Patents

Literature

208 results about "YTTERBIUM OXIDE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ytterbium(III) oxide is the chemical compound with the formula Yb2O3. It is one of the more commonly encountered compounds of ytterbium.

Yttria-based material coated chemical vapor deposition chamber heater

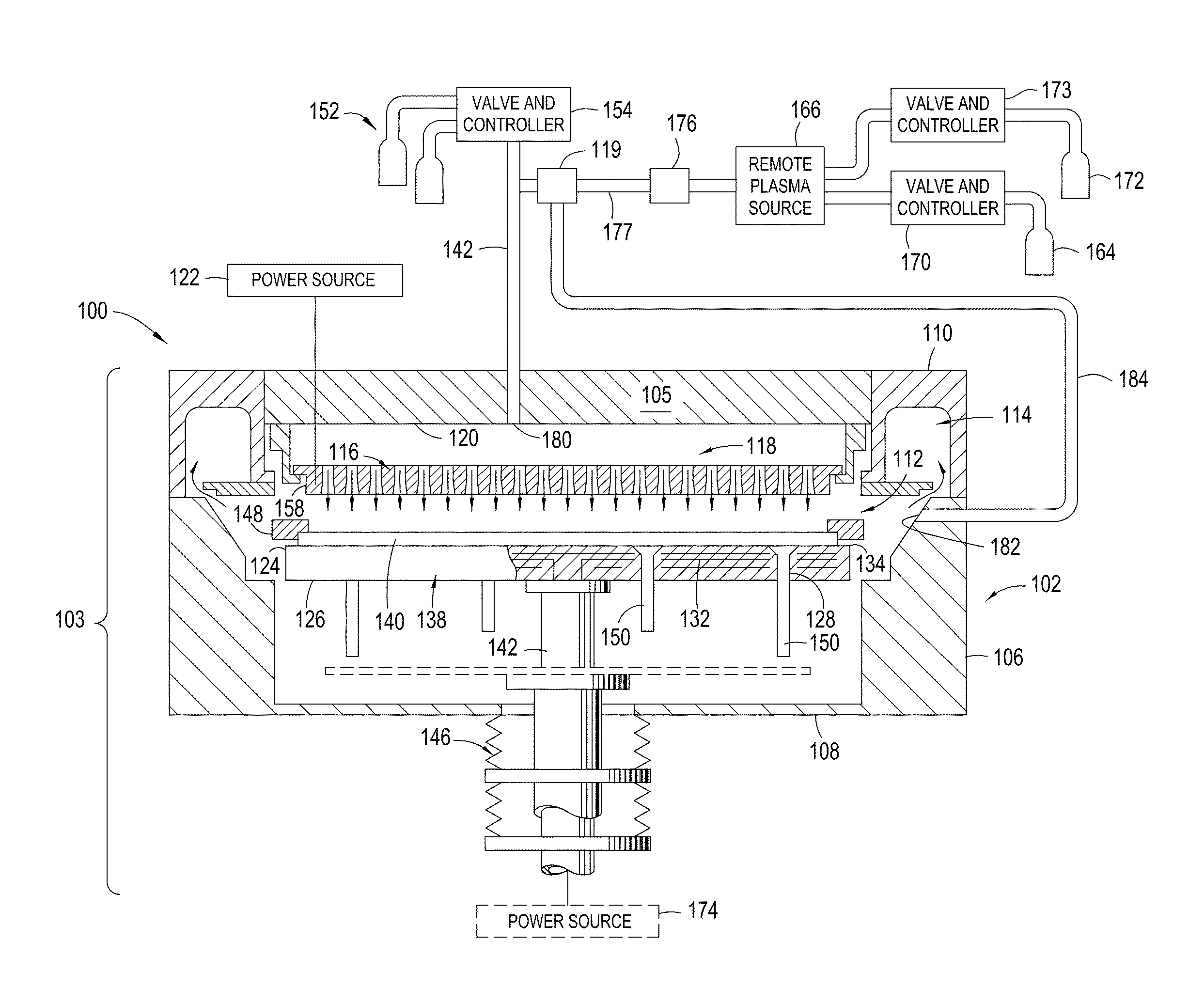

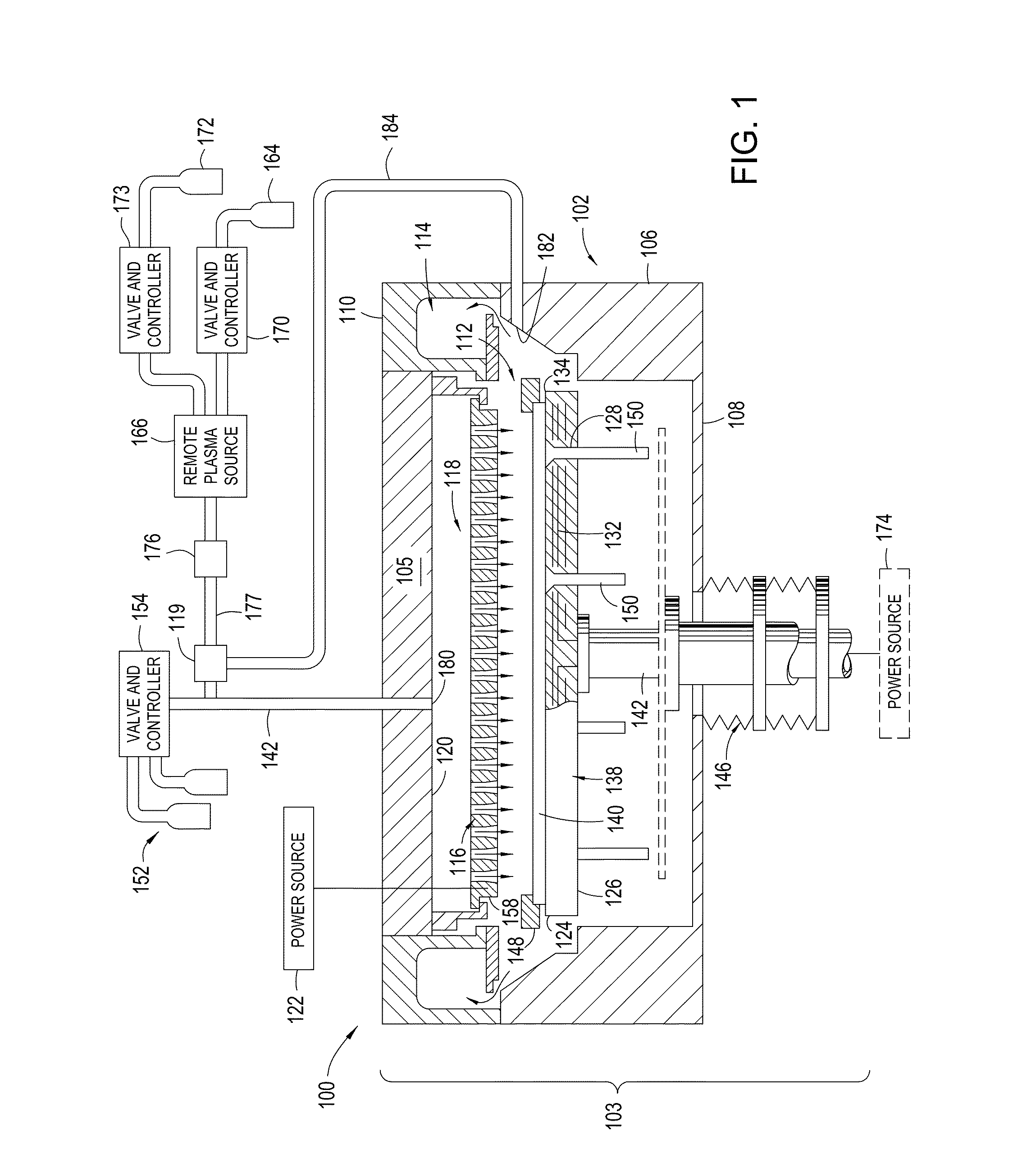

ActiveUS20140263272A1Improve wear resistanceImprove flexural strengthLiquid surface applicatorsMolten spray coatingYTTERBIUM OXIDEFlexural strength

Embodiments of the present invention generally relate to heated substrate supports having a protective coating thereon. The protective coating is formed from yttrium oxide at a molar concentration ranging from about 50 mole percent to about 75 mole percent; zirconium oxide at a molar concentration ranging from about 10 mole percent to about 30 mole percent; and at least one other component, selected from the group consisting of aluminum oxide, hafnium oxide, scandium oxide, neodymium oxide, niobium oxide, samarium oxide, ytterbium oxide, erbium oxide, cerium oxide, and combinations thereof, at a molar concentration ranging from about 10 mole percent to about 30 mole percent. The alloying of yttrium oxide with a compatible oxide improves wear resistance, flexural strength, and fracture toughness of the protective coating, relative to pure yttrium oxide.

Owner:APPLIED MATERIALS INC

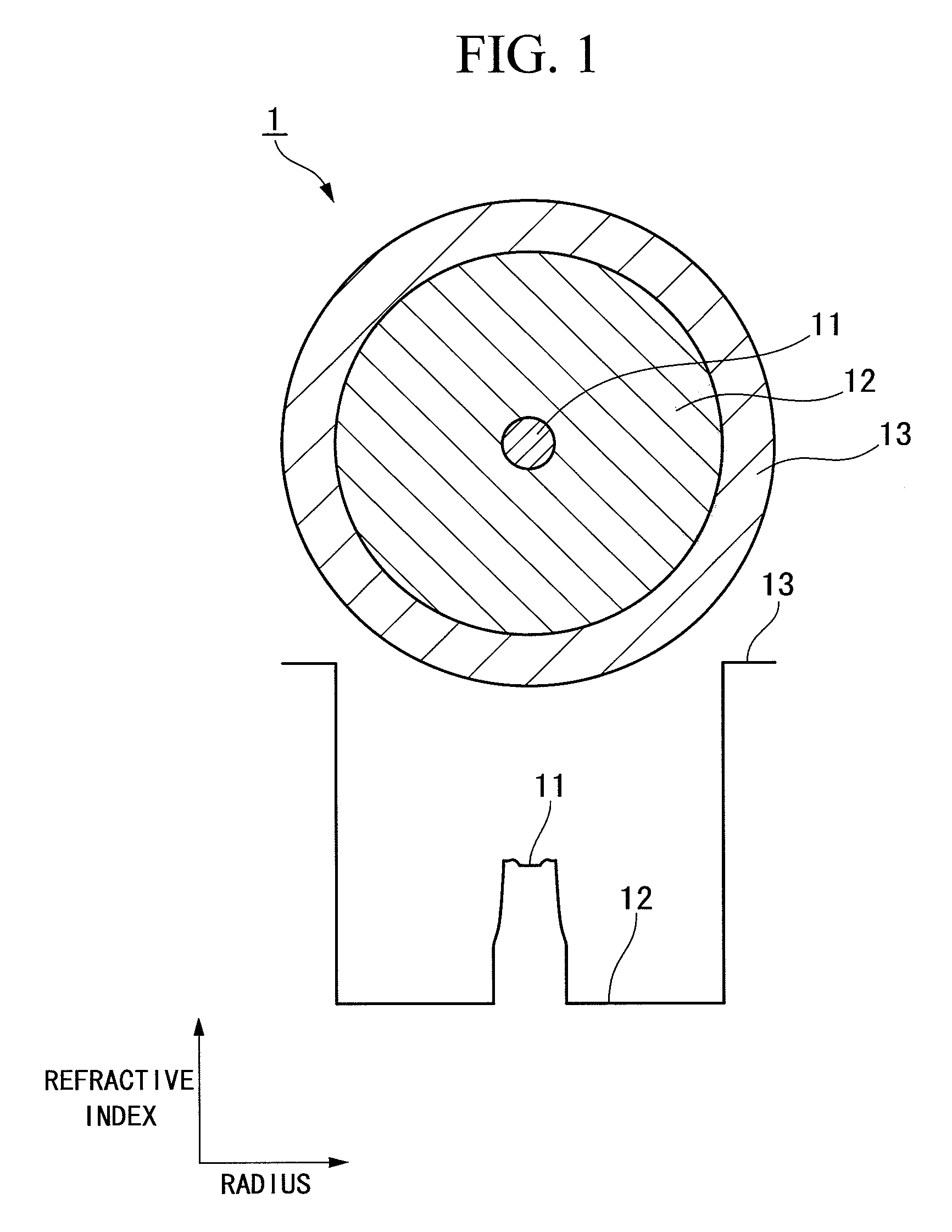

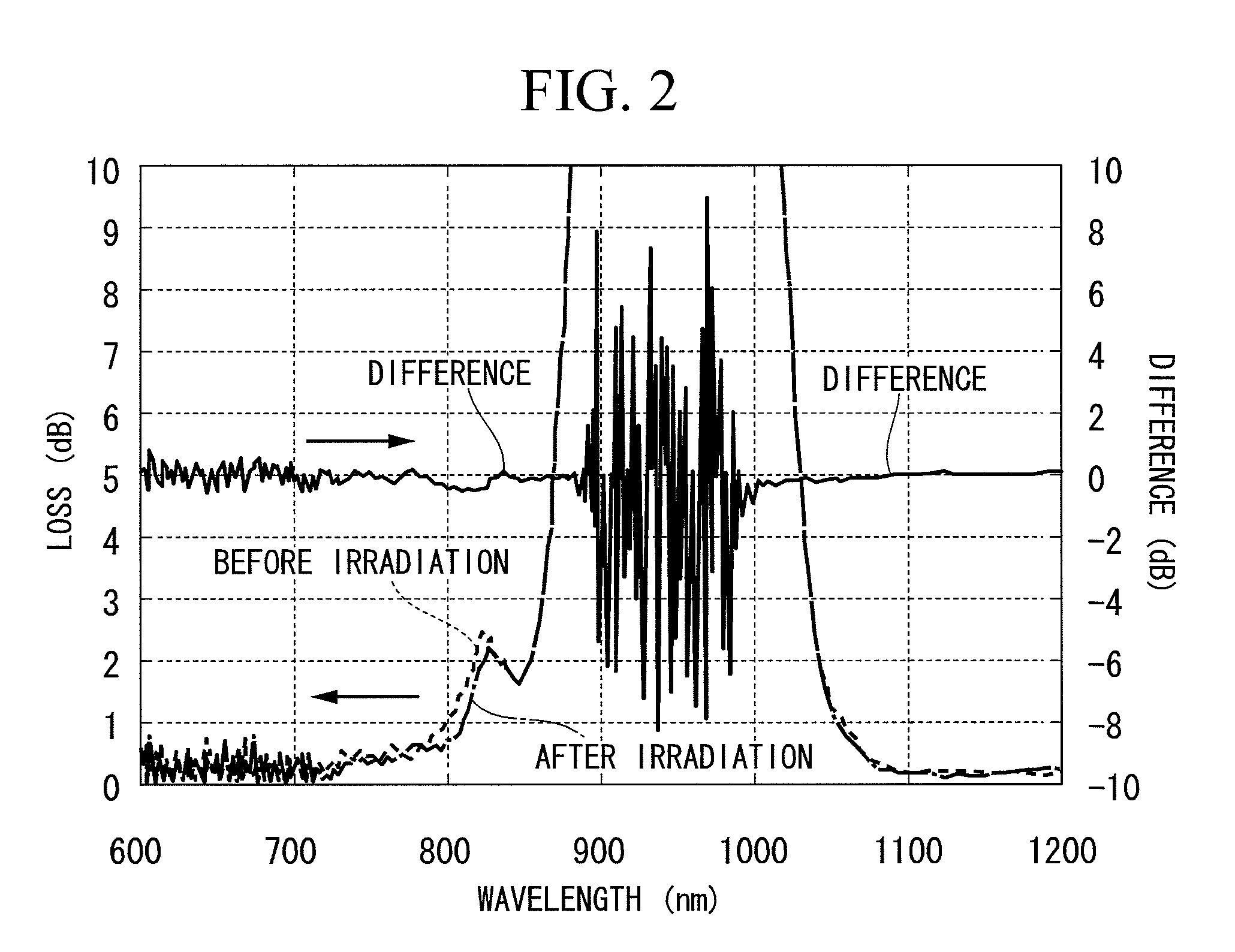

Ytterbium-doped optical fiber, fiber laser, and fiber amplifier

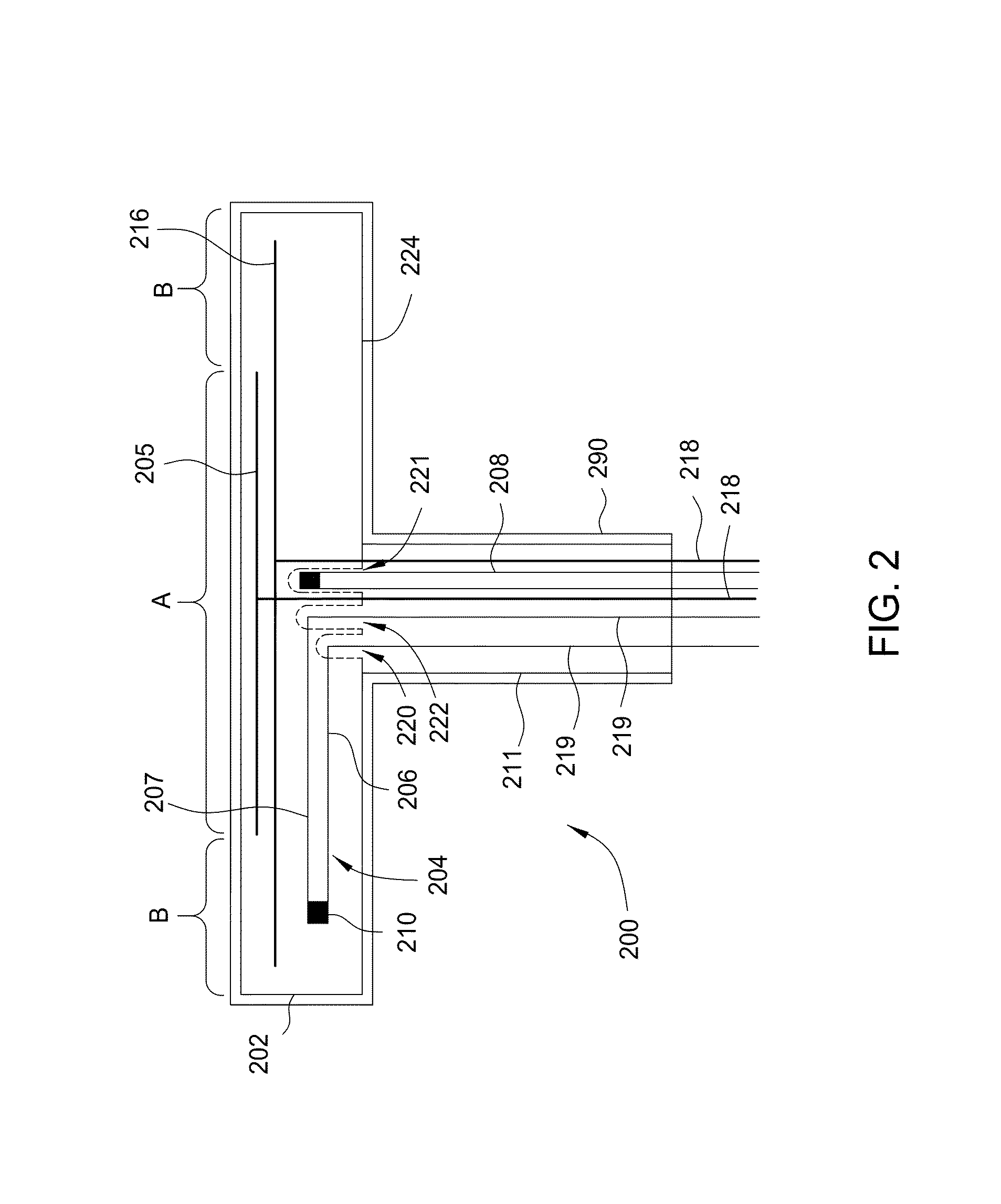

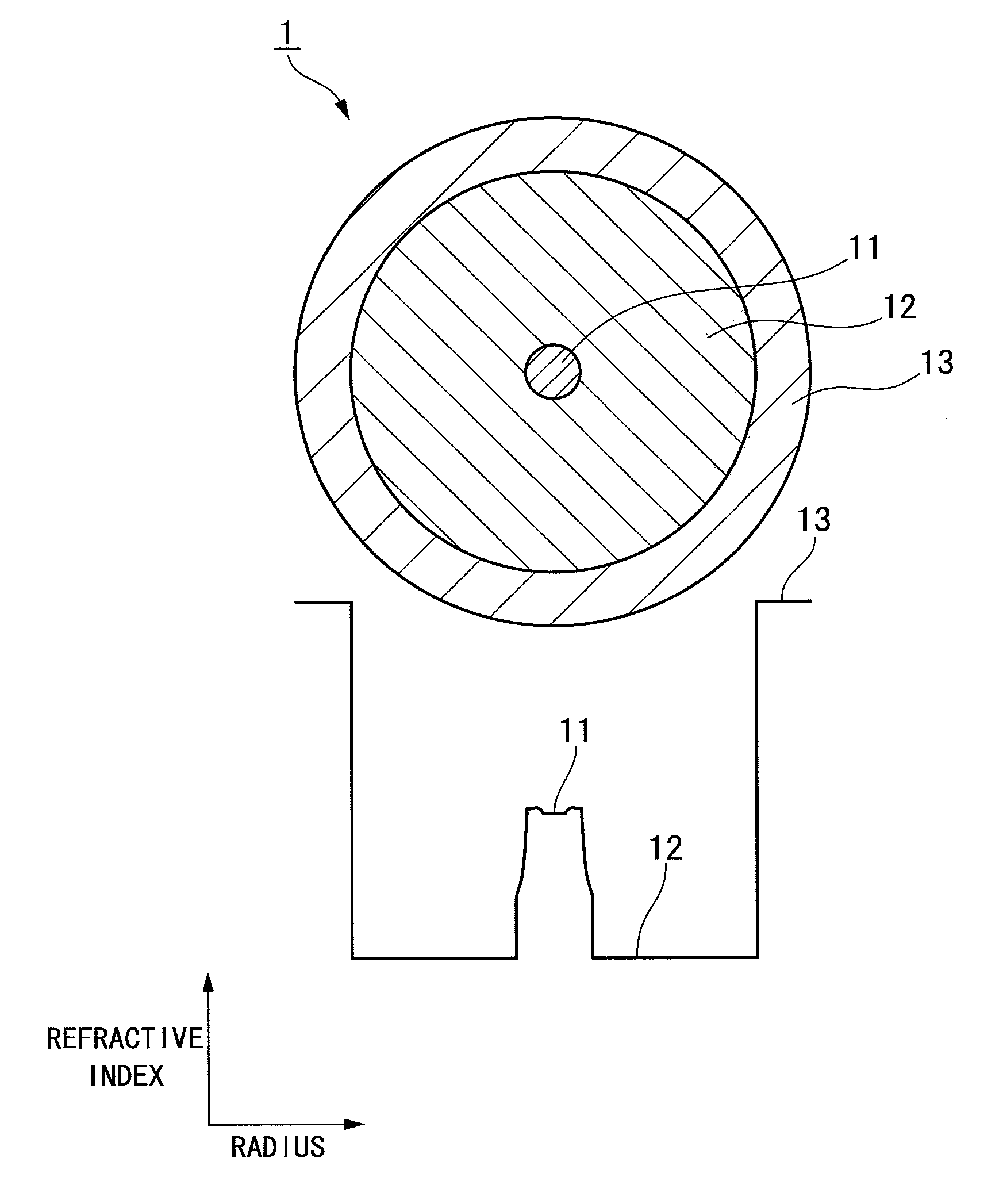

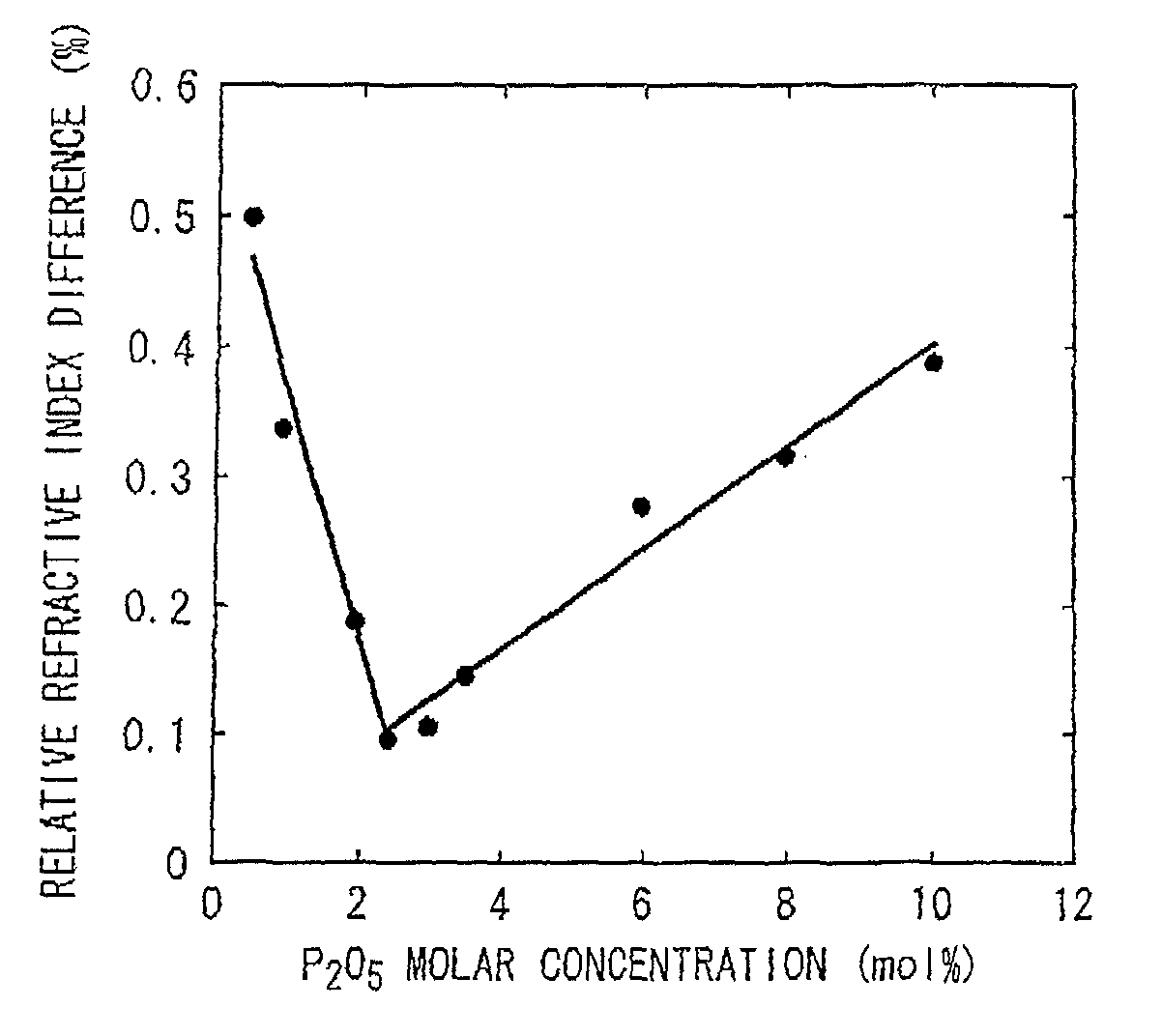

ActiveUS8363313B2Avoid small quantitiesSuperior optical amplificationLaser using scattering effectsOptical fibre with polarisationYTTERBIUM OXIDEDiphosphorus

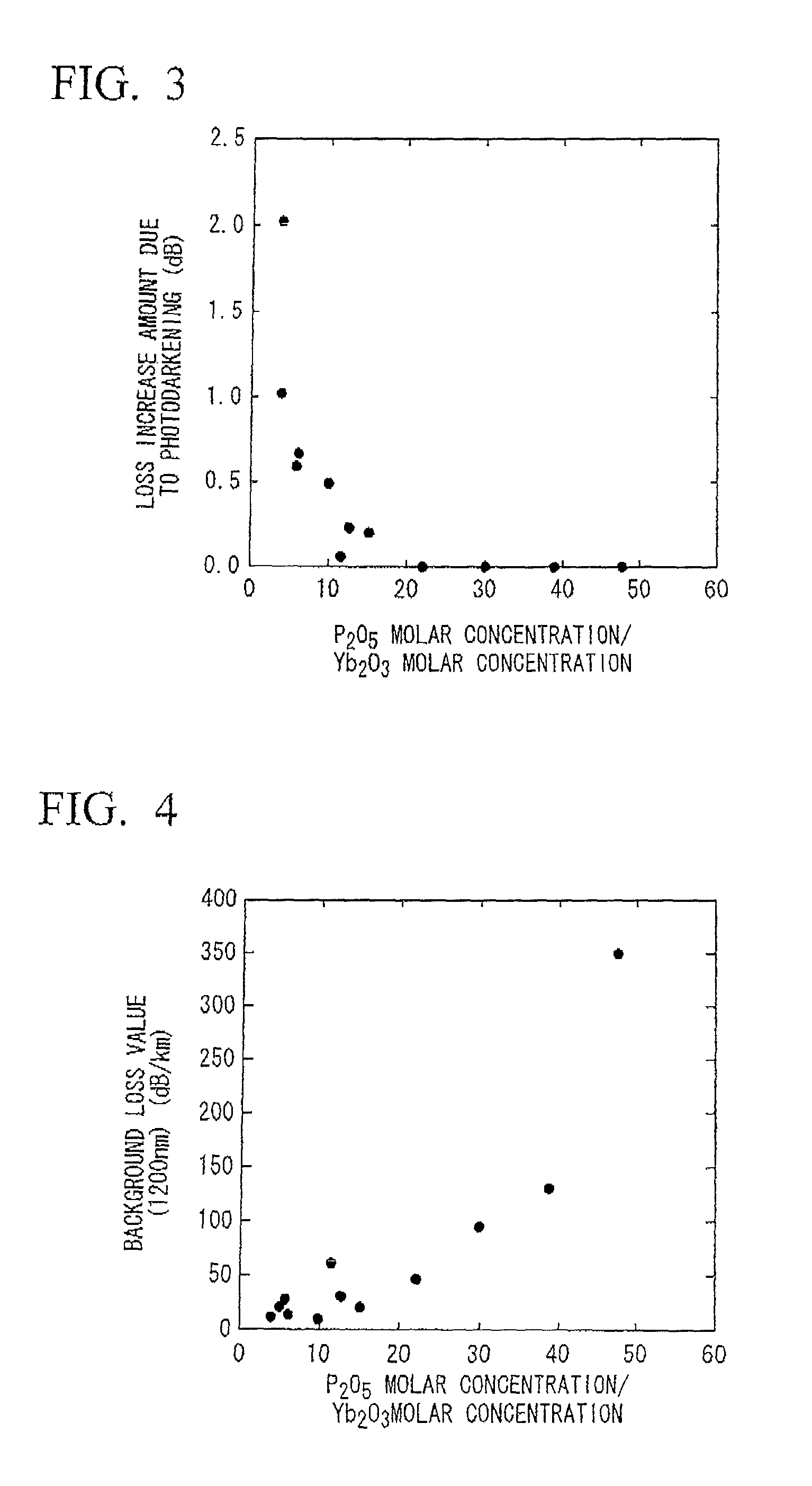

An ytterbium-doped optical fiber of the present invention includes: a core which contains ytterbium, aluminum, and phosphorus and does not contain germanium; and a cladding which surrounds this core. The ytterbium concentration in the core in terms of ytterbium oxide is 0.09 to 0.68 mole percent. The molar ratio between the phosphorus concentration in the core in terms of diphosphorus pentoxide and the above ytterbium concentration in terms of ytterbium oxide is 3 to 30. The molar ratio between the aluminum concentration in the core in terms of aluminum oxide and the above ytterbium concentration in terms of ytterbium oxide is 3 to 32. The molar ratio between the above aluminum concentration in terms of aluminum oxide and the above phosphorus concentration in terms of diphosphorus pentoxide is 1 to 2.5.

