Patents

Literature

161 results about "Gray iron" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

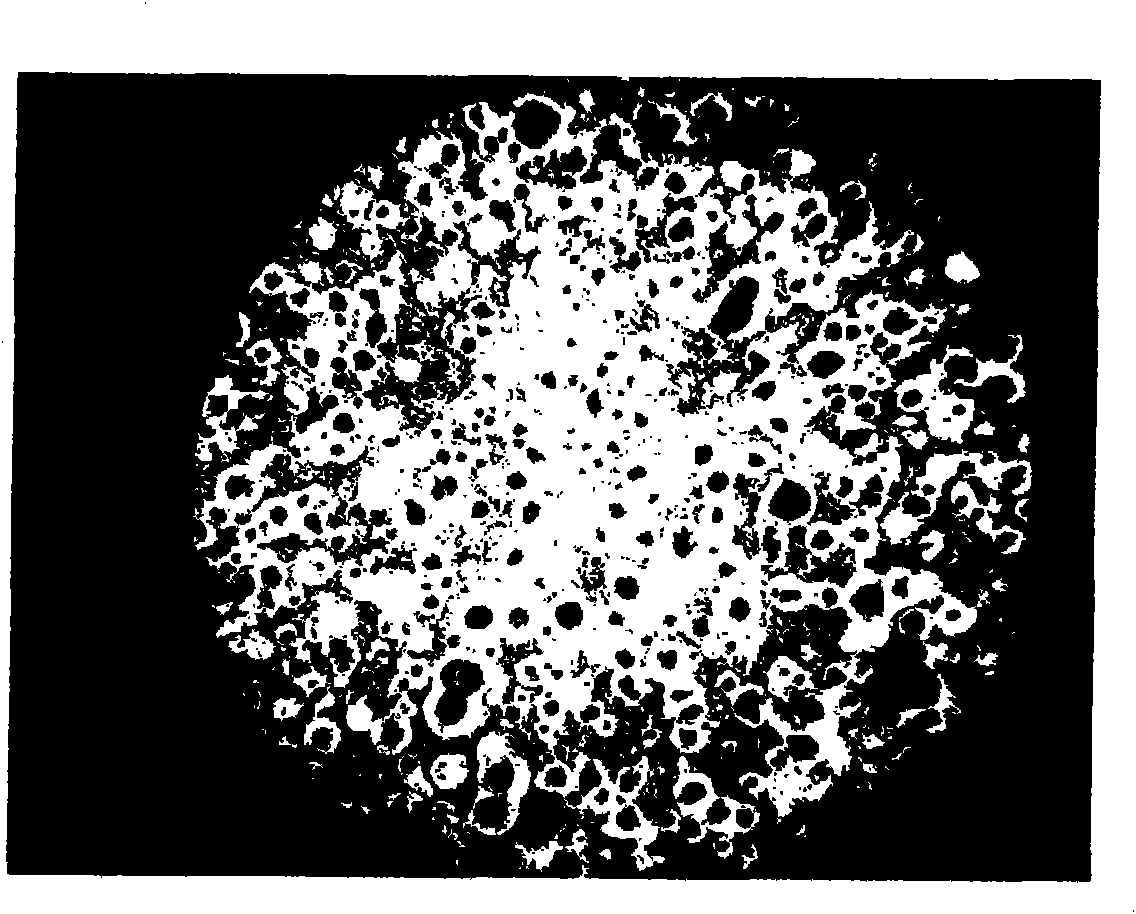

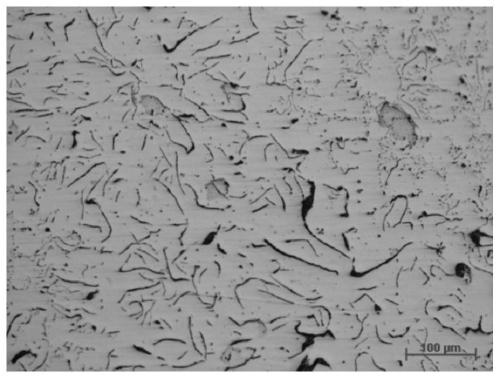

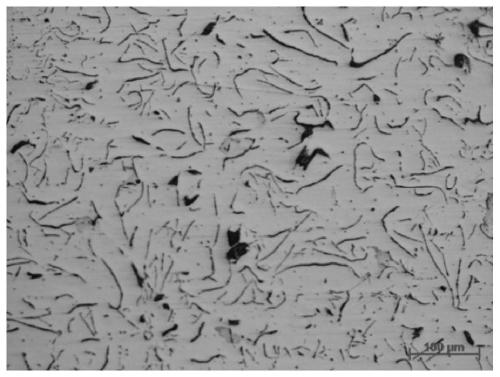

Gray iron, or grey cast iron, is a type of cast iron that has a graphitic microstructure. It is named after the gray color of the fracture it forms, which is due to the presence of graphite. It is the most common cast iron and the most widely used cast material based on weight.

Water-based paint for iron casting through lost foam casting die

InactiveCN102921880AHigh temperature strengthSuitable for high temperature breathabilityFoundry mouldsFoundry coresSODIUM METAPHOSPHATECellulose

The invention discloses a water-based paint for an iron casting through a lost foam casting die. The paint comprises refractory aggregate, binders, a suspending agent, additives and a dispersing agent, wherein the refractory aggregate comprises high aluminum powder, zircon powder and pyrophyllite; the binders comprise silica sol or white emulsion, polyvinyl acetate emulsion, bentonite and sodium hexametaphosphate; the suspending agent comprises sodium carboxymethylcellulose; the additives comprise Tween, octanol, sodium carbonate, cryolite and iron oxide powder; and the dispersing agent is water. According to the paint, suitable ingredients are chosen, the content is adjusted, a suitable mixing process is adopted, and therefore performances such as normal temperature and high-temperature strength, suitable high-temperature permeability and good leveling property, suspension property and painting performance of a coating can be satisfied completely. The paint is suitable for gray iron castings with different trademarks and enables the expendable casting die to be stripped with the iron casting easily, particularly for stripping in flakiness of a sintered coating during cleaning, and the possibilities for diverse defect generation on the surface of the iron casting are reduced; and simultaneously, pollution of coating components to the environment is reduced greatly due to the selection of phosphate assistant.

Owner:XUZHOU PENGJU SNAPDRAGON ARTS & CRAFTS

Gray iron casting moulding sand and preparation method thereof

The invention discloses gray iron casting moulding sand which is prepared from the following raw materials in parts by weight: 250-280 parts by weight of quartz sand, 40-45 parts by weight of sepiolite, 160-170 parts by weight of loess, 30-35 parts by weight of shell powder, 20-25 parts by weight of titanium dioxide, 40-45 parts by weight of grass meal, 2-3 parts by weight of acrylic emulsion, 30-40 parts by weight of silicon carbide, 10-15 parts by weight of pulverized coal, 50-60 parts by weight of gypsum, 3-4 parts by weight of zinc stearate, 10-15 parts by weight of bentonite, 3-4 parts by weight of ammonium dihydrogen phosphate, 4-5 parts by weight of sodium bicarbonate, 2-3 parts by weight of sodium dodecyl benzene sulfonate, 4-6 parts by weight of urea, 10-12 parts by weight of flour, 40-45 parts by weight of wood-bamboo powder and a proper amount of water. The sepiolite, the loess, the bentonite and the like are calcined, thus the gray iron casting moulding sand has excellent plasticity and caking property; by using the shell powder, the grass meal, the wood-bamboo powder and the like, the air permeability is increased; by using the titanium dioxide, the dispersity is increased and the high-temperature collapsibility is good; by using the pulverized coal, the surface of a casting is bright. The yield of the casting is increased.

Owner:张志功

Anti-vein precoated sand and preparation method thereof

InactiveCN103567357AAnti-sticking sand strengthStrong anti-veining abilityFoundry mouldsFoundry coresSesbania gumPhenol

The invention discloses anti-vein precoated sand and a preparation method thereof. The anti-vein precoated sand is prepared from the following raw materials in parts by weight: 80-90 parts of quartz sand, 15-25 parts of menaccanite, 10-15 parts of spodumene, 2-3 parts of boric acid, 2-3 parts of thermoplastic phenolic resin, 0.5-1 part of thermosetting phenol resin, 5-10 parts of cement clinker, 4-7 parts of sulphite liquor, 3-5 parts of corn flour, 2-3 parts of sesbania gum, 1-2 parts of ammonium benzoate, 0.5-0.8 part of gamma-aminopropyl triethoxy silicane, 3-6 parts of dioctyl phthalate, 7-11 parts of urotropine, 2-4 parts of calcium stearate and 3-5 parts of composite powder. The anti-vein precoated sand has strong anti-sand burning and anti-vein capacities, also has the characteristics of high strength, good liquidity, low gas evolution, good heat resistance, good gas permeability and the like, can obviously reduce or eliminate defects of vein, sand burning, pores and the like, effectively improves quality of the inner surface and the outer surface of a casting and is applicable to production of a gray iron bulb iron steel casting.

Owner:TONGLING JINGWEI FLUID SCI & TECH

Special paint for evaporative pattern cast iron and manufacturing method of special paint

The invention relates to special paint for evaporative pattern cast iron and a manufacturing method of the special paint. The special paint comprises the following components: 45-55 parts of bauxite, 30-35 parts of spar powder, 3-7 parts of mica powder, 10-14 parts of kieselguhr, 1-2 parts of attapulgite, 1.5-2.5 parts of sodium bentonite, 1-2 parts of meerschaum, 1.5-2.5 parts of artificial starch, 0.05-0.1 part of hydroxyethyl cellulose, 2-4 parts of emulsion powder, 0.2-0.4 parts of sodium carbonate, 0.1-0.3 part of antifoaming agent, 0.1-0.3 part of surfactant and water with the weight accounting for 35-45% of the total weight of the other components. The thickness of a single coated coating of the paint is between 0.55mm and 0.7mm; and coating can ensure no flowing, and prevent exposure of a facade and cracks of a corner. The coating with the appropriate thickness is good in air permeability, and the paint is particularly suitable for castings with complicated inner cores, such as thin-wall gray iron castings with complicated inner cavities, like an engine body, a cylinder cover and a vent pipe.

Owner:安徽中兴华汉机械有限公司

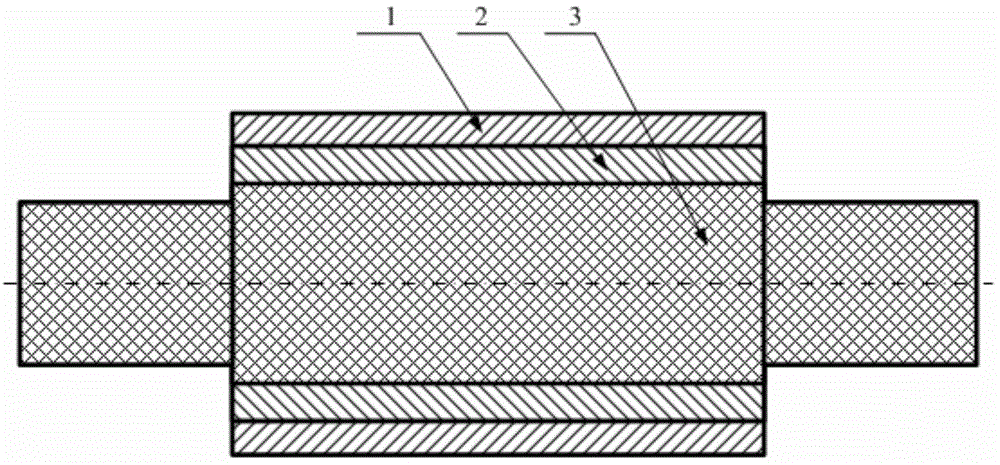

Wear-resisting roll used for steel rolling intermediate mill frame and manufacturing method thereof

ActiveCN104148399ASimple heat treatment processShort heat treatment timeRollsMetal rolling arrangementsSocial benefitsAlloy

A wear-resisting roll used for a steel rolling intermediate mill frame and a manufacturing method thereof belong to the technical field of steel rolling. The wear-resisting roll is composed of outer layer alloy nodular cast iron, inner layer high strength gray iron and a hot rolled middle carbon round steel roll shaft with high strength. The outer layer alloy nodular cast iron and the inner layer high strength gray iron are formed through centrifugal casting in a composite mode, and the inner layer high strength gray iron is integrated with the hot rolled middle carbon round steel roll shaft with high strength, and the composite wear-resisting roll with high strength is obtained. The wear-resisting roll has the advantages of being simple and convenient in production process, long in service life, low in production cost and the like. In addition, good economic and social benefits are achieved through application and popularization.

Owner:枣庄瑞兴机械制造有限公司

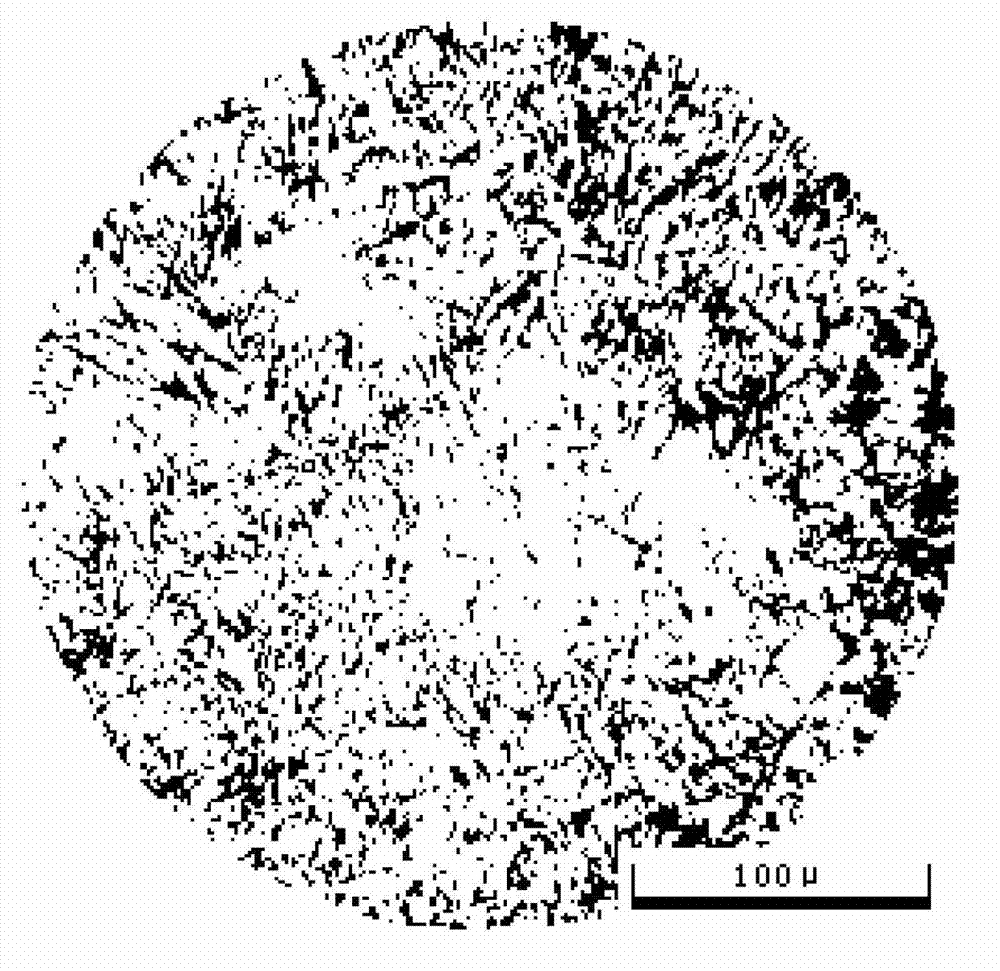

Multi-component alloy as-cast bainite gray cast iron cylinder jacket

The present invention relates to a multivariant alloying cast bainite gray iron cylinder sleeve. The chemical components of the multivariant alloying cast bainite gray iron cylinder sleeve are counted according to the weight percentage as follows: C: 3.0 to 3.4 percent; Si: 2.2 to 2.6 percent; Mn: 0.6 to 1.0 percent; P: more than 0 but smaller than or equal to 0.1 percent; S: more than 0 but smaller than or equal to 0.1 percent Cu: 0.6 to 1.0 percent; Mo: 0.2 to 0.5 percent; Chrome: 0.1 to 0.3 percent; Nb: 0.05 to 0.12 percent; V: 0.05 to 0.2 percent; Titanium: 0.07 to 0.15 percent; and the remaining are Fe. After the optimized alloying elements are added in the cylinder sleeve of the present invention, compound kinetosome is gained, and the compound kinetosome is better than the present cast bainite kinetosome of the cylinder sleeve and the staying quality is improved; the mechanical property (including the intensity of tension and the rigidity) equals to the present cylinder sleeve, but the production cost reduces and the cost performance increases.

