Patents

Literature

1570results about How to "Improve shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

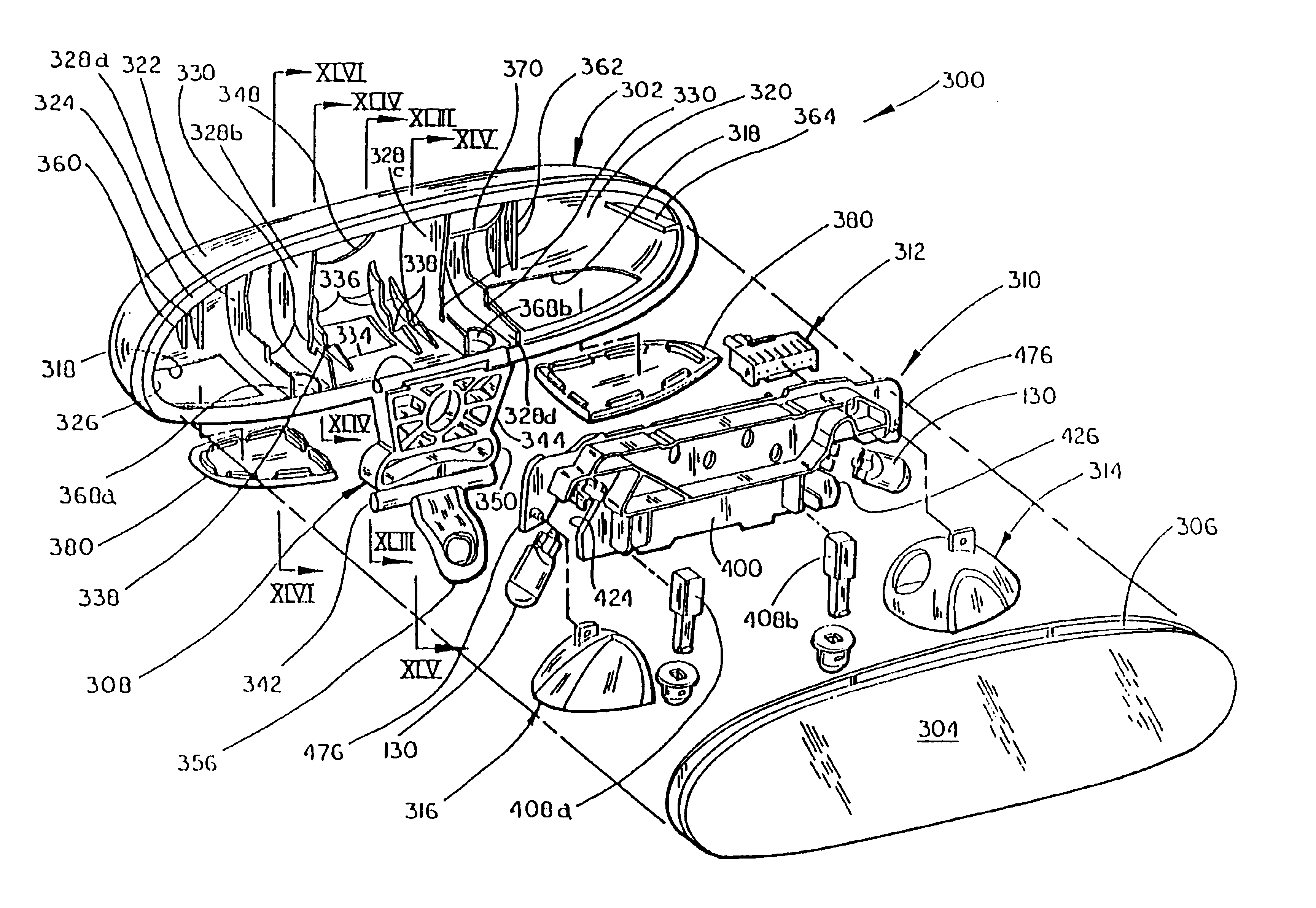

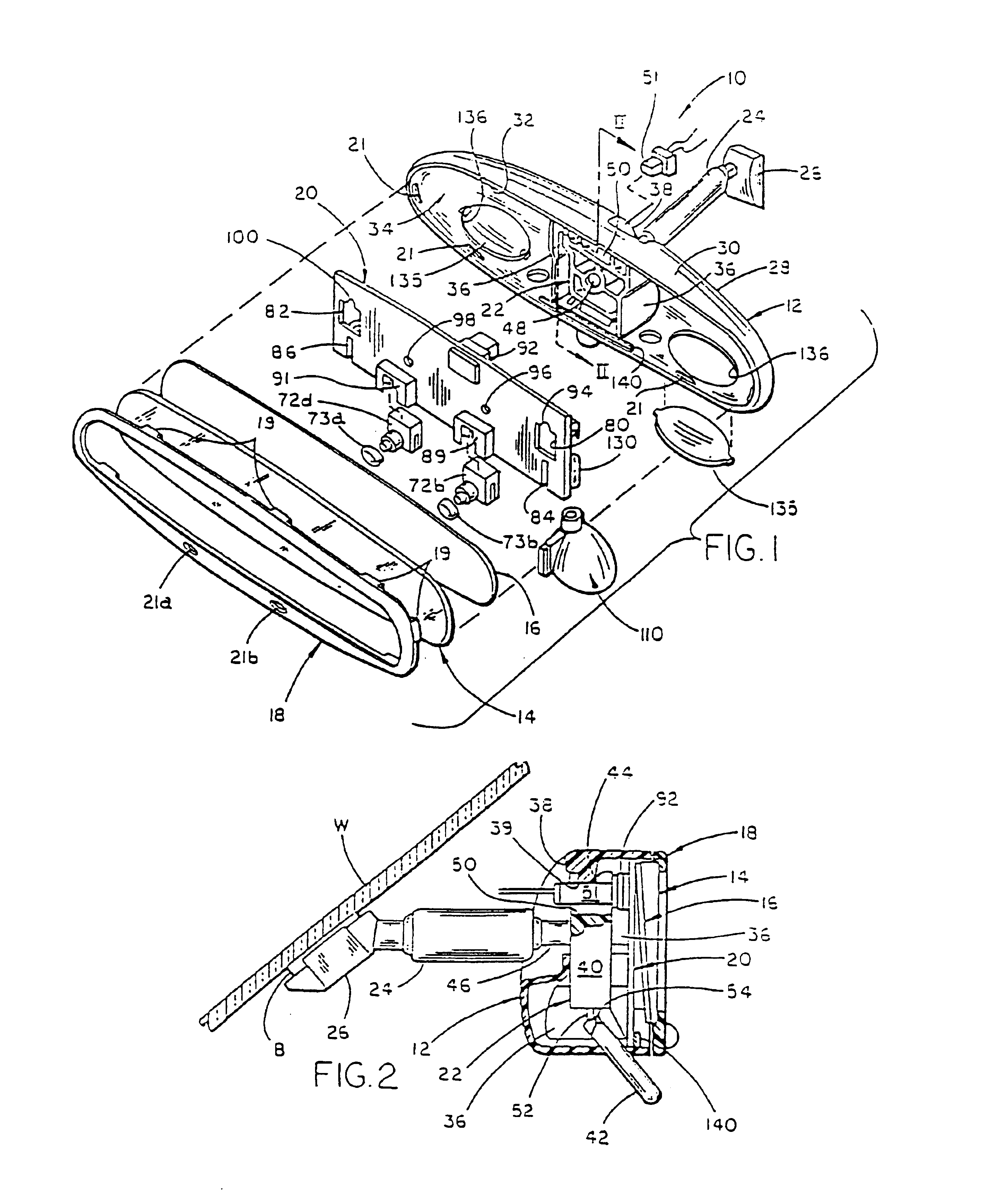

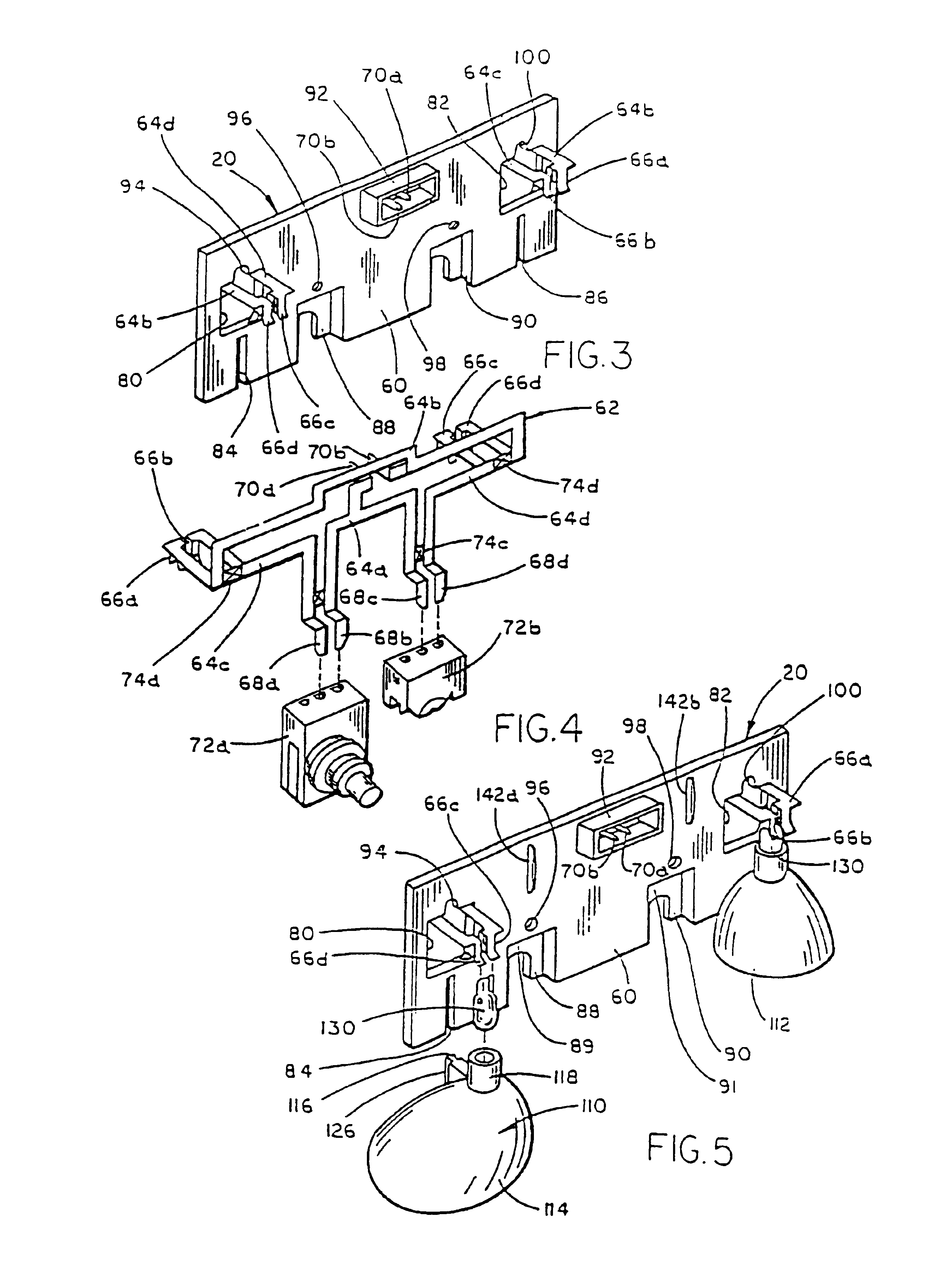

Modular rearview mirror assembly

InactiveUS6877888B2Increased durabilityImprove reliabilityLighting elementsClosed circuit television systemsPolymer resinElectrical devices

An interior rearview mirror assembly for vehicles incorporates a reflective mirror element for viewing by a user of the mirror assembly, a lip formed from moldable polymeric resin selected to expand sufficiently when heated to allow snap in insertion of the reflective mirror element while the lip is warm and flexable, a carrier located to the rear of the reflective element such that the carrier is closer to a windshield of the vehicle than the mirror element when the mirror element is mounted in the vehicle, at least one electrical accessory, and an electrical connector adapted to receive a connector from the vehicle electrical system with the electrical accessory connected to the electrical connector. Preferably, the electrical accessory is supported by the carrier and is selected from a variety of electrical devices, lamps, lights, sensors and the like.

