Patents

Literature

3363results about How to "Improve dyeing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

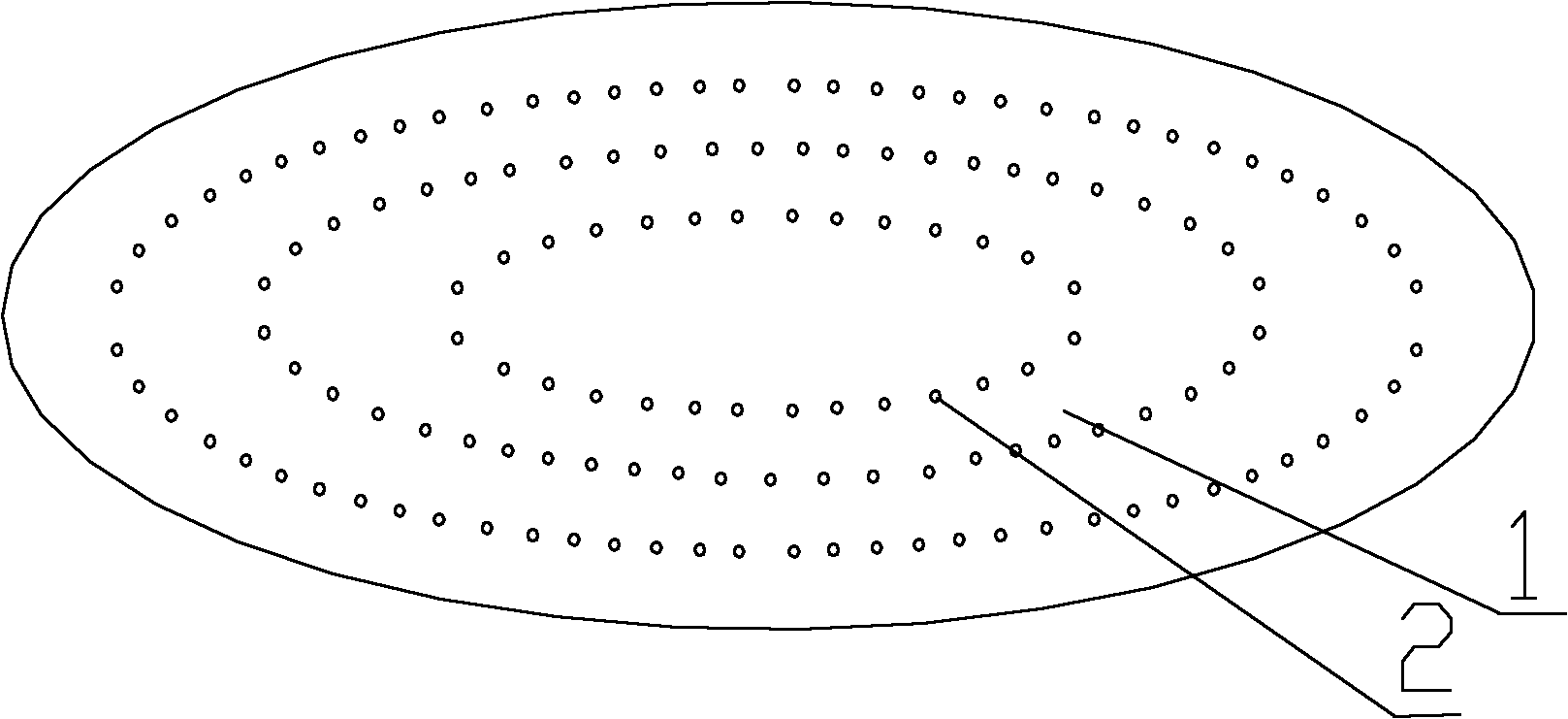

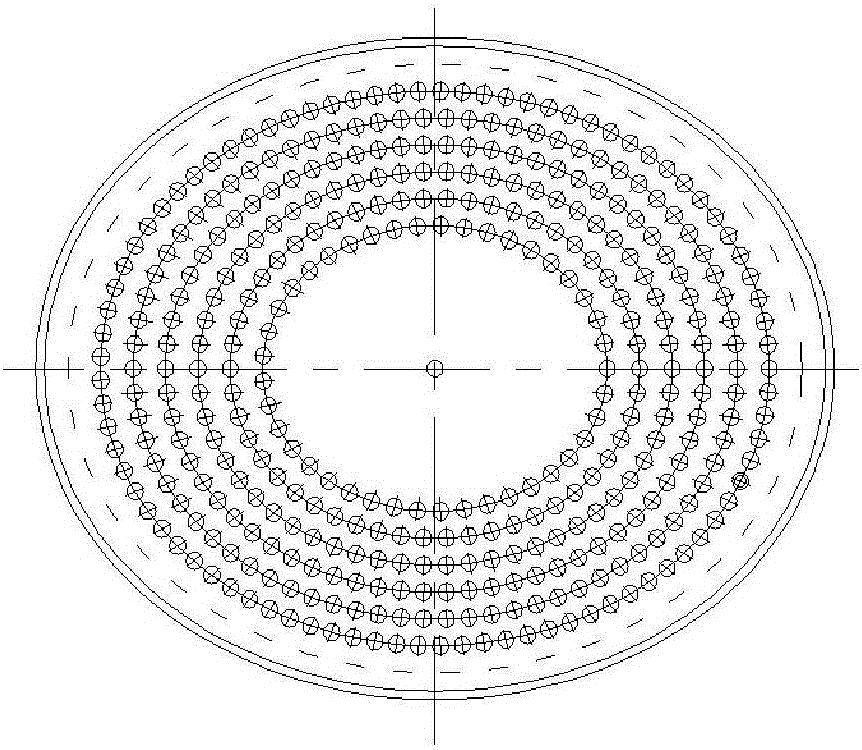

Special-shaped spinneret plate for spinning heavy denier yarns

InactiveCN102851757AImprove cooling uniformityImprove dyeing effectFilament/thread formingPolymer scienceSpinning

A special-shaped spinneret plate for spinning heavy denier yarns comprises an elliptic body (1). 90-192 spinning holes (2) are arranged on the body (1). One side of each spinning hole (2) is a feed inlet. The other side of each spinning hole (2) is a discharge outlet. The plurality of spinning holes (2) are arranged in a three-layered concentric ellipse structure from inside to outside. The spinneret plate is capable of producing glazed heavy denier yarns of 300-500D. Due to heavier filament number, diameters of micropores are slightly larger than those of round holes of products of conventional specification, and flow speed of melts in the micropores can be lowered effectively. In addition, the ellipse spinneret plate is different from conventional round spinneret plates, distribution of the micropores is facilitated, enhancement of cooling effect of spun fibers is facilitated, cooling uniformity of the heavy denier yarn is improved, and dyeing effect of the heavy denier yarn is also improved.

Owner:JIANGSU HUAYA FIBER

Copolyester as well as preparation method and application thereof

InactiveCN102030893AImprove dyeing effectLow investment costMonocomponent copolyesters artificial filamentDisperse dyeSide chain

The invention discloses copolyester and a preparation method and application thereof. The copolyester comprises binary acid components and binary alcohol components, wherein in the binary acid components, the content of the terephthalic acid structural unit is more than 90mol%; and in the binary alcohol components, the content of the ethylene glycol structural unit is 70-99mol%, and the content of the aliphatic dihydric alcohol structural unit which contains side chains and less than 6 carbon atoms is 1-30mol%. The copolyester also comprises a polyethylene glycol structural unit. Because the aliphatic dihydric alcohol structural unit which contains side chains and less than 6 carbon atoms and the polyethylene glycol structural unit are added to the copolyester, the copolyester can be made into fiber with the known method, and the fiber can be made into fabric. The prepared finished product has good dyeing property on disperse dye at normal temperature and pressure, thus the high equipment investment and operation cost resulted from high-temperature and high-pressure dying can be reduced.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

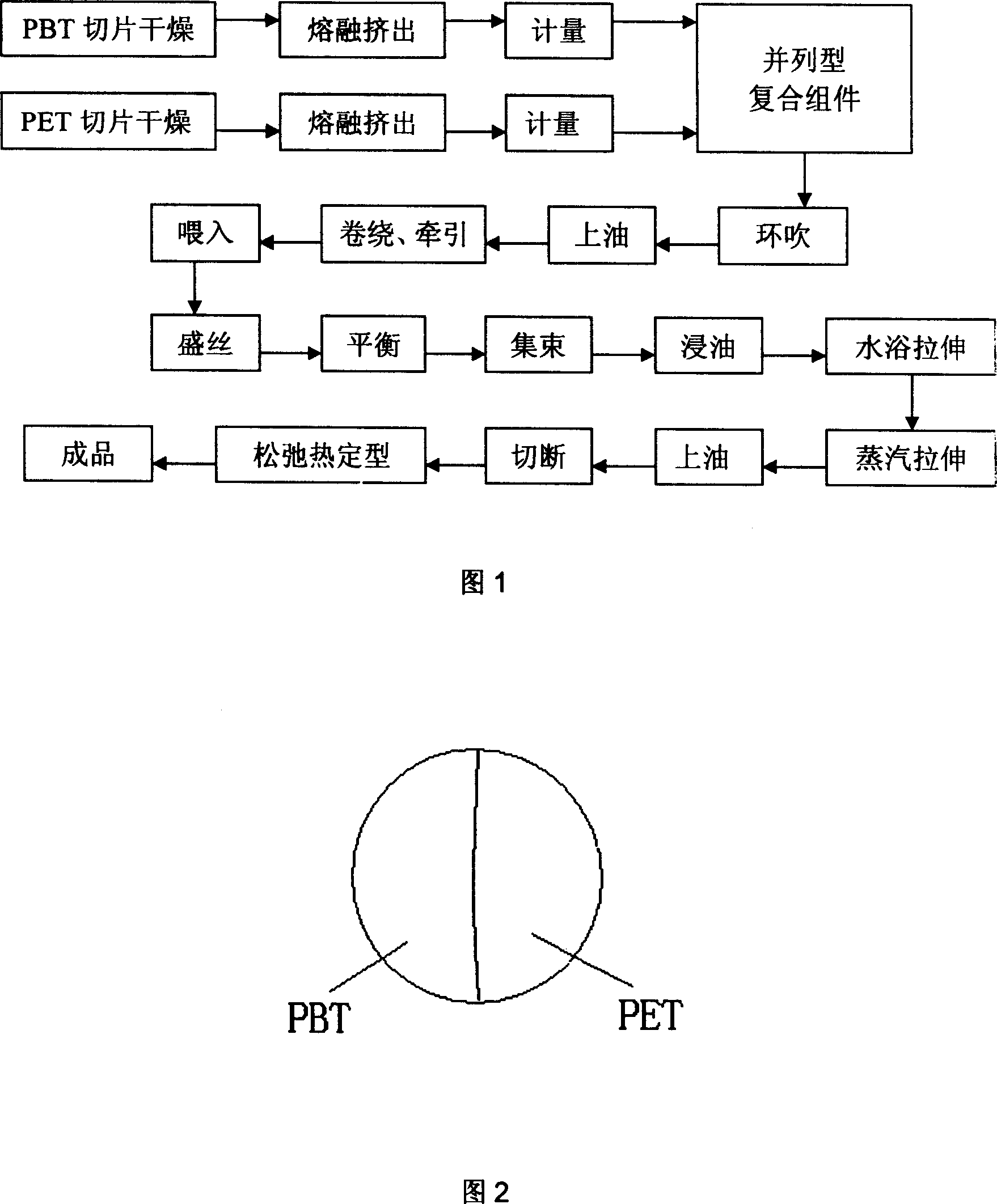

Method for preparing PBT/PET 3-D crimped fiber and use thereof

InactiveCN1962968AIncrease elasticityHigh modulusFilament/thread formingConjugated synthetic polymer artificial filamentsFiberHeat resistance

The invention involves a product method of PBT / PET 3D crimp fiber fabrication which includes steps: (1) PBT biopsies are composed with the PET on the after drying; (2) PET slices are after drying, through high-temperature melting e composite; (3) After blowing Central, greasing winding drive, feed, Sheng be parallel wire composite fiber winding wire; After balancing, cluster, the Baptist tensile oil bath, steam tensile, greasing cut off heat and relaxation to be stereotyped PBT / PET 3D curly fibers. The fibers produced through the method are system of the fiber's flexibility, dyeability and heat resistance and used in flexible woven and knitted fabrics such as high-end sportswear, stretch jeans and strait jacket, Nonwovens and filler widely.

