Patents

Literature

9742 results about "Processing accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

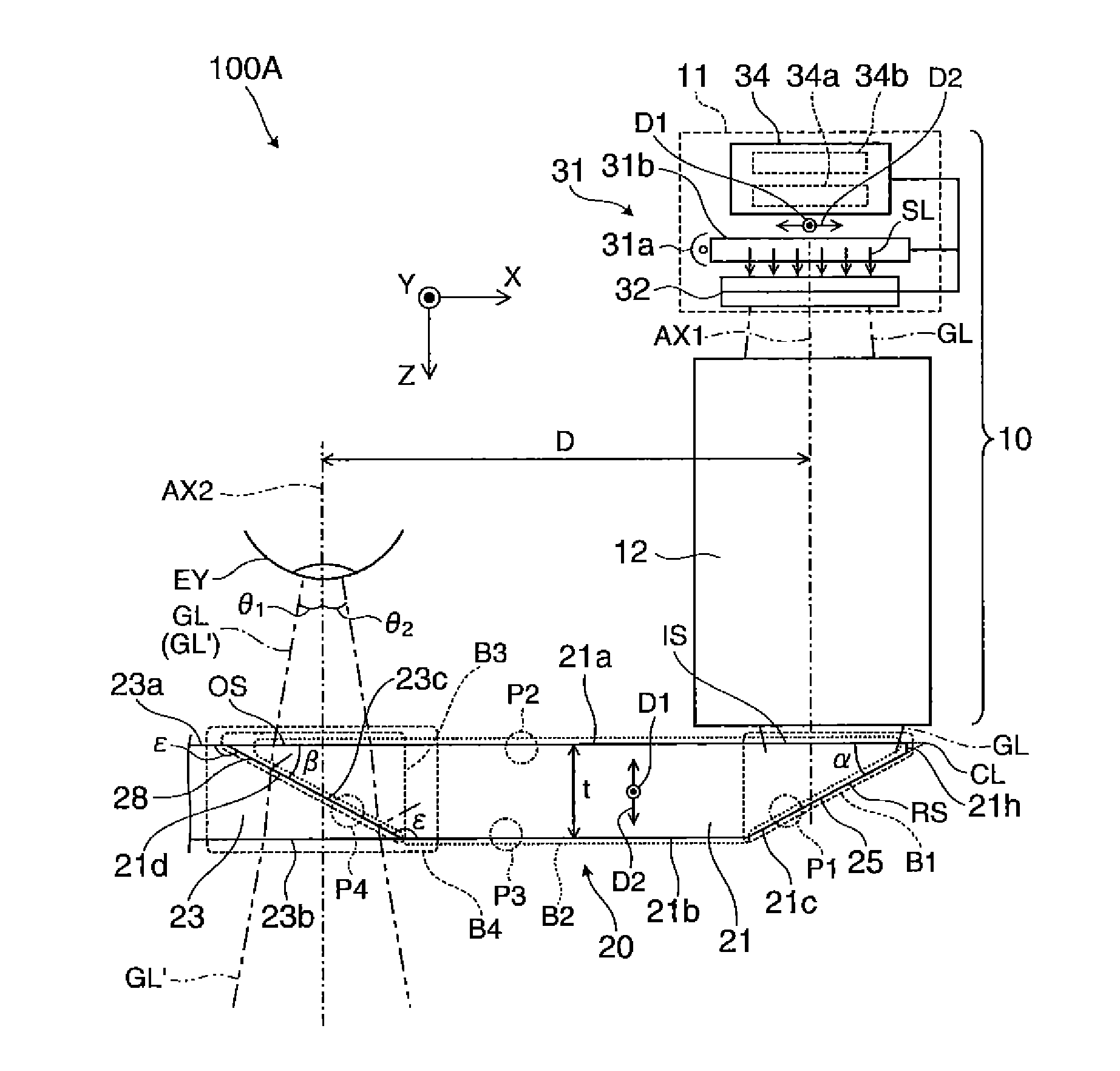

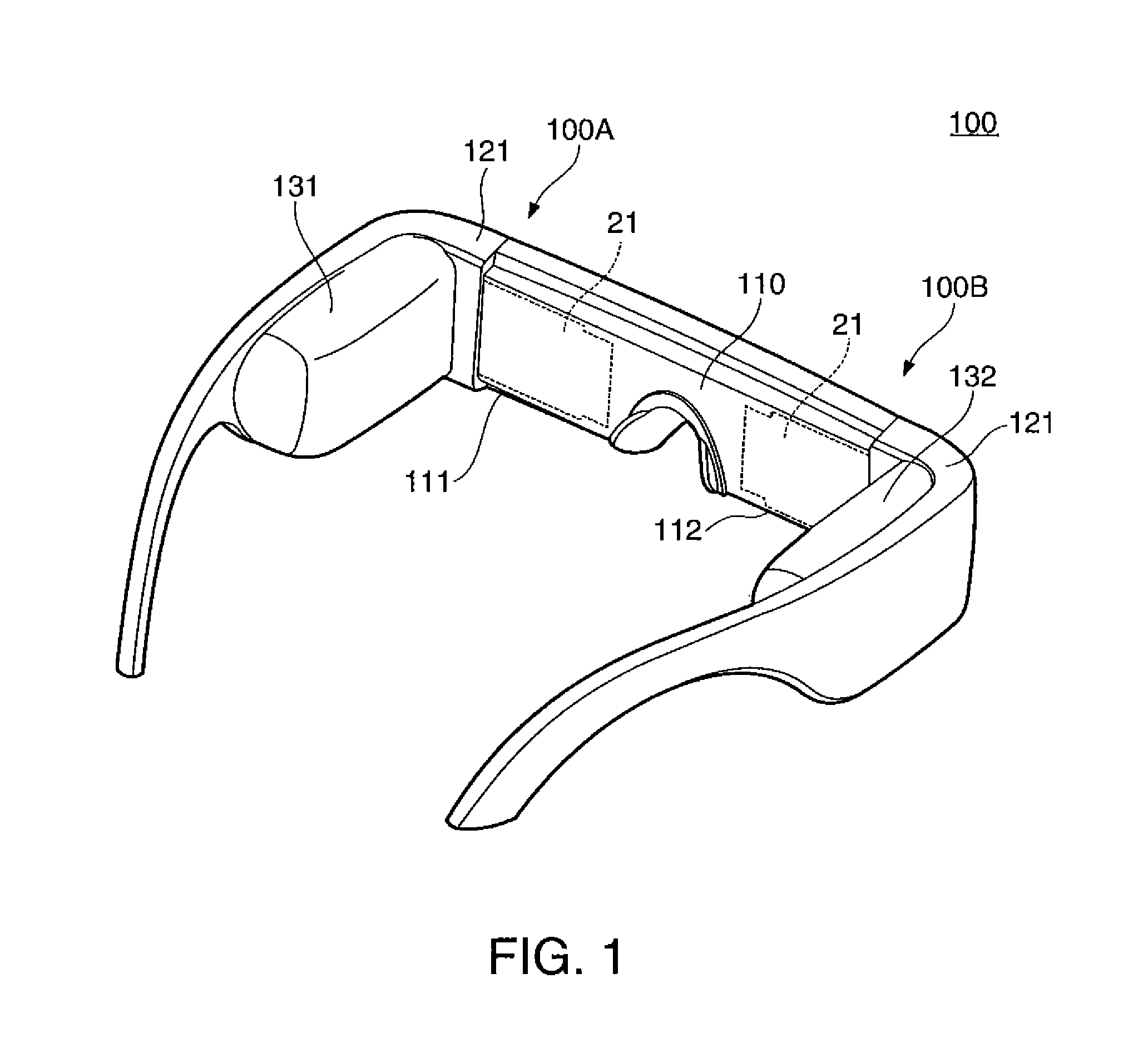

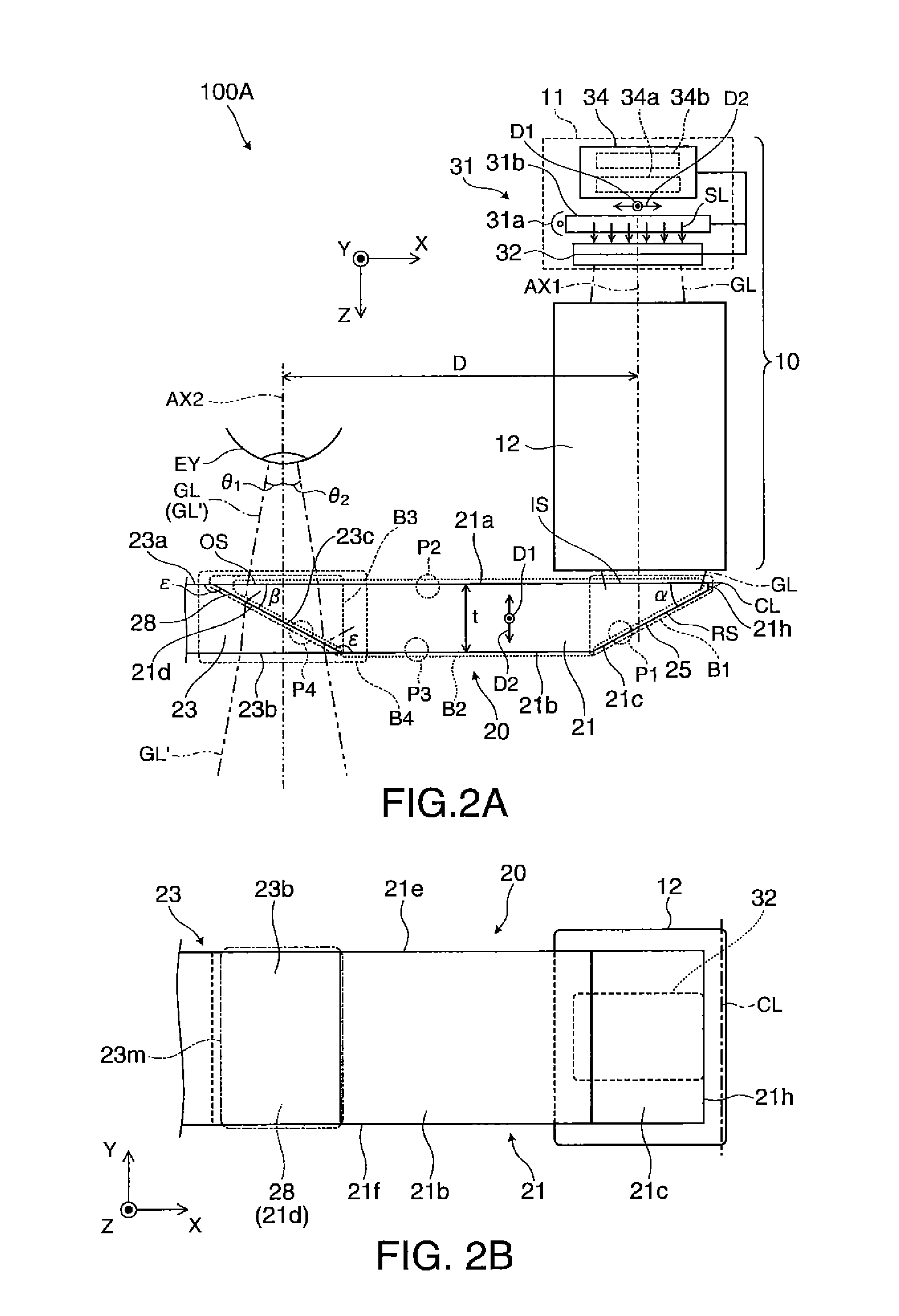

Virtual image display device

ActiveUS8587869B2Quality improvementSuppressing observationOptical light guidesSteroscopic systemsAngle of incidenceLight guide

A half mirror layer has an angle dependency in which when an angle of incidence becomes larger than the angle of incidence range of image light, reflectance increases, such that it is possible to prevent unintended light, which is emitted to a light transmitting member from a light guiding member and is reflected inside a light transmitting member, from being returned to a light emission portion of the light guiding member after passing through the half mirror layer as a reflective film at a relatively large angle of incidence. Therefore, it is possible to prevent the image light passed through the light transmitting member from becoming ghost light while mitigating the demand for increasing processing accuracy of the light transmitting member, and bonding accuracy between the light guiding member and the light transmitting member.

Owner:SEIKO EPSON CORP

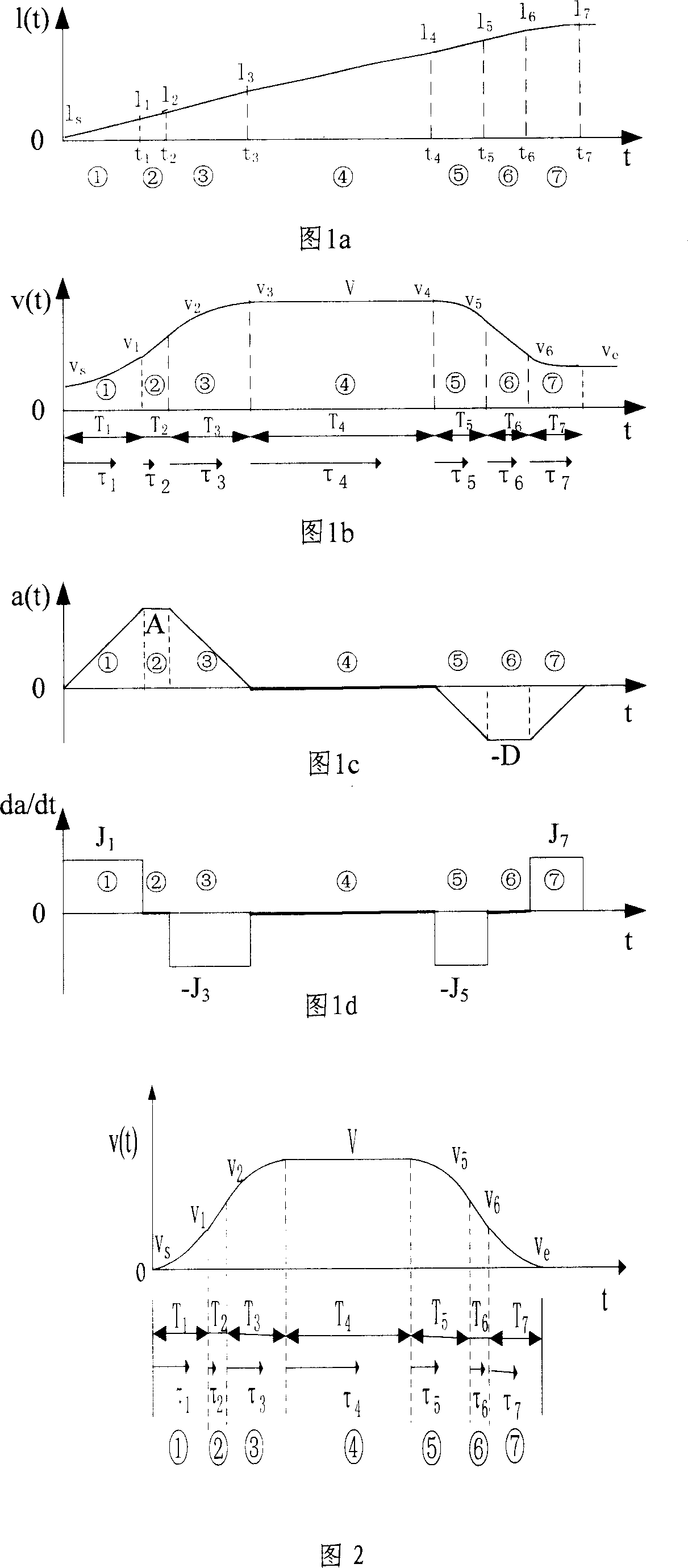

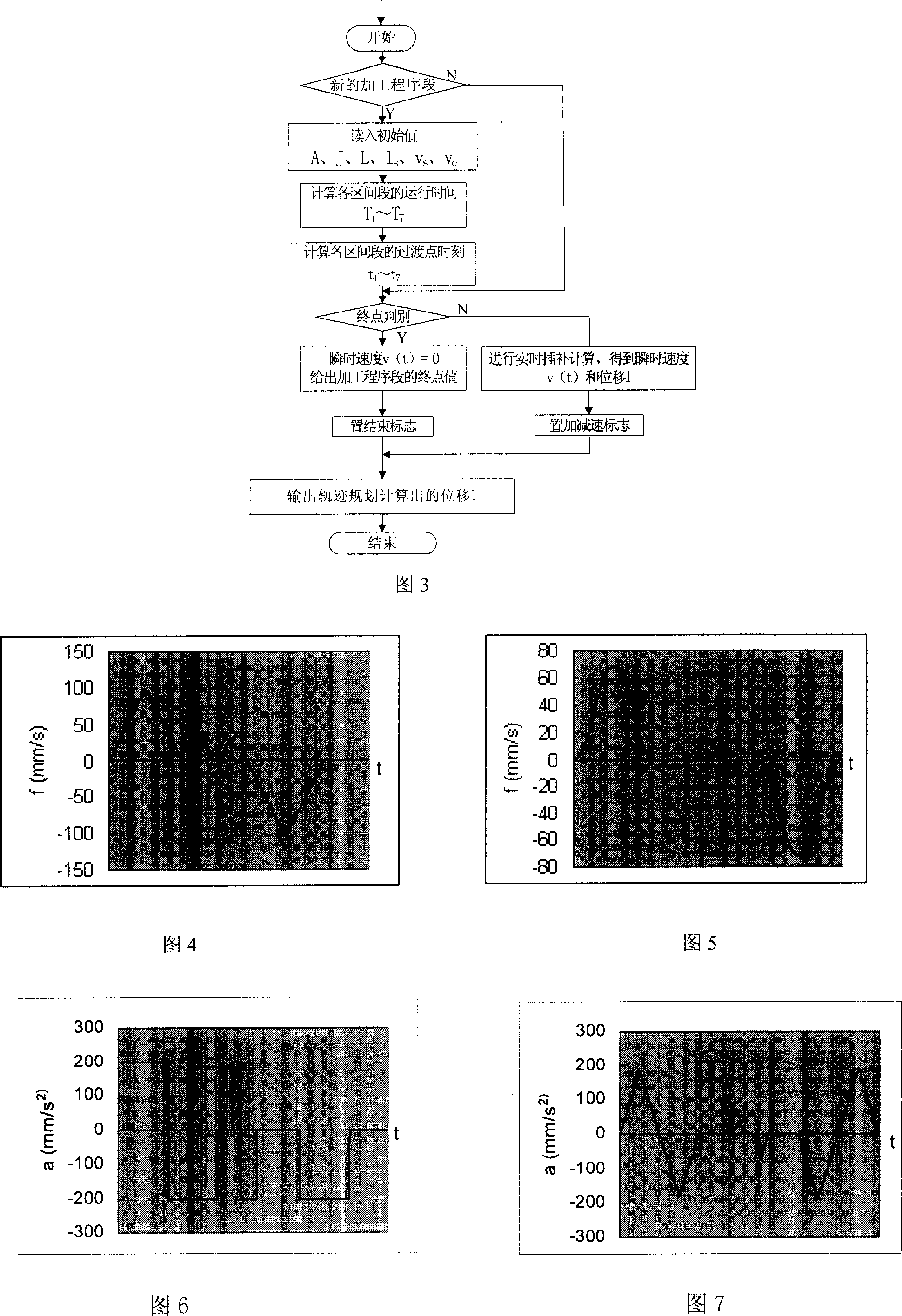

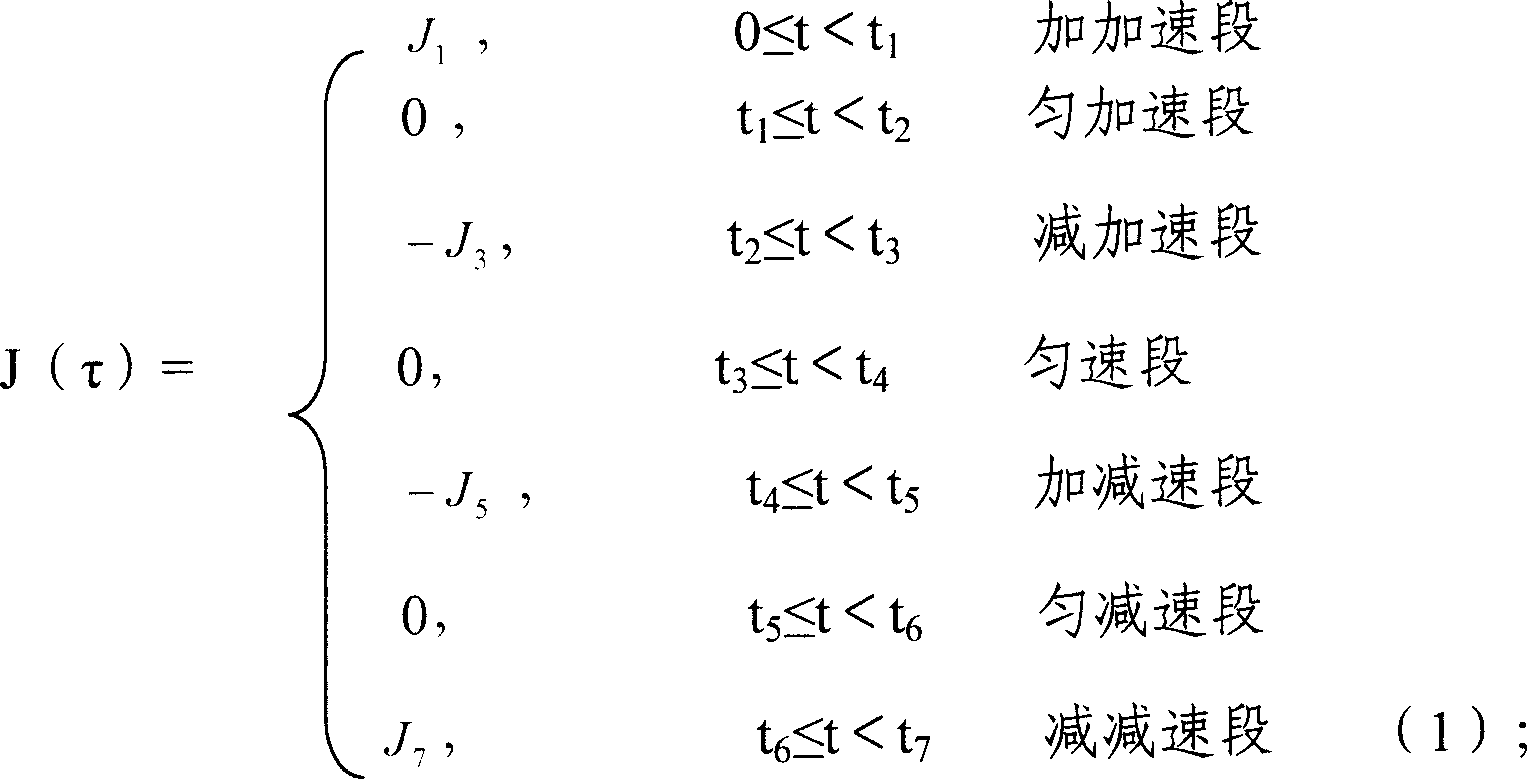

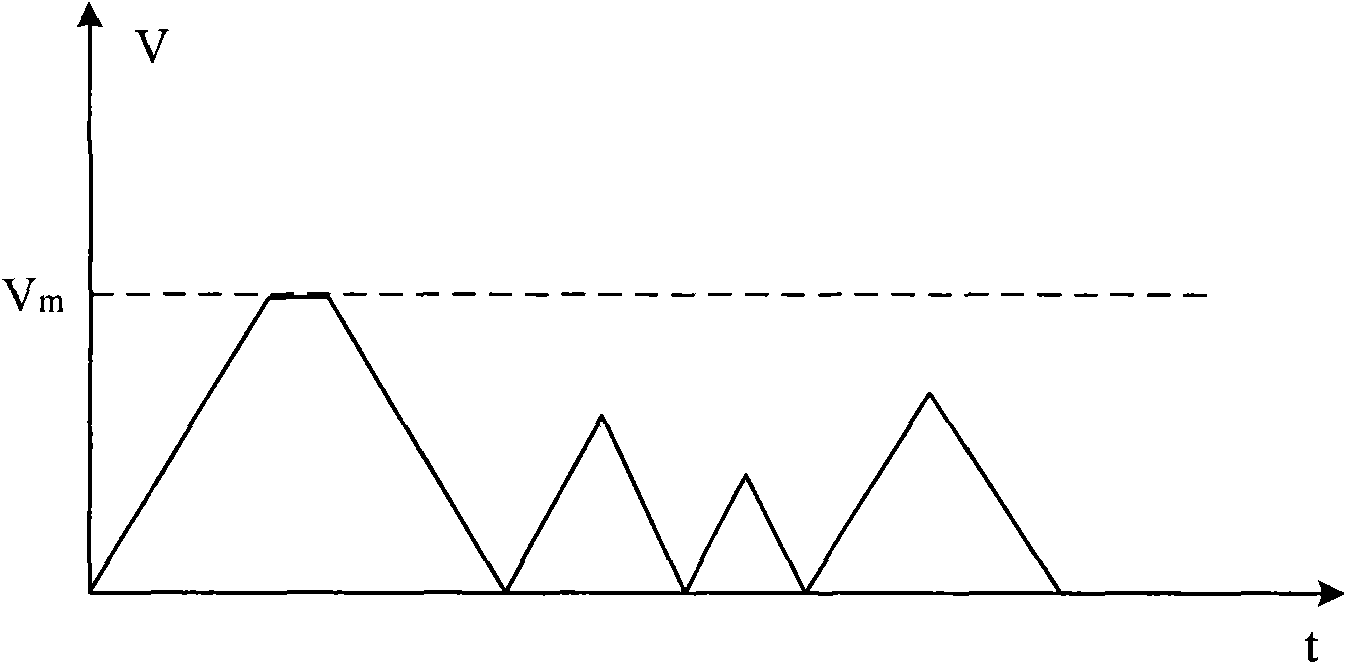

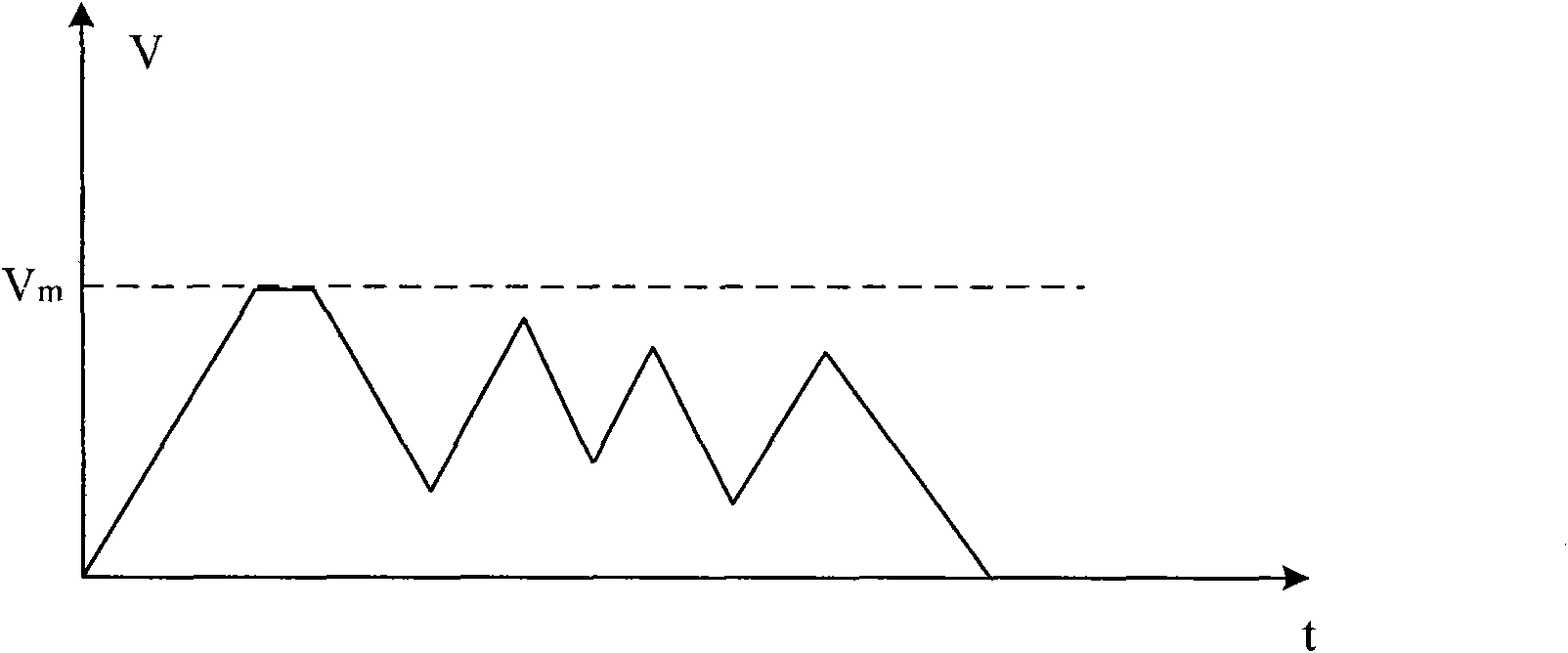

Speed control method used for numerical control machine

InactiveCN1971457AReduce shockImprove smoothnessComputer controlSimulator controlNumerical controlControl theory

The invention discloses acceleration and deceleration controlling means used in numerical control machine, the concept of 'add-acceleration' is introduced against the dynamic property of the controlled member, the add-acceleration is constant in stage of acceleration and deceleration, the two physical quantities of acceleration and add-acceleration are setting; the segmented handling method of add-accelerating sections, uniform accelerating sections, decelerated accelerating sections, uniform speed sections, add-decelerating sections, uniformly-retarded sections and decelerated deceleration sections is adopted, after the interval discrimination, the real-time interpolating calculation in every interval is exceeded based on the integral relation between the add-acceleration, acceleration, speed and displacement, the S type velocity curve is formed to realize the flexible acceleration and deceleration control; the destination discrimination process is proceeded before the interpolating calculation can increase the machining precision of the acceleration and deceleration control. The method is simple, the impact is small, the speed is smooth, the machining precision is high and the flexible control can be realized.