Owner:FUJIKURA LTD

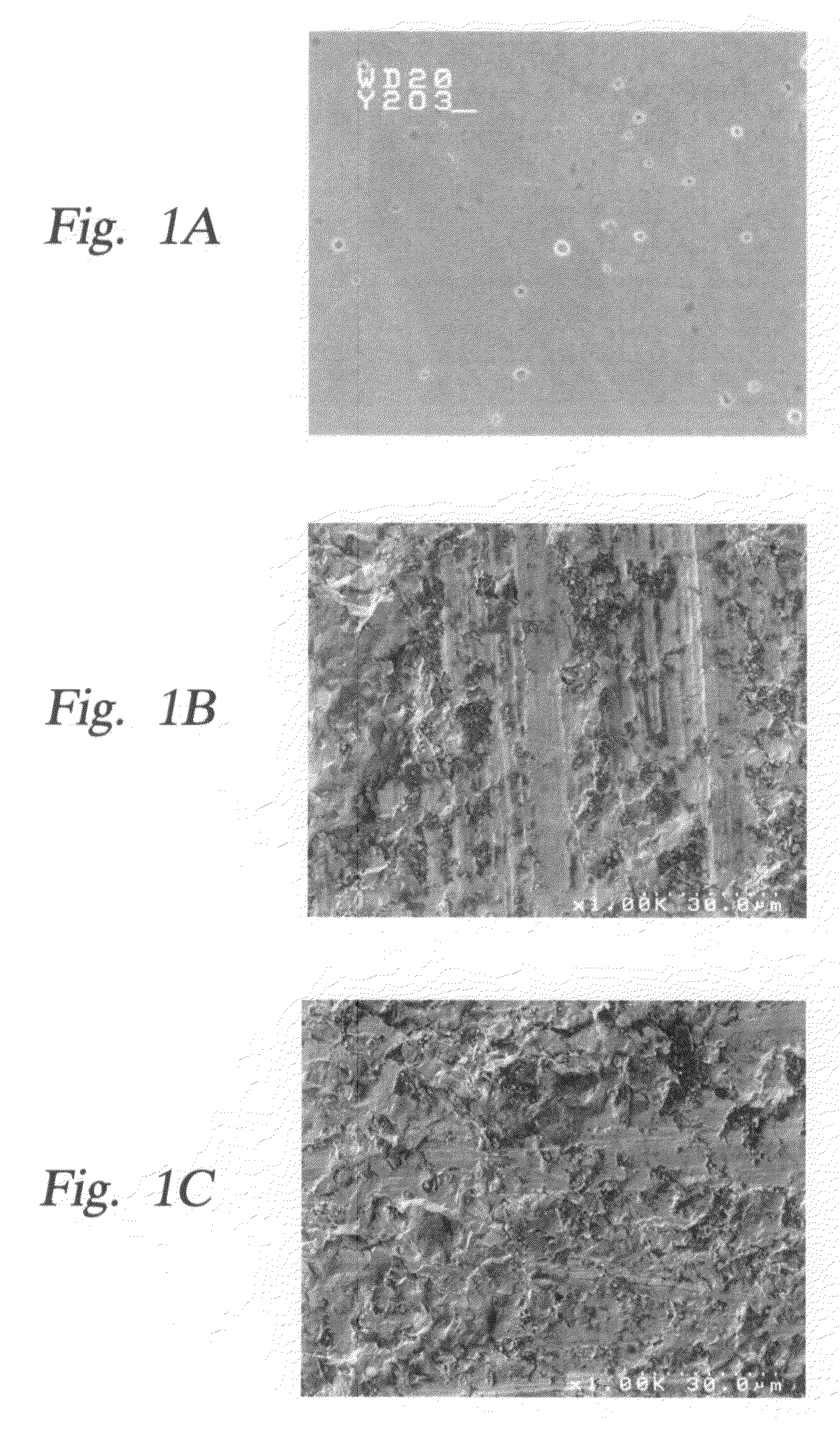

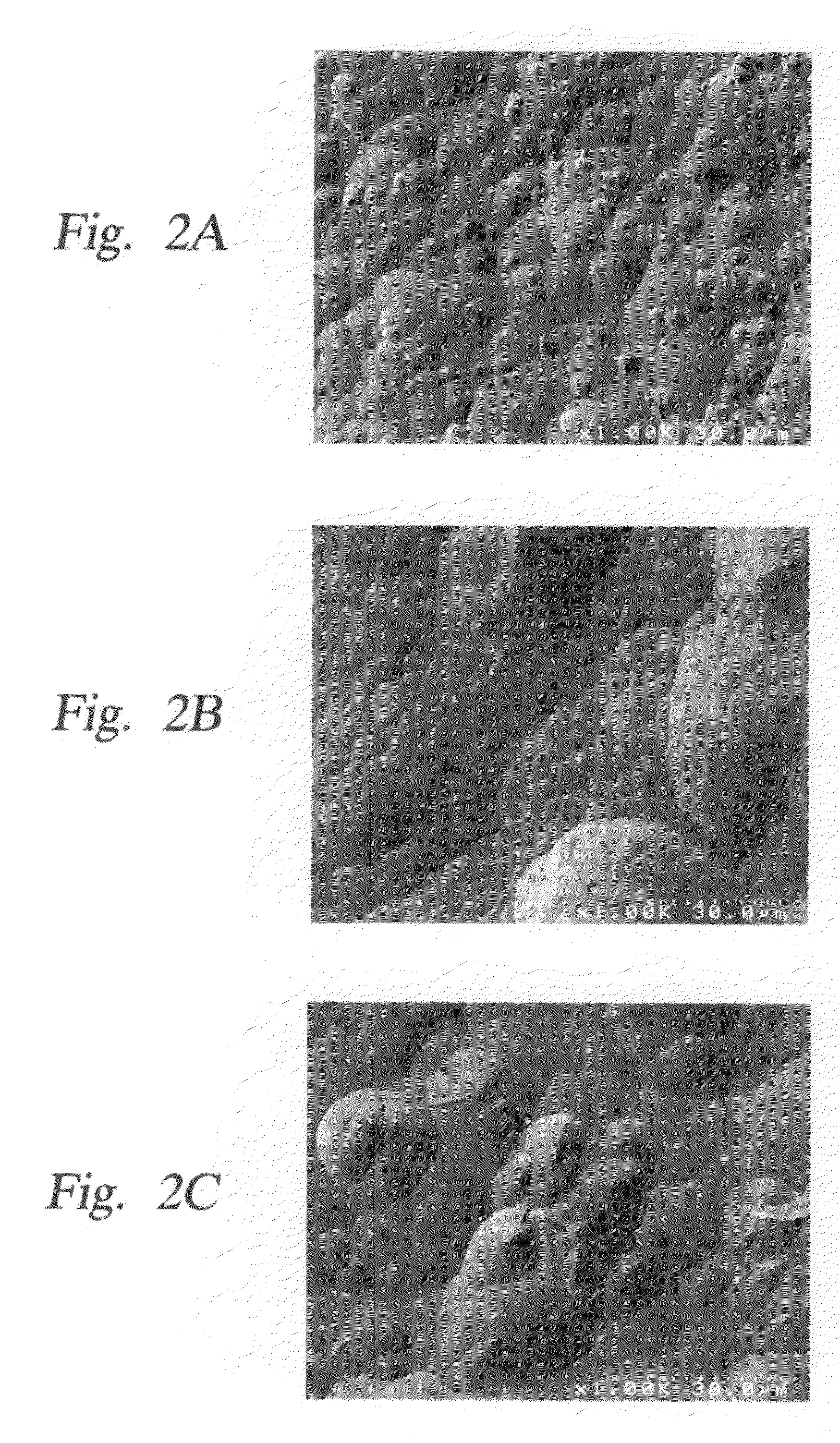

Method and apparatus which reduce the erosion rate of surfaces exposed to halogen-containing plasmas

ActiveUS20080264565A1Improve plasma resistanceImprove corrosion resistanceElectric discharge tubesSemiconductor/solid-state device manufacturingYTTERBIUM OXIDEErosion rate

A ceramic article which is resistant to erosion by halogen-containing plasmas used in semiconductor processing. The ceramic article includes ceramic which is multi-phased, typically including two phase to three phases. The ceramic is formed from yttrium oxide at a molar concentration ranging from about 50 mole % to about 75 mole %; zirconium oxide at a molar concentration ranging from about 10 mole % to about 30 mole %; and at least one other component, selected from the group consisting of aluminum oxide, hafnium oxide, scandium oxide, neodymium oxide, niobium oxide, samarium oxide, ytterbium oxide, erbium oxide, cerium oxide, and combinations thereof, at a molar concentration ranging from about 10 mole % to about 30 mole %.