Owner:DONGHUA UNIV

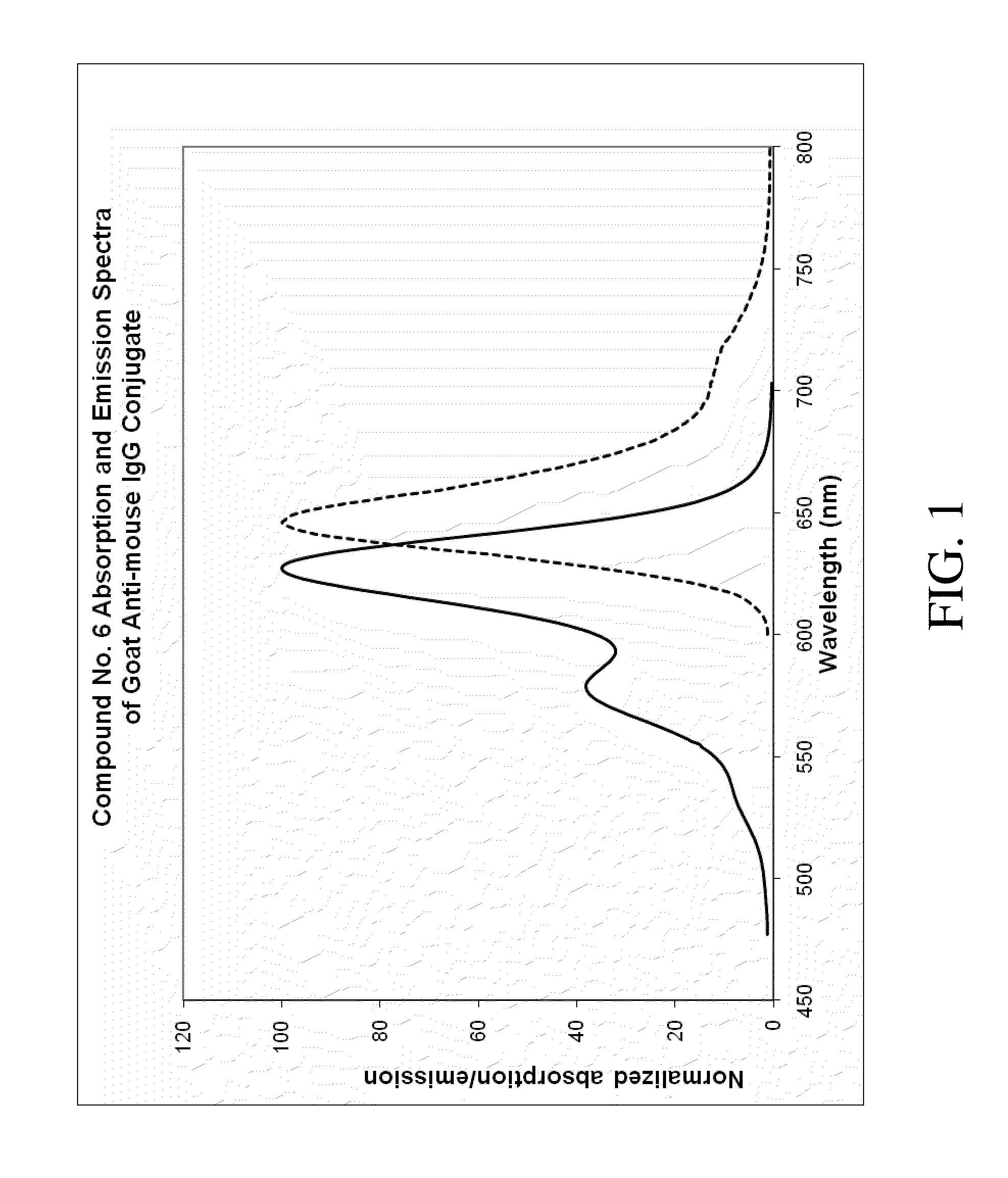

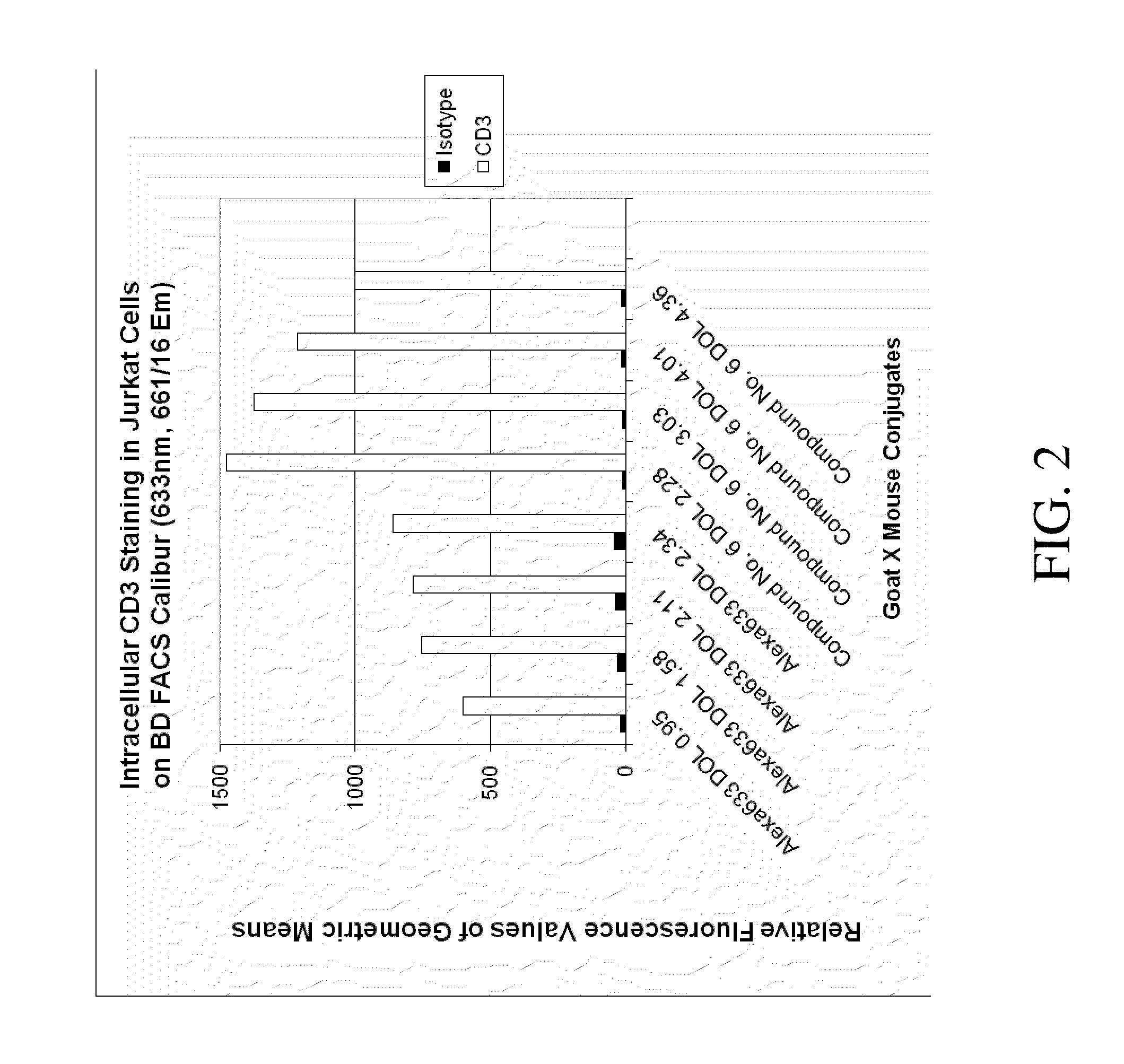

Heterocycle-substituted xanthene dyes

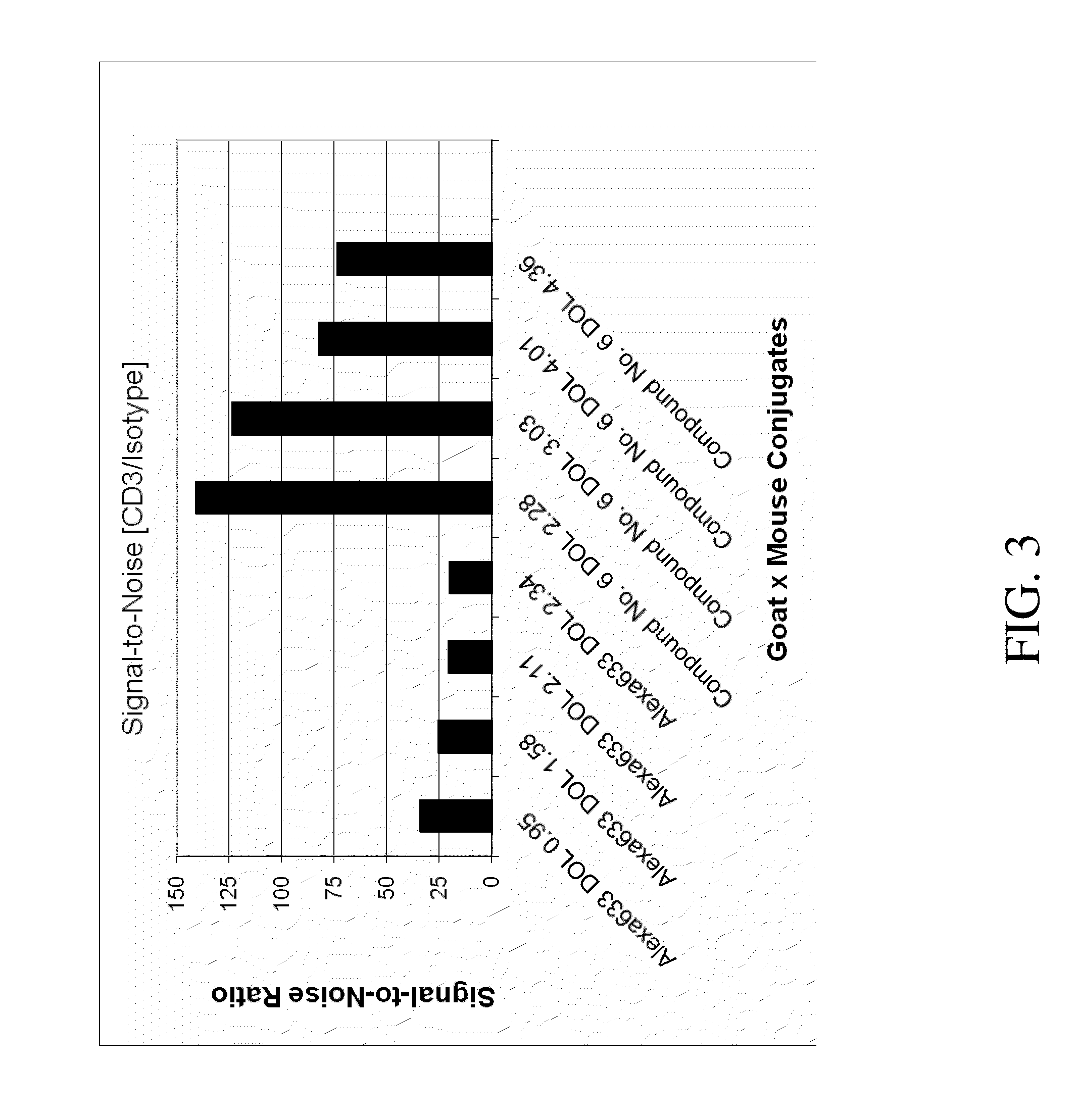

ActiveUS20110136201A1Increase brightnessImprove photostabilitySugar derivativesSamplingDiseaseXanthene dye

The present invention relates to fluorescent dyes in general. The present invention provides a wide range of fluorescent dyes and kits containing the same, which are applicable for labeling a variety of biomolecules, cells and microorganisms. The present invention also provides various methods of using the fluorescent dyes for research and development, forensic identification, environmental studies, diagnosis, prognosis, and / or treatment of disease conditions.

Owner:BIOTIUM INC

Dyeable polyolefin containing polyetheramine modified functionalized polyolefin

InactiveUS6127480AGood paintabilityExcellent mold flowabilityEngine sealsCellulosic plastic layered productsPolymer sciencePolyolefin

This invention concerns a composition comprising a blend of polyolefin with the reaction of a functionalized polyolefin and polyetheramine in which the polyetheramine is grafted into the functionalized polyolefin in a customary mixing apparatus. A process for producing the reaction product of functionalized polypropylene and polyetheramine by melting with polypropylene in a customary mixing apparatus is also disclosed. Blends of the present invention are advantageously useful to prepare paintable automotive body parts. This invention further includes dyeable polyolefin compositions containing the reaction product of functionalized polyolefin and polyetheramine. Dyeable polyolefin fibers, including polypropylene fibers, are disclosed, which may be made by melt spinning, and which may be employed to make woven and non-woven fabric.

Owner:JPMORGAN CHASE BANK N A AS COLLATERAL AGENT

Flame retardant aromatic polycarbonate resin composition and molded articles thereof

InactiveUS6727303B2Hinder propertyImprove thermal stabilitySpecial tyresSkin careOrganic groupPolyester resin

A flame retardant aromatic polycarbonate resin composition comprising:(1) 100 parts by weight of resin components comprising 50 to 100 wt % of an aromatic polycarbonate resin (component A-1), 0 to 50 wt % of a styrene-based resin (component A-2) and 0 to 50 wt % of an aromatic polyester resin (component A-3); and(2) 0.1 to 10 parts by weight of a silicone compound (component B) which contains an Si-H group and an aromatic group in the molecule based on 100 parts by weight of the total of the resin components, whereinthe silicone compound is at least one selected from silicone compounds which have (1) an Si-H group content (Si-H content) of 0.1 to 1.2 mols / 100 g and (2) a content of an aromatic group represented by the following general formula (1) (aromatic group content) of 10 to 70 wt %:wherein X's are each independently an OH group or the residual monovalent organic group having 1 to 20 carbon atoms, and n is 0 or an integer of 1 to 5, with the proviso that when n is 2 or more, X's can differ from one another, and molded articles thereof.A halogen-free polycarbonate resin composition having excellent transparency and dripping preventing properties and molded articles thereof are provided according to the present invention.

Owner:SHIN ETSU CHEM IND CO LTD +1

Disperse dye composition and application thereof

ActiveCN102031017AFull hueExcellent color fastnessOrganic dyesDyeing processPhotochemistryDisperse dye

The invention discloses a disperse dye composition and application thereof and particularly relates to a disperse dye which has good dyeing effect under an alkali condition and application thereof. The dye composition comprises a dye and an aid in a mass ratio of 1:1-1:2, wherein the dye is selected from any one or more of a dye I, a dye II, a dye III and a dye IV. The disperse dye composition can be widely applied to a full-polyester dyeing process, a synchronous polyester / cotton scouring, bleaching, dispersing and dyeing process, a polyester / cotton dispersing high-temperature active dye one-bath process, a polyester / cotton dispersing constant-temperature active dye one-bath two-step process and the like and has good dyeing effect. The disperse dye composition can realize synchronous performance of a pretreatment process and a dyeing process, can be used together with other active dyes, has wide application and contributes to shortening process time and lowering production cost.

Owner:浙江创元染料有限公司

Method for preparing foamed ceramic insulation board by waste glass ceramic wafer

The invention discloses a method for preparing a foamed ceramic insulation board by a waste glass ceramic wafer, belonging to the field of preparation technology of the foamed ceramic insulation board. The method comprises the steps of: washing the waste glass ceramic wafer with clear water, drying and grinding by ball milling to obtain waste glass ceramic powder with the fineness less than or equal to 100mu m; mixing the waste glass ceramic powder, pulverized fuel ash, furnace slag, coal gangue, ceramic tailings, foaming agent and modifying agent according to the mass ratio of (30-40):(10-15):(5-7):(10-18):(25-35):(1.8-2.2):(1.1-1.5); putting the mixture into a ball grinding mill, carrying out wet grinding and evenly mixing to form mixed slurry; drying by a pressure type spray granulation dryer and putting the dried product into a foaming refractory mould coated with aluminum oxide; heating to 1120-1150 DEG C in a heating furnace; and finally, annealing, cooling and cutting to obtain the foamed ceramic insulation board. The method is low in production cost and simple in technology, and can be used for continuously preparing the porous foamed ceramic insulation board with large size; and the product is good in performances.

Owner:ANSHENG SCI & TECH DEP

Modified tussah silk fabric with functionalized nanometer chitosan and nanometer titanium dioxide

ActiveCN102677465AImprove adsorption efficiencyRealize functional fillingLiquid/gas/vapor removalDry-cleaning apparatus for textilesUltravioletEngineering

The invention relates to modified tussah silk fabric with functionalized nanometer chitosan and nanometer titanium dioxide. The modified tussah silk fabric is prepared by the steps in sequence: weaving the tussah silk fabric by utilizing tussah filament, preparing finishing liquor and finishing tussah silk fabric; and the technical problems that the existing textile materials in the modification technology can not effectively improve the properties that the tussah silk fabric has damage to the environment, is easy to wrinkle, not anti-bacterial and easy to shrink, has poor dyeing property, poor comfortableness and function, and the like can be solved, the comprehensive properties that the tussah silk fabric is anti-wrinkle, soft, anti-bacterial, shrink-proof, self-cleaning and ultraviolet ray-resistant, as well as the adsorption efficiency of dye, and the like can be improved and enhanced, and the tussah silk fabric has the technical benefits of being lower in preparation cost, simple in process, environment-friendly and easy to realize, etc.

Owner:EASTERN LIAONING UNIV

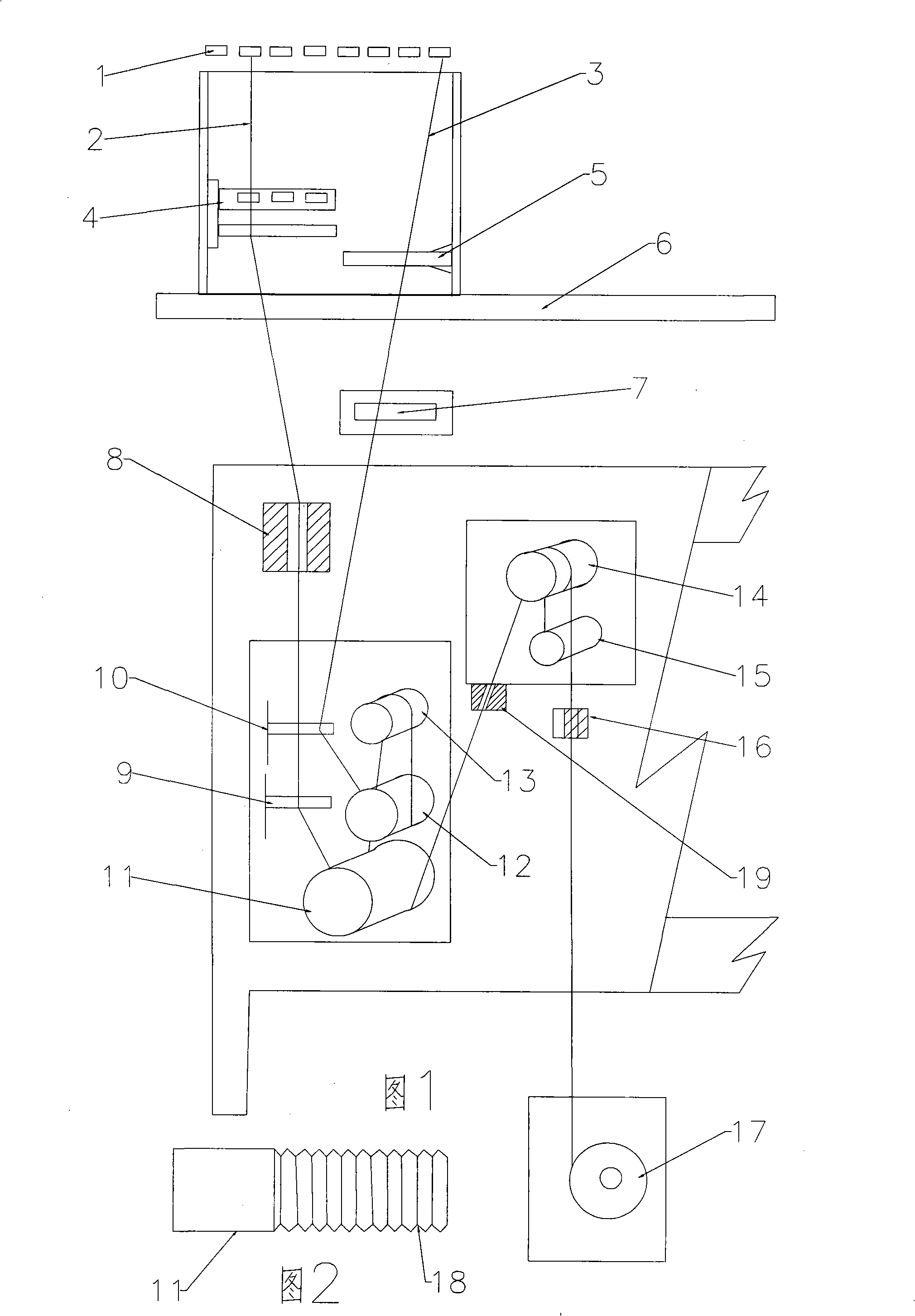

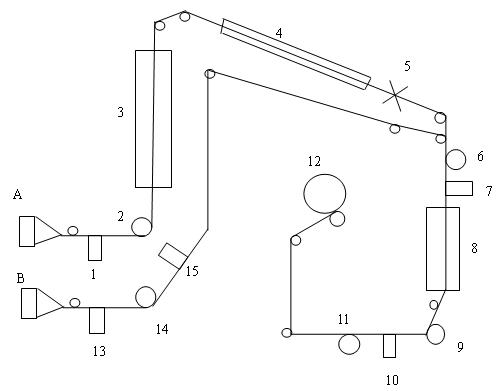

Terylene half speed blended spinning-type ammonia-substituted fiber blended spinning method and its apparatus

InactiveCN101265627AMeet the target requirementsStable Intrinsic IndexFilament/thread formingHeating/cooling textile fabricsYarnSingle stage

The invention designs a blending method and a device for terylene medium-speed blended ammoniac fibers, and includes section transporting and screening, section drying, screw extrusion, melting and spinning, and air blast cooling. The invention is characterized by the following steps: respectively enter POY spinning and FDY spinning after cooling, entering a nozzle for oiling after POY spinning, and then entering a pre-network; entering a tanker for oiling after FDY spinning, entering the pre-network, entering hot-rolling and drafting, enabling POY filaments and FDY filaments to enter into a guiding flute-type draw-off godet for combining and compounding, entering a go-between after compounding, hot-rolling and sizing, and winding and forming after entering a primary network. The blending method for the terylene medium-speed blended ammoniac fibers can produce FDY and POY composite network yarn by the single-stage process, the combined network yarn ITY product produced by the method has stable inner index and quality, little influencing factor, uniform waster-water shrinkage rate, stable chromaticity, and great economic benefit.

