Patents

Literature

15118results about "Wrapper twisting/gathering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

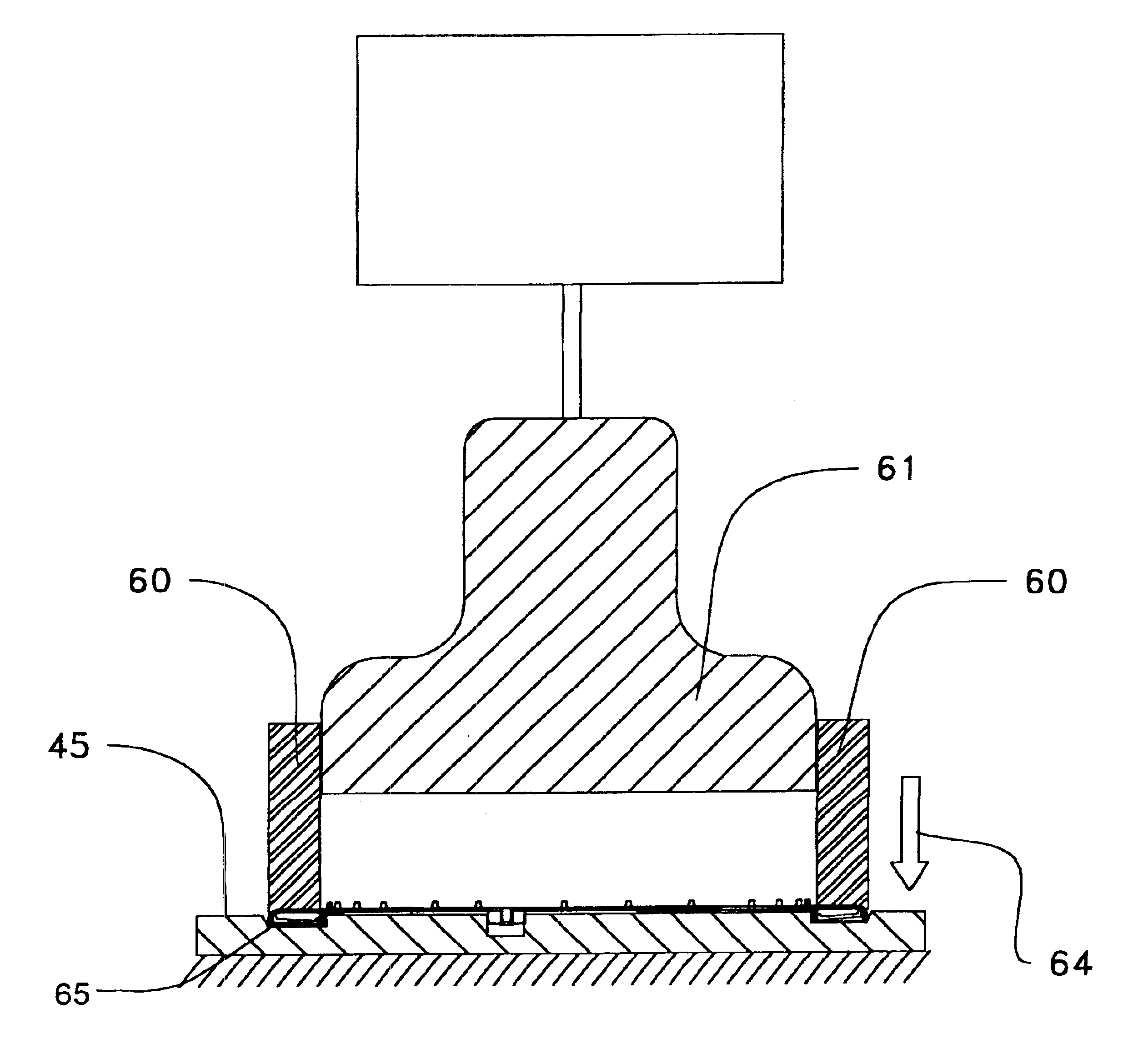

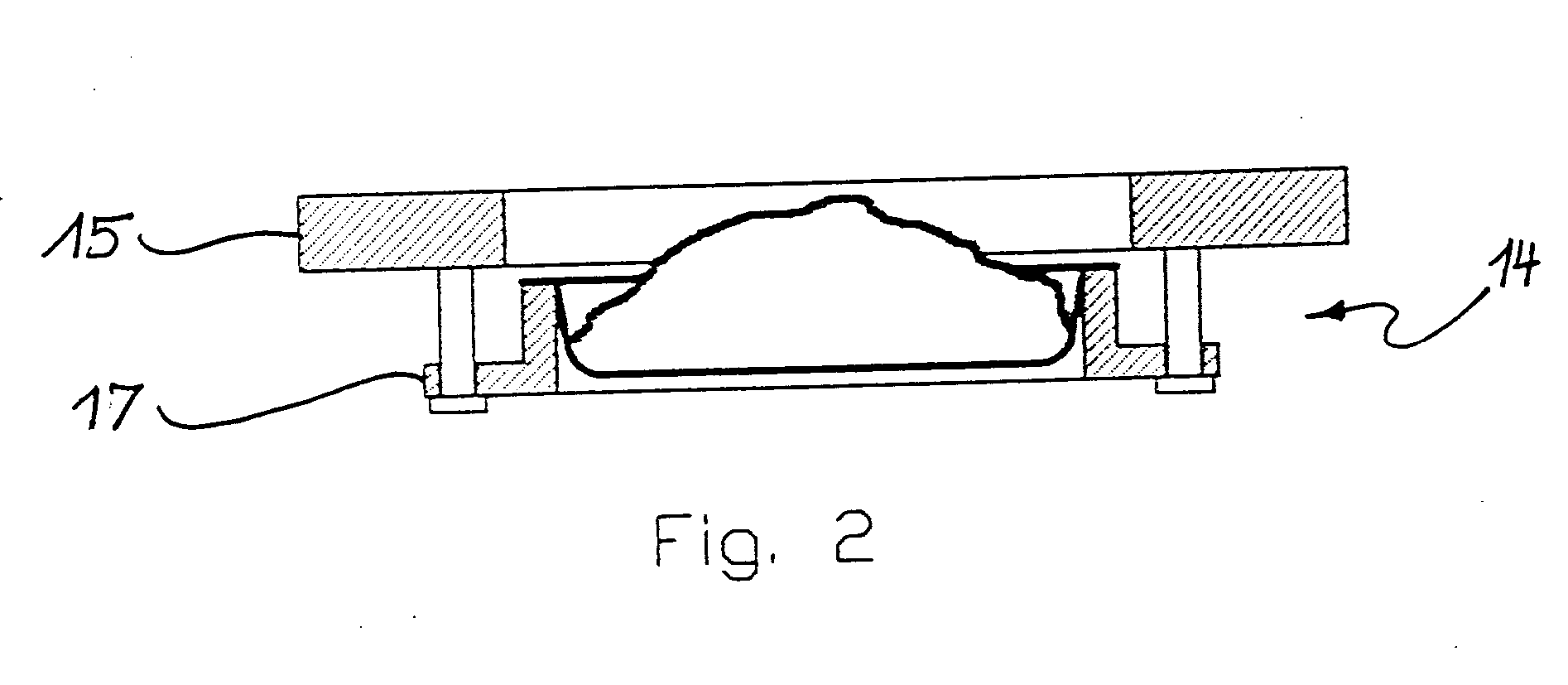

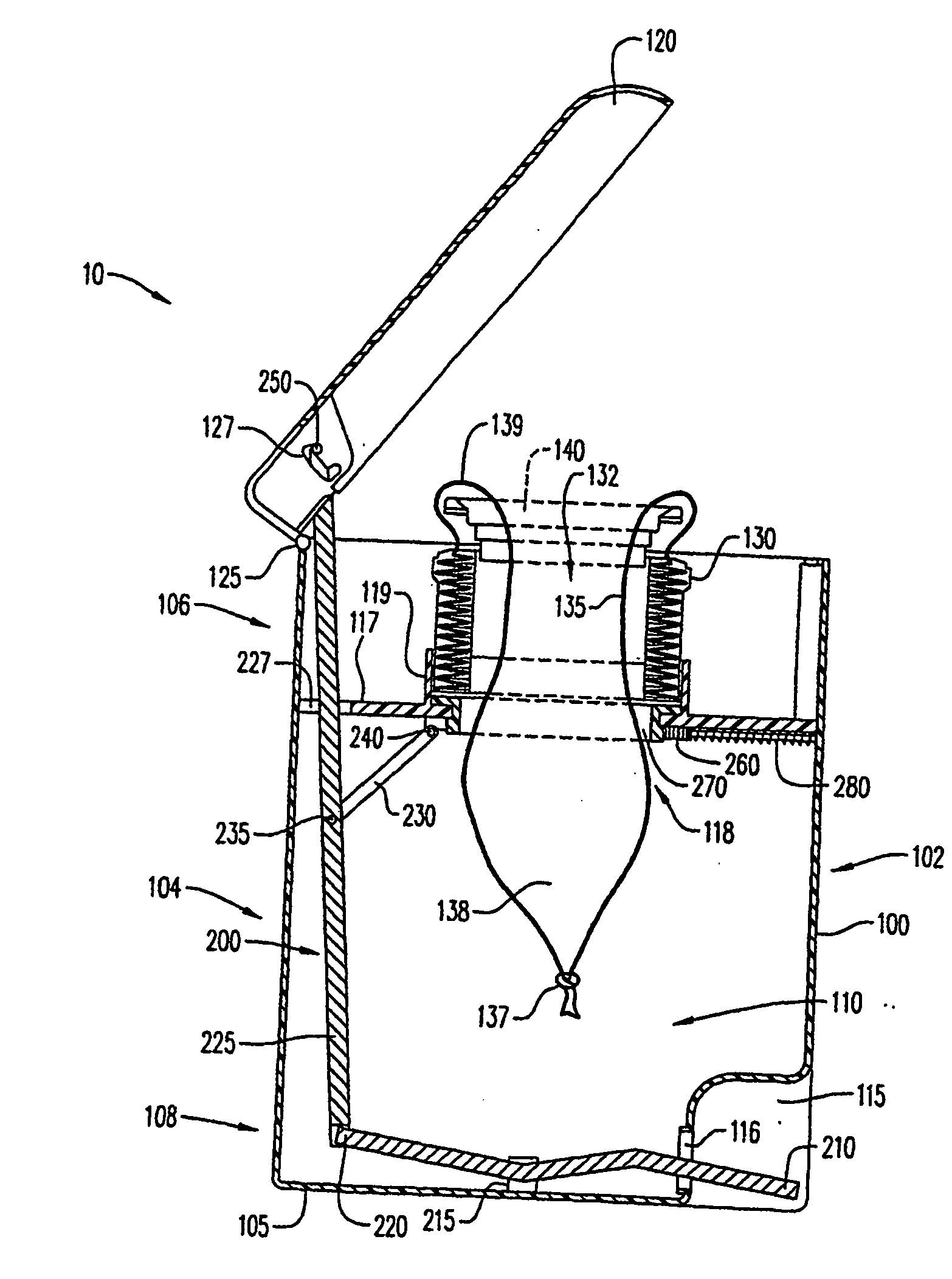

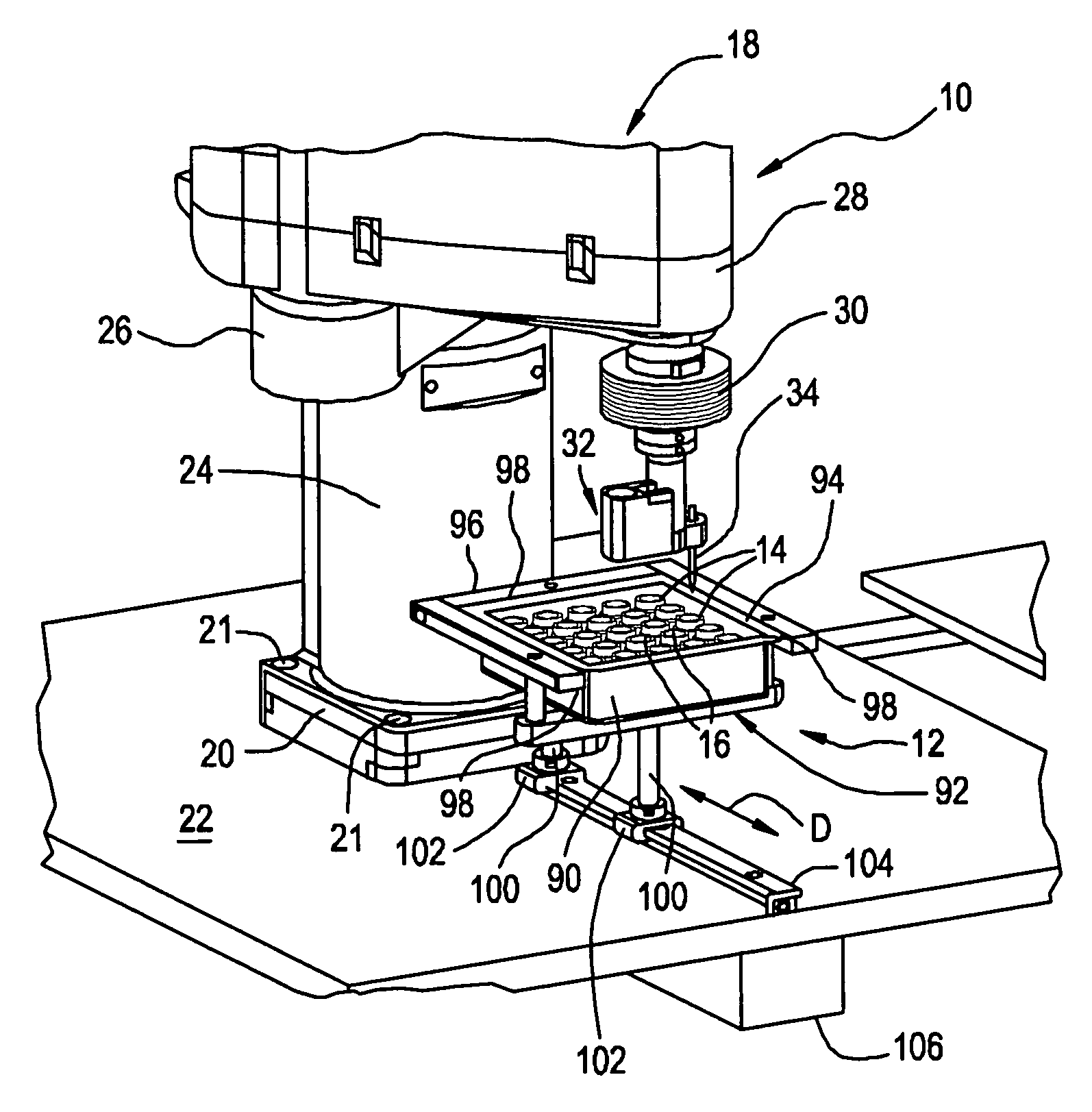

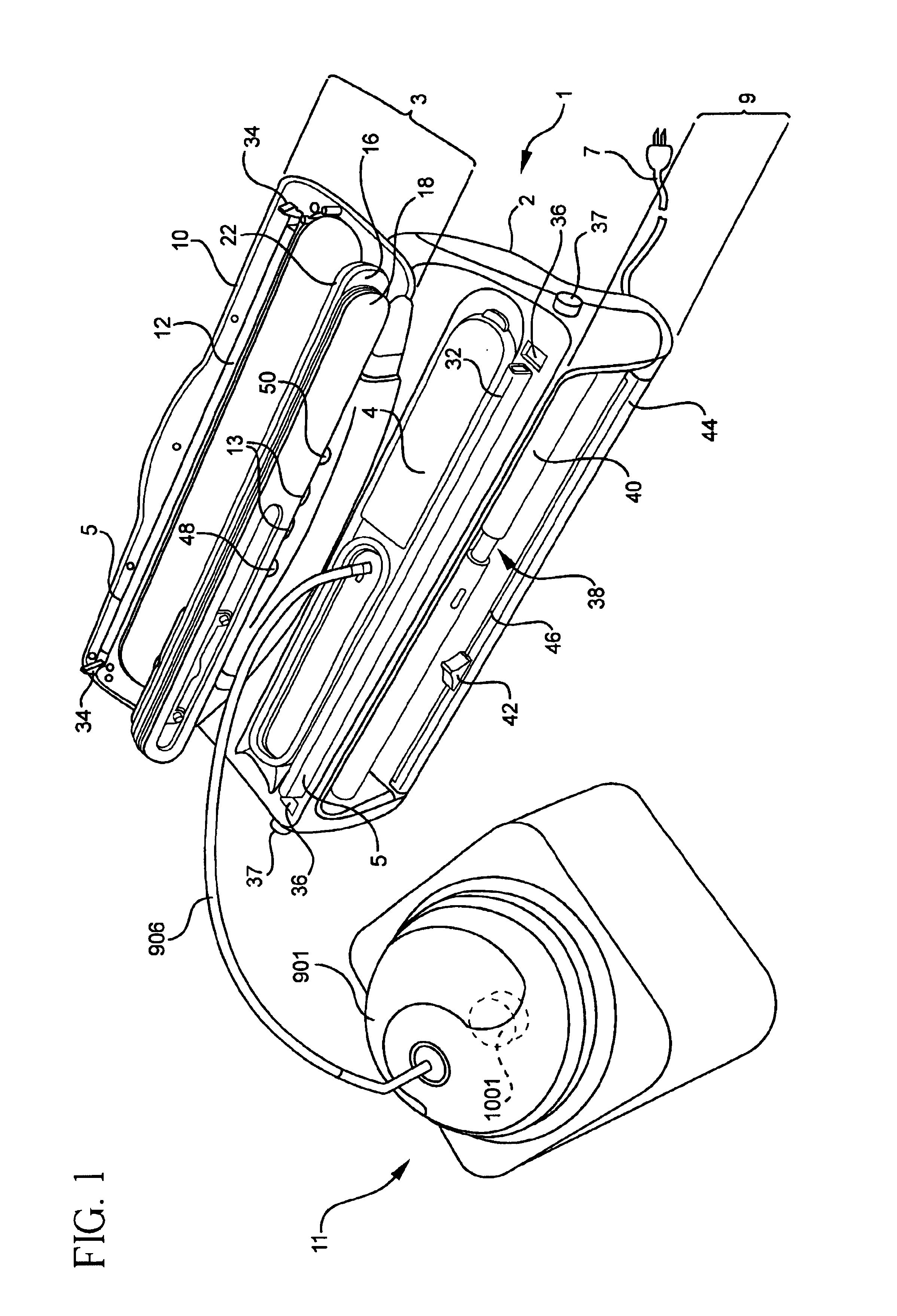

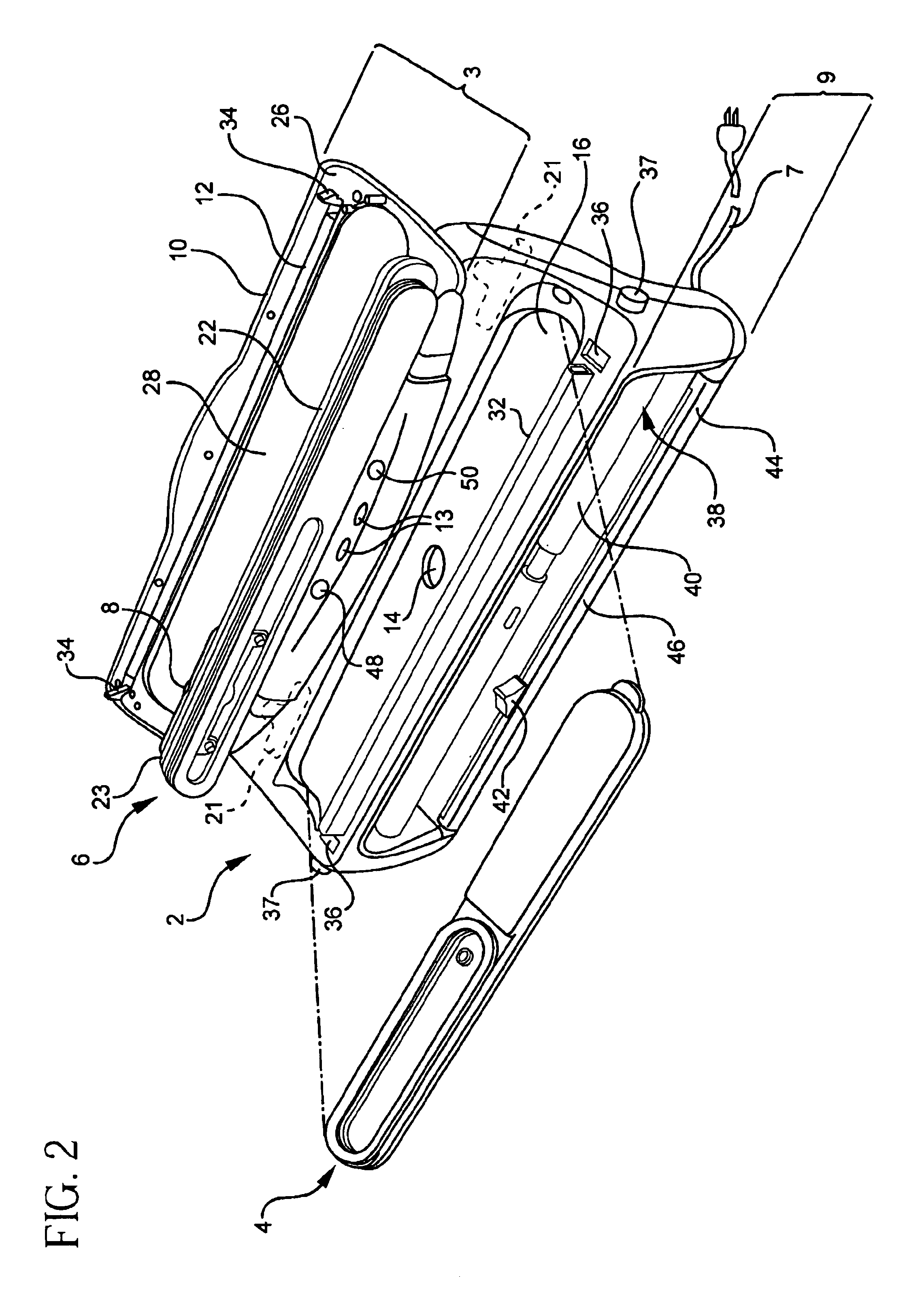

Method for assembling a package for sutures

InactiveUS6915623B2Not slowing downReduce manufacturing costSuture equipmentsSurgical needlesCounterboreUltrasonic generator

