Patents

Literature

6742results about "Melt-holding vessels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

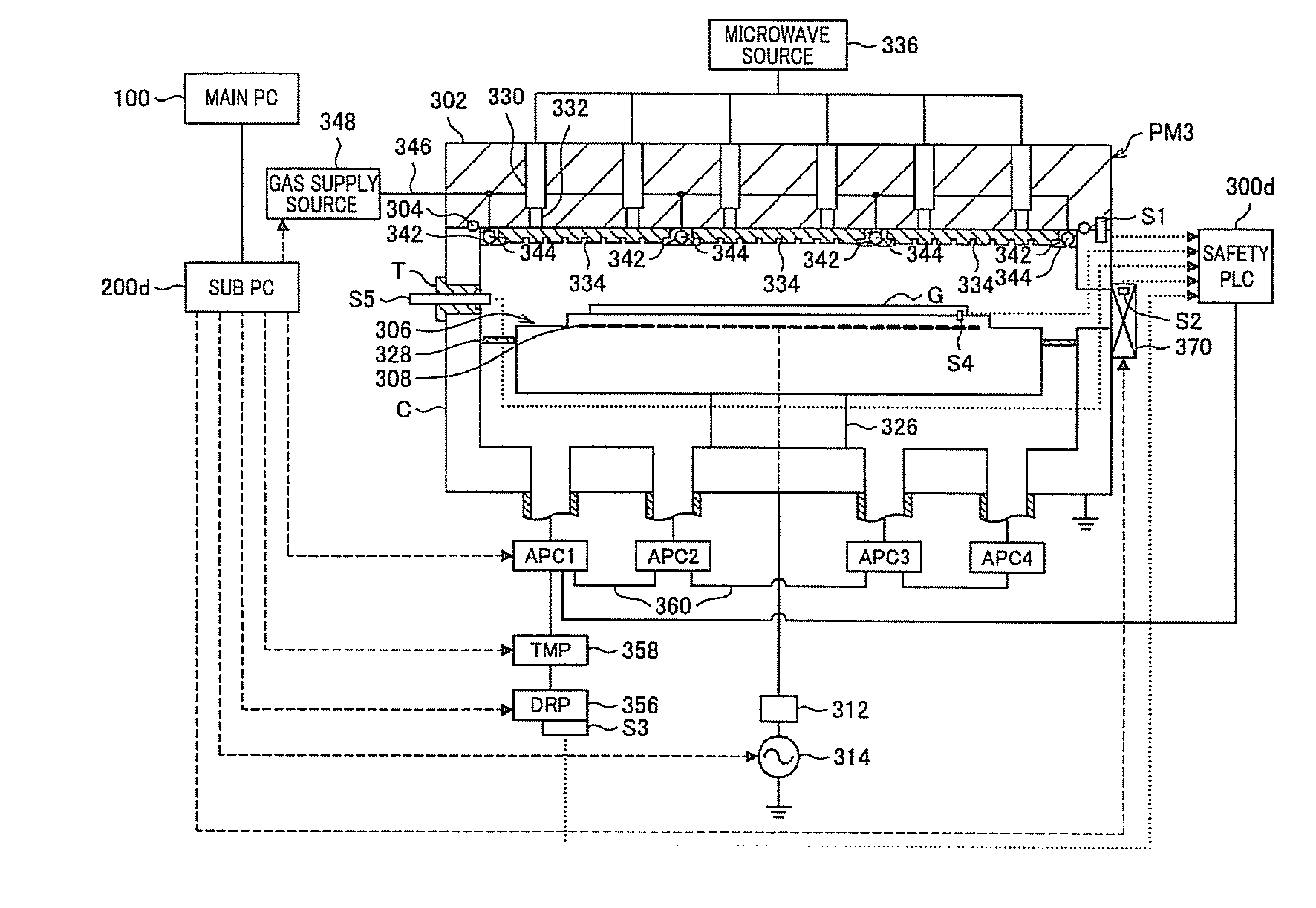

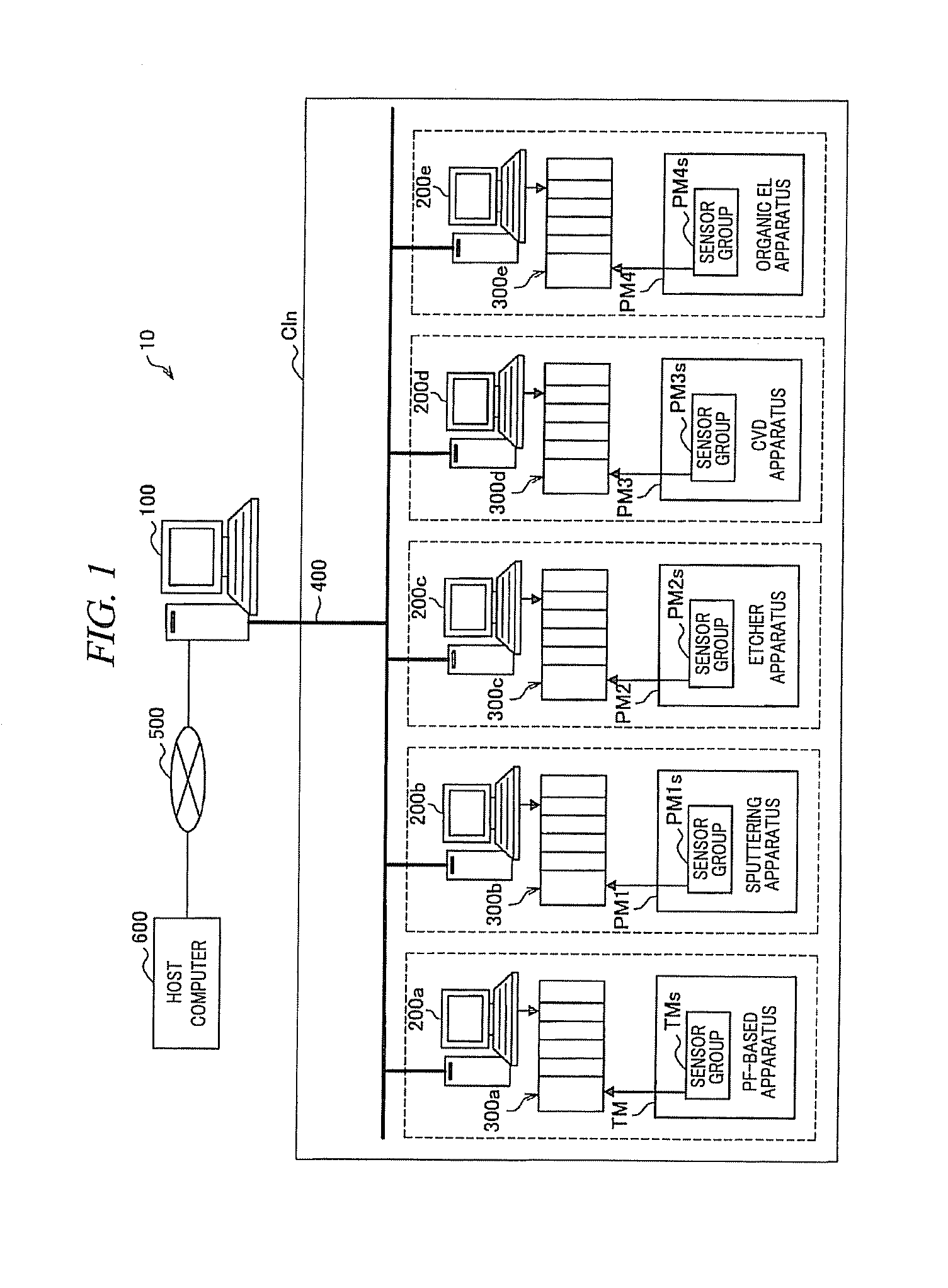

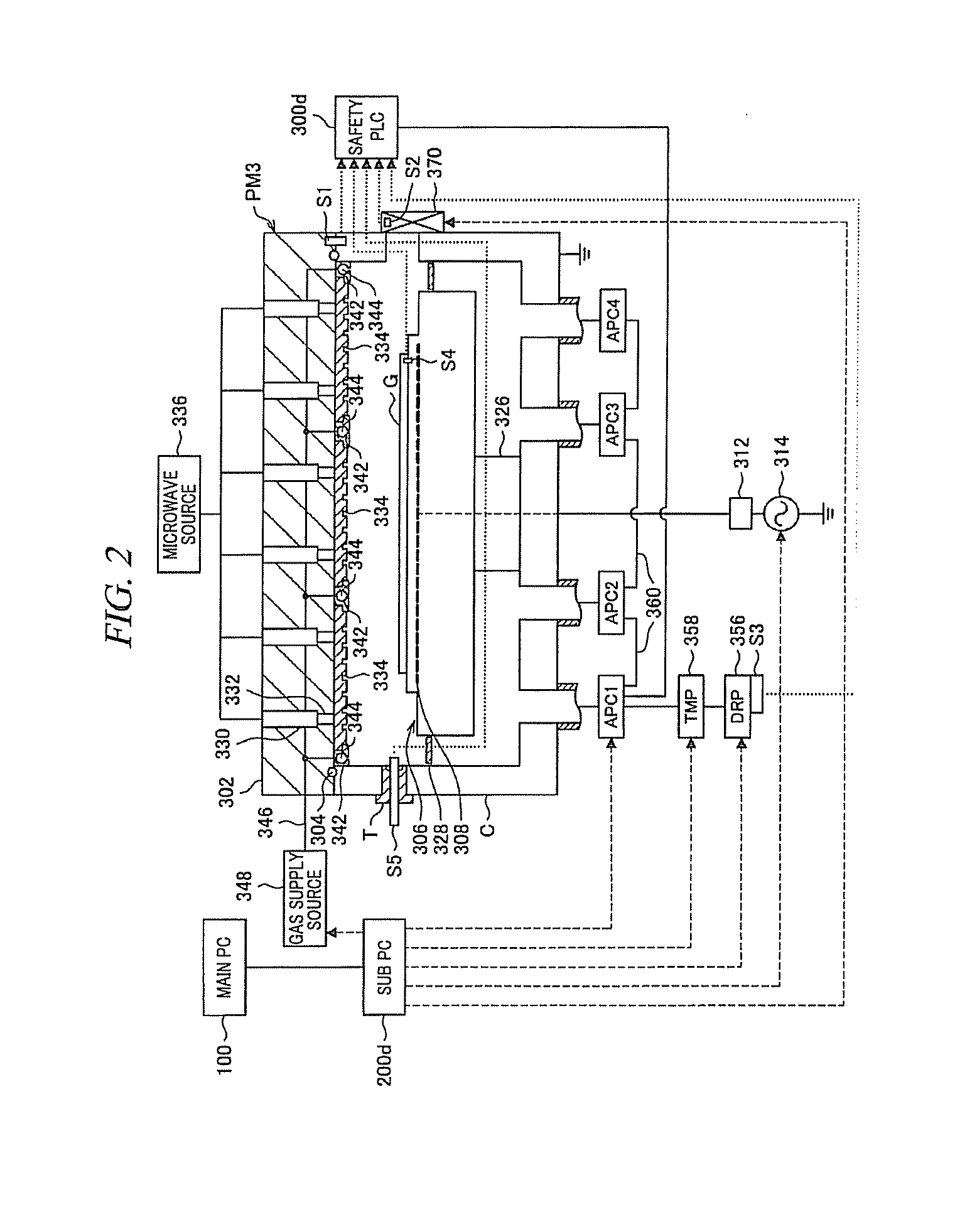

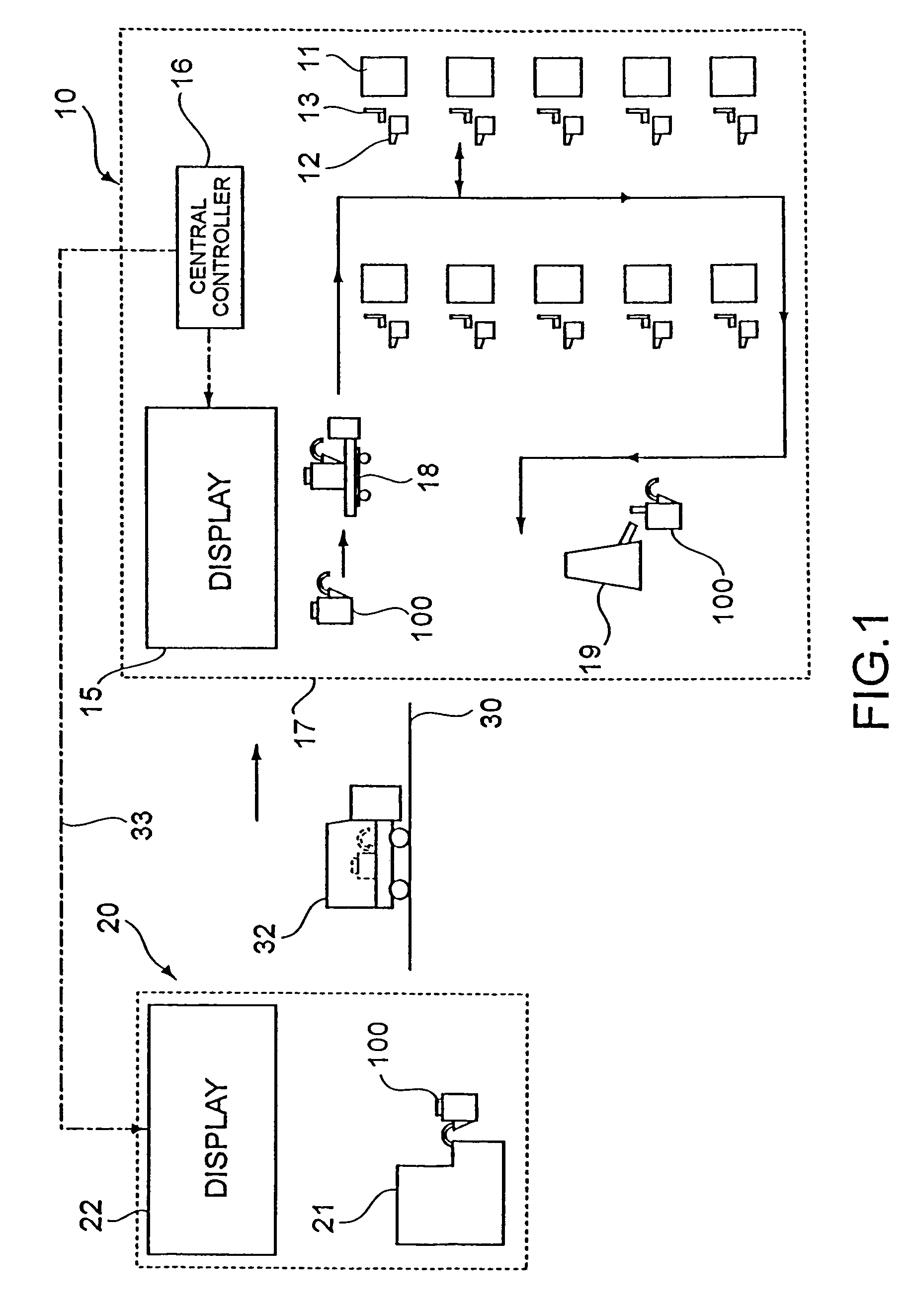

Substrate processing system, substrate processing method and storage medium storing program

A substrate processing system includes a controller that outputs a control signal for controlling a substrate processing apparatus; and a software interlock component that outputs an interlock signal if a predetermined interlock condition is satisfied. In the substrate processing apparatus, a multiple number of devices of the same kind are provided and each device is selected to be either an interlocked state or a non-interlocked state with other devices. The software interlock component outputs an interlock signal to any one of the multiple number of devices of the same kind if it is determined that the multiple number of devices satisfy the predetermined interlock condition. If any one of the multiple number of devices of the same kind receives the interlock signal, the multiple number of devices are interlocked according to an instruction of the interlock signal regardless of an interlocked state or a non-interlocked state of the devices.

Owner:TOKYO ELECTRON LTD

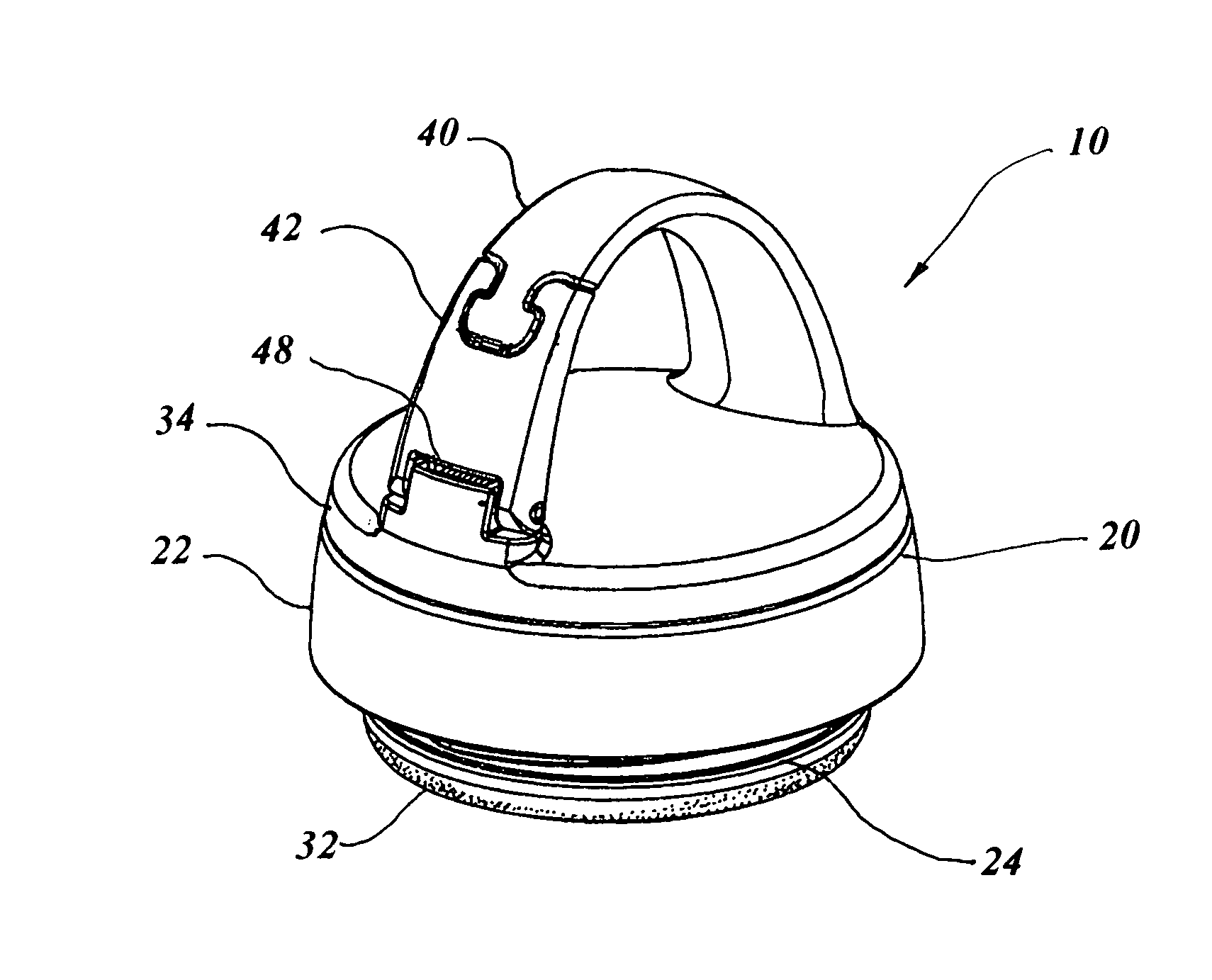

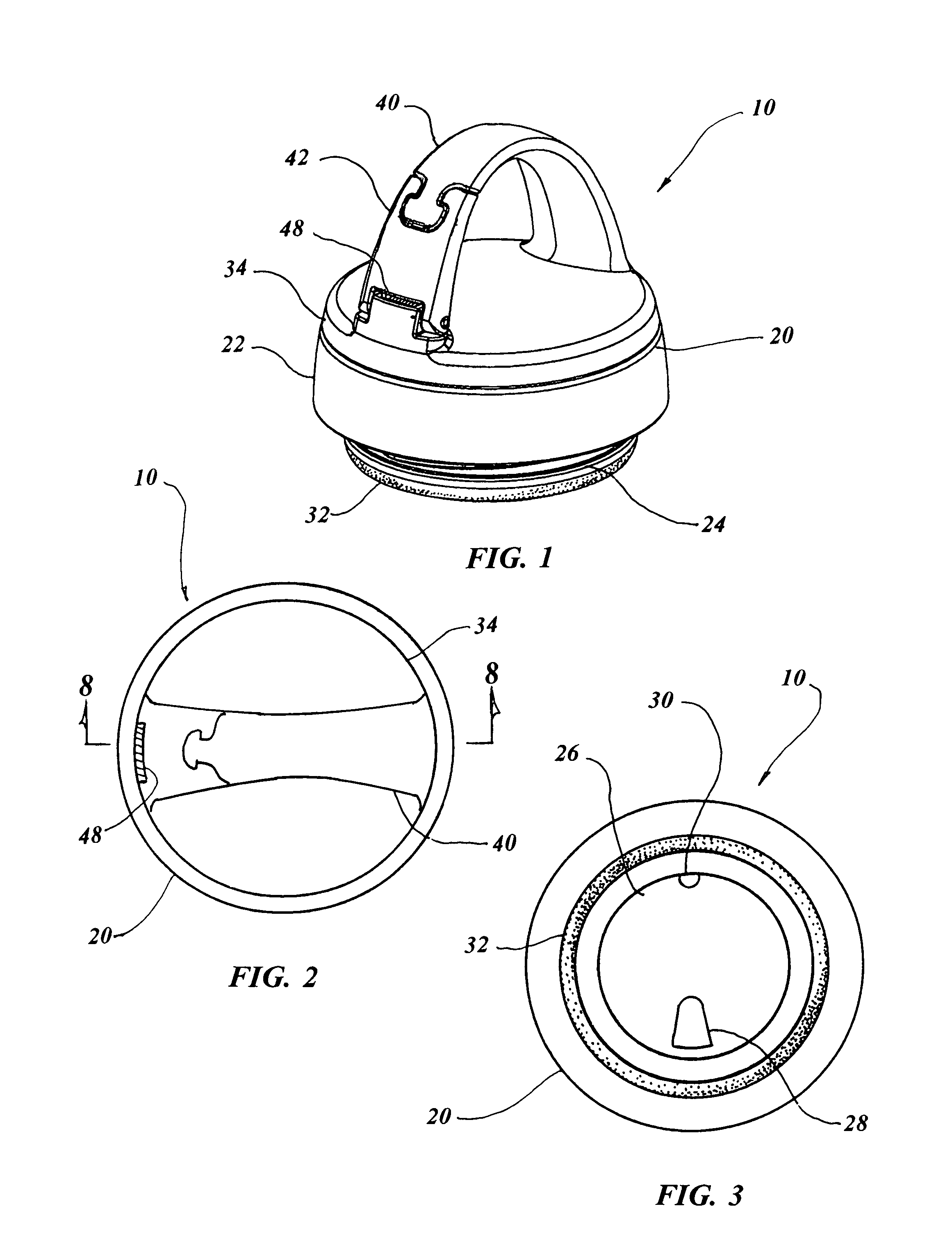

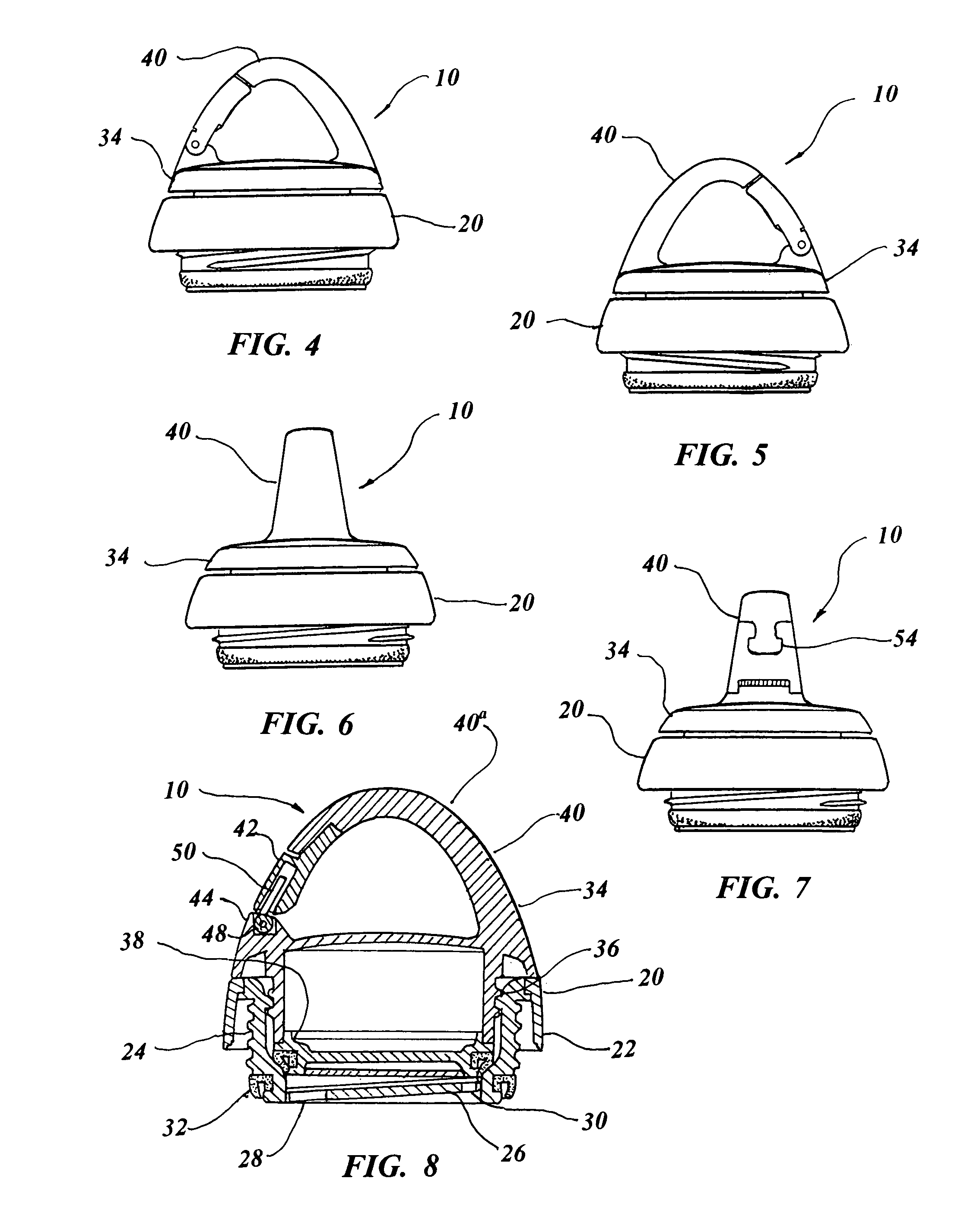

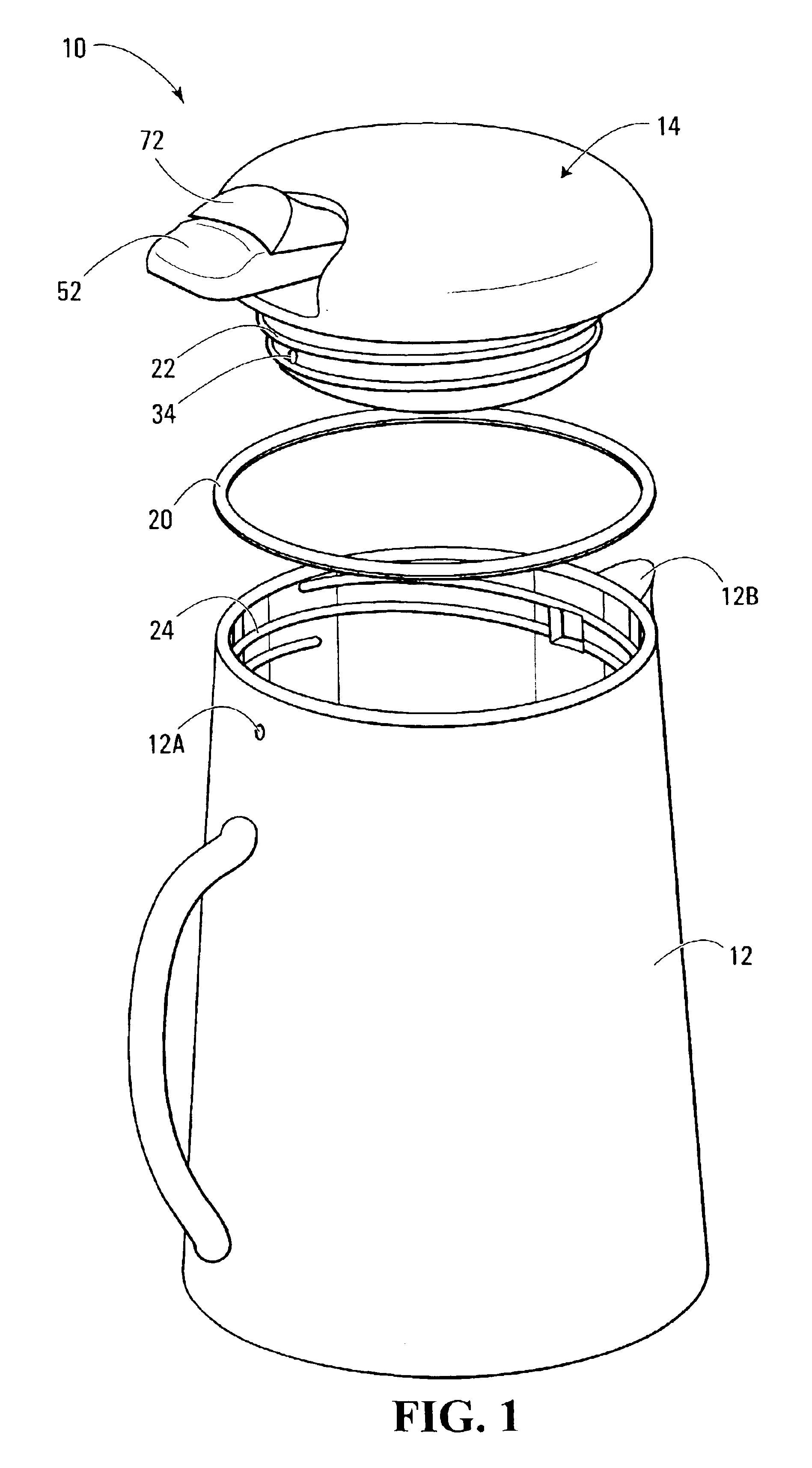

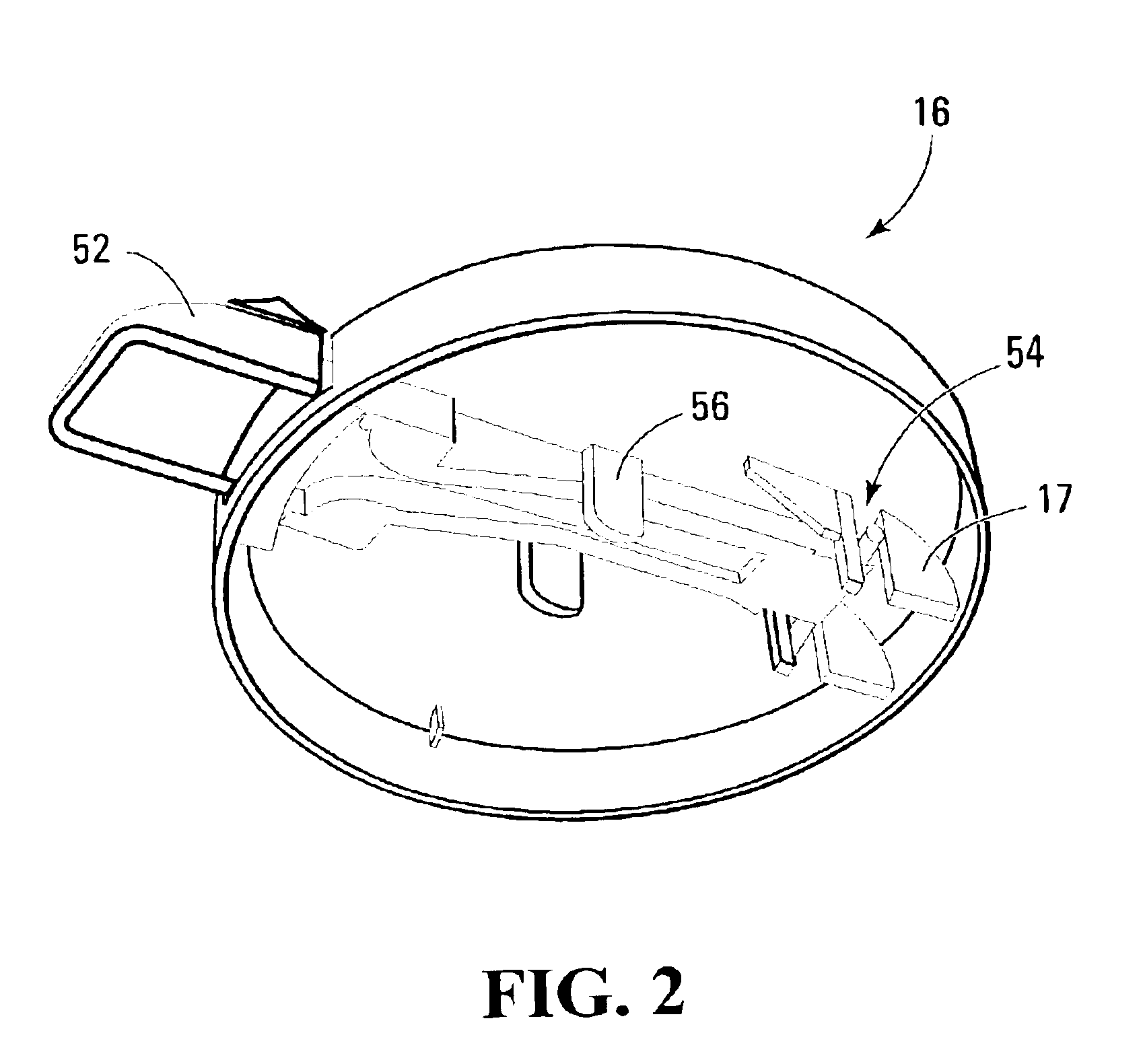

Latched handle container lid

A container lid with a latch handle is taught that incorporates a drinking lip, having a flared brim, configured to interface with a liquid container. A lip sealing ring is disposed on the drinking lip creating a watertight fit between the lip and the container. A lid body, having lid male threads, is configured to interface with container lid female threads, and the lid body includes a bottom cover which forms a dead air space for insulation purposes within the lid. The lid body incorporates a vertical arched handle with a snap-in hinged spring loaded latch for quick release attachment of the container lid and container securely to an object. A lid sealing ring is disposed on the lid body forming a watertight fit between the lid body and the container drinking lip.

