Patents

Literature

3851results about "Liquid/gas/vapor removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

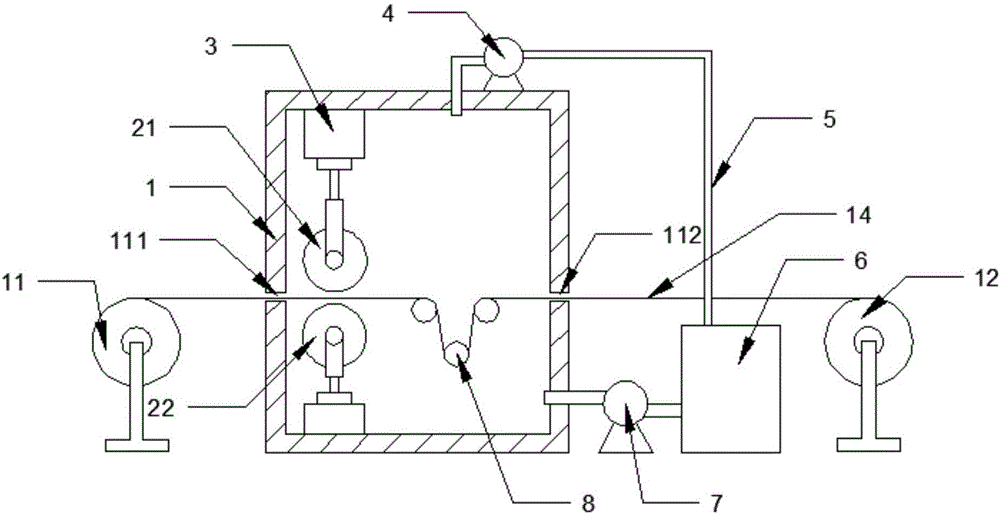

Energy-conserving textile fabric washing device

InactiveCN107326567AWash thoroughlySolve incomplete cleaningLiquid/gas/vapor removalTextile treatment machine arrangementsAgricultural engineeringWater pipe

The invention discloses an energy-conserving textile fabric washing device. The washing device comprises a case. A cleaning room, a drying room and a disinfection room are formed in an inner cavity of the case in sequence from left to right. A fixed support on the left side face of the case is fixedly connected with a feeding roller through a fixed shaft. A fixed support on the right side face of the case is fixedly connected with a discharge roller through a fixed shaft. A feeding opening is formed in the upper portion of the left side face of the case. A discharge opening is formed in the upper portion of the right side face of the case. The upper surface of the case is fixedly connected with a water storage tank, and the bottom of the left side face of the water storage tank is fixedly connected with a water pipe fixedly connected with a booster pump. The energy-conserving textile fabric washing device has the advantages of thoroughly cleaning and disinfecting cloth, effectively recycling cleaning fluid to avoid water body pollution and effectively utilizing heat in the drying room. The problems are solved that existing textile fabric wastes energy and cannot be cleaned thoroughly.

Owner:秦泽坤

Method for finishing wool fabric by compositing chitosan/TiO2

ActiveCN103981694AImprove the efficiency of grafting reactionGood antibacterialLiquid/gas/vapor removalUltrasonic/sonic fibre treatmentCooking & bakingPollution

The invention provides a method for finishing wool fabric by compositing chitosan / TiO2, which comprises the following steps: A)pretreating fabric; B)preparing composite finishing liquor, taking butyl titanate and dissolving in ethanol, adding diethanolamine, uniformly stirring and adding mixed liquor mixed by ethanol and water, heating, stirring under a backflow state to form nano TiO2 sol; adding chitosan, citric acid and sodium hypophosphate in the nano TiO2 sol, uniformly stirring to obtain the composite finishing liquor; C)finishing wool fabric, placing wool fabric in the composite finishing liquor, dipping and padding twice, wherein mangle expression is 85% and padding temperature is 50-65%; D)predrying; E)baking; F)washing; and G)drying. According to the finishing method, chitosan and nano TiO2 sol are employed as the composite finishing liquor, the finished wool fabric has good antibiosis, shrinkproof, ultraviolet resistance and anti-insolation performances; the finishing method generates no pollution on human body and environment, and the finished wool fabric has good hand feeling.

Owner:ZHEJIANG ZHONGXIN DYEING & FINISHING CO LTD

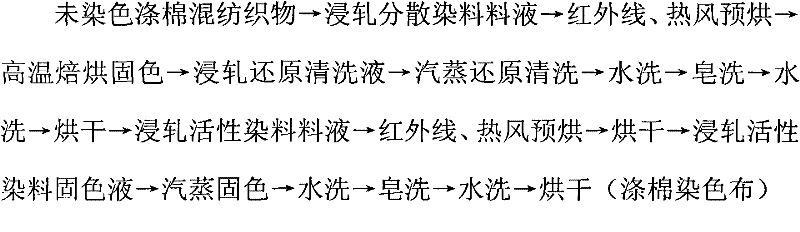

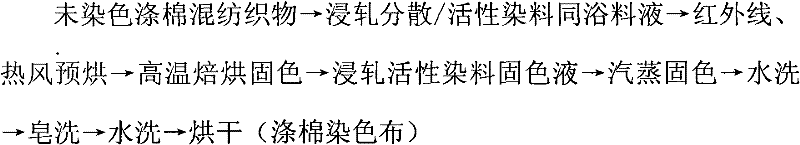

One-bath one-step process for dispersing/reactive dye of cotton-polyester blended fabric

InactiveCN102409565AReduce contentReduce consumptionSolvent-treatmentLiquid/gas/vapor removalFiberPolyester

The invention relates to a one-bath one-step process for a dispersing / reactive dye of a cotton-polyester blended fabric. The one-bath one-step process mainly comprises the following steps performed on the cotton-polyester blended fabric: dispersing / reactive dye one-bath pad dyeing; infrared and hot-air drying in advance; high-temperature baking fixation; padding in a reactive dye fixation solution; steam fixation; water washing; soaping; water washing; drying; terylene dyeing; and obtaining finished cloth. The one-bath one-step process is characterized by fully padding an unstained cotton-polyester blended fabric in a dispersing / reactive dye one-bath solution, introducing infrared and hot air so as to dry 60-70% of water in the fabric in advance, baking at high temperature so as to dye and fix color for polyester fibers, fully padding in the reactive dye fixation solution, performing steam fixation so as to dye and fix color for cotton fibers, and performing the processes of water washing, soaping and water washing so as to fully develop color on the fabric and fully wash off the surface dyeing on the fabric, thereby finishing a dyeing process. The dry and wet grinding fastness can fully meet the customer demand.

Owner:XIANGFAN NEW NO 45 PRINTING & DYEING

Modified tussah silk fabric with functionalized nanometer chitosan and nanometer titanium dioxide

ActiveCN102677465AImprove adsorption efficiencyRealize functional fillingLiquid/gas/vapor removalDry-cleaning apparatus for textilesUltravioletEngineering

The invention relates to modified tussah silk fabric with functionalized nanometer chitosan and nanometer titanium dioxide. The modified tussah silk fabric is prepared by the steps in sequence: weaving the tussah silk fabric by utilizing tussah filament, preparing finishing liquor and finishing tussah silk fabric; and the technical problems that the existing textile materials in the modification technology can not effectively improve the properties that the tussah silk fabric has damage to the environment, is easy to wrinkle, not anti-bacterial and easy to shrink, has poor dyeing property, poor comfortableness and function, and the like can be solved, the comprehensive properties that the tussah silk fabric is anti-wrinkle, soft, anti-bacterial, shrink-proof, self-cleaning and ultraviolet ray-resistant, as well as the adsorption efficiency of dye, and the like can be improved and enhanced, and the tussah silk fabric has the technical benefits of being lower in preparation cost, simple in process, environment-friendly and easy to realize, etc.

Owner:EASTERN LIAONING UNIV

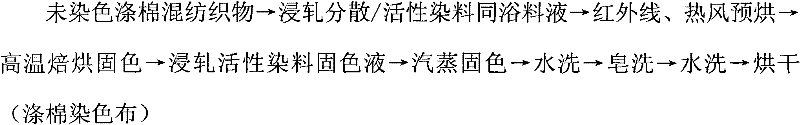

Cloth printing and dyeing device

ActiveCN105332189ADry evenlySimple structureLiquid/gas/vapor removalTextile treatment machine arrangementsEngineeringMechanical engineering

The invention provides a cloth printing and dyeing device. The cloth printing and dyeing device is used for dyeing cloth and comprises a first box, a second box, a cloth rolling roller set, a first cloth roller, a second cloth roller, transitional rollers and a communicating pipe. The first box is arranged above the second box, the body wall of the first box comprises a first outer shell, a first inner shell and a first heating cavity between the first outer shell and the first inner shell, and the cloth rolling roller set is arranged in the first box. The body wall of the second box comprises a second outer shell, a second inner shell and a second heating cavity between the second outer shell and the second inner shell, a plurality of heating pieces are arranged in the second heating cavity, and a plurality of cloth winding rollers are arranged in the second box and used for changing the direction of cloth. The first heating cavity is communicated with the interior of the second box through the communicating pipe. Exhaust holes are formed in the first outer shell and are away from the port, located in the first heating cavity, of the communicating pipe. The cloth printing and dyeing device is simple and practical in structure, uniform in dyeing and firm, and the purpose of saving energy is achieved by recycling heat.

Owner:湖州众创小微创业园企业管理股份有限公司

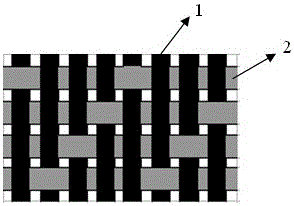

Mulberry silk and cuprammonium rayon yarn interwoven fabric and weaving method thereof

InactiveCN101532199ALow costImprove comfortLiquid/gas/vapor removalDyeing processYarnCuprammonium rayon

The invention provides a fabric, in particular to a mulberry silk and cuprammonium rayon yarn interwoven fabric. The fabric is interwoven by the mulberry silk and the cuprammonium rayon yarn, wherein warp is made of the mulberry silk, while weft is made of the cuprammonium rayon. The invention also provides a method for weaving the fabric, which is a method of interweaving the mulberry silk warp and the cuprammonium rayon yarn weft into the fabric, wherein the cuprammonium rayon yarn as the weft is subjected to predrying treatment before use; process steps of the warp and the weft are as follows: the warp adopts reeled silk to be subjected to rolling, primary twisting, doubling, second twisting, skeining, degumming, dyeing, rolling, warping and weaving; and the weft adopts cone winded yarns to be subjected to roll separating, twisting, skeining, dyeing, rolling, quilling, predrying and weaving. The method provides the product interwoven by the mulberry silk and the cuprammonium rayon yarn, and adds new content for colorful silk variety.

Owner:上海丝绸集团股份有限公司

Moisture-absorbing and perspiring anti-bacterial fabric and preparation technology thereof

InactiveCN105421055AImprove antibacterial propertiesSoft and wear-resistantBiochemical fibre treatmentLiquid/gas/vapor removalWater basedMoisture

The invention relates to a moisture-absorbing and perspiring anti-bacterial fabric and a preparation technology thereof. The moisture-absorbing and perspiring anti-bacterial fabric is blended and weaved by the following raw materials in parts by weight: 40 to 80 parts of bamboo fibers, 40 to 80 parts of long staple, 10 to 30 parts of ramie, 10 to 30 parts of coolmax fibers, 10 to 20 parts of corn fibers, 10 to 20 parts of Delight fibers, and 5 to 20 parts of Tancel, and then is treated by anti-bacterial finishing liquid; the anti-bacterial finishing liquid comprises 5 to 10 parts of chitosan, 5 to 10 parts of silk fibroin, 0.5 to 3 parts of butyl ricinoleate sodium sulfate, 0.5 to 3 parts of lemon acid, 0.5 to 2 parts of butyl methacrylate, 5 to 8 parts of dodecyl diphenyl ether sodium disulfonate, 5 to 10 parts of hydroxypropyl methyl cellulose, 5 to 10 parts of polyhexamethylene biguanidine, 5 to 15 parts of organosilicon quaternary ammonium salt, 3 to 8 parts of dodecyl trimethyl ammonium chloride, and 5 to 10 parts of water-based polyurethane. The moisture-absorbing and perspiring anti-bacterial fabric has the advantages that the anti-bacterial property is higher, the moisture-absorbing, perspiring, anti-pilling and air-ventilation properties are realized, the softness is realized, and the abrasion is resisted; the moisture-absorbing and perspiring anti-bacterial fabric is particularly suitable for being applied to the fields of underwear, overwear, sportswear and bedding articles.

Owner:杜名胜

Production method of wool/Coolmax/mulberry silk/polyester fiber blended fabric

InactiveCN102560930ATo soften waterSolve the adhesionLiquid/gas/vapor removalLiquid/gas/vapor treatment of indefinite length materialsFiberPolyester

The invention relates to a production method of a wool / Coolmax / mulberry silk / polyester fiber blended fabric, which is characterized in that the blended fabric is made of 60% of Australasian wool, 20% of Coolmax fibers, 15% of polyester fibers, and 5% of mulberry silk by dyeing, recombing, spinning, weaving and dyeing and finishing. The fabric has good color fastness, is non-fading and is breathable.

Owner:江苏华西村纺织服装有限公司

Method for producing cowhide fiber base fabric

InactiveCN102660844AReduce pollutionReduce manufacturing costLiquid/gas/vapor removalTextile disintegration and recoveryNatural fiberFlame resistance

The invention belongs to the field of cowhide materials, and particularly relates to a method for producing a cowhide fiber base fabric. The cowhide fiber base fabric is made of cowhide fibers by means of nonwoven technology and by performing fine combing lapping, airflow lapping, spunlace pre-needling, needling reinforcement, pressing, dyeing, drying, trimming and packaging after uncoiling leftover cowhide. The cowhide fiber base fabric is breathable, moisture-absorbent and comfortable, has all properties of natural fibers including fluffiness, resilience, flame resistance, softness, no abnormal odor and the like, can be made into genuine leather products including garments, cases, sofas, shoes and the like, and is an effective substitute product for genuine leather. Raw materials of the cowhide fiber base fabric are the leftover cowhide and discarded cowhide, production cost is saved, and environmental pollution is reduced.

Owner:朱晓华 +1

Water-soluble hot melt lining cloth and production method thereof

ActiveCN101353843AEasy to operateGood water solubilityFibre treatmentLiquid/gas/vapor removalInterliningMetallurgy

The invention discloses a water-soluble fusible interlining which is characterized in that longitudinal shrinkage and latitudinal shrinkage of the cotton interlining are less than or equal to one percent respectively and the formaldehyde emission is less than or equal to 50mg / kg. After the interlining is joined with a fabric by ironing, the interlining is treated in the water at the temperature of 35 DEG C for 15 seconds and separated with the fabric. The water-soluble fusible interlining has good water-soluble performance, low longitudinal shrinkage and latitudinal shrinkage, good environmental protection performance and easy operation of the production method.

