Patents

Literature

1015 results about "Sand casting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sand casting, also known as sand molded casting, is a metal casting process characterized by using sand as the mold material. The term "sand casting" can also refer to an object produced via the sand casting process. Sand castings are produced in specialized factories called foundries. Over 60% of all metal castings are produced via sand casting process.

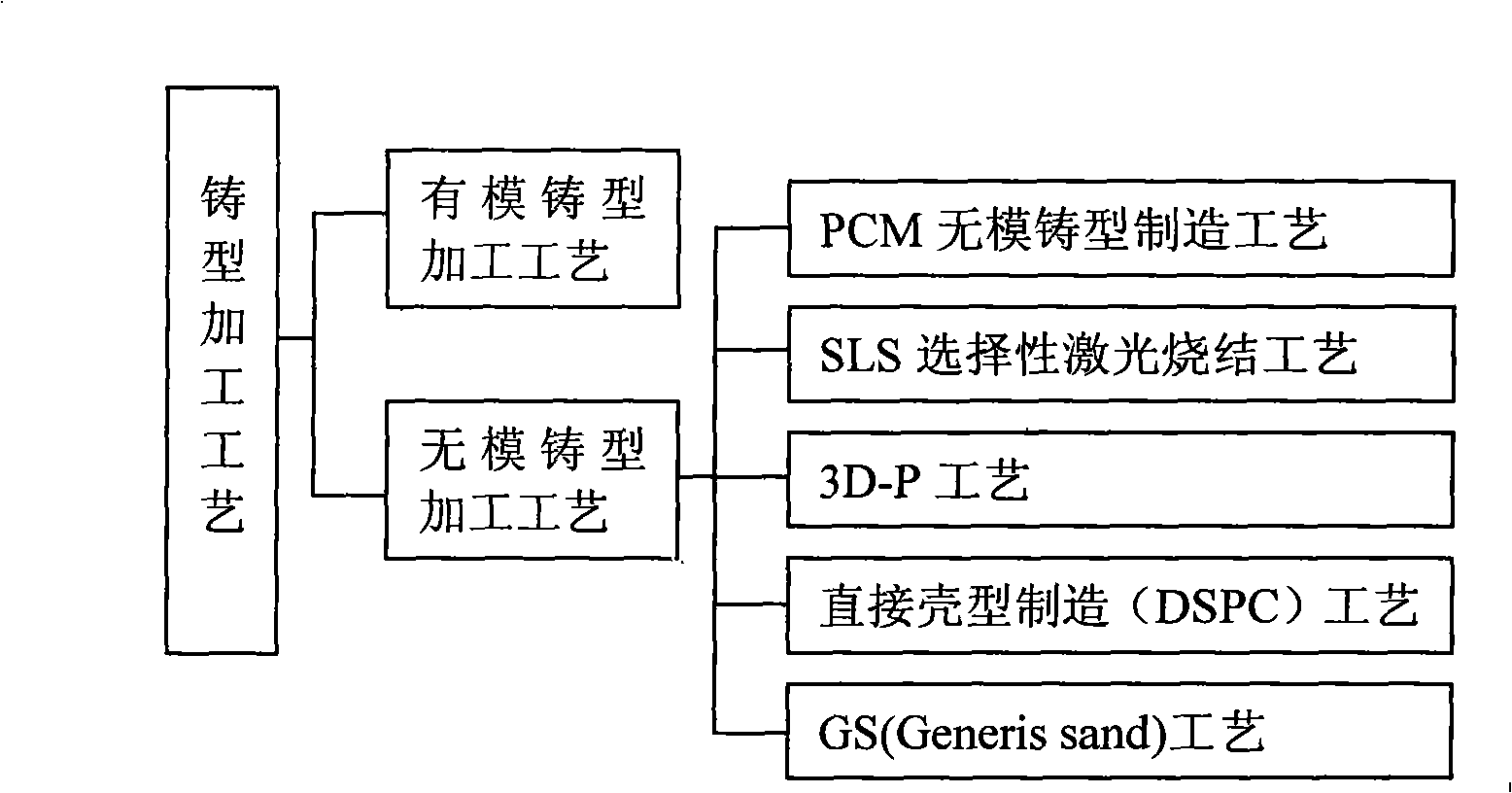

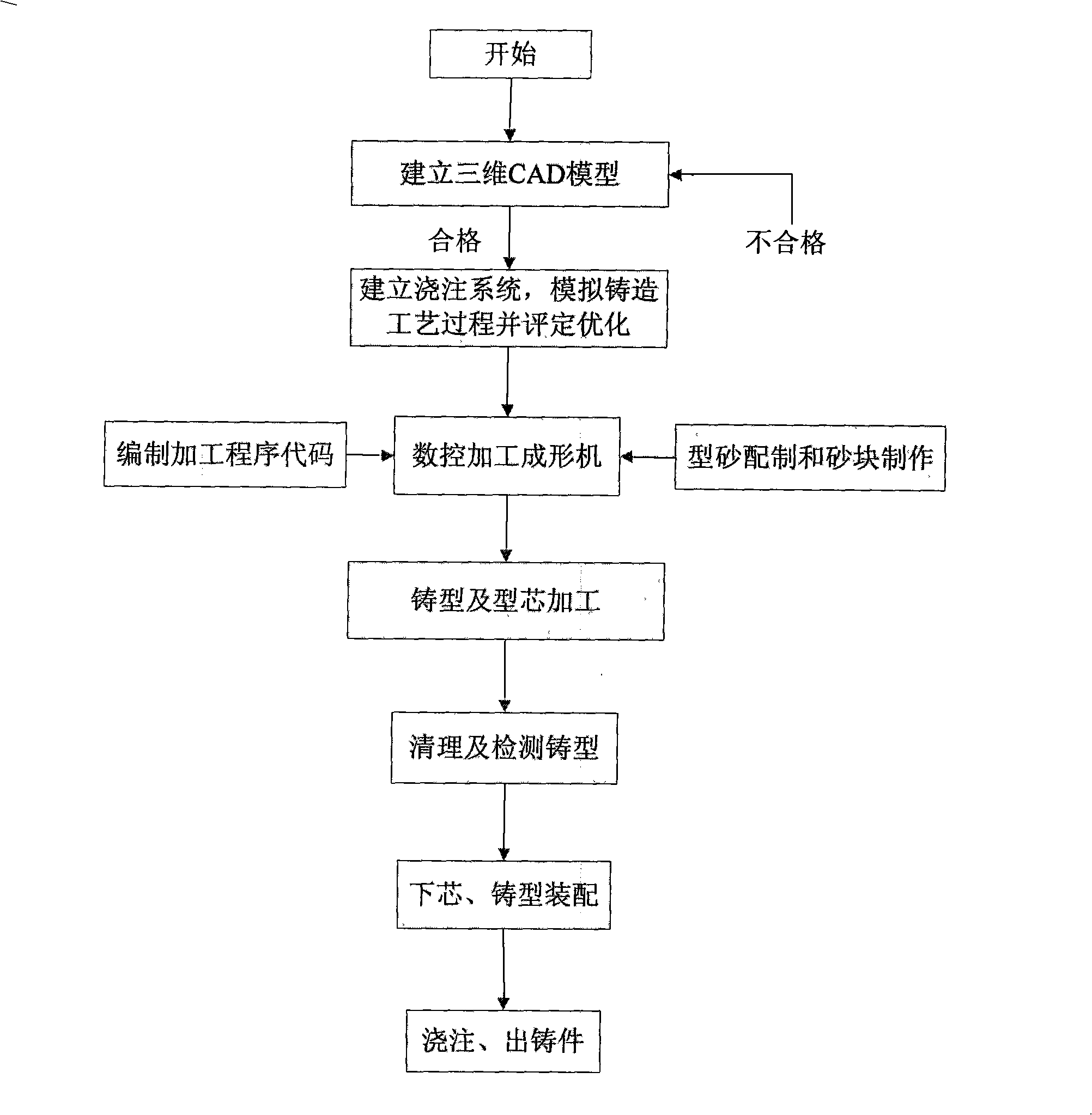

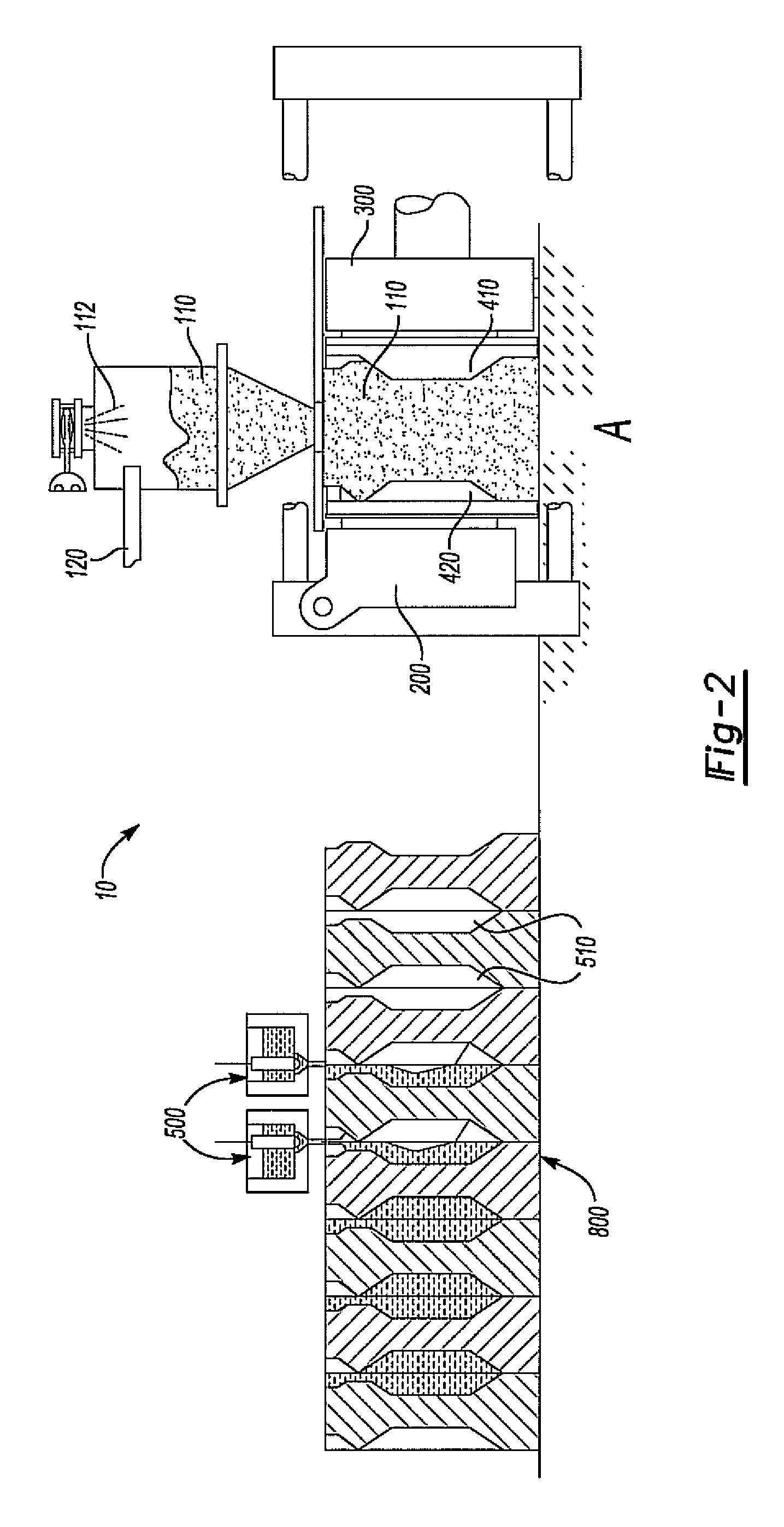

Non die-casting type digitalization fast manufacturing method

ActiveCN101259526ADigitalWith precisionProgramme controlCasting plantsNumerical controlManufacturing technology

The invention discloses a casting manufacturing method for general sand casting, which pertains to a digital-driven rapid manufacturing casting technology. The steps of the process are: the establishment of a model, the establishment of a casting system, the simulation of the casting process, the evaluation and the optimization; a molding sand with a certain proportion is mixed for preparation according to the requirements of the performance of a cast, thus preparing a sand billet; a procedure code is compiled according to the shape of a processing cavity, and the procedure code is input to a sand numerical control machine tool; the cast and a core are processed; the cast is cleared and detected; the core setting and the assembly of the cast are carried out; and the casting is carried out to form the cast. The casting manufacturing method adopts the casting and the cutting machining technologies for organic combination, which is a new cast production method. The numerical control cutting technology is adopted for processing the complicated large cast directly, which can not only eliminate the chain for manufacturing the mold, but can also improve the processing precision of the cast, reduce the thickness of the cast, improve the rigidity and reduce the weight; furthermore, the method has the green advantages of saving materials and reducing energy consumption.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

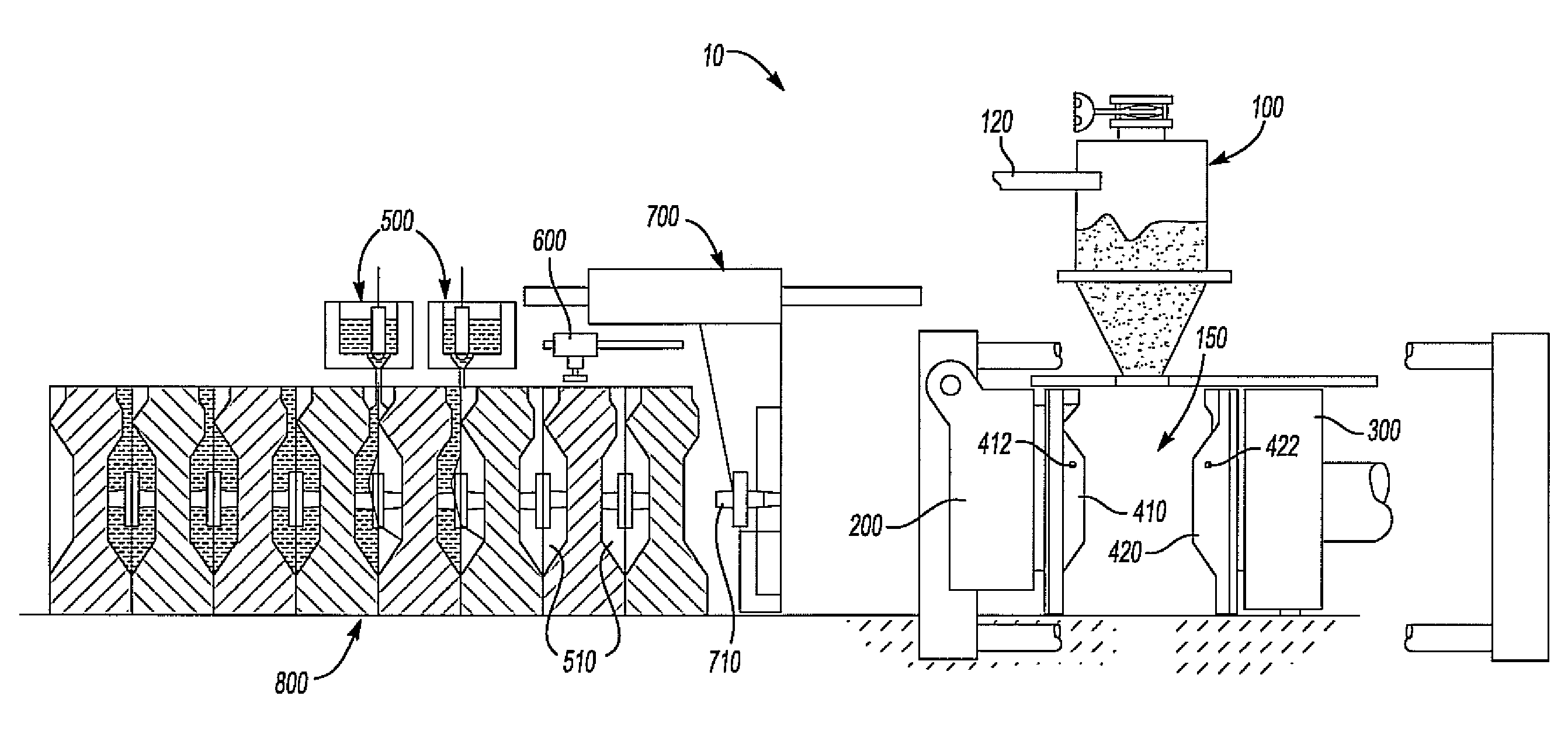

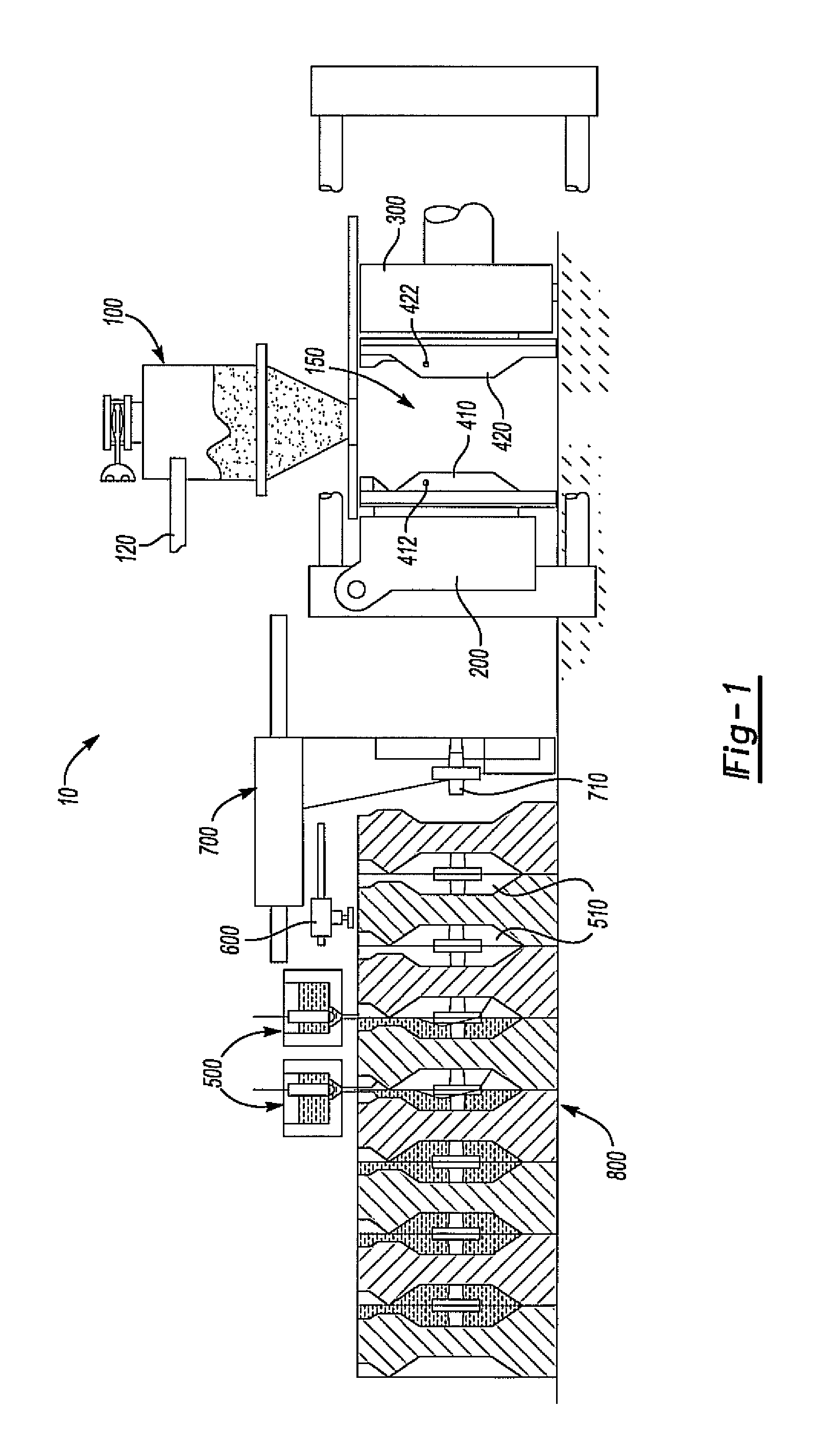

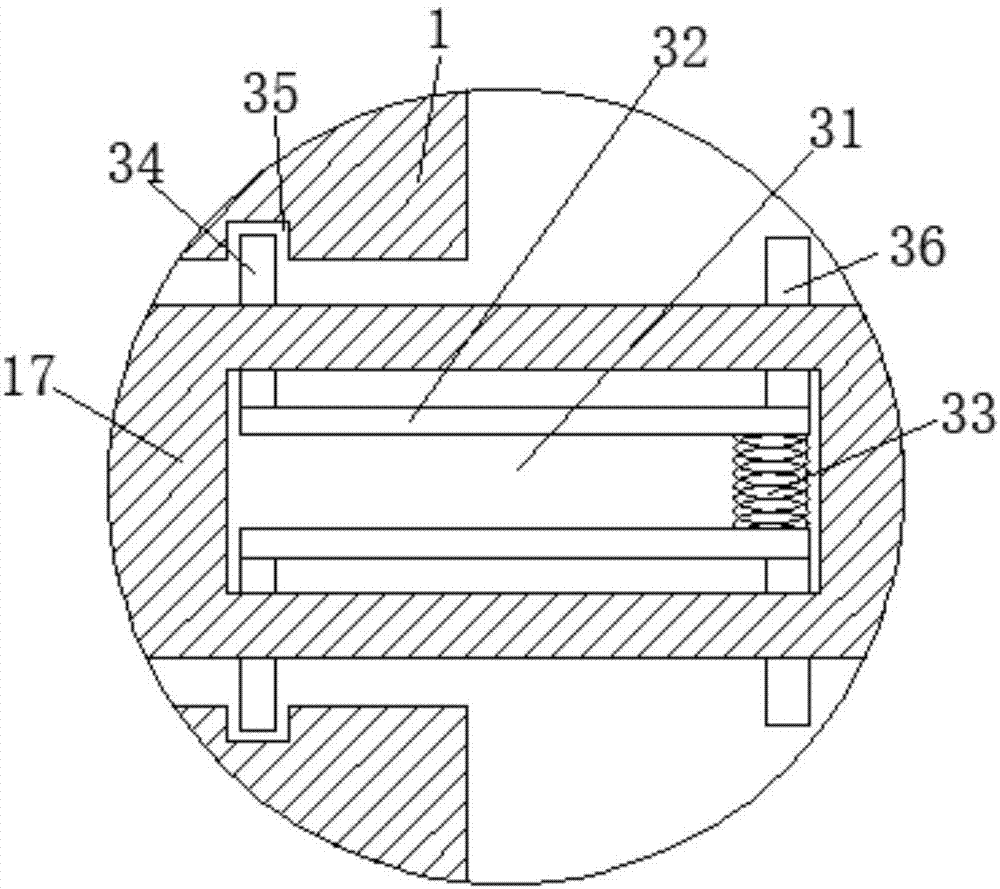

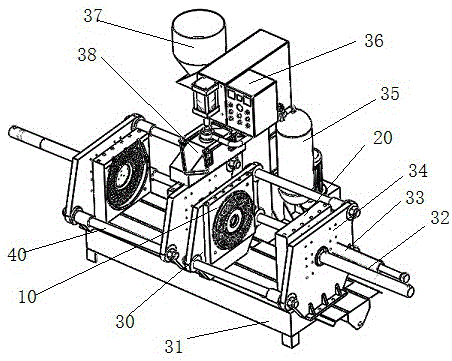

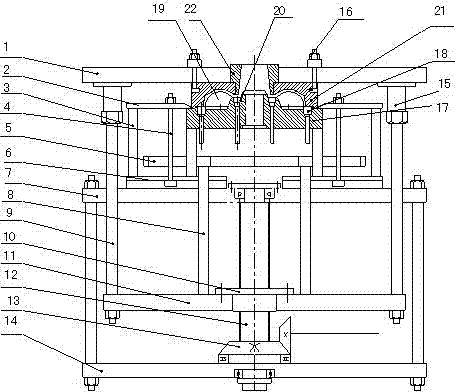

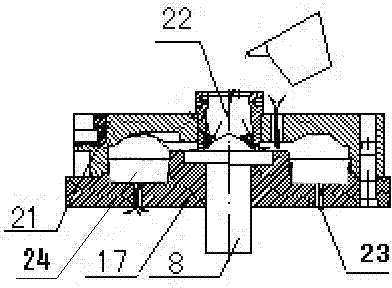

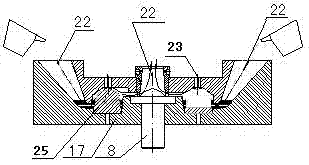

Molding and casting machine

ActiveUS20080135205A1Improved swing movementEasy to adjustPig casting plantsCasting safety devicesMolding machineSand casting

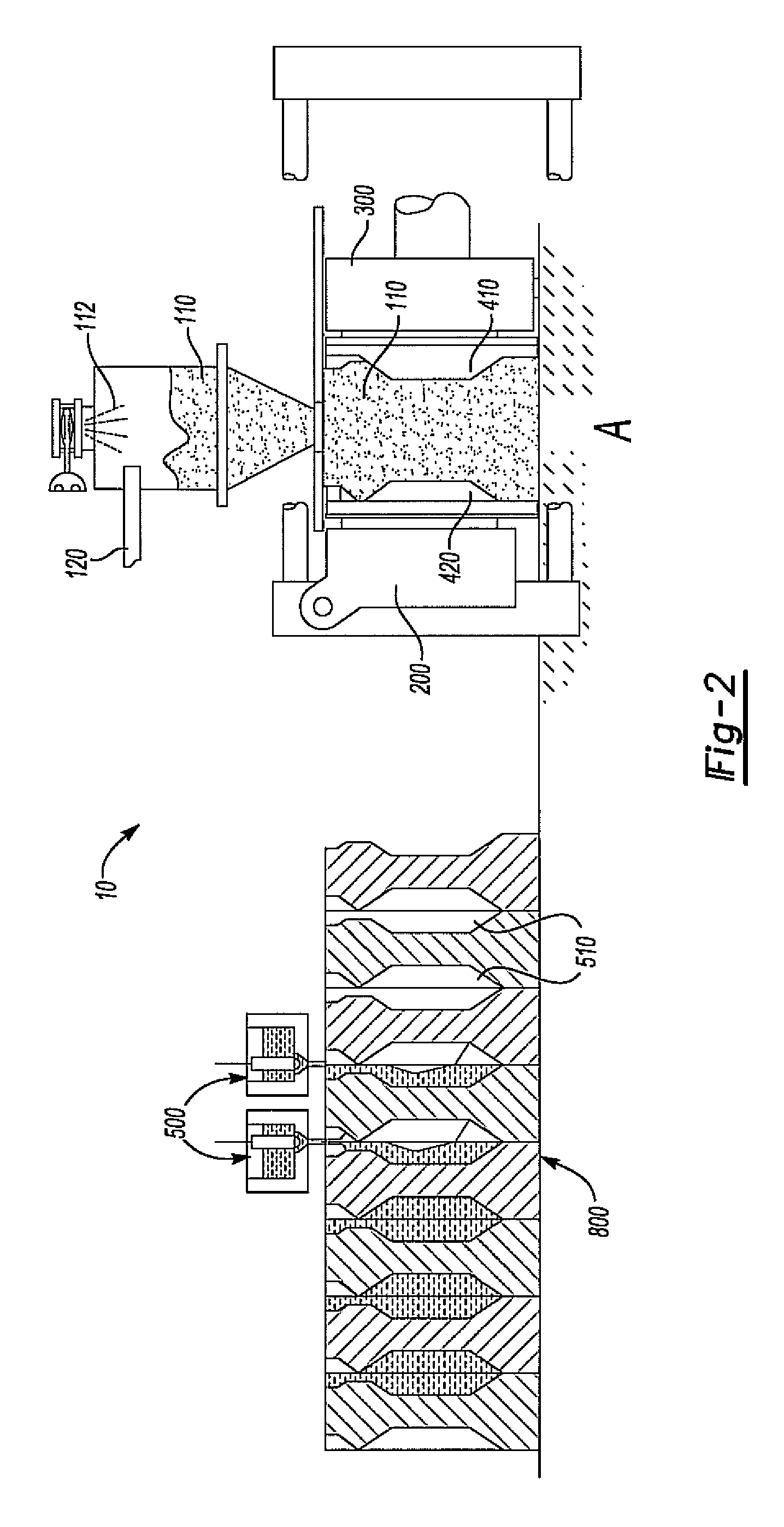

Disclosed is a sand casting molding machine for double indexing molds in a mold string. The machine can include a shot chamber having sand, a swingable squeeze head, a lateral squeeze head, a core setter, a mold hold down, a mold retention device and a mold string conveyor.

