Patents

Literature

225results about How to "Guaranteed feel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

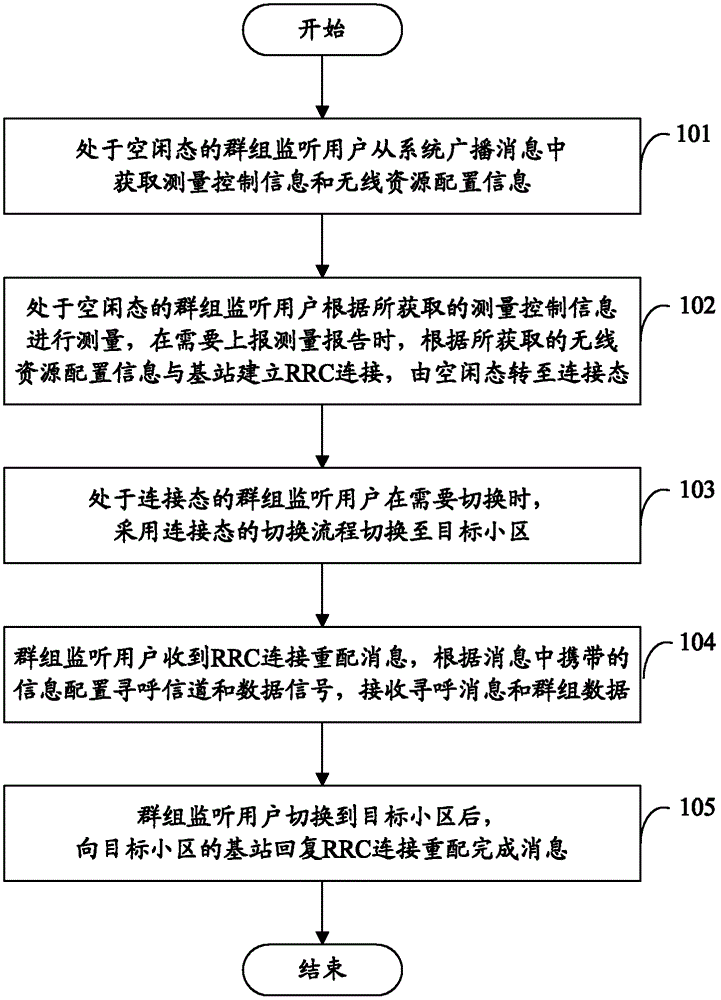

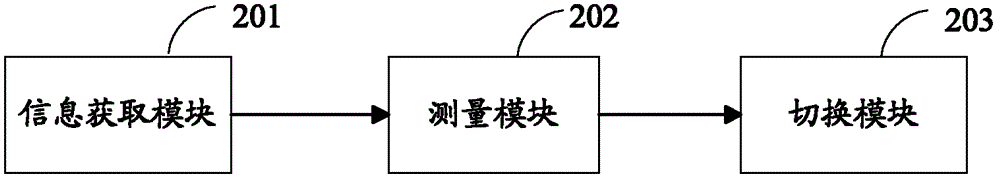

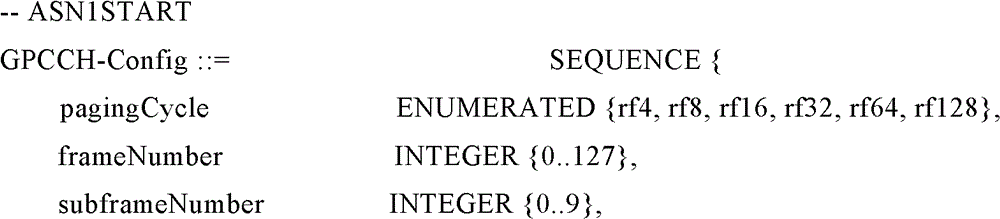

Switching method used for group monitoring user and terminal thereof

ActiveCN103067864AImprove accuracyGuaranteed feelBroadcast service distributionRadio Resource ControlWireless resources

The invention provides a switching method used for a group monitoring user and a terminal thereof. The method comprises the following steps that the group monitoring user in an idle state acquires measurement control information and wireless resource configuration information from a system broadcast message; the group monitoring user in the idle state carries out measurement according to the acquired measurement control information and initiates radio resource control (RRC) connection establishment process when a measurement report needs to be reported; according to the acquired wireless resource configuration information, the group monitoring user in the idle state establishes RRC connection with a base station and the idle state is converted into a connected state; the group monitoring user in the connected state uses a switching process of the connected state to switch to a target cell when the switching is needed. By using the method and the terminal of the invention, the group user can be supported to carry out the effective and fast switching.

Owner:TD TECH COMM TECH LTD

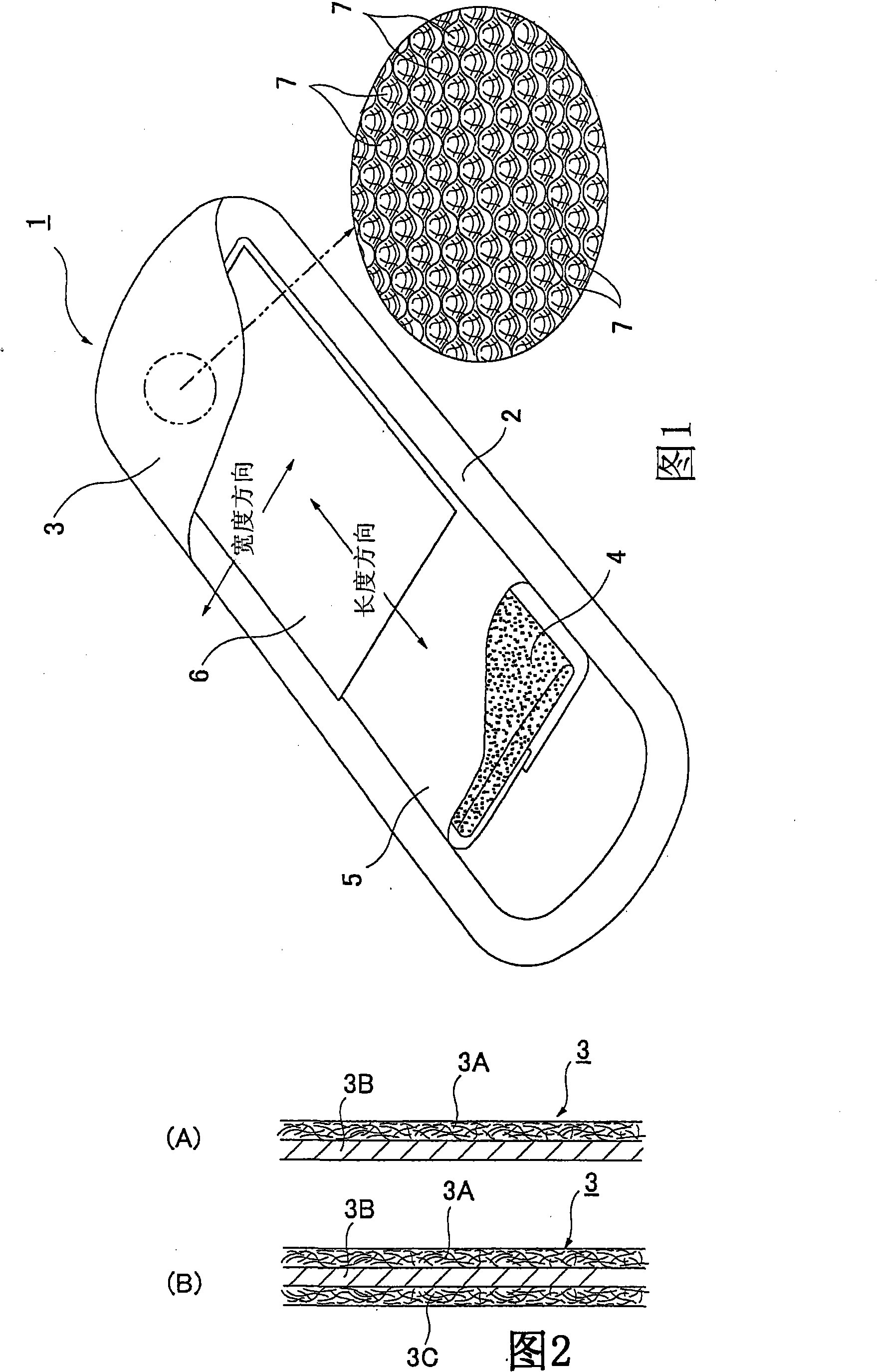

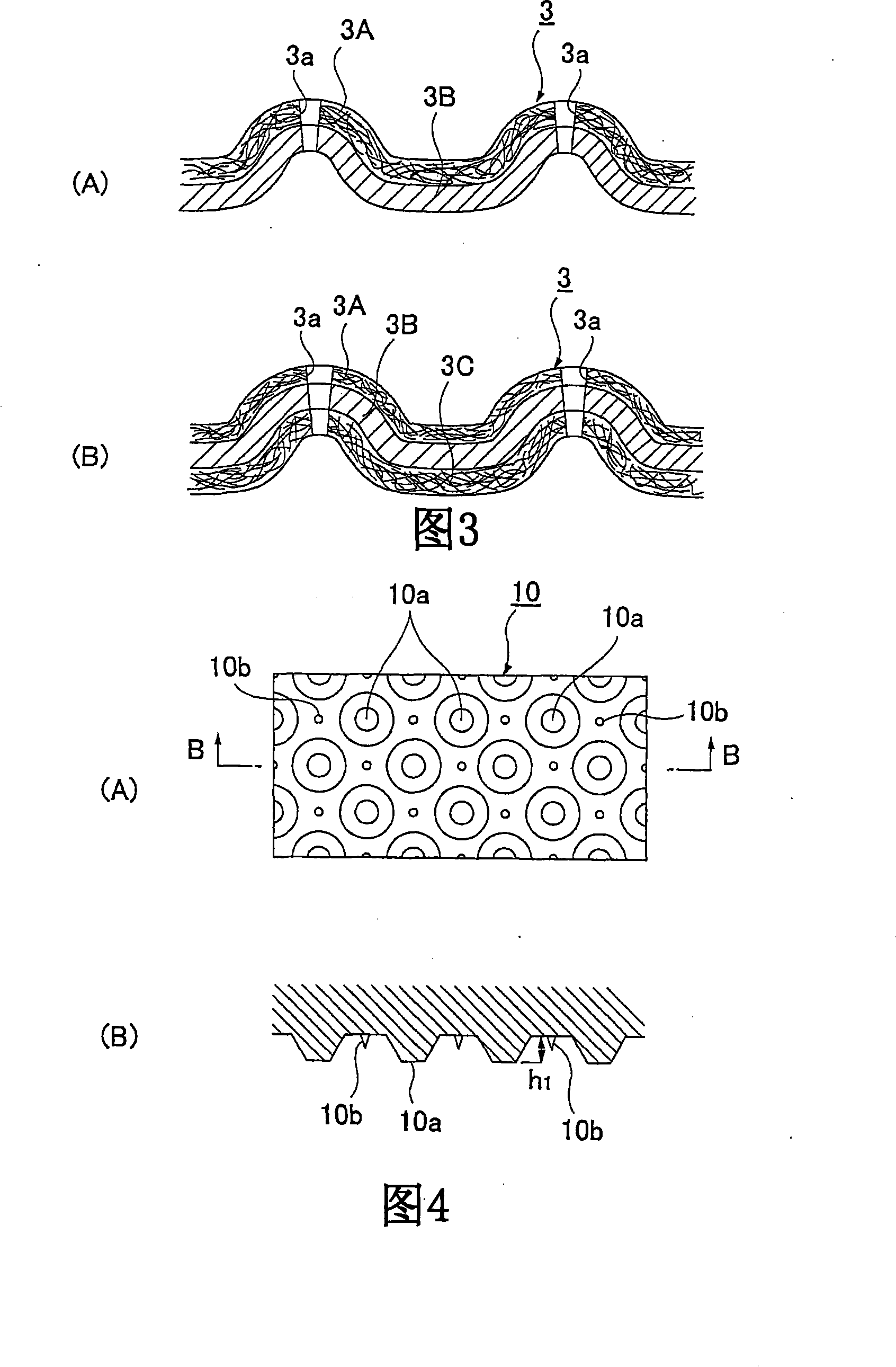

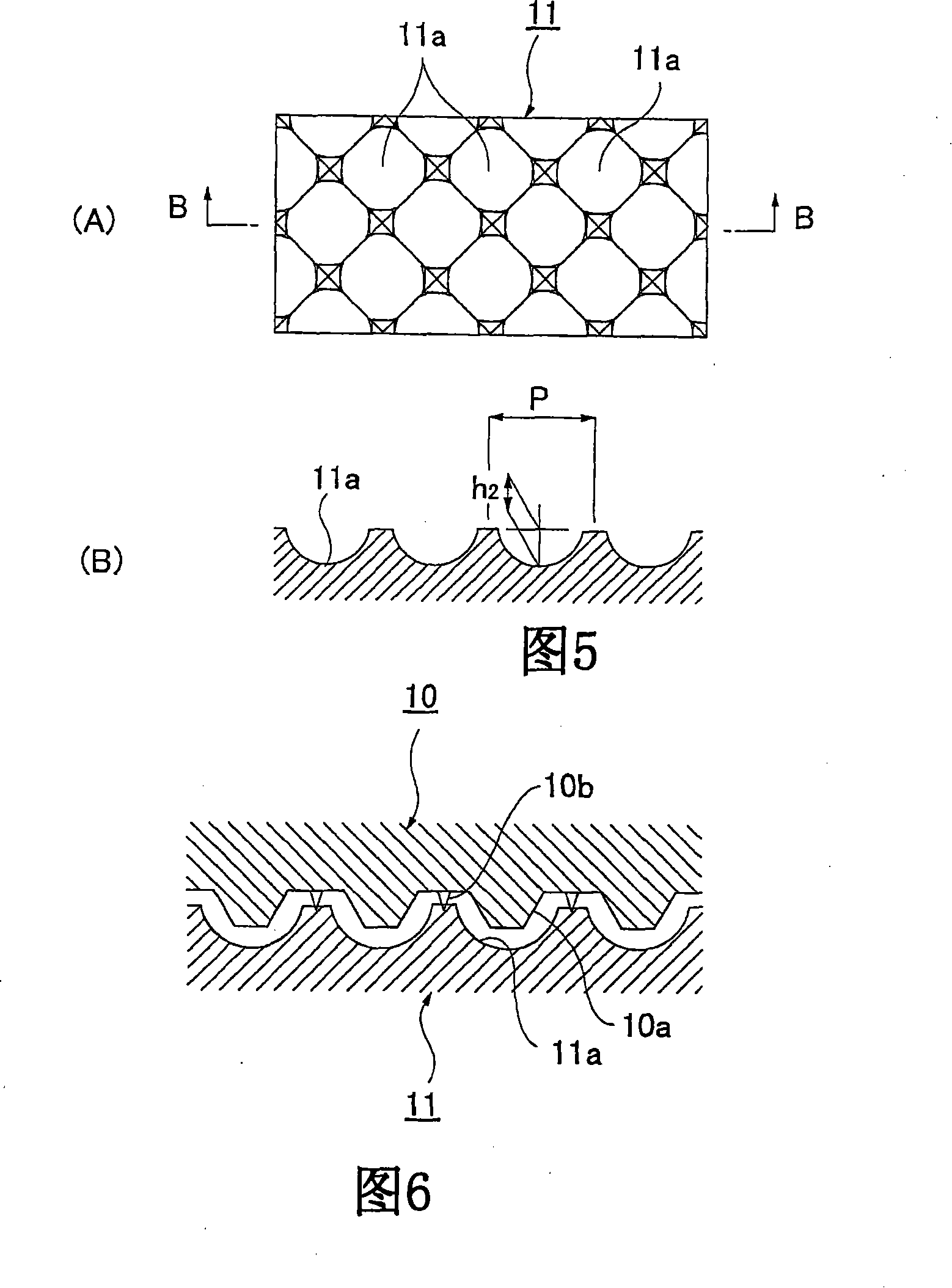

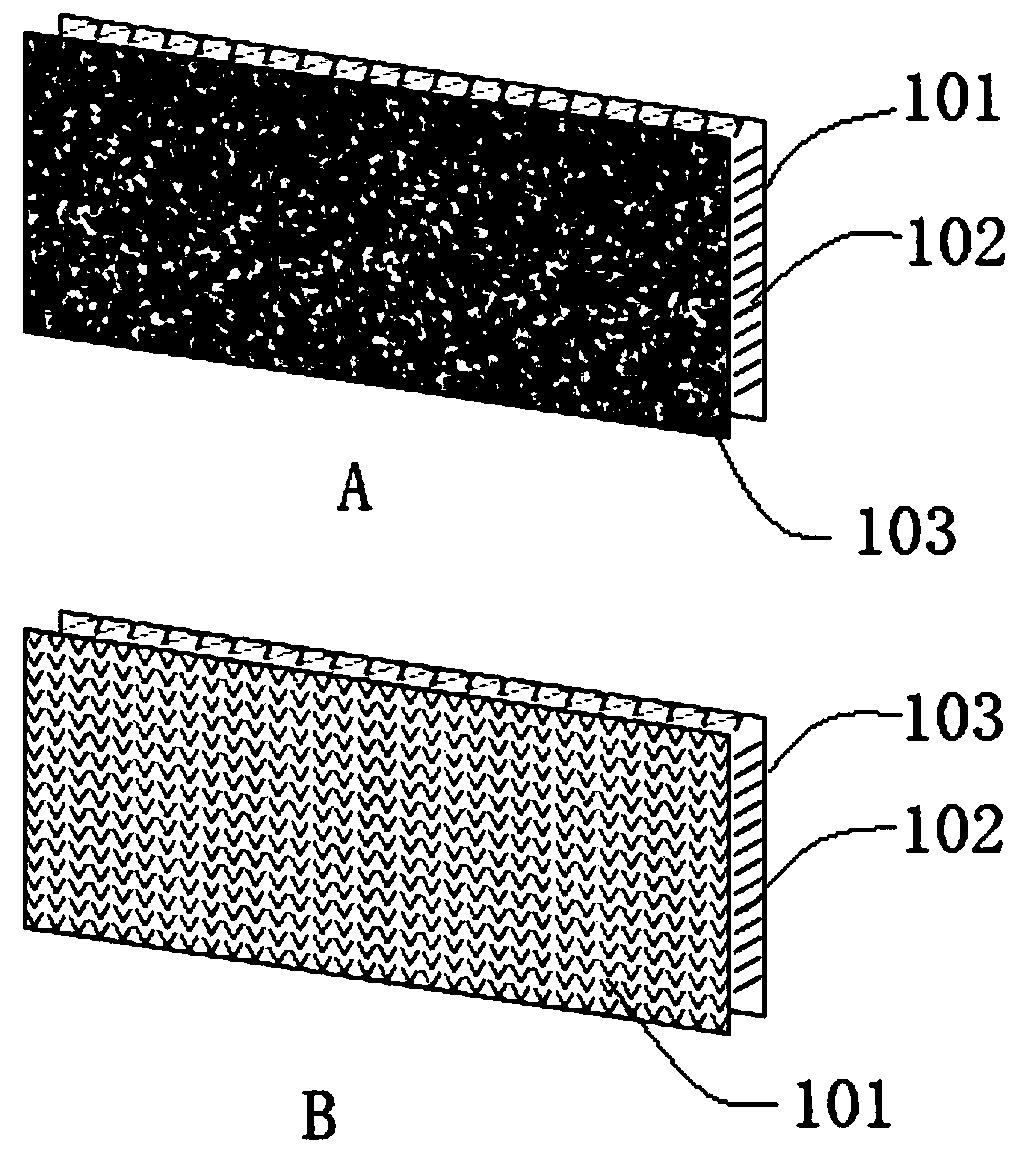

Absorbency substance

ActiveCN101152114AHolds shape firmlyGuaranteed cushioning effectAbsorbent padsBaby linensSkin contactPlastic film

The present invention provides an absorbability article which has cubic effect, high buffering property, and can keep concave-convex form not only under drying condition but also under the condition of absorbing sap by improving the form retentivity of concave-convex embossed pattern. The absorbability article (1) is provided with an absorbing body (4) between permeating front side and back side thin sheets (3) and (2), wherein, the front side thin sheet (3) is a multi-layer sheet which at least comprises a nonwoven cloth layer (3A) forming the skin contacting surface and a plastic film layer(3B) laminated on the non skin contacting surface of the nonwoven cloth layer, the plastic film layer (3B) is composed of material with a melting point lower than the nonwoven cloth. Under the heating condition with a melting point higher than the melting point of the plastic film layer (3B) and lower than the melting point of the nonwoven cloth layer (3A), the concave-convex embossing process composed of a plurality of projecting parts (7, 7......) projecting outside is executed to the front side thin sheet (3), and the hole making process is executed to the top of the convex embossed pattern or the bottom of the concave embossed pattern of the concave-convex embossed pattern.

