Patents

Literature

109results about How to "Guaranteed fastness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

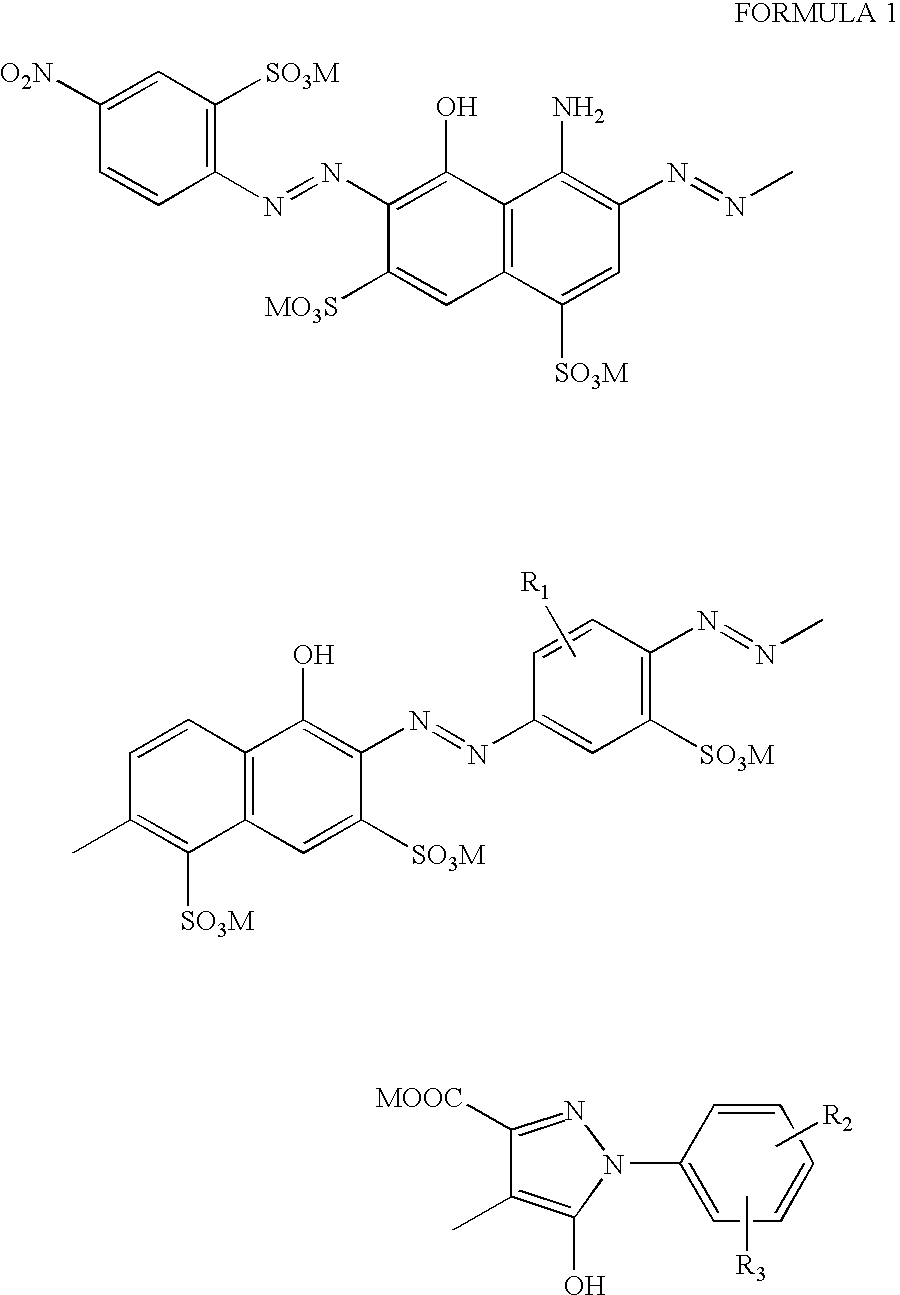

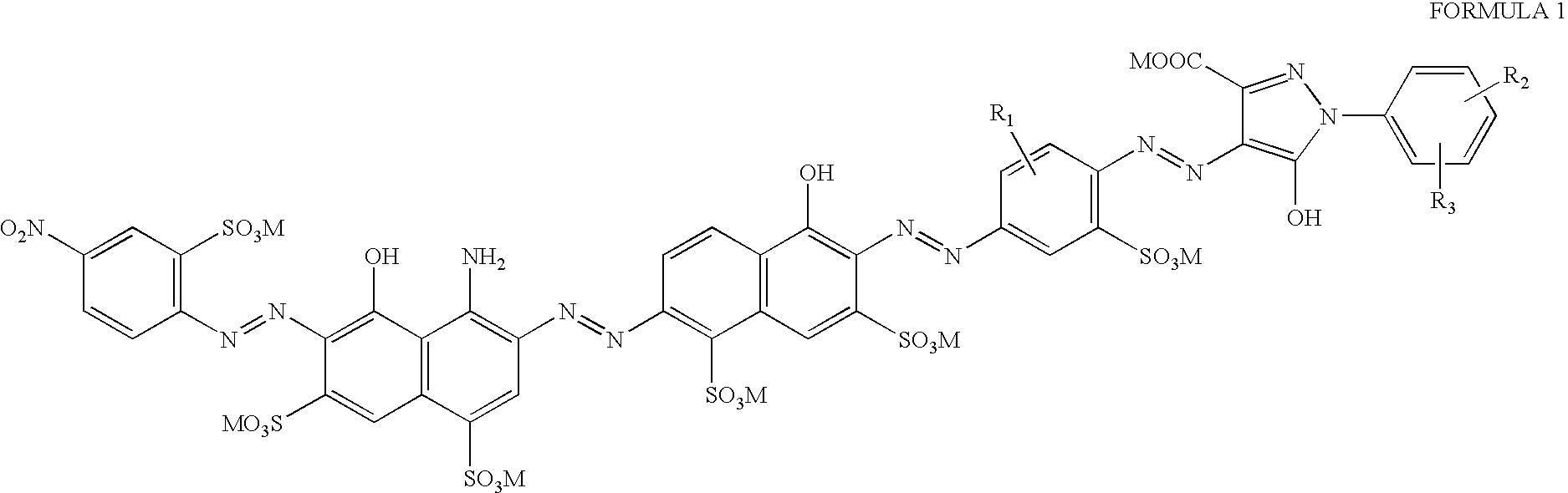

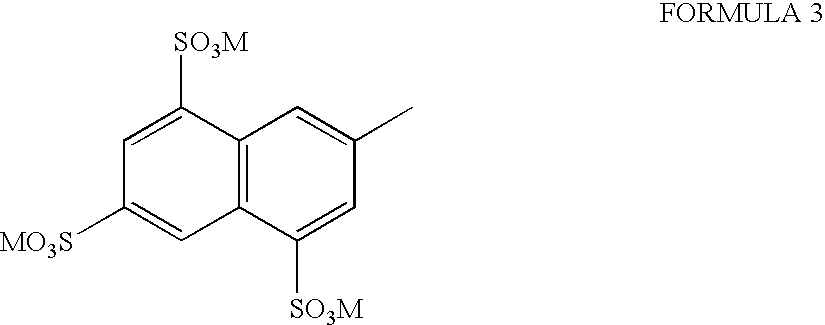

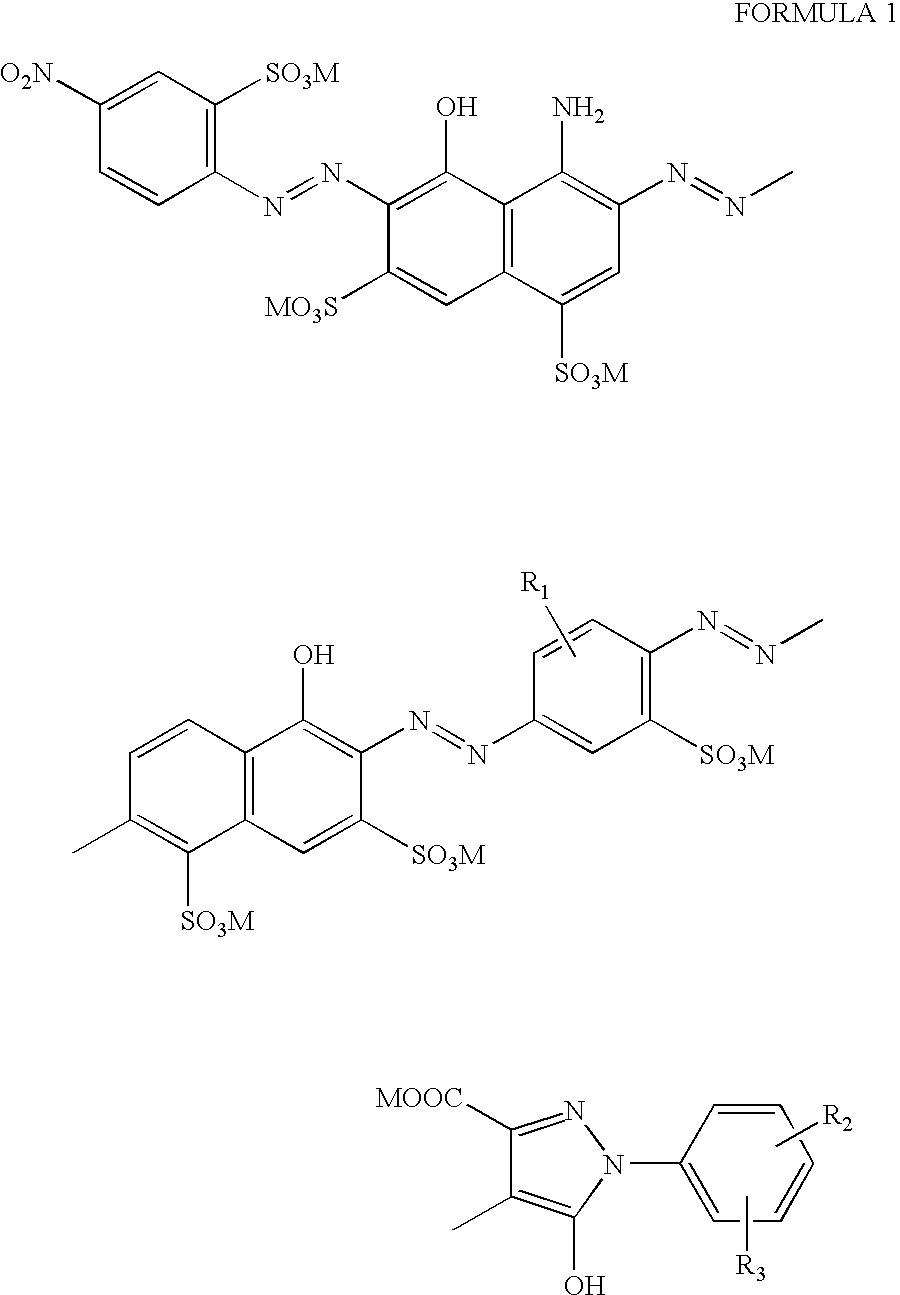

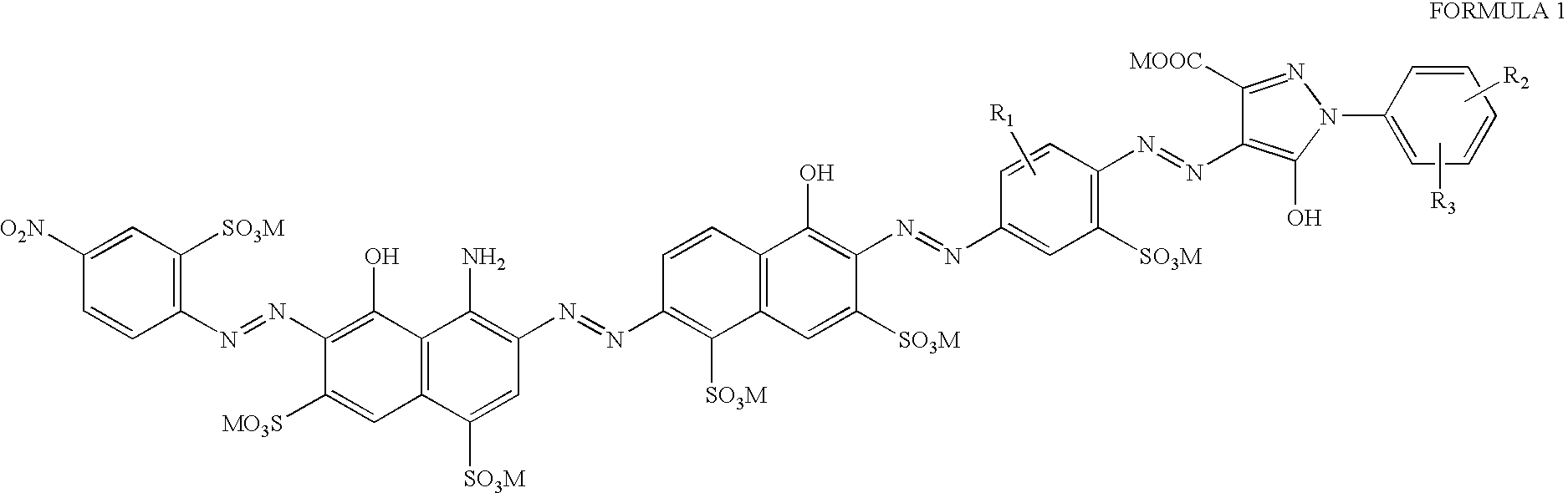

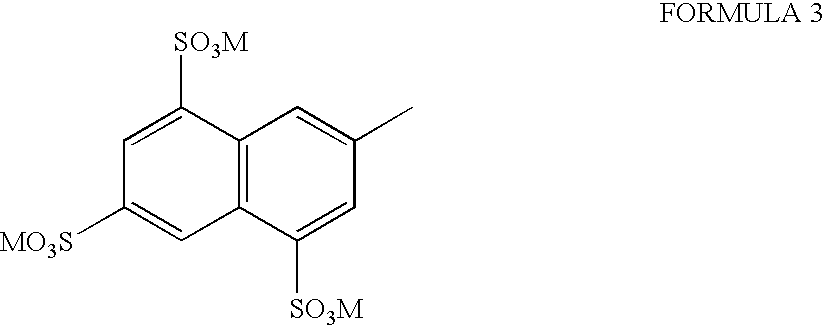

Black ink composition, ink set, ink cartridge, inkjet recording method and recorded product

InactiveUS7465346B2Guaranteed fastnessImprove printing qualityDisazo dyesMeasurement apparatus componentsPolymer scienceColoring agents

Owner:SEIKO EPSON CORP

Dyeing method for multilevel-color jean yarns

The invention relates to a dyeing method for multilevel-color jean yarns. The dyeing method comprises the following steps: carrying out modification treatment on yarns by adopting a cationic modifying agent; padding 1-2 paths of pigment printing paste on the treated yarns at a room temperature and drying; then carrying out continuous rolling and dyeing by indigo blue and sulfur dyestuff or overdyeing of the indigo blue and the sulfur dyestuff. The jean yarns produced by the dyeing method are bright in color and luster, good in color fastness, pure in colored light and low in room-temperature dyeing power consumption; the quantity of indigo blue dyeing grooves is reduced by priming a high-fastness pigment; a process flow is shortened, the pollution discharge is reduced and the production cost is reduced.

Owner:SHANDONG DAIYIN TEXTILE GROUP SHARE CO LTD

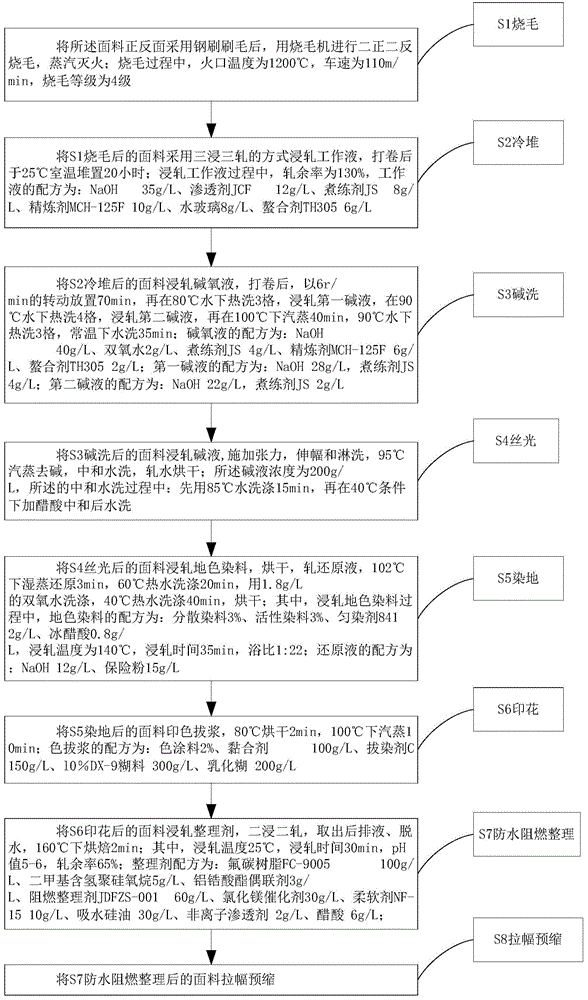

Dyeing and printing technology of camouflage fabric

InactiveCN105040490AImprove tensile propertiesImprove printing and dyeing adsorption functionDyeing processWoven fabricsCamouflagePolyester

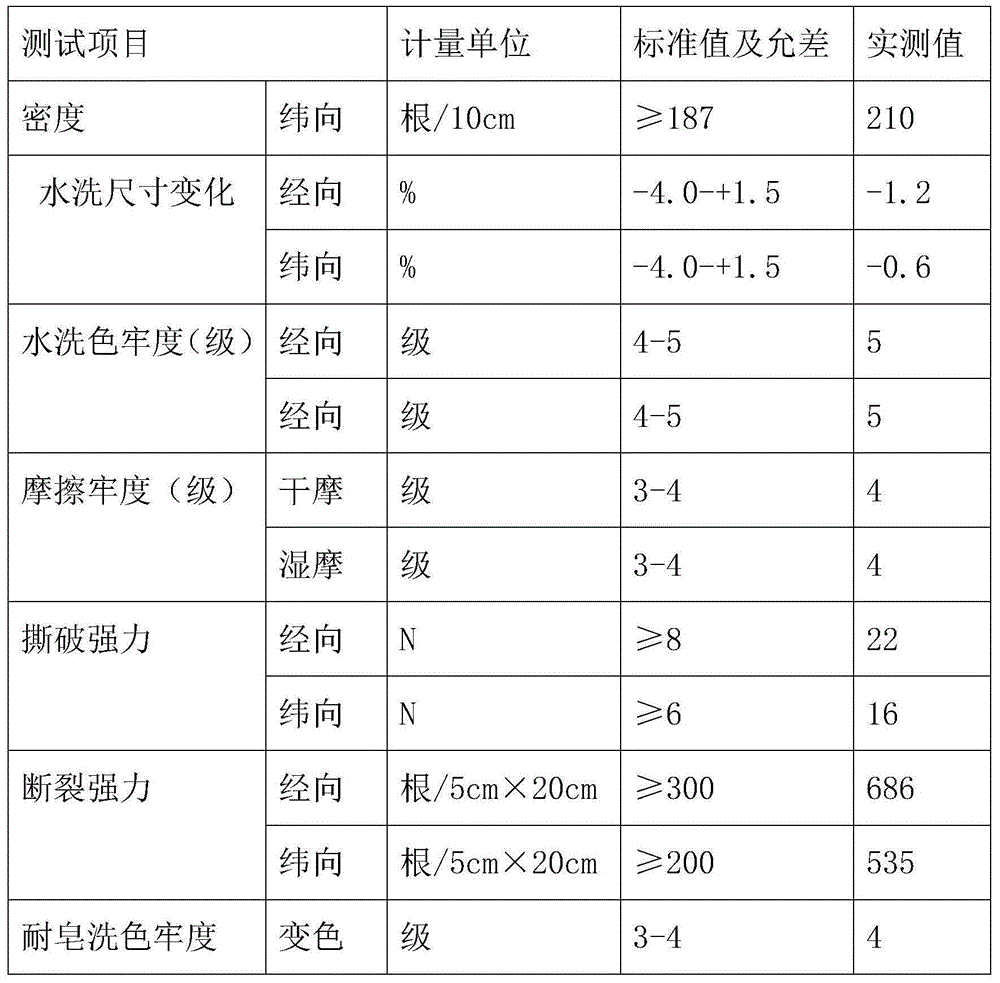

The invention discloses a dyeing and printing technology of a camouflage fabric. The camouflage fabric is prepared by blending and interweaving the following raw materials in percentage by weight: 30%-50% of cotton fiber, 30%-50% of polyester fiber, 10%-30% of spandex fiber and 10%-20% of spun silk fiber. The dyeing and printing technology comprises the following steps: S1 singeing; S2 cold heaping; S3 alkaline washing; S4 mercerizing; S5 ground dyeing; S6 printing; S7 waterproof and flame-proof treatment; and S8 stentering pre-shrinking. According to the dyeing and printing technology of the camouflage fabric, the high color fastness of the dyed ground color and the front and rear stability of the color of the camouflage fabric can be ensured; the camouflage printing requirements can be met; the quality repeatability is good; and the quality index of the finished product can meet the customer requirements.