Owner:THYSSENKRUPP WAUPACA

Vacuum evanescent die casting process

InactiveCN102974762AHigh precisionNo uneven wall thicknessFoundry mouldsFoundry coresModel compositionAfter treatment

The invention discloses an evanescent die process. The evanescent die process is characterized by comprising the following steps of: selecting foaming plastic beads, manufacturing a model; enabling the beads to expand to be in a certain size through hot water pre-frothing, steam pre-frothing and vacuum pre-frothing, curing and frothing forming; clustering model composition, coating a model; vibrating and shaping; pouring and displacing; and cooling and cleaning, wherein the full mold casting ramoff is simple, a casting piece can be hoisted out when a sand box is inclined or can be directed hoisted out form the sand box, the casting piece and dried sand are naturally separated, and the separated dried sand is reused after treatment. According to the process, a die is not required to be taken out, and a parting plane and a sand core are not required, and thus the casting piece has no flash, no burrs and no pattern tapers, and the dimension error caused by core combination is reduced; and compared with the conventional sand casting method, for the evanescent die process, the 40%-50% machining time is reduced.

Owner:CHANGTU COUNTY JIPAI MACHINERY CASTING

A Method of Numerical Simulation of Casting Macrosegregation

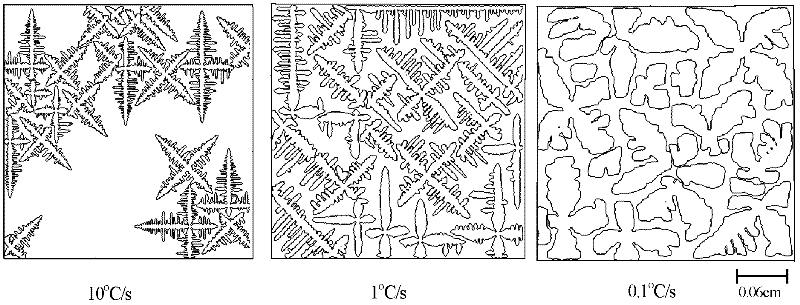

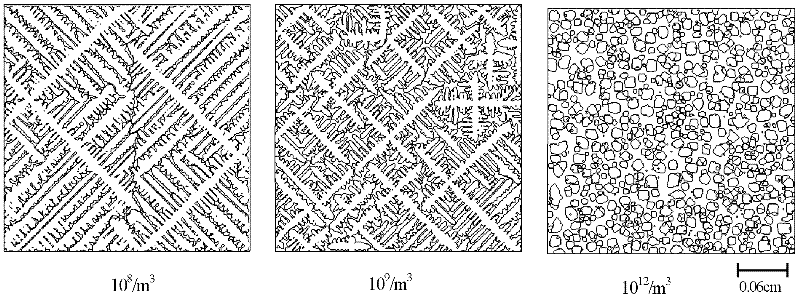

The invention relates to a method for macrosegregation numerical simulation of a casting, aiming at solving the problems of long computation time, low precision and unsuitability for predication of castings with large size or complex shapes in the traditional macrosegregation. The method comprises the following steps of: performing mesh generation on a selected dendritic crystal growth microcosmic computation field; computing dendritic crystal growth shapes during alloy solidification under different maximum nucleation densities from a microcosmic scale, and outputting a solid phase fraction-average dendritic crystal solid phase feature diameter curve; performing macro-scale mesh generation on the casting; computing a mass, momentum, energy and composition conservation equation from a macrocosmic scale; computing a solid phase fraction by using a Newton downhill method; and computing a pasty zone permeability model from a macrocosmic scale by adopting a linear interpolation technologybased on the solid phase fraction-average dendritic crystal solid phase feature diameter curve under a given nucleation density. The method disclosed by the invention is suitable for macrosegregationnumerical simulation in sand casting and metal mold casting of various sizes and complex shapes.

Owner:HARBIN UNIV OF SCI & TECH

Ultrahigh-strength rare earth-magnesium alloy board and preparation method thereof

The invention provides an ultrahigh-strength rare earth-magnesium alloy board and a preparation method thereof, relating to a magnesium alloy board and a preparation method thereof. By the invention, the problems of rough grains, non-uniform structure and poor performance of the magnesium alloy board prepared by the existing rolling method are solved. The ultrahigh-strength rare earth-magnesium alloy board is prepared from the components in percentage by mass: 2.0-17.0% of Gd, 3.0-18.0% of Y, 0.5-3.5% of Zn, 0.1%-1.5% of Zr and 76.0-94.0% of Mg. The preparation method comprises the following steps of: firstly preparing a rare earth-magnesium alloy cast ingot by sand casting, metal casting or semi-continuous casting; then homogenizing and annealing, cutting into rolling blanks, and then carrying out breakdown rolling to obtain a rolled board; and finally aging to obtain the ultrahigh-strength rare earth-magnesium alloy board. The preparation method provided by the invention is mainly used for preparing ultrahigh-strength rare earth-magnesium alloy boards.

Owner:HARBIN INST OF TECH

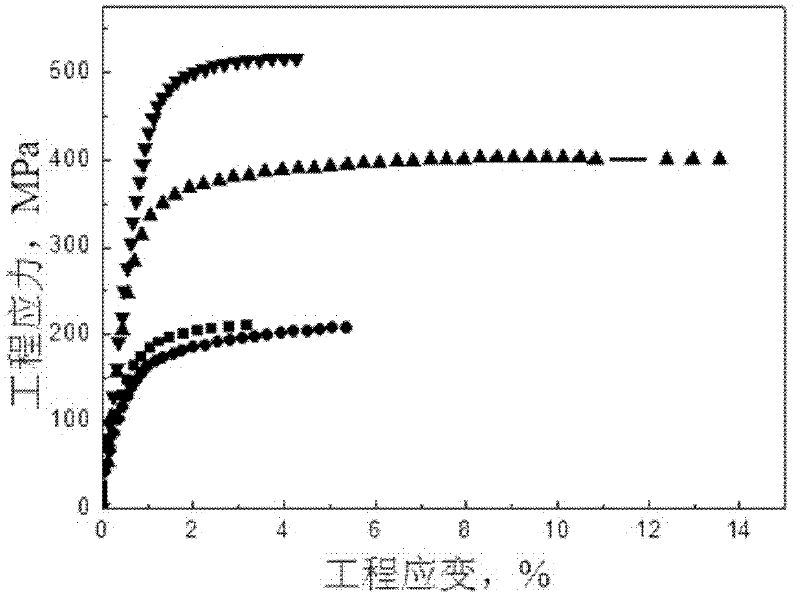

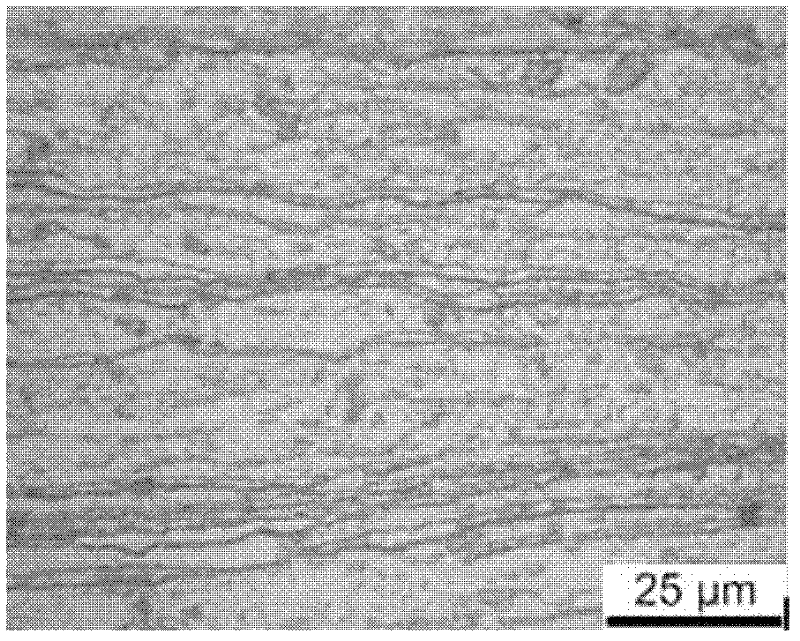

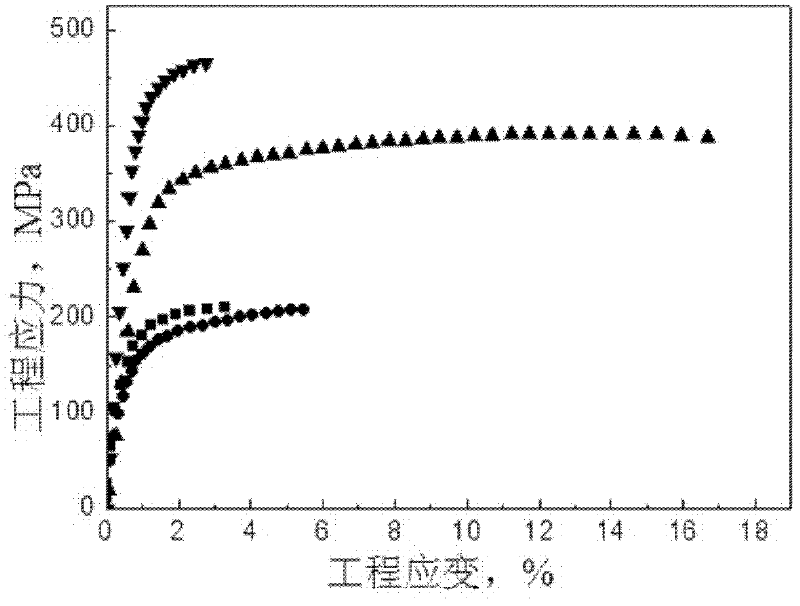

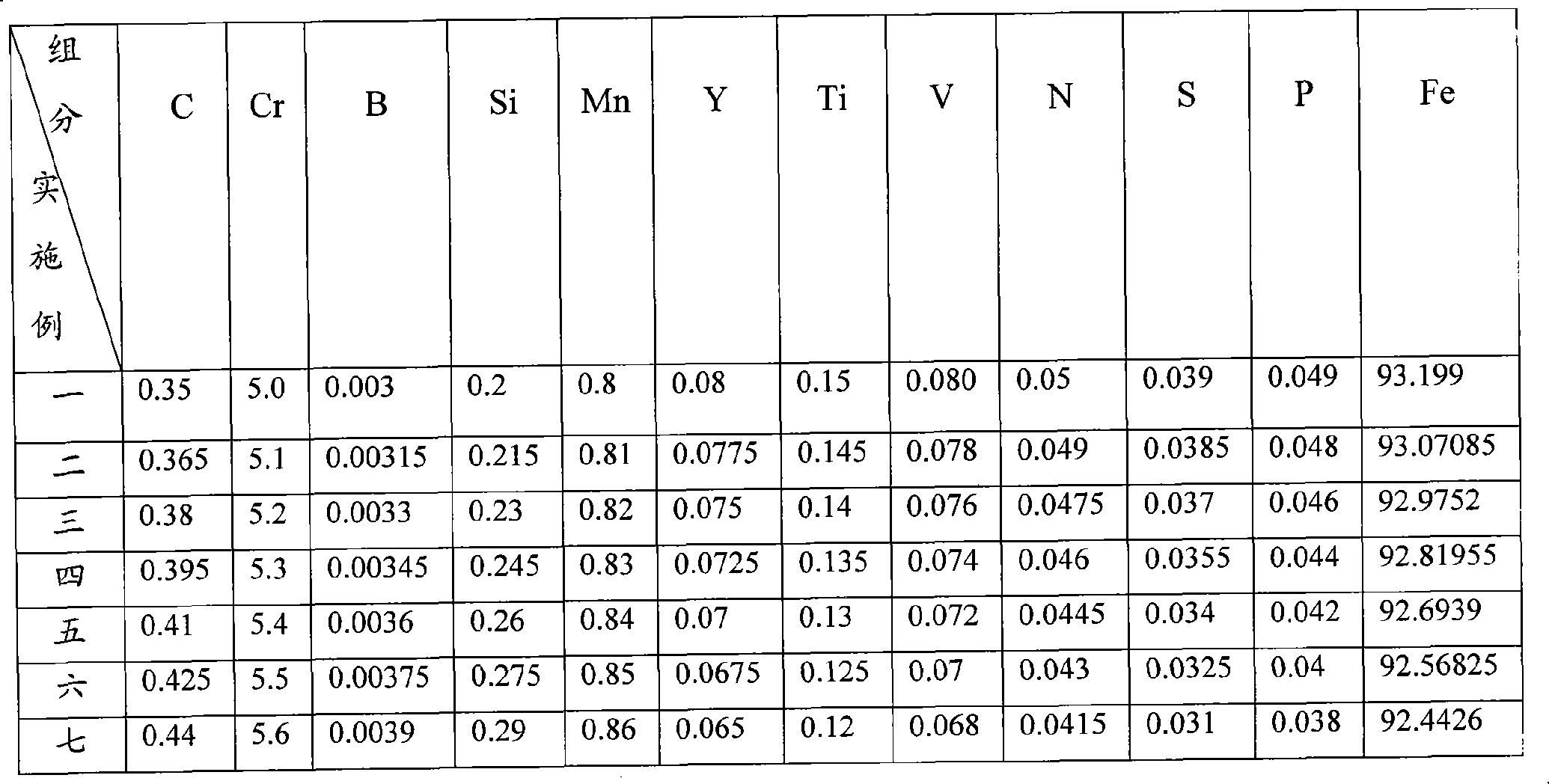

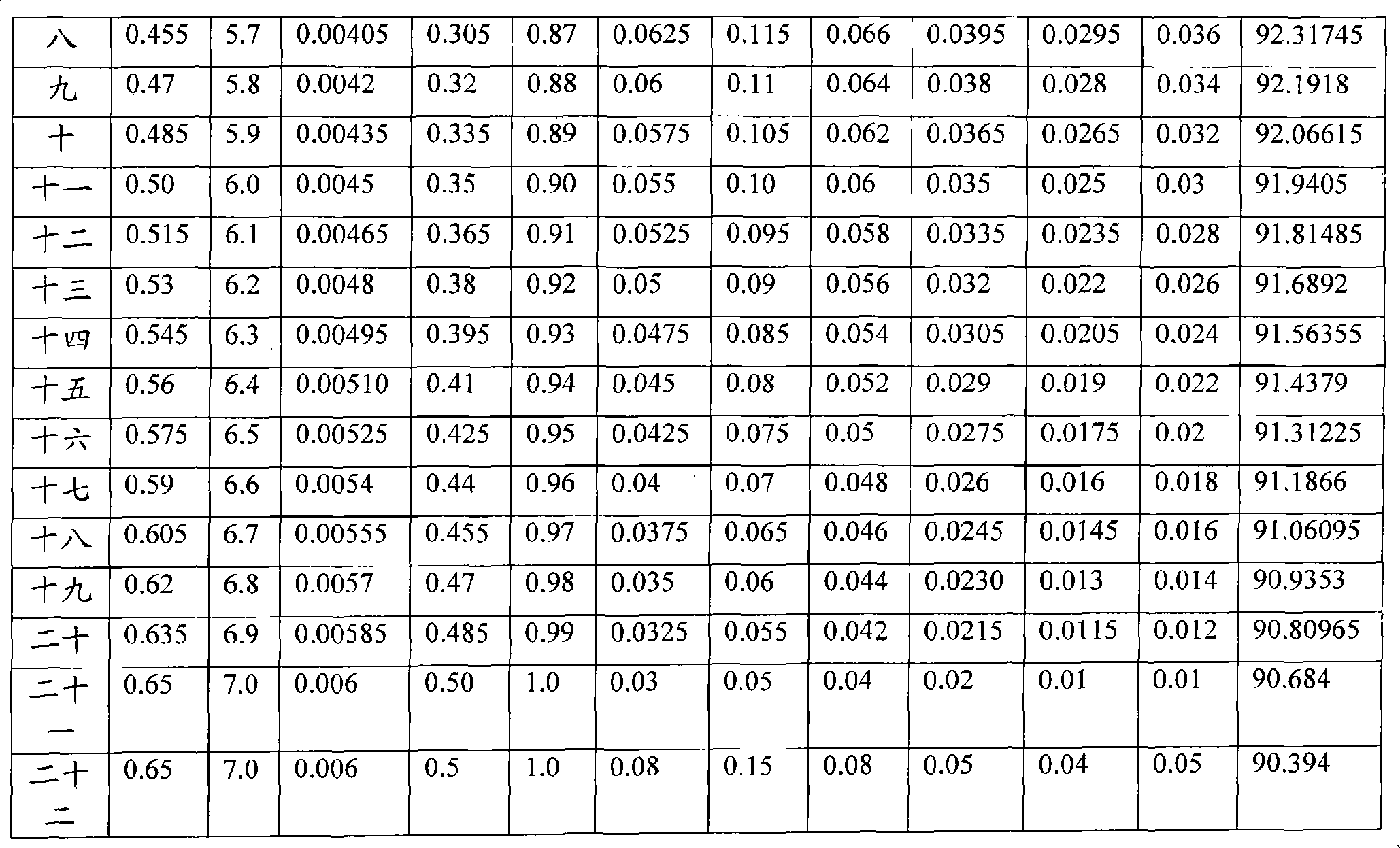

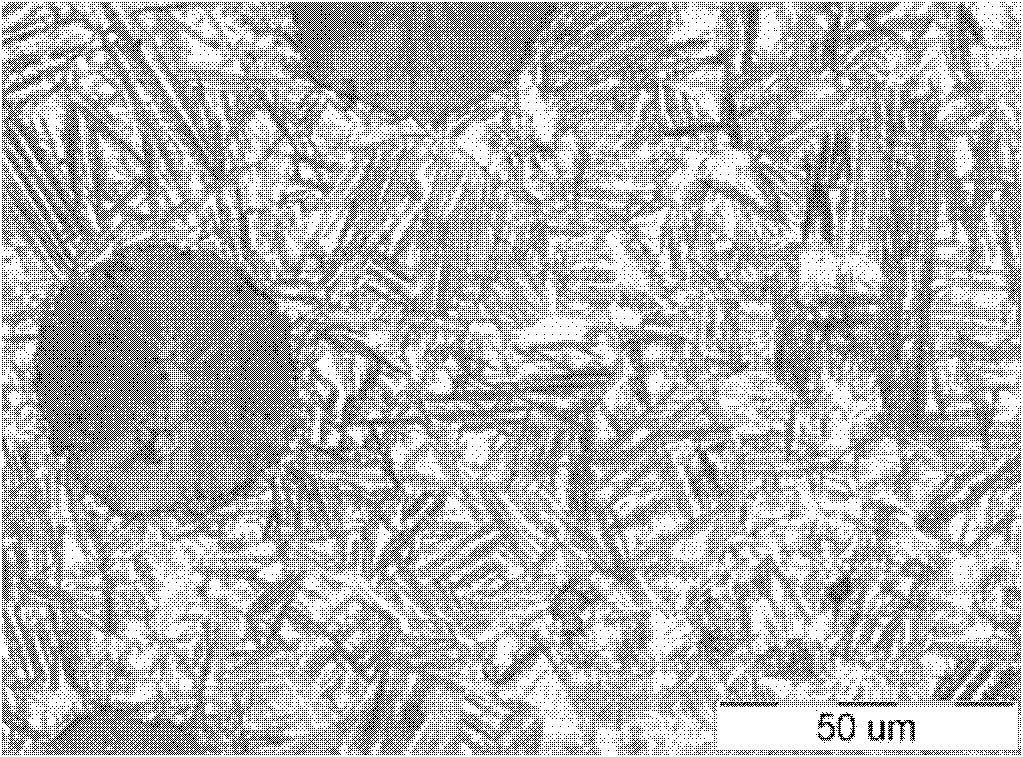

Non-molybdenum non-nickel middle chrome wear resistant steel casting and heat treatment method thereof

The invention belongs to the technical field of metal wear-resistant materials and particularly relates to a wear-resistant casting steel part which is free of molybdenum-nickel and medium-chromium and a heat treatment method thereof. The wear-resistant casting steel part which is free of molybdenum-nickel and medium-chromium comprises the components of the following mass percentages: 0.35 to 0.65 wt percent of C, 5.0 to 7.0 wt percent of Cr, 0.003 to 0.006 wt percent of B, 0.2 to 0.5 wt percent of Si, 0.8 to 1.0 wt percent of Mn, 0.03 to 0.08 wt percent of Y, 0.05 to 0.15 wt percent of Ti, 0.04 to 0.08 wt percent of V, 0.02 to 0.05 wt percent of N, less than 0.04 wt percent of S, less than 0.05 wt percent of P and the balance of ferrite. The wear-resistant casting steel part which is free of molybdenum-nickel and medium-chromium can be manufactured by an electric furnace using a sand casting. The invention carries out step quenching by using two types of quenching oils with different temperatures, thus leading to depth of more than 60mm of the quenching full hardening layer of the cast steel, high hardness, good uniformity of the hardness, and no cracks in the heat treatment. The casting steel is free of expensive alloying elements such as molybdenum or nickel, raw materials resource is rich, the manufacture cost is low and economic benefit is good.