Owner:ZYNP GRP

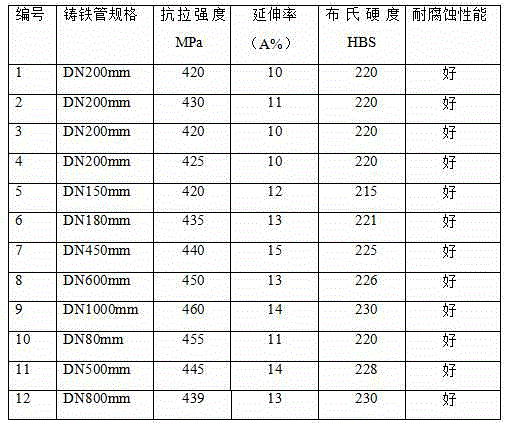

Method for preparing centrifugal nodular cast iron pipe

ActiveCN104480382AImprove appearance qualityRefining material organizationLiquid surface applicatorsCoatingsIRON PREPARATIONSCast iron pipe

The invention discloses a method for preparing a centrifugal nodular cast iron pipe. The method discloses the preparation process of the centrifugal nodular cast iron pipe of high quality, the preparation process comprises a series of operation processes of molten iron preparation, nodulizing of molten iron, centrifugal casting, annealing treatment, pipe body shaping and coating protection and the like. The method is suitable for preparation of cast iron pipes of the specification of DN 80-1000 mm, the application range is wide, and the preparation process is simple. The cast iron pipe prepared through the method has the characteristics of being high in appearance quality, fine in material structure, high in production efficiency, long in service life and the like, and compared with existing steel pipes and gray iron pipes, the cast iron pipe prepared through the method has better decay resistance and tensile property.

Owner:SICHUAN CHUANJIAN PIPES

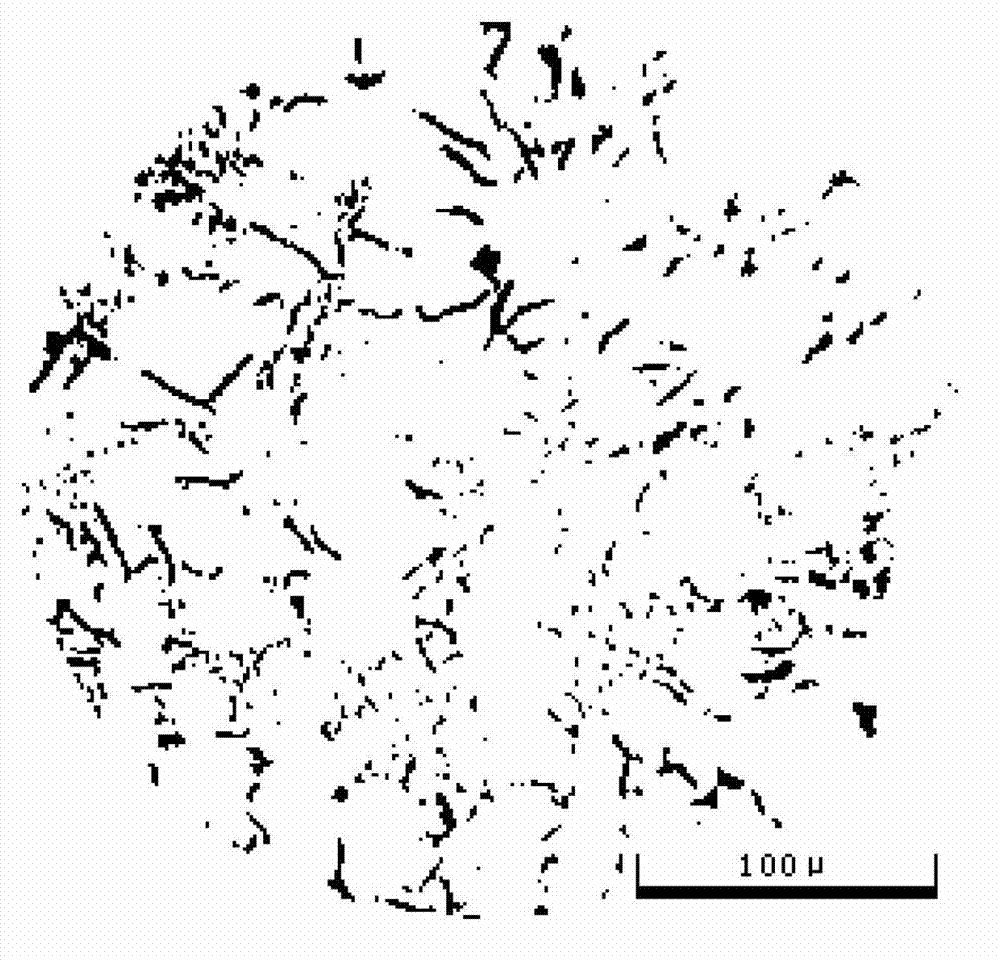

High tensile strength gray iron alloy

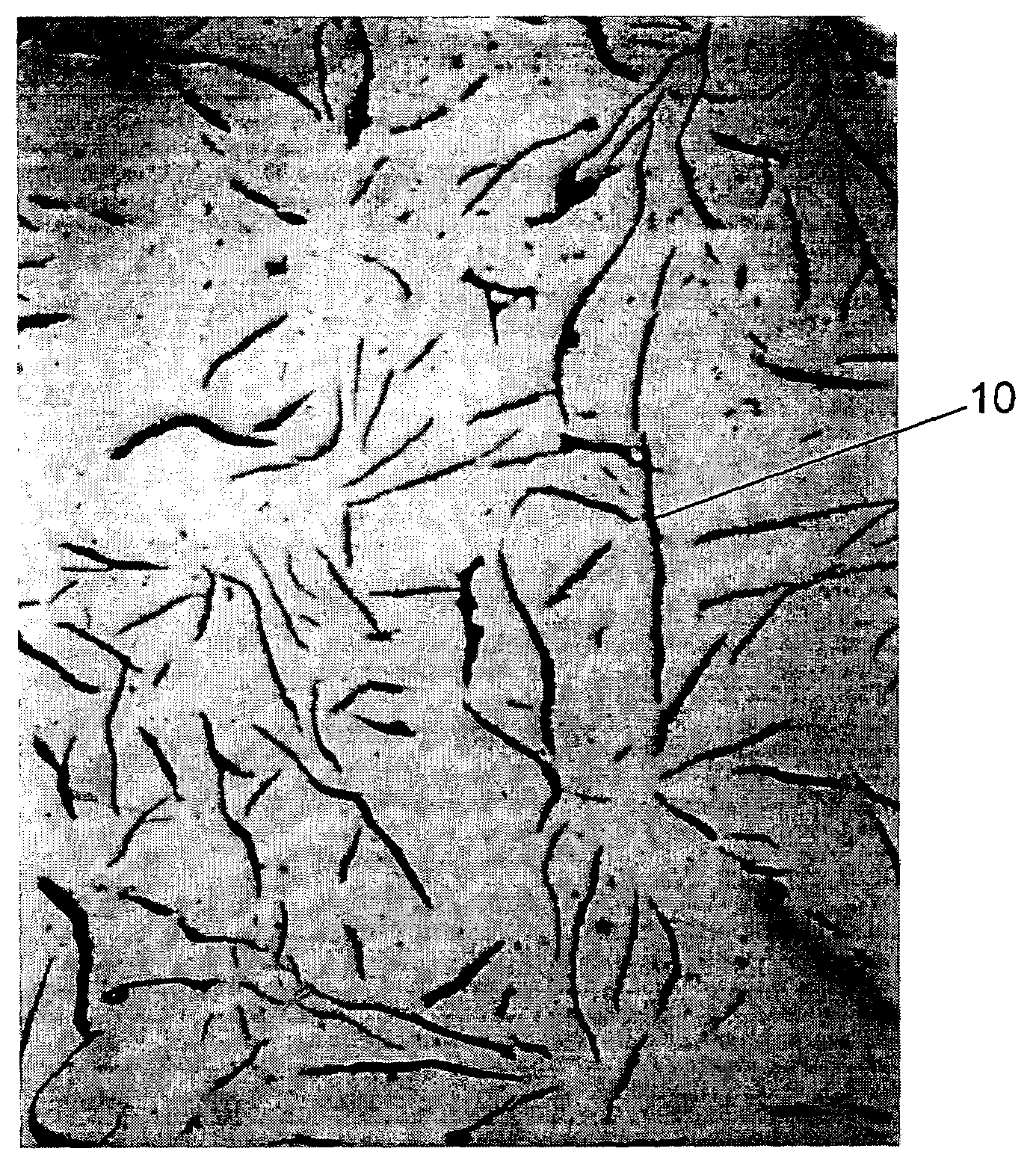

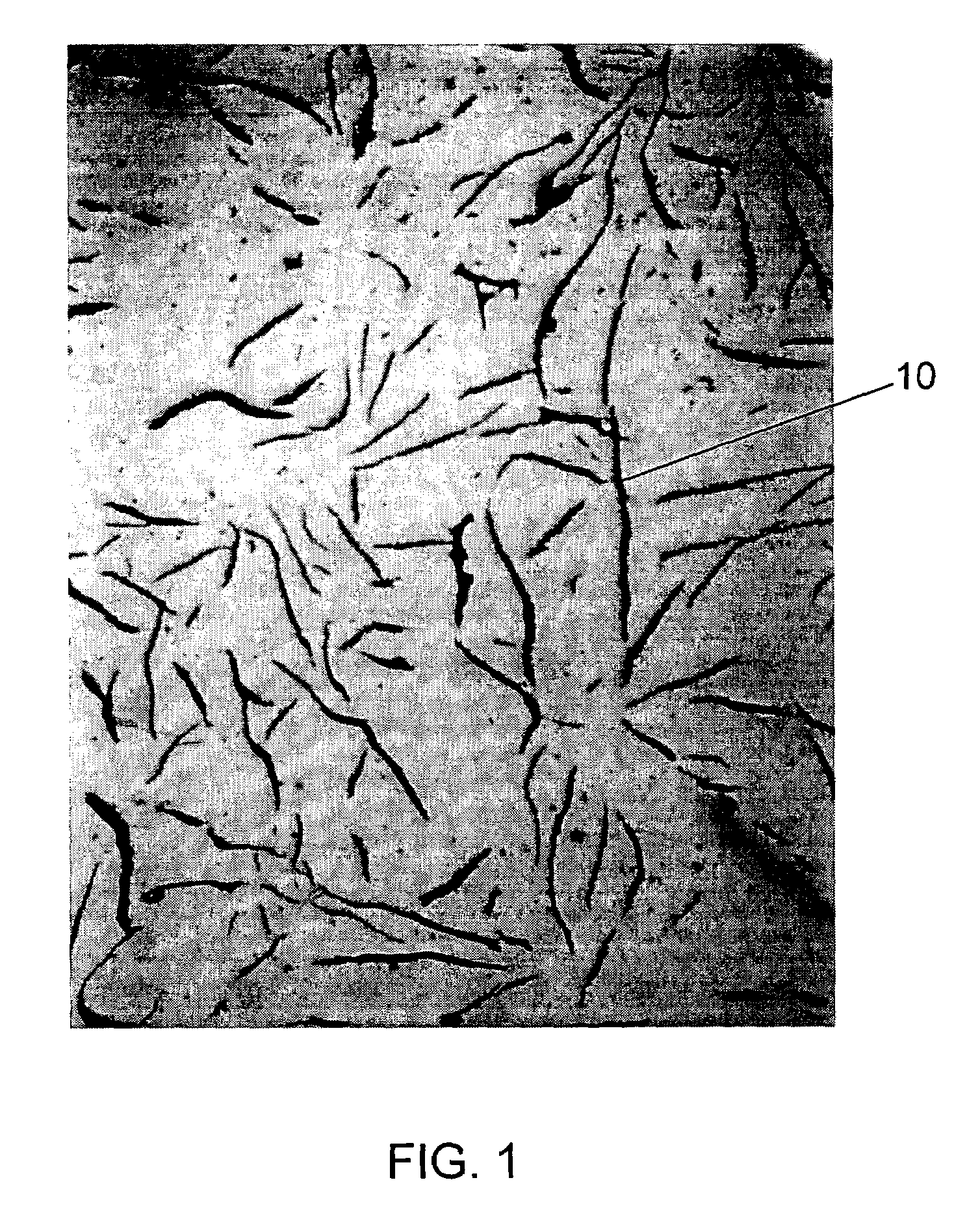

A gray iron alloy having a composition comprising about 4.10% to about 4.25% carbon equivalent, about 3.5% to about 3.65% carbon, about 0.4% to about 0.9% manganese, about 1.5% to about 1.9% silicon, less than about 0.12% phosphorous, less than about 0.17% sulfur, about 0.6% to about 0.8% molybdenum and about 0.3% to about 0.6% copper, and where said carbon is predominantly present as free carbon having a Type A flake graphite microstructure. The alloy is particularly useful in the manufacture of brake drums and other articles requiring a combination of high tensile strength and good thermal conductivity.

Owner:ROYAL BANK OF CANADA

Alloy gray iron material for vehicle covering mould and its preparation method

InactiveCN1693525AEasy to processStrong self-hardening abilityIncreasing energy efficiencyHardnessWear resistance

An alloyed gray pig iron used for the die of the covering part of car contains C (2.8-3.2 wt.%), Si (1.8-2.2), Mn (0.6-0.9), P (0-0.08), S (0-0.03), Cr (0.1-0.5), Cu (0.2-1.0), Mo (0.1-0.5), Ni (0.3-0.5) and Fe (rest). Its preparing process includes such steps as proportionally mixing raw materials, smelting, casting, audio induction quenching, heating to 850-950 deg.C, and quenching in air. Its advantages are high hardness and high mechanical performance.

