Automobile mold casting cast by compounding ductile iron and gray iron, gating system and casting method

A technology for automotive molds and pouring systems, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., and can solve problems such as reducing the mechanical properties of workpieces, oxidation inclusions, and affecting the quality of double-liquid composite castings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. In addition, those skilled in the art can make corresponding combinations of features in the embodiments in this document and in different embodiments according to the descriptions in this document.

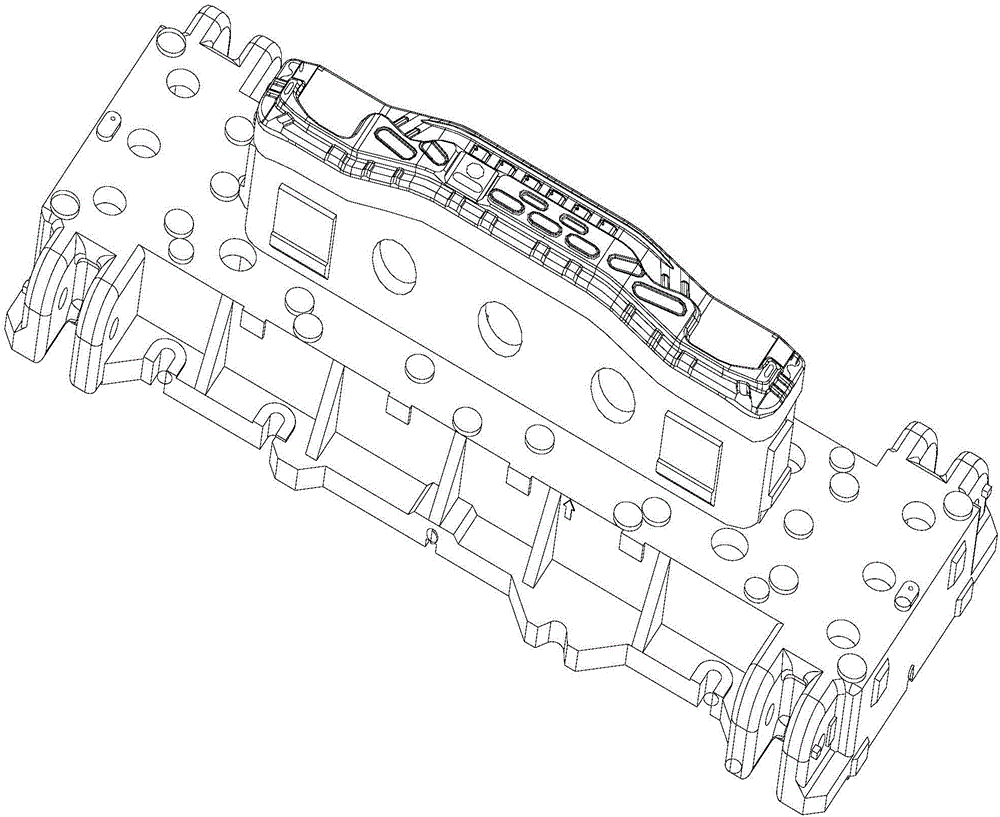