Owner:中国科学院沈阳计算技术研究所有限公司 +1

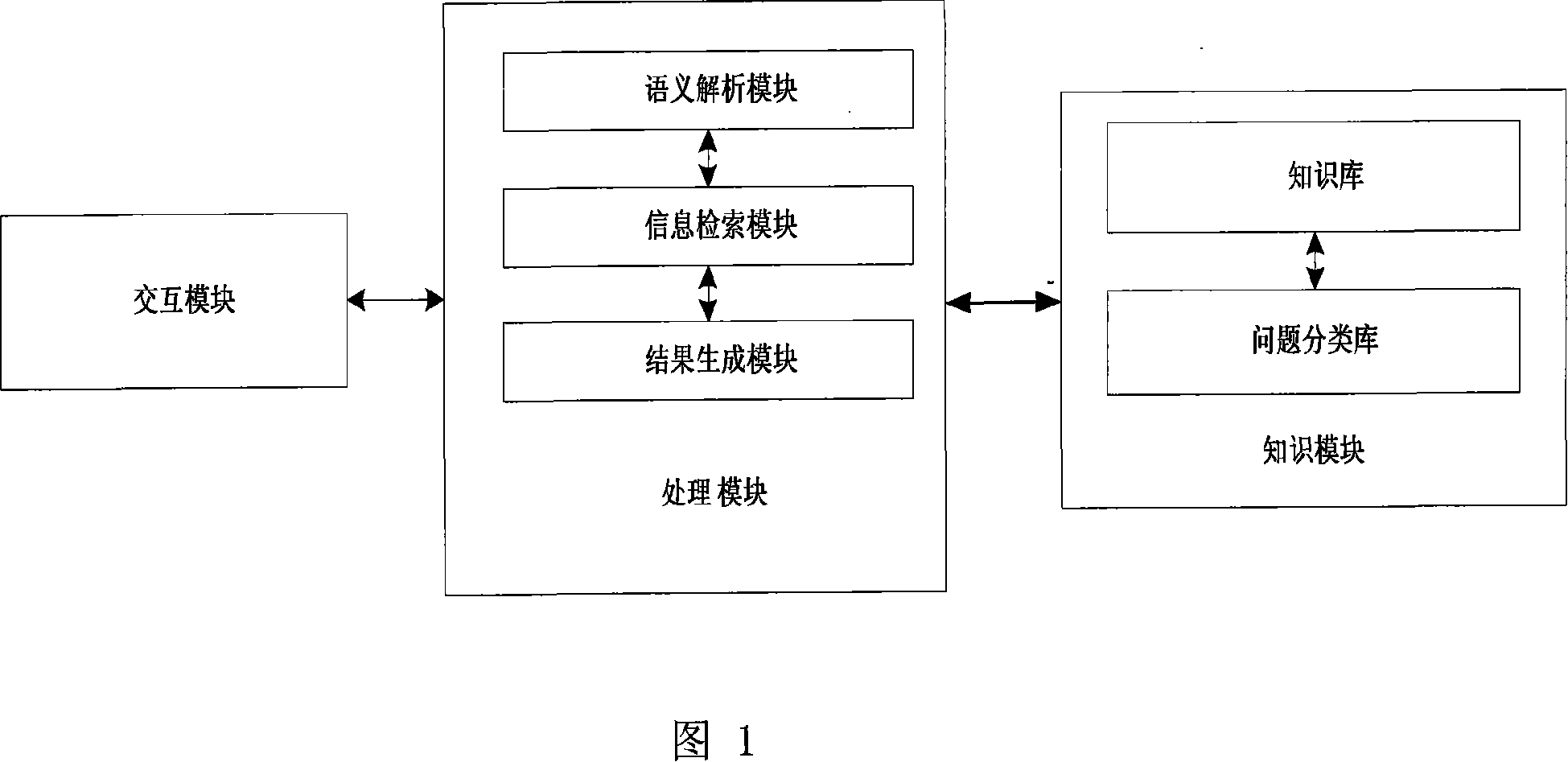

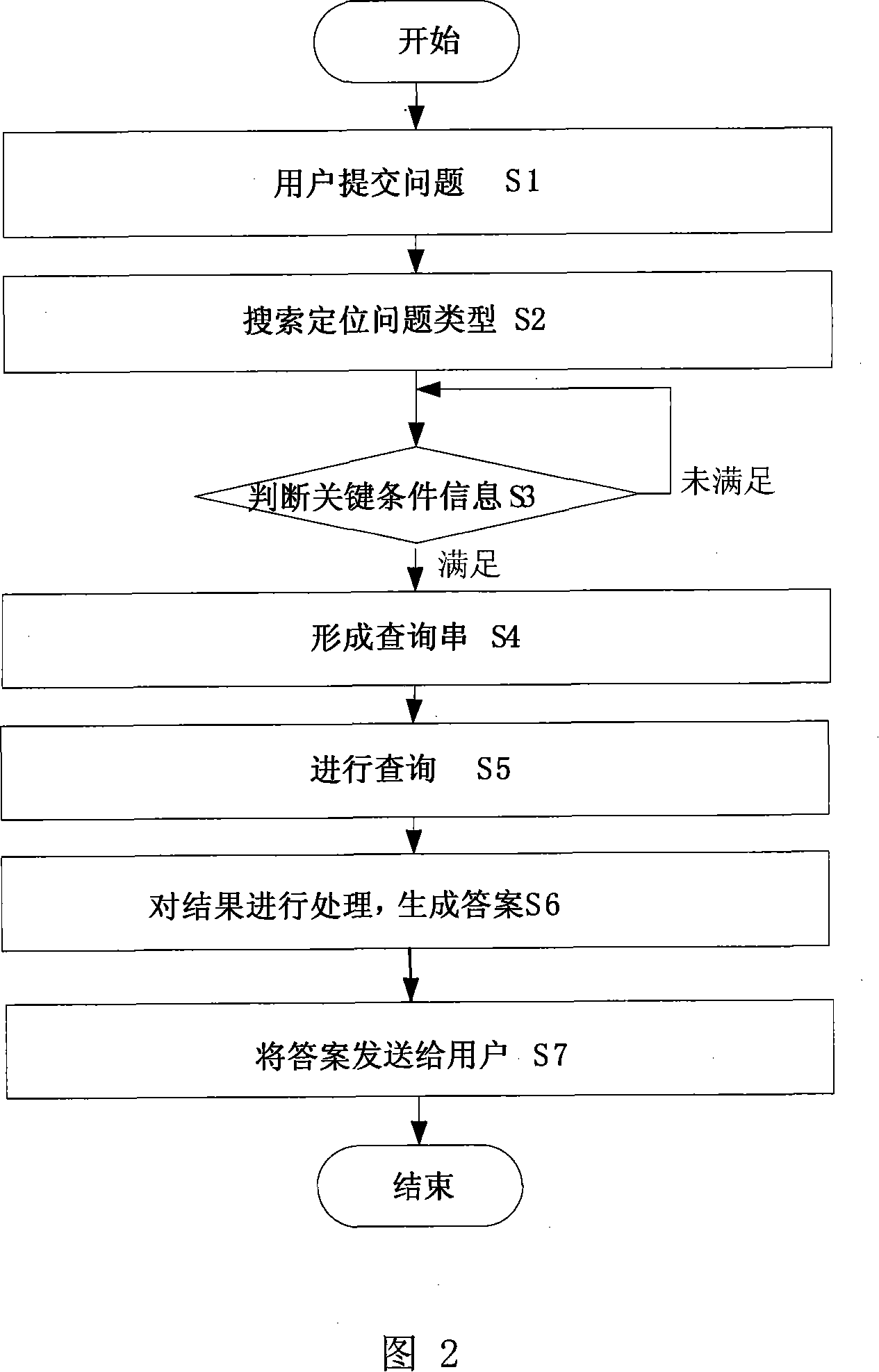

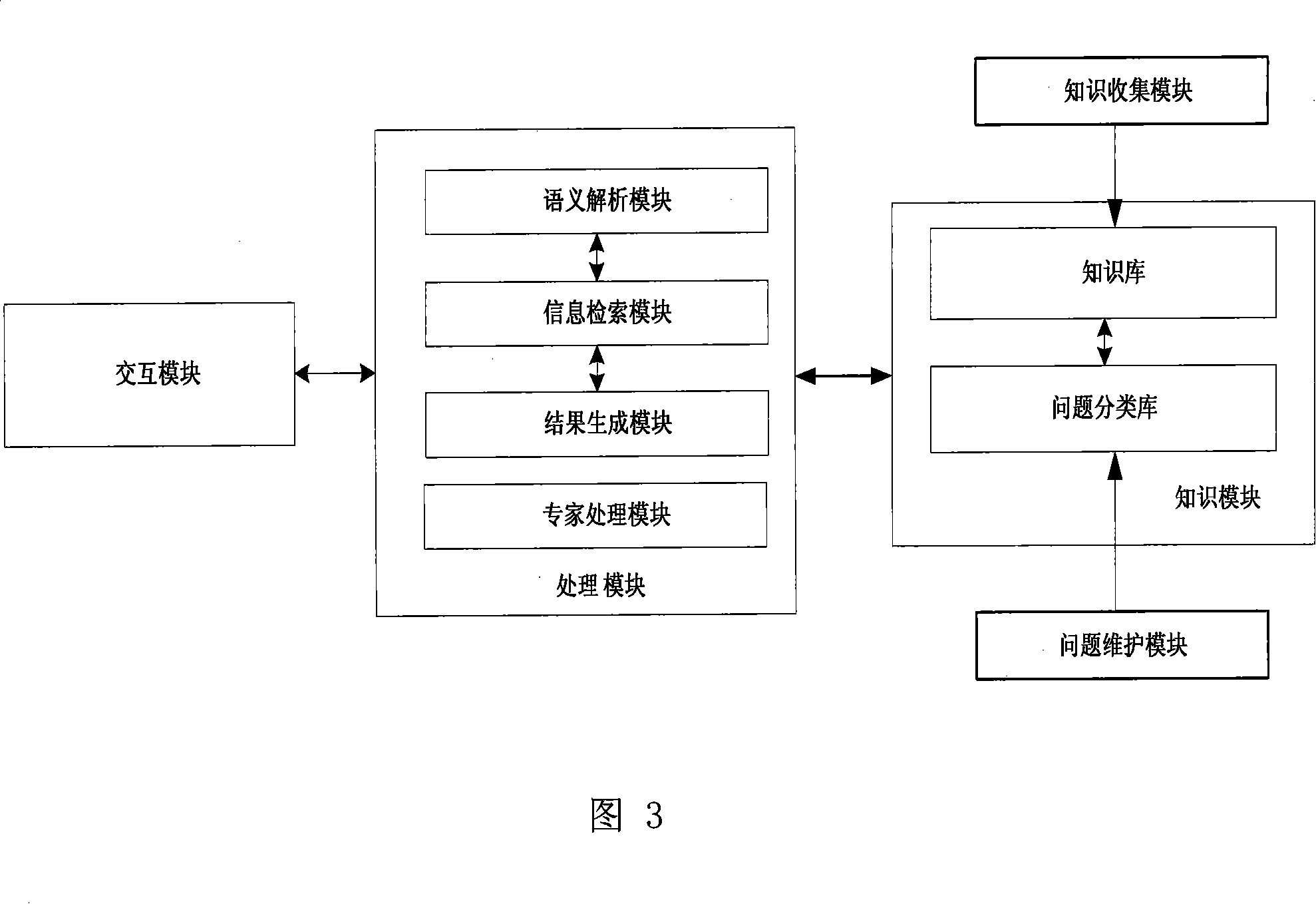

Intelligent interactive request-answering system and processing method thereof

InactiveCN101118554AImprove the ability to handle user issuesImprove accuracyDigital data information retrievalSpecial data processing applicationsInformation searchingQuestion answer

The present invention discloses an intelligent interactive question-answering system, which includes a knowledge module used to provide information for the user to query; an interactive module used for information interaction between the system and the user; and a processing module used for searching the answering information in knowledge module according to the question of the user; the knowledge module includes a question classification base used to store the question information and a knowledge base used to store the answering information; the processing module includes a semantic analysis module used to analyze the natural language for the problem of the user to generate query conditions; an information searching module used to search in the knowledge base according to the query condition; and a result generation module used to generate answers according to the searching results. The present invention discloses a question-answering processing method of an intelligent interactive question-answering system simultaneously. The present invention provides a rapid and simple system and method for obtaining the demanded information, so as to improve the processing ability for problems and the processing accuracy.

Owner:ZTE CORP

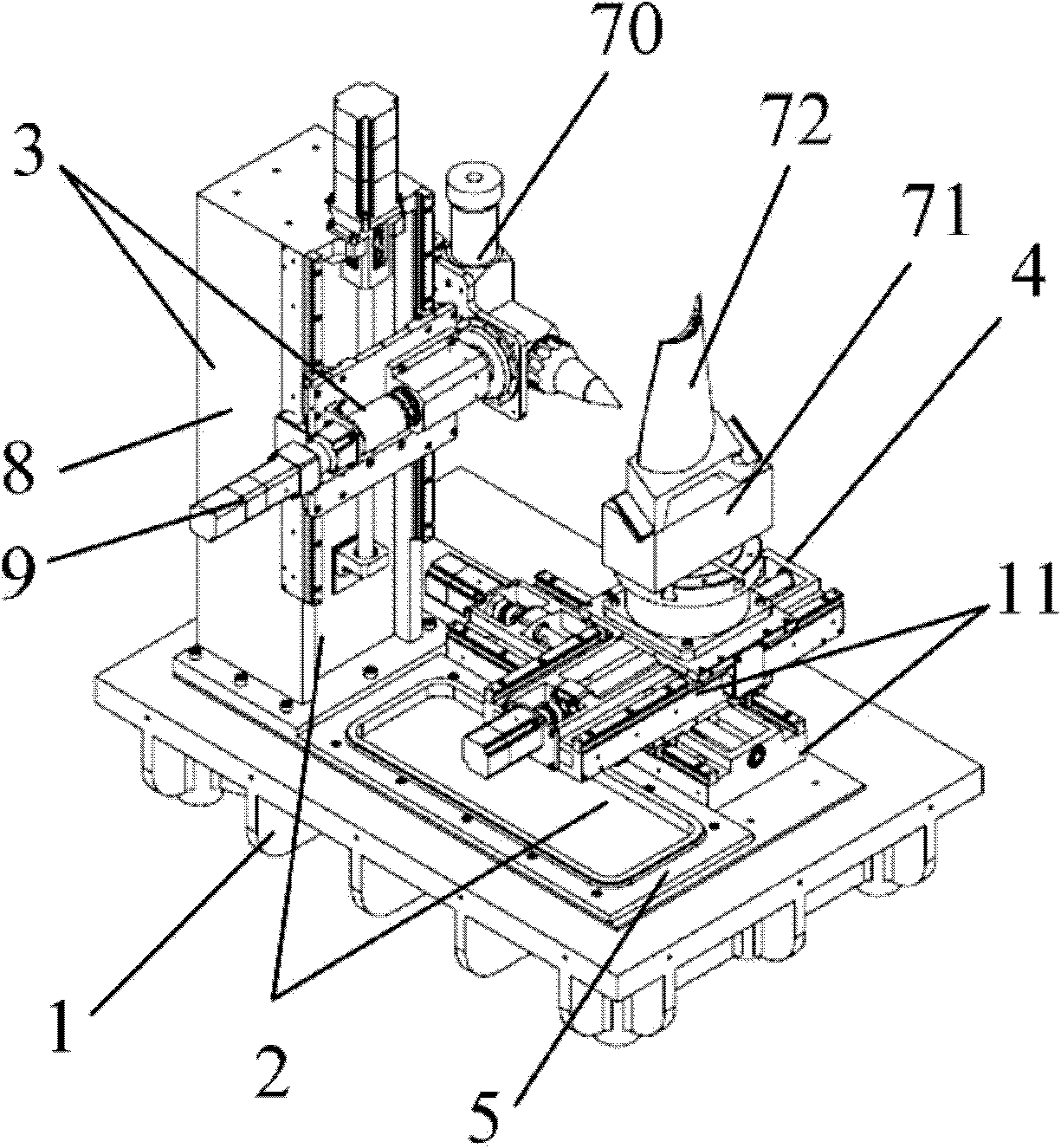

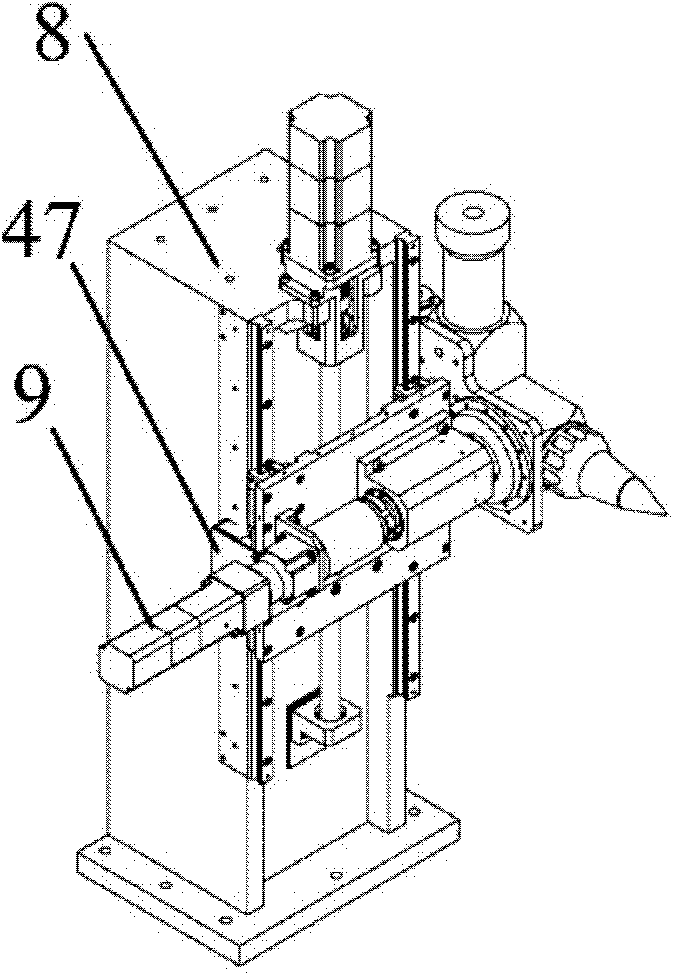

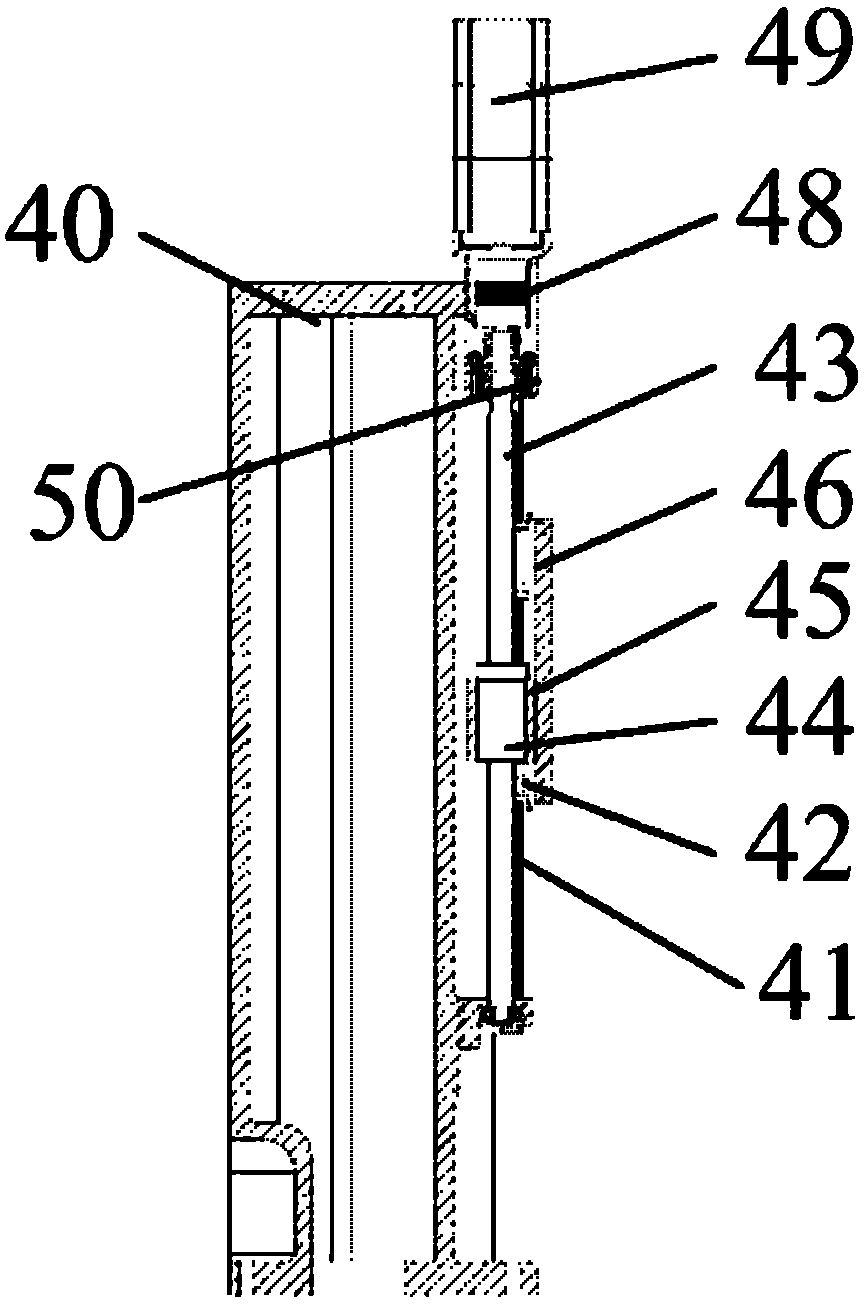

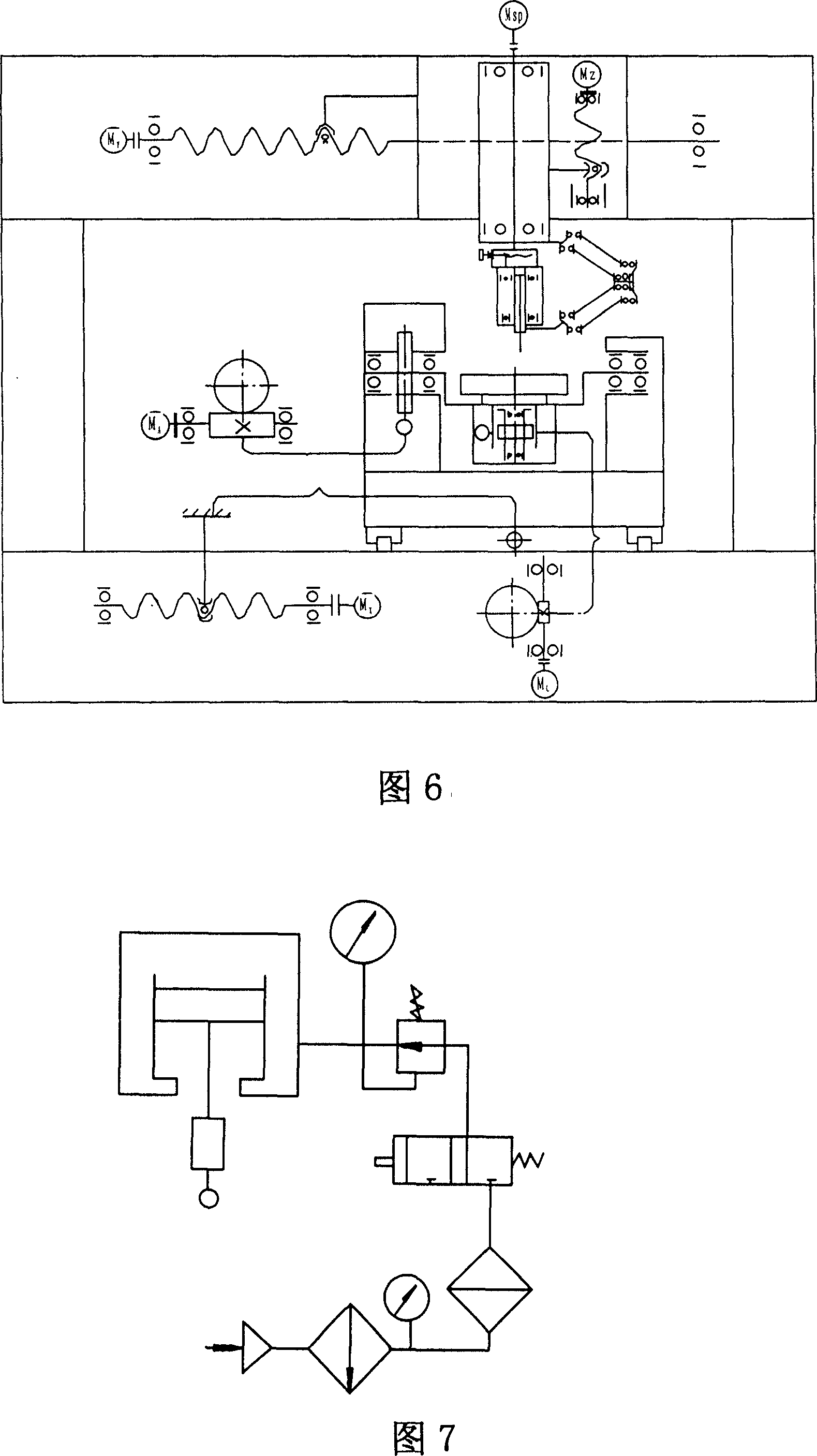

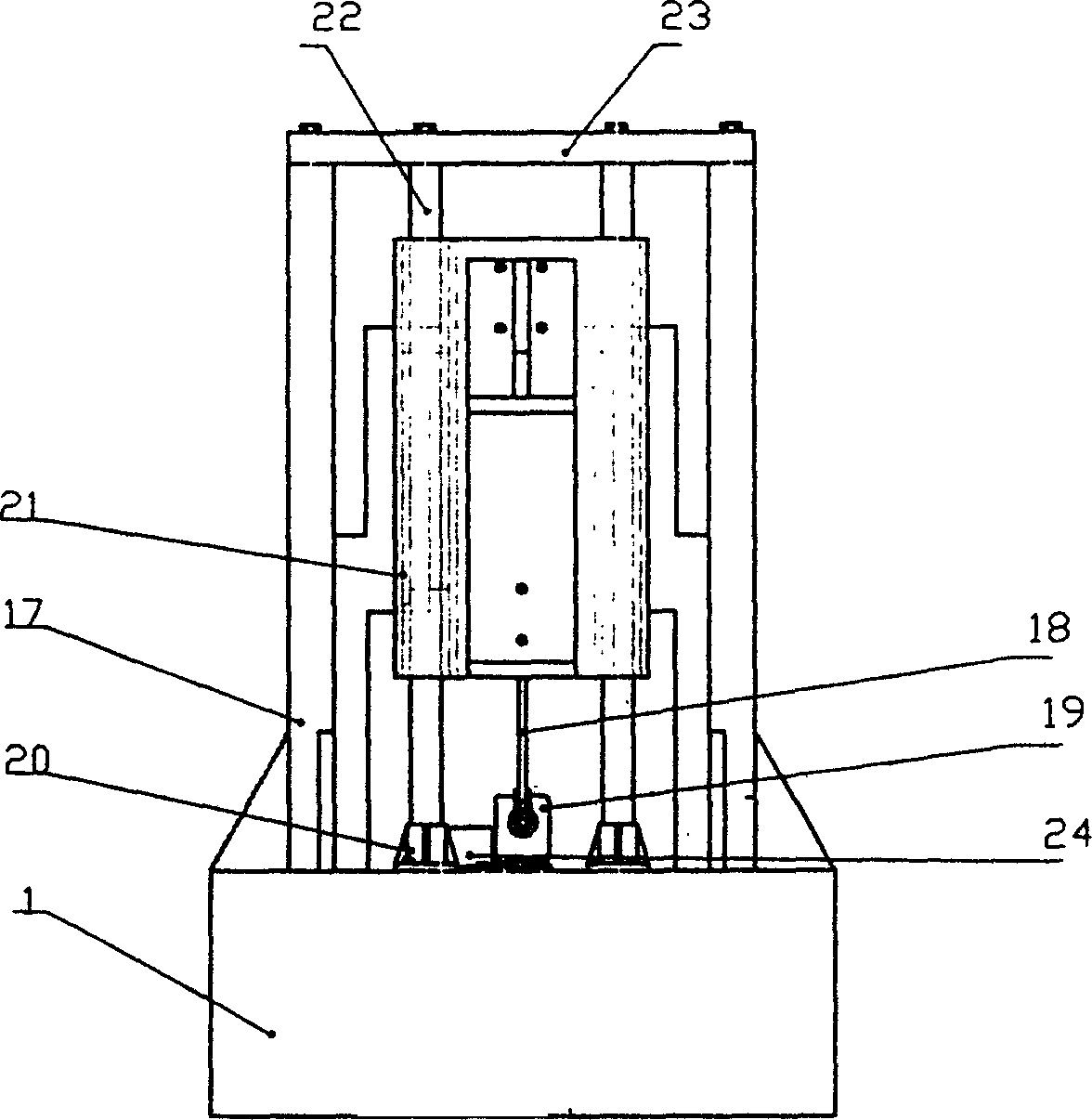

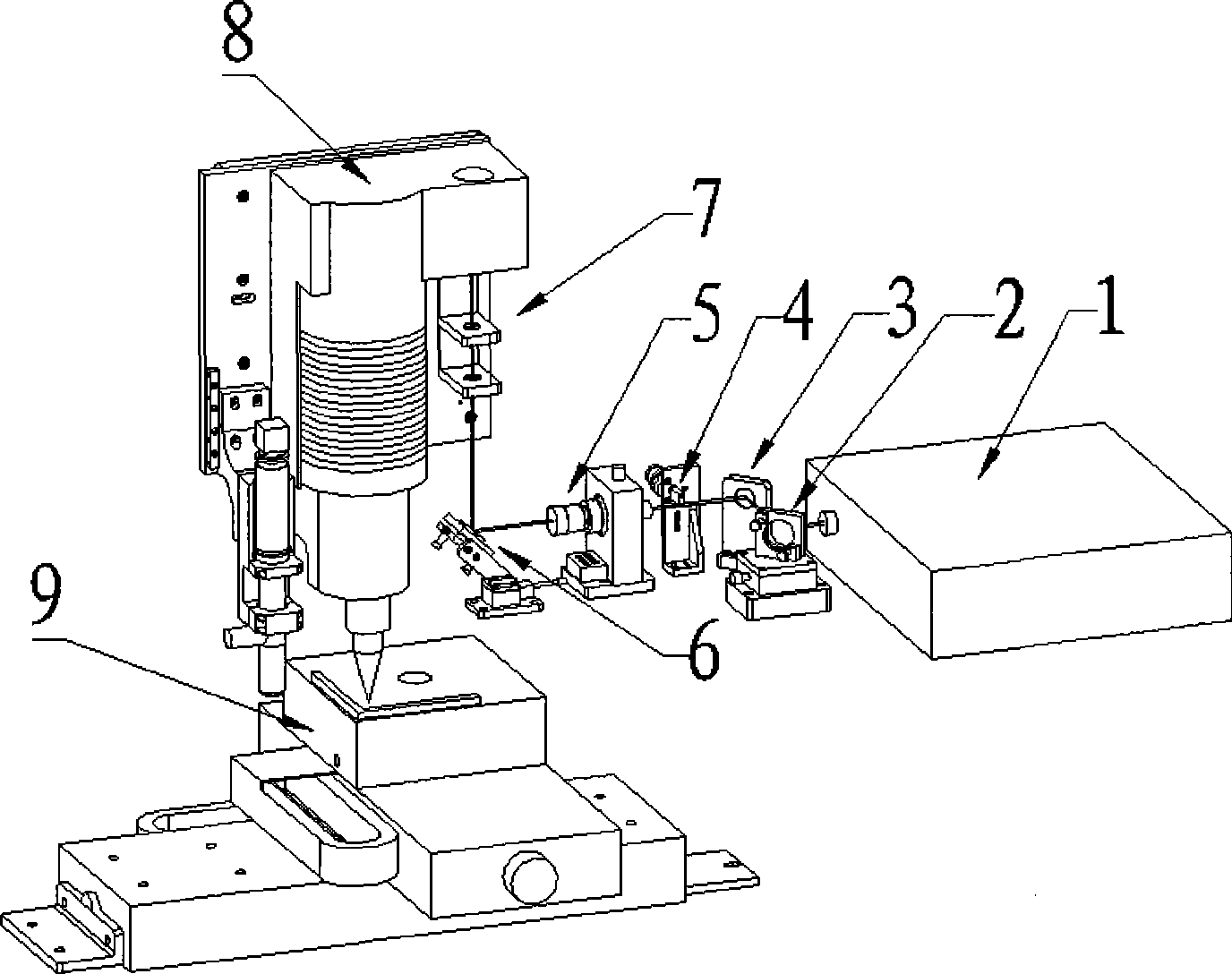

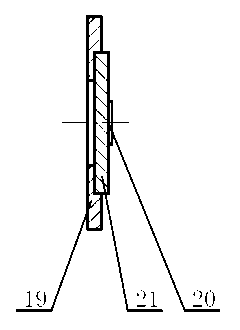

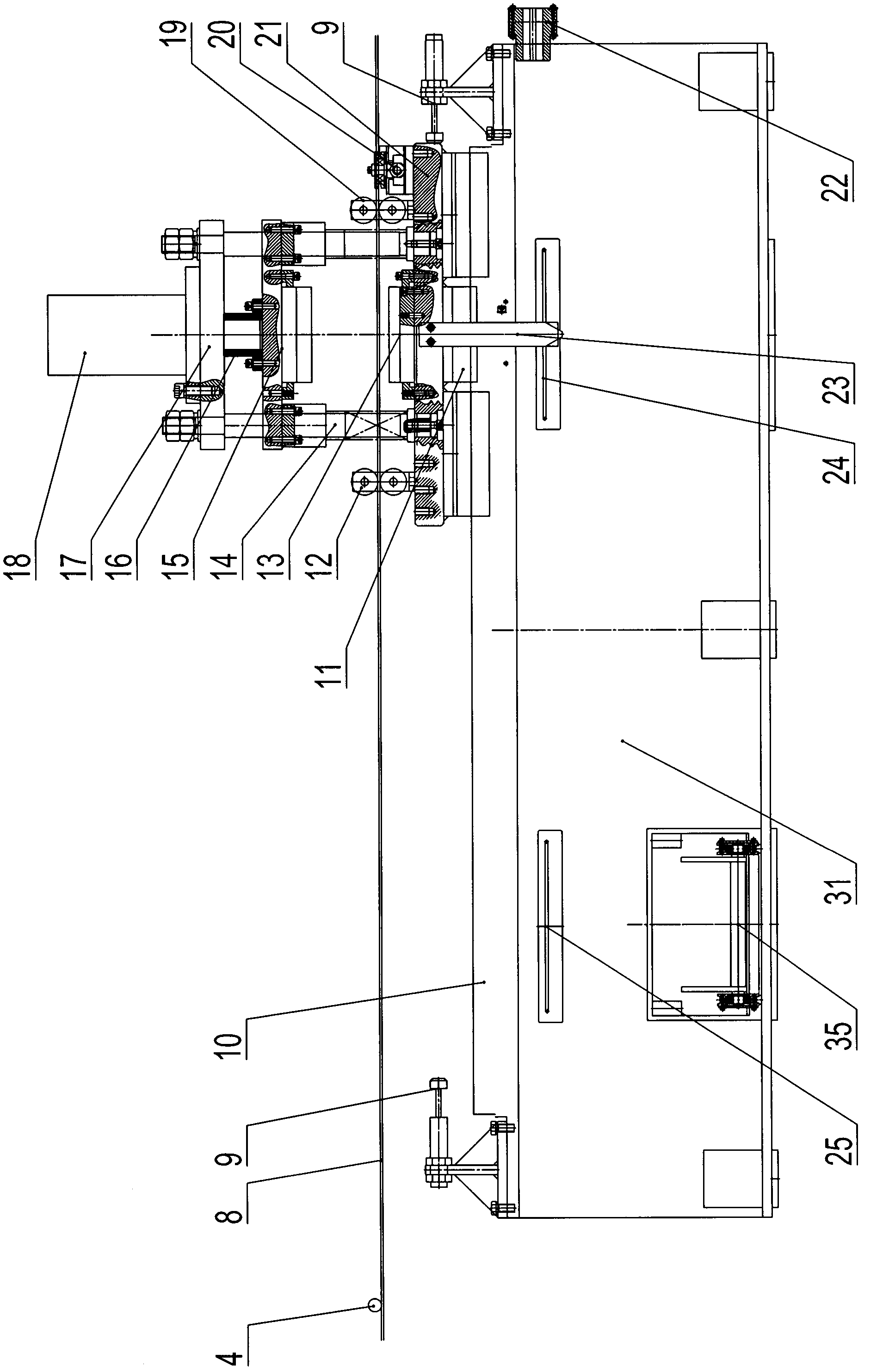

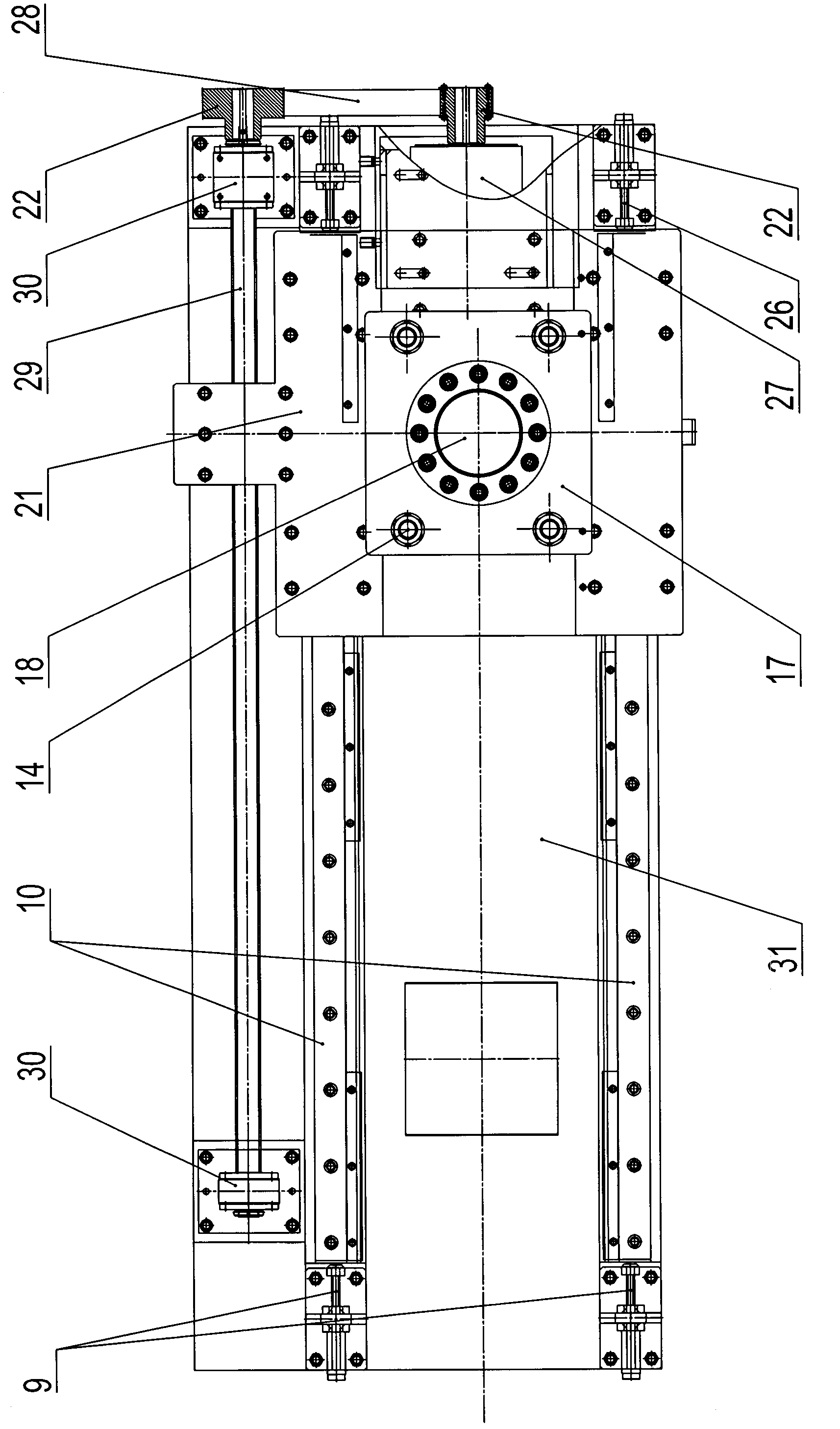

Five-axis linkage laser processing machine

InactiveCN102000911ASimple designEasy to processLarge fixed membersLaser beam welding apparatusLaser processingTorque motor

The invention discloses a five-axis linkage laser processing machine which comprises a base (1) and a machine body (2), wherein the machine body (2) comprises an upright column module (3) and a platform module (4) which are installed on the base (1), the upright column module (3) comprises a Z-axis submodule (8) and an A-axis rotary motion module (9), the Z-axis submodule (8) is provided with a Z-axis slide carriage (46) which moves in the vertical direction, the slide carriage is provided with the A-axis rotary motion module (9), a laser head (70) is installed at the end of an A axis and rotates along with the A axis, the platform module (4) consists of an XY workbench (11) and a C-axis rotary motion module (10) installed on the workbench, a C axis is driven by a torque motor (52) and is provided with a rotary workbench (53), and a workpiece is vertically installed on the rotary workbench through a special clamp. The invention has the advantages of novel structure layout, compact size and high processing accuracy and can also greatly enhance the processing efficiency.