Owner:DAIO PAPER CORP

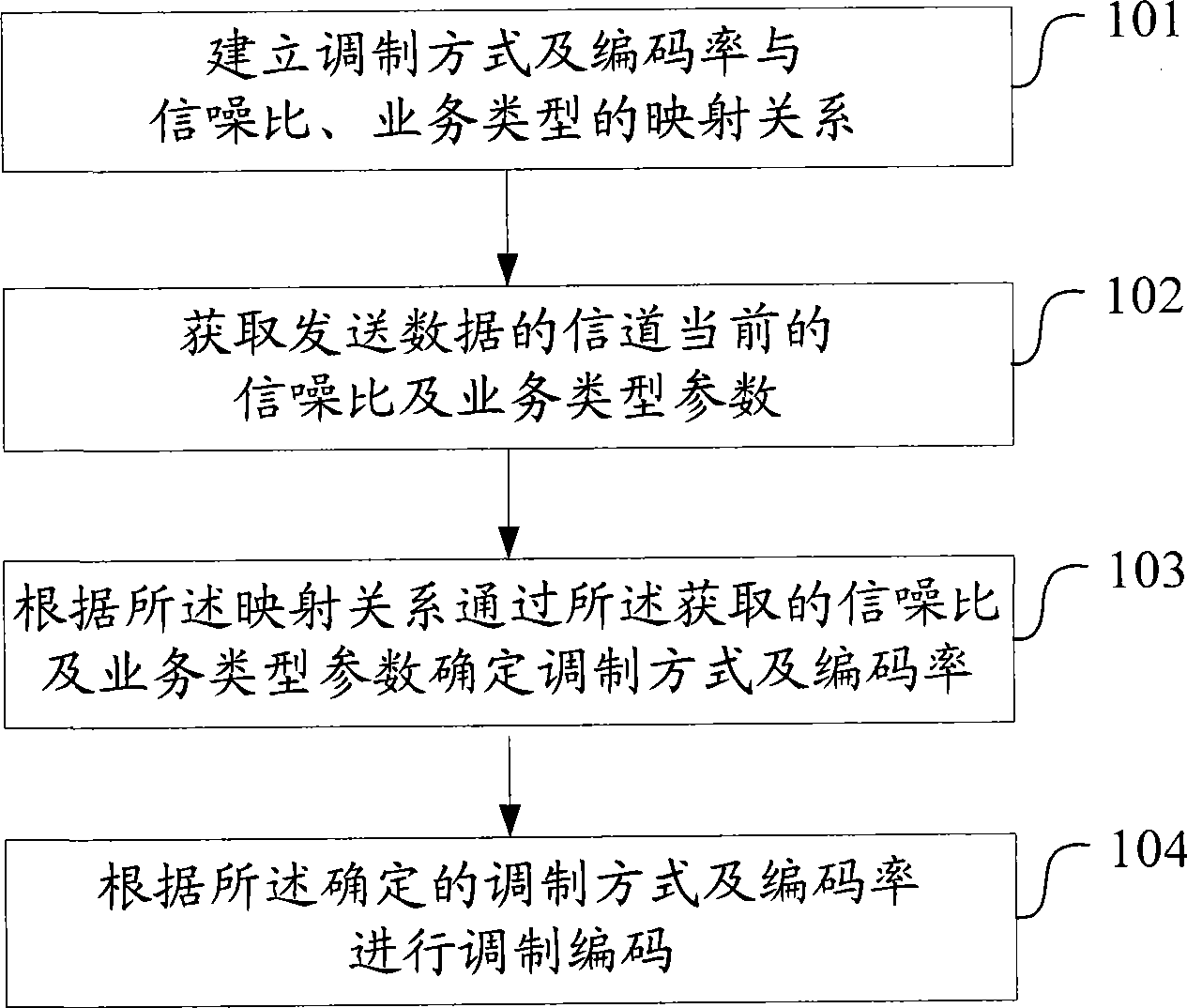

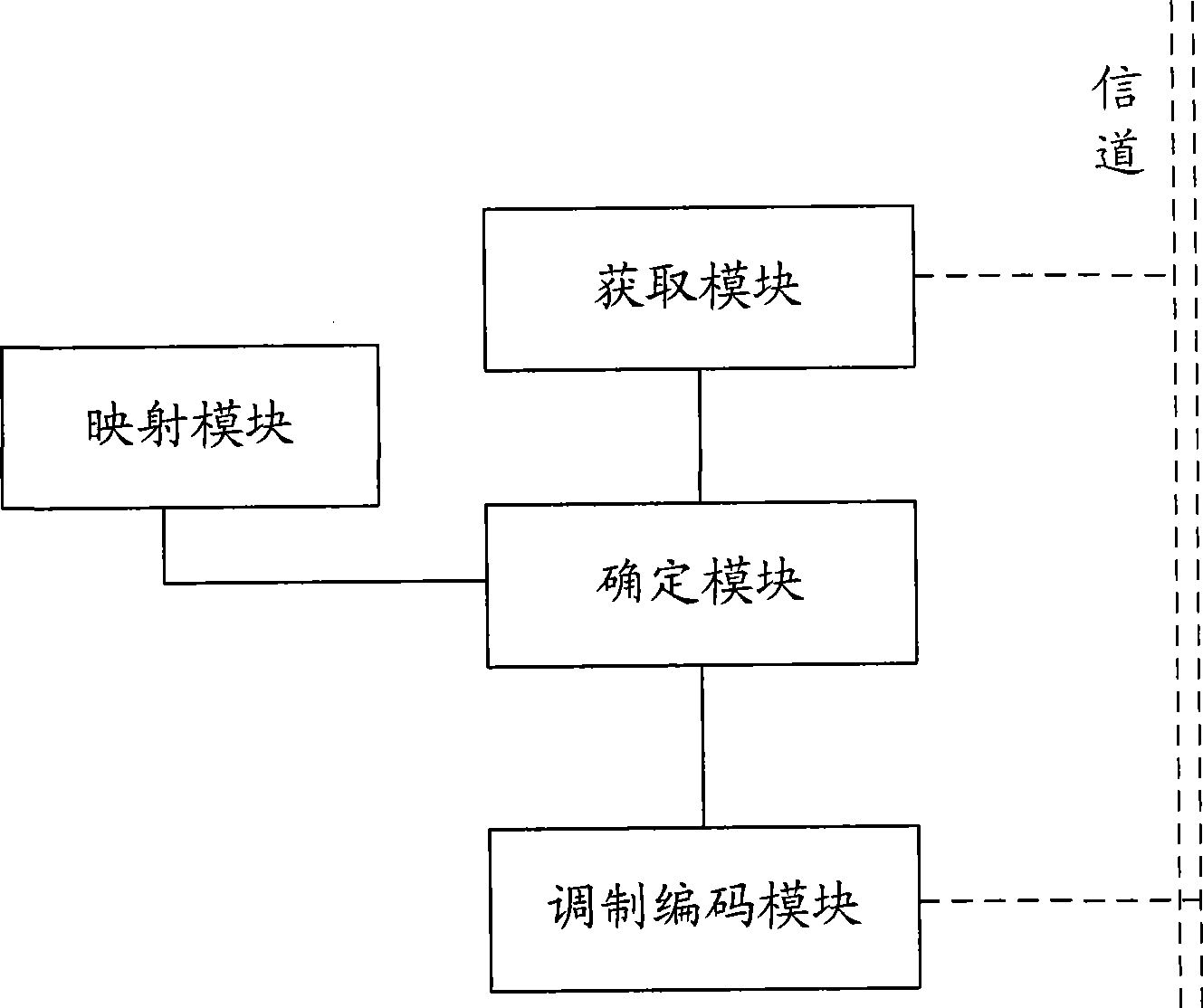

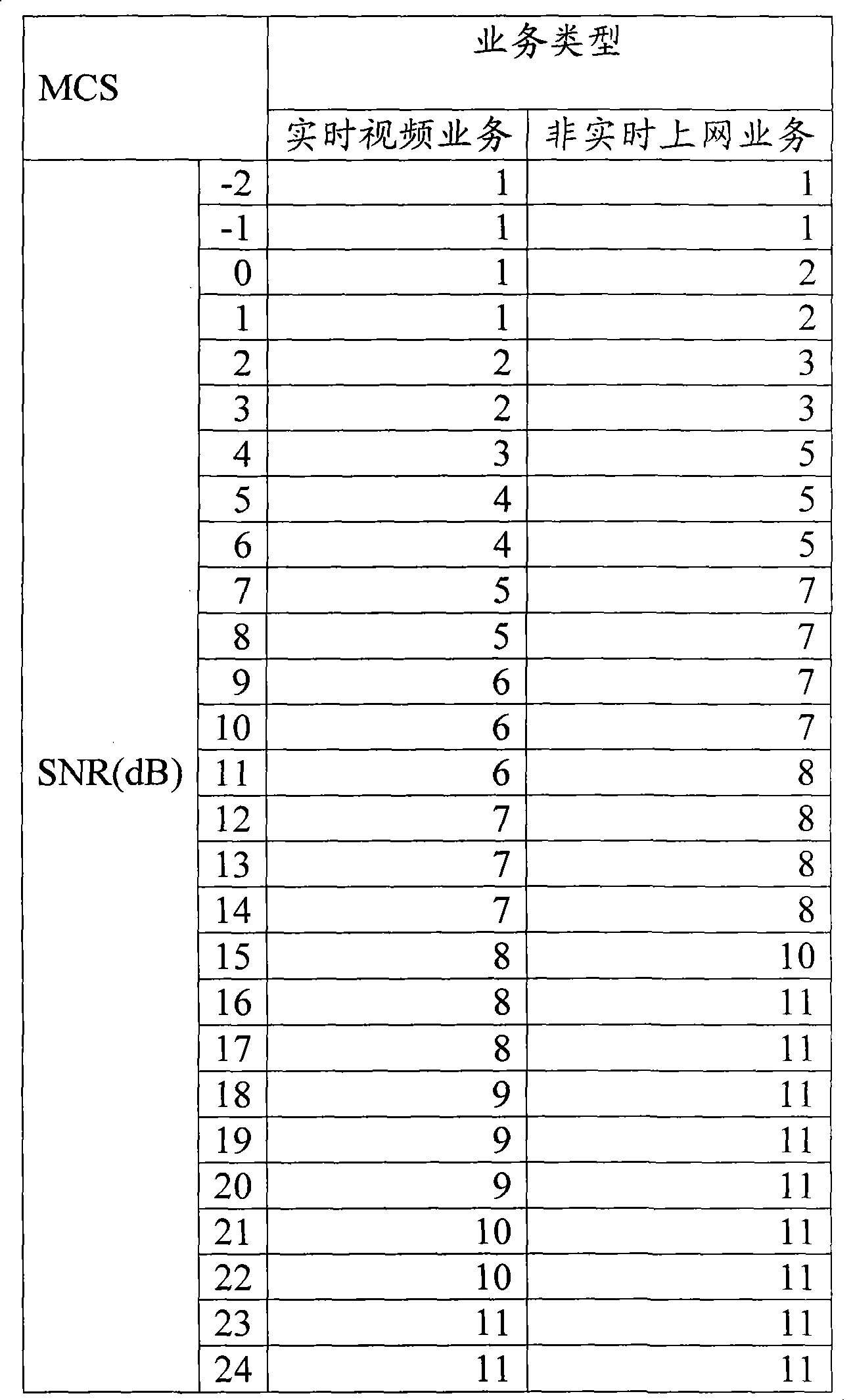

Adaptive modulation coding method and apparatus

ActiveCN101399630AAdaptableImprove spectral efficiencyError preventionMultiple carrier systemsSignal-to-noise ratio (imaging)Error ratio

The invention discloses a self-adaptive modulation and coding method and a device thereof. The method comprises the following steps: obtaining the existing signal-to-noise ratio and service type parameters of a channel transmitting data; determining the modulation mode and coding rate according to the signal-to-noise ratio and the service type parameters; and modulating and coding according to the determined modulation mode and coding rate. The self-adaptive modulation and coding method and the device have strong service adaptability, can perform the modulation and coding according to different service types used by users, which can guarantee the feeling of the users, maximize the frequency spectral efficiency of the system and reduce the error rate.

Owner:CHINA MOBILE COMM GRP CO LTD

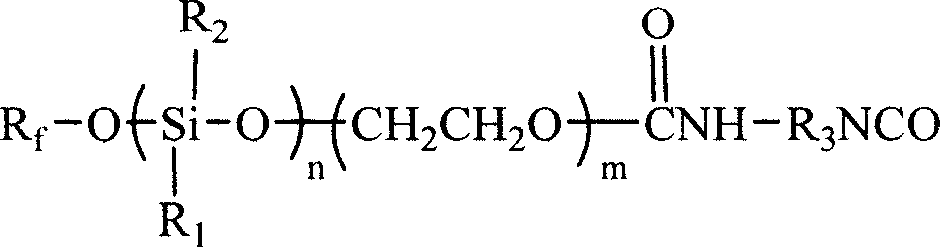

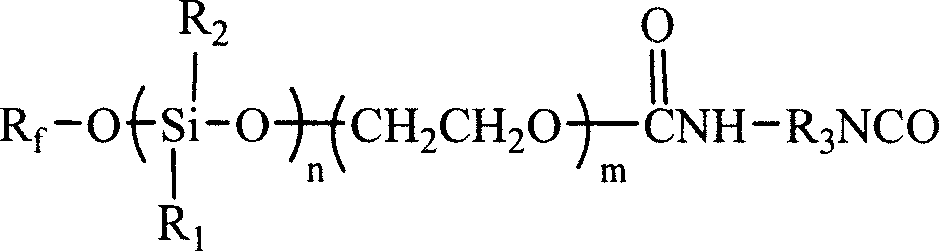

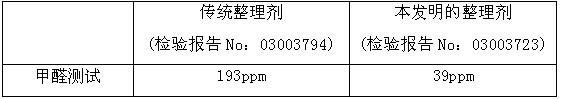

Waterproof, grease proof treating compound of fluorine silicon modified polyurethane, and preparation method

ActiveCN101003946AImprove mechanical stabilityAcid-base stability without limitationFibre typesLeather surface finishingFiberChemical structure

The present invention relates to a fluorosilicone modified polyurethane water-proofing oil-proofing finishing agent and its preparation method. Said invention also provides its chemical structure formula. It is characterized by that it uses perfluor-olefin, hydroxyl silicon oil, epoxyethane and diisocyanate as raw material and makes them undergo the process of synthesis treatment so as to obtain the invented emulsion-fluorosilicone modified polyurethane water-proofing oil-proofing finishing agent.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