Owner:芜湖市瑞都服装贸易有限公司

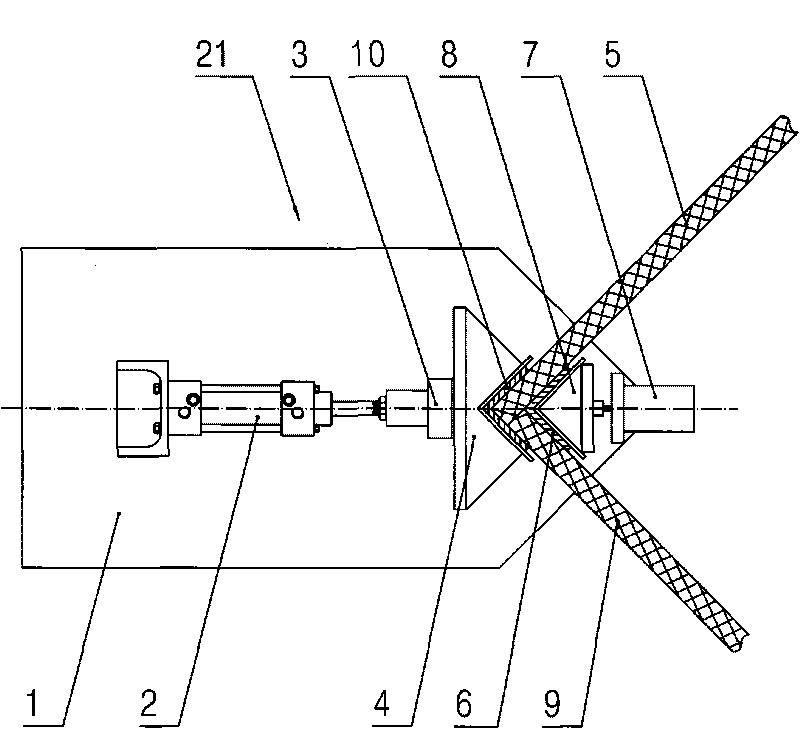

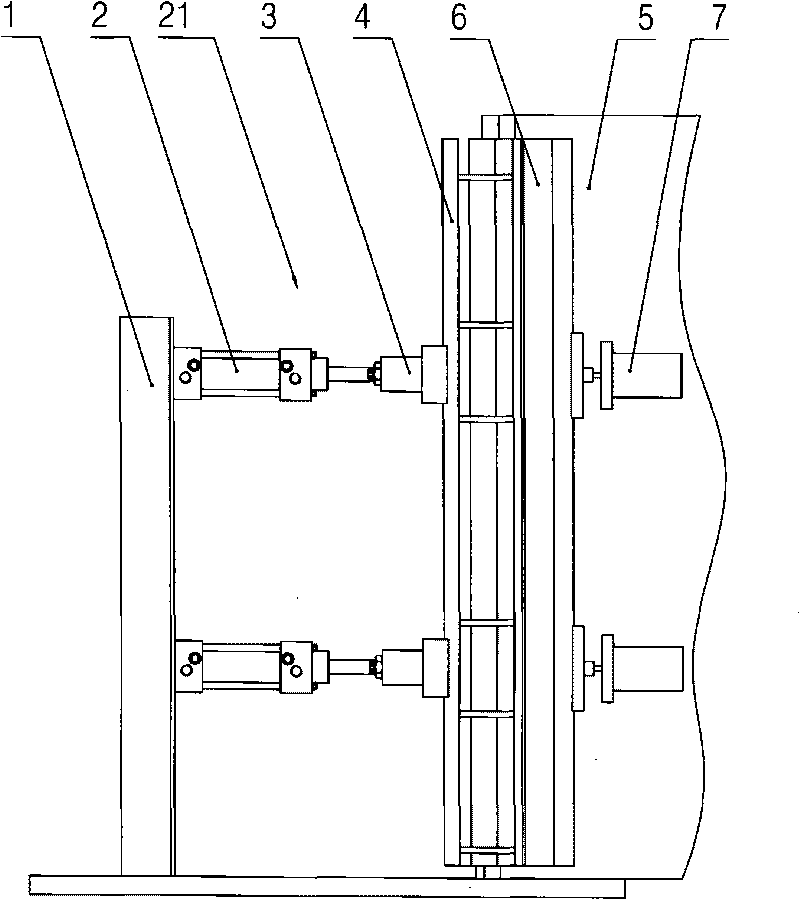

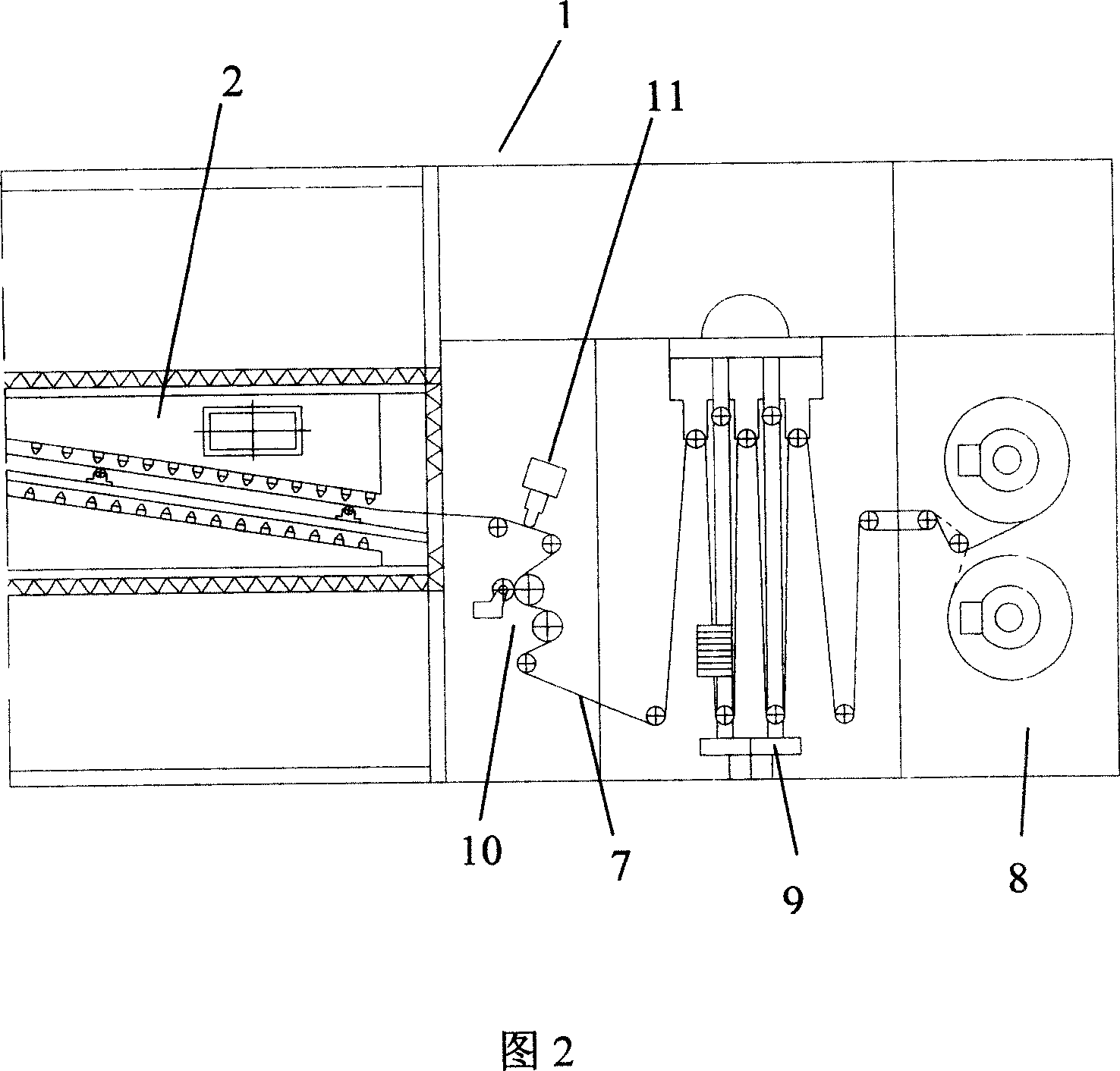

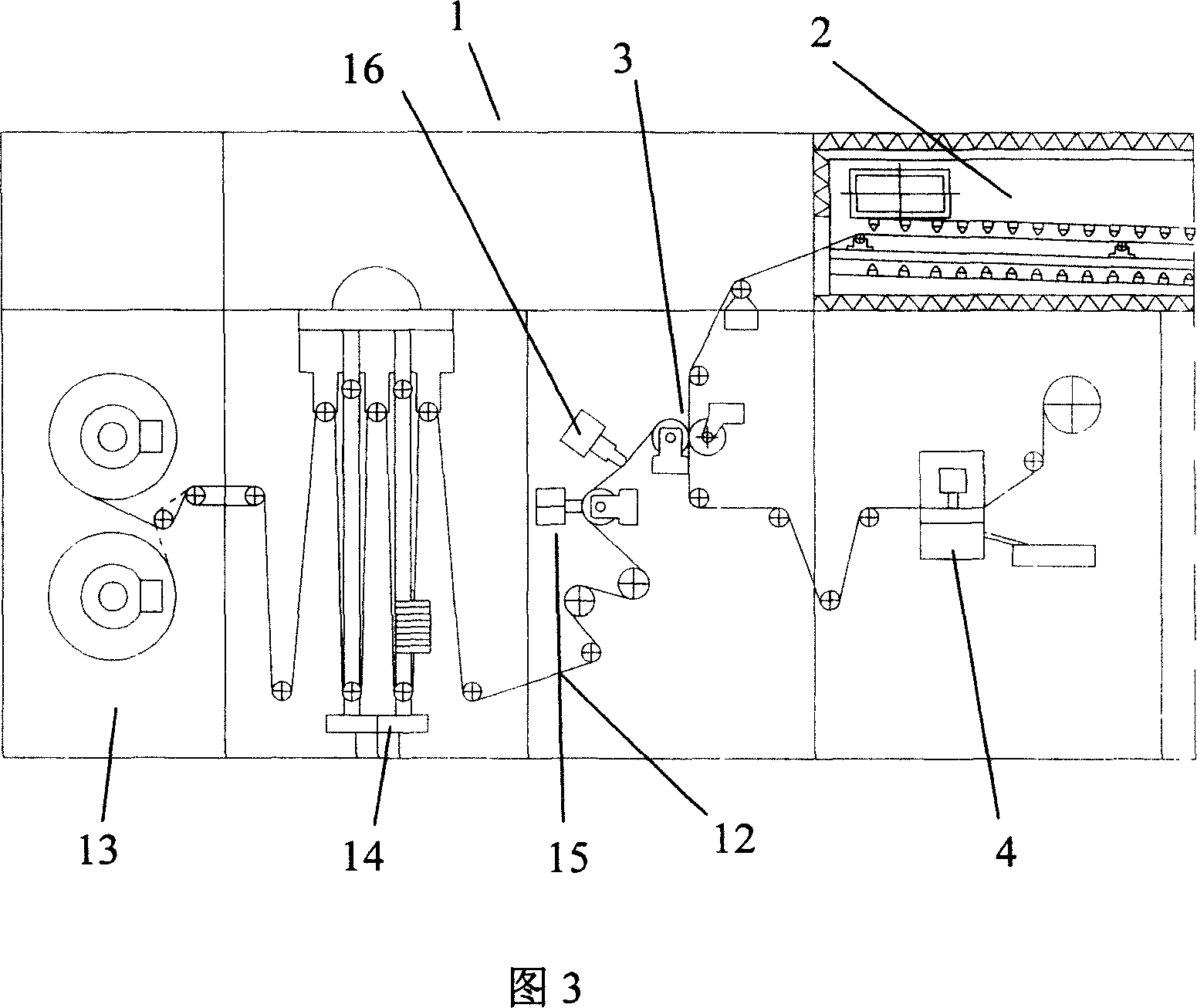

Full-automatic single-wheel numerical control circling welding machine and circling welding method thereof

InactiveCN103433408AEasy to adjustQuality assuranceWire ringsResistance welding apparatusNumerical controlMachine parts

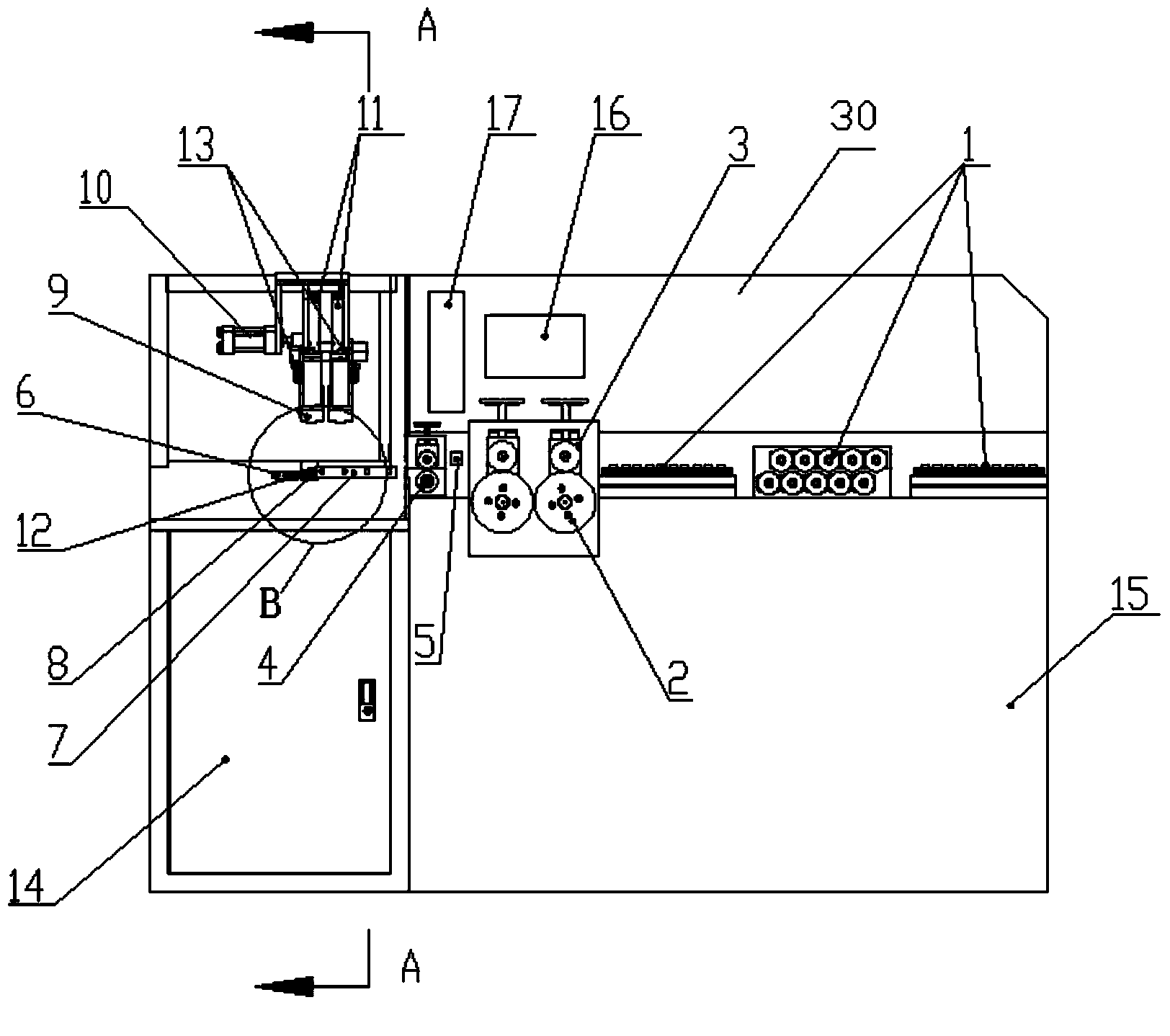

The invention relates to a full-automatic single-wheel numerical control circling welding machine which comprises a machine body and a working table. The full-automatic single-wheel numerical control circling welding machine is characterized in that the machine body is sequentially provided with a straightening mechanism, a feeding mechanism, a guide line plate, a cut-off device, a single-wheel forming mechanism and a butt-weld mechanism according to the processing sequence, and the single-wheel forming mechanism comprises a forming wheel which conducts contour machining on workpieces. According to the full-automatic single-wheel numerical control circling welding machine, the single forming wheel is used for achieving contour machining, flexible adjusting of the specifications of machining parts is achieved, a starting point cutter device is used so that starting point cutting-off can be achieved in the machining process, errors caused by a cutter can be reduced, the butt-weld mechanism can effectively guarantee the welding precision and firmness, and therefore workpiece quality is guaranteed.

