Patents

Literature

12515results about "Molten spray coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

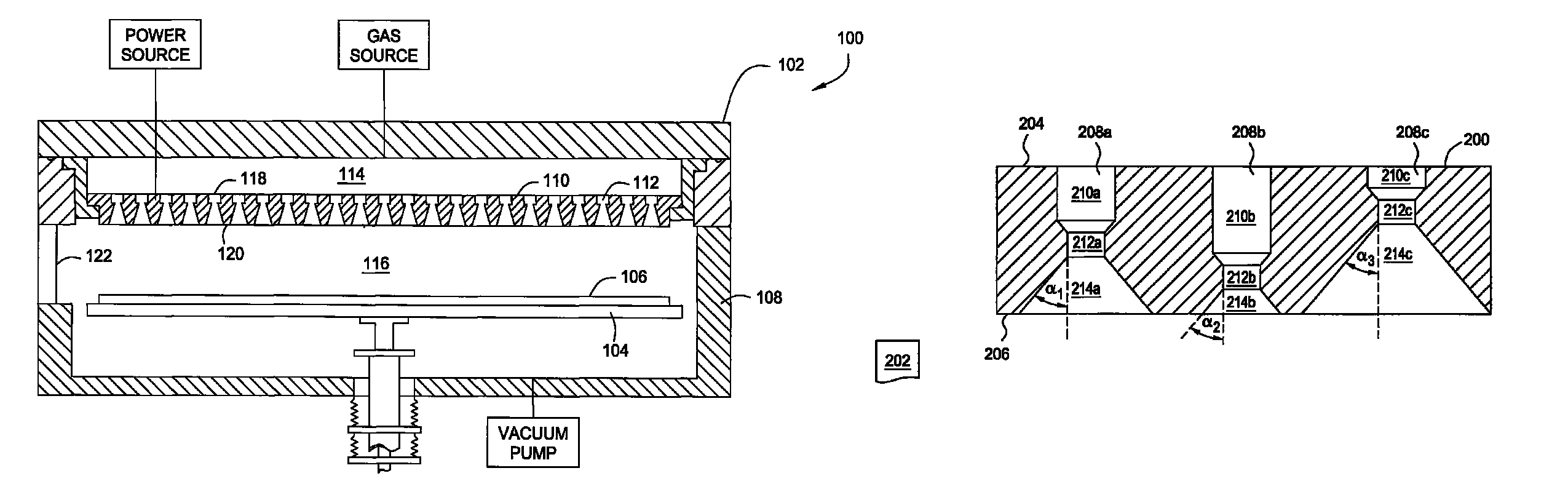

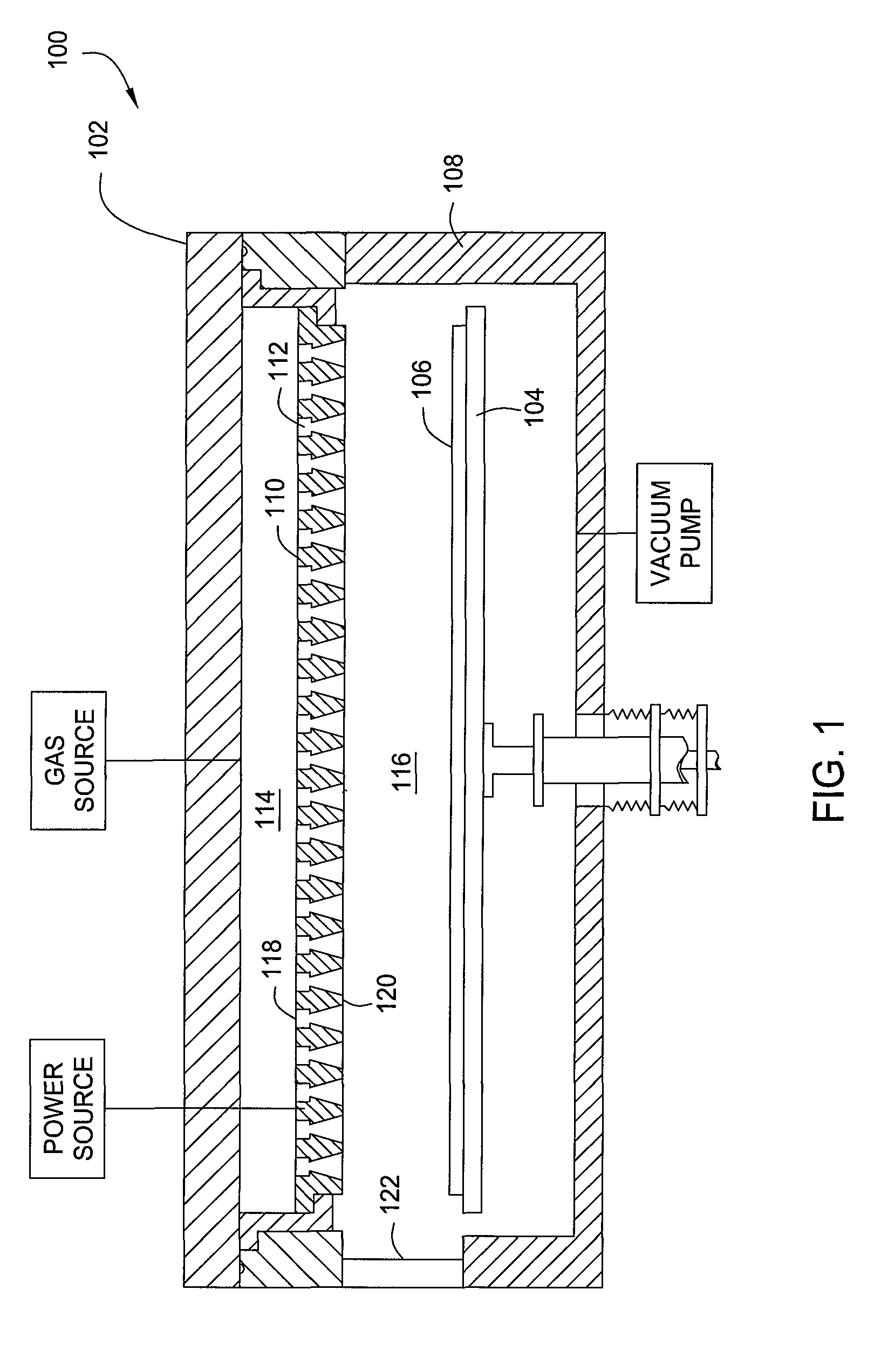

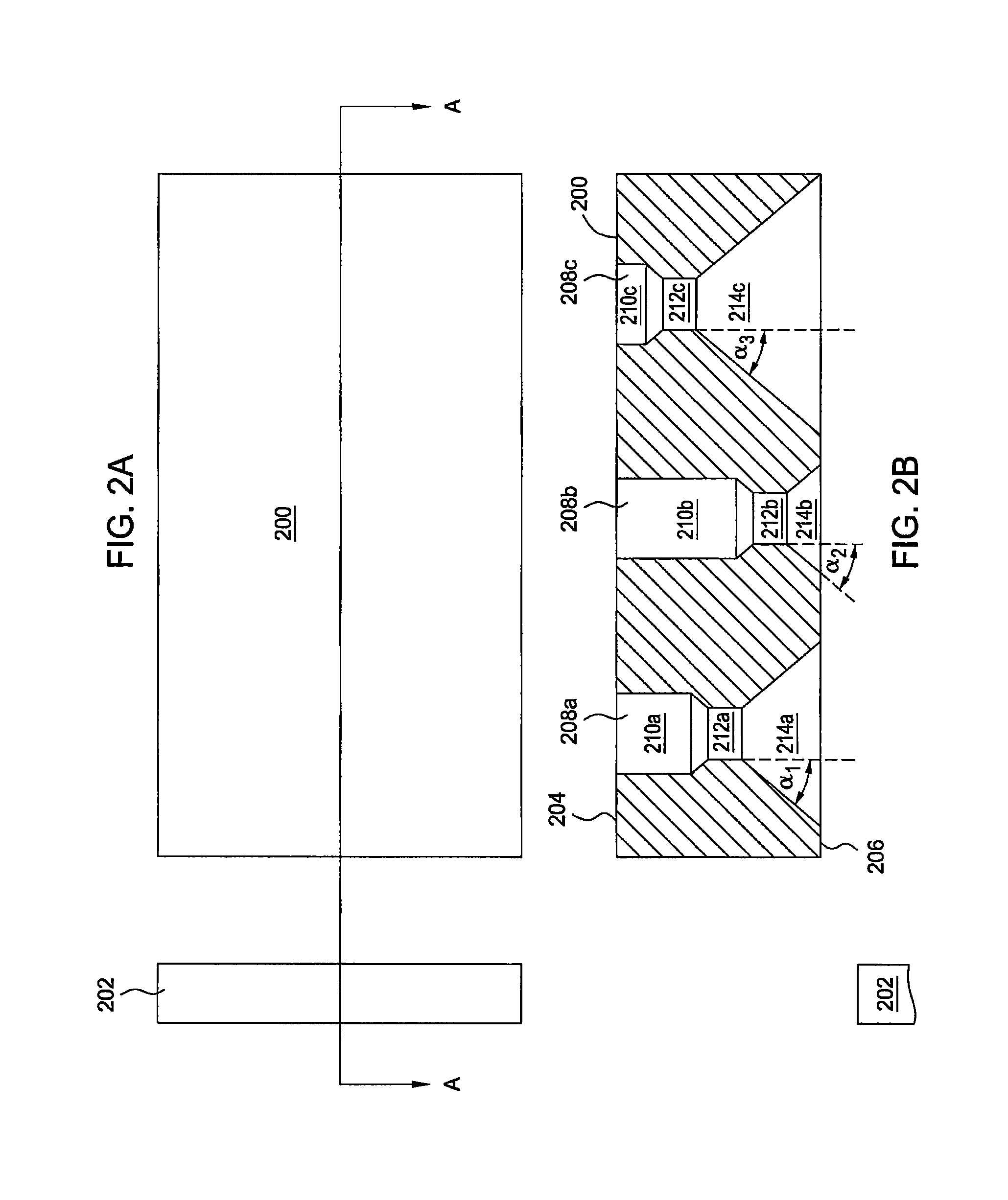

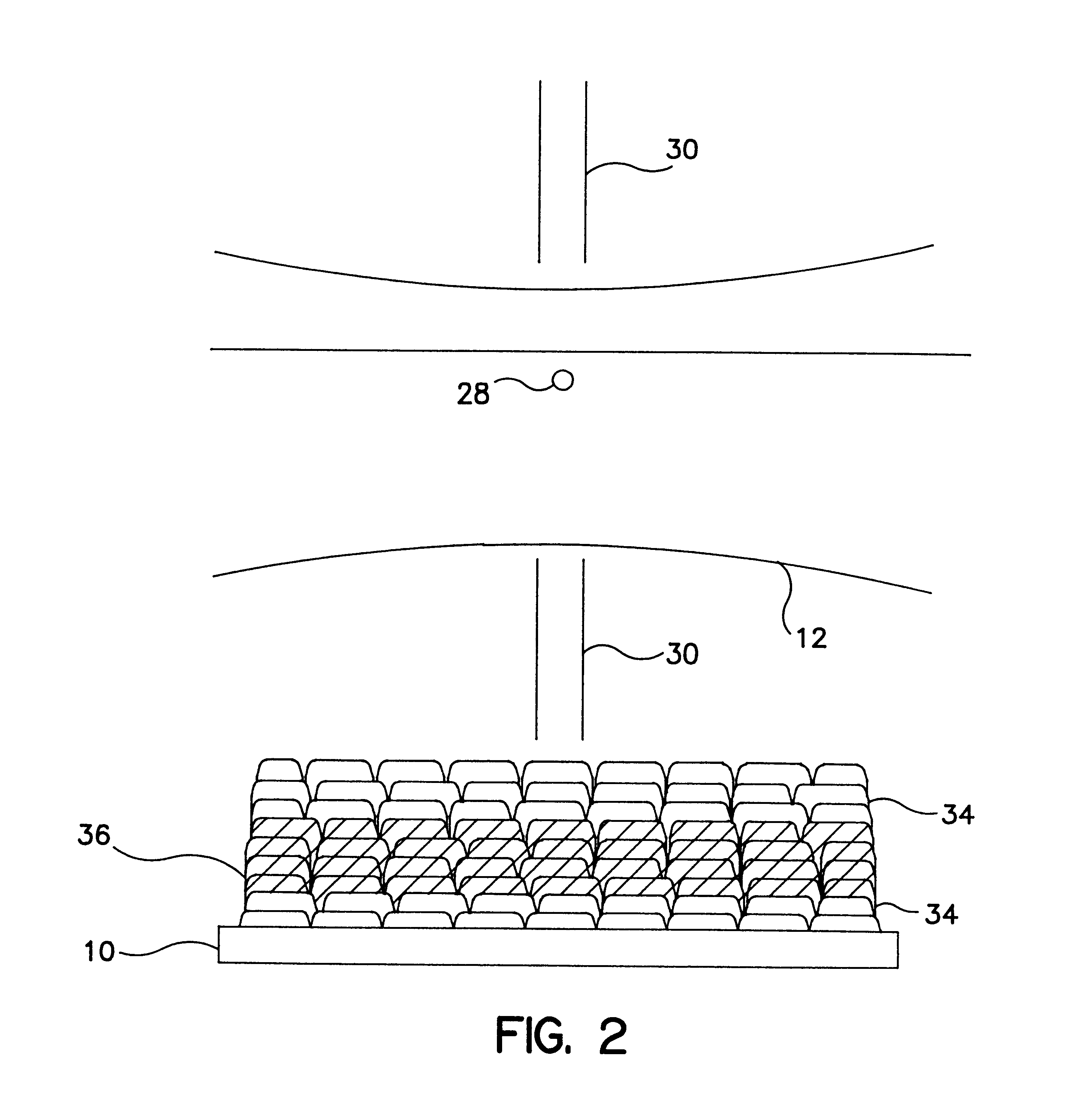

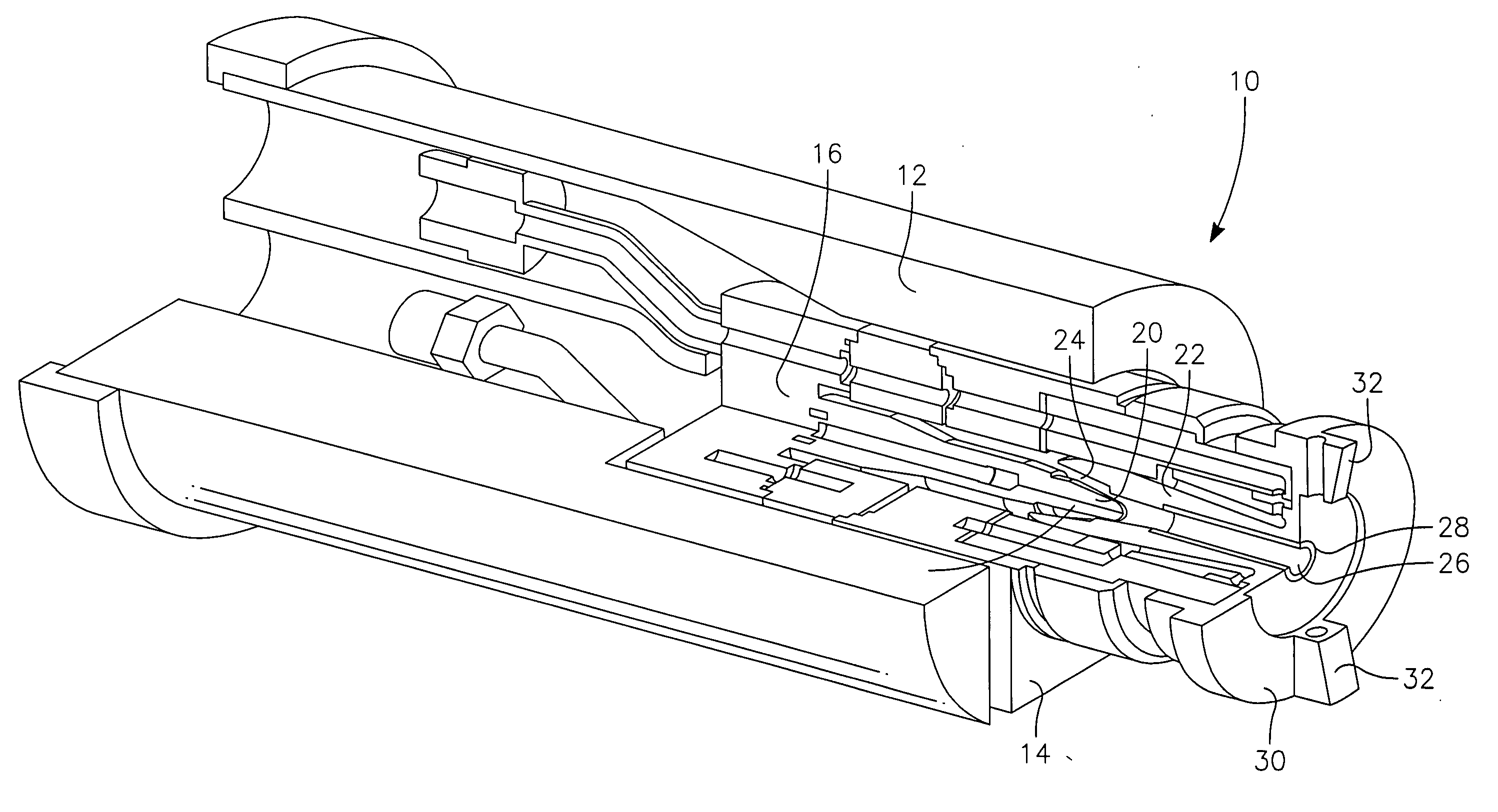

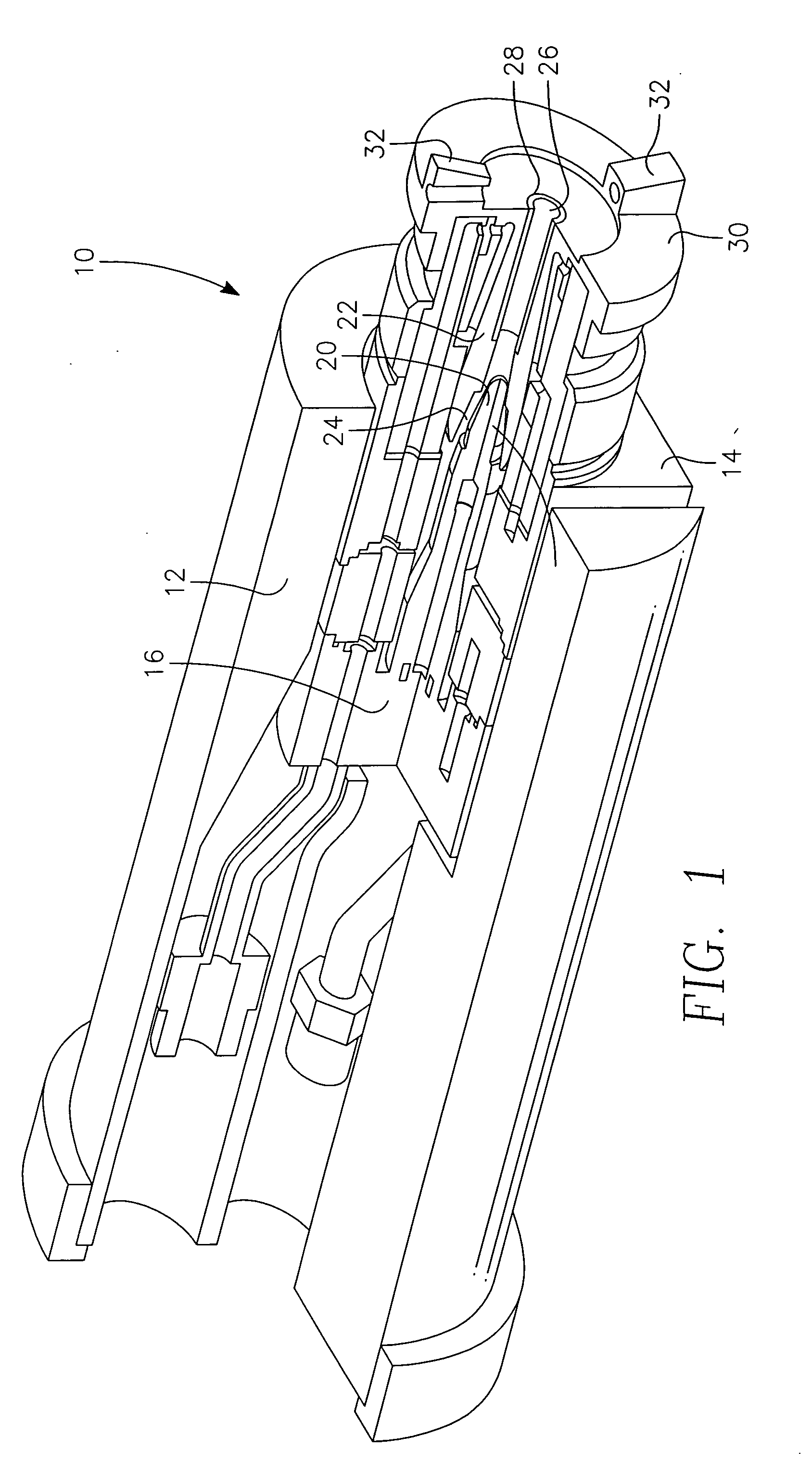

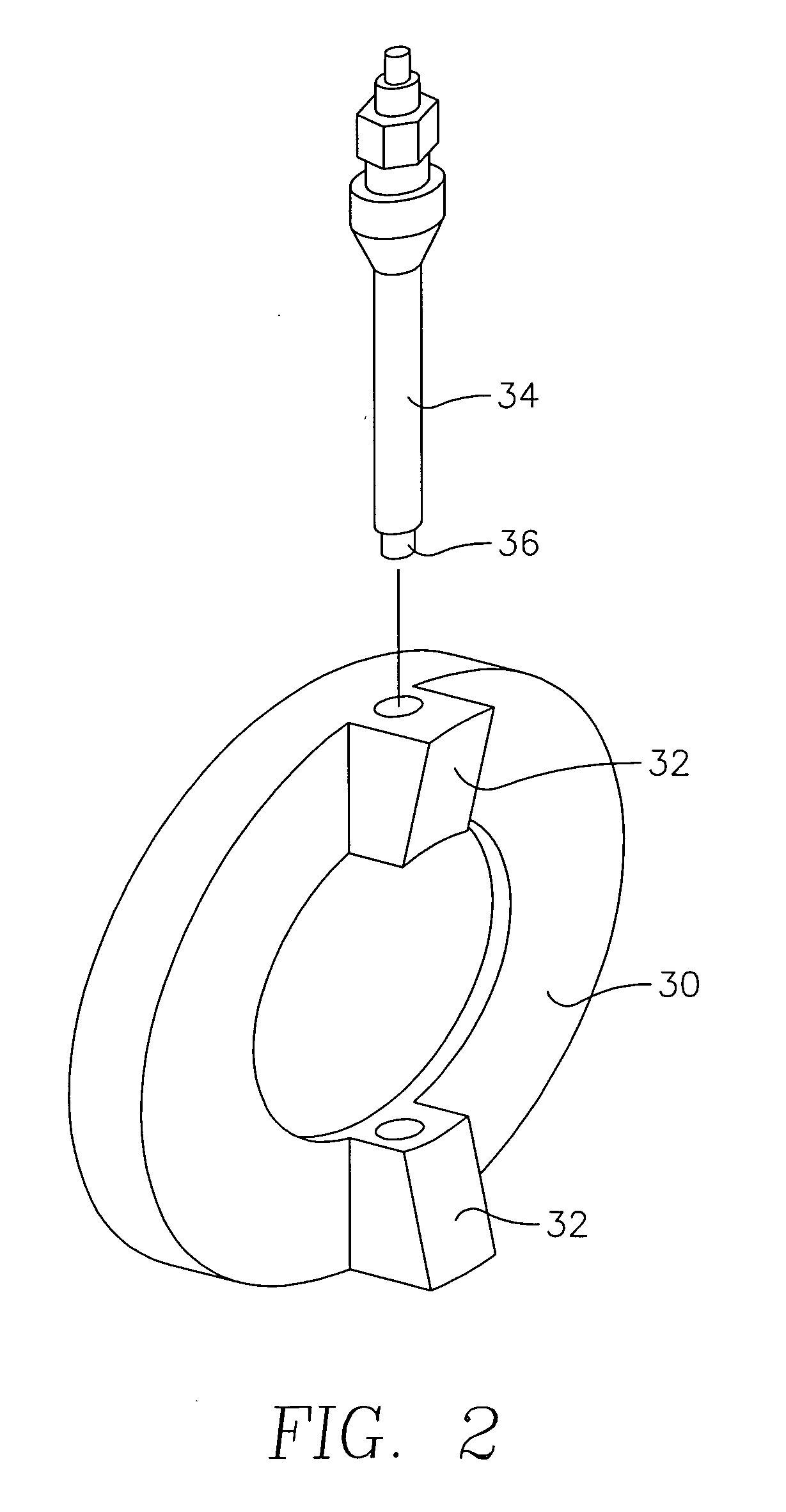

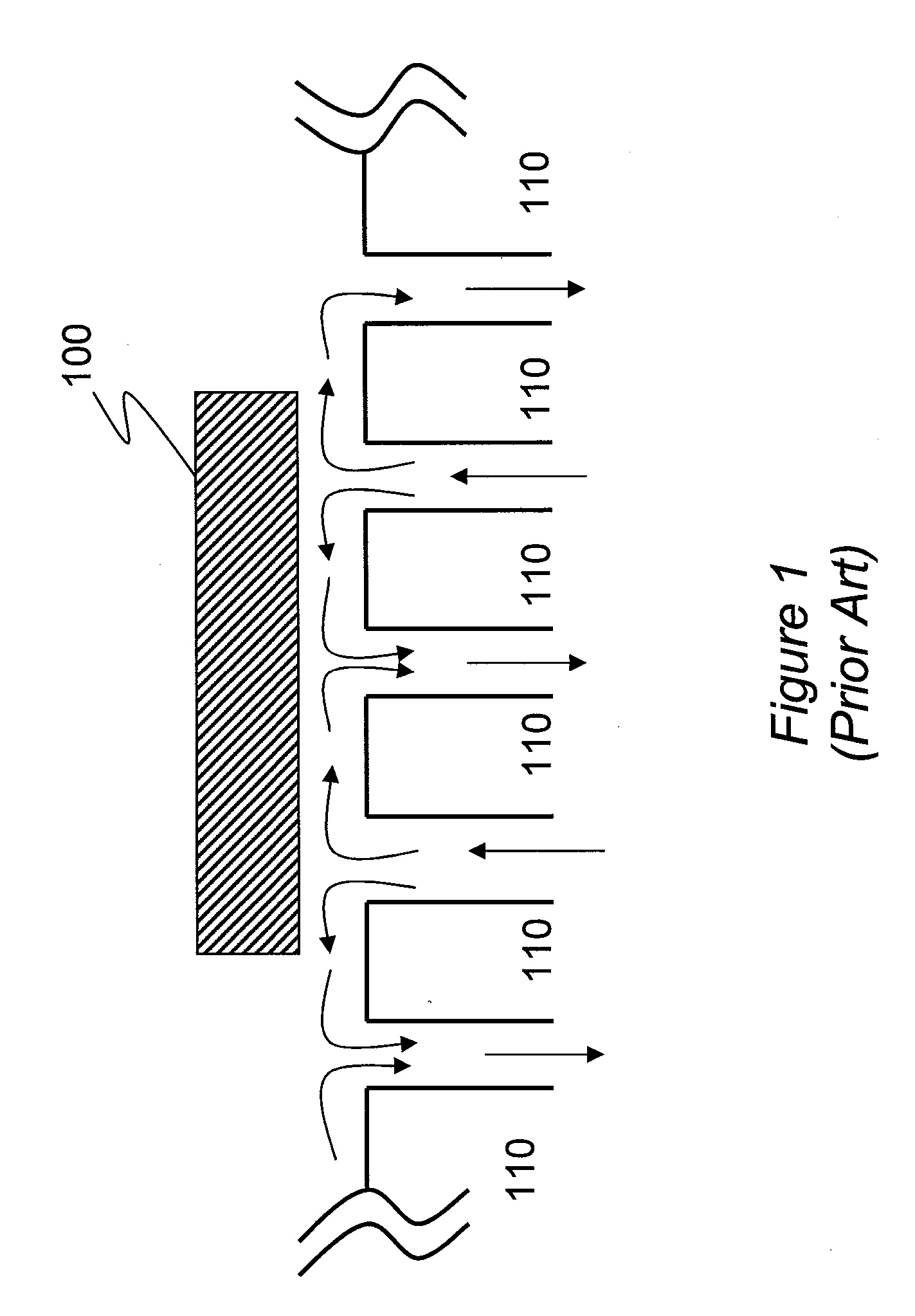

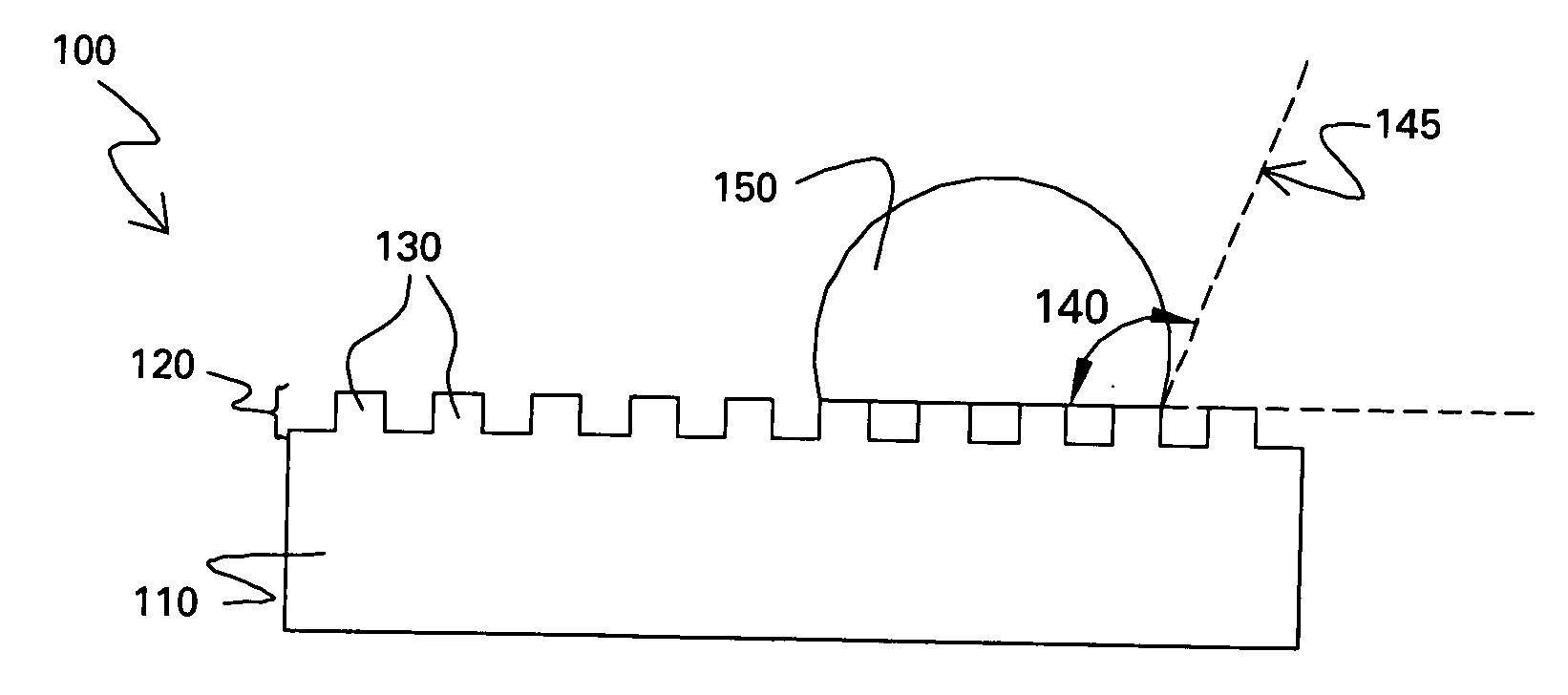

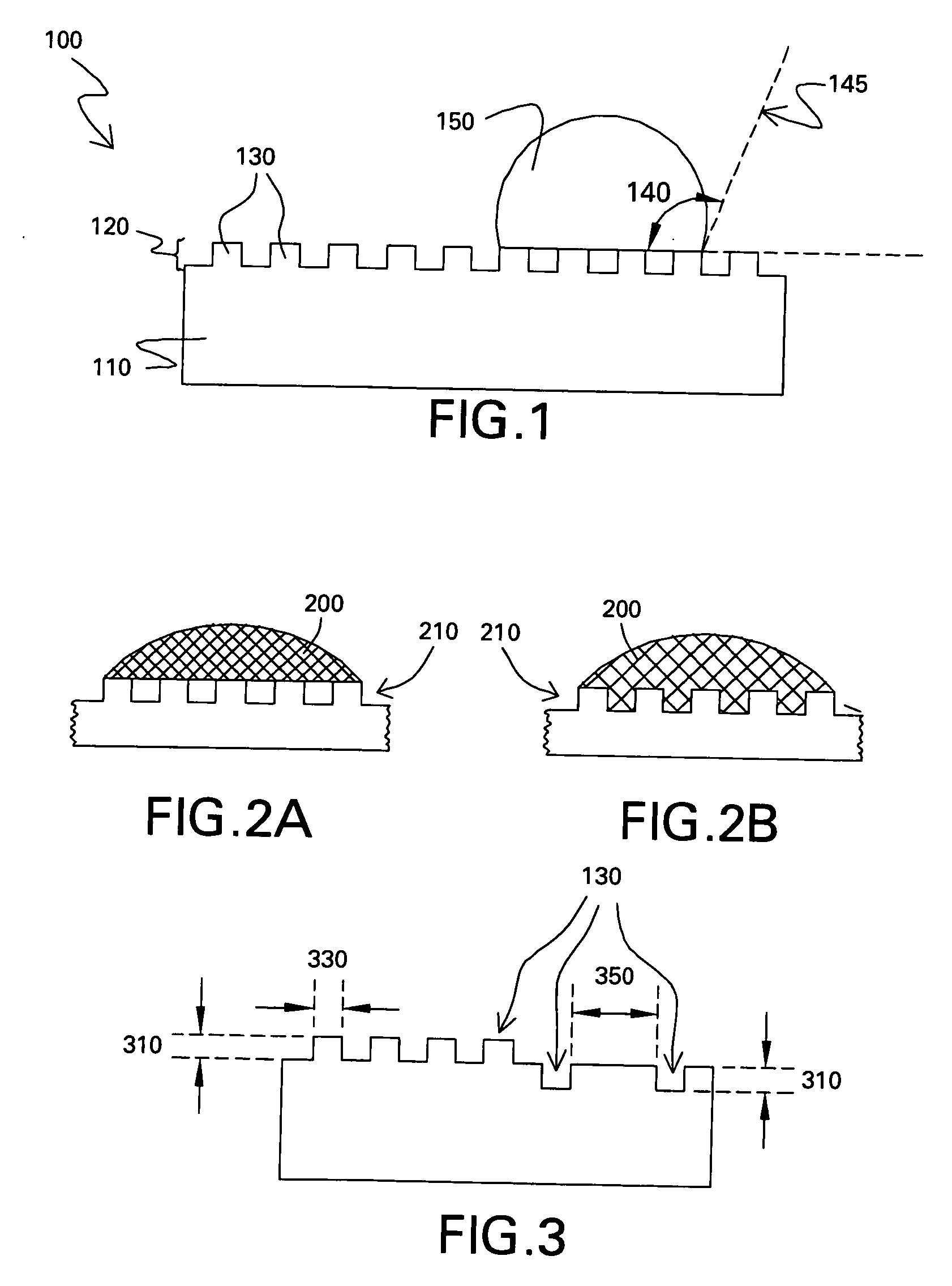

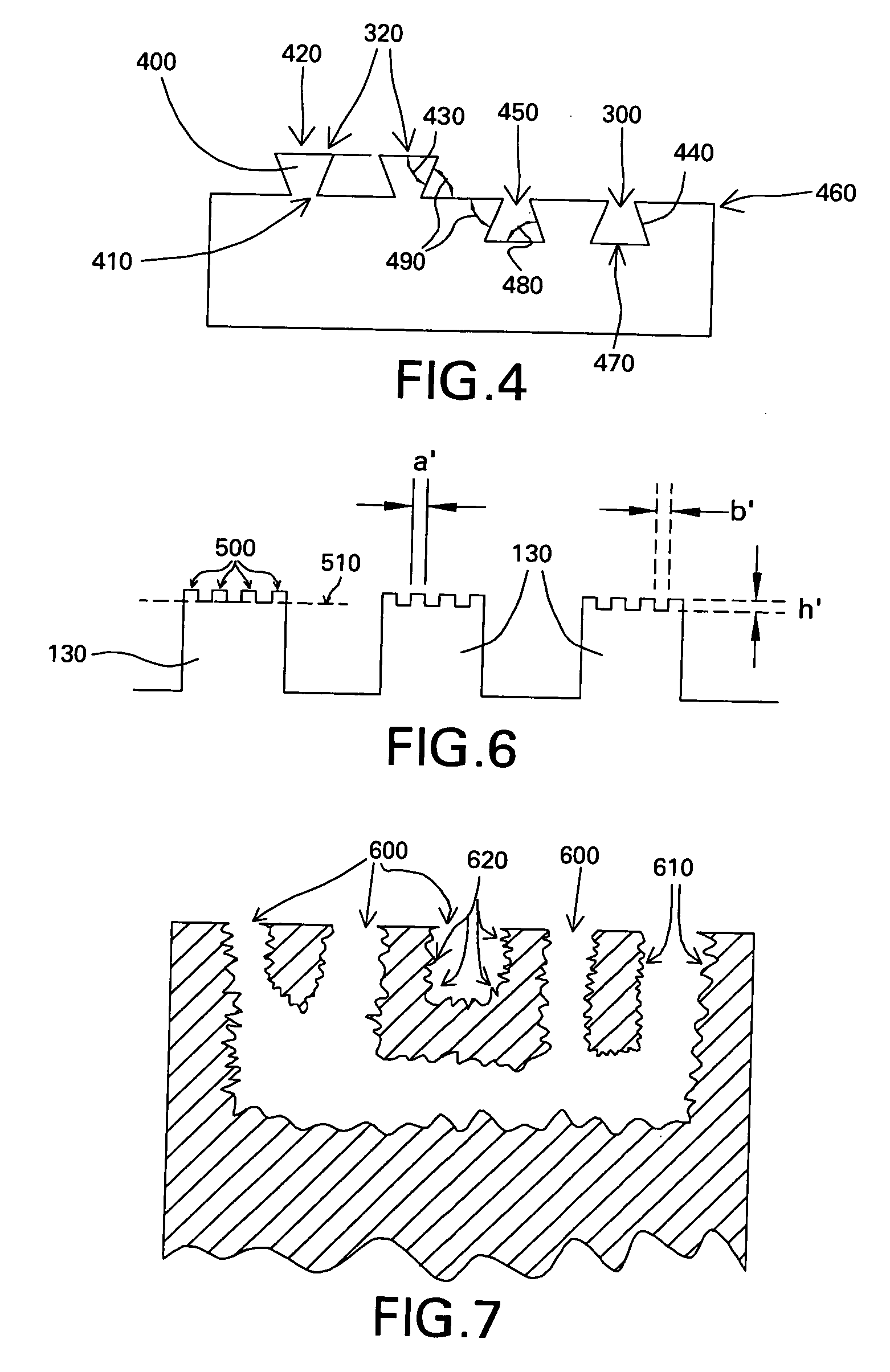

Diffuser plate with slit valve compensation

InactiveUS8328939B2Uniform plasma distributionUniform film thicknessLiquid surface applicatorsMolten spray coatingEngineeringMechanical engineering

The present invention generally comprises a diffuser plate for a PECVD chamber. The diffuser plate comprises a plurality of hollow cathode cavities. The edge of the diffuser plate that will reside closest to a slit valve within a processing chamber may have the shape and / or size of the hollow cathode cavities adjusted to compensate for the proximity to the slit valve. By adjusting the shape and / or size of the hollow cathode cavities closest to the slit valve, the diffuser plate may permit a uniform plasma distribution across the processing chamber and thus, a uniform film thickness upon a substrate during a PECVD process.