Owner:DONNELLY CORP

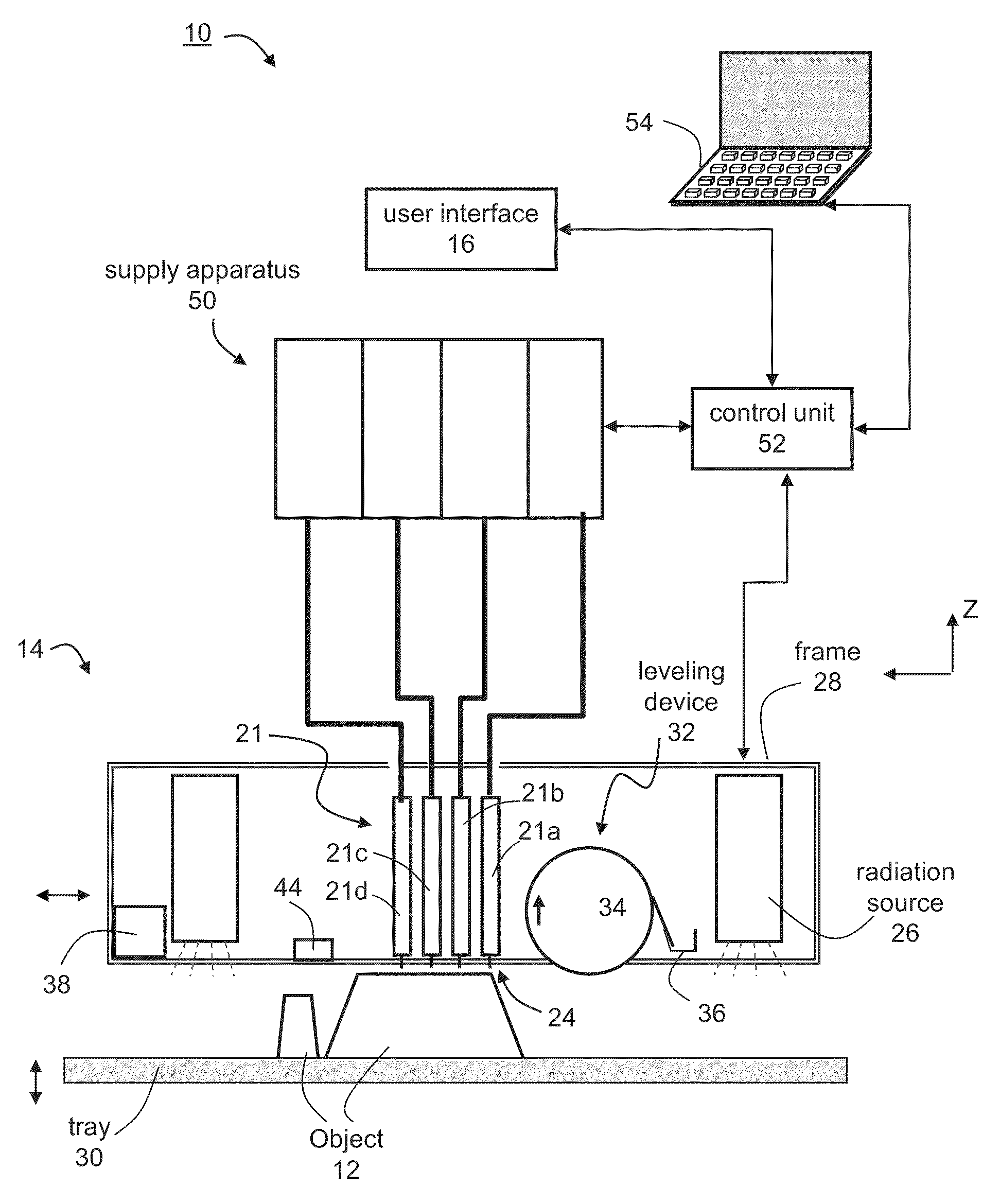

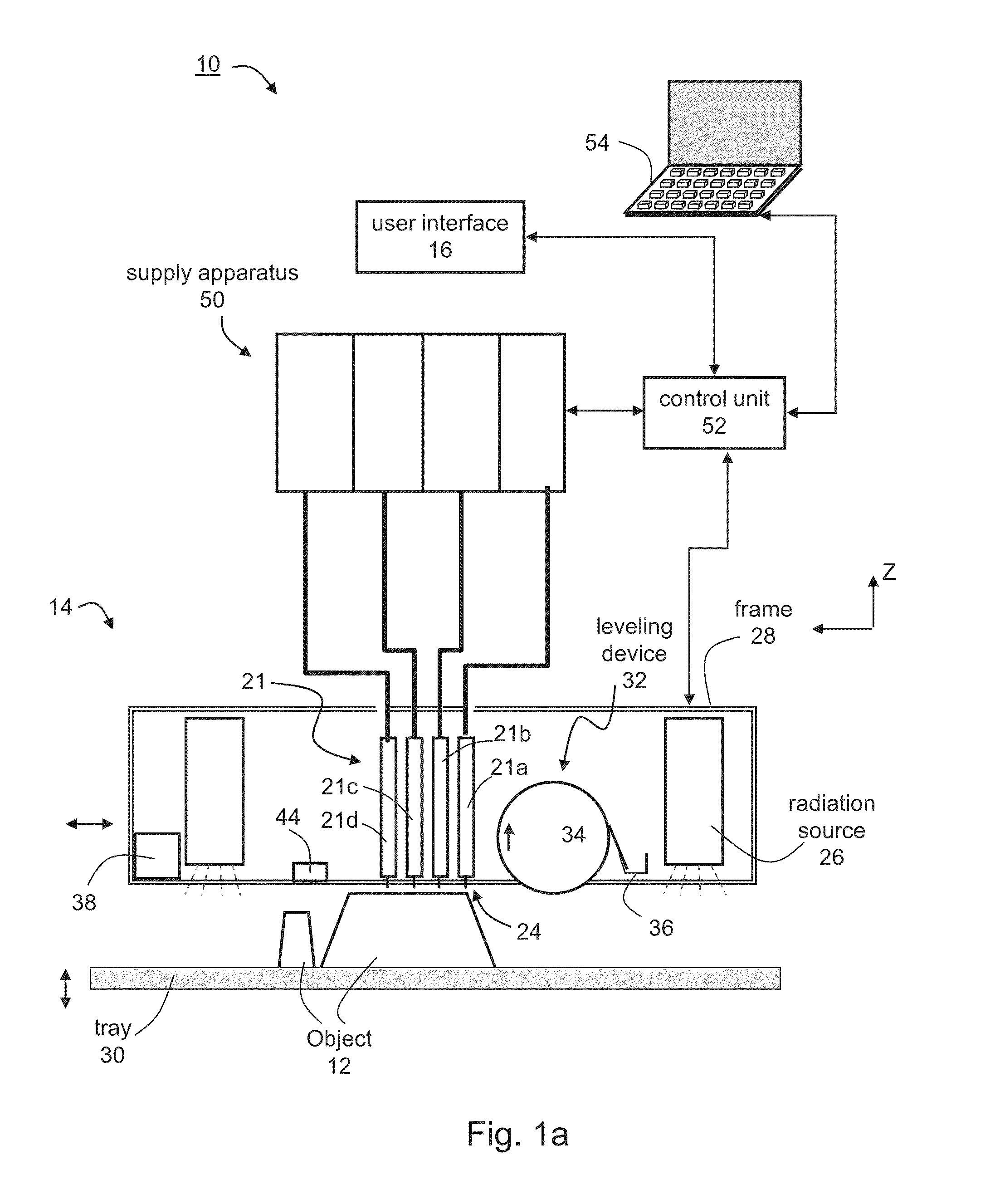

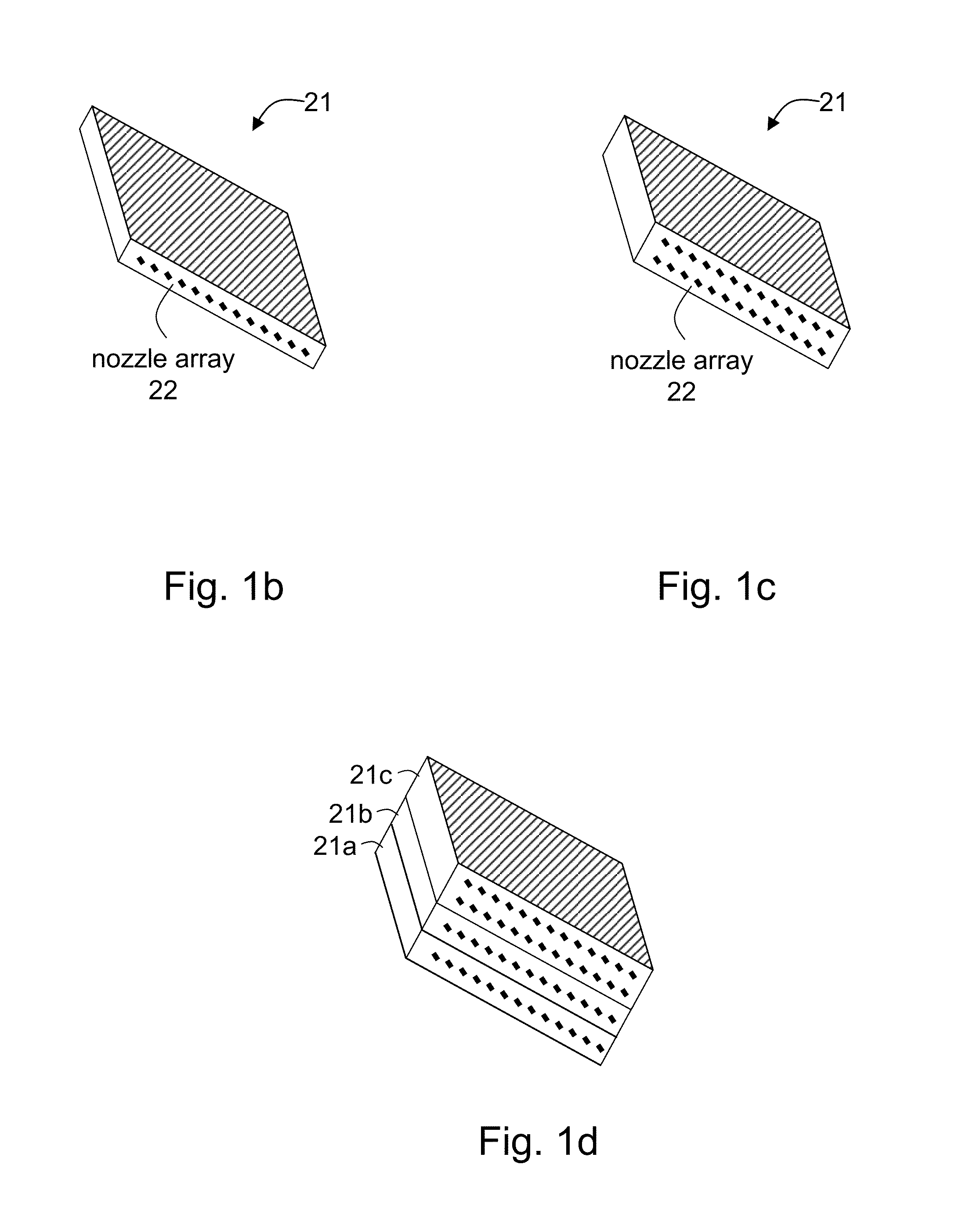

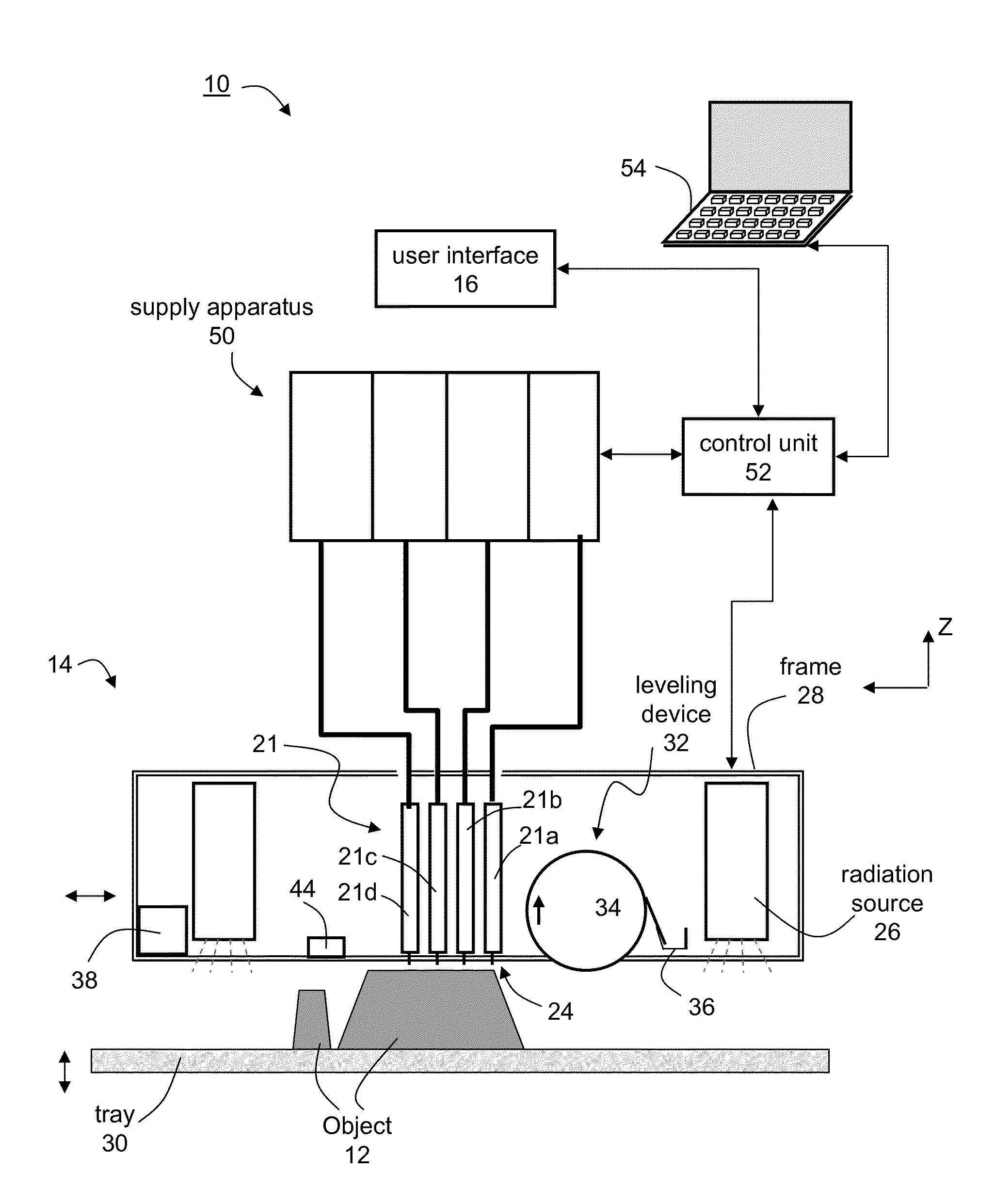

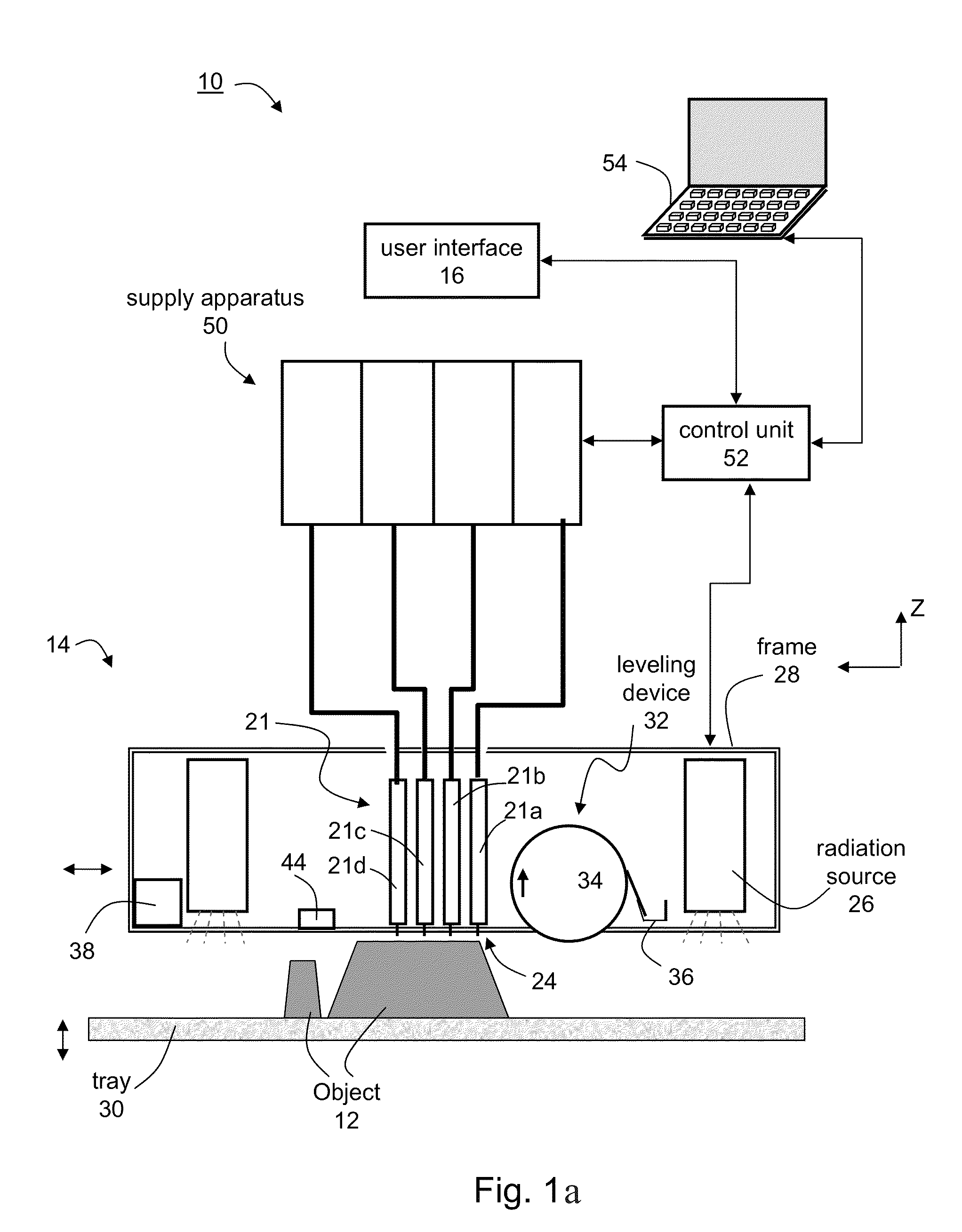

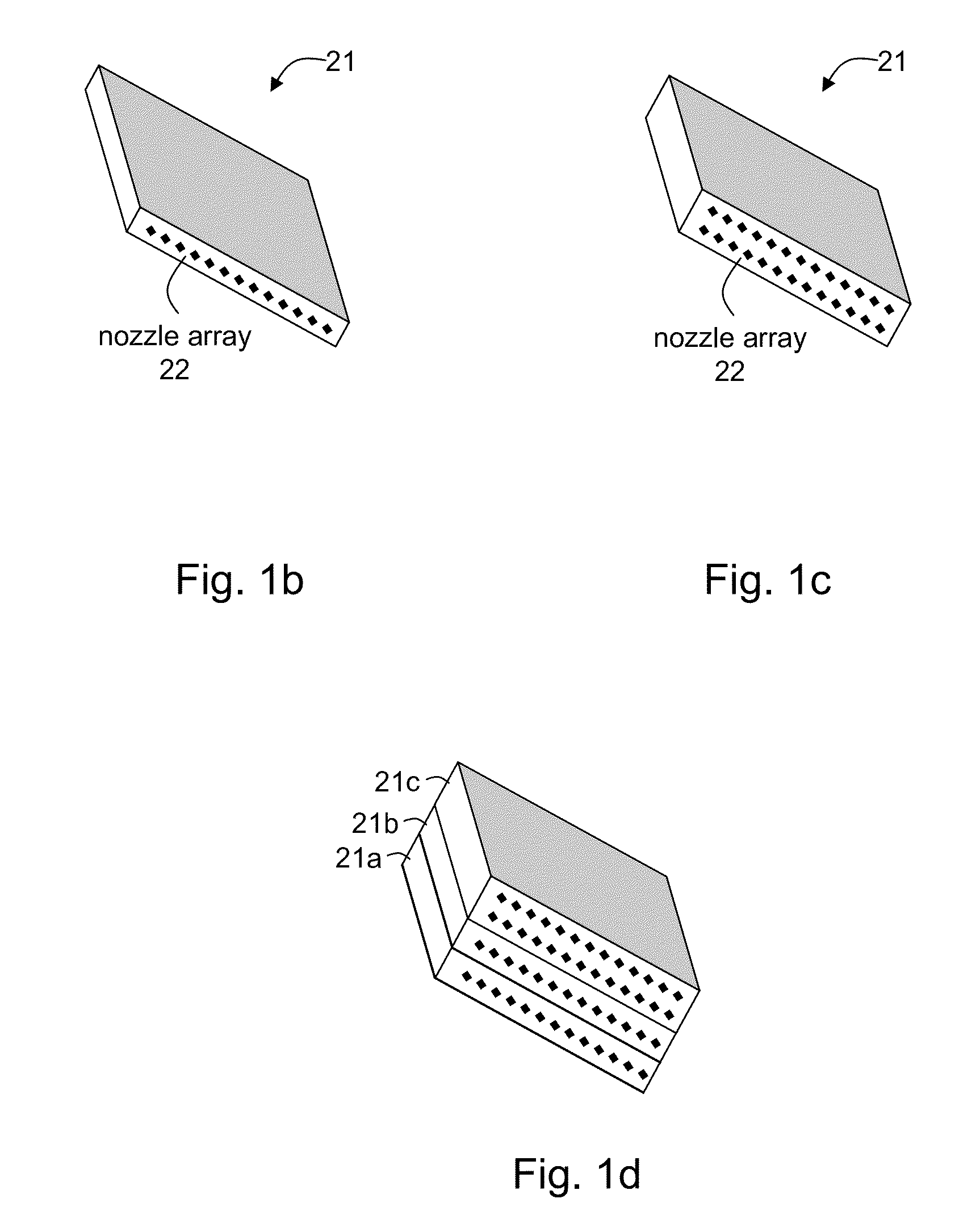

Solid freeform fabrication using a plurality of modeling materials

ActiveUS9031680B2Easy to burnImprove shrinkageAdditive manufacturing apparatusAdditive manufacturing with liquidsOperation modeSolid freeform fabrication

A system and methods for solid freeform fabrication of an object is disclosed. The system comprises a solid freeform fabrication apparatus having a plurality of dispensing heads, a building material supply apparatus configured to supply a plurality of building materials to the fabrication apparatus, and a control unit configured for controlling the fabrication apparatus and the supply apparatus based on an operation mode selected from a plurality of predetermined operation modes.