Owner:曹平

Ultra-low shrinkage rate purified cotton lining cloth and production method thereof

The invention discloses a purified cotton interlining with an ultra-low shrinkage, and a production method thereof. Longitudinal shrinkage and latitudinal shrinkage of the cotton interlining are less than or equal to 0.8 percent respectively and the formaldehyde emission is less than or equal to 50mg / kg. The production method thereof sequentially comprises the steps of sewing, singeing, bleaching, mercerizing, re-bleaching, drying, dyeing, post-processing, shrink-proof finishing and powder point coating. The cotton interlining the invention has low longitudinal shrinkage and latitudinal shrinkage, good environmental protection performance and easy operation of the production method.

Owner:曹平

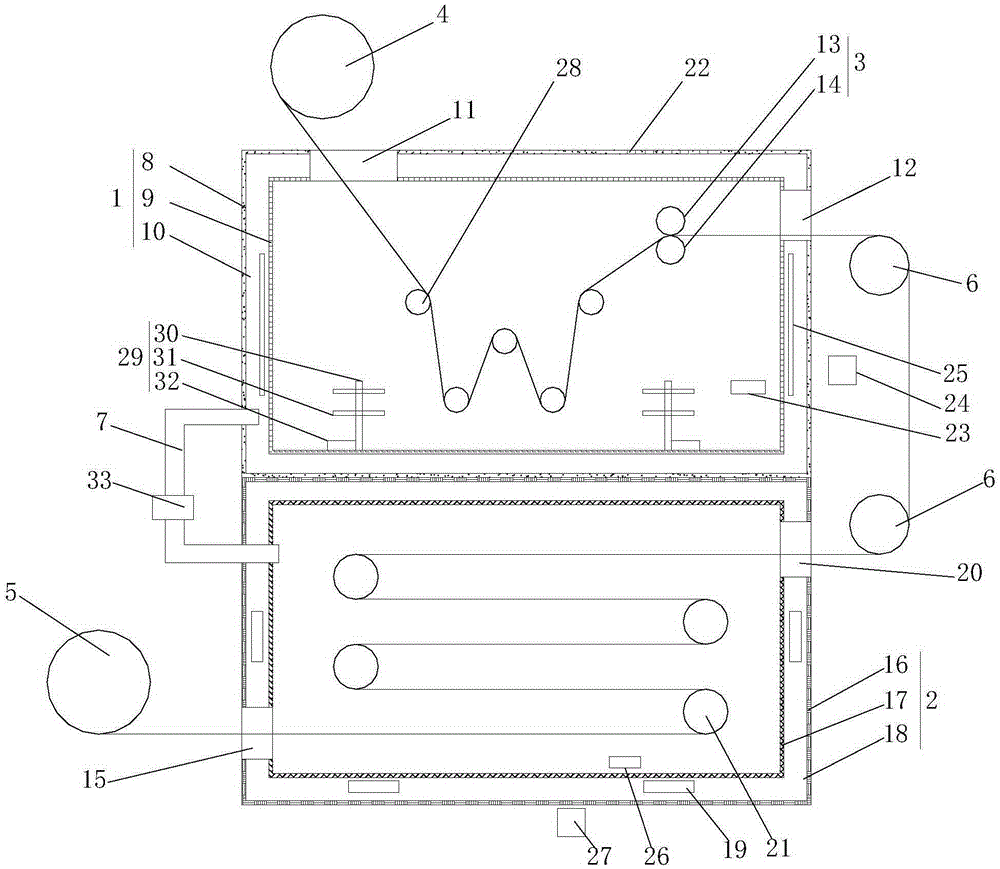

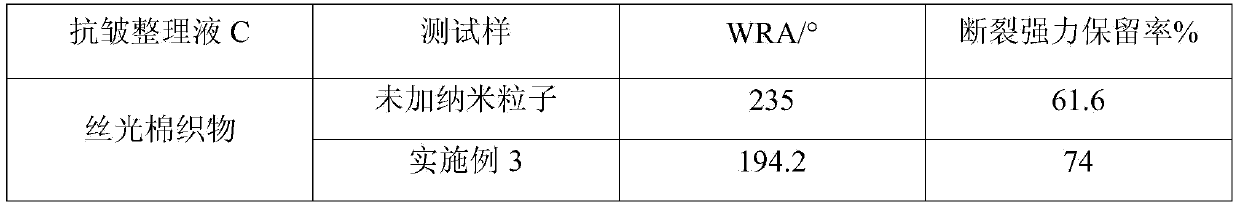

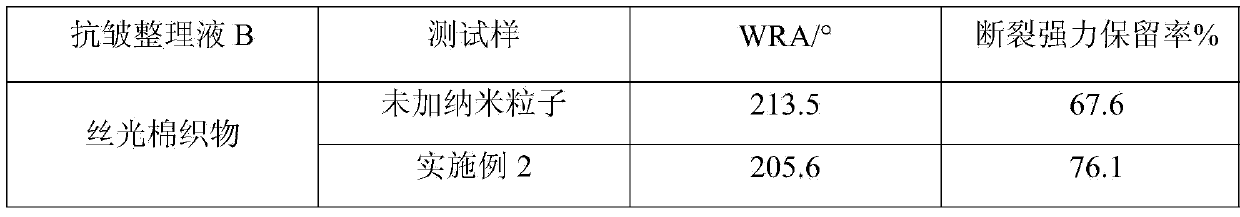

Nanometer material reinforced cotton fabric crease-resistant finishing liquid and application of crease-resistant finishing liquid

InactiveCN103572588AEnhanced tensile breaking strengthIncreased wrinkle recovery angleHeating/cooling textile fabricsLiquid/gas/vapor removalEngineeringSolvent

The invention relates to a nanometer material reinforced cotton fabric crease-resistant finishing liquid and an application of the crease-resistant finishing liquid. The finishing liquid comprises a nanometer material, a crease-resistant finishing agent, a catalyst, an initiator, a strong protective agent and a solvent-water. The finishing method comprises the steps of dipping a cotton fabric into the crease-resistant finishing liquid for 3-5min; respectively dipping and rolling for two times, wherein the liquid entrainment rate is 80-85%; drying and baking. The nanometer material reinforced cotton fabric crease-resistant finishing liquid is superior to a conventional crease-resistant finishing liquid and has the characteristics that the tensile strength of the fabric can be remarkably improved, the problem that the strength of an existing crease-resistant finishing fabric is reduced can be obviously improved, and the nanometer material reinforced cotton fabric crease-resistant finishing liquid and the application of the crease-resistant finishing liquid have wide application prospects and market prospects.

Owner:DONGHUA UNIV +1

Cotton fabric high-efficiency dyeing and finishing process

InactiveCN104988713AImprove hydrophilicityImprove dye uptakeSucessive textile treatmentsLiquid/gas/vapor removalFiberInorganic salts

The invention discloses a cotton fabric high-efficiency dyeing and finishing process including modification treatment, scouring and dyeing in one bath, soaping, color fixation, post-finishing, drying, sizing, calendering, and coiling. Ultrasonic waves are used for pretreatment; at the same time, before a dyeing process, a fabric is subjected to low temperature plasma treatment, then the fiber fabric is subjected to modification treatment with 2,3-epoxypropyltrimethylammonium chloride and finally is treated by chitosan, and thus the fabric dyeing degree is increased, and the difficulty of the subsequent dyeing steps is reduced; with adopting of scouring and dyeing in one bath, the efficiency is increased, and the cost is reduced; in the dyeing process, a large amount of alkaline substances and inorganic salts are not used, natural dyes are used, and at the same time, a colophony powder is added as a color fixing agent, so that the color fixing effect is enhanced, besides, the environmental pollution is avoided, and the requirements of environmental protection are met; montmorillonite is used for flame retardant treatment on the fabric, so that the flame retardancy of the fabric is high; and with increase of anti-yellowing finishing, a final fabric does not easily turn yellow.

Owner:TAICANG SHUANGYU CHEM FIBER CO LTD

High-elastic low-shrinkage jean cloth and technology for same

The invention discloses high-elastic low-shrinkage jean cloth and a technology for the same. The jean cloth is interweaved by warp yarns and weft yarns in a principle of three warp yarns above and one weft yarn under. The concrete processes are spooling, warping, sizing and dyeing linkage, weaving, checking gray fabric, after-treatment processing, checking finished product and packing. The invention relate to high-elastic low-shrinkage jean cloth and a technology for the same. A 3 / 1 twill-weave is applied; cotton bale T400 warps spandex weft yarns, short fiber pure polyester warps the spandex or blending cotton type warps spandex weft yarns; denier of the spandex is 70D to 105D; draft multiple is 3.5 to 4.5; warp direction tightness of the yarns on a machine is 45% to 75%; weft direction tightness of the yarns on the machine is 38% to 55%; the blank cloth is post-treatment processed according to the concrete processes, so finished product amplification can be narrowed, so weft shrinkage can be reduced; a problem produced during clothing and washing water processing links can be effectively solved; with specific weft-warp yarns, specific weaving machining technology and specific post-treatment process, weft extension of the jean cloth can reach no less than 35%, reversion rate no more than 2.5% and weft shrinkage rate no more than 10%.

Owner:佛山市立笙纺织有限公司

Method for producing waterproof moisture permeability fabric based on water foaming system

ActiveCN102744940ASolve pollutionBubble ratio increaseSynthetic resin layered productsLaminationMicro nanoWater based

The invention relates to a method for producing waterproof moisture permeability fabric based on a water foaming system. The method comprises the following steps: (1), water proofing and calendaring treatments on fabric; (2), preparation of water base coat foaming coating adhesive; (3), preparation of water surface coat foaming coating adhesive; and (4), a dry-method coating process. According to the fabric and the method, an environment-friendly water coating agent and a specific foaming system are developed; a simple coat processing technology is adopted; the high-waterproof moisture permeability fabric in a micro-nano hole structure is produced; by adopting the waterproof moisture permeability fabric produced by the invention, the waterproof property can be equal to that of a 10000mm water column; and the moisture permeability amount can be up to 7000g / m 2*24h by adopting a reverse cup method and is near to 2500g / m 2*24h by adopting an upright cup method.

