Patents

Literature

2192 results about "Pulse power supply" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

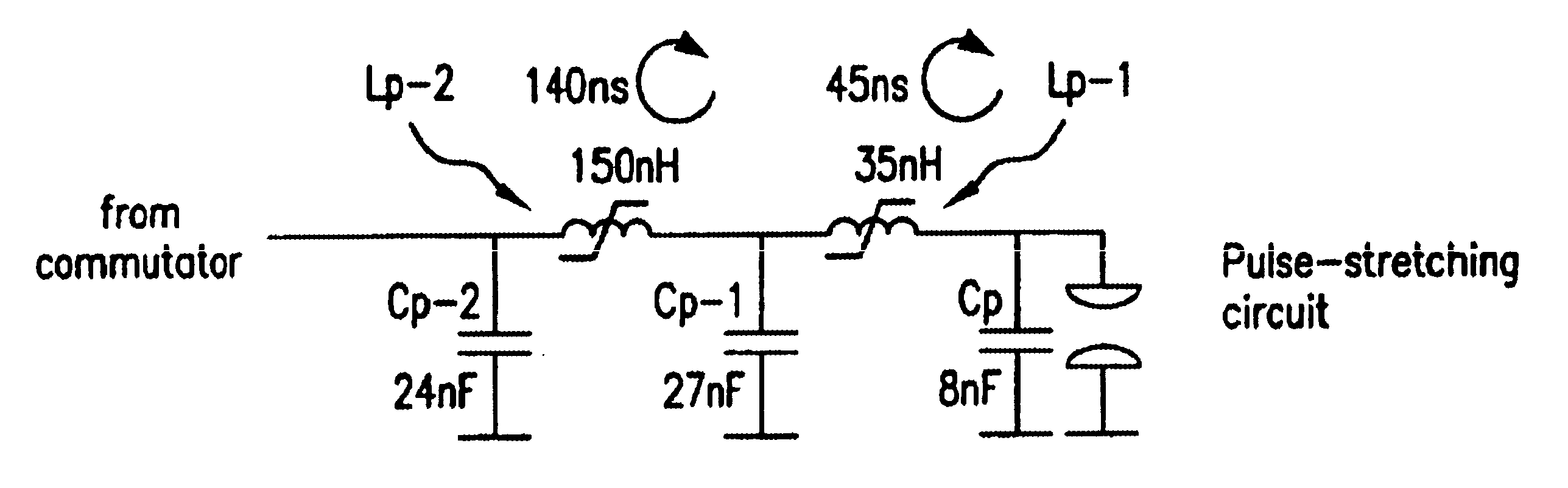

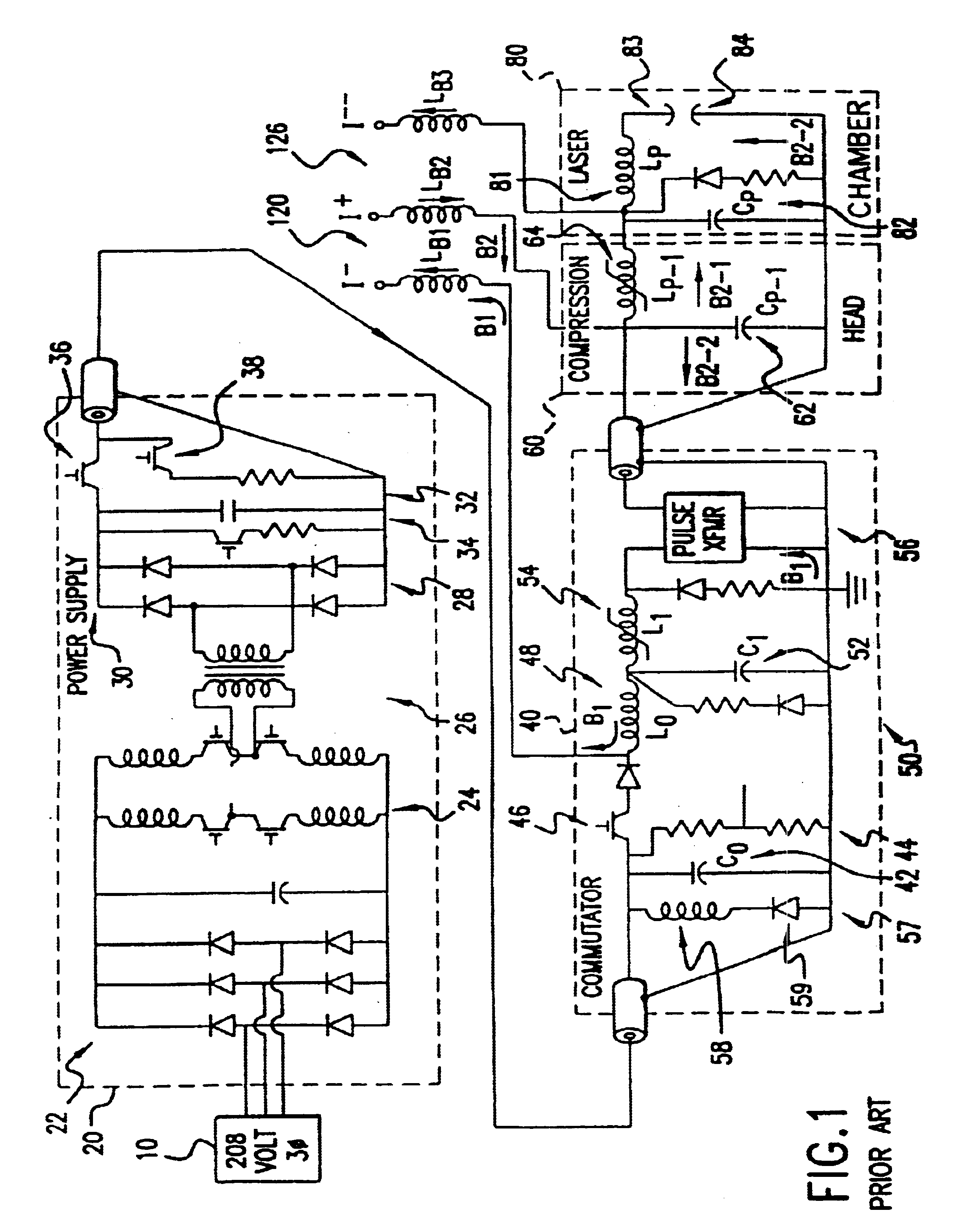

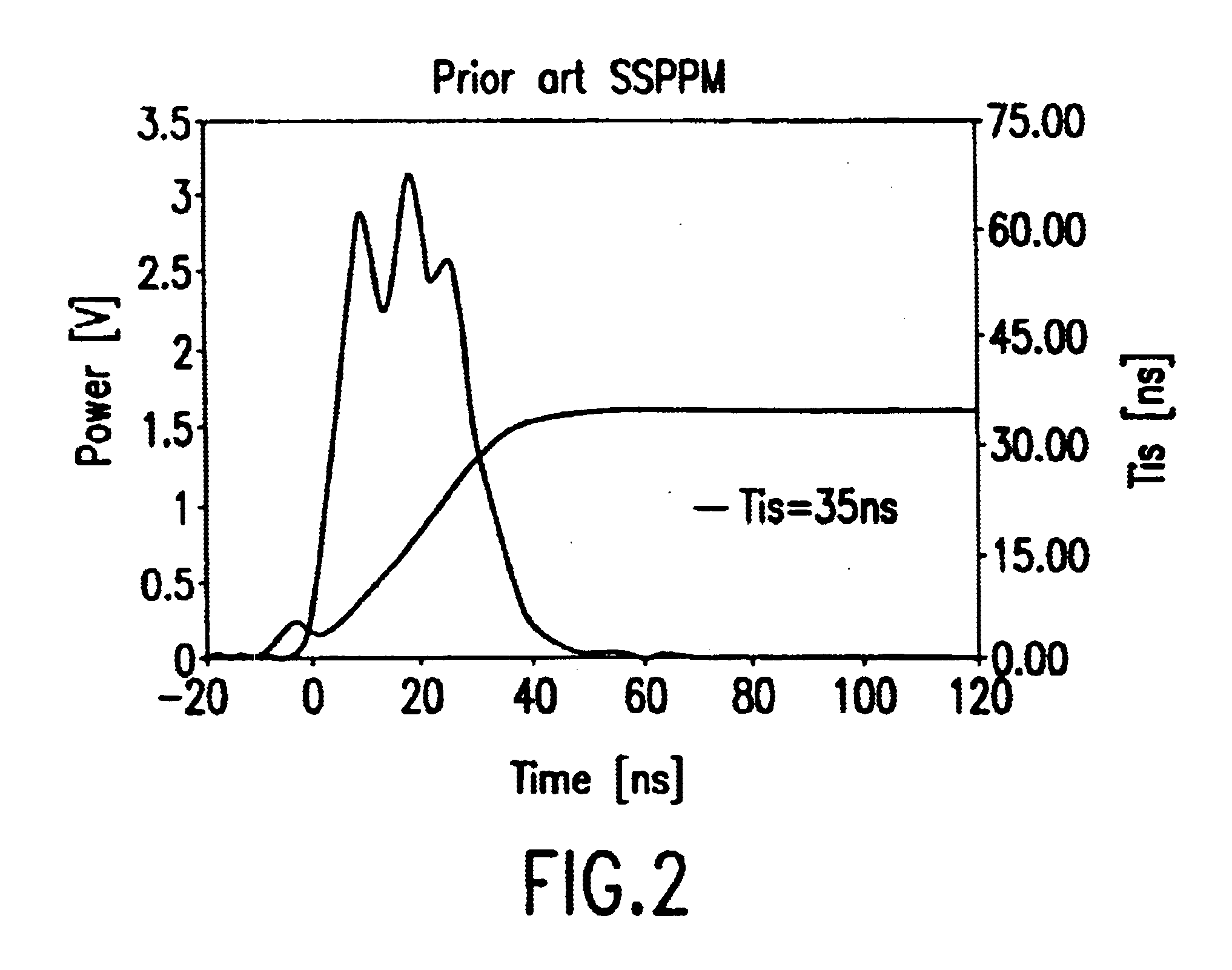

Long-pulse pulse power system for gas discharge laser

A long pulse power system for gas discharge lasers. The system includes a sustainer capacitor for accepting a charge from a high voltage pulse power source. A peaking capacitor with a capacitance value of less than half the sustainer capacitance provides the high voltage for the laser discharge.

Owner:CYMER INC

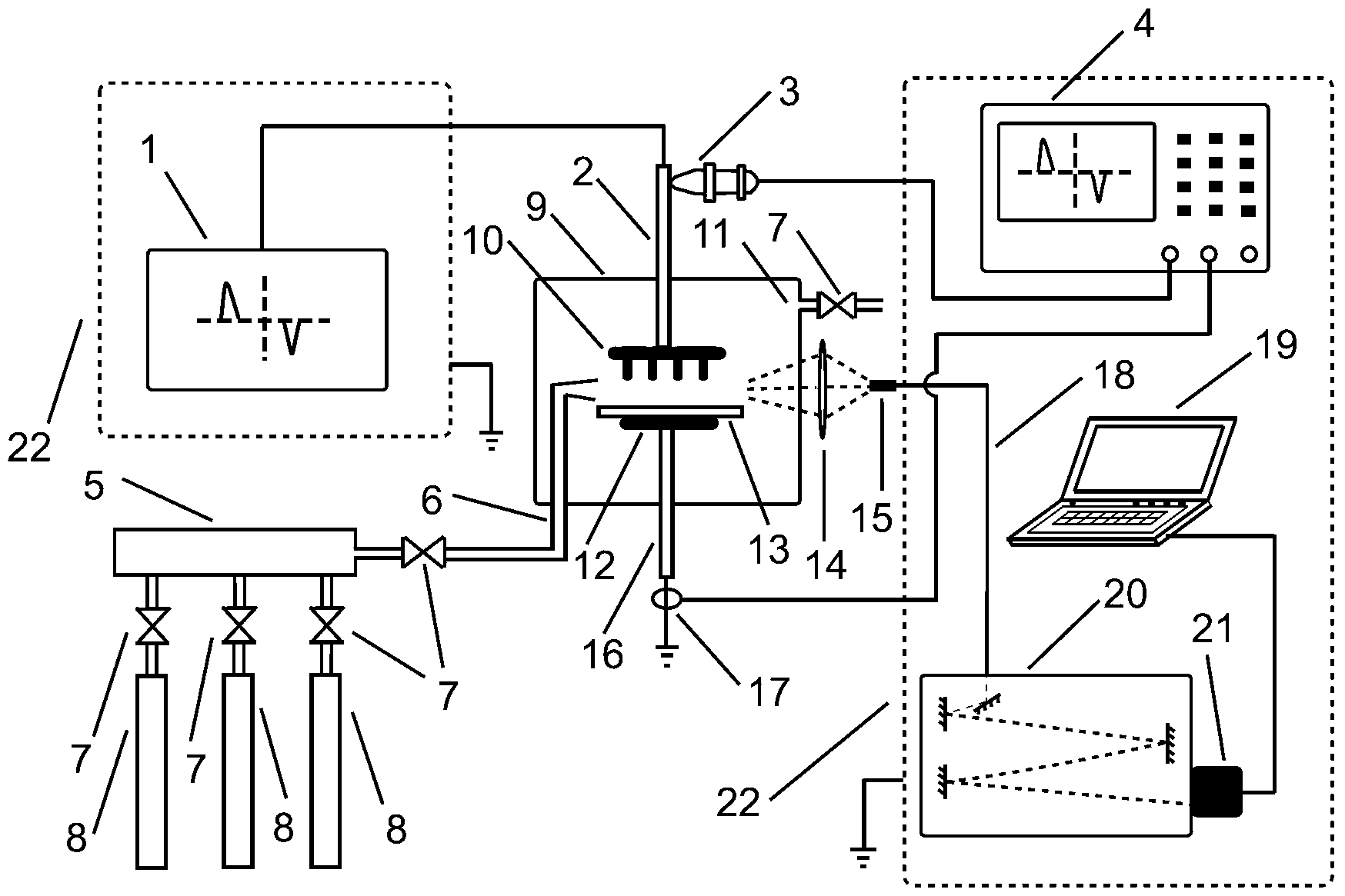

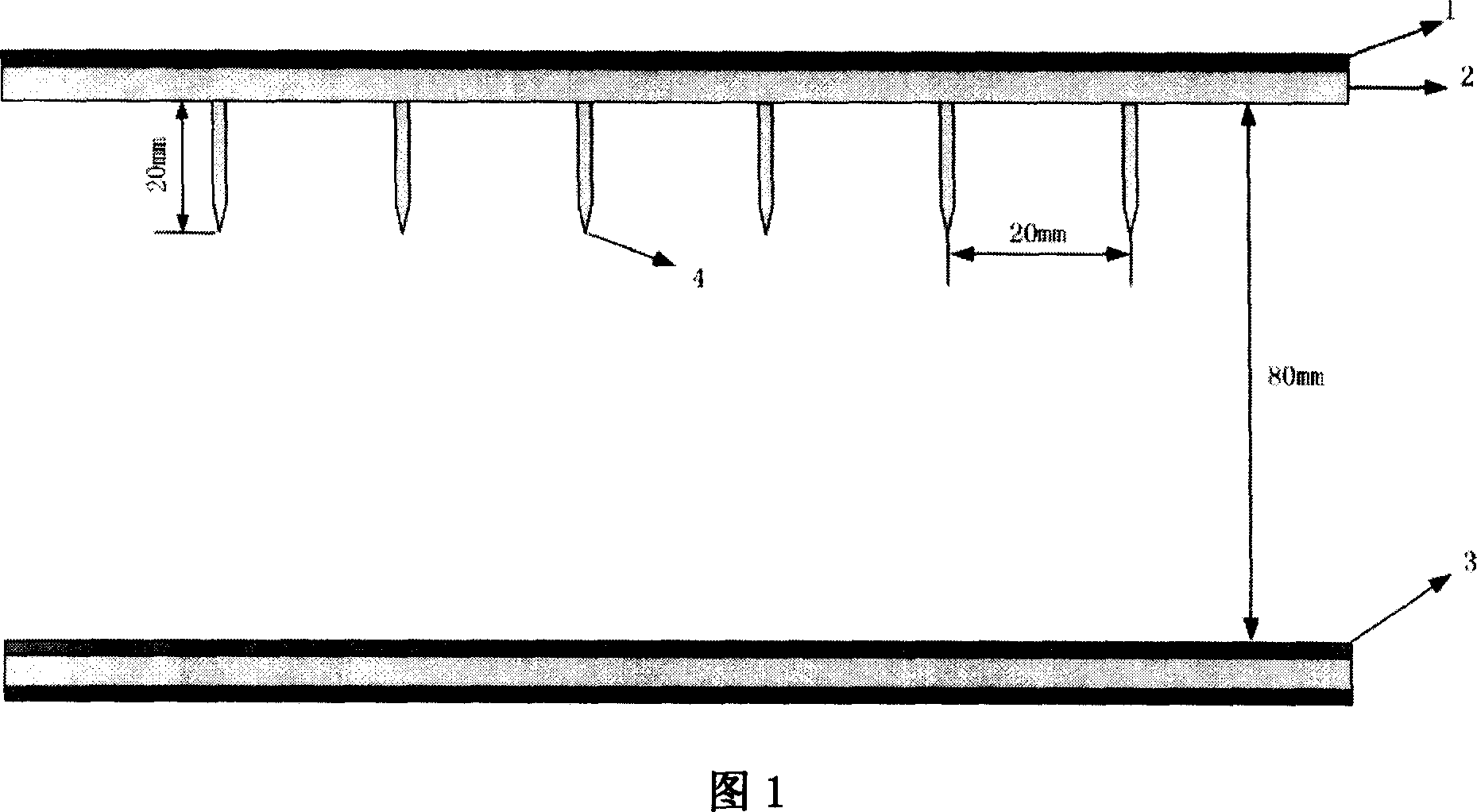

Experimental apparatus for acquiring large-area uniform discharge plasmas

InactiveCN103245655AIncrease electron densityImprove energy utilizationAnalysis by thermal excitationPlasma techniqueDischarge measurementsElectron density

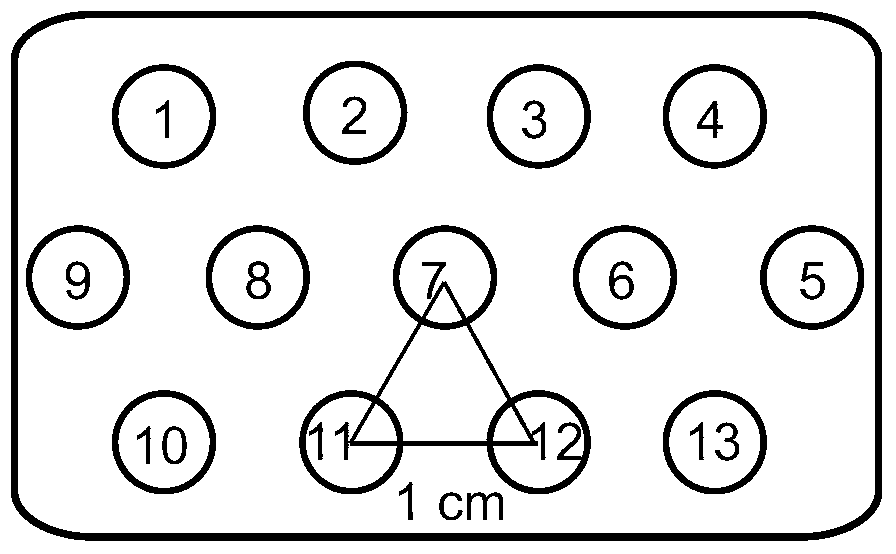

The invention relates to an experimental apparatus for acquiring large-area uniform discharge plasmas, which belongs to the technical field of plasmas. The experimental apparatus comprises a bipolar nanosecond pulse power supply, a reactor, multi-needle-to-plate electrodes, a gas distribution system, a spectral measurement system and a discharge measurement system, wherein the bipolar nanosecond pulse power supply drives dielectric barrier discharge of air and other gas mixtures among the multi-needle-to-plate electrodes in the reactor, and the gas mixtures are input to the reactor through the gas distribution system; the spectral measurement system collects photonic information of plasma discharge in real time and inputs the photonic information to a computer for spectral analysis; and the discharge measurement system collects discharge voltage and current of the high-voltage nanosecond pulse power supply in real time, and the discharge voltage and current are displayed through a digital oscilloscope. By virtue of the bipolar nanosecond narrow-pulse power supply, the large-area discharge plasmas are generated without a magnetic field; and the generated plasmas are uniform, diffusive, high in electron density, high in energy utilization ratio, low in energy consumption and easy to control in a discharge process.

Owner:DALIAN UNIV OF TECH

Plasma sterilizing-purifying device and method for air sterilizing and purifying

ActiveUS20120269677A1Improve reliabilityEasy to useMechanical apparatusLighting and heating apparatusVoltage pulseNickel chromium alloy

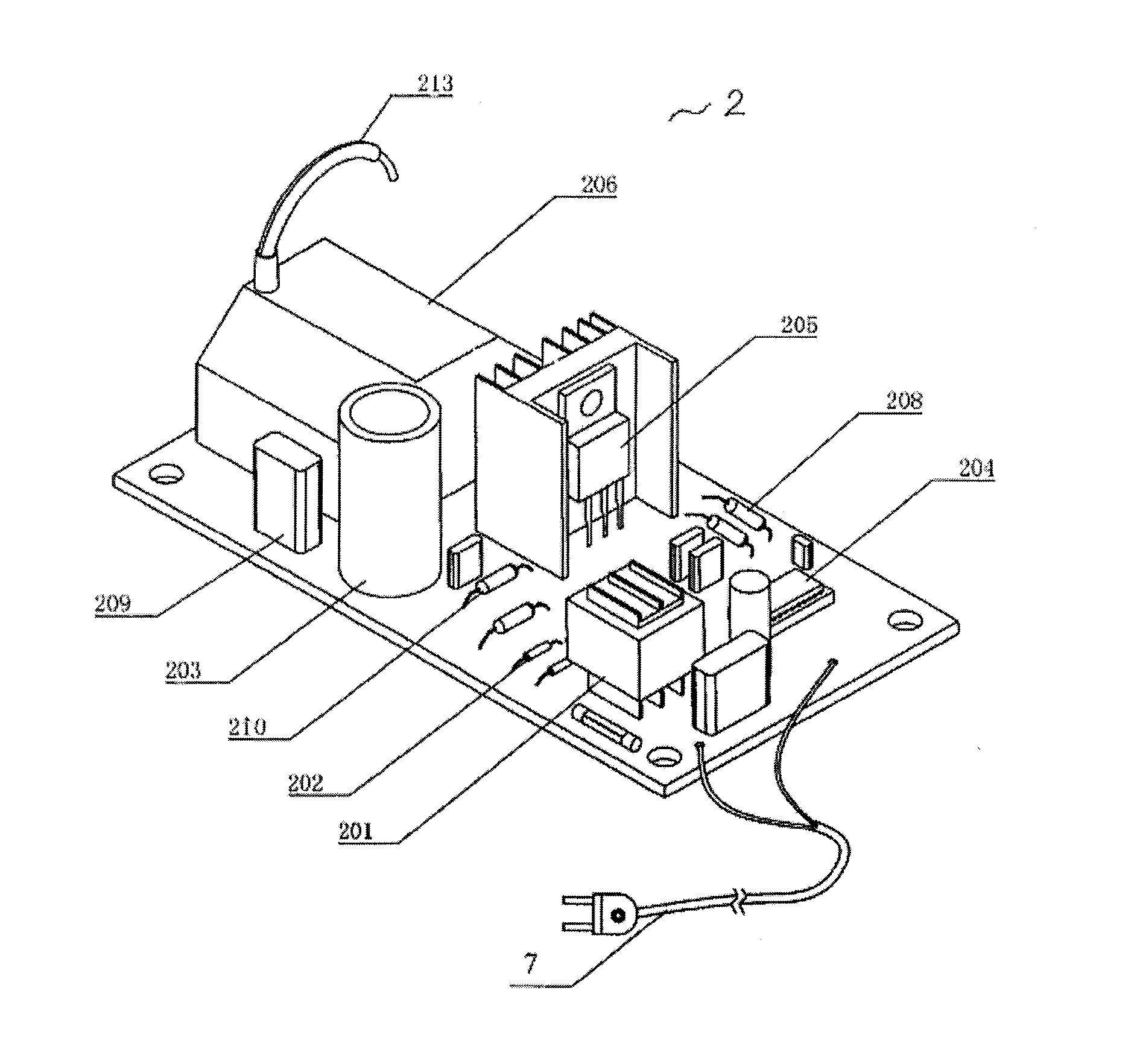

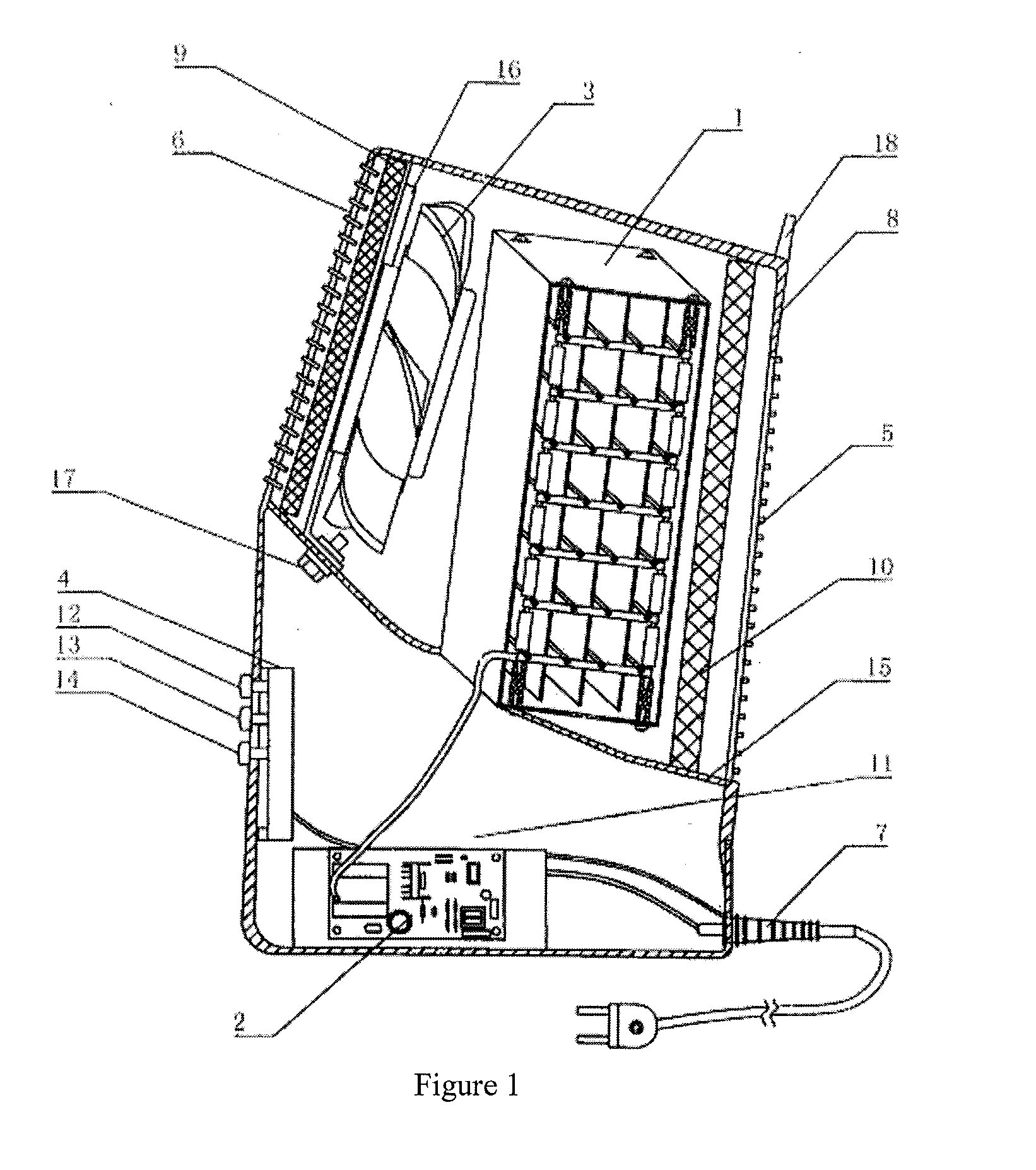

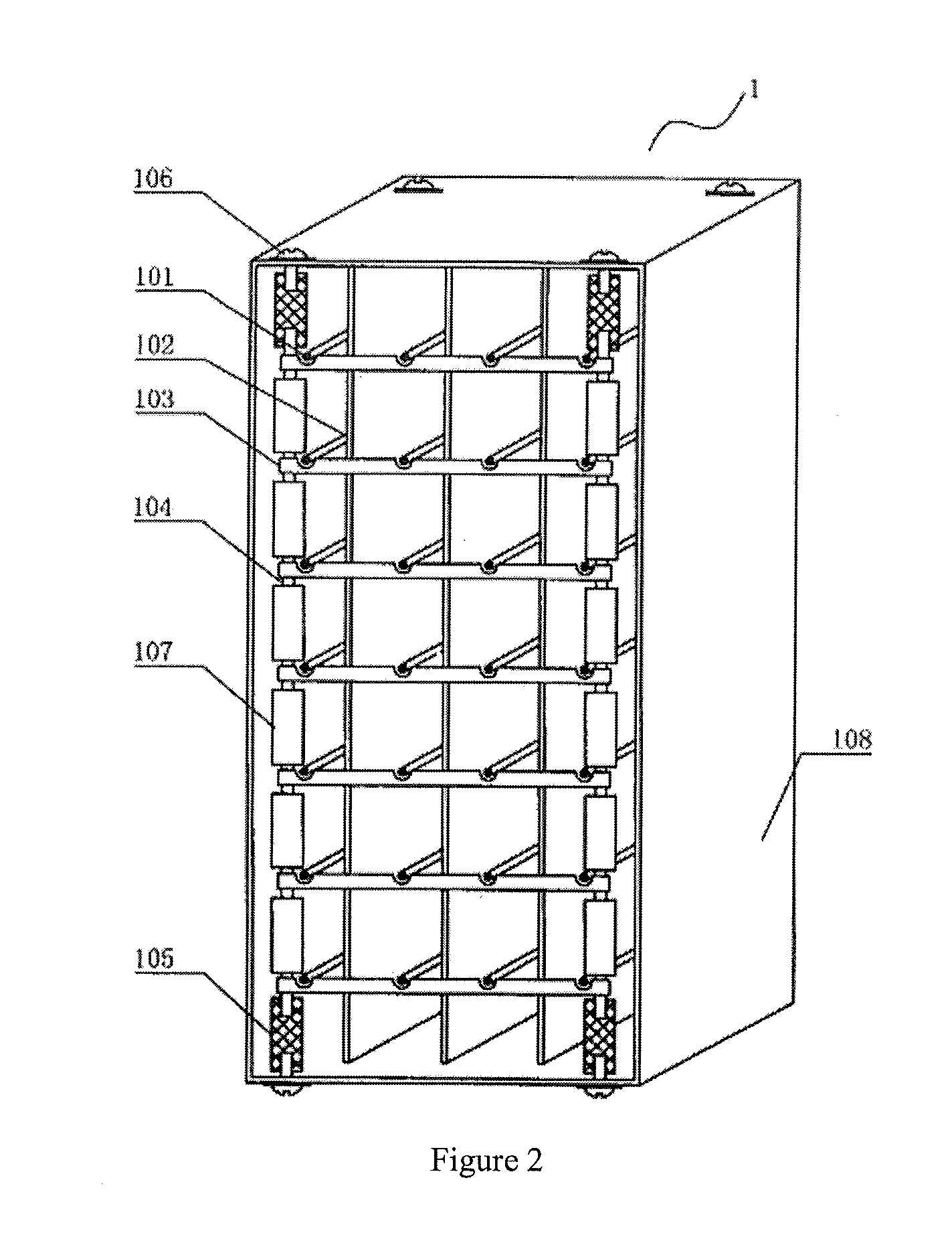

The present invention belongs to the technical field of air sterilizing and purification and in particular relates to a plasma air sterilizing and purifying device and an air sterilizing and purifying method. The plasma air sterilizing and purifying device comprises a plasma reactor, a pulse power supply, a fan component, a control device, a power adaptor, and a housing case, wherein the reactor is provided with positive electrodes formed by several nickel-chromium alloy wires or nickel-chromium alloy belts, and the two ends of each positive electrodes are fixed in the corresponding grooves on the micro-discharge preventive conductor rail; and a pulse power supply has a digital control circuit with an oscillator, an error amplifier and a PWM comparator inside which converts signals into a digital control current to control the width of the high-voltage pulse.