Owner:XI AN JIAOTONG UNIV

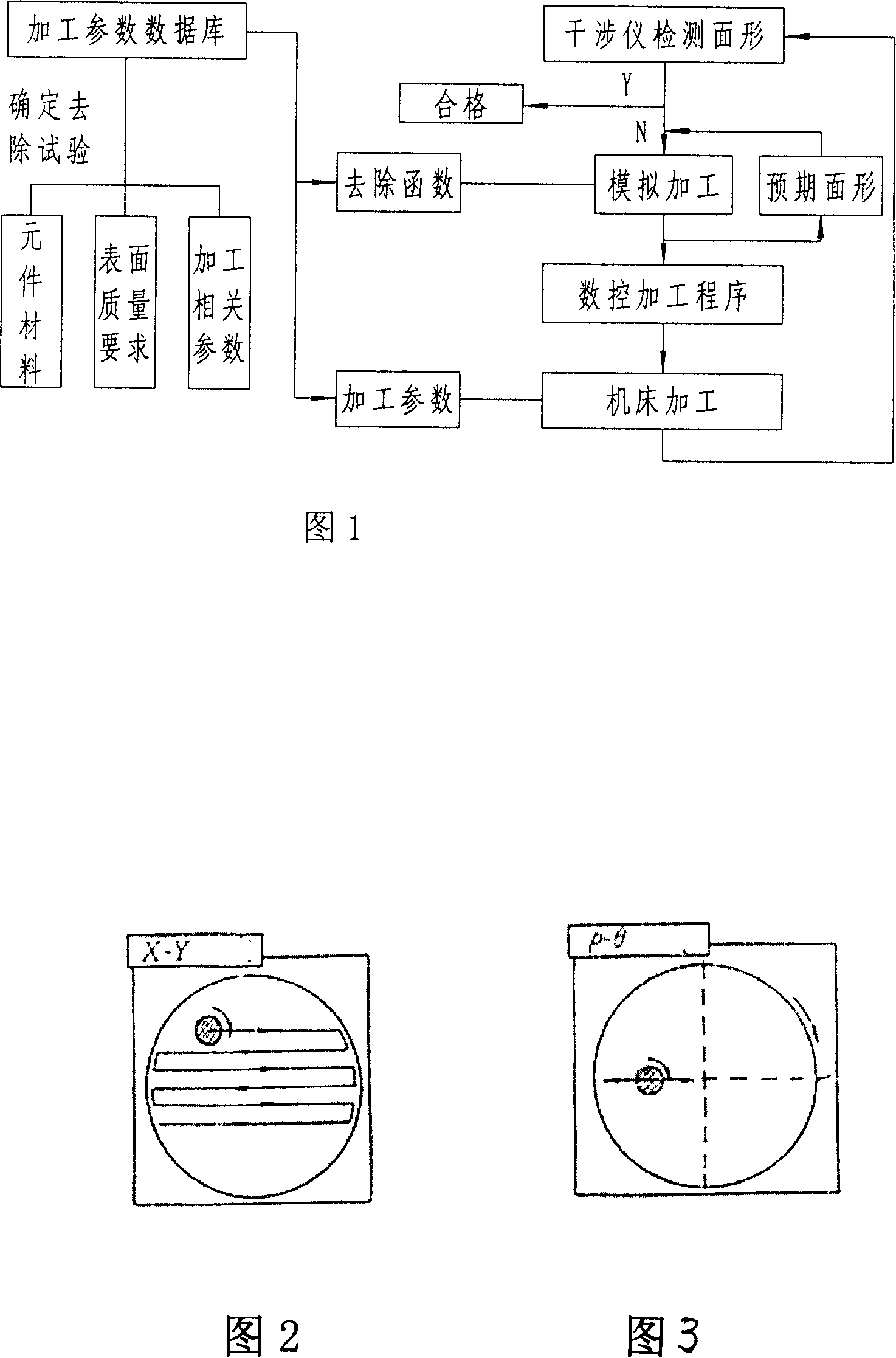

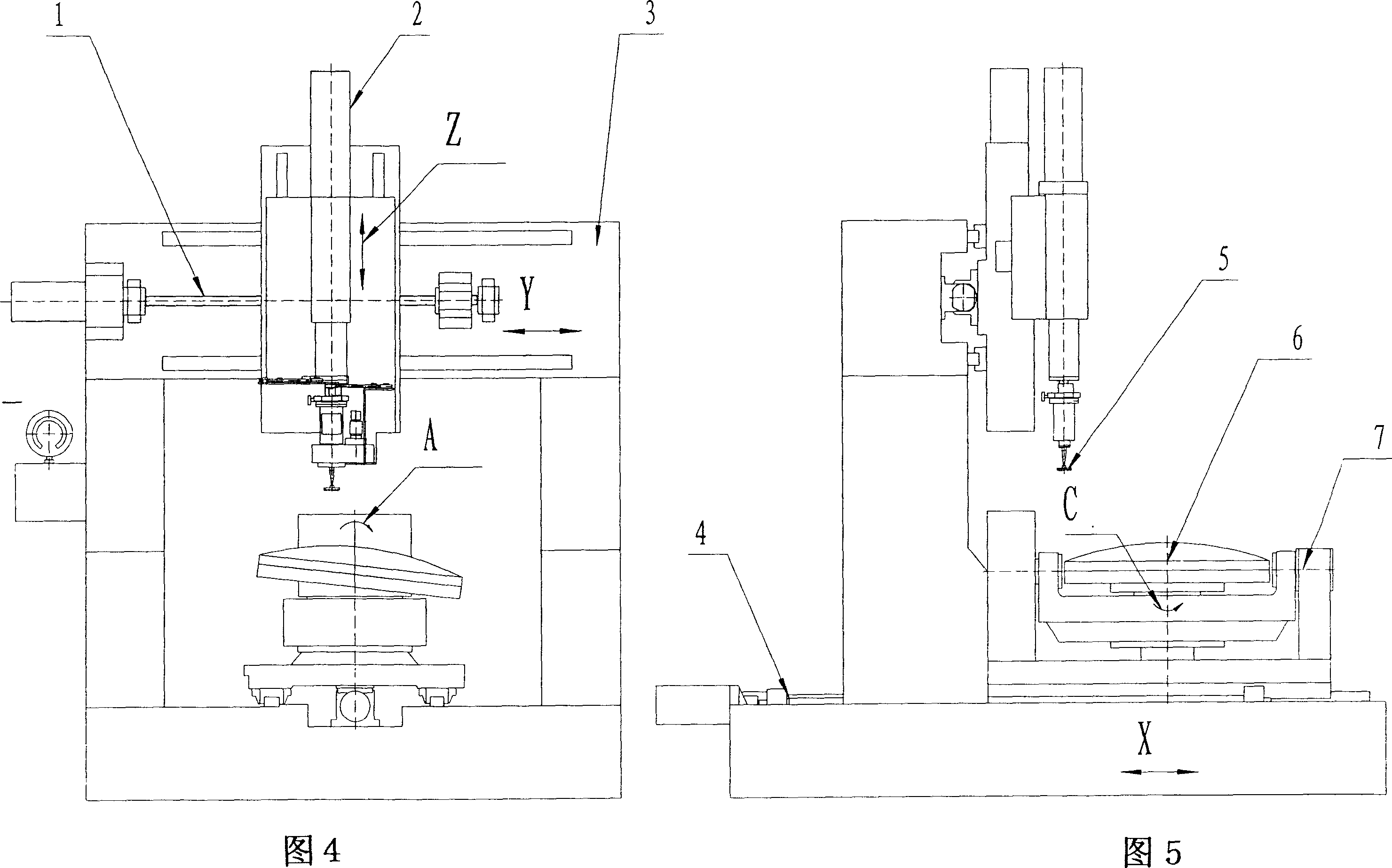

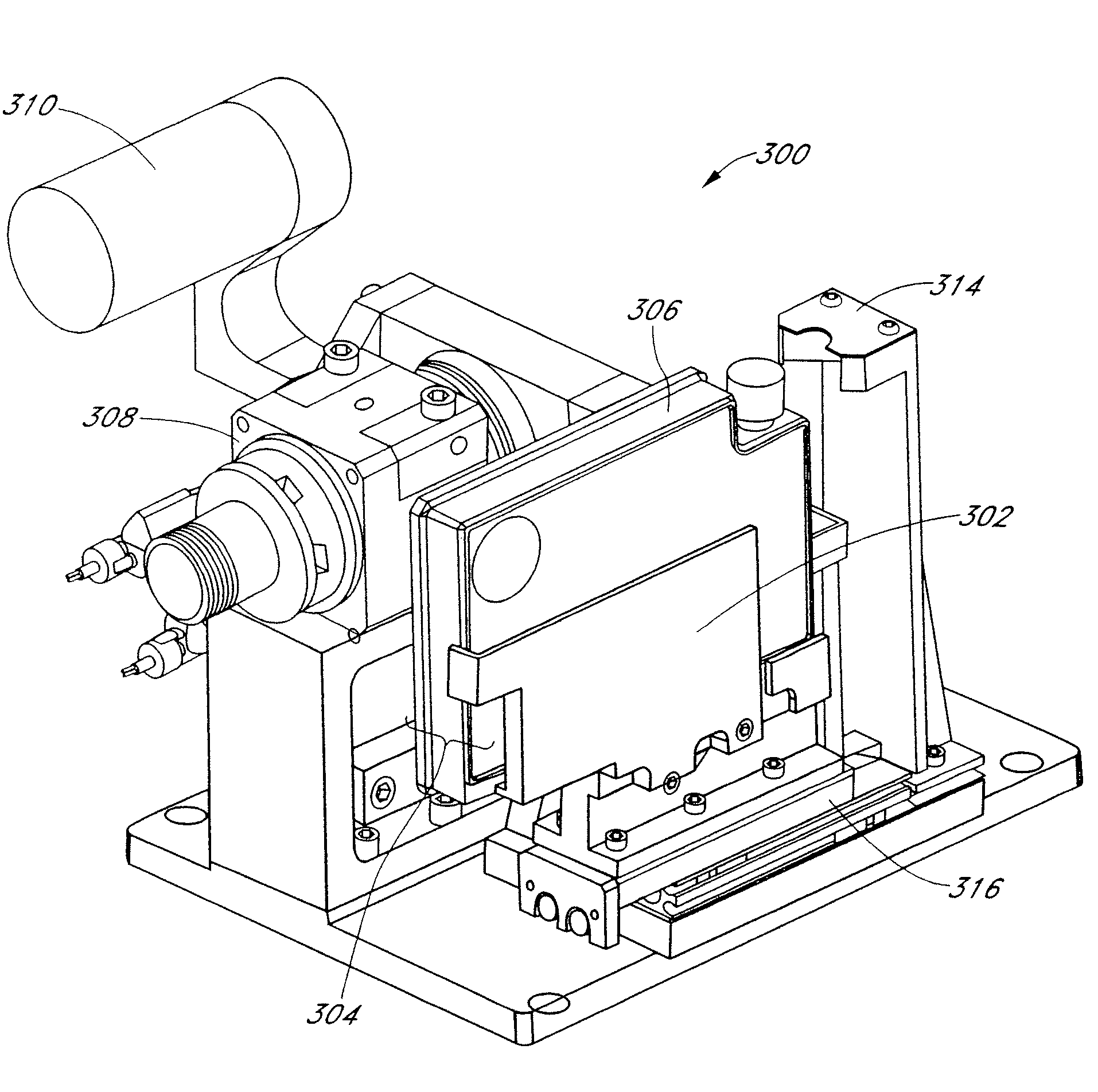

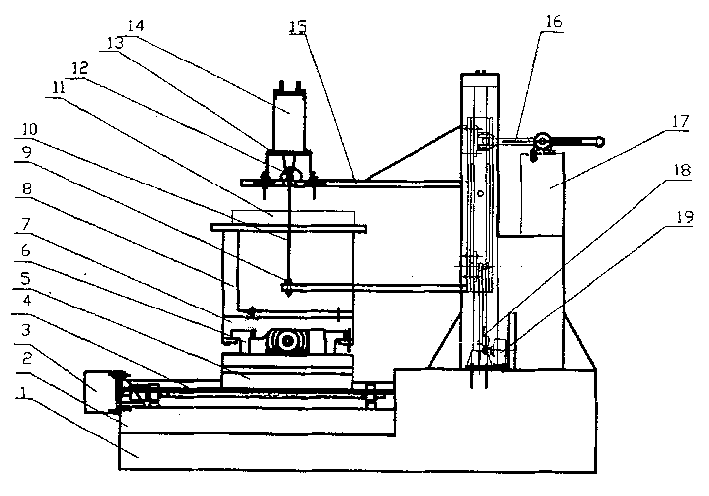

Efficient numerically controlled polishing process and apparatus for great aperture aspherical optical elements

InactiveCN101088705AReduce dependenceImprove efficiencyOptical surface grinding machinesOptical surfaceMachining process

The efficient numerically controlled polishing process and apparatus for great aperture aspherical optical elements belongs to the field of precise optical machine technology. The polishing process includes: constituting polishing process model based on the profile data obtained through measurement with interferometer or other instrument, determining the machining path, speed, pressure and other parameters of the element under the control of computer to perform simulating machining, verifying the technological parameters based on the simulating machining results and determining the ultimate technological parameters, creating NC program and machining. The present invention has high machining efficiency and high machining precision.

Owner:CHANGCHUN EQUIP TECH RES INST

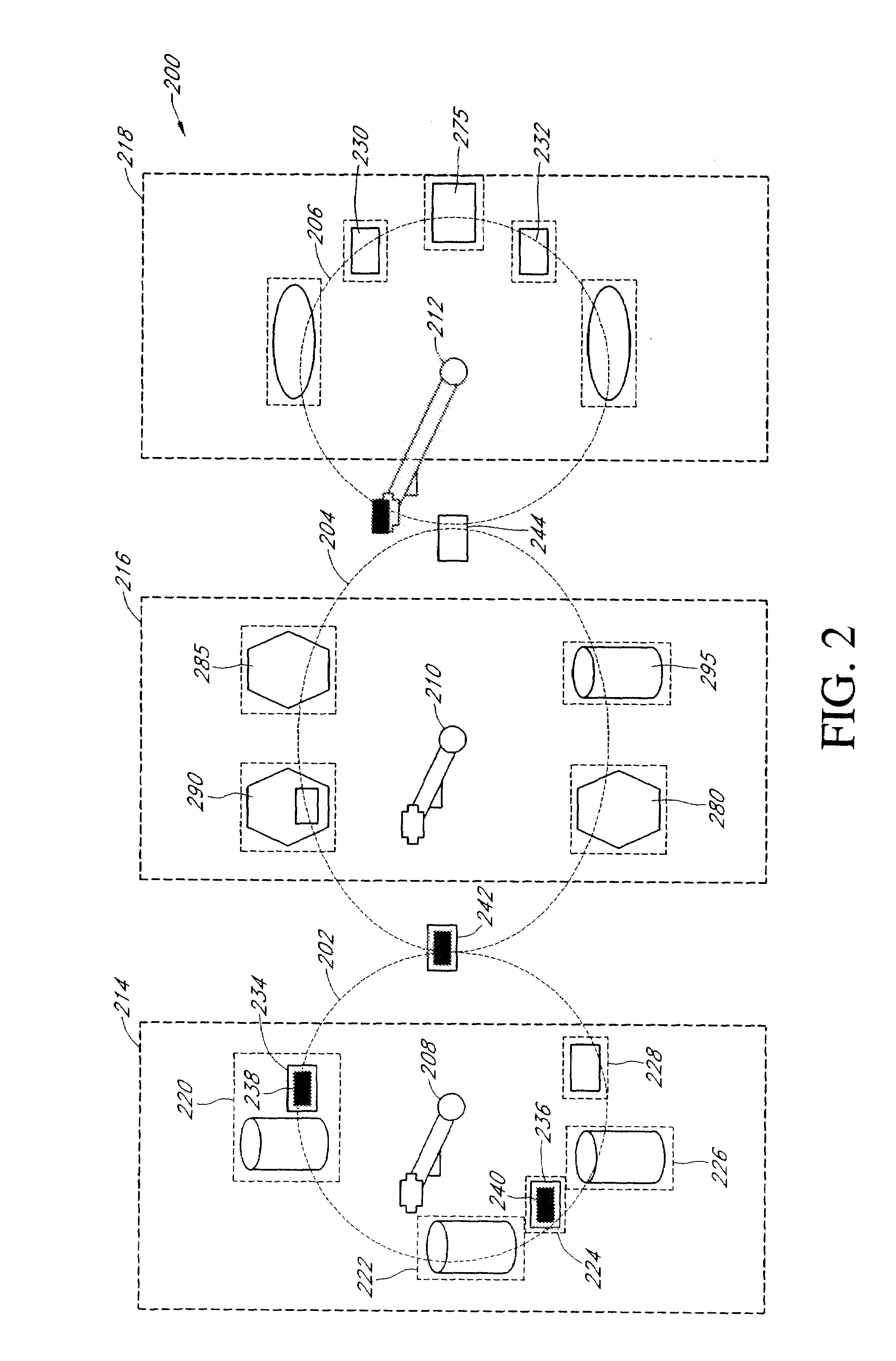

Compound profiling devices, systems, and related methods

InactiveUS20090042281A1Bioreactor/fermenter combinationsSequential/parallel process reactionsEngineeringCell separation

Owner:IRM

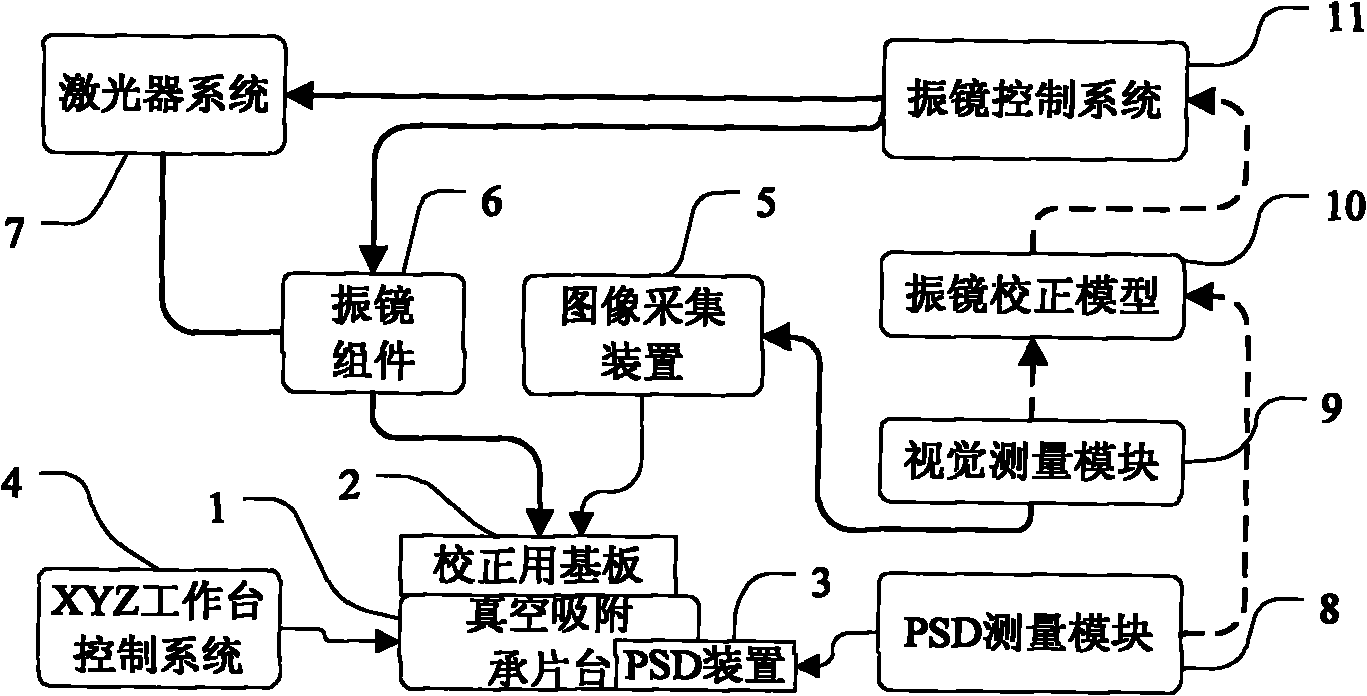

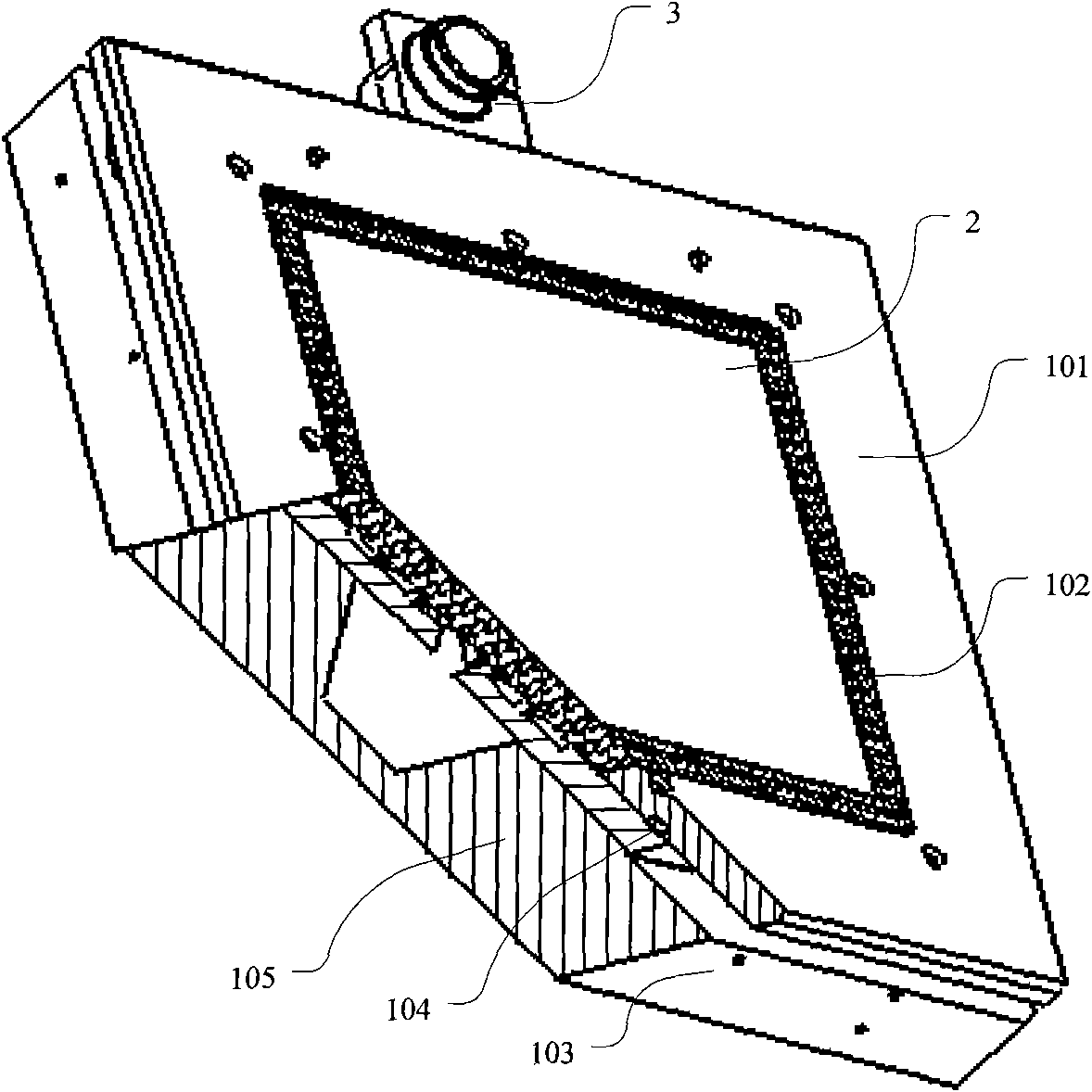

Galvanometer system correction device and correction method thereof

InactiveCN101804521AGood dynamic tracking abilitySolve the problem of calibration inefficiencyLaser beam welding apparatusGalvanometerCorrection method

The invention provides a galvanometer system correction device and a correction method thereof, and relates to the technical field of precision laser processing equipment. A honeycomb panel is arranged in the middle of the outer frame of a bearing platform, a base plate for corrective is absorbed on the honeycomb panel, and the vacuum chamber of the honeycomb panel is connected with a dust collector; a PSD sensor for measuring the actual output light spot center position of the laser of a galvanometer system is arranged on the vacuum absorption bearing platform; a CCD image acquisition device is arranged above the base plate for correcting, and then is provided with a light intensity regulating module and an image acquisition board card; and a visual measurement algorithm module is arranged. The invention can effectively inhibit the precision drift of the galvanometer system, improve the efficiency of the galvanometer system when in correction model updating and in real-time correction calculation operation, improve the automatic degree of equipment, reduce the labor intensity of an operator, greatly improve the processing precision of equipment, product quality and production efficiency, has simple structure and unique principle and method, and is particularly suitable for precision laser processing equipment to use.

