Method for microwave sintering of sialon ceramic material

A microwave sintering, ceramic material technology, applied in sustainable manufacturing/processing, climate sustainability, chemical industry, etc., can solve the problems of high energy consumption, low efficiency restrictions, etc., to reduce the sintering densification temperature and prevent crack propagation , the effect of improving the shrinkage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

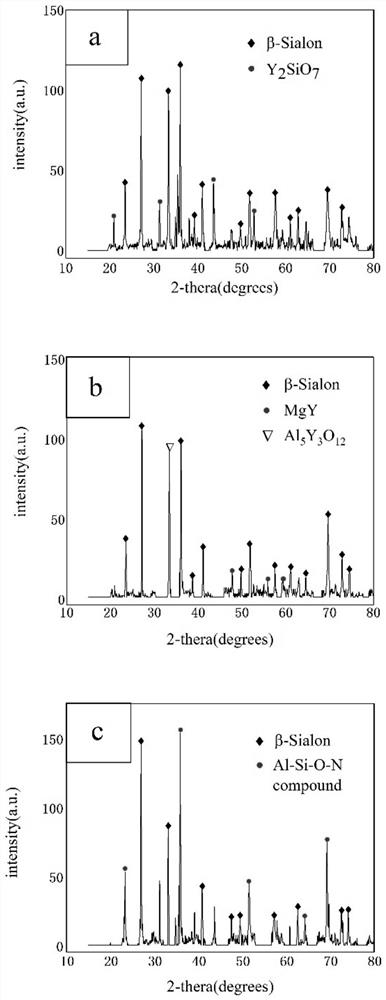

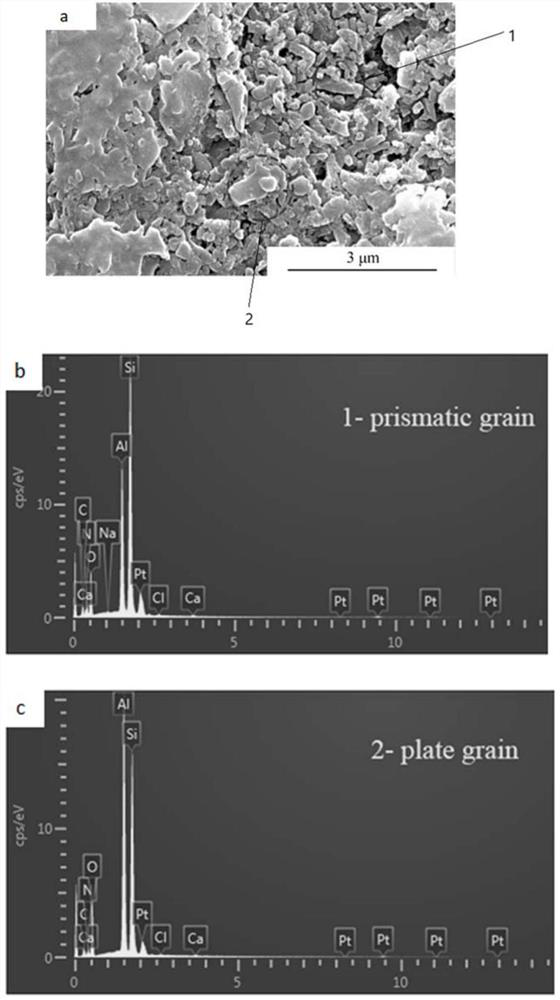

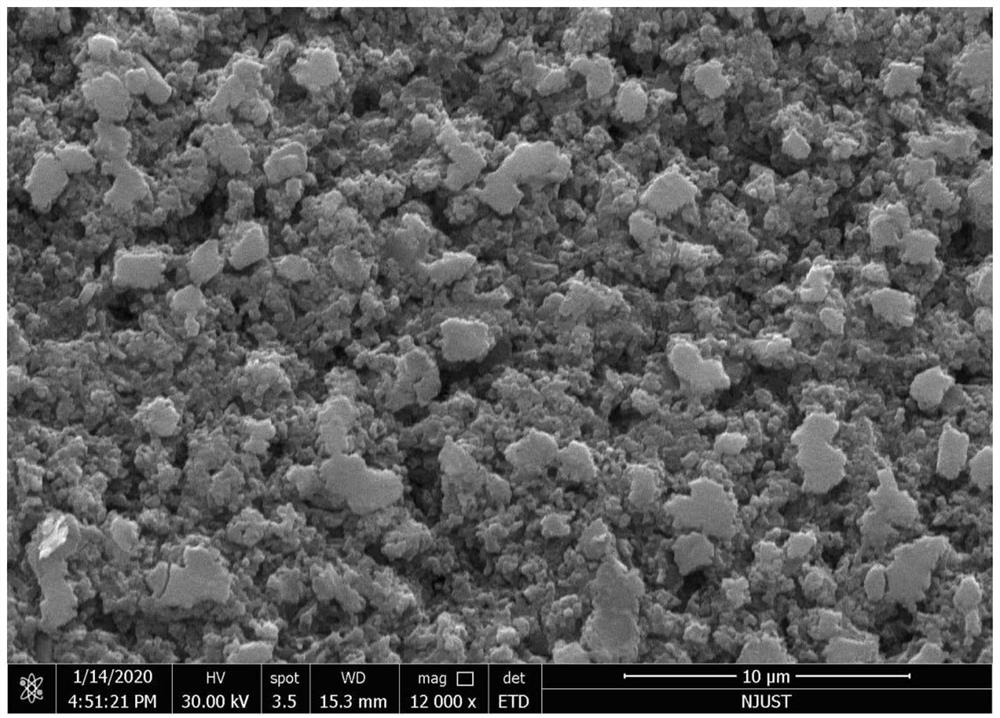

Embodiment 1

[0045] A sialon ceramic material and its microwave sintering process, specifically: proportioning by mass fraction, silicon nitride 72.37wt.%, aluminum nitride 6.98wt.%, aluminum oxide 17.65wt.%, while adding a suitable sintering aid Combination, the mass percentage of each sintering aid is as follows: yttrium oxide 3wt.%, mix the prepared raw material powder, use industrial absolute ethanol and corundum balls as the mixing medium, and pass the mixed raw material powder through a planetary ball mill for 24 hours, and add PVA 2 hours before taking it out. Vacuum drying is carried out after the ball milling, the drying temperature is 110°C, the dry powder is sieved and granulated through a 100-mesh sieve, the interior of the cemented carbide mold is coated with oil, and then the sieved powder is filled into the mold, and the graphite Apply a pressure of 200 MPa to the mold, hold the pressure for 2 minutes, cold press and demould. The samples after demoulding were put into the i...

Embodiment 2

[0047] A sialon ceramic material and its microwave sintering process, specifically: proportioning by mass fraction, silicon nitride 70.12wt.%, aluminum nitride 6.77wt.%, aluminum oxide 17.11wt.%, while adding a suitable sintering aid Combination, the mass percentage of each sintering aid is as follows: 5wt.