Owner:晋江龙之族工贸发展有限公司 +1

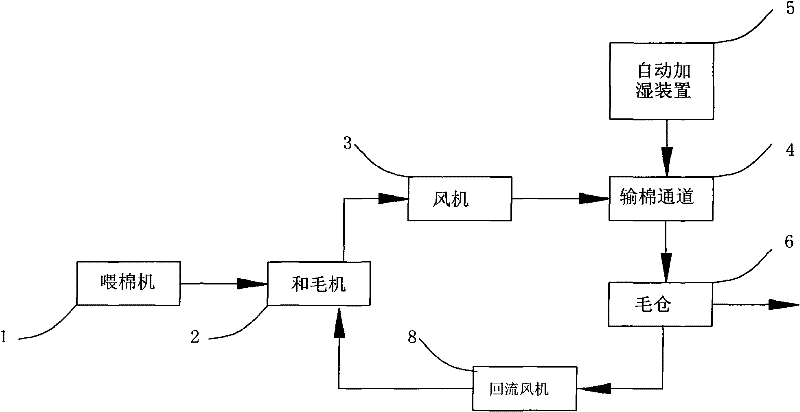

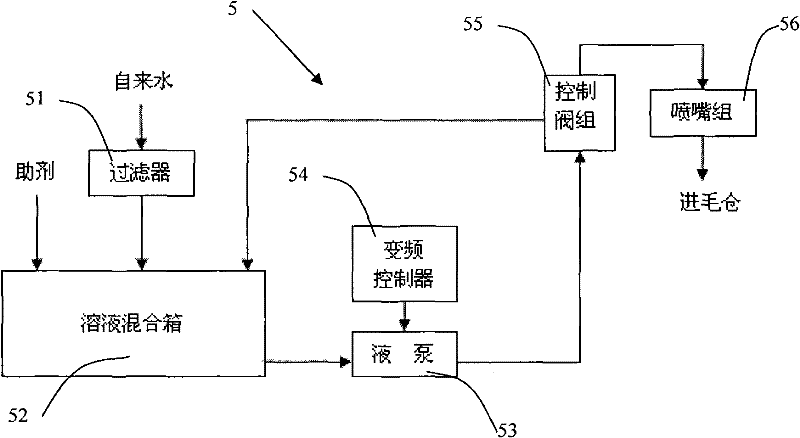

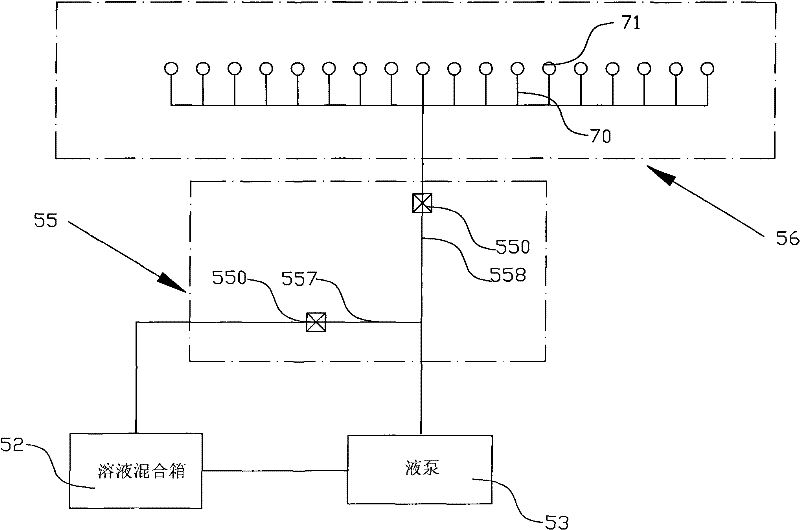

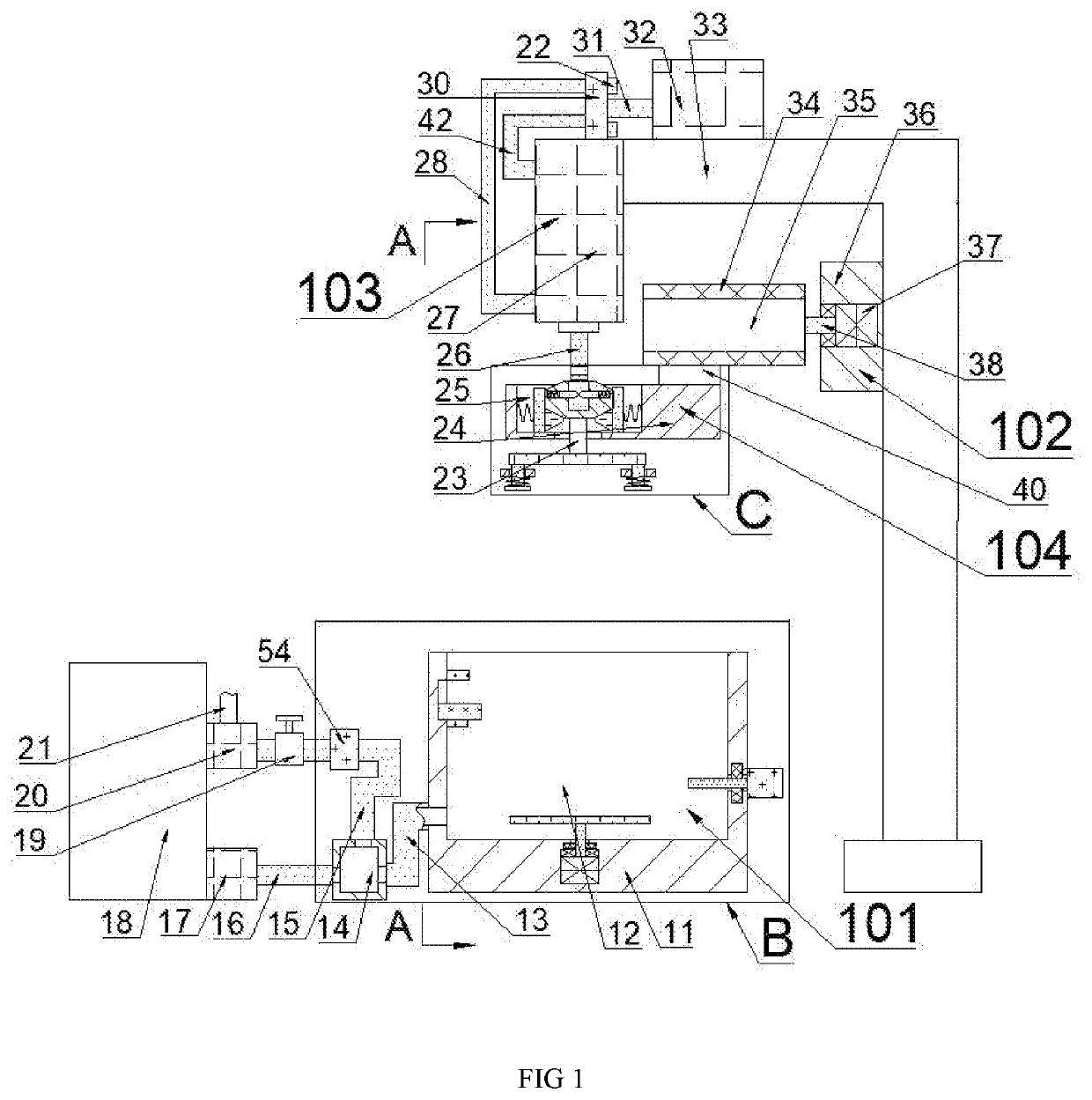

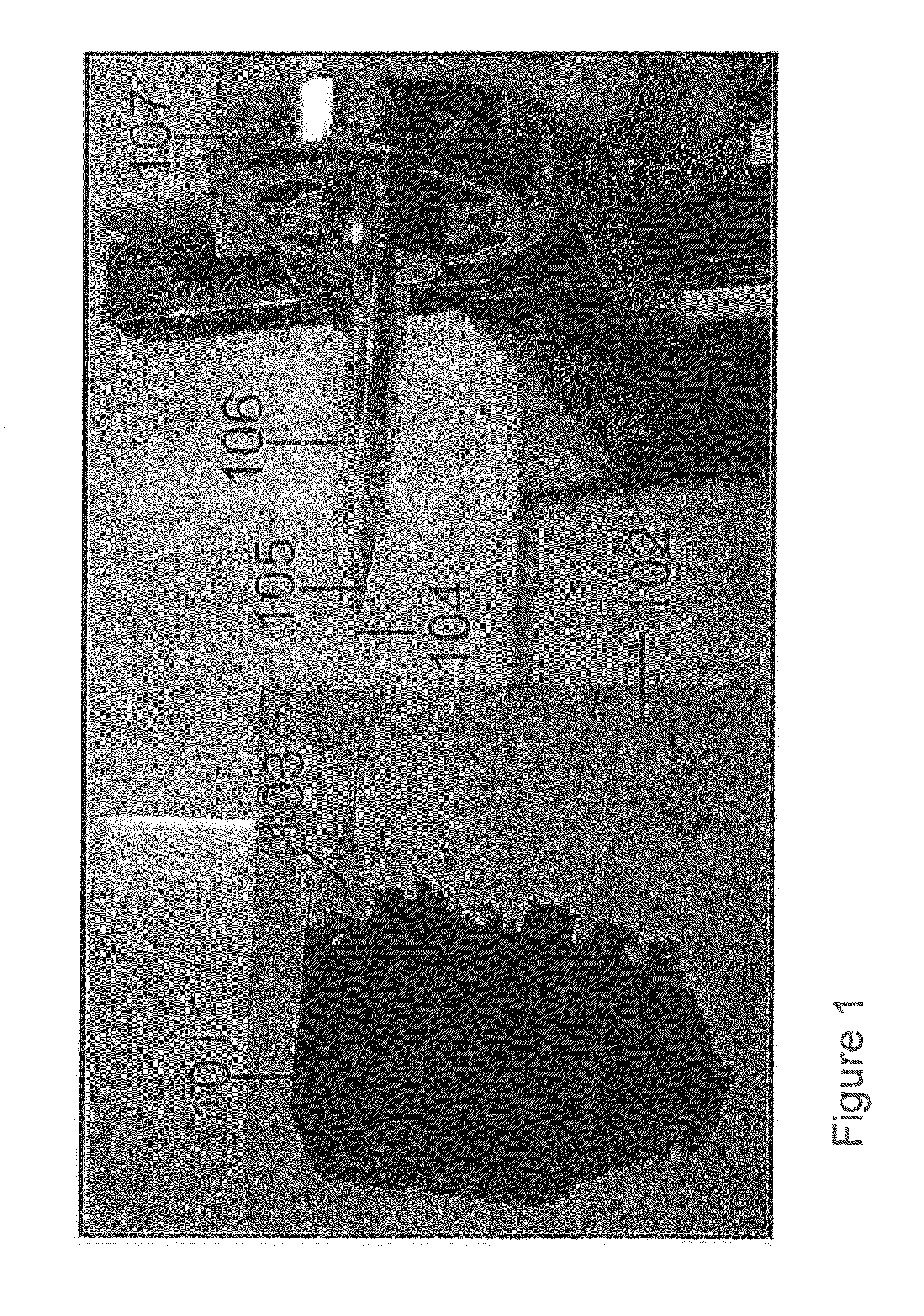

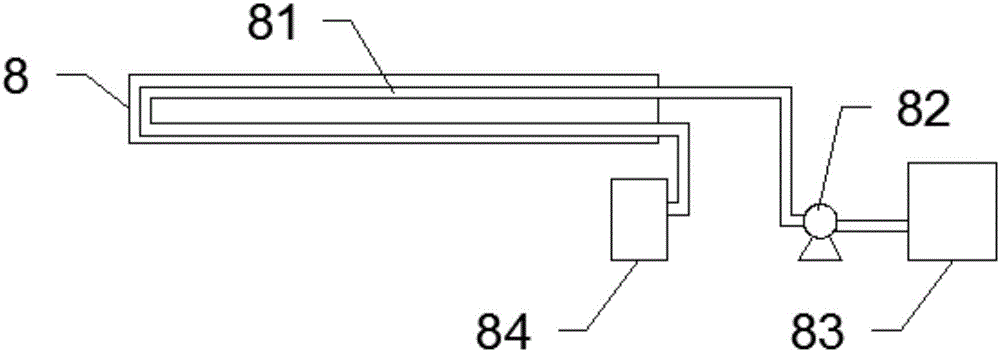

Fiber pretreatment device and method

InactiveCN102453982AReduce labor intensitySave spaceContinuous processingLiquid/gas/vapor removalYarnFiber

The invention discloses a fiber pretreatment device and method. The fiber pretreatment device comprises a cotton feeder, a wool mixer, a fan, a cotton conveying channel, an automatic humidification device and a wool bin which are connected in sequence by pipes; the automatic humidification device is connected with the cotton conveying channel; the fiber pretreatment device further comprises a reflow fan; the reflow fan is connected with the wool mixer and the wool bin through pipes; the wool bin is provided with an air blowing device; and the air blowing device is a ventilating pipe which is connected with an air blower. The method for humidifying manually for fiber pretreatment for a long time is changed, the working labor intensity is reduced, the defect of incontinuous production caused by manual humidification is overcome, and the reflow step, namely the secondary humidification step is adopted so that the fiber pretreatment can further meet the yarn spinning requirement and the fiber spinnability is improved.

Owner:上海第三十六棉纺针织服装厂有限公司

Method for single-sided fabric finishing

ActiveCN101748575ALow costCloth speed upLiquid/gas/vapor removalTextile treatment by spraying/projectingEngineeringWater repellent

The invention provides a method for single-sided fabric finishing, which comprises the following steps: 1) pre-drying fabric; 2) applying finishing solution on a single side of the fabric by means of spraying; and 3) drying the fabric obtained in the second step, and obtaining the finished fabric product after drying. The method has a simple technical process, and can greatly improve the production efficiency in fabric finishing. After the single-sided finishing, such as the single-sided water-repellent and oil-repellent finishing, the fabric not only can meet the requirements for water repellence and oil repellence, but also can be worn more comfortably, thereby improving the product grade.

Owner:CHINESE TEXTILE ACAD

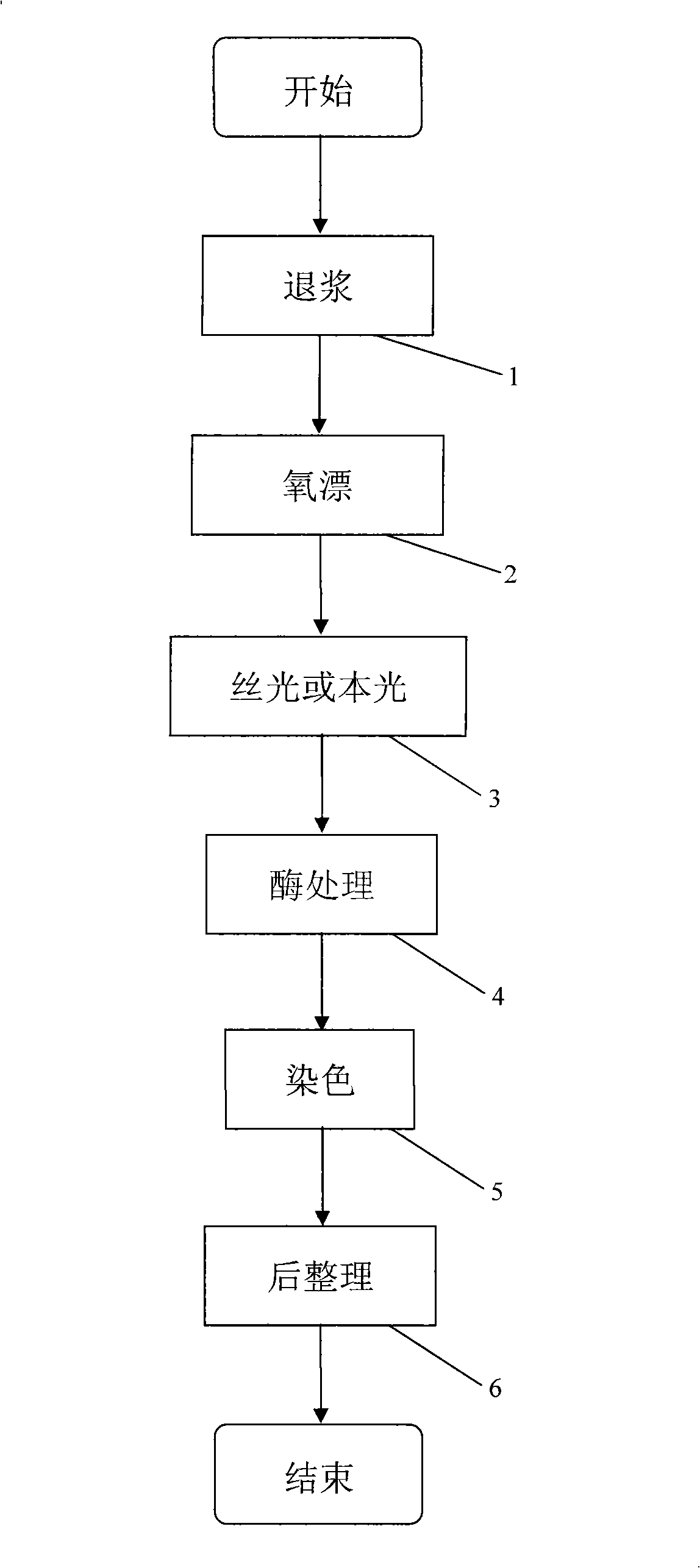

All-cotton fabric imitated tencel treating process

InactiveCN101338502AImprove applicabilitySimple processBiochemical fibre treatmentLiquid/gas/vapor removalFiberHigh density

The present invention discloses a cotton fabric tencel-like treatment process, which sequentially comprises the procedures as follows: desizing, oxide bleaching, mercerizing, enzyme treatment, dyeing, after-classification and other procedures. The present invention carries out the tencel-like treatment for cotton fabrics and increases the adaptability of cotton fabrics, so that the high-count and high-density poplin fabrics feels smooth and wears comfortable and permeable after the treatment. The tencel-like treatment for cotton fabrics is simple and the cost is low. In addition, the raw material for cotton fabrics is easily obtained and the tencel-like treatment increases the added value of the product. Through the tencel-like treatment, the price of the cotton fabrics is low and thus ordinary people can enjoy soft hand feeling, elegance, comfort and permeability of the tencel fiber.