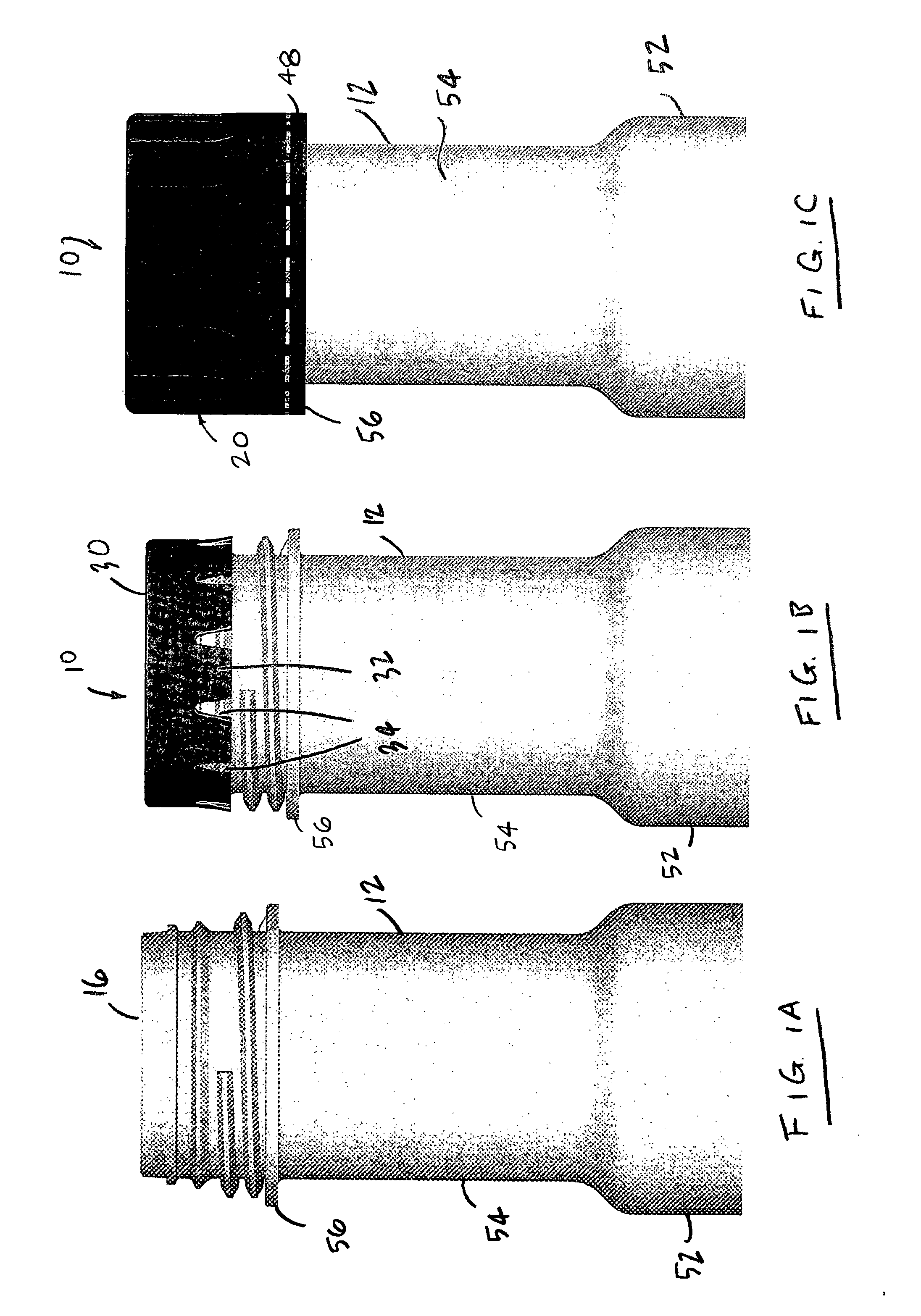

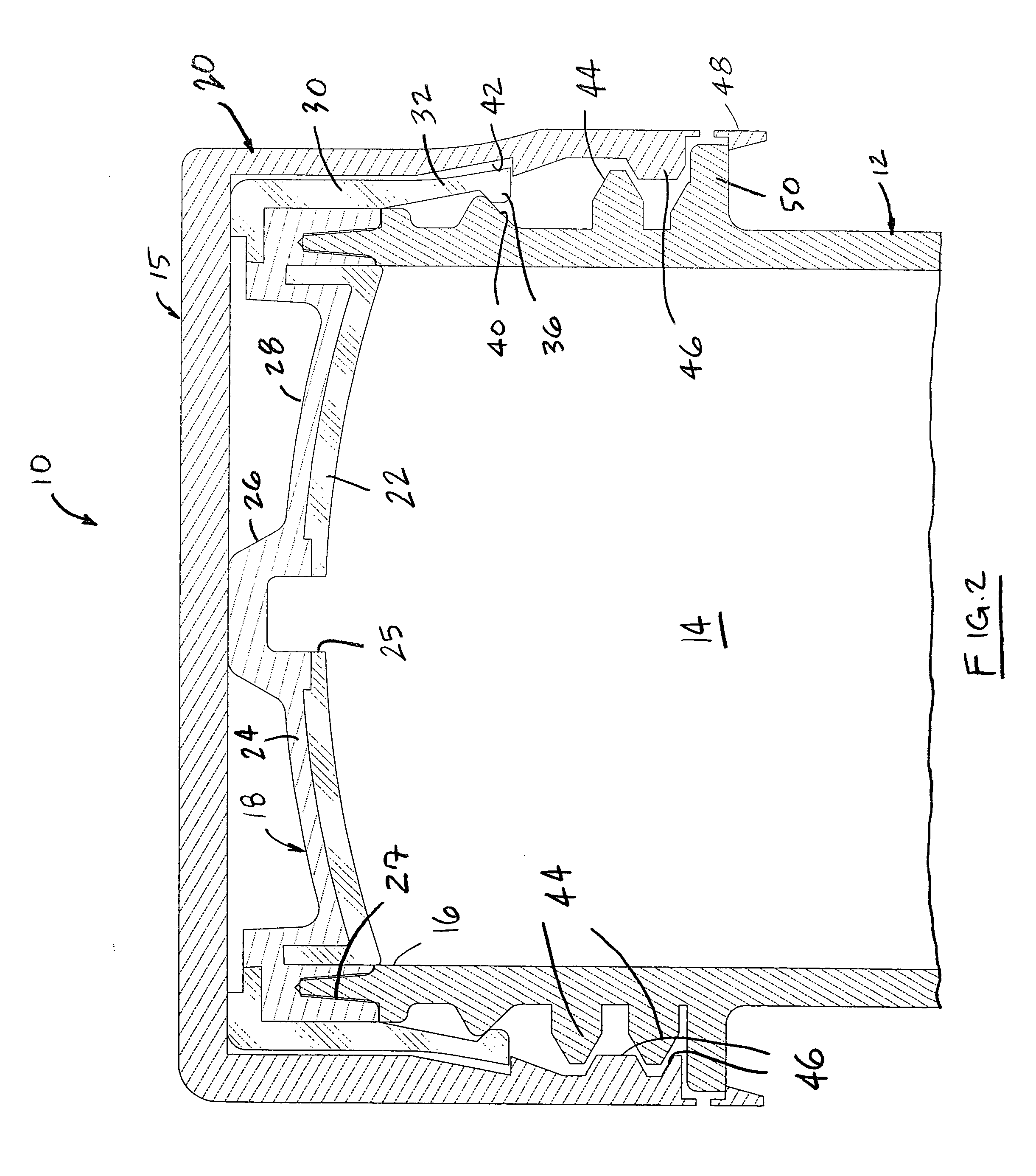

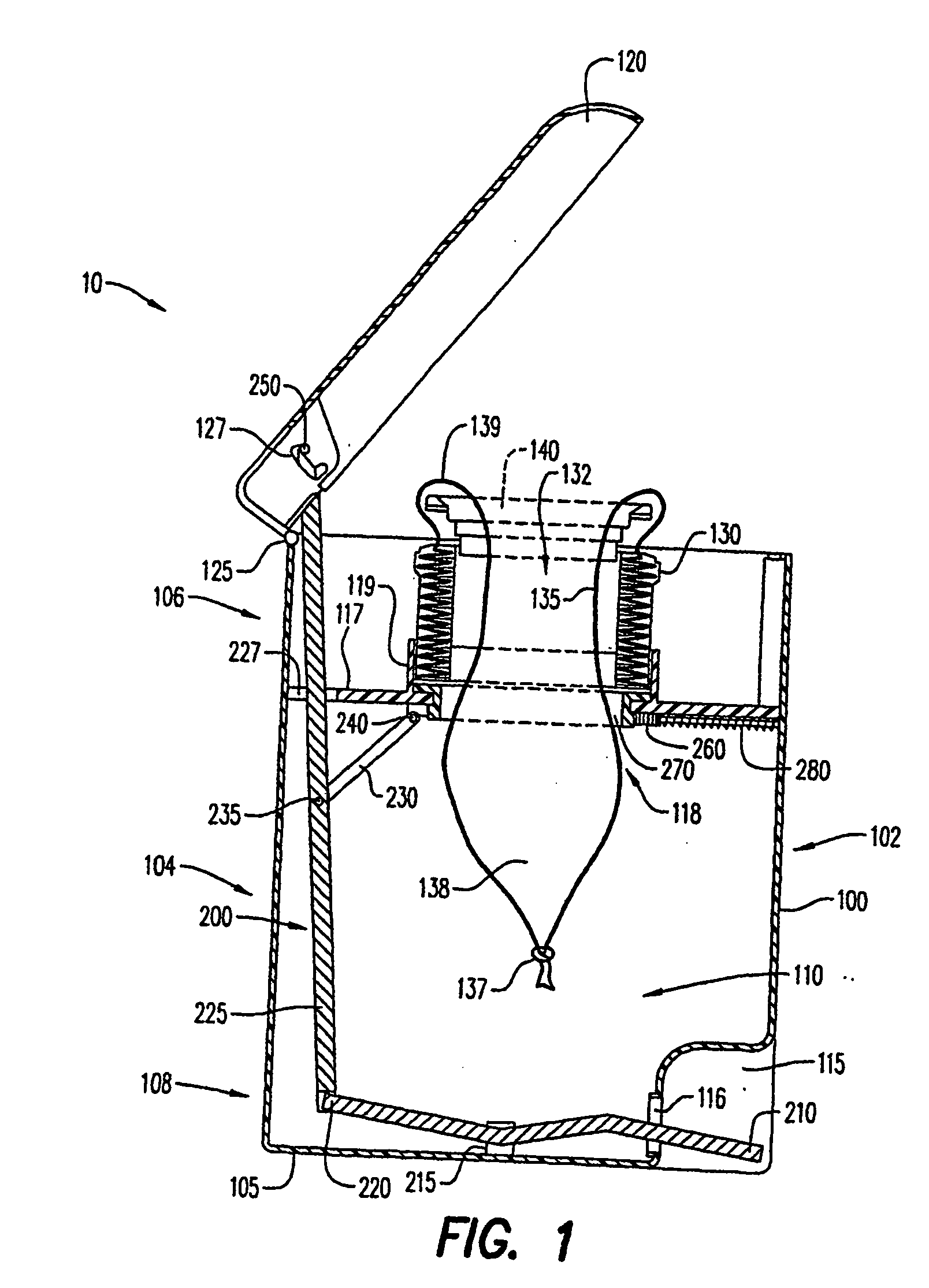

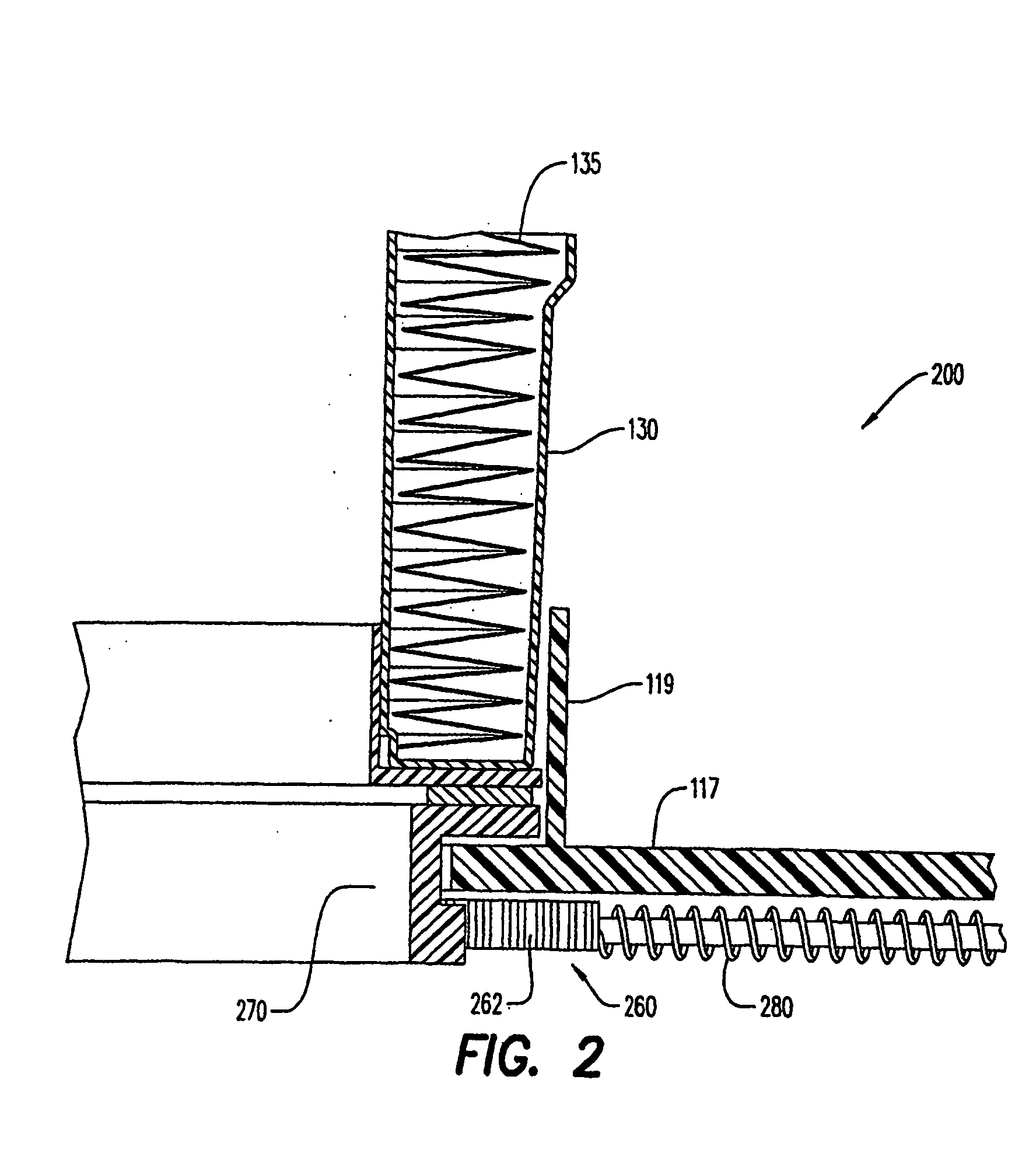

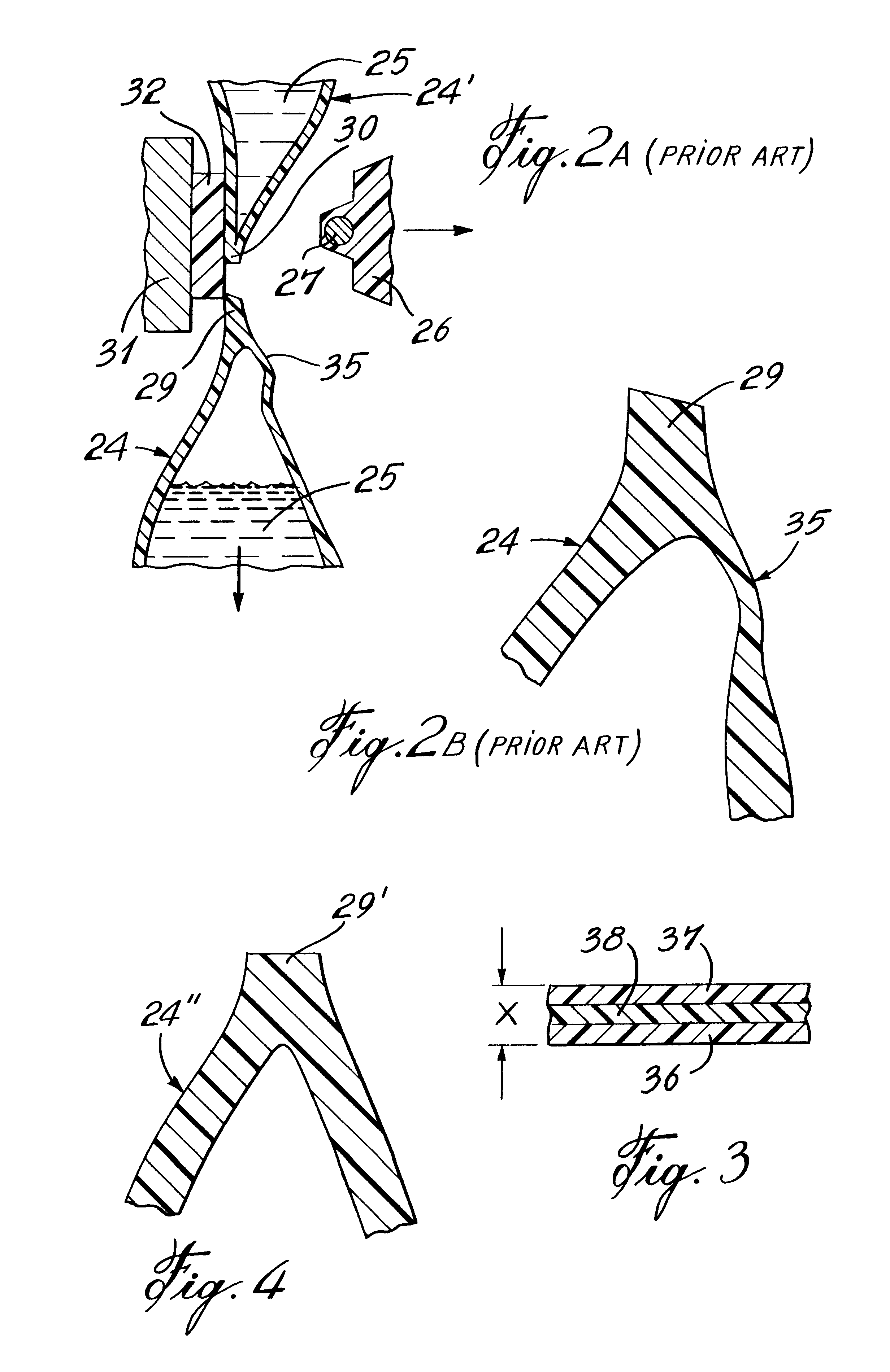

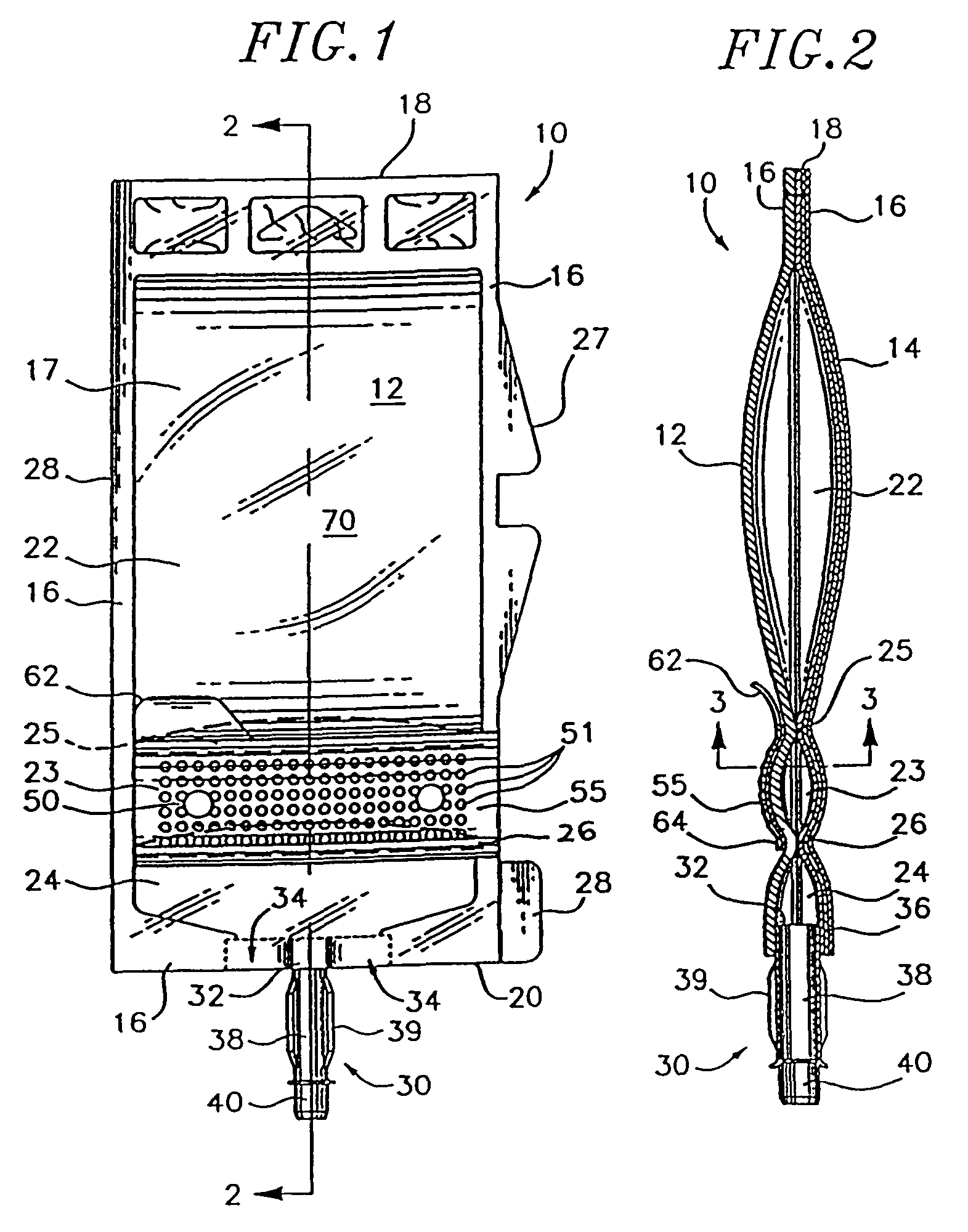

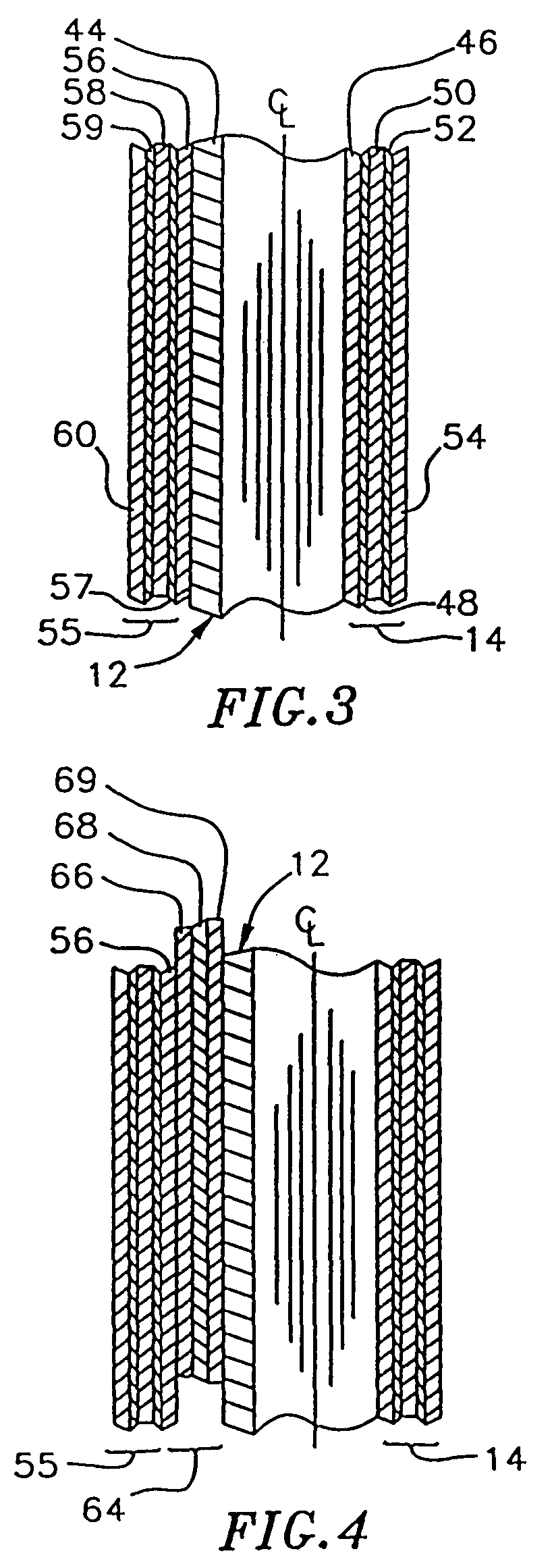

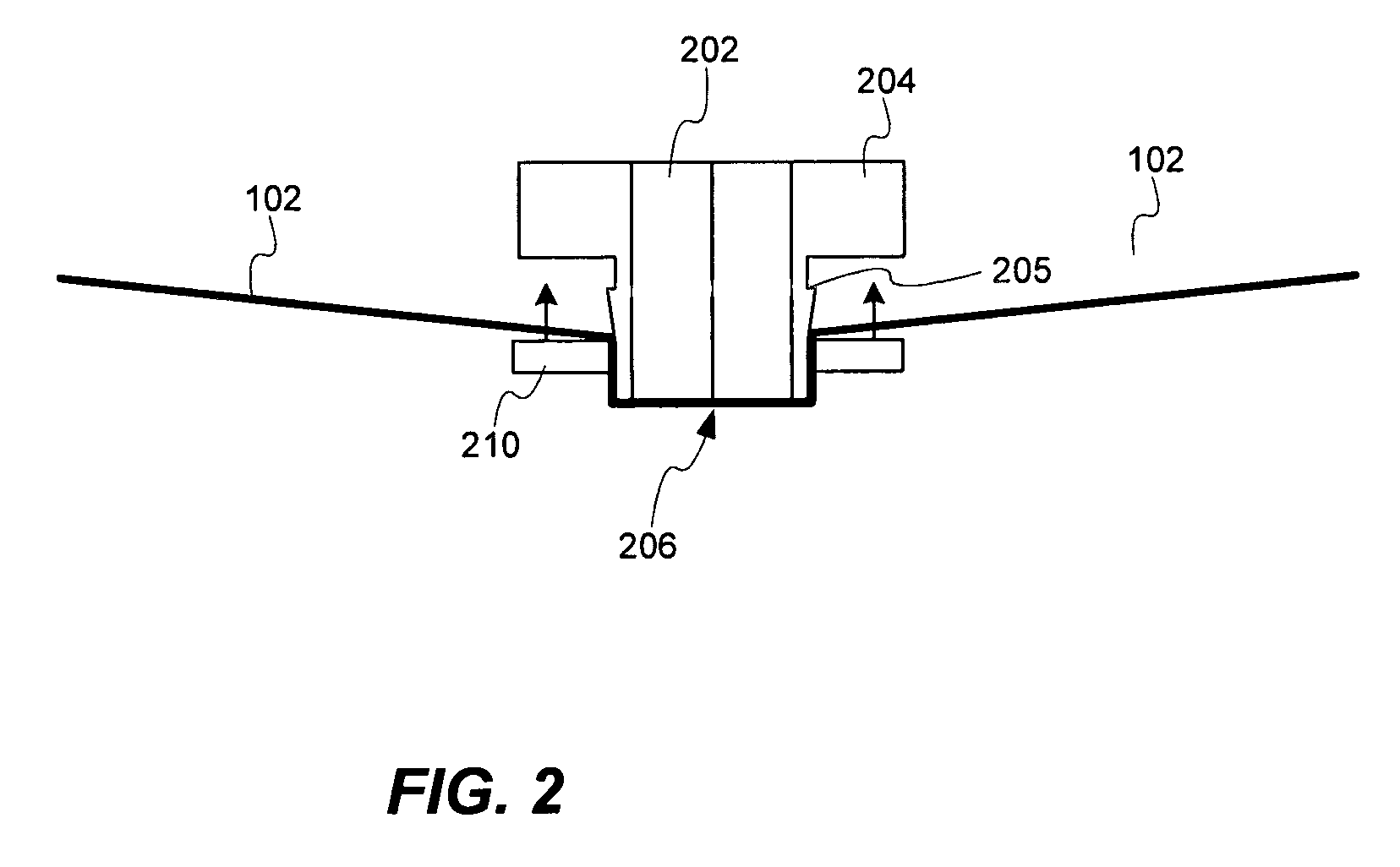

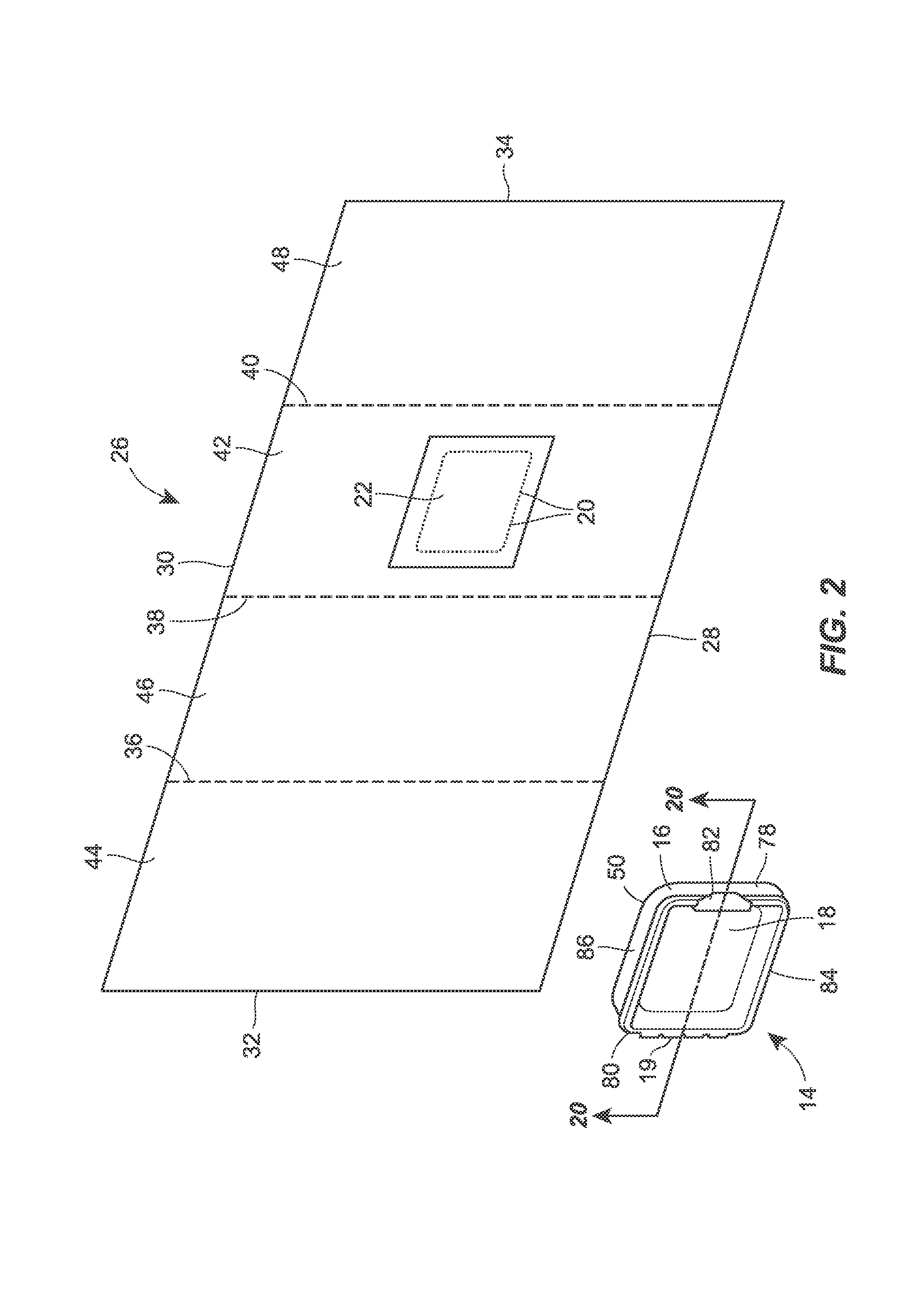

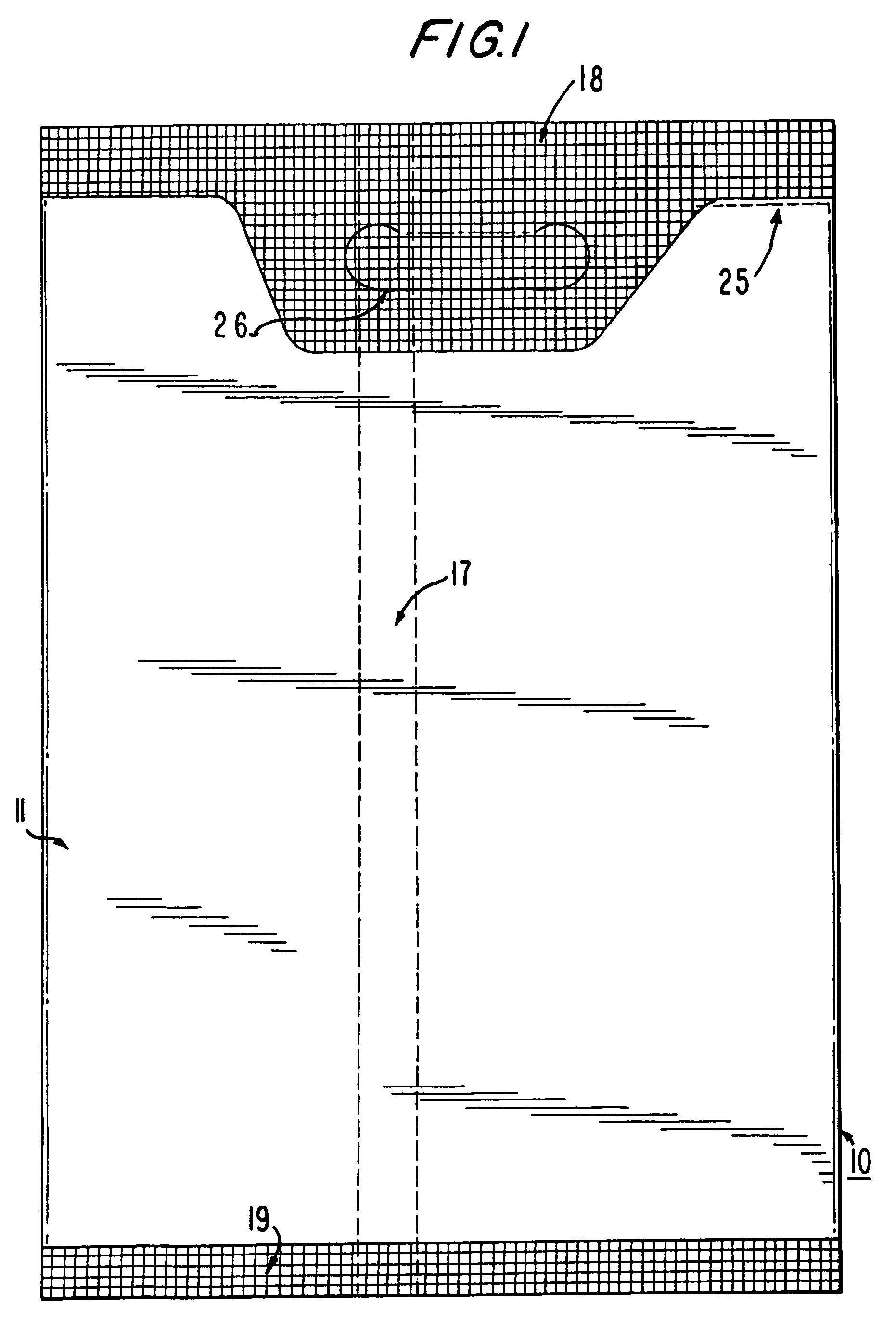

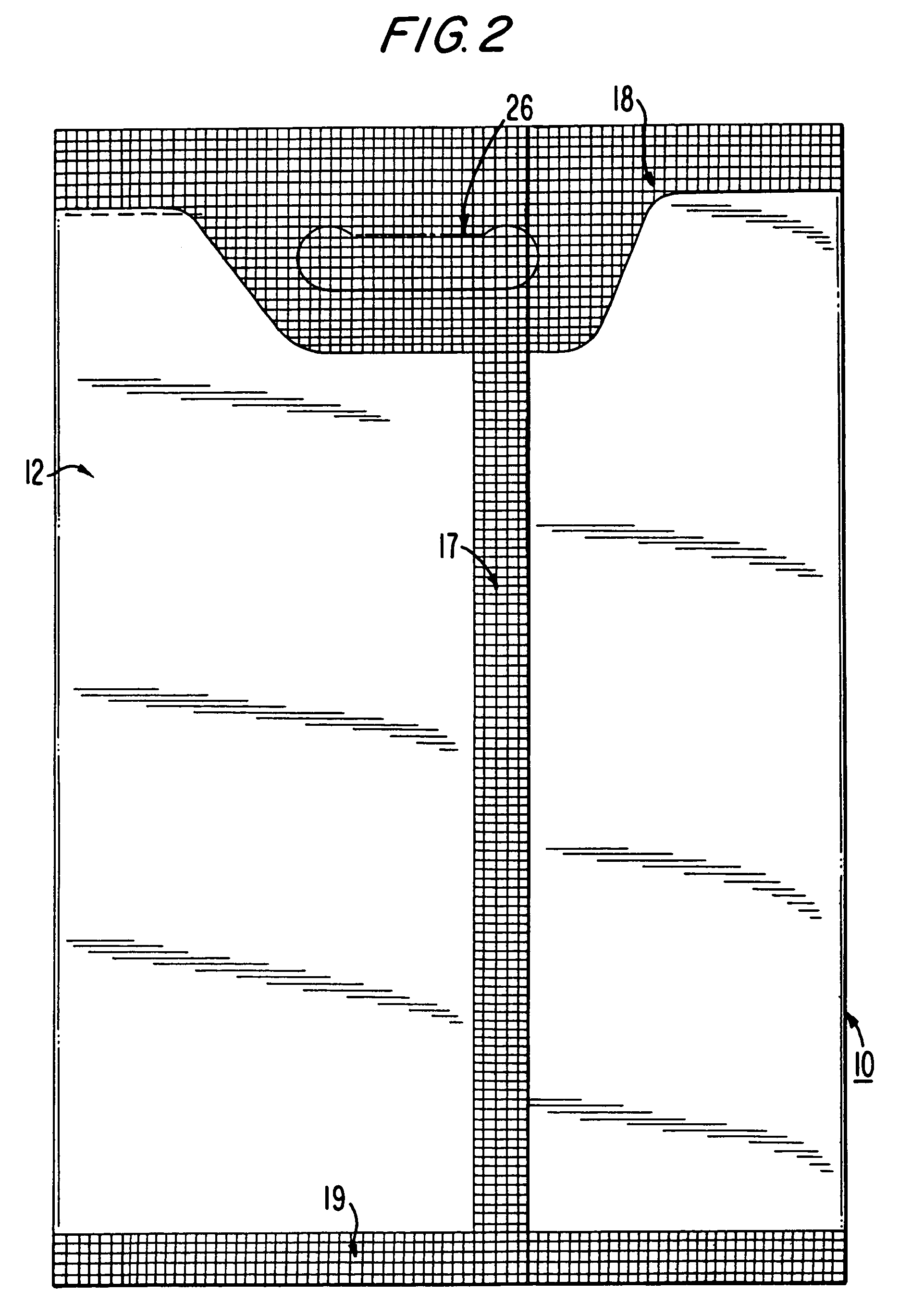

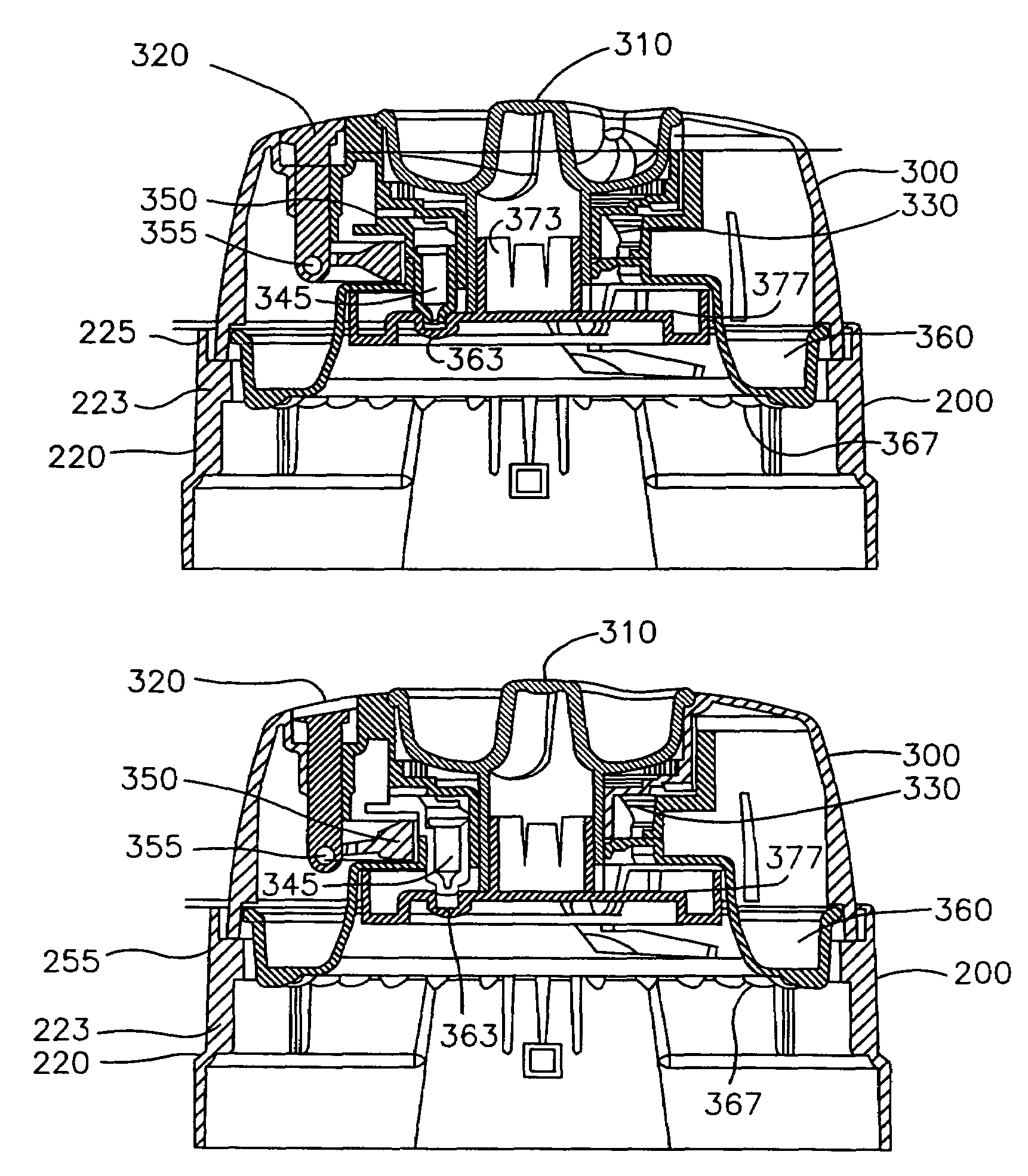

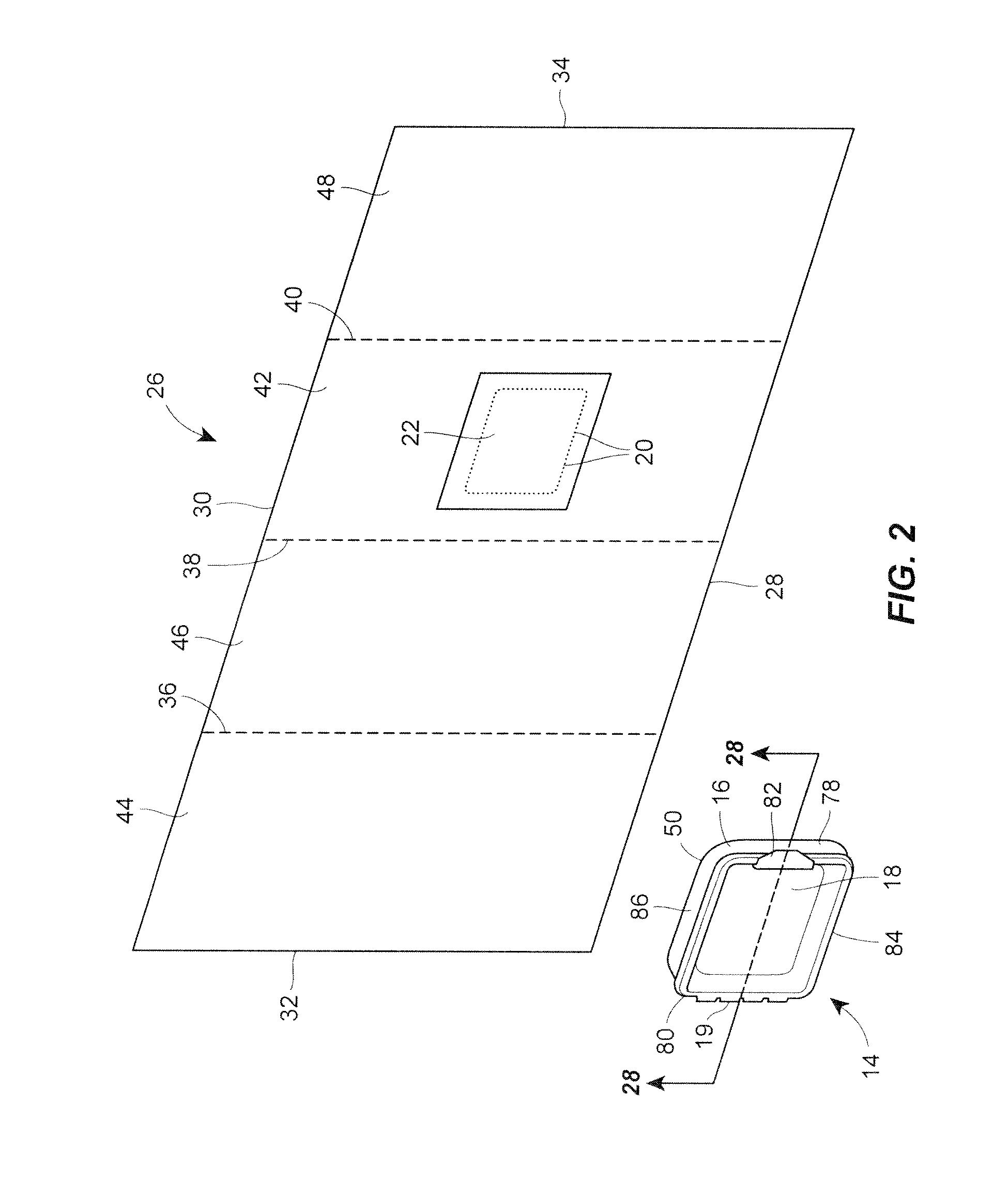

A novel method and apparatus for riveting a two-piece suture tray package. A two-piece suture tray assembly is provided having a top member and a bottom member. The top member has a top and a bottom, and plurality of rivet members extending down from the bottom of the top member. The rivet members have free ends. The bottom member has a top and a flat bottom surface, and a plurality of rivet receiving openings extending therethrough. A counterbore surrounds each rivet receiving opening in the flat bottom surface. An ultrasonic riveting apparatus is provided having a clamp member with a cavity, and an ultrasonic horn member having a flat bottom moveably mounted in the cavity. The assembly is mounted in the riveting apparatus and engaged by the clamp member. The flat bottom of the horn member engages the free ends of the rivet members, and when energized by an ultrasonic generator, causes the free ends of the rivet members to deform into the counterbores, such that the free ends are flat and in alignment with the bottom surface of the bottom member.

Owner:ETHICON INC