Owner:ZHEJIANG TIANQING ENVIRONMENTAL PROTECTION TECH CO LTD

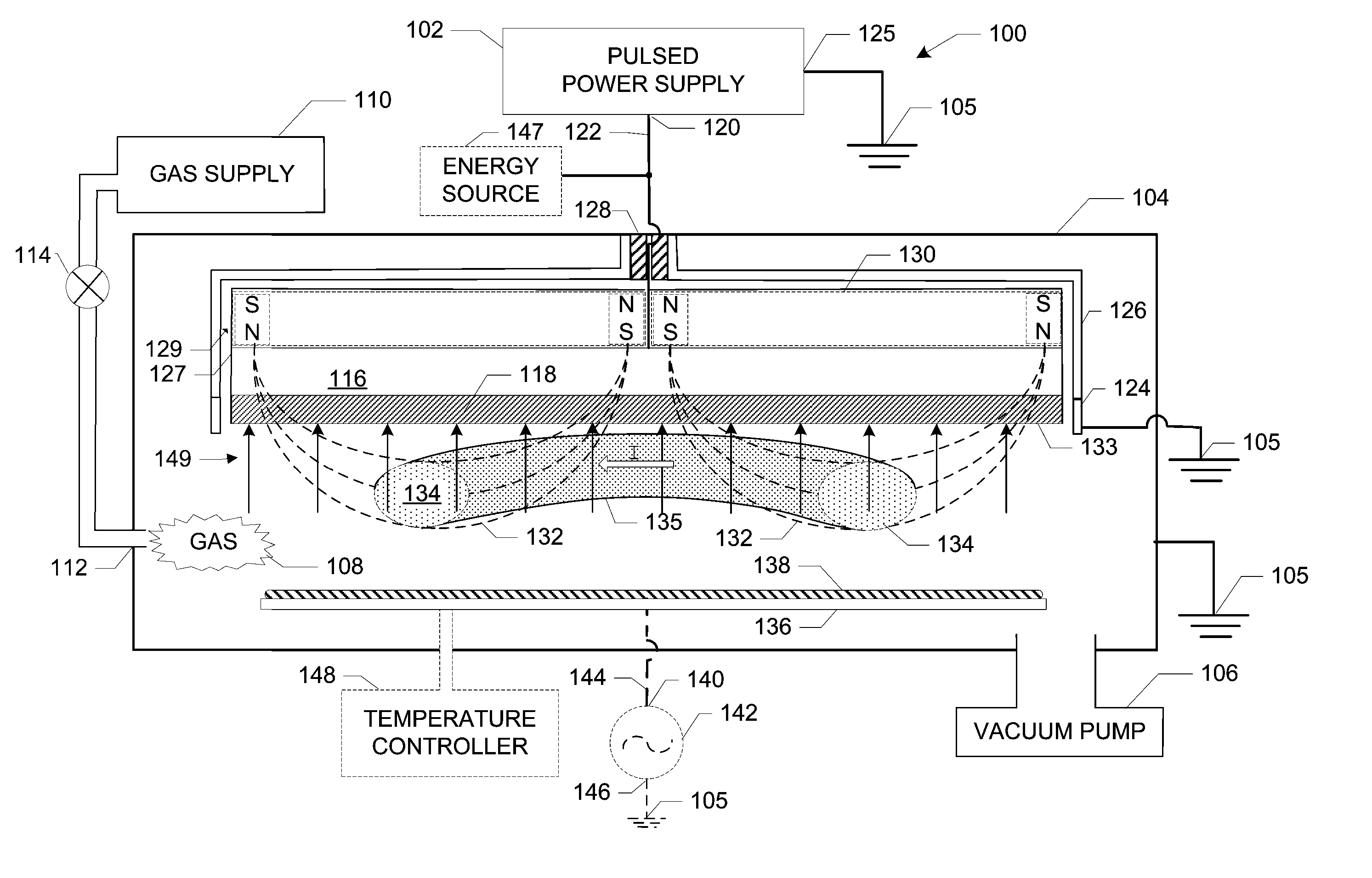

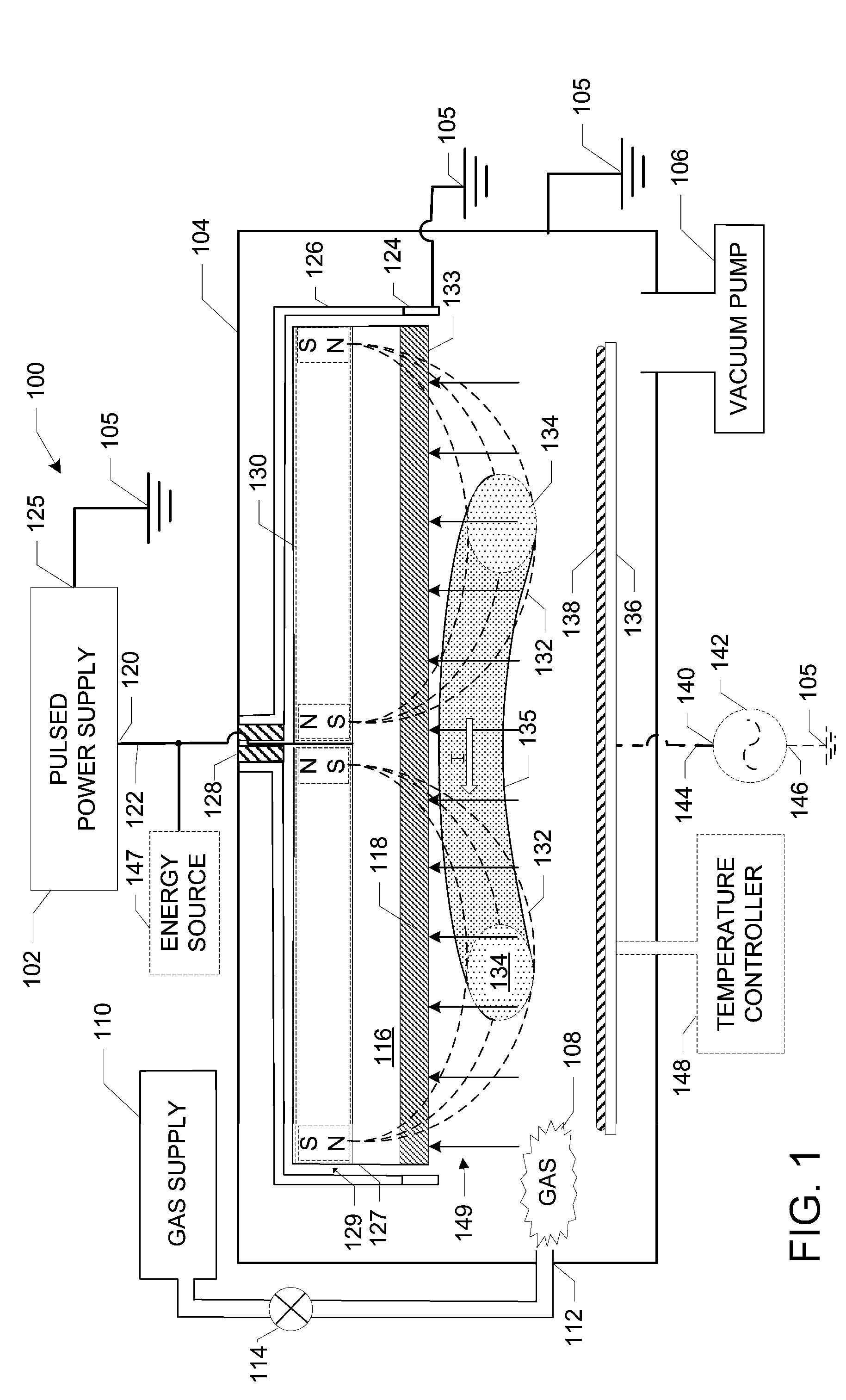

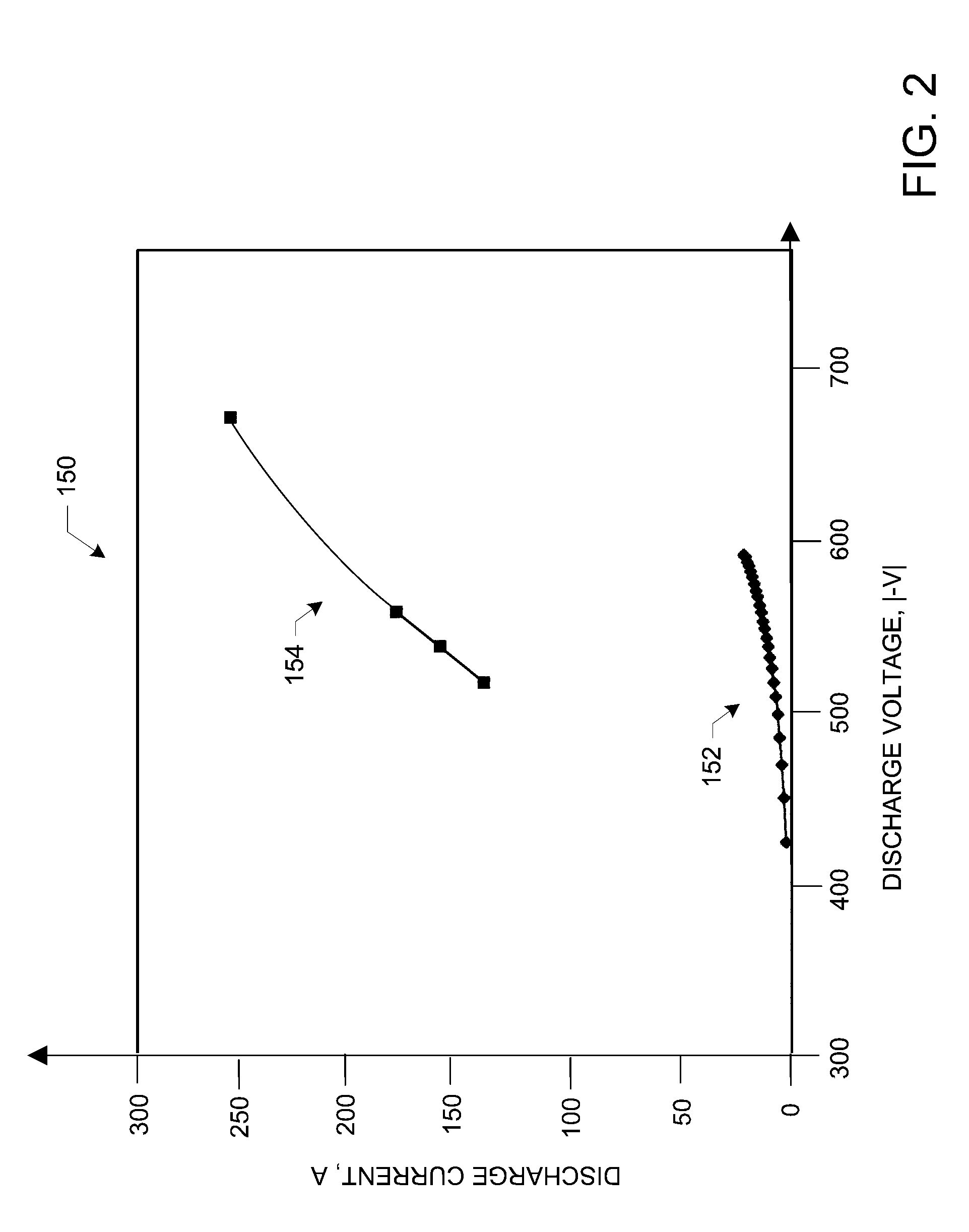

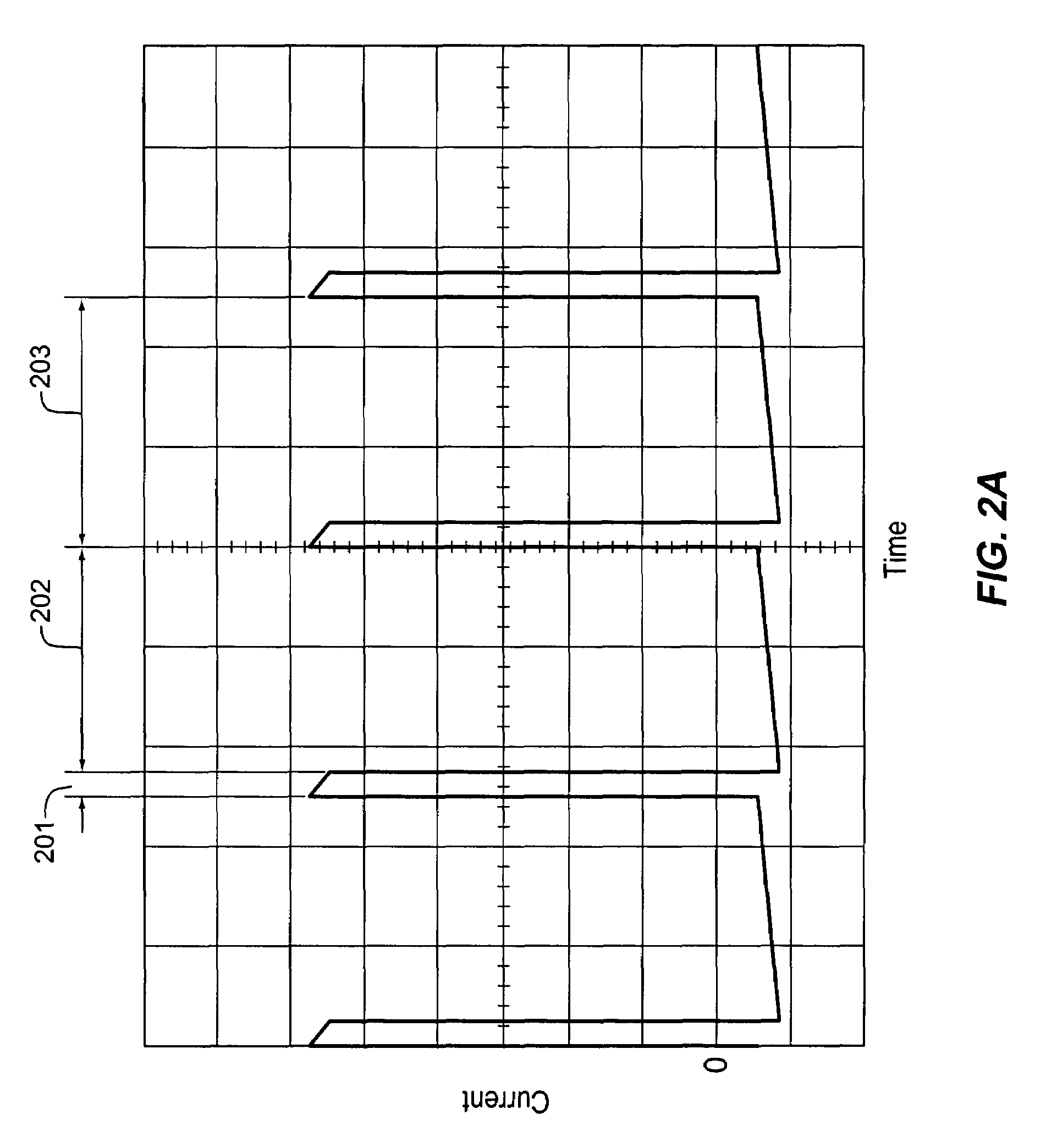

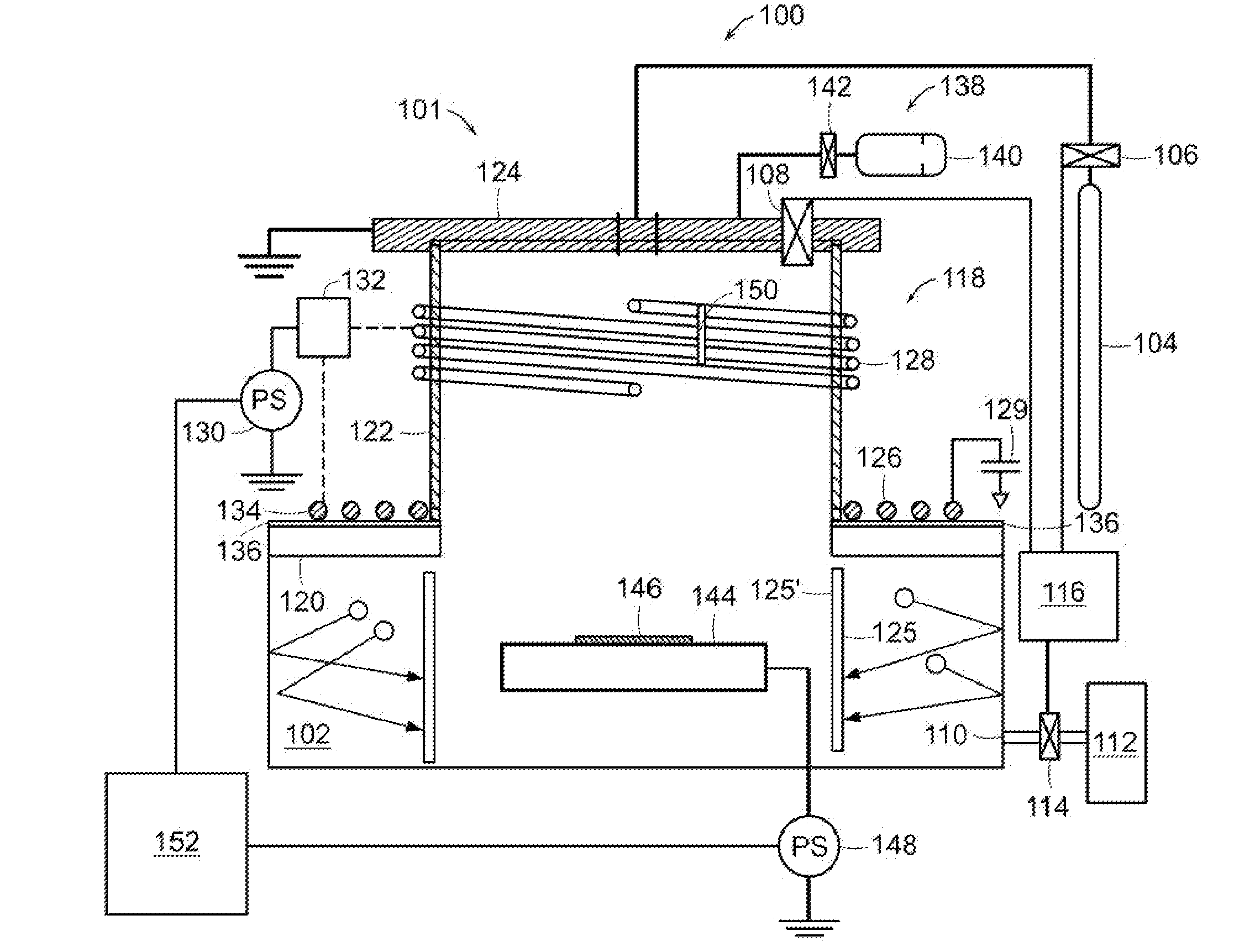

Methods and Apparatus for Generating Strongly-Ionized Plasmas with Ionizational Instabilities

Methods and apparatus for generating strongly-ionized plasmas are disclosed. A strongly-ionized plasma generator according to one embodiment includes a chamber for confining a feed gas. An anode and a cathode assembly are positioned inside the chamber. A pulsed power supply is electrically connected between the anode and the cathode assembly. The pulsed power supply generates a multi-stage voltage pulse that includes a low-power stage with a first peak voltage having a magnitude and a rise time that is sufficient to generate a weakly-ionized plasma from the feed gas. The multi-stage voltage pulse also includes a transient stage with a second peak voltage having a magnitude and a rise time that is sufficient to shift an electron energy distribution in the weakly-ionized plasma to higher energies that increase an ionization rate which results in a rapid increase in electron density and a formation of a strongly-ionized plasma.

Owner:ZOND

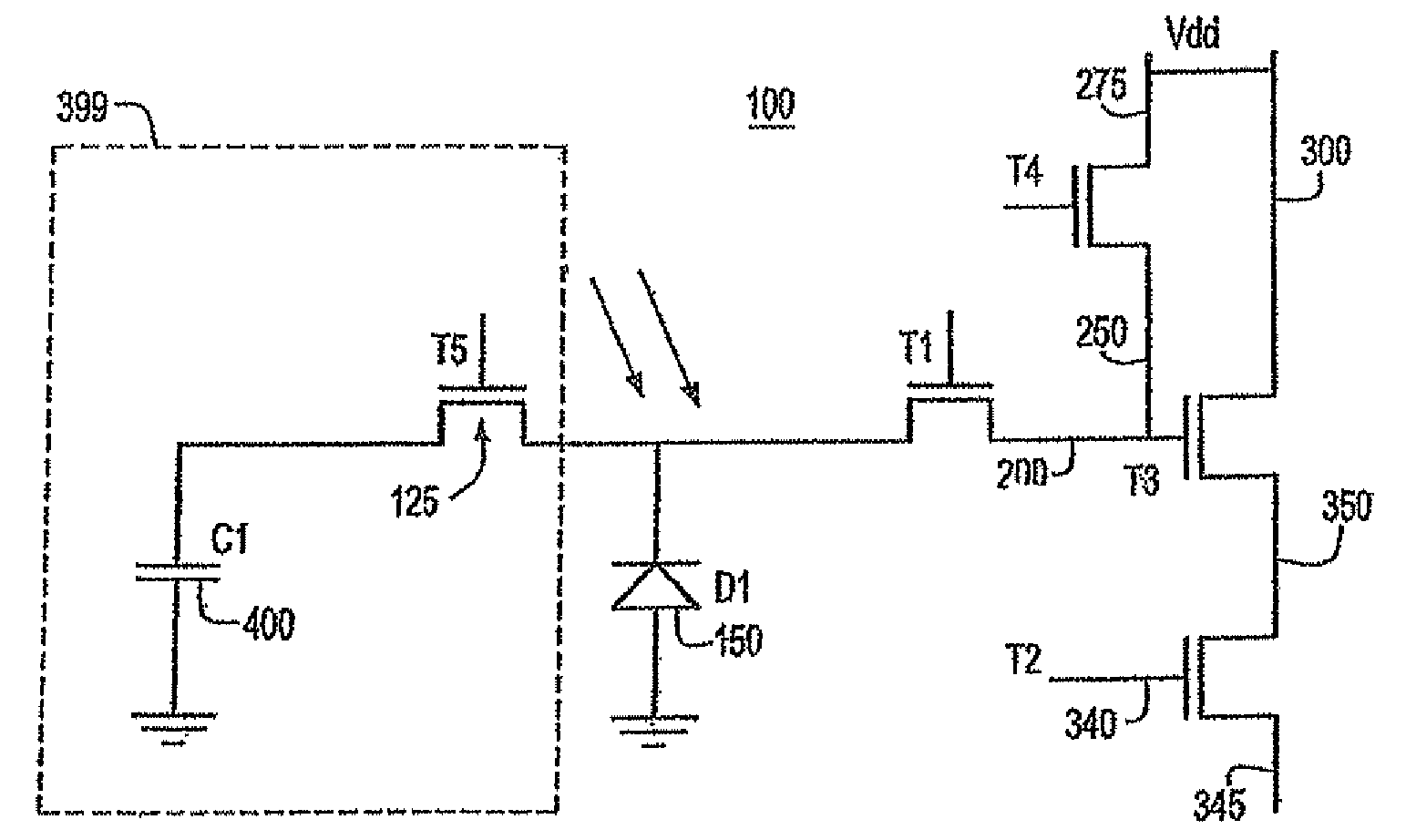

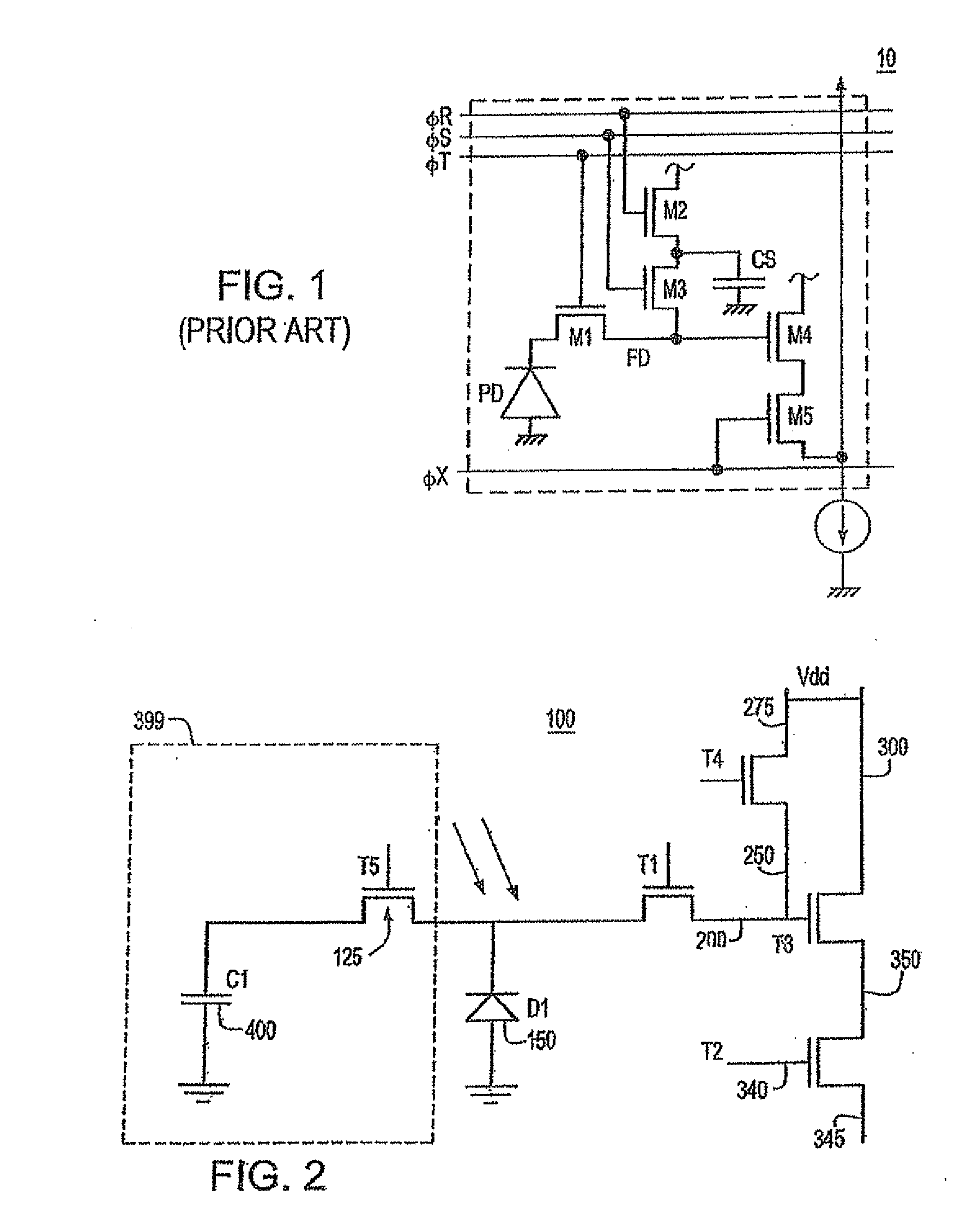

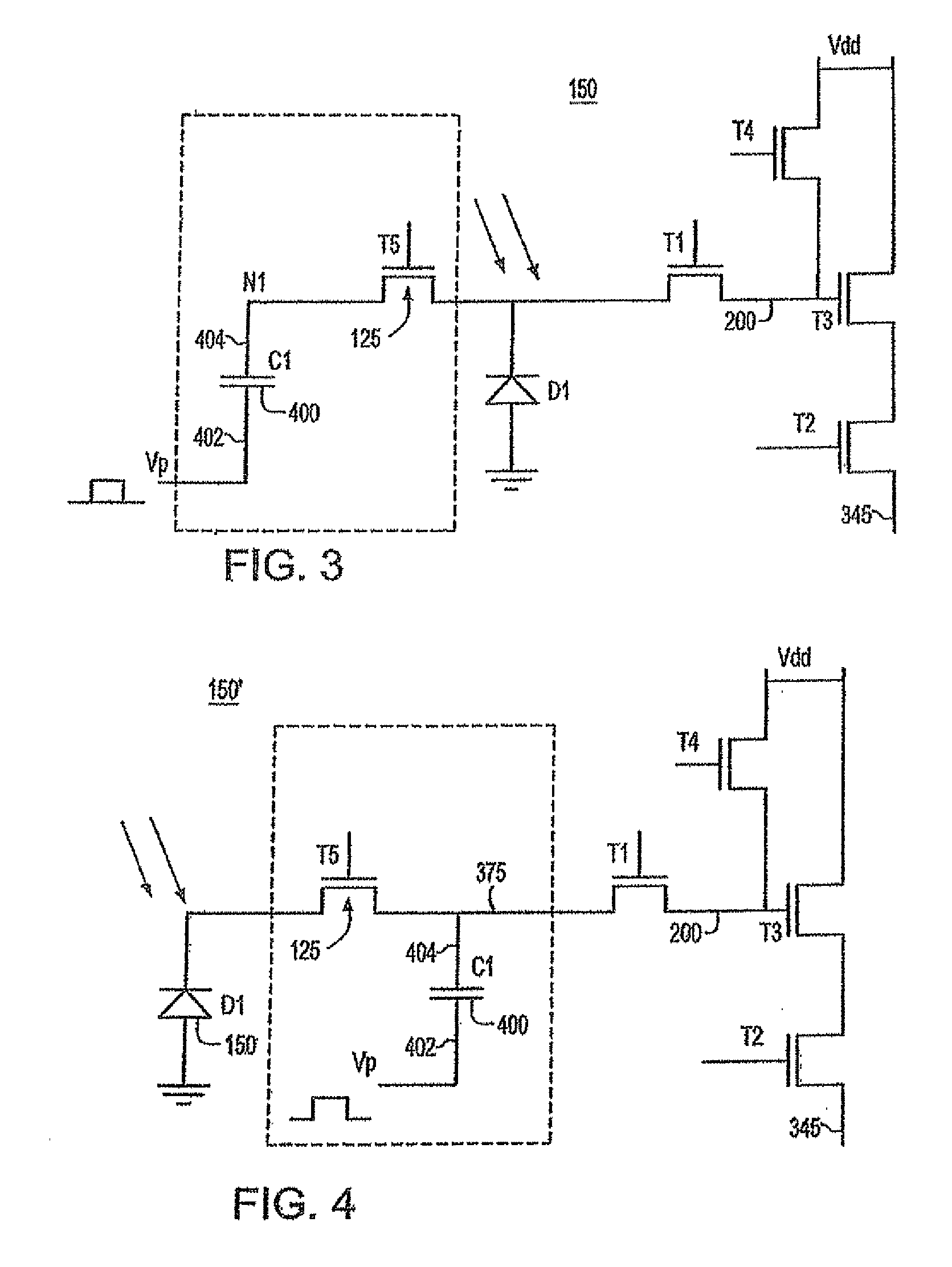

High dynamic range imaging cell with electronic shutter extensions

InactiveUS20090141155A1Improved extended dynamic rangeReduce capacitanceTelevision system detailsTelevision system scanning detailsCapacitanceHigh-dynamic-range imaging

A pixel sensor cell of improved dynamic range and a design structure including the pixel sensor cell embodied in a machine readable medium are provided. The pixel cell comprises a coupling transistor that couples a capacitor device to a photosensing region (e.g., photodiode) of the pixel cell, the photodiode being coupled to a transfer gate and one terminal of the coupling transistor. In operation, the additional capacitance is coupled to the pixel cell photodiode when the voltage on the photodiode is drawn down to the substrate potential. Thus, the added capacitance is only connected to the imager cell when the cell is nearing its charge capacity. Otherwise, the cell has a low capacitance and low leakage. In an additional embodiment, a terminal of the capacitor is coupled to a “pulsed” supply voltage signal that enables substantially full depletion of stored charge from the capacitor to the photosensing region during a read out operation of the pixel sensor cell. In various embodiments, the locations of the added capacitance and photodiode may be interchanged with respect to the coupling transistor. In addition, the added capacitor of the pixel sensor cell allows for a global shutter operation.

