Patents

Literature

3250 results about "Screw joint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A screw joint is a one-degree-of-freedom kinematic pair used in mechanisms. Screw joints provide single-axis translation by utilizing the threads of the threaded rod to provide such translation. This type of joint is used primarily on most types of linear actuators and certain types of cartesian robots.

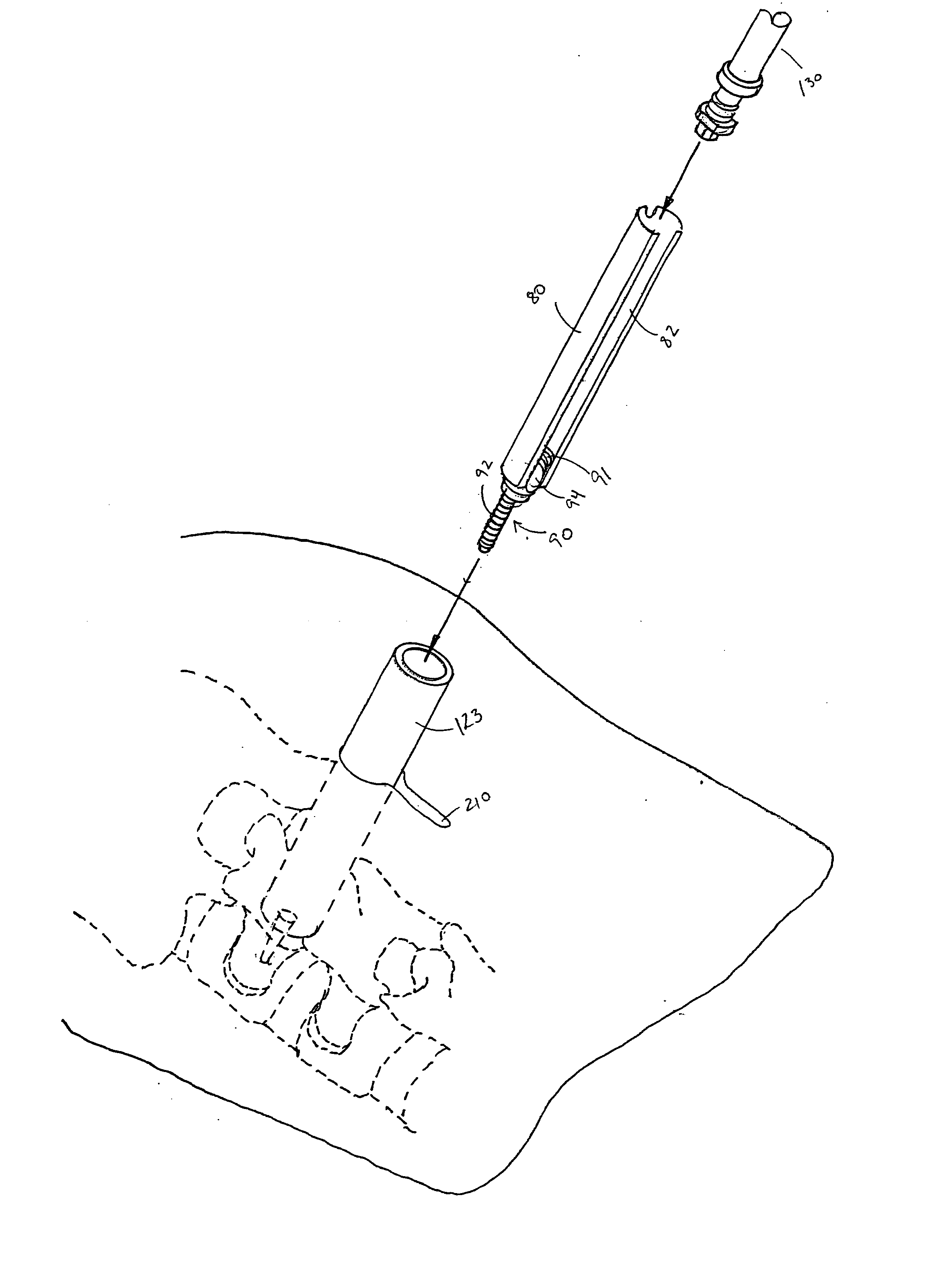

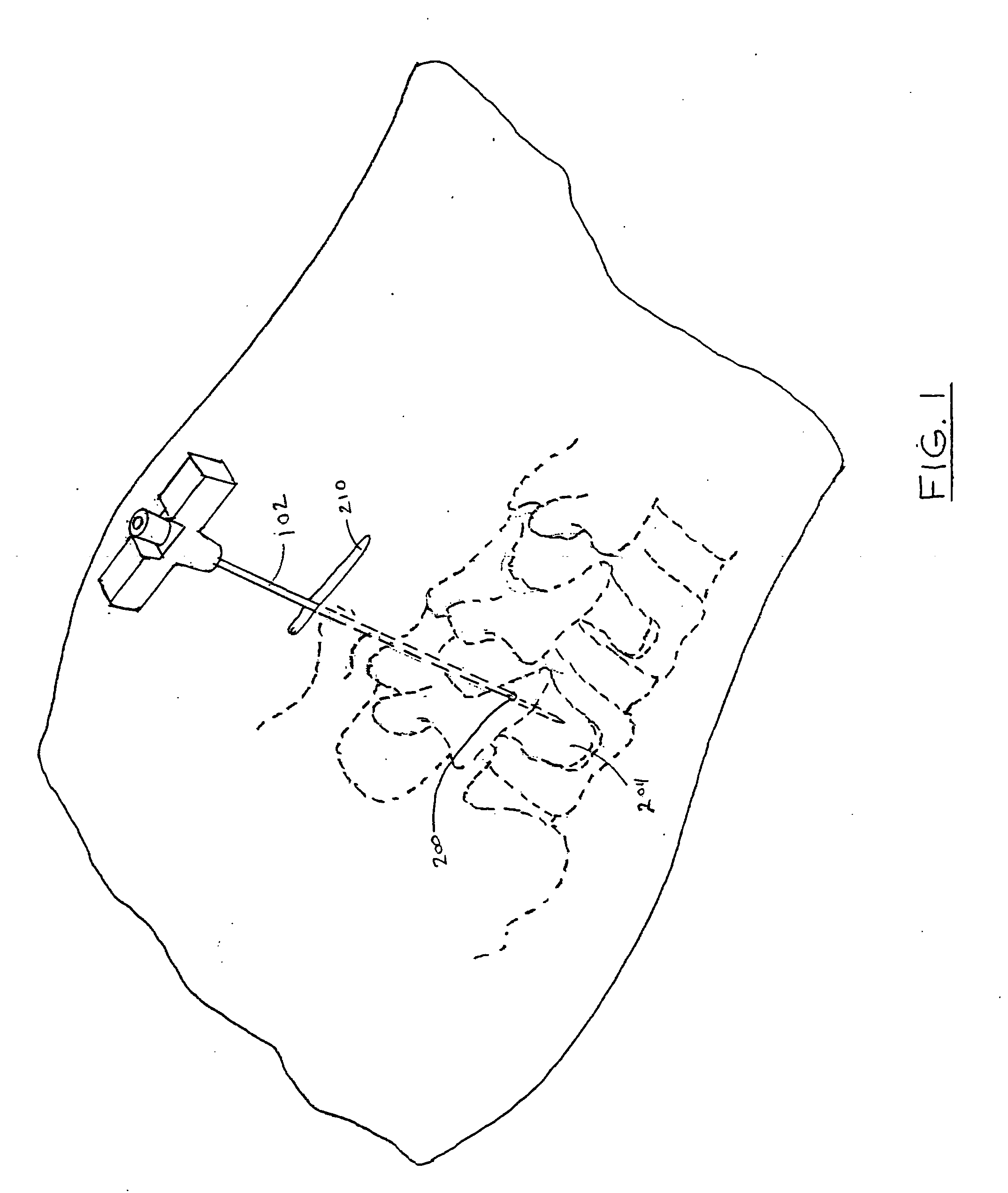

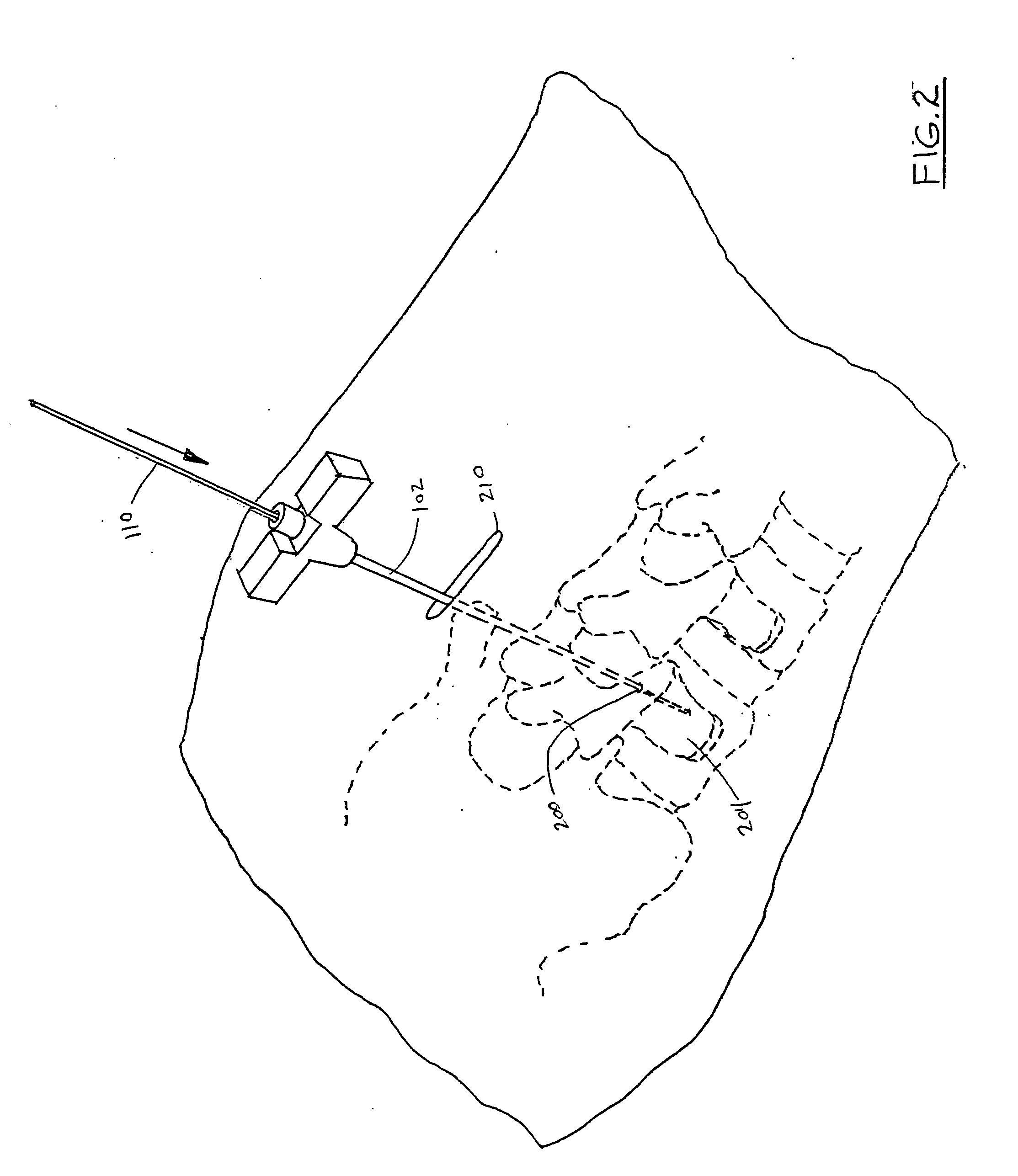

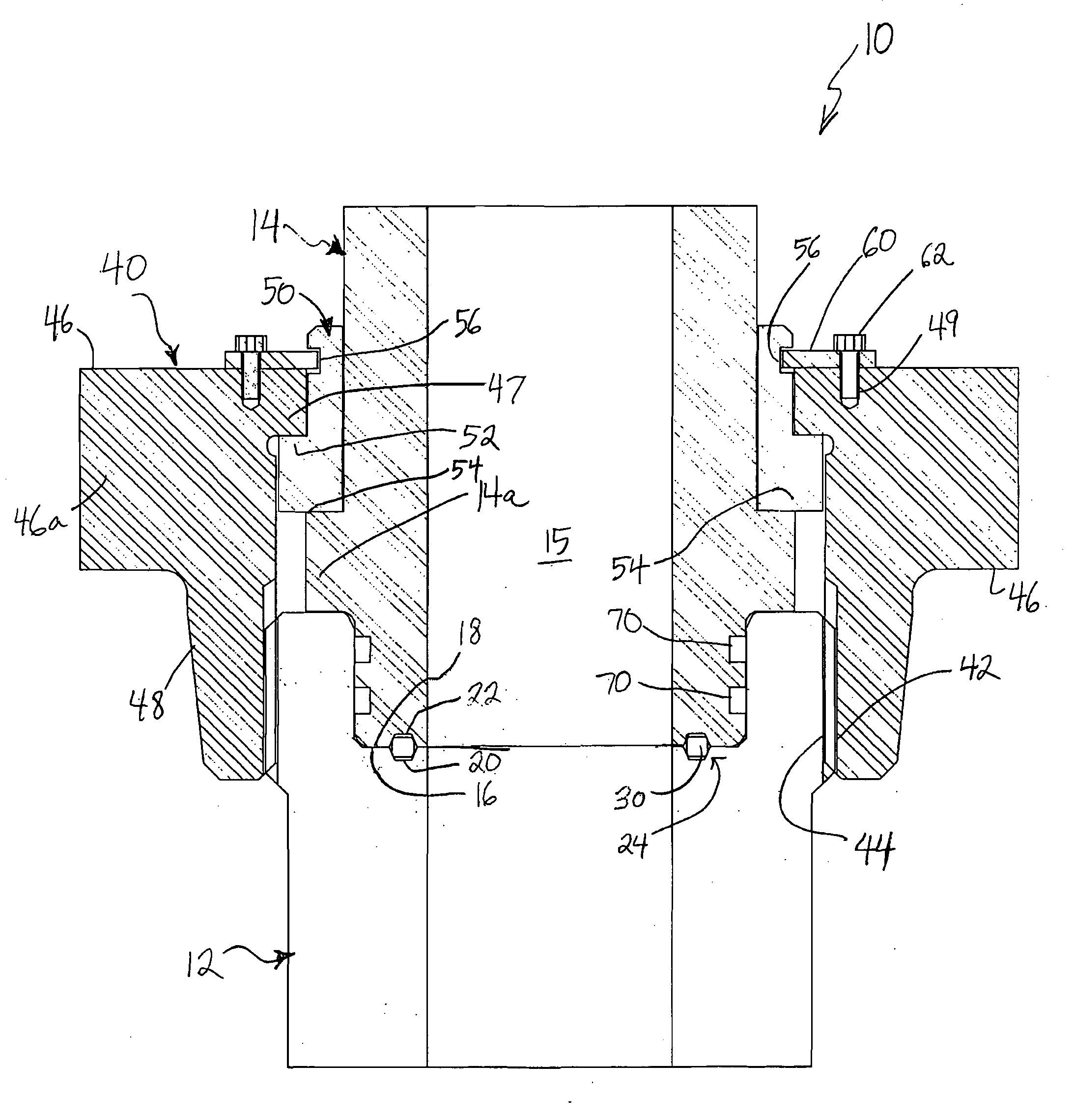

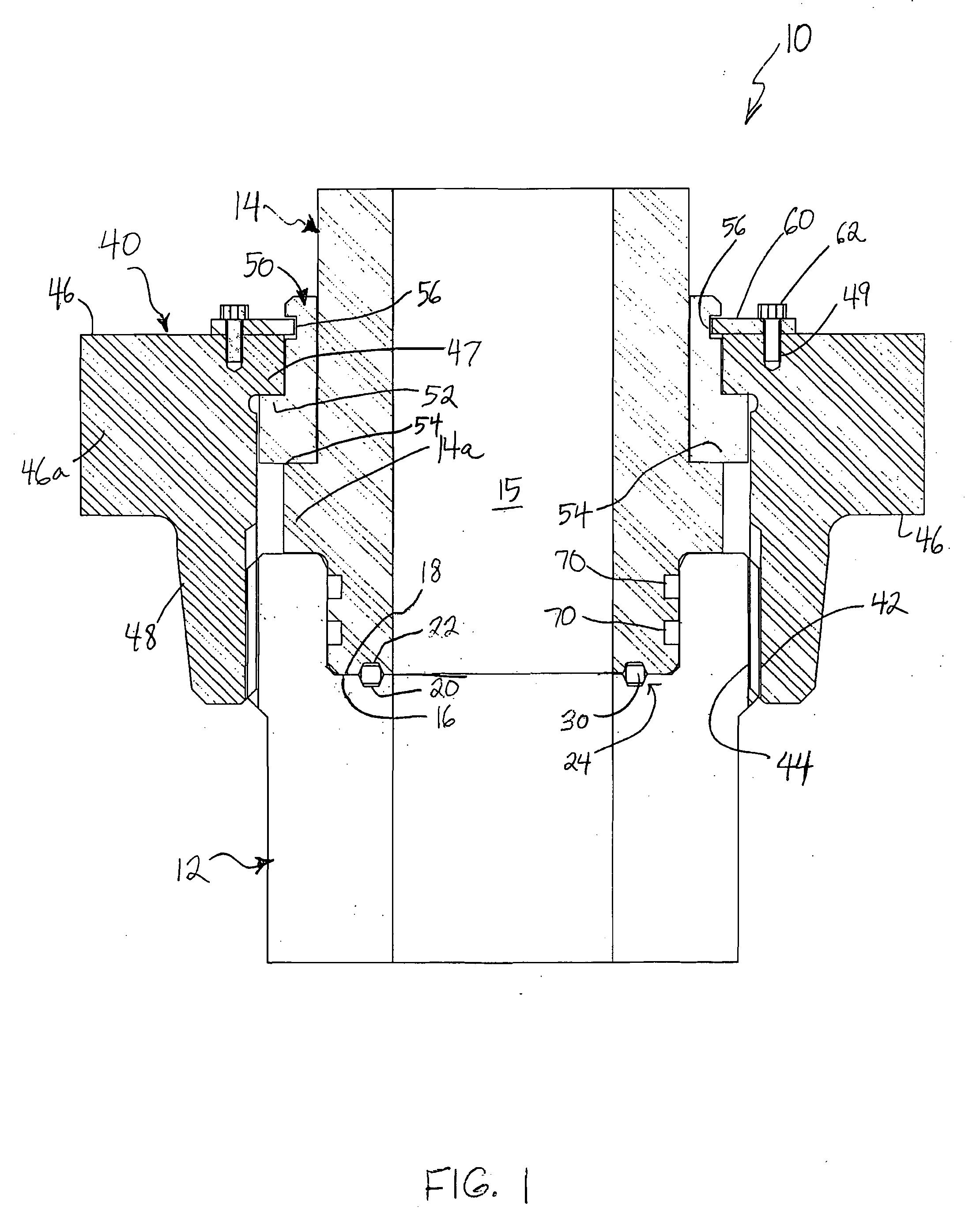

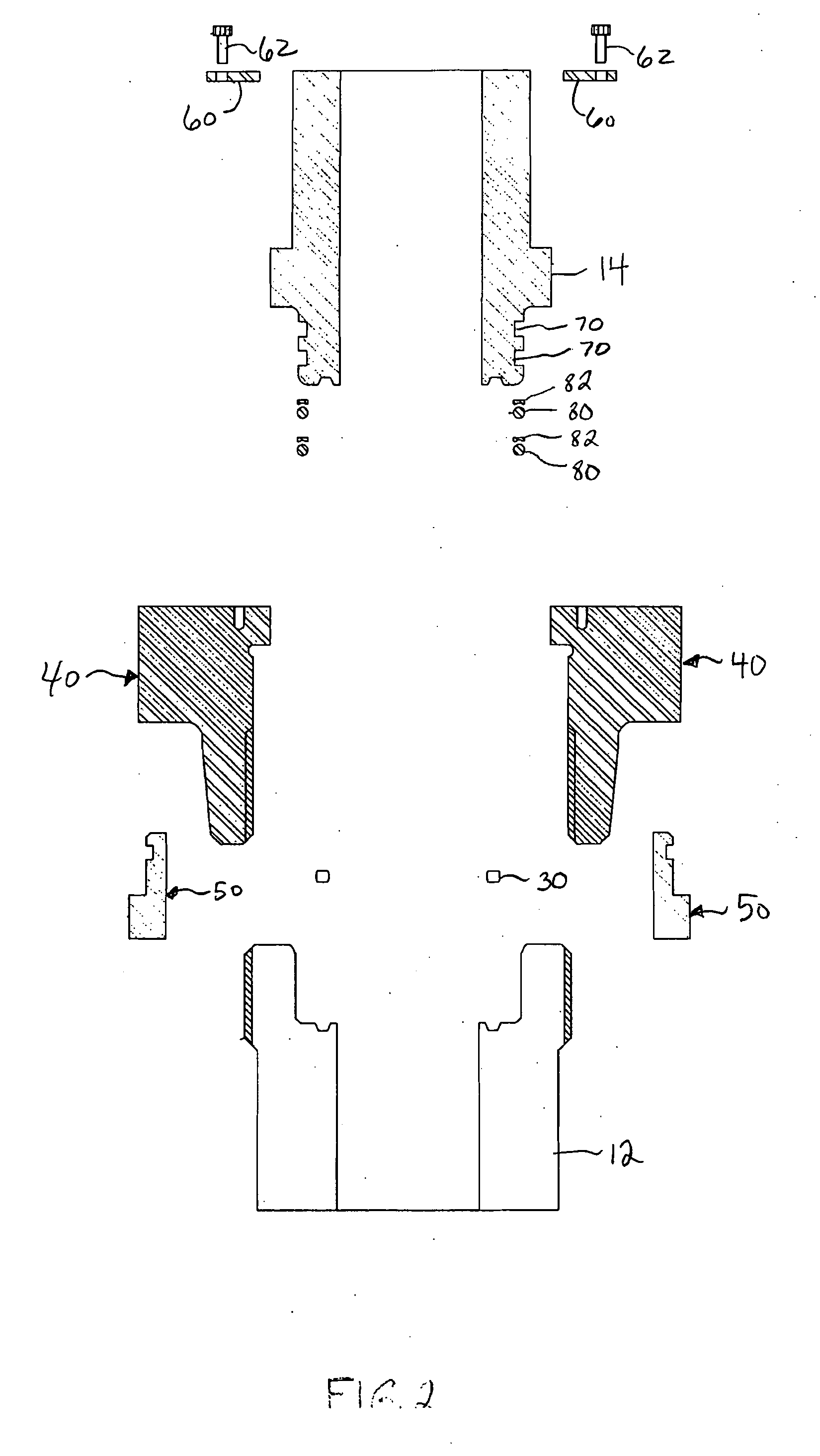

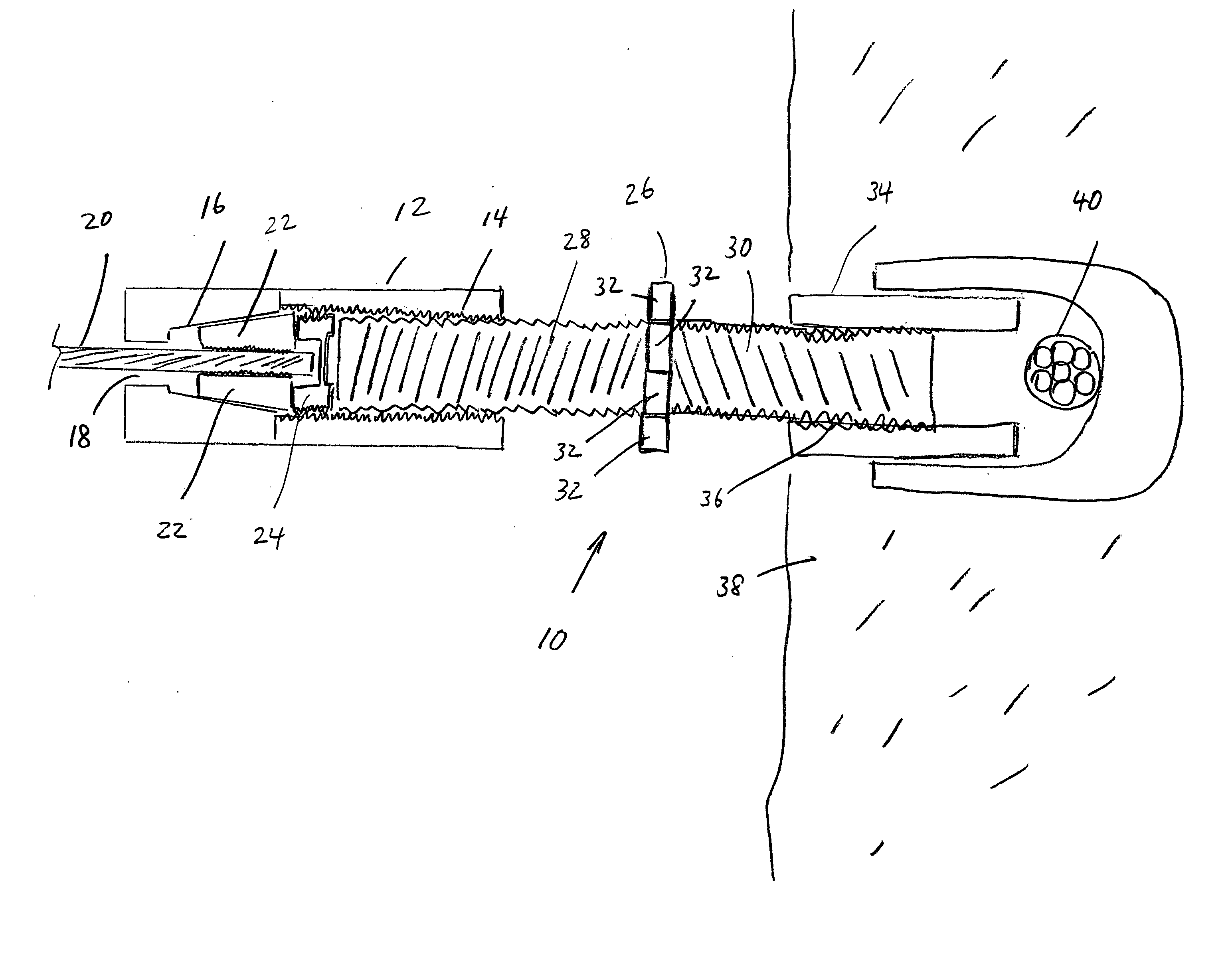

Sleeve assembly for spinal stabilization system and methods of use

ActiveUS20060293693A1Easy to installEasy to removeInternal osteosythesisDiagnosticsCouplingEm coupling

The present invention is a one or two-part sleeve assembly for use during minimally invasive spinal stabilization surgery. An outer sleeve is designed to slide over the coupling between a polyaxial screw and an inner sleeve so as to prevent the screw from becoming disengaged from the inner sleeve during surgery. The outer sleeve includes a lower generally cylindrical wall having a slot, and an upper extension having an outwardly protruding manipulation handle attached to it. The slot in the lower section extends the entire length of the cylindrical wall, giving it a generally “C” shaped cross section. This slot corresponds with a similar slot on the inner sleeve for receiving a stabilizing rod to be attached to the polyaxial screw during surgery. The interior diameter of the lower section is approximately the same as the outer diameter of the inner sleeve, so that the outer sleeve may slide snugly over the inner sleeve and the screw coupling. In addition, the edges of the cylindrical wall adjacent to the longitudinal slot are flattened so as to conform to the shape of the inner sleeve and the head portion of the polyaxial screw where it couples with the inner sleeve.