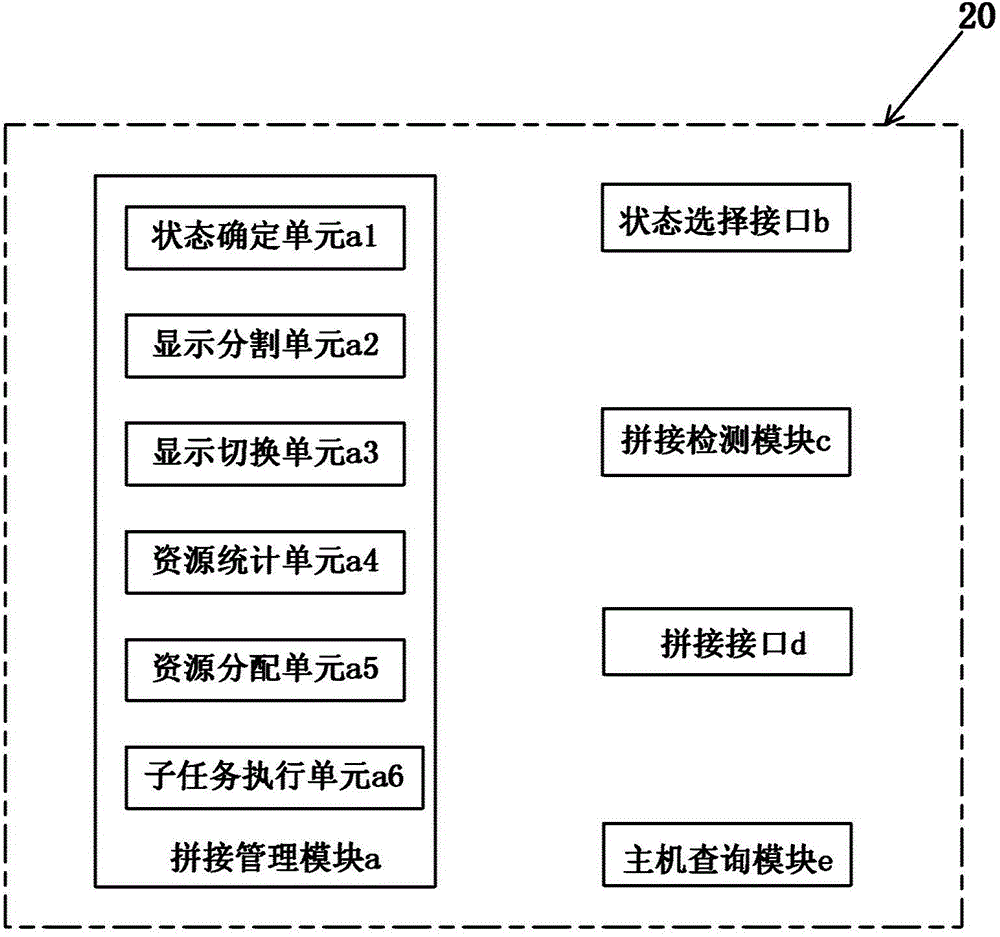

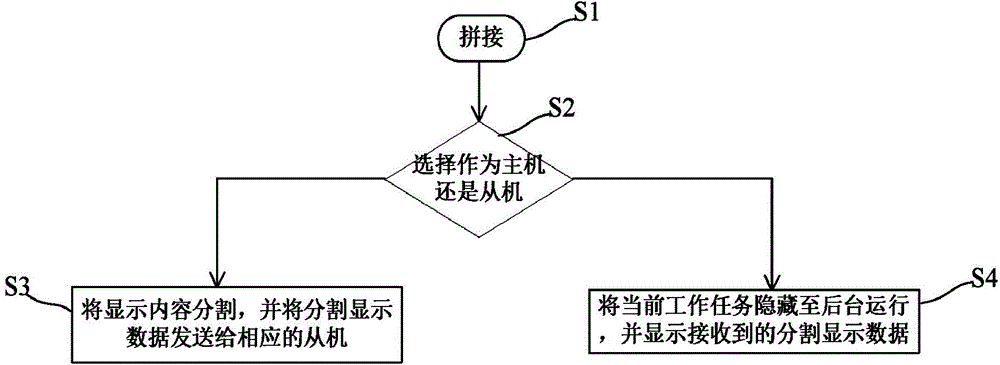

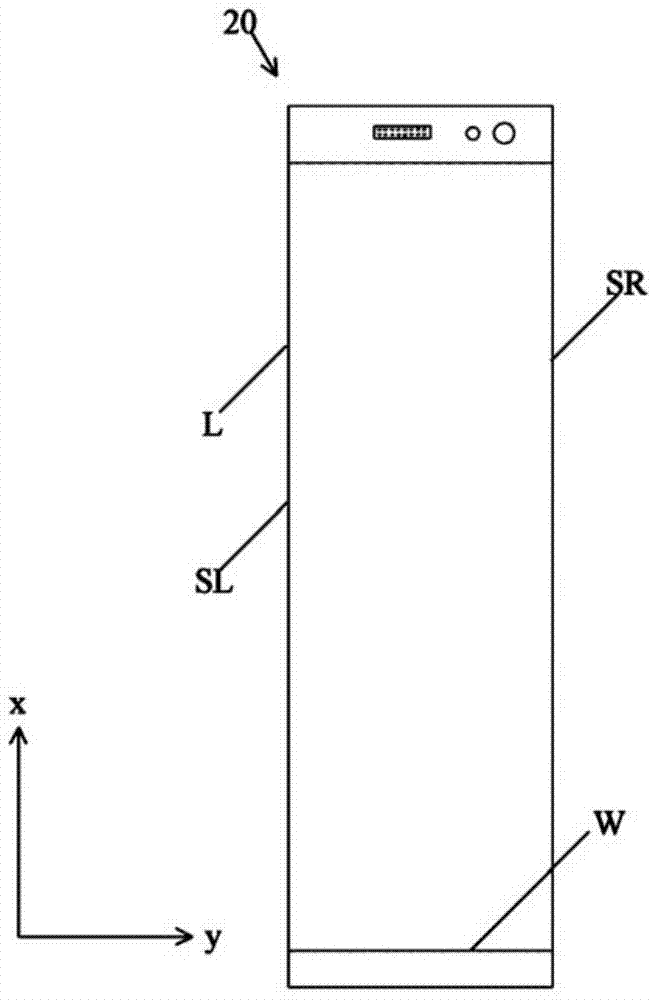

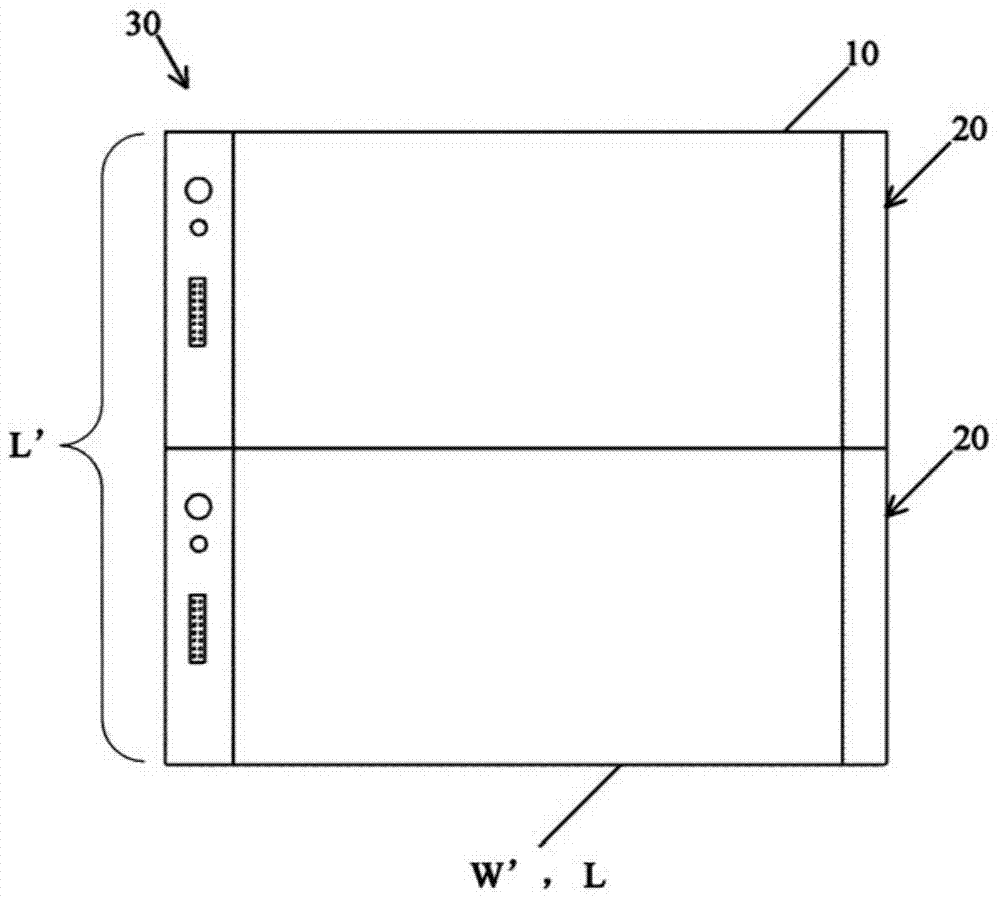

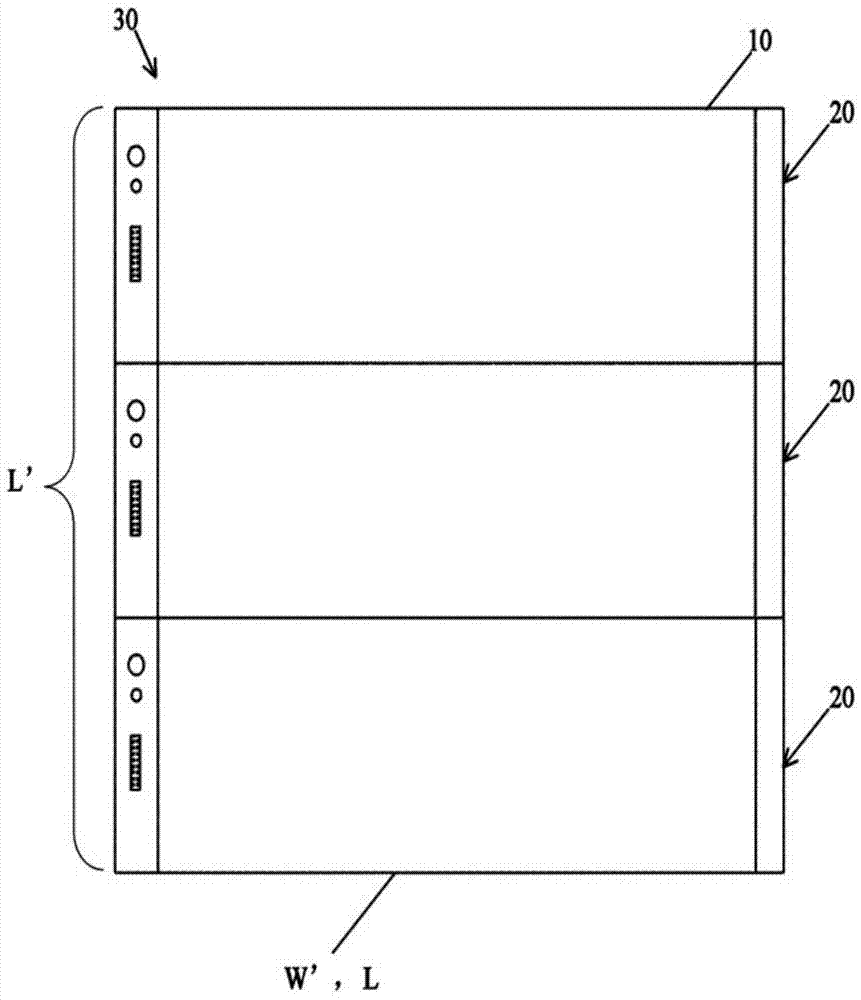

Mobile terminal, combined terminal equipment and splicing joint control method

ActiveCN104679470AMeet the needs of large display areaAvoid secondary pollutionSpecific program execution arrangementsDigital output to display deviceTerminal equipmentLarge screen

The invention relates to a mobile terminal, in particular to a mobile terminal, combined terminal equipment and a splicing joint control method of the mobile terminal. The mobile terminal capable of realizing splicing joint is characterized in that according to a state determination instruction, the mobile terminal selectively enters a host work state or a slave work state; a display division unit divides the display contents of a host according to display screen resources of each mobile terminal in the combined terminal equipment when the mobile terminal is used as the host to work, so that a plurality of division display data corresponding to a plurality of mobile terminals in the combined terminal equipment is obtained, and the corresponding division display data is sent to slaves; a display switching unit displays the received division display data when receiving the division display data from the host under the condition that the mobile terminals are used as the slaves. The contents displayed by the host can be displayed by the slaves, when the number of the slaves is great, the contents can be displayed to a user by a larger screen consisting of a plurality of slaves, and the requirement of people on the large display area can be met.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

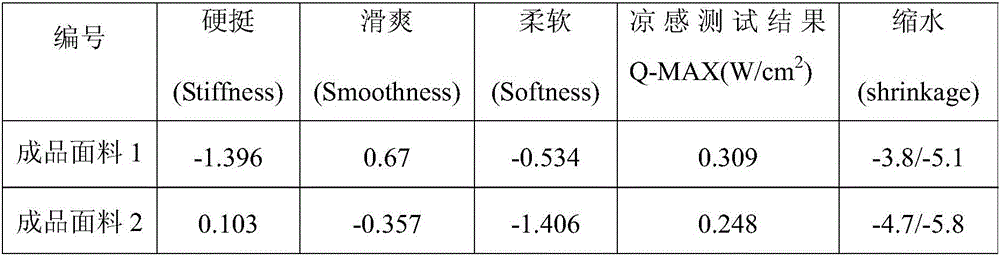

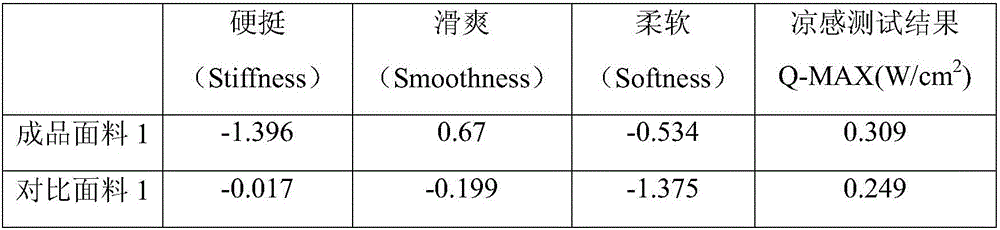

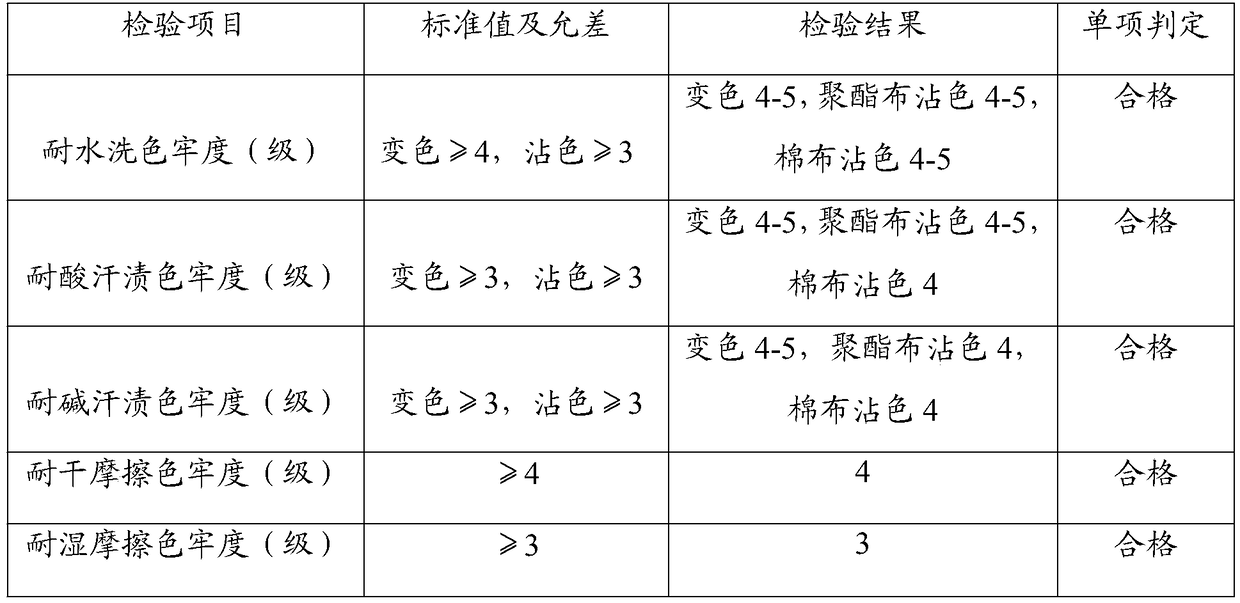

Knitted fabric containing cotton and having silky luster, handfeel and cool feeling and manufacturing method thereof

ActiveCN105734963ACompact structureNo blemishes on the clothWeft knittingBiochemical treatment with enzymes/microorganismsWoolDyeing

The invention provides knitted fabric containing cotton and having silky luster, handfeel and cool feeling and a manufacturing method thereof.The method includes the following steps that yarn is woven into gray fabric with a circular knitting machine, wherein the needle number of the circular knitting machine is 18-40, the yarn count is 20-80 S / 1, length 50 C of the yarn is 90-200 mm, and the gram weight of the gray fabric is 60-240 g / m<2>.The tissue structure of the gray fabric includes tabby, half cardigan, knitted cotton, rib, looped pile and ball wool or jacquard weave; open width alkali mercerizing, boiling-off, enzyme washing, dyeing, drying, soft stabilized finishing and preshrinking are conducted to finally obtain the knitted fabric containing cotton and having silky luster, handfeel and cool feeling.The knitted fabric containing cotton and having silky luster, handfeel and cool feeling has the advantages of being smooth, stiff, good in drapability, resistant to crease and small in shrinking amount and integrates smoothness, stiffness and crease resistance.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Mobile terminal and combined terminal device

ActiveCN104717330ARemove black borderKeep the feelTelephone set constructionsEngineeringTerminal server

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

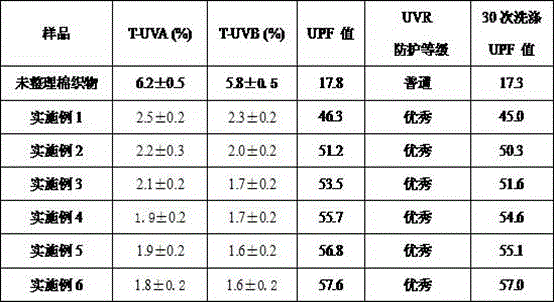

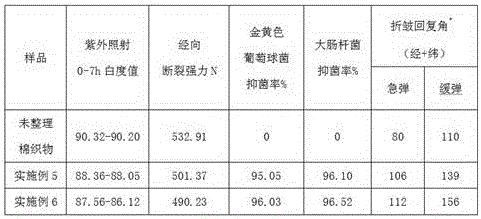

Modified-chitosan-containing anti-ultraviolet finishing agent for cotton fabric and anti-ultraviolet cotton fabric obtained by aid of anti-ultraviolet finishing agent

The invention provides a modified-chitosan-containing anti-ultraviolet finishing agent for cotton fabric and anti-ultraviolet cotton fabric obtained by aid of the anti-ultraviolet finishing agent. The modified-chitosan-containing anti-ultraviolet finishing agent for the cotton fabric is a uniformly mixed solution of 3,4,5-trimethoxybenzoyl chitosan, a crosslinking agent, a penetrant and an acetic acid or lactic acid solution, wherein the crosslinking agent is organic polycarboxylic acid or amino-modified silicone oil emulsion; the penetrant is either JFC or peregal O. The anti-ultraviolet cotton fabric with anti-ultraviolet, anti-bacterial and anti-crease finishing functions is obtained through double-dip double-nip, water washing and drying, the anti-ultraviolet, anti-bacterial and anti-crease finishing functions are high in durability, the cotton fabric still maintains the original style of the fabric after finishing, the hand feel, the strength, the whiteness and the color of the cotton fabric are not affected, and the original human body affinity is maintained; the finishing agent is simple in composition and easy to prepare, and a finishing process is simple and environment-friendly.

Owner:EASTERN LIAONING UNIV

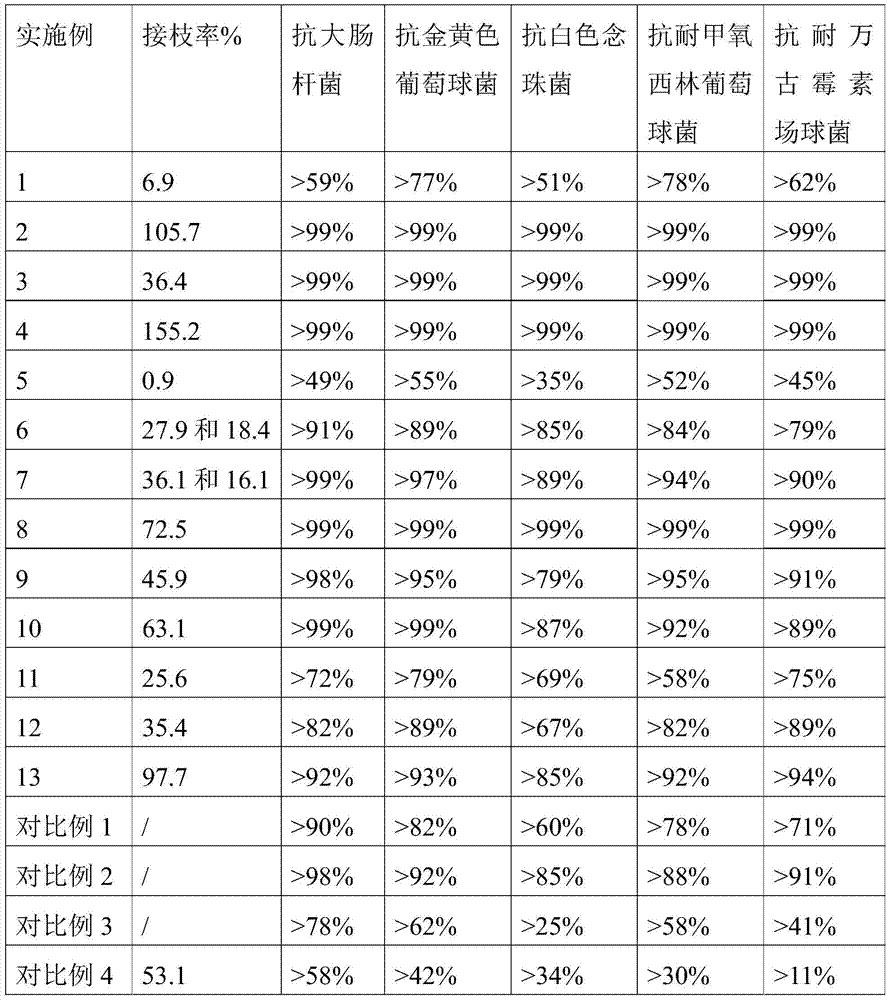

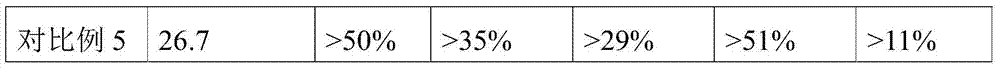

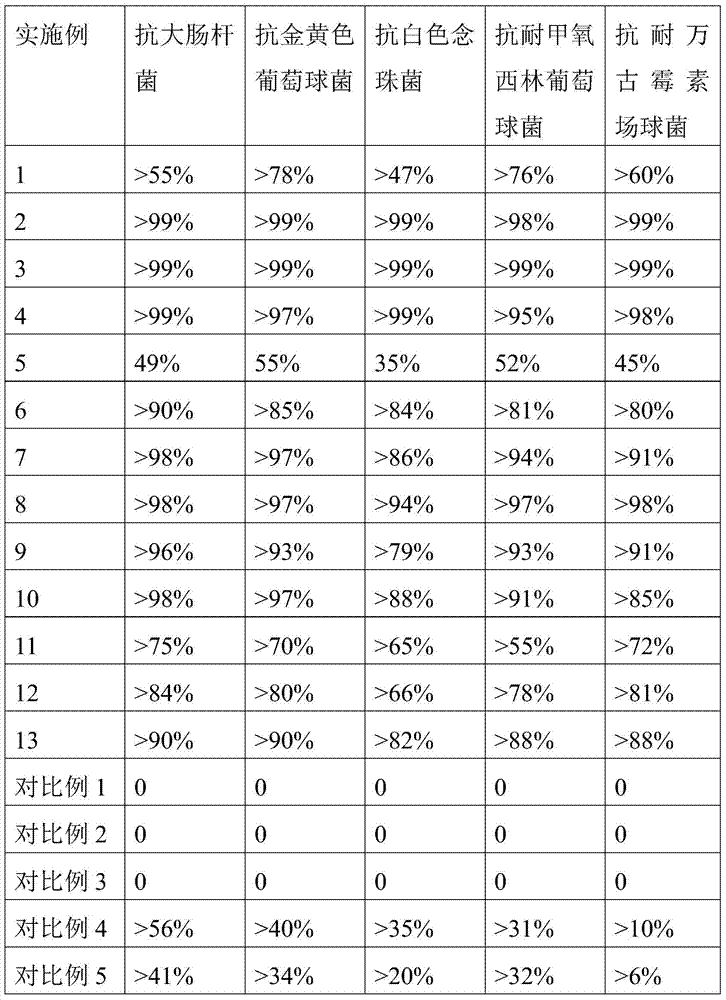

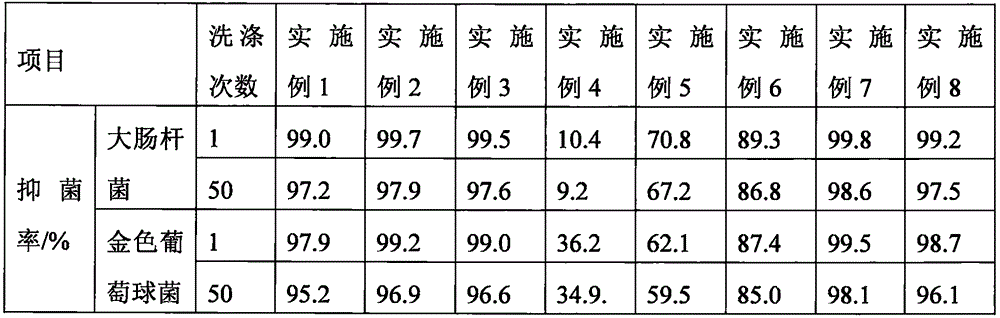

An antibacterial textile product and a preparing method thereof

InactiveCN107044053AStrong combination fastnessExcellent abrasion resistanceFibre treatmentPolymer scienceIonic liquid