Owner:LIN SHIN SHUOH

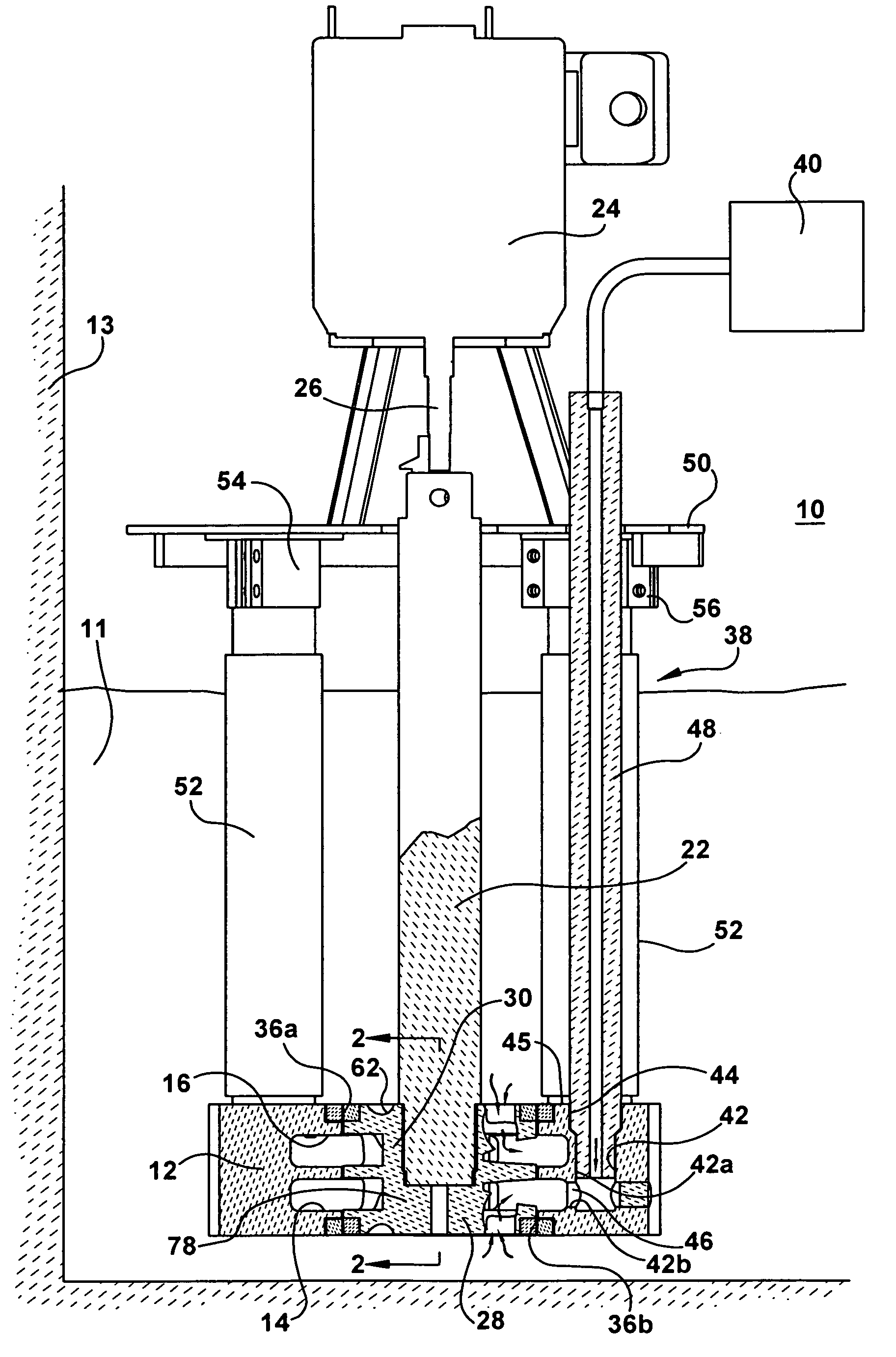

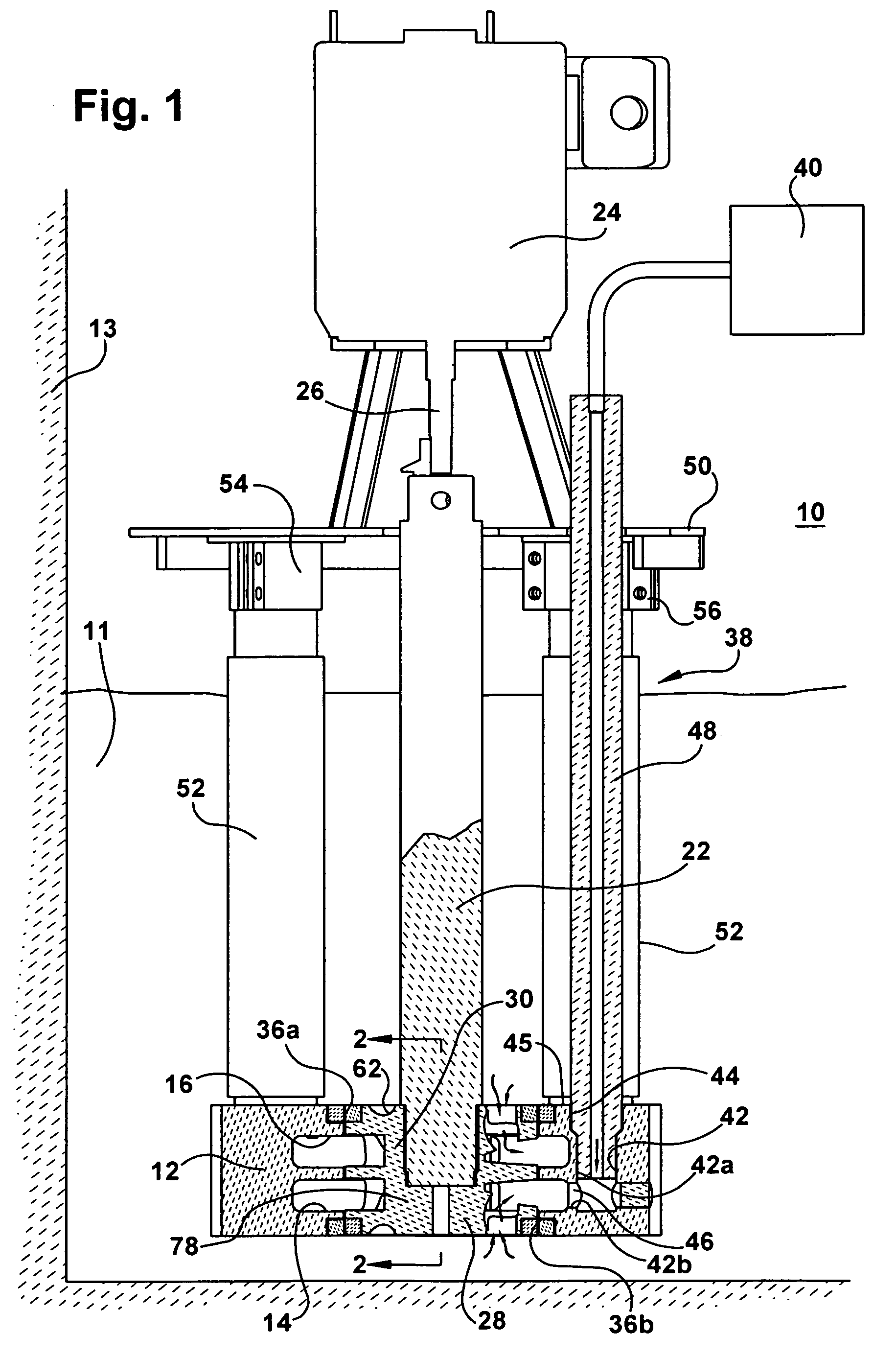

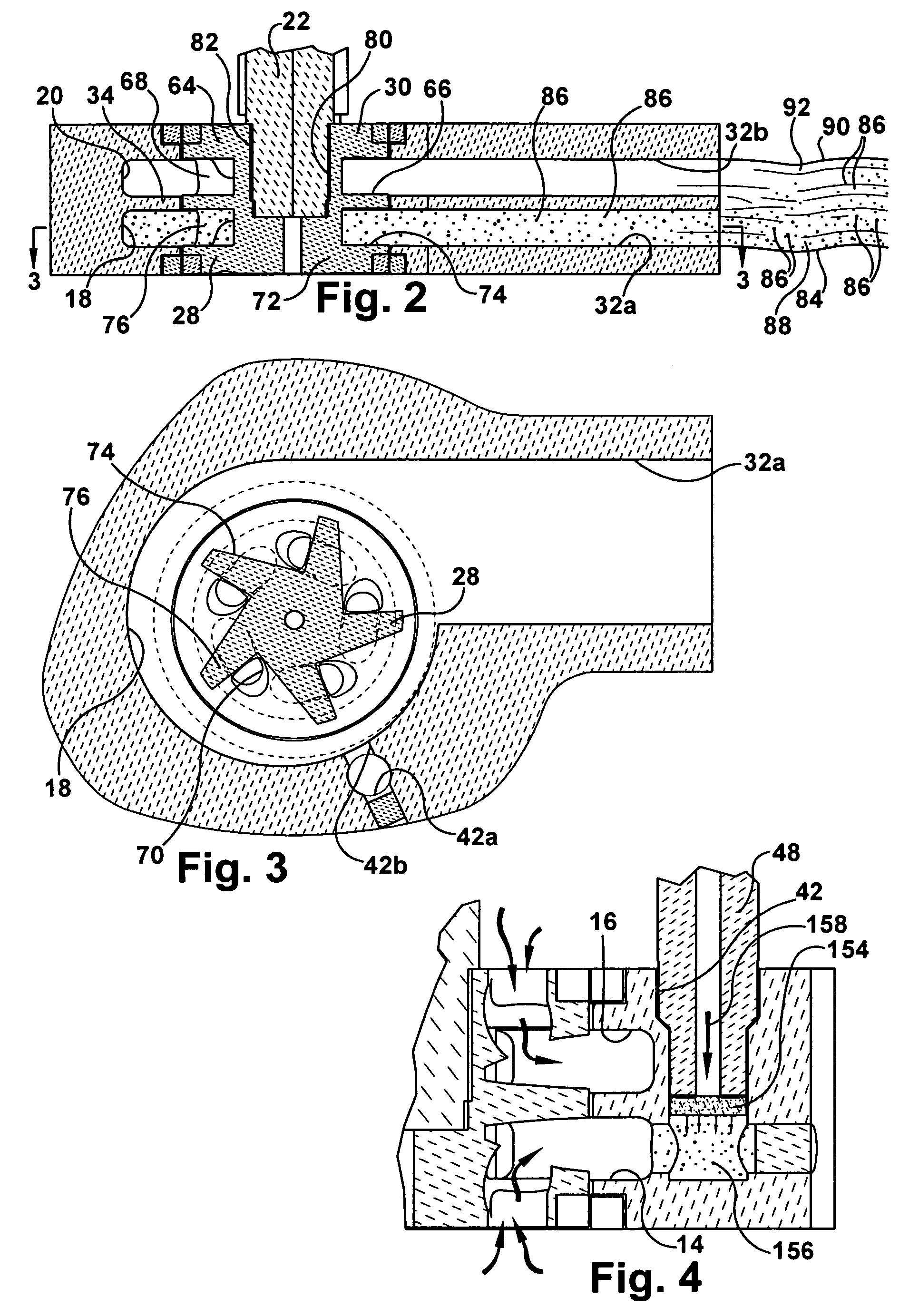

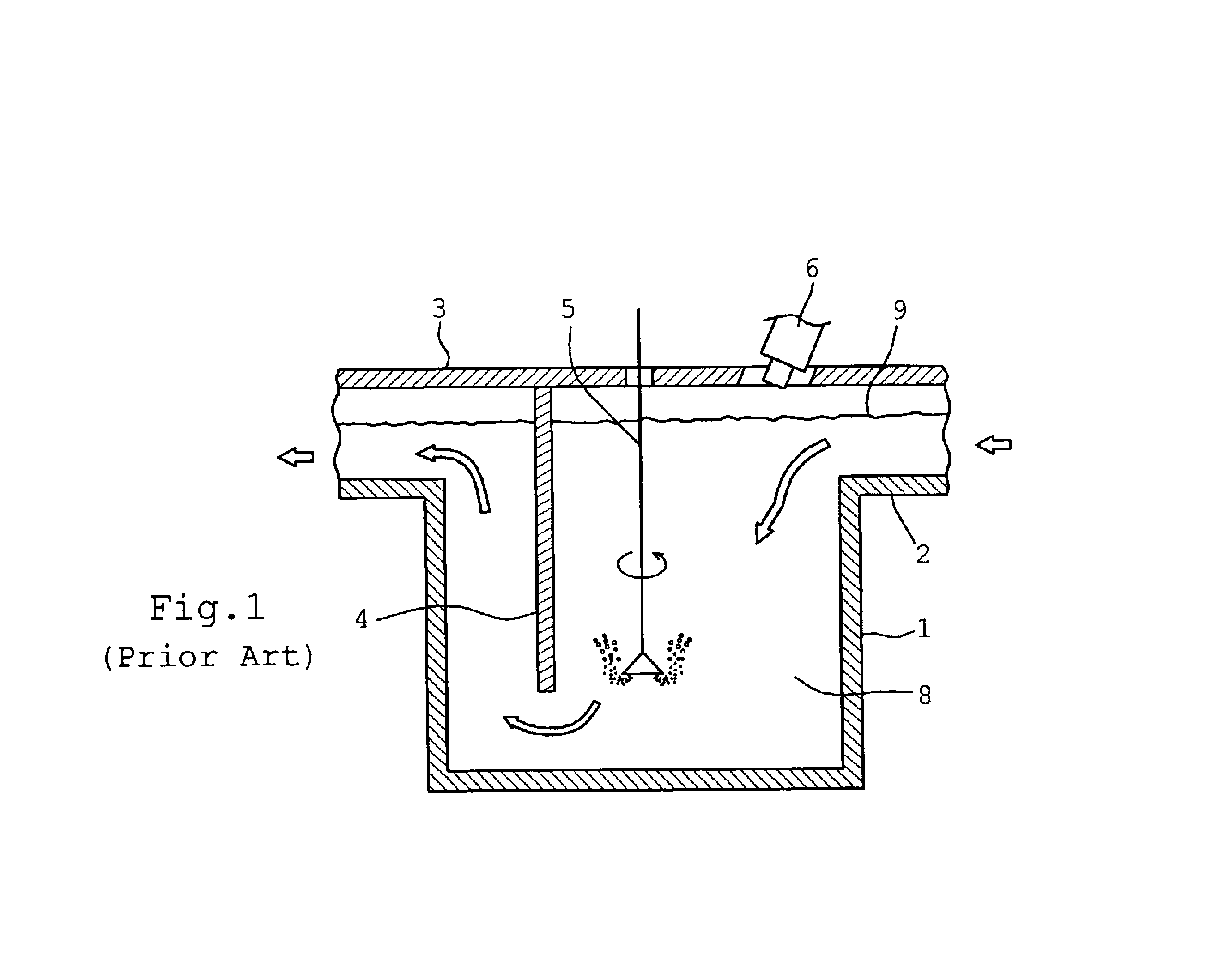

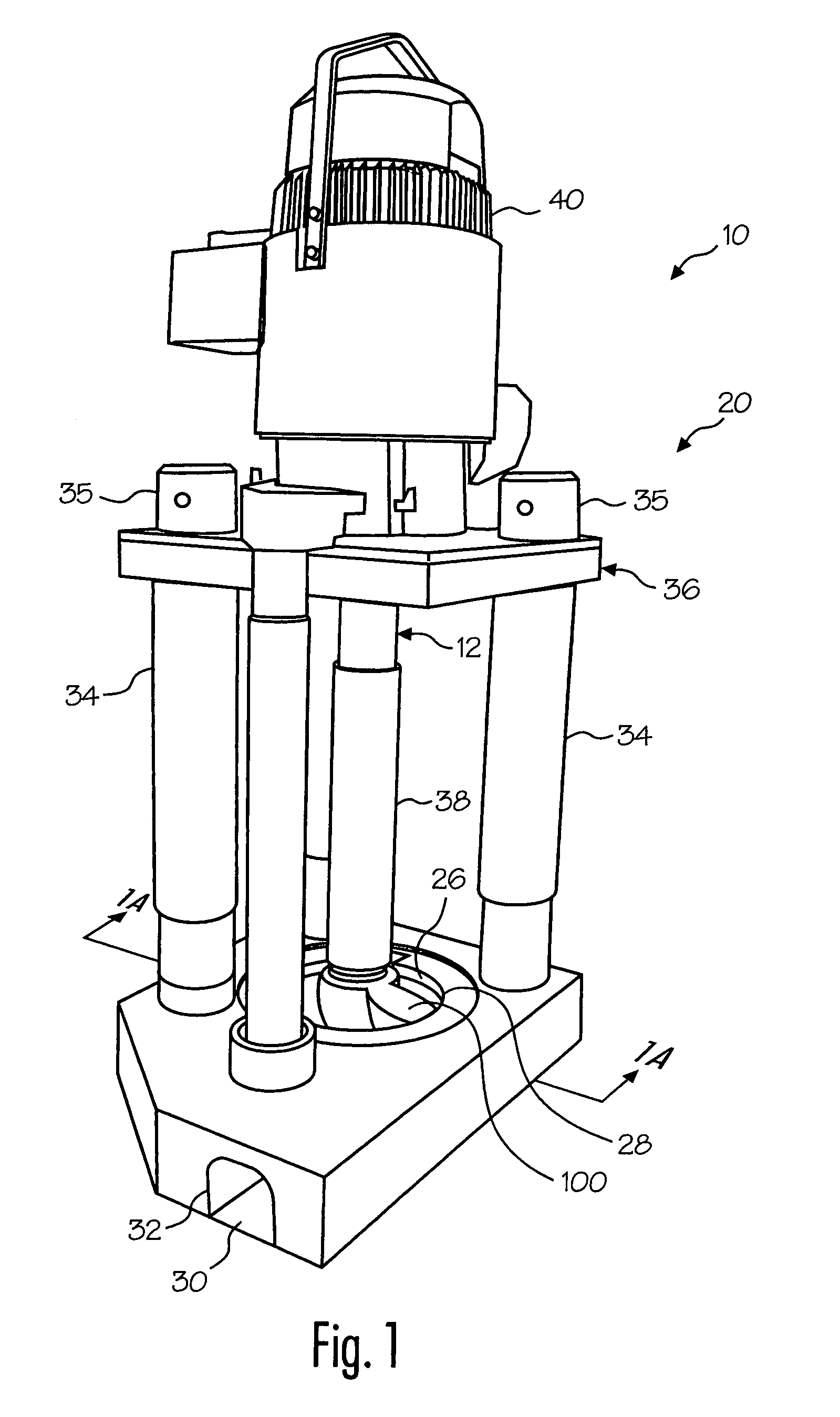

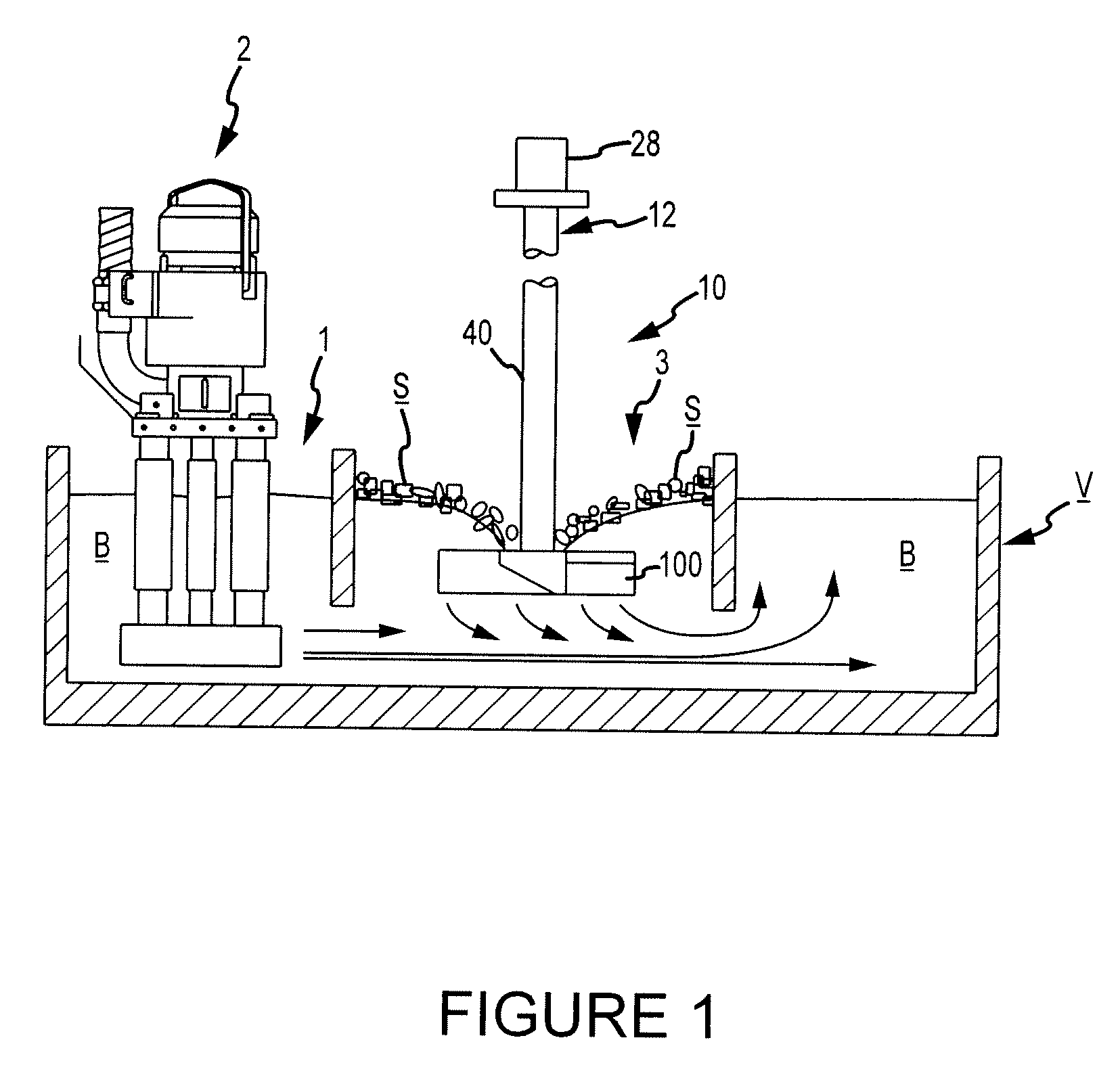

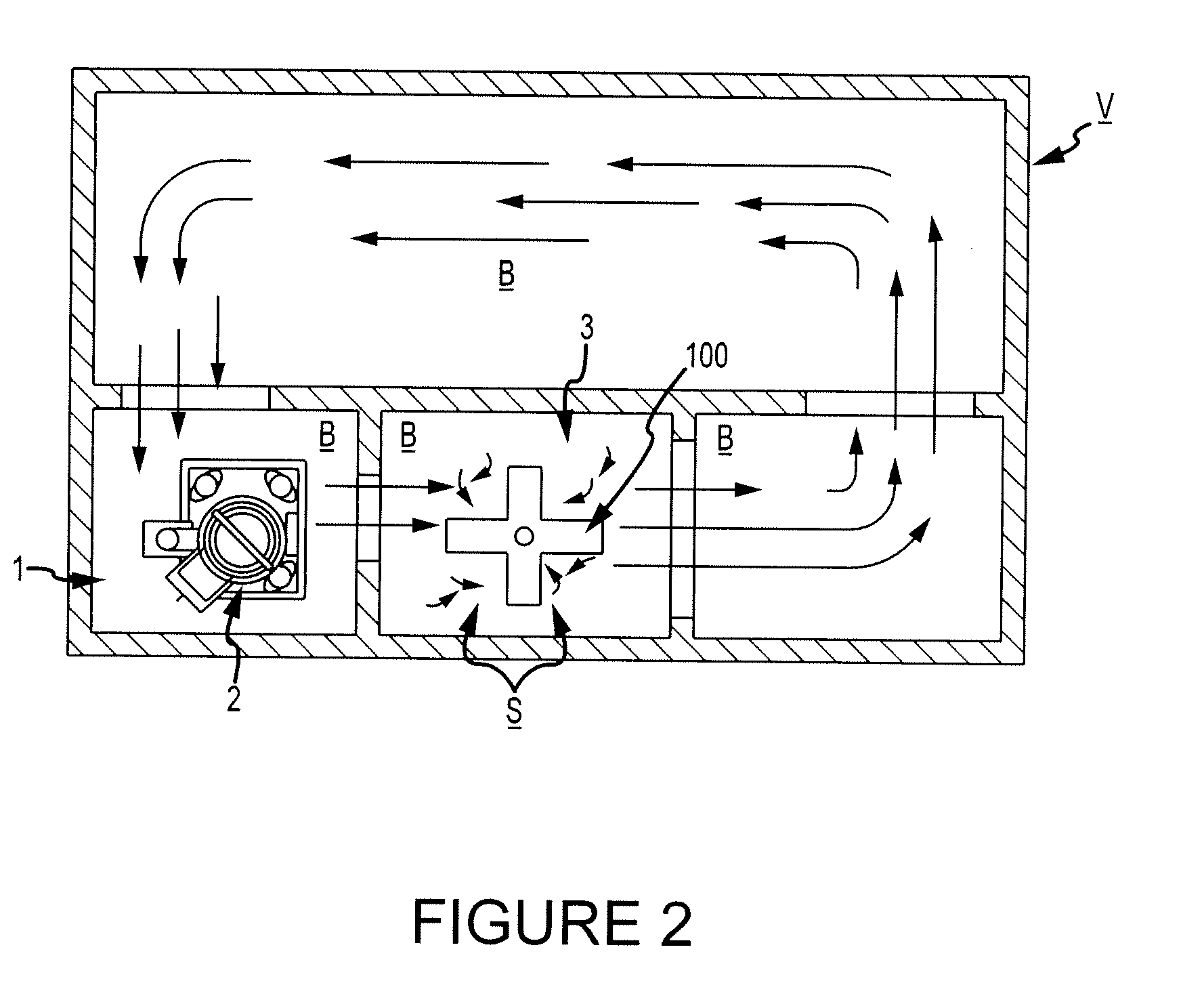

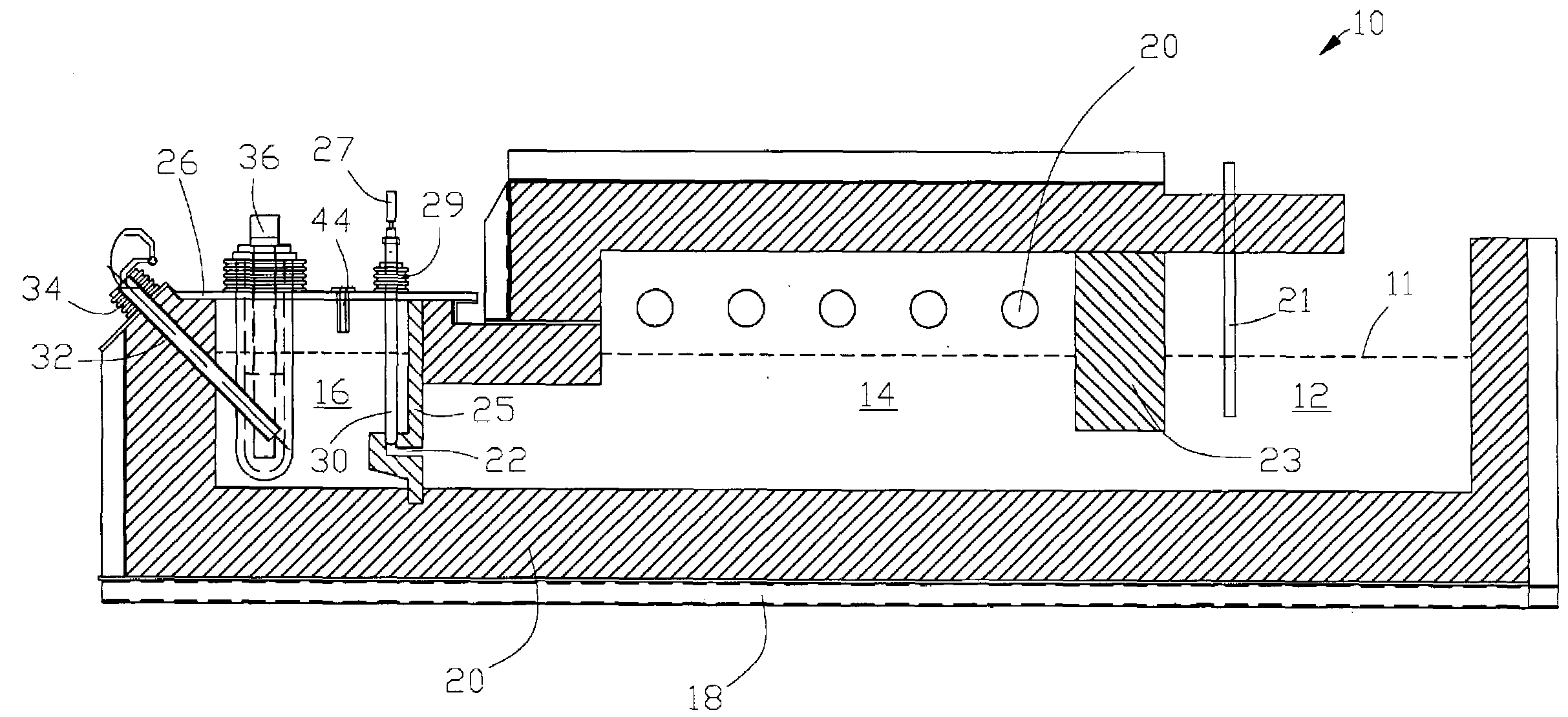

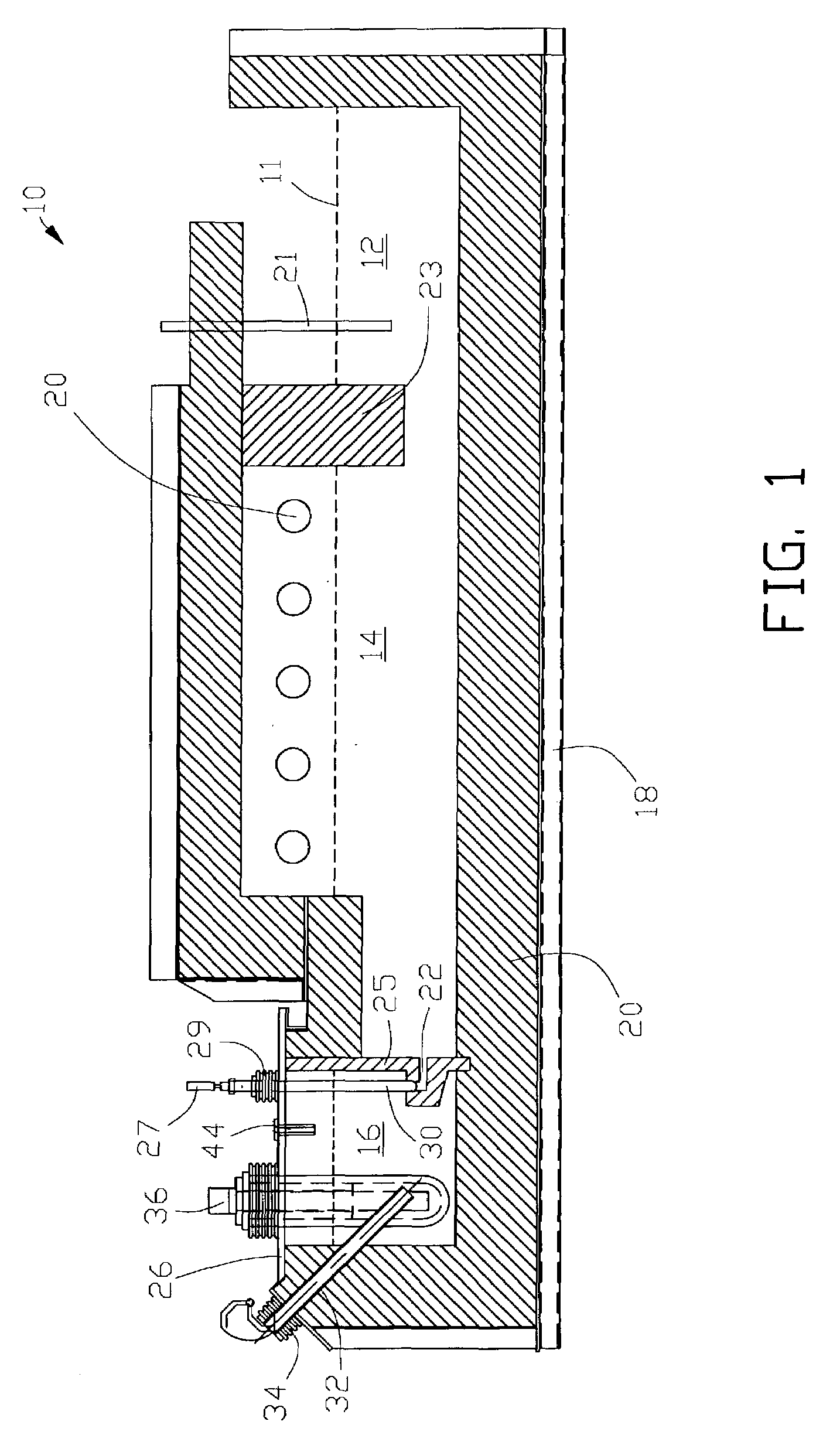

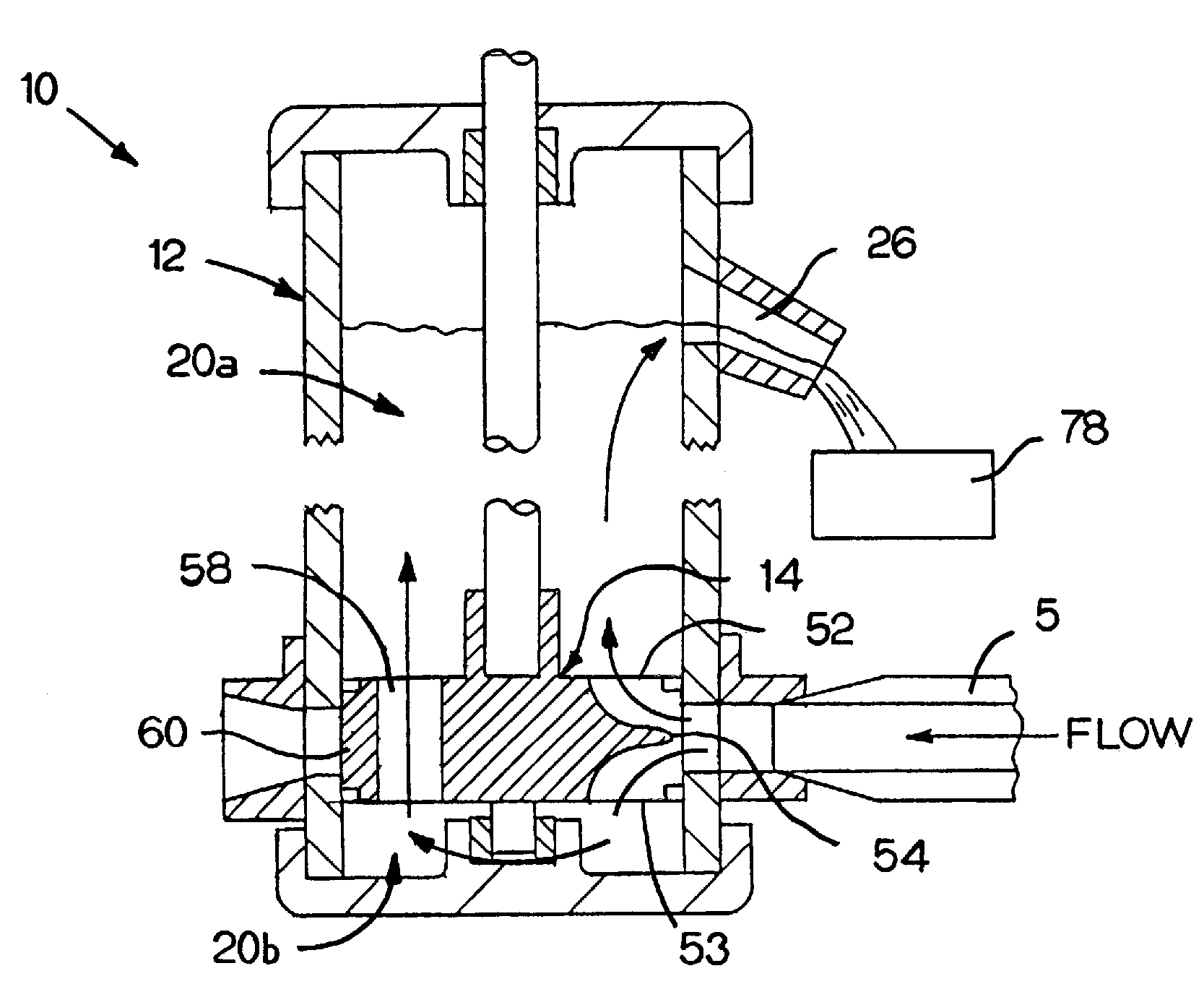

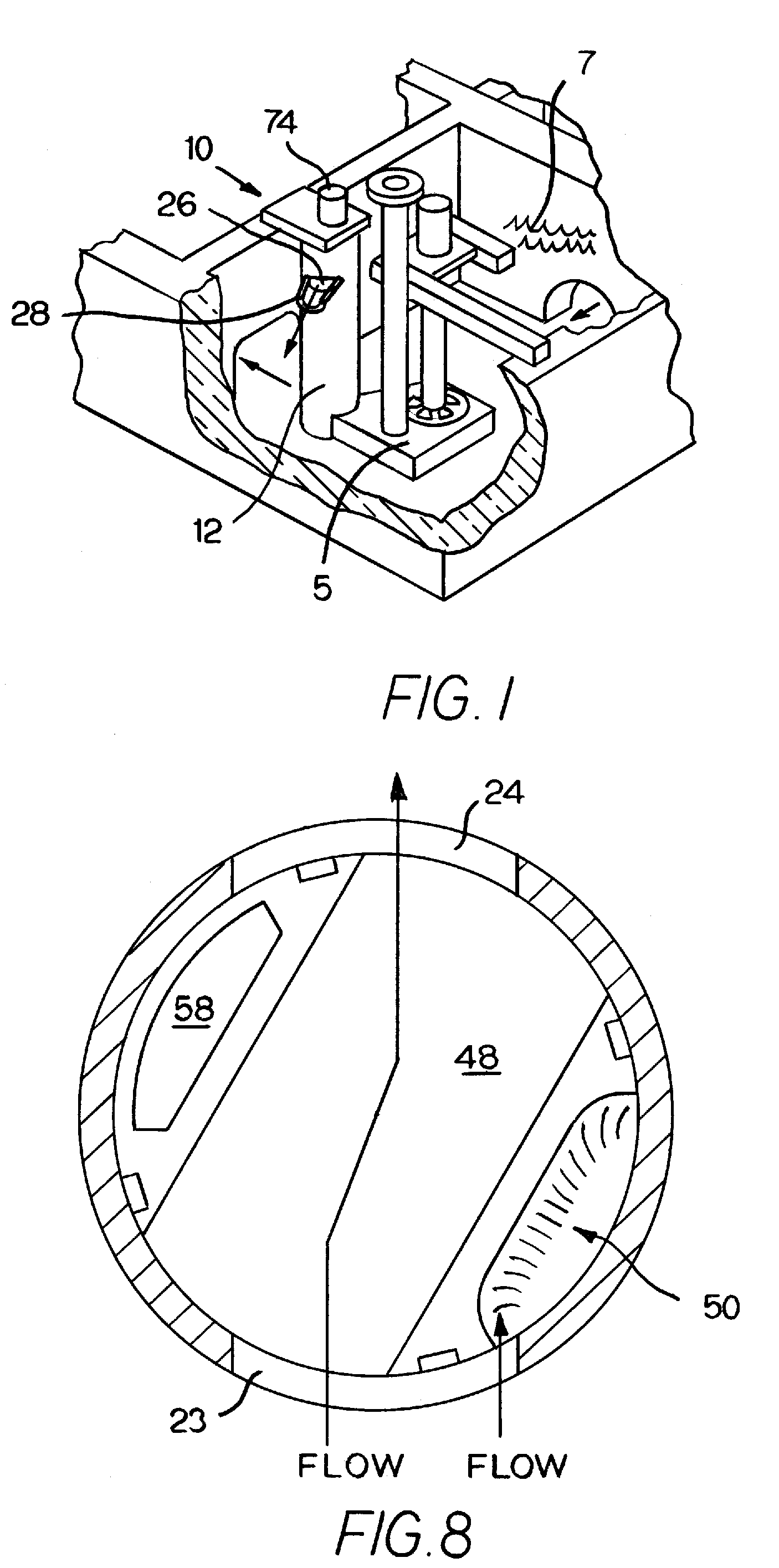

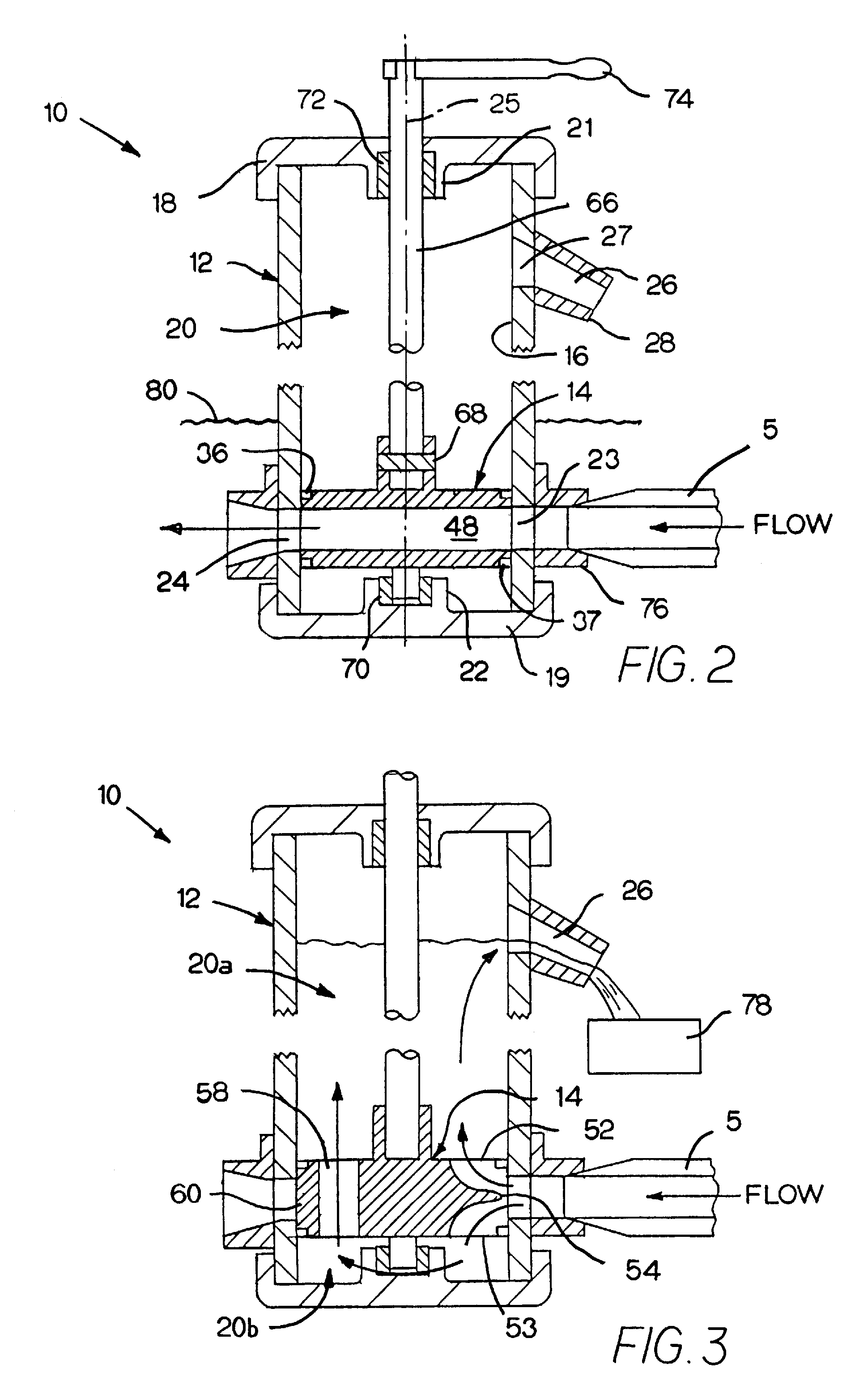

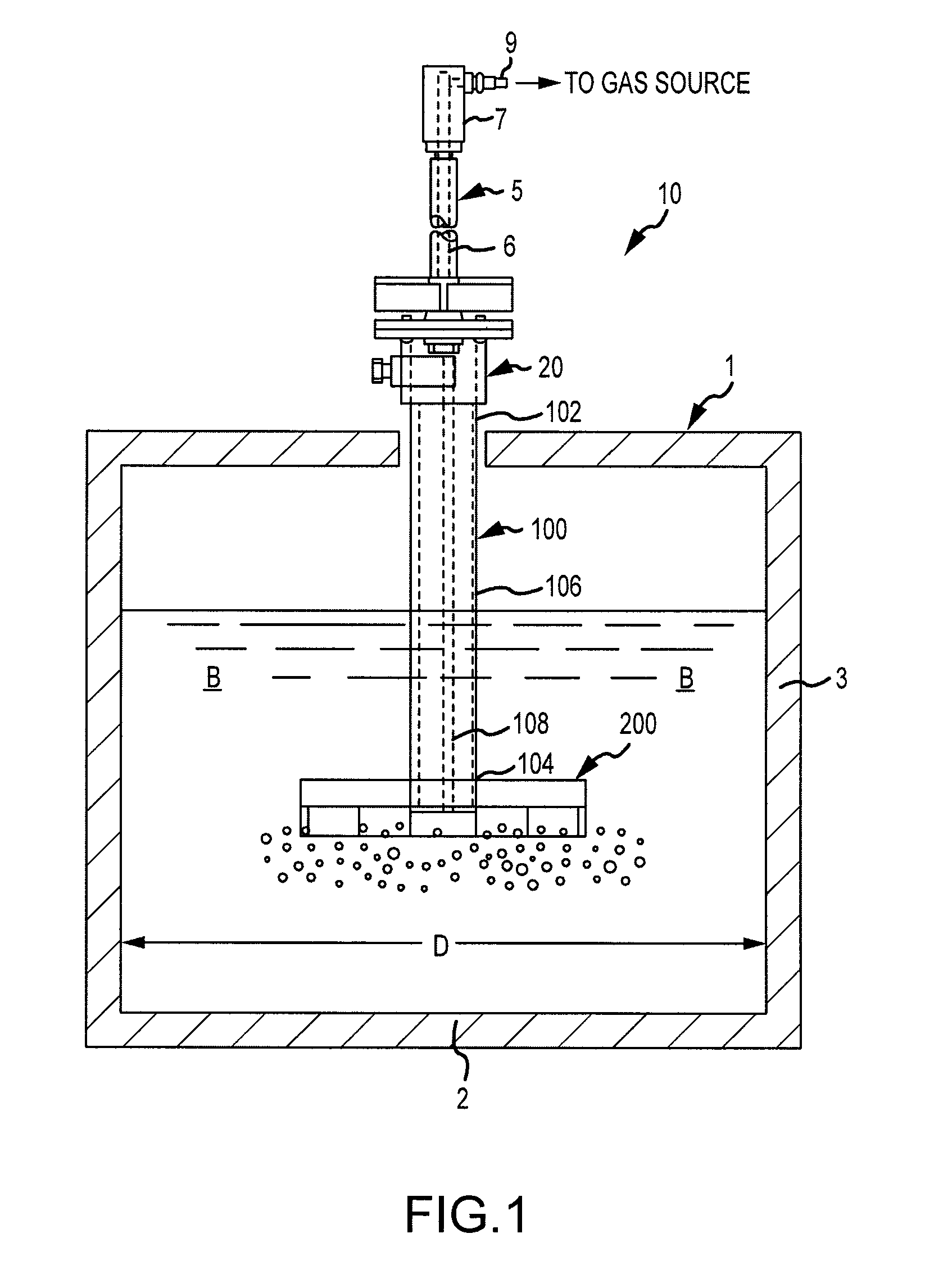

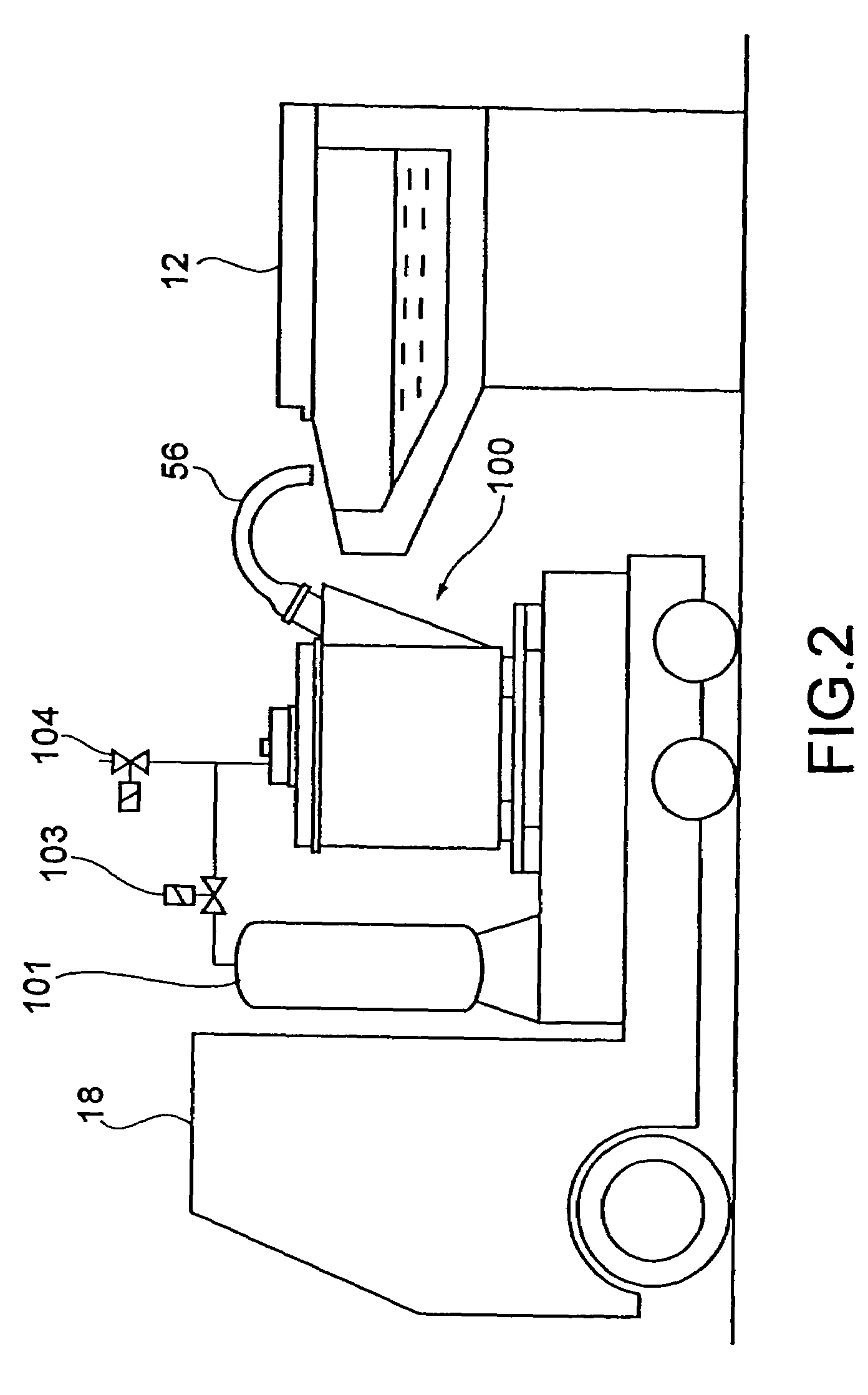

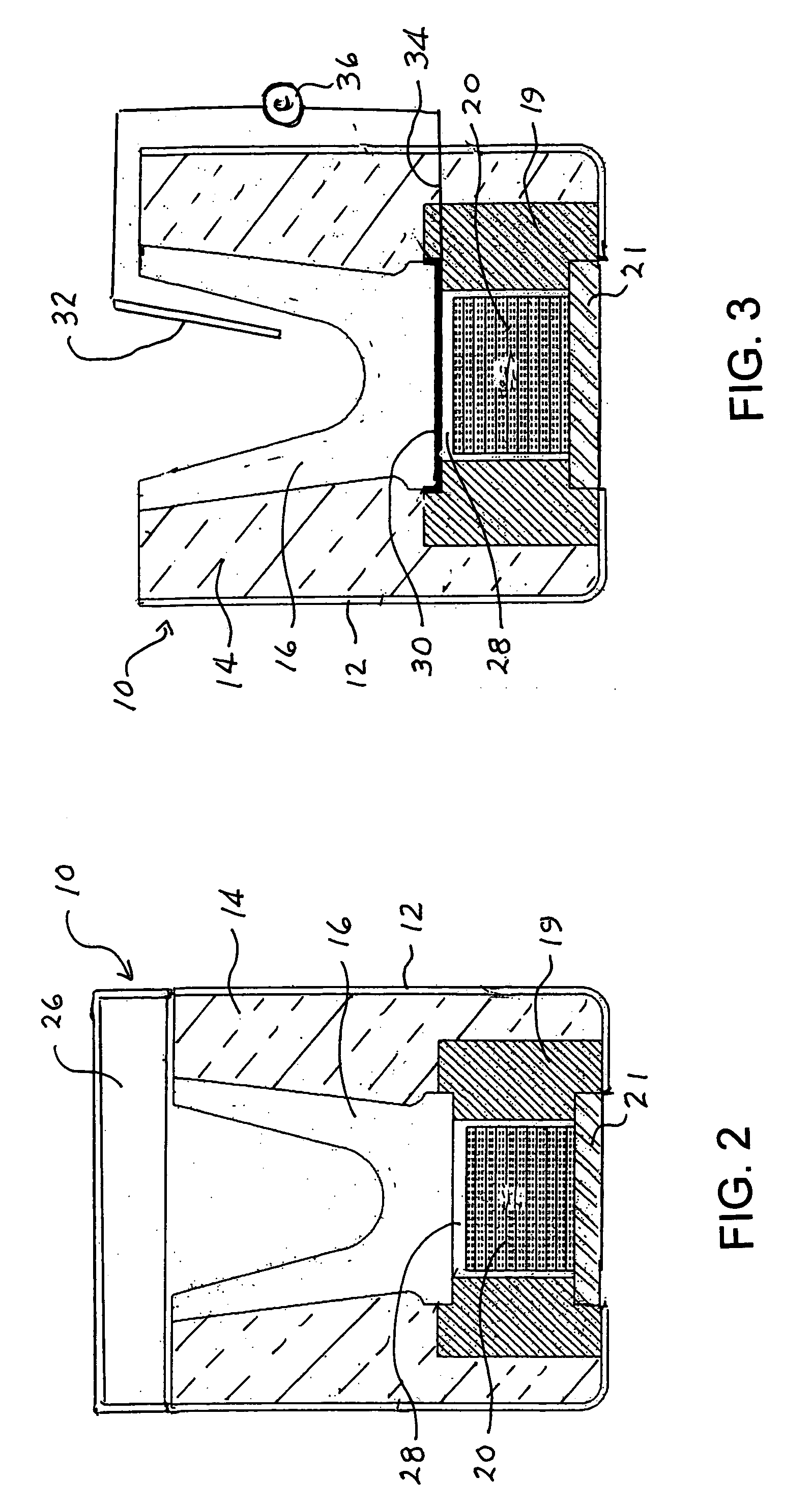

Gas mixing and dispersement in pumps for pumping molten metal

InactiveUS7476357B2Well mixedEfficient pumpingMelt-holding vesselsCharge manipulationImpellerPump chamber

A molten metal pump including a pump base with an inlet and outlet, a mixing impeller chamber for mixing gas and molten metal, a pumping impeller chamber for pumping molten metal. First and second impeller members supported by a shaft are adapted to rotate in mixing and pumping chambers respectively. The impeller members may be integrally formed of a single impeller or separate impellers on one or more shafts. A gas passageway extends from a gas source to the mixing chamber in the base. A gas dispersement pump includes a base with an impeller chamber and inlet and an outlet. An impeller is mounted to a shaft and adapted to be rotated in the impeller chamber. A gas passageway extends from a gas source to a gas outlet proximate to the impeller chamber. A gas dispersement member of porous refractory material is adapted to disperse gas from the gas passageway. In a gas dispersement and gas / molten metal mixing pump, the dispersement member disperses the gas stream entering the mixing chamber where the gas is mixed with molten metal. Molten metal is pumped in the pumping chamber. A gas / molten metal mixture is discharged from the mixing chamber and molten metal is discharged from the pumping chamber.

Owner:THUT BRUNO H

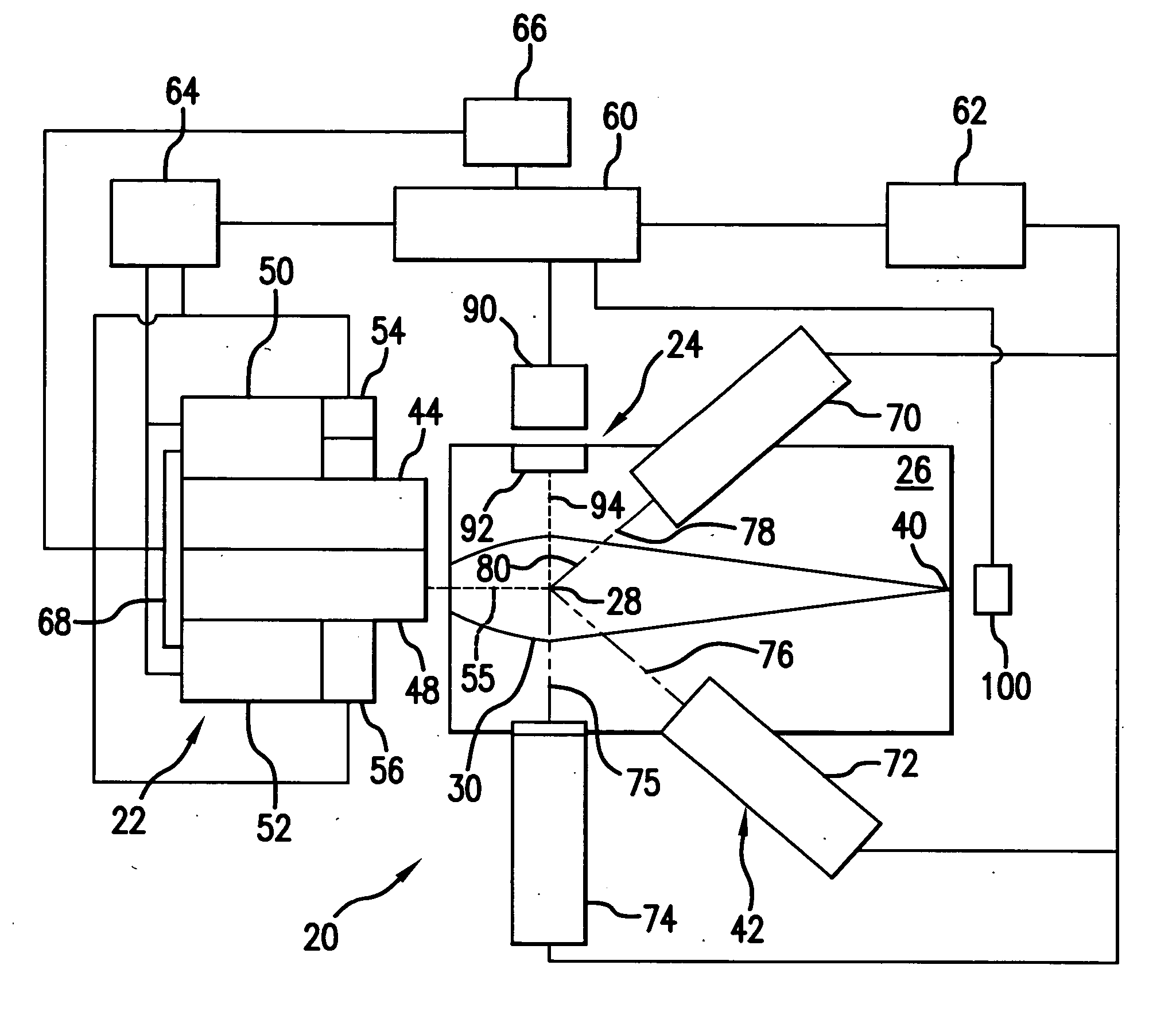

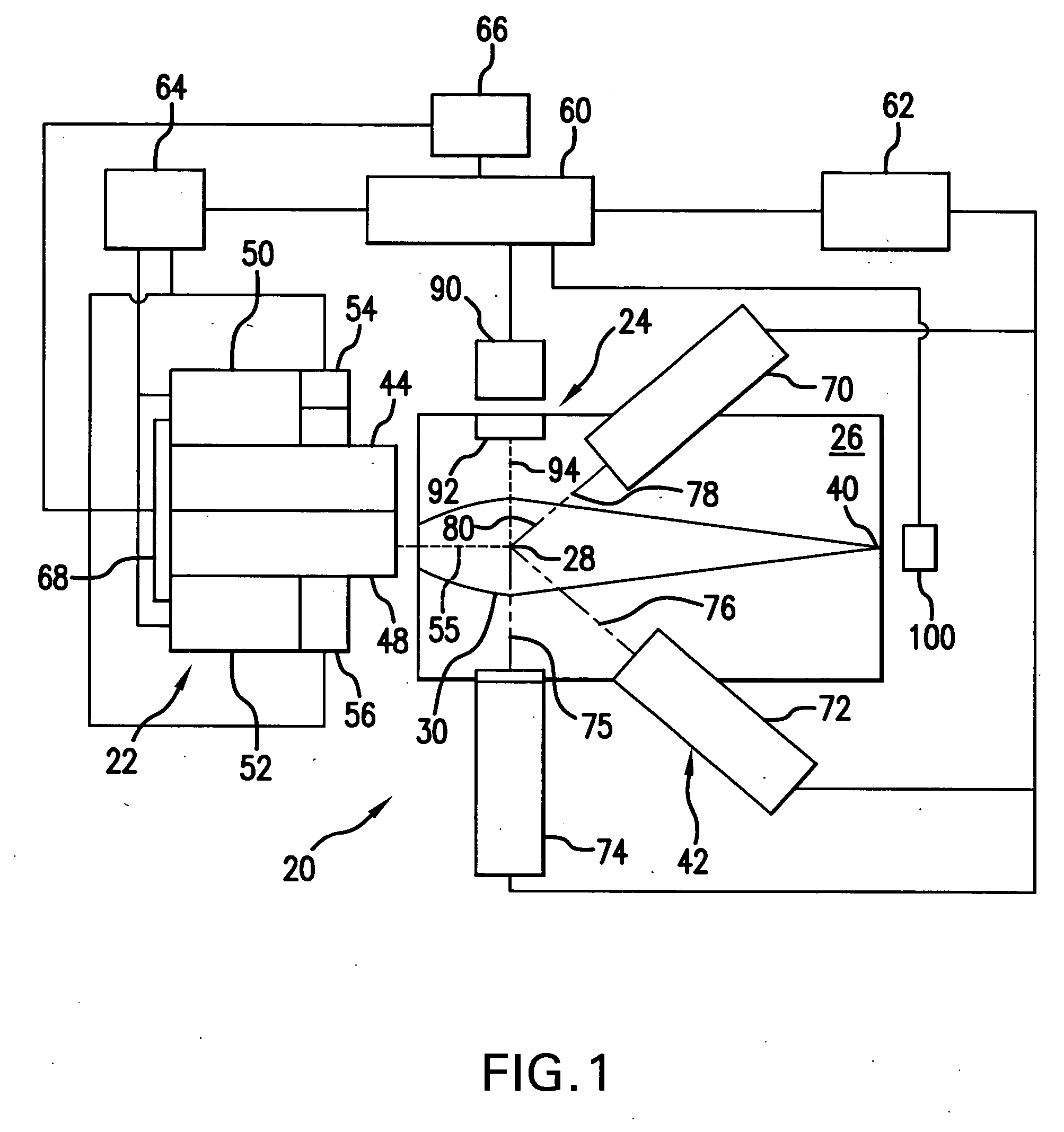

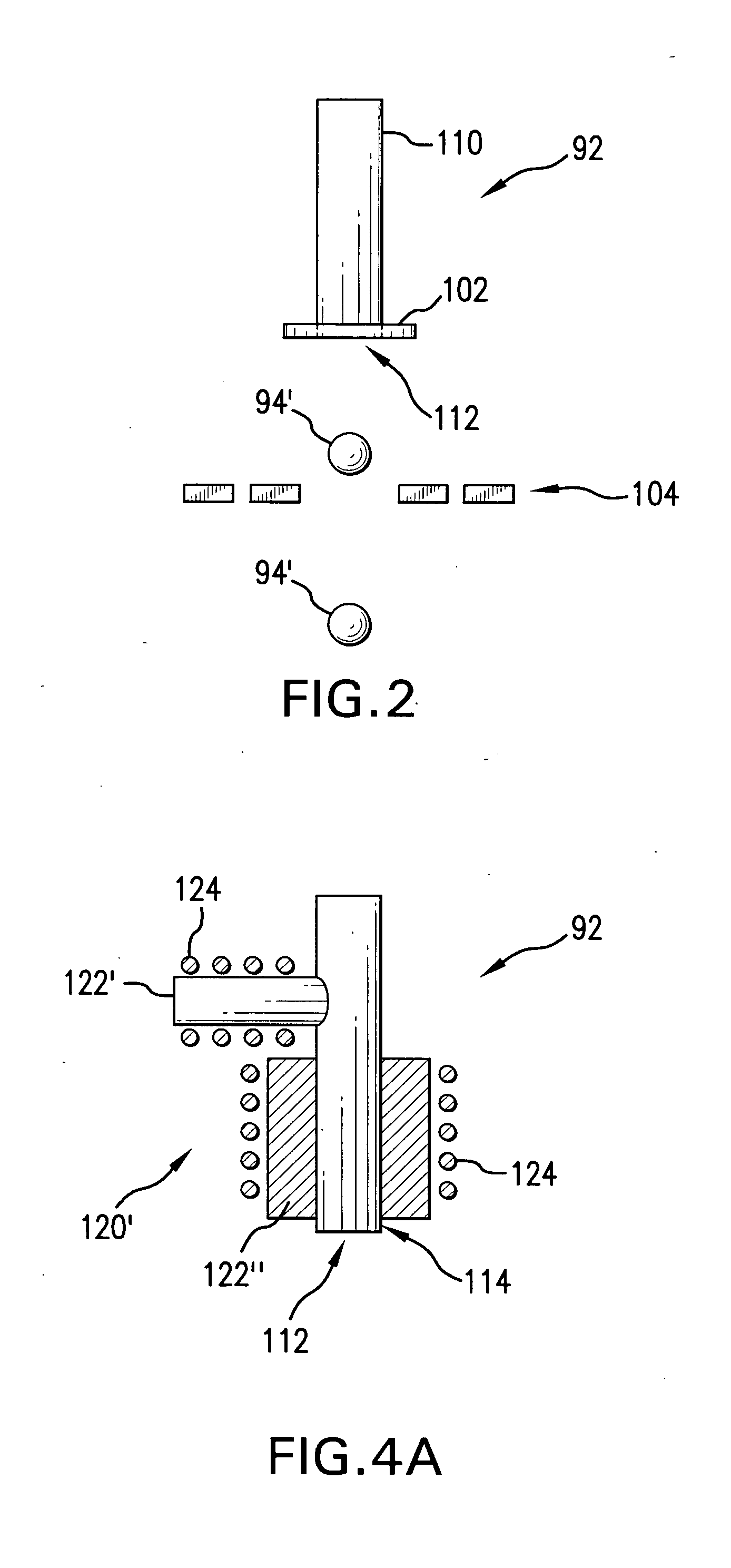

Method and apparatus for EUV plasma source target delivery

An EUV plasma formation target delivery system and method is disclosed which may comprise: a target droplet formation mechanism comprising a magneto-restrictive or electro-restrictive material, a liquid plasma source material passageway terminating in an output orifice; a charging mechanism applying charge to a droplet forming jet stream or to individual droplets exiting the passageway along a selected path; a droplet deflector intermediate the output orifice and a plasma initiation site periodically deflecting droplets from the selected path, a liquid target material delivery mechanism comprising a liquid target material delivery passage having an input opening and an output orifice; an electromotive disturbing force generating mechanism generating a disturbing force within the liquid target material, a liquid target delivery droplet formation mechanism having an output orifice; and / or a wetting barrier around the periphery of the output orifice.