Owner:APPLIED MATERIALS INC

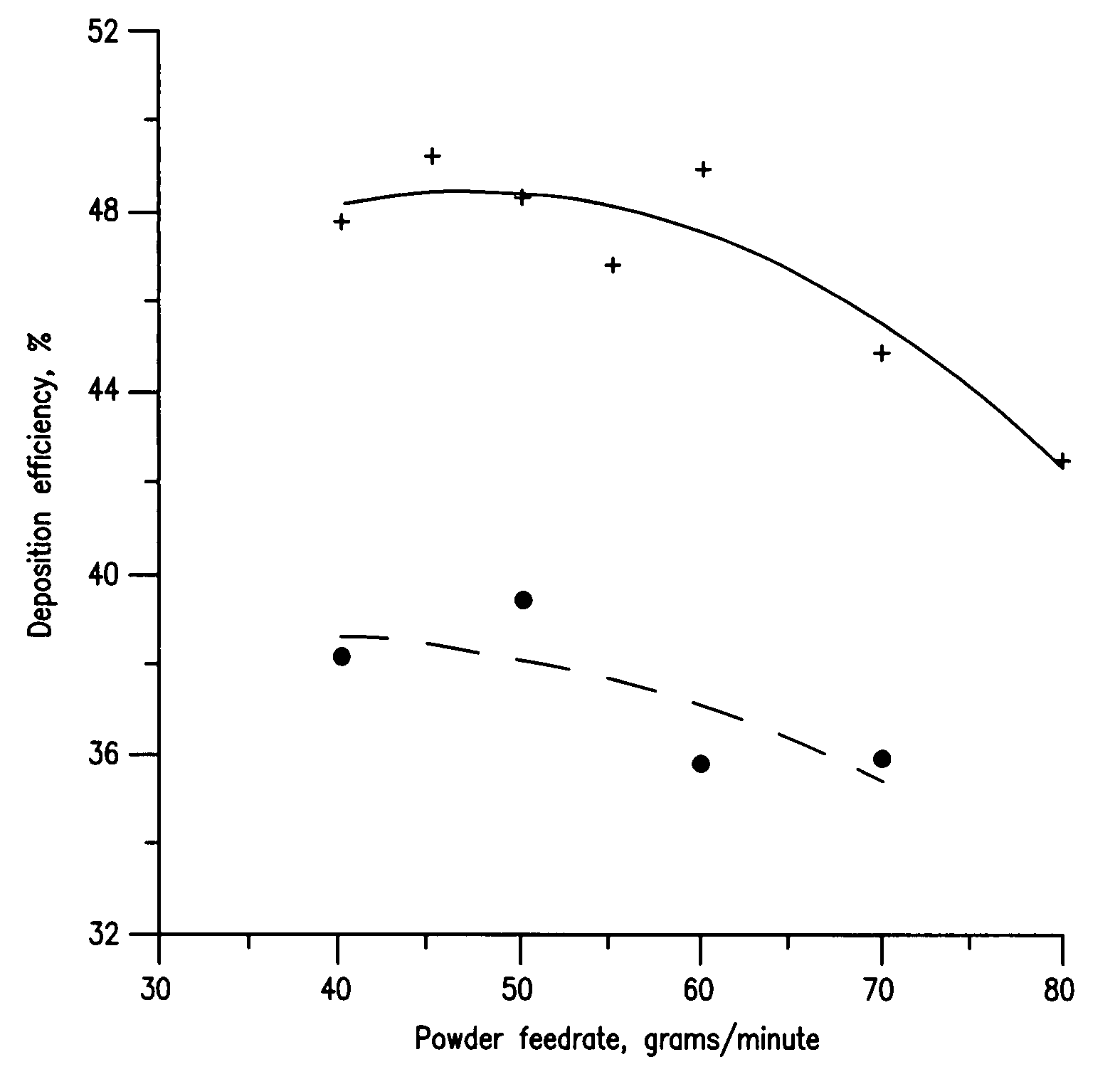

Blade tip coatings

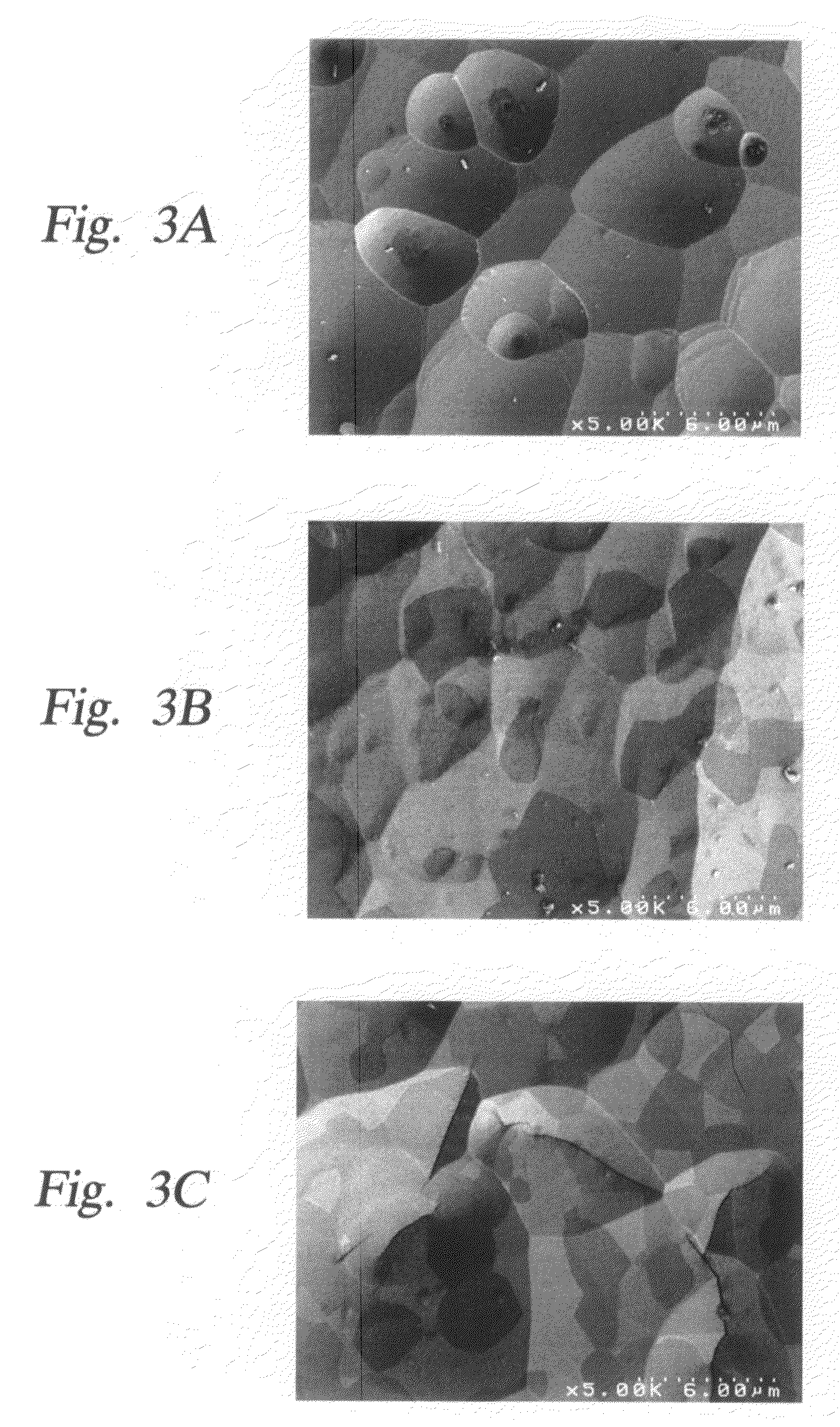

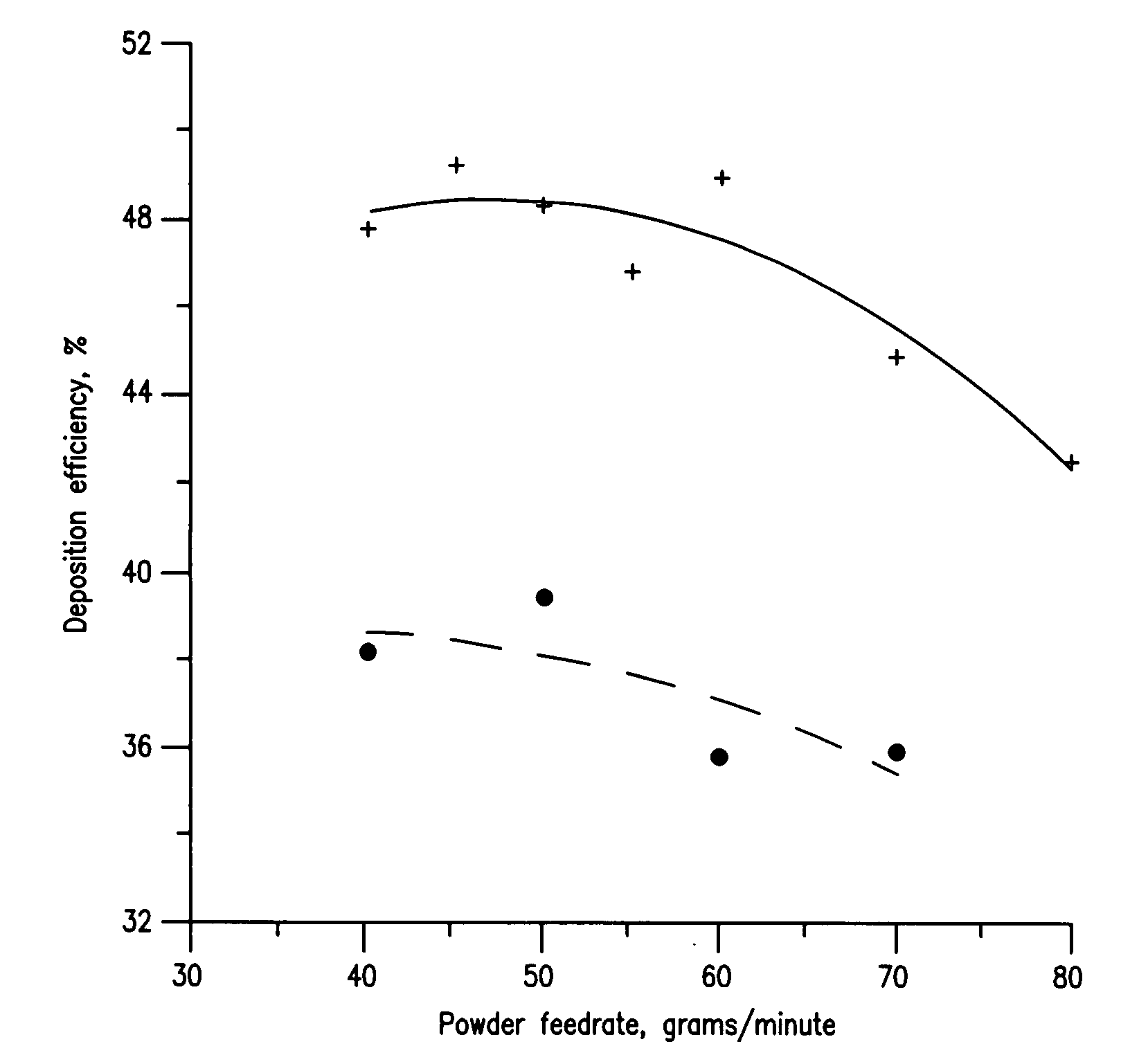

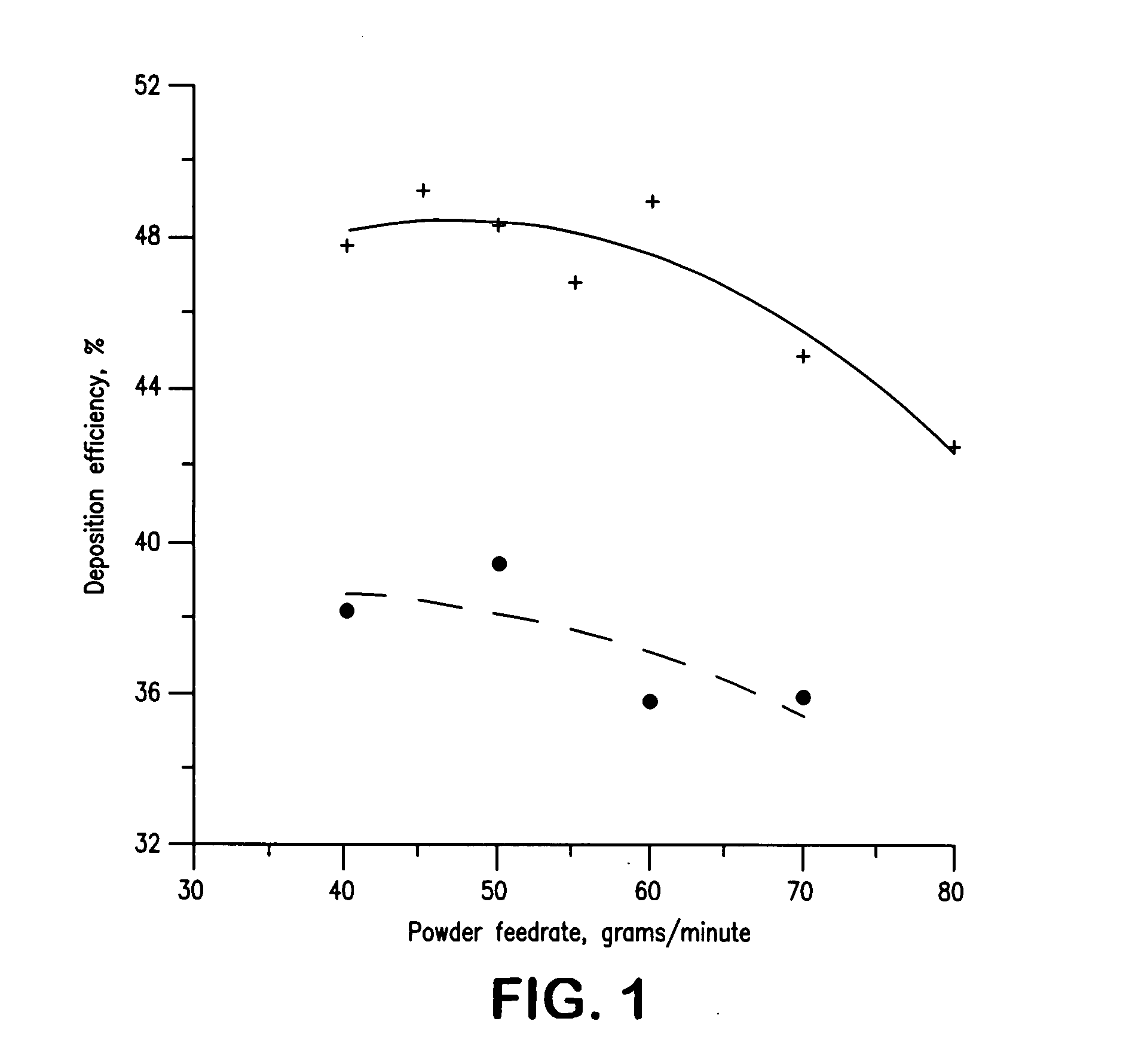

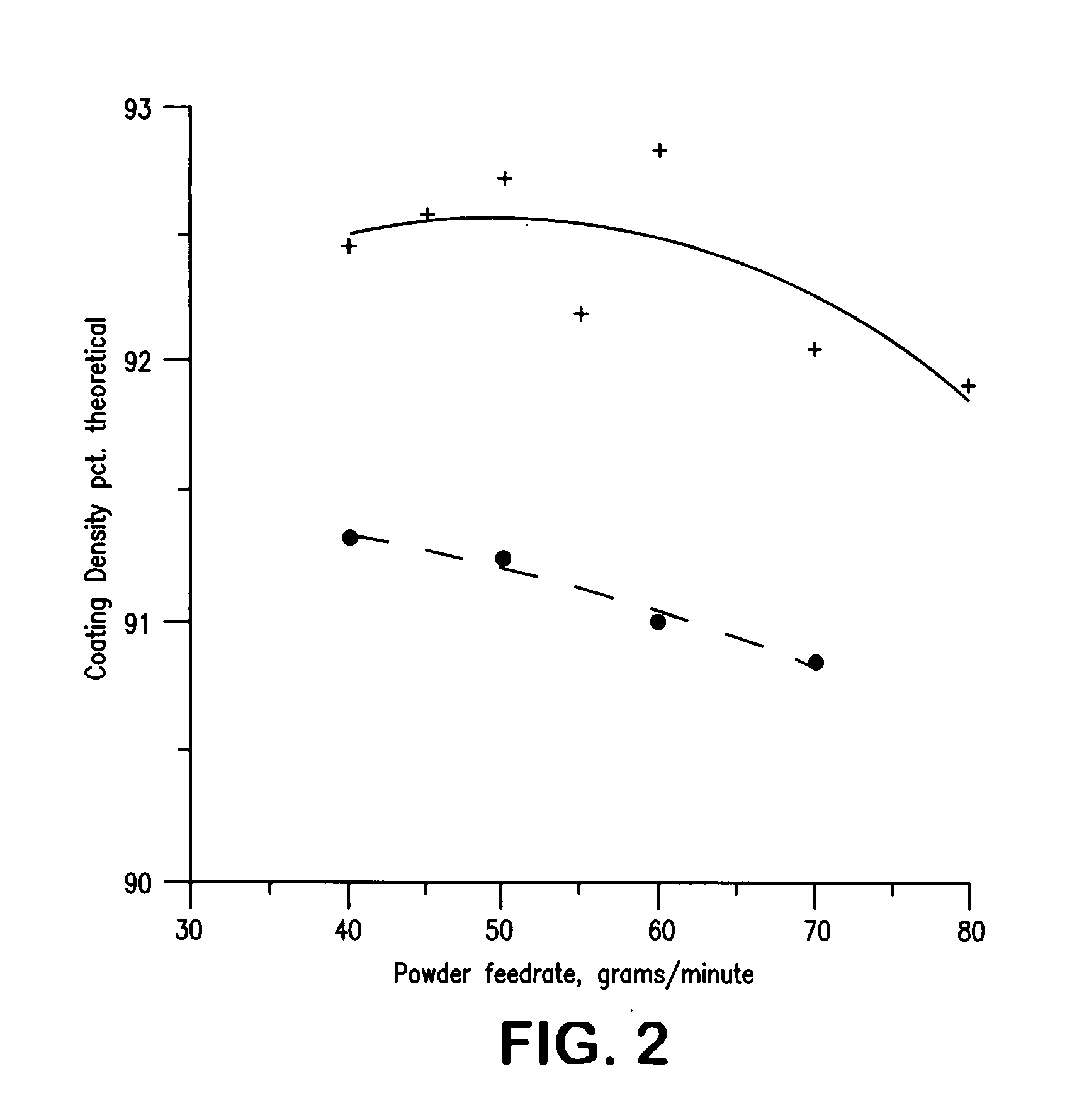

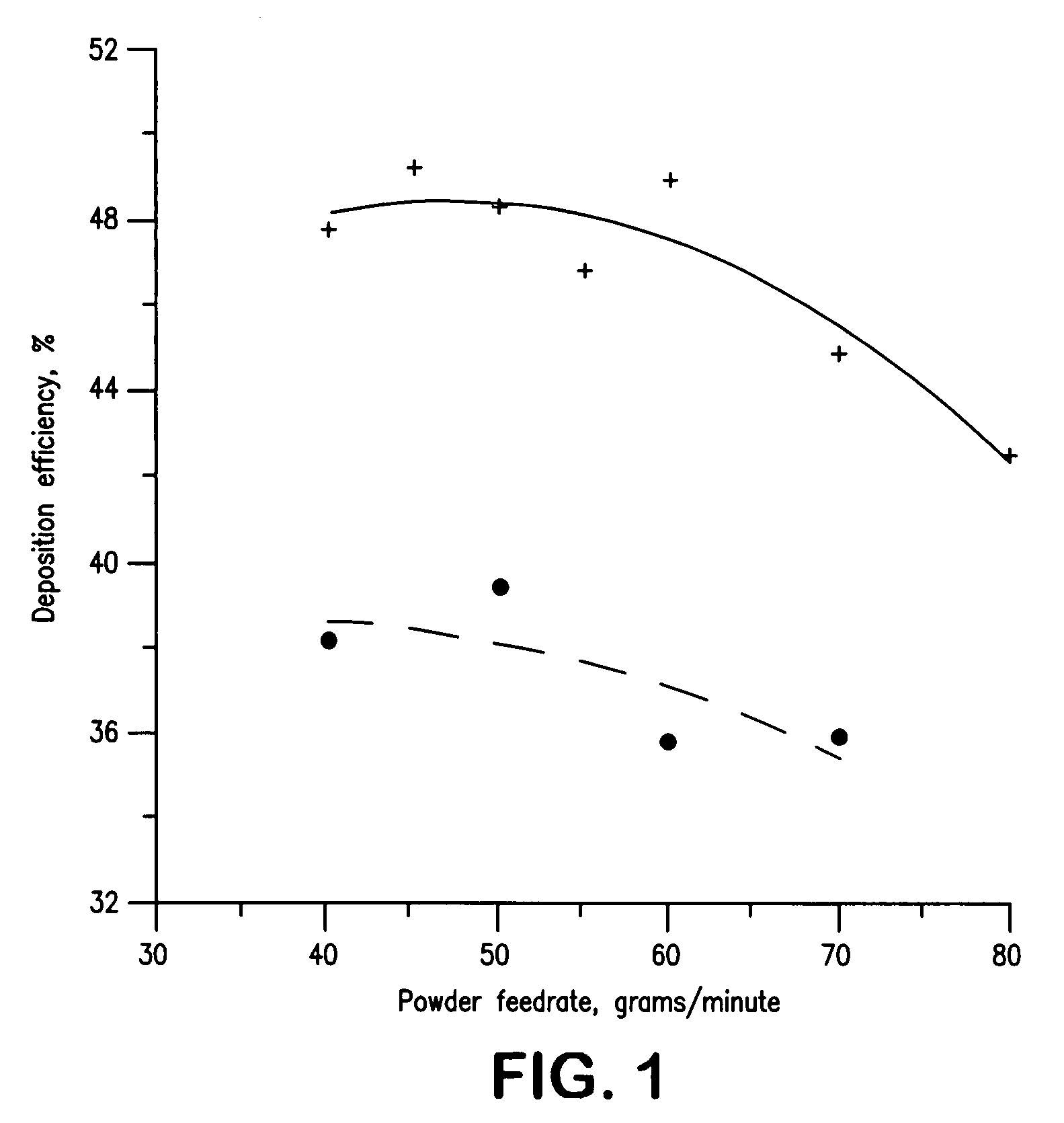

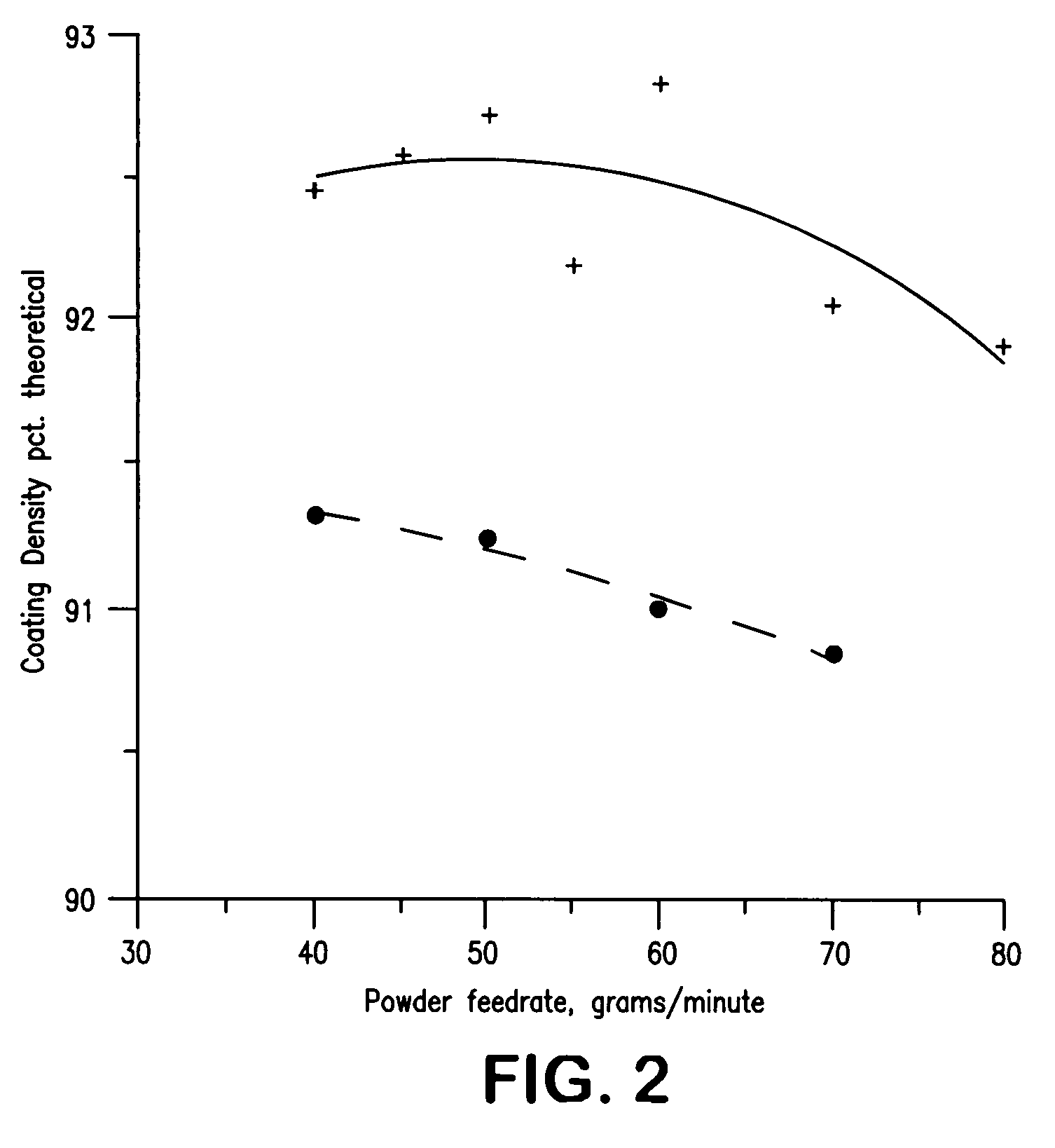

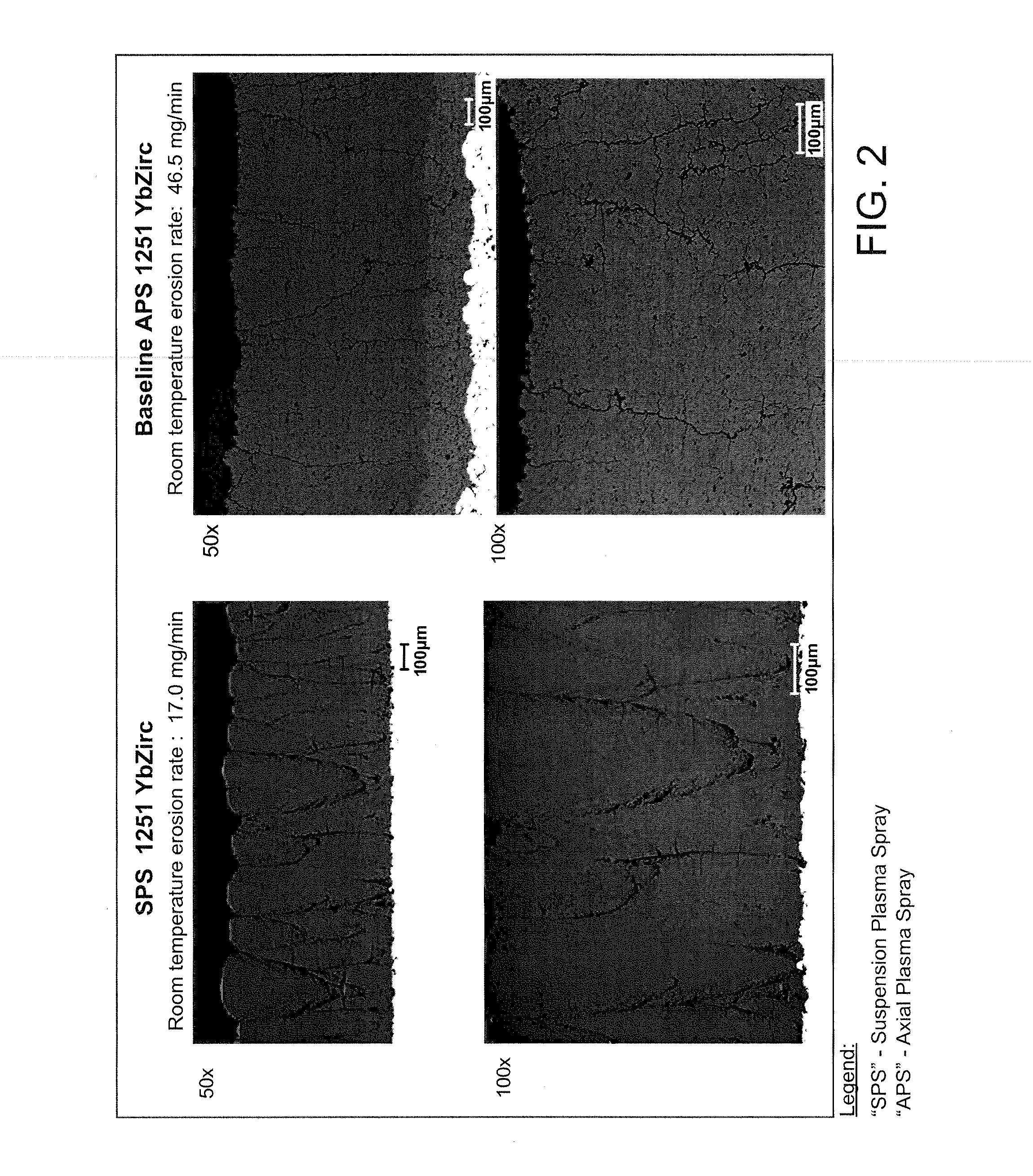

This invention relates to blades for a gas turbine engine, said blades having an inner end adapted for mounting on a hub and a blade tip located opposite the inner end, and wherein at least a portion of the blade tip is coated with a thermally sprayed coating of a high purity yttria or ytterbia stabilized zirconia powder, said thermally sprayed coating having a density greater than 88% of the theoretical density with a plurality of vertical macrocracks substantially homogeneously dispersed throughout the coating in which a cross-sectional area of the coating normal to the blade tip exposes a plurality of vertical macrocracks extending at least half the coating thickness in length up to the full thickness of the coating and having from about 5 to about 200 vertical macrocracks per linear inch measured in a line parallel to the surface of the blade tip and in a plane perpendicular to the surface of the blade tip, and said high purity yttria or ytterbia stabilized zirconia powder comprising from about 0 to about 0.15 weight percent impurity oxides, from about 0 to about 2 weight percent hafnium oxide (hafnia), from about 6 to about 25 weight percent yttrium oxide (yttria) or from about 10 to about 36 weight percent ytterbium oxide (ytterbia), and the balance zirconium oxide (zirconia).

Owner:PRAXAIR ST TECH INC

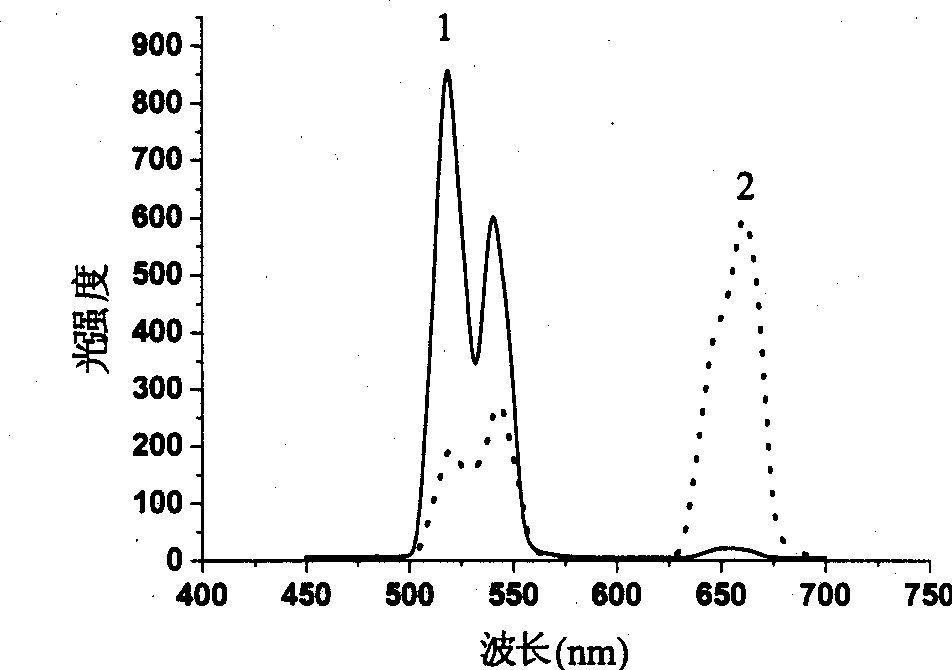

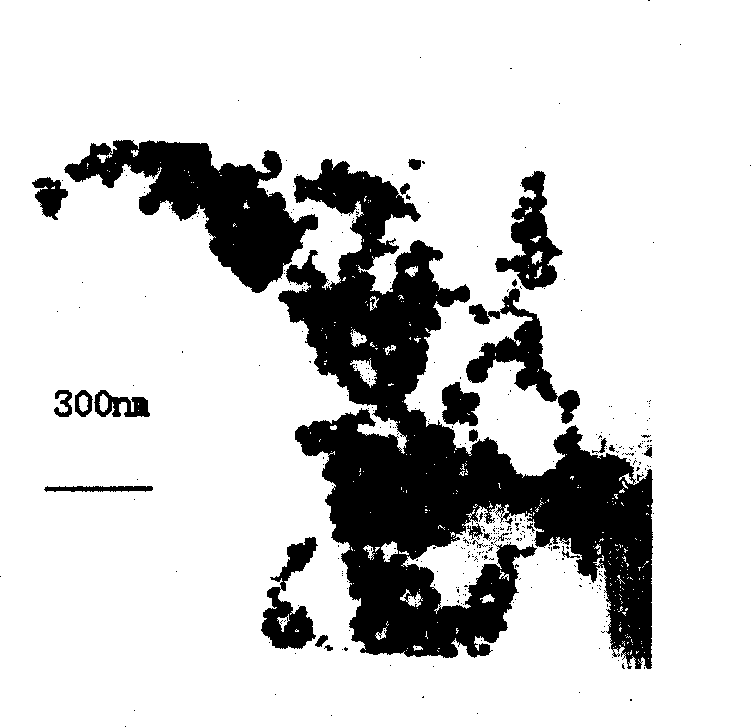

Up converting fluorescent material with nanometer level molybdate substrate and its prepn

The present invention belongs to the field of nano fluorescent material. Lanthanum oxide (or yttrium or gadolinium oxide), ytterbium oxide and erbiom oxide (or thulium or holmium oxide) are first dissolved in acid to prepare solution; complexone and sodium or potassium molybdenate are added into the solution to produce precipitate, which is centrifugally separated and water washed to prepare aqueous gel, aqueous gel or further prepared alcoholic gel is finally cinerated in a high temperature furnace or heated in a hydrothermal reactor to obtain the nano level up converting fluorescent material. The said material has lanthanum molybdenate as matrix and ytterbium molybdenate and erbium molybdenate as dopant. The material thus prepared has small and homogeneous size, average size 50-60 nm and high light glowing strength and may meet the requirement as biological molecular fluorescent mark material.

Owner:CAPITALBIO CORP +1

Blade tip coating processes

InactiveUS20080026160A1Increase temperatureLiquid surface applicatorsMolten spray coatingYTTERBIUM OXIDEThermal spraying

This invention relates to processes for coating blades for a gas turbine engine, said blades having an inner end adapted for mounting on a hub and a blade tip located opposite the inner end, and wherein at least a portion of the blade tip is coated with a thermally sprayed coating of a high purity yttria or ytterbia stabilized zirconia powder, said thermally sprayed coating having a density greater than 88% of the theoretical density with a plurality of vertical macrocracks substantially homogeneously dispersed throughout the coating in which a cross-sectional area of the coating normal to the blade tip exposes a plurality of vertical macrocracks extending at least half the coating thickness in length up to the full thickness of the coating and having from about 5 to about 200 vertical macrocracks per linear inch measured in a line parallel to the surface of the blade tip and in a plane perpendicular to the surface of the blade tip, and said high purity yttria or ytterbia stabilized zirconia powder comprising from about 0 to about 0.15 weight percent impurity oxides, from about 0 to about 2 weight percent hafnium oxide (hafnia), from about 6 to about 25 weight percent yttrium oxide (yttria) or from about 10 to about 36 weight percent ytterbium oxide (ytterbia), and the balance zirconium oxide (zirconia).

Owner:PRAXAIR ST TECH INC

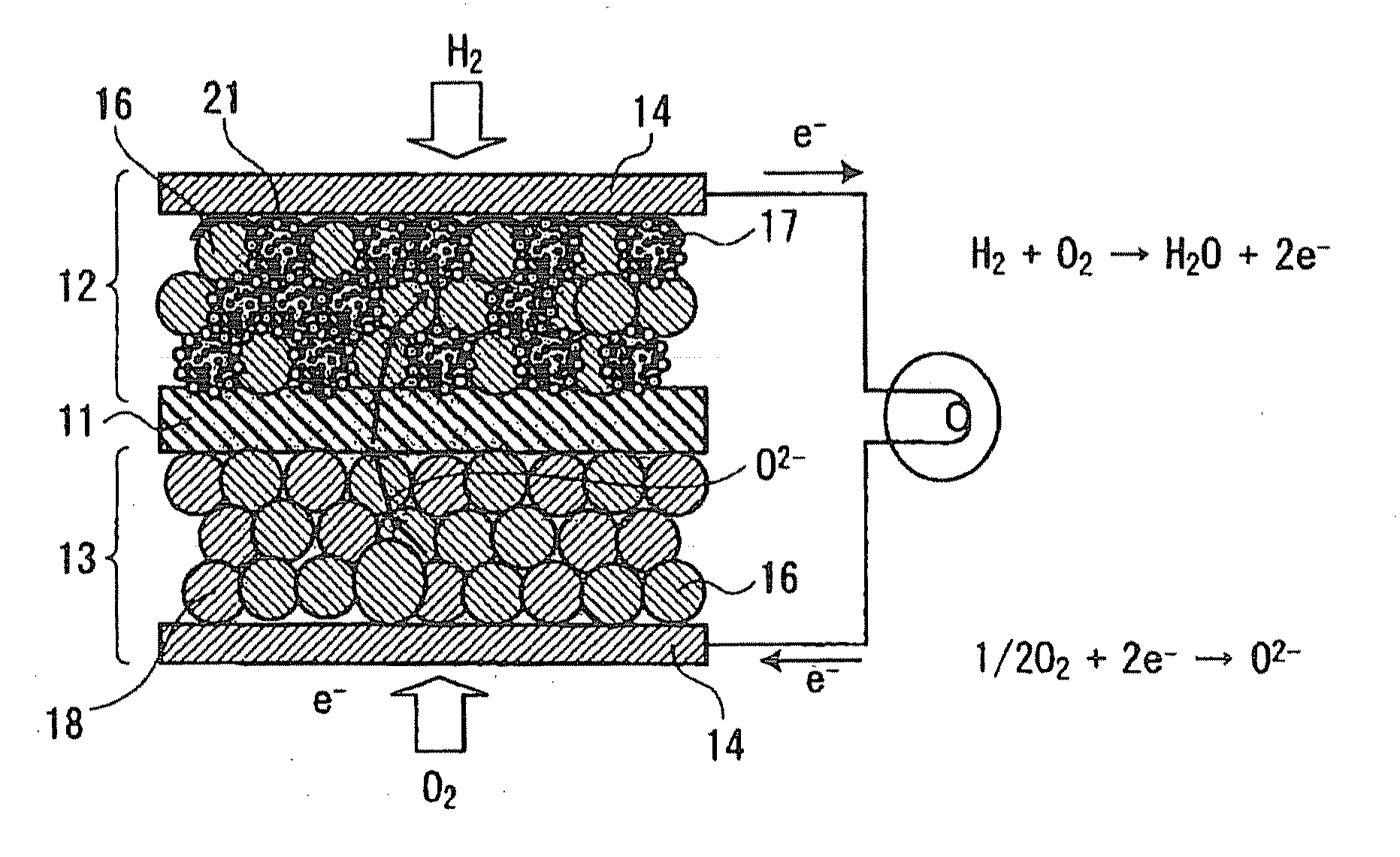

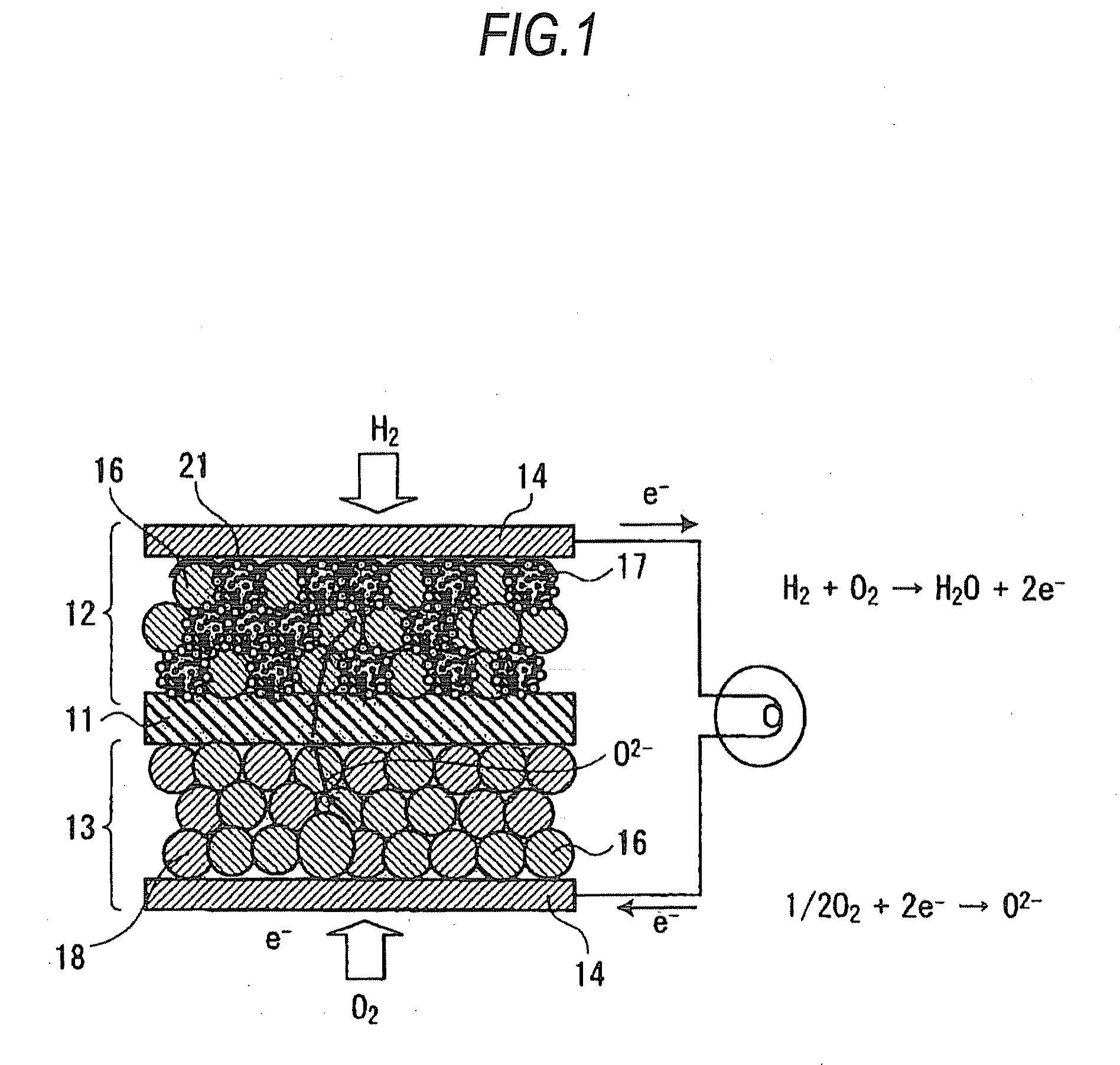

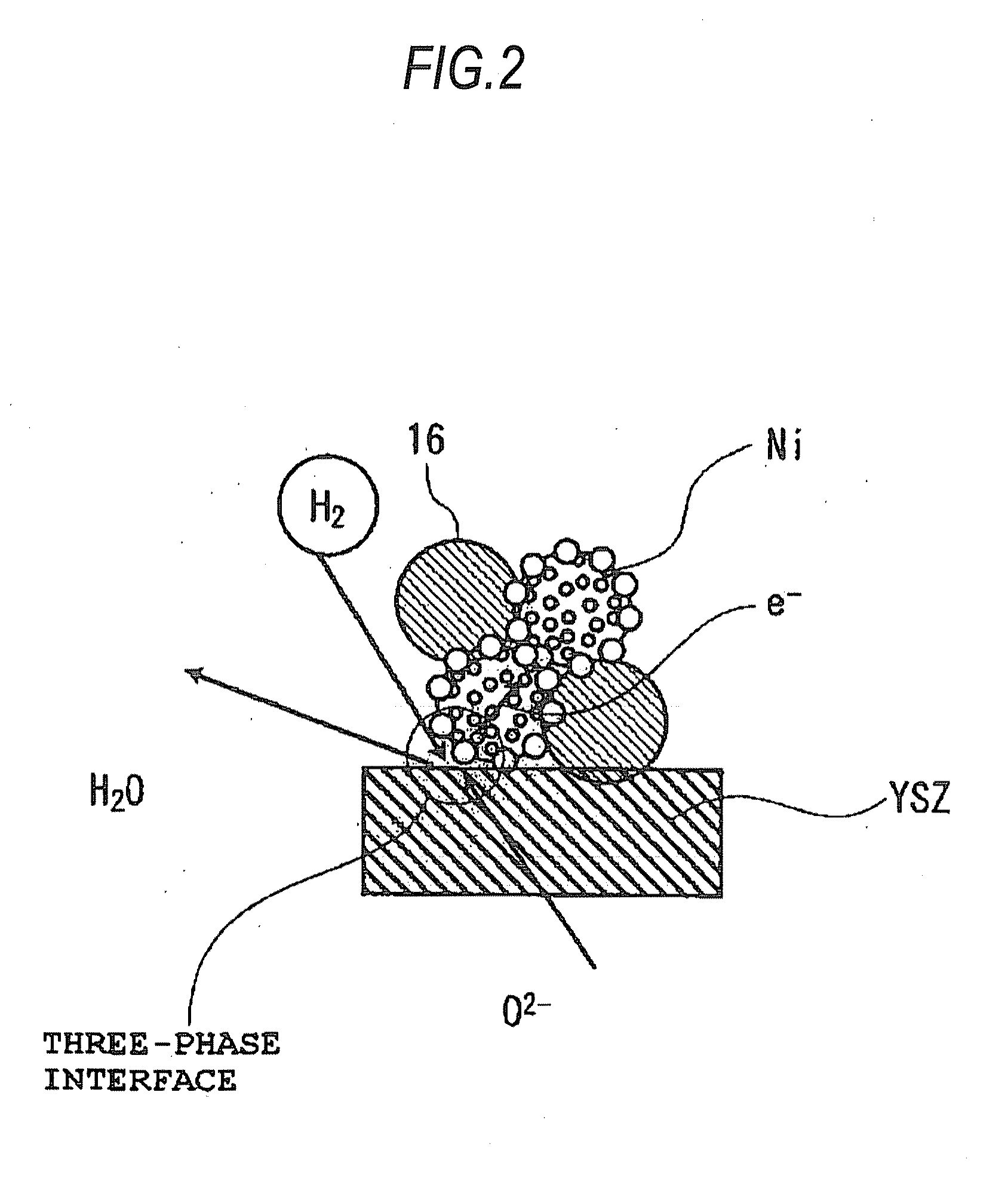

Fuel electrodes for solid oxide electrochemical cell, processes for producing the same, and solid oxide electrochemical cells

InactiveUS20090068533A1High catalytic activityImprove output performanceFuel cells groupingFinal product manufactureYTTERBIUM OXIDEYttrium

A fuel electrode for a solid oxide electrochemical cell includes: an electrode layer including a mixed phase constituted of zirconia stabilized with yttrium oxide, ytterbium oxide, or scandium oxide and of an oxide selected from the group including an aluminum-based oxide and a magnesium-based composite oxide, said oxide having, supported on a surface part thereof, particles of at least one member selected from nickel, cobalt, and nickel-cobalt alloys; a meshy wiring formed on a surface layer part of the electrode layer and made of a material having higher electronic conductivity than the electrode layer; and a current collector which overlies the electrode layer and is in contact with at least the wiring.

