Patents

Literature

91results about How to "Improve the depth of staining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A method for improving the dyeing depth of cellulose fiber fabrics with chitosan

ActiveCN102268823AImprove accessibilityImprove responseDyeing processVegetal fibresEpoxyCooking & baking

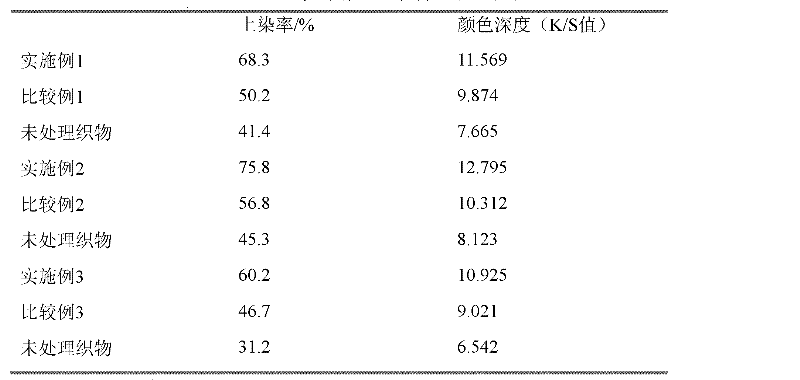

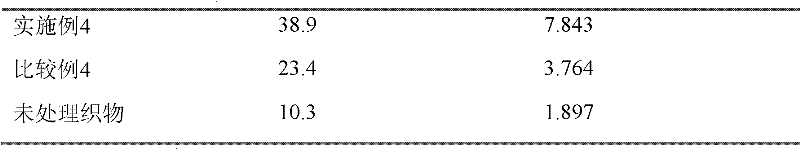

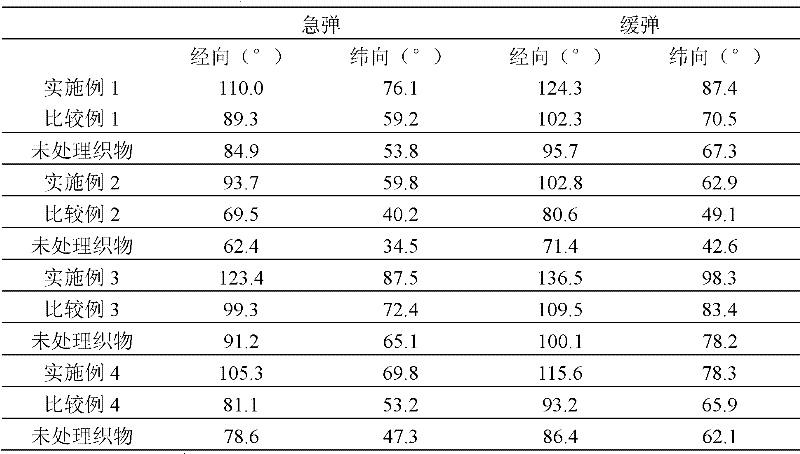

The invention relates to a method for improving the dye depth of cellulose fiber fabrics by using chitosan. In the method, a polycarboxylic acid solution is used as a solvent and a cross-linking agent of chitosan and epoxy chloropropane is used as a cross-linking agent, and chitosan is covalently grafted to the surface of the cellulose fiber fabrics through padding, preliminary drying and baking at a high temperature. The combining strength of chitosan and the cellulose fiber fabrics is increased greatly, the electrostatic repulsion between the cellulose fiber fabrics and anionic dyes is reduced, the dye-uptake of dyes and the color depth of the fabrics are improved obviously, and the crease resistance of the cellulose fiber fabrics processed by using the method is improved obviously.

Owner:CHANGZHOU UNIV

Vat dye dyeing method using supercritical CO2 fluid

The invention is applicable to the field of dyeing technologies, and provides a vat dye dyeing method using a supercritical CO2 fluid. The vat dye before a reduction reaction is dissolved by a supercritical CO2 fluid; polyester fiber, cellulosic fiber, protein fiber and fabric thereof are dyed; meanwhile, a cosolvent is added to improve the solubility of the vat dye in the supercritical CO2 fluid, the dyeing depth and the like; moreover, a natural fiber swelling agent is added for the vat dye to enter the fiber for dyeing, thereby greatly saving the water resources and realizing a perfect dyeing effect.

Owner:CHENGDU TEXTILE COLLEGE

Solubilizing and dyeing method of supercritical CO2 fluid disperse dye

The invention is applicable to the field of a dyeing process and provides a solubilizing and dyeing method of a supercritical CO2 fluid disperse dye. According to the solubilizing and dyeing method, supercritical CO2 fluid is used for dissolving a disperse dye; a solubilizing agent is added to dye a fiber textile; meanwhile, dyeing process conditions including pressure, temperature and time and the like are optimized, and the solubility, the dyeing depth and the like of the disperse dye in the supercritical CO2 fluid are improved.

Owner:CHENGDU TEXTILE COLLEGE

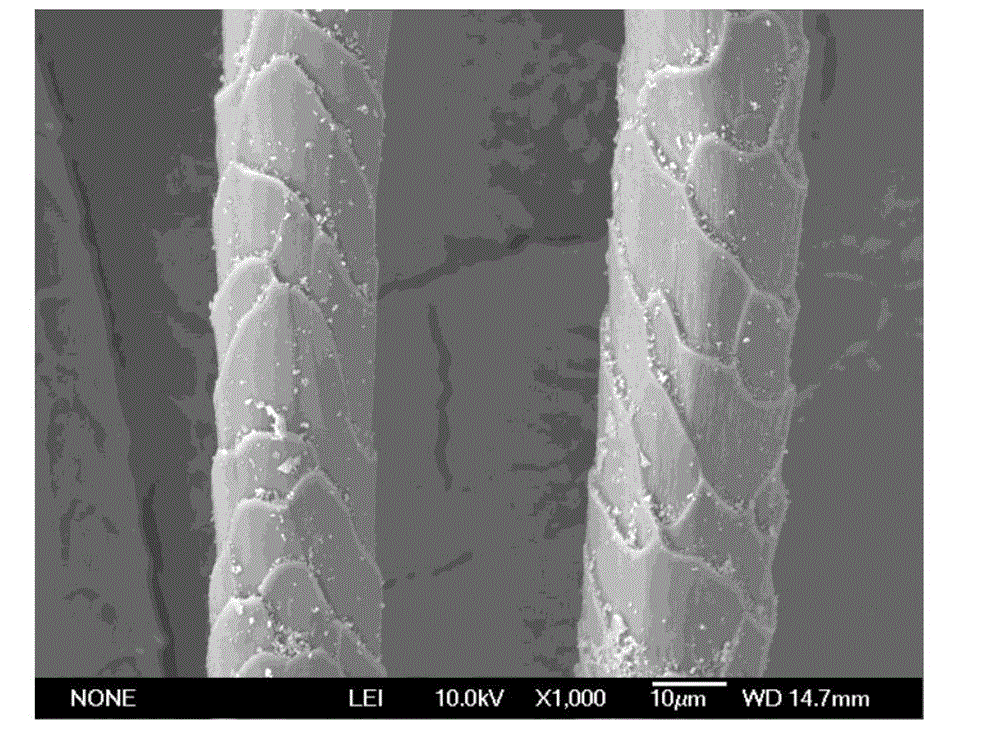

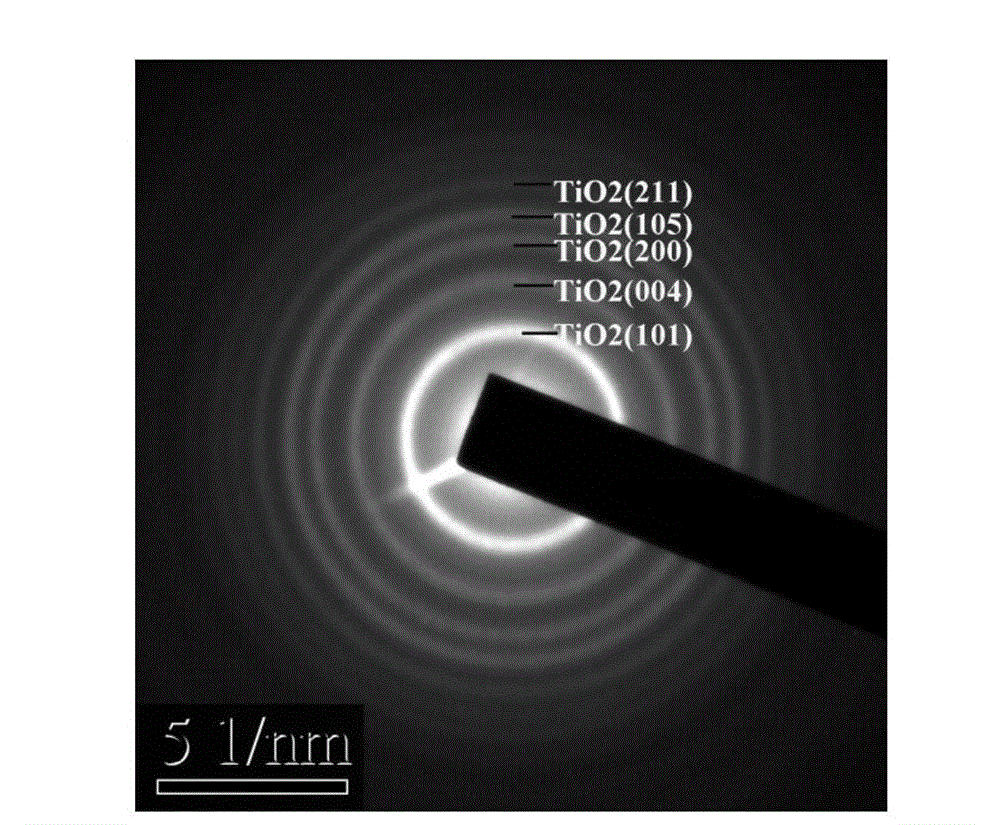

Method for modifying surfaces of wool fibers by using tetrabutyl titanate and chitosan