Owner:ASML NETHERLANDS BV

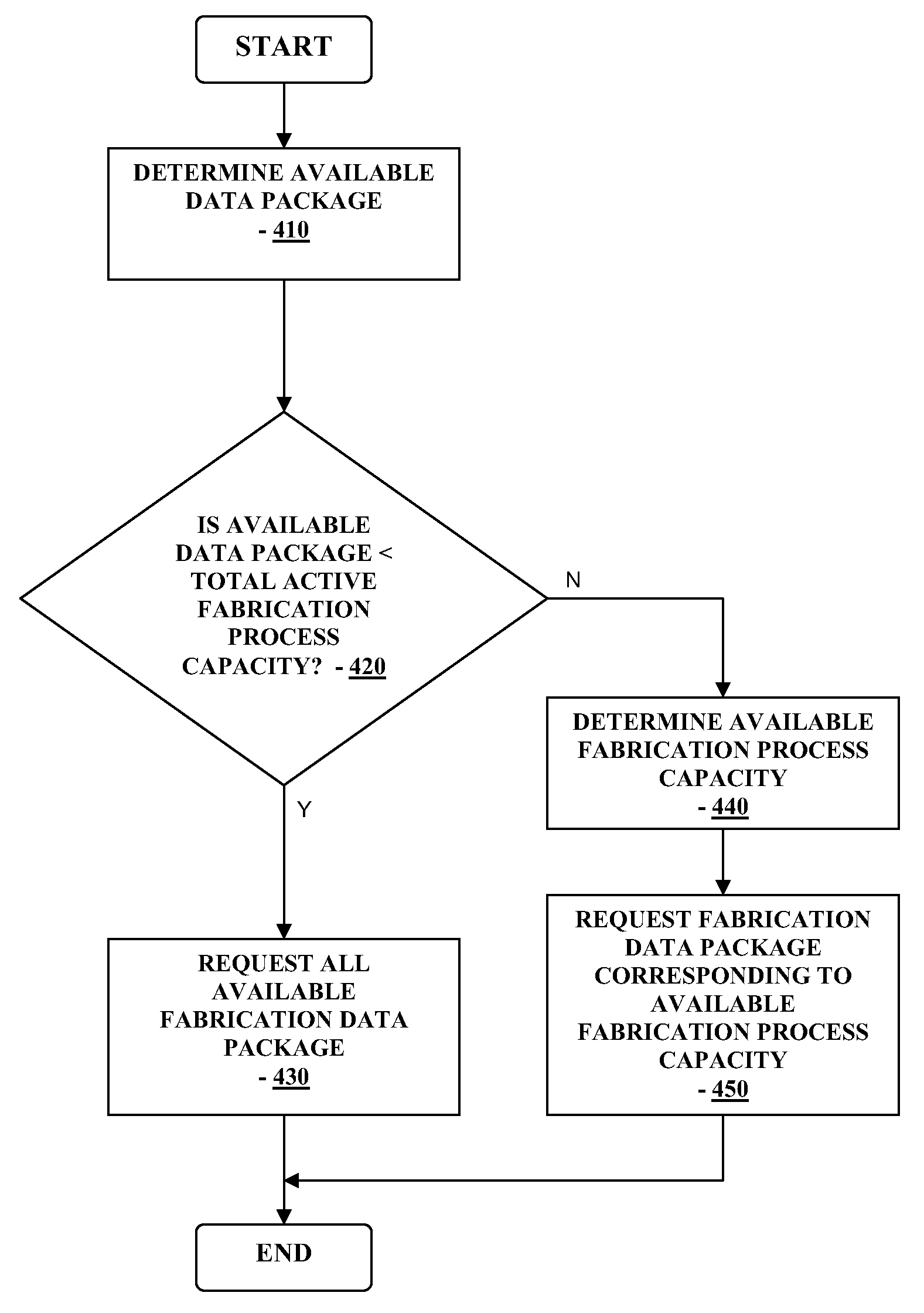

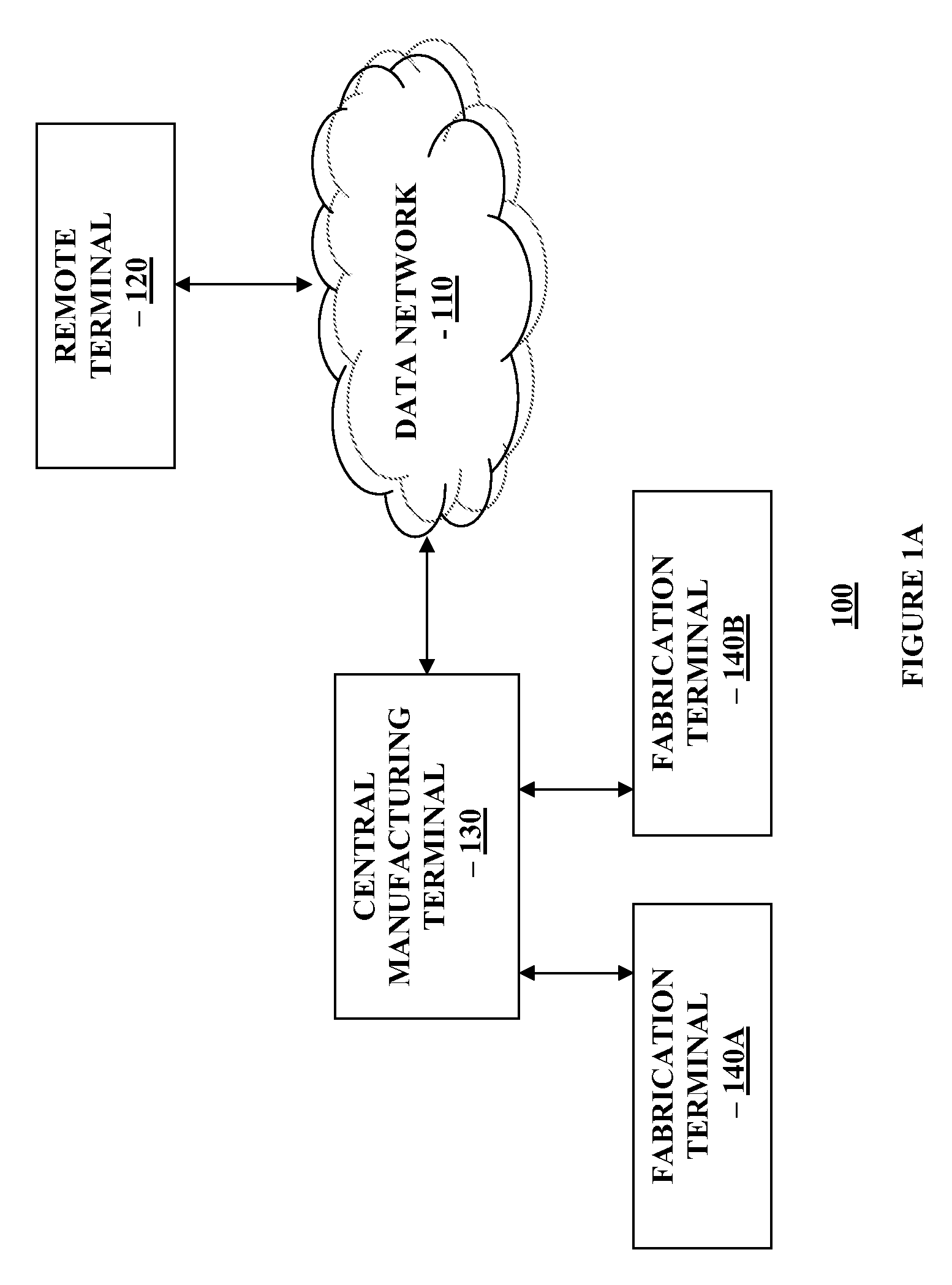

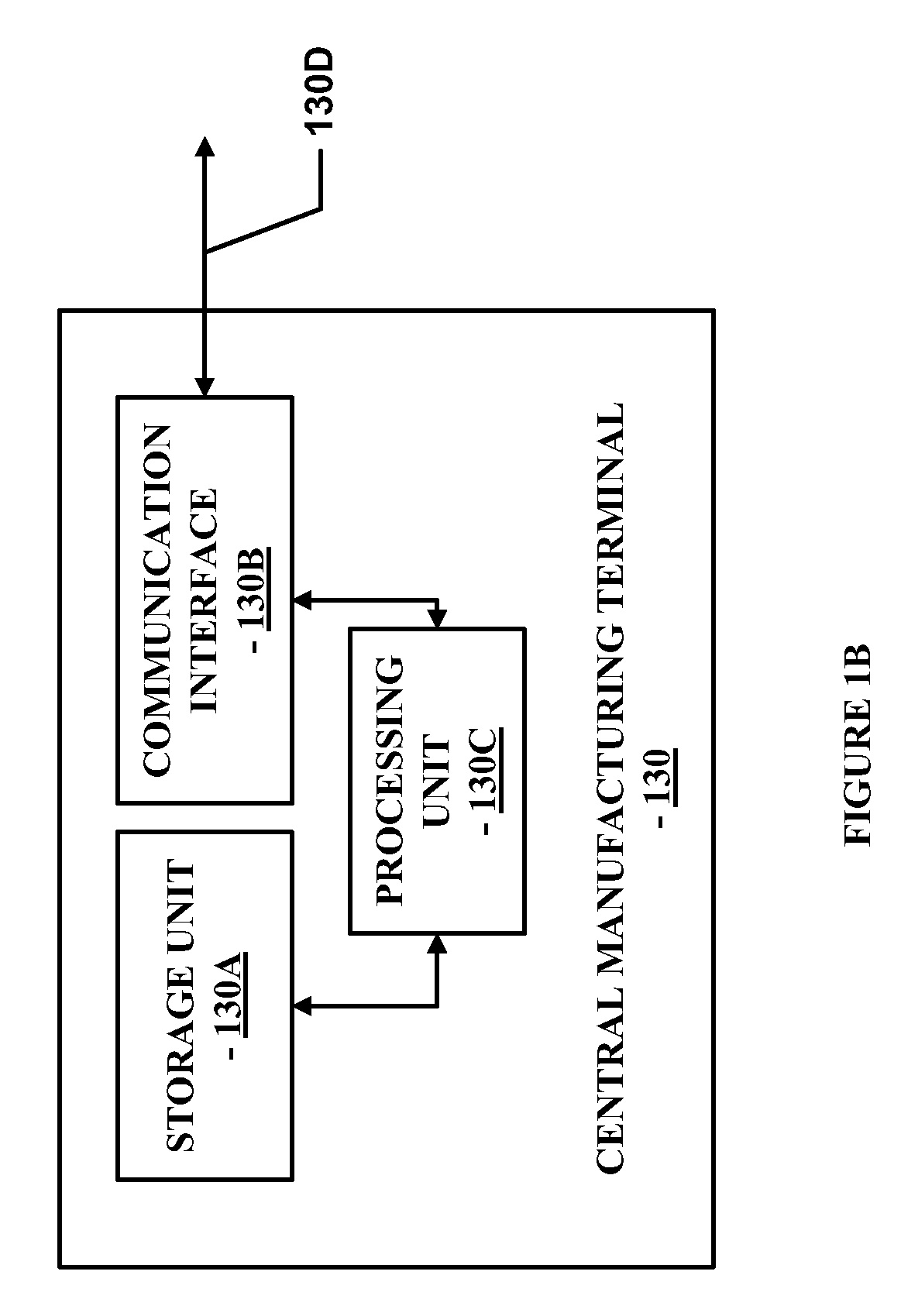

Method and system for providing automated high scale fabrication of custom items

Method and system for providing volume manufacturing of customizable items including receiving a data package including a plurality of manufacturing parameters, each of the plurality of manufacturing parameters associated with a unique item, verifying the received data package, and implementing a manufacturing process associated with the received data package is provided.

Owner:ALIGN TECH

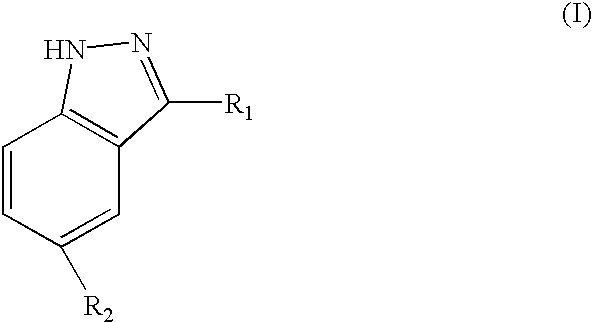

Indazole compounds, pharmaceutical compositions, and methods for mediating or inhibiting cell proliferation

InactiveUS6919461B2Melt-holding vesselsGroup 4/14 element organic compoundsDiabetic retinopathyDisease

Indazole compounds that modulate and / or inhibit cell proliferation, such as the activity of protein kinases are described. These compounds and pharmaceutical compositions containing them are capable of mediating, e.g., kinases-dependent diseases to modulate and / or inhibit unwanted cell proliferation. The invention is also directed to the therapeutic or prophylactic use of pharmaceutical compositions containing such compounds, and to methods of treating cancer as well as other disease states associated with unwanted angiogenesis and / or cellular proliferation, such as diabetic retinopathy, neovascular glaucoma, rheumatoid arthritis, and psoriasis, by administering effective amounts of such compounds.

Owner:AGOURON PHARMA INC

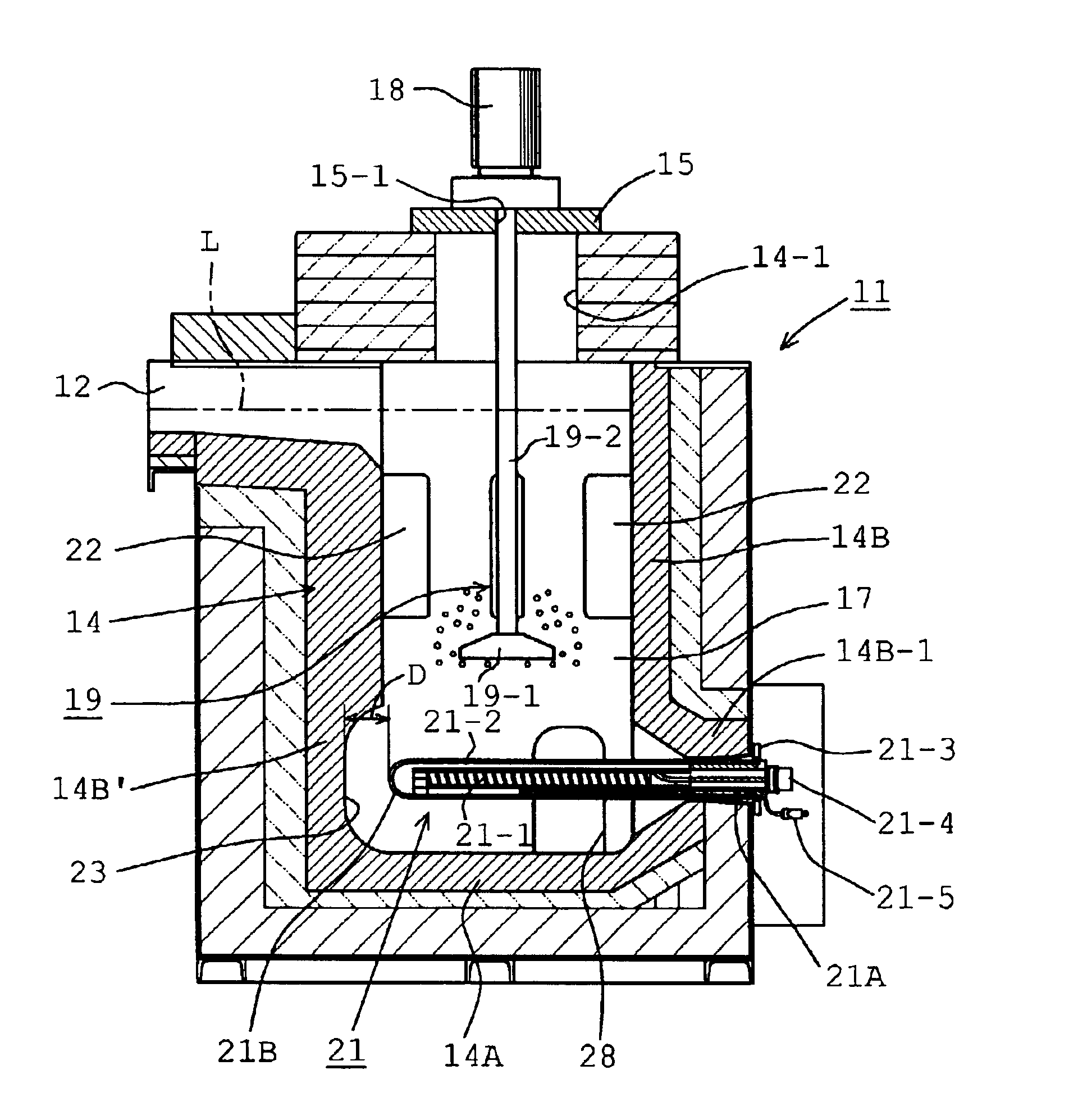

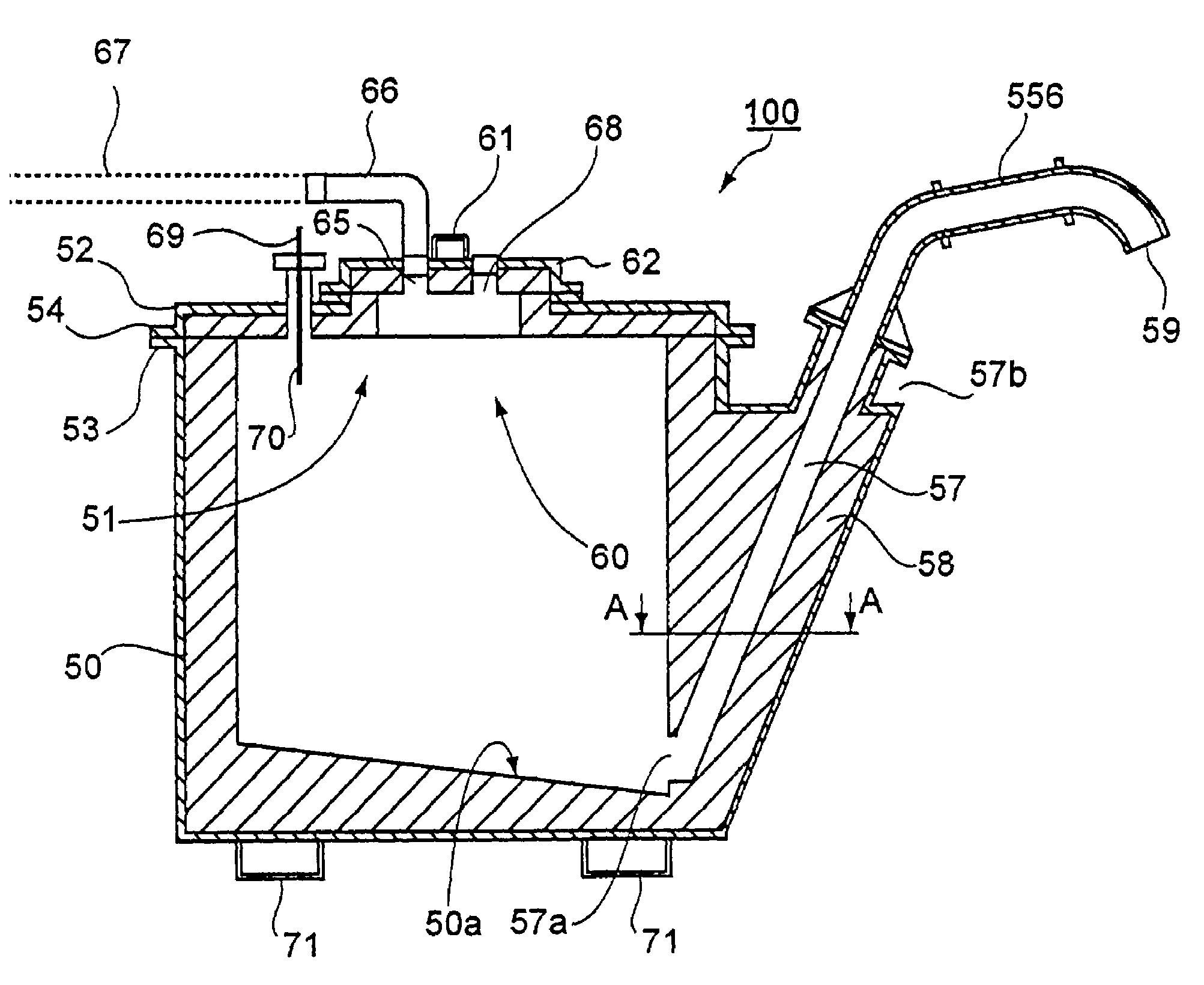

Inline degassing apparatus

InactiveUS6887424B2Reduce the amount requiredSmall volumeMelt-holding vesselsMechanical apparatusNon-metallic inclusionsSolid solution

An inline degassing apparatus for removing solid solution gases as well as nonmetallic inclusions from molten metal in a degassing container, to which the molten metal is continuously introduced for degassing operation and from which the degassed molten metal is continuously removed. A rotary diffusing device is arranged in the degassing container for generating bubbles of inert gas diffused into the molten metal, thereby entrapping solid solution gases as well as nonmetallic inclusions into the bubbles, which are then floated and separated. Heaters are provided, which extend, in a cantilever fashion, from a side wall of container at a position adjacent the bottom wall of the container substantially parallel to the bottom wall.