Owner:INNOVATIVE SPINE LLC

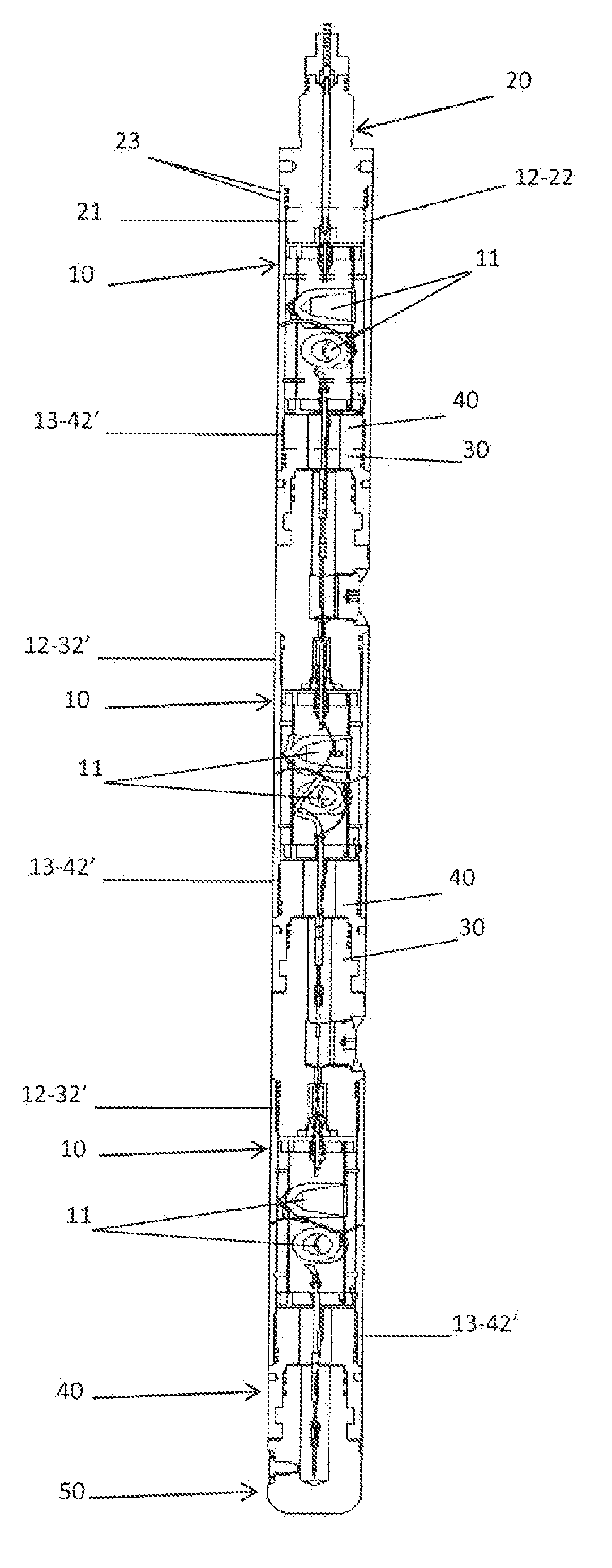

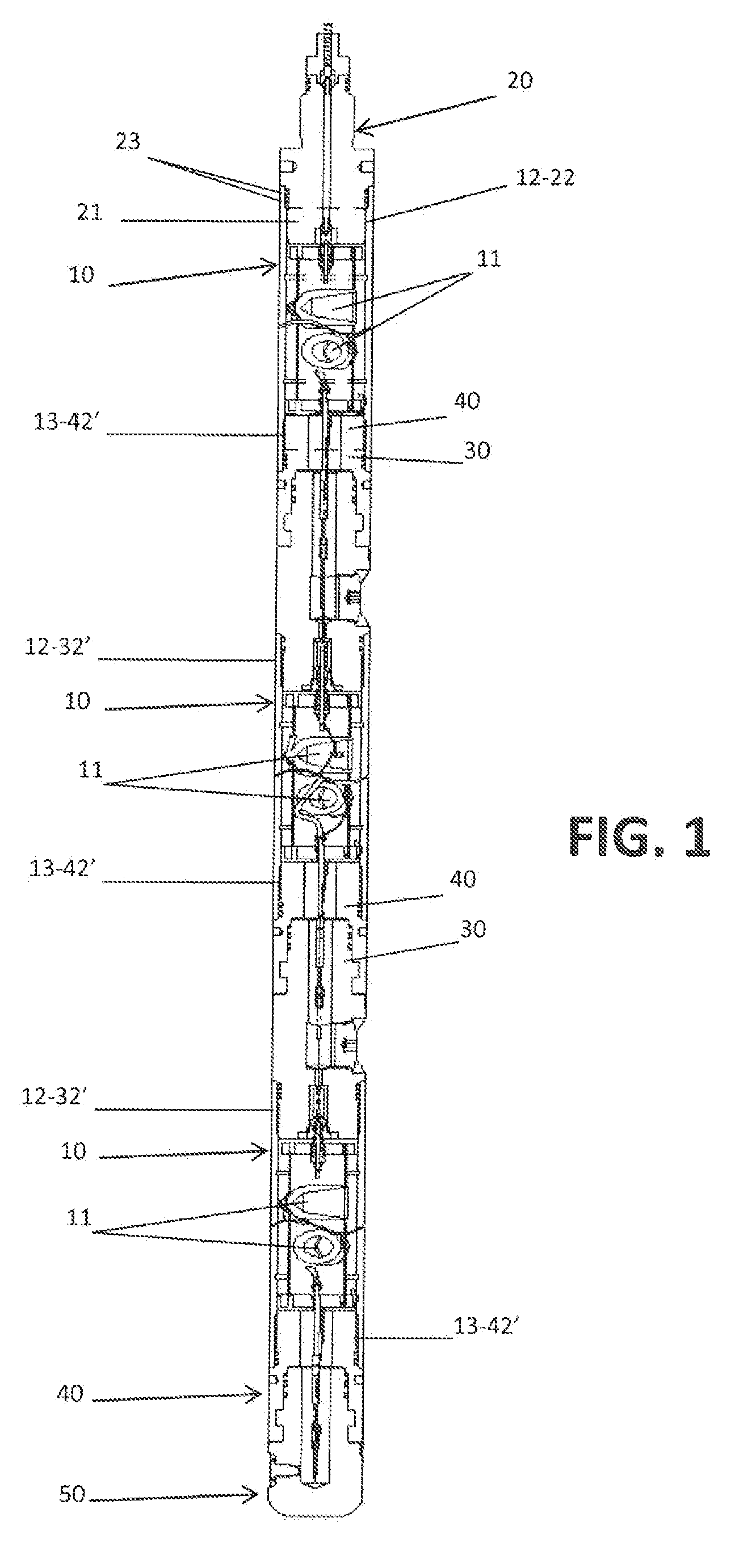

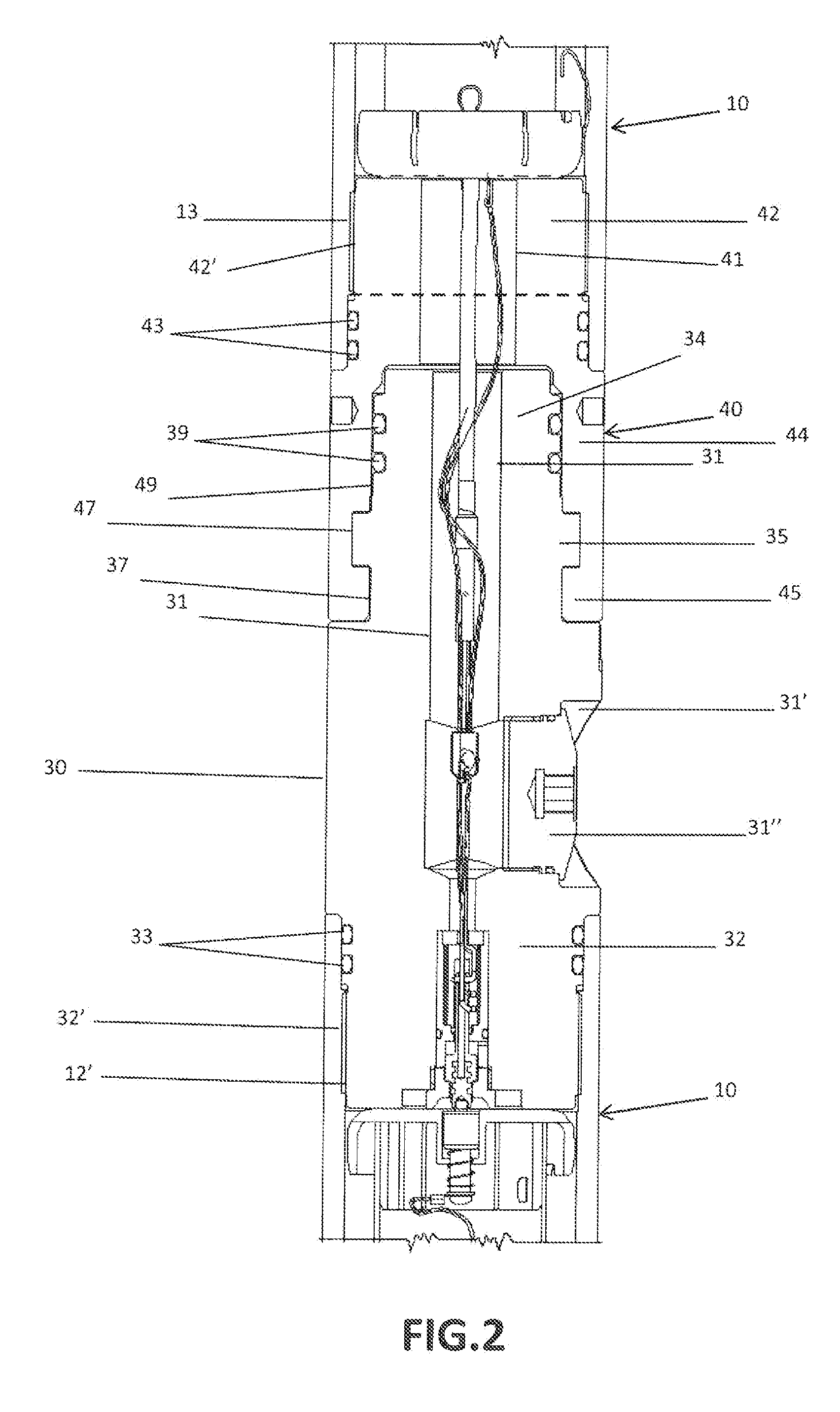

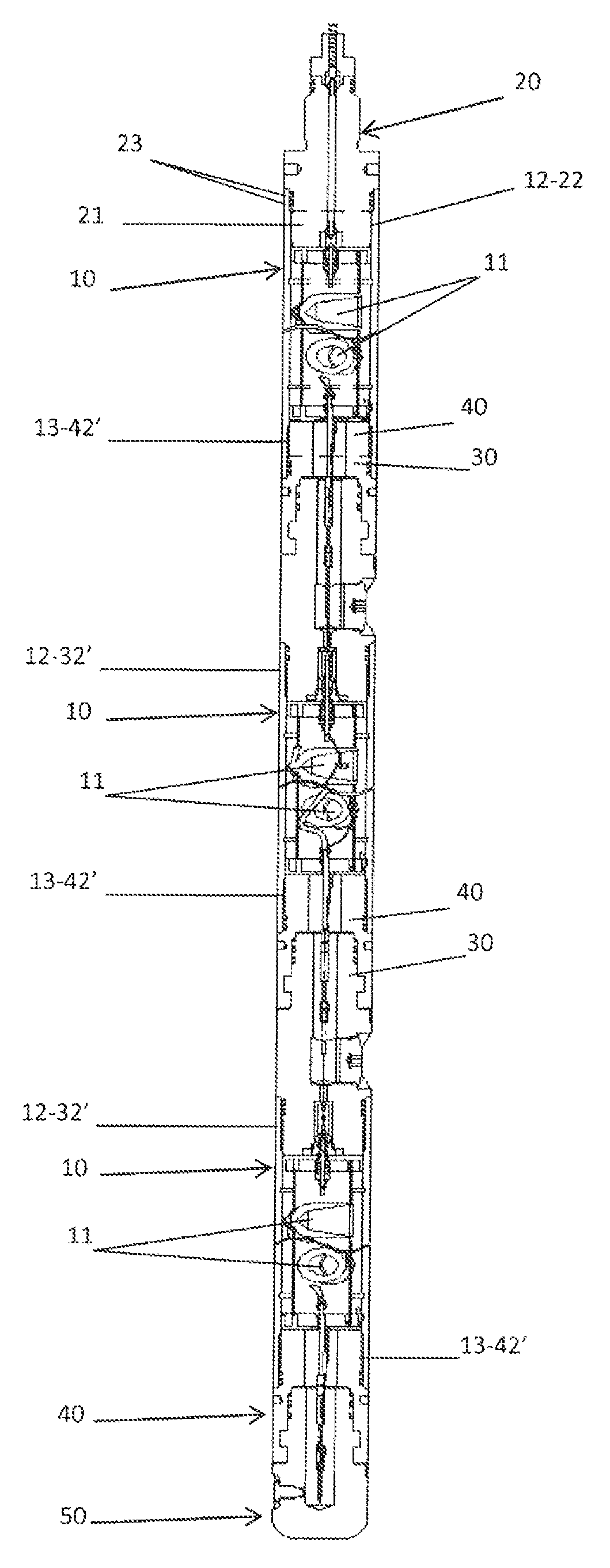

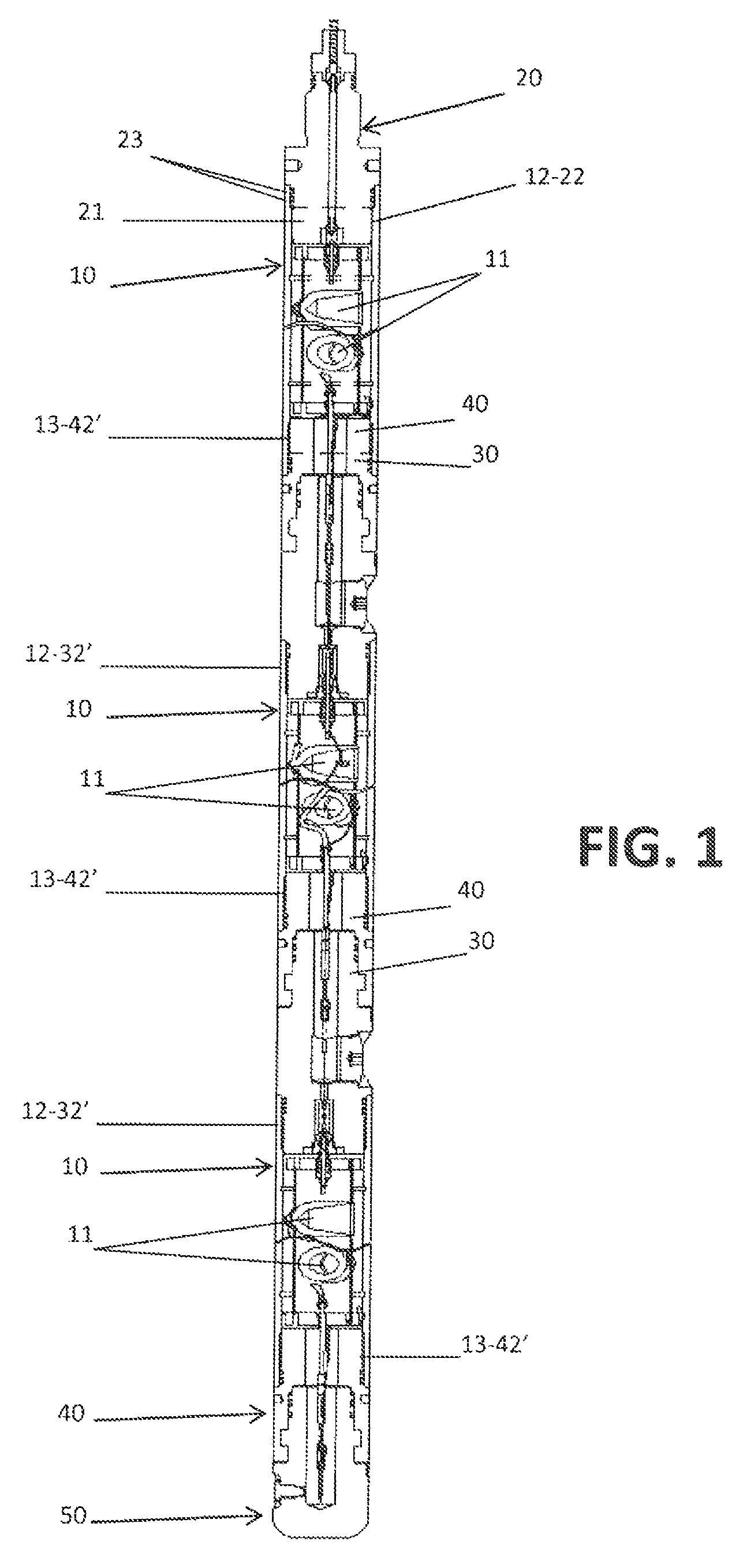

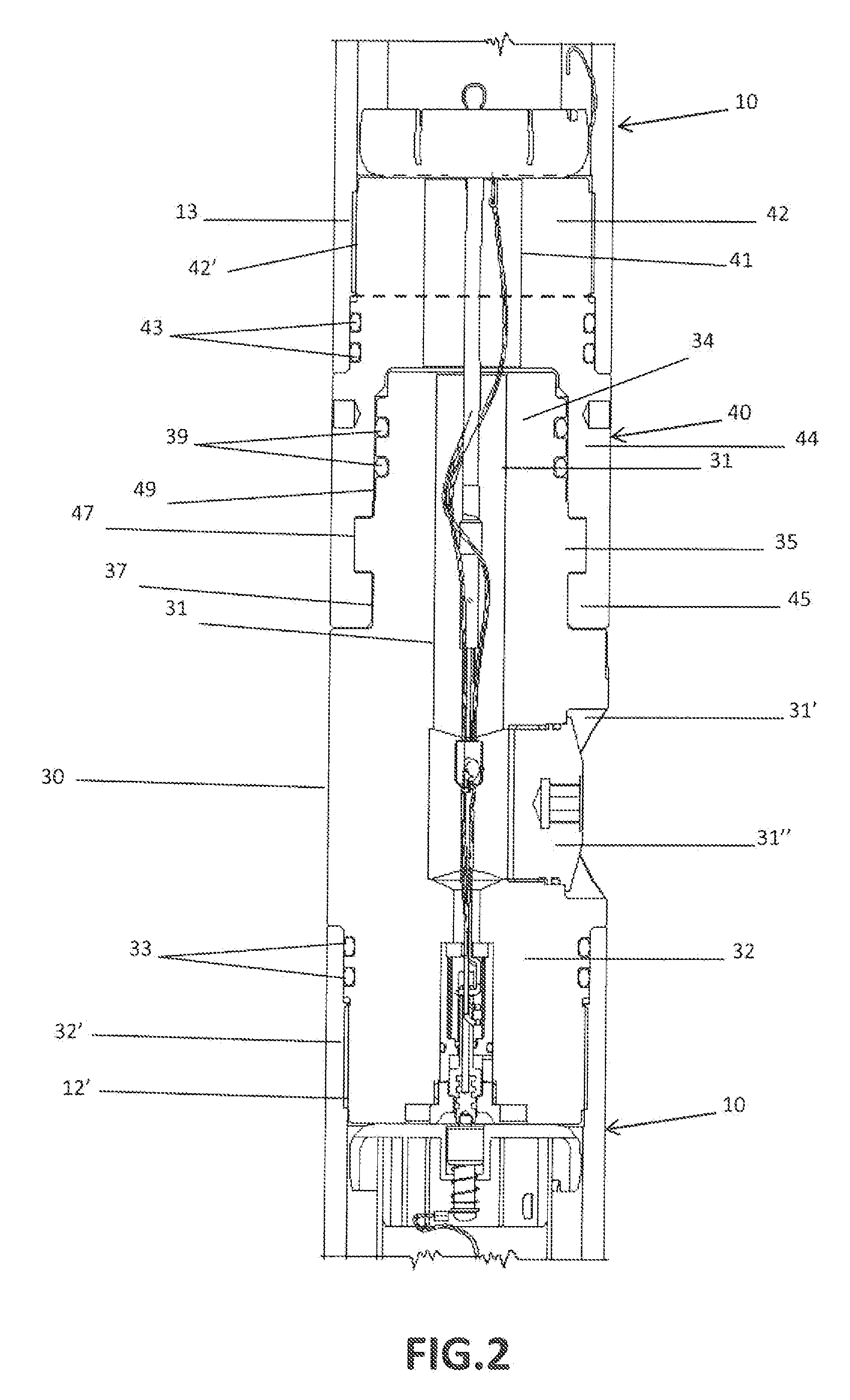

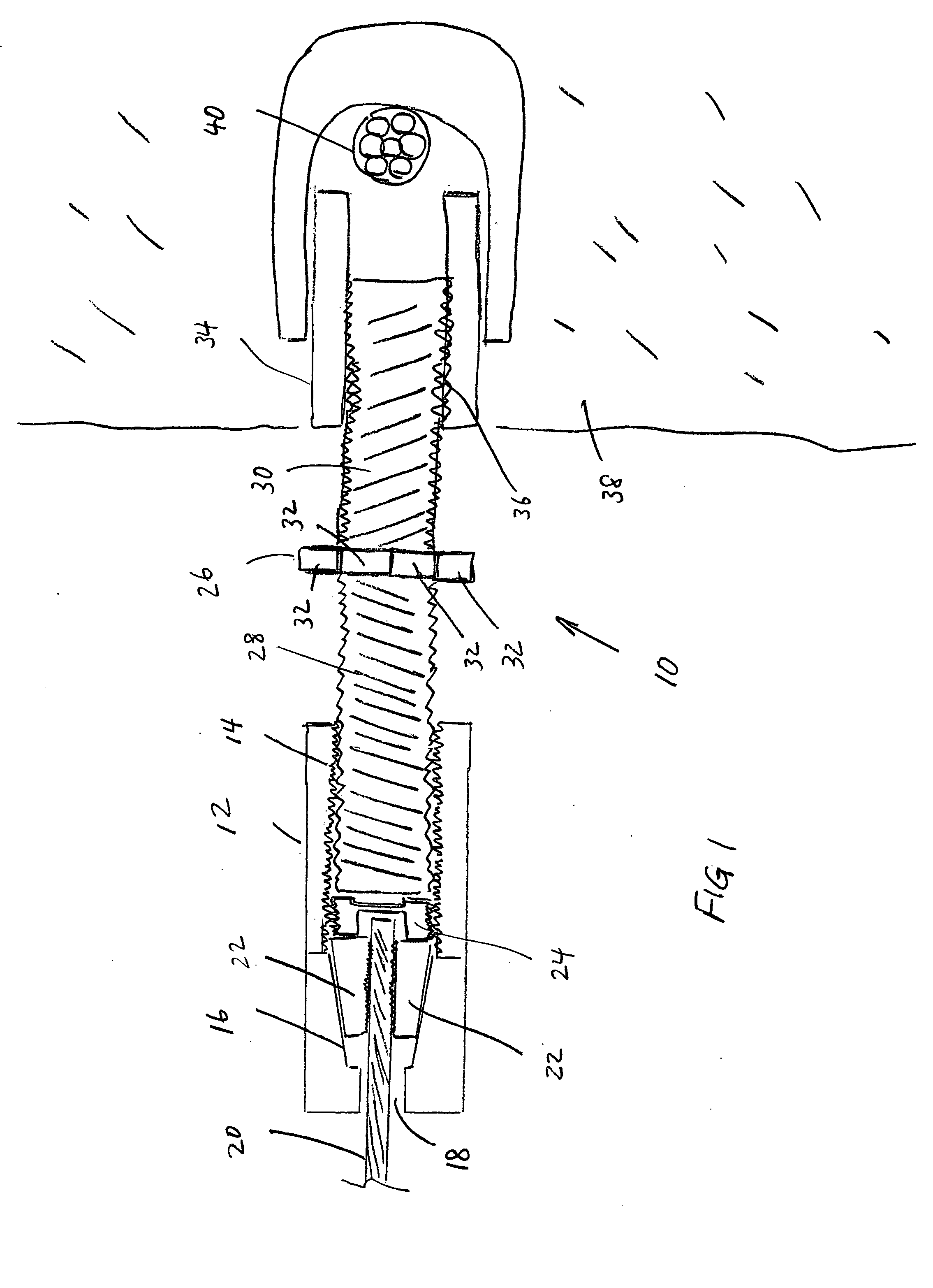

Electromechanical assembly for connecting a series of perforating guns for oil and gas wells

ActiveUS20130008639A1Extended service lifeReduce in quantityFluid removalEngineeringMaterial Perforation

Mechanical connector for the connection and assembly of guns used in the perforation of petroleum producing wells. Each gun has a hollow cylindrically shaped housing whose ends have threaded joints. Explosive shipped-charges are radially set in respective peripheral slots of the gun. Guns are coaxially joined in vertical position within the casing of the well, forming an assembly that includes the firing head and a bottom sub. The joints between consecutive guns and between the bottom sub and the lowermost gun, include tubular adaptor pieces and intermediaries that have respectively a threaded joint end and an opposing end constituted by a bayonet-type locking joint formed by a single reinforced latching bayonet locking tab.

Owner:TASSAROLI

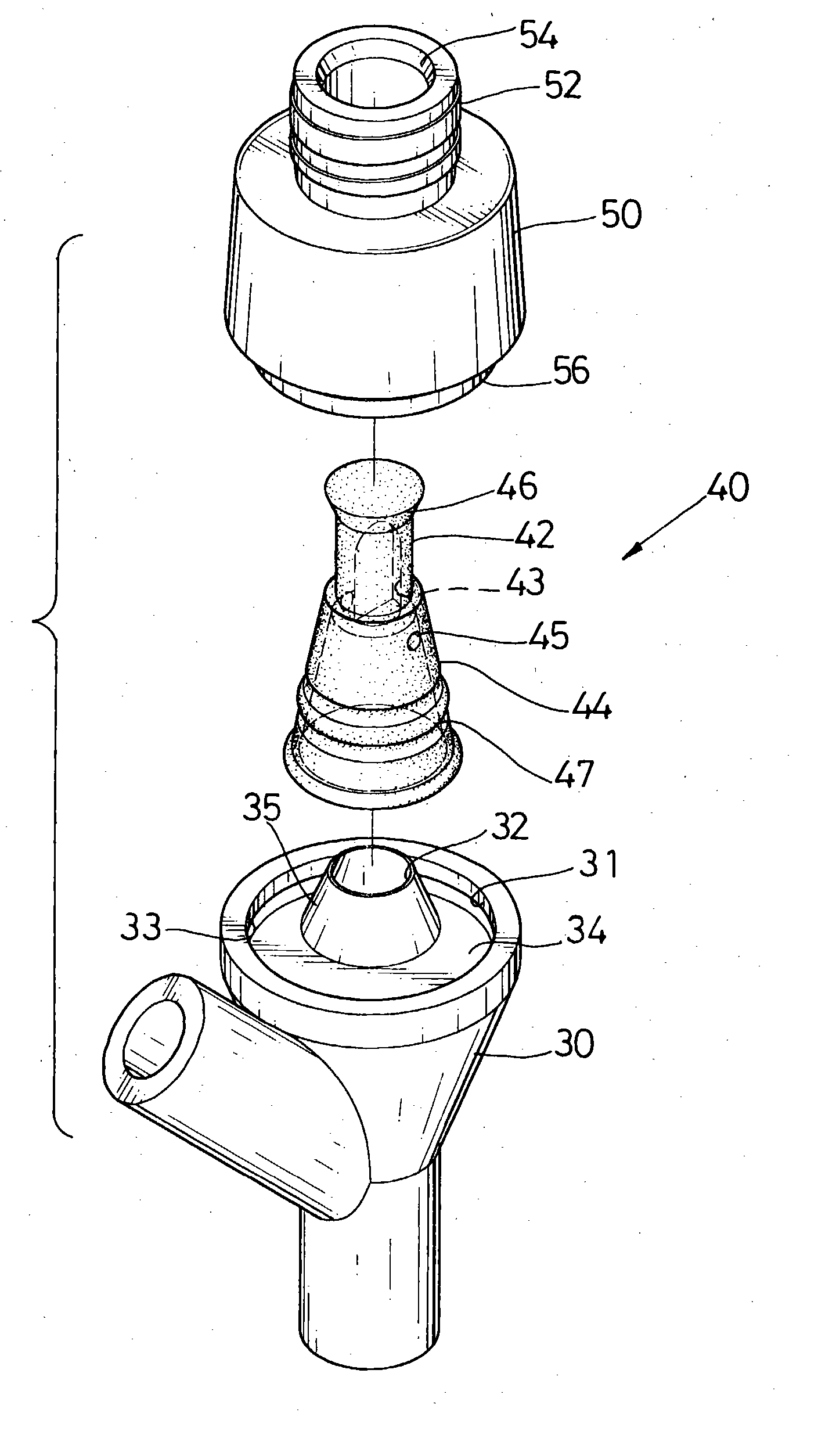

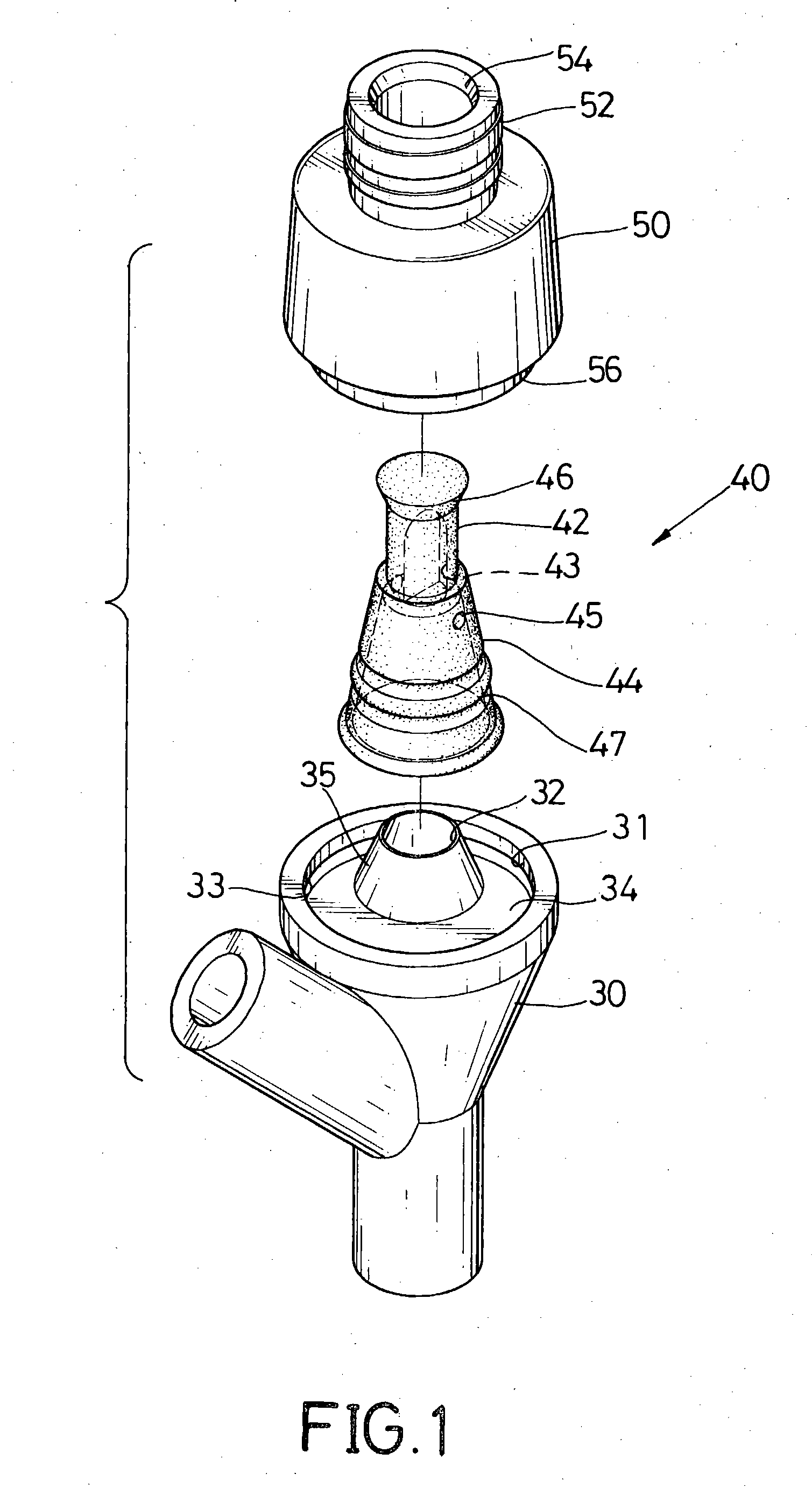

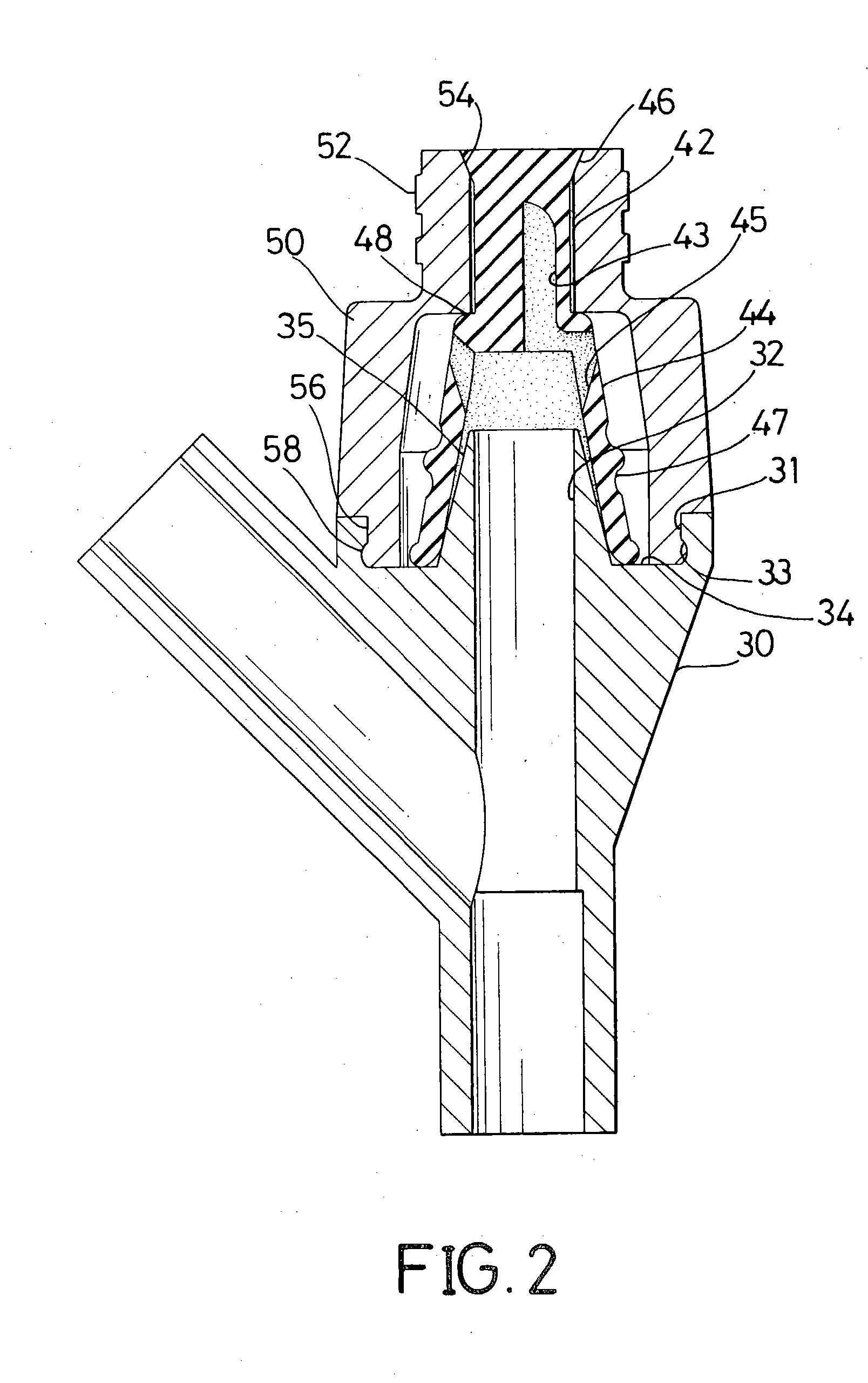

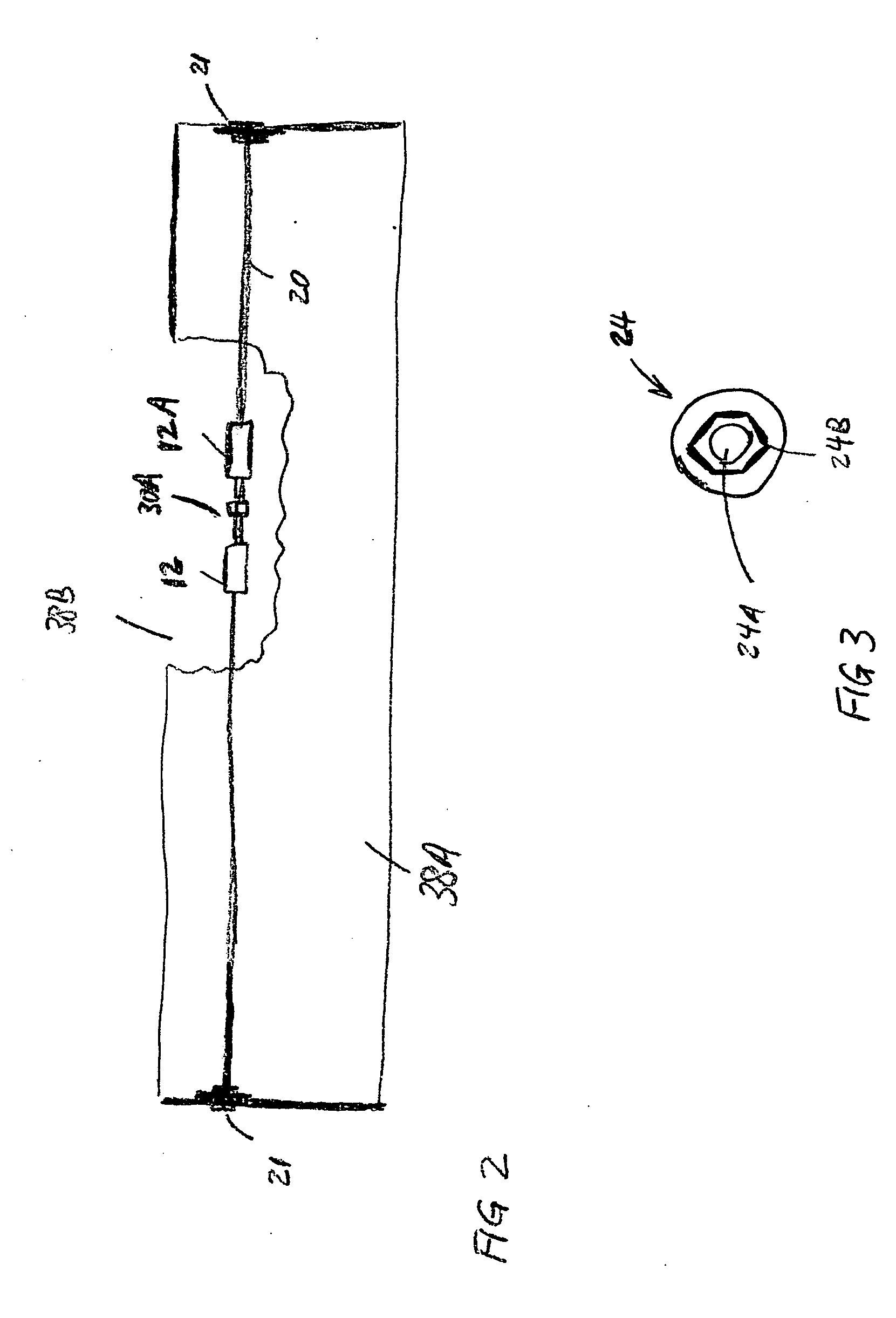

Injection joint for an intravenous (IV) device tube

An injection joint for an IV device tube has a connector with a sealed injection port. The sealed injection port has an injection port socket, a resilient plug and a cap. The resilient plug is mounted in the injection port socket and has a tapered flange and multiple through holes. The cap has a threaded nipple and is securely mounted in the injection port socket around the resilient plug. The tapered flange selectively blocks the threaded nipple. When adding medicinal solution to the injection joint, a syringe without a needle but with an inner threaded opening is screwed onto the threaded nipple of the cap. Pushing the tapered flange into an axial passage in the neck allows the medicinal solution to pass through the through holes and into the injection port socket. The present invention improves the safety to medical personnel when injecting solution into the injection joint.

Owner:HSI CHIN TSAI

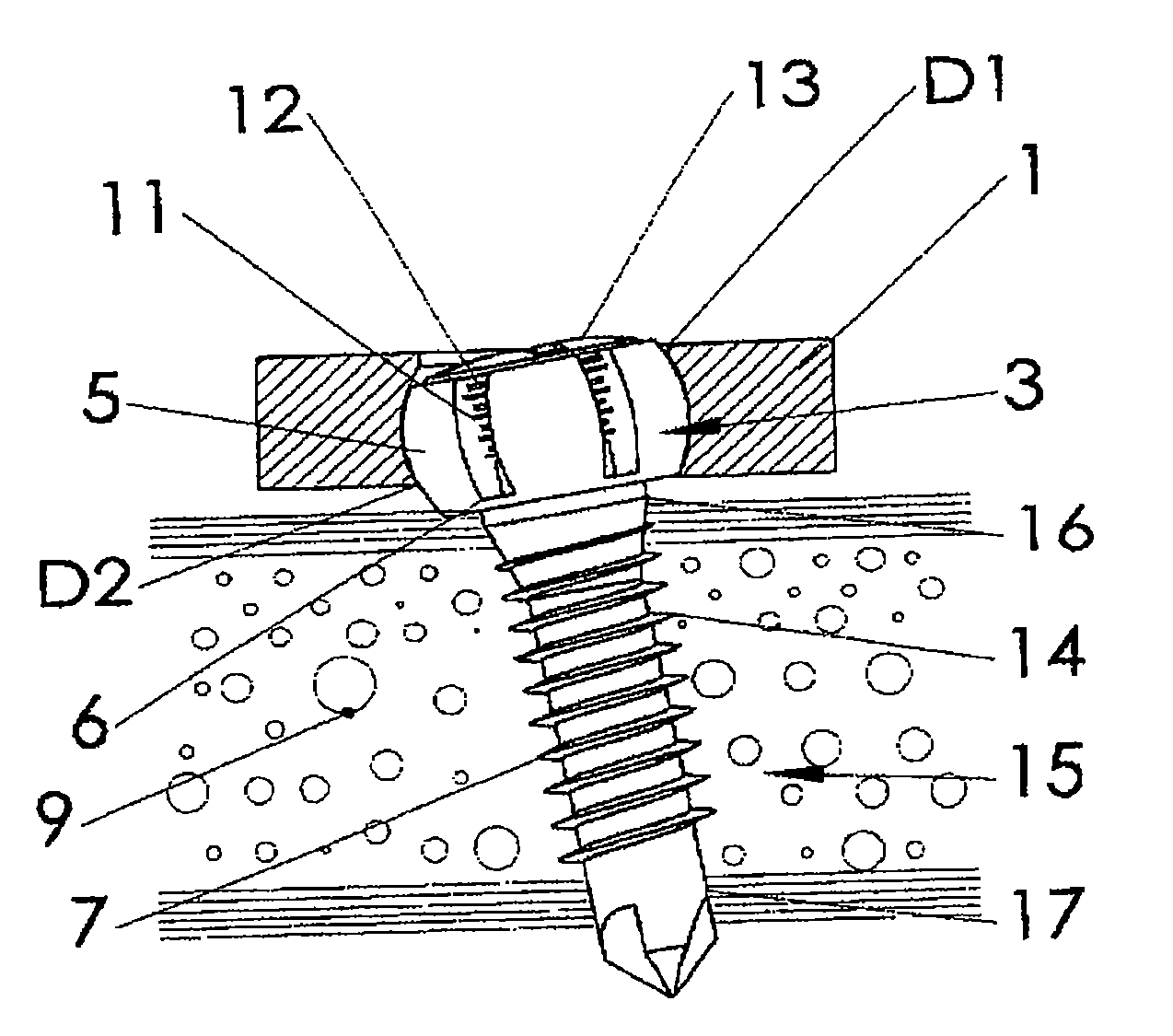

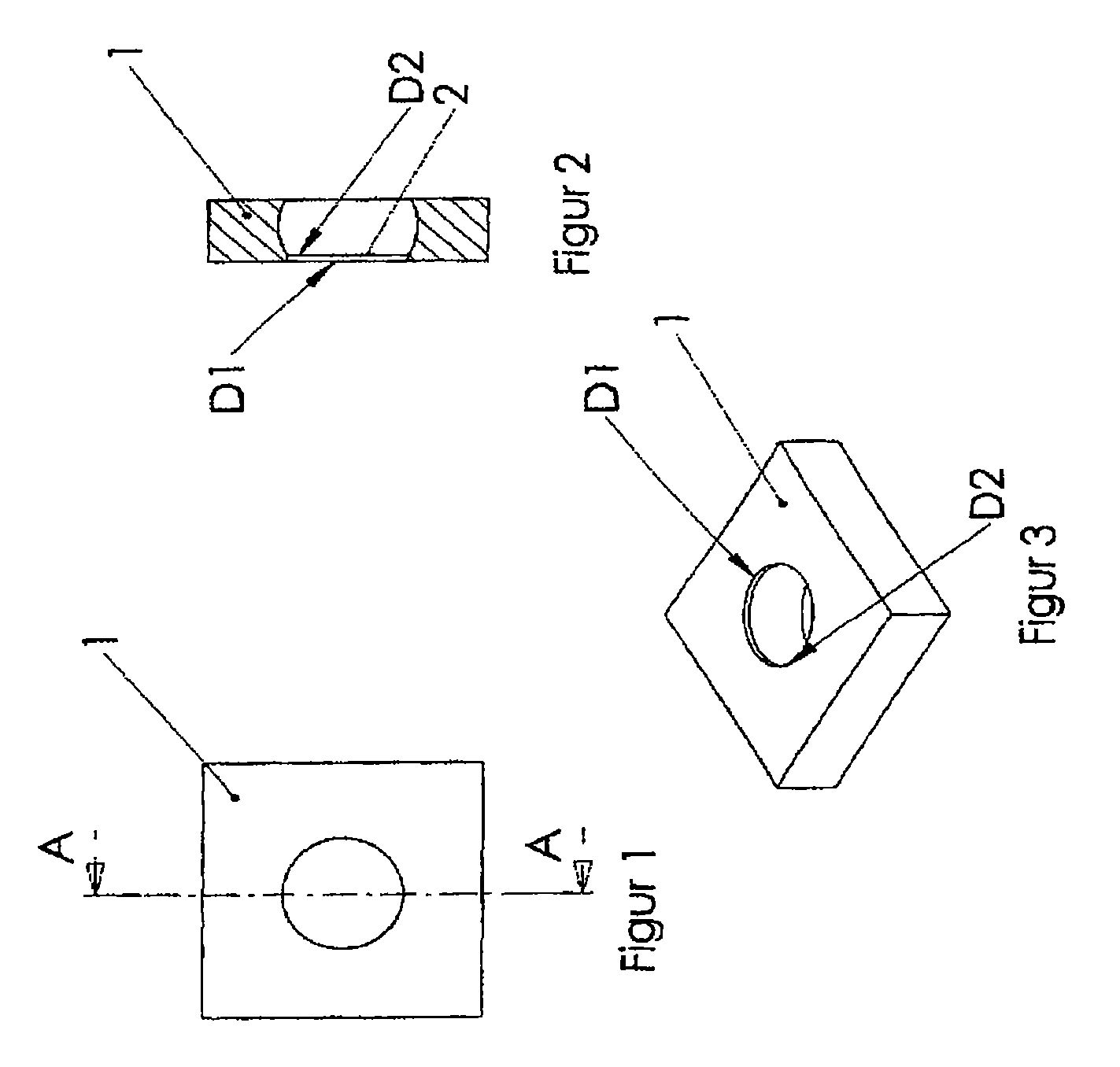

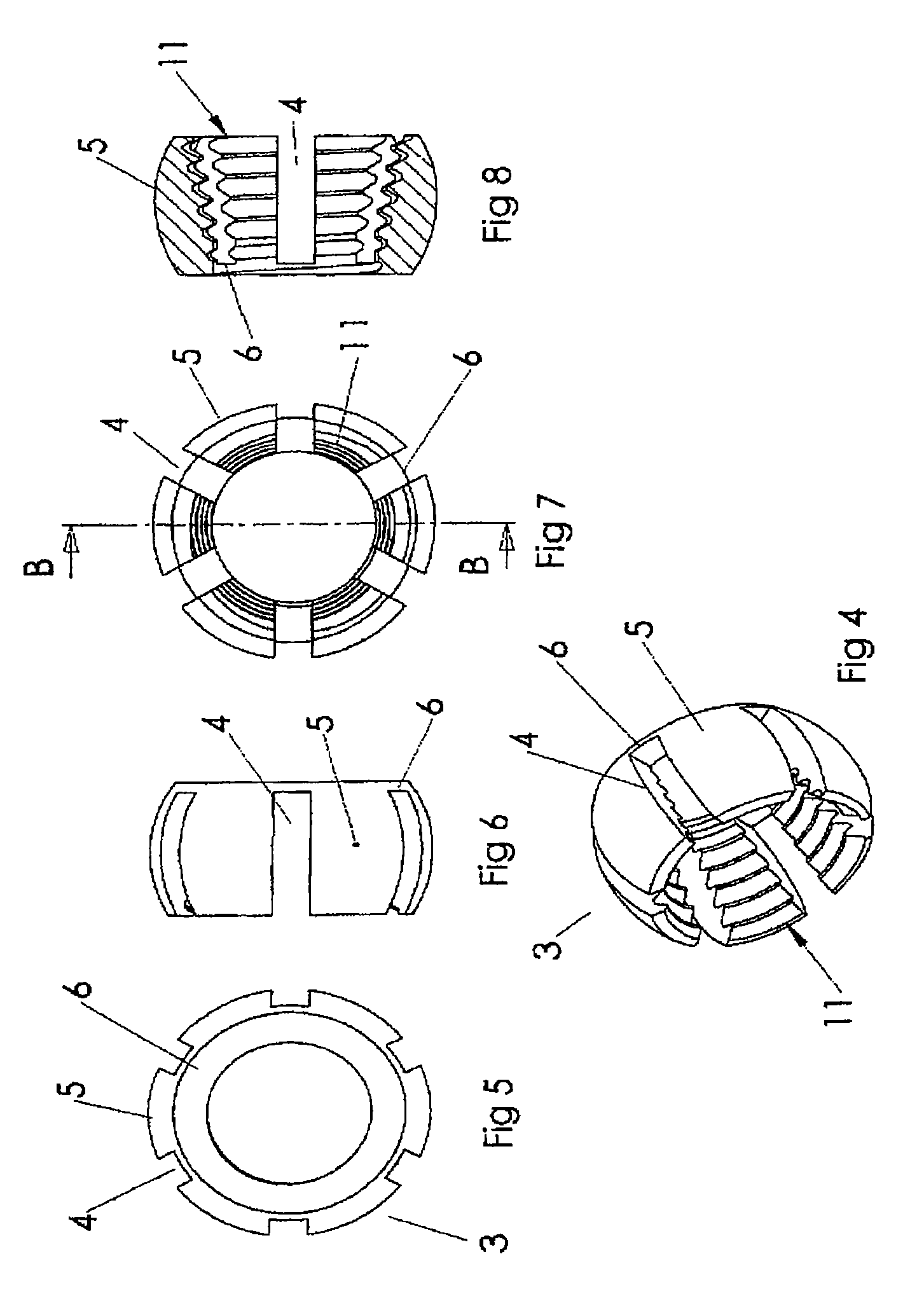

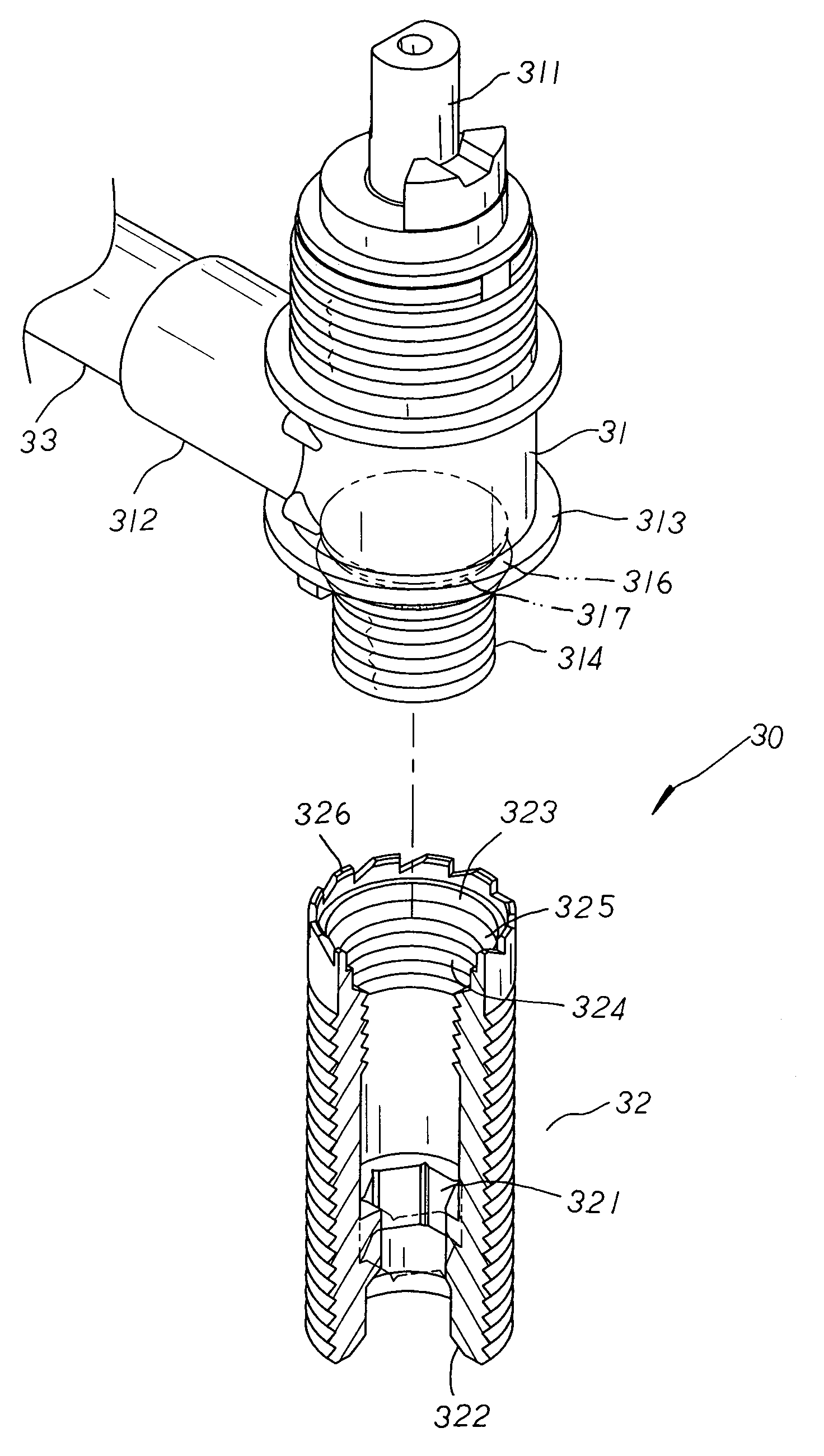

Bone fixation assembly

InactiveUS20070233116A1Eliminate the problemDental implantsInternal osteosythesisBone tissueEngineering