Owner:浙江誉华集团湖州印染有限公司

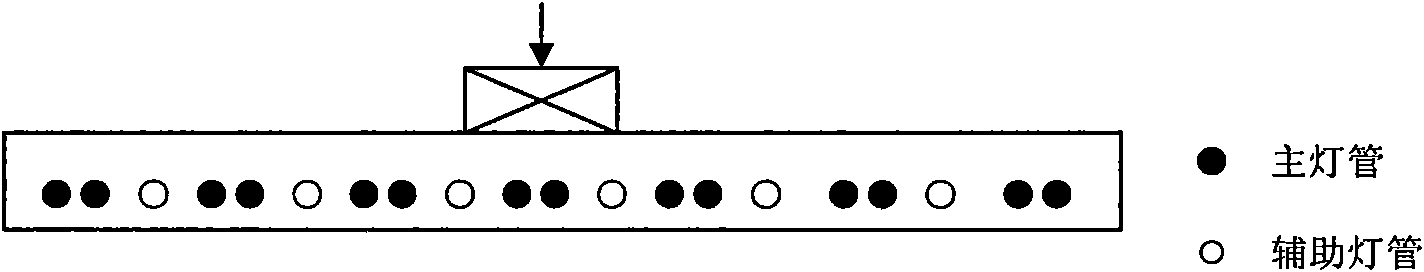

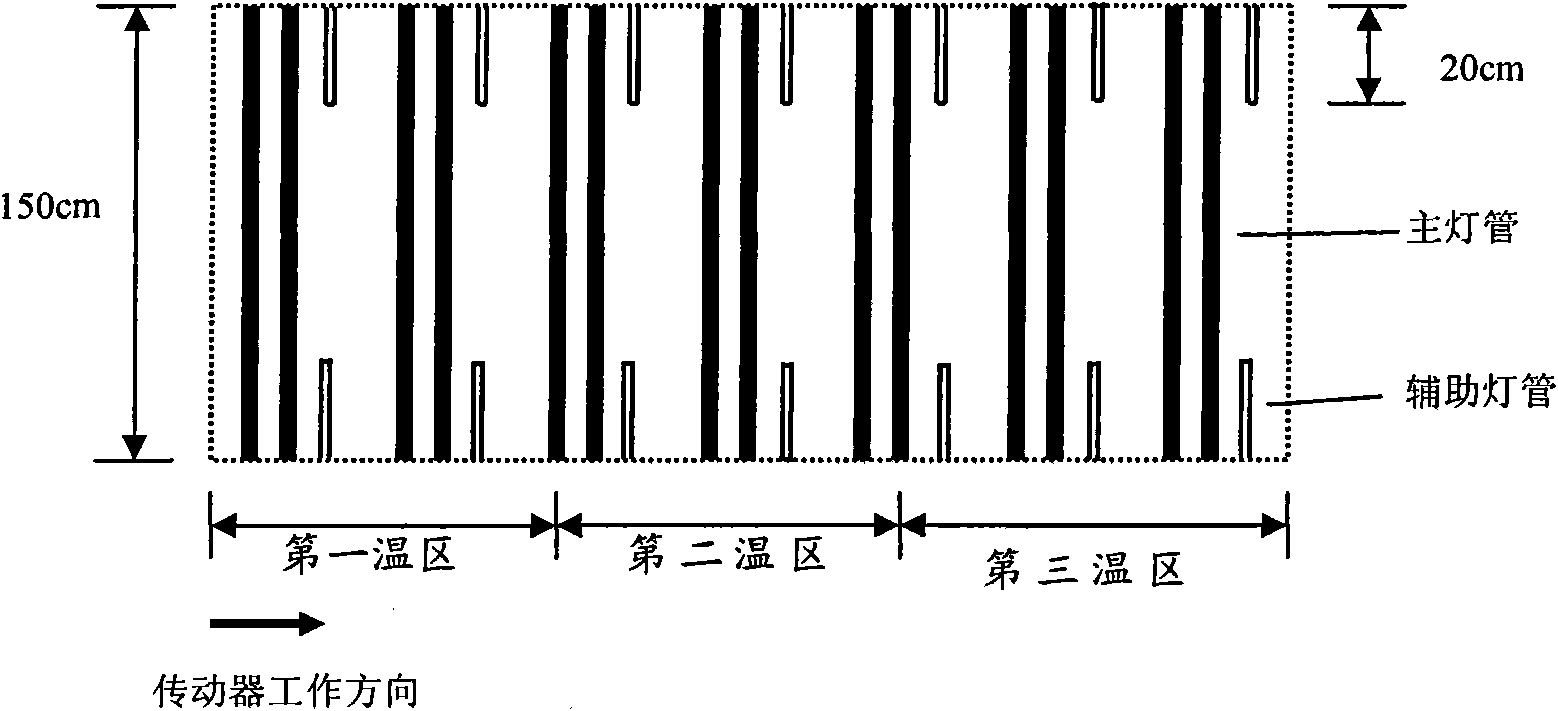

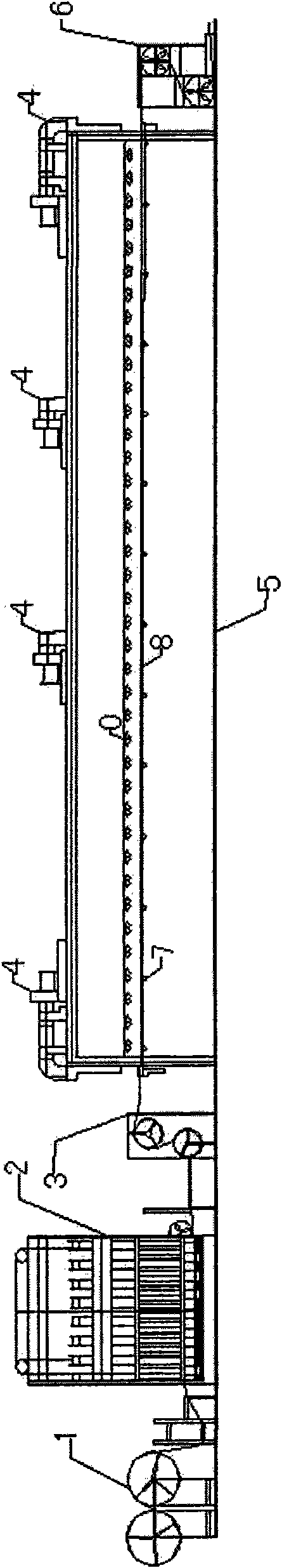

Dry method production line of water-based ecological synthetic leather

InactiveCN101942768AIncrease productivityRealize full environmental protectionSucessive textile treatmentsLiquid/gas/vapor removalProduction lineLeather industry

The invention provides a dry method production line of water-based ecological synthetic leather, which comprises a driver, a coating table and an oven, wherein the driver is used for conveying release paper or base clothes; the coating table is used for sizing on the release paper or the base clothes for one time or many times to form a single-layer or multi-layer water-based resin coating; the oven is used for drying the single-layer or multi-layer water-based resin coating; and medium wave infrared drying equipment is arranged in the oven. The production line of the invention has the advantages of safety, energy saving and high production efficiency, has double functions of production lines of the traditional dry method and the traditional wet method for producing leather, realizes the complete environment protection of the synthetic leather industry, and enables the quality of the processed water-based ecological synthetic leather to be more excellent.

Owner:丽水市优耐克水性树脂科技有限公司

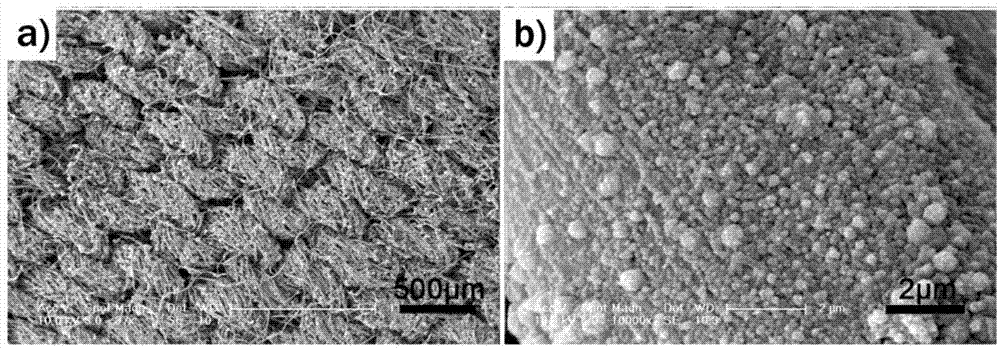

Graphene/fiber fabric preparation method, graphene/fiber fabric and sensor

InactiveCN105951427AImprove mechanical propertiesEfficient compositePhysical treatmentLiquid/gas/vapor removalFiberRoom temperature

The invention relates to a graphene / fiber fabric preparation method, which is characterized by comprising the following steps of 1) immersing fiber fabric in a bovine serum albumin solution at a room temperature, drying the fiber fabric, and cleaning the fiber fabric by utilization of deionized water so as to obtain cationized fiber fabric; 2) immersing the cationized fiber fabric obtained in the step 1) into a graphene oxide solution, and drying to obtain graphene oxide / fiber fabric; 3) immersing the graphene oxide / fiber fabric obtained in the step 2) into a reducing agent, cleaning by utilization of the deionized water, and drying to obtain the graphene / fiber fabric. The preparation method provided by the invention has the advantages that the technology is simplified, the graphene / fiber fabric prepared according to the preparation method is well compounded with graphene, and the effects of stable resistance, high sensitivity, security and environmental friendliness are achieved.

Owner:SHENZHEN MICRO & NANO INTEGRATED CIRCUITS & SYST RES INST

Negative ion far infrared Raschel blanket production technology

ActiveCN104141196AStrong biological wave emission functionGood deodorizing effectWarp knittingLiquid/gas/vapor removalEngineeringOperability

The invention discloses a negative ion far infrared Raschel blanket production technology which mainly comprises steps as follows: (1), yarn selection; (2), moistening; (3), weaving; (4), boiling-off; (5), uniformly dyeing; (6) reduction cleaning; and (7), afterfinish. According to the production technology, negative ion far infrared polyester filament yarn and polyester low stretch yarn are taken as raw materials to be woven into related texture on a warp knitting machine, afterfinish is performed after uniformly dyeing is performed, the technological step is simple, the operability is high, and a functional negative ion far infrared Raschel blanket is developed through the optimization design of the whole process; the produced negative ion far infrared Raschel blanket has remarkable characteristics in the aspect of function, comfort and the like, not only has good hand feeling and softness, but also has temperature increasing and health-care physical therapy effects.

Owner:ZHEJIANG TRUELOVE CARPET IND SCI & TECH

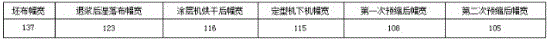

Production method for enabling pure mulberry silk fabric to have natural elasticity style in weft direction

ActiveCN101634097AWeft stress balance and stabilityGuaranteed uniformityLiquid/gas/vapor removalHeating/cooling textile fabricsFiberMoisture absorption

The invention discloses a production method for enabling a pure mulberry silk fabric to have a natural elasticity style in a weft direction. The technological processes sequentially comprise blank silk weaving, preprocessing, cooked smelting, bleaching, water washing, pickling, dewatering or squeezing, coiling, baking stentering and check mounting, wherein the cooked smelting comprises primary smelting and secondary smelting. The baking stentering comprises the following steps: firstly, carrying out baking shaping on a wool carpet finishing machine and then at least carrying out stentering processing for more than two times on a stentering machine. The technological processes of the blank cloth weaving comprise the selection of wefts, the selection of the twisting degree and the twisting direction of the wefts and the twisting direction arrangement of weft combination. Because the pure mulberry silk fabric does not depend on elastic fibre, such as urethane elastic fibre and the like, and adopts blank silk woven by super-strong twisting real silk wefts to carry out the methods of degumming, stentering, shaping and processing so as to enable a pure real silk fabric to obtain better weft direction elasticity and excellent elastic restoring force, the fabric is not easy to crack and has relatively flexible hand feel and good moisture absorption and air permeability, and a dress article made by the fabric shapes the body and has convenient movement, good form retention, small dimensional change rate and small seam slippage.

Owner:DALI SILK ZHEJIANG

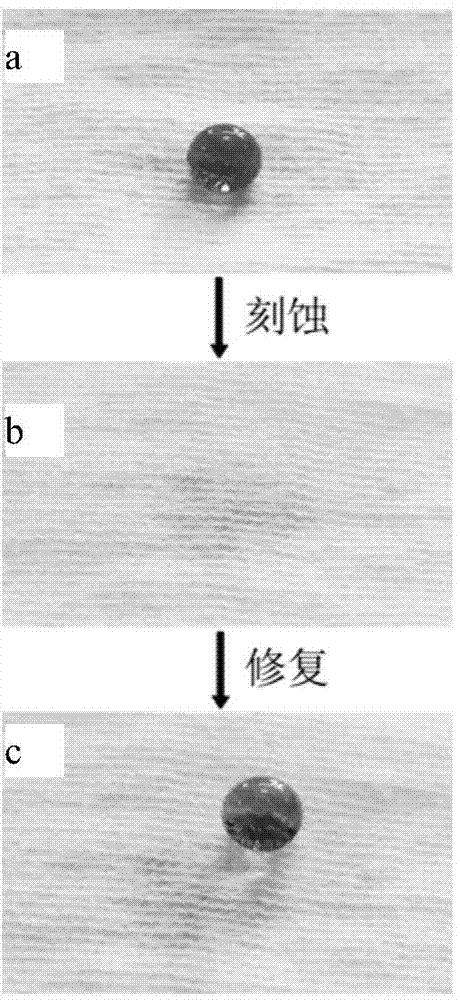

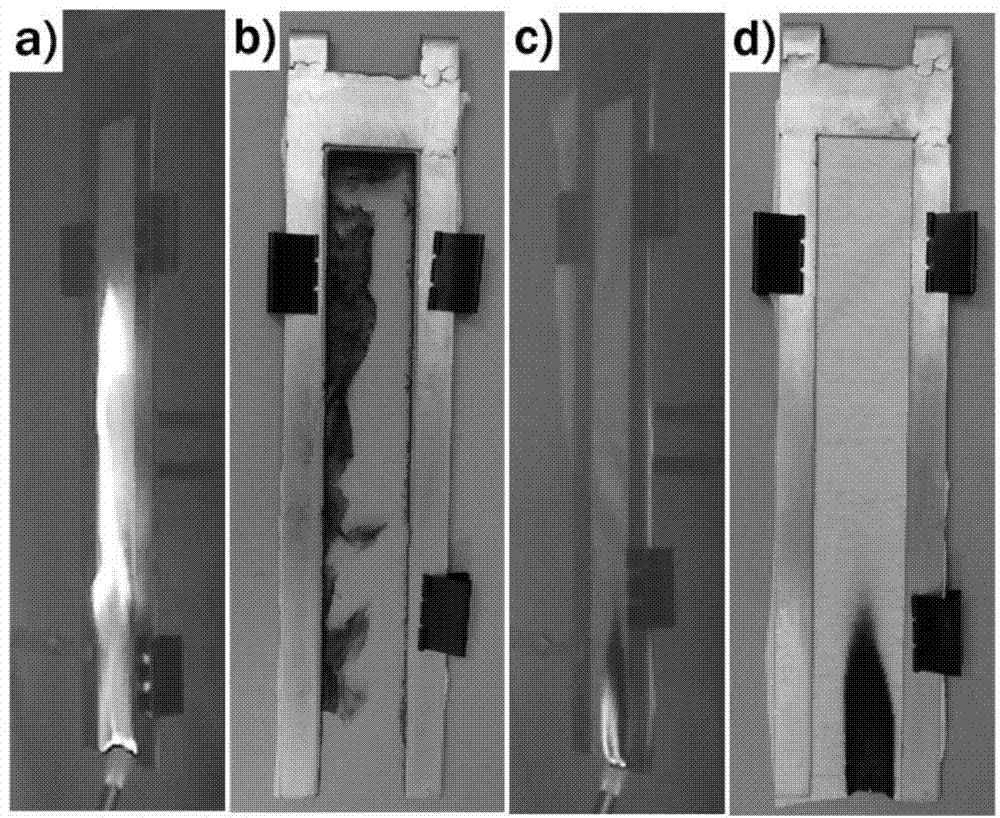

Production method of self-repairing super-hydrophobic flame retardation coat layer

InactiveCN104711856AEasy to prepareExtend your lifeLiquid/gas/vapor removalVegetal fibresSelf repairLong acting

The invention relates to a production method of a self-repairing super-hydrophobic flame retardation coat layer, and belongs to the technical filed of production self-repairing super-hydrophobic flame retardation coat layers. The method comprises the following steps: a self-extinguishing flame retardation coat layer is made through a simple technology, and a self-repairing super-hydrophobic film is used to protect the flame retardation function easily destroyed by water. The method comprises the steps of substrate processing, solution preparation and three-layer film assembling. The substrate is not restricted by the size or shape of a fabric, and is suitable for various common fabrics. Terylene is modified with the self-repairing self-hydrophobic flame retardation coat layer, only 10cm of the fabric is blackened after the obtained fabric is ignited and burns for 12s, and the remaining portion of the fabric is completely not influenced by flame. The contact angle of the modified fabric is 160DEG, and the super-hydrophobicity can be rapidly restored after being destroyed. The method used in the invention has simple program, has the advantages of long acting and energy saving, can be used in various fabrics, and is expected to be widely applied in the fields of packaging, home finishing and buildings.