Owner:PYROTEK JAPAN +1

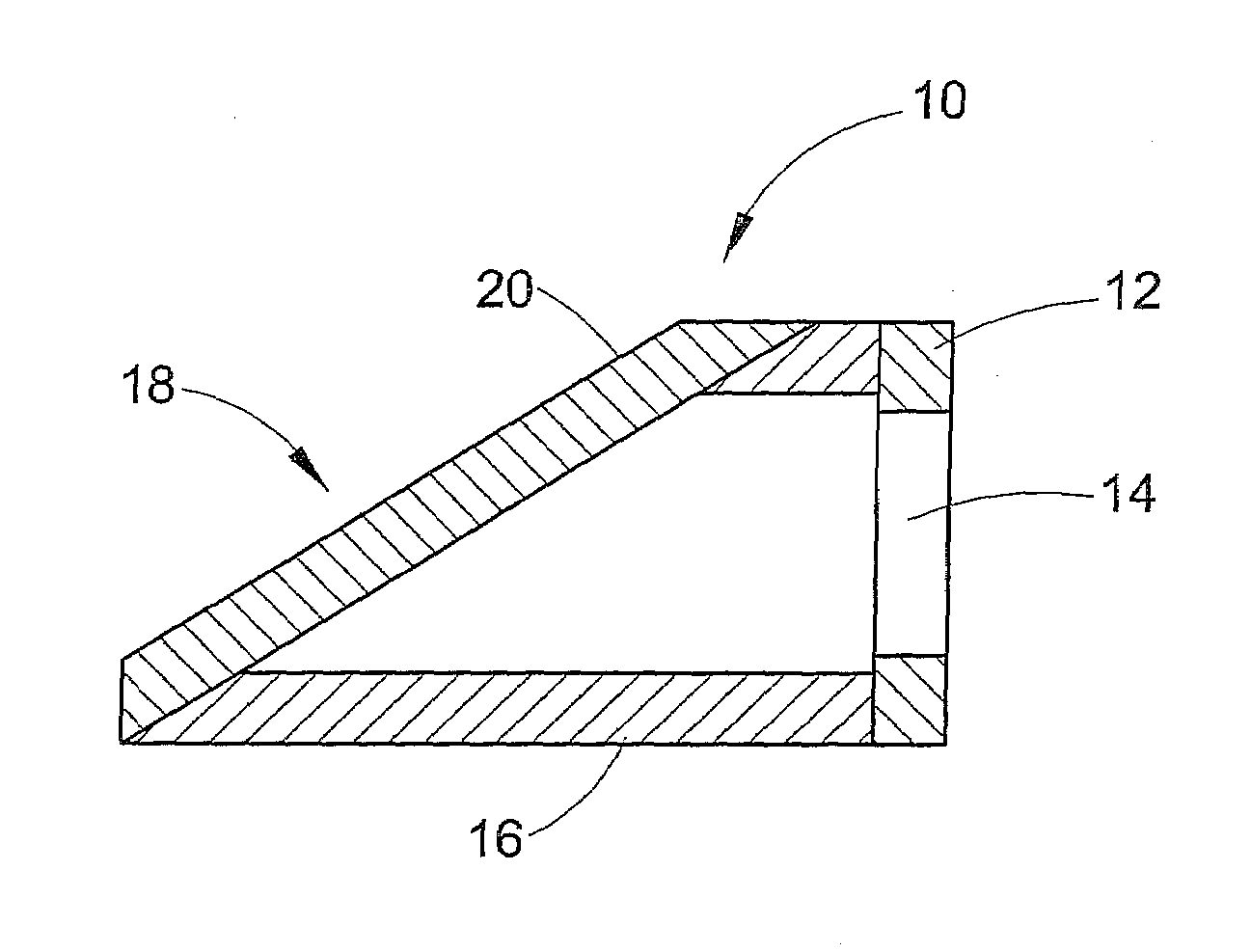

Bonded particle filters

InactiveUS7157043B2Significant portionMelt-holding vesselsMolten metal pouring equipmentsMolten metalMaterials science

An apparatus for filtering molten metal held in a vessel before the metal enters the dosing tube. The filtering apparatus includes an attachment portion that mounts to the dosing tube, a filter body connected to the attachment portion and a planar surface attached to an end of the filter body opposite the attachment portion. The filter body can include a beveled end opposite the attachment portion where the planar surface is attached. The apparatus can be made from a bonded-particle material made from silicon carbide or aluminum oxide held together by an aluminum-resistant binder.

Owner:METAULLICS SYST +1

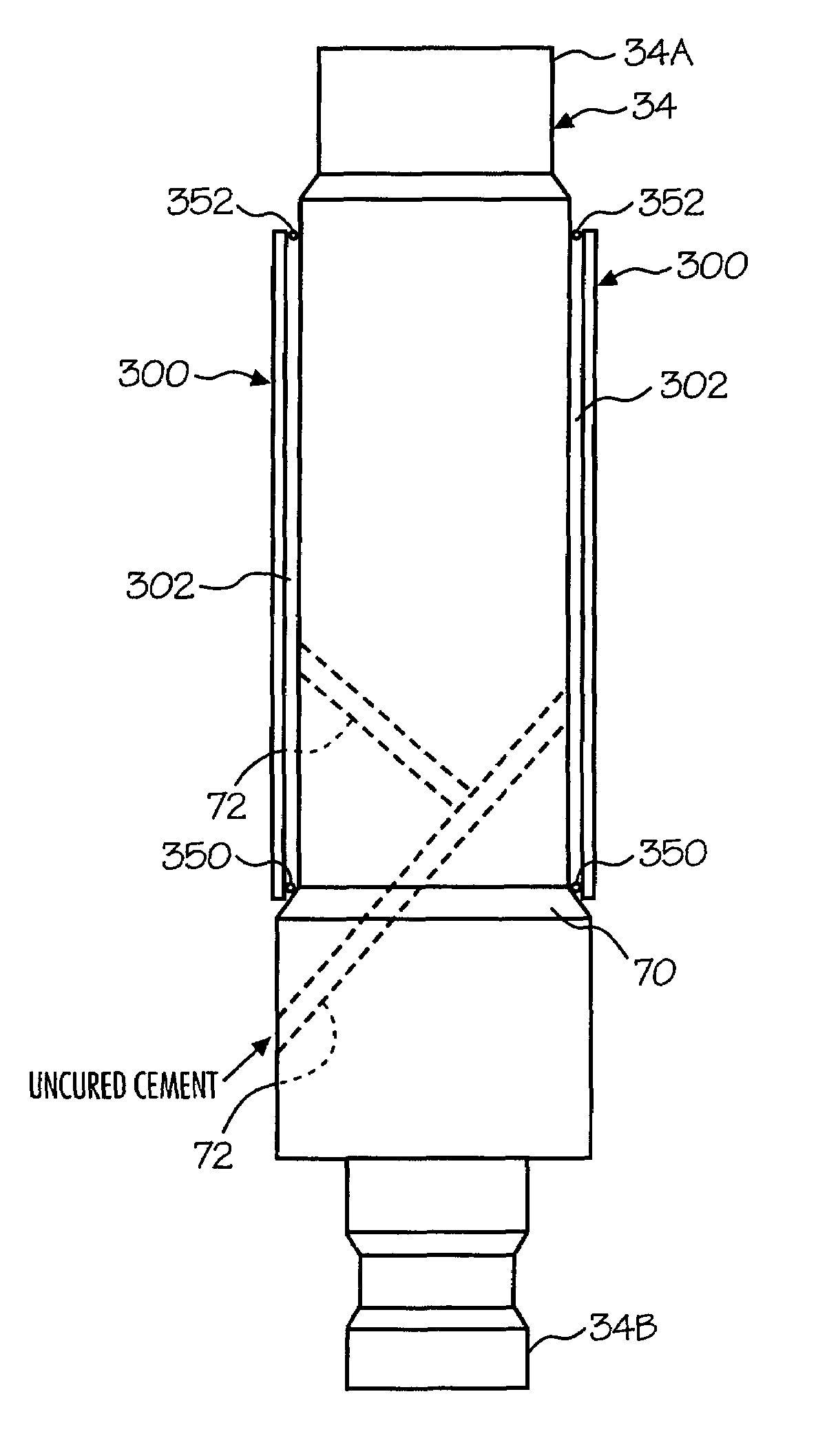

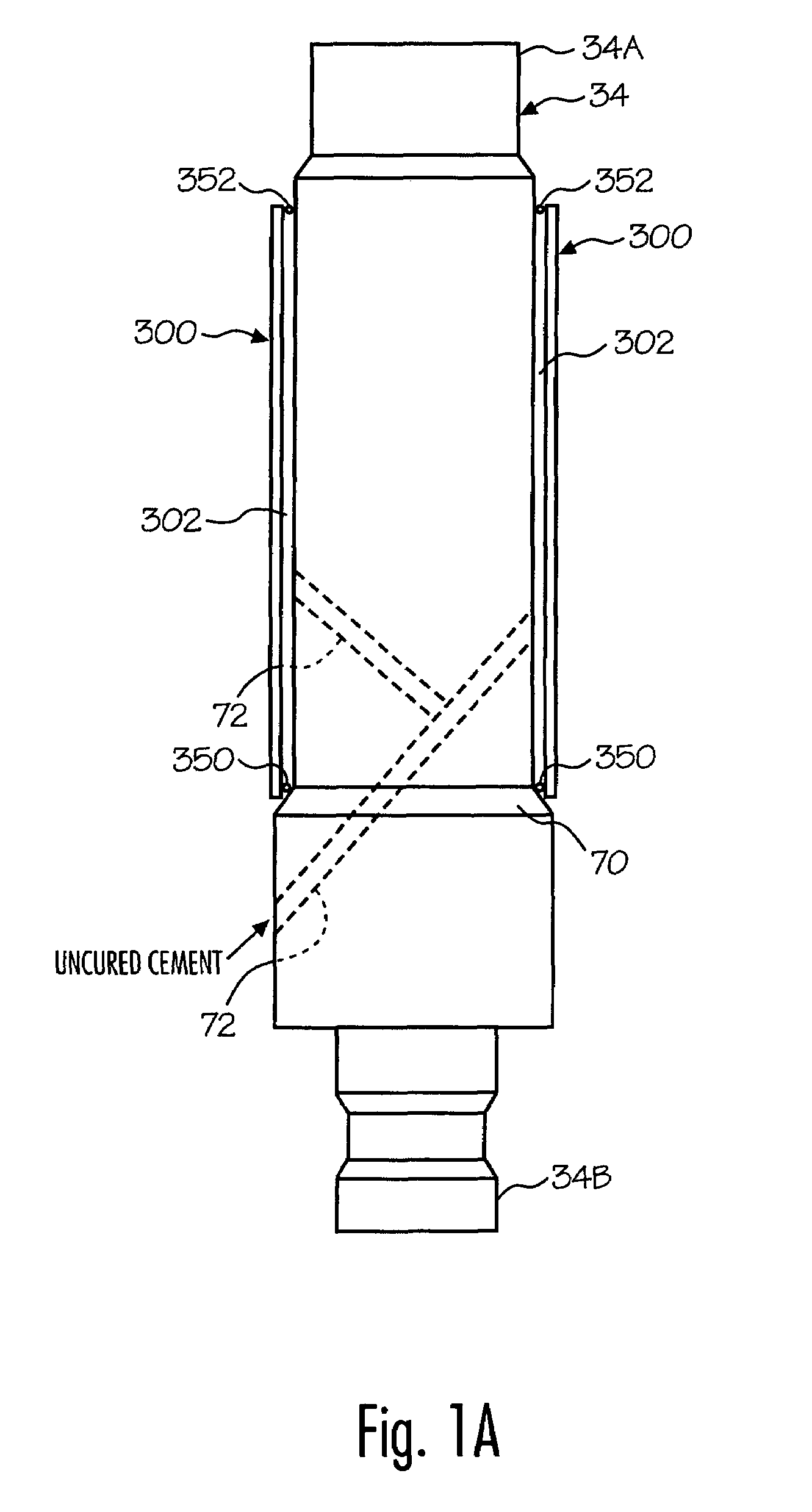

Protective coatings for molten metal devices

ActiveUS7507367B2Reduce componentsPrecise positioningSpecific fluid pumpsPump componentsMolten metalCoating

Disclosed are components covered with a protective coating for use in a molten metal bath (or comparable environment) and devices including such components. The protective coating is preferably a ceramic sleeve adhered to a non-coated component by cement. A component with the protective coating is more resistant to degradation in molten metal than is the component without the coating, and may be manufactured by the process of (a) placing the protective coating over the non-coated component, and (b) injecting cement into the space between the non-coated component and protective coating, wherein at least some of the cement is injected through a passage in either the non-coated component or the protective coating.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

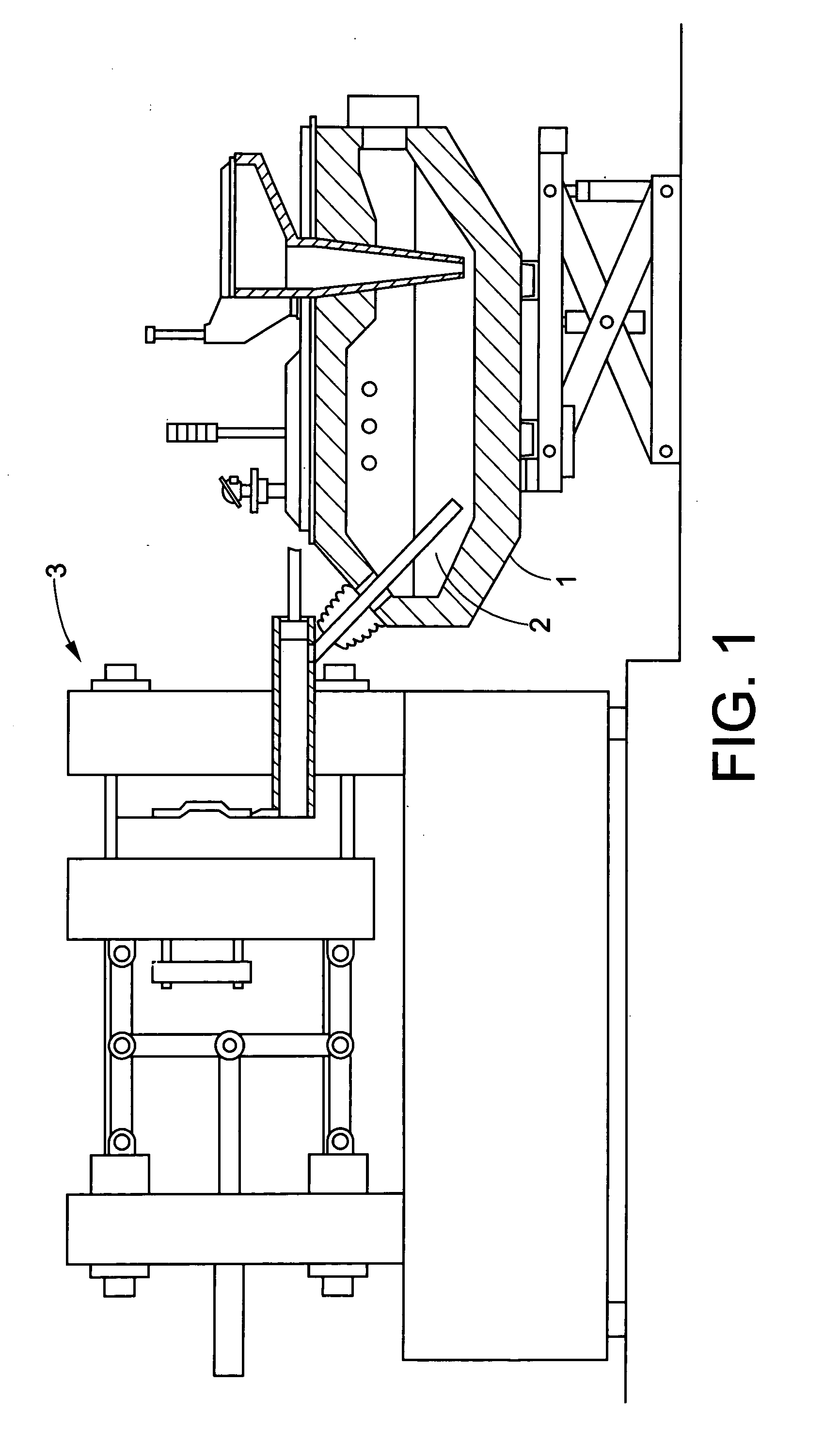

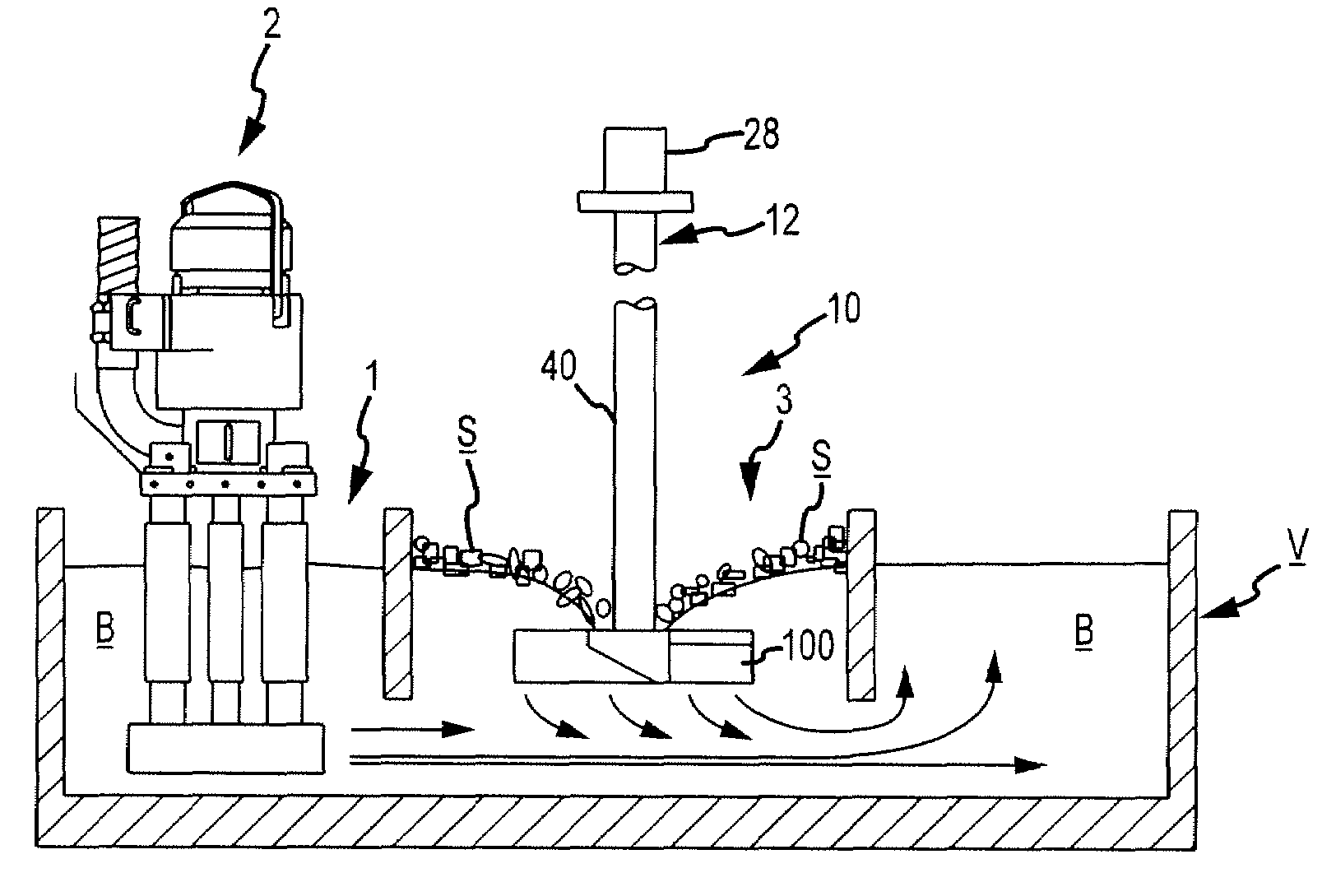

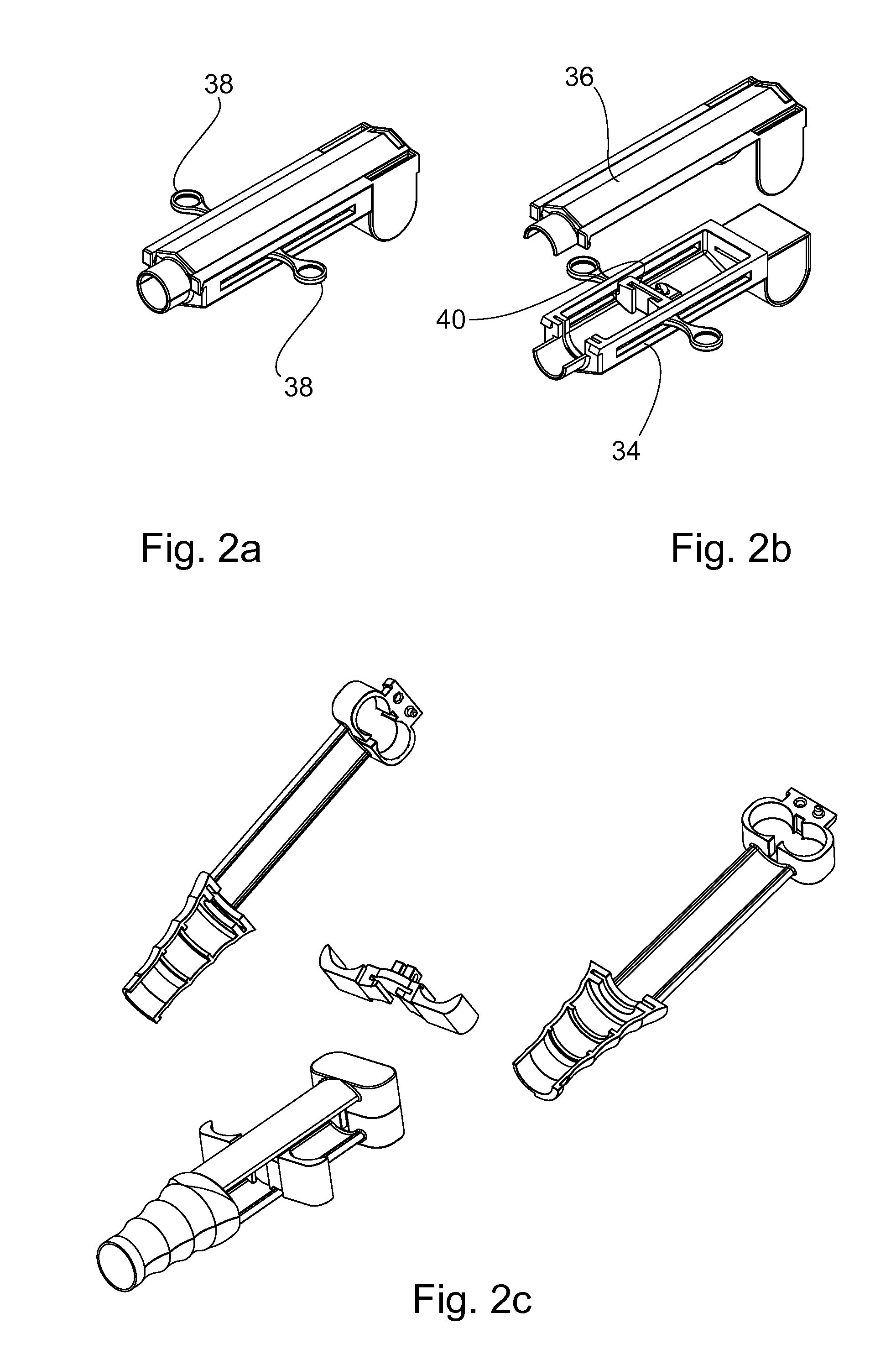

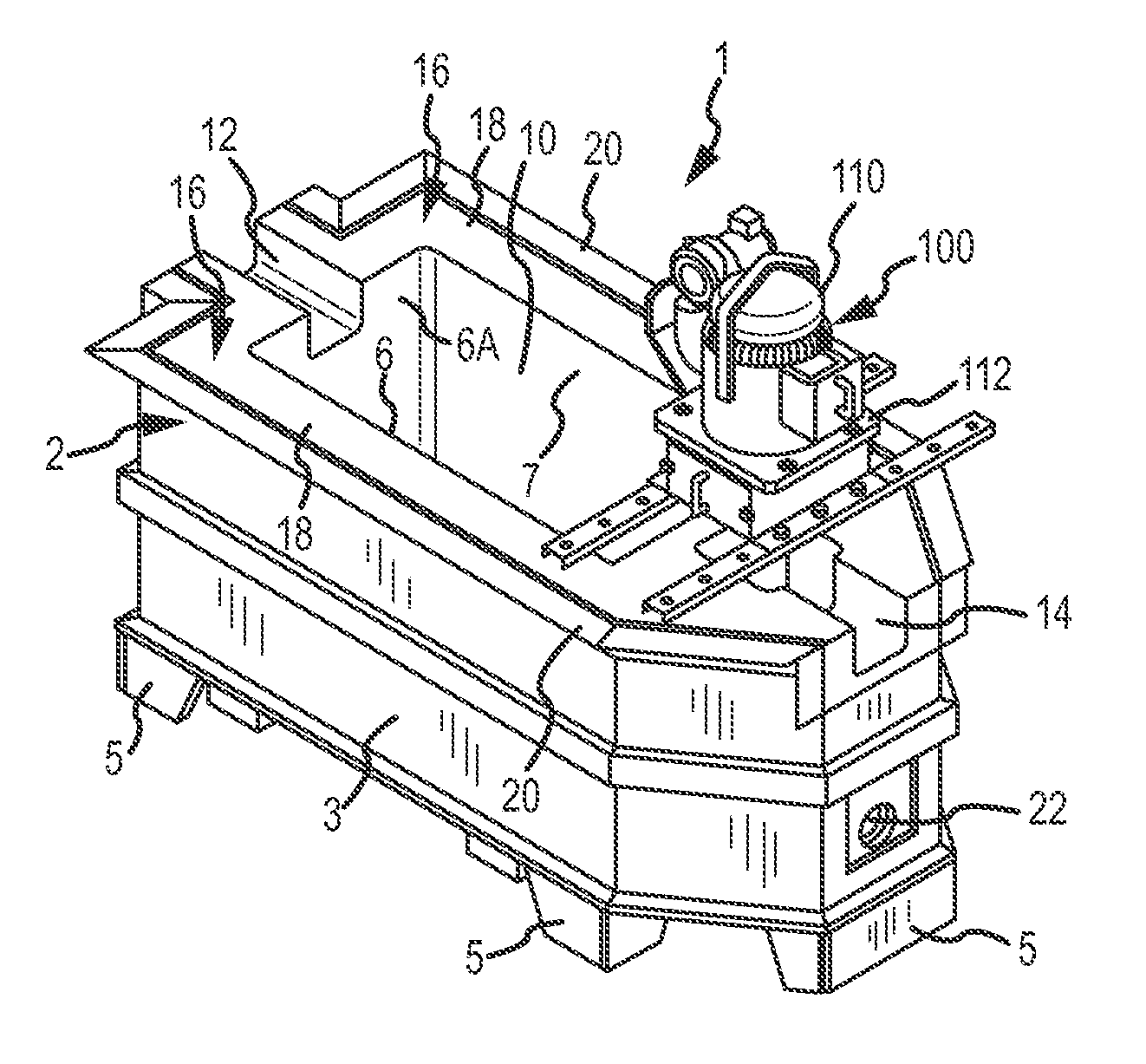

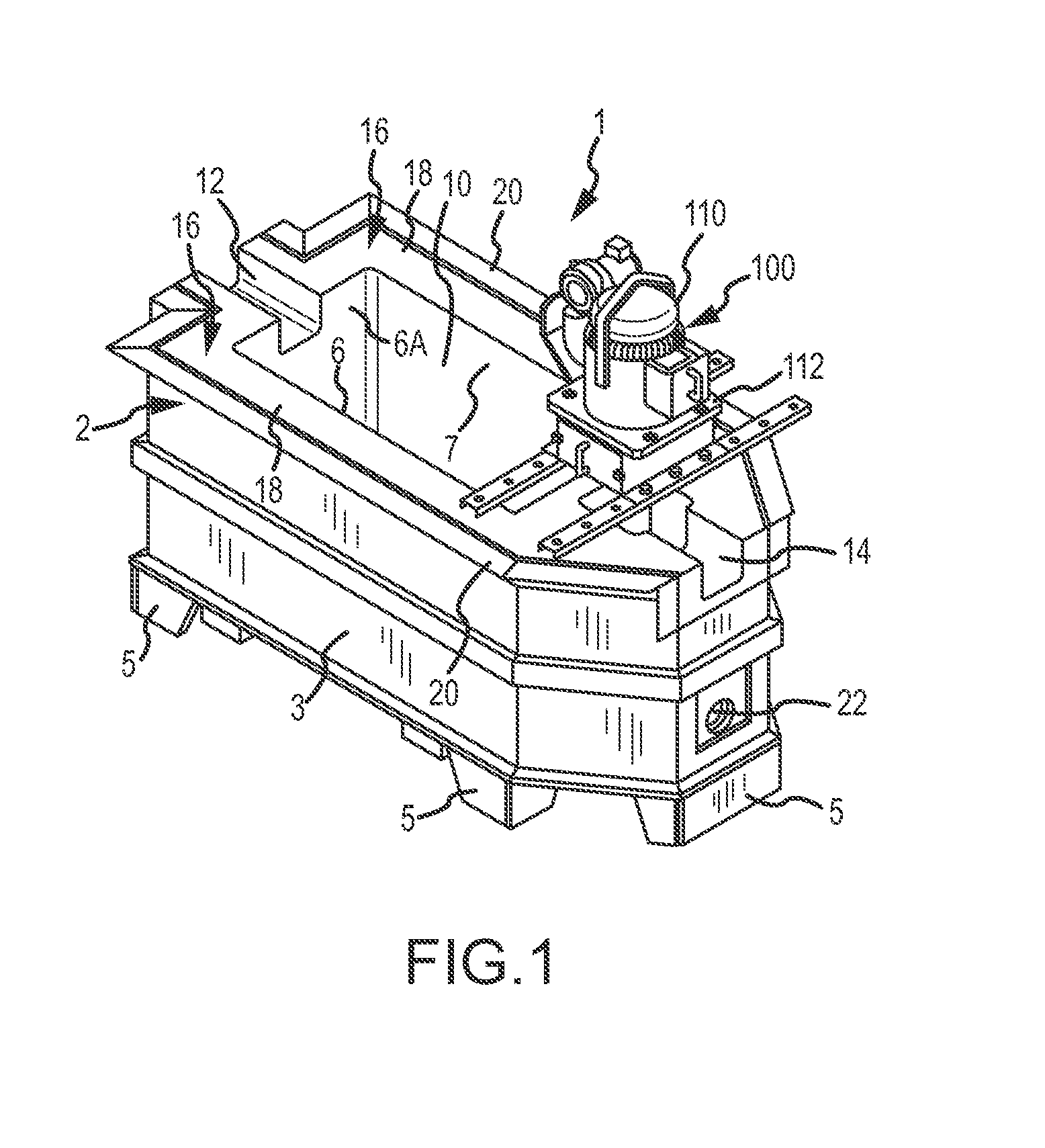

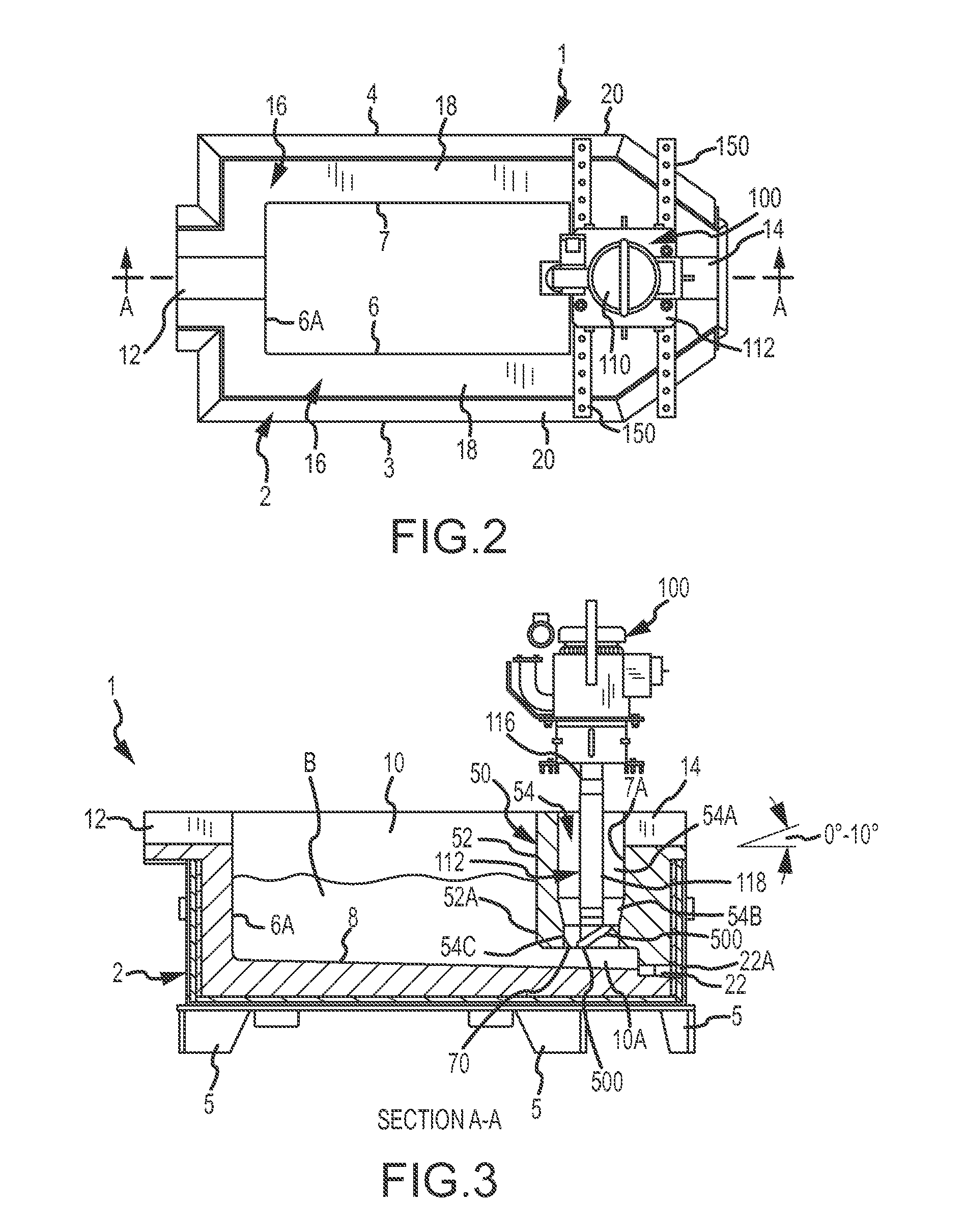

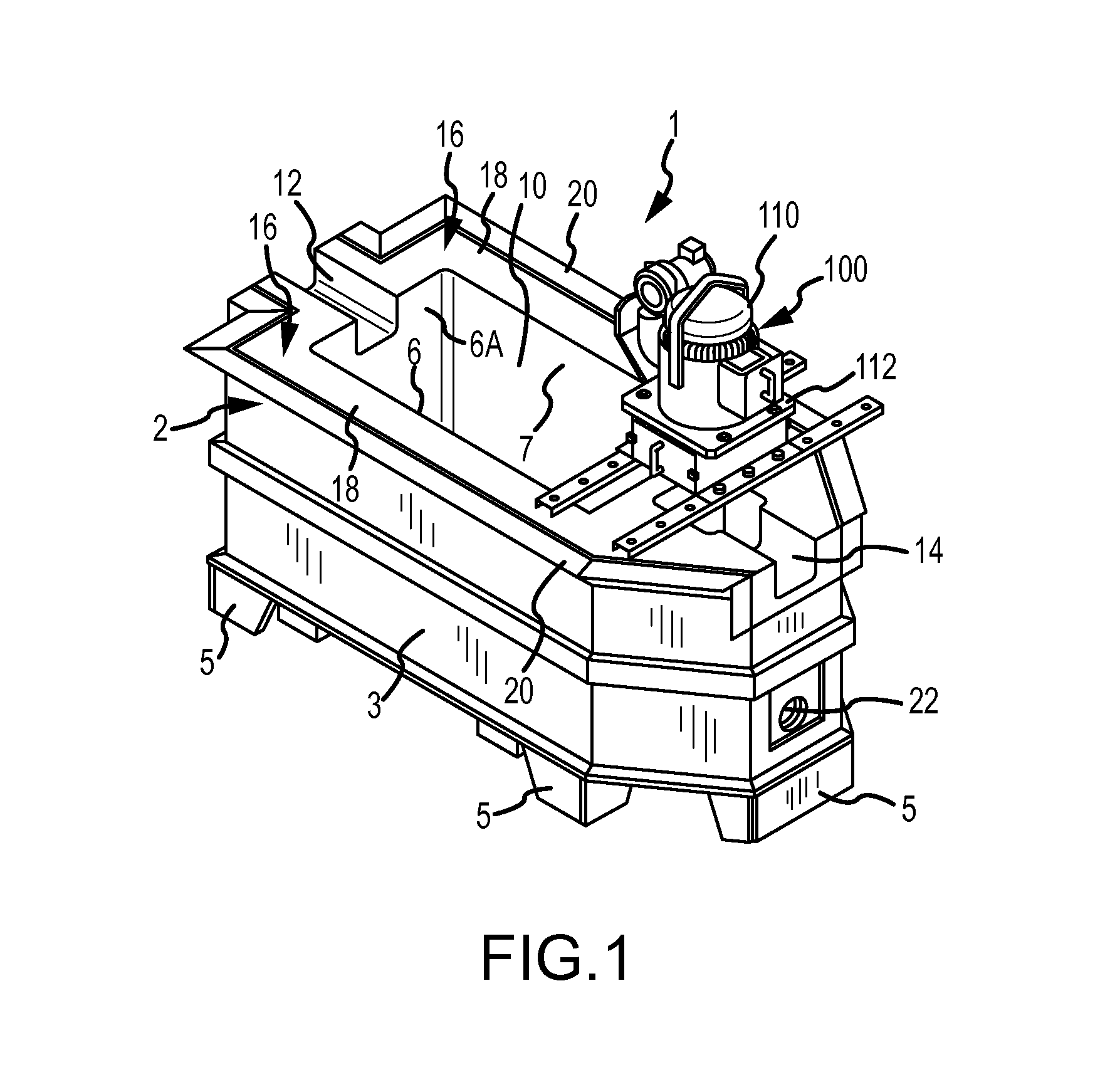

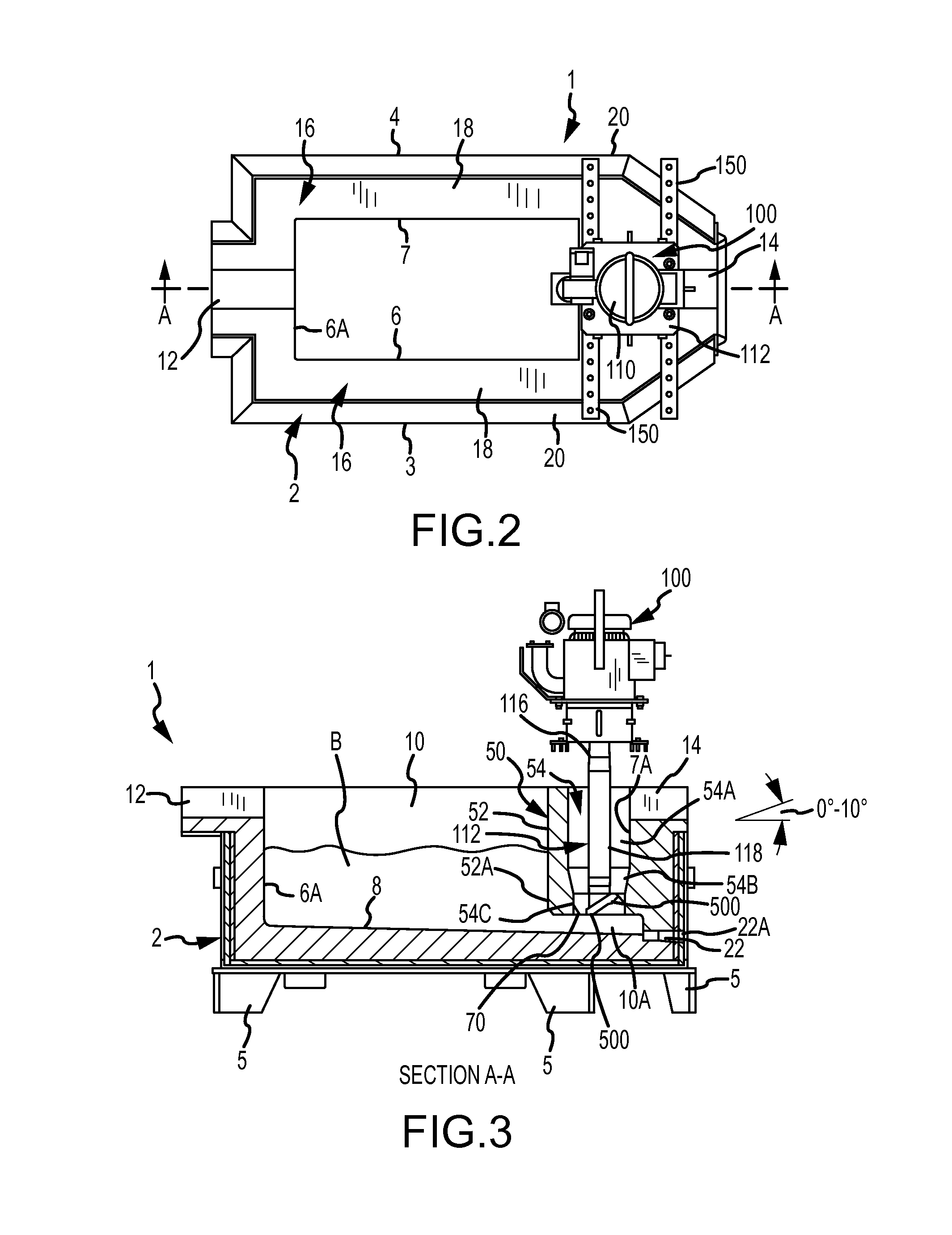

Scrap melter and impeller therefore

InactiveUS20080230966A1Reduce jammingReduce cloggingMelt-holding vesselsStirring devicesImpellerDrive shaft

A device for submerging scrap metal includes: (a) a drive source, (b) a drive shaft having a first end and a second end, the first end being connected to the drive source, and (d) an impeller connected to the second end of the drive shaft, the impeller preferably having two or more outwardly-extending blades. Preferably, each of the blades has a portion that directs molten metal at least partially downward. The impeller design leads to lower operating speeds, lower vibration, longer component life and less maintenance. Additionally, the impeller preferably has a connective portion. The connective portion is used to connect the impeller to the shaft and preferably comprises a nonthreaded, tapered bore extending through the impeller.