The present invention pertains to an arrangement, as well as a method, for fastening and fixing of first element, in the form of an implant, against the second element, in the form of bone tissue, during surgical use of a screw joint, by means of a screw with a conical head with a cone toward the screw tip, said head having an outside thread with a small pitch, which is intended to be screwed into the implant, and a main thread on the stem of the screw, which has greater pitch than the thread of the screw head, and said thread is intended to be screwed into the bone tissue, in which said first element, the implant, has a spherical hole, in which a ductile sleeve is arranged in the form of a sleeve divided into segments, flanges, and has a spherical shape that matches the spherical shape of hole, and said sleeve has a conical threaded inside shape that is complementary to the outer threaded shape of the screw head, in which screw, when tightened, can fasten the implant in any desired angle, relative to the other element, and fix the screw joint in this position.

Owner:SPHEROFIX

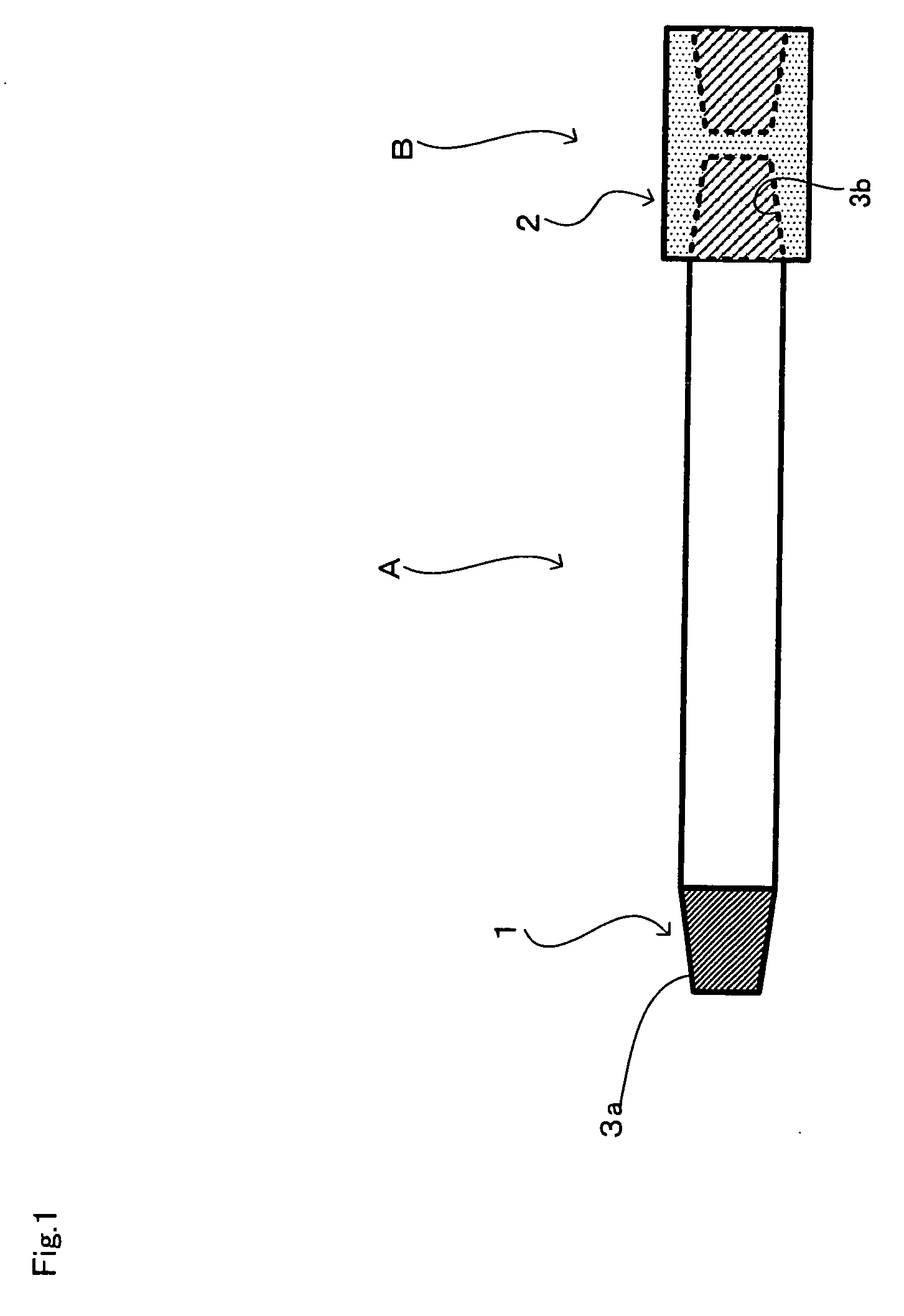

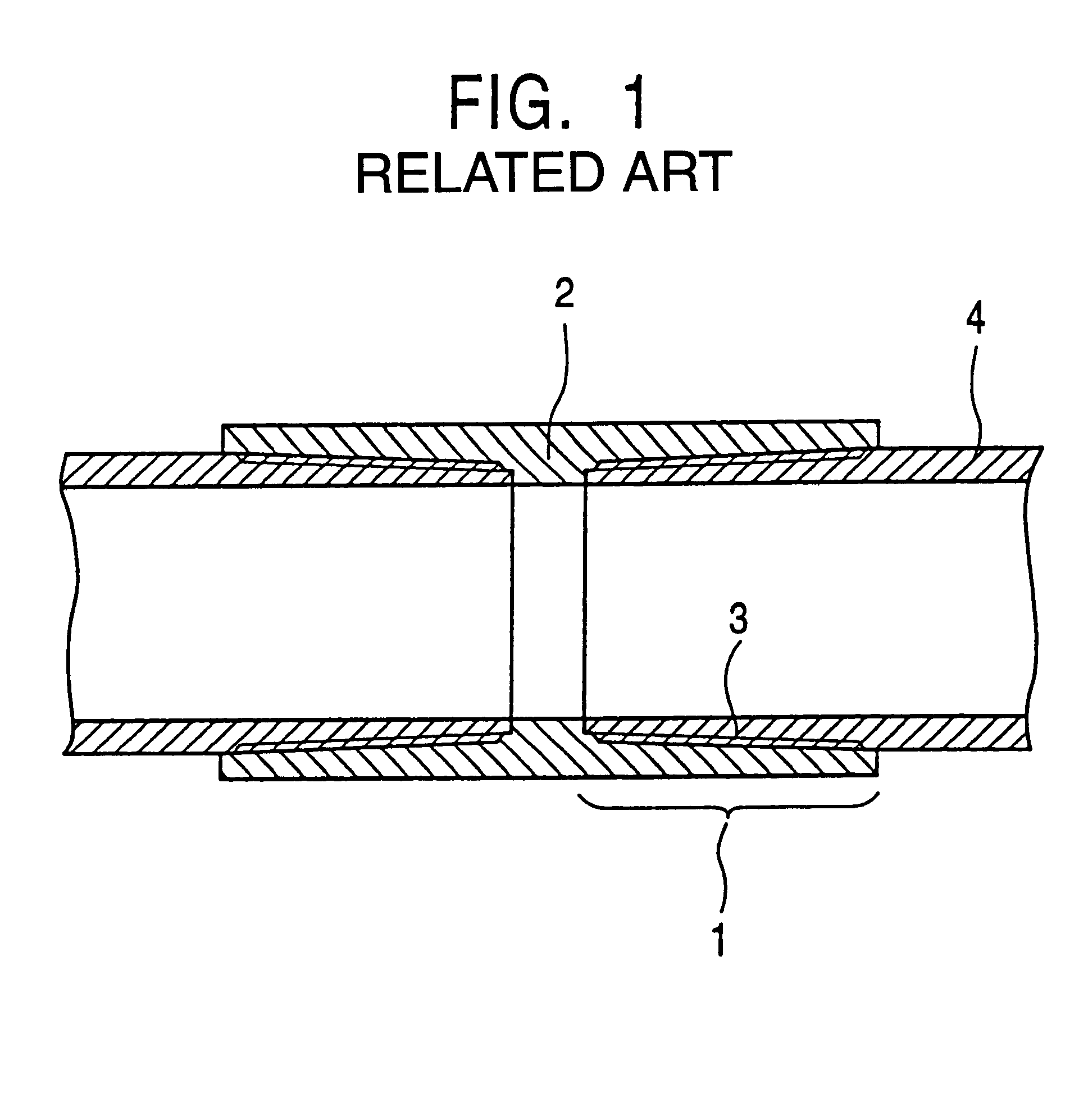

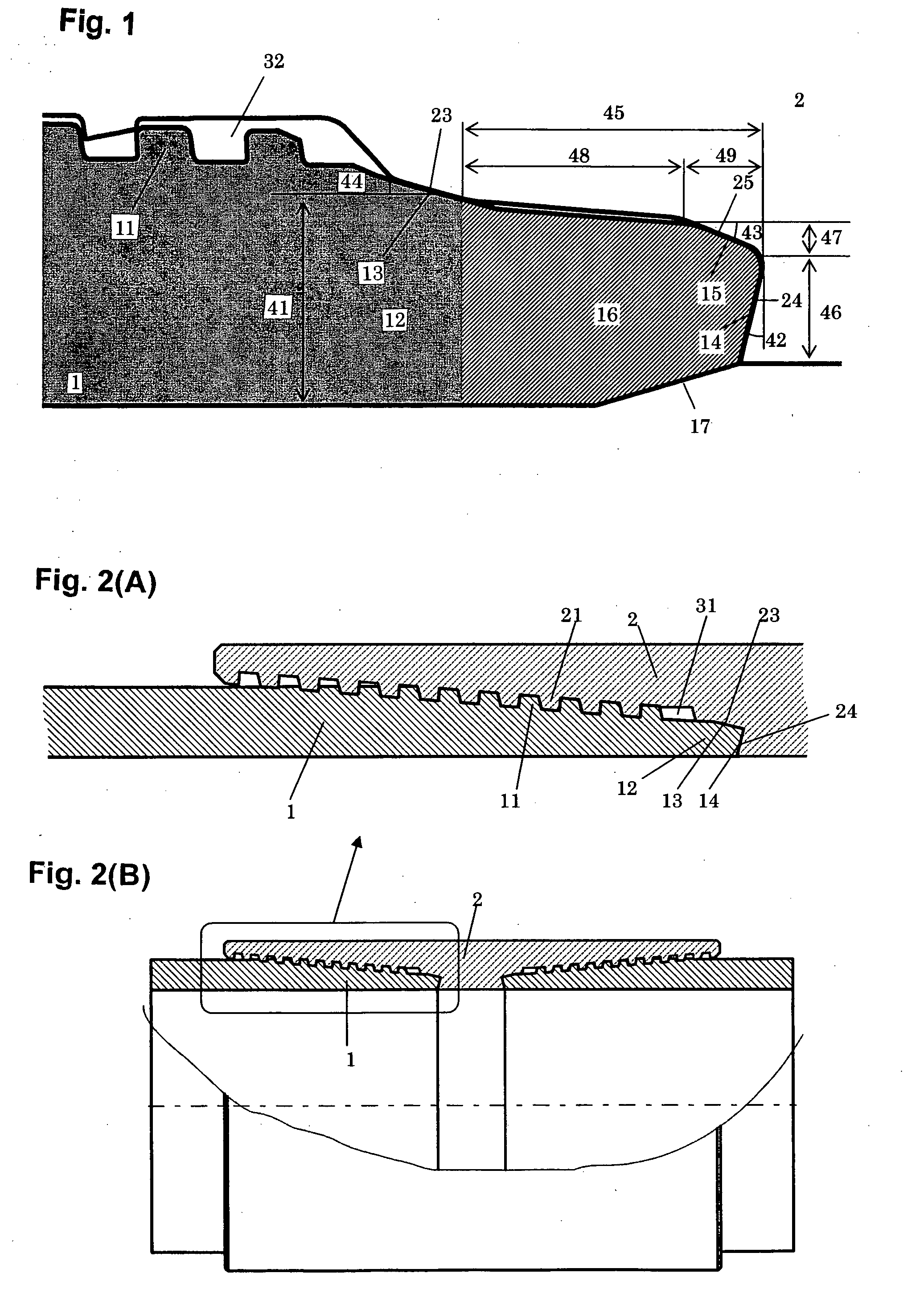

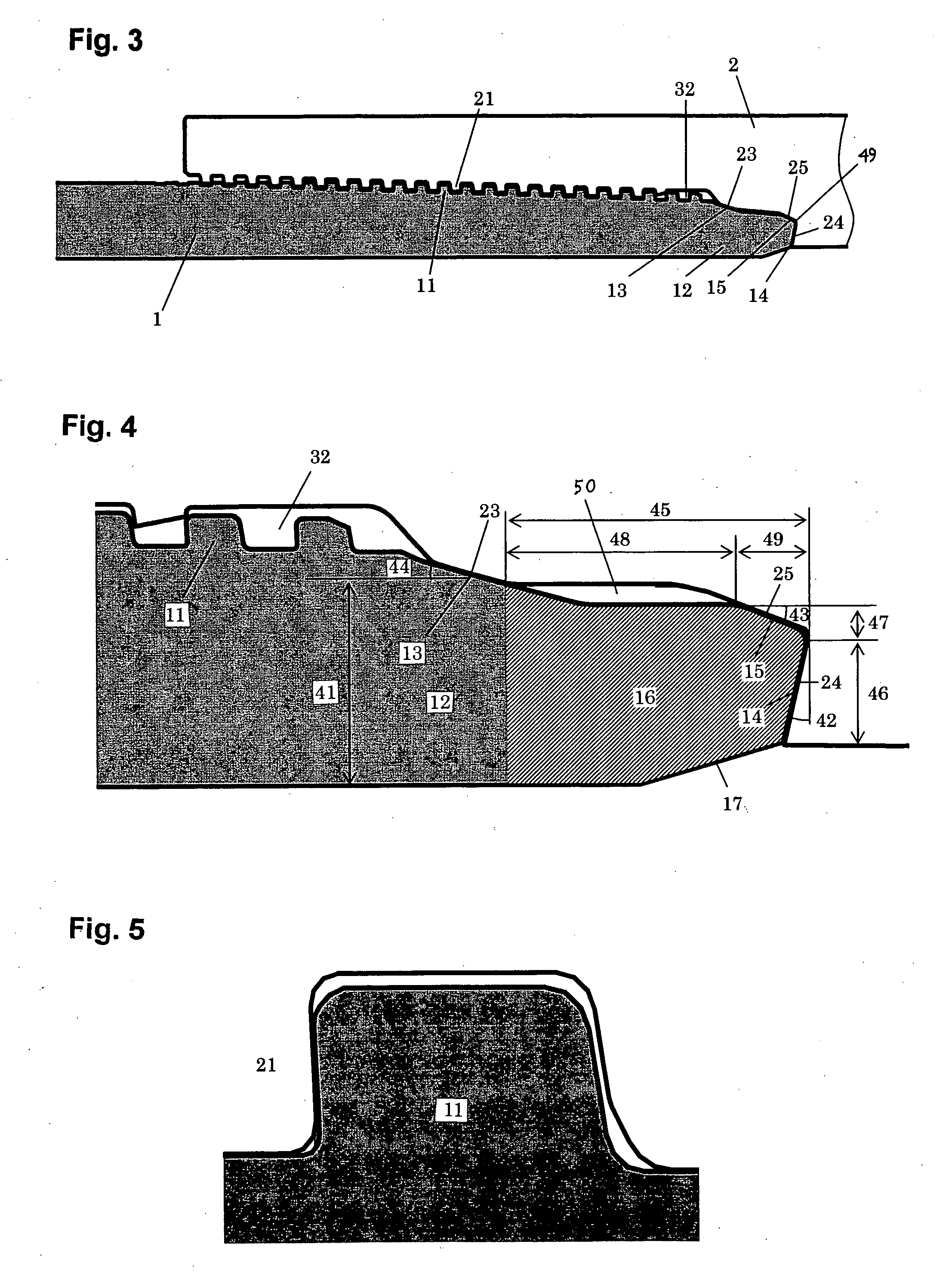

Threaded joint for steel pipes

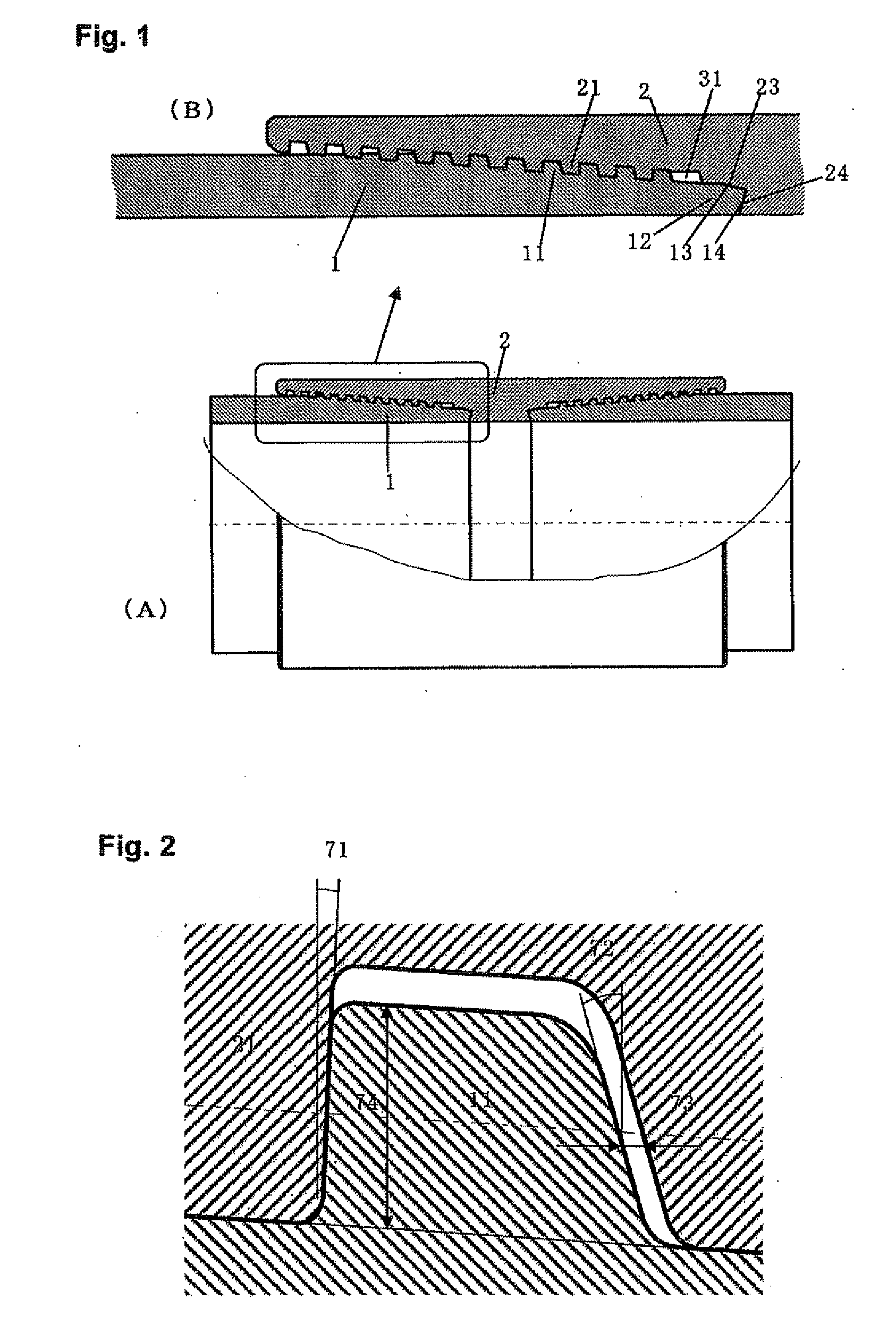

ActiveUS20050248153A1Increase wall thicknessImprove sealingDrilling rodsHose connectionsEngineeringScrew thread

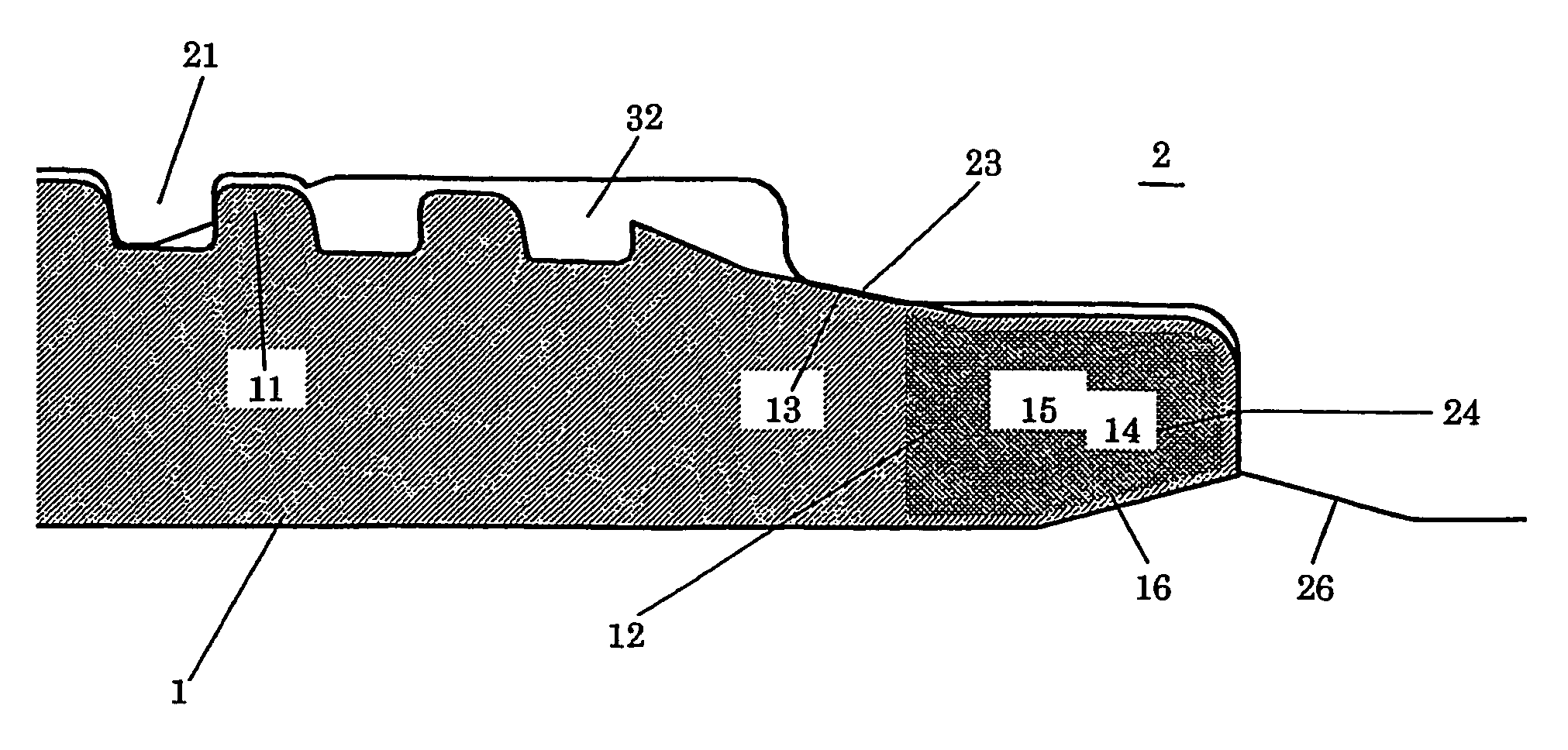

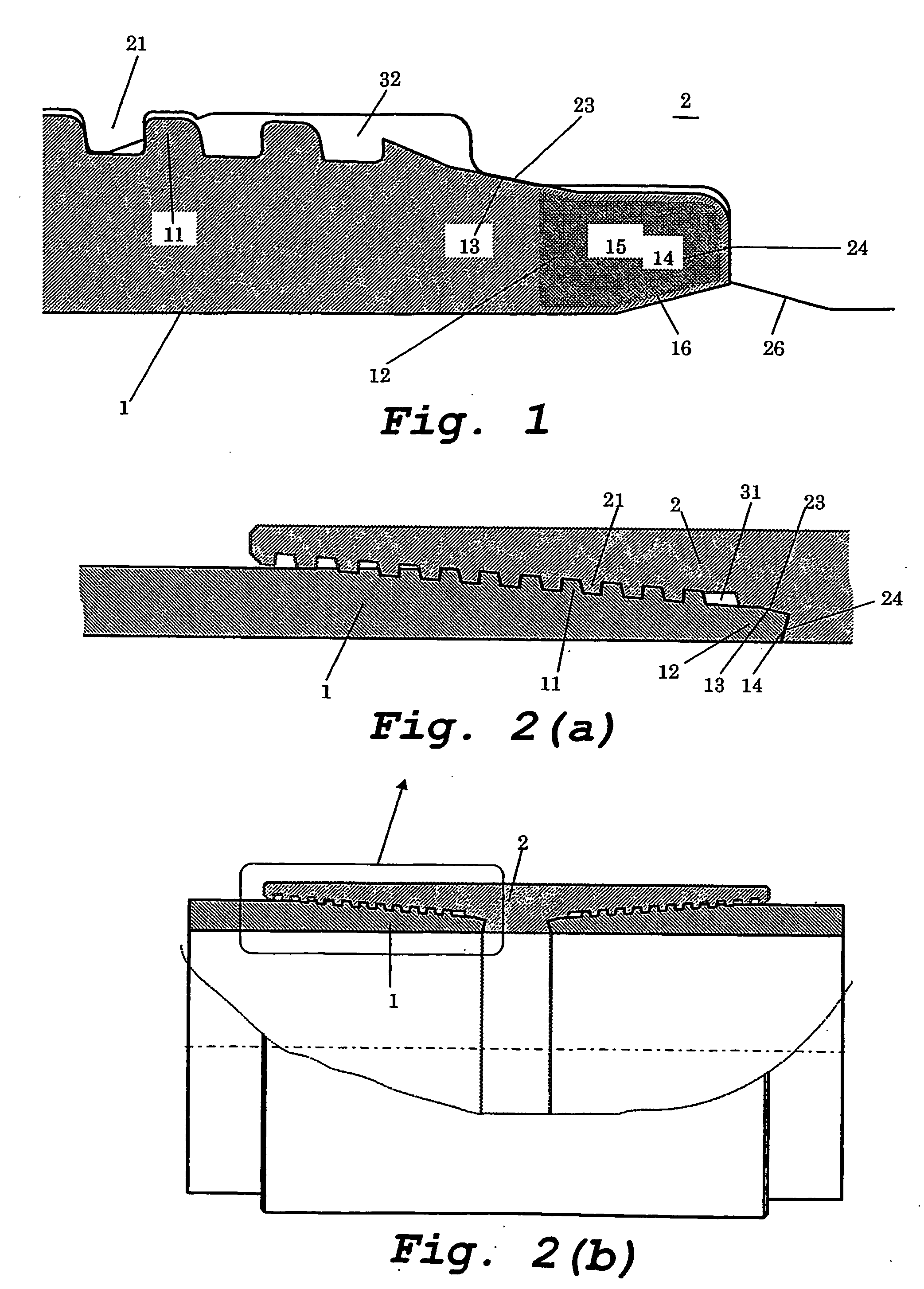

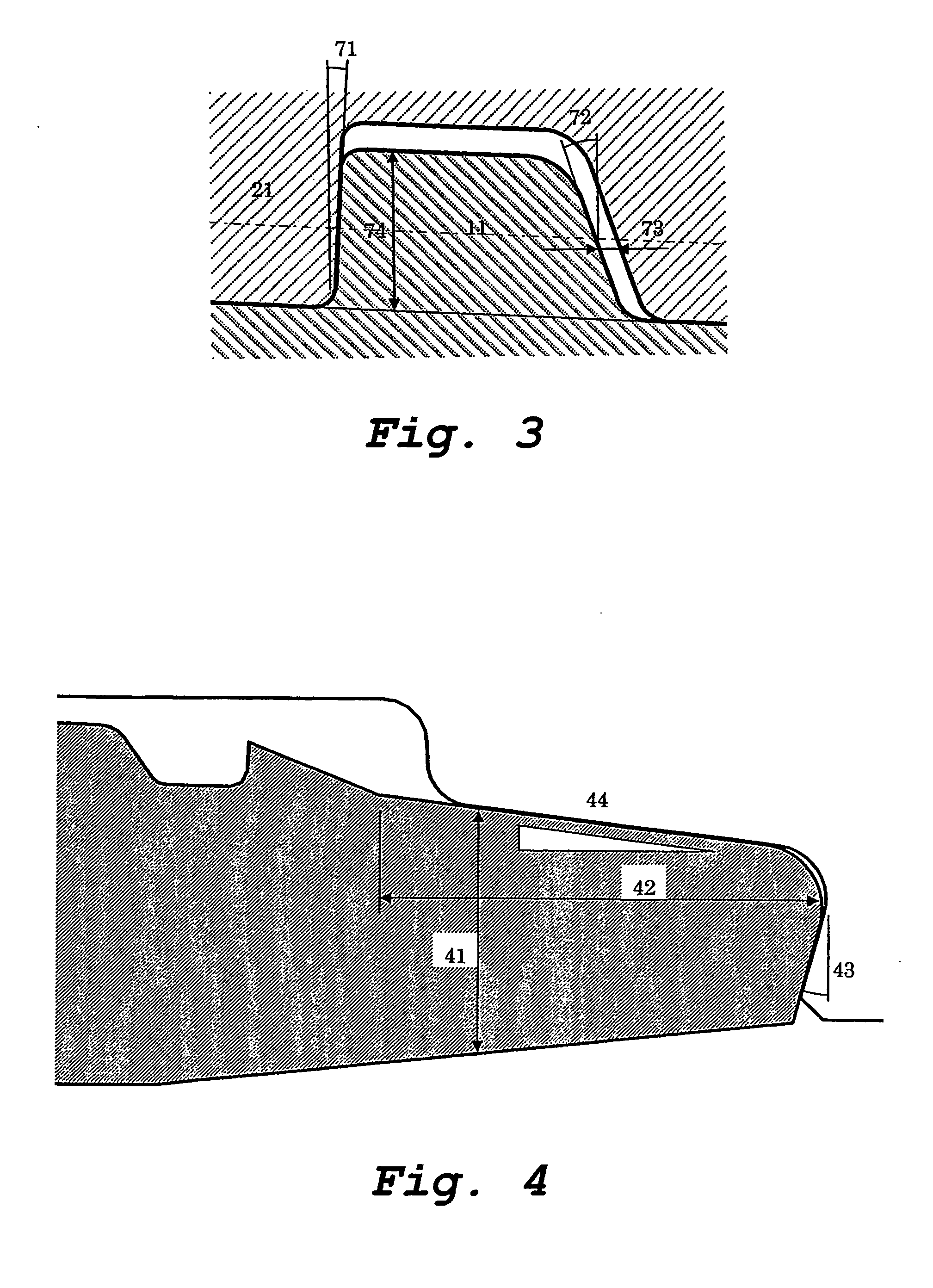

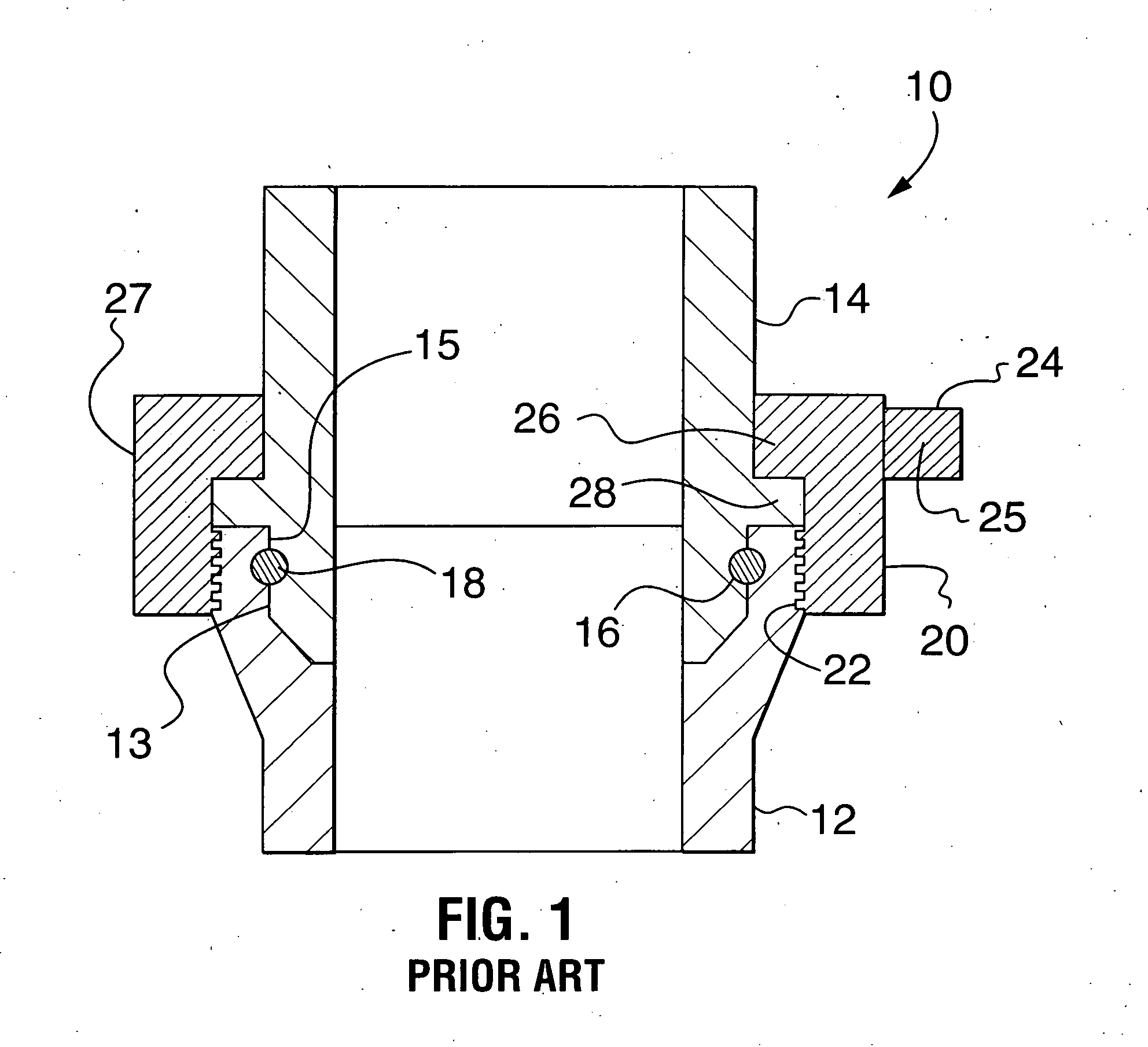

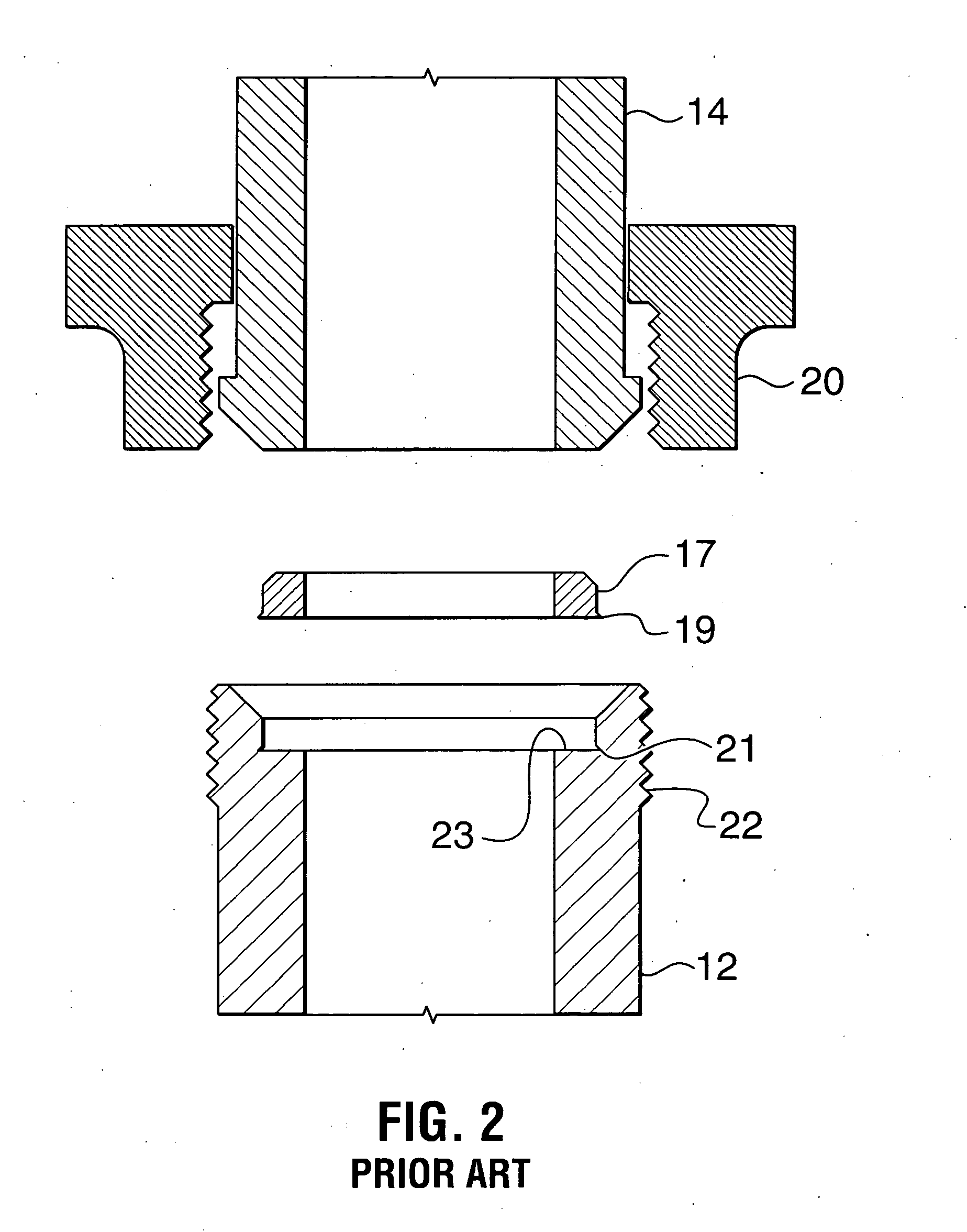

A threaded joint for steel pipes comprises a pin (1) and a box (2). The pin has male thread (11), a sealing surface (13), and a shoulder surface (14) located on the end face of the pin. Correspondingly, the box has female thread (21), a sealing surface (23), and a shoulder surface (24) which can mate or contact with the corresponding portions of the pin. The shoulder surface (14) of the pin (1) is provided at an end face of the pin. The sealing surface (13) of the pin (1) is located on a pipe end side near the male thread (11). A a nose portion (15) is provided on the pin (1) between the sealing surface (13) and the shoulder surface (14), the nose portion (15) being not in contact with a corresponding portion of the box (2).