Owner:SHENZHEN UNIV

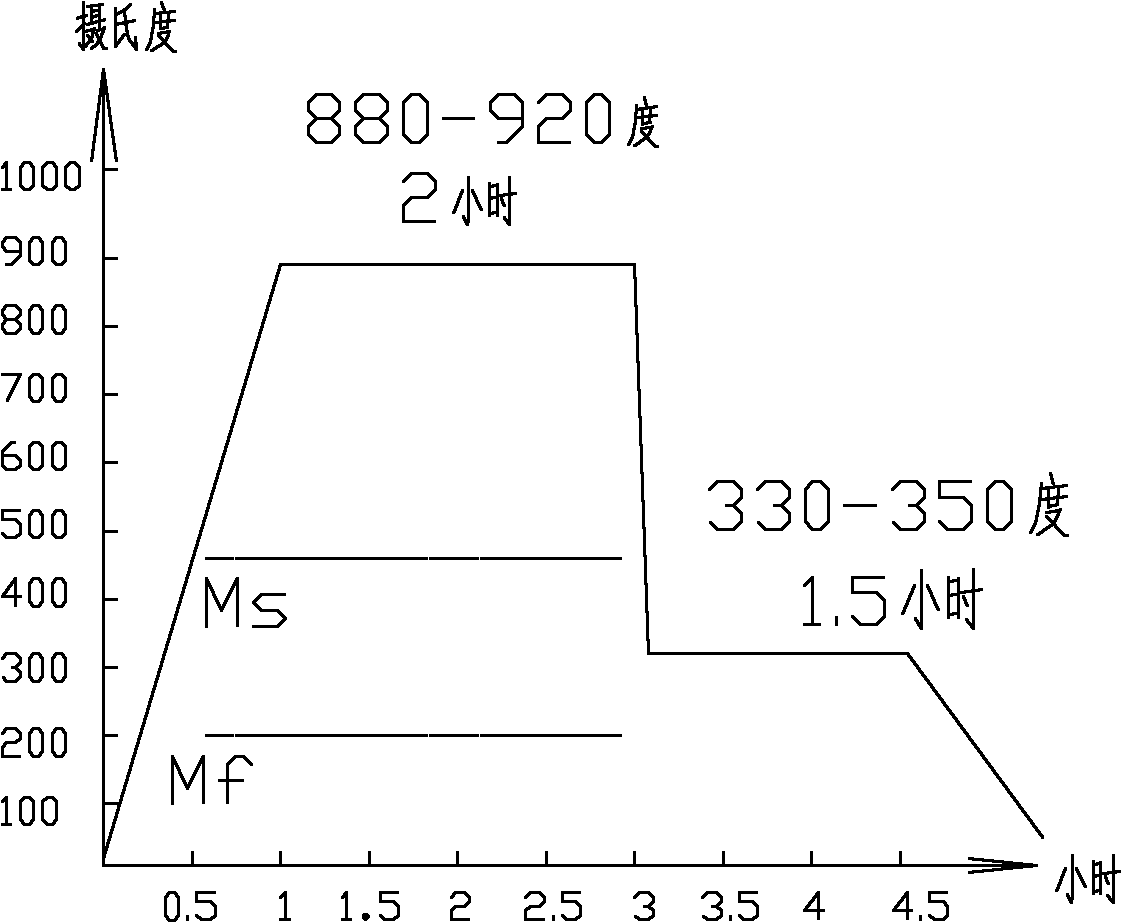

Method for manufacturing austempered ductile iron (ADI) front axle of heavy truck by sand casting

InactiveCN102218504AImprove integrityImprove fatigue lifeFoundry mouldsFurnace typesVolumetric Mass DensityQuenching

The invention discloses a method for manufacturing an austempered ductile iron (ADI) front axle of a heavy truck by sand casting. By the method, nickel molybdenum copper austempered ductile iron (ADI) front axle of the heavy truck is produced by a furane resin sand molding process, and the problems that the internal density and the performance reliability of ADI products are difficult to guarantee and the mechanical properties of the ADI products are low are solved. The method has the following steps of: firstly, casting a blank of the nickel molybdenum copper alloyed spheroidal graphite cast iron front axle by the furane resin sand molding process; secondly, performing the surface shot peening strengthening and isothermal quenching heat treatment; and finally machining the front axle parts. By the method, casting is replaced by forging, and the iron is replaced by steel, the comprehensive mechanical properties are obviously higher than those of common spheroidal graphite cast iron and forged steel, the weight of truck parts is reduced, the investment of heavy forging equipment and dies is saved, the cost is reduced, the production cycle is shortened, energy is saved, the emission is reduced, and the economic benefit and the social benefit are obvious.

Owner:DALIAN XINZHONG GRP +1

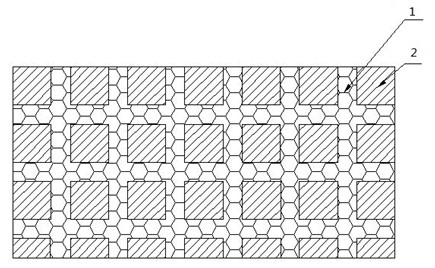

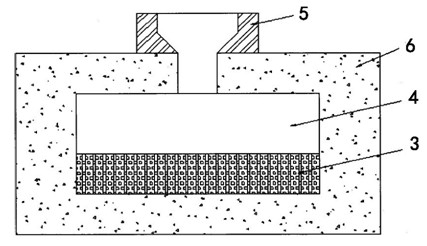

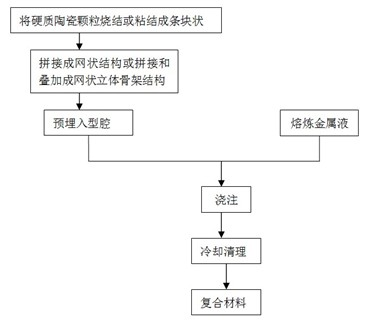

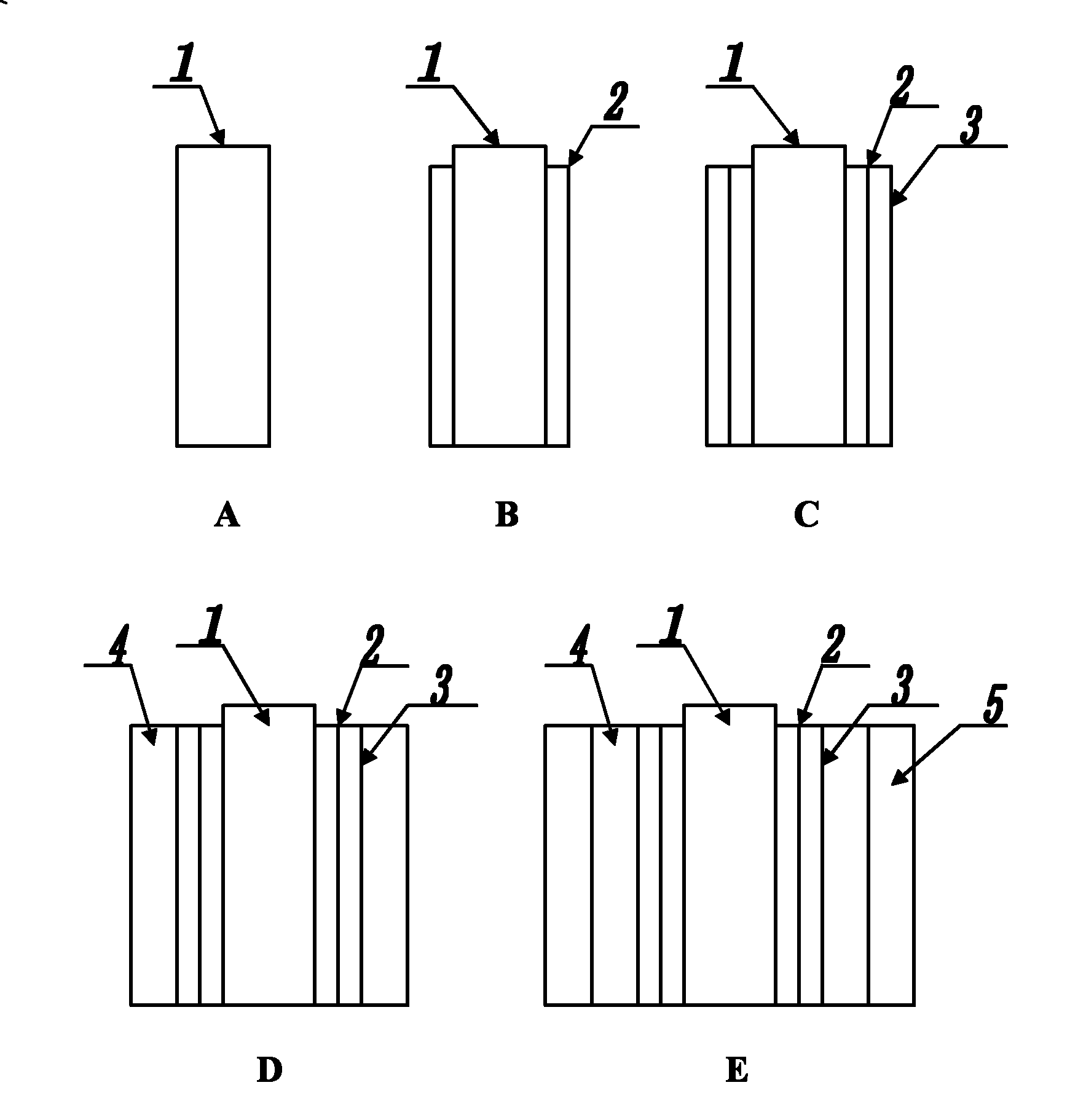

Method for preparing ceramic particle reinforced steel-based mesh material

The invention provides a method for preparing a ceramic particle reinforced steel-based mesh material, which comprises: forming a mixture of hard ceramic particles and alloy powder into strip blocks by powder sintering or by using and adhesive; joining the strip blocks into a corresponding mesh structure or joining and overlapping the strip blocks into mesh three-dimensional framework structure; and performing normal sand casting or lost foam casting, namely melting a substrate metal material, pouring the molten substrate metal material in a molding cavity, allowing the molten substrate metal material to cool and condense at room temperature, removing sand and obtaining the ceramic particle reinforced steel-based mesh material. The obtained ceramic particle reinforced steel-based mesh material gives full play to the high wear resistance of the ceramic particle hard phase and the toughness of the steel base; and the method with convenience for regulation and reliable process solves the problem of incomplete reaction of the composite material, nonuniform reinforcing phase particle distribution, pollution weakening on a reinforcing phase interface and the like and is used in wear resistance fields of mines, power, metallurgy, coal, building materials and the like.

Owner:KUNMING UNIV OF SCI & TECH

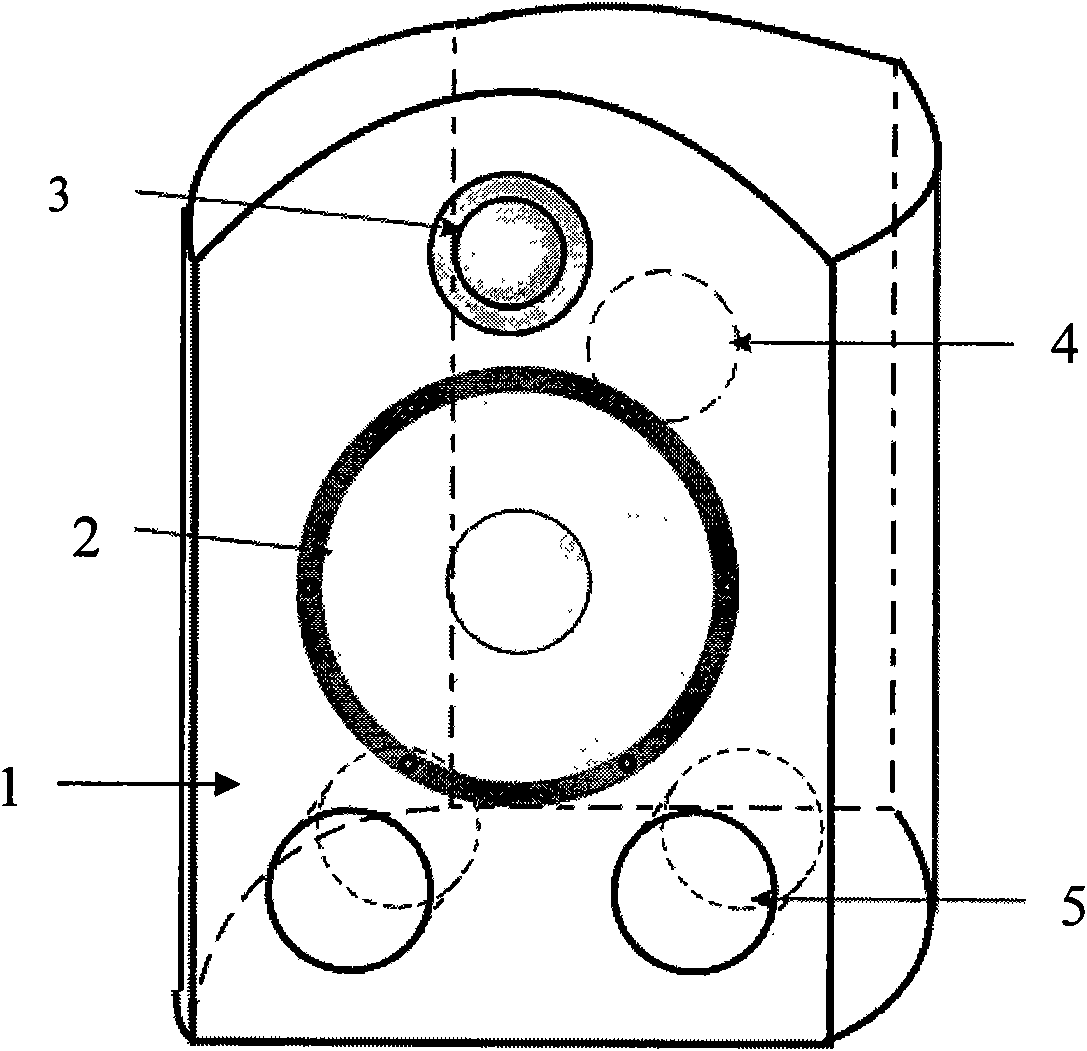

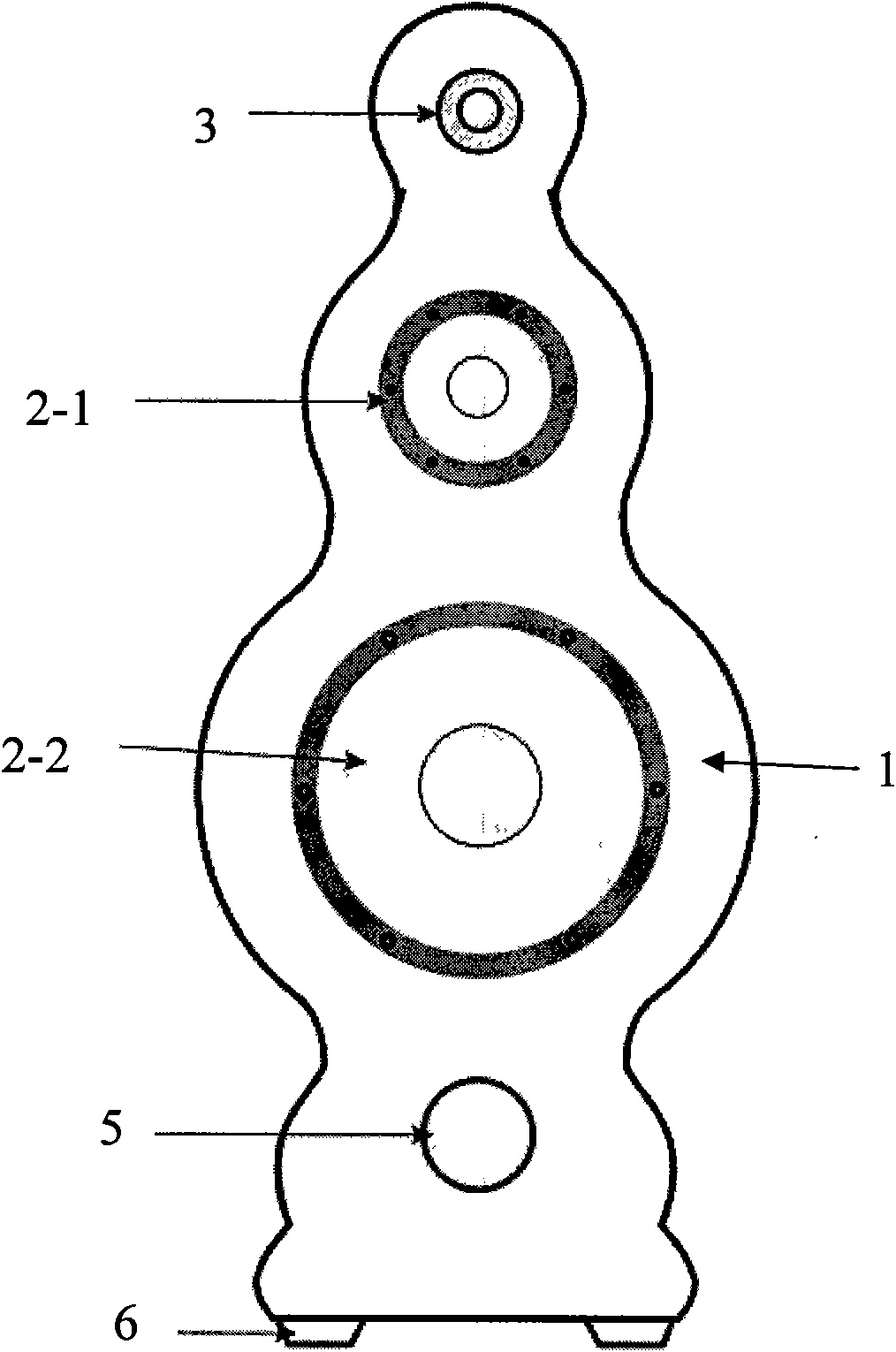

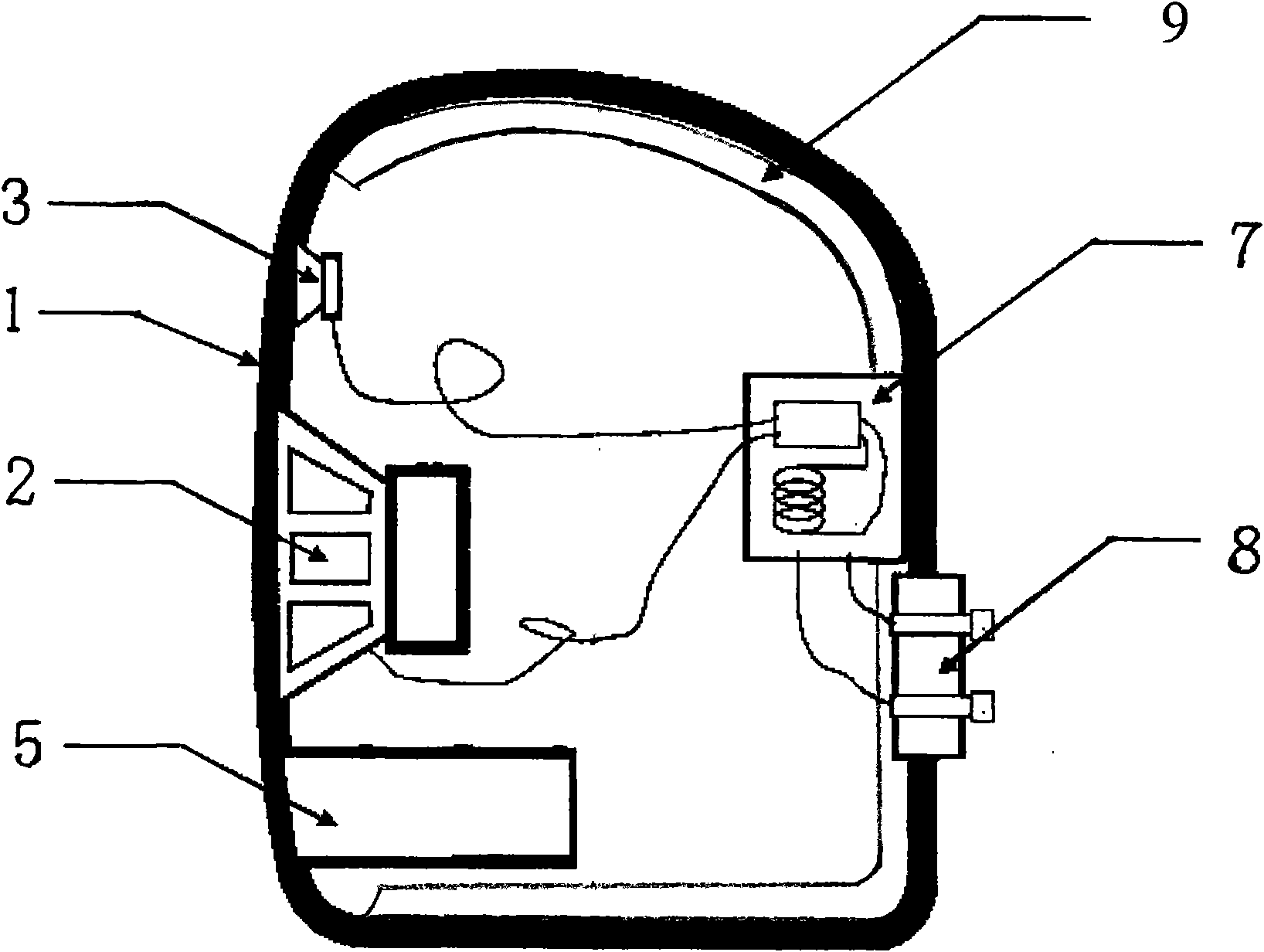

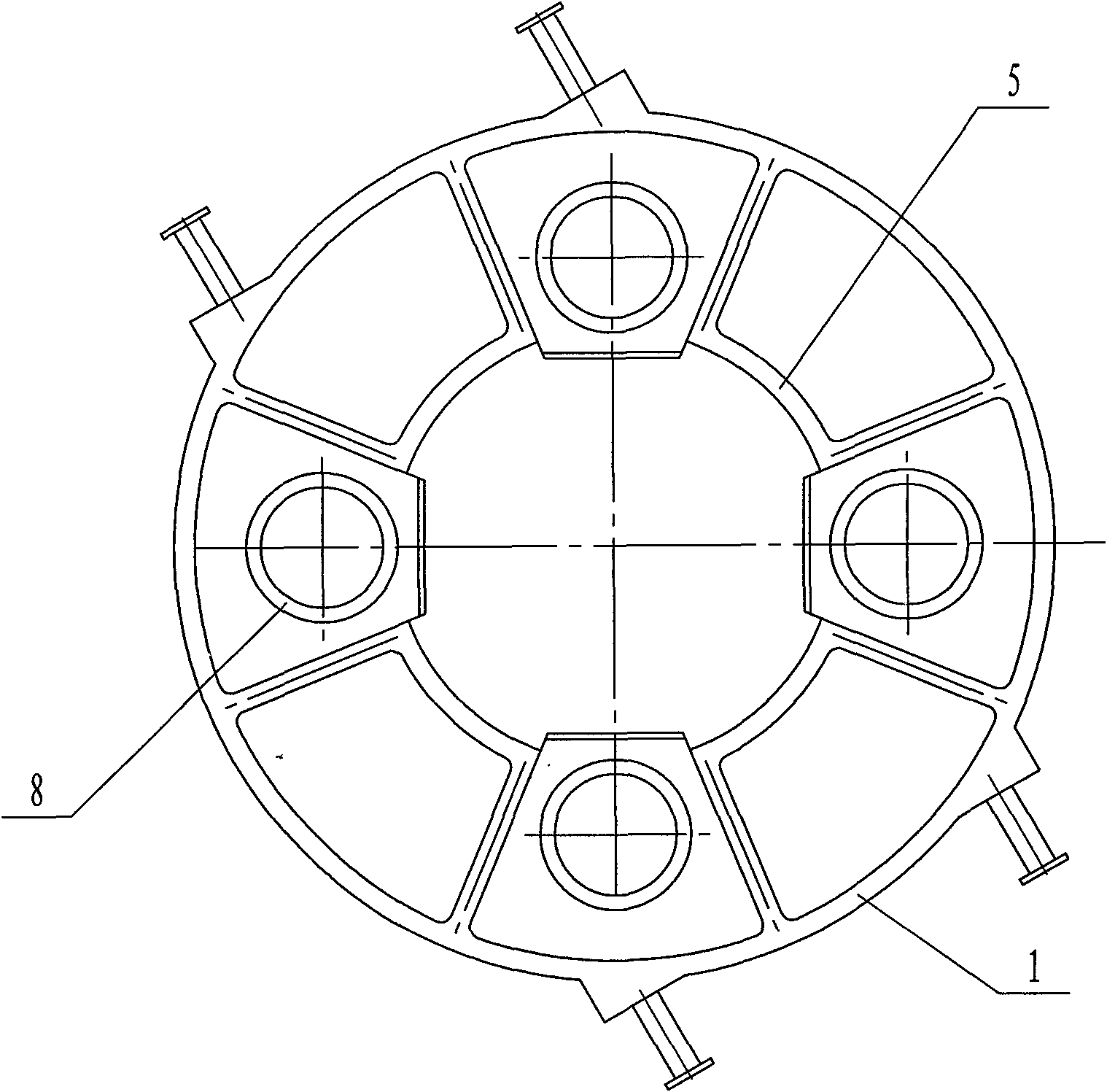

Magnesium alloy integrally cast sound box and manufacturing method thereof

InactiveCN101572851AImprove acoustic propertiesImprove sound insulationTransducer detailsPublic address systemsLoudspeakerAbsorption layer

