Circular sponge sticking and gluing mechanism

A round sponge and gluing technology, which is applied in coatings, devices for coating liquid on the surface, etc., can solve problems such as processing troubles and achieve a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

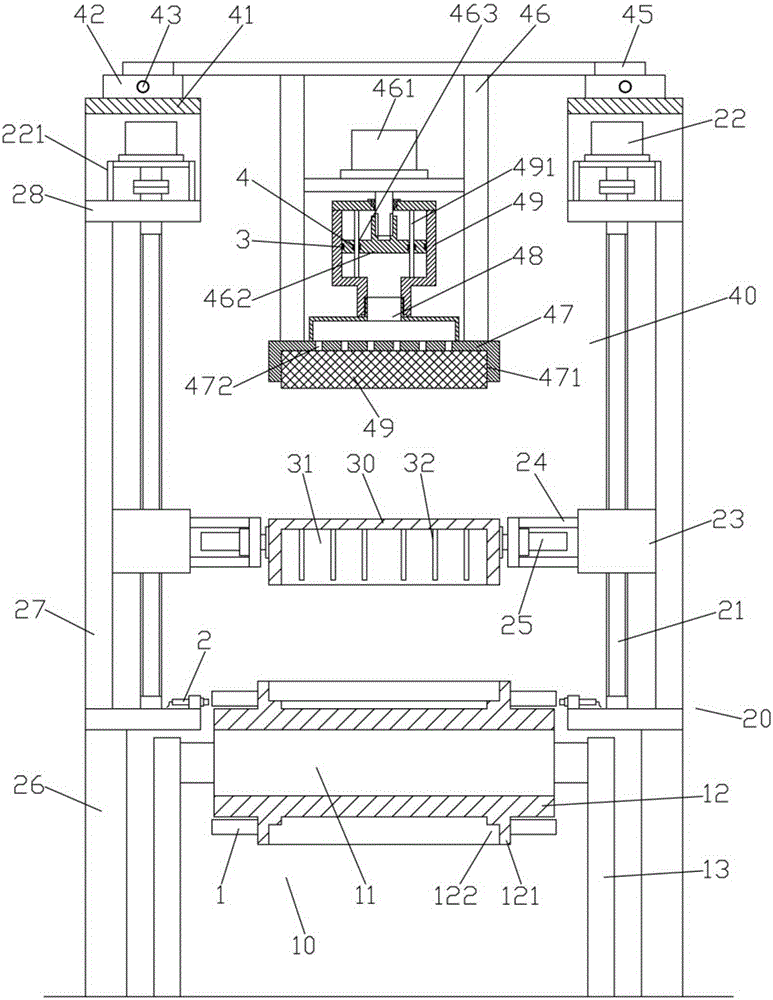

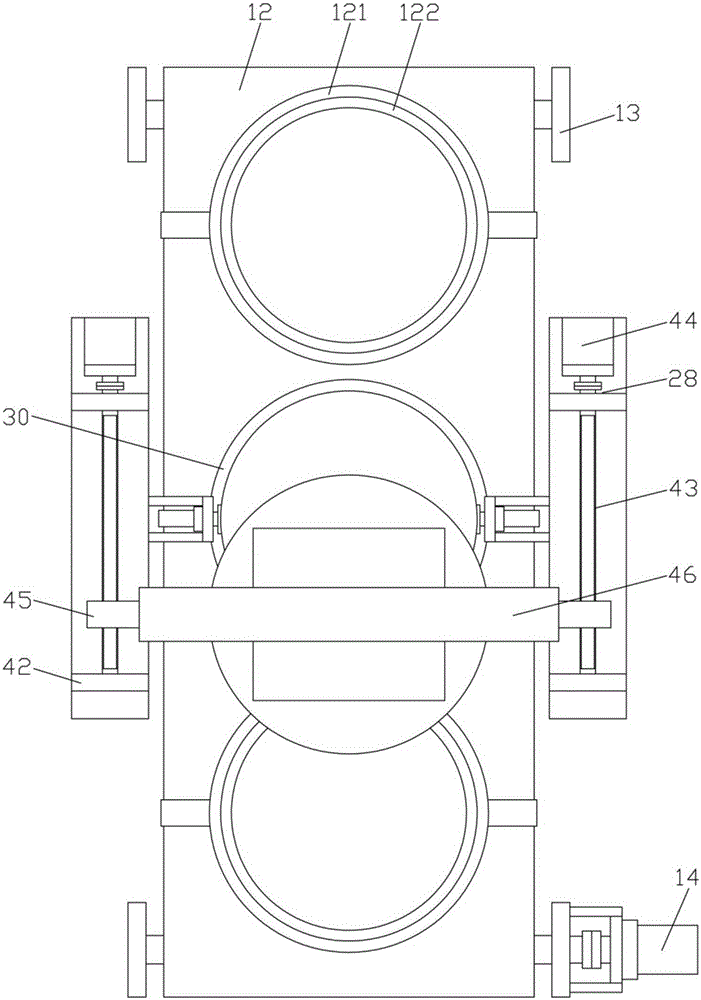

[0019] Examples, see e.g. Figure 1 to Figure 2 Shown, a kind of circular sponge pasting gluing mechanism comprises conveying device 10, and described conveying device 10 comprises two transmission rollers 11, and conveyer belt 12 is tensioned on two transmission rollers 11, and two transmission rollers 11 two The end is hinged with supporting legs 13, and the supporting legs 13 are fixed on the ground, and a driving motor 14 is fixed on one of the supporting legs 13, and the output shaft of the driving motor 14 is connected to the end of the supporting leg 13 stretched out by the drive roller 11 through a coupling. Connect, the conveyor belt 12 is evenly distributed with a plurality of circular raised rings 121, the ground on the left and right sides of the conveyor belt 12 is fixed with a clamping frame 20, the top of the clamping frame 20 is fixed with a transmission screw 21, a lifting The motor 22 and the gluing device 40, the lifting motor 22 drives the transmission scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com