Owner:VALLOUREC OIL & GAS FRANCE SAS +1

Threaded joint for steel pipes

InactiveUS20060228505A1Improve the lubrication effectLubricating property worsenEarth drilling toolsDrilling rodsViscous liquidAlkaline earth metal

A threaded joint for steel pipes for use in an oil well which has improved galling resistance and which is protected from rusting comprises a pin and a box each having a contact surface including a threaded portion and an unthreaded metal contact portion. The contact surface of at least one of the pin and the box has a lower layer of a viscous liquid or semisolid lubricating coating comprising at least wax and a fatty acid alkaline earth metal salt and not containing a harmful heavy metal such as lead and an upper layer of a dry solid coating formed from an aqueous resin coating composition, an organic solvent type coating composition, or an ultraviolet curing coating composition.

Owner:NIPPON STEEL CORP +1

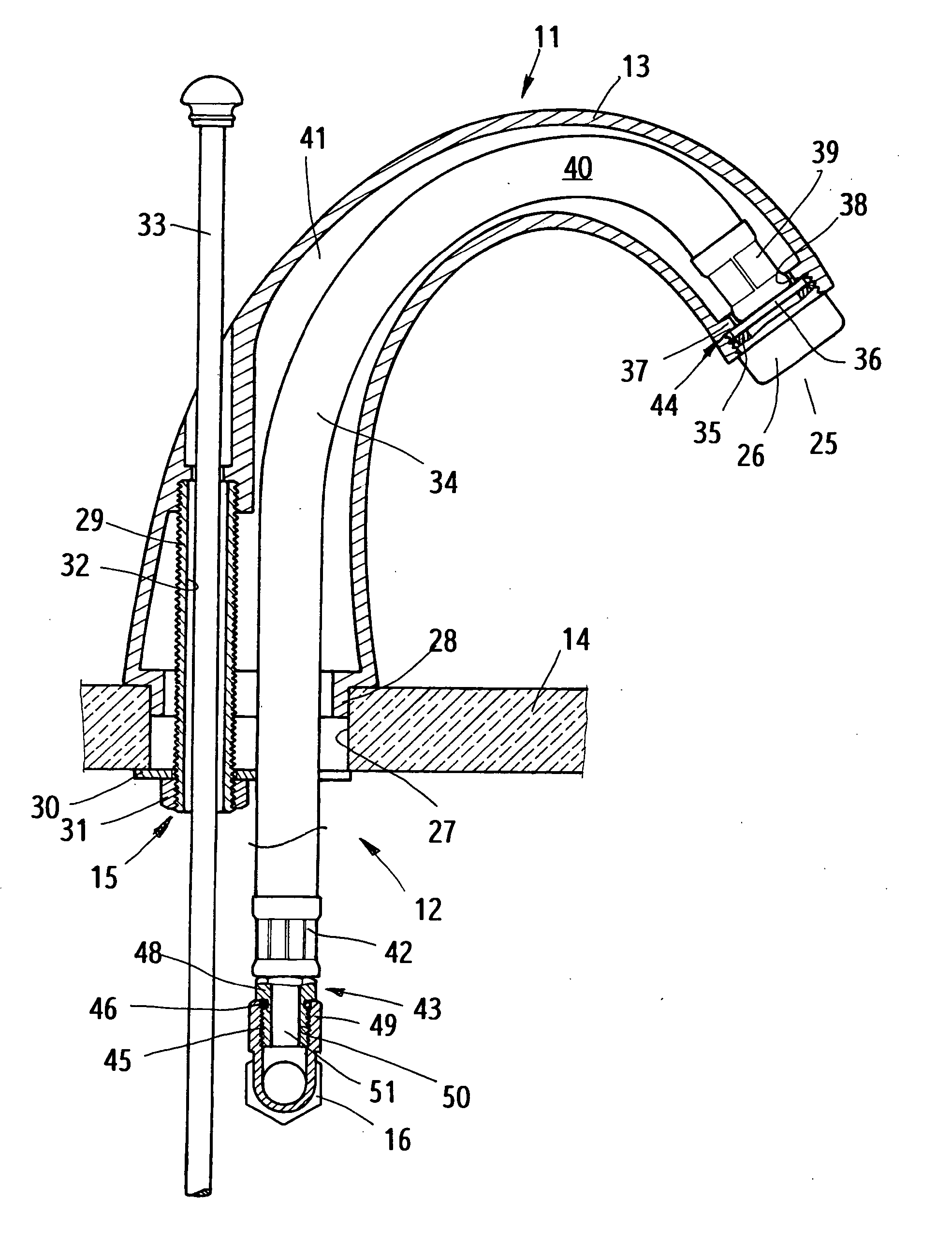

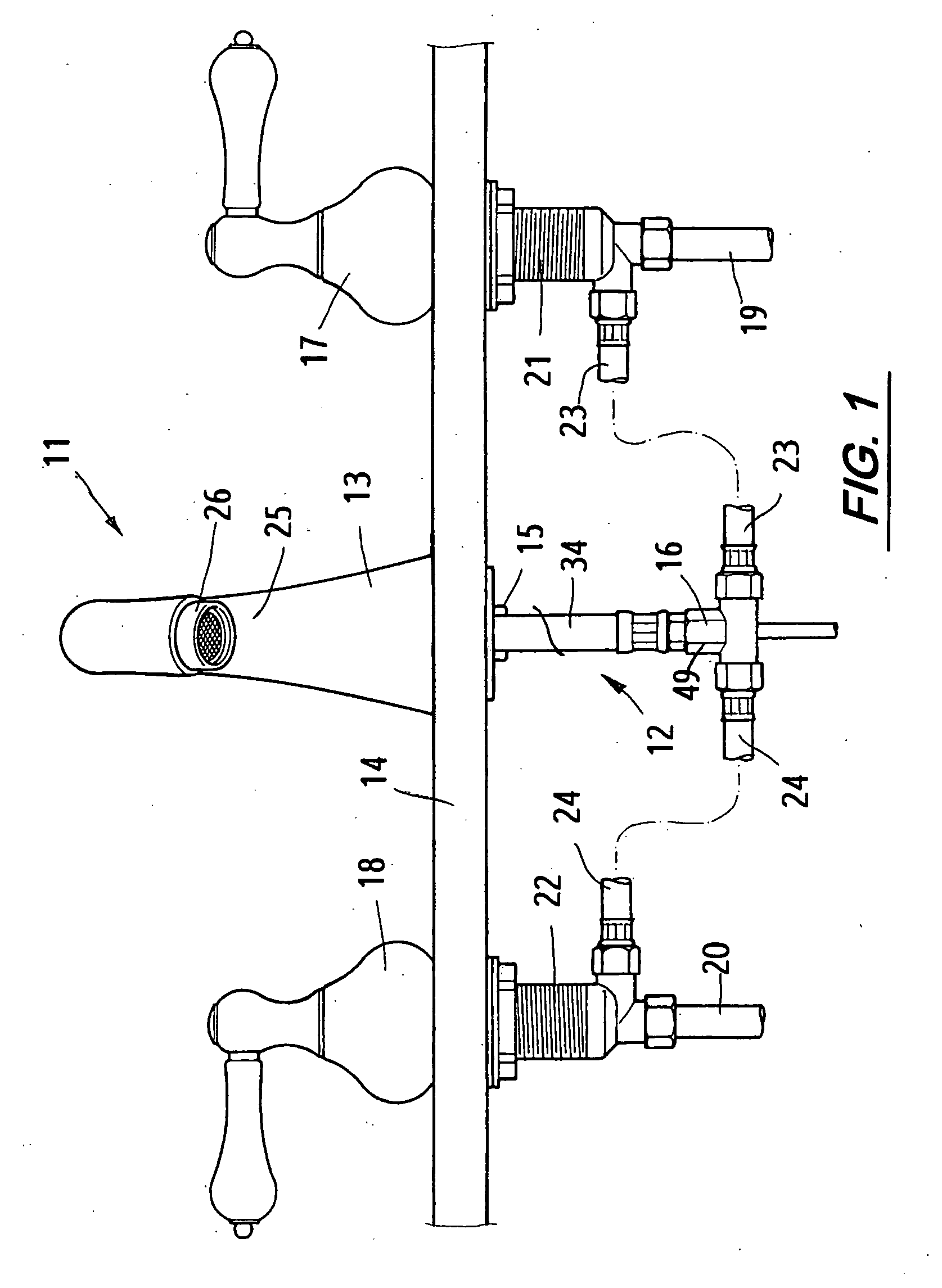

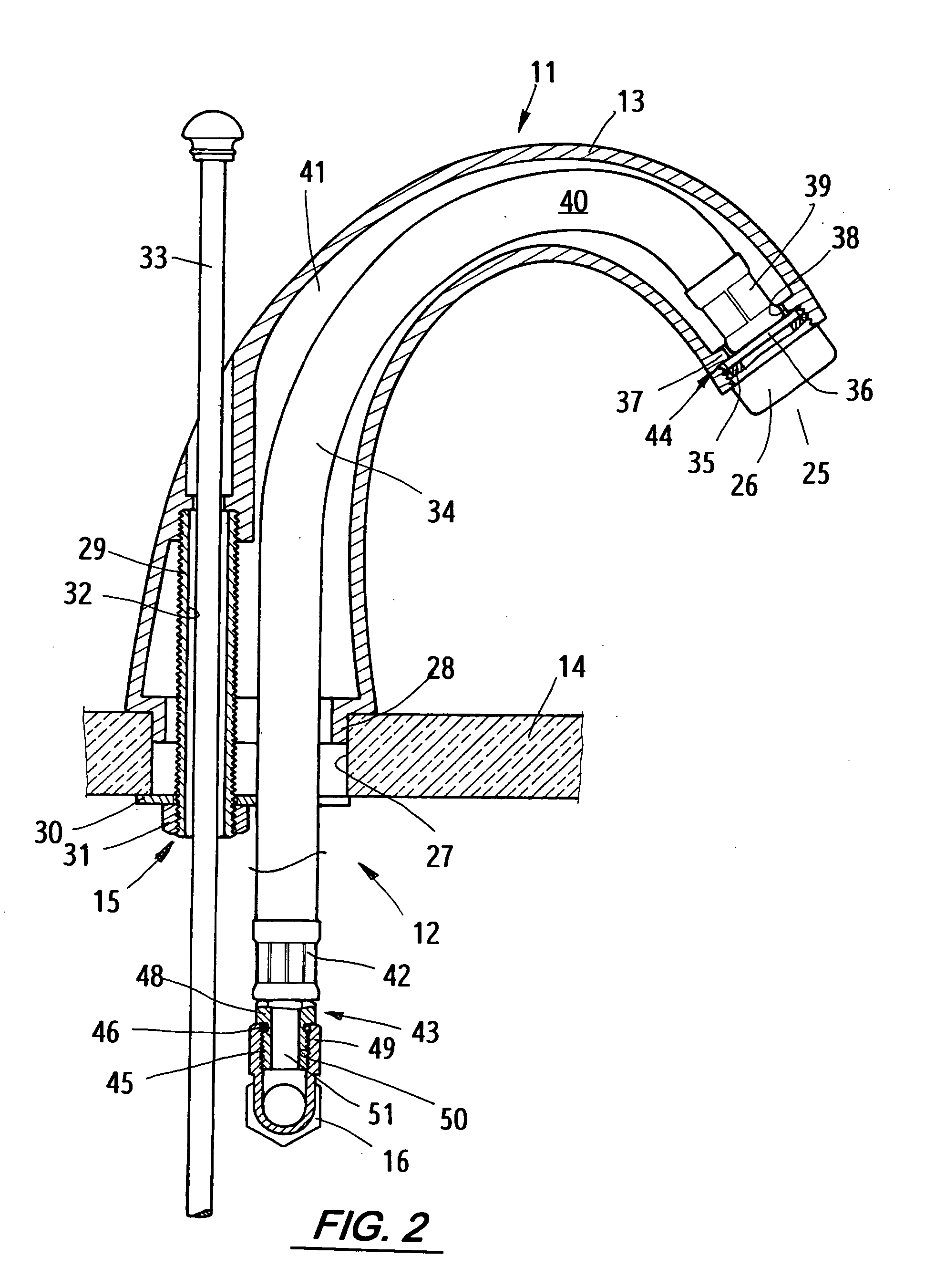

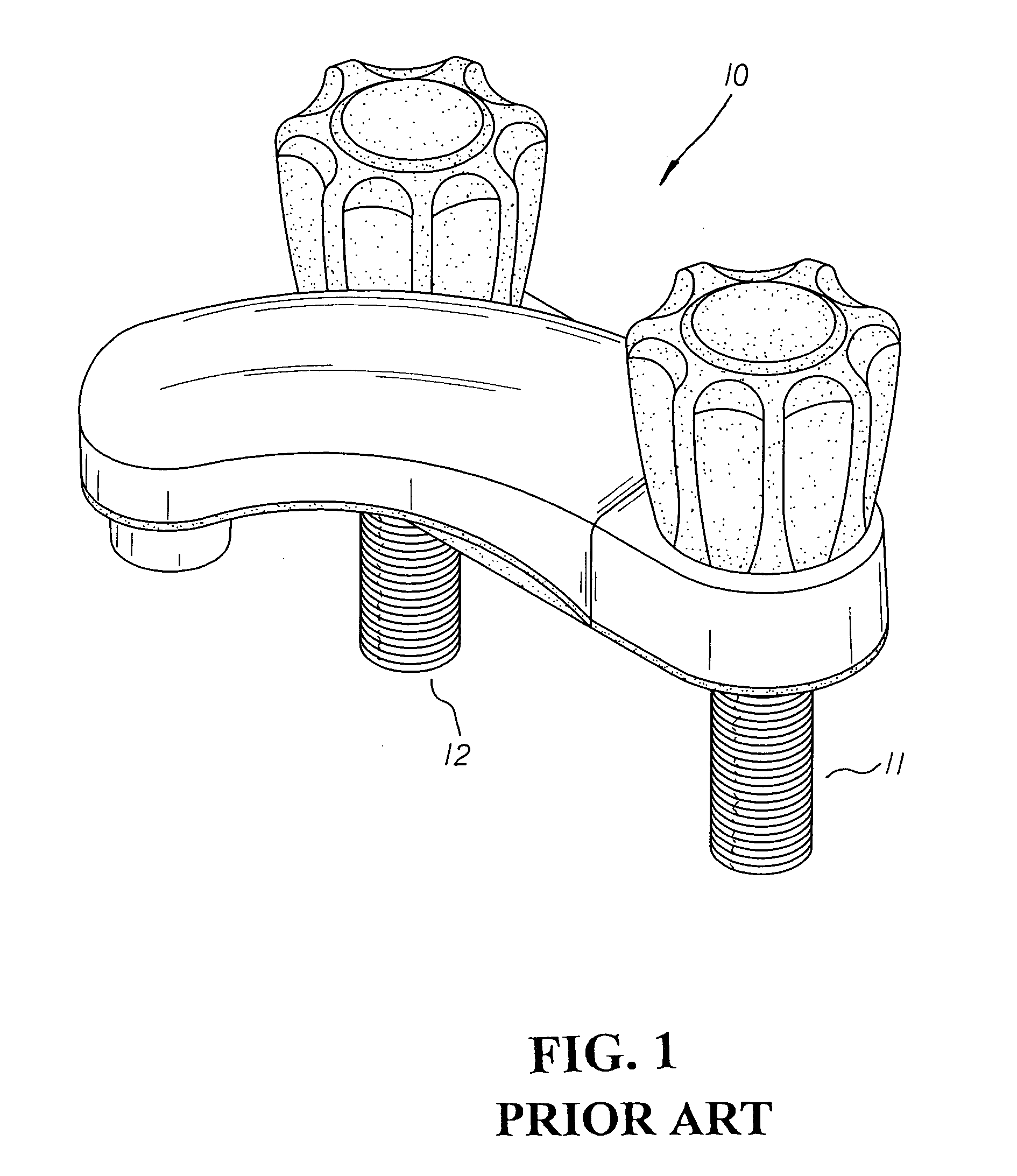

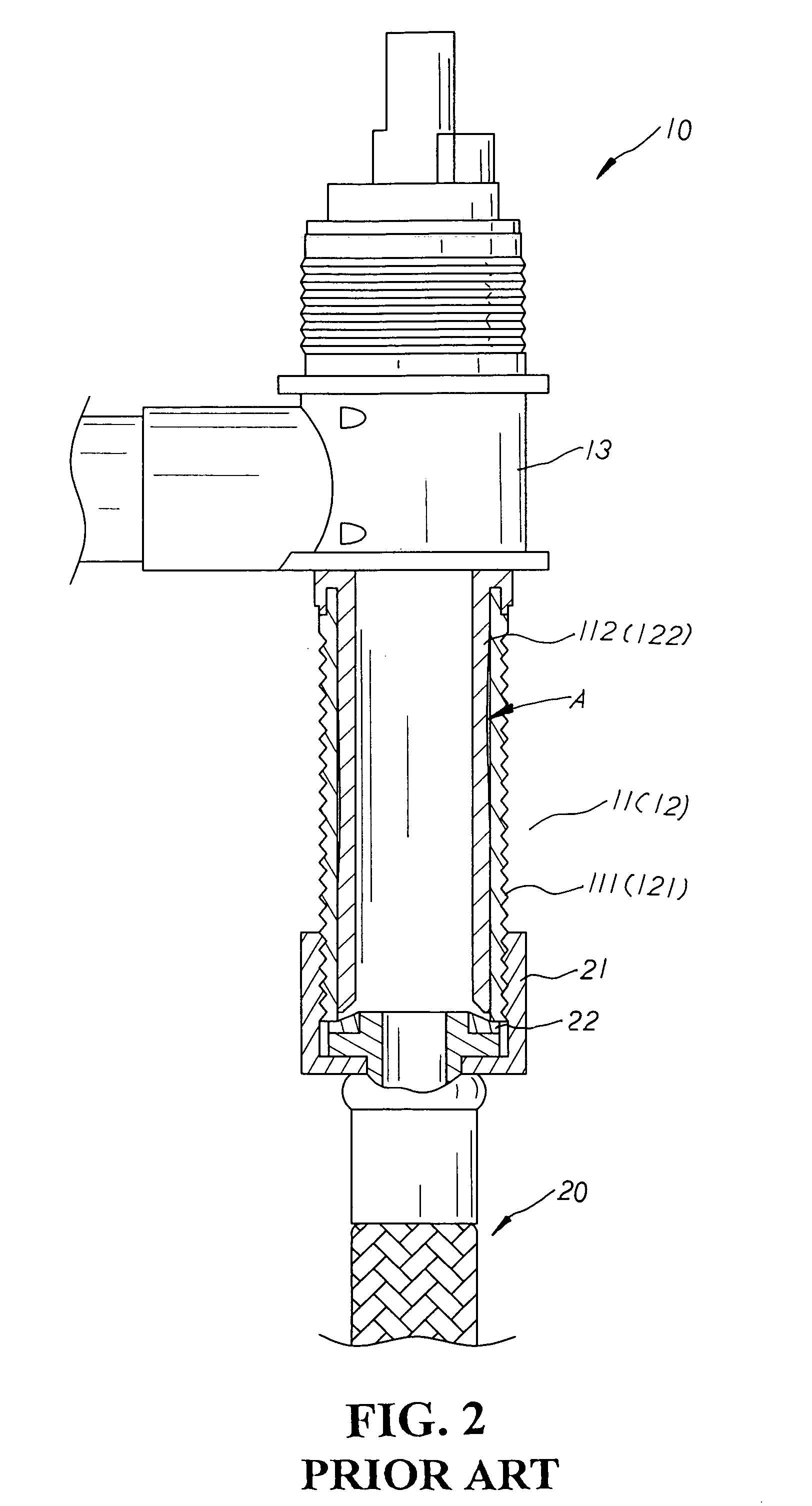

Water-flow guide device of faucet

InactiveUS20060124183A1Simple methodEasy to operateServomotor componentsDomestic plumbingWater flowEngineering

A water-flow guide device of faucet, which comprises a hollow space, a water outlet mounted with a positioning ring having a hole; one end thereof is riveted with a threaded connector, and then is inserted into the other end of the faucet; the other end of the water-supply pipe is riveted with a ring-shaped fastener, which is attached to the outer surface of a positioning ring; then, a washer and a bubble head are fastened to the outer end of the pipe; the other end of the water-supply pipe is connected with a T-shaped connector via a threaded connector so as to enable a cold-water valve and a hot-water valve to control the water to flow out of the water pipe without contact with the body of the faucet.

Owner:KUO LIAN JIE

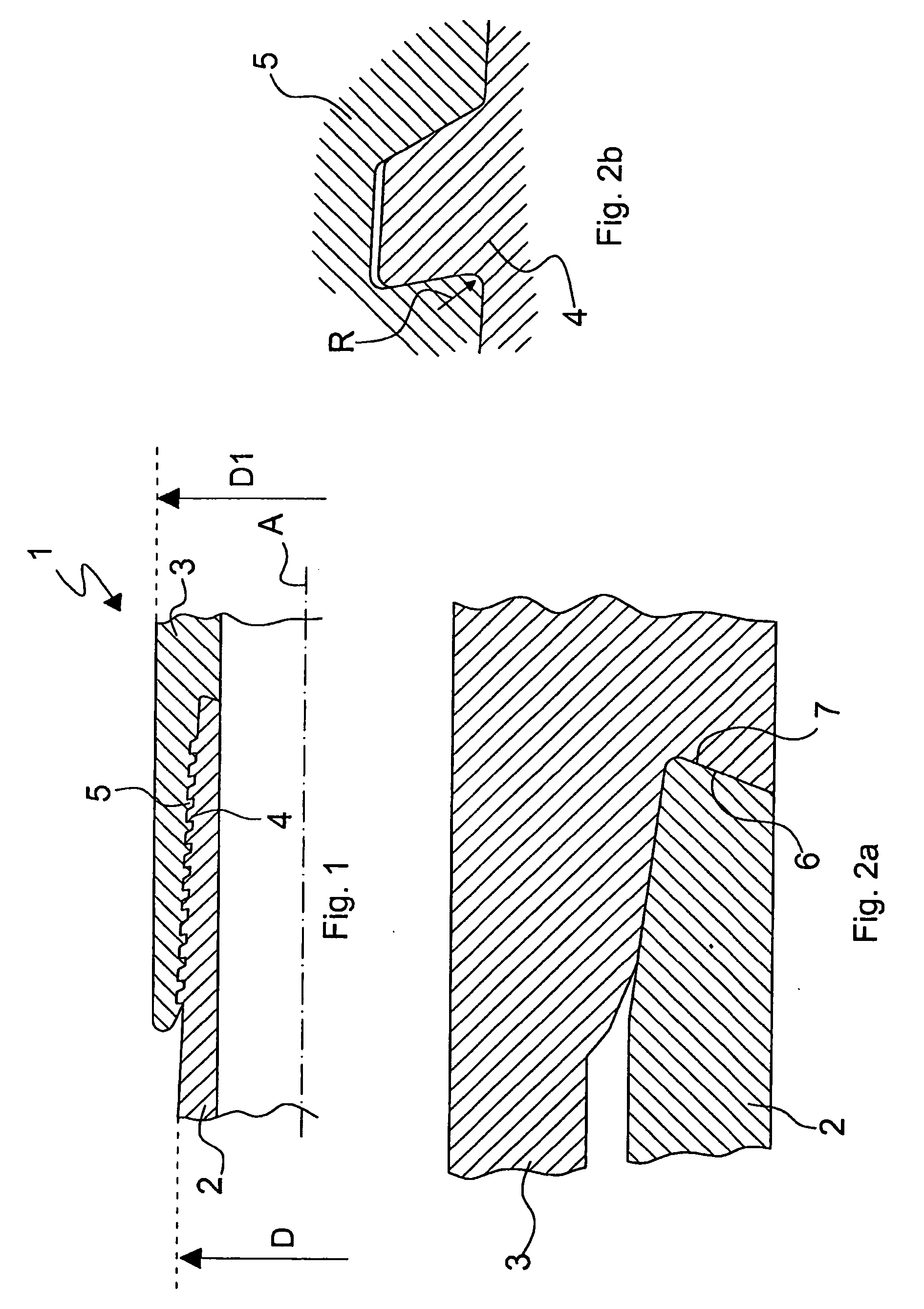

Threaded joint with high radial loads and differentially treated surfaces

ActiveUS20110042946A1Improve fatigue lifeImprove fatigue resistanceDrilling rodsPipe elementsEngineeringScrew thread

A threaded joint has an interference between thread roots of pin and thread crests of the box of value comprised between 1% and 5% of the average thickness of the connection, and a root to load flank radius R comprised in the range of 0.2 mm and 0.4 mm and a surface treatment comprising shot peening applied to the beginning and end of the threaded zone of the pin. In other embodiments the interference can be between thread roots of box and thread crests of the pin.

Owner:TENARIS CONNECTIONS

Hot/cold water tube connection structure for plastic faucets

InactiveUS7231936B2Avoid problemsStrengthen the connection structureServomotor componentsJoints with sealing surfacesCouplingEngineering

A hot / cold water tube connection structure for plastic faucets comprises a hot / cold water connector tube made up of a valve seat and a coupling tube wherein the valve seat has a screw tube extending downwards at the bottom of a stop ring, and a sealing ring mounted at an appropriate position of the screw tube thereon to form engaging rings at both sides thereof. The coupling tube has an oblique face indented at one end edge against which a water-sealing hoop mounted at a screw joint of a water inlet tube is securely abutted, and a coupling joint with an internal screw thread section disposed at the inner wall of the other end thereof. Therefore, the connector tube assembled can avoid the problem of gaps found in the conventional tube connection structure, and facilitate an easer replacement thereof due to its separate type of design for economical and eco-protection purposes.

Owner:CHANG KIM

Threaded joint sealed to internal and external pressures

Owner:TENARIS CONNECTIONS

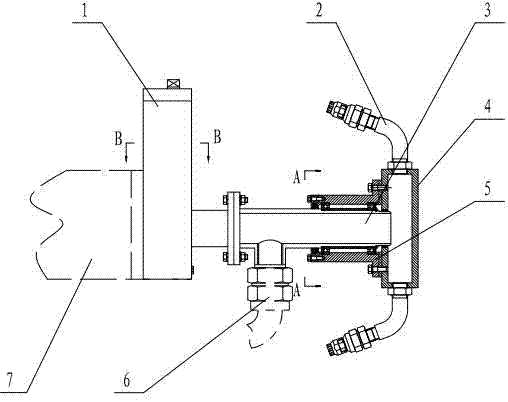

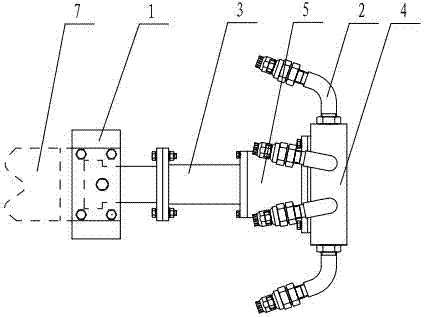

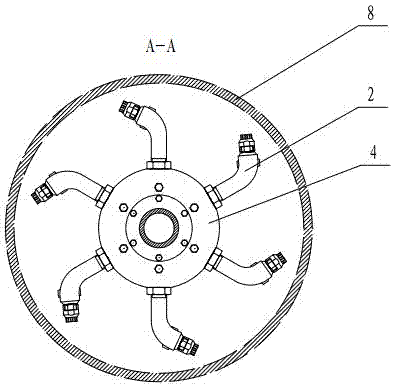

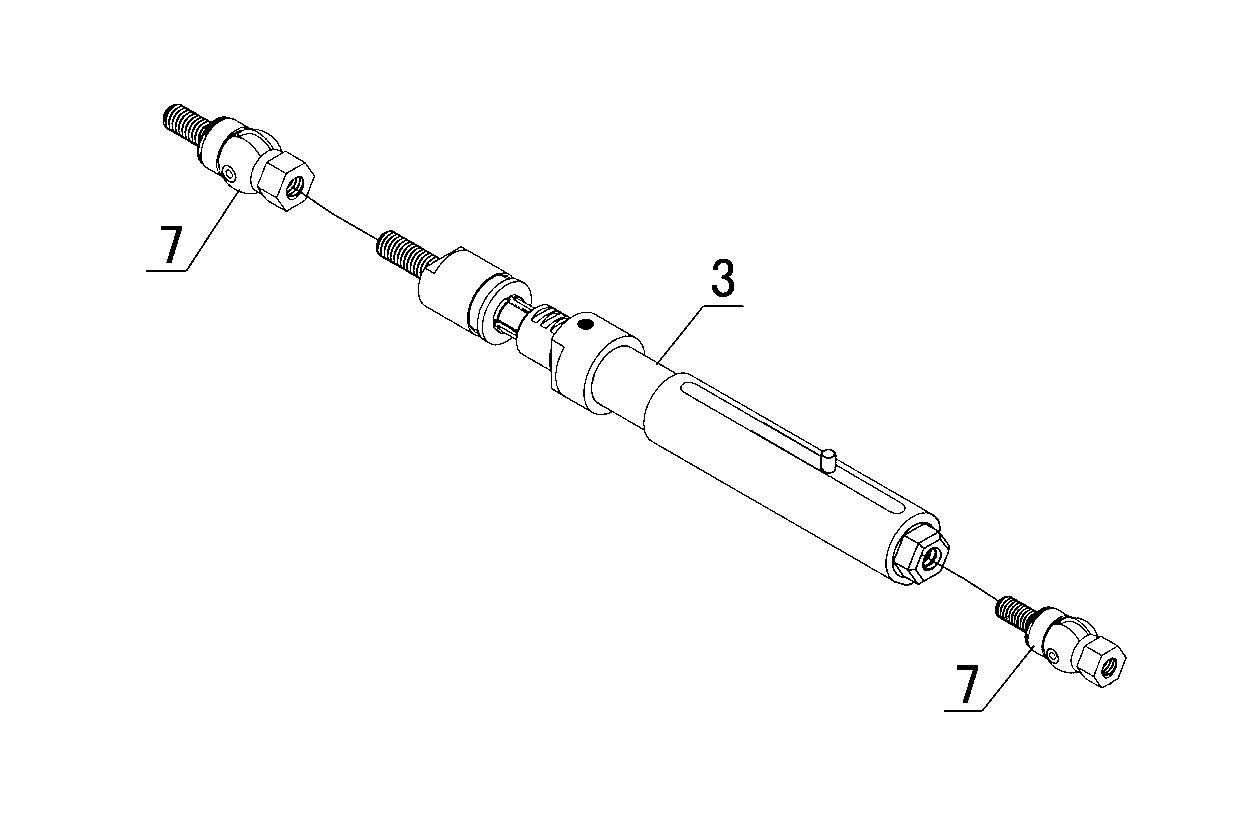

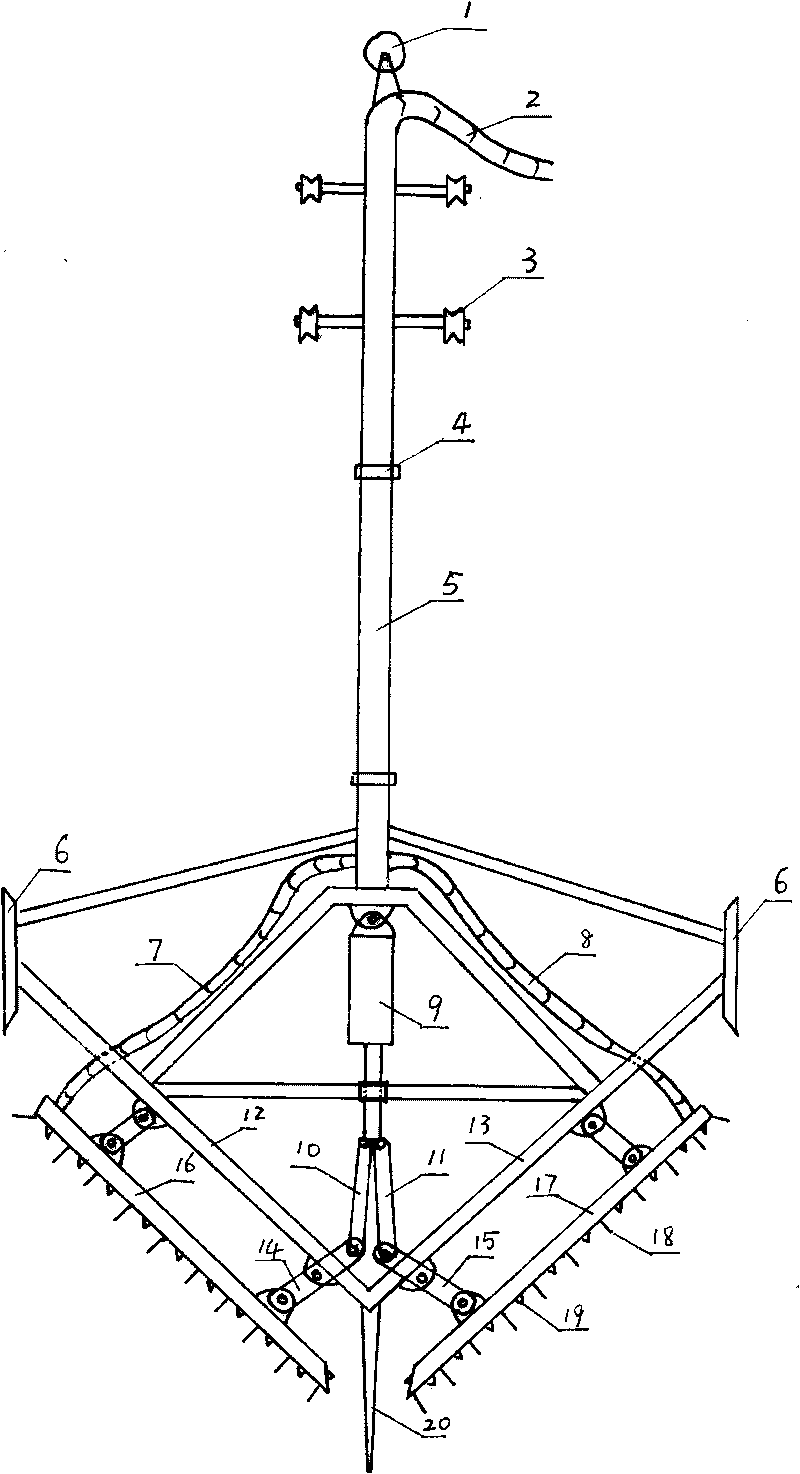

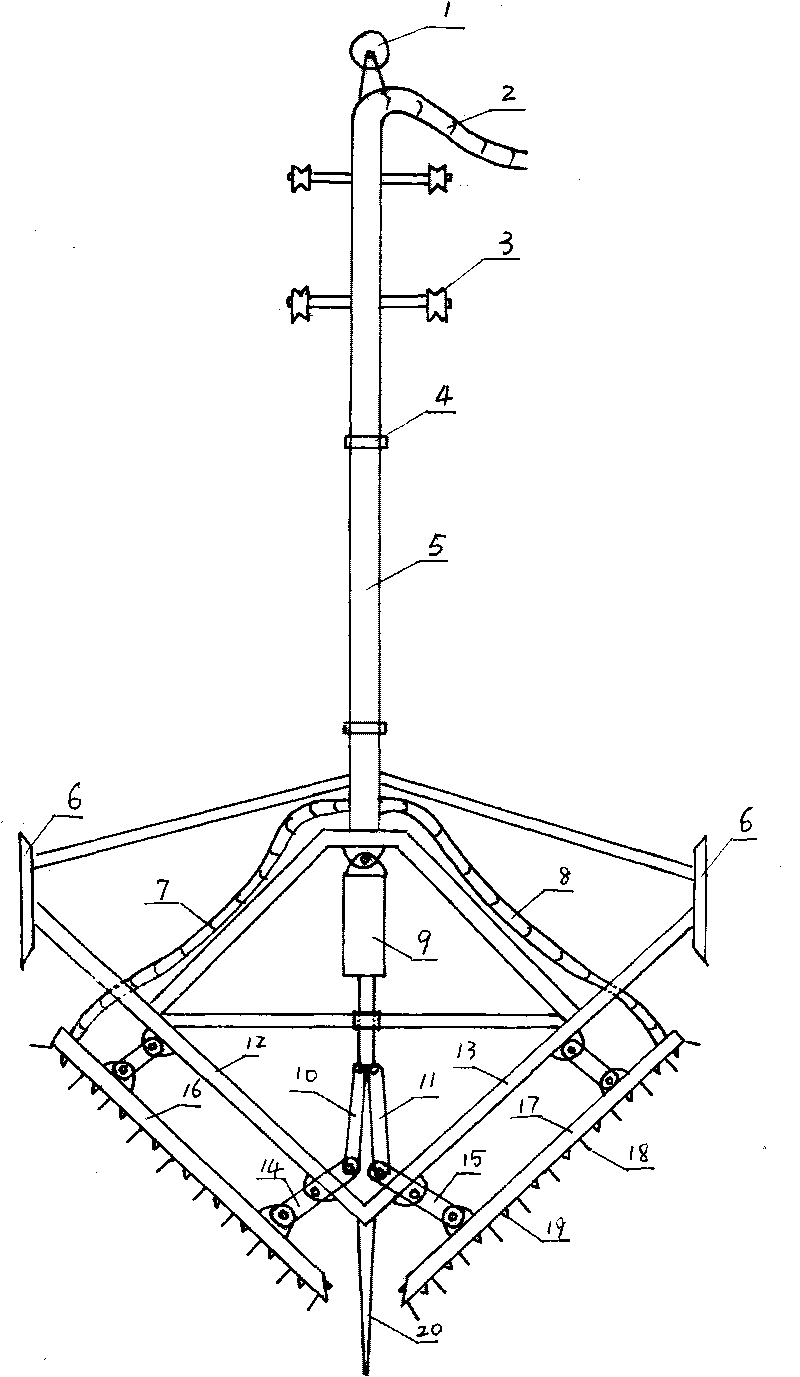

Spinning purging device for inner wall of steel pipe

ActiveCN102357492AAchieve spin effectTo achieve the purpose of purging the whole areaHollow article cleaningSpray nozzleEngineering

The invention discloses a spinning purging device for the inner wall of a steel pipe. The spinning purging device comprises a lead screw lifting device, a three-way cavity and a spinning nozzle device; the spinning nozzle device is connected with the lead screw lifting device through the three-way cavity; the spinning nozzle device comprises a rotary sleeve, a turntable and a nozzle; the nozzle comprises an air spray head, an inner screw joint and a bent pipe rod; one end of the bent pipe rod is fixedly connected with the air spray head through the inner screw joint, and the other end of the bent pipe rod is provided with a thread matched with a mounting hole of the turntable; the included angle of two end faces of the bent pipe rod is 120 degrees; and the mounting included angle between the air spray direction of the nozzle and the axis of the turntable is 0 to 90 degrees. By reasonably arranging the number and the angle of the nozzle, using the purging reacting force of compressed air and adjusting the flow rate and the pressure of the compressed air, the spinning speed is controlled, and the purpose of full-area purging of the inner wall of the steel pipe is fulfilled; a power source such as an electromotor or a motor or the like is not needed, so the energy consumption is reduced; and the spinning purging device is simple in integral structure and light in weight, and reduces the load of a cantilever.