Owner:COOPER PAUL V

Molten metal pressure pour furnace and metering valve

InactiveUS7279128B2Avoid flowMelt-holding vesselsMolten metal pouring equipmentsDifferential pressureMetallurgy

An apparatus and process are provided for discharging a dose of a molten metal from a pressure pour furnace. A heating chamber of the furnace is used to keep the molten metal at a selected temperature. A sealing port between the heating chamber and a pressure chamber allows selectively filling of the pressure chamber with molten metal from the heating chamber by inserting or removing a sealing means from the sealing port. The sealing means inserted in the sealing port also provides a means for preventing back flow of the molten metal to the heating chamber when the pressure chamber is pressurized. Differential pressure sensing of the pressure of the molten metal in the pressure chamber and the pressure of the pressurizing gas in the pressure chamber can optionally be used to achieve an accurate measured discharge from the pressure chamber as the level of molten metal decreases from repeated discharges of doses from the furnace. The sealing plate in which the sealing port is disposed and the sealing means selectively inserted or removed from the sealing port can be used as a metering valve between two molten metal containing components such as a launder and a pressure chamber of a pressure pour furnace.

Owner:HI T E Q

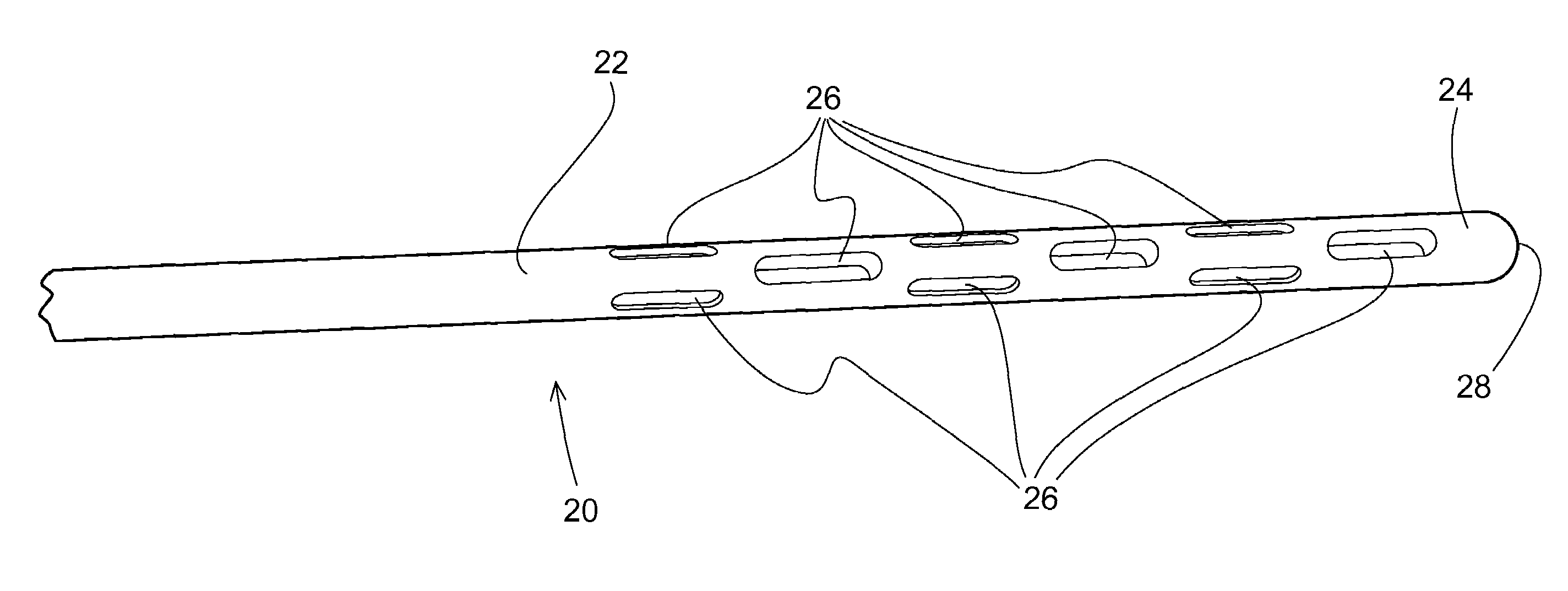

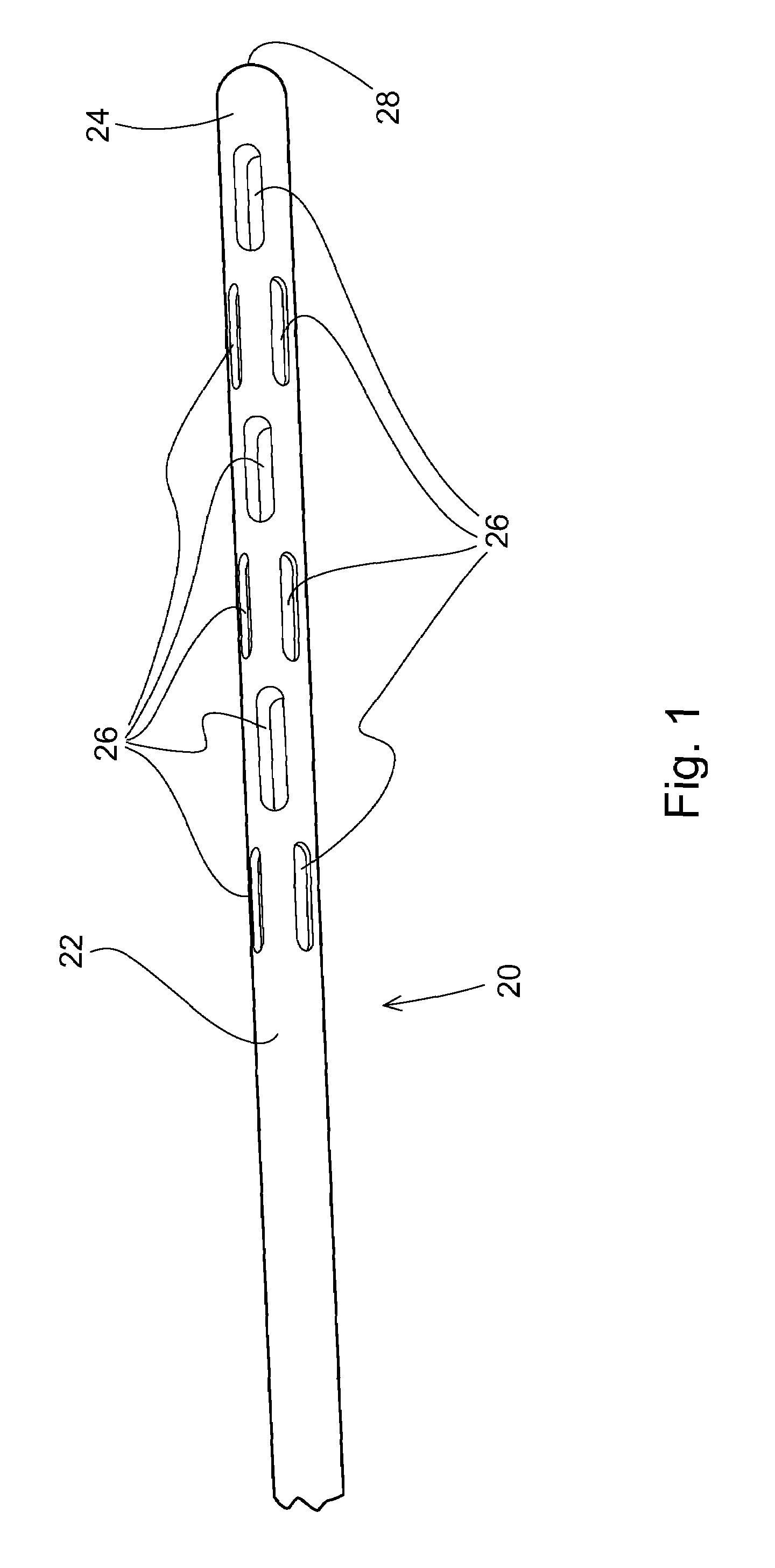

Closed System and Method for Atraumatic, Low Pressure, Continuous Harvesting, Processing, and Grafting of Lipoaspirate

ActiveUS20080167613A1Reduce excessFat graft survivalMelt-holding vesselsMedical devicesFat graftingEngineering

A closed system for harvesting fat through liposuction, concentrating the aspirate so obtained, and then re-injecting the concentrated fat into a patient comprises as its main components a low pressure cannula having between about 7 to 12 side holes of about 1-2 mm by 2.0 to 4.0 mm, a spring loaded syringe holder with a helicoidal spring to apply a substantially constant pressure over the full excursion of the plunger, and a preferably flexible collection bag which is also preferably graduated, cylindrical over most of its body and funnel shaped at its bottom, all of which are connected through flexible tubings to a multi-port valve. The multi-port valve has two flutter / duck bill valves which restrict the fluid flow to a one way direction which effectively allows the syringe to be used to pump fat out of a patient and into a collection bag in a continuous manner. After the bags are centrifuged to concentrate the fat, the excess fluids are separated and the valve is re-connected to permit the syringe pump to reverse fluid flow to graft the concentrated fat back into the patient.

Owner:LIPOCOSM LLC

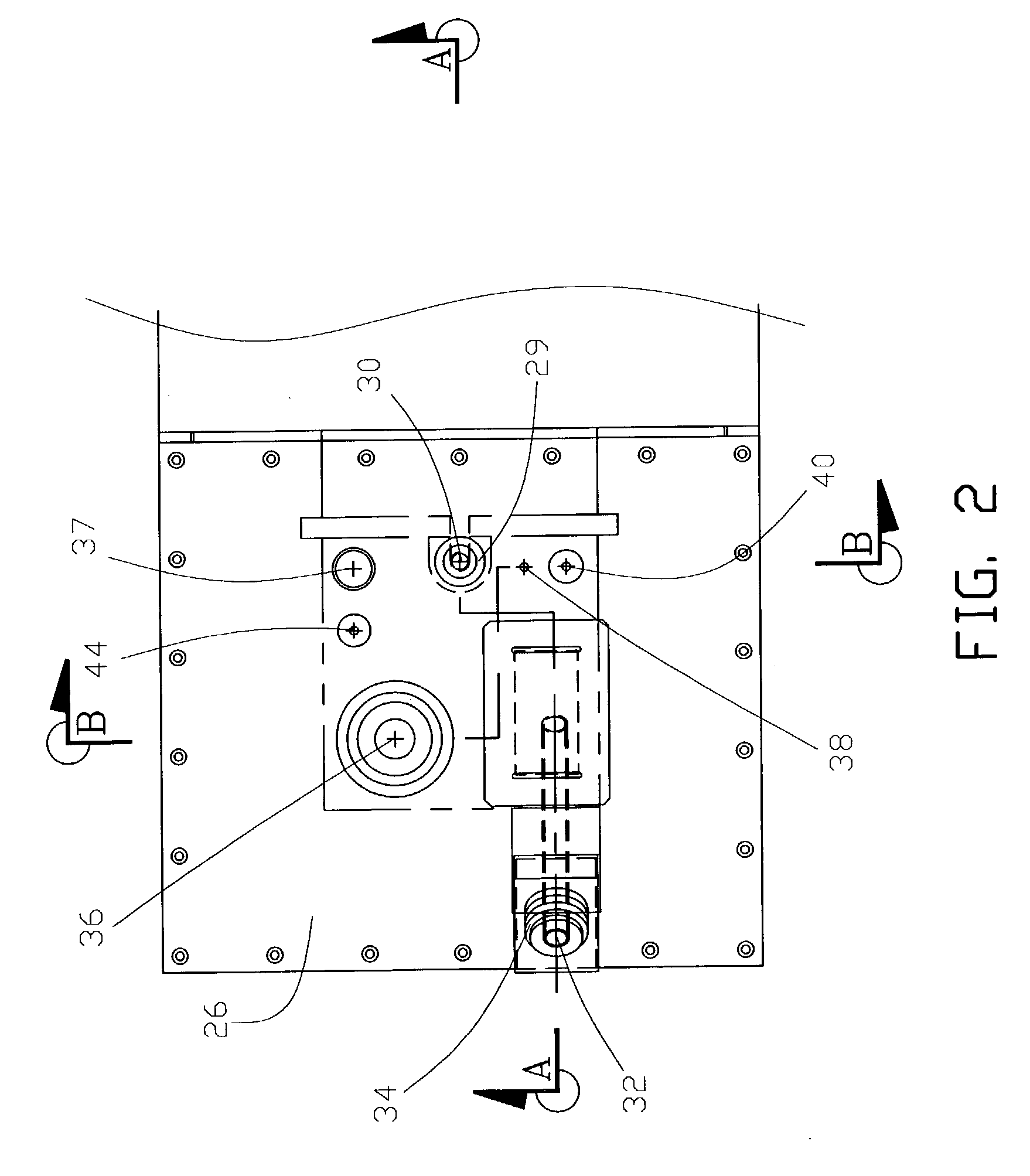

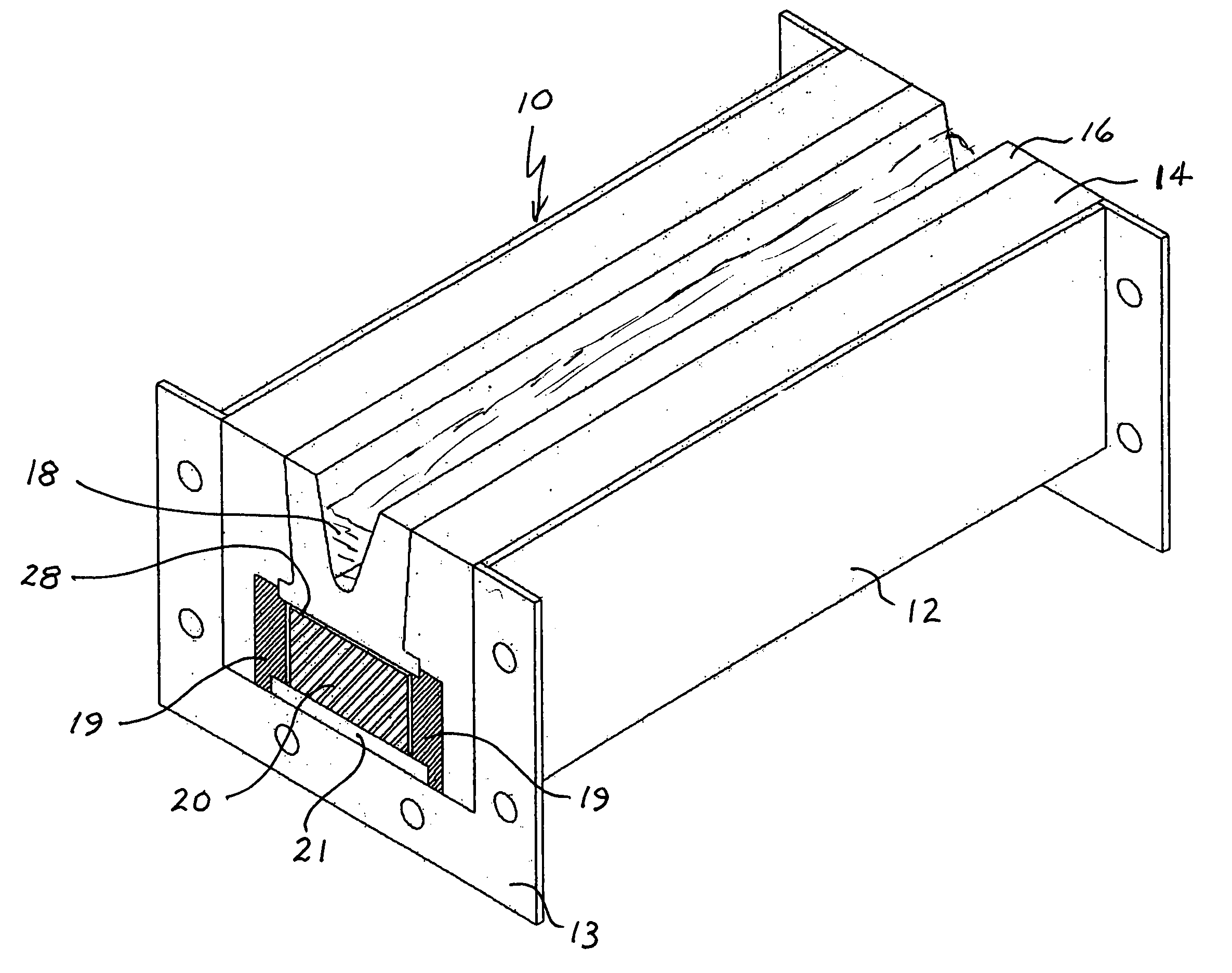

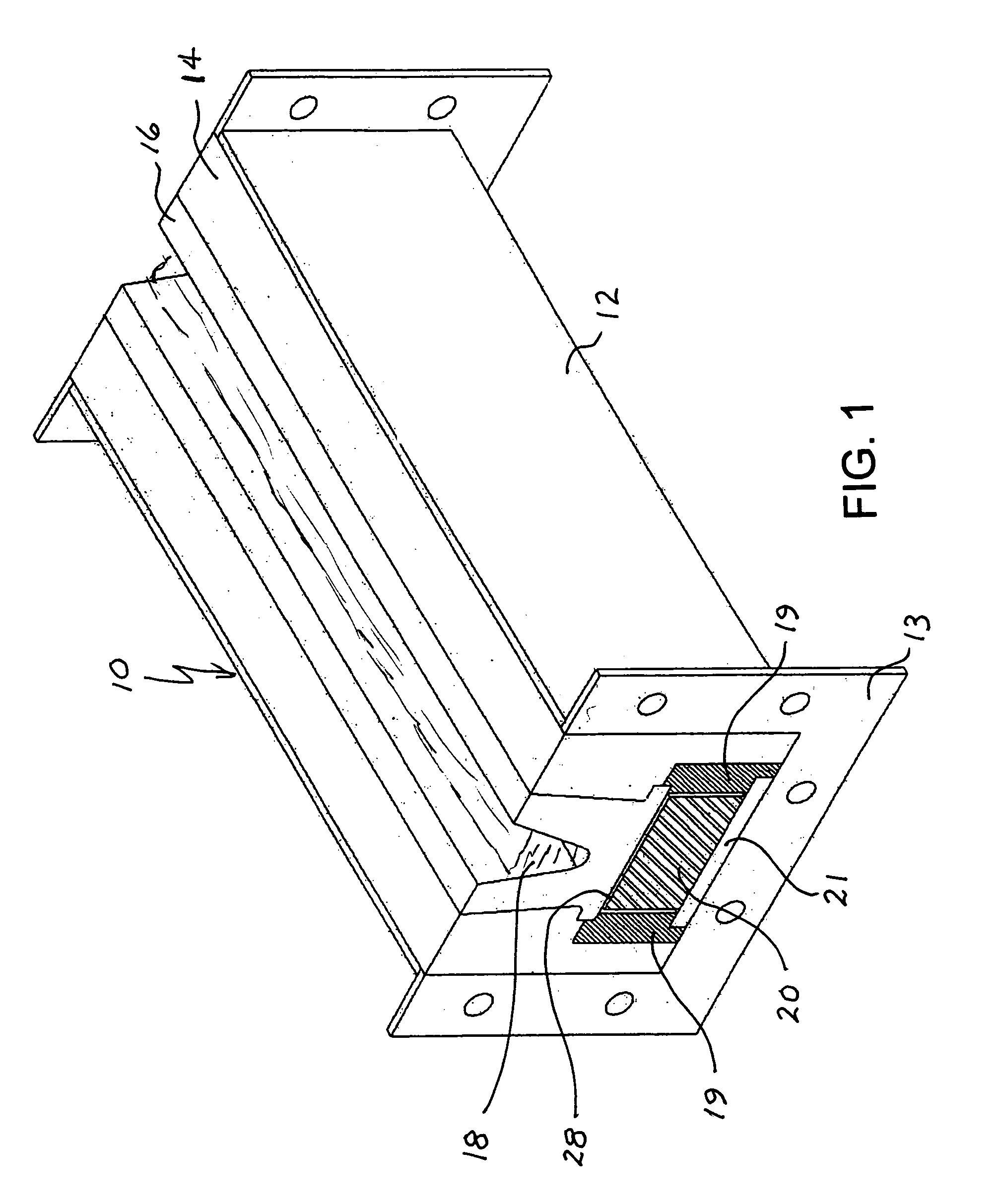

Method of forming transfer well

ActiveUS20160082507A1Melt-holding vesselsMolten metal pouring equipmentsMarine engineeringMolten metal

The invention relates to systems for transferring molten metal from one structure to another. Aspects of the invention include a transfer chamber constructed inside of or next to a vessel used to retain molten metal. The transfer chamber is in fluid communication with the vessel so molten metal from the vessel can enter the transfer chamber. A powered device, which may be inside of the transfer chamber, moves molten metal upward and out of the transfer chamber and preferably into a structure outside of the vessel, such as another vessel or a launder.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Dual recycling/transfer furnace flow management valve for low melting temperature metals

InactiveUS7543605B1Eliminate needIncrease flow rateMelt-holding vesselsMolten metal pouring equipmentsControl valvesFlow management

A furnace flow control valve for use within a bath of molten metal. The flow control valve includes a vertically-disposed elongated tubular stator, which is configured to receive flow from a molten metal pump. The valve has a rotor which is sealing rotatable within the stator between: a full re-circulation position, where flow from the pump passes un-hindered through the valve; a full transfer position, where flow from the pump is redirected into the vertically disposed stator and out of the valve; and a partial re-circulation / partial transfer position where flow from the pump both passes through the valve and is transferred up and out of valve through the stator.

Owner:MORANDO JORGE A

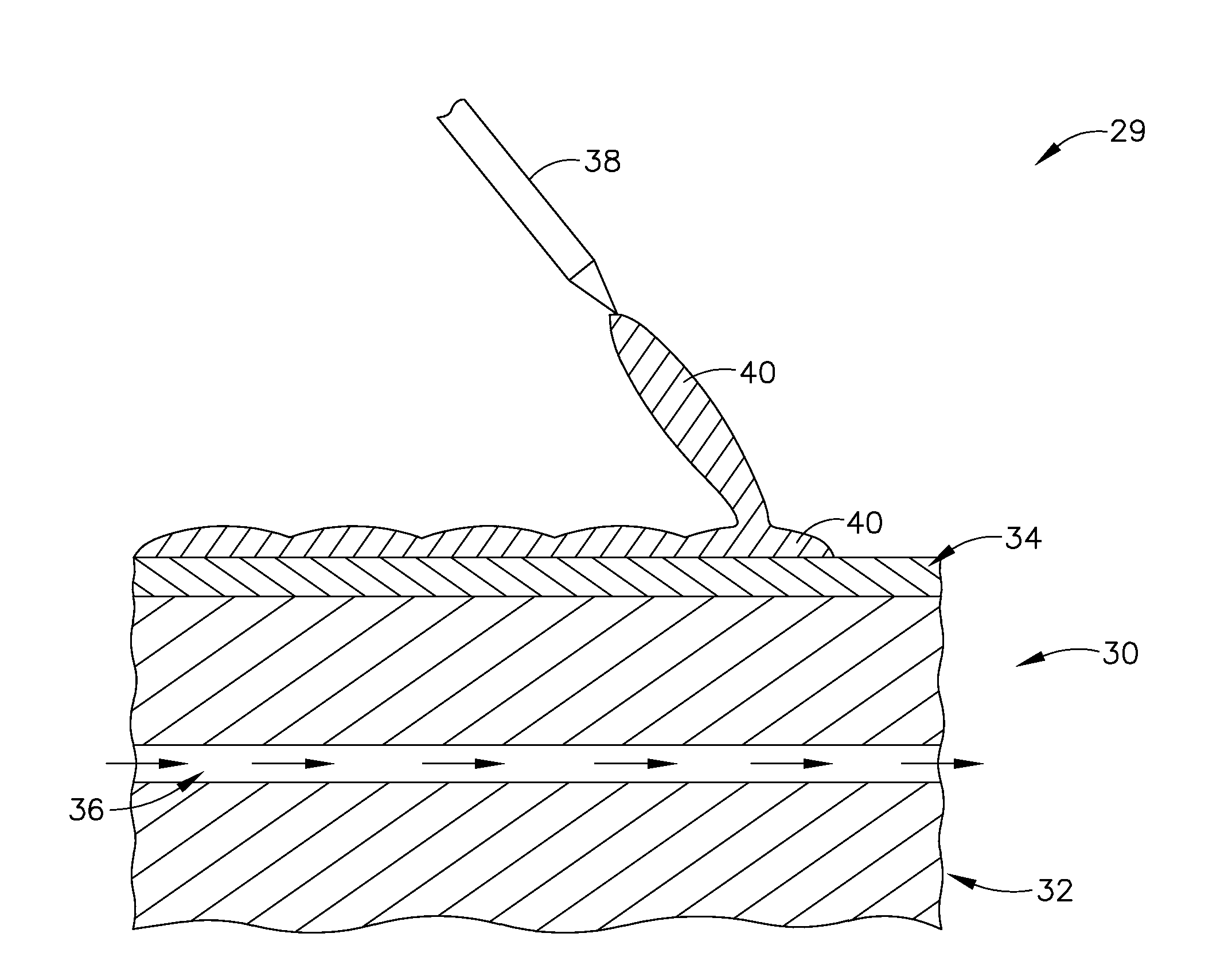

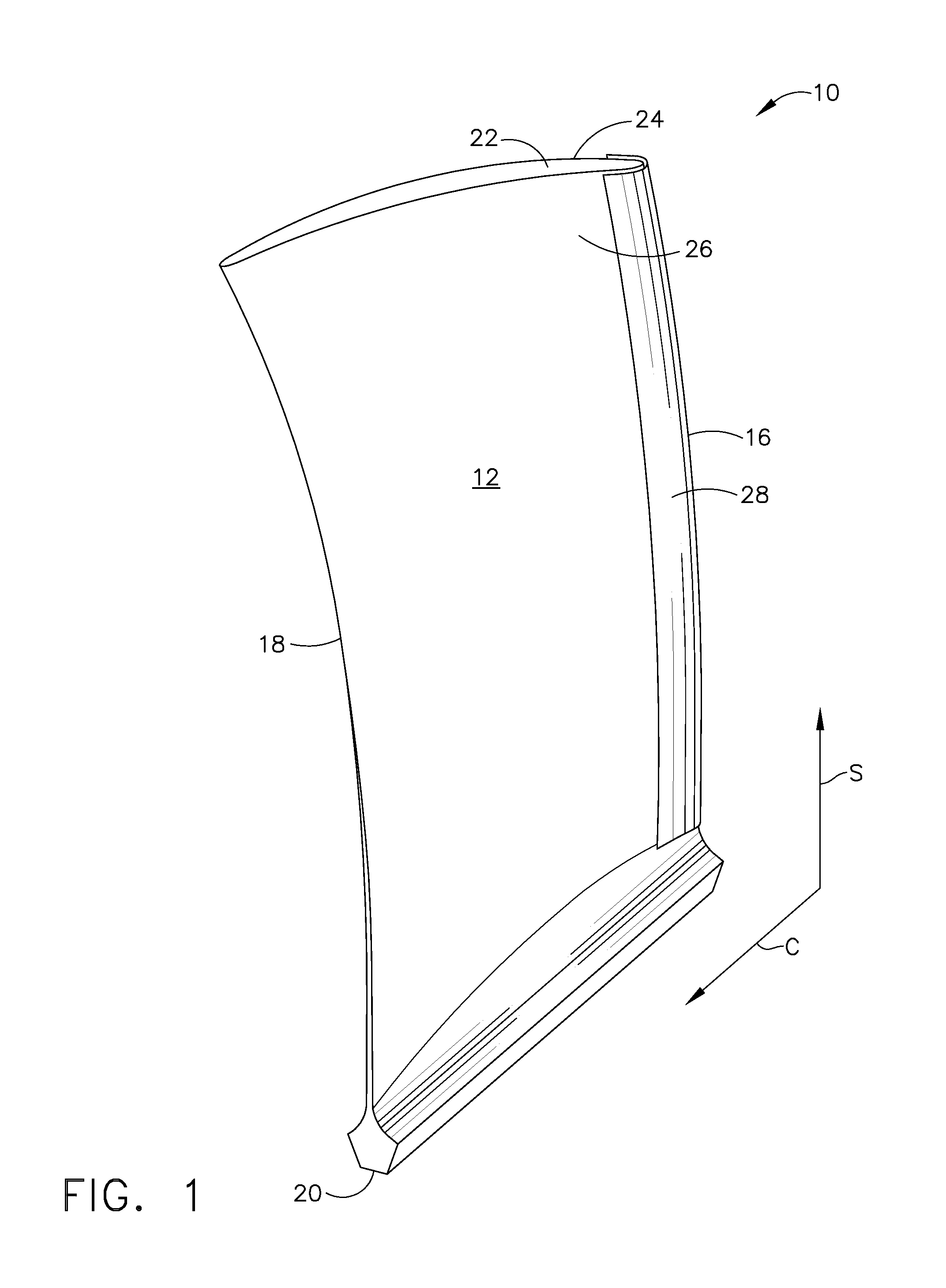

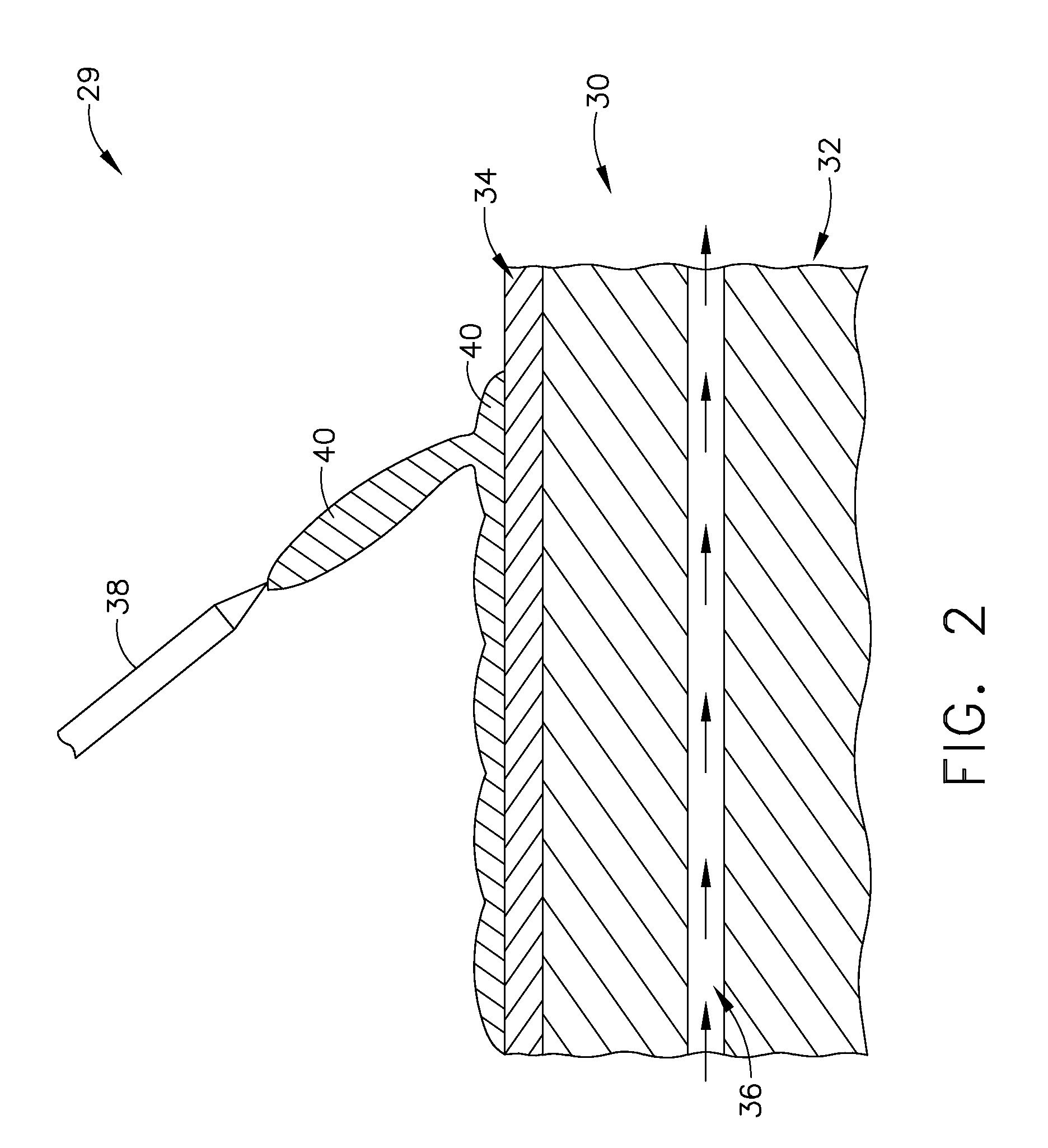

High temperature additive manufacturing systems for making near net shape airfoils leading edge protection, and tooling systems therewith

InactiveUS20100242843A1Reduce pollutionMolten spray coatingVacuum evaporation coatingLeading edgeNear net shape

Tooling systems including a mandrel for receiving, and providing shape to, a metallic deposit applied using a high temperature additive manufacturing device; a metallic cladding applied to the mandrel for reducing contamination of the metallic deposit; and at least one cooling channel associated with the mandrel for removing heat from the system.

Owner:GENERAL ELECTRIC CO

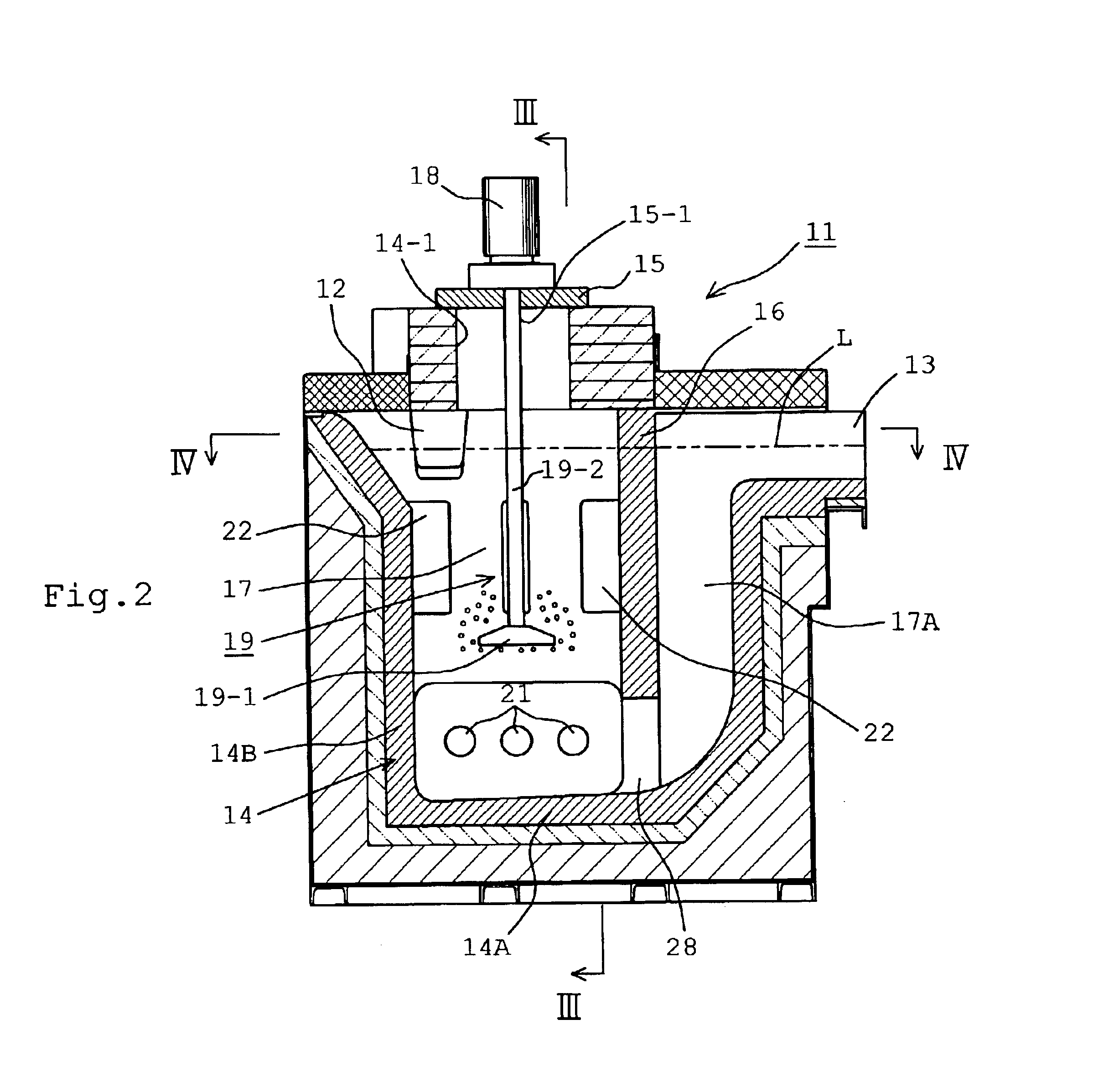

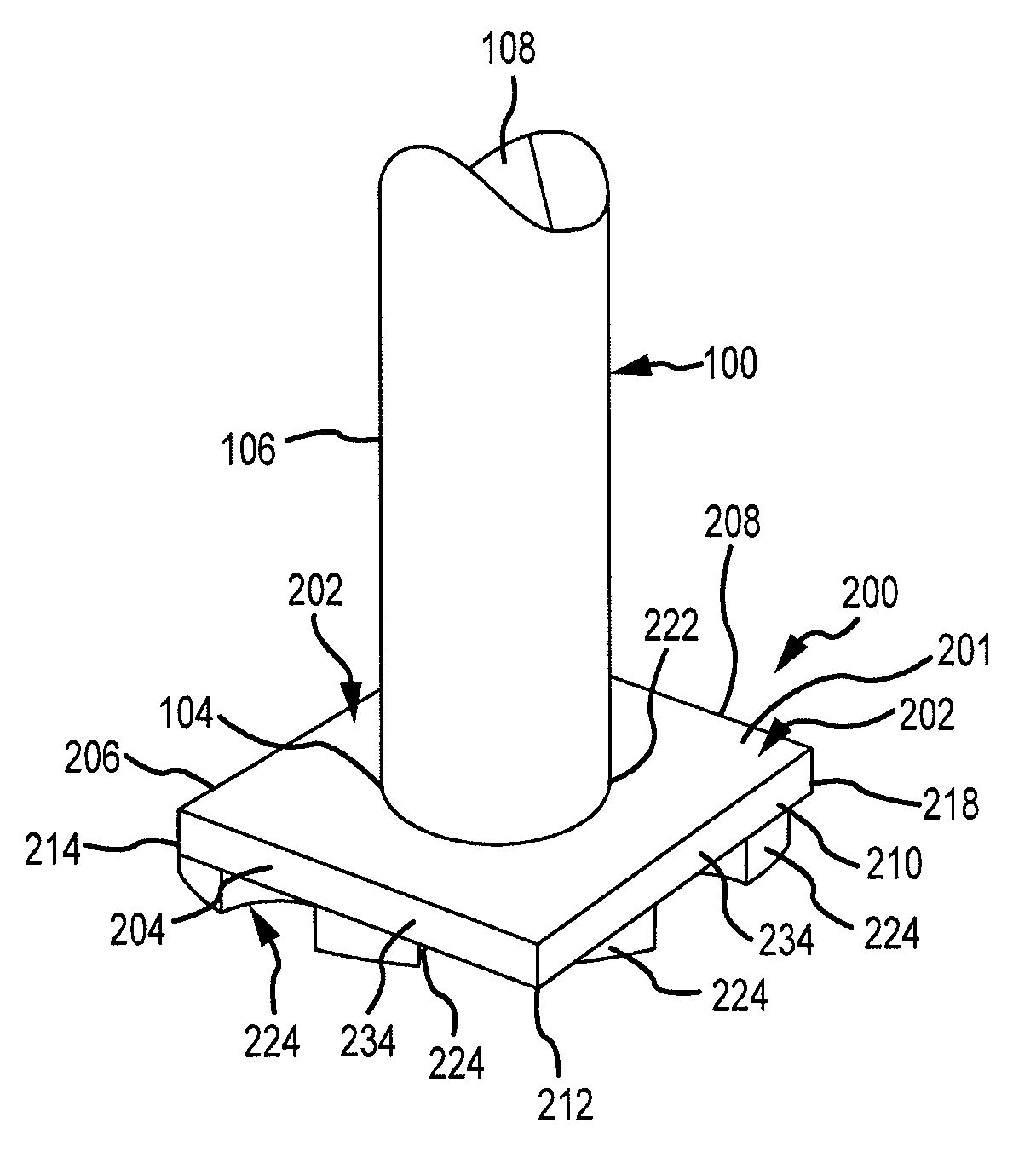

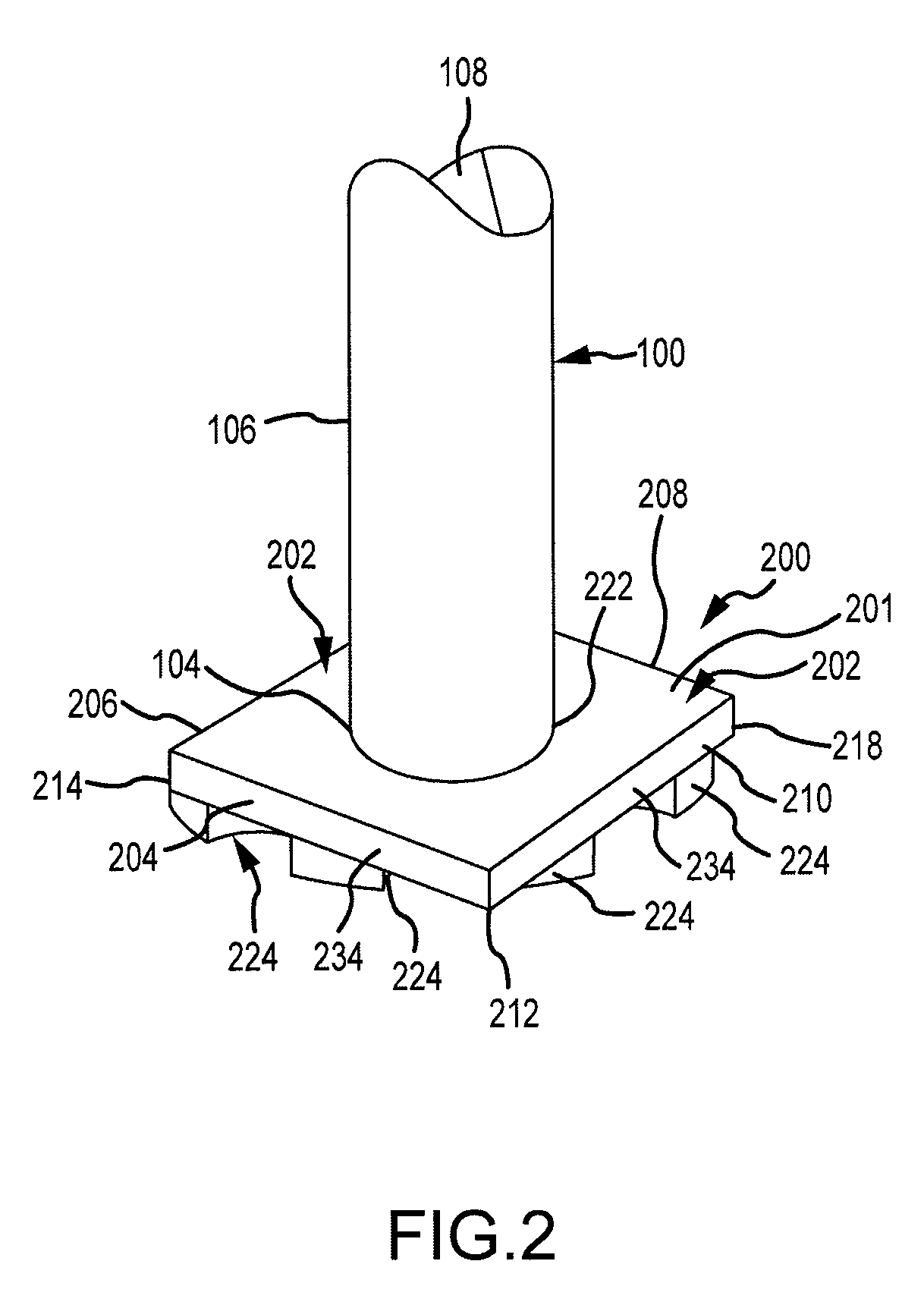

Rotary degasser and rotor therefor

ActiveUS8535603B2Efficiently circulatedWell mixedMelt-holding vesselsStirring devicesImpellerDegasser