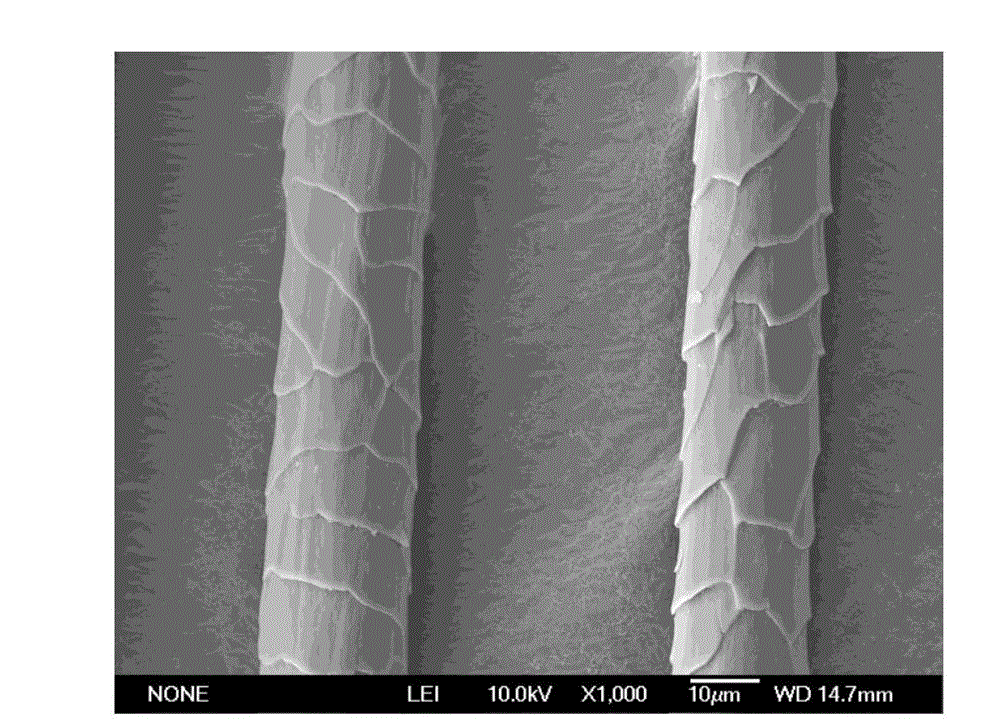

InactiveCN102912634ALittle strength damageSolve the problem of dyeingAnimal fibresPre treatmentWool fiber

The invention discloses a method for modifying surfaces of wool fibers by using tetrabutyl titanate and chitosan; and the method is implemented in the following steps of: (1) soaking wool fibers in a sodium carbonate solution; pretreating the wool fibers in the sodium carbonate solution; and washing and drying the pretreated wool fibers; (2) preparing a chitosan mixed solution with low molecular weight; (3) preparing a precursor solution; (4) adding the chitosan mixed solution with low molecular weight to the precursor solution, so as to prepare a modifying solution; and (5) carrying out aftertreatment on the modified wool fibers, so as to finish the modification of the wool fibers by using the tetrabutyl titanate and the chitosan. Nanometer titanium dioxide and chitosan films are directly loaded on the surfaces of the wool fibers; and problems of difficulty in heavy-shade dyeing, poorer antibacterial property, low color fastness to sunlight and easiness for felting shrinkage in the wool fibers obtained by the traditional modifying method are solved.

Owner:XI'AN POLYTECHNIC UNIVERSITY

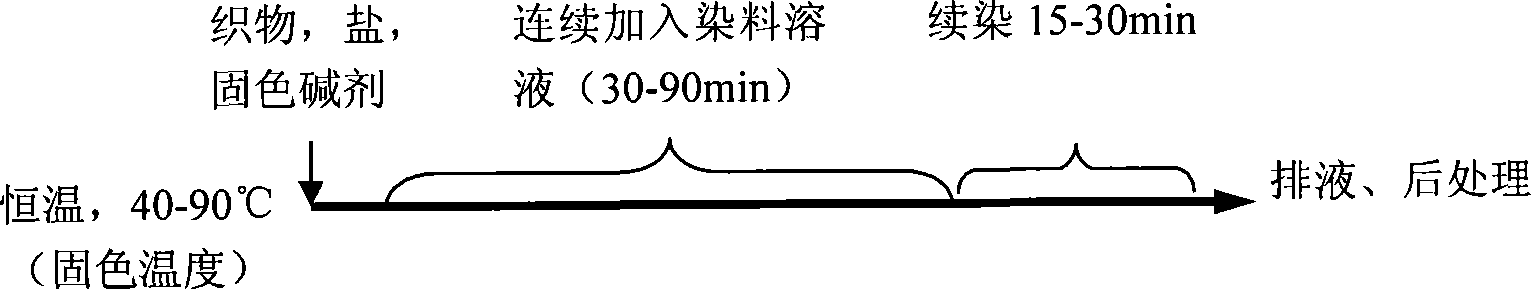

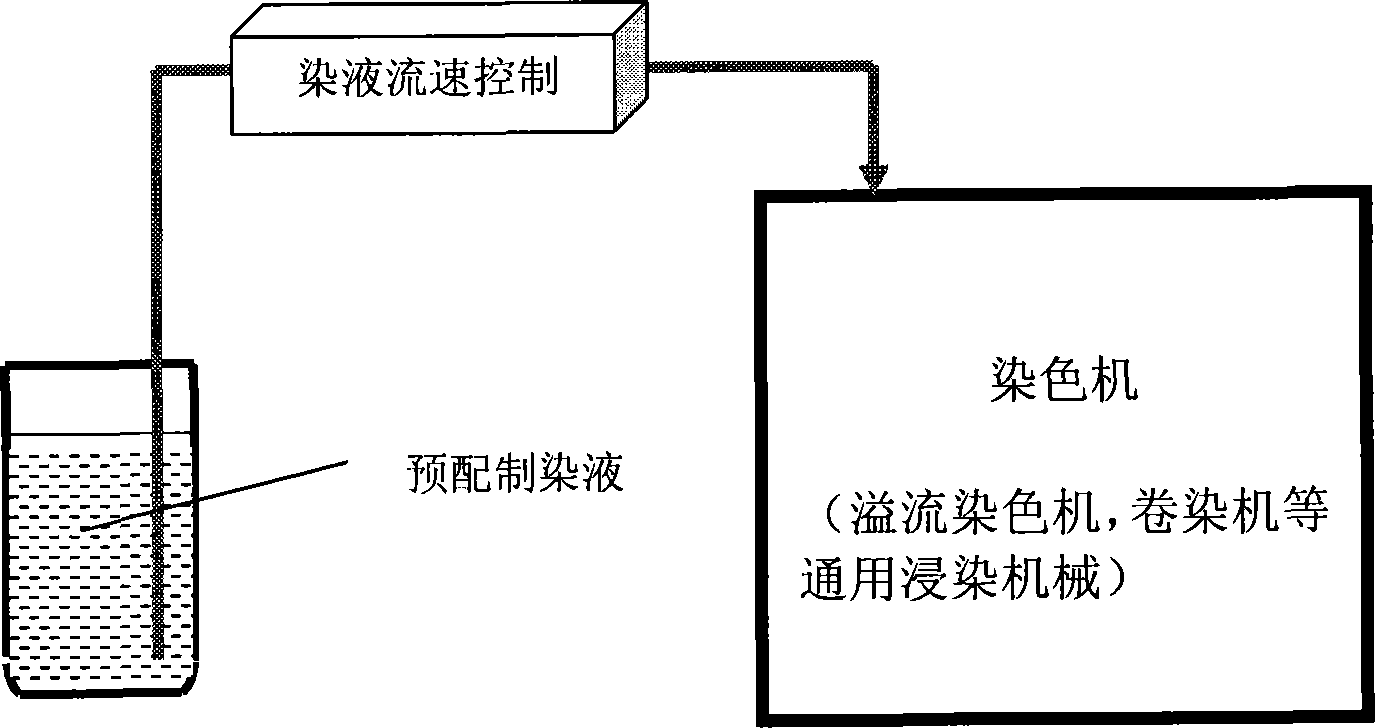

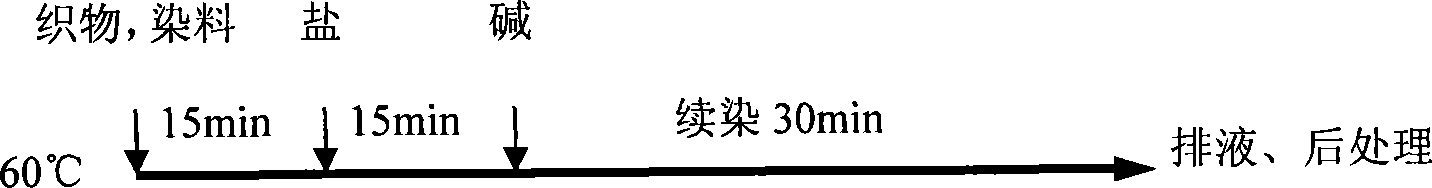

Dyeing method for improving reactive dye fabric tray dyeing color strength

The invention relates to a dyeing method for improving the dip-dye color depth of an active dye fabric, which includes: (1) when dyeing is started, adding the fabric, salt and a fixing agent, alkali, into a dye bath at the constant temperature of 40 to 90 DEG C to be operated for 10 to 30 minutes to lead the fabric to uniformly absorb the salt and alkali agent; (2) then using a continuous liquid adding device to add the dye slowly for 30 to 90 minutes, then continuously dying for 15 to 30 minutes; (3) after dyeing is finished, the fabric is washed by water, washed by soap, washed by water and then dried. The invention can acquire the color deeper than that of a normal technique, can remarkably save the dye, reduce the discharging of contaminations and is suitable for the developing direction of ecological energy-saving dyeing technique. The dyeing method is suitable for the dyeing of the fiber woven fabric and the knitting of fibrin such as cotton poplin, khaki and knitting, etc. The effect is extremely remarkable when dyeing a dark color.