Owner:STRATASYS LTD

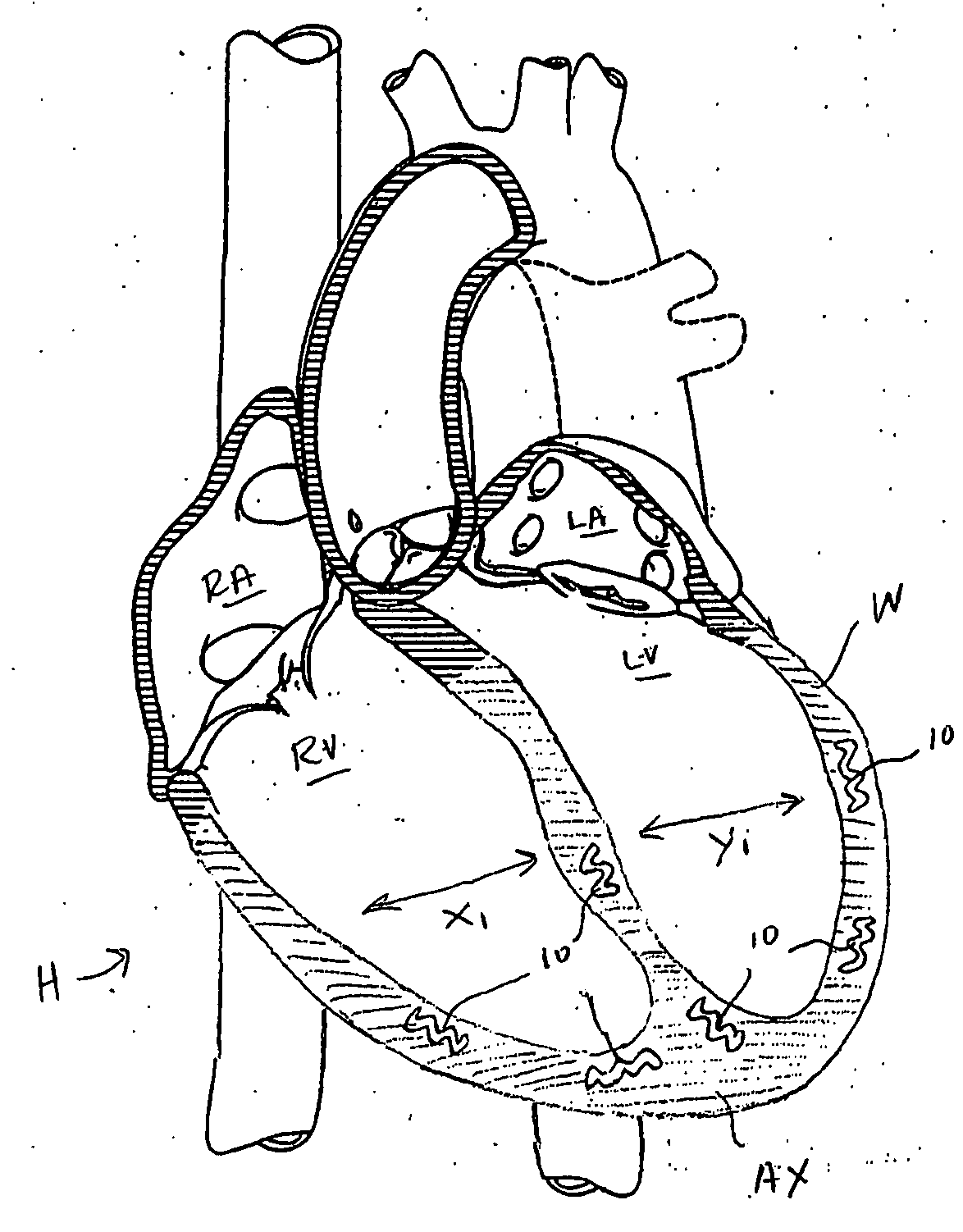

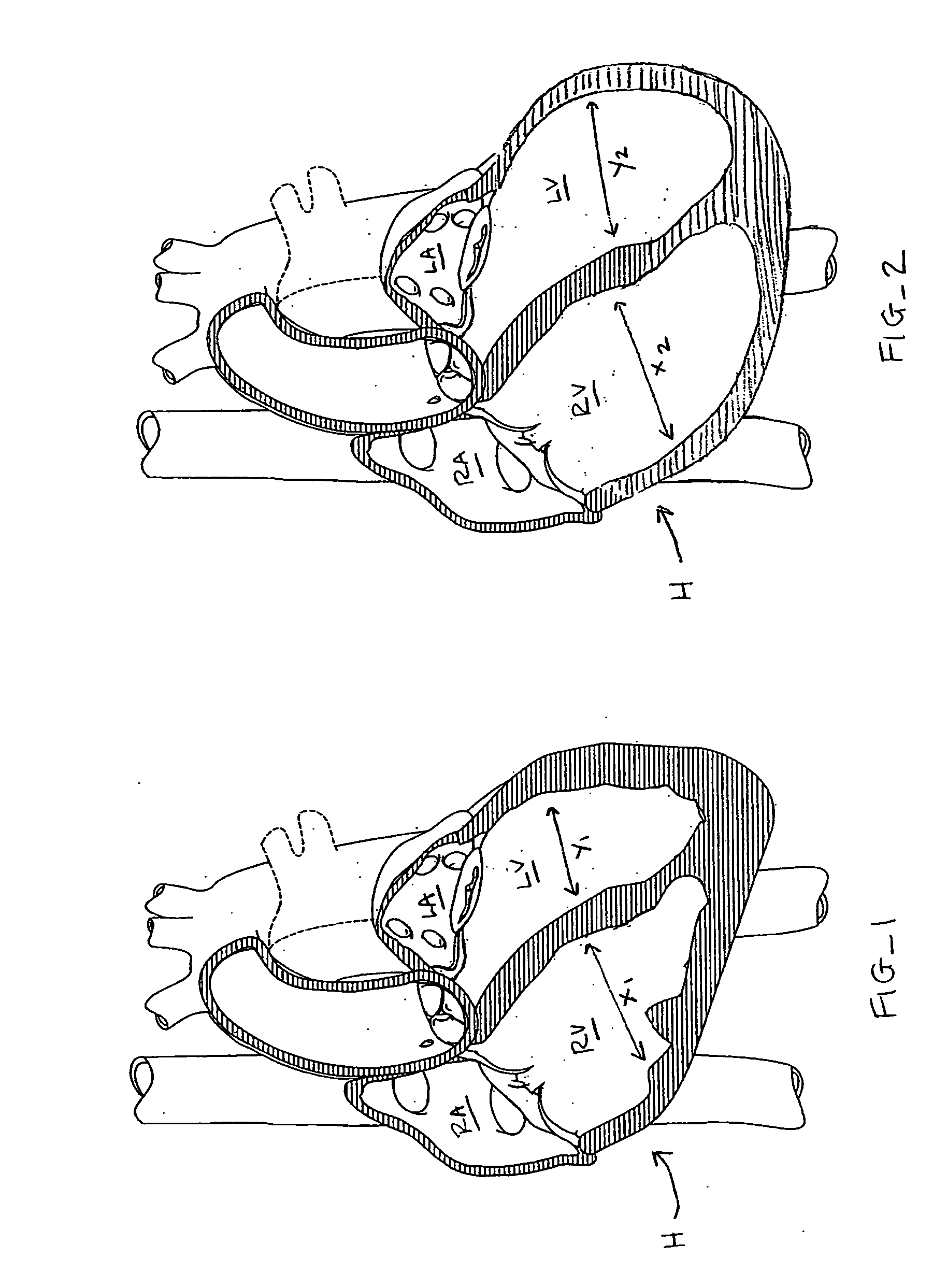

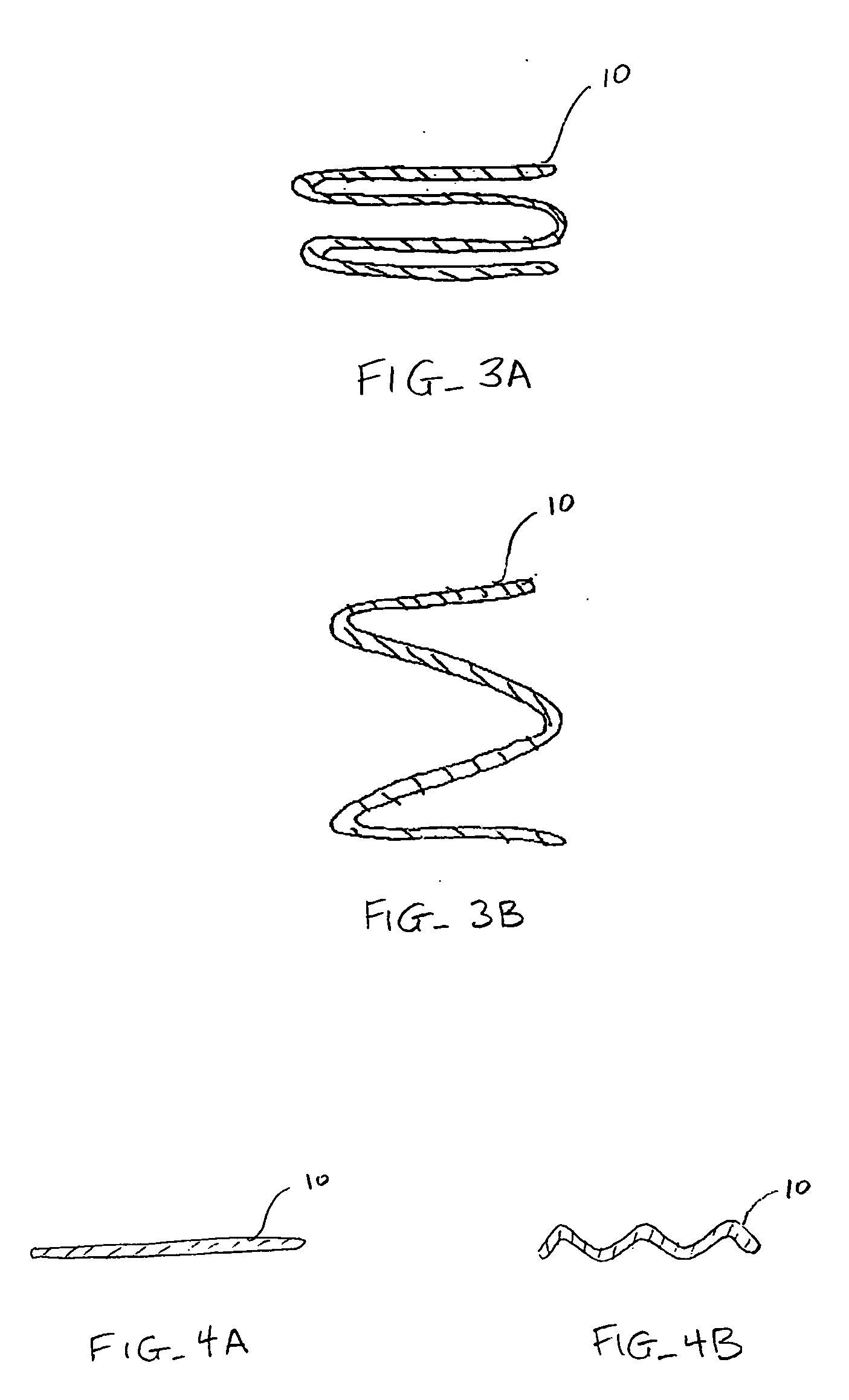

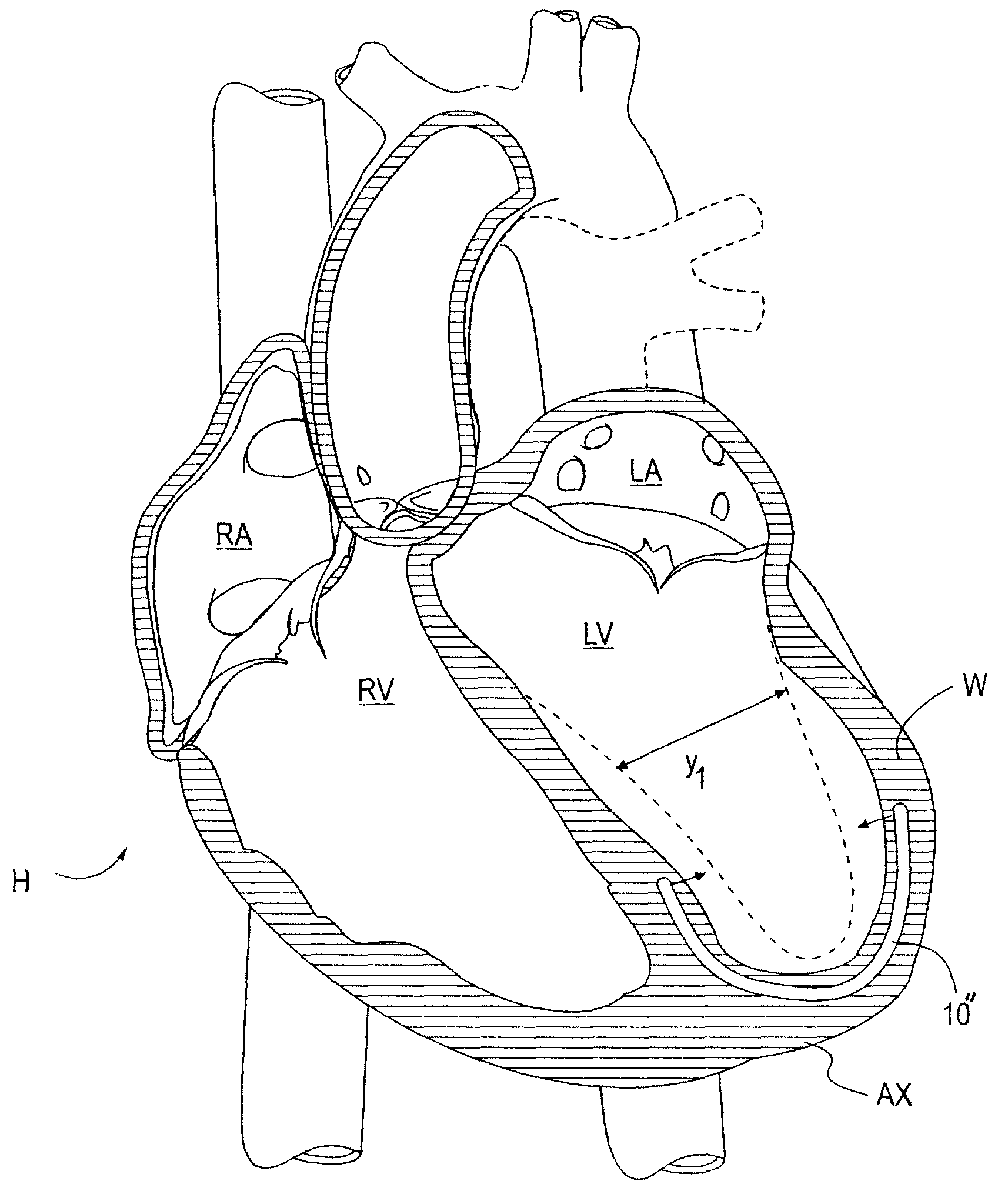

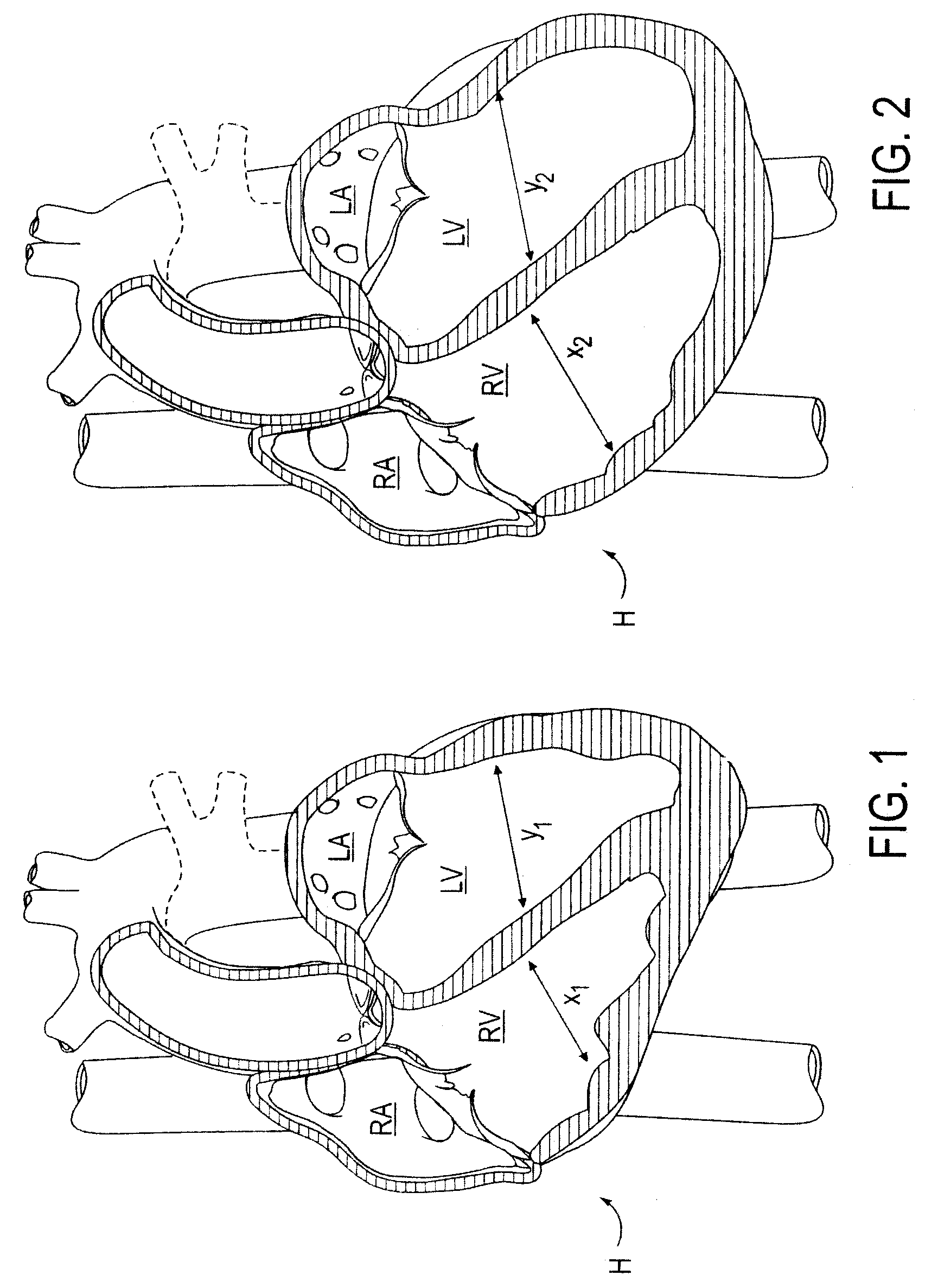

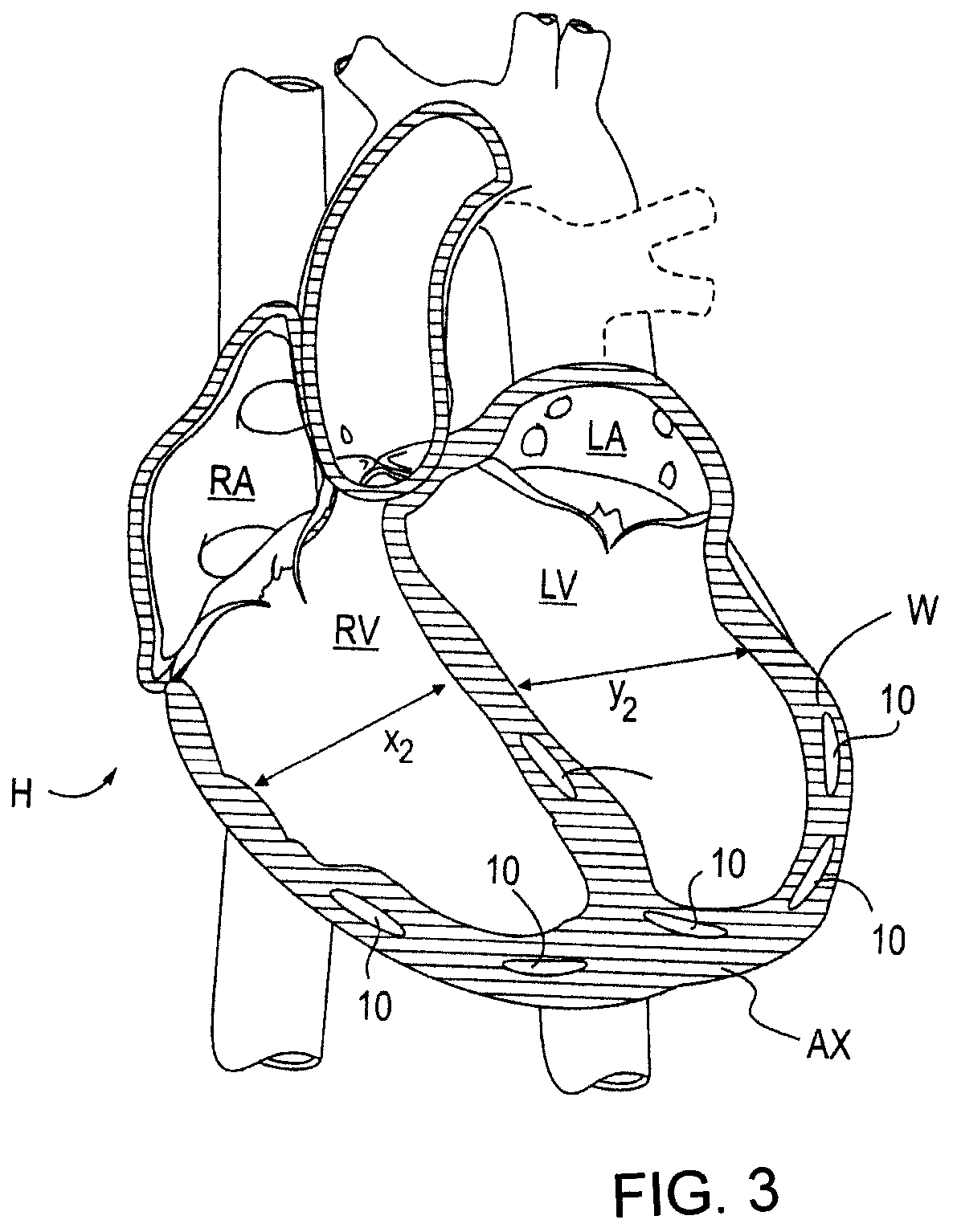

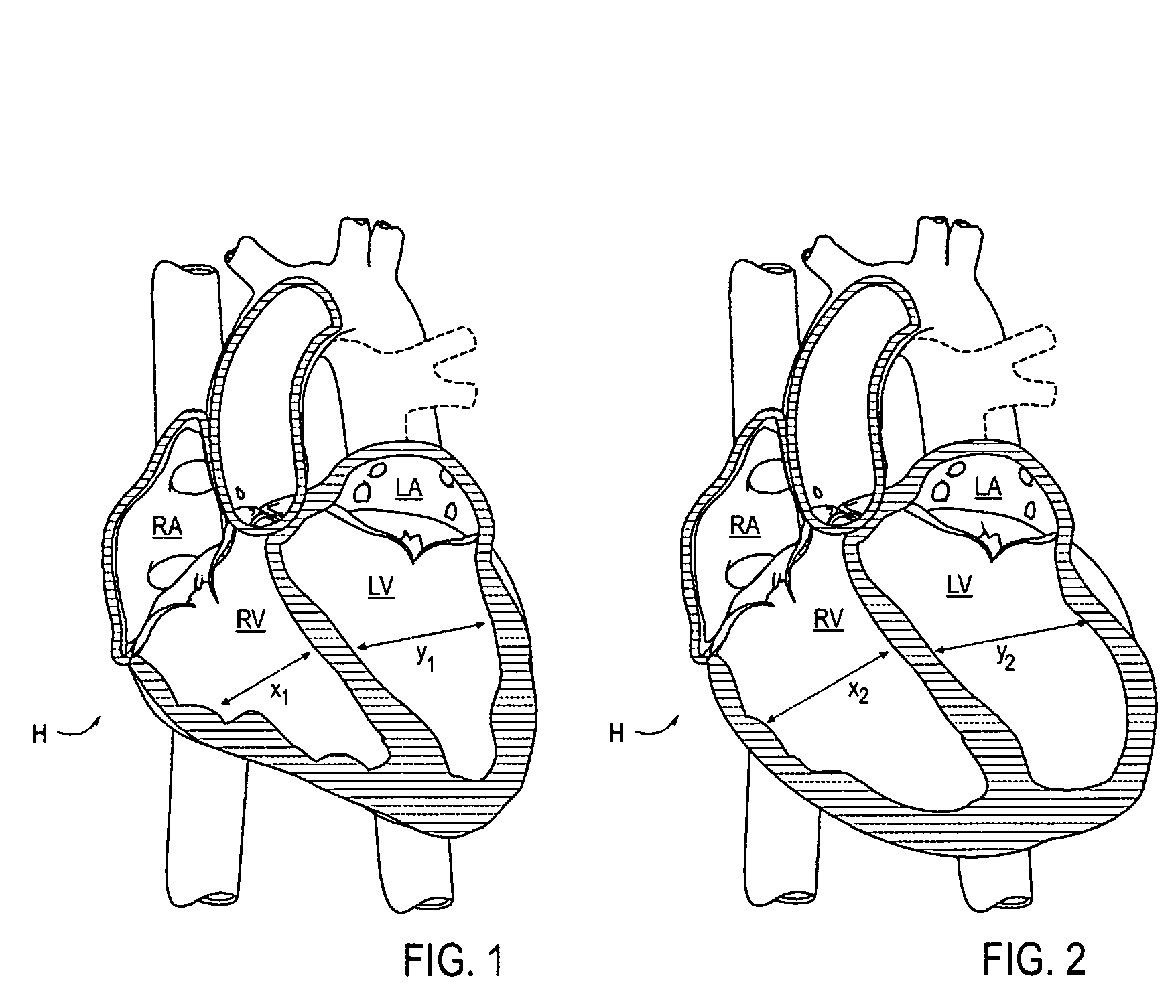

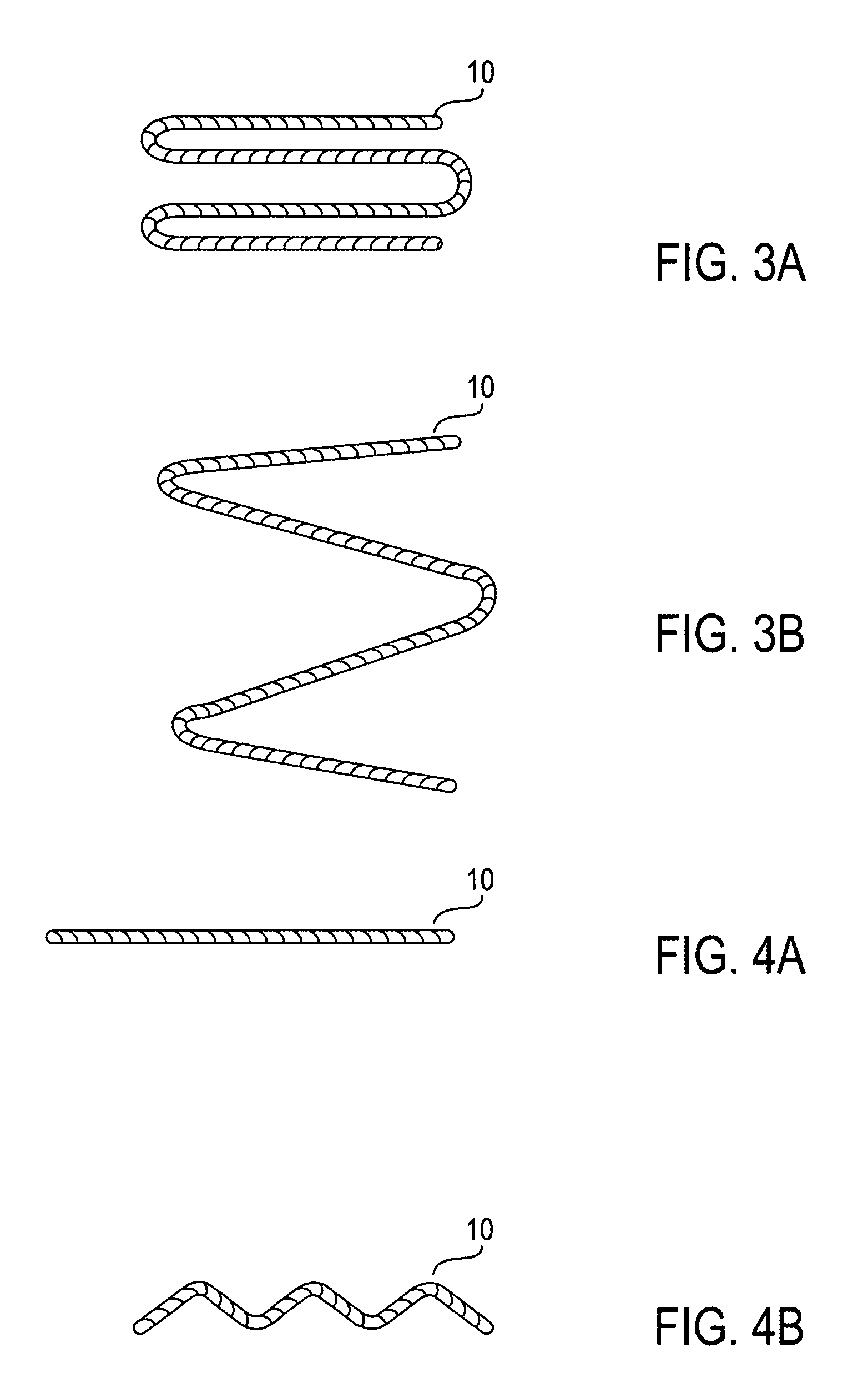

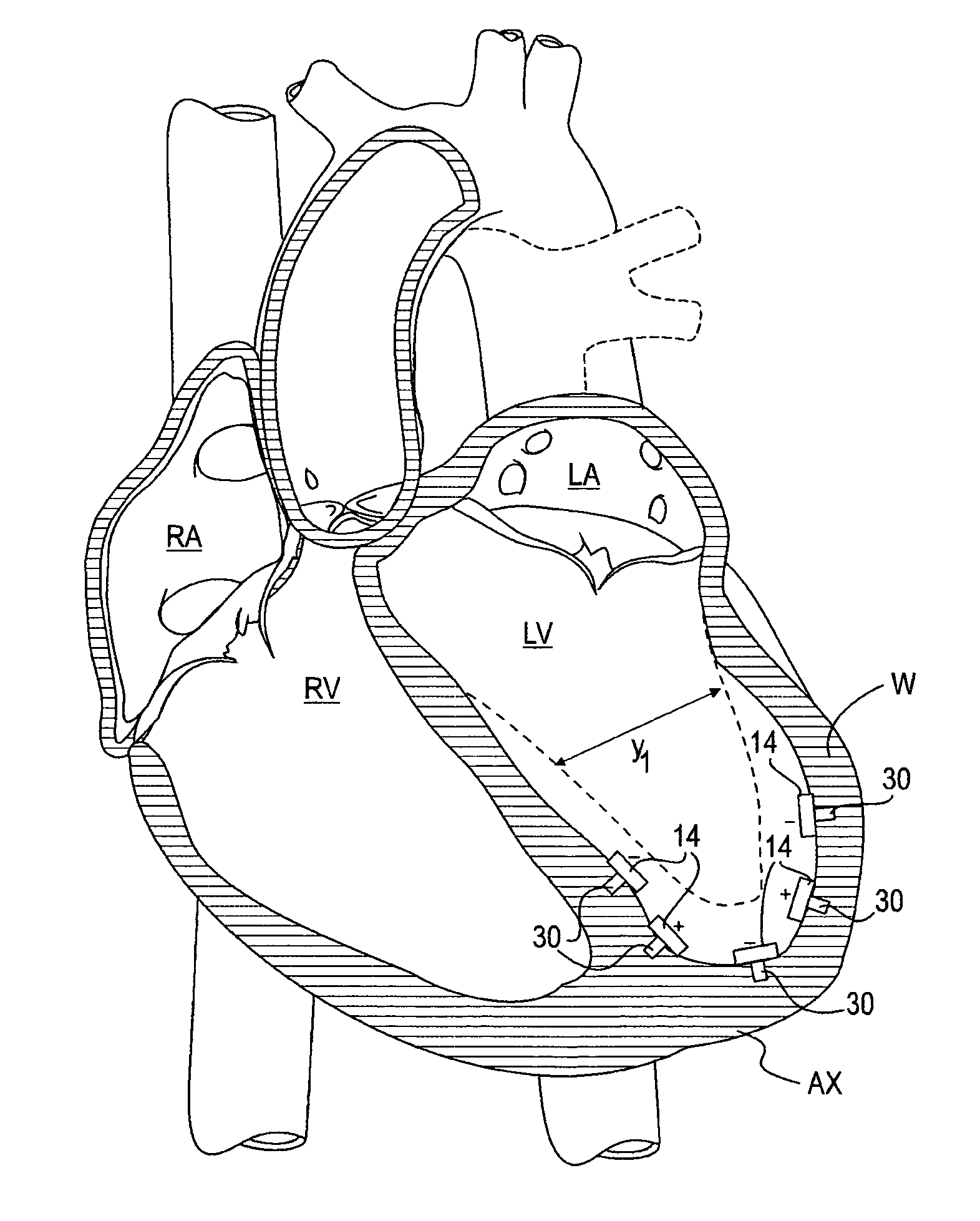

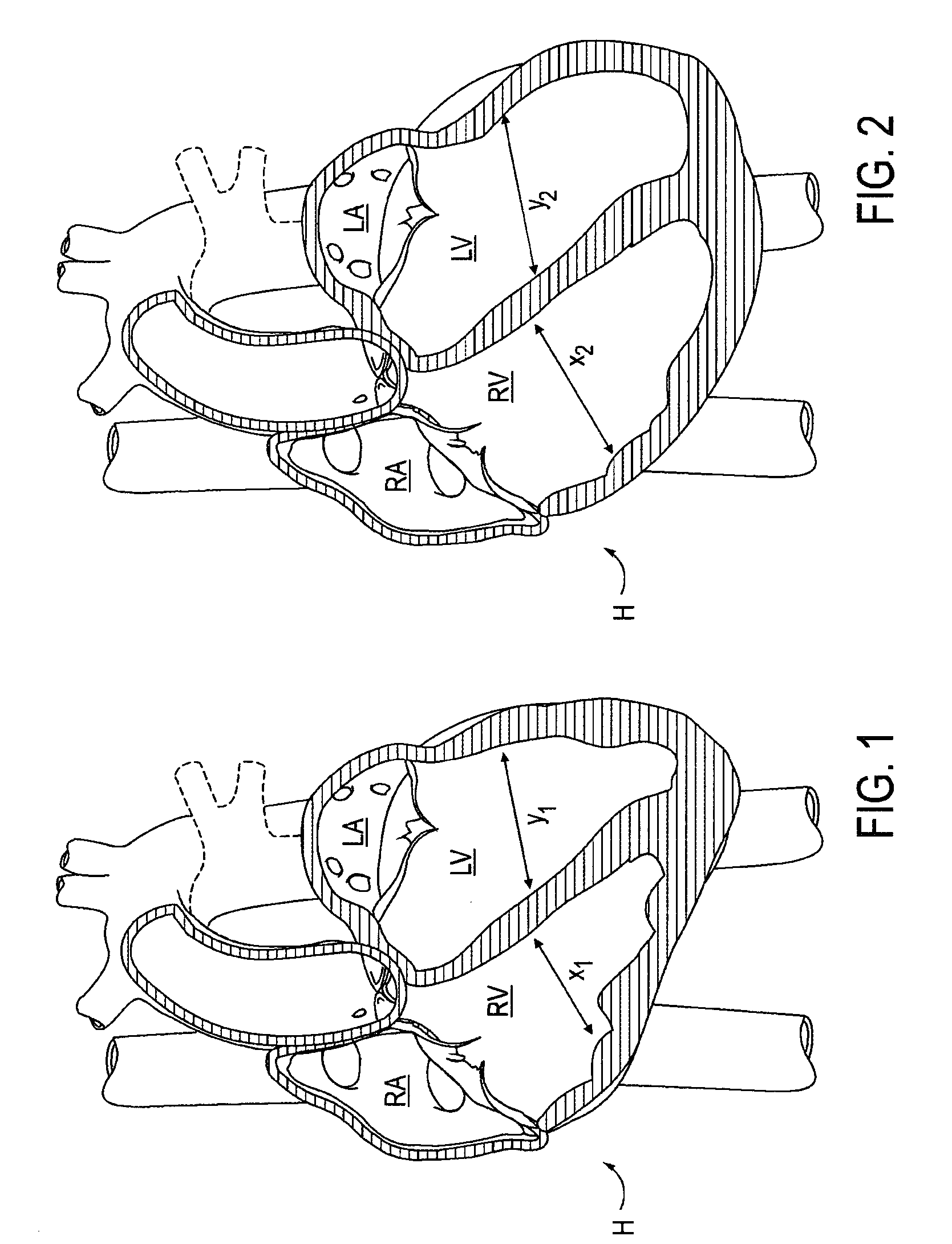

Shape memory devices and methods for reshaping heart anatomy

InactiveUS20060015002A1Improve shrinkageReduce widthSuture equipmentsSurgical needlesCardiac surfaceHeart anatomy

Systems, methods and devices are provided for treating heart failure patients suffering from various levels of heart dilation. Such heart dilation is treated by reshaping the heart anatomy with the use of shape memory elements. Such reshaping changes the geometry of portions of the heart, particularly the right or left ventricles, to increase contractibility of the ventricles thereby increasing the stroke volume which in turn increases the cardiac output of the heart. The shape memory elements have an original shape and at least one memory shape. The elements are implanted within the heart tissue or attached externally and / or internally to a surface of the heart when in the original shape. The elements are then activated to transition from the original shape to one of the at least one memory shapes. Transitioning of the elements cause the associated heart tissue areas to readjust position, such as to decrease the width of the ventricles. Such repositioning is maintained over time by the elements, allowing the damaging effects of heart dilation to slow in progression or reverse.