Owner:TONGKUN GRP

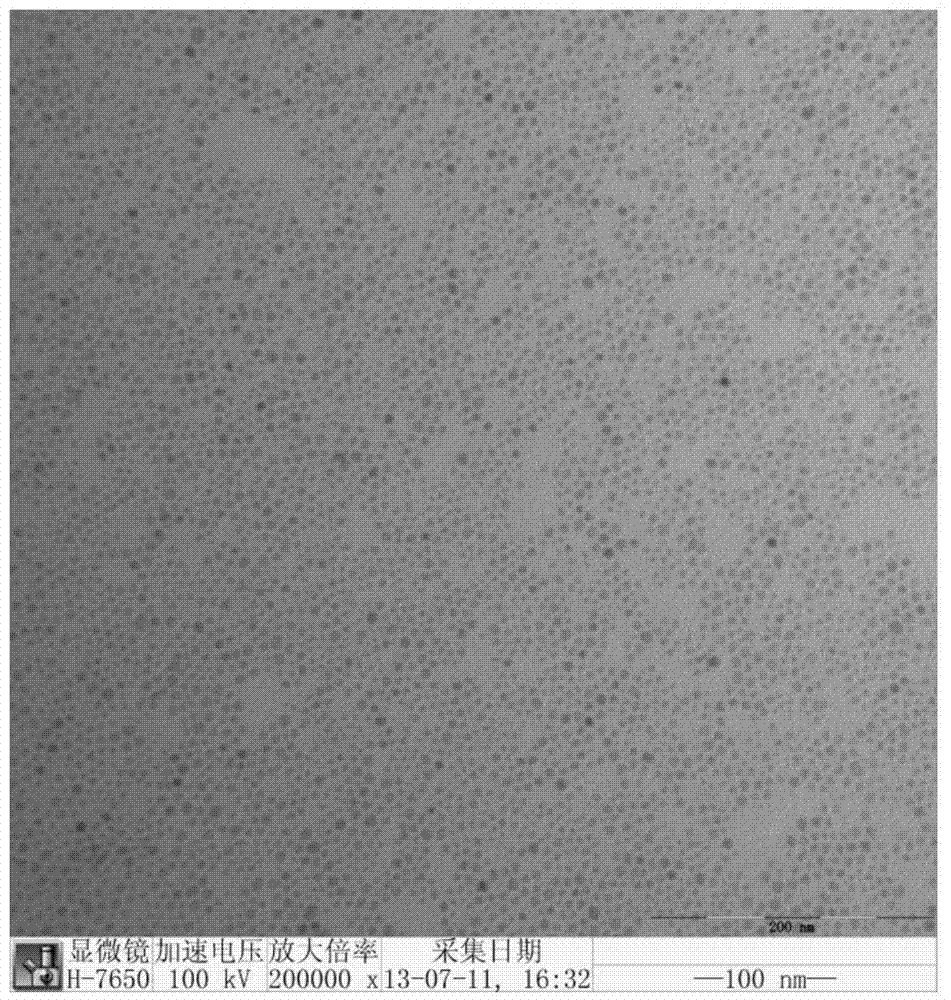

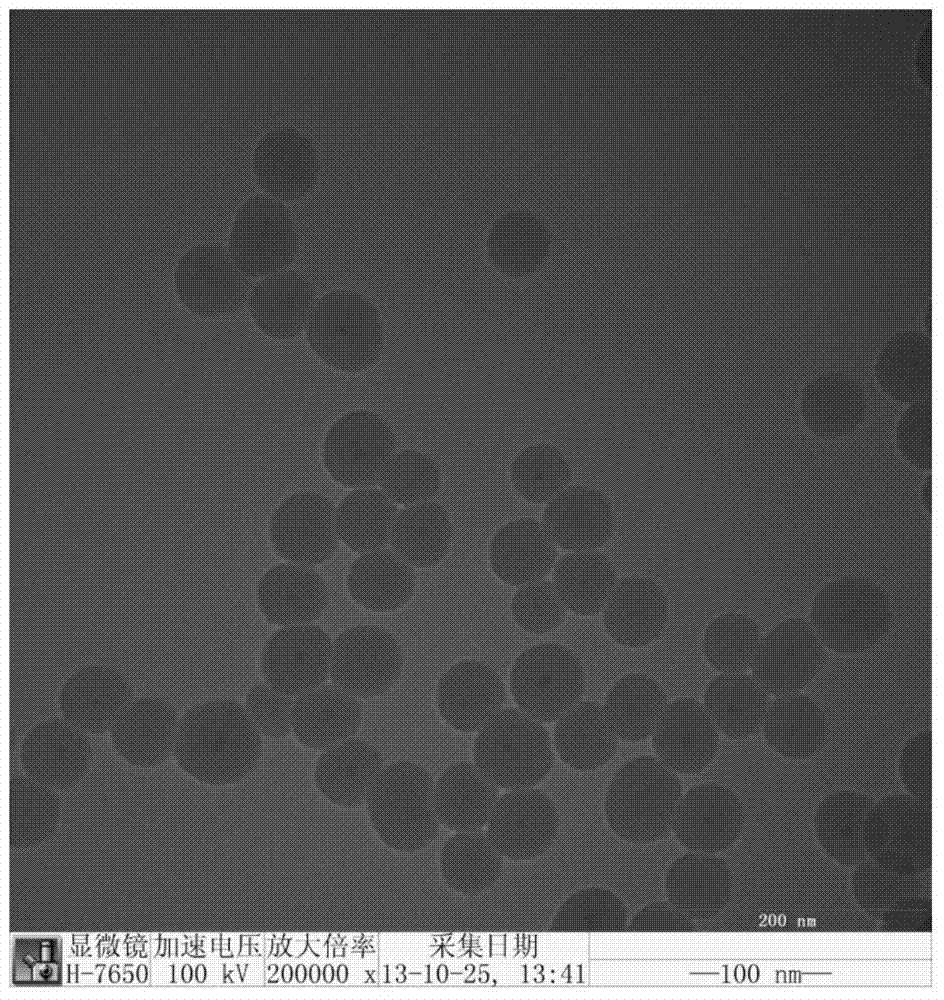

Preparation method and application of magnetic silicon dioxide composite microsphere

ActiveCN103903827AEasy to separateSmall particle sizeMicrobiological testing/measurementInorganic material magnetismProtein targetMicrosphere

The invention relates to a preparation method and application of a magnetic silicon dioxide composite microsphere. Superparamagnetic ferroferric oxide nano particles of which the diameter ranges from 4 nm to 30 nm are prepared through a high-temperature pyrolysis method, a silicon dioxide shell of which the thickness ranges from 5 nm to 20nm covers the outer surfaces of the magnetic ferroferric oxide nano particles through a reverse microemulsion method, amination modification is conducted on the silicon dioxide surface, glutaraldehyde is used as a crosslinking arm, ligand protein is connected into, and protein separation is conducted through specific binding of ligand protein and target protein. The prepared magnetic microsphere is small in particle diameter and good in monodispersity, the composite microsphere with amine is large in specific surface area, nucleophilic addition is utilized, after the crosslinking arm glutaraldehyde is connected into, multiple kinds of ligand protein can be connected into, and then multiple kinds of target protein can be separated. The method is suitable for rapid separation and application of protein in biological samples, and has wide application prospect and great application value in the biomedical field and other fields.

Owner:HARBIN YICAI NEW MATERIAL

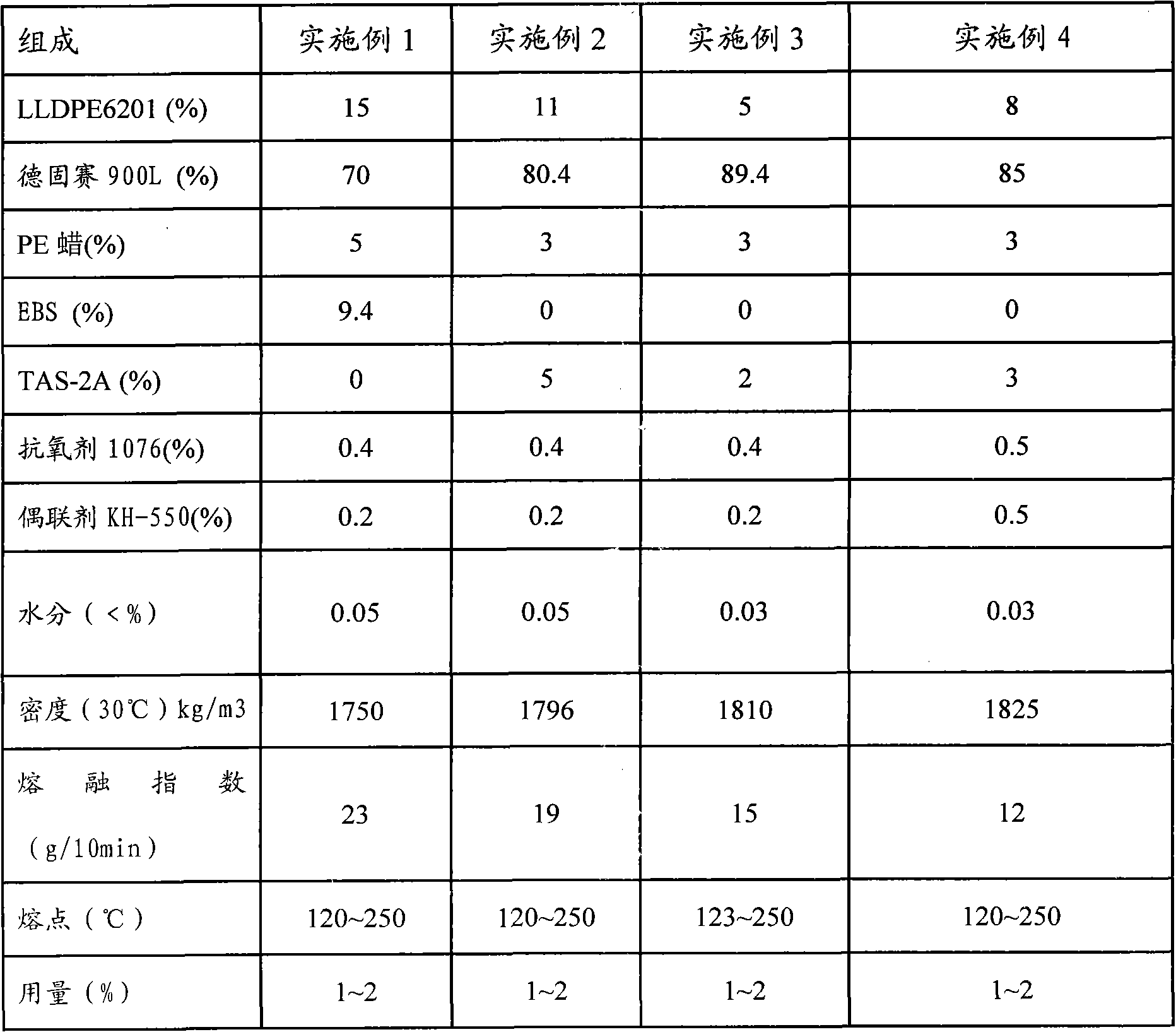

Black master batch and preparation method thereof

The invention discloses a black master batch and a preparation method thereof. The black master batch comprises the following components in percentage by weight: 5-15% of carrier resin, 70-90% of carbon black, 5-15% of dispersion lubricating agent and 0.6-1% of other auxiliaries. The black master batch prepared by the formula disclosed by the invention has the characteristics of high carbon black concentration, good dyeing effect, good dispersion high blackness brightness and no influence to mechanical properties of products compared with the existing black master batch, thus being widely applied to polyolefine resin and ABS (acrylonitrile butadiene styrene) resin.

Owner:SHENZHEN KEJU NEW MATERIAL

Vat dye dyeing method using supercritical CO2 fluid

The invention is applicable to the field of dyeing technologies, and provides a vat dye dyeing method using a supercritical CO2 fluid. The vat dye before a reduction reaction is dissolved by a supercritical CO2 fluid; polyester fiber, cellulosic fiber, protein fiber and fabric thereof are dyed; meanwhile, a cosolvent is added to improve the solubility of the vat dye in the supercritical CO2 fluid, the dyeing depth and the like; moreover, a natural fiber swelling agent is added for the vat dye to enter the fiber for dyeing, thereby greatly saving the water resources and realizing a perfect dyeing effect.

Owner:CHENGDU TEXTILE COLLEGE

Method for preparing functional composite woolly elastic fiber

The invention relates to a method for preparing functional composite woolly elastic fiber, comprising the following steps: (1) preparing uvioresistant fine-denier polyester pre-oriented yarn (a) with the method of adding uvioresistant masterbatch; (2) carrying out composite spinning with low viscosity polyester (PET) or modified PET and polyethylene terephthalate (PTT) to prepare fully-drawn self-winding composite elastic fiber (b); and (3) stretching and false twisting the uvioresistant fine-denier polyester pre-oriented yarn (a) on a false-twisting texturing machine, converging the uvioresistant fine-denier polyester pre-oriented yarn (a) and the fully-drawn self-winding composite elastic fiber (b) in the position of a second roller, combining the uvioresistant the fine-denier polyesterpre-oriented yarn (a) and the fully-drawn self-winding composite elastic fiber (b) through an interlacing machine, shaping the uvioresistant the fine-denier polyester pre-oriented yarn (a) and the fully-drawn self-winding composite elastic fiber (b) through a second heating box, and winding the uvioresistant the fine-denier polyester pre-oriented yarn (a) and the fully-drawn self-winding composite elastic fiber (b) into a composite yarn, contracting the PET / PTT self-winding composite elastic fiber with the elasticity and the contractibility in the core layer of the composite woolly elastic fiber to show the elasticity of the composite yarn, and making the uvioresistant fine-denier polyester pre-oriented yarn to float on the surface layer of the composite yarn to show the uvioresistant performance of the composite yarn. Therefore, the uvioresistant composite woolly elastic fiber is prepared.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

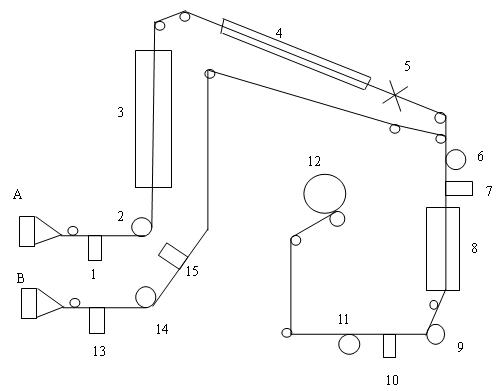

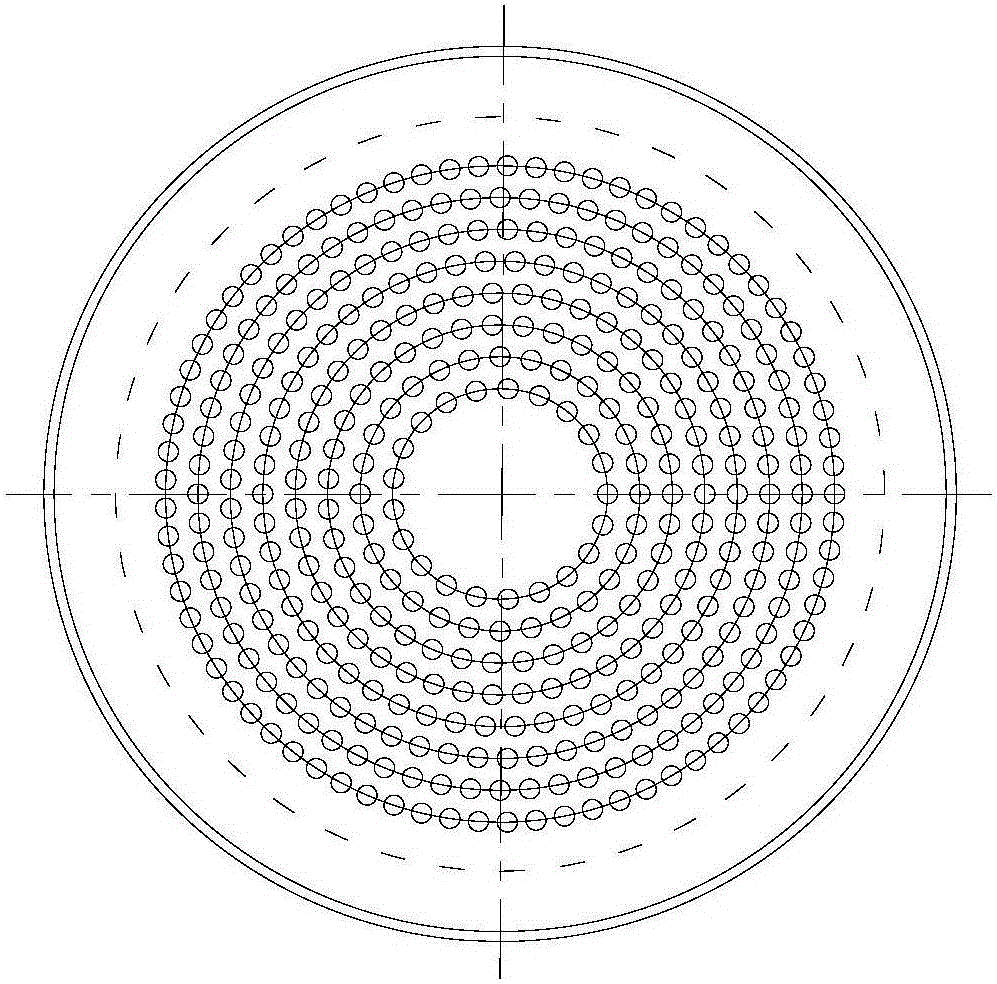

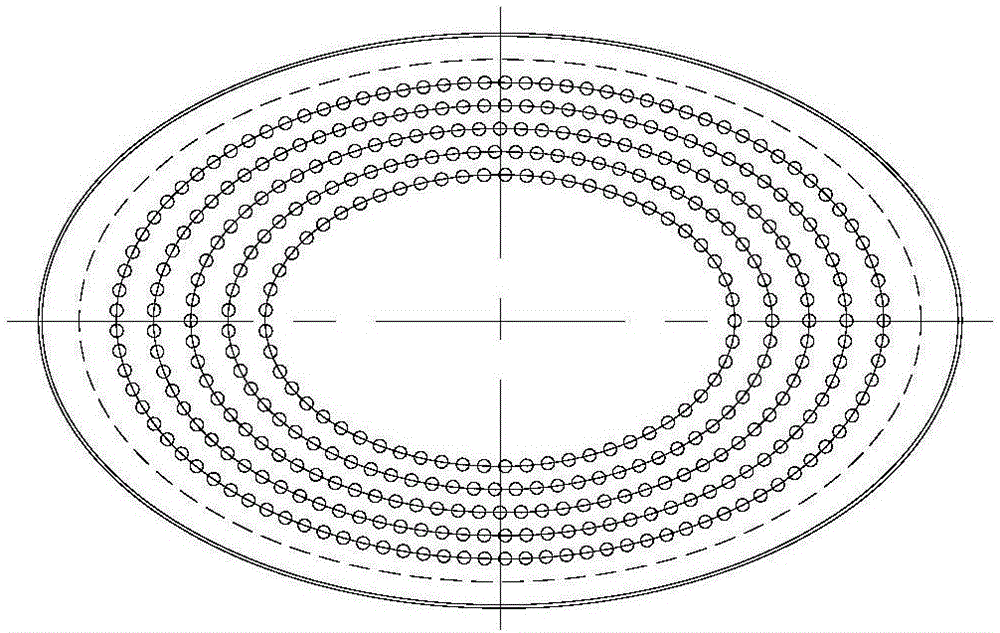

Multi-hole polyester fiber DTY (draw textured yarn) and preparation method thereof

ActiveCN106283253AIncreased access to polyester interiorImprove cooling effectSpinnerette packsMonocomponent copolyesters artificial filamentFiberYarn

The invention relates to a multi-hole polyester fiber DTY (draw textured yarn) and a preparation method thereof. According to the preparation method, modified polyester is spun to prepare the multi-hole polyester fiber DTY by the aid of a multi-hole spinneret plate; spinneret holes in the multi-hole spinneret plate are elliptically arrayed, namely, the hole centers of the spinneret holes are positioned on concentric ellipses, the concentric ellipses are series ellipses, long axes of the all ellipses are collinear, short axes of the all ellipses are collinear, the modified polyester is used for preparing a POY (polyester pre-oriented yarn) and then further processed to obtain the multi-hole polyester fiber DTY. A preparation method of the modified polyester includes the steps: performing reaction for terephthalic acid and ethylene glycol to prepare terephthalic acid ethylene glycol ester; adding the terephthalic acid and dihydric alcohol with branching chains, and performing reaction for mixture to prepare terephthalic acid dihydric alcohol ester; continuing to react to obtain the modified polyester. According to the method, prepared fibers are excellent in performance, the deviation ratio of linear density of the DTY is smaller than or equal to 2.0%, a breaking strength CV (variation coefficient) value is smaller than or equal to 4.0%, a breaking elongation CV value is smaller than or equal to 8.0%, and a CV value of crimping shrinkage rate is smaller than or equal to 8.0%.

