Metal mold sand coating device for casting upper mold of brake drum

A metal mold sand-coated and brake drum technology, which is applied to casting molding equipment, casting molds, molding machines, etc., can solve the problems of insufficient compactness of sand shooting, easy breakage, and long time required for hardening of sand-coated layers, etc., to achieve Short hardening time, high compactness, and improved reuse efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

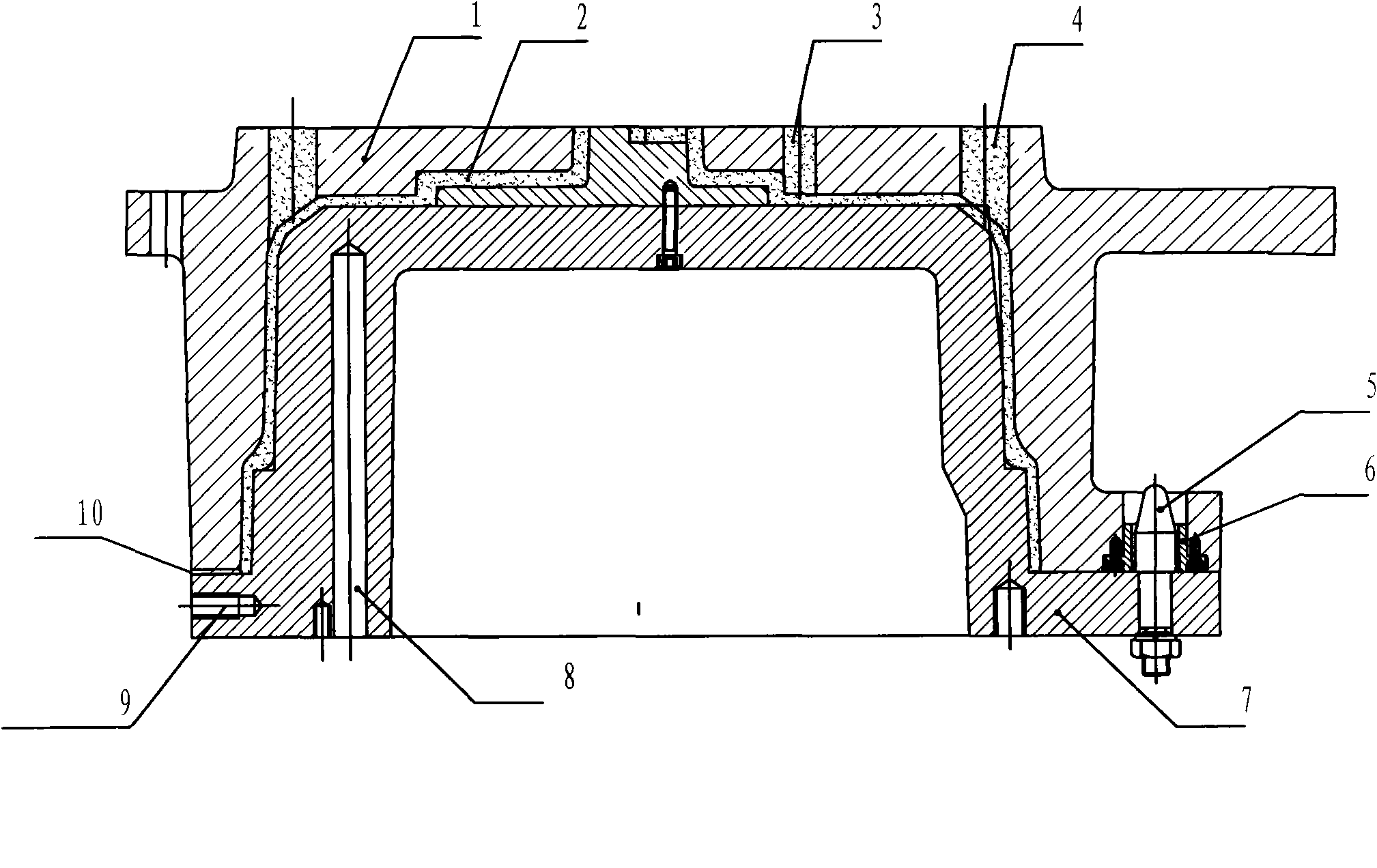

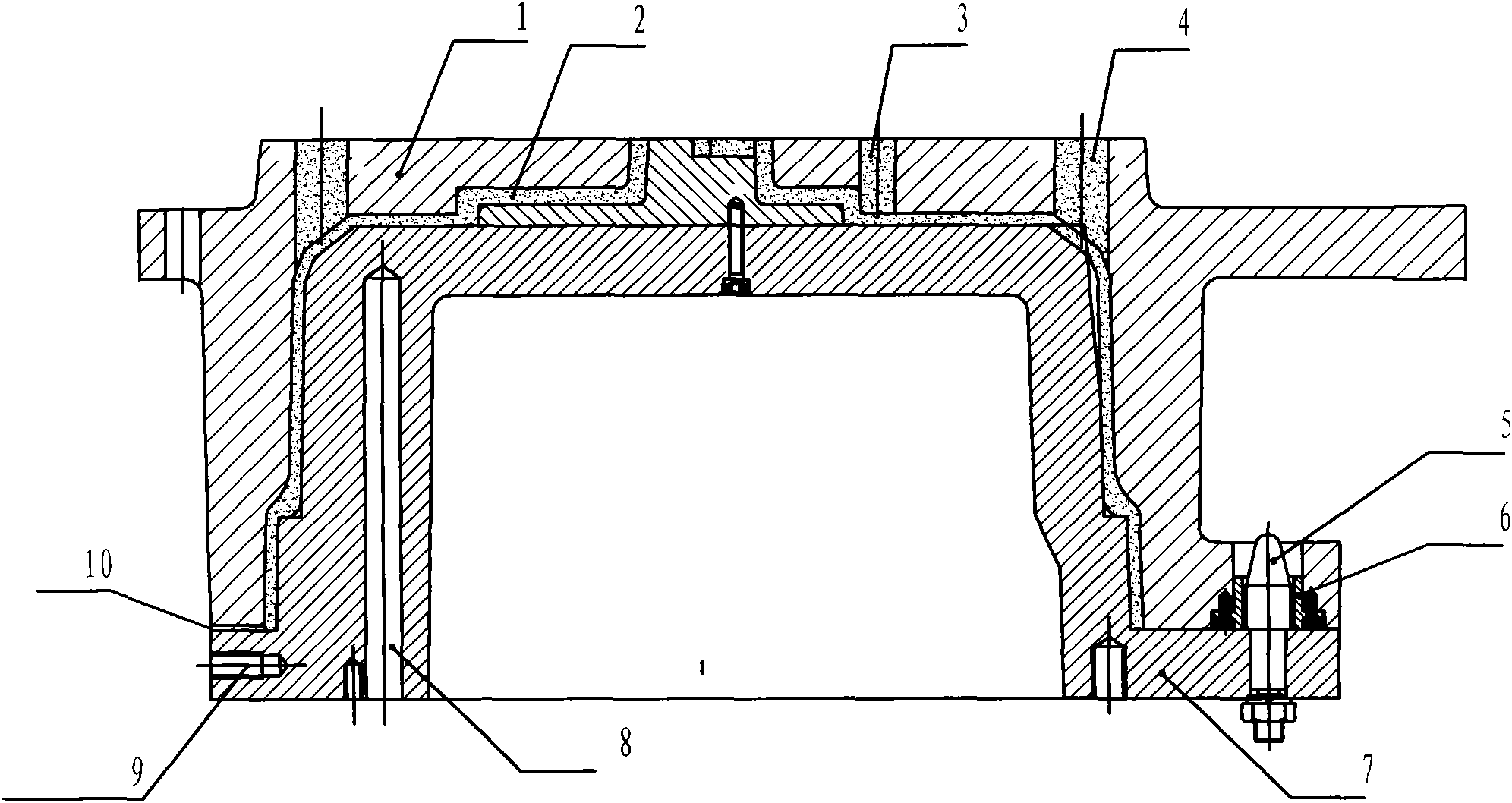

[0012] Metal mold sand covering device for casting brake drum upper mold, including upper sand box 1 and upper mold body 7, on the upper sand box 1 are respectively provided with vent hole 3 and sand shooting hole 4, positioning pin 5 and positioning pin The sleeve 6 crimps the upper sand box 1 and the upper mold body 7 together to form a sand-covered gap 2. The thickness of the sand-coated gap 2 is 6-10 mm, and is respectively fixed in the upper mold body 7. There are electric heating tubes 8 and temperature sensors 9, and an exhaust groove 10 is arranged at the end of the opening of the upper mold body 7, that is, the end of the sand-covered gap 2 formed after the upper sand box 1 and the upper mold body 7 are crimped together.

[0013] The wall thickness of the upper mold body 7 is 20-40 mm. The upper sand box 1 is an iron sand box made of gray iron 200. The wall thickness of the upper sand box 1 is 20-40 mm.

[0014] The thickness of the sand-covered gap 2 is preferably 7 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com