Patents

Literature

170results about How to "Meet the machining accuracy requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

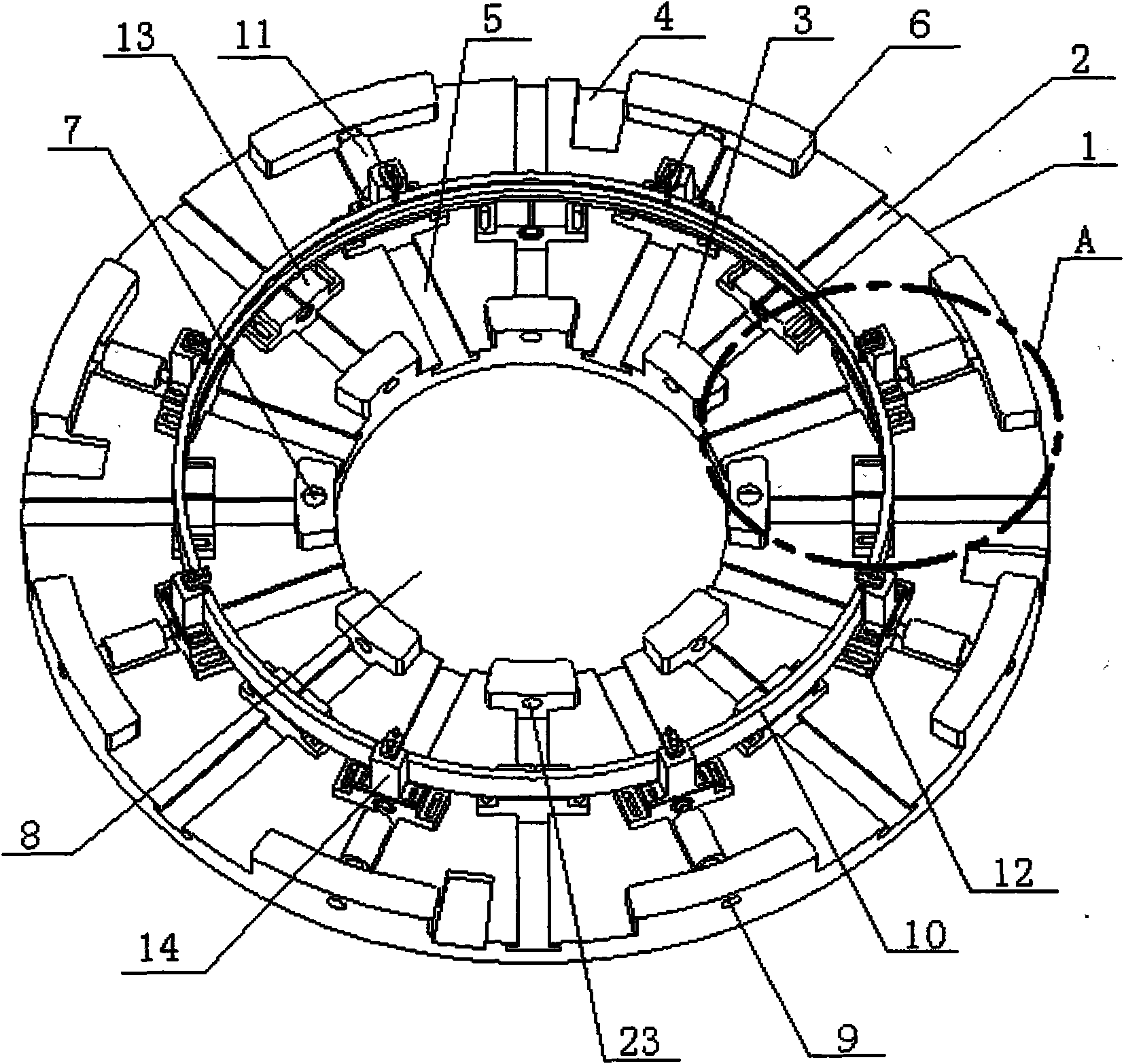

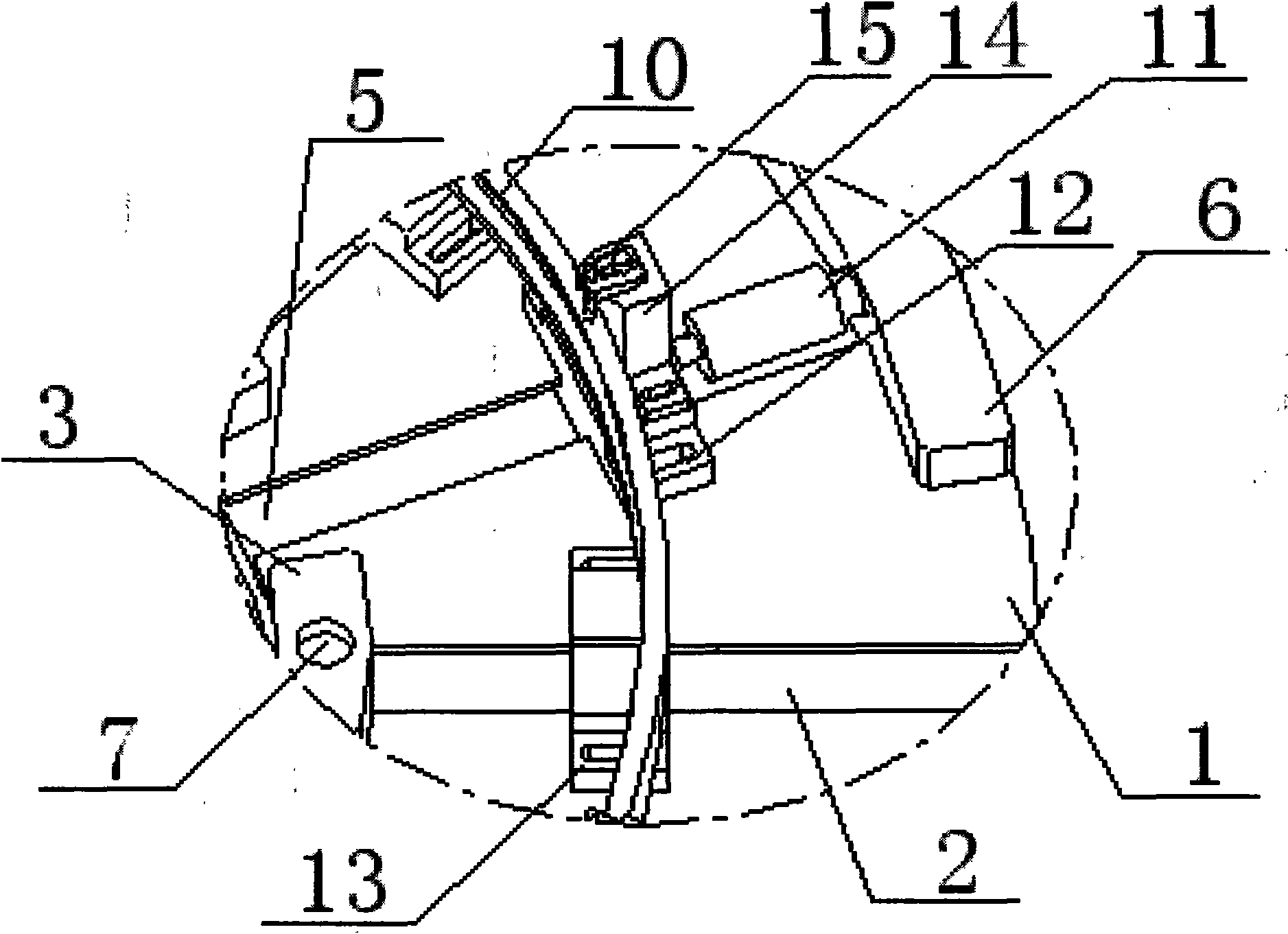

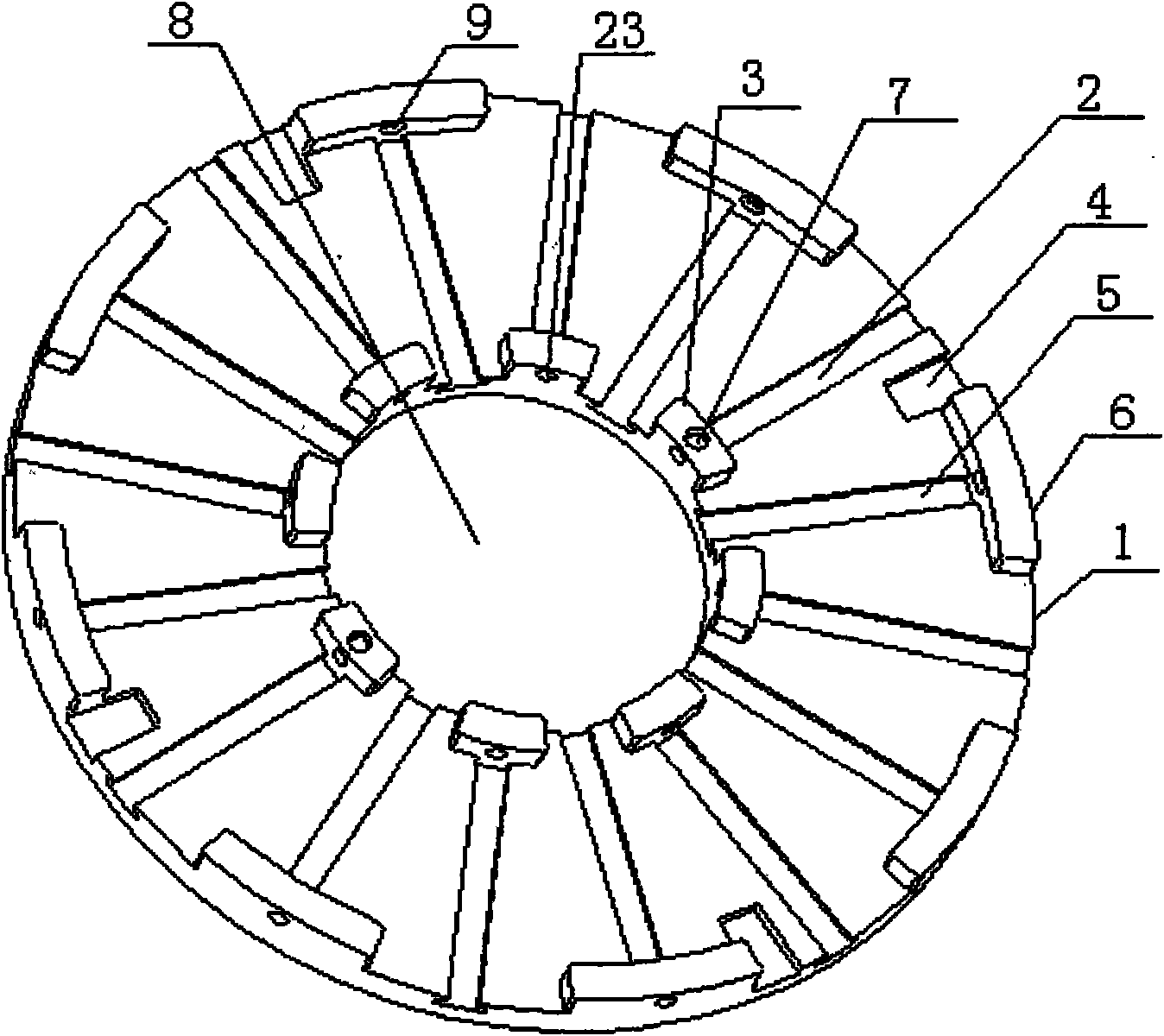

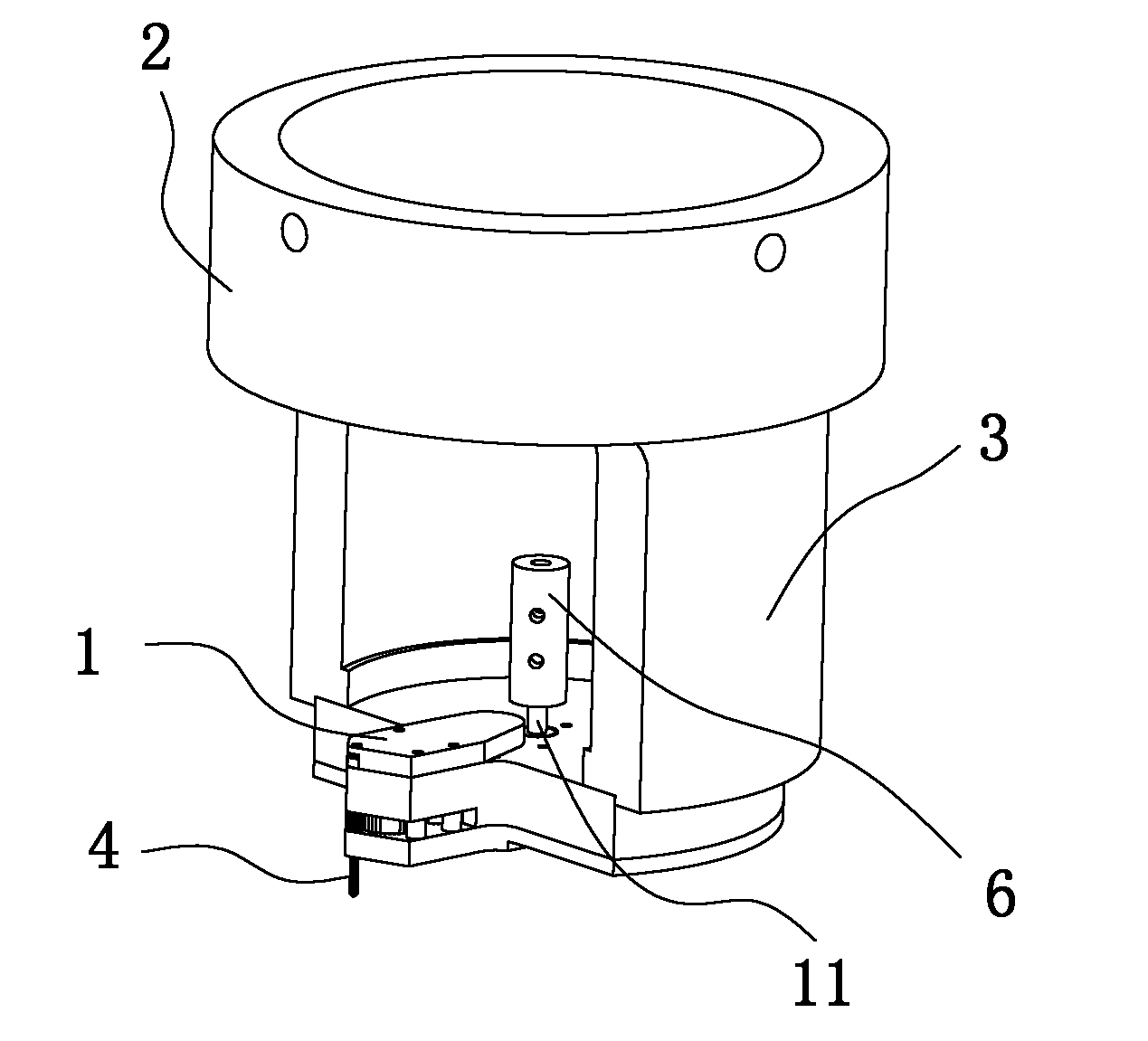

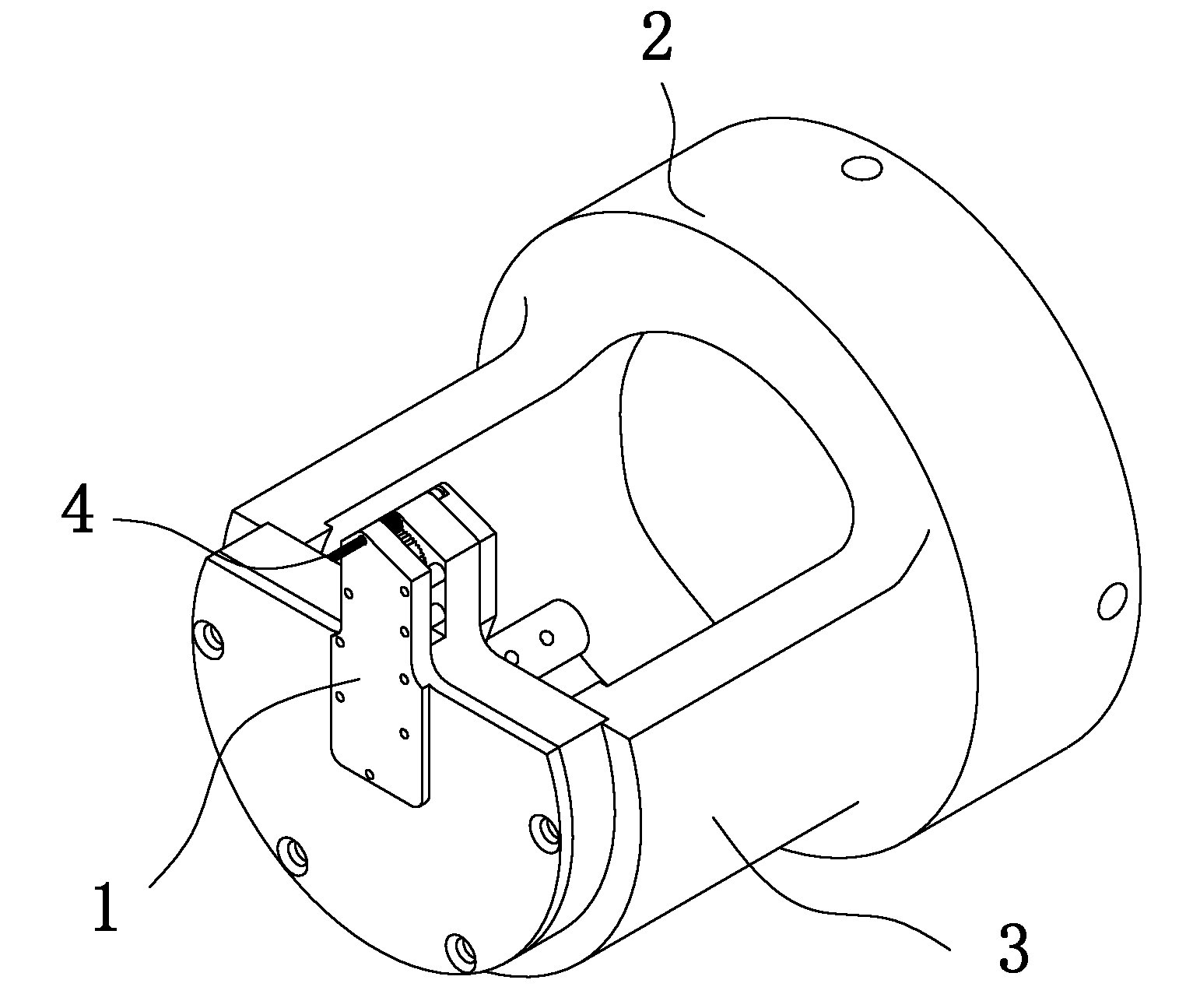

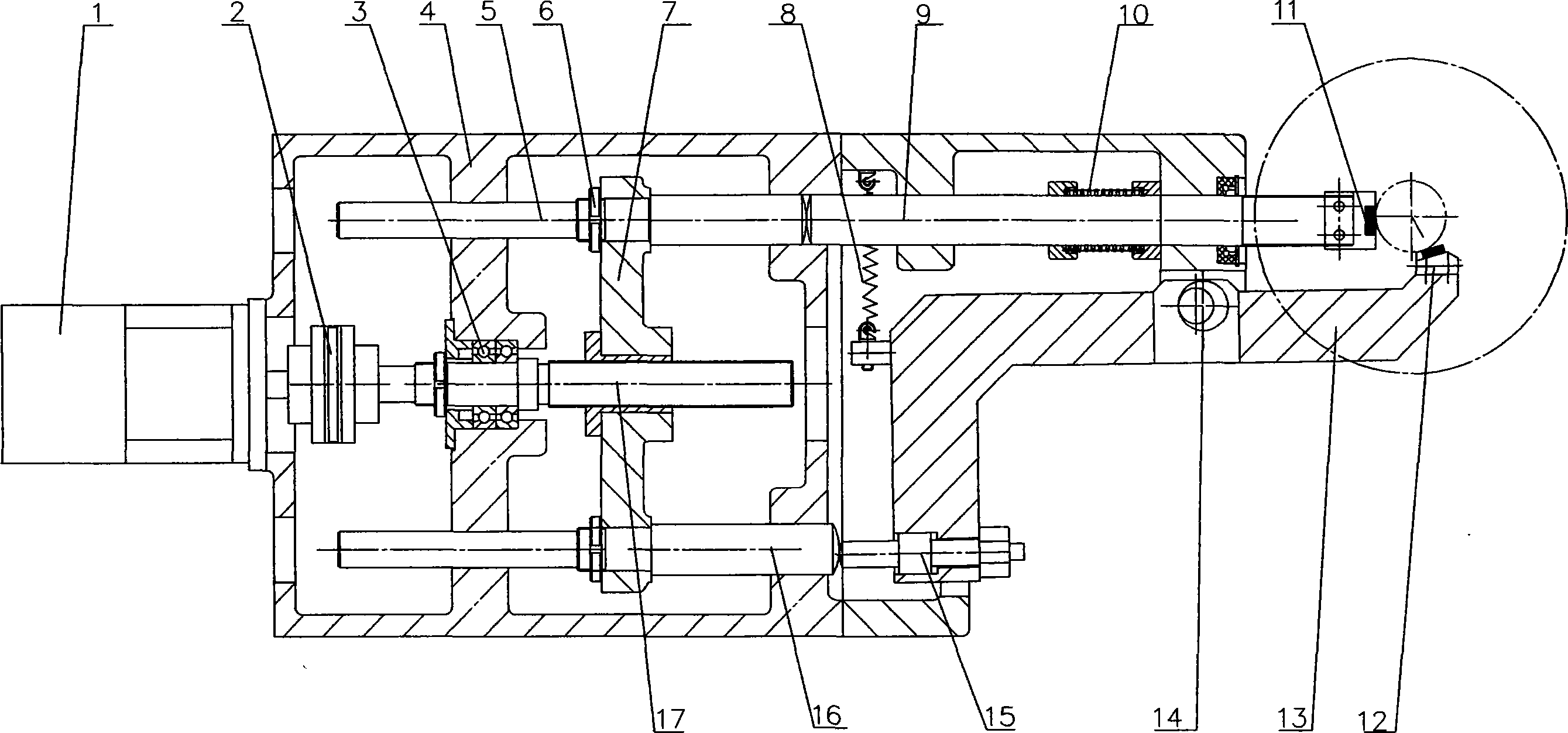

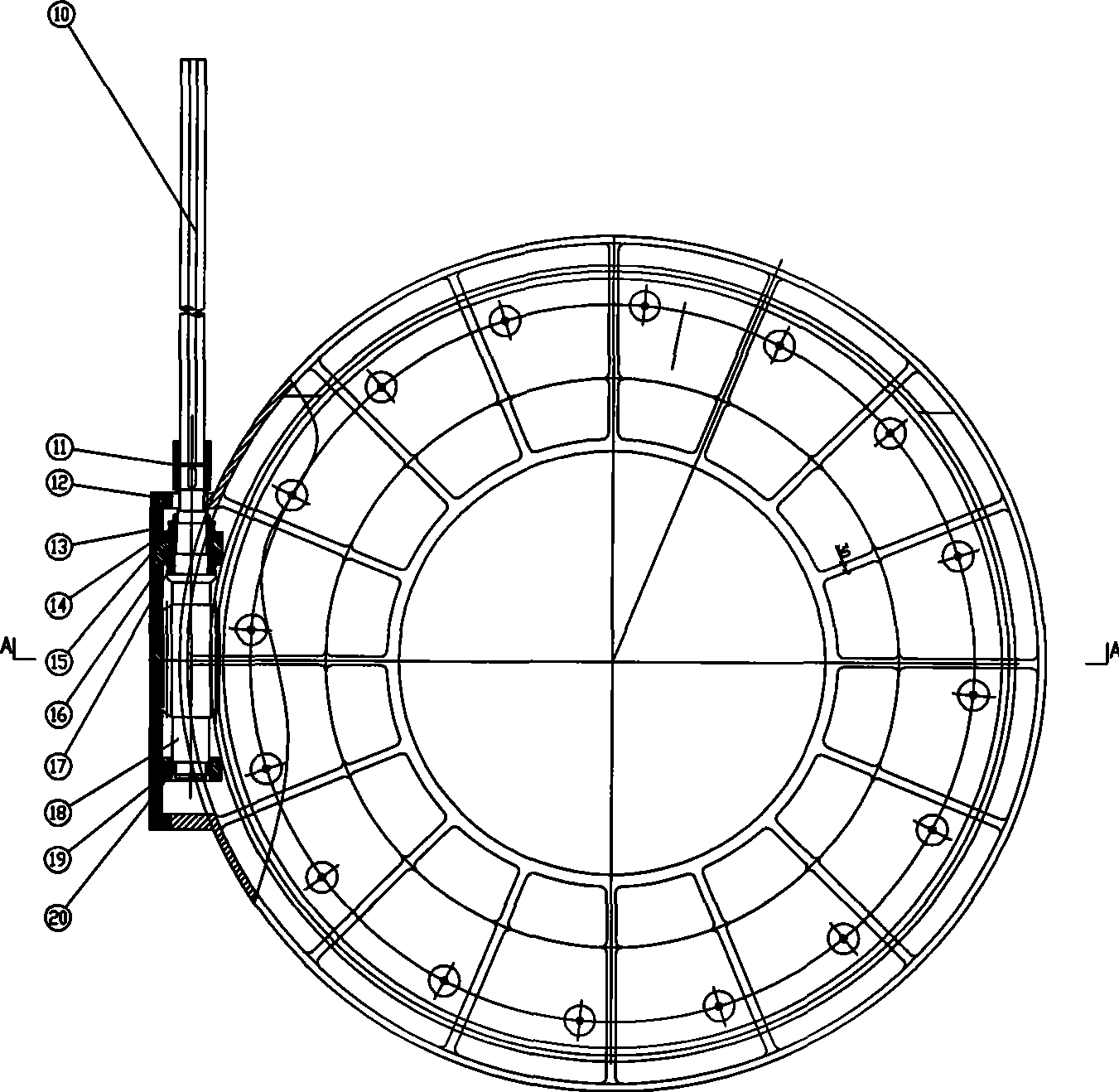

Annular thin-wall article clamping device and using method thereof

ActiveCN101954604AGuaranteed accuracyReduce labor intensityAutomatic conveying/guiding stockPositioning apparatusEngineeringThin walled

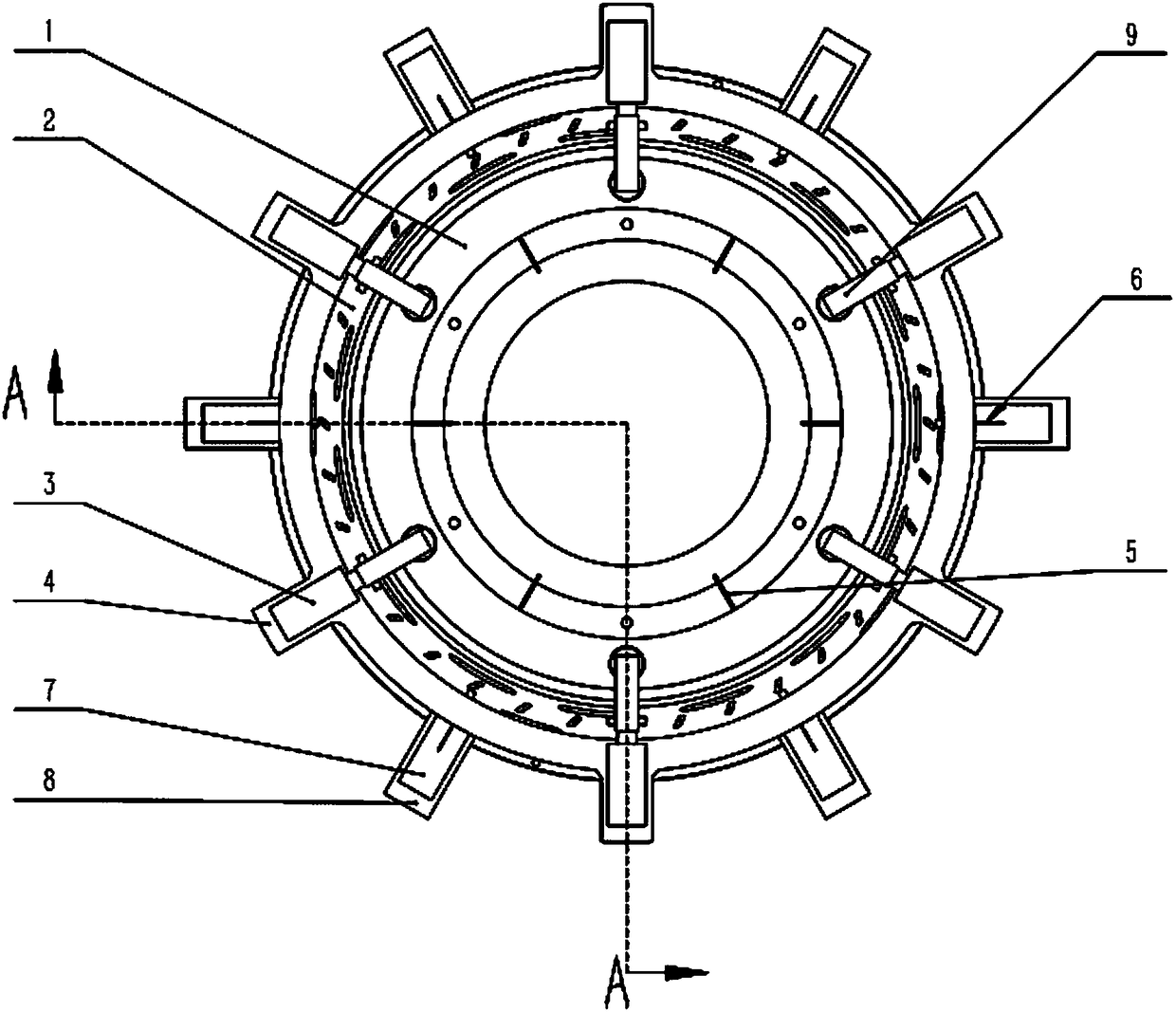

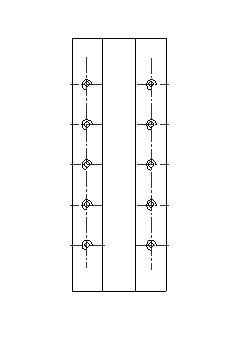

The invention provides an annular thin-wall article clamping device and a using method of the device. The clamping device comprises an annular chassis; the chassis is provided with a radial regulation mechanism of a locating workpiece; the radial regulation mechanism is divided into an inner radial regulation mechanism and an outer radial mechanism; two radial regulation mechanisms position workpiece respectively from the inner side or the outer side of the workpiece; the chassis is respectively provided with track-directed sliding grooves for the two radial adjustment mechanisms; the inner end of the sliding groove of the inner radial regulation mechanism is provided with a stopping block; the outer end of the sliding groove of the outer radial regulation mechanism is provided with the stopping block; the sliding grooves of the two groups of radial regulation mechanisms are disposed at intervals; one of the two groups of radial regulation mechanisms is provided with an axial compacting mechanism for fixing the workpiece; and the axial compacting mechanism is displaced alternatively between the two groups of radial regulation mechanisms when turning the workpiece. The clamping device can realize the processing of two side walls of the workpiece by clamping the workpiece once, and is fit for the clamping of the workpieces with different specifications. The device has the characteristics of high use rate, strong practical applicability, good generality, time saving and labor saving, light labor intensity, high production efficiency and the like.