Owner:BC P INC CHINA NAT PETROLEUM CORP +3

High-pressure threaded union with metal-to-metal seal, and metal ring gasket for same

A metal ring gasket provides a high-pressure temperature tolerant metal-to-metal seal between subcomponents of a threaded union. The metal ring gasket is received in an annular cavity formed between mating surfaces of the subcomponents of the threaded union. The metal ring gasket is capable of maintaining a fluid seal even at very high temperatures resulting from direct exposure to fire. At high fluid pressures the metal ring gasket is energized because hoop stress induced by the fluid pressure forces the metal ring gasket into tighter contact with the subcomponents of the threaded union.

Owner:OIL STATES ENERGY SERVICES +1

Metal ring gasket for a threaded union

ActiveUS20050082829A1Reliable high-pressure sealImprove sealingFlanged jointsFluid pressure sealed jointsHigh pressureScrew thread

A metal ring gasket for a threaded union provides a high-pressure, fluid-tight, metal-to-metal seal between subcomponents of a fluid conduit. The metal ring gasket is made of carbon steel or stainless steel depending on a composition of the fluid to be conveyed through the conduit. The metal ring gasket has beveled corners and is received in a beveled annular groove on mating surfaces of the subcomponents of the threaded union. When compressed in the annular groove between the subcomponents, the metal ring gasket creates an energized, high-pressure, fluid-tight seal that is highly resistant to pressure and is capable of maintaining a seal even at elevated temperatures resulting from direct exposure of the fluid conduit to fire.

Owner:OIL STATES ENERGY SERVICES +1

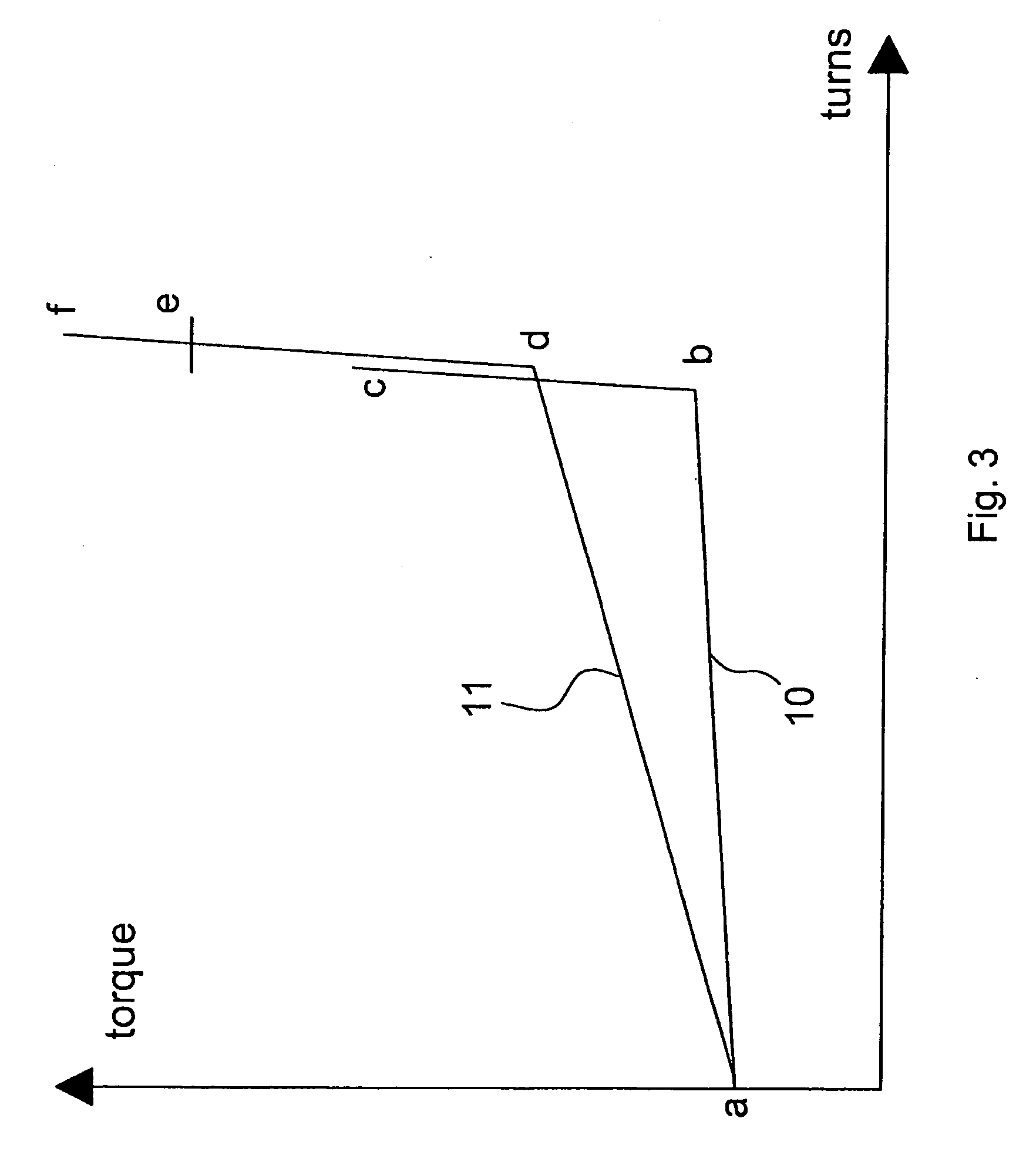

Screwing Tool And Method For Controlling The Tightening Angle Of Screwed Joints

InactiveUS20090139738A1Easy to controlEliminate inaccuraciesConstructionsSpannersHand heldControl theory

The invention proposes a method for controlling the tightening angle of screwed joints when tightening is effected using a hand-held screwing tool, wherein the torque is monitored until a predefined threshold value is reached, the angle of rotation is measured from the point the threshold value has been reached, the relative rotation of the screwing tool relative to the screwed joint is measured from the point the threshold value has been reached, and the screwing tool is switched off when a predetermined angle of rotation is reached, taking into account the relative angle of rotation of the screwing tool relative to the screwed joint as a corrective value.

Owner:C & E FEIN GMBH & CO KG

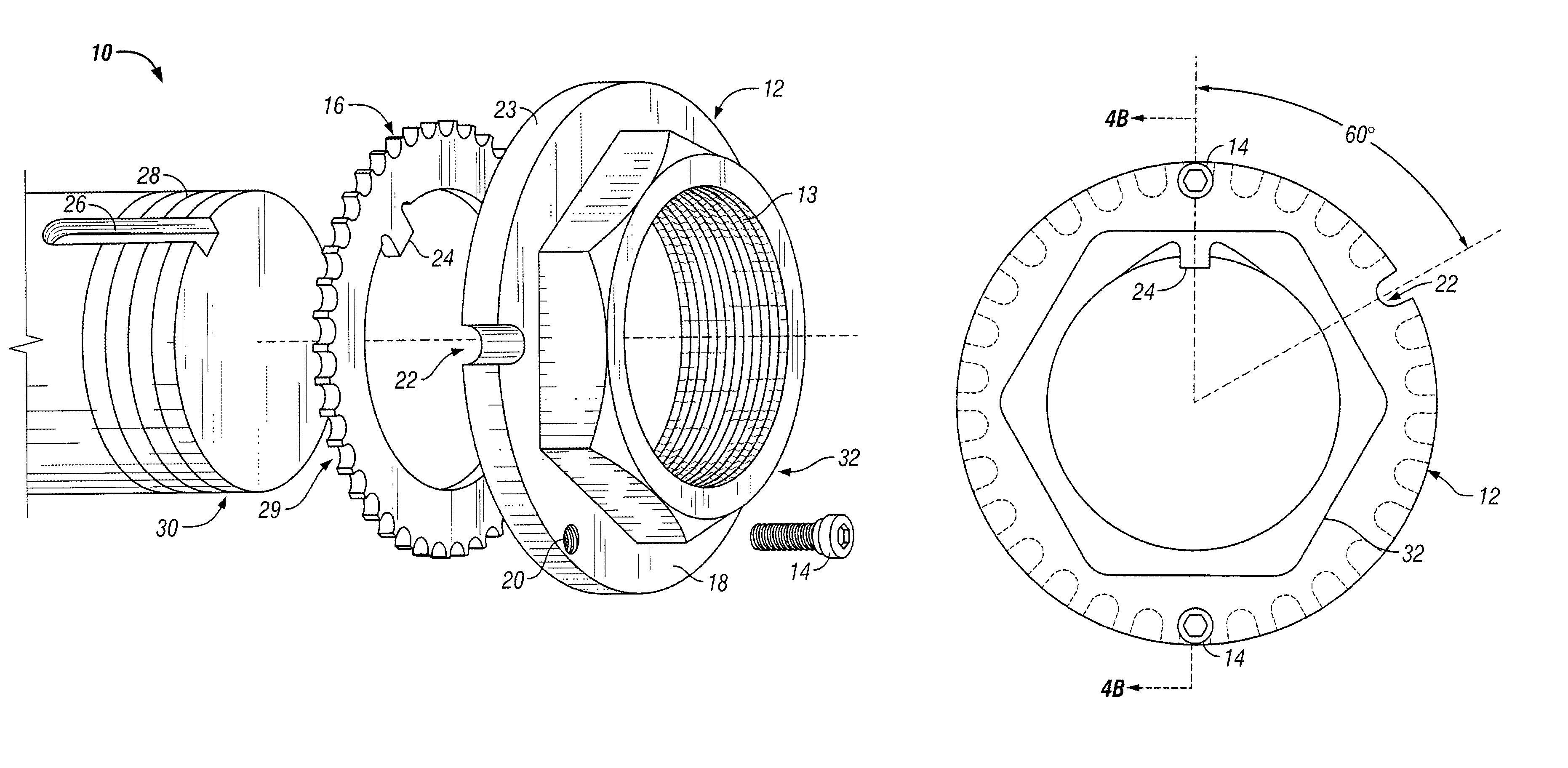

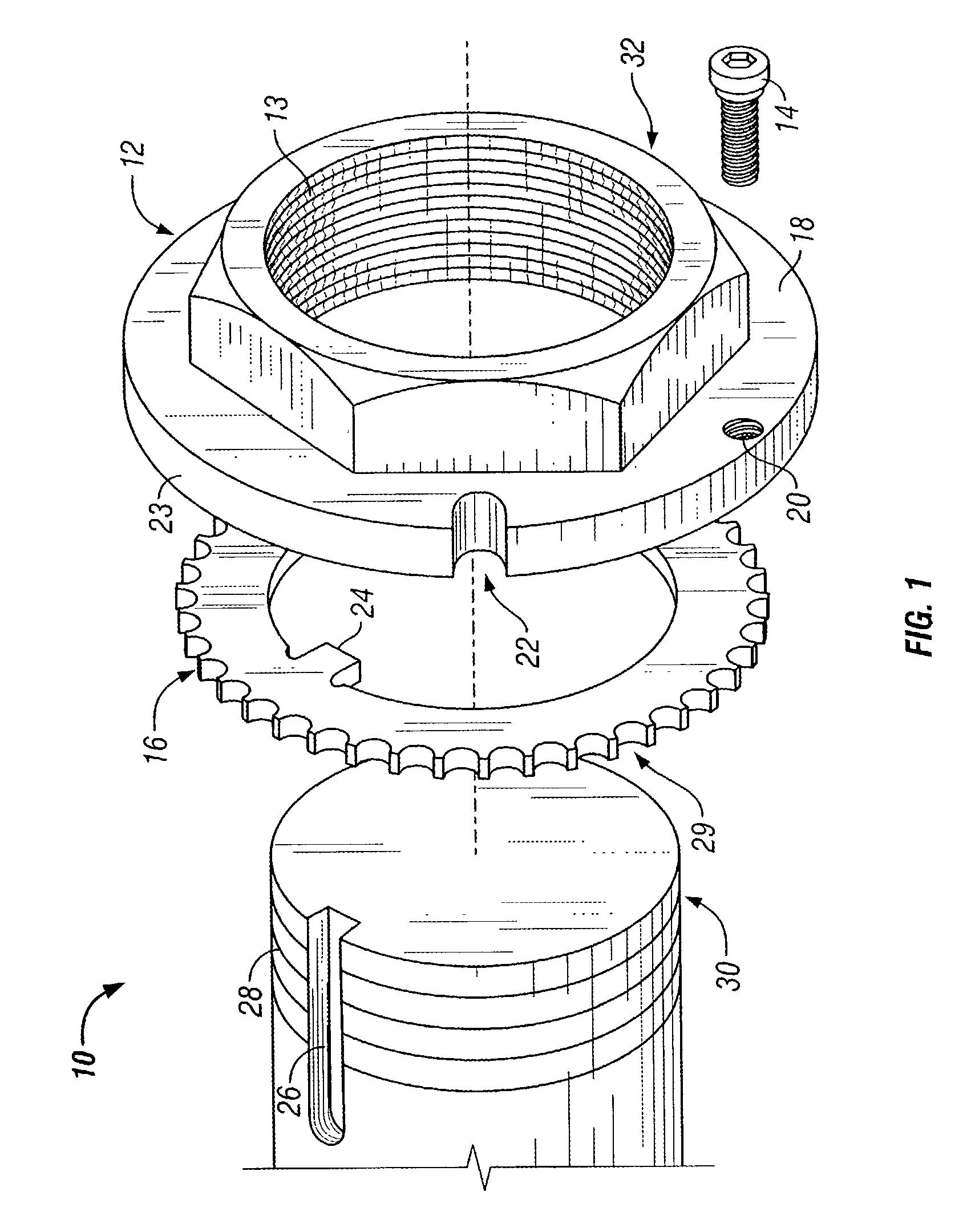

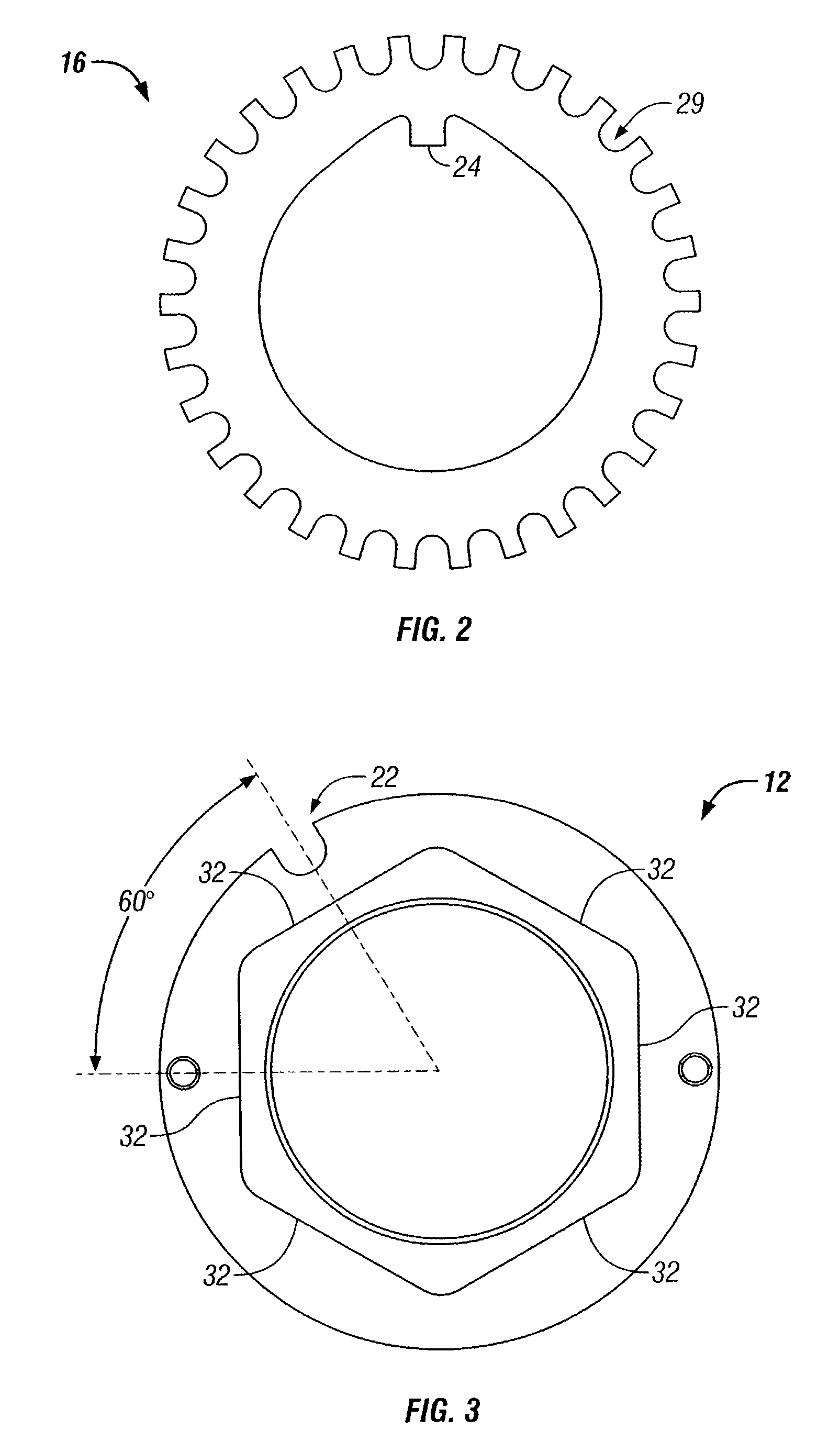

Locking fastener for threaded joint with sight gauge

A locking fastener assembly having a threaded member with a slot, a threaded rotatable fastener having a flange, the flange having a periphery and including at least one aperture extending through the flange, wherein the threaded rotatable fastener is engageable with the threaded member. The flange on the nut further includes a notch along the periphery of the flange. The locking fastener assembly also contains a retainer having an outer margin defining a plurality of notches and a protruding member, wherein the protruding member is engageable with the slot on the threaded member. A locking pin is also provided, wherein the locking pin is engageable with at least one of the threaded apertures in the flange and at least one of the notches in the retainer. In a preferred embodiment, the locking pin is aligned with at least one notch in the retainer when the notch on the flange is aligned with at least one notch on the retainer.

Owner:OKABE CO LTD

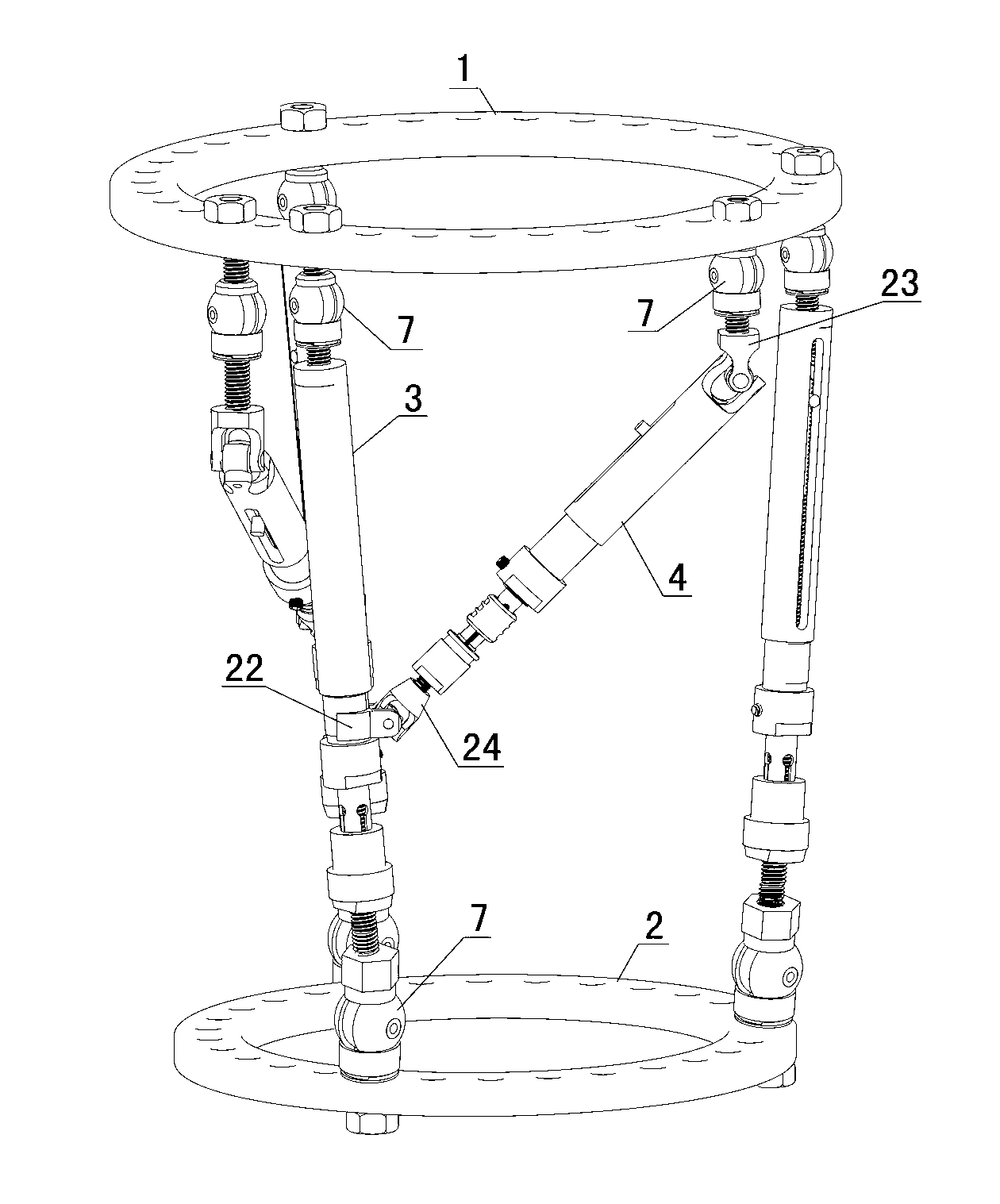

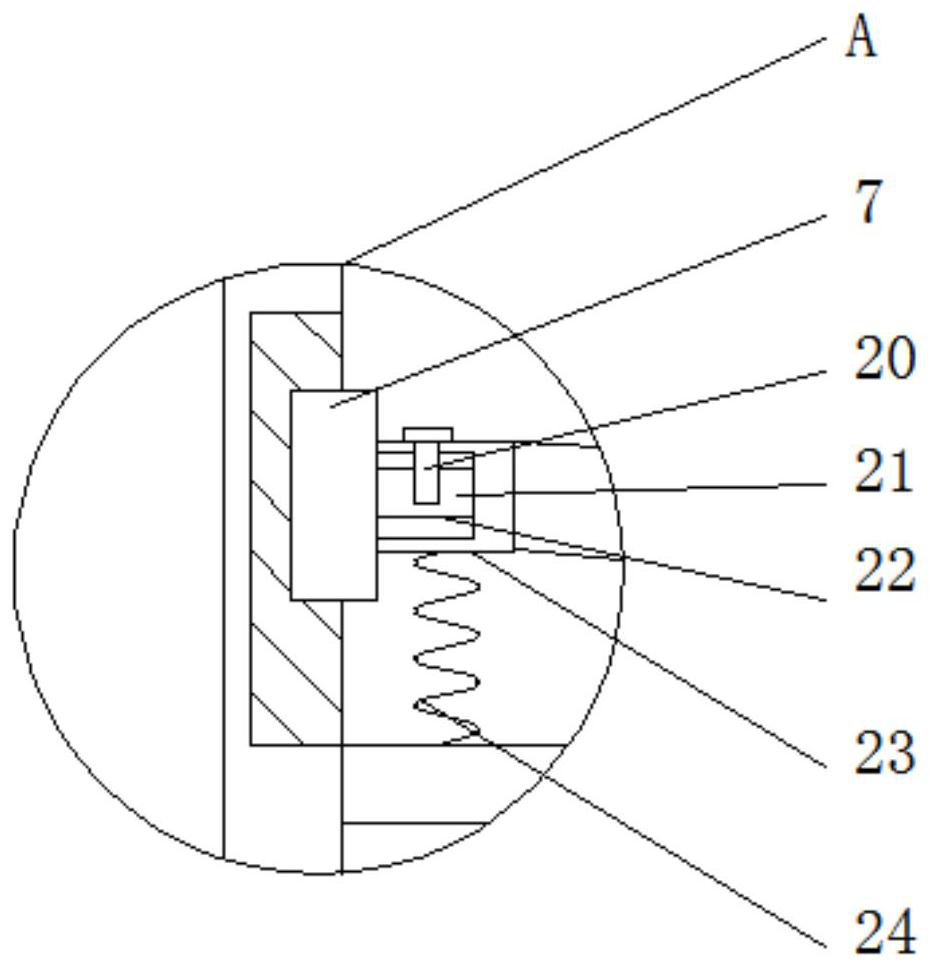

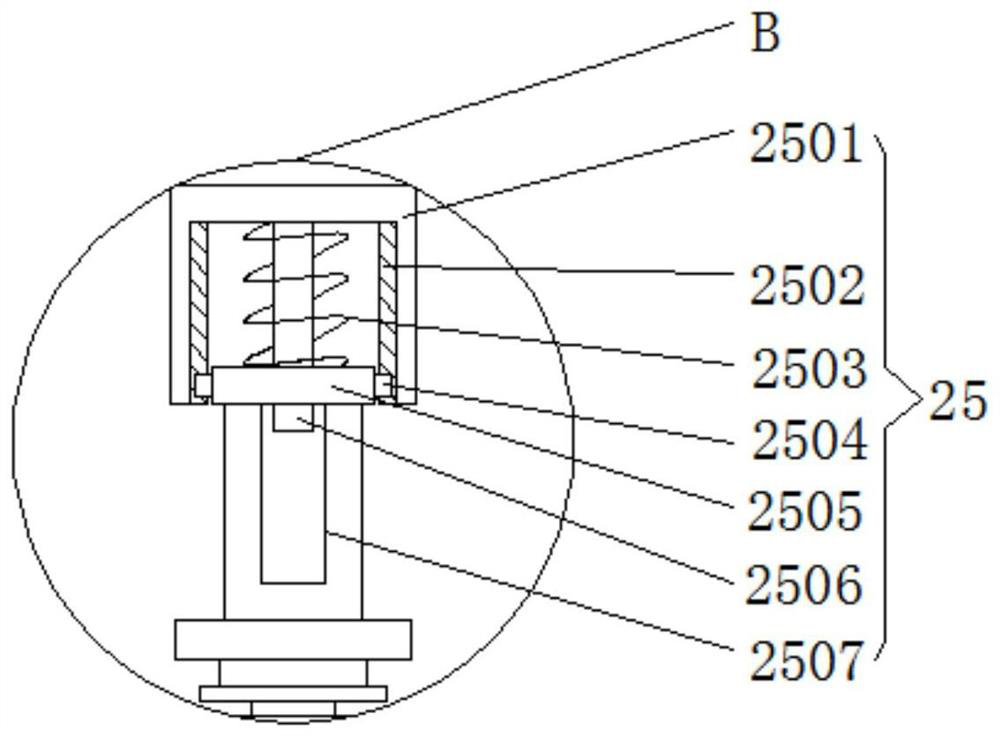

Damping joint for external bone fixator and regulating type bionic external bone fixator

ActiveCN103006303AFix fixitySolve the paradox problem of free spinsExternal osteosynthesisExternal fixatorClassical mechanics

The invention relates to a damping joint for an external bone fixator and a regulating type bionic external bone fixator. The damping joint for the external bone fixator comprises a damping joint head A, a damping joint head B, a damping joint pin shaft, a gasket groove, a butterfly gasket, a U-shaped fixing clip and a gasket cover, wherein the damping joint head A comprises a spherical damping joint hinge seat and a threaded damping joint connector A arranged on the spherical damping joint hinge seat, the damping joint head B comprises a damping joint hinge plate and a threaded damping joint connector B arranged on the damping joint hinge plate, the damping joint hinge plate is connected with the spherical damping joint hinge seat through the damping joint pin shaft, and the diameter of the damping joint hinge plate is smaller than the diameter of the spherical damping joint hinge seat. The regulating type bionic external bone fixator with the damping joint has the advantages of simple structure, light weight, low cost, regulating capability and flexible operation, and targeted and personalized combination and regulation can be realized.

Owner:夏和桃

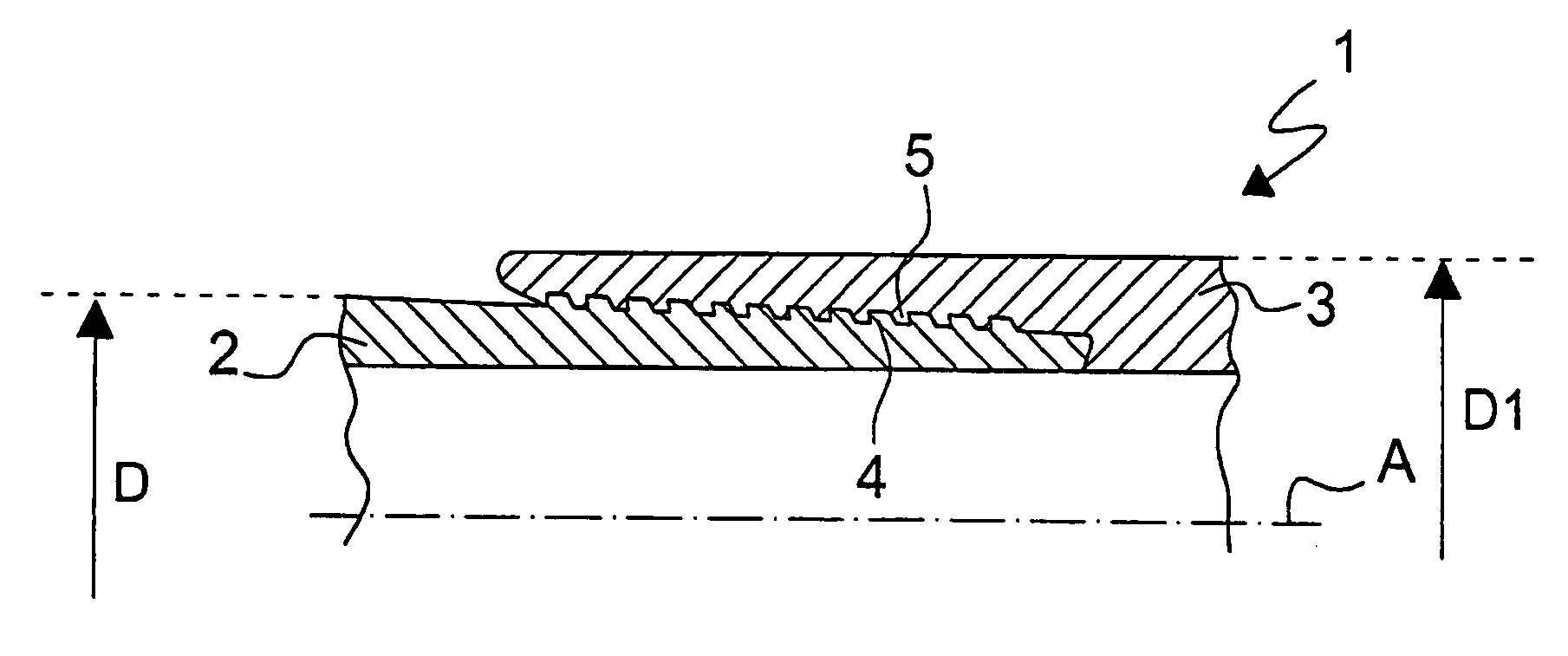

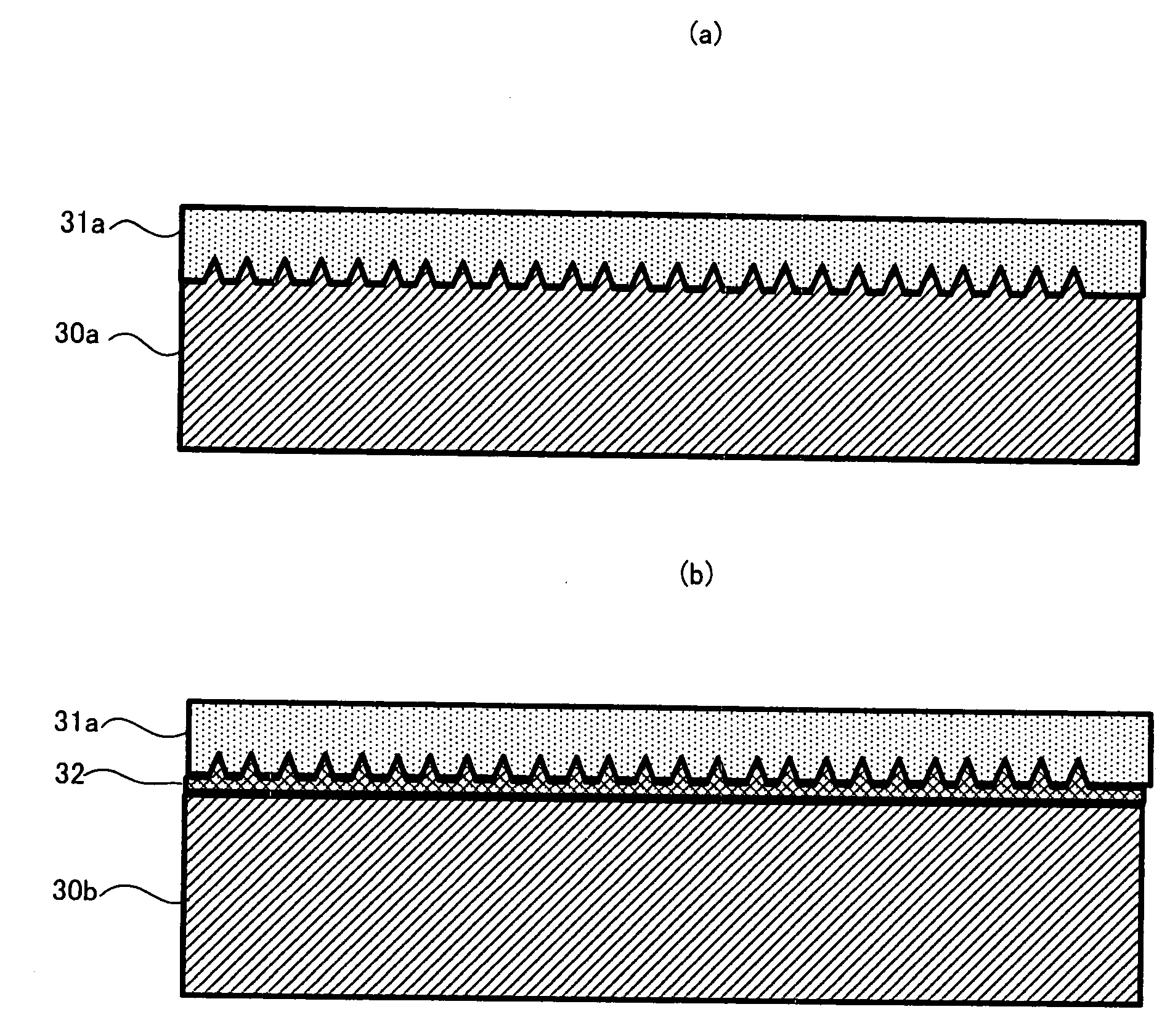

Screw Joint for Steel Pipe and Process for Manufacturing Thereof

A threaded joint for a steel pipe comprises a pin and a box with a contact surface having a threaded part and a unthreaded metal contact part, wherein a solid lubricating film containing one or more kinds of lubricating powders selected from graphite, mica, calcium carbonate and kaolin, a copper powder, and a binder is formed on at least one contact surface of the pin and the box.An object of the present invention is to provide a threaded joint for a steel pipe which allows for repeated fastening and loosening of a threaded joint without adversely influencing on a human body and environment, and is excellent in galling resistance, rust preventing property and gas tightness.