An antibacterial textile product and a preparing method thereof are disclosed. The method includes triggering production of active free radicals on a textile substrate, and performing polymerization with an organic monomer containing an ionic liquid. The textile product prepared by the method has a durable wide-spectrum antibacterial function. The range of a suitable textile product substrate is wide. The method is simple, feasible, low in cost, suitable for batch production and easy to popularize.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

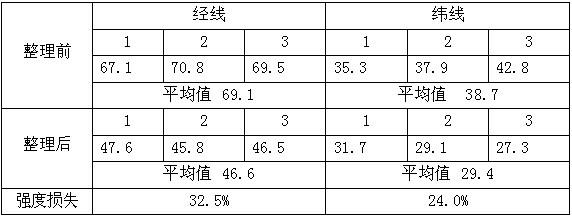

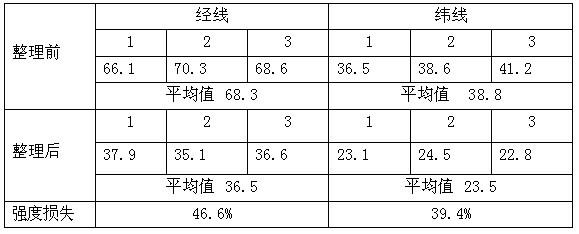

Denim-apparel fold finishing agent and fold finishing method

InactiveCN101851860AReduce formaldehyde contentReduce tear lossFibre treatmentDenimPolyvinyl alcohol

The invention relates to a denim-apparel fold finishing agent and a fold finishing method. The denim-apparel fold finishing agent comprises the following in percentage by weight: 30 to 35 percent of etherification 2D resin, 4 to 5 percent of catalyst, 5 to 10 percent of modified polyvinyl alcohol, 8 to 10 percent of cationic resin, and the balance of deionized water. The denim-apparel fold finishing method comprises the steps of preparing finishing liquid, soaking raw material in the finishing liquid, grasping folds with hands, drying, baking the obtained product in an oven, rubbing the obtained product with hands, spraying potassium permanganate, washing the obtained product with water, and the like. The denim-apparel fold finishing agent has relatively low formaldehyde content, thereby greatly reducing the loss of tearing force. The denim-apparel fold finishing method has the advantages of solving the problem that denim apparel is big in loss of tearing force, maintaining the original hand feel of the denim apparel to the utmost extent, ensuring that the denim apparel is easy to absorb softener and solid folds are easy to finalize and simplifying the production process of solid fold finishing.

Owner:东莞市广利行洗涤原料有限公司

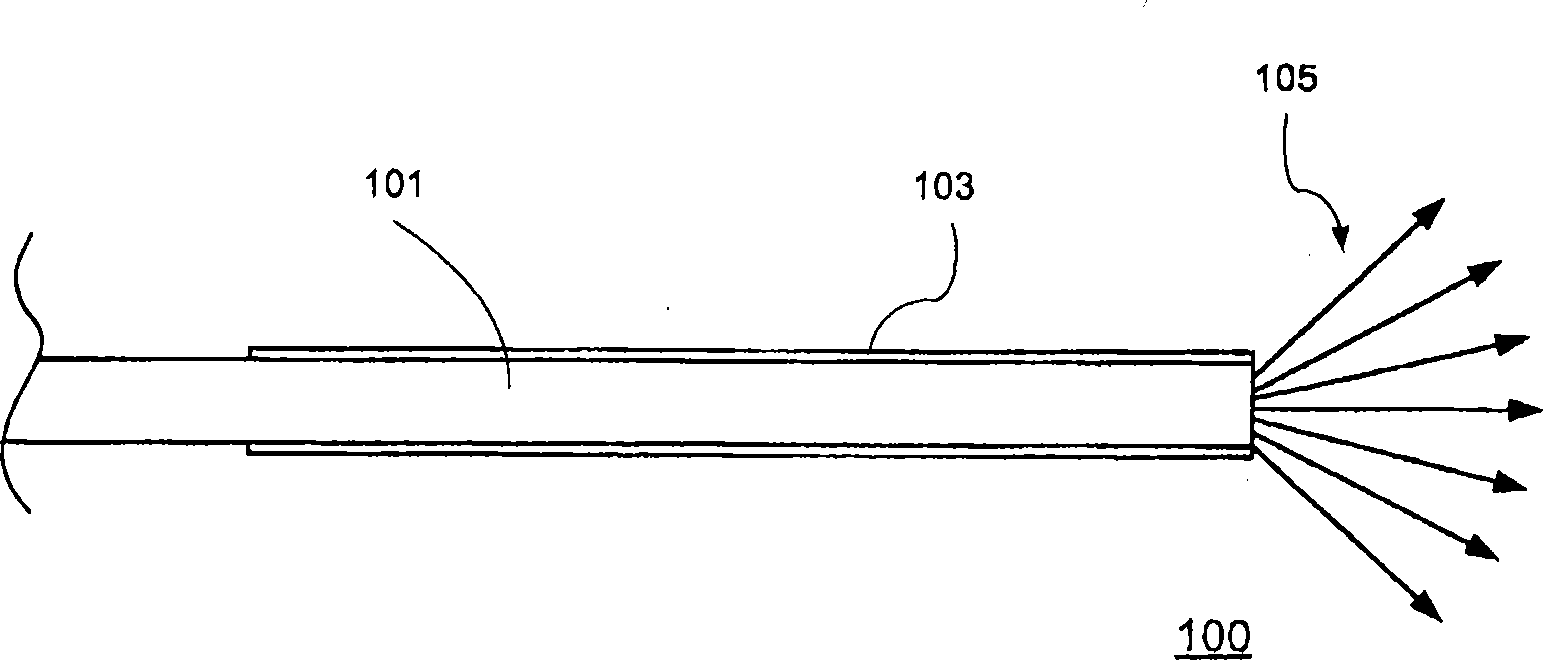

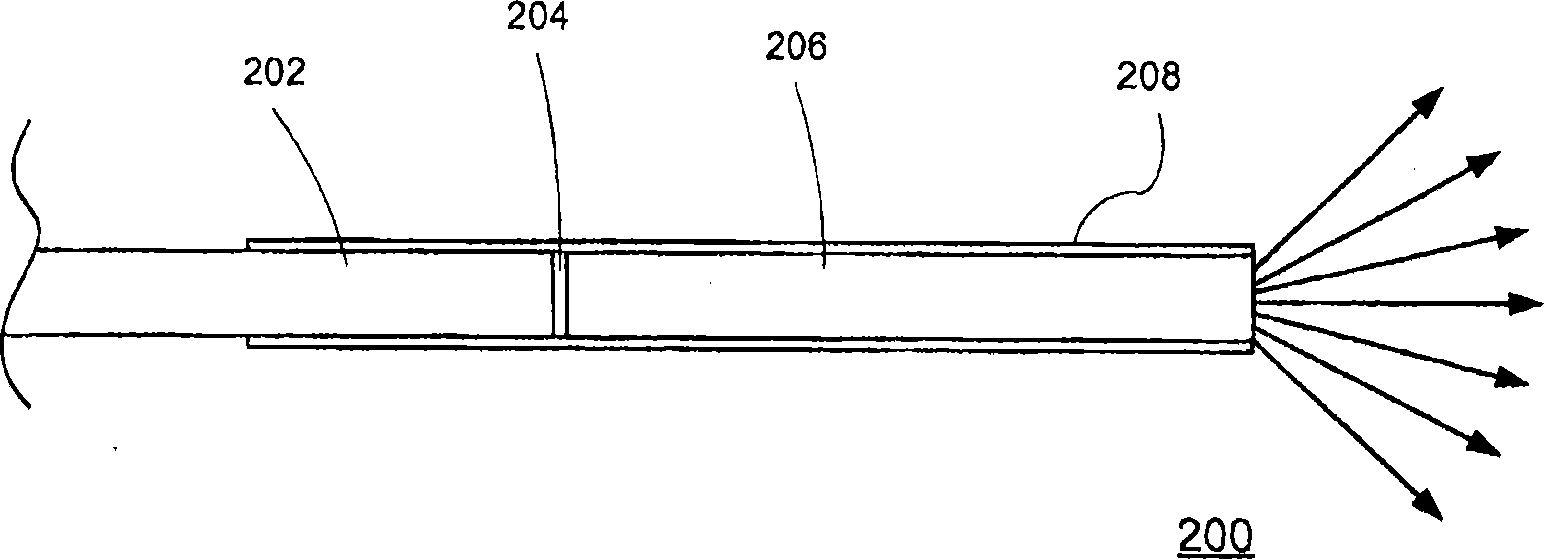

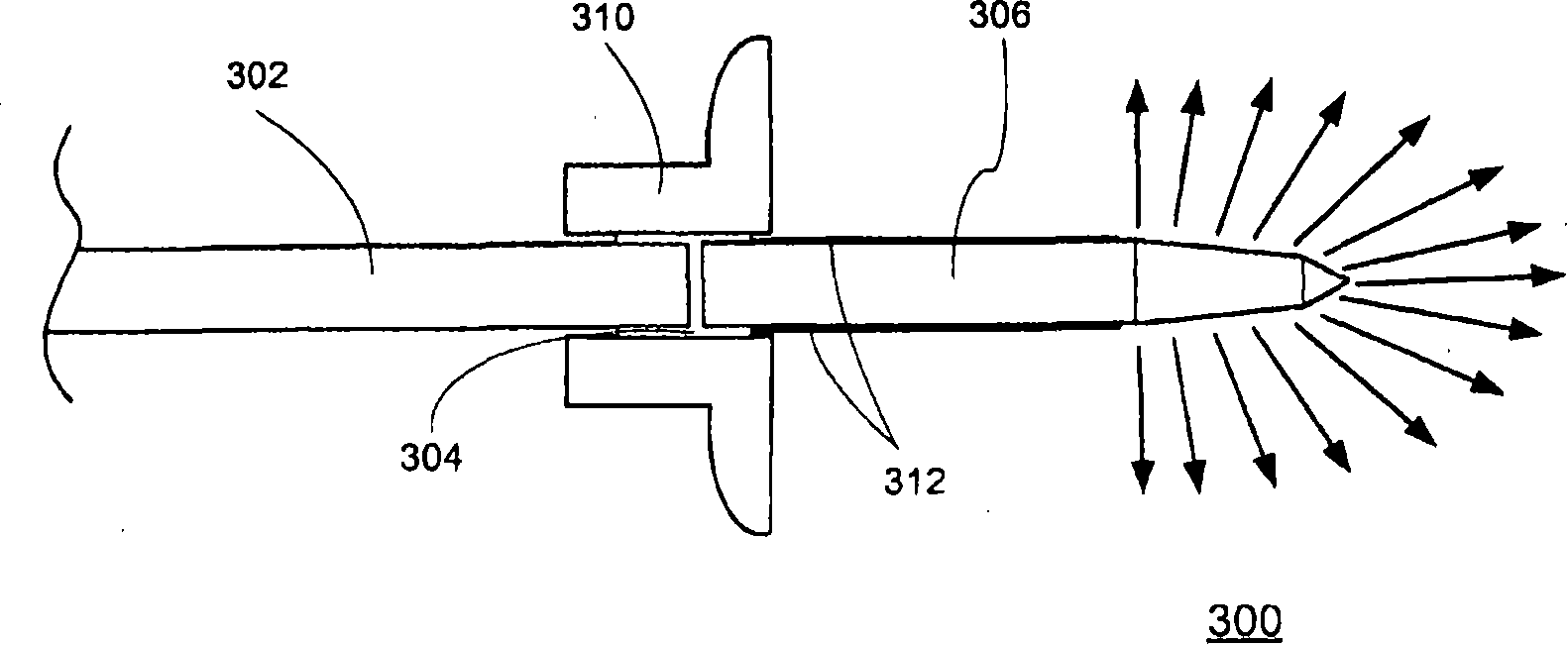

Thermally robust illuminator probe tip

In embodiments of the invention, a plastic optical fiber is bonded to a high temperature distal part to form a thermally robust illumination probe. The distal part is short in length, is made of a high temperature material(s), has a proper shape for guiding light in a desired application, and may be coated with a reflective coating to ensure that the light rays trapped within the part do not escape when the side of the part is in contact with high refractive index or absorptive materials. The distal part may be made of high temperature material(s) such as high temperature plastic rods, glass optical fibers, and so on. The distal end may be tapered or sculpted to a desired configuration. The plastic optical fiber and the high temperature distal part may be joined, using an optical adhesive, inside a steel cannula, a plastic hub, an optical connector, etc.

Owner:ALCON INC

Preparation method of non-lining down-proof fabric

The invention is applicable to the fabric processing field, and provides a preparation method of non-lining down-proof fabric. The method comprises the following step of: performing cold batch treatment, open-width desizing treatment, presetting treatment, freshening treatment, dyeing treatment, fixation treatment, resin finishing, setting treatment and calendering treatment to chinlon fabric. The preparation method realizes the purpose that a final finished product has smooth, light and soft feeling, air permeability and faddish light sensation, down prevention and other features of fabric of cold protective clothing, is applied to down coat manufacture, is used for people to get rid of heavier mode for passing the winter, and produces a new consumption concept.

Owner:SHENGHONG GRP CO LTD

Soft sheepskin-imitating polyurethane resin, preparation method thereof, and method of producing sheepskin-imitating artificial leather therewith

ActiveCN105671989AImprove immersionMuch infiltrationGlovesPolyurea/polyurethane coatingsN dimethylformamideWear resistance

The invention relates to soft sheepskin-imitating polyurethane resin which includes the following components: wet-method polyurethane resin, N,N-dimethylformamide, paper pulp powder, a hand feeling agent, a permeation agent, an anti-crimping agent and an oily color material. The invention also relates to a method of producing sheepskin-imitating artificial leather with the soft sheepskin-imitating polyurethane resin, wherein the method includes the following steps: 1) impregnating a base cloth in a soft sheepskin-imitating polyurethane resin mixture liquid; 2) regulating sizing quantity through extrusion, and performing solidification, water washing, drying and polishing to prepare wet-method base; and 3) performing veneering and vacuum grain suction to the wet-method base to prepare the sheepskin-imitating artificial leather. The sheepskin-imitating artificial leather has a soft and light feel, has fine and elastic hand feeling, is high in tear strength and good in weather and wear resistance, has a soft and natural surface color, has full grains and has strong stereoscopic sense.

Owner:SHANGHAI HUIDE TECH CO LTD

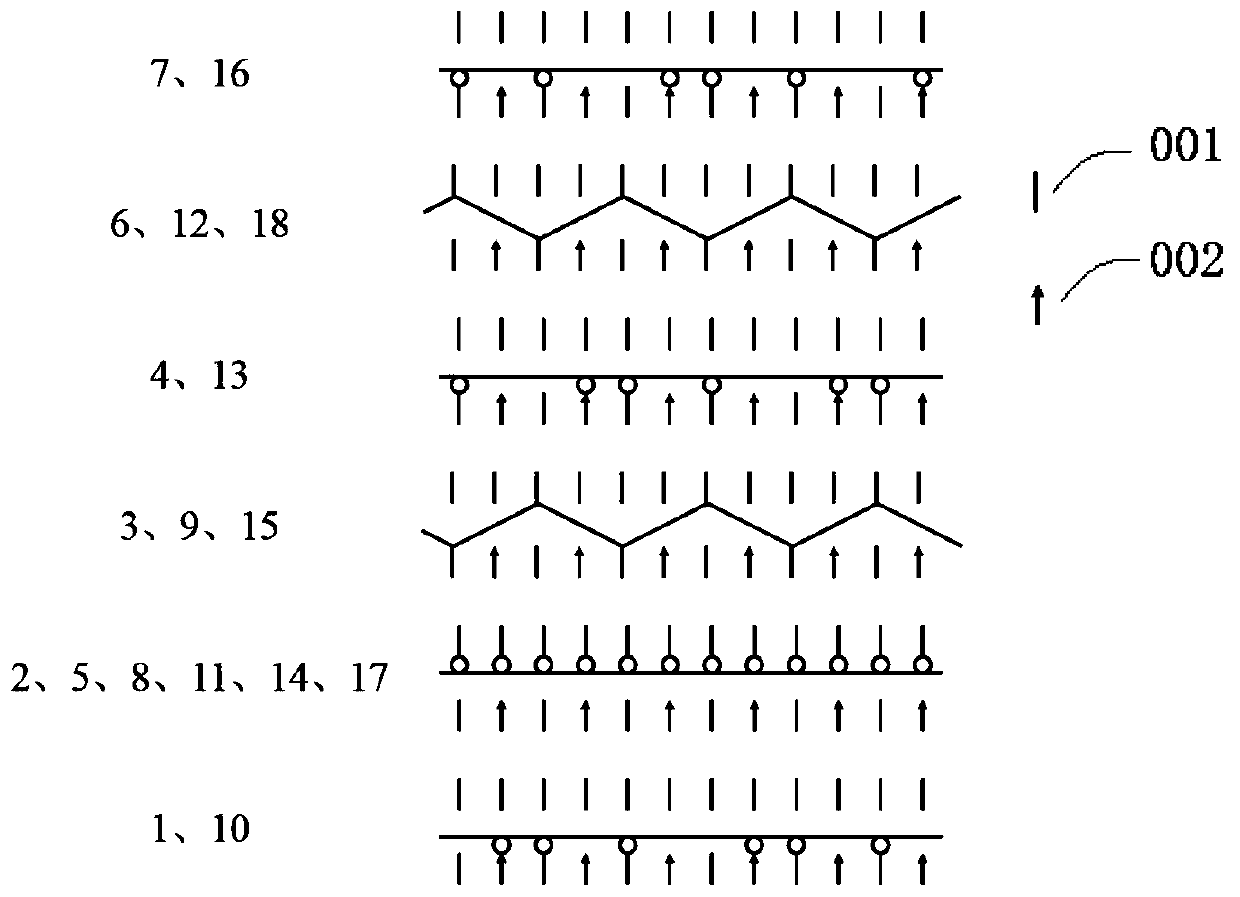

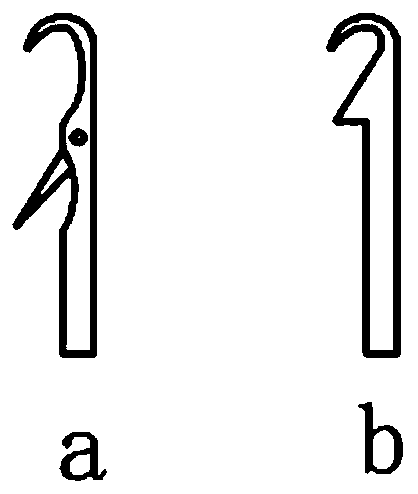

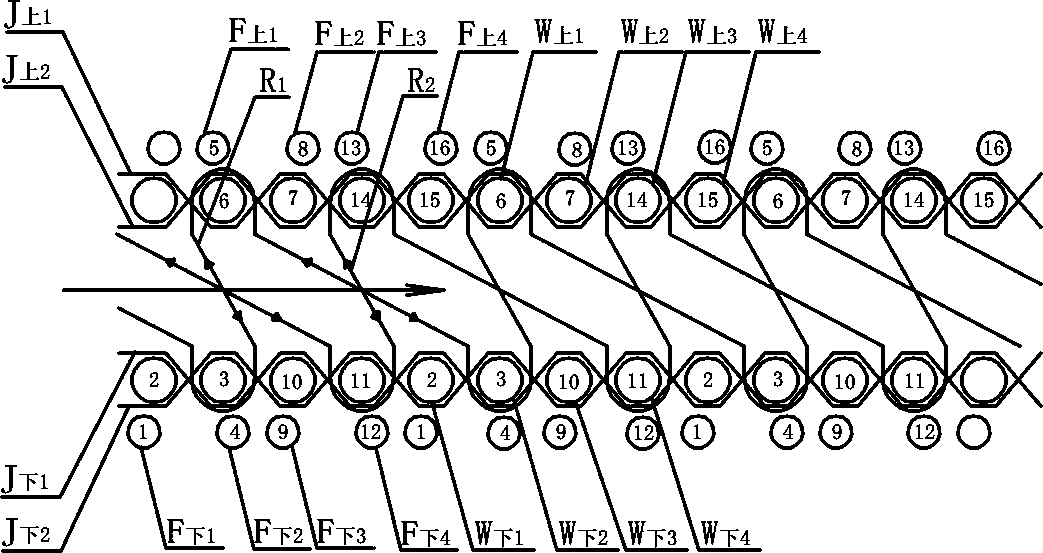

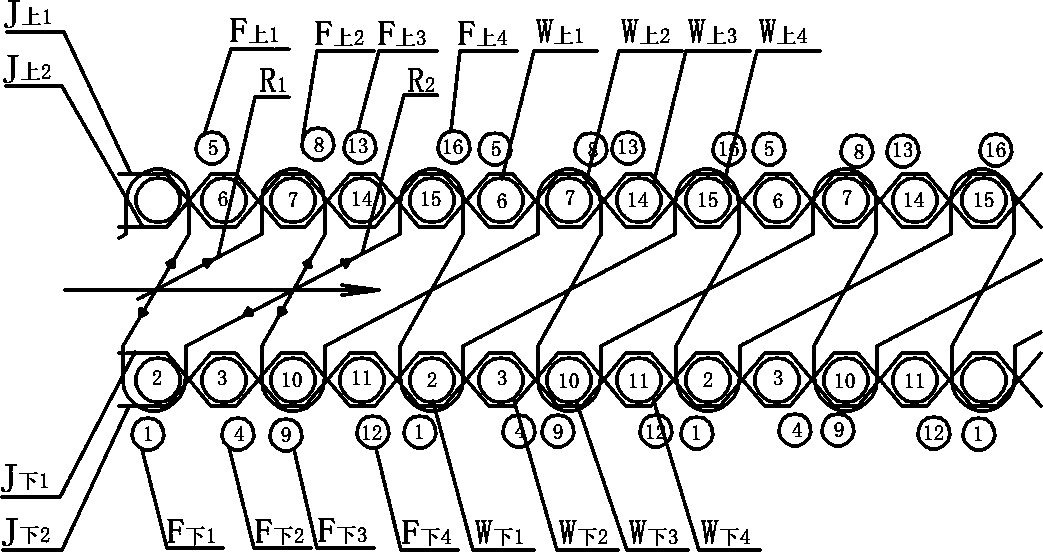

Two-sided weft-knitted cut-pile knitted fabric and knitting method thereof

ActiveCN110760980AReduce the problem of hair sheddingOmit the link of fleece treatmentCircular knitting machinesYarnStructural engineering