Owner:GLOBALFOUNDRIES INC

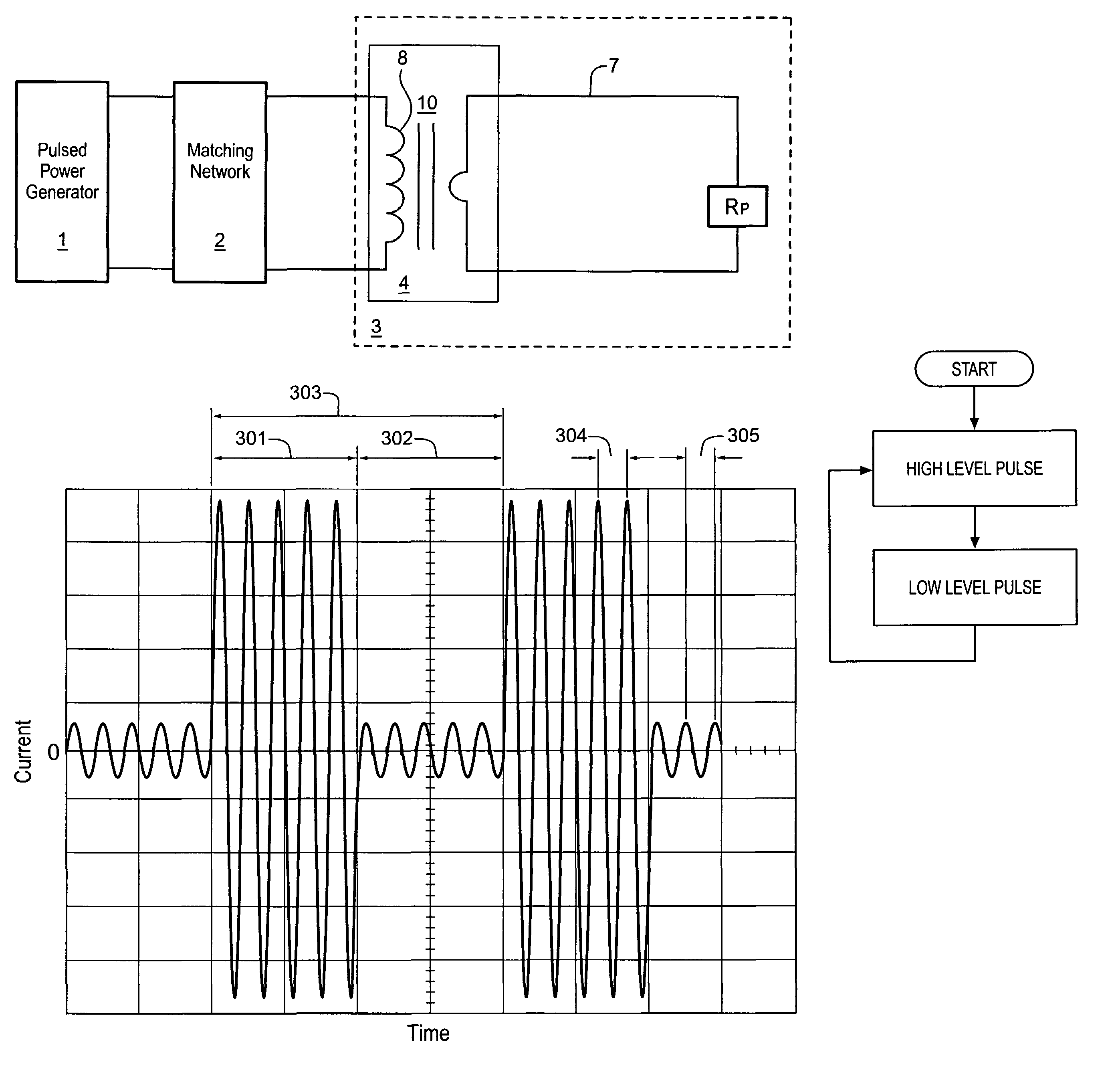

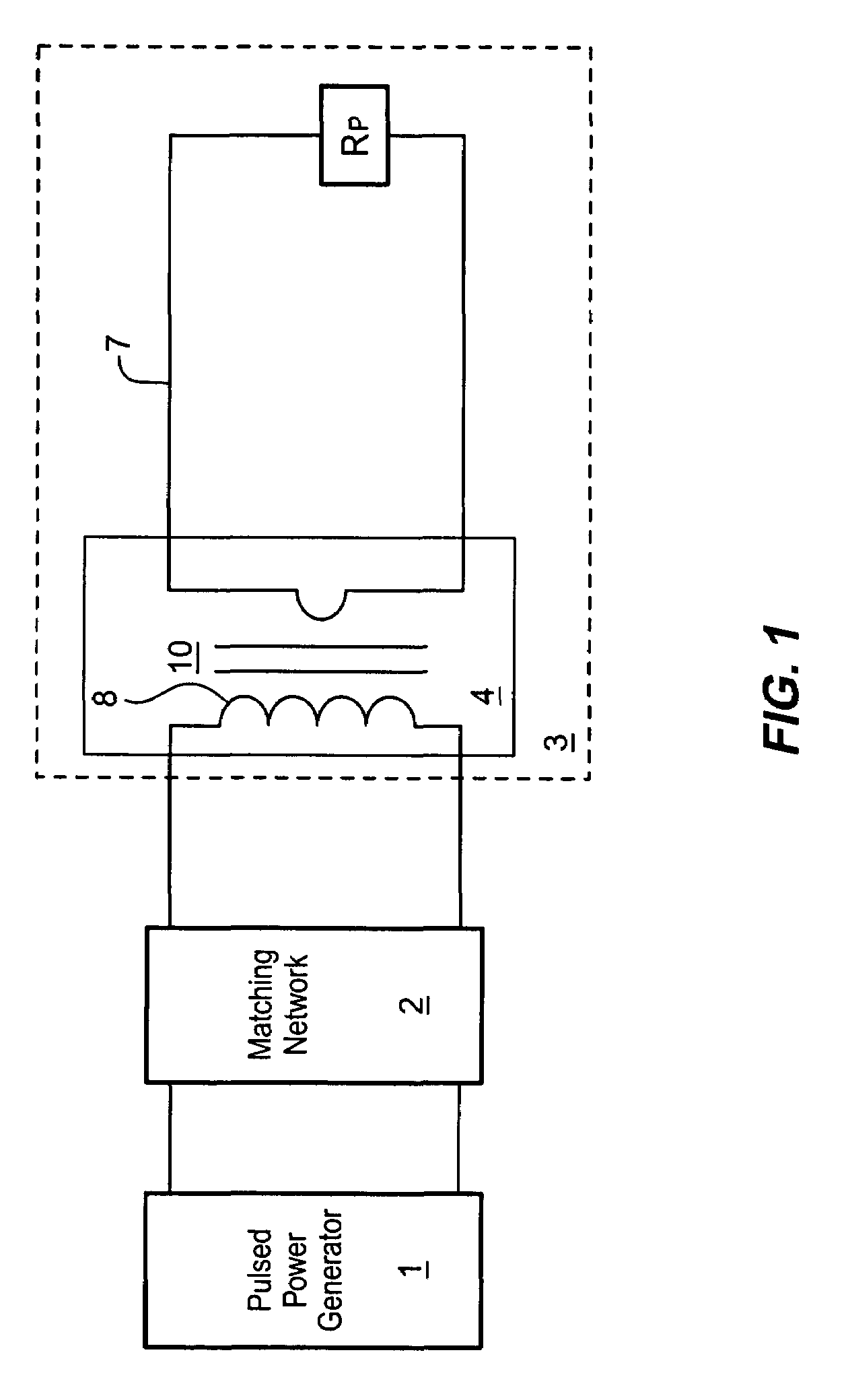

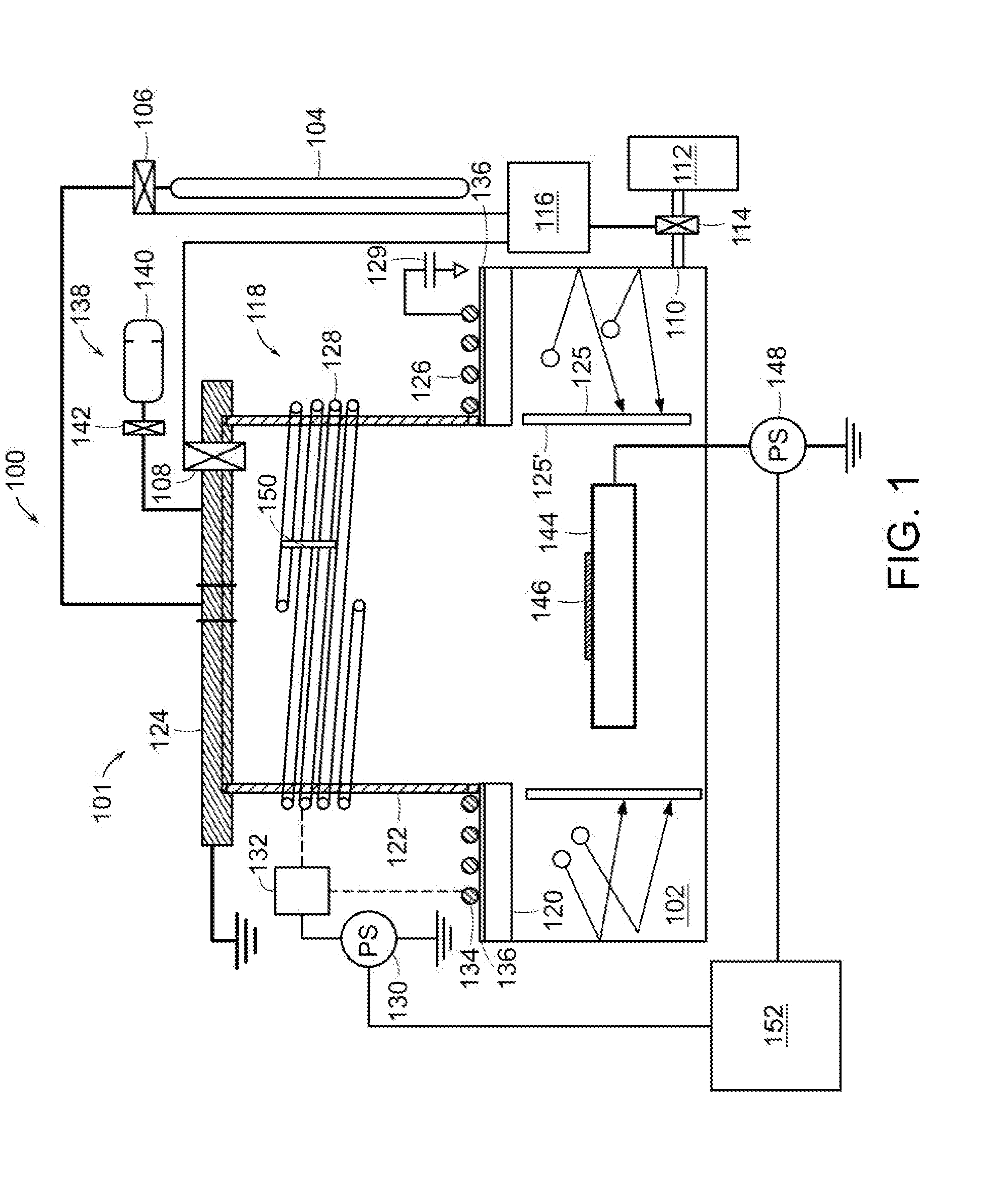

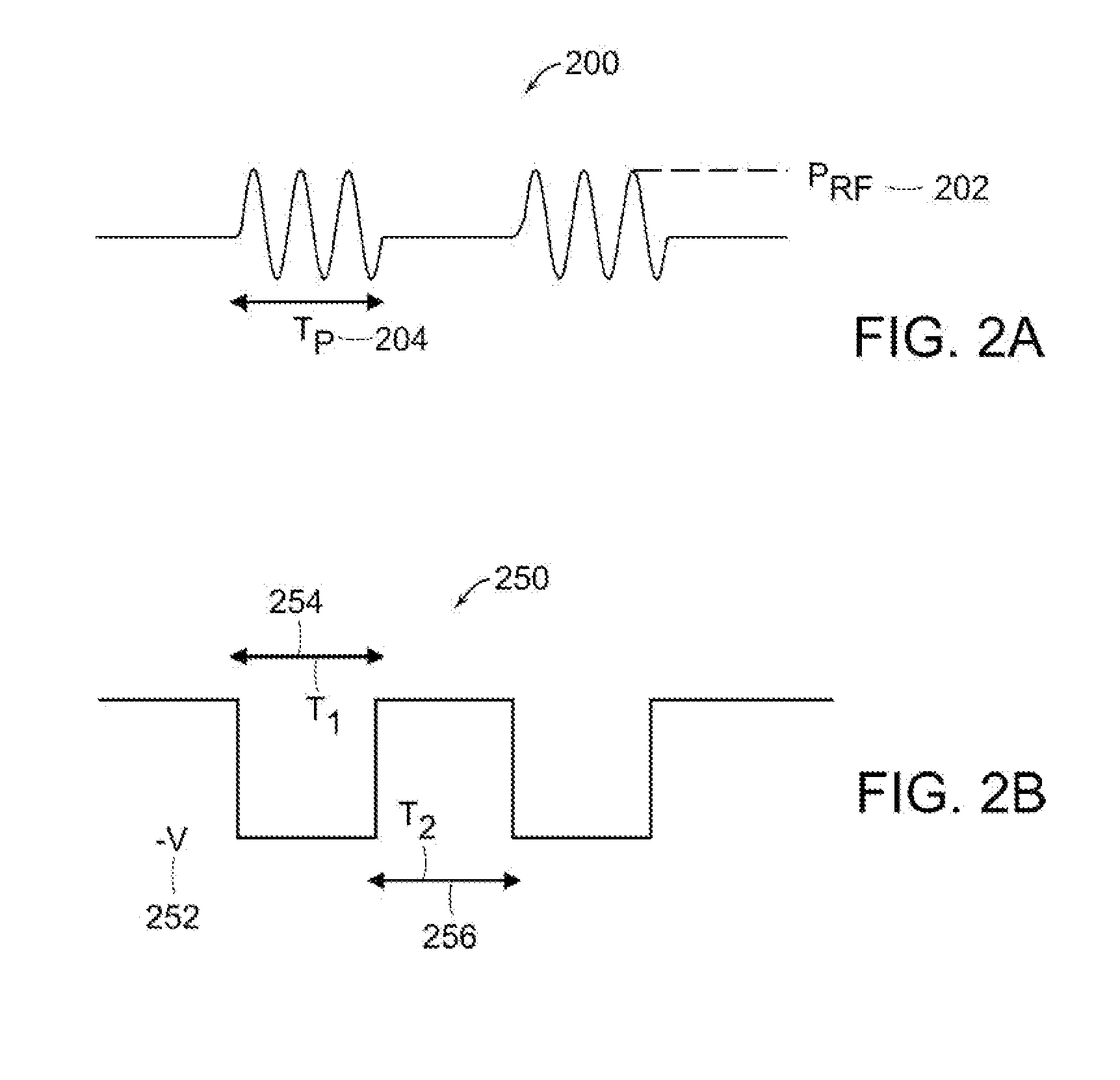

Pulsed excitation of inductively coupled plasma sources

ActiveUS7115185B1Improve reaction speedElectric discharge tubesElectric arc lampsReaction rateInductively coupled plasma

The reaction rate of a feed gas flowed into a plasma chamber is controlled. In one embodiment a pulsed power supply repeatedly applies a high power pulse to the plasma chamber to increase the reaction rate of plasma within the chamber, and applies a low power pulse between applications of the high power pulses.

Owner:AES GLOBAL HLDG PTE LTD

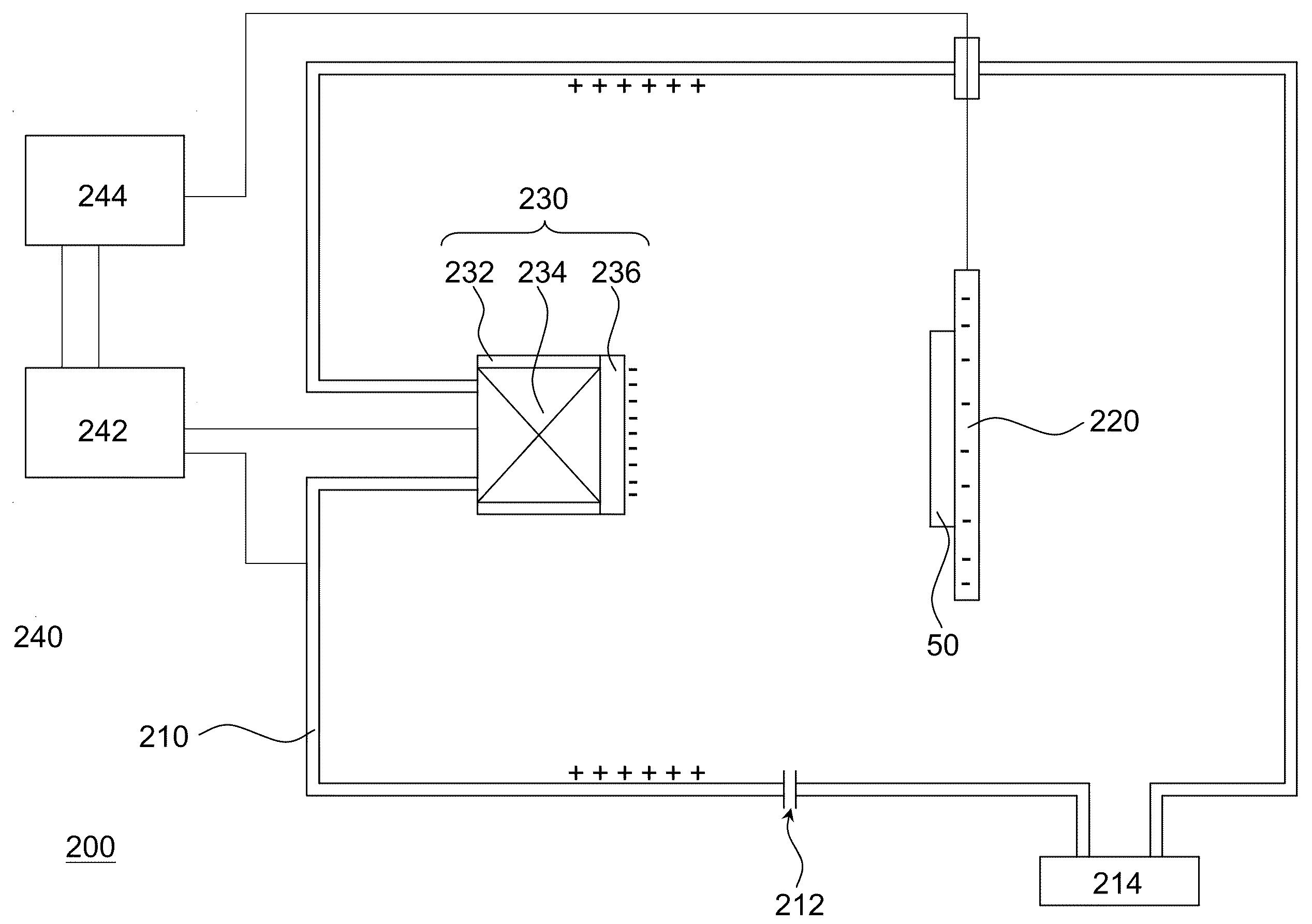

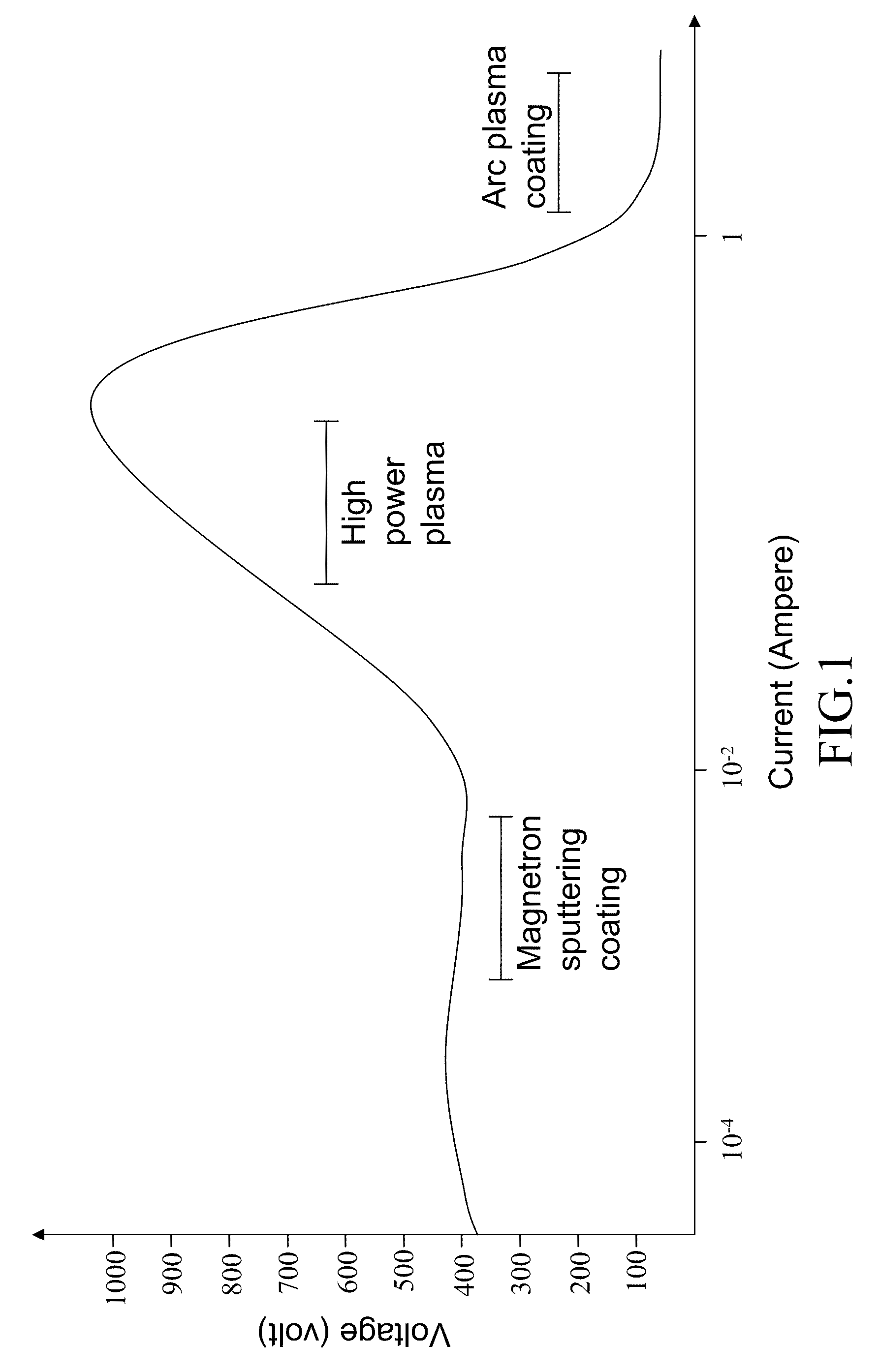

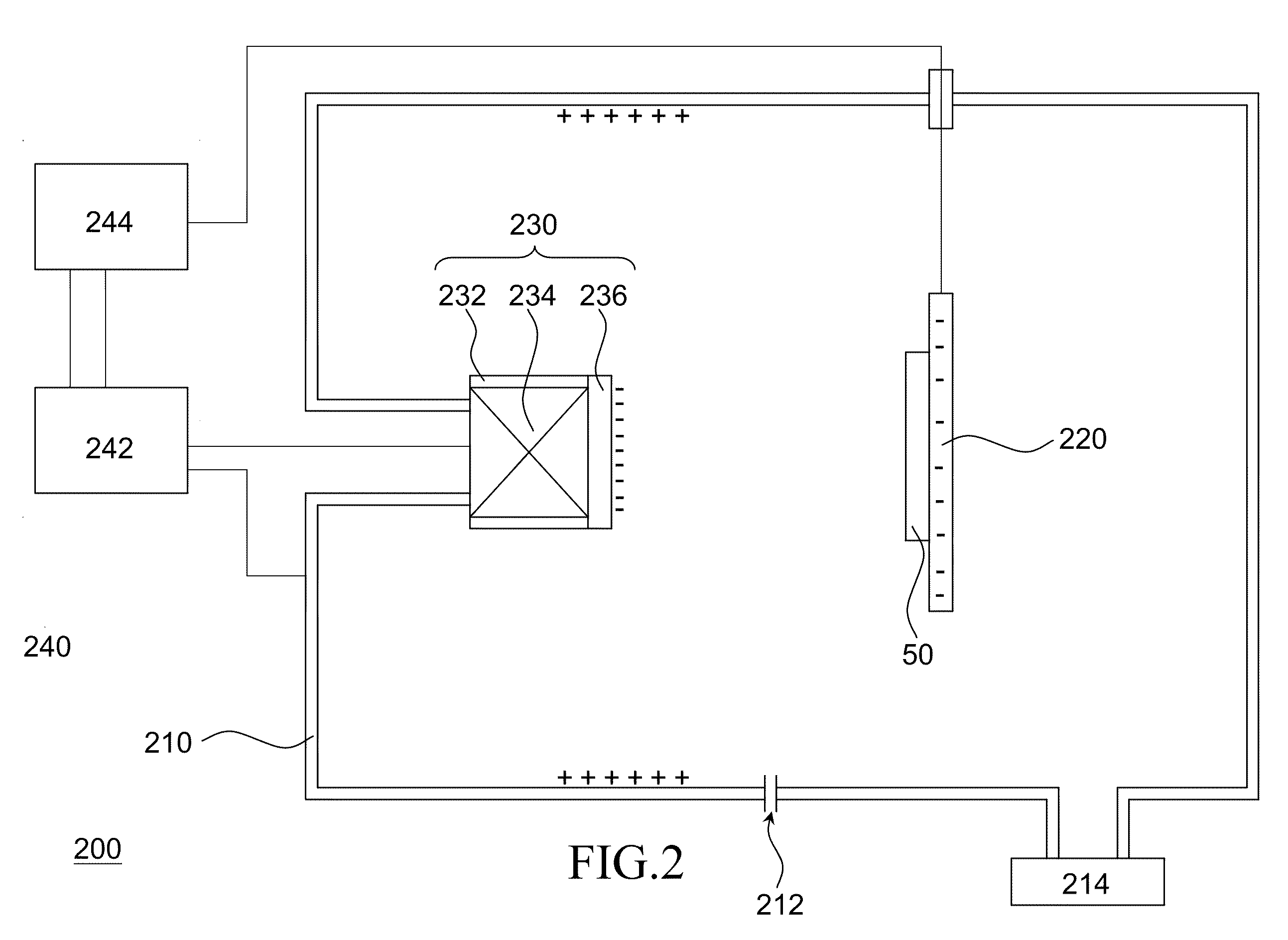

High-power pulse magnetron sputtering apparatus and surface treatment apparatus using the same

InactiveUS20110011737A1High coatingImprove adhesionCellsElectric discharge tubesSputteringReactive gas

A magnetron sputtering apparatus suitable for coating on a workpiece is provided. The magnetron sputtering apparatus includes a vacuum chamber, a holder, a magnetron plasma source and a high-power pulse power supply set, wherein the magnetron plasma source includes a base, a magnetron controller and a target. A reactive gas is inputted into the vacuum chamber, and the holder supporting the workpiece is disposed inside the vacuum chamber. The magnetron plasma source is disposed opposite to the workpiece, wherein the magnetron controller is disposed in the base, and the target is disposed on the base. The high-power pulse power supply set is coupled to the vacuum chamber, the magnetron plasma source and the holder, and a high voltage pulse power is inputted to the magnetron plasma source to generate plasma to coat a film on the surface of the workpiece.

Owner:INST NUCLEAR ENERGY RES ROCAEC

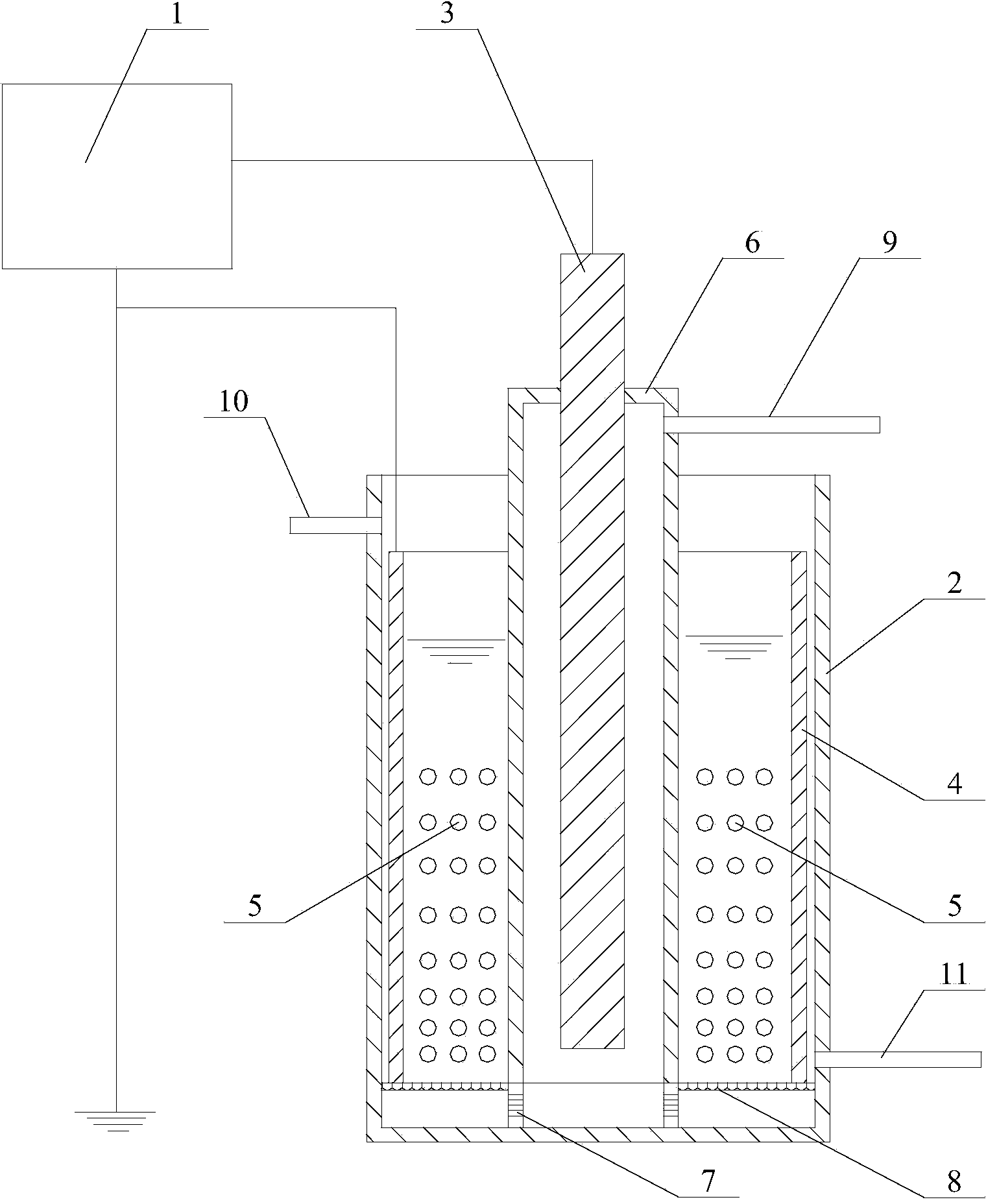

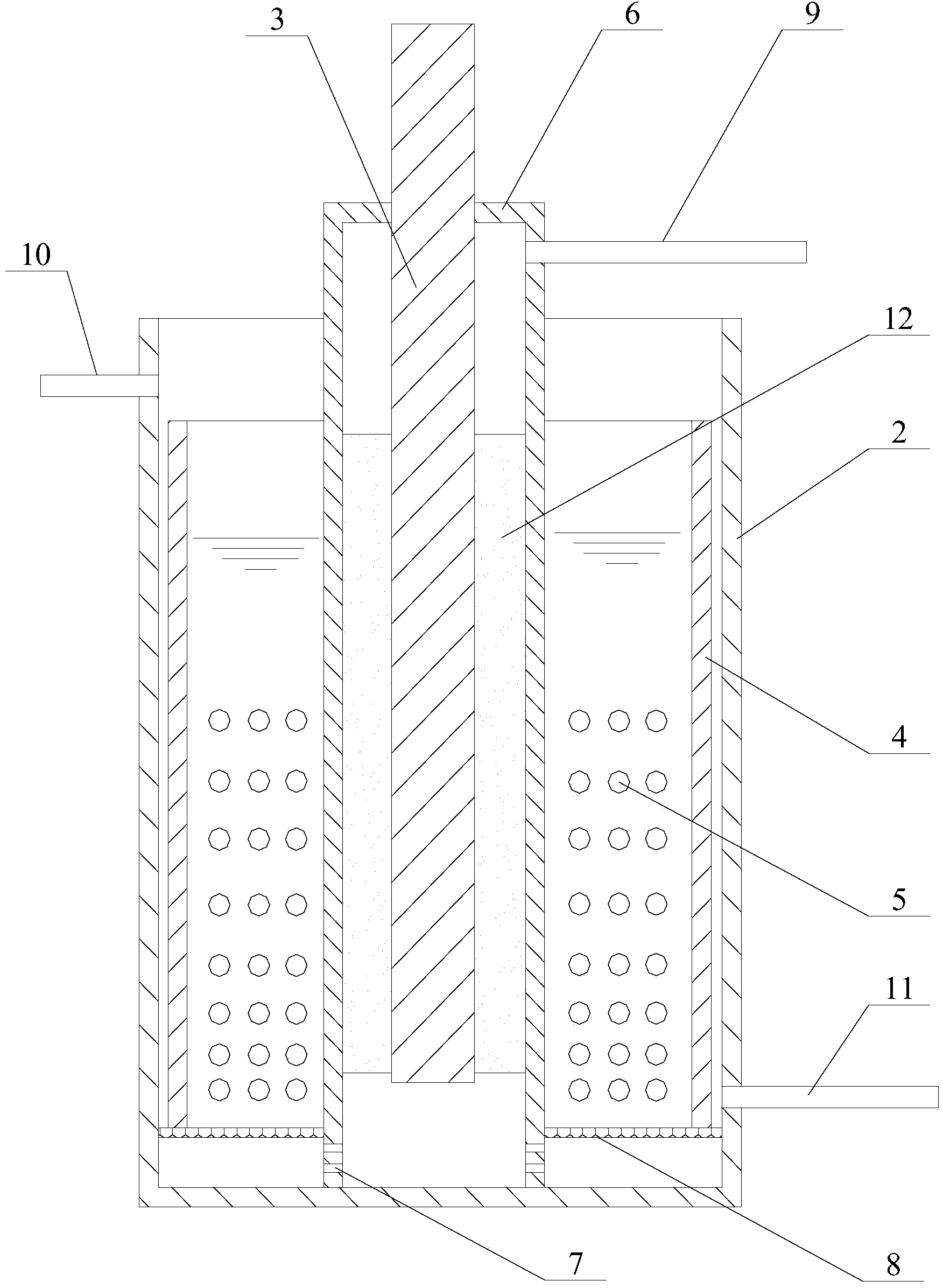

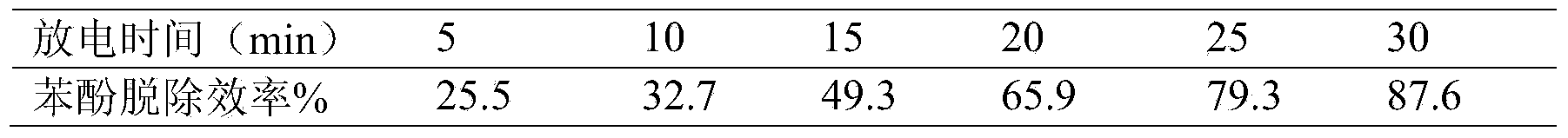

Dielectric barrier discharge water treatment device and method

InactiveCN103482720AIncrease chance of contactImprove mass transfer efficiencyWater/sewage treatment by irradiationWater/sewage treatment by electrochemical methodsLow voltageHigh pressure