Owner:MICARDIA CORP

Solid freeform fabrication using a plurality of modeling materials

ActiveUS20130073068A1Easy to burnImprove shrinkageAdditive manufacturing apparatusAdditive manufacturing with liquidsOperation modeSolid freeform fabrication

Owner:STRATASYS LTD

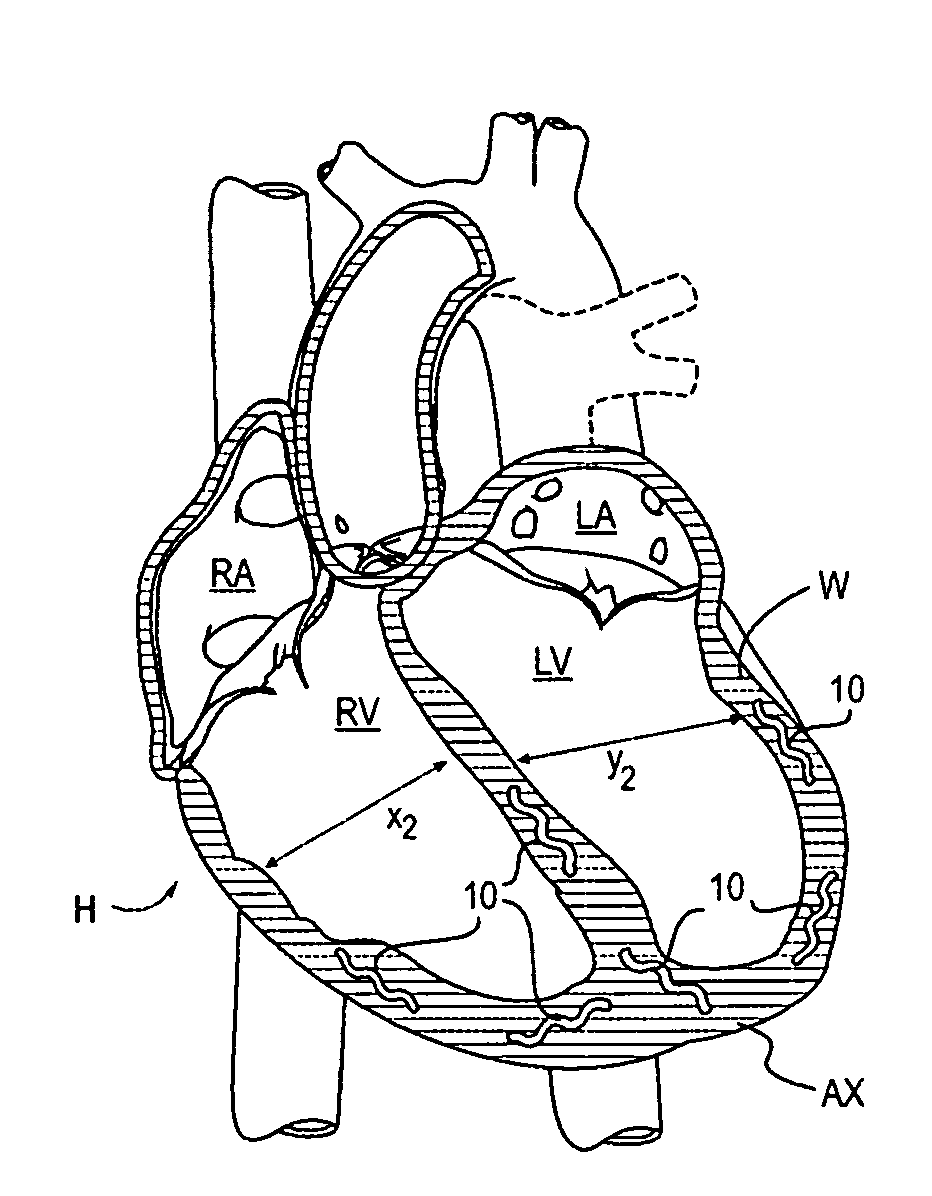

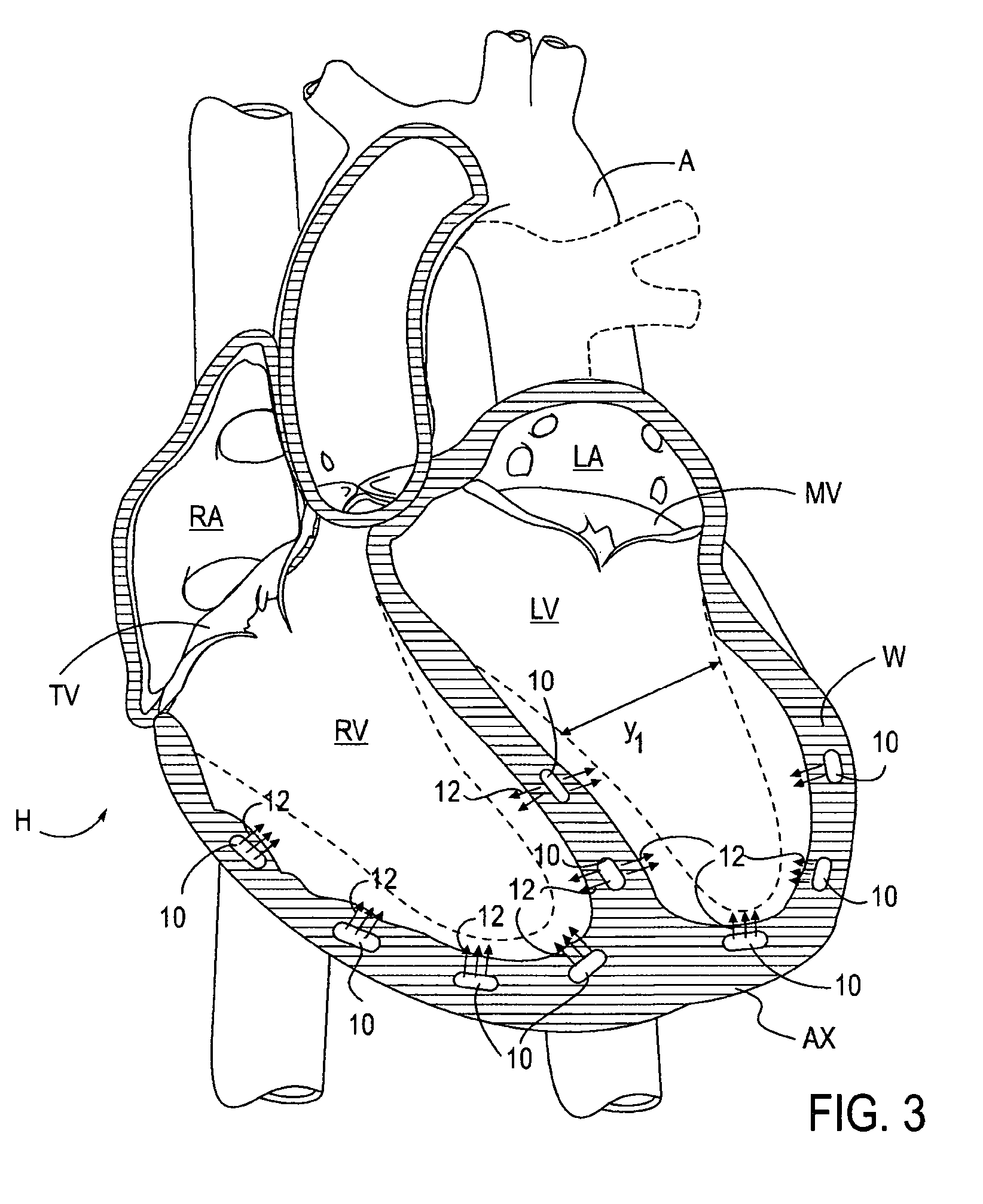

Methods and systems for cardiac remodeling via resynchronization

InactiveUS7877142B2Improve shrinkageReduce widthHeart stimulatorsProsthesisElectricityExternal pacemakers

Systems, methods and devices are provided for improving the hemodynamic efficiency of a patient's heart by implanting one or more reinforcement elements on or with the heart and providing electrical stimulation to the heart. The reinforcement elements may include magnetic and / or shape memory material and are configured to reshape the heart so as to boost the heart's mechanical energy during a response to the electrical stimulation. In some embodiments, at least one reinforcement element includes an electrode configured to sense electrocardiogram signals within the heart. An electrical stimulation device such as an implantable or external pacemaker / defibrillator may be configured to control delivery of electrical pulses to the heart based on the sensed electrocardiogram signals. In addition, or in other embodiments, at least one reinforcement element includes an electrode configured to deliver the electrical pulses to the heart.

Owner:MICARDIA CORP

Shape memory devices and methods for reshaping heart anatomy

InactiveUS7285087B2Improve shrinkageReduce widthSuture equipmentsSurgical needlesCardiac surfaceHeart Part

Owner:MICARDIA CORP

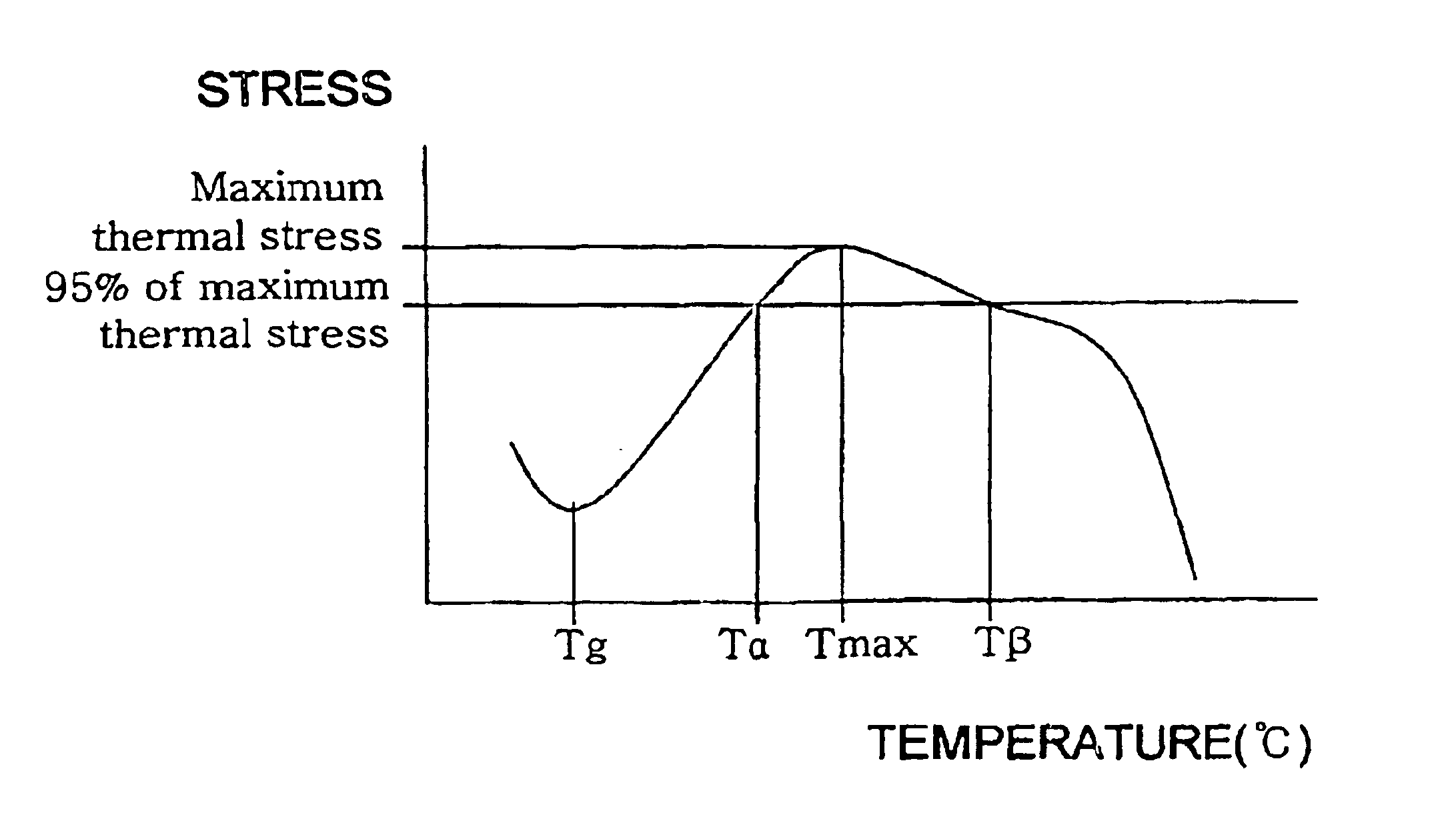

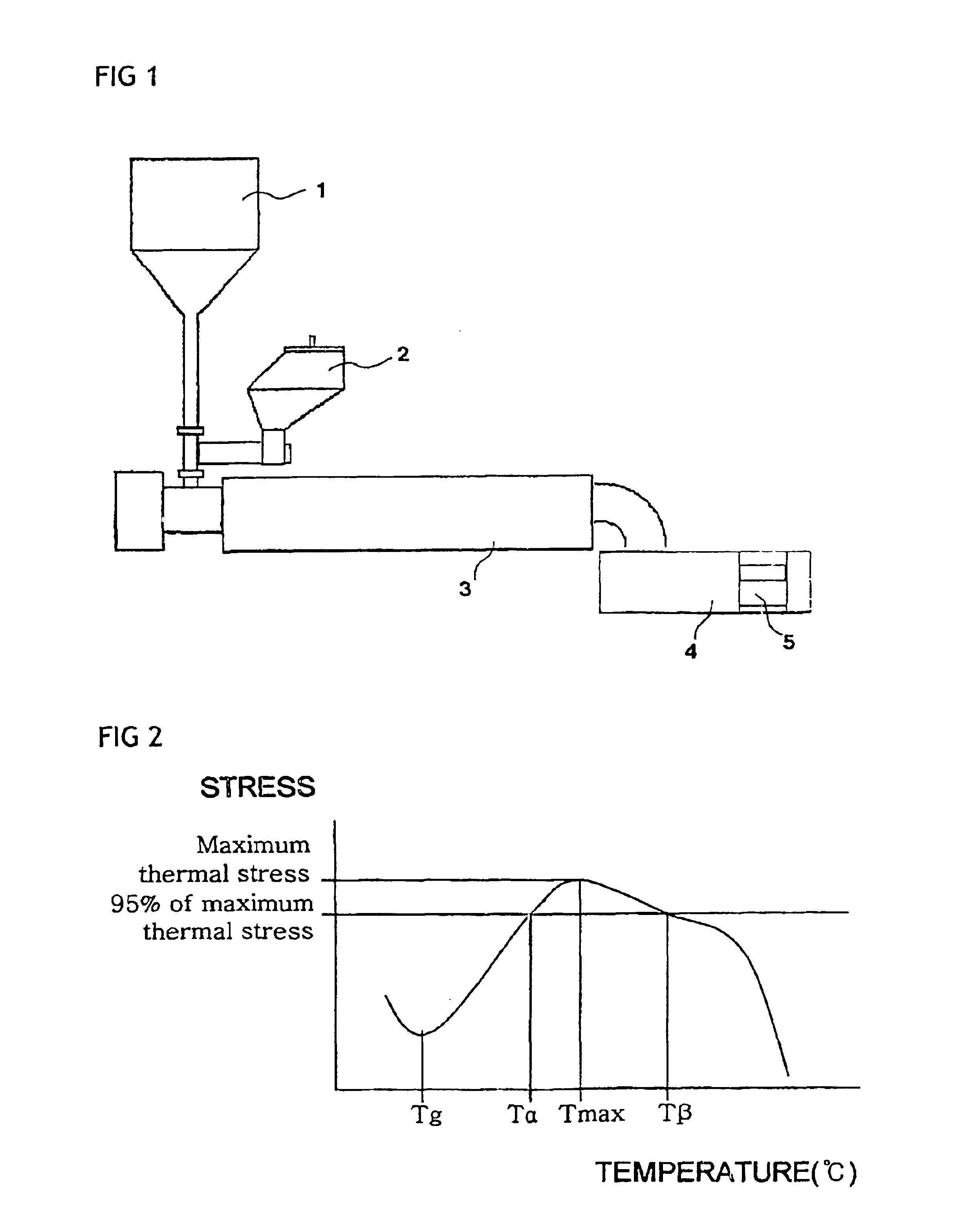

Sea-island typed conjugate multi filament comprising dope dyeing component and a process of preparing for the same

InactiveUS6838172B2Improve shrinkageImprove fastnessFilament/thread formingConjugated synthetic polymer artificial filamentsPolyesterYarn

The present invention relates to a dope dyed sea-island type conjugate multifilament. In the dope dyed sea-island type conjugate multifilament, which comprises easy soluble polymer as a sea component and polyester as an island component, the island component contains a dope dyed component selected from the group consisting of carbon black, pigments and dyestuffs and the temperature range (Tα-Tβ) showing more than 95% of the maximum thermal stress of yarns is from 120° C. to 210° C. The dope dyed sea-island type conjugate multifilament of the present invention has an excellent thermal shrinkage property and excellent wash fastness and light fastness, and the dyeing process thereof can be omitted after producing a woven or knitted fabric because a dope dyed component is contained in the island component (ultra fine yarn). The dope dyed sea-island type conjugate multifilament of the present invention is useful as yarns for warp knit fabrics used in production of women's apparel.

Owner:KOLON IND INC

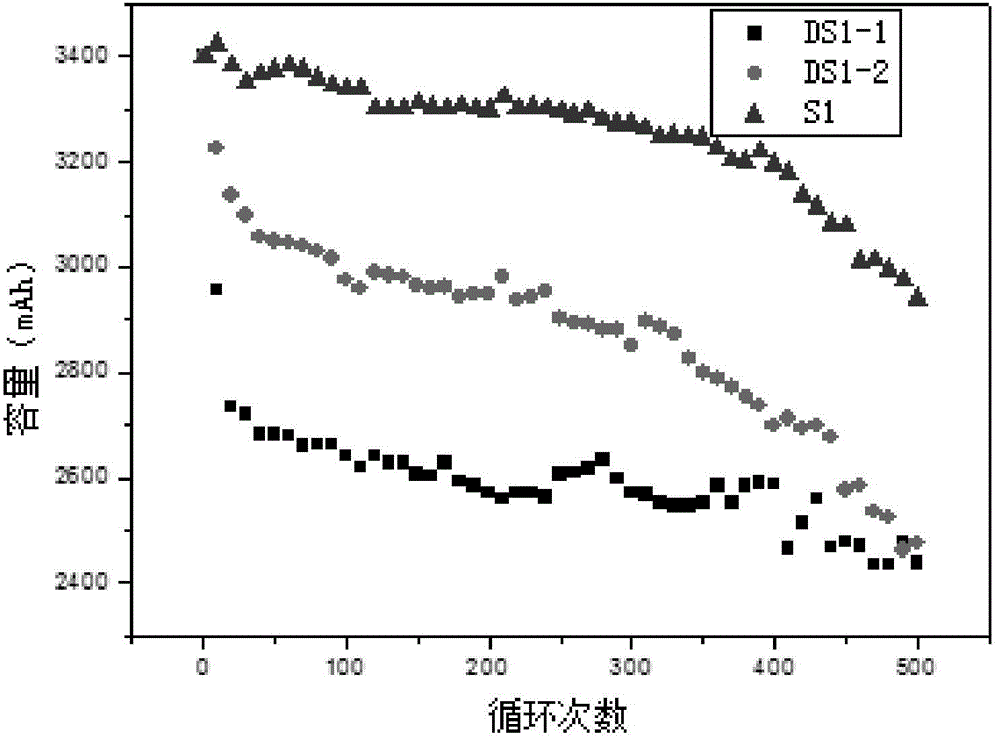

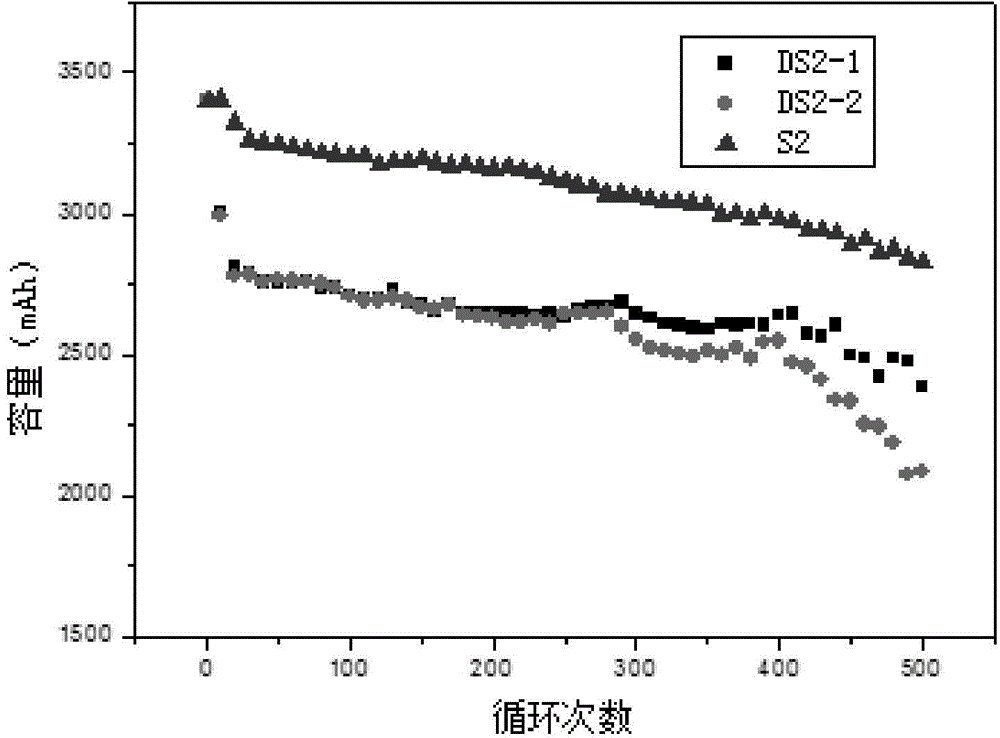

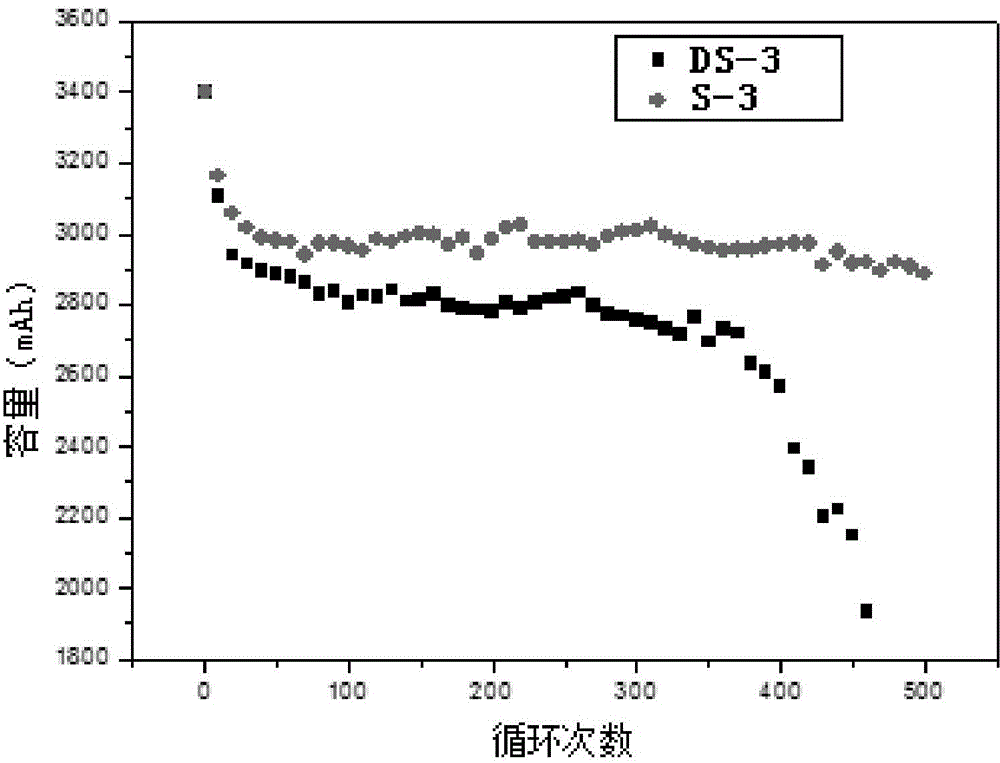

Electrolyte solution for high-capacity lithium-ion battery, preparation method and lithium-ion battery