Owner:KK TOSHIBA

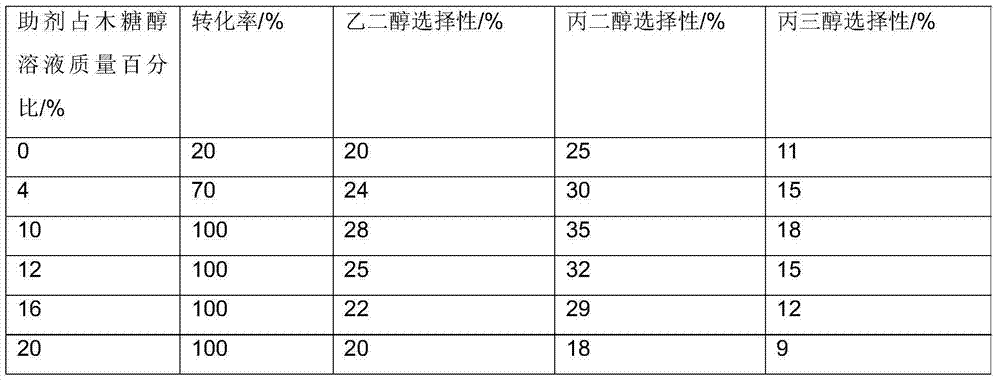

Method for preparation of low carbon alcohol by hydrogenolysis of sugar and sugar alcohol

InactiveCN104710277AEasy to achieve separationOrganic compound preparationPreparation by OH group eliminationGadolinium oxideGlycerol

The invention relates to a method for preparation of low carbon alcohol by hydrogenolysis of sugar and sugar alcohol. The method adopts sugar and sugar alcohol as the raw materials, takes one or more than two of iron, cobalt, nickel, copper, zinc, tin, platinum, ruthenium, palladium, iridium and other transition metals as the catalyst active component, and employs a rare earth oxide like promethium oxide, gadolinium oxide, terbium oxide, holmium oxide, erbium oxide, thulium oxide, cerium oxide, lanthanum oxide, praseodymium oxide, neodymium oxide, scandium oxide, yttrium oxide, dysprosium oxide, europium oxide, samarium oxide, ytterbium oxide, lutecium oxide and the like as the assistant. Under a temperature of 150-320DEG C and an H2 pressure of 1-20MPa, catalytic hydrocracking is carried out in a water solution to obtain ethylene glycol, propylene glycol, glycerol and other low carbon alcohols. The method provided by the invention has the advantages that: the rare earth oxide is added as the assistant to realize hydrocracking of sugar and sugar alcohol, rare earth oxides are insoluble in water and easy to separate, and at the end of reaction, the reaction system has no need for additional acid to neutralize.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Silicon nitride heating body and its pressureless lower temperature sintering producing method

InactiveCN1849017ABreak through space limitationsStrong acid and alkali resistanceHeating element materialsYTTERBIUM OXIDEFurnace temperature

A silicon nitride heat body is prepared from silicon nitride of 70-95%, Ytterbium oxide of 0.1-10%, aluminum nitride of 0-5%, boron nitride of 0-5 %, aluminum oxide of 0.1-10%, silicon oxide of 0.1-10%, cerium oxide of 0.1-10% and magnesium oxide of 0.1-10%. Its preparing method includes weight out raw materials in weight radio as said preparation and ball-grinding them for 2-48hr., drying and dry-pressing them to be biscuit, placing heat wire in biscuit for making it be green bodies being set in furnace for depasting, placing green bodies into graphite crucible and burying it in silicon nitride at furnace temperature of 1500-1800 deg.c for sintering of 0.5-4hr..

Owner:SHENZHEN JINKE SPECIAL MATERIALS CO LTD

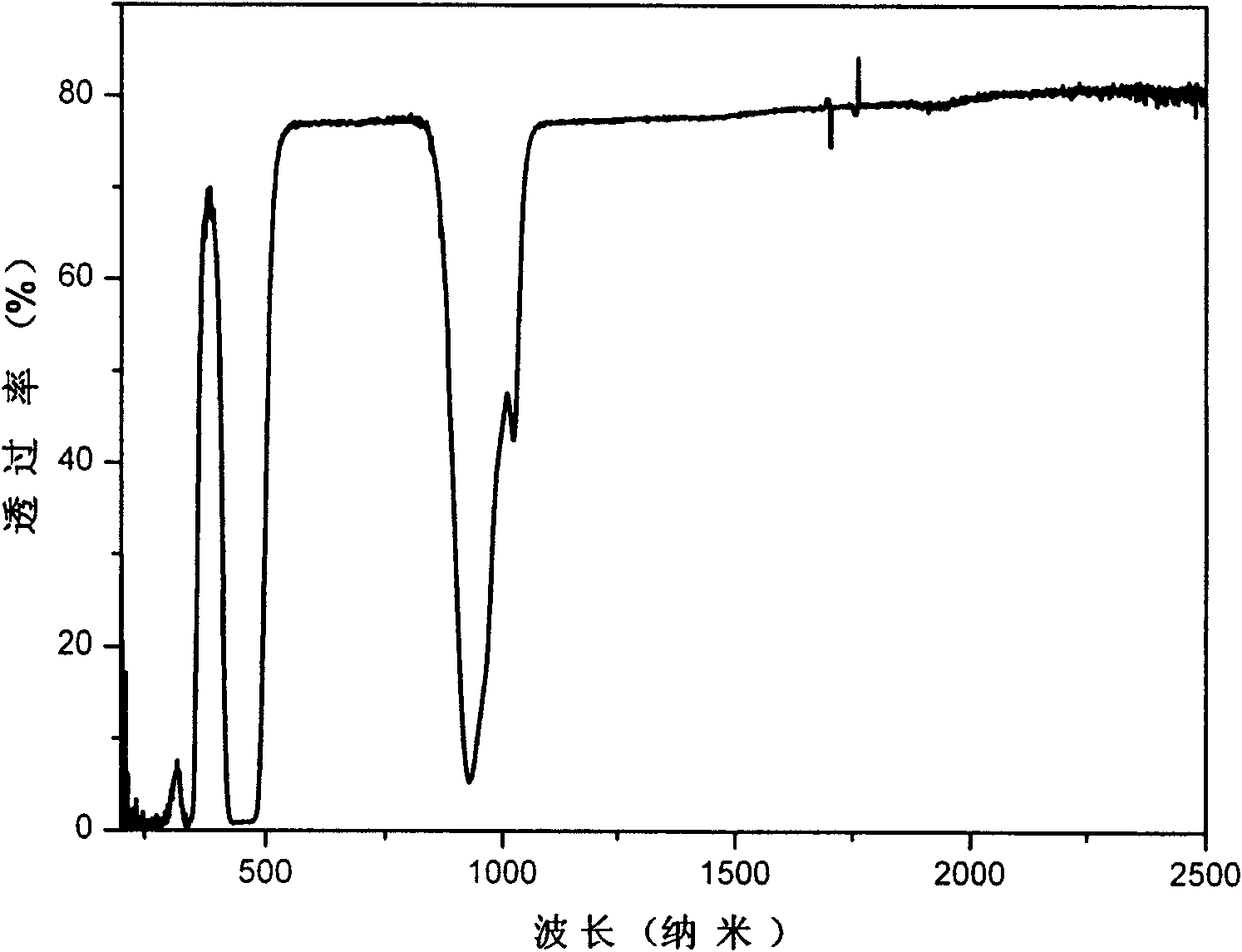

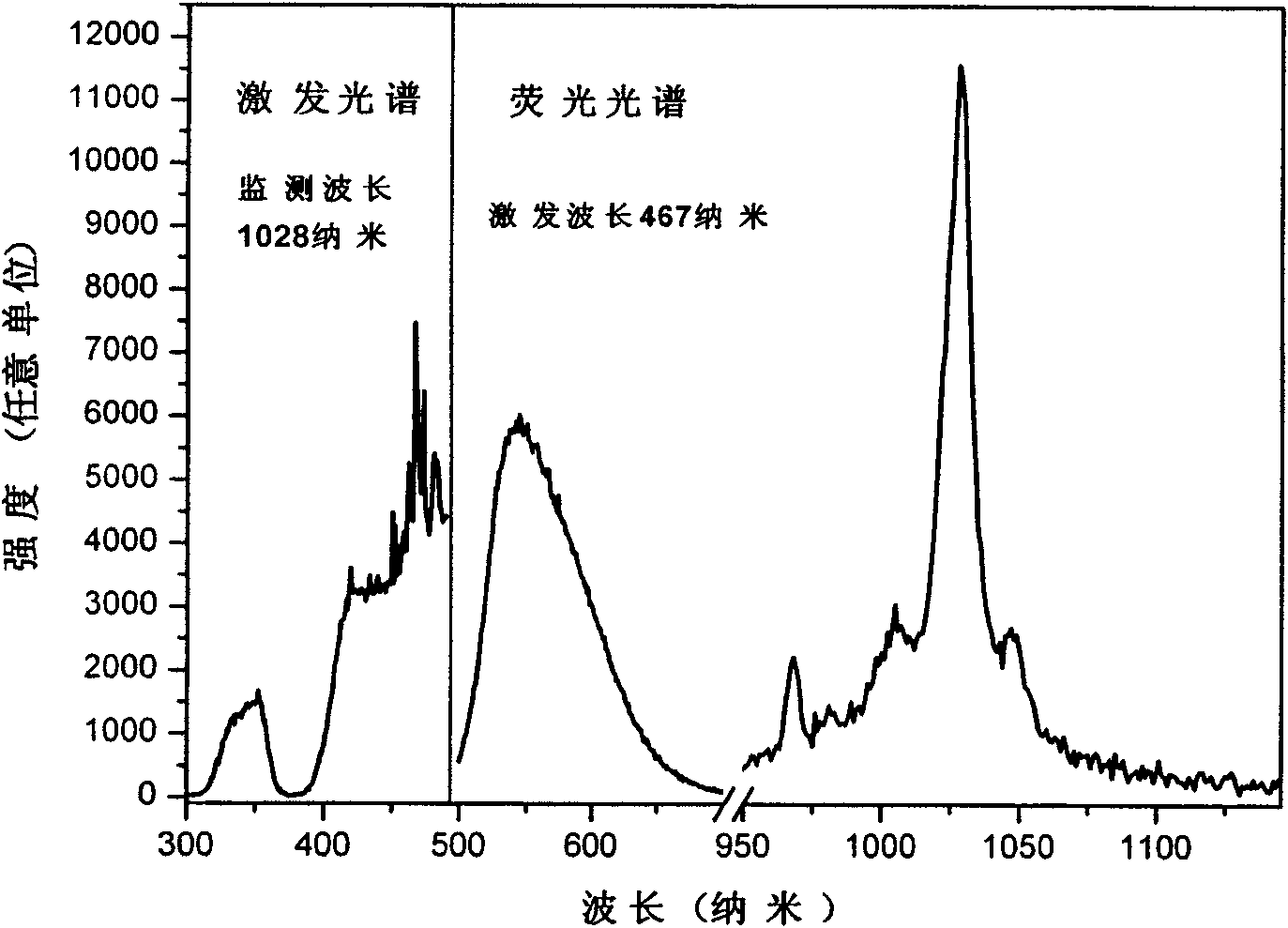

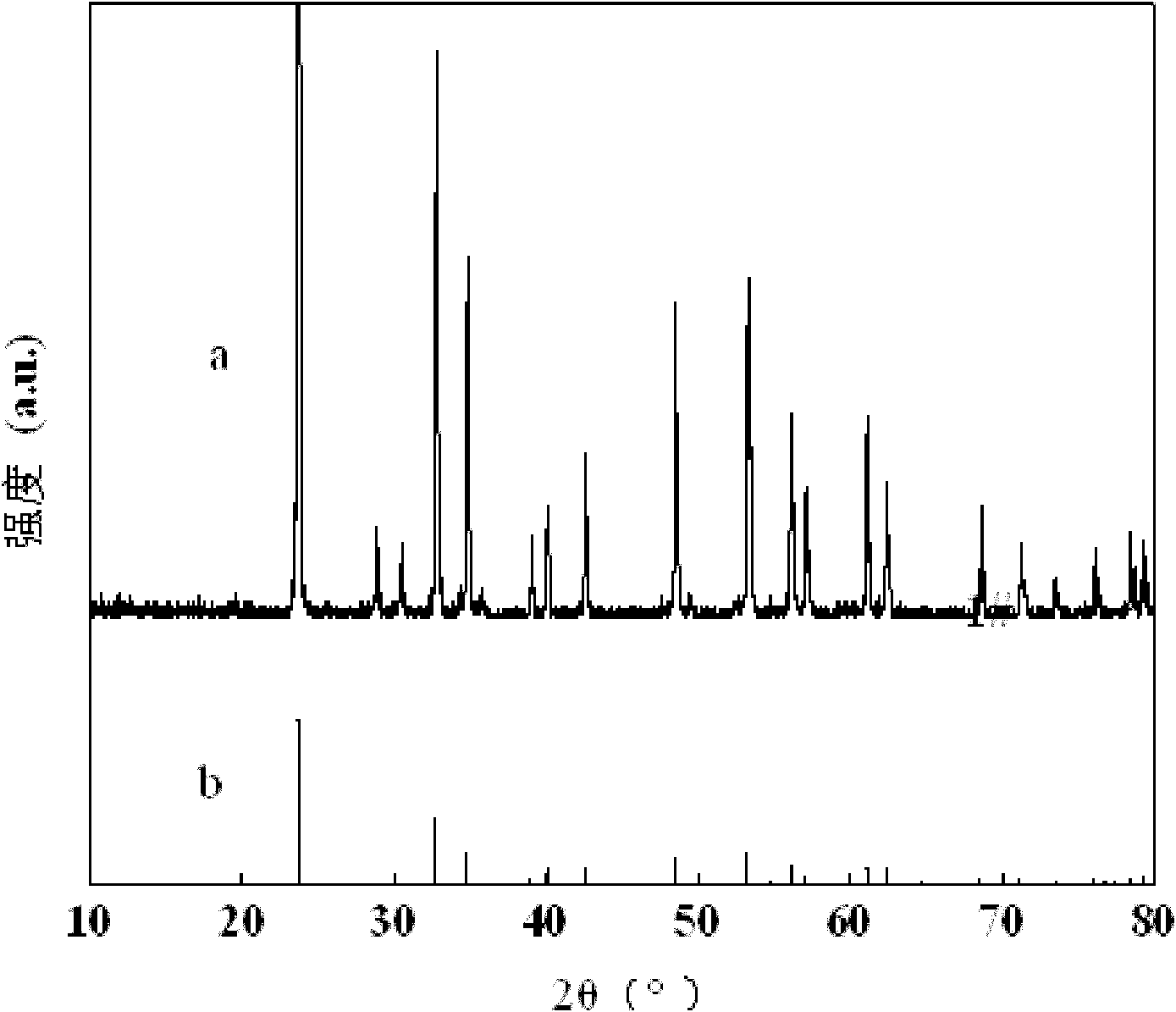

Transparent ceramic and preparation method thereof

The invention relates to a transparent ceramic and a preparation method thereof; the structural formula of the transparent ceramic is LnxYbyY(3-x-y)Al5O12 or LnwYbzY(2-w-z)O3, wherein, x is not less than 0.003 and not more than 0.03, y is not less than 0.006 and not more than 1.5, w is not less than 0.002 and not more than 0.02, z is not less than 0.004 and not more than 1 and Ln represents lanthanide element Ce, Tm, Pr or Tb. The preparation method comprises the following steps: adopting yttrium oxide, aluminum oxide and ytterbium oxide of which purities are not less than 99.9% and using one of cerium oxide, thulium oxide, praseodymium oxide and terbium oxide as raw materials, proportioning the raw materials powder according to the structural formula of the transparent ceramic, preparing ceramic powder material by adopting wet milling and using absolute ethanol as medium, drying the powder, pelleting, performing, pressing with 200MPa of cold isostatic pressing and obtaining LnxYbyY(3-x-y)Al5O12 or LnwYbzY(2-w-z)O3 transparent ceramic. The invention can increase the conversion efficiency of single crystal silicon and polysilicon solar cells.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

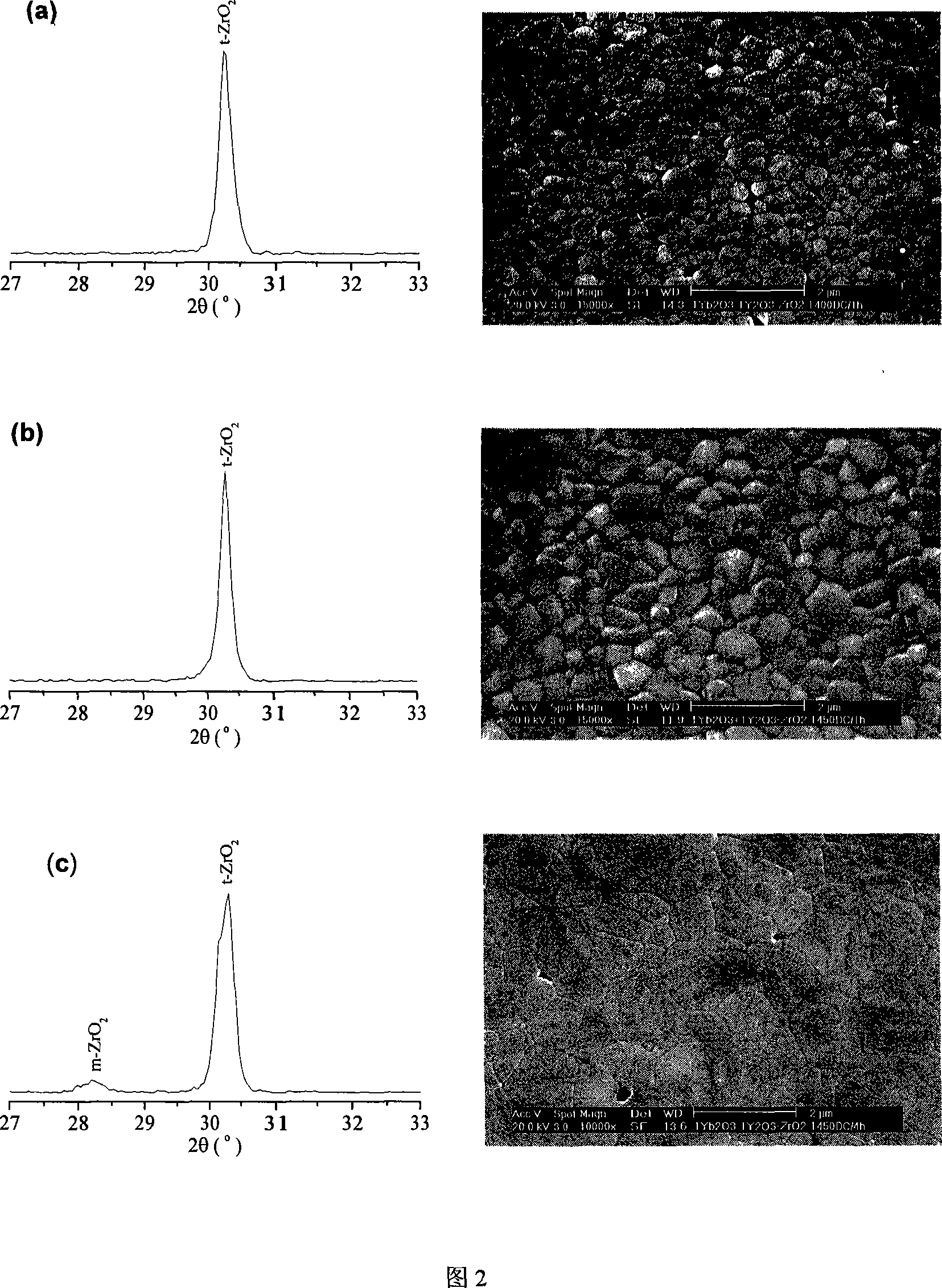

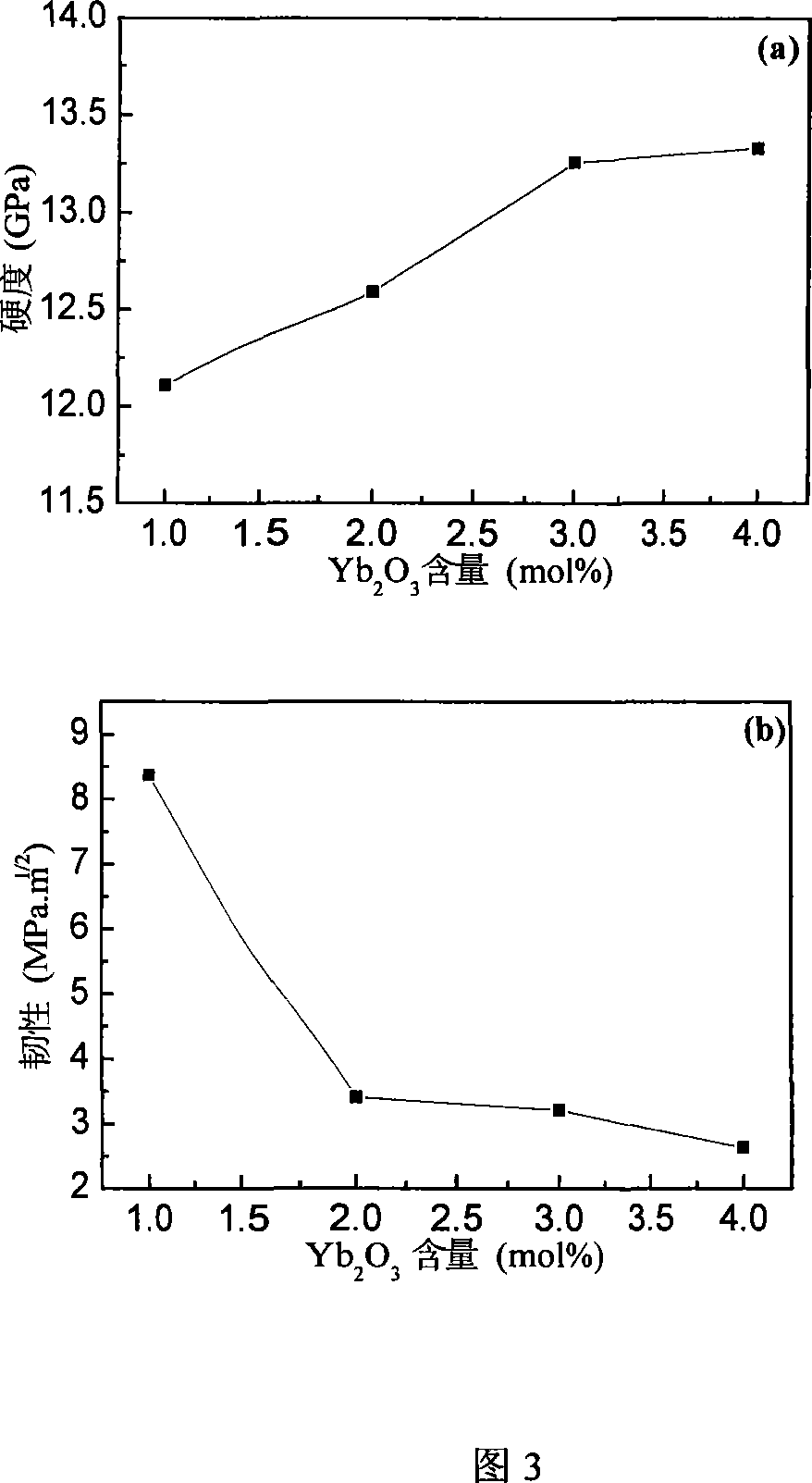

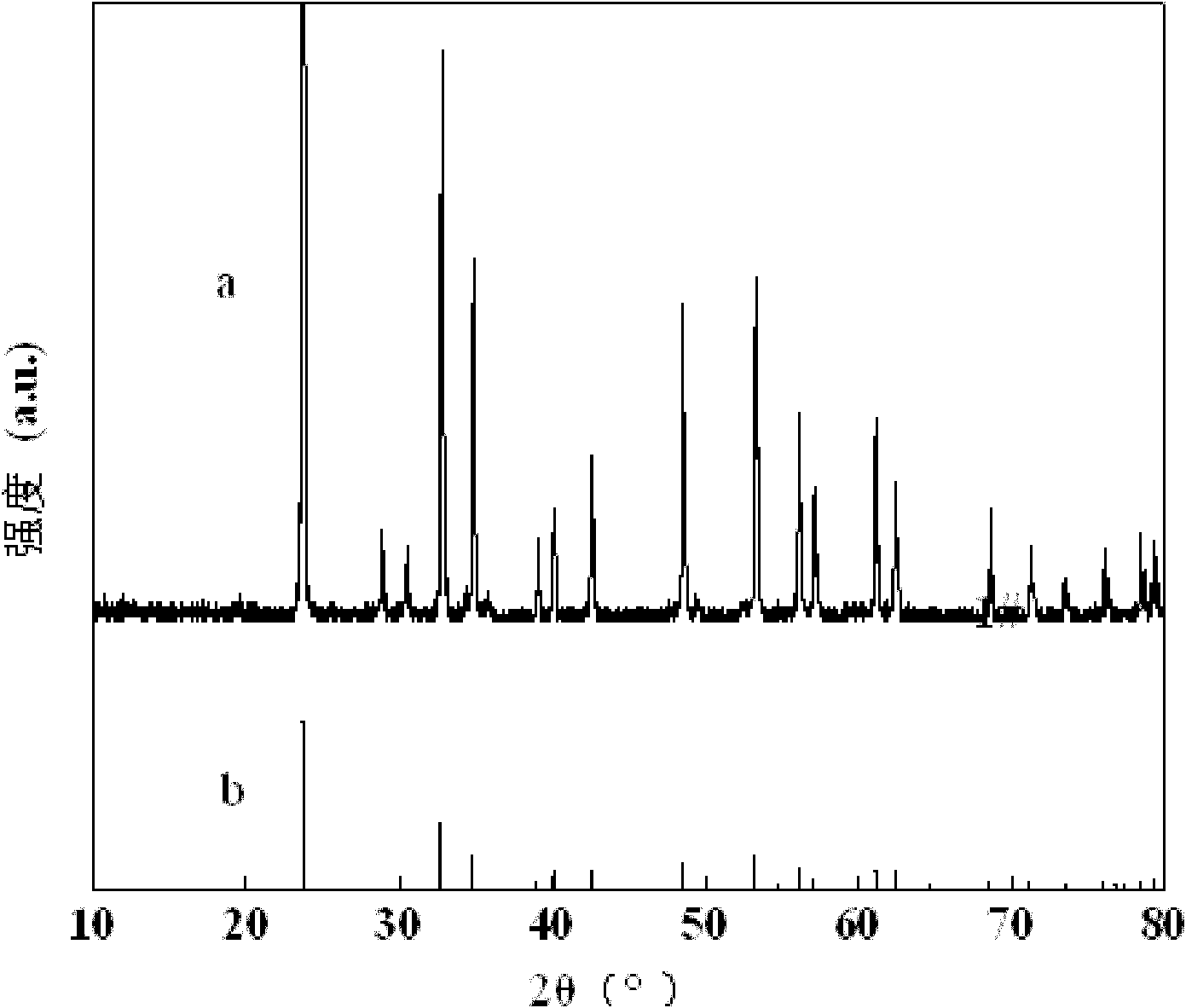

Zirconium oxide ceramic material of ytterbium oxide and yttrium oxide costabilize

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

High Purity Ytterbium, Sputtering Target Made Thereof, Thin Film Containing the Same, and Method of Producing the Same

InactiveUS20100260640A1Obtained efficiently and stablyEasy to purifyCellsVacuum evaporation coatingYTTERBIUM OXIDEMolten state

Provided is a method of producing high purity ytterbium, wherein the high purity ytterbium is obtained by reducing crude ytterbium oxide in a vacuum with reducing metals composed of metals having a low vapor pressure, and selectively distilling ytterbium. Additionally provided are methods of achieving the high purification of ytterbium which has a high vapor pressure and is hard to refine in a molten state, and high purity ytterbium obtained thereby. Further provided is technology for efficiently and stably obtaining a sputtering target made of high purity material ytterbium, and a thin film for metal gates containing high purity material ytterbium.