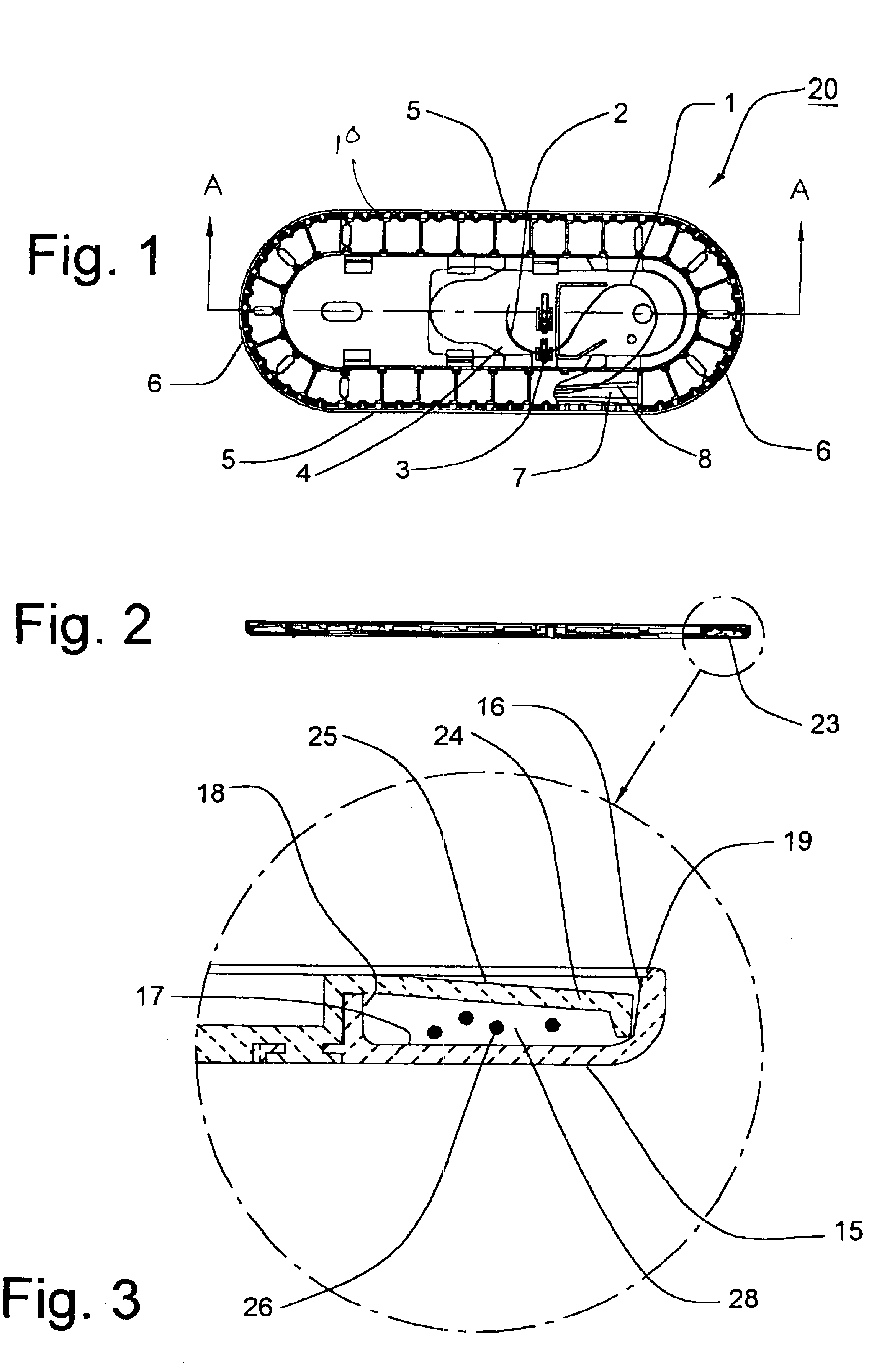

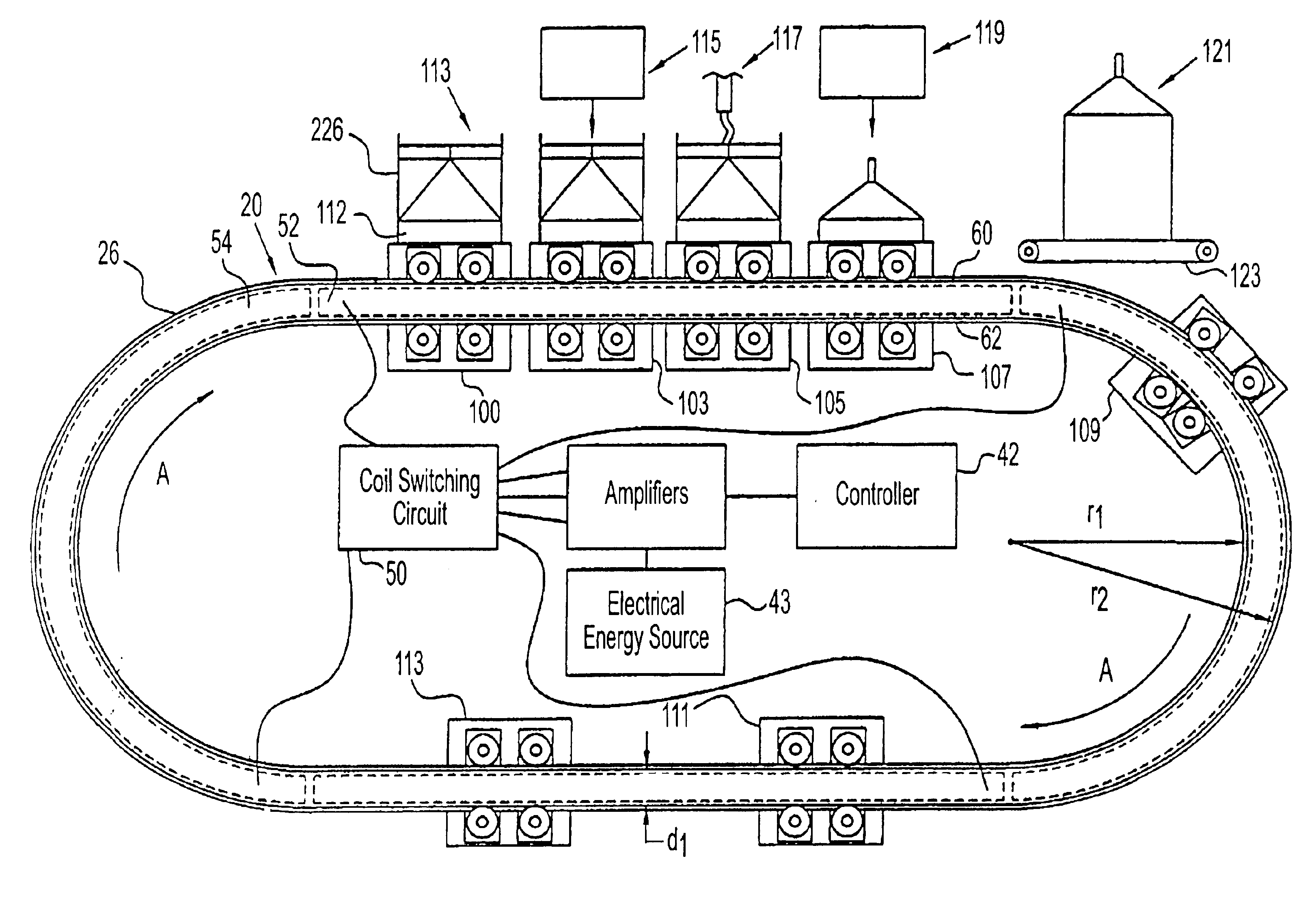

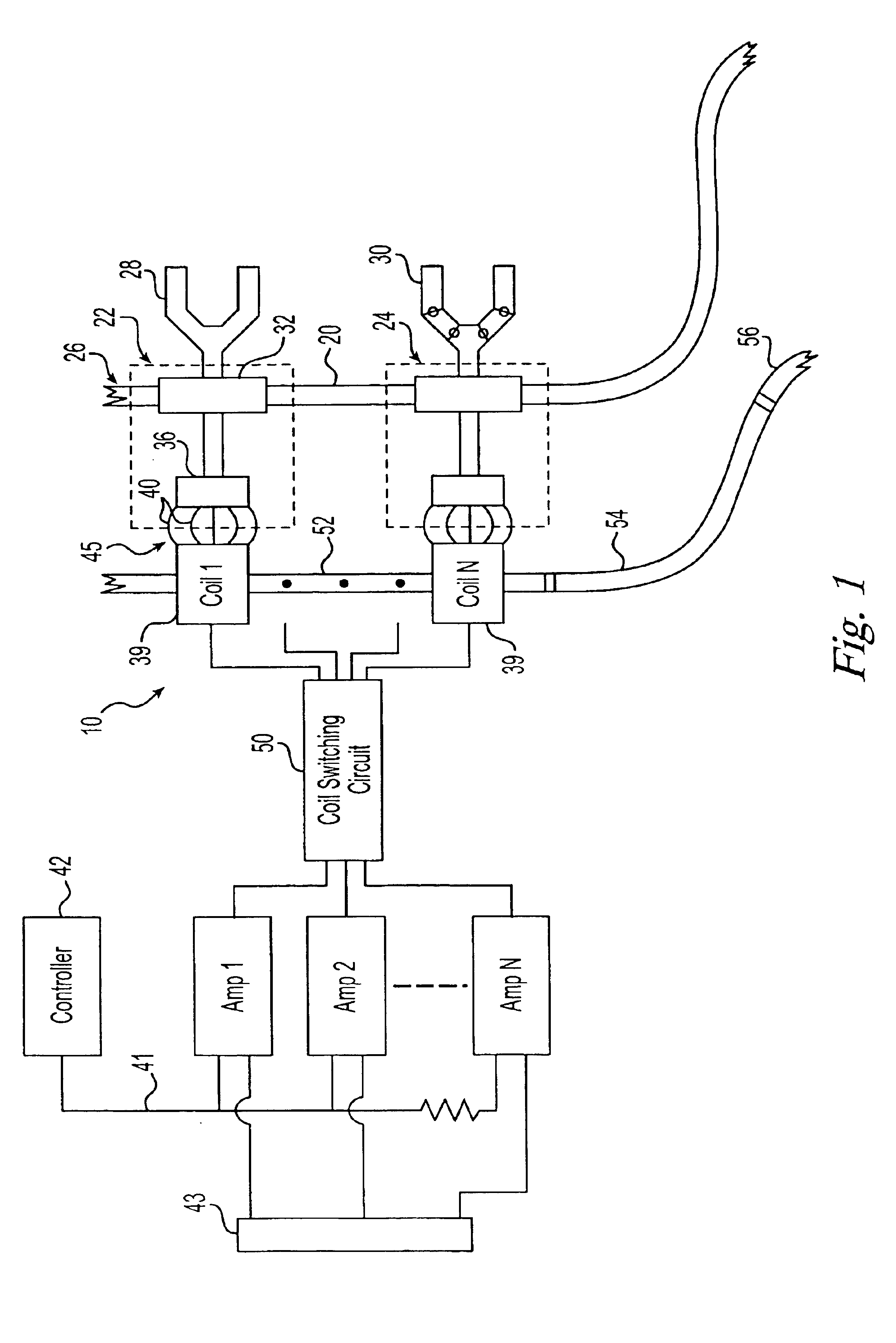

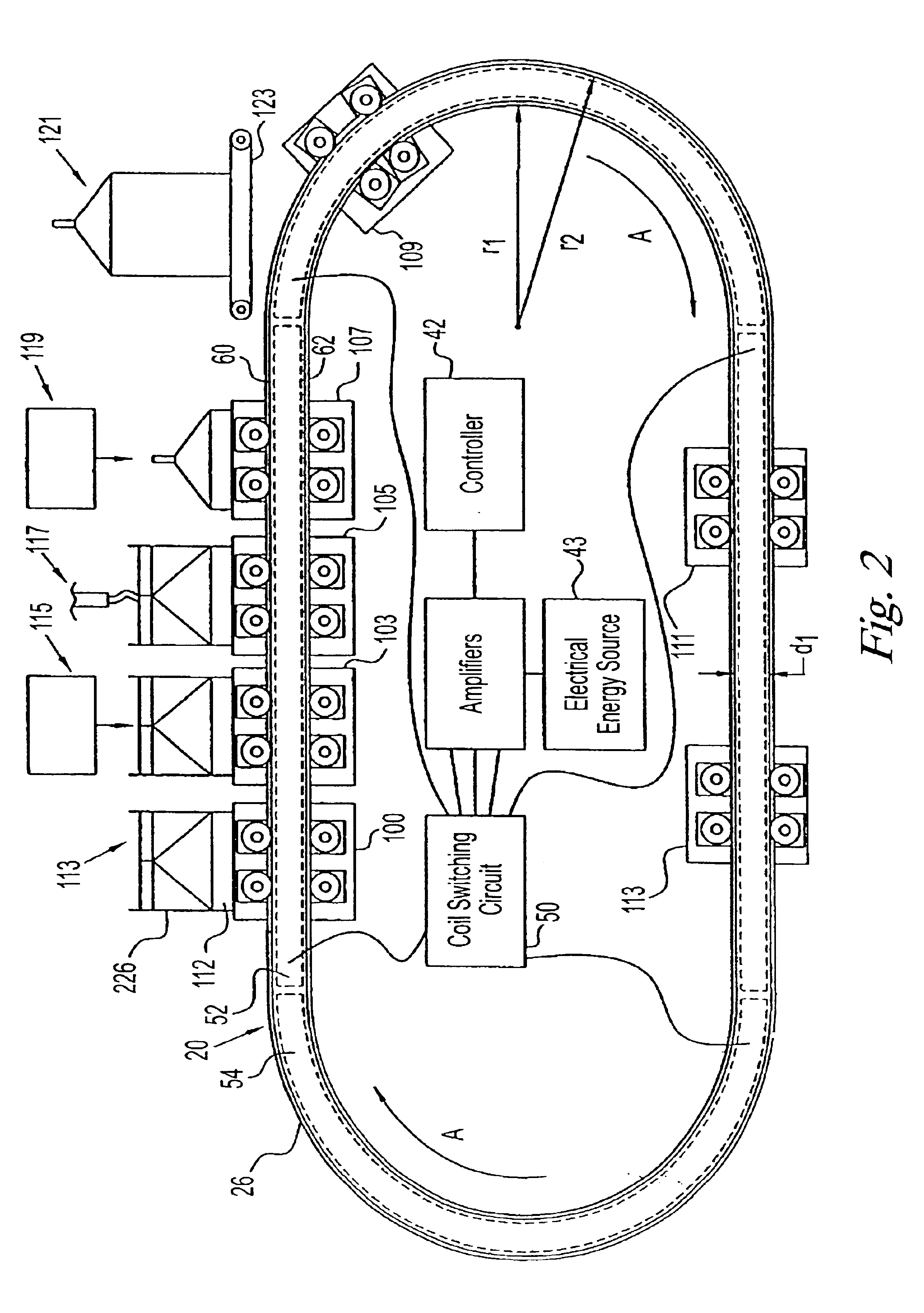

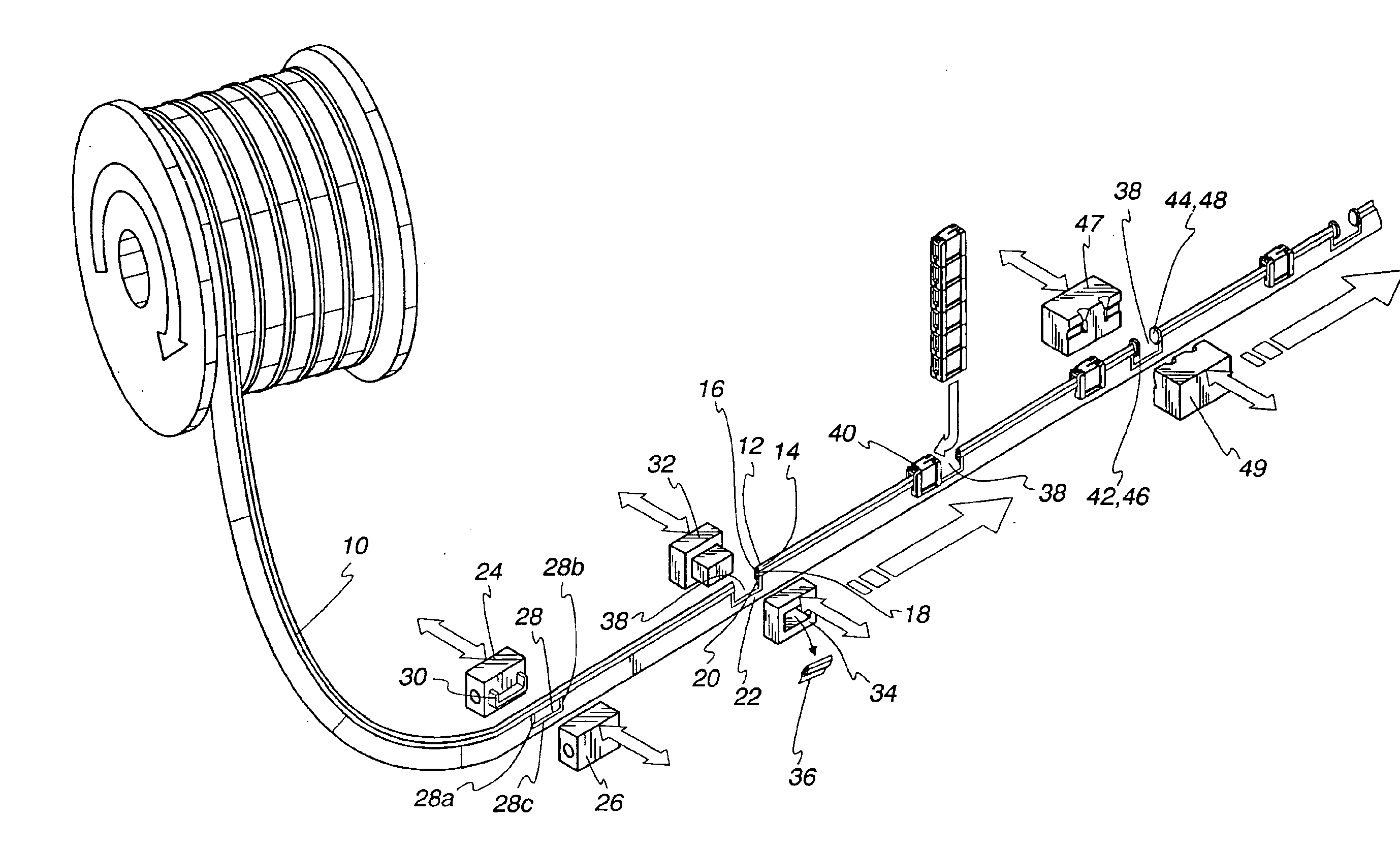

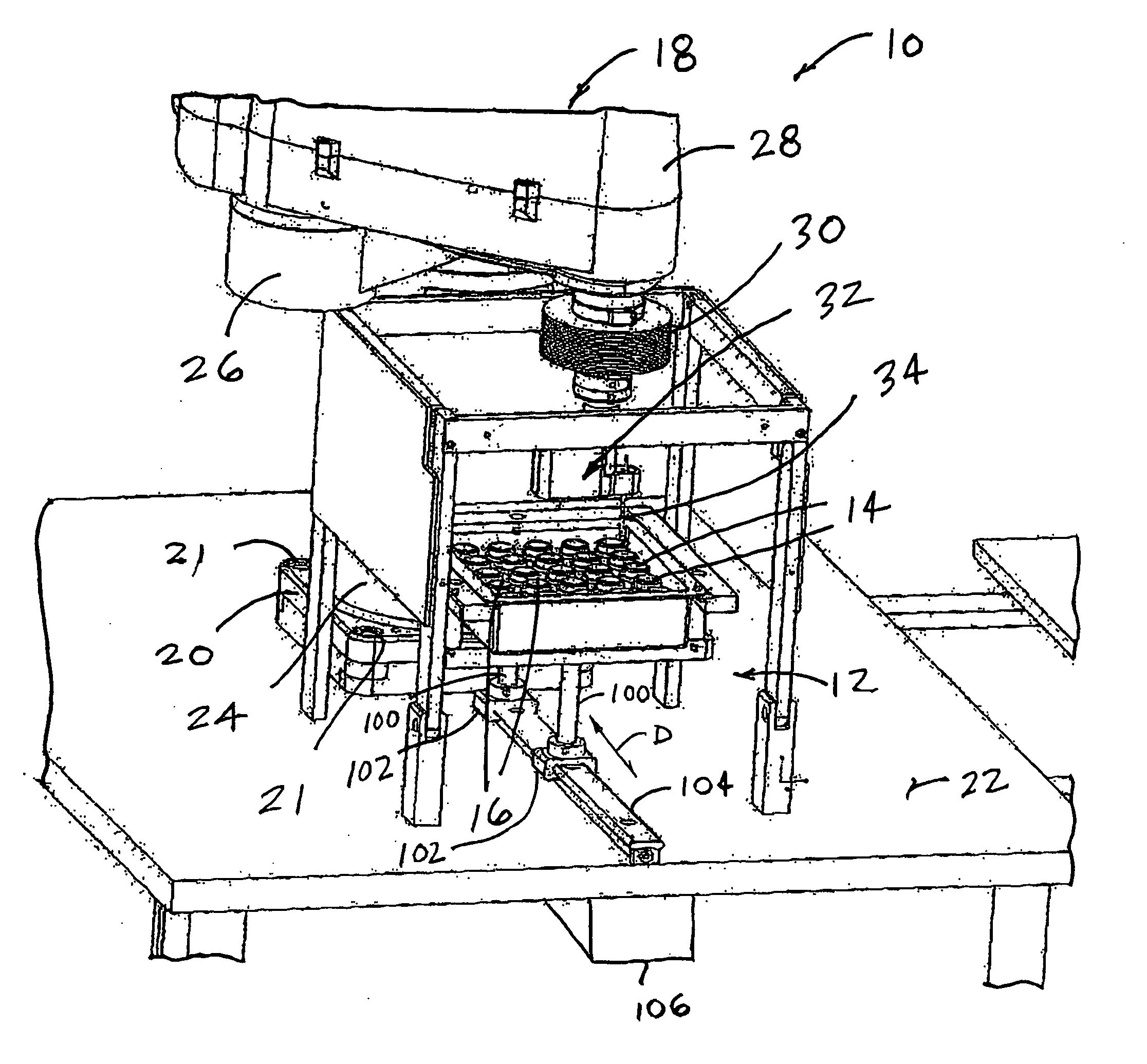

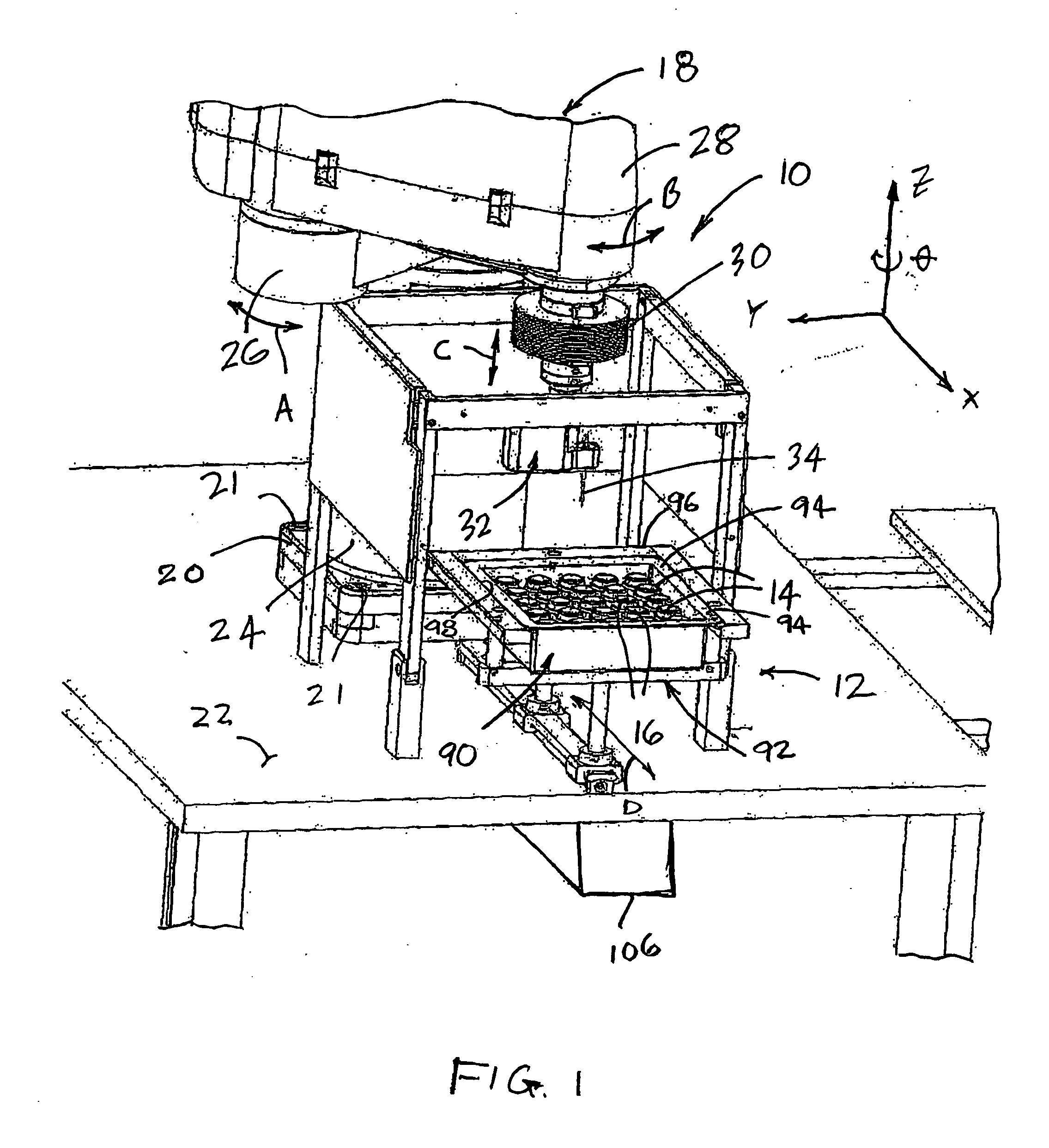

Variable motion system and method

InactiveUS6876896B1Motor/generator/converter stoppersDC motor speed/torque controlMotion parameterEngineering

The invention relates to a system and a method for performing a manufacturing operation at a predetermined position relative to a first path. The system includes a plurality of first elements mounted for movement relative to the first path. The first elements have a plurality of motion parameters which are independently controllable. Active elements are operatively associated with reactive elements to produce relative movement between the first elements and the first path, with the active elements controlling the relative movement. A controller controls the activation of the active elements and a first tool is associated with each first element for performing at least part of the manufacturing operation. The system may also include at least one second element and a second path. The method includes the steps of mounting a plurality of first carriages for movement relative to a first path, operatively associating a plurality of active elements with at least one reactive element to produce relative movement between the first carriages and the path, associating a first tool with each first carriage for performing at least part of the manufacturing process, and controlling the activation of the active elements.