Owner:TAIYUAN UNIV OF TECH

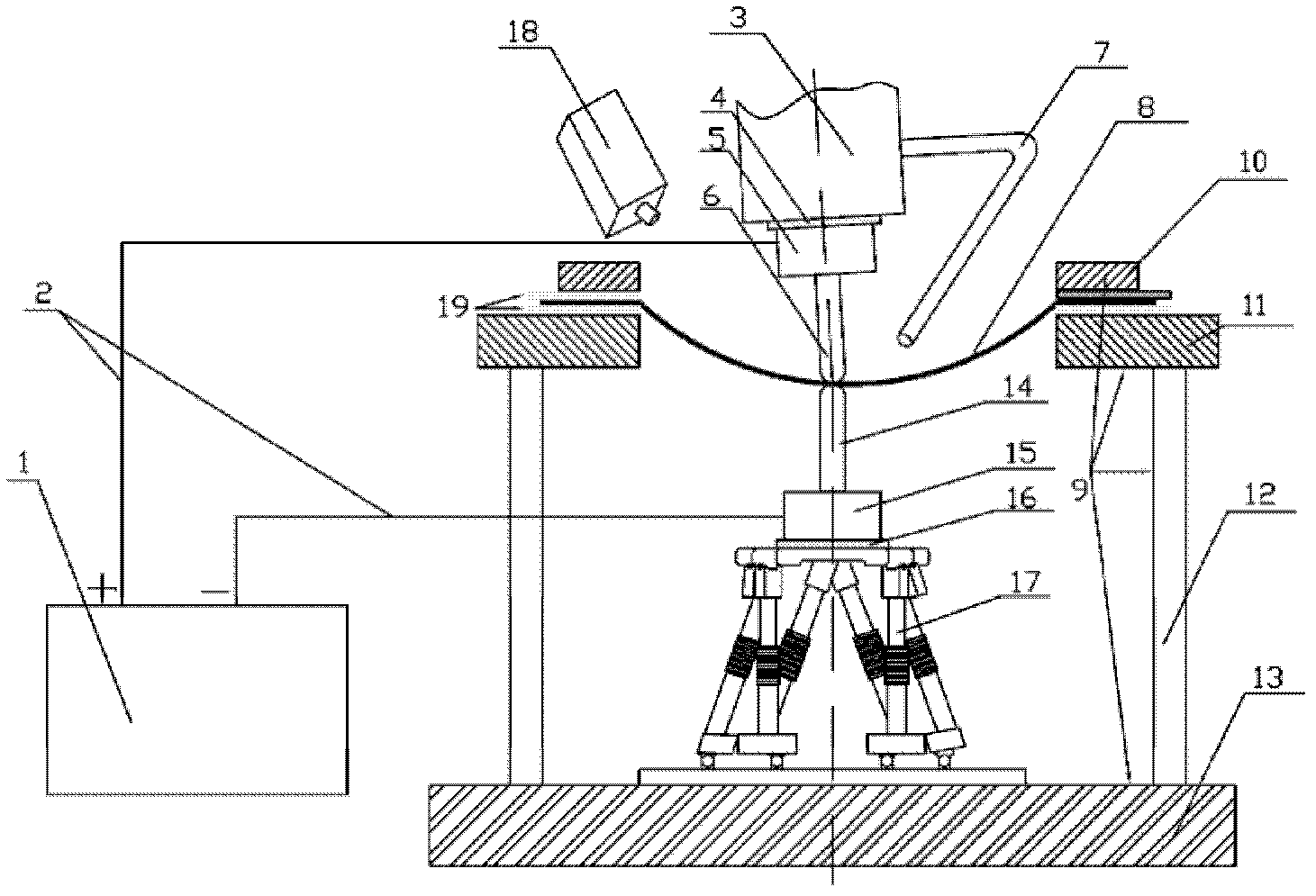

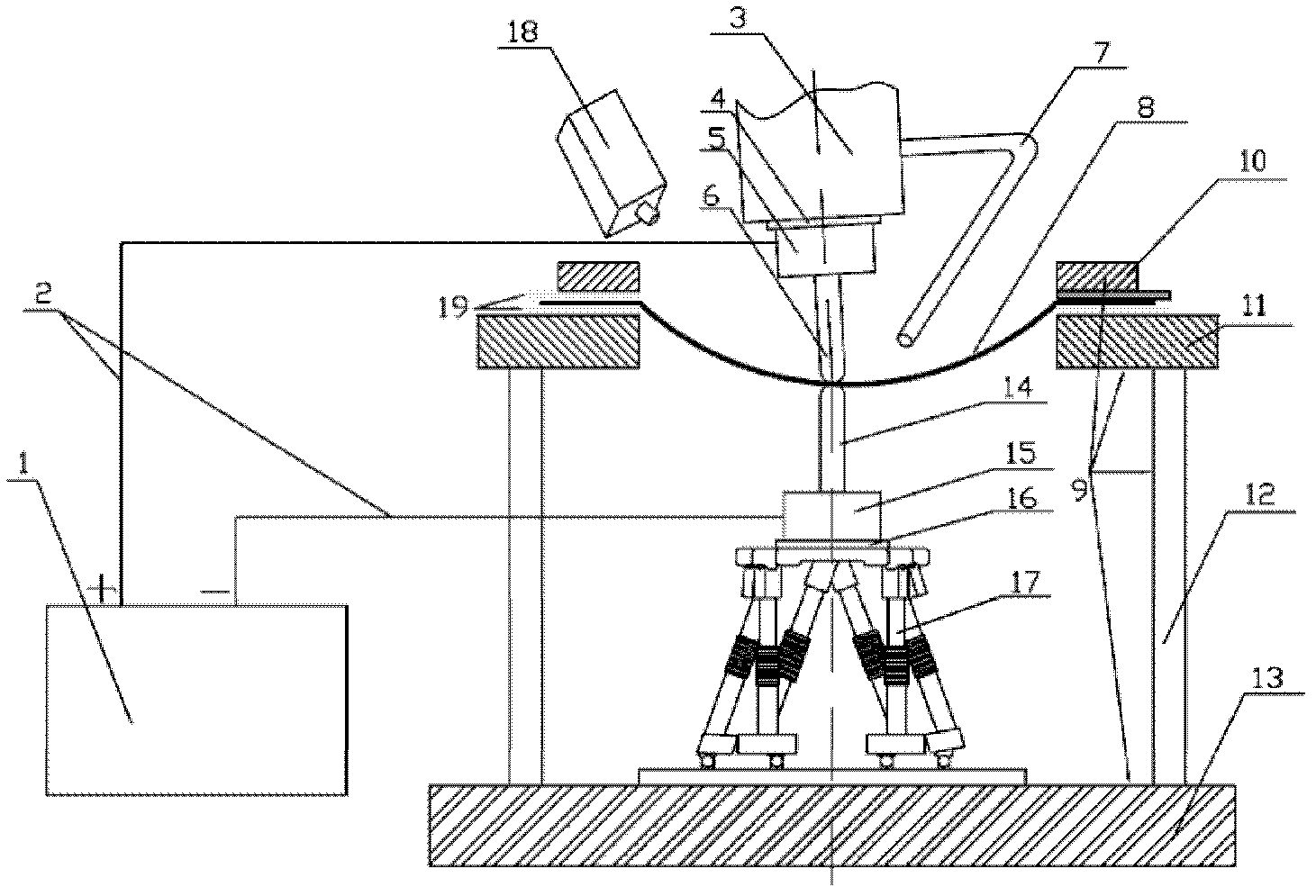

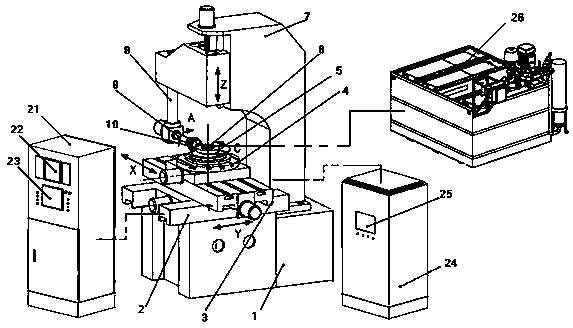

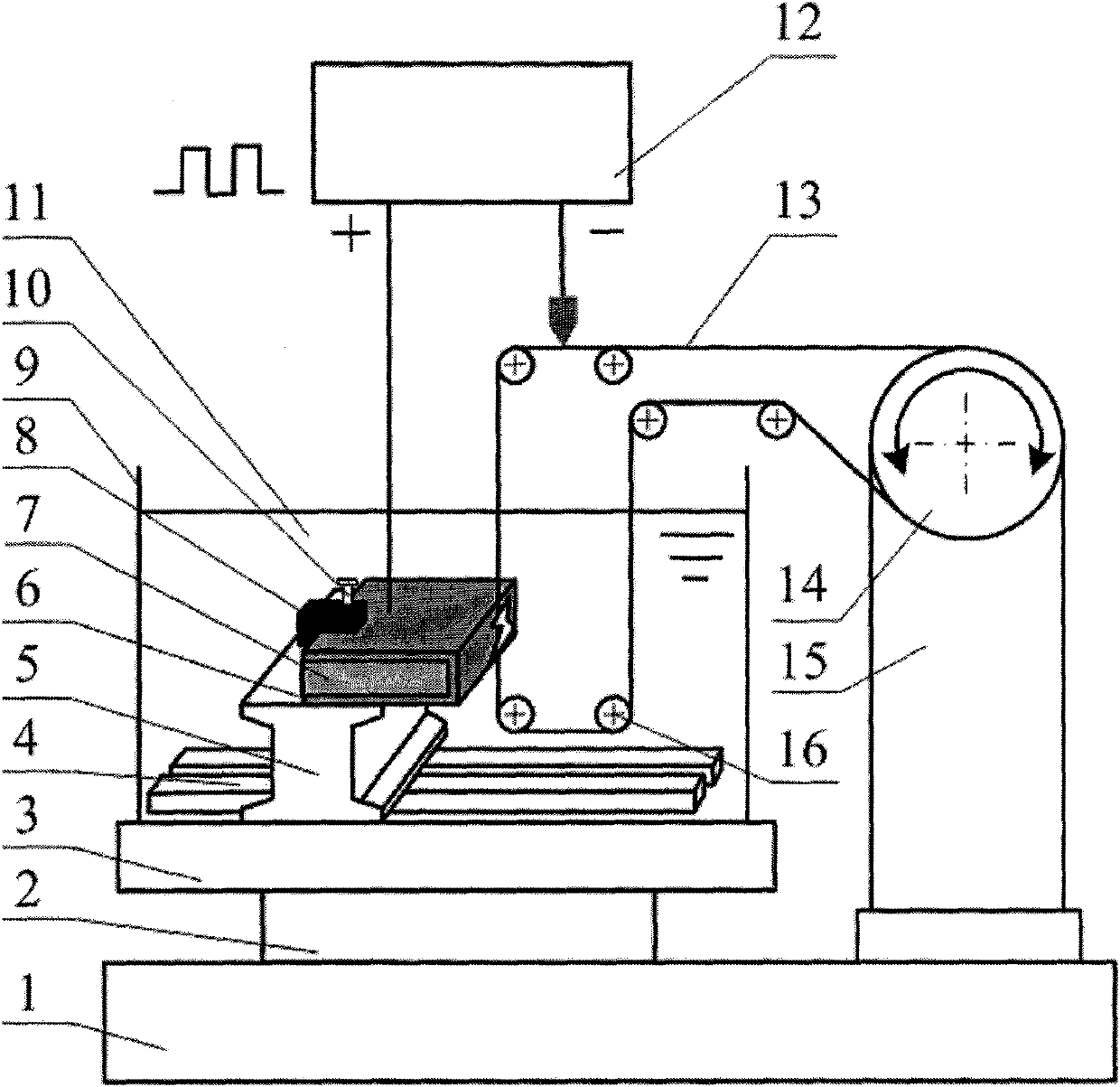

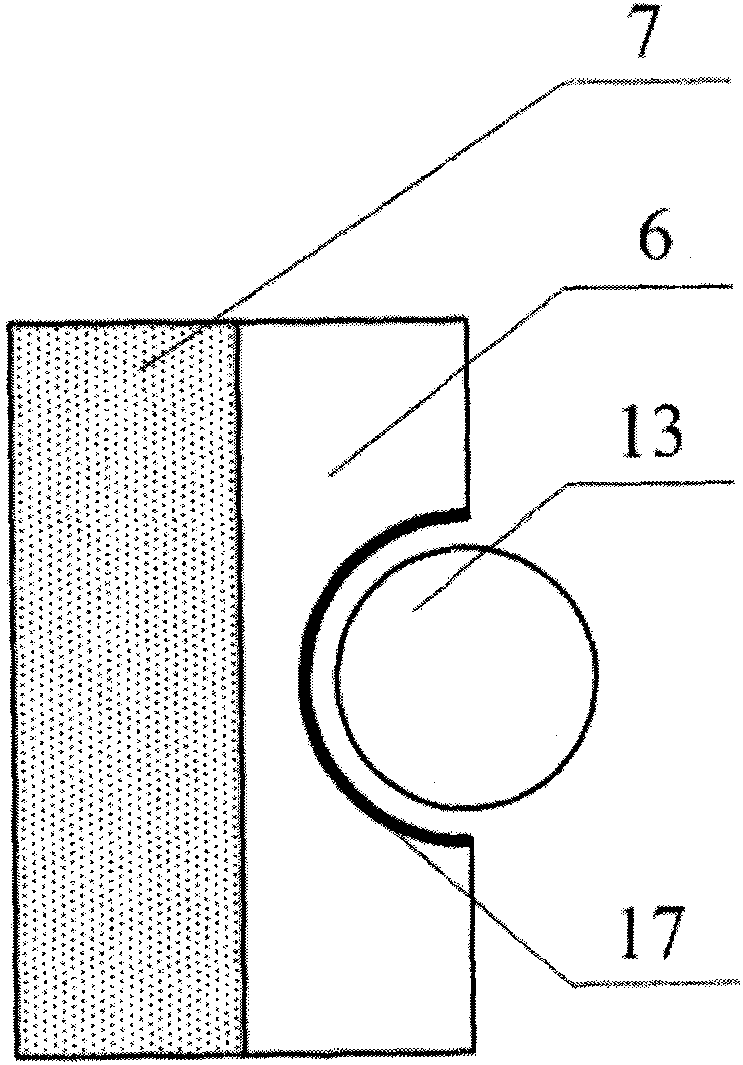

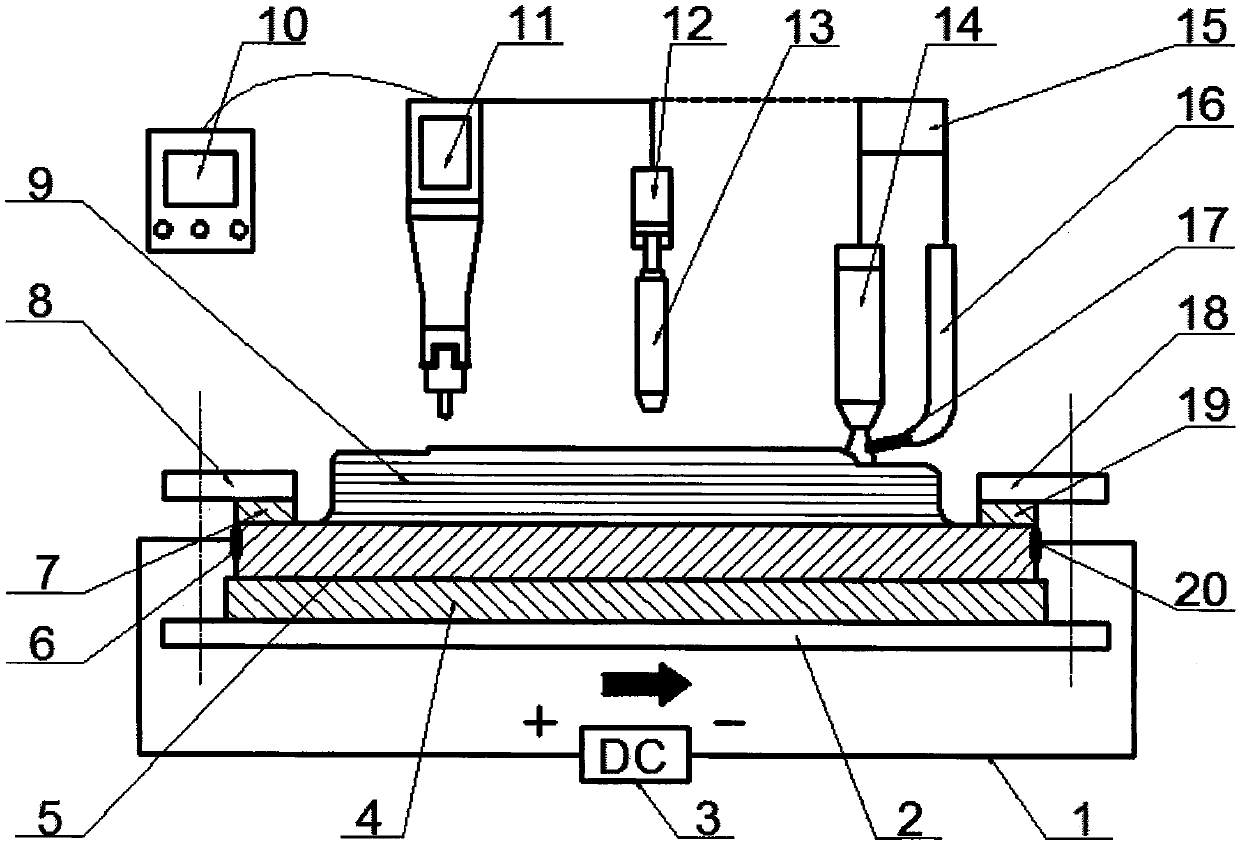

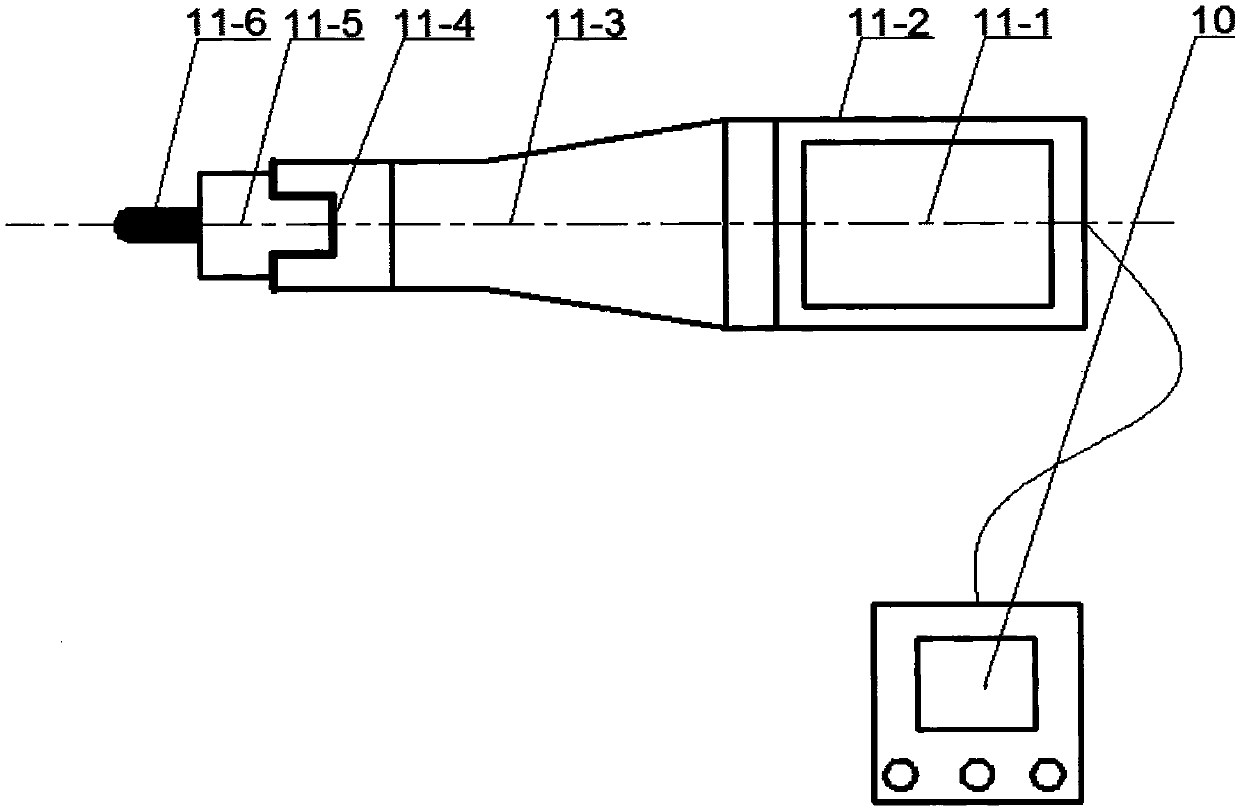

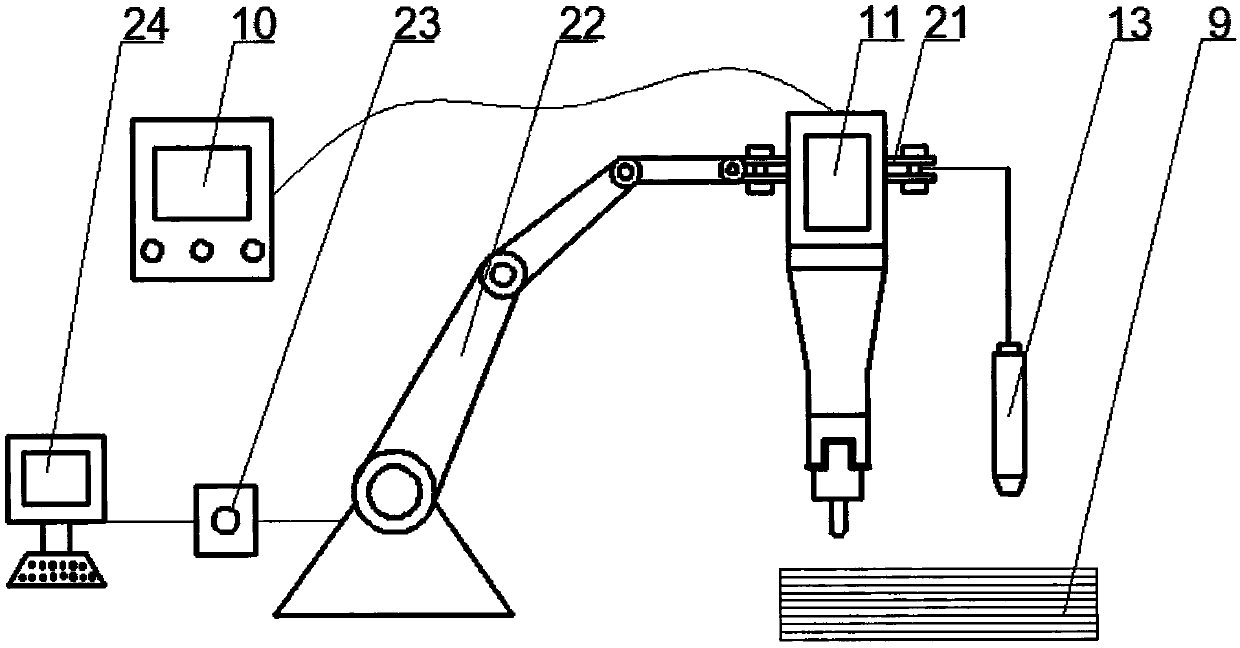

Electroplastic incremental forming device and method for plates

ActiveCN102527830ALower yield stressHigh geometric accuracyMetal-working feeding devicesPositioning devicesNumerical controlHigh energy

The invention relates to an electroplastic incremental forming device and an electroplastic incremental forming method for plates. The device comprises a five-axis numerical control forming machine tool, a six-axis parallel robot machining system, a plate forming clamp, a high energy pulse power supply, an infrared thermometer, and a compressed air cooling system embedded in the machine tool, wherein an upper forming pressing head is arranged at the tail end of a spindle of the five-axis numerical control forming machine tool; the six-axis parallel robot machining system is arranged on a working table of the machine tool; the top of the six-axis parallel robot machining system is provided with a lower forming pressing head; the plate forming clamp is fixed on the working table of the machine tool; positive and negative poles of the high energy pulse power supply are connected with the upper forming pressing head and the lower forming pressing head through high current-carrying conductors respectively so as to form a current loop among the high energy pulse power supply, the upper forming pressing head, the lower forming pressing head and the plates; a camera of the infrared thermometer is aligned with a central area of each plate; and the compressed air cooling system is aligned with a forming area of each plate. Compared with the prior art, the invention has the advantages of high efficiency, energy conservation, high machining precision, high surface quality and the like.

Owner:SHANGHAI JIAO TONG UNIV

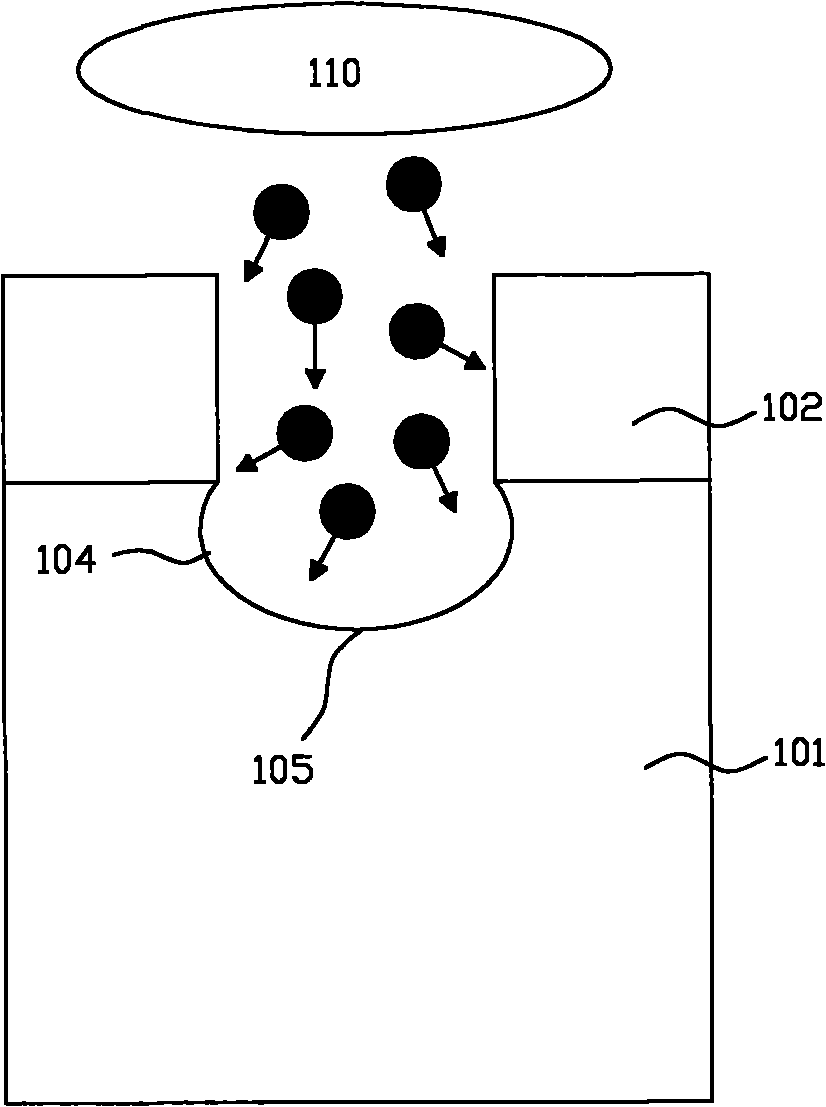

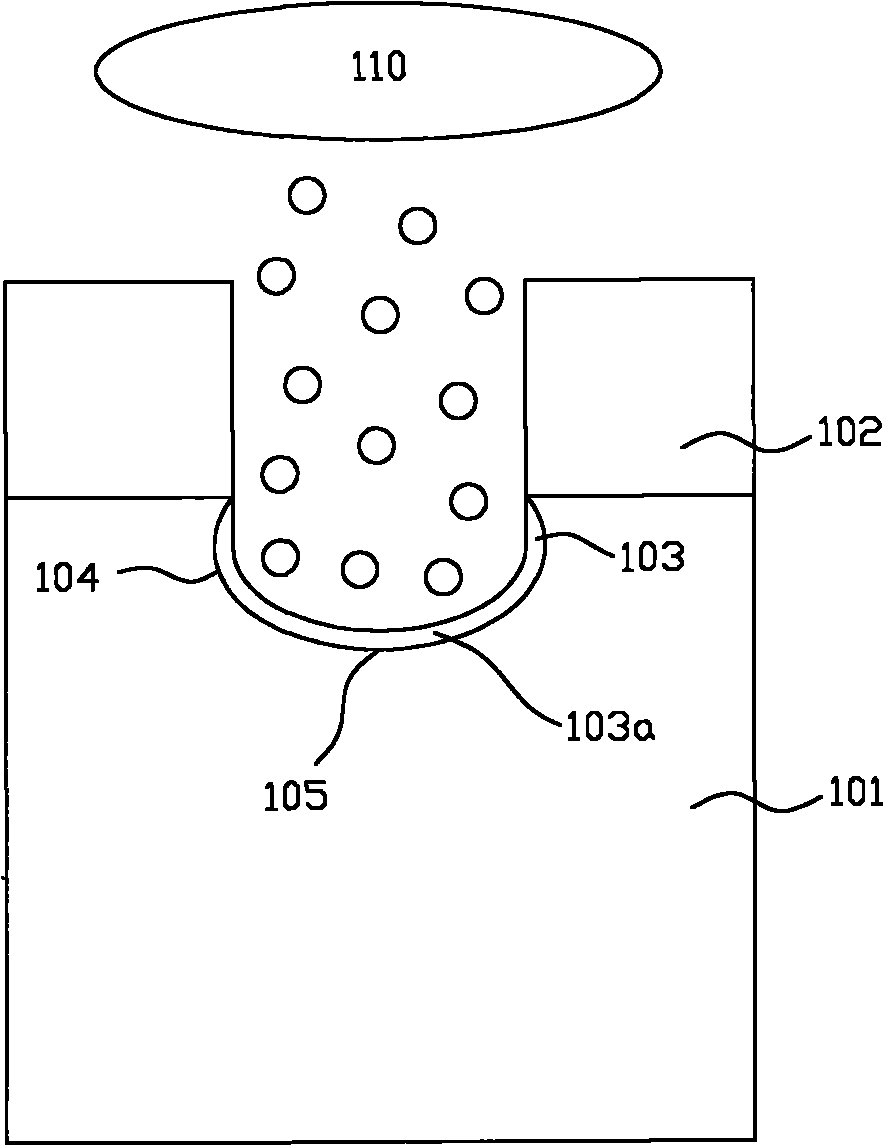

Plasma doping with enhanced charge neutralization

A plasma doping apparatus includes a pulsed power supply that generates a pulsed waveform having a first period with a first power level and a second period with a second power level. A plasma source generates a pulsed plasma with the first power level during the first period and with the second power level during the second period. A bias voltage power supply generates a bias voltage waveform at an output that is electrically connected to a platen which supports a substrate. The bias voltage waveform having a first voltage during a first period and second voltage with a negative potential that attract ions in the plasma to the substrate for plasma doping during a second period. At least one of the first and second power levels of the RF waveform is chosen to at least partially neutralize charge accumulating on the substrate.

Owner:VARIAN SEMICON EQUIP ASSOC INC

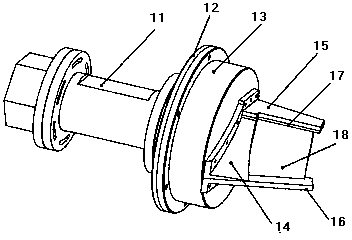

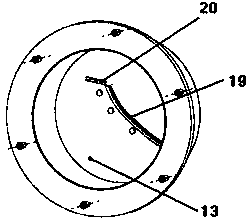

Blisk blade electrolytic finishing forming device and blisk blade machining forming method

InactiveCN103624350AMeet the machining accuracy requirementsReasonable structural designElectrochemical machining apparatusElectrolysisControl system

The invention discloses a blisk blade electrolytic finishing forming device and a blisk blade machining forming method. The device comprises a five-axis four-linkage electrolytic machining machine tool, a forming cathode, an intelligent pulsed power supply, a control system and an electrolyte conveying device, the forming cathode is arranged on the five-axis four-linkage electrolytic machining machine tool and used for machining a blade, the intelligent pulsed power supply and the control system are connected with the five-axis four-linkage electrolytic machining machine tool, and the electrolyte conveying device is connected with the forming cathode for machining the blade. The electrolytic finishing forming device is reasonable in design, high in machining efficiency, especially high in machining precision, capable of achieving free-form surface blisk blade finishing well, and capable of meeting the aero-engine blisk blade machining precision requirement. The machining forming method is strong in operability, high in work efficiency, high in precision of the machined and manufactured blisk blade and capable of overcoming the defects in the prior art.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

Deep silicon etching method

ActiveCN101962773AImprove the selection ratioFast etch rateSemiconductor/solid-state device manufacturingPulse power supplySilicon chip

The invention provides a deep silicon etching method. The method comprises a step of etching a silicon chip surface which is not covered by a photoresist layer first to form an etched surface and a side wall which is vertical to the etched surface basically; and the method also comprises the following steps of: a first depositing step, namely performing isotropic deposition for covering a barrierlayer on the etched surface, the side wall and the surface of the photoresist layer; a first etching step, namely performing anisotropic etching for removing the barrier layer covered on the etched surface so as to expose the etched surface, wherein the photoresist layer is prevented from being etched by the barrier layer covered on the photoresist layer; a second etching step, namely performing the isotropic etching for etching the exposed etched surface, wherein the side wall is prevented from being etched by the barrier layer covered on the side wall and the photoresist layer is not damaged in the isotropic etching; and repeating the depositing step, the first etching step and the second etching step circularly until reaching a predetermined etching depth. The method does not need complex equipment such as a low-frequency pulse power supply and the like, contributes to maintenance, and reduces equipment cost.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

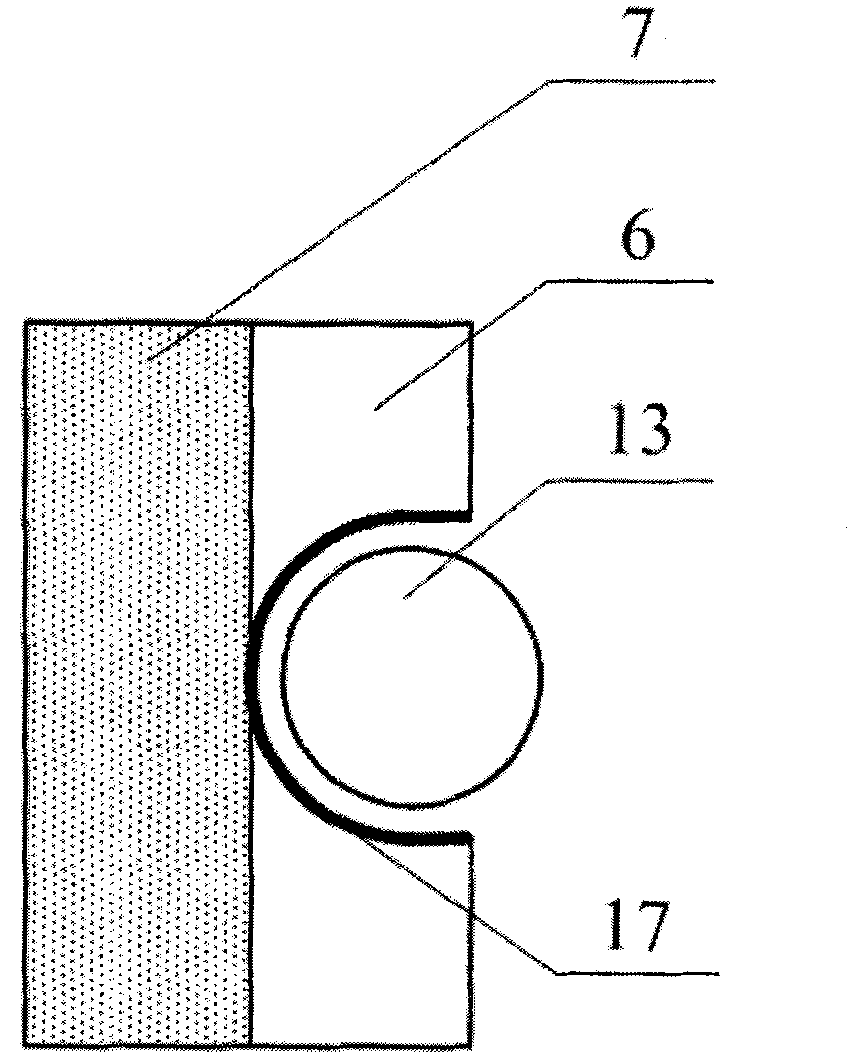

Method and device for machining insulating ceramic by reciprocating wire-cut electrical discharge machining

The invention relates to the technical field of insulating ceramics machining. In order to solve the problems that the conventional insulating ceramic machining method and device are low in machining accuracy and low in quality of the machined surface, the invention provides a method for machining insulating ceramic by reciprocating wire-cut electrical discharge machining. The method comprises the following steps of: immersing insulating ceramics of which the outer surface is fixed with an auxiliary electrode in electrospark liquid or kerosene working solution; putting a wire electrode into the working solution, connecting the auxiliary electrode and the wire electrode to the anode and cathode of a high-frequency pulse power supply respectively, and controlling the distance between the auxiliary electrode and the wire electrode until electrical discharge can be realized; and controlling relative motion between the wire electrode and the insulating ceramics according to the machining requirement. The invention also provides a device, wherein the insulating ceramics of which the outer surface is fixed with the auxiliary electrode and the wire electrode are arranged in the electrospark liquid or kerosene working solution and are connected with the anode and cathode of the high-frequency pulse power supply respectively; and the insulating ceramics are fixed on a work table and are driven by the work table to move. The method is stable in machining process and favorable for popularization and application.

Owner:HARBIN INST OF TECH

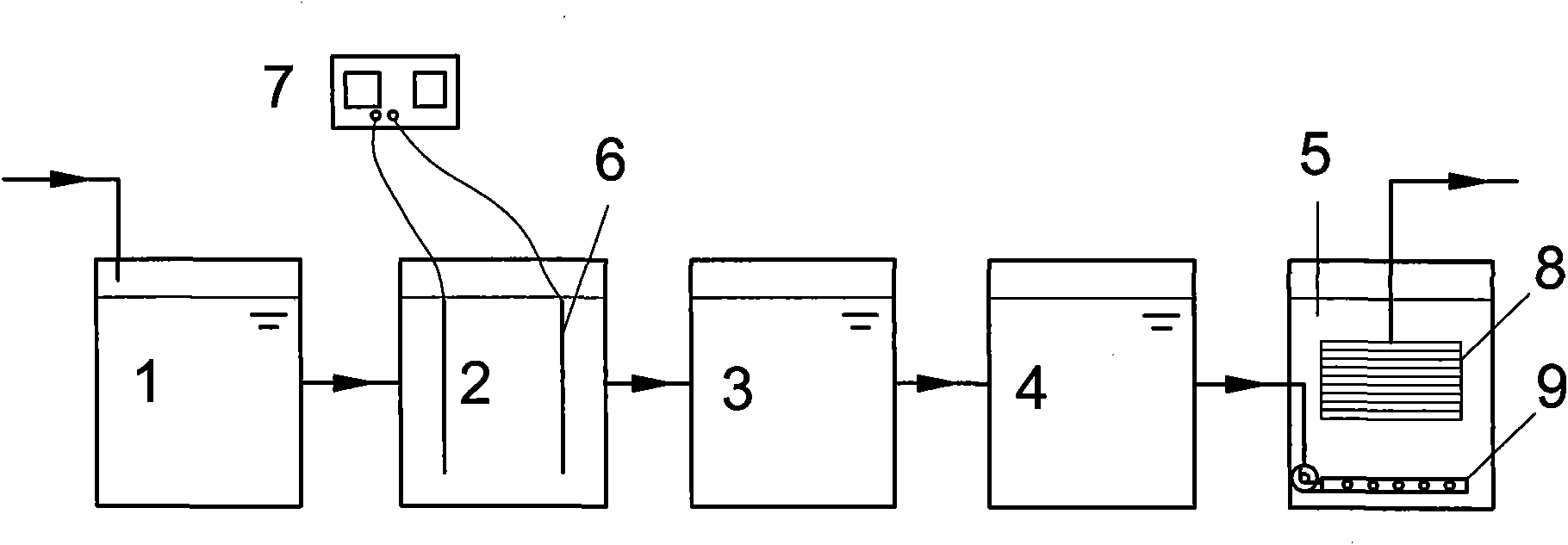

Method and device for processing pharmaceutical wastewater by pulse electrocoagulation-MBR

ActiveCN101560040AOvercoming passivationOvercoming polarizationWater/sewage treatment bu osmosis/dialysisTreatment with aerobic and anaerobic processesDecompositionWater quality

The invention relates to a method and a device for processing pharmaceutical wastewater by pulse electrocoagulation-MBR. The main process of the method is a pulse electrocoagulation-chemical oxidation-MBR process. The device sequentially comprises a regulating reservoir, an electrocoagulation reactor, a chemical oxidation pond, an anoxic pond and a membrane bioreactor, wherein the electrocoagulation reactor adopts a pulse power supply for power supply, overcomes the problem that a polar plate is susceptible to passivation, has the characteristics of low energy consumption and high process efficiency, and can remove a major part of pollutants in the wastewater; the chemical oxidation pond plays a role in strong oxidative decomposition and converts difficult-to-degrade substances into biodegradable minor molecule substances; and the anoxic pond and the membrane bioreactor form an A / O process, the membrane bioreactor can effectively degrade organic substances, ammonia nitrogen and other pollutants in the wastewater, the processed waster water is filtered by a membrane and the effluent can reach an industrial grade A level. The process has the advantages of impact load resistance, stable effluent quality and low investment cost.

Owner:GO HIGHER ENVIRONMENT GRP CO LTD

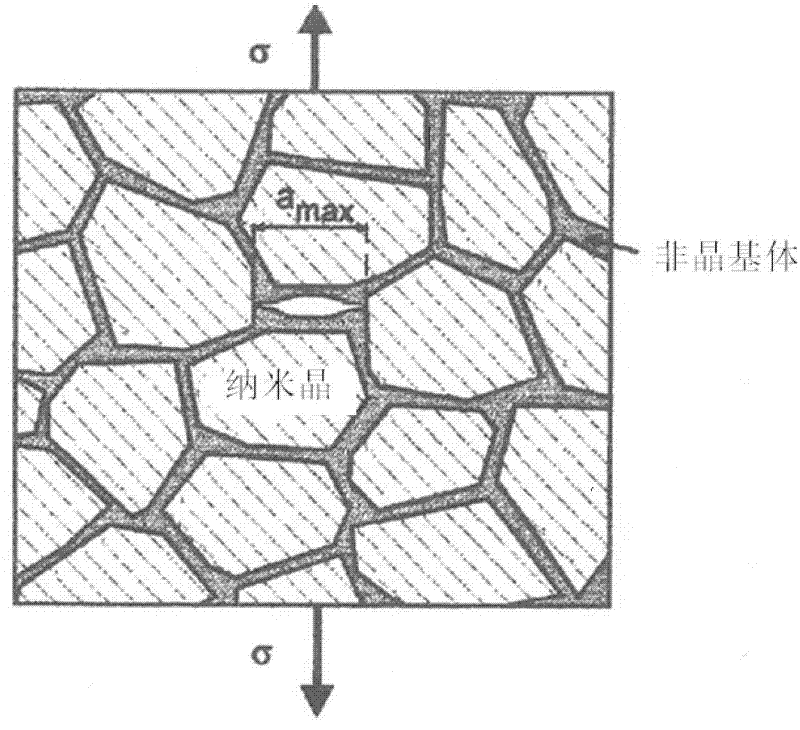

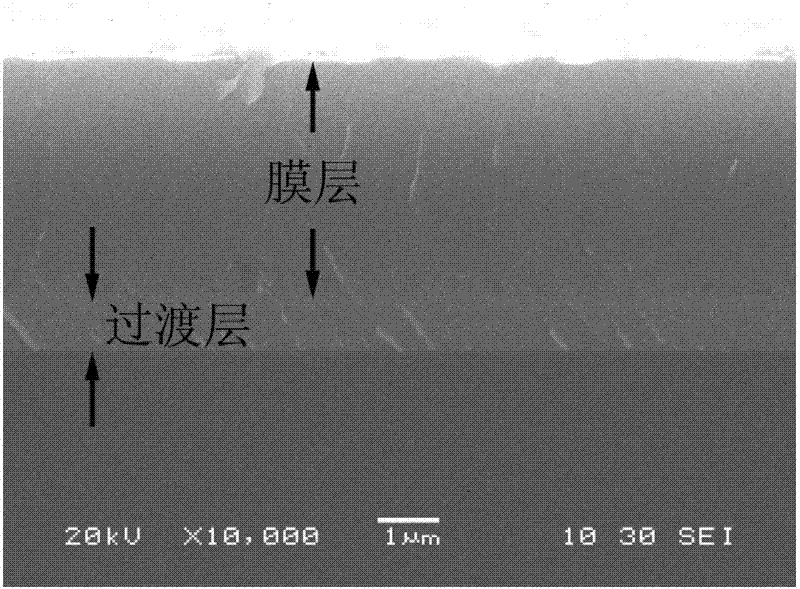

Preparation method of abrasion-resistant and oxidation-resisting TiAlSiN nanometer composite superhard coating

InactiveCN102653855AImprove antioxidant capacityVacuum evaporation coatingSputtering coatingSputteringPower flow

The invention discloses a preparation method of an abrasion-resistant and oxidation-resisting nanometer composite TiAlSiN superhard coating. The preparation method is characterized in that a basal body is pretreated and placed in electrical arc and magnetron sputtering composite deposition equipment, a pillar arc Ti target is used as a Ti source, and the power supply current of the pillar arc controls the sputtering rate of the pillar arc Ti target; a flat surface Si target and a flat surface Al target are used as sources of corresponding elements, the flat surface Si target and the flat surface Al target are placed on the inner wall of a furnace body in an opposite manner, and the sputtering rates of the targets are controlled by adjusting the power of a medium-frequency pulse power supply; high-purity Ar is adopted as a main ionization gas, and an effective glow discharge process is guaranteed; and high-purity N2 is adopted as a reacting gas, is ionized and combined with the Ti, Si and Al elements so as to deposit on the surface of the basal body to form a TiAlSiN coating. The thickness of the prepared TiAlSiN coating is 3.5 micrometers, and the microhardness of the coating is 40 GPa; and the friction factor is 0.7, the antioxidation temperature of the TiAlSiN coating achieves 1000 DEG C, and the TiAlSiN coating has good antioxidation property and abrasion-resistant property.