A device for dispersing gas into molten metal includes an impeller, a drive shaft having a gas-transfer passage therein, and a first end and a second end, and a drive source. The second end of the drive shaft is connected to the impeller and the first end is connected to the drive source. The impeller includes a first portion and a second portion with a plurality of cavities. The first portion covers the second portion to help prevent gas from escaping to the surface without entering the cavities and being mixed with molten metal as the impeller rotates. When gas is transferred through the gas-transfer passage, it exits through the gas-release opening(s) in the bottom of the impeller. At least some of the gas enters the cavities where it is mixed with the molten metal being displaced by the impeller. Also disclosed are impellers that can be used to practice the invention.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

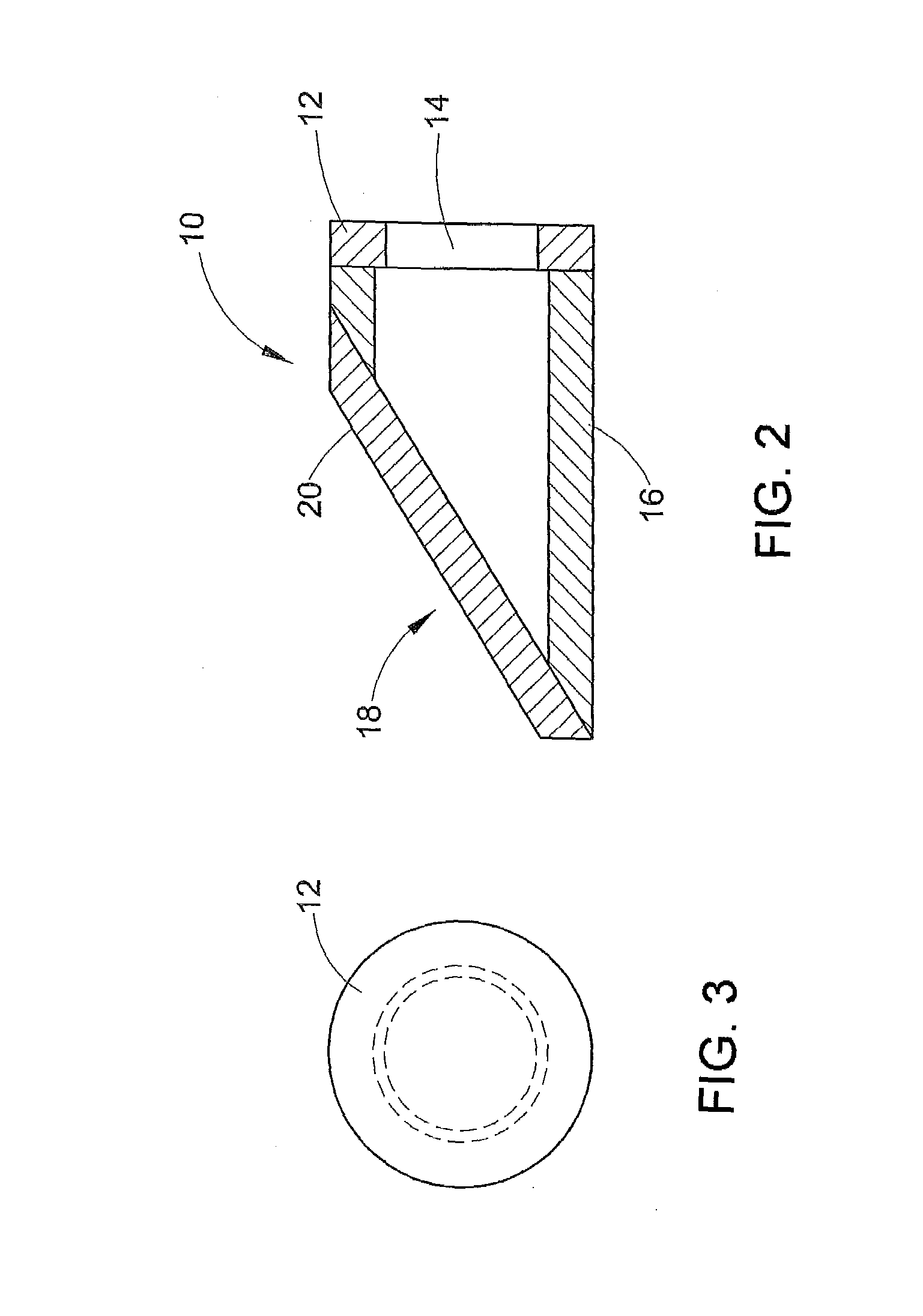

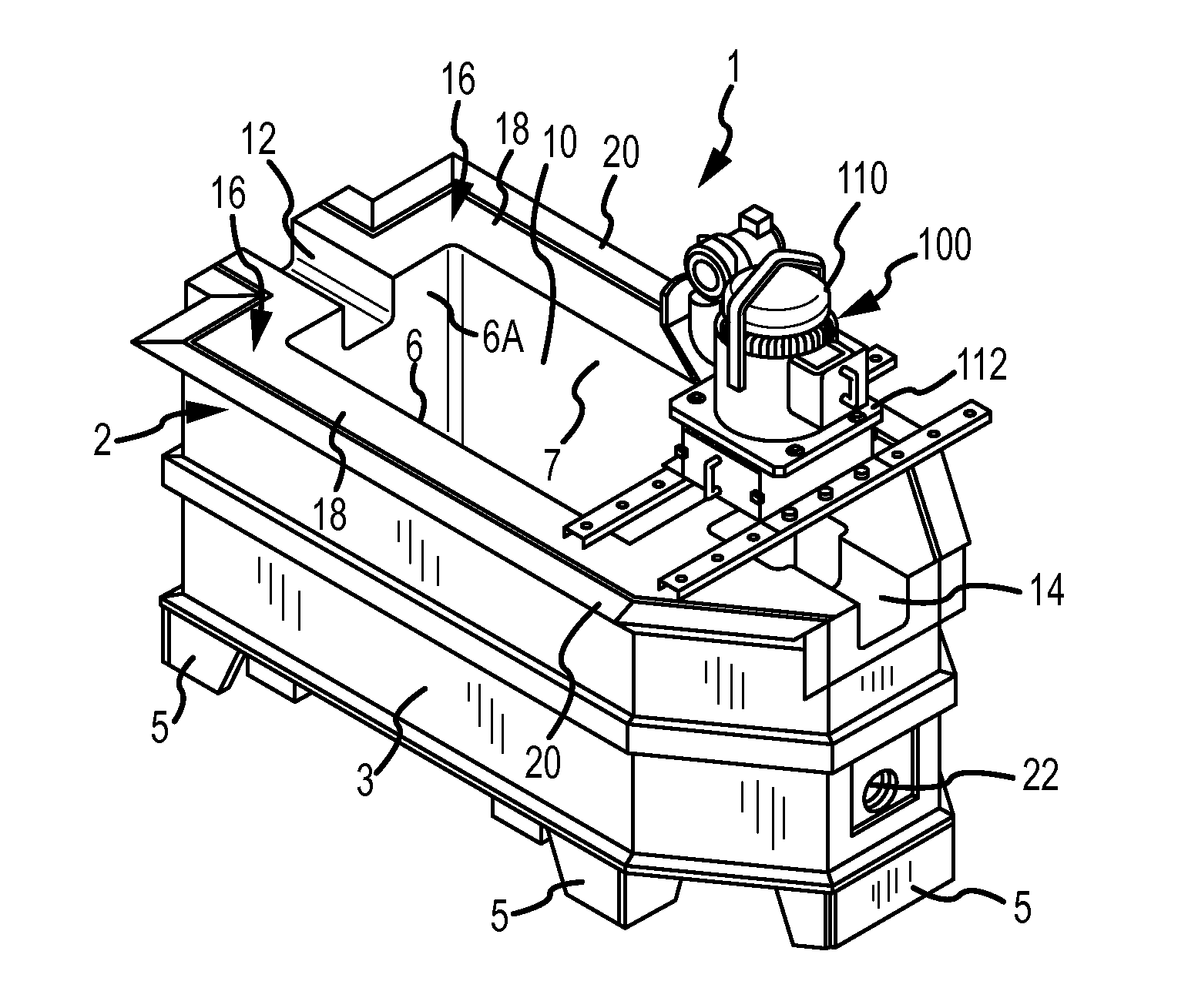

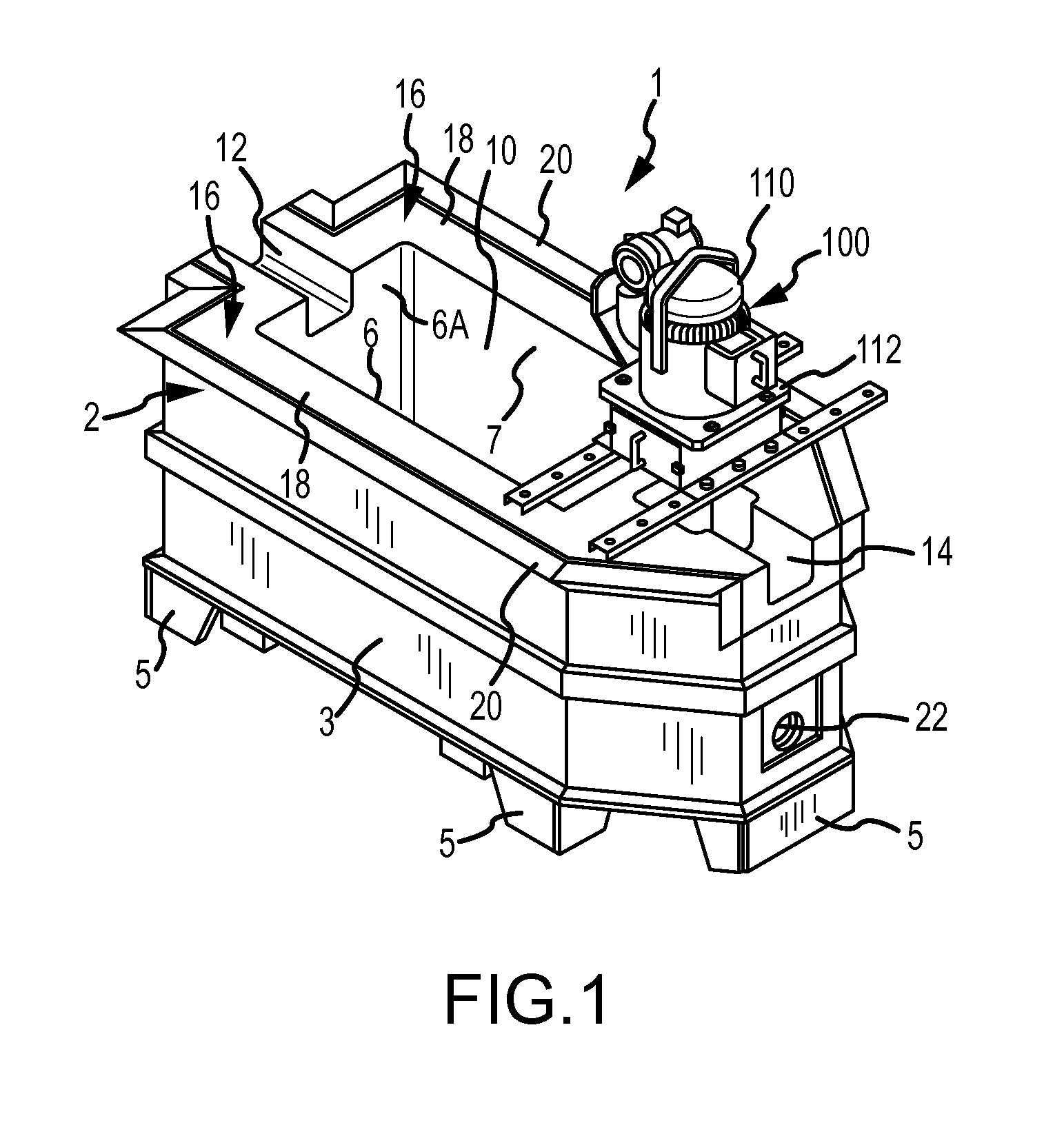

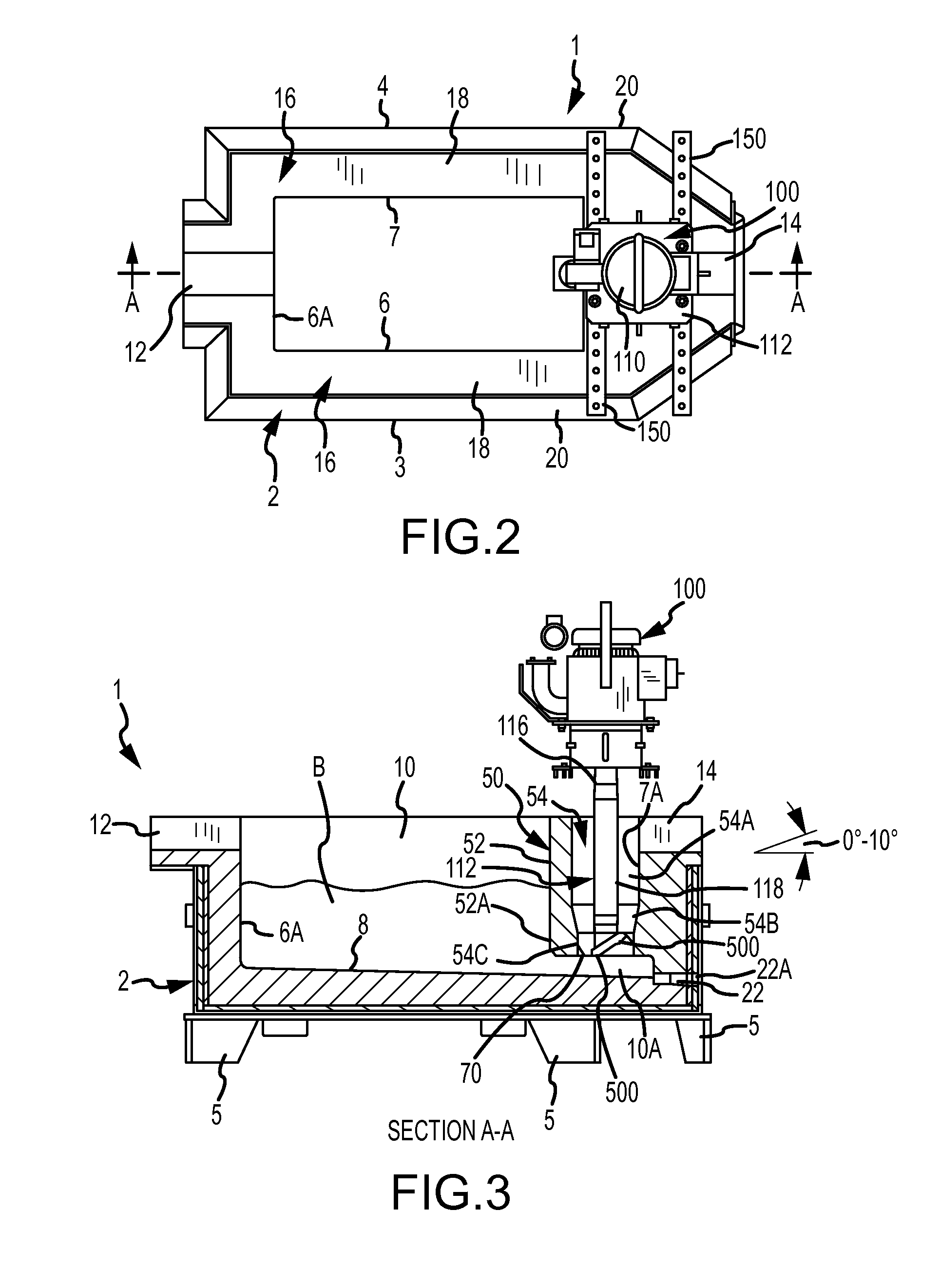

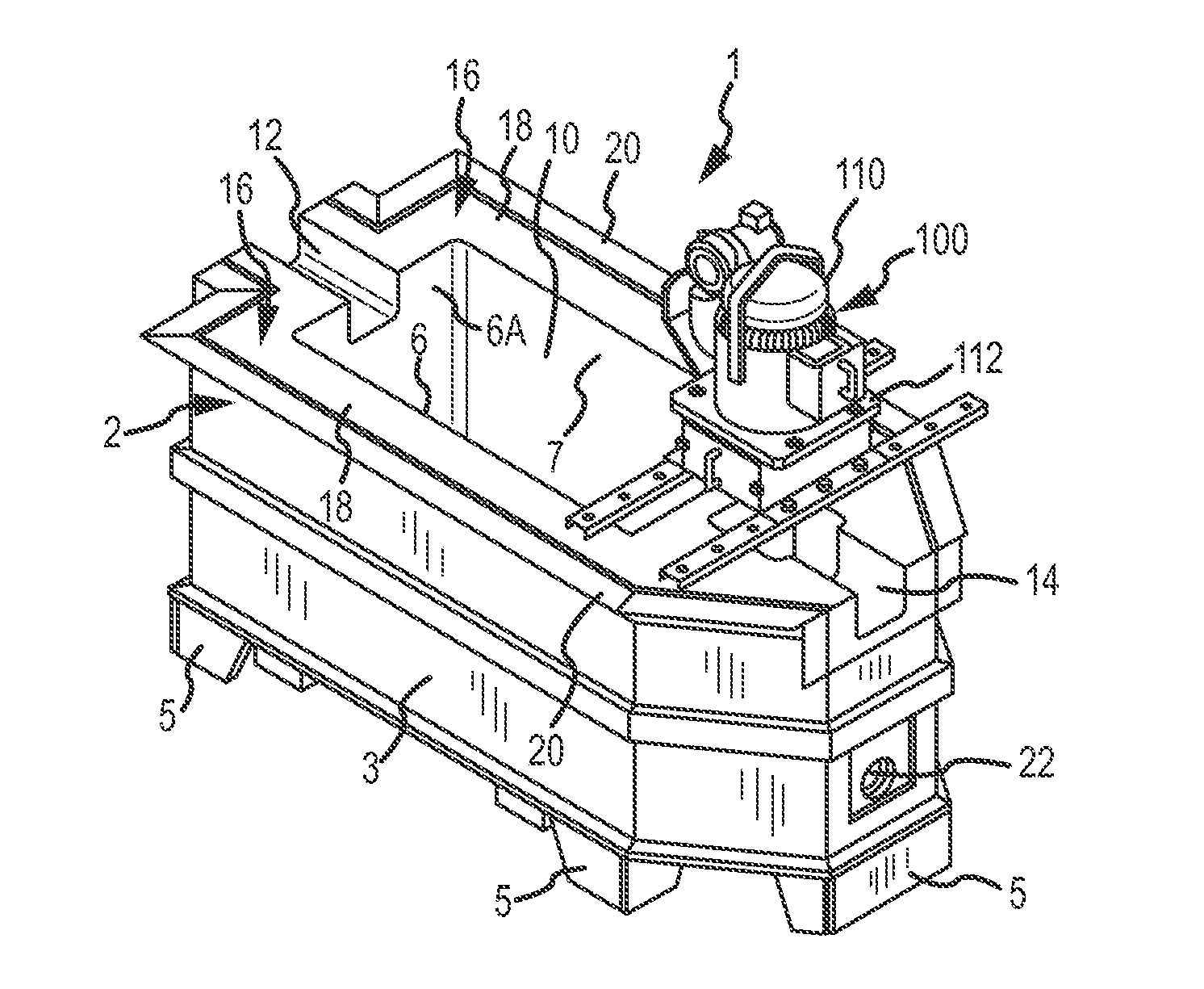

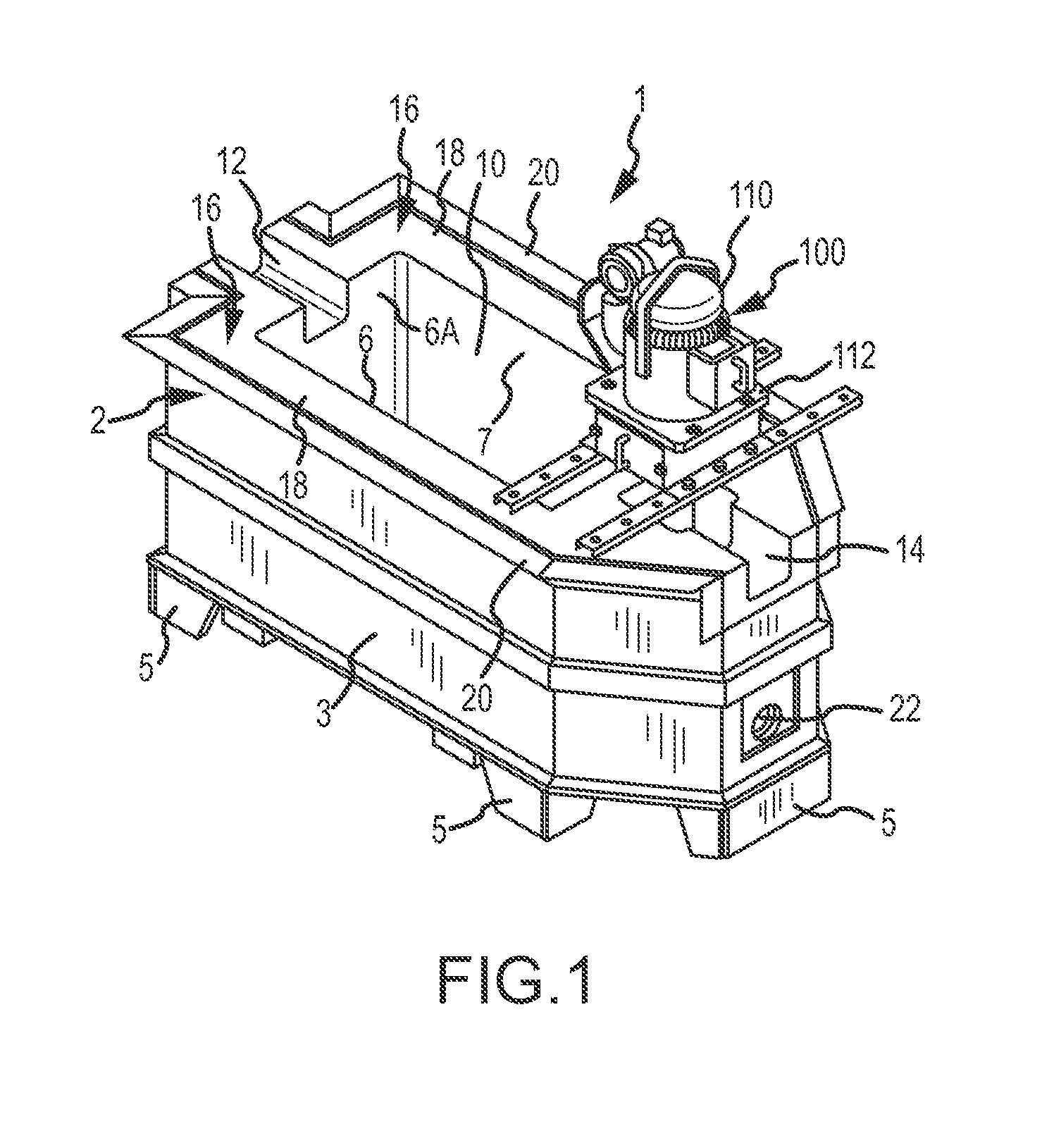

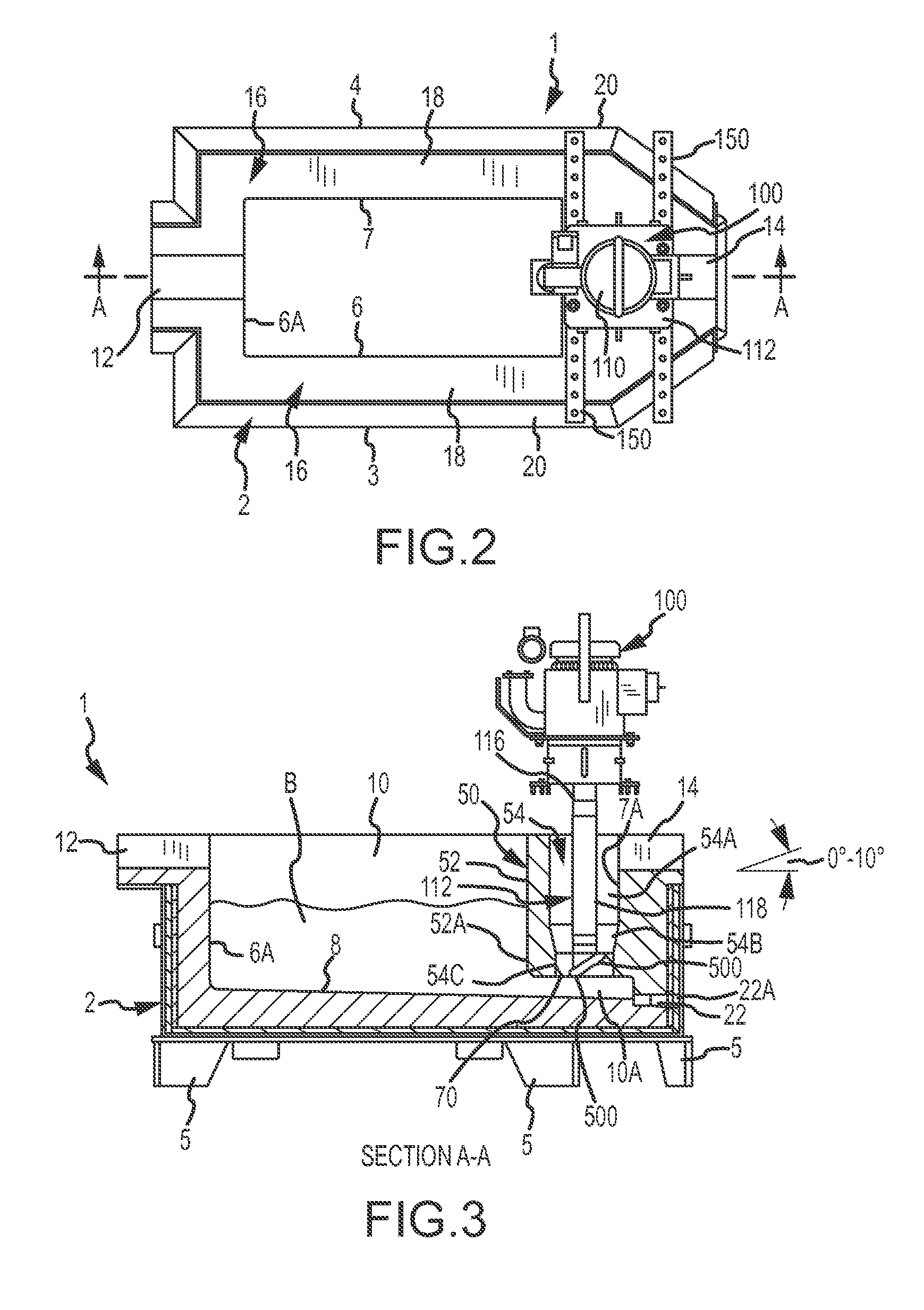

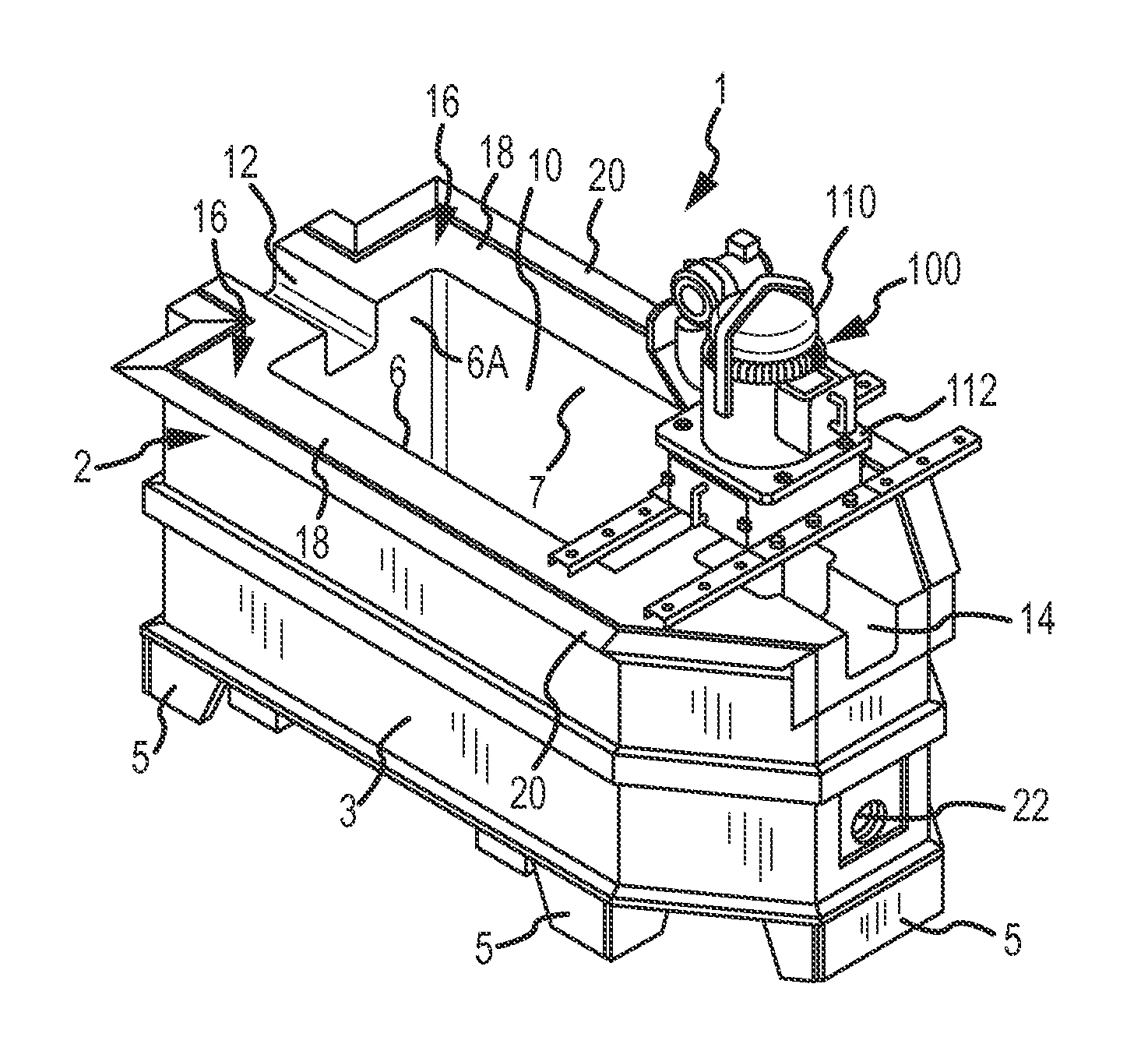

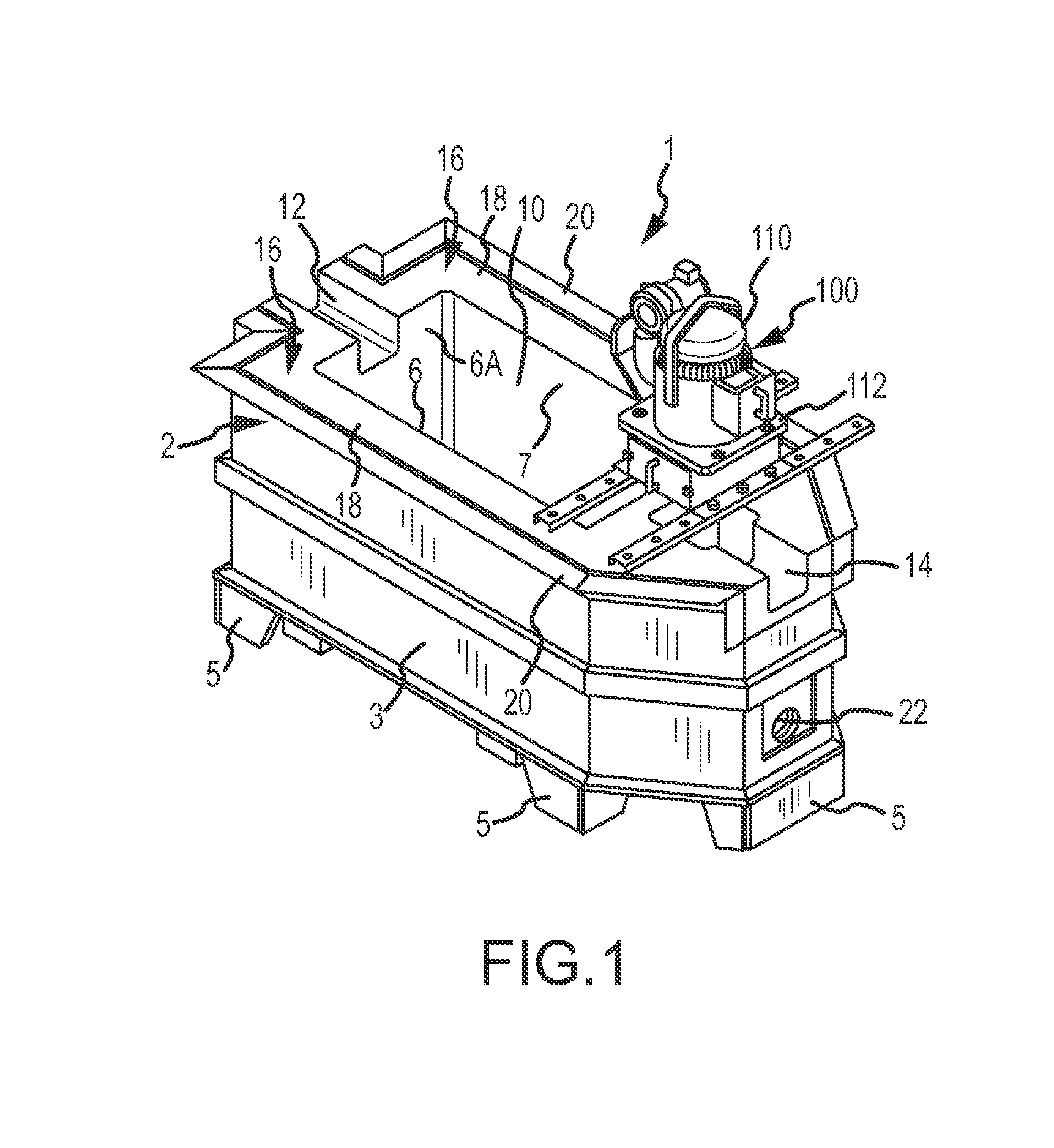

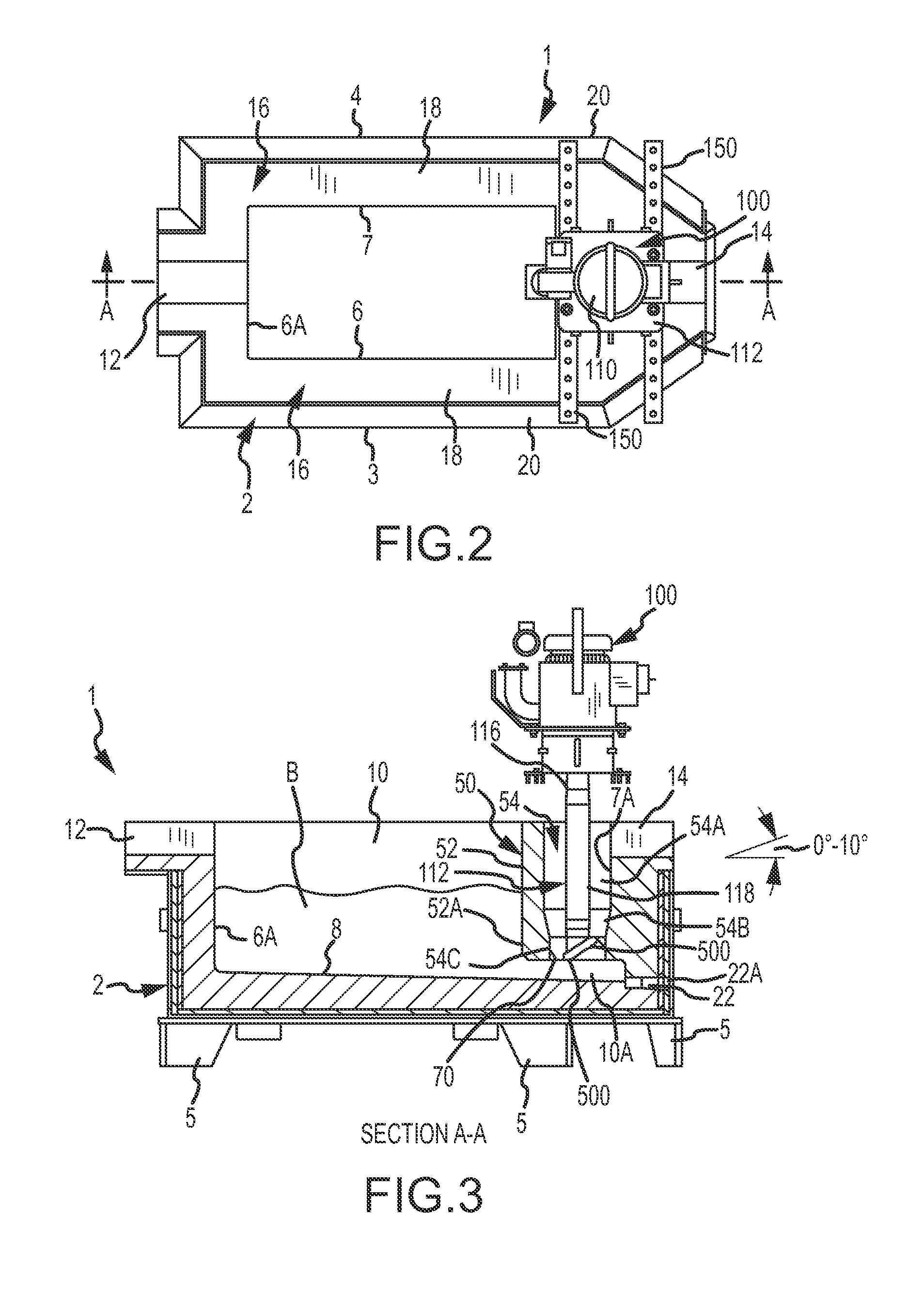

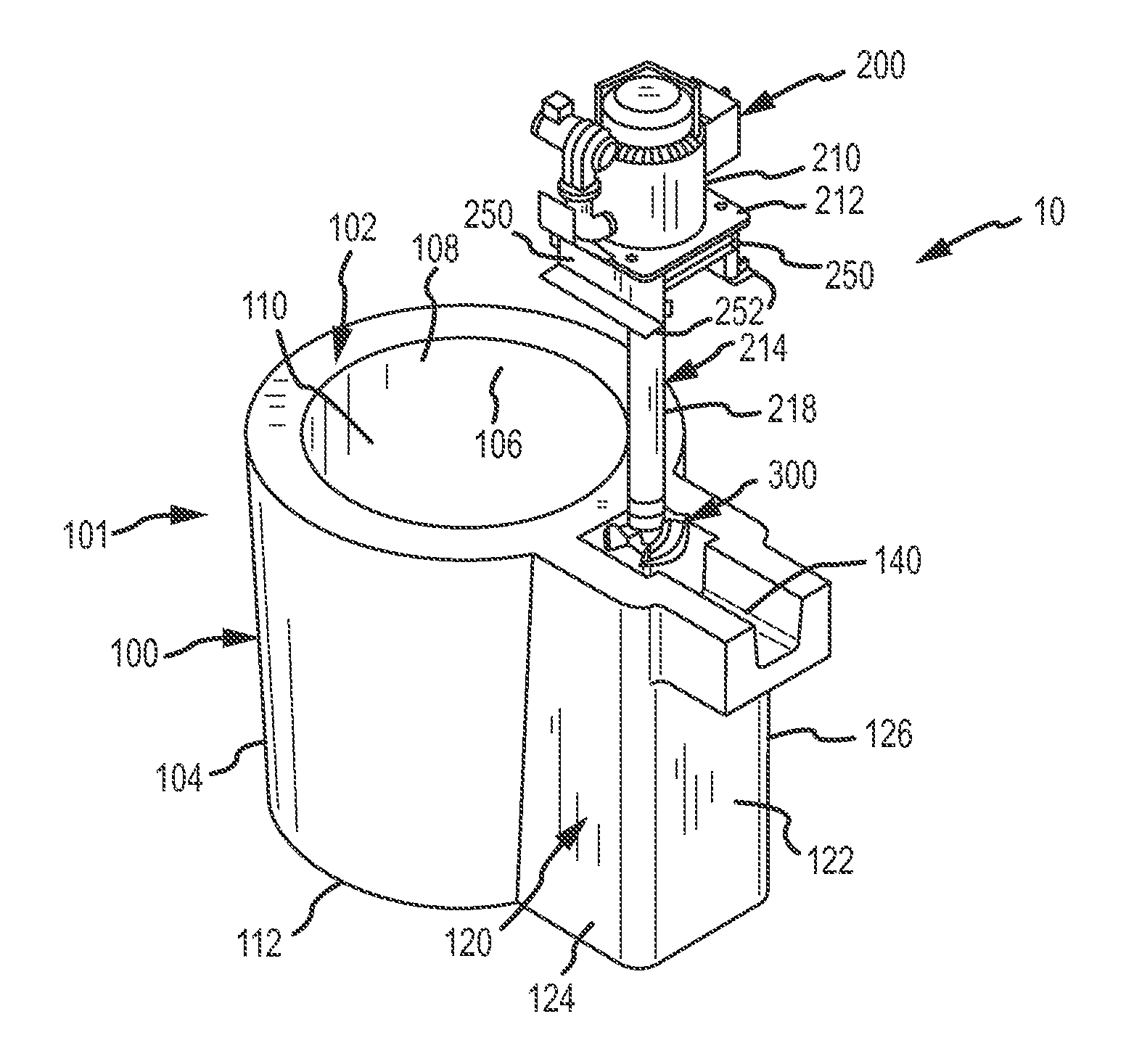

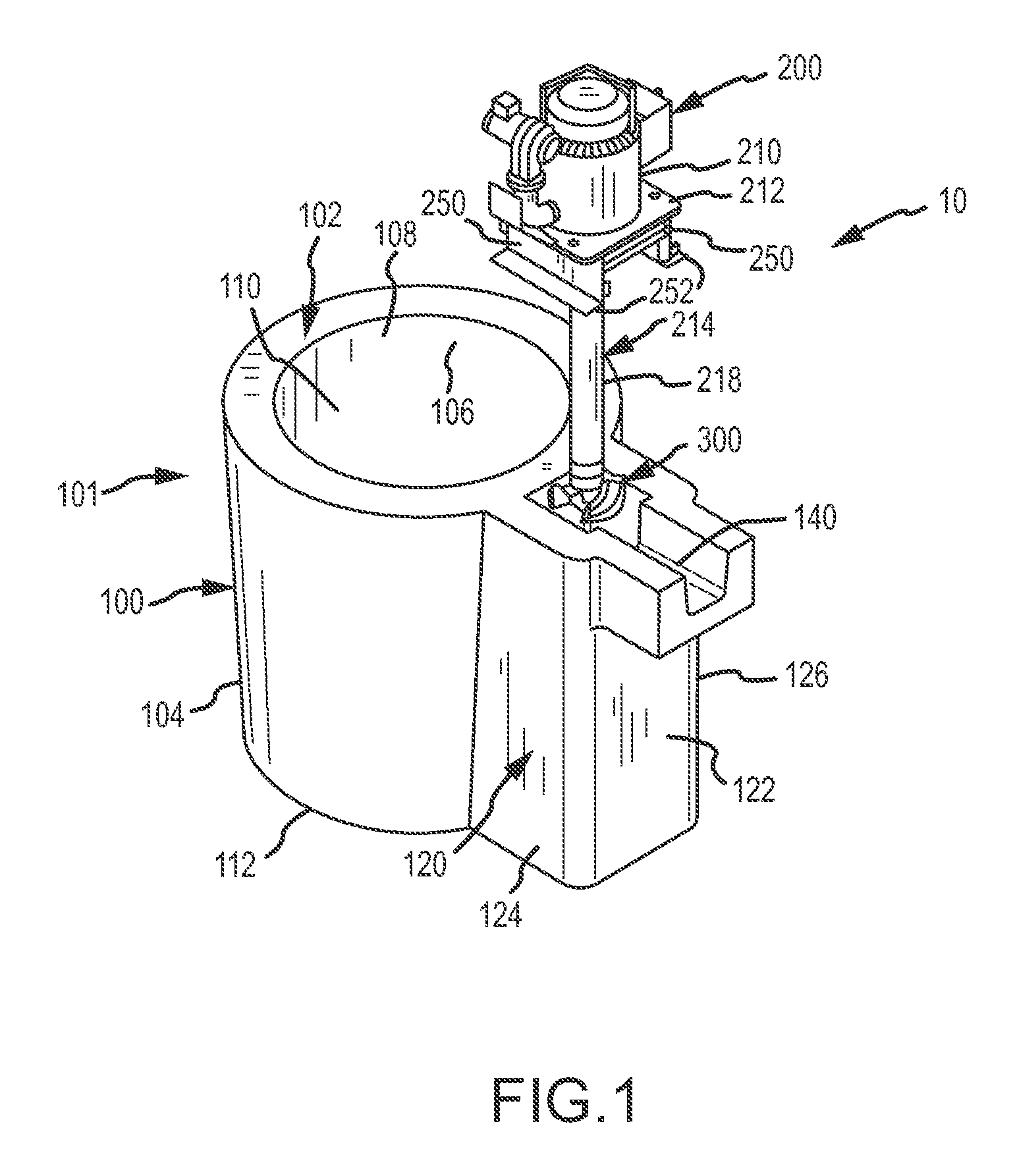

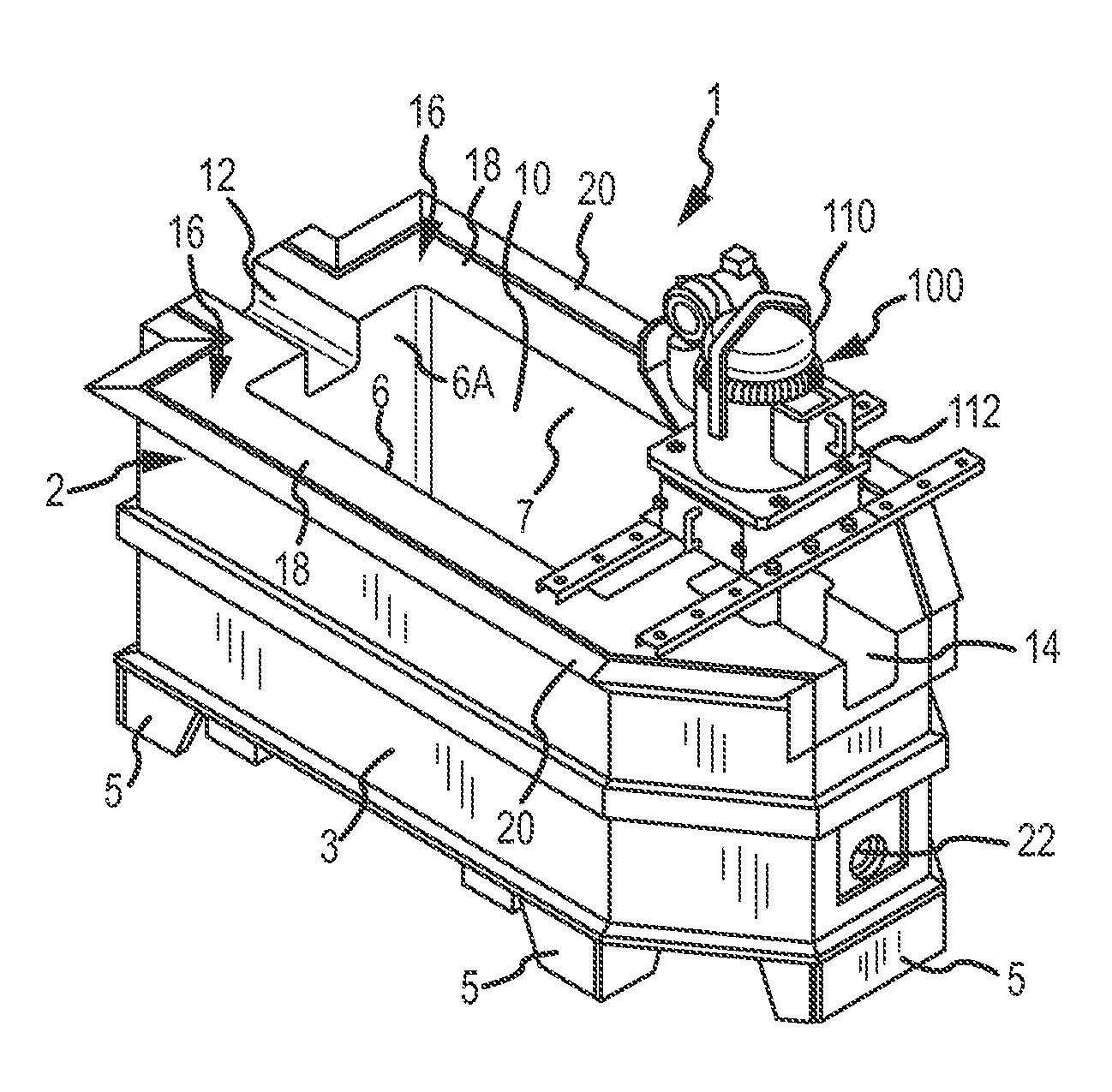

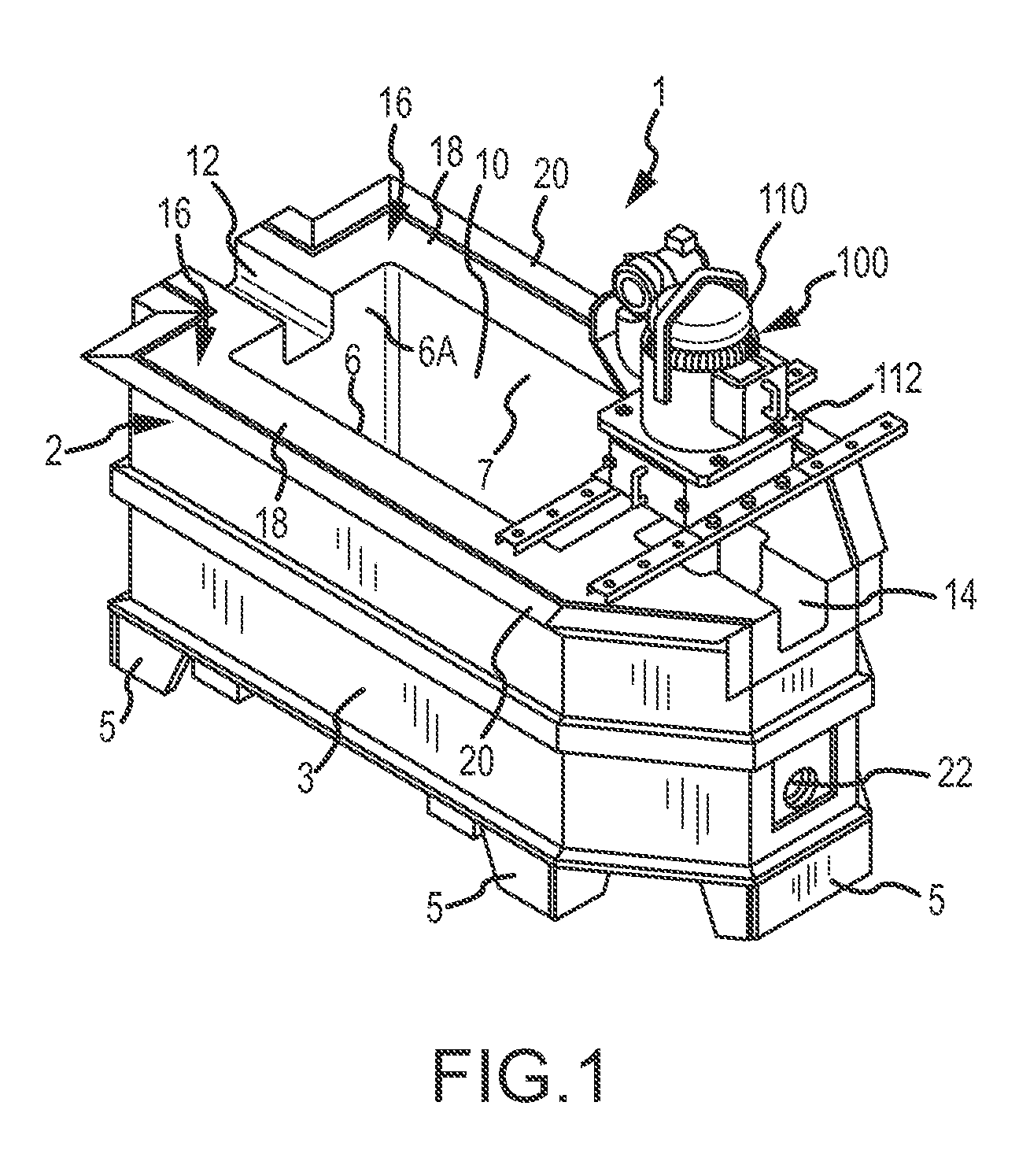

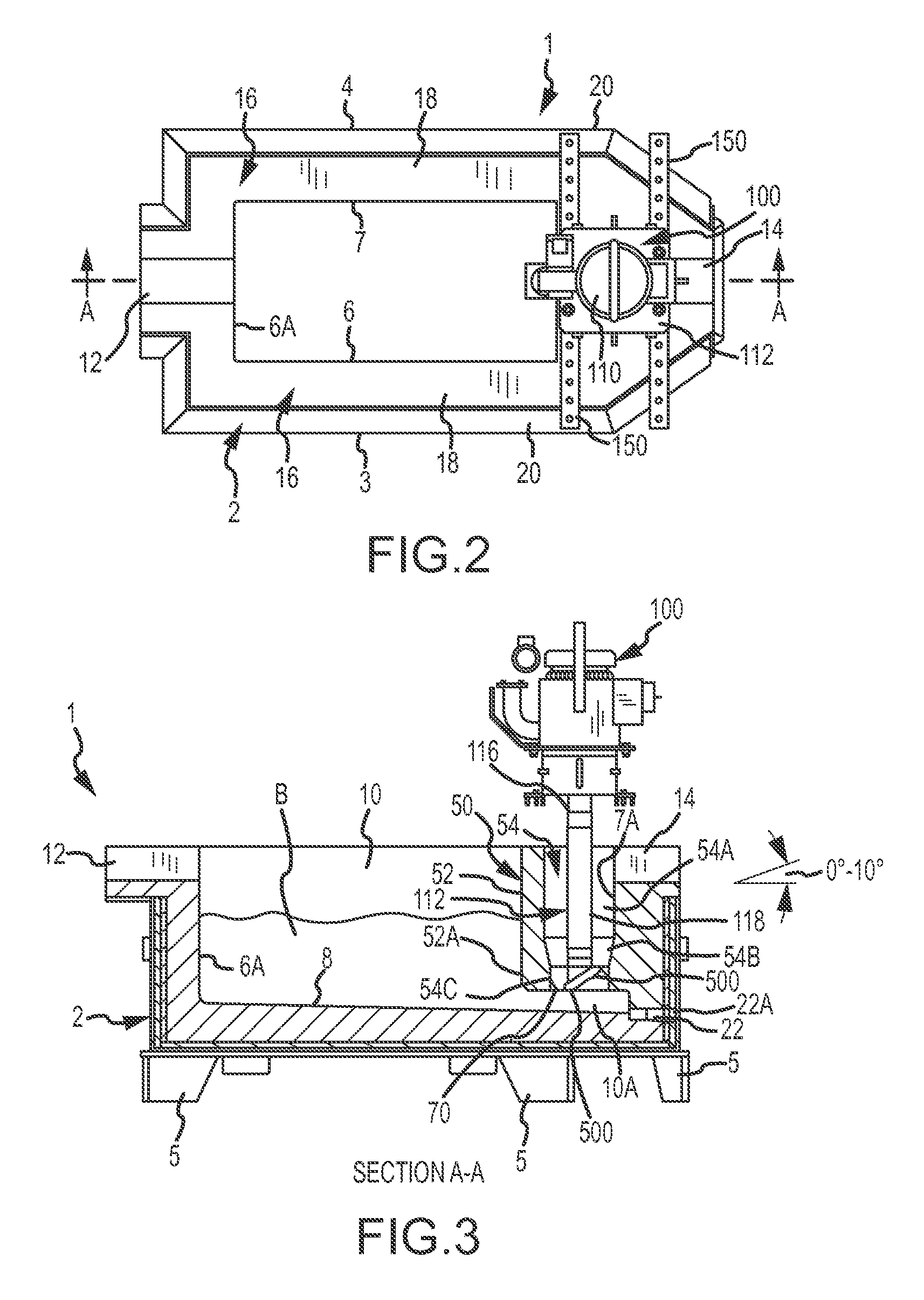

Transfer well system and method for making same

ActiveUS20130292426A1Melt-holding vesselsMolten metal pouring equipmentsMarine engineeringMolten metal

The invention relates to systems for transferring molten metal from one structure to another. Aspects of the invention include a transfer chamber constructed inside of or next to a vessel used to retain molten metal. The transfer chamber is in fluid communication with the vessel so molten metal from the vessel can enter the transfer chamber. A powered device, which may be inside of the transfer chamber, moves molten metal upward and out of the transfer chamber and preferably into a structure outside of the vessel, such as another vessel or a launder.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

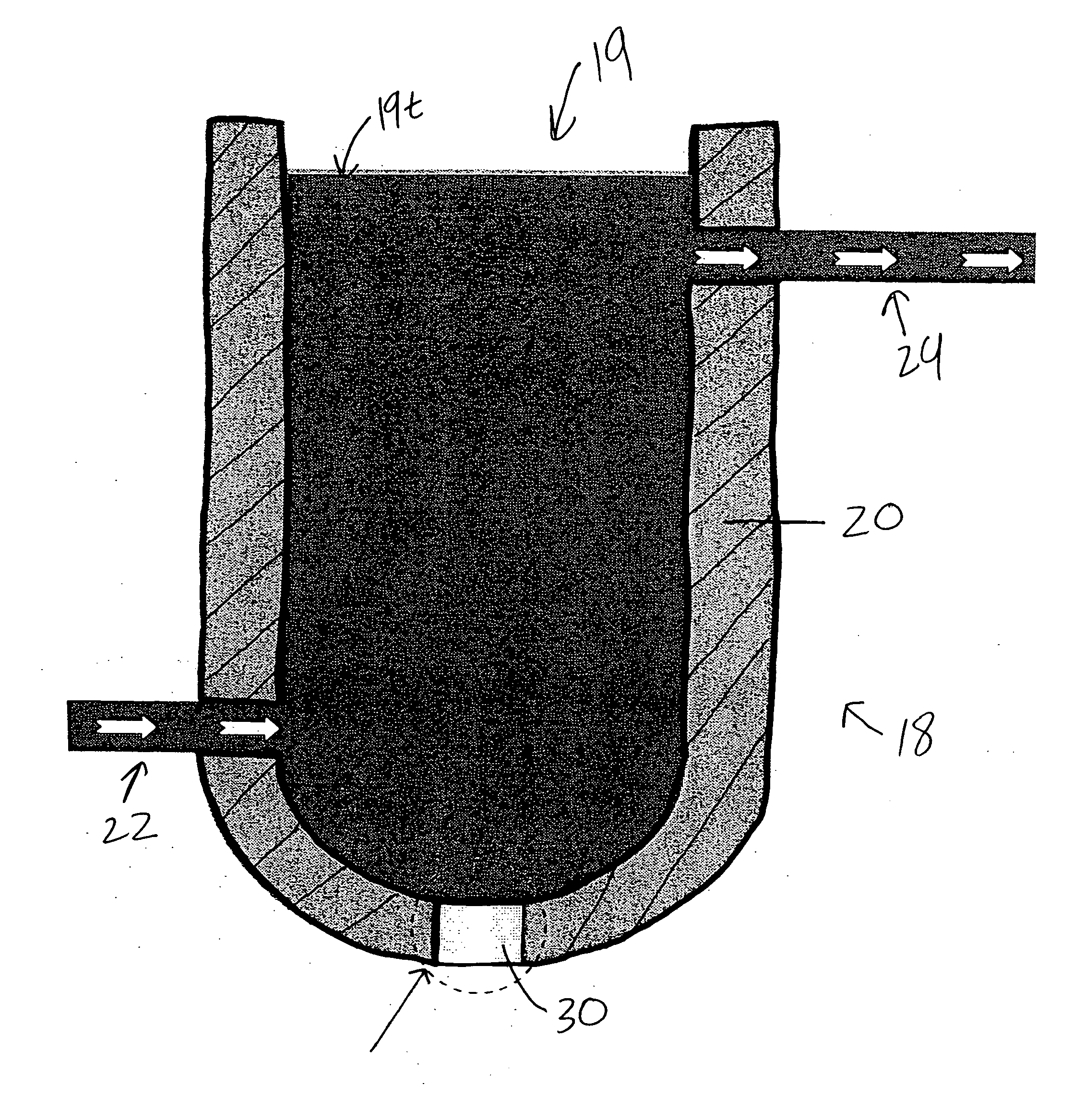

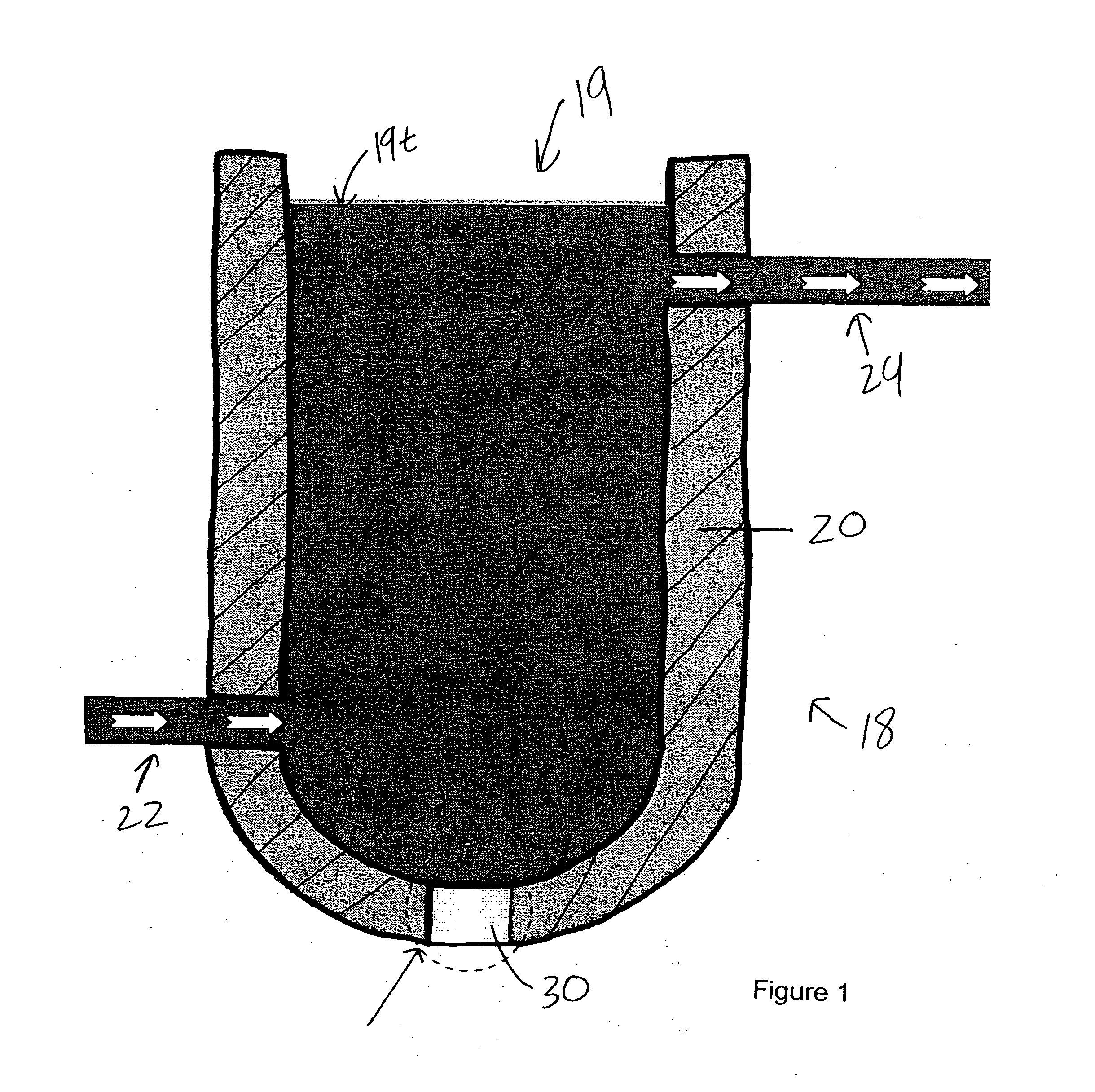

Receptacle for handling molten metal, casting assembly and manufacturing method