Owner:DONGFANG TURBINE CO LTD

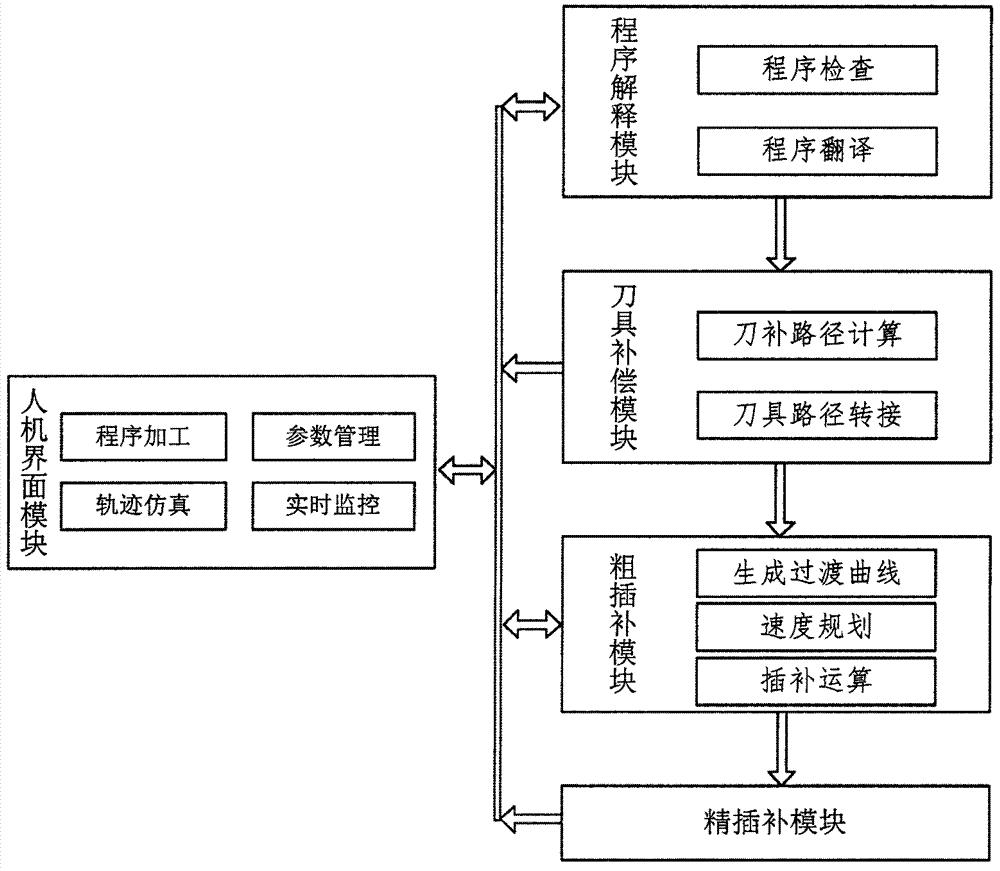

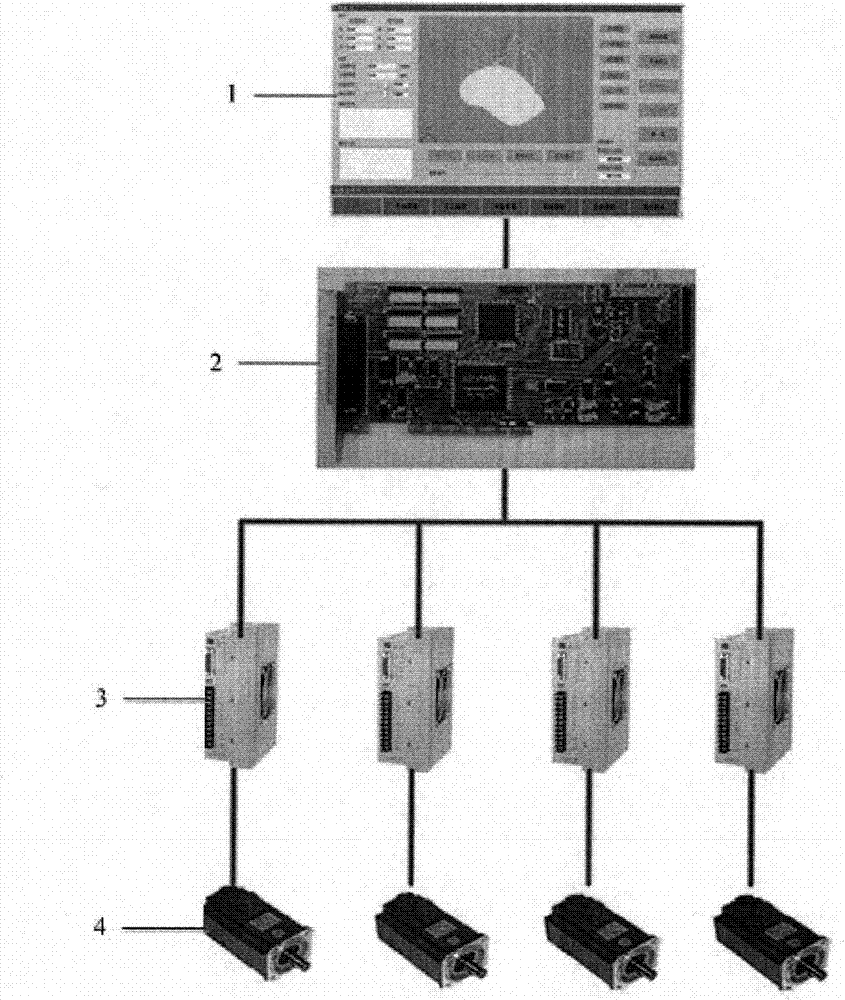

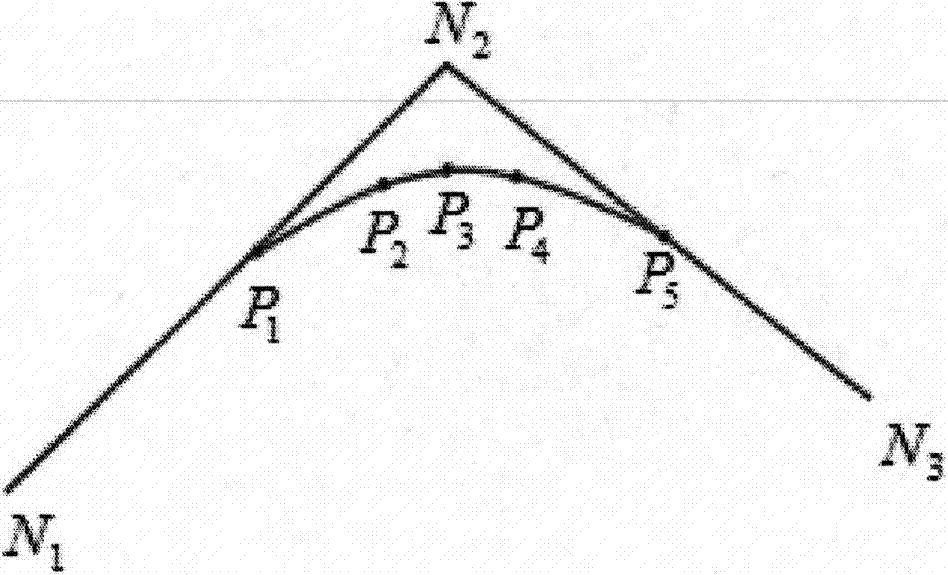

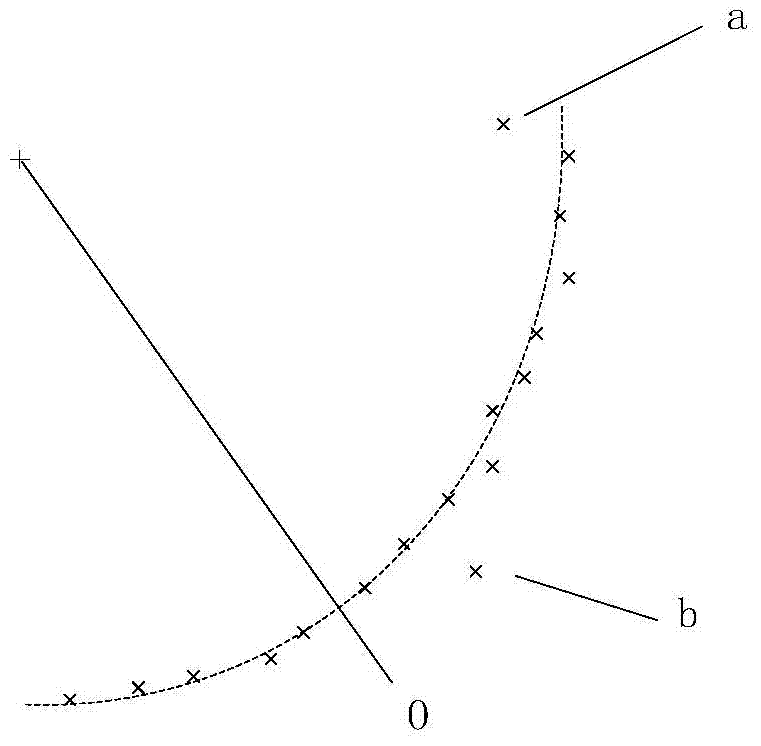

Real-time smooth transition interpolation method of small high-speed and high-accuracy numerical control machining line segment

InactiveCN103699056AStable speedSmooth motionNumerical controlNumerical controlHuman–machine interface

The invention discloses a real-time smooth transition interpolation method of a small high-speed and high-accuracy numerical control machining line segment. The real-time smooth transition interpolation method is characterized by comprising an HMI (Human Machine Interface) module, a program interpretation module, a cutter compensation module, a rough interpolation module and an accurate interpolation module, wherein the HMI module is used for transmitting a numerical control machining program to the program interpretation module, program interpretation can be carried out by the program interpretation module, information of a machining path can be extracted, cutter compensation can be carried out by the cutter compensation module, information of a cutter path can be obtained, the information can be transmitted to the rough interpolation module, smooth transition connection can be carried out on adjacent line segments nearby an adapting point by adopting a cubic B-spline curve passing a control point, a smooth cutter path in continuous curvature can be generated, the smooth cutter path can be subjected to speed planning and interpolation operation, interpolation data can be sent to the accurate interpolation module, and processed data which is subjected to accurate interpolation operation can be sent to a driver so as to drive a numerical control machine tool to move. According to the real-time smooth transition interpolation method disclosed by the invention, the running of the machine tool is more smooth and stable, the computation efficiency is high, the algorithm is simple, and the real-time smooth transition interpolation method is suitable for a high-speed and high-accuracy machining numerical control machine tool.

Owner:JIAXING UNIV

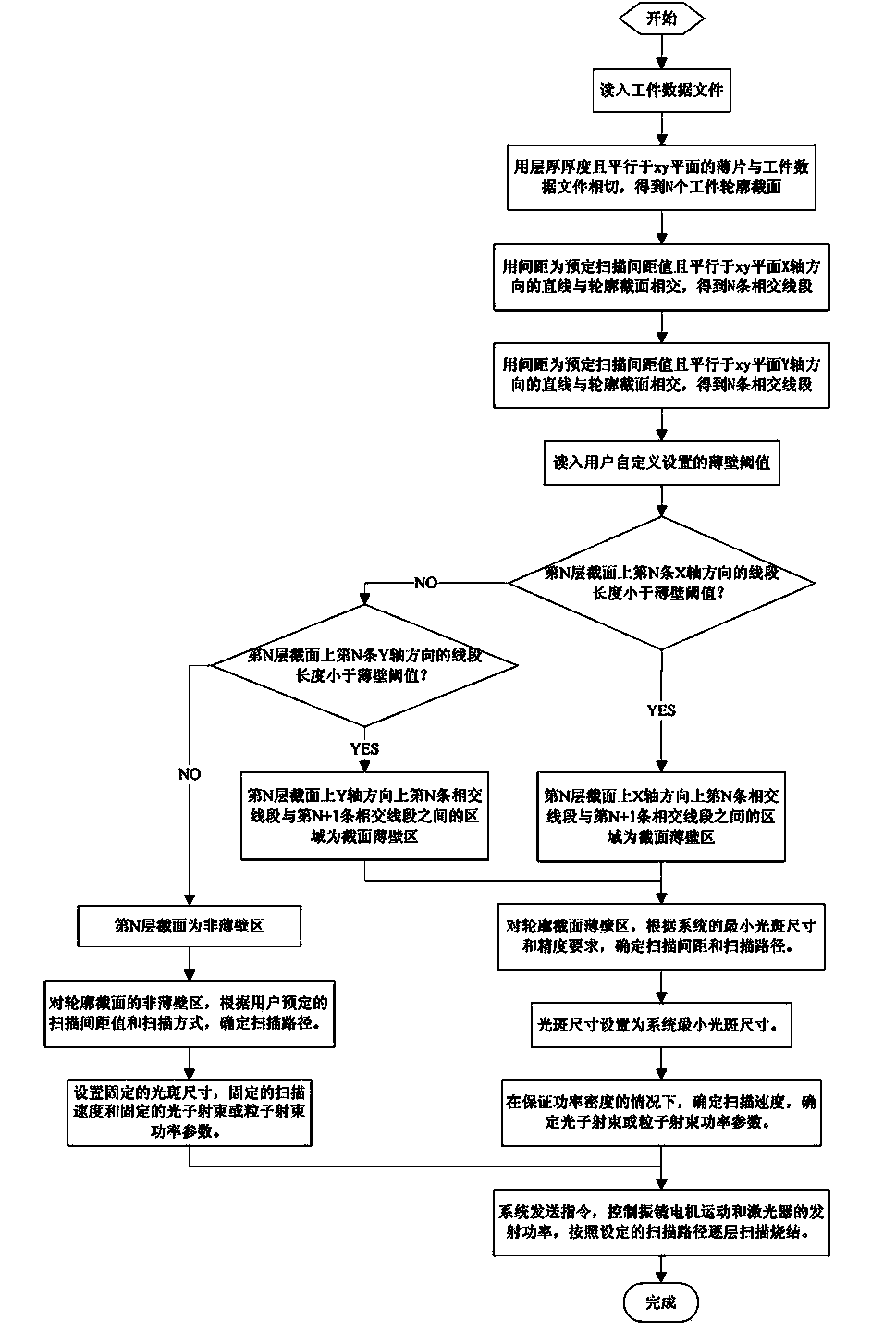

Scanning method for manufacturing three-dimensional object layer by layer

ActiveCN103639411AUniform efficiencyEqualization accuracyAdditive manufacturing apparatusCeramic shaping apparatusMachine partsParticle beam

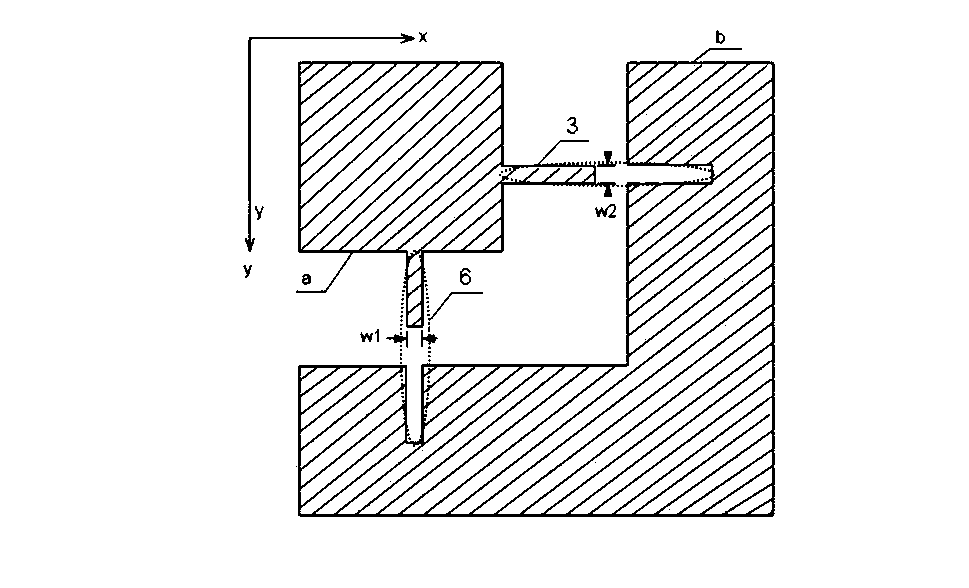

A scanning method for manufacturing a three-dimensional object layer by layer comprises the following steps: (1), dividing each section layer of a three-dimensional object to be manufactured into a thin-wall area and a non-thin-wall area: setting a threshold of the gap width of the section profile of the three-dimensional object, and according to the gap width of the section profile in x / y direction, dividing a coating area required to be scanned into a thin-wall area and a non-thin-wall area, wherein the thin-wall area is an area of which the gap width of the section profile is smaller than the threshold and the non-thin-wall area is an area of which the gap width of the section profile is greater than or equal to the threshold; (2), according to the thin-wall area and the non-thin-wall area, scanning area by area, wherein the non-thin-wall area is scanned, relatively high photon beam or particle beam power and relatively large light spot diameter are selected, and when the thin-wall area is scanned, relatively low photon beam or particle beam power and relatively large light spot diameter are selected. By the scanning method, constraints of efficiency and precision in the process of manufacturing the three-dimensional object layer by layer are balanced to the maximum extent, so that the efficiency is ensured and the accuracy and the surface quality of a machined part are ensured.

Owner:HUNAN FARSOON HIGH TECH CO LTD

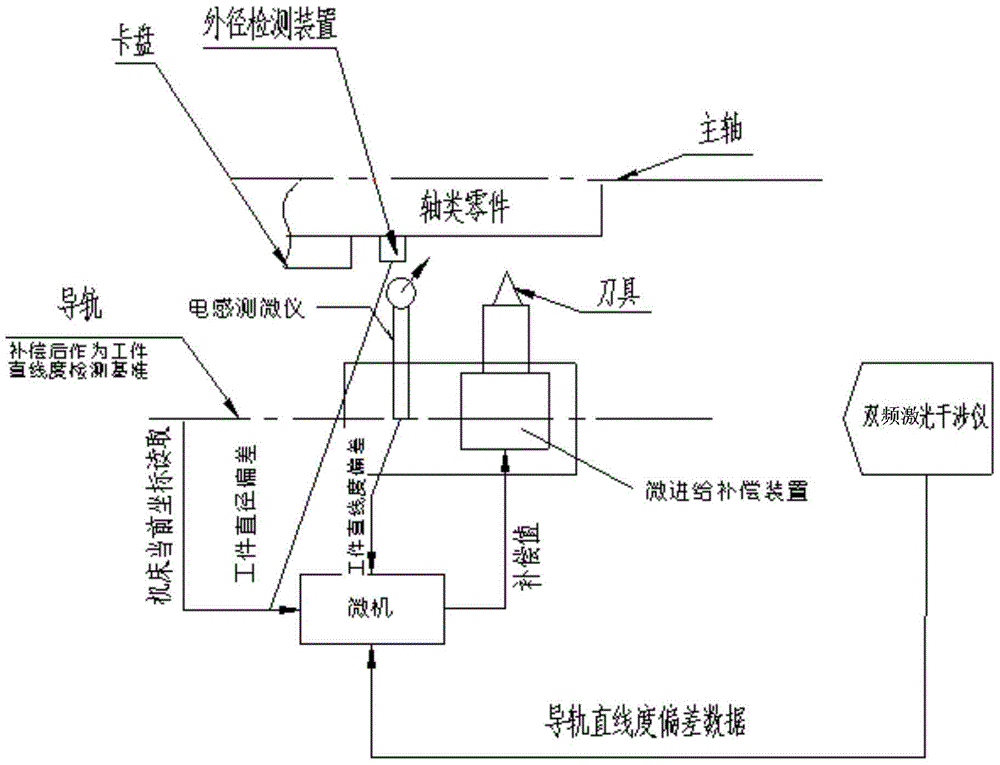

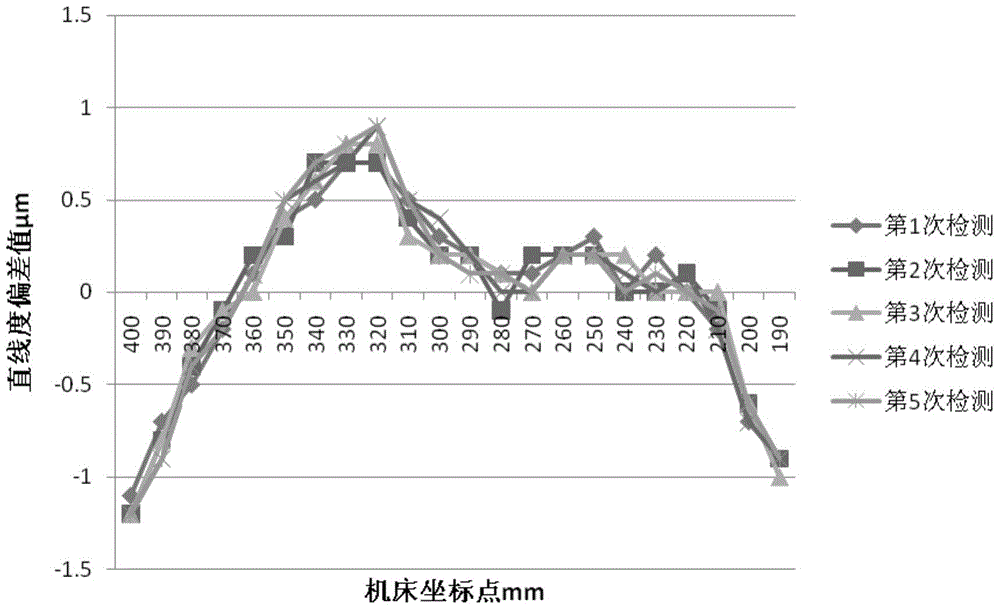

High-precision shaft part machining method based on multiple times of detection and compensation

ActiveCN105171521AImprove surface roughnessRealize measurementAutomatic control devicesFeeding apparatusDigital controlMachine tool

Provided is a high-precision shaft part machining method based on multiple times of detection and compensation. The deviation of straightness accuracy of a guide rail, deviation of straightness accuracy of a part and deviation of the size of the part are compensated with a micro-feeding compensation device as additional hardware aiming at a digital controlled lathe. A cubic spline function is established, two times of compensation is conducted on the deviation of straightness accuracy of the guide rail through an interpolation method, the compensated guide rail serves as a standard, the straightness accuracy of the part is detected, and compensation machining is conducted on the deviation of straightness accuracy of the part and the deviation of the size of the part through the micro-feeding compensation device, so that machining of high-size-precision and high-straightness-accuracy shaft parts is achieved. The actual machining precision of the lathe is higher than the maximum machining precision of the lathe, so that the requirement for machining precision of the part is met. The straightness accuracy and positioning precision of the compensated guide rail can achieve the submicron-order precision.