Owner:TETRA LAVAL HLDG & FINANCE SA

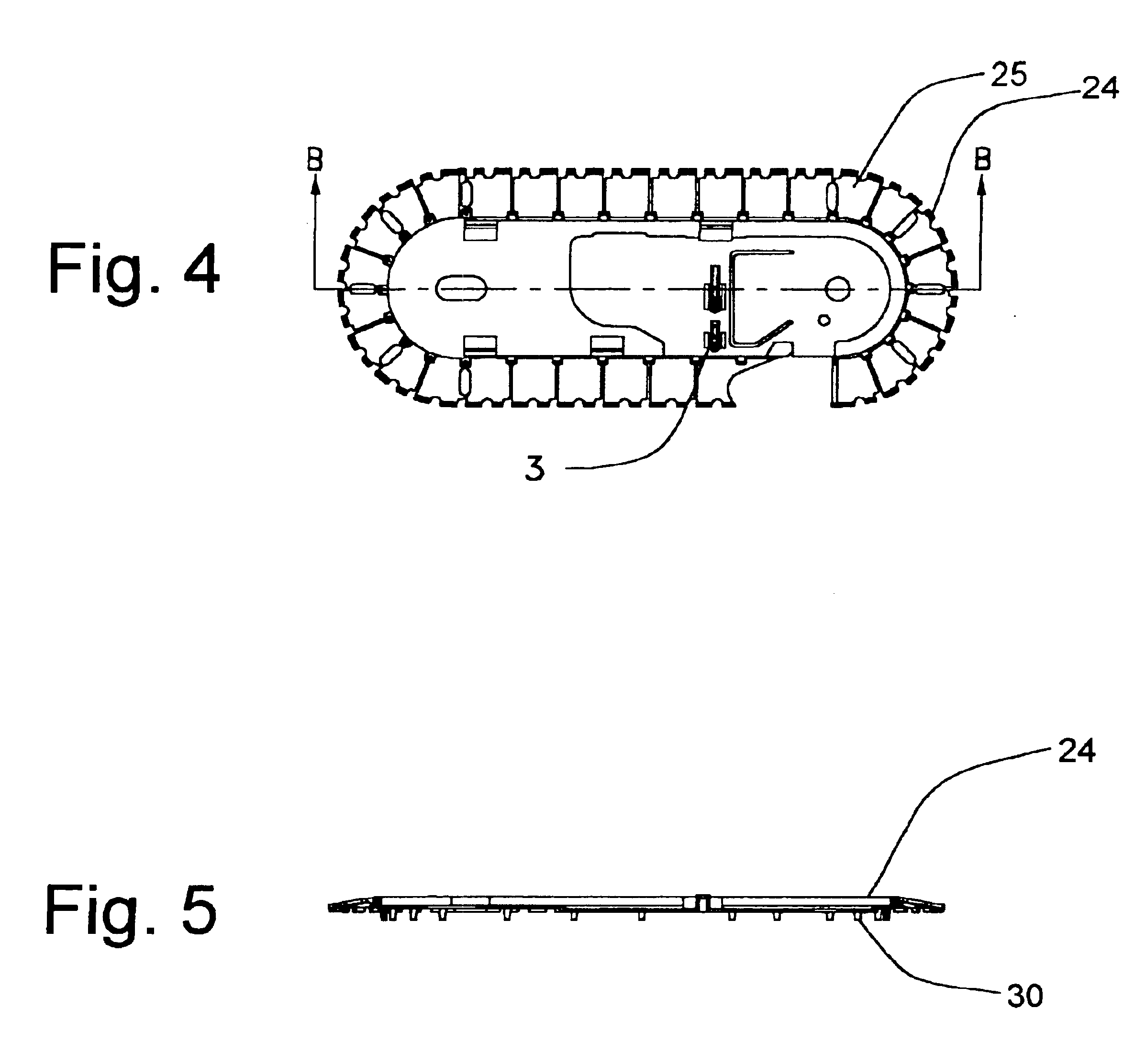

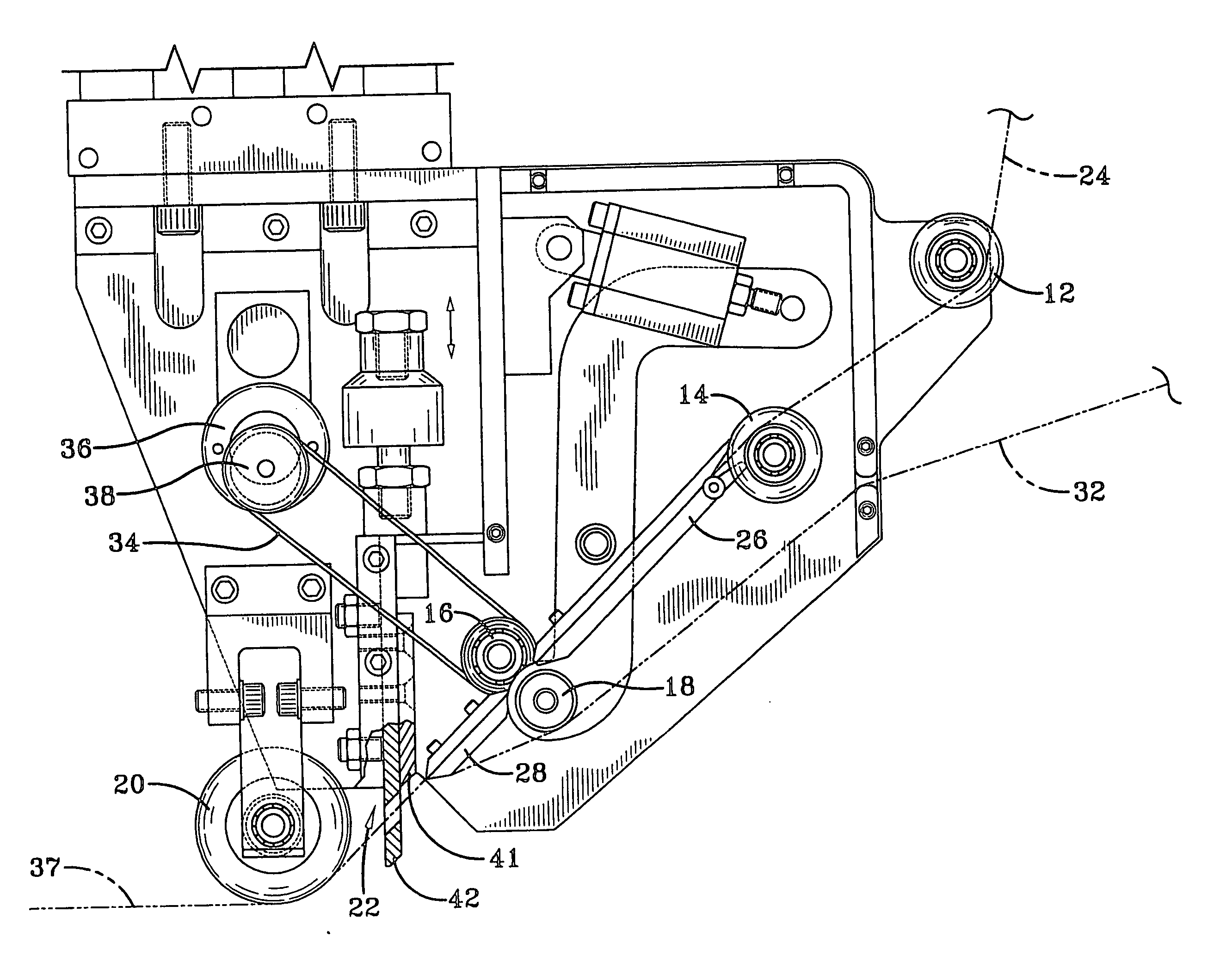

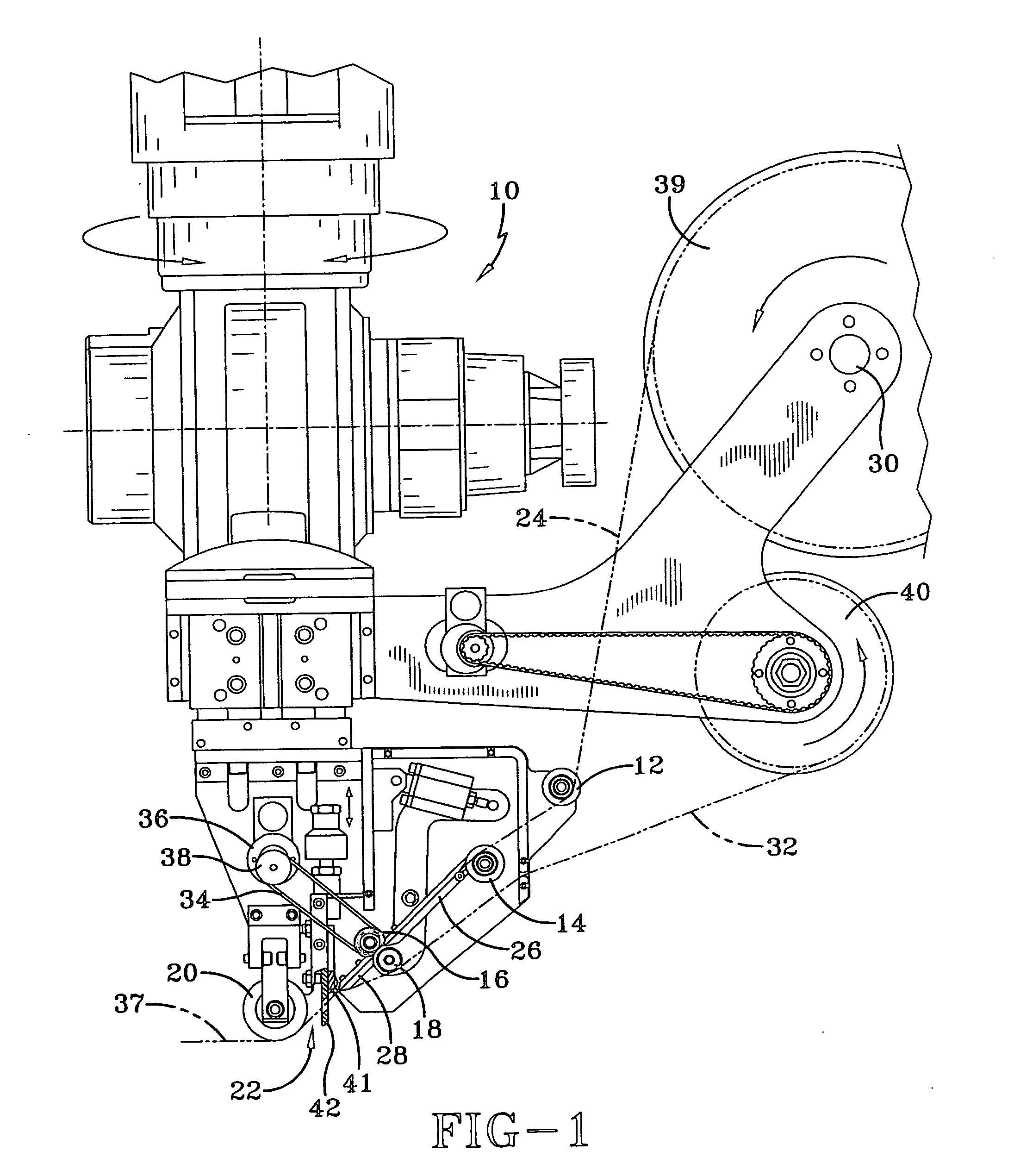

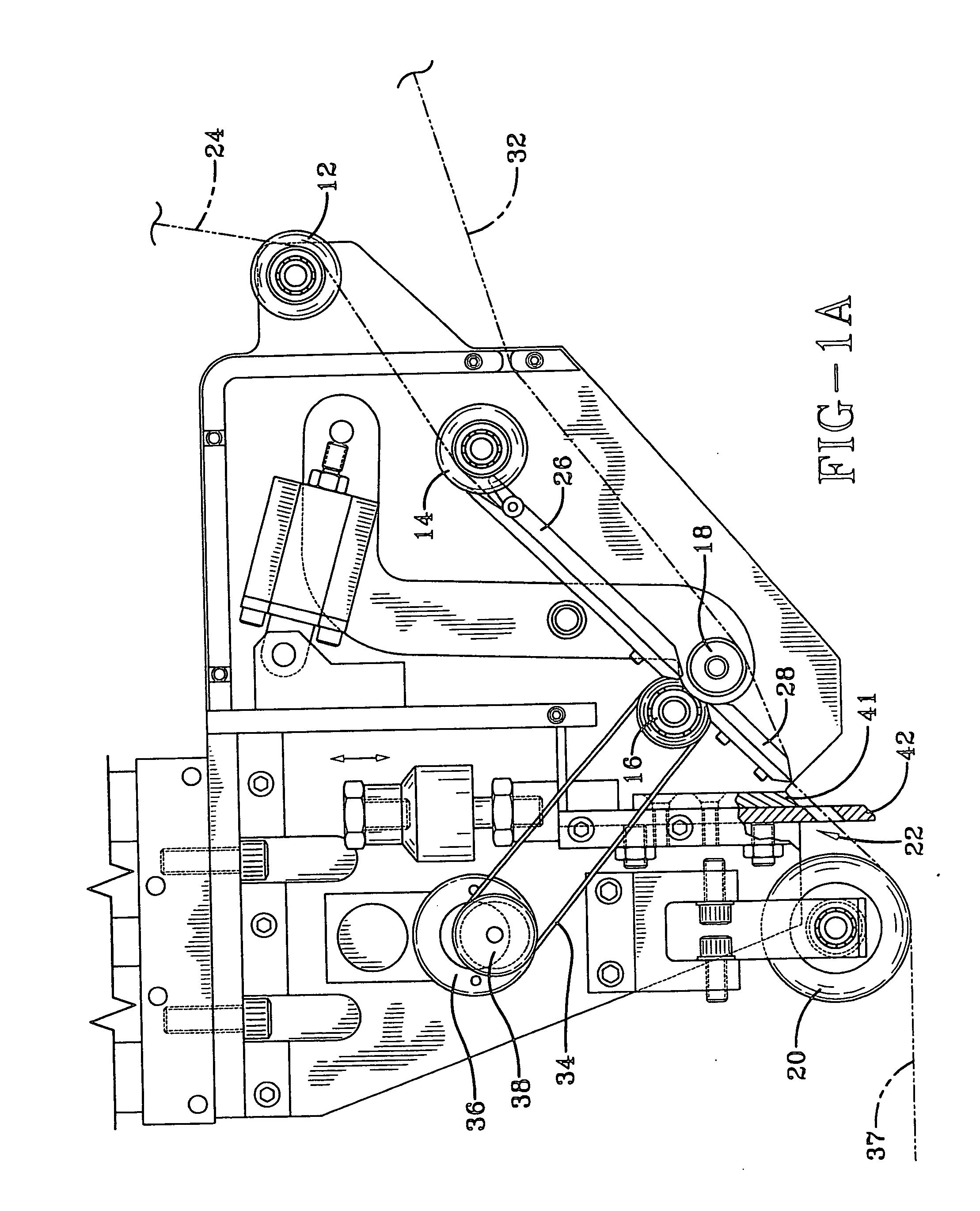

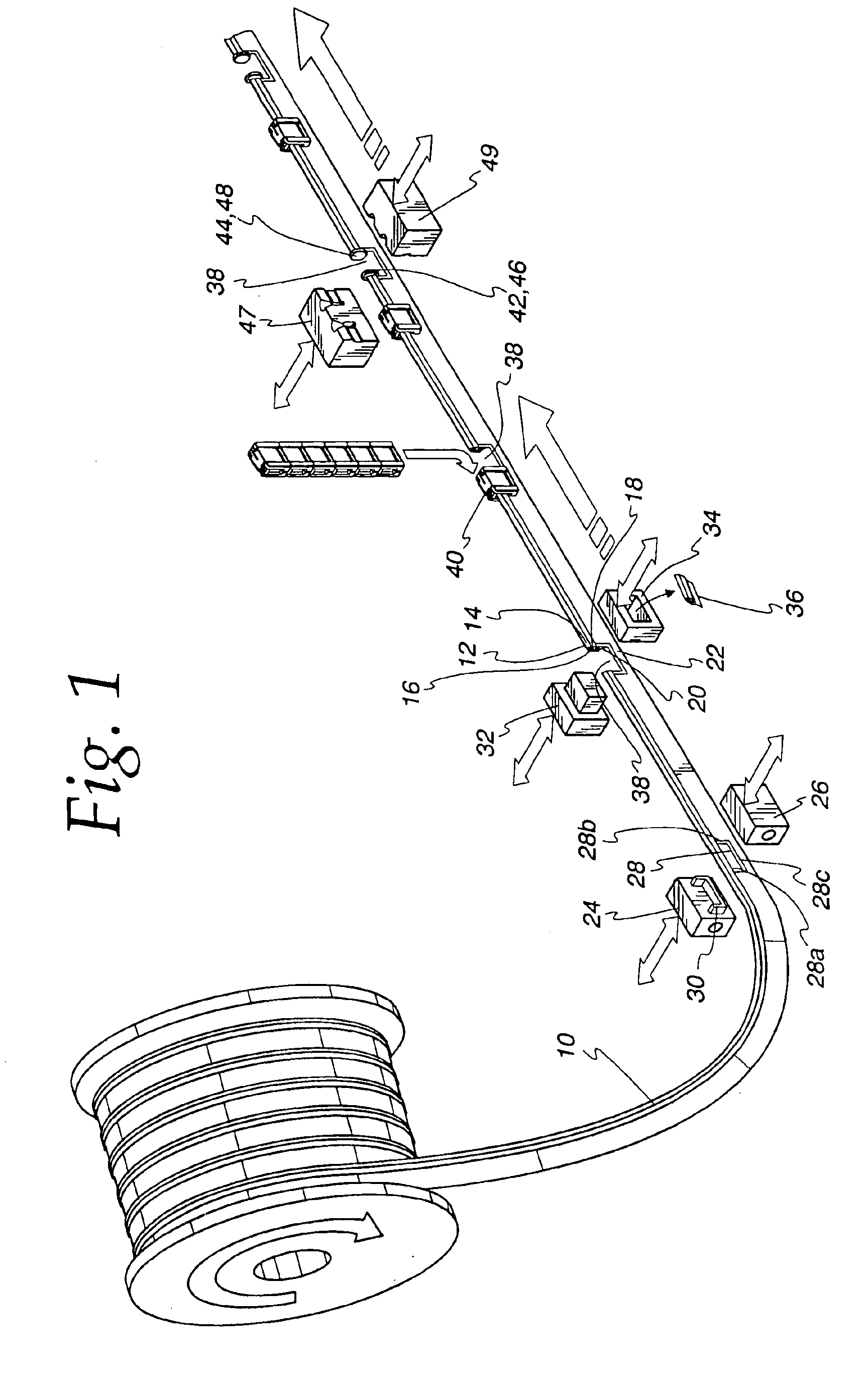

Composite tape laying apparatus and method

ActiveUS20050109451A1Simple procedureMaximizes material throughputLamination ancillary operationsControlling laminationFiberMagnetic tape

A fully automated method and apparatus is disclosed to laminate various structural articles with a layer of resin impregnated fiber tape. The tape laying member removes a releasable backing layer from the tape being employed, then deposits the unbacked tape on the surface of the structural article, and finally severs the end of the tape being deposited. An automated cut and restart procedure is employed in the present tape laying member to increase tape throughput.

Owner:TRELLEBORG SEALING SOLUTIONS GERMANY

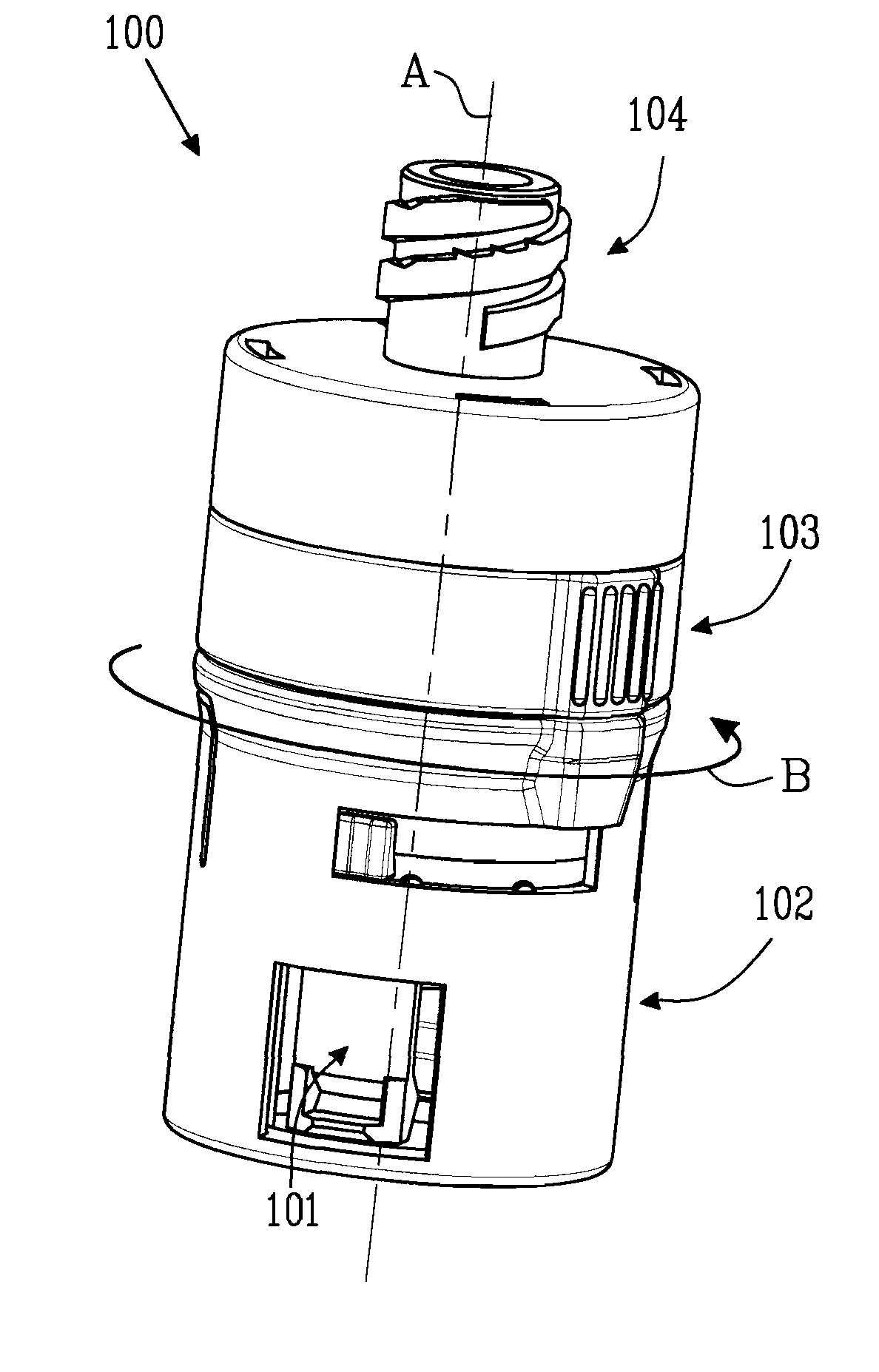

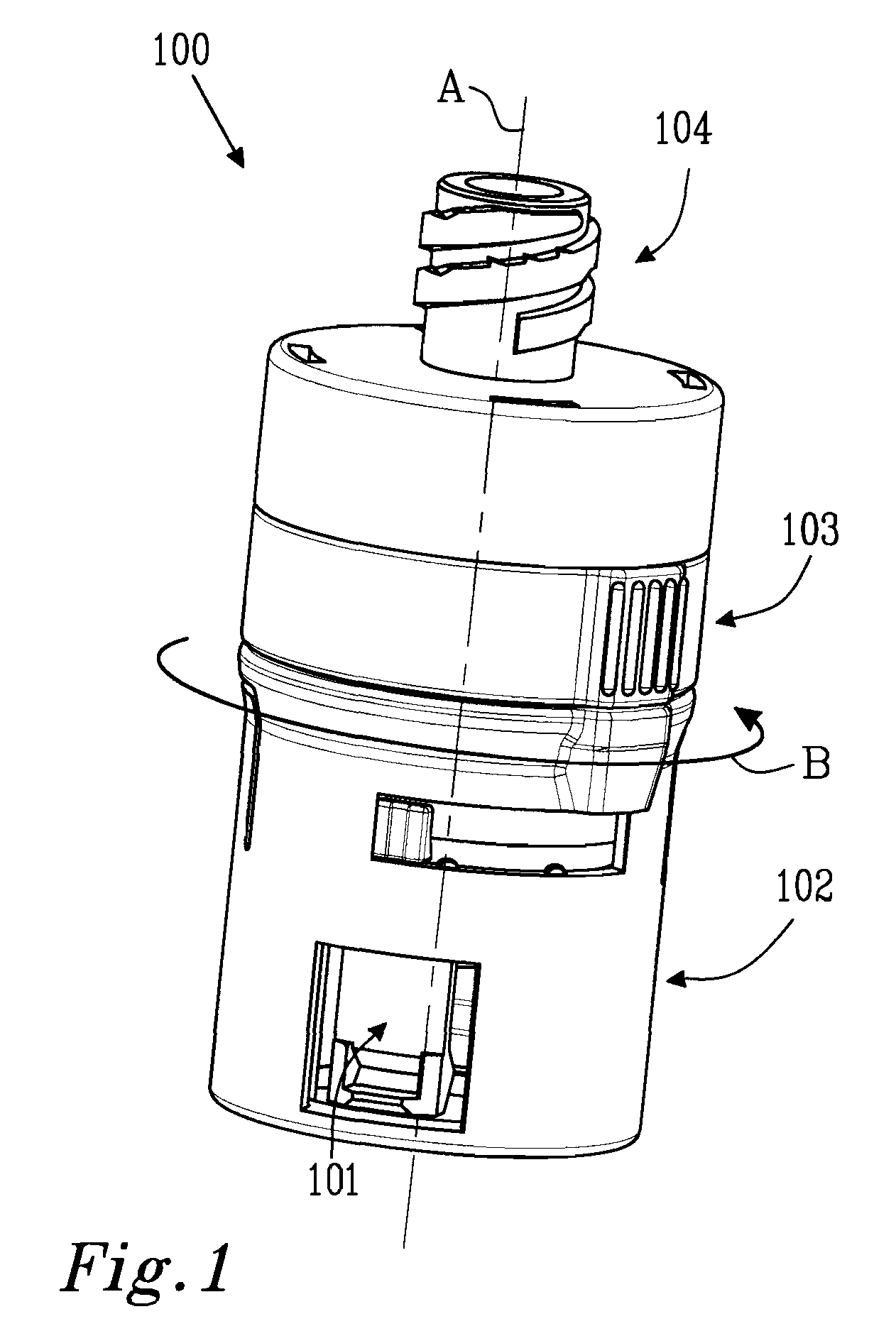

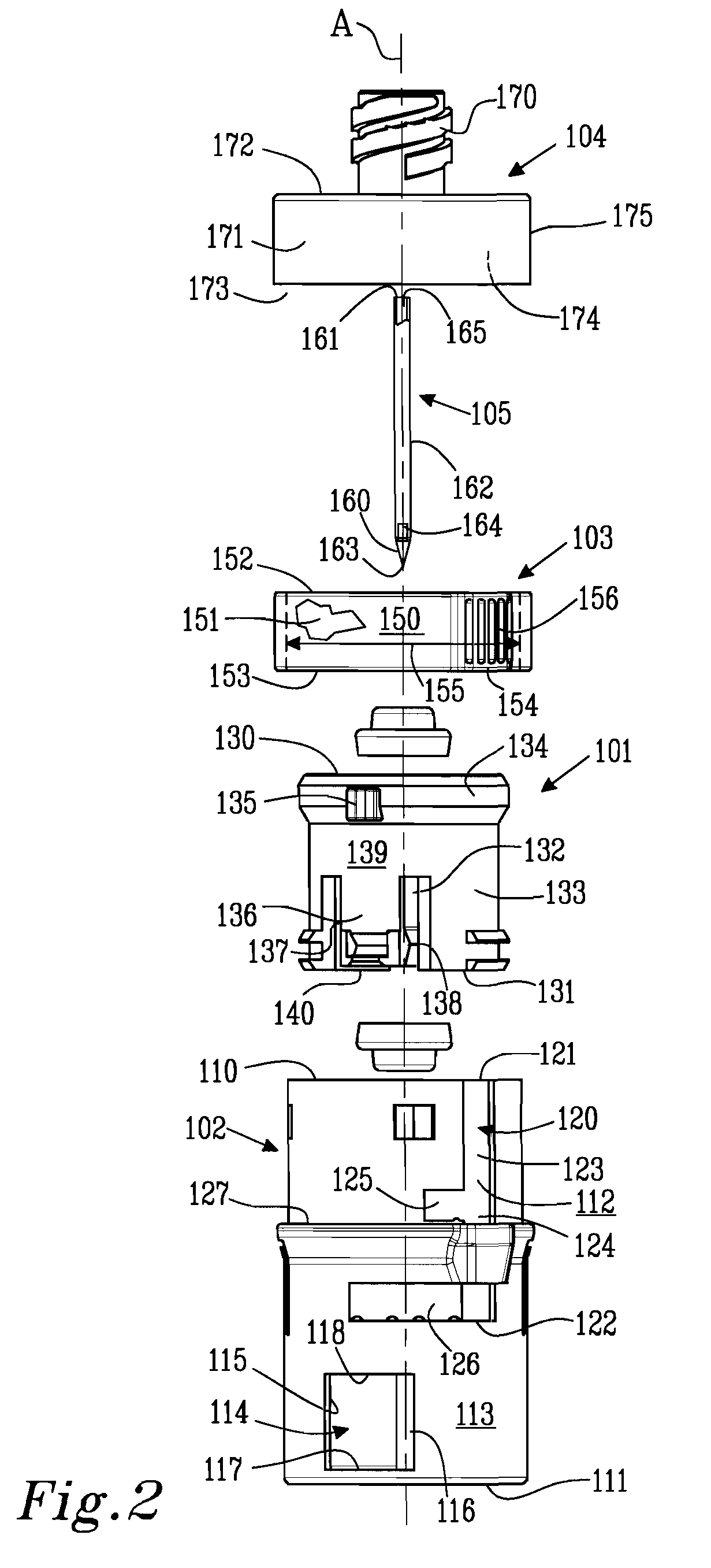

Piercing member protection device

ActiveUS8287513B2Avoid connectionPrevent disengagementCapsLiquid fillingEngineeringElectrical and Electronics engineering