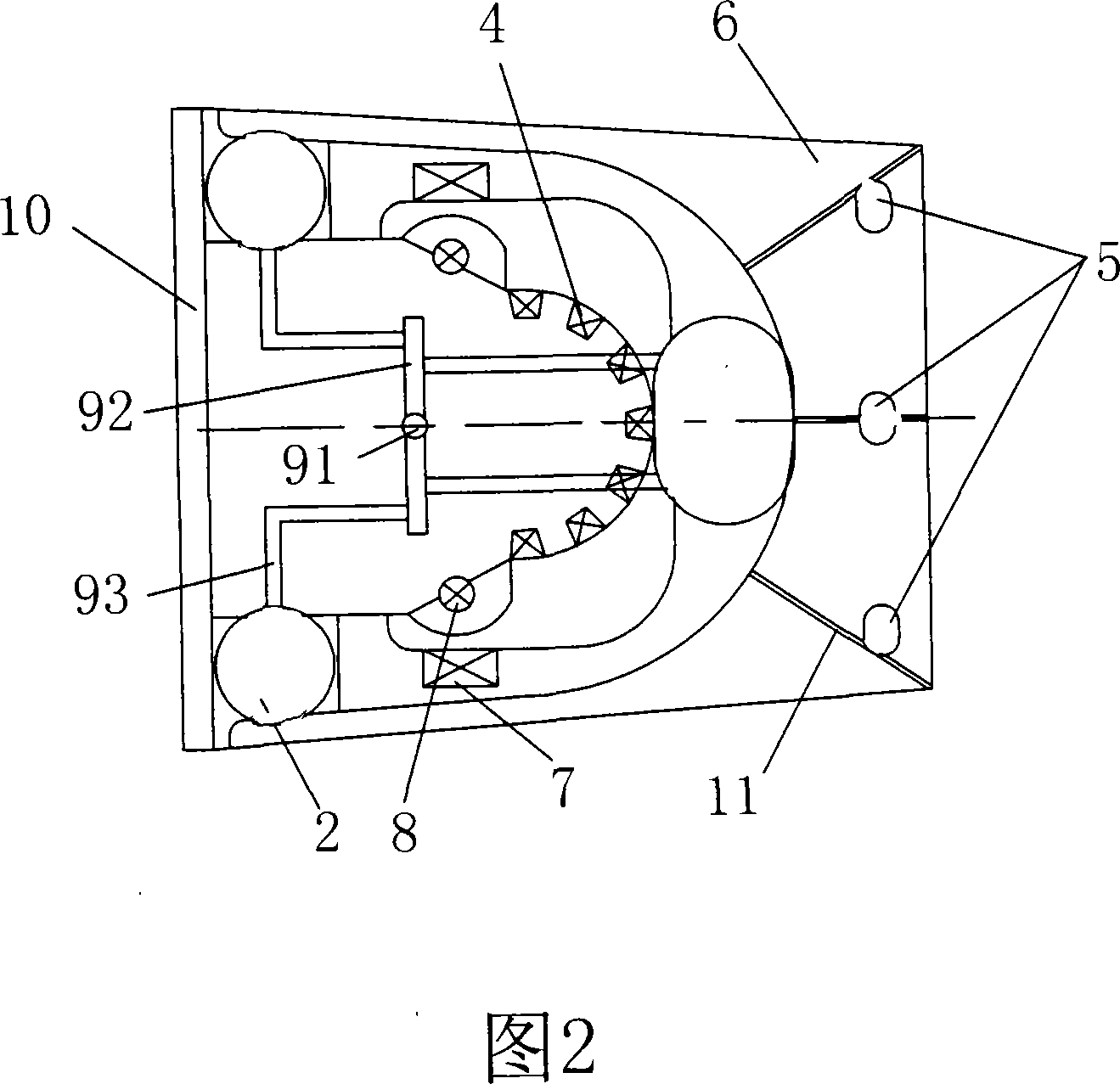

The invention relates to a magnesium alloy integrally cast sound box which comprises a sound box body (1), wherein, a high-frequency loudspeaker (10), a medium / low-frequency loudspeaker (11) and an electronic frequency divider (7) are installed in the sound box body (1), the sound box body (1) is connected with a wiring post (8) through a wire, and a sound absorption layer (9) is arranged on the inner wall of the sound box body (1). The sound box body (1) is a magnesium alloy integrally cast structure, and a high-frequency loudspeaker hole (3) is arranged at the upper part of the sound box body (1); a medium / low-frequency loudspeaker hole is arranged at the middle part of the sound box body (1); and a sound-wave reversed phase hole (5) is arranged at the lower part of the sound box body (1). The manufacturing method comprises the following steps: the magnesium alloy is melted in a smelting furnace in the air or under the protective atmosphere, and the casting core can adopt a wooden core, metal core, and the like, by various molding and casting processes such as sand casting, metal mold casting, and the like; the magnesium alloy adopted in the method comprises the following component of Mg-X alloy, wherein, X can be an element such as Ni, Zr, Al, Cu, and the like, and one or more of the elements can be adopted to be combined with Mg to form binary, ternary or polynary magnesium alloy; and the sound box is characterized in that the seamless sound box body can be conveniently in any shape and complex structure. The invention has the advantages of simple structural process, low manufacturing cost and good tone color.

Owner:SHENYANG AEROSPACE UNIVERSITY

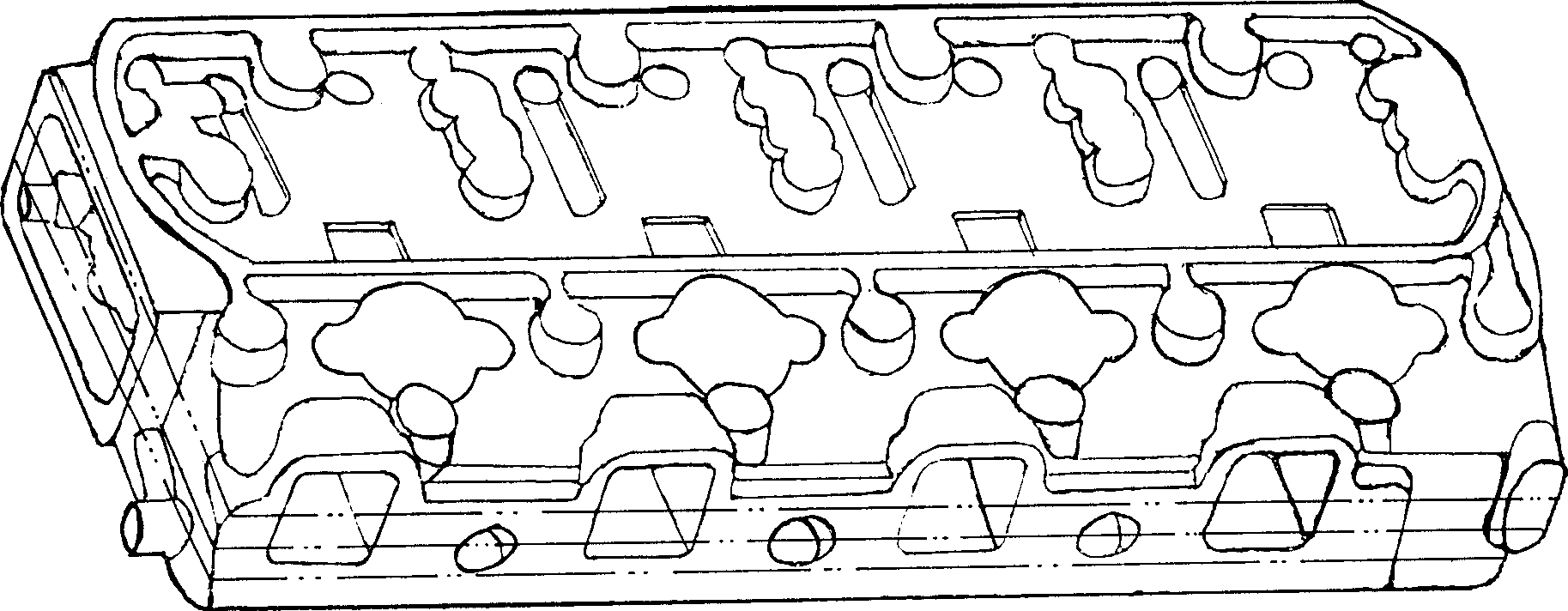

Lost-foam casting process for cylinder body and cylinder cap of diesel engine and gasoline engine

InactiveCN1843657AReduce labor intensityReduce consumptionFoundry mouldsFoundry coresDiesel engineLost-foam casting

The invention discloses a method for casting disappear mould of the cover of diesel engine and petrol engine that based on disappear mould technique, which can solve the problems of present sand casting technique with high material consumption, heavy cast, and environment pollution, etc. The invention slices matter into several mould plates to prepare the mould; than filling the material of disappear mould into mould to attain the mould plate of disappear mould which is the same with said matter; dipping disappear mould dope on the mould plate and arranging it into sand tank to be vibrated and poured to melt mould plate into carbon monoxide and carbon dioxide to be discharged to attain the cast of said matter. The invention has the advantages that save raw material, reduce labor intensity and improve property.

Owner:ANHUI TIANYU MACHINERY

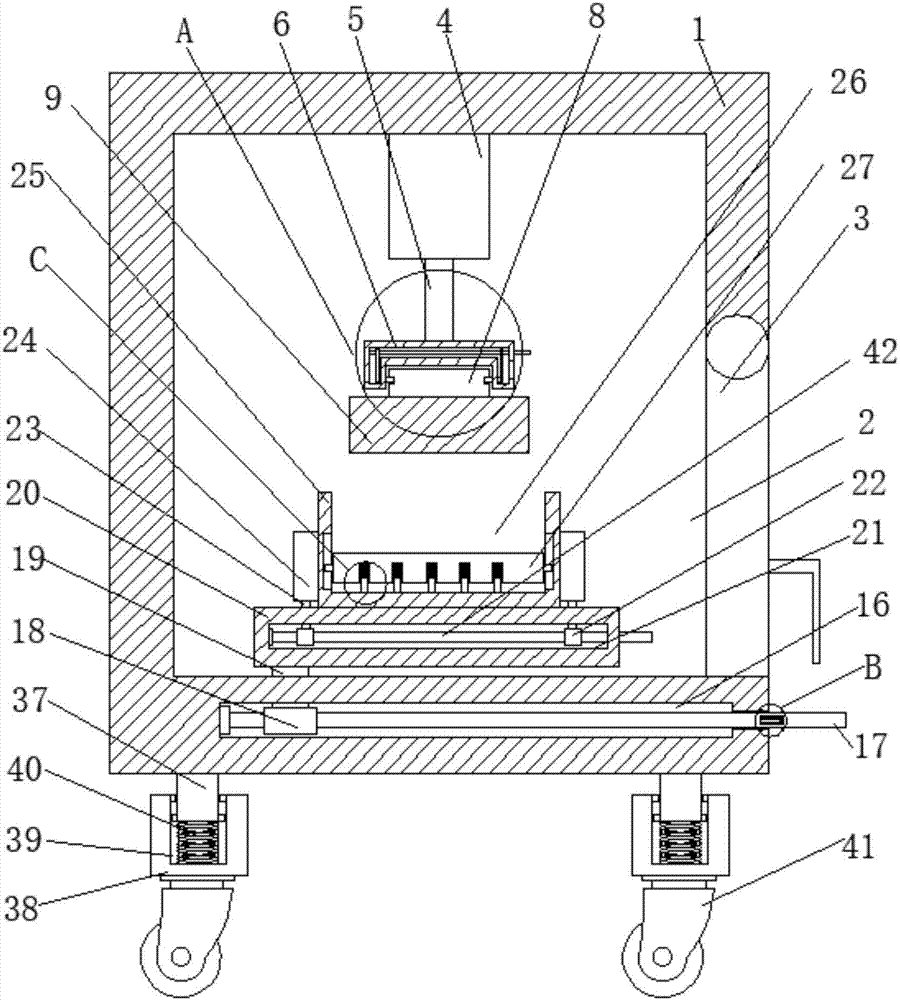

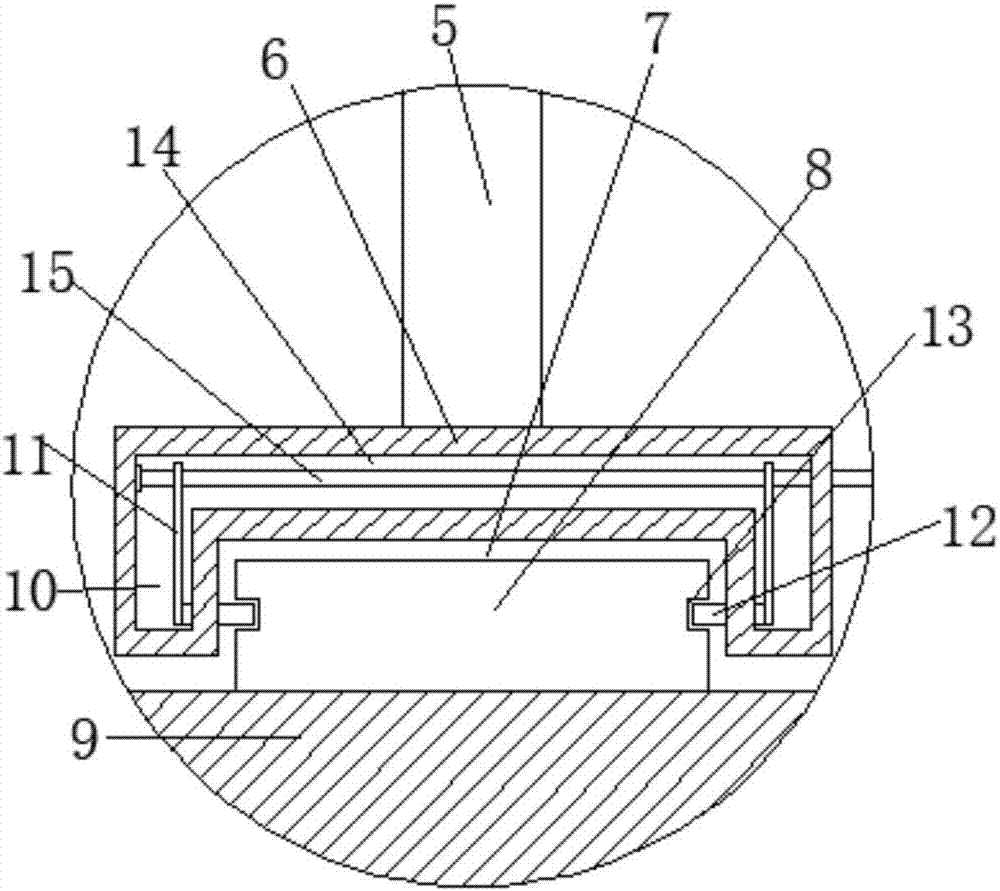

Sand casting die assembly

ActiveCN107876709AAvoid disassembly and replacementEasy to disassemble and replaceMoulding machinesCompression moldingSand casting

The invention discloses a sand casting die assembly comprising a shell which is of a hollow structure. One side wall of the shell is further provided with a feed port of which the opening position isrotatably connected to a cover plate, and the inner wall of the upper side of the shell is fixedly connected to a cylinder; the output end of the cylinder is connected to a piston rod, and the end, far away from the cylinder, of the piston rod is connected to a mounting plate of which the lower end is further provided with a die; the upper end of the die is provided with a mounting block, and thelower side wall of the mounting plate is provided with a mounting groove matched with the mounting block; the mounting plate is internally provide with two cavities arranged symmetrically, and the cavities are internally provided with first slide bars arranged vertically; the opposite side walls of the two first slide bars are both provided with first clamping blocks which penetrate the cavities;and the side wall of the mounting block is provided with a first slot matched with the first clamping blocks. According to the sand casting die assembly disclosed by the invention, a clamping sand mould is simple and firm, and the die for compression molding is easy to remove and displace; and the die assembly is wide in application scope.

Owner:马鞍山市海华金属制品有限公司

Molding and casting machine

ActiveUS7806161B2Easy to moveEasy to adjustPig casting plantsCasting safety devicesMolding machineSand casting

Disclosed is a sand casting molding machine for double indexing molds in a mold string. The machine can include a shot chamber having sand, a swingable squeeze head, a lateral squeeze head, a core setter, a mold hold down, a mold retention device and a mold string conveyor.

Owner:THYSSENKRUPP WAUPACA

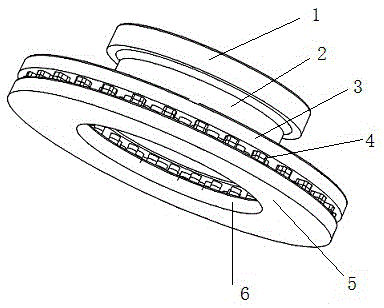

Workblank manufacturing method of automobile brake disc

InactiveCN105458184AAchieve productionSave materialFoundry mouldsMoulding machinesSand castingCasting defect

The invention discloses a workblank manufacturing method of an automobile brake disc, and belongs to the field of automobile accessory manufacturing. The method comprises the following steps that firstly, according to design paper of the brake disc, and a precoated sand shell mold and a sand core mold are designed and manufactured; secondly, the sand shell mold or sand core mold is placed on a sand shell or sand core automatic forming machine to manufacture a precoated sand casting sand shell model and a sand core model; thirdly, pouring is carried out; and fourthly, a casting is taken out and cleaned. The beneficial effects that production of the brake disc workblank can be efficiently achieved, materials and manpower are saved, mechanical allowance is reduced, casting defects are reduced, the yield is improved, and automation production is easily achieved are achieved.

Owner:YUZHOU KUNLUN MOLD CO LTD

Precision casting process of large casting

ActiveCN103920852ARealize precision casting technologyHigh strengthFoundry mouldsFoundry coresWaxSlurry

The invention discloses a precision casting process of a large casting. The precision casting process comprises the following steps: preparing a wax mold, and finishing; preparing a shell mold sand mold; dewaxing; roasting a shell mold; fabricating the sand mold; venting; casting to obtain the casting. Respective advantages of precision casting and sand casting processes are combined, and the precision casting technique of the large casting is achieved. The shell mold disclosed by the invention is steeped and adhered by slurry which is specially prepared for a plurality of times, is subjected to manual sand floating, and is subjected to segmented heating roasting, and a high-strength shell mold is formed, so as to achieve the strength requirements of casting the large casting. Mixed sand with alkaline phenolic resin is injected into a sand box, so that the precision casting process is relatively good in strength and relatively stable, the surface accuracy of the casting can be further improved, and the quality of the casting is improved.

Owner:SANMING CITY YIJUN MACHINERY FOUNDRY

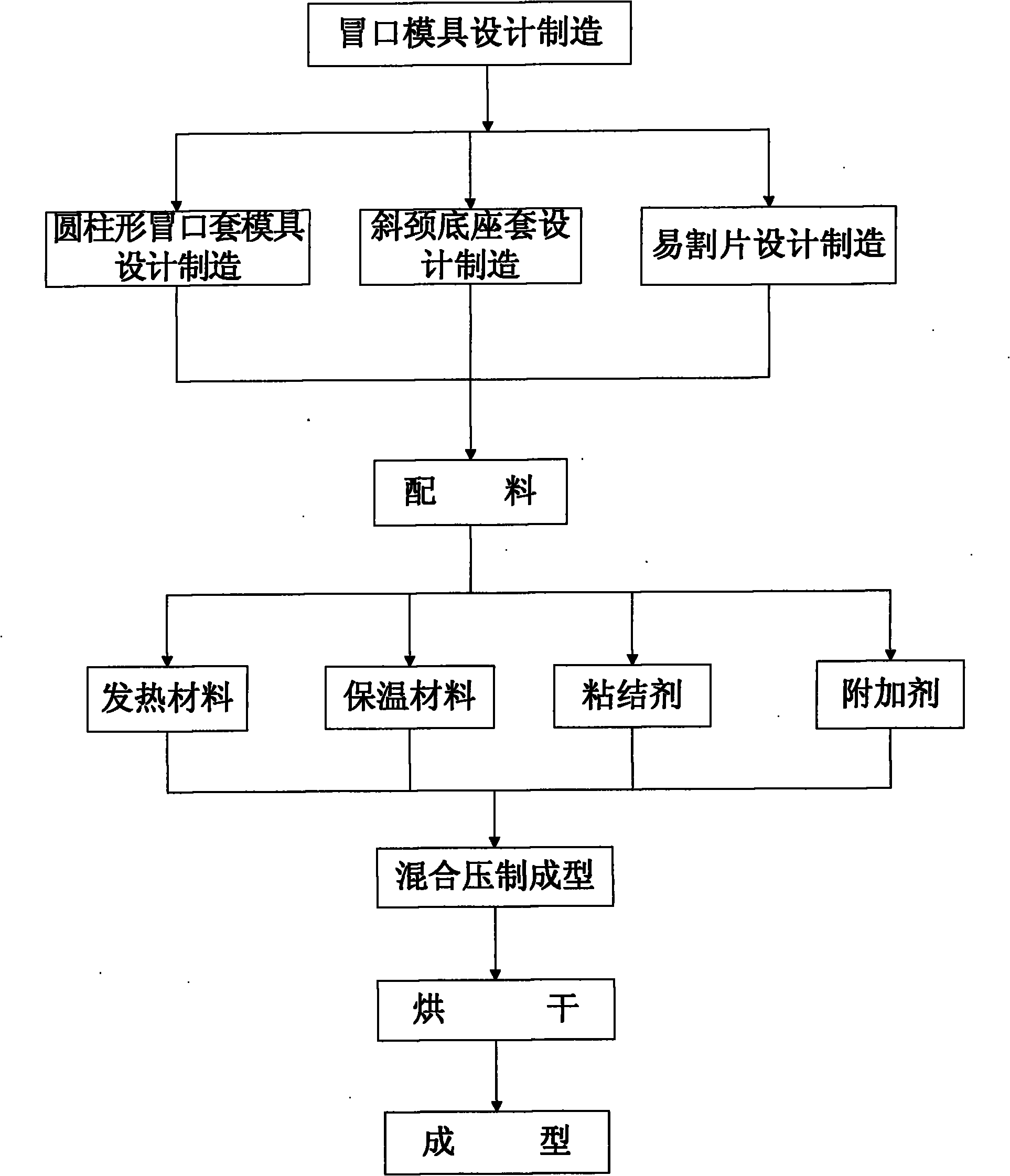

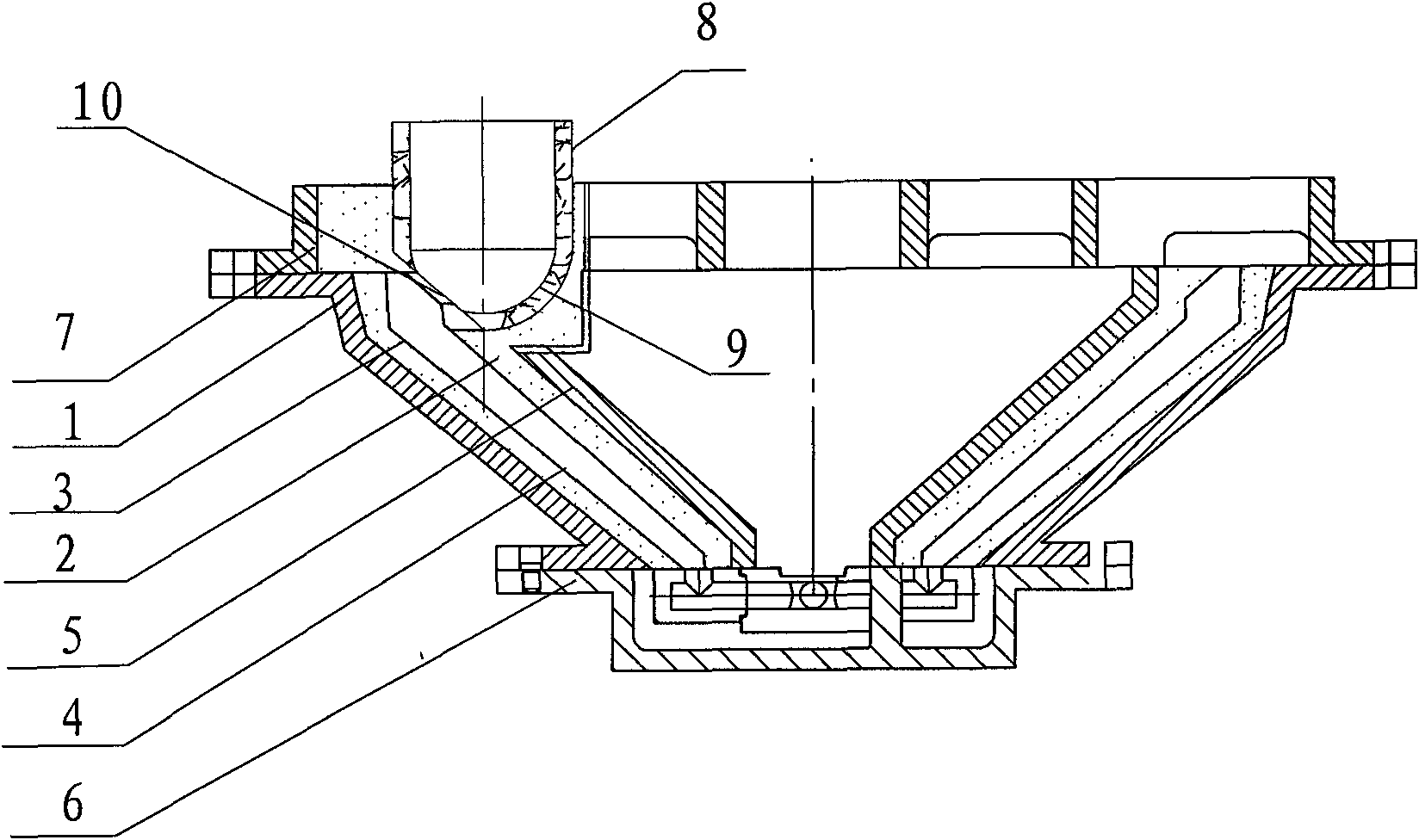

Manufacturing method of heating/heat-insulated washburn risers on inner/outer metal mold sand casting manganese steel crushing wall or rolling mortar wall

ActiveCN101954457AGood high temperature fire resistanceIncrease temperatureFoundry mouldsFoundry coresProduction rateEconomic benefits

The invention discloses a manufacturing method of heating / heat-insulated washburn risers on inner / outer metal mold sand casting manganese steel crushing wall or rolling mortar wall, which comprises the following steps: (1) calculating the effective feeding distances of risers based on the fact that a crushing wall or a rolling mortar wall is the structural characteristic of a uniform-wall thickness annular closed casting and is the main thermal center, and determining the quantity, the shapes, the sizes and the positions of the risers; (2) respectively designing and manufacturing components of the heating / heat-insulated risers; (3) assembling components of heating / heat-insulated riser sleeves; assembling an outer metal mold with spread molding sand and an inner metal mold with spread molding sand and a tapered neck riser seat sleeve on a casting bottom plate, fastening the outer metal mold and the inner metal mold, covering a top box provided with the upper halves of the heating / heat-insulated riser sleeves, fastening with the outer metal mold and the inner metal mold into a whole casting mold, casting, and knocking off the risers after uncovering. By using the method to produce the manganese steel casting risers, the invention achieves obvious feeding effect, increases the production rate of the casting process, reduces the riser cutting cost and increases the economic benefits.

