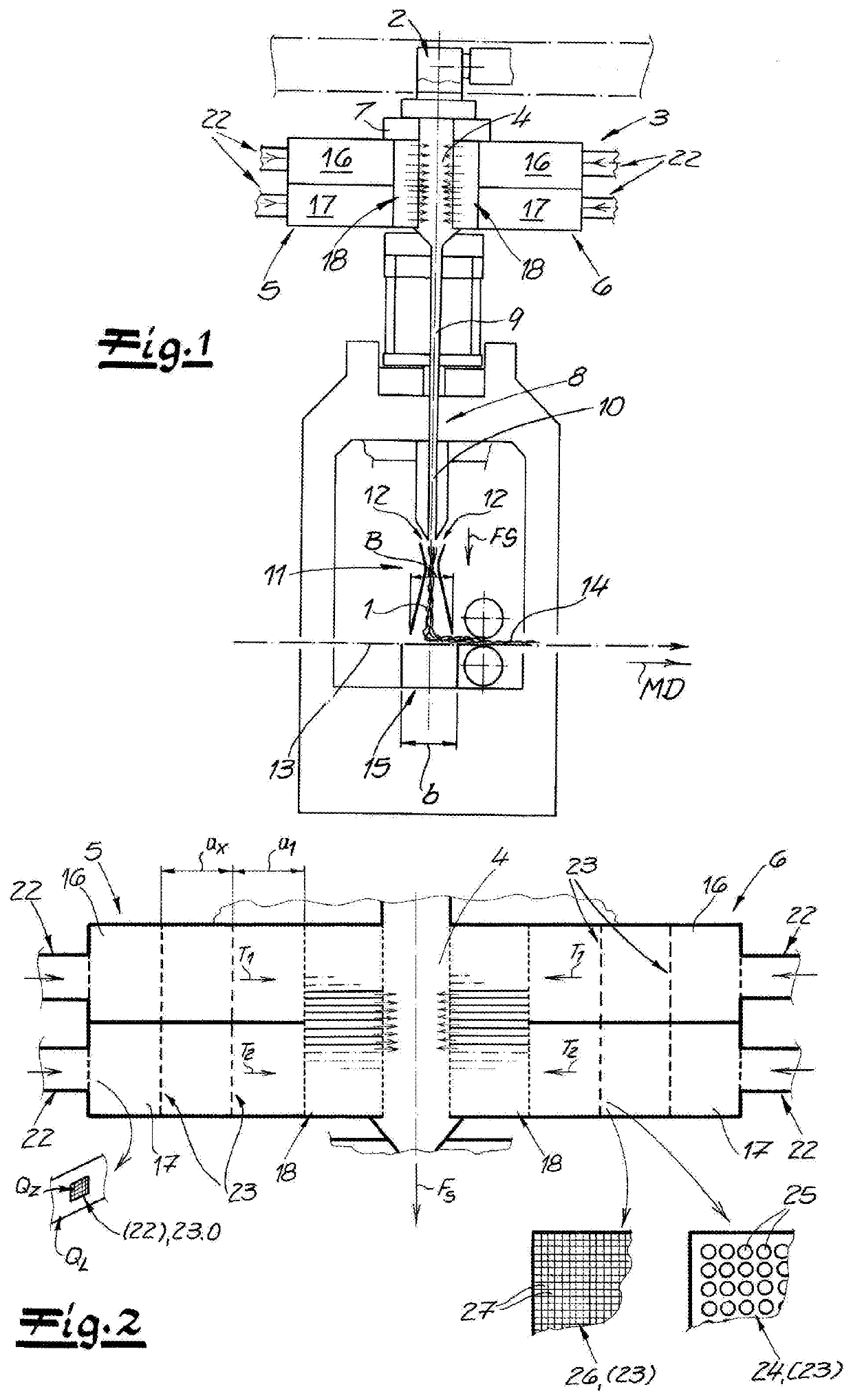

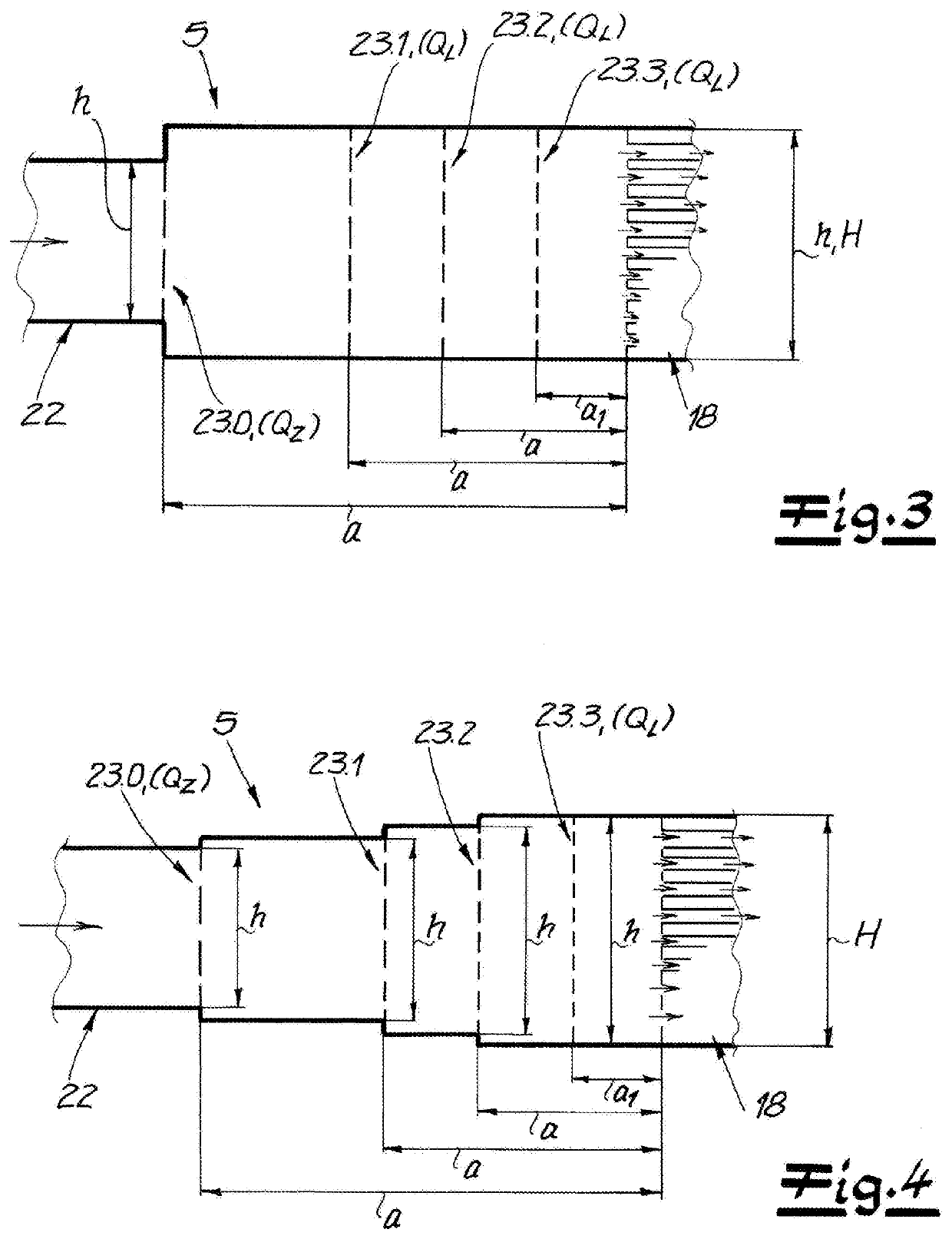

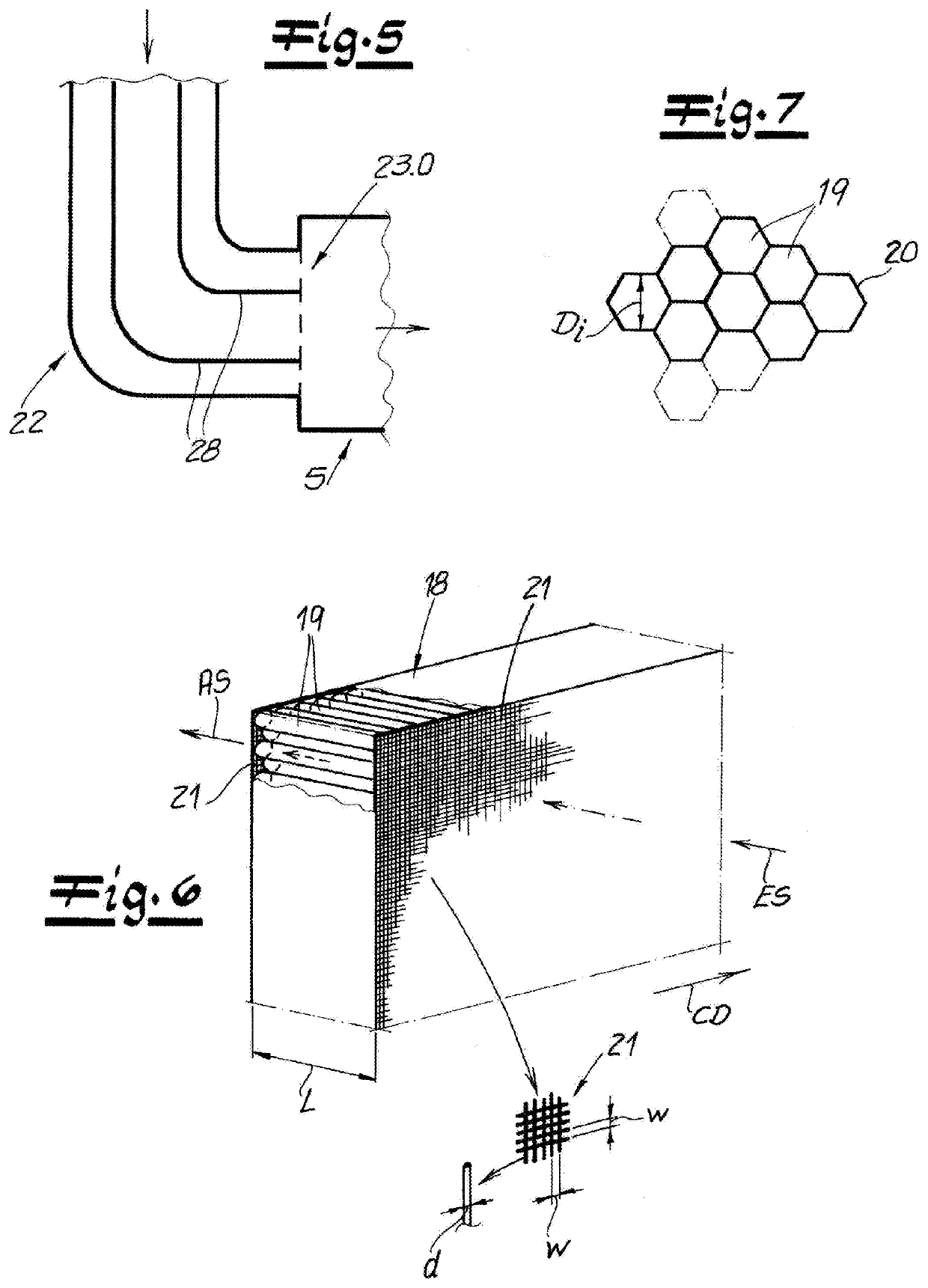

Manufacture of spun-bonded nonwoven from continuous filaments

ActiveUS20190360138A1Achieve speedLittle equipment setupArtificial thread manufacturing machinesFilament/thread formingCooling chamberAirflow

An apparatus for making spunbonded nonwovens has a spinneret for emitting continuous thermoplastic filaments in a filament-travel direction, a cooling chamber downstream in the direction from the spinneret for cooling the spun filaments with cooling air, two manifolds on opposite sides of the cooling chamber opening transversely of the direction into the cooling chamber, and a respective conduit having a conduit cross-sectional area and connected to each manifold for feeding cooling air thereto. The conduit cross-sectional area increases toward the manifold to a manifold cross-sectional area, and manifold cross-sectional area is at least twice as large as the conduit cross-sectional area. At least one flow straightener is provided upstream from the cooling chamber in each manifold for orienting air flow in an air-flow direction, and at least one perforated planar homogenizing element is provided in each manifold for homogenizing the cooling air flow.