The invention discloses a two-sided weft-knitted cut-pile knitted fabric and a knitting method thereof. The fabric comprises a piled layer, a flat layer and a connection layer, the connection layer isconnected with the flat layer and the piled layer, and loop formation and loop cutting for pile formation of the piled layer are completed in one step. The weft-knitted cut-pile knitted fabric is knitted by a circular weft knitting machine, cylinder needles include knife needles and latch needles, dial needles include latch needles, and accordingly front and back faces of the fabric can be different in loop density, and the loop density of the flat layer of the fabric is larger than that of the piled layer; due to one-step completion of loop formation and cutting of the piled layer, production cost is saved, and production efficiency is improved; owing to the connection layer, fixation and isolation effects on the flat layer and the piled layer are achieved, dimensional stability of the fabric is improved, and exposure of pile yarns or connection yarns of the fabric is reduced. By adoption of the knitting method, procedures of a fabric compounding process are avoided, safety of the fabric is guaranteed, and the method has a promising application prospect in garment fabrics, home textile fabrics, industrial fabrics and the like.

Owner:JIANGNAN UNIV

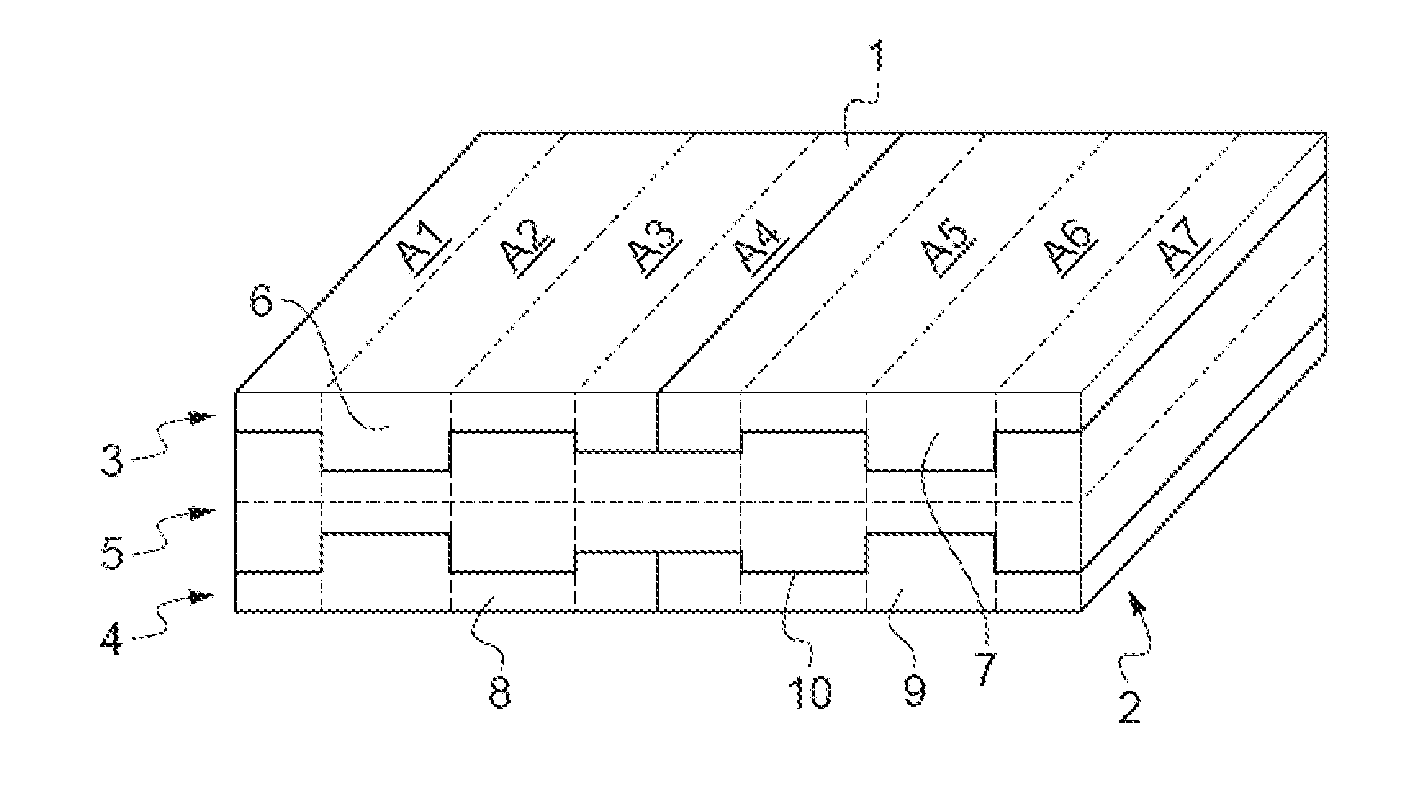

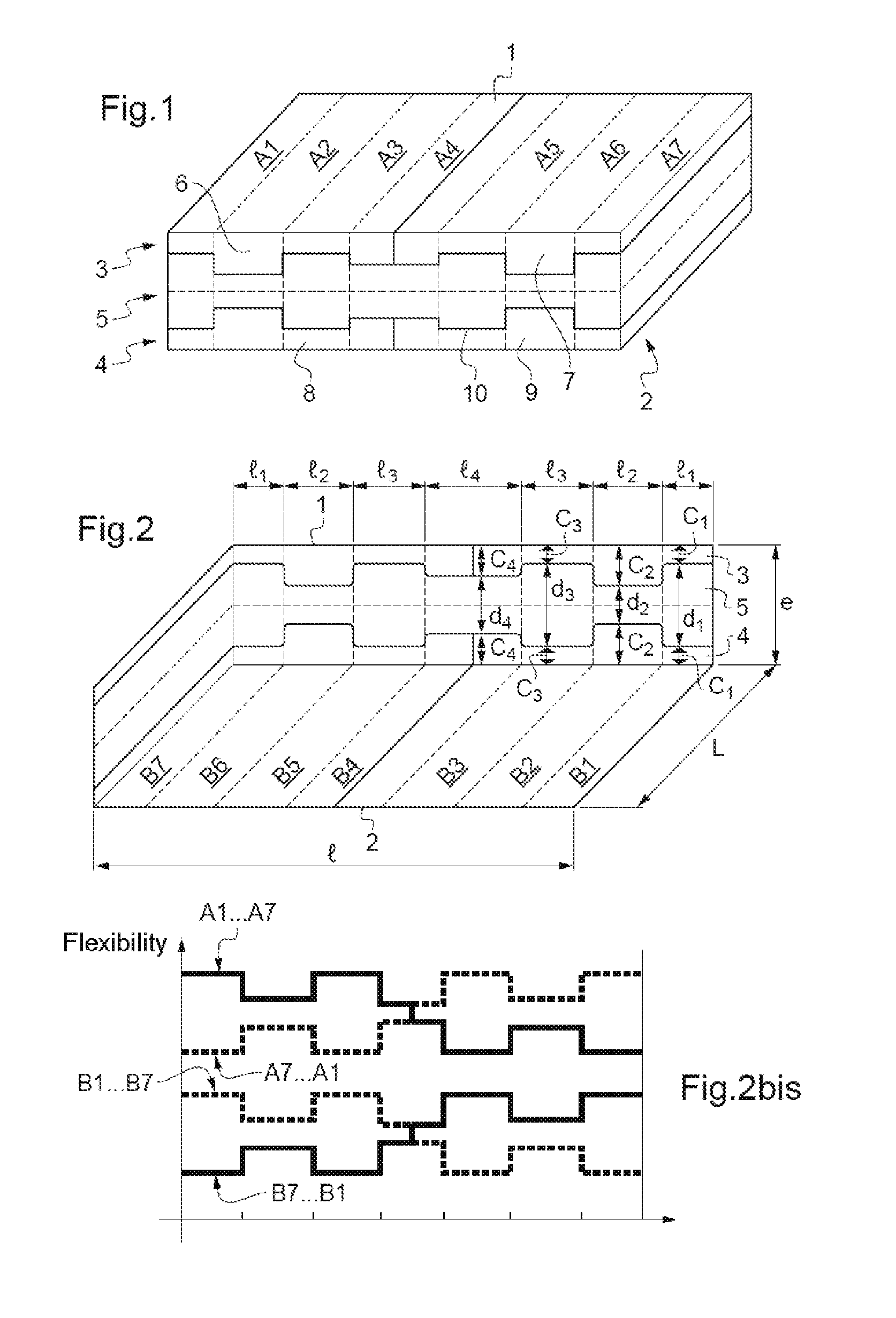

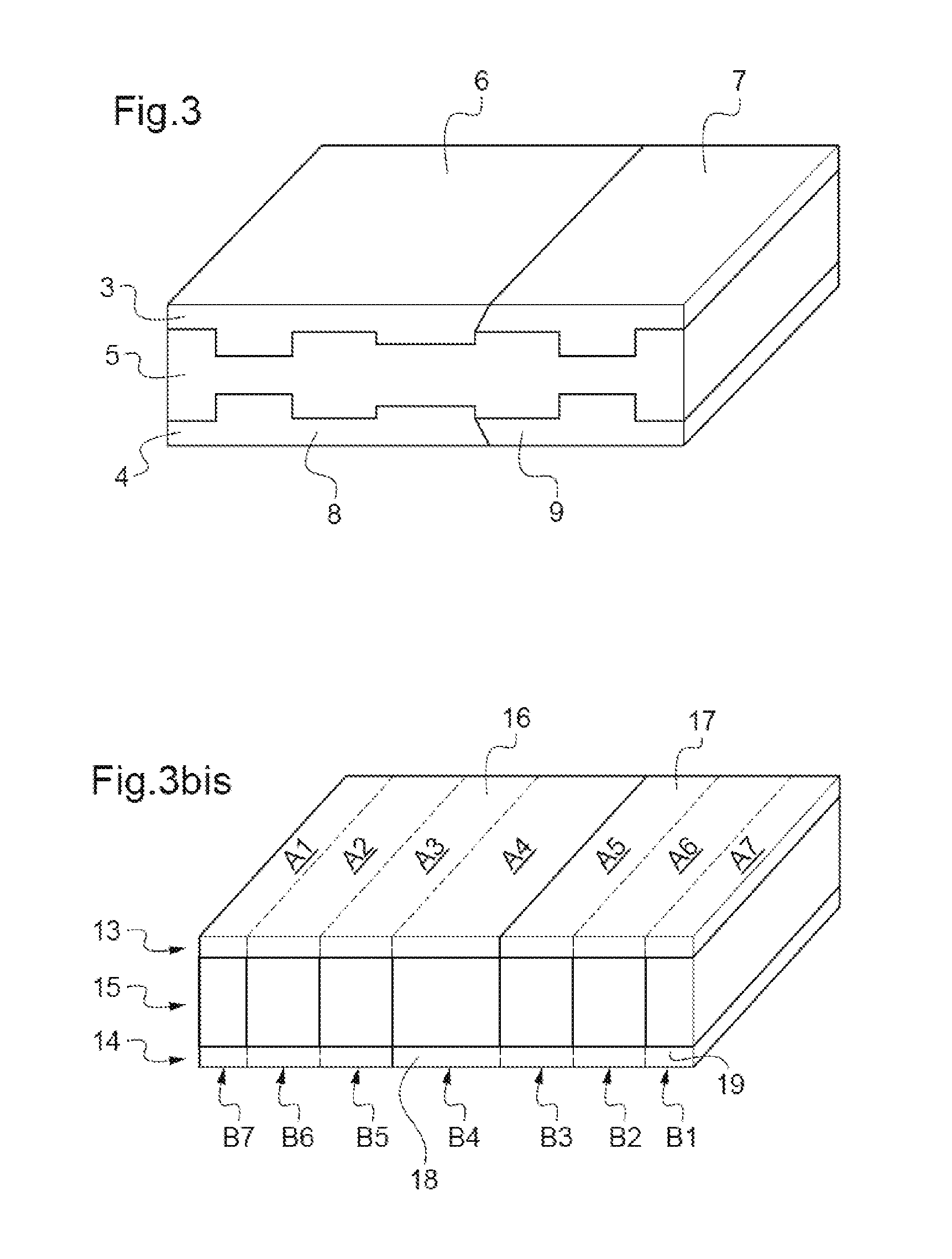

Four-sided reversible bedding element

A bedding element including a first large principal face opposite a second large principal face and divided lengthwise into portions that define. on the first large principal face, first successive receiving areas (A1 to A7) of which a first succession (A1 to A7) defines a first resting area and of which a second succession (A7 to A1) opposite the first defines a second resting area; and on the second large principal face, second successive receiving areas (B1 to B7) of which a first succession (B1 to B7) defines a third resting area and of which a second succession (B7 to B1) opposite the first defines a fourth resting area. The portions of the bedding element that define these receiving areas have differentiated mechanical characteristics so that the four resting areas have four different receiving profiles.

Owner:SPORTIS FABIENNE +2

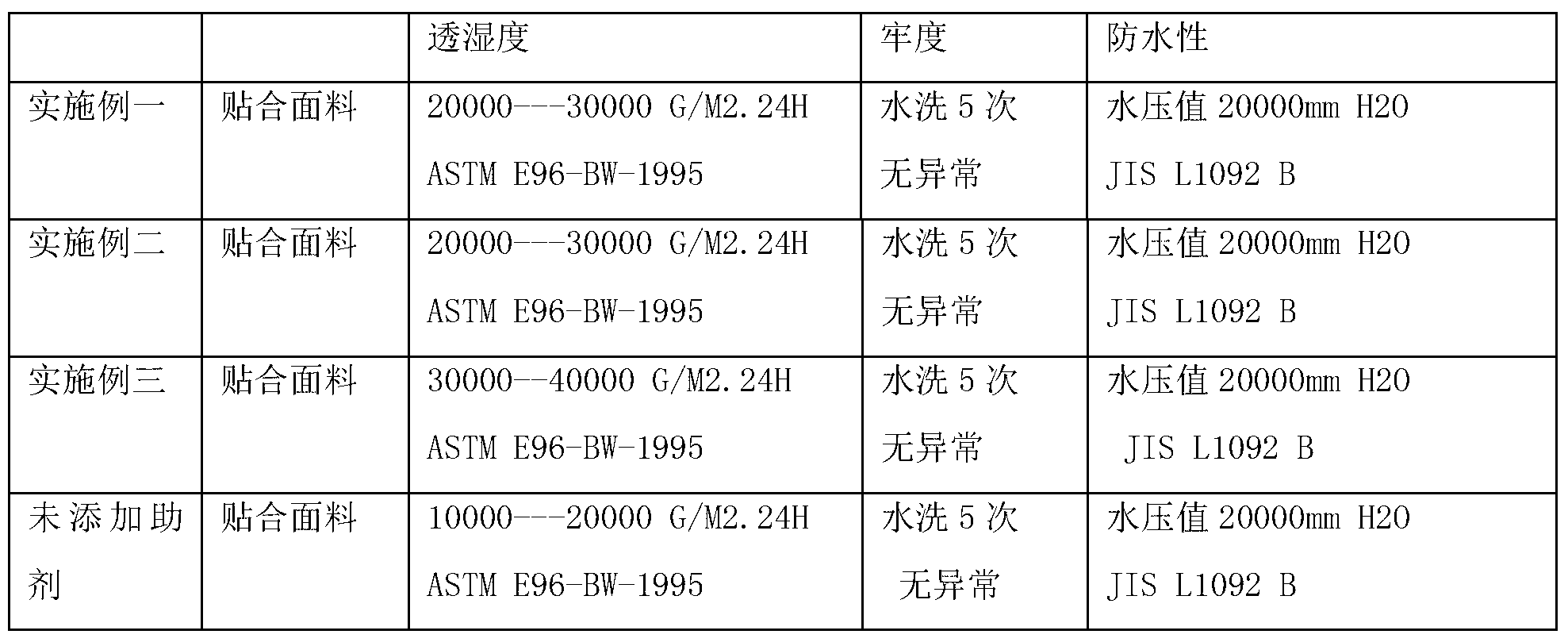

Method for manufacturing bonded fabric with improved moisture permeability

ActiveCN103317809AGood moisture permeabilityGuaranteed feelLamination ancillary operationsLaminationMoisture permeabilityRelease liner

The invention discloses a method for manufacturing a bonded fabric with improved moisture permeability. The bonded fabric comprises a surface adhesive layer, a bottom adhesive layer and a fabric layer, and the method for manufacturing the bonded fabric comprises the following steps of: a, preparing an adhesive, namely preparing the bottom adhesive and the surface adhesive, wherein a primary adhesive of the surface adhesive is added in the bottom adhesive preparation, so that the moisture permeability can be improved; b, coating the surface adhesive on release paper, and drying the surface adhesive so as to form the surface adhesive layer; c, coating the bottom adhesive on the surface of the surface adhesive layer, and semi-drying the bottom adhesive; d, uncoiling the fabric layer and the release paper at a same speed, bonding the fabric layer and the bottom adhesive layer under a pressure of 4-6 kg / cm<2> so as to form a semi-finished product, and coiling the semi-finished product; and e, after the semi-finished product is cured, stripping away the release paper. According to the manufacturing method, the proportions of the surface adhesive and the bottom adhesive in the bonded fabric are improved, and hydrophilic waterproof and moisture-permeable polyurethane resin in the surface adhesive is added in the bottom adhesive, therefore, the moisture permeability of the bottom adhesive is improved, and then the moisture permeability of the bonded fabric can be improved, so that the waterproof and moisture-permeable properties of the bonded fabric break through 20K / 20K.