Owner:APPLIED MATERIALS INC

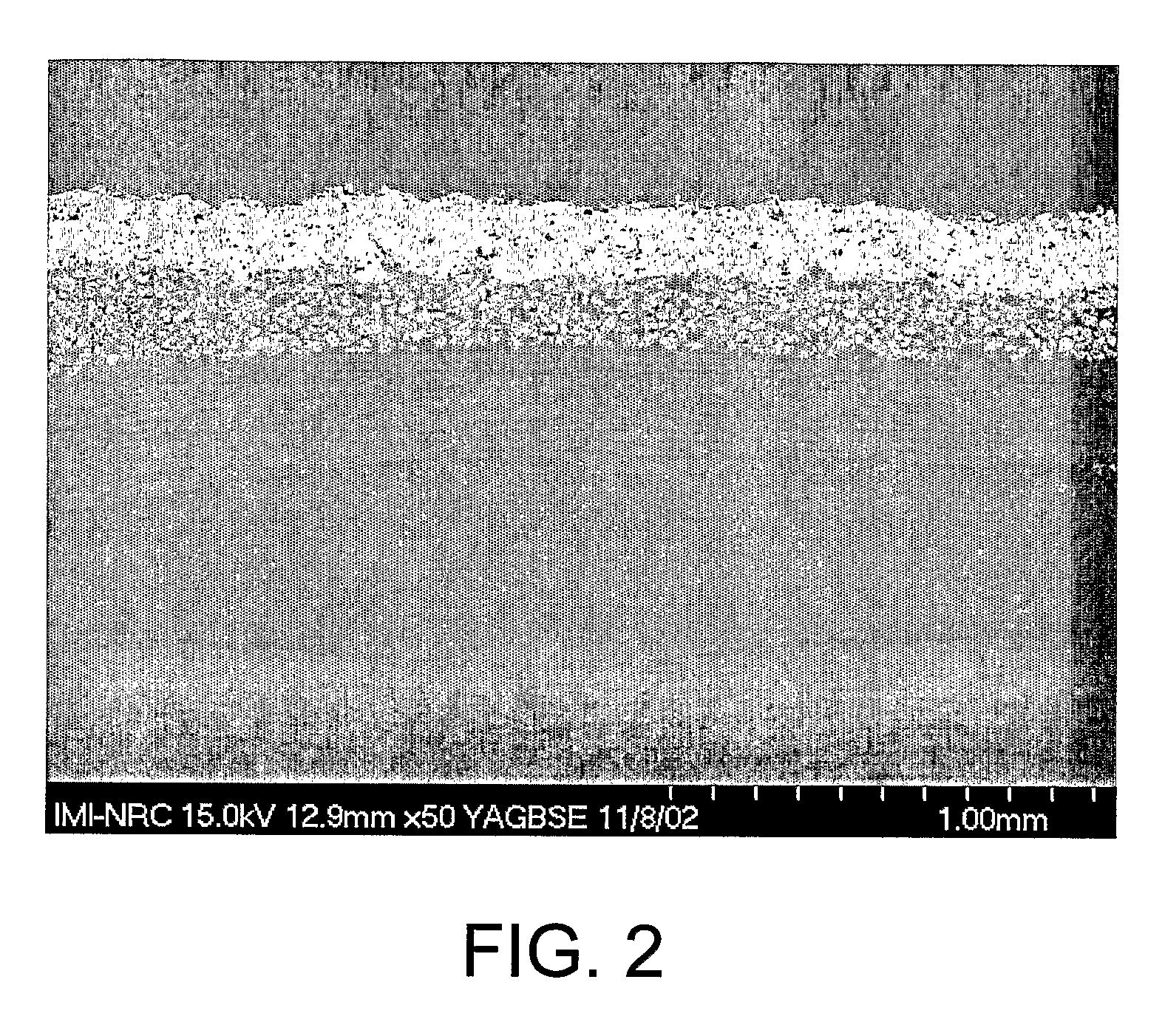

Laser-produced porous structure

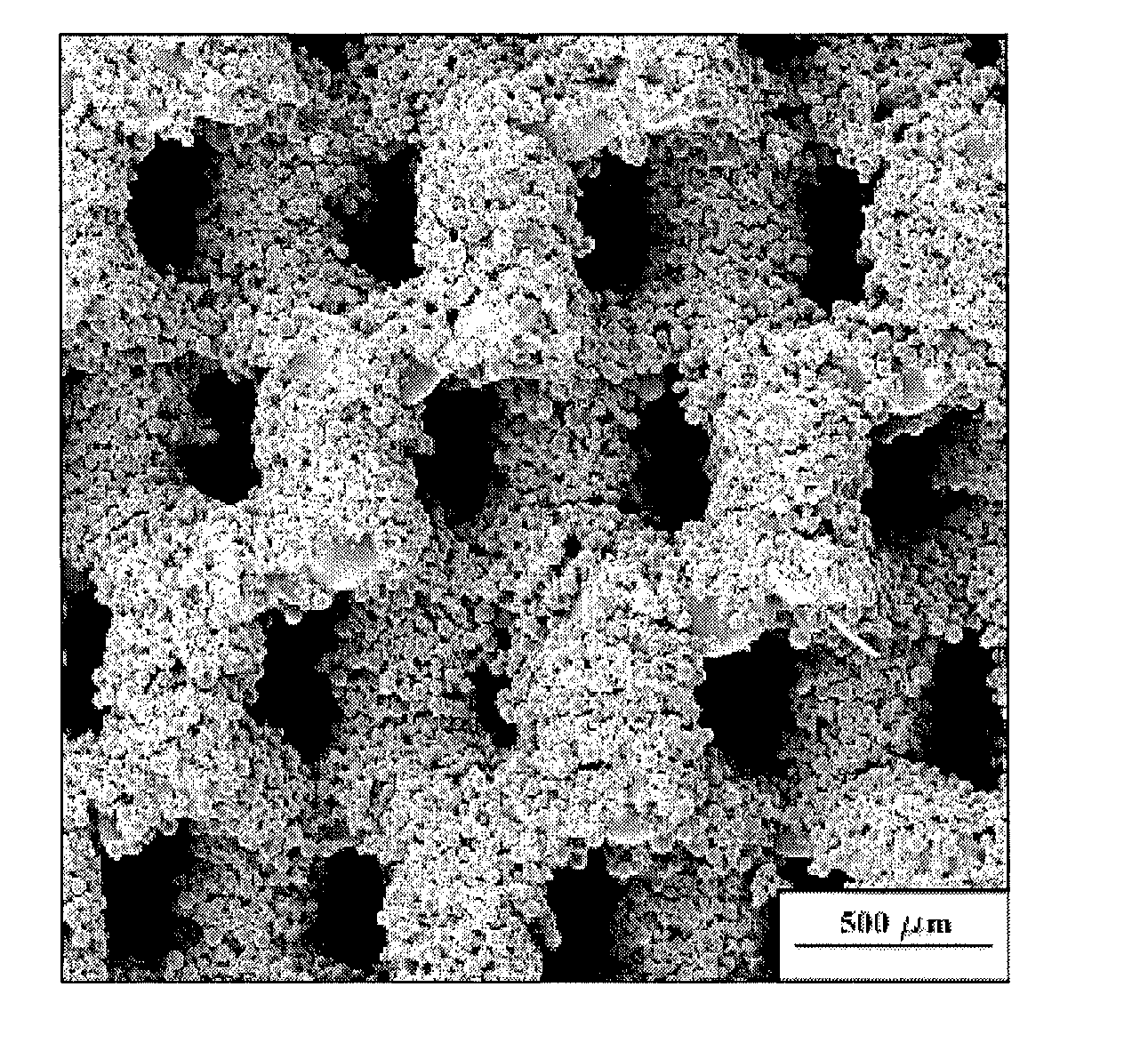

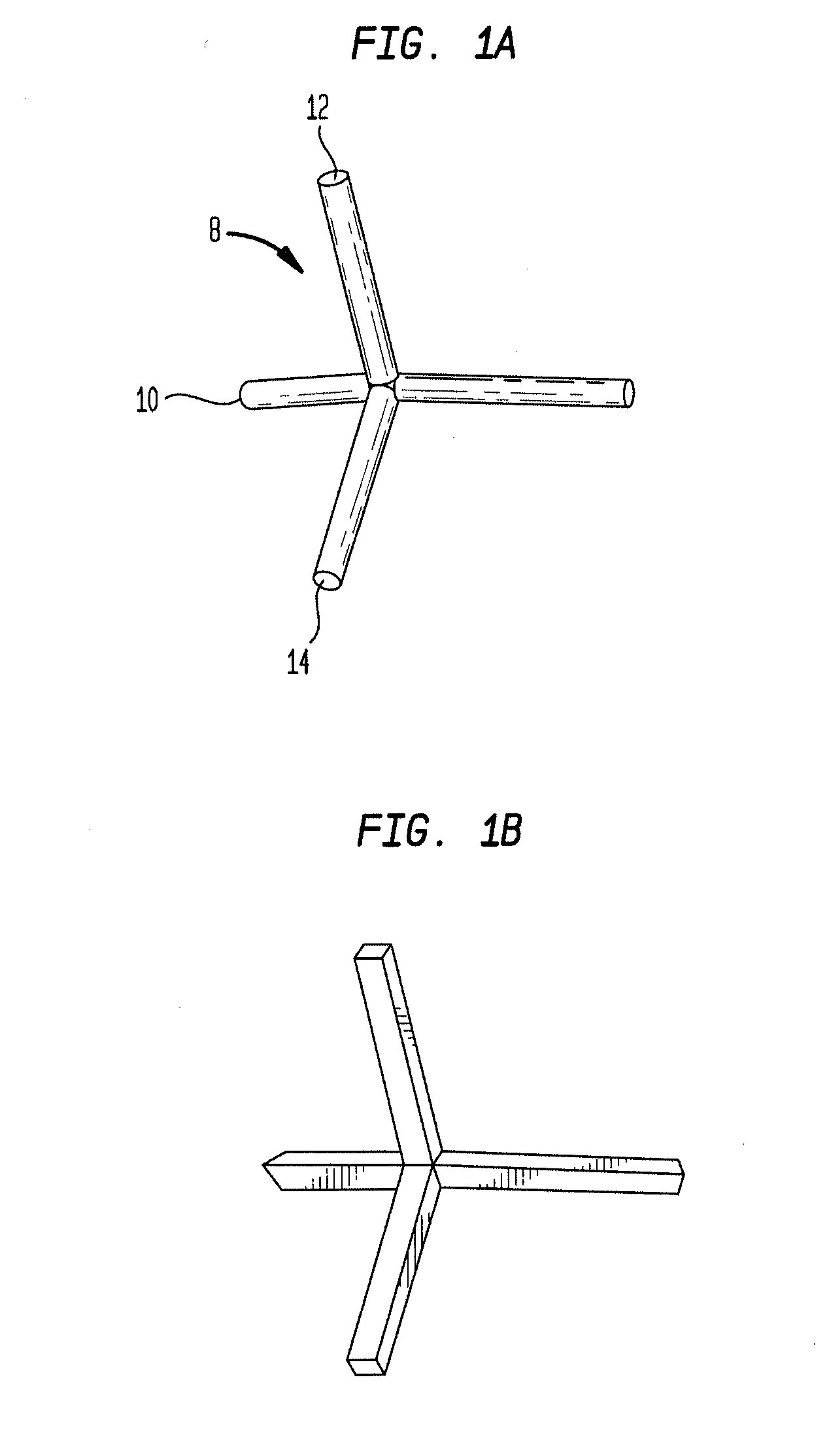

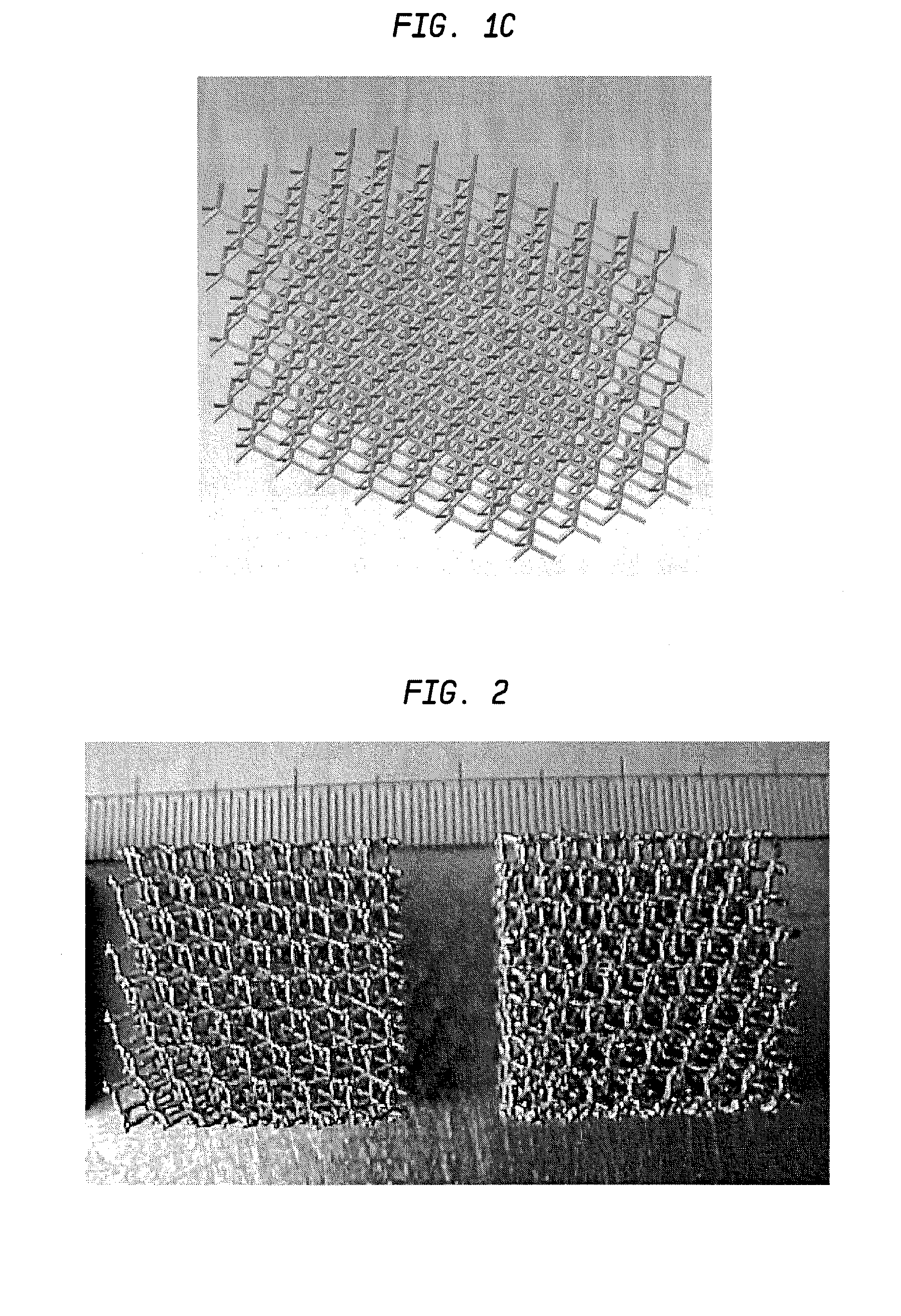

The present invention disclosed a method of producing a three-dimensional porous tissue in-growth structure. The method includes the steps of depositing a first layer of metal powder and scanning the first layer of metal powder with a laser beam to form a portion of a plurality of predetermined unit cells. Depositing at least one additional layer of metal powder onto a previous layer and repeating the step of scanning a laser beam for at least one of the additional layers in order to continuing forming the predetermined unit cells. The method further includes continuing the depositing and scanning steps to form a medical implant.

Owner:UNIV OF LIVERPOOL +1

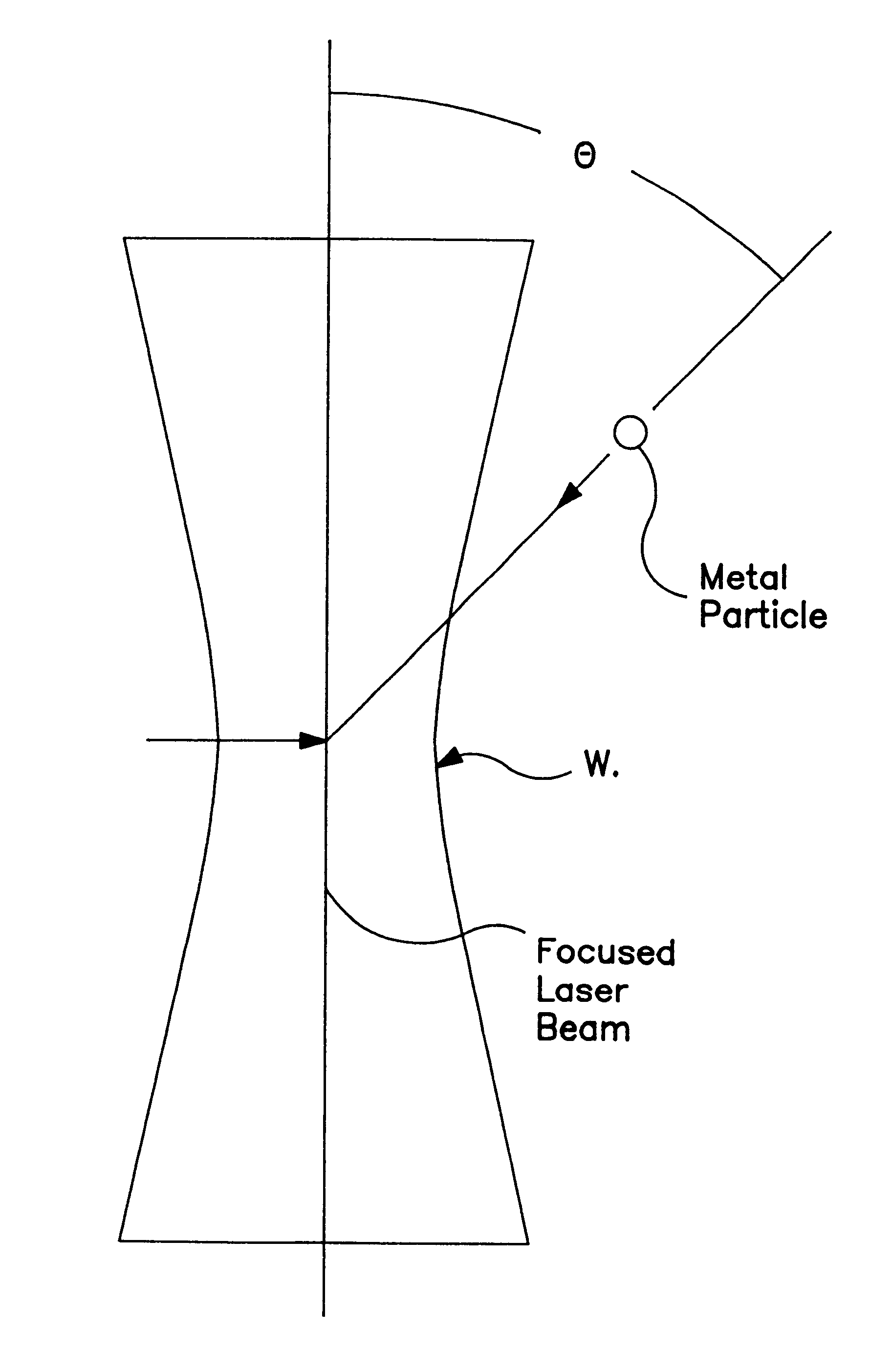

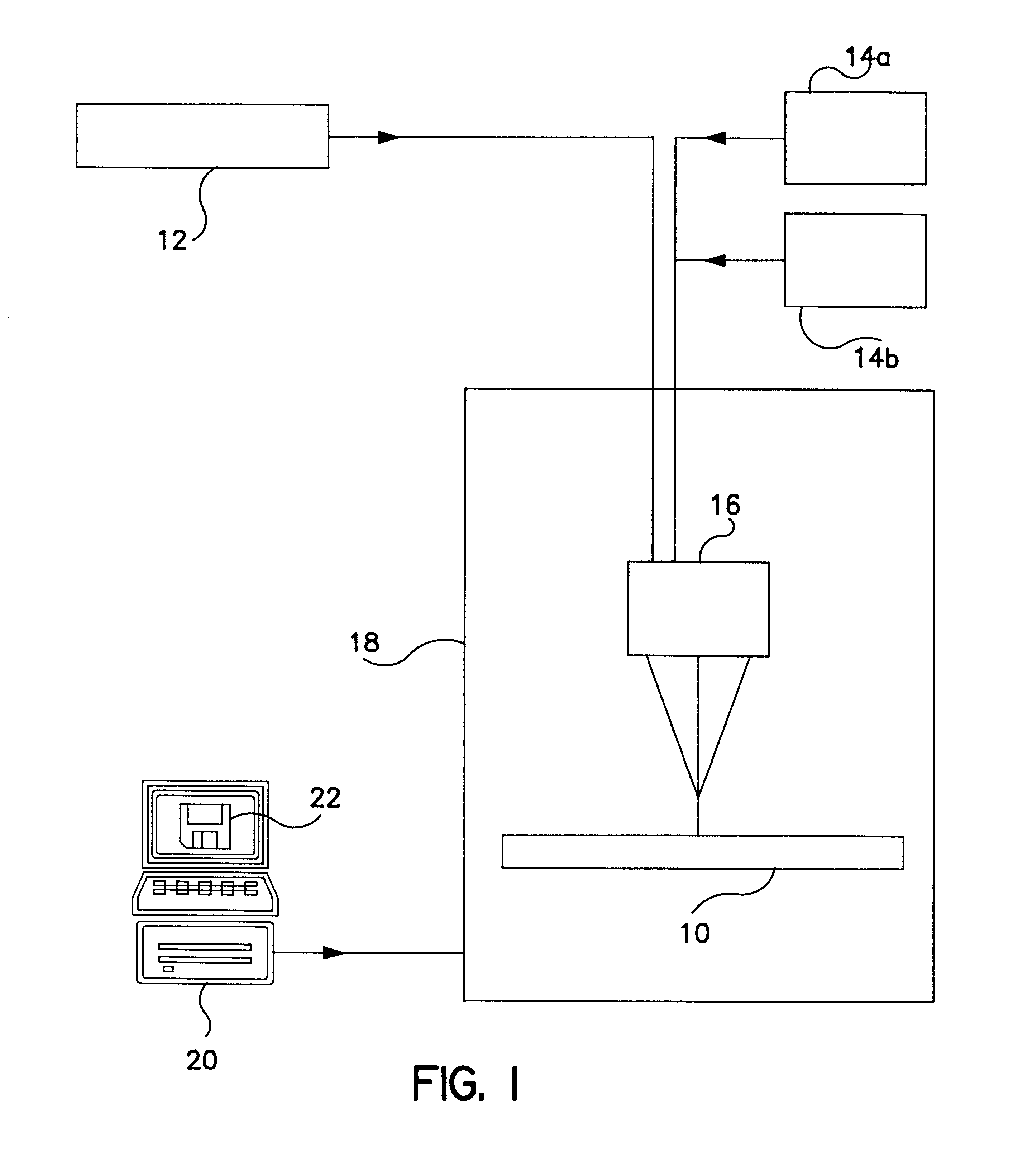

Precision spray processes for direct write electronic components

InactiveUS6251488B1Keep for a long timeIncrease probabilityMolten spray coatingVacuum evaporation coatingElectrical resistance and conductanceElectronic component

This invention combines the precision spray process with in-flight laser treatment in order to produce direct write electronic components. In addition to these components, the process can lay down lines of conductive, inductive, and resistive materials. This development has the potential to change the approach to electronics packaging. This process is revolutionary in that components can be directly produced on small structures, thus removing the need for printed circuit boards.

Owner:OPTOMEC DESIGN CO

Yttria-based material coated chemical vapor deposition chamber heater

ActiveUS20140263272A1Improve wear resistanceImprove flexural strengthLiquid surface applicatorsMolten spray coatingYTTERBIUM OXIDEFlexural strength

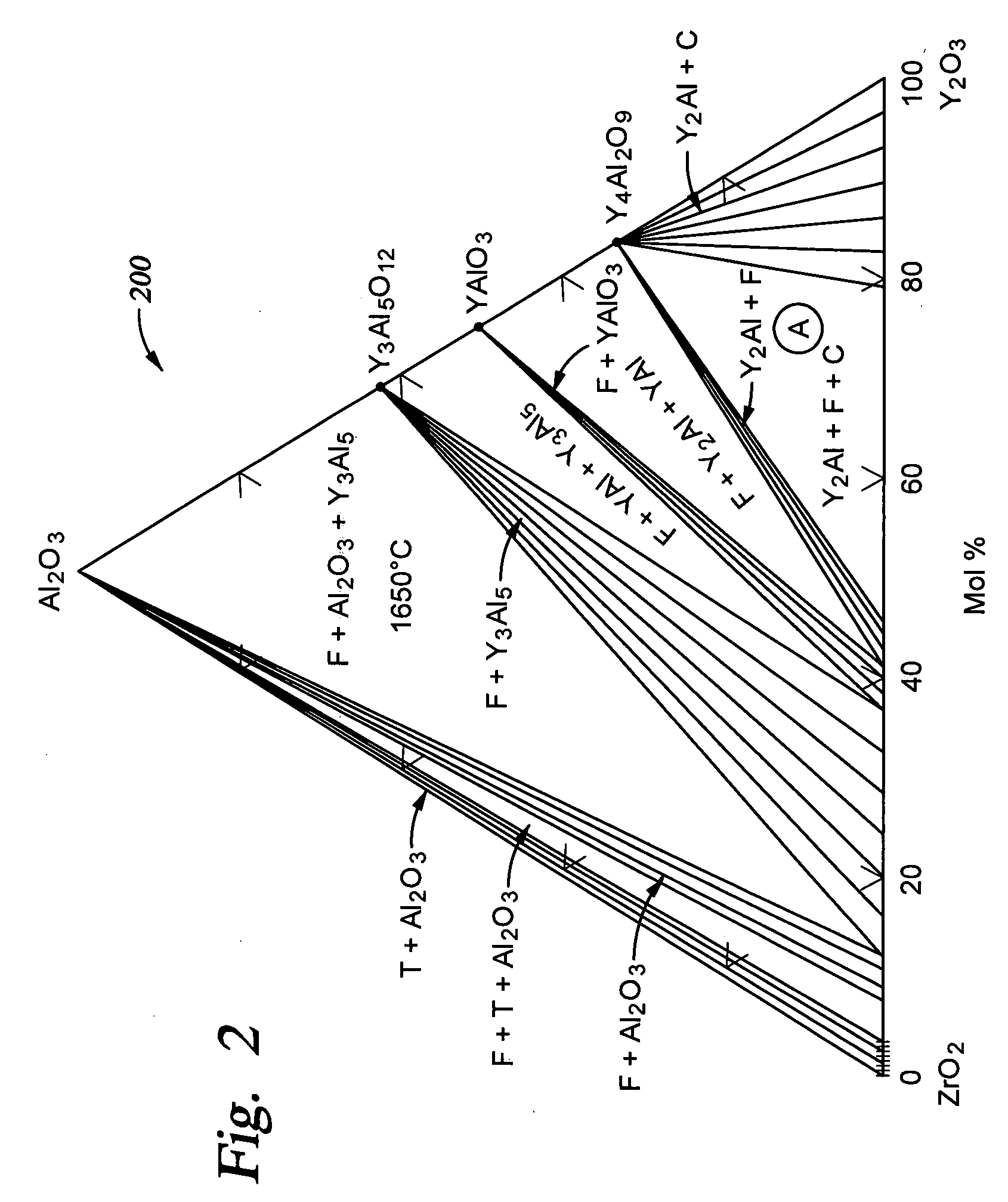

Embodiments of the present invention generally relate to heated substrate supports having a protective coating thereon. The protective coating is formed from yttrium oxide at a molar concentration ranging from about 50 mole percent to about 75 mole percent; zirconium oxide at a molar concentration ranging from about 10 mole percent to about 30 mole percent; and at least one other component, selected from the group consisting of aluminum oxide, hafnium oxide, scandium oxide, neodymium oxide, niobium oxide, samarium oxide, ytterbium oxide, erbium oxide, cerium oxide, and combinations thereof, at a molar concentration ranging from about 10 mole percent to about 30 mole percent. The alloying of yttrium oxide with a compatible oxide improves wear resistance, flexural strength, and fracture toughness of the protective coating, relative to pure yttrium oxide.