Owner:马胜利

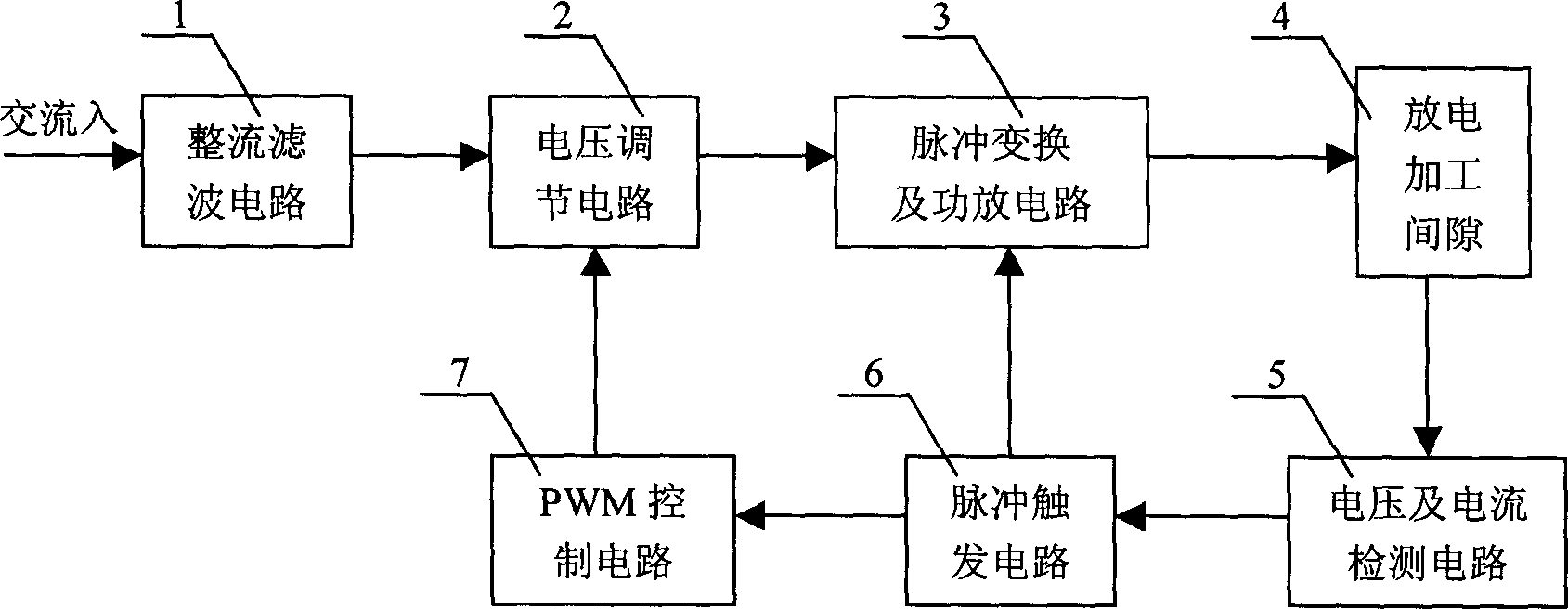

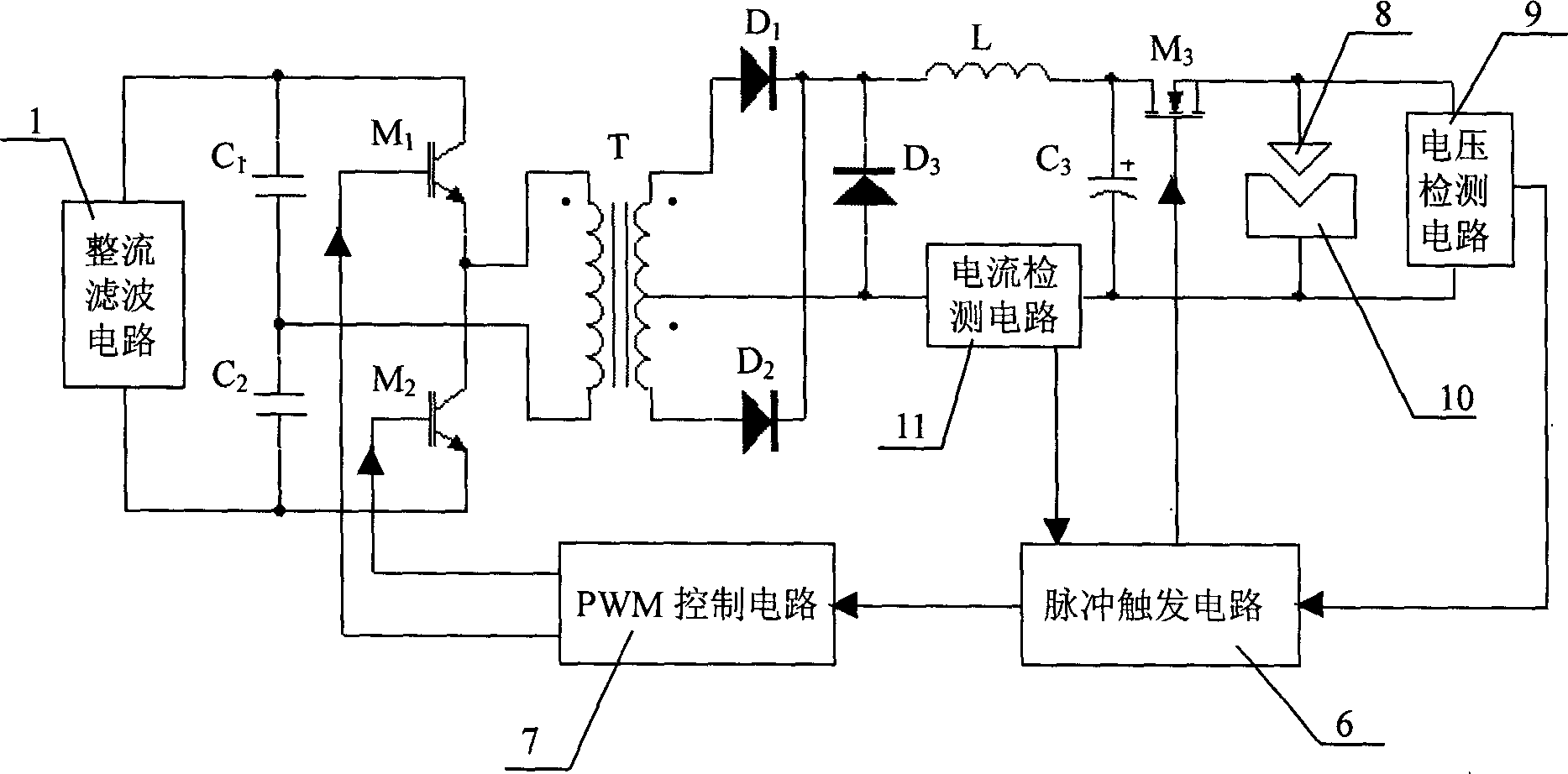

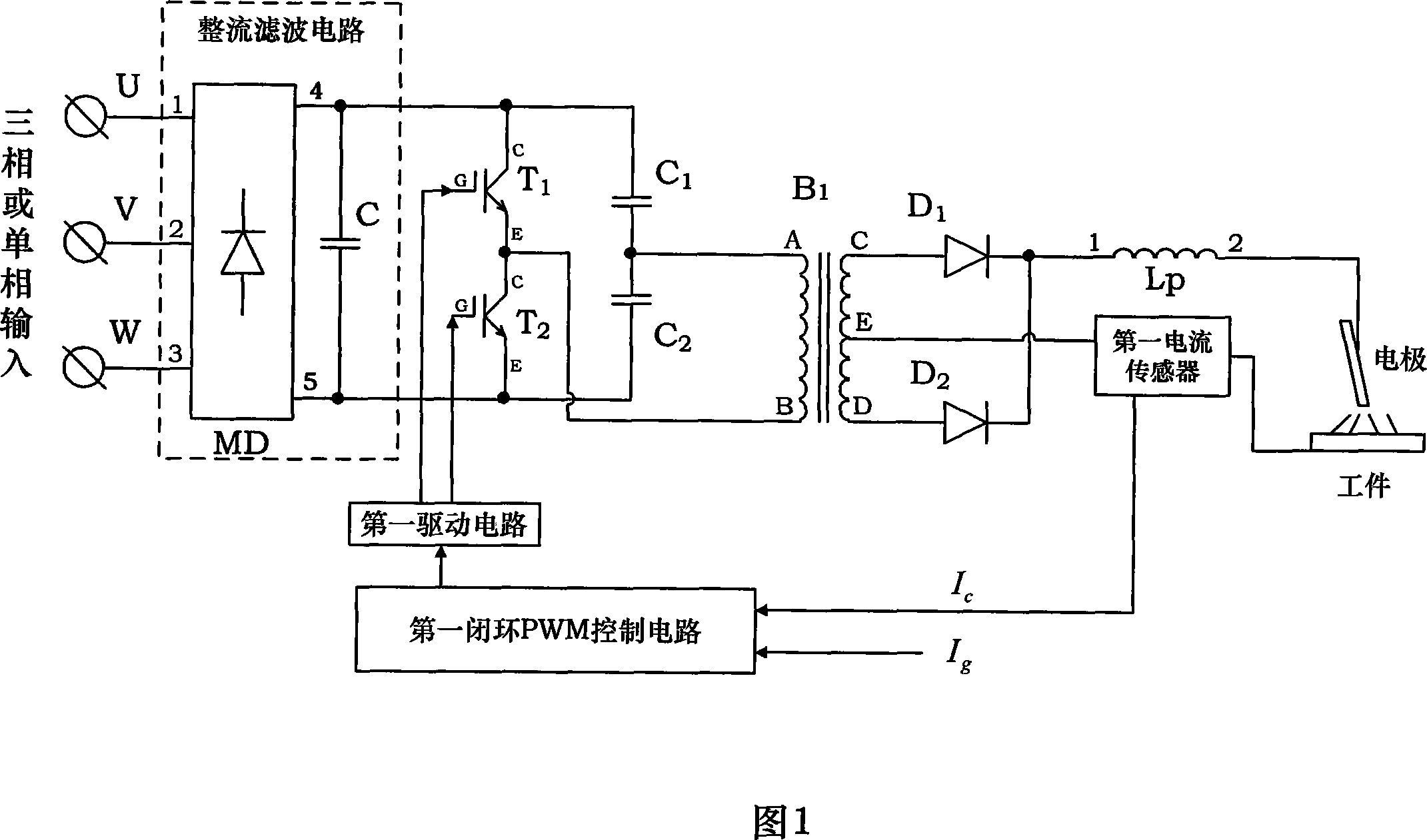

Voltage-regulating energy saving spark machining pulse power supply

ActiveCN1772425AIndependently adjustable pulse widthIndependently adjustable pulse intervalElectric circuitsMachine maintenanceEngineering

The present invention relates to machining technology, and is especially one voltage regulating energy saving spark machining pulse power supply. The pulse power supply includes rectification and filtering circuit, voltage regulating circuit, pulse converting and power amplifying circuit, voltage and current detecting circuit, pulse triggering circuit and PWM control circuit. The pulse power supply can provide no-load puncture voltage of about 100 V to the machining spark interval before puncture and machining maintenance voltage of about 25 V to the machining spark interval after puncture, and has the features of adaptive voltage regulation and equal current pulse width. The present invention can realize the independent regulation of pulse voltage, pulse width and pulse interval in wide ranges, and has no current limiting resistor with high power consumption and thus 2 times raised electric energy utilization rate.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

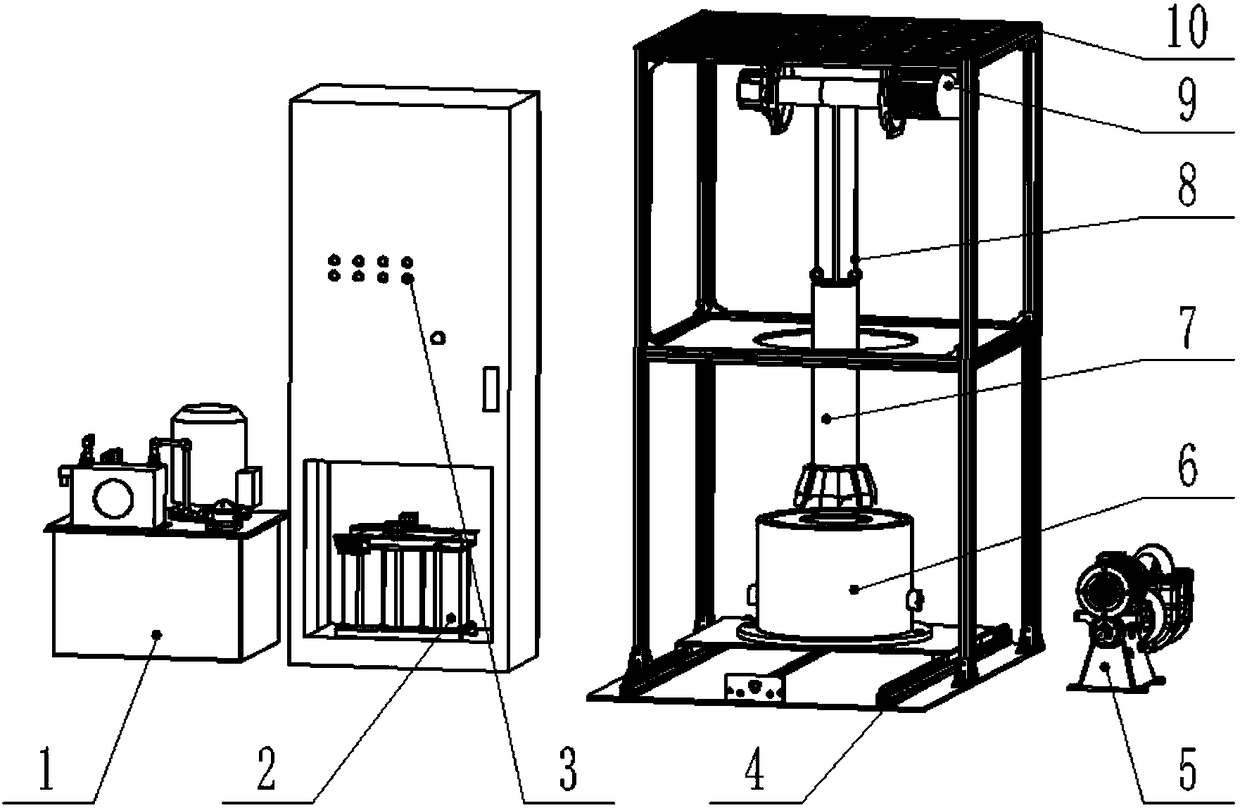

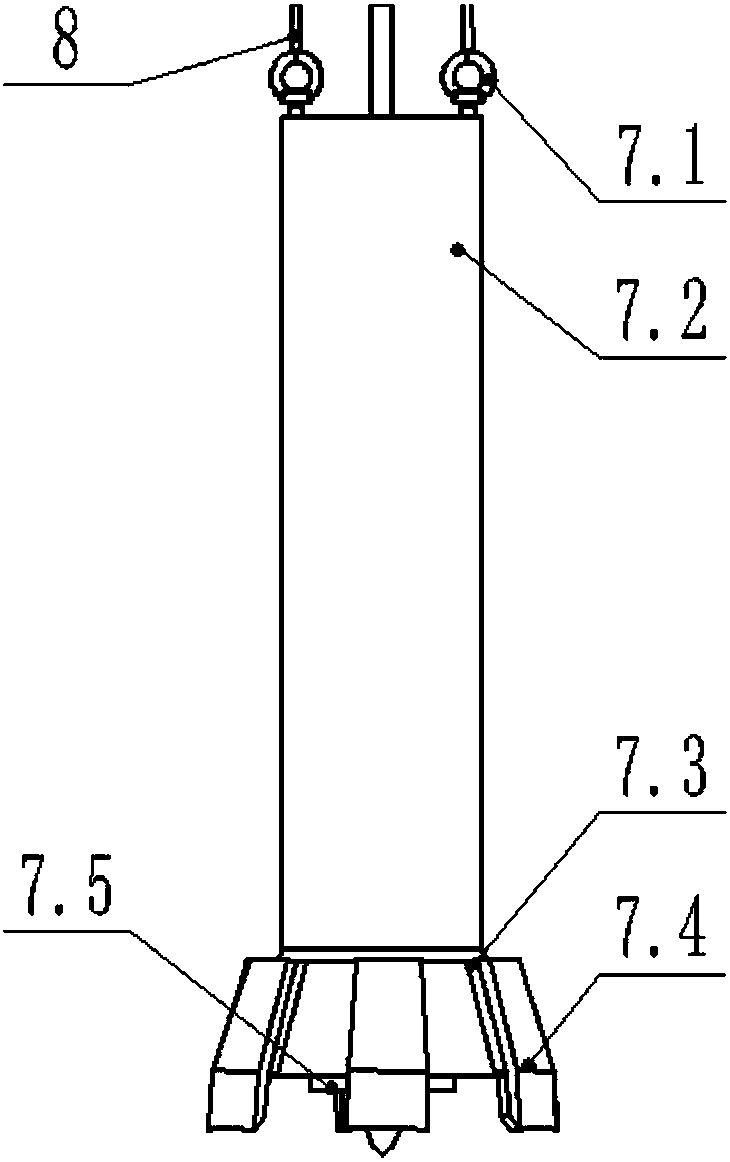

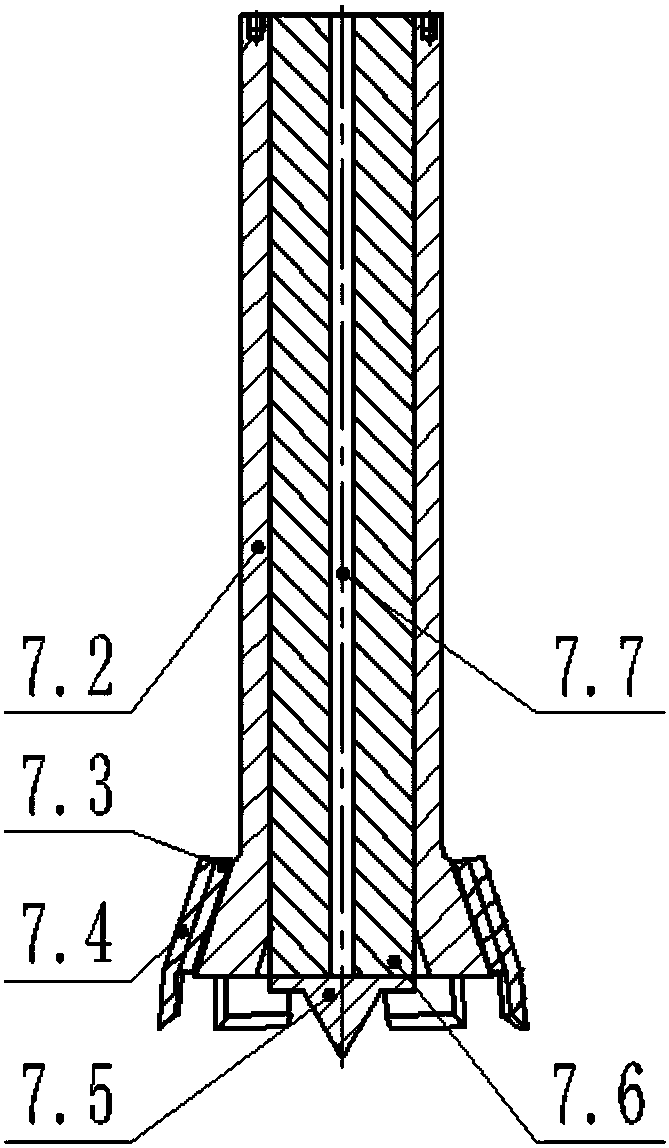

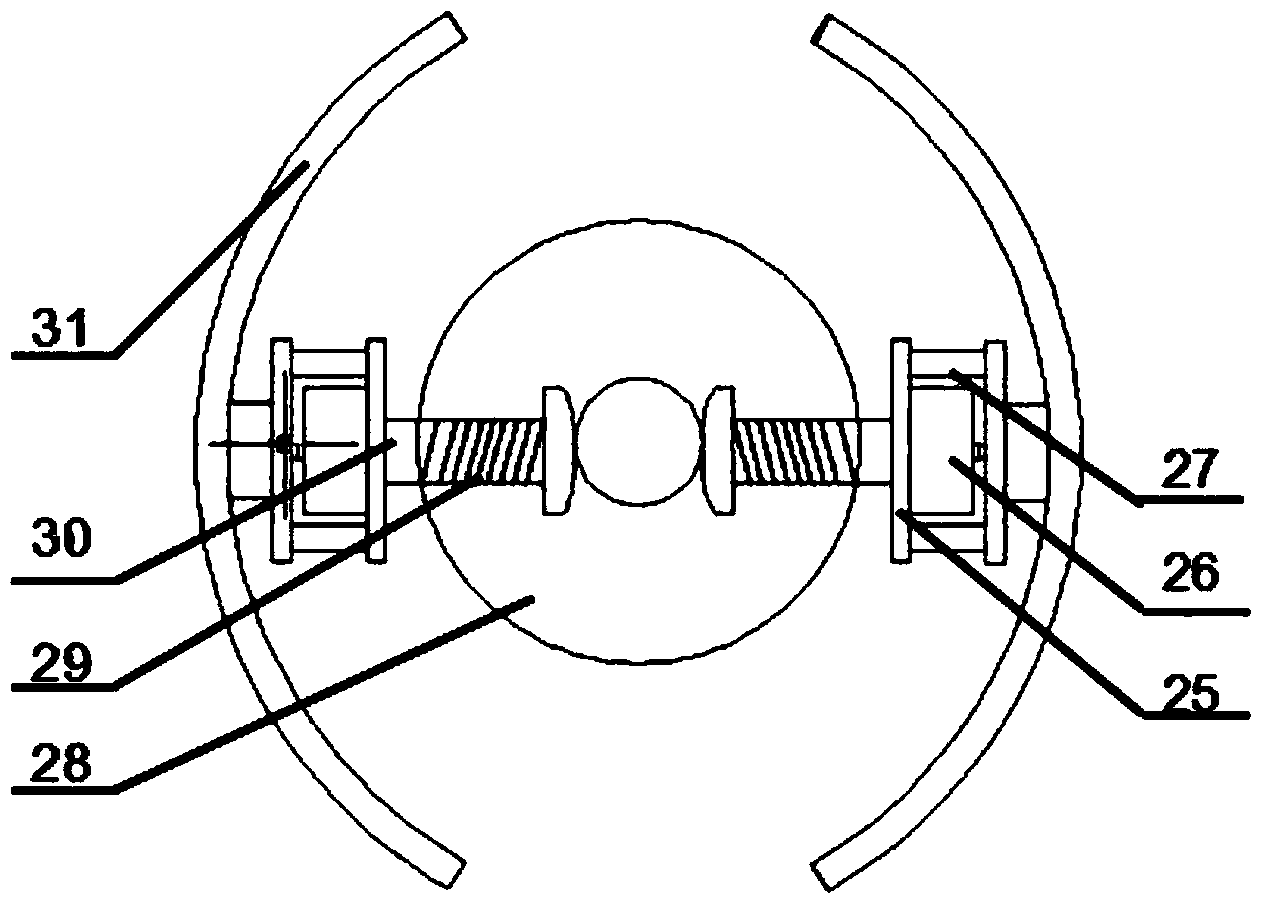

Electric pulse rock-breaking dill bit and experimental facility thereof

ActiveCN108222838AImprove energy efficiencyImprove drilling qualityMachine part testingDrill bitsLow voltageElectrical impulse

The invention discloses an electric pulse rock-breaking dill bit and an experimental facility thereof. The electric pulse rock-breaking experimental facility comprises a confining pressure pumping station, a pulsed power supply, a PLC control device, a confining pressure cylinder horizontal-moving device, a water inlet and outlet pump, a confining pressure cylinder assembly, a high-pressure electric pulse rock-breaking drill bit body, and the like. The high-voltage pulsed power supply is used for transmitting high-voltage pulse electricity from a high voltage electrode to a low voltage electrode through a cable, the high-voltage pulse electricity meeting certain conditions breaks through rocks firstly to generate a discharge channel, a plasma channel expands when heated, when the pressureexceeds the stress intensity of the rocks, and the rocks are broken and the high-voltage pulse discharge drilling is realized. The high-pressure electric pulse rock-breaking experimental facility cansimulate the high voltage environment of deep drilling in the earth, electric pulse drilling experiments carried out on high temperature and high pressure deep wells and ultra-deep wells are more close to actual drilling environments, experimental studies on the geometrical shape, distribution, spacing and electrode materials of electrodes of high-voltage electric pulse rock-breaking drill bit inthe deep wells and the ultra-deep wells can be realized, and the high-voltage pulse discharge drilling has broad development prospects.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN) +1

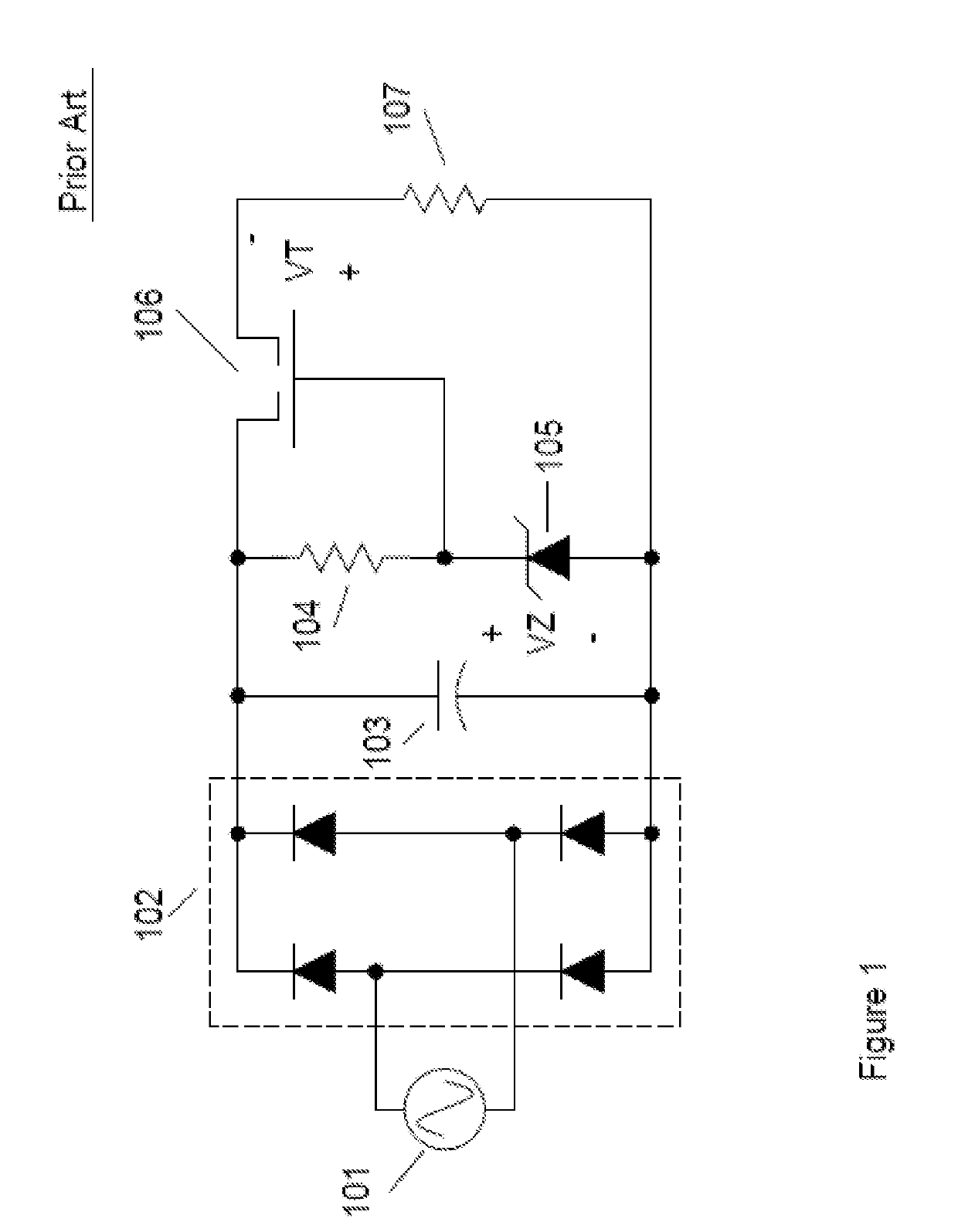

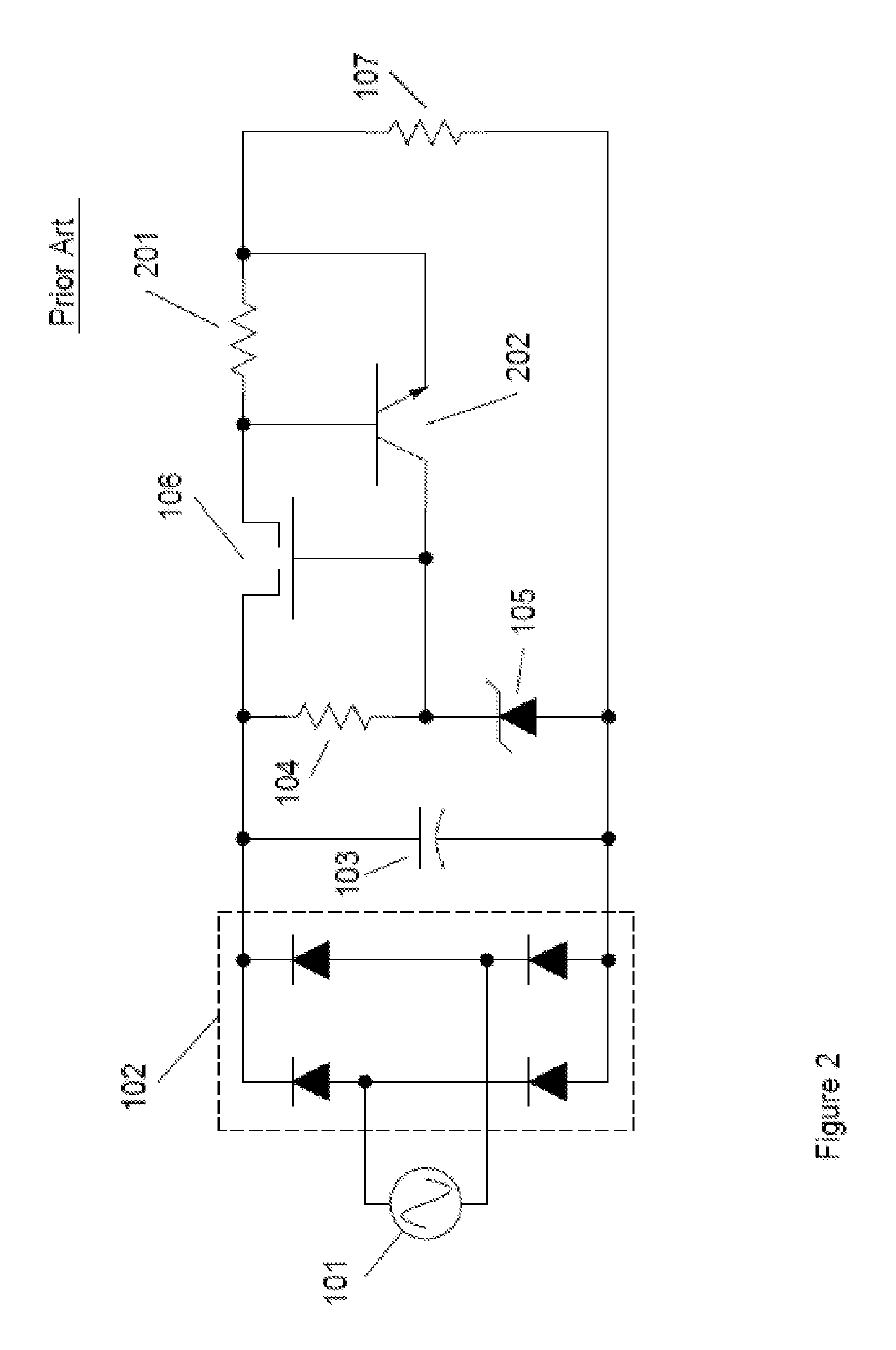

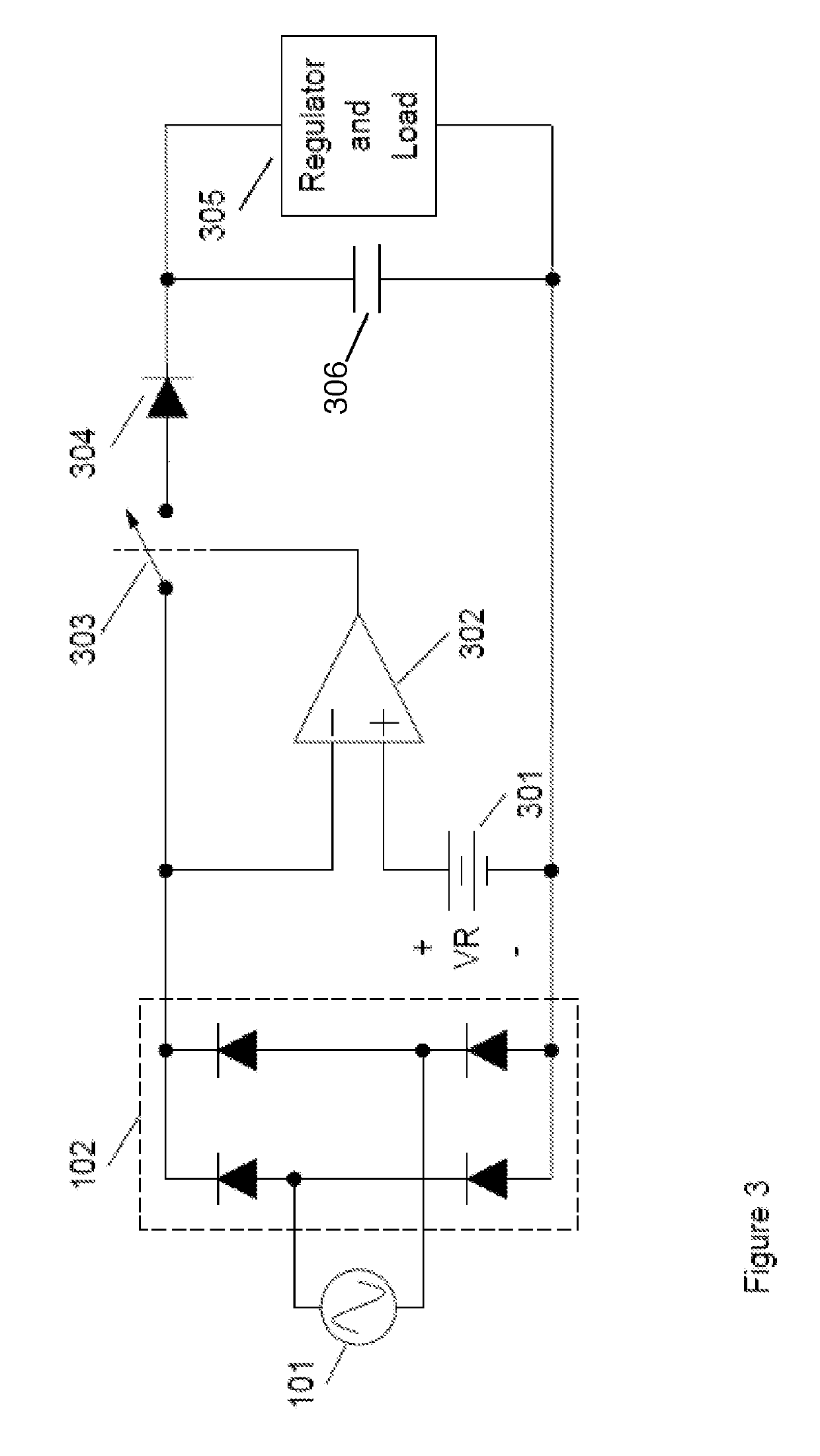

High efficiency ac direct to DC extraction converter and methods

ActiveUS20190238060A1Reduce power consumptionLow costAc-dc conversion without reversalDc-dc conversionMOSFETElectronic switch

An improved AC direct to DC extraction conversion system is described. The AC direct to DC extraction conversion system consists of an efficient electronic switch employed to provide controlled pulsed power to a storage device. The AC to DC converter in one minimal version consists of a pair of N-MOSFET transistors, a voltage divider, a storage element and a pair of diodes. The design enables high efficiency with minimal components that may be fully integrated onto silicon.