Owner:TRYD TEXTILE FIBER TECH

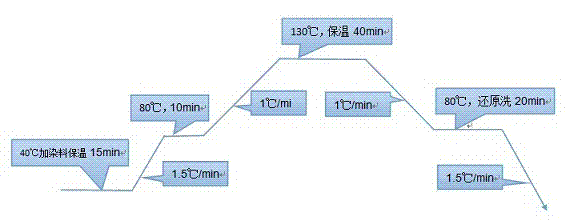

Polyester taslan fabric moisture absorbing and sweat releasing dyeing and finishing process

InactiveCN104762837AFully absorbedGuaranteed fastnessSucessive textile treatmentsHeating/cooling textile fabricsPolyesterPulp and paper industry

The invention discloses a polyester taslan fabric moisture absorbing and sweat releasing dyeing and finishing process. The production process includes: cold stacking, open-width desizing, in-cylinder finishing scouring, overflow dyeing, reducing cleaning, finishing, cylinder discharge, dehydration width opening, and shaping. Specifically, the finishing adopts moisture absorbing and sweat releasing, overflow washing is conducted after reducing cleaning, and a moisture absorbing and sweat releasing assistant is added after washing the fabric surface clean to carry out finishing. The process ensures sufficient textile desizing, makes the capillary effect of the taslan fabric reach the best state, so that the textile can fully absorb the moisture absorbing and sweat releasing assistant to enhance the moisture absorbing and sweat releasing effect, and the fabric can be resistant to washing. The process avoids or reduces the generation of watermark problem, and has very good practical effect.

Owner:WUJIANG FUHUA WEAVING

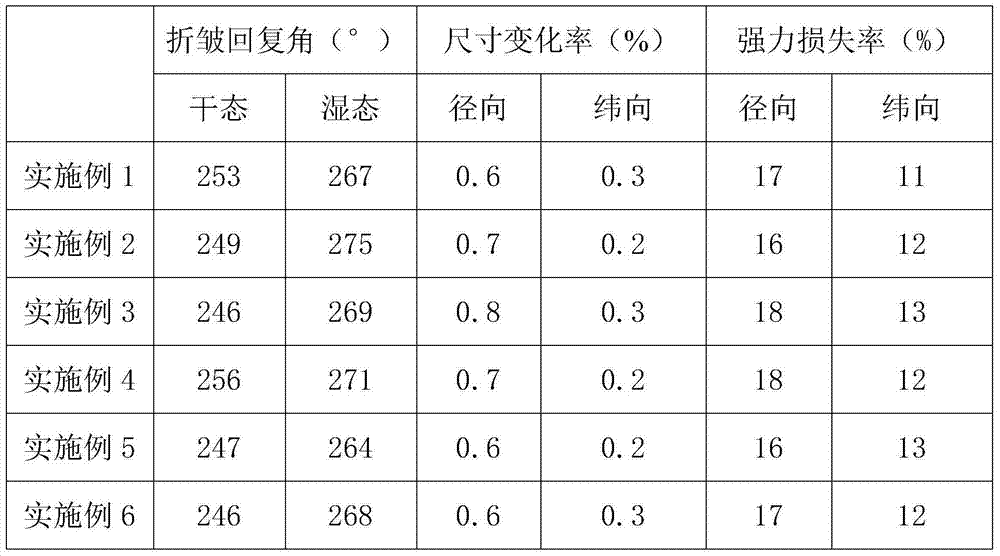

Noniron finishing method of silk fabric

InactiveCN104762821AGood shrink resistanceGuaranteed feelBiochemical fibre treatmentAnimal fibresWarm waterEngineering

The invention discloses a noniron finishing method of a silk fabric. The noniron finishing method particularly comprises the following steps: moistening and rinsing the silk fabric with warm water twice, refining and expanding the silk fabric by using a biological enzyme, after rinsing with warm water, padding the expanded silk fabric in a wash and wear finisher containing silk fibroin, citric acid and chitosan quaternary ammonium salt, then predrying the silk fabric, tentering at constant temperature, baking at high temperature, washing with water and drying, and pressing-packaging to obtain the noniron finished silk fabric. According to the noniron finishing method, a biological enzyme technology is combined with a padding technology, the silk fabric is subjected to noniron finishing by using the silk fibroin, the citric acid and the chitosan quaternary ammonium salt, so that the noniron finishing method has the advantages of simple and effective, environmental-friendly and biological effects. The silk fabric prepared by adopting the noniron finishing method reaches a noniron degree, and has a good crease-resisting and deformation-resisting capabilities; the dyeing performance of the fabric is improved; the handfeel, the style and the mechanical property of the fabric are reserved, and thus the noniron finishing method is an ideal noniron finishing method of the silk fabric.

Owner:SUZHOU WILDER IND & TRADE

Titanium dioxide textile and preparation method thereof

The invention provides a titanium dioxide textile and a preparation method thereof.The titanium dioxide textile is prepared from, by weight, 100-200 parts of pure cotton cloth, 20-60 parts of a titanium dioxide antibacterial agent, 0-1 part of a dispersing agent, 5-10 parts of a binder, 1-2 parts of a thickener, 200-300 parts of alkali liquor and 20-50 parts of water, wherein the titanium dioxide antibacterial agent is mainly prepared from tetrabutyl titanate, 1-acetoxy-3-propane sulfoacid imidazole bromine salt and a metal organic framework material.Accordingly, the prepared titanium dioxide antibacterial textile is good in antibacterial effect, strong in fabric affinity and good in washing fastness, is environmentally friendly and keeps the hand feeling of fabric fibers.

Owner:上海钛盾生物科技有限公司

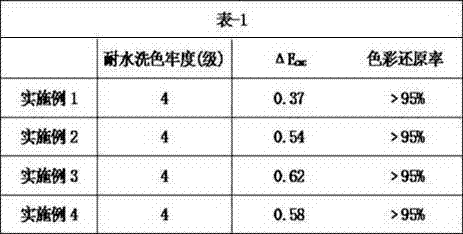

Water-based nano pigment ink for textile printing

The invention relates to ink and in particular relates to water-based nano pigment ink for textile printing. According to the formula, the ink mainly comprises the following components in parts by weight: 12.4-18.6 parts of water-based pigment slurry, 9.5-14.9 parts of a water-based resin, 5.3-9.6 parts of a quick-dry type solvent, 5.4-9.8 parts of a moisturizing solvent, 0.5-2 parts of a surfactant, 0.05-0.2 part of an antibacterial agent and 50.9-65.55 parts of deionized water. According to the ink disclosed by the invention, textiles do not need to be preheated and heated, and the ink refers to healthy and environment-friendly water-based nano pigment ink which can be directly printed on the textiles. Moreover, a digital ink-jet printing textile prepared by the ink has excellent color fastness to washing, color reduction rate and excellent handfeel.

Owner:南京鼎科纳米技术研究所有限公司

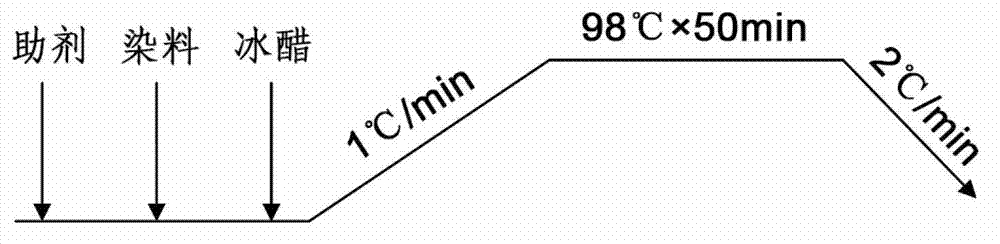

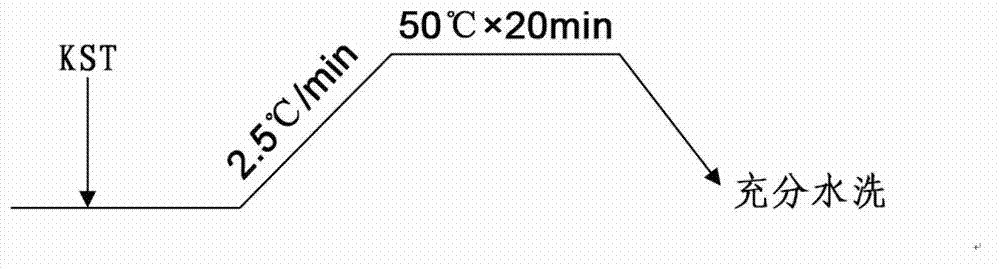

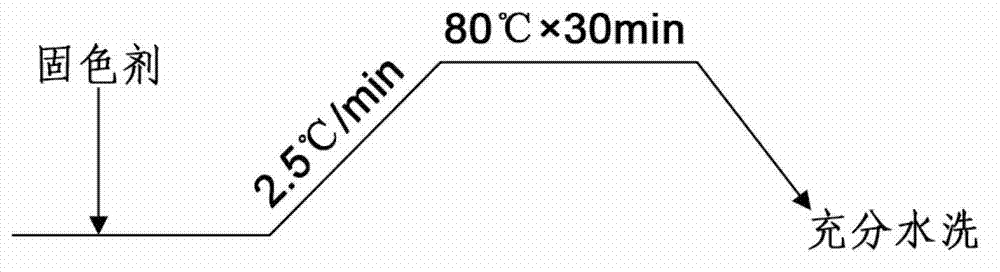

Deep color dyeing and finishing technique of poly lactic acid (PLA) fiber and gossamer fiber blending fabrics

ActiveCN102864663AGuaranteed StrengthGuaranteed feelHeating/cooling textile fabricsDry-cleaning apparatus for textilesChemistryAfter treatment

A deep color dyeing and finishing technique of poly lactic acid (PLA) fiber and gossamer fiber blending fabrics comprises the following steps of greige cloth sewing, preliminary shaping, preliminary treatment, dyeing, fixation, dehydration and an after treatment process. The deep color dyeing and finishing technique of PLA fiber and gossamer fiber blending fabrics uses a dual-bathing method to dye. A mesotherm type disperse dye is used for dyeing (enabling color to be deep) PLA fibers, and a carrier is added during dyeing. An environment-friendly mesotherm direct dye is used for dyeing (enabling color to be deep) gossamer fibers, fixation treatment is carried out after dyeing, fibers with two components can be dyed into a deep color simultaneously, and strength and feeling of the PLA fibers and the gossamer fibers are guaranteed.

Owner:ZHEJIANG DANENG TEXTILE PRINTING & DYEING

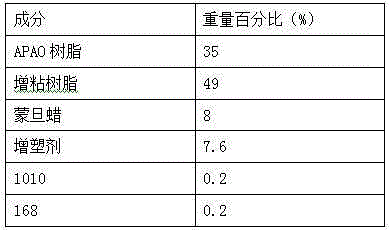

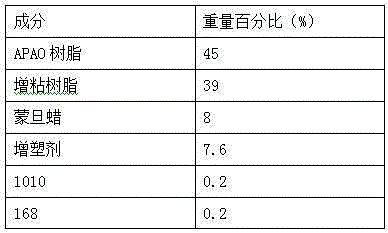

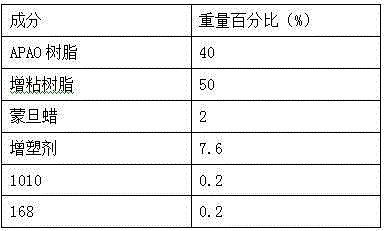

Tissue paper compounding hot melt adhesive and preparation method thereof

InactiveCN105219299AHigh active ingredientFast curingMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesPlasticizerPetroleum resin

The invention relates to a tissue paper compounding hot melt adhesive which is composed of, by mass, 20-45% of APAO resin, 30-60% of tackifying resin, 2-15% of a plasticizer, 1-15% of montan wax and 0.2-0.8% of an antioxidant. The APAO resin has a propylene content of 60-75%, a glass transition temperature of -40 DEG C to -20 DEG C, and a viscosity of 3000-10000cps under a temperature of 190 DEG C. The tackifying resin is hydrogenated petroleum resin with a softening point of 60-90 DEG C. the tissue paper compounding hot melt adhesive provided by the invention does not contain water, such that no water penetrates into the tissue paper during a tissue paper production process. Therefore, tissue paper performances such as hand feeling, strength and comfortableness can be ensured, and paper quality decrease caused by water penetration can be avoided. The adhesive also has the advantages of high curing speed, excellent strippability, long exposure time, good fluidity, good safety, good environment friendliness, no toxicity, and no odor. The adhesive has a good application prospect.

Owner:熊红兵

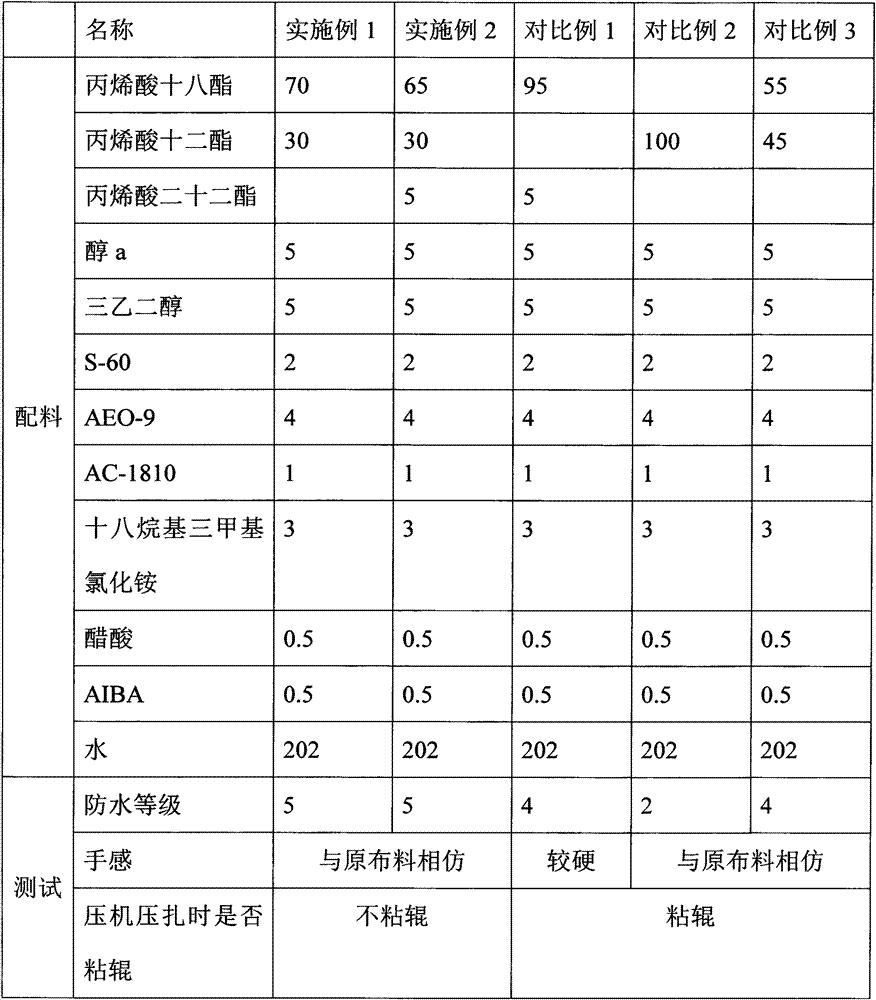

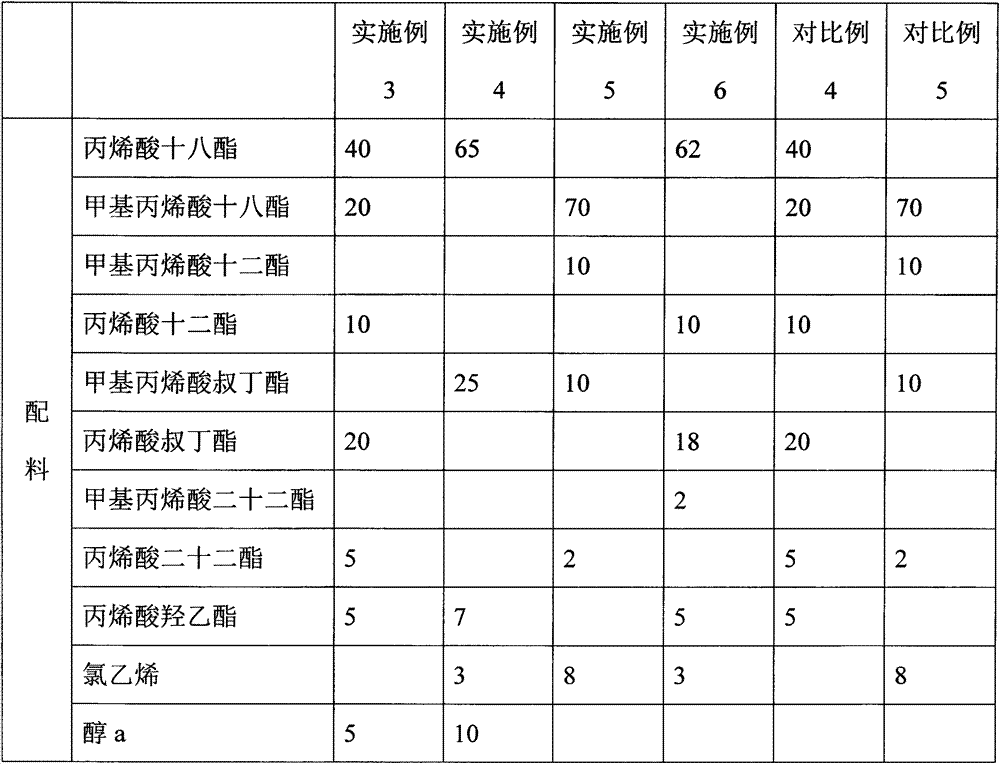

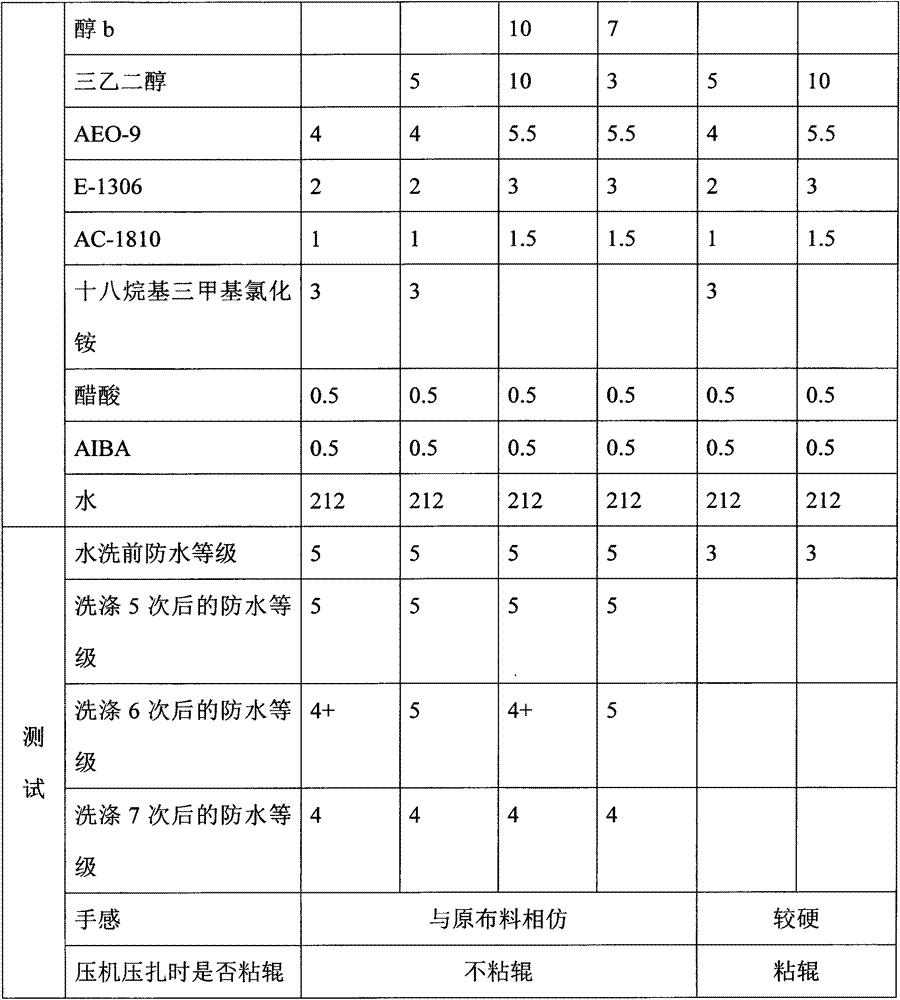

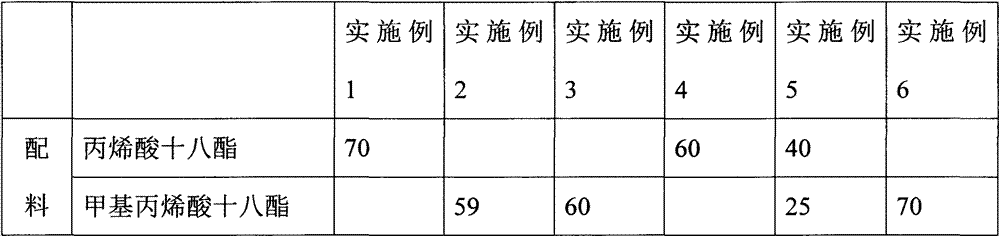

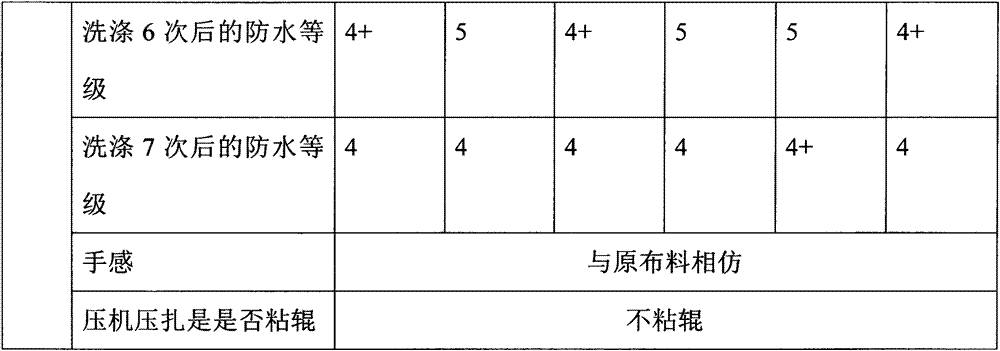

Composition dispersing liquid for fabric waterproof treatment

InactiveCN106884327AImprove waterproof performanceImprove washabilityLiquid repellent fibresAlcoholOrganic group

The invention discloses a composition dispersing liquid for fabric waterproof treatment. The composition dispersing liquid comprises a non-fluorine acrylate polymer, a non-fluorine surfactant, an alcohol-containing composition and water, wherein the non-fluorine acrylate polymer contains at least 60wt% of acrylate unit with C14-C18 alkyl and at most 40wt% of acrylate unit with C1-C12 alkyl; the alcohol-containing composition contains a compound shown in the formula of R-[Si(CH3)2O]x-[Si(CH3)(R1)O]y-Si(CH3)2R, R1 is a monovalence organic group at least containing three carbon atoms and a hydroxyl group, R is R1 or C1-C4 alkyl, and x and y are positive integers. The composition dispersing liquid for fabric waterproof treatment has the advantages that the stability is good, the roll sticking is avoided in the cloth rolling process after the fabric is impregnated, the treated fabric has excellent fireproof property and good washing-resistant property, and the original hand feel of the fabric can be well maintained; the continuous processing property of the dispersing liquid is excellent.