Owner:APPLIED MATERIALS INC

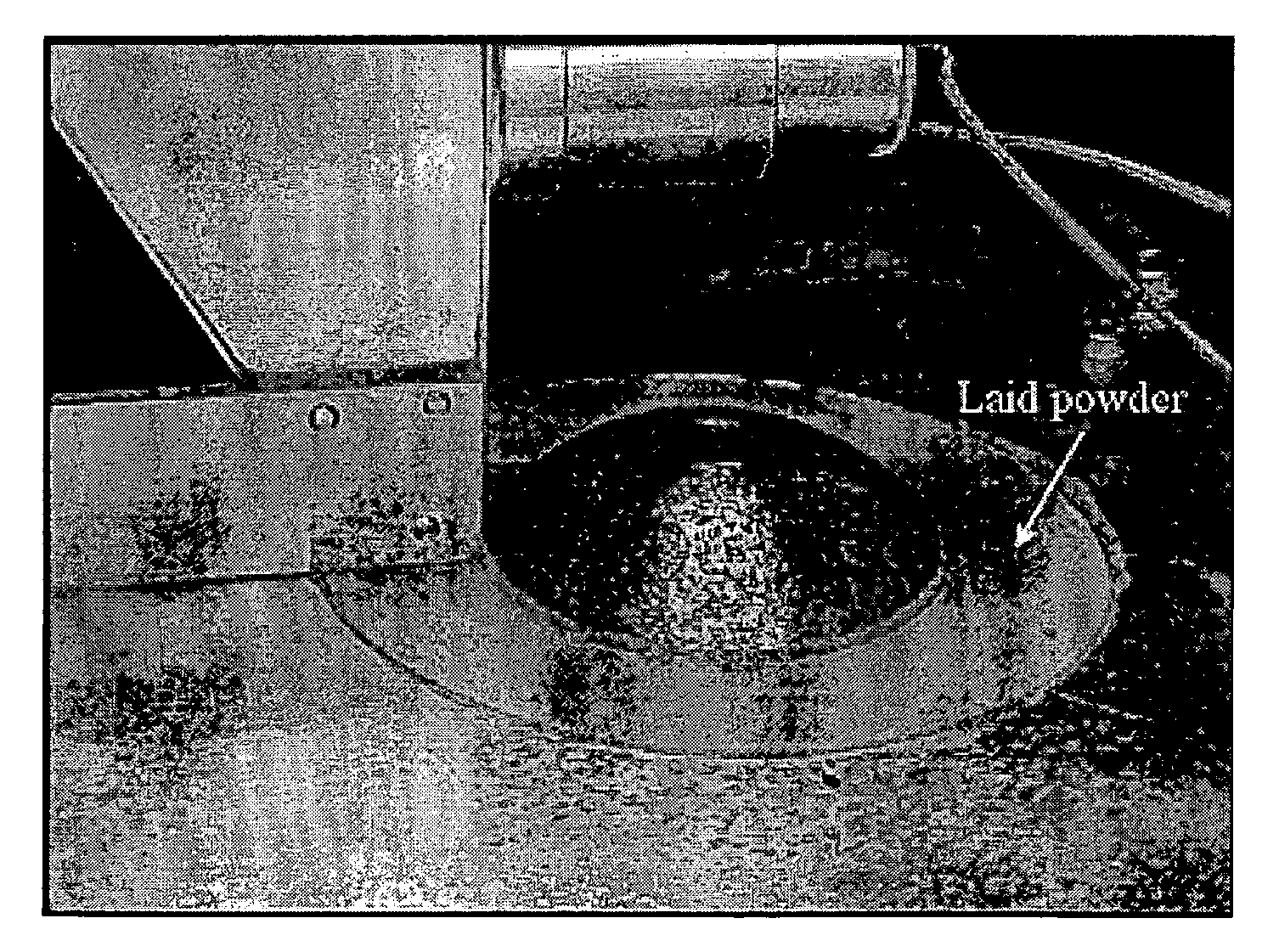

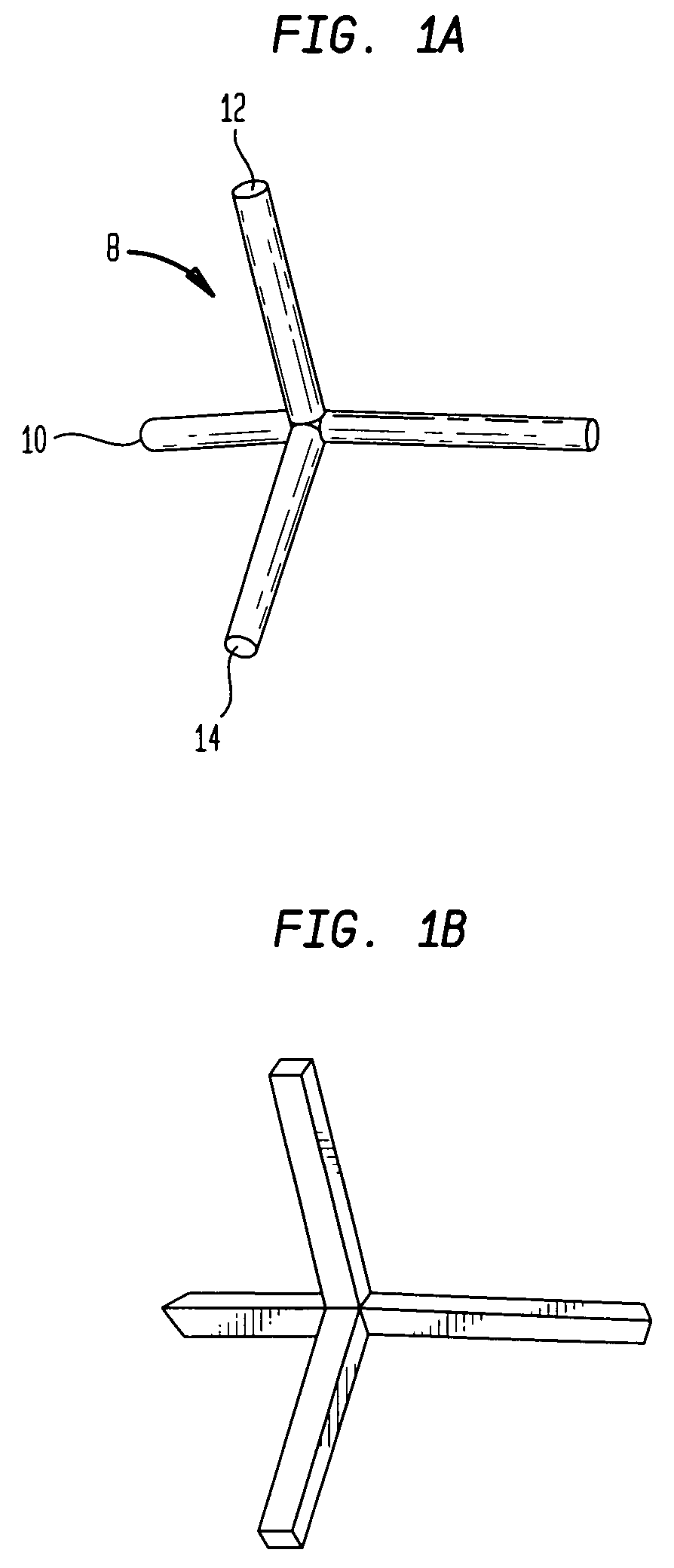

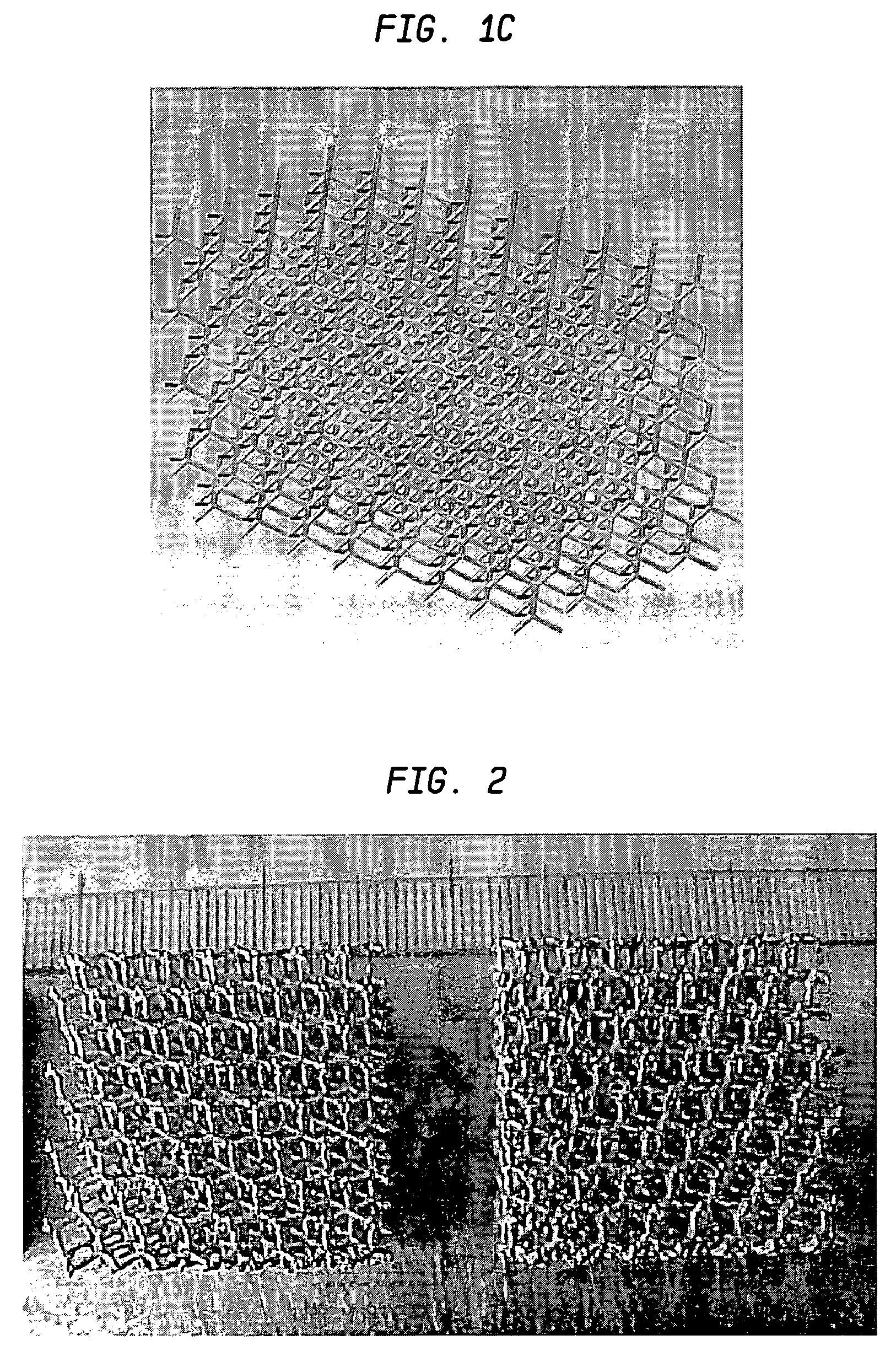

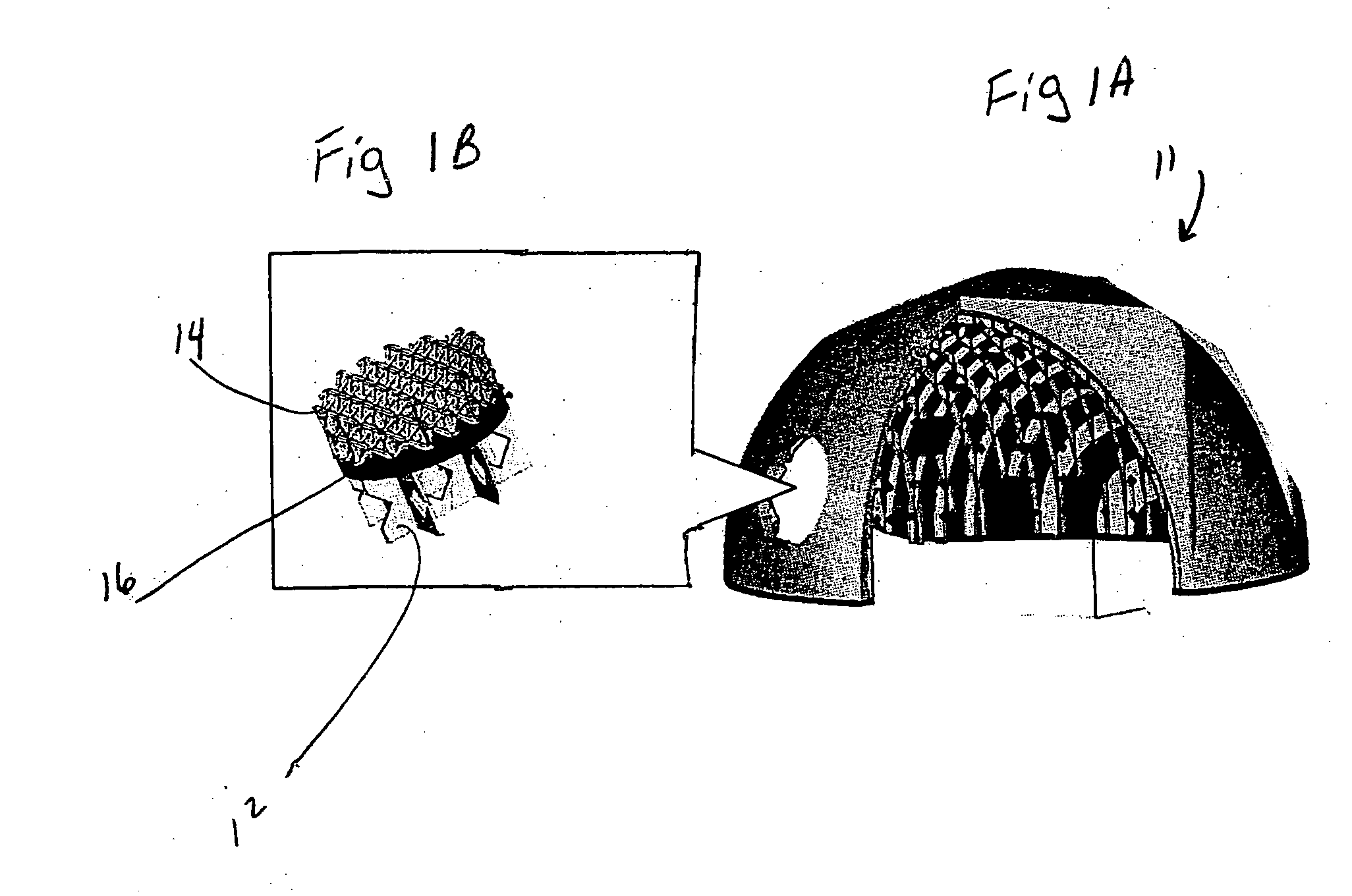

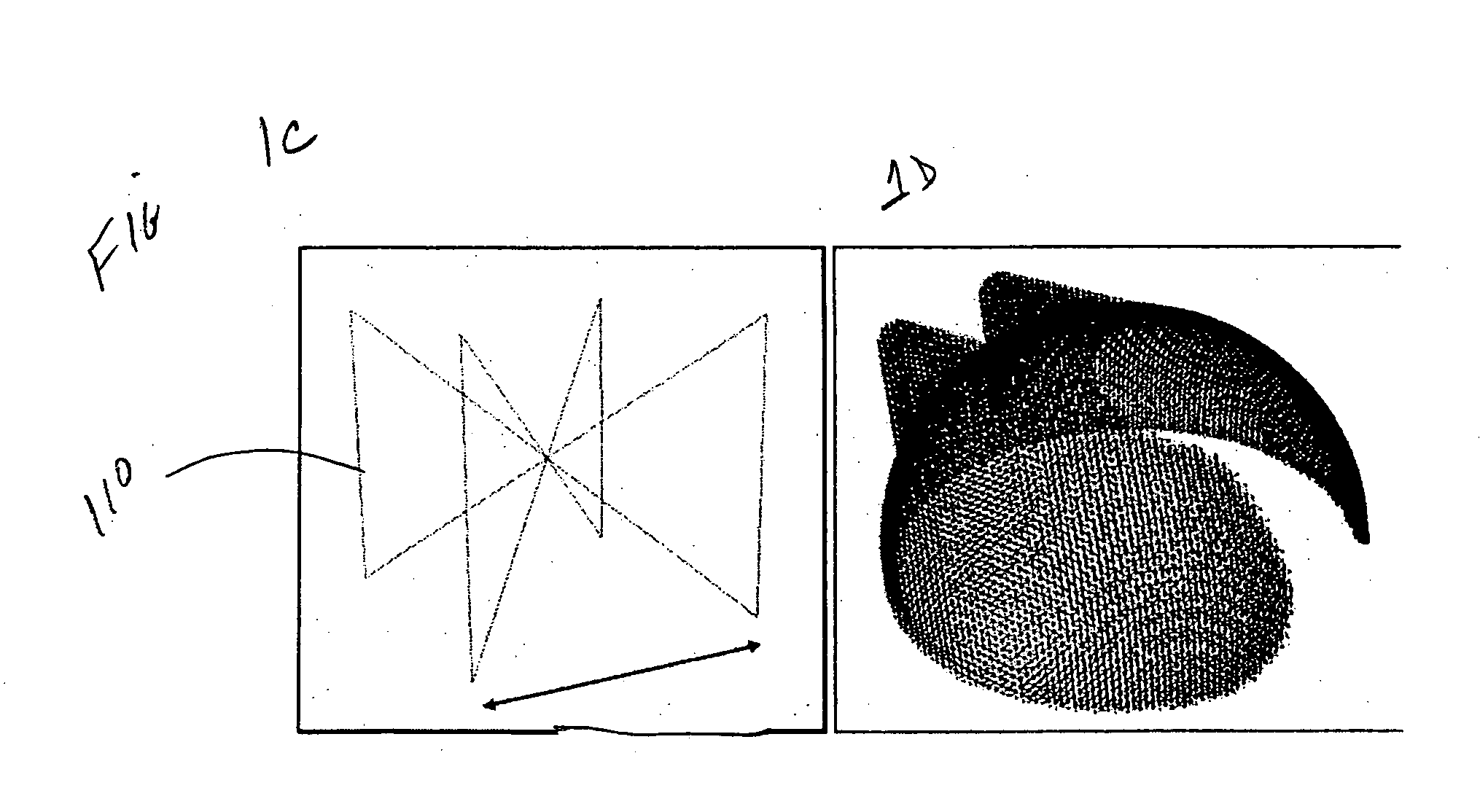

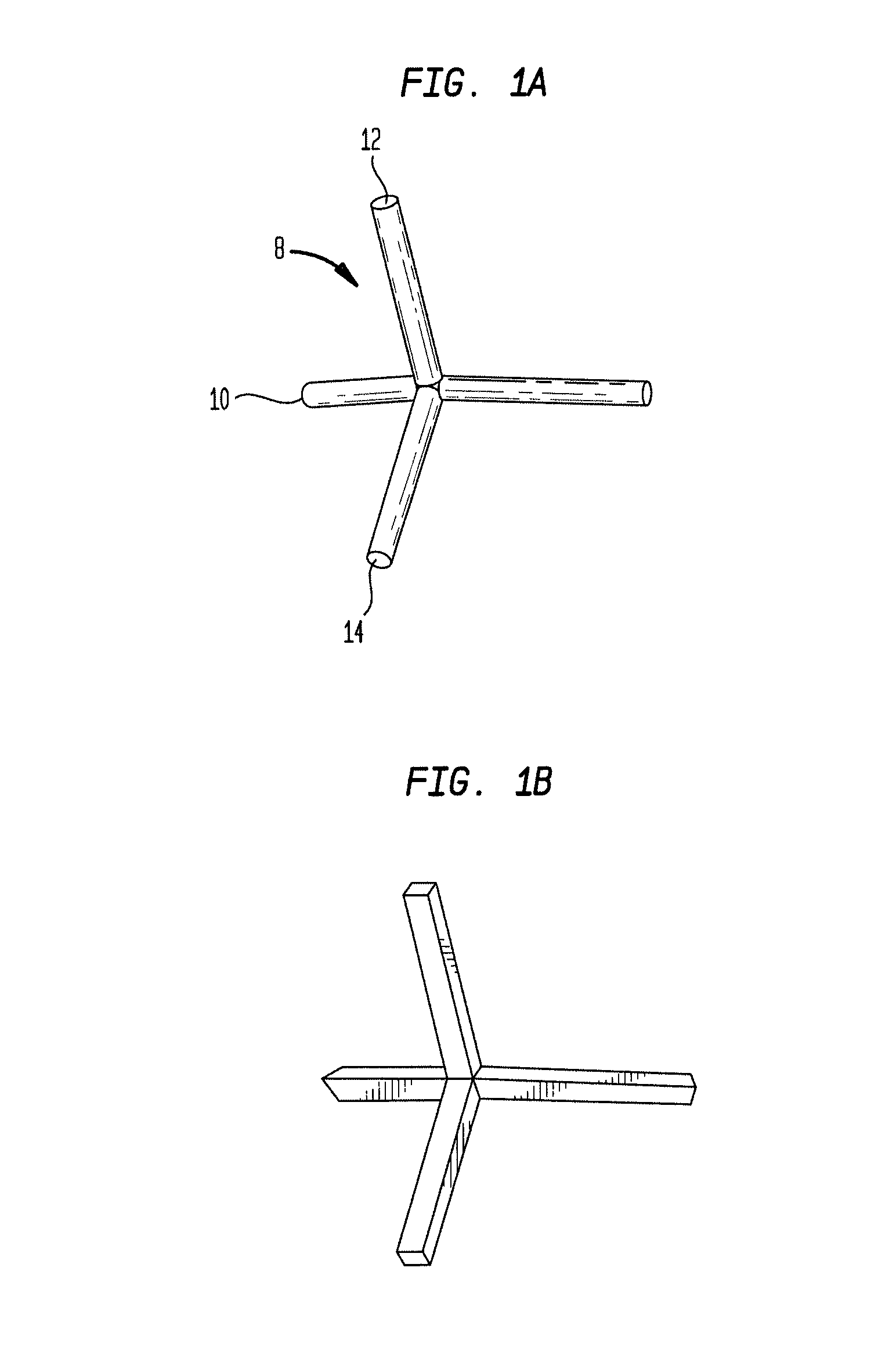

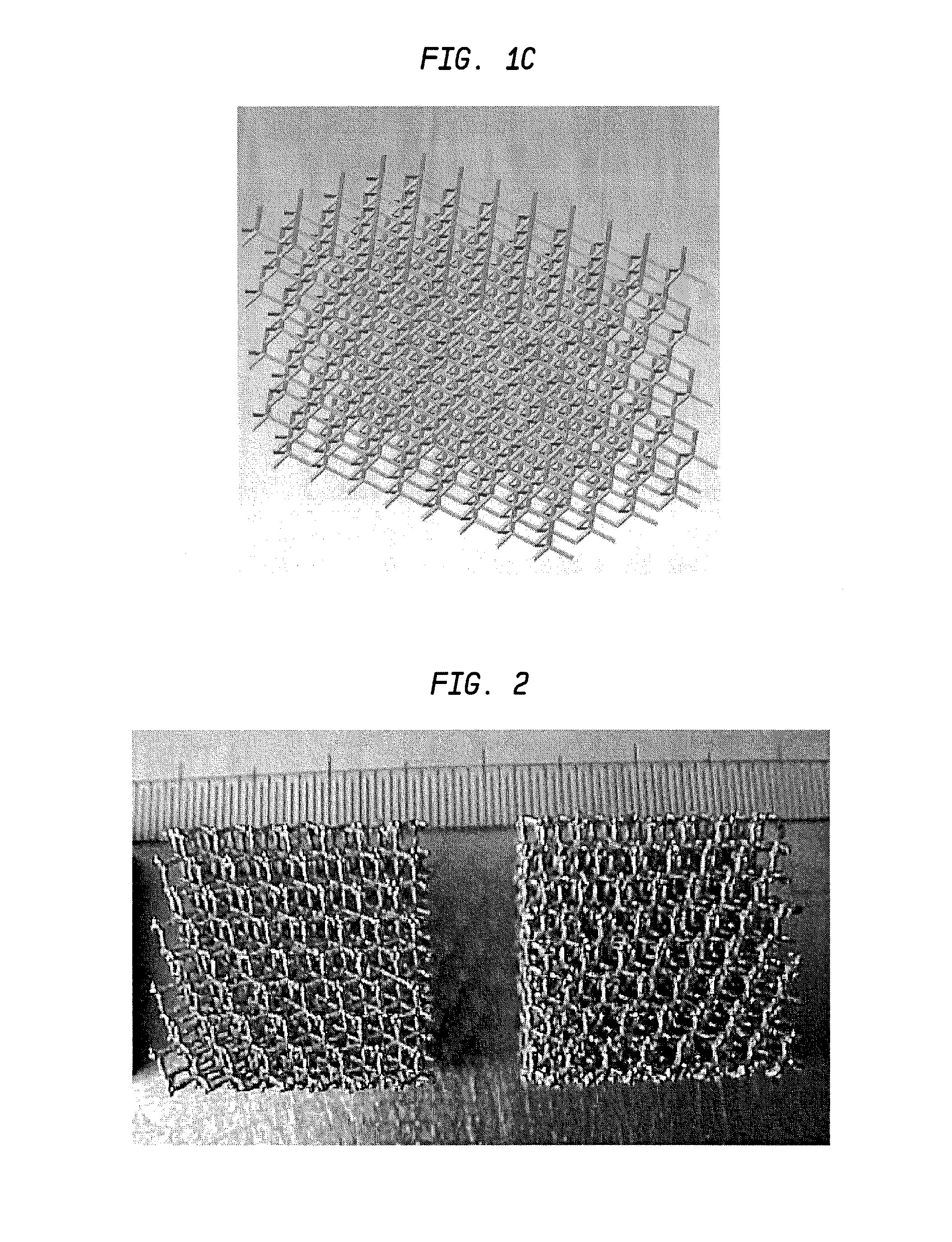

Laser-produced porous surface

ActiveUS20070142914A1Promote bone ingrowthGood stiffness characteristicsAdditive manufacturing apparatusMolten spray coatingLight beamMetal powder

A method of forming an implant having a porous tissue ingrowth structure and a bearing support structure. The method includes depositing a first layer of a metal powder onto a substrate, scanning a laser beam over the powder so as to sinter the metal powder at predetermined locations, depositing at least one layer of the metal powder onto the first layer and repeating the scanning of the laser beam.