Owner:THE 45TH RES INST OF CETC

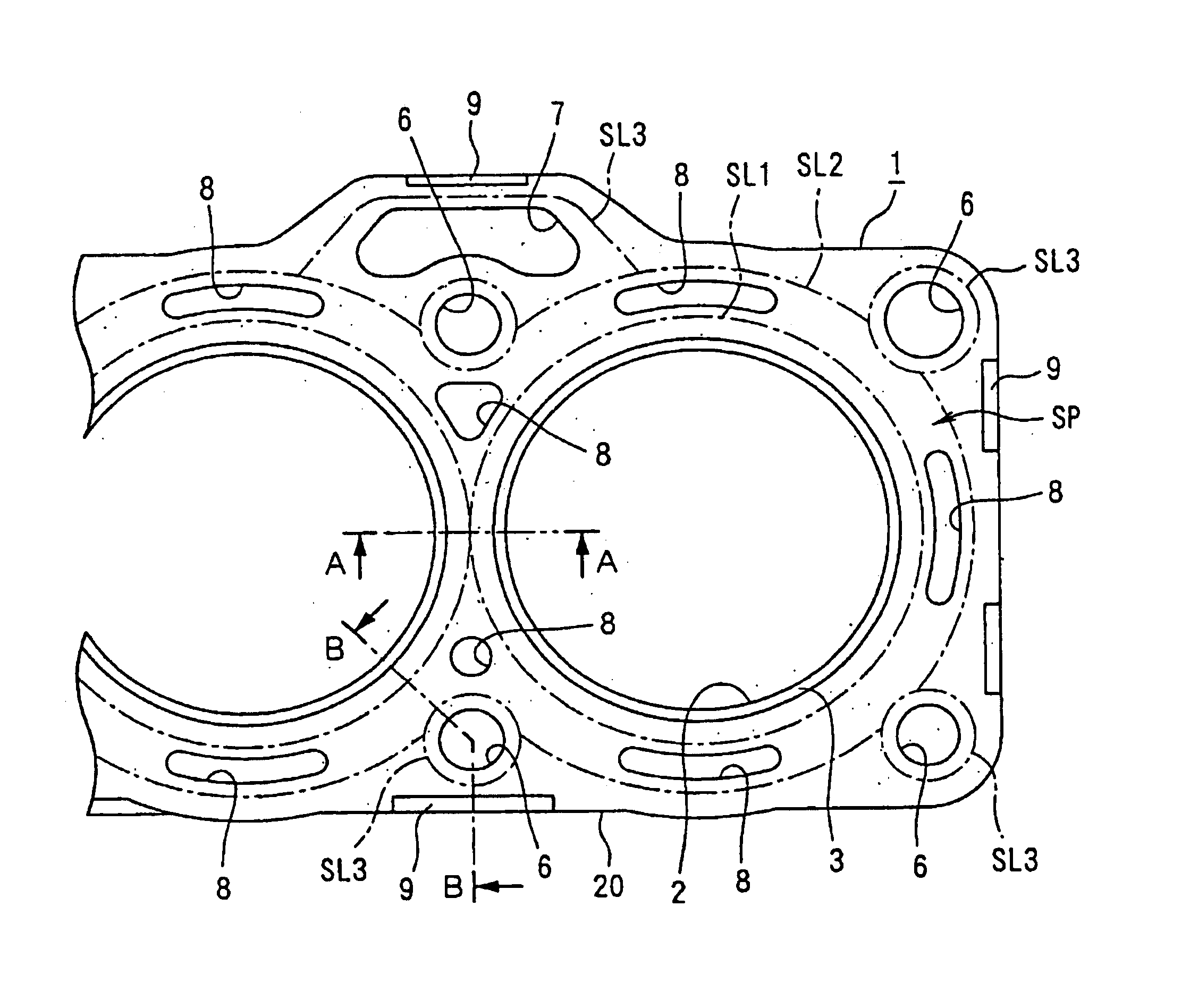

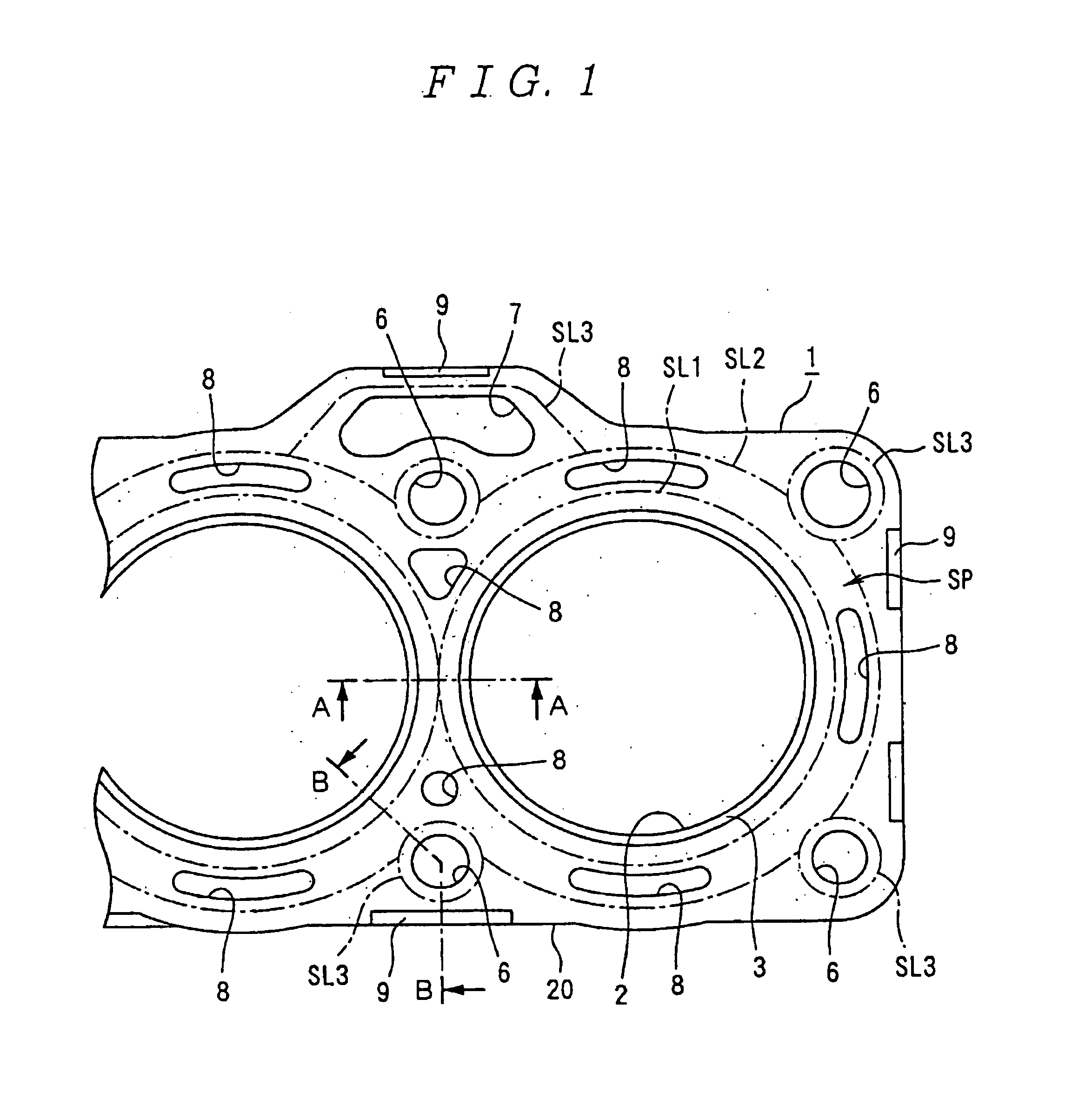

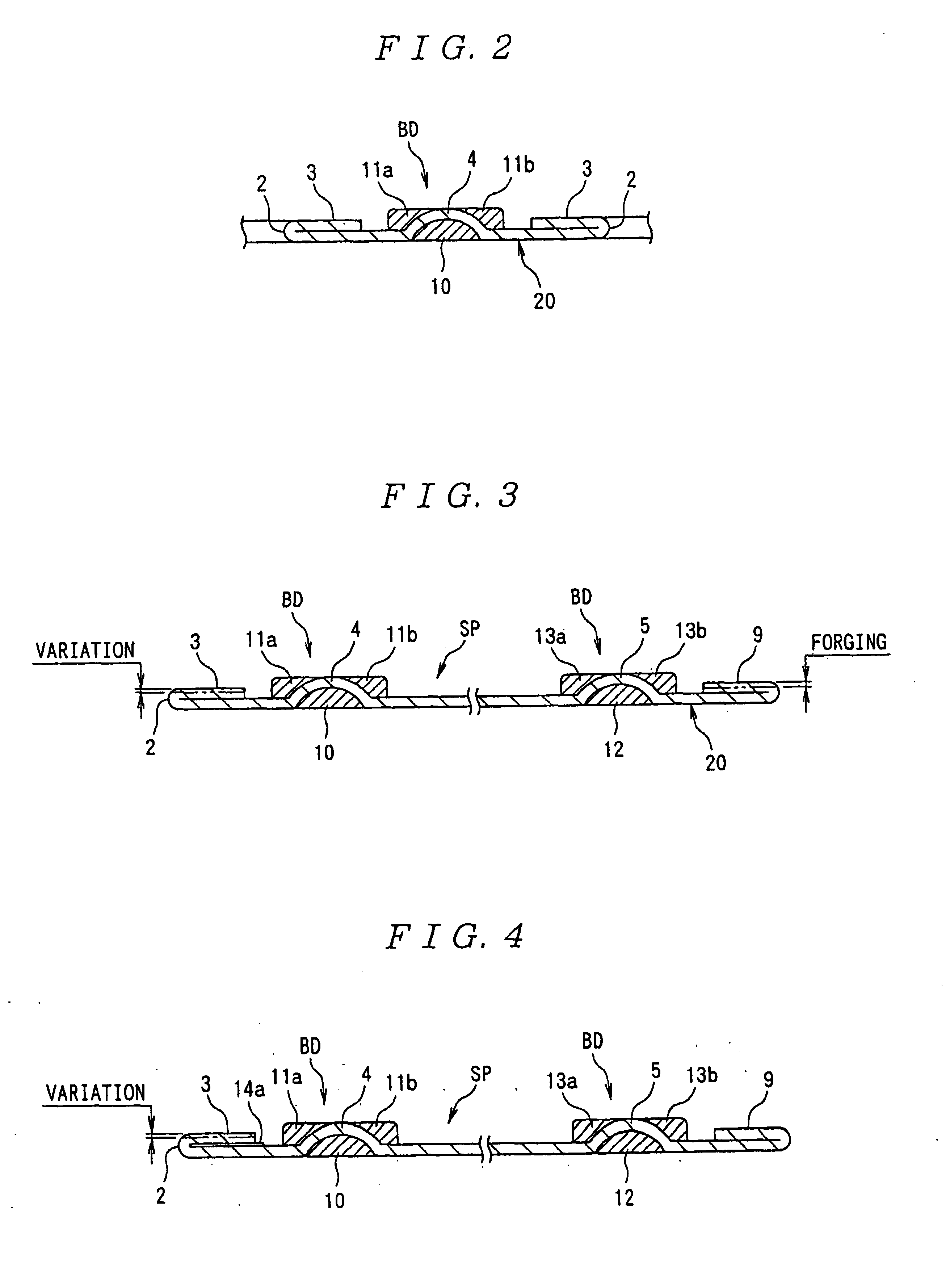

Metallic gasket

InactiveUS7025358B2Improve machining accuracyImprove cooling effectEngine sealsSealing arrangements for enginesCombustion chamberCooling effect

A metallic gasket comprising a base plate having a first thickness-increased portion 3 formed at a peripheral edge on a combustion chamber opening 3 side of a base plate, and a first seal line SL1 and a second seal line SL2 arranged on the outer side of said first thickness-increased portion 3. No openings other than a cooling water hole 8 exist between said two seal lines. Beads formed along said seal lines SL1 and SL2 each consist of a convex metal bead raised only upward from an upper surface of said base plate and a rubber bead made of an elastic sealing material fixed to a convex portion and a concave portion of said metal bead. This structure of said metallic gasket can improve a processing accuracy of said metal bead and also enhance cooling effects on said metallic gasket itself and said joint surfaces of an engine, between which said metallic gasket is disposed.

Owner:JAPAN METAL GASKET CO LTD

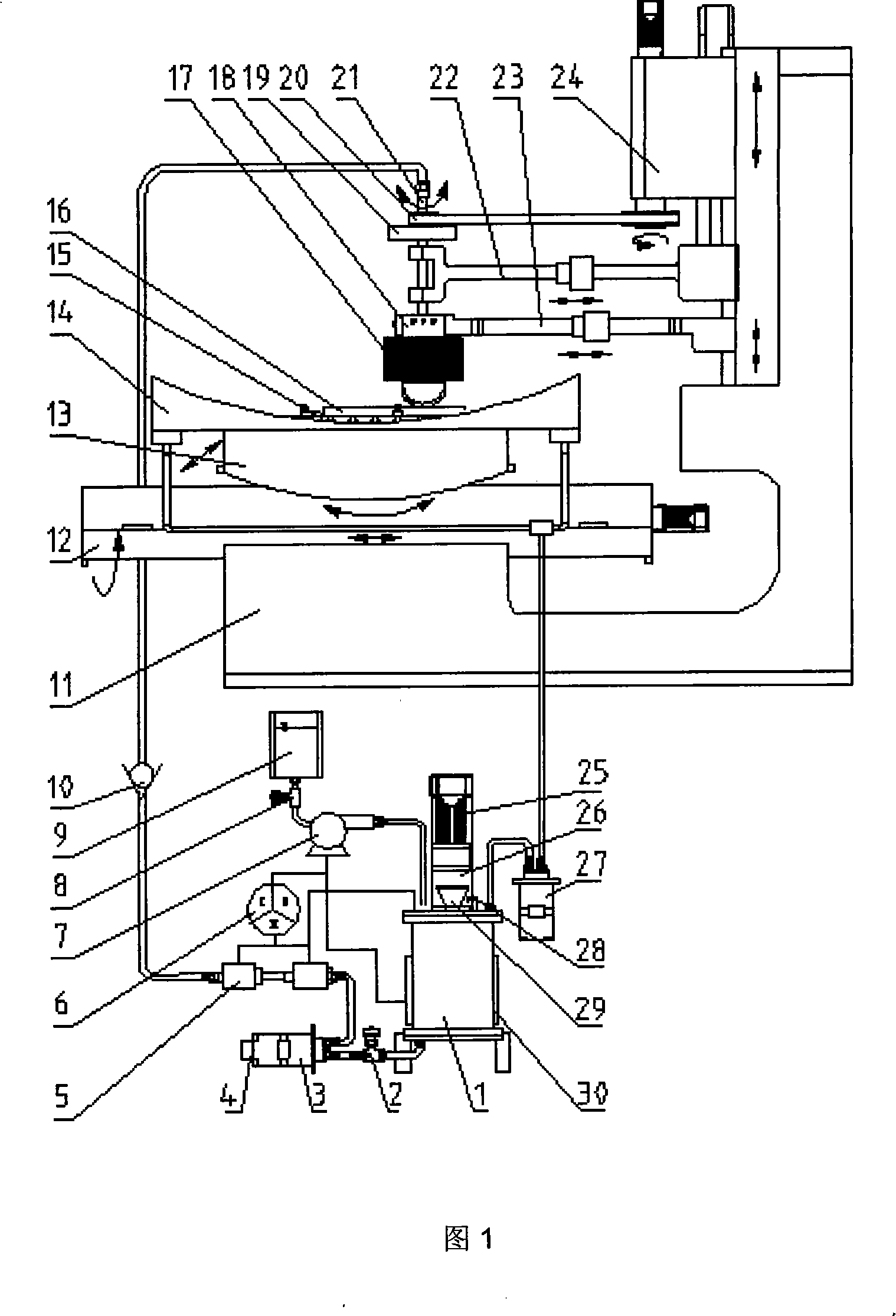

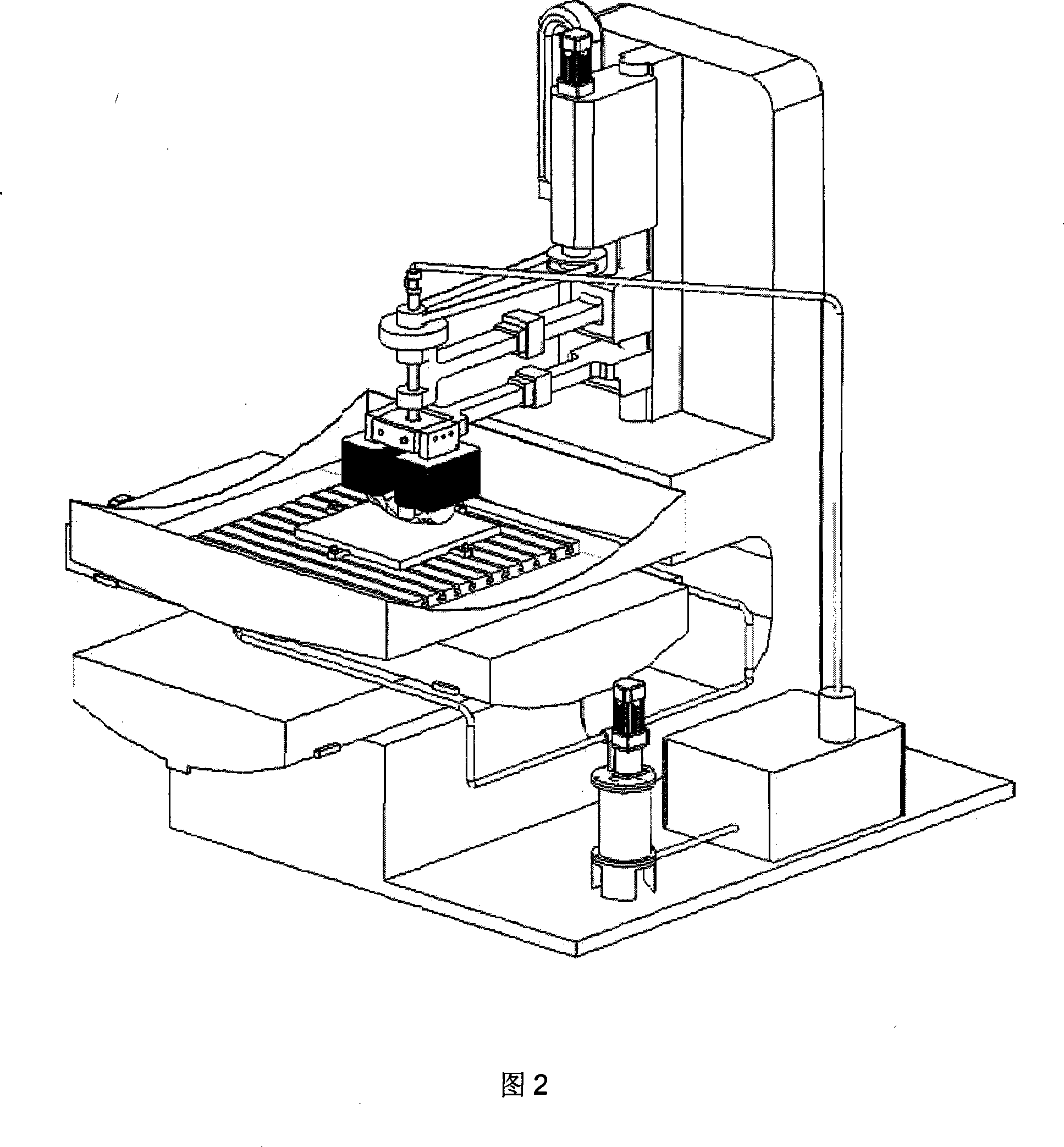

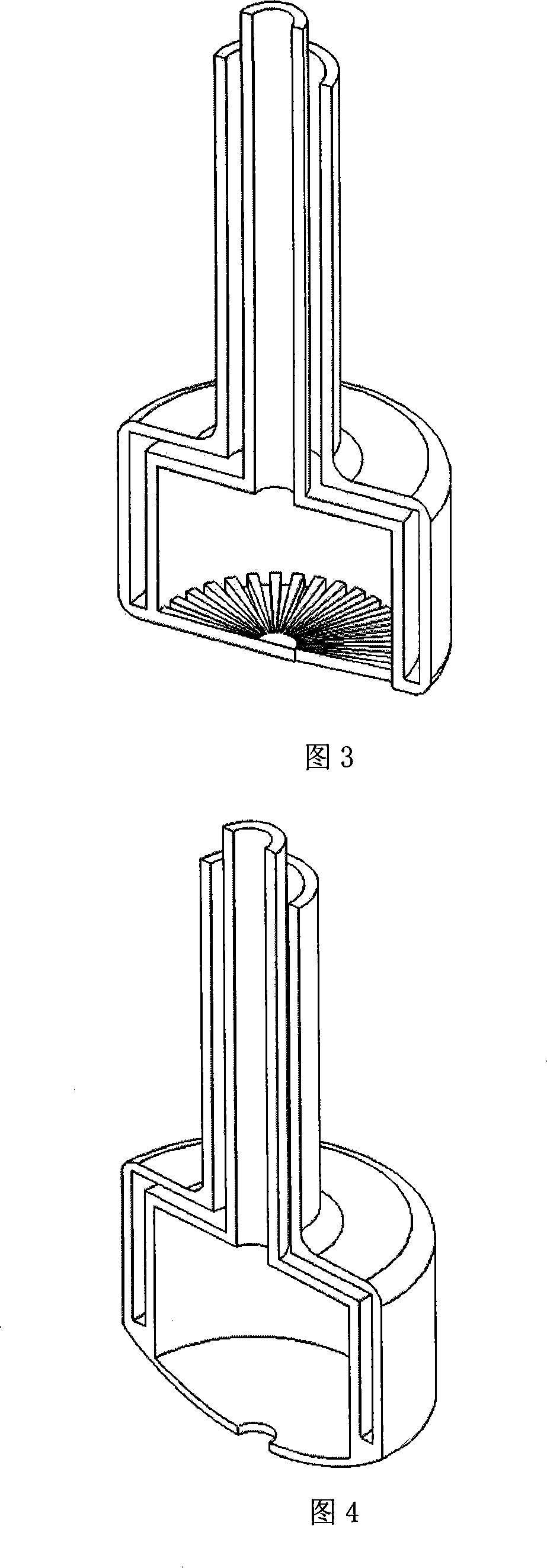

Precise magnetic flowage polishing system for optics parts and method thereof

InactiveCN101224556AImprove processing efficiencyEasy clampingOptical surface grinding machinesPeristaltic pumpTemperature control

The invention relates to an optical part magnetic rheologic precise polishing system and a method; magnetic rheologic liquid which flows out of a liquid storage cylinder is pressurized by a peristaltic pump and then enters a polishing head through a rotating connector and a guide pipe; the clearance between a workpiece and the polishing head is fully filled by the magnetic rheologic liquid; under the action of electromagnetic field, the magnetic rheologic liquid is transformed from the liquid state to the half-solid state so as to form a flexible grinding head used for polishing. The polishing head of the invention is not directly contacted with the workpiece; the polishing heads with different shapes and specifications can be replaced according to the processed workpiece; a computer automatic control device can realize the viscousity control and the temperature control of the magnetic rheologic liquid, and different polishing efficiency and precisions can be obtained by changing the factors such as magnetic field and rotation speed, etc.; the method of the invention can process the curved workpieces and plane workpieces with different shapes, more particularly the ultra-precise polishing of the large plane optical parts; the system has the advantages of high processing efficiency, wide applicable range, high processing precision and convenient operation.

Owner:DONGHUA UNIV

Ultrasonic wire cutting saw for hard-fragile material processing

InactiveCN1488480ASimple structureIncrease productivityStone-like material working toolsWire cuttingEngineering

The invention is a kind of supersonic wave tangent line saw for hard and crisp material, which comprises the bed, longitudinal working slide flat, transversal work slide flat, piece bracket, diamond line saw, supersonic wave vibrating device, saw reciprocating motion mechanism and electricity control device, the supersonic vibrating device is fixed on the upper arm of the C type work bracket through screw, the electrical signal is transformed into mechanical vibration, and enlarges the amplitude through a pole, the diamond saw vibrates as wave, it generates reciprocating motion through cranked rod, C type work bracket, slide flat seat. The saw is in linear high frequency vibration state and reciprocating motion; the invention is simple and has a high productivity.

Owner:沈阳工业学院

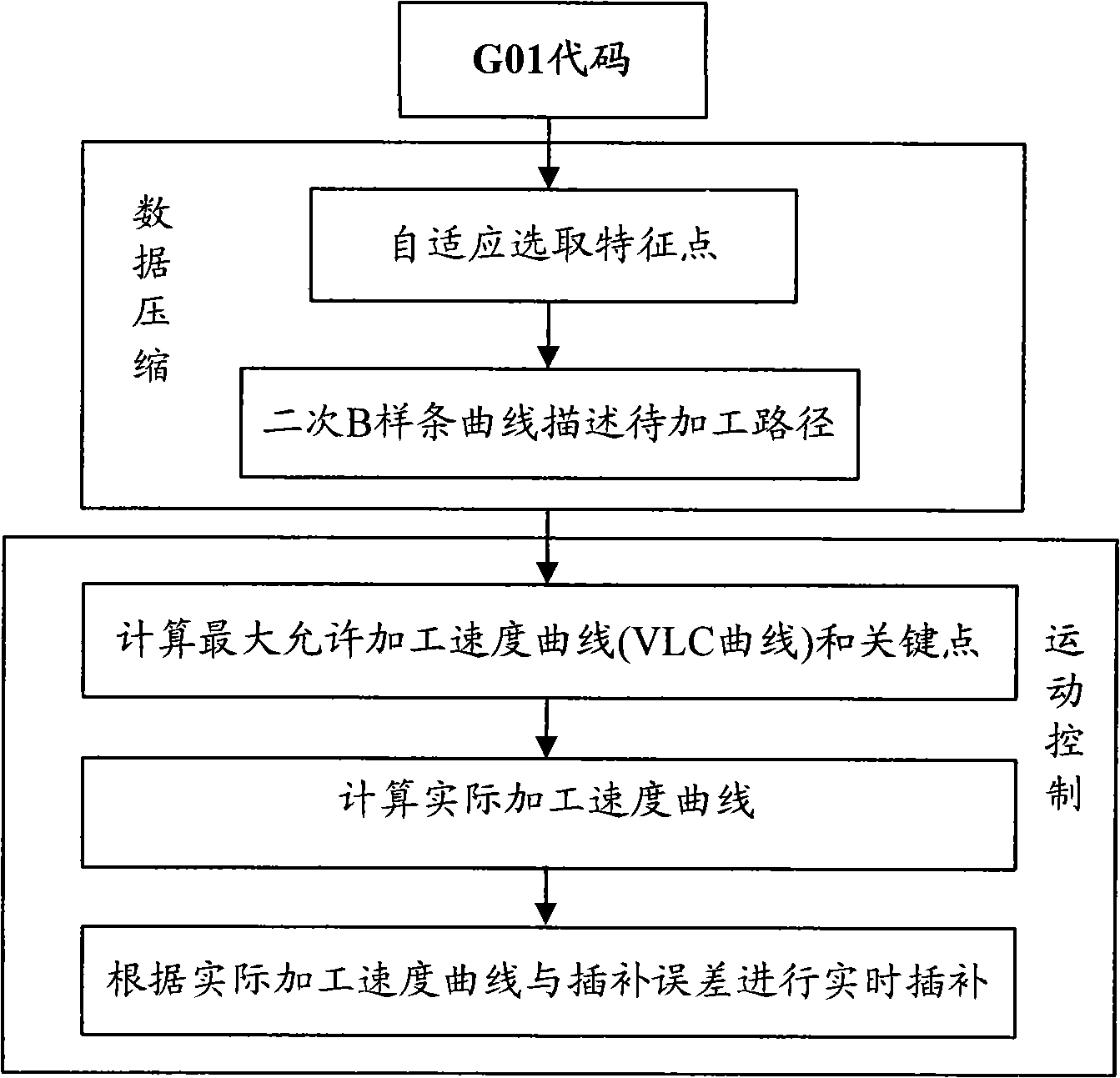

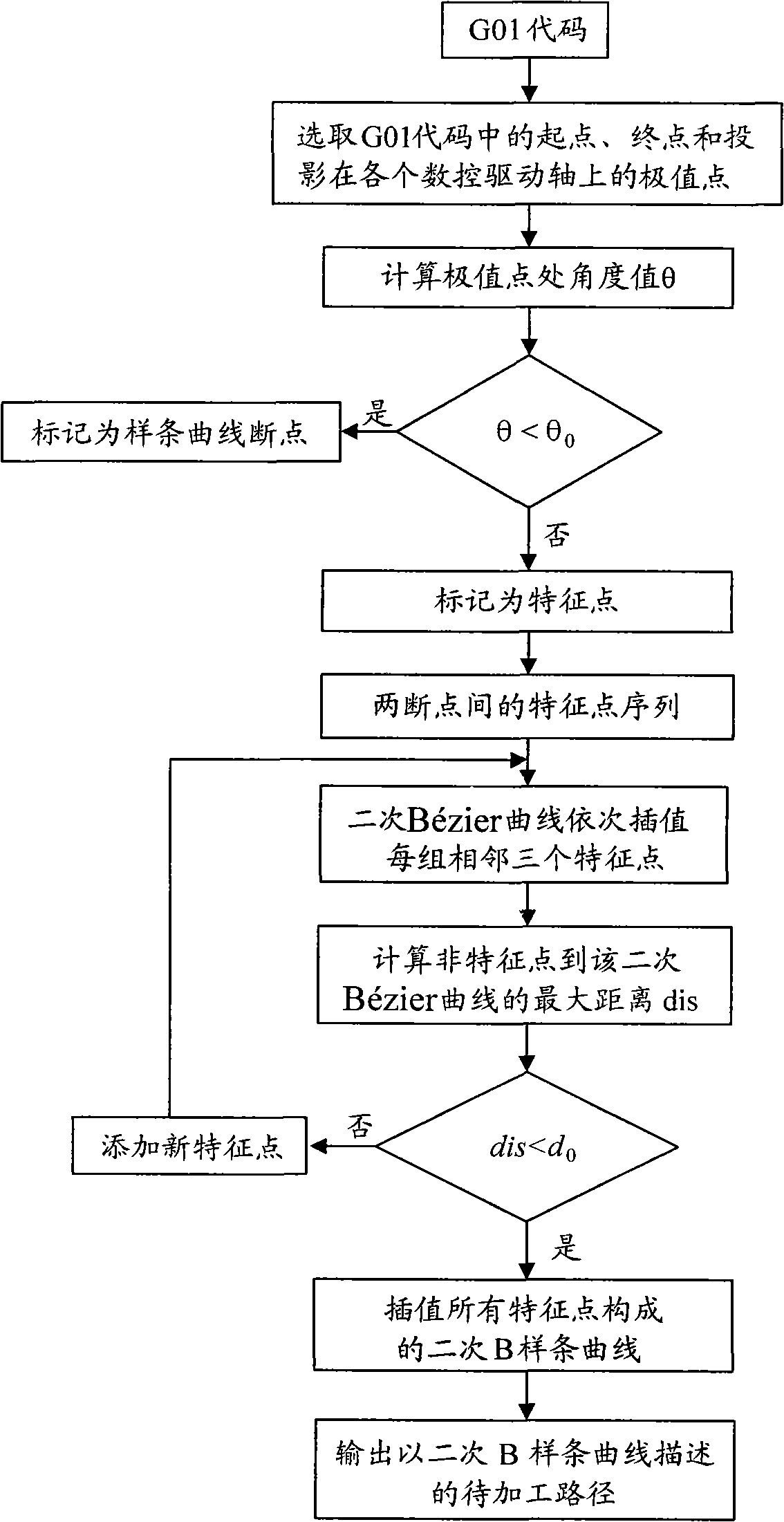

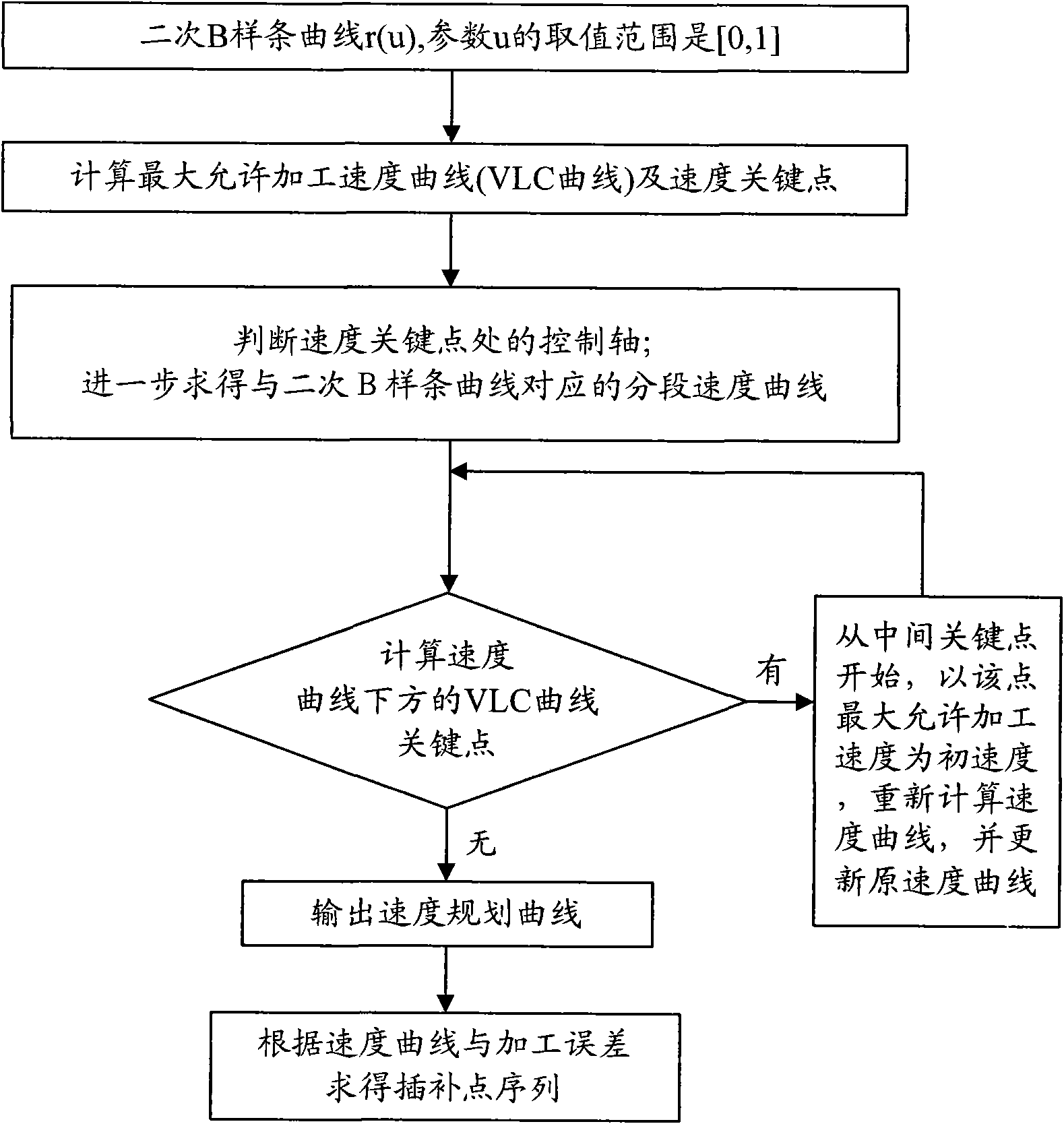

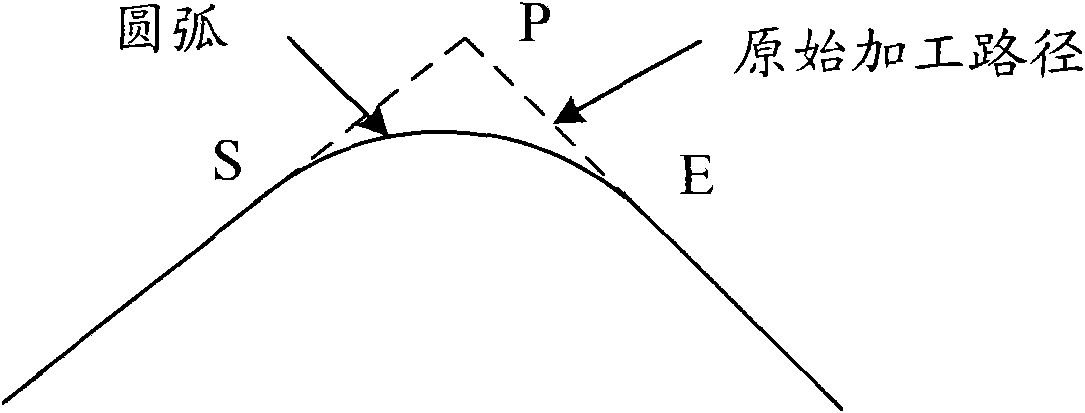

Method for fitting and interpolating G01 code based on quadratic B spline curve

InactiveCN101539769AAccurate descriptionMeet the precision requirementsProgramme controlAutomatic control devicesNumerical controlApplicability domain

The invention discloses a method for fitting and interpolating a G01 code based on a quadratic B spline curve, comprising the following steps of: by an adaptive approach selecting each characteristic point of each group of small line segment which is described by the G01 code; fitting a route which is to be processed with the quadratic B spline curve of all the characteristic points; according to the characteristic of the quadratic B spline curve and the limit of the acceleration of each driving shaft of the numerical control machine, simultaneously obtaining the maximum permissible machining velocity curve (VLC curve) of the quadratic B spline curve and the each speed key point on the VLC curve; according to the each speed key point, the control axis of the each key point, the maximum permissible machining velocity and the VLC curve, computing real machining velocity; according the real machining velocity curve and a interpolating error computing interpolating point and completing real-time interpolation. The invention has fast computing velocity, high machining precision, stable working performance and wide application range, can complete the interpolating computation of the spline curve in real time and meet digital control processing requirement of fast velocity and high precision under a premise that the preset precision of the system is met.

Owner:ACAD OF MATHEMATICS & SYSTEMS SCIENCE - CHINESE ACAD OF SCI

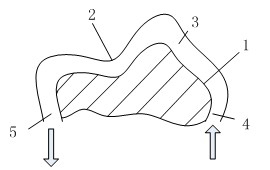

Novel method and special device for precisely processing titanium alloy joint prosthesis by curved-surface turbulence

InactiveCN102152240AIncrease profitImprove processing efficiencyAbrasive blasting machinesTitanium alloySacroiliac joint

The invention relates to a novel method for precisely processing a titanium alloy joint prosthesis by curved-surface turbulence. The novel method comprises the steps of: structuring a constraint runner on an outer surface of the titanium alloy joint prosthesis, introducing an abrasive grain flow into the constraint runner, and grinding and polishing the outer surface of the titanium alloy joint prosthesis in a turbulence state. A special device for the method provided by the invention comprises the titanium alloy joint prosthesis, a die arrangement model of the titanium alloy joint prosthesis covers the outer surface of the titanium alloy joint prosthesis, the constraint runner is formed between the outer surface of the titanium alloy joint prosthesis and the inner surface of the die arrangement model of the titanium alloy joint prosthesis, an inlet of the constraint runner is connected with an abrasive grain flow inlet pipeline, and an outlet of the constraint runner is connected with an abrasive grain flow outlet pipeline. The special device in the invention has the beneficial effects of simple structure, easiness for design and manufacture, high processing efficiency and processing precision and uniformity in processing.

Owner:ZHEJIANG UNIV OF TECH

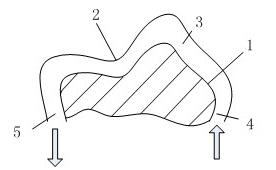

Picosecond laser machining apparatus for processing nozzle micropore

InactiveCN101502914AReduce thermal effectsImprove processing efficiencyLaser beam welding apparatusProcessing accuracyOptical processing

The invention provides a picosecond laser processing device for fuel nozzle microporous processing, which consists of a picosecond laser, a calibrating system and helical optical processing system. An output terminal of the picosecond laser is provided with a first reflecting mirror and the first reflecting mirror is connected with a second reflecting mirror; an output terminal of the second reflecting mirror is provided with an optical gate and an output terminal of the optical gate is connected with a beam extending lens; an output terminal of the beam extending lens is connected with a third reflecting mirror which is connected with the helical optical processing system through the calibrating system. The device is applicable to the fuel nozzle microporous processing and has the advantages of small thermal effect produced in the processing, smooth nozzle edge, no burr on the internal wall and high processing efficiency and accuracy; the diameter of the nozzle can be adjusted and the minimum is up to 60 um; the shape can be ensured to be cylindrical and the diameter depth ratio is up to 1:20, thus greatly increasing the processing accuracy and quality of the nozzle.