Owner:JILIN UNIV

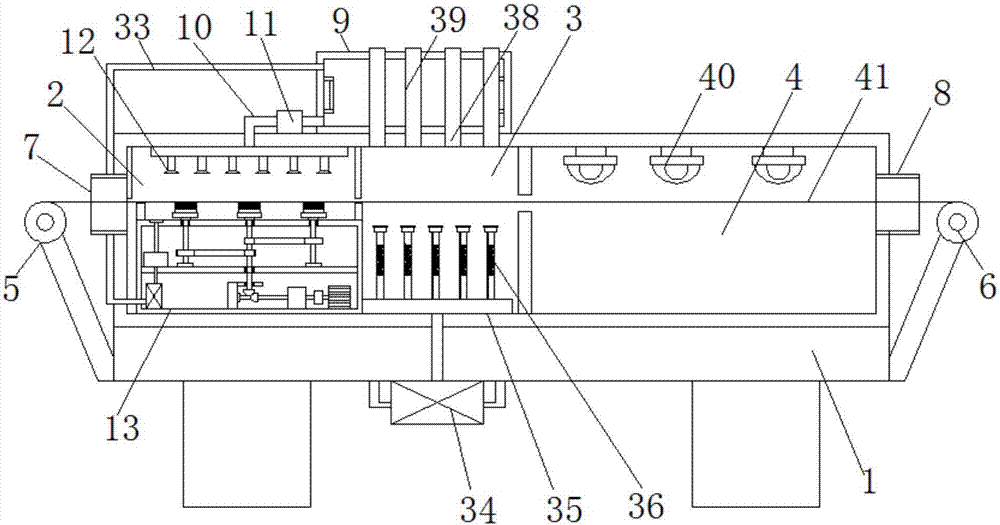

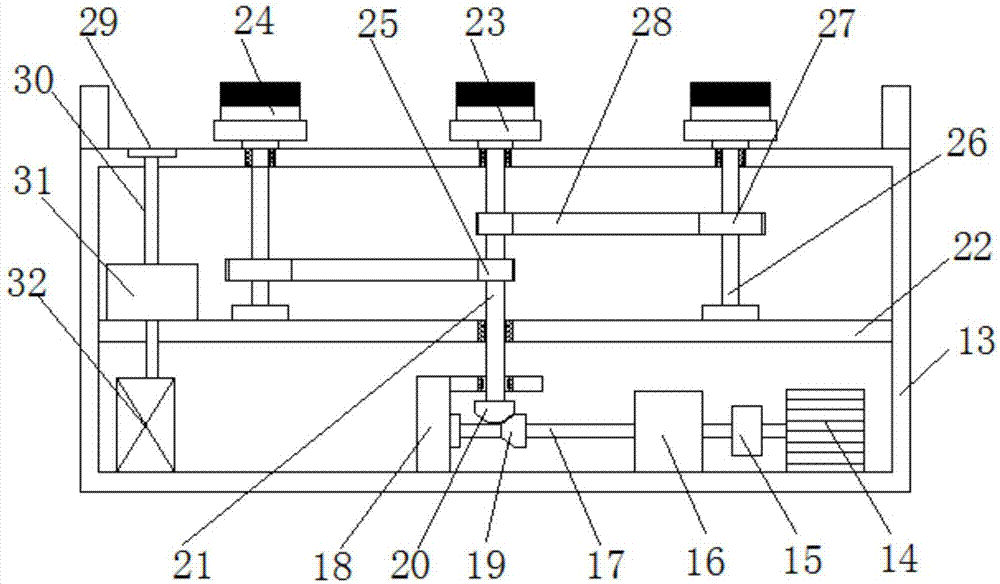

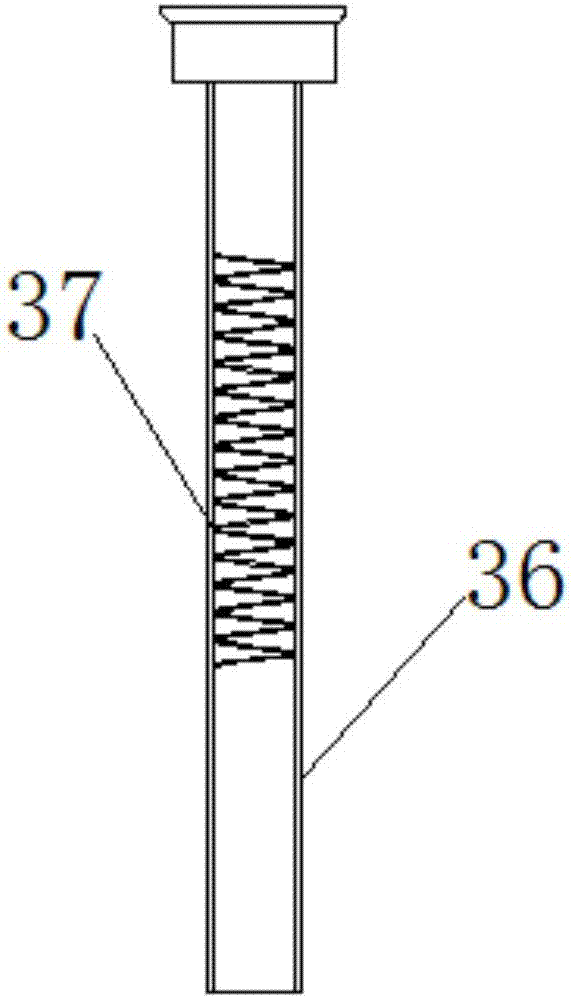

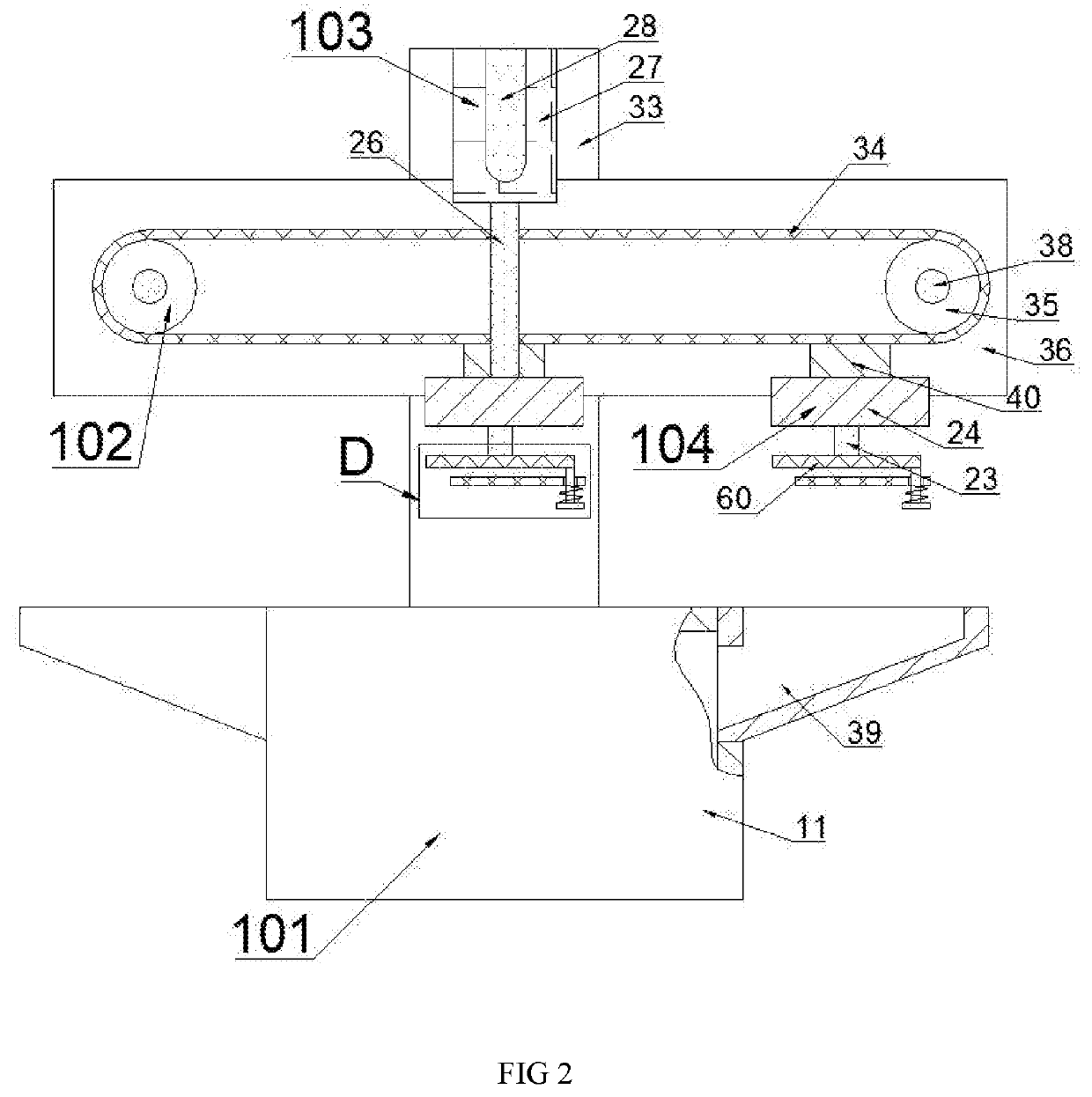

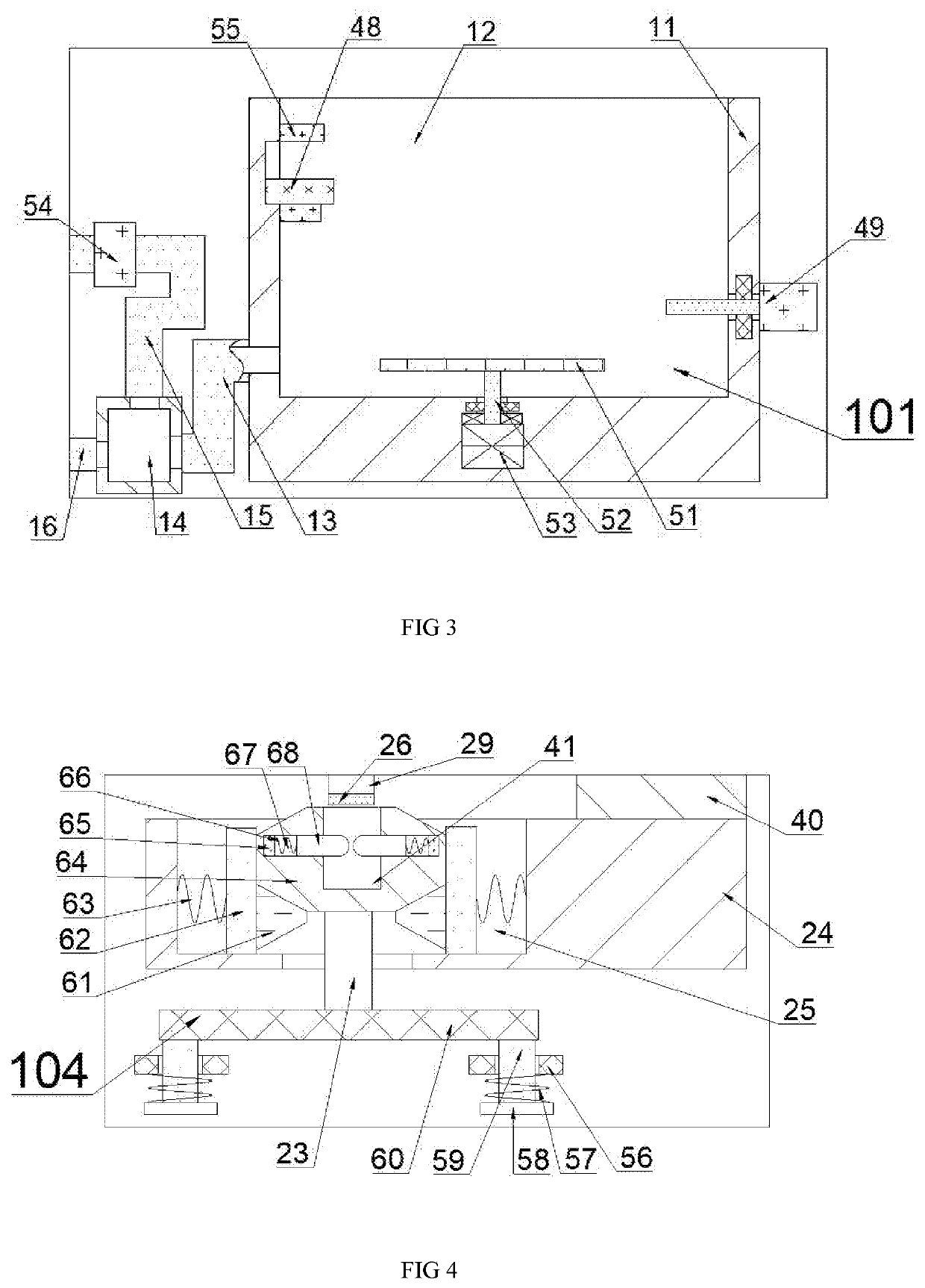

Blue calico printing and dyeing equipment imitating traditional process

InactiveUS20200181821A1Quality improvementIncrease productivityLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor removalProcess engineeringMechanical engineering

The invention discloses a blue printing cloth printing and dyeing device which imitates the traditional process, and includes a dye box. A dyeing device is provided on the right side of the dye box, and an L-shaped support post is provided on the right side of the dye box. A conveying device for conveying cloth is provided on the column, and a lifting device on the upper side of the conveying device is provided on the support column. The lifting device provides lifting movement for the dyeing cloth. As for the holding device for holding the cloth, the cloth dyeing cylinder of the present invention can indirectly detect the concentration of the dye solution through the PH value detection, and the liquid level detection mechanism and the PH value detector can be used to control the liquid pump supply to achieve automatic control of the dye solution concentration and The liquid level height improves the printing and dyeing quality. The conveying mechanism drives the two groups of clamping mechanisms to move to the upper side of the cloth dyeing cylinder and the air-drying place. The lifting mechanism can drive the clamping mechanism to lower into the cloth dyeing cylinder for dyeing. Therefore, the present invention can replace manual Printing and dyeing with traditional techniques can improve production efficiency.