Owner:诸暨市振华液压科技有限公司

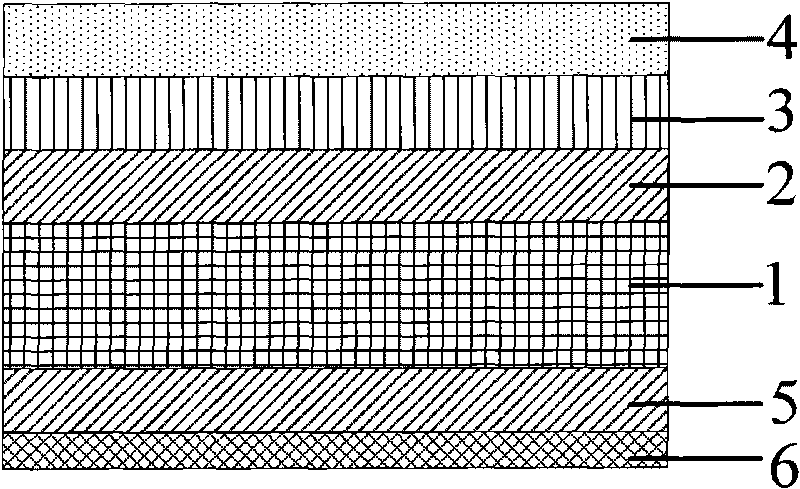

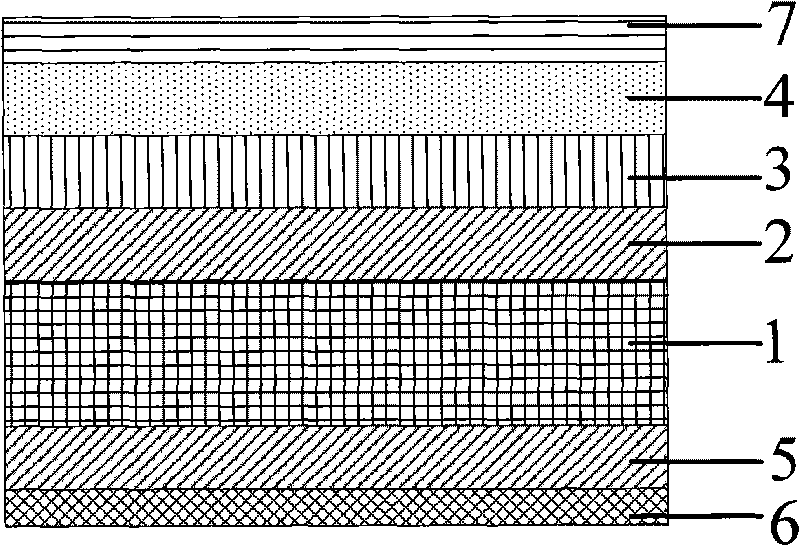

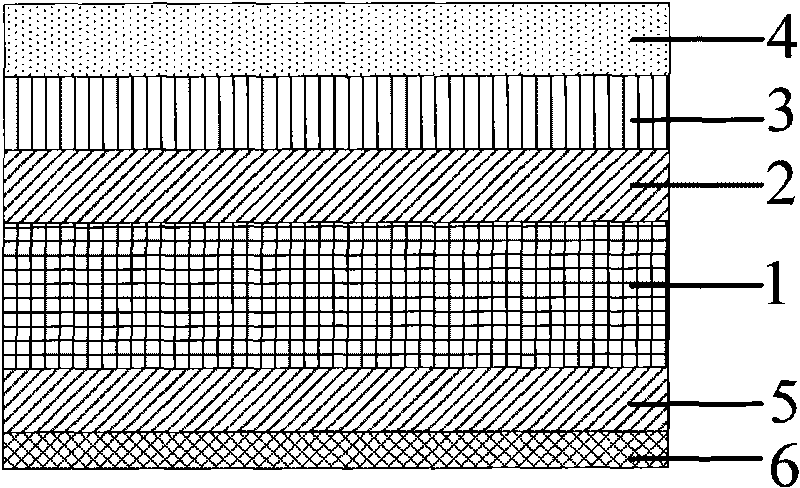

Tent fabrics and preparation method thereof

InactiveCN104859231AKeep warmGood dyeing effectSynthetic resin layered productsVegetal fibresHemp fiberPolyester

The invention discloses tent fabrics and a preparation method of the tent fabrics. The tent fabrics comprise base cloth and waterproof coating. The base cloth comprises, by weight 50-65% of polyester fiber, 15-25% of hemp fiber is, 10-20% of bamboo fiber and 5-10% of wool fiber. The tent fabrics adopt special waterproofing treatment and dyeing processing, not only ensure the waterproof washing color fastness, the color fastness to light and the waterproof effect, but also ensure the wearability to the largest extent through the fiber blending weaving, and enable the blending fibers to have good-strength, anti-bacteria, heat-insulation, uvioresistant and anti-static effects.

Owner:湖州丝葳纺织有限公司

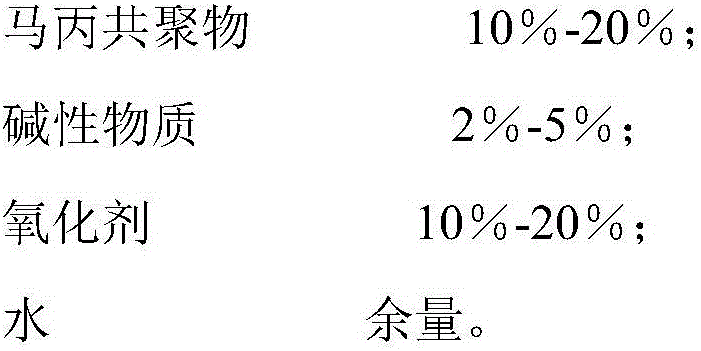

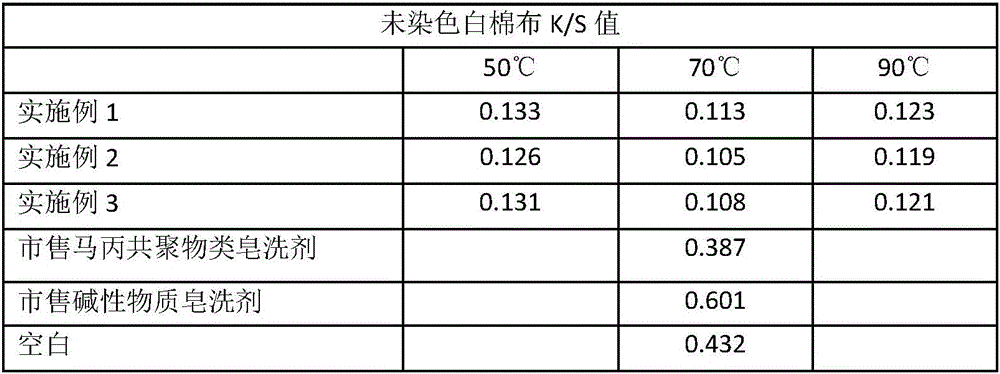

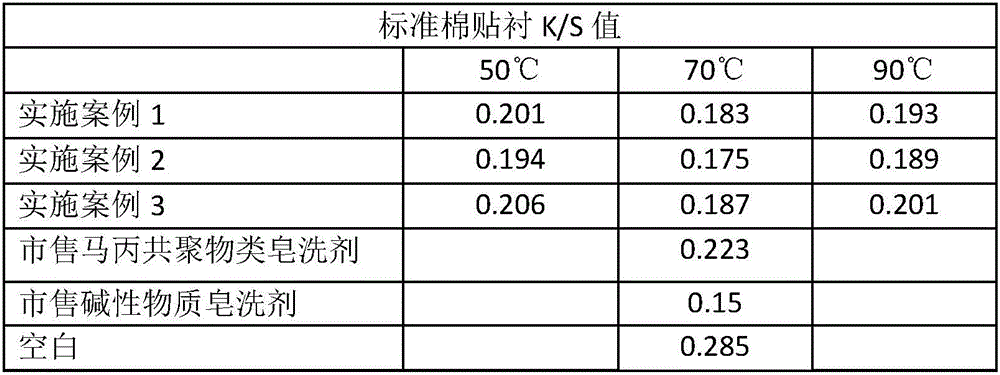

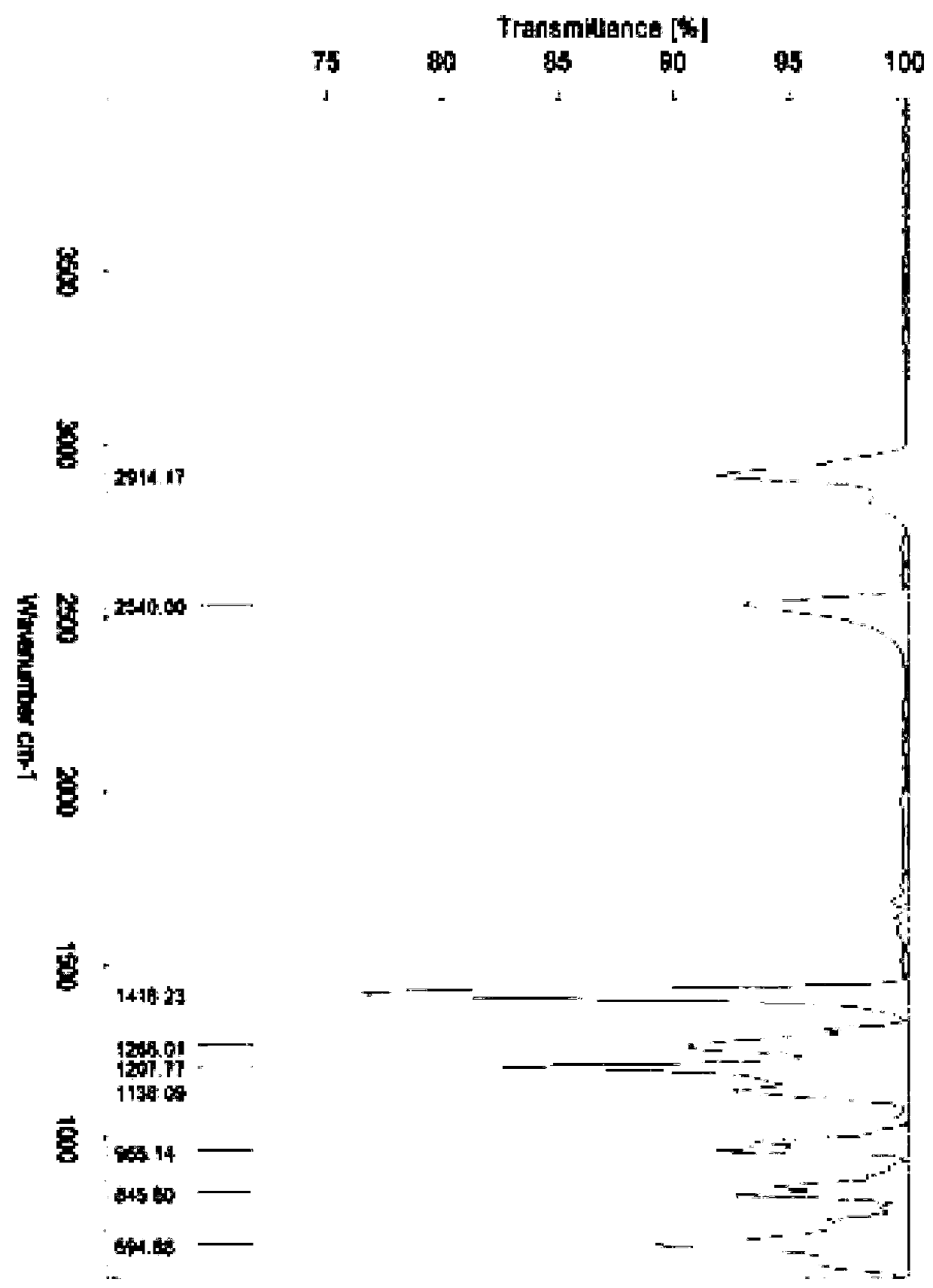

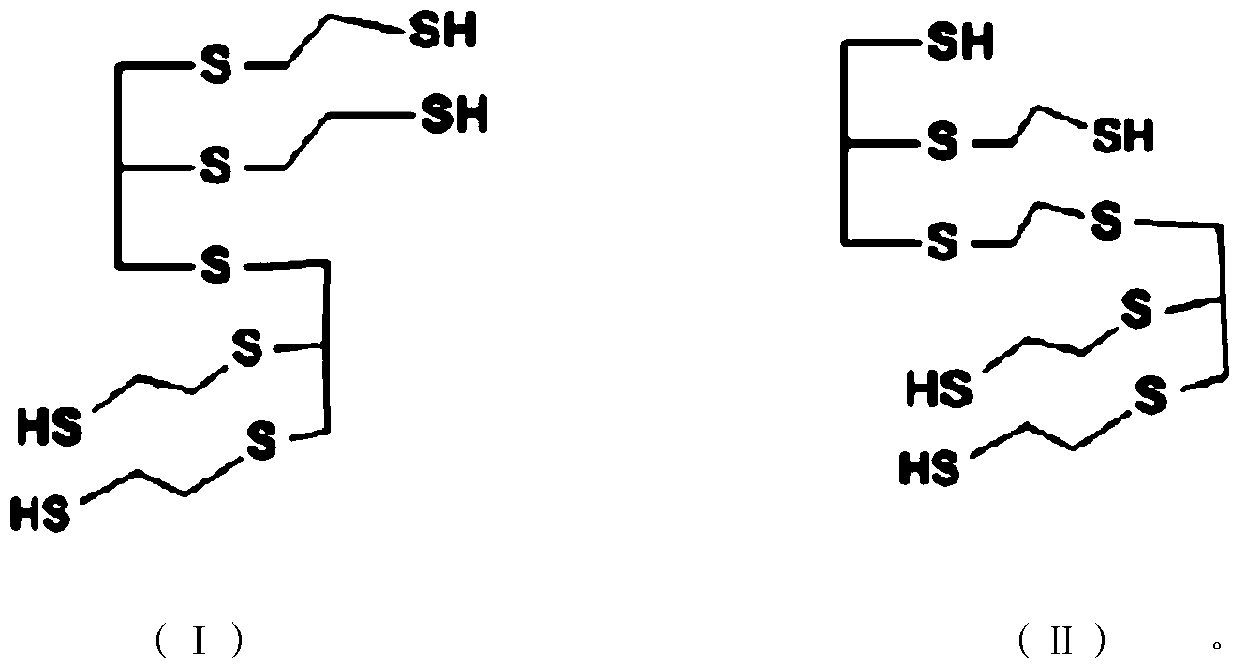

Low-temperature reactive dye soaping agent as well as preparation method and application thereof

InactiveCN106566726AGuaranteed anti-staining effectGood compounding effectDetergent compounding agentsOrganic non-surface-active detergent compositionsReactive dyeMethyl acrylate

The invention discloses a low-temperature reactive dye soaping agent as well as a preparation method and an application thereof. The low-temperature reactive dye soaping agent comprises the following components in percentage by mass: 10%-20% of a maleic-methyl acrylate copolymer, 2%-5% of an alkaline substance, 10%-20% of an oxidant and the balance of water.

Owner:苏州联胜化学有限公司

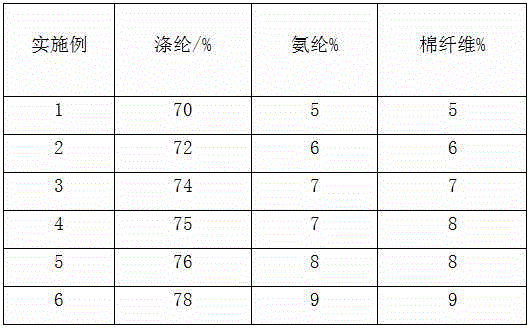

Camouflage clothing fabric and manufacturing method thereof

The invention discloses a camouflage clothing fabric and a manufacturing method thereof, wherein the camouflage clothing fabric comprises a piece of basic cloth and a waterproof coated layer; the piece of basic cloth is woven by polyester fiber, hemp fiber, cotton fiber and Coolplus fiber in a mixed way; the weight percent of the polyester fiber is from 50 percent to 60 percent; the weigh percent of the cotton fiber is from 5 percent to 15percent; the weight percent of the hemp fiber is from 15 percent to 25 percent; and the weight percent of the Coolplus fiber is from 15 percent to 25 percent. According to the invention, special waterproof processing and dyeing technology are adopted, so the color fastness of resisting washing away and the fastness of resisting light color and good waterproof effect are ensured; at the same time, the using performance also ensured at maximum; and the method of weaving fiber in a mixed way is adopted, so the mixed woven fiber has good effects of good intensity, using performance, bacteria resistance, heat preservation, ultraviolet light resistance and static electricity resistance.