Owner:JIANGSU HENGLI CHEM FIBER

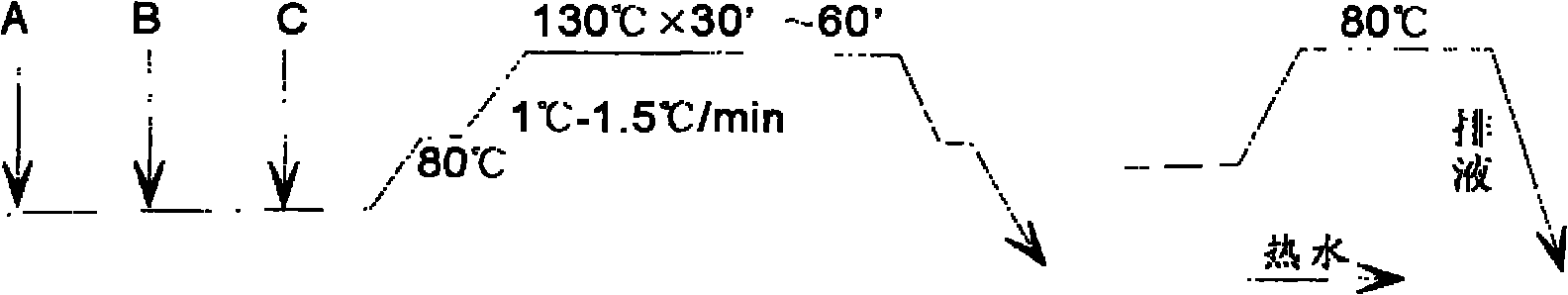

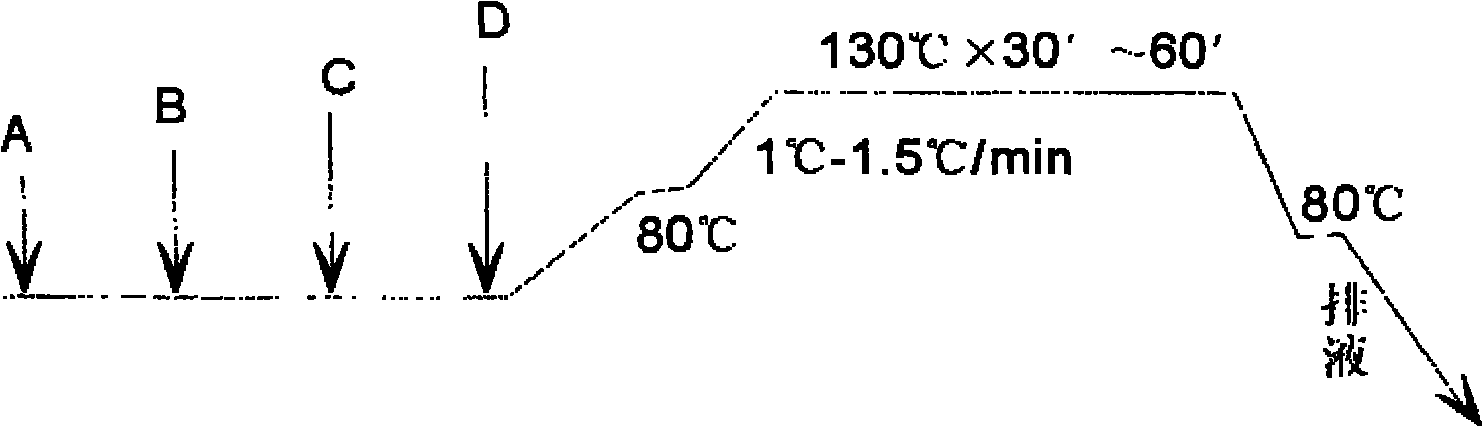

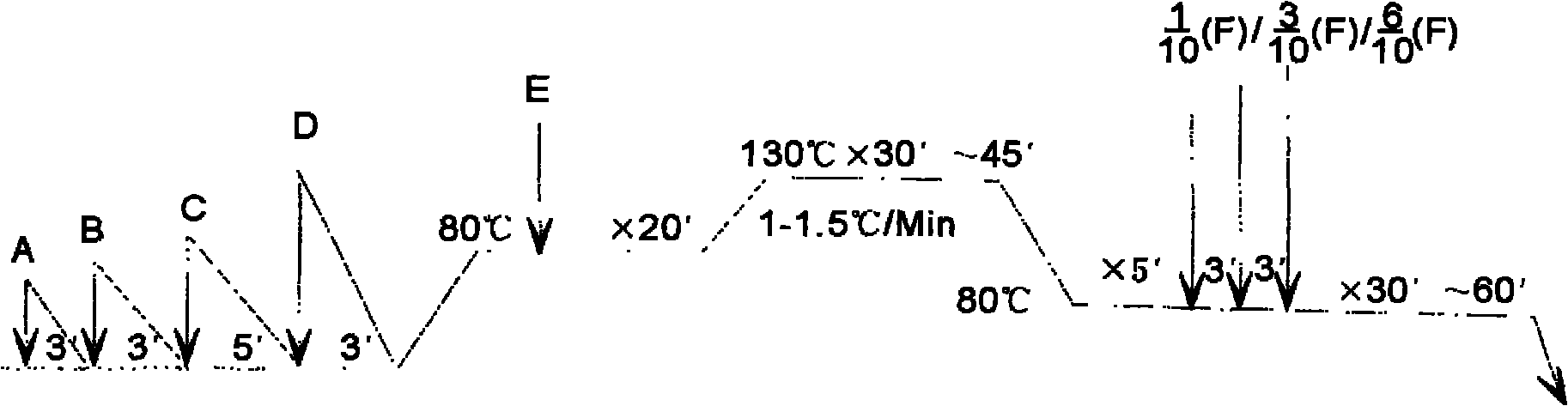

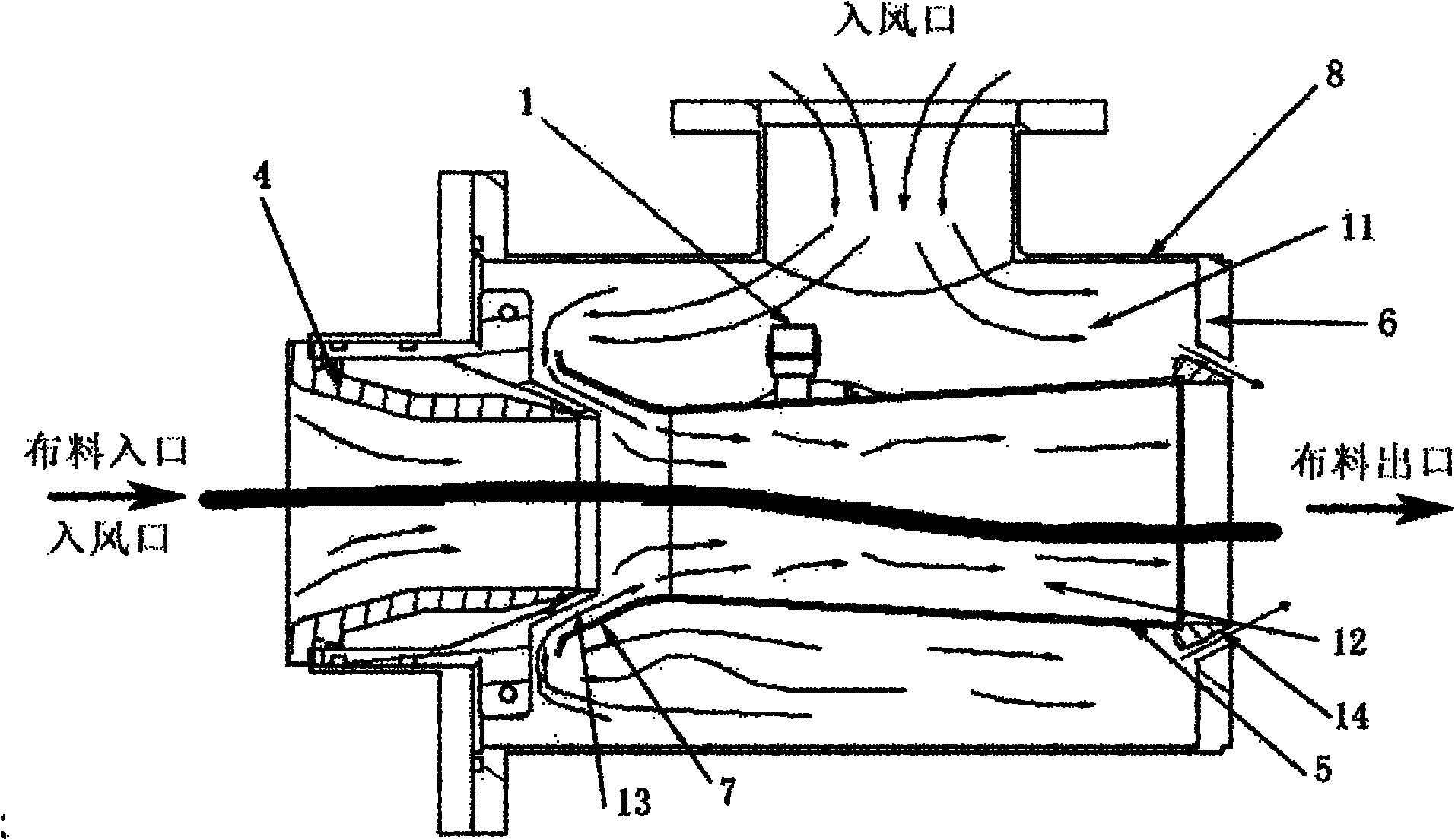

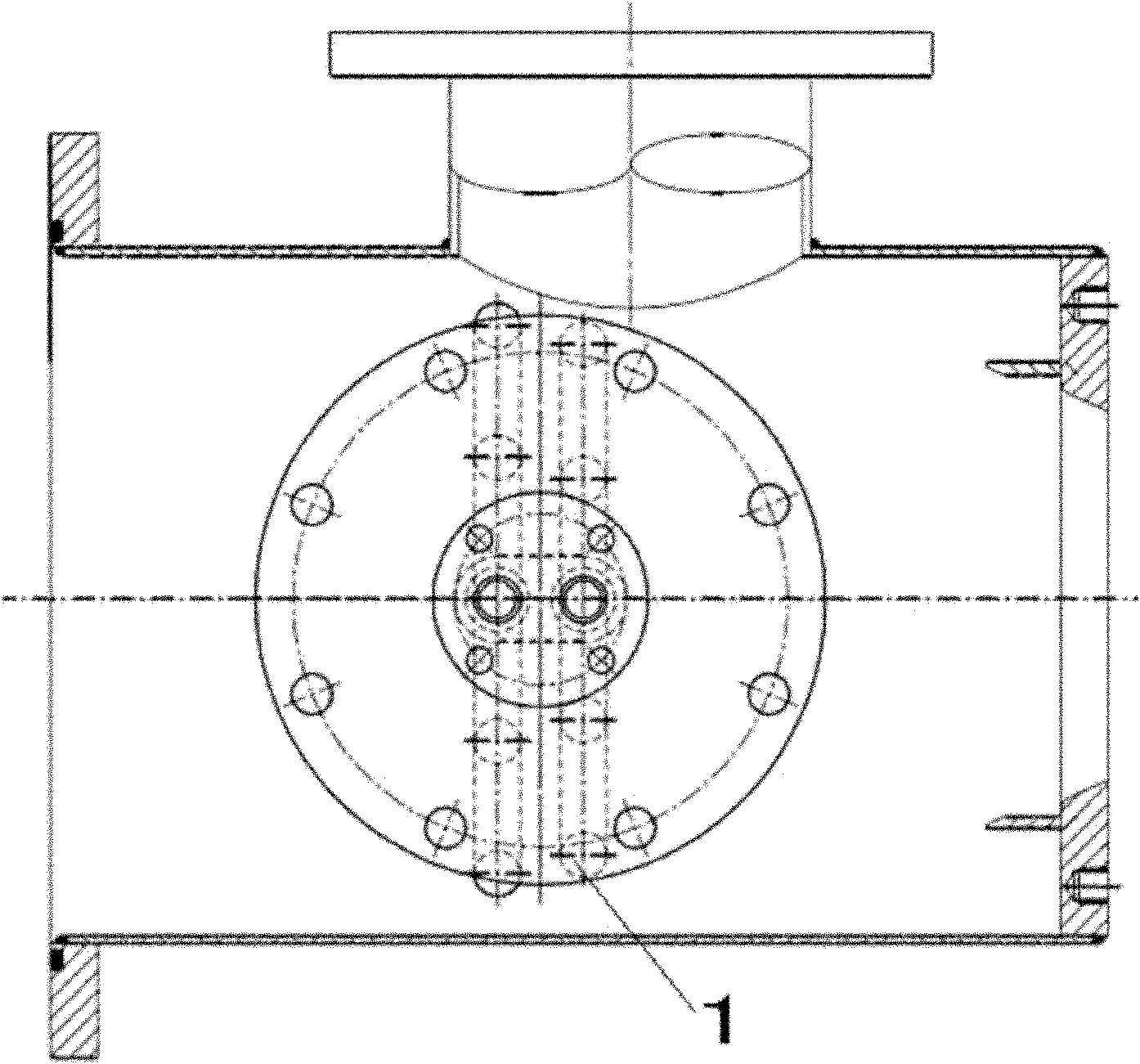

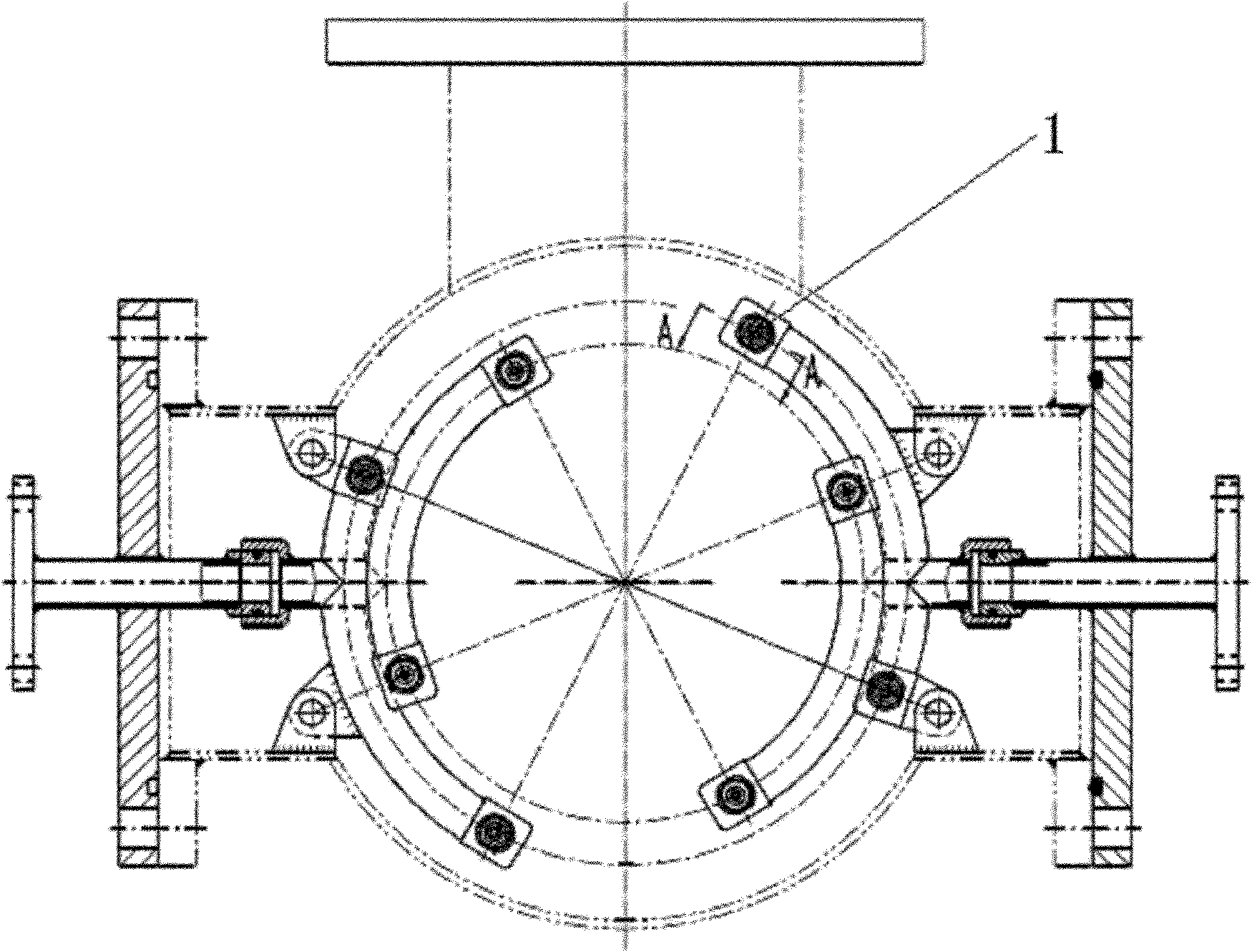

Atomizing nozzle structure of high-temperature high-voltage air flow dyeing machine and control method thereof

InactiveCN102080318AGood level dyeingSuitable for processing environmentLiquid/gas/vapor treatment of propelled fabricsTextile treatment machine partsSpray nozzleHigh pressure

The invention discloses an atomizing nozzle structure of a high-temperature high-voltage air flow dyeing machine and control method thereof. The nozzle structure comprises a front nozzle cover, an inner main stream pipe, a rear nozzle head and a sleeve, wherein the sleeve is sleeved outside the inner main stream pipe, and two ends of the sleeve are respectively connected with the front nozzle cover and the rear nozzle head through a connecting piece; the sleeve is provided with an air inlet which is connected with a fan; and the sleeve and the inner main stream pipe form a circular outer chamber atomizing region; a nozzle head is arranged in the outer chamber atomizing region and is fixed on the outer wall of the inner main stream pipe, and the nozzle head is connected with a dye liquid pipeline; and the outer chamber atomizing region is provided with two outlets which are connected with a channel through which the cloth to be dyed passes in the inner main stream pipe. The invention also provides a control method based on the atomizing nozzle structure of the high-temperature high-voltage air flow dyeing machine. According to the types of the cloth to be dyed, the number of the nozzle heads started in the nozzle structure, the flow rate of the nozzle heads, the air flow of the fan and the temperature process curves adopted are defined. According to the invention, the levelling property is high, and the problem of cloth blocking can not happen.