Owner:SHANGHAI UNIV

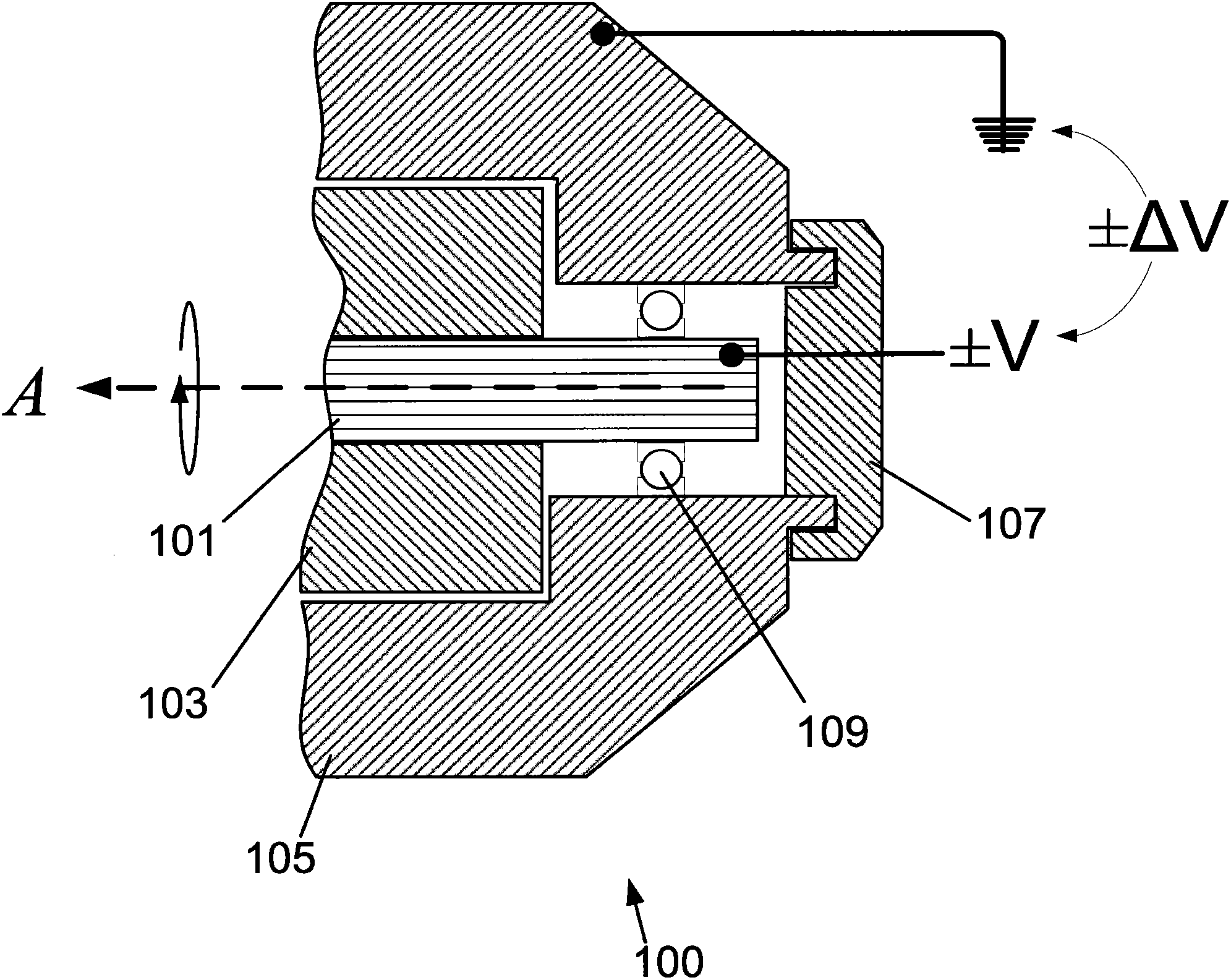

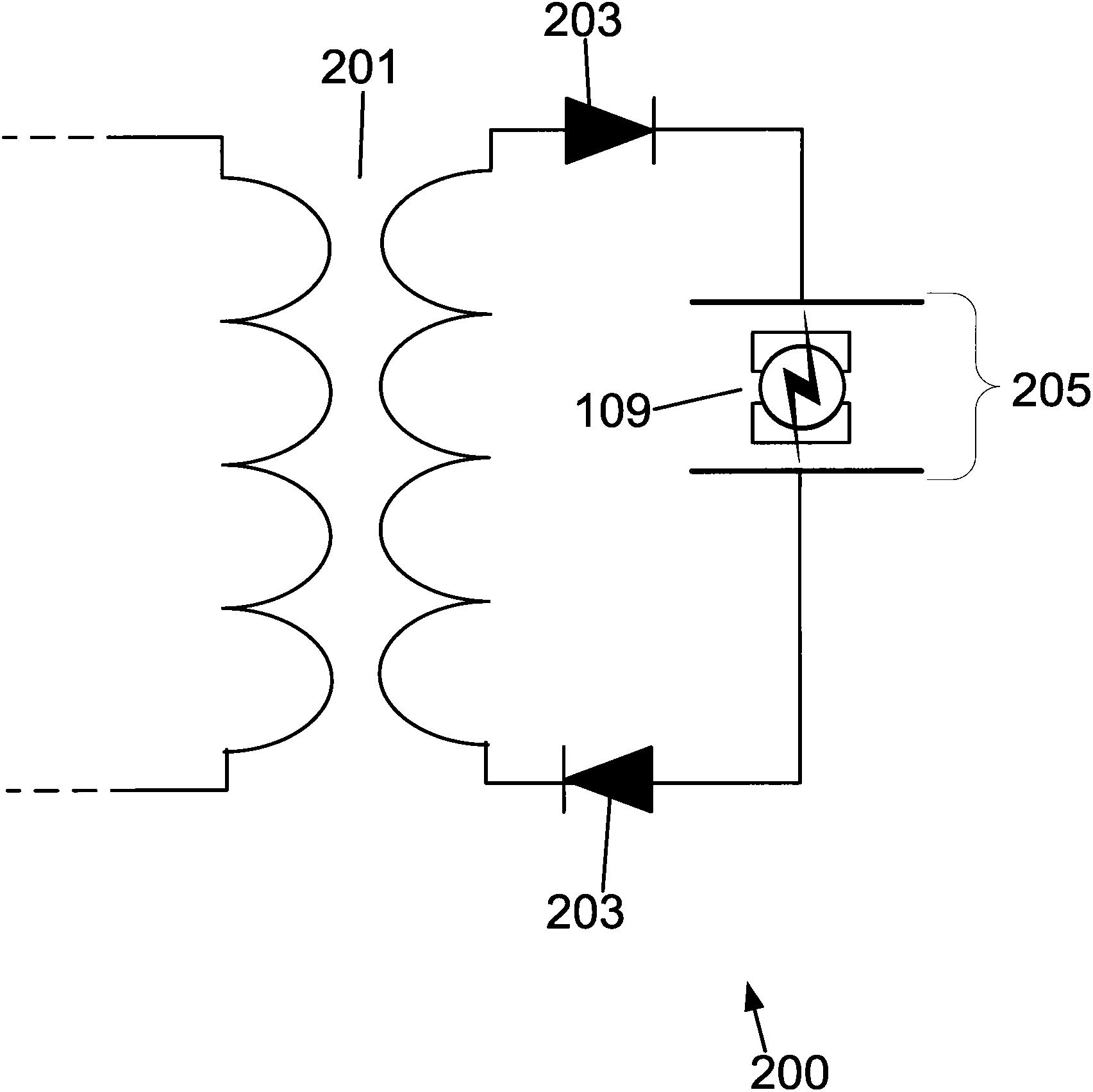

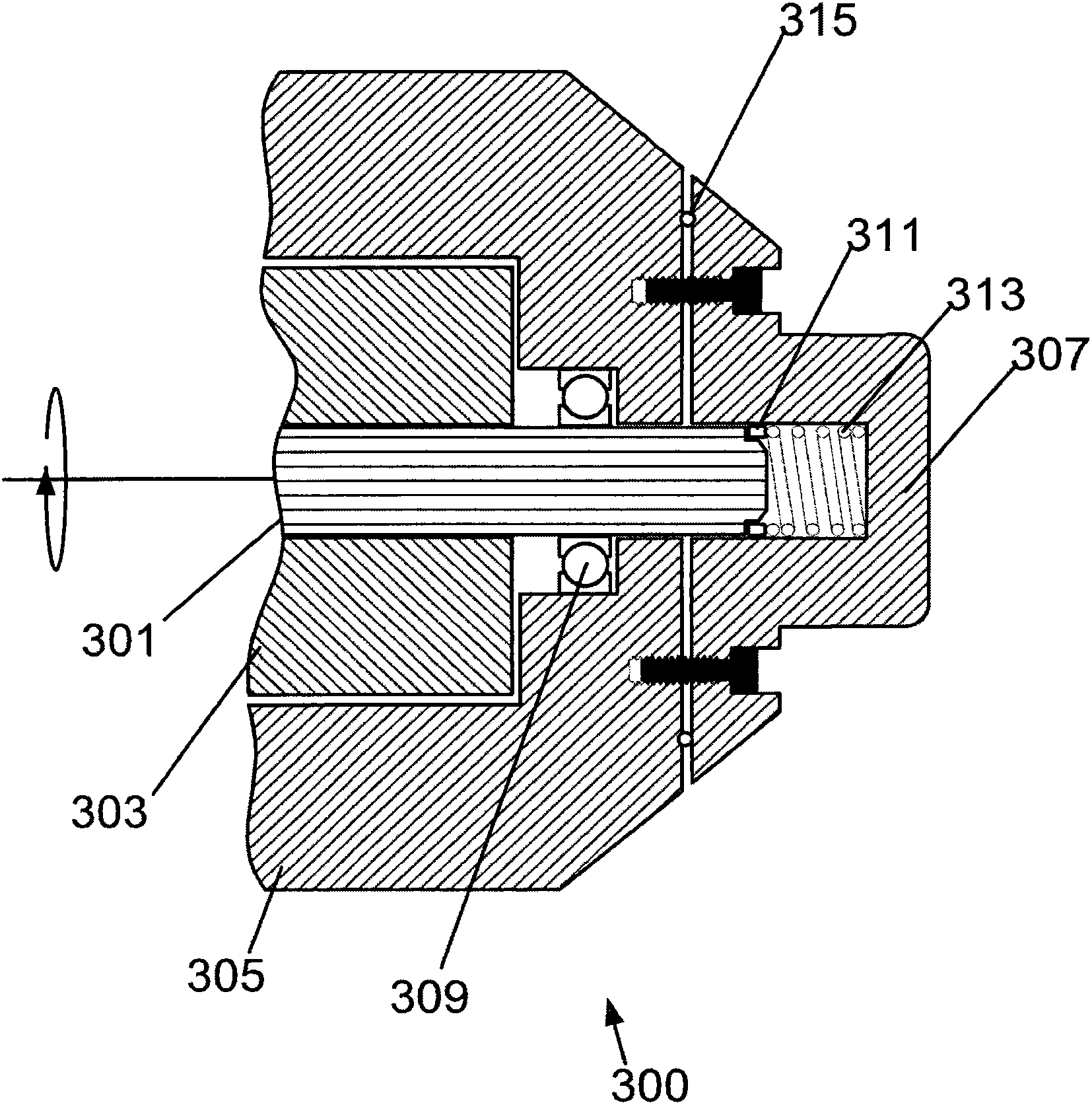

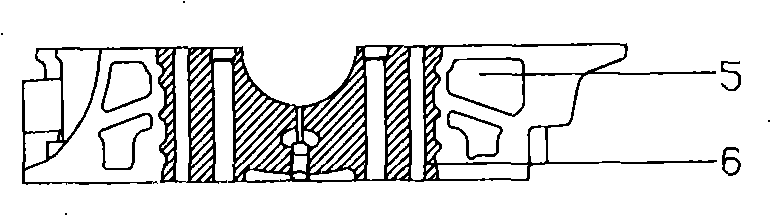

Electrical bearing ground device

An assembly, system and method are provided for discharging a rotating shaft encompassed by a stationary housing. The system includes an annular charge-dissipating component and a biasing element oriented to apply an axial force to the charge-dissipating component, holding it in contact with the shaft and the housing while the shaft is rotating. The biasing element may be a coil spring or a wave spring. A shaft grounding upgrade kit includes a conductive ring member and a cylindrical spring having a diameter that is the same as that of the conductive ring member. The spring constant of the cylindrical spring is such that the spring holds the conductive ring member within the housing in contact with the shaft and the housing. The conductive ring member may be constructed of gray iron and the cylindrical spring is one of a wave spring and a coil spring.

Owner:CATERPILLAR INC

Method for producing castings by utilizing waste scrap iron and waste steel

ActiveCN101892415AEnhanced magnetic fieldFully filledProcess efficiency improvementIntermediate frequencyMechanical property

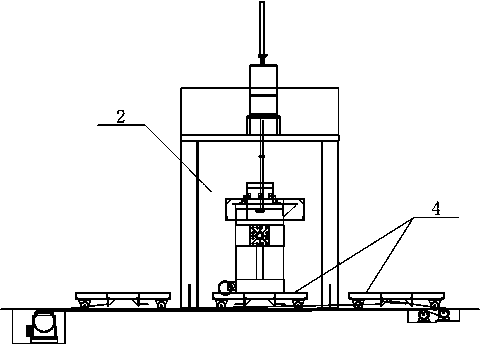

The invention discloses a method for producing castings by utilizing waste scrap iron and waste steel. The method comprises the following steps of: paving a layer of scrap iron at the bottom of an intermediate frequency furnace; injecting a furnace bottom carburant; adding scrap returns; filling gaps with the scrap iron; adding the waste steel; filling the gaps among the waste steel with the scrap iron; turning on power for preheating; increasing power to full load; when furnace burden at a furnace mouth descends, poking the furnace and charging until all taken raw materials are added into the intermediate frequency furnace; when all taken components are molten and the distance from the surface of molten iron to the furnace mouth is 10 to 15cm, sampling the molten furnace and performing forehearth laboratory analysis; adjusting elements in the molten iron according to an analysis result to make the content of the elements in the molten iron meet a requirement; pouring the adjusted molten iron by a method for producing gray iron castings or nodular iron castings to prepare the gray iron castings and the nodular iron castings. By using the method, the castings of which the chemical components, the metallographic structures and the mechanical properties meeting requirements can be produced; and the difficulty in adjusting the chemical components in a melting process can be reduced.