Owner:BEIJING SATELLITE MFG FACTORY

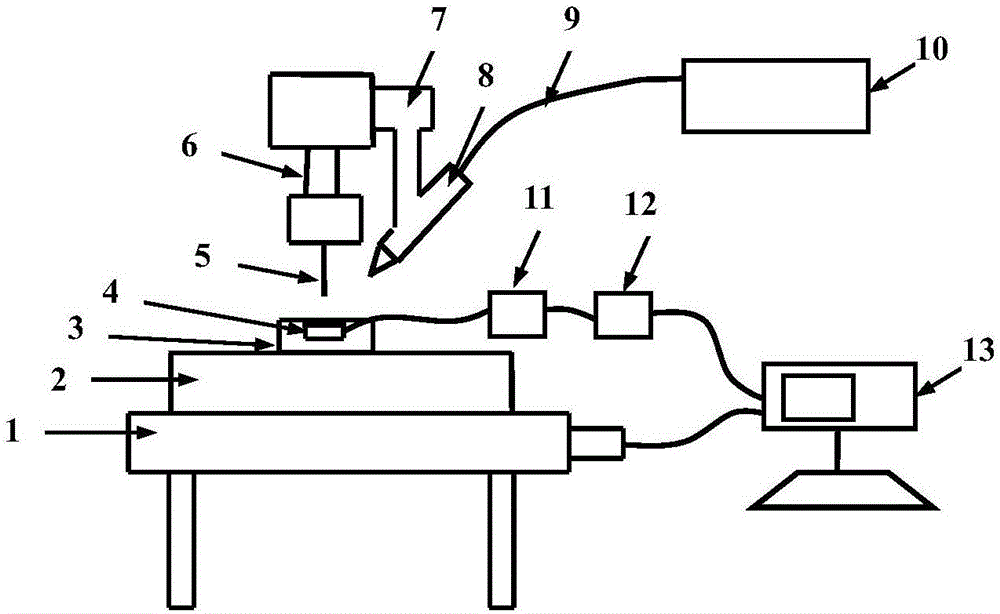

Laser heating-assisted milling device capable of real-time monitoring tool wear

ActiveCN106216745AEasy to monitor onlineImprove efficiencyMeasurement/indication equipmentsMilling equipment detailsNumerical controlMilling cutter

The invention discloses a laser heating-assisted milling device capable of real-time monitoring tool wear. The laser heating-assisted milling device capable of real-time monitoring tool wear comprises a milling device, a laser heating device and a real-time monitoring device. The milling device comprises a CNC (Computer Numerical Control) milling machine table, a milling cutter and a workpiece fixed to the CNC milling machine table; the laser heating device comprises a laser focus head; a laser light is incident on the surface of the workpiece through the laser focus head; the real-time monitoring device comprises a plurality of acoustic emission sensors, a signal processing module, a data acquisition processing module and an industrial personal computer; the acoustic emission sensors are arranged on the workpiece and are used for detecting acoustic emission signals of the milling cutter at a milling state; the acoustic emission signals are processed through the signal processing module and the data acquisition processing module and then are stored in the industrial personal computer; and through processing and analyzing, the real-time wear condition of the milling cutter is obtained.

Owner:HARBIN INST OF TECH

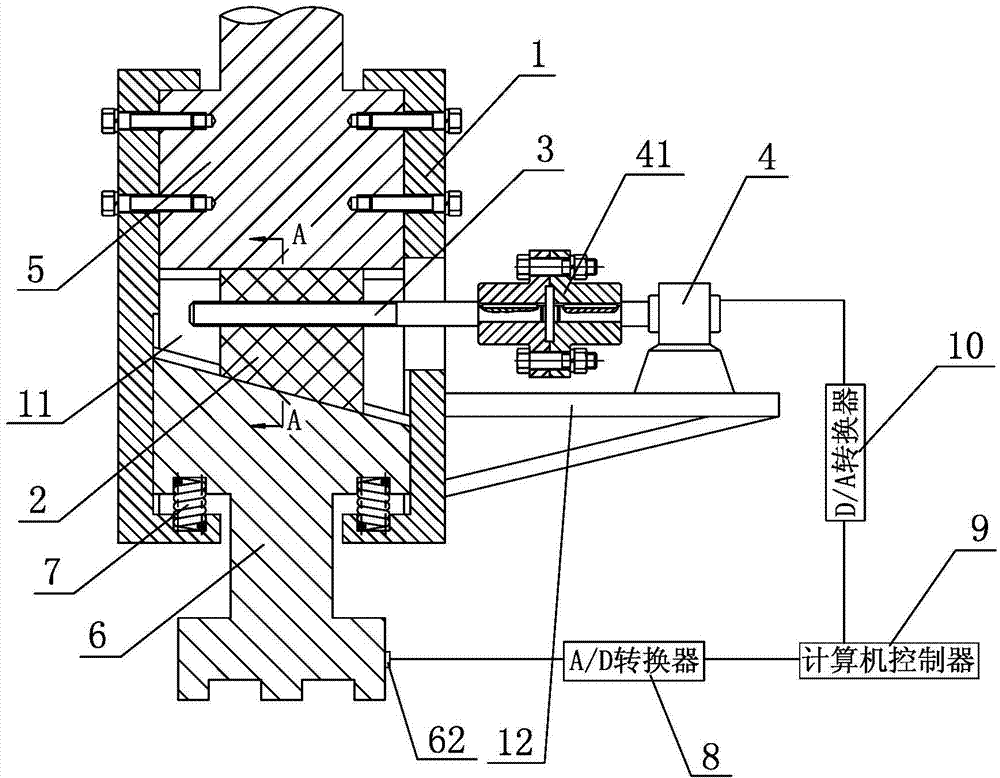

Length adjusting device for link of press machine

InactiveCN103538281ANot easy to damageImprove machining accuracyPressesComputer control systemMechanical engineering

The invention discloses a length adjusting device for a link of a press machine. The length adjusting device is characterized by comprising a connecting rack, a wedge, an adjusting screw, a motor and a computer control system. The lower end of the link of the press machine is fixedly connected inside the connecting rack. A die holder used for fixing an upper die is disposed inside the connecting rack and in vertical sliding fit with the connecting rack. A wedged cavity forms between the lower end of the link and the upper end of the die holder. The wedge is disposed inside the wedged cavity and respectively in sliding fit with the lower end of the link and the upper end of the die holder. The wedge is screwed to the adjusting screw. The motor is fixedly mounted on the connecting rack and connected with the adjusting screw. A lock spring is vertically disposed between the die holder and the connecting rack. A displacement sensor is fixed at the bottom of the die holder. The length adjusting device has the advantages that online control can be performed in real time with the adjusting device, machining precision of a machined work piece can be improved greatly, the requirements of high precision stamping parts for machining precision can be met, and qualification rate of products is high.

Owner:NINGBO UNIV

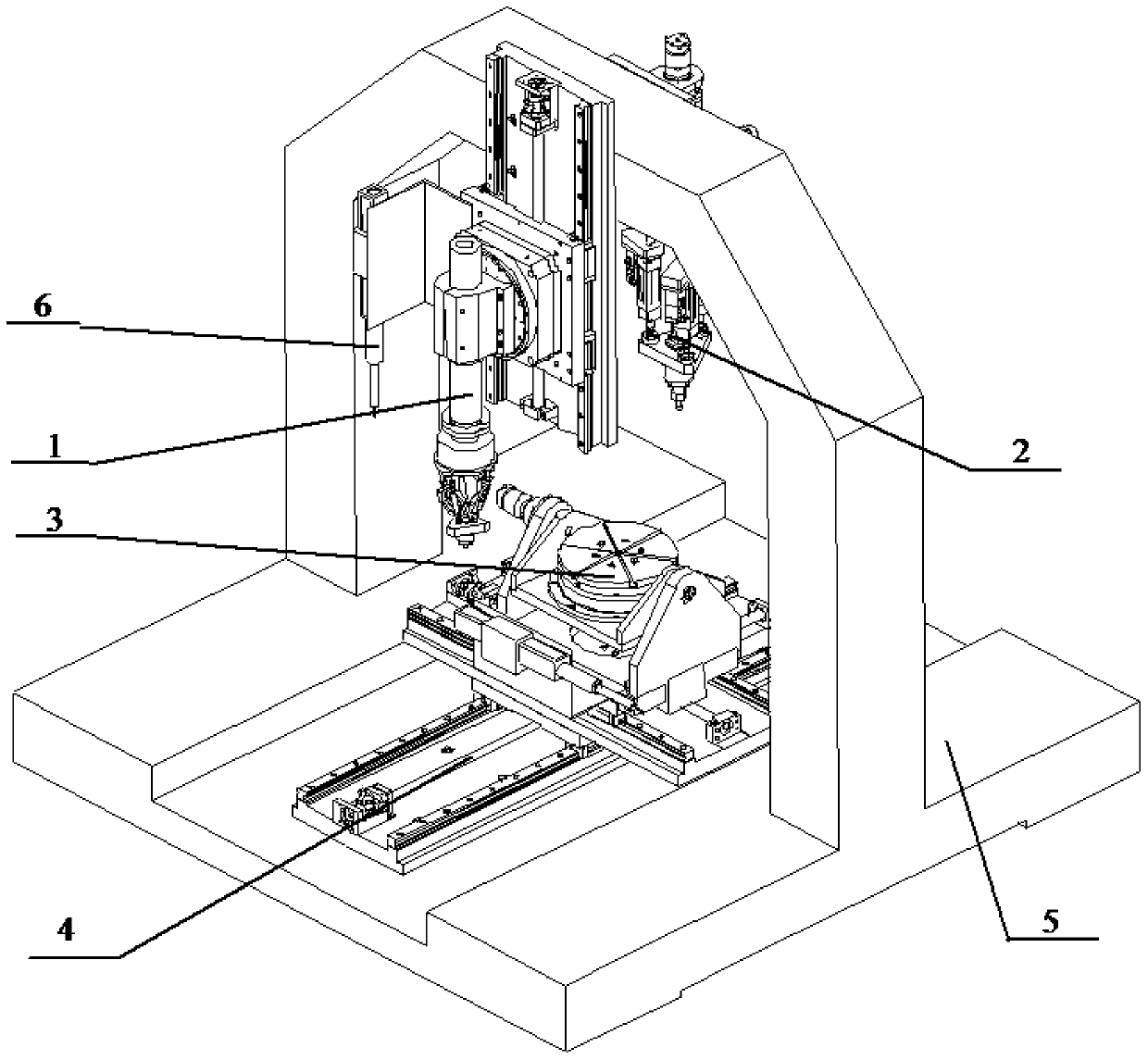

Gantry type rough and finish composite five-axis precision machine tool and processing method thereof

PendingCN110548908AQuick removalEnsure complete removalMilling machinesFeeding apparatusMilling cutterEngineering

The invention relates to a gantry type rough and finish composite five-axis precision machine tool and a processing method thereof and belongs to the field of precision machine tools. A rack is horizontally arranged; an X-Y feeding component is installed on the rack; a two-axis turntable component is installed on the X-Y feeding component through a Y-direction sliding plate; a sharp knife processing component and a fast removing component are installed on the two sides of a middle cross beam in a gantry shape through a guide rail seat and a vertical plate respectively; and a detector is installed on a sliding plate of the sharp knife processing component. The gantry type rough and finish composite five-axis precision machine tool has the characteristics of high processing efficiency and processing precision and can meet the processing precision requirement for rough milling semi-finish milling; by adopting a five-axis linkage processing method, multi-angle flexible processing can be realized, and the processing process from a blank to a finished product can be completed at one time; as a two-axis turntable is compact in structure, high in rotation precision and good in rapid response characteristic, the gantry type rough and finish composite five-axis precision machine tool has better use reliability; and with three-direction rotation and one sharp knife feeding system moving in a longitudinal feeding direction, multi-dimensional adjustment of a milling cutter processing angle is realized.

Owner:JILIN UNIV

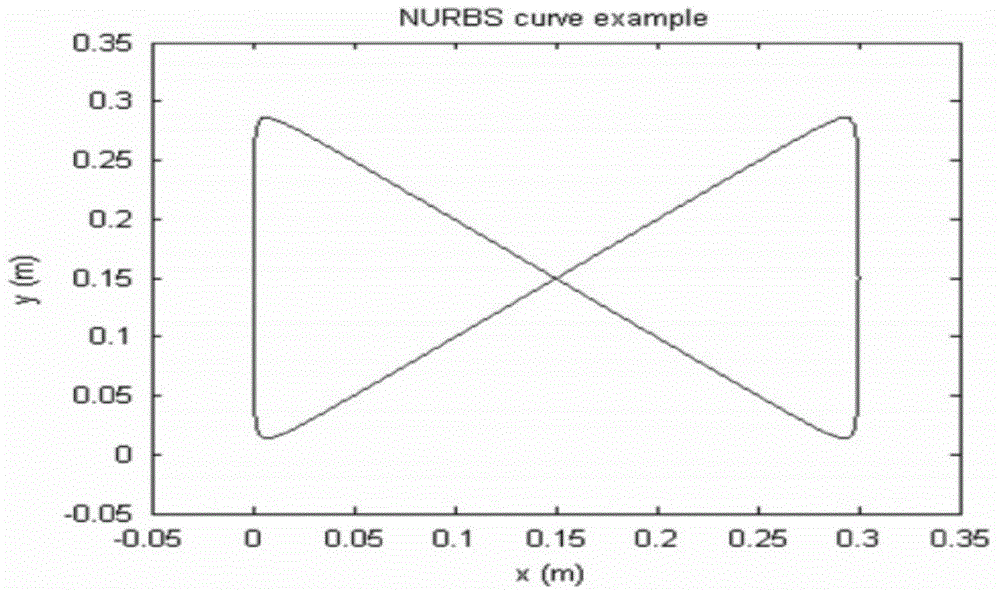

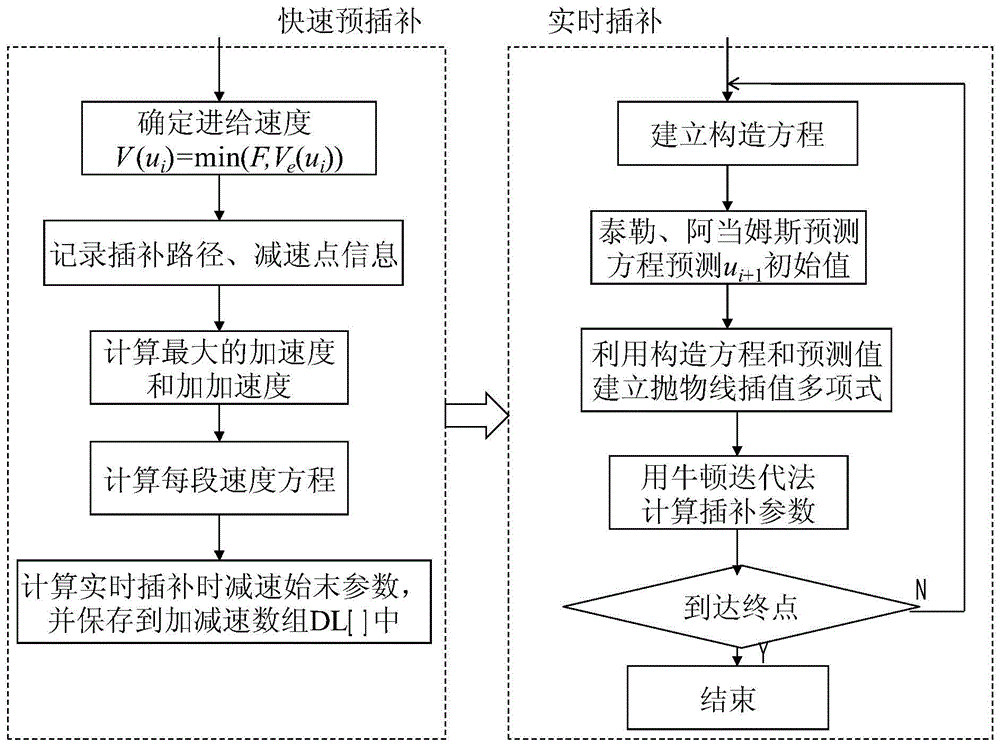

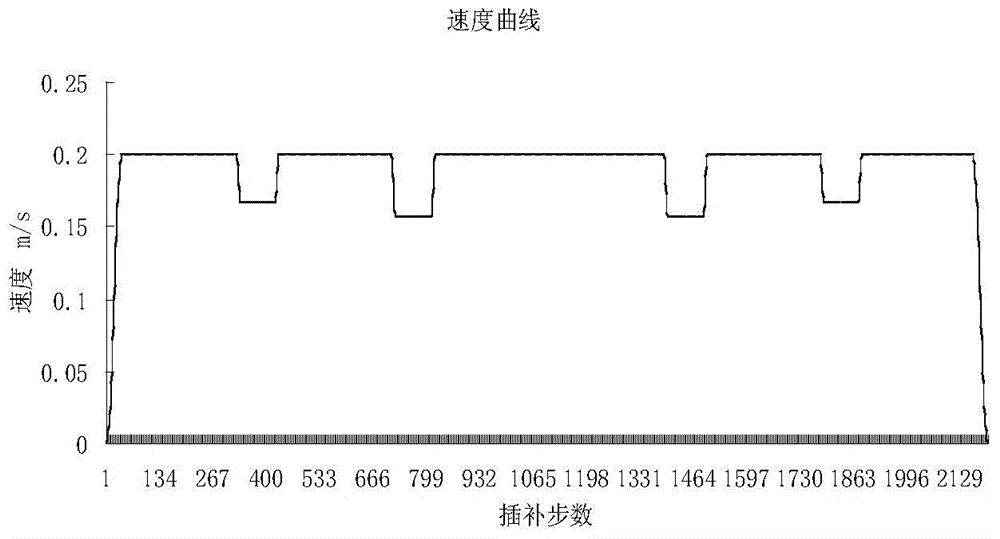

Spline curve interpolation algorithm for high quality processing

InactiveCN104597845AImprove machining accuracyGuaranteed contour accuracyNumerical controlNumerical controlAlgorithm

The invention discloses a spline curve interpolation algorithm for high quality processing, and the spline curve interpolation algorithm for high quality processing comprises the following steps: quickly pre-interpolating the numerical control machining curve, recording the length of the interpolation path and the maximum / minimum value of the acceleration / deceleration process; calculating the maximum acceleration and most much acceleration of the acceleration / deceleration process, having subsection on the acceleration / deceleration process, calculating quadratic polynomial speed equations of each section; obtaining the speed equation according to the pre-interpolating stage at the real time interpolating stage, adopting the strategy that the theory chord length is close to the practical chord length for building the construction function, estimating the initial value of the interpolation parameter and building the parabolic interpolation polynomial, using the Newton iteration method for exactly calculating the interpolation parameter. The speed plan adopts five-section S curve acceleration / deceleration control algorithm for guaranteeing continuous change of the speed and accelerated speed, the bounded change of the accelerated acceleration speed and the running stability of the machine tool; the calculation of the interpolation parameter adopts the combination of parabolic interpolation method and Newton iteration method for controlling the feeding speed fluctuation of the real time interpolation in the ideal level and satisfying the high quality processing requirement.

Owner:中国科学院沈阳计算技术研究所有限公司

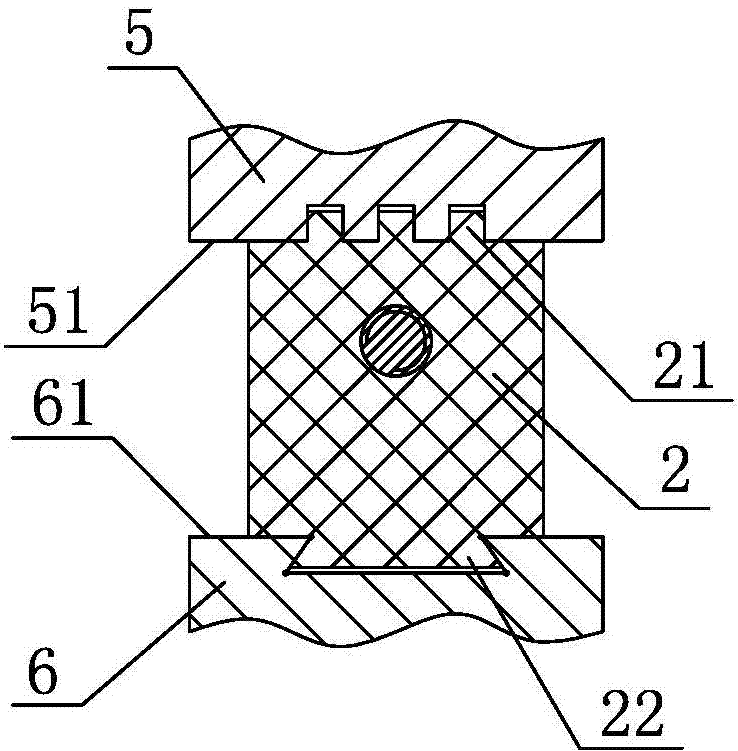

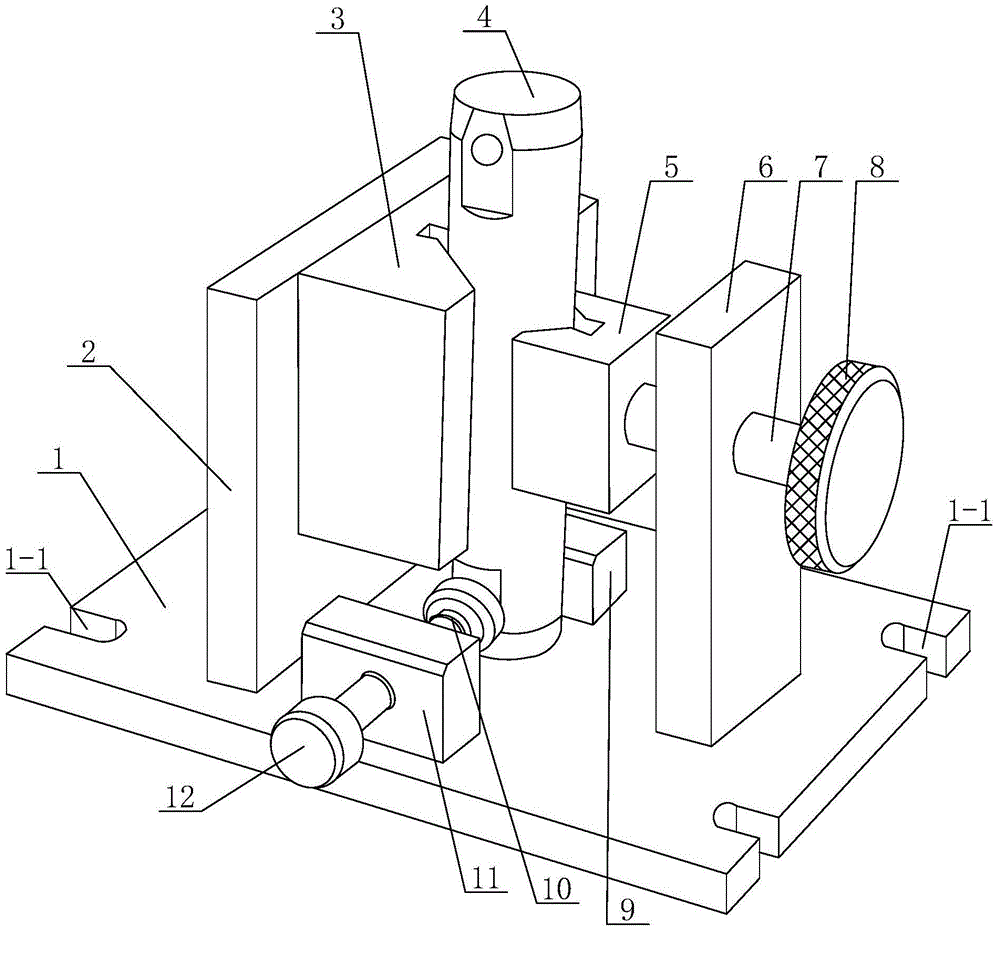

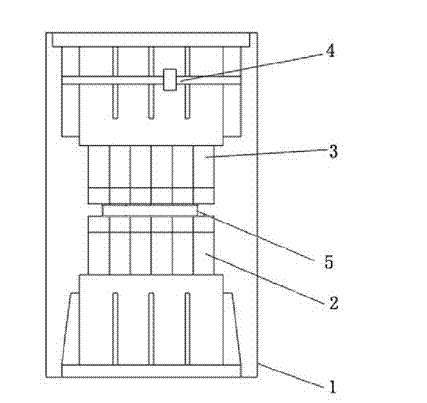

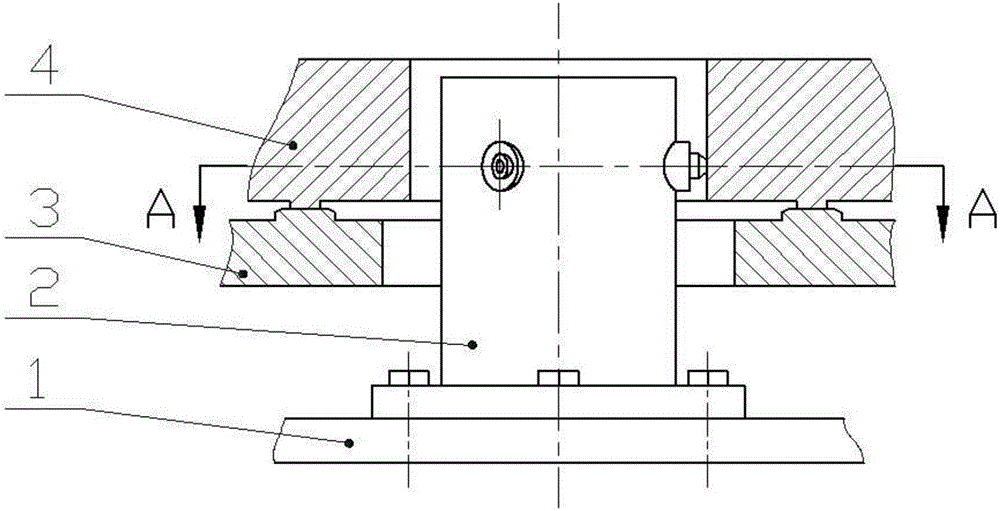

Cylindrical workpiece end flat-milling and clamping device

InactiveCN105666177AReasonable designSimple structurePositioning apparatusMetal-working holdersEngineeringMachining

The invention discloses a cylindrical workpiece end flat-milling and clamping device which comprises a bottom plate, a V-shaped groove sizing block, a V-shaped groove pressure head, a driving threaded rod and a positioning block. A first vertical plate and a second vertical plate are fixedly arranged on the upper side of the bottom plate. The V-shaped groove sizing block is fixedly arranged on one side of the first vertical plate. The driving threaded rod is arranged on the second vertical plate. The V-shaped groove pressure head is hinged to one end of the driving threaded rod. A circular handle is fixedly mounted at the other end of the driving threaded rod. The positioning block and a support are fixedly arranged on the upper side of the bottom plate and located between the V-shaped groove sizing block and the V-shaped groove pressure head. A pressing shaft used for rapidly and tightly pressing a workpiece is mounted in an unthreaded hole in the middle of the support in a sliding mode. An elastic element is arranged between the end of the pressing shaft and the support. The cylindrical workpiece end flat-milling and clamping device has the following characteristics of quick positioning, good positioning accuracy, high machining precision, reasonable design, simple structure and convenient clamping.