Owner:DONGHUA UNIV

Precious wood imitating dyeing method

InactiveCN106078990AImprove reliabilityExtended permeation pathPressure wood treatmentWood treatment detailsPositive pressureSodium sulfate

The invention discloses a precious wood imitating dyeing method. The precious wood imitating dyeing method comprises the following technology steps that firstly, dye liquor is prepared, the dye liquor is prepared through three kinds of dyestuff including reactive red, reactive yellow and reactive blue according to the mass ratio of (2-3):(4-7):1, sodium chloride or sodium sulfate with the concentration of 5 g / L-40 g / L is added to serve as a dyeing accelerant, and sodium carbonate or ammonium chloride or propylene glycol with the concentration of 20 g / L-60 g / L is added to serve as a dye fixing agent; and secondly, impregnation dyeing is conducted, dyed wood is immersed in the dye liquor with the concentration of 0.5%-5% and the bath ratio of 1:(10-40) in a vacuum impregnation tank, dyeing is conducted in a negative pressure and positive pressure alternating manner, the dye liquor sufficiently seeps into the wood, and the surface, the inner portion and the outer portion of the dyed wood are uniform. The method has the beneficial effects that the wood treated through the provided precious wood imitating dyeing formula and the provided dyeing method is clear in texture, the total color difference between the wood color and the target wood color is smaller than or equal to 1.5 NBS, and permeability and color uniformity of the dyeing liquor are good.

Owner:梅州市汇胜木制品有限公司 +1

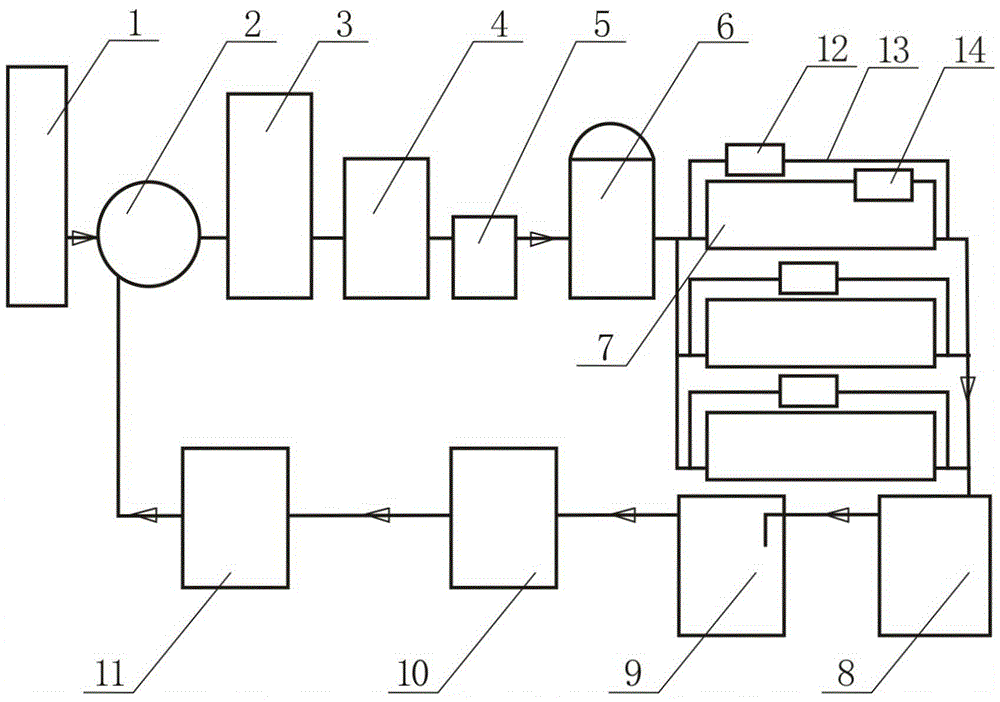

Supercritical CO2 waterless dyeing system and cloth dyeing method thereof

InactiveCN105297320AImprove permeabilityImprove solubilityTextile treatment containersSolvent treatment with solvent recoveryCirculating pumpCotton material

The invention discloses a supercritical CO2 waterless dyeing system and a cloth dyeing method thereof. The method comprises the following steps of A, preparing and storing of CO2; B, cooling; C, pressurizing; D, heating, wherein a heating device is utilized for enabling CO2 to form supercritical fluid, and the supercritical fluid is heated to 120-150 DEG C; E, dyeing, wherein a circulating pump pushes a mixture of the supercritical fluid and dye to circularly flow inside a circulation channel, cloths inside a pressure kettle are dyed, the pressure inside the pressure kettle is 28-30 MPA, the temperature is 120-150 DEG C, the circulation flowing time is 20-40 min, and the circulation flow is not smaller than 10 M<3> per hour; F, pressure relieving, wherein a nanoscale color masterbatch is dissolved through the supercritical CO2 fluid, the cloths are dyed, and dyeing technological conditions such as pressure, temperature and time are optimized at the same time so as to improve the dyeing efficiency and dyeing quality.

Owner:梁鼎天 +1

Method for promoting pigment dyeing by using cellulase

InactiveCN102505532AImprove dye uptakeImprove the depth of stainingBiochemical fibre treatmentDyeing processTextile printerAdhesive

The invention relates to a method for promoting pigment dyeing by using cellulase, belonging to the technical field of textile printing and dyeing. The method comprises the following steps of: (1) processing the cotton fabric with cellulase so that the cellulase is uniformly adsorbed on the cotton fabric; and taking out the fabric, rapidly centrifugally dewatering and drying the fabric; and (2) prompting the pigment dyeing by virtue of the cellulase adsorbed on the surface of the fabric; directly immersing the fabric in an anionic pigment dyeing solution; stirring and dyeing; after the dyeingis finished, adding an anionic adhesive for color fixation; and finally, taking out the fabric and dewatering, drying and baking the fabric. According to the invention, affinity of the anionic pigment with the cotton fabric is enhanced by using the cellulase; and the color depth of the fabric dyed with pigment can be improved without performing cationization pretreatment on the cotton fabric and environmental influence is little.

Owner:QINGDAO UNIV

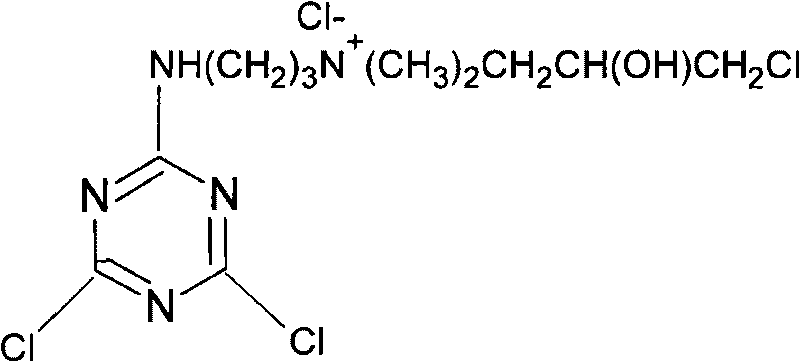

Modification method of cellulose fiber fabric and salt-free dyeing method

InactiveCN101760962AReduced charge repulsionHigh affinityDyeing processVegetal fibresSalt freeCellulose fiber

The invention relates to a modification method of a cellulose fiber fabric, which comprises the following steps: preparing stem grafting liquid, wherein the stem grafting liquid is based on total weight and contains 0.5-10 percent of 2-hydroxy-3-chloropropyl triazine ammonium chloride compound, 0.1-8 percent of sodium hydroxide, 0.1-1 percent of penetrating agents and water for allowance; placing the stem grafting liquid and fabric into a dyeing machine, operating for 60-200 minutes at a temperature of 40-70 DEG C and washing the fabric after temperature drop; or placing the stem grafting liquid and fabric into a padder to pad for 4-12 hours, wherein the padding ratio is 100 percent, and the dapping temperature is 20-40 DEG C; and washing the fabric after padding. The dyeing method of the modified fabric comprises the following steps: adding reactive dye liquor into the dyeing machine, wherein the dye liquor is based on the weight, contains no salt and has the bath ratio of 1:7-20; rising the temperature of the dye liquor to be 45-85 DEG C, adding 8-15 g of sodium carbonate for the dye liquor / liter, taking the fabric out after the heat is preserved for 45-50 minutes, washing the fabric with clean water and washing with washing liquid containing the sodium carbonate and washing powder, wherein the washing temperature is 60-85 DEG C, and the washing time is 10-30 minutes; and finally taking the machine out after the fabric is washed with clean water again.

