Polyester taslan fabric moisture absorbing and sweat releasing dyeing and finishing process

A technology for moisture absorption and perspiration and moisture absorption and perspiration auxiliary agent, which is applied in the field of moisture absorption and perspiration dyeing and finishing of fabrics, can solve the problems of unsatisfactory moisture absorption and perspiration processing and finishing effect, decreased moisture absorption and perspiration effect, and water droplets on the cloth surface, etc. Achieve excellent moisture absorption and perspiration effects, maintain hand feel, and reduce watermarks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

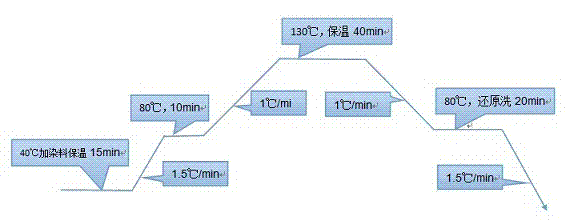

[0027] A moisture-absorbing and sweat-wicking dyeing and finishing process for polyester taslan fabrics is carried out according to the following procedures: cold stacking, open-width desizing, in-cylinder retraining, overflow dyeing, reduction cleaning, finishing, out of the tank, dehydration, opening width, and setting. The finishing adopts moisture absorption and perspiration finishing. After reduction washing, overflow washing is used. After the cloth surface is washed, moisture absorption and perspiration aids are added for finishing.

[0028] The working fluid for retraining in the cylinder is made of soda ash and penetrant in a weight ratio of 19:4, and 30 times the total weight of the two is added with deionized water to prepare an aqueous solution, in which the penetrant is penetrant OT-3.

[0029] The cold stack impregnation solution is made of H 2 0 2、 Mix NaOH and refining agent at a weight ratio of 5:10:1, add 34 times the weight of the three to form an aqueous s...

Embodiment 2

[0042] A moisture-absorbing and sweat-wicking dyeing and finishing process for polyester taslan fabrics is carried out according to the following procedures: cold stacking, open-width desizing, in-cylinder retraining, overflow dyeing, reduction cleaning, finishing, out of the tank, dehydration, opening width, and setting. The finishing adopts moisture absorption and perspiration finishing. After reduction washing, overflow washing is used. After the cloth surface is washed, moisture absorption and perspiration aids are added for finishing.

[0043] The working fluid for re-training in the tank is made by mixing soda ash and penetrating agent at a weight ratio of 20:3, adding 32 times the total weight of the two deionized water to prepare an aqueous solution, and the penetrating agent is penetrating agent OT-3.

[0044] The cold stack impregnation solution is made of H 2 0 2、 Mix NaOH and refining agent at a weight ratio of 5:10:1, add 30 times the weight of the three to form ...

Embodiment 3

[0057] A moisture-absorbing and sweat-wicking dyeing and finishing process for polyester taslan fabrics is carried out according to the following procedures: cold stacking, open-width desizing, in-cylinder retraining, overflow dyeing, reduction cleaning, finishing, out of the tank, dehydration, opening width, and setting. The finishing adopts moisture absorption and perspiration finishing. After reduction washing, overflow washing is used. After the cloth surface is washed, moisture absorption and perspiration aids are added for finishing.

[0058] The working fluid for re-training in the tank is made by mixing soda ash and penetrating agent at a weight ratio of 21:5, and adding 34 times the total weight of the two deionized water to prepare an aqueous solution, and the penetrating agent is penetrating agent OT-3.

[0059] The cold stack impregnation solution is made of H 2 0 2、 Mix NaOH and refining agent at a weight ratio of 5:10:1, add 31 times the weight of the three to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com