Owner:WANG MING

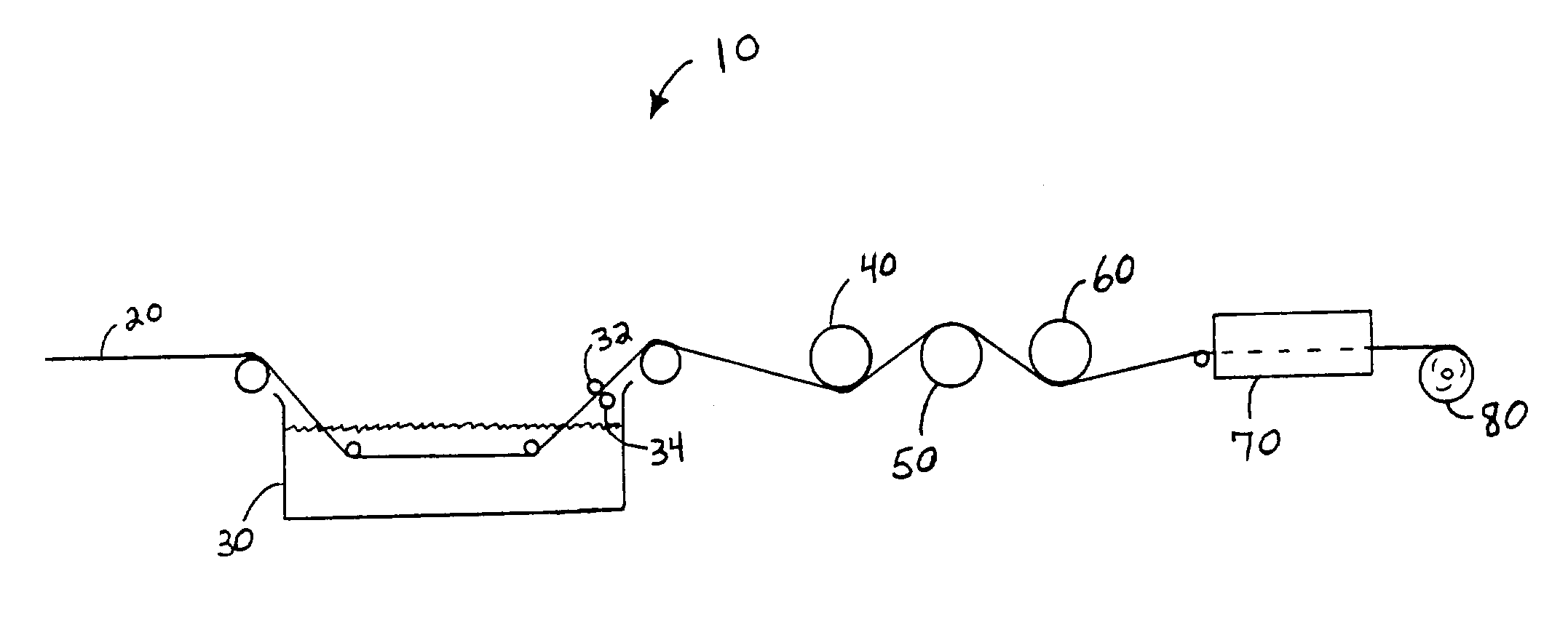

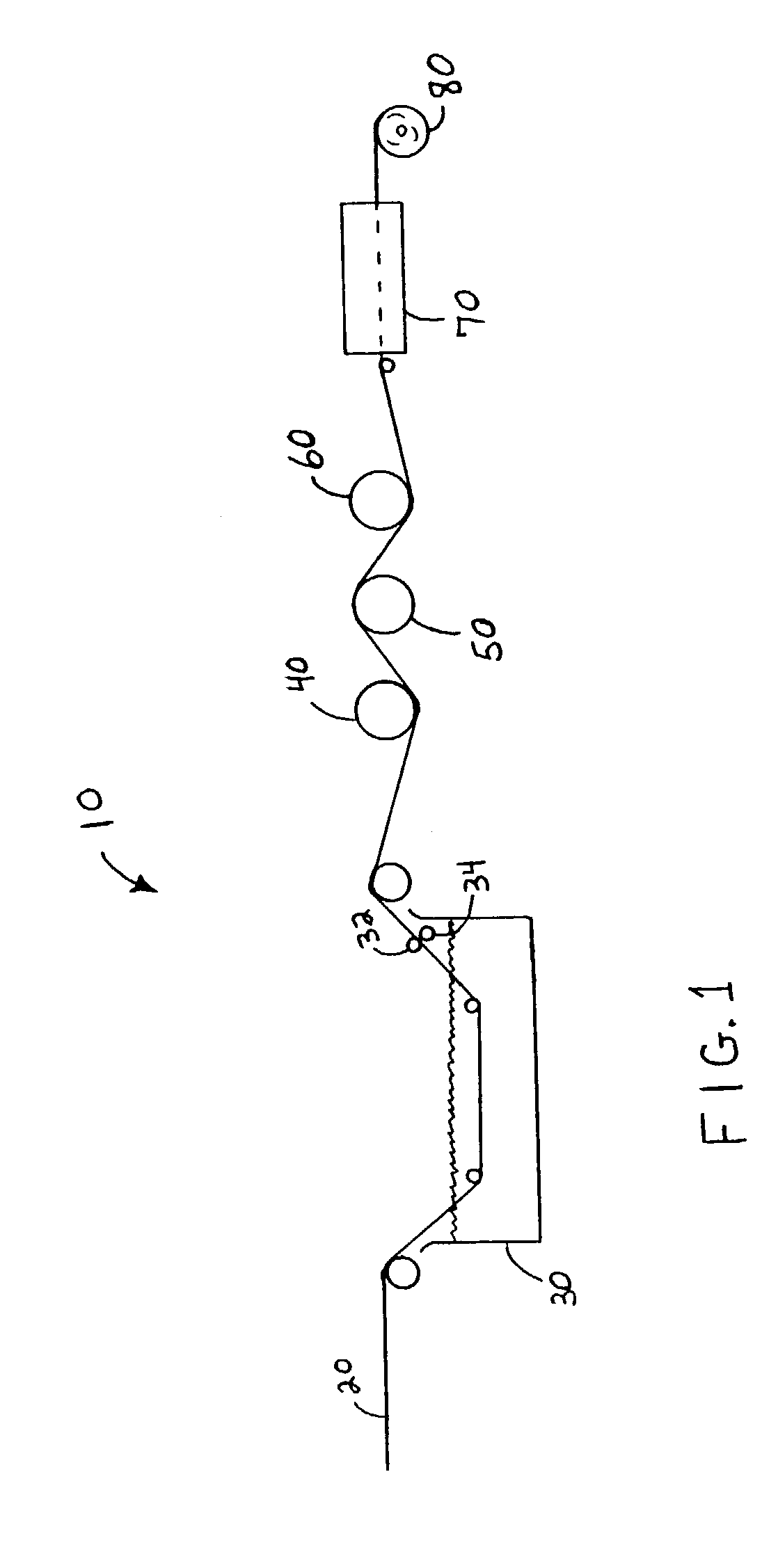

Method for treating fibrous web materials

InactiveUS7001562B2Drying using combination processesDrying solid materials with heatFiberMaterials science

Owner:KIMBERLY-CLARK WORLDWIDE INC

Production method for polyester cotton oxygen bleaching and disperse dyestuff dyeing one bath process

ActiveCN104213398AOxygen bleachingTo achieve the purpose of cost reductionMercerising of indefinite length fabricsSingeingDisperse dyeOxygen

The invention a printing and dyeing method, and especially relates to a production method for a polyester cotton oxygen bleaching and disperse dyestuff dyeing one bath process. The method comprises the following steps: selecting a sample cloth, carrying out pretreatment desizing, pre-setting a grey, singeing the grey, mercerizing, preparing a complex formulation assistant according to a formula, using the complex formulation assistant according to a ratio, designing a dyeing formula, carrying out jar dyeing on the cloth sample, carrying out hot setting, singeing the obtained color body, washing by water, drying, carrying out oiling setting, carrying out after-finishing calendering, carrying out after-finishing full decatizing, and examining the obtained finished product. The production method for the polyester cotton oxygen bleaching and disperse dyestuff dyeing one bath process has obvious energy saving and emission reduction effects, and the handle elasticity, the color fullness and various quality indexes of fabrics obtained in the invention can meet requirements of different clients.