Owner:UNIV OF LIVERPOOL +1

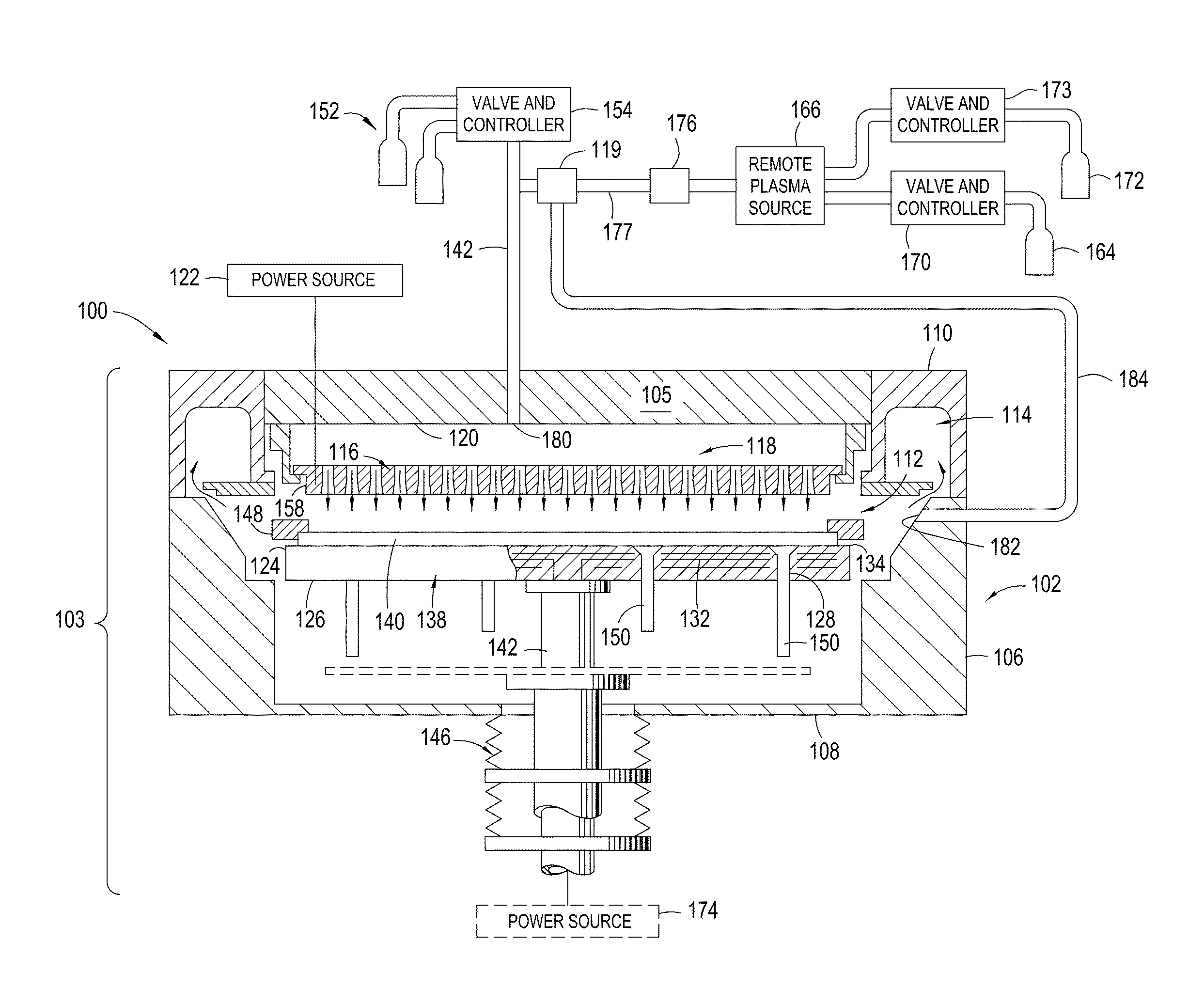

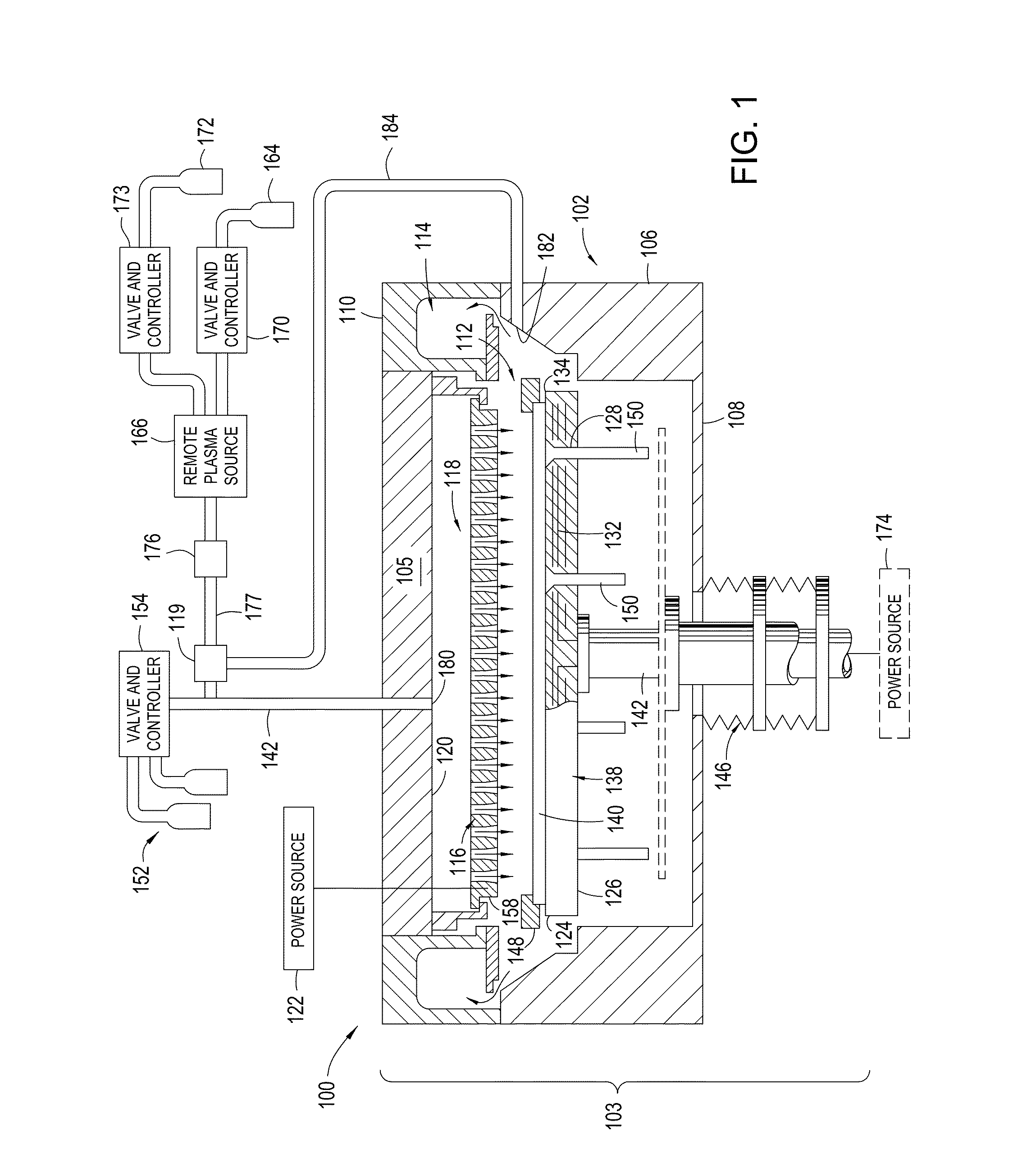

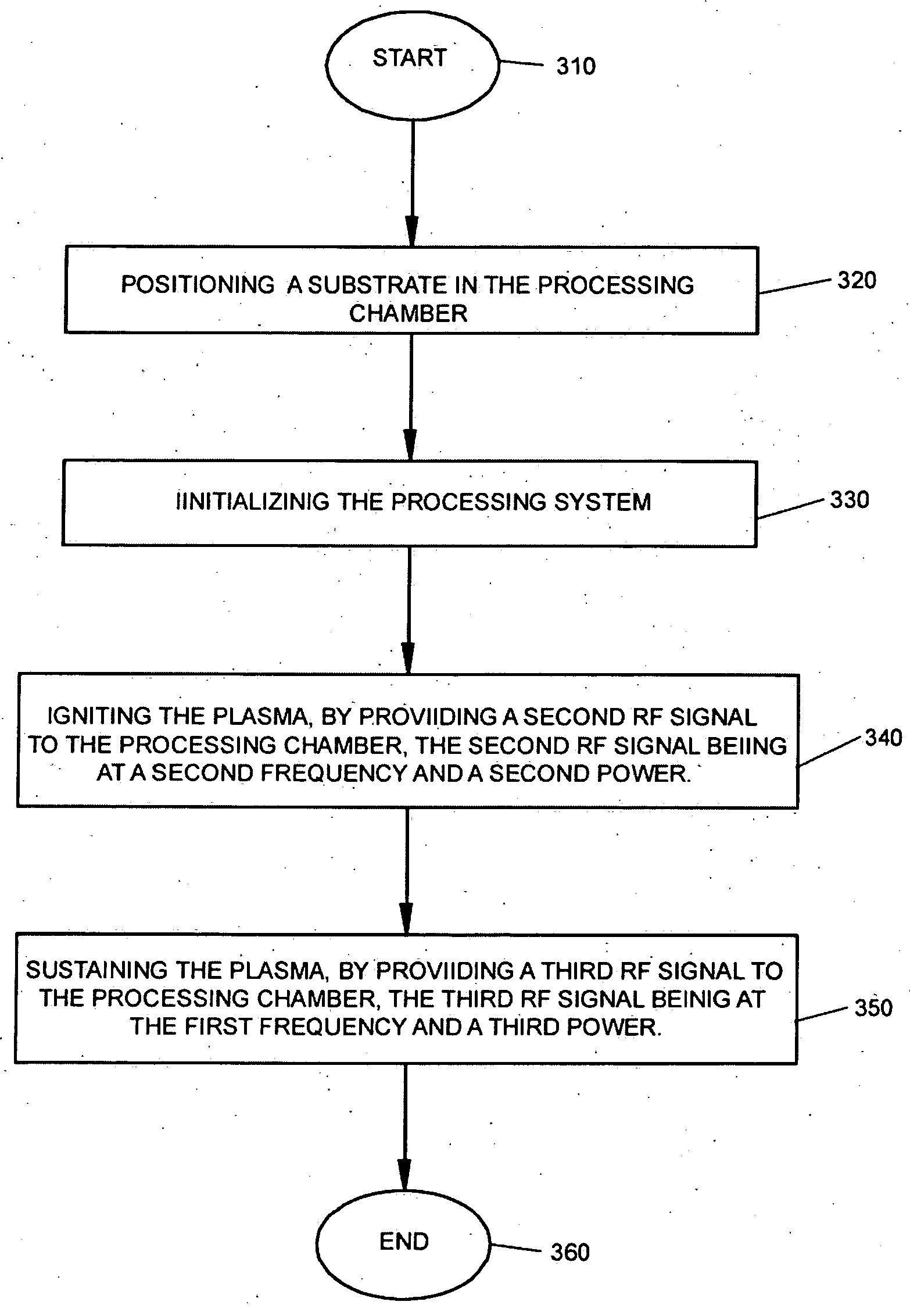

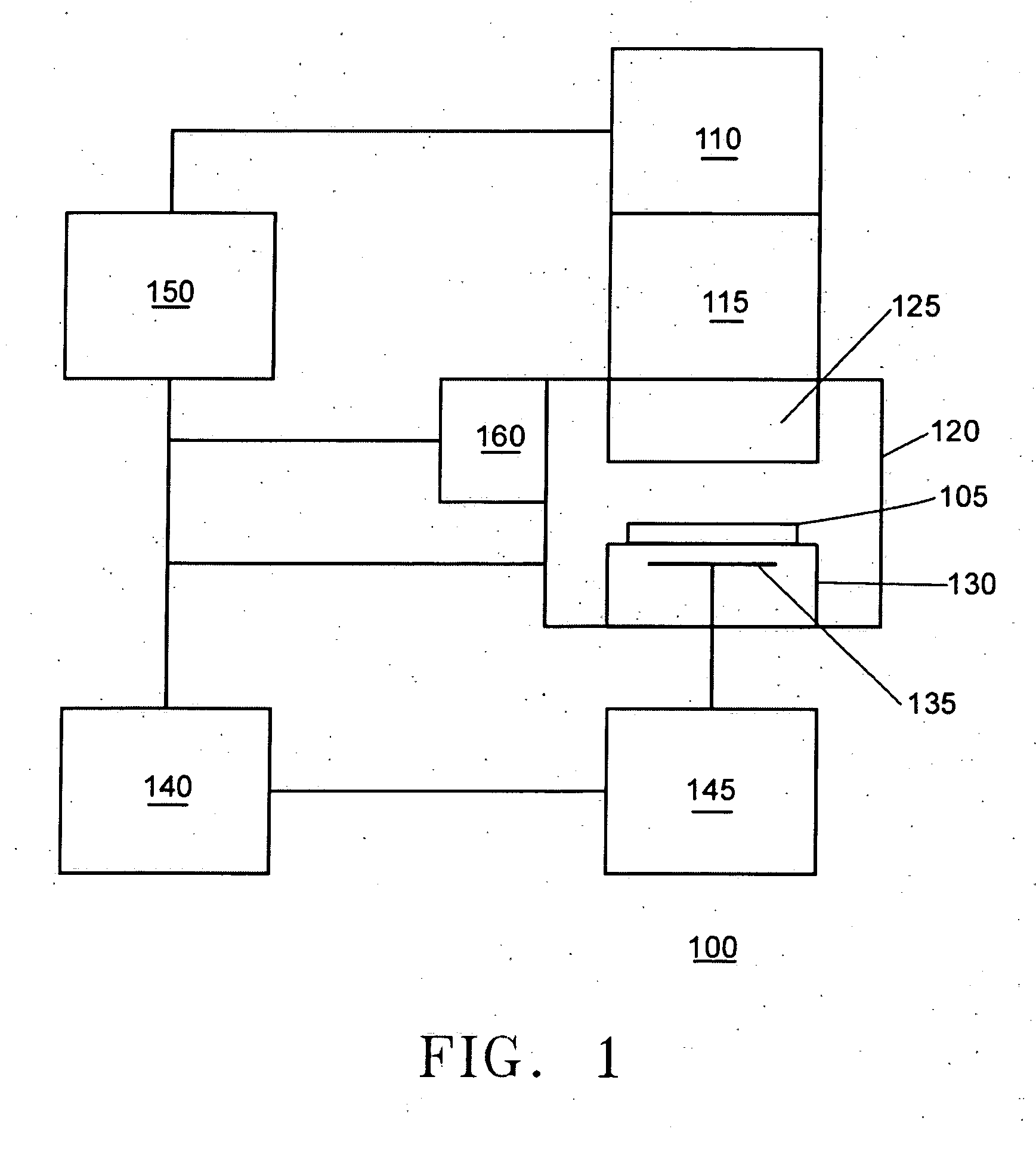

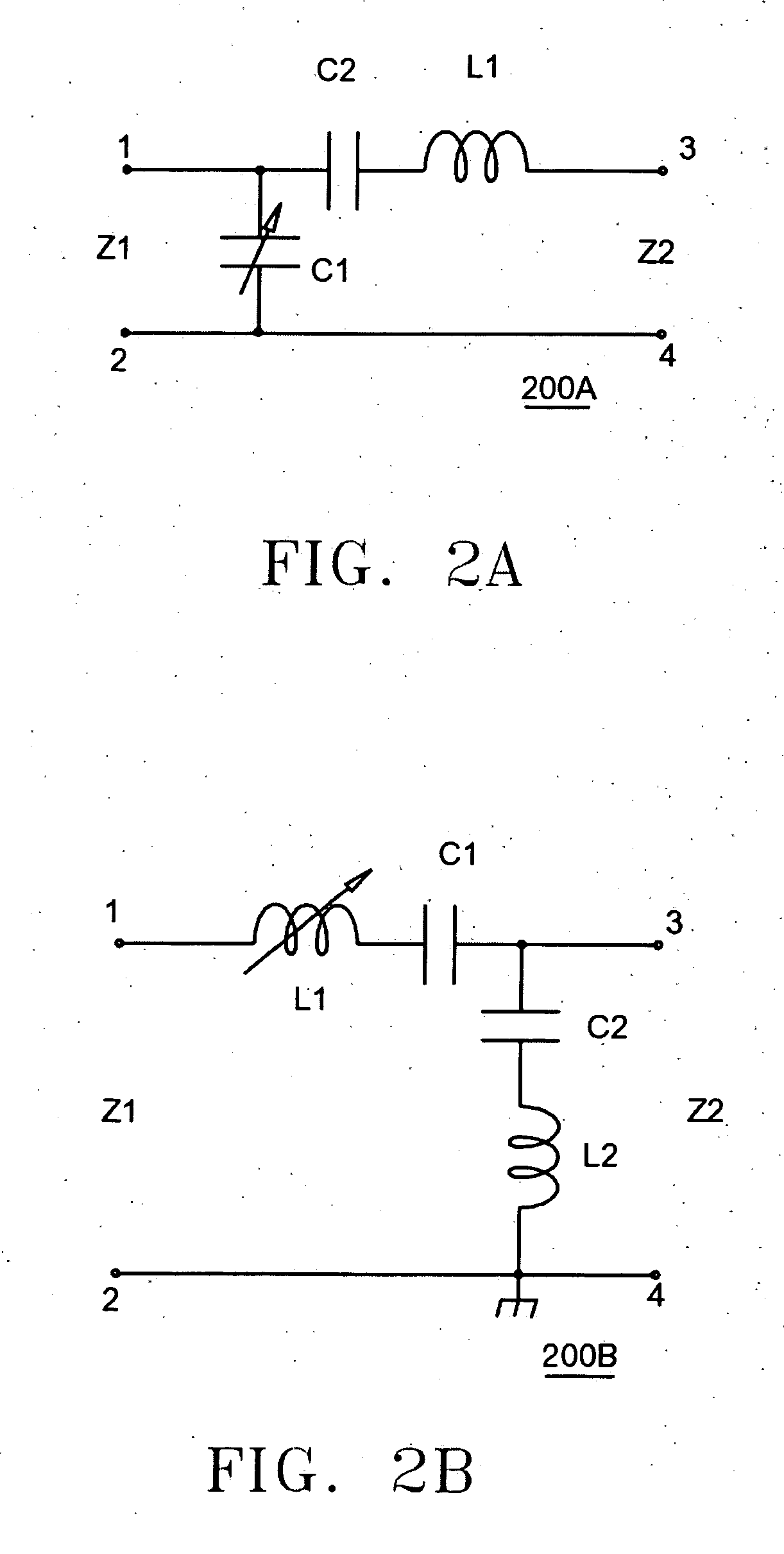

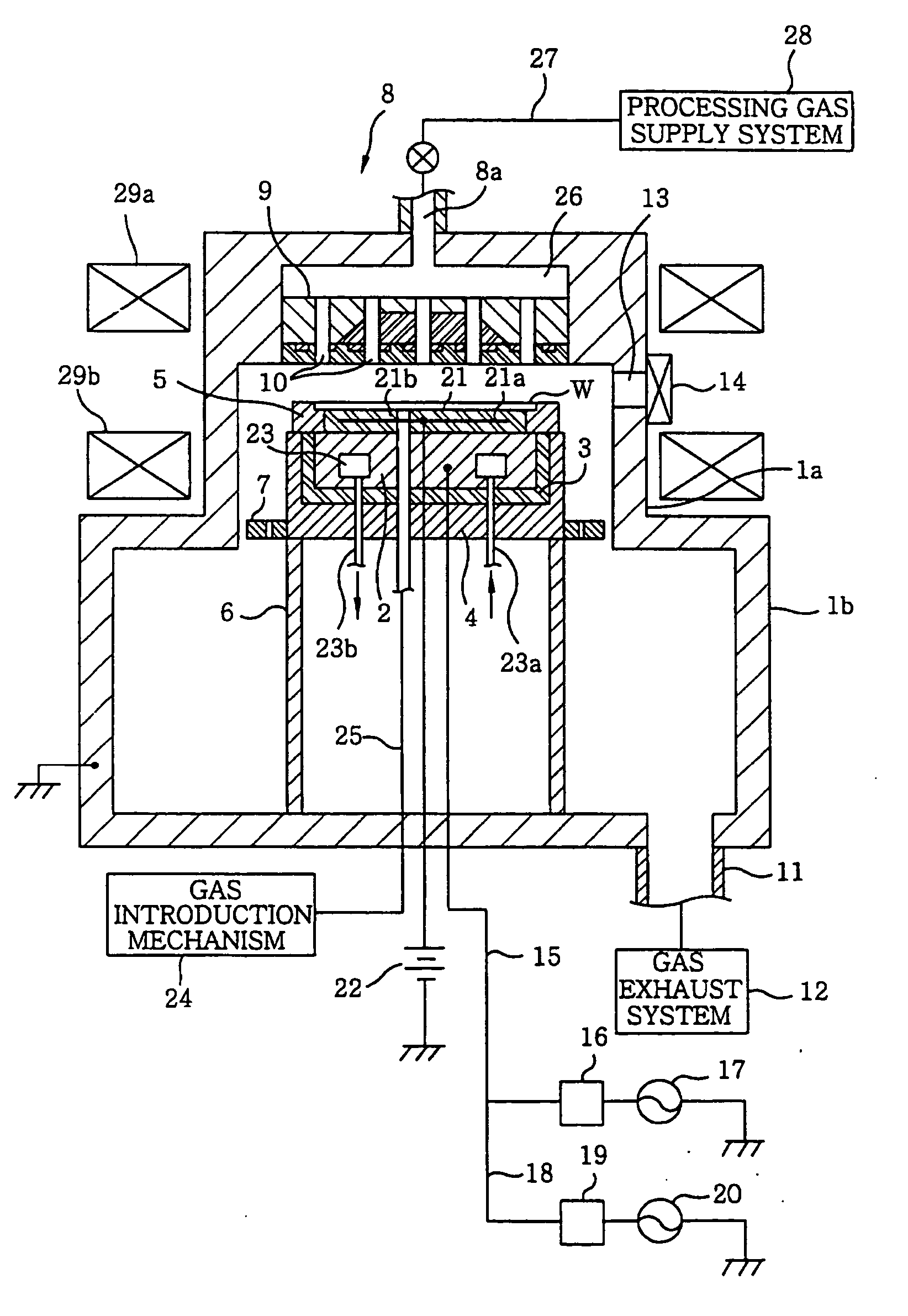

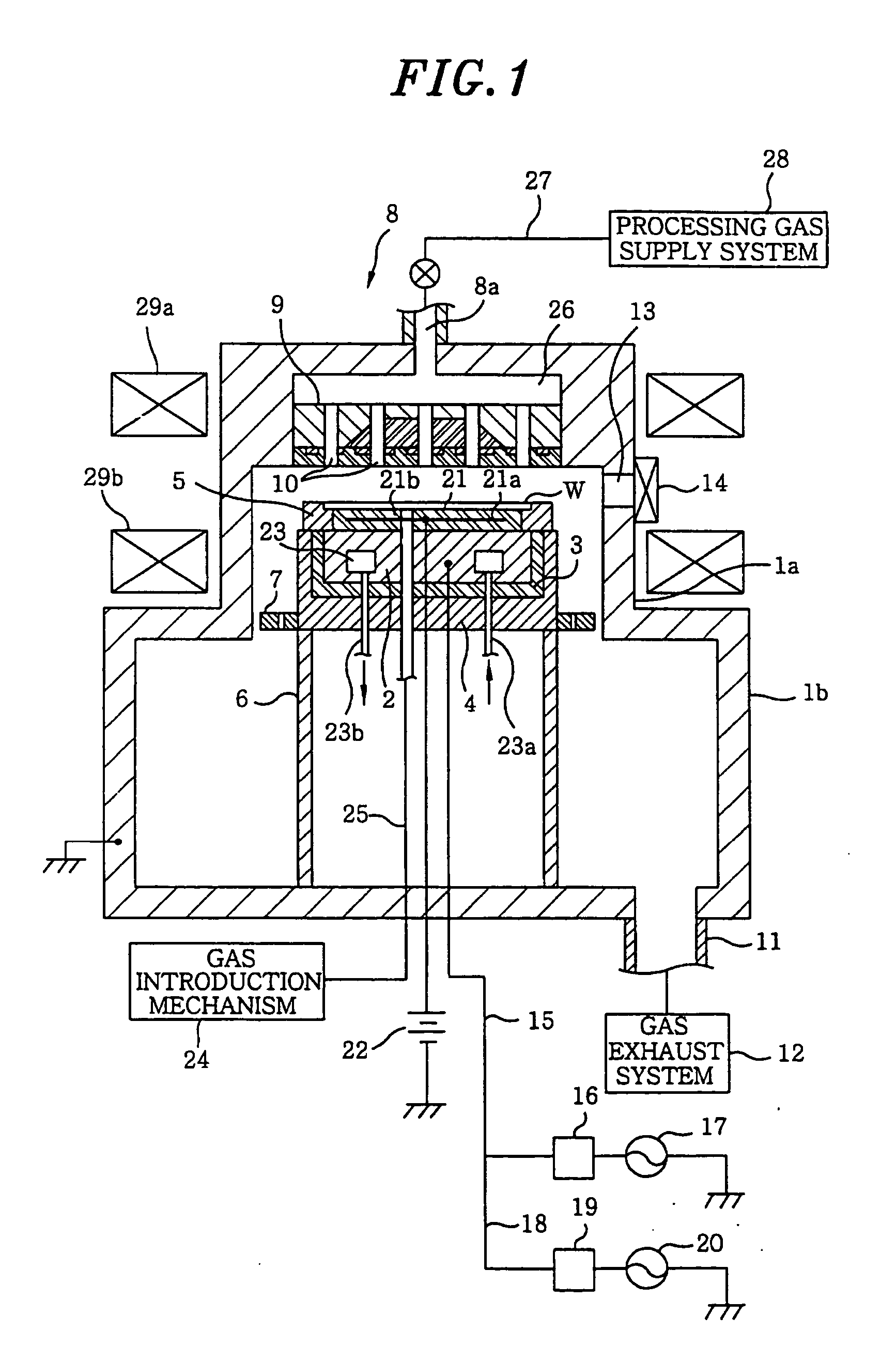

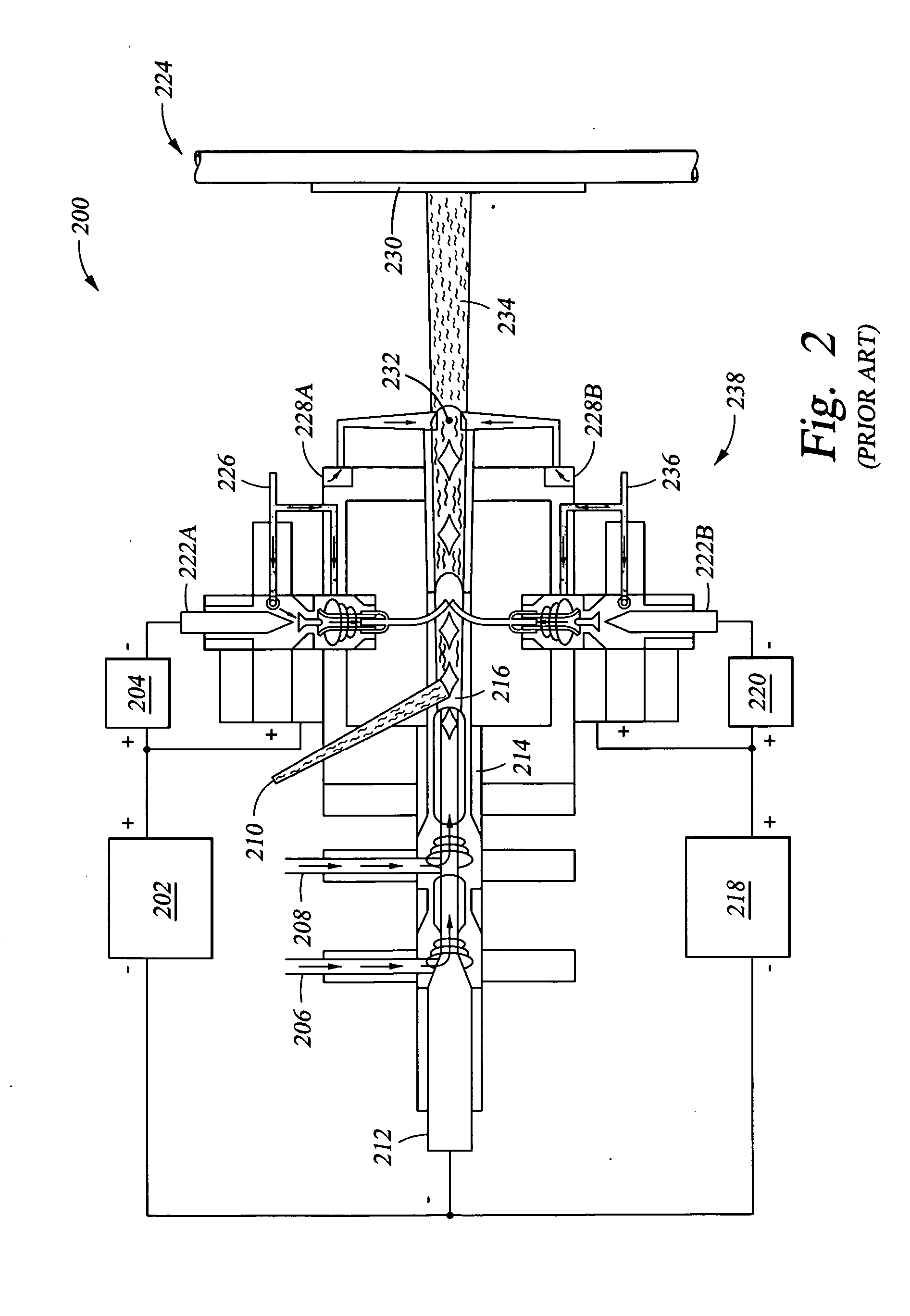

Plasma processing system

A processing system having a processing chamber that includes a substrate holder and an electrode. The processing system can include a pressure control system, gas supply system, and monitoring system. A multi-frequency RF source is coupled to the electrode using a reduced-element matching network having a single variable element. The multi-frequency RF source is set to a first frequency to ignite a plasma and to a second frequency to maintain the plasma.

Owner:TOKYO ELECTRON LTD +1

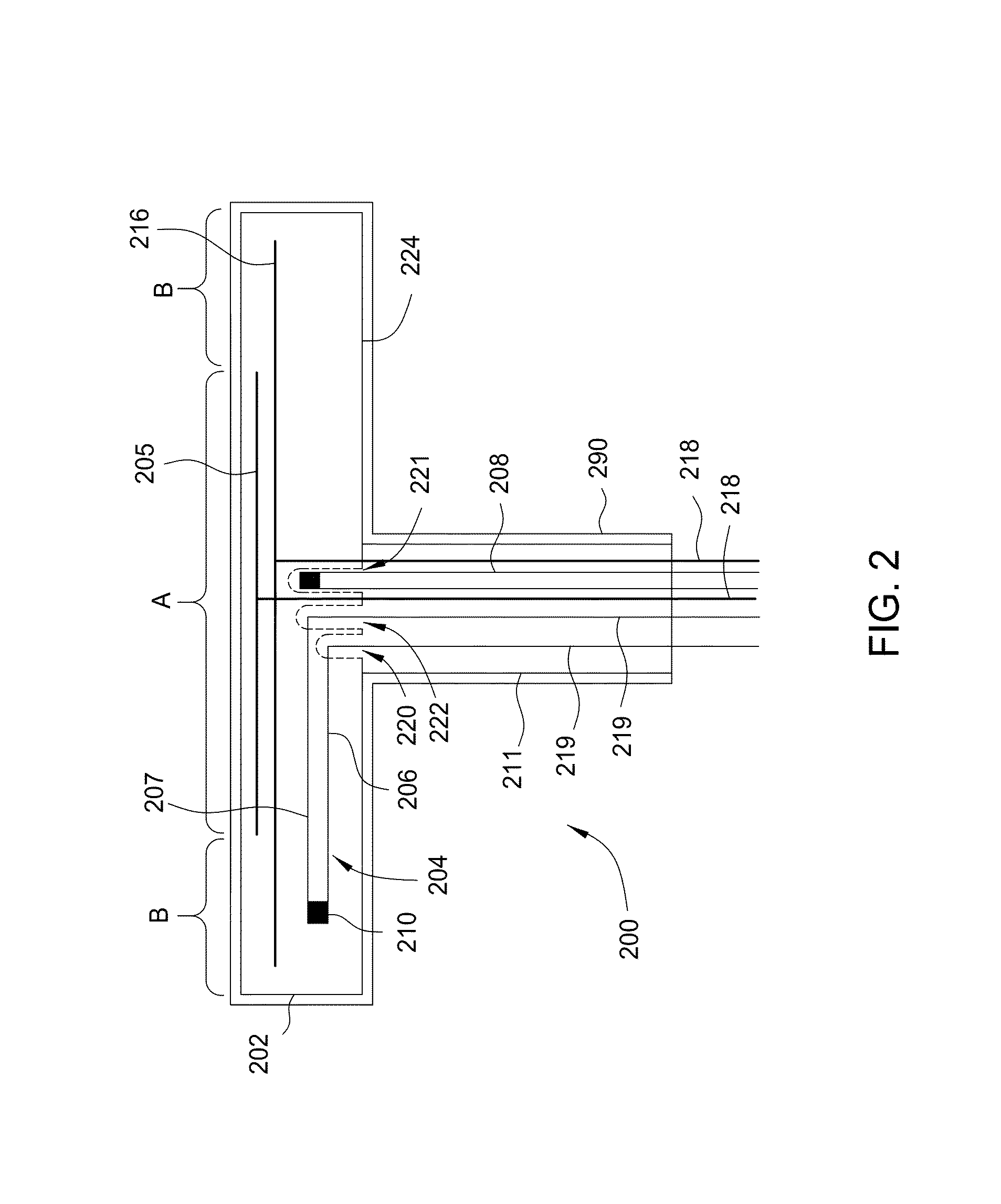

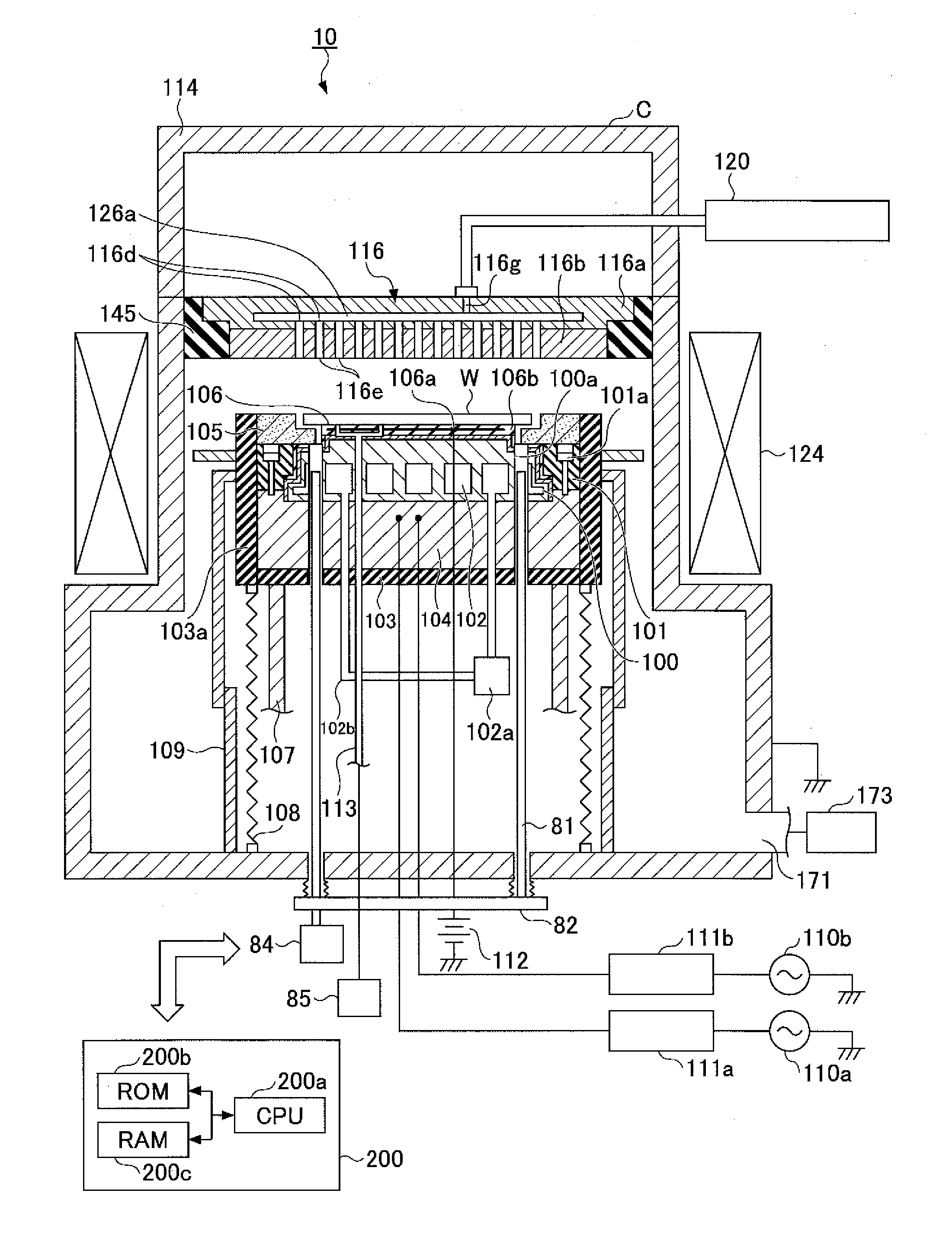

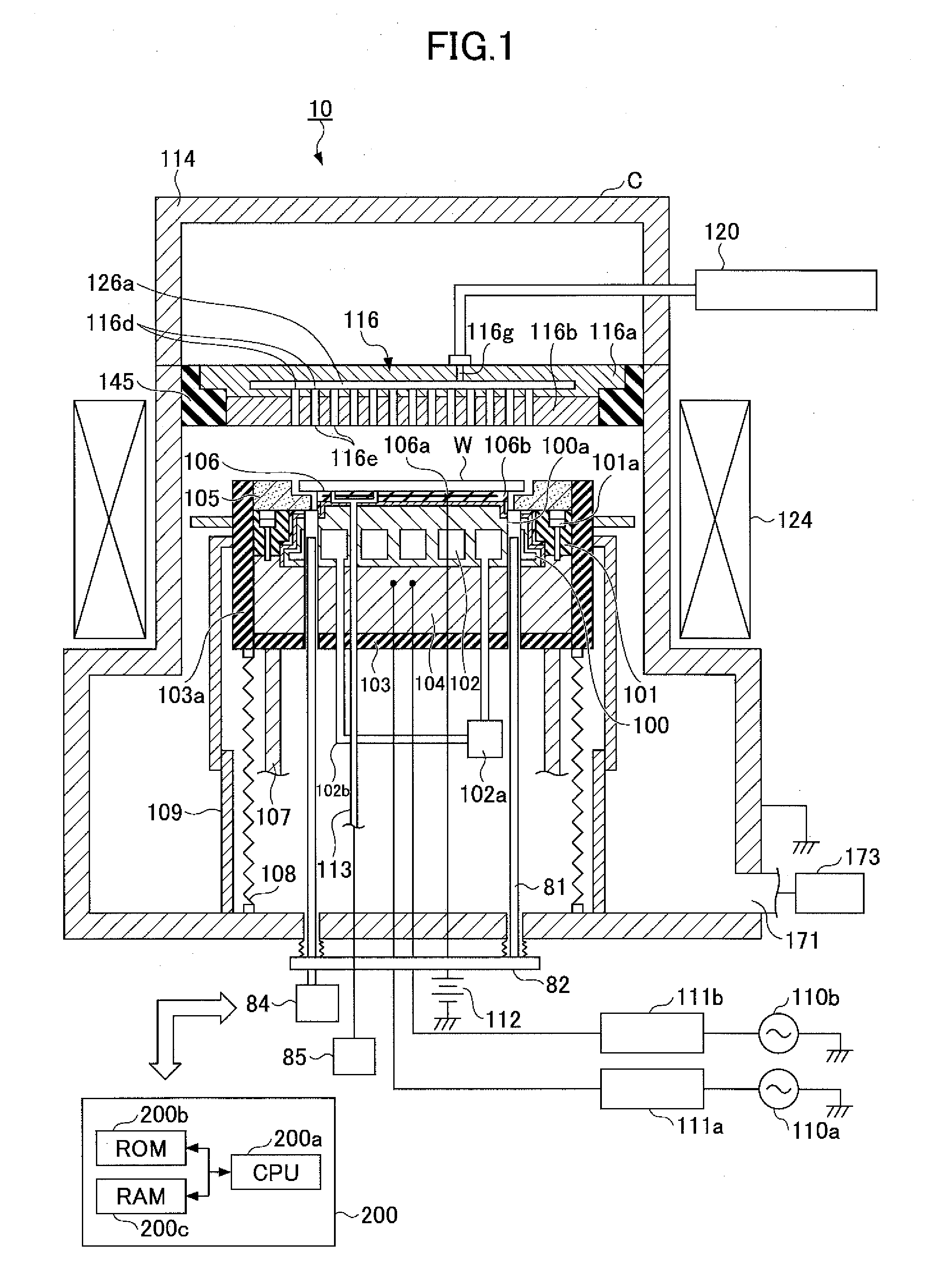

Substrate processing apparatus and susceptor

ActiveUS20140202386A1Increase temperatureLiquid surface applicatorsMolten spray coatingHigh frequency powerSusceptor

A substrate processing apparatus includes a chamber, a susceptor to receive a substrate and provided in the chamber, a gas supply source to supply a predetermined gas into the chamber, and a high frequency power source to treat the substrate by plasma. The susceptor includes a first ceramics base member including a flow passage to let a coolant pass through, a first conductive layer formed on a principal surface and a side surface on a substrate receiving side of the first ceramics base member, and an electrostatic chuck stacked on the first conductive layer and configured to electrostatically attract the wafer received thereon. A volume of the flow passage is equal to or more than a volume of the first ceramics base member. The high frequency power source is configured to supply high frequency power to the first conductive layer.

Owner:TOKYO ELECTRON LTD

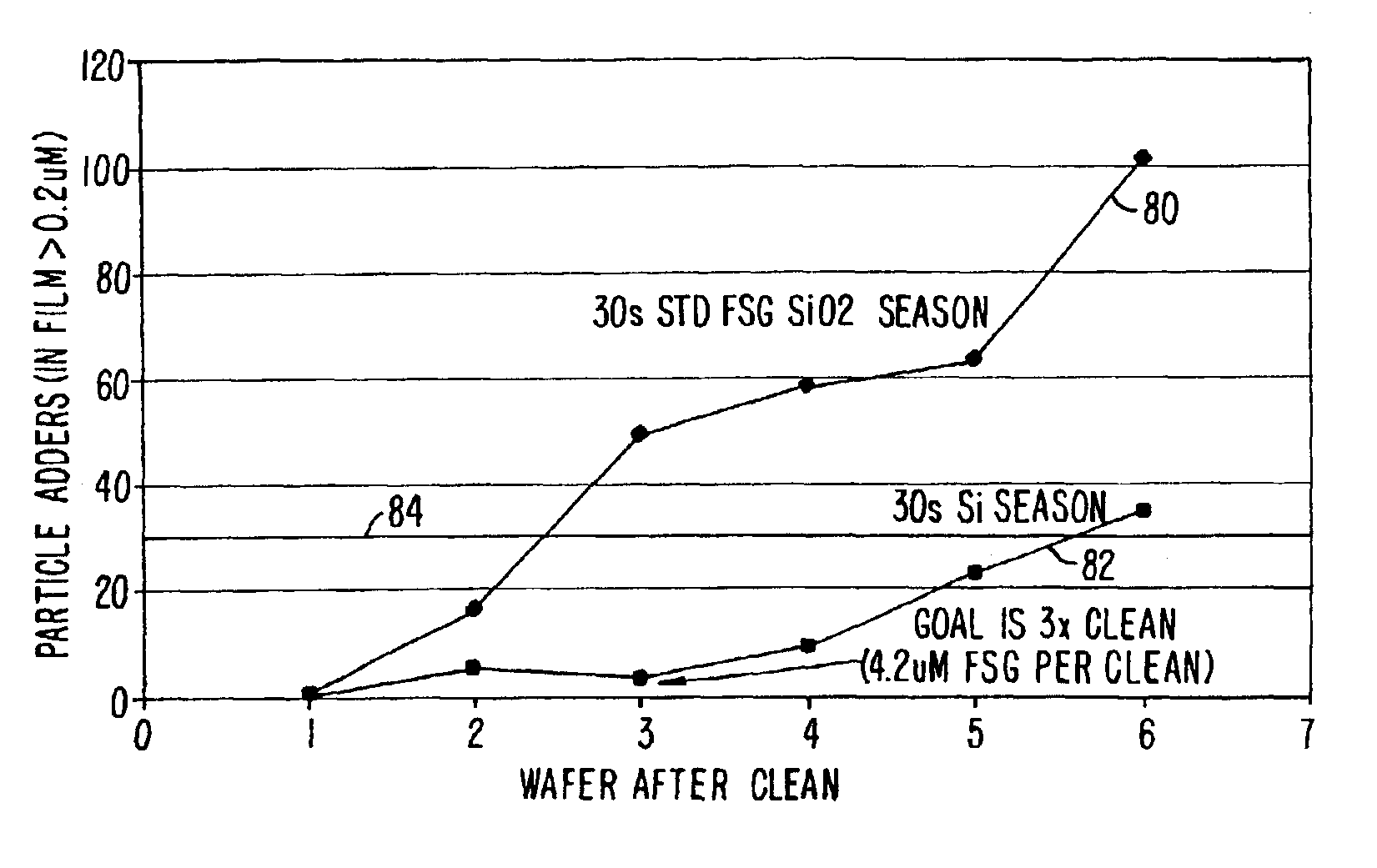

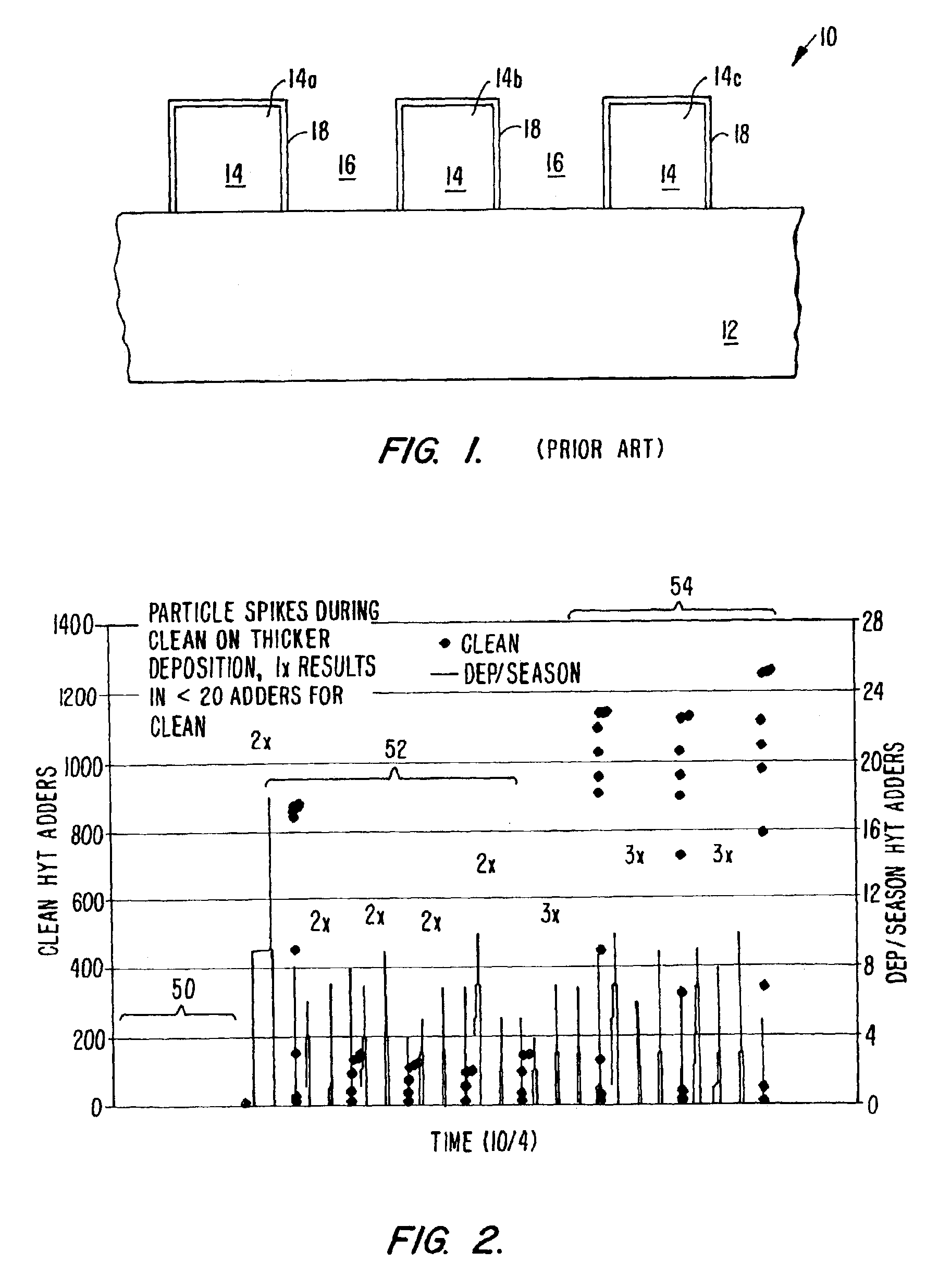

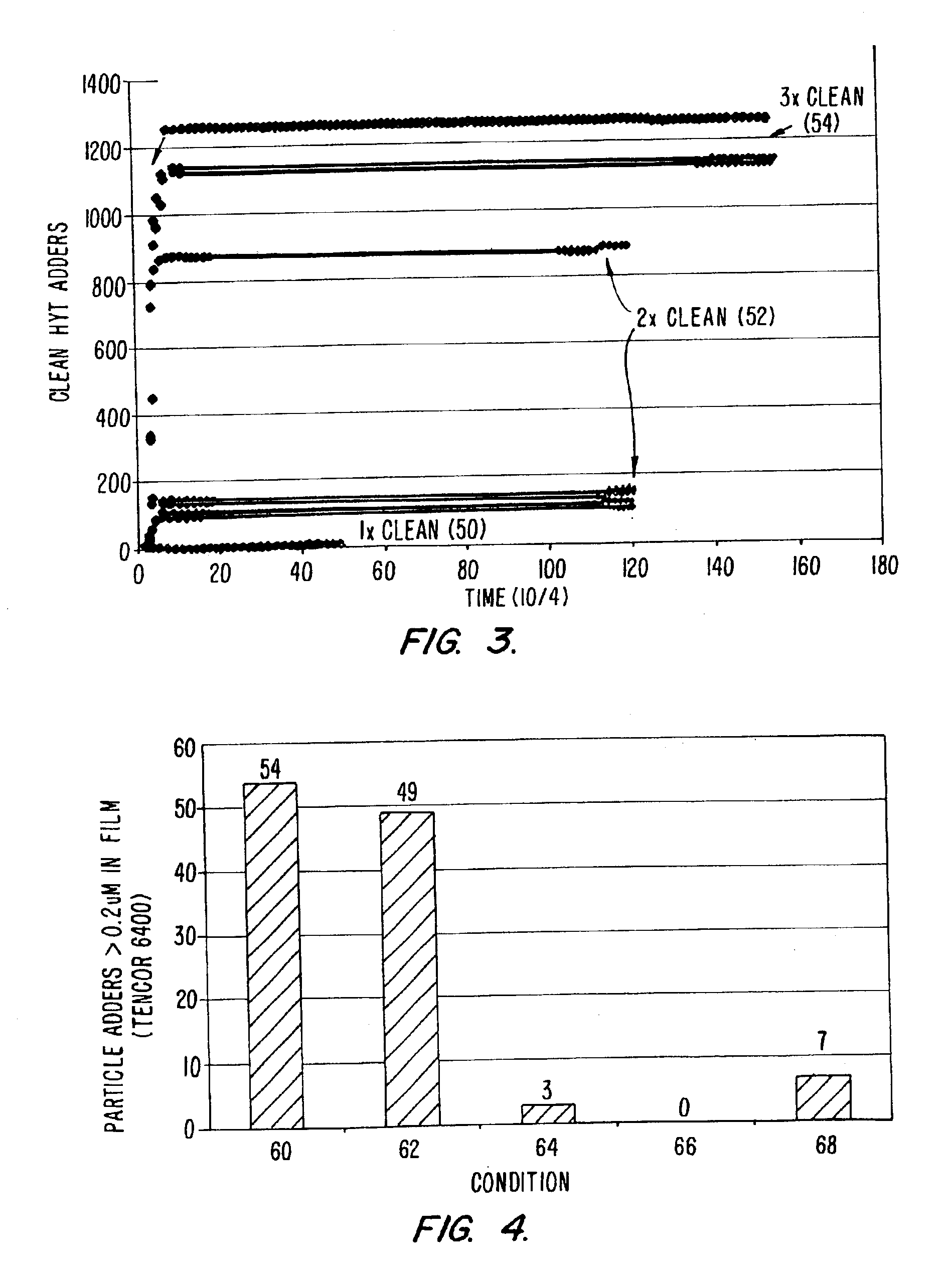

Si seasoning to reduce particles, extend clean frequency, block mobile ions and increase chamber throughput