Owner:西安合力汽车配件有限公司

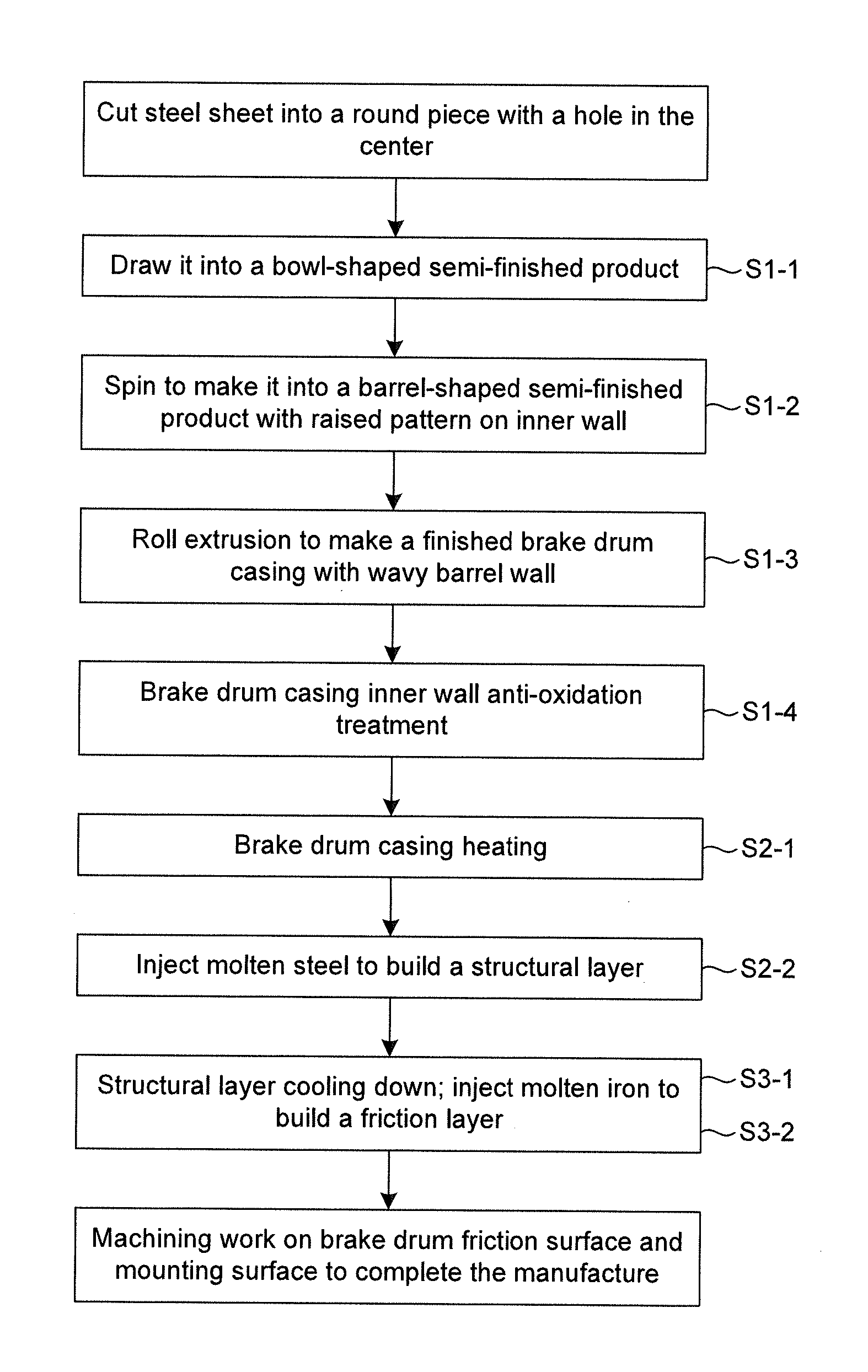

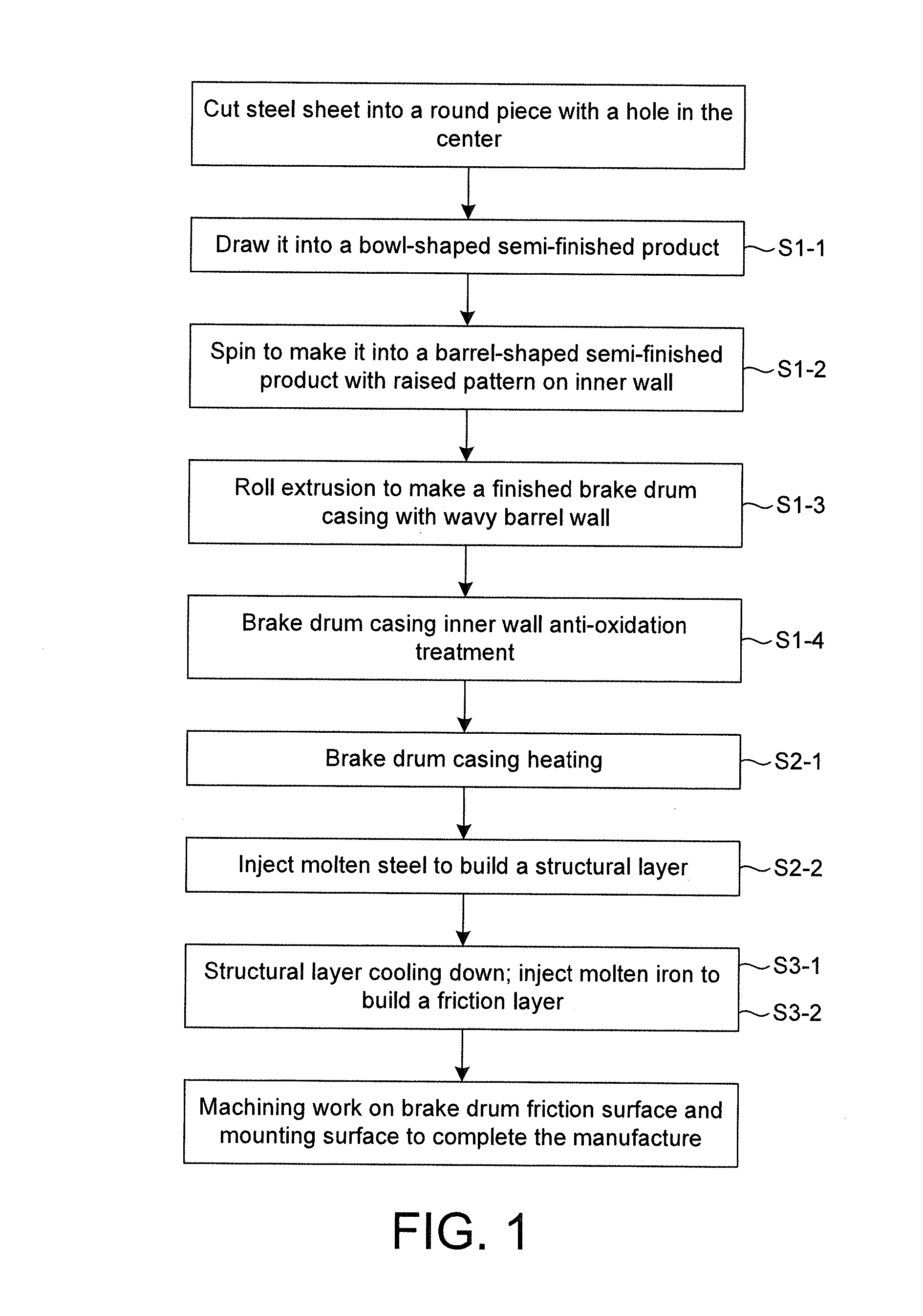

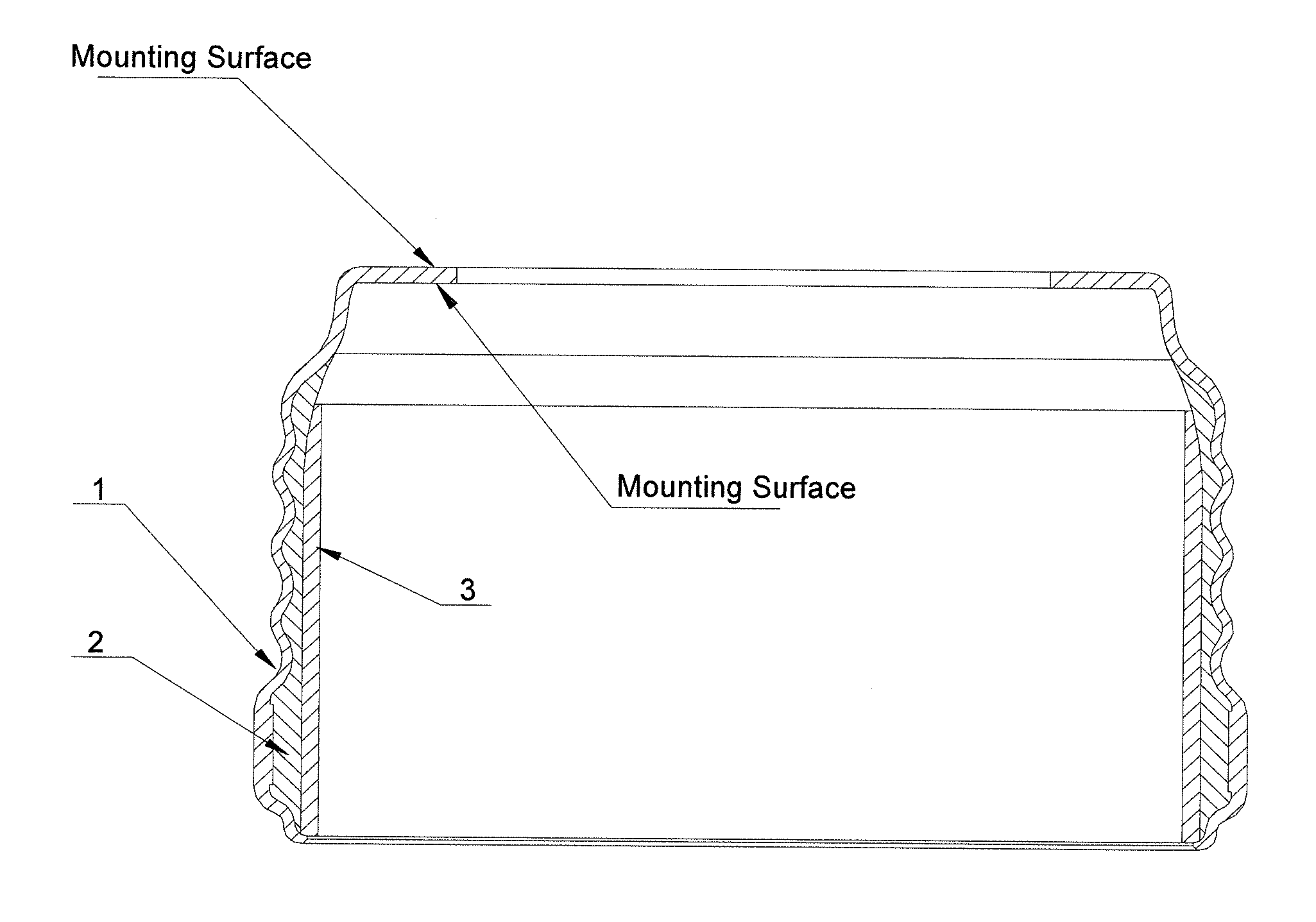

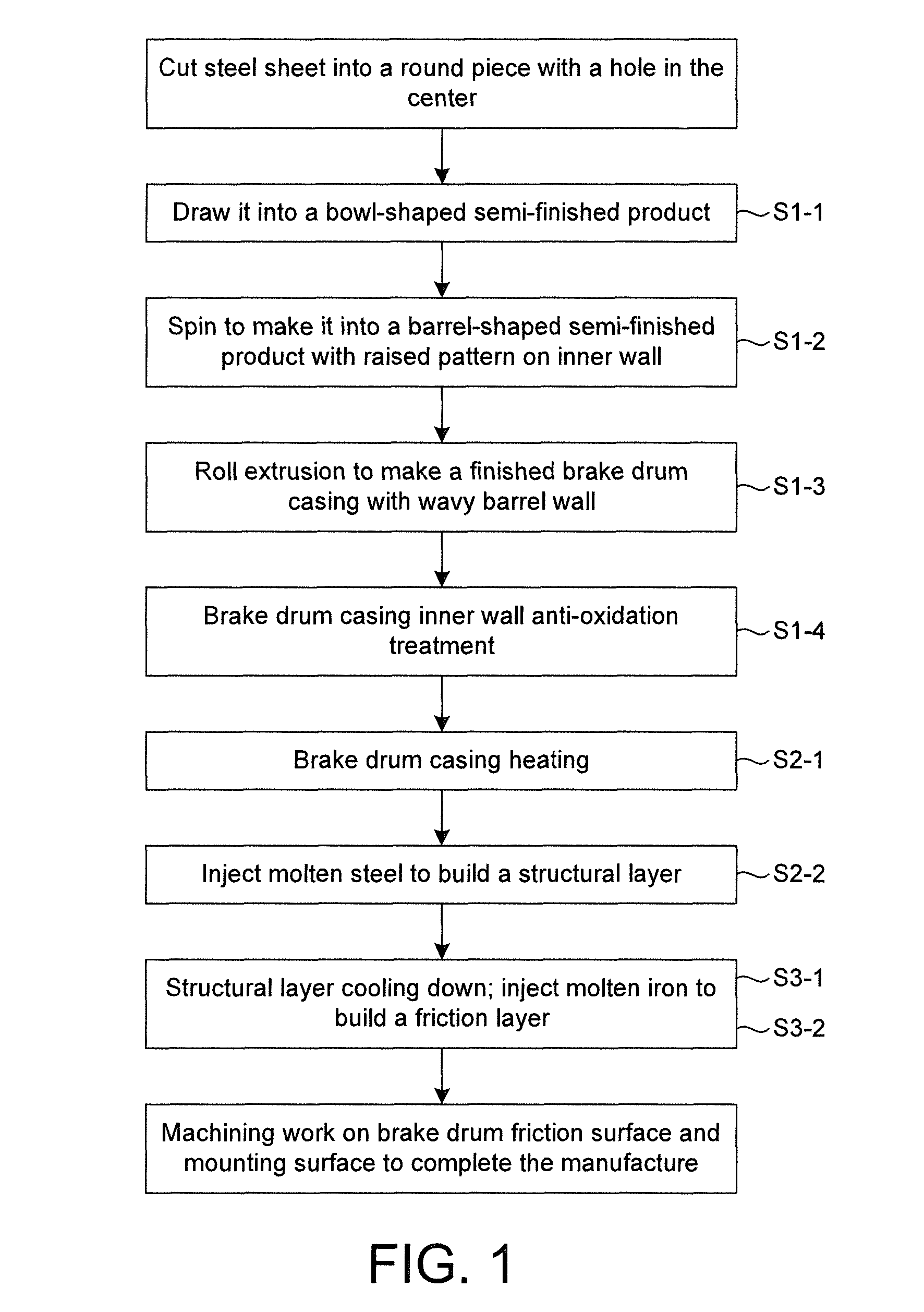

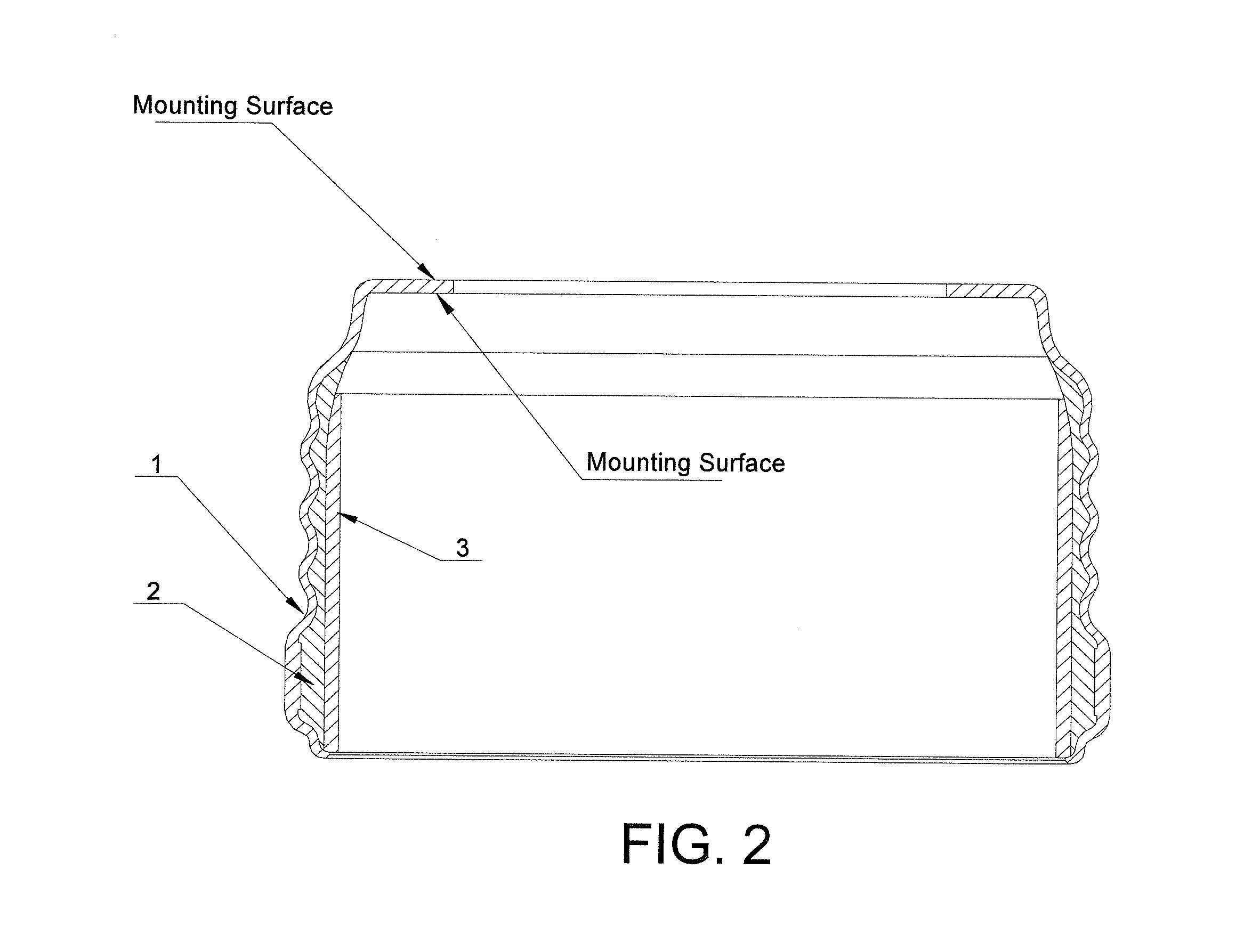

Method for producing brake drum and a brake drum

ActiveUS20140034433A1High strengthImprove thermal conductivityMetal rolling stand detailsBraking drumsMetallic materialsAlloy