Owner:XIAN ZHIYUE ELECTROMECHANICAL TECH

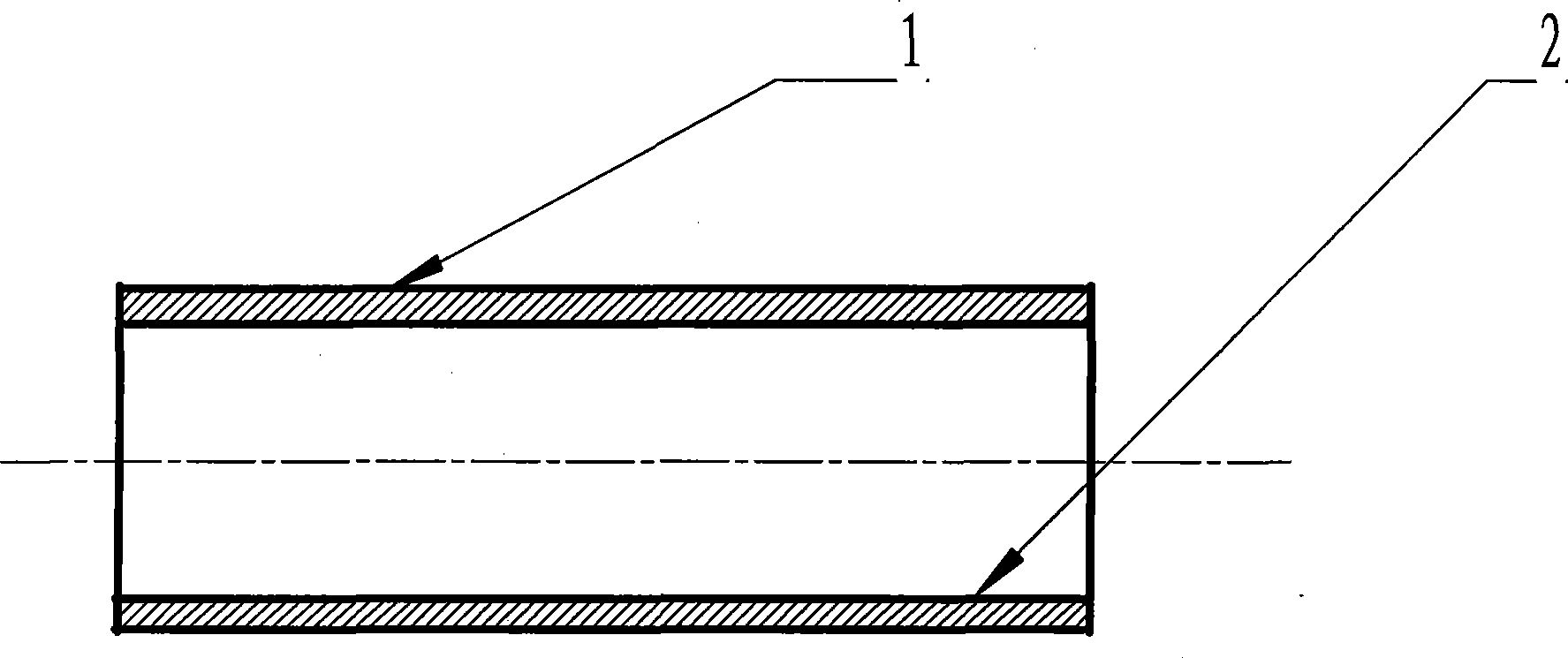

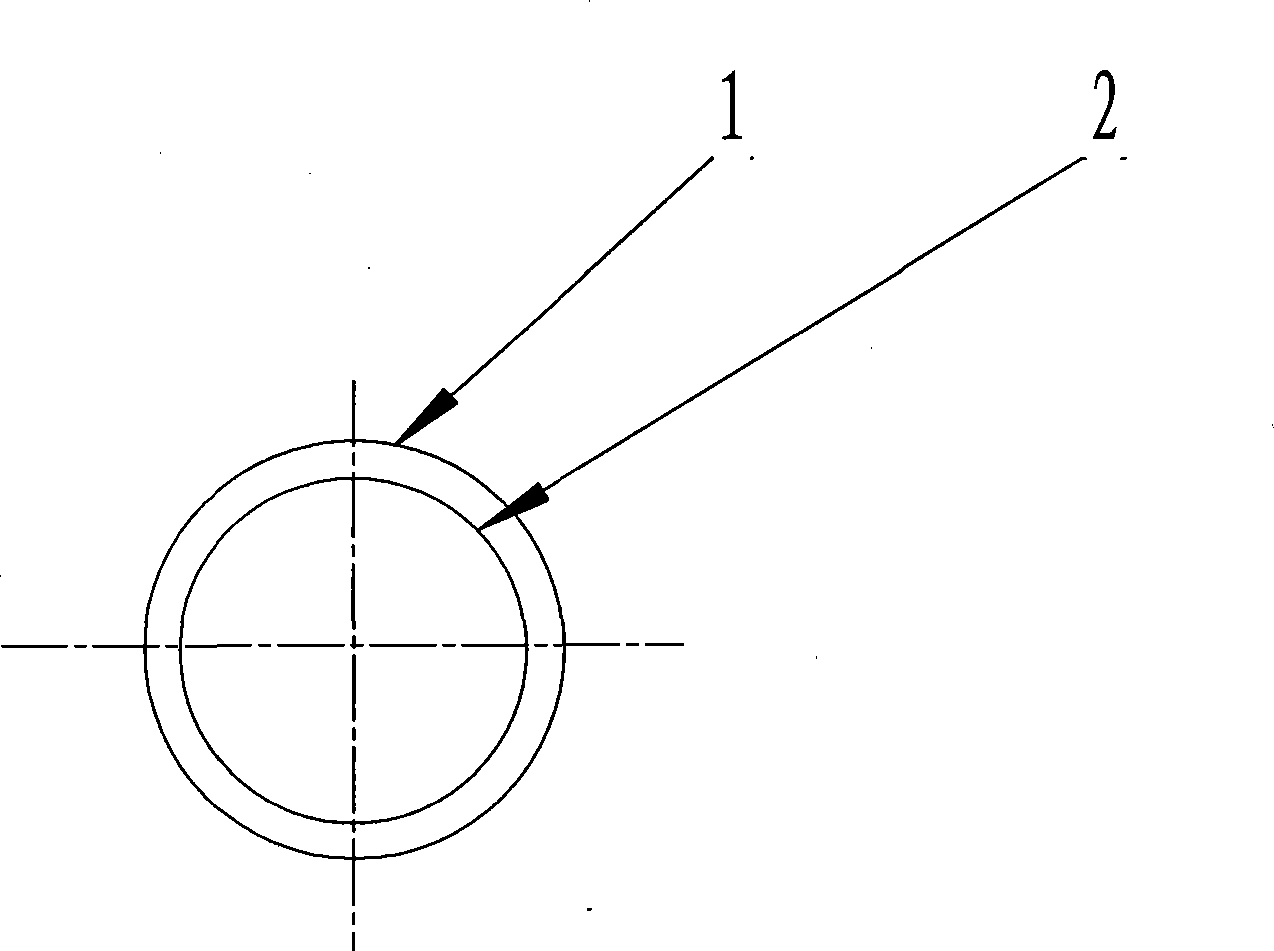

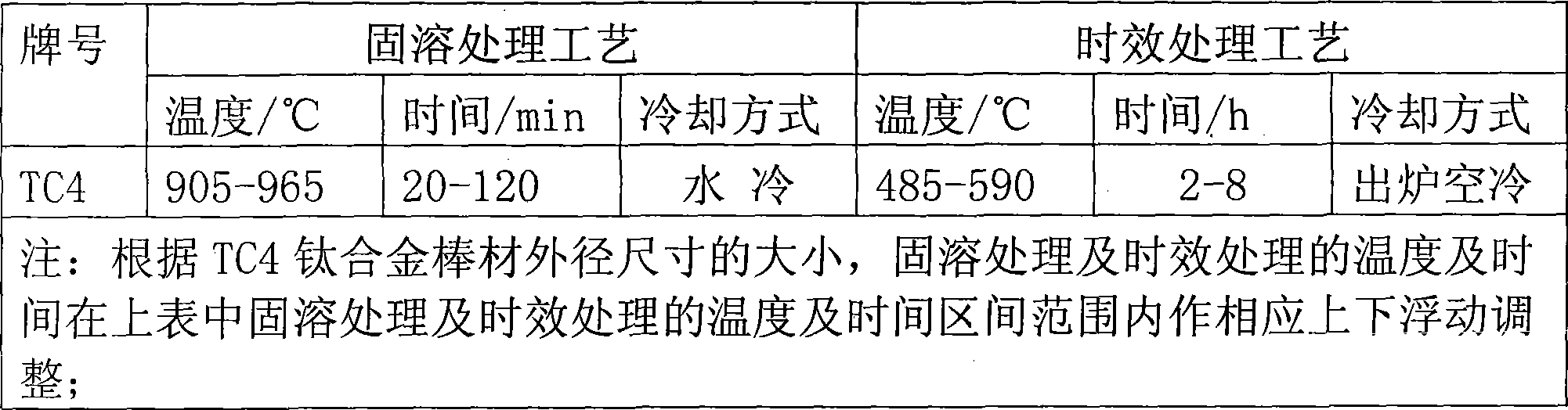

Technique for processing honing tube

ActiveCN101462225AMeet mechanical performance requirementsMeet the machining accuracy requirementsTitanium alloyMachining process

The invention relates to a processing technique for a honing pipe in the fields of aerospace and pressure machinery and the like, in particular to the processing technique for the honing pipe with the tensile strength of not less than 1,140 MPa, the yield strength of not less than 1,030 MPa, the tensile stretch of not less than 16 percent and the specific elongation of not less than 38 percent, and higher requirement on the processing precision. The adopted process is to select a TC4 titanium alloy bar material with proper dimension to finish the processing of the honing pipe with the stated dimension and requirements through the steps of straightening, boring deep holes, honing, turning, polishing and the like according to the processes of roughing, open die forging and heat treatment. The processing technique is simple and efficient with low cost, and satisfies the use requirements on high-performance honing pipes in the fields of aerospace and pressure machinery and the like in China.

Owner:BAOJI YONGSHENGTAI TITANIUM IND

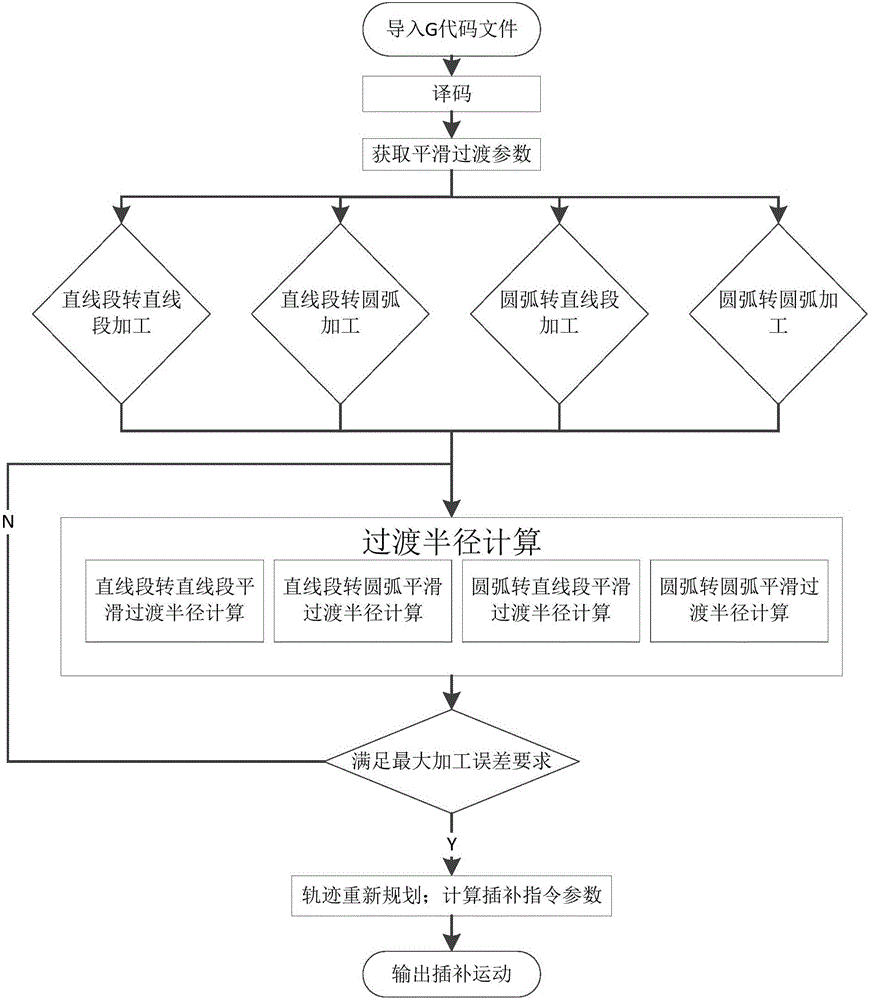

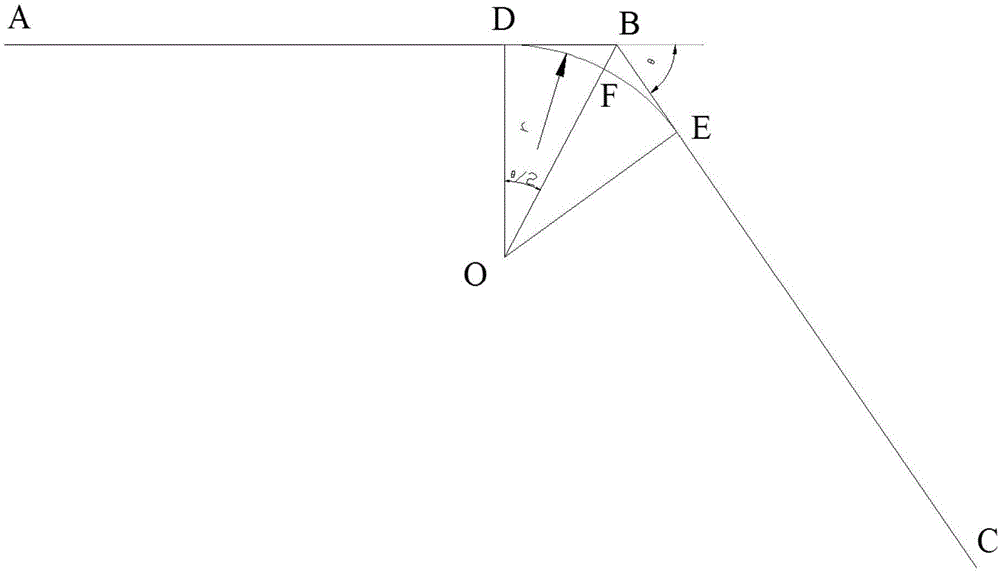

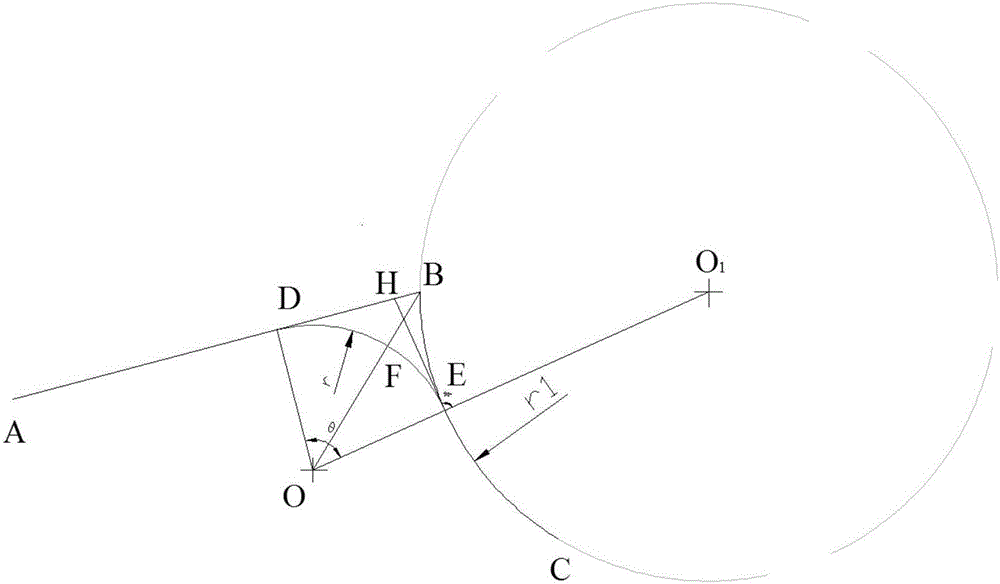

CNC processing smooth transition method and device

InactiveCN106227152AAchieve smoothnessMeet the machining accuracy requirementsNumerical controlControl theoryLine segment

The invention discloses a CNC processing smooth transition method and device. The method is used for outputting pulses capable of controlling a servo controller, and the pulses drive the servo controller to control a servo motor to achieve track processing of the servo motor. The method includes the steps that smooth transition parameters are obtained; the radius of a target transition arc segment is obtained, wherein a transition arc segment is obtained according to the smooth transition parameters and a preset arc radius, and the transition arc segment is subjected to error inspection to obtain the target transition arc segment and the corresponding radius; interpolation instruction parameters are obtained, wherein track planning is carried out again according to two line segments and the target transition arc segment, and the interpolation instruction parameters are obtained; the pulses are obtained, wherein interpolation calculation is carried out according to the interpolation instruction parameters, and the pulses are obtained. Smoothness of CNC processed parts is achieved, certain processing precision requirements are met, and the method and device are easy to achieve, short in development period and stable in function.

Owner:HEFEI UNIV OF TECH

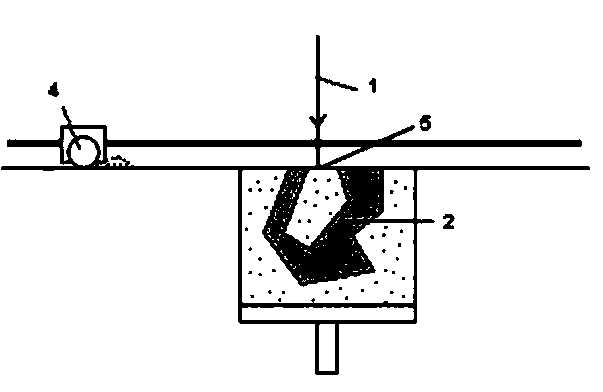

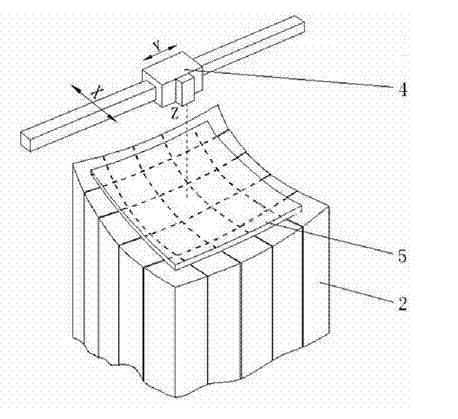

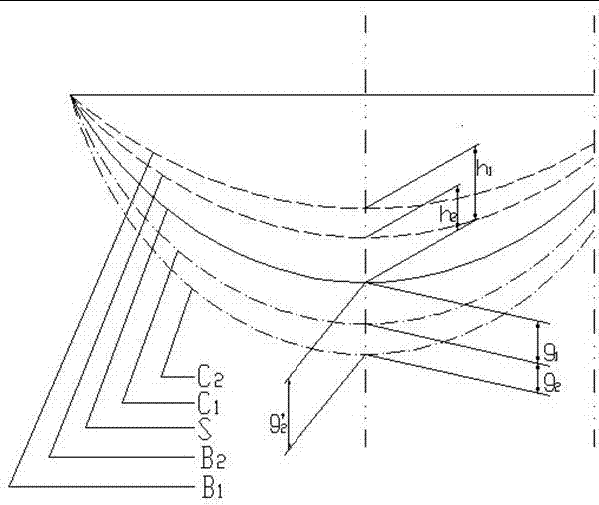

Method and device for forming plates through gradual approximation bending

InactiveCN102500672ASolve the problem of bending springbackResolve reboundMetal working apparatusNumerical controlMeasuring instrument

The invention discloses a method and a device for forming plates through gradual approximation bending on a three-dimensional numerical control plate bending machine (1). The method comprises the following steps of: performing targeted iteration gradual approximation bending by utilizing a resilience rule of a plate (5), comparing a shape of an actually formed curved surface B of the plate (5) subjected to pressing resilience with a shape of a theoretical target curved surface S through online measurement, and setting an approximation bending pressing curved surface C for limited approximation pressing according to an error offset value h after resilience. By the device, an online laser three-dimensional coordinate measuring instrument (4) connected with a computer is arranged on the three-dimensional numerical control plate bending machine (1). Complex mechanical calculation is not needed, the problem of bending resilience of a ship plate can be rapidly solved on line in real time, as long as the approximation bending pressing is performed for 1 to 3 times generally, the requirement on machining accuracy can be met, the problem of resilience of a numerically controlled bent plate is rapidly and effectively solved, the forming accuracy of a three-dimensional curved surface ship plate is guaranteed, and the method and the device have simple and rapid effects.