Owner:湖州丝葳纺织有限公司

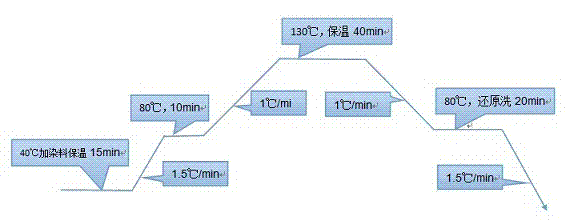

Slub dyeing technique for bamboo charcoal modified polyester fibre

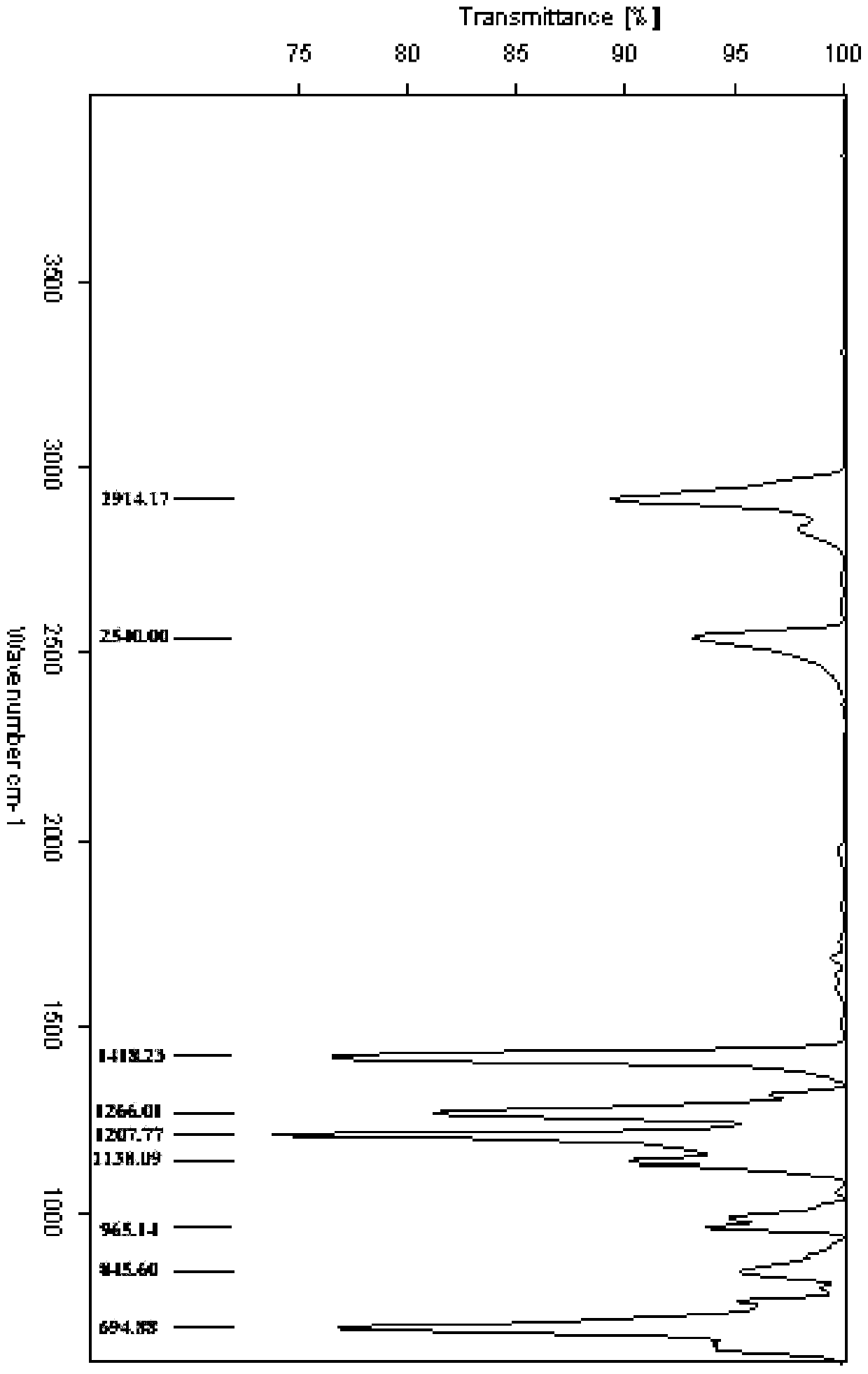

InactiveCN101041936ADo not change colorGuaranteed fastnessDyeing processMonocomponent polyesters artificial filamentPolyesterAcetic acid

The invention relates to a dye method of bamboo charcoal modified polyester fiber, which uses Ascracen disperse cation dye produced by German Desda Fabric Dye Company. And the method comprises that coming bamboo charcoal modified polyester fiber to be arranged in high-temperature drying machine to operate for 3-5min at 30-40Deg. C, adding 0.3-0.5g / L glacial acetic acid and 2.5-4g / L glauber salt to operate for 5-10min, adding dye to operate for 5-10min, increasing temperature at 1-2Deg. C / min, stopping increasing temperature when the temperature is 80+-2Deg. C, and holding temperature for 10-15min, increasing temperature to 100-115Deg. C at 0.75-1Deg. C / min, to operate for 40-60min, discharging liquid and washing, then arranging the dyed bamboo charcoal modified polyester fiber into soap detergent, to process for 20-30min at 80-90Deg. C. The invention can be used dye bamboo charcoal modified polyester fiber, with better dye effect, high color stability and no hurt on copper ammonia fiber in the dye process.

Owner:HEILAN HOME

Polyester taslan fabric moisture absorbing and sweat releasing dyeing and finishing process

InactiveCN104762837AFully absorbedGuaranteed fastnessSucessive textile treatmentsHeating/cooling textile fabricsPolyesterPulp and paper industry

The invention discloses a polyester taslan fabric moisture absorbing and sweat releasing dyeing and finishing process. The production process includes: cold stacking, open-width desizing, in-cylinder finishing scouring, overflow dyeing, reducing cleaning, finishing, cylinder discharge, dehydration width opening, and shaping. Specifically, the finishing adopts moisture absorbing and sweat releasing, overflow washing is conducted after reducing cleaning, and a moisture absorbing and sweat releasing assistant is added after washing the fabric surface clean to carry out finishing. The process ensures sufficient textile desizing, makes the capillary effect of the taslan fabric reach the best state, so that the textile can fully absorb the moisture absorbing and sweat releasing assistant to enhance the moisture absorbing and sweat releasing effect, and the fabric can be resistant to washing. The process avoids or reduces the generation of watermark problem, and has very good practical effect.