Owner:ZHEJIANG HANGMIN STOCK

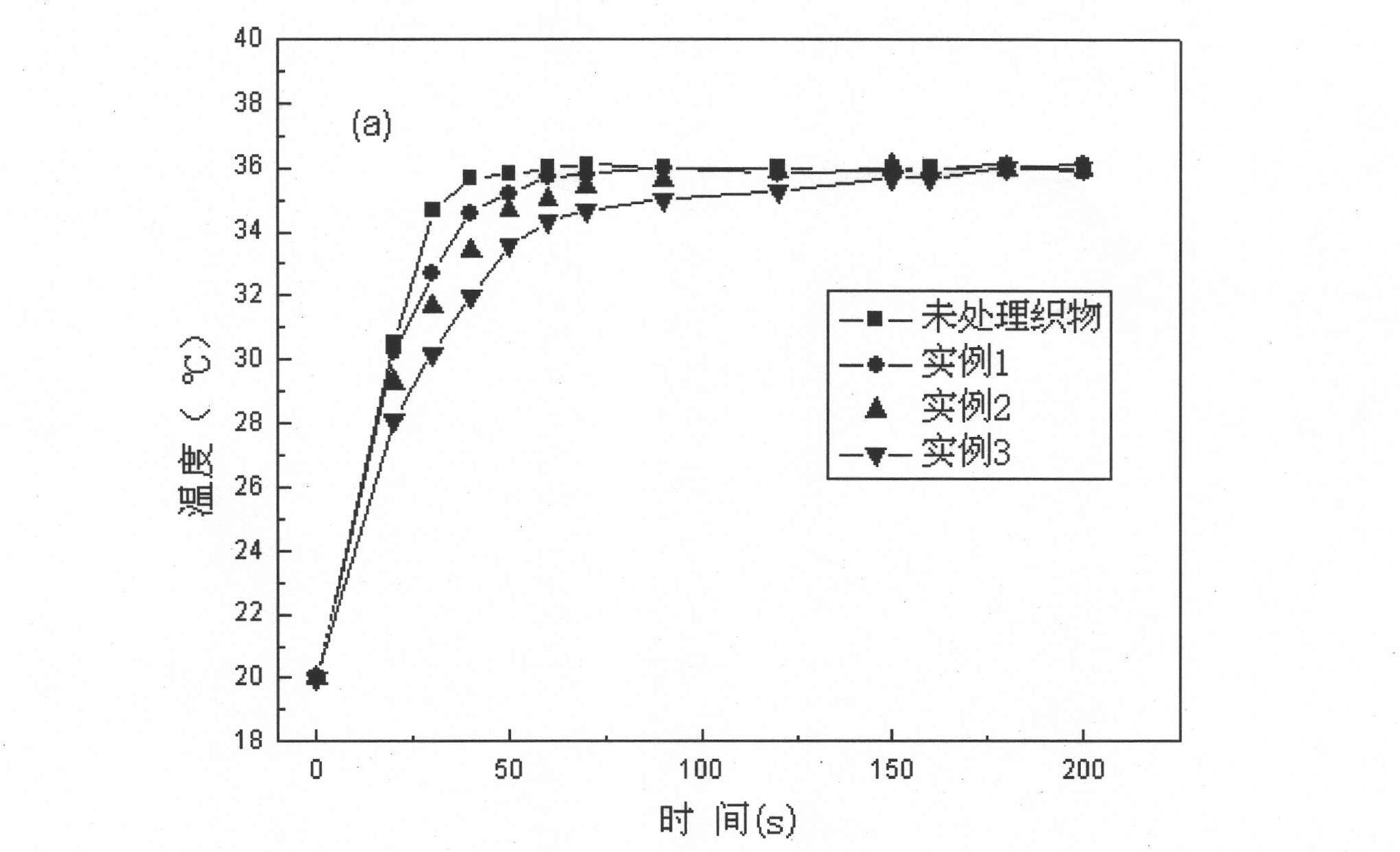

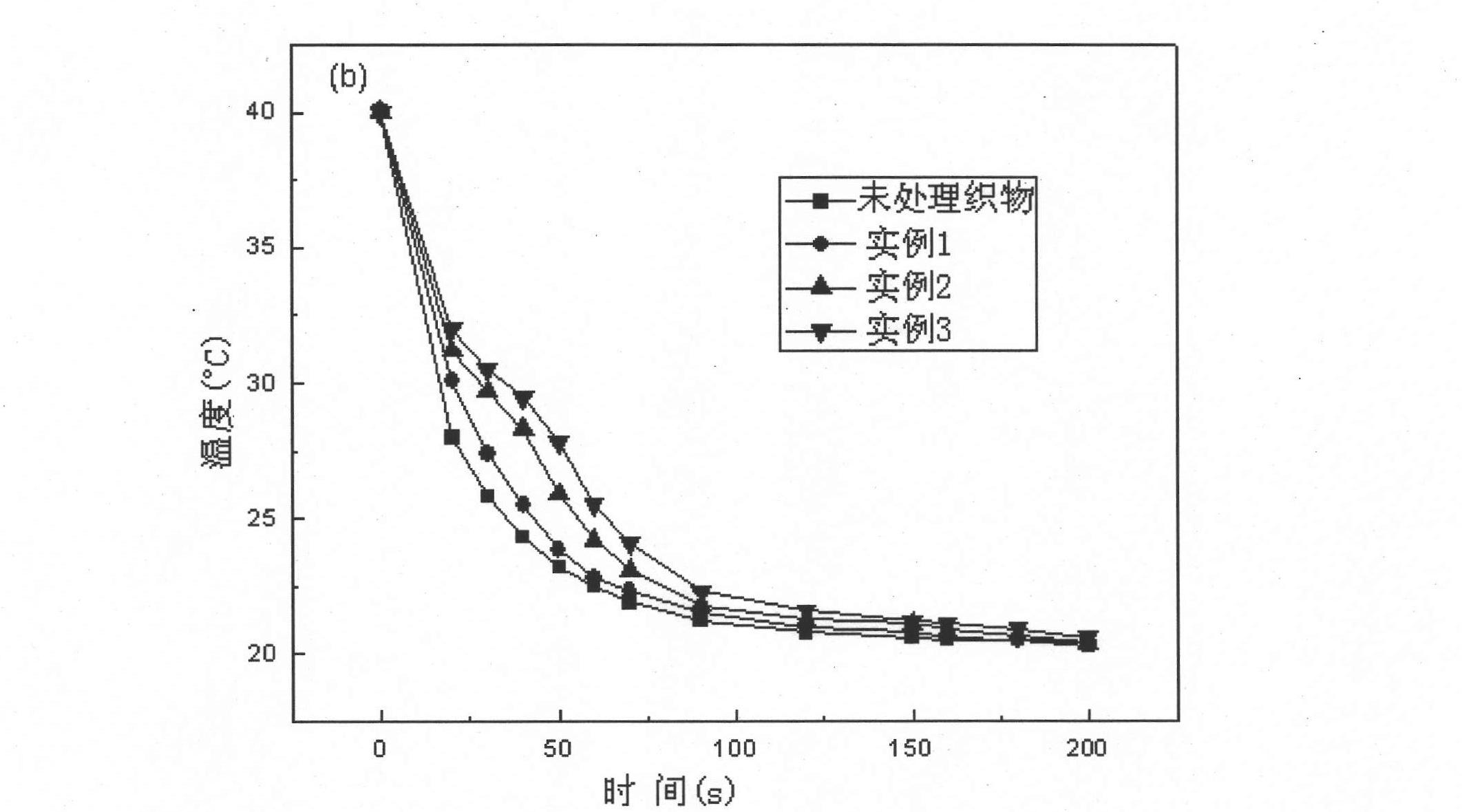

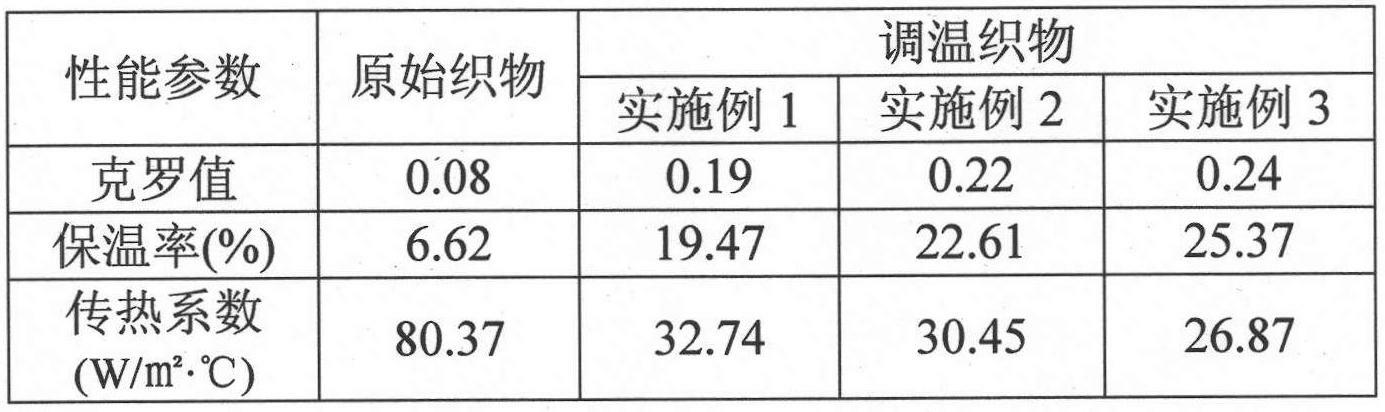

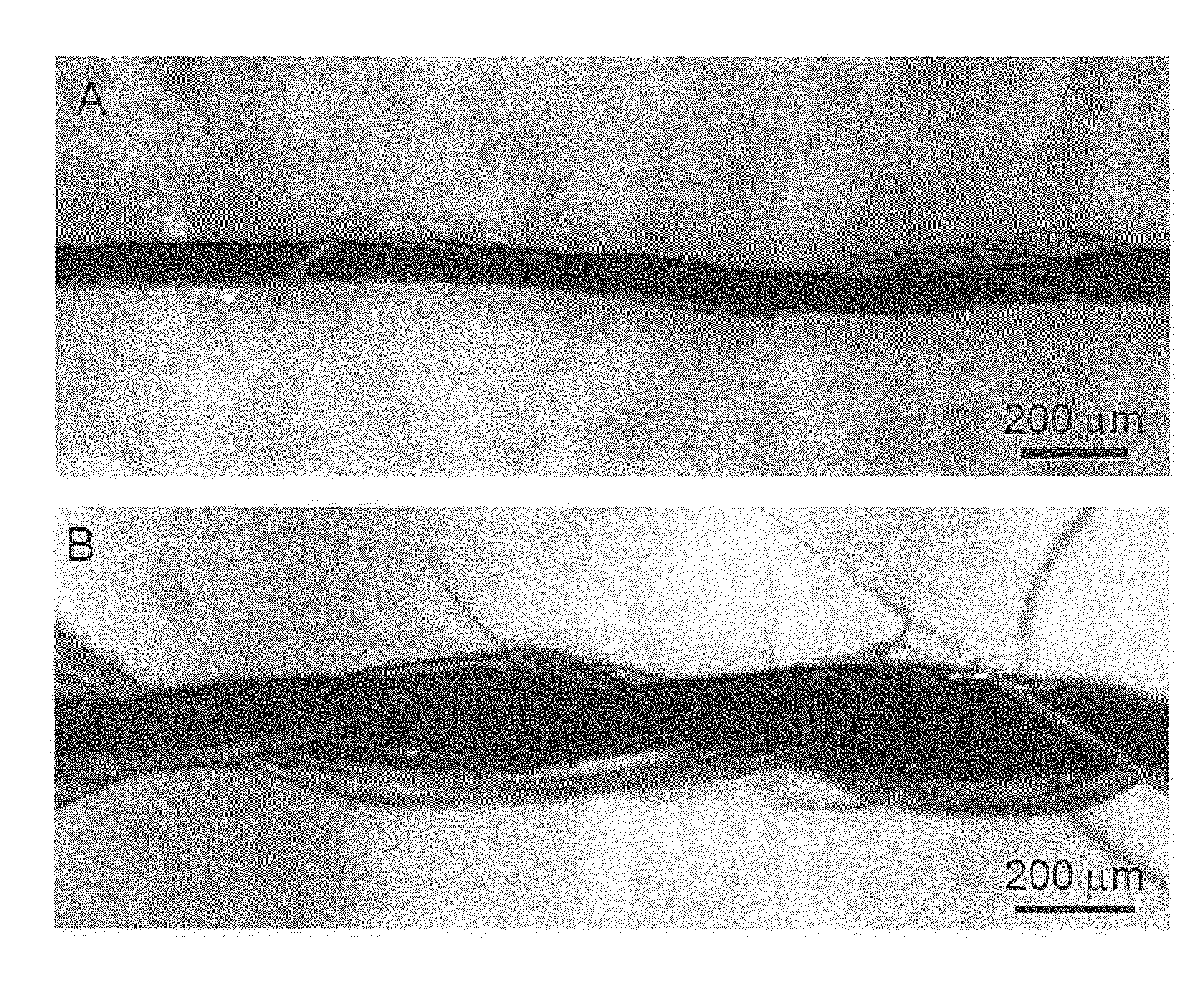

Method for preparing temperature regulation textile by sol-gel technology

InactiveCN102677471AAvoid disadvantagesLow priceFibre treatmentLiquid/gas/vapor removalParaffin waxUrea

The invention discloses a method for preparing temperature regulation textile by a sol-gel technology. The method for preparing the temperature regulation textile by the sol-gel technology comprises the steps of adding tetraethoxysilane into mixed liquid of ethanol and water to prepare tetraethoxysilane liquid preparation liquid, and adjusting pH value to 2-4; respectively adding paraffin wax, water and an emulsifying agent into a high-speed emulsion machine to prepare paraffin core emulsion; slowly dropping the tetraethoxysilane liquid preparation liquid into the paraffin core emulsion, and adding synthetic latex to prepare phase change micro-capsule finishing liquid; settling the phase change micro-capsule finishing liquid on the textile through a two-soaking and two-rolling method, and baking to obtain the temperature regulation textile. According to the invention, by adopting the sol-gel method and the phase change micro-capsule finishing liquid taking tetraethoxysilane as wall material and paraffin as core material to prepare the temperature regulation textile, the defect that polymers such as urea resin and the like are taken as the wall material is solved, the heat conduction efficiency and the physical and chemical stability are improved, and the excellent non-toxic and harmless performances are provided.

Owner:DONGHUA UNIV

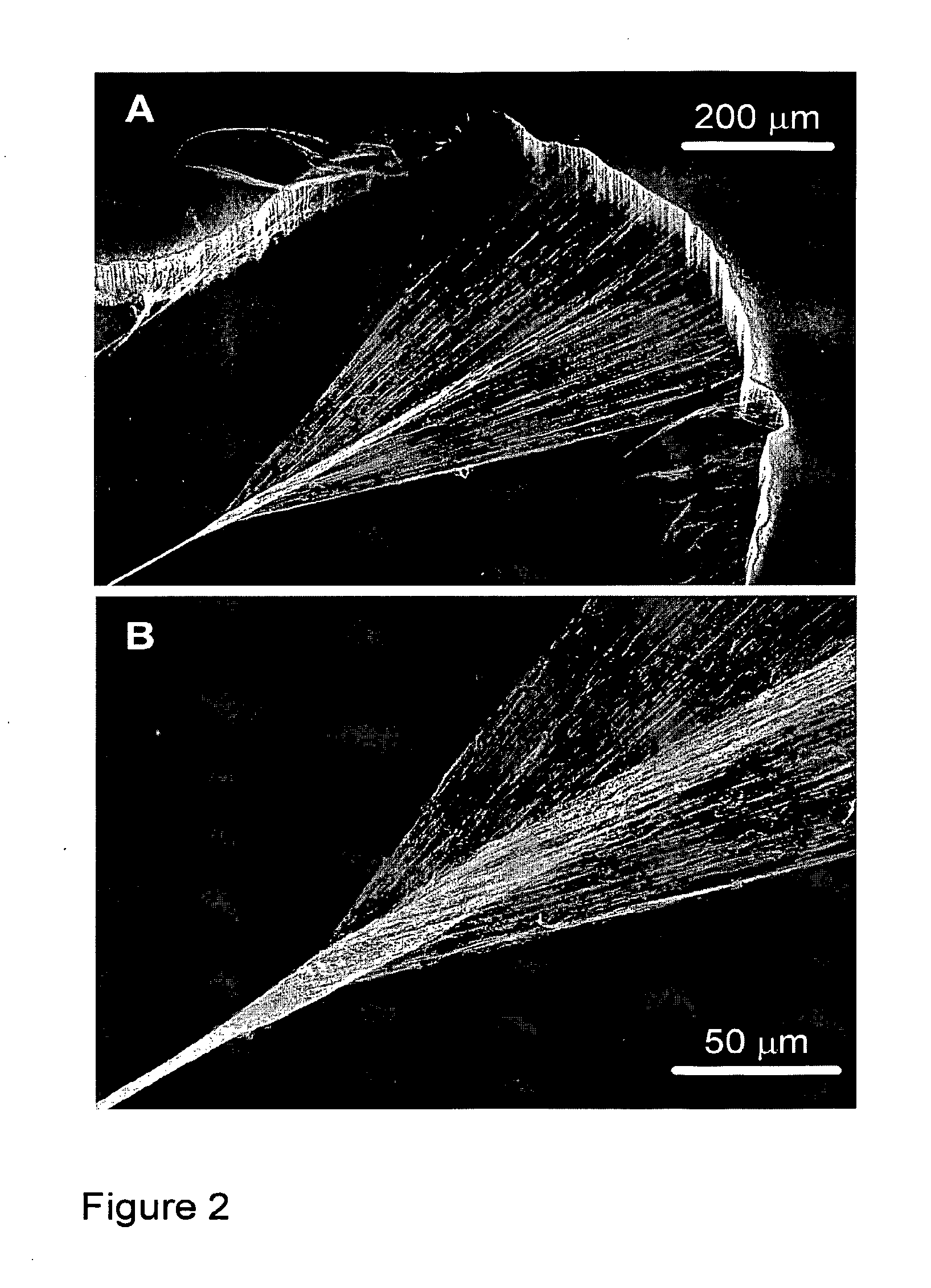

Fabrication and application of nanofiber ribbons and sheets and twisted and non-twisted nanofiber yarns

ActiveUS20150308018A1High strengthImprove yarn strengthMaterial nanotechnologyNon-insulated conductorsFiberHigh resistance

The present invention is directed to nanofiber yarns, ribbons, and sheets; to methods of making said yarns, ribbons, and sheets; and to applications of said yarns, ribbons, and sheets. In some embodiments, the nanotube yarns, ribbons, and sheets comprise carbon nanotubes. Particularly, such carbon nanotube yarns of the present invention provide unique properties and property combinations such as extreme toughness, resistance to failure at knots, high electrical and thermal conductivities, high absorption of energy that occurs reversibly, up to 13% strain-to-failure compared with the few percent strain-to-failure of other fibers with similar toughness, very high resistance to creep, retention of strength even when heated in air at 450° C. for one hour, and very high radiation and IJV resistance, even when irradiated in air. Furthermore these nanotube yarns can be spun as one micron diameter yarns and plied at will to make two-fold, four-fold, and higher fold yarns. Additional embodiments provide for the spinning of nanofiber sheets having arbitrarily large widths. In still additional embodiments, the present invention is directed to applications and devices that utilize and / or comprise the nanofiber yarns, ribbons, and sheets of the present invention.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