Owner:SHANDONG SURELY MACHINERY CO LTD

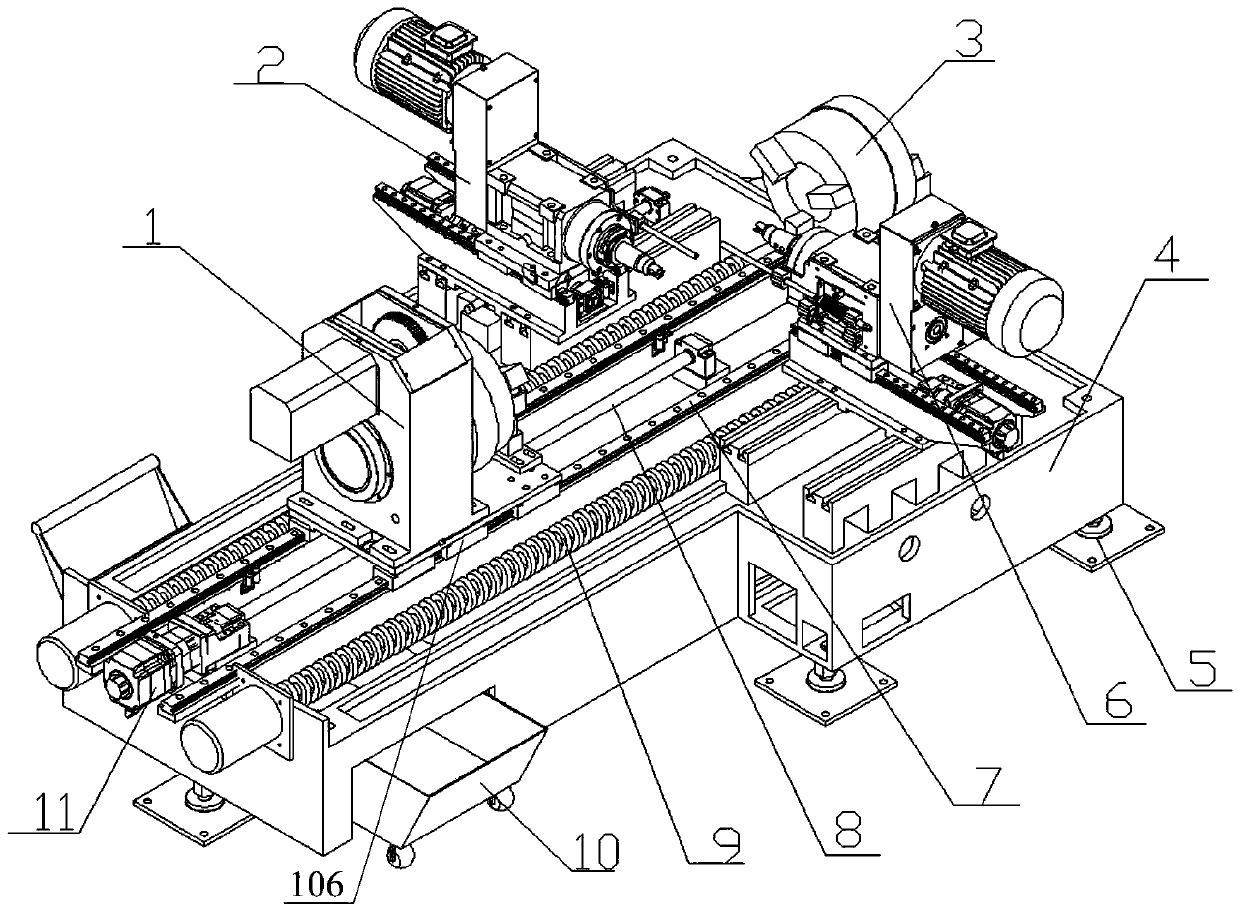

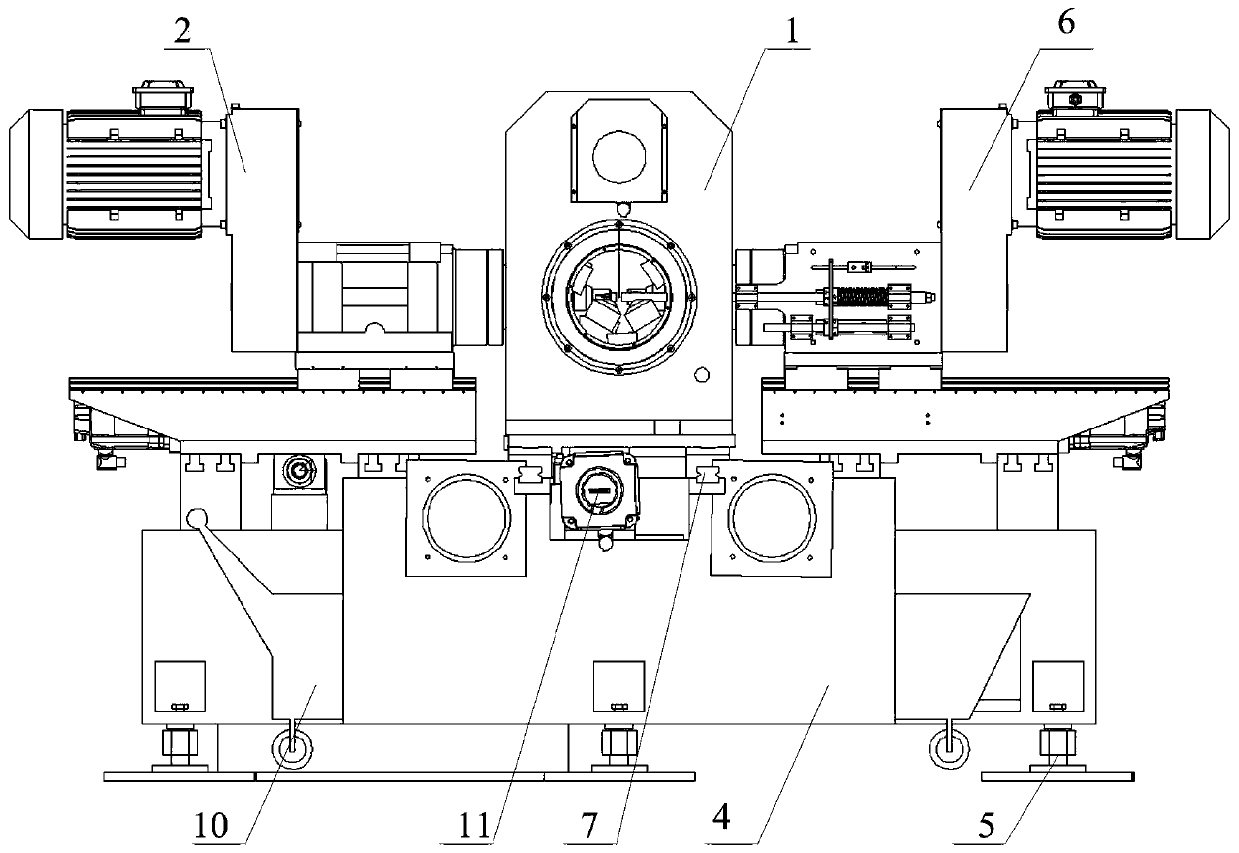

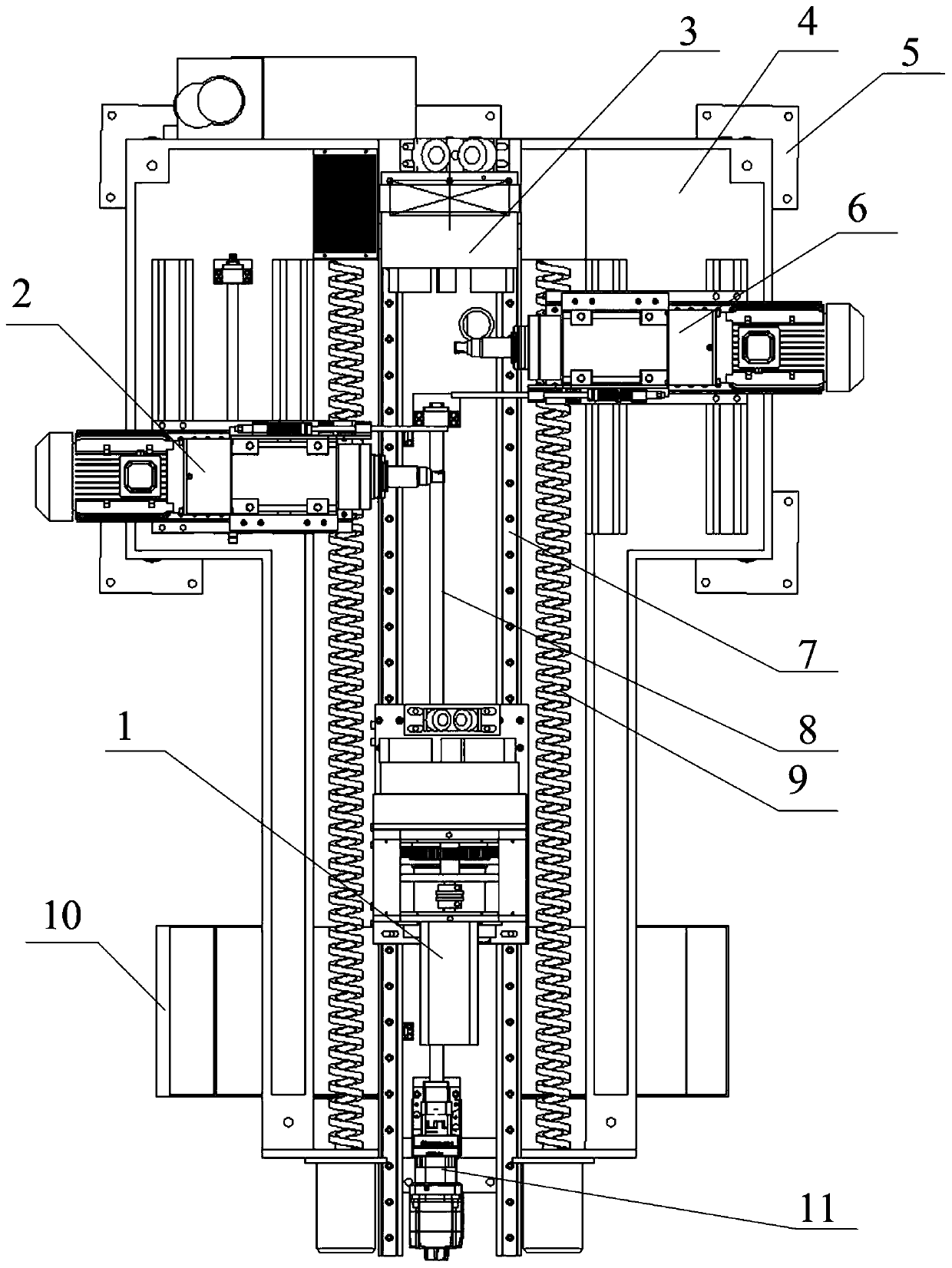

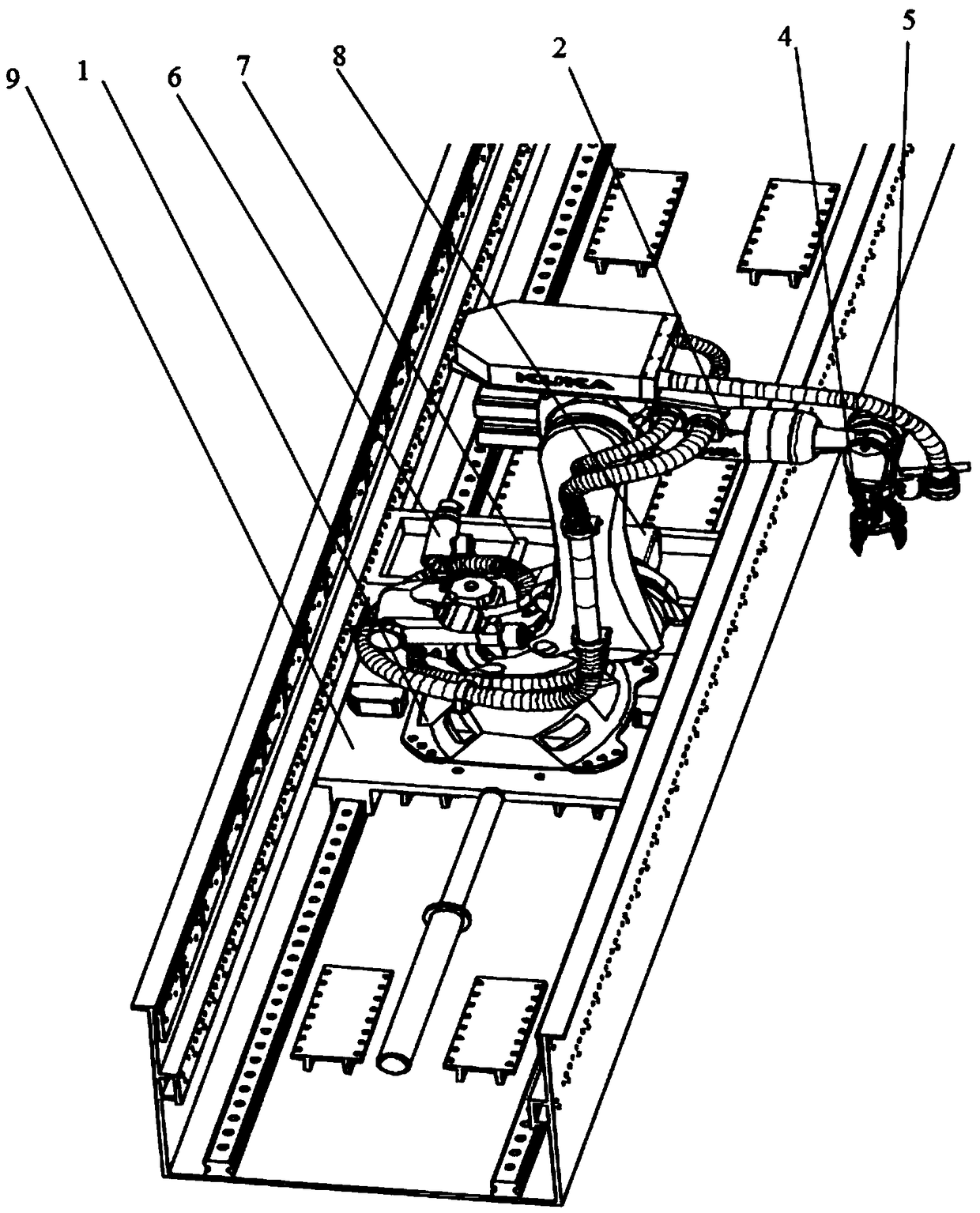

Pipe blind hole-based drilling and milling machine tool capable of realizing multi-station machining

ActiveCN110695396AMeet the machining accuracy requirementsReduce participationMilling machinesFeeding apparatusLinear motionBall screw

The invention discloses a pipe blind hole-based drilling and milling machine tool capable of realizing multi-station machining, and belongs to the field of machining. The pipe blind hole-based drilling and milling machine tool capable of realizing multi-station machining comprises a spindle box, a No.1 drilling and milling head, a fixing chuck, a machine tool base, horizontal adjusting seats, a No.2 drilling and milling head, linear sliding way guiding rails, a linear ball screw, a spiral chip removal machine, a chip removal trolley, a dragging servo motor, a nut and a leftward-and-rightward adjustment mechanism. According to the pipe blind hole-based drilling and milling machine tool capable of realizing multi-station machining, power is provided by the servo motor for the linear motion and the rotation motion, the linear positioning accuracy is controlled to be 0.005 mm, the rotation positioning accuracy is 5 arc minutes, and the pipe machining accuracy requirements can be met completely. According to the machine tool, participation of operators is reduced, the labor intensity is reduced, the working efficiency is improved, and the machine tool has the advantages of easiness in operation, low labor intensity, capability of saving time and labor and the like.

Owner:长春北兴激光工程技术有限公司

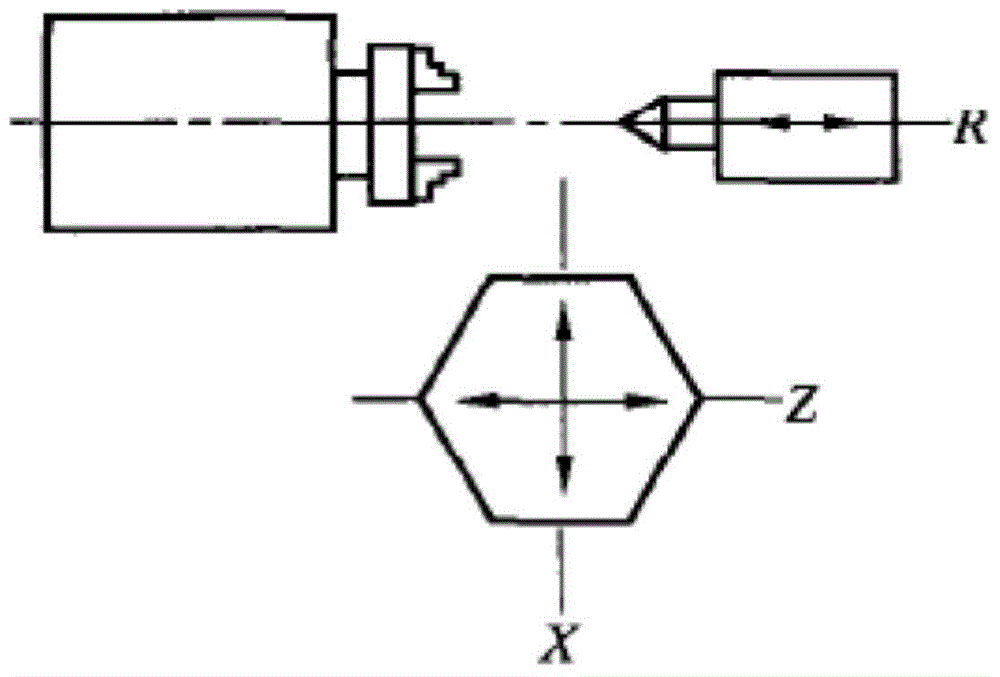

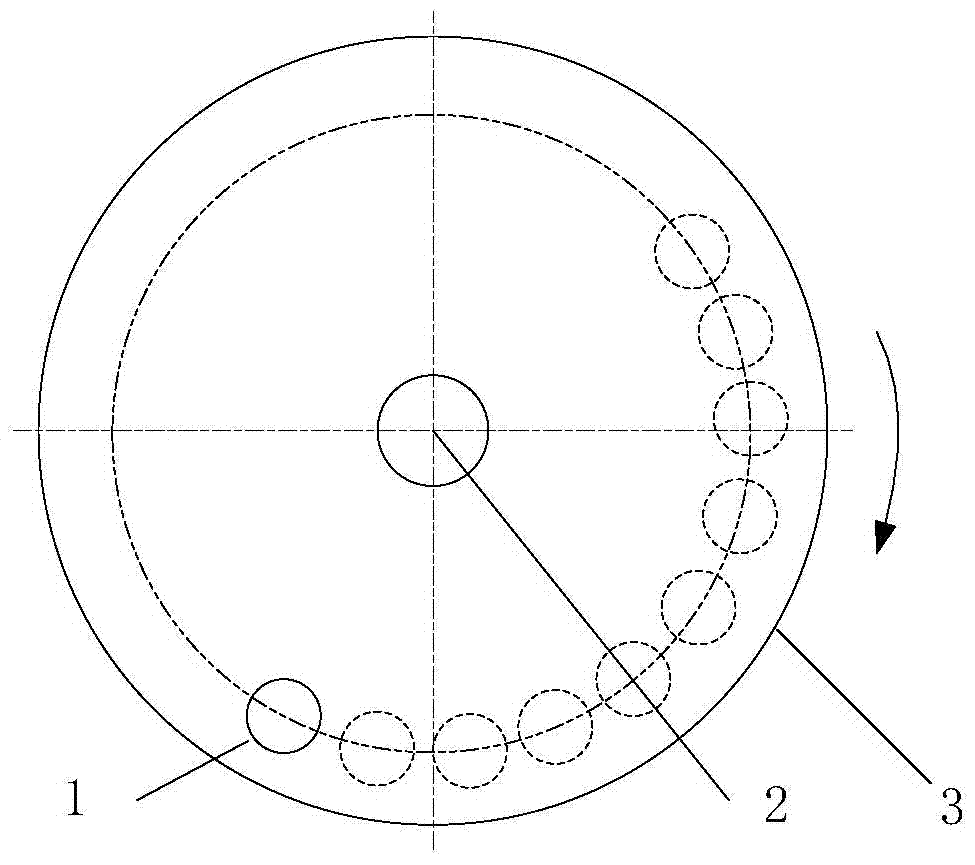

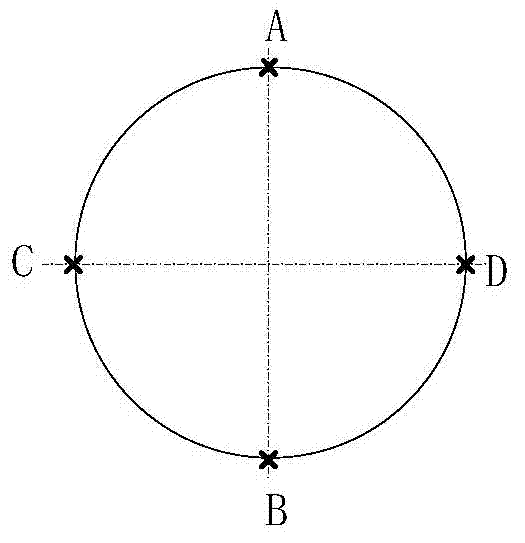

Rotary-table center positioning method for spindle-driving-five-shafts machining center

InactiveCN103921170ASolve the positioning problemMeet the machining accuracy requirementsMeasurement/indication equipmentsLarge fixed membersMachine toolComputer science

The invention discloses a rotary-table center positioning method for a spindle-driving-five-shafts machining center, aiming to solve the technical problem that an existing rotary-table center positioning method for the spindle-driving-five-shafts is poor in implementation. The technical scheme is that center coordinates of a ring gauge under different rotary angles of a rotary table are acquired multiple times and are matched into a circular curve to acquire the circular center and determine the table center. By the method, the problem about positioning of the table center of the spindle-driving-five-shafts machining center under the end milling condition can be effectively solved, the positioning accuracy can reach 0.001mm through detection, and requirements of a machine for machining accuracy can be met.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

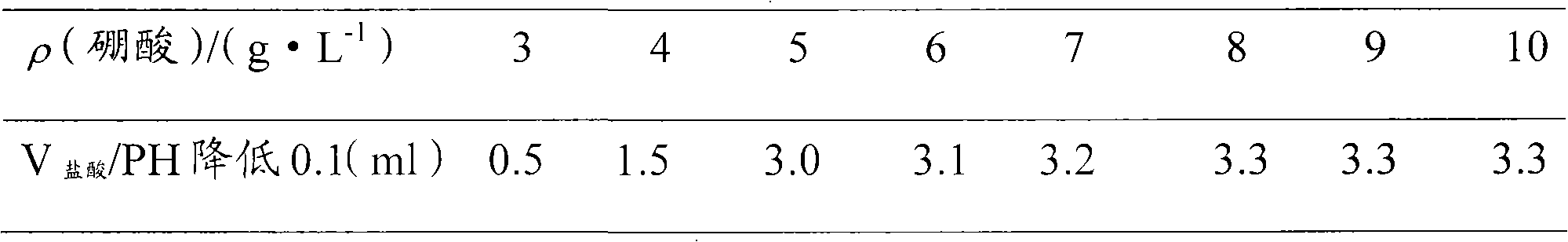

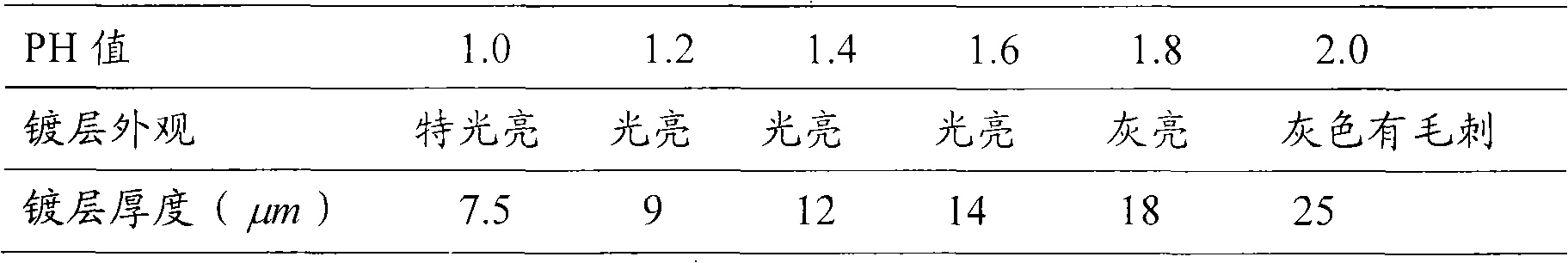

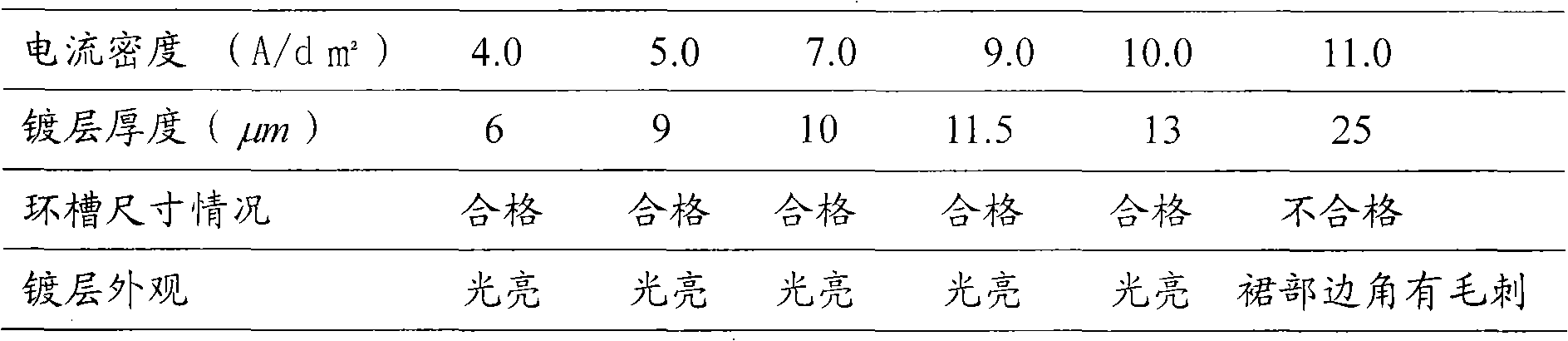

Aluminium alloy surface electric plating iron machining process

A process for galvanizing iron on an aluminum alloy surface includes the following steps: (1) glaring, an aluminum alloy galvanized component is provided and carries out glaring treatment; (2) washing, the galvanized component after glaring treatment is washed; (3) zincing, the galvanized component after washing carries out zinc impregnation; (4) galvanizing, a plating bath is provided, electroplating solution mixed by ferrous chloride of 350g / L, sodium chloride of 10g / L, manganese chloride of 3g / L and boric acid of 5g / L is added into the plating bath, the pH value of the electroplating solution is 1.2, the galvanized component is put in the plating bath and carries out electrolytic reaction for 8 min at the temperature of 45 DEG C, the current density is 4A / dm<2>; (5) neutralizing the electroplating solution, the galvanized component after galvanization carries out the treatment of neutralizing the electroplating solution; (6) the galvanized component carries out rust-proofing treatment and natural airing to obtain a finished product. The plating formed on the surface of the aluminum alloy galvanized component has even thickness and glaring appearance, and mass production can be realized.

Owner:薛玉田

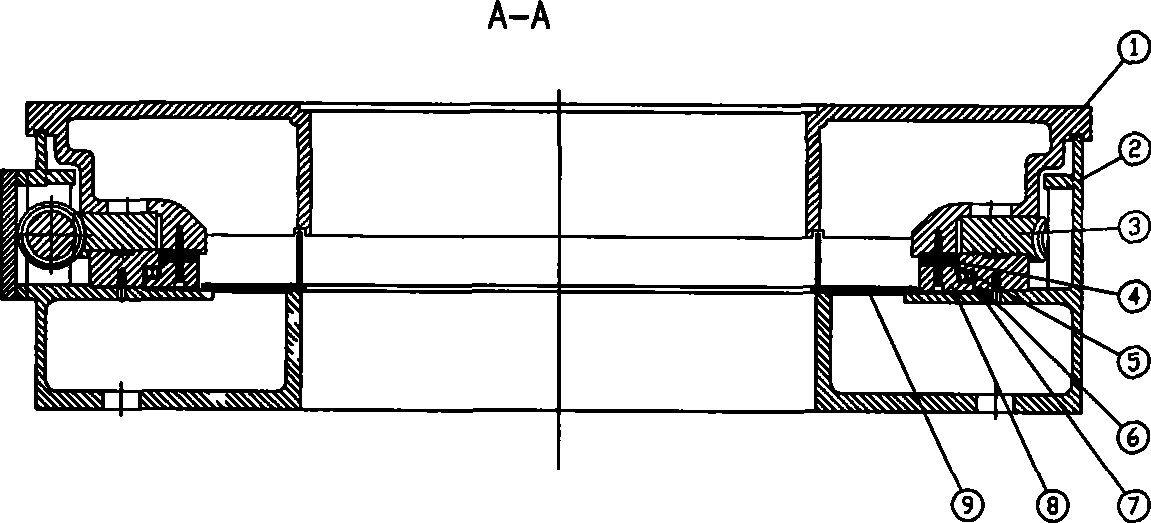

High-precision tensioning device

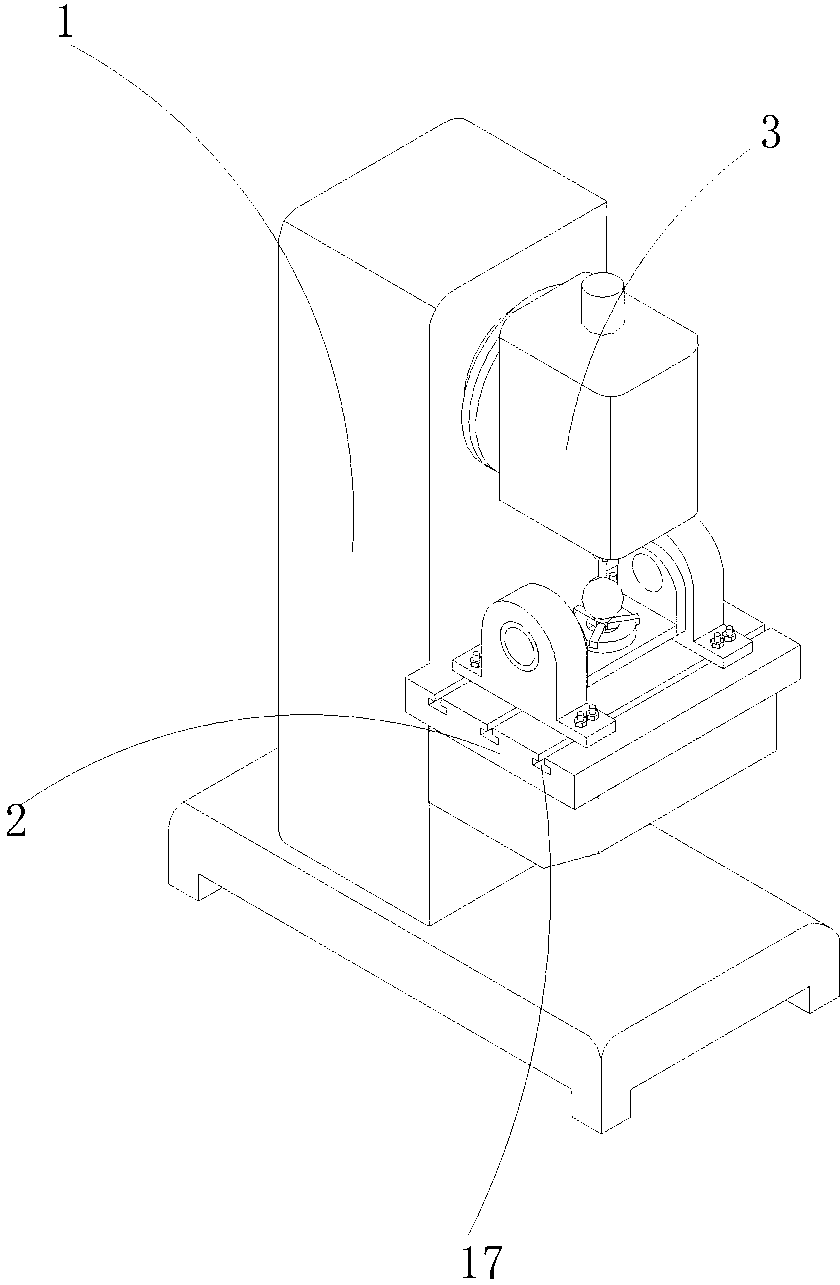

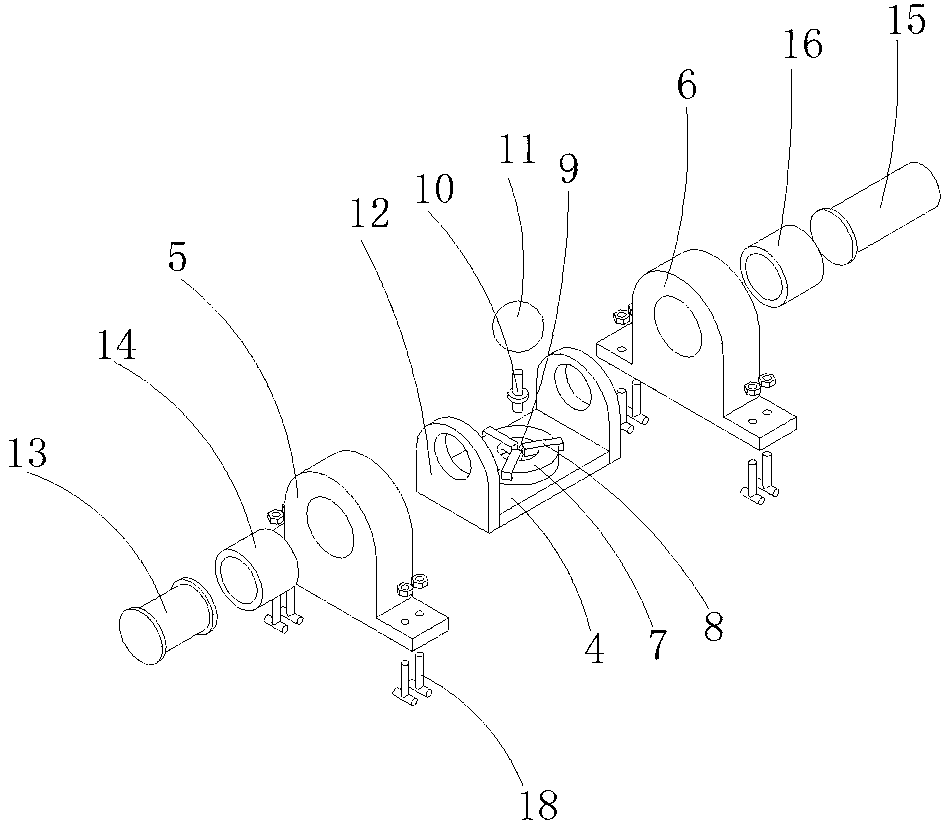

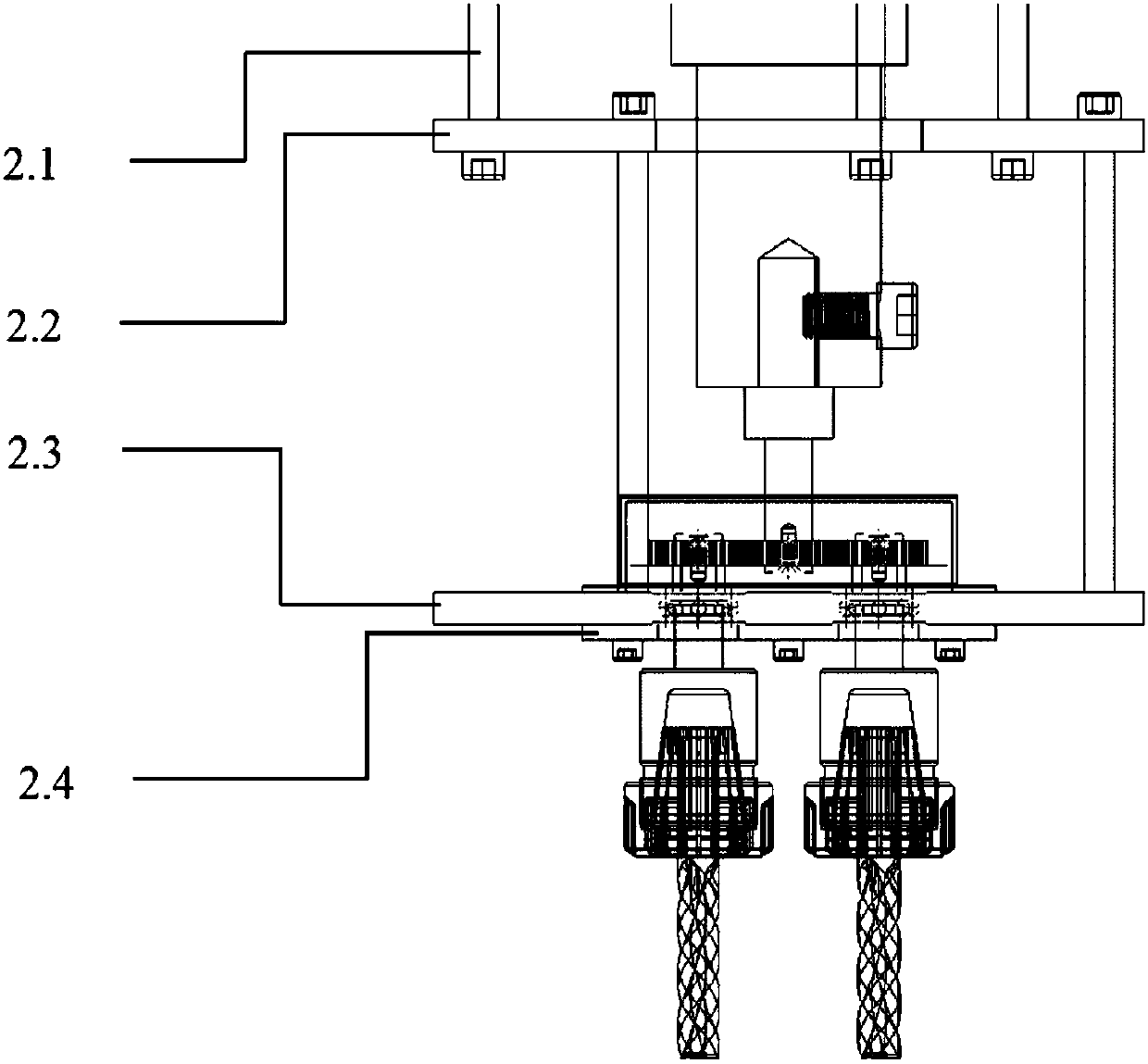

ActiveCN105880659AHigh positioning accuracyStable and synchronous tensionSleeve/socket jointsWork clamping meansEngineeringClosed loop