Owner:SUZHOU DELPHI LASER

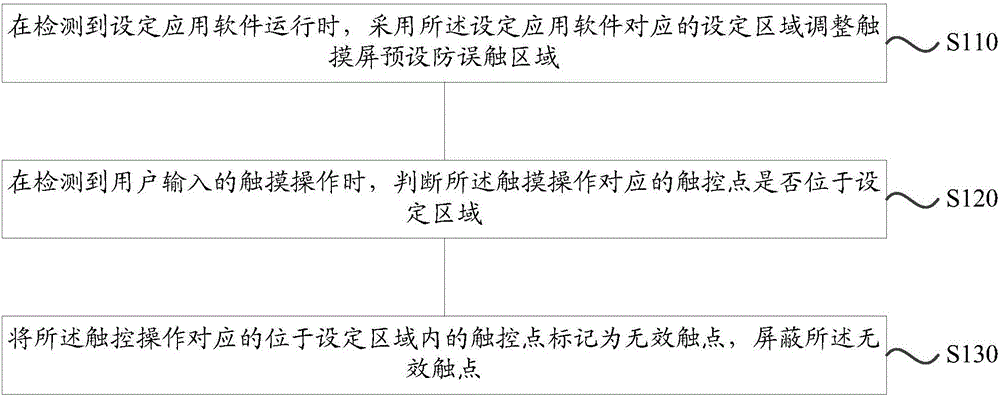

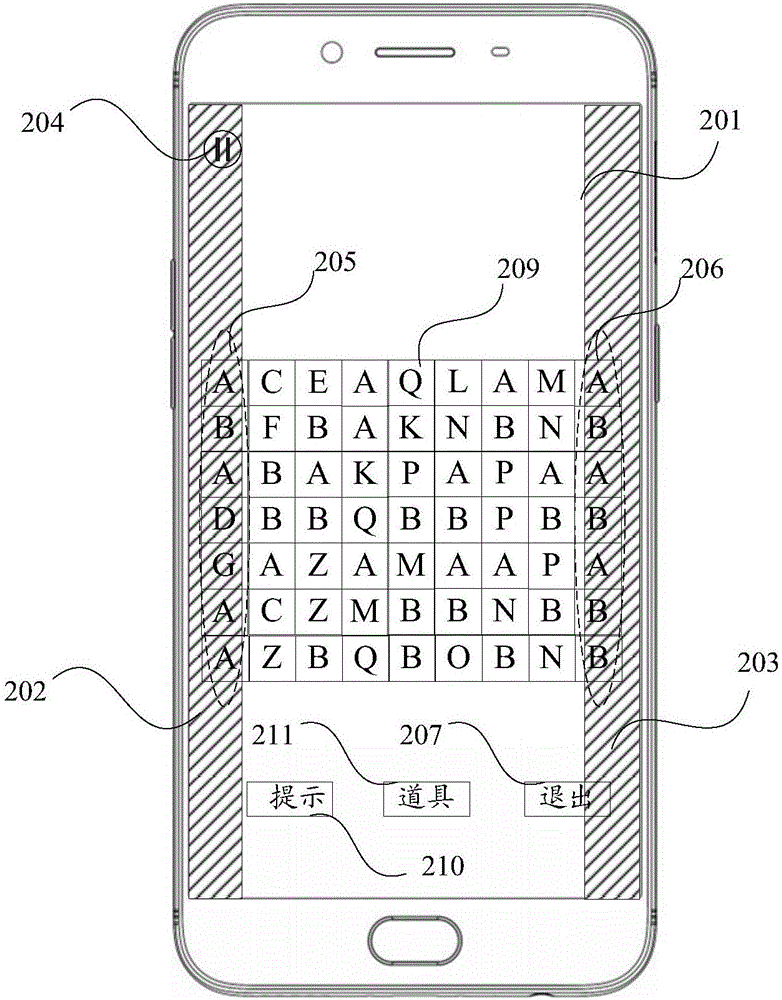

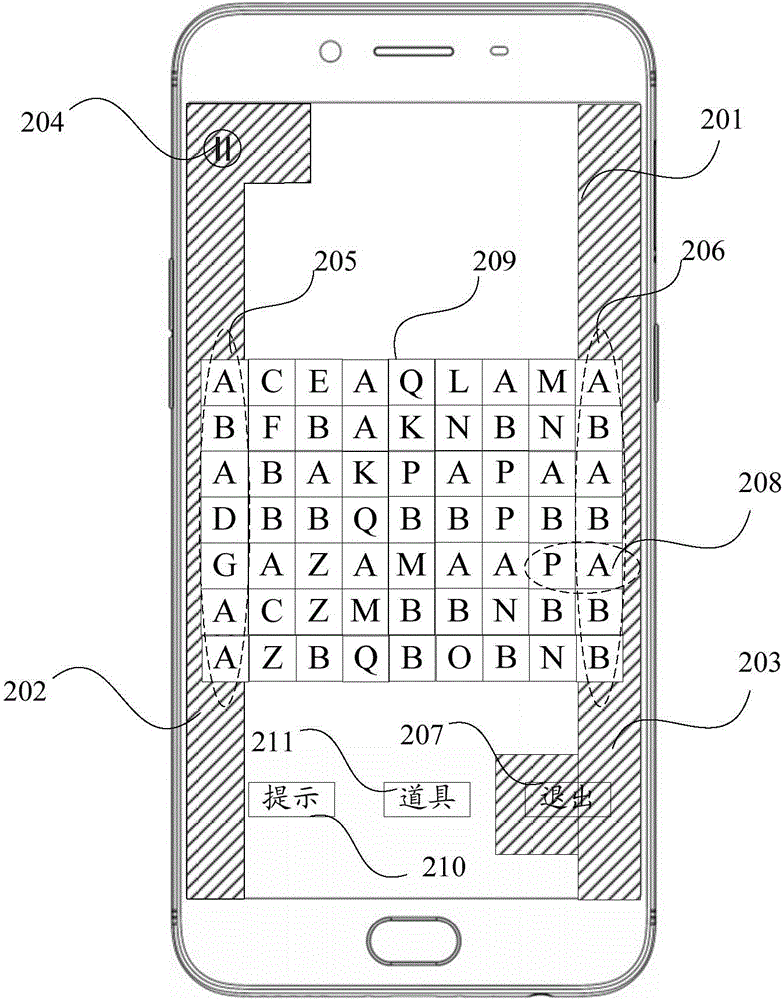

Control method and device for touch operation on mobile terminal, and mobile terminal

ActiveCN106527818AImprove processing accuracySolve the problem of not being able to adaptively prevent user misoperationInput/output processes for data processingUser inputApplication software

The embodiment of the invention discloses a control method and device for a touch operation on a mobile terminal, and the mobile terminal, and relates to the technical field of touch. The method comprises the following steps of: when a detection result shows that set application software operates, adopting a set area corresponding to the set application software to regulate a preset anti-mistaken-touch area of a touch screen, wherein the position, the shape and the area of the set area correspond to the application software which operates at present; when a touch operation input by a user is detected, judging whether the touch point corresponding to the touch operation is positioned in the set area; and labelling the touch point which is positioned in the set area and corresponds to the touch operation as an ineffective contact, and shielding the ineffective contact. By use of the embodiment of the invention, the problem that the misoperation of the user can not be adaptively prevented since an existing anti-mistaken-touch area is constant is avoided, and an effect on improving the reporting accuracy of the touch point so as to improve the processing accuracy of a touch event in the terminal can be achieved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

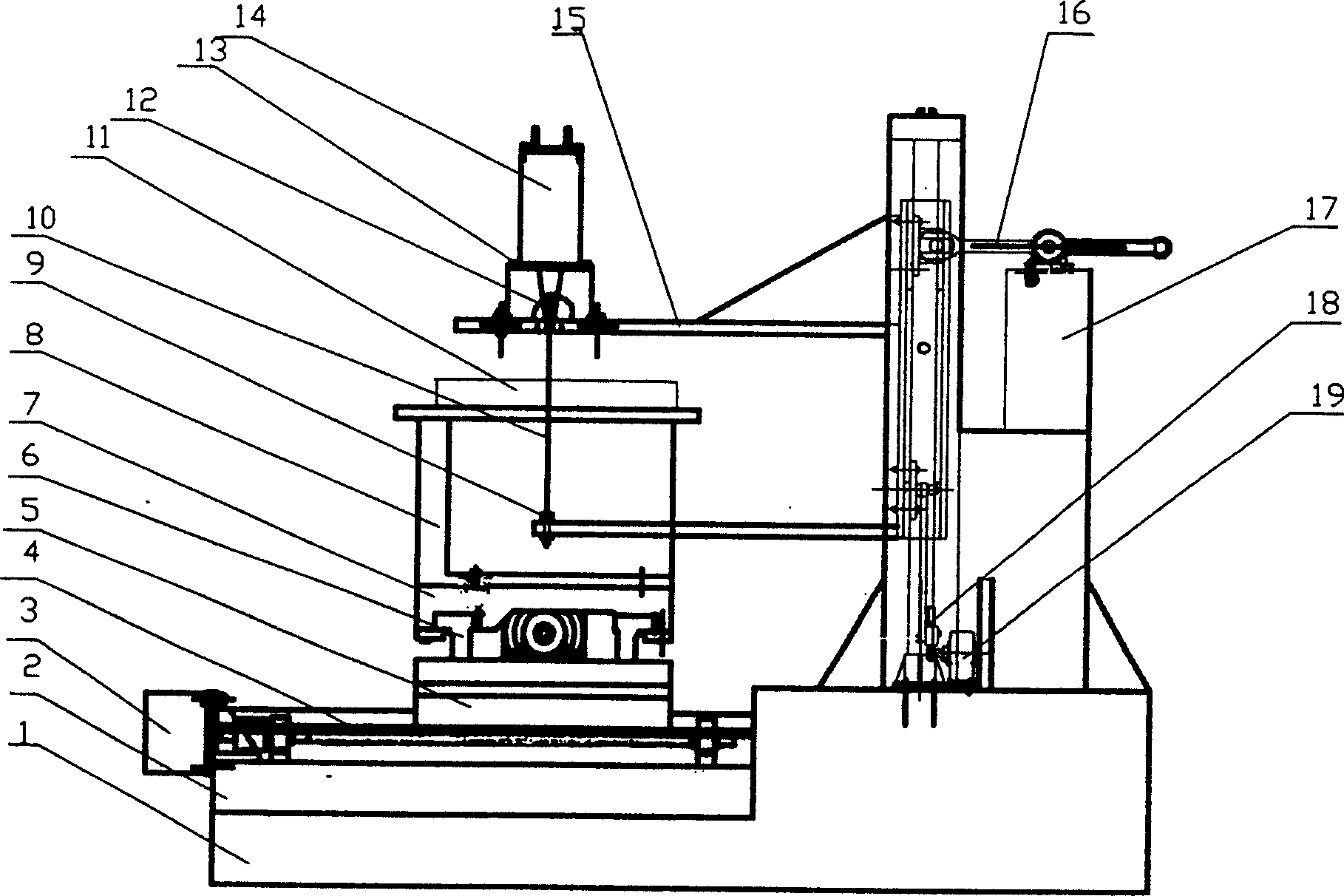

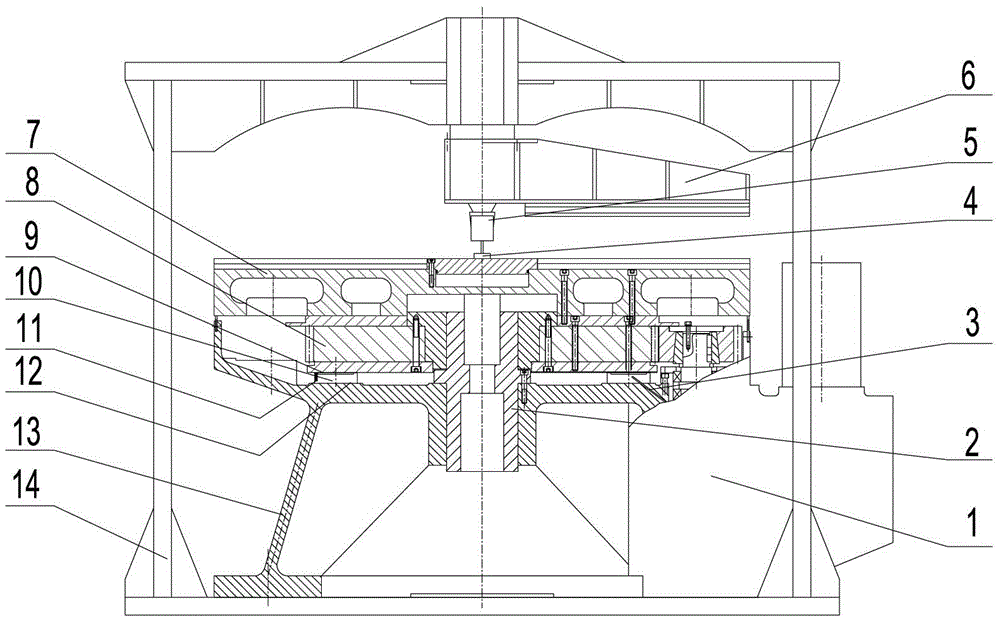

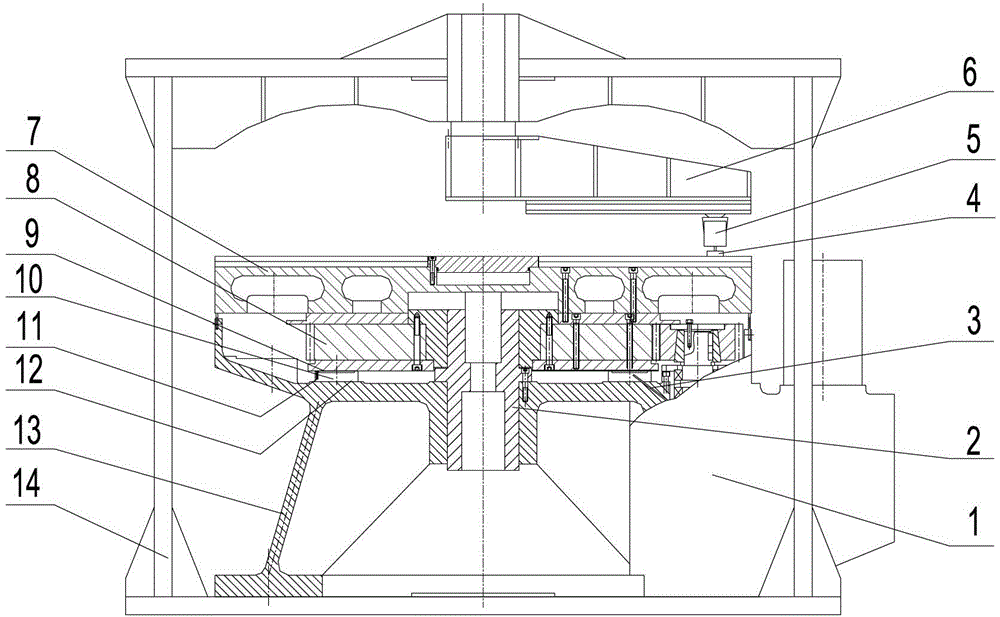

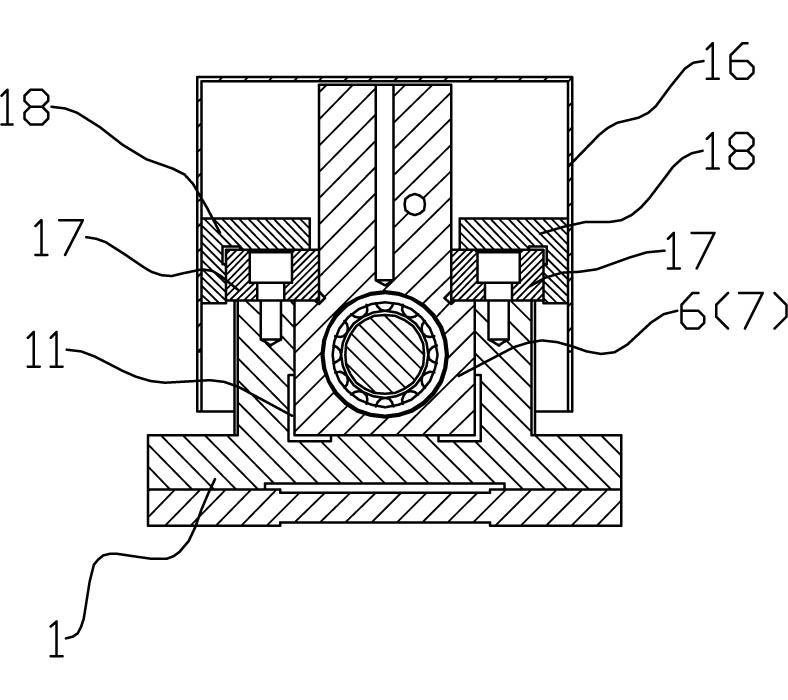

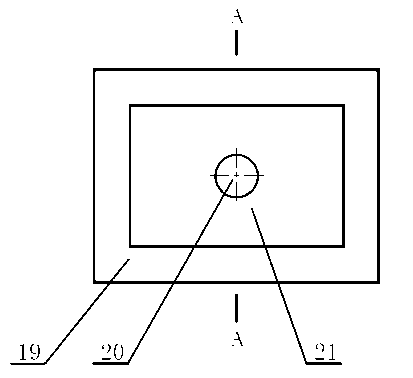

Quantitive type experimental device for dynamic and static performances of static-pressure rotary table

ActiveCN102980755AStructural parameter optimizationImprove machining accuracyMachine part testingElectricityEddy current

The invention provides a quantitive type experimental device for dynamic and static performances of a static-pressure rotary table, and belongs to the field of machinery design and manufacture. According to the experimental device, a loading device (5) and a loading arm (6) are used for changing magnitude of loads or changing oil supply pressure to control the distance between a static-pressure oil cushion (10) and a rotary table disc chuck (7), a pressure sensor (12) is used for measuring pressure in an oil cavity, an eddy current displacement sensor (11) is used for measuring the thickness of an oil film, a thermocouple temperature sensor (3) is used for measuring oil temperature, a force sensor (4) is used for obtaining magnitude of loading force, a pressure gauge a (15) on a multi-head pump at an oil inlet in the oil cavity is used for measuring pressure of the oil inlet of the oil cavity, and a pressure gauge b (16) arranged between an oil pump and the multi-head pump is used for measuring the oil supply pressure of the static-pressure rotary table. By means of the experimental device, a test of the dynamic and static performances of the static-pressure rotary table is carried out under the condition that temperature is between minus 10 DEG C and 60 DEG C and pressure is not more than 100 MPa, and the experimental device provides guarantee for solving problems in engineering, optimizing structural parameters of the rotary table, and improving machining precision of the rotary table.

Owner:BEIJING UNIV OF TECH

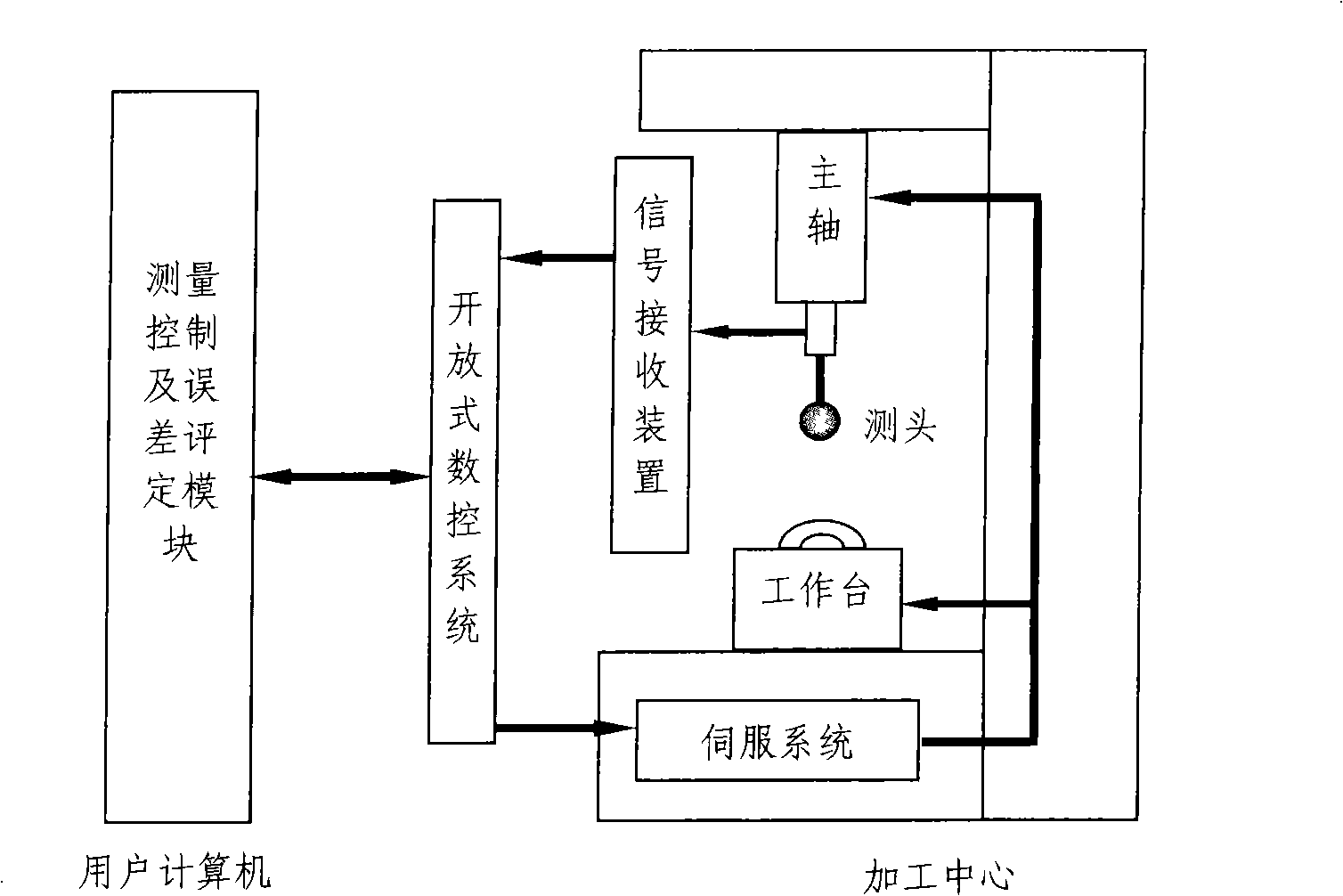

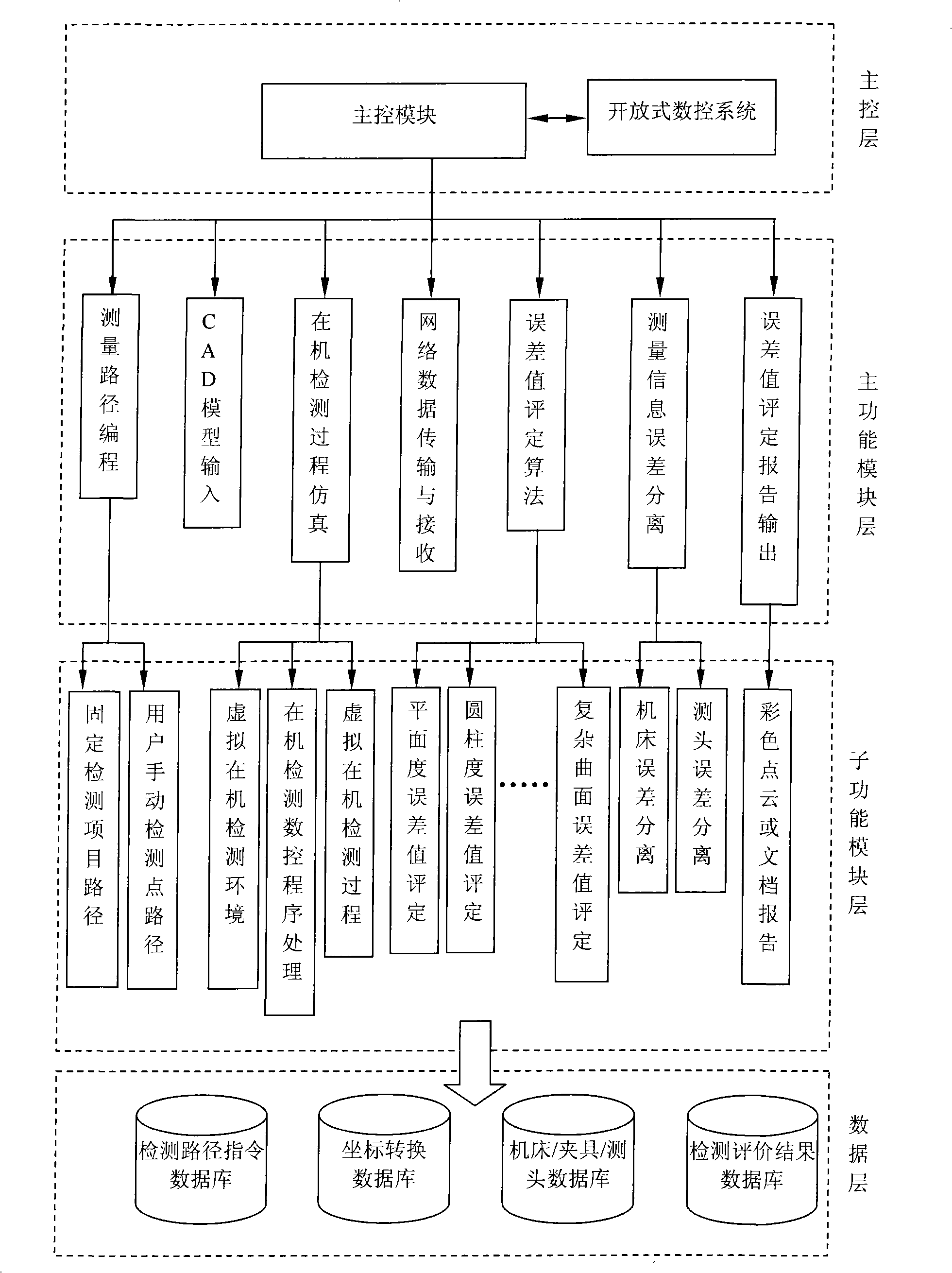

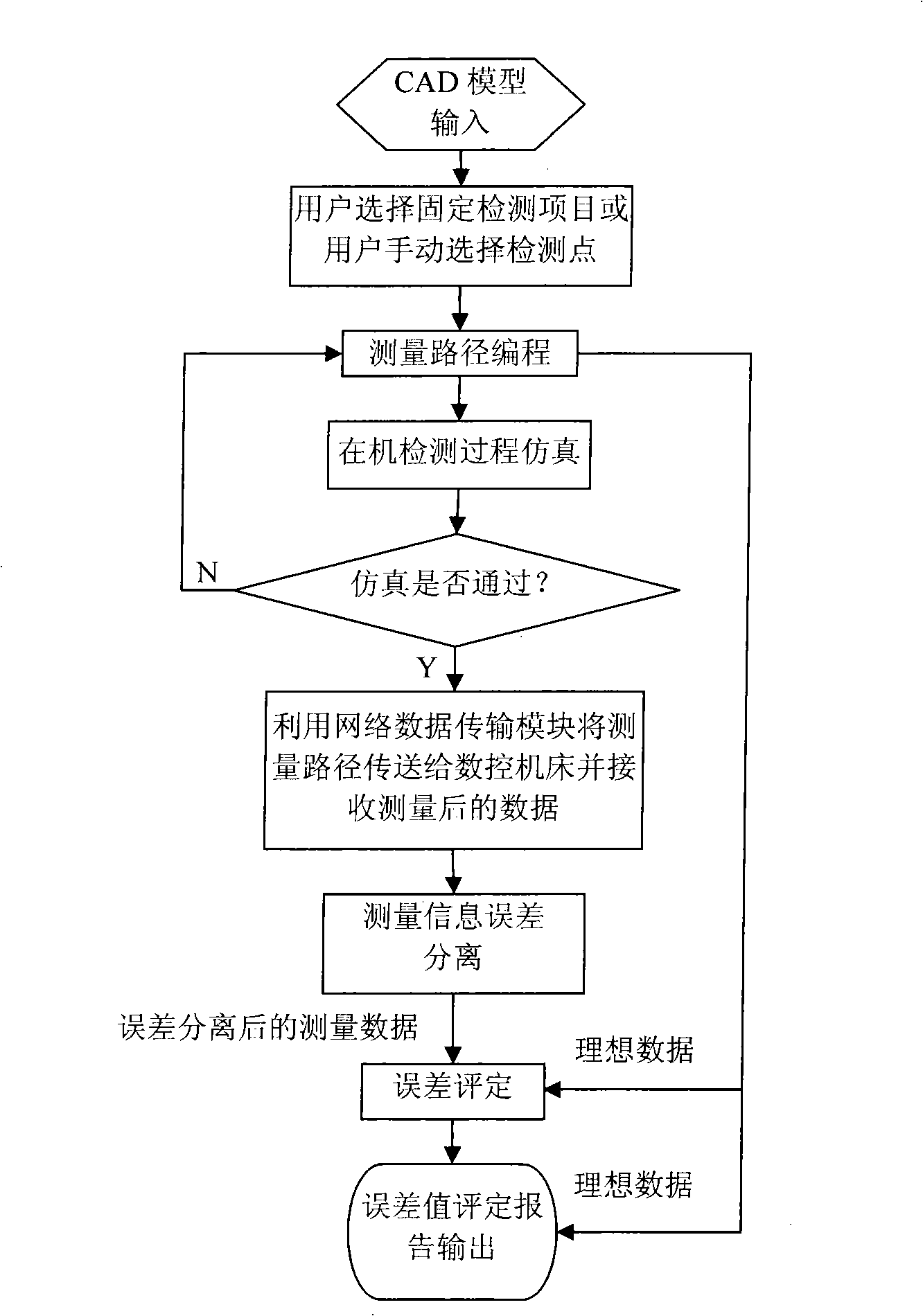

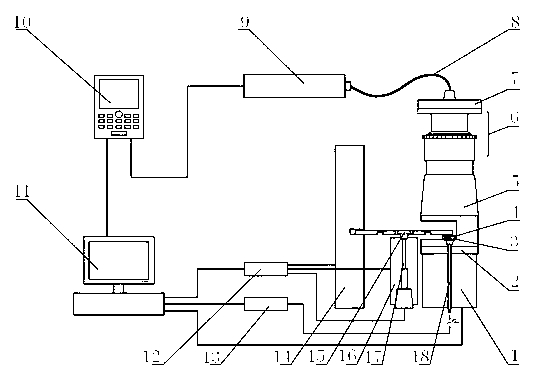

On-machine quality detecting system for complex space type surface

ActiveCN101342664AGuaranteed machining accuracyIncrease productivityProgramme controlComputer controlCommunications systemData exchange

The invention discloses a complex space surface on-machine quality test system, comprising a processing center, three coordinate probes and a measuring signal receiver. The processing center is used to process parts and is equipped with an open numerical control system. The probes are controlled by the numerical control system of a numerically controlled machine tool, and are used to obtain the geometrical measurement value of the discrete points on the surface of the workpiece which has been processed. The measuring signal receiver is used to receive the infrared signals sent by the probes, and transmits the signals to the numerical control system. The numerical control system transmits the measurement value signals to the computer of the user through a communication system, and controls the main shaft of the numerically controlled machine tool to stop moving at the same time. The computer of the user which is provided with a measurement control and error evaluation module is used to exchange data with the numerical control system through the communication system, and evaluates the error and gives an evaluation result based on the ideal value and measurement value of measuring points through the measurement control and error evaluation module. The complex space surface on-machine quality test system can inspect the quality of the workpiece at any moment during processing, guarantees the processing precision of the workpiece, and saves time.