Owner:高勋绿色智能装备(广州)有限公司

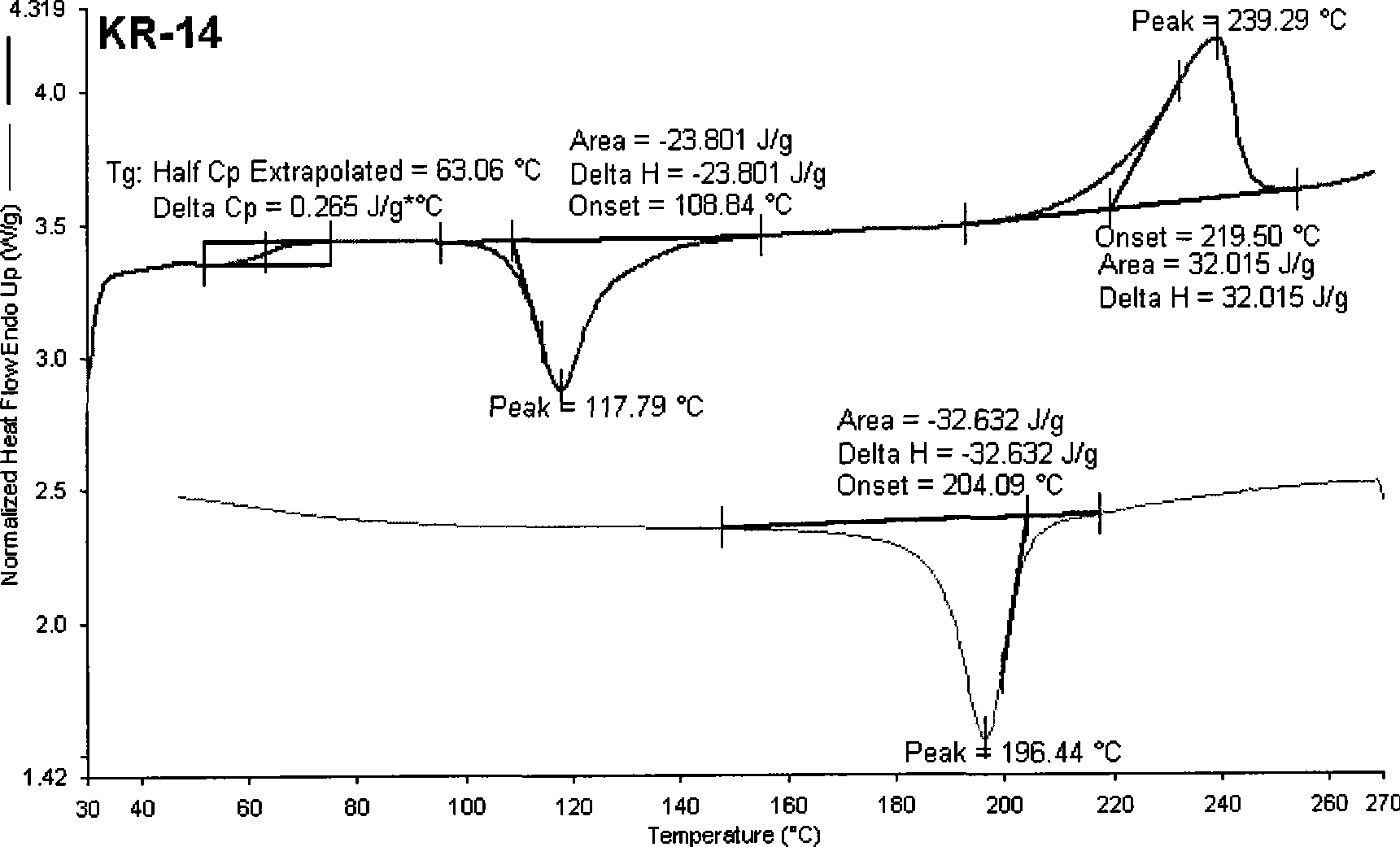

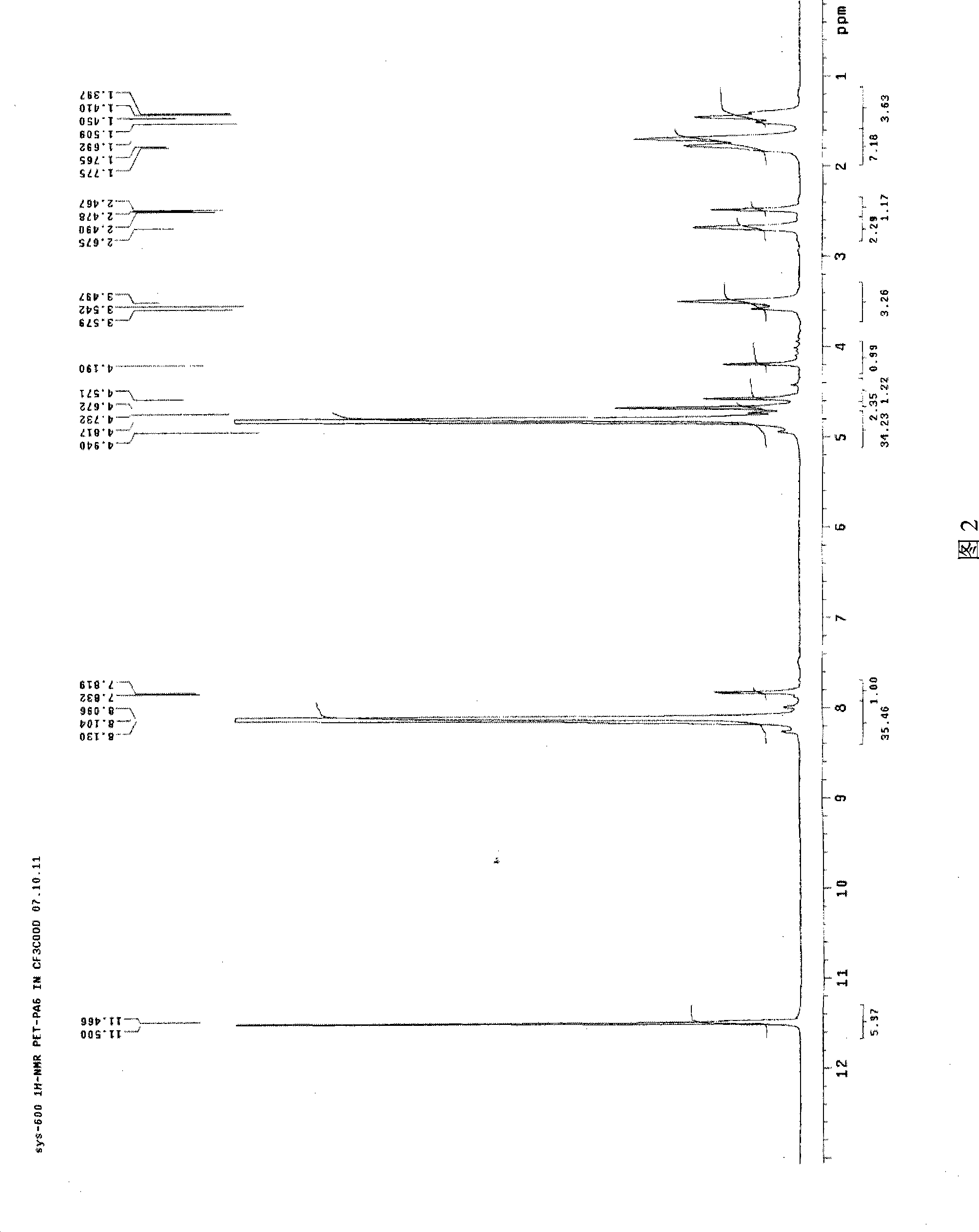

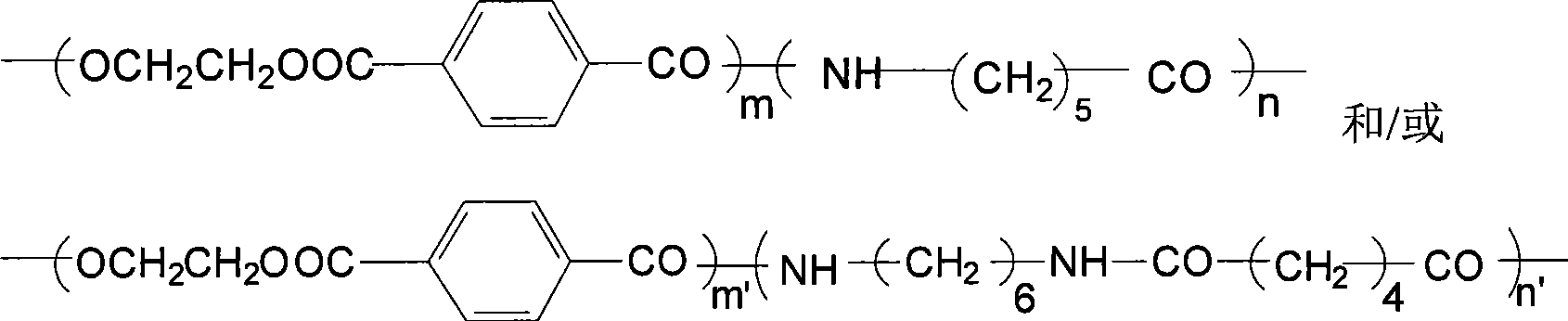

Acidic dyeable polyester and method for preparing acidic dyeable polyester and fiber thereof

ActiveCN101450990AUniform dyeingAffinityMonocomponent copolyesters artificial filamentDyeing processFiberFormate

The invention relates to acidic dyeable polyester and a method for preparing acidic dyeable polyester chip and fiber. The method comprises the steps of performing transesterification or esterification to p-phenyl dimethyl formate or p-phenyl dicarboxylic acid and glycol, adding polyamide such as nylon 6 and / or nylon 66 during polyester polymerization so as to prepare polyester chip, drying the polyester chip and using a conventional spinning machine to spin so as to prepare the polyester fiber used for the dyeing of acid dye. The polyester fiber thoroughly solves the problem that polyester and polyamide are not compatible, ensures uniform dyeing of acid dye, and enables spinning workstage to proceed smoothly. In addition, as the preparation of the polymer adopts a process similar to polyester polymerization for polymerization on a common polyester polymerization device, the method is simple to operate, easy to perform industrial production and low in cost.

Owner:CHINESE TEXTILE ACAD

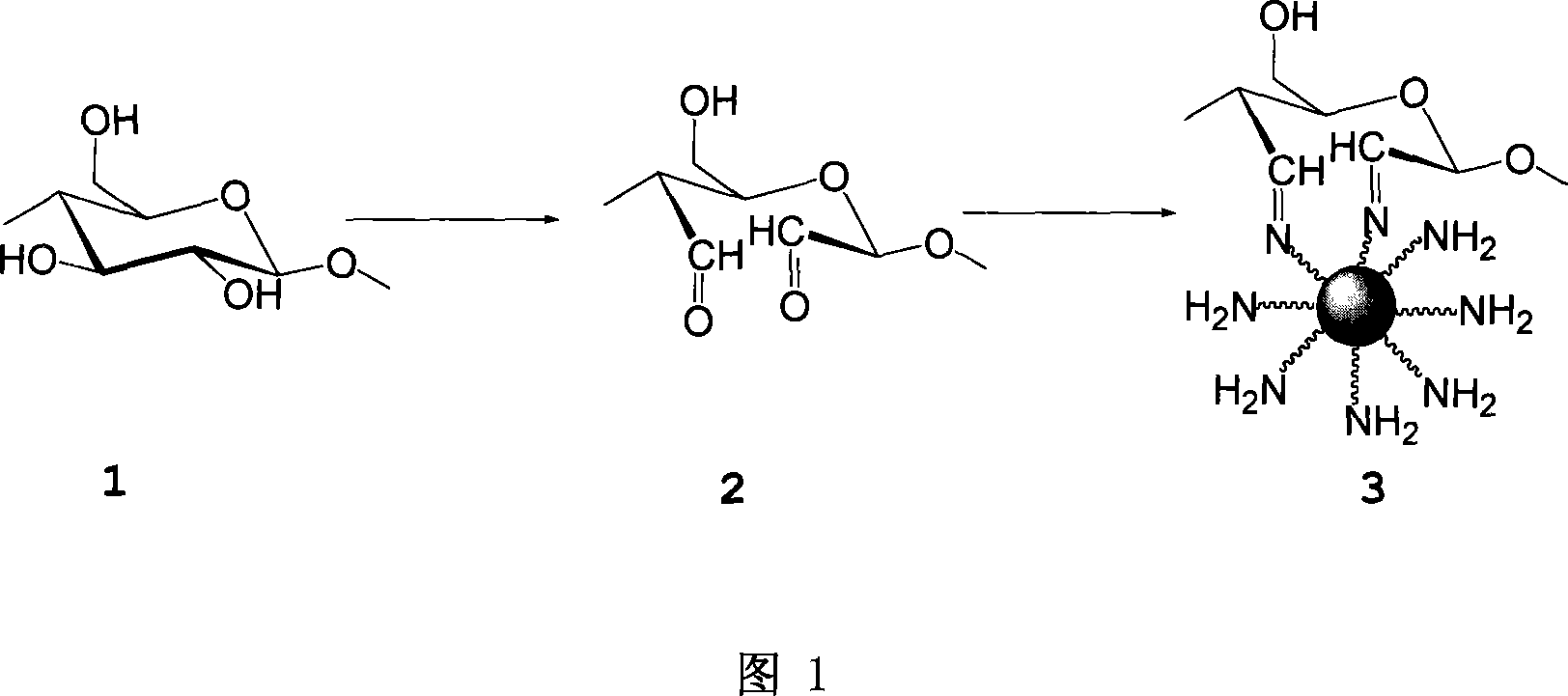

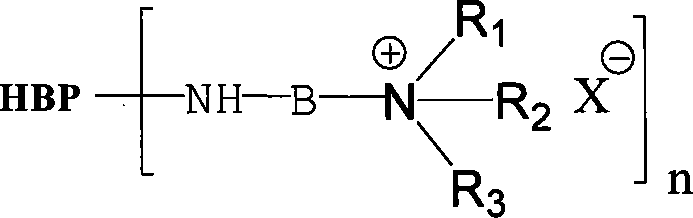

Fibrilia grafting amination modifying process

InactiveCN101225602AQuick responseImprove grafting efficiencyDyeing processVegetal fibresFiberReaction rate

The invention discloses a linen fiber modification method, in particular to a linen fiber graft aminization modification craft, belonging to the technical field of printing and dyeing, which is characterized in that the linen fiber is selectively oxidized with oxidant solution such as sodium periodate, and oxidation linen fiber is obtained; the surface aldehyde group of the oxidation linen fiber is reacted with the surface amino of amine-terminated overbranched compound and the quaternary ammonium salt, which are combined by covalent bond, and the graft aminization linen fiber is prepared; the abundant amino, imino group and quaternary ammonium branched chain are introduced on the surface of obtained fiber, which can increase significantly the dyeing performance of linen fiber, and simultaneously increase the pliability softness, hygroscopicity and antibacterial performance of linen fiber. The linen fiber modification method has the advantages of fast reaction rate, high graft efficiency, good fastness, convenient and easy operation, realization of non-salt dyeing for linen fiber after modification treatment, environment protection, simplified normal dyeing craft and wide potential application.

Owner:SUZHOU UNIV

Modified chemical fiber using natural protein fiber superfine powder and production process thereof

InactiveCN1594682AMeet the processing performanceGood hygroscopicityConjugated synthetic polymer artificial filamentsProtein fiberMelt spinning

The object of the invention is to provide a modified chemical fiber using natural protein fiber superfine powder and production process thereof. The modified chemical fiber is processed by superfine protein powder and chemical fiber material, in which the protein powder is 5-10%, fiber material is 90-95%. The modified chemical fiber using natural protein fiber superfine powder has an improved wettability, a good anti-static property, a good dyeing performance, and has the effects of wool-like and silk-like. The material is natural protein fiber material with a low price and broad source. The melt spinning and wet spinning will not change the processing craft of the traditional chemical fiber and has a good economic performance.

Owner:WUHAN TEXTILE UNIV

Cotton-simulated terylene short fiber and preparation method thereof

ActiveCN101831727AGuaranteed spinnabilitySimple processHollow filament manufactureFilament manufacturePolyesterState of art

The invention provides a cotton-simulated terylene short fiber. Concave pits are formed on the surface of the cotton-simulated terylene short fiber; and the cotton-simulated terylene short fiber comprises 0-1 percent by weight of calcium sulphate, 1-10 percent by weight of PEG (Polyethylene Glycol) and 1-10 percent by weight of ECDP (Easy Cationic Dyeable Polyester). The invention also provides a preparation method of the cotton-simulated terylene short fiber, comprising the following steps of: slicing the PET; drying a mixture of the calcium sulphate, the ECDP and the PEG and fusing and spinning the mixture into a terylene raw filament at 270-280DEG C by using a profile spinneret; carrying out winding, doffing, balanced bundle collection, wire guiding, pre-stretching and oiling; after primary or secondary stretching, dissolving out partial calcium sulphate in the soaking process by alkali treatment to form mocropores on the surfaces of fibers; and finally carrying out tense heat setting, curling, loosed heat setting, cutting and packaging to obtain the cotton-simulated terylene short fiber. The invention solves the problems that a compound spinning process in the prior art is not only complicated, but also has low yield and makes up the defects that the terylene has poor hydrophilicity and the textile is humid and muggy to wear.