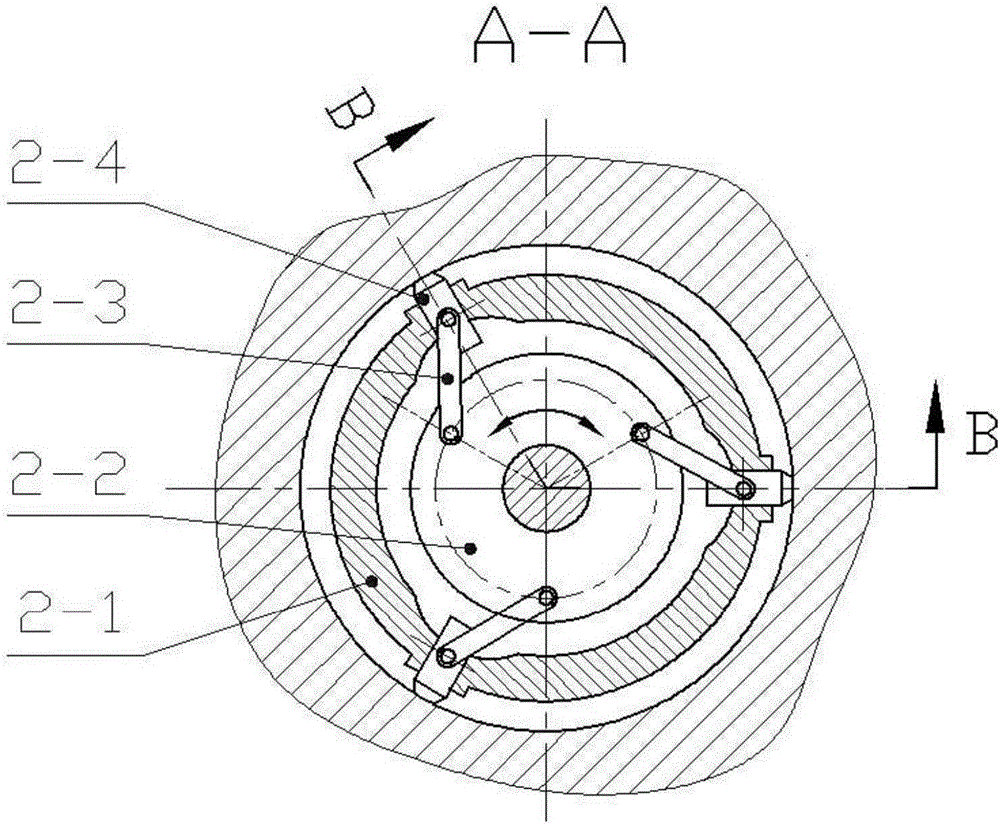

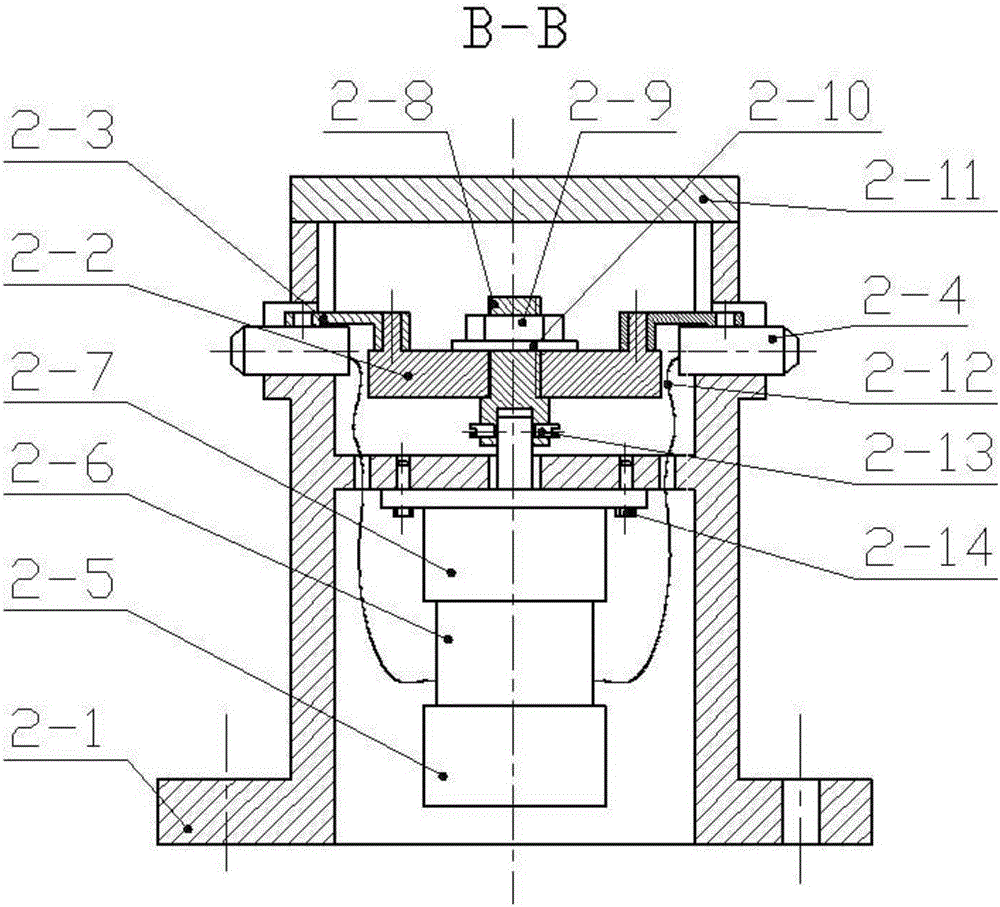

The invention provides a high-precision tensioning device. The high-precision tensioning device is composed of a stepping motor (2-6), an encoder (2-5), a harmonic reducer (2-7), a rotating disc (2-2), a connecting rod (2-3), a contact (2-4), a force sensor (2-12), a rotating disc connecting piece (2-8), a spacer (2-10), a nut (2-9), a bolt (2-14), a fastening screw (2-13), a shell (2-1) and an end cover (2-11). The tensioning device disclosed by the invention can realize closed-loop control of tensioning force and is used for improving the tensioning precision. If the processing and assembling error meets the design requirement, three contacts can be stably and synchronously tensioned, and the wheel hub positioning precision is improved. According to the invention, synchronous movement of the three contacts is realized by adopting a simple crank block mechanism, the closed-loop control of tensioning force is realized by adopting universal components and parts, the adjustment precision can reach extremely high degree, and the machining precision requirement of the existing wheel hub is met.

Owner:CITIC DICASTAL

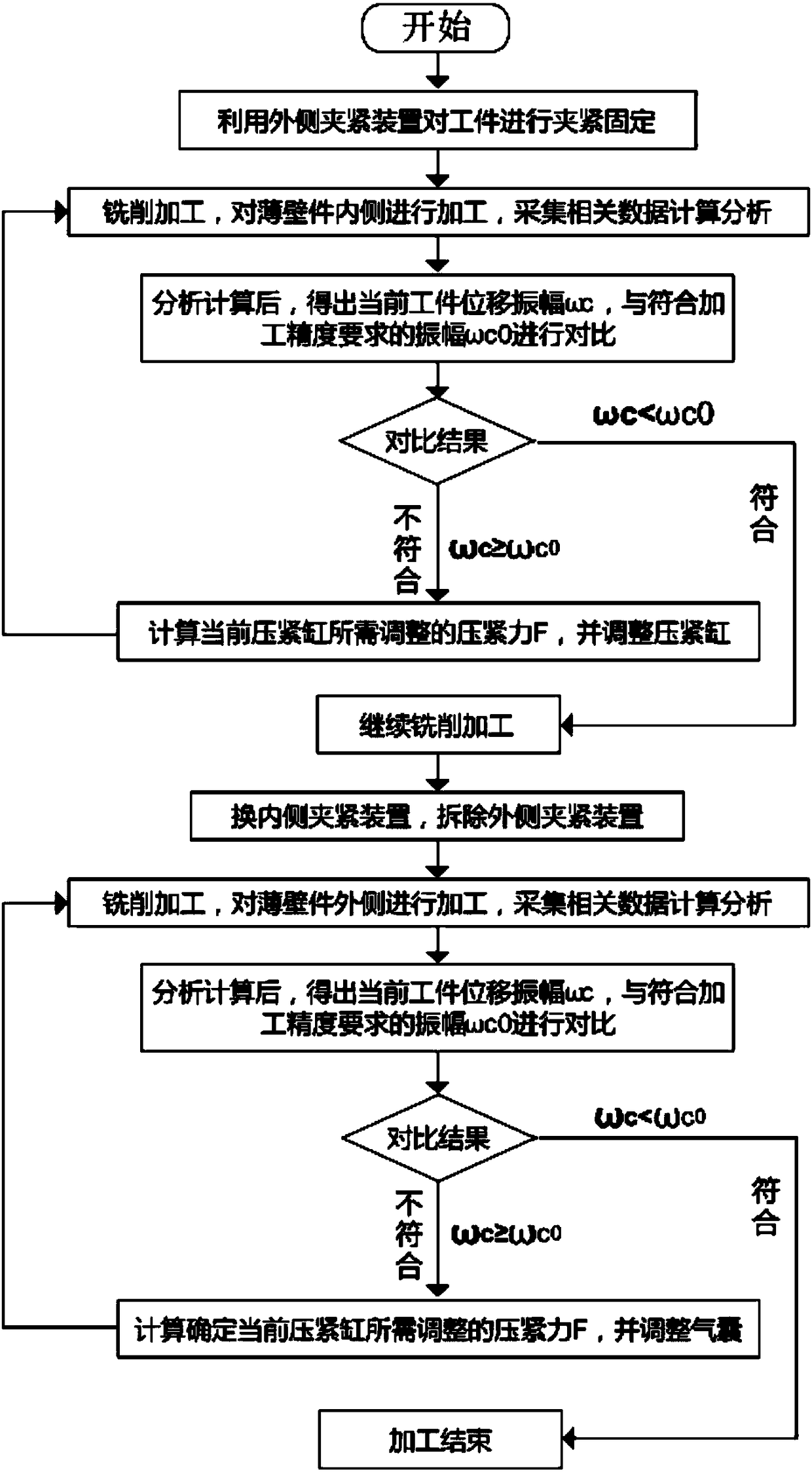

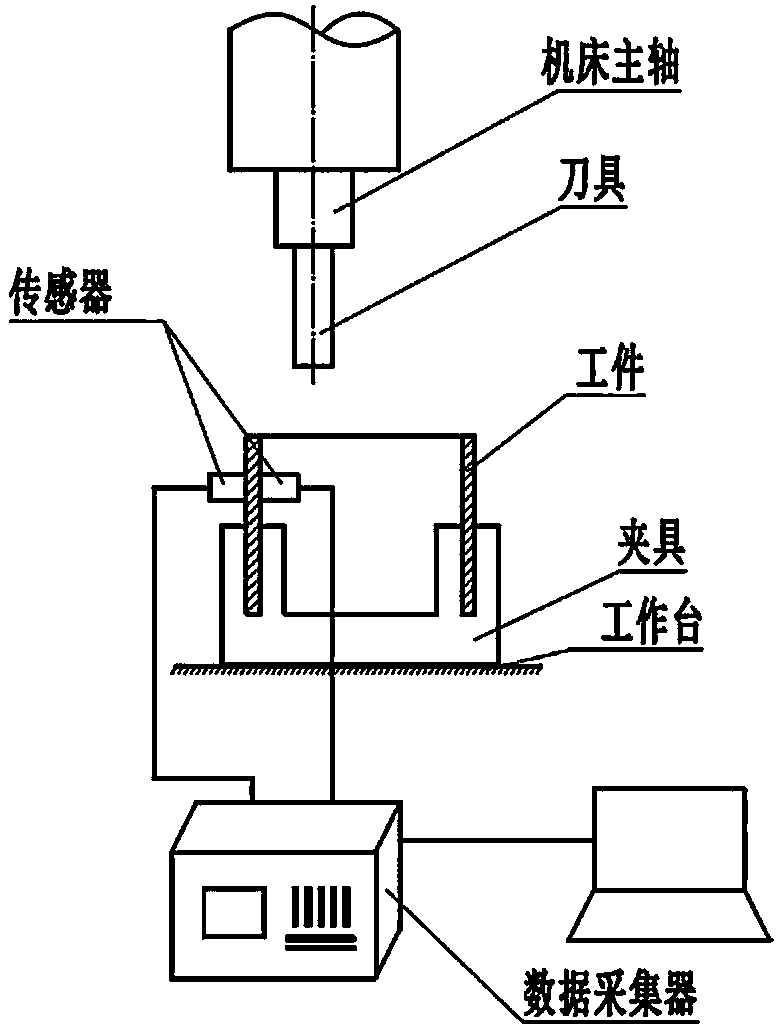

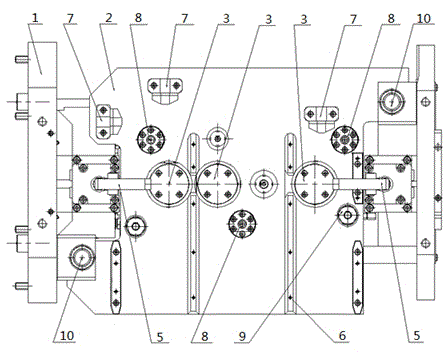

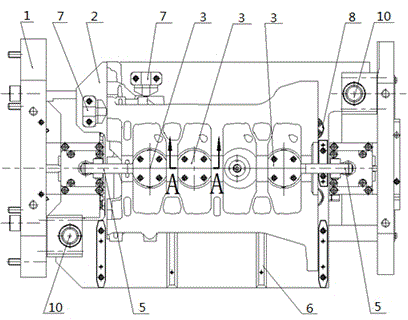

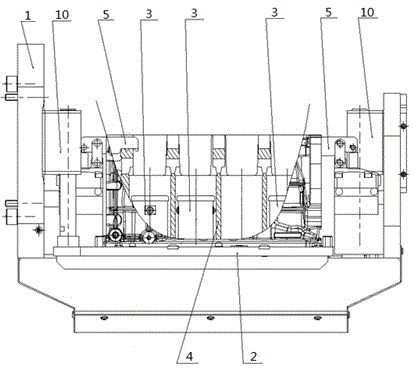

Thin-walled casing part non-chatter processing method and processing fixture thereof

InactiveCN108481052AImprove product qualityMeet the machining accuracy requirementsAutomatic control devicesMeasurement/indication equipmentsComputer control systemAirbag deployment

A thin-walled casing part non-chatter processing method and a processing fixture thereof, the processing method of the present invention includes the steps of monitoring the condition of a casing during processing by a sensor and determining whether the current processing state of the casing satisfies processing accuracy requirements, if the processing accuracy requirements are not satisfied in result of chatter, adjusting the pressing force of a pressing device in real time by a computer control system to increase the rigidity and dynamic damping of the thin-walled casing part. The fixture includes a work piece outboard clamping device and a work piece inboard clamping device mounted on a base, and the casing is arranged between the work piece outboard clamping device and the work piece inboard clamping device during processing. The work piece outboard clamping device includes an upper compression cylinder and a lower compression cylinder, the work piece inboard clamping device includes an airbag base having an upper airbag and a lower airbag mounted thereon. The top of the airbag base is also provided with an empty pressure corner cylinder. The processing method of the present invention is simple to operate and can ensure the processing accuracy.

Owner:XI AN JIAOTONG UNIV

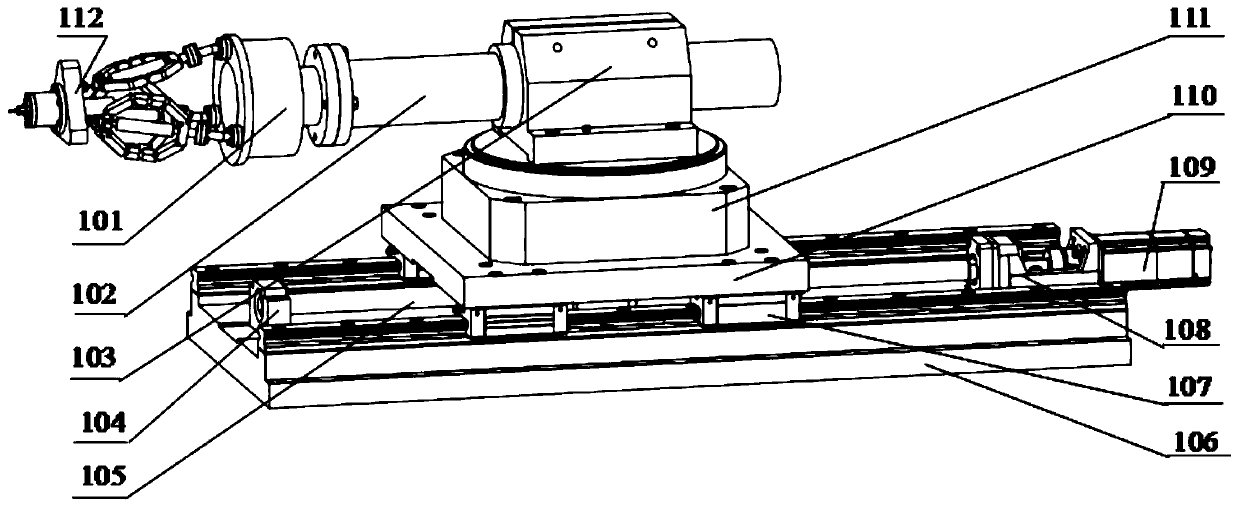

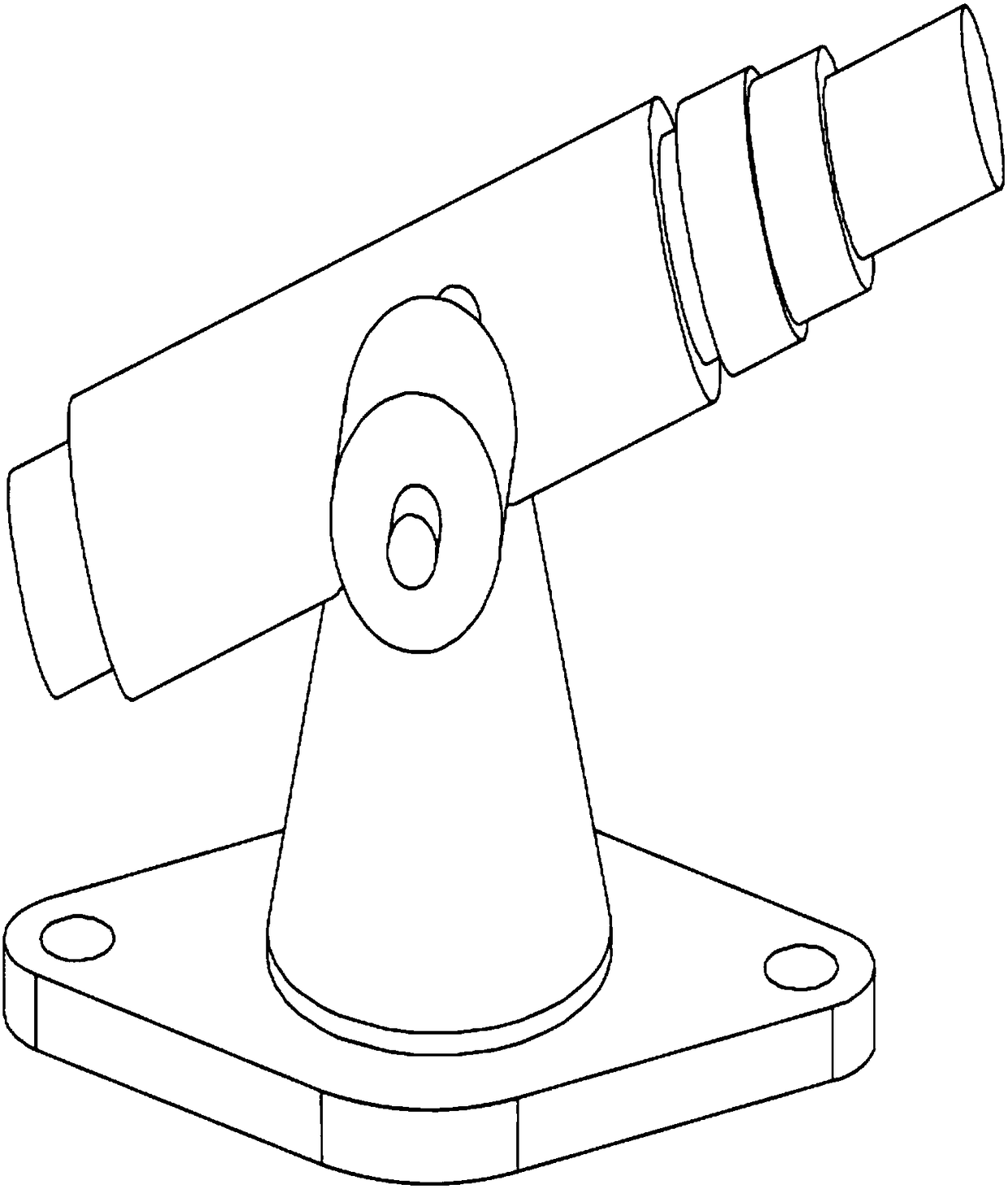

Processing tool and processing method for novel net rack bolt ball

ActiveCN103213030AMeet the machining accuracy requirementsSimple and fast operationPrecision positioning equipmentComputer scienceDrill

The invention relates to a processing tool, in particular to a processing tool and a processing method for a novel net rack bolt ball. A numerically-controlled dividing apparatus comprises a Y-shaft dividing base; the left end of the Y-shaft dividing base is provided with a left dividing disc base positioned together with the Y-shaft dividing base; the right end of the Y-shaft dividing base is provided with a right dividing disc base positioned together with the Y-shaft dividing base; the Y-shaft dividing base is internally provided with an X-shaft index chuck; the X-shaft index chuck is internally provided with uniformly distributed clamping strips which are slidably connected with the X-shaft index chuck; a clamping interface is internally provided with a bolt ball centering pin which is in clamped with the clamping interface; the upper part of the bolt ball centering pin is provided with a bolt ball; and the bolt ball and an operation drill are correspondingly distributed. The processing method is implemented through the following steps: processing a bolt ball relief hole; positioning a bolt ball; processing a split surface; and drilling holes. The processing tool for the novel net rack bolt ball is compact in structure; and the processing tool and the processing method can be used for effectively improving the processing precision, improving the processing efficiency and lowering the cost.