Owner:TIANJIN UNIV

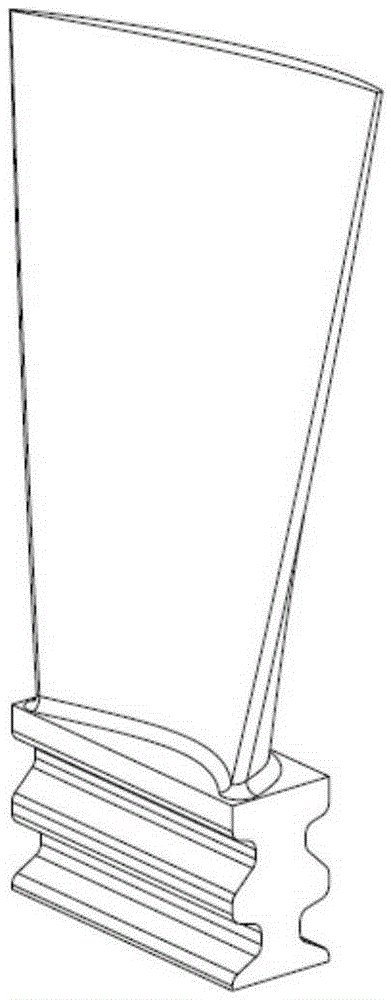

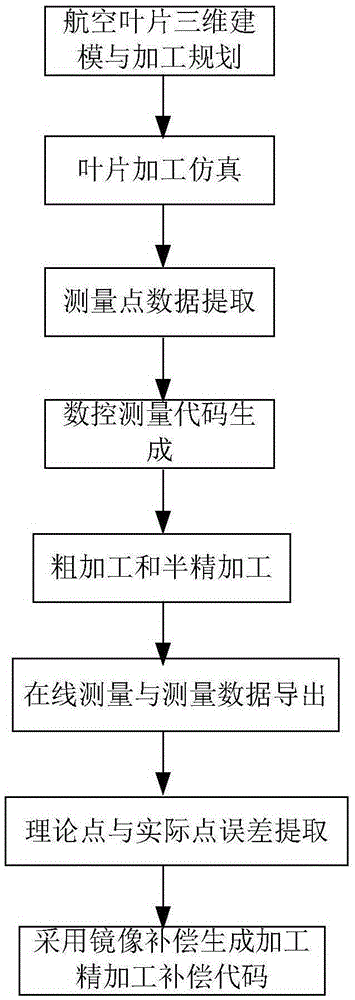

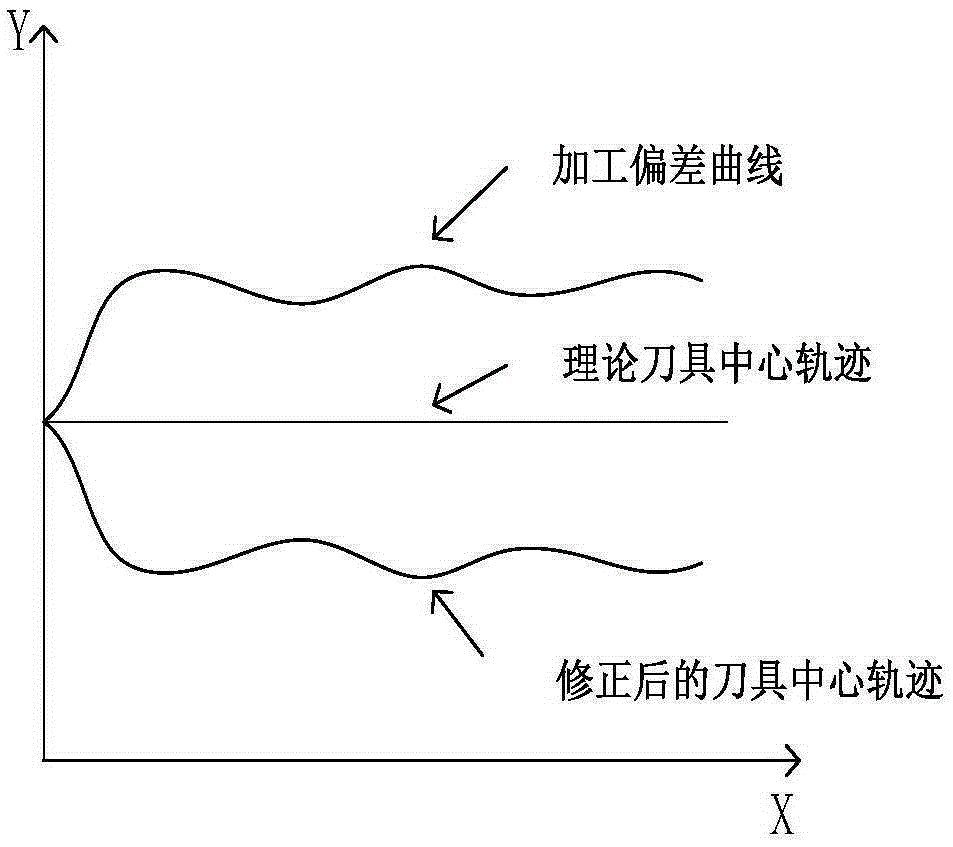

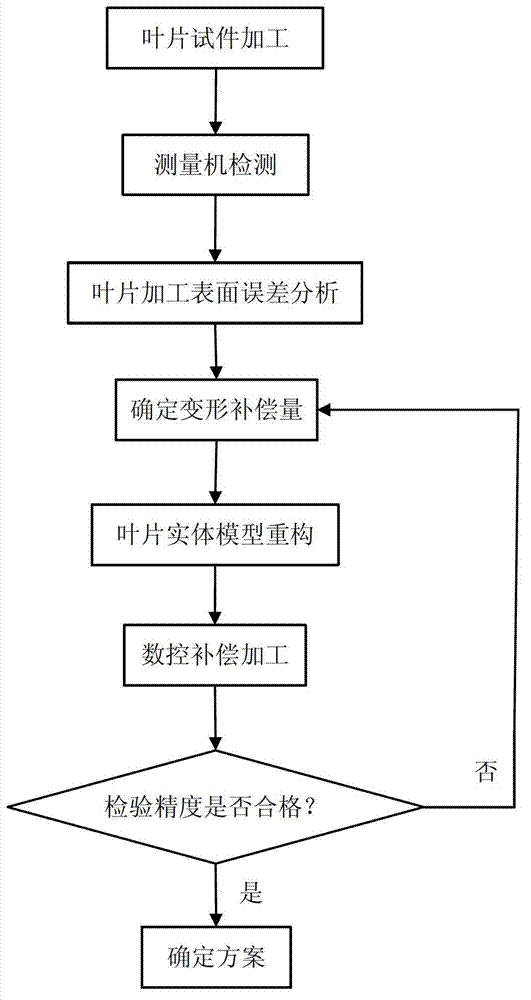

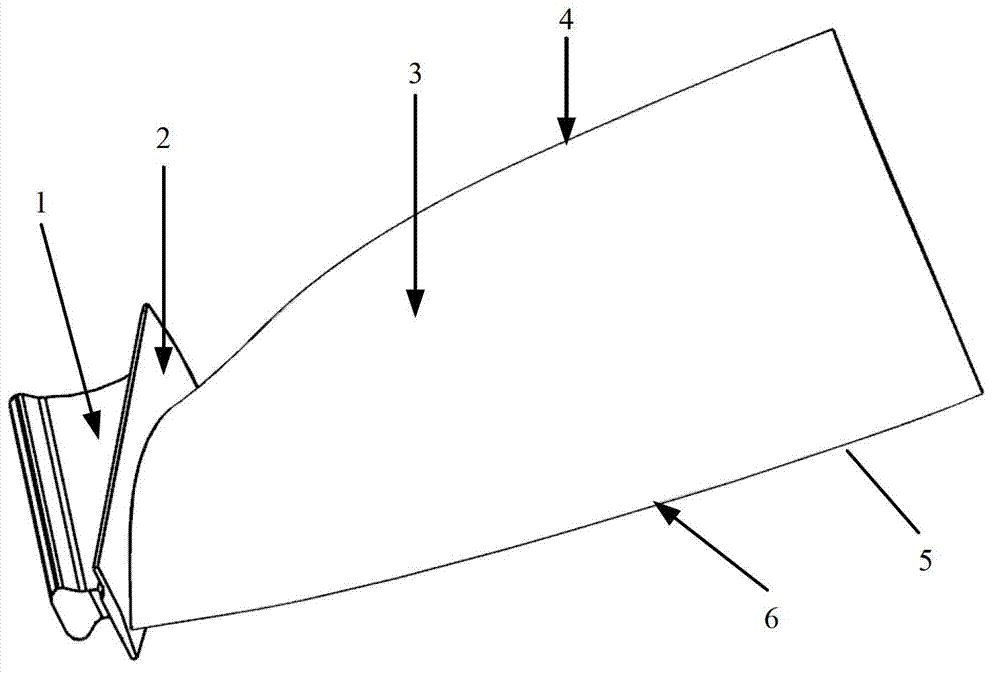

Aviation thin-wall blade compensation processing method

InactiveCN105242637AThe direct effect is obviousSavings are inconsistentProgramme controlComputer controlAviationNumerical control

The invention relates to an aviation thin-wall blade compensation processing method and belongs to the field of compensation processing of precision parts in the mechanical engineering field. For the problems that it is hard to predict deformation and error in the blade processing process, and it is difficult to control the processing precision and the like, the method carries out precise predicted compensation processing by obtaining measurement point coordinates of the parts in the processing process and by utilizing the processes of digital modeling, numerical control machining, off-line inspection path planning, point-cloud fitting and processing code regeneration and the like, so that the purposes of on-line measurement and deformation compensation and the like of the aviation thin-wall blades are achieved, the problem of difficult processing deviation suppression in the processing process of free-form surface parts of blades at present is overcome, machining precision of the kind of blades can be improved, rejection rate is reduced, and machining quality of the thin-wall blades are obviously improved.

Owner:HUAZHONG UNIV OF SCI & TECH

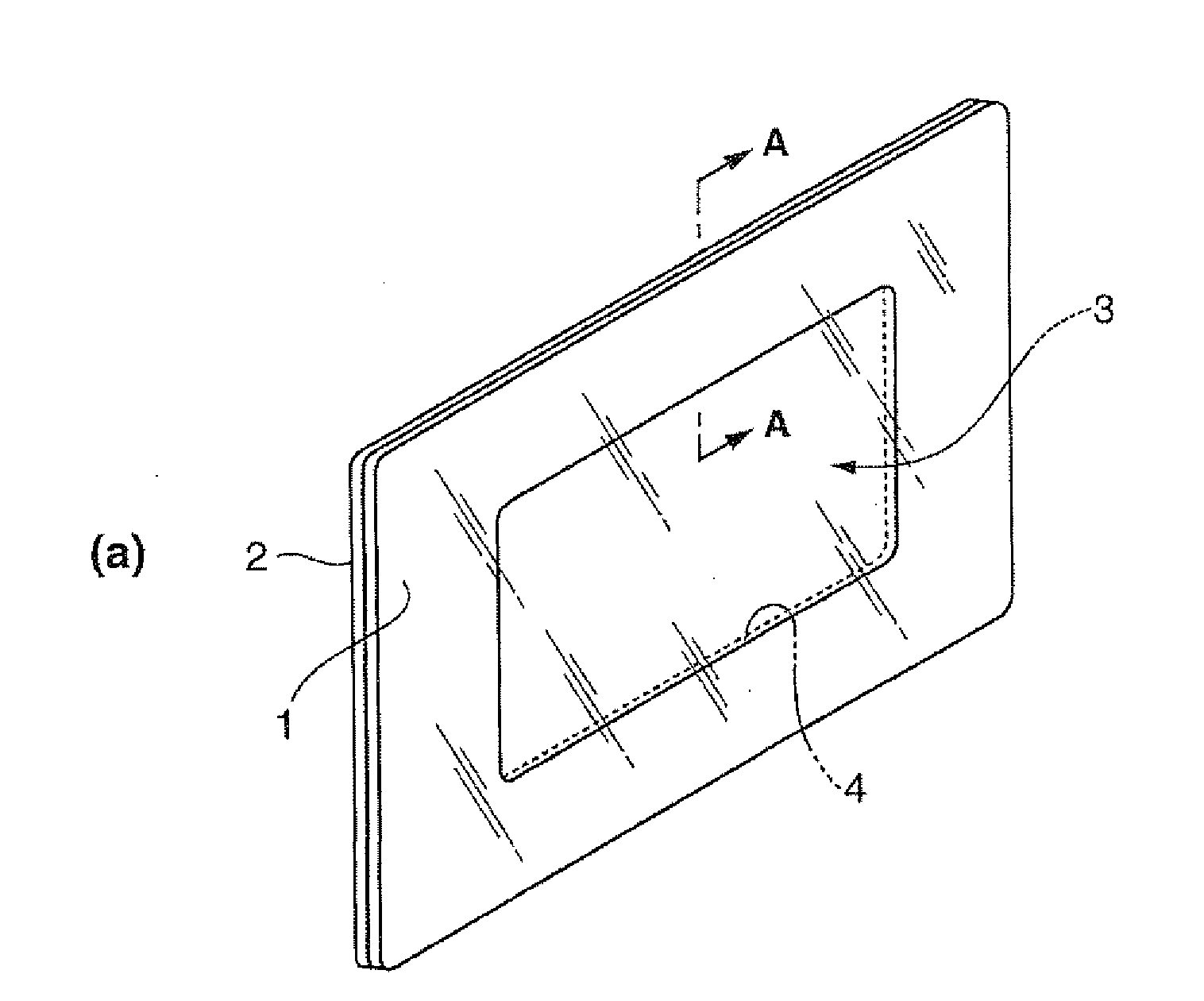

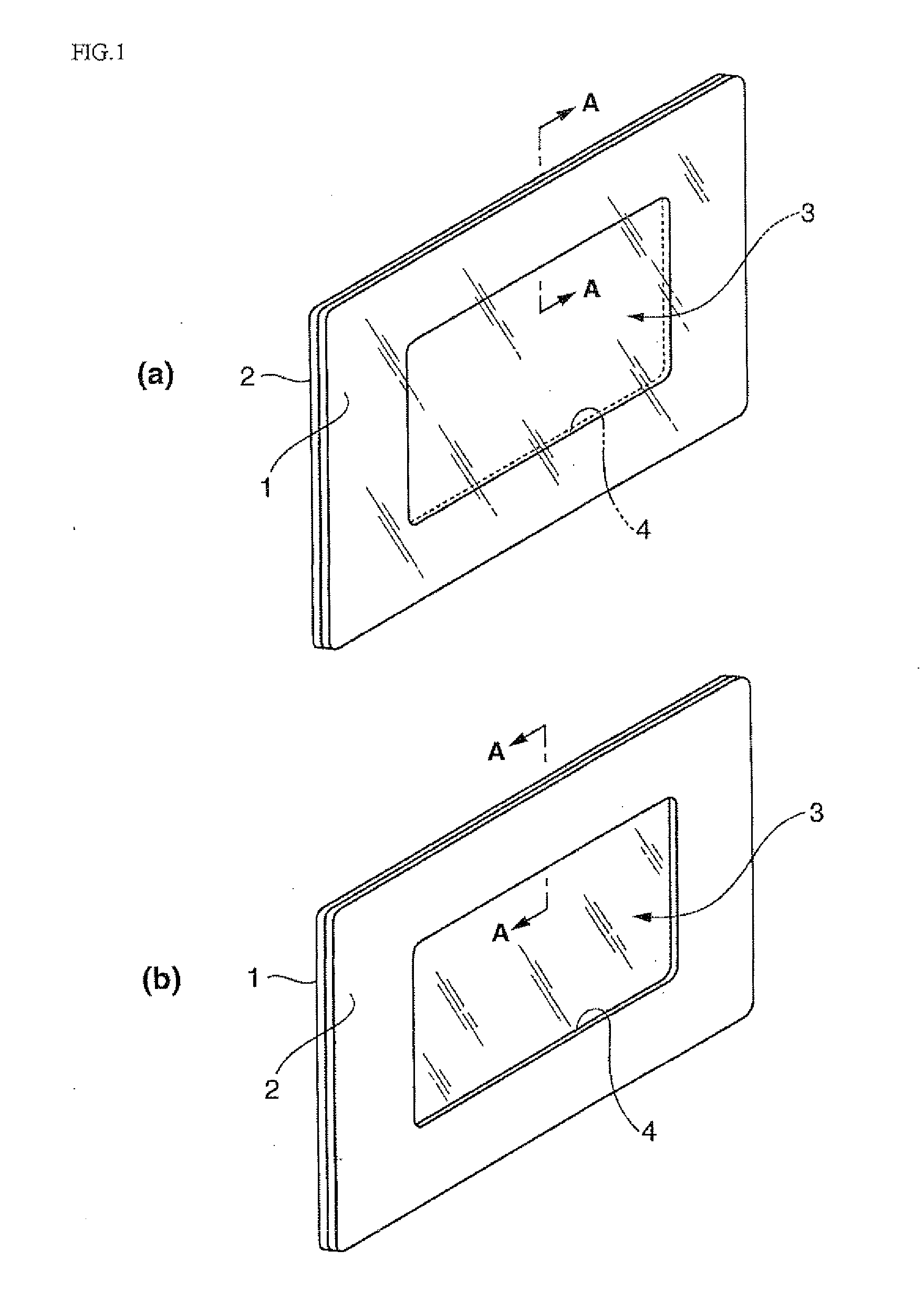

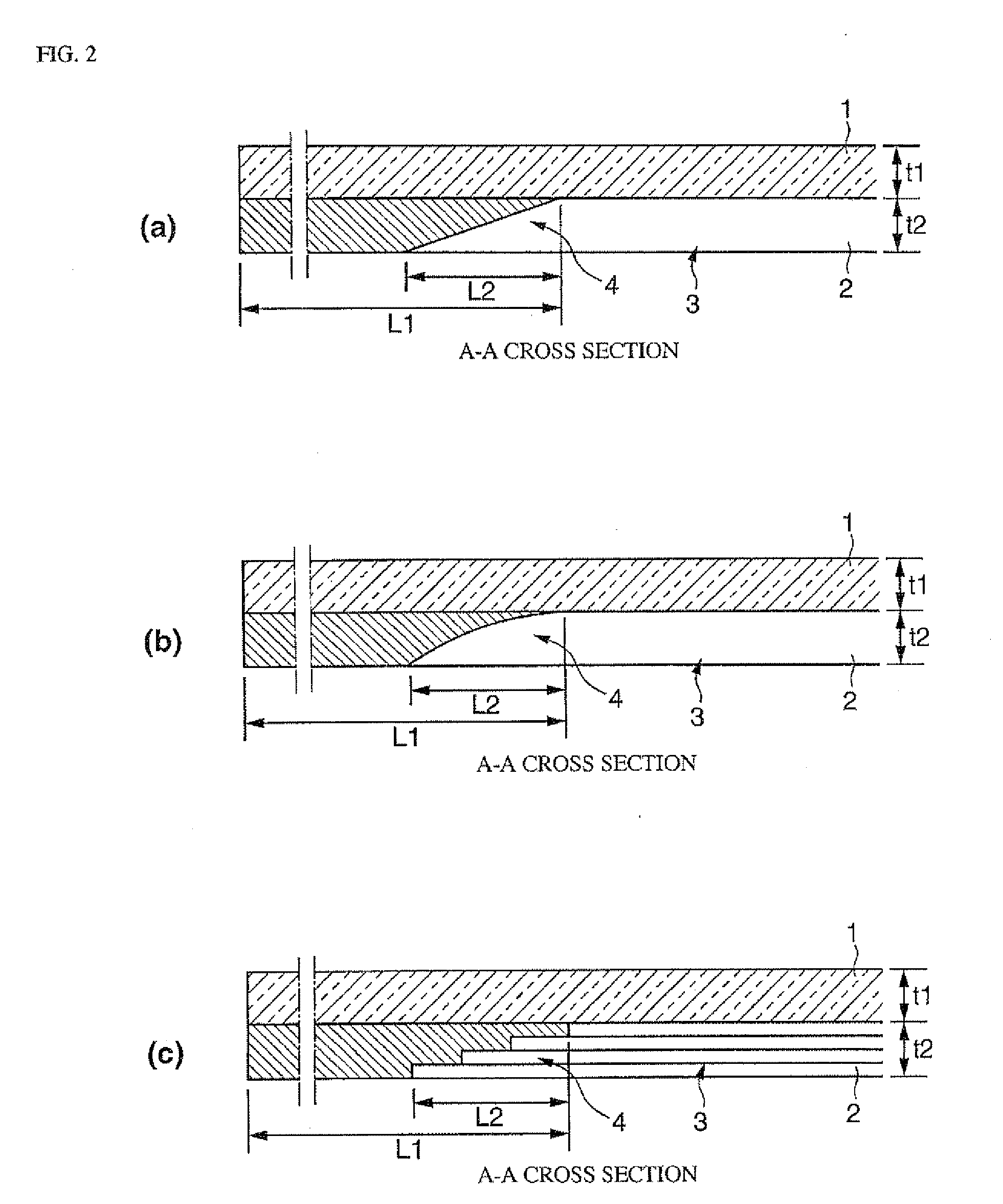

Panel-shaped molded product

The present invention relates to a panel-shaped molded product having a laminated structure which is produced from a resin and used for side doors, back doors, hoods, roofs, etc., and exhibits a more excellent finishing accuracy without occurrence of bleed-out along an inner periphery of a frame part and fine distortions on a design part. The panel-shaped molded product of the present invention is a molded product having a laminated structure which is obtained by injection-molding the frame part (2) on one surface of the plate-shaped design part (1) wherein an inner peripheral portion (4) of the frame part (2) is closely attached to the design part, and has a thickness changing region where a thickness of the frame part is reduced toward the side of a center of the frame part such that a ratio between a width of the thickness changing region and the thickness of the frame part (2), and a ratio between a width of the thickness changing region and a width of the frame part (2) are respectively adjusted to satisfy specific relationships.

Owner:MITSUBISHI ENG PLASTICS CORP

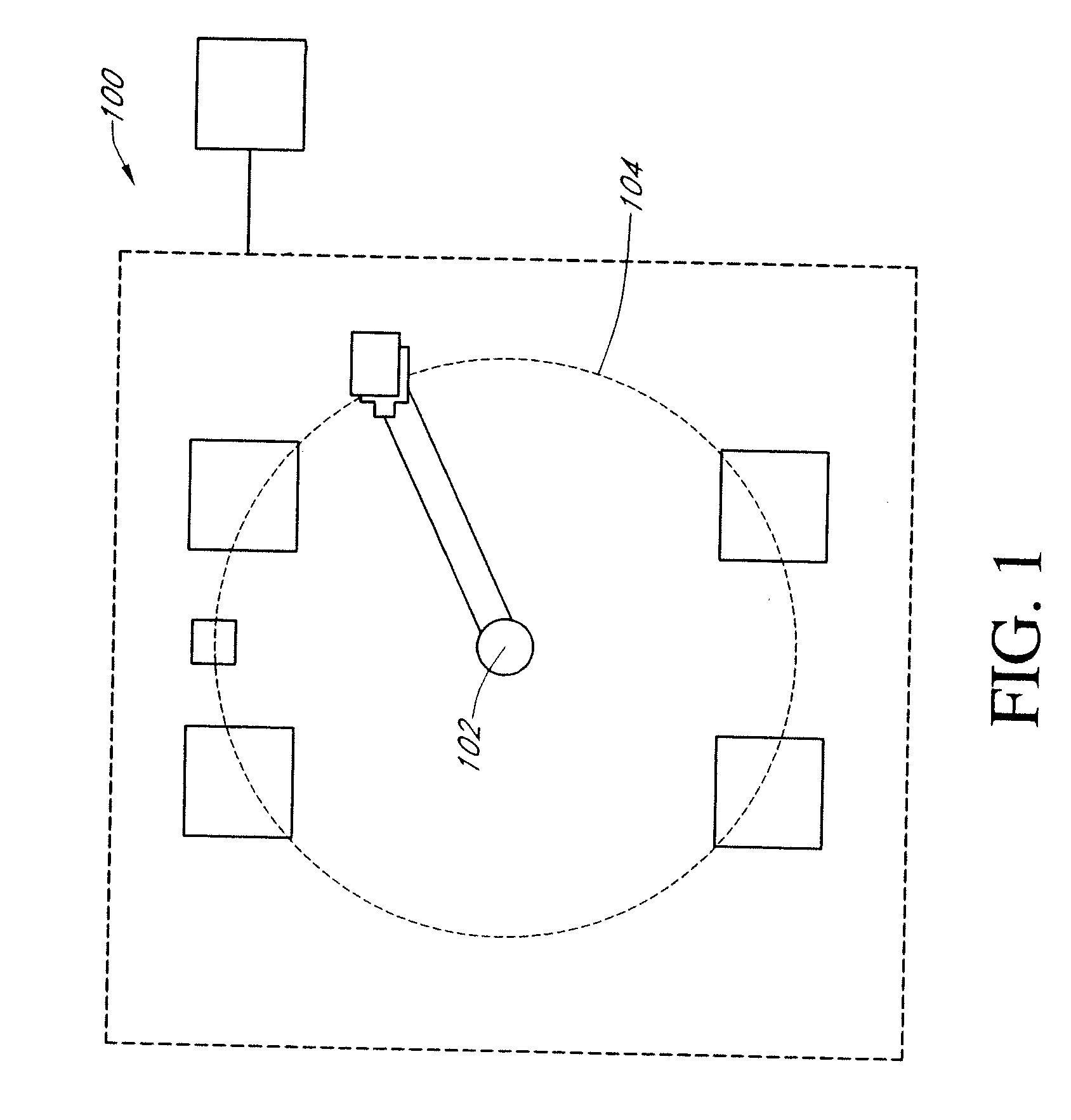

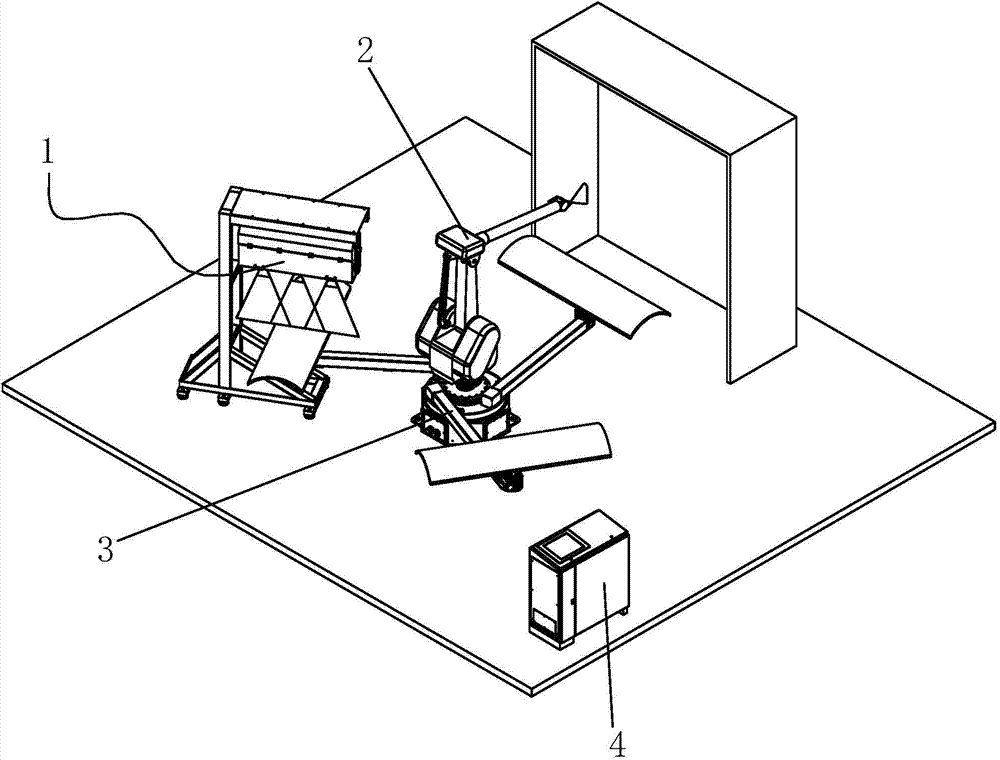

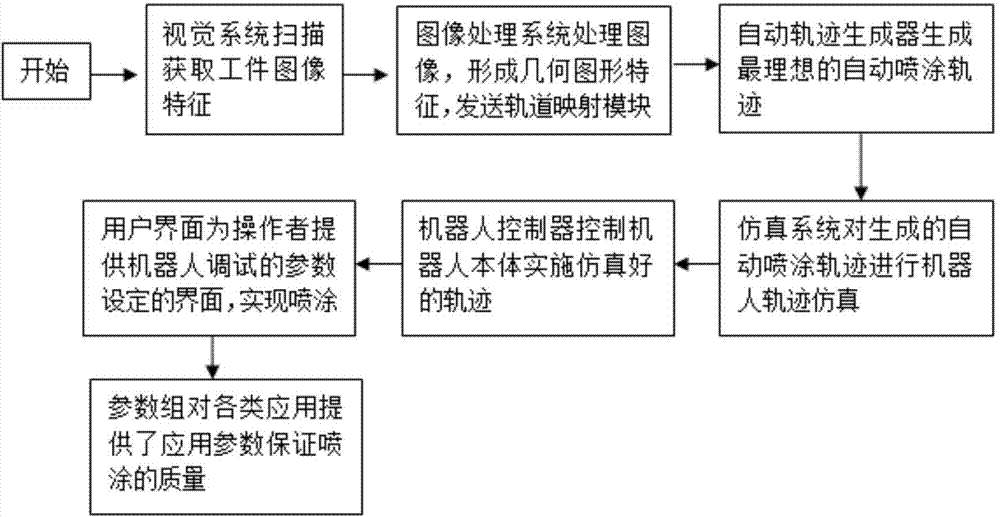

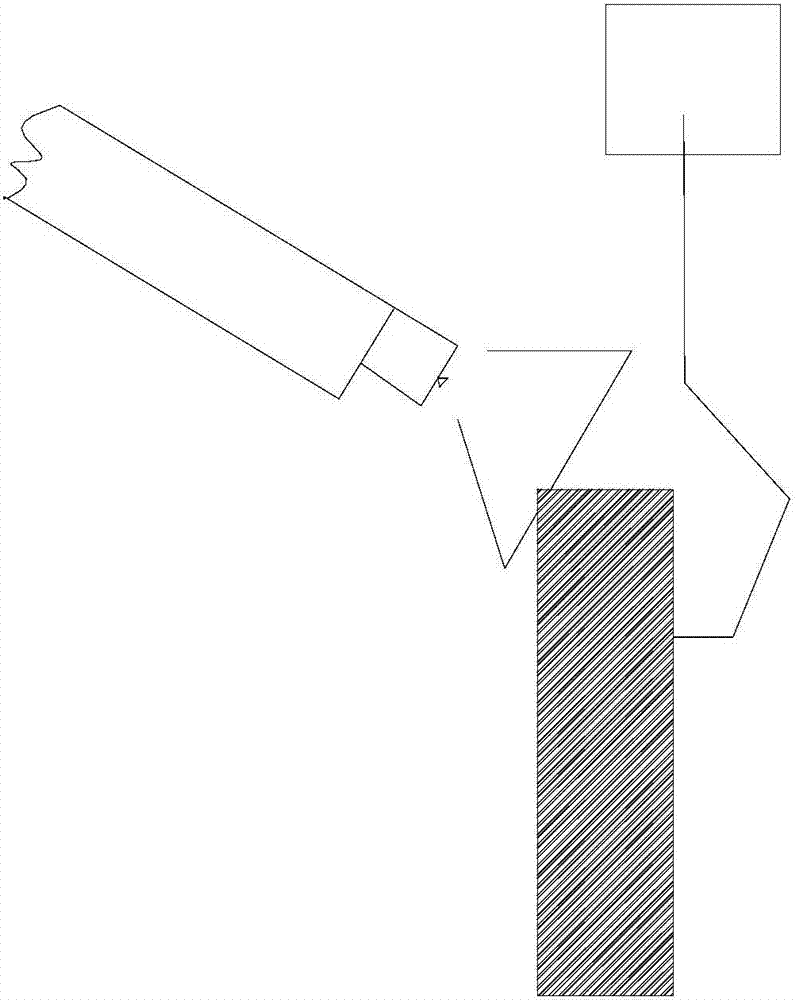

Control method of robot automatic spraying system

The invention discloses a control method for a robot automatic spraying system. The control method of the robot automatic spraying system comprises the following steps of (1) acquiring feature data of a workpiece to be sprayed; (2) processing acquired data by using an image processing system; (3) automatically generating a track; (4) simulating; (5) controlling a user interface; (6) determining a spraying parameter; and (7) performing spraying. The control method of the robot automatic spraying system has the advantages of high automation degree, high machining precision, wide application range and the like. Different workpiece spraying tracks can be generated automatically, the operation difficulty of a user is reduced, the traditional manual programming on single different-model workpieces to be sprayed is replaced, consumed time on spraying is shortened, and the production efficiency is improved.