Owner:JINQIU TEXTILE ARRANGEMENT +1

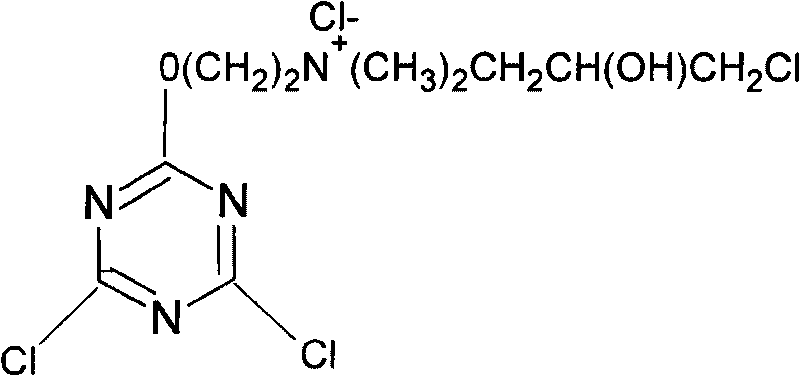

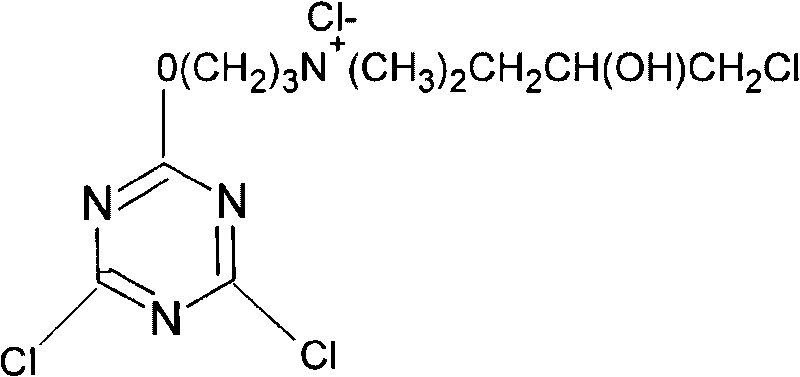

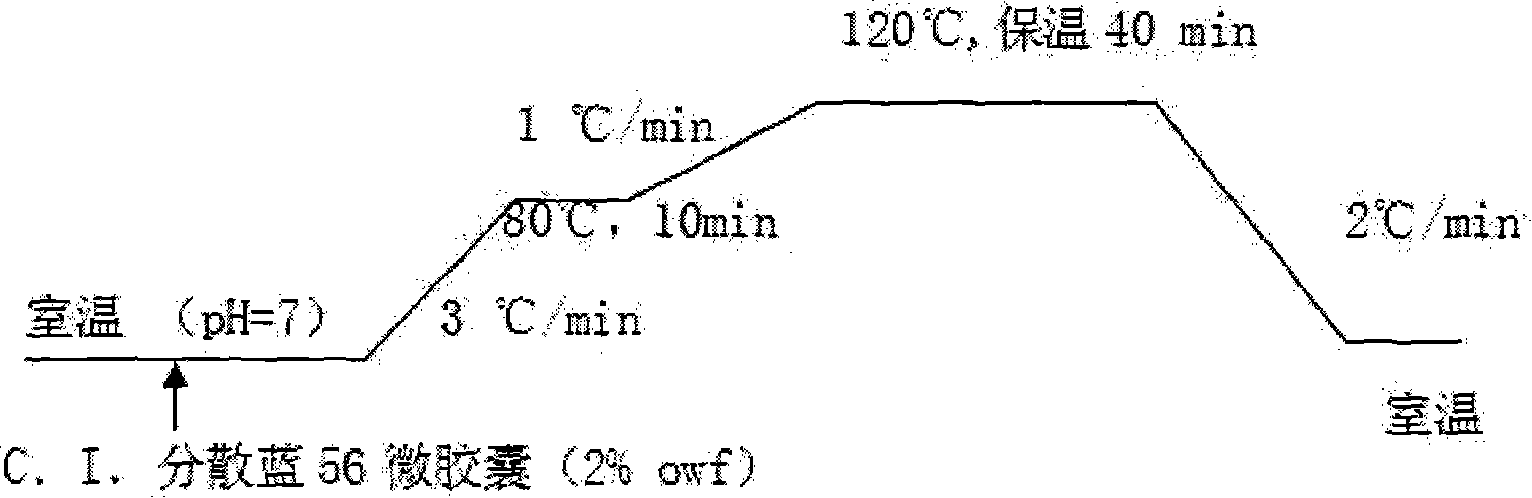

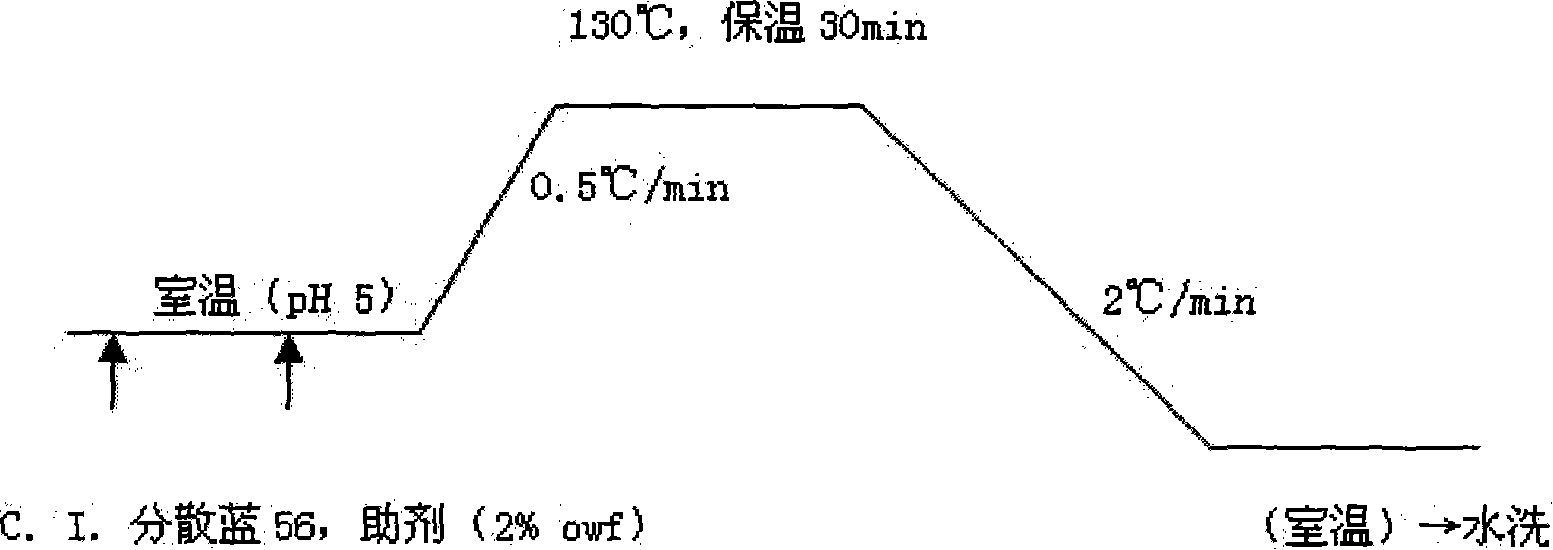

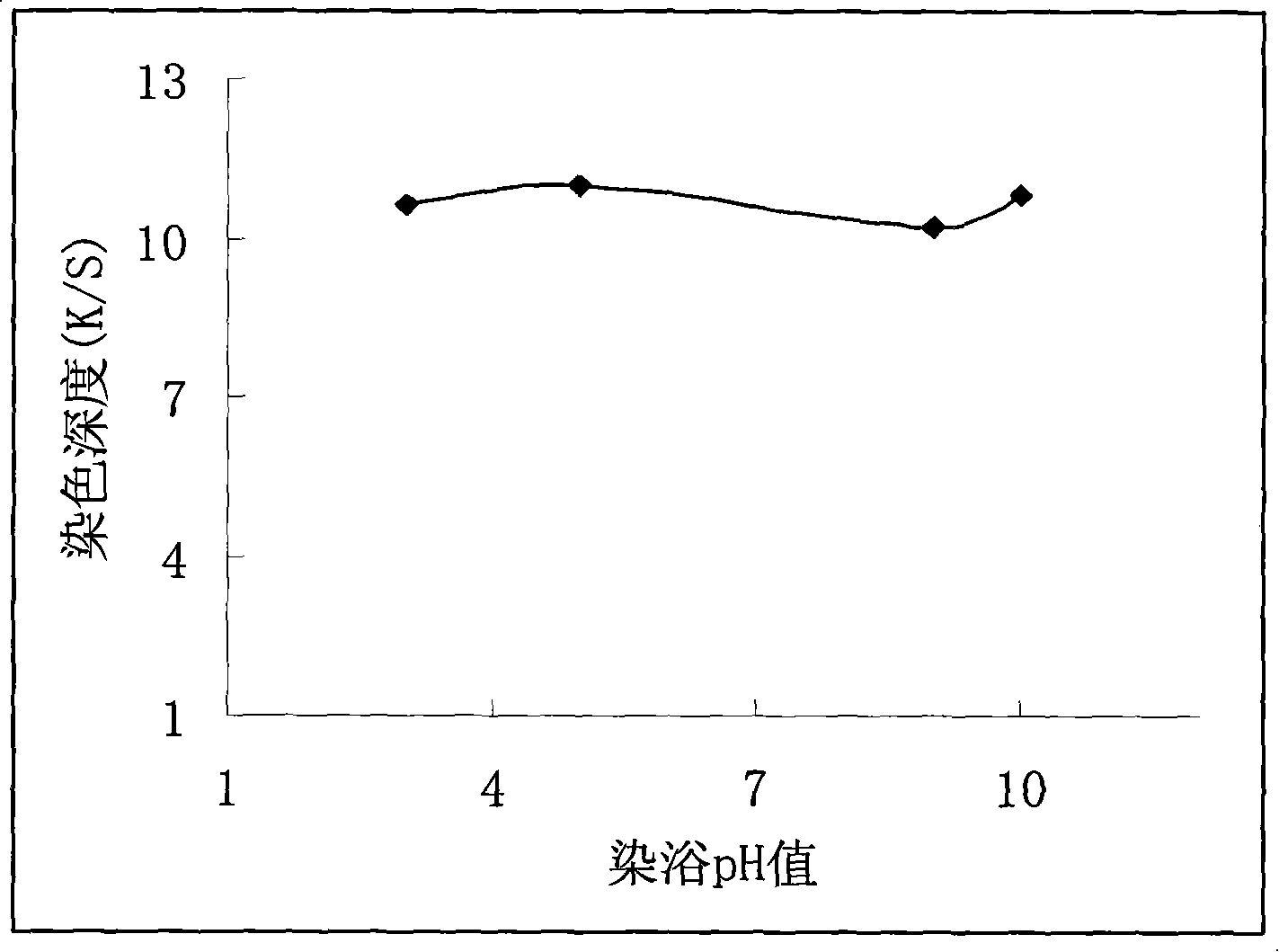

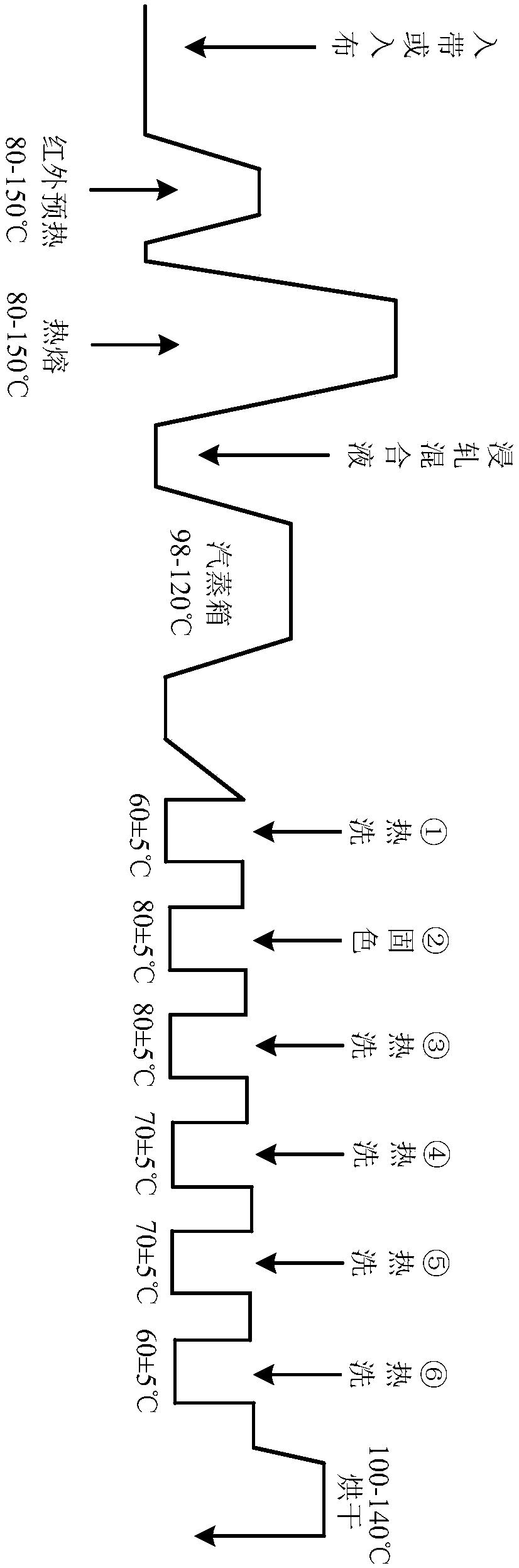

Microcapsule disperse dyeing process for superfine fibre synthetic leather

InactiveCN101200857AReduce chromaImprove the depth of stainingDyeing processDisperse dyeRoom temperature