Owner:JX NIPPON MINING& METALS CORP

Fused silica ceramic material containing ytterbium oxide and preparation method thereof

The invention relates to a fused silica ceramic material containing ytterbium oxide and a preparation method thereof, belonging to the field of high-temperature structural ceramic materials. The ceramic material is prepared from the following materials by weight percentage: 97% to 99% of fine fused silica powder and 1% to 3% of fine ytterbium oxide powder. The preparation method comprises the following steps: dry-mixing the fine fused silica powder and the fine ytterbium oxide powder; wet-mixing the mixture by adding polyvinyl alcohol solution as binding agent; further sieving, stirring and ageing the mixture to obtain the perform body for molding the green body; molding the green body by a hydraulic press with the molding pressure being higher than or equal to 50MPa; drying and sintering the green body at 1,200 to 1,400 DEG C; and standing for 1 to 3 hours to obtain the fused silica ceramic material containing ytterbium oxide. The invention provides a novel high-temperature structural material for glass melting, ferrous and non-ferrous metallurgy, electronics, military missiles, spacecraft and other fields in China and has wide application prospect and great significance in strengthening the national defense.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Nano-antibacterial inorganic composite coloured metal coating layer material

InactiveCN1618888AExcellent adhesionExcellent abrasion resistanceMulticolor effect coatingsYTTERBIUM OXIDEHigh resistance

An antibacterial composite inorganic color nano-paint for metal is prepared from quartz containing nanoparticles, feldspar, ZrO2 containing nanoparticles, borax cerium oxide, copper oxide, sodium carbonate, Se powder, ytterbium oxide, fluorspar, potassium nitrate, cabolt oxide, MnO2, Al2O3 containing nanoparticles, lanthanum oxide, and Ag contained silica gel. Its advantages are high adhesion and tightness, no poison, and high resistance to corrosion, oxidation, abrasion, acid, alkali and high temp.

Owner:朱克勤

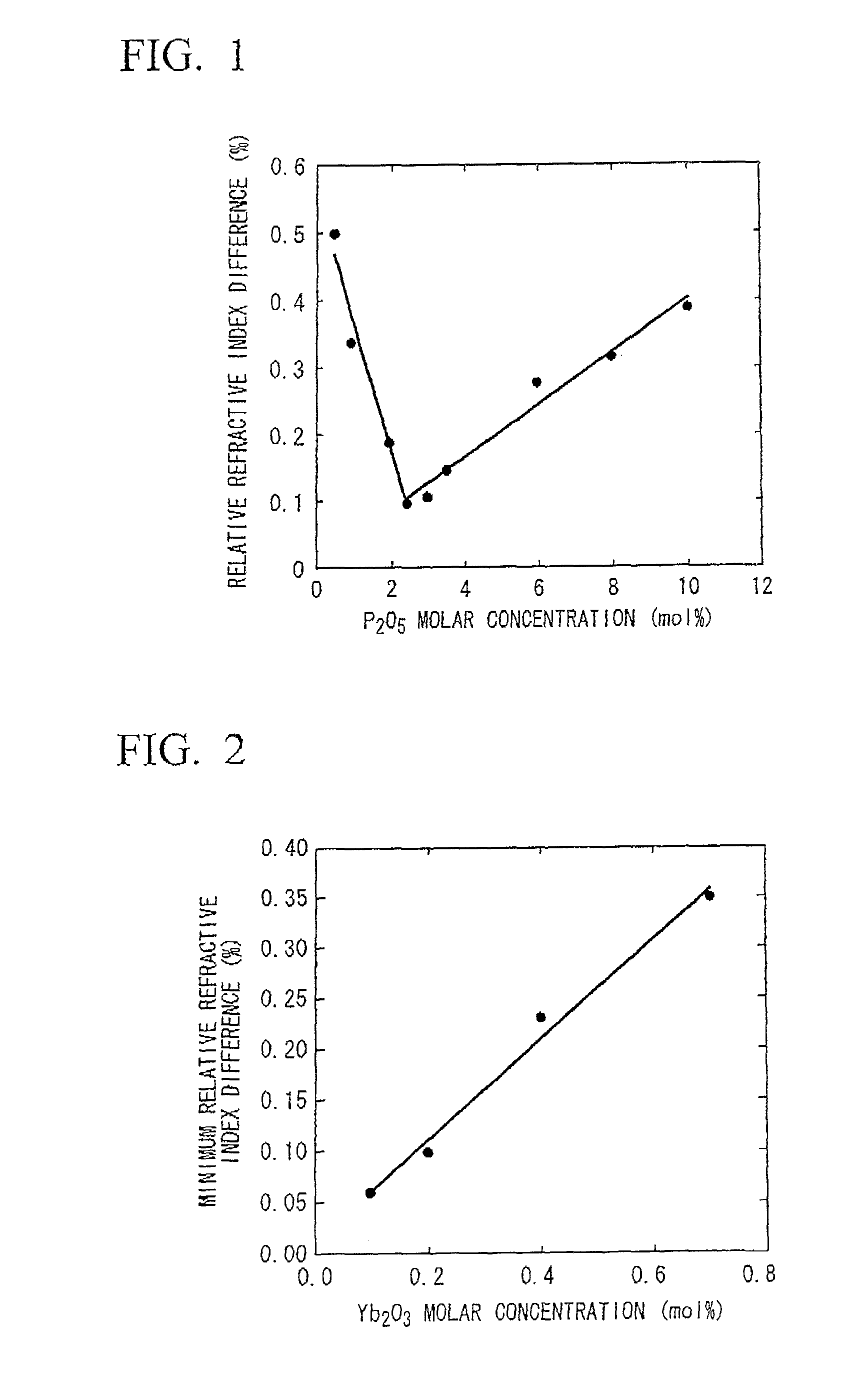

Ytterbium-doped optical fiber

ActiveUS8774590B2High indexInhibiting photodarkening and background lossCladded optical fibreActive medium materialYTTERBIUM OXIDERelative refractive index

Provided is an ytterbium-doped optical fiber including a core containing at least ytterbium, aluminum and phosphorous and a clad surrounding the core, wherein a molar concentration of diphosphorus pentoxide with respect to phosphorus in the core is equal to a molar concentration of aluminum oxide with respect to aluminum in the core, wherein a ratio of a molar concentration of diphosphorus pentoxide with respect to phosphorus in the core to the molar concentration of ytterbium oxide with respect to ytterbium in the core is higher than or equal to 10 and lower than or equal to 30, and wherein a relative refractive index difference between the core and the clad is higher than or equal to 0.05% and lower than or equal to 0.30%.

Owner:FUJIKURA LTD

Holmium/ytterbium-codoped bisumth tungstate fluorescent powder and preparation method thereof

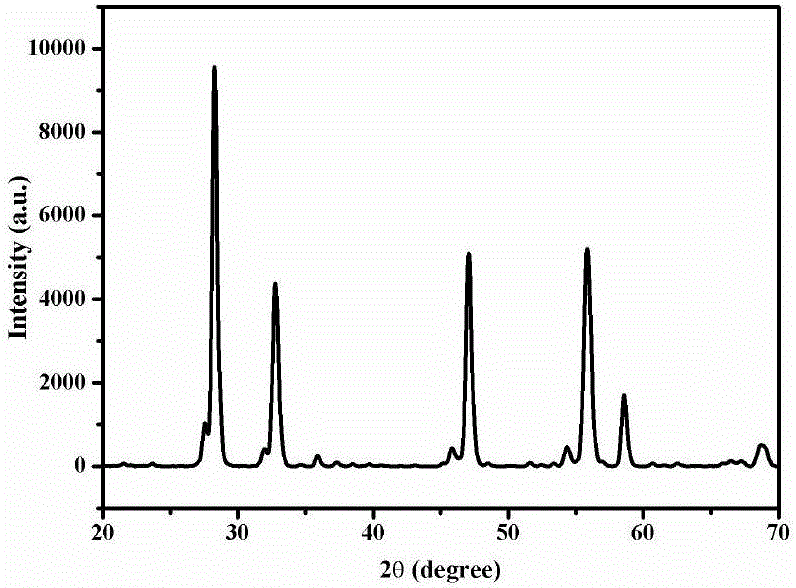

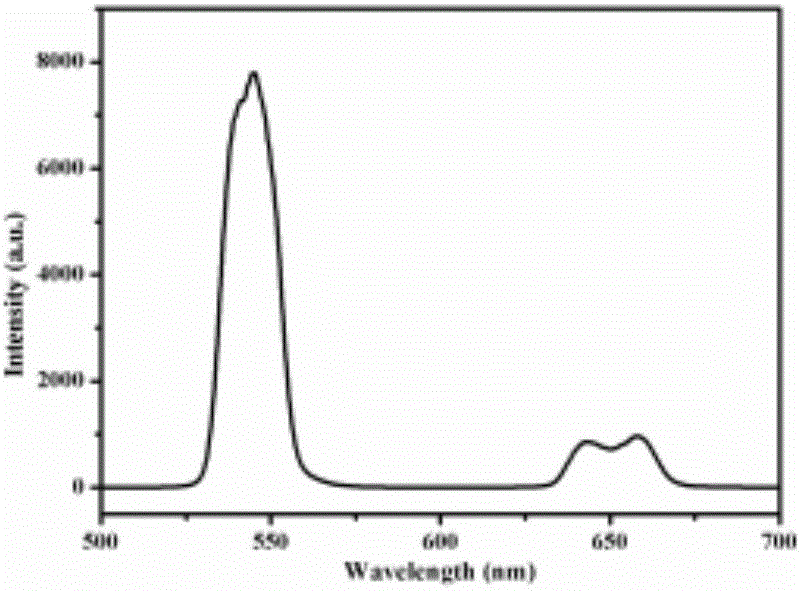

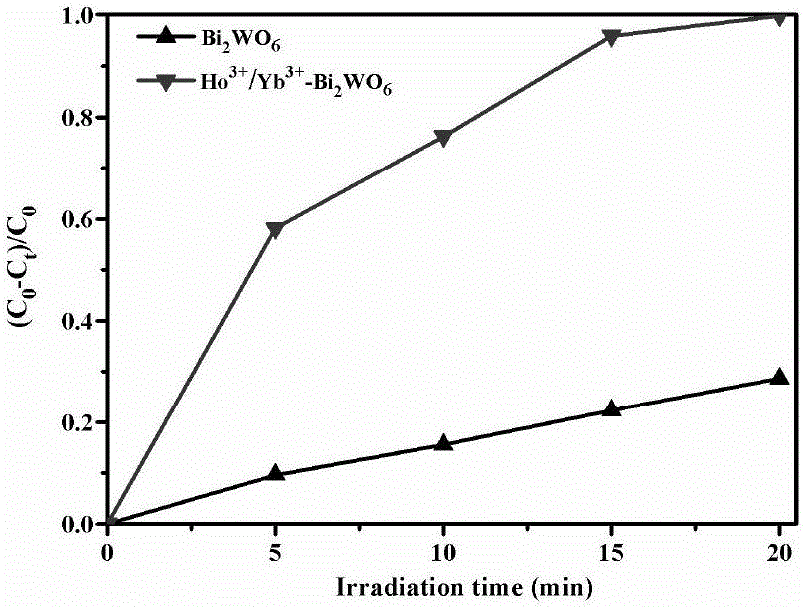

InactiveCN106753371ASimple ingredientsLow costHeterogenous catalyst chemical elementsLuminescent compositionsYTTERBIUM OXIDETungstate

The invention discloses a holmium / ytterbium-codoped bisumth tungstate fluorescent powder and a preparation method thereof. The preparation method comprises the following steps: by using bismuth nitrate pentahydrate, sodium tungstate, holmium oxide and ytterbium oxide as raw materials and ethanediol and dilute nitric acid as solvents, mixing the solution according to the stoichiometric proportion of Bi(2-x-y)HoxYbyWO6 (0<=x<2, and 0<=y<2) to form a uniform suspension, carrying out high-temperature reaction in a hydrothermal reaction kettle, centrifugating, washing, drying, and carrying out heat treatment to obtain the holmium / ytterbium-codoped bisumth tungstate fluorescent powder. The mixing ratio and the technological parameters for hydrothermal treatment, heat treatment and the like are controlled in the preparation process to obtain the powder with different fluorescence intensity levels. The preparation method has the advantages of simple technique and procedure, wide parameter adjustable range, high repeatability and low cost, and has commercial prospects. The fluorescent powder has important application values in the fields of ceramic raw powder, visible-light photocatalysis, solar cells and photoelectric sensors.

Owner:DALIAN POLYTECHNIC UNIVERSITY

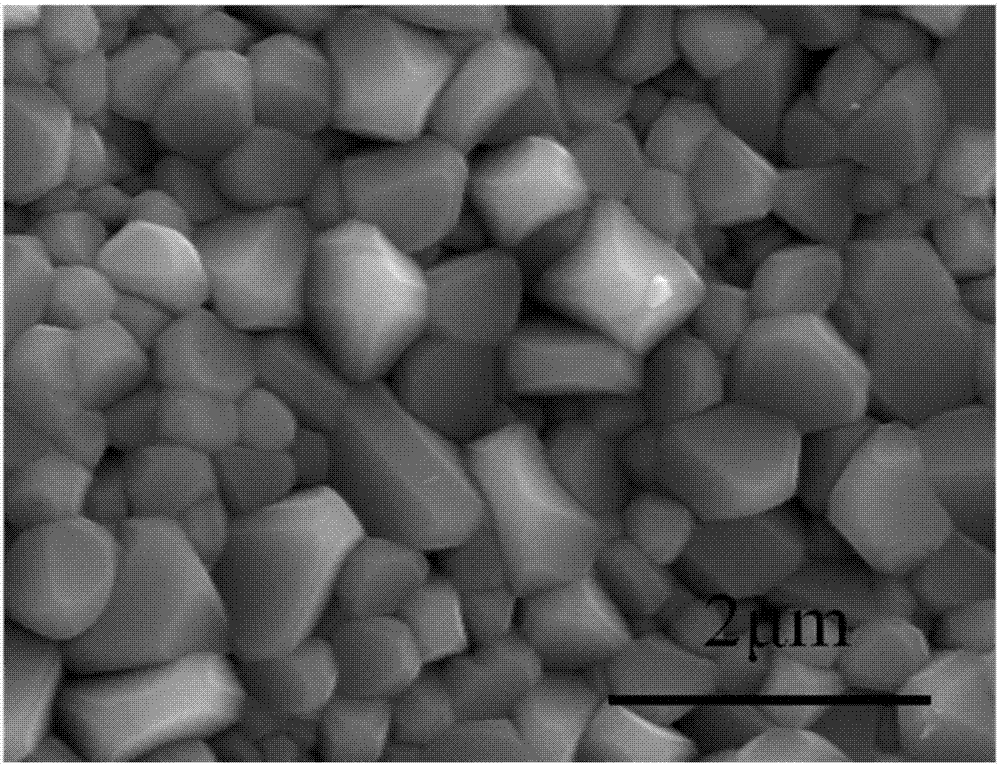

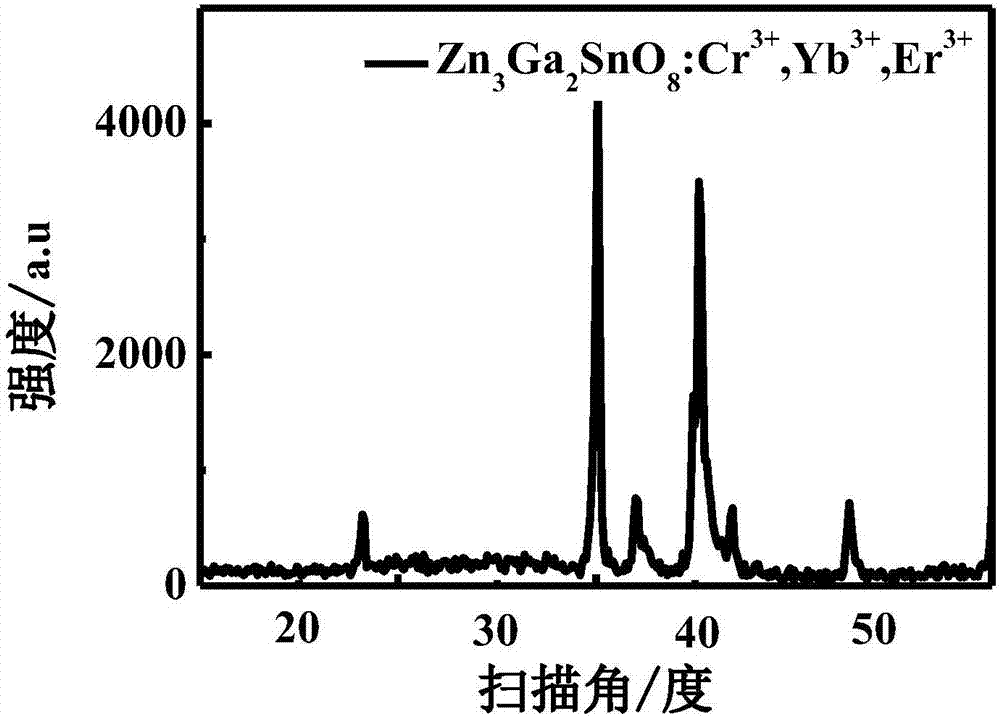

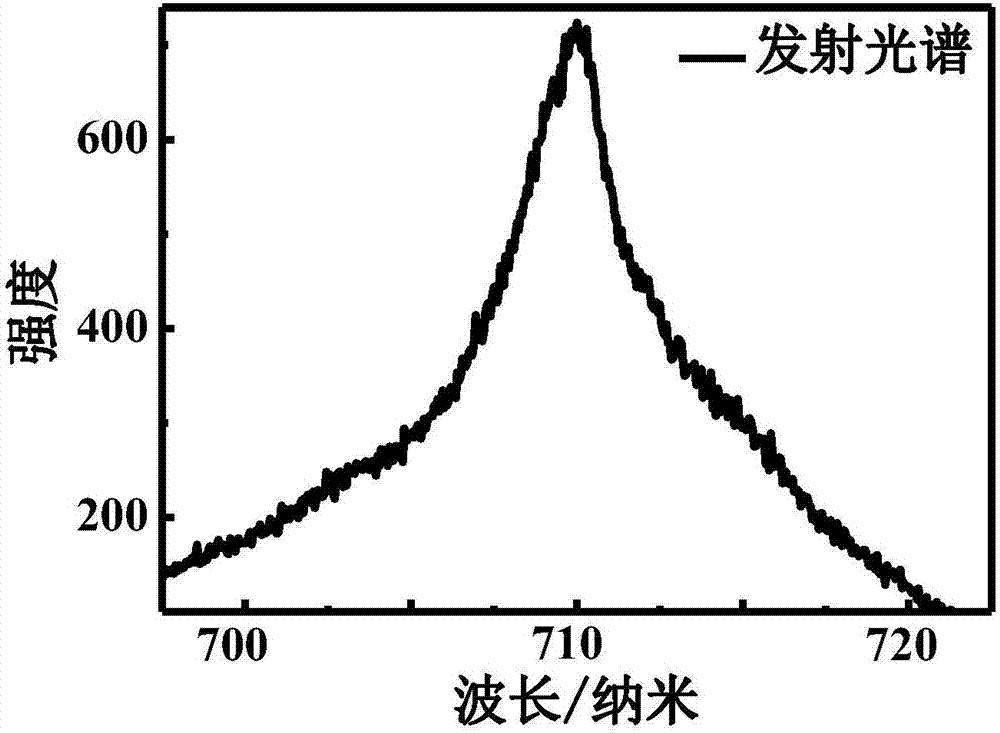

Near infrared up-conversion long afterglow luminescent material and preparation method thereof

The invention discloses a near infrared up-conversion long afterglow luminescent material and a preparation method thereof. The preparation method comprises the following steps: (1) weighing raw materials, and evenly mixing raw material powder, wherein the raw materials comprises a raw material A, a raw material B, a raw material C, and a raw material D, the raw material A is chromium oxides or corresponding salts, the raw material B is oxides of erbium or thulium or corresponding salts, the raw material C is ytterbium oxides or corresponding salts, and the raw material D is oxides of zinc, gallium / aluminum, or germanium / tin or corresponding salts; and (2) pressing and moulding mixed powder obtained in the step (1) to obtain a blank sample; (3) solid-phase sintering the blank sample obtained in the step (2) at a high temperature; and (4) cooling the sintering product to obtain the target material. A high temperature solid phase method is adopted, the prepared material, which is doped by Cr<3+> and Er<3+> / Tm<3+> and takes Yb<3+> as the sensitizing agent, has a near infrared excited up-conversion luminescence function and a super long time afterglow performance and can be used as a high performance functional material applied to related fields.

Owner:SHANDONG UNIV

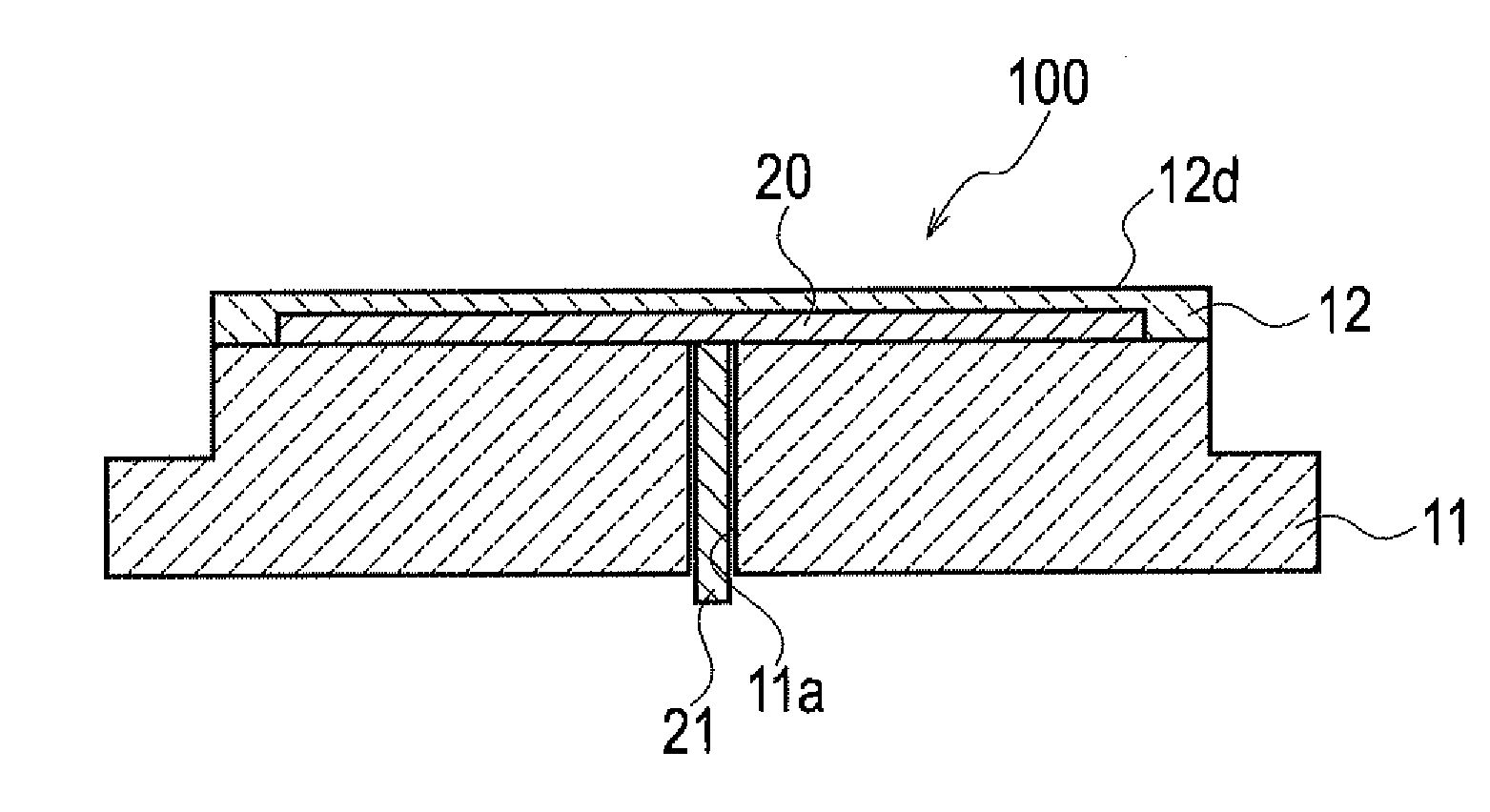

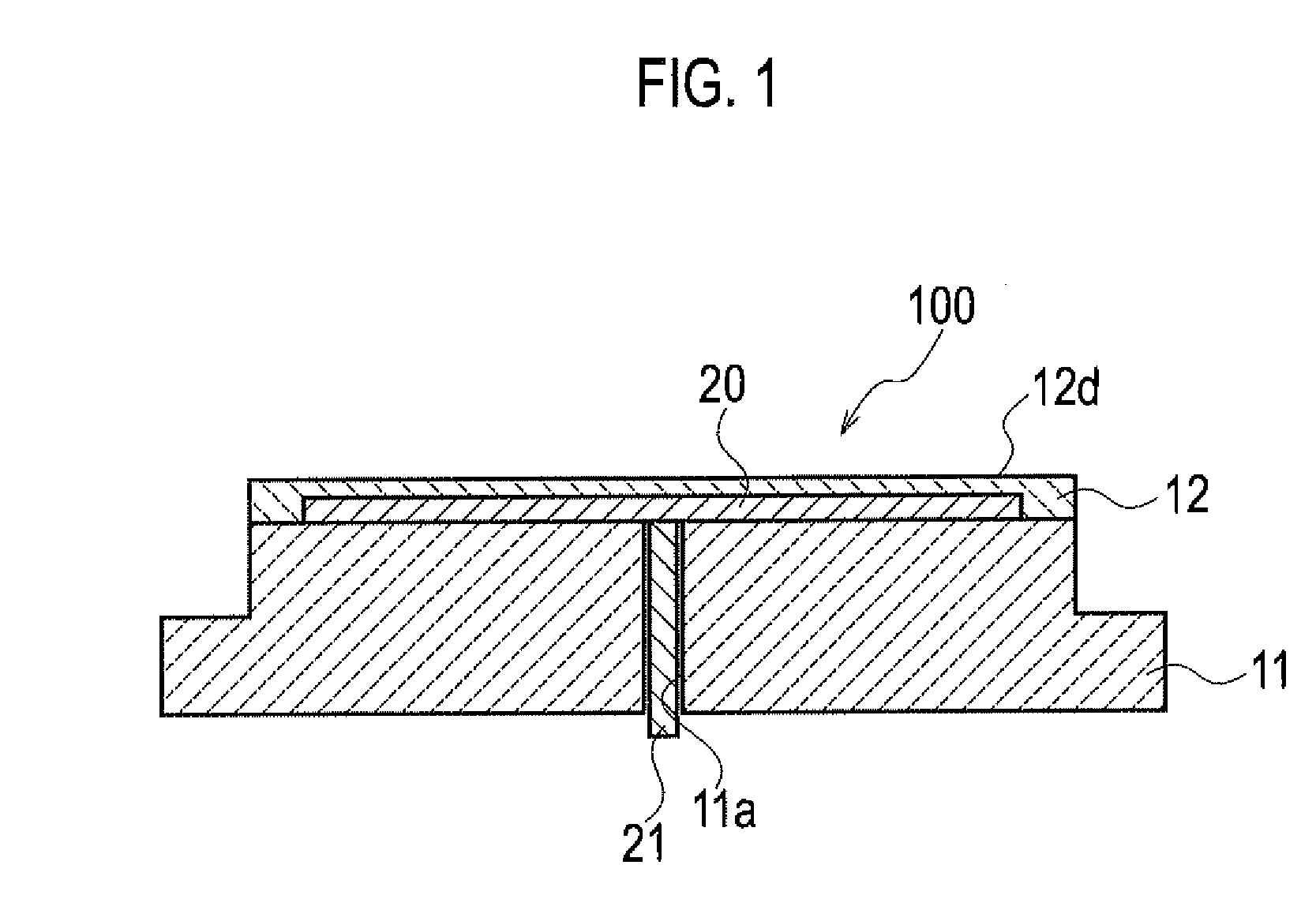

Electrostatic chuck and method for manufacturing the same

ActiveUS20090243235A1Improve responseHigh resistivitySemiconductor/solid-state device manufacturingChucksYTTERBIUM OXIDEYttrium

The electrostatic chuck includes a base including an aluminum nitride-containing member; a dielectric layer formed on the base including a member having a volume resistivity of at least 1×1015 Ω·cm at a temperature range of about 25° C. to about 300° C. and including 2 to 5% by mass of yttrium oxide, 2 to 5% by mass of ytterbium oxide, and a balance of aluminum nitride based on the total mass of the dielectric layer; and an electrode embedded under the dielectric layer so as to be positioned between the dielectric layer and the base, configured to generate an electrostatic absorption force.