Owner:INTELESOL LLC

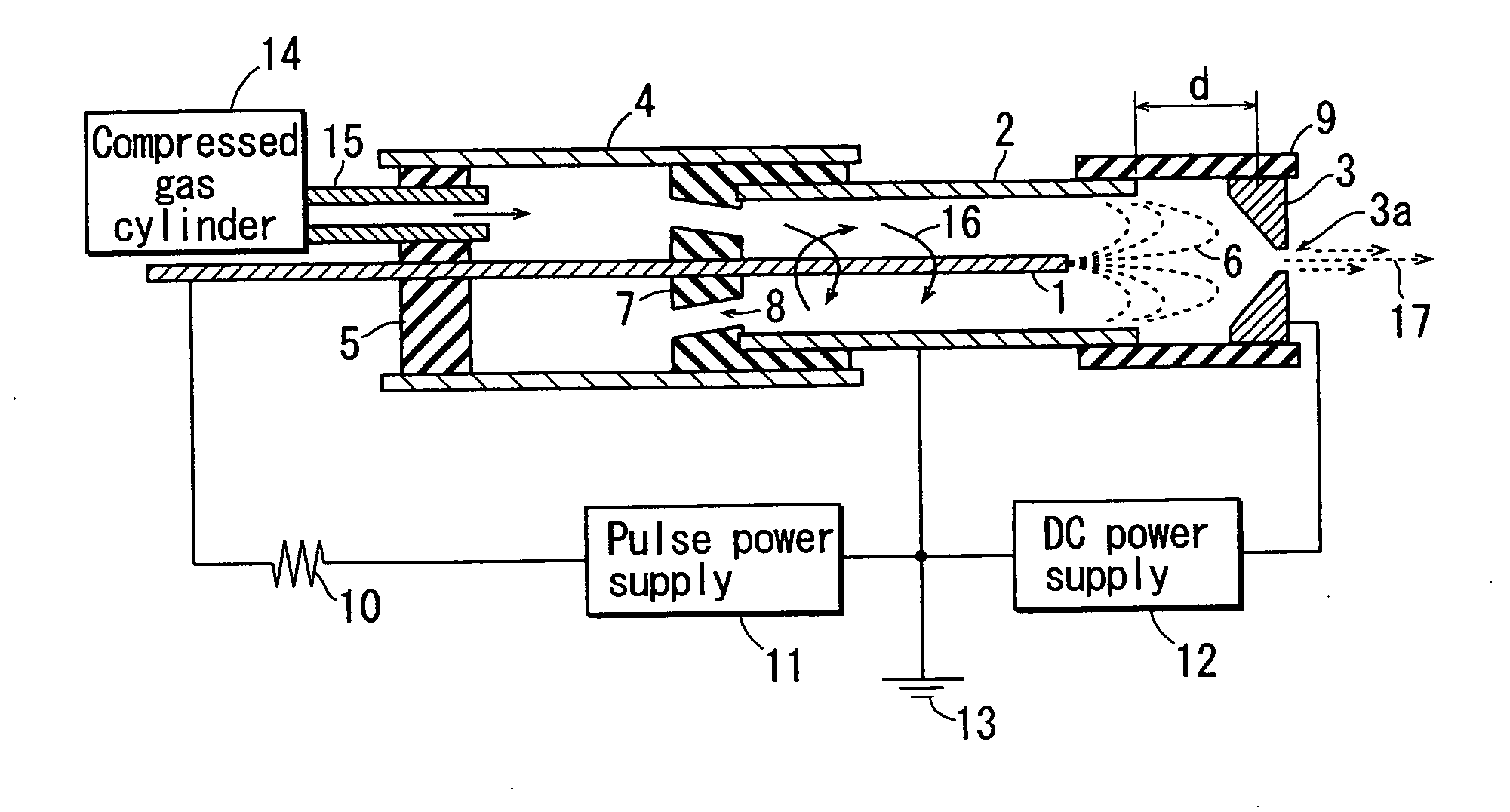

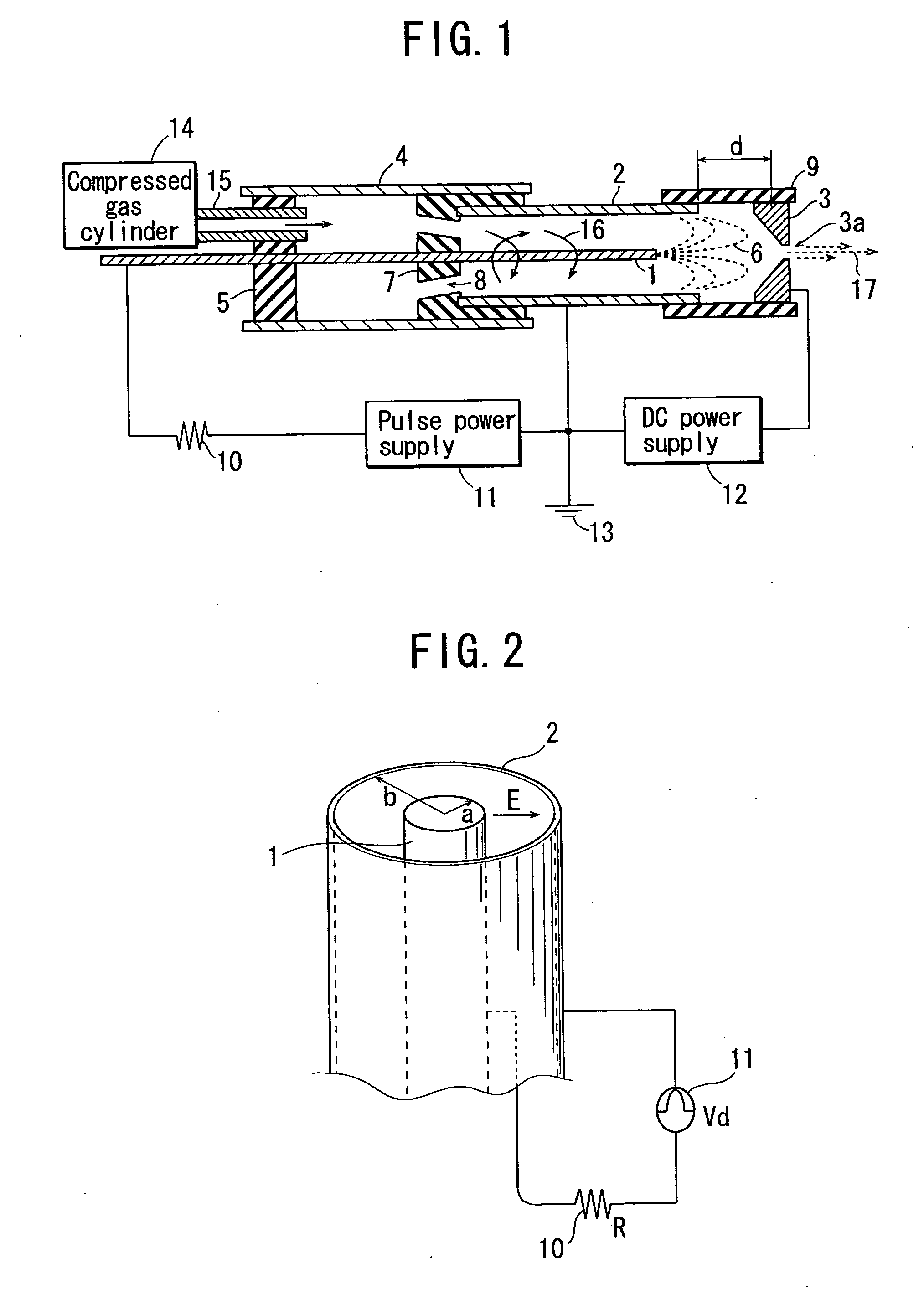

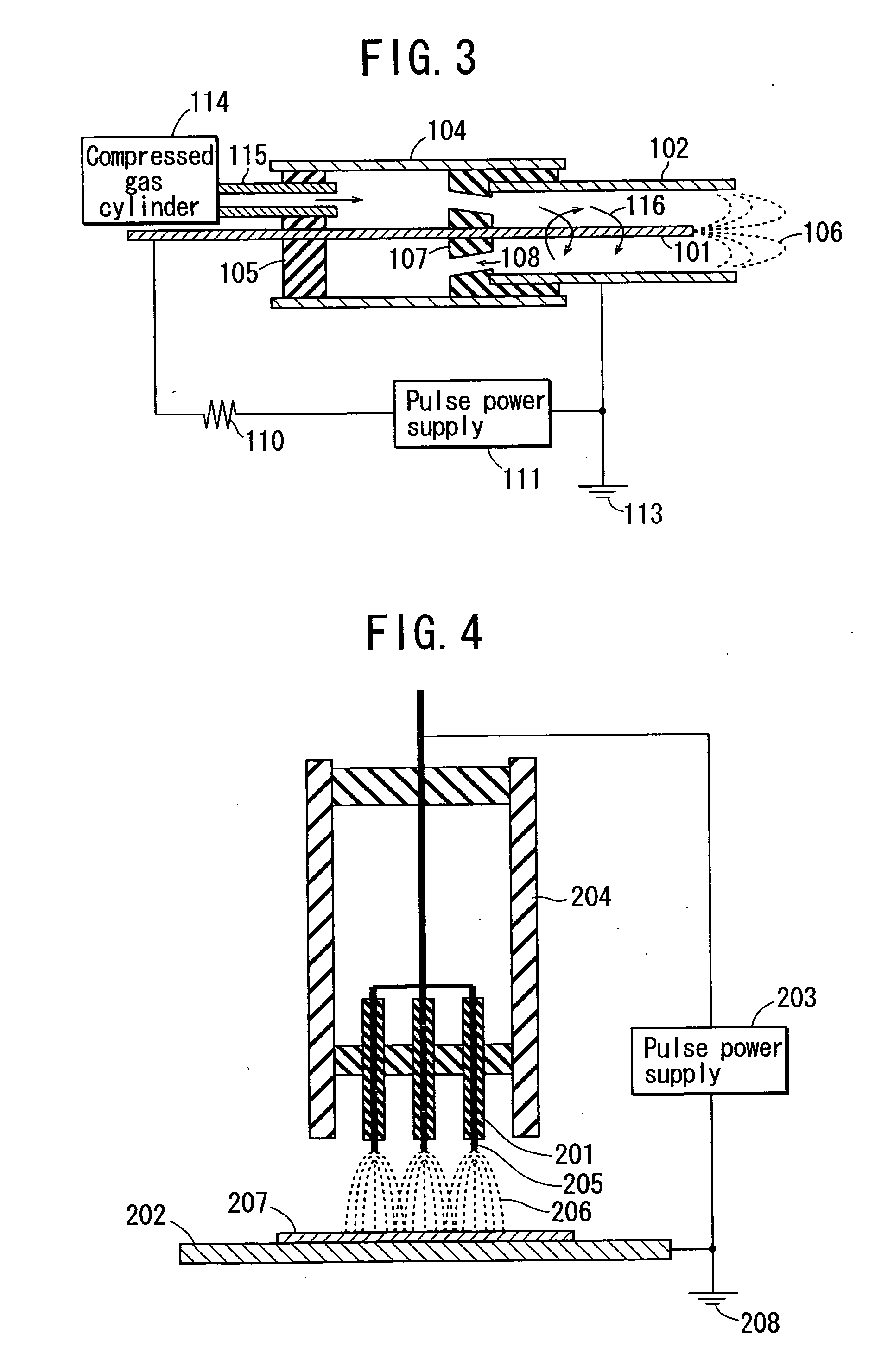

Plasma Generation Device

InactiveUS20080050291A1Dissolve fastMeet high requirementsEnergy based chemical/physical/physico-chemical processesPlasma techniqueElectric dischargeAtmospheric pressure

A plasma generation device that can efficiently generate plasma at atmospheric pressure without producing arc discharge is provided. The plasma generation device, which comprises an electrode bar 1, a cylindrical electrode 2, and a pulse power supply 11 generating a pulse voltage, generates plasma by an electric discharge induced between the electrode bar 1 and cylindrical electrode 2 by applying a predetermined pulse voltage to a point between the electrode bar 1 and cylindrical electrode 2.

Owner:YUTAKA ELECTRONICS IND

Technical for manufacturing jewelry by using hard gold

InactiveCN101810387AHigh hardnessIncrease elasticityJewelleryElectroforming processesManufacturing technologyEngineering

The invention provides a process for manufacturing jewelry by using hard gold. The technique mainly comprises the following steps of: 1, molding; 2, opening a jelly mould; 3, injecting wax; 4, trimming the wax; 5, applying silver oil; 6, manufacturing a raw blank; 7, removing the wax; 8, removing silver; 9, welding; 10, modifying the mould; 11, picking stones and embedding stones; 12, treating the surface; and 13, carving by laser. The method ensures that the molecular structure of gold changes by utilizing hard gold jewelry manufacturing technology and applying the metal reinforcing technology in aerospace science and technology to jewelry manufacture and adjusting temperature, pH value, current, pulse power supply, additive and other technical parameters of electrotyping solution in an electrotyping process, thereby effectively improving the hardness and the elasticity of the gold. On the premise of ensuring the purity of the gold, the hardness of the gold is 4 times that of the traditional gold, so that the technique requirements of the fashion jewelry design are met. The gold jewelry and art decorations manufactured by the method cannot be easily scratched or deform, so that the artistic quality of the jewelry and decorations can be greatly improved.

Owner:惠州市博艺黄金珠宝有限公司

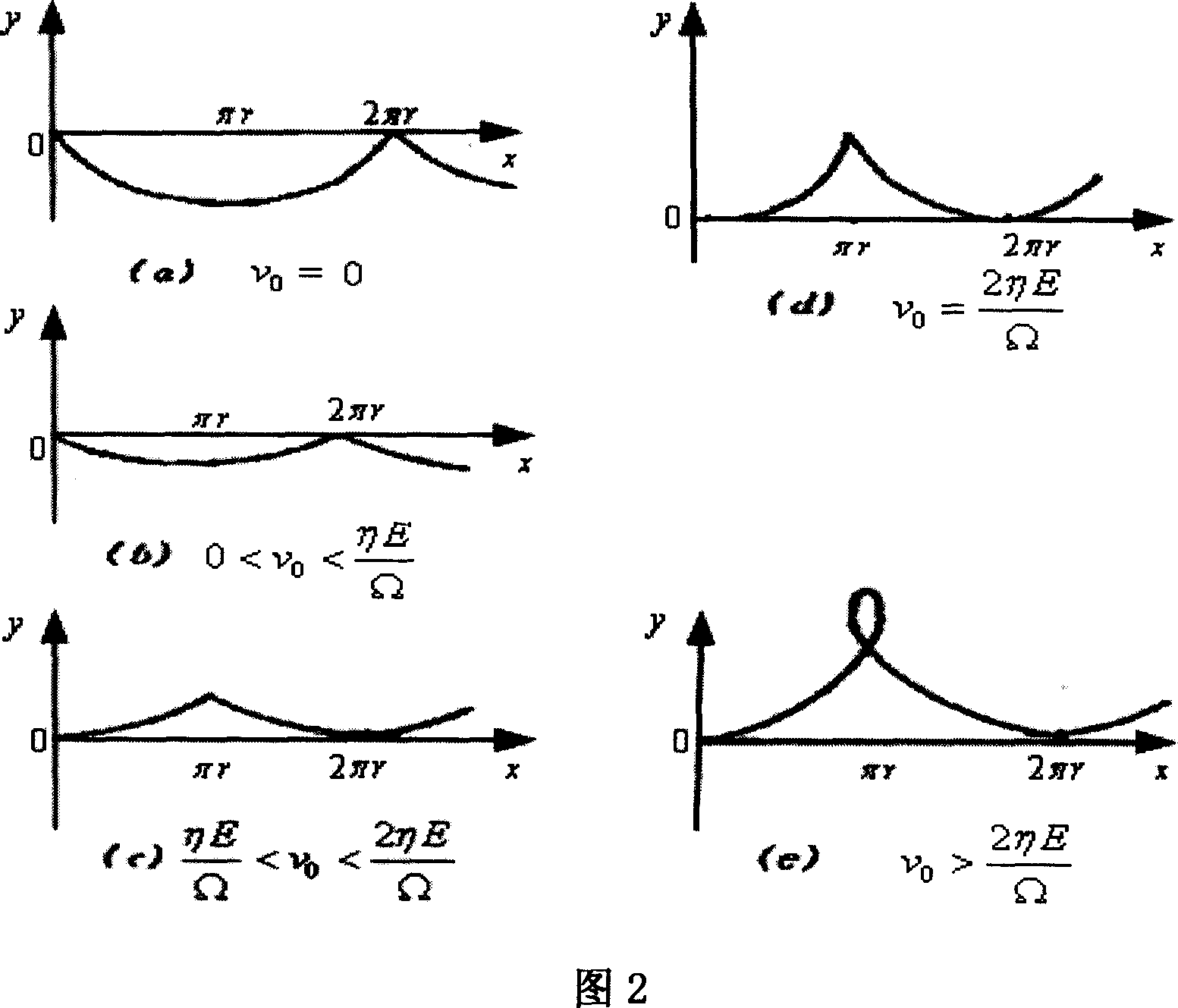

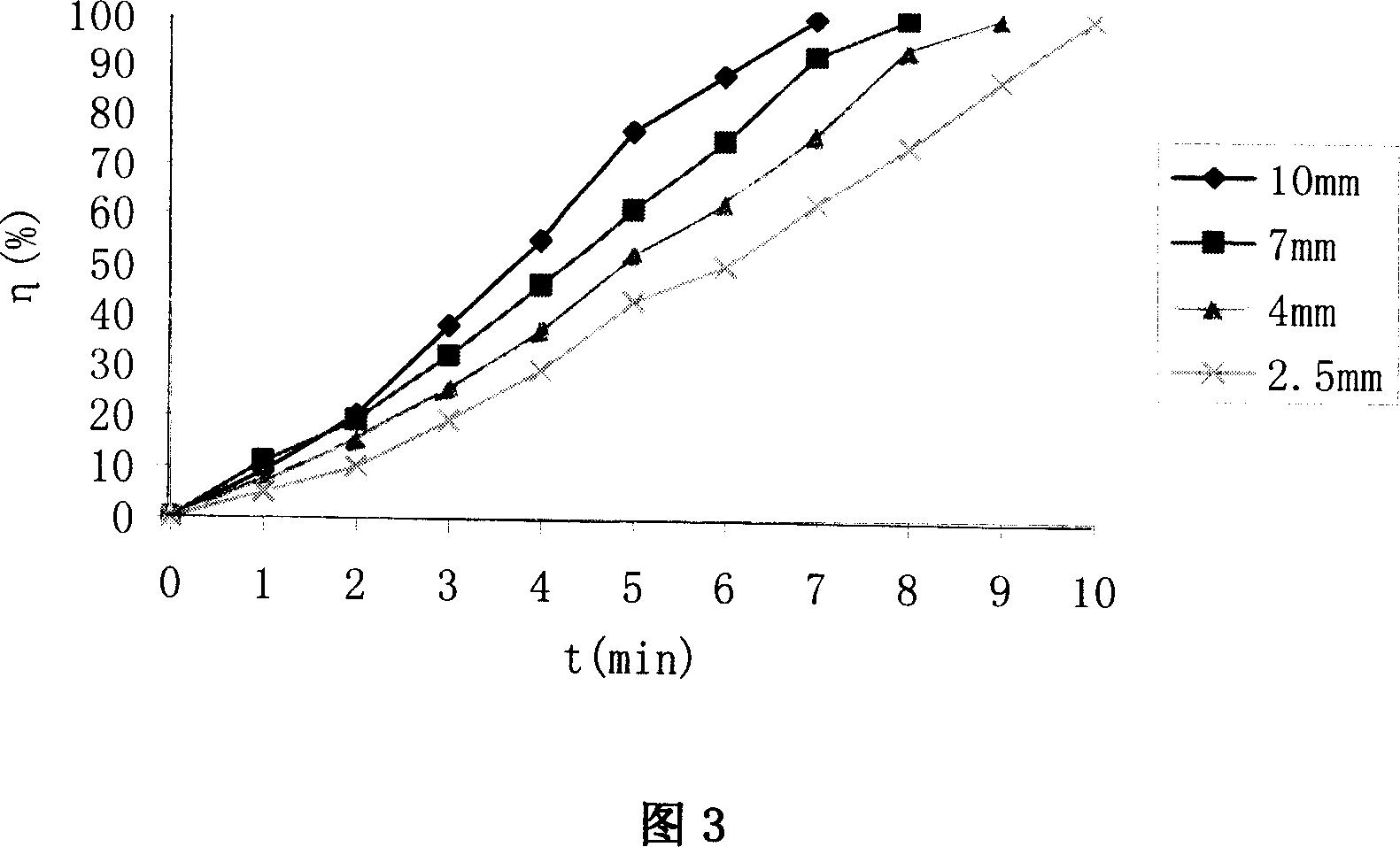

Indoor air purification method by using medium for blocking off low-temperature plasma generated by discharge

The invention discloses a method of room air purification with low temperature plasma generated by dielectric resistance discharging. The harmful gas of air can be wiped off by dielectric resistance discharging plasma which is in magnetic field: the needle plate electrode is the reaction electrode, the dielectric resistance discharging can be realized by inserting a dielectric-slab which is 1mm-5mm in thickness at the side of the plate electrode, the distance of the needle electrode is 6mm-30mm, the nanosecond frontal high-voltage narrow pulse power supply is applied to the two ends of the needle plate electrode, the voltage is 10kv-60kv, the permanent magnet is mounted on the two ends of the electrode; The harmful gas of air can be wiped off by pulse discharging plasma which is in magnetic field. At the base of parallel magnetic field, the harmful gas can be wiped off by the low temperature plasma generated by the nanosecond frontal pulse dielectric resistance discharging in the invention, so the purification efficiency is improved greatly.

Owner:XI AN JIAOTONG UNIV

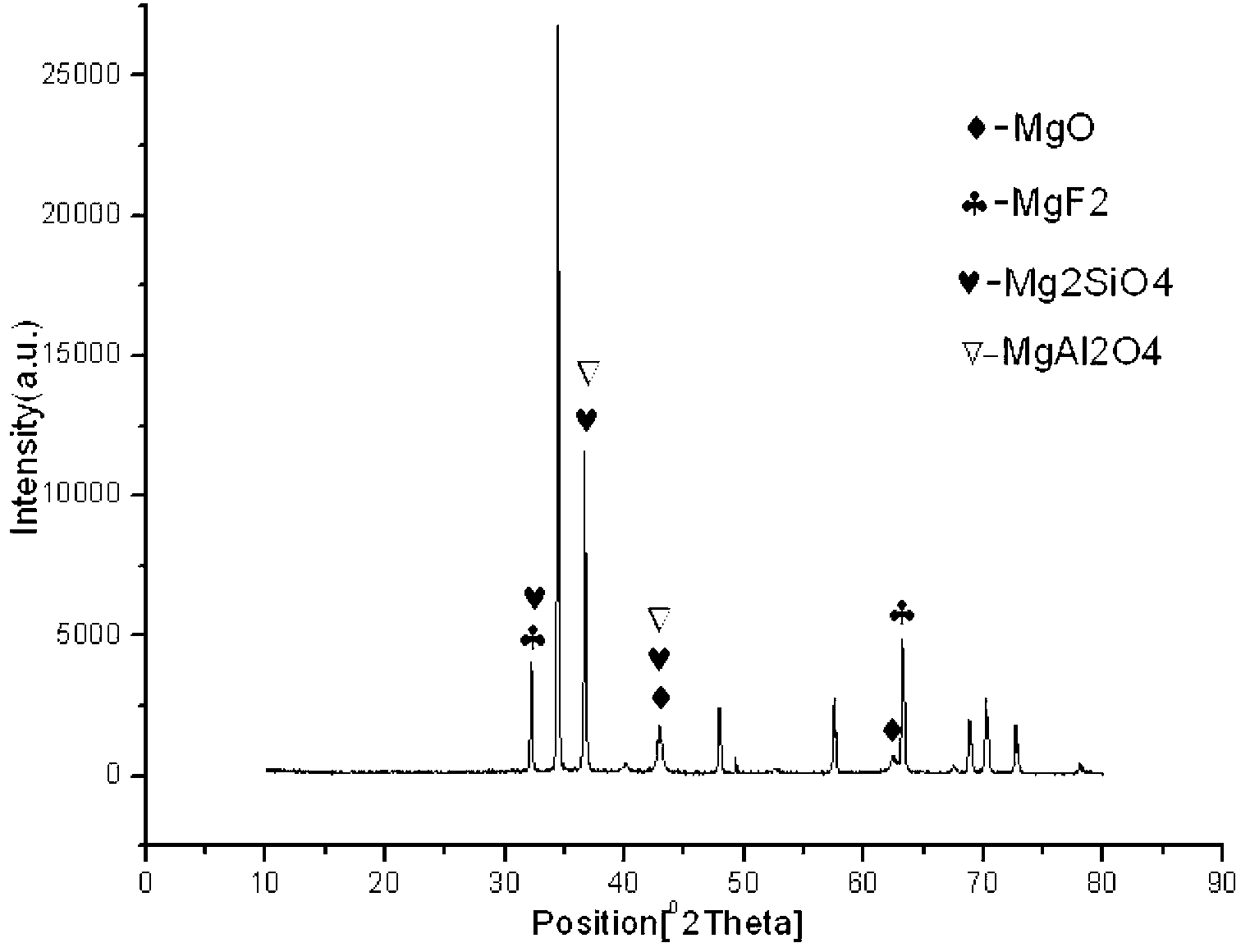

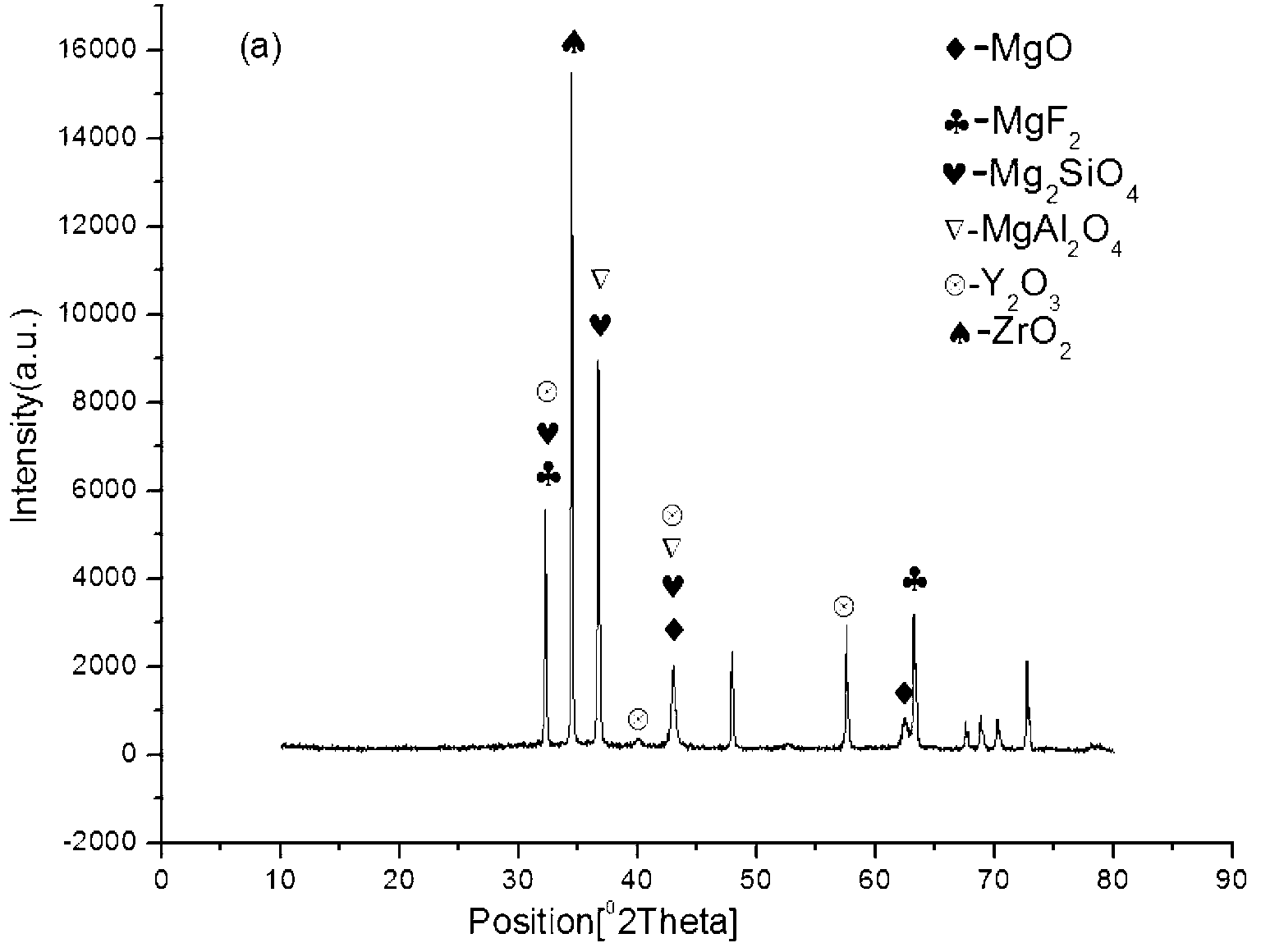

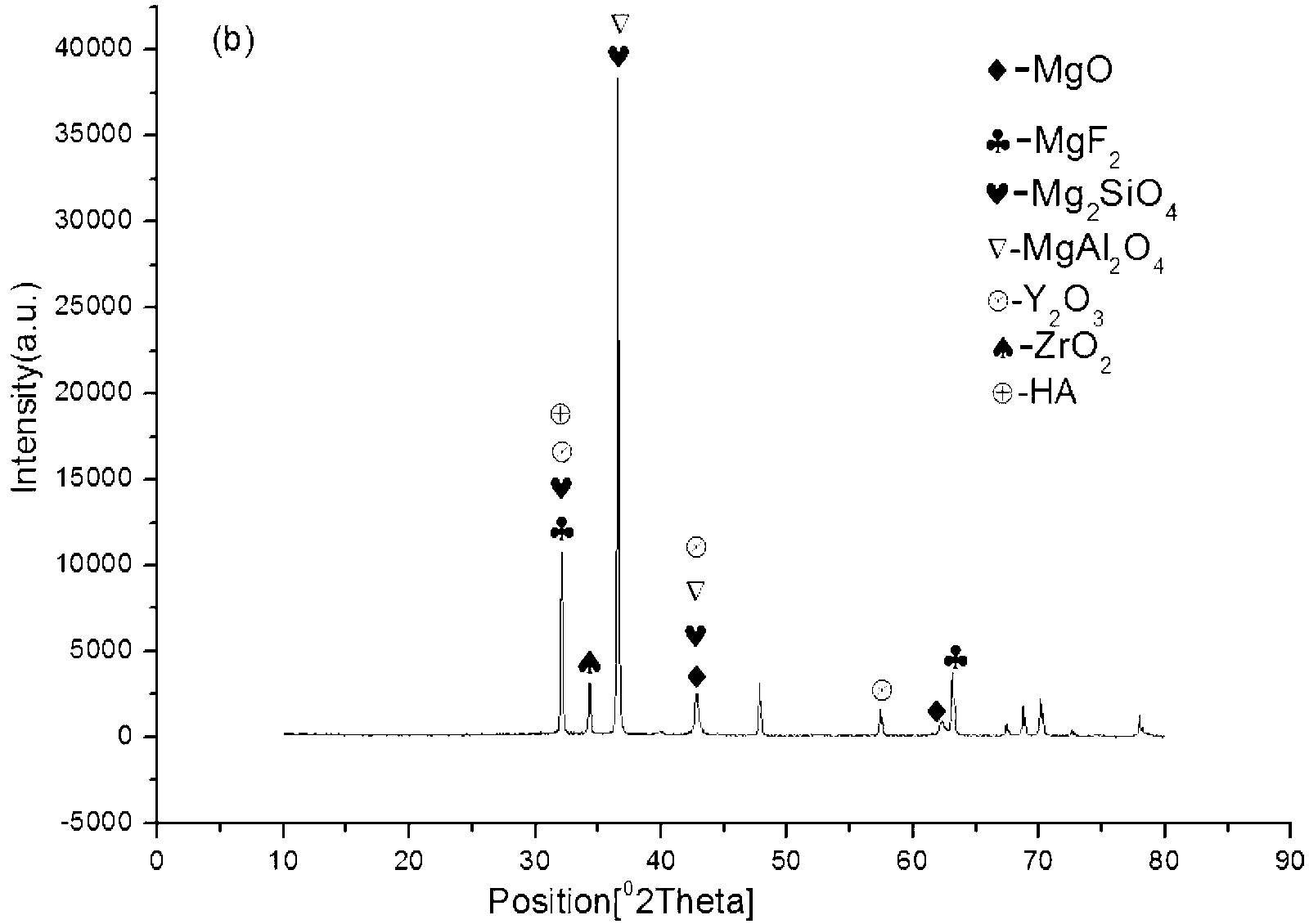

Method for preparing magnesium-based ceramic coating by micro-arc oxidation-electrophoretic deposition

InactiveCN103194782ABiologically activeImprove corrosion resistanceAnodisationElectrophoretic coatingsPlasma electrolytic oxidationMicro arc oxidation

The invention discloses a method for preparing a magnesium-based ceramic coating by micro-arc oxidation-electrophoretic deposition. The method comprises the following steps of: immersing preheated magnesium alloy taken as an anode in an electrolyte, taking a micro-arc oxidation stainless steel electrolytic cell as a cathode, adopting a direct-current pulsed micro-arc oxidation device, carrying out micro-arc oxidation for 10-25 minutes under the conditions that the electric current is 10-20A / dm<2>, the duty ratio is 37.5-50%, and the temperature of the electrolyte is 20-30 DEG C, taking out the anode, naturally drying, thus obtaining magnesium alloy subjected to micro-arc oxidation; immersing the magnesium alloy subjected to micro-arc oxidation and taken as the anode in electrophoretic deposition liquid, taking the stainless steel electrolytic cell as the cathode, adopting a pulsed power supply, carrying out electrophoretic deposition treatment for 10-30 minutes under the conditions that the voltage is 250-350V, and the duty ratio is 37.5-50%, naturally cooling, thus obtaining the magnesium-based ceramic coating. The adhesive force of the biological nanometer coating is obviously enhanced, the toughness and the corrosion resistance of the coating are improved, and the coating has certain biological activity.