% of yttrium oxide, 1wt.% of samarium oxide, mix the prepared raw material powder, use industrial absolute ethanol and corundum balls as the mixing medium, and mix the mixed raw material powder The bodies were ball milled in a planetary ball mill for 24 hours, and PVA was added 2 hours before removal. Vacuum drying is carried out after the ball milling, the drying temperature is 110°C, the dry powder is sieved and granulated through a 100-mesh sieve, the interior of the cemented carbide mold is coated with oil, and then the sieved powder is filled into the mold, and the graphite Apply a pressure of 200 MPa to the mold, hold the pressure for 2 minutes, cold press and demould....

Embodiment 3

[0049] A sialon ceramic material and its microwave sintering process, specifically: proportioning by mass fraction, silicon nitride 68.63wt.%, aluminum nitride 6.63wt.%, aluminum oxide 16.74wt.%, while adding a suitable sintering aid Combination, the mass percentage of each sintering aid is as follows: 7wt.% of yttrium oxide, 1wt.% of magnesium oxide, mix the prepared raw material powder, use industrial absolute ethanol and corundum ball as the mixing medium, and mix the mixed raw material powder The bodies were ball milled in a planetary ball mill for 24 hours, and PVA was added 2 hours before removal. Vacuum drying is carried out after the ball milling, the drying temperature is 110°C, the dry powder is sieved and granulated through a 100-mesh sieve, the interior of the cemented carbide mold is coated with oil, and then the sieved powder is filled into the mold, and the graphite Apply a pressure of 200 MPa to the mold, hold the pressure for 2 minutes, cold press and demould....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Actual density | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Actual density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com