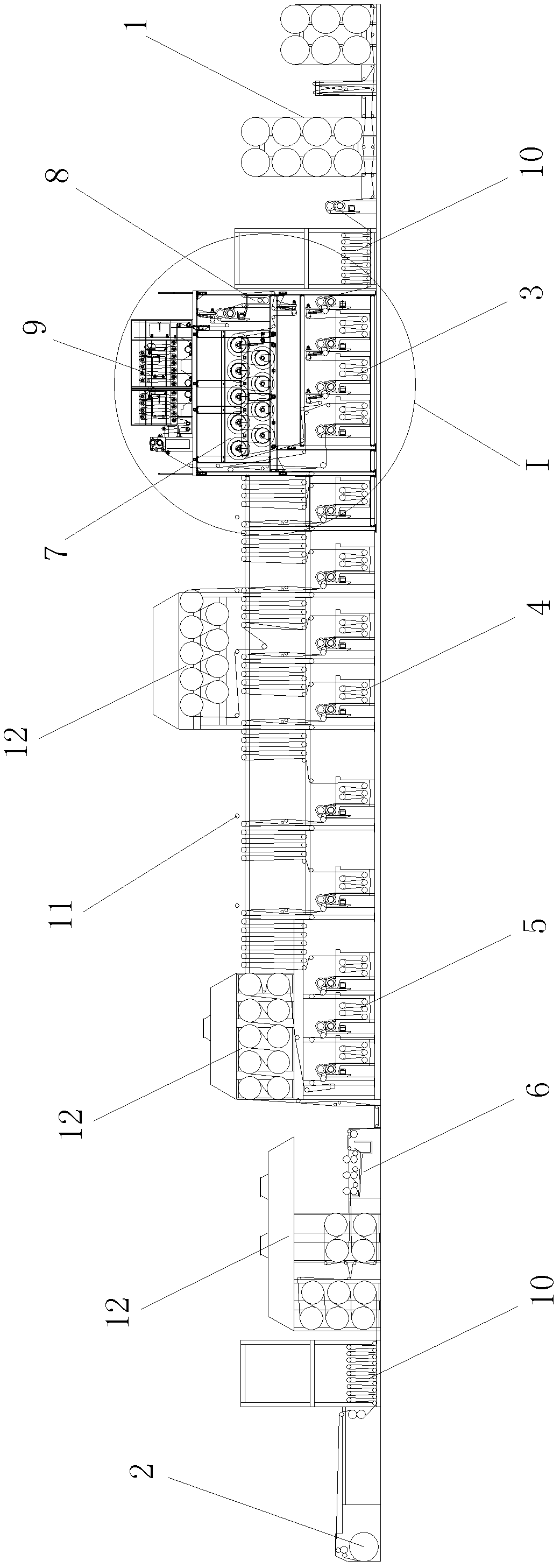

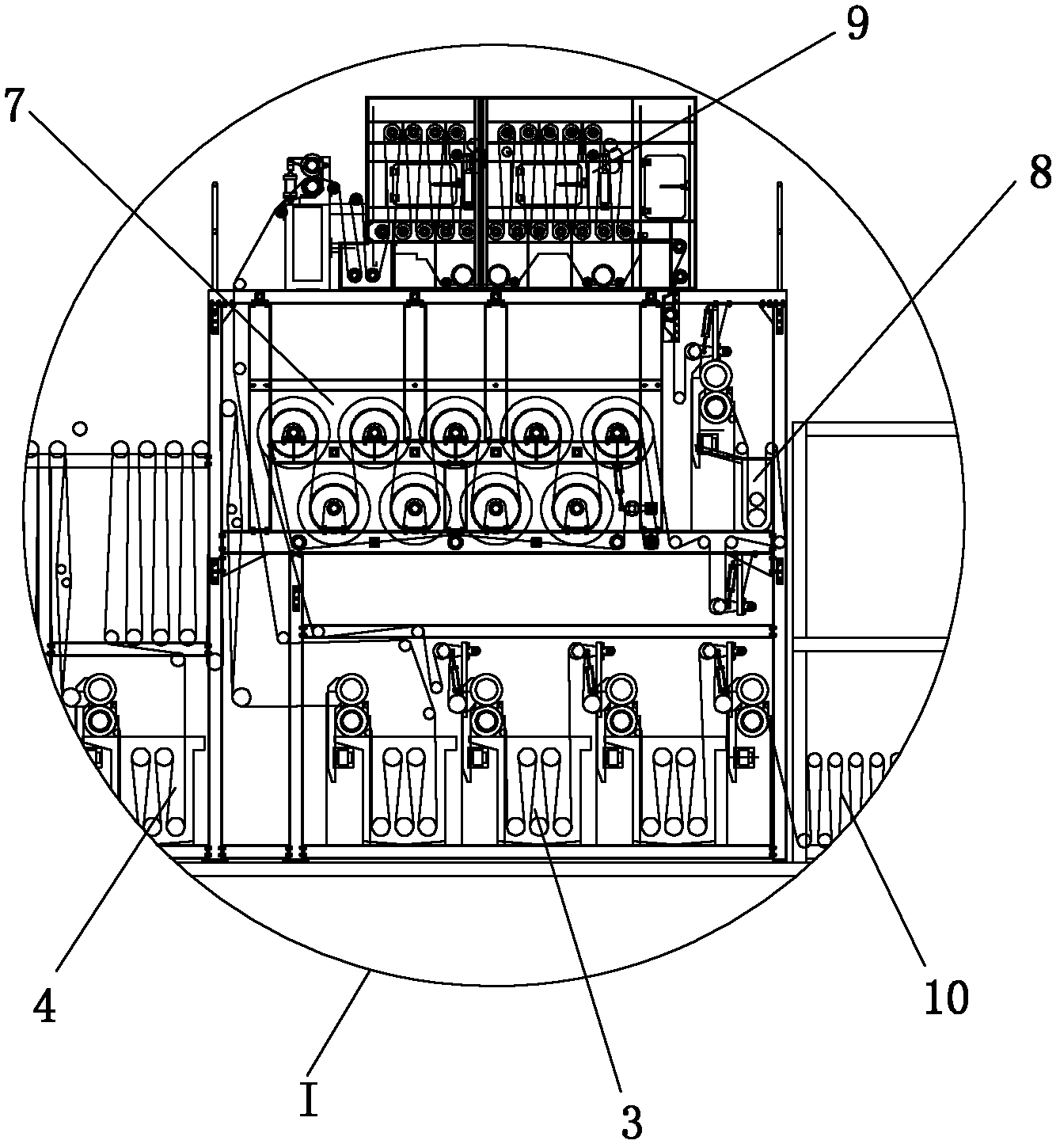

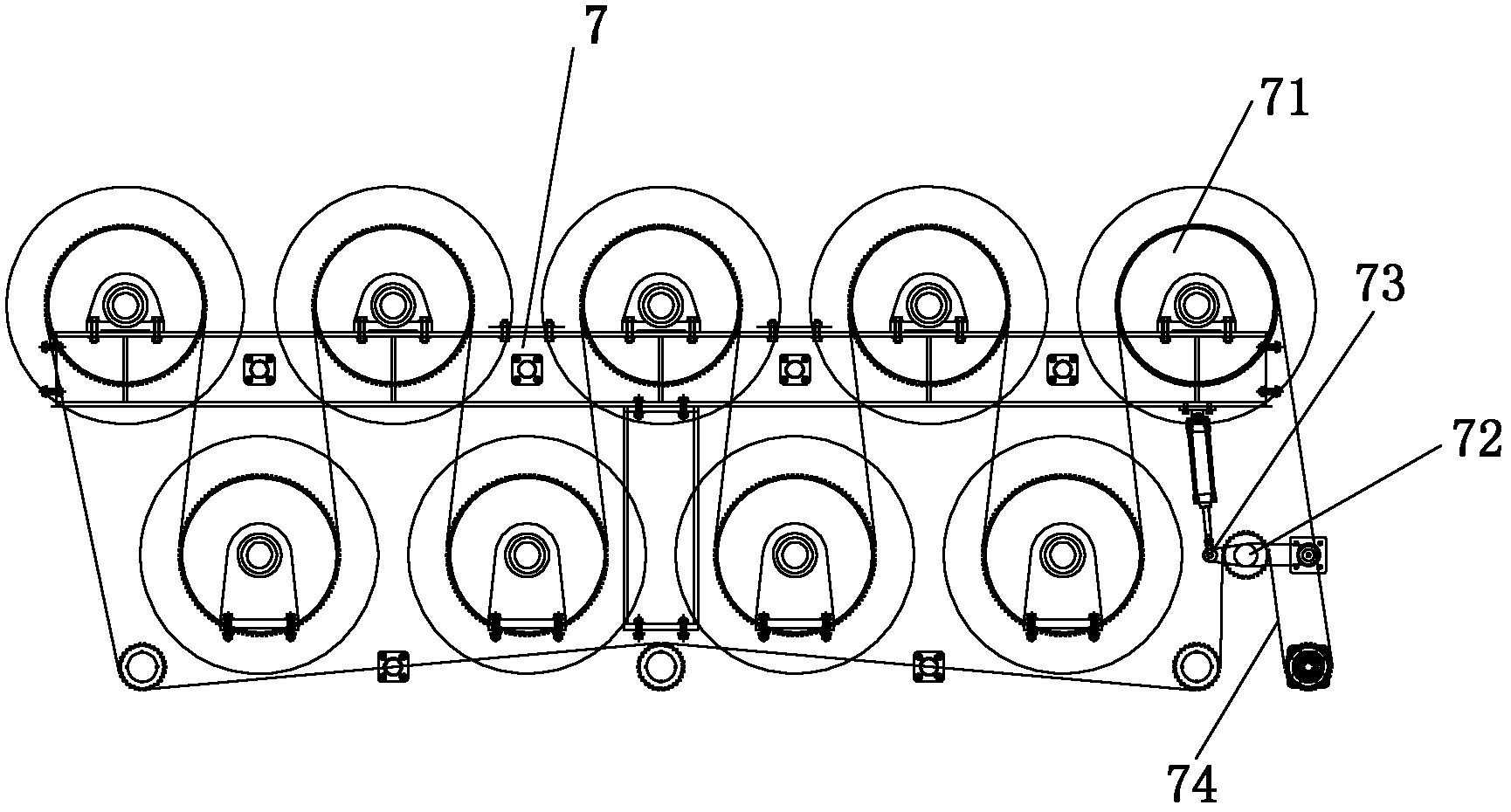

Multifunctional denim warp dyeing machine

InactiveCN102605582ARealize compound dyeingImprove dyeing effectSucessive textile treatmentsLiquid/gas/vapor removalPulp and paper industryPre treatment

The invention provides a multifunctional denim warp dyeing machine, which comprises a to-be-dyed warp rack and a dyed warp reel. A warp pretreatment tank, a warp dyeing groove, a washing tank and a slashing tank are successively arranged between the to-be-dyed warp rack and the dyed warp reel, wherein the warp pretreatment tank is used for removing impurities of warps and washing the warps, the warp dyeing tank is used for dyeing the warps by indigo dyes or sulfur dyes, the washing tank is used for washing the dyed warps, a combined drying barrel, a small colorful dyeing tank and a steaming box are successively disposed between the warp pretreatment tank and the warp dyeing tank, the combined drying barrel is used for colorfully dyeing the warps, and the small colorful dyeing tank dyes the warps by reduced dyes. The problems that when warps are dyed, a color selection range is narrow, color fastness is poor, and the warps cannot be dyed by bright-colored dyes are resolved; after the dyed warps are woven into denim, the characteristics that the warps of the denim are colorful while wefts of the denim are white can be kept; composite dyeing by the aid of the indigo dyes or the sulfur dyes can be realized, and a dyeing effect is good.

Owner:HAINING DENIM WEAVING CO LTD

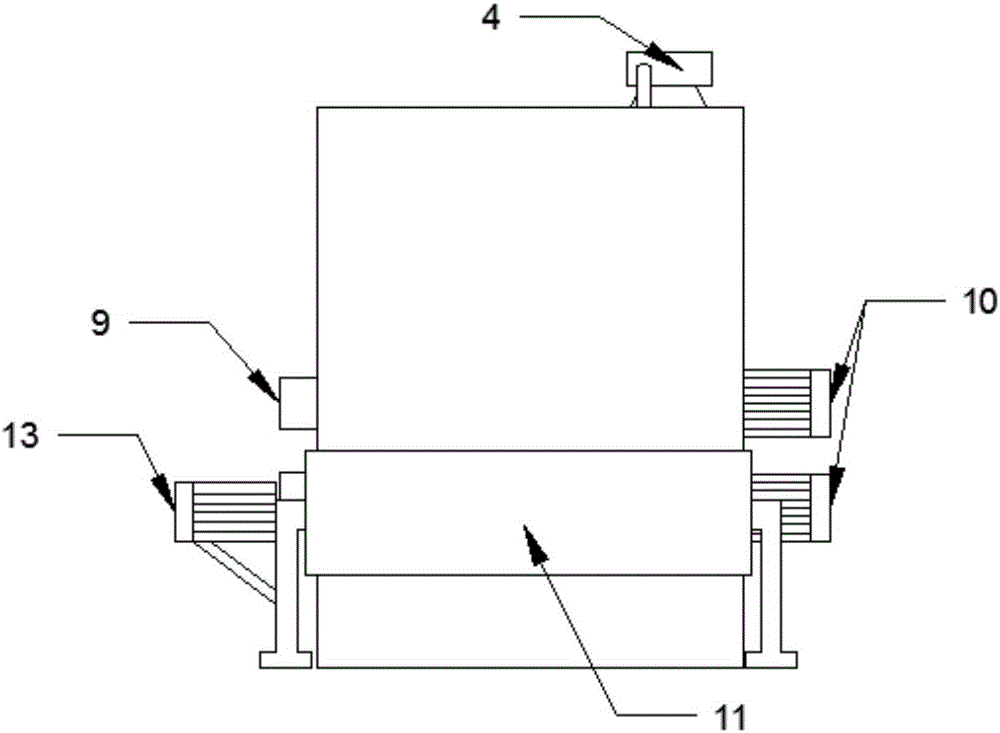

Novel drying device

InactiveCN106222912ASimple structureReasonable designHeating/cooling textile fabricsLiquid/gas/vapor removalPulp and paper industrySizing

The invention provides a novel drying device, which comprises a box body. An inlet and an outlet are arranged on symmetrical positions on two side walls of the box body; an upper heating roller and a lower heating roller are arranged, close to the inlet, in the box body; axes of the upper heating roller and the lower heating roller are parallel to the inlet; a gap between the upper heating roller and the lower heating roller corresponds to the position of the inlet; the upper heating roller and the lower heating roller are connected with a hydraulic mechanism capable of controlling the upper heating roller and the lower heating roller to lift up and down. The drying device provided by the invention is simple in structure and reasonable in design; the distance between the heating rollers can be adjusted according to different cloth, so that a better drying effect is ensured; after being dried, the cloth passes through a cooling and shaping roller, so that the sized cloth is effectively cooled and shaped, and the sizing quality is improved; in addition, a dehydrating device is also arranged in the box body, so that the dried cloth cannot be soaked secondarily.

Owner:TIANJIN JIAXUAN TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com