Owner:WUJIANG FUHUA WEAVING

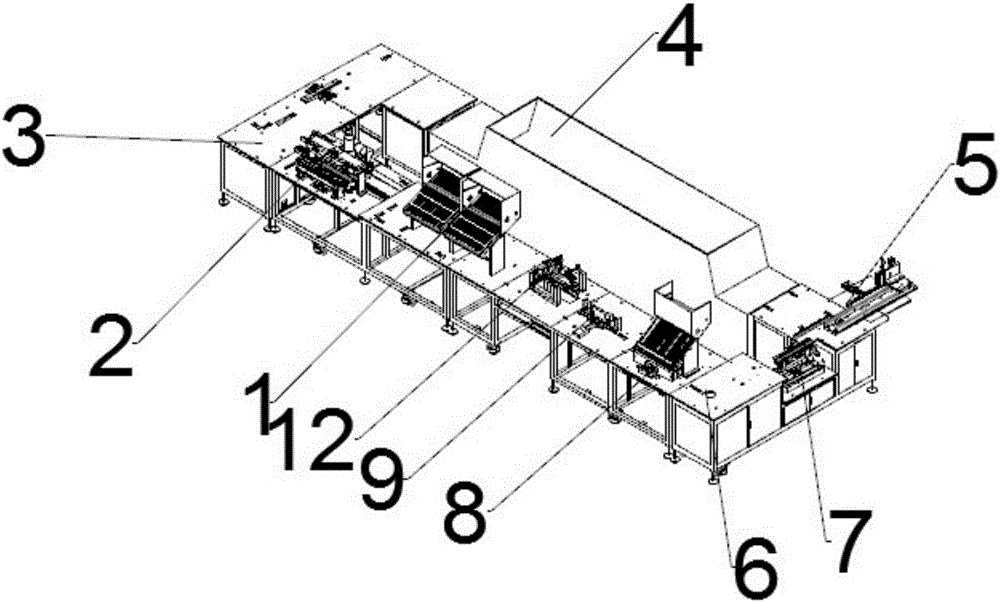

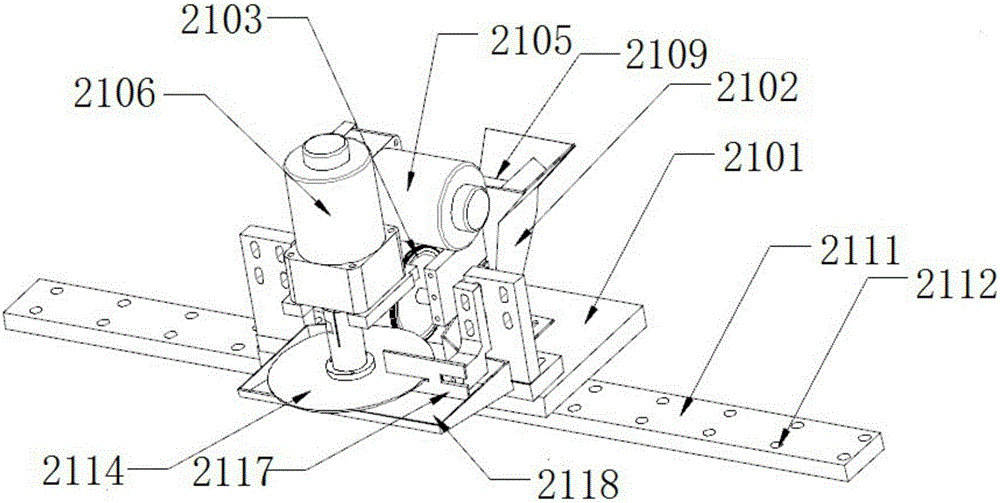

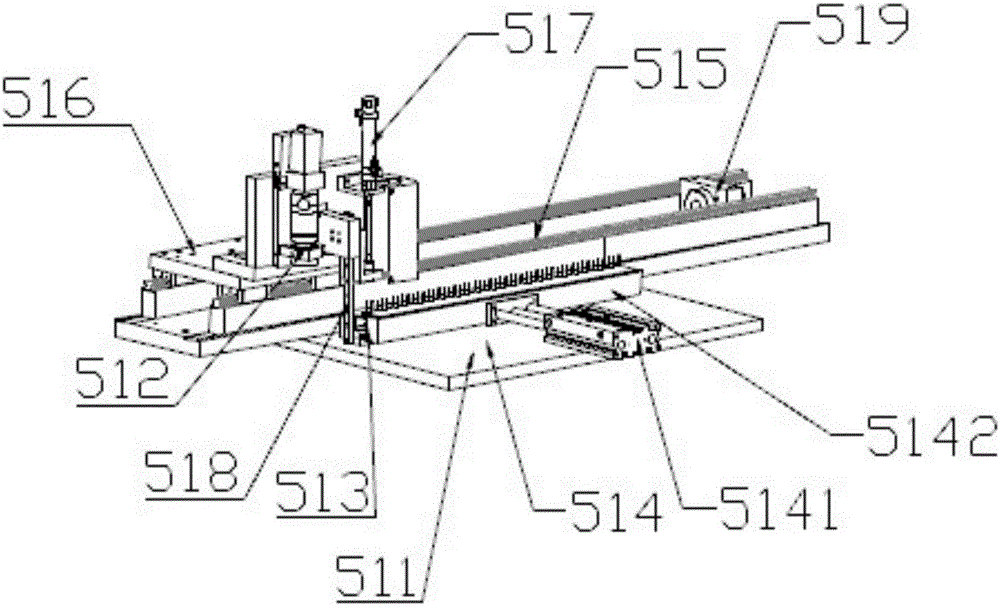

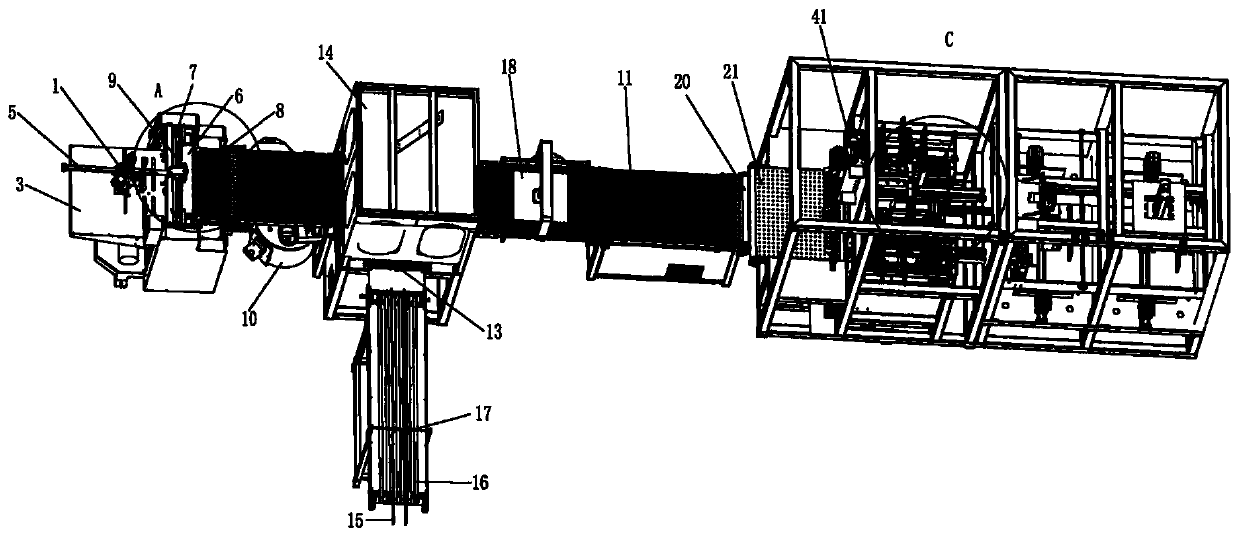

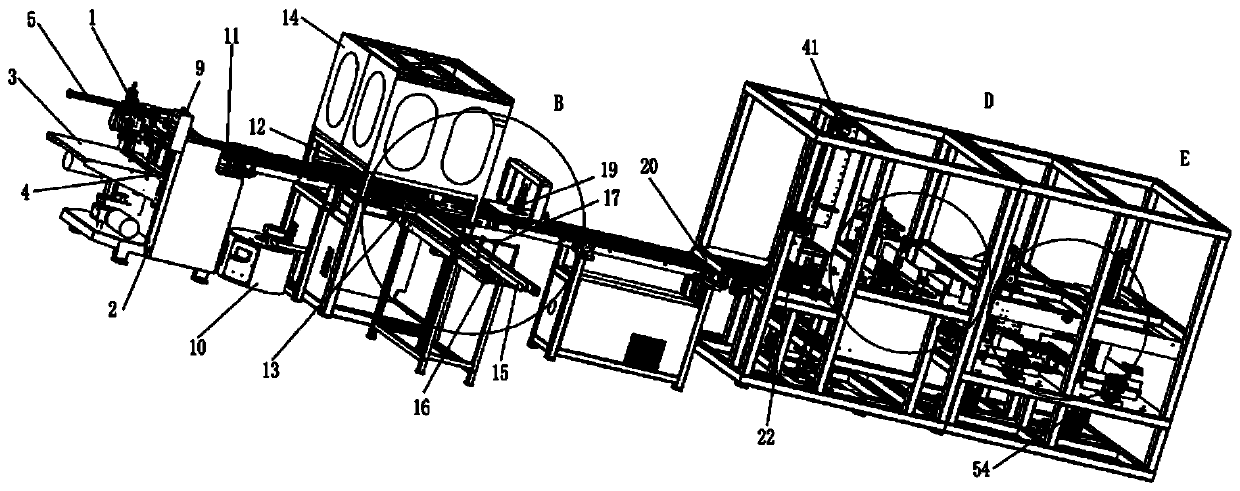

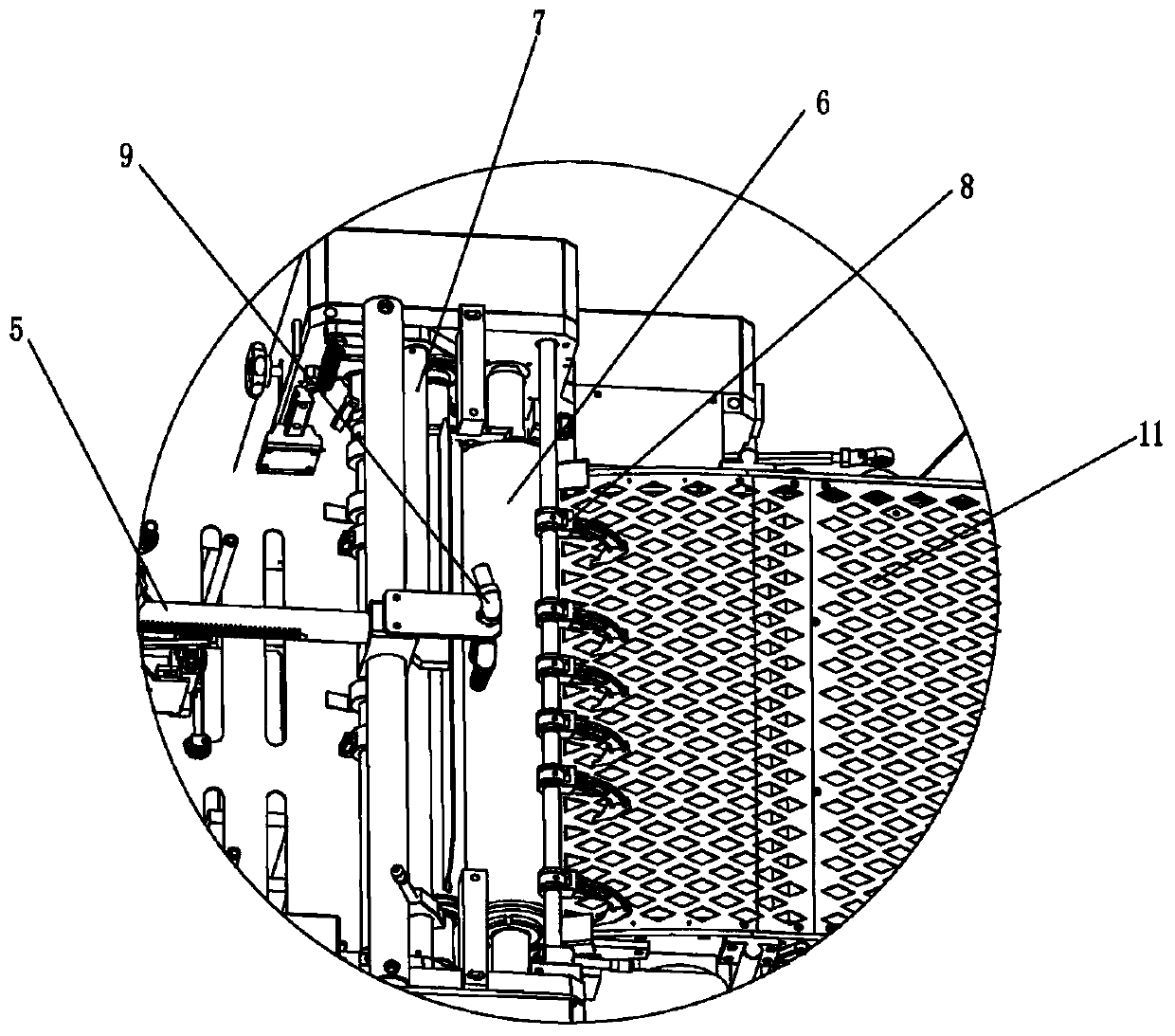

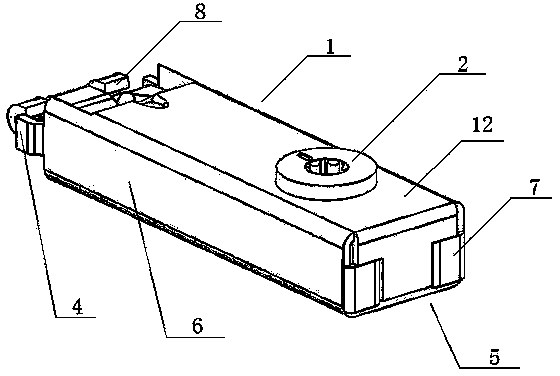

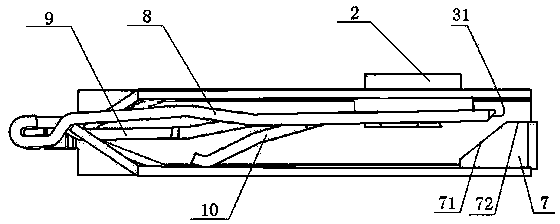

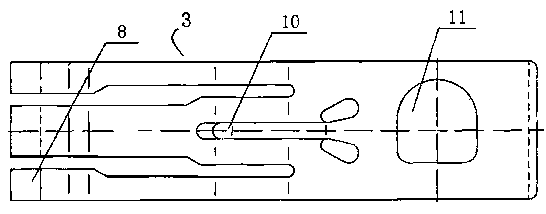

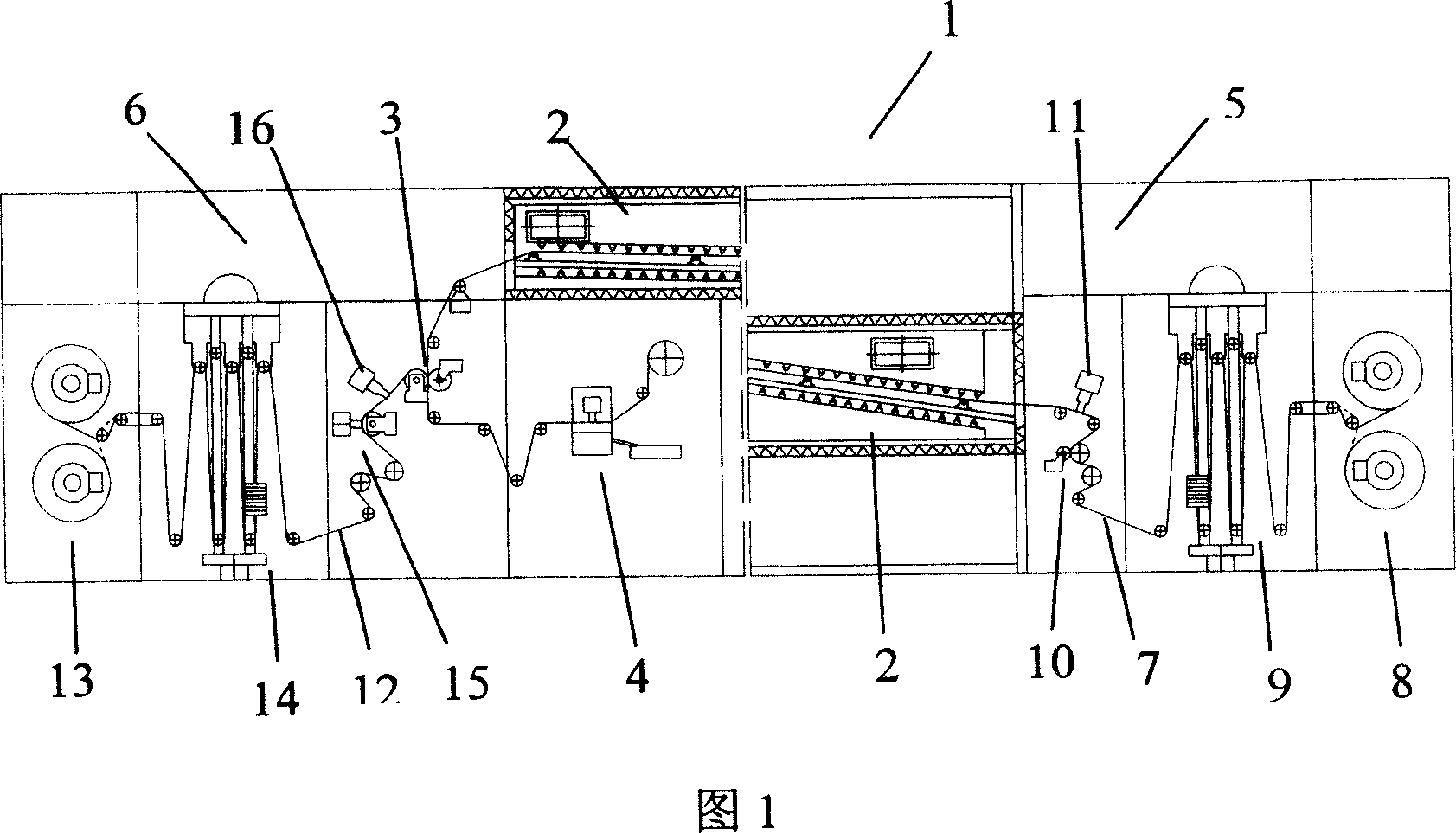

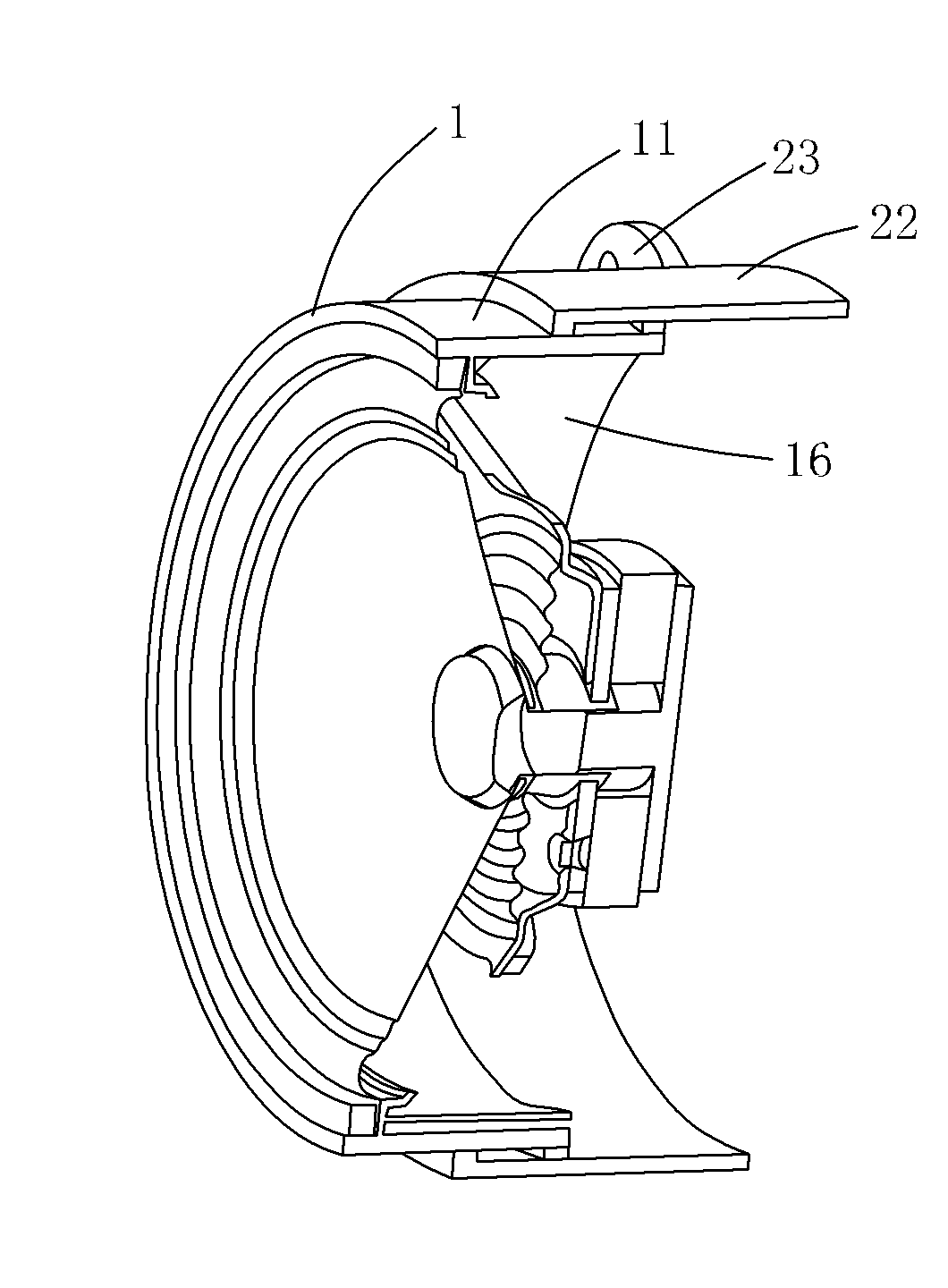

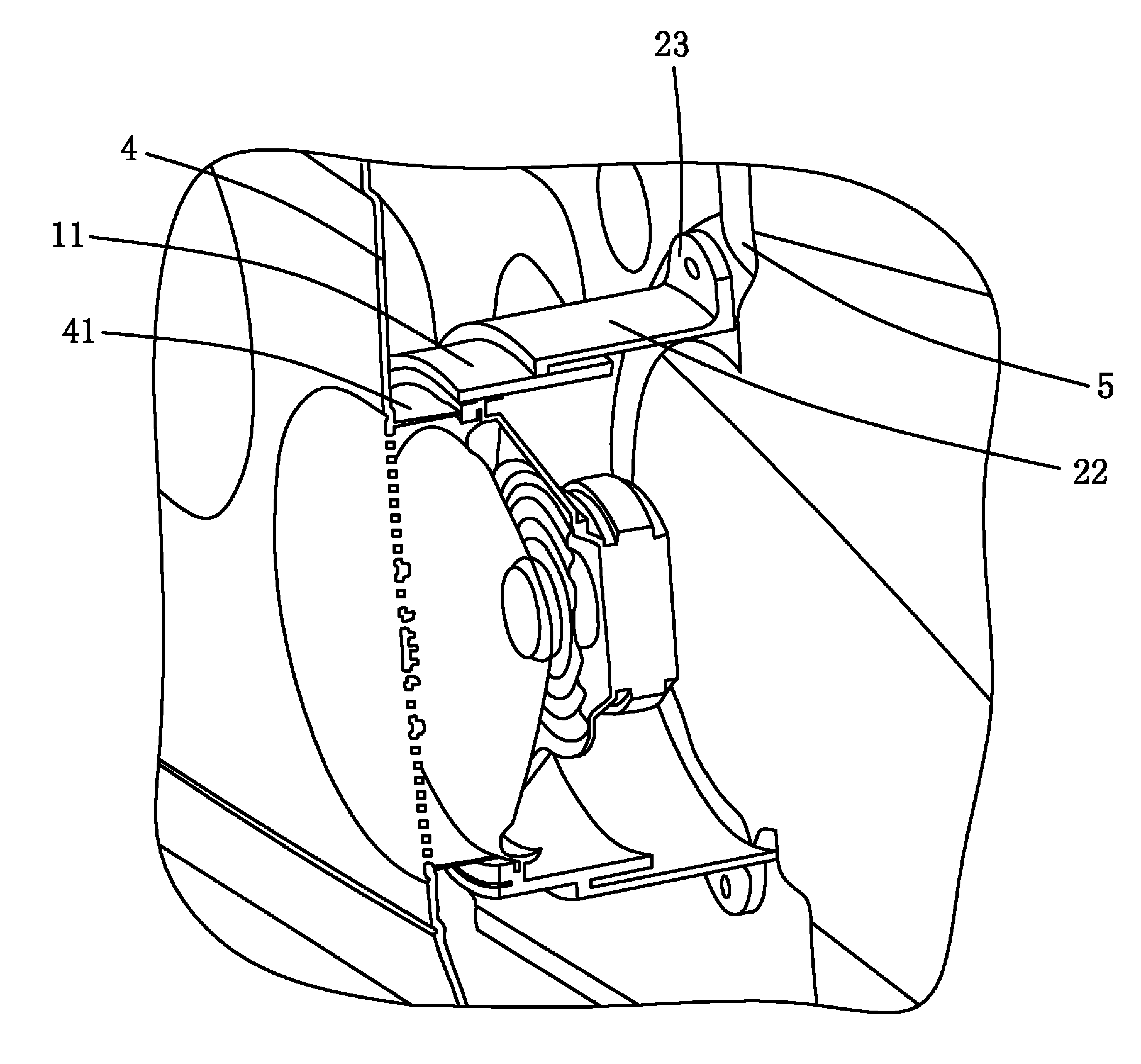

Single-wing intravenous needle assembling machine

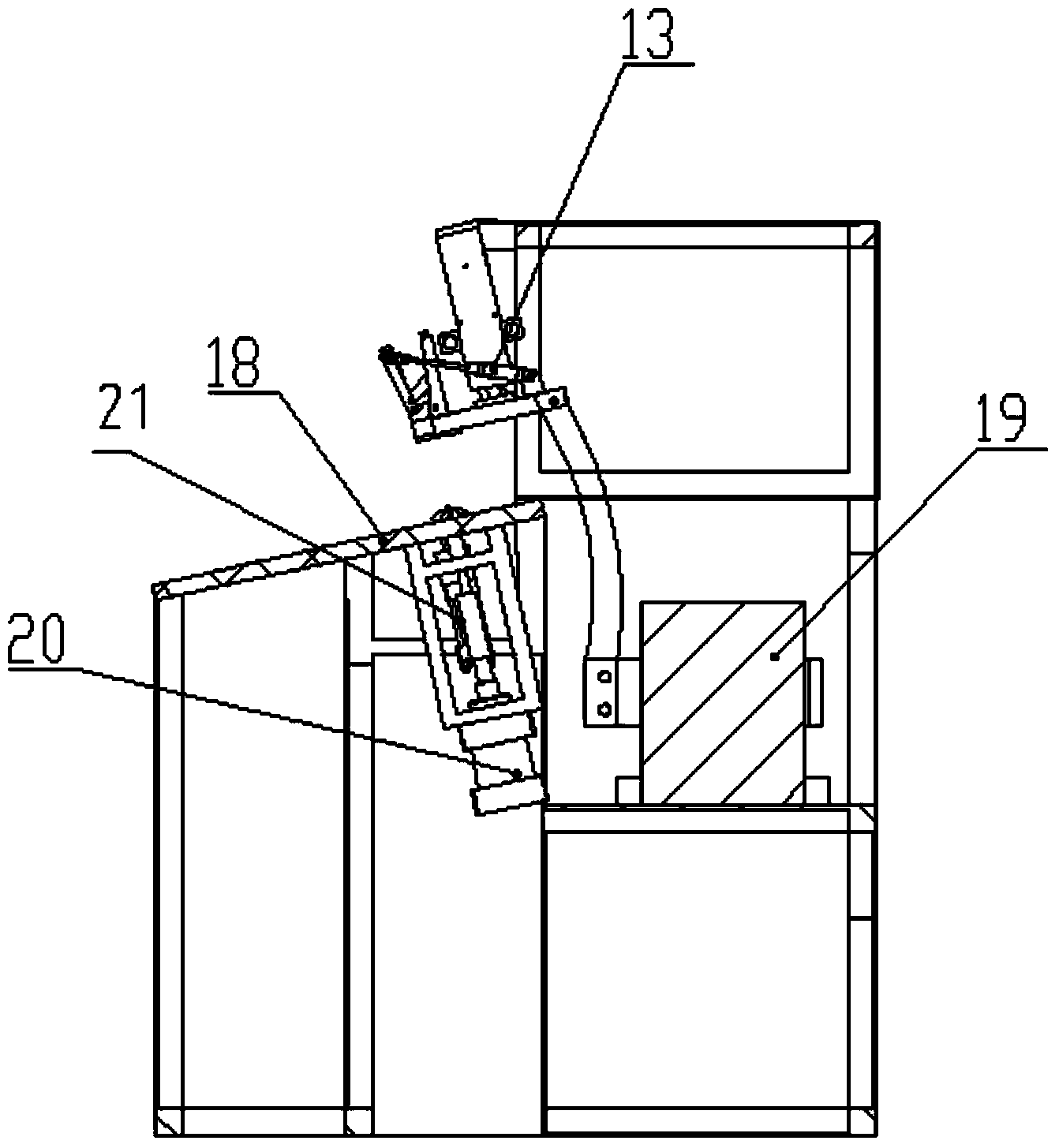

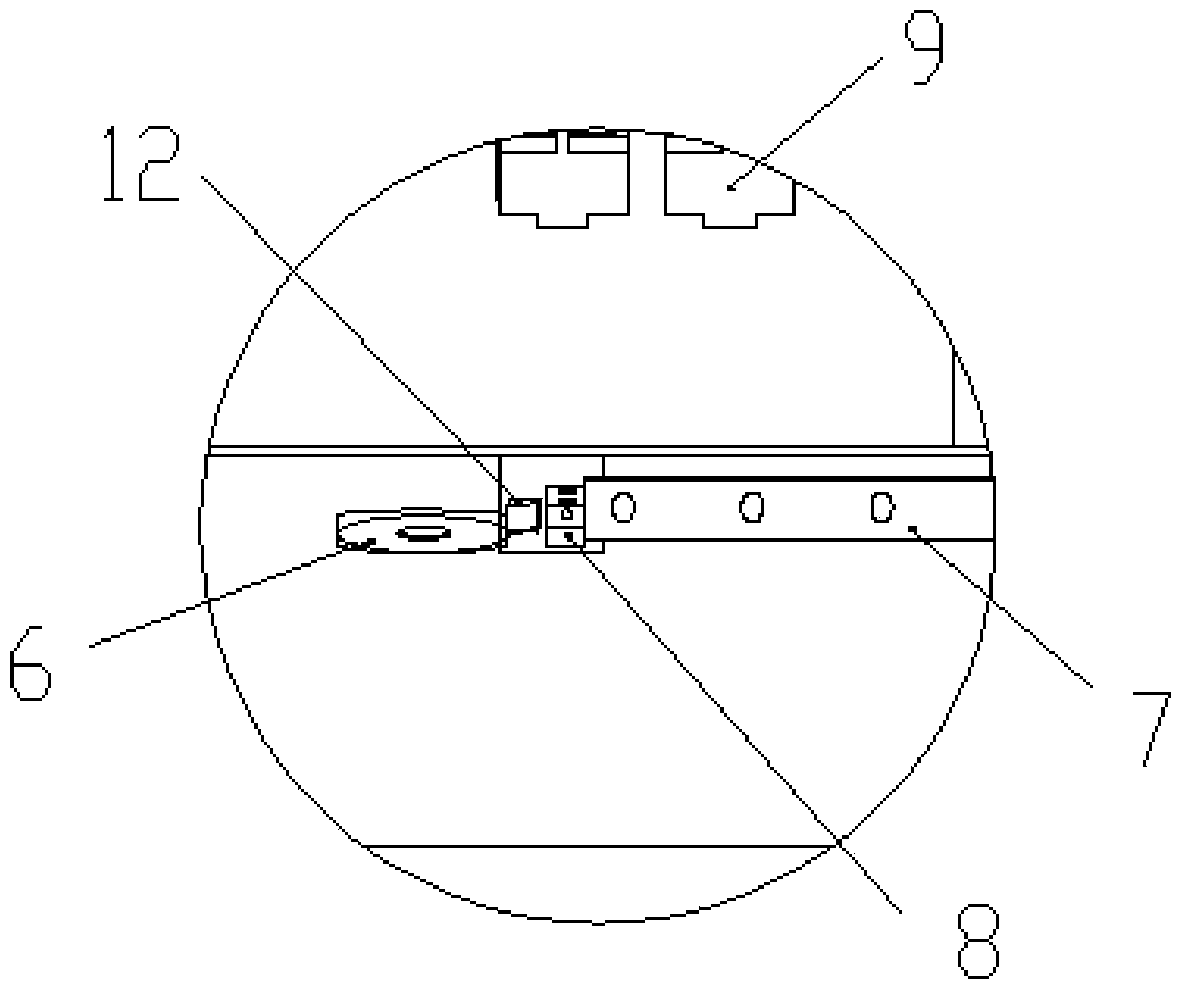

The invention belongs to the field of production of medical apparatus, and particularly relates to a single-wing intravenous needle assembling machine. The single-wing intravenous needle assembling machine comprises a wing charging device (1) for positioning a wing into a carrier (13); starting with the wing charging device (1), a needle charging assembly (2) is connected to a conveyor belt at the back of the wing charging device (1); a right-angle conveying assembly (3) is connected to a conveyor belt at the back of the needle charging device (2); an oven (4) is connected to a conveyor belt at the back of the right-angle conveying assembly (3); a return needle detecting assembly (5) is connected to a conveyor belt at the back of the oven (4); a first air testing device (7) is connected to a conveyor belt at the back of the return needle detecting assembly (5); a carrier reversing device (6) is arranged at the back of the first air testing device (7). With the adoption of the single-wing intravenous needle assembling machine, a single-wing intravenous needle is hardly attached with bacteria during being assembled, so that the safety is high; in addition, the single-wing intravenous needle assembling machine is high in automation degree, so that the assembling efficiency can be greatly improved, and mass production can be achieved; the whole design of the single-wing intravenous needle assembling machine is reasonable, and the structure is simple.