Owner:CARMEL PHARMA

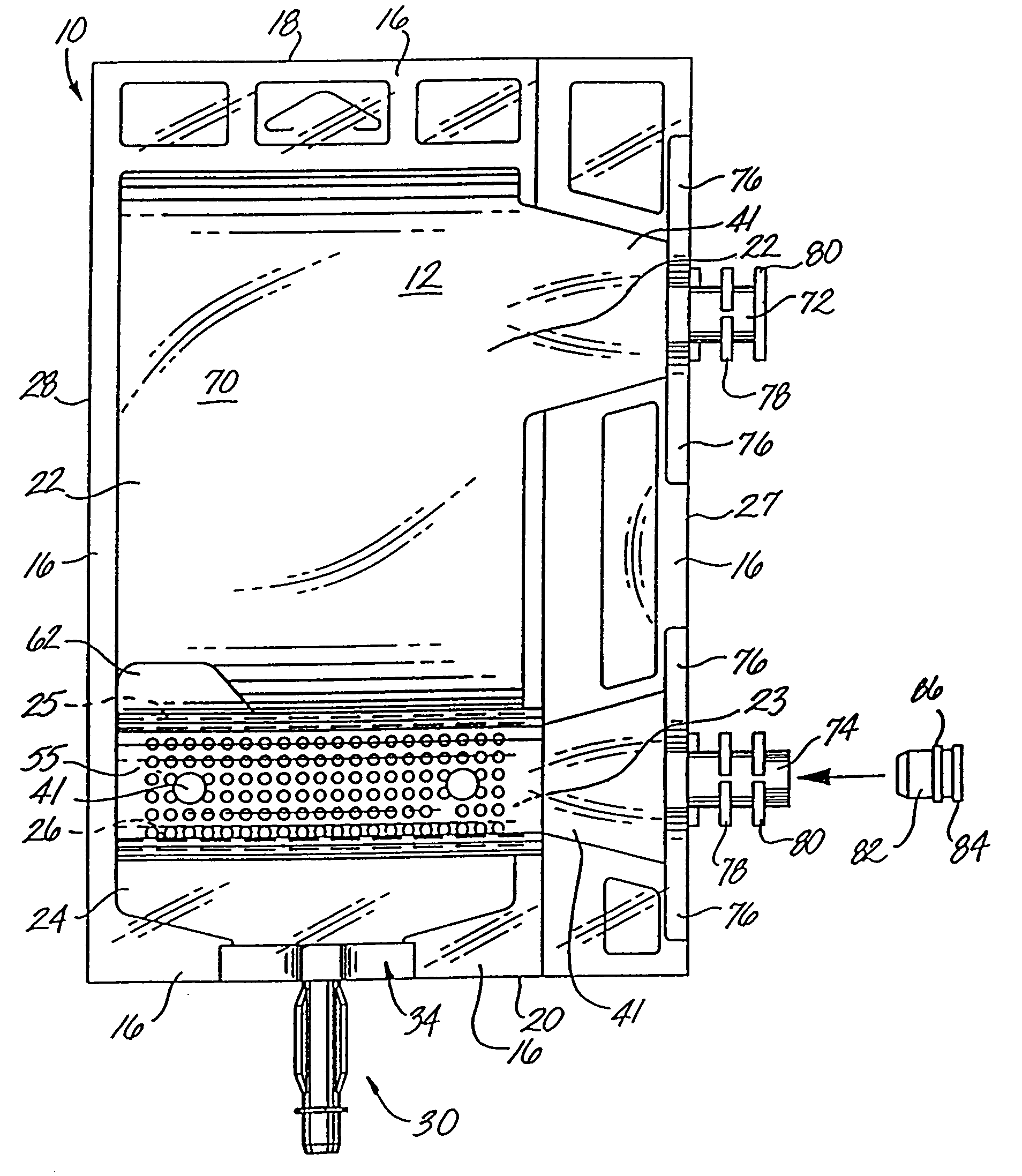

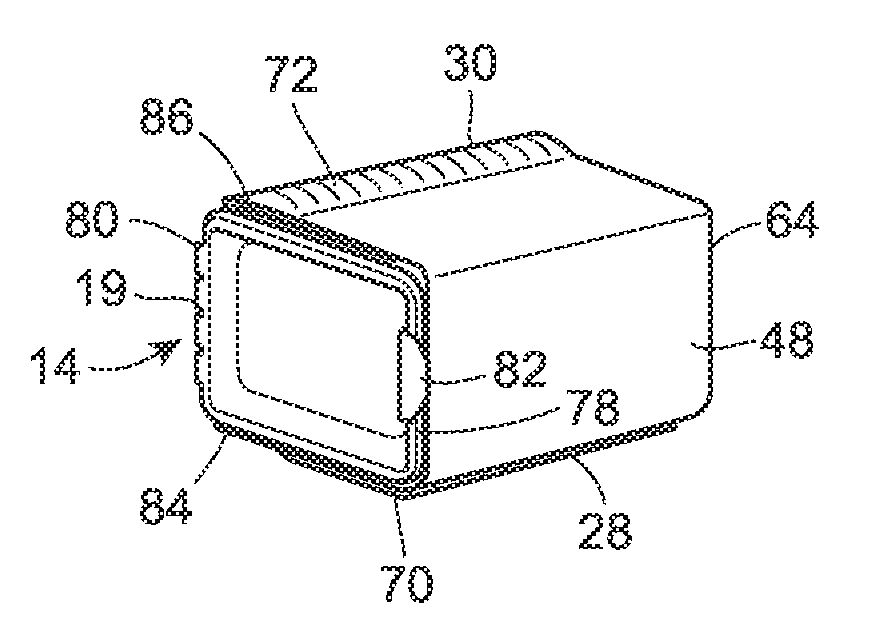

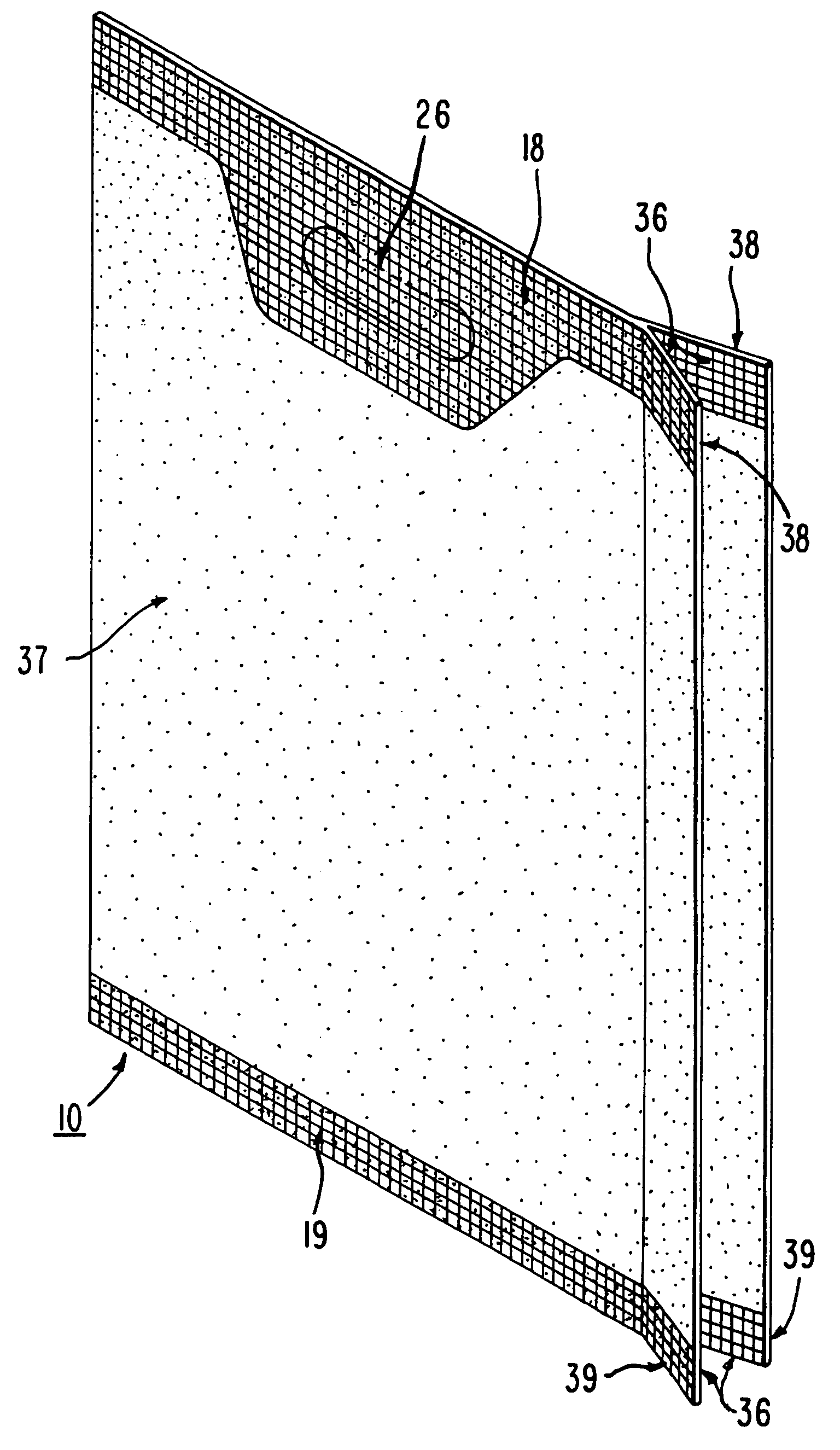

Container closure with overlying needle penetrable and thermally resealable portion and underlying portion compatible with fat containing liquid product, and related method

InactiveUS20060231519A1Avoiding seal integrity problemGood product containmentCapsLiquid fillingLiquid productFormulary

A container and method are provided for storing fat containing liquid products, such as infant or baby formula, or other milk-based products. The container includes a body defining a storage chamber for receiving the aseptic fat containing liquid product, and a first aperture in fluid communication with the storage chamber. The body does not leach more than a predetermined amount of leachables into the fat containing liquid product and does not undesirably alter a taste profile of the fat containing liquid product. A container closure assembly includes a stopper receivable within the first aperture for hermetically sealing the storage chamber. The stopper includes a first material portion defining an internal surface in fluid communication with the storage chamber forming at least most of the surface area of the container closure that can contact any fat containing liquid product within the storage chamber and that does not leach more than a predetermined amount of leachables into the fat containing liquid product or undesirably alter a taste profile of the fat containing liquid product. A second material portion of the stopper either (i) overlies the first material portion and cannot contact any product within the storage chamber, or (ii) forms a substantially lesser surface area of the container closure that can contact any product within the storage chamber in comparison to the first material portion. The second material portion is needle penetrable for filling the storage chamber with product, and a resulting needle aperture formed in the second material portion is thermally resealable such as by the application of laser energy to seal the product within the storage chamber. A sealing portion of the container closure is engageable with the body prior to needle filling the storage chamber to thereby form a substantially dry hermetic seal between the container closure and body.

Owner:MEDINSTILL DEV

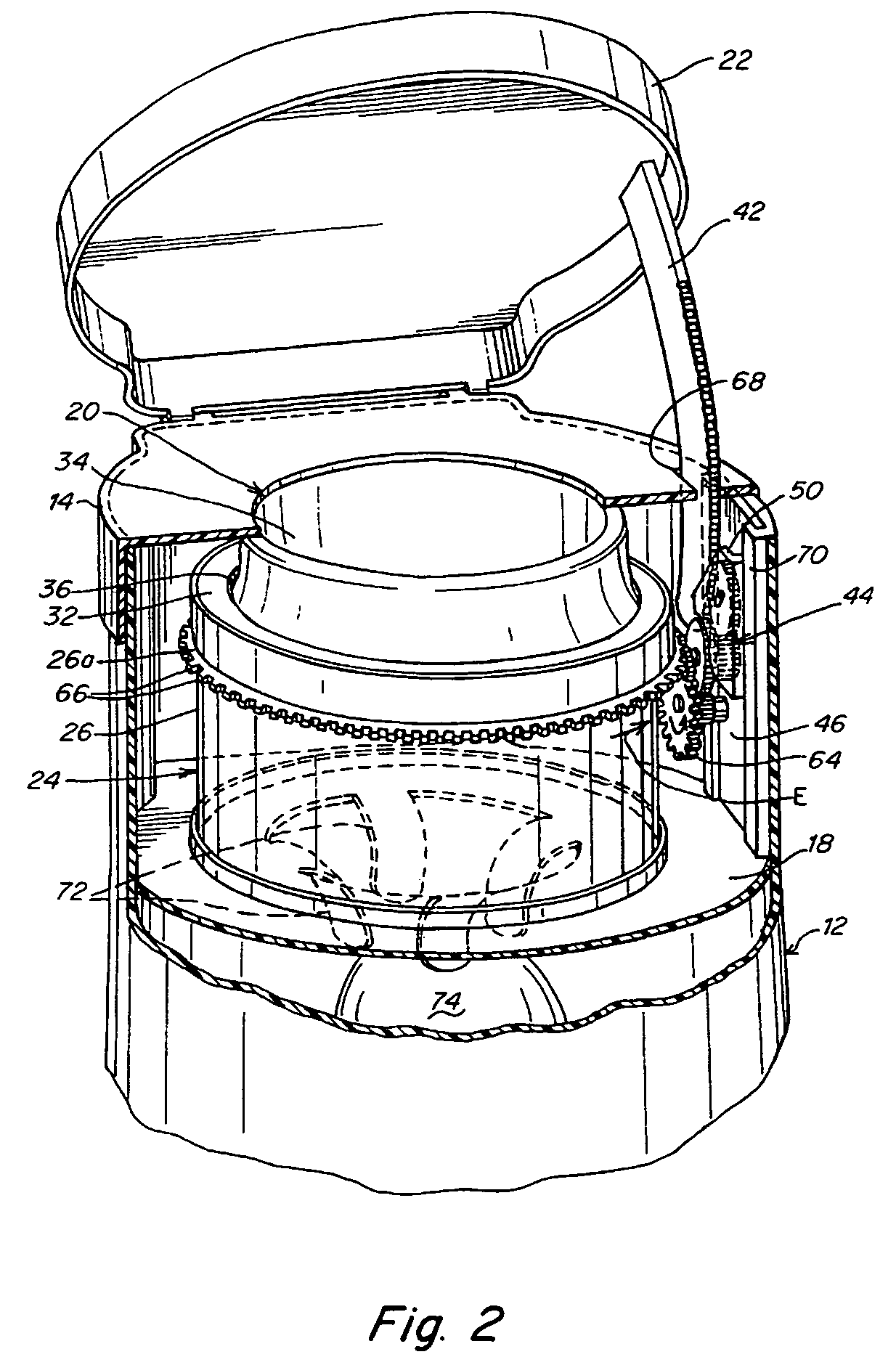

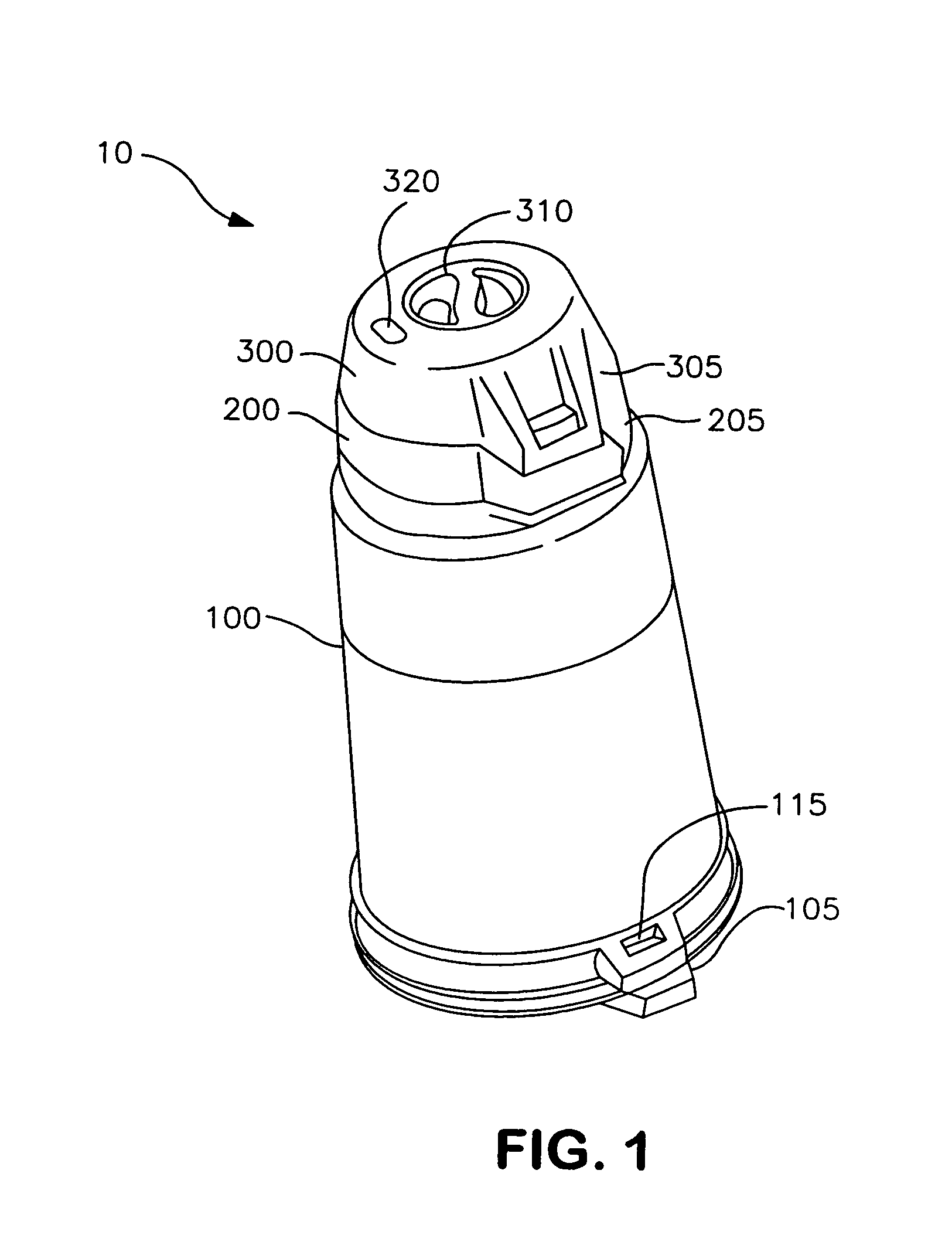

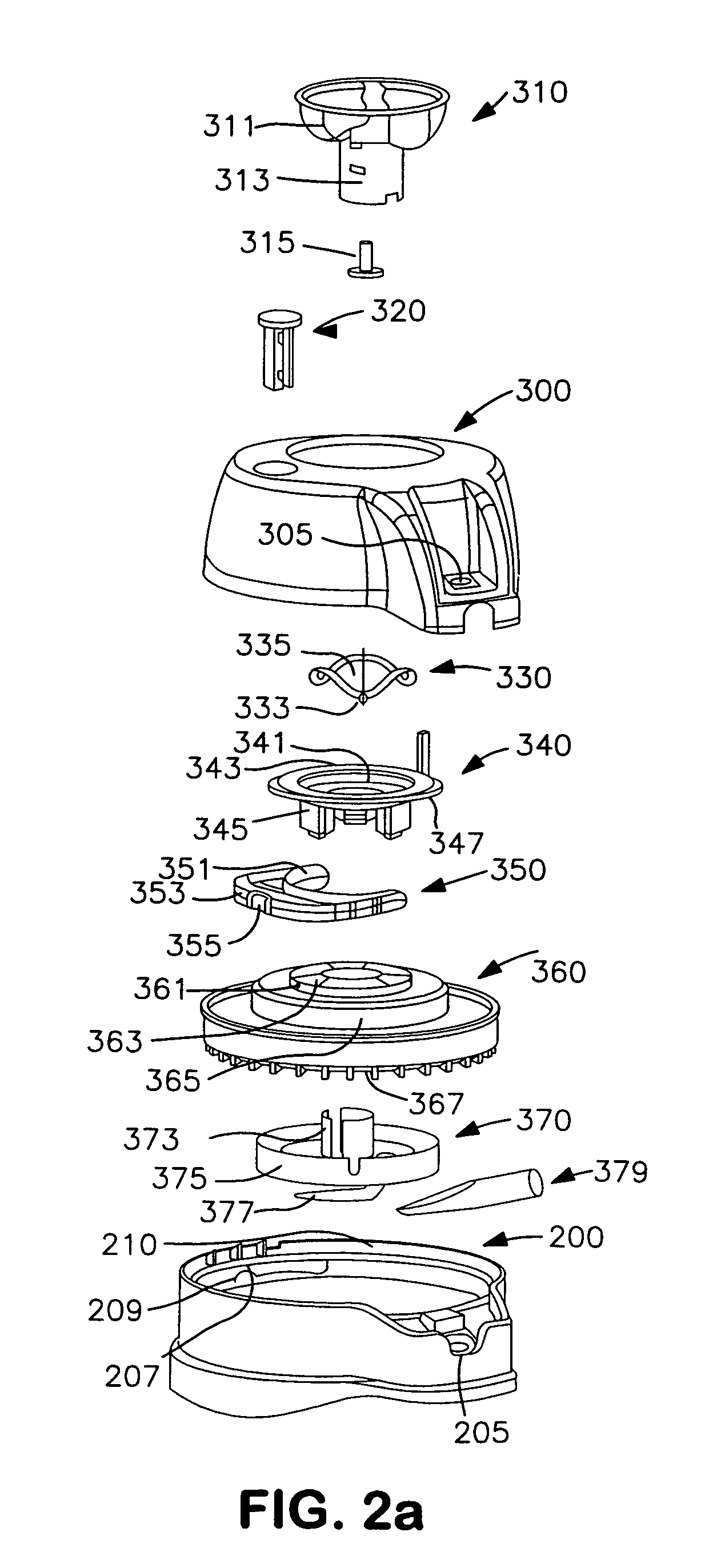

Waste disposal device including a sensing mechanism for delaying the rotation of a cartridge

InactiveUS7712285B2Effectively contains and prevents the release of odors from waste packagesEasy to disassembleContact operating partsLarge containersWaste materialWaste disposal

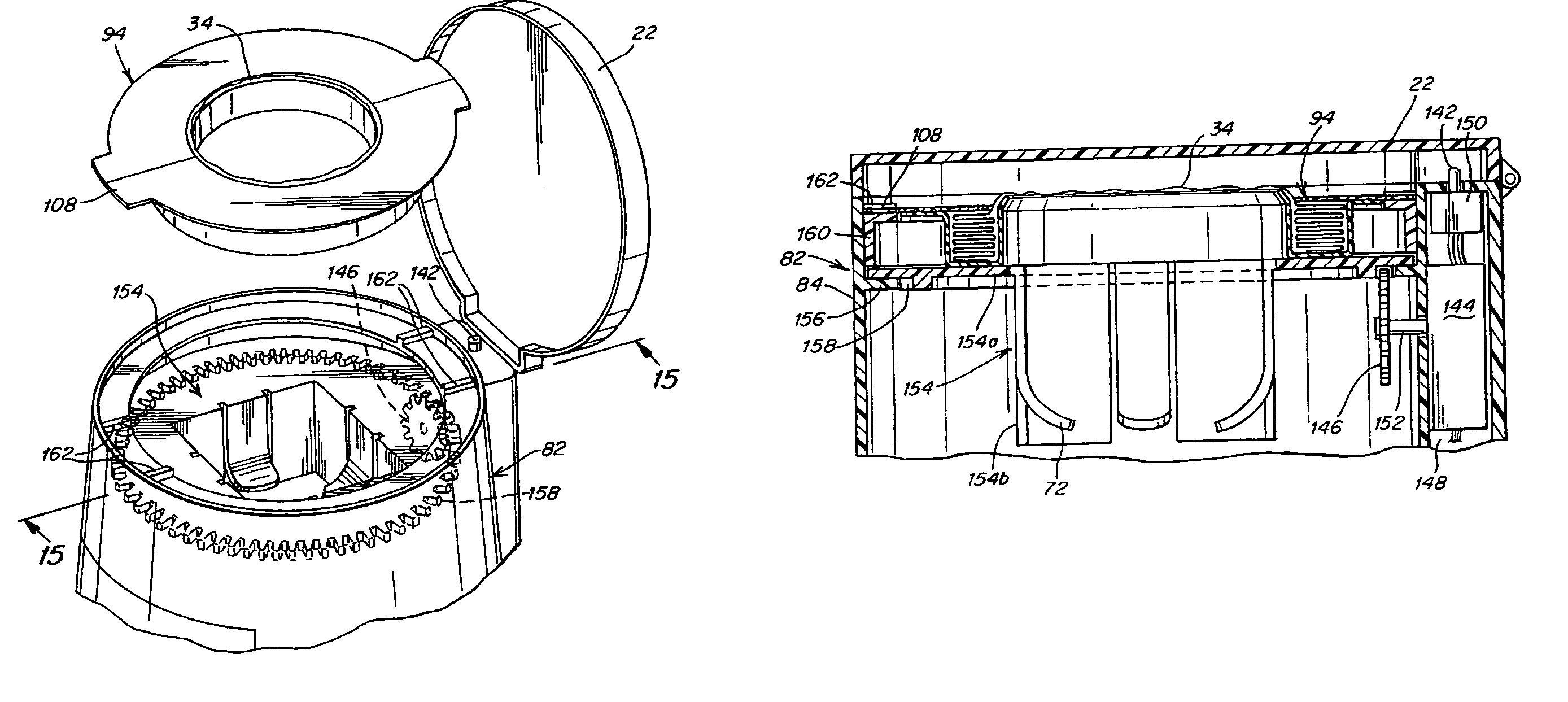

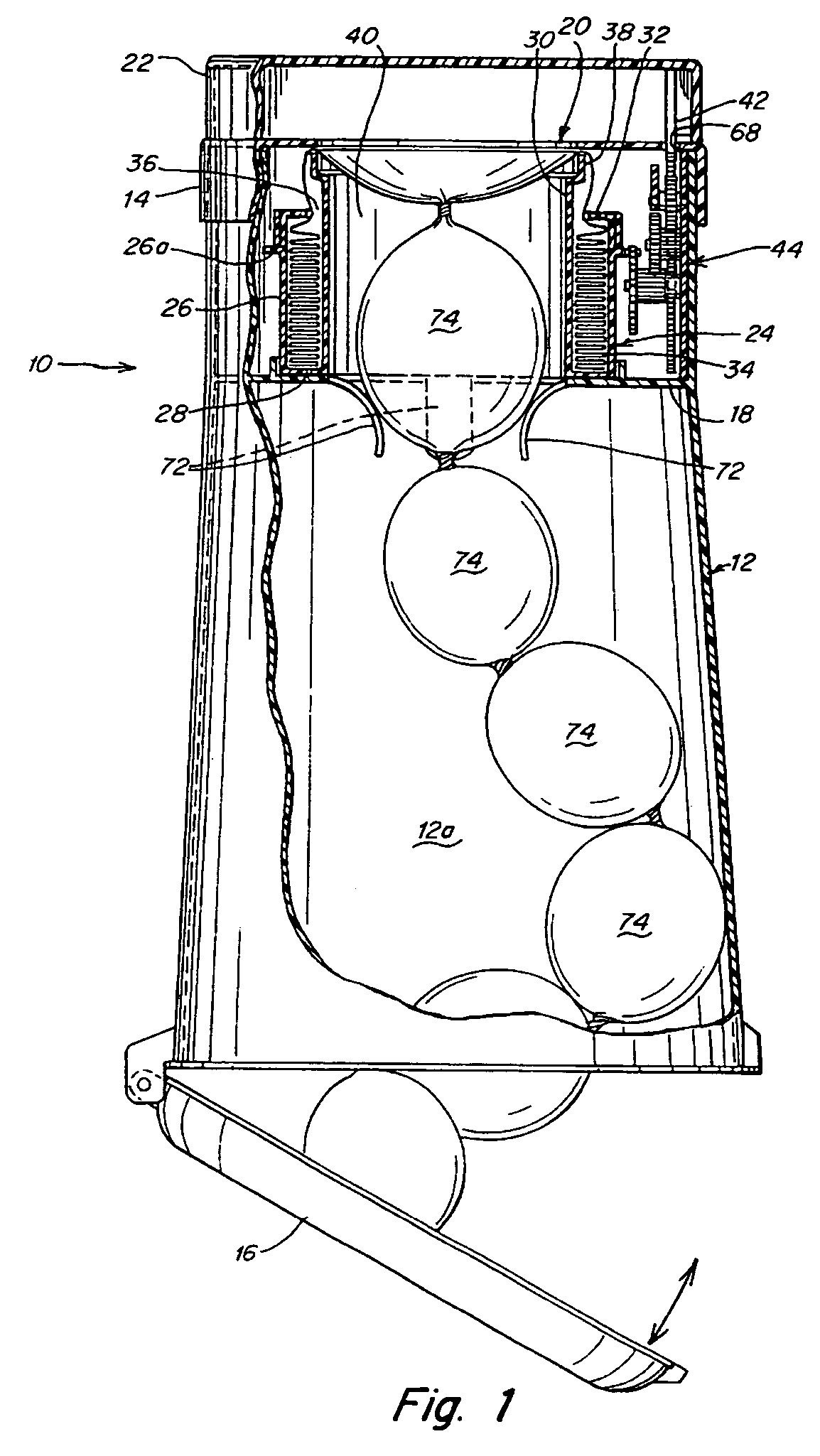

A waste disposal device including a sensing mechanism for delaying the rotation of a cartridge. The waste disposal device comprises a container defining a waste chamber for receiving encapsulated waste in a flexible tubing. The rotatable cartridge contains the flexible tubing. A lid is coupled to the device and is capable of moving between an open and closed position on the container. A rotation mechanism is operatively configured to engage the rotatable cartridge. A sensing mechanism is arranged to allow for delay in rotation of the cartridge until the lid assumes the closed position so that the waste is encapsulated in the flexible tubing after the closing of the lid, and after the subsequent twisting of the flexible tubing about the waste material caused by the rotation of the cartridge.