The present invention discloses a dyeing process using disperse dye microcapsules for the superfine fiber synthetic leather. The dyeing process includes two steps: (1) C.I. disperse blue 56 dye microcapsules are 2 percent owf, liquor ratio is 1:30, pH is 3 to 10, the room temperature is raised to 80 DEG C to 100 DEG C at 0.5 to 3 DEG C / min, and the temperature is kept for ten to forty minutes; (2) The temperature is raised to 120 DEG C to 140 DEG C at 1 to 3 DEG C / min, after being kept for ten to seventy minutes, the temperature is decreased to the temperature is reduced to the room temperature at 1 to 2 DEG C / min, and the superfine fiber synthetic leather is dyed. Applicable to industrialized production, the method has the advantages of simple steps, good dyeing performance and less pollution.

Owner:DONGHUA UNIV

Preparation method of nylon 6 having high hygroscopicity, high dyeing property and high elasticity

InactiveCN102911366AIncrease elasticityIncrease the content of terminal amino groupsFiberPolymer science

The invention provides a preparation method of nylon 6 having high hygroscopicity, high dyeing property and high elasticity, The method is characterized by adding 50-85 parts of caprolactam, 5-8.5 parts of ring-opening agent, 0.3-6 parts of dicarboxylic acid blocking agent and 0.3-6 parts of composite amine modifier into to a reaction vessel; under the protection of nitrogen, preparing composite amine / polyamide performed polymer through ring opening, normal-pressure polymerization and reduced-pressure polymerization; adding polyether with same number of moles as the dicarboxylic acid blocking agent, preparing composite amine / polyether / polycaprolactam copolymer in the presence of a catalyst through normal-pressure polymerization and reduced-pressure polymerization; and extracting and drying to obtain the final product of nylon 6 with high hygroscopicity, high dyeing property and high elasticity. According to the invention, the method has simple process, production can be performed by using existing equipment, and nylon 6 not only has excellent physical and mechanical properties, but also has good spinnability, optical / thermal stability, elasticity, hygroscopicity and dyeing property, thus not only having enhanced dying depth and dying uniformity, but also being capable of being applied to chemical fiber, engineering plastics, membrane materials and the like.

Owner:TIANJIN POLYTECHNIC UNIV

Deep color dyeing and finishing technique of poly lactic acid (PLA) fiber and gossamer fiber blending fabrics

ActiveCN102864663AGuaranteed StrengthGuaranteed feelHeating/cooling textile fabricsDry-cleaning apparatus for textilesChemistryAfter treatment

A deep color dyeing and finishing technique of poly lactic acid (PLA) fiber and gossamer fiber blending fabrics comprises the following steps of greige cloth sewing, preliminary shaping, preliminary treatment, dyeing, fixation, dehydration and an after treatment process. The deep color dyeing and finishing technique of PLA fiber and gossamer fiber blending fabrics uses a dual-bathing method to dye. A mesotherm type disperse dye is used for dyeing (enabling color to be deep) PLA fibers, and a carrier is added during dyeing. An environment-friendly mesotherm direct dye is used for dyeing (enabling color to be deep) gossamer fibers, fixation treatment is carried out after dyeing, fibers with two components can be dyed into a deep color simultaneously, and strength and feeling of the PLA fibers and the gossamer fibers are guaranteed.

Owner:ZHEJIANG DANENG TEXTILE PRINTING & DYEING

Method for improving degree of exhaustion during wood dyeing

InactiveCN105643745AIncrease polarityImprove solubilityPressure wood treatmentWood treatment detailsAcetone / EthanolSupercritical fluid extraction

The invention discloses a method for improving the degree of exhaustion during wood dyeing and belongs to the technical field of wood dyeing. The method specifically comprises the following steps: adjusting the moisture content of wood to be 50-100%, carrying out supercritical CO2 fluid extraction by adopting a mixed solution containing acetone, ethanol and one or more fatty alkyl tertiary amines as an entrainer, and then carrying out pressure relief at a rate of 1.0-10.0 MPa / min to obtain pretreated wood; soaking the pretreated wood in a mixed solution containing one or more active dye liquids and sodium sulfate to obtain dyed wood; and conducting fixation and soaping on the dyed wood. The method is simple in process, and has the advantages that not only can the degrees of exhaustion and fixation of an active dye in wood be improved, but also the dyeing depth can be improved.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

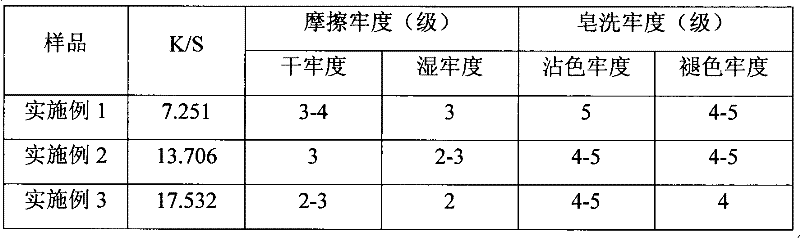

Method for increasing dyeing depth of para-aramid fibers and fabrics

The invention discloses a method for increasing the dyeing depth of para-aramid fibers and fabrics. A mechanical method is utilized to pretreat para-aramid, so that the fiber surfaces of the para-aramid are roughened, or regulated by a processing process, the internal structures of fibers are improved, so that the surface density of the fibers is decreased, and thereby a fibrillated or air hole-like structure is formed; after pretreatment agent is applied to carry out surface deoiling treatment on the treated para-aramid, screened dye is adopted, a high-temperature and high-pressure dyeing process is adopted, a dyeing auxiliary which is prepared from dyeing carrier, surfactant, electrolyte and the like is added in the process of dyeing to dye the para-aramid 1414 fibers and fabric, and after flood removal, washing and drying, required color and dyeing depth can be achieved. When the dyeing method disclosed by the invention is applied to dye para-aramid 1414 fibers and fabric, the degree of dyeing reaches more than 80 percent, the color depth value K / S can reach more than 16, the color fastness to rubbing of dyeing reaches level 3-4, and the color fastness to staining reaches level 4-5. After the process of dyeing the para-aramid 1414 fibers and fabric, the strength drop is less than 15 percent.

Owner:SINOPEC YIZHENG CHEM FIBER +1

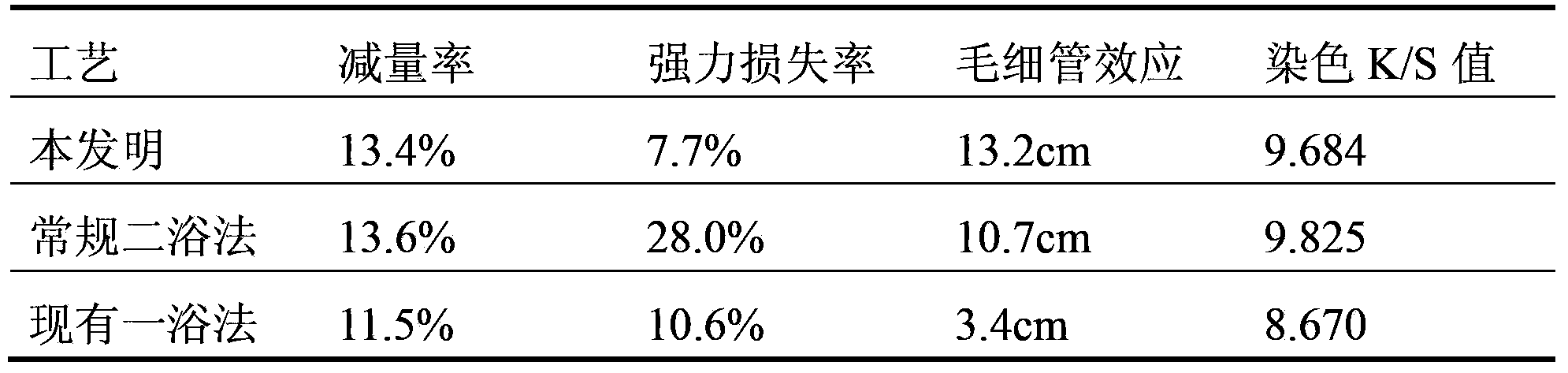

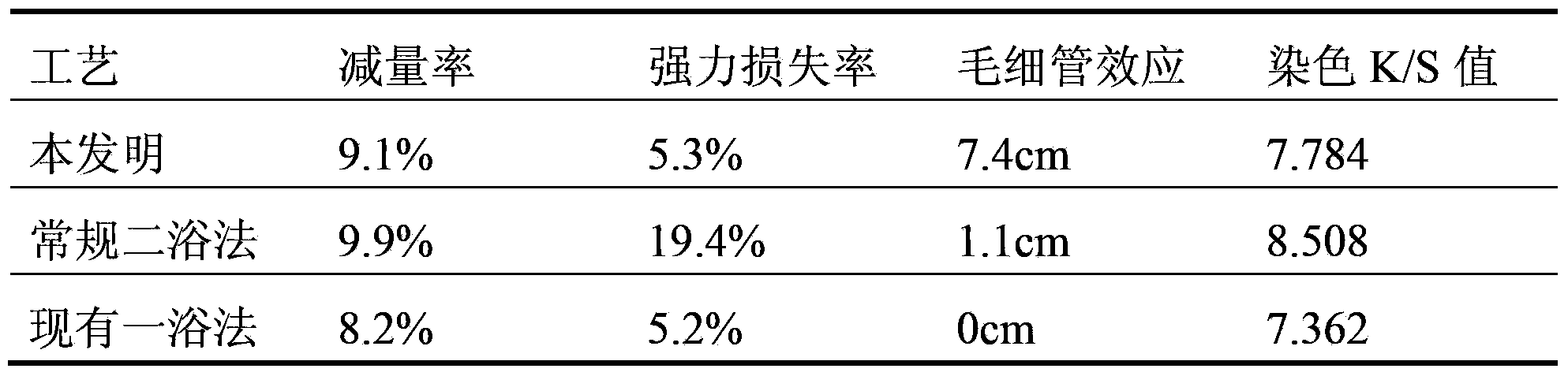

Technique for promoting dye permeability and depth of active dye

ActiveCN108103694AIncrease penetration timeAvoid the problem that it is not easy to penetrate into the fiberLiquid/gas/vapor removalTextile storageTextile printerFiber