Owner:XUZHOU SILK FIBER TECH

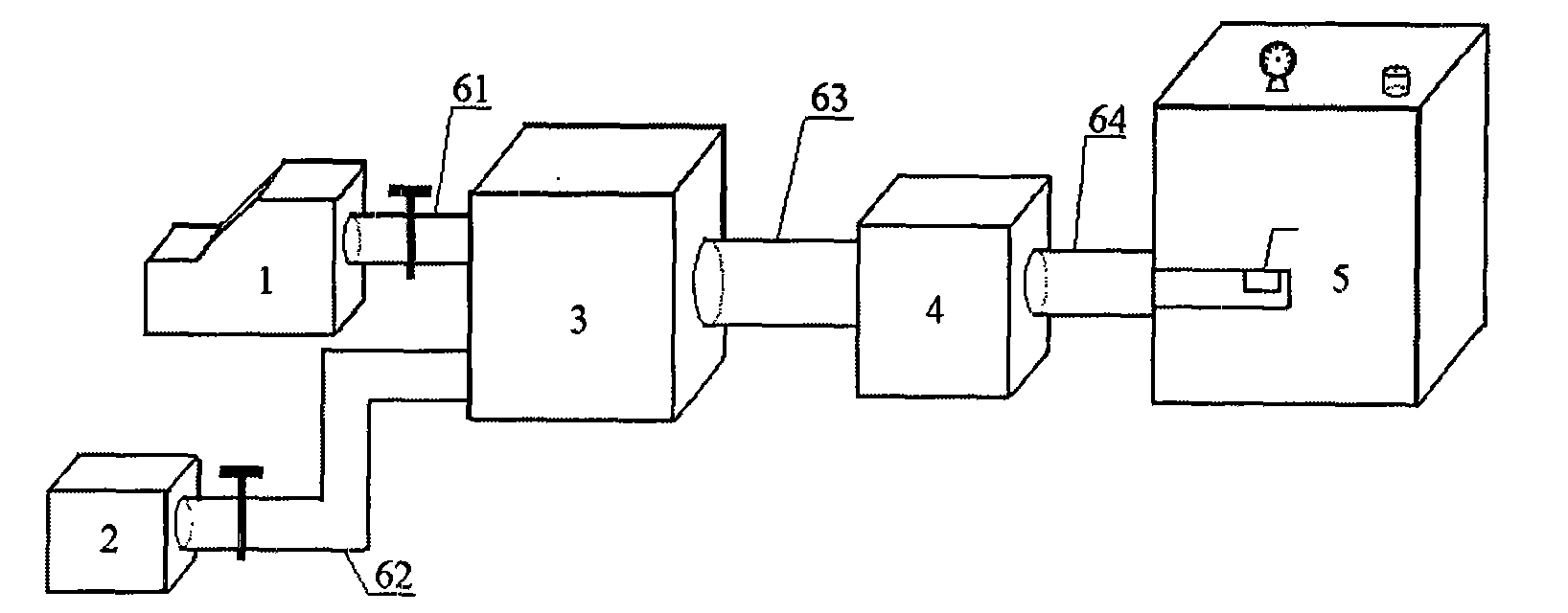

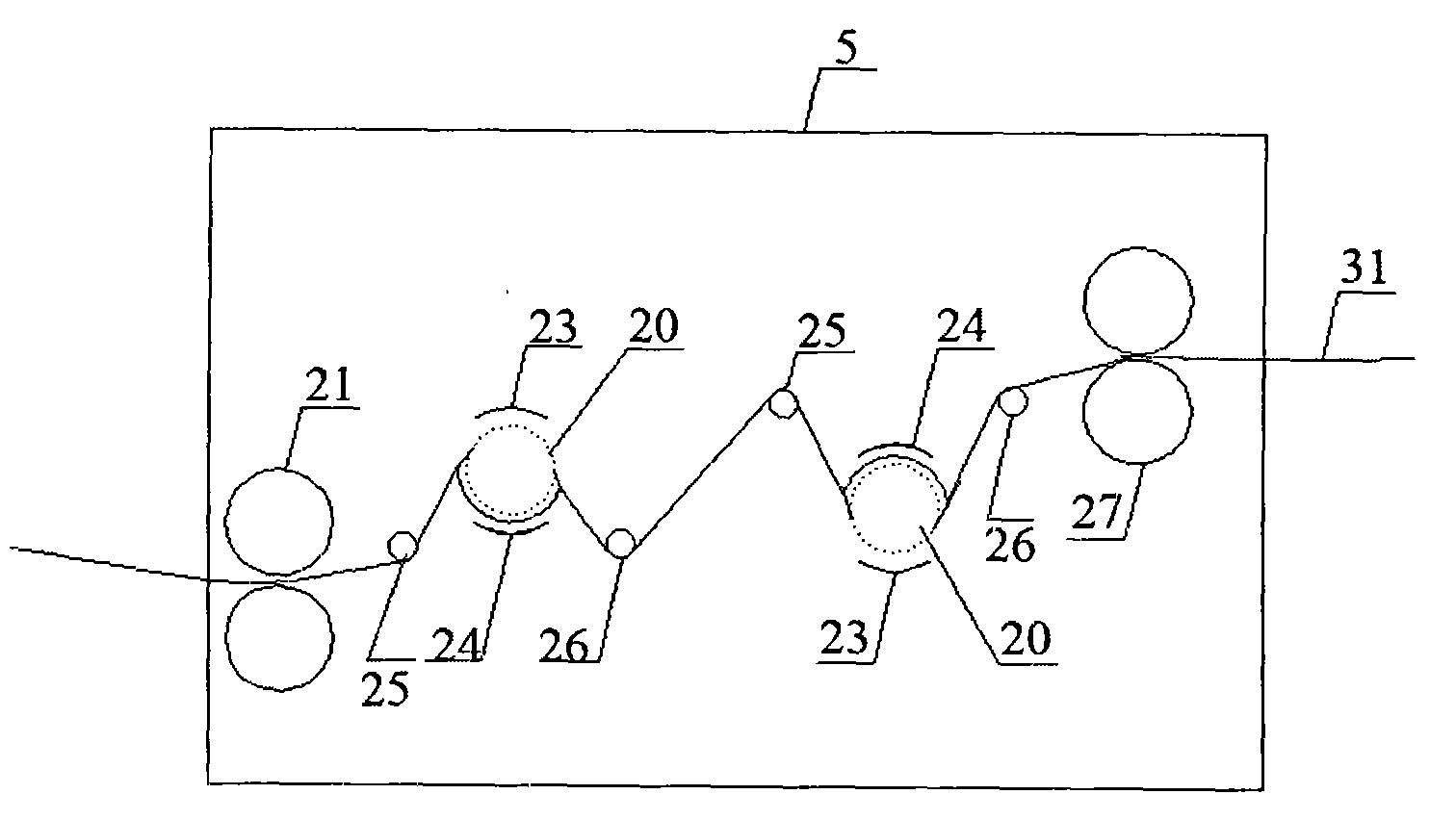

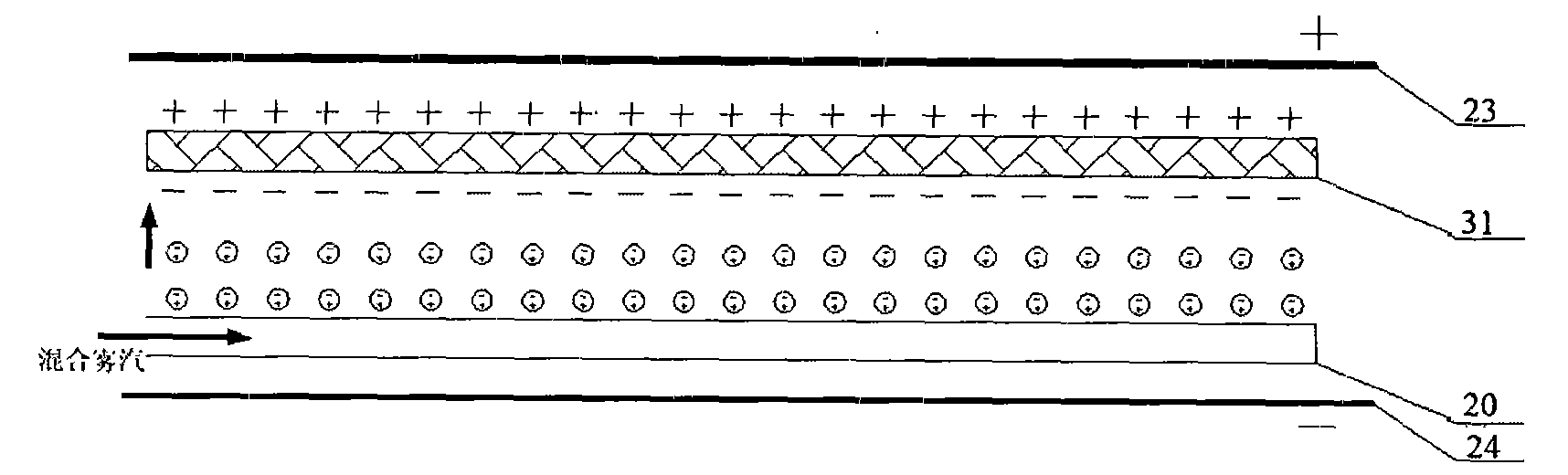

Textile dyeing method

InactiveCN102002834AIncrease profitSmall particle sizeTextile treatment containersTextile treatment with treating outlet contectFiberTextile printer

The invention relates to a method for dyeing textile materials and products thereof, and belongs to the field of textile printing and dyeing processing. In the method, prepared dye solution is subjected to ultrasonic atomization to form dye solution microbeads, and the dye solution microbeads directionally infiltrate the textile under the action of certain pressure and an electric field so as to complete the dyeing process. Due to the adoption of the technical scheme, dye solution atomized microbeads prepared from the dye solution through a high-frequency ultrasonic atomizer have smaller grain size, a small dispersion range on the textile and more fine and smooth dyeing effect; the dye solution atomized microbeads enter fibers more easily under the action of the air pressure and the electric field, and have better dyeing effect; and the atomized microbeads carry less solution, the utilization rate of the dye is high, water can be saved and the environmental pollution is lightened. The dyeing method has a wide application range, low energy consumption and light pollution, and is suitable for small-batch and multi-variety printing technology development direction.

Owner:WUHAN TEXTILE UNIV

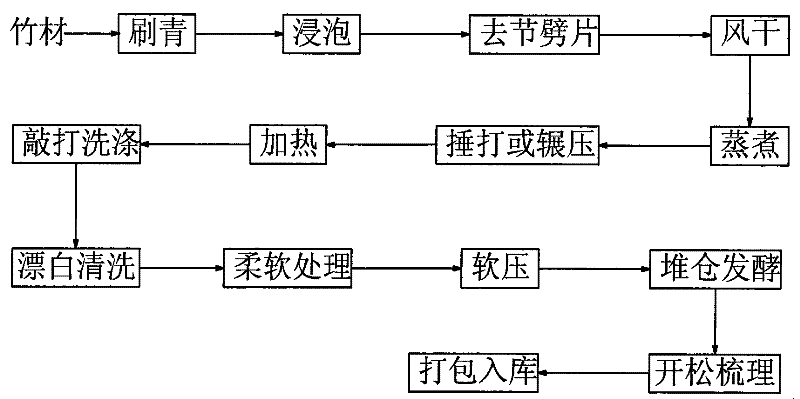

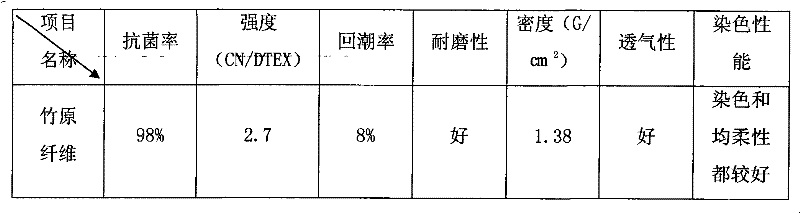

Solvent method for biologically preparing bamboo fiber

ActiveCN101538743BHigh antibacterial rateHigh strengthWood working apparatusMechanical fibre separationCardingBlack liquor

The invention provides a technology for preparing bamboo fiber by 1, 4-butanediol in a solvent method, which comprises the steps of preparing bamboo into bamboo filaments; soaking the bamboo filaments in the solvent and heating to remove lignin, hemicellulose and other impurities on the surface of the cellulose; preparing into coarse bamboo fibre; beating the coarse bamboo fibre, washing with water simultaneously, and then spin-drying through a centrifuge; bleaching and cleaning; conducting mellowing to the bamboo fiber; soft-impressing the bamboo fiber; stowing fermentation and curing, and finally obtaining the bamboo fiber with spinnability after opening and carding. The solvent adopted by the invention has high boiling point and stable chemical property and can be recycled; the whole technological process does not generate black liquor and seriously pollute the environment, and belongs to clean techniques; the obtained natural bamboo fiber has the remarkable advantages of moisture absorption, quick dry, coolness, comfort, antibacterium, deodorization and the like; and the method has low cost and good economic benefit and environmental protection benefit.

Owner:FUJIAN HAIBOSI CHMEICAL TECH

Extraction of natural gromwell dye and application thereof

The invention relates to extraction of natural gromwell dye and application thereof. The extraction comprises the following steps of: crushing gromwell, ultrasonically extracting the crushed gromwell at a certain temperature by using ethanol solution as a solvent to obtain pasty natural gromwell dye, and adding an emulsifying agent into the pasty natural gromwell dye to perform emulsification so as to obtain aqueous solution of the natural gromwell dye. The natural gromwell dye used for dyeing protein, cotton, polyester fibers, yarns or fabrics has good dyeing effect. The natural dye is extracted from the gromwell, and the solvent is reclaimed for reuse, so the environment is not polluted; and the dye extraction process is simple, and the natural gromwell dye has stable quality and broad market prospect.

Owner:CHANGZHOU UNIV +1

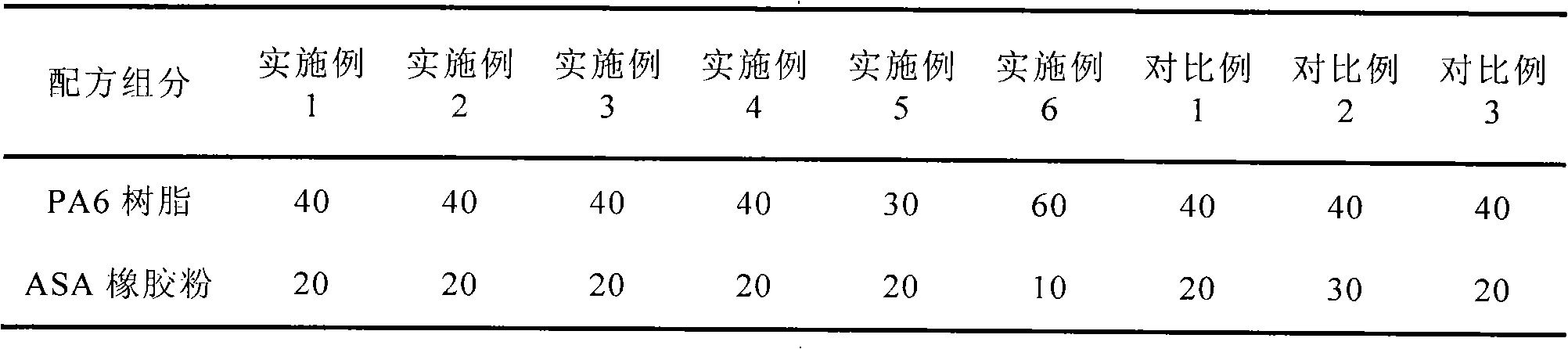

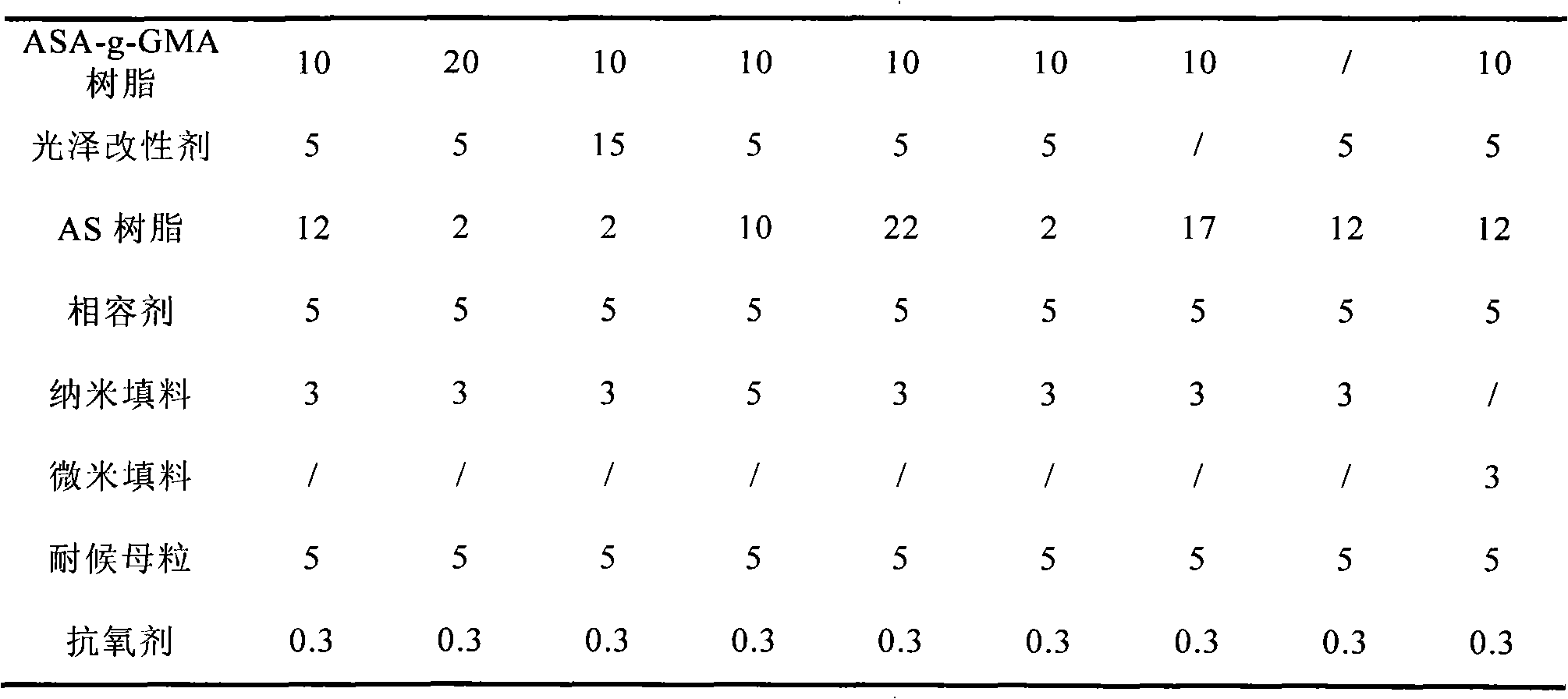

Alloy resin composition and preparation method thereof

The invention relates to an alloy resin composition and a preparation method thereof. The composition comprises the following components in part by weight: 30-60 parts of polyamide resins, 15-50 parts of ASA (Acetylsalicylic Acid) rubber powder, 10-20 parts of ASA-g-GMA (Glycidyl Methacrylate) resins, 5-15 parts of glossy modifiers, 0-30 parts of AS (Arsenic) resins, 1-8 parts of compatilizers, 5-10 parts of weather-resistant master batch, 1-5 parts of nano fillers and 0.05-0.5 part of antioxidant. The preparation method comprises the following steps of: adding the mixture of all raw materials expect for the weather-resistant master batch to a main charging hole of a double-screw extruder, adding the weather-resistant master batch from a side charging hole, and then carrying out extrusion and pelleting to obtain the product. The alloy resin composition obtained in the method has a softer leopard surface matting effect, a more glossy shiny side lighting effect and better low temperature impact resistance and weather resistance, and is especially suitable for automobile interiors and exteriors with high requirements, such as instrument frames, air outlets of air conditioners, storage boxes, doorknobs, cosmetic mirrors, heat-radiating gratings, rearview mirrors, middle post plates, license plates and the like above wasitlines.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Antimicrobial pearl viscose fiber, preparation method and application thereof

InactiveCN101270508AExpand the range of dosageRaise the ratioMonocomponent cellulose artificial filamentArtifical filament manufactureAntibiosisViscose fiber

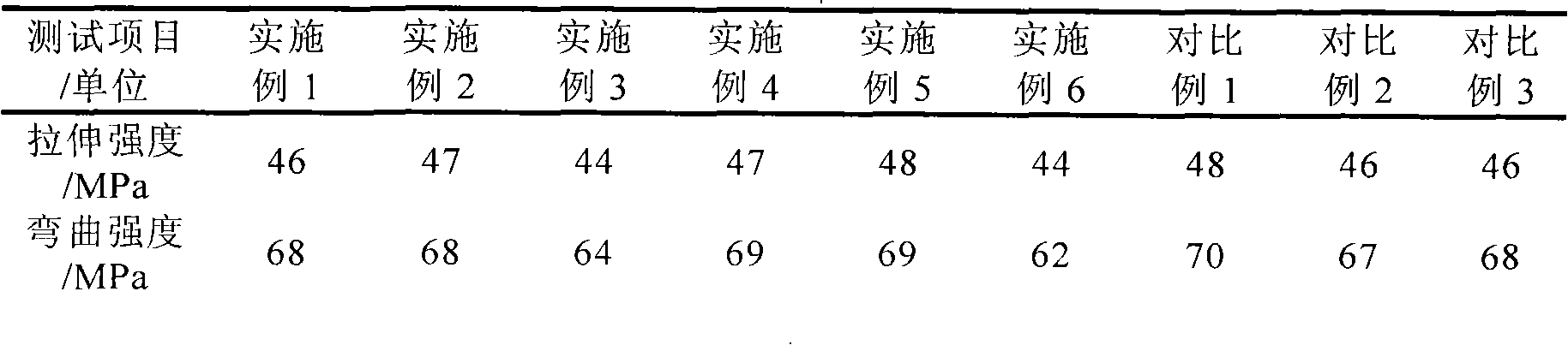

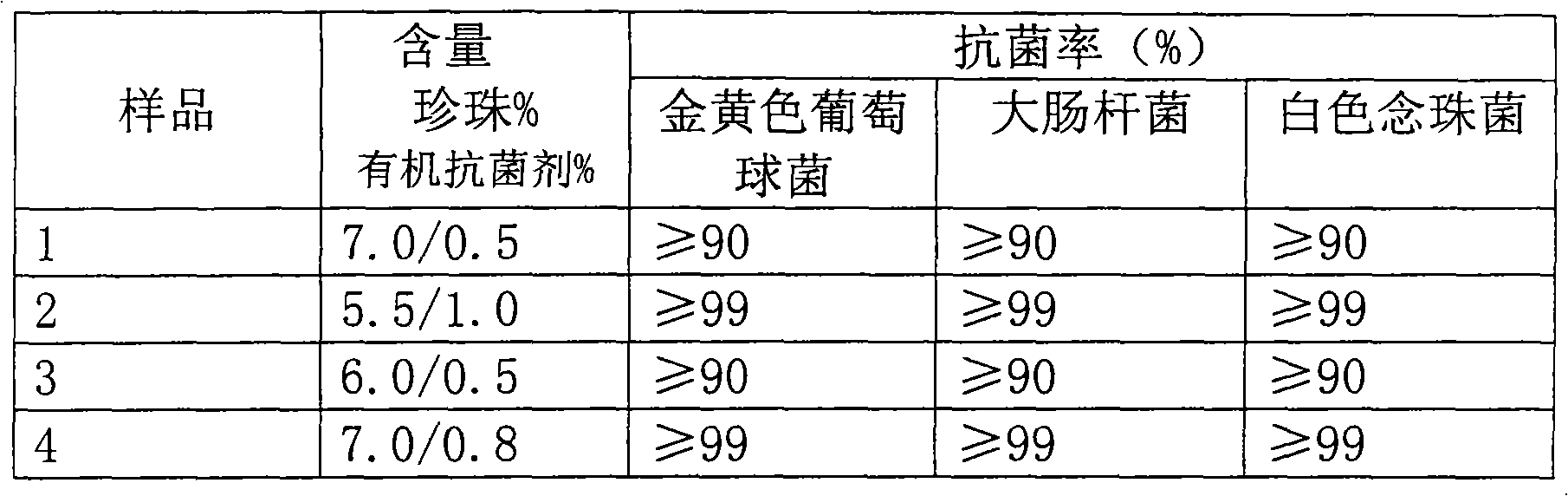

The invention discloses an antibiosis pearl mucilage glue fiber as well as a manufacture method and application thereof. The fiber is manufactured by mixing the mucilage glue, pearl powder accounting for 5.5 to 7.0 percent of the total weight of the fiber as well as organic antimicrobial accounting for 0.5 to 1.0 percent of the total weight of the fiber. The antibiosis pearl mucilage glue fiber of the invention not only has the advantages of pure savageness, being degradable and excellent chromaticity but also has the functions of smart appearance, smooth and cool hand feeling and being softer than pure cotton that are specifically owned by pearl; the fiber also has particularly comfort feeling when contacting with skin and the function of antibiosis and health care.