Owner:PLAYTEX PROD INC

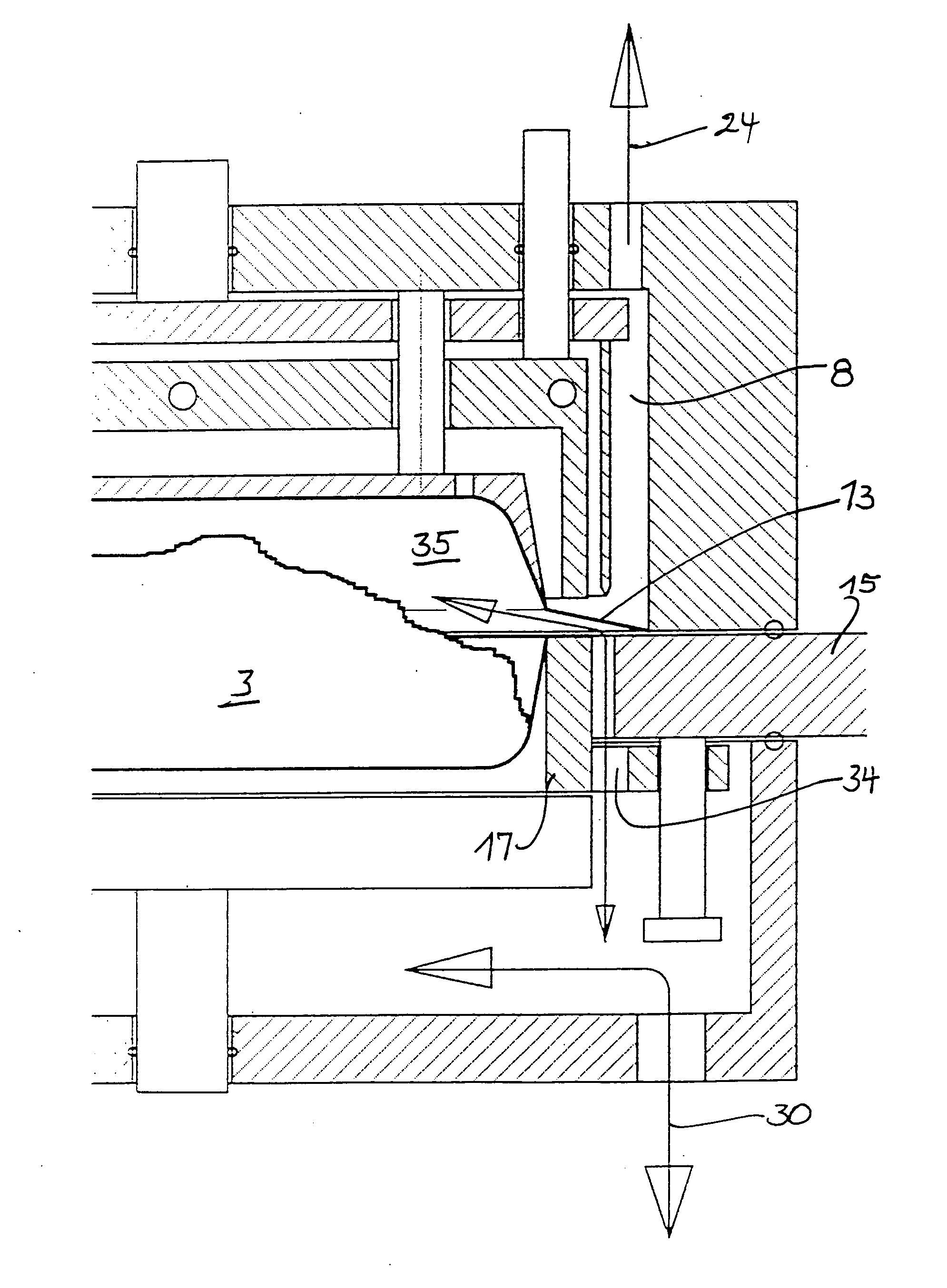

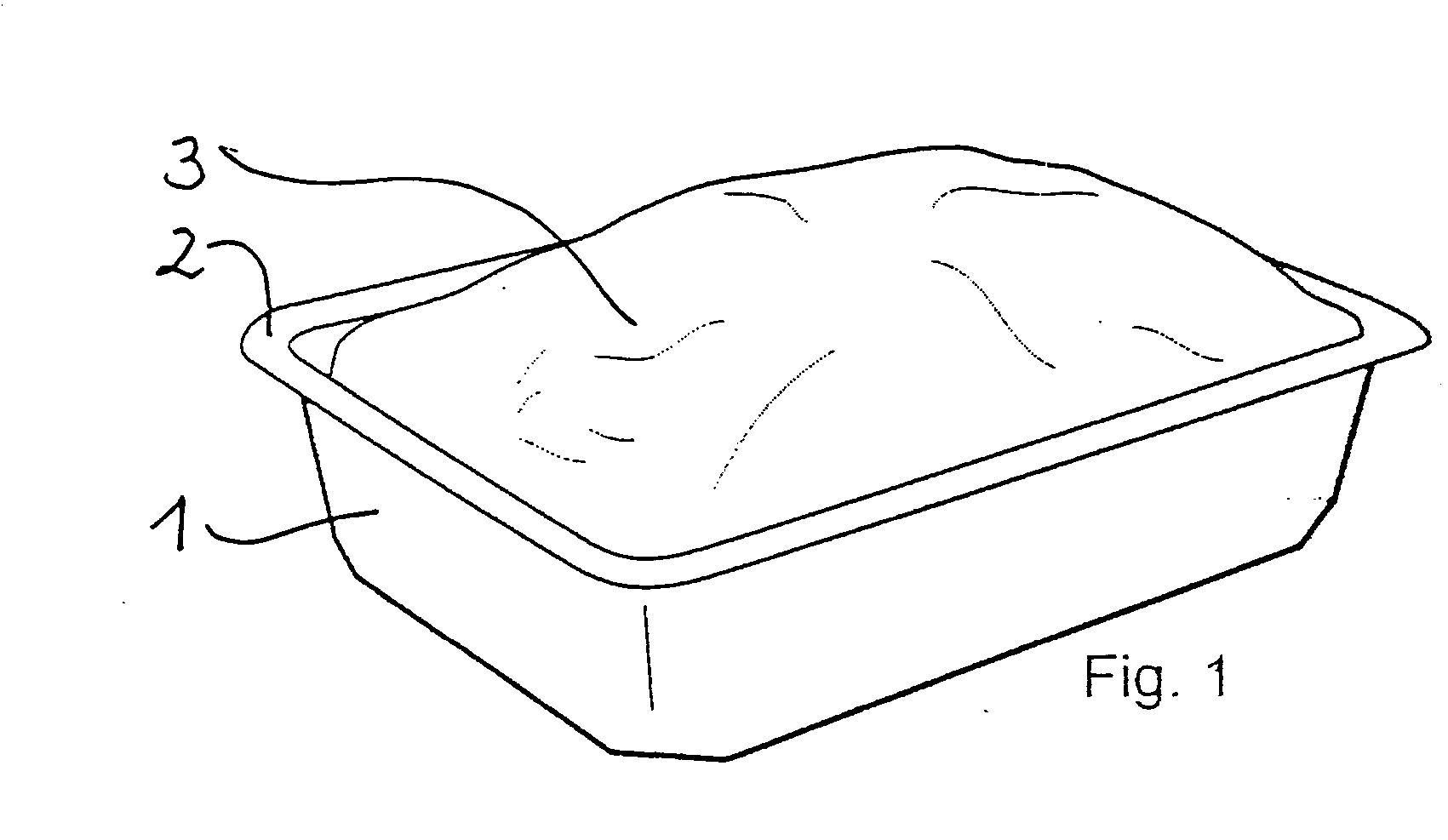

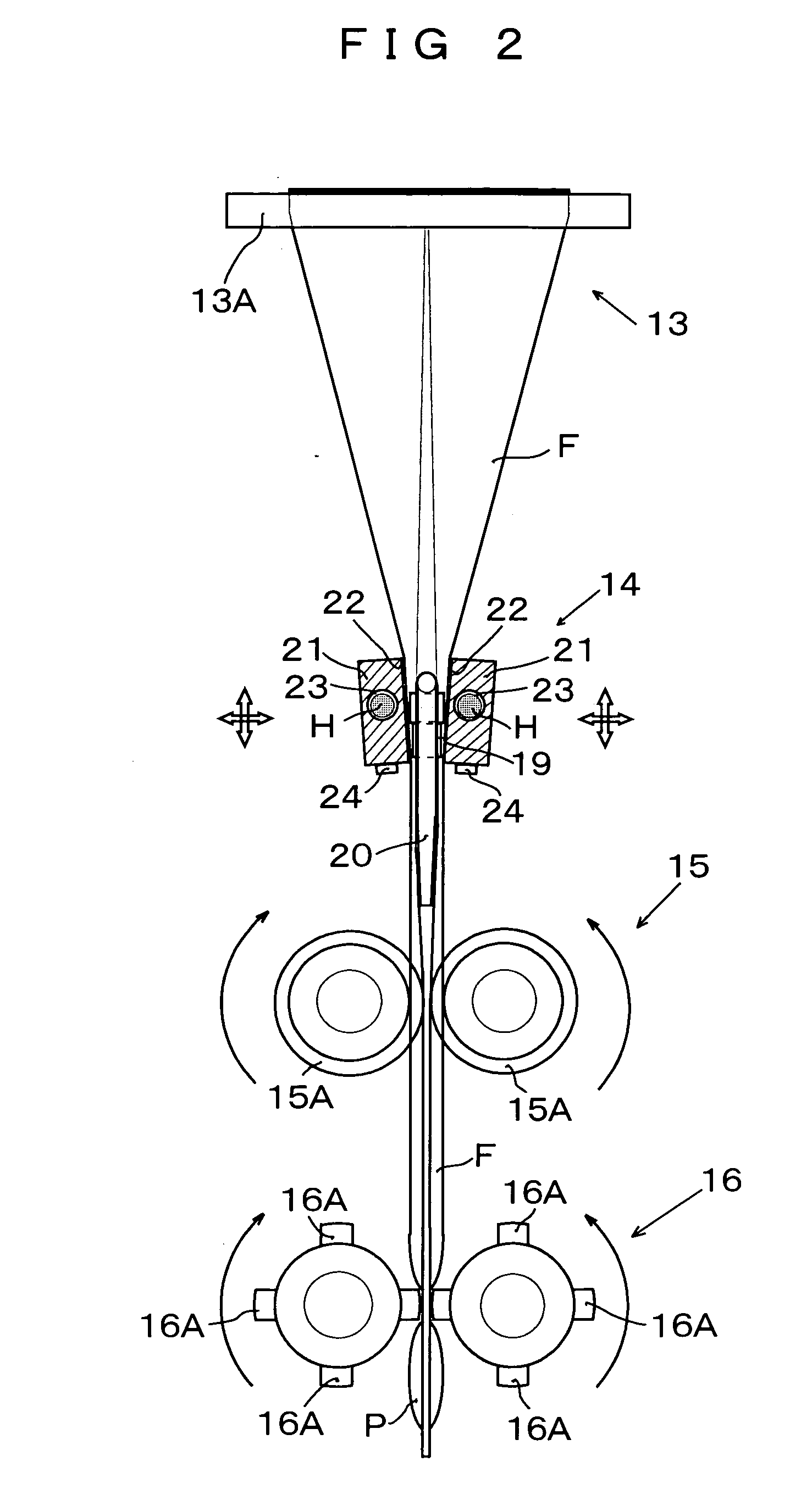

Method and packaging machine for packaging a product arranged in a tray

InactiveUS20050257501A1Reliable manufacturingImprove presentationPackaging by pressurising/gasifyingPackaging under vacuum/special atmosphereEngineeringPackaging machine

A method for packaging a product arranged in a tray is provided. An upper film located in a distance above the product is clamped along an edge surrounding the tray and is deformed in a direction extending away from the product. Subsequently, evacuating of the space surrounding the product is performed, then a raising of the tray towards the upper film and finally a sealing of the film and of the edge of the tray. In this way, the seam of the upper film and the edge of the tray is attained to be free from creases such that a long-living and good looking package is produced. Additionally, a packaging machine for performing the method is provided.

Owner:CREAVIS GES FUER TECH +1

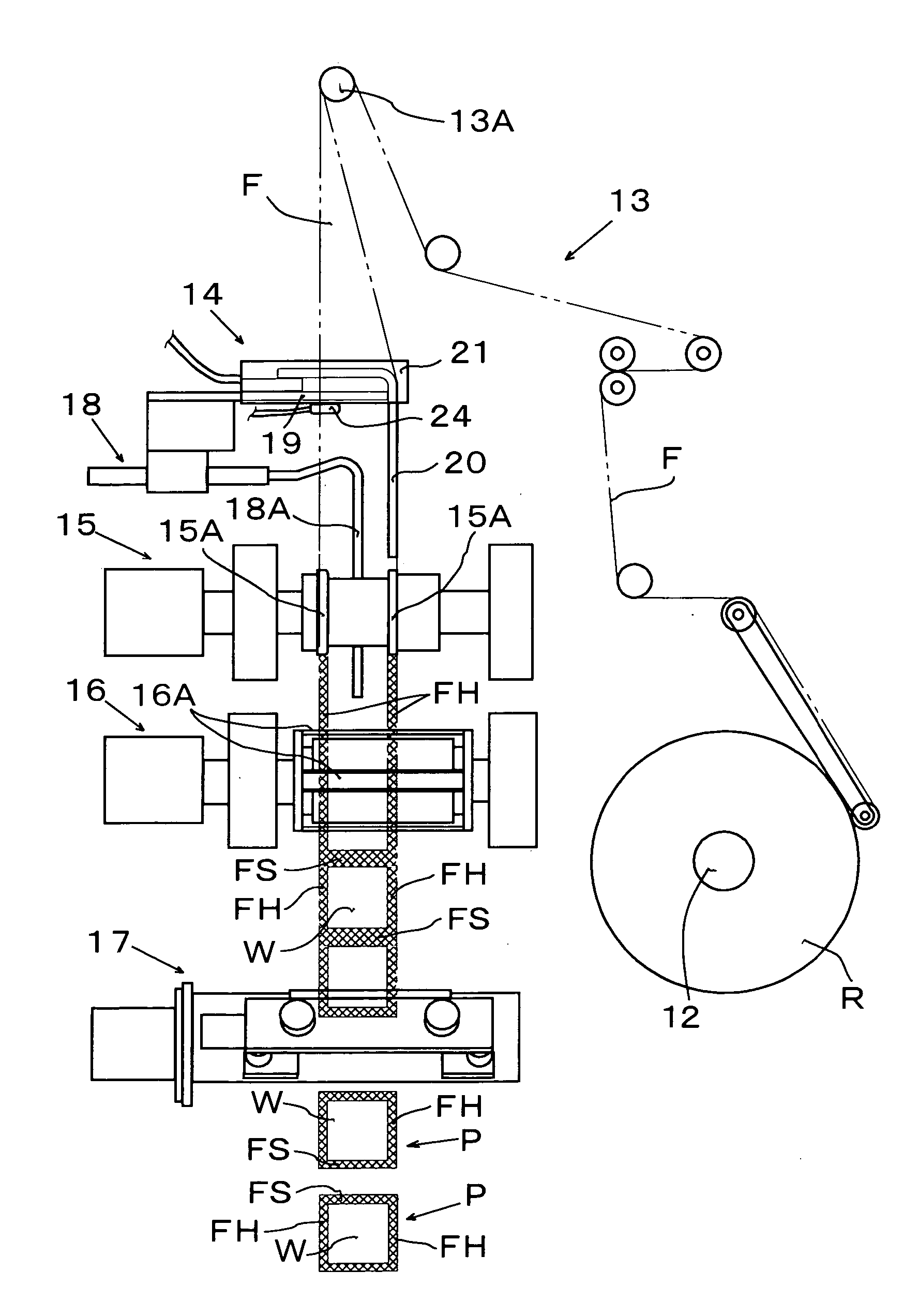

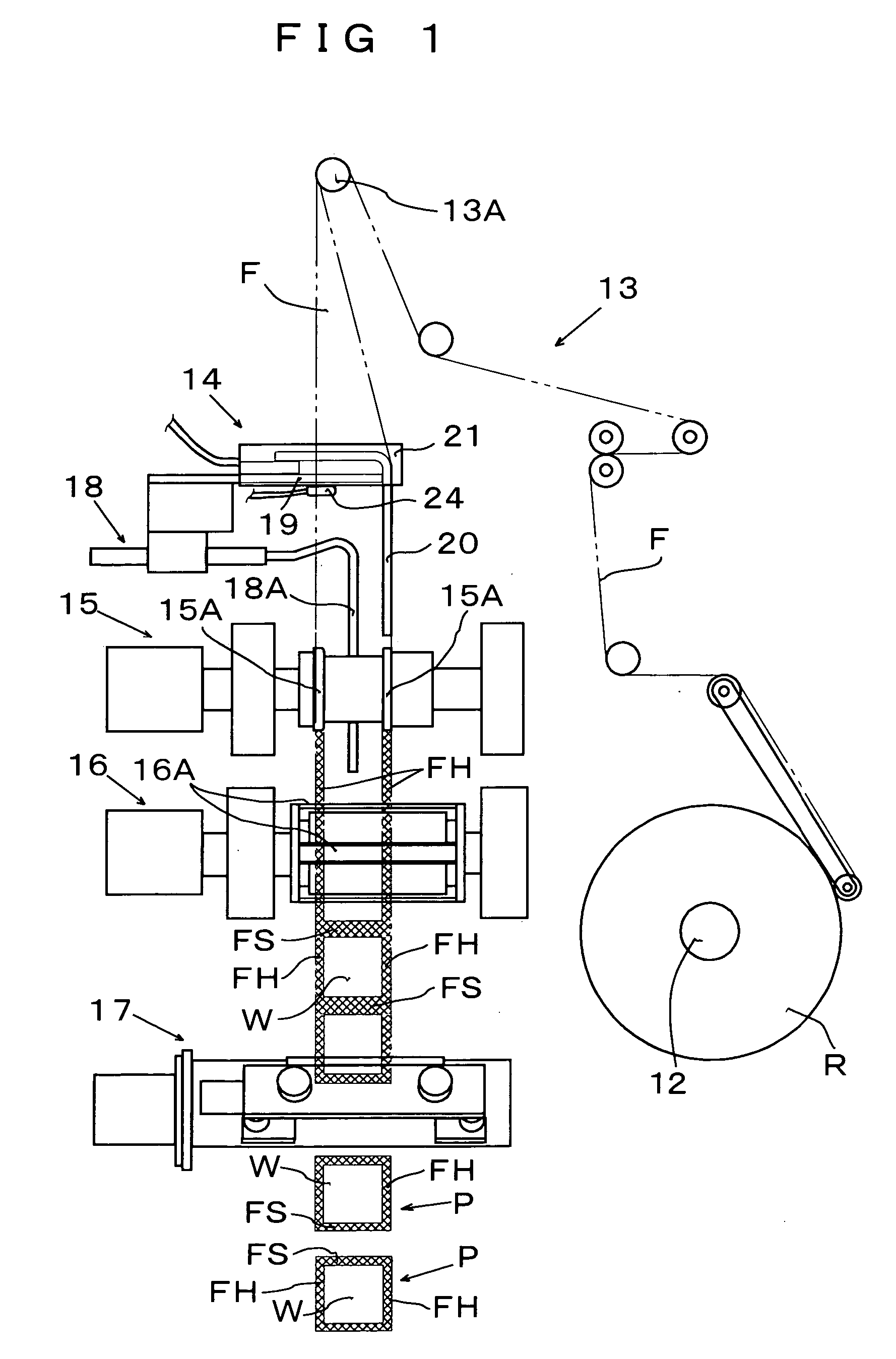

Filling and packaging machine

InactiveUS20060021300A1Melted excellentlyImperfect heat sealingWrappers shrinkagePaper-makingEngineeringSupport surface

A filling and packaging machine capable of supplementing the shortage of heat quality without lowering package speed when a film is heat-sealed while being pressurized by a vertical sealing mechanism, comprising a film folding mechanism having an inner surface guide member for guiding the film laterally, formed on the inner surface side of the film folded up into two parts, a pair of right and left pre-heating block members having tilted support surfaces or are support surfaces formed along the width-direction of the film on the outer surface side of the film through a specified interval from the inner surface guide member so that the interval on the upstream side of the film in feeding direction is larger than the interval on the downstream side, and heaters installed in the pre-heating block members.

Owner:NIPPON SEIKI CO LTD

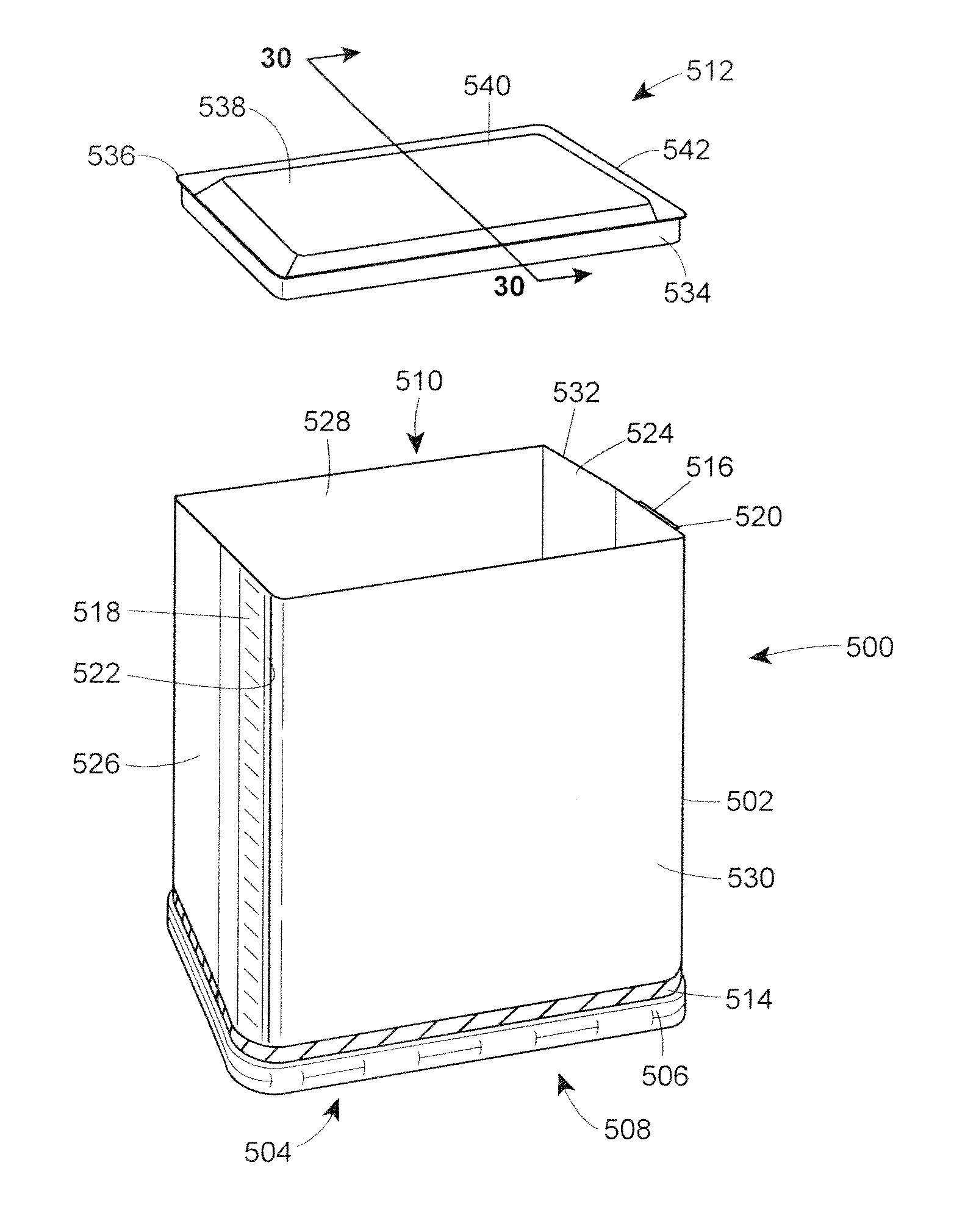

Waste storage device

InactiveUS20050044819A1Create efficientlySolve the lack of spaceRefuse receptaclesWrapper twisting/gatheringWaste disposalEngineering

The present invention discloses an automated sealing waste disposal apparatus using tubular material.

Owner:CHOMIK RICHARD S +5

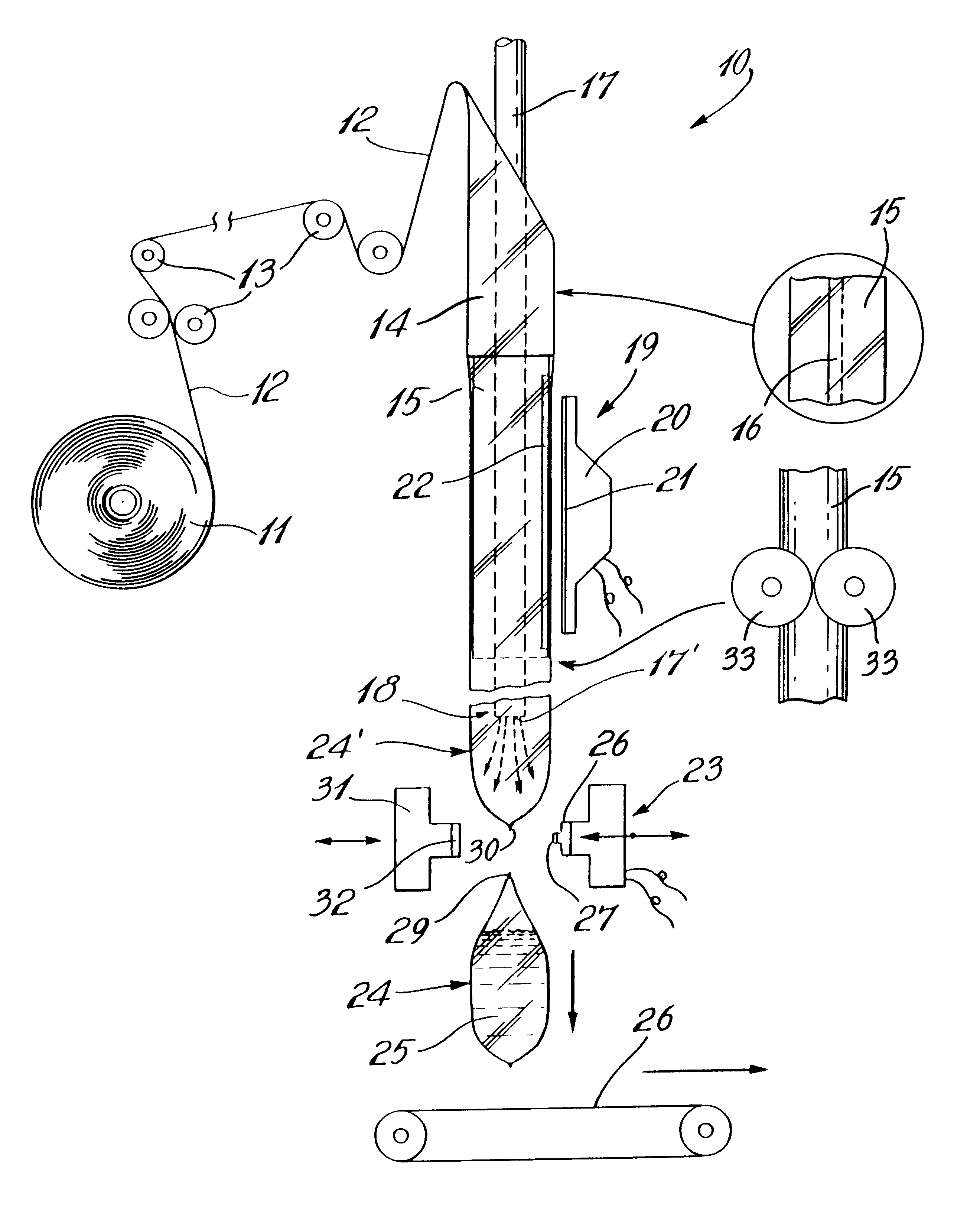

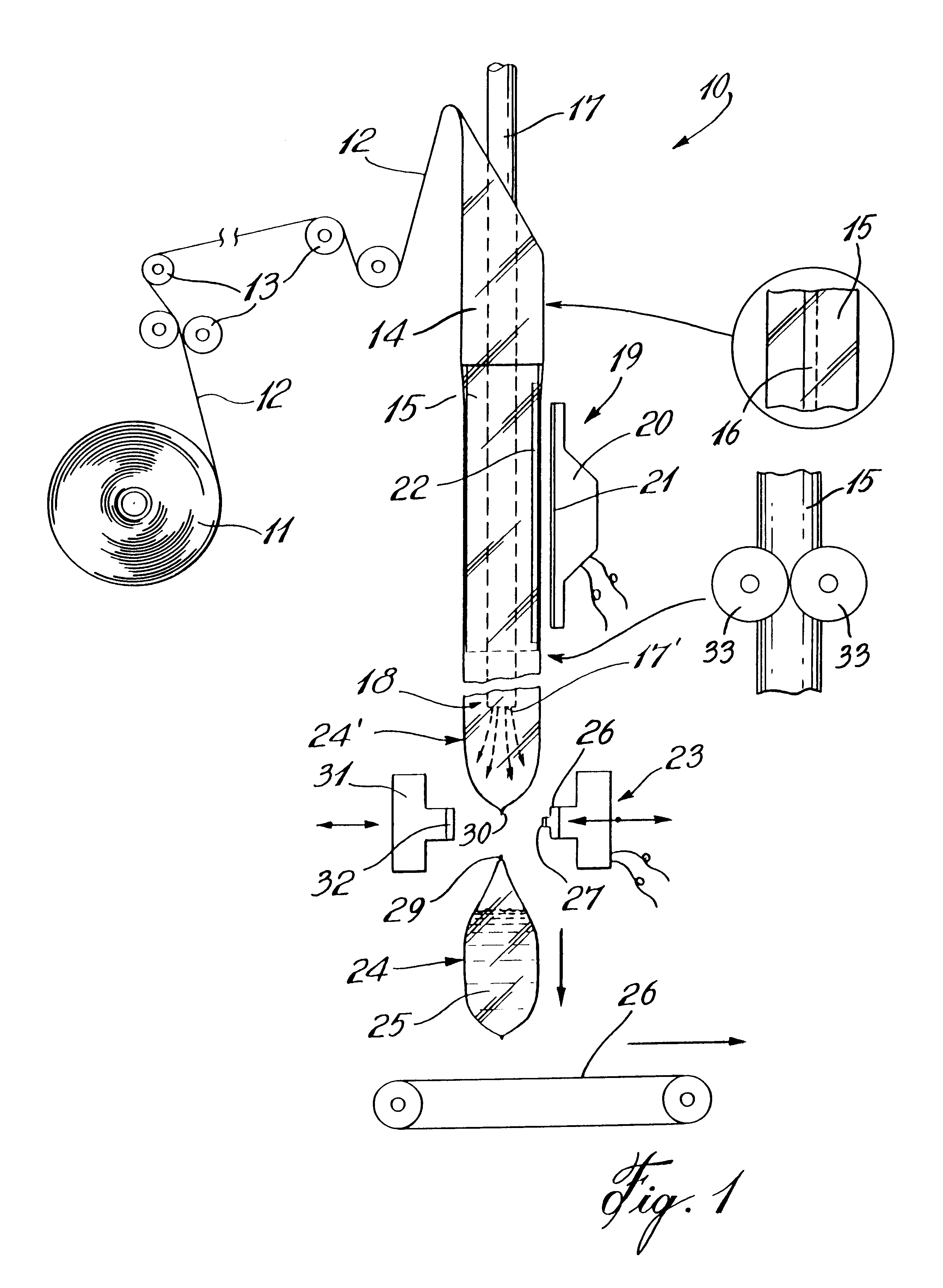

High-speed pouch forming, sealing and filling machine, method of operation, and multi-layer film therefore

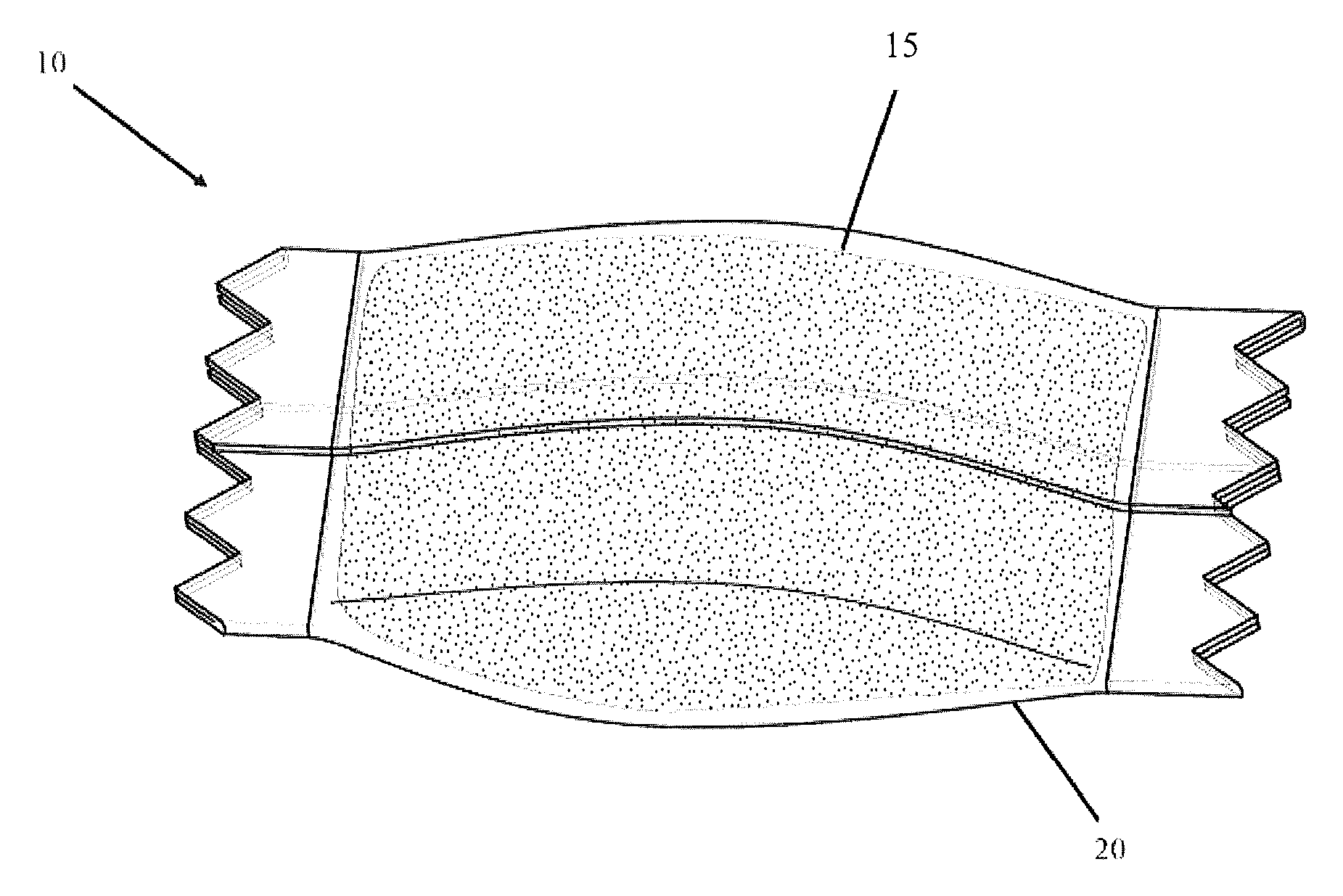

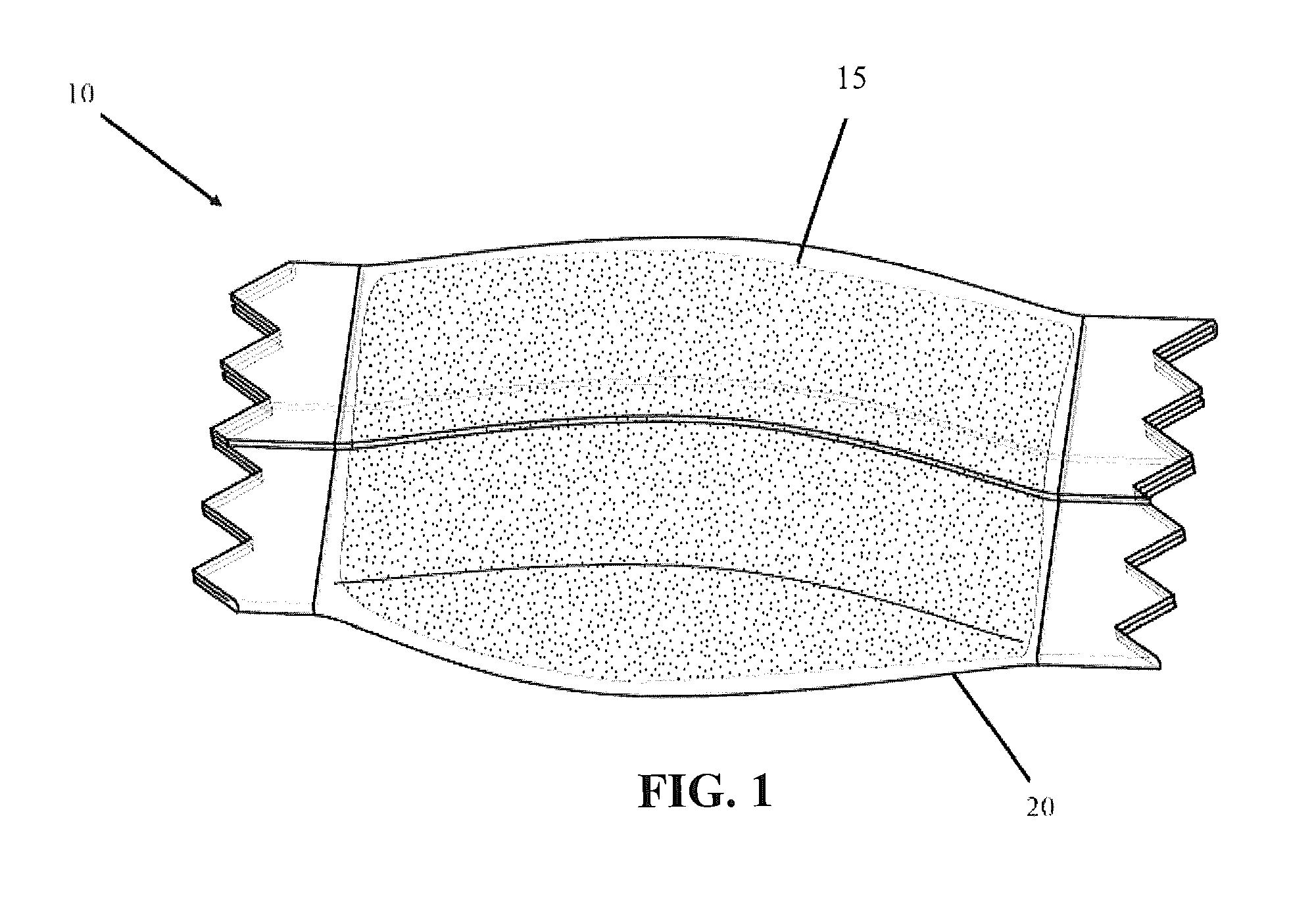

InactiveUS6237308B1Improve methodImprove throughputSynthetic resin layered productsWrapper twisting/gatheringPuncture resistanceEngineering