The invention belongs to the technical field of textile printing and dyeing, and particularly relates to a technique for promoting dye permeability and depth of active dye. The dyeing processing flowis pretreatment fabric->dye padding->piling->first drying->padding with fixation fluid->gas steaming-> high temperature soaping->second drying-> post finishing; the piling temperature is 20-26 DEG C and the piling time is 4-10 hours. The method can increase the permeation time of the dye in the inner part of the fabric, avoid the problems that the continuous dyeing padding time is short and the dye is directly dried after dyeing and the dye is not easy to permeate to the inner part of fiber, avoid the problems of too early fixation of dye and fiber due to the mixing of the cold rolling dye andthe fixation fluid and the dye permeability effect of the active dye goes bad, and promote the permeability of dye; the dye can be fully dissolved and absorbed and spread to the fiber; the techniqueis good for the reaction of dye and fiber in the subsequent fixation, and able to improve the dyeing rate and the utilization rate of the dye; through contrast, the dyeing depth can be promoted by about 15%, and the dyeing cost is greatly reduced.

Owner:鲁丰织染有限公司

Method for increasing dyeing depth of cochineal of cotton fabric

ActiveCN108625197AImprove modification efficiencyImprove the depth of stainingDyeing processChemistryAmmonium

The invention discloses a method for increasing a dyeing depth of cochineal of a cotton fabric and in particular relates to a method for modifying a cotton fabric by using a biquaternary ammonium saltcation modifier to further increase a dyeing depth of cochineal of the cotton fabric. After being modified by using the biquaternary ammonium salt cation modifier, the cotton fabric is grafted with abiquaternary ammonium salt, the modified cotton fabric is dyed with cochineal, and then the dyeing depth of the cochineal in the cotton fabric is increased. By adopting the modification method, a newway is provided for solving the problem that a cotton fabric cannot be dyed with cochineal, meanwhile a new idea is provided for dyeing cotton fabrics with natural dyes, and the method has very wideapplication prospects.

Owner:SHAOXING JIANG HUA CHEM

Production method of ultra-black wool worsted fabric

InactiveCN108060497AHigh blacknessAdd depthSucessive textile treatmentsWoven fabricsPolyesterWorsted

The invention discloses a production method of ultra-black wool worsted fabric. According to the method, wool tops after wool mercerizing shrink-proof treatment are selected as raw materials, and theraw materials are successively subjected to dyeing, back washing, secondary dyeing, sliver mixing, carding, combing, re-combing, roving, spun yarns, cabling tube, yarn steaming, weaving, wet finishing, dry finishing and functional colour-increased finishing to prepare finished products. Wool and polyester fibers are all treated with secondary dyeing to increase the color thickness after dyeing, and auxiliaries are used for processing to increase blackness and color depth of the fabric; secondly, wool fibers and the polyester fibers are subjected to the back washing after top dyeing, secondarydyeing is conducted again, and dye-uptake of dye and the color depth are further increased; meanwhile warps and wefts of the fabric are made by the secondarily dyed wool which is treated with the re-combing and spinning later, so that the color depth and apparent depth of the black worsted fabric produced are greatly deepened; finally, an intensifier deep agent and a penetrating agent are used forfurther processing in a soft padding groove during a finishing process, thereby further improving the dyeing depth of the wool fabric.

Owner:兰州三毛实业有限公司

Dyeing process of reactive dye

The invention belongs to the technical field of dyeing processes and particularly provides a dyeing process of a reactive dye. The dyeing process of the reactive dye comprises the following steps of 1 pretreatment including water washing and acid pickling, 2 dyeing, 3 accelerating through salting, 4 fixation through calcined soda adding and 5 aftertreatment including two-time soap boiling, water washing and drying. The dyeing process of the reactive dye is simple in operation, even in dyeing and quick in dyeing and coloring, and an M-type dye can have higher dye-uptake rate and fixation rate, dyeing depth is better, water washing times are decreased, water resources are saved, production cost is reduced, and dyeing efficiency is improved.

Owner:JIANGSU SHUANGYING TEXTILE TECH

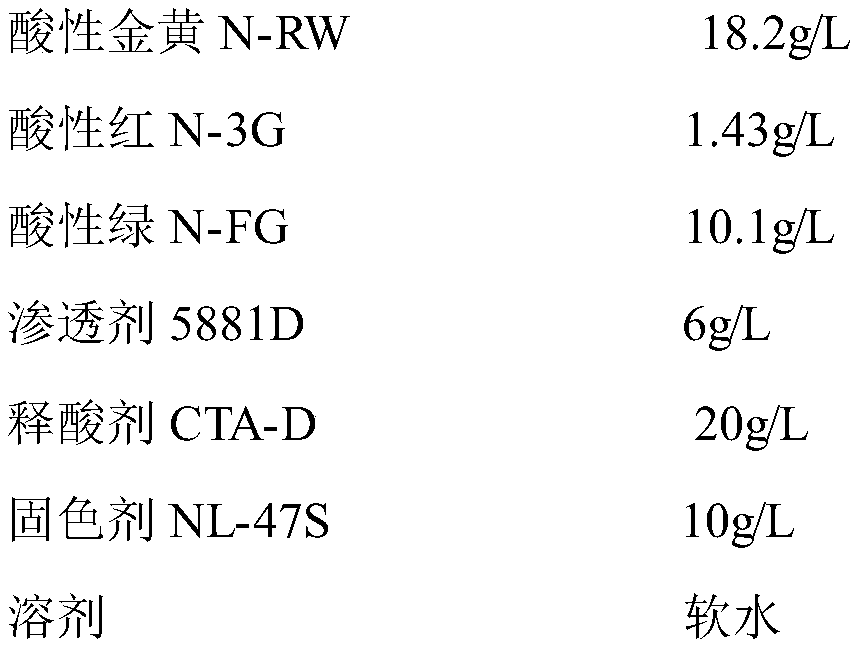

Acid dye continuous pad dyeing method for polyamide woven tapes

The invention discloses an acid dye continuous pad dyeing method for polyamide woven tapes. The acid dye continuous pad dyeing method sequentially includes steps of 1, pretreating the polyamide woventapes; 2, drying the polyamide woven tapes by infrared rays or hot air; 3, simultaneously carrying out pad dyeing by acid dye liquor and color fixing agents; 4, carrying out steaming dyeing and primary color fixing treatment; 5, carrying out hot washing; 6, carrying out secondary color fixing treatment; 7, carrying out hot washing; 8 carrying out drying; 9, dropping tapes. The acid dye continuouspad dyeing method has the advantages that the polyamide woven tapes have bright colors by the aid of acid dye steaming processes and color fixing one-bath dyeing schemes, the dye depths of the polyamide woven tapes can be effectively increased, the acid dye continuous pad dyeing method is good in deep dyeing property in polyamide woven tape dyeing procedures, and the polyamide woven tapes can be dyed with rich dark colors by the aid of the acid dye continuous pad dyeing method; pad dyeing is carried out on the polyamide woven tapes by acid dye, combined effects can be realized by an early color fixing scheme and a late color fixing scheme, the dye and the woven tapes are firmly combined with one another by chemical bonds, and the problem of poor color fastness of existing polyamide woven tapes after burning-preventive finishing is carried out on the existing polyamide woven tapes can be effectively solved by the aid of the acid dye continuous pad dyeing method.

Owner:CHENGDU HAIRONG TECHNICAL TEXTILES CO LTD

Strip dyeing method for corn fibers

The invention relates to a strip dyeing method for corn fibers. The method comprises the following processes of: 1, dyeing, namely filling the corn fiber strips into a dye vat, rotating the dye vat, adding polyol ester liquid into the dye vat, rotating the dye vat, adding a carrier, namely polyolefin elastomer (POE) liquid, into the dye vat, rotating the dye vat, adding univadine diiodofluorescein (DIF) into the dye vat, rotating the dye vat, adding univadine DPS into the dye vat, rotating the dye vat for minutes, adding a disperse dye, namely Terasil sulfadiazine (SD), into the dye vat, rotating the dye vat, starting to raise the temperature to 70+ / -2 DEG C at the temperature rise speed of 1.5 to 2 DEG C per minute, raising the temperature to 90+ / -2 DEG C by keeping the temperature rise speed at 1 DEG C per minute, keeping the temperature for 10 seconds, raising the temperature to 110+ / -2 DEG C at the temperature rise speed of 1 DEG C per minute, keeping the temperature for 20 to 30 minutes, lowering the temperature to 50+ / -2 DEG C at the temperature descent speed of 2 DEG C per minute, and discharging the liquid; and 2, performing post treatment, namely adding the dyed corn fiber into the dye vat, adding soaping liquid 209, sodium bicarbonate and sodium hydrosulfite into the dye vat, raising the temperature to between 60 and 65 DEG C, keeping the temperature for 15 to 20 minutes, and discharging the liquid. The homochromatism, the dyeing uniformity and the stability of dyeing are improved by the method; the dyeing effect is good; and the color fastness is good. The injury to the fibers in the dyeing process is low.