Owner:NGK INSULATORS LTD

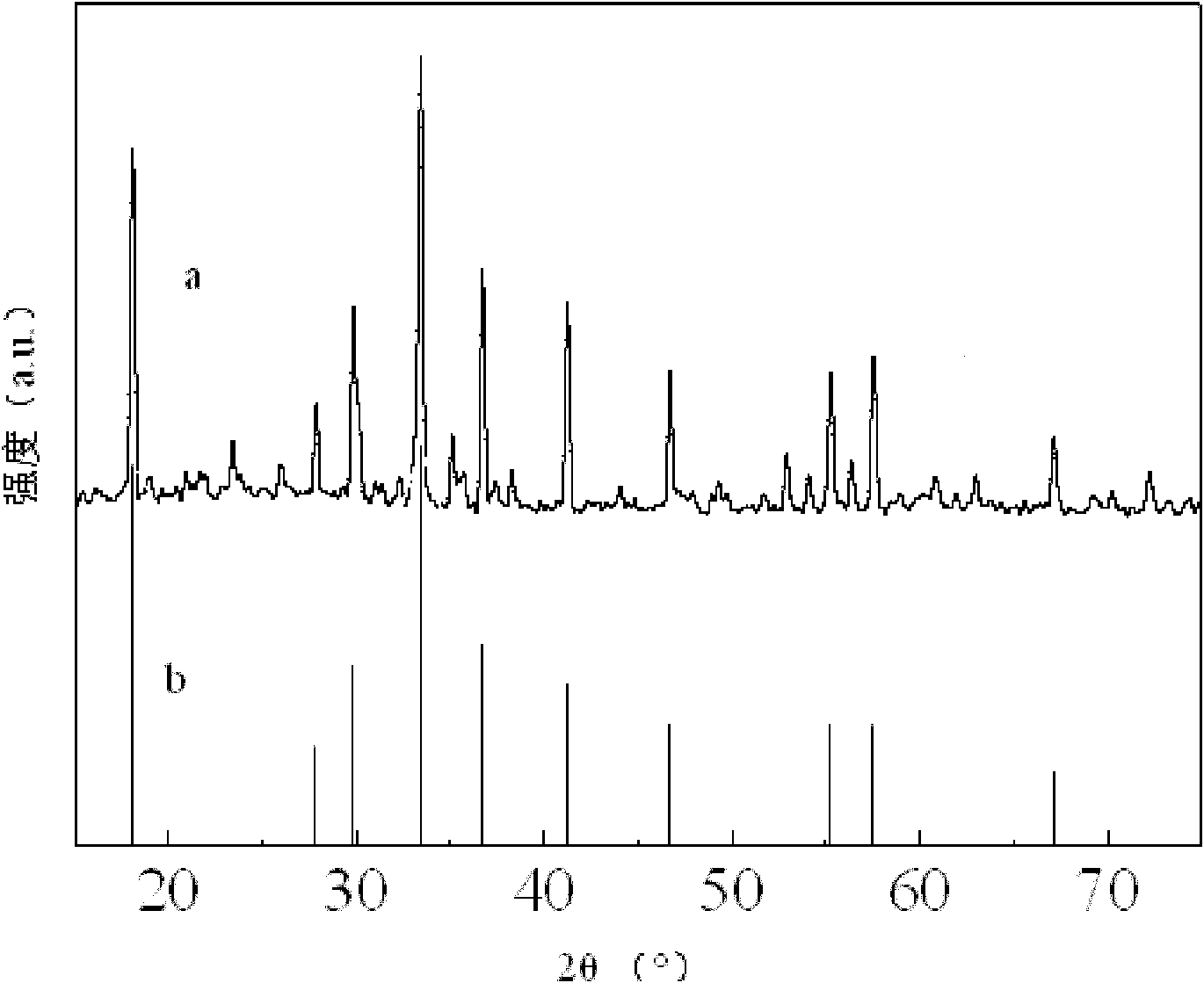

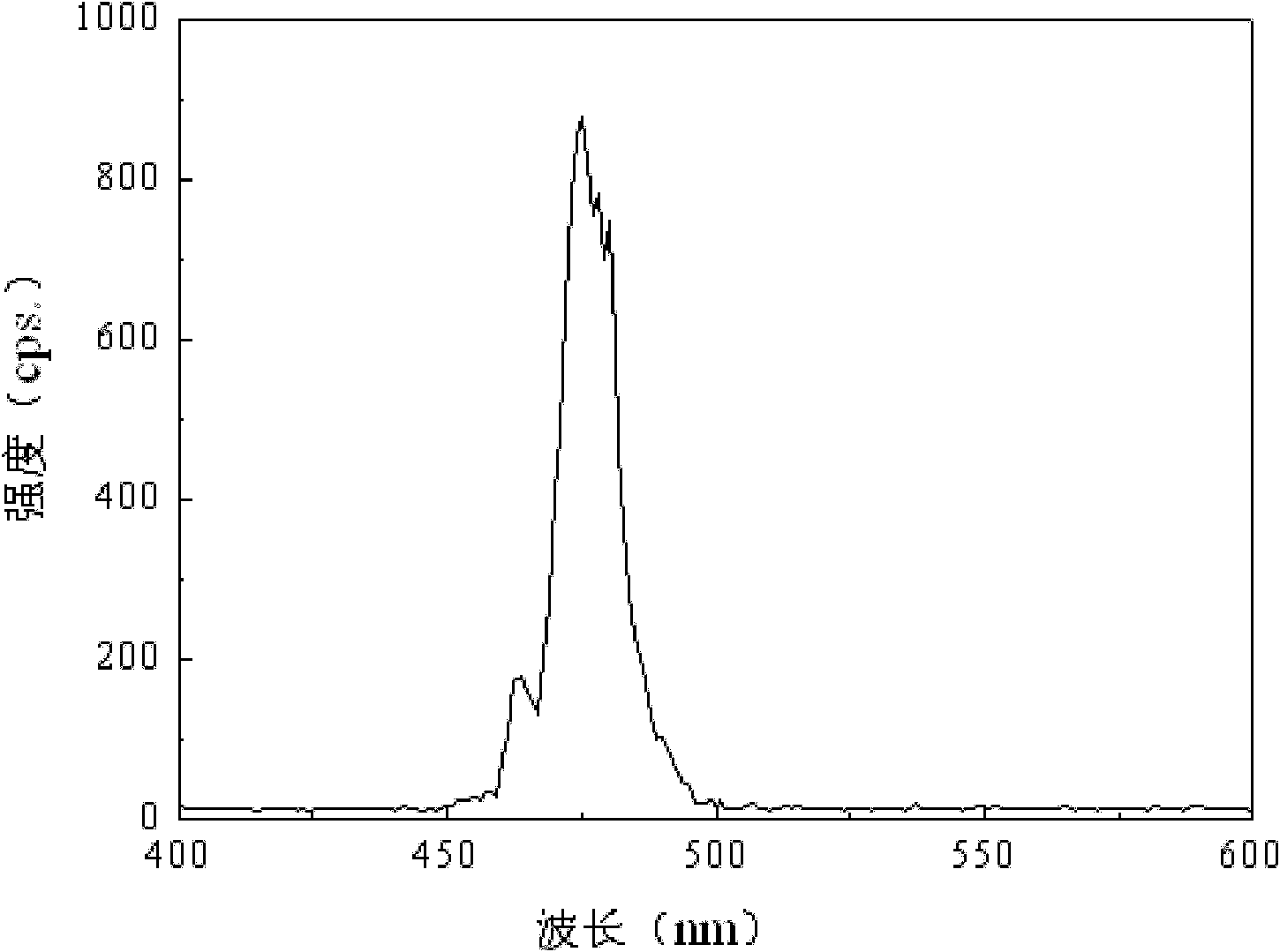

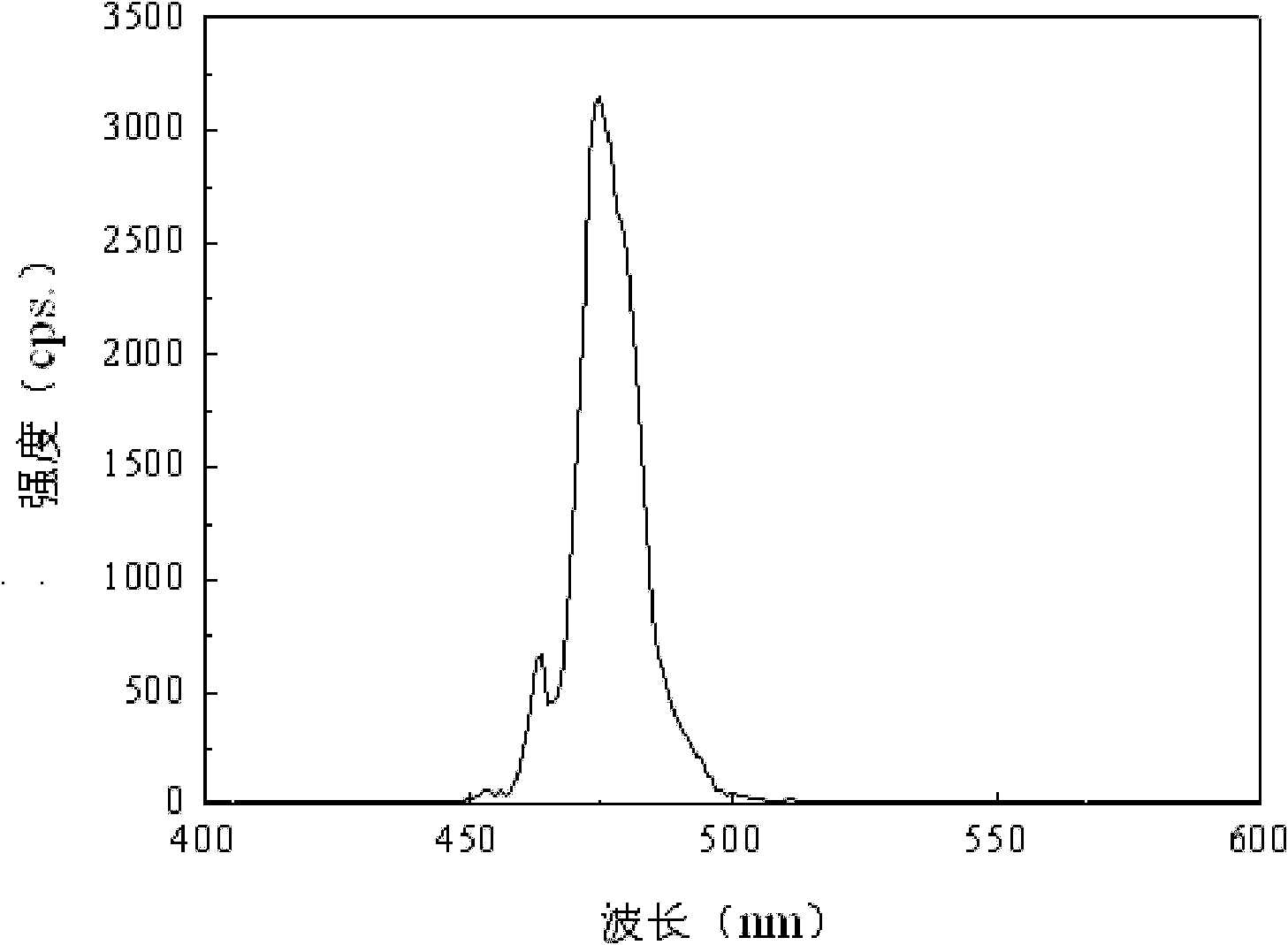

Ytterbium and thulium codoped dodecacalcium heptaluminate polycrystal and preparation method thereof

The invention discloses an ytterbium and thulium codoped dodecacalcium heptaluminate polycrystal and a preparation method thereof, relating to dodecacalcium heptaluminate polycrystal and a preparation method thereof, and solving the technical problem that the conventional blue material does not contribute to application due to wide blue wavelength distribution. The ytterbium and thulium codoped dodecacalcium heptaluminate polycrystal is prepared from calcium oxide, aluminum oxide, ytterbium oxide and thulium oxide, wherein the molar ratio of the calcium oxide to the aluminum oxide is 12:7; the amount of substance of the ytterbium oxide is 0.042-0.42 percent of that of the calcium oxide; and the amount of substance of the thulium oxide is 0.042-0.21 percent of that of the calcium oxide. The method comprises the following steps of: grinding the calcium oxide, the aluminum oxide, the ytterbium oxide and the thulium oxide powder; sheeting; and sintering under an air atmosphere to obtain the ytterbium and thulium codoped dodecacalcium heptaluminate polycrystal. Single blue light emission with wavelength of 460-490nm is obtained under excitation of light with wavelength of 980nm. The polycrystal can be used in the fields of light storage technology, optoelectronic technology, sensor technology and submarine optical cable communication.

Owner:HARBIN INST OF TECH

Silicon carbide refractory material and preparation method thereof

The invention belongs to the technical field of refractory materials, and provides a silicon carbide refractory material and a preparation method thereof. The silicon carbide refractory material comprises, by weight, 25-40 parts of silicon carbide powder, 4-8 parts of silica fume , 1-5 parts of aluminum powder, 5-13 parts of titanium dioxide, 5-10 parts of zirconium oxide, 0.5-3 parts of polyhedral oligomeric silsesquioxane, 0.5-2 parts of molybdenum carbide, 0.5-2 parts of silicon boride, 0.5-1.5 parts of erbium acetate, 0.5-1.5 parts of ytterbium oxide, 1-3 parts of diamond and 3-5 parts ofbinding agent. The preparation method comprises the following steps: mixing the silicon carbide powder, the silica fume, the aluminum powder, the titanium dioxide and the zirconium oxide, grinding themixture to obtain first mixed powder, reacting the erbium acetate, the ytterbium oxide and the diamond to obtain second mixed powder, mixing the first mixed powder with the second mixed powder, mixing the obtained mixture with other components in the formula, and firing the obtained mixture to obtain the silicon carbide refractory material. By means of the technical scheme, the problems that in the prior art, a refractory material is poor in oxidation resistance and not high in strength are solved.

Owner:唐山市瑞兆碳化硅制品有限公司

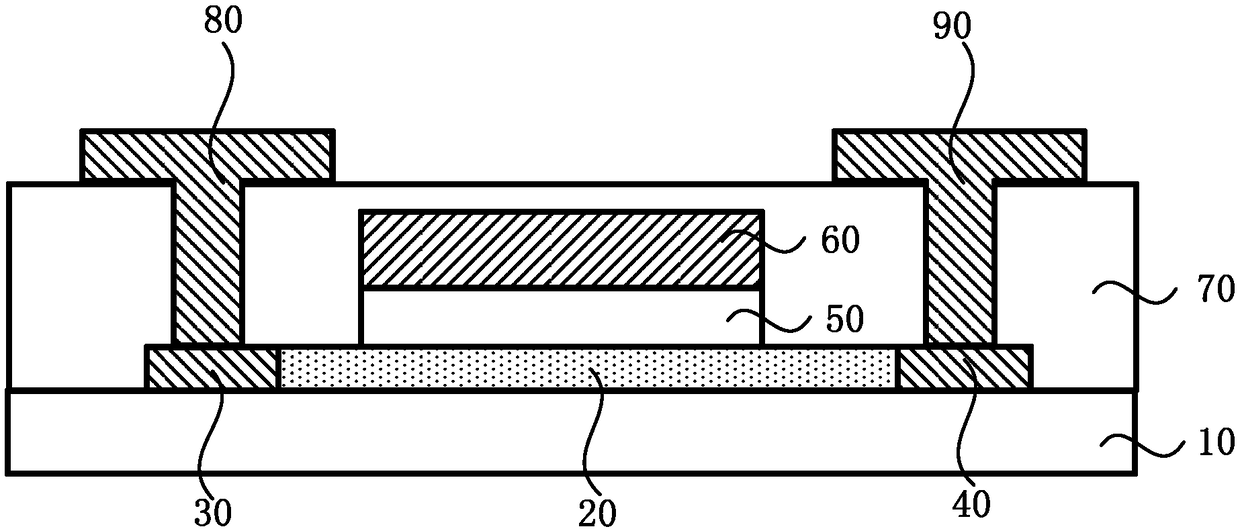

Composite metal oxide semiconductor, thin-film transistor and application

PendingCN110767745AReduced oxygen vacanciesMobility is not affectedTransistorSolid-state devicesYTTERBIUM OXIDEOxygen vacancy

The invention discloses a composite metal oxide semiconductor. The composite metal oxide semiconductor is formed by doping rare earth oxide in metal oxide, wherein the composite metal oxide can effectively inhibit the concentration of oxygen vacancy in a thin-film under the lower doping concentration of ytterbium oxide or praseodymium oxide, and meanwhile, the mobility of the composite metal oxidesemiconductor can be kept at a higher value; the key is that the formed film can avoid the influence on I-V characteristics and stability by illumination, and the stability of the metal oxide semiconductor device under illumination can be greatly improved. The invention also provides a thin-film transistor based on the composite metal oxide semiconductor and an application thereof.

Owner:SOUTH CHINA UNIV OF TECH

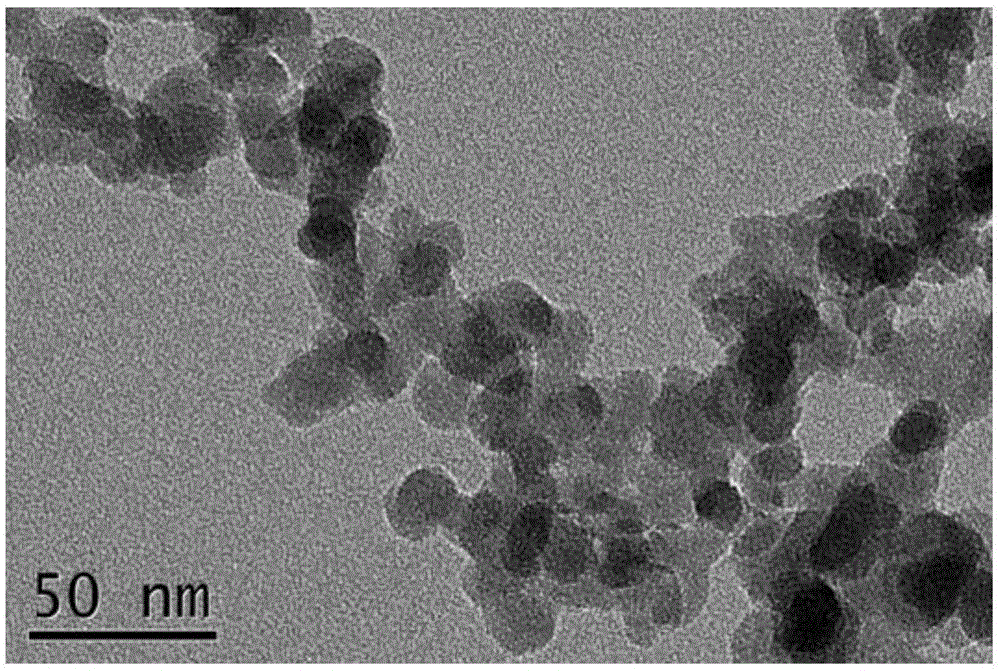

Pure-phase rare-earth zirconate nanometer material and preparation method thereof

ActiveCN106588004AHigh coefficient of thermal expansionStable phase structure at high temperatureYTTERBIUM OXIDECerium nitrate

The invention relates to a pure-phase rare-earth zirconate nanometer material and a preparation method thereof, wherein the nanometer material is Gd<0.2>Yb<0.2>Y<0.6>)<2>(Zr<1-x>Ce<x>)<2>O<7>. The preparation method comprises the steps that gadolinium oxide, yttrium oxide, ytterbium oxide, cerium nitrate and zirconium oxychloride are mixed to obtain a mixture; dilute nitric acid is added into the mixture; dissolution is performed to obtain a mixed rare-earth nitrate solution; the mixed rare-earth nitrate solution is put into a reaction kettle; ammonia water is added; co-precipitation reaction is performed to form a hydroxide colloidal solution, and the colloidal solution is used as a precursor; the precursor is prepared into slurry by a hydro-thermal reaction method; and the slurry is subjected to cleaning, pelleting and compacting to prepare the pure-phase rare-earth zirconate nanometer material. A prepared thermal barrier coating material has the advantages that the thermal expansion coefficient is high; the high-temperature phase structure is stable; and the material is more suitable for practical application.

Owner:CHINA BUILDING MATERIALS ACAD

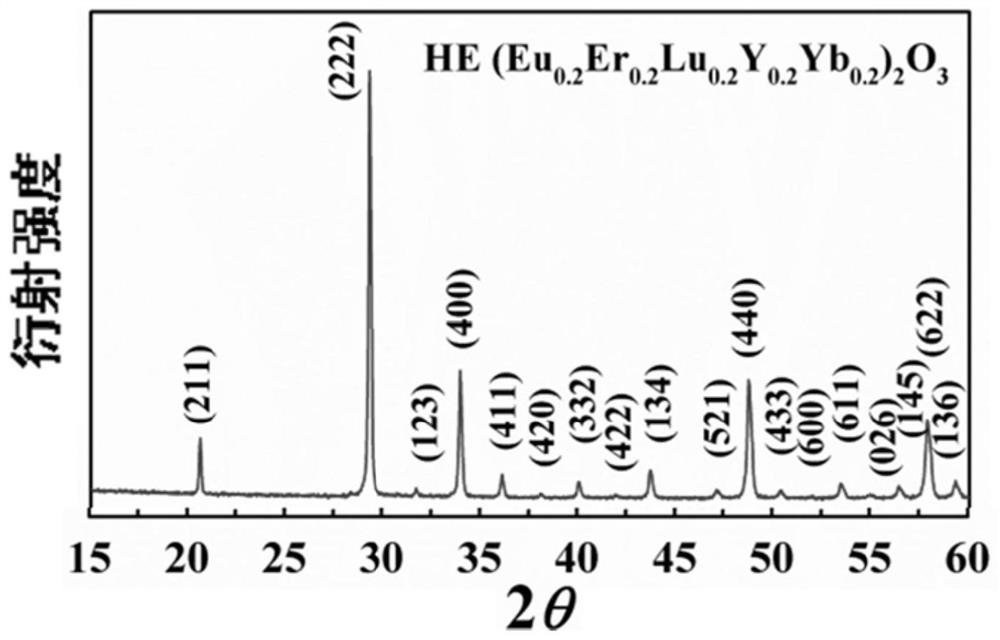

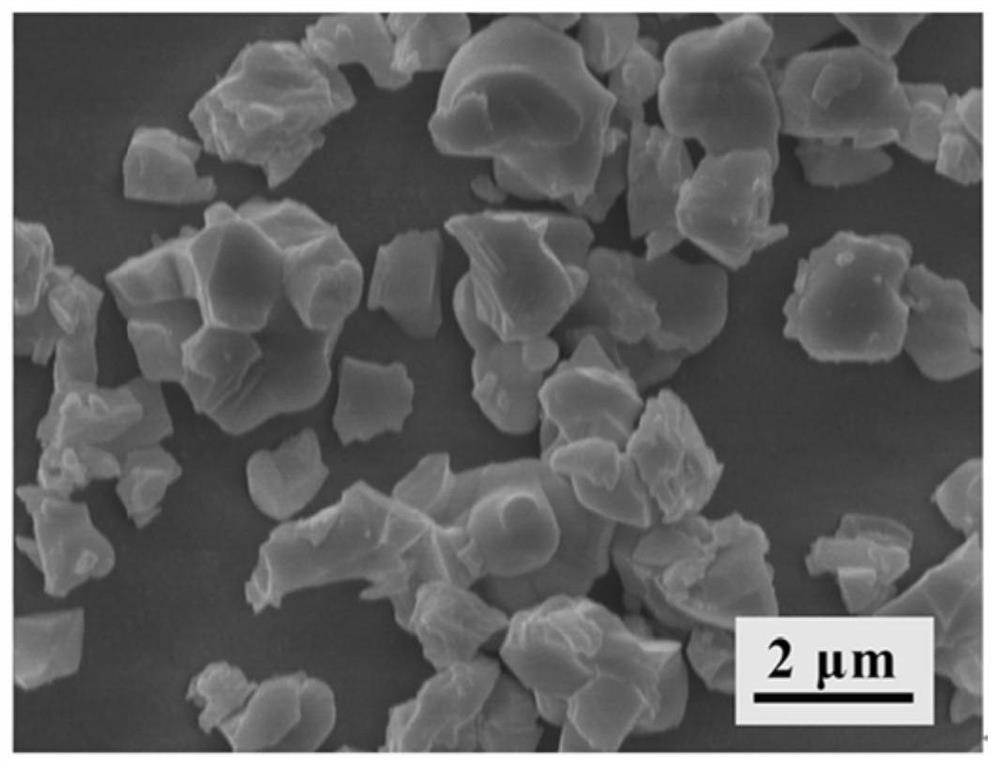

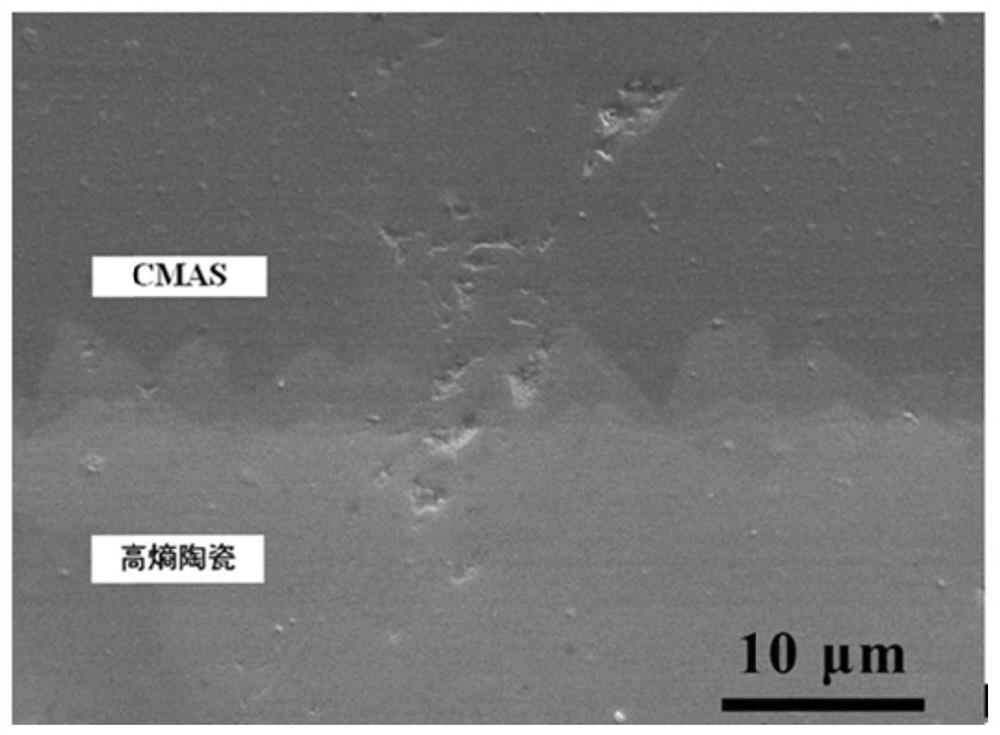

High-entropy ceramic material resistant to CMAS corrosion and preparation method and application thereof

The invention provides a high-entropy ceramic material resistant to CMAS corrosion, a preparation method and an application thereof, the high-entropy ceramic material comprises the following raw materials: at least three of samarium oxide, europium oxide, erbium oxide and lutetium oxide, yttrium oxide and ytterbium oxide, and the amounts of substances of the raw materials are the same. The preparation method comprises the following steps: optionally selecting at least three of samarium oxide, europium oxide, erbium oxide and lutetium oxide, and conducting mixing with yttrium oxide and ytterbium oxide to obtain uniformly mixed slurry; and drying the slurry to obtain mixture powder, and carrying out pressureless calcination on the dried powder to obtain the high-entropy ceramic powder material. Analysis shows that the high-entropy ceramic powder material has the characteristics of high purity and strong CMAS corrosion resistance, the preparation method is simple and suitable for industrial production, and the high-entropy ceramic powder material has excellent application prospect in the field of thermal barrier coating materials.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