Owner:梁启明

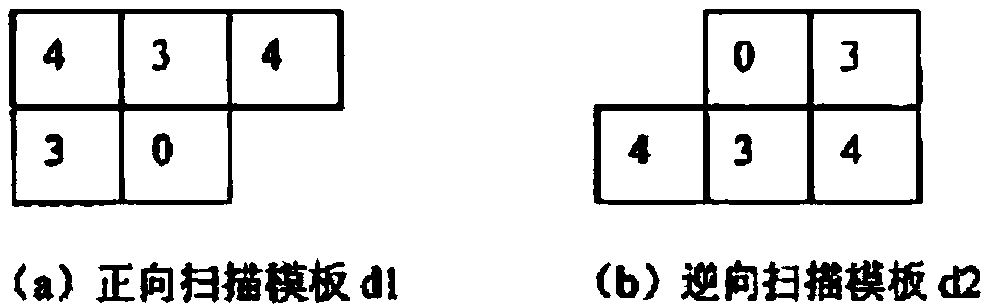

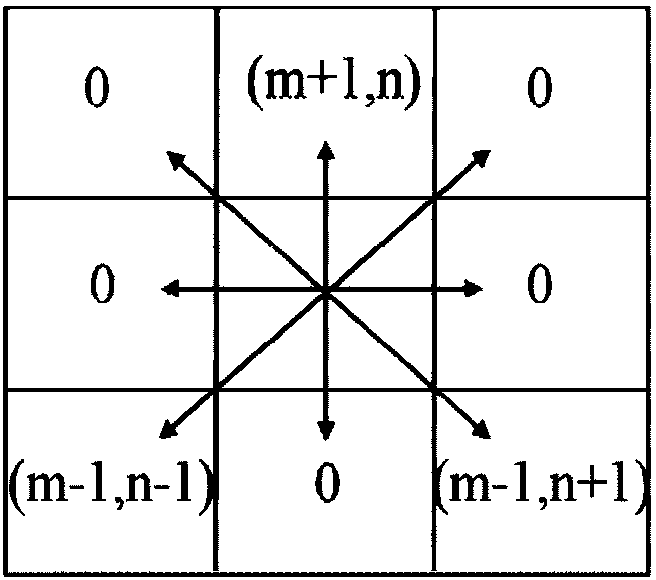

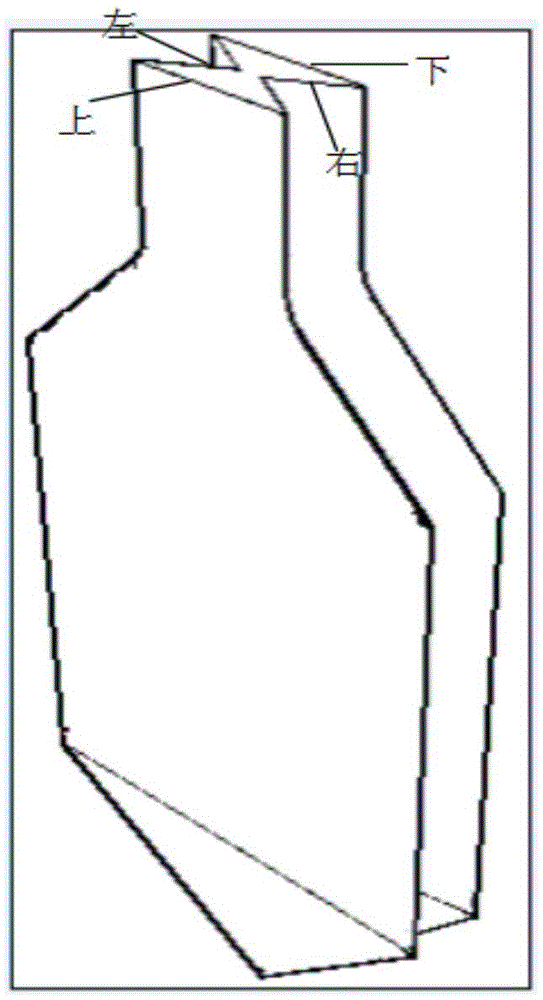

Adaptive plane layering method based on additional material remanufacturing point cloud model

ActiveCN108022307ASkip the resurfacing processImprove efficiencyAdditive manufacturing apparatusImage data processingPoint cloudInter layer

The invention relates to an adaptive plane layering method based on an additional material remanufacturing point cloud model. The method comprises: step one, a layering direction is determined; step two, a layering height is determined; to be specific, traverse of point cloud coordinates is carried out to obtain a zmin and a zmax, difference processing is carried out on the zmin and the zmax to obtain a layering height; step three, an inter-layer point cloud mapping relationship is constructed; step four, a surface error is defined; to be specific, a surface error P is defined to express a surface difference degree between two slices, wherein sigma is equal to Rmax and the Rmax expresses a maximum value a radial width R of a projection point cloud; and step five, a layering thickness is determined. According to the adaptive plane layering method, the maximum value of the radial width R of the projection point cloud is used as a surface error and thus an adaptive layering height is determined by iteration; the algorithm implementation process is clear; and both efficiency and precision are considered.

Owner:ARMOR ACADEMY OF CHINESE PEOPLES LIBERATION ARMY

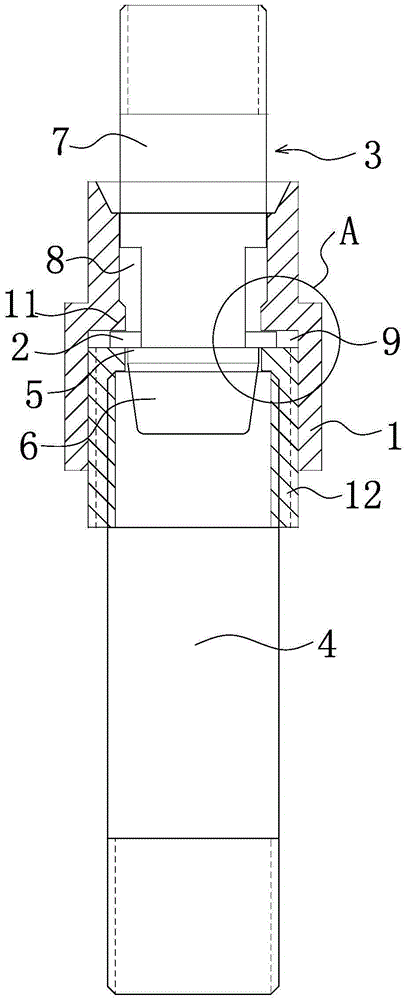

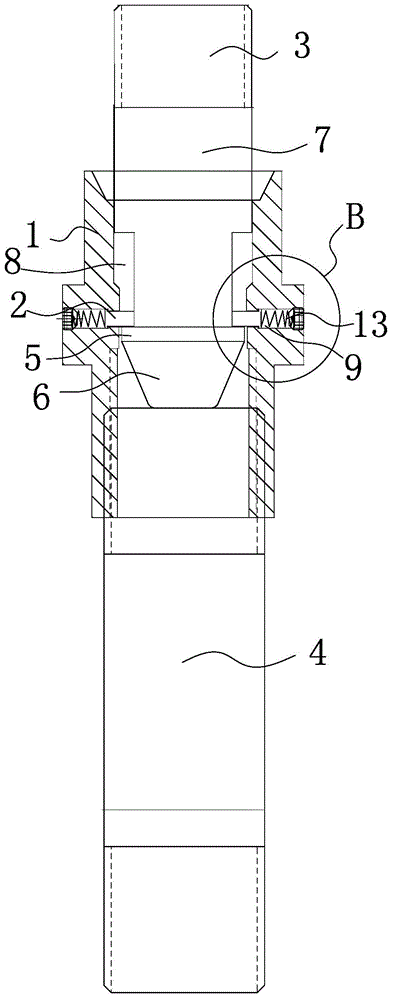

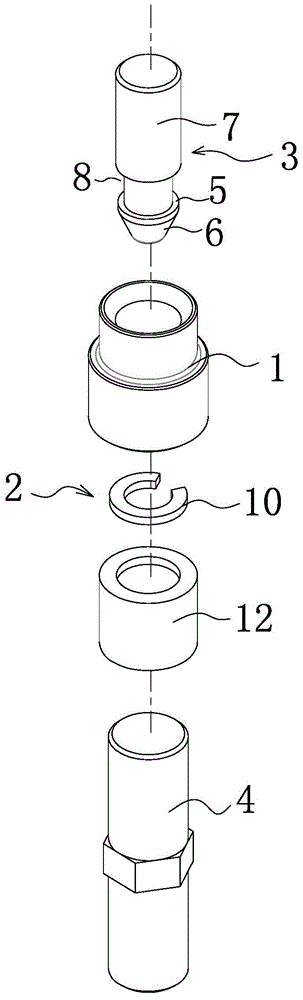

Elastic clamping type connecting piece

The invention belongs to the technical field of buildings and relates to an elastic clamping type connecting piece. The elastic clamping type connecting piece comprises a connecting nut, wherein the upper end and the lower end of the connecting nut are through. An elastic clamping part is movably connected into the connecting nut. A connector clip is inserted in one end of the connecting nut. The other end of the connecting nut is in screw joint with a screw joint part. The connector clip is provided with a clamping platform. When the connector clip is inserted into the clamping part, the clamping part can move in the direction far from the axis line of the connecting nut; when the clamping platform on the connector clip passes through the clamping part, the clamping part can move in the direction close to the axis line of the connecting nut to make the clamping part clamp the clamping platform. The elastic clamping type connecting piece can be used for connection of two objects and is convenient to assemble, convenient and fast to connect and firm and reliable in connection.

Owner:浙江兆弟技术有限公司

Automatic up-and-bottom cover box integration molding machine

PendingCN110281580AFit tightlyAvoid it happening againBox making operationsPaper-makingMolding machinePaperboard

The invention discloses an automatic up-and-bottom cover box integration molding machine which comprises a rack. A conveying device, a gluing device, a paperboard covering device, a laminating device, a first edge folding device and a press-fitting device are sequentially arranged on the rack from left to right. The gluing device is used for coating a glue on the upper layer of surface paper; the paperboard covering device and the laminating device are used for laminating a paperboard and the surface paper; the first edge folding device comprises a glue dispensing device, a lower side plate device, a positioning and lug-folding device and a surface paper standing device so as to be used for placing side plates at the front end and the back end of the paperboard, automatically positioning the side plates onto the paperboard, and standing surface paper on the periphery of the paperboard; and the press-fitting device comprises a second edge folding device and a bubble pressing device so as to be used for inwards press-fitting the surface paper and carrying out bubble pressing treatment on an up-and-bottom cover box. The automatic up-and-bottom cover box integration molding machine provided by the invention is simple in overall structure, only two side plates need to be cut, corner gluing and a mold are not needed, automatic edge folding and bubble pressing are realized, the production cost is greatly reduced, the automation degree is high, the processing efficiency is high, the bonding firmness is high, and the application range is wide.

Owner:东莞市坚基包装机械有限公司

Carton splicing machine

InactiveCN101746078AImprove pasting efficiencyGuaranteed strengthContainer making machineryCartonPiston rod

The invention discloses a carton splicing machine capable of increasing the splicing speed and firmness, which comprises a machine base on which at least one paper corner protector splicing device. The structure of carton splicing machine comprises a chassis on which a pressure cylinder and an apical plate which form a fitting with each other are arranged, a pressure plate is arranged on the end part of the piston rod of the pressure plate cylinder, an apical plate is arranged on the end part of the piston rod of the apical plate cylinder, corner protector grooves and corner protector tappetsforming a fitting with the corner protector grooves are respectively arranged on respective side parts of the pressure plate which are adjacent to the apical plate. Through mechanized operation, the carton splicing machine not only ensures the splicing force application to reliably ensure the splicing firmness but also greatly increases the splicing efficiency. In addition, the carton splicing machine can splice four corners of a carton in one go so as to further increase the carton splicing efficiency.

Owner:ZHANGJIAGANG DESHUN MACHINERY

Garment and antibacterial zipper

InactiveCN103892522AGuaranteed antimicrobial propertiesGuaranteed the stability of the antibacterial effectSlide fastenersInjection molding processPhysical strength

The invention provides an antibacterial zipper. The antibacterial zipper is formed by mixing a zipper base material and an antibacterial raw material in an injection molding mode. The antibacterial raw material is an inorganic antibacterial agent. According to the antibacterial zipper, after the zipper base material and the antibacterial raw material are mixed, zipper teeth of the zipper are made through the injection molding process, and the zipper can be formed; the antibacterial raw material is the inorganic antibacterial agent, and stability of the whole antibacterial effect of the antibacterial zipper can be guaranteed and the antibacterial effect of the antibacterial zipper is guaranteed due to the inorganic antibacterial agent; meanwhile, the coloring technology of the zipper teeth of the antibacterial zipper is not affected after the inorganic antibacterial agent is added, and physical strength and color fastness performance of the plastic-steel zipper can be well guaranteed. The invention further provides a garment with the antibacterial zipper.

Owner:ZHEJIANG WEIXING IND DEV

Top dyeing and post-processing method of flame retardant polyester fiber

InactiveCN101457489ADo not change colorGuaranteed fastnessDry-cleaning apparatus for textilesDyeing processDisperse dyeAcetic acid

The invention relates to wool top dyeing of flame-retardant polyester fibers and a post-treatment method thereof. The method comprises the following steps: the flame-retardant polyester fiber wool top is placed in a wool top dyeing machine and operates for 3-5 min at the temperature of 40-50 min, glacial acetic acid is added and PH Value is adjusted to 5-6, monoammonium phosphate and Yuri Huading DIF are added for operating for 5-10min, disperse dye is added for operating for 5-10 min before the temperature rises, the temperature stops rising until 85 DEG C, then the temperature is maintained for 10-15 min, the temperature rises to 100-120 DEG C for operating for 30-60 min, liquor drainage and flushing are carried out with a bath ratio of 1:20-50; the dyed flame-retardant polyester fiber wool top is put into lotion soap with 2-5% of fiber fabric by weight, the lotion soap is processed for 20-30 min at the temperature of 80-90 DEG C, or, the dyed the flame-retardant polyester fiber wool top is first placed in bath consisting of 0.5-2g / L sodium hudroxide , 0.5-2g / L rongalite and 0.5-1g / L nonionic surface active agent for being processed for 20-30 min at the temperature of 70-80 DEG C and then placed in glacial acetic acid bath with 1-4% of fiber fabric by weight for being processed for 10-15 min at the temperature of 40-45 DEG C; the bath ratio is 1:20-1:50. The wool top dyeing of the invention features good levelling of dyeing and high color fastness of dyeing wool top.

Owner:HEILAN HOME

Black ink composition, ink set, ink cartridge, inkjet recording method and recorded product

InactiveUS20070263056A1Guaranteed fastnessImprove printing qualityDisazo dyesMeasurement apparatus componentsPolymer scienceColoring agents

Owner:SEIKO EPSON CORP

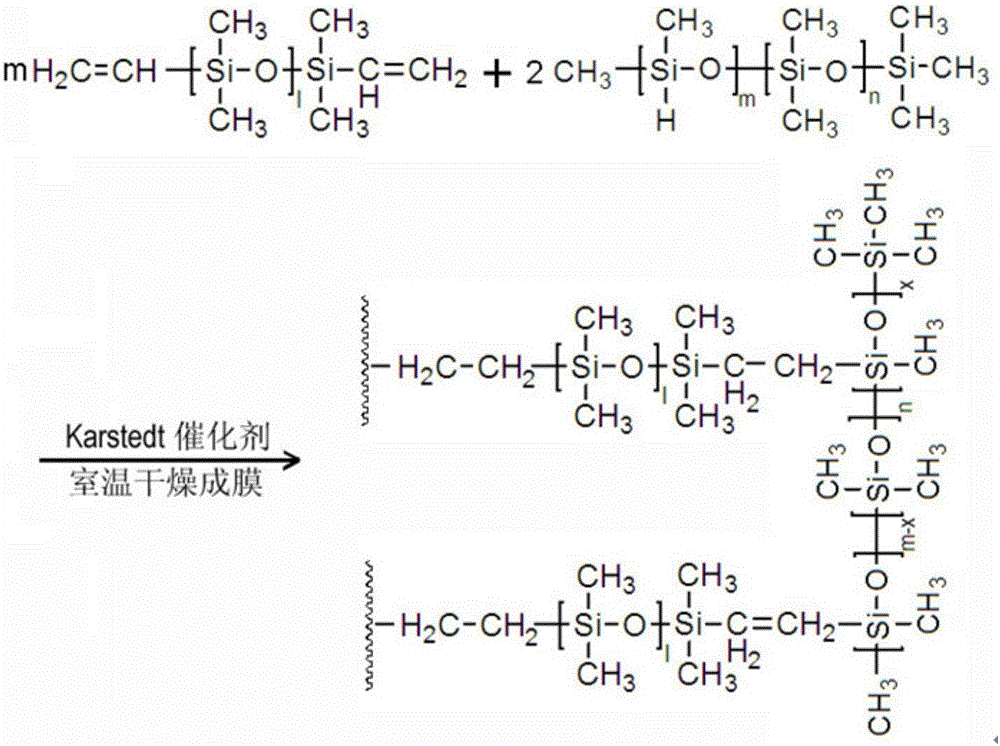

Polysiloxane, preparation system thereof, polysiloxane-polyurethane-titanium dioxide mixed paint and application of paint

ActiveCN106832306AWith super hydrophobic functionStrong UV shielding effectPolyurea/polyurethane coatingsRadiation-absorbing paintsPolyurethane adhesiveUltraviolet

The invention relates to the technical field of functional preparation of outdoor fabrics, and particularly relates to a polysiloxane, a preparation system thereof, a polysiloxane-polyurethane-titanium dioxide mixed paint and application of the paint. According to the invention, a multifunctional coating having self cleaning performance, ultraviolet resistance and superhydrophobicity is prepared from low-cost polysiloxane, polyurethane adhesive and titanium dioxide powder. A multifunctional outdoor fabric can be obtained by applying the multifunctional coating to a blended warp knitting fabric through a simple process. By using the ultraviolet absorption capability of titanium dioxide, the product can greatly degrade organic pollutants on the surface of the fabric; and meanwhile, the coating taking polysiloxane as a main component can not be subjected to photodegradation of the titanium dioxide, thereby favorably ensuring the anti-aging fastness of the fabric. The product itself has a superhydrophobic function, thereby being capable of effectively blocking a large amount of water droplets outdoors. The product has the advantages of low raw material cost, simple process and low technological transformation difficulty, thereby being suitable for industrial production.