Owner:广西长城机械股份有限公司

Method for casting large main-bearing seat

The invention is concerned with molding method for large tape of headstock seat, relating to workout molding technology, make wood mould, make sand casting, close box, molding, cooling and clear casting. Workout molding technology to produce headstock seat by plot out the plane of mould and make wood mould according to the process demand and locate the wood mould on the mould plane. Make casting mould and set cold iron and close box to dry sand casting. Melt casting mould liquid and during the melting process, blow inert gas and feed the wire. Pour the casting, keep temperature and carry heat treatment by routine method. This method takes exothermic risers with same number of moulds to replace the existing micro - particle riser, and this saves the pouring amount of melting liquid and avoids the limitation of shrinkage of the shaped cold iron when it is on the surface of bearing hole. When during the pouring, it forms the anaerobic condition to enhance the purity of steel water and the produce of impurity between two oxidations and the dissection capability of thick part of casting is satisfied.

Owner:SHANGHAI HULIN HEAVY IND +1

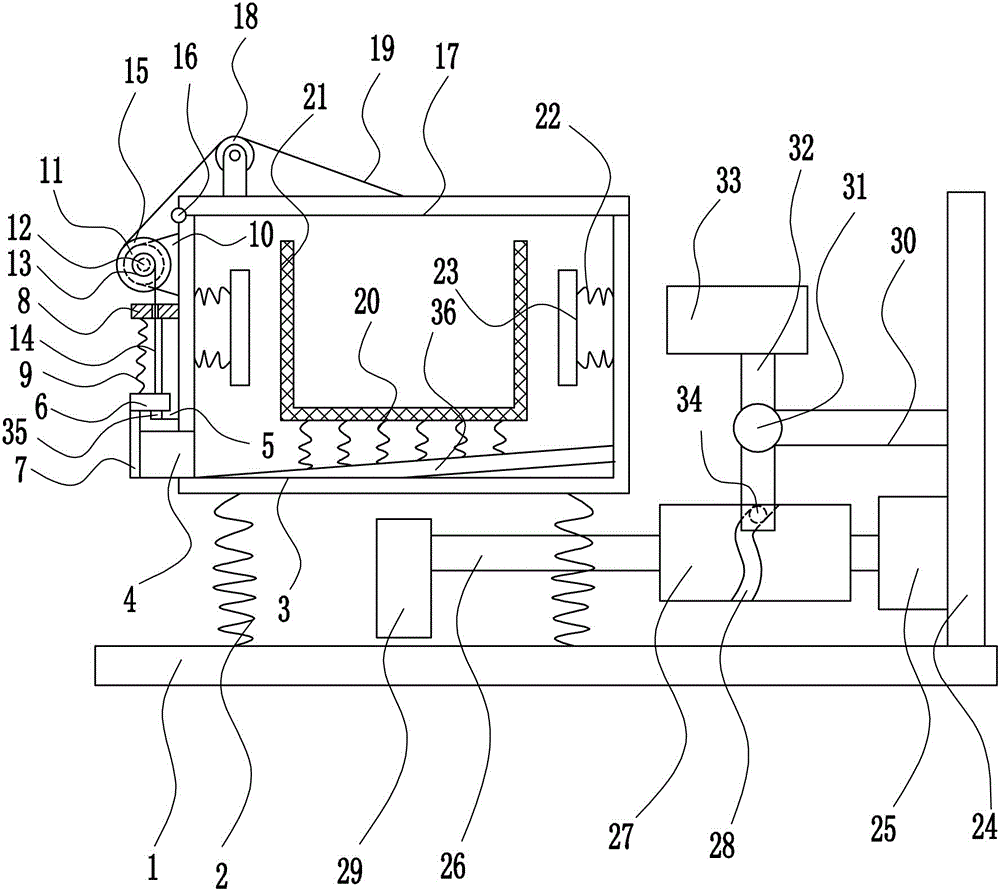

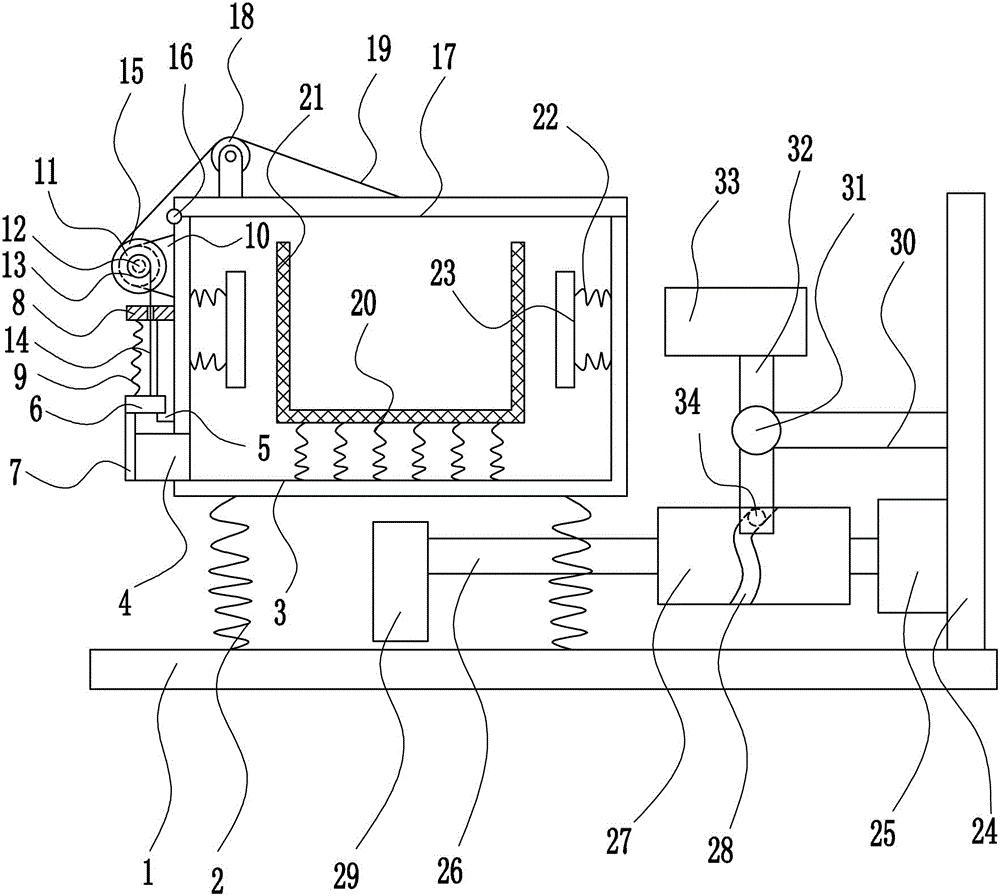

Shakeout machine for sand casting of automobile engine part

The invention belongs to the field of automobile engine part manufacturing, and particularly relates to a shakeout machine for sand casting of an automobile engine part. The technical effect that the shakeout machine for sand casting of the automobile engine part which is good in shakeout effect, rapid in shakeout rapid and convenient to operate is provided is achieved. In order to achieve the technical effect, the provided shakeout machine for sand casting of the automobile engine part comprises a bottom plate, first springs, a vibrating case, a sand outlet, a sliding rail, a sliding block, a baffle, a fixing plate, a second spring, a mounting base, a first motor, a first rotary shaft and the like. The first springs are symmetrically connected with the left side of the top of the bottom plate in a hook connecting mode. The top ends of the first springs are connected with the vibrating case in a hook connecting mode. The shakeout machine achieves the effects of good shakeout effect, high shakeout speed and convenient operation, labor intensity of workers is relieved, the shakeout treatment speed is increased, the operation efficiency is improved, and the shakeout effect is good.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

High-strength heat-resisting magnesium alloy suitable for sand casting and preparation method thereof

The invention discloses high-strength heat-resisting magnesium alloy suitable for sand casting and a preparation method thereof. The high-strength heat-resisting magnesium alloy suitable for sand casting comprises, by mass, 7-11% of Gd, 1-4% of Y, 0.5-2.5% of Ag, 0.2-0.6% of Zr, 0.1-0.3% of B, lower than 0.02% of impurity elements and the balance Mg, wherein the impurity elements include Si, Fe, Cu and Ni. The preparation method comprises the steps of smelting and heat treatment. The Gd and the Y are used as main alloy elements of the high-strength heat-resisting magnesium alloy, the Ag is added into the alloy to improve the solid solution strengthening effect of rare earth alloy and refine a precipitated phase, a K2ZrF6 salt mixture and B2O3 are added to inhibit grain growth of the alloy in sand casting and follow-up solid solution process, reduce segregation of the elements Zr and B, improve the yield of the elements Zr and B and reduce the production cost of the magnesium alloy.

Owner:SHANGHAI JIAO TONG UNIV +1

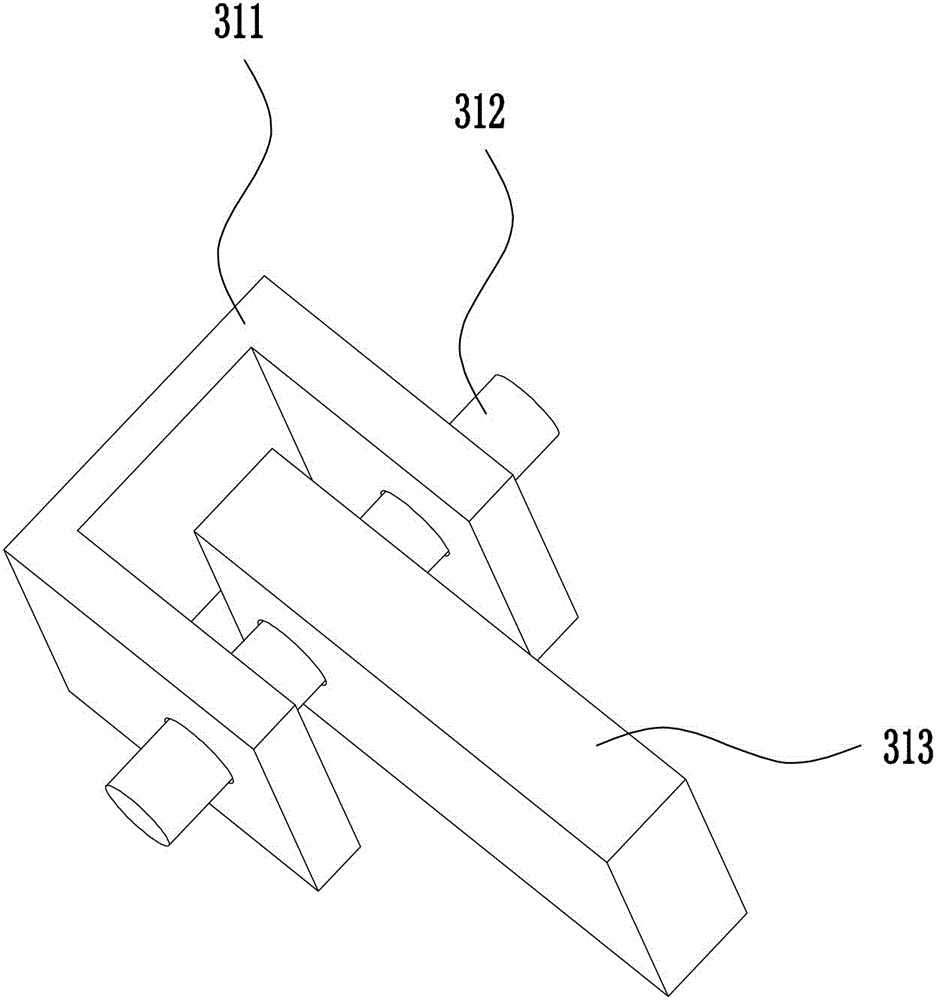

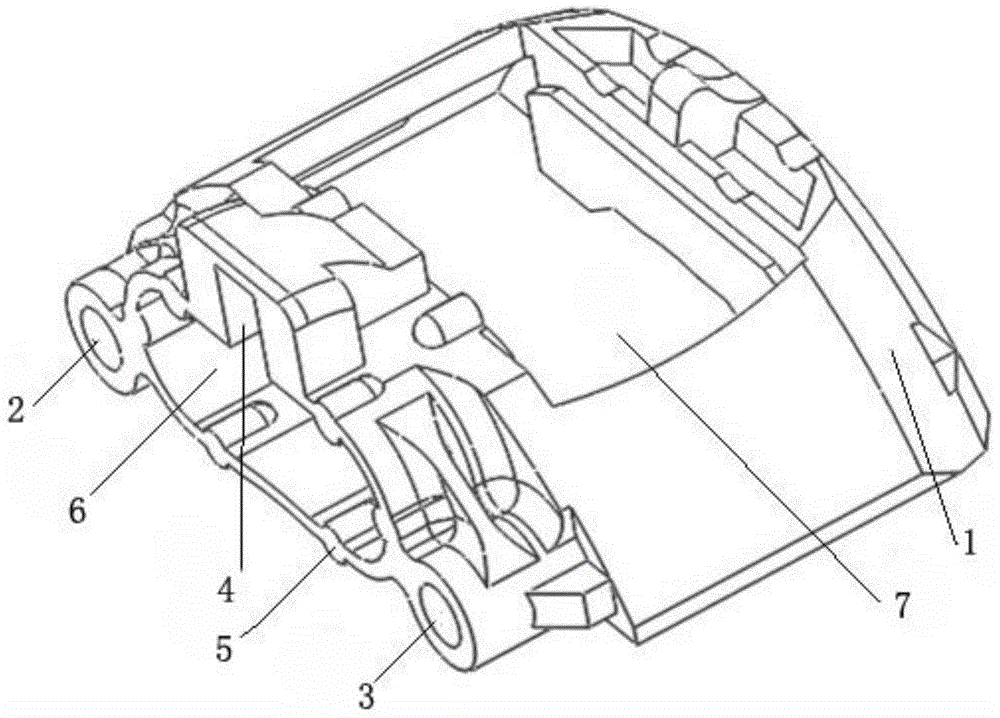

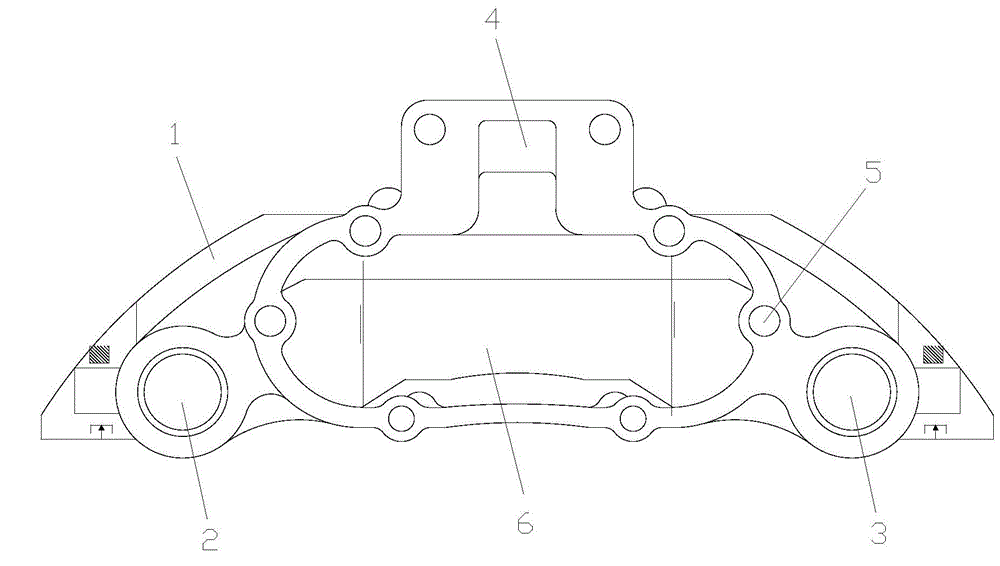

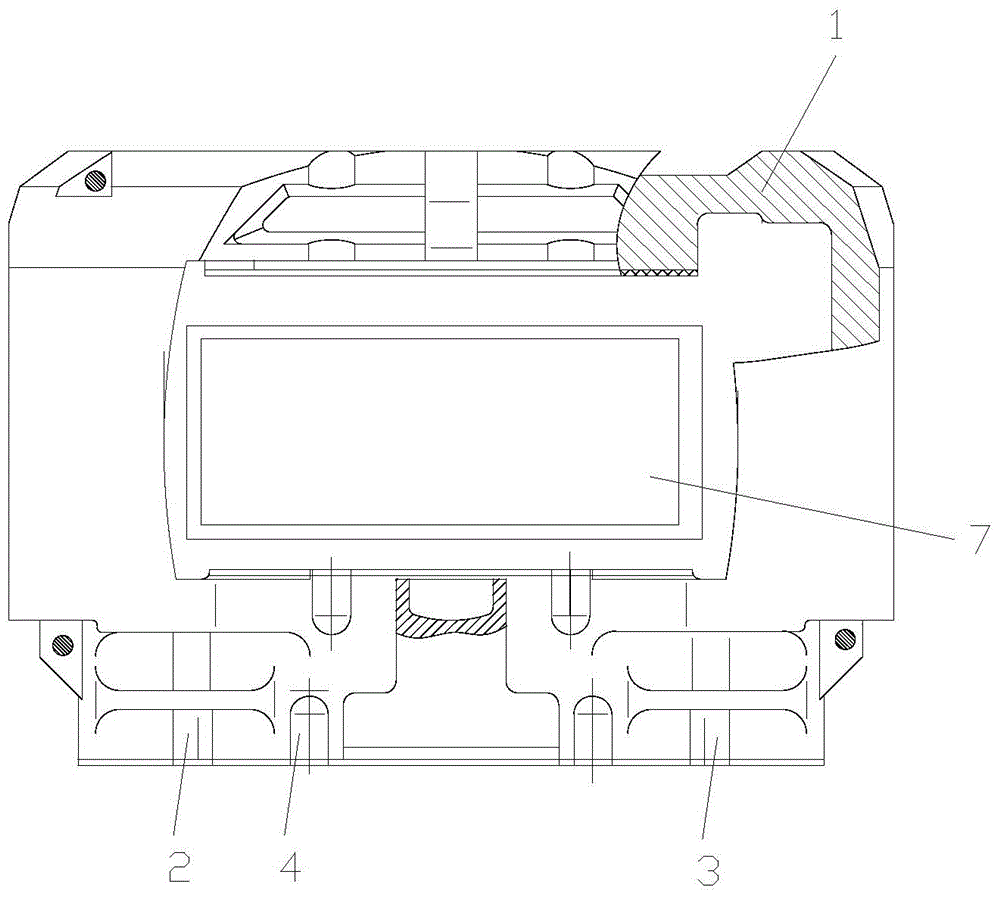

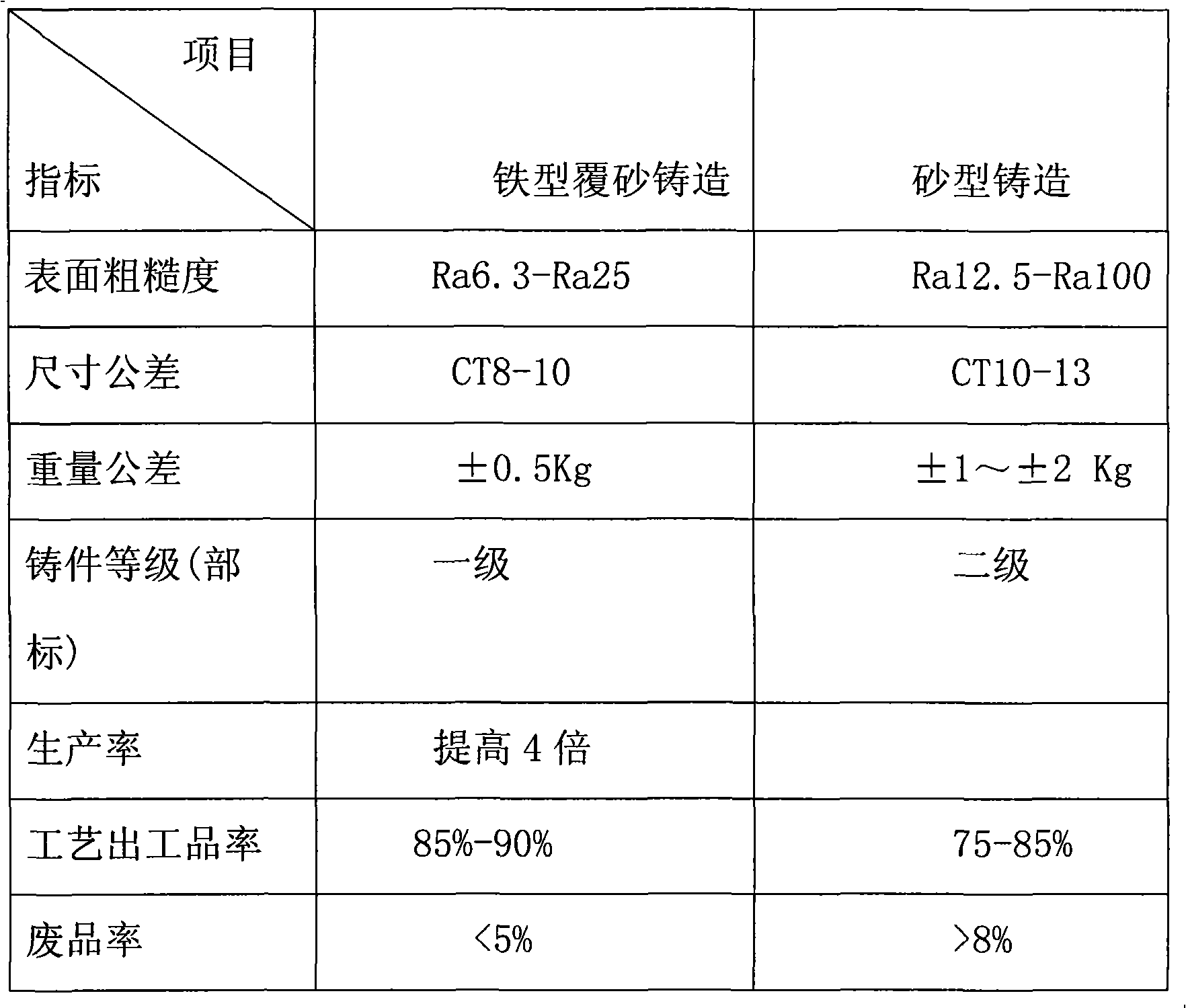

Iron-type coated-sand casting disc brake caliper body and producing method thereof

InactiveCN104791401AImprove process yieldImprove performanceFoundry mouldsMoulding machinesSand castingPulp and paper industry

The invention discloses an iron-type coated-sand casting disc brake caliper body and a producing method thereof, and belongs to the field of iron-type coated-sand casing. The iron-type coated-sand casting disc brake caliper body comprises a caliper main body, a left-end fixing and supporting installing hole site, a right-end fixing and supporting installing hole site, a brake air cylinder installing groove, a brake mechanism cover hole, a synchronous adjusting chain wheel cavity groove and a brake disc installing part. The left-end fixing and supporting installing hole site and the right-end fixing and supporting installing hole site are symmetrically arranged on the two ends of the caliper main body, the brake air cylinder installing groove is arranged on the upper portion of the middle of the caliper main body, the brake mechanism cover hole is formed in the one side of the middle of the caliper main body, the synchronous adjusting chain wheel cavity groove is formed in the middle of the caliper main body, and the brake disc installing part is arranged in the middle of the caliper main body. According to the iron-type coated-sand casting technology, the technology yield is high, the organization is compact and free of leakage, the overall performance is high, the used sand is little, the equipment investment is low, the production cycle is short, the effect is rapid, the equipment occupation area is low, the production efficiency is high, the manufacturing cost is low, and the environmentally friendly performance is good.