The present invention discloses a method for producing brake drum, wherein three different metallic materials are used for the three-layer construction; and two layers made of different molten metallic materials are cast based upon the prefabricated steel shell (with steel or gray iron for the structural layer and the Mo-containing, abrasion-resistant alloy cast iron for the braking friction layer) so that atoms from these two adjacent but different metallic layers inter-diffuse across the interface to form a solid fusant or an inter-metallic compound, thereby generating a very strong metallurgical bond. The present invention also provides a brake drum, comprising a brake drum shell, a structural layer inside the brake drum shell, and a friction layer inside the brake drum structural layer and for braking.

Owner:JIAXING STONE WHEEL

Method for preventing cast-in steel pipe from being burnt and sintered

ActiveCN102009158ASolve permSolve problems such as sintering failureFoundry mouldsFoundry coresRejection rateCoating

The invention discloses a method for preventing a cast-in steel pipe from being burnt and sintered. In the method, fireproof coating is coated on the inner wall of the cast-in steel pipe and a filler is uniformly filled in an inner cavity during the production of cast steel, spheroidal graphite cast iron and gray iron castings, wherein the fireproof coating forms a high-temperature resistant isolating layer on the inner wall of the steel pipe. As the fireproof coasting is coated on the inner wall of the cast-in steel pipe and the simple and cheap filler is filled in the inner cavity during the production of cast steel, spheroidal graphite cast iron and gray iron castings, the problems that the steel pipe cannot be penetrated through due to burning and sintering and the like are solved, the rejection rate because the steel pipe cannot be penetrated through due to burning and sintering is 0, the production cost is greatly lowered and the material waste is reduced.

Owner:SICHUAN HAIKE MACHINERY MFG

Production method of high-strength grey cast iron for automobile fittings

InactiveCN101525677AReduce contentReduce air bubblesProcess efficiency improvementFerrosiliconManganese

The invention discloses a production method of high-strength grey cast iron for automobile fittings. The method comprises the following procedures: batching procedure, charging procedure, smelting procedure and pre-furnace processing procedure. In the batching procedure, furnace charges used comprise scrap steel, remelting gray iron, manganese iron alloy, ferrosilicon alloy and a carburetant with the weight ratio of the scrap steel, the remelting gray iron, the manganese iron, the ferrosilicon alloy and the carburetant being 80-90:10-20:0.5-1.0:1.0-1.8:3.5-4.0 respectively. Compared with the prior art, the high-strength grey cast iron is generated by taking the scrap steel as a main raw material and adjusting various elements in the scrap steel. The high-strength grey cast iron is characterized in that few air bubbles are produced and cracks are not easily generated in castings if the grey cast iron is poured on the castings.

Owner:WUHU JINMAO FLUID TECH CO LTD

Preparation method of high-strength thin-wall gray iron casting

ActiveCN109023034AReduce the amount addedReduce the proportionProcess efficiency improvementChemical compositionNational standard

The invention discloses a preparation method of a high-strength thin-wall gray iron casting. 3-8% of pig iron, 50-65% of waste steel and 27-42% of returns are adopted as raw materials of molten iron liquid, the process method of smelting, primary recarburization, primary inoculation, secondary recarburization, secondary inoculation, casting, in-mold inoculation and annealing is adopted, and the high-strength thin-wall gray iron casting is obtained. The high-strength thin-wall gray iron casting is prepared from chemical components in percent by mass: 2.9-3.5% of C, 1.4-2.1% of Si, 0.7-1.1% of Mn, smaller than or equal to 0.05% of P, smaller than or equal to 0.08% of S, smaller than or equal to 0.03% of Cu, 0.031-0.043% of Sn, 0.01-0.03% of RE and the balance Fe and inevitable impurities. Bymeans of the preparation method, the high-strength thin-wall gray iron casting can be prepared, the cost of the high-strength thin-wall gray iron casting is low, and the comprehensive performance issuperior to the national standard with the casting shop name being HT250.

Owner:慈溪市中环机械厂

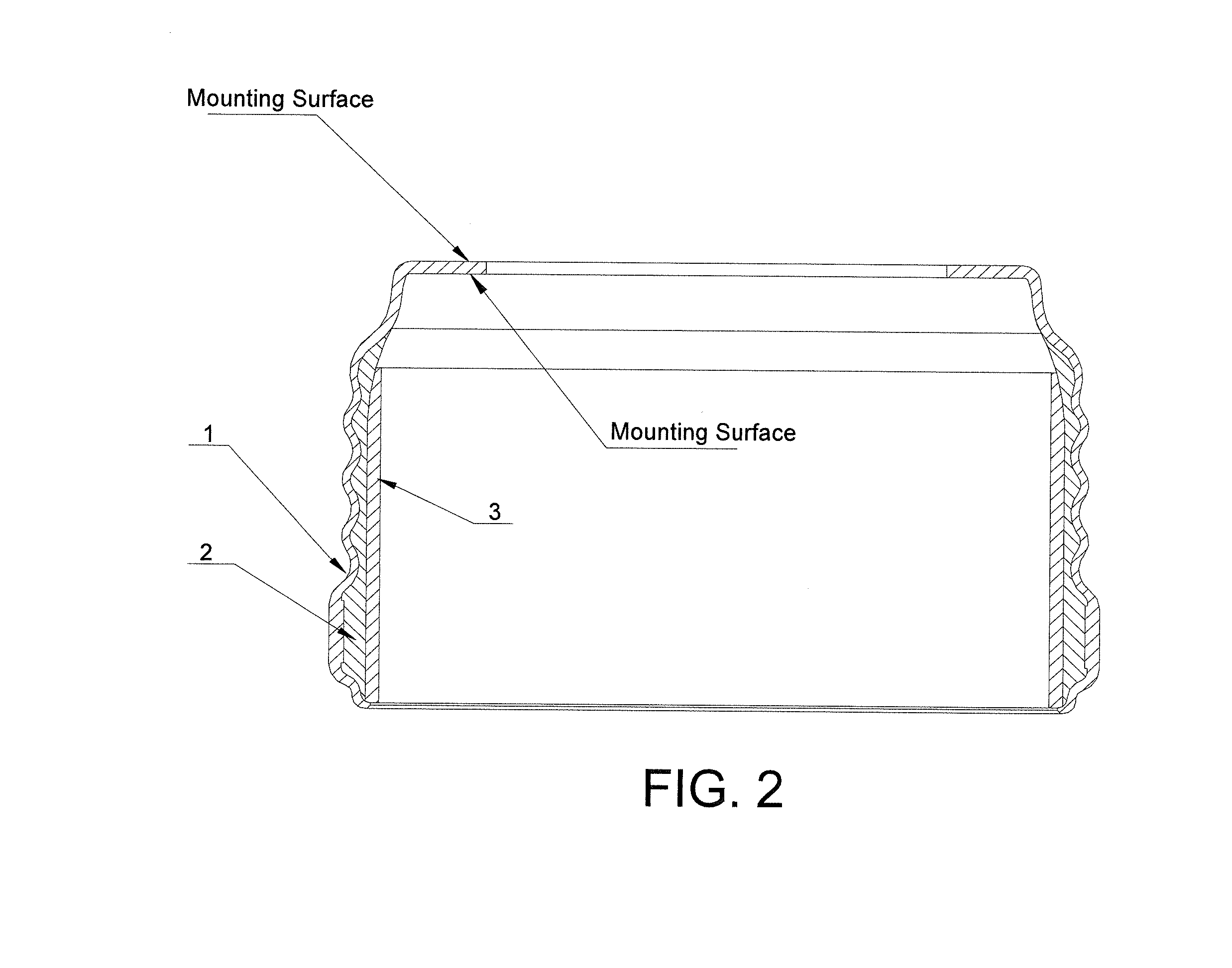

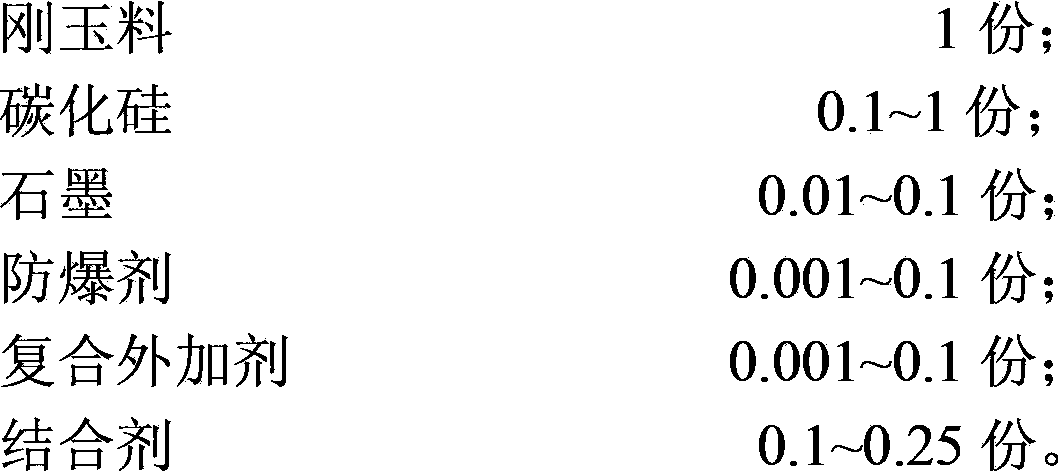

Wear resistance casting material for ladle

The present invention relates to a wear resistance casting material for ladle. The wear resistance casting material comprises, by weight, 1 part of a corundum material, 0.1-1 part of silicon carbide, 0.01-0.1 part of graphite, 0.001-0.1 part of an explosion-proof agent, 0.001-0.1 part of a composite additive, and 0.1-0.25 part of a binding agent. According to the present invention, the cement component-free inorganic nanometer binding agent is adopted, good quality electrofusion or sintering corundum or special grade alumina clinker is adopted as the main material, silicon carbide, graphite, an explosion-proof agent and the like are added, and variety and the number of a composite additive are optimized to prepare the wear resistance casting material with characteristics of rapid baking, high high-temperature strength, good high-temperature wear resistance, excellent thermal shock stability and good construction performance; and ladle bottom of the bottom washing type ladle with a capacity of one ton is used in gray iron casting, wherein the service life can be more than 3000 times and is more than two times the service life of the conventional material, and slag removing is easy.

Owner:天津振普筑炉衬里工程有限公司

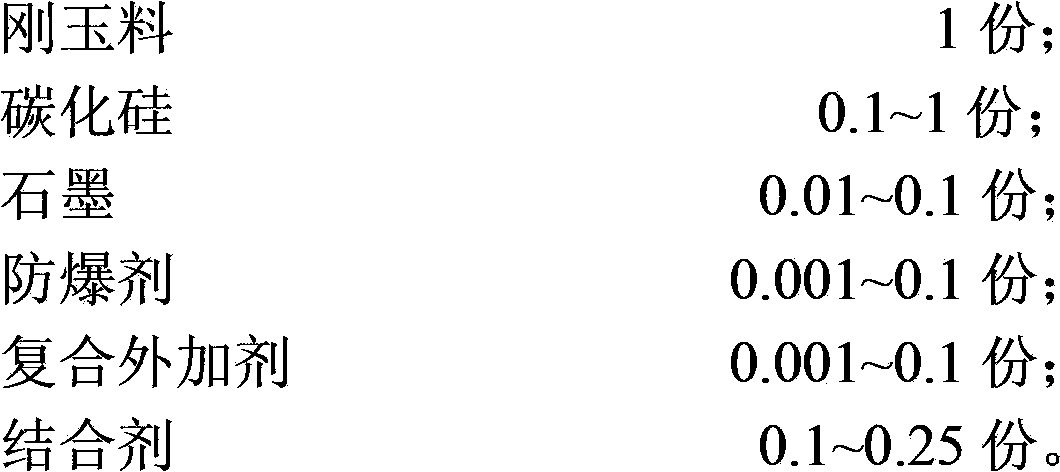

Automobile mold casting cast by compounding ductile iron and gray iron, gating system and casting method

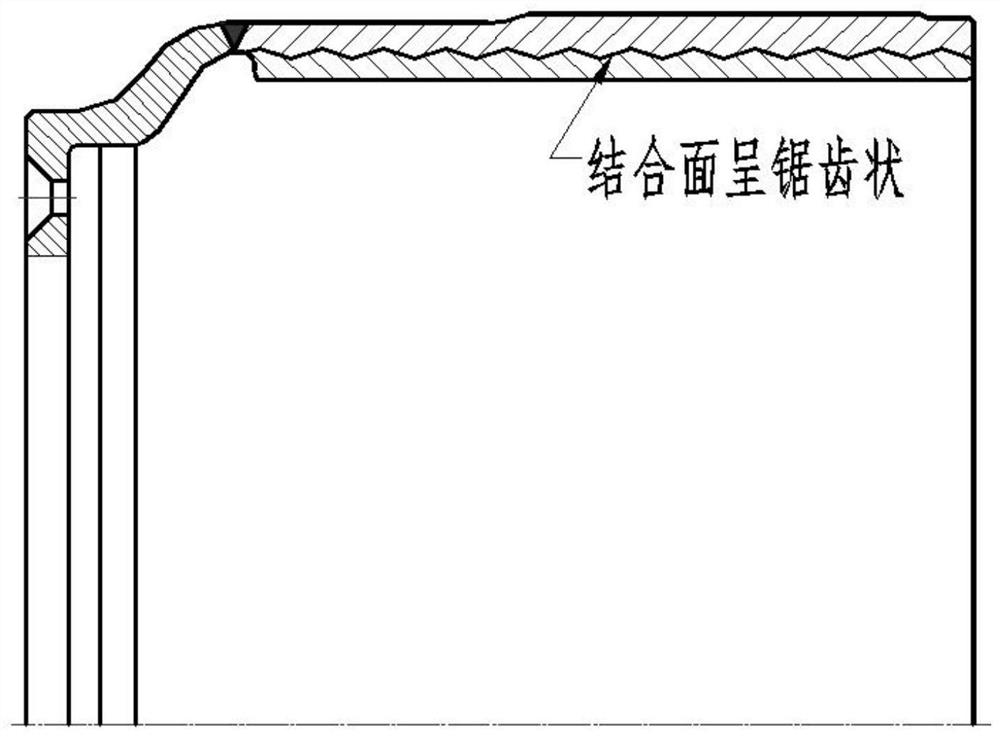

InactiveCN105798271AImprove casting qualityAvoid mixingFoundry mouldsFoundry coresDuctile ironUltimate tensile strength

The invention relates to an automobile mold casting cast by compounding ductile iron and gray iron, a gating system and a casting method. The automobile mold casting comprises a mold base and a working part, wherein the mold base and the working part are cast and formed at a time. The mold base is made of the gray iron. The working part is made of the ductile iron. Metallurgical bonding is adopted for the bonding face of the mold base and the working part. In this way, the mold base and the working part are integrally cast and formed at a time, and the casting production time is saved; and meanwhile, because machining standards of molds are basically consistent, the machining workloads are substantially reduced, the machining precision is substantially improved, the machining time is obviously shortened, the machining cost is reduced, the mold assembling and debugging difficulty is substantially lowered for bench workers, and the mold assembling and debugging time is substantially shortened for the bench workers. In addition, the metallurgical bonding is adopted for the bonding face of the mold base and the working part, the bonding face has good process performance, the bonding strength is high, and therefore the problem that the bonding face cracks is avoided.