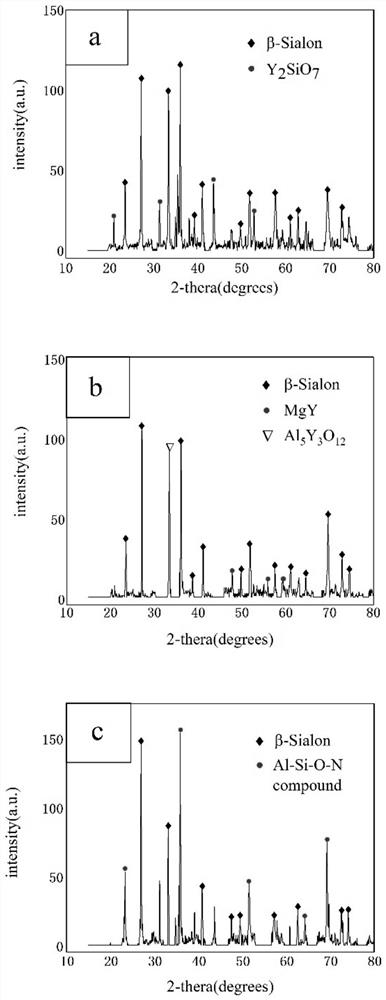

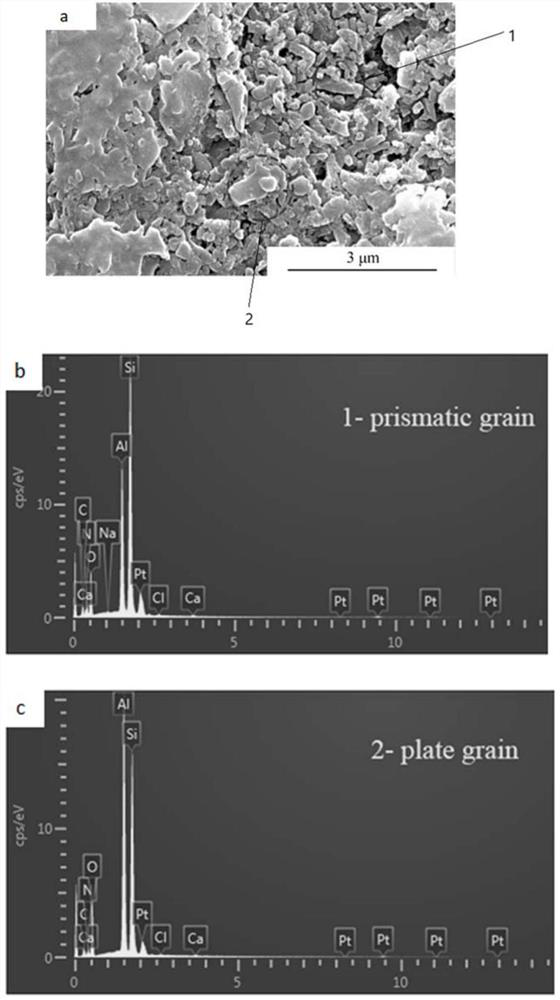

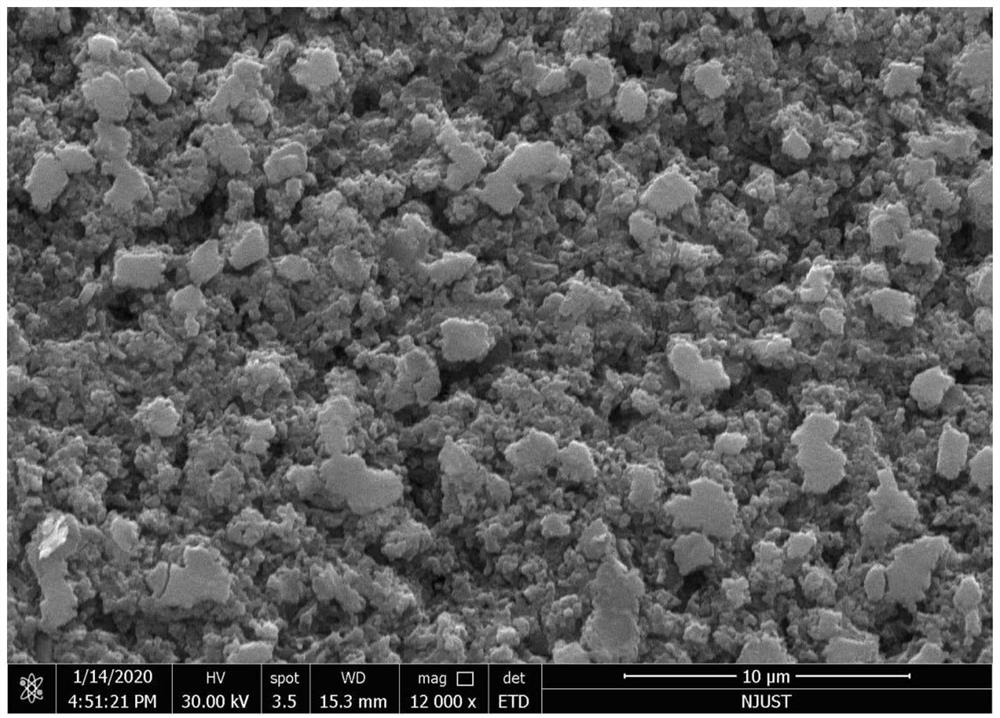

Method for microwave sintering of sialon ceramic material

ActiveCN111635236ARealize integrationHomogeneous material microstructureChemical industryYTTERBIUM OXIDEMicro nano

The invention belongs to the field of material preparation, and particularly relates to a method for microwave sintering of a sialon ceramic material. Micro-nanoscale silicon nitride powder, aluminumnitride powder and aluminum oxide powder are adopted as the raw materials, several of yttrium oxide, ytterbium oxide, magnesium oxide, magnesium silicon nitride and samarium oxide are arbitrarily selected as the sintering aid, and microwave sintering is conducted to obtain the sialon ceramic material. According to the method, micro-nanoscale silicon nitride powder, aluminum nitride powder and aluminum oxide powder are subjected to atom replacement in the microwave sintering process, and the sintering aid is added to synthesize a required phase, so that the sintering densification temperature can be effectively reduced, the production efficiency can be improved while the microstructure of the material is more uniform, and the integration of the phase synthesis and densification process is realized. The prepared ceramic material has high hardness and good fracture toughness on the basis of guaranteeing basic complete compactness, the actual density is 3.233g / cm<3>, the Vickers hardness is 14.3GPa, and the fracture toughness is 7.28MPa.m<1 / 2>.

Owner:NANJING UNIV OF SCI & TECH

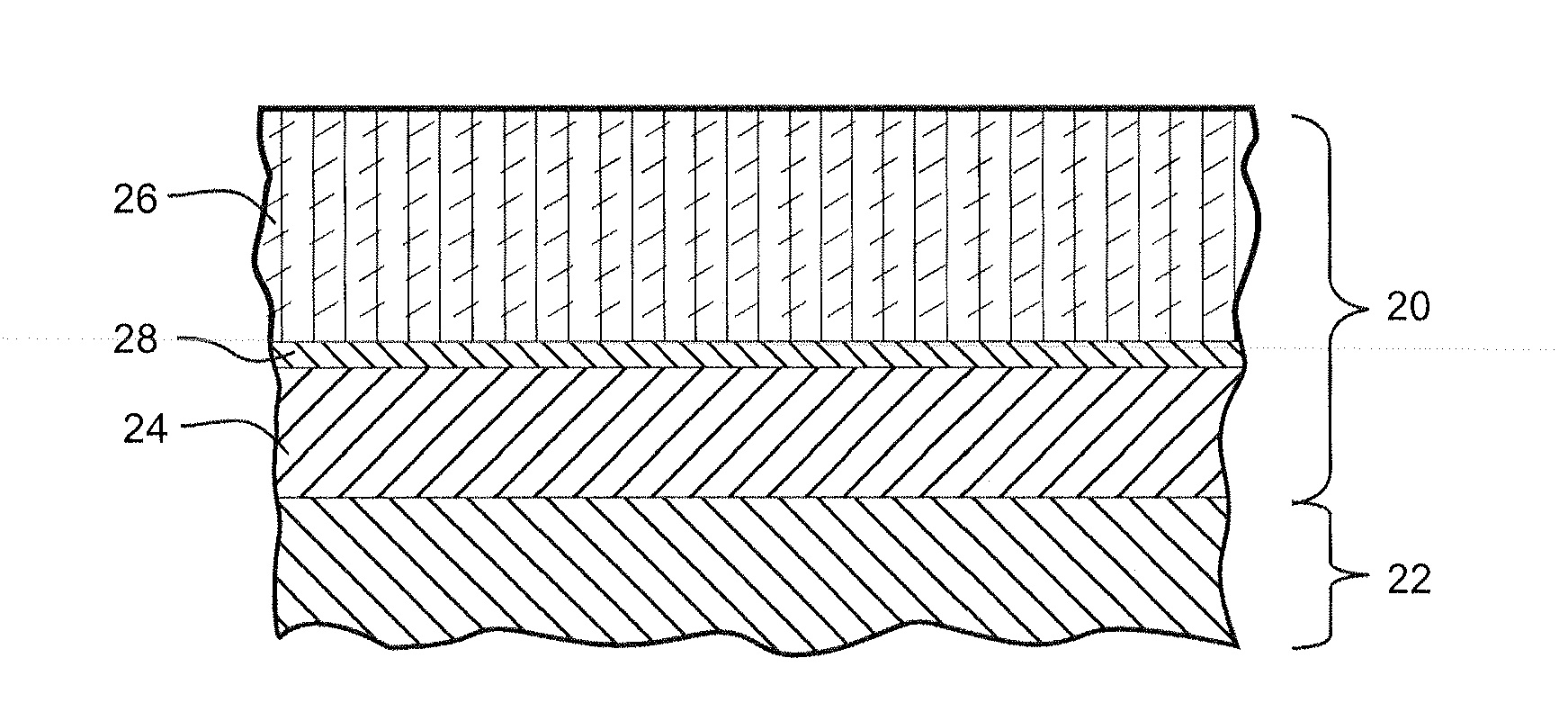

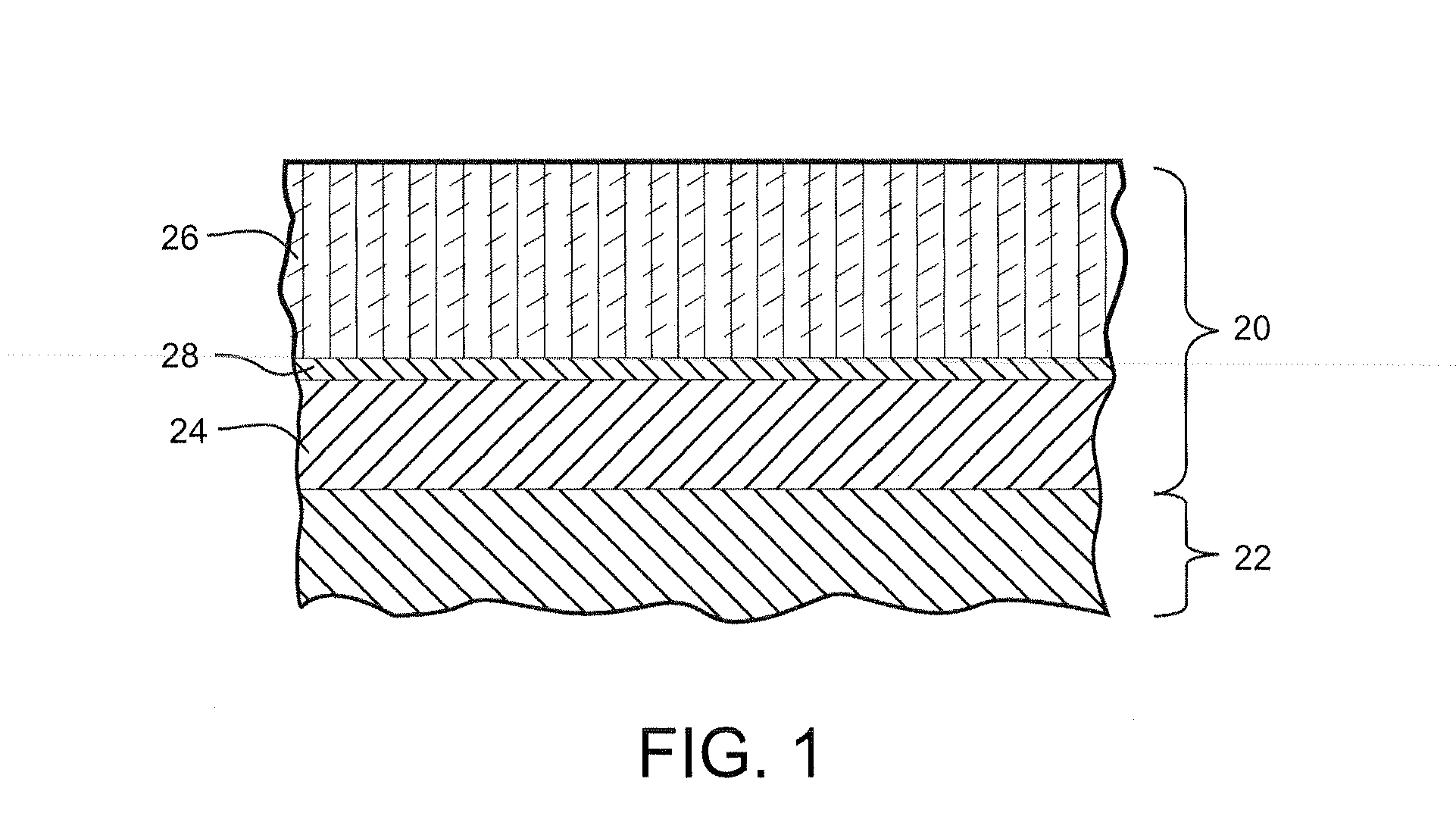

Novel architectures for ultra low thermal conductivity thermal barrier coatings with improved erosion and impact properties

InactiveUS20150233256A1Low thermal conductivityImprove corrosion resistanceMolten spray coatingBlade accessoriesYTTERBIUM OXIDEOxidation resistant

A thermal barrier coating system for metal components in a gas turbine engine having an ultra low thermal conductivity and high erosion resistance, comprising an oxidation-resistant bond coat formed from an aluminum rich material such as MCrAlY and a thermal insulating ceramic layer over the bond coat comprising a zirconium or hafnium oxide lattice structure (ZrO2 or HfO2) and an oxide stabilizer compound comprising one or more of the compounds ytterbium oxide (Yb2O3), yttria oxide (Y2O3), hafnium oxide (HfO2), lanthanum Oxide (La2O3), tantalum oxide (Ta2O5) or zirconium oxide (ZrO2). The invention includes a new method of forming the ceramic-based thermal barrier coatings using a liquid-based suspension containing microparticles comprised of at least one of the above compounds ranging in size between about 0.1 and 5 microns. The coatings form a tortuous path of ceramic interfaces that increase the coating toughness while preserving the ultra low thermal conductivity.

Owner:GENERAL ELECTRIC CO

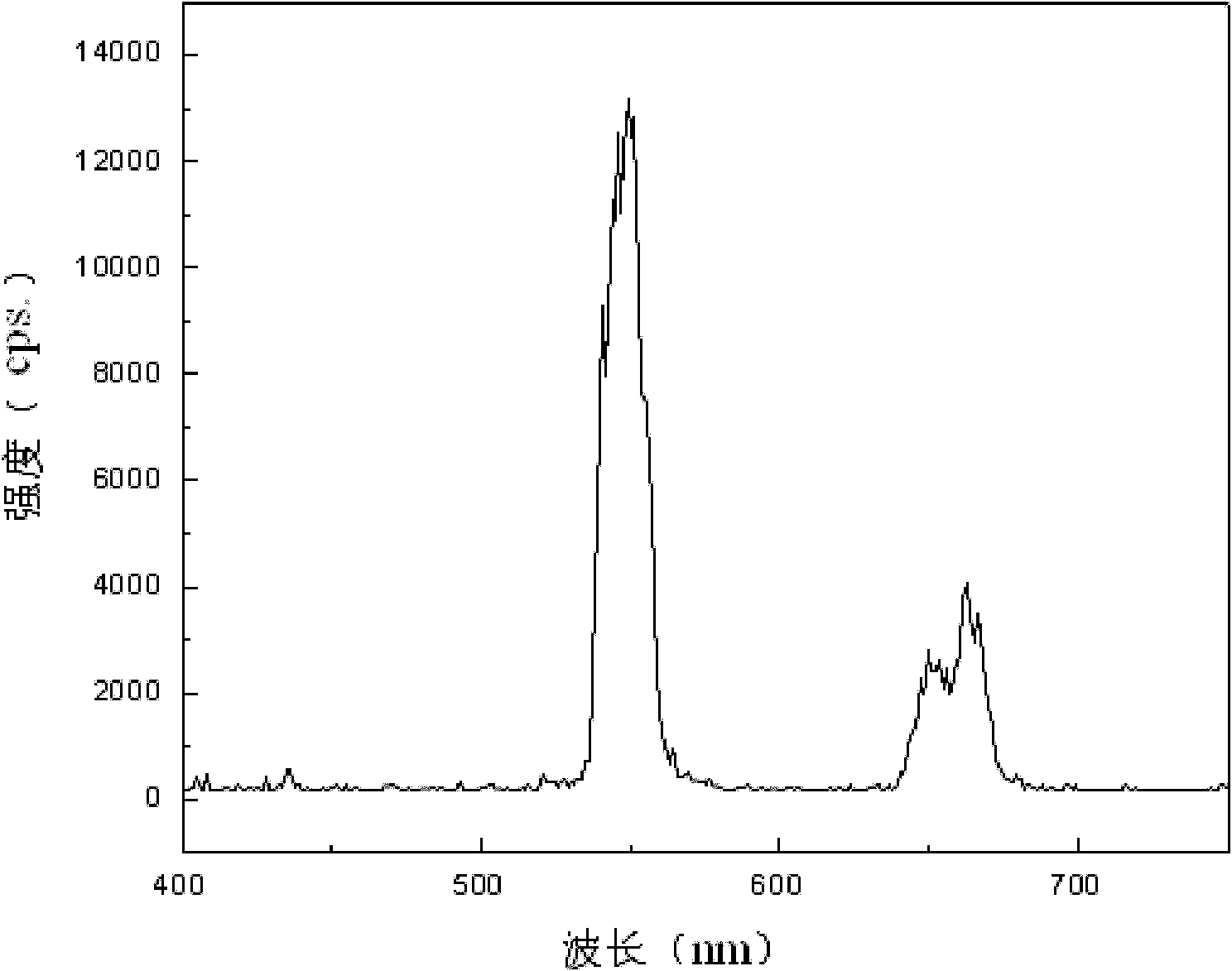

Ytterbium and holmium codoped lithium niobate crystals and preparation method thereof

InactiveCN102127814AImprove up-conversion luminous efficiencyGood resonance absorptionPolycrystalline material growthBy pulling from meltYTTERBIUM OXIDEHolmium

The invention discloses ytterbium and holmium codoped lithium niobate crystals and a preparation method thereof, and relates to doped lithium niobate crystals and a preparation method thereof, which solve the technical problems that the conventional lithium niobate crystals cannot be used as a laser crystal material. The ytterbium and holmium codoped lithium niobate crystals are prepared from niobium pentaoxide, lithium carbonate, ytterbium oxide and holmium oxide. The method comprises the following steps of: mixing the niobium pentaoxide, the lithium carbonate, the ytterbium oxide and the holmium oxide and baking to obtain polycrystal powder; growing crystals at equal diameter from the polycrystal powder in a single crystal growth furnace through seeding, necking, shouldering and folding by a crystal pulling method; and annealing to obtain the ytterbium and holmium codoped lithium niobate crystals. The ytterbium and holmium codoped lithium niobate crystals can emit red light and green light when activated by laser of 980nm and has a broad application prospect in the fields of optical data storage, submarine communication, optical display, color display, photoelectrons, medical diagnosis and the like.