Owner:希美埃(芜湖)机器人技术有限公司

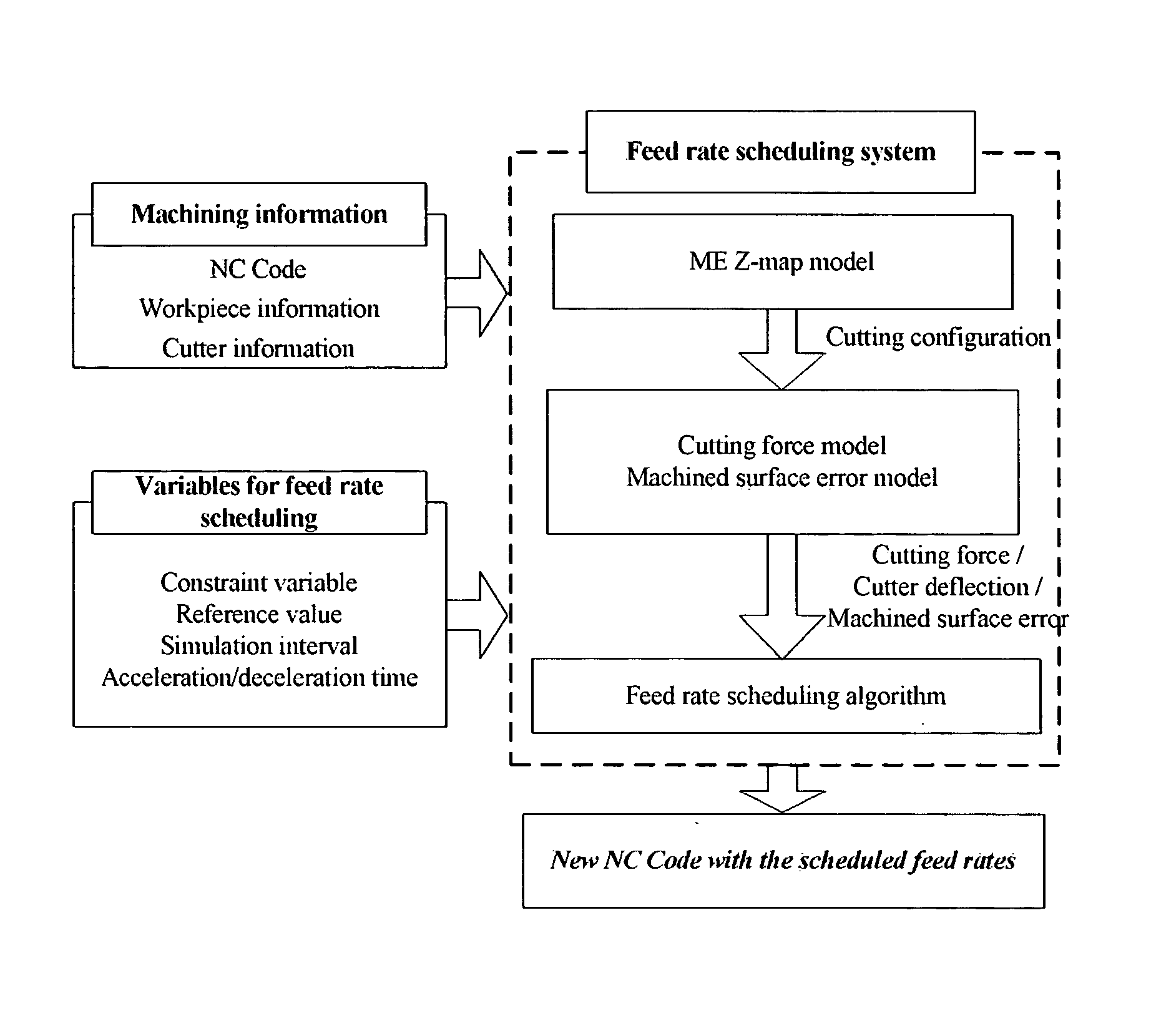

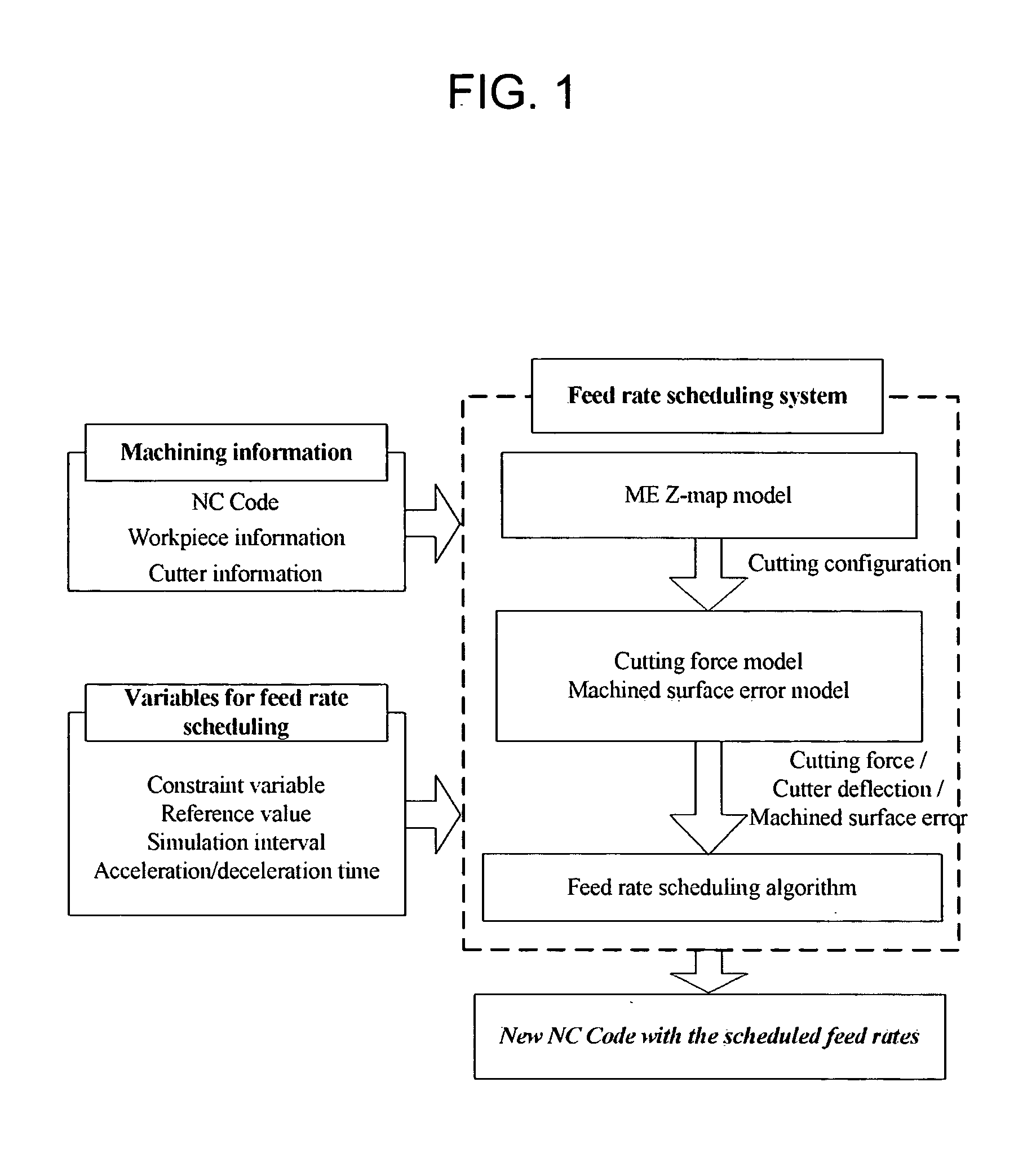

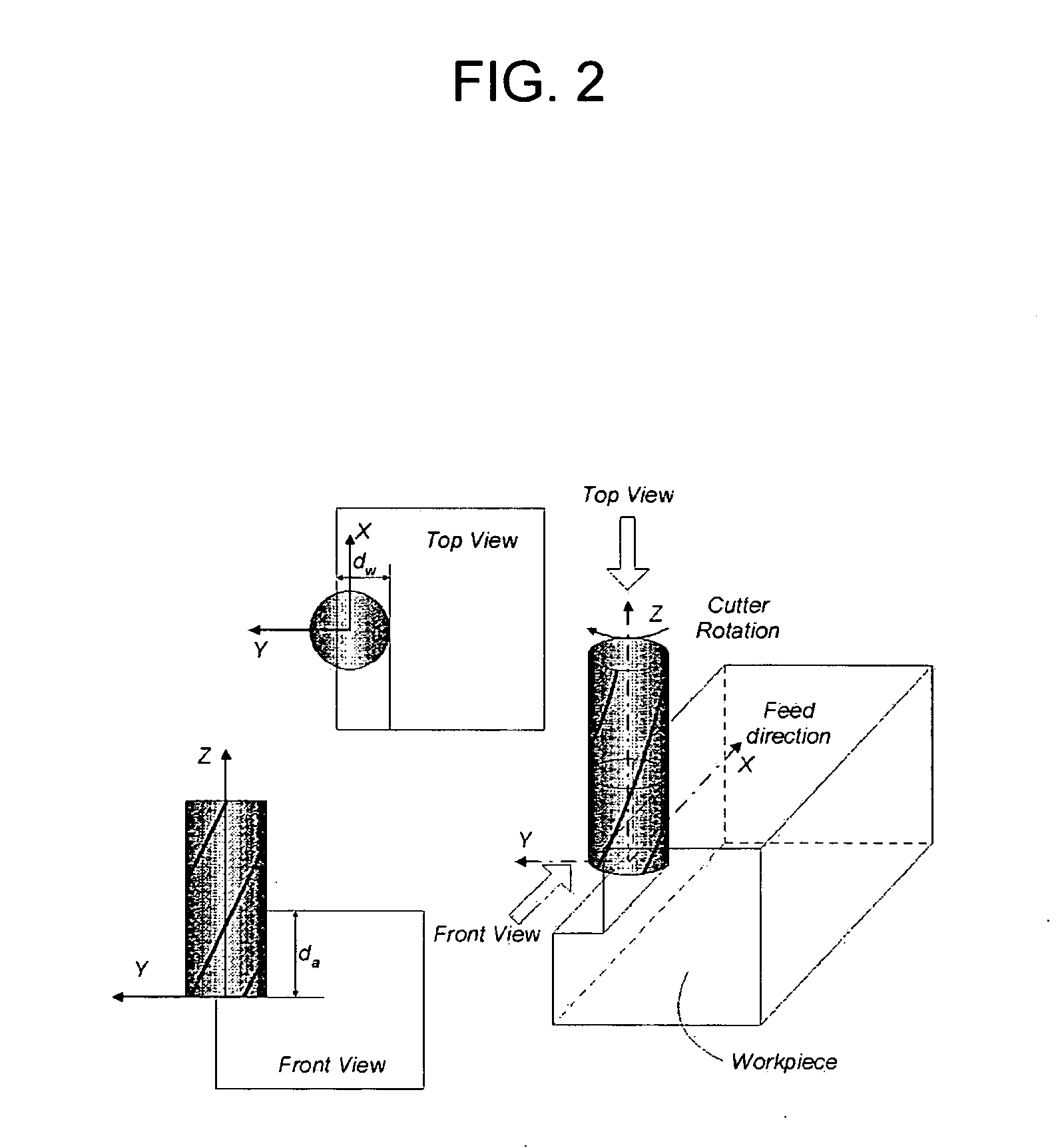

Off-line feed rate scheduling for reduction of machining time and enhancement of machining accuracy in CNC machining

InactiveUS20050113963A1Improve machining precisionIncrease productivityComputation using non-denominational number representationNumerical controlMachined surfaceSpecific rotation

An off-line feed rate scheduling method of a CNC machining process includes selecting a constraint variable and inputting a reference value related to the constraint variable; estimating a cutting configuration where a maximum constraint variable value (CVV) occurs through ME Z-map modeling; receiving the estimated cutting configuration and estimating a specific rotation angle (φs) where the maximum constraint variable value occurs through constraint variable modeling; calculating a feed rate that satisfies the reference value of the constraint variable at the estimated specific rotation angle; and applying the calculated feed rate to the NC code. Cutting force or machined surface error may be selected as a constraint variable depending on machining conditions.

Owner:POSTECH ACAD IND FOUND

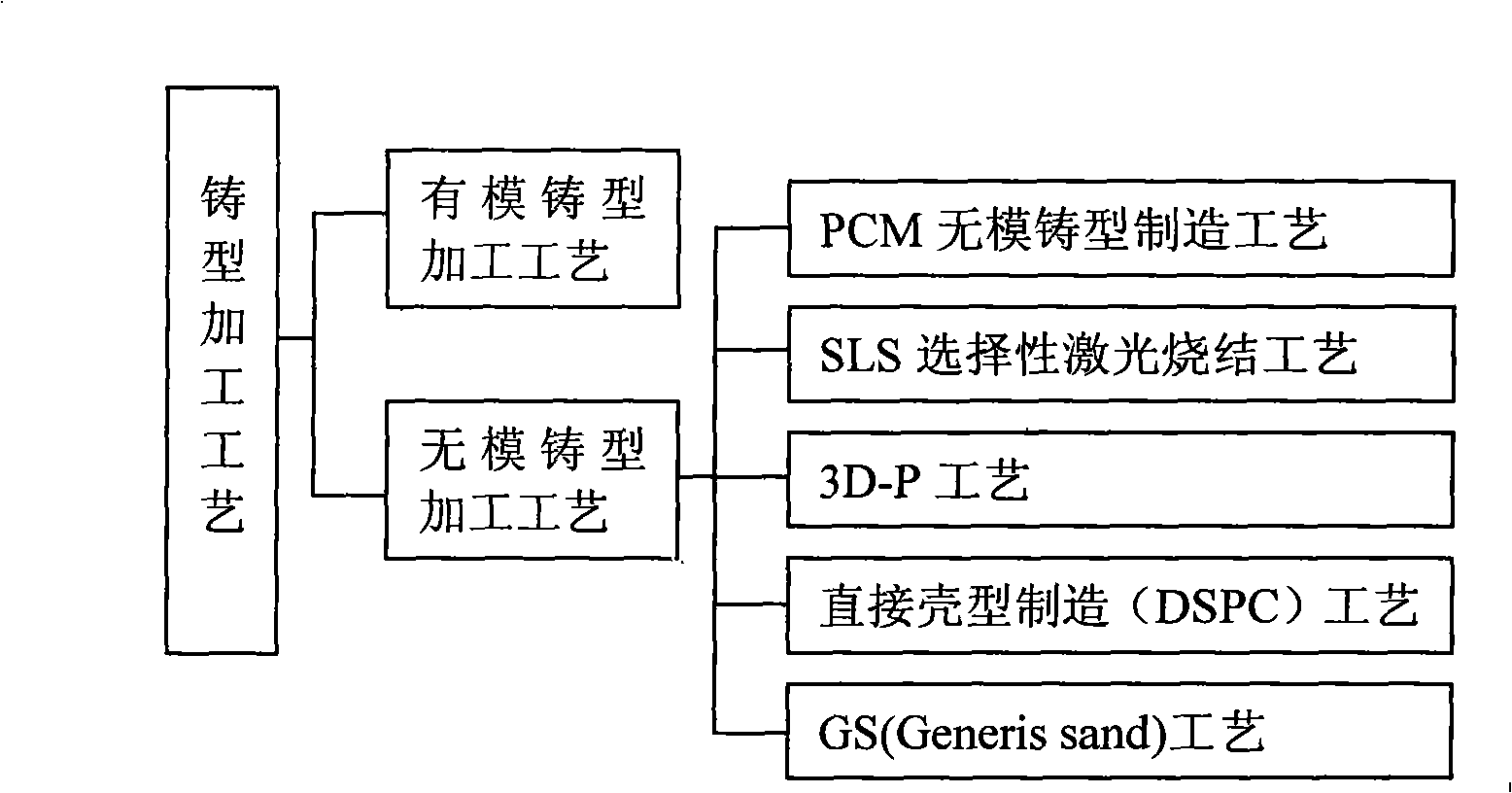

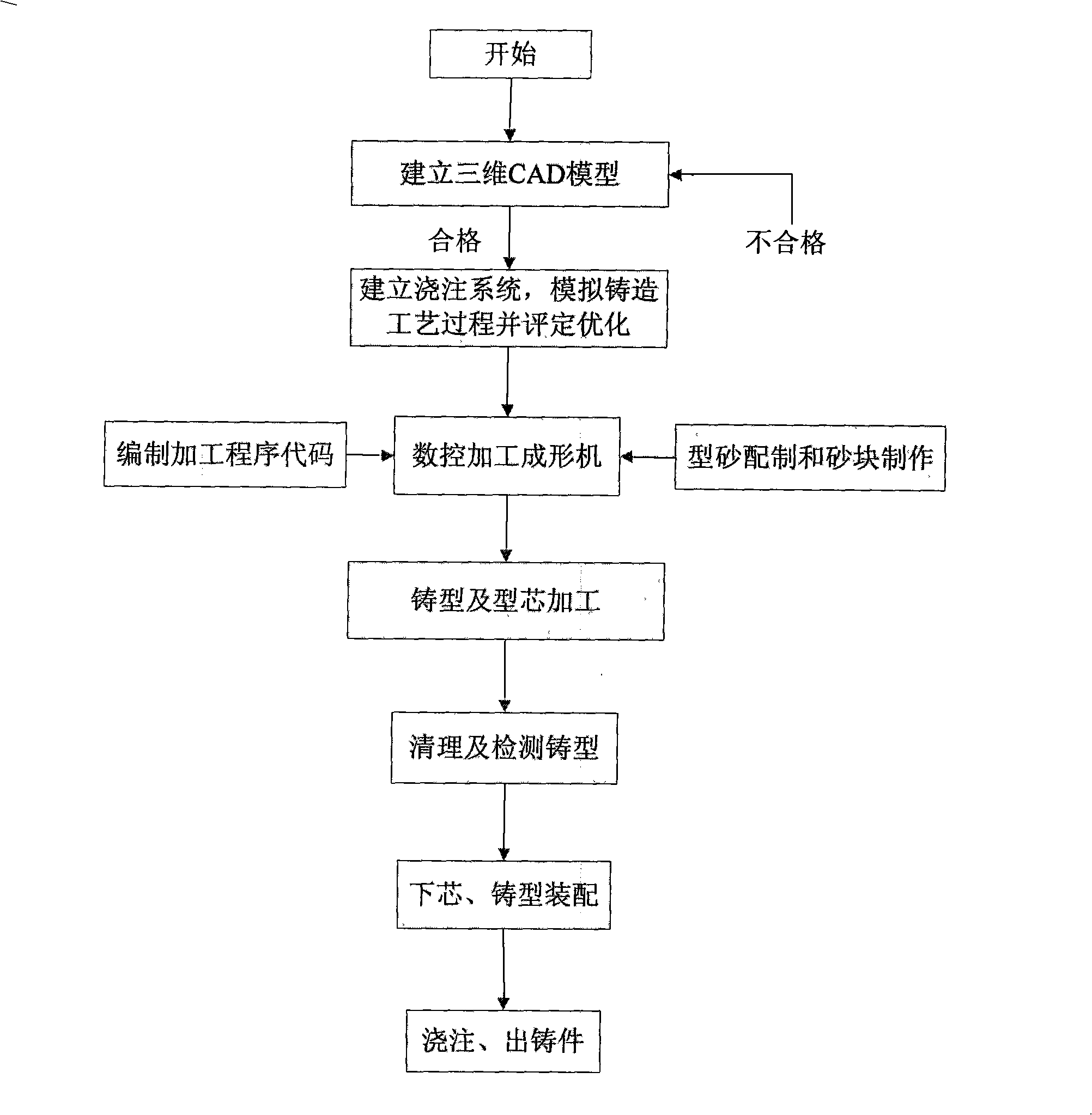

Non die-casting type digitalization fast manufacturing method

ActiveCN101259526ADigitalWith precisionProgramme controlCasting plantsNumerical controlManufacturing technology

The invention discloses a casting manufacturing method for general sand casting, which pertains to a digital-driven rapid manufacturing casting technology. The steps of the process are: the establishment of a model, the establishment of a casting system, the simulation of the casting process, the evaluation and the optimization; a molding sand with a certain proportion is mixed for preparation according to the requirements of the performance of a cast, thus preparing a sand billet; a procedure code is compiled according to the shape of a processing cavity, and the procedure code is input to a sand numerical control machine tool; the cast and a core are processed; the cast is cleared and detected; the core setting and the assembly of the cast are carried out; and the casting is carried out to form the cast. The casting manufacturing method adopts the casting and the cutting machining technologies for organic combination, which is a new cast production method. The numerical control cutting technology is adopted for processing the complicated large cast directly, which can not only eliminate the chain for manufacturing the mold, but can also improve the processing precision of the cast, reduce the thickness of the cast, improve the rigidity and reduce the weight; furthermore, the method has the green advantages of saving materials and reducing energy consumption.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

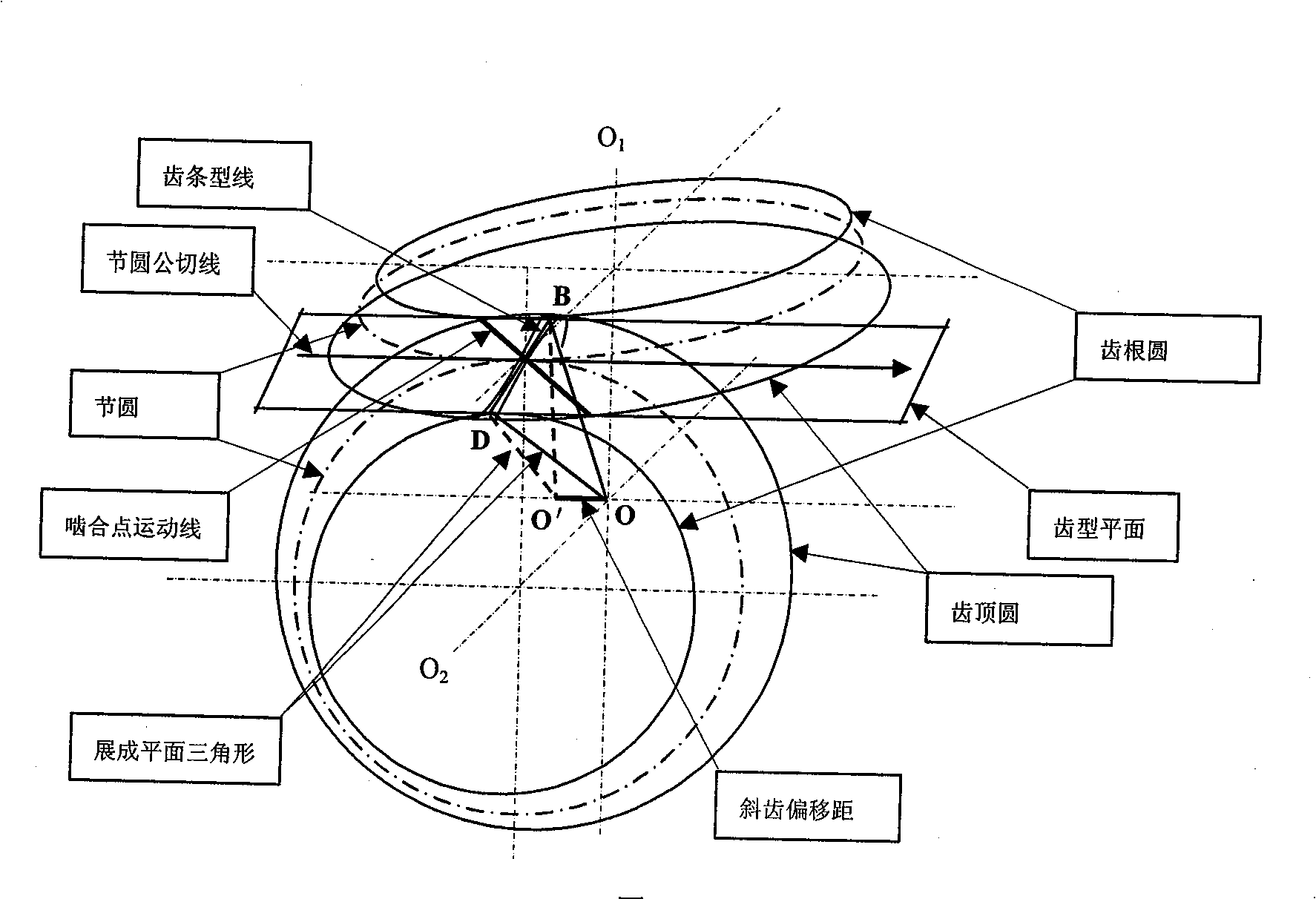

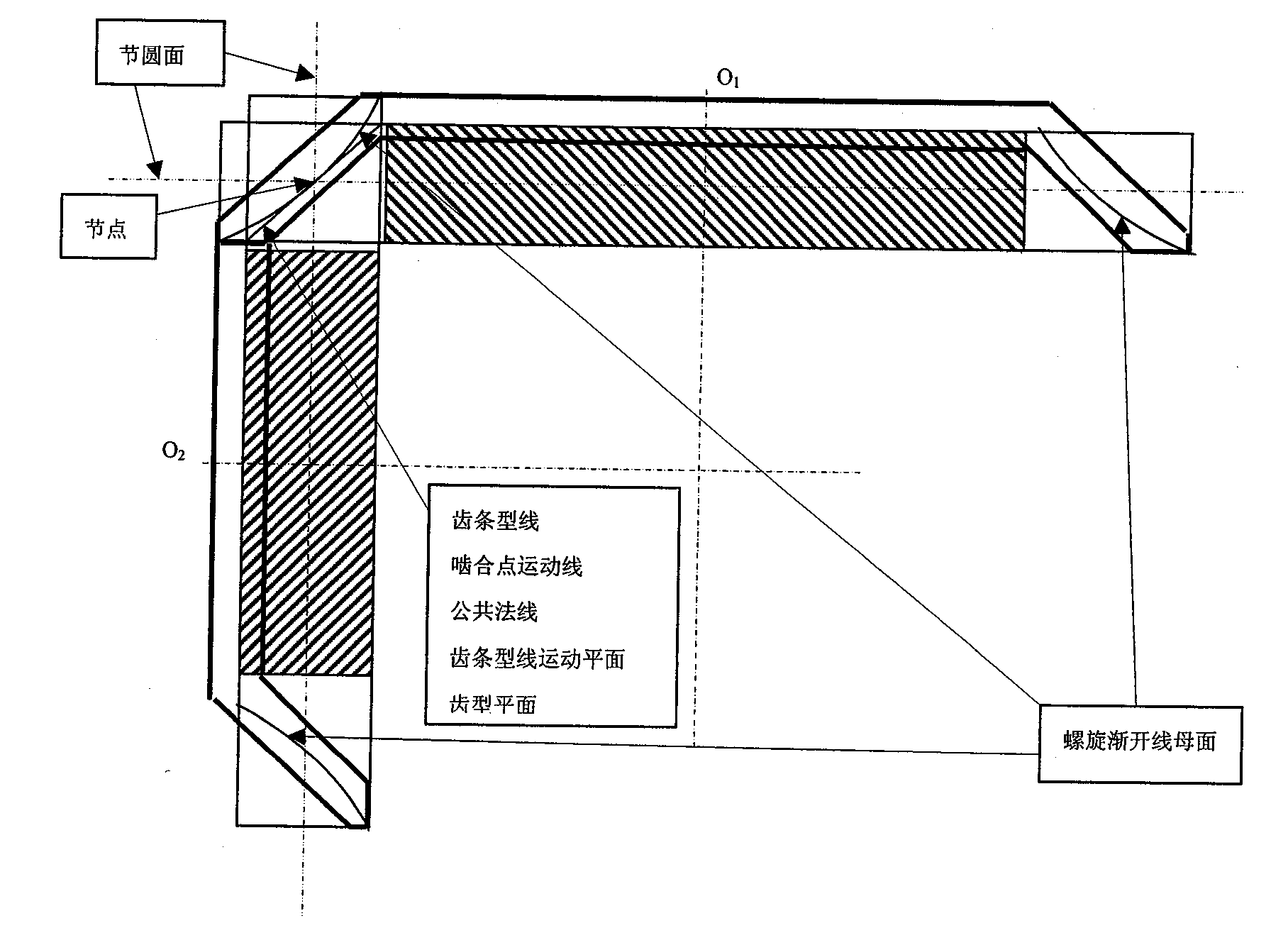

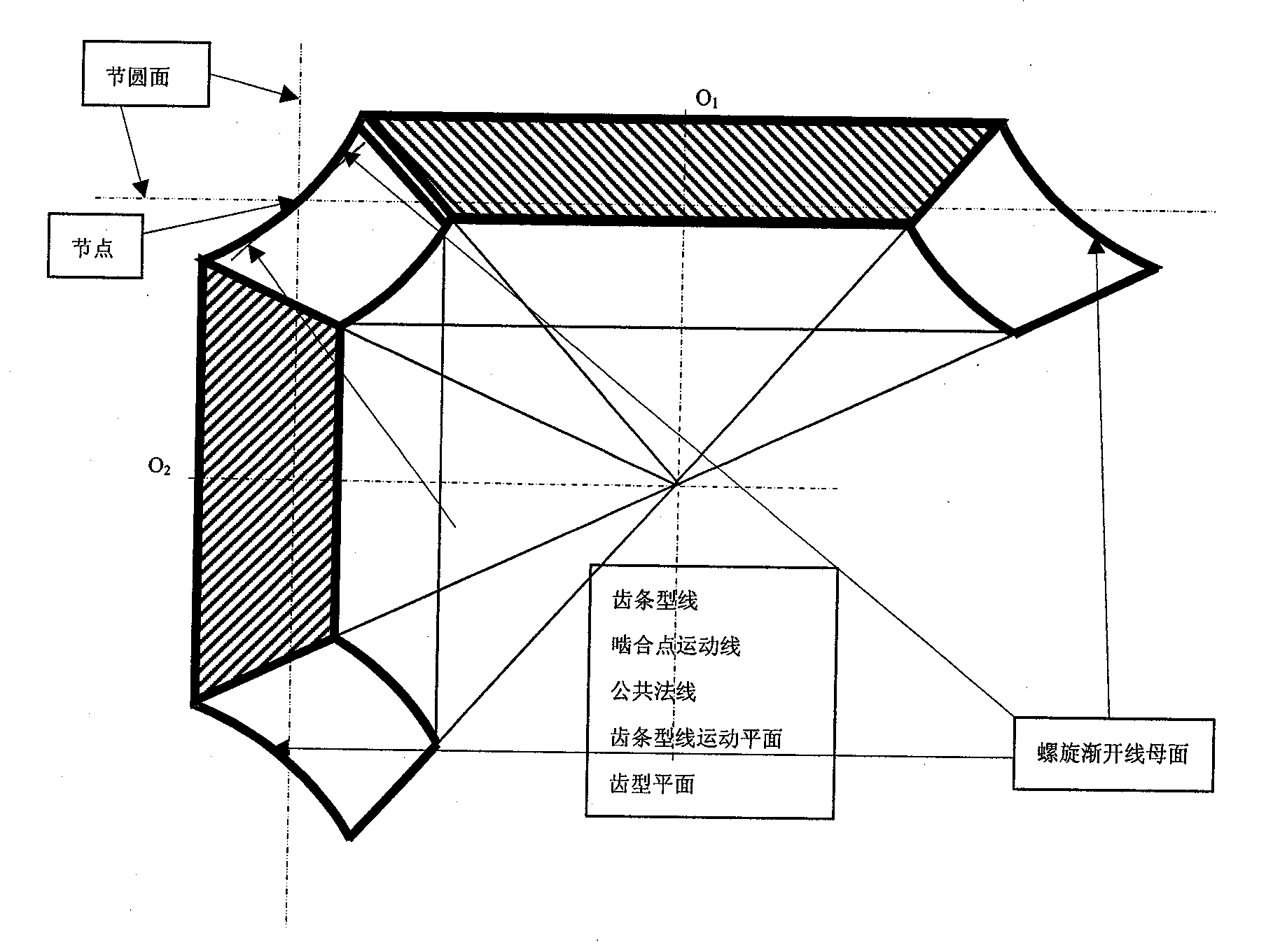

Helical involute gear and processing method thereof

InactiveCN101526129AEasy to processClear and easy to understand the transmission principlePortable liftingGear teethGear driveInvolute gear

The invention relates to a helical involute gear and a processing method thereof. The helical involute gear is characterized in that a tooth surface molded line is a helical involute which is a curve spread by a rack type line straightly moving along the pitch circle tangent line and pure-rolling with a gear pitch circle. The helical involute gear has clear and easy drive principle, can ensure the drive continuity and the drive uniformity, and can realize surface meshing with large meshing area so that the bearing capacity is strong; the helical involute gear has long meshing line and large superposition coefficient, especially, an inclined helical involute conical gear is easy to implement speed reduction at high speed ratio. The helical involute conical gear can realize the expansion processing, thereby having high processing accuracy, low processing cost and high processing tooth surface hardness, improving the motion stability of the gear and the bearing capacity, and prolonging the service life. Meanwhile, processing equipment required by the helical involute gear can be conveniently processed by utilizing the method, thereby solving the difficulties of large processing difficulty and high cost of a gear drive pair with intersecting axes.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