InactiveUS20130334744A1Simpler and less cumbersomeEasy to manufactureMelt-holding vesselsDischarging arrangementRefractoryEngineering

A receptacle for handling molten metal is provided. The receptacle has bottom and side walls and includes a refractory defining a cavity within which the molten metal is conveyed or contained. The receptacle has at least one channel extending within at least one of its walls. The channel has an inlet and an outlet. The inlet is connectable to a source for circulating a fluid within the channel. The outlet allows the fluid to be expelled from said channel. The channel allows, when the fluid is circulated in it, to regulate the temperature of the refractory and thereby of the metal conveyed or contained. A casting assembly and a method for casting the refractory are also provided.

Owner:PYROTECK INC

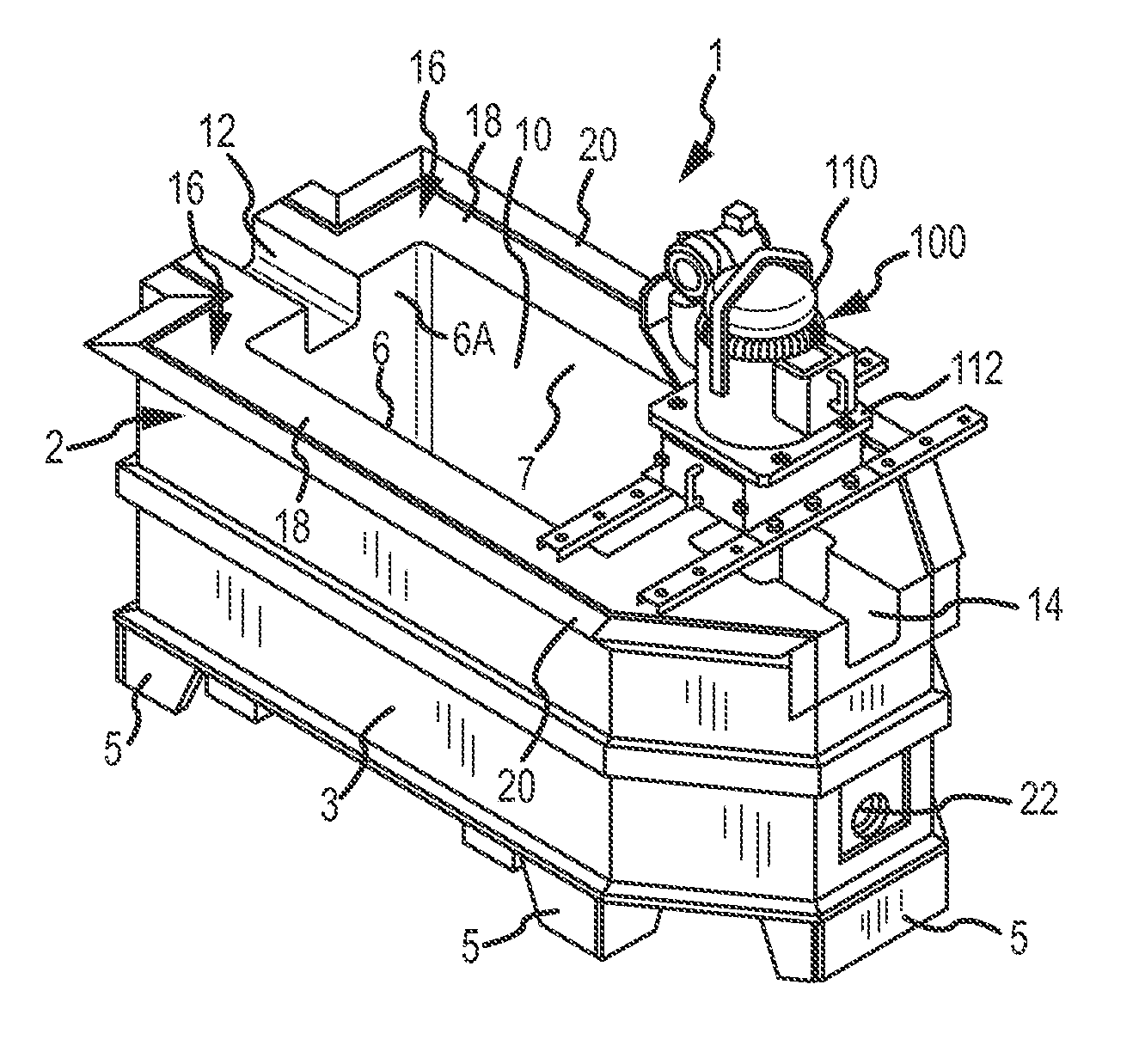

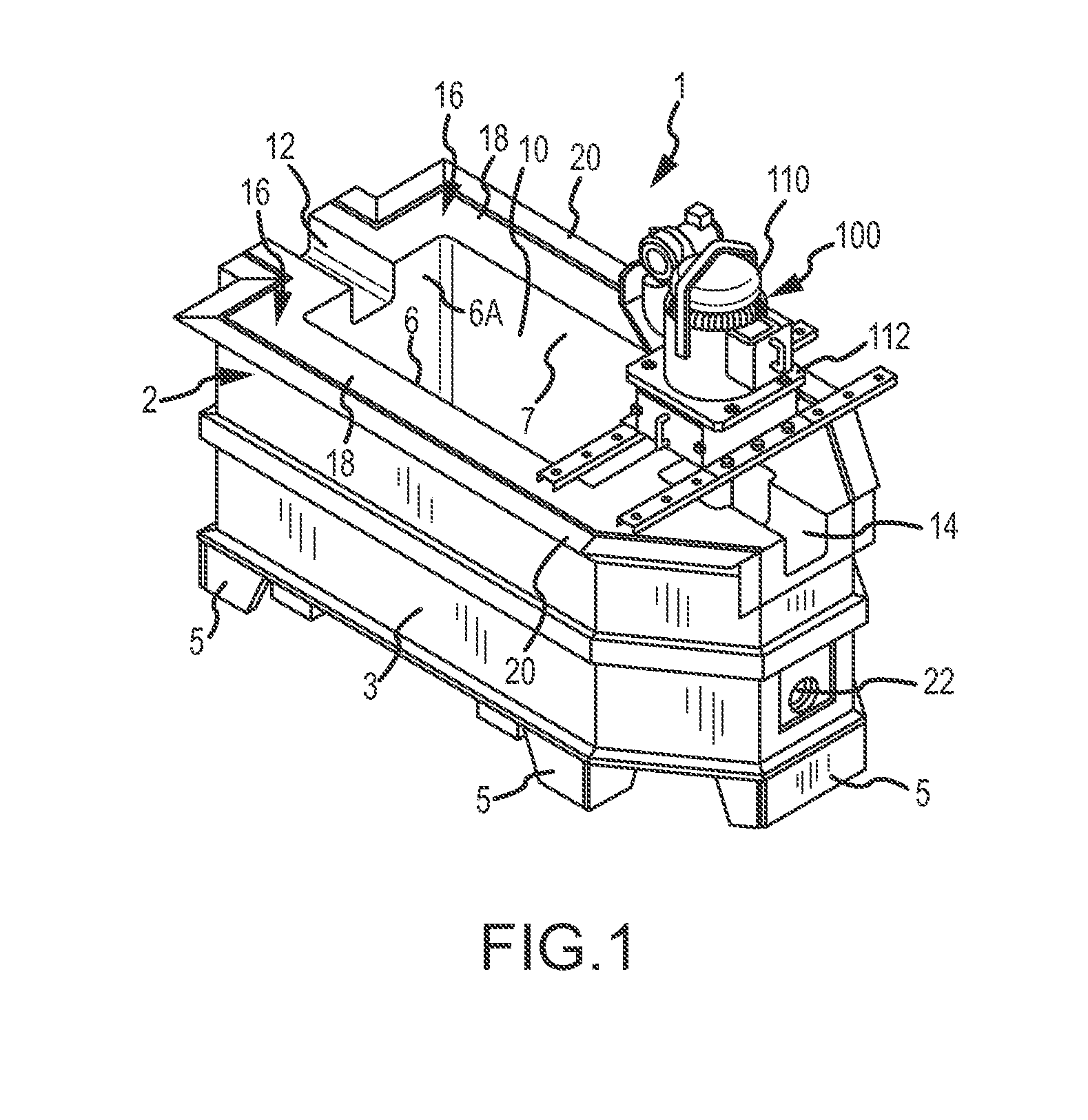

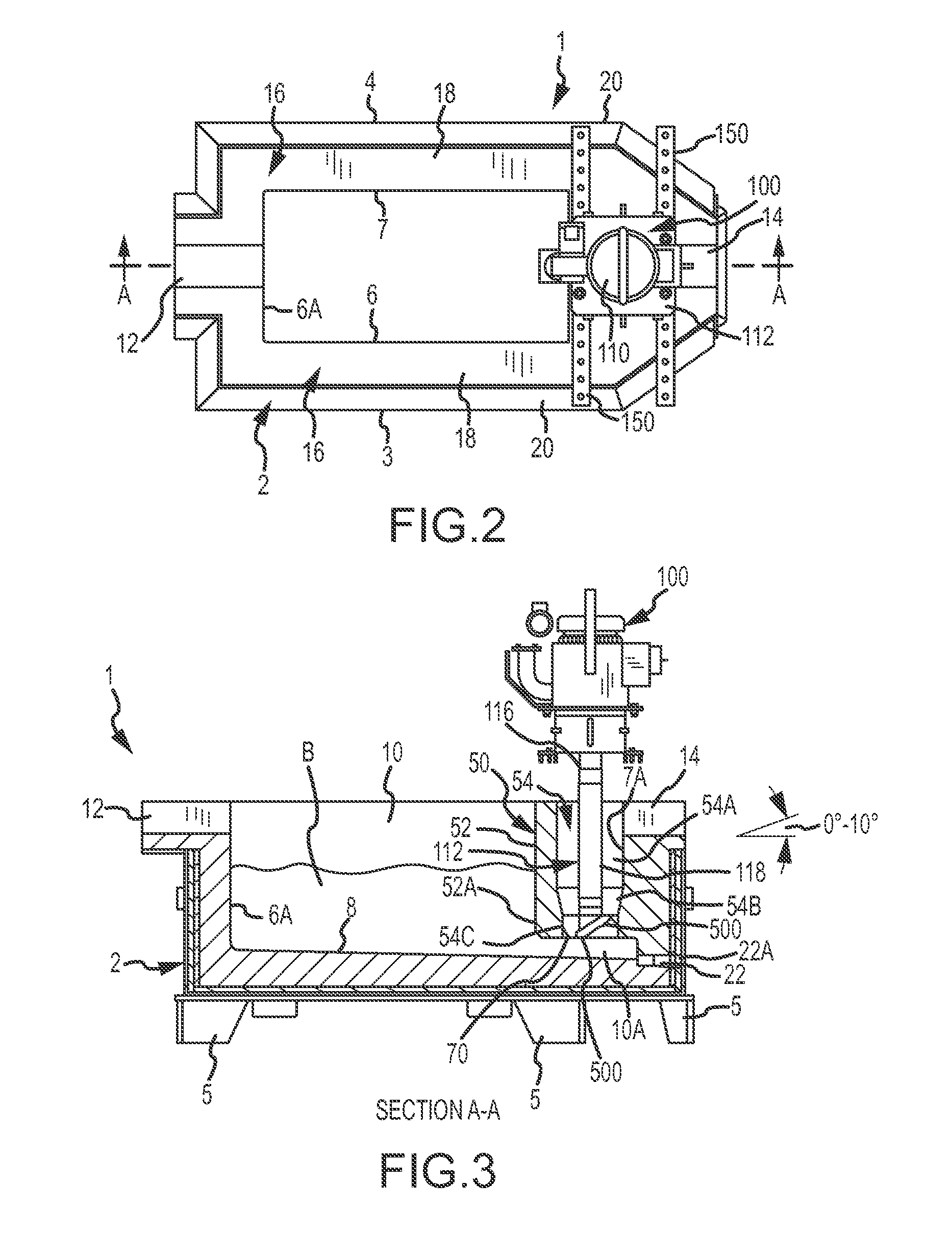

Molten metal transfer system and rotor

The invention relates to systems for transferring molten metal from one structure to another. Aspects of the invention include a transfer chamber constructed inside of or next to a vessel used to retain molten metal. The transfer chamber is in fluid communication with the vessel so molten metal from the vessel can enter the transfer chamber. A powered device, which may be inside of the transfer chamber, moves molten metal upward and out of the transfer chamber and preferably into a structure outside of the vessel, such as another vessel or a launder.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Molten metal transfer vessel and method of construction

ActiveUS20130299525A1Significant comprehensive benefitsFormation of dross in the ladle or launder are greatly reduced or eliminatedMelt-holding vesselsMolten metal pouring equipmentsMolten metalBuilding construction

The invention relates to systems for transferring molten metal from one structure to another. Aspects of the invention include a transfer chamber constructed inside of or next to a vessel used to retain molten metal. The transfer chamber is in fluid communication with the vessel so molten metal from the vessel can enter the transfer chamber. A powered device, which may be inside of the transfer chamber, moves molten metal upward and out of the transfer chamber and preferably into a structure outside of the vessel, such as another vessel or a launder.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