Owner:APPLIED MATERIALS INC

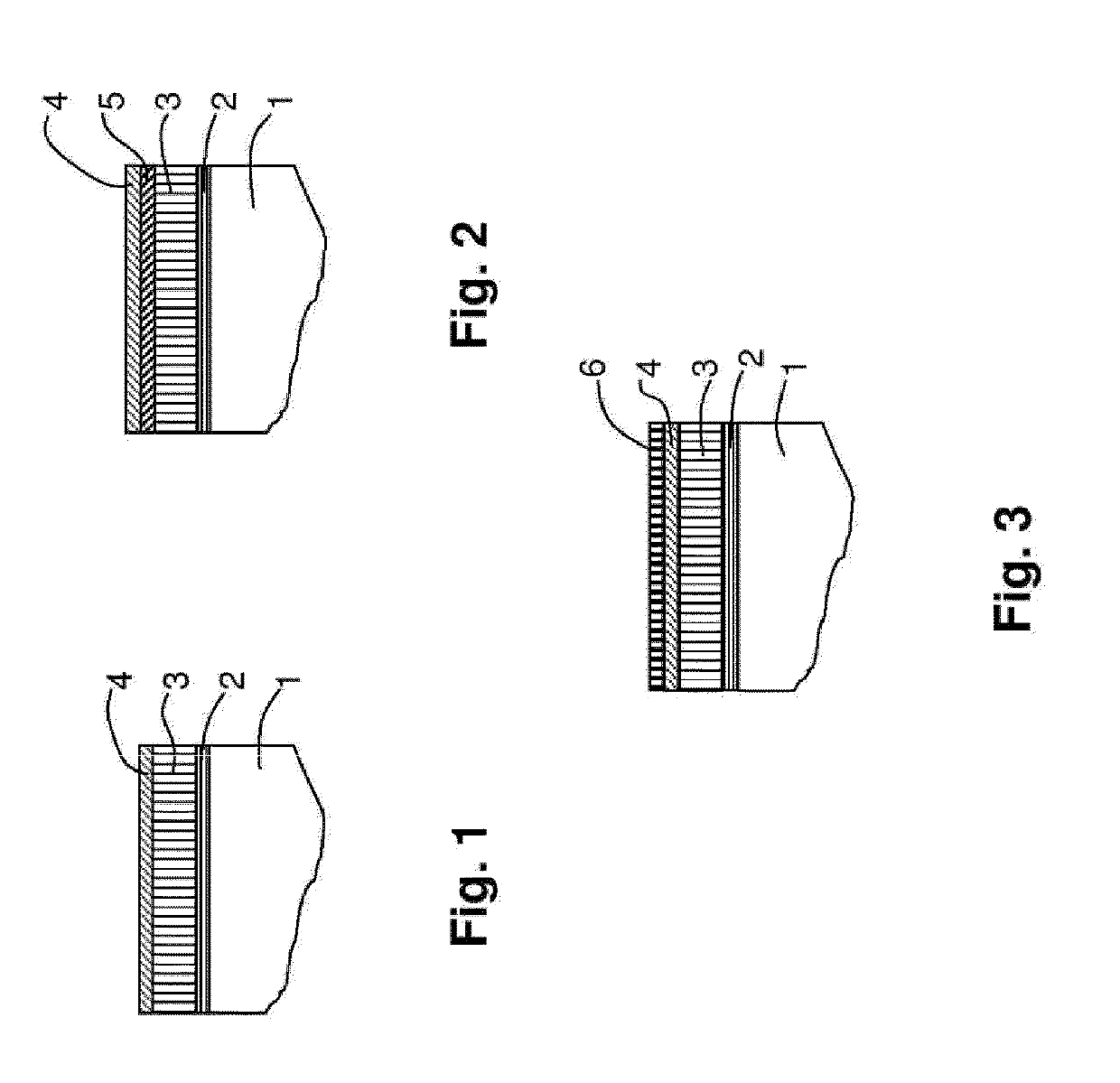

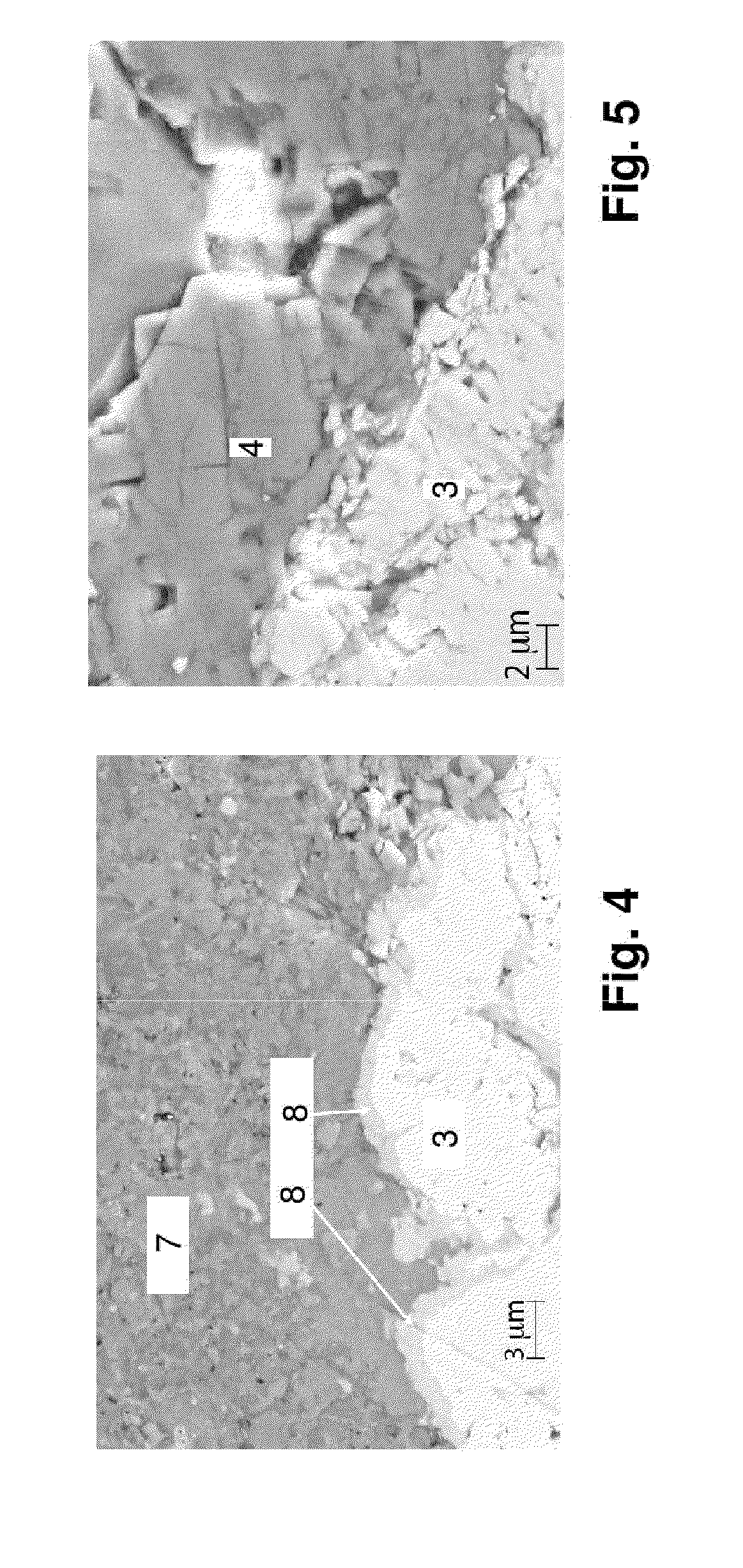

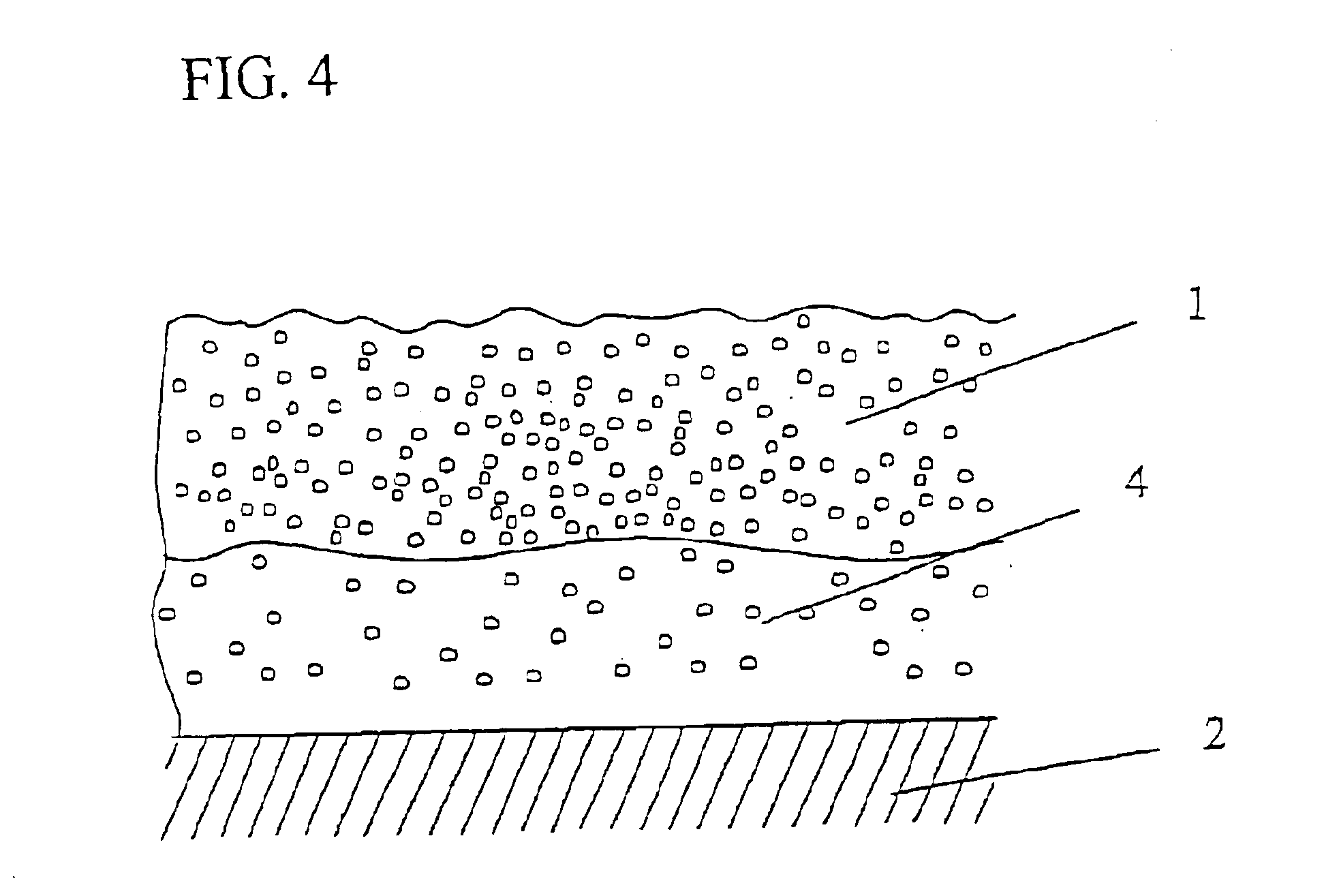

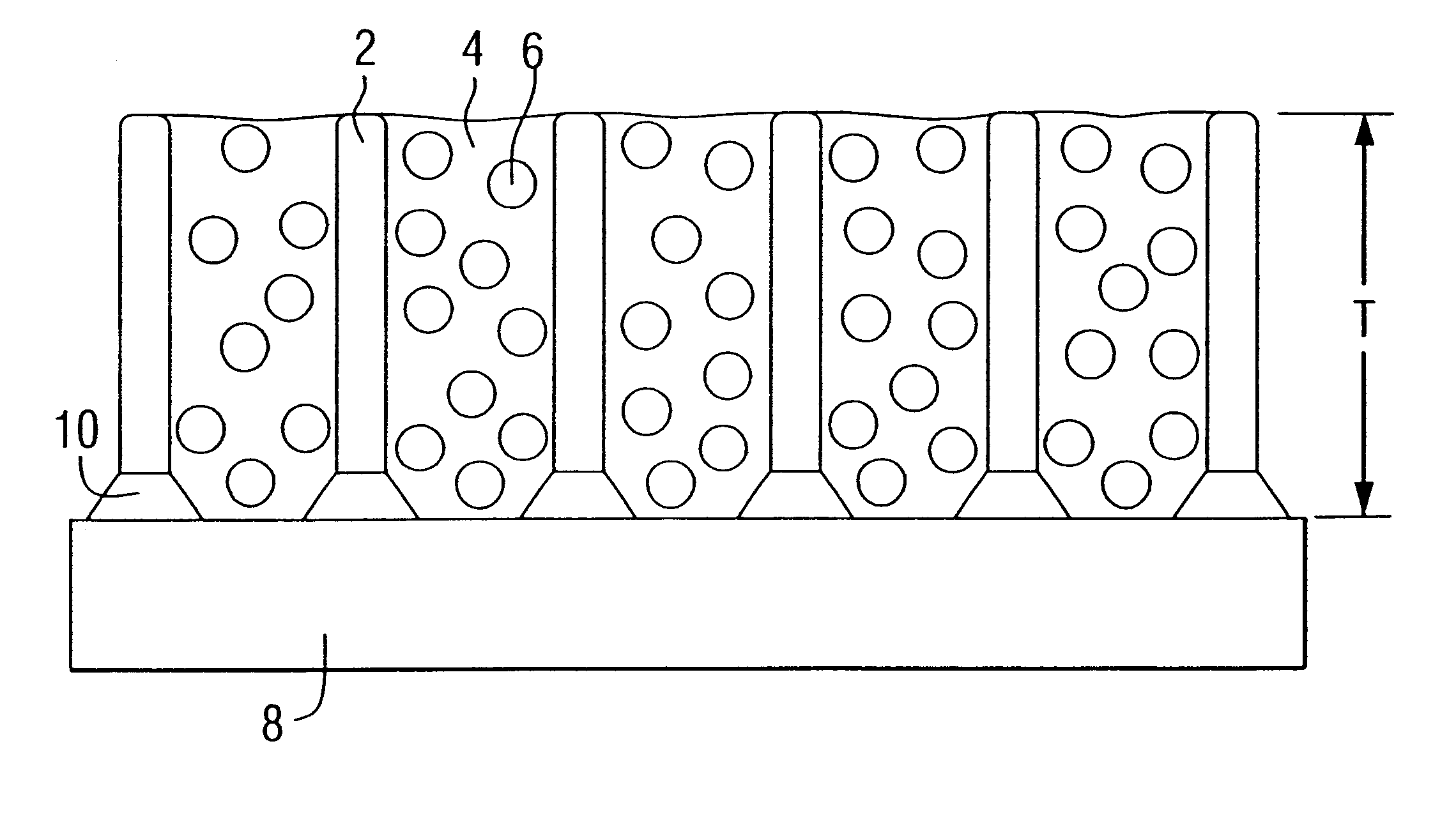

Multilayer thermal barrier coating

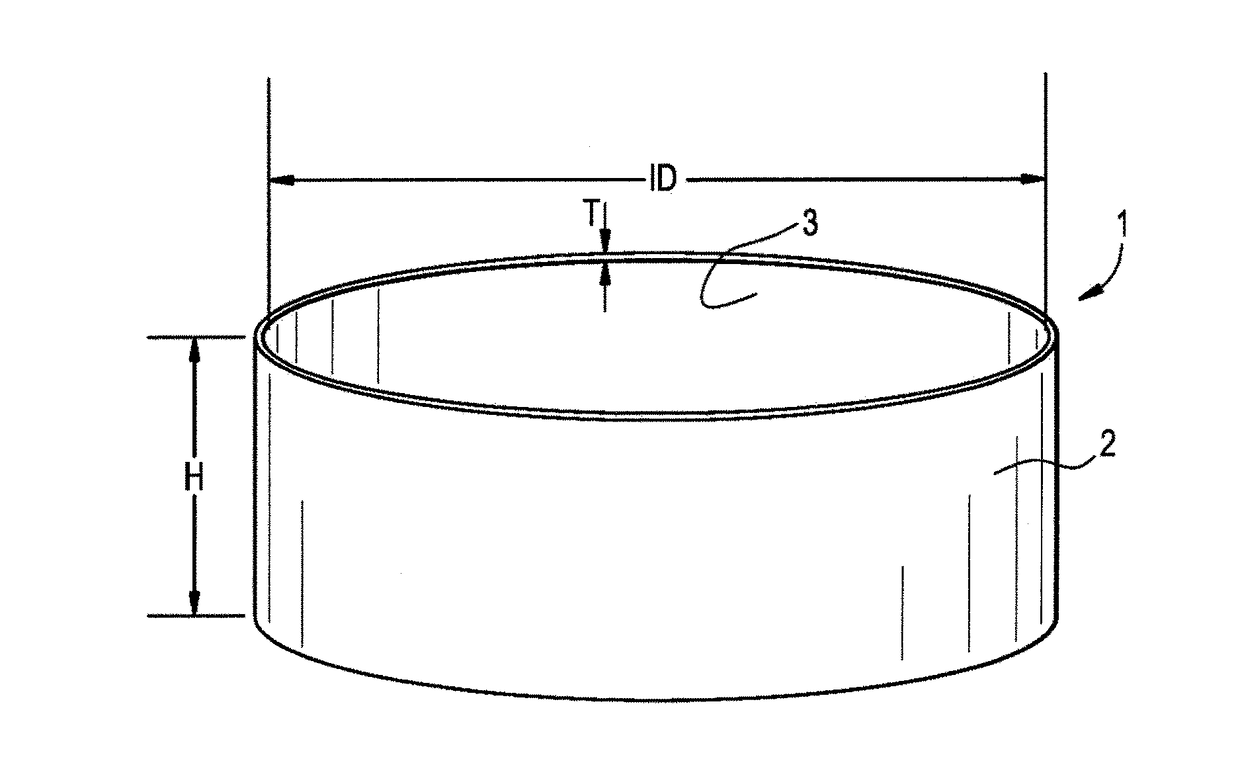

InactiveUS20090324989A1Improved thermal barrier coatingAttackLiquid surface applicatorsMolten spray coatingThermal barrier coatingZirconium oxide

Components (1) have a thermal barrier coating (2-6) on the surface thereof, wherein the thermal barrier coating includes at least one layer (3) having chemically stabilized zirconia, and wherein at least indirectly adjacent to the layer (3) with chemically stabilized zirconia and on its surface facing side, there is provided a protective layer (4) and / or a infiltration zone (5) which does not react with environmental contaminant compositions that contain oxides of calcium and which does not react with the material of the layer (3) having chemically stabilized zirconia. Methods for making such components as well as to uses of specific systems for coating thermal barrier coatings, can prevent CMAS.

Owner:ANSALDO ENERGIA IP UK LTD +1

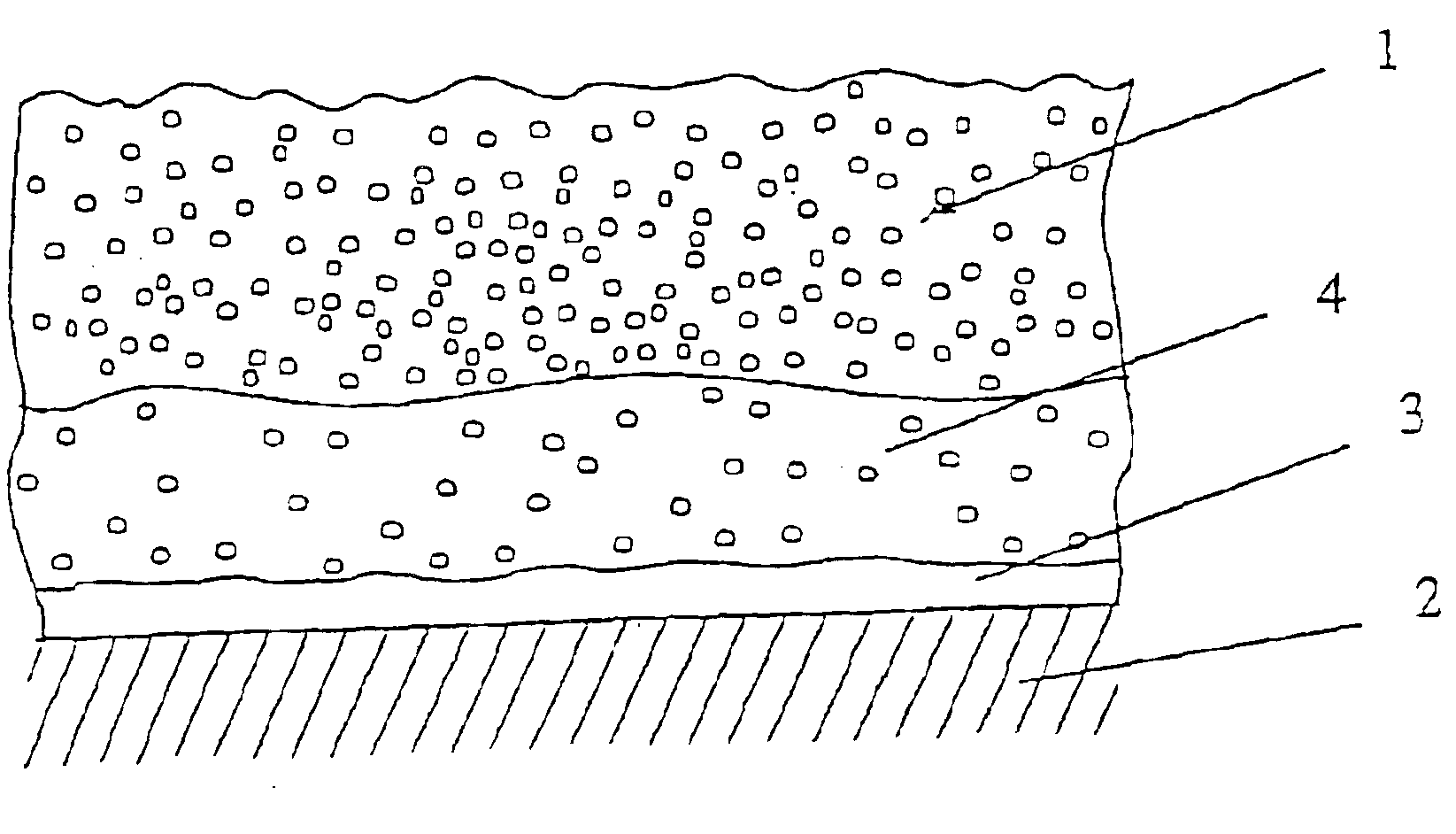

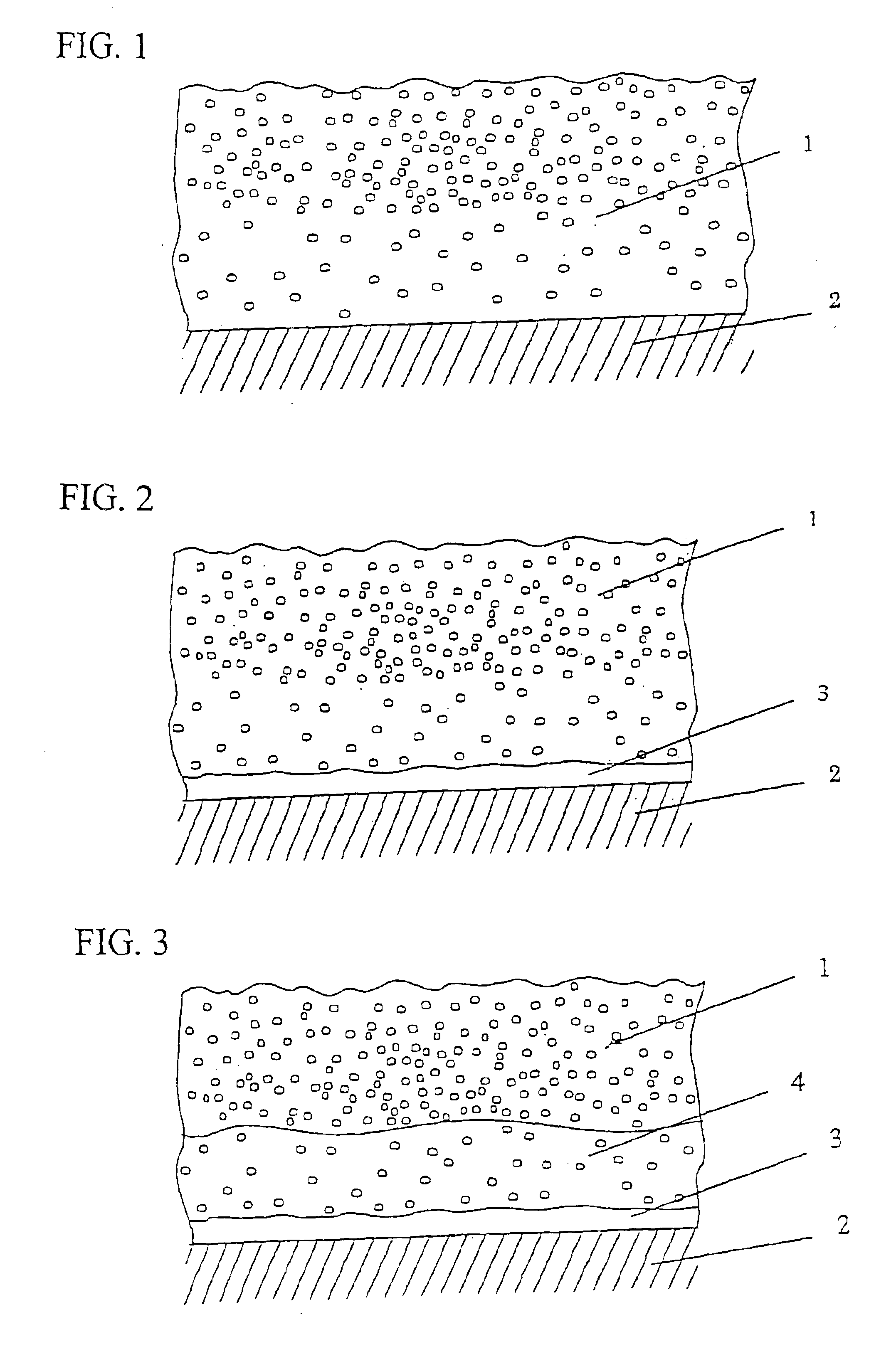

Method for coating internal surface of plasma processing chamber

InactiveUS6875477B2Improve the immunityMinimize thermal expansionLiquid surface applicatorsMolten spray coatingThermal expansionAlloy

The present invention comprises an aluminum base material 2 constituting the plasma processing chamber of the plasma processing apparatus, a bonding layer 3 deposited on the base material consisting of a transition metal or transition metal alloy that modifies the difference in thermal expansion coefficient of the base material and the material constituting a plasma contact surface, and the plasma contact surface 1 formed of a material selected from a group consisting of La2O3, LaAlO3, MgLaAl11O19, and a mixture of La2O3 and Al2O3 being a metal oxide including at least La and O deposited on the bonding layer 3 via a thermal spray process.

Owner:HITACHI HIGH-TECH CORP

Electron beam layer manufacturing

ActiveUS20110061591A1Obstruct passageProgramme controlAdditive manufacturing apparatusFree formClosed loop

A process and apparatus for free form fabrication of a three-dimensional work piece comprising (a) feeding raw material in a solid state to a first predetermined location; (b) depositing the raw material onto a substrate as a molten pool deposit under a first processing condition; (c) monitoring the molten pool deposit for a preselected condition; (d) comparing information about the preselected condition of the monitored molten pool deposit with a predetermined desired value for the preselected condition of the monitored molten pool deposit; (e) solidifying the molten pool deposit; (f) automatically altering the first processing condition to a different processing condition based upon information obtained from the comparing step (d); and repeating steps (a) through (f) at one or more second locations for building up layer by layer a three-dimensional work piece. The apparatus is characterized by a detector that monitors a preselected condition of the deposited material and a closed loop electronic control device for controlling operation of one or more components of the apparatus in response to a detected condition by the detector.

Owner:SCIAKY SA

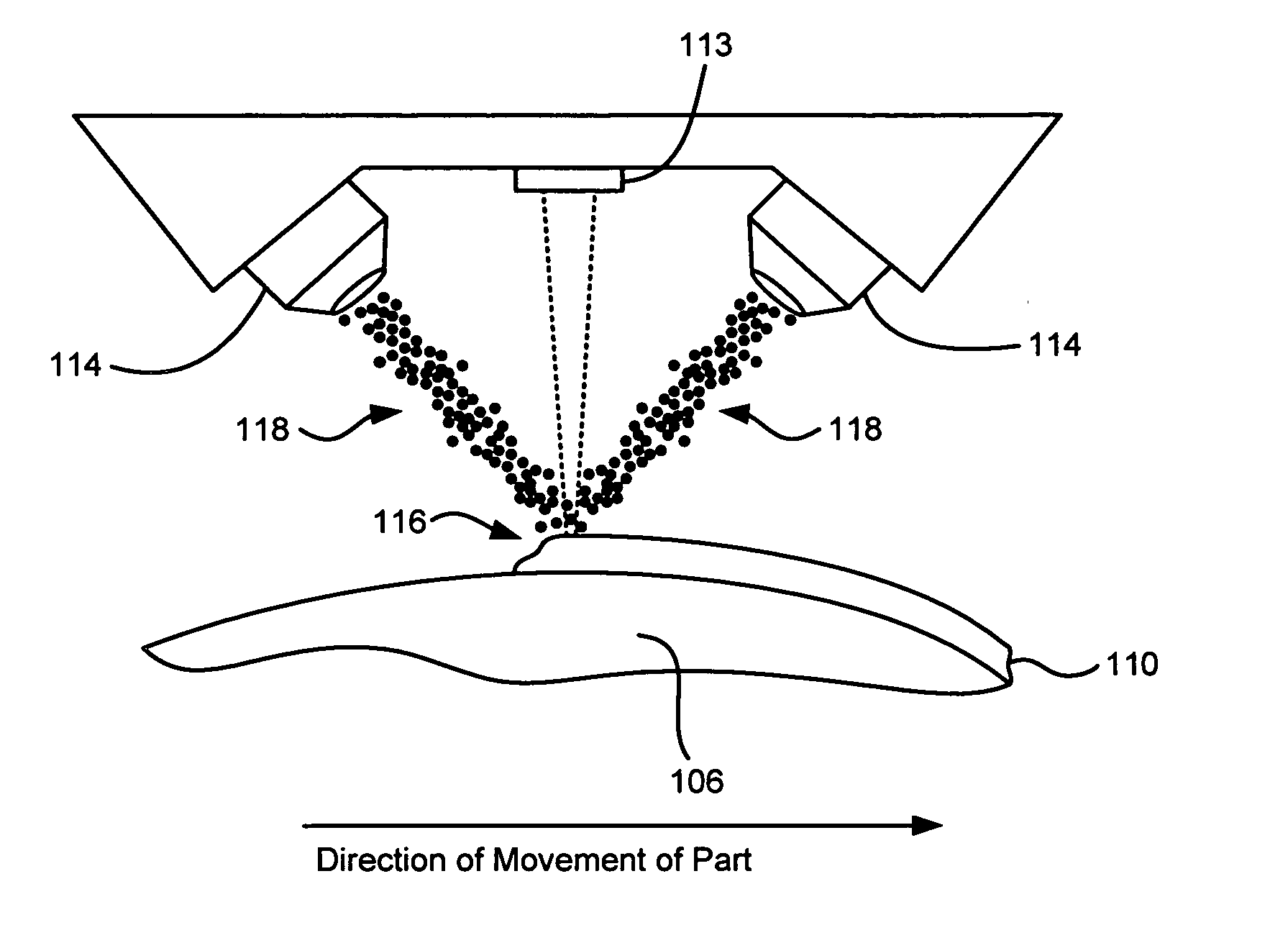

Plasma spraying for semiconductor grade silicon

A plasma spray gun configured to spray semiconductor grade silicon to form semiconductor structures including p-n junctions includes silicon parts such as the cathode or anode or other parts facing the plasma or carrying the silicon powder having at least surface portions formed of high purity silicon. The semiconductor dopant may be included in the sprayed silicon.

Owner:INTEGRATED PHOTOVOLTAICS

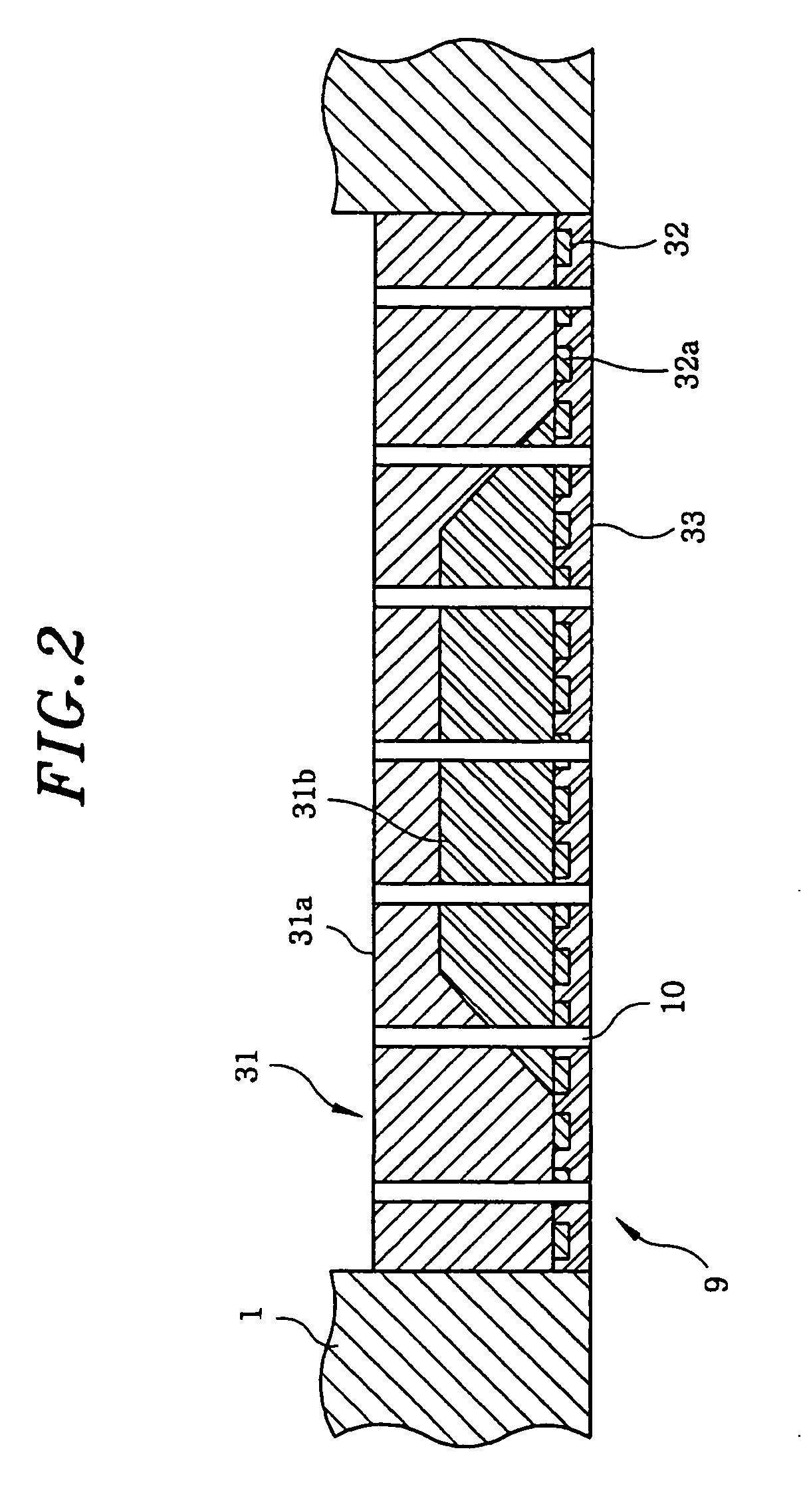

Thermally sprayed member, electrode and plasma processing apparatus using the electrode

ActiveUS20050211384A1High-frequency powerAvoid flowMolten spray coatingElectric discharge tubesThermal sprayingInter layer

A thermally sprayed member or an electrode includes a basic material, a thermally sprayed film formed on the surface of the basic material, the thermally sprayed film being made of an insulating ceramic and a metallic intermediate layer provided between the basic material and the thermally sprayed film for increasing a bonding force therebetween, wherein the thermally sprayed film side of the member is exposed to a high frequency plasma atmosphere and the electrode is intended to form a high frequency plasma on the side of the thermally sprayed film. The basic material includes a base portion made of a conductive material and a dielectric portion provided to include a part of a surface of the basic material. Further, the intermediate layer is comprised of a plurality of island-shaped parts isolated from each other.

Owner:TOKYO ELECTRON LTD

Segmented abradable ceramic coating

InactiveUS6102656AImprove wear resistanceSufficient resistanceMolten spray coatingPump componentsCeramic coatingWear resistance

A segmented abradable ceramic coating system having superior abradability and erosion resistance is disclosed. The system includes a duct segment having a metallic substrate, a MCrAlY bond coat on the substrate and a segmented abradable ceramic coating on the bond coat. The segmented abradable ceramic coating includes a base coat foundation layer, a graded interlayer and an abradable top layer for an overall thickness of preferably about 50 mils (1.270 mm). The coating is characterized by a plurality of vertical microcracks. By precisely controlling the deposition parameters, composition of the layers and layer particle morphology, segmentation is achieved, as well as superior abradability and erosion resistance.