Owner:HUBEI GUANCHUANG CASTING TECH CO LTD

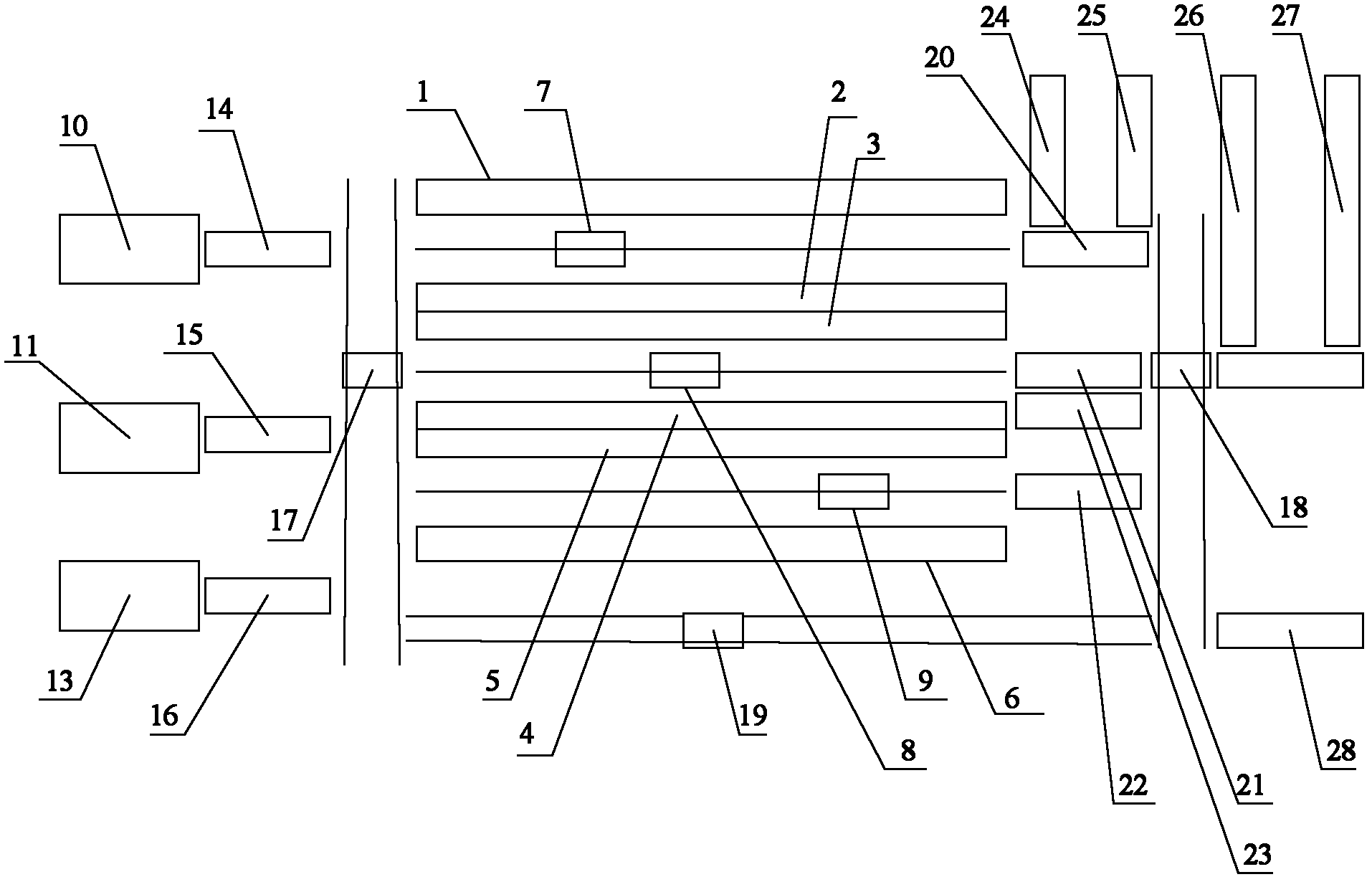

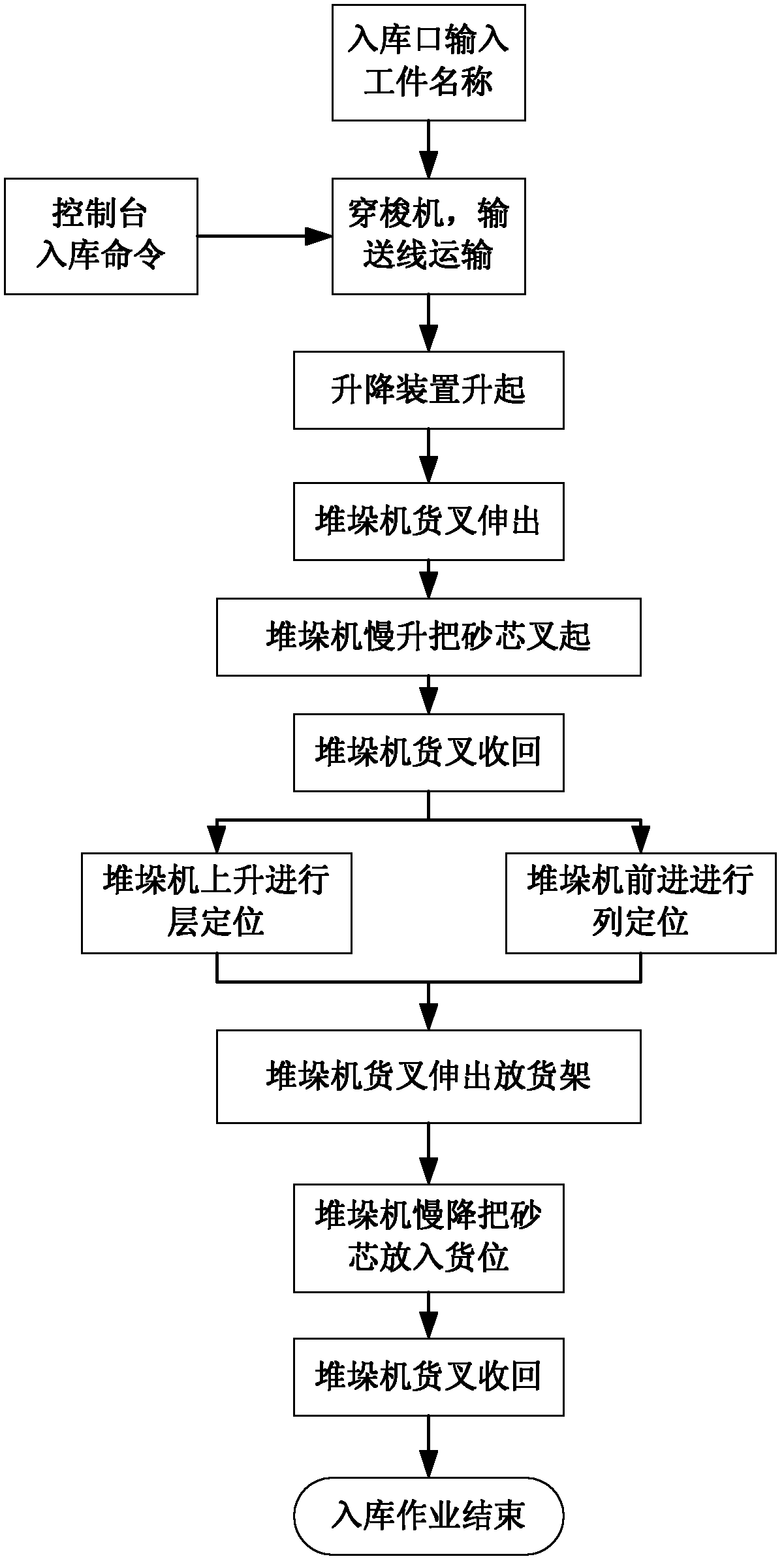

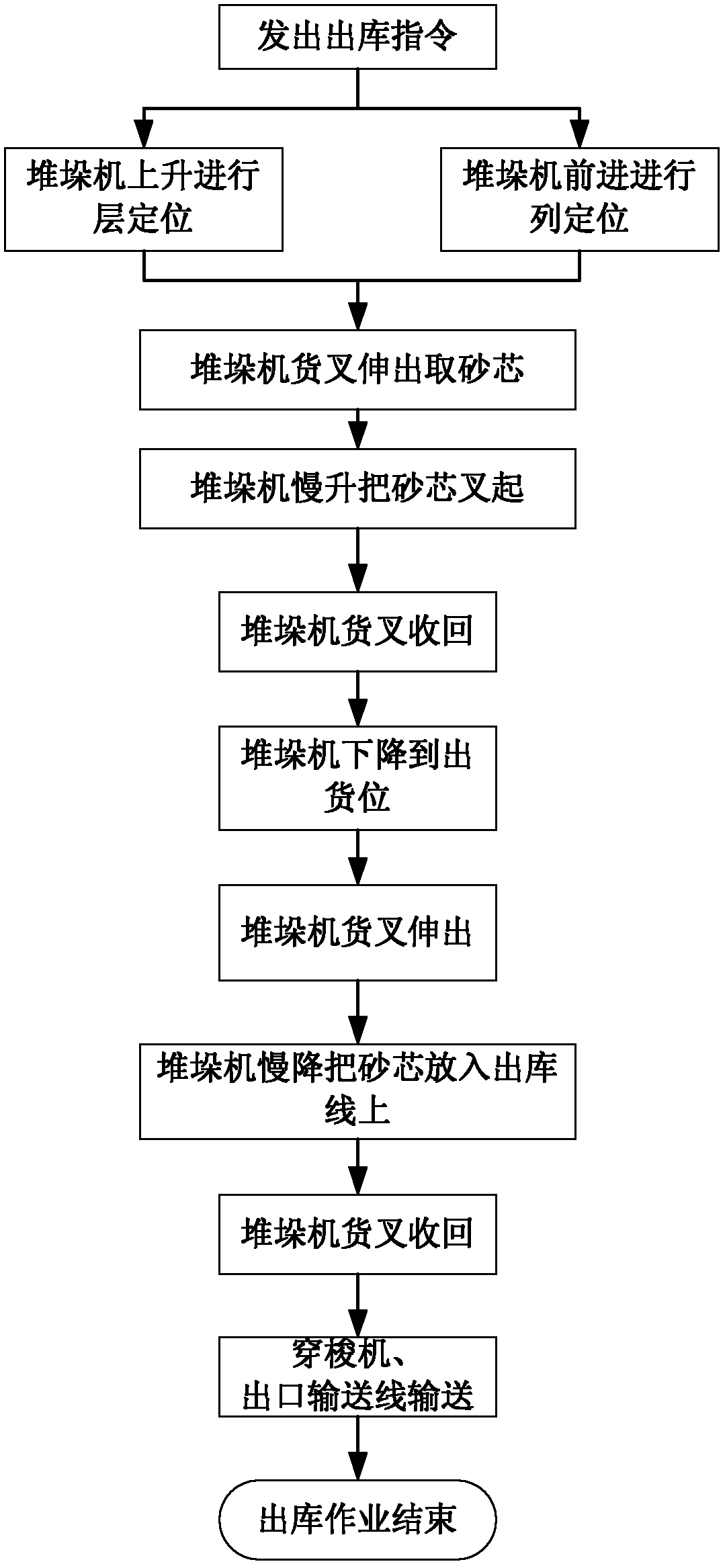

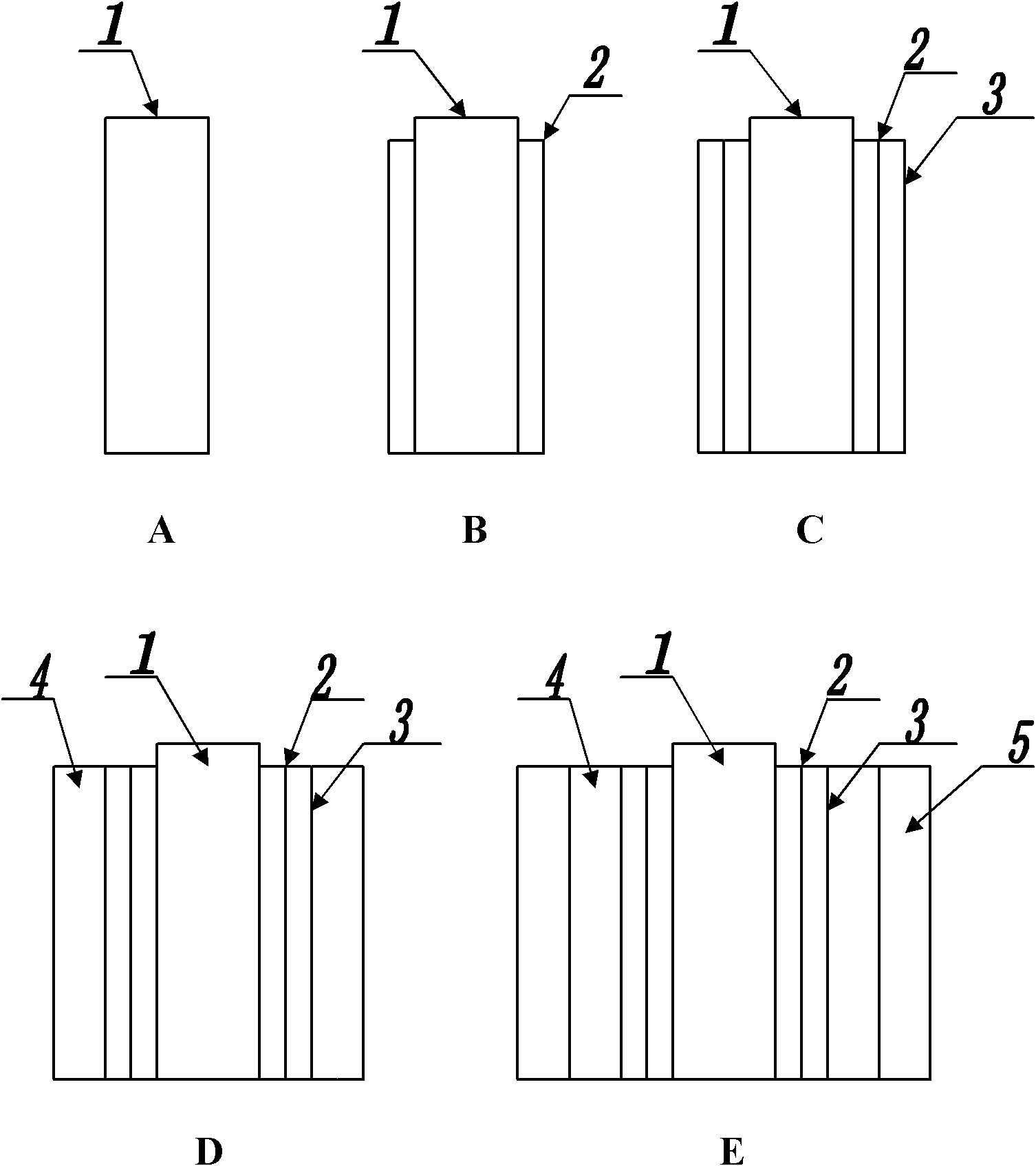

Intelligent storage system for casting sand cores

ActiveCN102530462AGuaranteed high speed operationSmall footprintStorage devicesAutomatic controlEngineering

The invention relates to an intelligent storage system for casting sand cores and is characterized in that the system comprises high-layer storage racks, a stacker system, a conveying system, an automatic control system and a computer storage management system. The intelligent storage system is a sand core storage management system integrating the advantages of high intelligent level, flexibility and sand core quality traceability, achieves the effect of collecting and tracking full-range dynamic information of sand core storage and retrieval process, is advantageous in high-speed rotation, simple operation, large storage capacity, less warehouse floor area, high space utilization rate and high efficiency, and has high economic and social values of improving technical level and management level of sand casting manufacture.

Owner:CRRC YANGTZE TONGLING CO LTD

Precision casting method of double-layer thin-wall bent pipe casting

InactiveCN102078919ASolve molding problemsQuality improvementFoundry mouldsFoundry coresWaxEconomic benefits

The invention discloses a precision casting method of a double-layer thin-wall bent pipe casting. Aimed at the shortcomings of the prior art, the method comprises the following steps: preparing a wax rod; pressing a soluble carbonyl core by taking the wax rod as a core rod; pressing an inner pipe wax mould by taking the soluble carbonyl core as a core rod; dissolving the soluble carbonyl core with hydrochloric acid to obtain the inner pipe wax mould; performing sand hanging, dewaxing, roasting of a mould shell and the pouring to obtain an inner pipe casting; performing quality inspection; if the inner pipe casting is qualified according to the inspection, preparing a resin sand core by taking the inner pipe casting as a core rod; preparing an integral resin sand casting mould of an exhaust pipe by taking an aluminum alloy metal sample of the exhaust pipe; and putting the resin sand core in the integral resin sand casting mould and performing preheating and pressure-regulation pouring to obtain the exhaust pipe casting. According to the invention, the problem in formation of a double-layer exhaust pipe is solved, and a reliable technical scheme is provided for the casting production. Meanwhile, the production cost is greatly reduced by using a casting formation method, the manufacturing period is shortened, the product quality is improved, and great economic benefits can be gained.

Owner:XIAN SUPERCRYSYAL SCI TECH DEV CO LTD

Material for aluminum electrolysis crust-breaking hammer

The invention relates to a material for an aluminum electrolysis crust-breaking hammer, which is characterized by comprising the following components in percentage by weight: 0.5%-3.0% of carbon, 3.5%-10.0% of manganese, 0.5%-1.0% of silicon, less than 0.05% of phosphorus, less than 0.05% of sulphur, 5.0%-20.0% of chromium, less than 0.05% of Ni and the balance of ferrum. The material for the aluminum electrolysis crust-breaking hammer is an iron alloy material and is prepared by using a lost foam casting or sand casting process. In the invention, The manganese content in the material for the crust-breaking hammer is increased and the chromium content is optimized, thereby the material effectively improves the strength and wear resistance of the aluminum electrolysis crust-breaking hammer, prolongs the service life of the hammer, extends the replacement period, reduces the production cost and effectively relieves the labor intensity.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

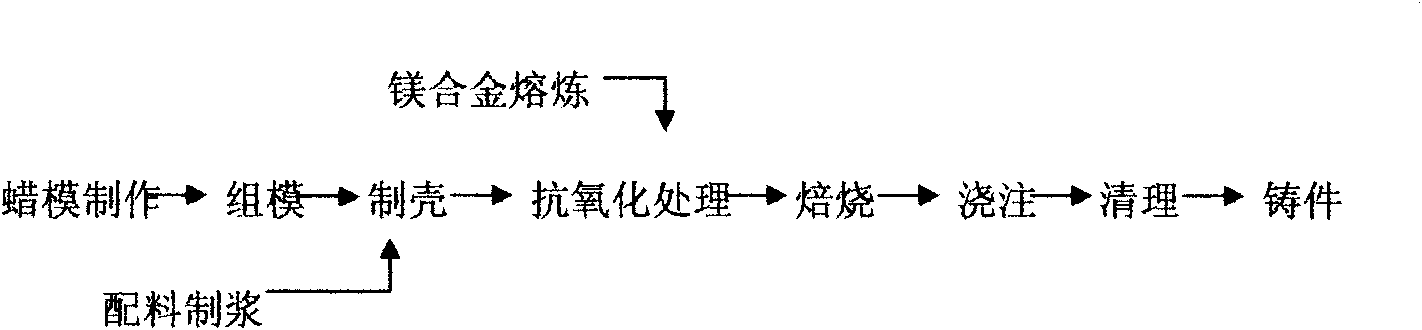

Water glass type magnesium alloy fusible pattern casting process

InactiveCN101658918ASolve the problem that heat treatment cannot be performedSolve the problem of high process energy consumptionFoundry mouldsFoundry coresAdhesiveHeat treated

The invention discloses a water glass type magnesium alloy fusible pattern casting process which belongs to the field of fusible pattern casting and comprises the following procedures: (1) making a wax pattern; (2) making a water glass type shell suitable for making magnesium by using water glass as an adhesive and using quartz powder and aluminum bauxite as powder materials; (3) melting by the melting process of the magnesium alloy; (4) casting; and (5) cleaning a cast. The viscidities of a surface layer of the type shell and a reinforcing layer are higher than the viscidities of a traditional process; the number of the layers is less than that of a traditional process; hot water is used for dewaxing; compared with the traditional process, hardening processing is not added; baking temperature is largely lower than that of the traditional process; and the hot water of boric acid is used for immersing the type shell for avoiding oxidizing the magnesium alloy to replace gas protection, thereby reducing substance consumption and energy consumption, improving the environment and reducing the production cost. The invention replaces a magnesium alloy gypsum type fusible pattern casting process to solve the problem of large pits and crystal grains on the surface of the cast, replaces a sand casting process to solve the problems of high roughness and low dimension precision of the surface of a diamantine cast and replaces a die-casting process to solve the problem that a die cast of the magnesium alloy cannot be thermally treated. The invention is applied to form the cast of the magnesium alloy.