Owner:VALLOUREC OIL & GAS FRANCE SAS

Threaded joint for steel pipes

InactiveUS20060197343A1Improve adhesionImprove the immunitySleeve/socket jointsPipe supportsEpoxyEngineering

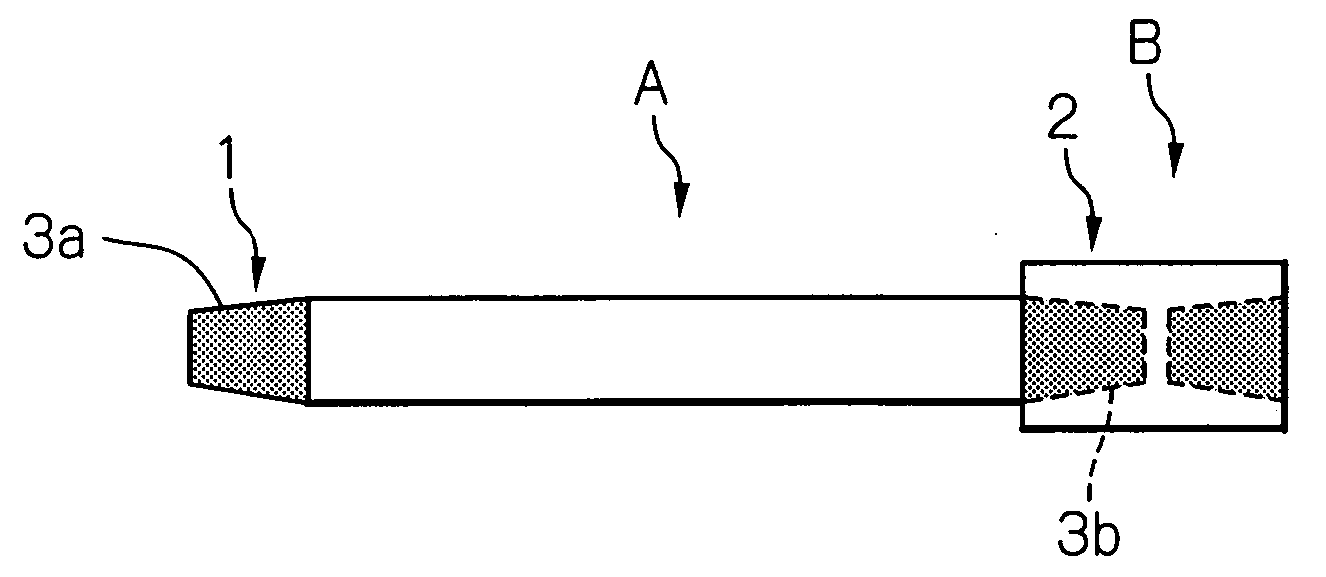

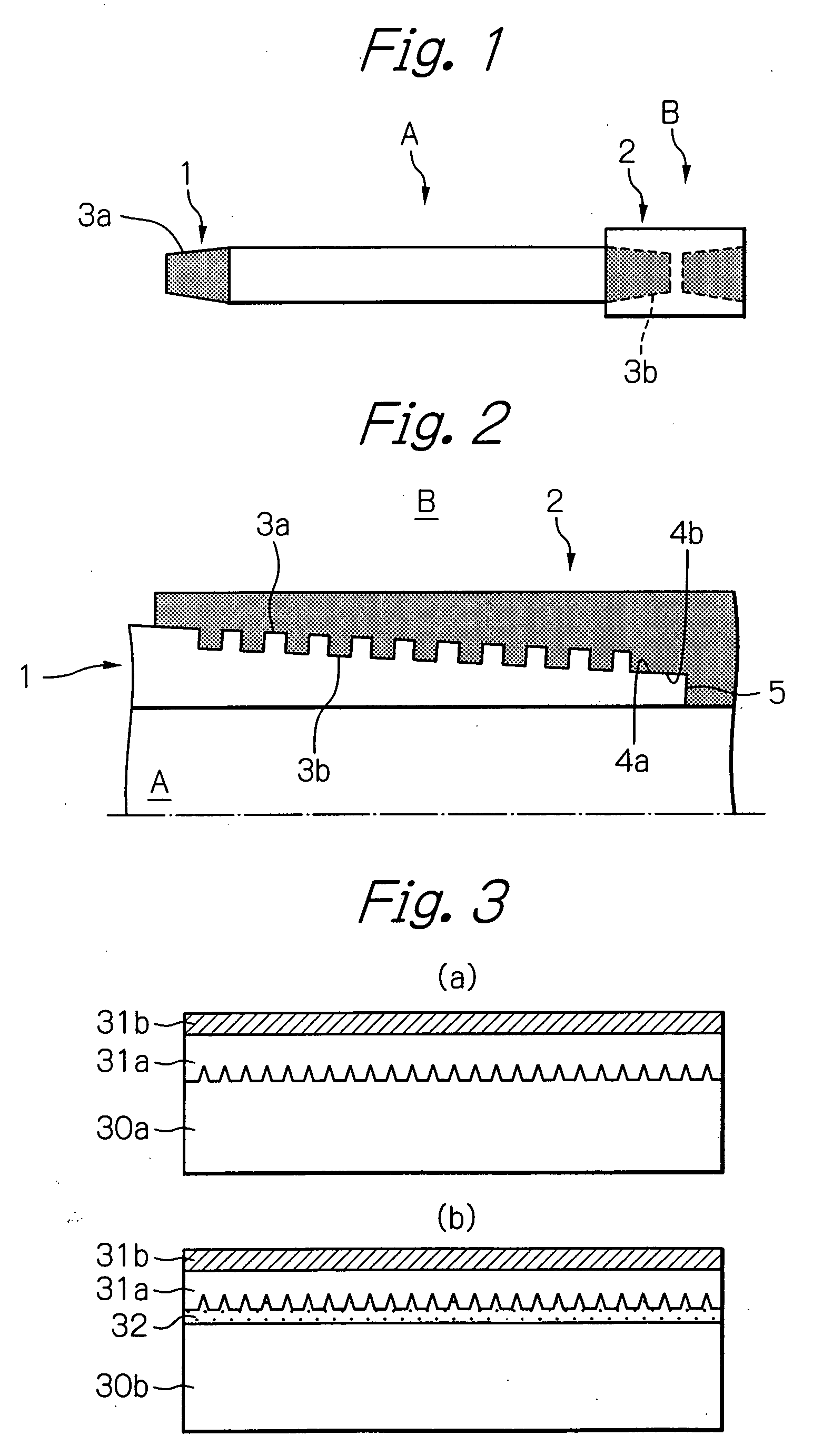

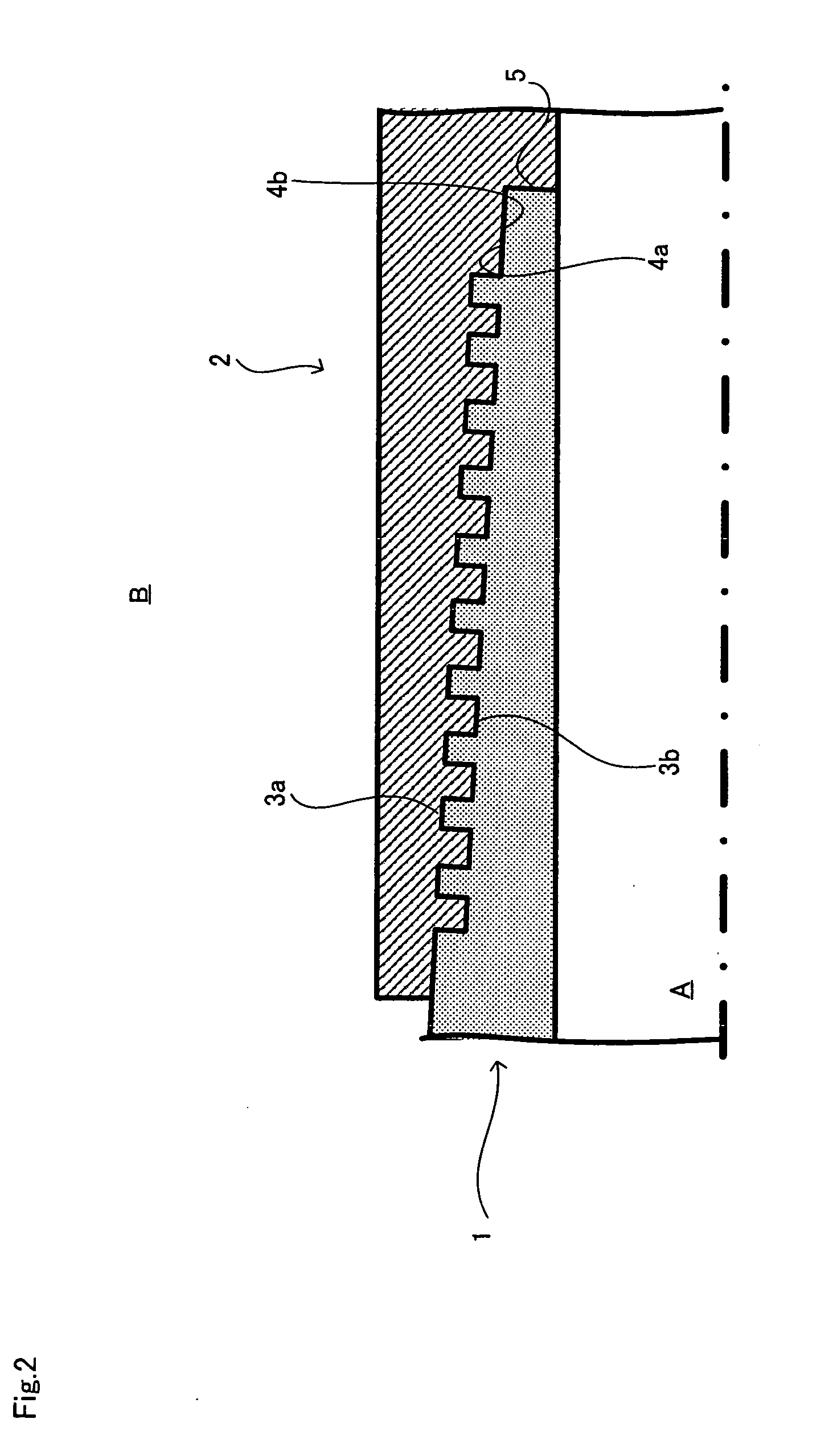

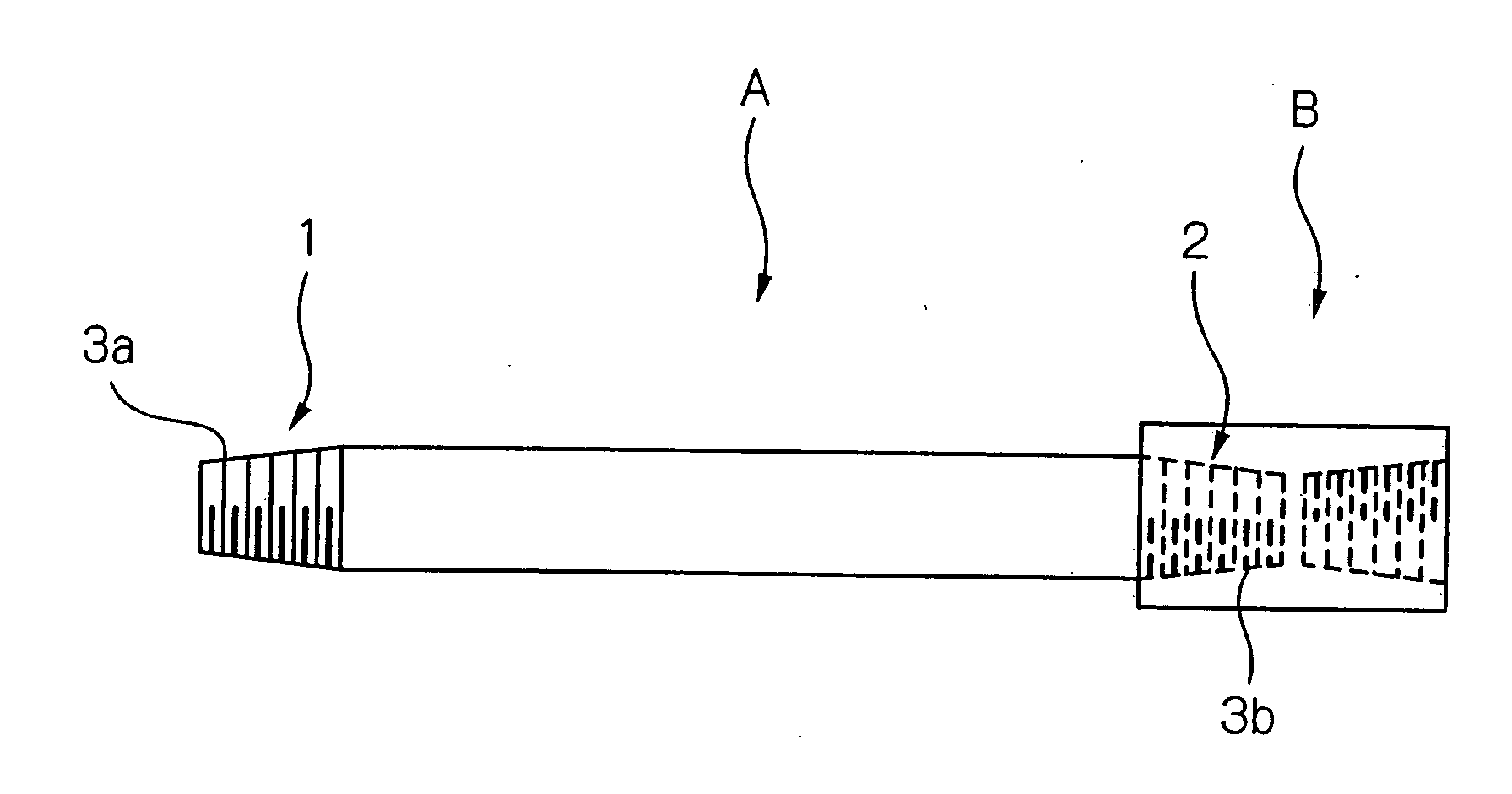

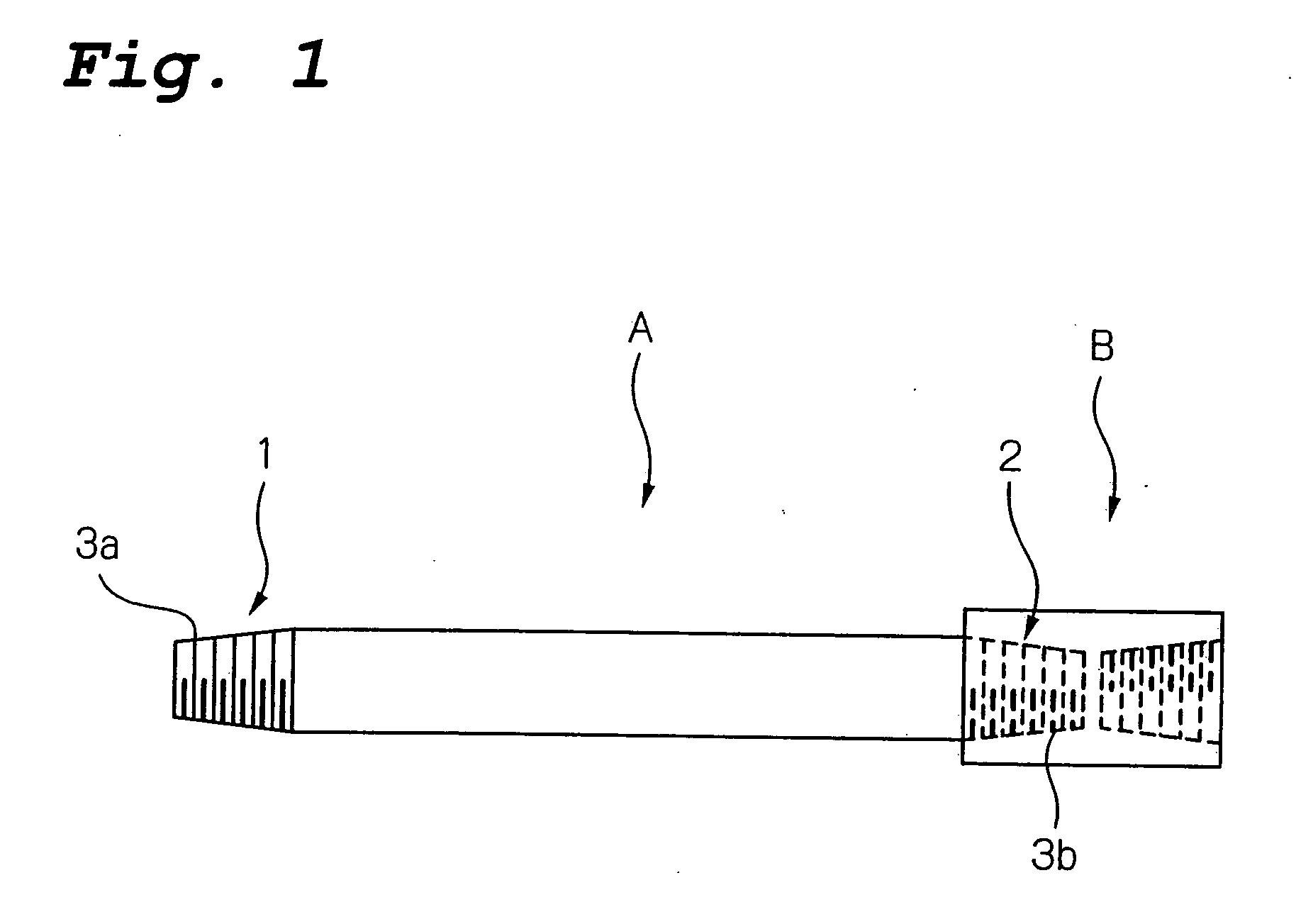

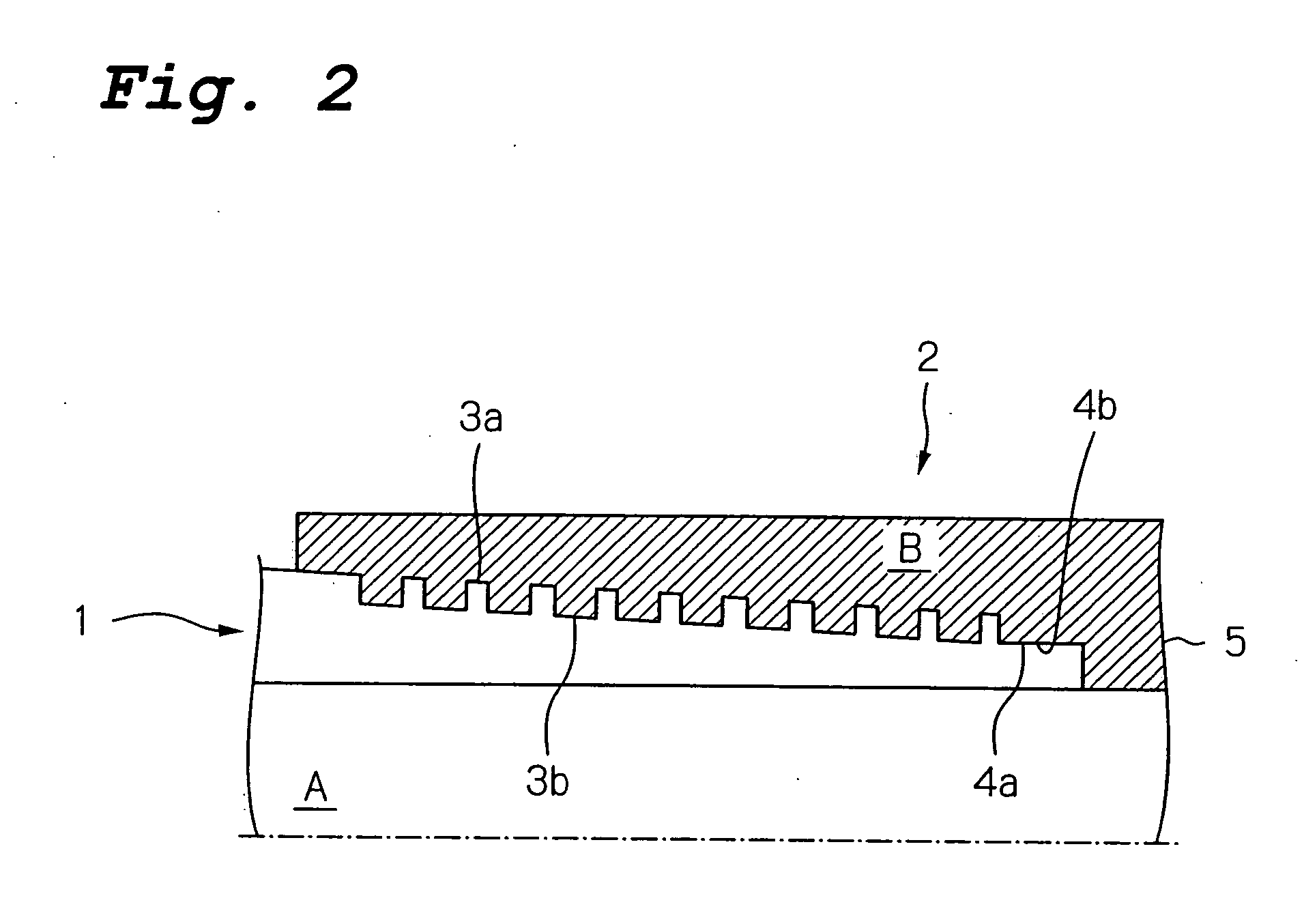

A threaded joint for steel pipes comprises a pin (1) and a box (2) each having a threaded portion (3a or 3b) and an unthreaded metal-to-metal contact portion (4a or 4b) as contact surfaces which contact each other when the joint is fastened. The contact surfaces (3a and 4a and / or 3b and 4b) of at least one of the pin (1) and the box (2) are coated with a lower layer of a solid lubricating coating containing a solid lubricating powder (e.g., molybdenum disulfide, tungsten disulfide, or graphite) and a binder (e.g., an epoxy or other organic resin) and an upper layer of a solid corrosion protective coating formed by an organic resin which does not contain solid particles.