Owner:UNITED TECH CORP

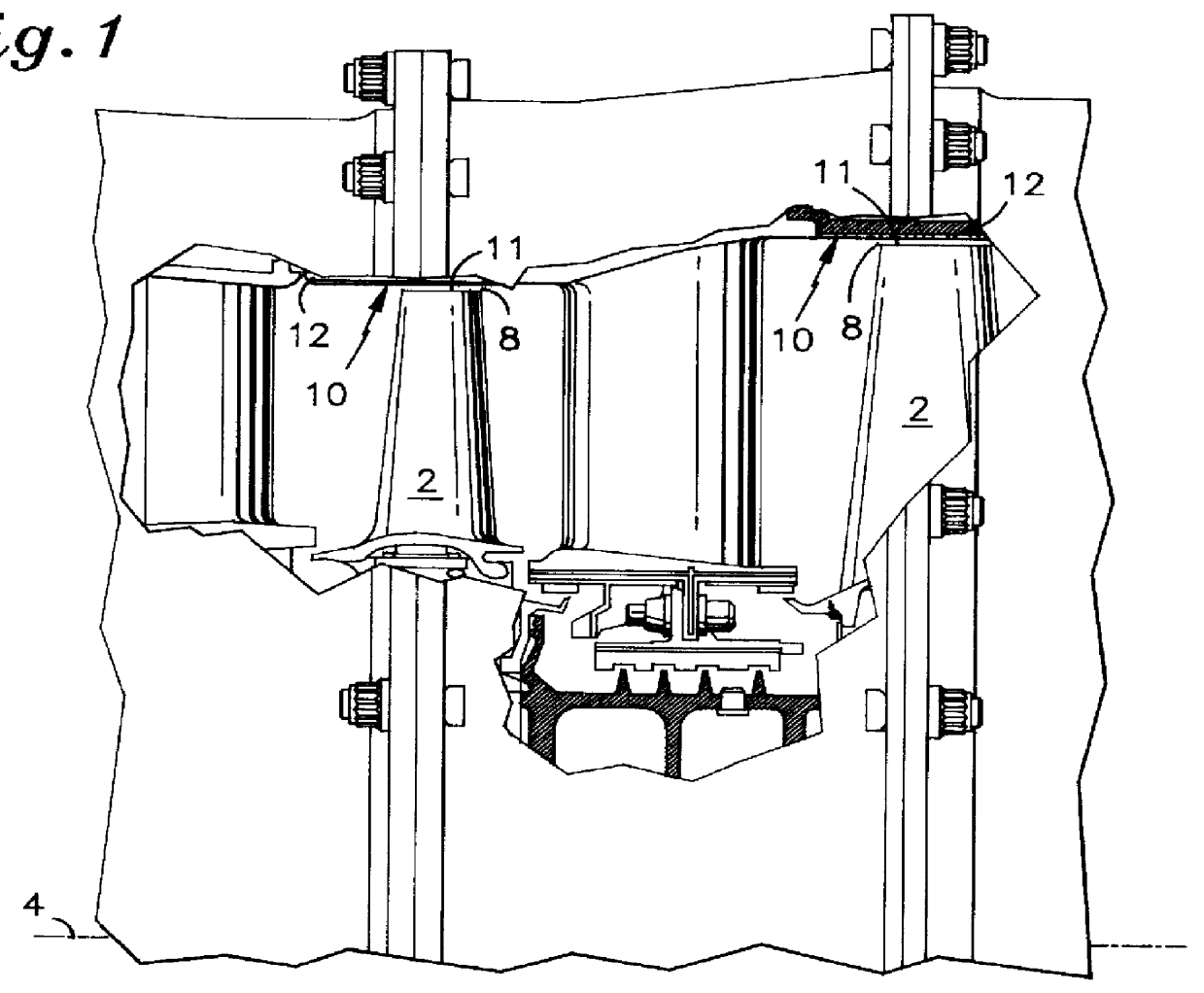

Process kit design to reduce particle generation

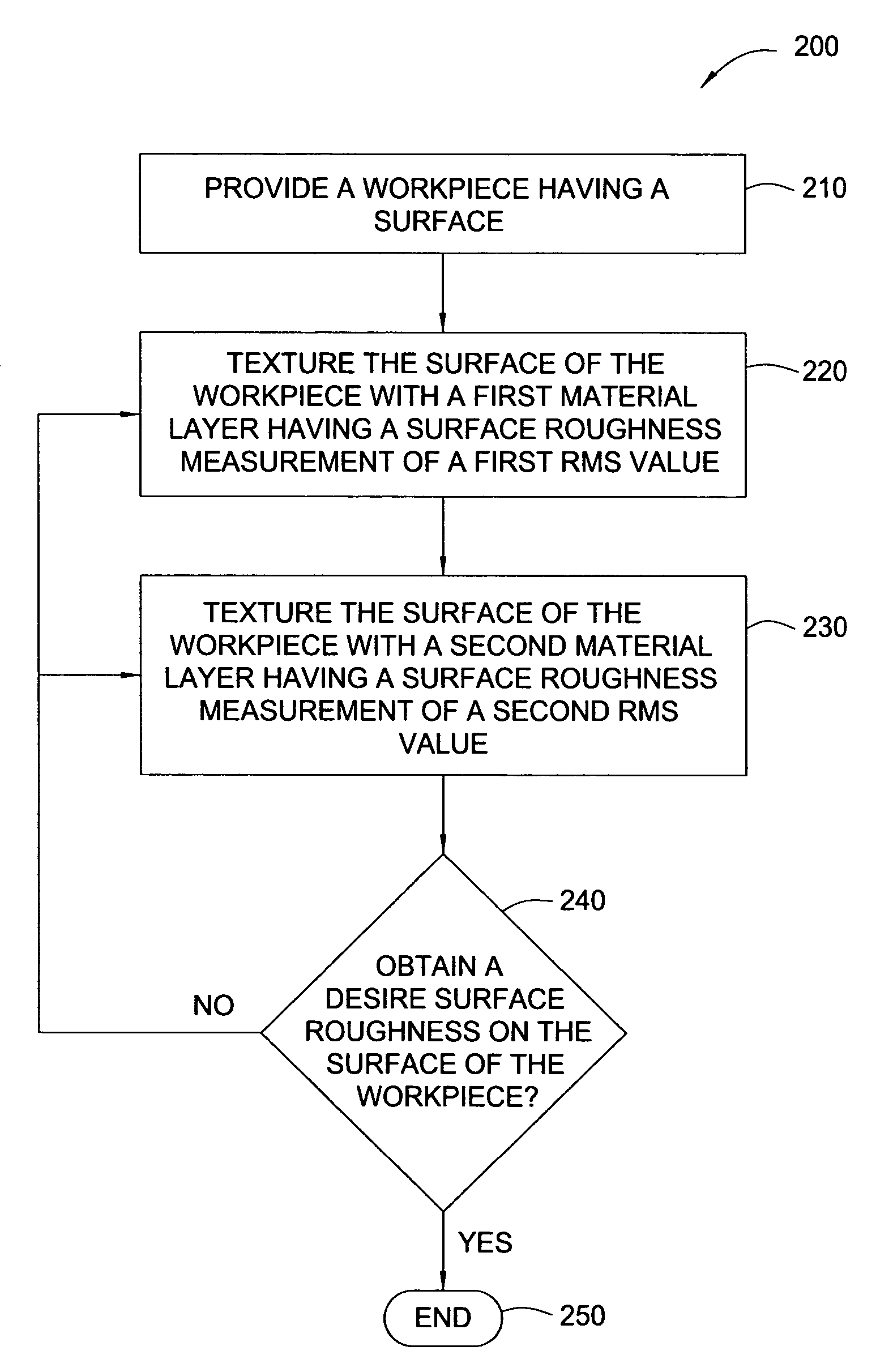

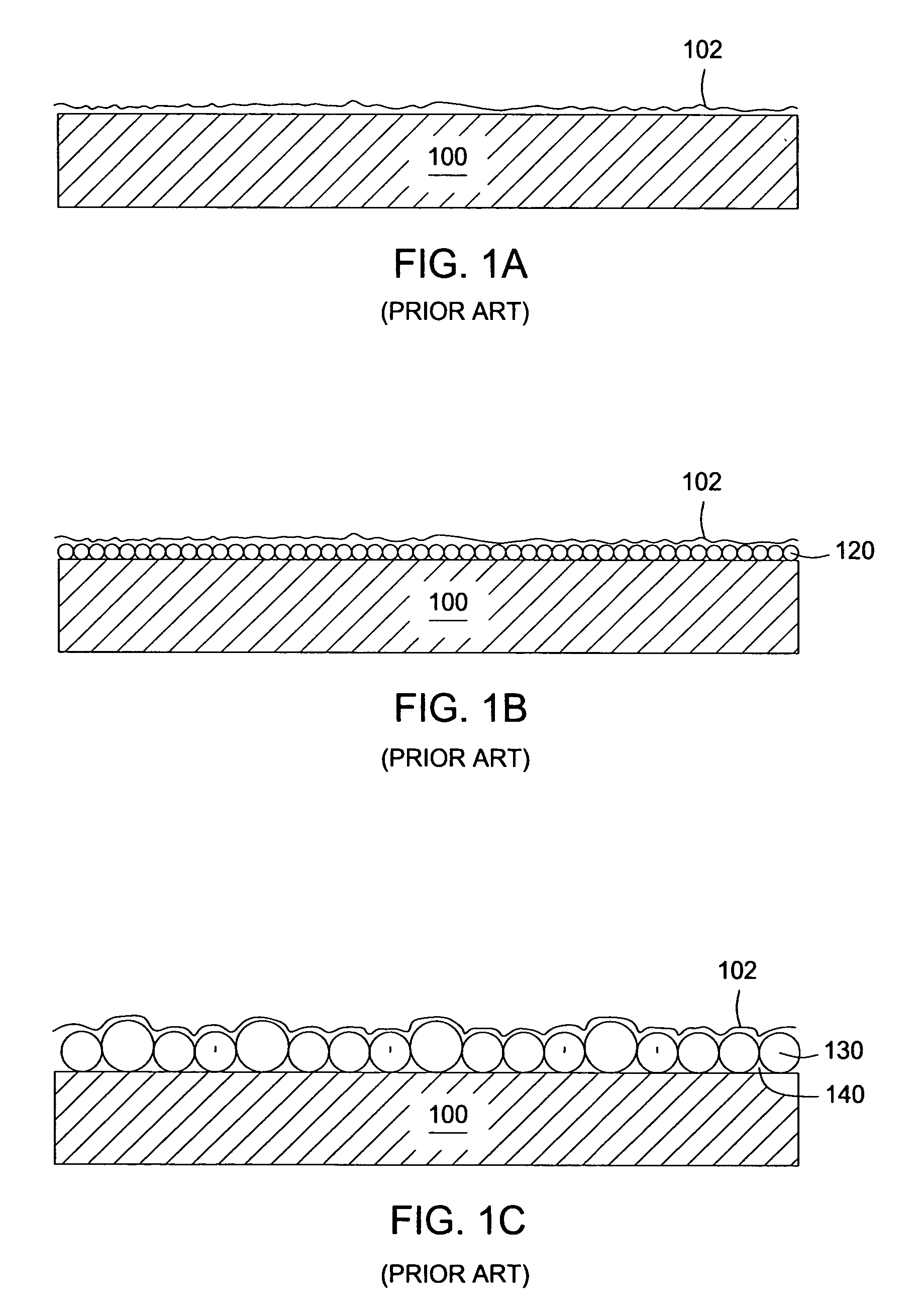

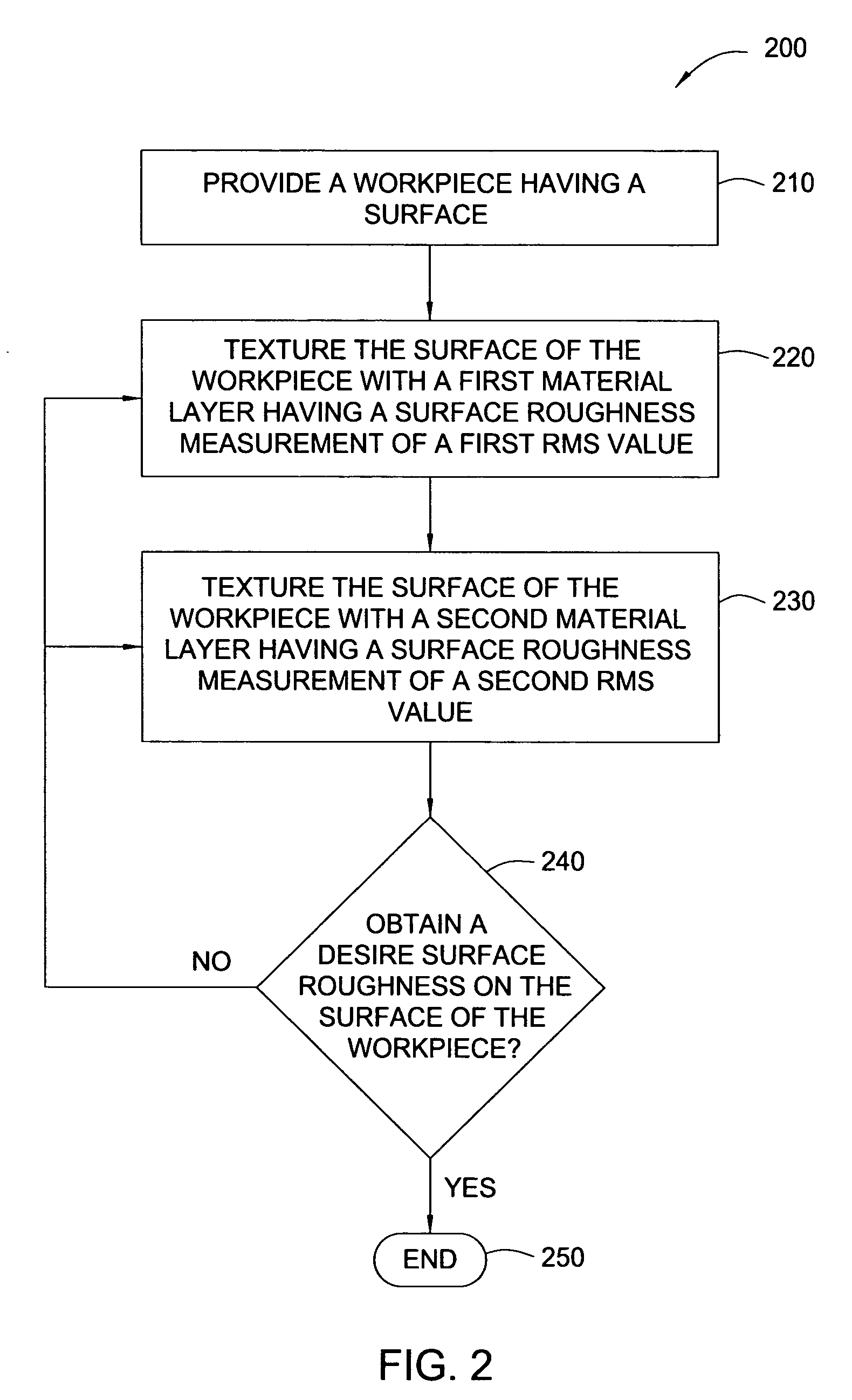

InactiveUS20060292310A1Reduce pollutionRough textureLiquid surface applicatorsMolten spray coatingThermal sprayingMetallurgy

A method for making a process kit and a process kit design which has reduced particle generation during substrate processing are provided. The internal surface of the process kit design are textured by coating its surface with a first material layer having a smaller RMS surface roughness measurement and arc spraying with a second material layer or additional material layers having a larger RMS value. The first material layer can be coated by bead blasting, plating, arc spraying, thermal spraying, or other processes. In addition, the invention also provides selective coating of internal surface of the process kit with a protective layer and arc spraying the surface pf the protective layer with another material layer, which may be of the same material as the material of the internal surface of the process kit.

Owner:APPLIED MATERIALS INC

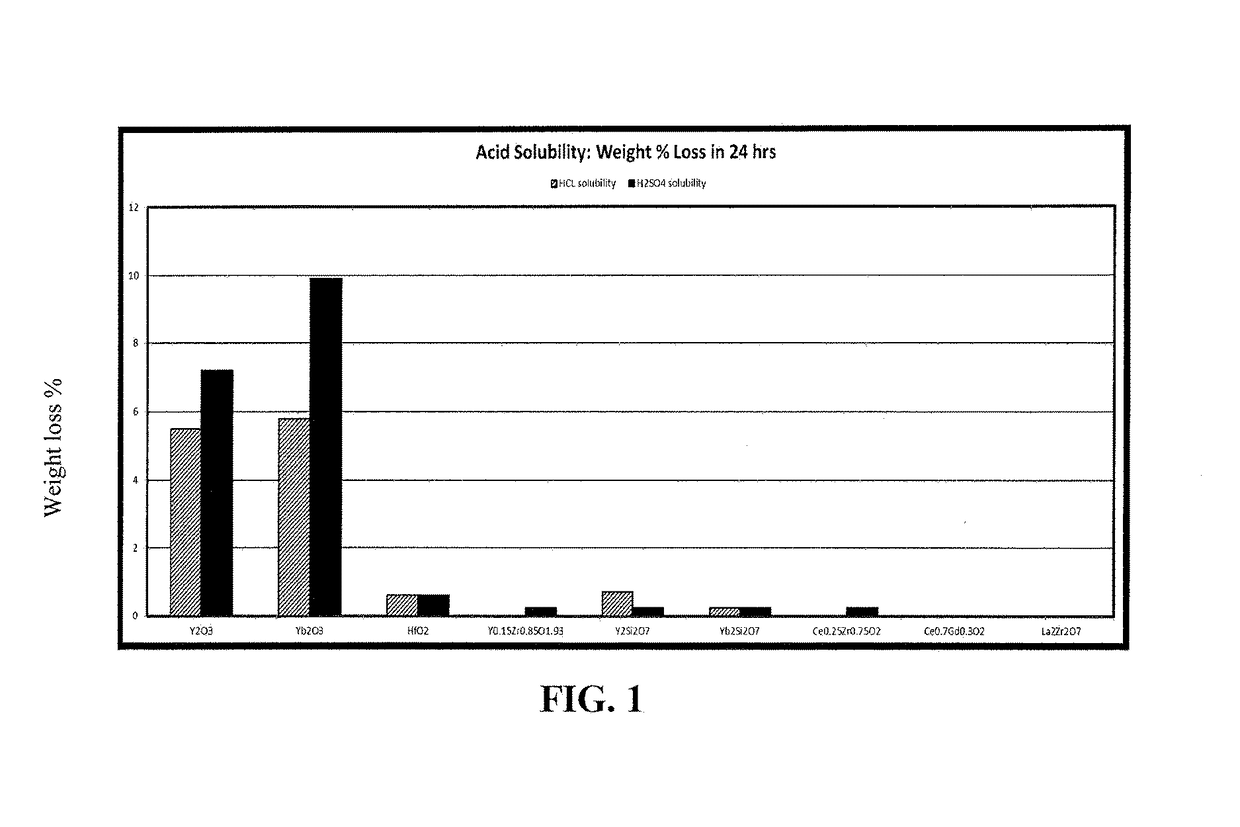

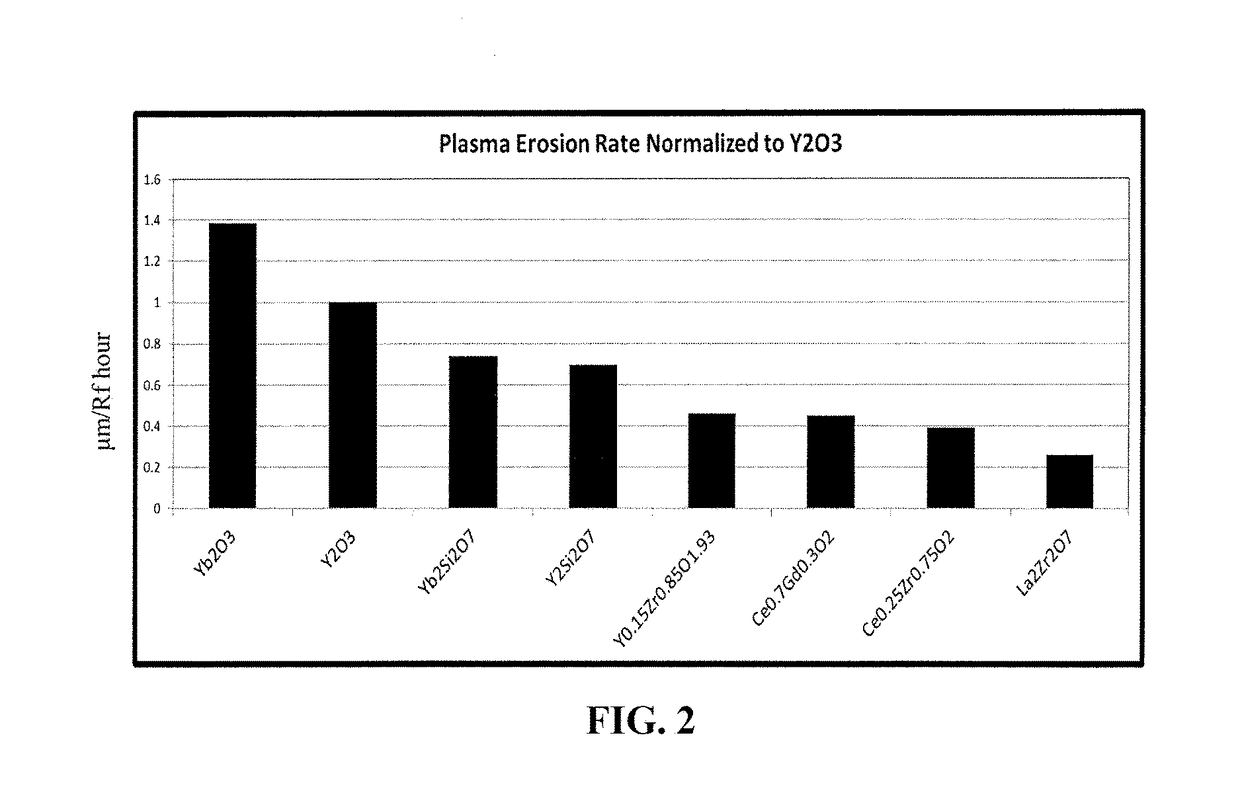

Coated semiconductor processing members having chlorine and fluorine plasma erosion resistance and complex oxide coatings therefor

ActiveUS20170301519A1High tensile bond strengthReduce pollutionMolten spray coatingElectric discharge tubesSolid solutionPlasma sprayed

A semiconductor processing member is provided, including a body and a plasma spray coating provided on the body. The coating is an ABO or ABCO complex oxide solid solution composition, where A, B and C are selected from the group consisting of La, Zr, Ce, Gd, Y, Yb and Si, and O is an oxide. The coating imparts both chlorine and fluorine plasma erosion resistance, reduces particle generation during plasma etching, and prevents spalling of the coating during wet cleaning of the semiconductor processing member.

Owner:FM INDS

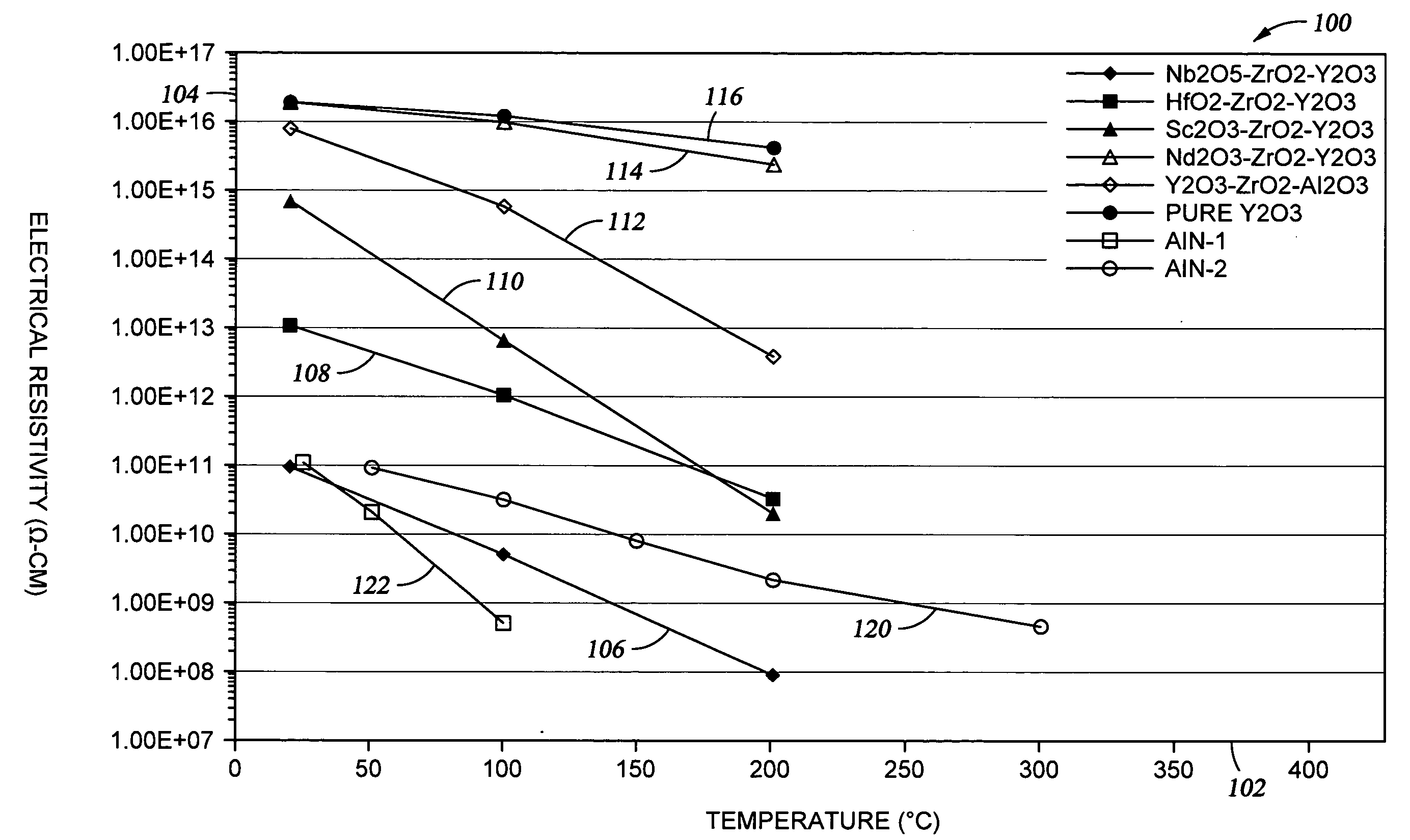

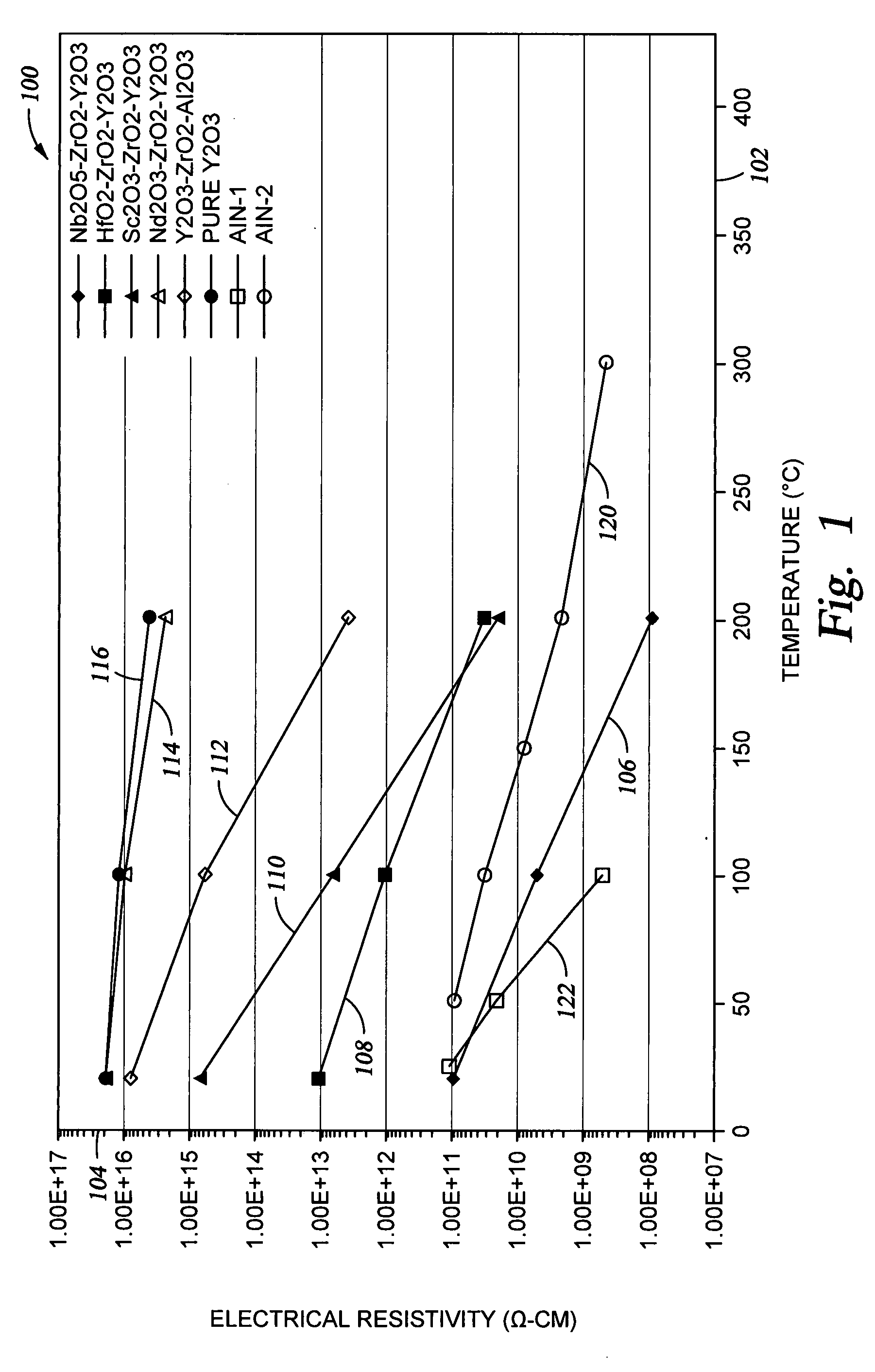

Method of coating semiconductor processing apparatus with protective yttrium-containing coatings

InactiveUS20080213496A1Improve plasma resistanceTailored mechanical propertiesMolten spray coatingVacuum evaporation coatingSolid solutionYttrium

Methods of applying specialty ceramic materials to semiconductor processing apparatus, where the specialty ceramic materials are resistant to halogen-comprising plasmas. The specialty ceramic materials contain at least one yttrium oxide-comprising solid solution. Some embodiments of the specialty ceramic materials have been modified to provide a resistivity which reduces the possibility of arcing within a semiconductor processing chamber.

Owner:APPLIED MATERIALS INC

Laser-produced porous structure

The present invention disclosed a method of producing a three-dimensional porous tissue in-growth structure. The method includes the steps of depositing a first layer of metal powder and scanning the first layer of metal powder with a laser beam to form a portion of a plurality of predetermined unit cells. Depositing at least one additional layer of metal powder onto a previous layer and repeating the step of scanning a laser beam for at least one of the additional layers in order to continuing forming the predetermined unit cells. The method further includes continuing the depositing and scanning steps to form a medical implant.

Owner:UNIV OF LIVERPOOL +1

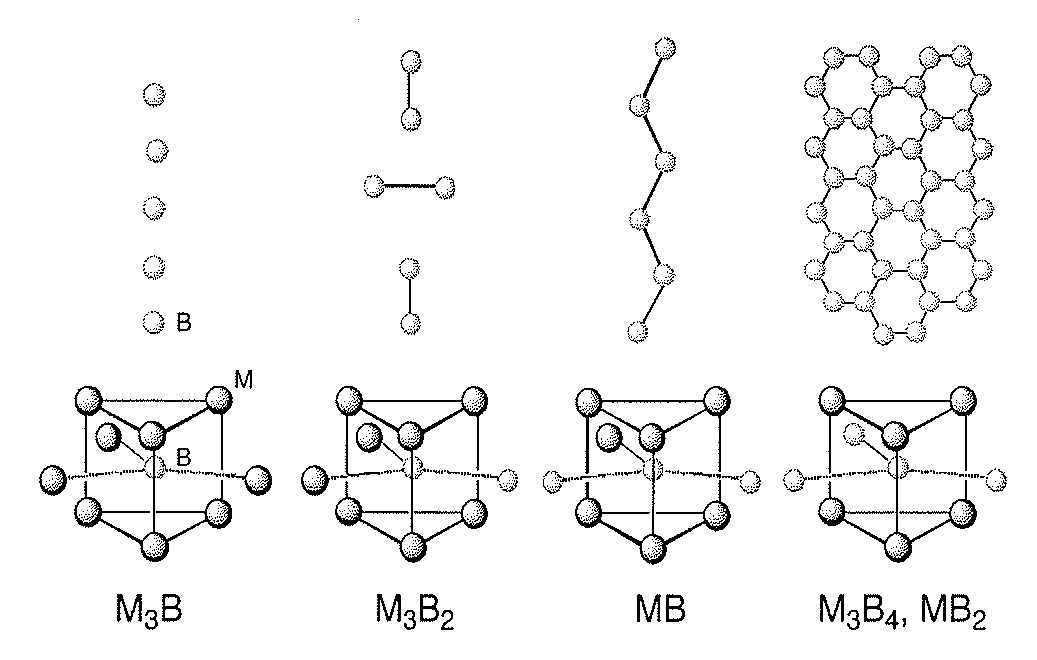

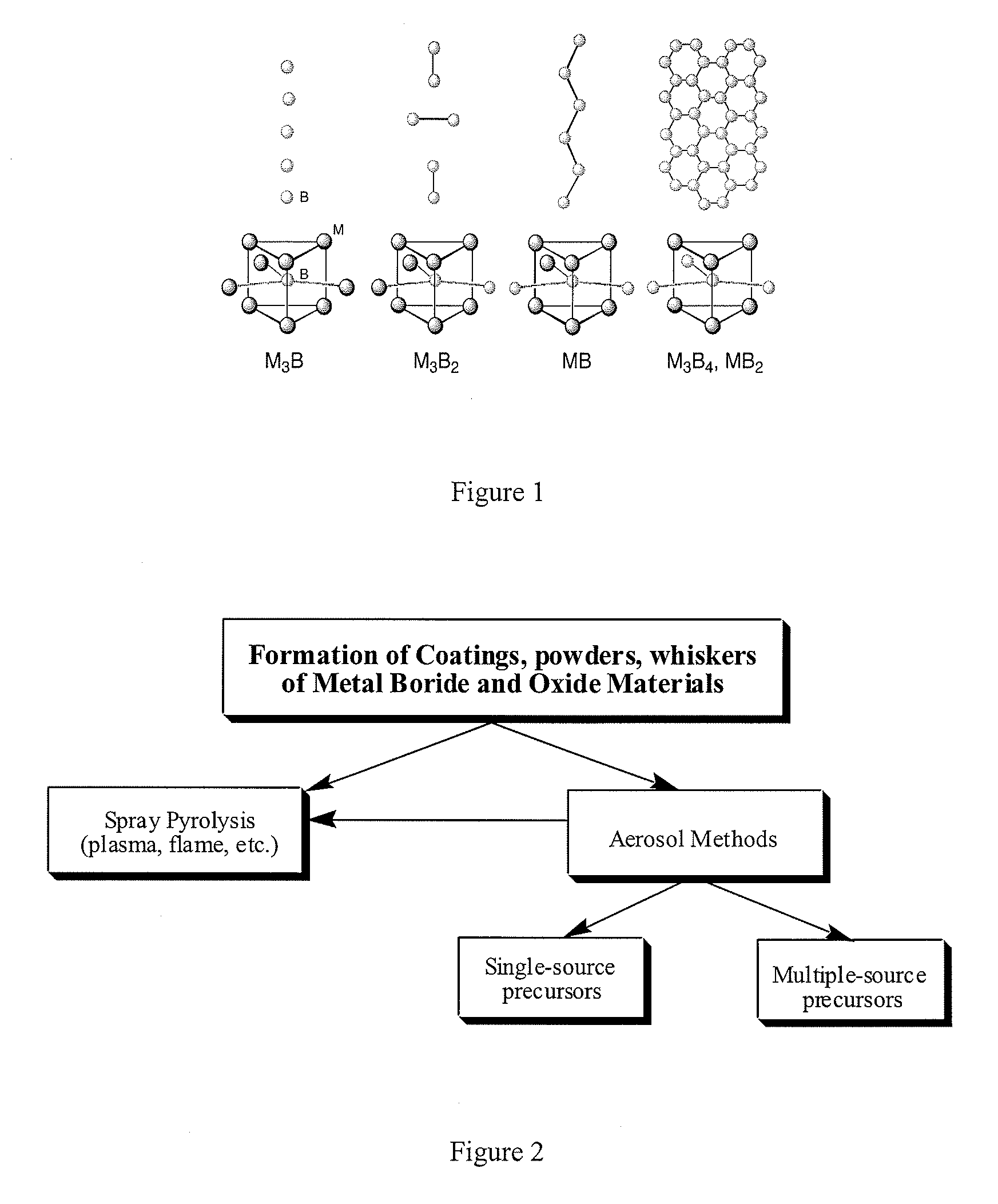

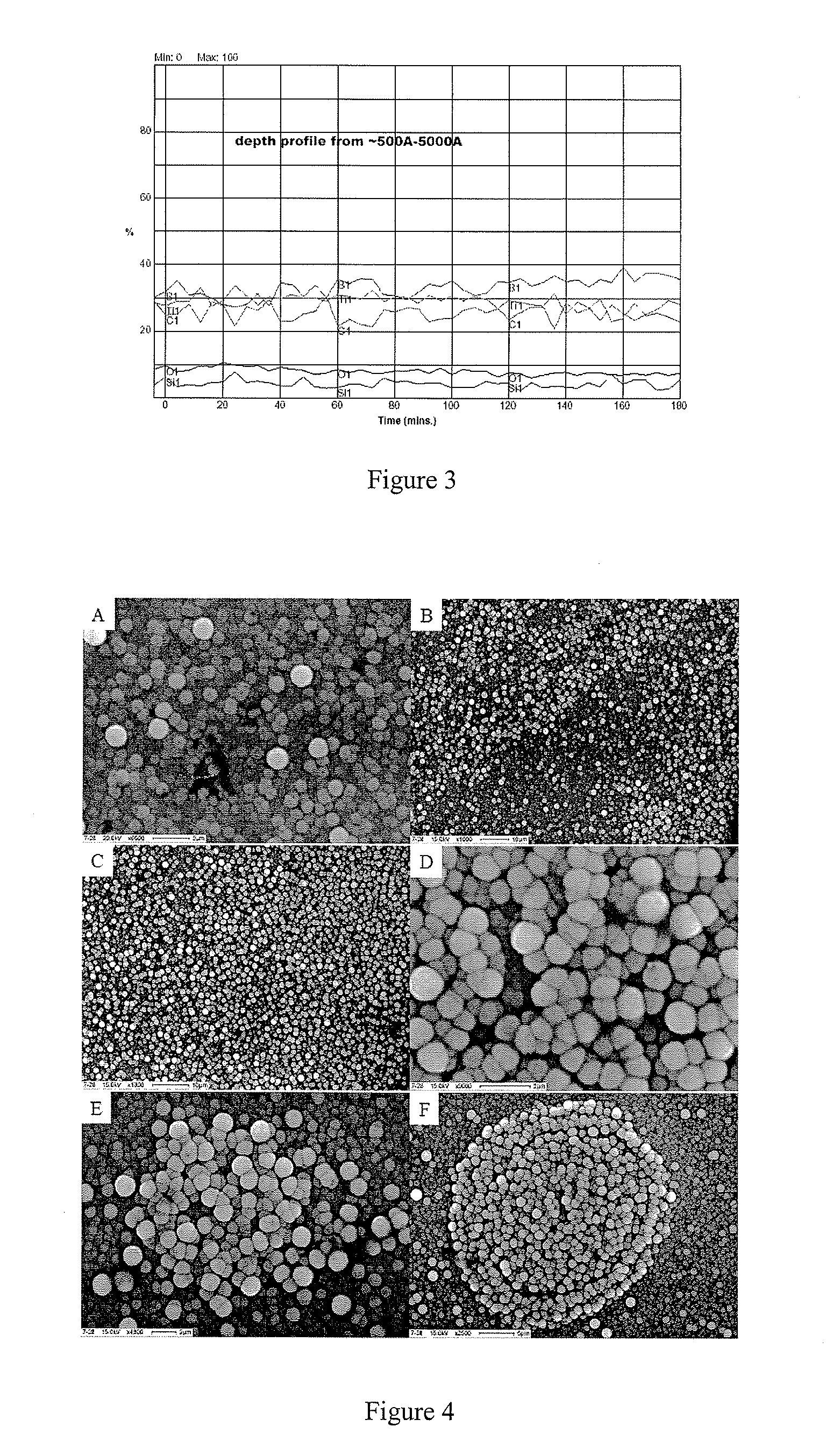

Systems and Methods of the Formation of Solid State Metal Boride and Oxide Coatings

InactiveUS20080003425A1Easy to implementMolten spray coatingLayered productsCelsius DegreeMicrometer

A system and method for the formation of novel small particles, thin films, and coatings of solid state metal boride material. The metal boride materials may be formed using aerosol methods and / or spray pyrolysis to form a generally uniform, thin film coating of boride compound spheres. Boride solutions or compounds are sprayed via a gas nebulizer in a reactor containing a substrate and heated to approximately 900° Celsius. The boride compounds form uniform, spherical particles of approximately one micrometer in diameter. The boride compounds are extremely strong, non-reactive, dense, and, when prepared as films or coating, adhere very well to substrates, such as metals.