InactiveCN104900916AAvoid direct contactInhibit cathode decompositionFinal product manufactureElectrolyte accumulators manufactureElectrolytic agentElectrical battery

The invention discloses an electrolyte solution for a high-capacity lithium-ion battery. The electrolyte solution includes non-aqueous solvent, lithium hexafluorophosphate, negative electrode film forming additive, positive electrode surface activity inhibiting additive and transition metal ion complexant; the negative electrode film forming additive includes organic ester negative electrode film forming additive of 1 to 10wt% of the total electrolyte solution and inorganic lithium salt negative electrode film forming additive of 0.5 to 2wt% of the total electrolyte solution; the positive electrode surface activity inhibiting additive includes fluorinated ether additive of 1 to 5wt% of the total electrolyte solution and nitrile additive of 0.1 to 5wt% of the total electrolyte solution; the transition metal ion complexant is of 0.1 to 1.0wt% of the total electrolyte solution. The electrolyte solution is adaptive to the high-capacity lithium-ion battery and is capable of optimizing the circulating performance and high-temperature storage performance of the lithium-ion battery. The invention further provides a preparation method of the electrolyte solution and the high-capacity lithium-ion battery adopting the electrolyte solution.

Owner:GUANGZHOU TINCI MATERIALS TECH

Magnetic devices and methods for reshaping heart anatomy

InactiveUS7402134B2Improve shrinkageIncrease volumeHeart valvesSurgical needlesCardiac surfaceHeart Part

Systems, methods and devices are provided for treating heart failure patients suffering from various levels of heart dilation. Heart dilation treated by reshaping the heart anatomy with the use of magnetic forces. Such reshaping changes the geometry of portions of the heart, particularly the right or left ventricles, to increase contractibility of the ventricles thereby increasing the stroke volume which in turn increases the cardiac output of the heart. The magnetic forces are applied with the use of one or more magnetic elements which are implanted within the heart tissue or attached externally and / or internally to a surface of the heart. The various charges of the magnetic forces interact causing the associated heart tissue areas to readjust position, such as to decrease the width of the ventricles. Such repositioning is maintained over time by the force of the magnetic elements, allowing the damaging effects of heart dilation to slow in progression or reverse.

Owner:MICARDIA CORP

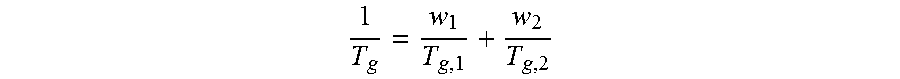

Compositions for the preparation of void-containing articles

ActiveUS7273894B2Efficiently formedEfficient voidingSynthetic resin layered productsFoundry mouldsPolyesterCellulose

Disclosed are novel compositions for the preparation of void-containing articles comprising a polymer matrix and a voiding agent The voiding agent comprises at least one first polymer and at least one second polymer, which are selected on the basis of physical properties such as glass transition temperature, tensile modulus, melting point, surface tension, and melt viscosity. Shaped articles such as sheet, film, bottles, tubes, labels, and sleeves may prepared from these compositions. Also disclosed are polyester shrink films prepared using a voiding agent comprising a novel blend of cellulosic and olefinic polymers. The resulting shrink films have better opacity, lower density, reduced shrink force, and improved printability as compared with most standard voiding agents. The films are useful for sleeve label and other shrink film applications and their lower density allows them to be readily separated from soft drink bottles, food containers and the like during recycling operations.

Owner:EASTMAN CHEM CO

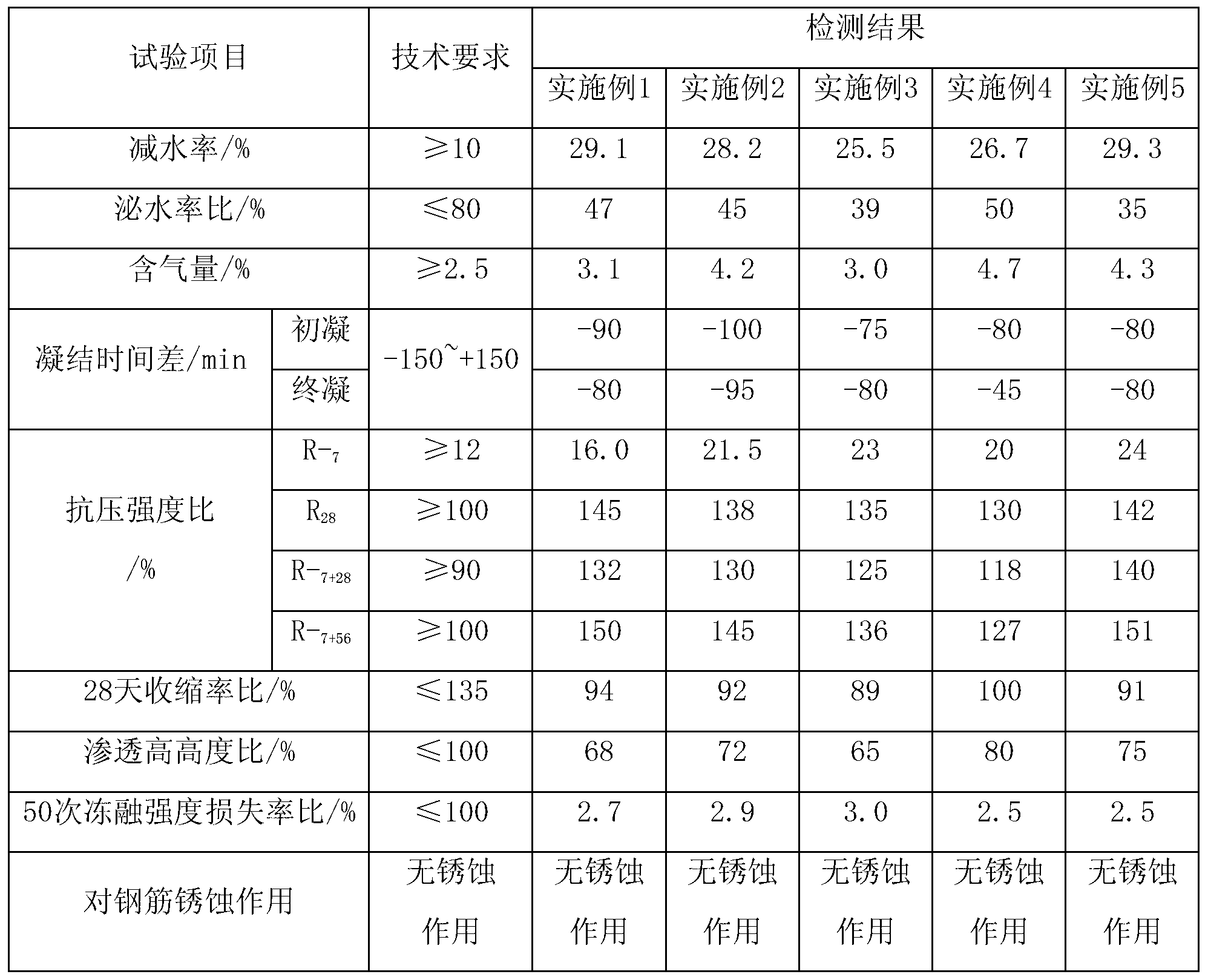

High-early-strength antifreezing polycarboxylic-acid composite water reducing agent and application thereof

The invention relates to a high-early-strength antifreezing polycarboxylic-acid composite water reducing agent and application thereof, belonging to the field of construction materials. The invention aims to provide a high-early-strength antifreezing polycarboxylic-acid composite water reducing agent and application thereof. The high-early-strength antifreezing polycarboxylic-acid composite water reducing agent is prepared from the following raw materials in parts by weight: 17.5-32.5 parts of polycarboxylic-acid water reducing agent, 1-3 parts of sodium lignosulfonate, 7-36 parts of early-strength admixture, 2-8 parts of antifreezing agent, 0-0.5 part of air entraining agent and 20-72.5 parts of water. The early-strength admixture is composed of 1-8 parts by weight of organic early-strength component and 6-28 parts by weight of inorganic early-strength component. The high-early-strength antifreezing polycarboxylic-acid composite water reducing agent has the advantages of high early strength, favorable anti-freeze-thawing effect and the like.

Owner:CHINA 19TH METALLURGICAL CORP CHENGDU CONSTR +1

Modacrylic Shrinkable Fiber and Method for Manufacturing The Same

A modacrylic shrinkable fiber according to the present invention is containing a polymer composition obtained by mixing 50 to 99 parts by weight of a polymer (A) containing 40 wt % to 80 wt % of acrylonitrile, 20 wt % to 60 wt % of a halogen-ontaining monomer and 0 wt % to 5 wt % of a sulfonic-acid-containing monomer, and 1 to 50 parts by weight of a polymer (B) containing 5 wt % to 70 wt % of acrylonitrile, 20 wt % to 94 wt % of an acrylic ester and 1 wt % to 40 wt % of a sulfonic-acid-containing monomer containing a methallylsulfonic acid or metal salts thereof or amine salts thereof, in which a total amount of the polymer (A) and the polymer (B) is 100 parts by weight. In this way, a modacrylic shrinkable fiber that has a favorable color development property after dyeing and a high shrinkage ratio even after dyeing is obtained.

Owner:KANEKA CORP

Acrylic shrinkable fiber and method for production thereof

InactiveUS20070098982A1Low heat resistanceCompatibilityYarnThin material handlingPolymer scienceSpinning

An object of the present invention is to provide a dyeable acrylic shrinkable fiber that only slightly shrinks when dyed and has a high shrinkage percentage even after dyeing. By spinning an incompatible spinning solution, the above object can be achieved, and a dyeable acrylic shrinkable fiber that only slightly shrinks when dyed and has a high shrinkage percentage even after dyeing can be provided.

Owner:KANEKA CORP

Novel rubber protective wax

The invention discloses a novel rubber protective wax which comprises the following components in percentage by weight: 14-20 percent of paraffin, 55-60 percent of mixed crystal wax, 24-30 percent ofmicrocrystalline wax and 1-2 percent of polyethylene wax. The invention has favorable seal performance and can reinforce the ozone and ageing resistance of a rubber product and prolong the service life of the rubber product.

Owner:上海绿菱特种蜡制品厂

High performance concrete with steel slag as admixture and aggregate and preparation method thereof

The invention discloses a high performance concrete with steel slag as an admixture and aggregate and a preparation method thereof. The concrete is composed of a cementing material, aggregate, a water reducer and mixing water. The cementing material is prepared by compounding, by mass, 50 to 80% of cement, 10 to 30% of superfine steel slag powder and 10 to 30% of superfine mineral slag, wherein the specific surface areas of the superfine steel slag powder and the superfine mineral slag are respectively controlled to be 400 to 600 m<2> / kg and 400 to 500 m<2> / kg. The aggregate is composed of broken stone, steel slag sand and river sand, wherein the particle size of the steel slag sand is 5 to 10 mm, the steel slag sand is used to partially replace the broken stone, and the addition amount of the steel slag sand is 20 to 50%. The high efficiency water reducer is dissolved in water in advance and then added with the mixing water. The preparation method provided by the invention is simple and can prepare concrete with a grade in a range of C20 to C60 and substantially improve the comprehensive utilization rate of the steel slag; and the prepared concrete has good work performance, mechanical properties, etc. and substantially improved endurance.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

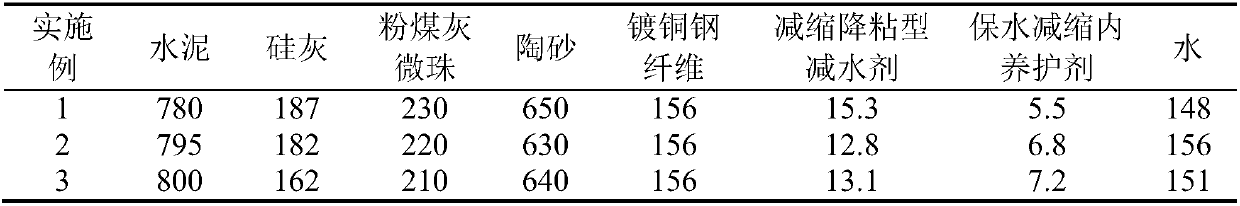

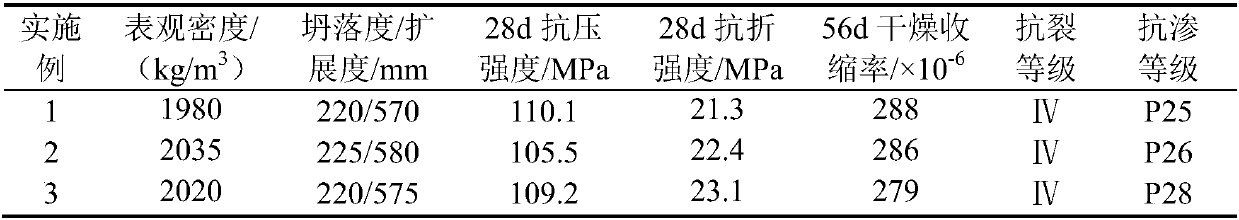

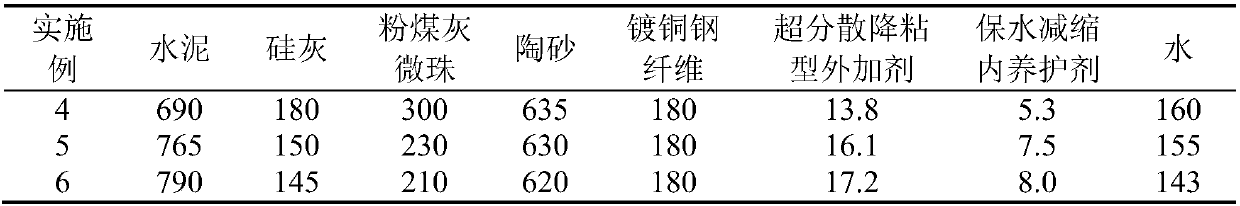

Light low-shrinkage super-high performance concrete and preparation method thereof

The invention discloses light low-shrinkage super-high performance concrete which is prepared from cement, coal ash beads, silica fume, pottery sand, a brass coated steel fiber, shrinkage and viscosity reduction type water reduction agent, a water-retention shrinkage-reduction inner curing agent and water as main raw materials. According to the concrete, the pottery sand is adopted as aggregate, the self weight of the concrete is reduced, and a high-strength and dense 'arch housing' interface area is formed on the surface of the pottery sand by using a pre-mixing process, so that the interfacestrength is improved, and the mechanical properties and the anti-penetrability performance of the concrete are improved; due to the adoption of the shrinkage and viscosity reduction type water reduction agent and the coal ash beads, the working performance and the density of the concrete are improved; due to the adoption of the pre-wetted pottery sand and the developed water-retention shrinkage-reduction inner curing agent, reduction of wetness inside the concrete is retarded, the self-shrinkage and the drying shrinkage of the concrete are reduced, and the volume stability of the concrete isimproved. While the self weight of the concrete is reduced, the light low-shrinkage super-high performance concrete disclosed by the invention is good in working performance, mechanical property, anti-penetrability and durability, and has significant practical application values.

Owner:WUHAN UNIV OF TECH

Curing agent for filling iron tailings and preparation method thereof

The invention discloses a curing agent for filling iron tailings and a preparation method thereof and belongs to the technical field of mine safety. The curing agent comprise the following components in parts by mass: 0-70 parts of fly ash, 10-80 parts of superfine mineral slag powder, 0-70 parts of superfine steel slag powder, 0-20 parts of an alkaline activator, 0-20 parts of an sulfate activator, 0.1-1 part of a foam stabilizer and 2-5 parts of a microcapsule in which aluminum powder is used as a core material. The preparation method of the curing agent comprises the steps of firstly weighting fly ash, superfine mineral slag powder, superfine steel slag powder, alkaline activator, sulfate activator and foam stabilizer according to the blending ratio of the components of the curing agent, adding all the components in a stirrer, quickly stirring for 5-15 minutes, adding microcapsule in which aluminum powder is used as a core material and slowly stirring for 2-5 minutes to obtain the curing agent for filling iron tailings. The curing agent for filling iron tailings provided by the invention has strong curing capability and is simple and controllable in use and operation.

Owner:罗强

Amorphous polyaryletherketone and blends thereof for use in additive manufacturing

ActiveUS20170096576A1High melt flowHigh viscosityAdditive manufacturing apparatusAdditive manufacturing with liquidsFused filament fabricationAdditive layer manufacturing

A material for use in a fused filament fabrication (FFF) printer comprises a polyaryletherketone (PAEK) having an amorphous morphology. In some embodiments, the material also includes a PAEK having a semi-crystalline morphology.