Owner:FUJIAN ZHONGHE

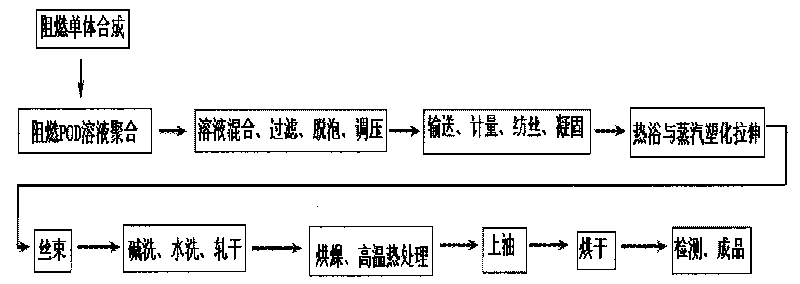

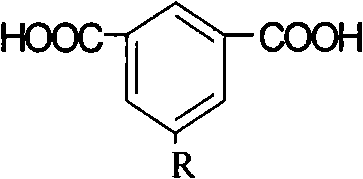

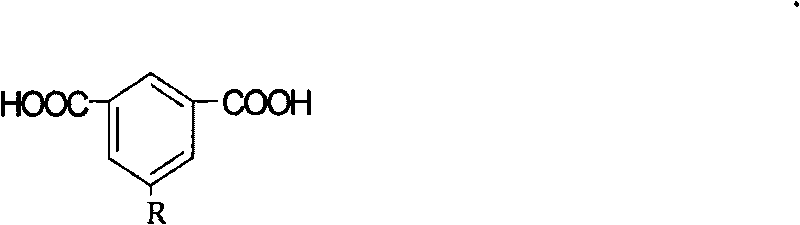

Method for preparing special aromatic polyoxadiazole and flame-retardant high-temperature resistant polyoxadiazole fiber thereof

ActiveCN101735455ASingle structureEasy to synthesizeWet spinning methodsMonocomponent synthetic polymer artificial filamentChemistryDecomposition

The invention discloses a method for preparing special aromatic polyoxadiazole and flame-retardant high-temperature resistant polyoxadiazole fiber thereof. The special aromatic polyoxadiazole is prepared by the following method that the special aromatic polyoxadiazole is prepared from terephthalic acid, compound of which the structural general formula is expressed as formula I and hydrazine salt serving as monomers through condensation polymerization reaction. The polyoxadiazole fiber with high flame retardancy and high temperature resistance is prepared by using the special aromatic polyoxadiazole as a raw material. The fiber number of the prepared polyoxadiazole fiber is 1 to 20 dtex, the breaking strength is 2.5 to 5 cN.dtex-1, the elongation at break is 10 to 40 percent, the initial modulus is 50 to 250 cN.dtex-1, the moisture regain is 5.0 to 12.0 percent, the limited oxygen index is 30 to 38 percent, and the initial decomposition temperature is above 480 DEG C. The fiber can be widely used in the fields of protective products, filter materials, electric insulating materials, frictional sealed materials, various industrial textiles, high-temperature resistant paper, aviation and aerospace materials and the like.

Owner:JIANGSU BAODE NEW MATERIAL

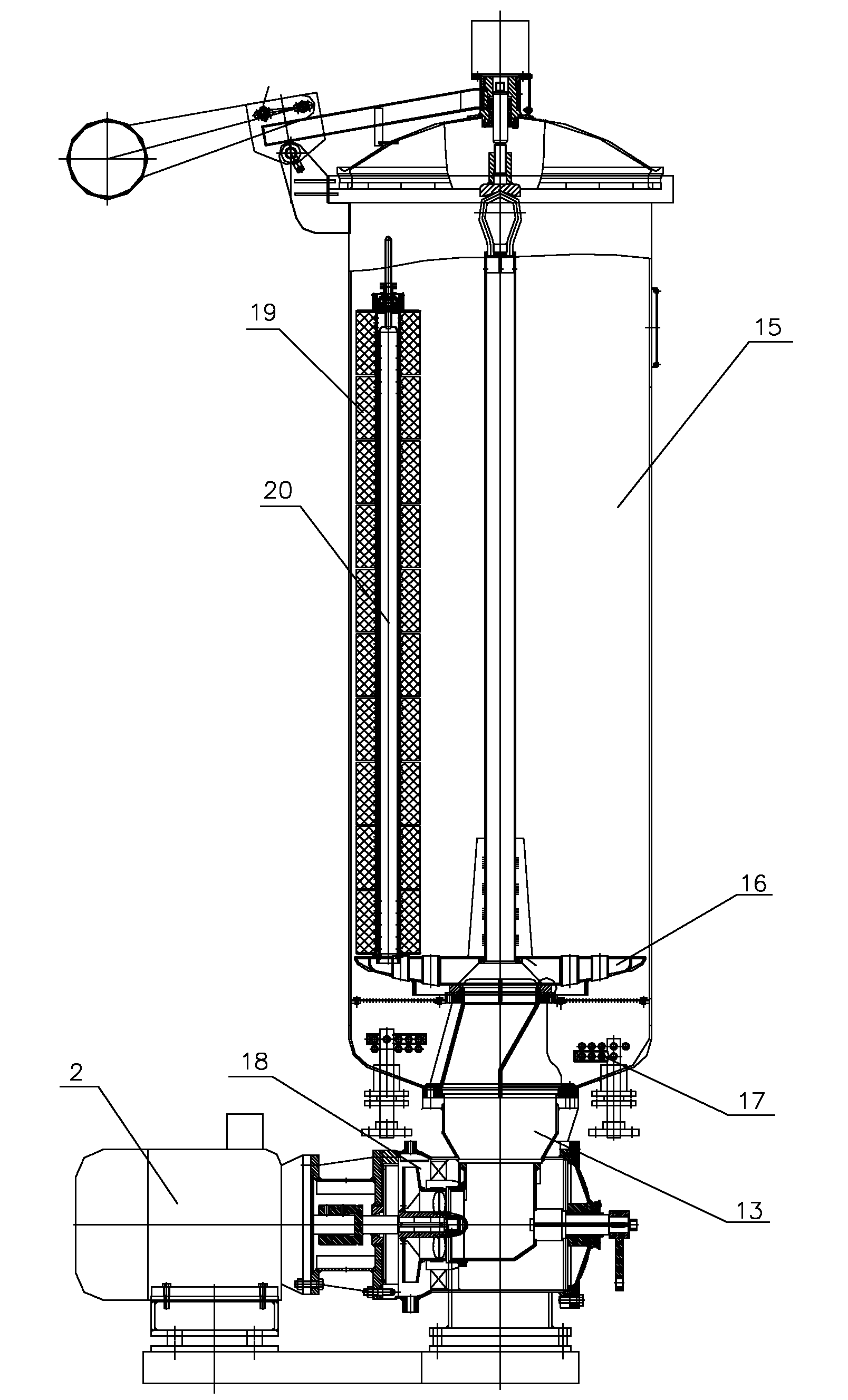

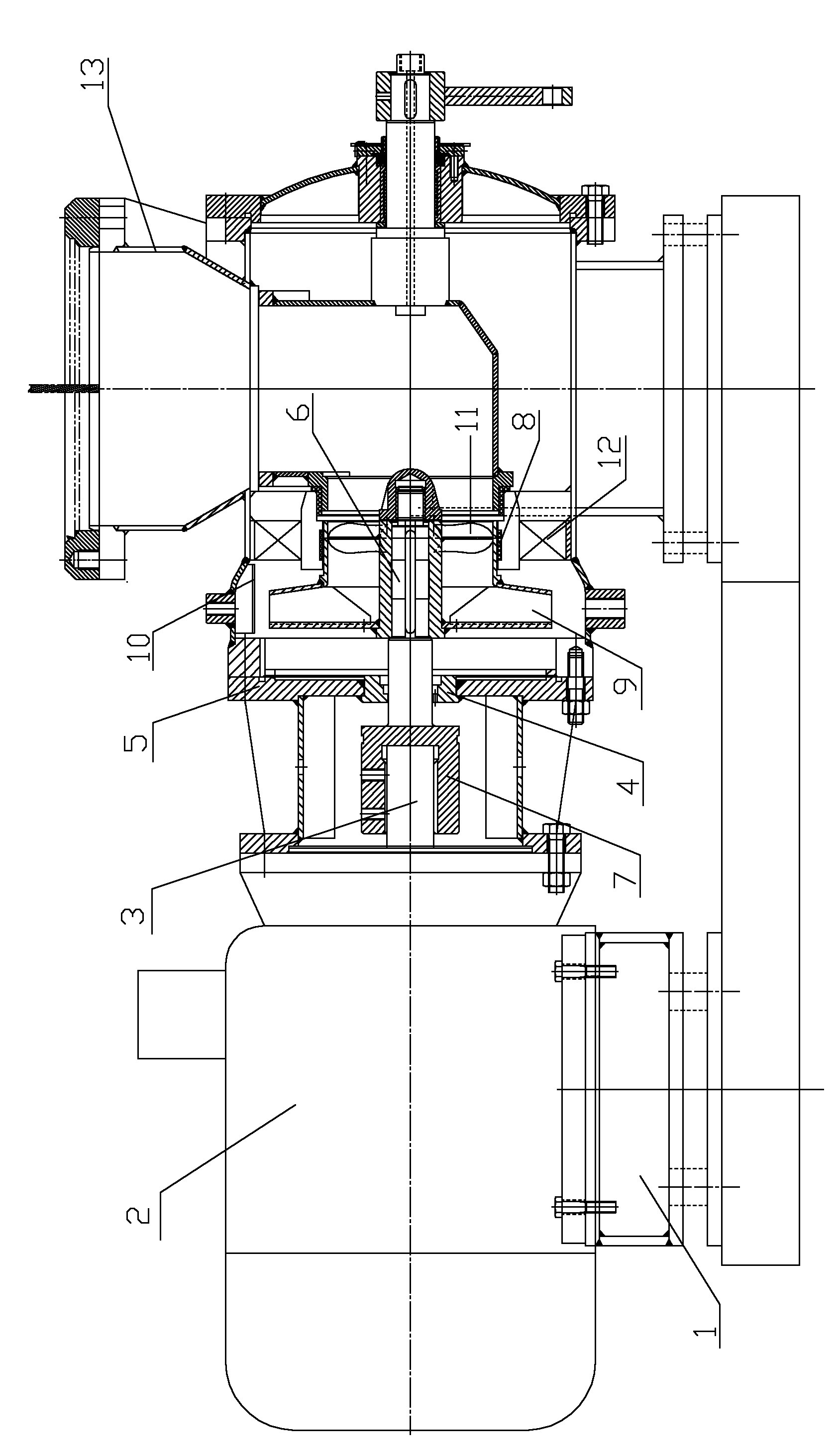

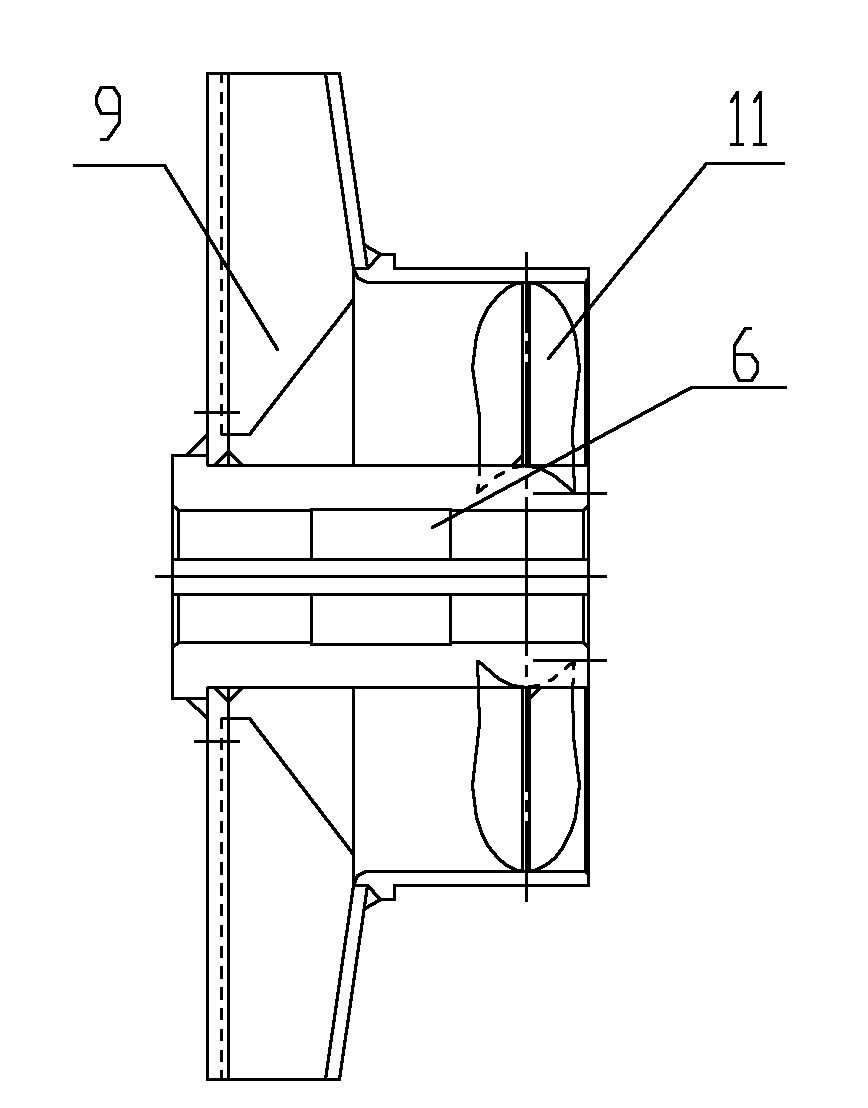

Ultralow bath-ratio yarn dyeing machine with three-level vane pump

InactiveCN102134793ACycle fastAvoid layer chromatic aberrationTextile treatment using short bath ratio liquorTextile treatment machine arrangementsYarnThree level

The invention discloses an ultralow bath-ratio yarn dyeing machine with a three-level vane pump, comprising a dye vat, a yarn stand and a vane pump, wherein the bottom of the yarn stand is a yarn stand disk; the yarn stand disk is provided with a hole communicated with a dye liquor input channel in the dye vat; the vane pump is arranged below the whole dye vat and is a three-level vane pump; a shaft of the three-level vane pump is connected with an internal motor shaft coaxially; the dye vat is connected with the inlet of the three-level vane pump; the three-level vane pump comprises an axial flow level, a centrifugal level and a fixed guide vane level; the axial flow level and the centrifugal level are connected with the motor in sequence through the same transmission shaft; dye liquor flows into the axial flow level through an in-flow channel; the dye liquor flowing out of the axial flow level directly enters the inlet of the centrifugal level; and the dye liquor flowing out of the centrifugal level enters an out-flow channel after passing through the fixed guide vane level. During work, the dye liquor in the dye vat does not exceed the yarn stand disk all the time and the bath ratio is lower than 1:3. The ultralow bath-ratio yarn dyeing machine can achieve required lift when the dye liquor in the yarn dyeing machine is lower than a spindle, so as to realize the low bath ratio of the yarn dyeing machine as well as the purpose of saving energy and reducing emission.