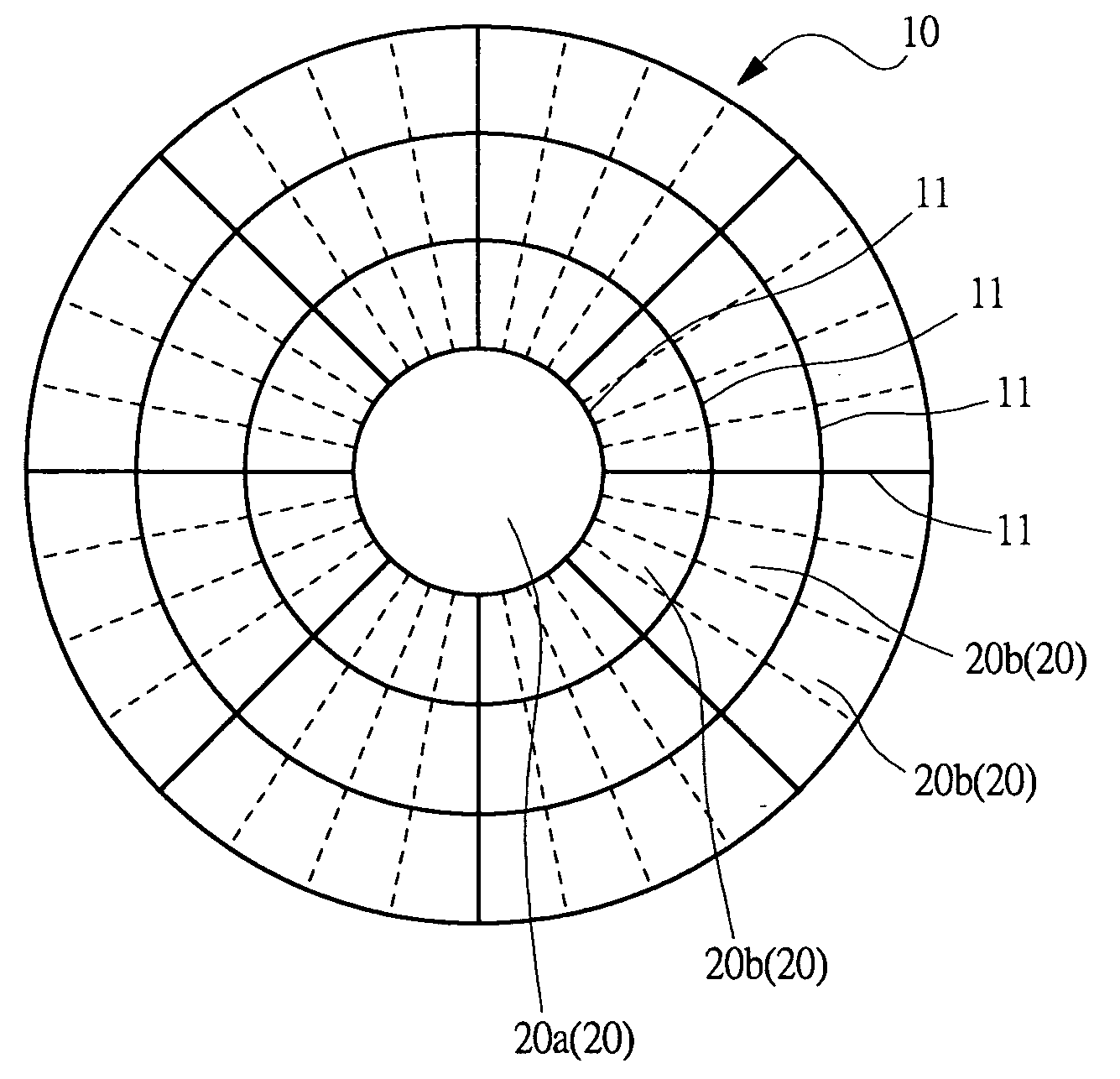

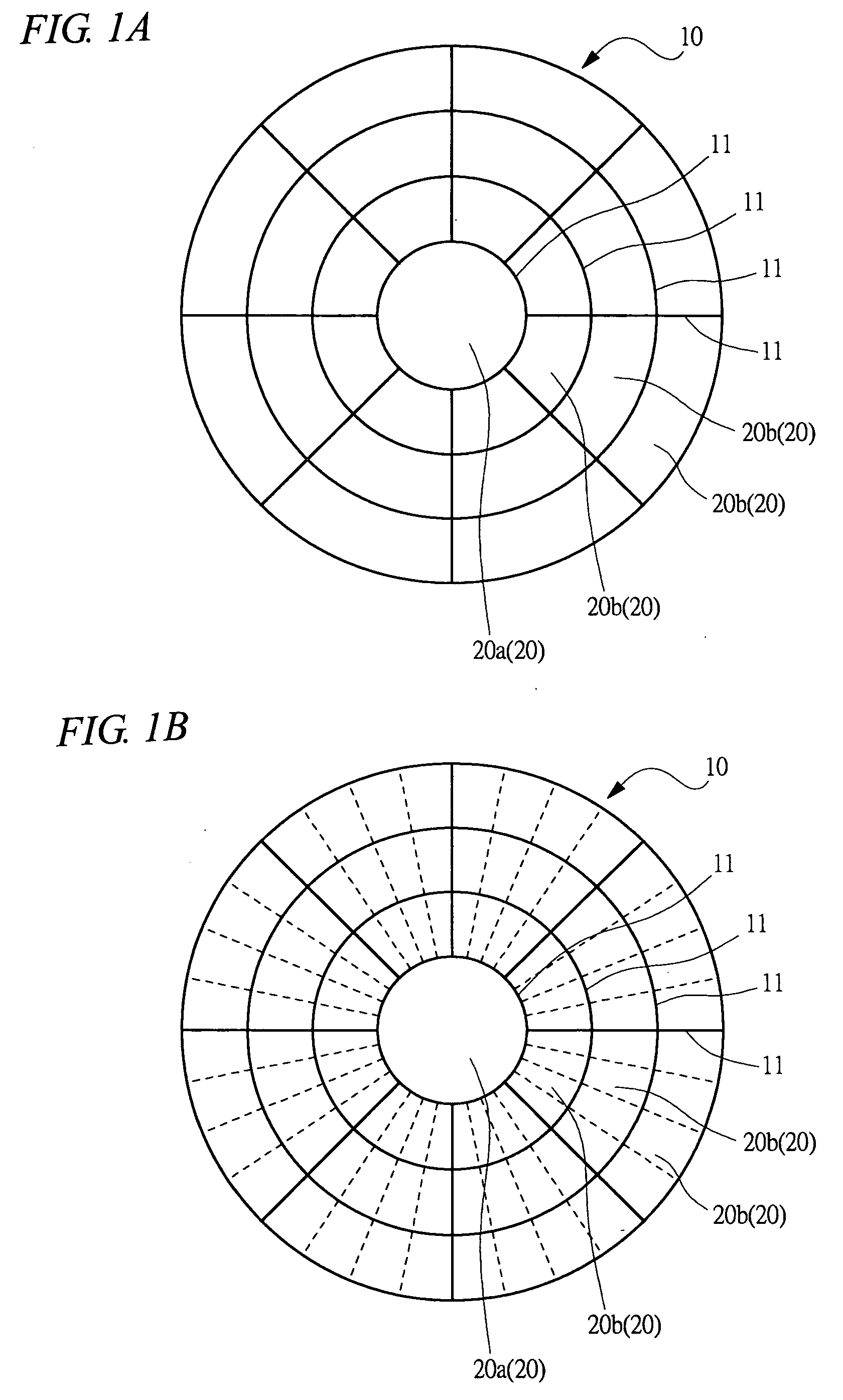

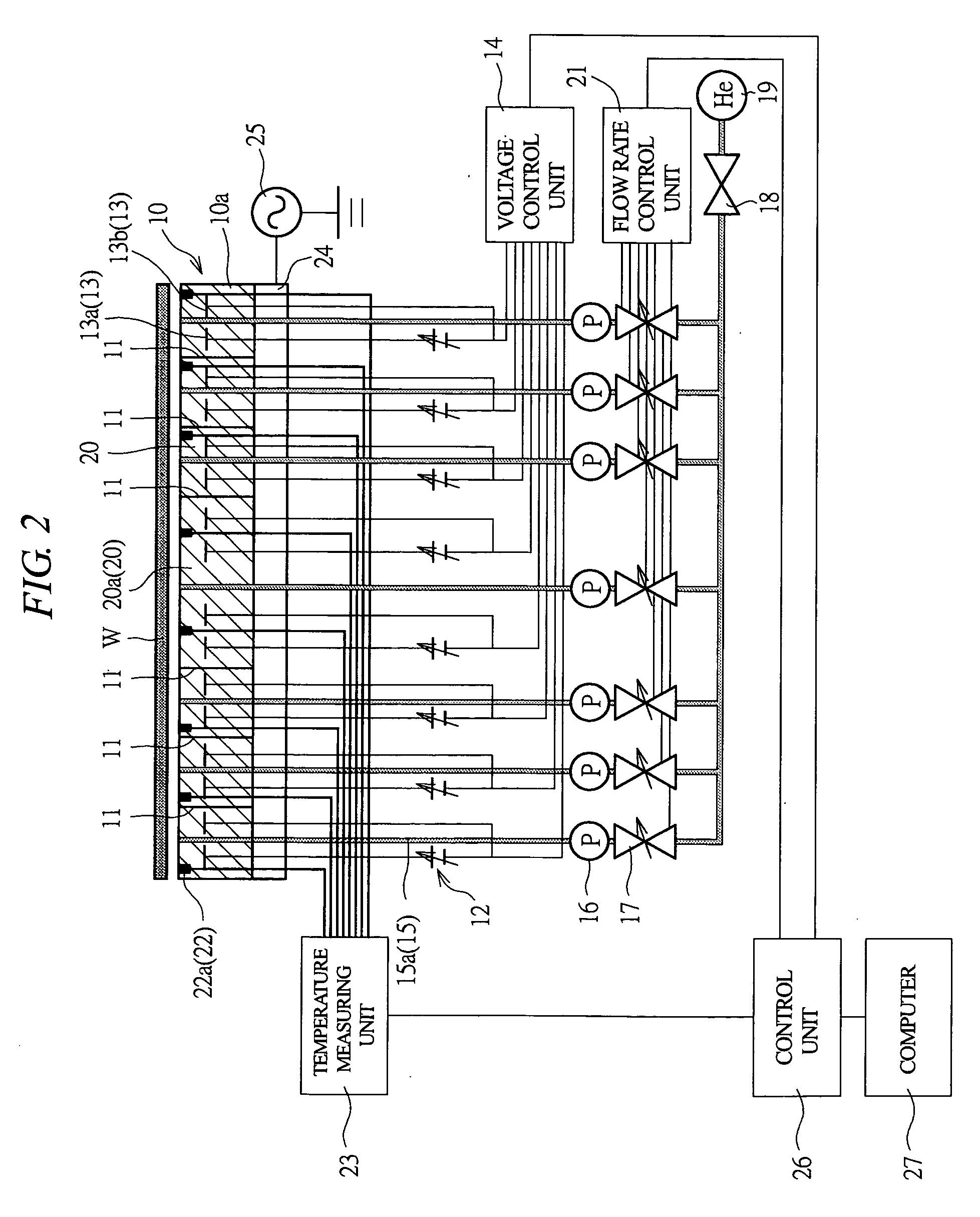

Semiconductor manufacturing apparatus, semiconductor manufacturing method and wafer stage

InactiveUS20050095776A1Improve equalityImprove machining accuracySemiconductor/solid-state device manufacturingTemperature controlFluorescence

A stage main body of a wafer stage having electrostatic chuck function is sectioned into plural chucking areas with partition members. Each chucking area includes electrodes capable of changing an applied voltage, a helium supply pipe and a fluorescent thermometer. The distribution of the temperature of a wafer is grasped at real time by measuring the temperature of the wafer corresponding to the plural chucking areas. A local temperature correction for the wafer is carried out by adjusting the electrostatic chucking force in the chucking area corresponding to a necessary temperature corrective area. By achieving the temperature control within the wafer surface in this way, the equality in wafer processing, which is affected by the wafer temperature, is secured thereby eliminating the inequality in processing accuracy of the wafer processing within a wafer surface.

Owner:TRECENTI TECHNOLOGIES INC

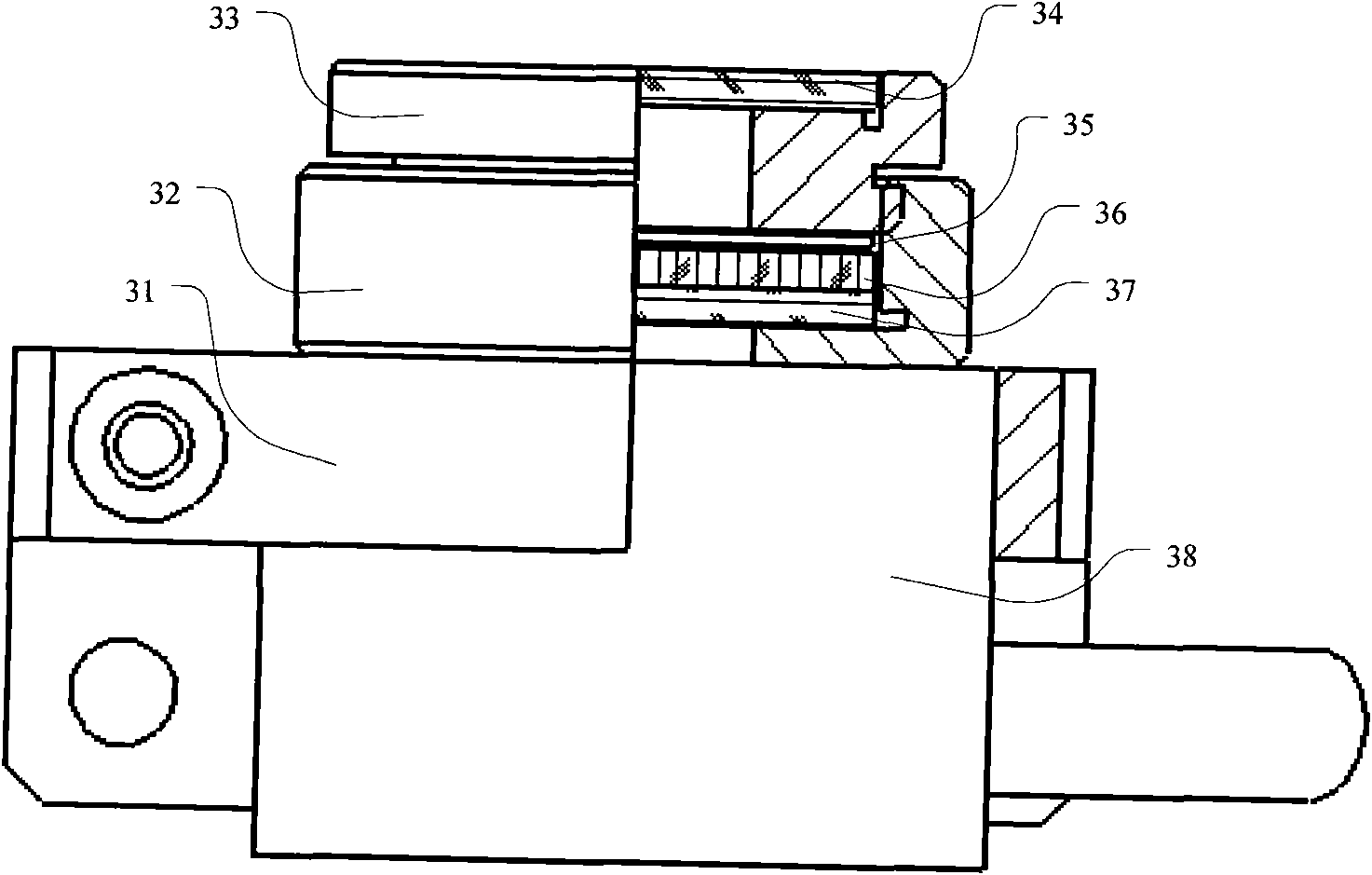

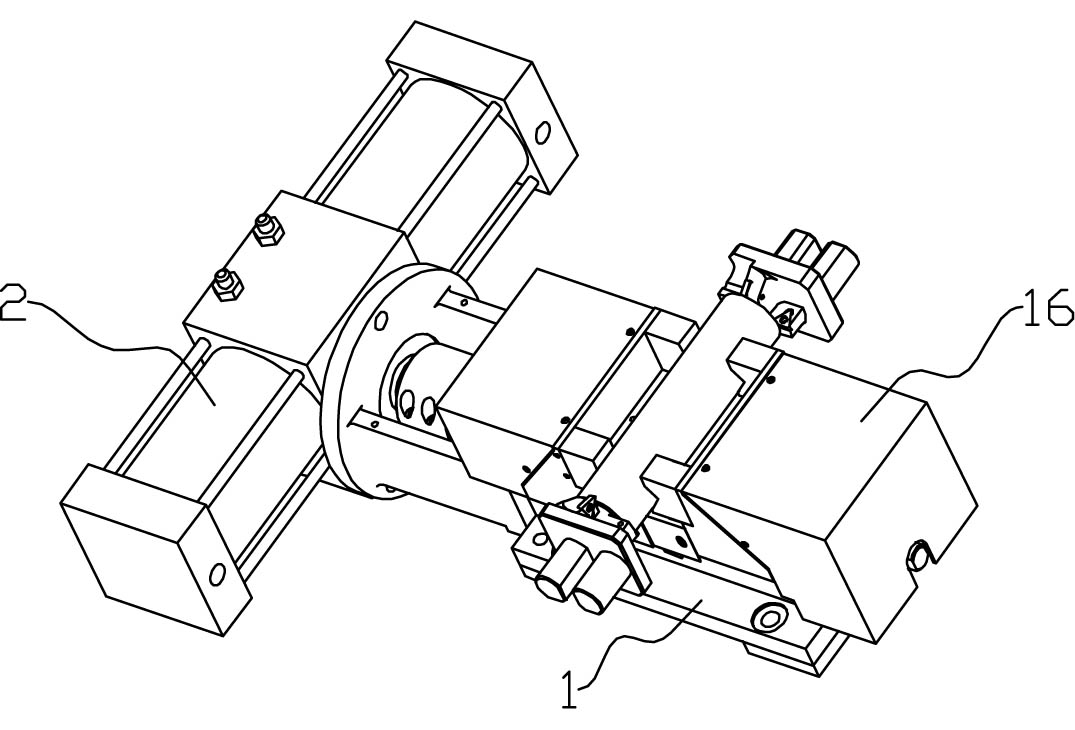

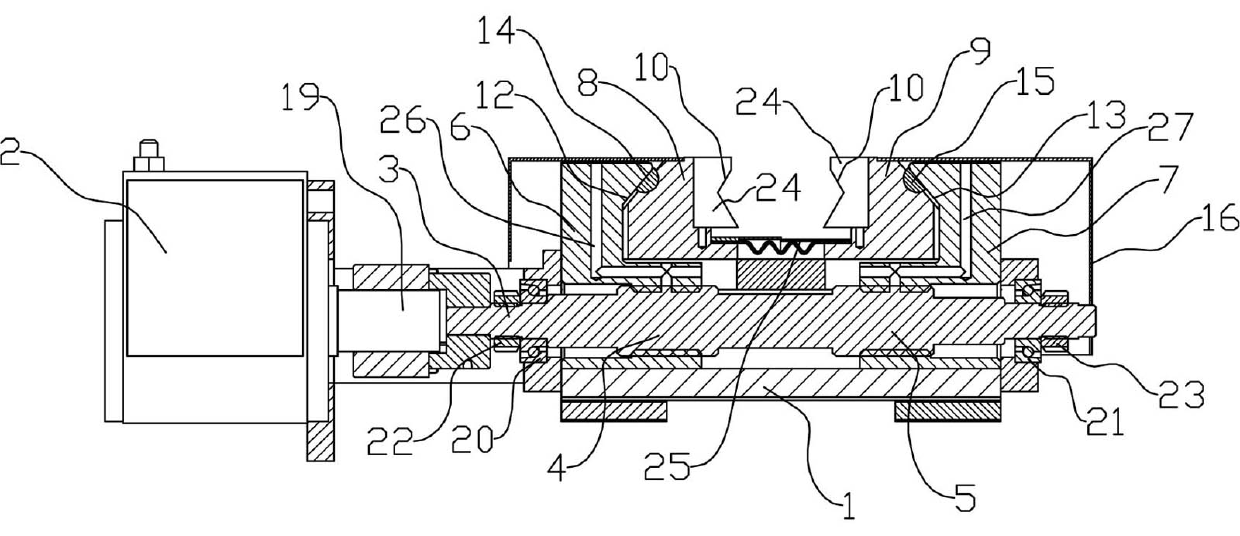

Bidirectional clamping mechanism

InactiveCN101905428AImprove machining accuracyPositioning apparatusMetal-working holdersEngineeringMiddle line

The invention discloses a bidirectional clamping mechanism, which comprises a base and a power mechanism. A rotating shaft of the power mechanism is connected with a screw; a first threaded part and a second threaded part are arranged on the screw at intervals; and the first threaded part and the second threaded part have the same thread pitch and opposite threaded directions. A first nut and a second nut are sleeved outside the first threaded part and the second threaded part; a first slide block and a second slide block are arranged on the first nut and the second nut respectively; and opposite clamping openings are formed on the first slide block and the second slide block. Due to the adoption of the structure, the bidirectional clamping mechanism makes the first nut and the second nut move to the middle part synchronously under the driving of the screw during work, clamps columnar workpieces through the clamping openings on the first slide block and the second slide block, keeps the consistency of the center lines of the positioned and clamped workpieces with a machining tool, and improves the machining accuracy.

Owner:邝锦富

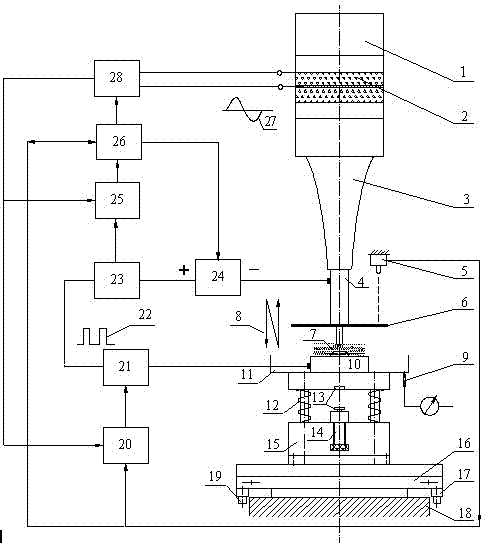

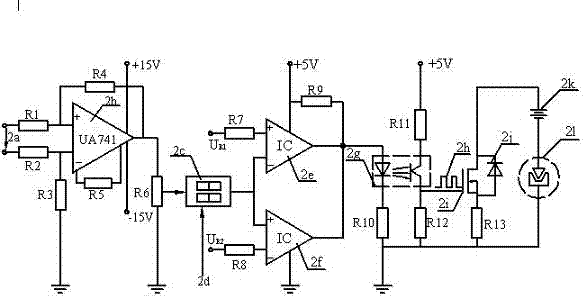

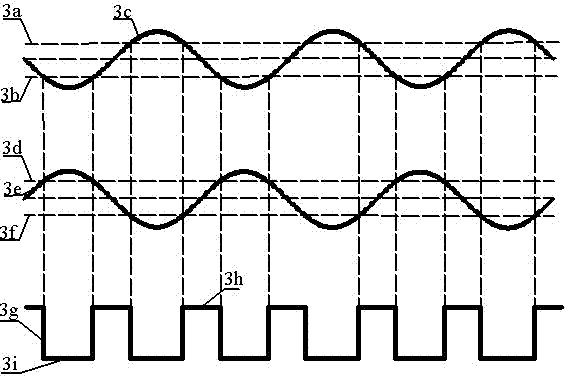

Micro and fine machining method for material difficult to machine and machining system

ActiveCN102513622AImprove machining clearance processImprove local processing performanceMechanical vibrations separationElectric circuitsUltrasonic cavitationElectrolysis

The invention relates to a micro and fine machining method for a material difficult to machine and a machining system, belonging to the technical field of composite, precise, micro, fine and special machining. In the method and the machining system for implementing the method disclosed by the invention, ultrasonic modulation, low-voltage discharge and electrolysis are effectively compounded, a micro and fine discharge-electrolysis function is organically combined with ultrasonic frequency vibration identical frequency and synchronization, and discharge of machining products and circular update of a working fluid are realized under the actions of ultrasonic cavitation and spark discharge explosive force, so that a gap machining process is improved effectively, localized machining performance is enhanced, machining accuracy and surface quality can be further enhanced while high machining efficiency is achieved, machining can be realized in a static fluid simultaneously, and complex pressure flow and circular supply of the working fluid to the system is not required; and during processing, contact of the workpiece with an electrode under a certain constant pressure is kept, continuous and stepless micro pressure adjustment can be performed by using a magnetic adjusting mechanism, and a precision stable-speed micro feeding system necessary for electrolytic machining and a servo feeding system necessary for electric spark machining are not required, so that the equipment research cost can be reduced greatly.

Owner:扬州健行电子科技有限公司

Micro-blanking automation device of pulsed laser driven flying sheet loading plate and method thereof

The invention discloses a micro-blanking automation device of a pulsed laser driven flying sheet loading plate and a method thereof. The micro-blanking automation device comprises a laser generation system, an automatic forming system and a control system. The laser generation system is composed of a laser controller, a laser emitter and optical fiber. The automatic forming system is composed of an end cover, a focusing lens cone, a machine body, a micro-blanking working platform, a three-dimensional movable chuck, a base, a variable magnetic field device, a rotary table multi-station device, a restraint layer-flying sheet integration sheet, a restraint layer-flying sheet integration sheet storage device and a recovery device. Pulsed laser is used as a forming power source, the restraint layer-flying sheet integration sheet is used for performing transformation between optical energy and mechanical energy, and automation of a micro-blanking technology of the pulsed laser driven flying sheet loading plate is achieved. The automatic forming system is independent relatively, processing accuracy cannot be interfered by the outside, personal error is avoided, a laser optical-path and the micro-blanking working platform are accommodated in the machine body, and safety of experimental operation is improved.

Owner:JIANGSU UNIV

Roll forming processing method for online punching and production line

The invention relates to a roll forming processing method for online punching and a production line in the technical field of sheet roll forming. The method comprises the following steps of: emptying, leveling, punching, roll forming, cutting and blanking. The punching step comprises the following specific steps of: detecting a real-time displacement signal of the linear motion of a sheet; driving a punching mechanism to move at an accelerated speed according to the displacement signal and drive the sheet to a set punching position along the movement direction of the sheet; driving the punching mechanism to track the linear motion of a coiled sheet and keep moving synchronously with the sheet; in a process of keeping synchronous movement with the sheet, allowing the punching mechanism to punch a hole at the set position on the sheet; and returning the punching mechanism to an initial position. The invention also provides the production line for implementing the method. Punching is performed after a servo motor controlled by a programmable logic controller (PLC) drives a workbench to track the sheet. The processing method and the production line can improve sheet processing accuracy and increase sheet processing speed and can be used for molding, punching and processing sheets with fixedly shaped cross sections.

Owner:YANGZHOU NANYANG WELDING PIPE MOLD CO LTD

Small straight-line section interpolation method of numerical control system on basis of multicycle optimal corner

InactiveCN101556472AFast processingFast cutting speedProgramme controlComputer controlLine segmentProcessing accuracy

The invention relates to a small straight-line section interpolation method of a numerical control system on the basis of multicycle optimal corner, comprising the following steps of: on the basis of processing precision and limitation of maximum processing speed, determining interpolation parameters of an optimal corner with multicycle trasition of each corner on a processing path according to geometric parameters at the corner on the processing path, the maximum acceleration of each driving shaft of a machine tool and an optimized target; adjusting the interpolation parameters of the optimal corner of each corner and leading the processing speed of two ends of each small straight-line section to meet reachability requirement; and then carrying out interpolation of straight line sections and corners to all the small straight-line sections on the processing path, connecting interpolate point sequences of the straight line sections with interpolate point sequences of corners, sequentially outputting the interpolate point sequences in real time, and driving a numerical control machine tool to conduct actual processing. The method can effectively improve the whole processing speed, has fast calculating speed, meets the requirement of real time processing, has stable and reliable working performance and strong practicability and can be applicable to various three-shaft numerical control machine tool with different types.

Owner:ACAD OF MATHEMATICS & SYSTEMS SCIENCE - CHINESE ACAD OF SCI

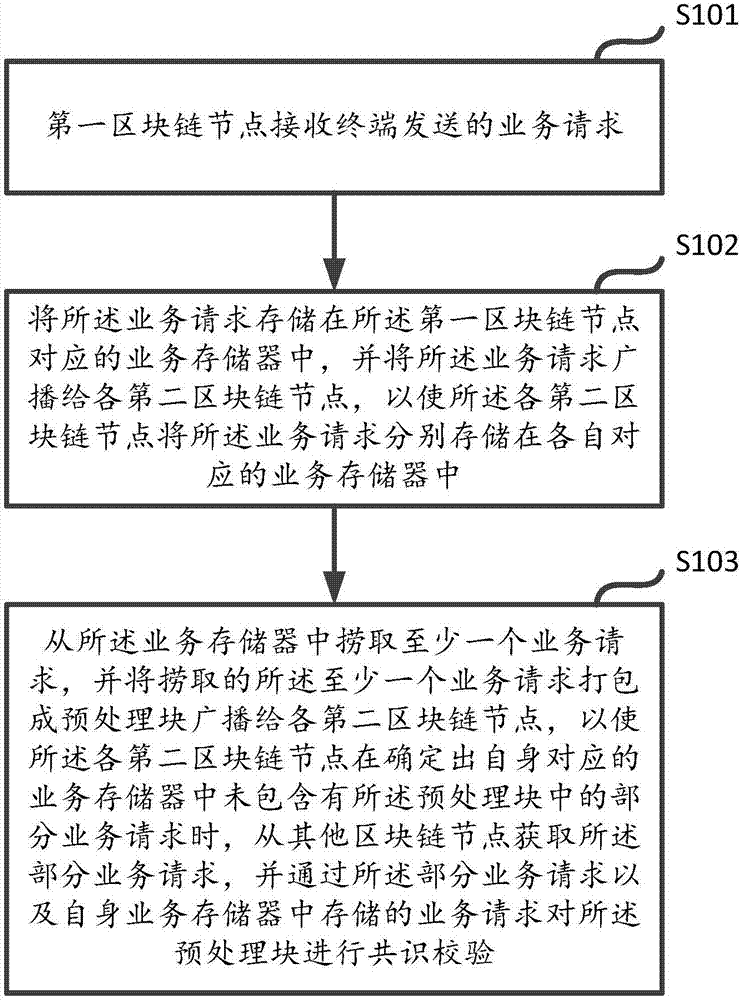

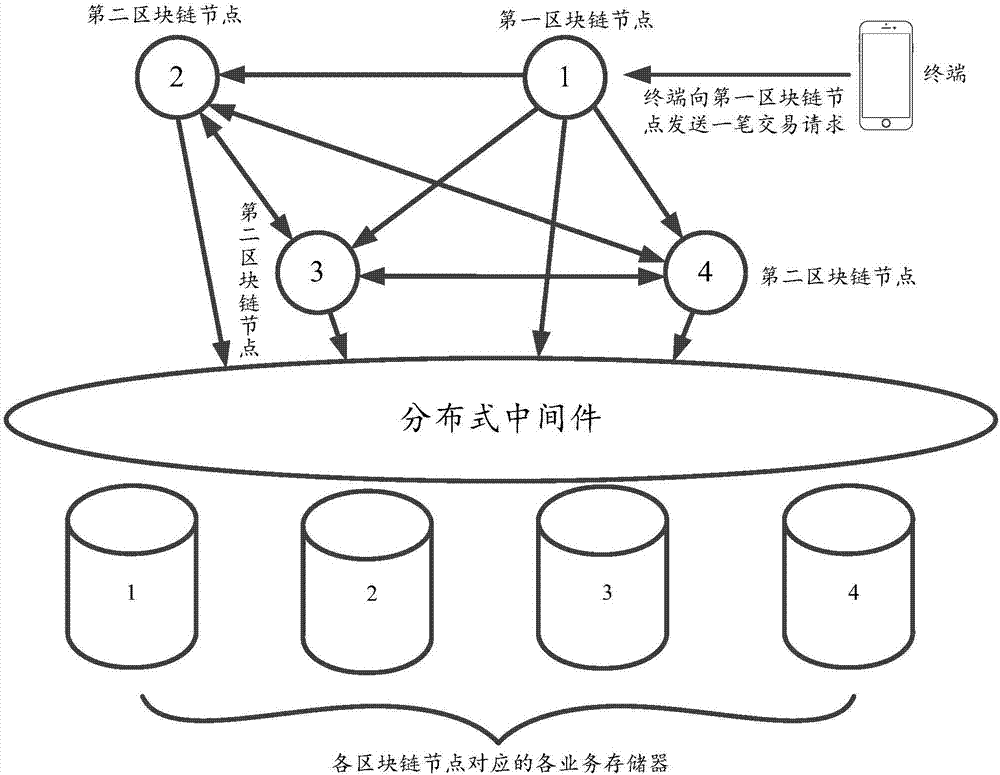

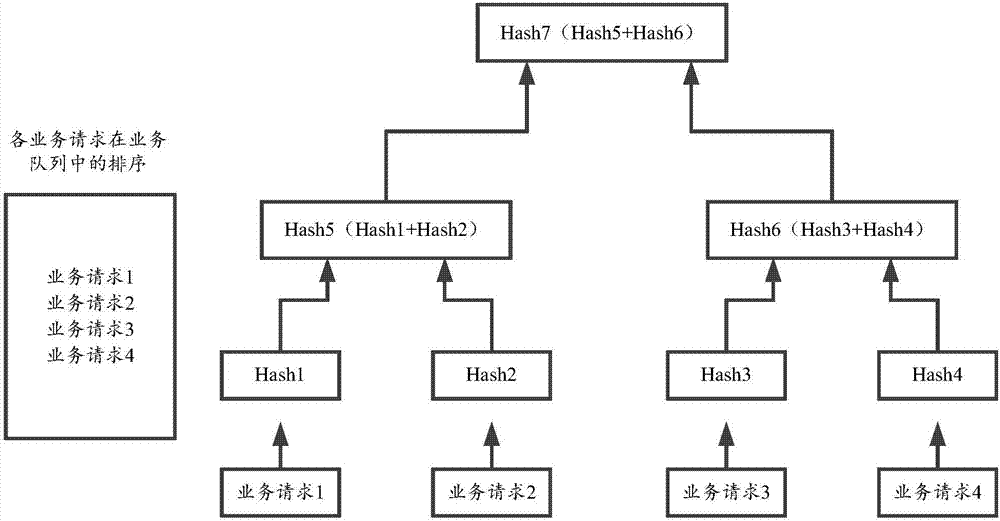

Service check method and device

ActiveCN107040585ACircumstances to reduce adverse effectsImprove business processing accuracyFinanceCryptography processingBroadcastingDistributed computing

The invention discloses a service check method and device. According to the method, a first block chain node packages at least one service request gotten from own service memory into a preprocessing block and broads the preprocessing block to each second block chain node; if each second block chain node discovers that partial service requests in the preprocessing block are not contained in the service memory corresponding to each second block chain node, each second block chain node can obtain the partial service requests from other block chain nodes and carries out consensus check the preprocessing block through the partial service requests and the service requests stored in own service memory. After each second block chain node receives the preprocessing block, if each second block chain node discovers that the partial service requests in the preprocessing block are not contained in the service memory corresponding to each second block chain node, the consensus check for the preprocessing block is not directly considered to be unsuccessful, the consensus check is carried out on the preprocessing block by obtaining the partial missed service requests from other block chain nodes, so the service processing accuracy of the whole block chain service is effectively improved.

Owner:ADVANCED NEW TECH CO LTD

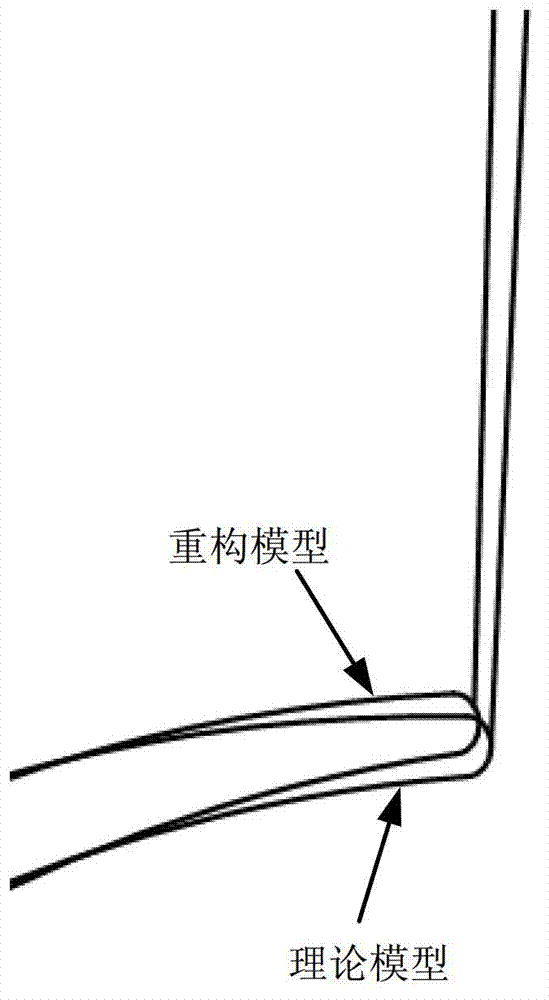

Method for compensating precision milling deformation of thin-wall blade

InactiveCN102880756AThe direct effect is obviousImprove machining accuracySpecial data processing applicationsMaximum errorEngineering

The invention provides a method for compensating precision milling deformation of a thin-wall blade. The method includes extracting blade sections perpendicular to a parameter v-direction; measuring error mean values of the various sections after the blade is machined according to an initial three-dimensional model and using the error mean values as primary compensation quantities for the sections; reconstructing a three-dimensional blade model after the various sections are primarily compensated; machining the blade according to the reconstructed three-dimensional blade model; measuring maximum error values of the various sections; computing precise deformation compensation quantities for the various sections; secondarily reconstructing a three-dimensional blade model after the various sections are compensated according to the precise deformation compensation quantities; machining the blade according to the secondarily reconstructed three-dimensional blade model; and measuring errors of the various sections to judge whether design requirements are met or not. The method is favorable for improving the machining precision of the blade and the profile tolerance of the surface of the blade and reducing compensation frequency, machining frequency and workload of follow-up working procedures.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com