Owner:NIPPON STEEL CORP

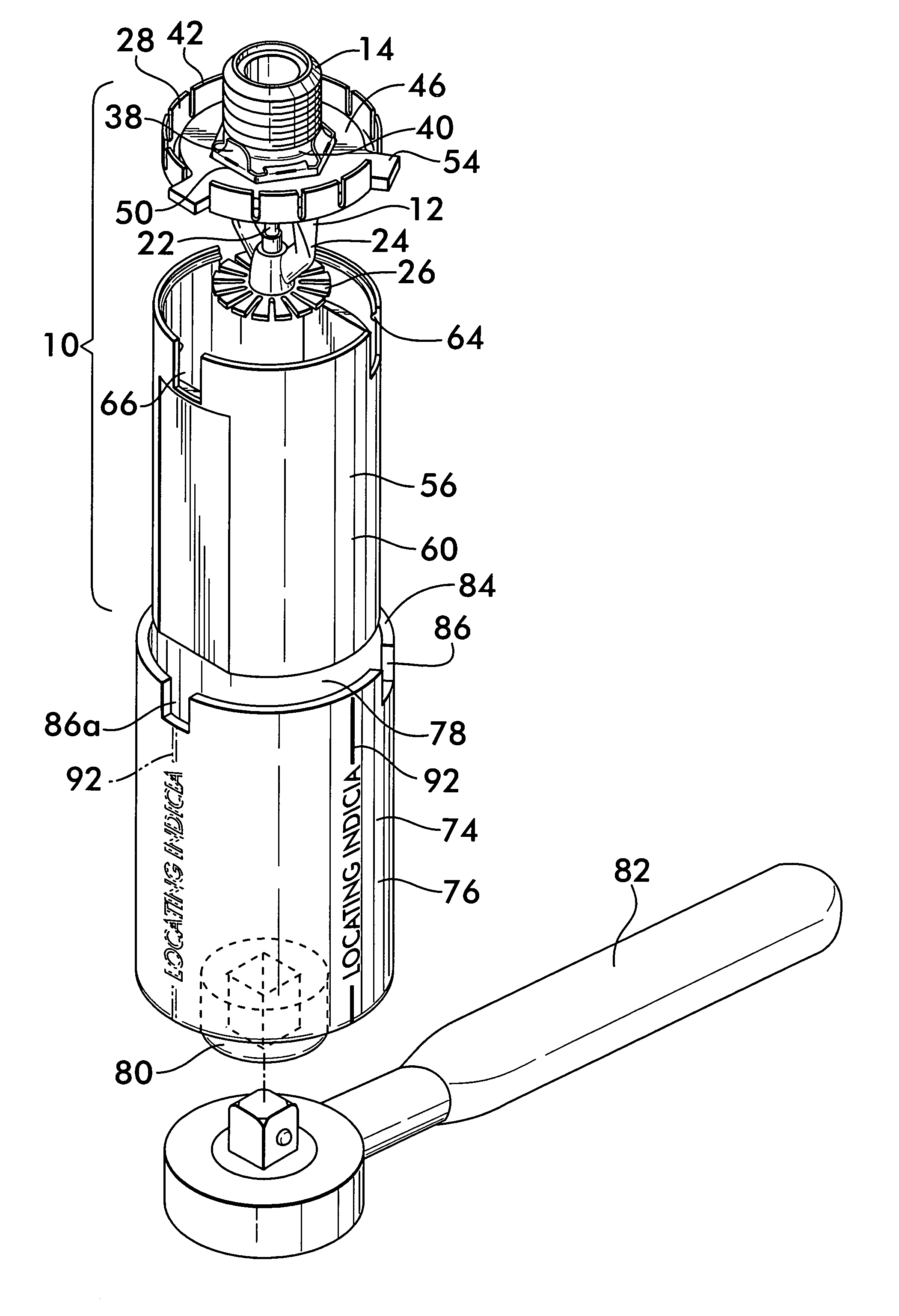

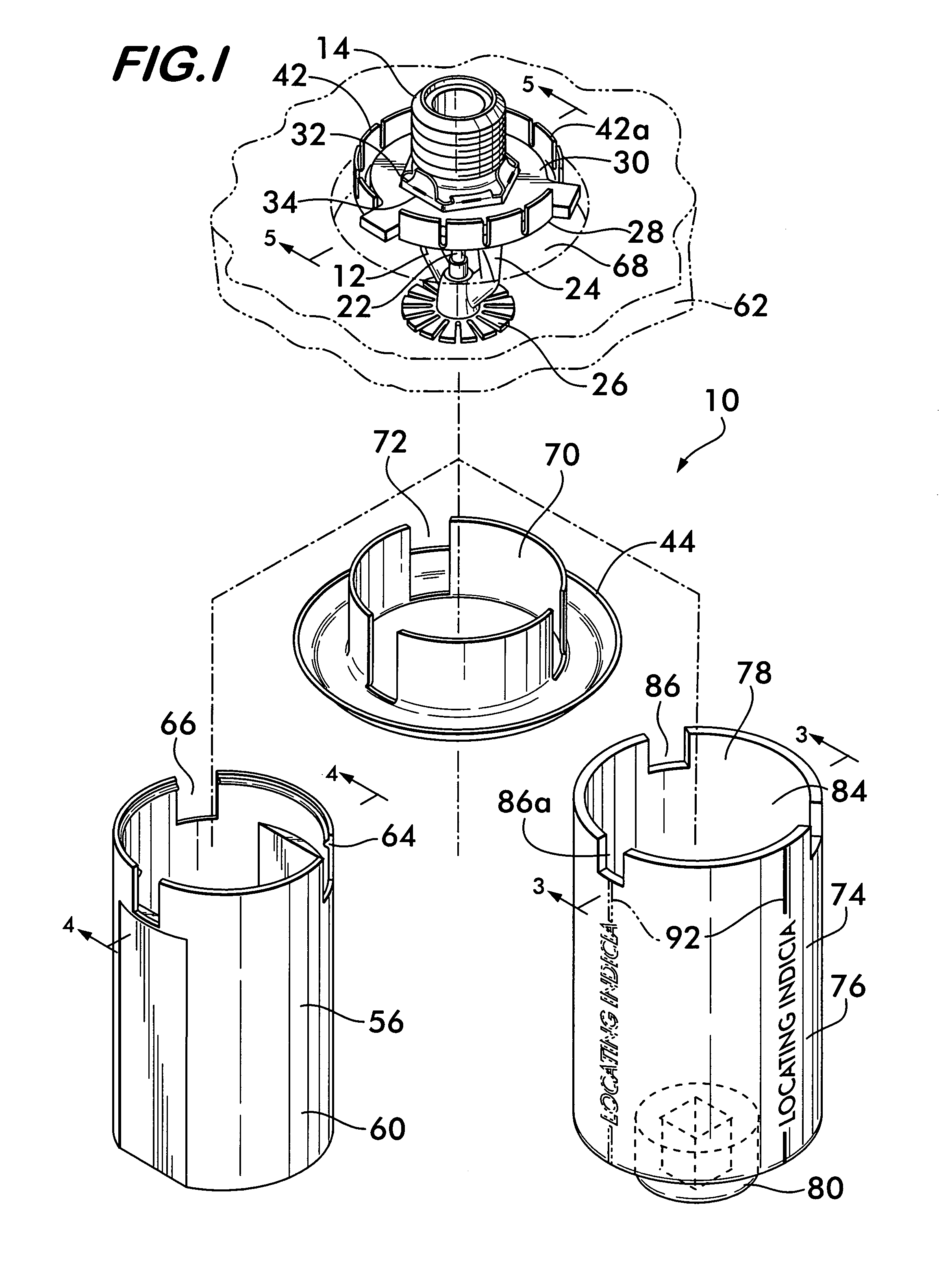

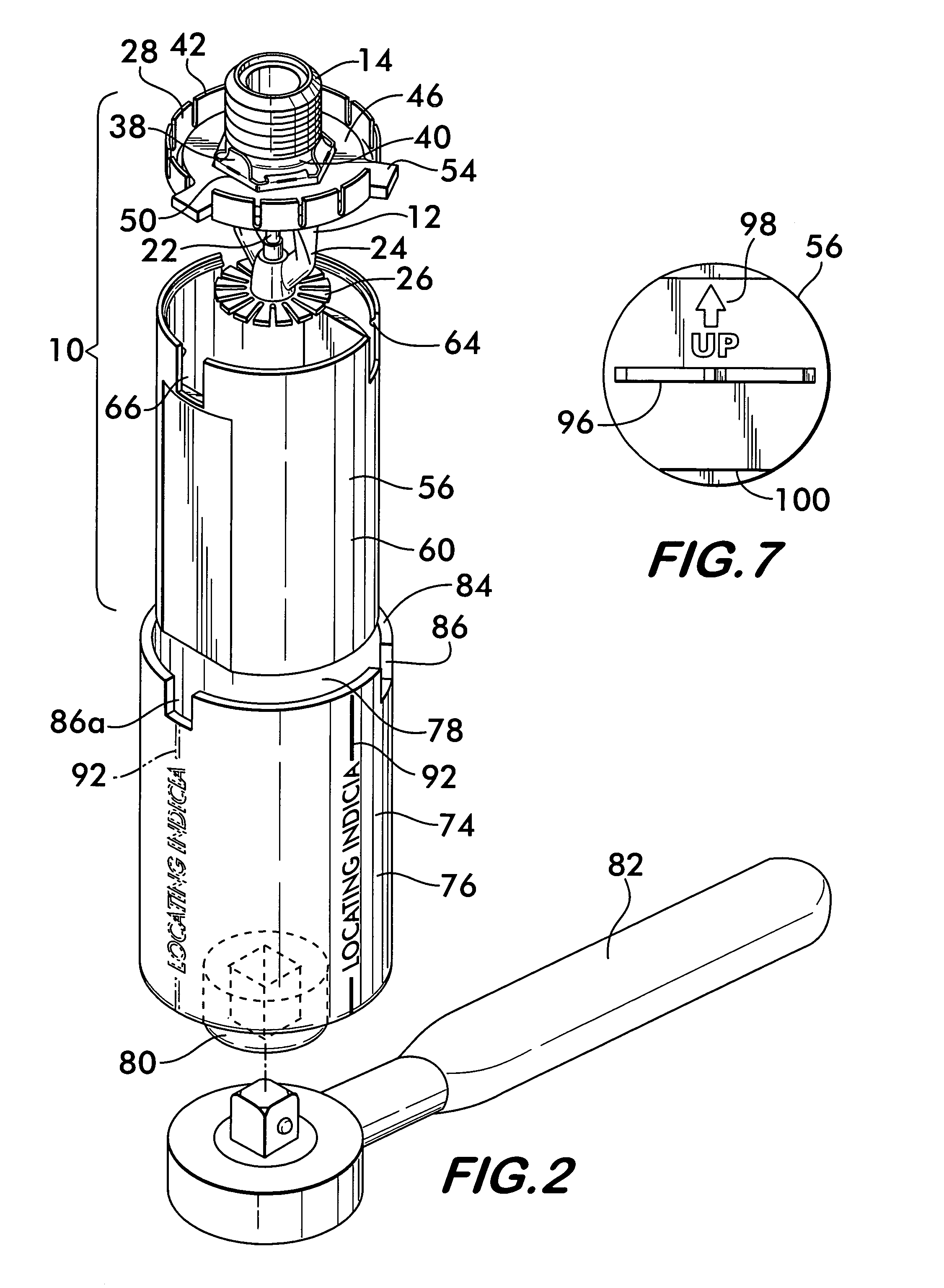

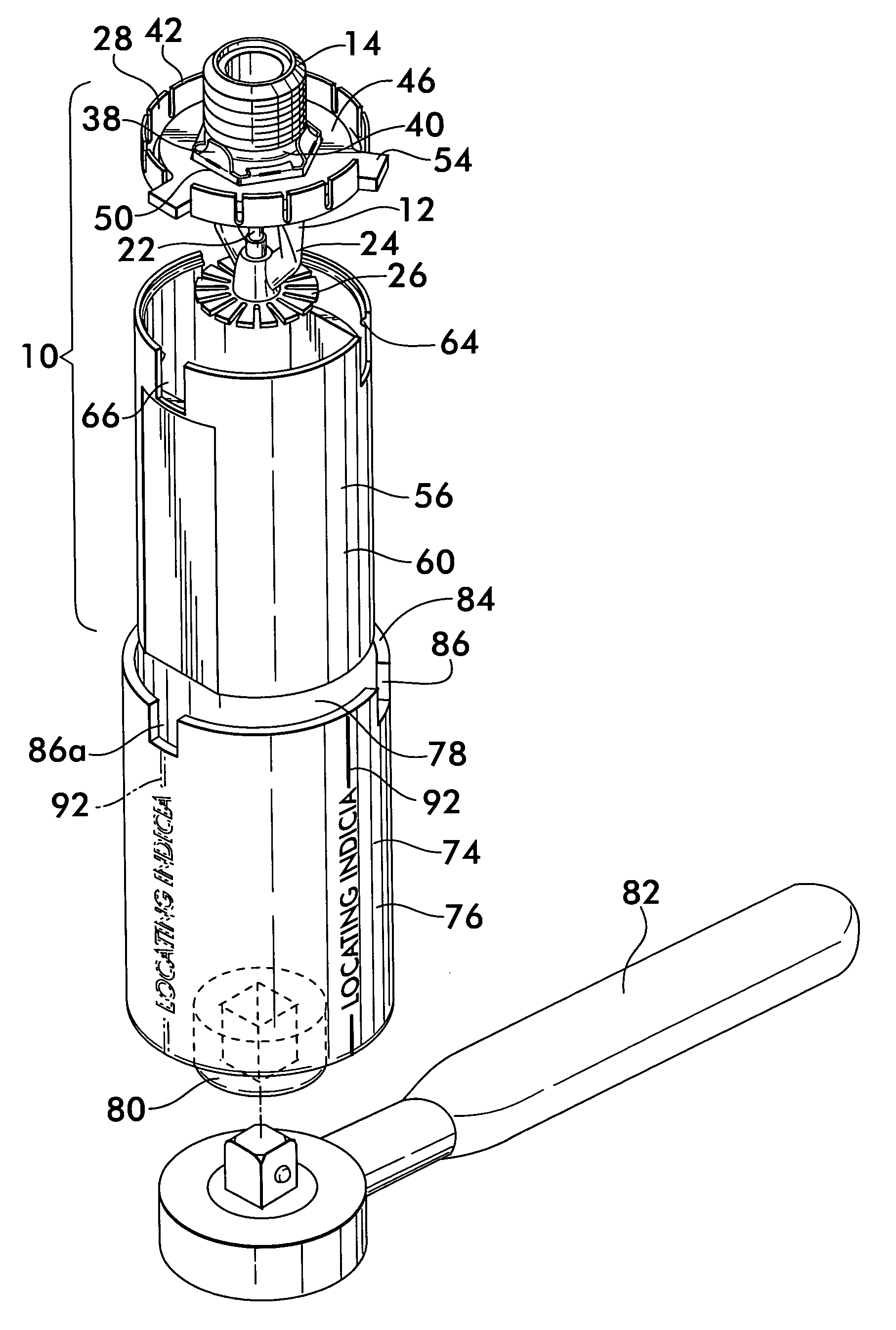

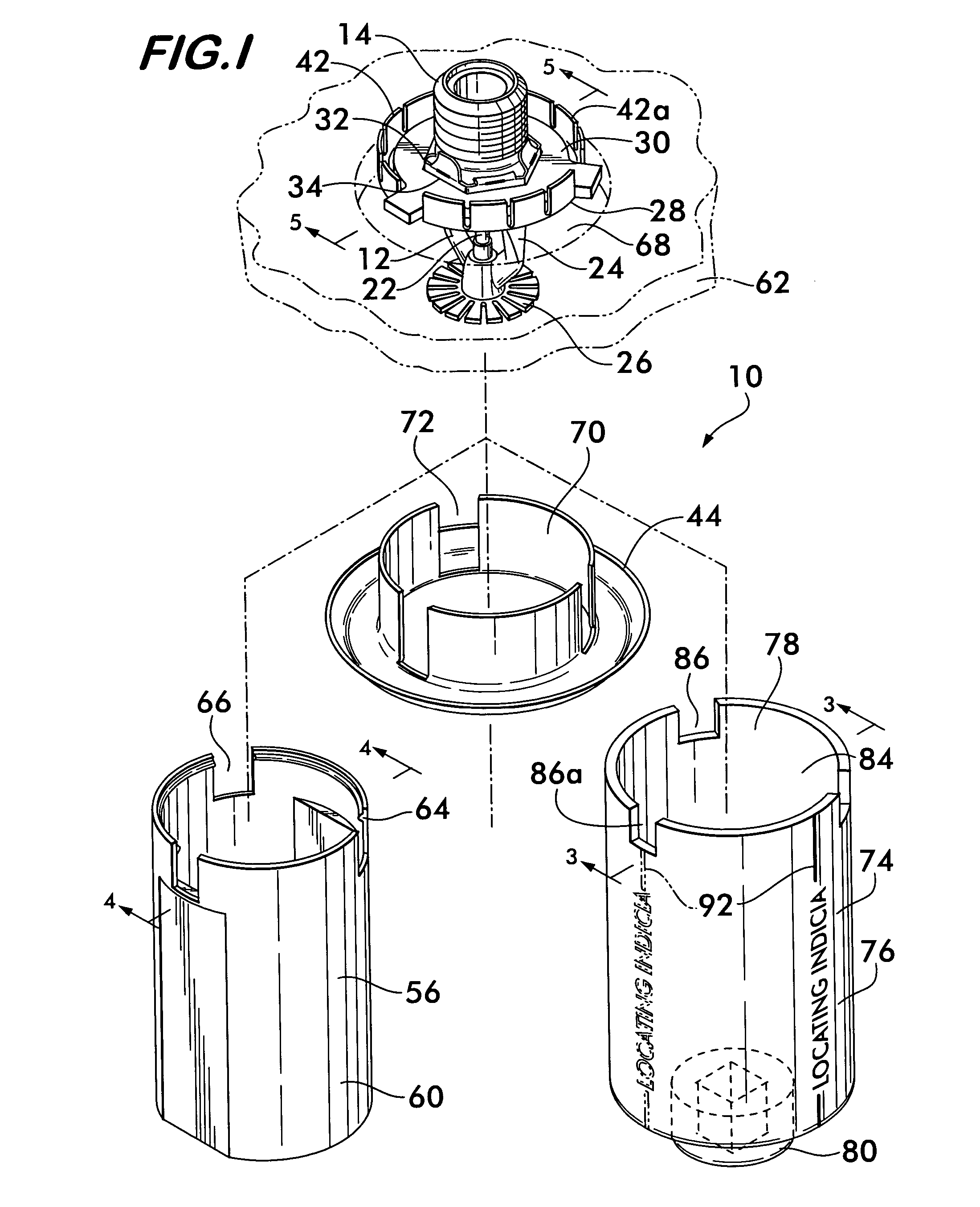

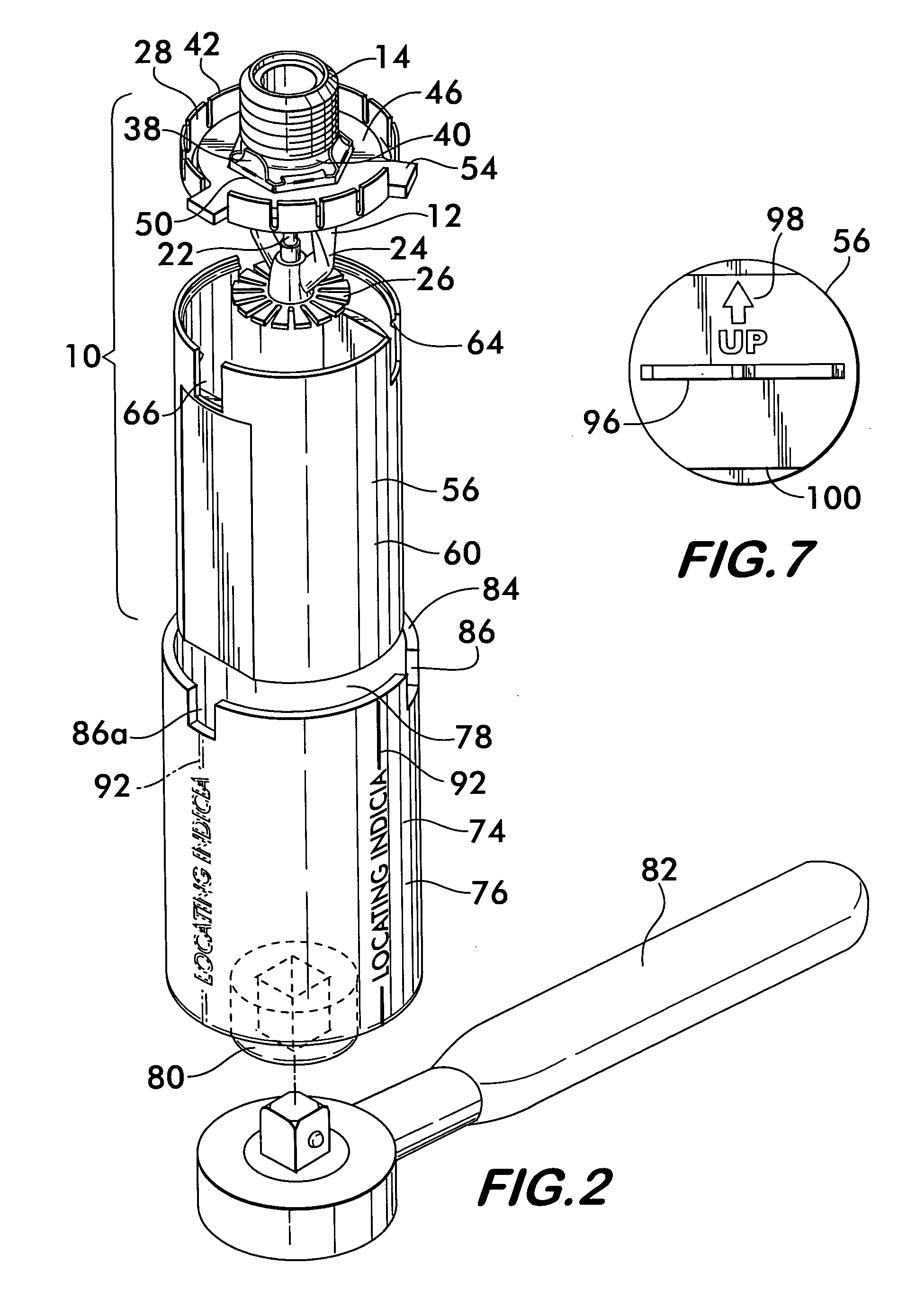

Torque plate for sprinkler head

A torque plate for use with a sprinkler head in a fire suppression system is disclosed. The torque plate has a base from which one or more fingers project transversely. The torque plate is mounted on the sprinkler head. A protective cover surrounds the sprinkler head. The fingers project outwardly beyond the cover, allowing a tool to engage them. The tool is formed from an elongated body having a cavity that is sized to receive the cover. One end of the body interfaces with a wrench, the other end has one or more axially extending slots sized to receive the fingers of the torque plate. The sprinkler plate has a threaded nipple that engages a threaded fitting on the sprinkler system. Torque is applied to engage the nipple with the fitting by engaging the slots of the tool with the fingers and turning the tool with the wrench.

Owner:VICTAULIC

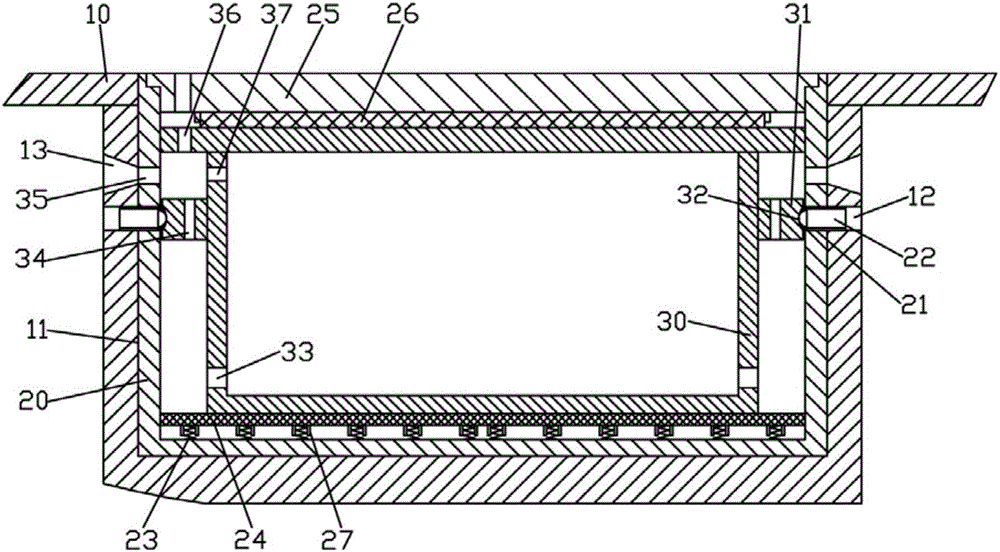

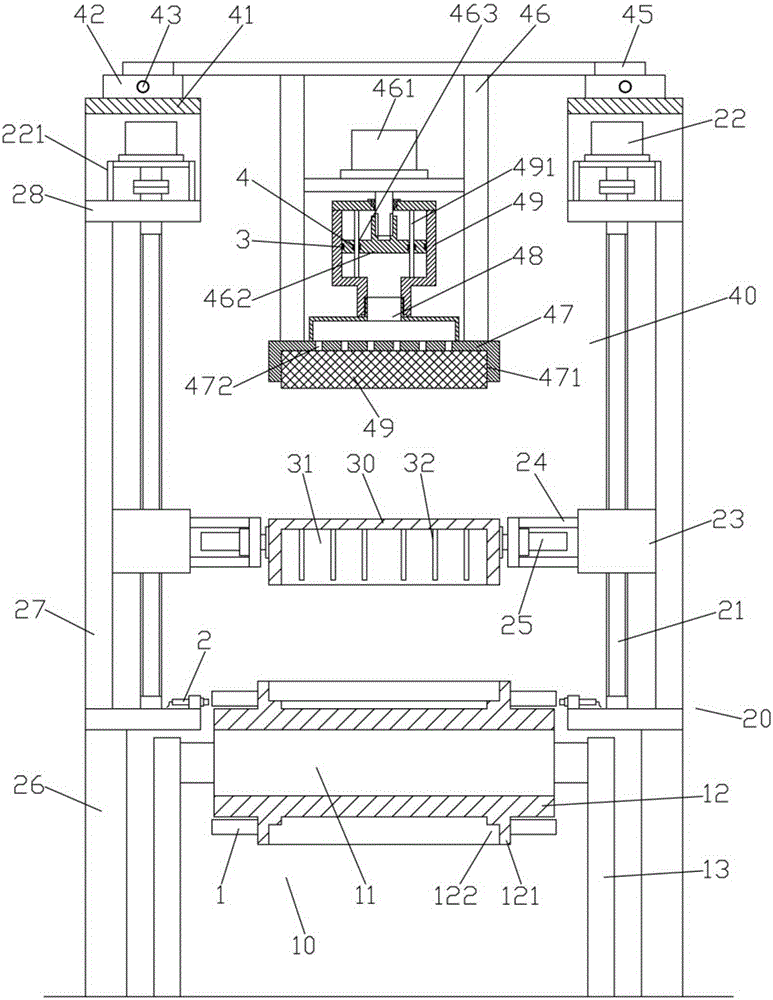

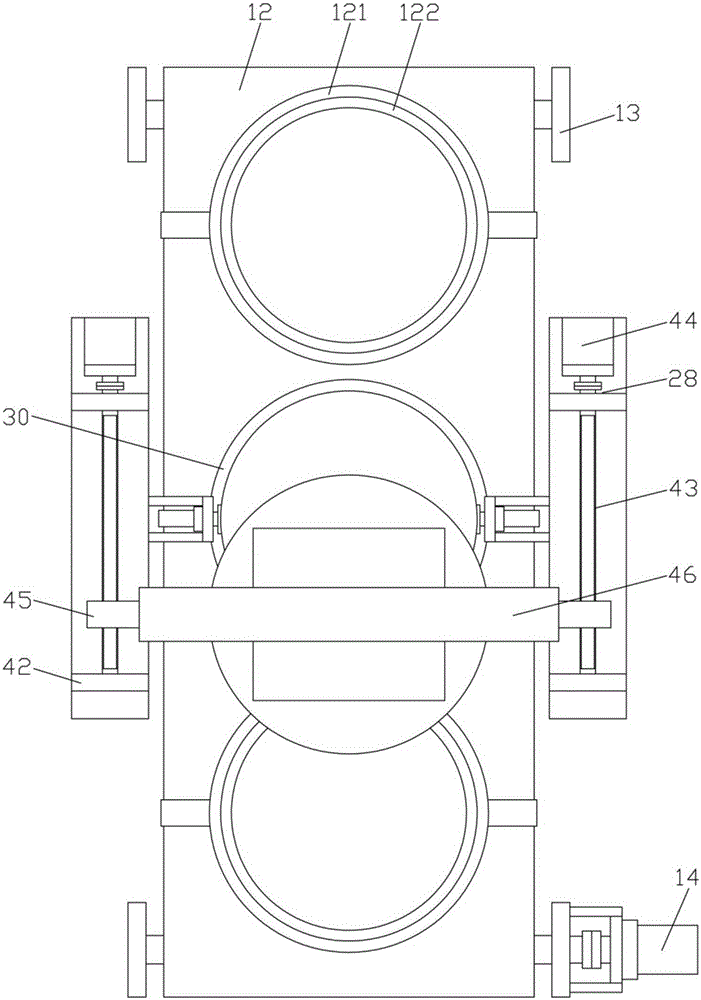

Electric vehicle battery arrangement structure having buffer effect

ActiveCN105118939AHas a cushioning effectExtended service lifeBattery isolationSecondary cellsVehicle frameElectric-vehicle battery

The invention discloses an electric vehicle battery arrangement structure having the buffer effect. The electric vehicle battery arrangement structure comprises a frame, wherein a battery arrangement groove is formed in the middle of the frame, a battery case protection housing is inserted and fixed in the battery arrangement groove in a sleeved mode, the side wall of the battery case protection housing is provided with multiple screw-joint through holes, the side wall of the battery arrangement groove is also provided with multiple through holes, the through holes correspond to the screw-joint through holes in a one-to-one mode, ball plungers are connected in the screw-joint through holes in a screwed mode, a battery case is arranged in the battery case protection housing, the outer side wall of the middle of the battery case is provided with an annular positioning portion, steel balls of the ball plungers are nested into concave holes formed in the annular positioning portion, multiple buffer springs are fixed to the bottom surface of the battery case protection housing, a buffer pad is arranged on the buffer springs, and the battery case presses and abuts against the buffer pads. When an electric vehicle runs, the battery case has the buffering effect, and the service life is prolonged. In addition, vent holes are formed in the battery case and enables a certain amount of heat in the battery case to be discharged out, and the safety is improved.

Owner:SUZHOU JOYDEER E BICYCLE

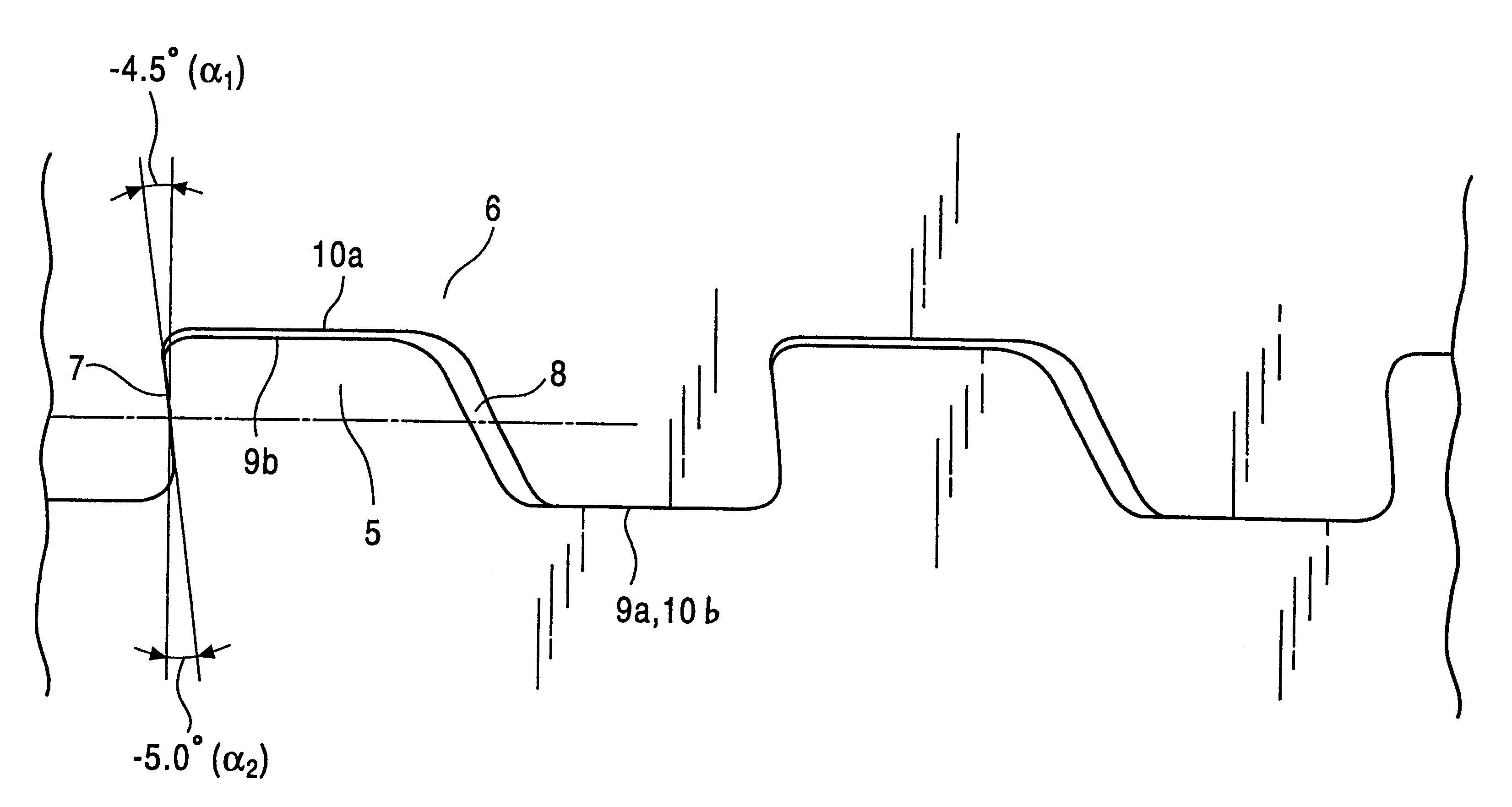

Oil well pipe screw joint, and threading method and apparatus therefor

An oil-country-tubular threaded joint can withstand tensile forces, and in addition, other forces such as compression and bending forces, thus producing highly improved characteristics in regard to the prevention of fluid leakage. The oil-country-tubular threaded joint is formed of male screw threads and female screw threads which have a load face whose load flank angles are in a range of -3° to -25°, in which the load flank angles are varied at a position at which the load face is divided in the height direction of the male screw thread into an upper side and a lower side so that an upper load flank angle is smaller than a lower load flank angle by 0.5° to 2.0°. Also, a thread-machining apparatus for the oil-country-tubular threaded joint uses chasers having cutting edges which are shaped so as to correspond to thread shapes for machining screw threads whose flank angles are partly of negative values for the oil-country-tubular threaded joint. In the apparatus, the cutting edges which are to be used from the beginning to the end of thread-machining are arranged on the individual chasers sequentially according to the shape, and the chasers are on one rotational body so as to machine screw threads at a rate of one pitch per rotation of the rotational body. This allows negative screw threads of quality higher than in conventional cases to be cut in a reduced time.

Owner:KAWASAKI STEEL CORP

Electromechanical assembly for connecting a series of perforating guns for oil and gas wells

Mechanical connector for the connection and assembly of guns used in the perforation of petroleum producing wells. Each gun has a hollow cylindrically shaped housing whose ends have threaded joints. Explosive shipped-charges are radially set in respective peripheral slots of the gun. Guns are coaxially joined in vertical position within the casing of the well, forming an assembly that includes the firing head and a bottom sub. The joints between consecutive guns and between the bottom sub and the lowermost gun, include tubular adaptor pieces and intermediaries that have respectively a threaded joint end and an opposing end constituted by a bayonet-type locking joint formed by a single reinforced latching bayonet locking tab.

Owner:TASSAROLI

Tensioning anchor suitable for blind-hole tendon anchoring and tendon repair

A tendon anchor system includes an anchor body adapted to receive a tendon through one end. The anchor body has a threaded coupling at the other end. A retaining device is disposed within the anchor body for retaining the tendon within the anchor body. An anchor is disposed within an anchoring structure. The anchor has a threaded coupling. The threaded coupling in the anchor has an opposite thread direction to the threaded coupling in the anchor body. A jack screw threadedly engages with both the threaded coupling in the anchor body and in the anchor.

Owner:HAYES SPECIALTY MACHINING

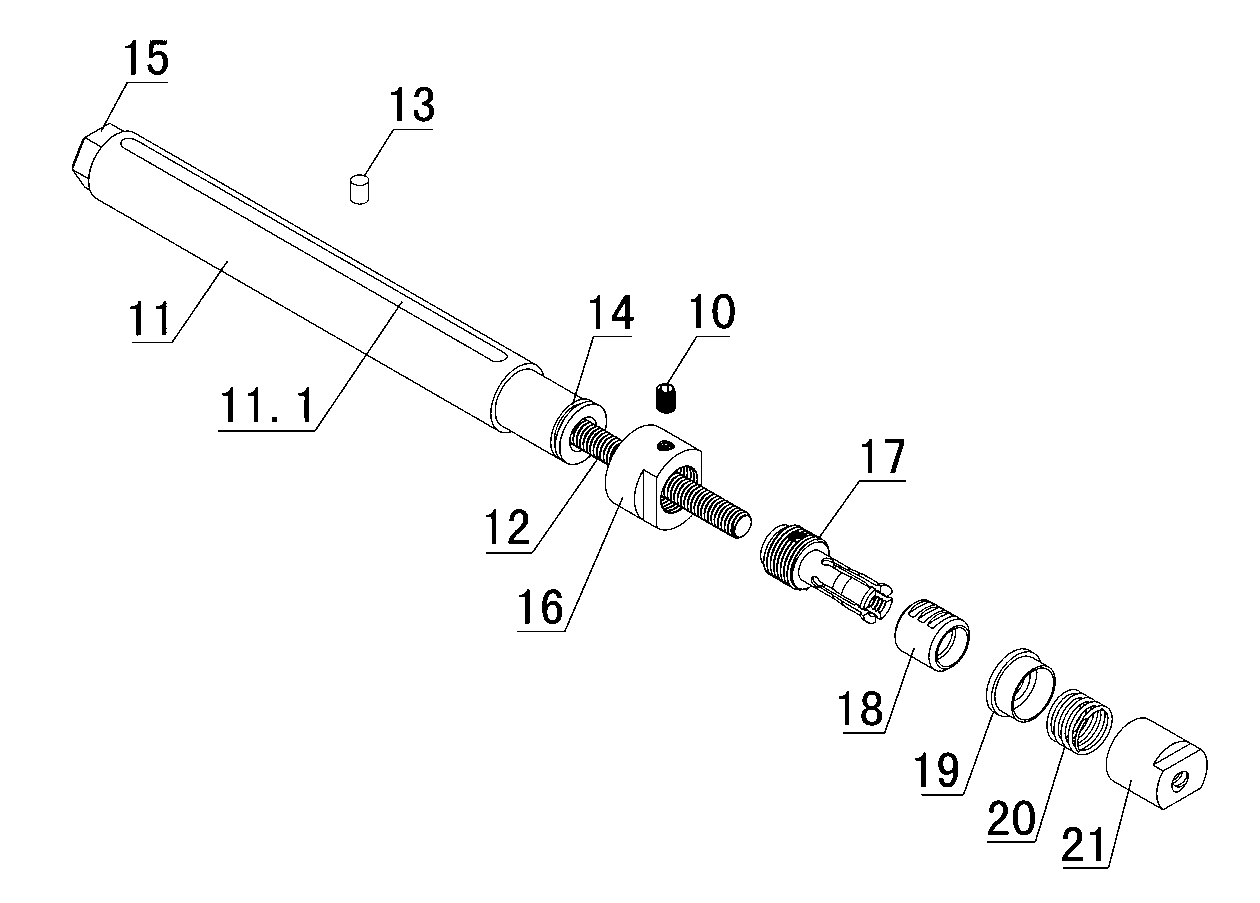

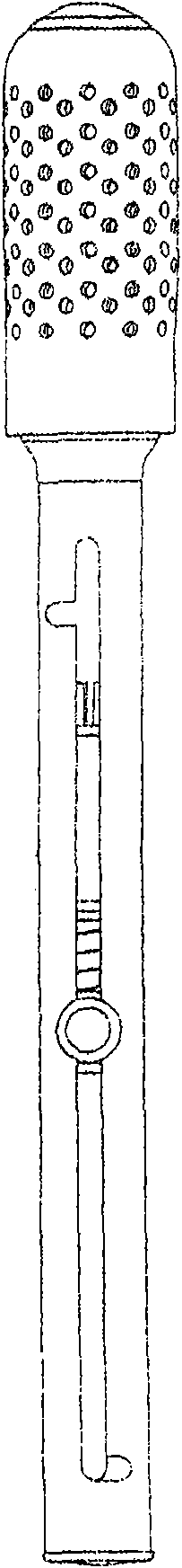

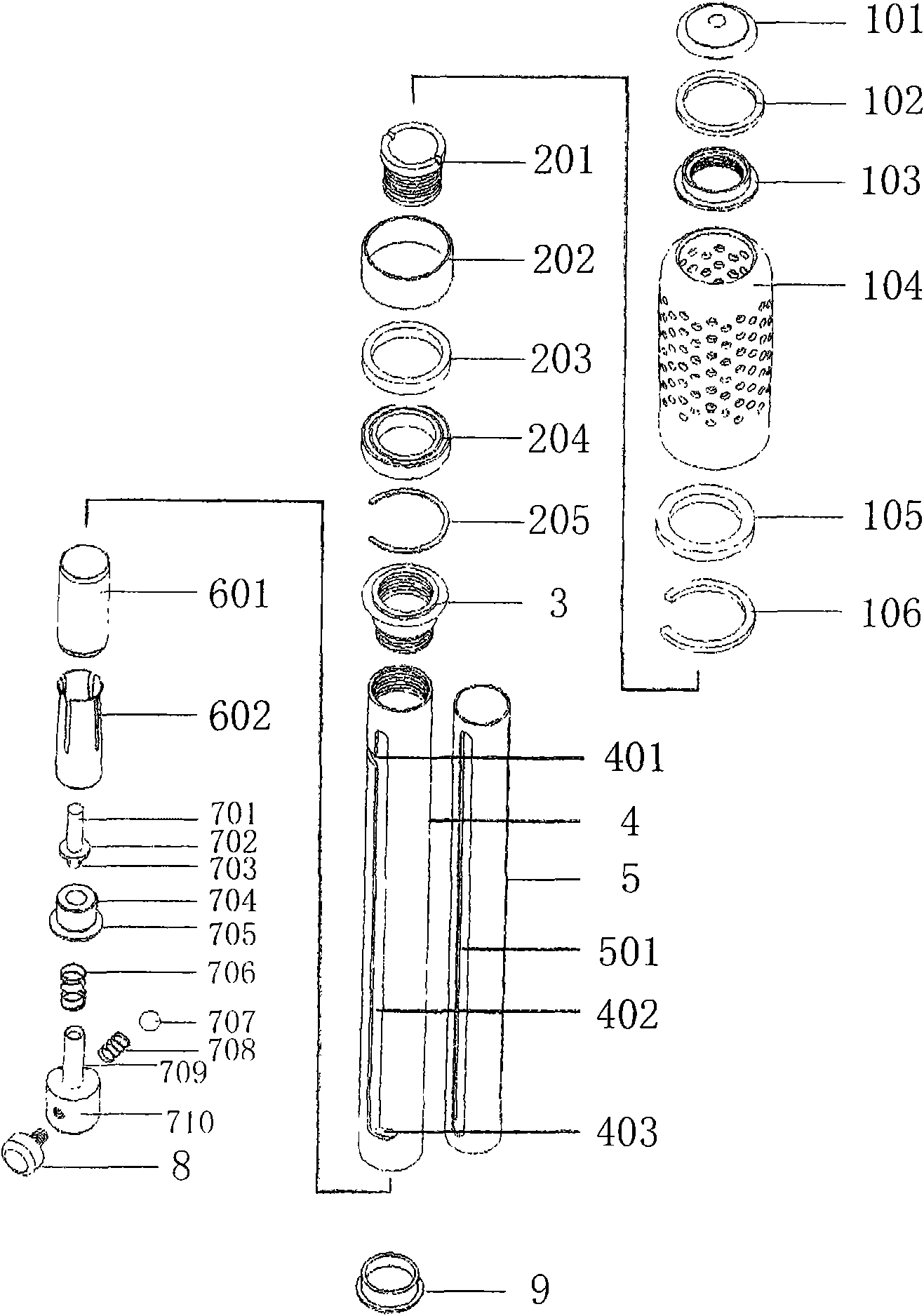

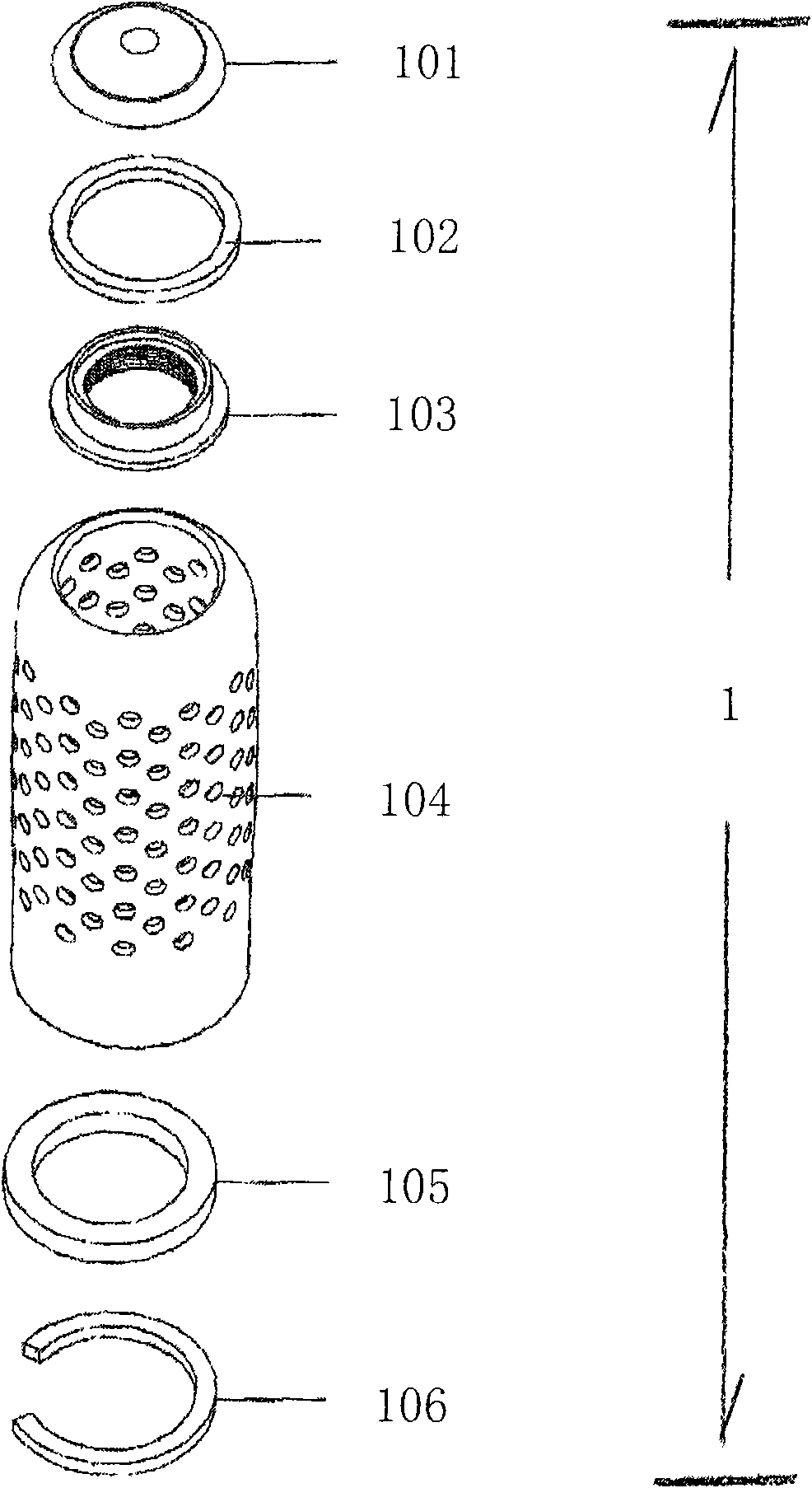

Aroma massage magnet therapy moxibustion rod

InactiveCN101632620AWith high temperature resistanceNot easy to demagnetizeDevices for heating/cooling reflex pointsElectrotherapyMedicineMassage

The invention provides an aroma massage magnet therapy moxibustion rod which comprises a moxibustion head component, a connection component, a screw joint, an outer pipe, an inner pipe, a swath shrinking clamp component, a thrusting component, a push button and a sealing cover, wherein the moxibustion head component comprises a moxibustion head which is internally provided with a magnetic ring; the moxibustion head component and the connection component are magnetically connected, and the magnetic connection enables the moxibustion head component and the connection component to be simultaneously rolled and plugged; the connection component is connected with the upper part of the screw joint through threads; the lower part of the screw joint is connected with the upper end of the outer pipe through a thread; the swath shrinking clamp component and the thrusting component are tightly matched and connected; the push button passes through a vertical elongated push button slide way hole on the wall of the outer pipe and a vertical elongated push button slide way hole on the wall of the inner pipe and is connected with the thrusting component. The aroma massage magnet therapy moxibustion rod realizes safety, small size, simplicity, convenience and multiple functions, saves swaths and has inimitable advantages compared with the same products of the prior art.