Owner:ZHEJIANG KANGDE NEW MATEIRALS

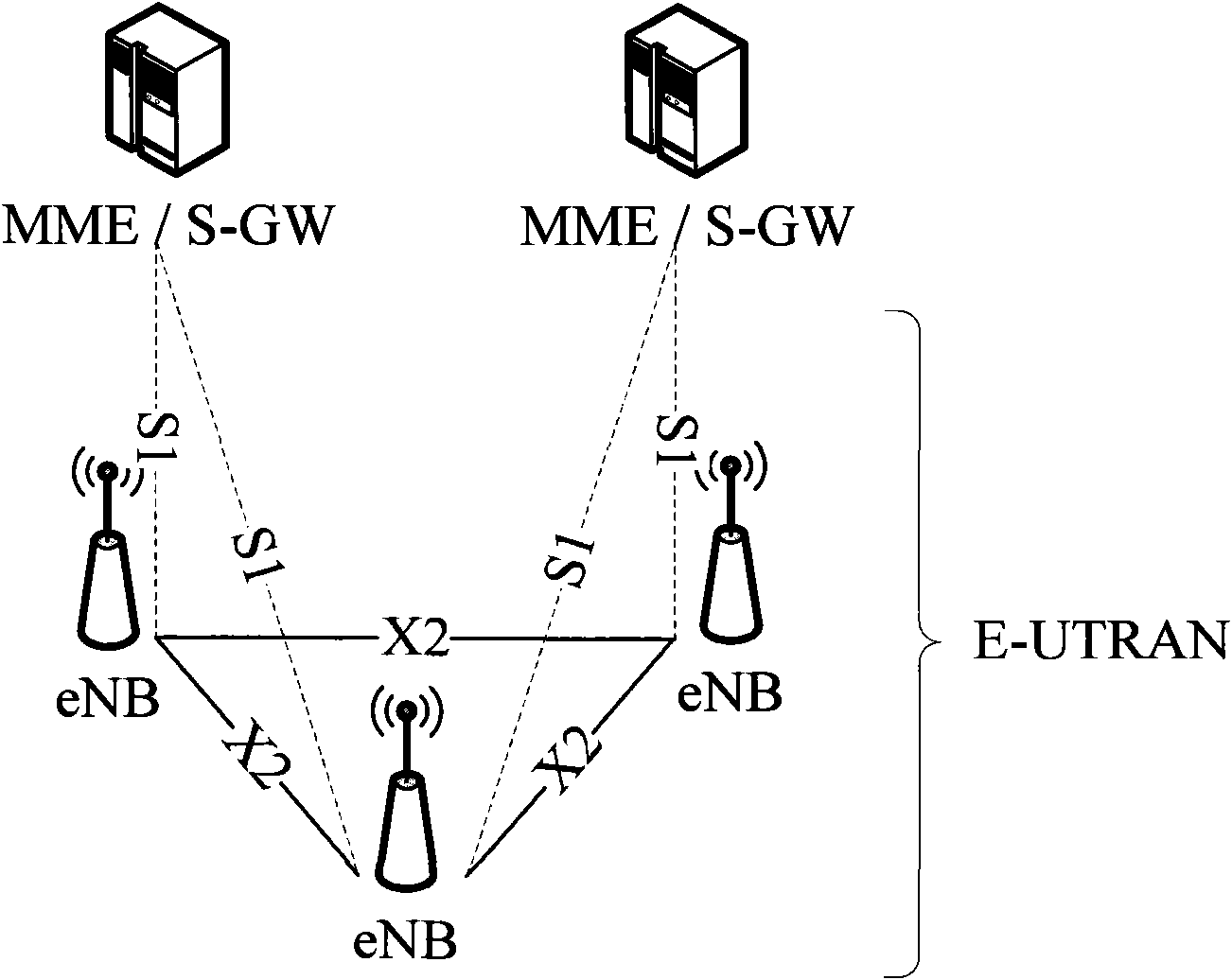

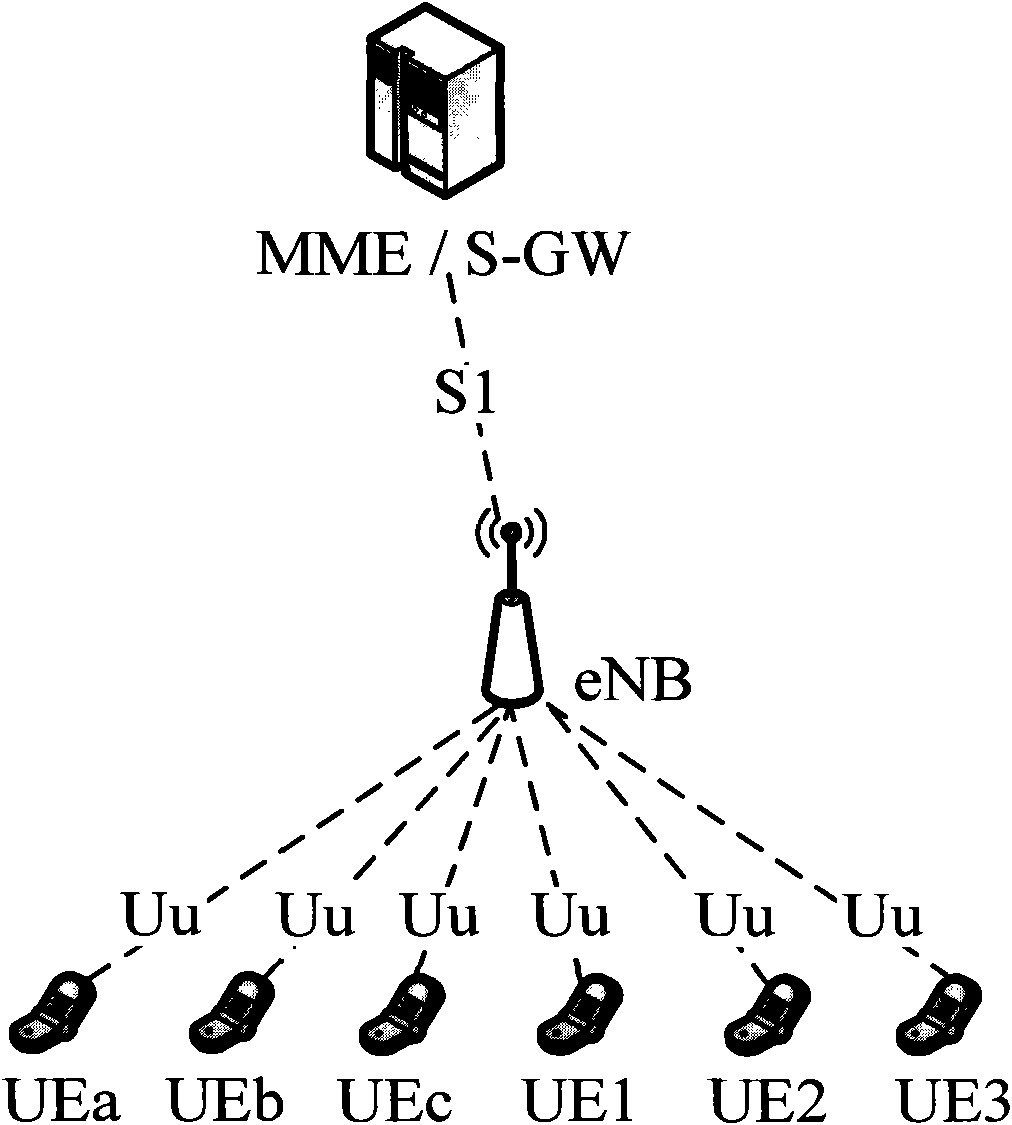

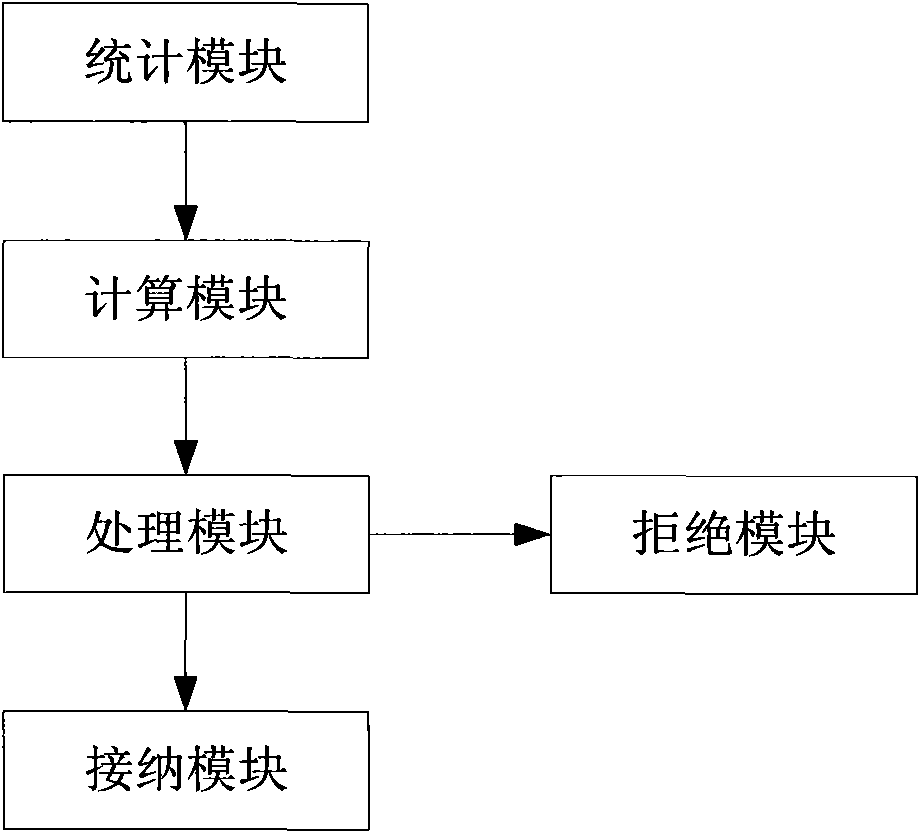

Resource admission control method and apparatus thereof, and base station

ActiveCN102340831AProtect interestsGuaranteed feelNetwork traffic/resource managementAssess restrictionAir interfaceUser equipment

The invention discloses a resource admission control method and an apparatus thereof, and a base station; therefore, it is avoided that user service qualities of other operators are damaged, wherein the damages are caused by over occupation of air interface resources. The resource admission control method comprises the following steps that: real-time or periodic statistics is carried out on an occupation situation of air interface resources by a base station; when user equipment (UE) initiates a service request, the base station determines whether the service initiated by the UE is allowed to be accessed or not according to the occupation situation of the air interface resources.

Owner:如东文园投资开发有限公司

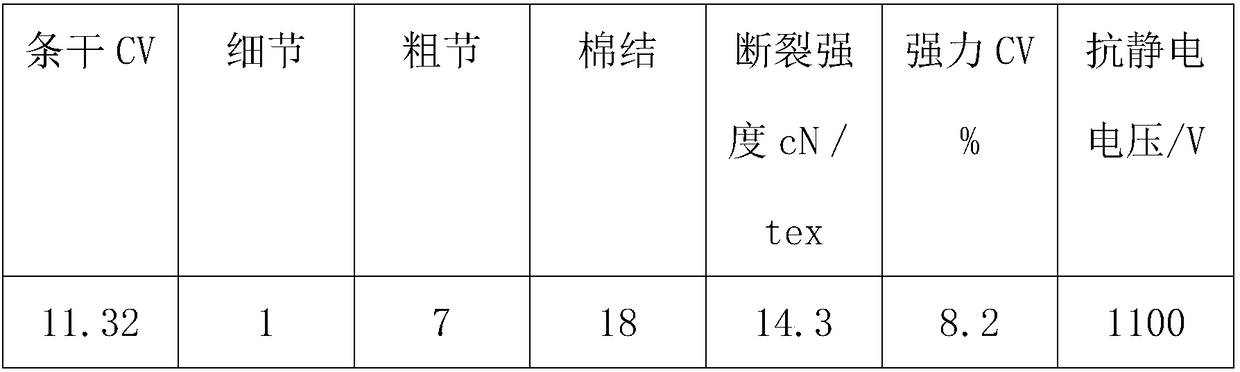

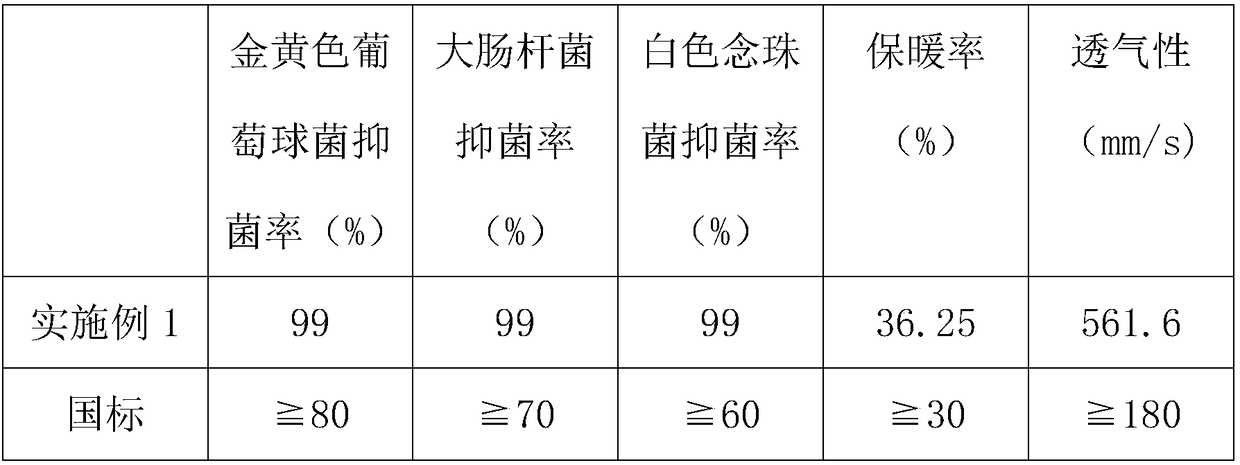

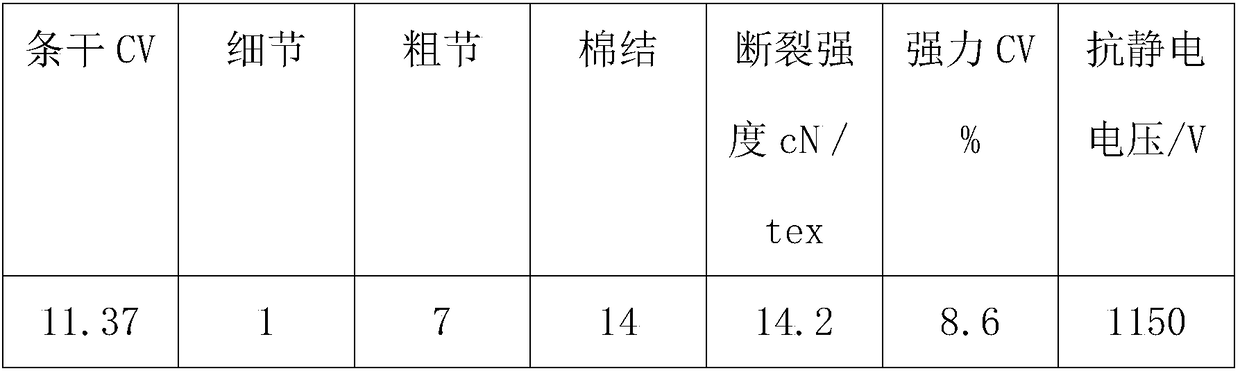

Heating-antibacterial antistatic and high-simulation cashmere blended knitting yarn and fabric thereof

InactiveCN108442001AGood antibacterial effectWith heating and antistaticWeft knittingWarp knittingYarnCarding

The invention discloses heating-antibacterial antistatic and high-simulation cashmere blended knitting yarn. Blend fibers are subjected to blowing, cotton carding, drawing, roving, yarn spinning and spooling to prepare into the heating-antibacterial antistatic and high-simulation cashmere blended knitting yarn, wherein the blend fibers are composed of wool, acrylic fibers, chinlon, dacron, viscosefibers and high-simulation cashmere fibers, and the chinlon, the dacron and the viscose fibers are compounded with graphene; the dacron accounts for 20% to 30% of the total mass of the blend fibers,the chinlon accounts for 5% to 15% of the total mass of the blend fibers, the viscose fibers account for 15% to 25% of the total mass, the acrylic fibers account for 5% to 10% of the total mass of theblend fibers, the high-simulation cashmere fibers account for 30% to 40% of the total mass of the blend fibers, and the wool accounts for 5% to 15% of the total mass of the blend fibers. According tothe heating-antibacterial antistatic and high-simulation cashmere blended knitting yarn, by adding the chinlon, the dacron and the viscose fibers compounded with the graphene, the good heating, antibacterial and bacterium inhibition effect is achieved; the antibacterial effect of the woven fabric on staphylococcus aureus, escherichia coli and candida albicans is up to 99% or above; the static problem can be effectively solved, and the whole fabric has the anti-static effect.