Owner:ZHEJIANG UNIV OF TECH

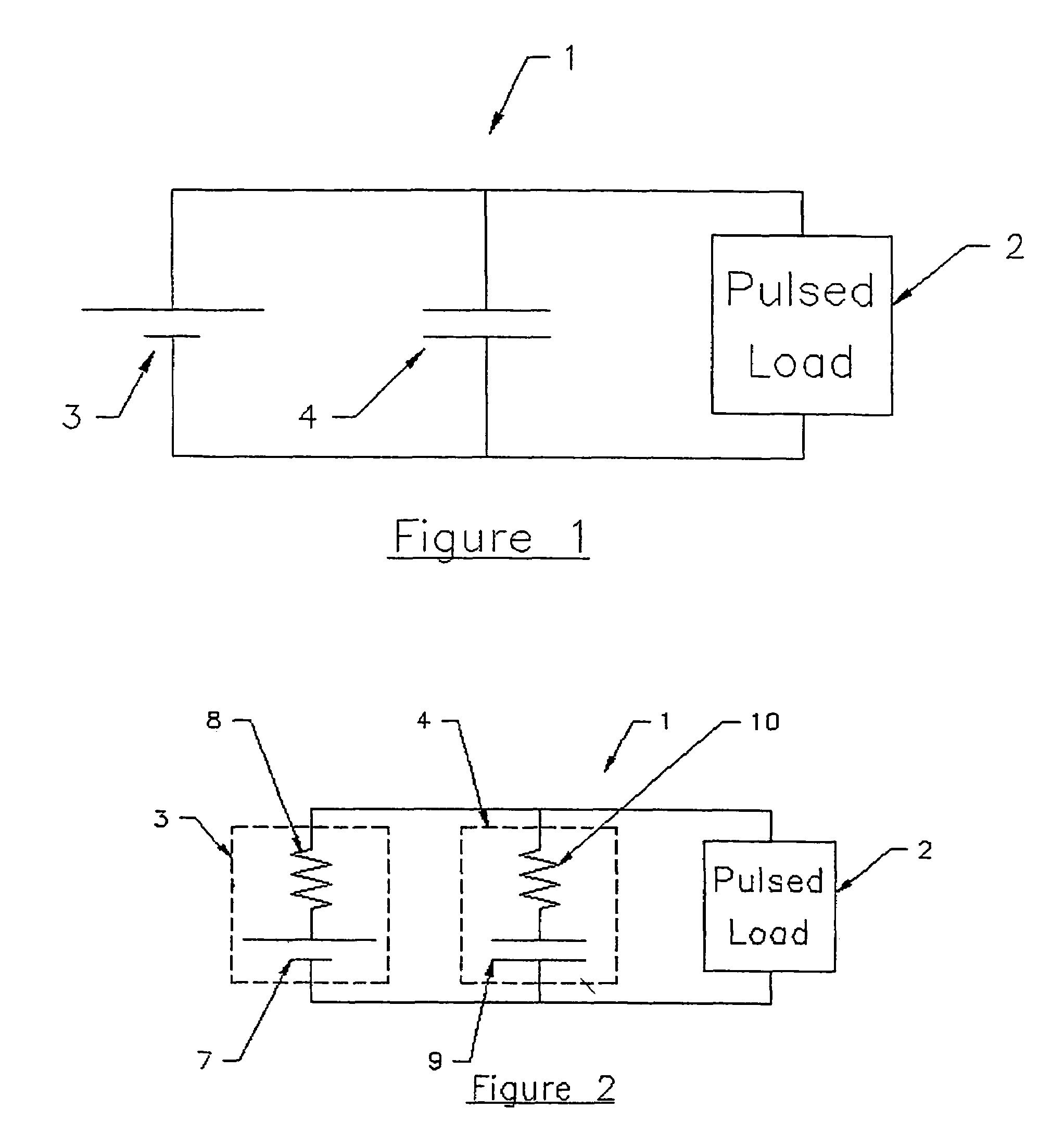

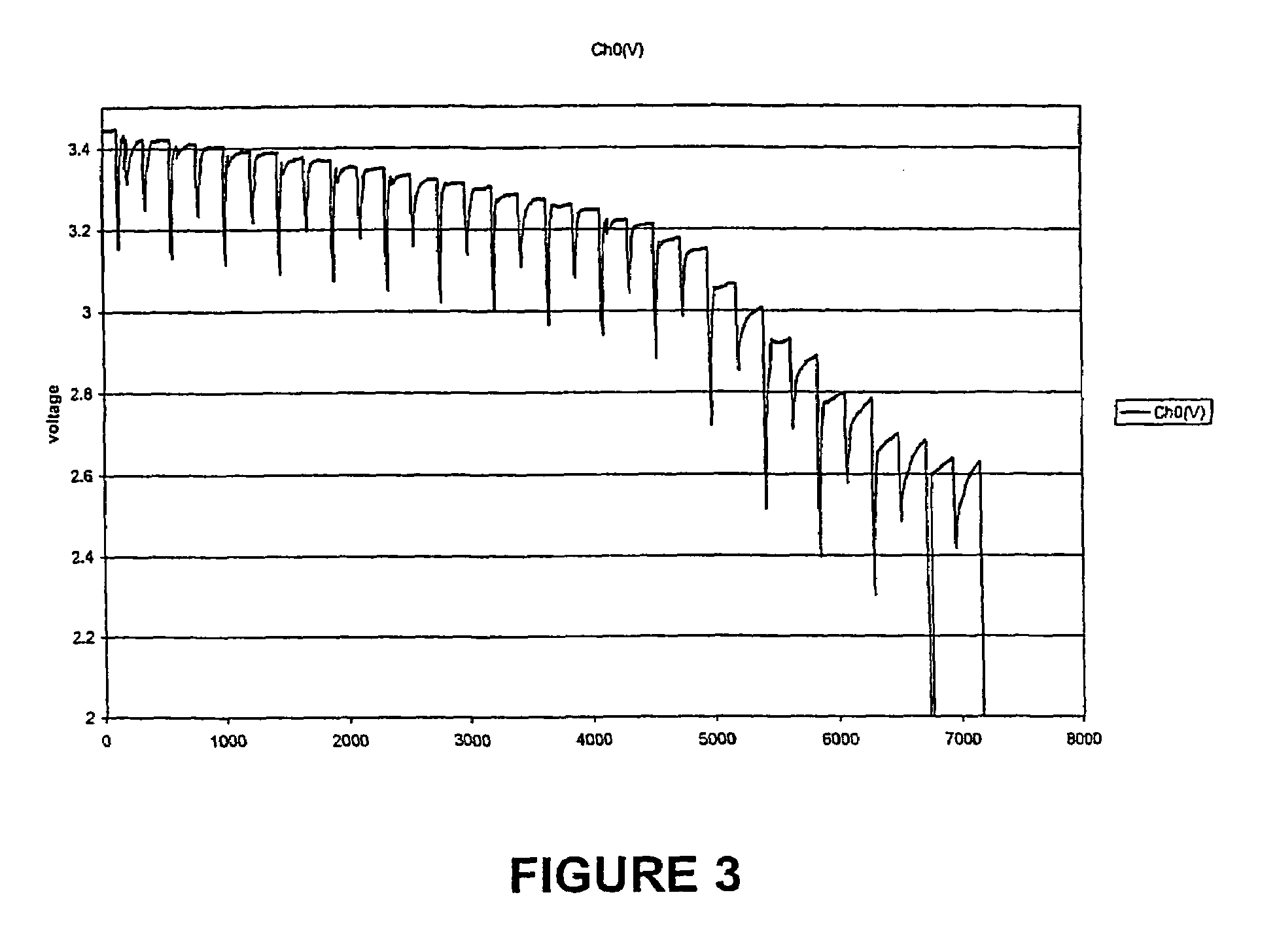

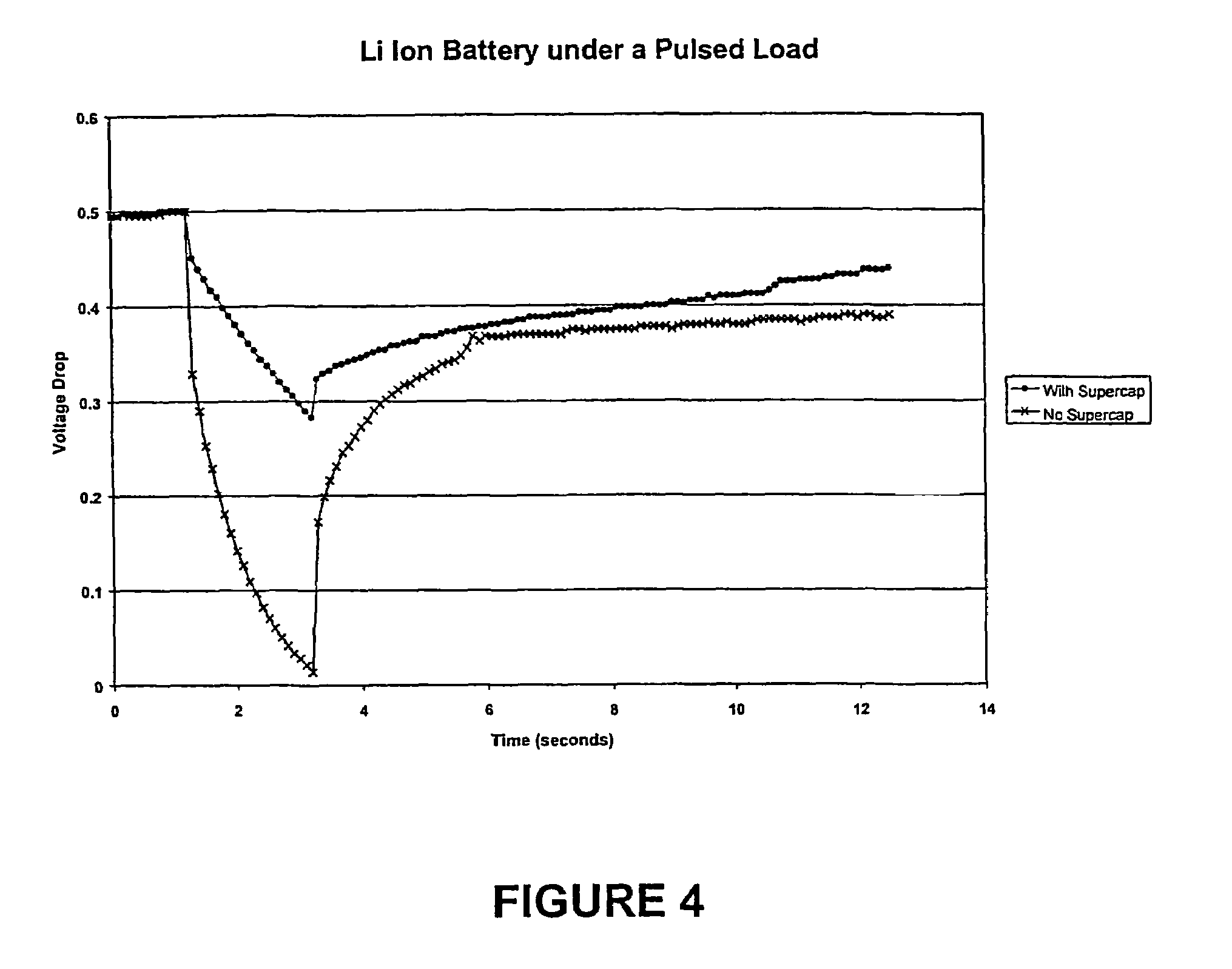

Power supply for a pulsed load

InactiveUS6998822B2Batteries circuit arrangementsAnalogue computers for electric apparatusPulse loadLow load

A power supply (1) for a pulsed load (2) includes a first energy storage device in the form of a battery (3) which is in parallel with a second energy storage device in the form of a supercapacitor (4). Battery (3) and supercapacitor (4) are respectively modelled as: an ideal battery (7) in series with an internal resistance (8); and an ideal capacitor (9) in series with an equivalent series resistance (ESR) (10). Through use of a supercapacitor (4) having a low ESR with respect to the resistance (8), the power supply (1) facilitates continuity of supply to load (2). That is, during peak demand more of the load current will be supplied by supercapacitor (4) due to the lower ESR. Moreover, during times of lower load current demands the battery recharges the supercapacitor. This reduces the peak current needed to be provided by the battery and thereby improves battery longevity.

Owner:CAP XX LTD

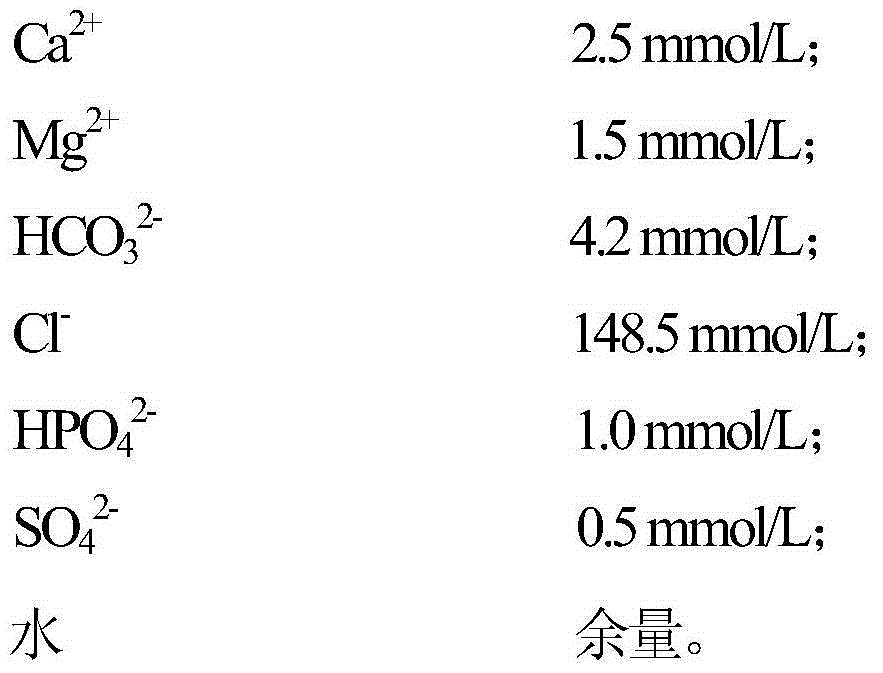

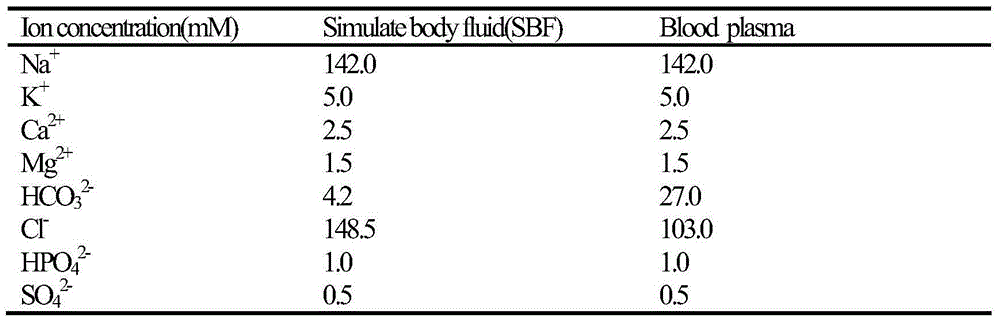

Preparation method and application of antibacterial bio-ceramic film with titanium or titanium alloy surface containing copper

ActiveCN104674321AAvoid corrosionIncrease growth rateSurgerySurface reaction electrolytic coatingPulse power supplyTitanium alloy

The invention discloses a preparation method and application of an antibacterial bio-ceramic film with the titanium or titanium alloy surface containing copper and belongs to the technical field of treating metal surfaces. The preparation method comprises the following steps: preparing a Ca, P and Cu containing porous hard ceramic layer under a single square wave pulsed power supply mode; and carrying out hydrothermal treatment or alkali treatment to obtain the CuO / HA antibacterial bio-ceramic film. According to the preparation method disclosed by the invention, the prepared ceramic layer and a matrix are in metallurgical bonding and are good in bioactivity and obvious in antibacterial effect; the prepared antibacterial bio-ceramic film is suitable for dental implant in the field of oral cavities as well as bone union plates, bone nails and the like of orthopaedics; and the ceramic layer is good in protein adsorbability and adhesion, increment and differentiation abilities of cells and is capable of greatly shortening the bonding time of the traditional medical implanting material and bones.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

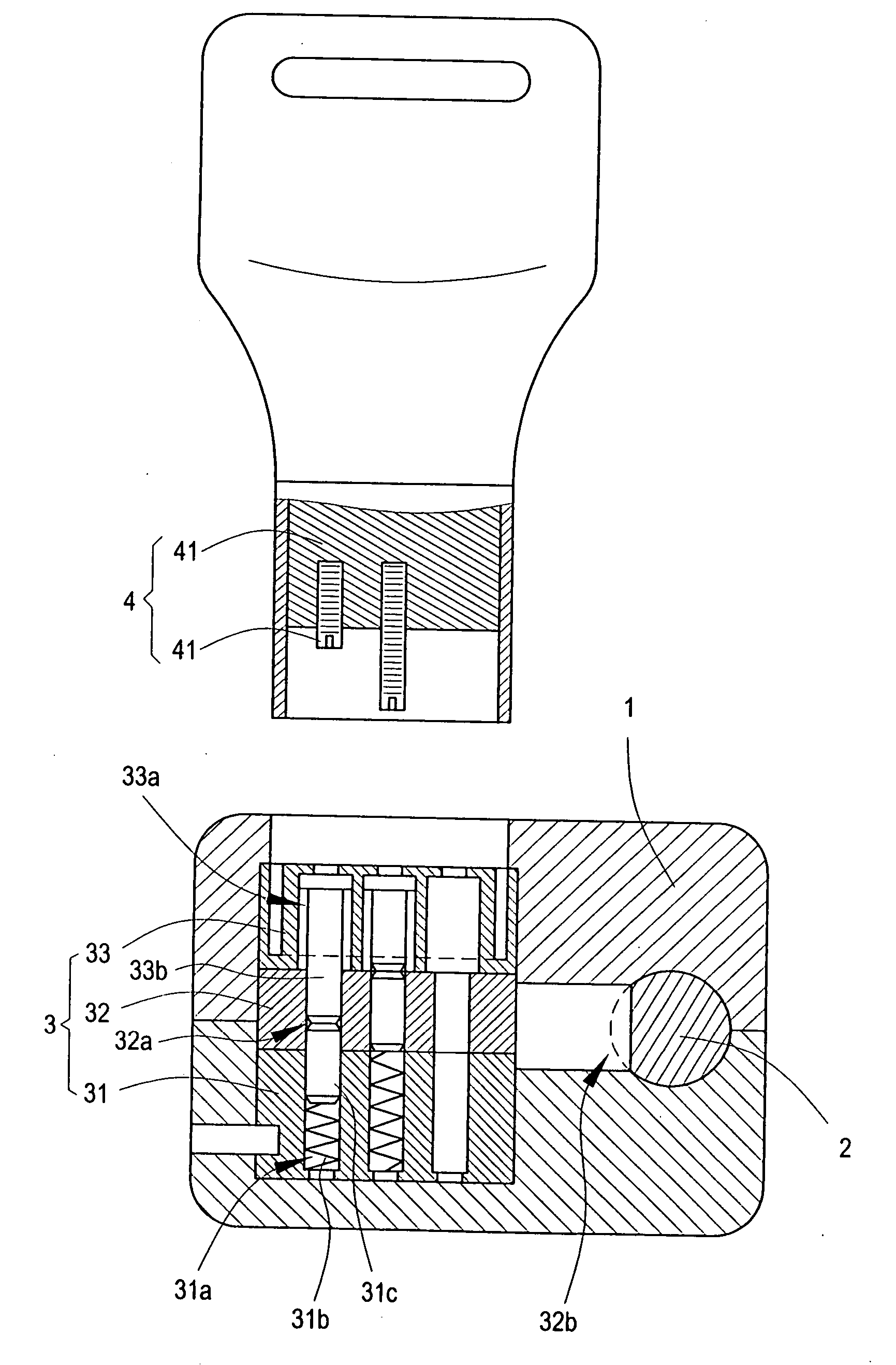

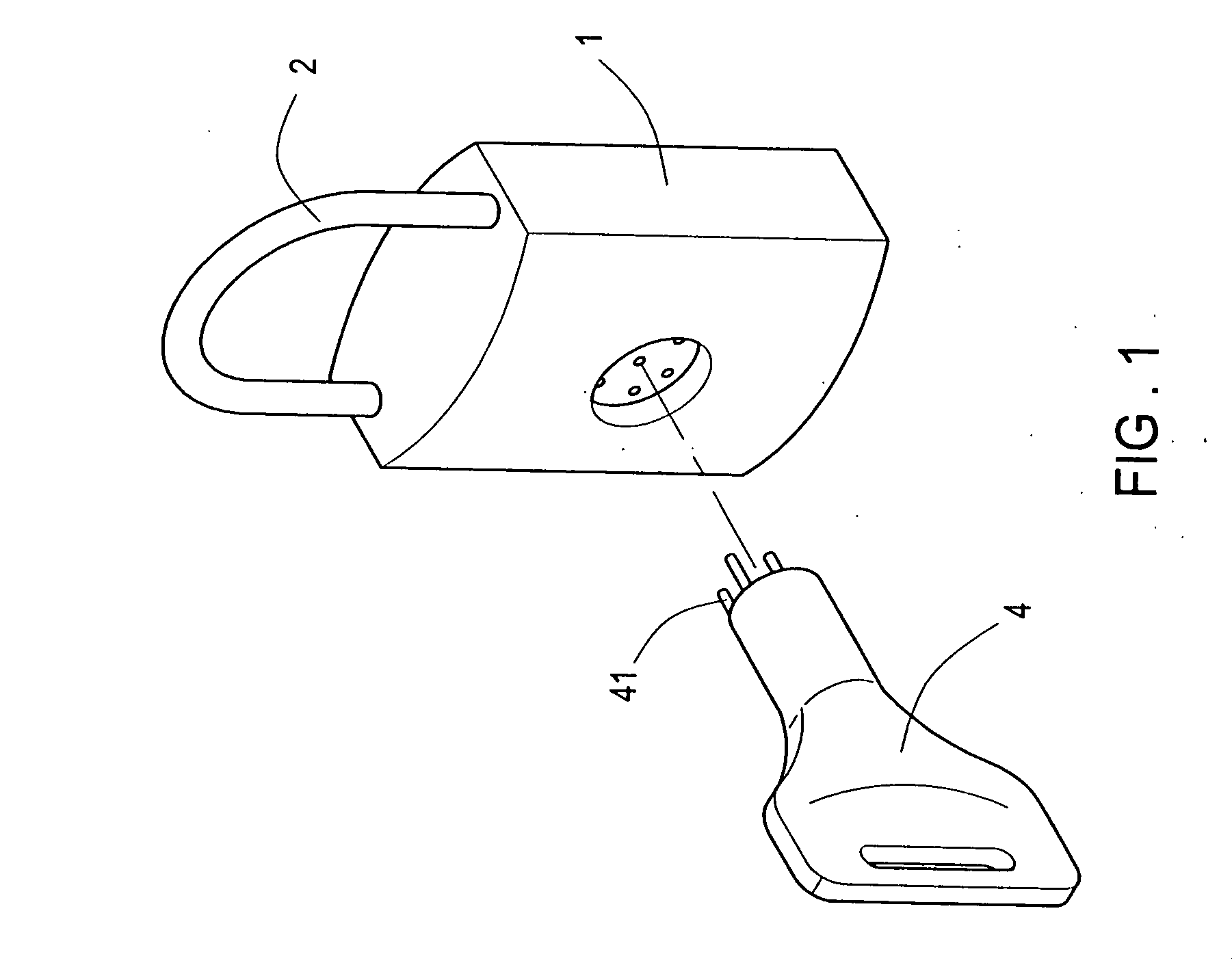

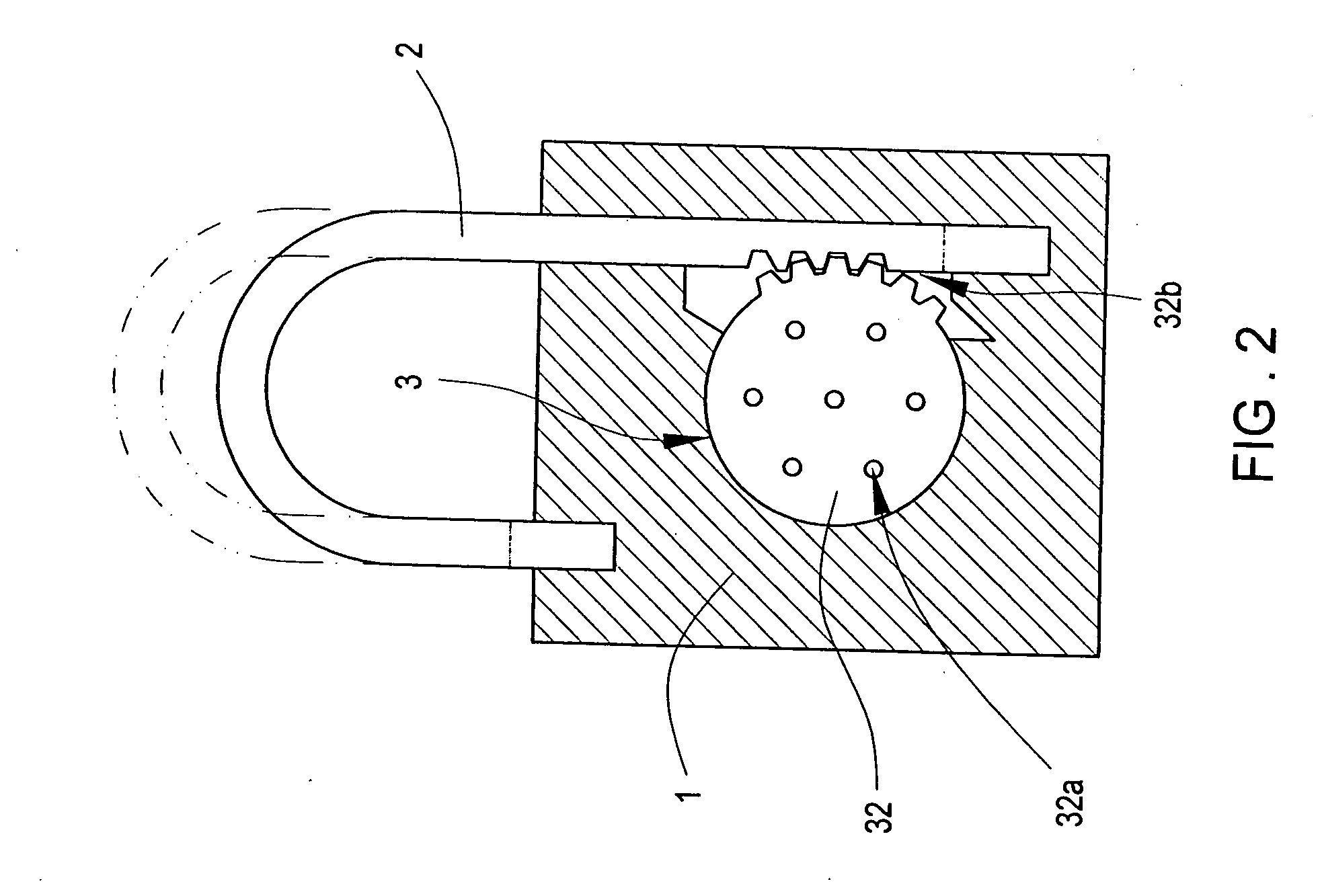

Dual power protective device for power supply

A lock cylinder includes a sliding fastening bolt, and an unlocking mechanism disposed in a housing. The characteristics thereof are that the unlocking mechanism is consisted of a fixed cylindrical block, a lock cylinder core and a pressing cylindrical block that are all provided with a plurality of corresponding orifices, respectively. A portion of the orifices at the fixed cylindrical block and the pressing pin cylindrical block is provided with spring pins and a pressing pin respectively. The lock cylinder core further impels the fastening bolt by an interlocking mechanism while a key is provided with an inserting pin for inserting into the orifice at the pressing cylindrical block to push the pressing pin inward that further pushes the spring pin into the orifice at the fixed cylindrical block, thus further turning the lock cylinder core and impelling the sliding fastening bolt for unlocking and obtaining an optimal anti-theft effect.

Owner:LIU SHUN MING

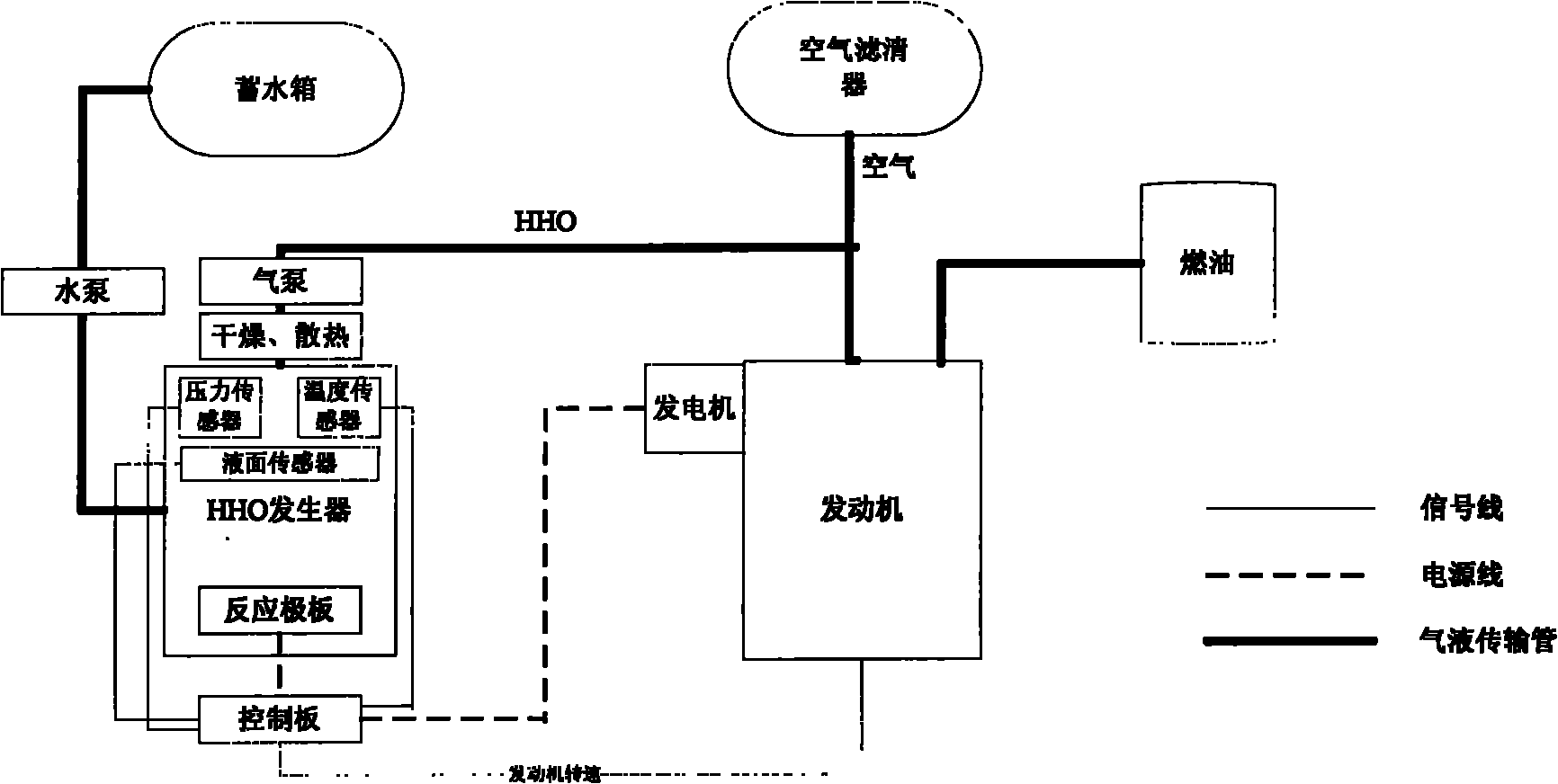

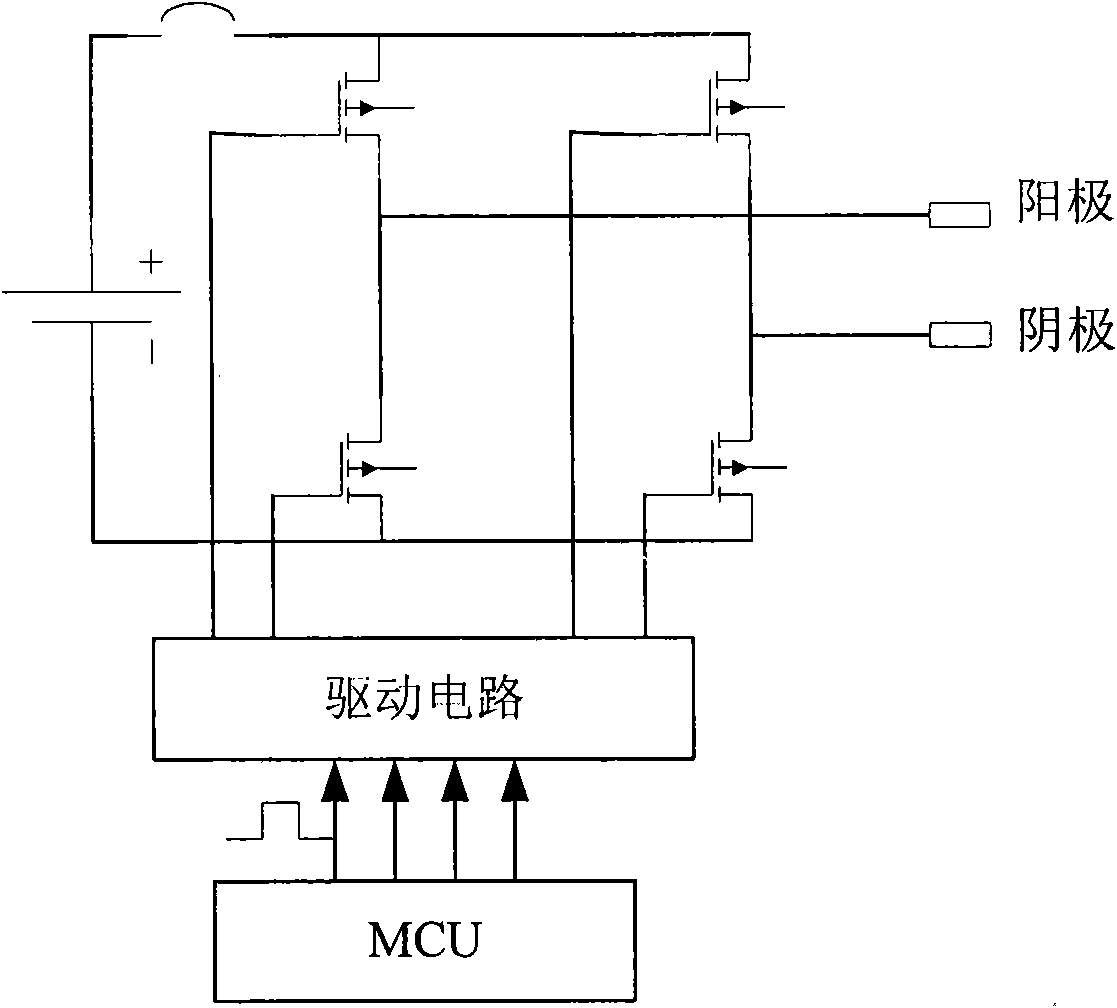

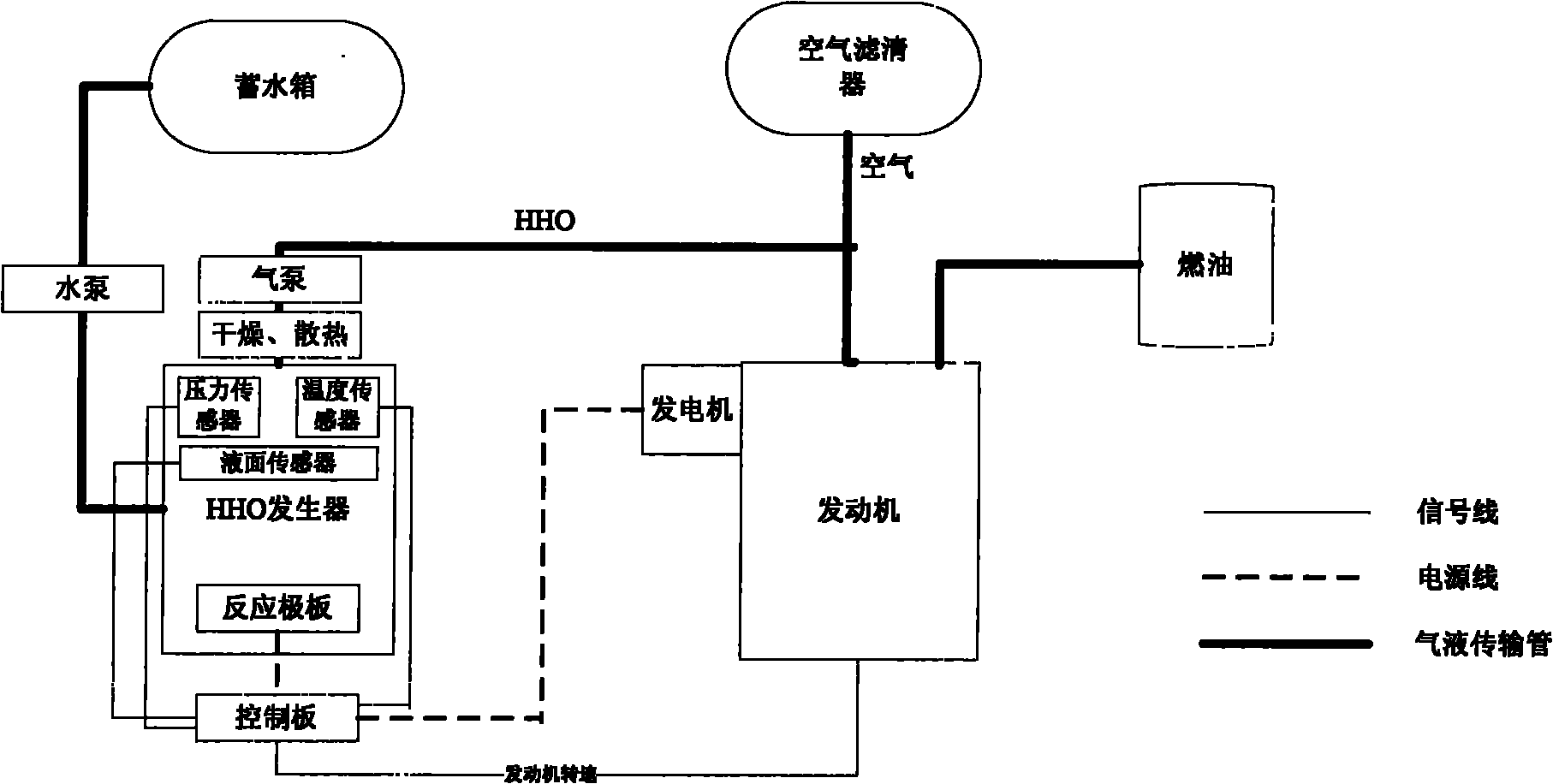

Auxiliary combustion system of vehicle-mounted hydrogen and oxygen generator

ActiveCN101900059AImprove efficiencyImprove electrolysis efficiencyElectrolysis componentsNon-fuel substance addition to fuelElectrolysisWater storage tank

The invention discloses an auxiliary combustion system of a vehicle-mounted hydrogen and oxygen generator. The auxiliary combustion system comprises a hydrogen and oxygen mixed gas generator, a pulse power supply control board, a water storage tank and a pulse power supply; the hydrogen and oxygen mixed gas generator is an airtight metal container, plugged with a positive metal electrode and a negative metal electrode, filled with electrolyte and connected with a gas inlet of an engine through a gas guide tube; the water storage tank is connected with the hydrogen and oxygen mixed gas generator; the pulse power supply control board is respectively connected with the metal electrodes and the pulse power supply; the pulse power supply generates controllable alternating current through the pulse power supply control board, and the alternating current is added onto the electrodes in the hydrogen and oxygen mixed gas generator; and hydrogen and oxygen which are separated out by electrolyzing are together injected into the engine for assisting combustion. In the invention, the alternating current pulse power supply is adopted as an electrolysis power supply, thus the electrolysis efficiency is effectively improved; and closed-loop control is formed by adopting pressure, temperature and oxygen sensors so as to improve the efficiency of the engine, reduce the power consumption and reduce the discharge value.