Owner:AREVO INC

Void-containing polyester shrink film with improved density retention

InactiveUS20060121219A1Improve shrinkageLow densityWrappers shrinkageShrinkage connectionsPolyesterSoft drink

Owner:EASTMAN CHEM CO

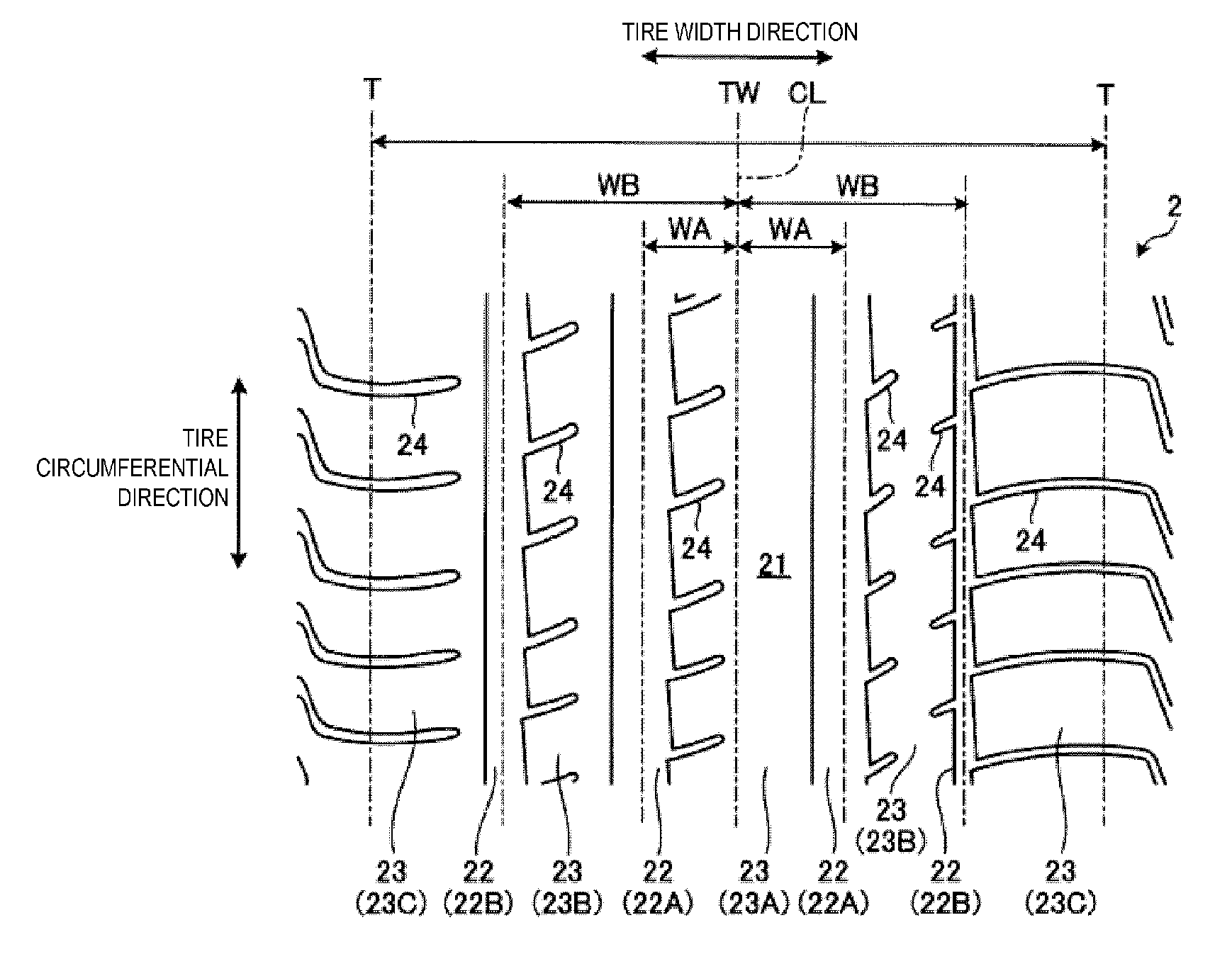

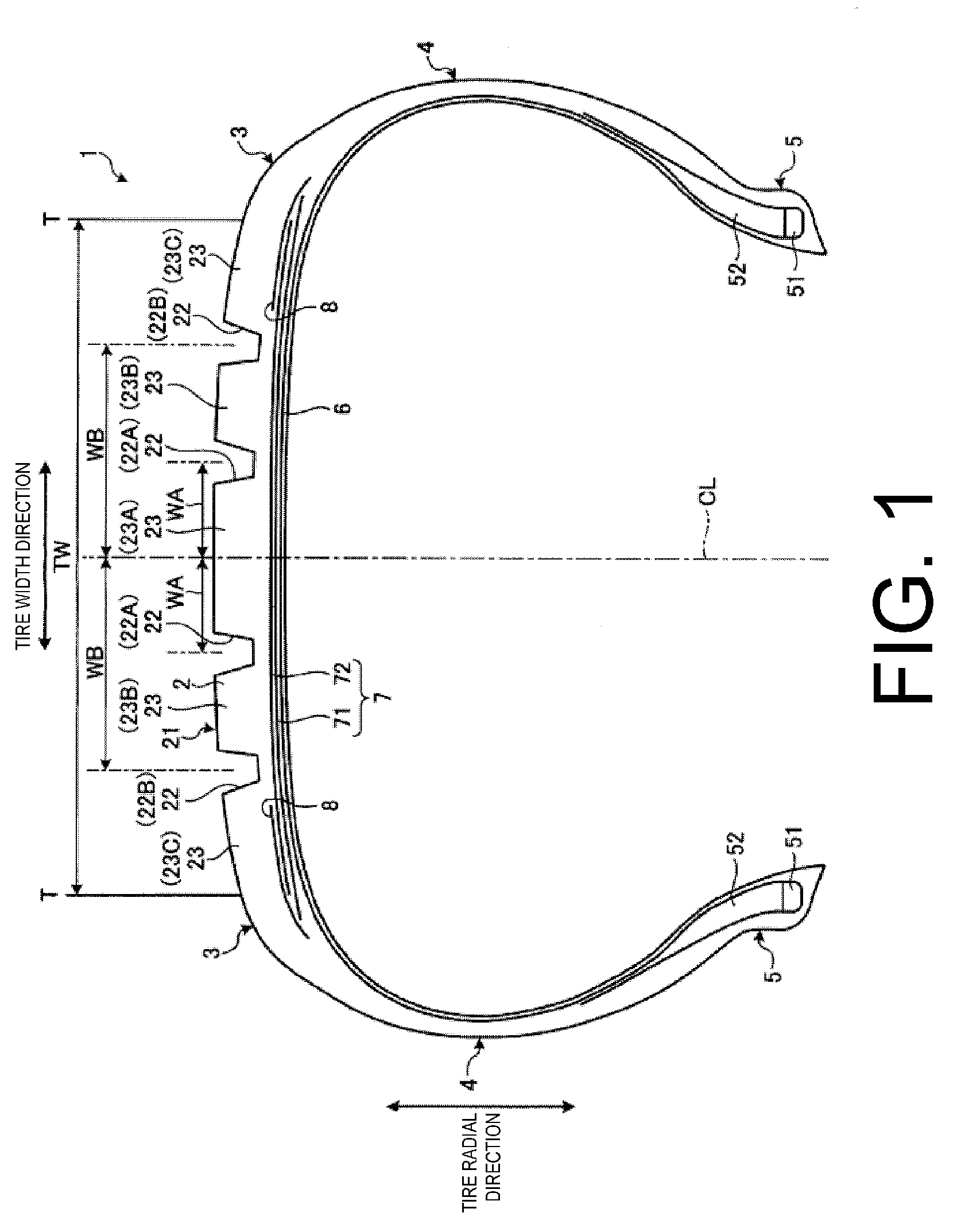

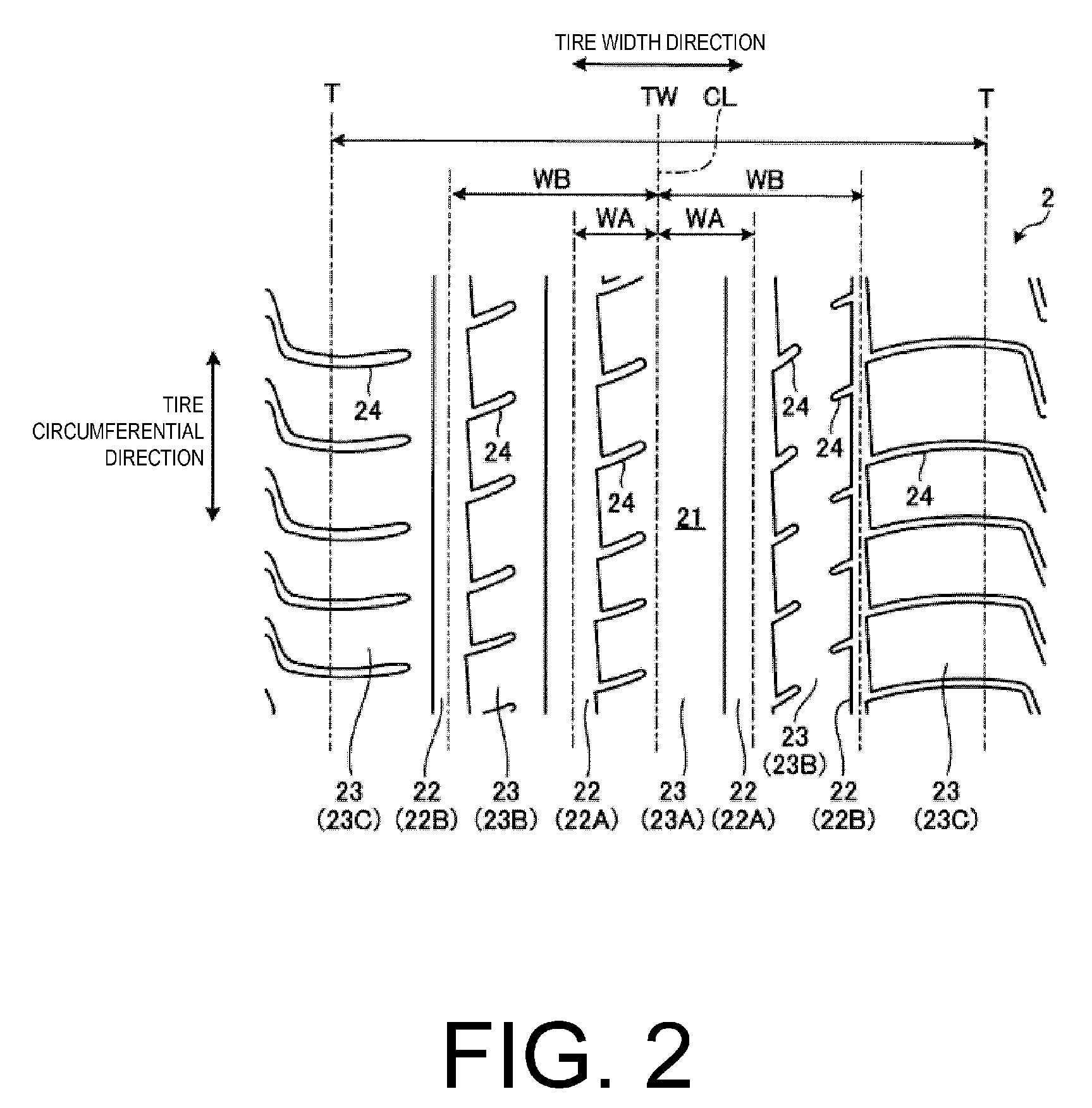

Pneumatic Tire

ActiveUS20130240101A1Improve steering stabilityImprove propertiesTyre tread bands/patternsNon-skid devicesEngineeringContact patch

The contact patch of the center land portion partitioned by the center side main grooves protrudes outward in the tire radial direction from the overall standard profile line of the tread portion. The maximum protruding amount is not less than 1.0% and not more than 2.5% of the tire width direction dimension of the center land portion. The contact patch of the intermediate land portion partitioned by the center side main groove and the shoulder side main groove protrudes outward in the tire radial direction from the standard profile line. The maximum protruding amount is not less than 0.7% and not more than 2.0% of the tire width direction dimension of the intermediate land portion. The maximum protruding amount of the center land portion is greater than the maximum protruding amount of the intermediate land portion.

Owner:YOKOHAMA RUBBER CO LTD

Compositions for the preparation of void-containing articles

ActiveUS20050118406A1Efficiently formedImprove performanceSynthetic resin layered productsFoundry mouldsCellulosePolyester

Disclosed are novel compositions for the preparation of void-containing articles comprising a polymer matrix and a voiding agent The voiding agent comprises at least one first polymer and at least one second polymer, which are selected on the basis of physical properties such as glass transition temperature, tensile modulus, melting point, surface tension, and melt viscosity. Shaped articles such as sheet, film, bottles, tubes, labels, and sleeves may prepared from these compositions. Also disclosed are polyester shrink films prepared using a voiding agent comprising a novel blend of cellulosic and olefinic polymers. The resulting shrink films have better opacity, lower density, reduced shrink force, and improved printability as compared with most standard voiding agents. The films are useful for sleeve label and other shrink film applications and their lower density allows them to be readily separated from soft drink bottles, food containers and the like during recycling operations.

Owner:EASTMAN CHEM CO

Modified water resistant low temperature white emulsoid

InactiveCN1377929AImprove water resistanceImprove low temperature resistanceMonocarboxylic acid ester polymer adhesivesChemical industryPolyvinyl acetate

The present invention relates to adhesive and discloses a kind of modified waterproof low temperature white emulsoid and its preparation. The modified waterproof low temperature white emulsoid is prepared by using polyvinyl acetate emulsion as base material, water solution of polyvinyl alcohol as emulsoid protector, ethylene-vinyl acetate emulsion as waterproof and low temperature modified and calcium carbonate as kaolin as adhesion intensifier. It has various specifications exceeding the chemical industry standard, excellent waterproof performance, good low temperature performance, simple production process, relatively lower cost and no toxicity and harm.

Owner:SHANGHAI UNIV OF ENG SCI

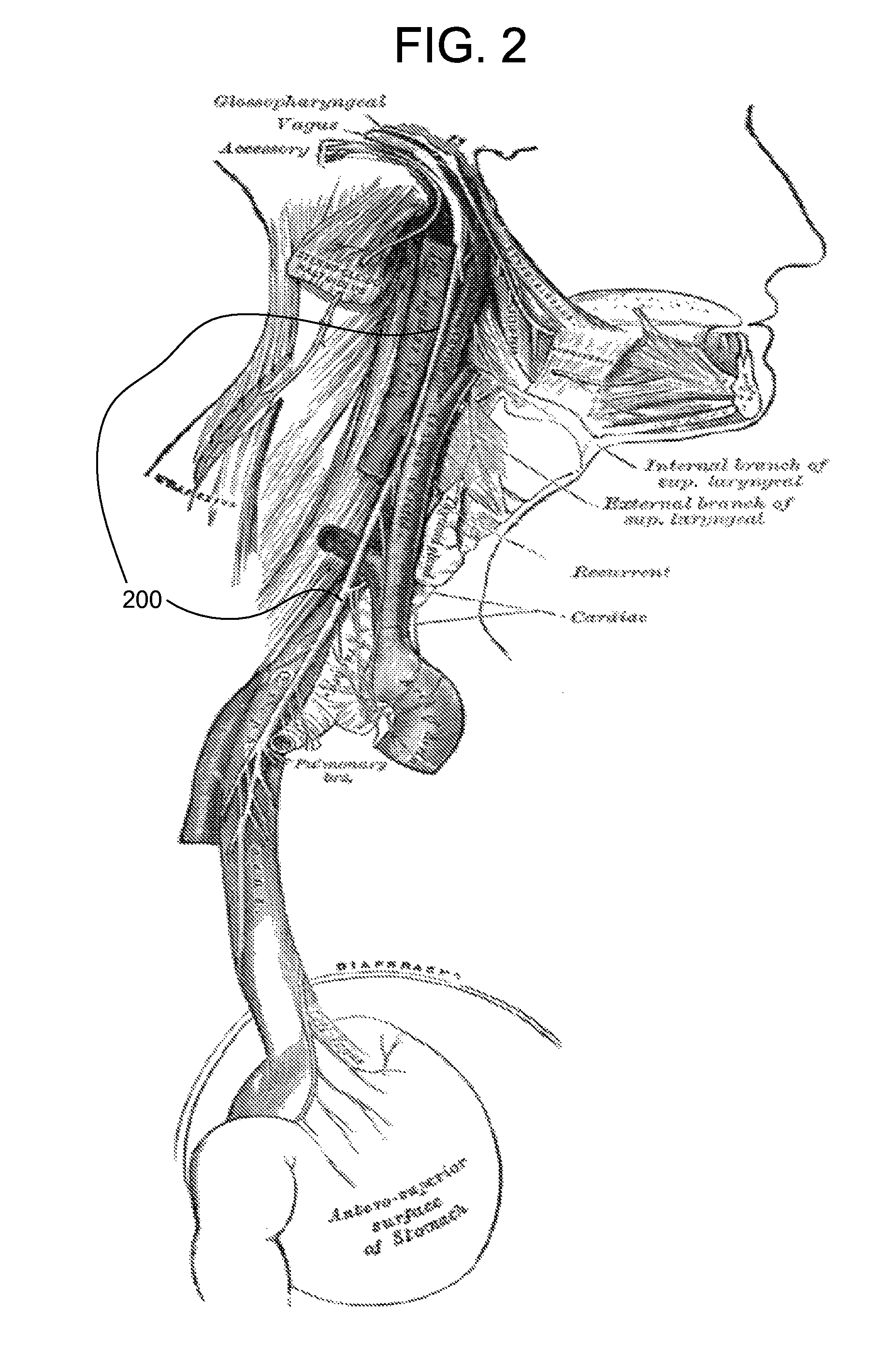

Electrical stimulation treatment of hypotension

Methods and devices for treating hypotension, such as in cases of shock, including septic shock and anaphylactic shock, wherein the treatment includes providing an electrical impulse to a selected region of the vagus nerve of a patient suffering from hypotension to block and / or modulate nerve signals that regulate blood pressure.