Owner:浙江东南网架股份有限公司

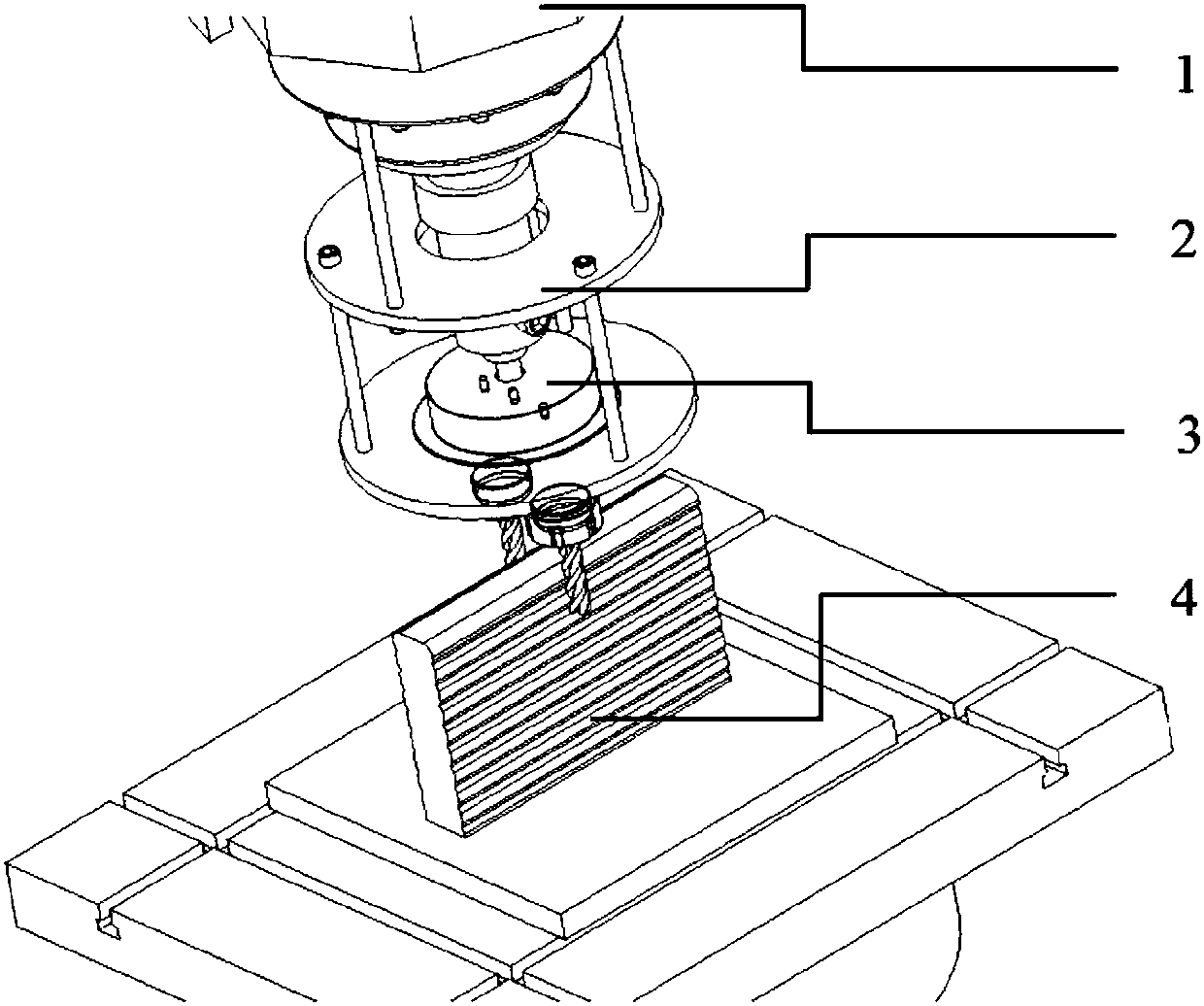

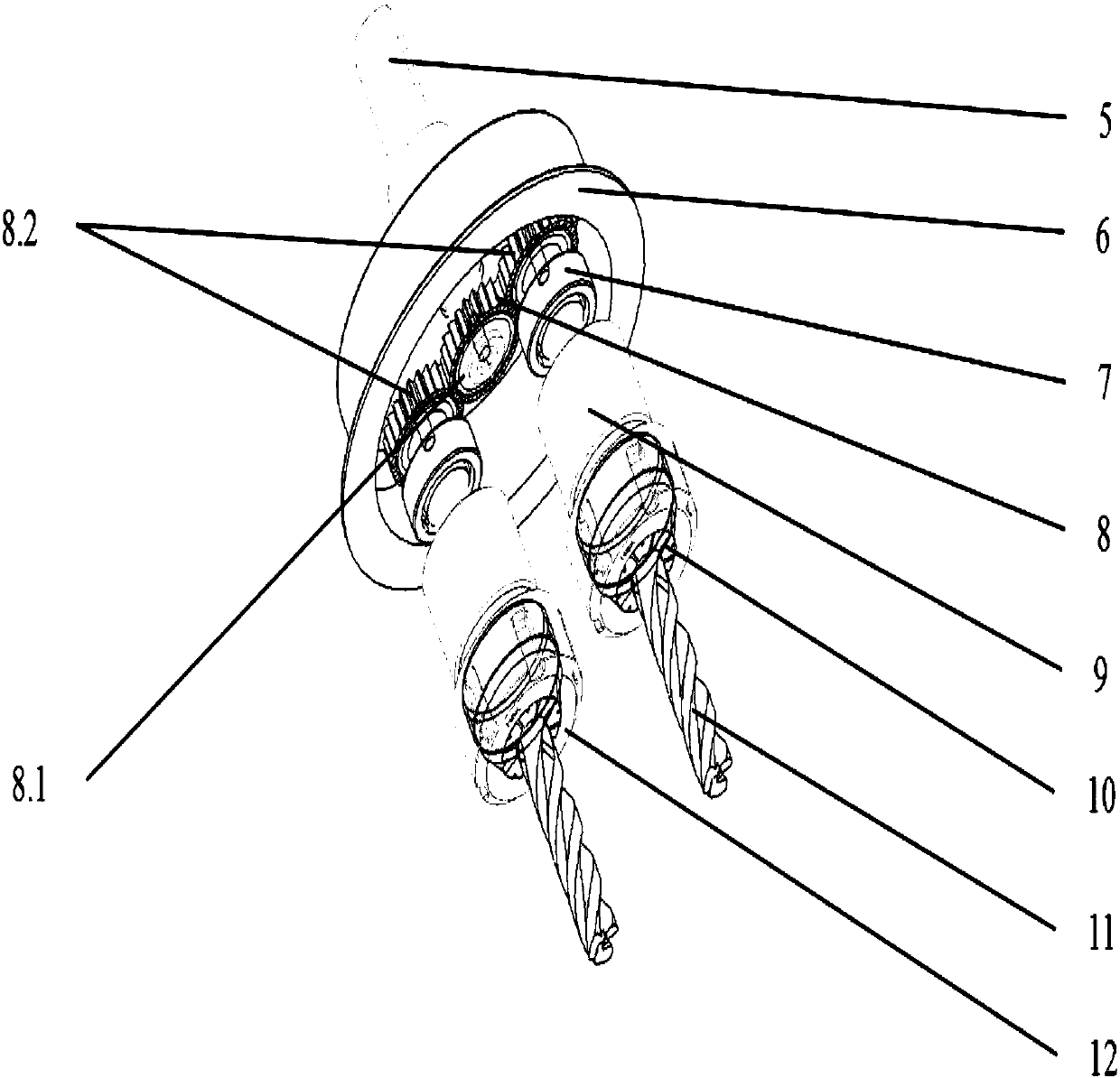

Robot milling double-shaft compound cutter device and method

ActiveCN107855569ASimple structureEasy to installMilling machinesMilling equipment detailsGear driveMilling cutter

The invention relates to a robot milling double-shaft compound cutter device and a method, and belongs to the field of cold and hot compound working in machining. The device consists of a robot driving unit, a connecting bracket, a compound cutter device and a machined workpiece. The compound cutter device comprises a robot connecting shaft, an upper cover, a bearing, a gear set, a shank, a springchuck, milling cutters and a shank cap. The robot driving unit drives the milling cutters in the compound cutter device to rotate to machine the machined workpiece. The robot driving unit is fixedlyconnected with the robot connecting shaft of the compound cutter device to drive a driving gear. The driving gear drives two driven gears to oppositely rotate, so that the two milling cutters are driven to oppositely rotate to realize synchronous milling of double shafts by double side surfaces of the machined workpiece. The device is simple in structure, convenient to install and lower in cost, and replaces the milling cutters to change the side surface sizes of the machined workpiece, namely the thickness of a wall, so as to achieve the machining precision and the surface quality requirements.

Owner:BEIJING UNIV OF TECH

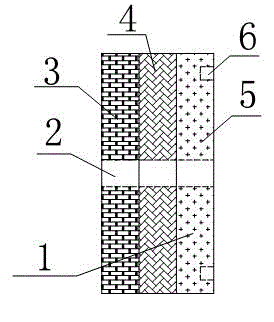

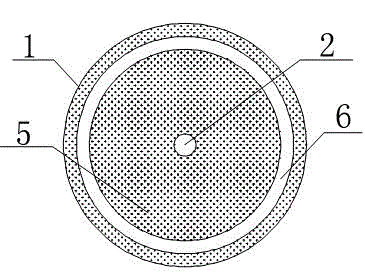

High-precision radiating grinding wheel

InactiveCN104416478AMeet the machining accuracy requirementsSolve the cooling problemBonded abrasive wheelsCircular discGraphite

The invention discloses a high-precision radiating grinding wheel, and relates to the field of industrial machinery. The high-precision radiating grinding wheel comprises a circular disc body which is divided into three layers, namely, a base layer, a heat transfer layer and a grinding layer which are sequentially arranged, wherein the base layer is prepared from aluminum alloy; the heat transfer layer is prepared from graphite; the grinding layer is prepared from microcrystalline fused alumina; a threaded hole is formed in the center of the circular disc body. The high-precision radiating grinding wheel has the advantage that the problems of the requirement on the processing precision of the grinding wheel, the radiating during processing, and the safety of connection of the grinding wheel and a grinding wheel can be solved.

Owner:SHANGHAI XIWANG ELECTRONICS TECH

Speed connection method for numerical control system

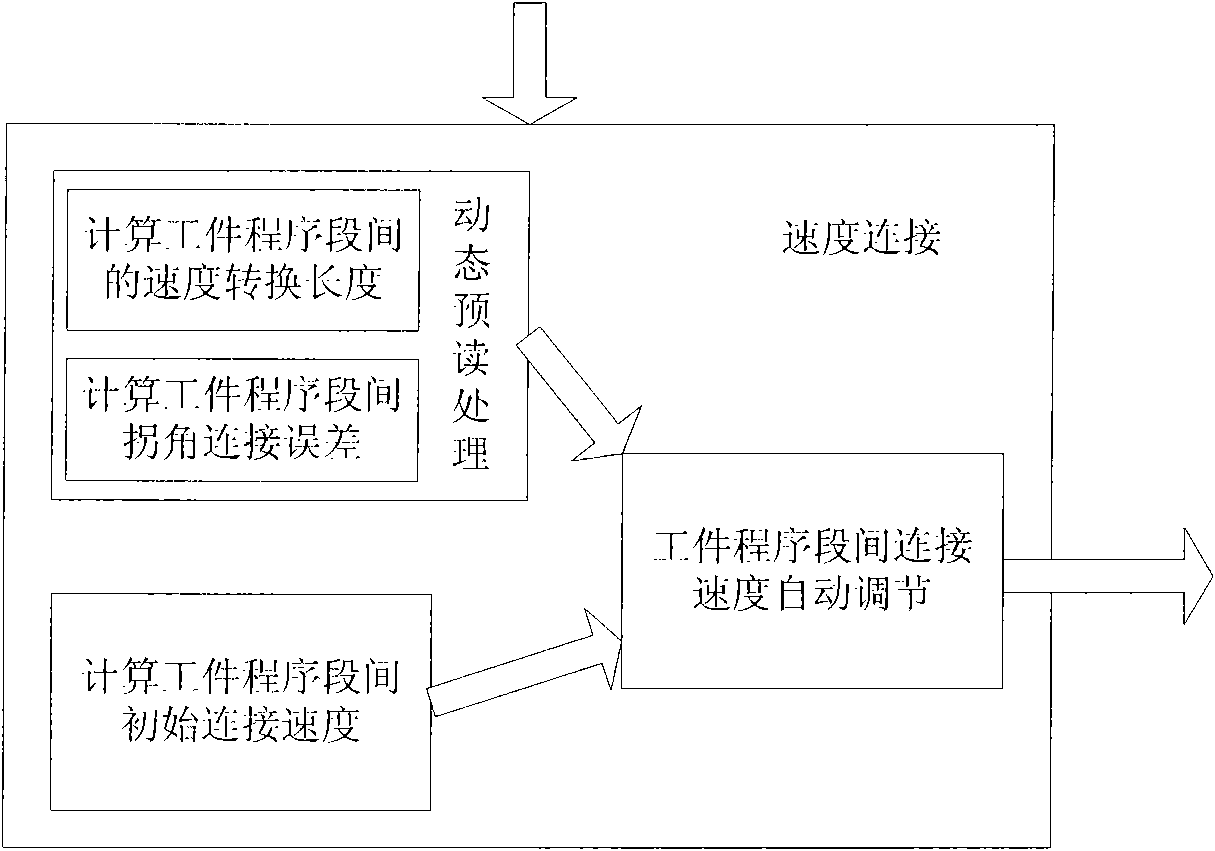

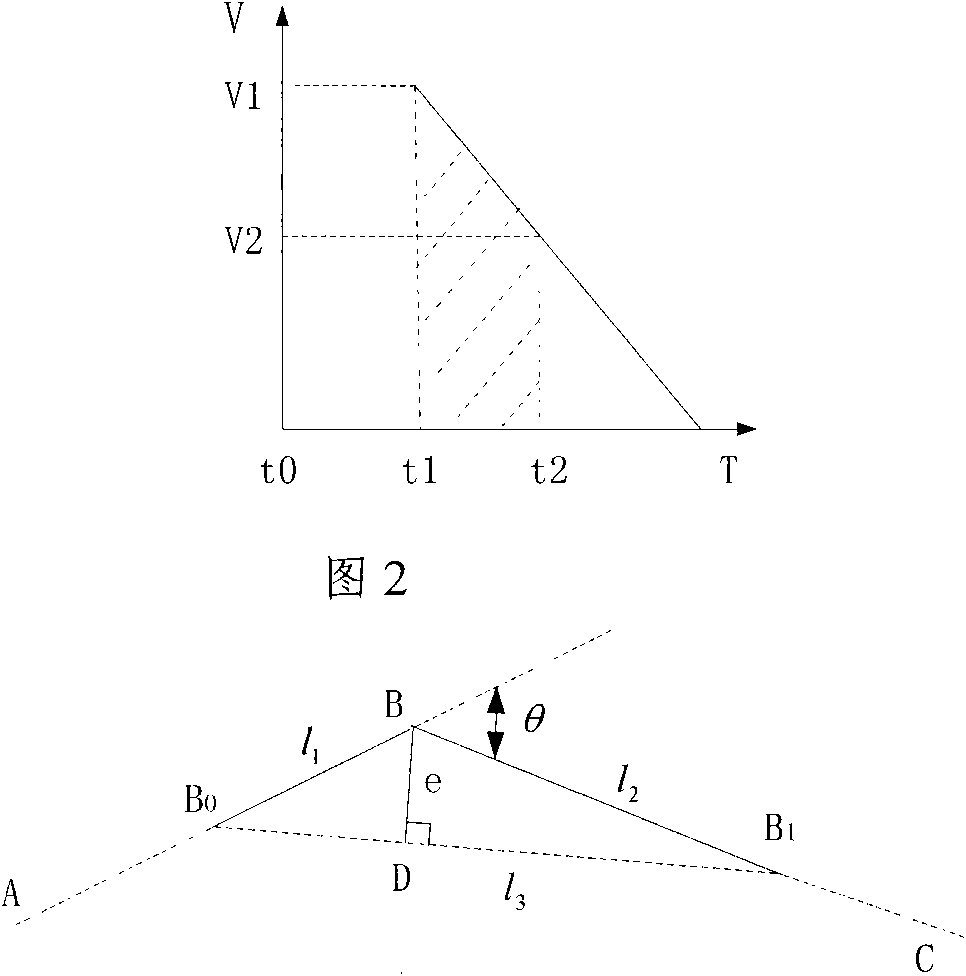

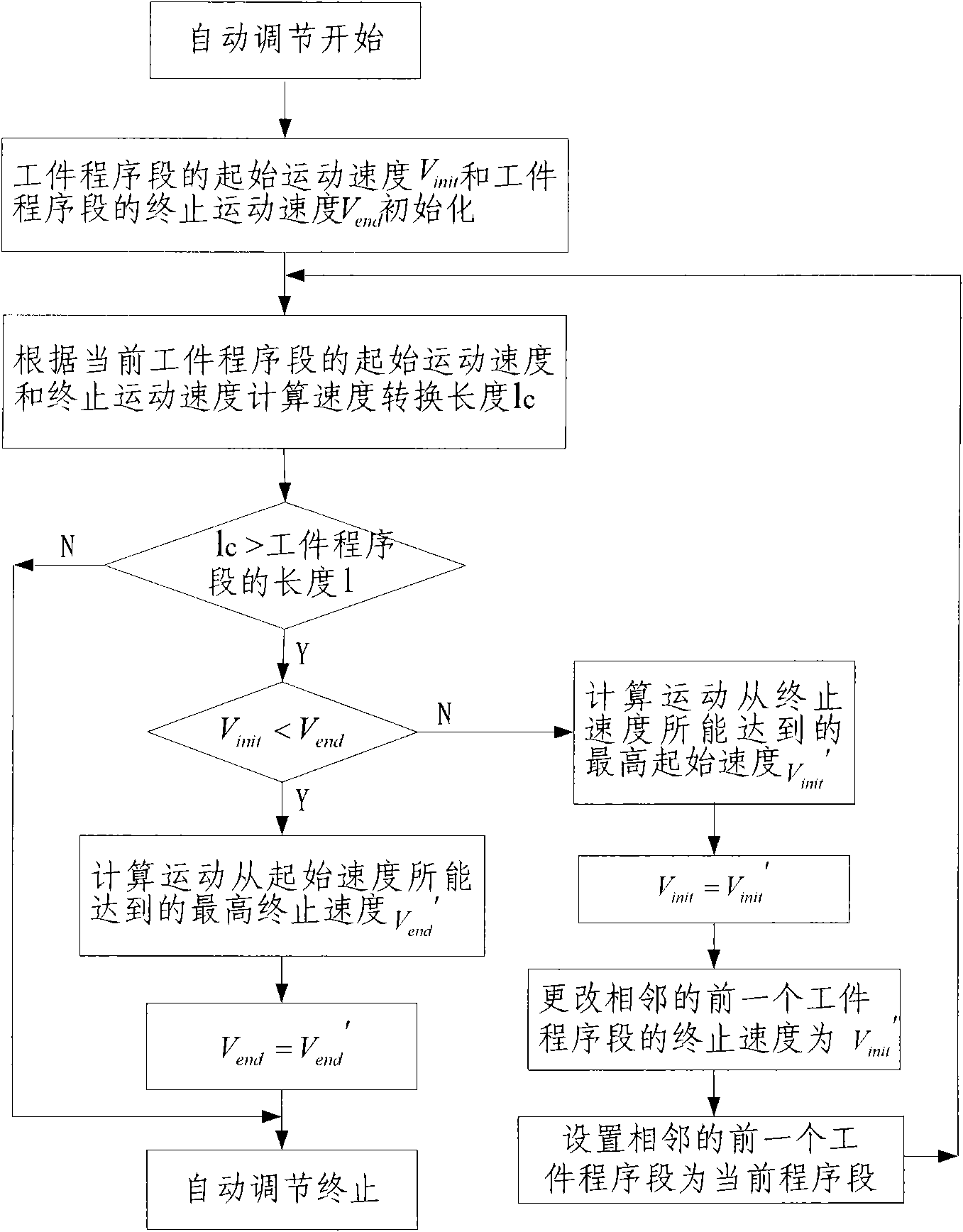

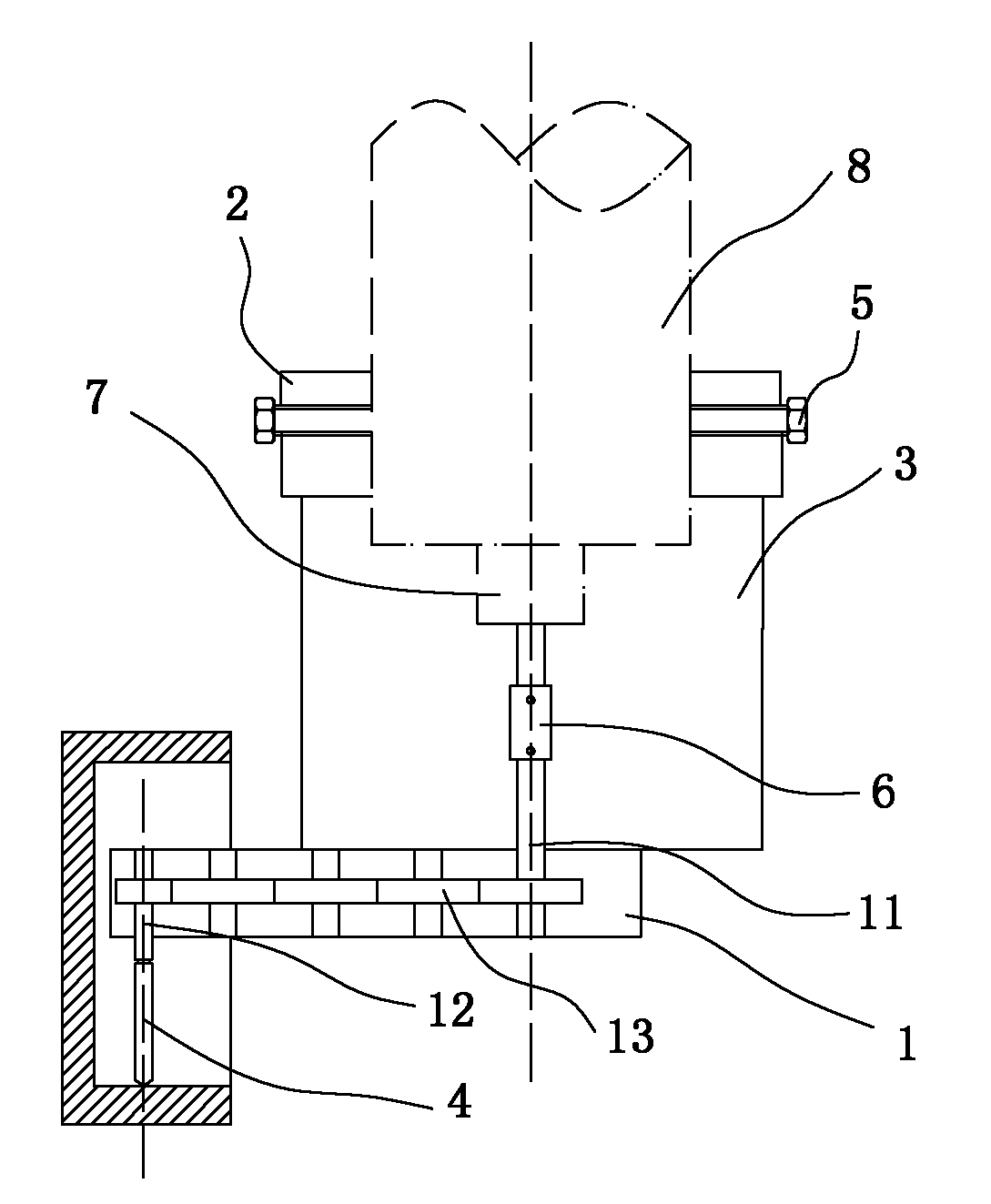

ActiveCN101620435AImprove execution efficiencyImprove machining accuracyNumerical controlProgram segmentProcessing accuracy

The invention relates to a speed connection method for a numerical control system, which comprises the following steps: performing dynamic pre-read processing on a workpiece program of the numerical control system to obtain the speed change length and the corner connection error between adjacent workpiece program segments; calculating the initial connection speed between the adjacent workpiece program segments according to the corner connection error, the programming feed speed of the workpiece program, and the processing precision required by a user; and automatically adjusting the connection speed between the adjacent workpiece program segments according to the preset maximum acceleration of each servo shaft of the numerical control system, the speed change length between the adjacent workpiece program segments and the initial connection speed between the adjacent workpiece program segments. The method greatly improves the execution efficiency of a numerical control machine tool, ensures that the connection error generated at a corner between any workpiece program segments in the moving process of the numerical control machine tool satisfies the working accuracy requirements of users, improves the control precision of the system, achieves the speed smooth transition, and can be matched with various acceleration and deceleration algorithms.

Owner:中国科学院沈阳计算技术研究所有限公司

Machining device for drilling and tapping inside small space

ActiveCN102490015AMeet the machining accuracy requirementsWell thought outFeeding apparatusOther manufacturing equipments/toolsEngineeringMachining

The invention relates to a device suitable for drilling and tapping machining inside a small space and provides a machining device for drilling and tapping inside a small space, wherein the machining device is suitable for drilling and tapping machining inside the small space and is high in machining precision, stable in product quality, low in labor intensity and applicable to large-batch production machining. The machining device comprises a gear case and a shaft sleeve for connecting main shaft sleeves of drilling and tapping equipment; the gear case is provided with an input shaft and an output shaft, which are identical in rotation direction and parallel to each other; the input shaft stretches out from the top face of the gear case and is superposed with an axis of the shaft sleeve; and the output shaft stretches out from the bottom face of the gear case. According to the invention, the gear case is utilized to realize the lateral translation of a drill bit, so that the drill bit can stretch into a narrow space to machine a radial blind hole in the inner wall of the narrow space under a state of keeping parallel to and equidirectional with the axis.

Owner:YANGZHOU WANFANG ELECTRONICS TECH

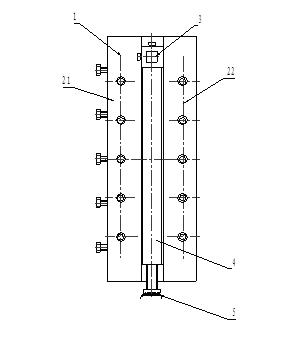

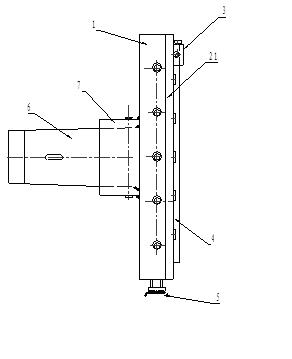

Adjustable knife rest

InactiveCN101954493APrecise positioningHigh precisionMetal-working apparatusPipe fittingMachine tool

The invention discloses an adjustable knife rest. The adjustable knife rest comprises an 80-degree tapered sleeve 6, a machine tool fixing sleeve 7, a 6136 small-planker dial plate 5 and a knife rest fixing block 1, wherein a rectangular groove is formed on the knife rest fixing block 1; two pressing plates 21 and 22 cover on the two sides of the rectangular groove; a knife clamping block 3 and a sliding block 4 are positioned in the rectangular groove and can slide in the rectangular groove; the two ends of the sliding blocks are connected with the knife clamping block 3 and the 6136 small-planker dial plate 5 respectively; the knife rest fixing block 1 is fixedly connected with the 80-degree tapered sleeve 6 and the machine tool fixing sleeve 7; and the machine tool fixing sleeve 7 is connected with a main shaft of the machine tool. In the knife rest, when pipe fittings are machined, the machining cutters of pipe fitting machines with different pipe diameters can be positioned through the 6136 small-planker dial plate 5 and a fine adjustment mechanism without disassembling the knife rest, installing or debugging the cutters, so the adjustable knife rest has the advantages of time saving, high efficiency, accurate positioning, high machining precision and capacity of meeting the requirements of the pipe fitting machines with different pipe diameters on the machining precision.