Owner:HEILAN HOME

Treating agent for facilitating dyeing of wicker weaving products

InactiveCN106217564AKeep for a long timeExtension of timeWood treatment detailsReed/straw treatmentPentaerythritolSodium ascorbate

The invention discloses a treating agent for facilitating dyeing of wicker weaving products. The treating agent comprises the following components of furfuryl alcohol, corn stigma boiling liquid, borax, urea, pink soak liquid, sodium ascorbate, pentaerythritol, water and an additive. Compared with a current wicker weaving product treating agent, the treating agent provided by the invention is simple in preparation method; a treatment method after preparation is simple; the dyeing ability of treated wicker weaving products is greatly improved, so that surface permeability and colourability of dye for wicker are greatly improved, and the dye can uniformly and rapidly enter the surface of the wicker; the average time for coloring and color fixing is shortened by 20% compared with that of untreated wicker products; the color fastness is good after dyeing; color is uniform; stability is high; and color fading cannot occur.

Owner:安徽阜南县万家和工艺品有限公司

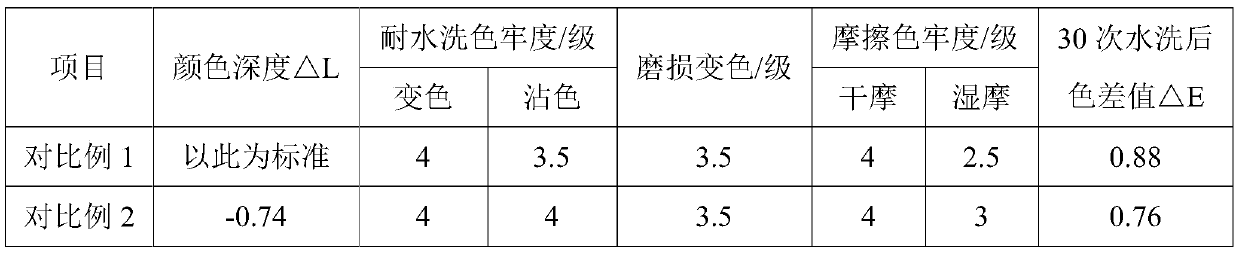

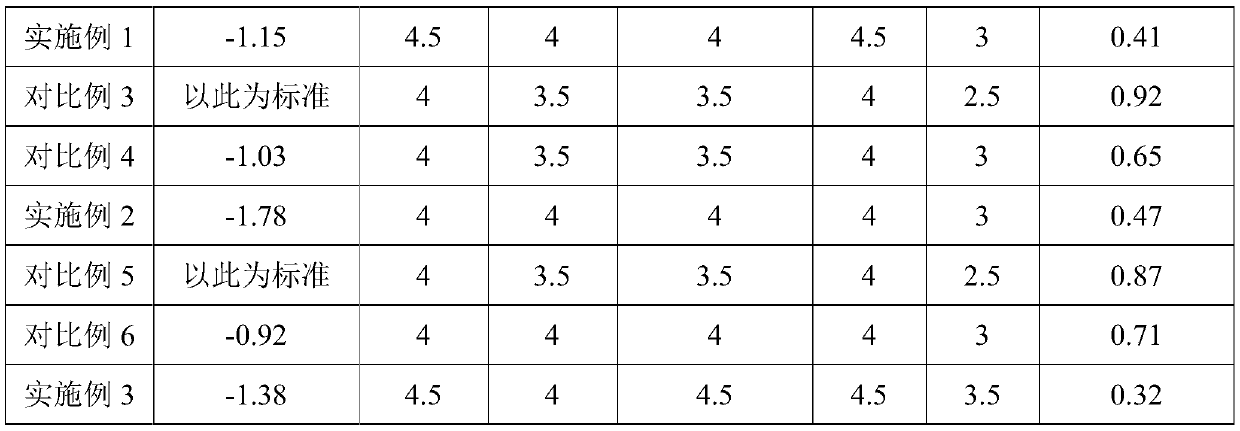

Method for improving active dyeing depth of pure cotton fabric

InactiveCN110952347AFull penetrationAdd depthTextile storage in wounded formLiquid/gas/vapor removalTextile printerPolymer science

The invention relates to the technical field of textile printing and dyeing, in particular to a method for improving active dyeing depth of a pure cotton fabric. According to the method for improvingthe active dyeing depth of the pure cotton fabric, the pure cotton fabric is dyed by the process of pressing, rolling and stacking, drying, steaming and color fixing, wherein the steaming and color fixing process comprises the steps of padding and color liquid fixing, steaming, water washing and soaping. According to the method for improving the active dyeing depth of the pure cotton fabric, the problem that the color quantity is low in continuous rolling dyeing is solved, the dyeing depth of the printed and dyed fabric can be improved by 25% or above on the original basis, the washable colorfastness of the dyeing fabric reaches 4 grade or above, the abrasion color change can reach 4 grade or above, the dry friction color fastness reaches 4 grade or above, the wet friction color fastnessreaches 3 grade or above, and the color change delta E after 30 times of water washing is within 0.5.

Owner:鲁丰织染有限公司

One-bath and one-step gelation crystallization dyeing method for ultrahigh strength and high-modulus polyethylene fibers

The invention discloses one-bath and one-step gelation crystallization dyeing method for ultrahigh strength and high-modulus polyethylene fibers. The method directly selects and introduces a planar molecular structure dye with specific size into a gel original liquid. By adding a certain phase inversion agent and at the same time, applying a programmed temperature phase inversion, preparation of the original liquid is realized by combining and cooperating the dye and gelation in the one bath and one step, thereby reducing adverse influences brought by a lot of tedious processes and a lot of auxiliary agents in a conventional method. With the dyeing method provided by the invention, the utilization rate of the dye can be increased greatly. The mesomorphic dye planar molecular effects can promote formation and orientation stability of a PE chain condensed submicroscopic nano-micron fiber scale lamellar crystal phase, and can improve and increase gelation spinning performance of colored ultrahigh strength and high-modulus UHMWPE. The method is environment-friendly and can save energy.

Owner:JIANGSU JONNYMA NEW MATERIALS CO TLD

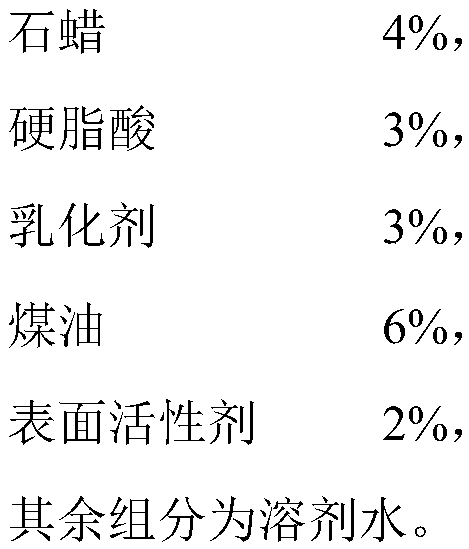

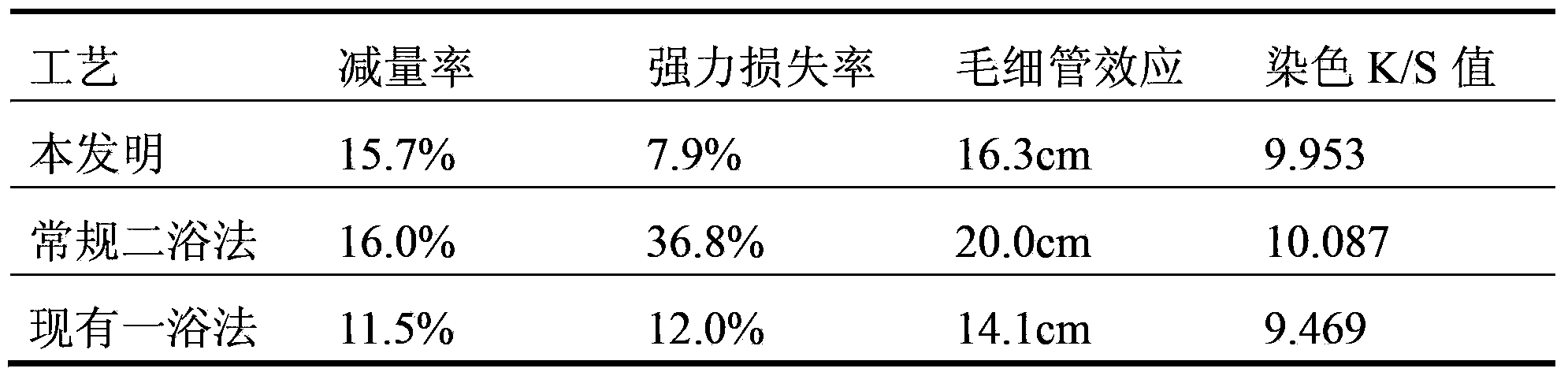

Terylene deweighting dyeing assistant, and preparation method and use thereof

ActiveCN104120609AEmission reductionGuaranteed polyester dyeing effectDyeing processAlkanePollutant emissions

The invention discloses a terylene deweighting dyeing assistant, and a preparation method and a use thereof. A raw material formula of the terylene deweighting dyeing assistant comprises, by mass, 10-15% of ethylene glycol monobutyl ether, 10-15% of 1,4-butanolide, 10-20% of fatty alcohol polyoxyethylene ether, 10-20% of secondary alkane sulphonate, and the balance water, wherein the molecular formula of the fatty alcohol polyoxyethylene ether is RO-(CH2CH2O)n-H, n is 7-9 or 15-20, and R is a C12-18 alkyl group; and the molecular formula of the secondary alkane sulphonate is R'SO3Na, and R' is a C10-13 alkyl group. The terylene deweighting dyeing assistant guarantees the terylene dyeing effect and the silk like effect and adopts a one-bath technology; and compared with traditional technologies, the technology has the advantages of saving of a lot of time, energy and substances, and great reduction of the pollutant emission.

Owner:QINGYUAN RUIHUA ADDITIVES CO LTD

Method for preparing multifunctional polymer-based nanometer ZnO composite tanning agent

InactiveCN103074455AEasy to prepareImprove stabilityTanning treatmentZinc Acetate DihydratePolymer chemistry

A method for preparing a multifunctional polymer-based nanometer ZnO composite tanning agent is characterized by comprising the following steps: preparing modified ZnO soils by taking zinc acetate as a nanometer particle precursor and diallyldimethylammonium chloride as a modifying agent, and preparing a polymer-based nanometer ZnO composite tanning agent for a leather retanning procedure through a soil-in-situ polymerization method. Through adoption of the method, nanometer ZnO is uniformly dispersed in a polymeric matrix, so that the stability of the polymer-based nanometer ZnO composite tanning agent is improved. When the method is applied to the leather retanning procedure, the dyeing depth of the leather can be greatly increased so that the K / S value of the dyed leather is increased by 98.26 %, the fullness of the leather is improved so that the tanned leather is thickened by 20.88 %, and the leather is endowed with good antibacterial property and aging resistance.