Owner:ZHEJIANG HENGFENG TOP LEISURE CO LTD

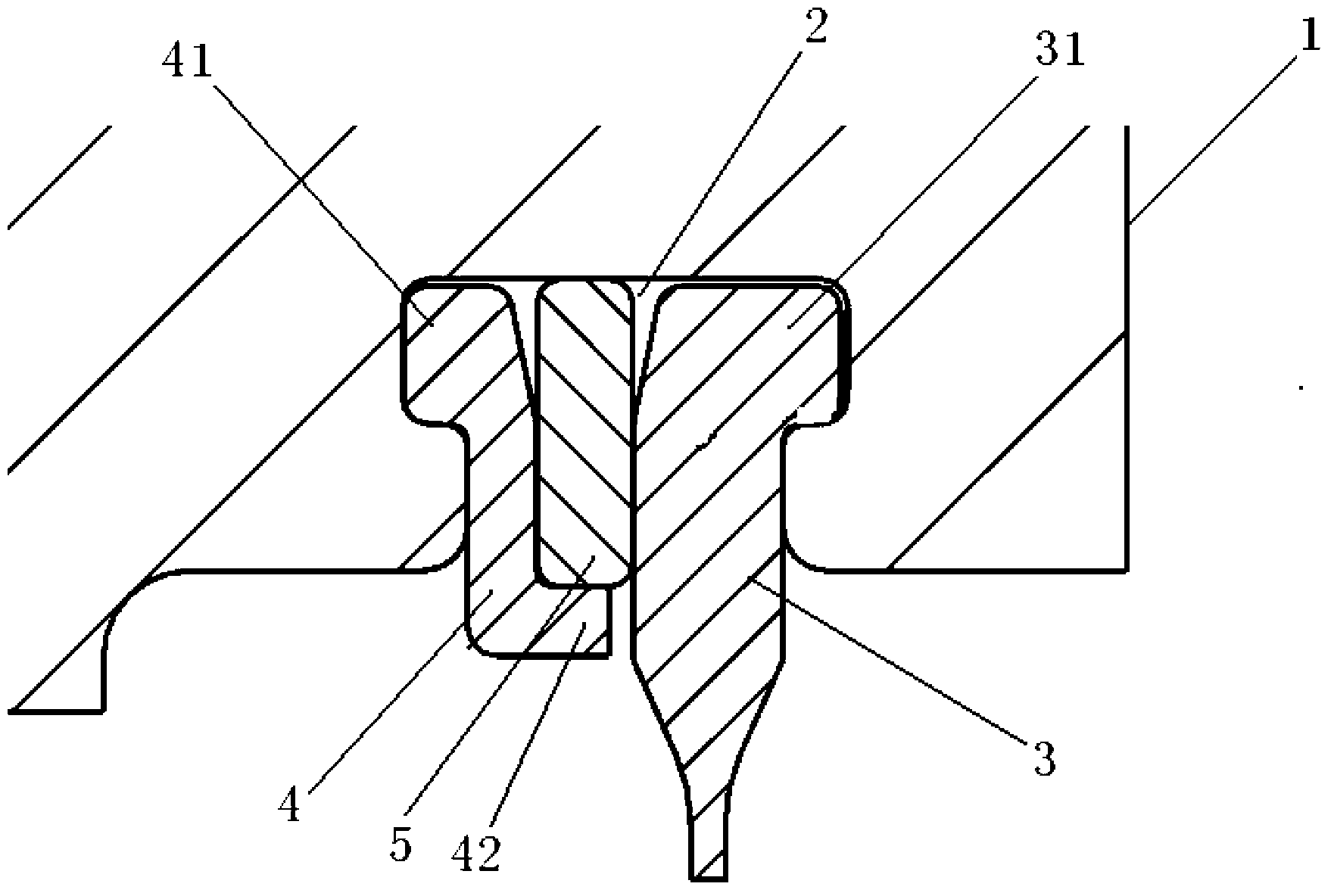

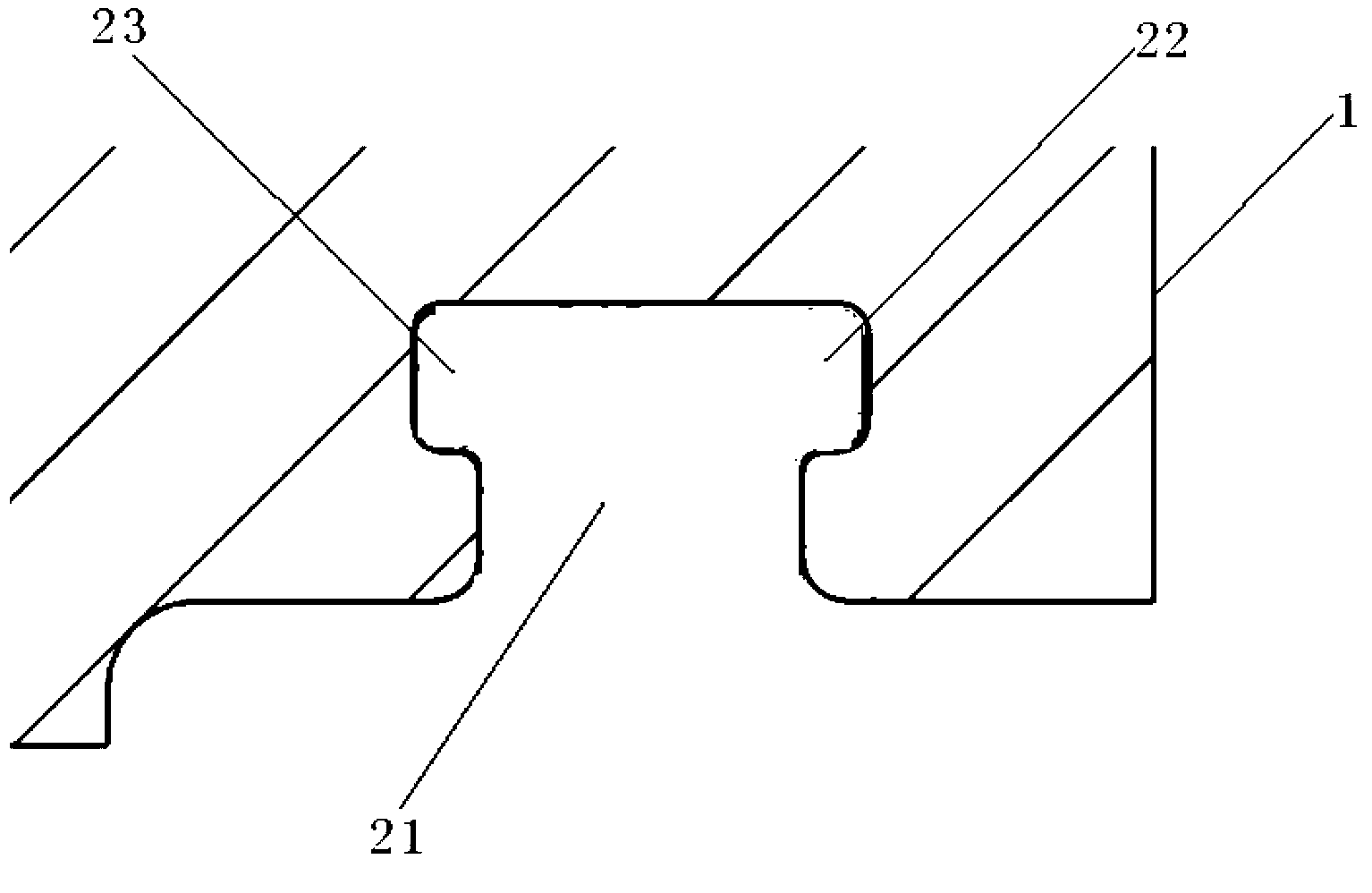

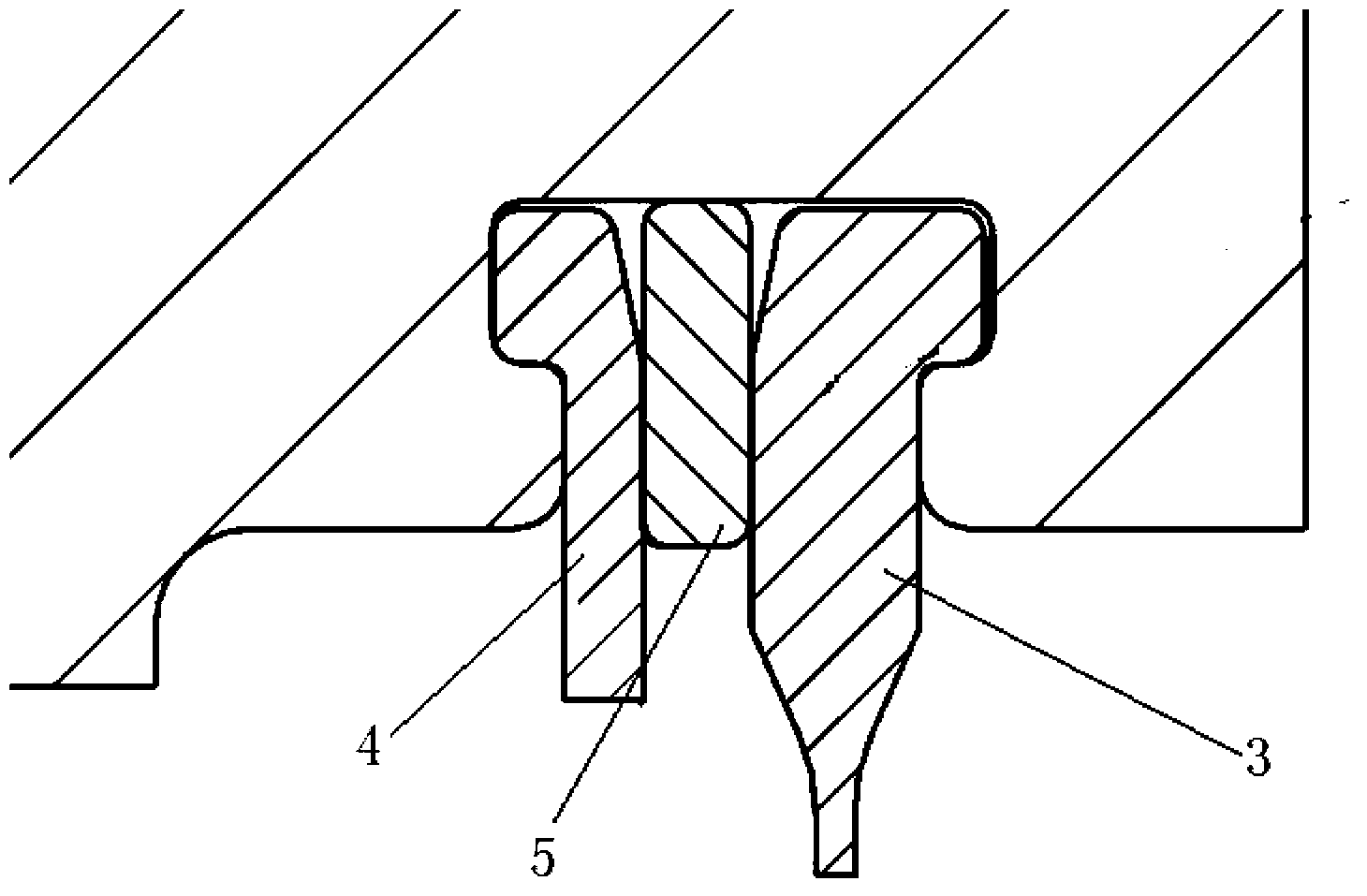

Steam sealing structure for steam turbines and assembling method thereof

ActiveCN102797512AImprove stabilityImprove reliabilityLeakage preventionMachines/enginesEngineeringSteam turbine

The invention provides a steam sealing structure for steam turbines. The steam sealing structure for steam turbines comprises a peripheral T-shaped slot, a steam sealing strip, a packing strip and a locking strip, wherein the steam sealing strip and the locking strip are arranged in a longitudinal clamping slot of the peripheral T-shaped slot, a first transverse elbow is clamped in a first transverse clamp slot, and a second transverse elbow is clamped in a second transverse clamp slot; and the packing strip is arranged between the steam sealing strip and the locking strip, the lower end of the locking strip is formed into a bent edge, and the bent edge is pressed on the lower surface of the packing strip. According to the steam sealing structure for steam turbines, the packing strip is arranged between the steam sealing strip and the locking strip, and through the packing strip, the steam sealing strip can be tensioned and tightly clamped in the peripheral T-shaped slot in the axial direction; and meanwhile, the bent edge formed at the lower end of the locking strip is pressed on the lower surface of the packing strip, so that the packing strip can be tightly compressed in the radial direction, in such a way, the steam sealing strip can be tightly fixed in the peripheral T-shaped slot, therefore, the occurrence of moving of the steam sealing strip can be effectively prevented, the assembling quality of the steam sealing strip can be ensured, and the operating stability and reliability of a steam turbine can be effectively improved.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

High-efficiency environment-friendly acidic soap washing agent, and preparation method thereof

ActiveCN110499218AGood anti-staining effectStrong dispersion abilityCationic surface-active compoundsOrganic detergent compounding agentsAcrylic acidSulfonic acid ester

The invention belongs to the field of fine chemistry, and more specifically relates to a high-efficiency environment-friendly acidic soap washing agent, and a preparation method thereof. The high-efficiency environment-friendly acidic soap washing agent comprises, by mass, 10 to 30 parts of carboxyalkylthiosuccinic acid, 30 to 50 parts of acrylic acid-2-acrylamido-2-methyl propyl sulfonic acid (AA / AMPS) copolymer 20 to 50 parts of sodium gluconate, 5 to 10 parts of hydrolytic polymaleic anhydride, 0.1 to 2 parts of a surfactant, 0.5 to 10 parts of a complexing agent, and 30 to 50 parts of water. When the high-efficiency environment-friendly acidic soap washing agent is used in cotton and cotton blended fabric reactive dye dying, surface dyeing removing effect is better, and fabric color fastness and brightness are ensured; the high-efficiency environment-friendly acidic soap washing agent contains no nitrogen and phosphorus, and is relatively high in acidity, so that the acid neutralizing process before common soaping can be avoided, waste discharge amount is reduced, human labor is saved, electricity cost is reduced, and better market advantages are achieved.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

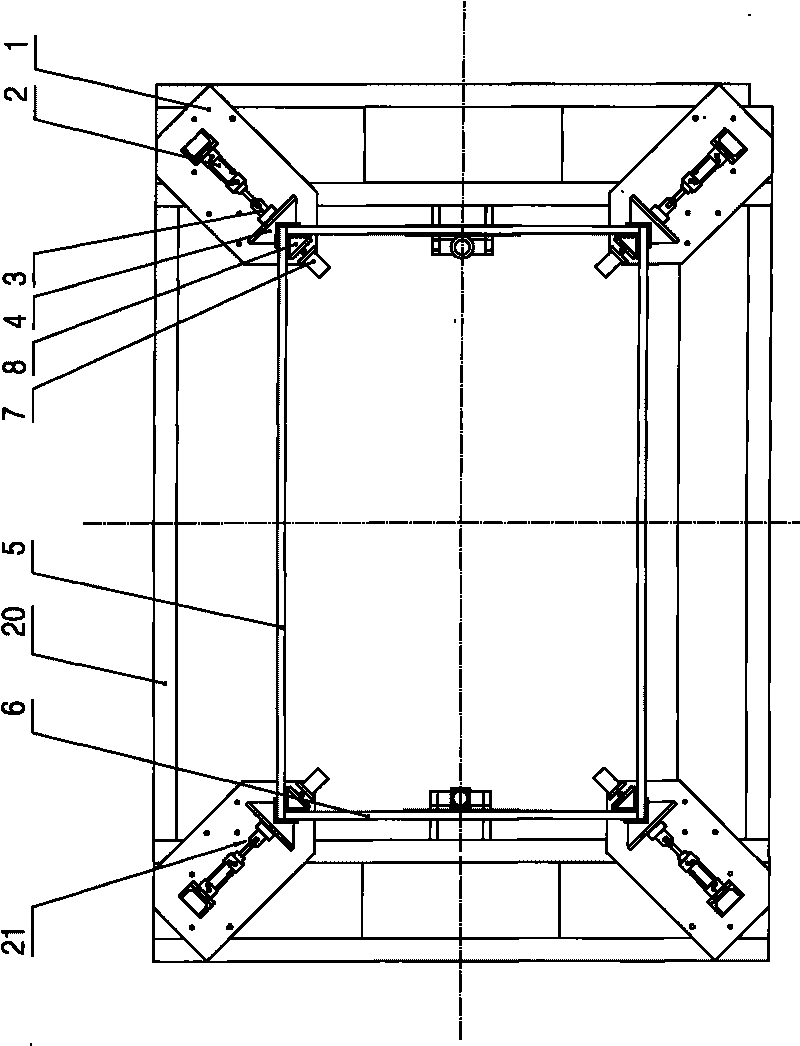

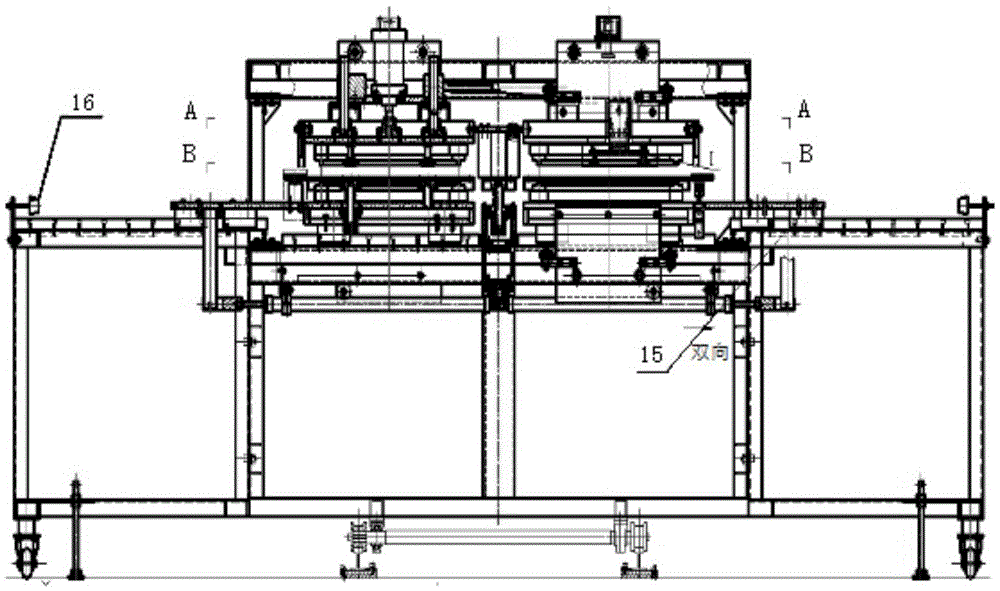

Automatic two-way blank-pressing ton bag machine

ActiveCN105619885AHigh degree of automationImprove work efficiencyEnvelopes/bags making machineryPaper-makingEngineeringWeld seam

The invention discloses an automatic two-way blank-pressing ton bag machine. The automatic two-way blank-pressing ton bag machine comprises two machines, namely an I type machine and an II type machine which are connected, wherein both the I type machine and the II type machine are ton bag machine bodies; each of the I type machine and the II type machine comprises a rack, a first air cylinder, a second air cylinder, a third air cylinder, a fourth air cylinder, a fifth air cylinder, a supporting mechanism, a floating plate, a pressure head, a plug board, a linear guide rail pair, a sucking disc, an upper heating knife and a lower heating knife. The automatic two-way blank-pressing ton bag machine is high in degree of automation, and can complete the whole action by switching on and off once, so that the working efficiency is greatly improved; an automatic gas sucking device is arranged for separating upper and lower sheets of a bag body so as to plug in the plug board conveniently, so that the firmness and the flatness of a welding seam are guaranteed; and welding is completed once, so that labor power is reduced, the labor intensity of a worker is reduced, and the working efficiency and the product quality are improved.