Owner:HENAN POLYTECHNIC UNIV

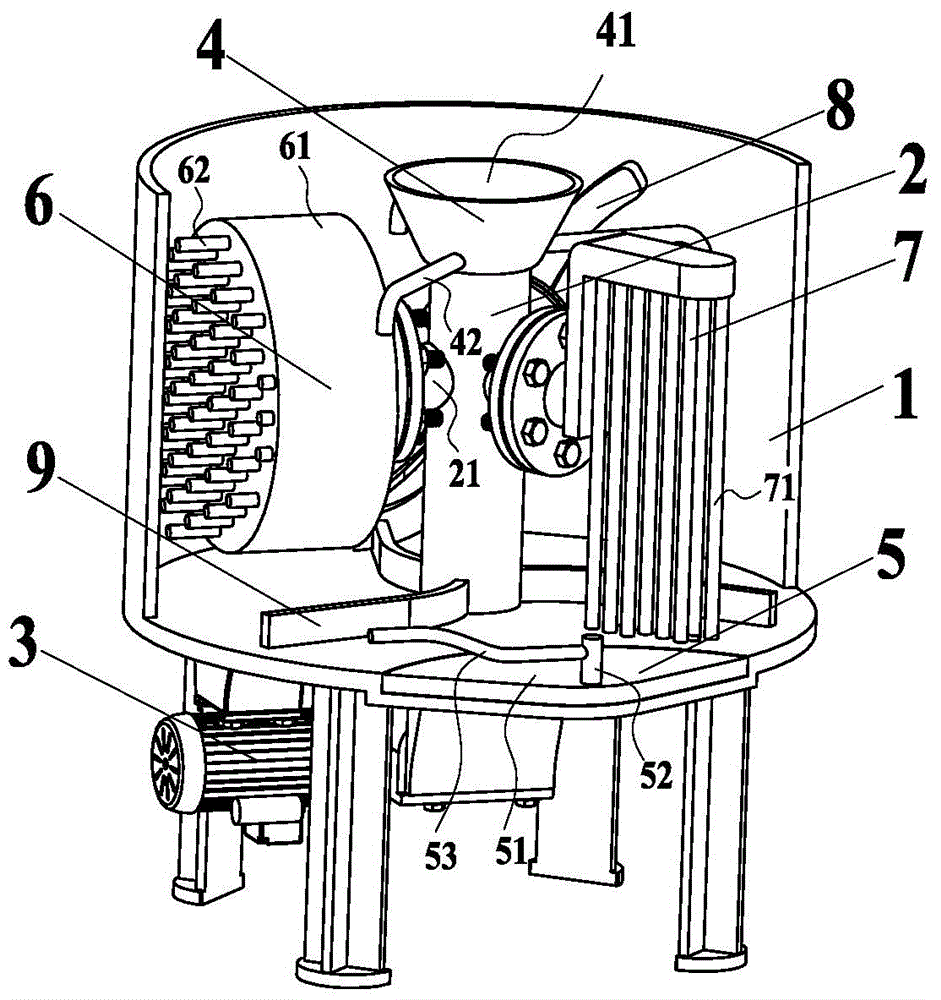

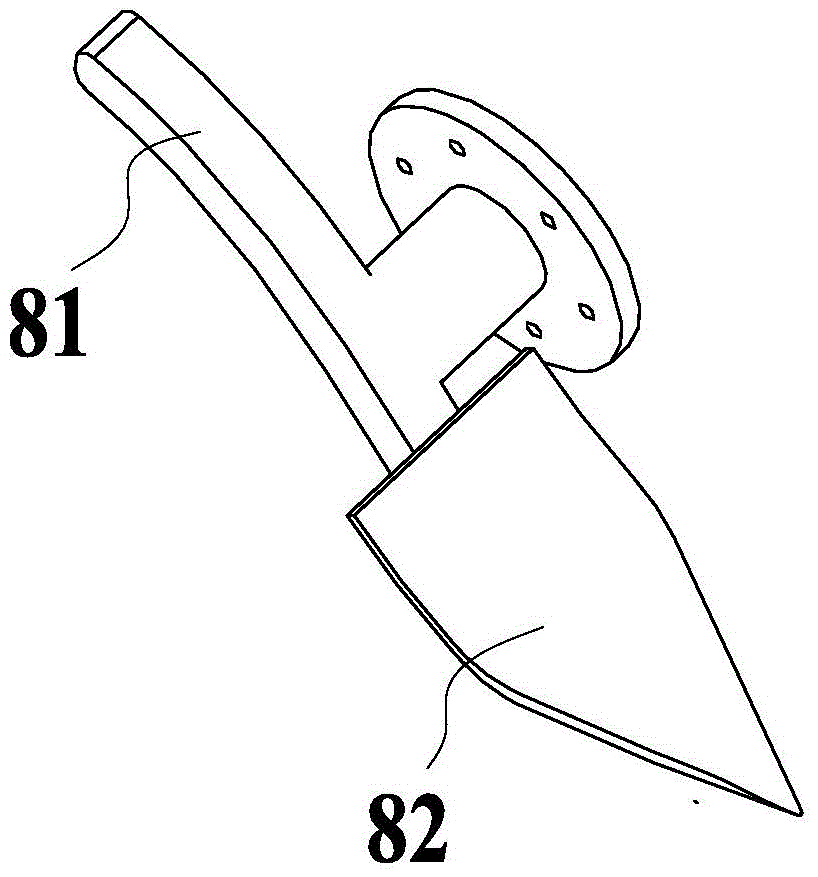

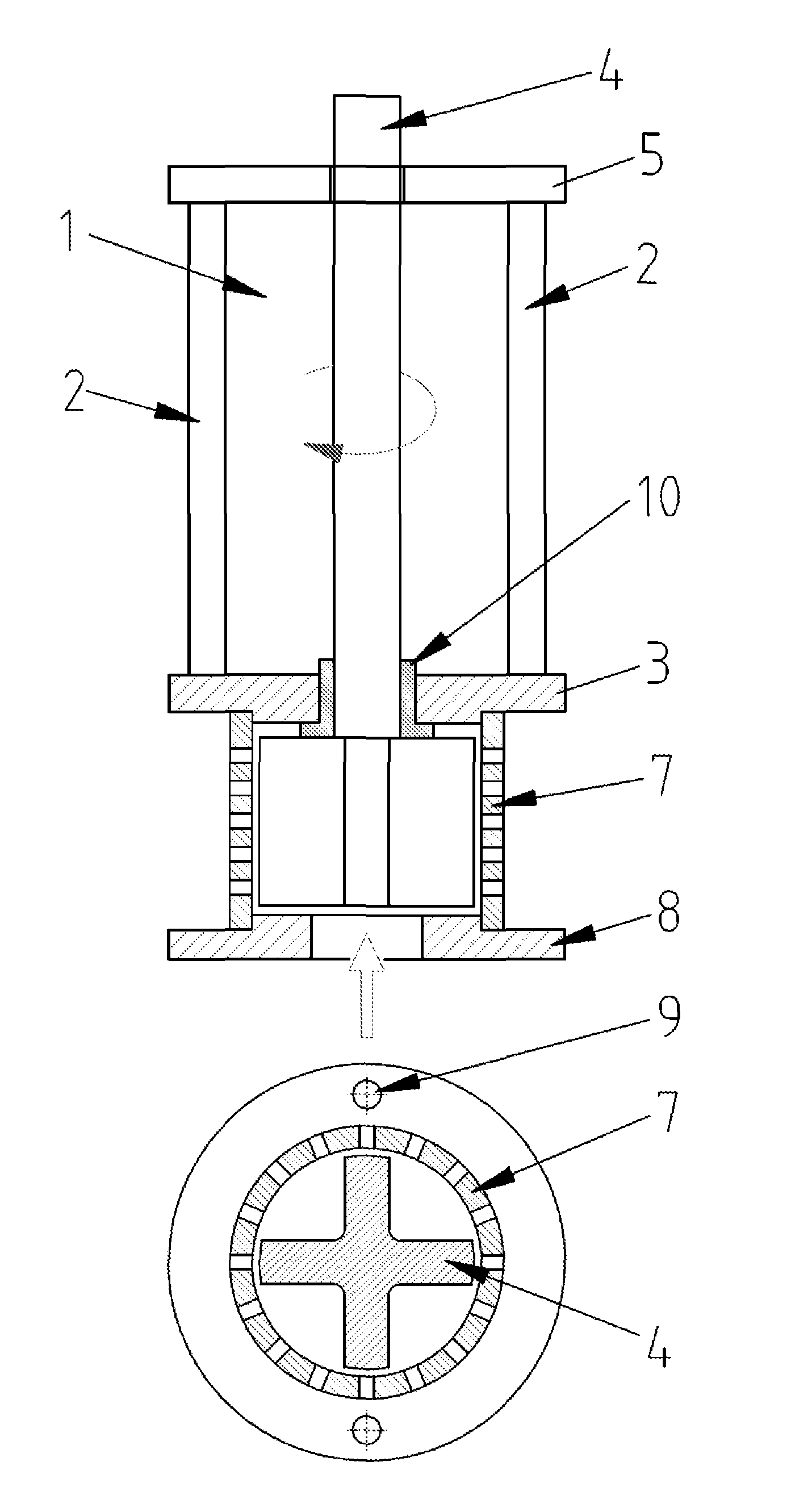

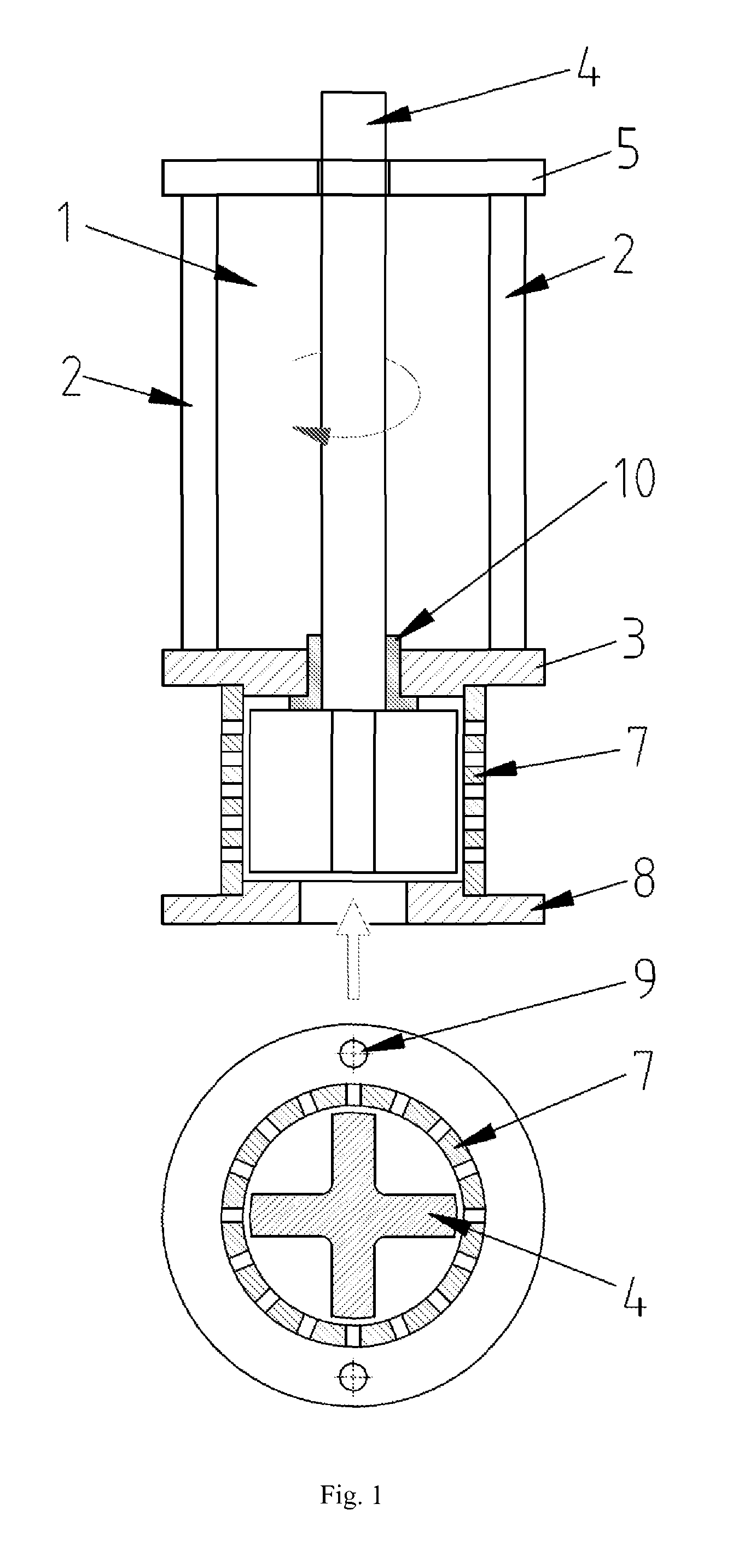

Sand mixing equipment

ActiveCN104815950AAchieve rollingAchieve grindingMould handling/dressing devicesDrive motorEngineering

The invention relates to foundry machinery, specifically to sand mixing equipment. The sand mixing equipment comprises a cylinder, a rotation shaft, a driving motor, a watering device, a valve device, a sand rolling device, a sand fluffing device, a sand-casting device and a scraper plate. The cylinder is a hollow cylinder structure. The bottom of the cylinder is provided with a fan-shaped opening. A support plate is arranged at the opening. The opening is used for releasing mixed sand. The support plate is provided with through-holes. The rotation shaft is installed at the middle part of the cylinder. The driving motor is positioned below the cylinder. The watering device is positioned above the rotation shaft. The valve device is installed at the bottom of the cylinder. The sand rolling device, the sand fluffing device, the sand-casting device and the scraper plate are uniformly installed on the periphery of the rotation shaft. The scraper plate is positioned at the bottom of the cylinder. The sand mixing equipment has a simple structure. By effectively integrating a muller, a sand fluffing rod, a plough and the scraper plate, rolling, grinding, stirring and turning-over of a material are realized, and sand-mixing efficiency of the sand mixer is enhanced.

Owner:南通乐士机械有限公司

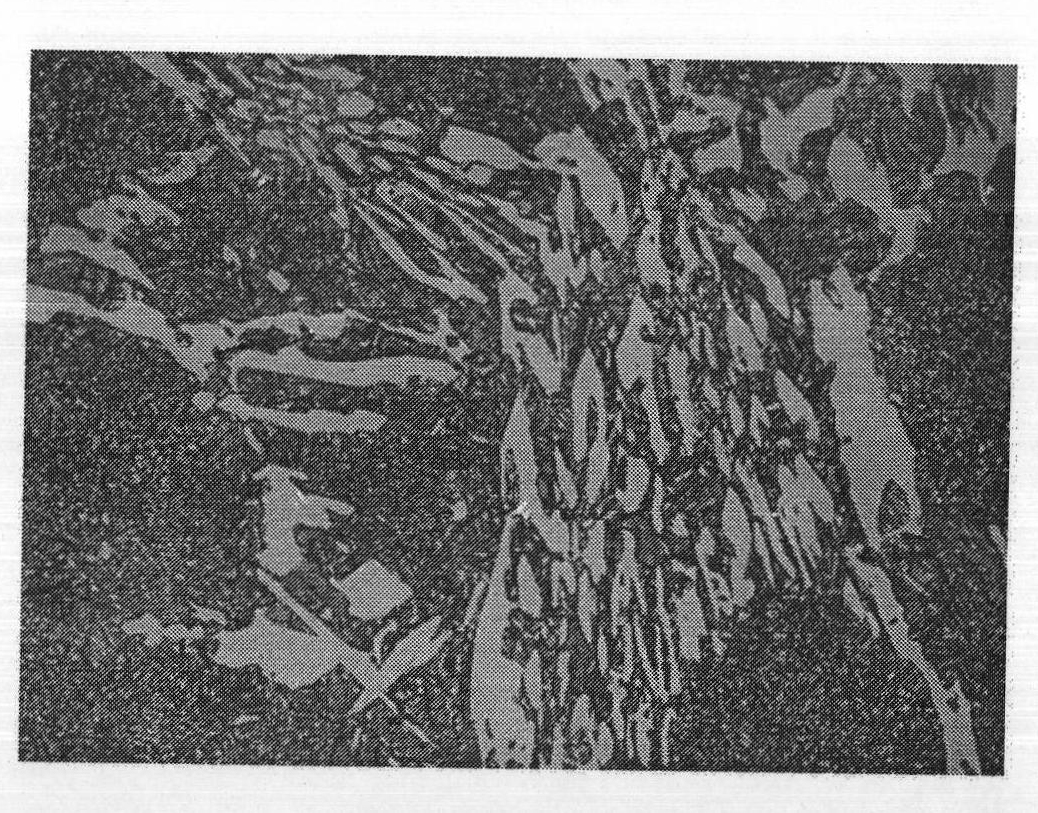

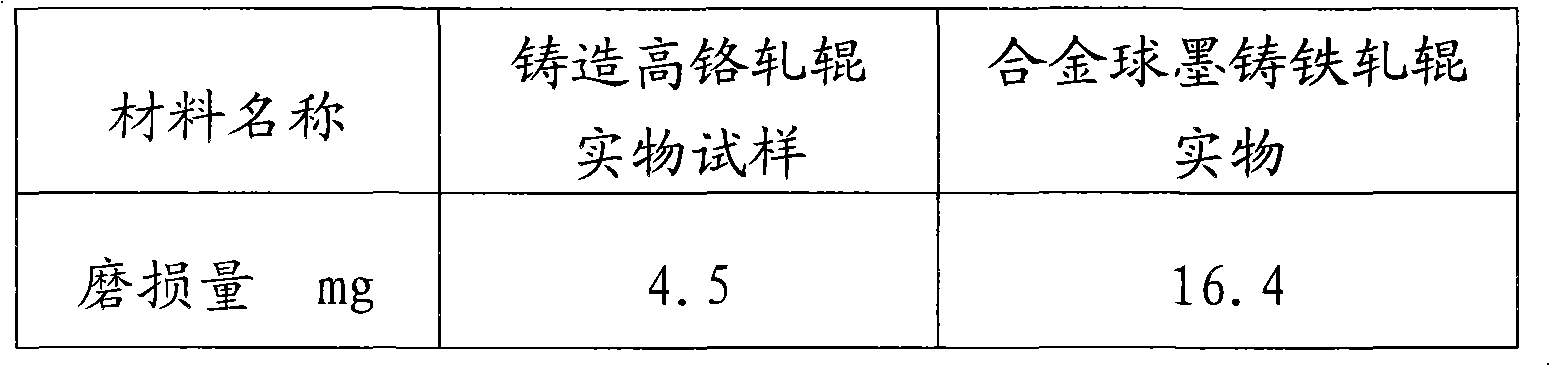

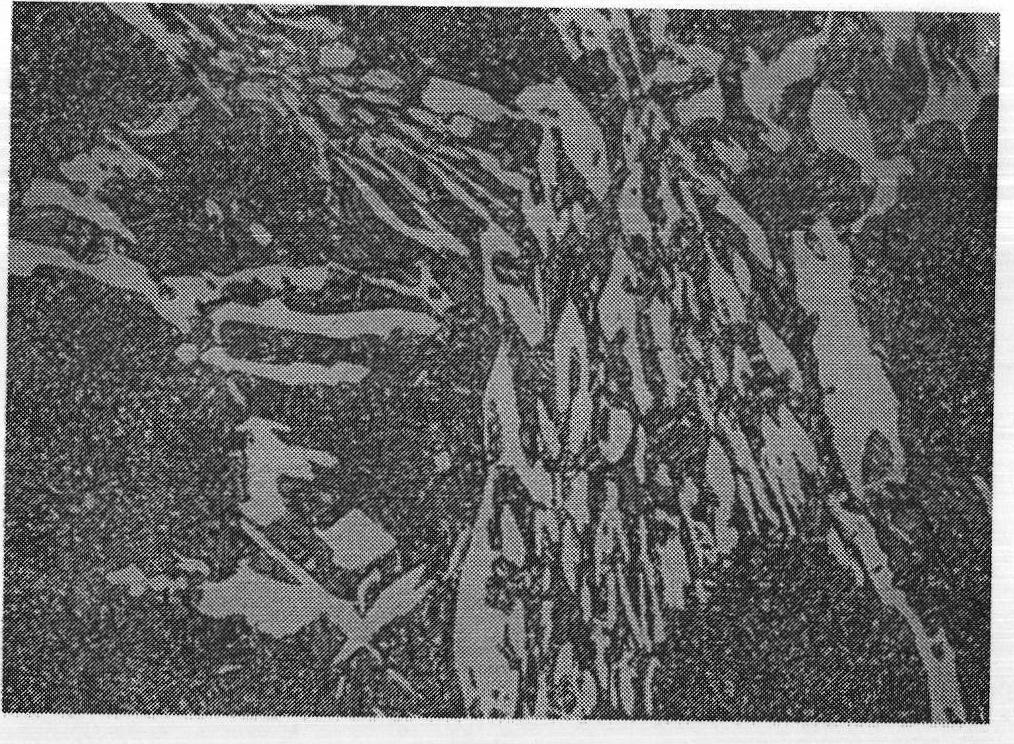

Preparation method of high-chromium roller for steel tube reducing mill or sizing mill and high-chromium roller prepared thereby

ActiveCN102251185AHigh hardnessReduce replacement cycleFoundry mouldsFurnace typesSand castingHardness

The invention discloses a high-chromium cast roller for a steel tube reducing mill or sizing mill and a preparation method thereof. The preparation method is characterized by optimizing the design of components, selecting the component proportioning of the roller according to the application of the roller and the specific in-service working conditions and technical requirements, and melting corresponding iron alloy, scrap steel and other raw materials to obtain required molten steel; carrying out centrifugal or sand casting to obtain blanks of a required size; and carrying out annealing, quenching, tempering and other thermal treatment on the cast blanks, and carrying out turning, milling and other machining operation to produce the high-chromium roller for a hot rolling seamless steel tube tension reducing mill and sizing mill. The surface hardness of the roller disclosed by the invention is obviously improved, and the macrohardness is up to 54-62 HRC, so that the service life of the high-chromium cast roller is increase by at least two times. Because of the increase of the wear resistance and service life, the replacement frequency of the roller is reduced, thereby saving the materials and production cost. Besides, the rolling capability and yield of the seamless steel tube unit is improved.

Owner:SHANDONG PROVINCE SIFANG TECHN DEV

Methylene blue adsorption testing method of bentonite

InactiveCN101806747AReduce labor intensityThe result is accurateMaterial analysis by observing effect on chemical indicatorSodium BentoniteNuclear chemistry

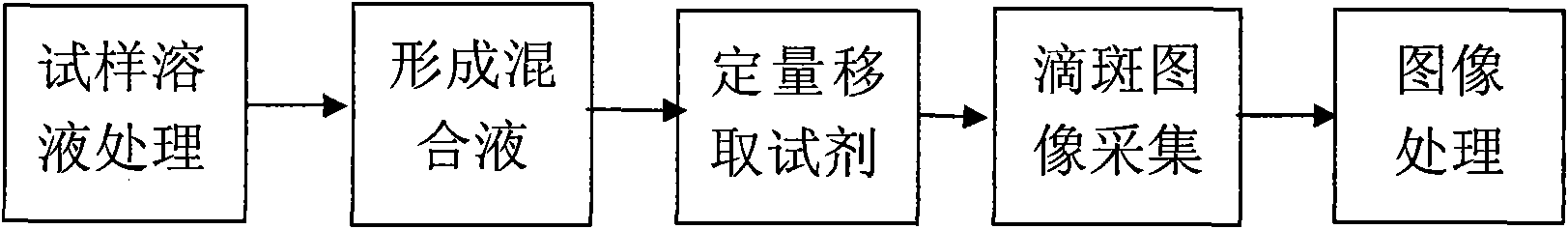

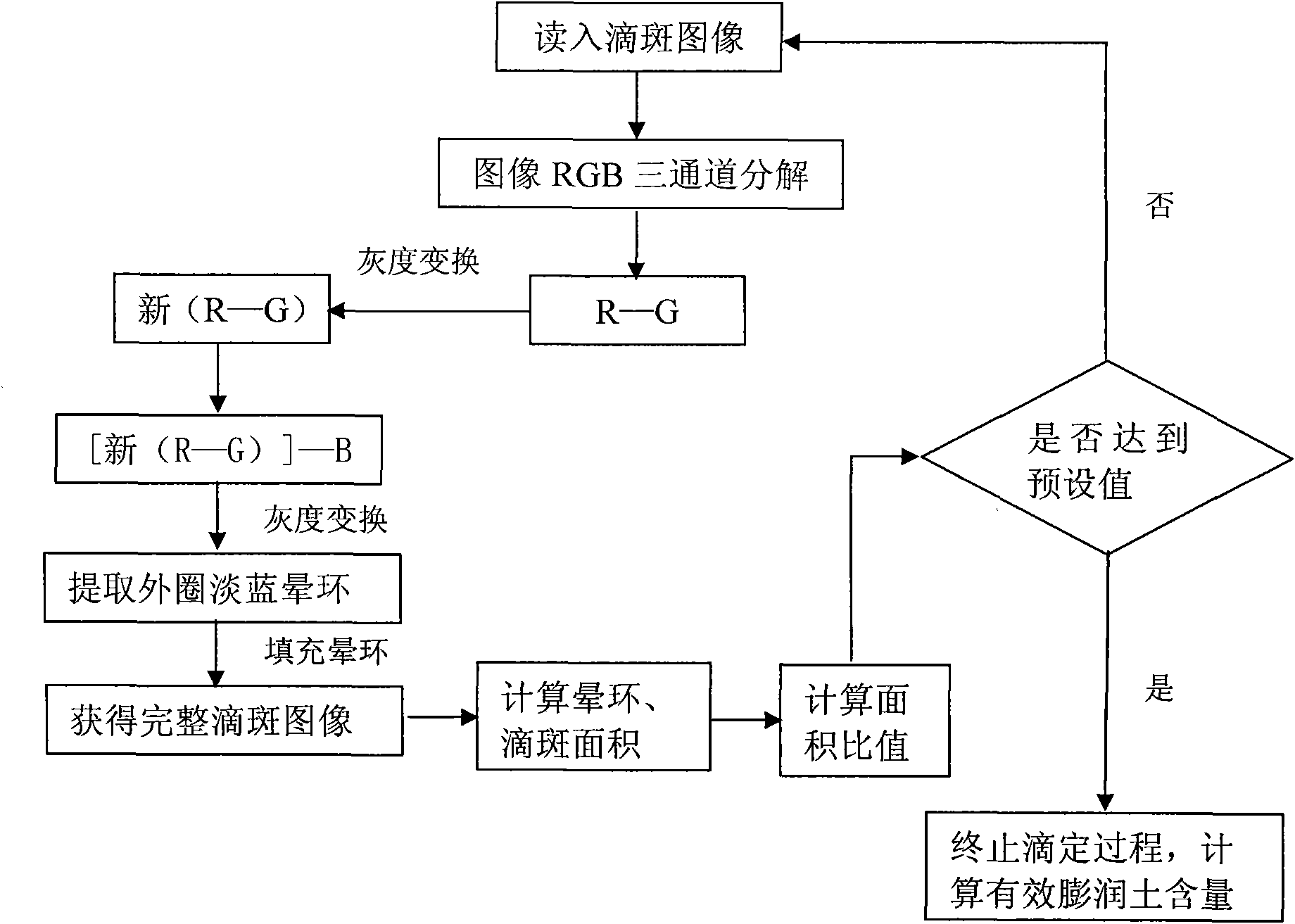

The invention relates to a methylene blue adsorption testing method of bentonite, which belongs to the field of methods for testing components of clay sand casting material, and solves the problems that a traditional detection method is quite complicated to operate, has lower determination precision, may titrate repeatedly and causes longer testing process. The testing method sequentially comprises a sample solution treatment step, a mixed solution forming step, a quantitative reagent shifting step, a drop spot image acquisition step and an image processing step. Aiming at bentonite methylene blue adsorption testing on a casting production line and the effective bentonite content determination in clay sand, the methylene blue adsorption testing method of bentonite can be realized on a computer, artificially and manually inputs an initial titration value, fully automatically sets and works, automatically acquires drop spot images and judges the final titration destination, can automatically calculate the methylene blue adsorption of bentonite and the effective bentonite content determination in clay sand, has accurate results, reduces the labor intensity of an experimenter, and improves the accuracy in judging the titration destination.