Owner:RUGAO CITY DINGYAN TEXTILE

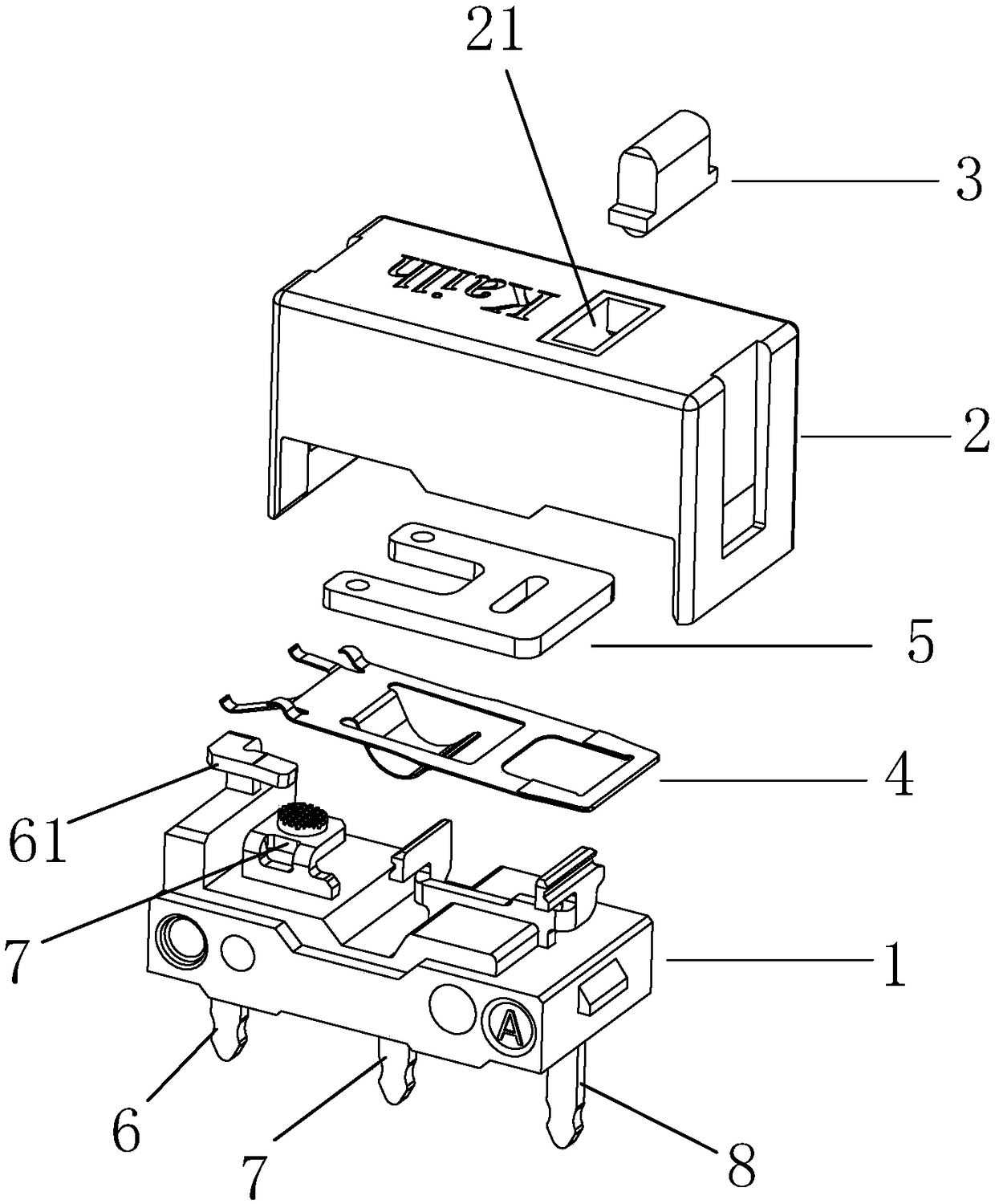

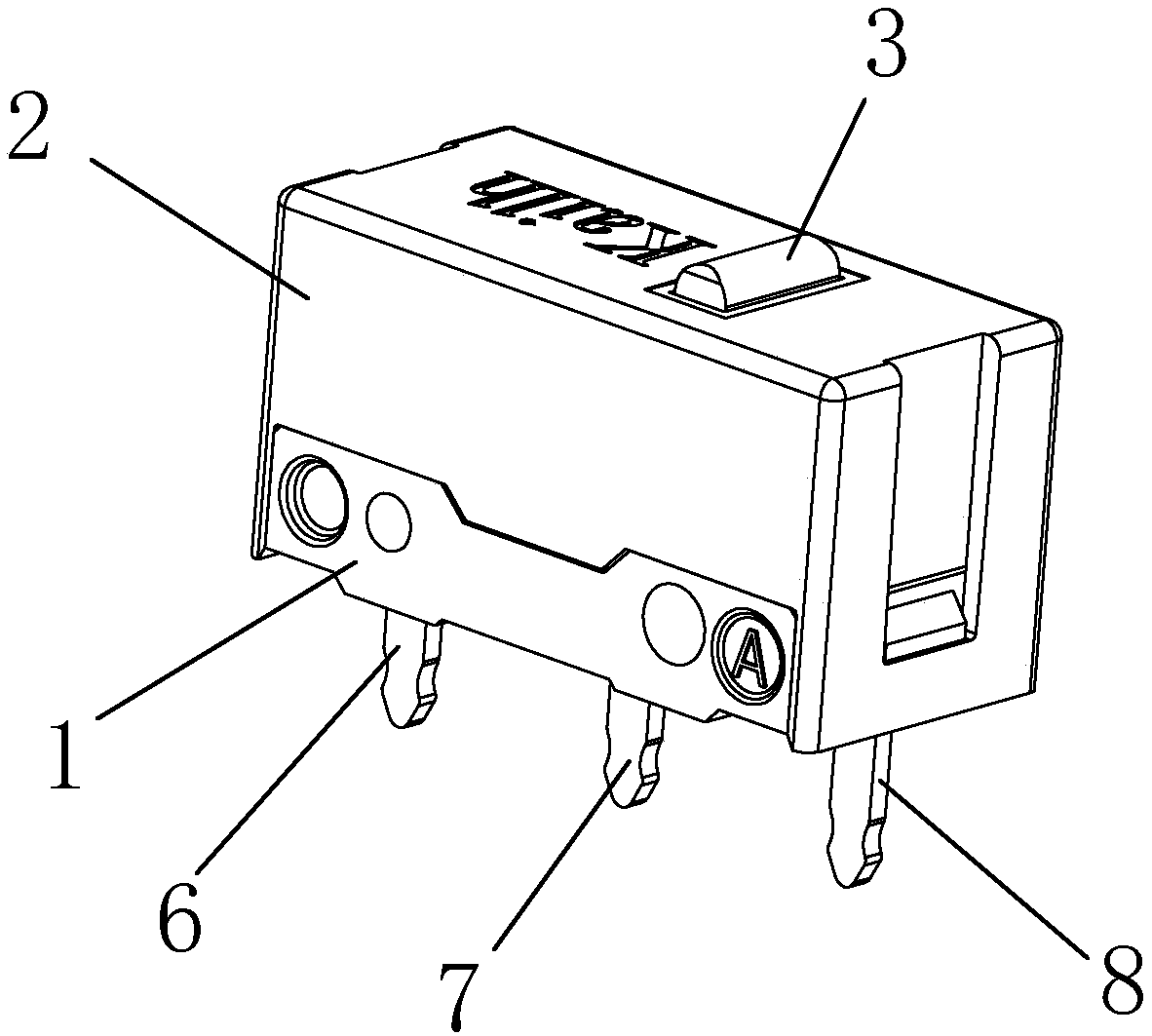

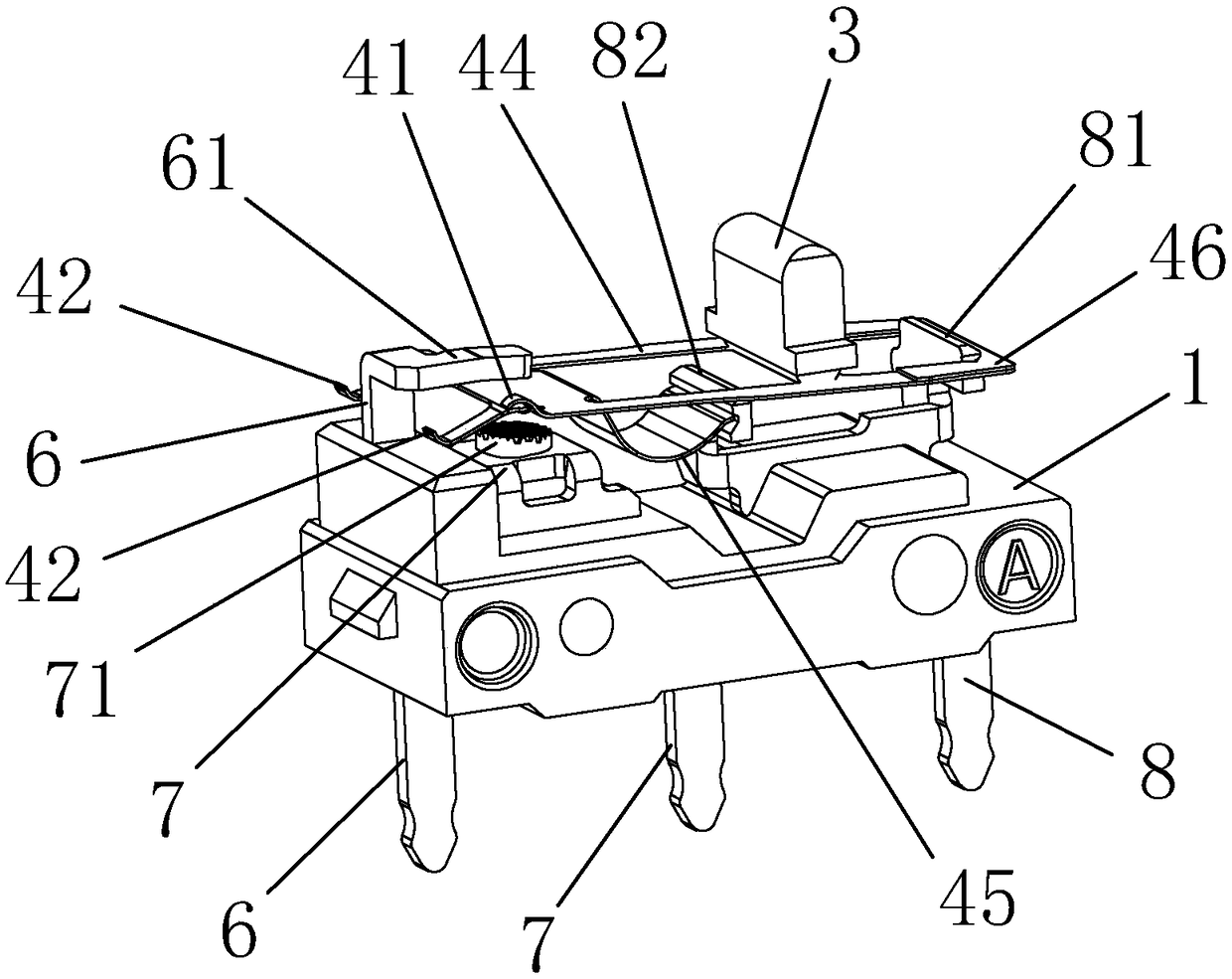

High-life mute micro-switch

PendingCN108281314AReduce impactRealize the noise reduction functionElectric switchesElastomerEngineering

The invention discloses a high-life mute micro-switch, which comprises a base, a cover covering the base, an elastic body and a flexible body, wherein the cover covers the base to form an accommodating cavity; a guide core is arranged in the accommodating cavity; an upper opening through which the upper end of the guide core passes is formed in the cover; the elastic body is arranged in the accommodating cavity and is located at the lower part of the guide core; the flexible body is arranged on the lower end surface of the cover and is located at the upper part of one end of the elastic body;a plurality of upper elastic strips are arranged at one end of the elastic body in a manner of extending upwards; the plurality of upper elastic strips are located below the flexible body; and when pressing on the guide core is released, the elastic body rebounds due to deformation recovery, and the upper elastic strips are prompted to touch the flexible body and flexibly deform, so that the impact force is reduced through generated buffer force to achieve the muting effect. The micro-switch disclosed by the invention has the muting function, a good muting effect is achieved, and meanwhile, the whole life is prolonged and reaches 80,000,000 times.

Owner:DONGGUAN CITY KAIHUA ELECTRONICS

Composition dispersion liquid used for water repellent treatment

InactiveCN106866872AImprove stabilityExcellent continuous processing performanceLiquid repellent fibresGrip property fibresCross-linkOrganic group

The invention discloses a composition dispersion liquid used for water repellent treatment. The composition dispersion liquid used for water repellent treatment contains a non-fluoroacrylate polymer, and a surfactant composition represented by R-[Si(CH3)2O]x-[Si(CH3)(R1)O]y-Si(CH3)2R; the non-fluoroacrylate polymer contains at least 59wt% or more of C14-30 acrylate monomers, at most 40wt% C1-12 acrylate monomers, and 1wt% or more a cross-linking monomer; R1 is used for representing an univalent organic group, R is used for representing R1 or C1-4 alkyl, x and y are selected from positive integers; and water is taken as a cosolvent. The composition dispersion liquid used for water repellent treatment is excellent in stability; roll banding in cloth banding after dipping is not caused; water resistance of fabric processed with the composition dispersion liquid used for water repellent treatment is excellent; washing fastness is high; the original handfeel of processed fabric can be maintained preferably; and the continuous processing performance of the composition dispersion liquid used for water repellent treatment is excellent.

Owner:ZHEJIANG KANGDE NEW MATEIRALS

Waterproof cloth surface flexible composite material and preparation method thereof

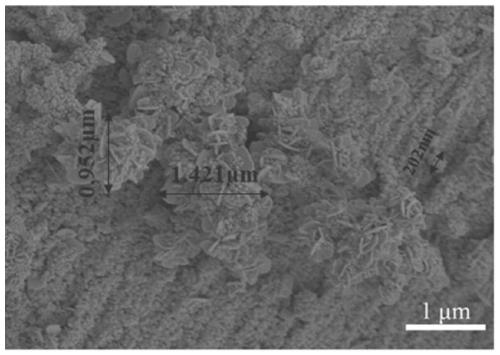

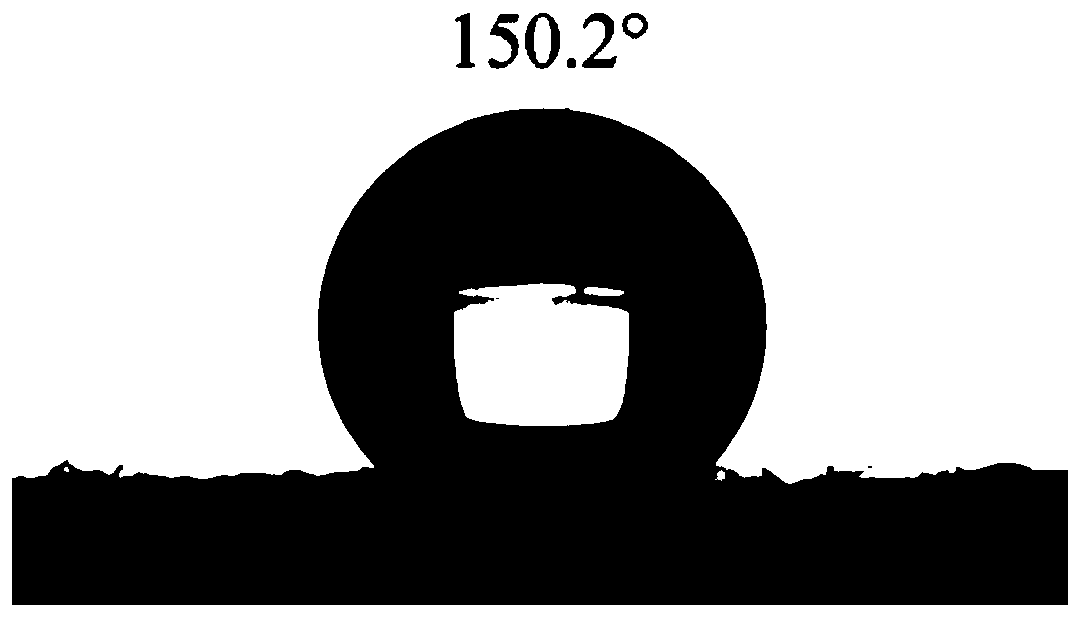

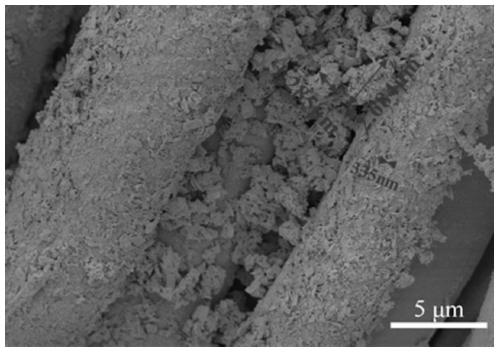

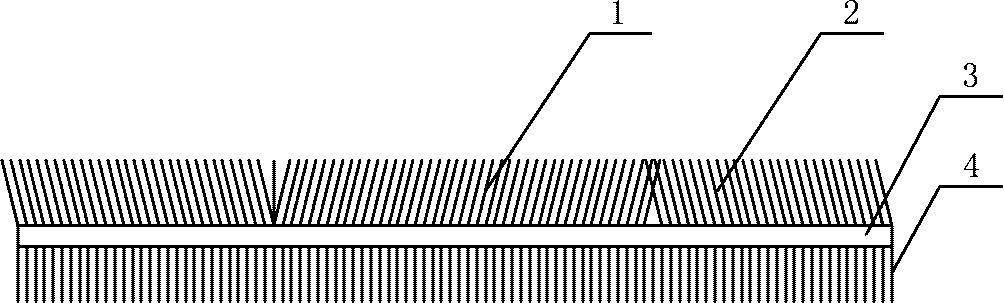

ActiveCN111593570AExcellent durabilityGuaranteed strongSynthetic resin layered productsLiquid repellent fibresFiberPolymer science

The invention discloses a waterproof cloth surface flexible composite material and a preparation method thereof. The waterproof cloth surface flexible composite material is characterized in that one surface of a super-hydrophobic fabric is bonded with a plastic film by using an adhesive to obtain the washable waterproof cloth surface flexible composite material. The preparation method comprises the following steps of diazotizing a fluorine-containing alkyl aniline monomer in a dilute acid solution of sodium nitrite to form fluorine-containing alkyl benzene diazonium salt; carrying out reduction reaction on the fluorine-containing alkylbenzene diazonium salt under the action of a reducing agent to obtain a fluorine-containing alkylbenzene free radical monomer; and carrying out in-situ single-electron free radical covalent graft polymerization reaction on the fluorine-containing alkylbenzene free radical monomer in the fabric fiber to obtain the super-hydrophobic fabric. As the super-hydrophobic fabric obtained through chemical grafting, the fiber surface coating is combined with the fiber through covalent bonds, so that the super-hydrophobic fabric has excellent fastness, the flexibility and the hand feeling of the fabric are not influenced, and the problems of poor fastness and poor hand feeling of the super-hydrophobic fabric obtained through methods such as the coating are solved.

Owner:SUZHOU UNIV

Single-layer and double-face velveting and weaving method thereof

InactiveCN104032454ASimple production processReduce manufacturing costMulti-ply fabricsThermoplasticEngineering

The invention discloses single-layer and double-face velveting and a weaving method thereof. The single-layer and double-face velveting comprises base cloth and suede on the two sides of the base cloth. The suede on one side is provided with a pattern formed by combining different bright areas and dark areas, and the suede on the other side is not provided with a pattern. Silk suede heads of the suede on the pattern side are formed by cut piles and pattern pile warp fixedly connected to weft of the base cloth, the pattern pile warp is woven by continuously inclining forwards or backwards within a certain length of section on the base cloth in the warp direction, and suede patterns are formed by the suede head forward-inclining erecting area or the suede head backward-inclining erecting area. The single-layer and double-face velveting does not need to be dyed or processed in a thermoplastics mode, the pattern formed by combining the bright areas and the dark areas can be formed on one face of the velveting only through weaving, and the face, not provided with the pattern, of the velveting is not affected, the comfort of face attached to the skin is good, and the single-layer and double-face velveting has the advantages that the production technology is simple, the requirement for equipment is low, and the manufacturing cost is low.

Owner:LIAONING CAIYI WILD SILK PROD

Process for preparing washing-free regenerated polyester woolen blankets

The invention discloses a process for producing regenerated polyester woolen blankets. The process includes weaving, pre-drying, pre-brushing, pre-polishing, pre-ironing, flat screen printing, color fixation by ageing integrated machines, stentering drying, brushing, semi-finished product polishing, finished product ironing and shearing and finished product manufacturing. The process has the advantages that the process is implemented by the aid of printing and solidifying integrated machines, accordingly, post-printing washing working procedures can be omitted, and the difficult problem of excessively high water consumption in terylene woolen blanket production procedures can be solved by the aid of the process.

Owner:SHANDONG XINSILU IND & TRADE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com