Owner:REIFENHAUSER GMBH & CO

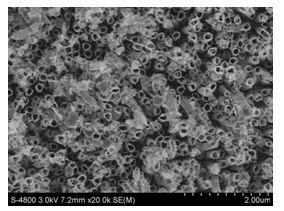

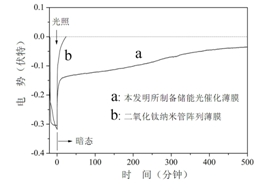

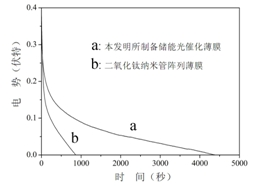

Preparation method of photocatalytic film with energy storage function

InactiveCN102677124AEvenly distributedDeposition stabilitySurface reaction electrolytic coatingCatalyst activation/preparationSolventCobalt

The invention relates to a preparation method of a photocatalytic film with an energy storage function. The method includes the following steps: mixing deionized water and glycol at mass ratio of 1:4; preparing ammonium fluoride solution with concentration of 0.25% through the mixed solvent of water and glycol; adding the ammonium fluoride solution into a reaction container, taking a titanium sheet as the anode and a platinum sheet as the cathode, oxidizing the anode for four hours under the voltage of 40V to form a titanium dioxide nanotube array film on the surface of the titanium sheet; after the reaction is finished, washing, drying and annealing, then taking the sample as the cathode and the platinum sheet as the anode, putting the cathode and the anode into a 5mmol / L cobalt saline solution which contains 0.04-0.1% interfacial agent for DC(Direct Current) deposition, wherein the distance between the cathode and the anode is 2cm; and finally washing and drying. In such a way, the photocatalytic film with the energy storage function can be obtained. The titanium dioxide nanotube array film prepared through the method has great bonding strength with a titanium matrix and the film has bigger specific surface area, which is good for the improvement and enhancement of the photocatalytic performance.

Owner:HEBEI UNIV OF TECH

Preparation method of plant antibacterial, antiviral, skin-care and health-care cellulose fibers

ActiveCN112210846ADeposition stabilityComplexation realizationConjugated cellulose/protein artificial filamentsCellulose/protein filament chemical after-treatmentBiotechnologyPhenolic content in tea

The invention provides a preparation method of plant antibacterial, antiviral, skin-care and health-care cellulose fibers. The preparation method is characterized by comprising the steps of preparingof a blended spinning stock solution, spinning and aftertreatment. Tea polyphenol and zinc elements are used for endowing the fibers with excellent antibacterial and antiviral functions, meanwhile, operation is assisted by the skin-care and health-care functions of collagen, so that the prepared functional cellulose fibers have antibacterial, antiviral, skin-care and health-care functions, the inhibition rate on staphylococcus aureus is larger than or equal to 92.6%, the inhibition rate on escherichia coli is larger than or equal to 93.8%, the inhibition rate on candida albicans is larger thanor equal to 90.3%, the inactivation rate on influenza A viruses is larger than or equal to 85.6%, the inactivation rate on influenza B viruses is larger than or equal to 86.2%, and the inactivation rate on herpes viruses is larger than or equal to 82.8%. The fibers contain multiple kinds of amino acid trace elements, and therefore good skin-care and health-care functions are achieved.

Owner:潍坊欣龙生物材料有限公司

Additive manufacturing device and method based on meniscus constrained electrodeposition

PendingCN113355702AAchieve Z-direction extensionDeposition stabilityAdditive manufacturing apparatus3D structure electroformingPipetteEngineering

The invention discloses an additive manufacturing device and method based on meniscus constrained electrodeposition, and belongs to the technical field of additive manufacturing. The additive manufacturing device comprises a vibration isolation module, an additive manufacturing motion platform, a precision positioning module, a monitoring module and an electrode module. By utilizing a meniscus constrained electrodeposition technology, electrodeposition is carried out in a liquid meniscus between the tip of a transfer pipette and a conductive substrate, a liquid bridge extends in multiple directions under movement of a movable sliding table, the relative positions of the substrate and the transfer pipette are compensated through precise cooperation movement of a six-axis PI motion console and the movable sliding table, the stable liquid bridge is continuously kept between the substrate and the transfer pipette, and therefore a complex uniform deposition structure with high quality, high compactness and high surface smoothness is formed. Forward micro-additive manufacturing of the submicron glass transfer pipette is achieved in a real sense, mechanical micro-motion and a microfluid technology are integrated through a localized electrochemical technology, and the whole deposition process is more stable and has higher ductility.

Owner:CHANGCHUN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com