Owner:SYRACUSE UNIVERSITY

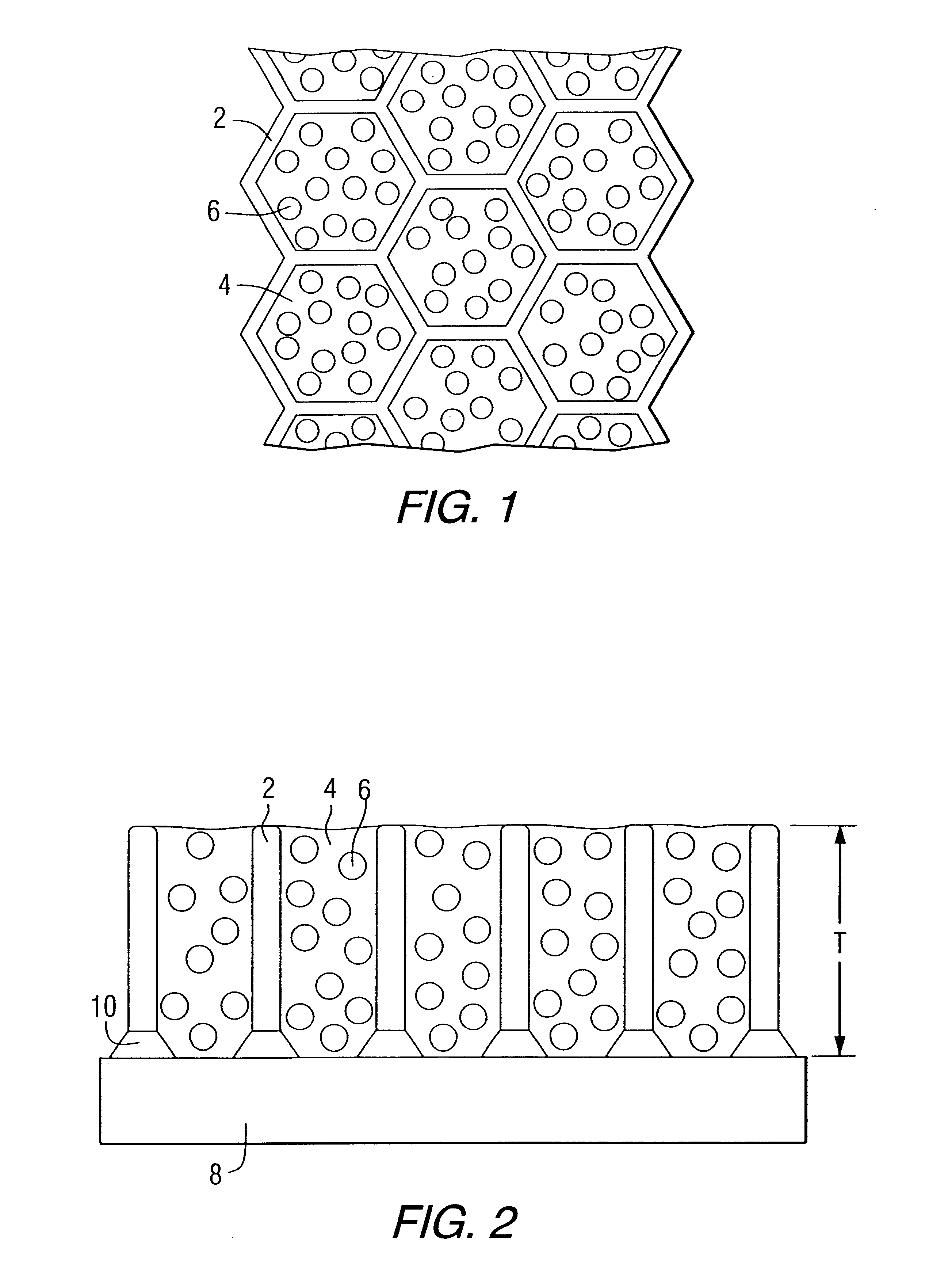

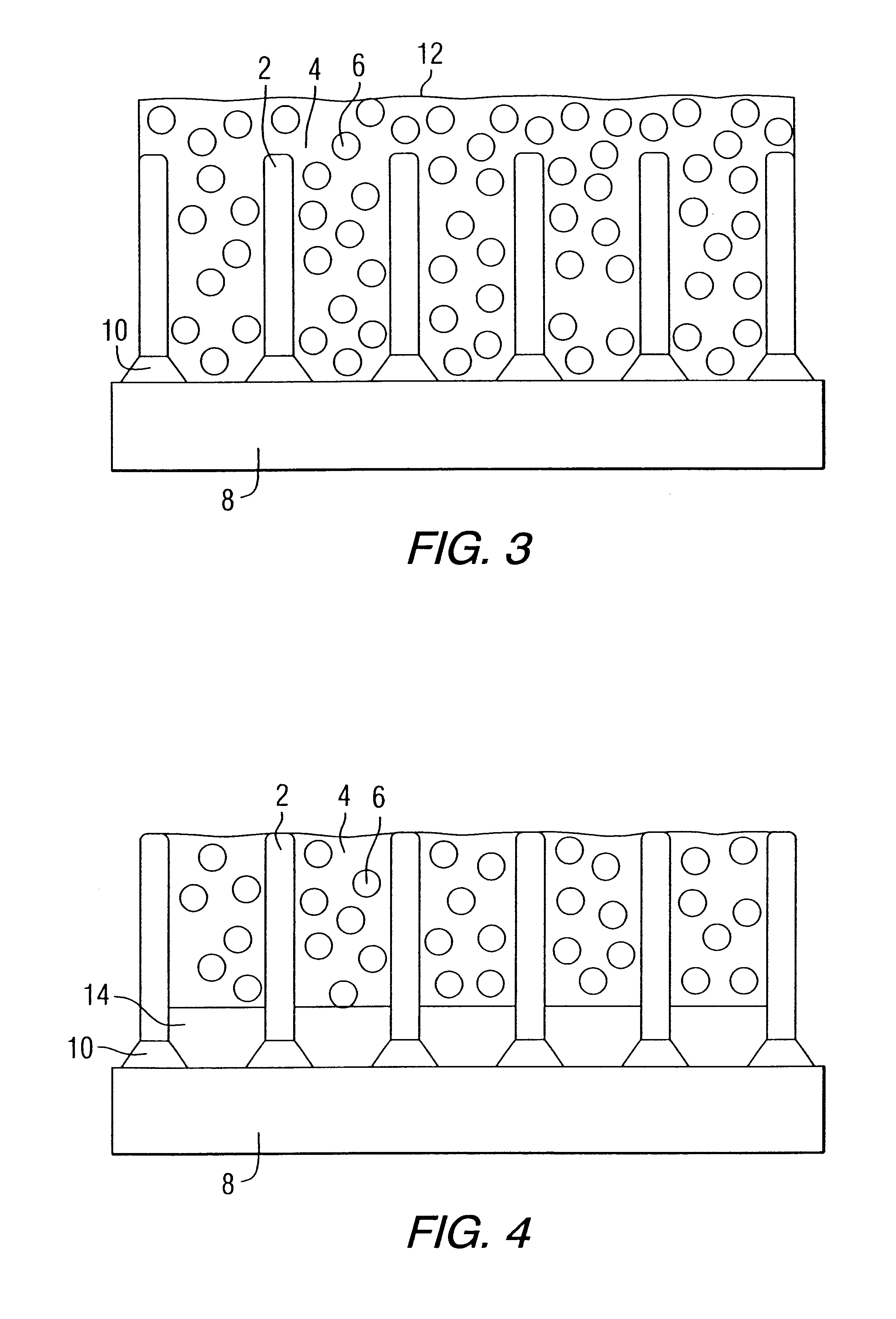

High temperature erosion resistant, abradable thermal barrier composite coating

InactiveUS6235370B1Improve wear resistanceImprove adhesionMolten spray coatingPump componentsCombustorHoneycomb

A composite thermal barrier coating system includes a honeycomb metallic structure filled with high thermal expansion ceramic hollow spheres in a phosphate bonded matrix. The composite thermal barrier coating system may be manufactured to thicknesses in excess of current thermal barrier coating systems, thereby imparting greater thermal protection. Superior erosion resistance and abrasion properties are also achieved. The composite thermal barrier coating is useful on combustion turbine components such as ring seal segments, vane segment shrouds, transitions and combustors.

Owner:SIEMENS ENERGY INC

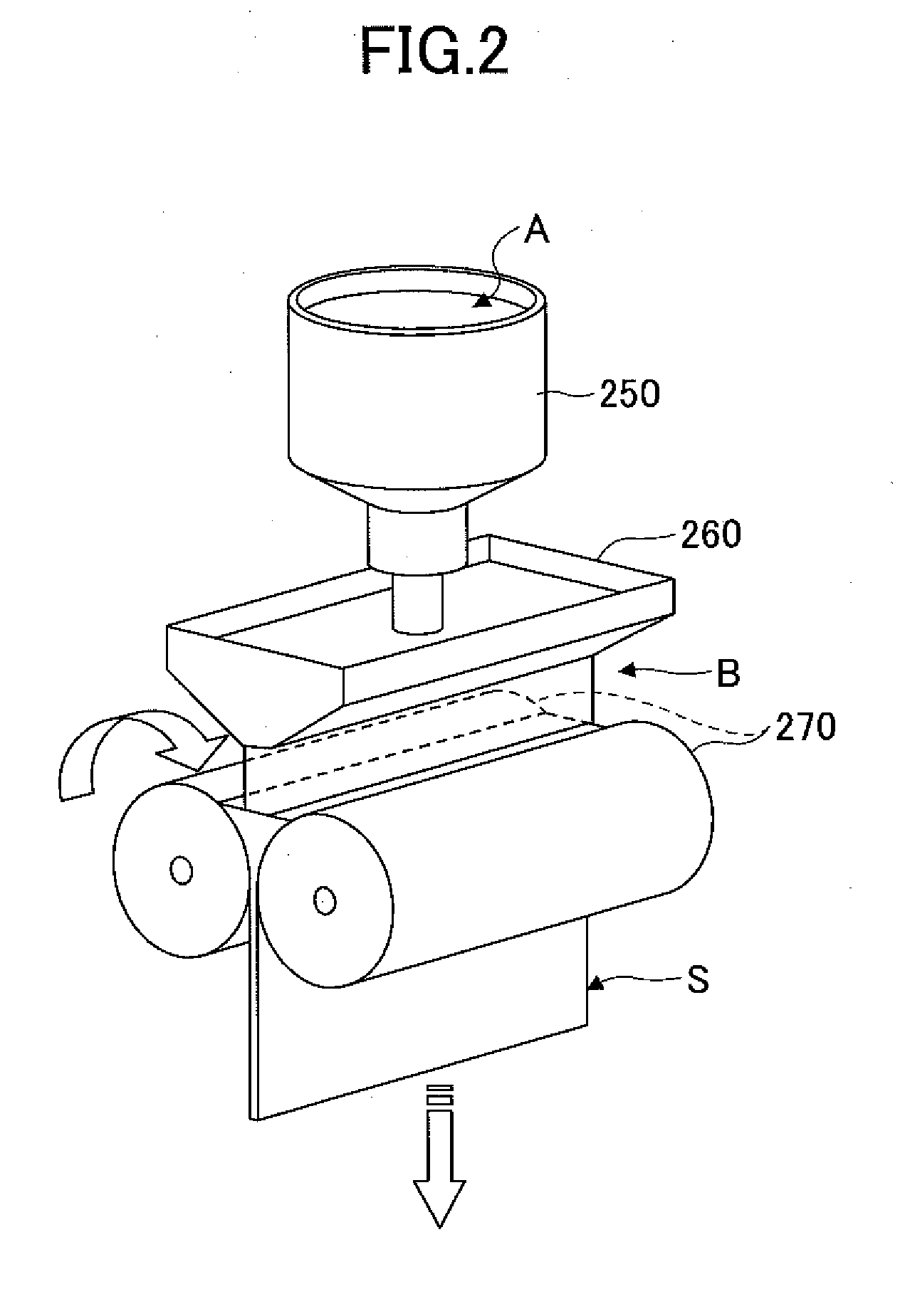

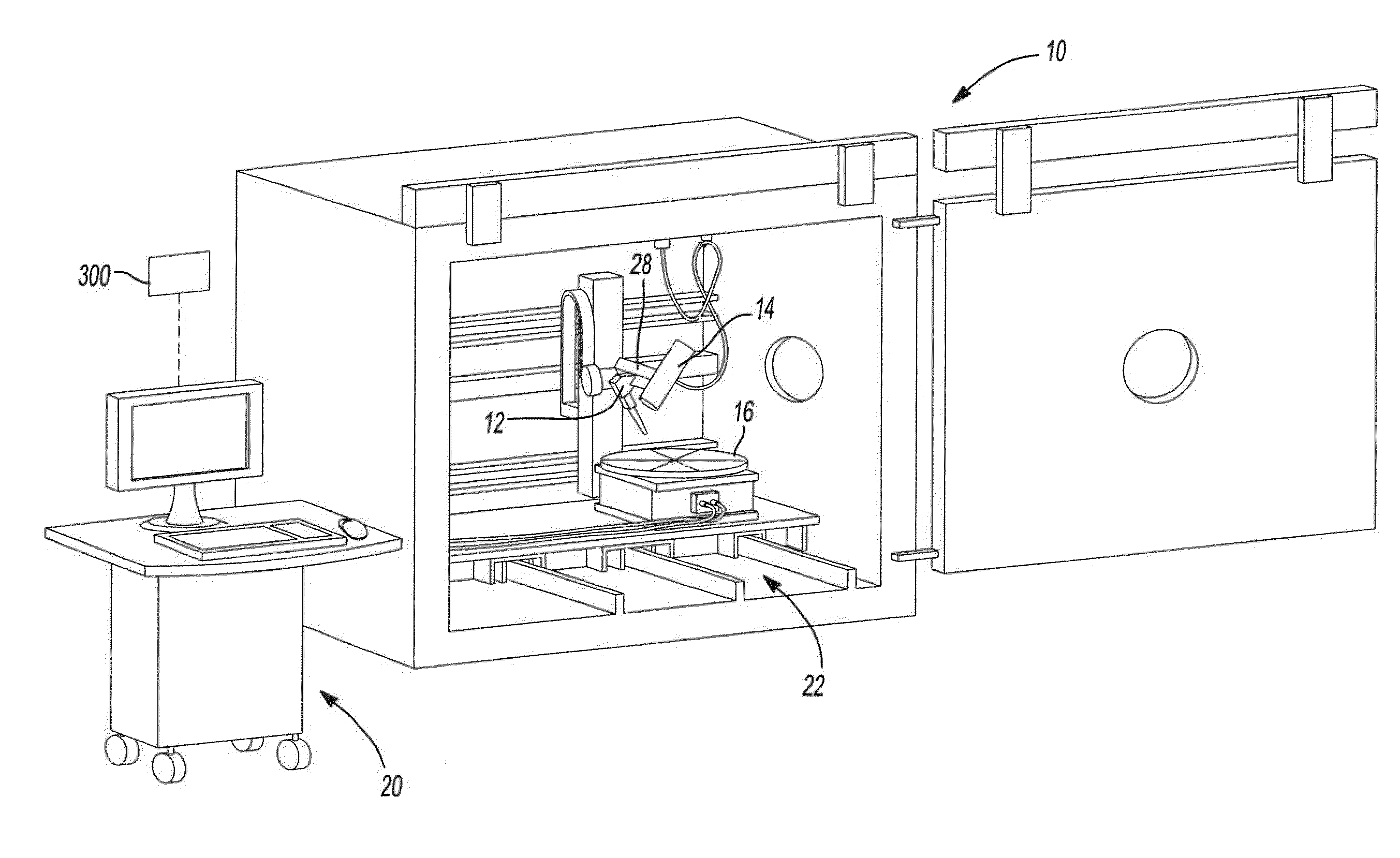

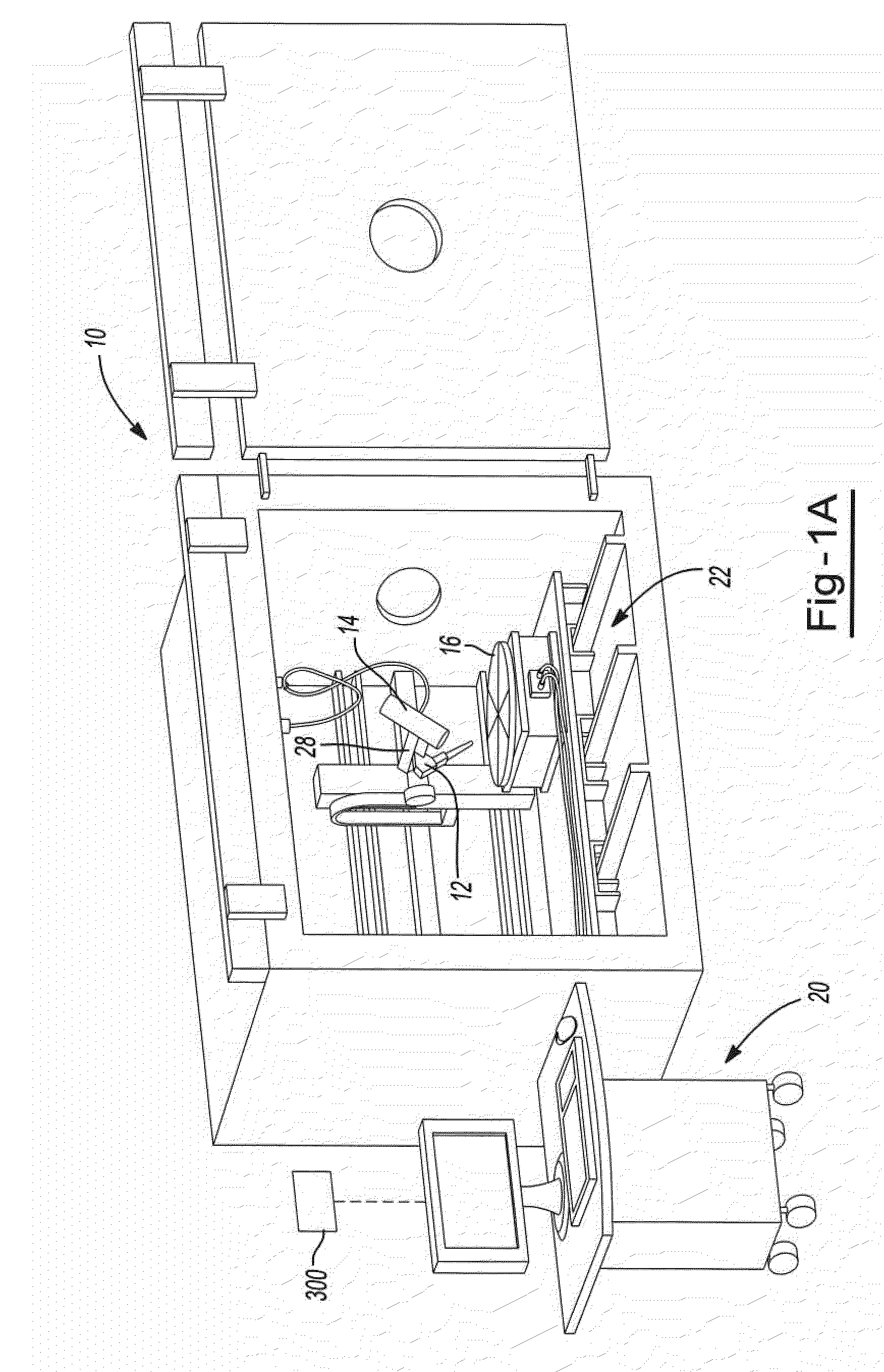

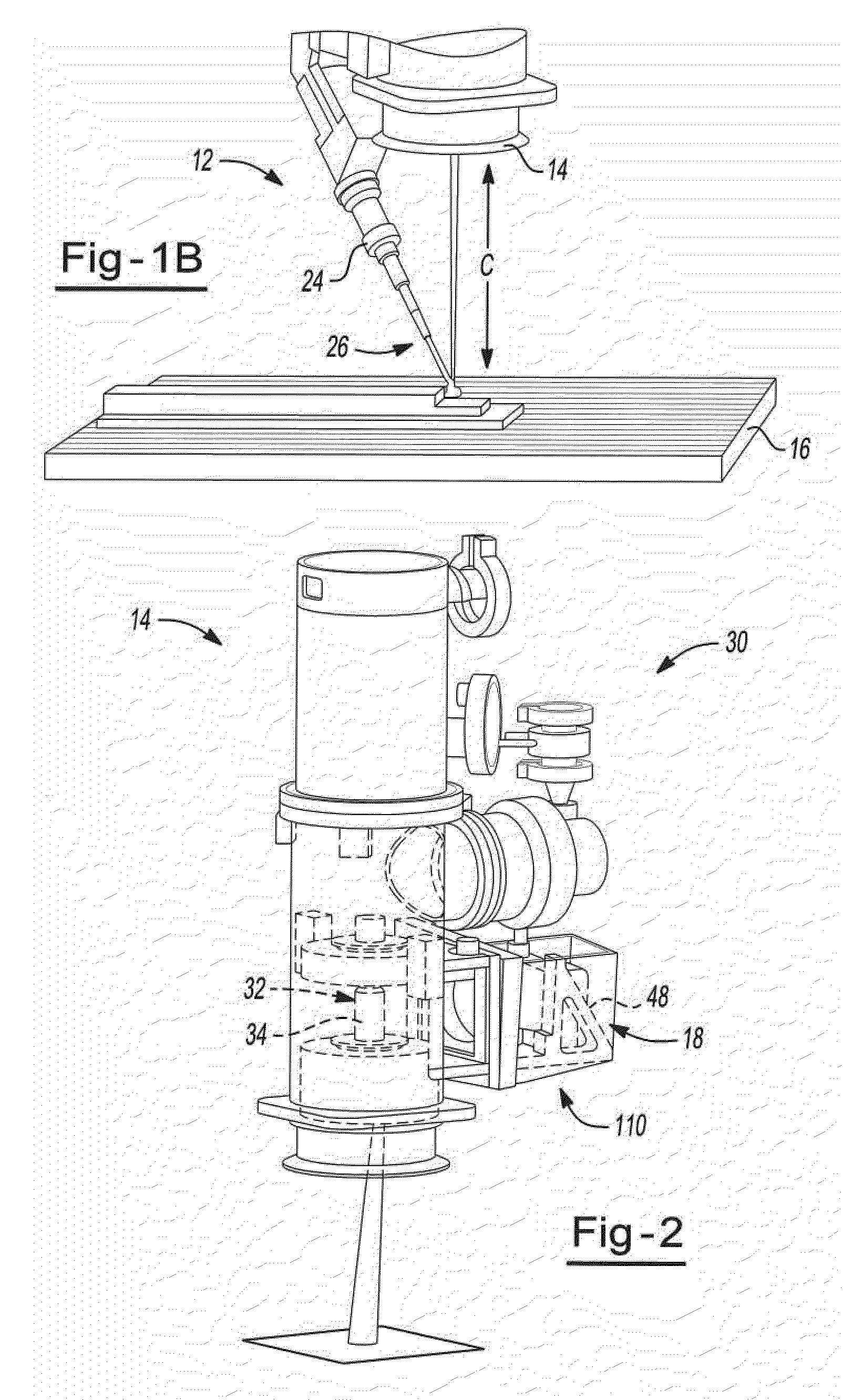

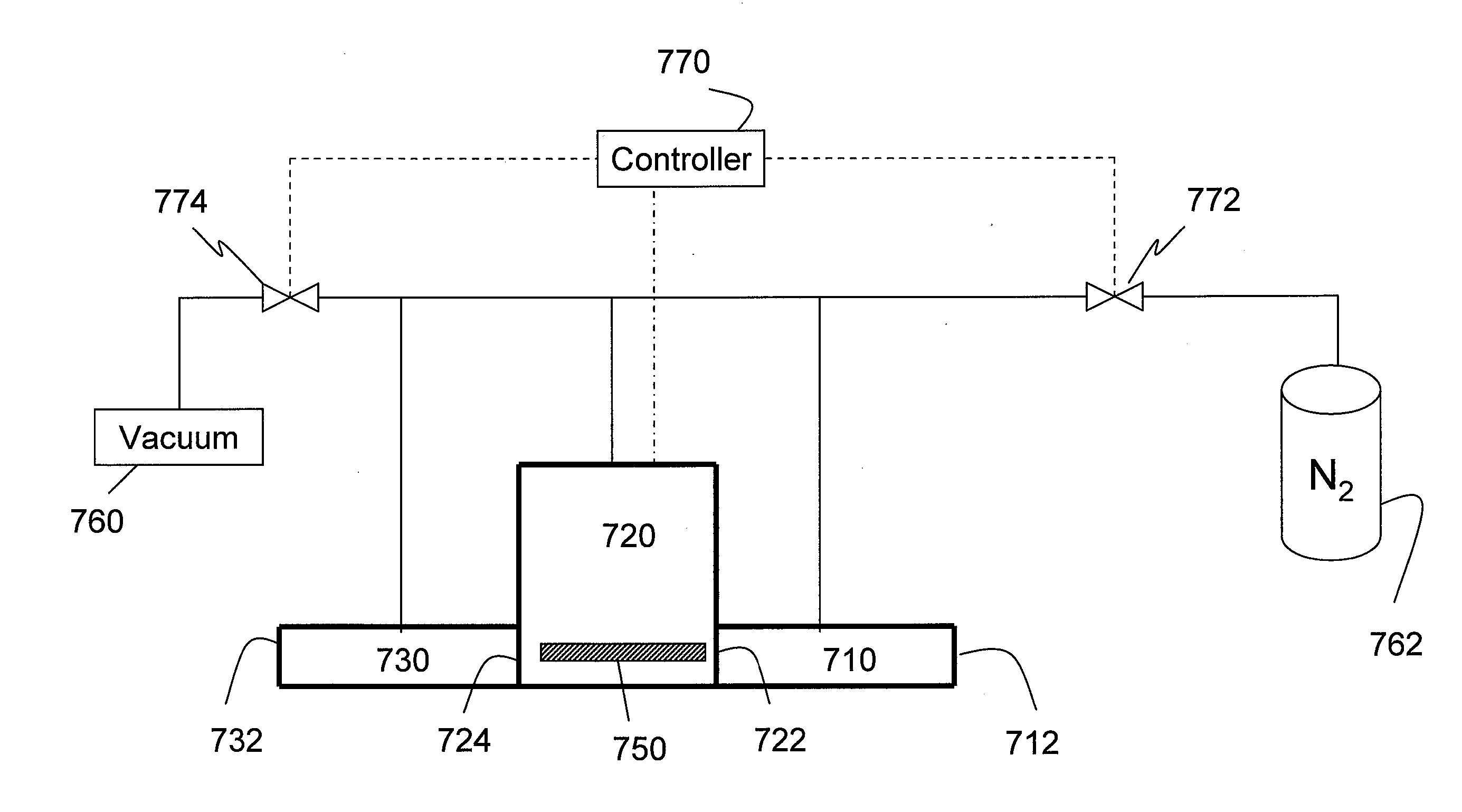

Method And Apparatus for Load-Locked Printing

ActiveUS20100201749A1Prevent oxidationAvoid contaminationInking apparatusMolten spray coatingElectrical and Electronics engineering3D printing

The disclosure relates to a method and apparatus for preventing oxidation or contamination during a circuit printing operation. The circuit printing operation can be directed to OLED-type printing. In an exemplary embodiment, the printing process is conducted at a load-locked printer housing having one or more of chambers. Each chamber is partitioned from the other chambers by physical gates or fluidic curtains. A controller coordinates transportation of a substrate through the system and purges the system by timely opening appropriate gates. The controller may also control the printing operation by energizing the print-head at a time when the substrate is positioned substantially thereunder.

Owner:KATEEVA

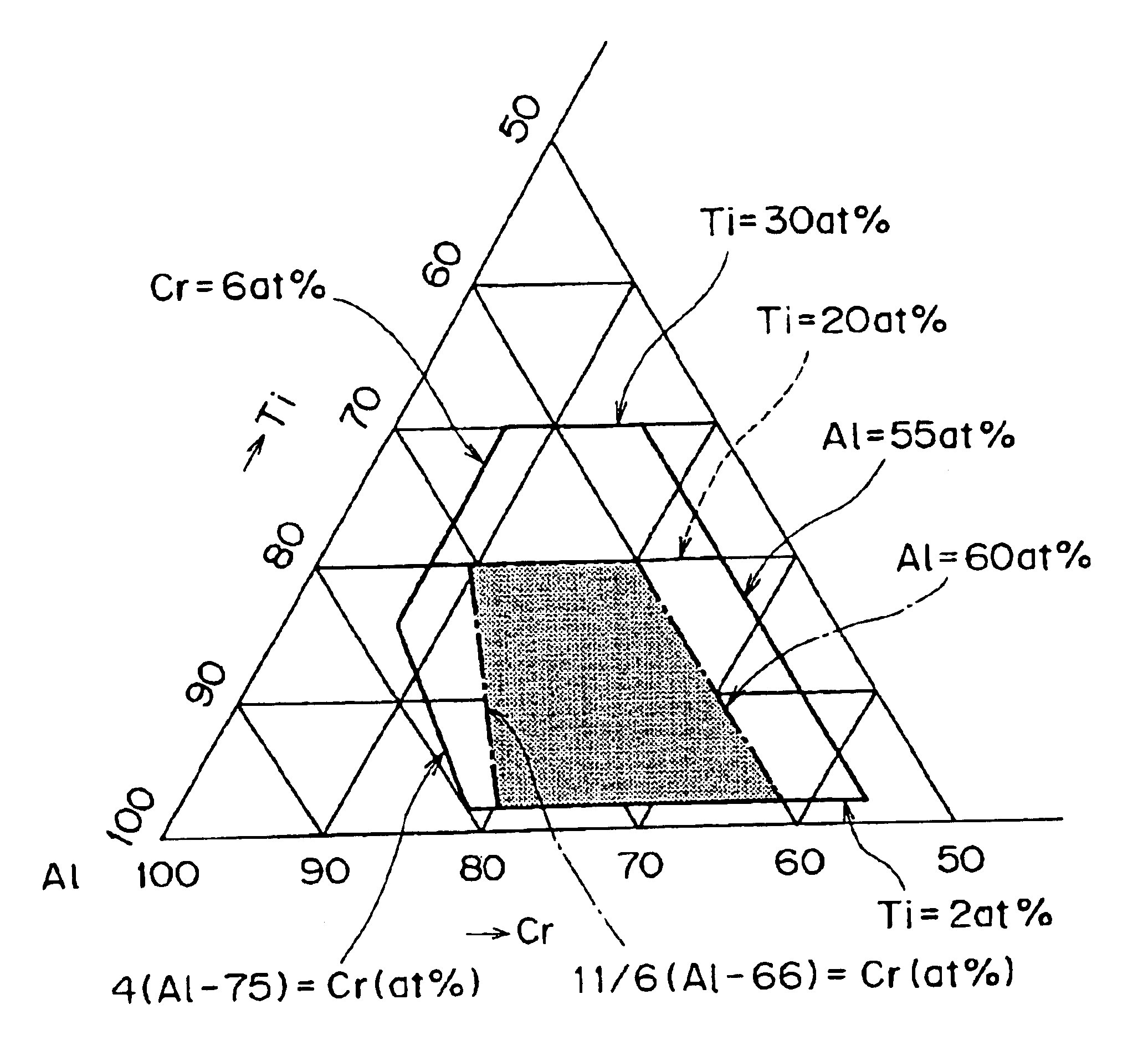

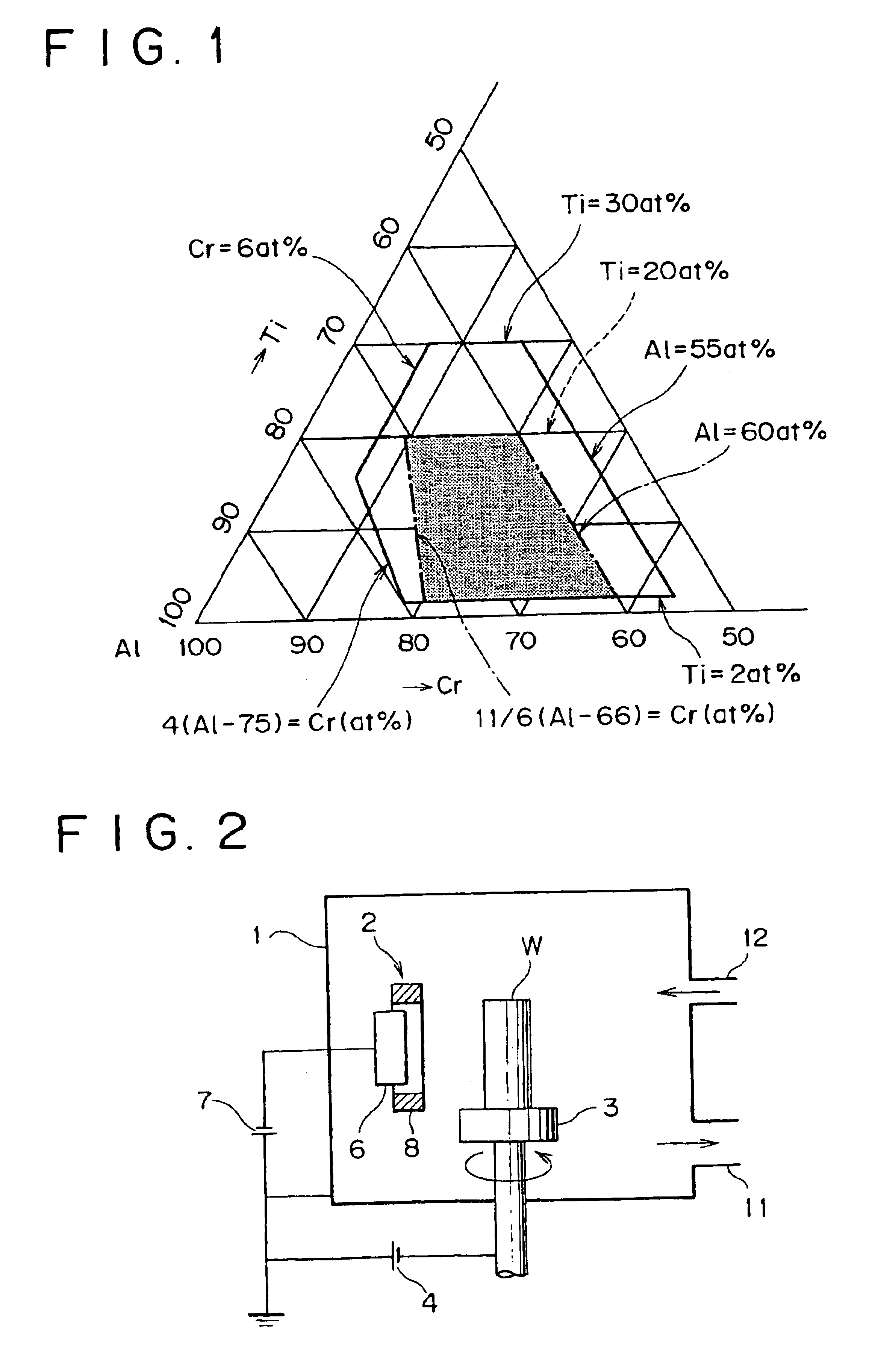

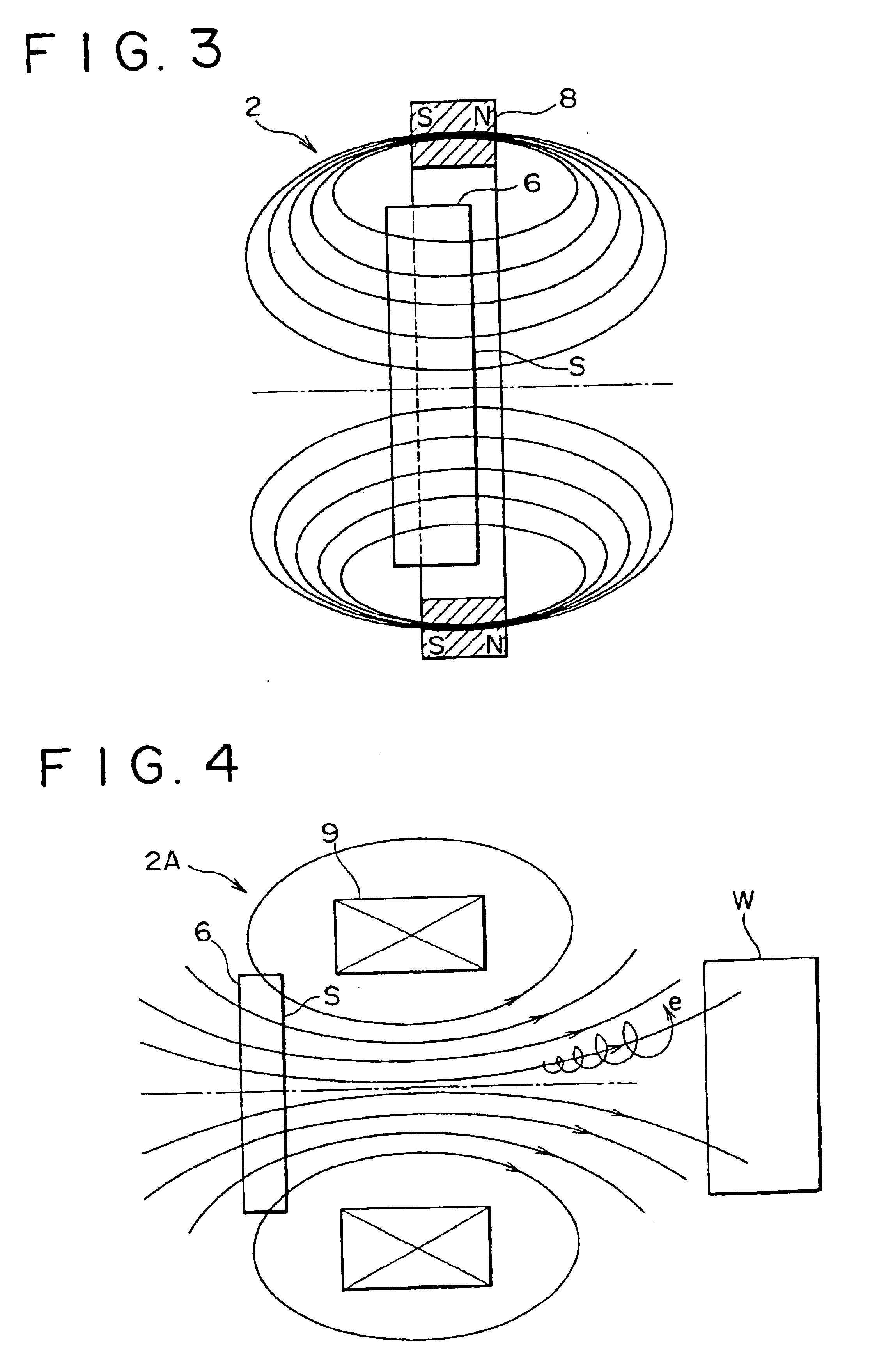

Hard film for cutting tools, cutting tool coated with hard film, process for forming hard film, and target used to form hard film

InactiveUS6824601B2Improve wear resistanceHigh-speed efficient cuttingMolten spray coatingOther chemical processesMetallurgyAtomic ratio

A hard film for cutting tools which is composed of(where a, b, c, and d denote respectively the atomic ratios Al, Cr, Si, and B, and e denotes the atomic ratio of N.)

Owner:KOBE STEEL LTD

Articles having low wettability and methods for making

InactiveUS20070031639A1Low liquid wettabilityAnodisationMolten spray coatingEngineeringContact angle

Owner:GENERAL ELECTRIC CO

Process for preparing nanostructured materials of controlled surface chemistry

InactiveUS6669823B1Good dispersionReduce hydrolysis rateMaterial nanotechnologyMolten spray coatingCharge carrierNanostructured materials

A process to prepare stoichiometric-nanostructured materials comprising generating a plasma, forming an "active volume" through introduction of an oxidizing gas into the plasma, before the plasma is expanded into a field-free zone, either (1) in a region in close proximity to a zone of charge carrier generation, or (2) in a region of current conduction between field generating elements, including the surface of the field generation elements, and transferring energy from the plasma to a precursor material to form in the "active volume" at least one stoichiometric-nanostructured material and a vapor that may be condensed to form a stoichiometric-nanostructured material. The surface chemistry of the resulting nanostructured materials is substantially enhanced to yield dispersion stable materials with large zeta-potentials.