Owner:湖南湖大三佳车辆技术装备有限公司 +3

Casting technology method for high-rigidity gray iron hydraulic valve body

InactiveCN101745606ASolve the technical problems of poor purity of molten iron and uneven metallographic structureIncrease stiffnessFoundry mouldsFurnace typesSilicon alloyStress relieving

The invention relates to a casting technology method for a high-rigidity gray iron hydraulic valve body, comprising the following steps: 1. adopting metal pouring: increasing the cooling speed of castings when pouring; 2. carrying out low alloying: adding alloying elements into molten iron for low alloying, controlling copper addition to about 0.5-0.8% as well as tin addition to 0.04-0.06%; 3. strengthening inoculation: carrying out inoculation on 0.2-0.3% of rare earth silicon alloy when molten iron is discharged, and carrying out stream inoculation while pouring; 4. eliminating casting residual stress: performing stress relieving annealing or vibration ageing to the valve castings, and eliminating or lowering residual stress in the castings; and 5. high-temperature annealing: carrying out high-temperature annealing before the cast is processed so as to eliminate chill spots and ensure even metallographic structure. The method solves the technical problems of poor molten iron purity and uneven metallographic structure of the hydraulic valve body cast by the high-rigidity gray iron; and the hydraulic valve body cast by the method has high rigidity and strong non-deformability.

Owner:SHANGHAI INSTITUTE OF TECHNOLOGY

Industrial preparing method of water-cooling metal mold centrifugal nodular cast iron pipe

The invention discloses an industrial preparing method of a water-cooling metal mold centrifugal nodular cast iron pipe. According to the method, pig iron is used, the technologies of molten iron preparing, molten iron nodulizing, centrifugal casting, annealing, shaping and coating are carried out, and then the finished cast iron pipe is obtained. The preparing method is suitable for preparing the high-quality metal mold centrifugal nodular cast iron pipe of DN80-1000 mm. The preparing process comprises a series of operation procedures such as molten iron preparing, molten iron nodulizing, centrifugal casting, annealing, shaping and coating, the preparing technology is simple, the prepared cast iron pipe has the advantages of being high in appearance quality, fine in material structure, high in production efficiency, long in service life and the like, and compared with an existing steel pipe and an existing gray iron pipe, the water-cooling metal mold centrifugal nodular cast iron pipe has better corrosion-resisting performance and tensile performance.

Owner:SICHUAN CHUANJIAN PIPES

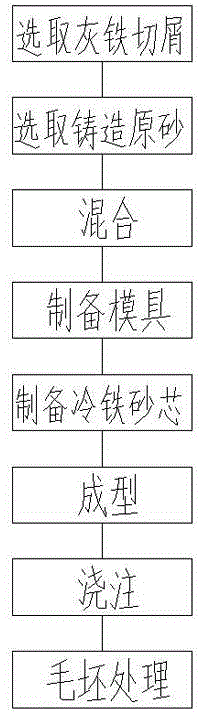

Cold iron sand core and method for producing air cylinder cover by using cold iron sand core

InactiveCN103909209AAdjust cooling speedPrevent shrinkageFoundry mouldsFoundry coresFuranCylinder head

The invention discloses a cold iron sand core. The cold iron sand core comprises following components in a ratio of all the components: gray iron cuttings, crude sand, furan resin, a curing agent and iron oxide in the ratio of 90 to 10 to 1.5 to 0.6 to 1.3. The invention further discloses a method for producing an air cylinder cover by using the cold iron sand core. The method comprises the following steps: preparing an aluminum cold core box mould; producing the cold iron sand core; producing an automobile engine air cylinder cover sand mould and a pouring system; forming an air cylinder cover blank casting. According to the cold iron sand core, a cast iron cutting mixture, namely the old iron sand core, is utilized, so that the cooling speed of castings is adjusted and the castings tend to be condensed at the same time, and furthermore, casting shrinkage cavities, shrinkage porosity, deformation and crack defects of the castings are prevented from occurring, matrix structures of cylinder castings can be thinned and the quality effect of the castings is improved. Meanwhile, the effects of cyclically and comprehensively utilizing waste cuttings to generate the cold iron sand core and saving the cost are also realized.

Owner:FANCHANG COUNTY JINKE CASTING

Process for producing nodular graphite cast iron and gray cast iron with cast iron filings in cupola furnace

A process for producing nodular graphite iron casting and gray iron casting frame cast iron filings in cupola furnace includes mixing said cast iron filings, coagulant, antioxidizing agent, carbon increaser, flux and water together, stirring, shaping blocks, coagulating, drying and charging them into cupola furnace. Its advantage is very low cost.

Owner:张德安

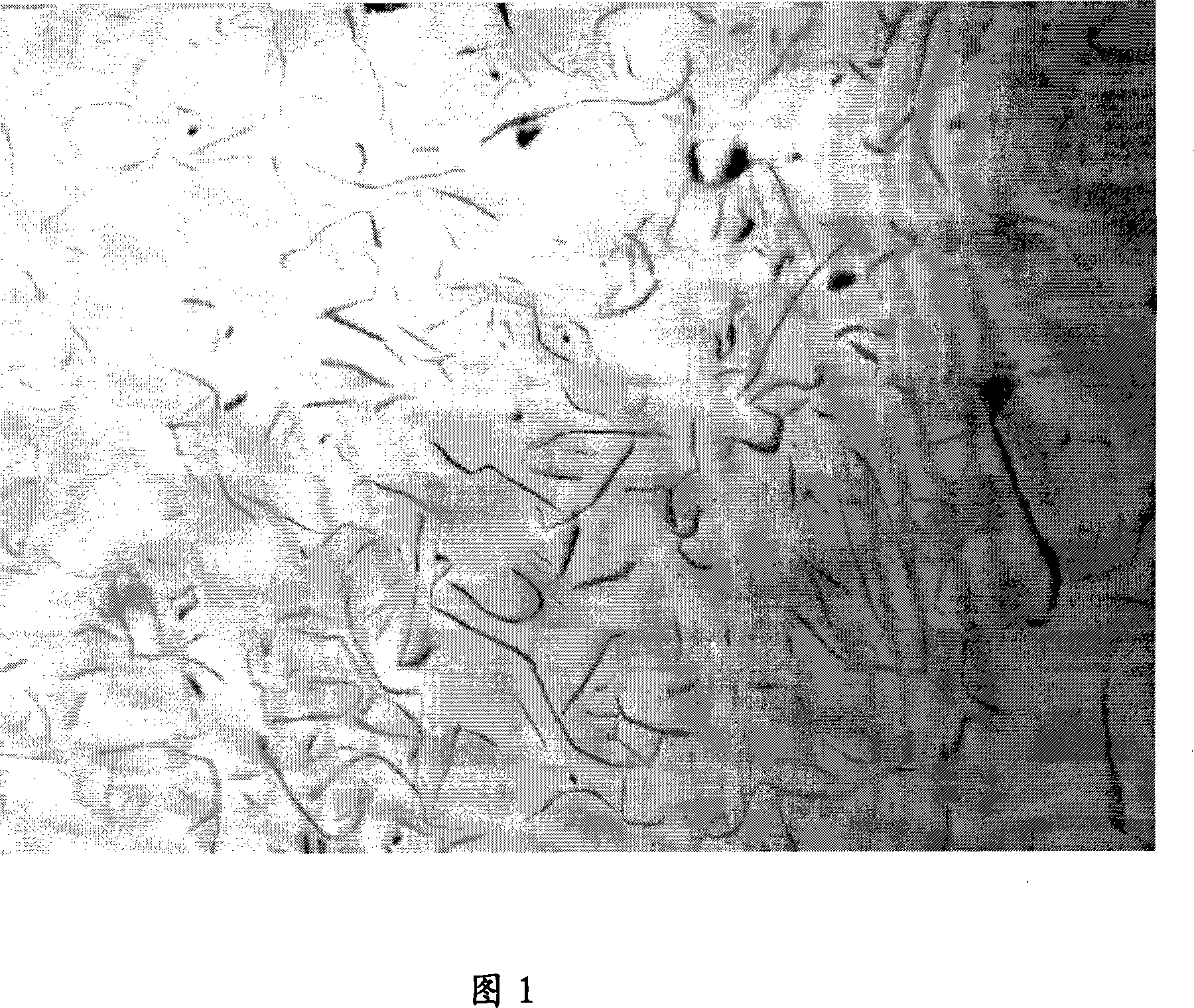

Method for preparing austenitic-bainitic high- strength alloy gray iron

The invention discloses a method for preparing austenitic-bainitic high-strength alloy gray iron and aims to solve technical problems that prior gray iron is not high in strength and hardness and low in toughness. The preparation method includes adding Q10 pig iron, ductile iron foundry returns and steel scrap to a intermediate frequency furnace, heating the mixture to a molten state, adding ferromolybdenum and electrolytic copper to obtain molten iron, performing inoculation by adding inoculants, adding a purifier and deslagging agents and finally using a method of isothermal salt bath to perform heat treatment to obtain the austenitic-bainitic and high- strength alloy gray iron. According to the method, the obtained austenitic-bainitic and high- strength alloy gray iron is compact in structure and stable in performance, the tensile strength is 600 MPa to 650 MPa after isothermal quenching, the Brinell Hardness is 345HBW to 369HBW, the strength and the hardness are large, the elongation rate is 4% to 5%, the toughness is good, and the method can be widely applied in fields of machinery, machine tools, metallurgy, automobiles and the like.