Owner:温宗金

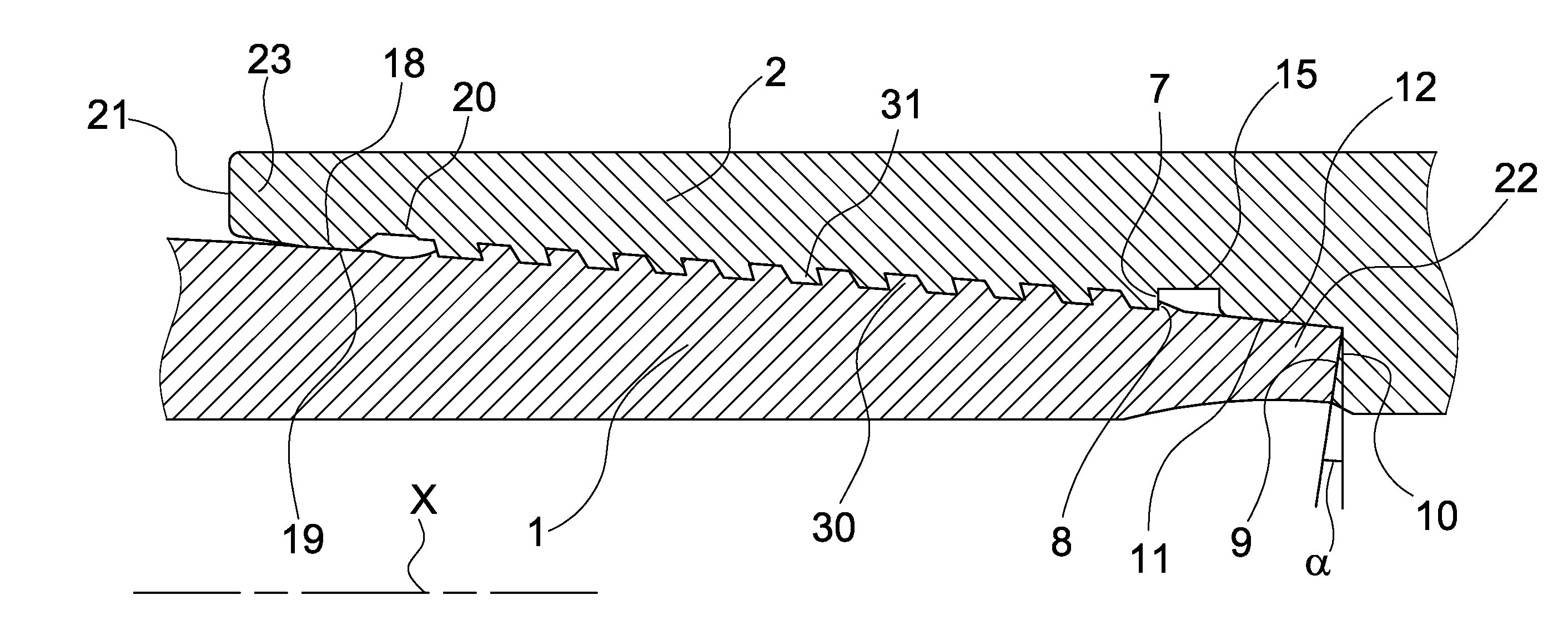

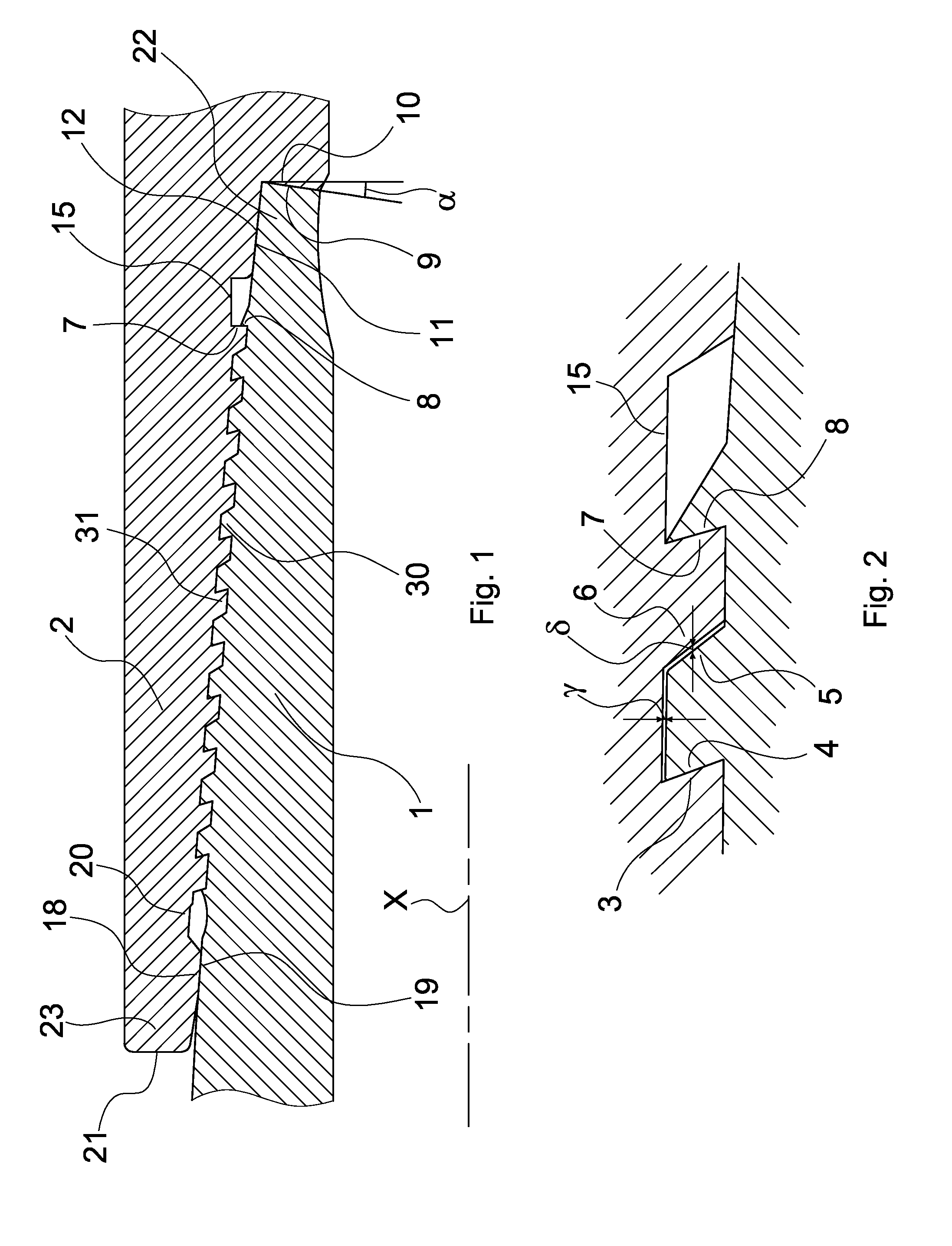

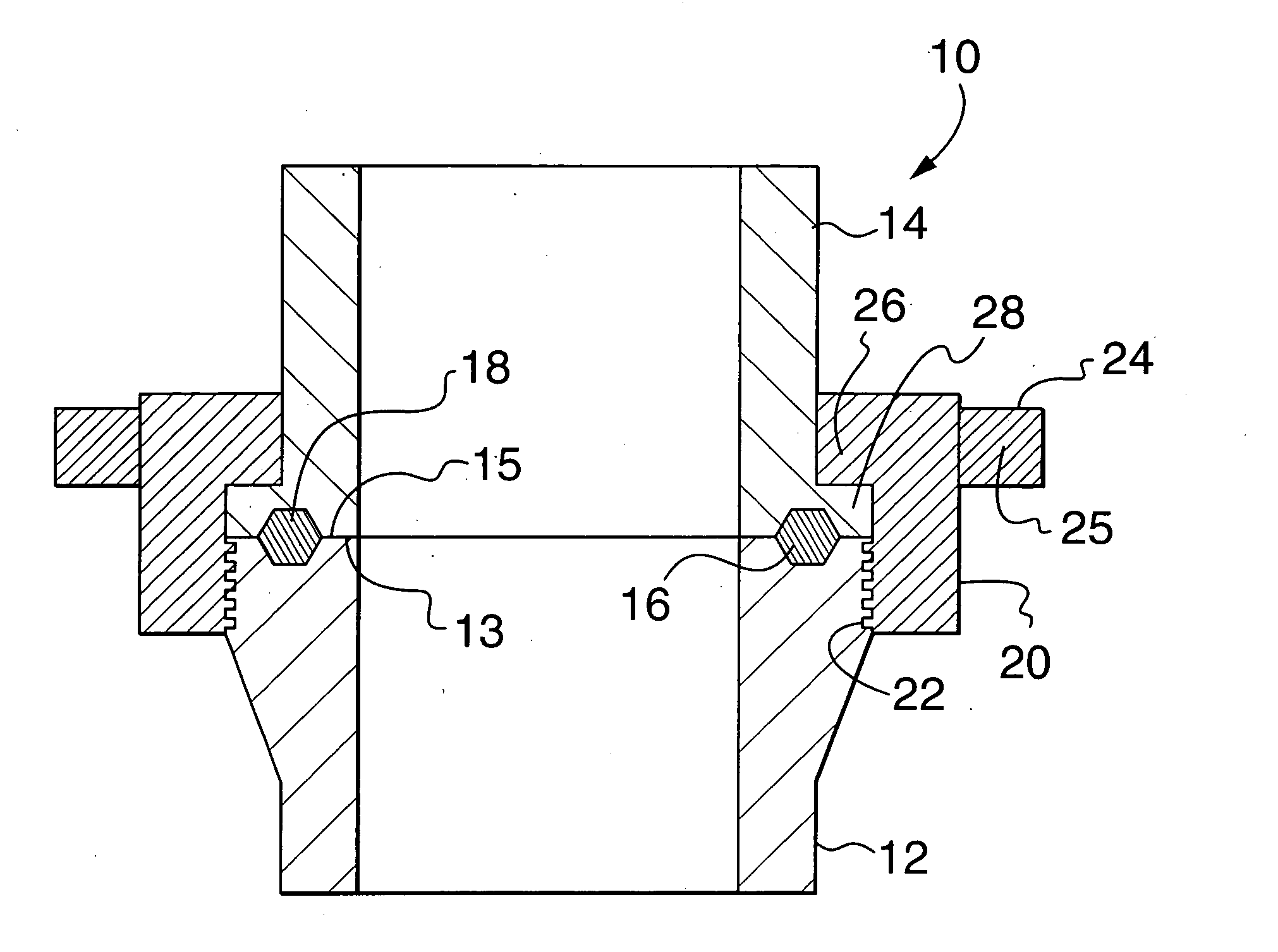

Threaded joint for steel pipes

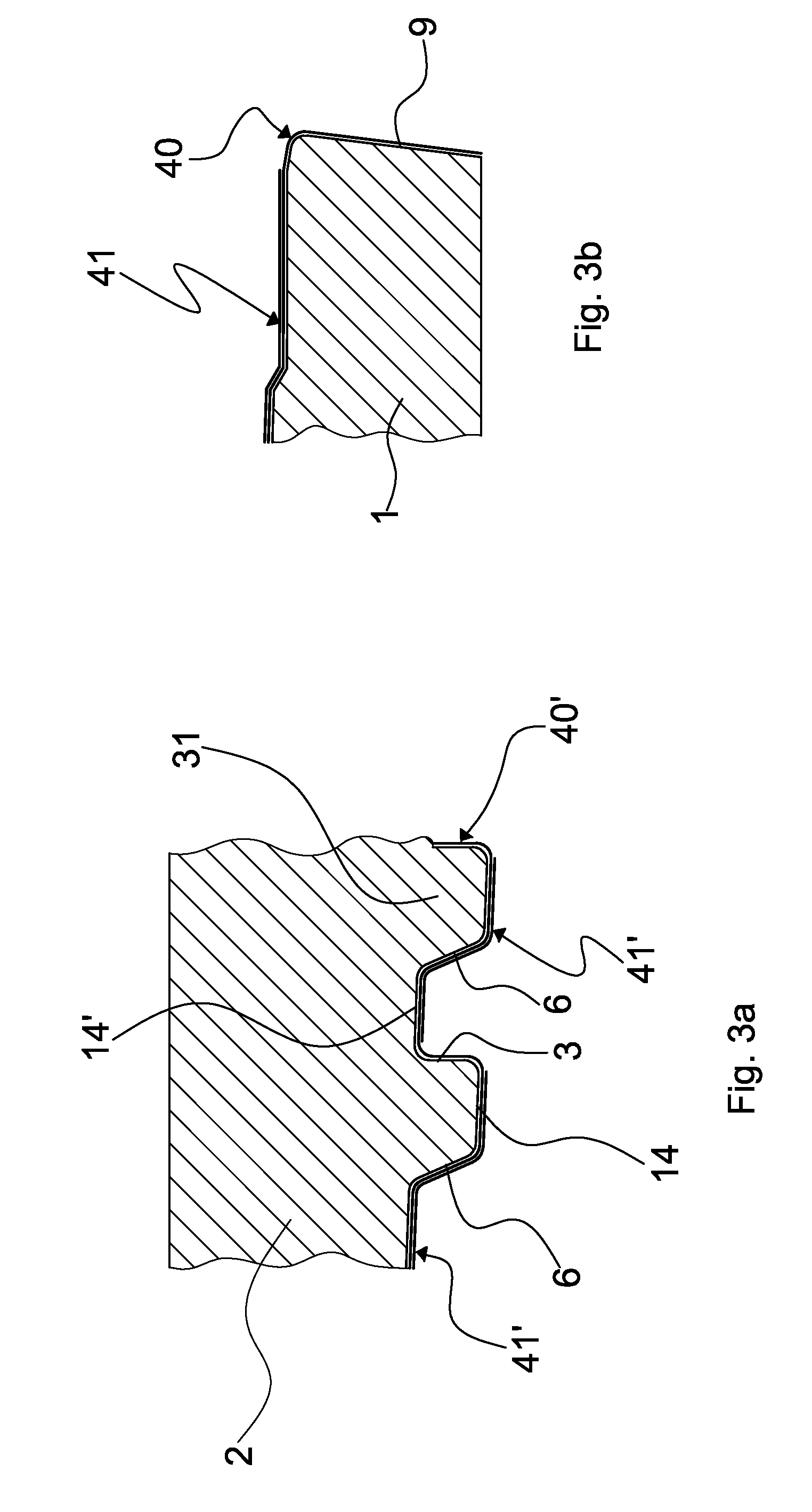

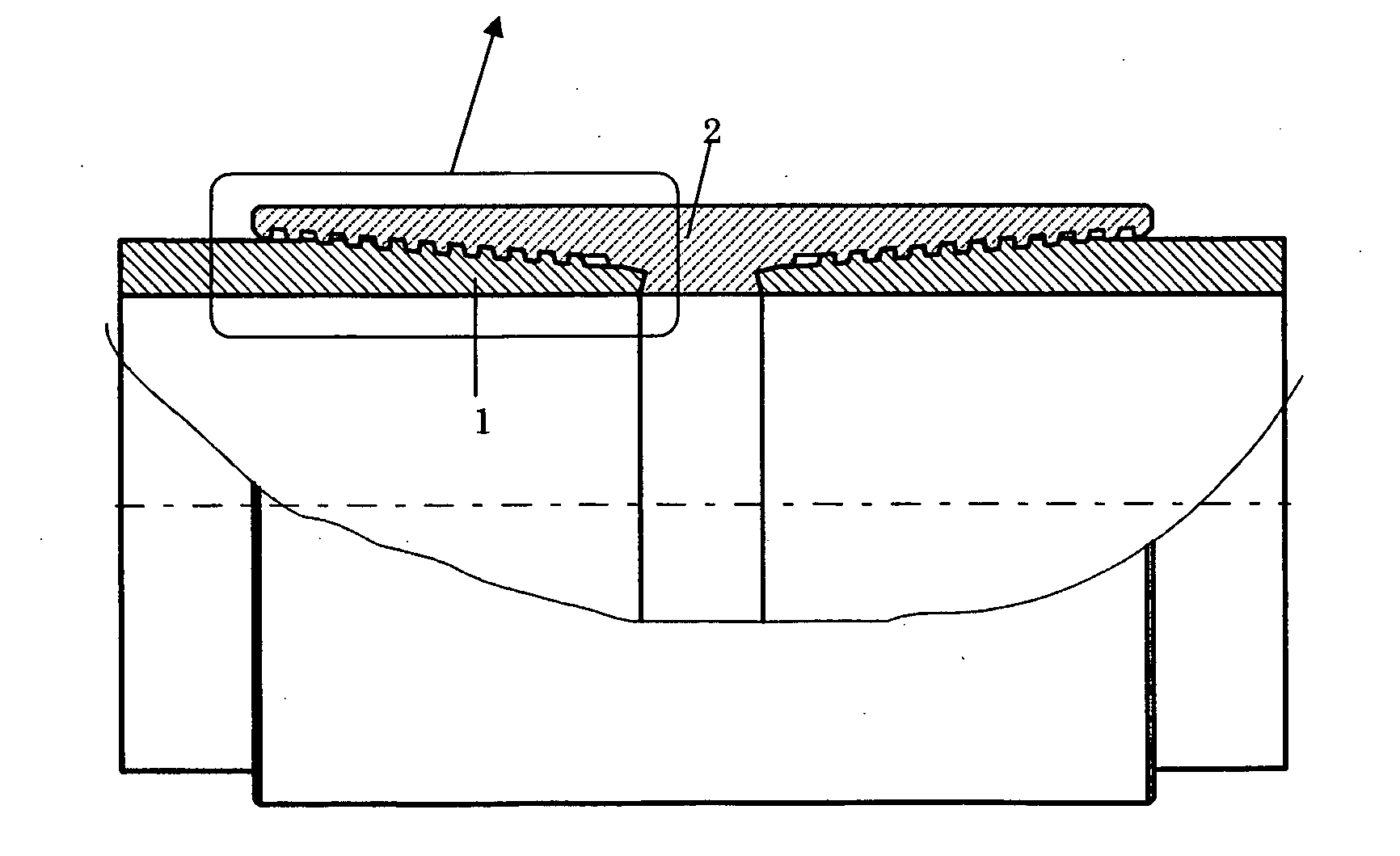

ActiveUS20110025051A1Improve stress resistanceImprove sealingDrilling rodsHose connectionsScrew threadScrew joint

A threaded joint for steel pipes comprising a pin (1) and a box (2). The pin has a male thread (11) and a lip (12) which comprises (i) a sealing surface (13) and (ii) a nose portion (16) provided with a shoulder surface. The box has a female thread (21), a sealing surface (23) and a shoulder surface. The shoulder surface of the pin comprises two distinct adjacent surfaces, main shoulder (14) in the inner side and sub shoulder (15) in the outer side. Correspondingly, the shoulder surface of the box comprises two distinct adjacent surfaces, main shoulder (24) in the inner side and sub shoulder (25) in the outer side. The main shoulder surfaces of the pin and box are disposed such as to prevent a radially inward deformation of the lip end, and the sub shoulder surfaces of pin and box are disposed such as to limit a radially outward deformation of the lip end. The main shoulder of the pin has a greater radial dimension than said sub shoulder of the pin, and at least the main shoulder surface of the pin is in axial abutment with at least the corresponding main shoulder surface of the box.

Owner:VALLOUREC OIL & GAS FRANCE SAS +1

Torque plate tool and method for sprinkler head installation

A tool and a method for installing a sprinkler head in a threaded fitting of a fire suppression system is disclosed. The sprinkler head is protected by a cover. The tool is formed from an elongated body having a cavity that is sized to receive the cover. One end of the body interfaces with a wrench, the other end has one or more axially extending slots sized to receive the fingers of a torque plate affixed to the sprinkler head. The sprinkler head has a threaded nipple that engages the threaded fitting. The nipple is engaged with the fitting and torque is applied to it by engaging the slots of the tool with the fingers and turning the tool with the wrench. The tool has an external index allowing the sprinkler head to be angularly oriented to direct its discharge stream.

Owner:VICTAULIC

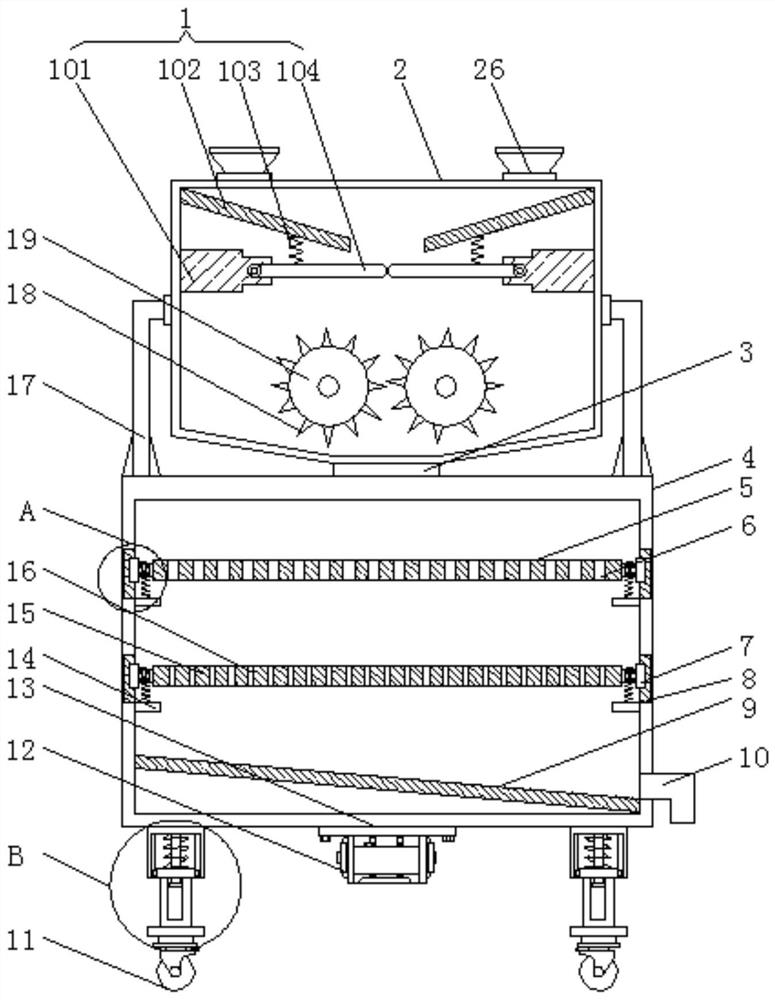

Ore smashing and screening device for mining

PendingCN111701709AAvoid affecting the broken effectMeet needsSievingScreeningMining engineeringElectric machine

The invention discloses an ore smashing and screening device for mining. The ore smashing and screening device comprises a screening box, wherein lifting mechanisms are installed at the four corners of the bottom of the screening box, idler wheels are installed at the bottoms of the lifting mechanisms, an installing plate is in screw joint with the center of the bottom of the screening box, a vibration motor is fixed to the bottom of the installing plate, a first screening plate and a second screening plate are installed in an inner cavity of the screening box respectively, fixation blocks aresymmetrically installed at the left and right ends of the first screening plate and the second screening plate, reset springs are connected to the bottoms of the fixation blocks, and supporting plates are installed at the ends, away from the fixation blocks, of the reset springs. According to the ore smashing and screening device, when to-be-smashed ore falls into the upper positions of feeding plates through charging openings, the feeding plates guide the ore into the upper positions of movable rods, at this moment, positioning springs are compressed to make the movable rods rotate downwards, then the ore continues to fall, thus the smashing and screening device can control the falling speed of the ore to a certain degree, and the situation that the smashing effect of the device is influenced when too much ore falls is avoided.

Owner:新沂市北沟镇福利厂

Circular sponge sticking and gluing mechanism

The invention discloses a circular sponge sticking and gluing mechanism which comprises a conveying device. The conveying device comprises two transmission rollers. A conveying belt is tensioned on the two transmission rollers. Supporting legs are hinged to the two ends of the two transmission rollers and fixed to the ground. A driving motor is fixed to one supporting leg. An output shaft of the driving motor is connected with one end of the transmission roller extending out of the supporting leg through a coupler. A plurality of circular protruding rings are uniformly distributed on the conveying belt. Clamping racks are fixed to the ground at the left side and the right side of the conveying belt. A transmission threaded rod, a lifting motor and a gluing device are fixed to the top of each clamping rack, and the lifting motors drive the transmission threaded rod to rotate. A movable block is in screw joint with each transmission threaded rod. A rotating rack is fixed to each movable block. Each gluing device comprises a gluing supporting plate. Each gluing supporting plate is fixed to a supporting plate above the corresponding clamping rack. The circular sponge sticking and gluing mechanism can grab and overturn circular sponges and apply glue to the circular sponges automatically, and the automation degree is high.

Owner:中山晋杰办公设备有限公司

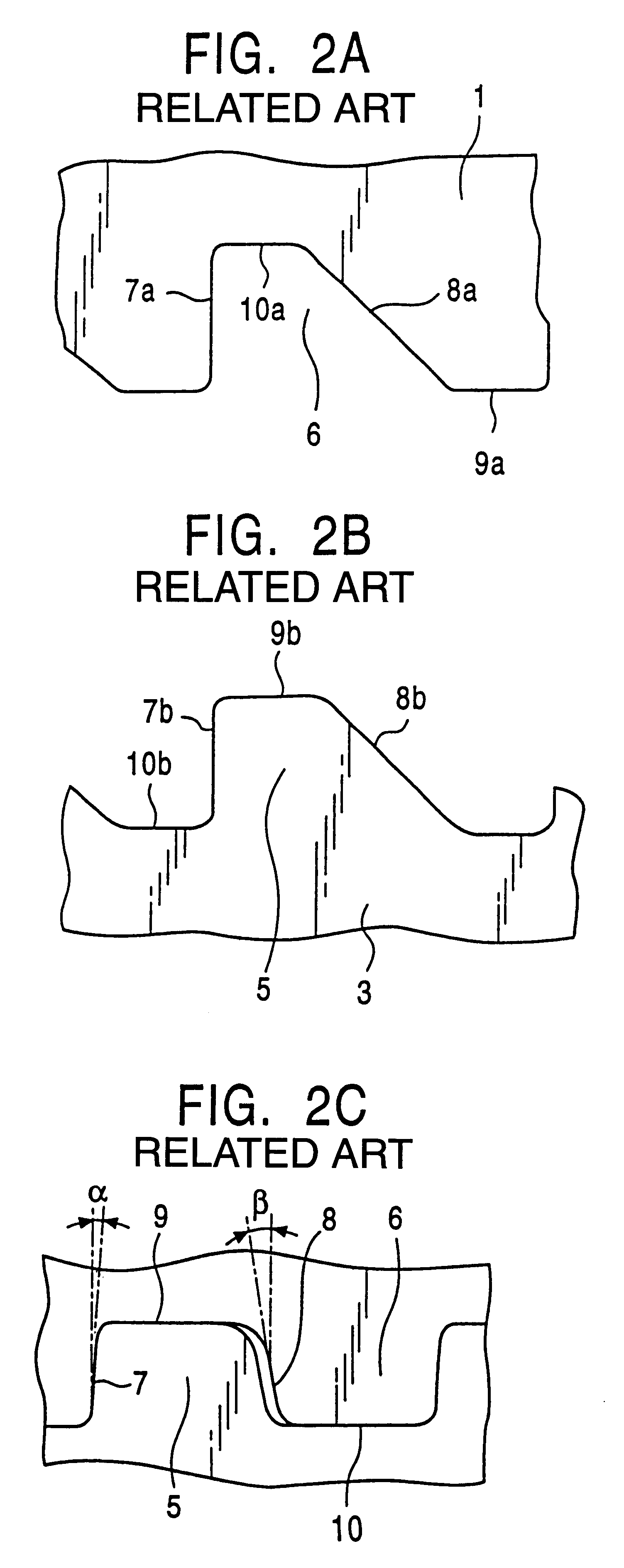

Threaded joint for steel pipes

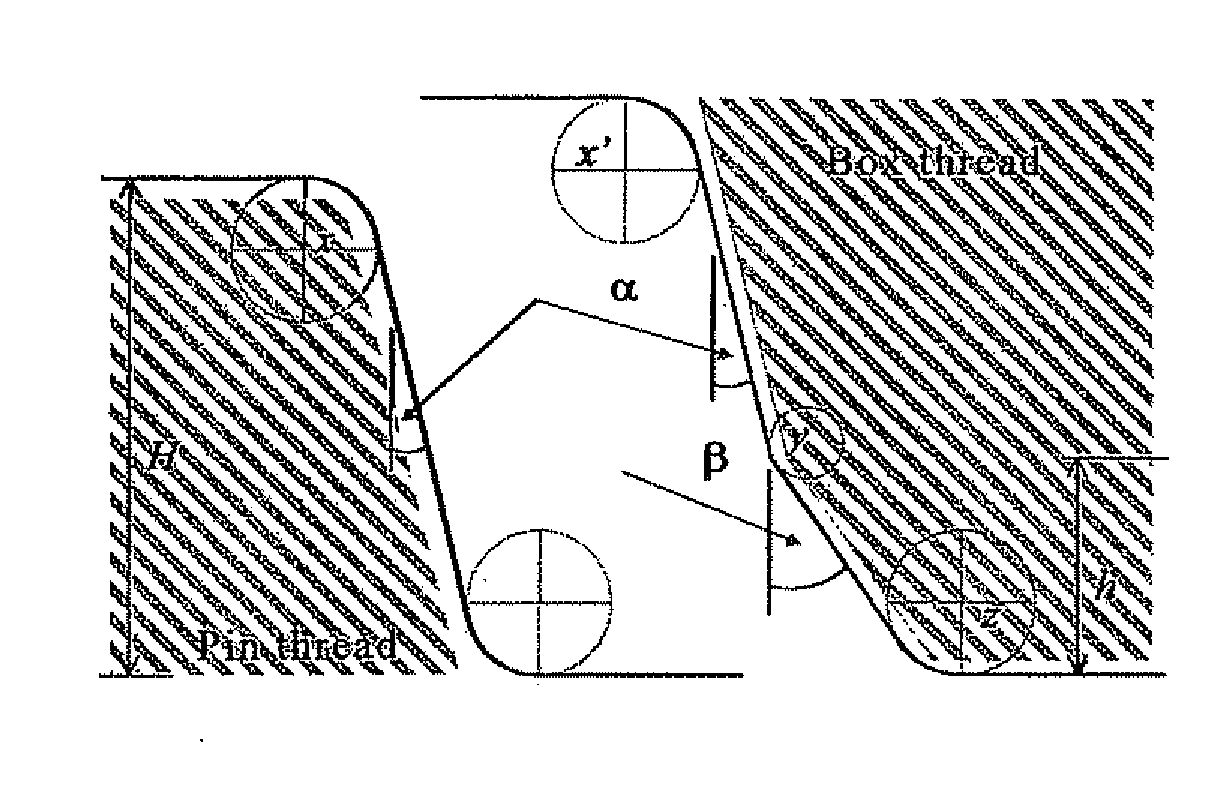

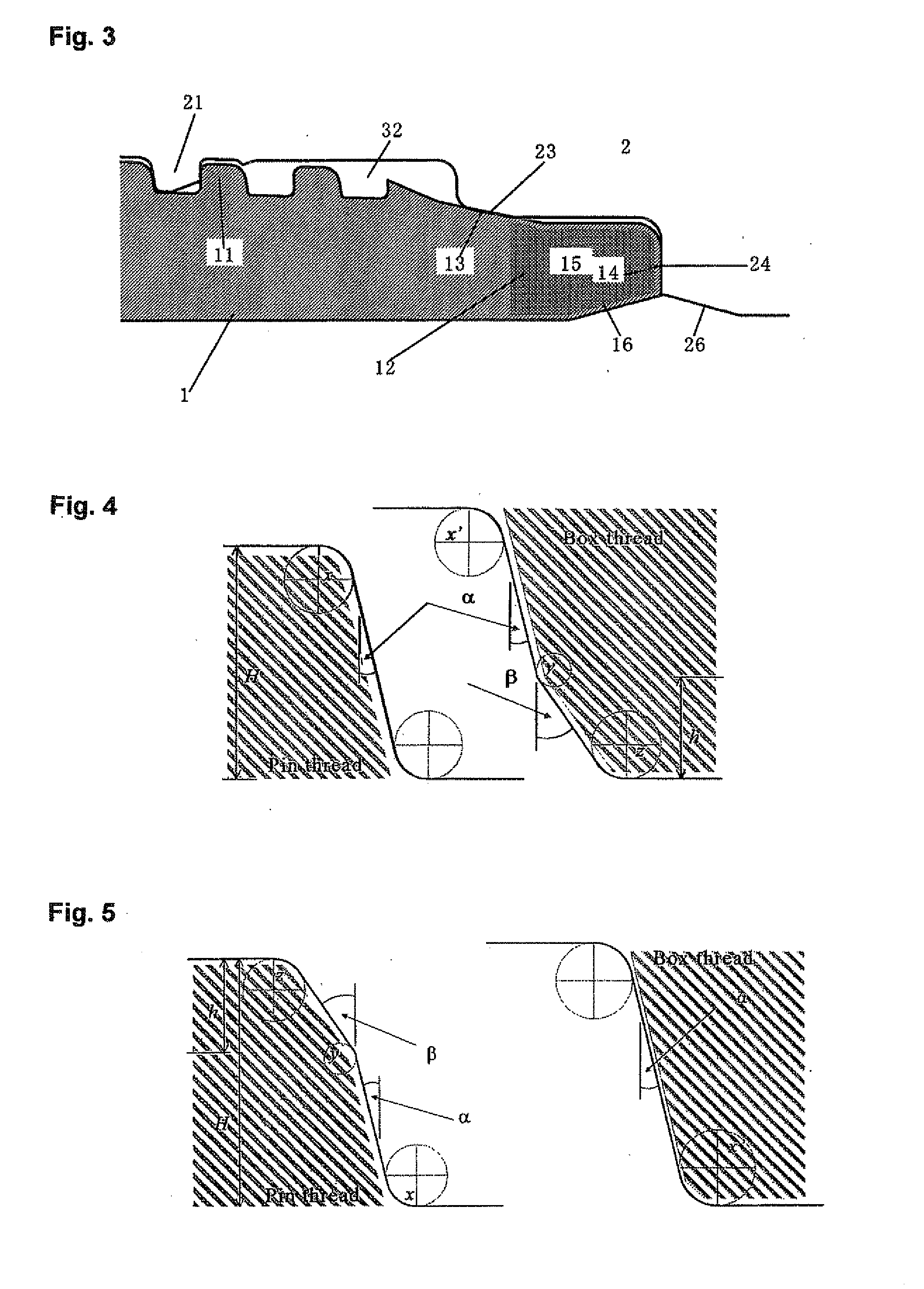

ActiveUS20100078936A1Easily inserted into boxSufficient forceDrilling rodsHose connectionsEngineeringScrew thread

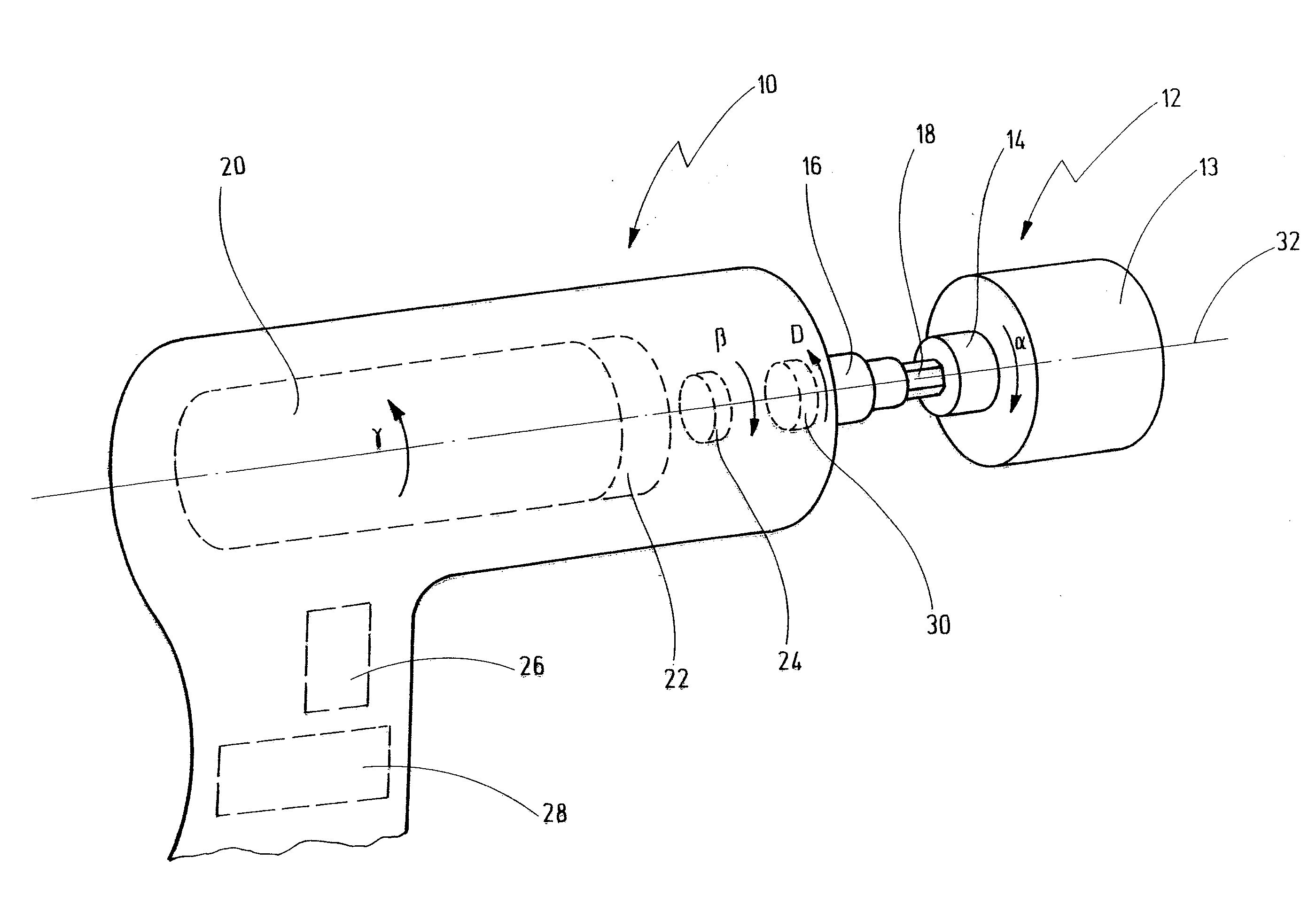

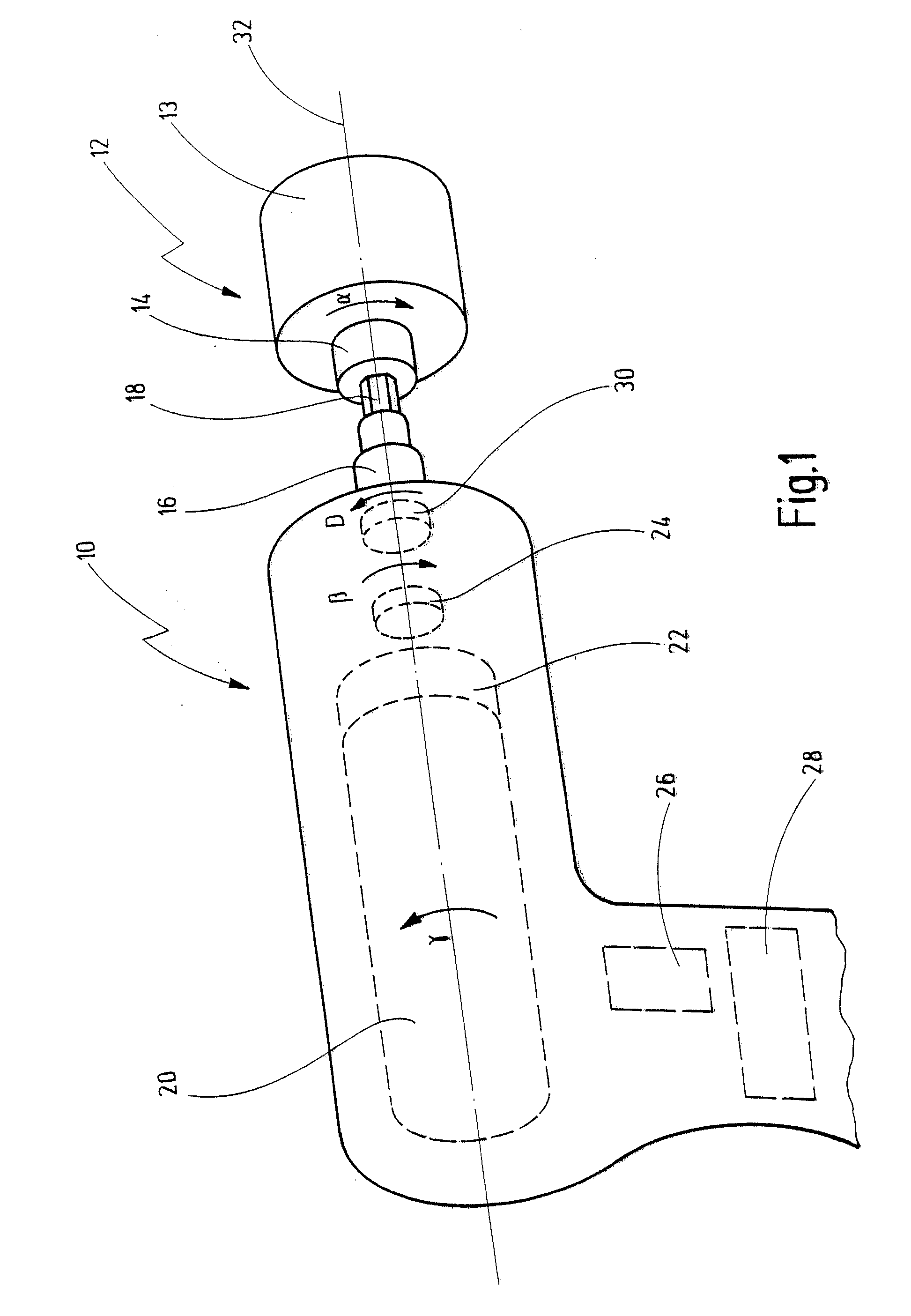

A threaded joint for steel pipes constituted by a pin having male threads and a box having female threads is improved with respect to ease of insertion of the pin and galling resistance of the threaded portions. The stabbing flanks of the threads in a complete thread portion of one of the pin and a box has a two-step stabbing shape having a chamfer. The two-step stabbing shape has a stabbing flank angle α of 5-45° and a chamfer angle β of 20-60°. The ratio h / H of the chamfer height h to the thread height H of the pin is 0.25-0.50, or the ratio of the cross-sectional area of the chamfered portion to the overall cross-sectional area of the stabbing flank is made at least a value corresponding to a chamfer height ratio h / H of 0.25 and at most a value corresponding to a chamfer height ratio of 0.50.

Owner:VALLOUREC OIL & GAS FRANCE SAS +1

Hydraulic grooving saw

The invention discloses a hydraulic grooving saw, comprising an upper water feeding hose, two water feeding pipes, two screw joints, left and right water feeding hoses and water spray nozzles, wherein the two screw joints for connecting two water feeding pipes are arranged at two ends of one water feeding pipe; the hydraulic grooving saw is characterized in that the lower end of a hydraulic shaft of a hydraulic oil cylinder is connected with a left connecting rod and a right connecting rod by pins, the lower ends of the left connecting rod and the right connecting rod are respectively connected with a left rocking arm and a right rocking arm by pins, the lower ends of the left rocking arm and the right rocking arm are respectively connected with a left sawing rod and a right sawing rod by pins, the middle parts of the left rocking arm and the right rocking arm are respectively connected with a left sawing frame and a right sawing frame by pins, a limit needle is located at the lower part of the grooving saw, a left guide plate and a right guide plate are respectively located at a left side and a right side of the grooving saw, and four trail wheels are located at the upper ends of the water feeding pipes.

Owner:南通阿斯通电器制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com