Owner:NANOPHASE TECH CORP

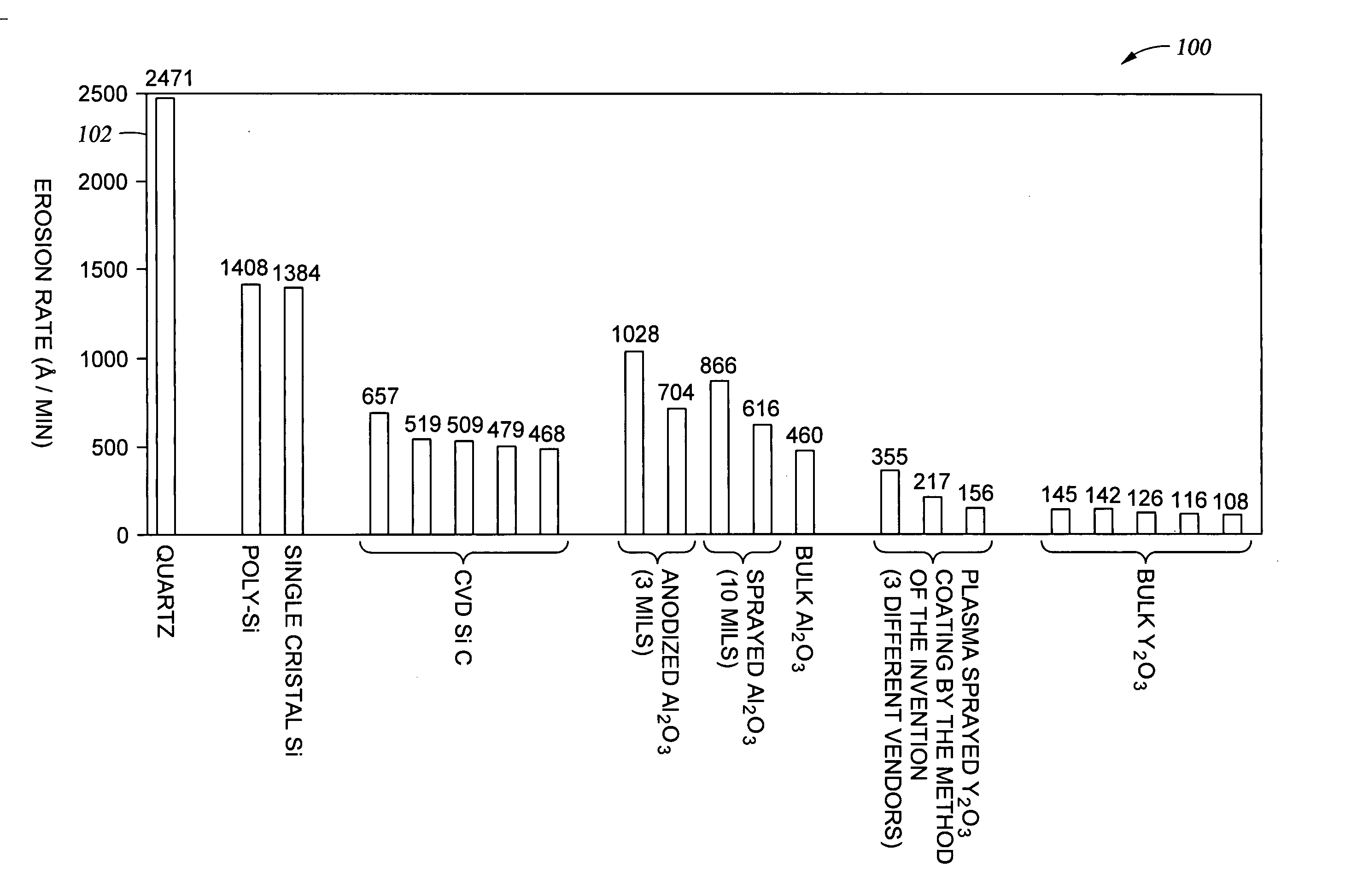

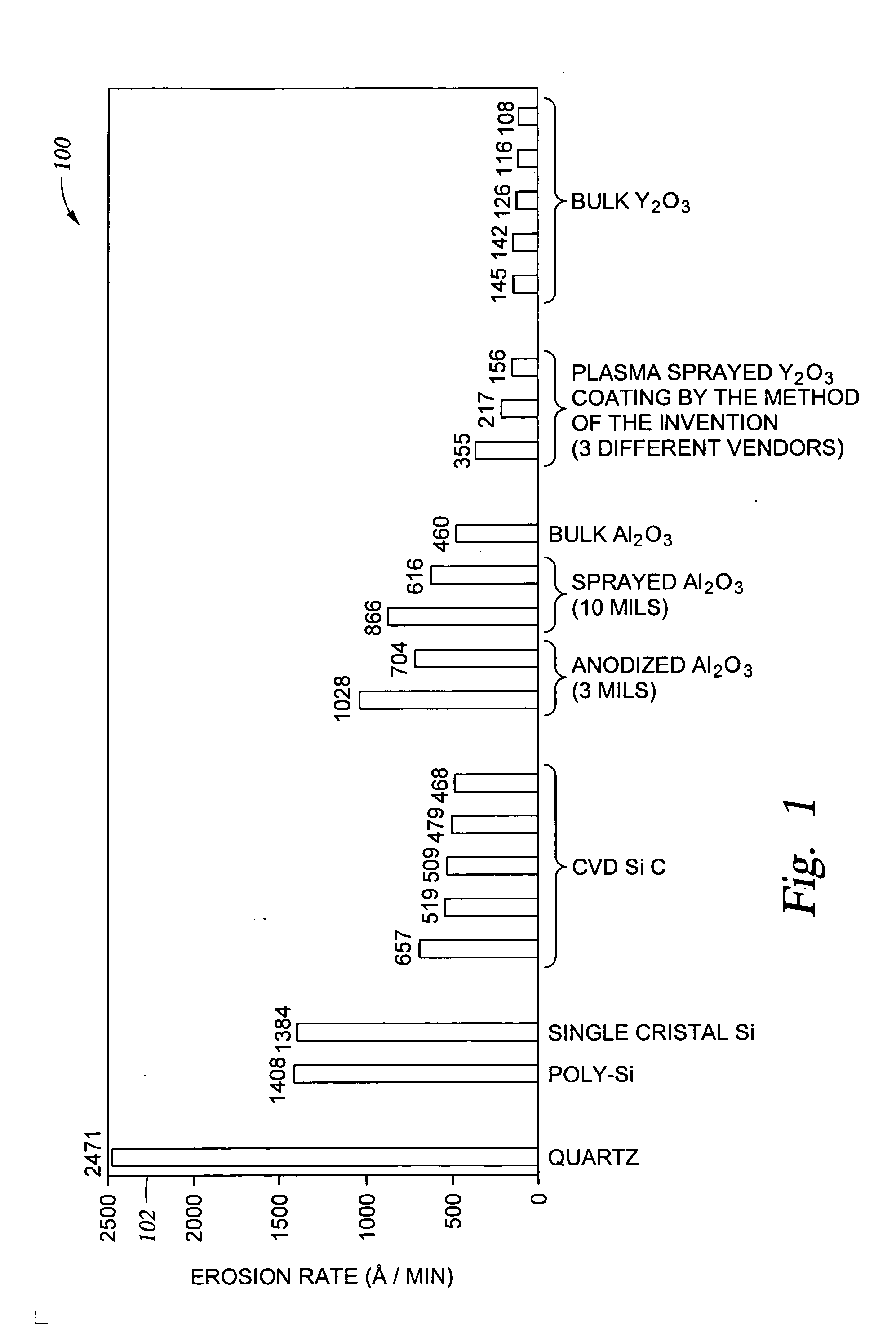

Clean, dense yttrium oxide coating protecting semiconductor processing apparatus

ActiveUS20050037193A1Extended service lifeExcellent plasma corrosion-resistanceLiquid surface applicatorsMolten spray coatingPlasma coatingChemical vapor deposition

Disclosed herein is a method for applying plasma-resistant coatings for use in semiconductor processing apparatus. The coatings are applied over a substrate which typically comprises an aluminum alloy of the 2000 series or the 5000 through 7000 series. The coating typically comprises an oxide or a fluoride of Y, Sc, La, Ce, Eu, Dy, or the like, or yttrium-aluminum-garnet (YAG). The coating may further comprise about 20 volume % or less of Al2O3. The coatings are typically applied to a surface of an aluminum alloy substrate or an anodized aluminum alloy substrate using a technique selected from the group consisting of thermal / flame spraying, plasma spraying, sputtering, and chemical vapor deposition (CVD). To provide the desired corrosion resistance, it is necessary to place the coating in compression. This is accomplished by controlling deposition conditions during application of the coating.

Owner:APPLIED MATERIALS INC

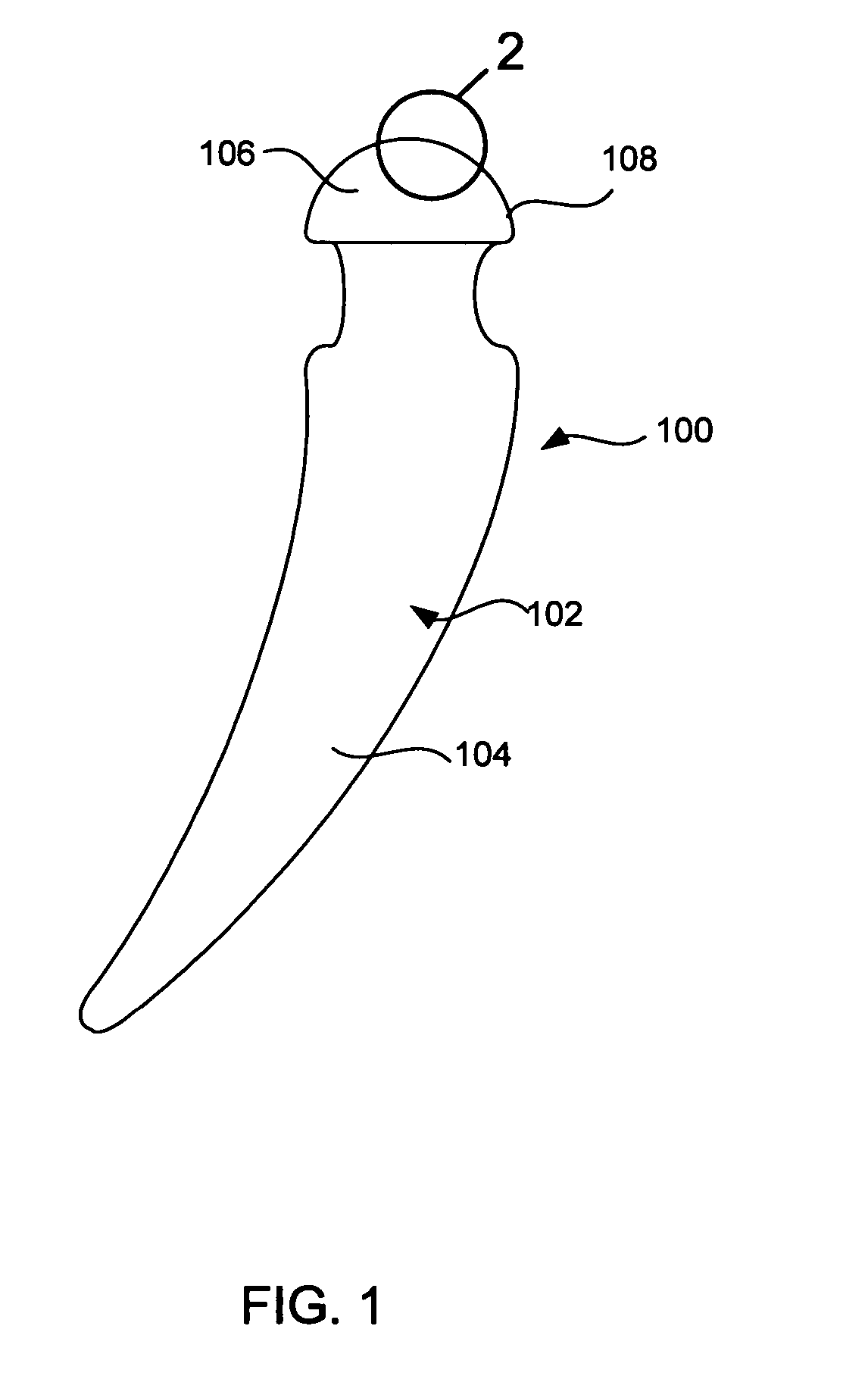

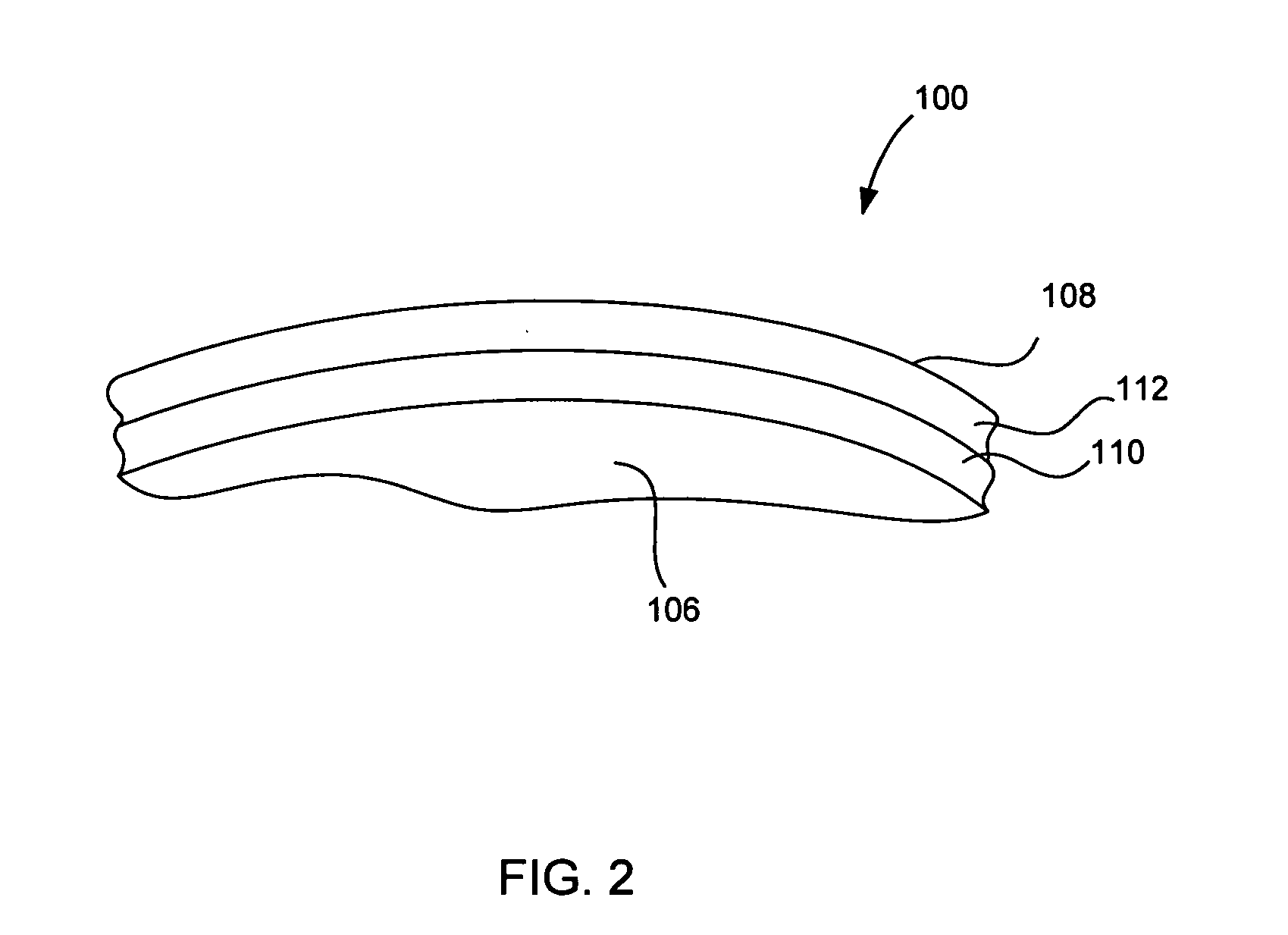

Laser based metal deposition of implant structures

InactiveUS20050123672A1Improved bearing propertyIncrease bone ingrowth propertyDental implantsFinger jointsArtificial jointsBone ingrowth

Owner:MEDICINELODGE

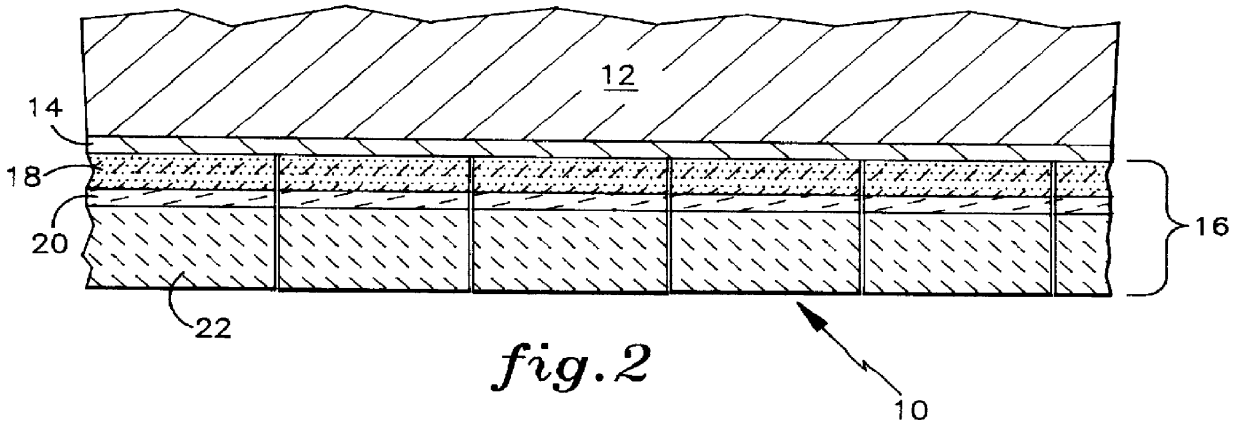

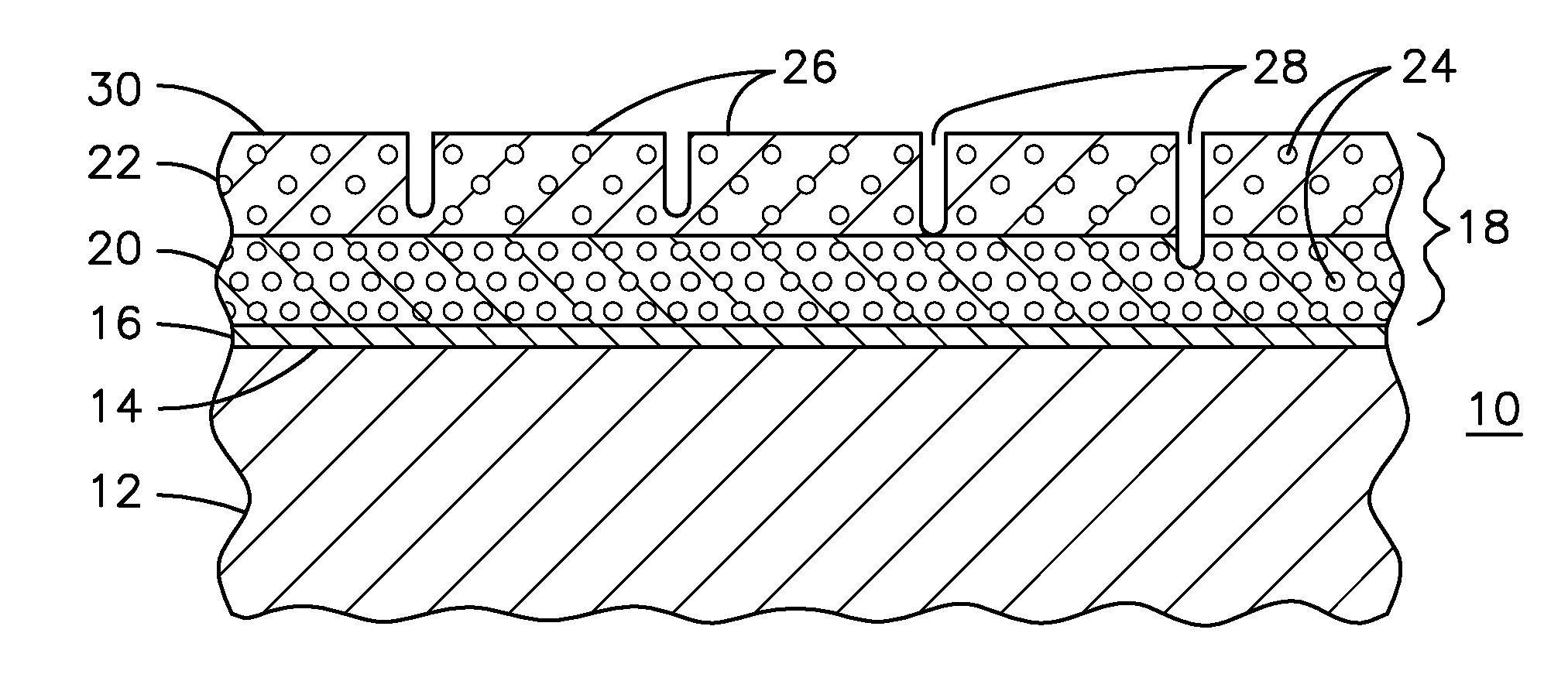

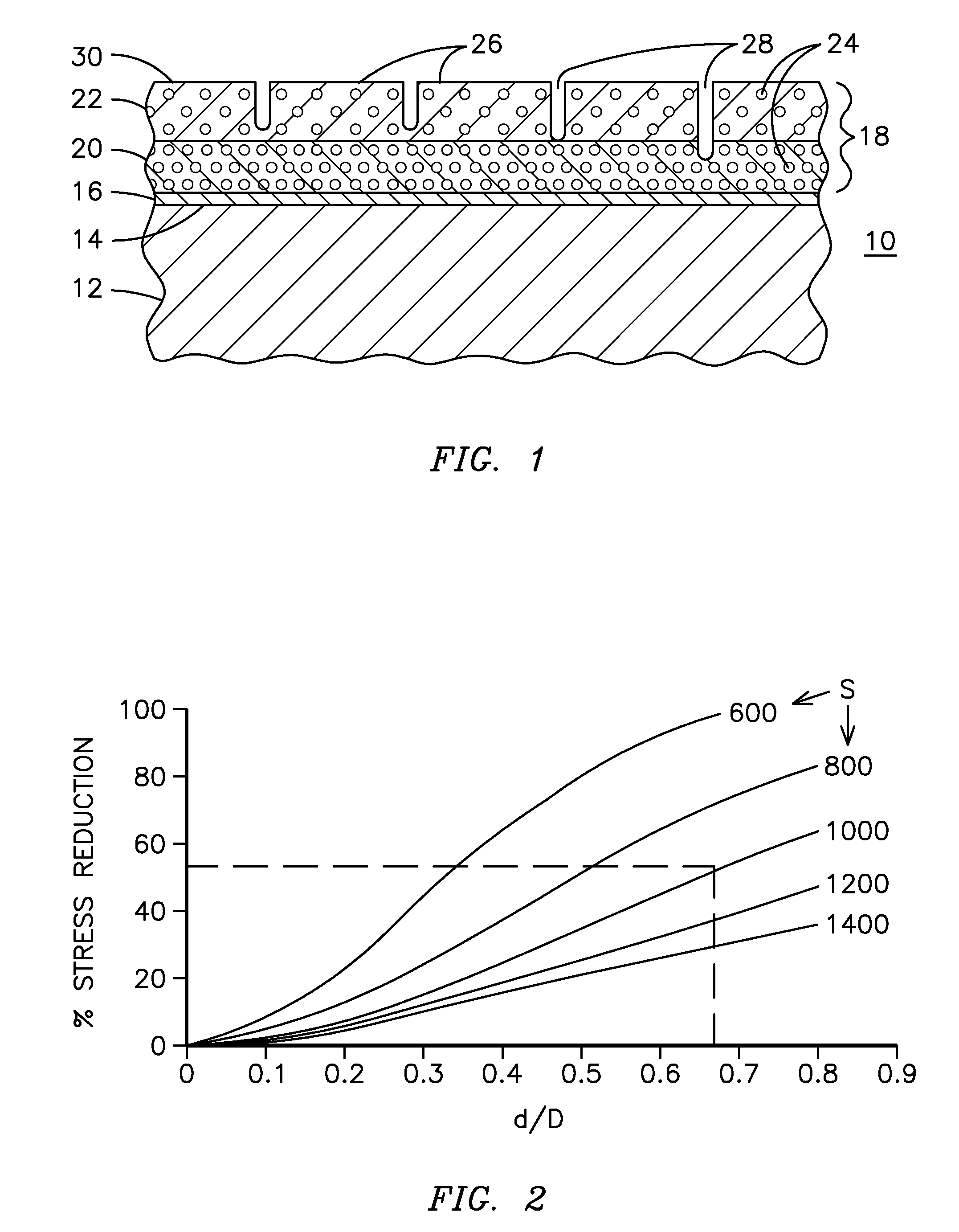

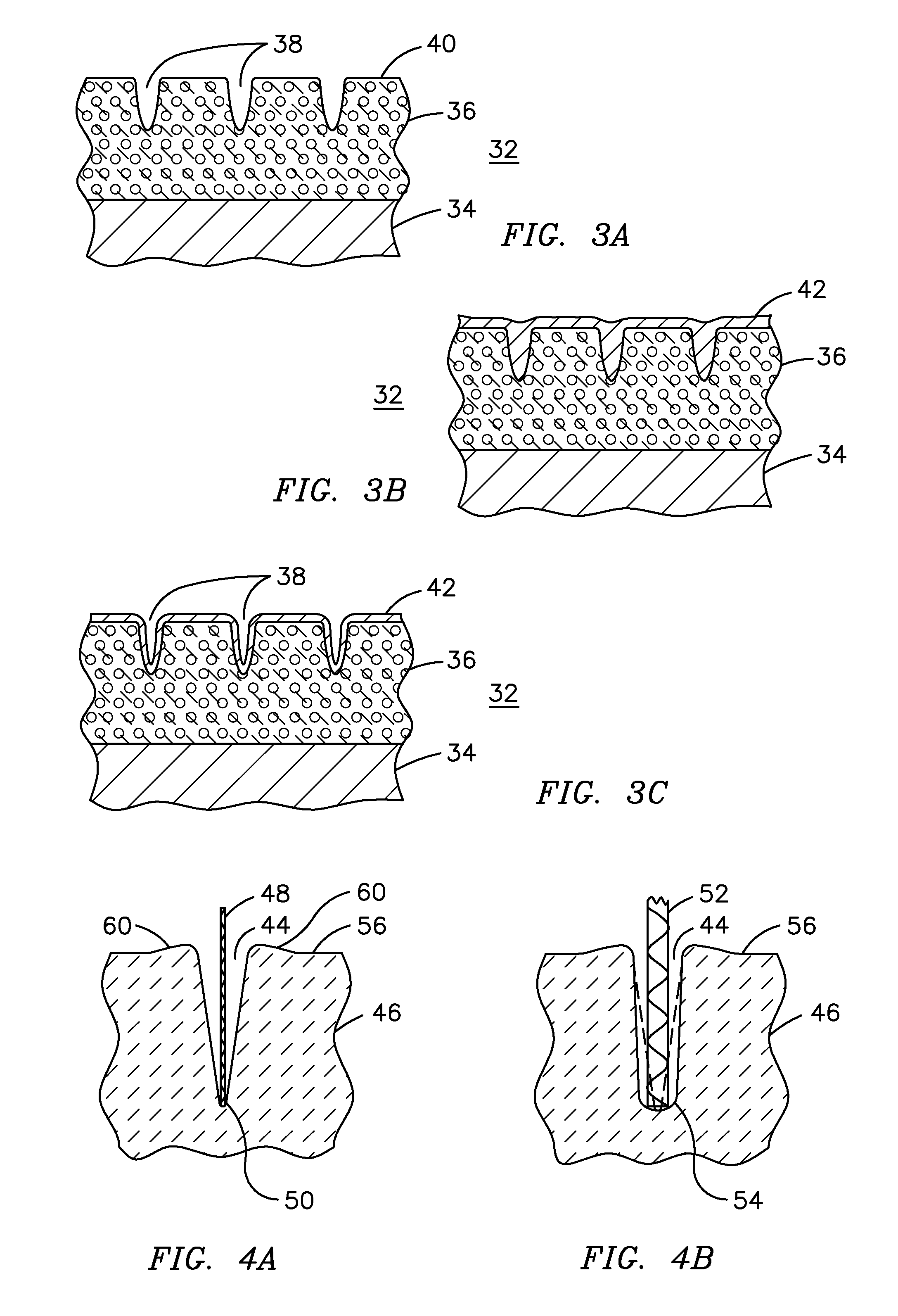

Segmented thermal barrier coating

A ceramic thermal barrier coating (TBC) (18) having first and second layers (20, 22), the second layer (22) having a lower thermal conductivity than the first layer for a given density. The second layer may be formed of a material with anisotropic crystal lattice structure. Voids (24) in at least the first layer (20) make the first layer less dense than the second layer. Grooves (28) are formed in the TBC (18) for thermal strain relief. The grooves may align with fluid streamlines over the TBC. Multiple layers (84, 86,88) may have respective sets of grooves (90), Preferred failure planes parallel to the coating surface (30) may be formed at different depths (A1, A2, A3) in the thickness of the TBC to stimulate generation of a fresh surface when a portion of the coating fails by spalling. A dense top layer (92) may provide environmental and erosion resistance.

Owner:SIEMENS ENERGY INC

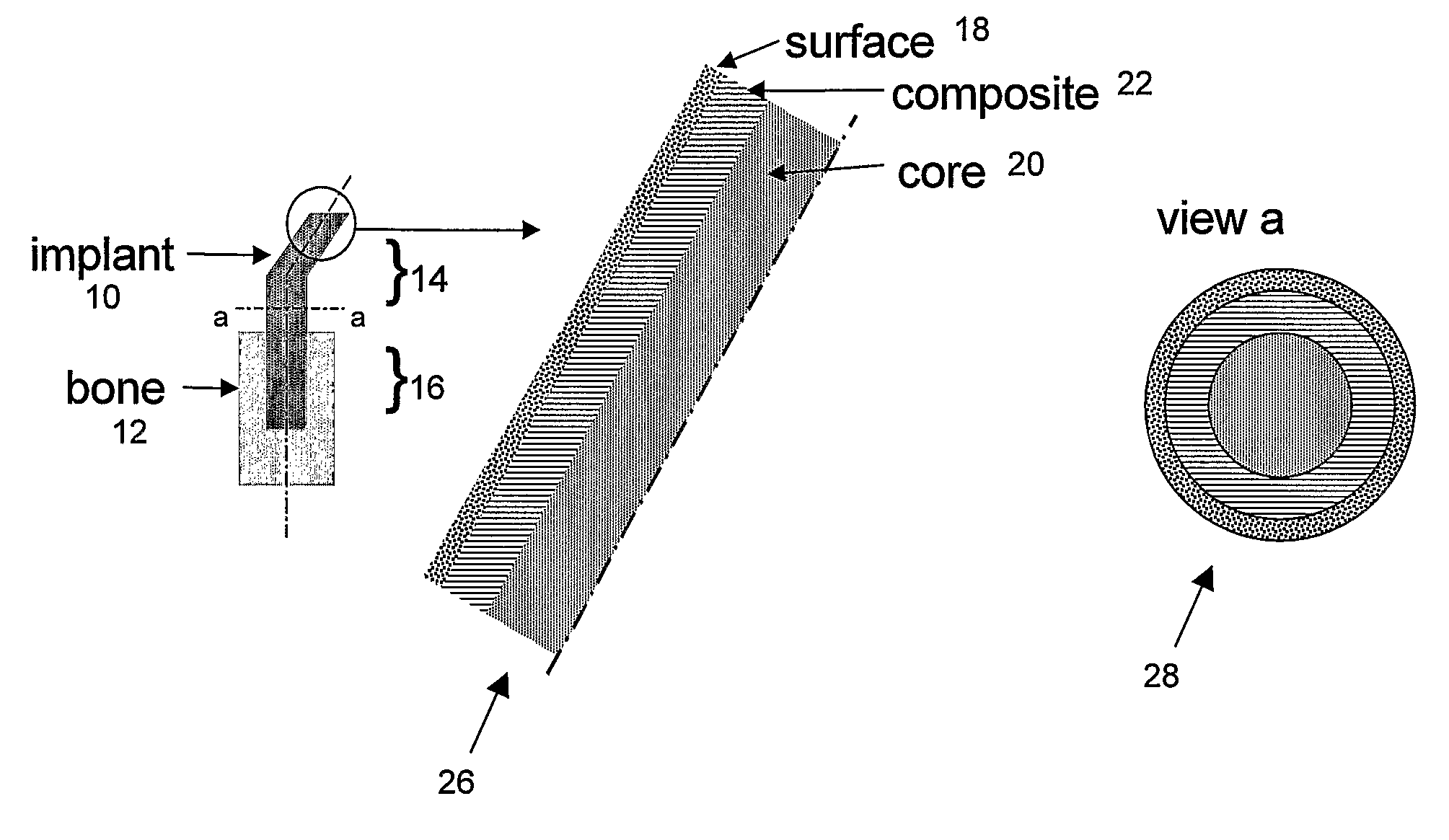

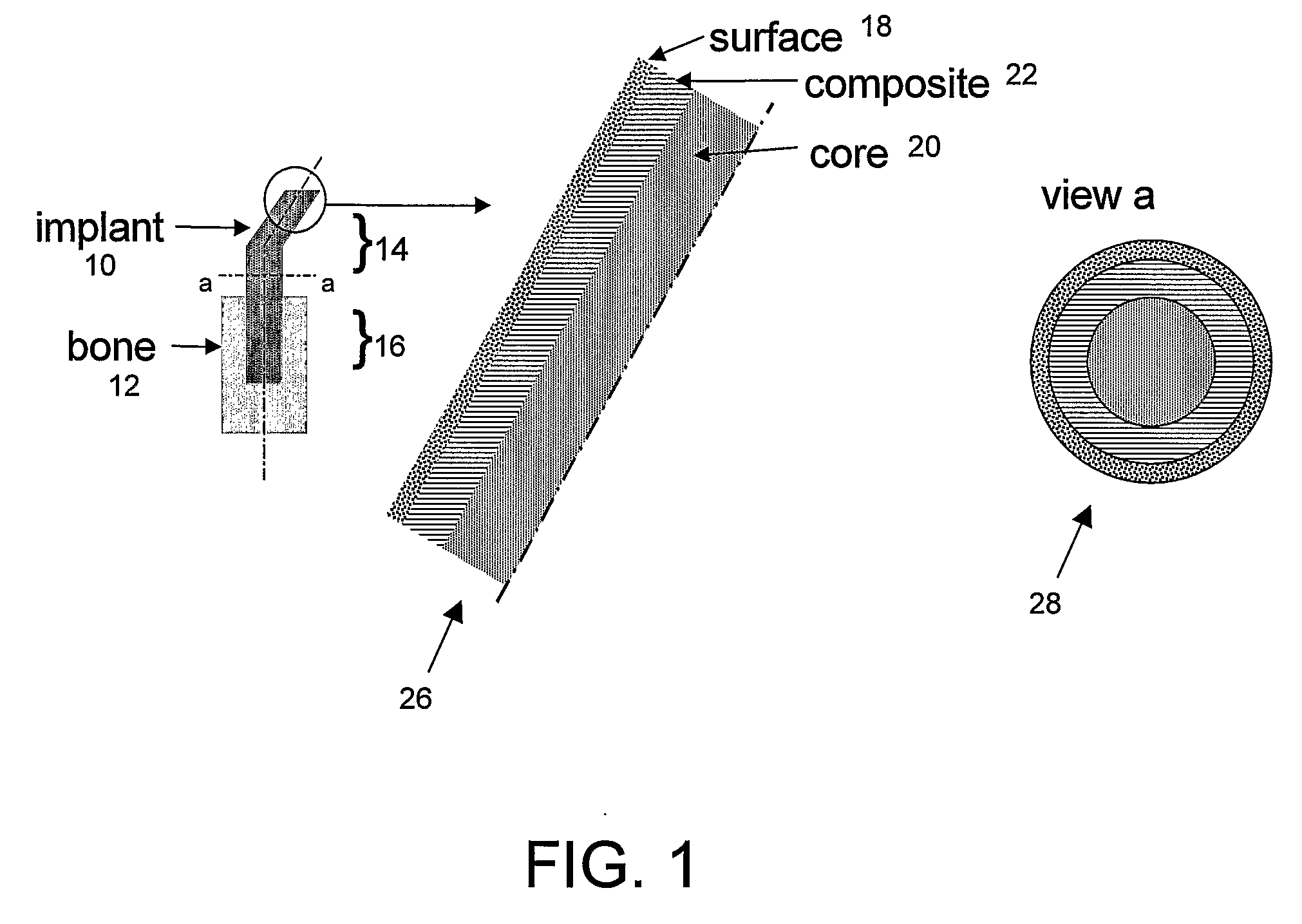

Implantable biomimetic prosthetic bone

InactiveUS20090177282A1Reduce riskMolten spray coatingLamination ancillary operationsNormal boneFiber-reinforced composite

Bone tissue at the interface of a bone implant is shielded from stresses found in normal bone because of the higher stiffness or rigidity in the implant versus in bone. The resulting “stress shielding” of the bone by the implant eventually results in resorption of bone at the bone-implant interface and ultimately necessitates replacement of the bone implant. To overcome these problems, an implantable biomimetic prosthetic bone having a porous surface, a fiber-reinforced composite structure, and a polymer-based core is disclosed. The prosthetic bone is a good match for structure, stiffness, viscoelastic properties, specific weight and overall structure as real bone or host tissues adjacent to the prosthetic bone. The prosthetic bone may be formed as a total hip prosthesis.

Owner:NAT RES COUNCIL OF CANADA

Laser-produced porous structure

The present invention disclosed a method of producing a three-dimensional porous tissue in-growth structure. The method includes the steps of depositing a first layer of metal powder and scanning the first layer of metal powder with a laser beam to form a portion of a plurality of predetermined unit cells. Depositing at least one additional layer of metal powder onto a previous layer and repeating the step of scanning a laser beam for at least one of the additional layers in order to continuing forming the predetermined unit cells. The method further includes continuing the depositing and scanning steps to form a medical implant.

Owner:UNIV OF LIVERPOOL +1

Corrosion resistant multilayer member

ActiveUS20070111030A1Improve corrosion resistanceRestrains particle contaminationMolten spray coatingElectric discharge tubesPorosityHalogen

A corrosion resistant member to be exposed to a halogen-containing gas atmosphere or a halogen-containing gas plasma atmosphere, comprising a substrate and a plurality of layers deposited thereon including a layer of rare earth fluoride providing the outermost surface and a layer of rare earth oxide having a porosity of less than 5% underlying the rare earth fluoride layer.

Owner:SHIN ETSU CHEM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com