Owner:ELECTROCORE

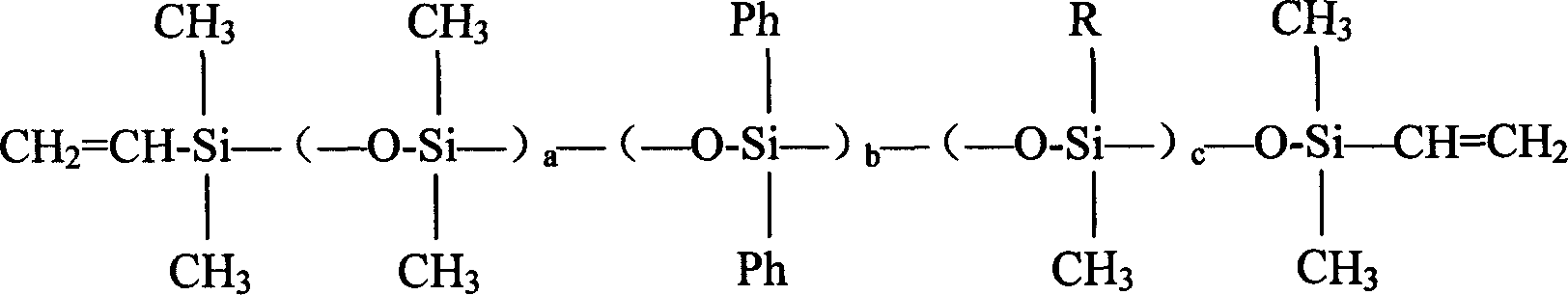

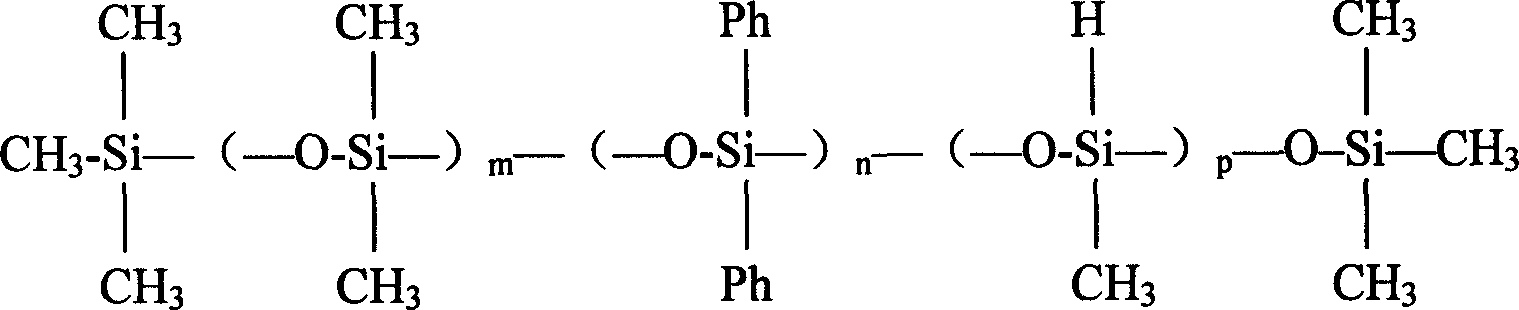

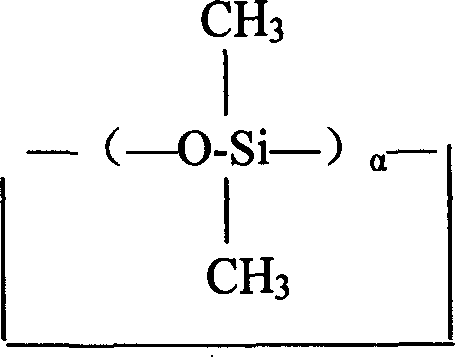

Organosilicon electronic encapsulation material

InactiveCN101016446ASimple preparation processSimple processOther chemical processesSemiconductor/solid-state device detailsHydrogenRefractive index

The invention discloses a organic silicon embedding material in embedding technical domain of electronic product, which is characterized by the following: It is composed by 100 wt ethenyl dead-end polymethyl phenyl group phenyl group oxosilane, 10-30 wt ethenyl metyl group silicon resin, 5-20 wt poly metyl group hydrogen phenyl group, 0.1-2 wt accelerant and 0.05-2 wt blocking agent, which is based on ethenyl dead-end polymethyl phenyl group phenyl group oxosilane. The light transmittance ratio of this material can reach 99% and refractive index can reach 1.49-1.53, which is fit for packaging of LED electronic product.

Owner:东莞市贝特利新材料有限公司

Moon-white Song-dynasty official and brother kiln glaze material, moon-white Song-dynasty official and brother kiln porcelain and preparation method of porcelain

The invention relates to moon-white Song-dynasty official and brother kiln porcelain, a moon-white Song-dynasty official and brother kiln glaze material and a preparation method of the porcelain. The moon-white Song-dynasty official and brother kiln porcelain comprises a porcelain body and a glaze layer, wherein a preform body for preparing the porcelain body consists of the following materials by weight percent: 30% of stone-layer porcelain clay, 40% of Mudaikou purple gold clay and 30% of Yuandi porcelain clay; the glaze material for preparing the glaze layer consists of the following materials by weight percent: 20%-35% of Baoxi Wutou glaze clay, 7%-10% of quartz powder, 2%-5% of Mudaikou purple gold clay, 18%-23% of limestone, 15%-20% of potassium feldspar, 17%-10% of kaolin and 8%-10% of talcum powder. The preparation method comprises the following steps: forming paste, drying the porcelain body, performing biscuit firing, applying internal and external glaze and performing glaze firing on the basis of the raw materials. The moon-white Song-dynasty official and brother kiln porcelain is pure and mild in glaze color, good in thermal stability and high in overall quality.

Owner:龙泉市建春青瓷厂

Processing method for low-elastic non-ironing knitted face fabric

InactiveCN101200852AShrunkGood color retentionWeft knittingBiochemical fibre treatmentAmmoniaComputer science

The present invention discloses a processing method of a low-elasticity, wrinkle-free knitted fabric, which includes steps: greige cloth weaving, boiling and bleaching, bio-enzyme washing, dyeing, softening, dehydration, scutching, drying, shaping and preshrinking. The present invention is characterized in that the processing steps of pre-relaxation and ammonia mercerization are added before boiling and bleaching, so that the whole processing steps are changed as greige cloth weaving, pre-relaxation, ammonia mercerization, boiling and bleaching, bio-enzyme washing, dyeing, softening, dehydration, scutching, drying, shaping and preshrinking; the pre-relaxation processing is to add refining agent of 0.5 to 1.5g / L, the processing temperature is between 90 and 130 DEG C, and the processing period is twenty to sixty minutes; in the step of ammonia mercerization, the pre-relaxed fabric receives the processing of ammonia mercerization in an ammonia mercerizing machine at the speed of 15 to 50m / min. The present invention ensures that the cotton and the blended elastic knitted fabric can have soft, smooth handfeel and high washing resistance and shape-keeping property.

Owner:浙江盛泰服装集团股份有限公司

Production method of wool/Coolmax/mulberry silk/polyester fiber blended fabric

InactiveCN102560930ATo soften waterSolve the adhesionLiquid/gas/vapor removalLiquid/gas/vapor treatment of indefinite length materialsFiberPolyester

The invention relates to a production method of a wool / Coolmax / mulberry silk / polyester fiber blended fabric, which is characterized in that the blended fabric is made of 60% of Australasian wool, 20% of Coolmax fibers, 15% of polyester fibers, and 5% of mulberry silk by dyeing, recombing, spinning, weaving and dyeing and finishing. The fabric has good color fastness, is non-fading and is breathable.

Owner:江苏华西村纺织服装有限公司

Method for preparing concrete by taking manganese residue-steel residue-limestone powder as admixture

The invention discloses a method for preparing concrete by taking manganese residue-steel residue-limestone powder as admixture. Raw materials comprise cementing material, aggregate, admixture and water. The cementing material is formed by compounding cement, manganese residue, steel residue and limestone powder, and an activator is an alkaline activator or a sulphate activator, specific surface areas of manganese residue micro power, steel residue micro power and the limestone powder are respectively controlled to be 400-600m<2> / kg, 500-800m<2> / kg and 600-900m<2> / kg. Small particle size continuous grading coarse aggregate is adopted, and the content of 5-20mm broken stone is higher than 85%. The activator is dissolved in water in advance and is doped with mixing water. The obtained concrete has good working performance, strength in 28 days is improved by about 8% compared with the concrete which independently adopts fine slag powder, cost is reduced by nearly 20%, durabilities such as contractility resistance, freezing resistance, marine denudation resistance and the like can be obviously improved. The process in the invention is simple, C20-C60 grade concrete can be prepared, industrial waste residue doping content in the concrete can be obviously improved, and good practical value can be obtained.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

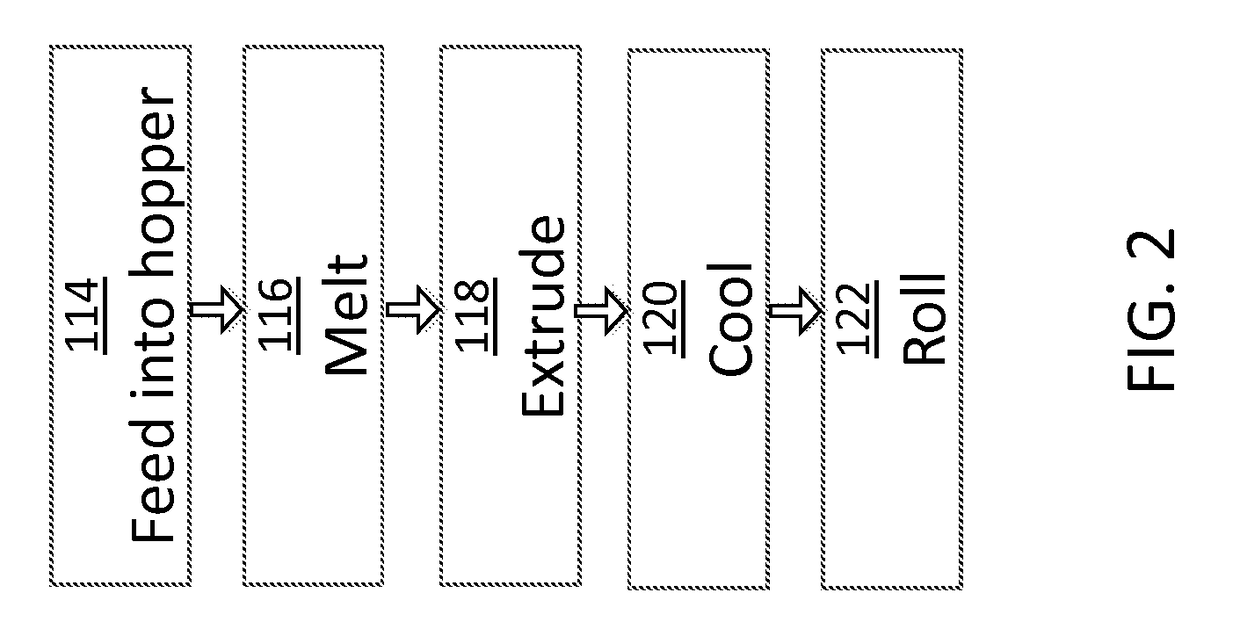

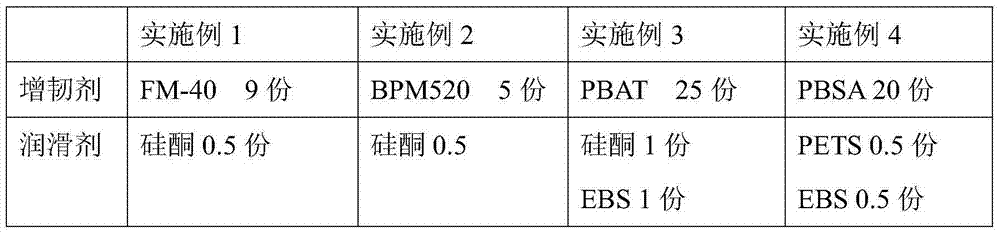

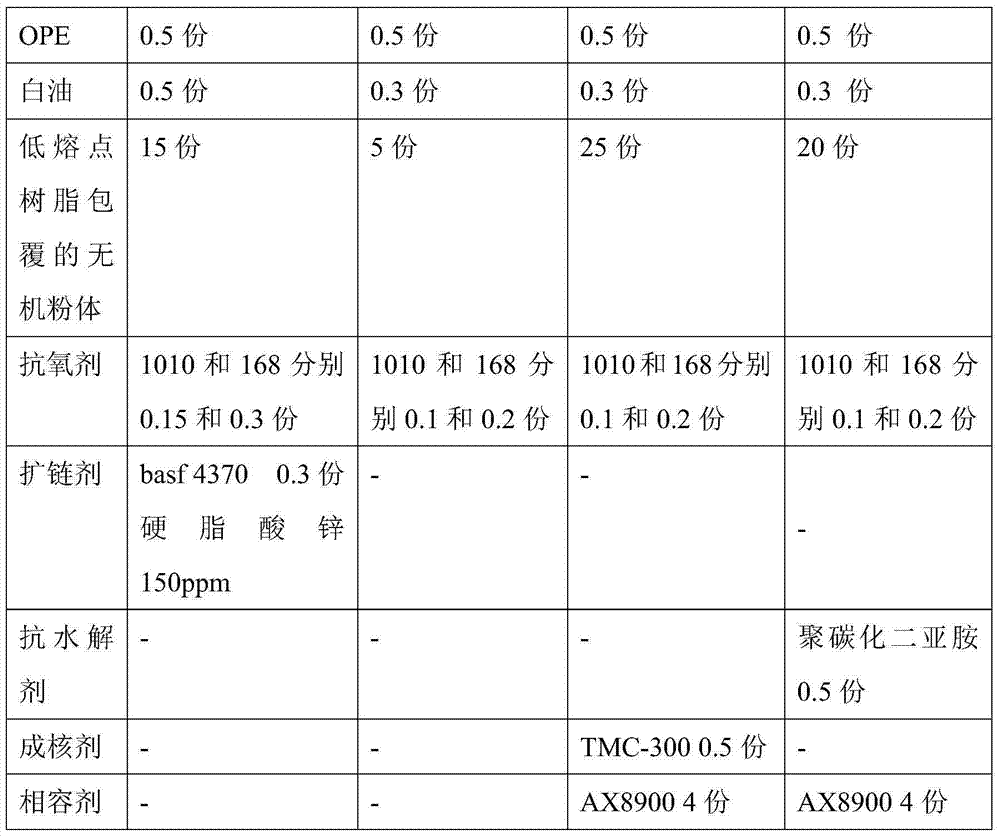

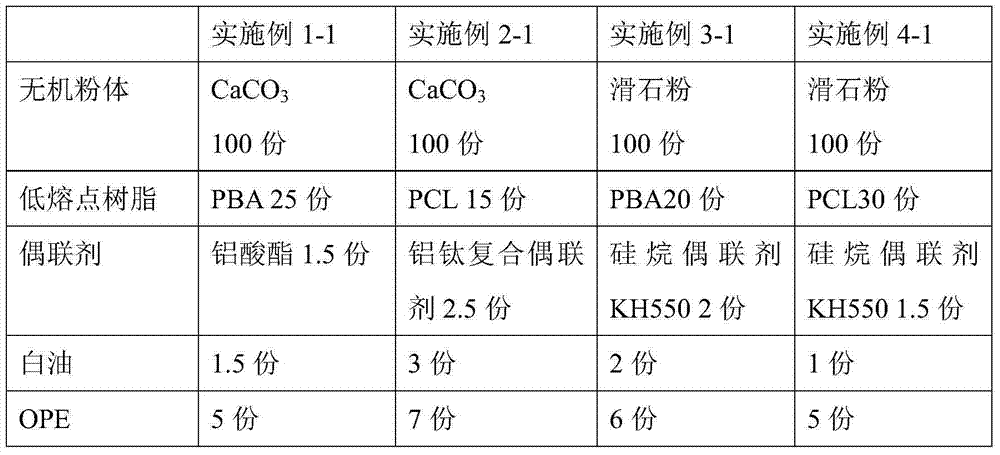

Polylactic acid toughened material for 3D printing and preparation method thereof

ActiveCN104725806AImprove toughnessImprove shrinkageAdditive manufacturing apparatusPolymer scienceAntioxidant

The invention discloses a polylactic acid toughened material for 3D printing, which comprises polylactic acid and the following components in percentage by mass (on the basis of polylactic acid): 5-25% of toughener, 0.5-2.0% of lubricant, 0.5-2.0% of oxidized polyethylene wax, 0.3-1.0% of white oil, 5-25% of low-melting-point resin-coated inorganic powder and 0.3-0.9% of antioxidant. The material prepared by the technical scheme has the advantages of favorable toughness, high extrusion forming regularity and favorable line roundness. The printing proves that the product has the advantages of low shrinkage, no edge lifting, no cracking, high cooling speed and favorable appearance and has wide printing application range.

Owner:SHENZHEN ESUN IND

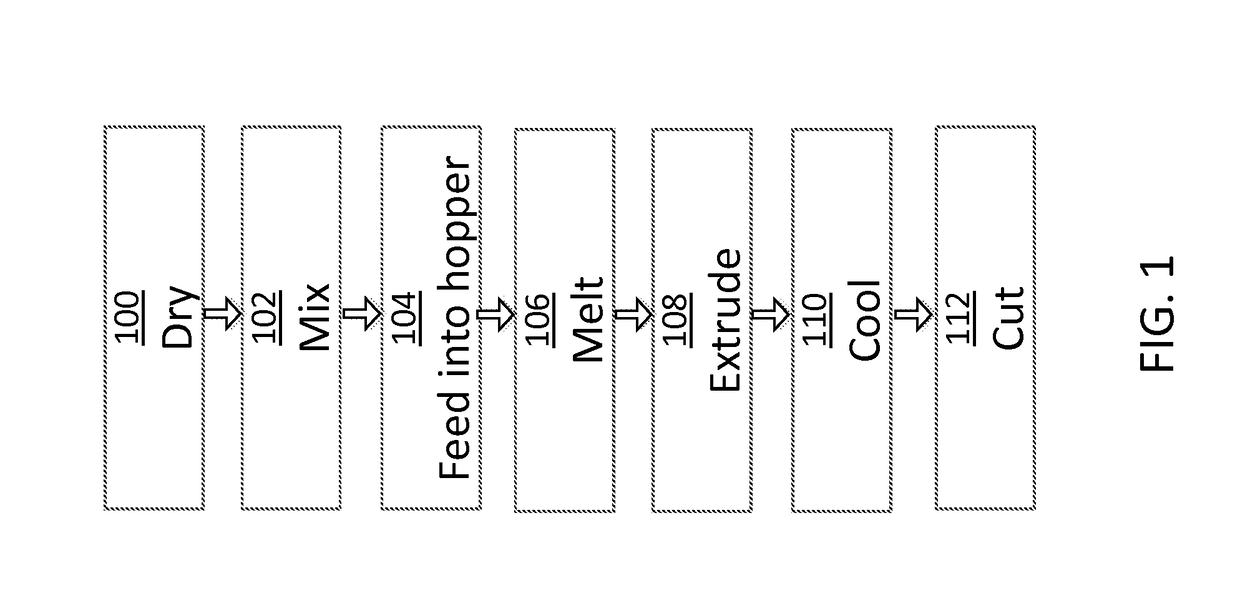

Electroconductive plastics and method of producing the same

ActiveCN101402776AImprove mechanical propertiesImprove shrinkageNon-conductive material with dispersed conductive materialGlass fiberPolymer substrate

The invention relates to a conductive plastic which consists of the following components by mass percentages: 30 percent to 70 percent of polymer matrix, 15 percent to 50 percent of glass fiber, 10 percent to 35 percent of conductive carbon black and 1 percent to 5 percent of modifier. The invention also provides a preparation method of the conductive plastic. The conductive plastic comprises the glass fiber and the conductive black, wherein, the glass fiber can enhance the mechanical performance of the conductive plastic, improve the shrinkage of the plastic, eliminate static electricity effectively and have good high temperature resistance simultaneously.

Owner:SHENZHEN WOTE ADVANCED MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com