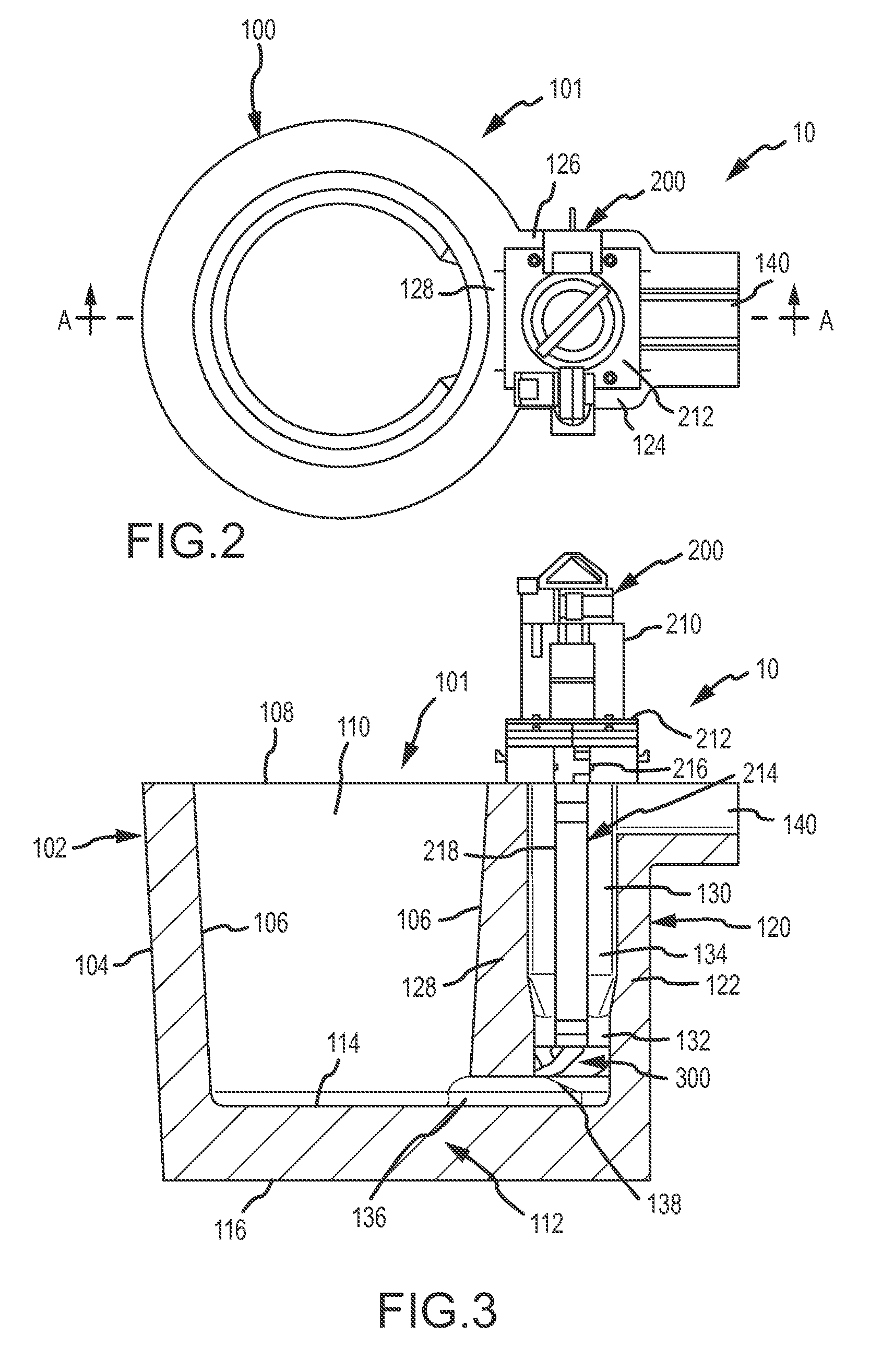

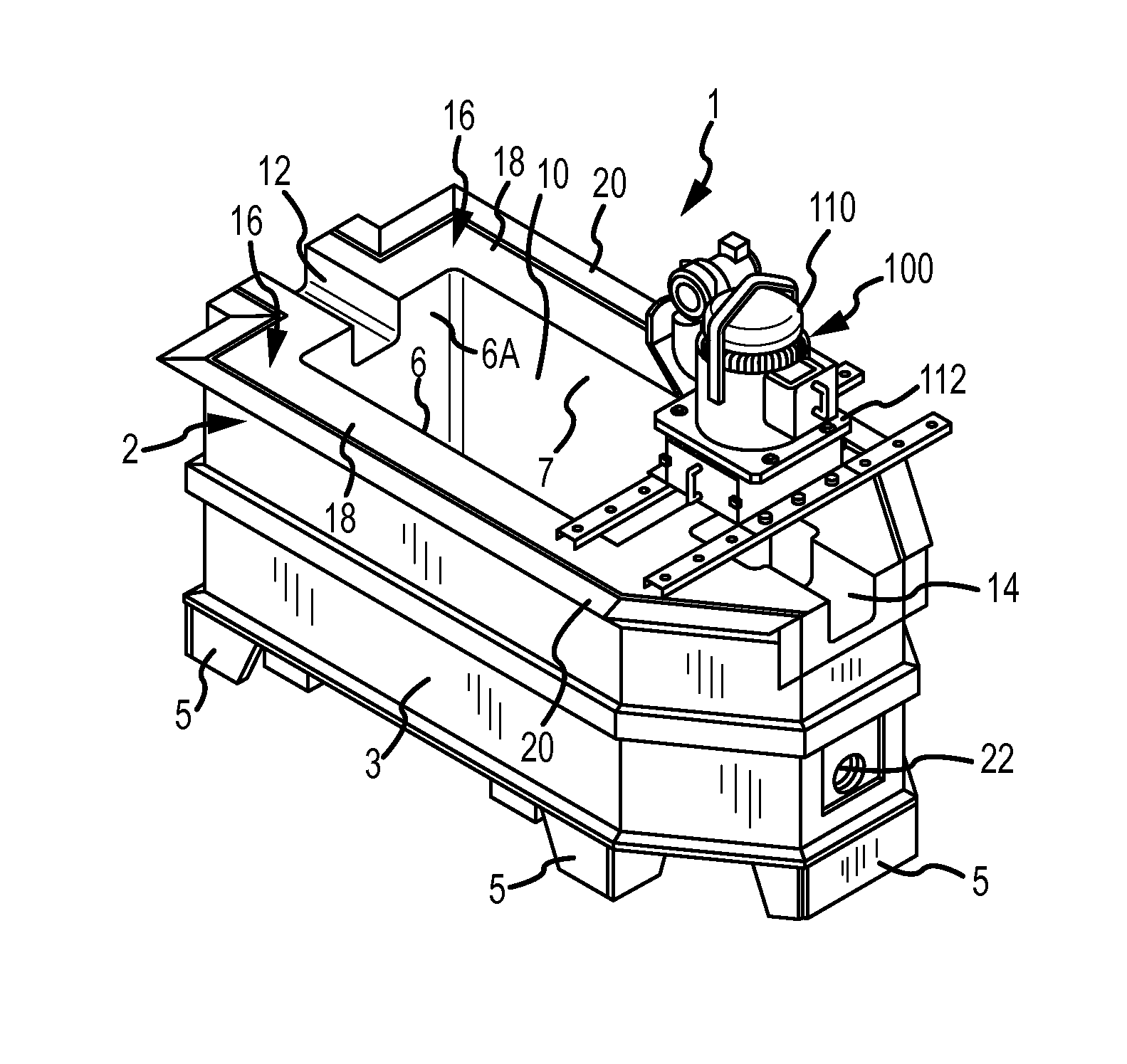

Molten metal transfer and degassing system

ActiveUS20130306687A1Keep the flowReduce the possibilityMelt-holding vesselsMolten metal pouring equipmentsEngineeringMolten metal

Aspects of the invention include a transfer chamber constructed inside of or next to a vessel used to retain and degas molten metal. The transfer chamber is in fluid communication with the vessel so molten metal from the vessel is pulled through the vessel by the pump as it is degassed. This helps maintain a generally constant flow of molten metal through the degassing vessel. Other aspects relate to a system and method for efficiently performing maintenance on components positioned in a vessel.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Ladle with transfer conduit

ActiveUS9011761B2Reduce the amount requiredReduce formationMelt-holding vesselsMolten metal supplying equipmentsMarine engineeringGuide tube

Disclosed is a transportable vessel for use in a factory for processing molten metal. The vessel is not connected to a reverbatory furnace and can be moved to different locations in the factory. The vessel includes a transfer conduit in communication with a cavity of the vessel. A molten metal pump can be positioned in the transfer conduit to move molten metal out of an outlet in communication with the transfer conduit and into another vessel without the need to tip or tilt the transportable vessel.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Molten metal transfer system and rotor

The invention relates to systems for transferring molten metal from one structure to another. Aspects of the invention include a transfer chamber constructed inside of or next to a vessel used to retain molten metal. The transfer chamber is in fluid communication with the vessel so molten metal from the vessel can enter the transfer chamber. A powered device, which may be inside of the transfer chamber, moves molten metal upward and out of the transfer chamber and preferably into a structure outside of the vessel, such as another vessel or a launder.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Degassing of molten alloys with the assistance of ultrasonic vibration

InactiveUS20070235159A1Reduce gas contentReduce heat transferMelt-holding vesselsLiquid degasificationNitrogen gasCavitation bubble

An apparatus and method are disclosed in which ultrasonic vibration is used to assist the degassing of molten metals or metal alloys thereby reducing gas content in the molten metals or alloys. High-intensity ultrasonic vibration is applied to a radiator that creates cavitation bubbles, induces acoustic streaming in the melt, and breaks up purge gas (e.g., argon or nitrogen) which is intentionally introduced in a small amount into the melt in order to collect the cavitation bubbles and to make the cavitation bubbles survive in the melt. The molten metal or alloy in one version of the invention is an aluminum alloy. The ultrasonic vibrations create cavitation bubbles and break up the large purge gas bubbles into small bubbles and disperse the bubbles in the molten metal or alloy more uniformly, resulting in a fast and clean degassing.

Owner:UNIV OF TENNESSEE RES FOUND +1

Transfer well system and method for making same

The invention relates to systems for transferring molten metal from one structure to another. Aspects of the invention include a transfer chamber constructed inside of or next to a vessel used to retain molten metal. The transfer chamber is in fluid communication with the vessel so molten metal from the vessel can enter the transfer chamber. A powered device, which may be inside of the transfer chamber, moves molten metal upward and out of the transfer chamber and preferably into a structure outside of the vessel, such as another vessel or a launder.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Molten metal transfer vessel and method of construction

ActiveUS9409232B2Formation of dross in the ladle or launder are greatly reduced or eliminatedEliminate useMelt-holding vesselsMolten metal pouring equipmentsMolten metalBuilding construction

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Container

InactiveUS7204954B2High heat conductivityObstructing flow passageMelt-holding vesselsBlast furnace componentsMetallurgyOperability

A container does not need a member such as a stoke and the like that are exposed to the molten metal therein, thus the necessity to replace the parts such as the stoke and the like can be eliminated. In addition, there is no structure like the stoke in the container, the operability for the preheating is improved thus the preheating can be performed effectively. In addition, since a flow passage is formed inside the lining with high heat conductivity, inner heat of the container is easily conducted to the flow passage. Thus, the decrease in temperature of the molten metal that flows inside the flow passage can be suppressed to the utmost.

Owner:HOEI SHOKAI CO LTD

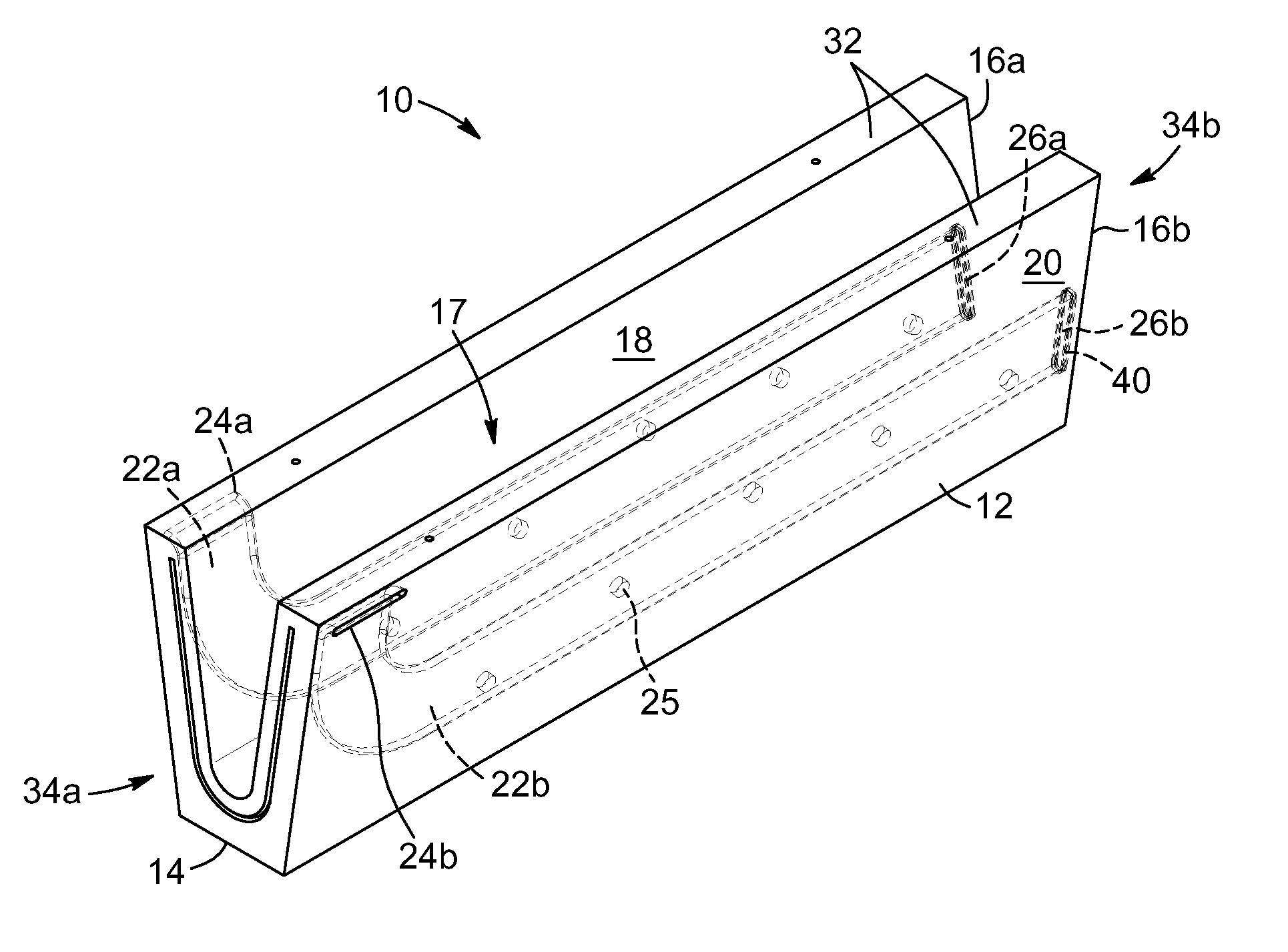

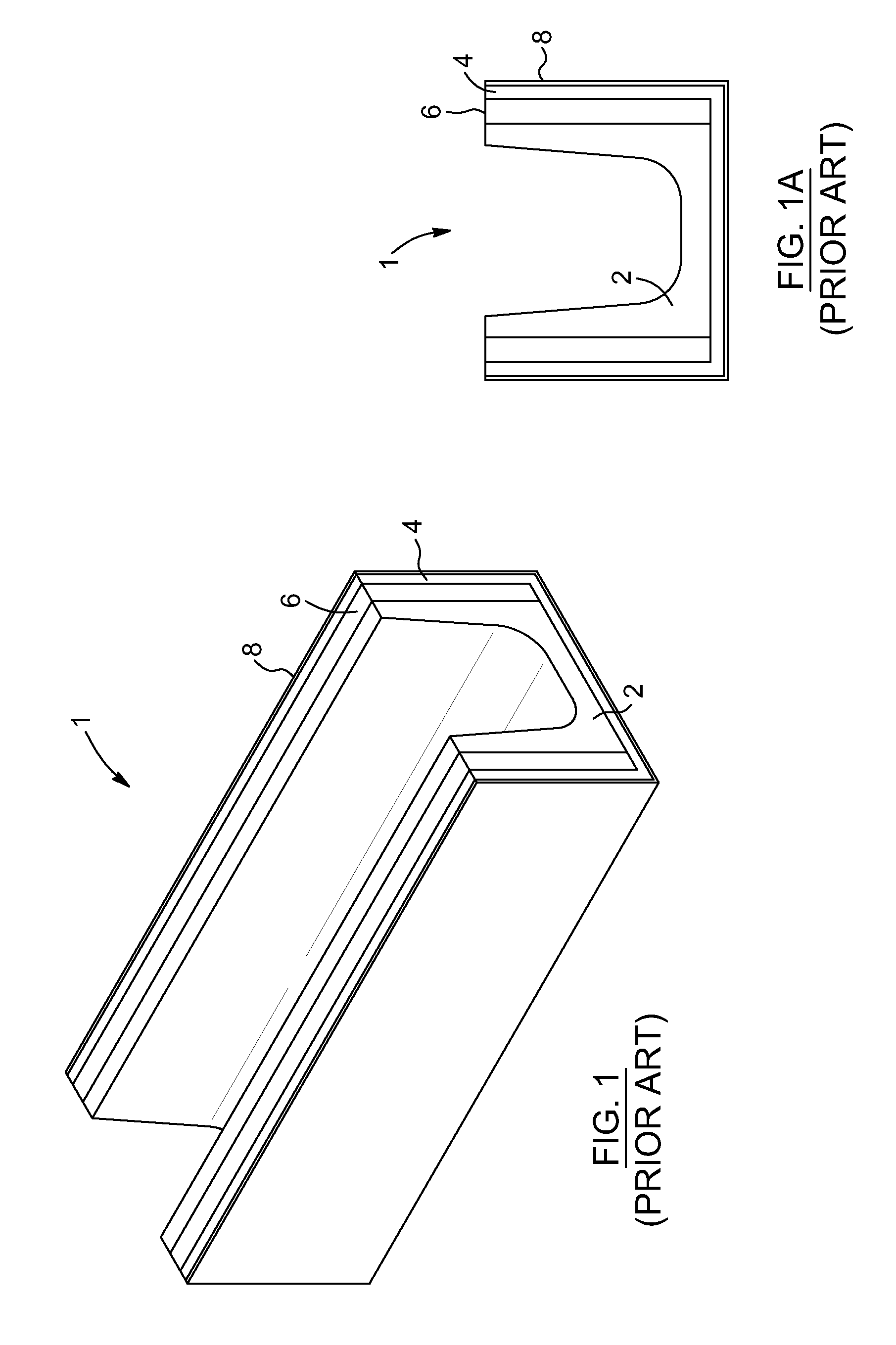

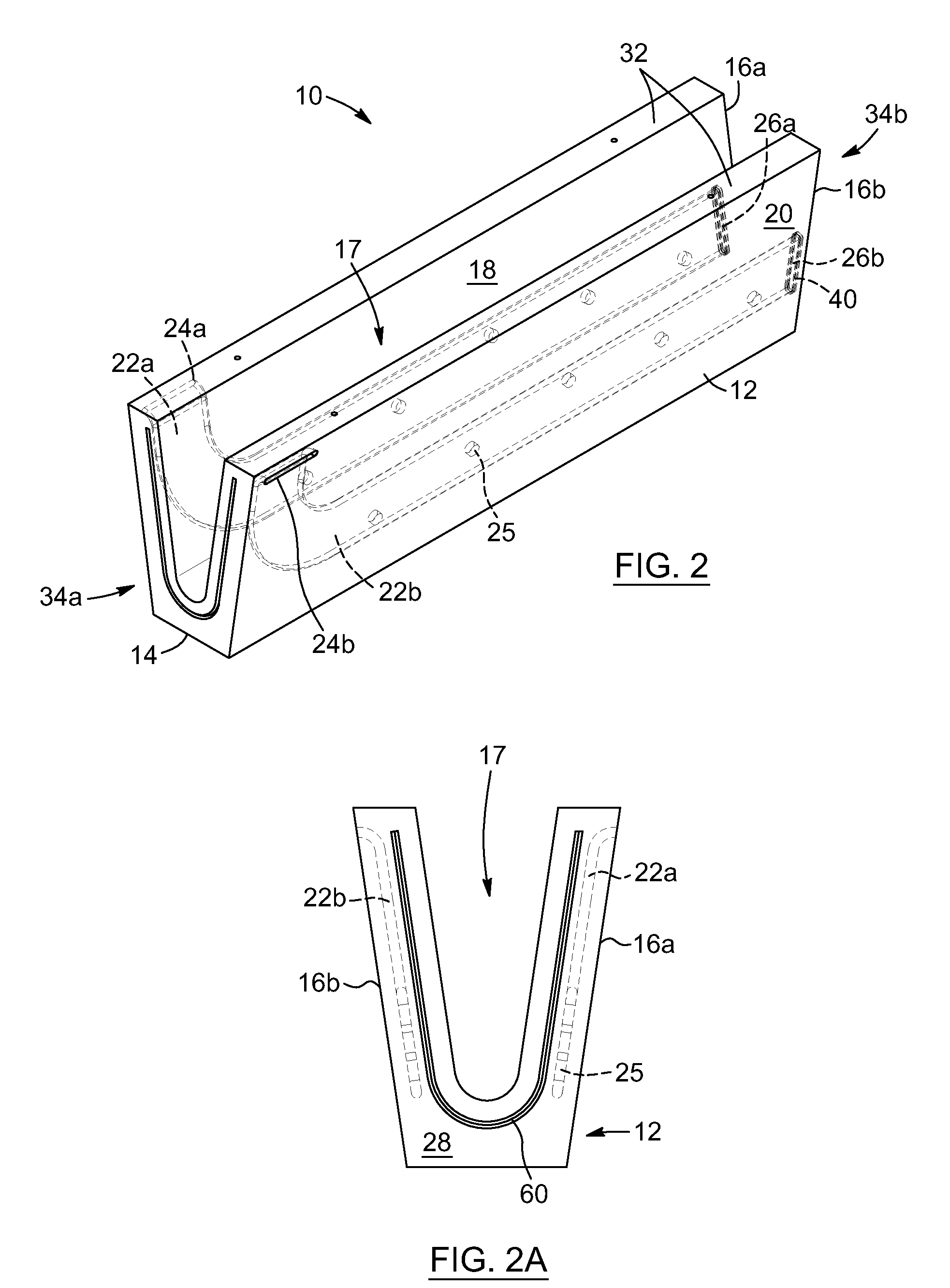

Heated trough for molten metal

A trough is described for carrying molten metal, comprising an outer shell defined by a bottom wall and two side walls, an insulating layer filling the outer shell and a conductive U-shaped refractory trough body for carrying molten metal, the trough body being embedded in the insulating layer. At least one heating element is positioned in the insulating layer, adjacent to but spaced apart from the trough body, to provide an air gap between the heating element and the trough body.

Owner:NOVELIS INC

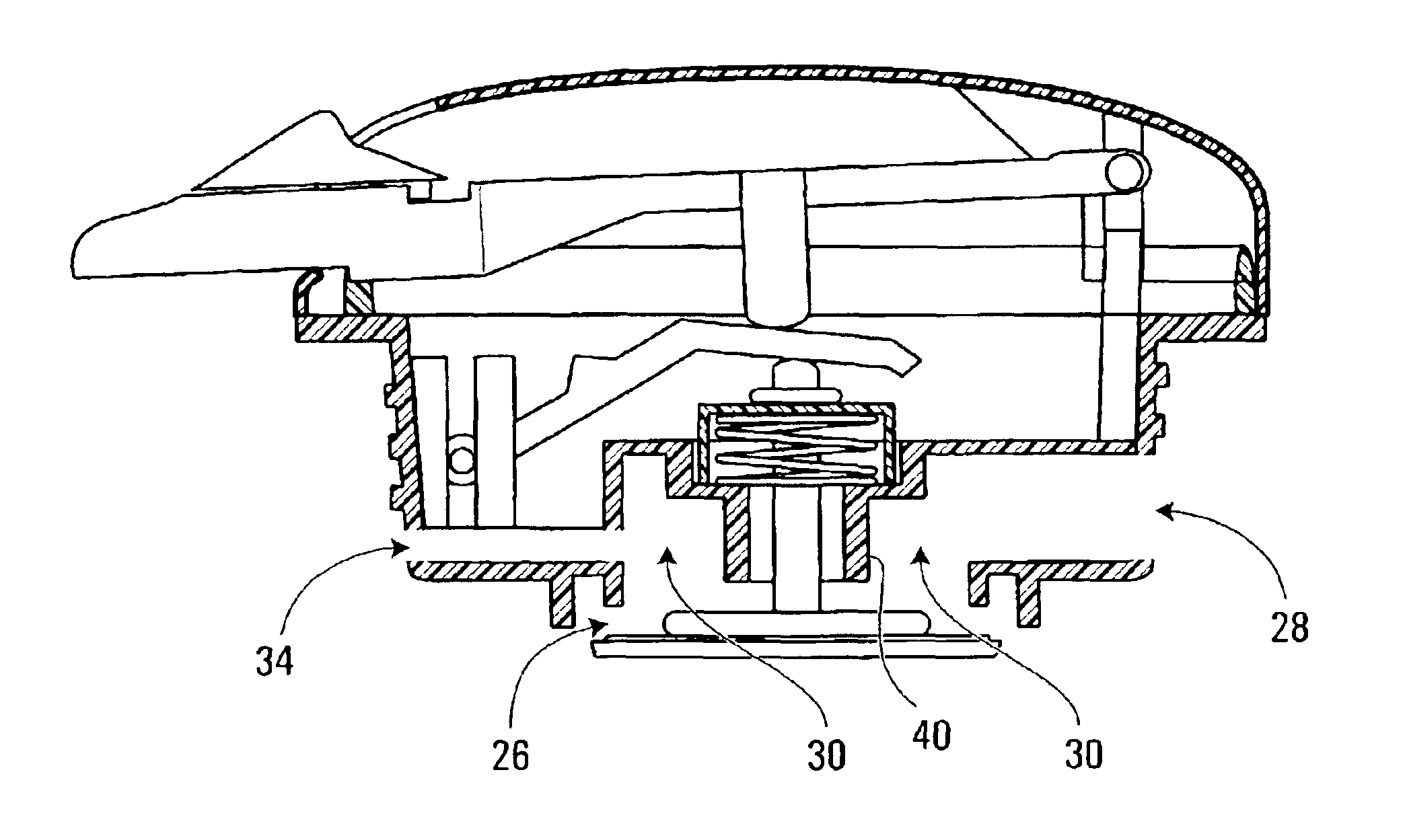

Cap for a container

InactiveUS6935536B2Reduce probabilityAvoid accidental dischargeMelt-holding vesselsMolten metal pouring equipmentsEngineeringActuator

Cap for a container, including a body having an inlet, a spout and a passageway therebetween. The cap also includes a valve movable between a first position wherein the passageway is blocked and a second position wherein the passageway is at least partly unblocked, the valve being biased towards the first position. Furthermore, the cap includes an actuator mounted to the body and engaging the valve. Selective control of the state of the valve is associated with movement of the actuator in a different direction than for securing the valve in the open position. The combination of movements required to lock the valve in the open position is sufficiently complex to reduce its probability of opening unintentionally. Meanwhile, the combination of movements is simple enough to be performed by a single finger.

Owner:TRUDEAU 1889

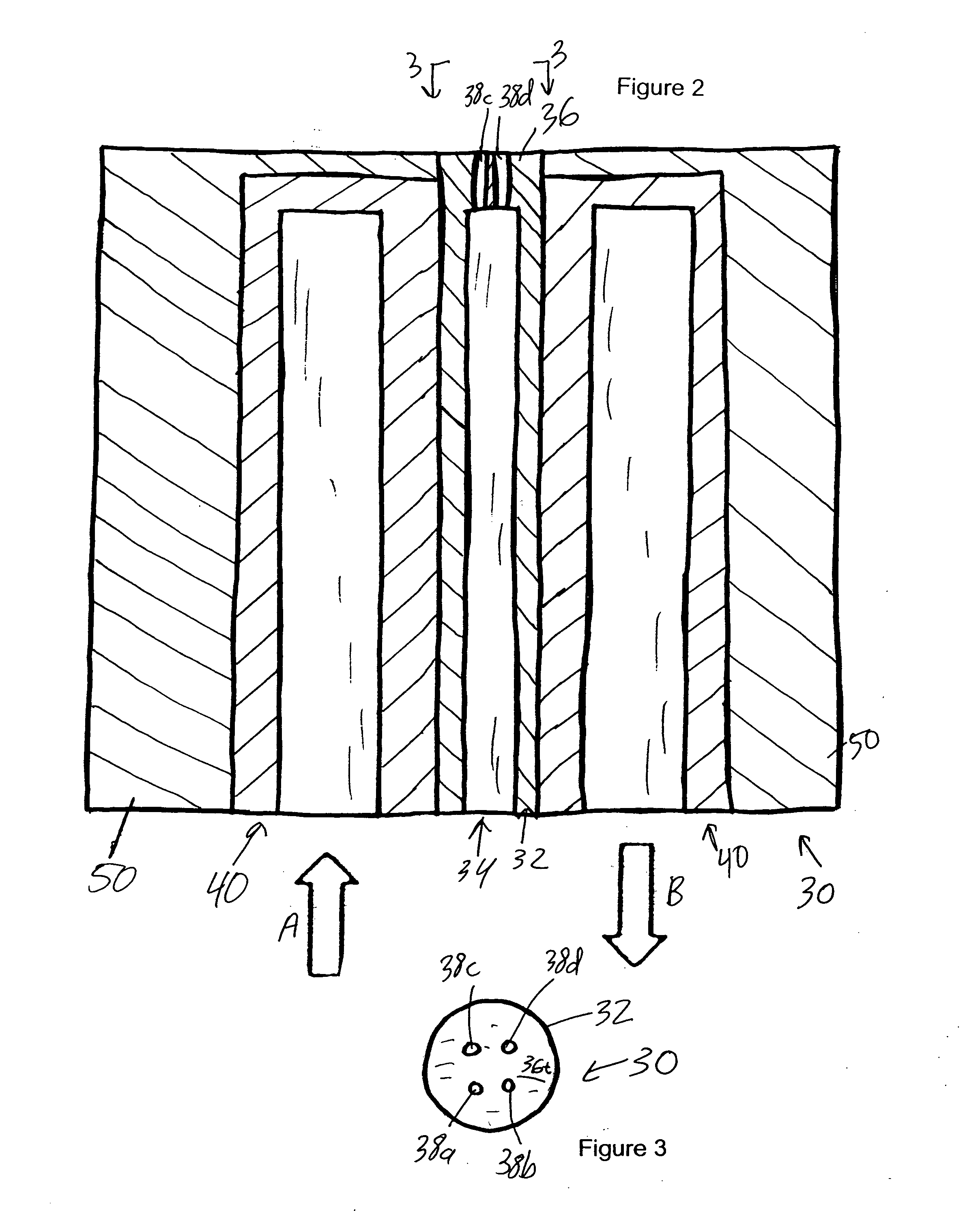

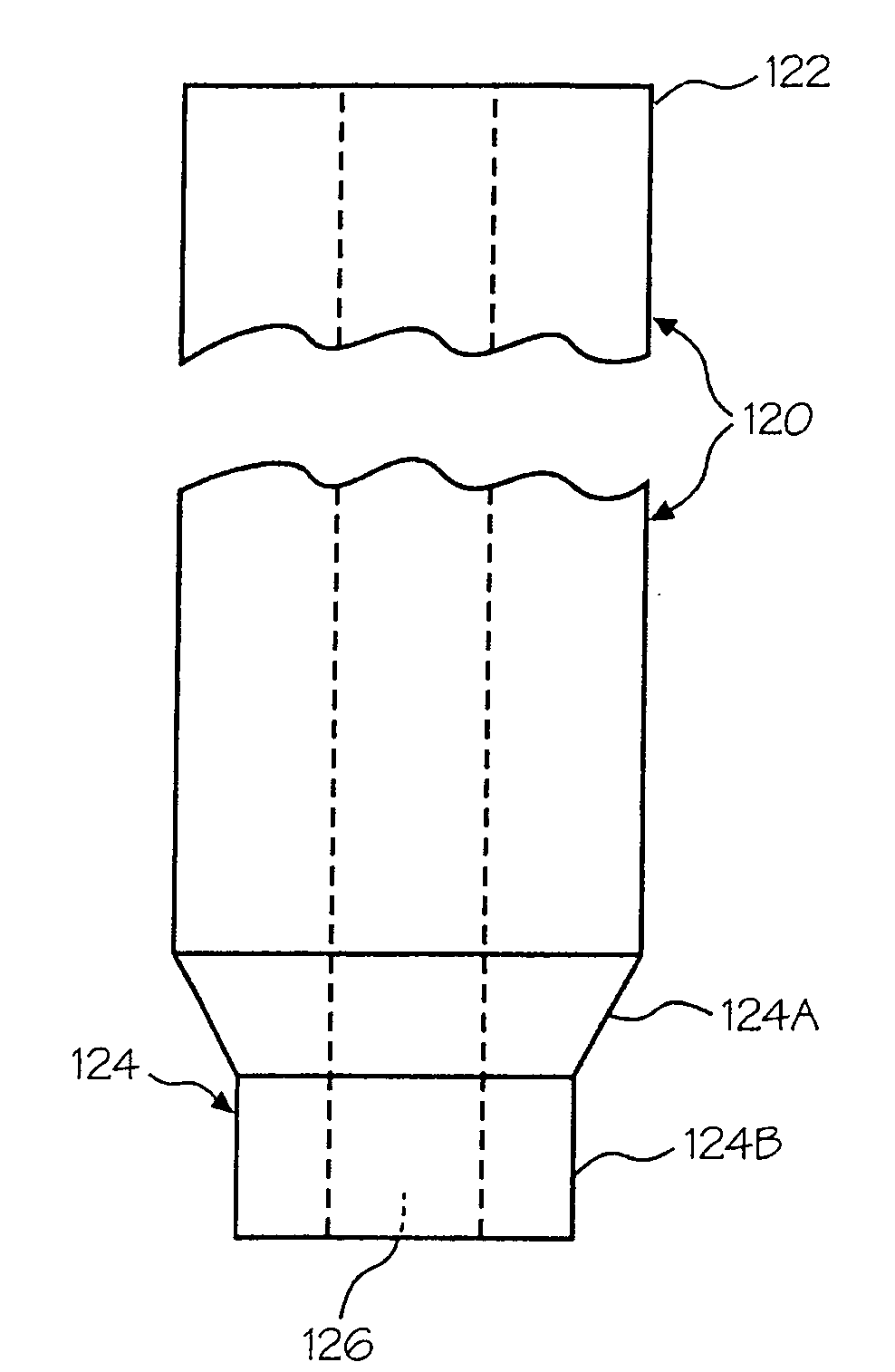

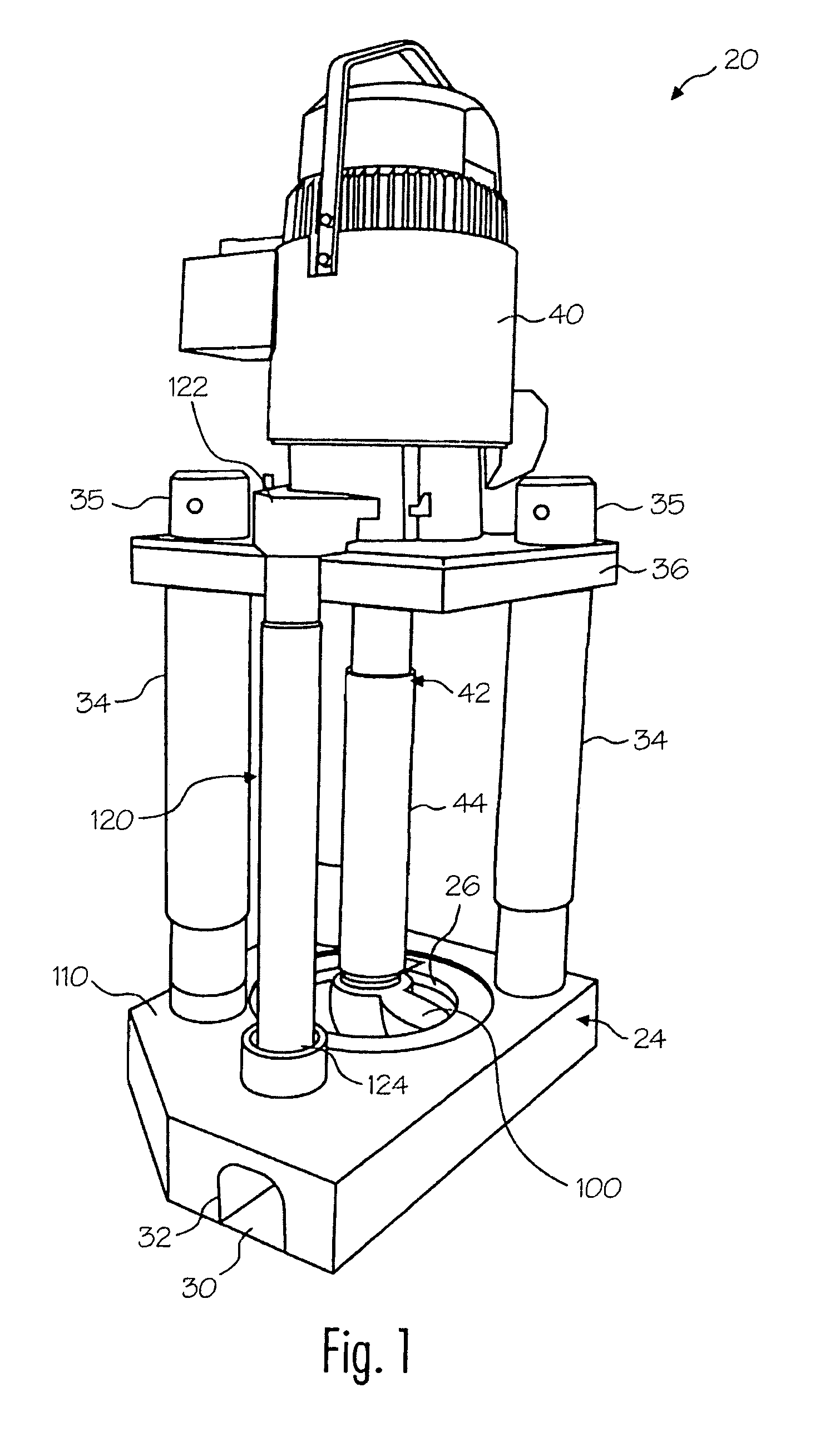

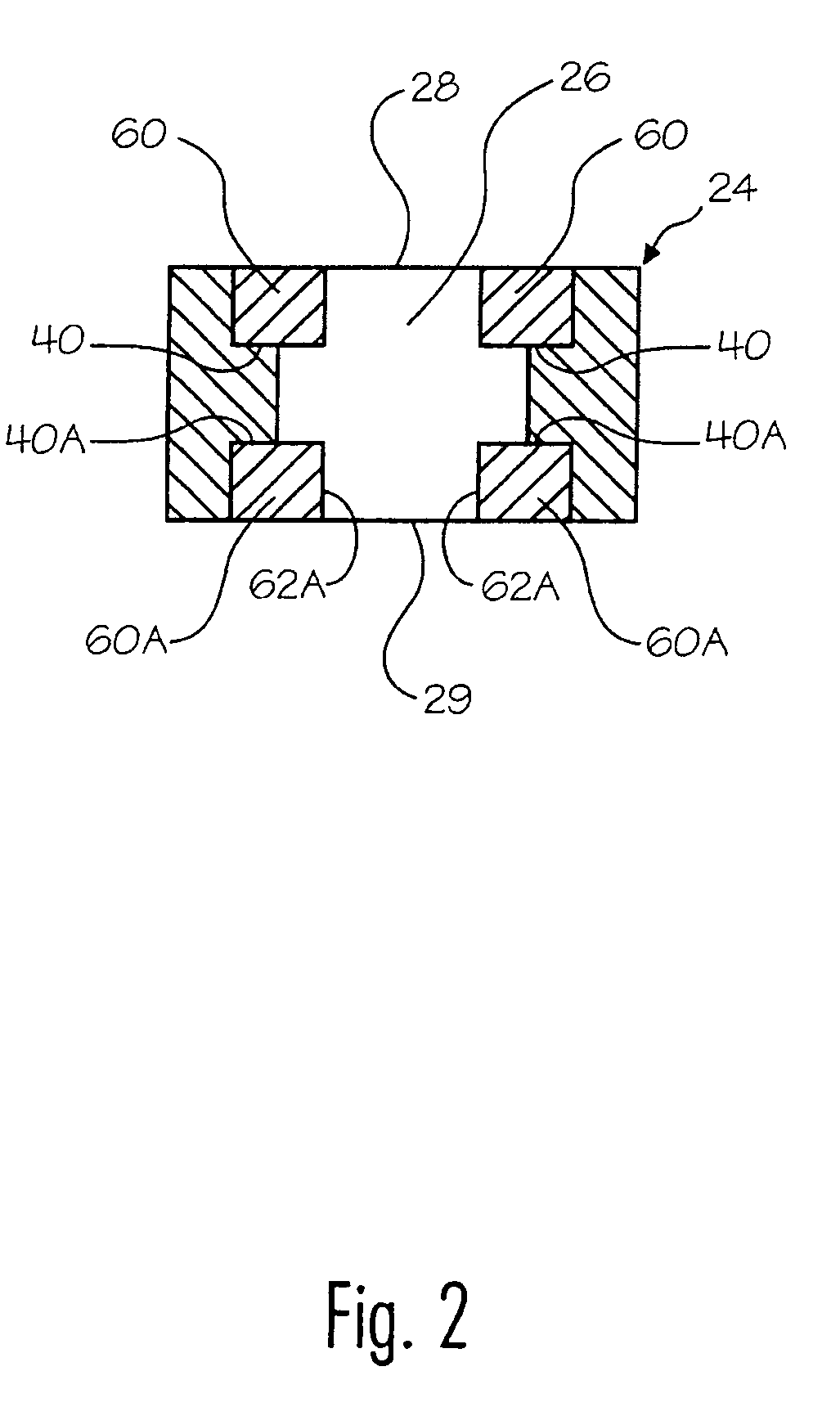

System for releasing gas into molten metal

InactiveUS20080211147A1Reduce amountIncrease the cross-sectional areaMelt-holding vesselsSpecific fluid pumpsMetallurgyProduct gas

A device for releasing gas into molten metal includes a base having a discharge. The discharge has a first section including a first cross-sectional area and a second section including a second cross-sectional area, wherein the first section is upstream of the second section and the first cross-sectional area is smaller than the second cross-sectional area. A gas-release opening is positioned so that it can release gas into one or more of the first section or the second section. As the molten metal moves from the first cross-sectional area to the second cross-sectional area gas is released into the molten metal and the molten metal flow helps to draw the gas into the flow, thereby lowering the pressure required to release gas into the molten metal. Metal-transfer conduits other than a discharge incorporated in a pump base are also disclosed, as are pumps including either a discharge or other metal-transfer conduit according to the invention.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Popular searches

Sputtering coating Semiconductor/solid-state device manufacturing Next instruction address formation Ion implantation coating Chemical vapor deposition coating Special data processing applications Programme control in sequence/logic controllers Programme total factory control Sealing Container/bottle contruction

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com