Owner:HARBIN INST OF TECH

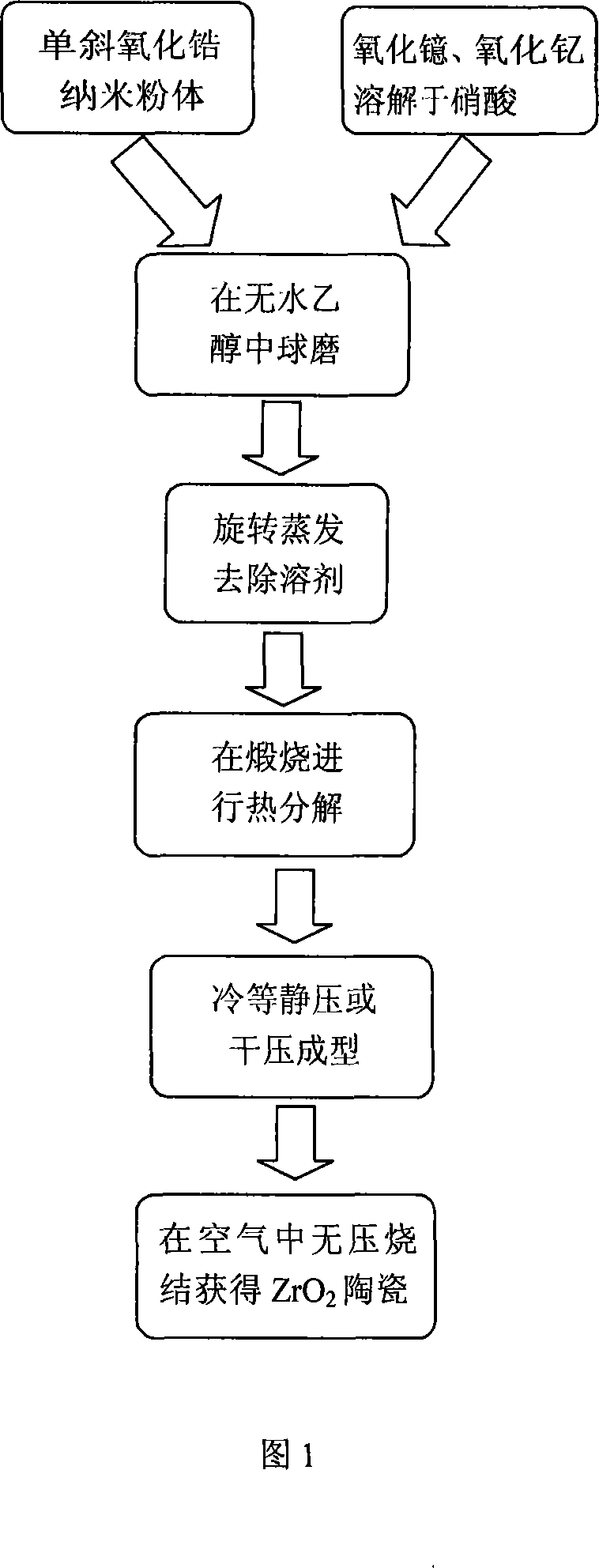

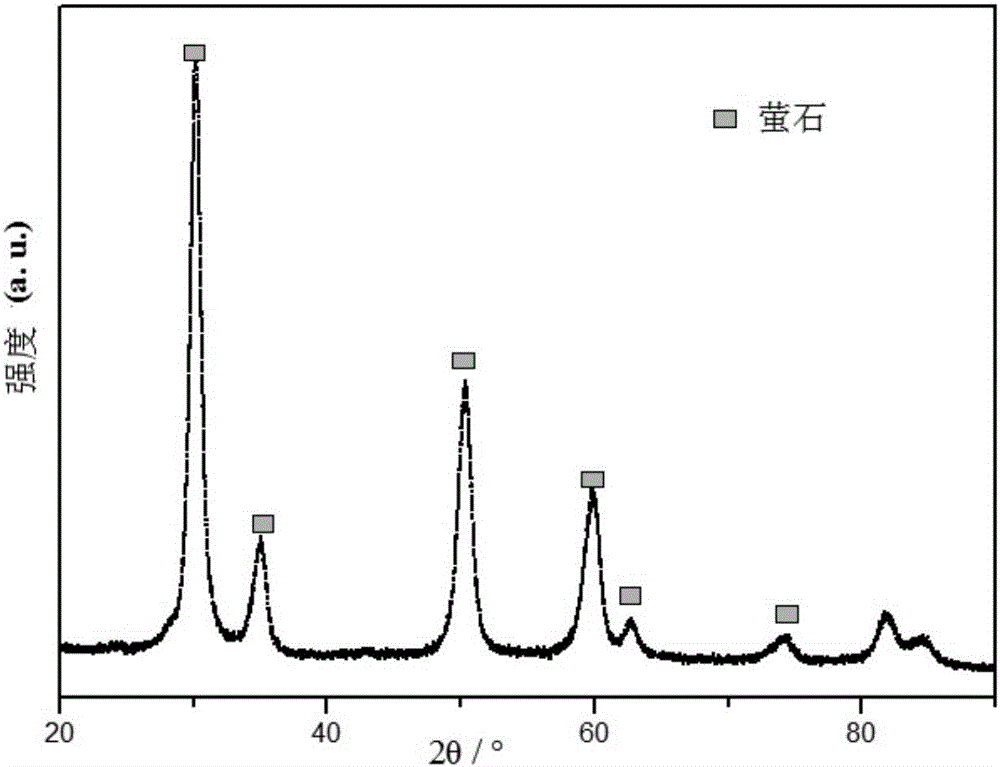

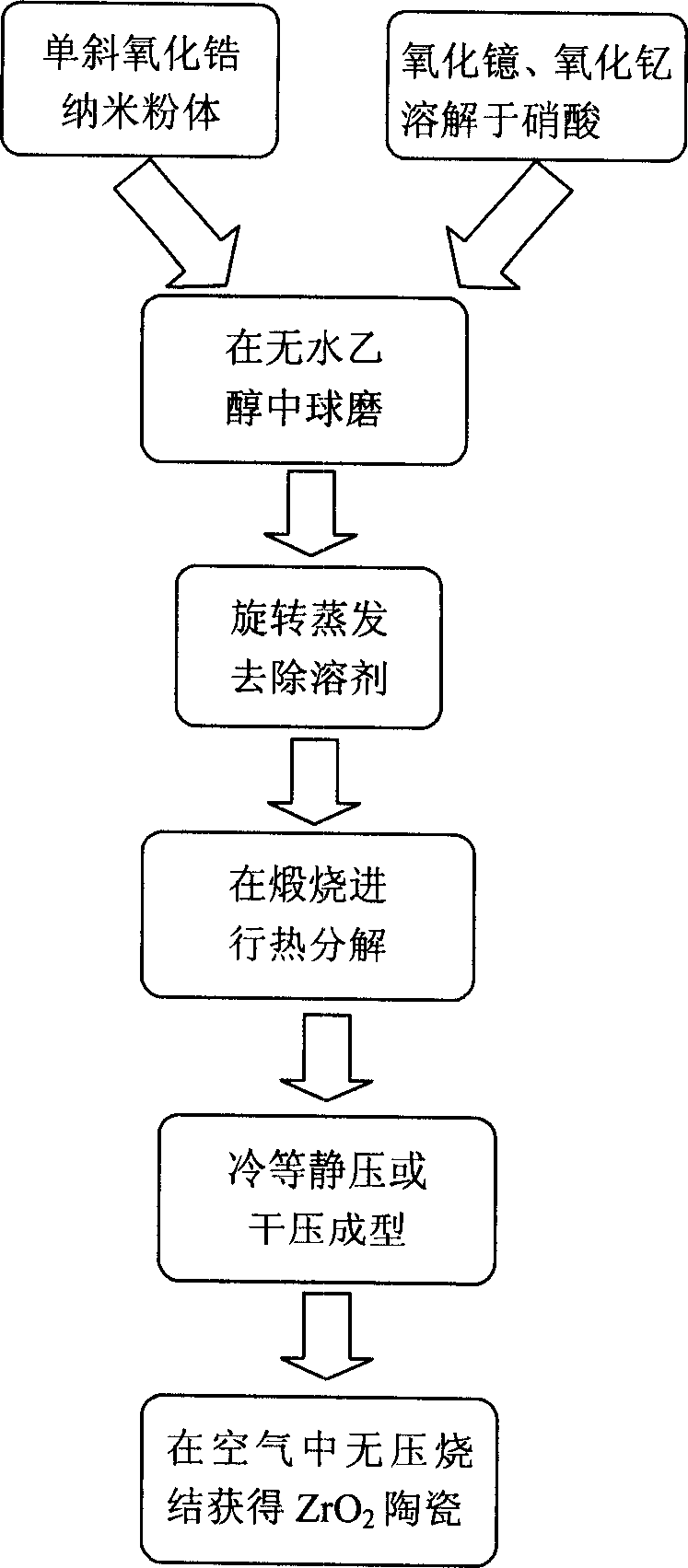

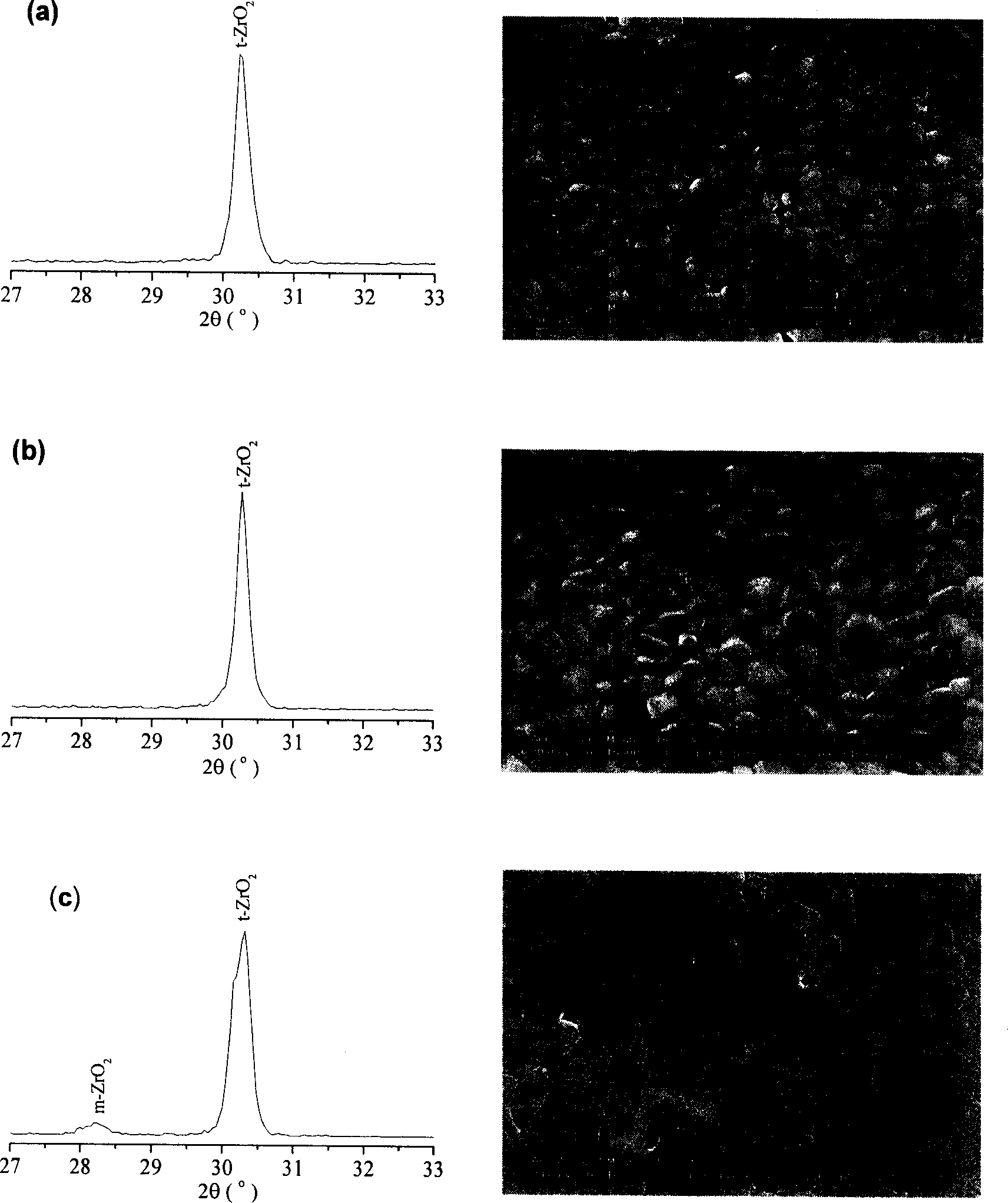

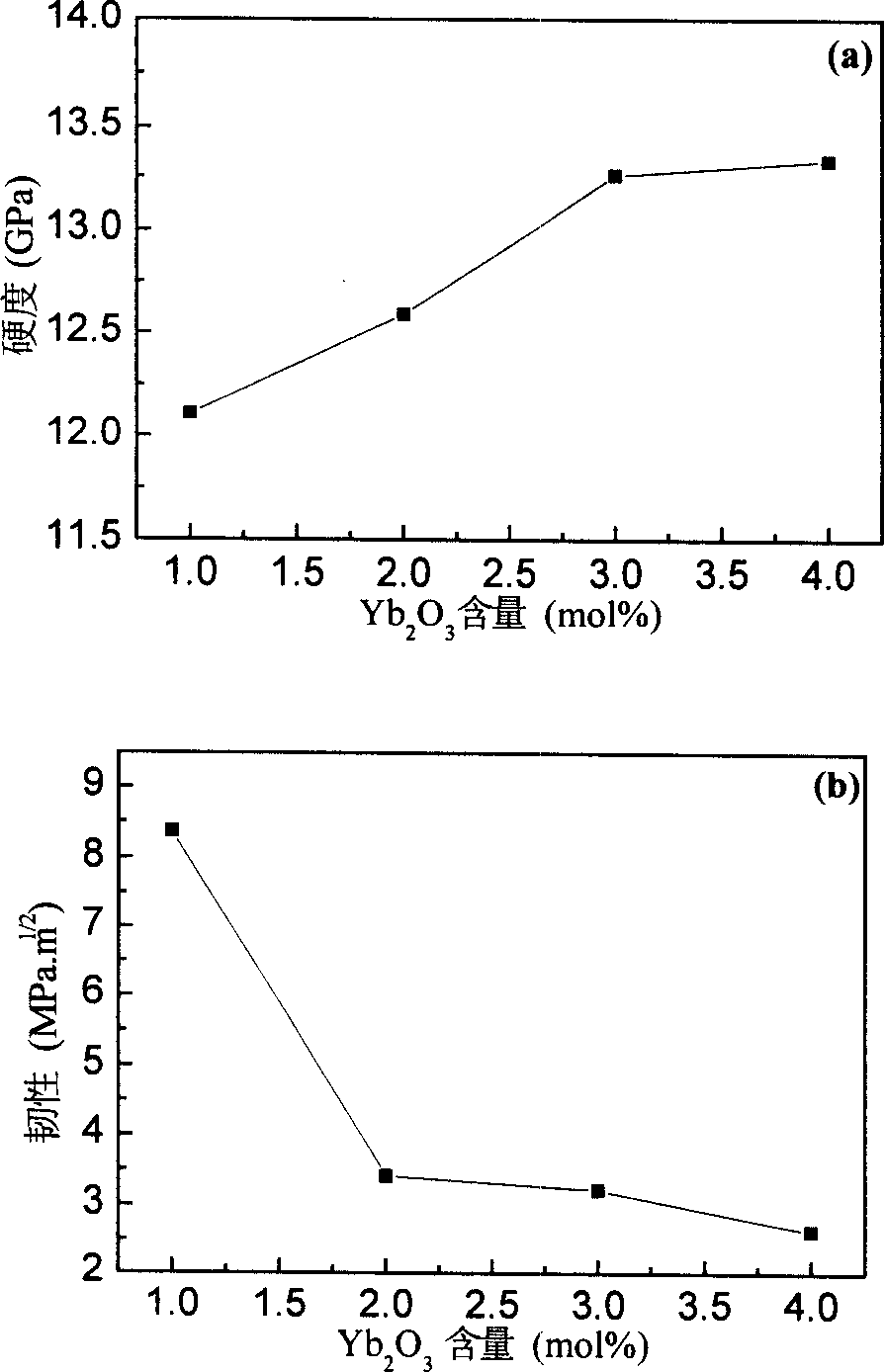

Ytterbium oxide and yttrium oxide co-stabilized zirconia ceramic material and its prepn process

The present invention features that two kinds of oxide, including ytterbium oxide and yttrium oxide, are used as the stabilizers simultaneously to coat nanometer zirconia powder and the obtained powder is sintered in the air and without pressure to obtain tetragonal zirconia polycrystal (TZP) and fully stabilized zirconia ceramic (FSZ) with low stabilizer content. The material includes Yb2O3, Y2O3 and monoclinic zirconia powder in purity over 99.9 wt%. The produced TZP ceramic contains Yb2O3 in 1.0-2.0 mol% and Y2O3 in 1.0-2.0 mol%, and the produced FSZ ceramic contains Yb2O3 in 3.0-4.0 mol% and Y2O3 in 1.0-2.0 mol%.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

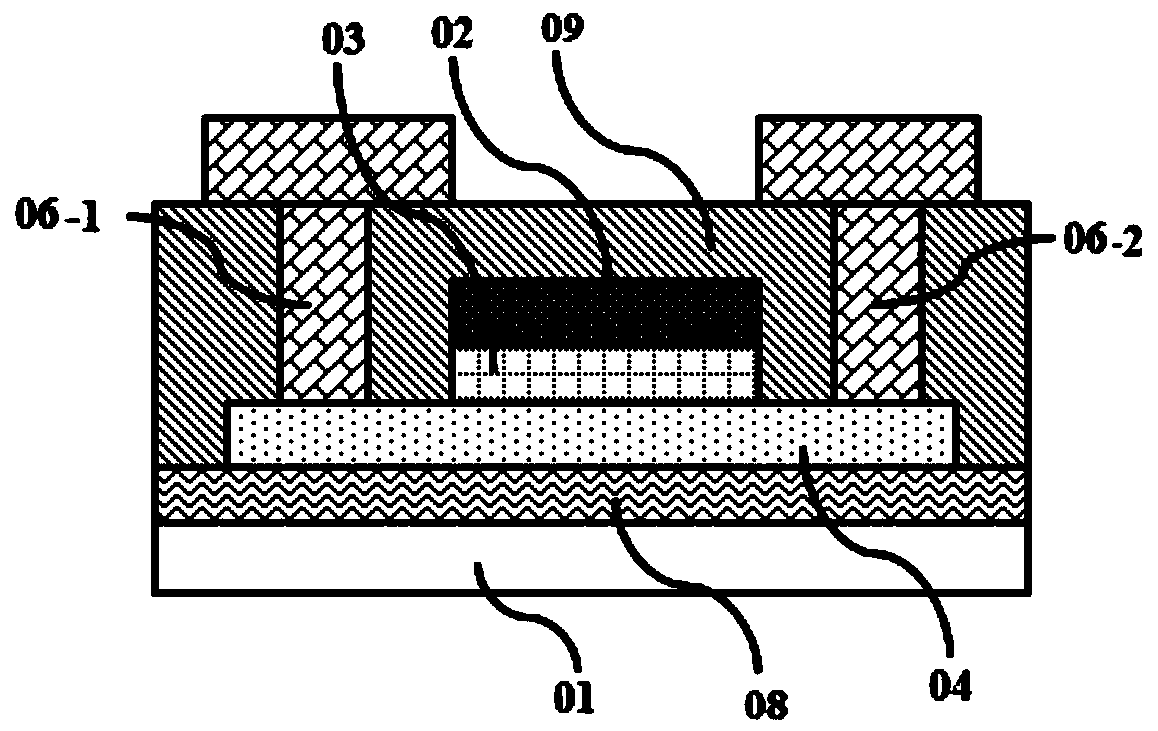

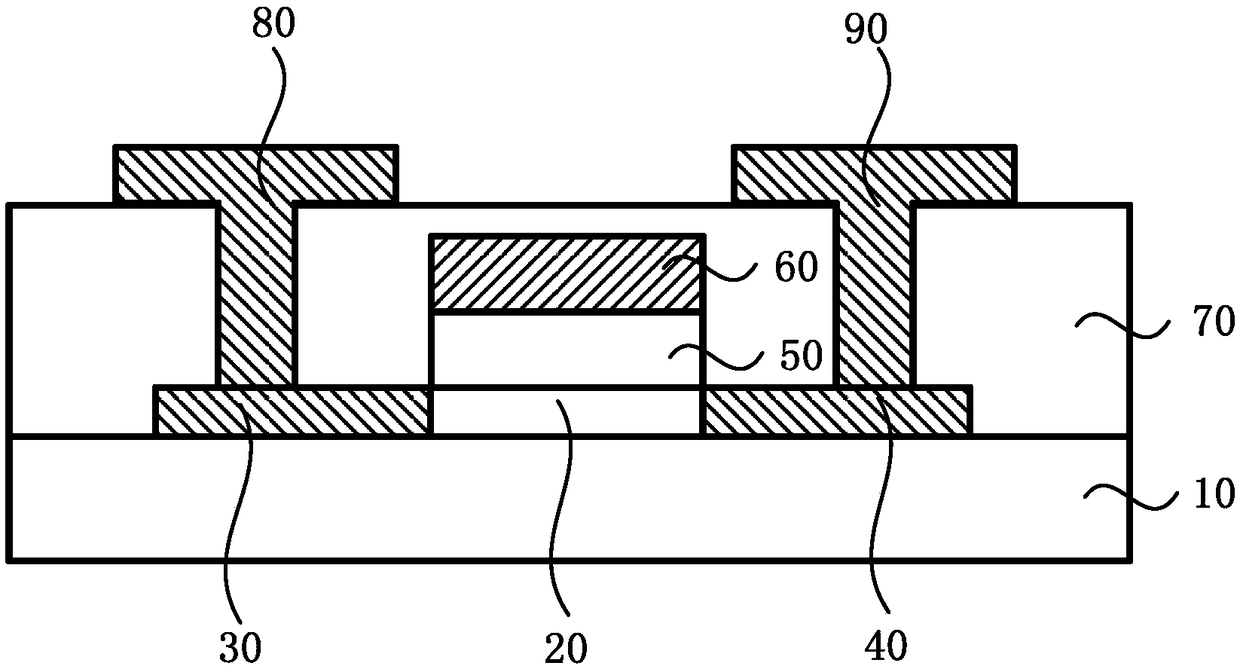

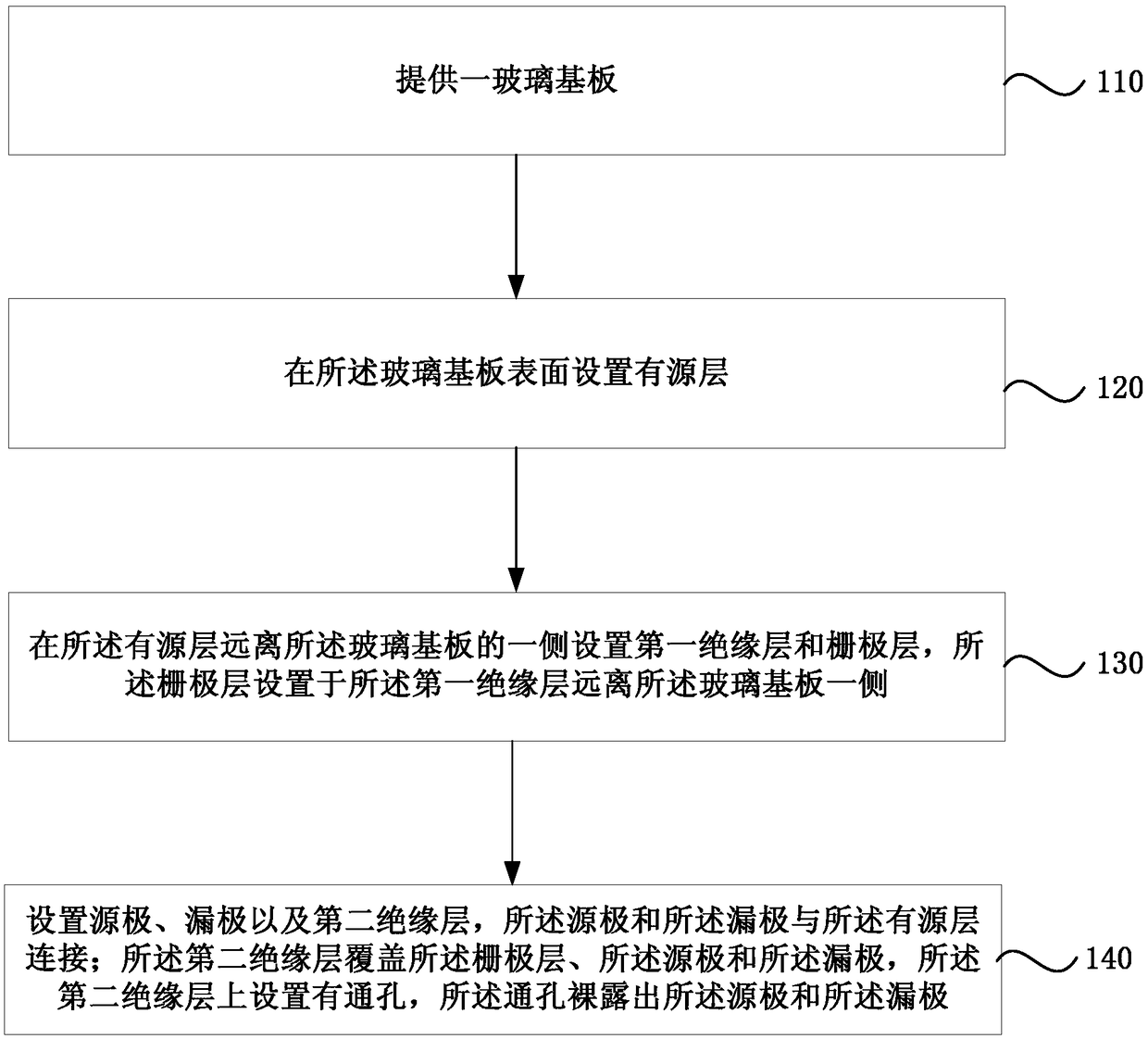

Thin film transistor, display panel, and manufacturing method of thin film transistor

ActiveCN108987470AImprove performanceImprove stabilityTransistorSemiconductor/solid-state device manufacturingYTTERBIUM OXIDERare earth

The embodiment of the invention discloses a thin film transistor, a display panel and a manufacturing method of the thin film transistor. The thin film transistor comprises an active layer arranged onthe surface of a glass substrate, and a source electrode and a drain electrode are connected with the active layer. A first insulating layer disposed on a side of the active layer remote from the glass substrate; A gate layer disposed on a side of the first insulating layer remote from the glass substrate; The second insulating layer covers the source electrode, the drain electrode and the gate electrode layer, and the second insulating layer is provided with a through hole, and the through hole exposes the source electrode and the drain electrode; The active layer is made of (MO) x (RO) y (TO) z, where 0 (x (1, 0001 <=y <= 0. 20, 0.0001 <=z <= 0. 20, x+y+z=1; MO is a metal oxide, and M comprises at least one of In, Zn and Ga; RO is a rare earth oxide, and RO comprises at least one of praseodymium oxide, terbium oxide, dysprosium oxide and ytterbium oxide; TO is a transition metal oxide, and TO comprises at least one of vanadium oxide, niobium oxide and tantalum oxide. Embodiments ofthe present invention provide a low cost top gate structure metal oxide thin film transistor.

Owner:深圳庸行科技有限公司

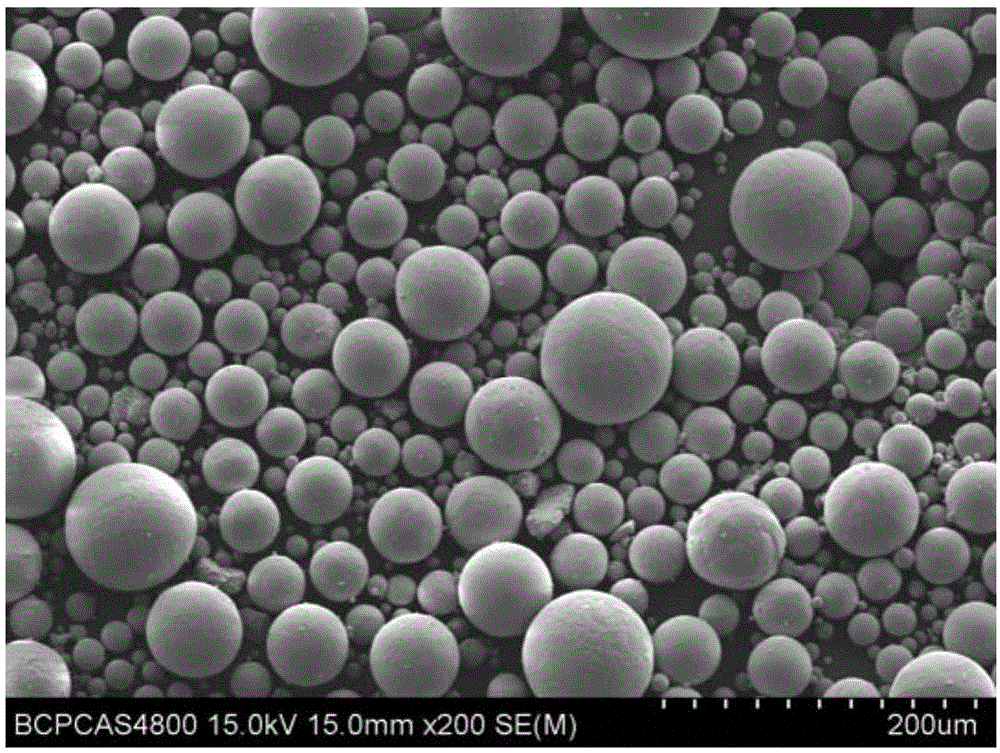

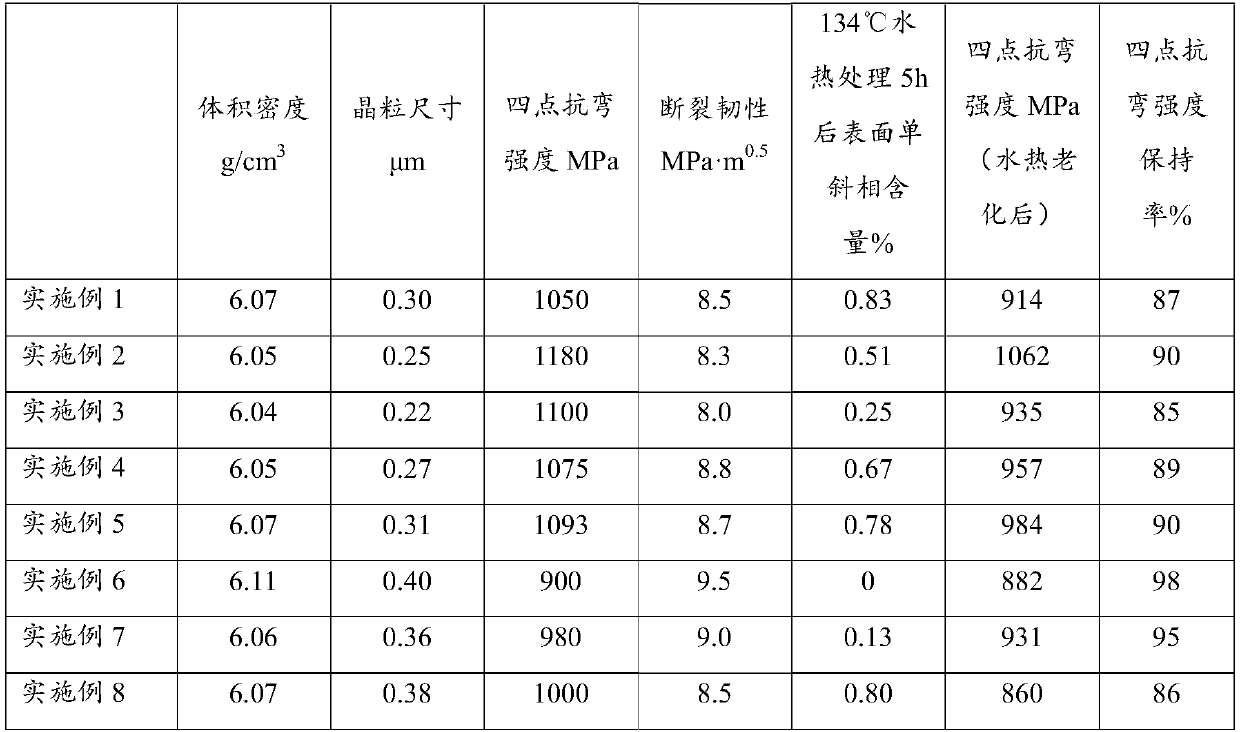

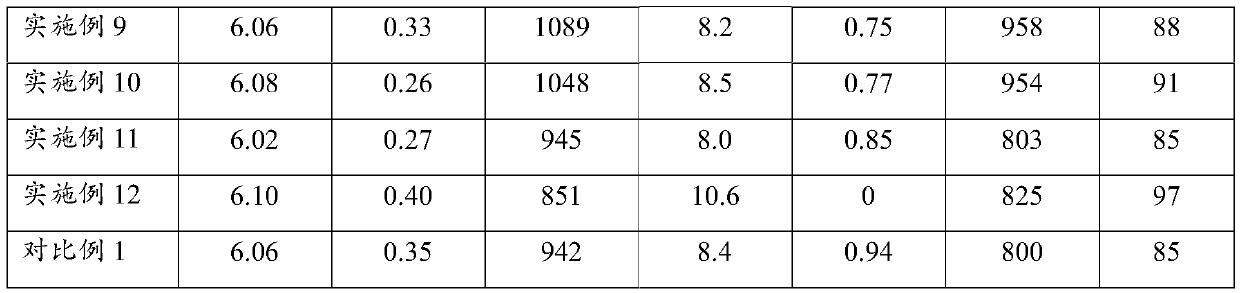

Zirconia ceramic bone implantation prosthesis and preparation method thereof

ActiveCN109095921AImprove performanceSimple processTissue regenerationProsthesisThermal ageingYTTERBIUM OXIDE

The invention provides a zirconia ceramic bone implantation prosthesis and a preparation method thereof. The preparation method comprises the following steps: mixing and grinding zirconia powder, a stabilizer A and silica sol to obtain slurry, wherein the stabilizer A is one or a mixture of two of yttrium oxide and ytterbium oxide by the weight of the zirconia powder as a standard; adding a solvent into the slurry, uniformly mixing, and carrying out spraying drying to obtain micro particles; putting the micro particles into a mold, and carrying out cold isostatic molding at 150-500MPa to obtain a raw blank; pre-sintering the raw blank at 700-1200 DEG C to obtain a biscuit; sintering the biscuit in a microwave sintering furnace at 900-1500 DEG C, and keeping warm for 0.2-2 hours to obtain azirconia ceramic; processing the zirconia ceramic to obtain the zirconia ceramic bone implantation prosthesis. According to the invention, by means of combination of Y / Yb and silica sol doping, pre-sintering and microwave sintering, the sizes of crystal granules, the density, the bending strength, the fracture toughness and the hydrothermal aging resistance of the zirconia ceramic bone implantation prosthesis are improved.

Owner:北京安颂科技有限公司

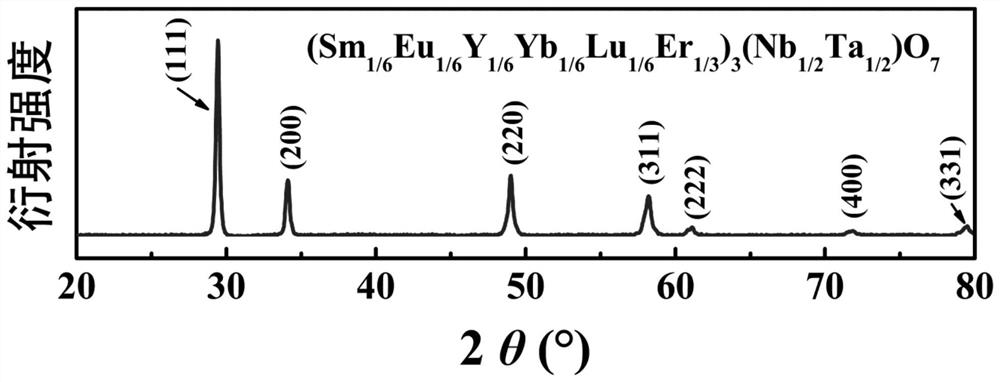

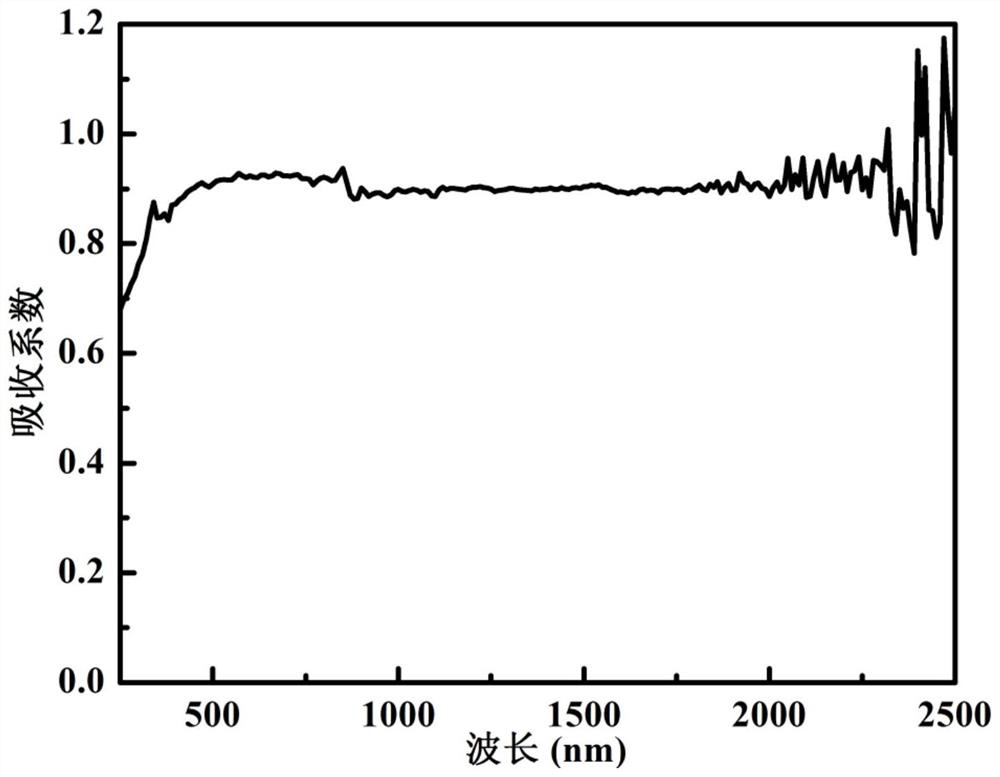

High-temperature-resistant near-infrared absorption high-entropy ceramic and preparation method thereof

The invention relates to high-temperature-resistant near-infrared absorption high-entropy ceramic and a preparation method thereof. The high-entropy ceramic is prepared from the following raw materials in equal molar ratio: 1 part of yttrium oxide, 1 part of neodymium oxide, 1 part of samarium oxide, 1 part of europium oxide, 1 part of ytterbium oxide, 1 part of erbium oxide, 1 part of niobium oxide and 1 part of tantalum oxide. The purity of the high-temperature-resistant near-infrared absorption high-entropy ceramic is not lower than 99wt%, the relative density is not lower than 98%, and theabsorptivity of the high-temperature-resistant near-infrared absorption high-entropy ceramic in a near-infrared band of 0.25-2.5 microns is not lower than 0.9. The high-temperature-resistant near-infrared absorption high-entropy ceramic is obtained by utilizing a high-entropy technology, introducing not less than 6 rare earth metal elements into niobium tantalate at the same time and adjusting the absorption energy level of the forbidden band width to enable the forbidden band width to be matched with the near-infrared wavelength, and the technological process is simple, rapid, flexible and controllable.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com