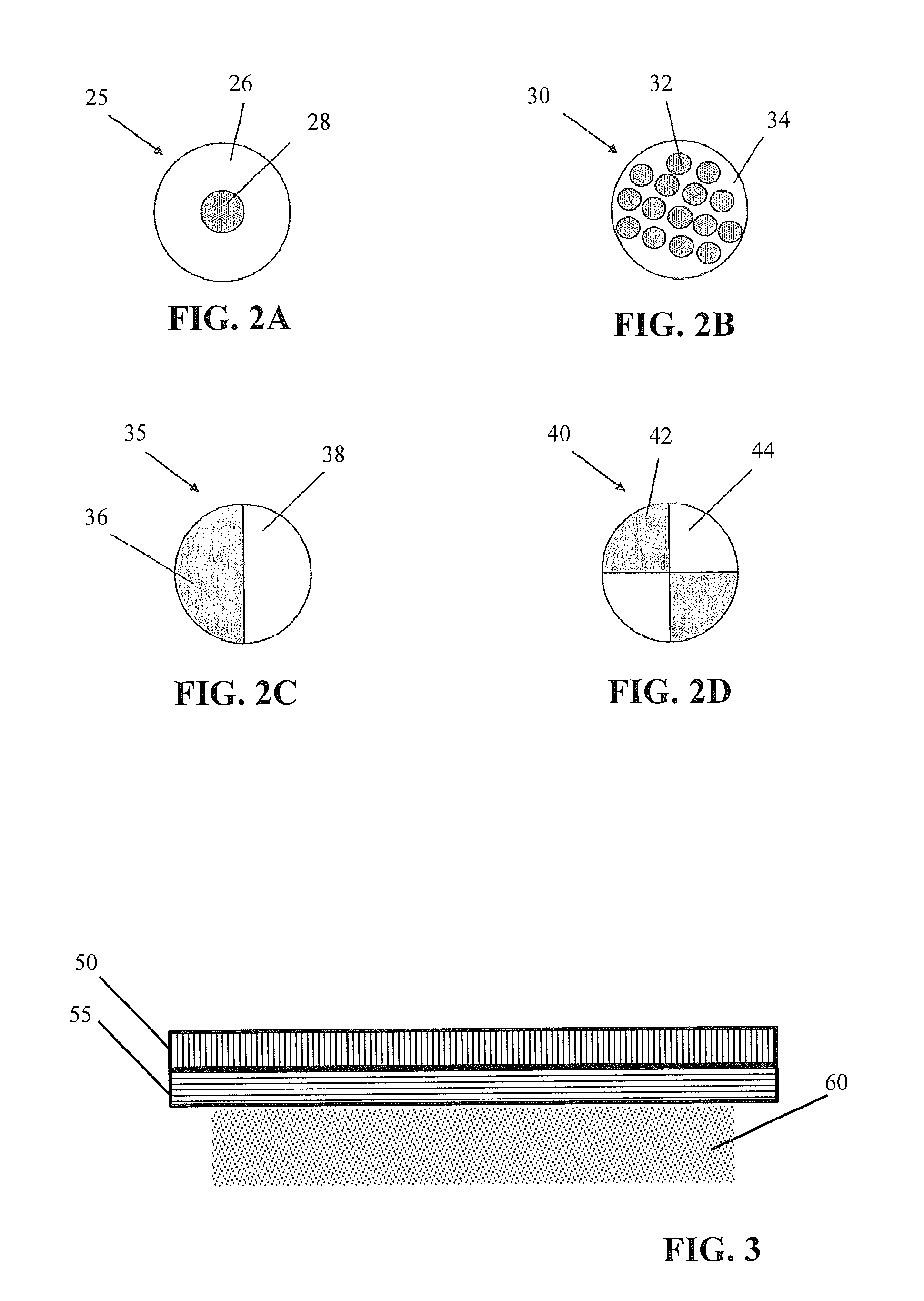

The multi-layer film structure having an inner sealing layer which comprises metallocene resin, a core which includes polypropylene copolymer and an outer layer and wherein the multi-layer film structure has a thickness within a range between about 50 and 70 microns (2.0-2.75 mil). By utilizing this thin film with specific properties the sealers may be operated at lower temperatures thereby resulting in an energy saving and they produce seals having improved seal strength of 30% to 50% as compared with known prior mono-layer polyethylene film. The seal initiation temperature is reduced by 10° C. to 15° C. and the film exhibits an improved machine direction tensile strength of 25% to 40% and an improvement of 30% to 50% in puncture resistance as compared with a 76 microns (3 mil) mono-layer polyethylene film. This results in a reduction in the sealing cycle time and an increase in the throughput of the machine. This results in a liquid pouch having a substantial improvement in drop test performance, puncture resistance and seal strength. The machine accomplishes better seals with less energy, requires less downtime for roll changes and maintenance and increase throughput.

Owner:GLOPAK INC

Nonwoven pouch comprising heat sealable binder fiber

Owner:R J REYNOLDS TOBACCO COMPANY

Method and apparatus for making reclosable plastic bags using a pre-applied slider-operated fastener

InactiveUS6871473B1Not adversely impactEasy to modifyEnvelopes/bags making machineryWire articlesThin membraneEngineering

A method and apparatus for making reclosable plastic bags is provided. In the method and apparatus, a fastener is attached to a moving flat web of plastic film, preferably in the direction of web movement and near the center of the web. A plurality of sliders are mounted to the fastener either before or after the fastener is attached to the flat web, but prior to conveying the web to a FFS machine. The flat web, with the slider-operated fastener already attached thereto, is then conveyed to a vertical or horizontal FFS machine where the flat web is formed into bags, and the bags are successively filled and sealed.

Owner:REYNOLDS PRESTO PRODS

Flexible multi-compartment container with peelable seals and method for making same

InactiveUS6996951B2Increase storage capacityIncrease capacityEnvelopes/bags making machineryBoxes/cartons making machineryThermoplasticDiluent

A flexible container is provided for the storage and administration of medical solutions. The container incorporates a transparent front sheet made from a planar layer of a polymer and an opposing rear sheet. The rear sheet is made from a planar laminate layer. The front and rear sheets are sealed together along a common peripheral edge to form a volume enclosure. The volume enclosure is constructed of materials having high oxygen and moisture barrier properties which allows the container thermoplastic to be stored for extended periods of time without degrading the contents. The volume enclosure is then inflated with a pressurized gas to permanently stretch the front and rear sheets outwardly and to thereby increase the volume capacity of the container. An alternative embodiment of the container incorporates multiple compartments, separated by peelable seals, for containing a diluent and a medicament. The seals are ruptured by manipulation of the container to thereby mix the contents together for delivery through standard IV arrangement to a patient.

Owner:B BRAUN MEDICAL

User installable vacuum seal apparatus for storage bags

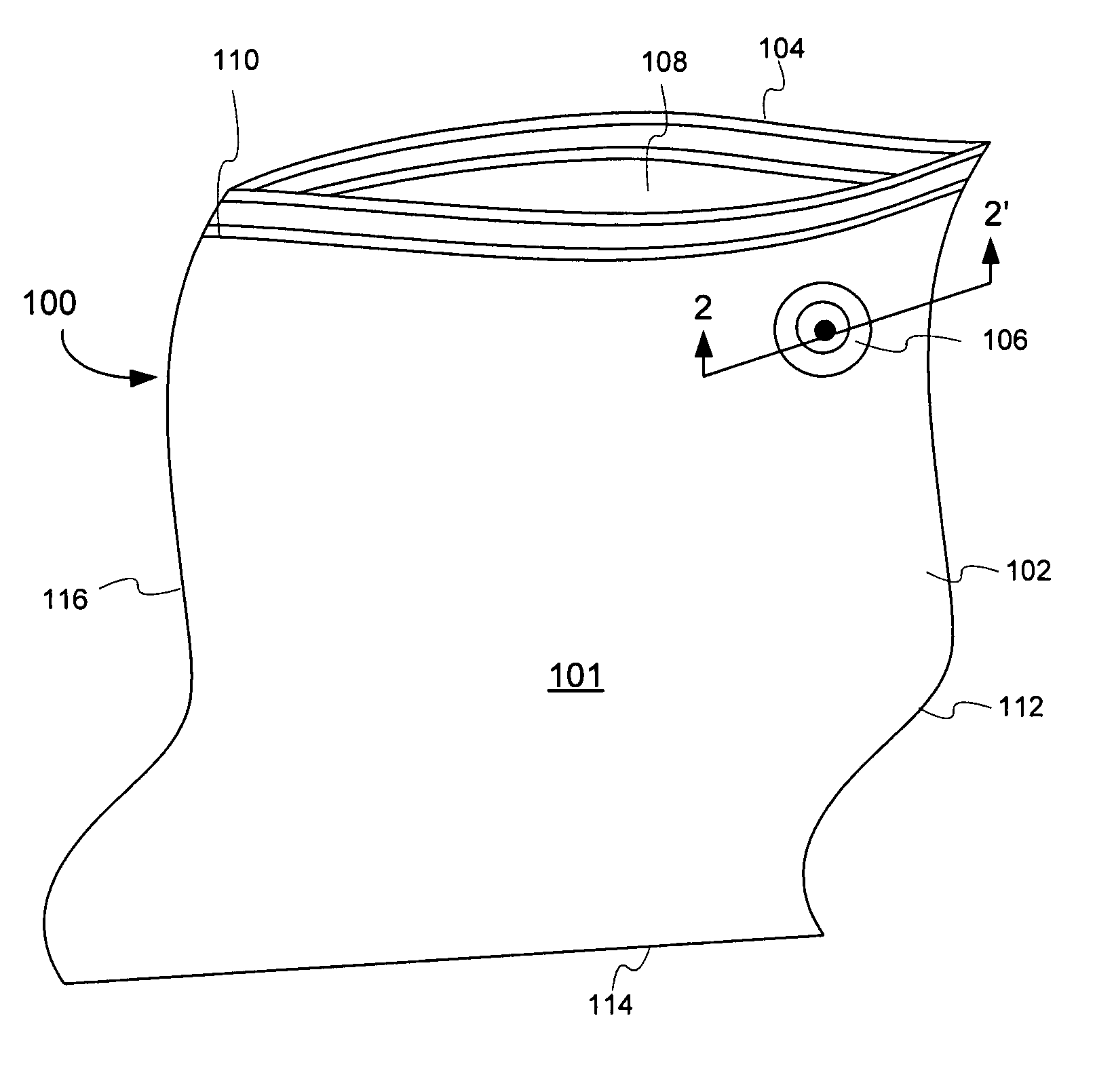

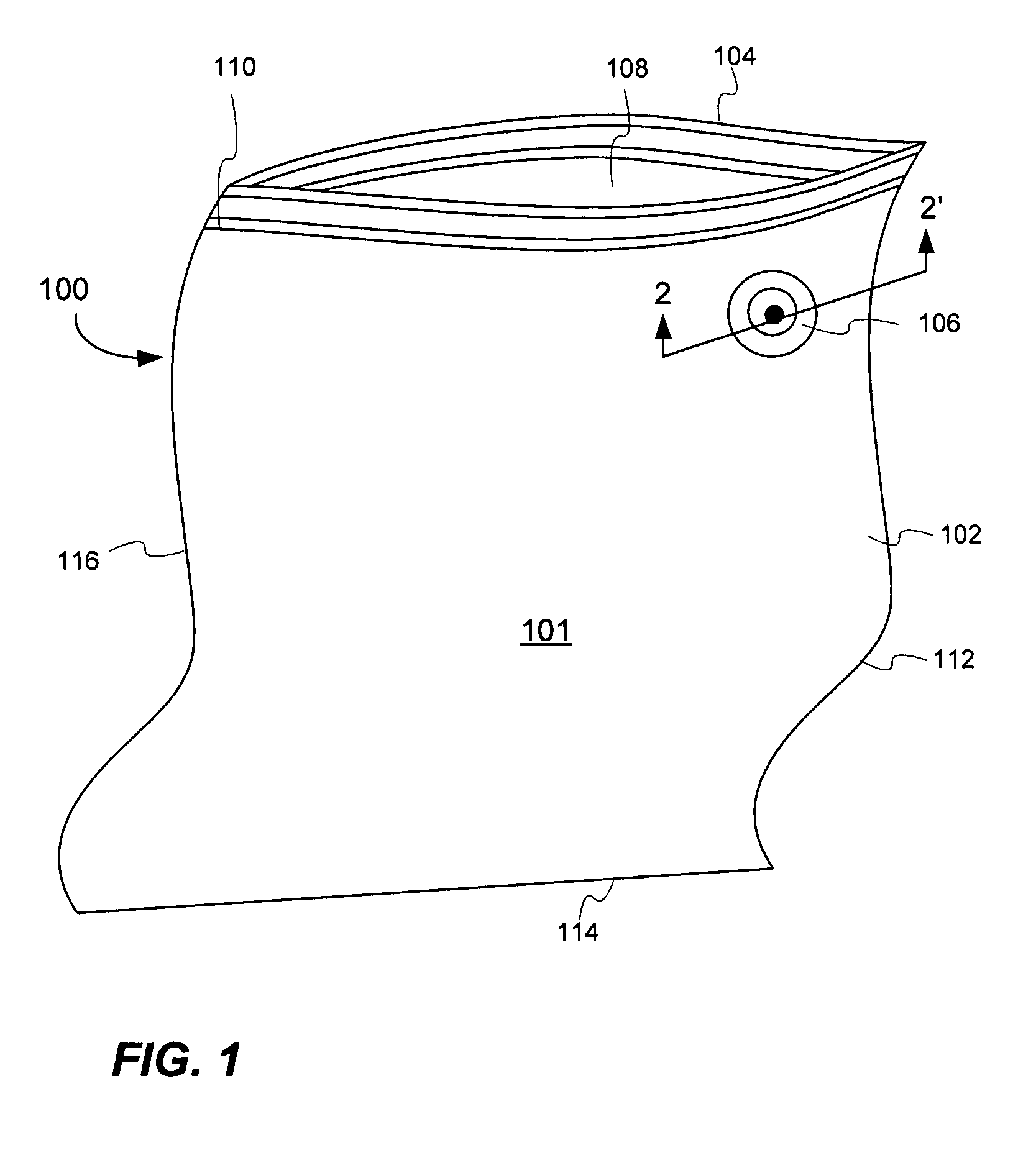

InactiveUS20050172577A1Conveniently removedWrapper twisting/gatheringPackaging under vacuum/special atmosphereVALVE PORTPlastic bag

A valve assembly for use with a self-sealing collapsible storage bag, the valve assembly having a first portion comprising a housing that has a sealing surface and contains a valve mechanism. A second portion has a sealing surface that is configured to mate with the sealing surface of the first portion. A snap mechanism is configured to allow the first and second portions to be snapped together with their respective sealing surfaces facing each other to form a substantially airtight seal. In operation, the first and second portions are positioned on opposing sides of a panel of a plastic storage bag, and snapped together so as to sandwich the panel between the first and second portions of the valve assembly. The plastic bag is pierced in the area of the valve assembly either during installation of the valve assembly, or later by insertion of a nozzle. Gas or fluid such as air may be selectively removed from or added to the interior of the storage bag through the valve mechanism.

Owner:SAFETY SOLUTIONS

Full-automatic bag-feeding type packaging machine

InactiveCN101837845AImprove packaging efficiencyAvoid the problem of not being able to hold the bagWrapper supporting apparatusWrapper twisting/gatheringRotating discPackaging machine

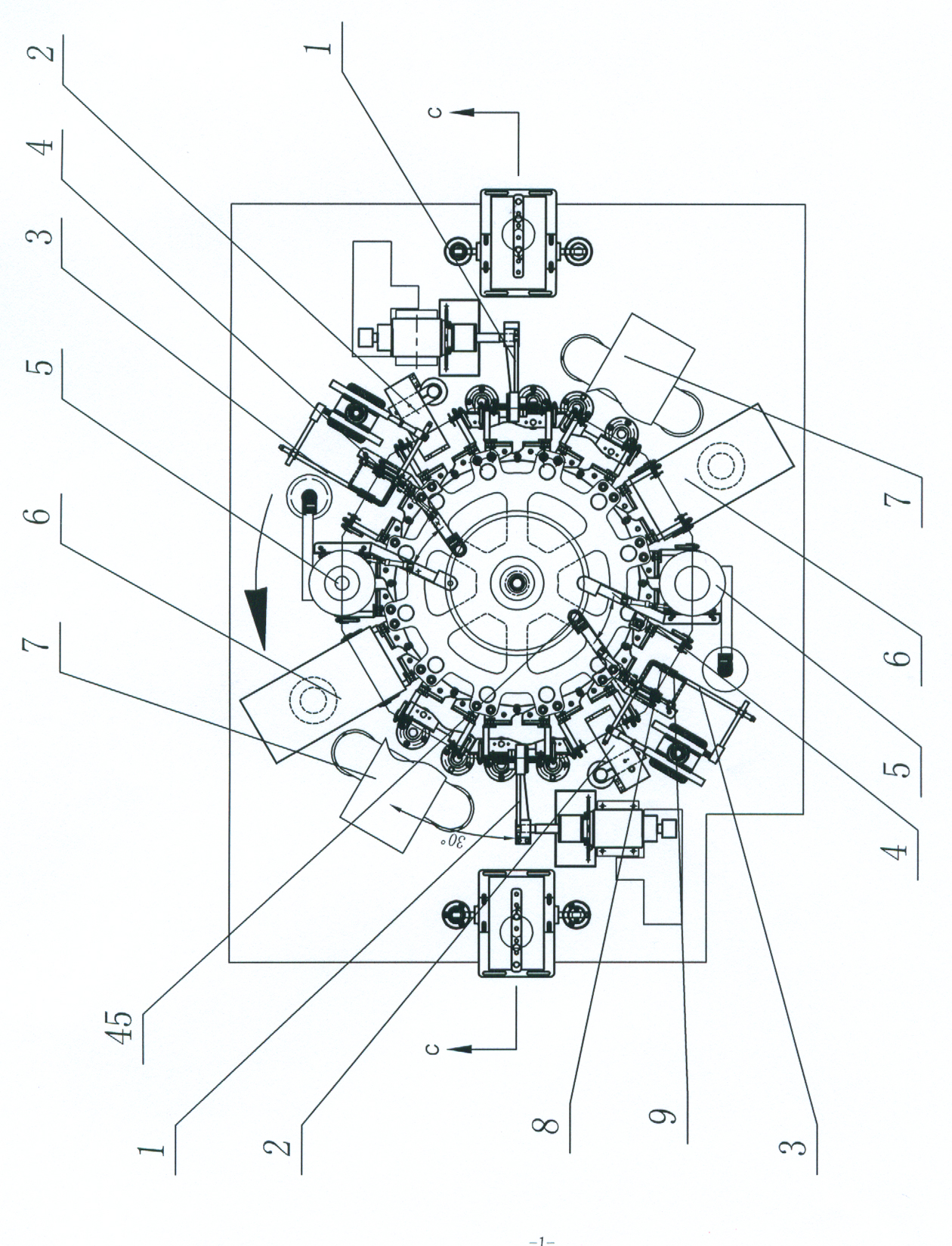

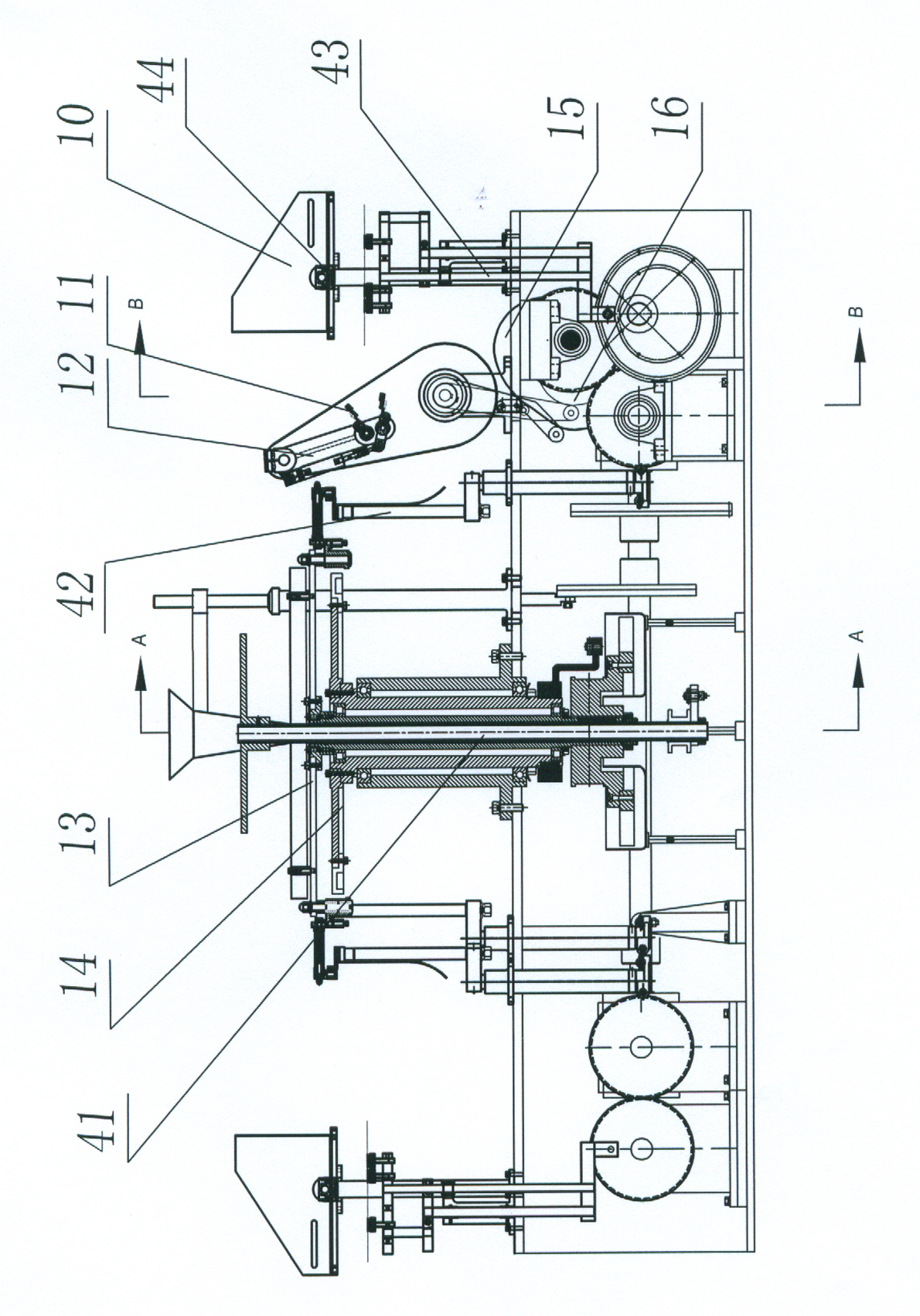

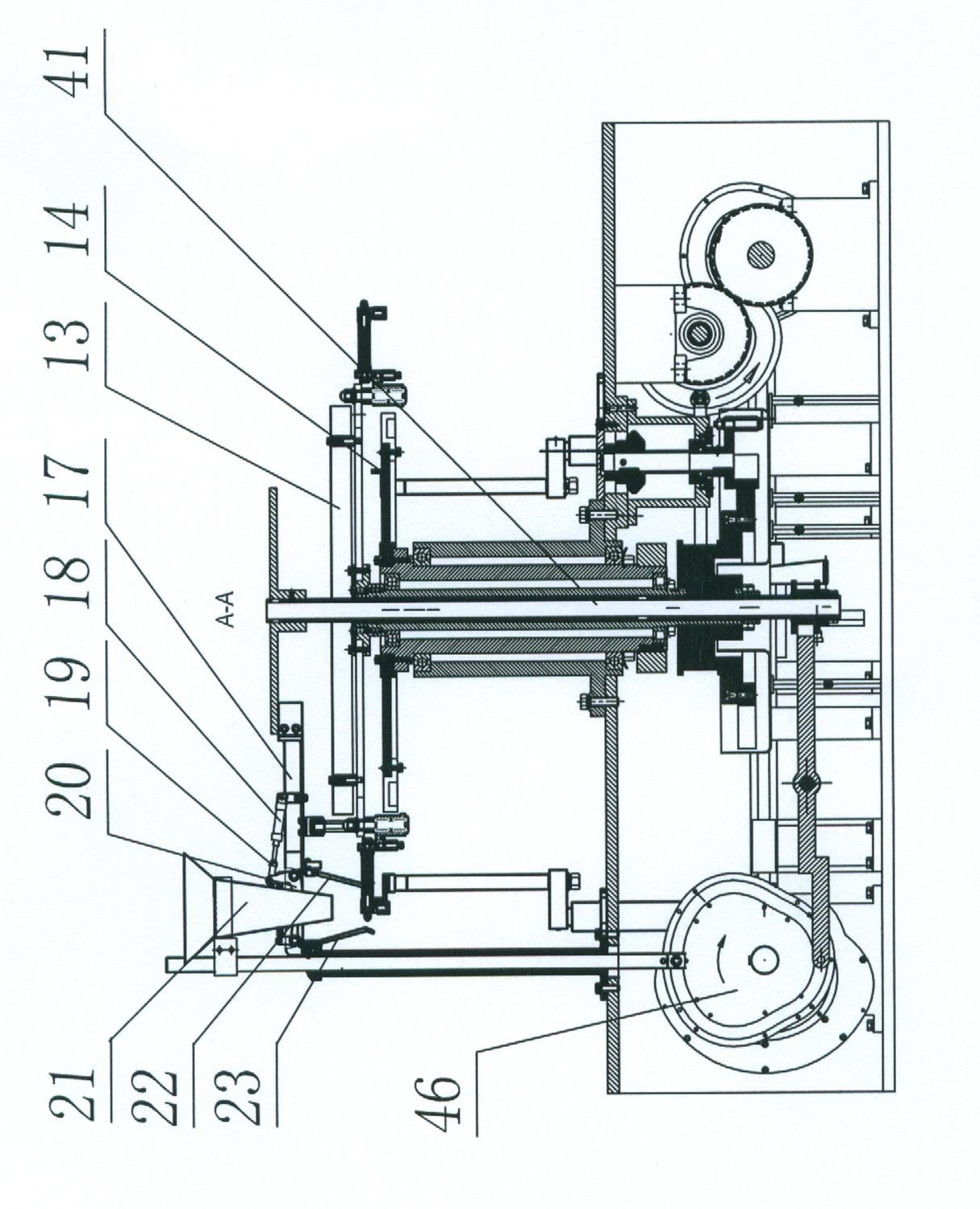

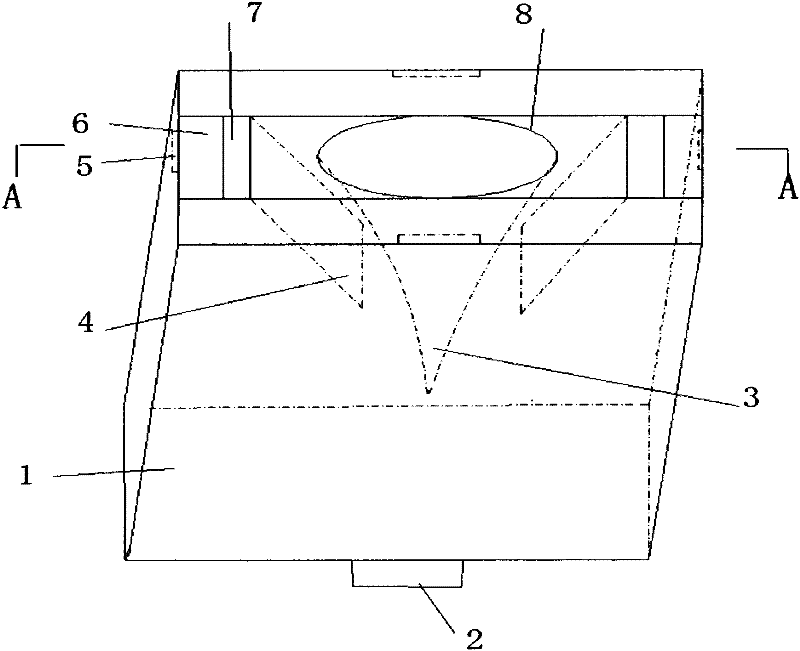

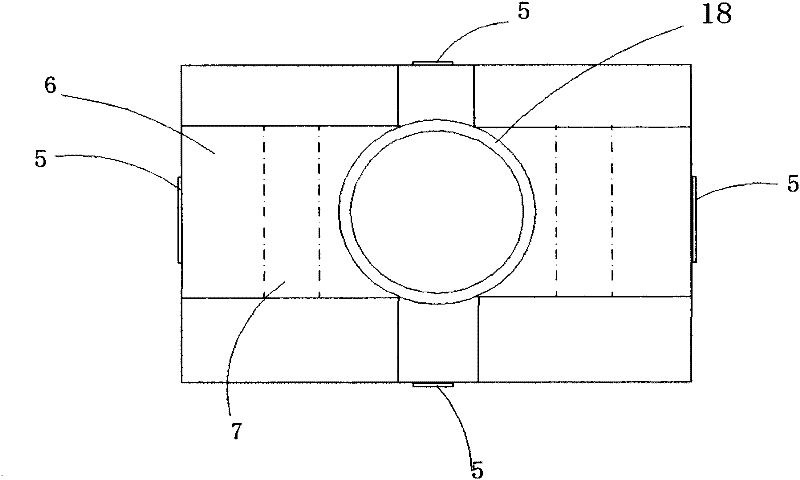

The invention discloses a full-automatic bag-feeding type packaging machine, comprising a rotating disc (13), a large cam (14), a bag feeding device (1), a marking device (2), a bag opening device (3), a material charging device (5), a heat-sealing device (6), a bag discharging device (7) and a bag bracing device (4). A bag clamping device (39) is arranged at the edges of the rotating disc (13); the bag feeding device (1), the marking device (2), the bag opening device (3), the material charging device (5), the heat-sealing device (6) and the bag discharging device (7) are all arranged outside the rotating disc (13); and the bag bracing device (5) is of a swing arm type and is movably mounted on the rotating disc (13). The packaging machine is characterized in that the bag feeding device (1), the bag opening device (3), the material charging device (5), the heat-sealing device (6) and the bag discharging device (7) are symmetrically arranged around the central point of the rotating disc (13); and the bag bracing device (4) is symmetrically arranged around the central point of the rotating disc (13). The full-automatic bag-feeding type packaging machine with the structure has the advantages of stable performance and high production efficiency.