Owner:高勋绿色智能装备(广州)有限公司

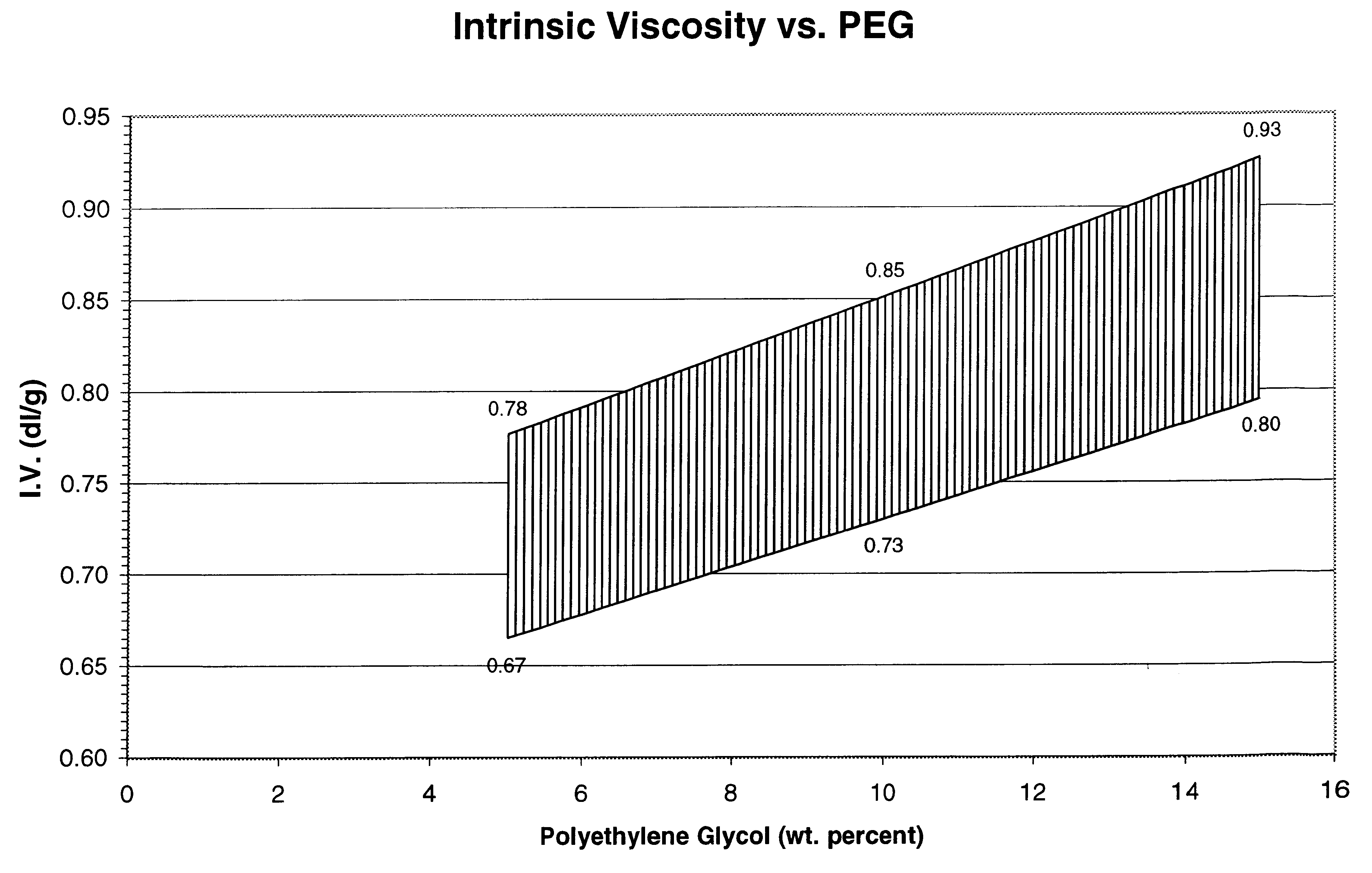

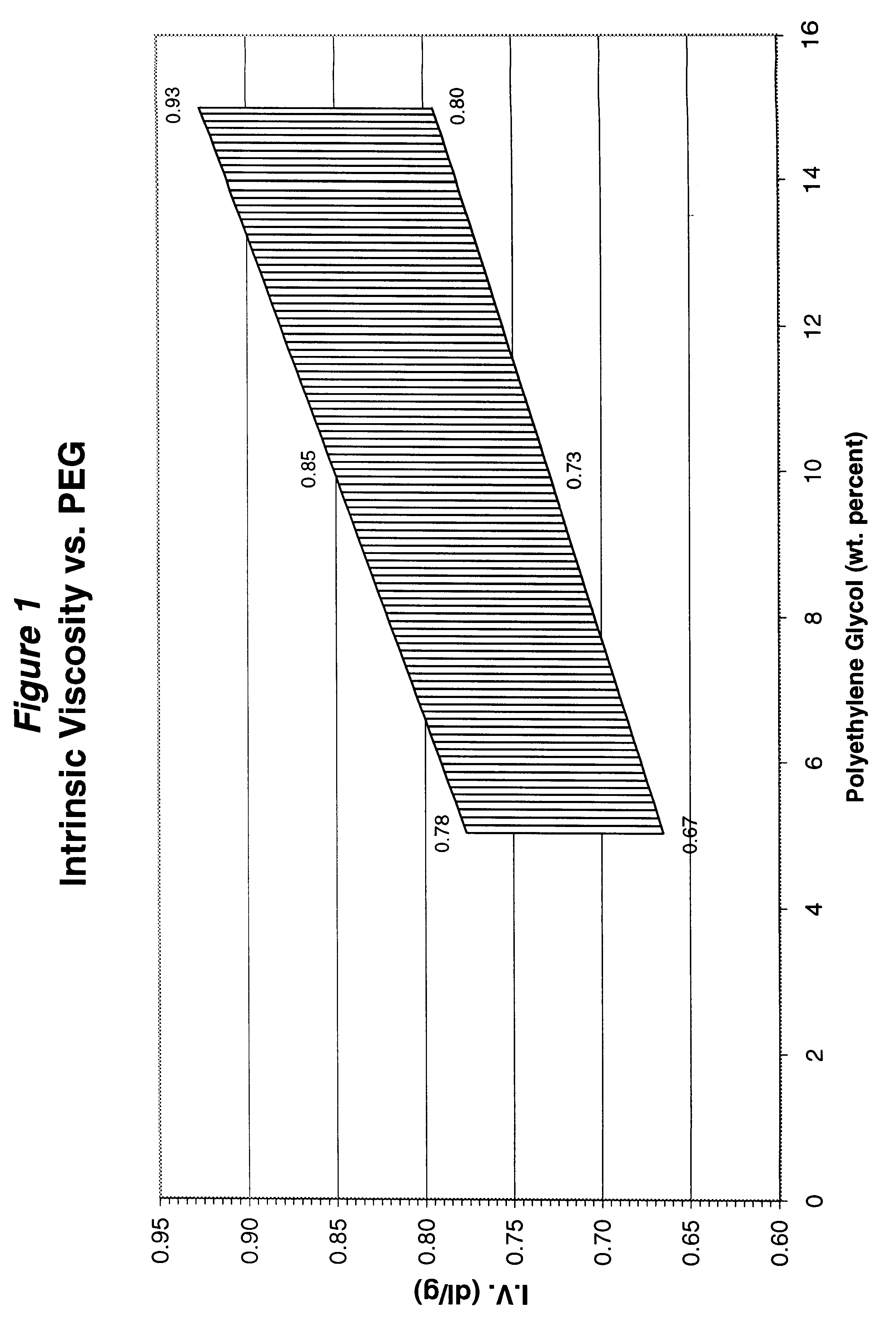

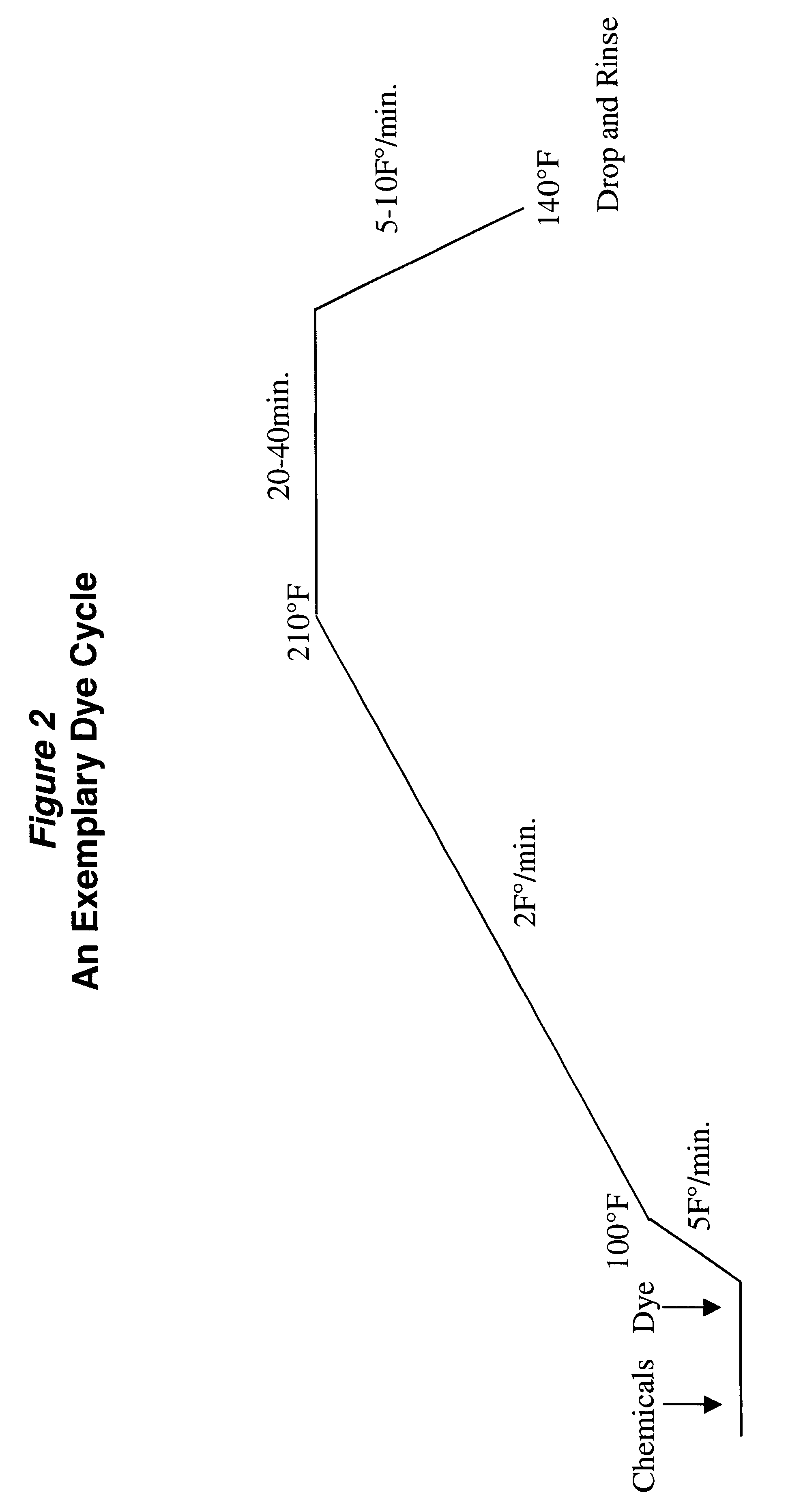

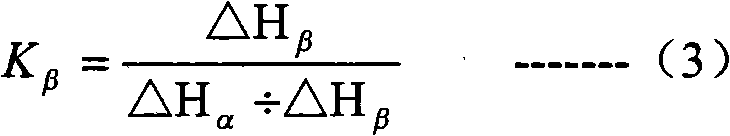

Polyethylene glycol modified polyester fibers and method for making the same

InactiveUS6291066B1Easy to dyeImprove dyeing effectProtective fabricsMonocomponent polyetheresters artificial filamentFiberYarn

Disclosed is a method of copolymerizing polyethylene glycol (PEG) and branching agent into polyethylene terephthalate (PET) to achieve a polyethylene glycol-modified polyester composition that can be spun into filaments. Fabrics made from fibers formed from the copolyester composition possess wicking, drying, stretching, abrasion-resistance, flame-retardancy, static-dissipation, dyeability, and tactility properties that are superior to those of fabrics formed from conventional polyethylene terephthalate fibers of the same yarn and fabric construction. Also disclosed are polyethylene glycol modified copolyester compositions, fibers, yarns, and fabrics.

Owner:FIBER IND INC

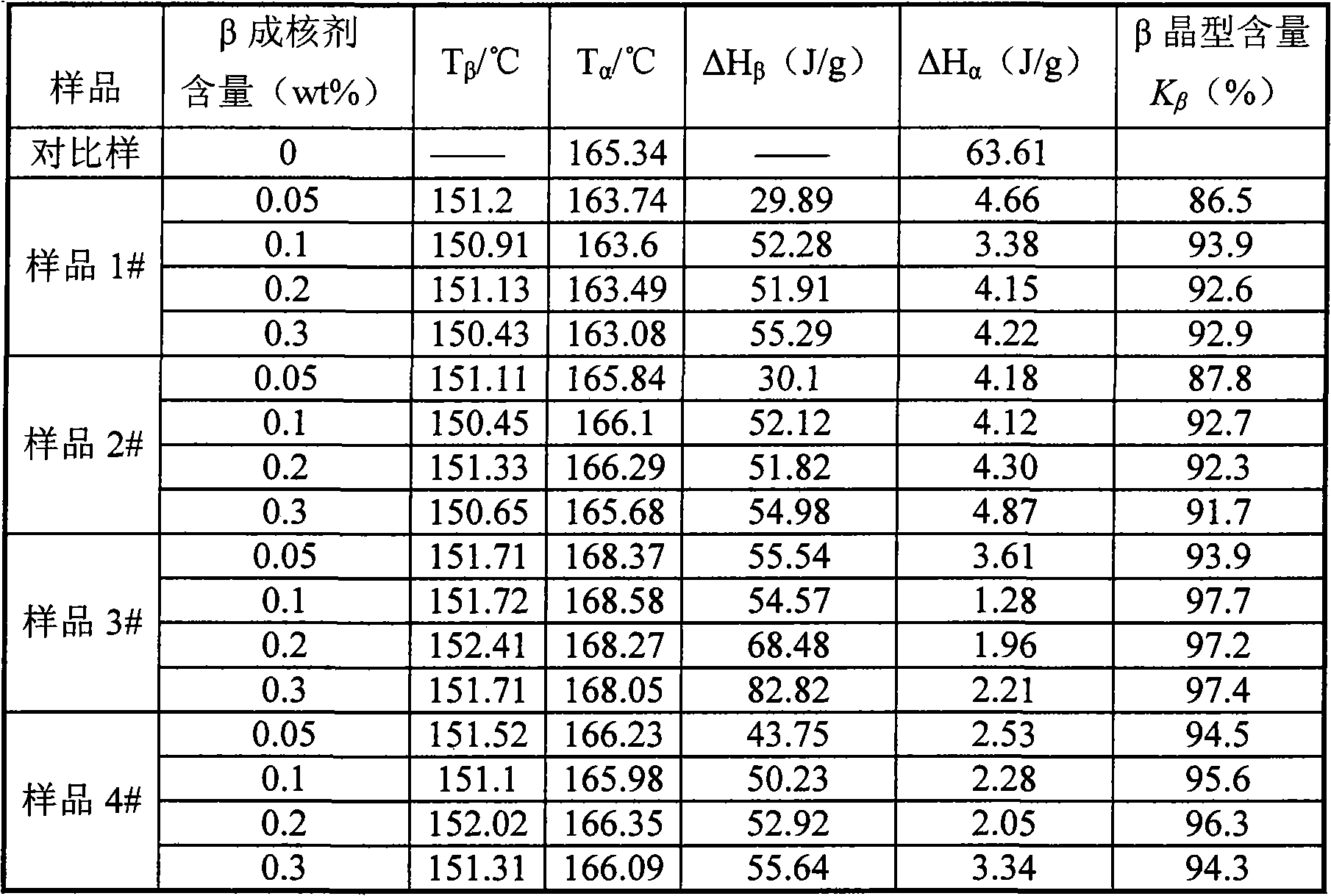

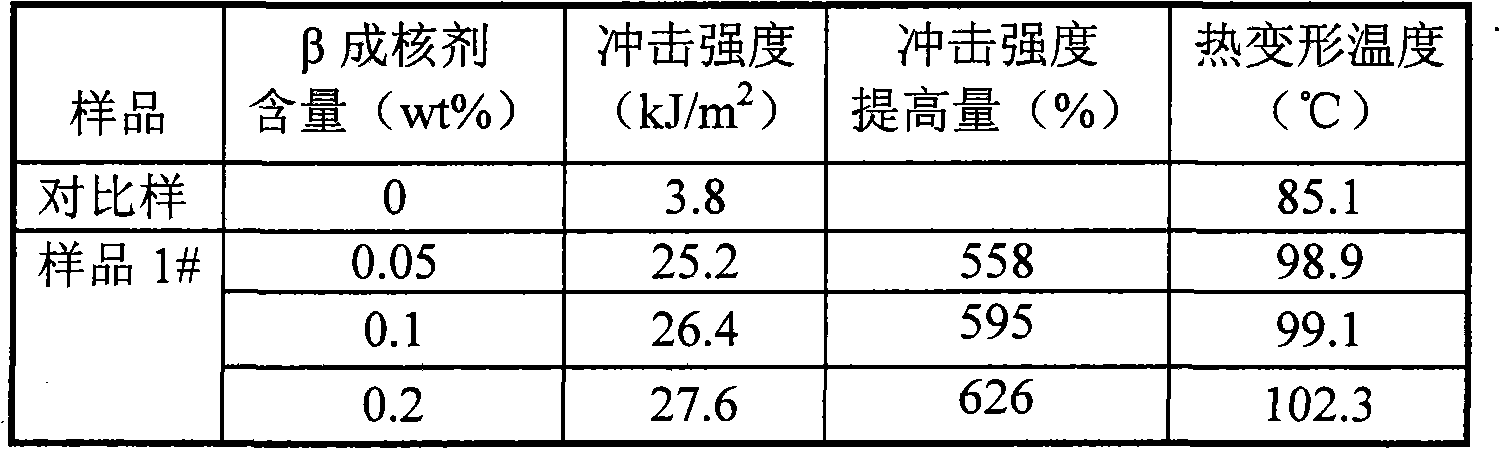

Application of carboxylic acid metal salt of tetrahydrophthalic anhydride as nucleating agent for polypropylene beta crystal form

ActiveCN102181092AHigh impact strengthHigh heat distortion temperatureDispersityHeat deflection temperature

The invention provides an application of a carboxylic acid metal salt of tetrahydrophthalic anhydride as a nucleating agent for a polypropylene beta crystal form. By adopting the carboxylic acid metal salt of tetrahydrophthalic anhydride as the nucleating agent, the generation of beta crystal form polypropylene can be induced efficiently; as tested by differential scanning calorimetry (DSC), the content of a beta crystal form is up to 86-97.7 percent; after nucleation modification by using the carboxylic acid metal salt of the tetrahydrophthalic anhydride, the punching strength of polypropylene is increased by 5-8 times, the heat deflection temperature is increased greatly, and high mechanical property is achieved; and moreover, the carboxylic acid metal salt has the advantages of chemical stability, high dispersity, coloring resistance, capability of improving the working quality of a product and wide application range in the field of materials special for polypropylene.

Owner:GCH TECH

Low-temperature dyeing and finishing technology of cottonette

InactiveCN105002730AProcess temperature changeLow processing temperatureBiochemical fibre treatmentHeating/cooling textile fabricsInorganic saltsDiastase

The invention discloses a low-temperature dyeing and finishing technology of cottonette. The technology comprises the following steps: pretreatment; preshaping; modification treatment; dyeing; mordant removing; soaping; color fixing; post-treatment; drying; shaping; calendaring; rolling. According to the technology, pretreatment is carried out through the adoption of helicase and alpha-amylase, and modification treatment is carried out before dyeing, so that the property of the cottonette is fundamentally modified, and the dye-uptake of the fabric is increased; during the dyeing procedure, large quantities of alkaline substances and inorganic salt are not used, and a levelling agent, a low-temperature dyeing accelerant, a migration inhibitor and a dispersing agent are added, so that the dye uniformity is improved; during the whole dyeing process, the temperature is lower than 80 DEG C, and the dyeing process belongs to low-temperature dyeing, so that energy consumption is reduced; self-cleaning treatment is added in post-treatment, so that the self-cleaning capacity, wrinkle resistance and water washable firmness of the fabric are improved; post-treatment is carried out through the adoption of silk fibroin and sericin, so that the pilling resistance and antistatic property of the cottonette are improved; the whole technology is environment-friendly and free of pollution.

Owner:TAICANG TIANLONG CHEM FIBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com