Owner:齐齐哈尔市精铸良铸造有限责任公司

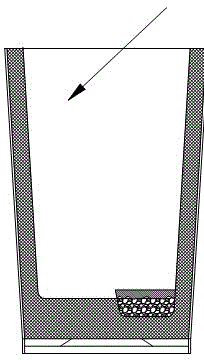

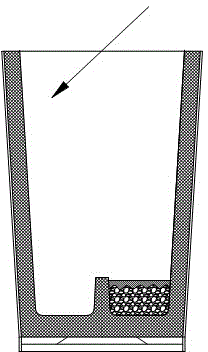

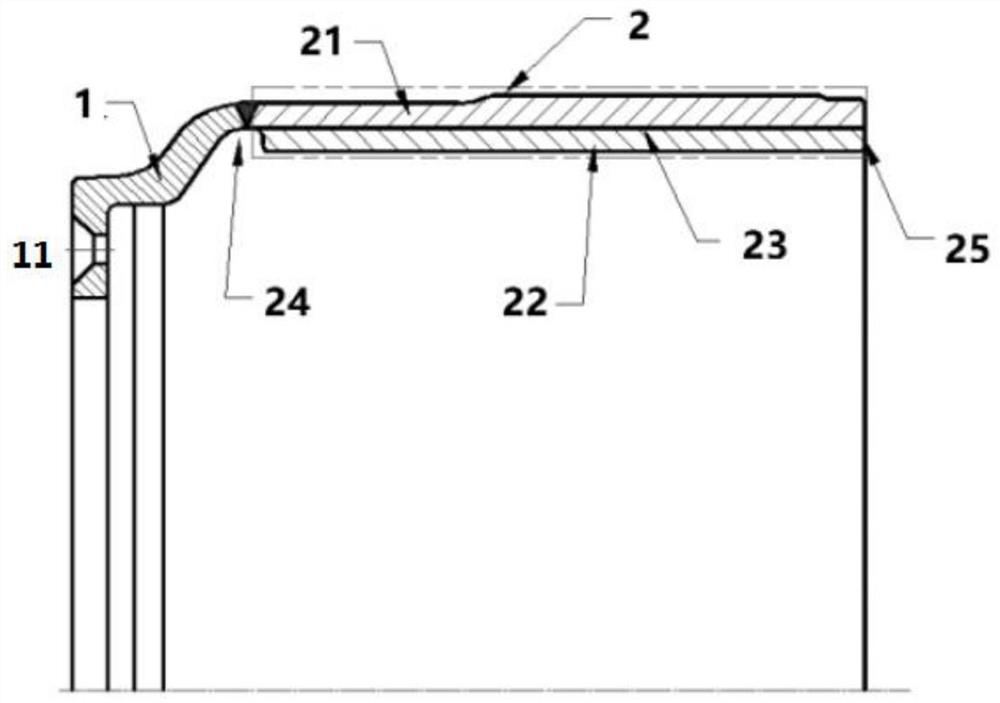

Novel composite material brake drum

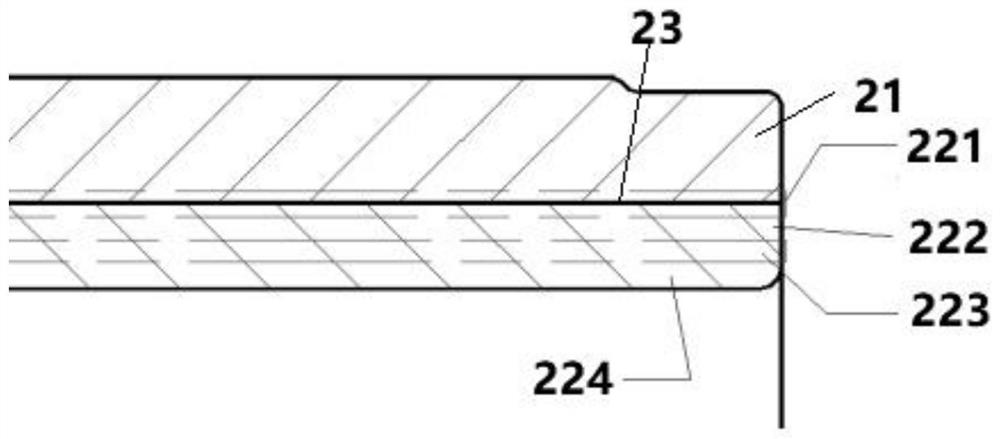

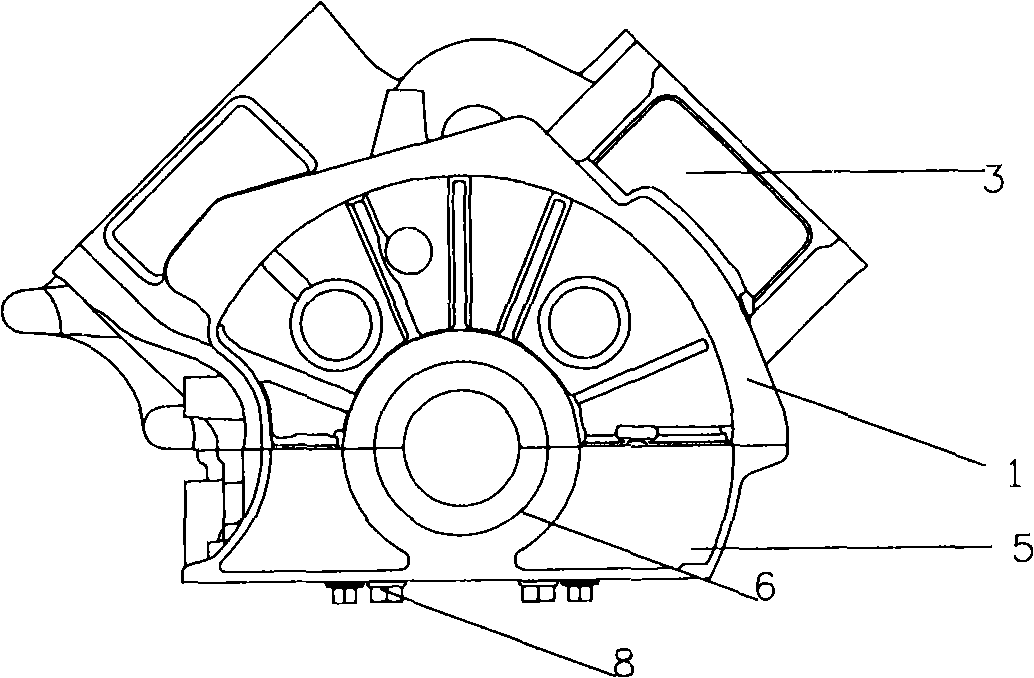

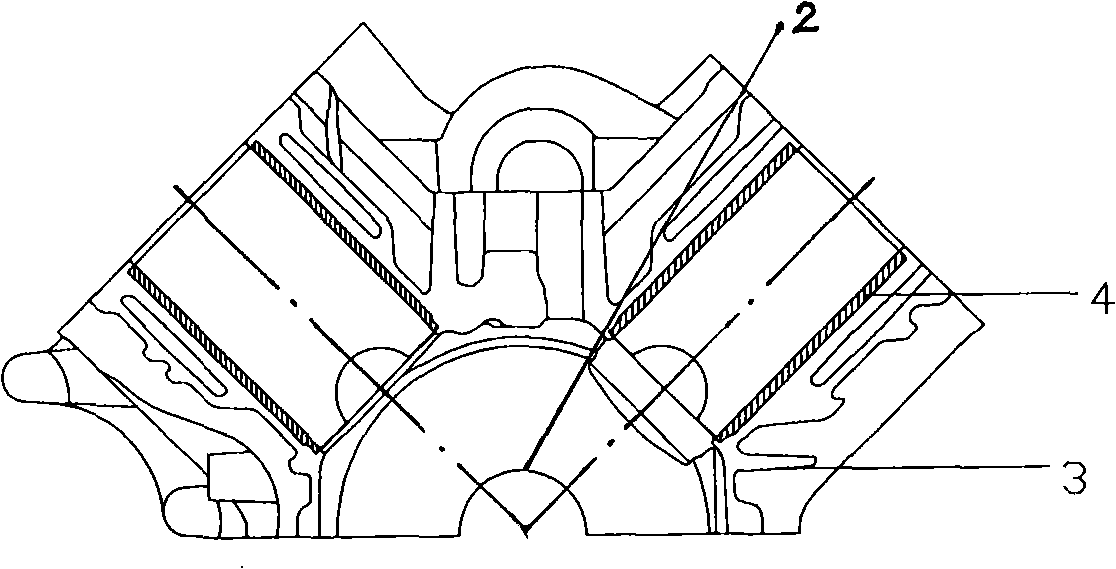

ActiveCN113481426AIncrease design weightImprove braking effectBraking drumsArc welding apparatusCentral layerGray iron

The invention provides a composite new material brake drum, and relates to the technical field of brake drums. An inner layer of a brake surface in the novel composite material brake drum is made of a gradually-changed wear-resistant gray iron material, and the gradually-changed wear-resistant gray iron material comprises a bonding layer, a near-bonding layer, a center layer and a brake surface layer which are stacked in sequence; and the content of C in the bonding layer, the near-bonding layer, the central layer and the braking surface layer is sequentially increased. In the gradually-changed wear-resistant gray iron material provided by the invention, the contents of C, Si, Mn, Cr and S are in gradual transition from the bonding layer to the braking surface layer, and the expansion and shrinkage rate of the gradually-changed wear-resistant gray iron material in the heating and cooling process can be in gradual transition with that of outer layer steel of the brake drum, so that the uniformity of a section temperature field of the brake surface material of the brake drum in the temperature change process is ensured, the thermal fatigue resistance of the material is improved, generation of cracks on the brake surface is delayed, and meanwhile, the requirement on the friction performance of the brake surface is met.

Owner:山西汤荣机械制造股份有限公司

V-type engines cylinder

The invention discloses a V-shaped engine cylinder body, which consists of an upper cylinder body with a V angle, a sleeve, a lower framework and a main bearing cover, wherein a positioning pin and a main bearing cover bolt are arranged on the main bearing cover. The V-shaped engine cylinder body has the advantages that a V angle structure of 90 degree is adopted for the cylinder body. The distortion or deformation of the sleeve and the oil consumption can be reduced because the structure of an upper cylinder body provided with a lower framework is adopted for the cylinder body, wherein the upper cylinder body is molded by aluminum alloy; the cylinder body is directly cast in the sleeve in the process of casting; gray iron is adopted as the material for the sleeve. The lower framework body is cast by aluminum alloy; ductile cast iron main bearing cover is adopted to be cast in the aluminum alloy. In the assemblies of the upper cylinder body and the lower framework, five positioning pins are arranged on four main bearing covers for positioning, so that the assembling positions among the main bearing cover, the framework and the cylinder body can be precise in the assembling process. The cylinder body is tightly connected with the left and the right rows of fastening bolts, so that the intensity of the main bearing cover is greatly improved, thus avoiding loosening and distortion or deformation of the main bearing cover in the process of high-speed operation of the engine.

Owner:CHERY AUTOMOBILE CO LTD

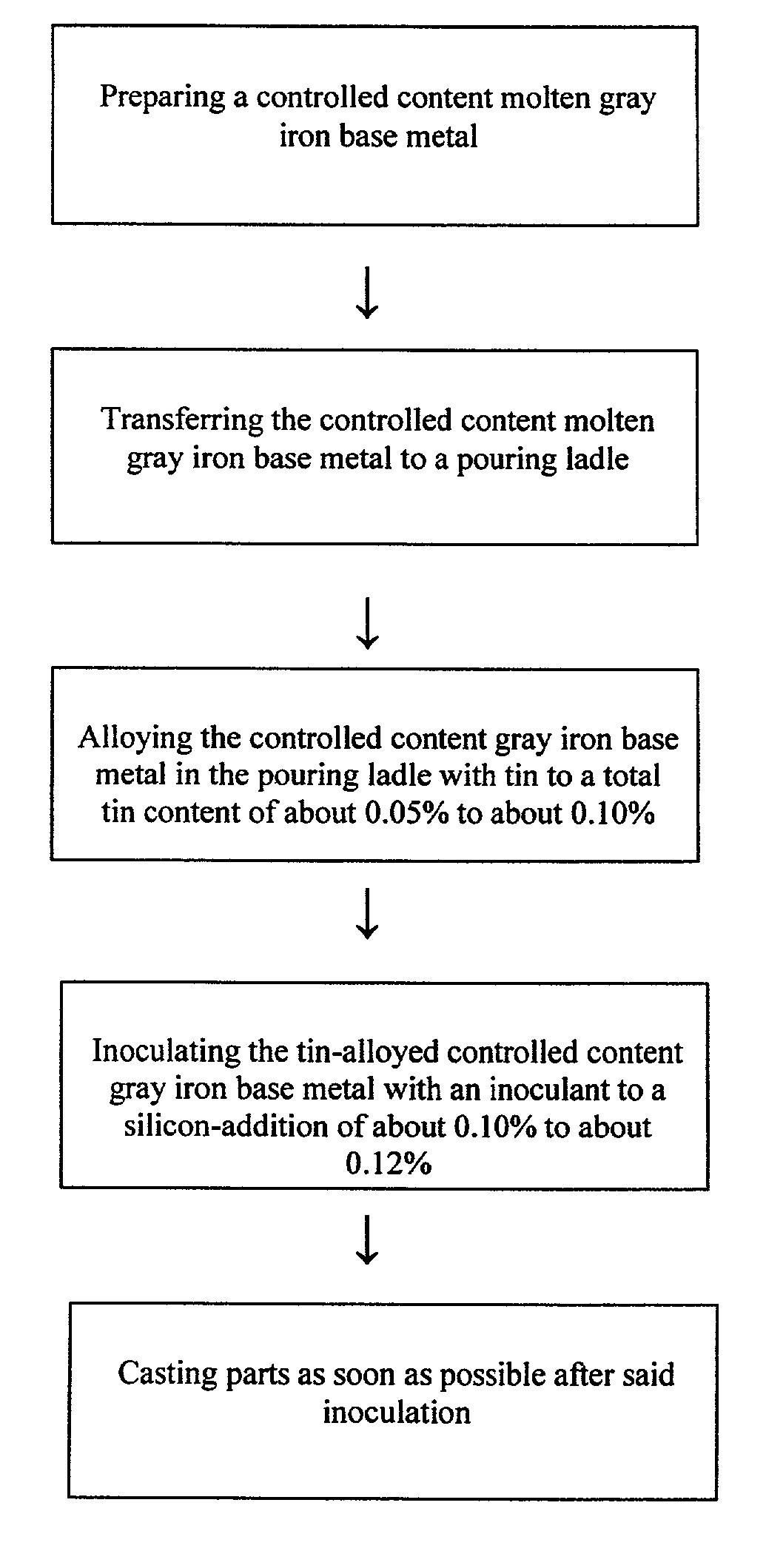

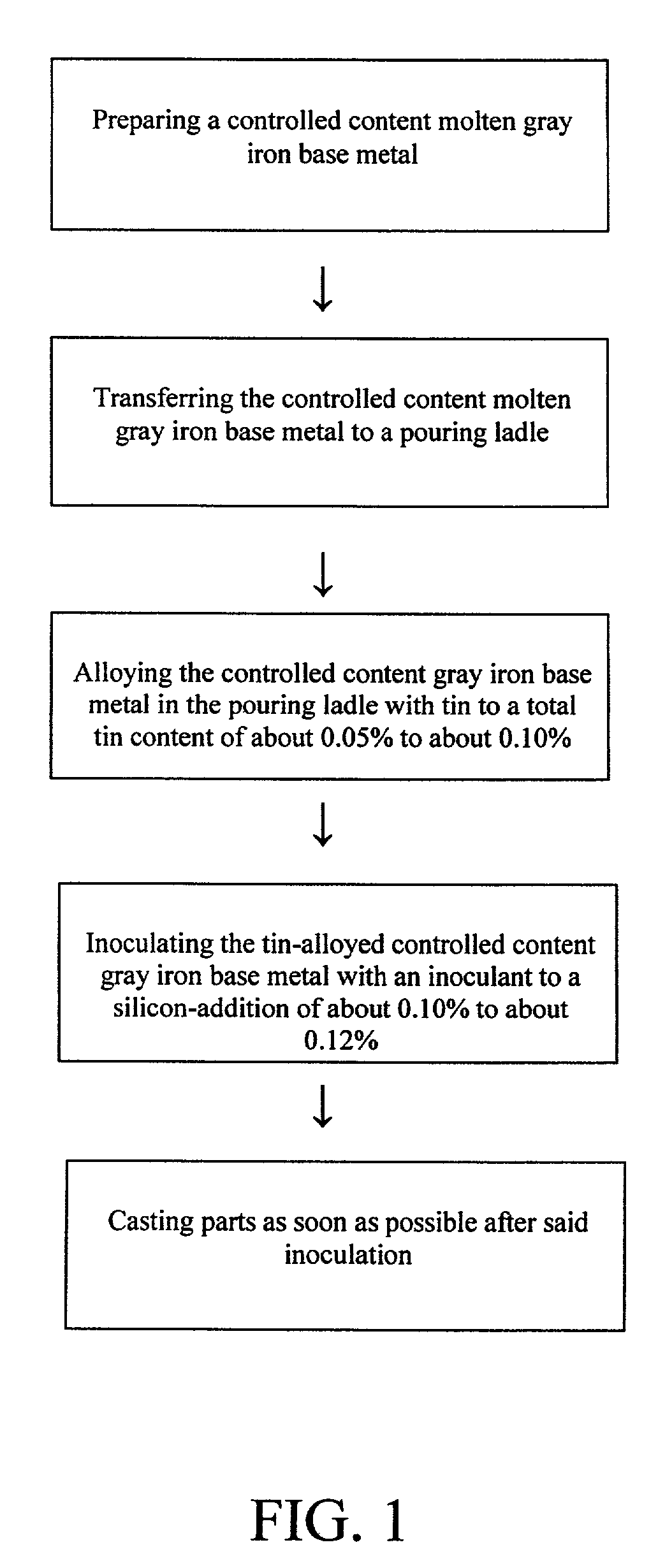

Method for manufacture of gray cast iron for crankcases and cylinder heads

InactiveUS6973954B2Reduce silicon contentMinimal inoculant additionCasingsCylinder headsCylinder headSulfur

A method of casting parts with gray iron includes the steps of providing molten gray iron metal with controlled carbon, silicon, phosphorous, sulfur, manganese and chromium content; alloying said molten gray iron metal, prior to pouring, with tin to a total tin content of about 0.05% to about 0.10%; inoculating said molten tin-alloyed gray iron metal, prior to pouring, with a gray iron inoculant to an additional silicon addition of from about 0.10% to about 0.12%; and casting the gray iron part from said molten, tin-alloyed inoculated gray iron metal as son as possible after said inoculation.