Owner:扬州华宇管件有限公司

Electrochemical machining device for multi-taper inner bores

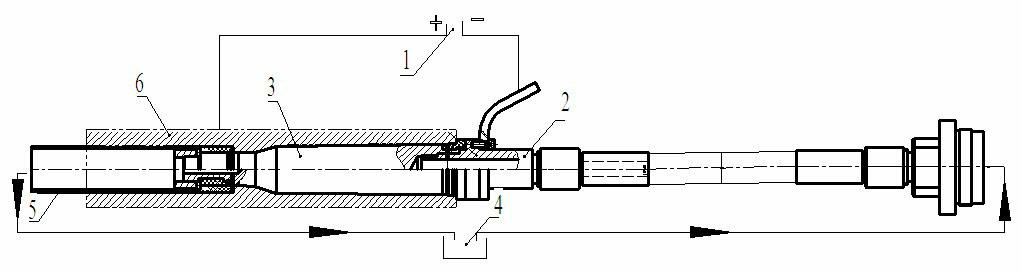

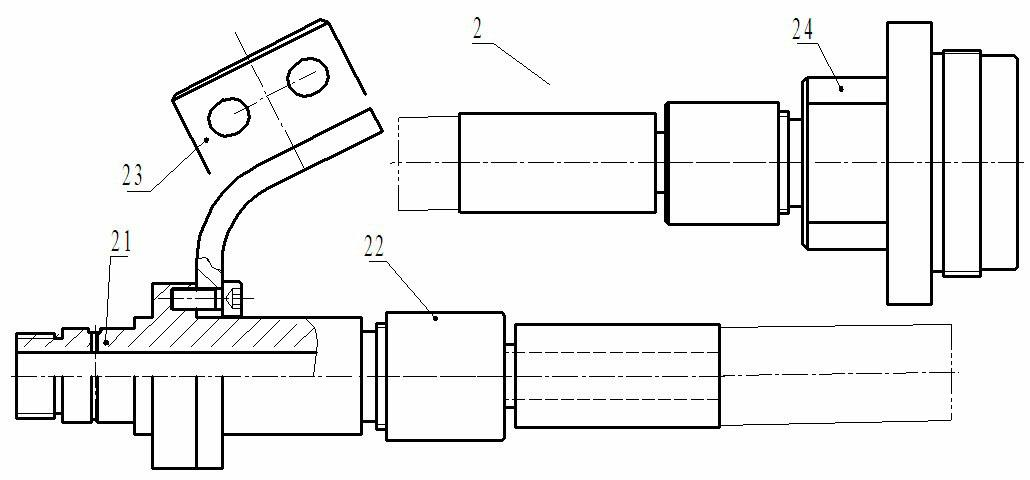

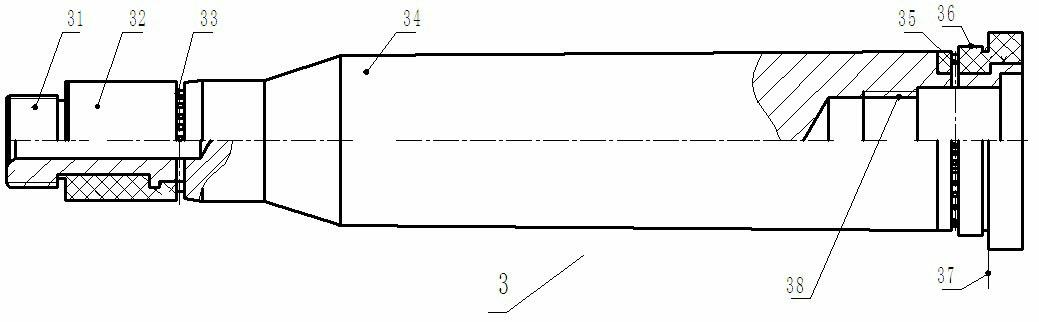

InactiveCN102489803ASmall clearanceReduce consumptionMachining electrodesElectrical-based machining electrodesElectricityEngineering

The invention discloses an electrochemical machining device for multi-taper inner bores. The device comprises a power supply, a liquid and electricity conducting component, a cathode member, an electrolyte system and a positioning drainage component, and is characterized in that: the liquid and electricity conducting component comprises a machine tool connector, a high-pressure liquid tube connector of which one end is correspondingly connected with the machine tool connector, a cathode connector connected with the other end of the high-pressure liquid tube connector, and a negative cable connecting bar positioned on the cathode connector; a right end of the positioning drainage component is connected with a left end of the cathode connector; the positioning drainage component and the cathode member are arranged in a preformed hole of a machined member; the electrolyte system is communicated with the machine tool connector and the positioning drainage component through a pipeline respectively; and the power supply is connected with the negative cable connecting bar of the liquid and electricity conducting component and the machined member through a lead respectively. The requirements on machining accuracy of the surface dimension and position of a multi-taper inner bore are met, the production efficiency is improved by 5 times, the energy consumption is reduced to be 1 / 3 of that of machining, and the reliability is obviously improved.

Owner:CHONGQING WANGJIANG IND

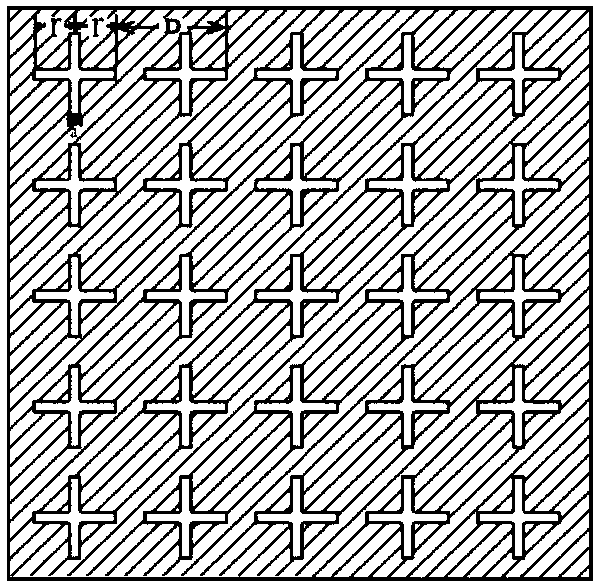

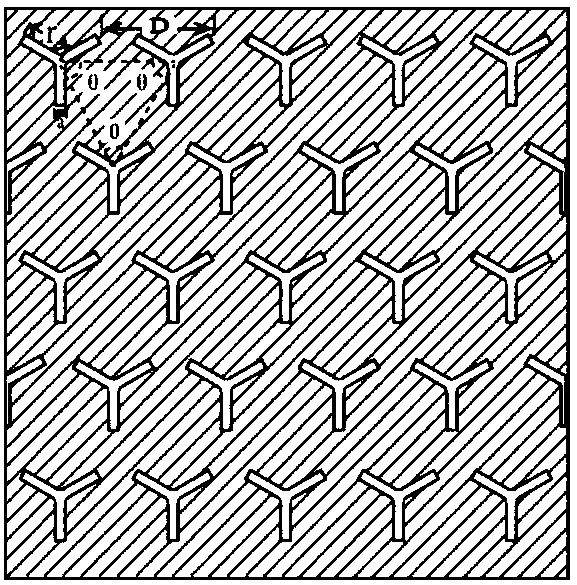

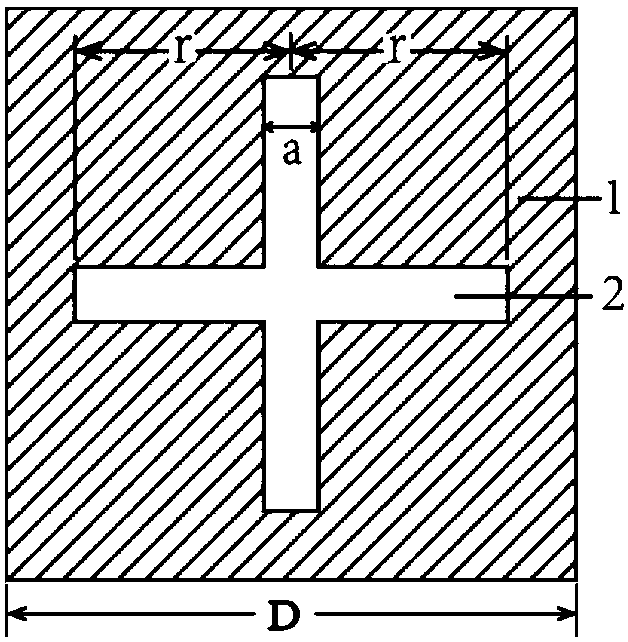

Central connected periodic structure-based textile product and preparation and application methods there

PendingCN107829192AWith plane symmetrySimple structureTransfer printing processWoven fabricsStructural unitStructure based

The invention relates to a central connected periodic structure-based textile product and preparation and application methods there. According to the central connected periodic structure-based textileproduct, conductive areas and non-conductive areas form a central connected periodic structure, wherein the non-conductive areas are not communicated with one another and are in a cross or Y-shaped central connected non-conductive structure, and every non-conductive area, together with a corresponding conductive structure, forms a cross periodic structure unit or a Y-shaped periodic structure unit. The central connecting periodic structure-based textile product can be applied to preparing light and soft textile products, which can shield electromagnetic wave hazards without affecting mobile communication 2G (second-generation, 3G (third-generation) or 4G (fourth-generation networks; compared with conventional electromagnetic shieling textile products which are integrally coated with metalor achieve certain conductive properties, the central connecting periodic structure-based textile product is only locally conductive, thereby achieving frequency selectively transmitting properties as well as good breathable, wearable and comfortable properties.

Owner:THE QUARTERMASTER EQUIP INST OF THE LOGISTICAL SUPPORT DEPT CMC

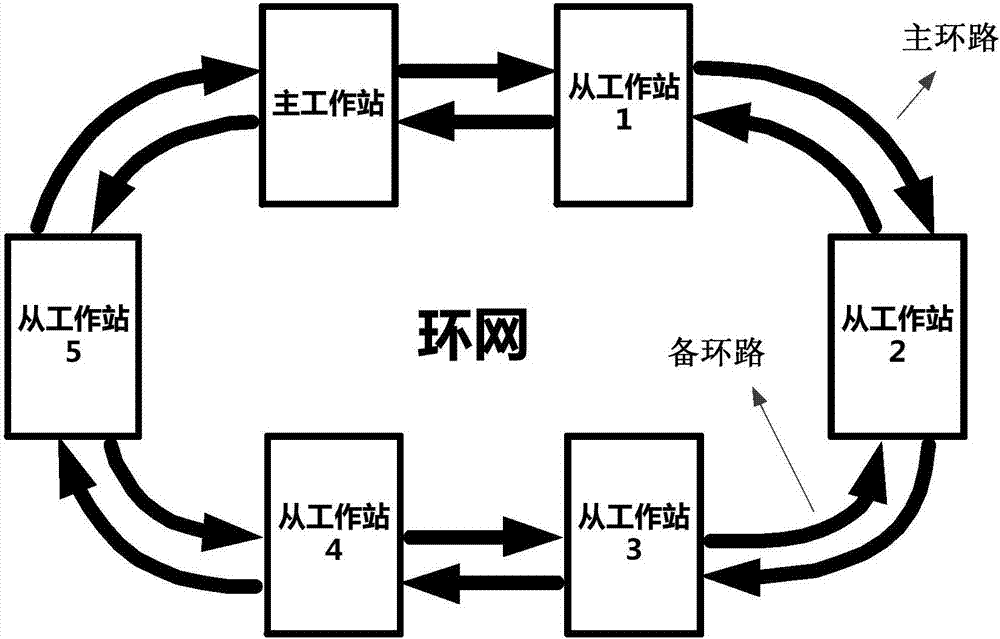

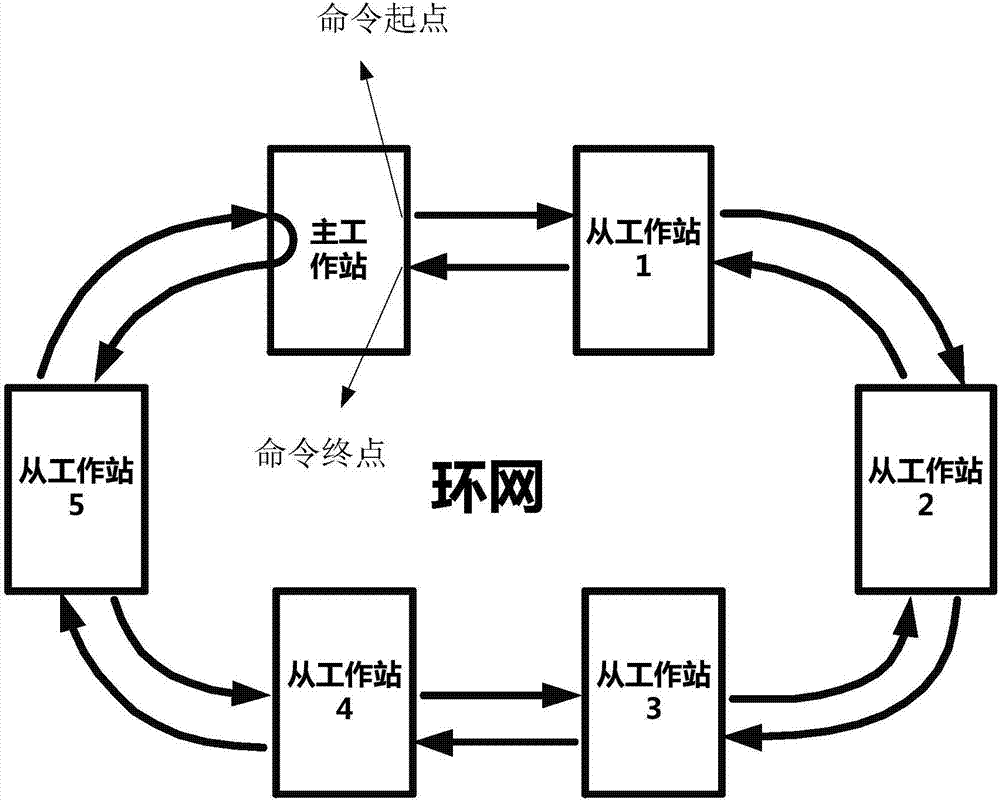

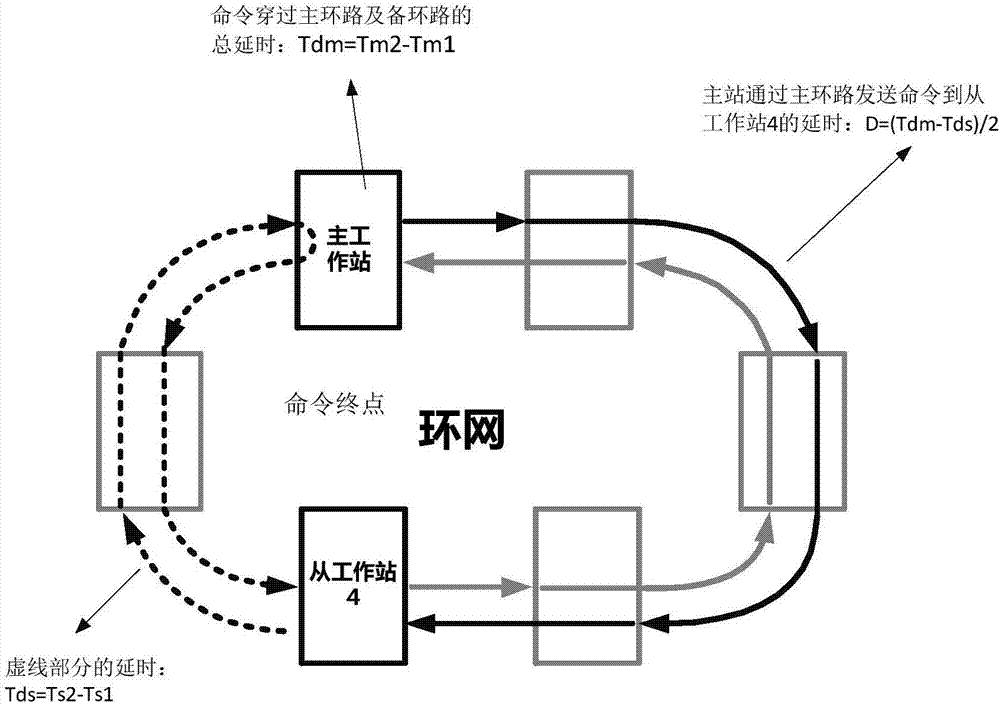

Time synchronization system based on industrial ring network, and working method thereof

InactiveCN106953708AMeet the machining accuracy requirementsPrecise synchronicityTime-division multiplexLoop networksTime informationNetwork connection

The invention relates to a time synchronization system based on an industrial ring network, and a working method thereof. The time synchronization system comprises a plurality workstations, a data transmission network module and a plurality of time counting modules, wherein the data transmission network module is used for providing network connections for the plurality of workstations, setting an arbitrary workstation among the plurality of workstations as network management control equipment, namely, a master workstation, setting the rest workstations as slave workstations, and establishing a main loop and a standby loop; the main loop starts from the master workstation, connects the slave workstations in sequence along a clockwise direction and finally forms a ring connection and returns to the master workstation; the standby loop starts from the master workstation, connects the slave workstations in sequence along an anticlockwise direction and finally forms a ring connection and returns to the master workstation; and each of the plurality of time counting modules is arranged in each workstation separately. According to the time synchronization system and the working method thereof, network transmission delay information and reference time information are calculated and issued in real time, and controlled equipment connected to the network dynamically corrects local time accordingly, thereby ensuring the synchronization performance among the equipment.

Owner:SHANDONG CHAOYUE DATA CONTROL ELECTRONICS CO LTD

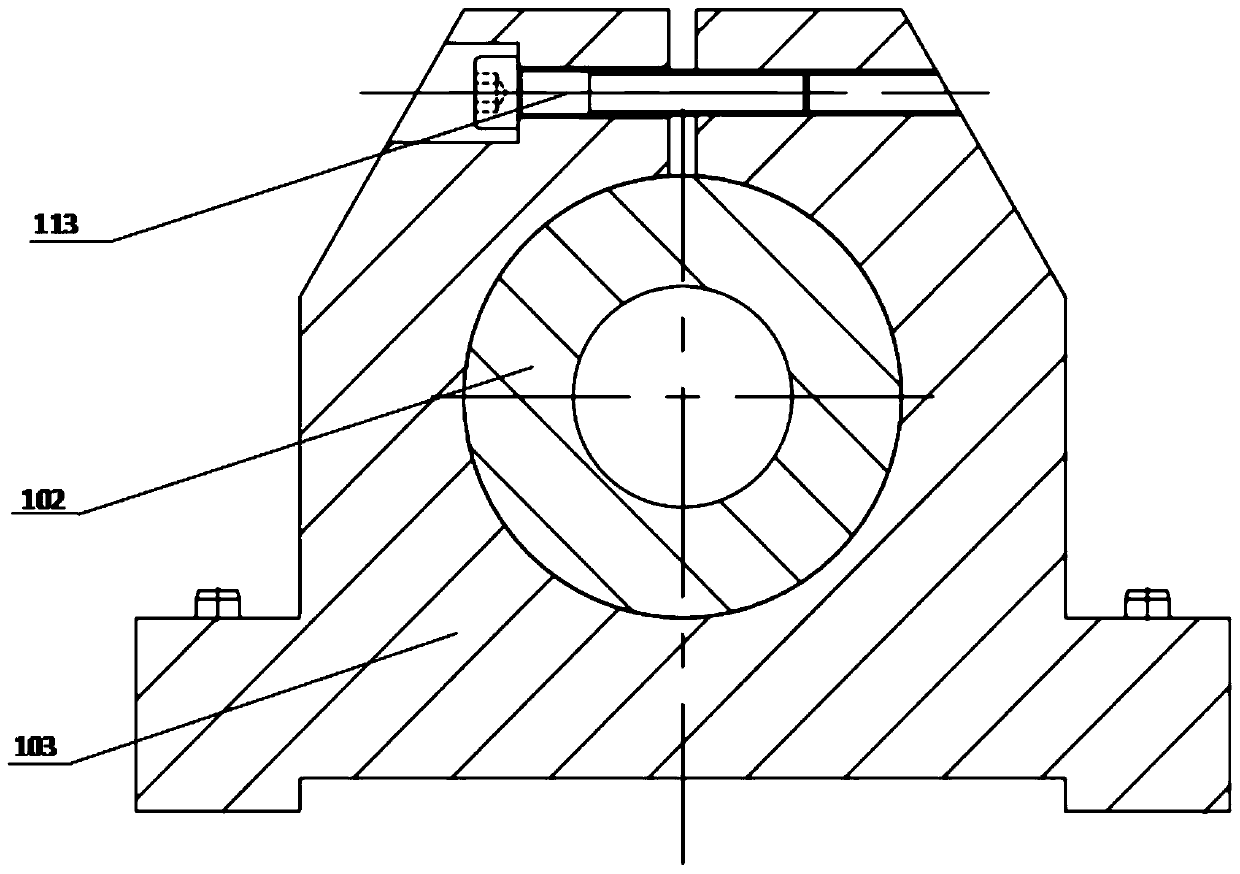

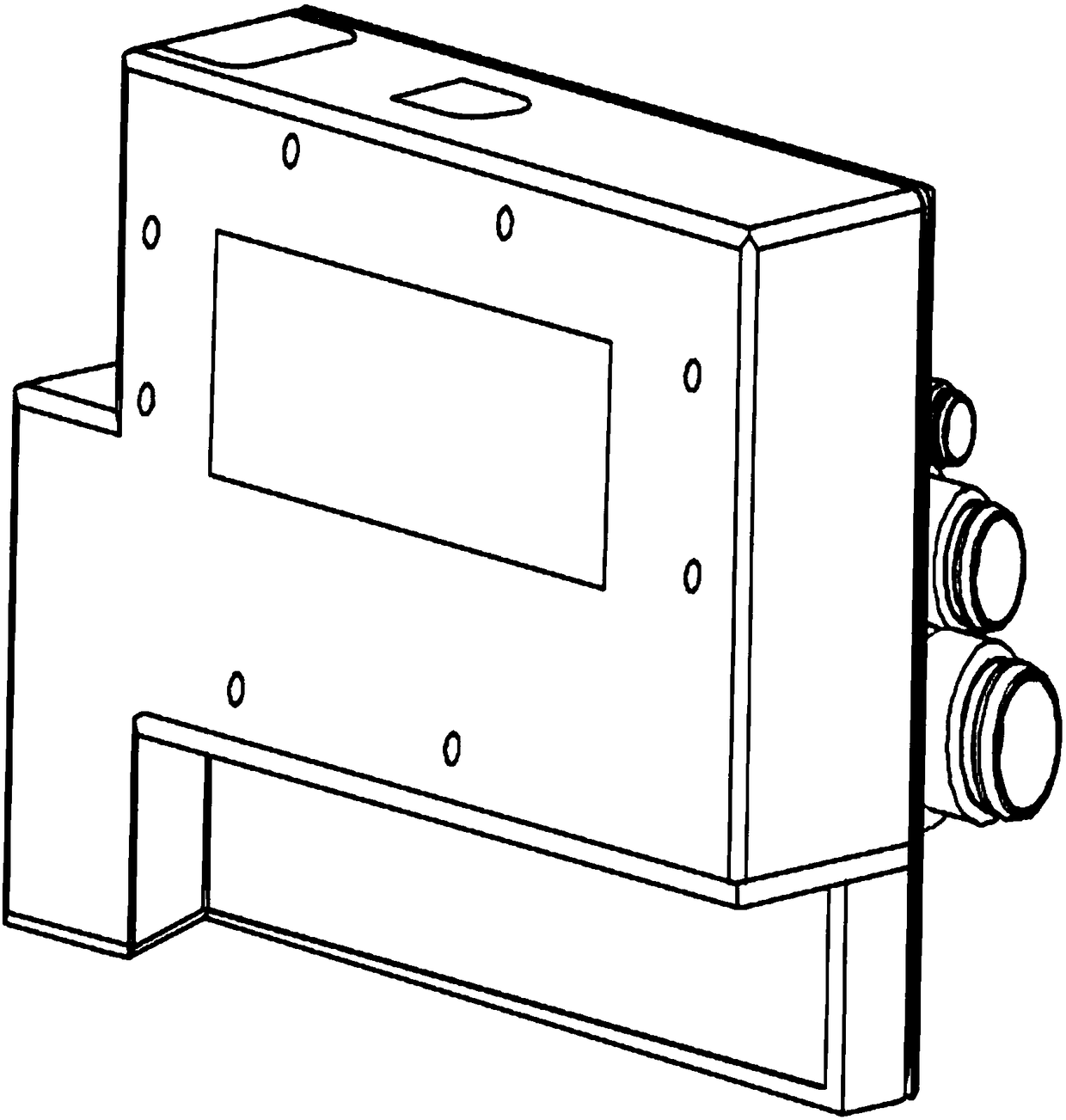

Servo autotracking support for bent axle grinding

InactiveCN101116944AAchieve rotationEasy to meet machining accuracy requirementsRevolution surface grinding machinesGrinding work supportsAutomatic controlBall bearing

The invention discloses a servo automatic tracing support device for crank shaft grinding process, a box body (4) is provided with a ball-bearing thread bar (17) and a servo motor (1), the ball-bearing thread bar (17) is provided with a driving connection rod (7), an upper driving rod (5) and a lower driving rod (16) fixed with the driving connection rod (7) are slidingly arranged on the box body (4), an upper support arm (9) with a first reset spring (10) is slidingly arranged on the box body (4), one end of the upper support arm (9) is driven with the upper driving rod (5) correspondingly while the other end is provided with an upper support alloy (11), the box body (4) also is pin-jointed with a lower support arm (13) with a second reset spring (8), one end of the lower support arm (13) is driven with the lower driving rod (16) correspondingly while the other end is provided with a lower support alloy (12), and the upper support alloy (11) and the lower support alloy (12) are distributed from 100 DEG C to 120 DEG C; the invention can conduct the automatic tracing and centering grinding process where the crank shaft grinding process is synchronized with the sand wheel feeding process, and effectively improve the accuracy and stability of crank shaft grinding process, and improves the automatic control degree of the machine tool, and increase the overall taste and value of the machine tool.

Owner:HUNAN HICAM PRECISION IND

Large-scale gear hobbing machine worktable

InactiveCN101543917ASimple structureCompact structureLarge fixed membersGear-cutting machinesHobbingRolling-element bearing

The invention relates to a revolving table of a large-scale gear hobbing machine, comprising a revolving worktable. The revolving table is characterized in that the revolving worktable, an inner upper ring and an outer ring are respectively connected by bolts; a large worm wheel is connected with the revolving worktable by a bolt; a radial roller and a large roller are installed among the inner upper ring, an inner lower ring and the outer ring; the outer ring is connected with a base of the worktable by a bolt; a worm is installed on a worm support through a first rolling bearing, a second rolling bearing, a third rolling bearing and a fourth rolling bearing which is positioned by a gland bush; a baffle is installed on the worm support and used for installing and positioning the first rolling bearing; and a connection shaft is connected with the worm through a spiale. The invention has the advantages of simple, compact and reasonable structure, convenient manufacture, lower cost, flexible and convenient clearance adjustment, and full satisfaction of requirement for processing precision of gears with large modulus and diameter, thereby being suitable for manufacturers for specially producing mass gears with large modulus and diameter.

Owner:无锡立达齿轮制造有限公司

Engine crankcase coarse positioning fixture and positioning method thereof

ActiveCN104669016AMeet the machining accuracy requirementsAccurate and reliable positioningPositioning apparatusMetal-working holdersEngineeringCrankcase

The invention discloses an engine crankcase coarse positioning fixture and a positioning method thereof. The fixture comprises a frame, a bottom plate and a plurality of expansion pin components. The bottom plate is mounted on the frame in an up-down movable manner through a driving device. Sliding rails and positioning members are arranged on the bottom plate. The engine crankcase coarse positioning fixture and the positioning method have the advantages of capability of positioning a crankcase reliably so as to meet processing accuracy requirements of technological standards.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Groove face machining device and groove face positioning method for large ship

InactiveCN108068122ASolving Machining ProblemsGuaranteed flatnessOther manufacturing equipments/toolsManipulatorManufacturing technologyLaser scribing

The invention discloses a groove face machining device and a groove face positioning method for a large ship and belongs to the technical field of industrial manufacturing. The groove face machining device comprises a mobile platform, a six-axis articulated industrial robot milling device and machining work pieces, wherein the mobile platform is arranged on a groove face of the ship and slides onthe groove face; the six-axis articulated industrial robot milling device is arranged on the mobile platform; the six-axis articulated industrial robot milling device comprises a six-axis articulatedserial industrial robot, a high-speed electric spindle, a probe and a laser sensor, wherein the high-speed electric spindle, the probe and the laser sensor are arranged at the tail end of the six-axisarticulated industrial robot milling device; the machining work pieces include a milling work piece, a laser scribing work piece and a laser drilling work piece; and the milling work piece, the laserscribing work piece and the laser drilling work piece all are installed on the mobile platform. The groove face machining device disclosed by the invention realizes integration of a common industrialrobot, the high-speed electric spindle, the machining work pieces and the like, thereby solving the problems about high cost, complicated machining process and low efficiency existing in an operationtask such as finish machining of the groove face of the large ship.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com