Owner:NINGBO INTELLIGENT MFG IND RES INST

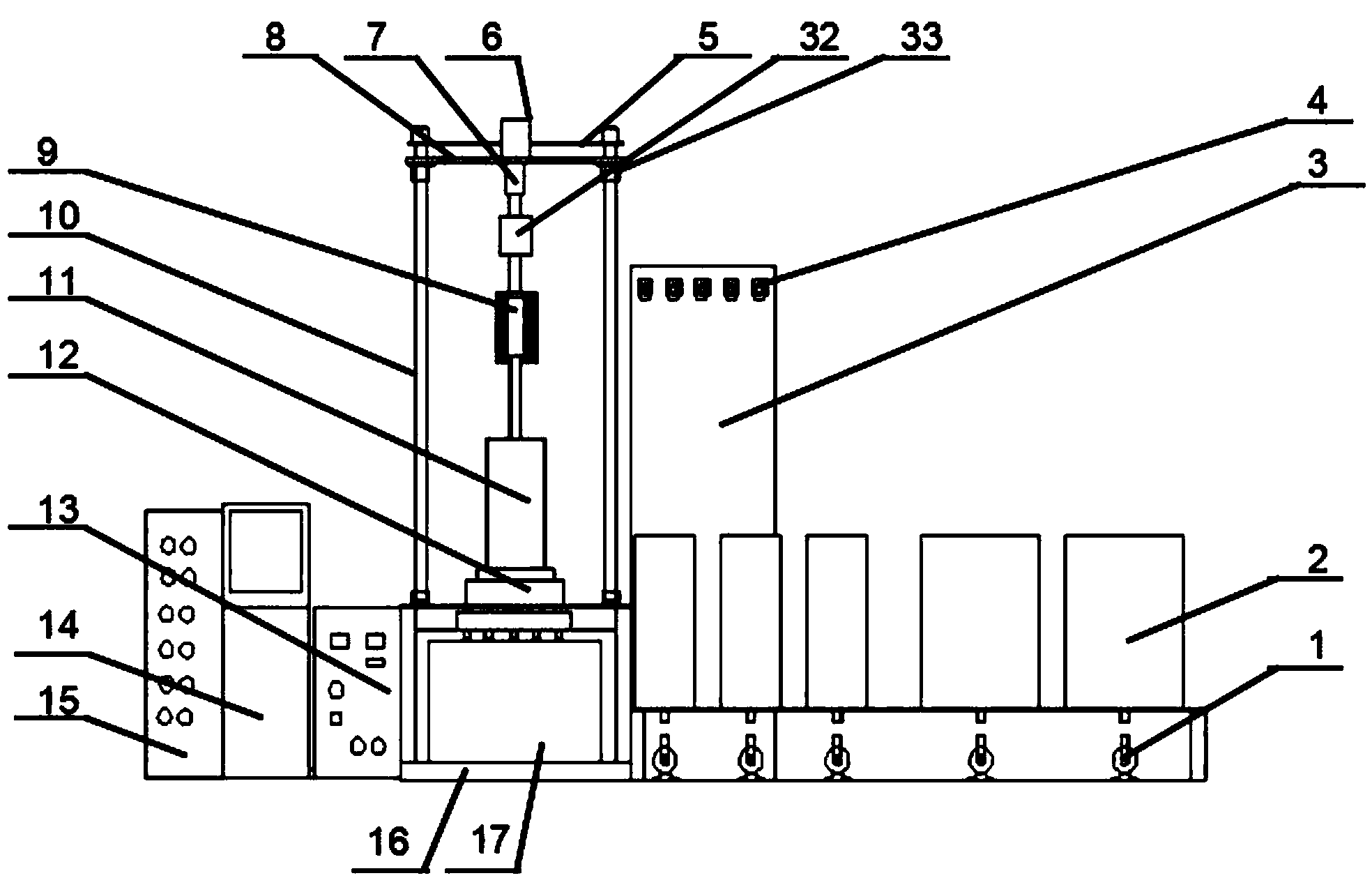

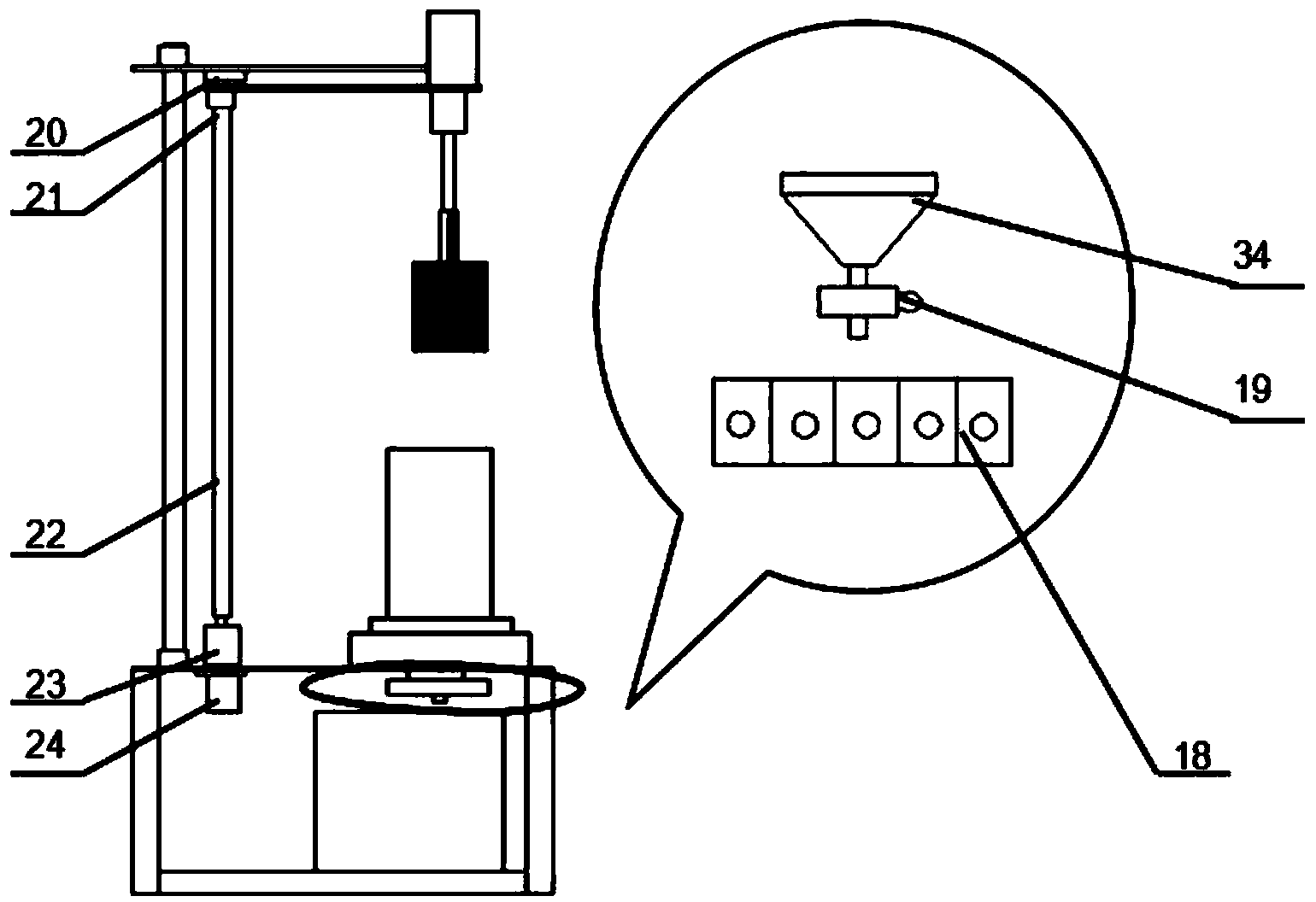

Brush electroplating repair experiment platform for oil cylinder barrel

InactiveCN103526243AIncrease labor intensityIncrease production capacityCellsRelative pressureProgrammable logic controller

The invention relates to a reproducing repair experiment platform and particularly relates to a brush electroplating repair experiment platform for an oil cylinder barrel. By adjusting four main parameters, which affect brush electroplating plating performances, such as brush electroplating voltage, relative movement speed of a workpiece and a plating pen, plating liquor flow rate, and relative pressure of the workpiece and the plating pen, optimal brush electroplating parameter value of the inner surface of the oil cylinder barrel can be obtained; the oil cylinder barrel is repaired through the obtained parameter value, so that dimension requirements and using performances can be satisfied well. According to the platform, a vertical structure is adopted, a plating brush adopts an inverter pulse power supply which is high in thickness measuring precision, and moreover, various parameters such as voltage are adjustable; the relative motion of the workpiece and the plating pen is decomposed into two major motions of linear feeding and rotation of the plating pen; each process step of the brush electroplating is automatically controlled by a PLC (Programmable Logic Controller); each of all different plating liquors has a respective specified plating liquor pump and a plating liquor box for realizing automatic applying and recycling. Besides, the brush electroplating repair experiment platform disclosed by the invention is simple and stable in structure, strong in practicability, high in automation degree, convenient to measure each parameter and capable of carrying out brush electroplating experiments, teaching and machining on the inner surface of a cylindrical workpiece.

Owner:GUANGXI UNIV

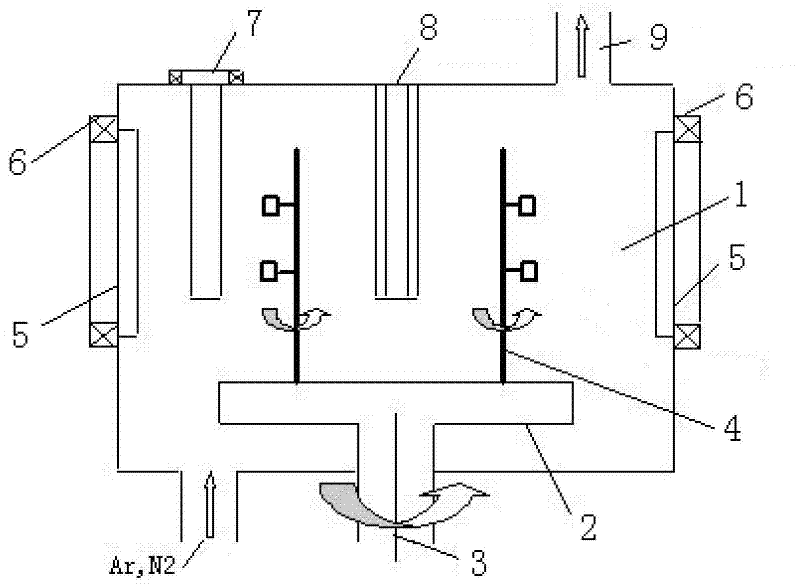

Electric arc additive and electric auxiliary ultrasonic impact reinforcing composite manufacturing method and device

InactiveCN109623100AReduce peakLow densityAdditive manufacturing apparatusArc welding apparatusMulti fieldPulse power supply

The invention relates to an electric arc additive and electric auxiliary ultrasonic impact reinforcing composite manufacturing method and device. The method is characterized in that an electric arc isused for melting a metal wire material; after the wire material is settled on a base sheet by one or more layers through a welding gun and a wire feeding mechanism, the base sheet and the settled layer are heated through a direct-current pulse power supply; and the temperature of the surface of the settled layer is acquired by a temperature sensor, and an ultrasonic impact device is used for carrying out ultrasonic impact on the surface of the settled layer when the temperature reaches a preset value. The device comprises the base sheet, a clamp, a workbench, the welding gun, the wire feedingmechanism, the temperature sensor, an ultrasonic generator, the ultrasonic impact device, an electrode, a wire, the direct-current pulse power supply and an insulating spacer. According to the method, pulse current auxiliary heating, ultrasonic impact reinforcing and an electric arc additive process are organically combined, the multi-field coupling effect of electricity, heat, sound and force isused for improving the forming precision of the settled layer and refining the grain size, so that the defects such as air holes and cracks and internal residual tensile stress generated in the electric arc additive process are eliminated, and the mechanical property of material is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

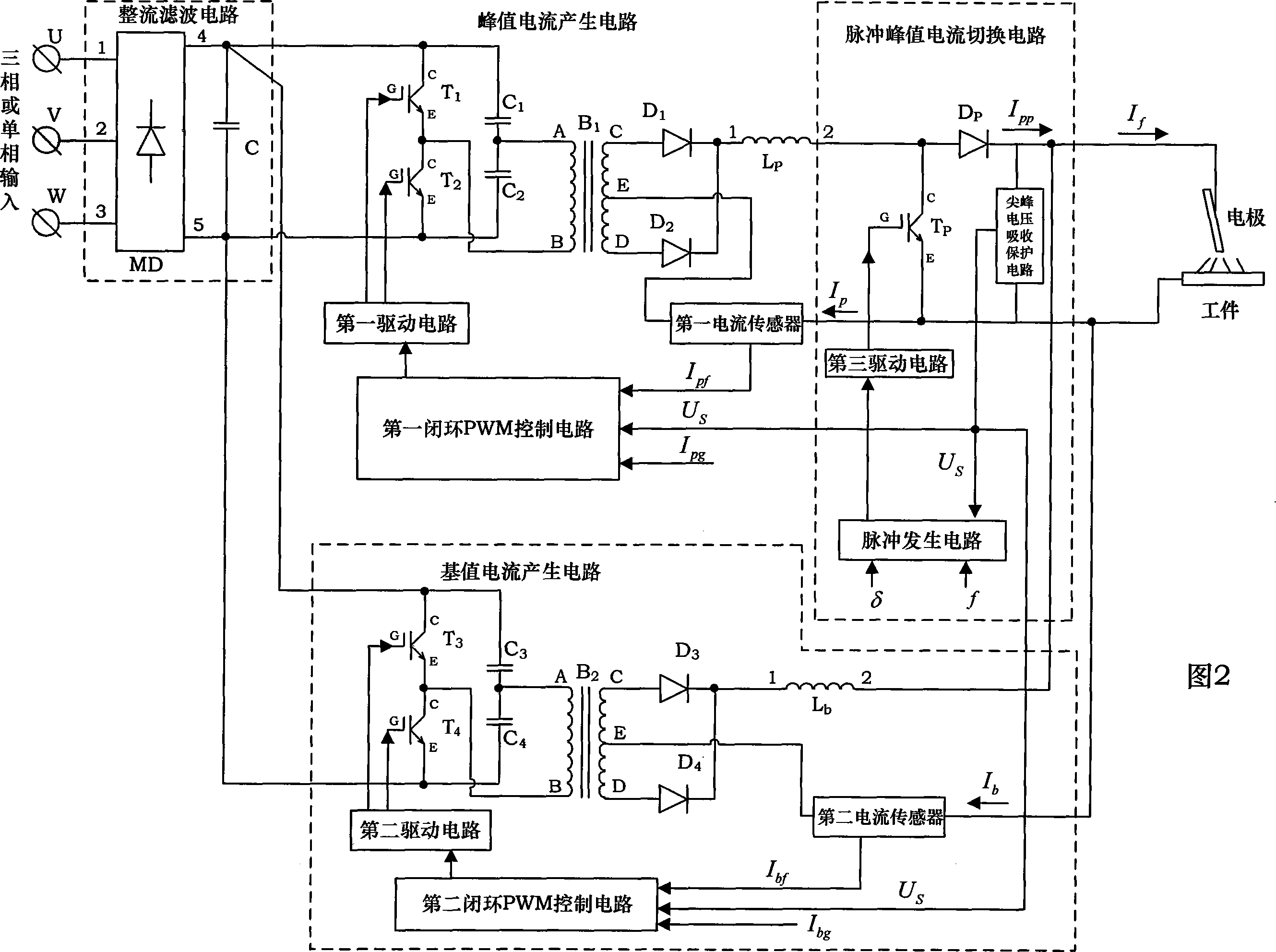

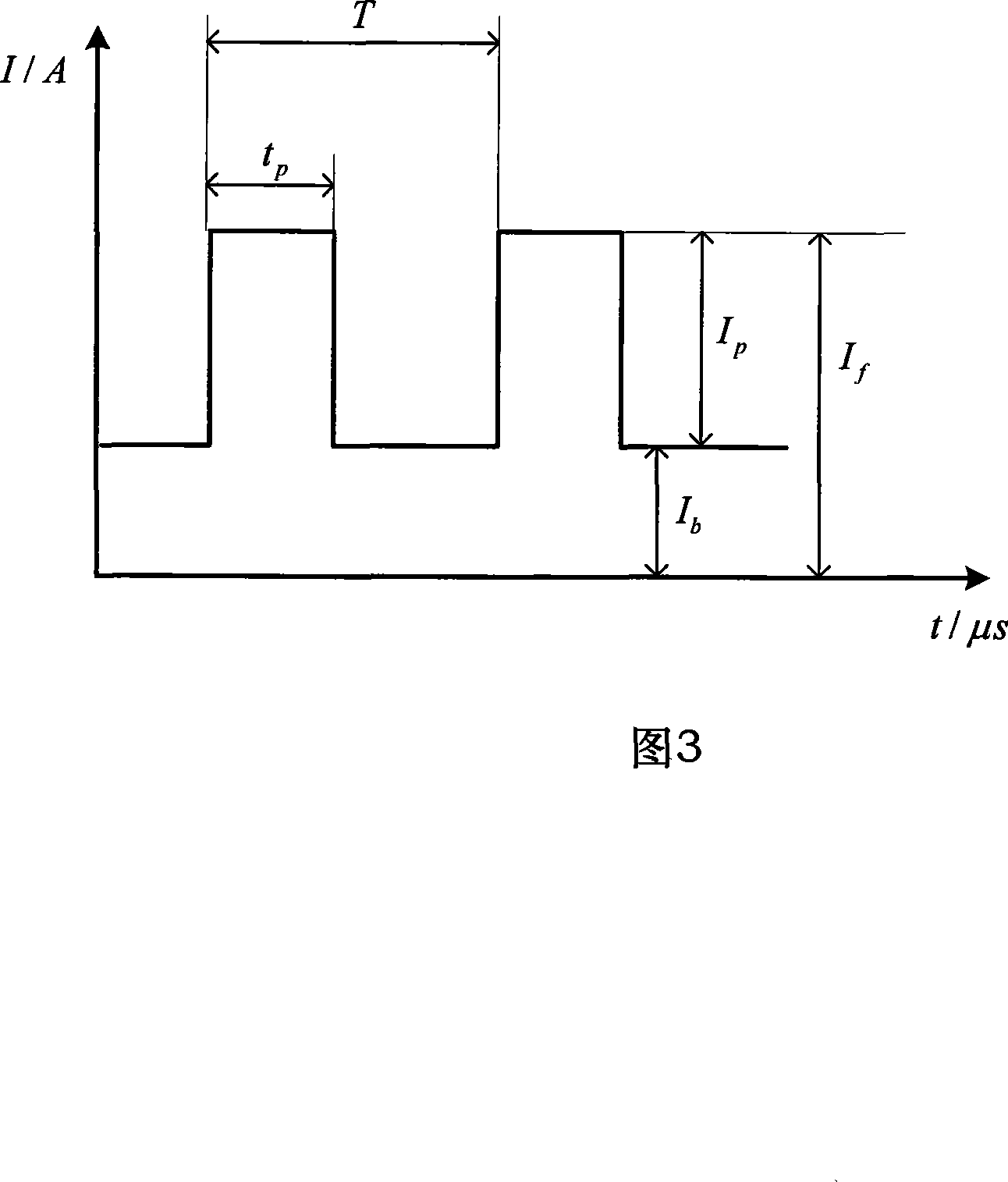

Ultrasonic square wave direct current pulse arc-welding power supply device

InactiveCN101125388AAchieve outputIndependent adjustable frequencyArc welding apparatusPeak valuePeak current

The present invention discloses a super audio square wave DC pulse power supply equipment used for electric arc welding, which mainly comprises a rectification filter circuit, a peak value current producing circuit, a pulse peak value current switching circuit and a background value current producing circuit. The background value current producing circuit is used for producing the background value current Ib, and is effected on the cathode end of the power diode DP, and the peak value current producing circuit is used for producing the peak value current Ip which outputs the pulse peak value current Ipp through a fifth power switch tube TP and the power diode DP, and then the background value current Ib and the pulse peak value current Ipp are piled, thereby getting the pulse current IF to supply the electrode and workpiece. The super audio square wave DC pulse power supply equipment of the present invention can realize the pulse current frequency not less than 20 kHz, and the pulse current amplitude value is 1 to 300 A, and the ascension rate of the pulse current is not less than 50 A / Mus.

Owner:BEIHANG UNIV

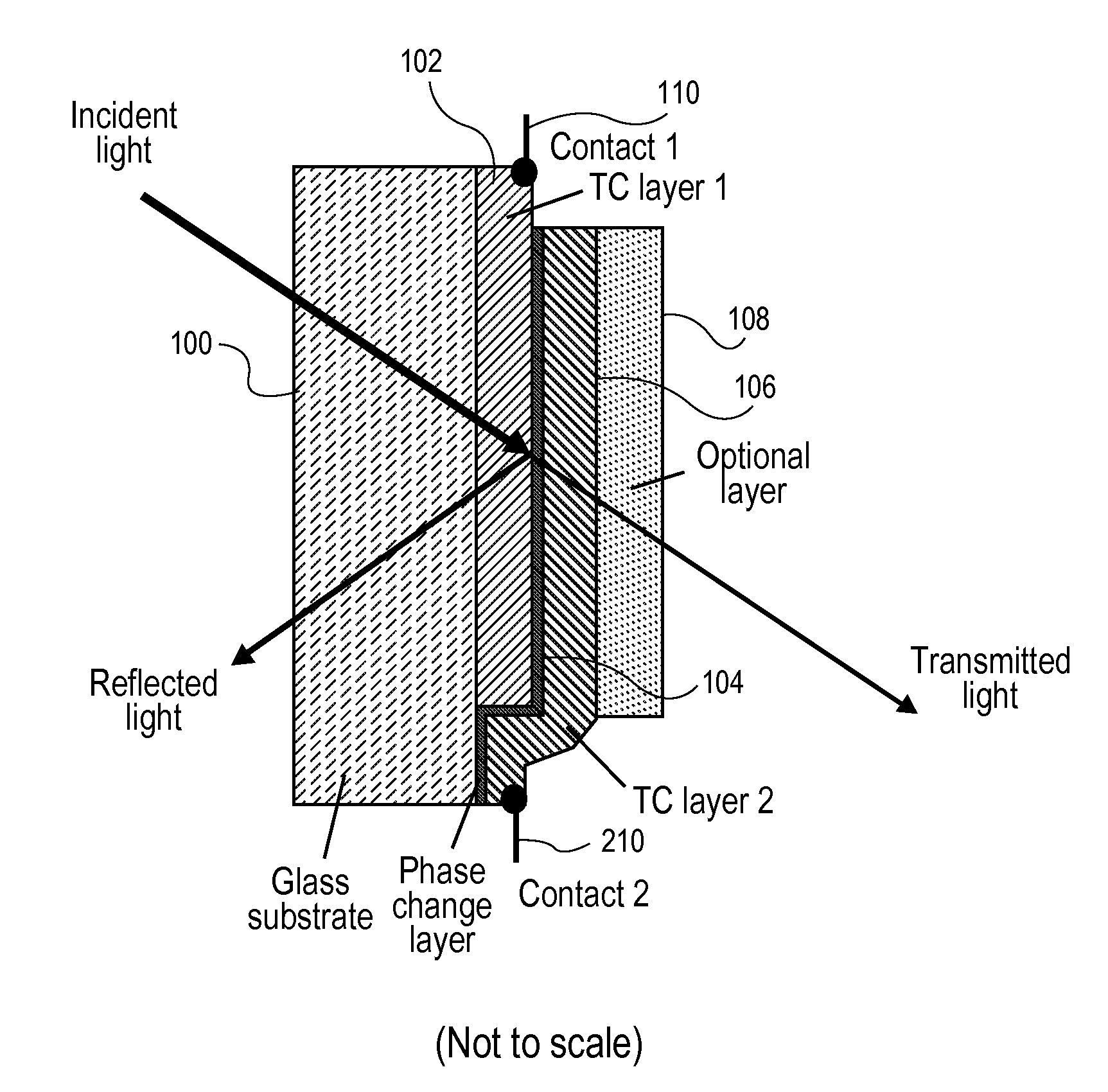

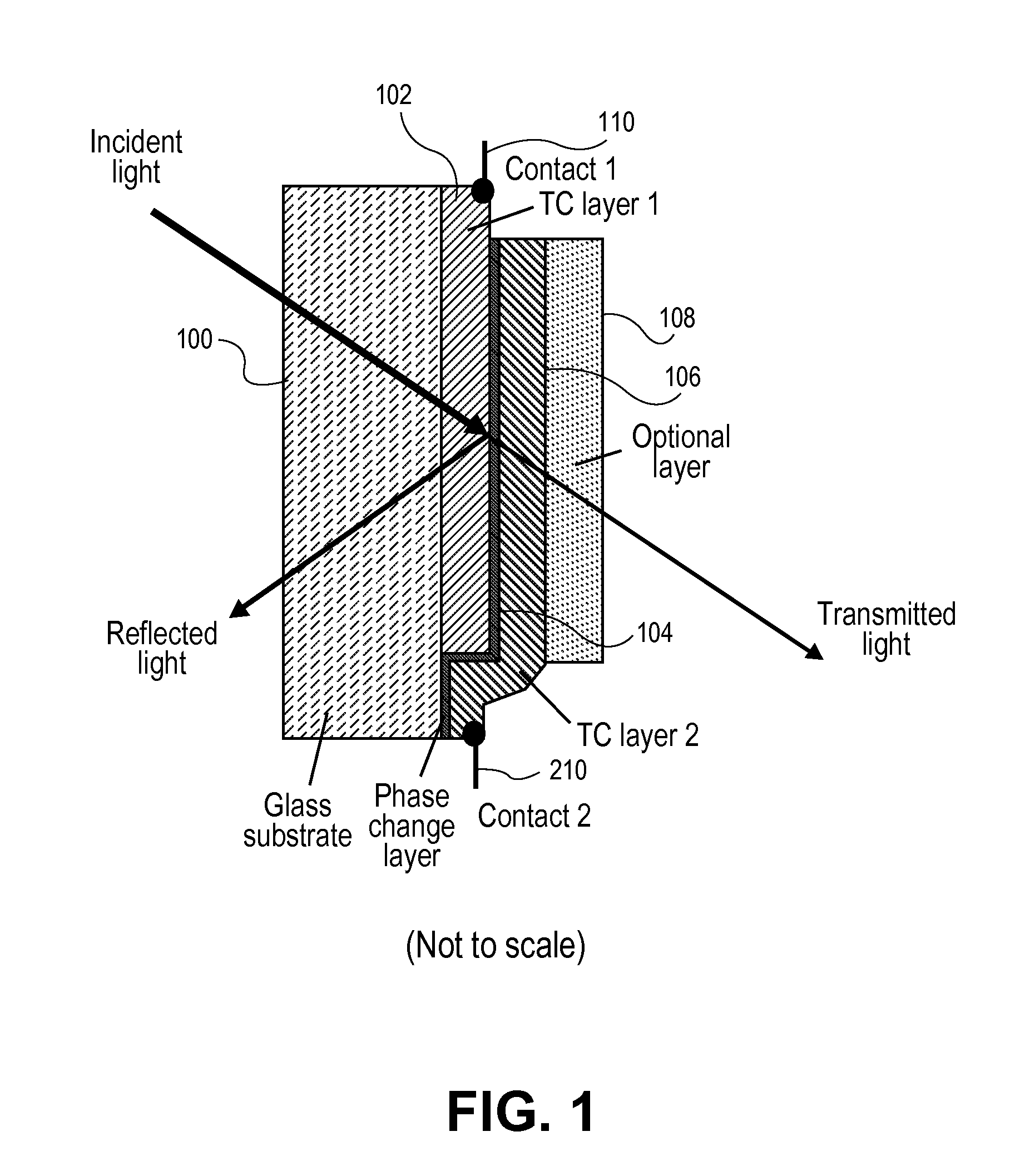

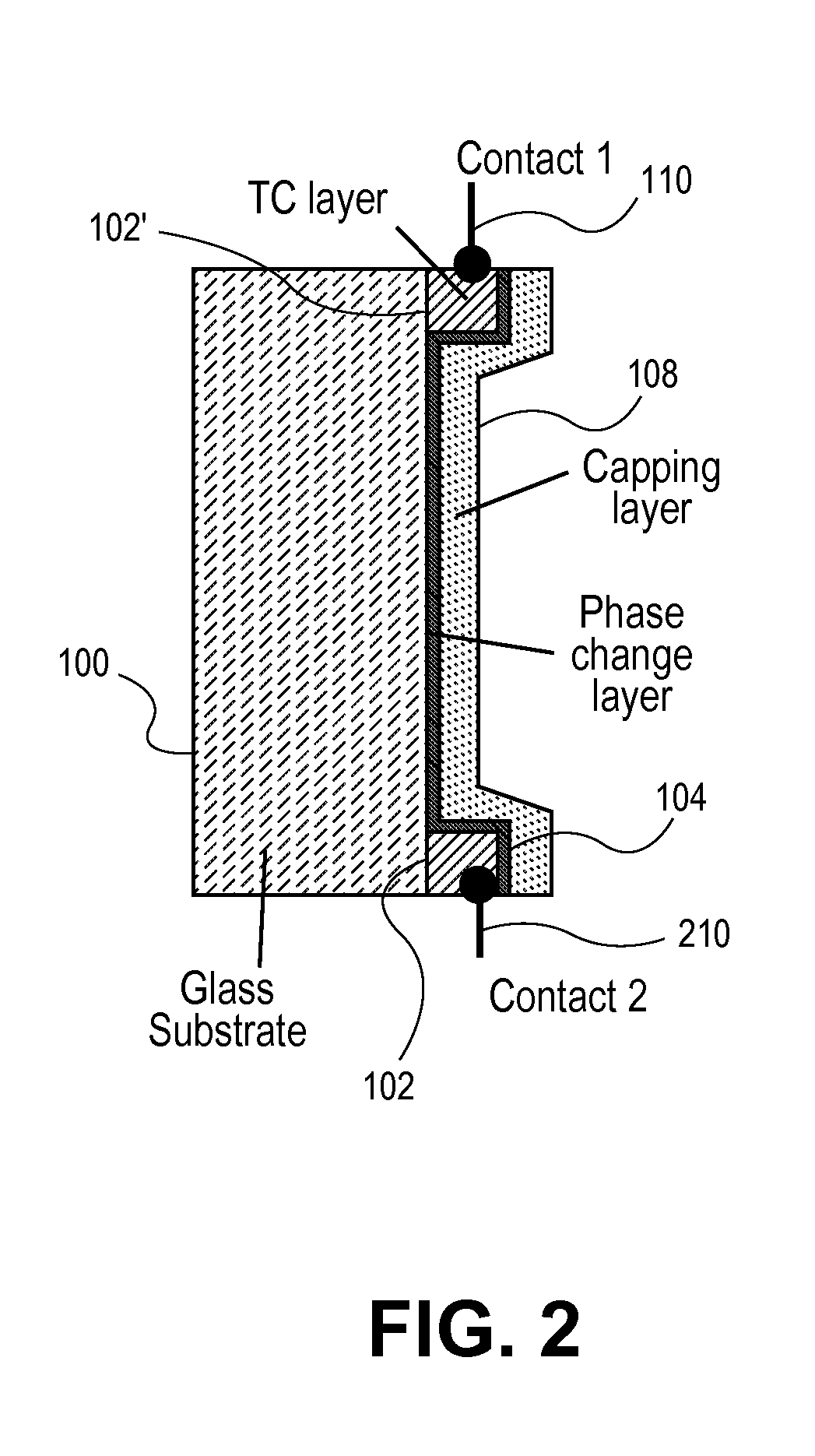

Phase change device

A phase change material is applied as a very thin film to a transparent substrate such as glass, which material when switched from the amorphous to the crystalline state and back again can affect the reflectivity / transmittance of the combined substrate-coating system. When used with glass panels in the fabrication of relatively large area window glass, the change in spectrally selective transmittance can be used to modulate the amount of sunlight passing through the glass, and thus reduce the amount of cooling required for an interior space in the summertime, and the amount of heating required of that same interior space in the wintertime, while also optimizing the use of visible daylight. Exemplary of a suitable phase change material for glass coating is GeSb or BiSn. Heating of the phase change material to initiate a change in phase can be provided by the application of electric energy, such as supplied from a pulsed power supply, or radiant energy, such as from a laser.

Owner:RGT UNIV OF CALIFORNIA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com