Owner:INT ENGINE INTPROP CO LLC

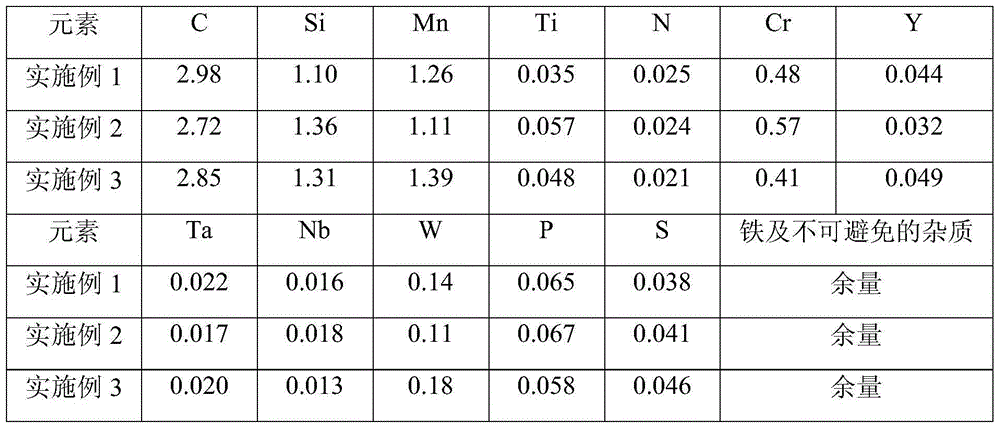

Preparation method of material suitable for diesel engine cylinder cover

InactiveCN110373601AHigh tensile strengthHigh strengthFoundry mouldsFoundry coresFoundryDiesel engine

The invention relates to a preparation method of a material suitable for a diesel engine cylinder cover. The preparation method of the material suitable for the diesel engine cylinder cover comprisesthe following steps of (1) adopting steel scraps and foundry return as furnace charges, sequentially adding into an intermediate frequency furnace, melting to obtain molten iron, and adding a petroleum coke carburant when the temperature of the molten iron reaches to 1400 DEG C; (2) when the temperature of the molten iron reaches to 1530 to 1560 DEG C, adding ferro manganese nitride, uniformly stirring, and tapping after preserving heat for 8 to 12 minutes; (3) adding an inoculator into a ladle for the first time, starting inoculation treatment for the second time when the molten iron in the ladle accounts for one third of the tapping amount, and adding a metal-stream inoculation agent for the third time in the molten iron pouring process; and (4) adopting a sand-lined metal mold casting mold for pouring to obtain a gray cast iron material suitable for the diesel engine cylinder cover. According to the preparation method of the material suitable for the diesel engine cylinder cover provided by the invention, through adding a nitrogen element, reducing the alloy element content, improving the inoculation times and combining a sand-lined metal mold process for casting, so that the mechanical property and the strength of the gray iron material are remarkably improved, and the cracking problem caused by low material strength and heat fatigue of the diesel engine cylinder cover at present are solved.

Owner:GUANGXI UNIV

Automobile engine cylinder cover and manufacturing method thereof

ActiveCN103949578AAdjust cooling speedPrevent shrinkageFoundry mouldsMould handling/dressing devicesCrazingMetallurgy

The invention discloses an automobile engine cylinder cover and a manufacturing method thereof. The automobile engine cylinder cover is a product prepared by the following raw materials and the manufacturing method, and comprises the raw material composition by weight: 90% of gray iron cuttings, 10% of casting roughing sand, 5% of a furan resin, and 1.0% of a curing agent. The method has the beneficial effects of effectively preventing generation of defects of casting shrinkage cavities, shrinkage porosity, deformation and cracks.

Owner:FANCHANG COUNTY JINKE CASTING

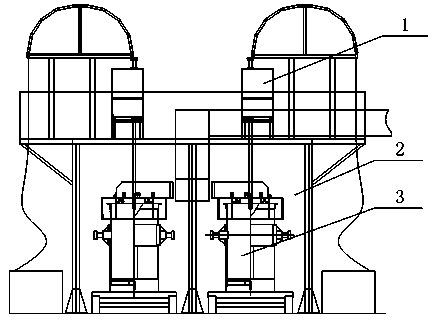

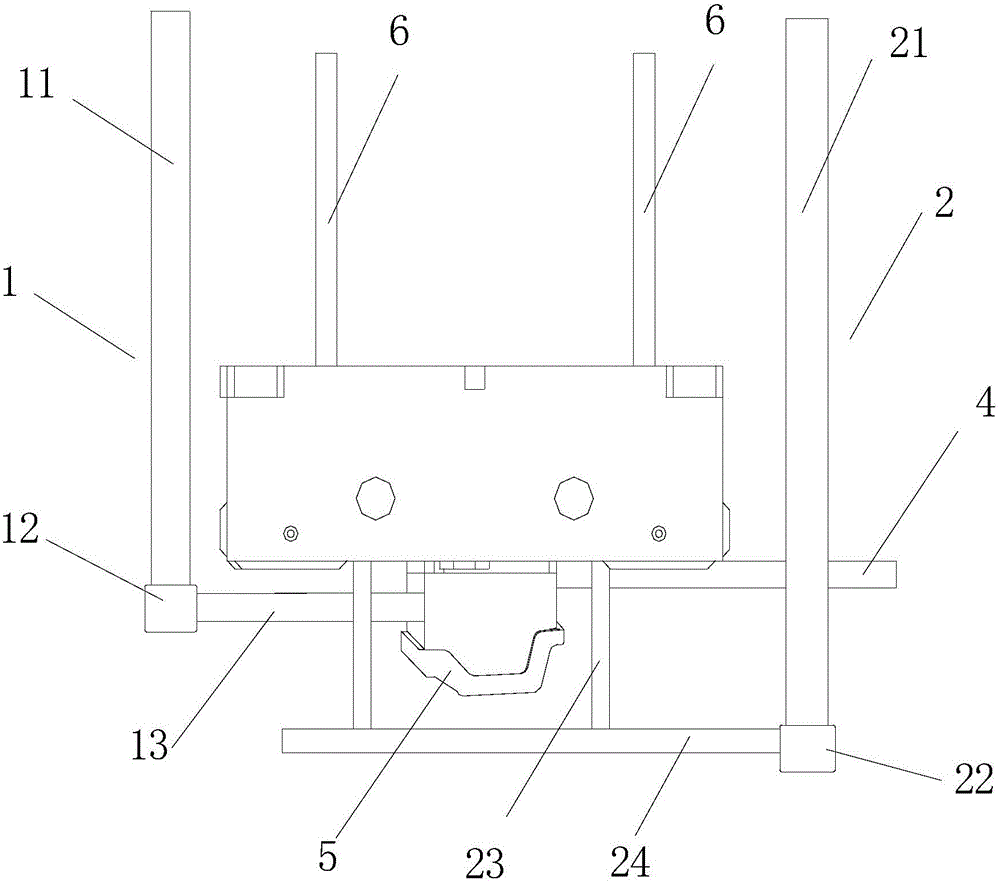

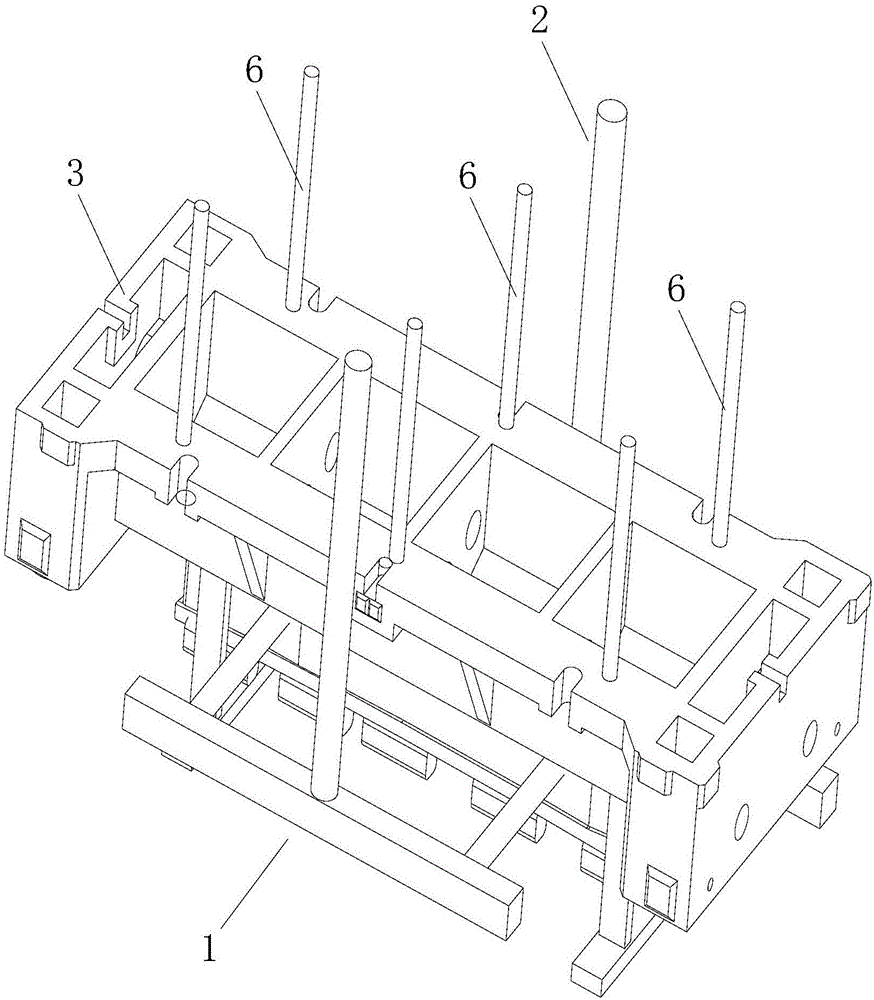

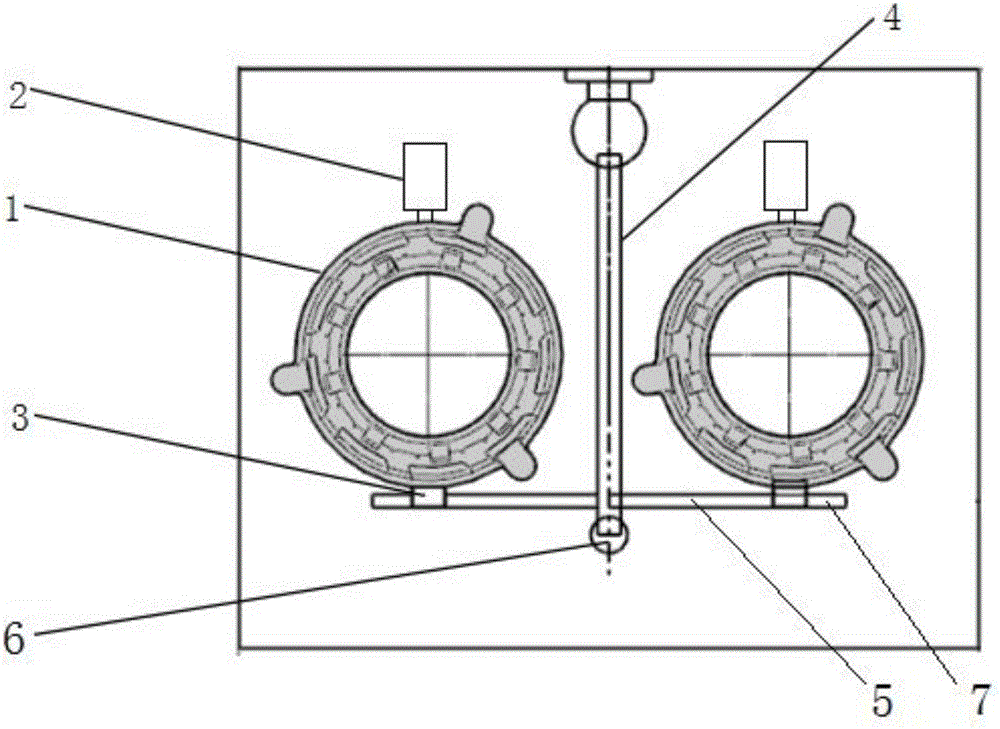

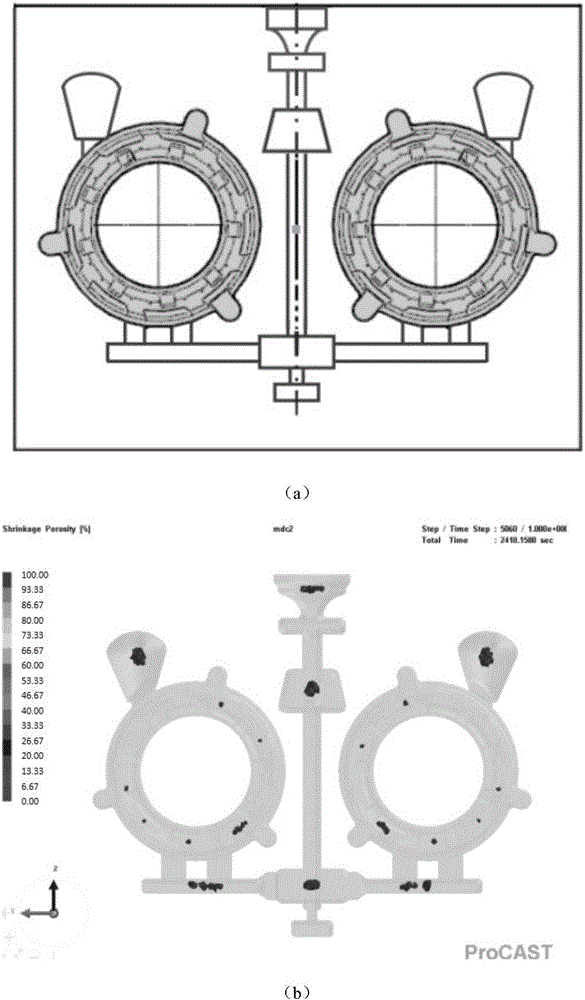

Running and feeding system on DISA line for producing annular thin-wall gray iron castings and design method of running and feeding system

InactiveCN106623793AHighlight substantive featuresEasy to crackFoundry mouldsFoundry coresEngineeringDesign methods

The invention relates to a running and feeding system on a DISA line for producing annular thin-wall gray iron castings and a design method of the running and feeding system. The running and feeding system comprises feeder heads and a pouring system, wherein the pouring system adopts a bottom pouring mode and comprises inner runners, a straight runner and transverse runners; two castings are distributed in each template; the two castings are symmetrically distributed by using the straight runner as an axis; the inner runners are arranged under each casting; the running and feeding is characterized in that the number of the runner under each casting is one, and the connecting position of the straight runner and the transverse runners is provided with a first buffer zone; the two inner runners are respectively communicated with the two transverse runners; a second buffer zone is arranged at one end, which is far away from the first buffer zone, of each transverse runner; the feeder heads are respectively arranged right above each casting.

Owner:HEBEI UNIV OF TECH

Processing process of gray iron production

InactiveCN104561430AReduce processing costsIncrease profitProcess efficiency improvementFoundryMedium frequency

The invention provides a processing craft of gray iron production. The invention aims at providing a processing process of gray iron production, and the processing process is simple in process and is convenient to process. According to the key points of the technical scheme adopted by the invention, the processing process of gray iron production comprises the following steps: (1) smelting ductile cast iron foundry returns, gray iron foundry returns, steel scrap and furnace burden of a carburant in a medium-frequency induction furnace, and stewing at 1550 DEG C for 5-10 minutes; (2) adding a silicon-barium inoculant accounting for 0.2-0.4% of the total weight of discharged iron to perform inoculation modification on discharged molten iron when discharging the molten iron; and (3) in a pouring process, adding 0.05-0.2% of silicon-barium inoculants into the pouring molten iron in a flow following manner to perform flow following inoculation on the pouring molten iron, thereby finishing processing. By adopting the processing process provided by the invention, on the premise of not affecting the metallographic structure or the mechanical property of the gray iron, in a process of producing gray iron casting, the ductile cast iron foundry returns are added to improve the utilization rate of the ductile cast iron foundry returns and reduce the processing cost of the gray iron.

Owner:HENAN WANXIANG SYST BRAKE

Method for producing brake drum and a brake drum

ActiveUS9016443B2High strengthImprove thermal conductivityBraking drumsBraking membersMetallic materialsAlloy

The present invention discloses a method for producing brake drum, wherein three different metallic materials are used for the three-layer construction; and two layers made of different molten metallic materials are cast based upon the prefabricated steel shell (with steel or gray iron for the structural layer and the Mo-containing, abrasion-resistant alloy cast iron for the braking friction layer) so that atoms from these two adjacent but different metallic layers inter-diffuse across the interface to form a solid fusant or an inter-metallic compound, thereby generating a very strong metallurgical bond. The present invention also provides a brake drum, comprising a brake drum shell, a structural layer inside the brake drum shell, and a friction layer inside the brake drum structural layer and for braking.

Owner:JIAXING STONE WHEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com