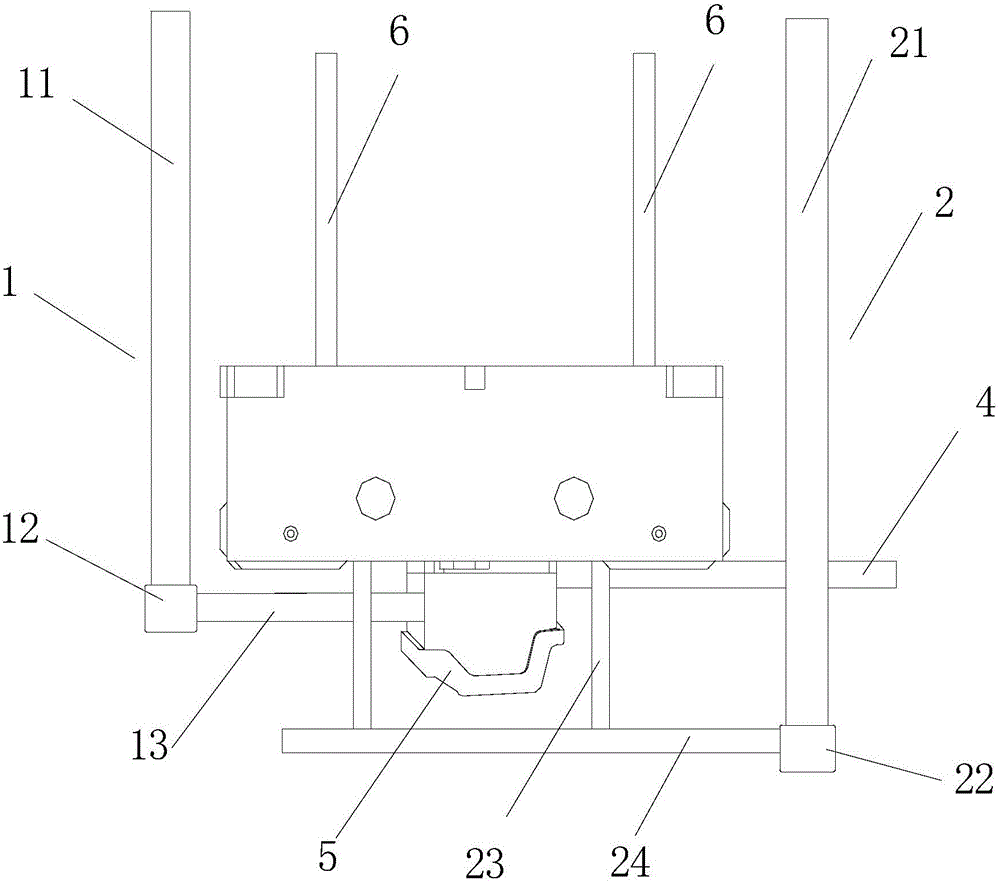

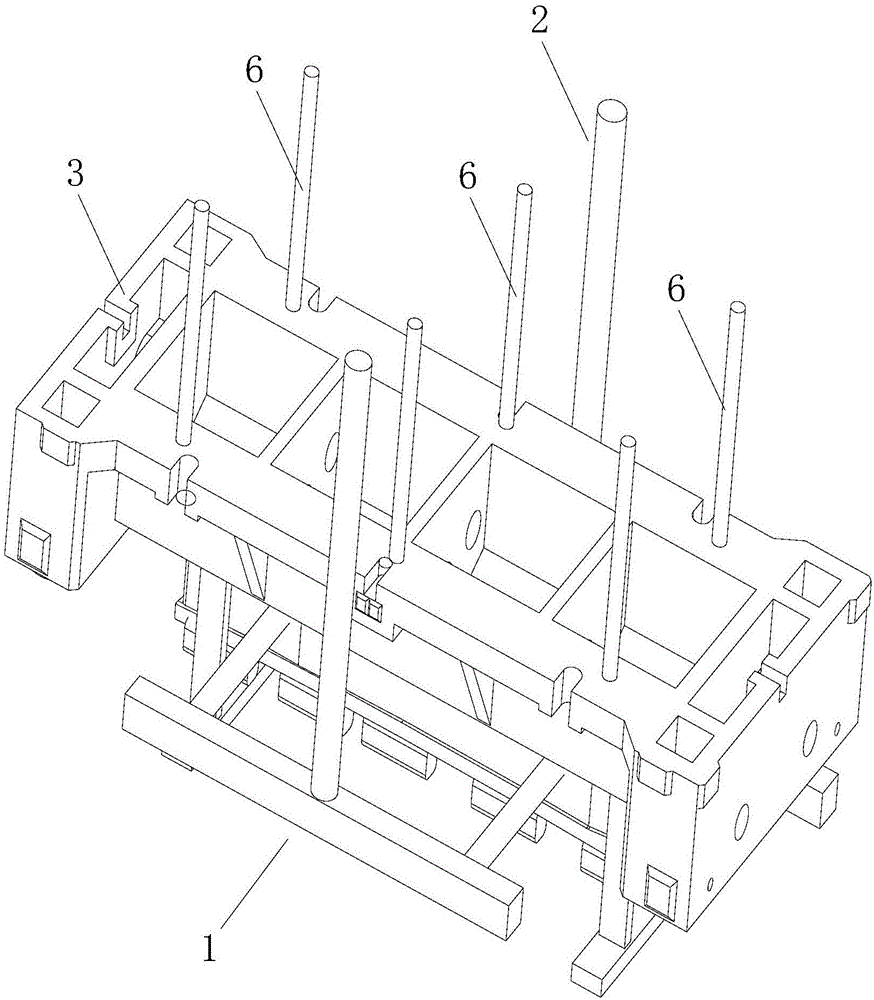

[0039] Embodiments of the present invention are as follows, see figure 1 , to represent an automobile mold casting of nodular iron and gray iron composite casting involved in an embodiment of this patent, the automobile mold casting is preferably a drawing mold or a flanging shaping mold, which includes a one-time casting mold The base and the working part, the material of the mold base is gray iron, the material of the working part is ductile iron, and the joint surface of the mold base and the working part is a metallu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com