Owner:HUAZHONG UNIV OF SCI & TECH

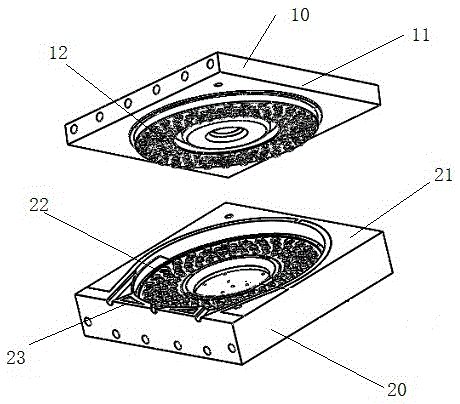

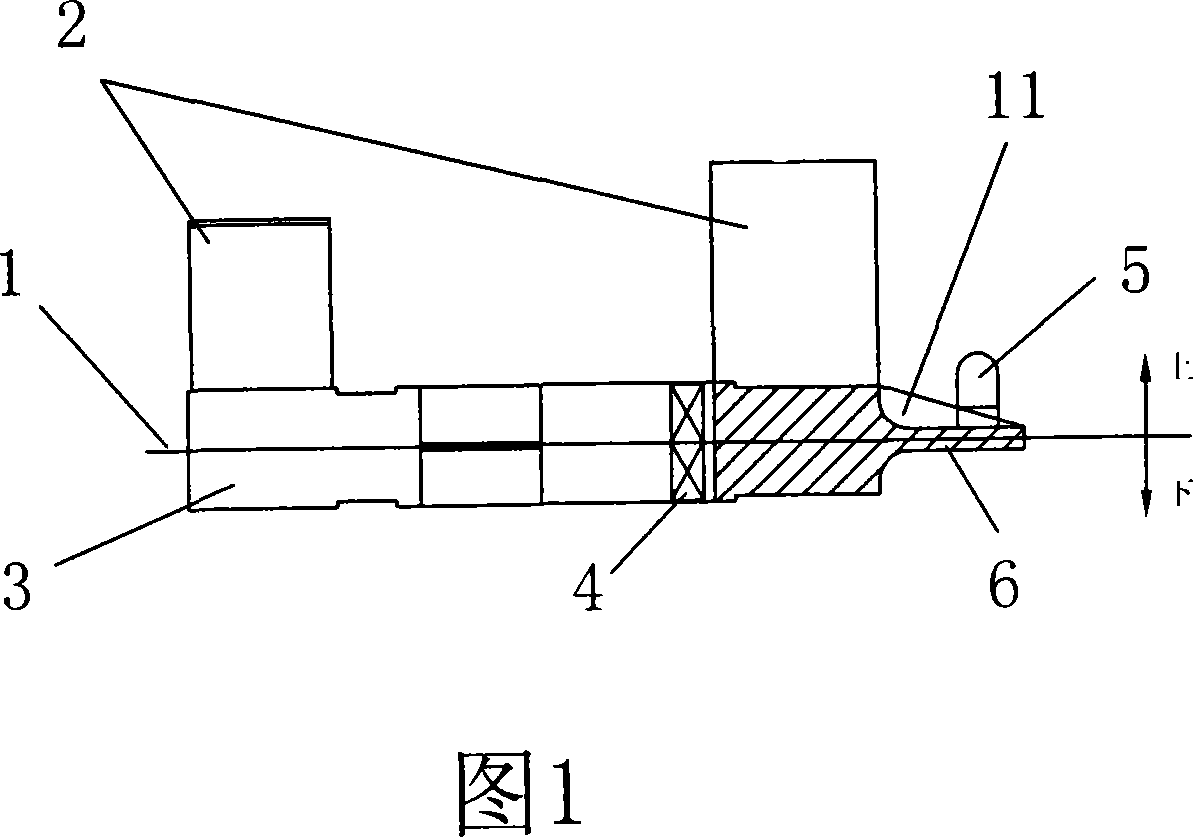

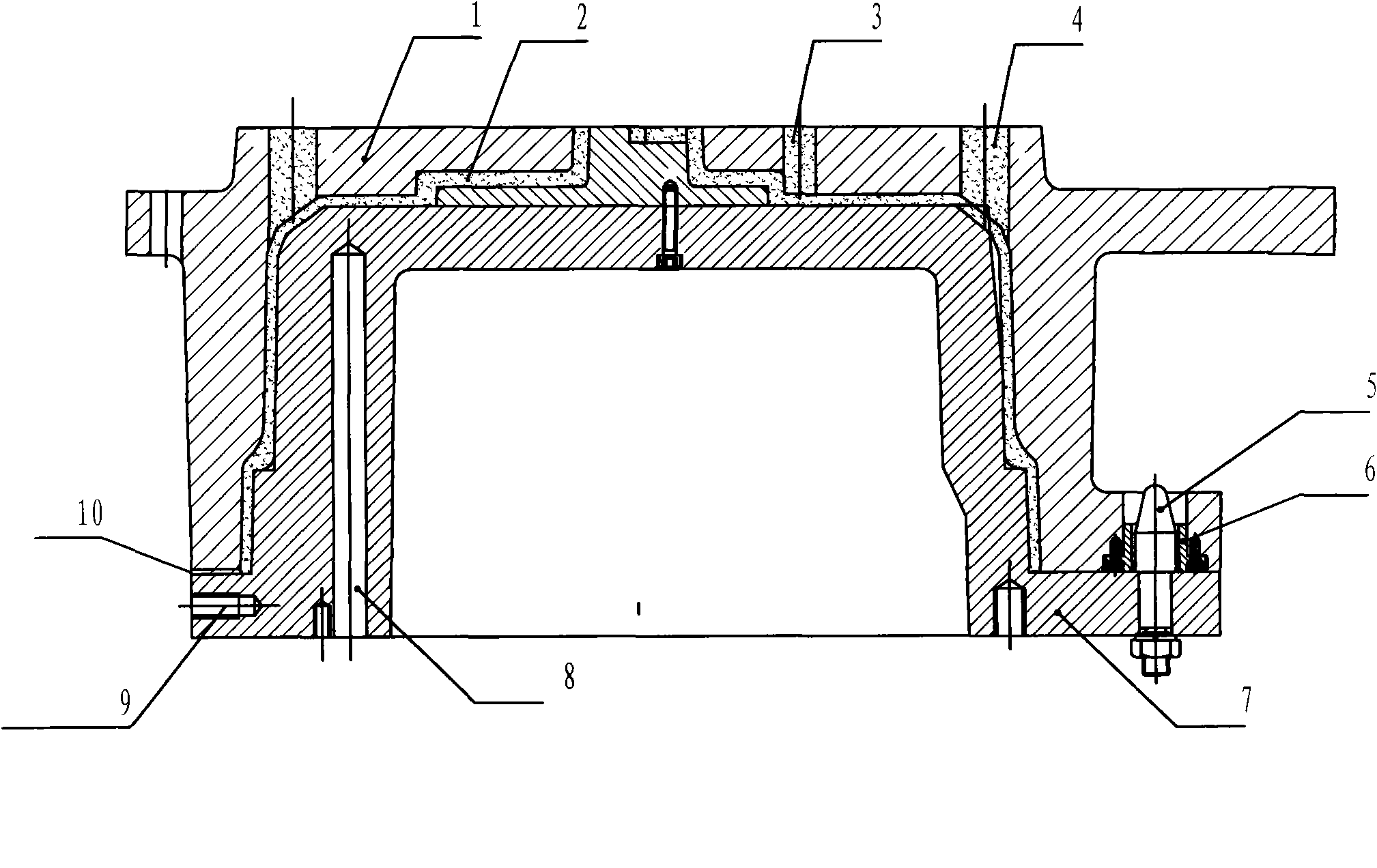

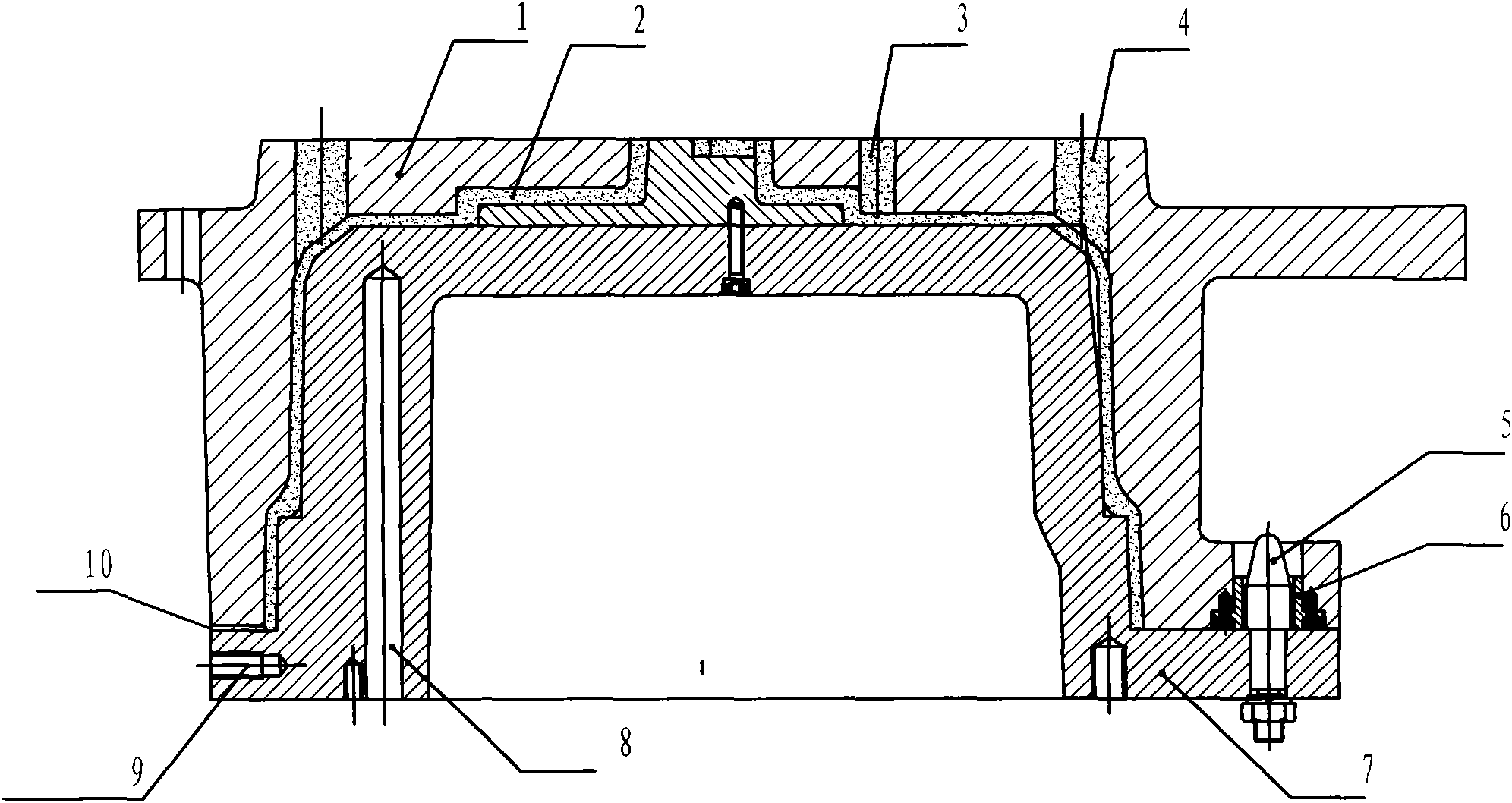

Metal mold sand coating device for casting upper mold of brake drum

InactiveCN102000781ASolve technical problems that are prone to breakageImprove firmnessFoundry mouldsMoulding machinesMetallurgySand casting

The invention discloses a metal mold sand coating device for casting an upper mold of a brake drum, aiming at solving the problems that the compactness of shot sand is insufficient, hardening an overlaying layer takes a long time, a sand box wall, an upper mold wall and a lower mold wall are thin, and the device is easy to rupture in the process of repeated use. The metal mold sand coating device for casting the upper mold of the brake drum comprises an upper sand box (1) and an upper mold body (7); the upper sand box (1) is provided with an exhaust hole (3) and a shot sand hole (4); a positioning pin (5) and a positioning pin sleeve (6) press the upper sand box (1) and the upper mold body (7) to form a sand casting gap (2); the sand casting gap (2) is 6-10mm thick; the upper mold body (7) is internally fixedly provided with an electric heater (8) and a temperature sensor (9); and an exhaust groove (10) is arranged at the opening end of the upper mold body (7), that is, the tail end of the sand casting gap (2) formed by pressing the upper sand box (1) and the upper mold body (7). The invention improves the recycling efficiency of the sand box and the mold.

Owner:山西汤荣机械制造股份有限公司

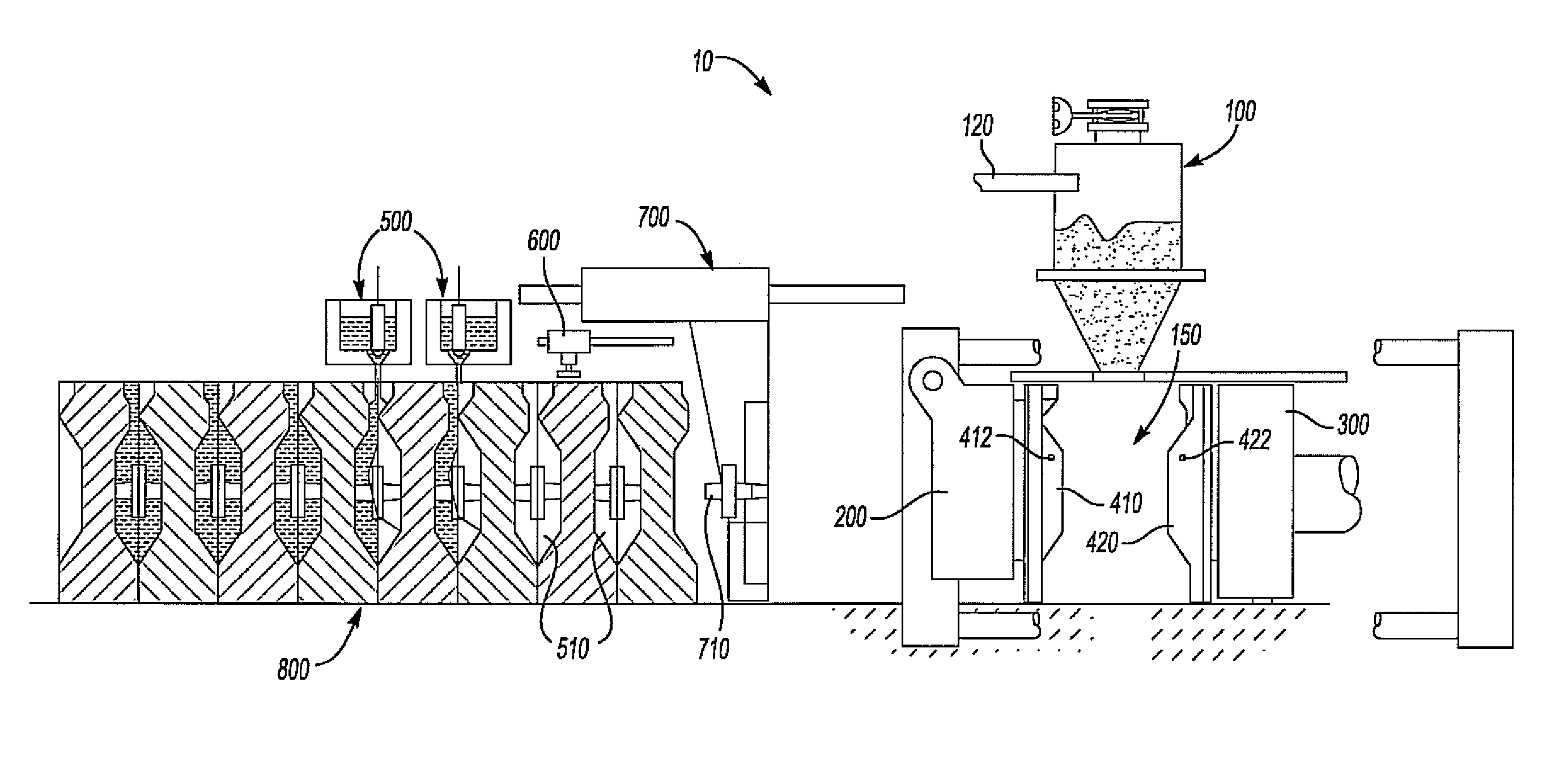

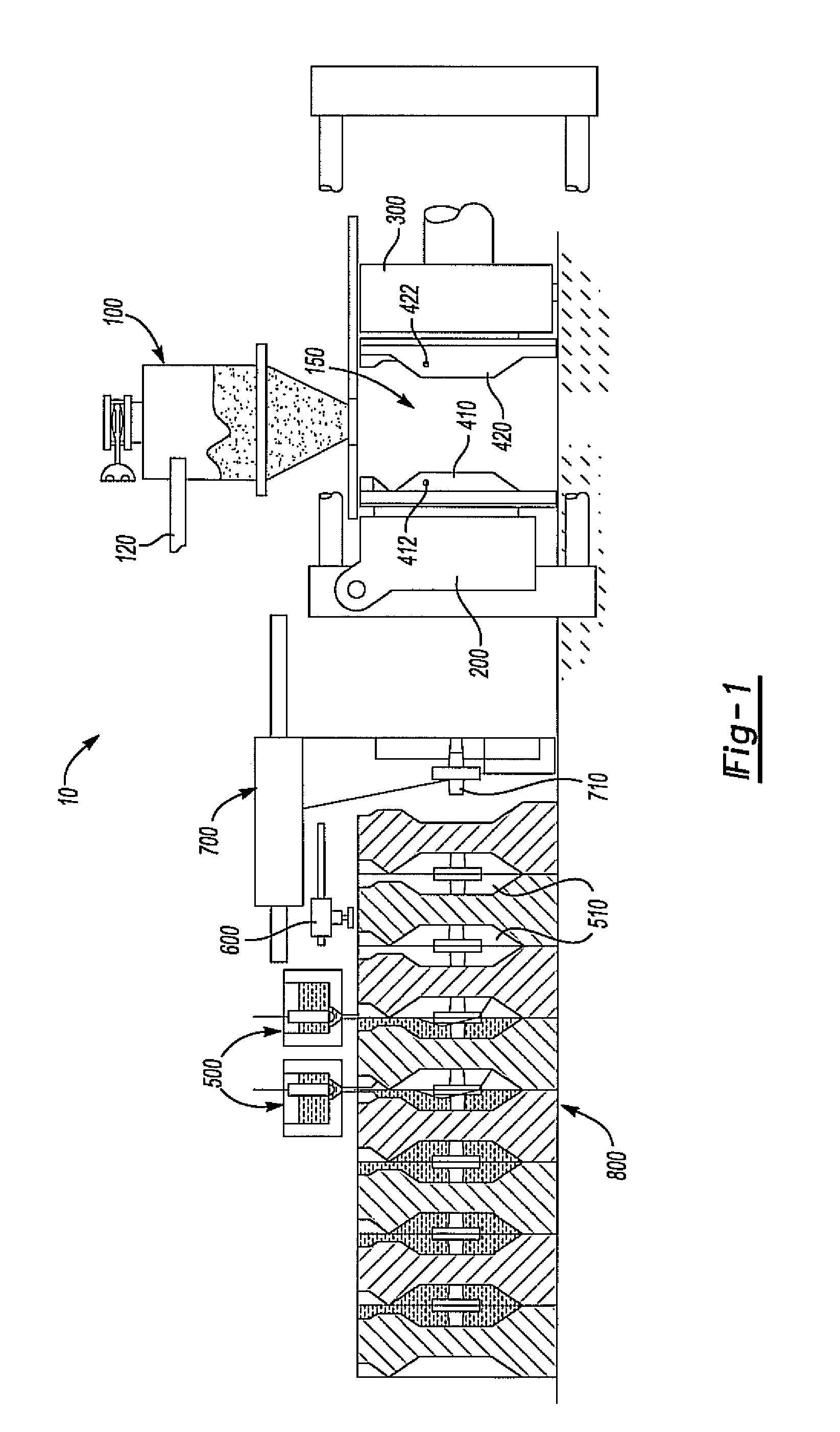

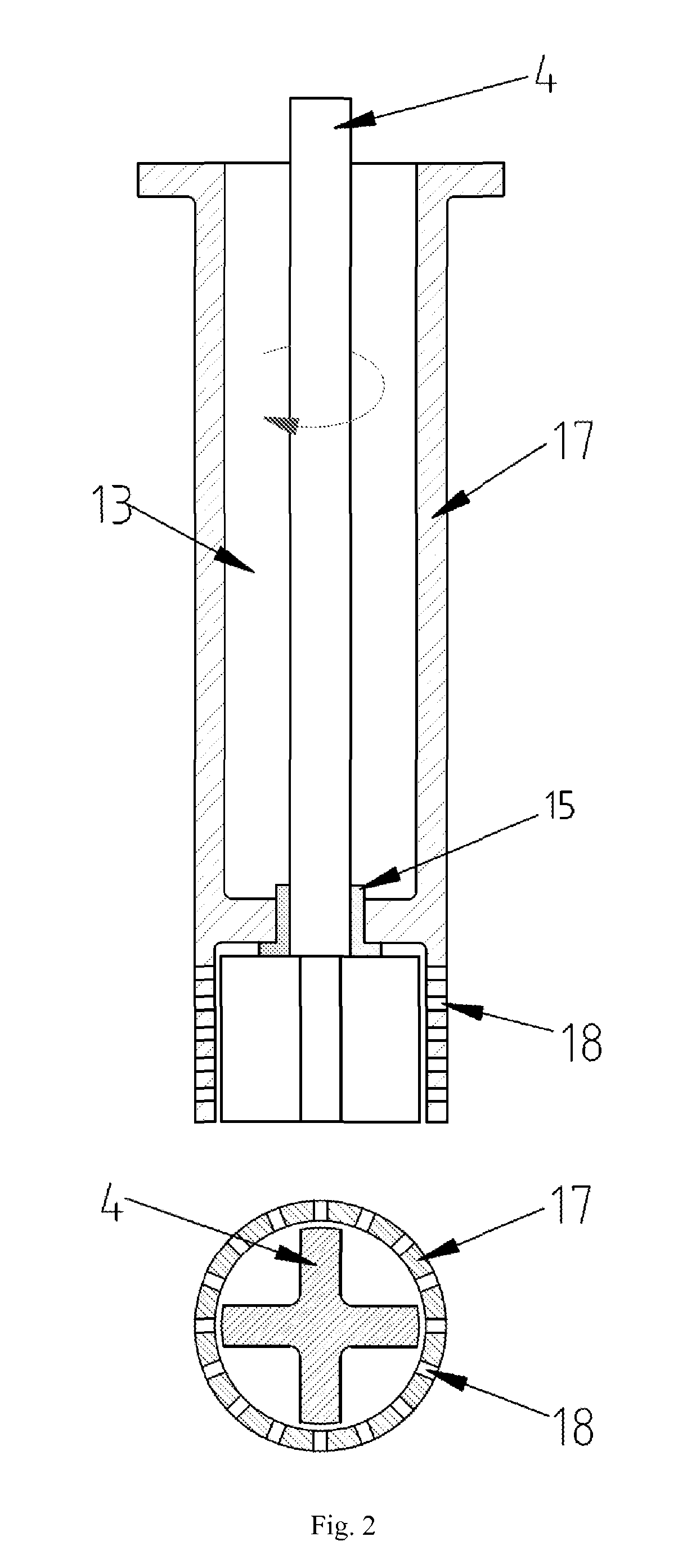

Apparatus and method for liquid metals treatment

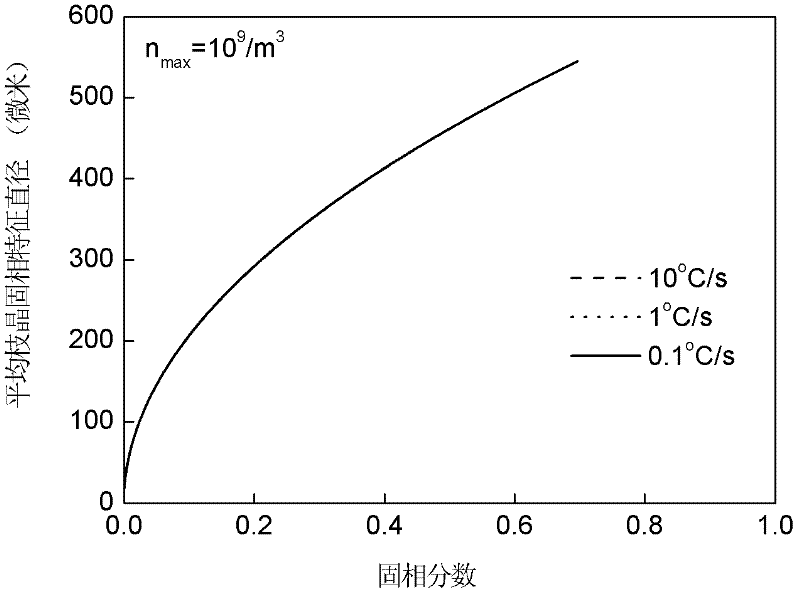

ActiveUS20130228045A1Improve efficiencySpeed up chemical reactionsStirring devicesCasting apparatusParticulatesGas phase

This invention relates to an apparatus (high shear device) and method for treating liquid metals by intensive melt shearing. The apparatus comprises a stator and a rotor with a small gap between them to provide intensive melt shearing for dispersing efficiently and distributing uniformly gas, liquid and solid phases in liquid metals without severe turbulence at the melt surface. The device can be extended to a multistage high shear pump by arranging individual rotor / stator assemblies either concentrically (one in another) or vertically. The device and high shear pump can be readily integrated into existing casting processes. The device is suitable for use in casting processes including high pressure die casting, low pressure die casting, gravity die casting, sand casting, investment casting, direct chill casting, twin roll casting, and any other casting process which requires liquid metal as a feedstock. In addition, the device is particularly suitable for providing conditioned liquid metal for both shape casting and continuous (or semi-continuous) casting of metallic materials, preparing high quality semi-solid slurries, solidification processing of particulate reinforced metal matrix composites, mixing immiscible metallic liquids and degassing of liquid metals prior to any casting processes.

Owner:BRUNEL UNIVERSITY

No-bake resin sand for sand casting of magnesium alloy and preparation method thereof

InactiveCN101804443AHigh strengthImprove breathabilityFoundry mouldsFoundry coresCombustionHigh intensity

The invention discloses no-bake resin sand for sand casting of a magnesium alloy in the technical field of metal processing and a preparation method thereof. The no-bake resin sand comprises the following components in percentage by weight: 51 to 100 percent of fine silica sand and 0 to 50 percent of coarse silica sand; the adding amount of resin is 0.8 to 2 percent of the total weight of the fine silica sand and the coarse silica sand of resin; the adding amount of a curing agent is 20 to 60 percent of the adding amount of the resin; and the adding amount of a fire retardant is 1 to 5 percent of the total weight of the fine silica sand and the coarse silica sand. The no-bake resin sand prepared by the invention has higher intensity, good air permeability and less gas evolution. In the casting process, due to the addition of the fire retardant, the reaction and combustion between magnesium and silica sand and impurities in the silica sand can be prevented, and magnesium alloy castings with excellent surface quality can be obtained.

Owner:SHANGHAI JIAO TONG UNIV

Gravity casting process of all-metal mould of coupler aluminum part

InactiveCN102211145AShorten the timeLow costFoundry mouldsFoundry coresSand castingMachining process

The invention relates to a gravity casting machining process of an all-metal mould of a hydraulic coupler shell, comprising the following process steps of: (1) mould preheating: placing the cleaned steel mould into a baking oven for warming and preheating, then spraying demoulding paint to the contact surface of a workpiece, heating again to 200-250 DEG C, keeping temperature, and then fixing a lower mould on a demoulding machine; (2) pouring: assembling a mould assembled in a positioning way through an upper mould and the lower mould of the demoulding machine, and then fast pouring previously refined liquid aluminum alloy into a cavity; and (3) demolding: firstly enabling the upper mould to be pass through a transmission device, enabling the upper mould to be firstly separated from the workpiece through an upper mould demoulding ejector plate and an upper mould fixing plate, and then ejecting the workpiece through a demoulding ejector plate and a discharging ejector plate. According to the gravity casting machining process disclosed by the invention, the manufacturing time of a sand core is saved and the cost of sand purchasing and waste sand cleaning is reduced by utilizing a sand casting process of the all-metal mould; in addition, the effect of a low-pressure casting process can be achieved by utilizing the all-metal mould.

Owner:HUNAN ZHONGTE HYDRAULIC ROTARY TRANSMISSION MACHINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com