Owner:NANJING HUJIANG COMPOSITE MATERIALS

Three-clamping lock

InactiveCN103486117AGuaranteed StrengthGuaranteed fastnessFriction grip releasable fasteningsStructural engineeringMechanical engineering

The invention relates to a three-clamping lock comprising a lock case, a three-clamping reed and an eccentric gear. The three-clamping lock is disposed in the lock case, a hole matched with the eccentric gear is formed in the three-clamping reed which moves frontwards and backwards through rotation of the eccentric gear in the hole, the lock shell is formed by stamping a seamless steel pip with a rectangular section, a rear cap is arranged at the rear end of the lock case, and a lower support used for supporting the rear end of the three-clamping reed is arranged on the inner side of the rear cover. By the three-clamping lock, manual torque is prevented from increasing to cause loosening of a lock head, and capability of lateral stopping is greatly improved; meanwhile, manufacturing cost is lowered greatly, and the reed and the eccentric gear are matched more stably and effectively.

Owner:LINGTONG EXHIBITION SYST

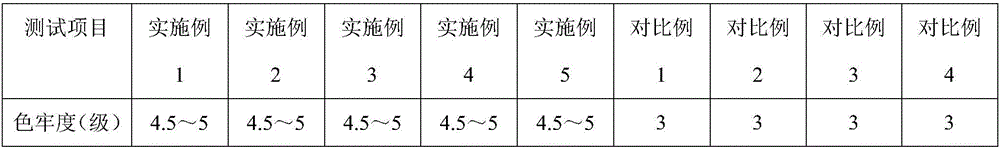

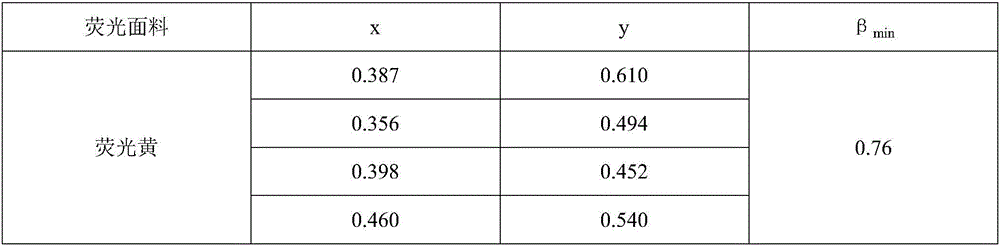

Production technology of fluorescent cotton fabric

InactiveCN105970667AMeet fashion requirementsImprove dye uptakeDyeing processWarm waterRoom temperature

The invention discloses a production technology of a fluorescent cotton fabric. The production technology is characterized by comprising the steps of 1, modification treatment of the cotton fabric, wherein the cotton fabric is immersed in a 18 g / L modifying agent solution, the pH is 10, the bath ratio is 30:1, the initial temperature is 30 DEG C, heating is conducted to 70 DEG C at the speed of 5 DEG C / min, the temperature is kept for 20 min, heating is conducted to 90 DEG C at the speed of 1 DEG C / min, the temperature is kept for 20 min, and the treated cotton fabric is taken out, washed with water and air-dried at room temperature; 2, treatment, wherein the cotton fabric is immersed in warm water of 60 DEG C for 30 min, and then the cotton fabric is taken out and air-dried at room temperature; 3, dye preparation, wherein sodium carboxymethylcellulose is added into water, stirring is conducted for 12 h to 24 h, water-soluble fluorescent dye is slowly added, and the materials are stirred and mixed to be uniform; 4, fluorescent dyeing, wherein the cotton fabric treated in the second step is immersed into dye prepared in the third step for dyeing, the pH ranges from 5 to 6, the bath ratio is 30:1, the initial temperature is 30 DEG C, heating is conducted to 60 DEG C at the speed of 5 DEG C / min, the temperature is kept for 20 min, heating is conducted to 90 DEG C at the speed of 1 DEG C / min, the temperature is kept for 50 min, and then the cotton fabric is taken out and air-dried.

Owner:UNIV OF JINAN

LED (Light Emitting Diode) lamp bulb light strip connecting portion structure and LED lamp bulb light strip and conducting wire connection method

InactiveCN104329640ASolve the problem of poor weldingGuaranteed fastnessPoint-like light sourceLight fasteningsEngineeringLED lamp

The invention relates to an LED (Light Emitting Diode) lamp bulb light strip connecting portion structure and an LED lamp bulb light strip and conducting wire connection method. A connecting portion is provided with an annular or semi-annular or fork-shaped bayonet which is used for clamping a conducting wire, and the bayonet is formed through dividing the connecting portion into three parts and molding the middle portion; during connection, the conducting wire is firstly snapped into the molded bayonet, namely being inserted into a ring or semi ring or being snapped into a fork, the bayonet is enabled to clamp the conducting wire, and then, welding is carried out. The LED lamp bulb light strip connecting portion structure and the LED lamp bulb light strip and conducting wire connection method have the advantages that the fastness of welding is ensured, the difficulty of welding is lowered, the problem of poor welding between the connecting portion and the conducting wire is solved, and the quality of a product is improved.

Owner:HAINING XIN GUANG YUAN LIGHTING TECH CO LTD

Wash fade slurry and method for fabricating imitated yarn-dyed wash fade fabric

The invention discloses wash fade slurry and a method for fabricating imitated yarn-dyed wash fade fabric. The wash fade slurry is prepared by the following components in parts by weight: 20-30 parts of starch, 30-40 parts of hydrolyzed casein, 3-5 parts of fluorocarbon waterproofing agent, 30-35 parts of water, 1-2 parts of PTF thickening agent, 0.2-0.3 parts of organosilicon flatting agent and 0.1-0.2 parts of polyether antifoaming agent. The method for fabricating the imitated yarn-dyed wash fade fabric comprises the following steps of (1) printing the wash fade slurry on the surface of grey fabric to form a decorating pattern, and drying, (2) coating the surface of the grey fabric printed by the wash fade slurry decorating pattern with dyed resin slurry, and drying, and (3) using warm water to wash the grey fabric, fading the wash fade slurry on the surface of the grey fabric and the dyed resin slurry coating the surface of the wash fade slurry, allowing the decorating pattern to appear on the surface of the grey fabric, and obtaining the imitated yarn-dyed wash fade fabric. The wash fade slurry is very soluble in water, and can be faded by using the warm water to conduct common water washing; no auxiliary agents are required to be added; and a wash fade effect is very stable.

Owner:HUAHAN QUANZHOU NEW FABRIC DEV

High color fastness dyeing and finishing process for polyamide polyester fabric

InactiveCN108468232ASmoothSoft touchDry-cleaning apparatus for textilesGrip property fibresColour fastnessPolyester

The invention provides a high color fastness dyeing and finishing process for a polyamide polyester fabric. Dyeing and finishing are carried out through desizing, dyeing, color fasting and aftertreatment processes, the dyeing and finishing process is simple and rapid and convenient to operate, a dyed polyamide polyester fabric is uniform in color, natural in color and soft and fine in fabric, various color fastness grades after dyeing are all greater than 4, that is, the color fastness grade is far greater than those of common polyamide polyester fabrics in the market, and the fabrics are high-quality polyamide polyester fabrics.

Owner:福建省晋江市浩沙制衣有限公司

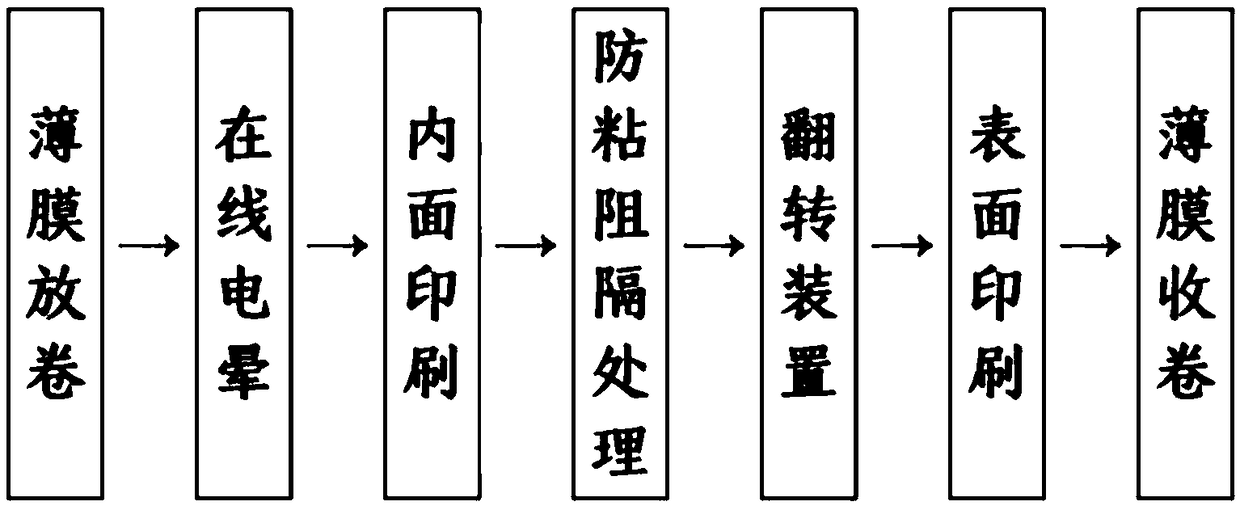

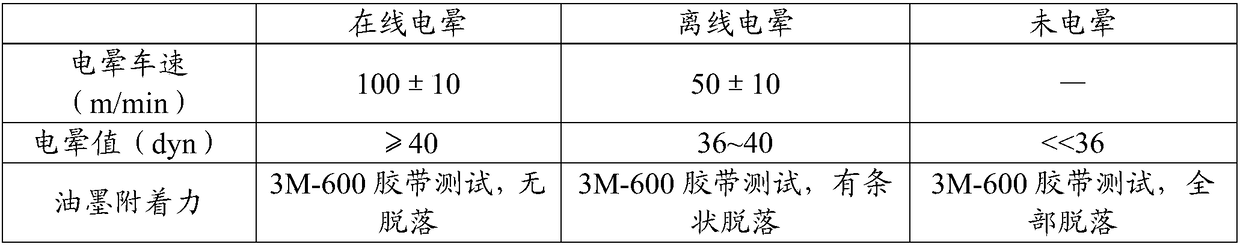

Double-sided printing method for plastic film

InactiveCN109177557AGuaranteed fastnessReduce surface tensionOther printing apparatusPrinting after-treatmentBarrier treatmentEngineering

The invention relates to a double-sided printing method for a plastic film. The method includes the steps that (1) a first surface of the plastic film is subjected to online corona treatment; (2) a second surface of the plastic film is subjected to printing treatment; (3) after the printing treatment, the second surface of the plastic film is subjected to adhesion prevention and barrier treatment;(4) the plastic film is overturned, so that the first surface of the plastic film is to be printed; and (5) the first surface of the plastic film is subjected to printing treatment and precisely aligned at printed images of the second surface. According the double-sided printing method for the plastic film, a traditional gravure inner printing technology is broken, and by adoption of overturningprinting technology through a gravure printer, precise alignment of printed images on the positive and negative surfaces is completed; through the online corona treatment, the synchronism of corona and printing and the stability of corona are greatly ensured; and through online coating adhesion prevention and barrier materials, the problem of ink adhering back is solved without affecting the strength of the composite.

Owner:三樱包装(江苏)有限公司

Polyvinyl chloride (PVC) plastic steel plate

InactiveCN101746087AGuaranteed fastnessRich in colorMetal layered productsTectorial membraneSheet steel

The invention provides a polyvinyl chloride (PVC) composite plastic steel plate. The front face of the steel plate is coated with a passivation layer, an adhesive layer is coated on the surface of the passivation layer, a PVC membrane layer is adhered on the adhesive layer, a protective membrane layer covers on the PVC membrane layer; and the back face of the steel plate is coated with a passivation layer, and a back paint layer is coated on the passivation layer. The invention can play roles of decoration, protection and attraction after the PVC membrane is adhered, has variable colors because the PVC membrane layer can achieve the effect of simulating wood grains, and can be used in industries of home appliances, decoration and the like.

Owner:SUZHOU HESHENG NEW MATERIALS

Bidirectional cold and hot matrix spreader for Chinese medicine plaster

InactiveCN1973811AKeep active ingredientsImprove efficacyPretreated surfacesLaminationEmulsionSprayer

The present invention relates to spreader, and is especially one kind of bidirectional cold and hot matrix spreader for Chinese medicine plaster. The matrix spreader for Chinese medicine plaster includes one casing, one roller conveyer inside the casing, one low temperature stoving channel below the roller conveyer and with arranged air nozzles and air exhaust ports, one film covering unit in the outlet of the stoving channel, one cutting unit, one water emulsion sprayer in the inlet of the stoving channel to spray water medicine emulsion islands onto the isolating film, and one hot melt adhesive sprayer in the outlet of the stoving channel. Spraying both water emulsion and hot melt adhesive to the Chinese medicine plaster can preserve the low temperature medicine components in the plaster, ensure the water-resisting fast adhesion of the plaster, raise the medicinal effect and increase the use period.

Owner:TIANJIN ZHONGBAO PHARMACY

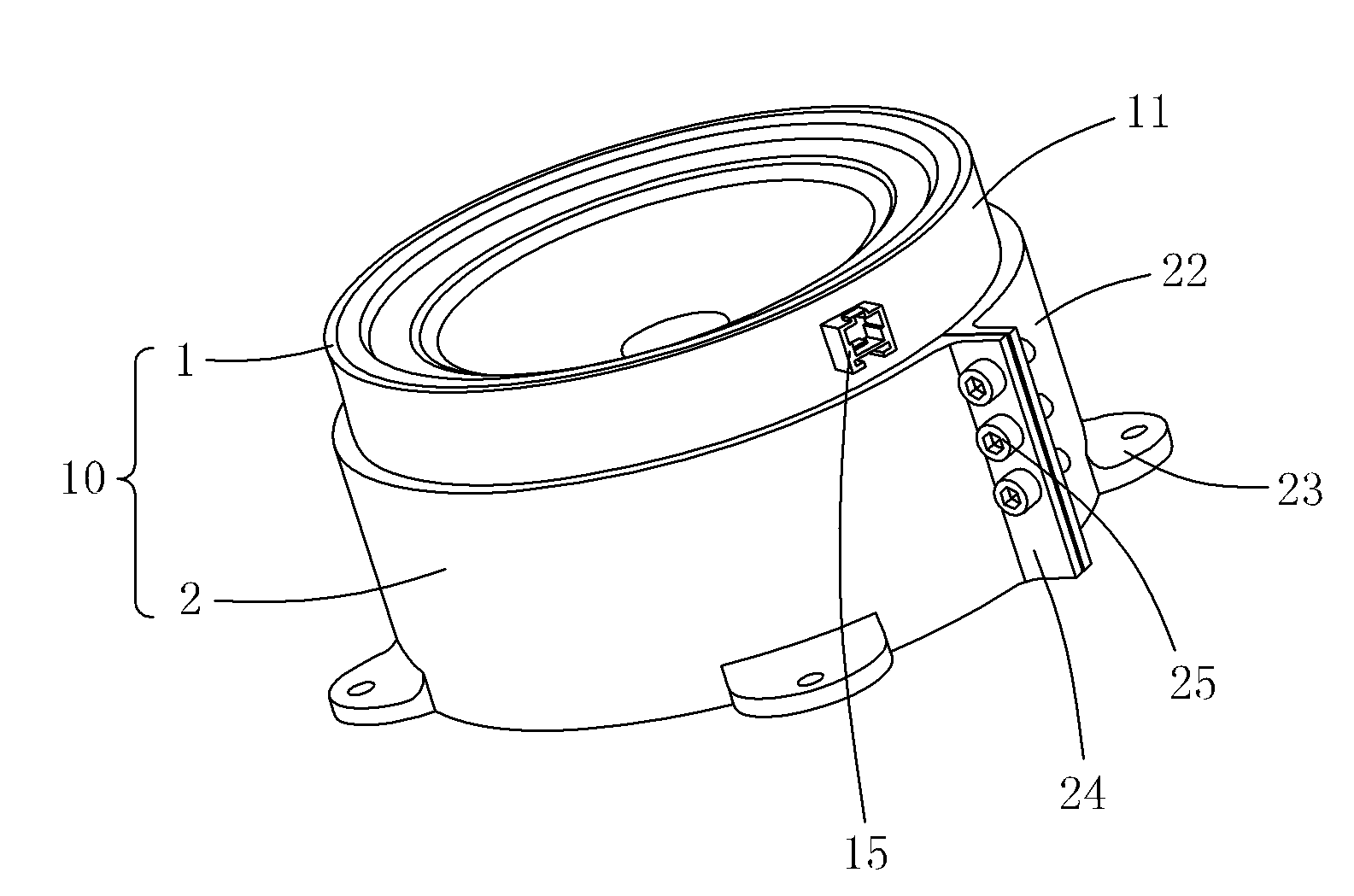

Speaker component with platformized basin stand

InactiveCN103179474AThe internal structure remains unchangedGuaranteed performance parametersAcoustic signal devicesTransducer casings/cabinets/supportsEngineeringLoudspeaker

The invention discloses a speaker component with a platformized basin stand. The speaker component comprises a basin stand and a speaker arranged on the basin stand, wherein the basin stand comprises an inner sleeve and an outer sleeve both of which are mutually embedded and sleeved; the inner sleeve is a continuous annular sleeve; the speaker is arranged at one end side of the inner sleeve; the outer sleeve is a discontinuous annular sleeve with an opening; buckling mechanisms for buckling the inner sleeve and the outer sleeve together are respectively arranged at the outer part of the inner sleeve and the inner part of the outer sleeve; and the buckling positions of the buckling mechanisms are adjustable, so that the whole height of the speaker is adjustable. Through the adjustment of the position relationship between the inner sleeve and the outer sleeve, the speaker can be mounted between door inner decorative plates and door metal plates of cars in different types to realize the need for the speaker car type platformization. The speaker component with the platformized basin stand can guarantee firmness of external installation of the speaker to avoid generating abnormal noise at a joint, has no deformation after tests at high temperature and low temperature, and can bear enough vibration and falling.

Owner:SAIC MOTOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com