Owner:SHAANXI UNIV OF SCI & TECH

Leather processing agent

InactiveCN110331238AStir wellGood detailsTanning treatmentLeather surface finishingHigh resistanceRapeseed

The invention discloses a leather processing agent. The leather processing agent comprises, by weight, 25-35% of sodium polyacrylate, 1-4% of an emulsifier, 1-4% of sodium tripolyphosphate, 1-4% of asilver loaded product, 1-4% of nano titanium dioxide, 5-15% of modified rapeseed oil, 15-25% of an amphoteric acrylic acid retanning agent, and 25-35% of water. The leather processing agent is used inthe fields of textile industry, leather or furry product industry, is capable of providing leather with antibacterial performance, mildew resistance, tightness, uniform dyeing degree, high dye uptake, high solvent resistance, and high grease resistance, so that using requirements can be satisfied.

Owner:中山市汇流化工科技有限公司

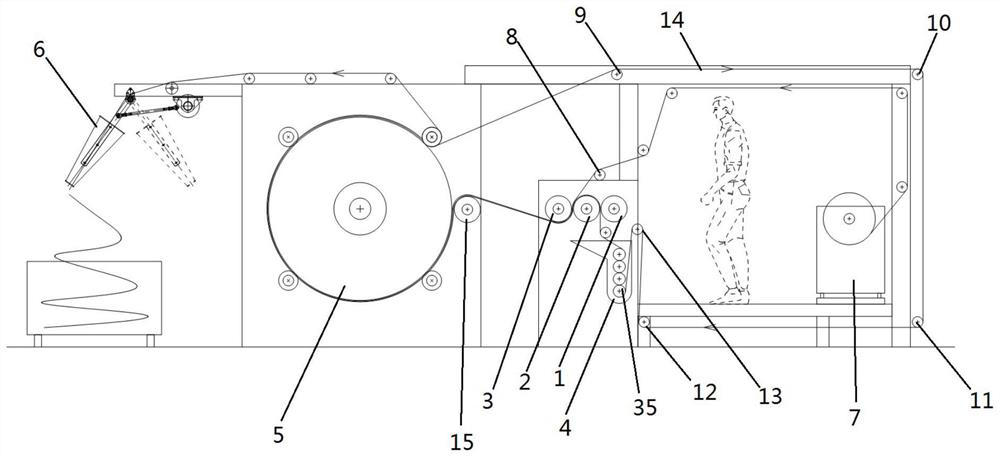

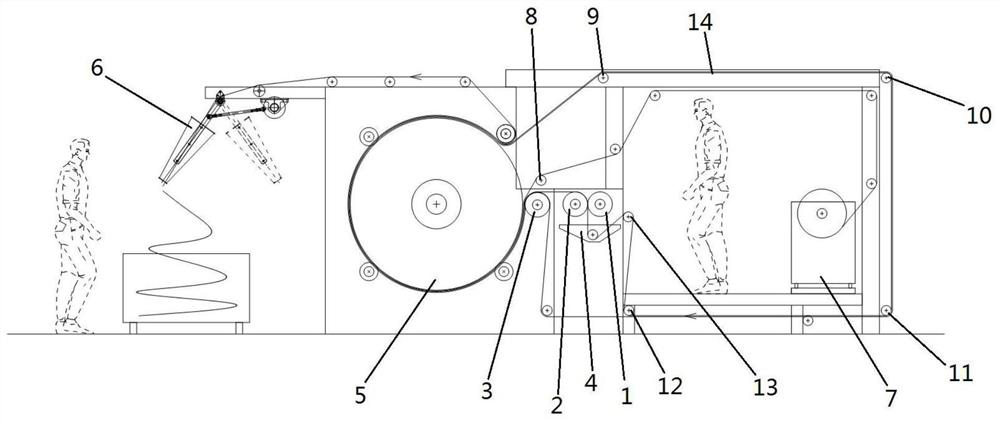

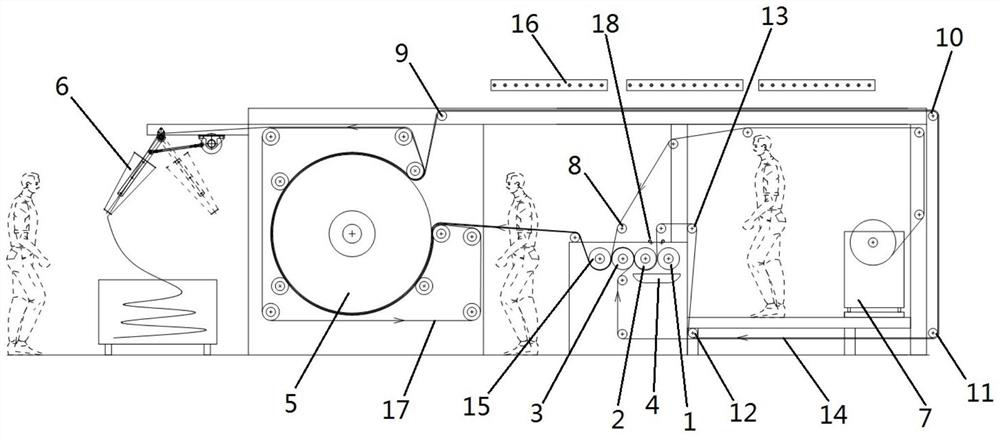

Multi-layer multi-time continuous rolling ageing dyeing mechanism and method

PendingCN111778666APromote migrationReduce liquid volumeSucessive textile treatmentsLiquid/gas/vapor removal by squeezing rollersMechanical engineeringContinuous rolling

The embodiment of the invention discloses a multi-layer multi-time continuous rolling ageing dyeing mechanism and a multi-layer multi-time continuous rolling ageing dyeing method, which are used for solving the technical problem that the liquid carrying amount of rolled cloth is too high in the existing rolling mode for cloth dyeing. The dyeing mechanism comprises a rolling device and a cloth guide wheel device. The rolling device at least comprises a first roller, a second roller and a third roller; the cloth guide wheel device at least comprises a first cloth guide wheel, a second cloth guide wheel, a third cloth guide wheel, a fourth cloth guide wheel, a fifth cloth guide wheel and a sixth cloth guide wheel; the moving track of the cloth is an irregular involute-shaped track; a cloth feeding device is located at the starting end of the involute-shaped track. A finished product collecting device is arranged at the tail end of the involute-shaped track, rolling points between the rollers are distributed on the involute-shaped track at intervals, the cloth guide wheels are distributed on the involute-shaped track at intervals, and the moving tracks of the cloth passing through a first heating device multiple times are arranged at intervals and are in a stacked shape.

Owner:李雅

Dyeing technique for dyeing processing yarn of activated dye for silk plied yarn

InactiveCN106120387AImprove protectionHigh coloring rateDry-cleaning apparatus for textilesBiochemical treatment with enzymes/microorganismsYarnDark color

The invention discloses a dyeing process of a dyeing process line of reactive dyes for silk strands, which is characterized in that it comprises the following steps: injecting water to increase temperature, adding a refining agent, pressurizing and increasing temperature, continuous refining, reducing pressure and draining liquid, washing with water, Dyeing, the present invention adopts the above process scheme, so that the coloring rate reaches more than 95%, the color fastness reaches more than 4 grades, and can dye very deep colors; the dyeing cycle is shortened by 30% compared with normal temperature skein dyeing, and the amount of dyed products is increased. more than 5 times, so the dyeing efficiency is greatly improved, and the bath ratio is only 1 / 2 of the original, which can save water and reduce the discharge of tail liquid; The removal speed is faster and the efficiency is higher. The raw silk degumming of the outer layer and the core of the whole silk strand is uniform and clean, so that the dye is easy to dye through the silk strand, and the coloring is uniform without white core, and the dyeing effect is good.

Owner:DONGTAI SUMENG KNITTING FASHION

Preparation method of silk peptide finishing agent for cotton fabric

InactiveCN106758208AImprove the depth of stainingGood flexibilityAnimal fibresFiltration membraneBlack tea

The invention provides a preparation method of a silk peptide finishing agent for a cotton fabric. The preparation method comprises the following steps: cleaning silks, then adding the cleaned silks into a dilute sulfuric acid solution, performing hydrolysis reaction, adding calcium chloride and sodium tartrate, regulating a pH value of the solution to 6 to 7, stirring, filtering, guiding a primary filter solution into a micro-filtration membrane to be filtered, and decompressing and concentrating the filtrate to obtain silk peptides; and finally adding the silk peptides, low-molecular-weight chitosan, citric acid, sodium hypophosphite, amino silicon oil and coconut oil fatty acid diethanol amide into deionized water, regulating the pH to 6 to 7, dispersing, thus obtaining the silk peptide finishing agent. By adopting the silk peptide finishing agent of the invention, the dyeing depth of three natural dyes, namely, black tea, logwood and Artemisia argyi for the cotton fabric can be improved, the soaping and friction fastness of the dyed fabric are slightly decreased, the strength is slightly decreased, the whiteness is maintained unchanged, and the softness is improved compared with that before the finishing.

Owner:JIANGSU AIXISHI TECH SERVICE CONSULTATION CO LTD

Dyeing process of wool fabric

The invention relates to a dyeing process of a wool fabric. The dyeing process comprises the steps such as preparing a dye mixed solution, dyeing by immersion bath, washing and drying. According to the dyeing process, an ionic liquid is used to gradually dissolve keratin on the surface of wool fiber under heating conditions to destroy a scale layer, a negative pressure and positive pressure interaction dyeing method improves penetration of the dyeing solution inside the wool fiber, so that the dyeing solution fully penetrates into the wool fiber to make the dyed wool fabric uniform inside andoutside, and the dyeing process can effectively improve the dyeing depth of the wool fabric. The dye mixed solution is heated to 30 to 90 DEG C, so that when the dyeing solution penetrates into the wool fabric, dye agent molecules have high activity so as to achieve a faster penetration speed and improve dyeing effect and efficiency.

Owner:JIANGYIN XINGWU WOOL FABRIC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com