Owner:WENZHOU READOR MACHINERY

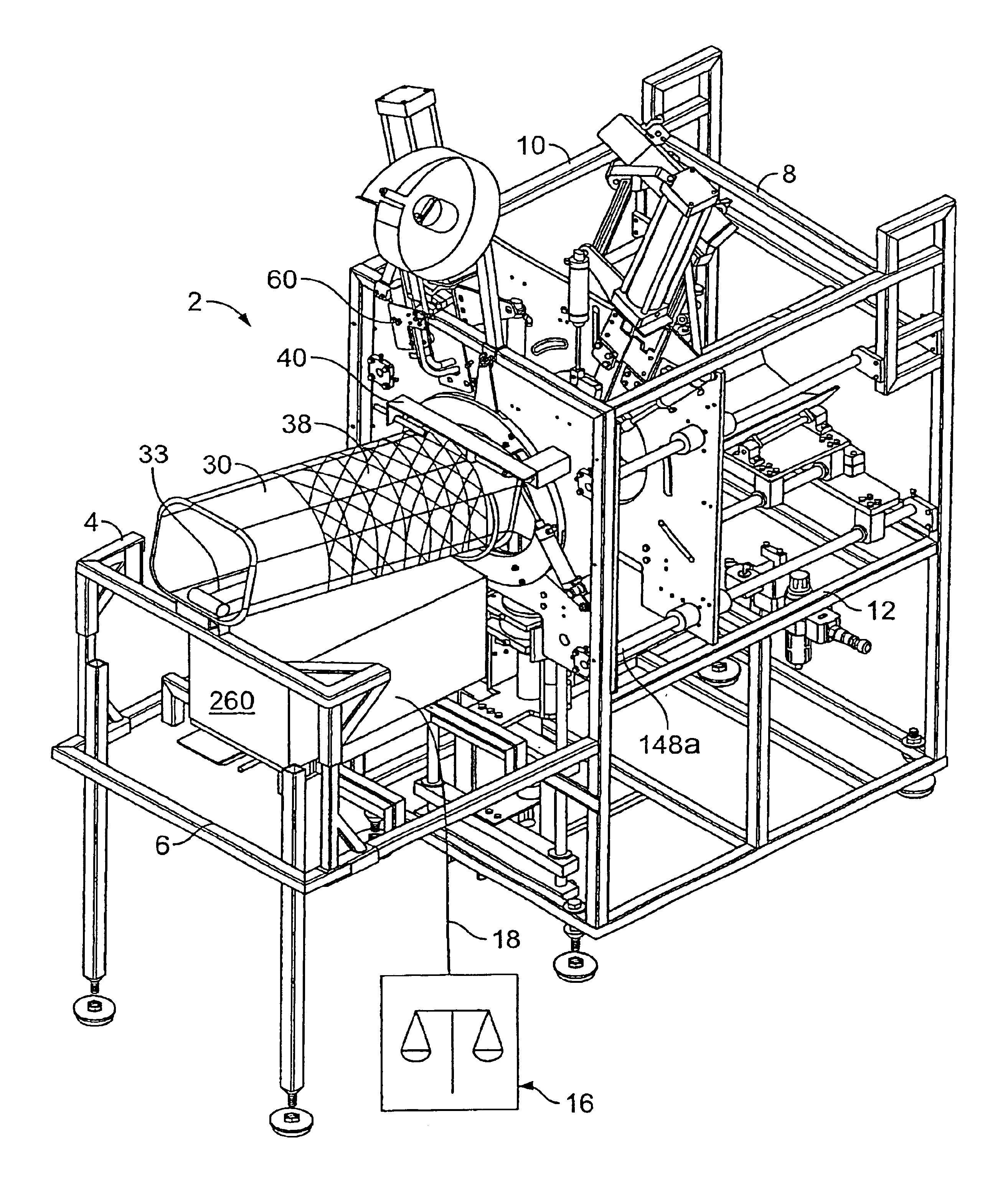

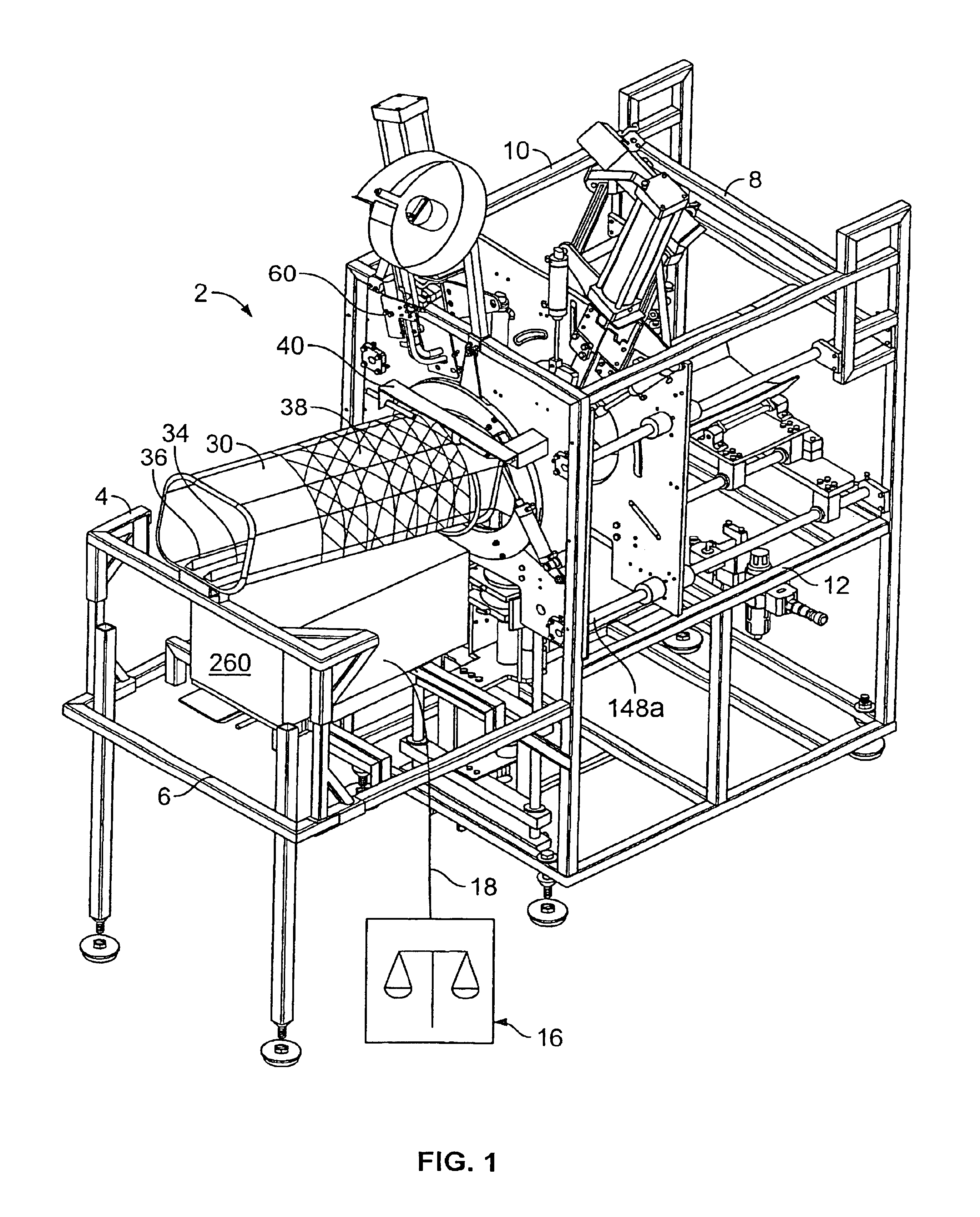

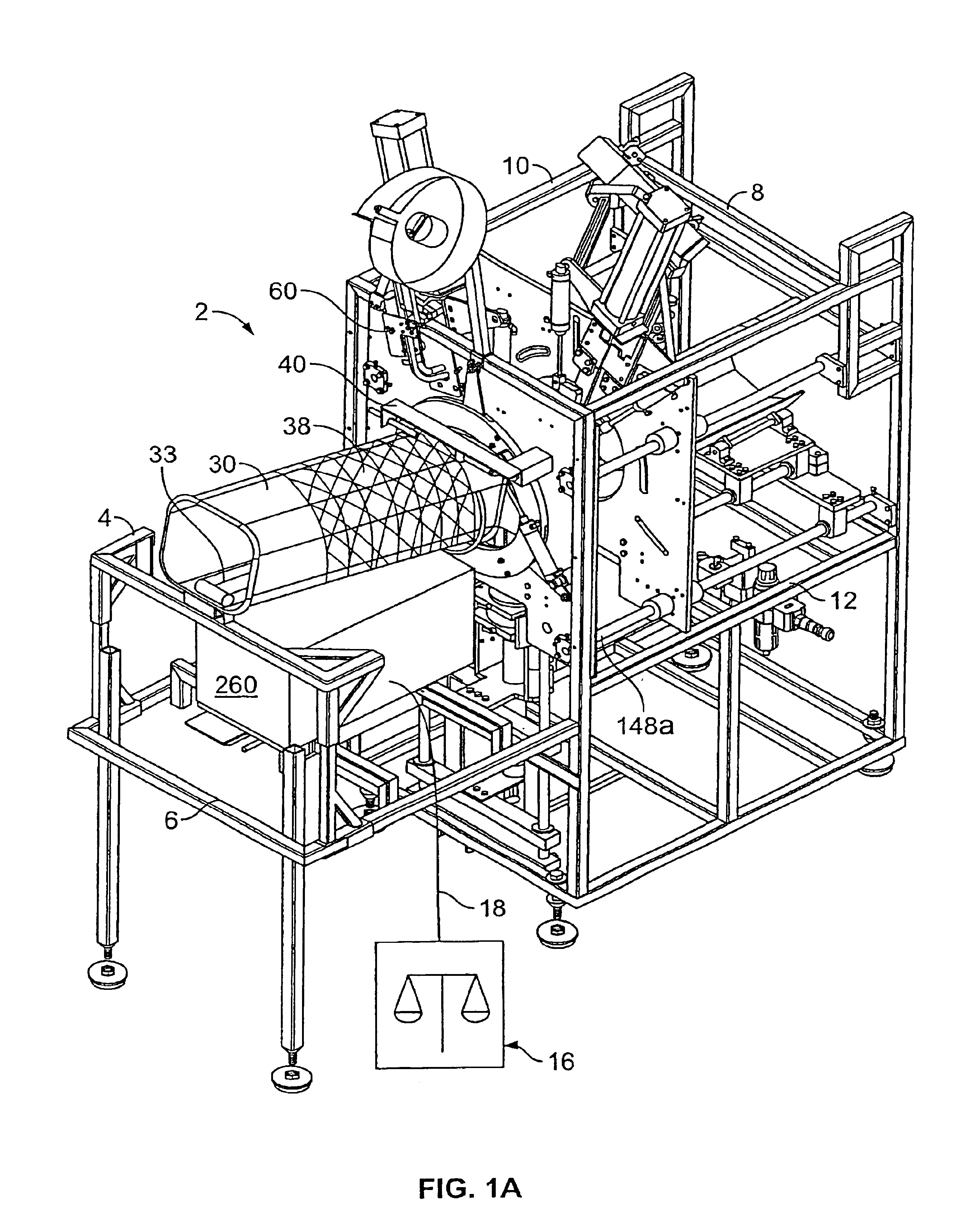

Apparatus for enclosing material in a net

InactiveUS6883297B2Uniform appearanceLighten the taskAffixing tagsSkinless sausage makingEngineeringMechanical engineering

An apparatus and method of enclosing material in a net and supplying a handle for ease of carrying the netted material, comprising clippers, irises, and a handle maker. A conveyor carries the material to a pair of irises. The irises gather the netting around the material, the first clipper cuts and closes the netting, and the handle maker forms a loop out of the severed netting. The second clipper attaches the loop back to the netting to form a handle. A scale can be used to weigh the material and a printer can create a label, with the weight or whatever other information is desired, for attachment to the netting.

Owner:POLY CLIP SYST

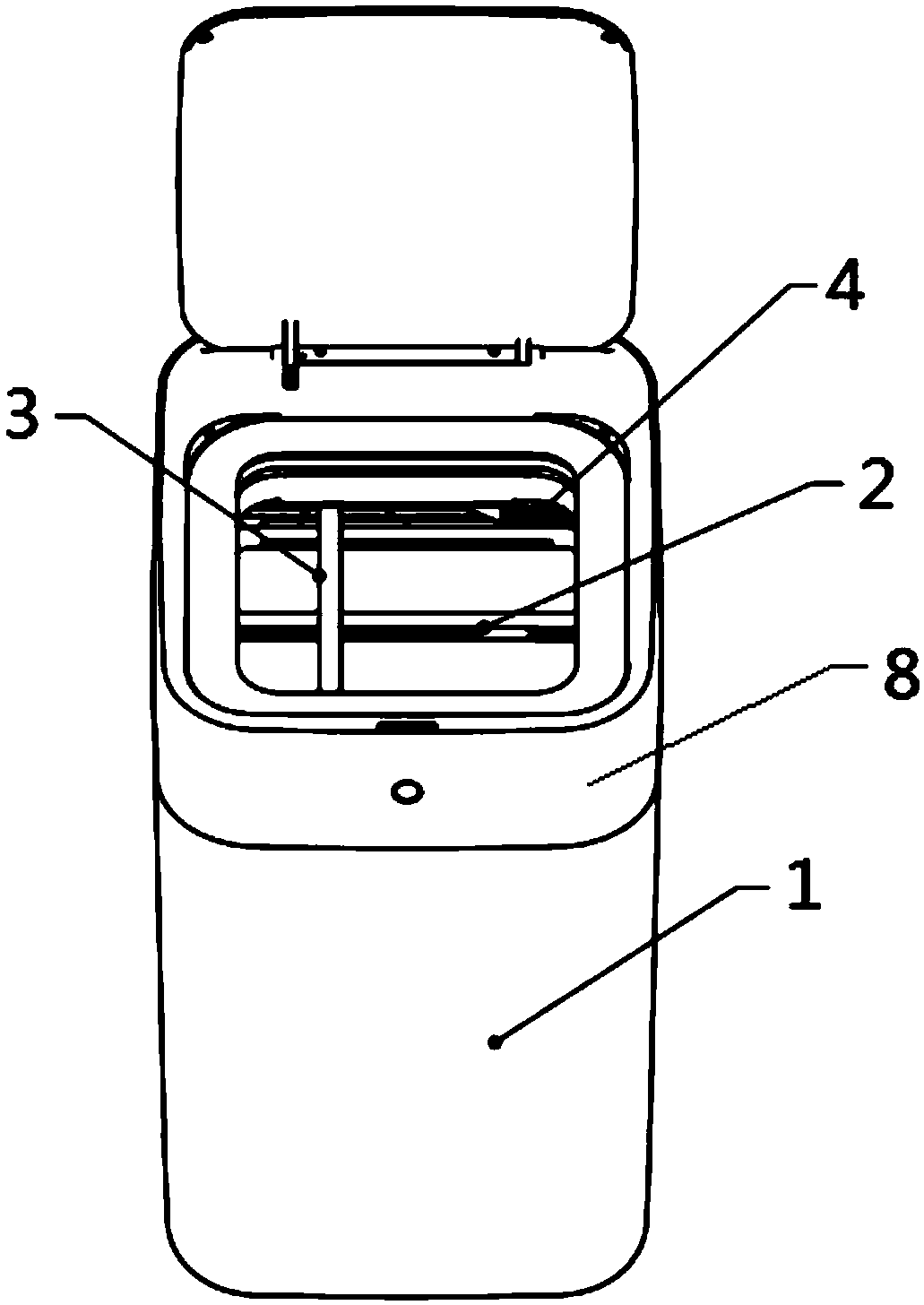

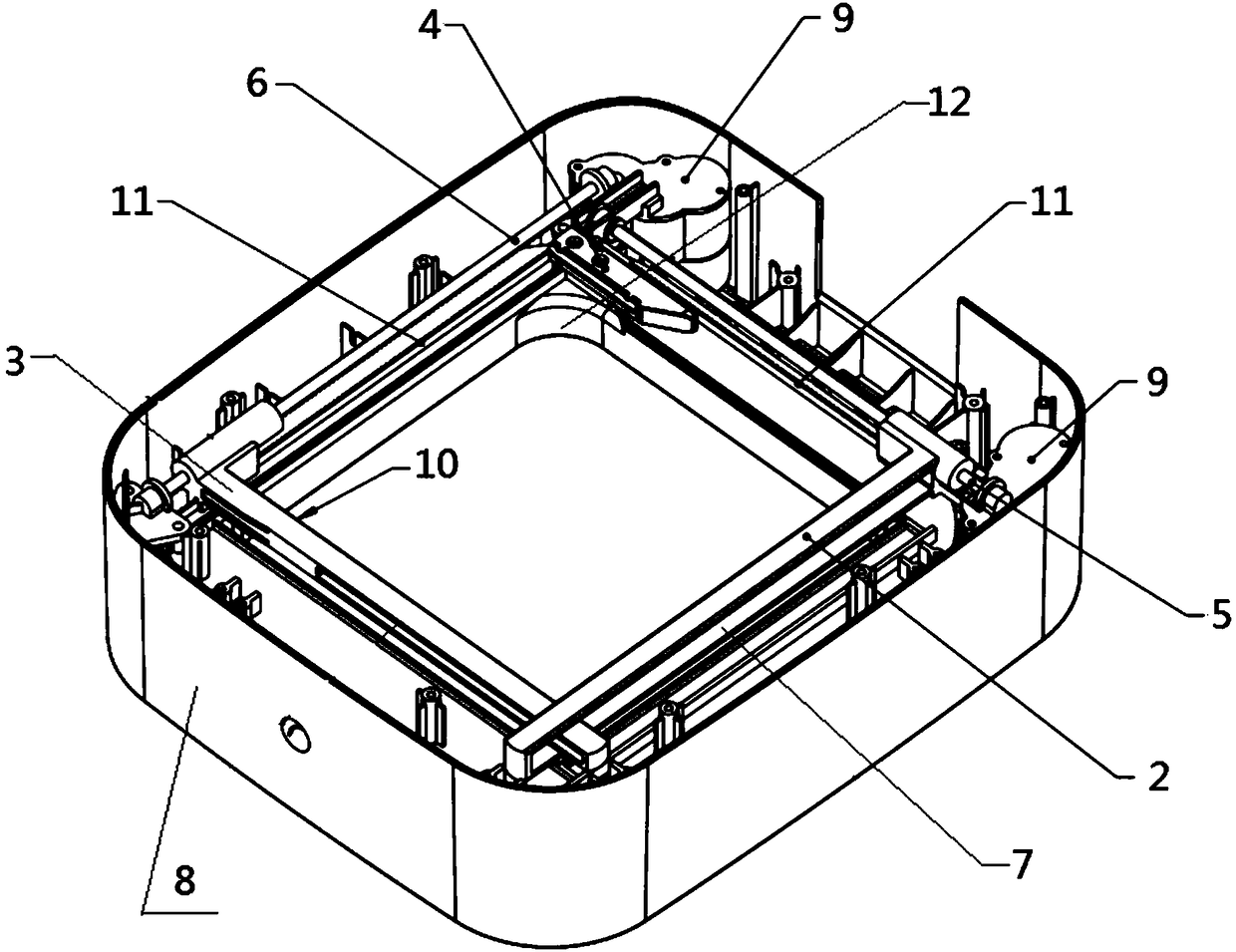

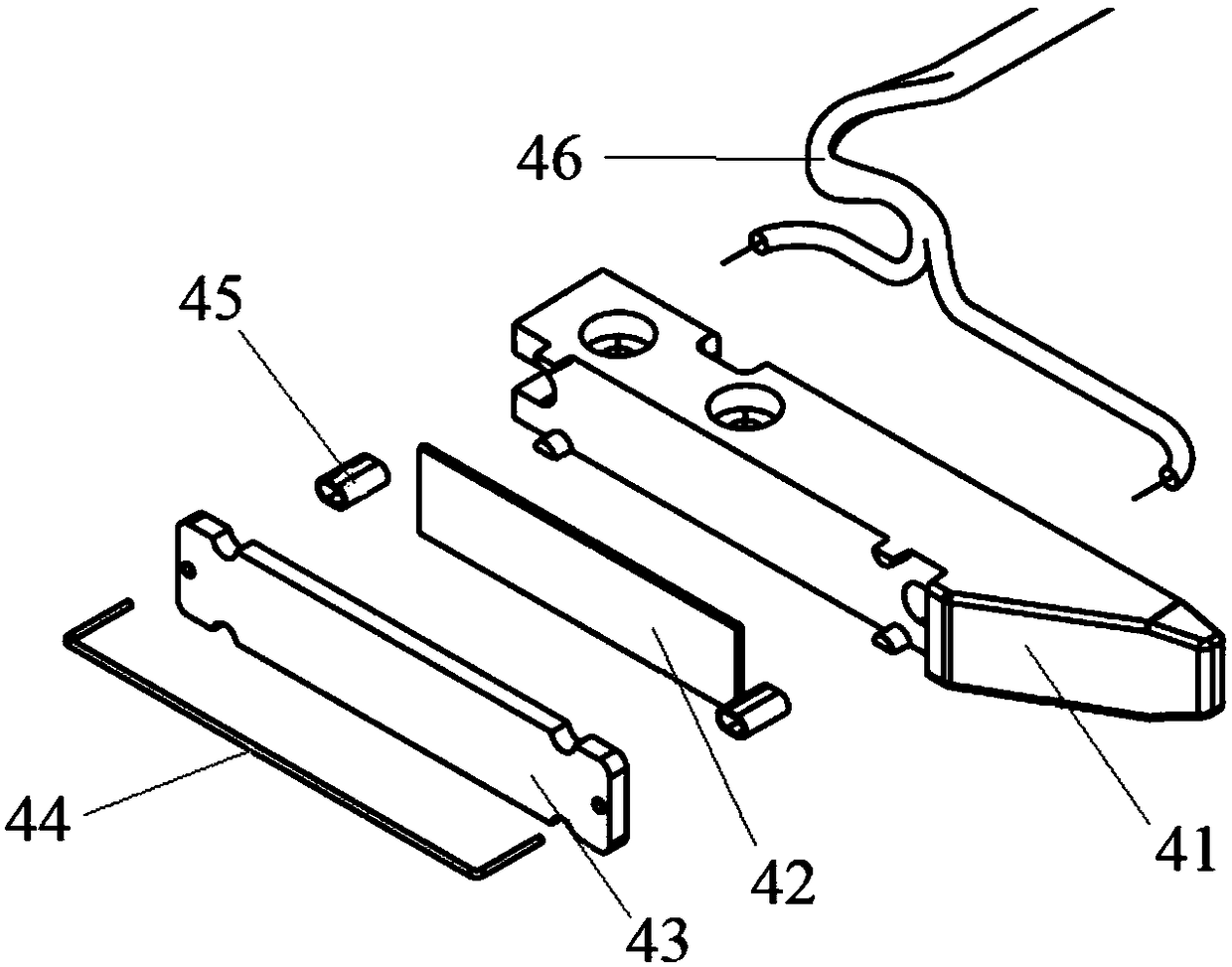

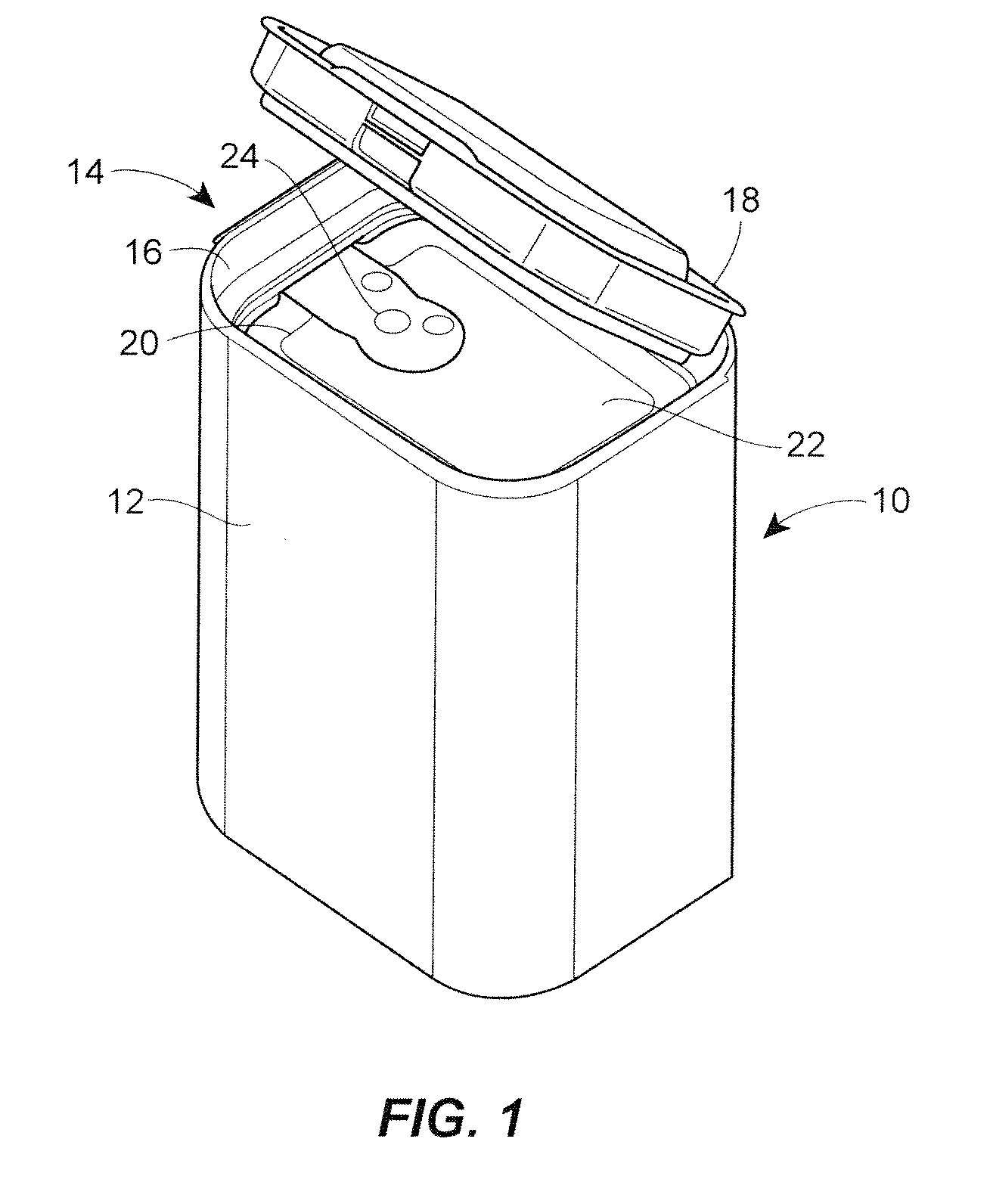

Garbage bag sealing mechanism and intelligent garbage can

PendingCN108584238ASolve the problems of poor sealing, weak sealing and weak bearing capacityRefuse receptaclesWrapper twisting/gatheringSemi automaticEngineering

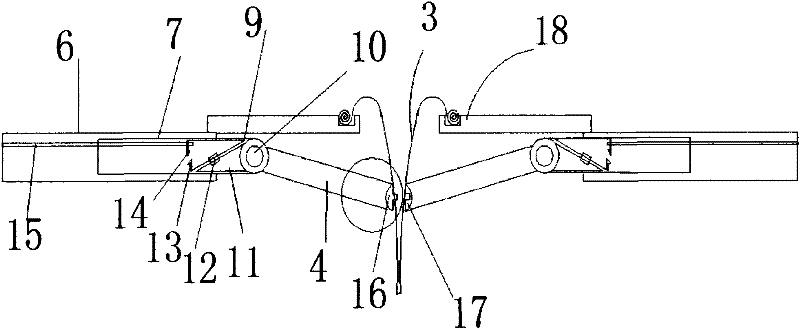

The invention discloses a garbage bag sealing mechanism and an intelligent garbage can. The garbage bag sealing mechanism is arranged in a garbage can body. The top of the inner wall of the garbage can body is provided with a first fixing edge and a second fixing edge intersecting with the first fixing edge. The garbage bag sealing mechanism comprises a first pressing rod and a second pressing rod, wherein the first pressing rod can slide along the second fixing edge so as to gather an opening of the garbage bag to the first fixing edge, the second pressing rod can slide along the first fixingedge so as to gather the opening of the garbage bag to the second fixing edge, and the first pressing rod and the second pressing rod can gather the garbage bag to the intersection position of the first fixing edge and the second fixing edge. A hot melting device used for conducing hot melting and sealing on the garbage bag is arranged close to the intersection position. The garbage bag sealing mechanism further comprises drive devices driving the first pressing rod and the second pressing rod to move. By the adoption of the arrangement, the problems that an existing intelligent garbage can is not provided with an automatic sealing mechanism, or the existing intelligent garbage can can only seal the garbage bag in a semi-automatic manner and be poor in garbage bag sealing performance, opening seal is infirm, and the bearing capacity is poor are solved.

Owner:SHANGHAI TOWNEW INTELLIGENT TECH CO LTD

Garbage can

InactiveCN102390643AAvoid breedingAvoid visual pollutionRefuse receptaclesWrapper twisting/gatheringEngineeringMagnet

The invention relates to a garbage can. The garbage can comprises a can body and a pedal switch, and is characterized in that: a packaging and storing device is arranged on the can body; the packaging and storing device comprises a conveying mechanism and a sealing mechanism which are arranged on the upper part of the can body symmetrically and move on the horizontal plane of the can body; the conveying mechanism is also provided with an outer plate fixed with the can body; a guide rail is arranged inside the outer plate; a movable inner plate is placed on the guide rail; a drive device is arranged on the outer plate; the outer plate is connected with the movable inner plate; the pedal switch is connected with the drive device electrically; a limit device comprises a plate piece and a V-shaped spring, wherein one end of the plate piece is fixed with the inner plate; circuit switches are arranged at an upper bayonet and a lower bayonet of the V-shaped spring; a long hole is formed in the upper bayonet of the V-shaped spring; the other end of the plate piece passes through the long hole to connect the V-shaped spring; the V-shaped spring is connected with a V-shaped baffle plate by a connecting piece; the V-shaped baffle plate is fixed to a rotating shaft; the sealing mechanism comprises package plates which are arranged symmetrically, wherein one end of each package plate is connected with the rotating shaft; the other end of each package plate is connected with a heating magnet; the upper part of the can body is also provided with an accommodating clamp slot; and a garbagebag is rolled in the accommodating clamp slot. By using the garbage can, garbage thrown in the garbage bag can be packaged and stored at any time, so that cross breading of bacteria is stopped, and the garbage can is safe and sanitary.

Owner:武振宇

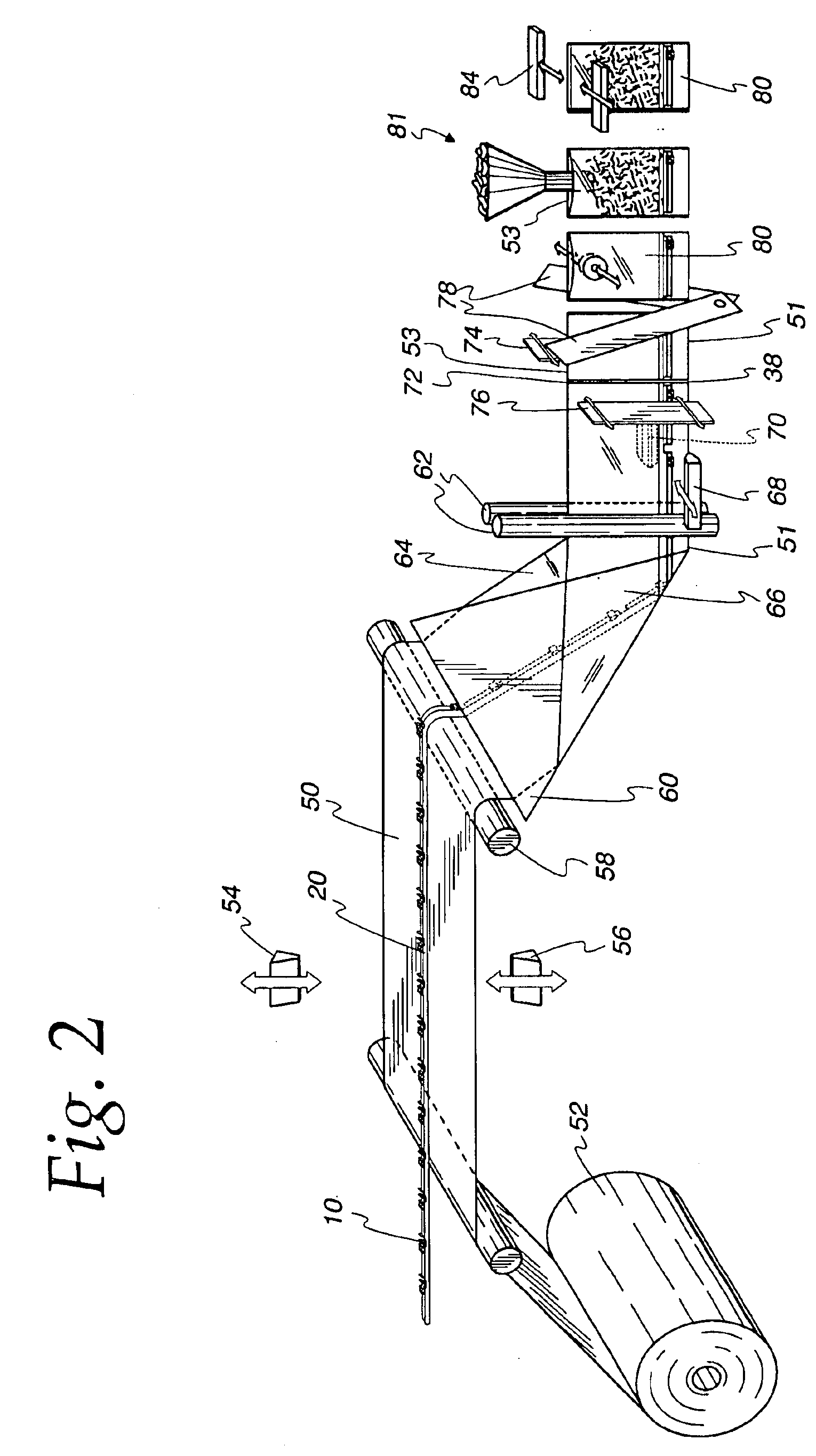

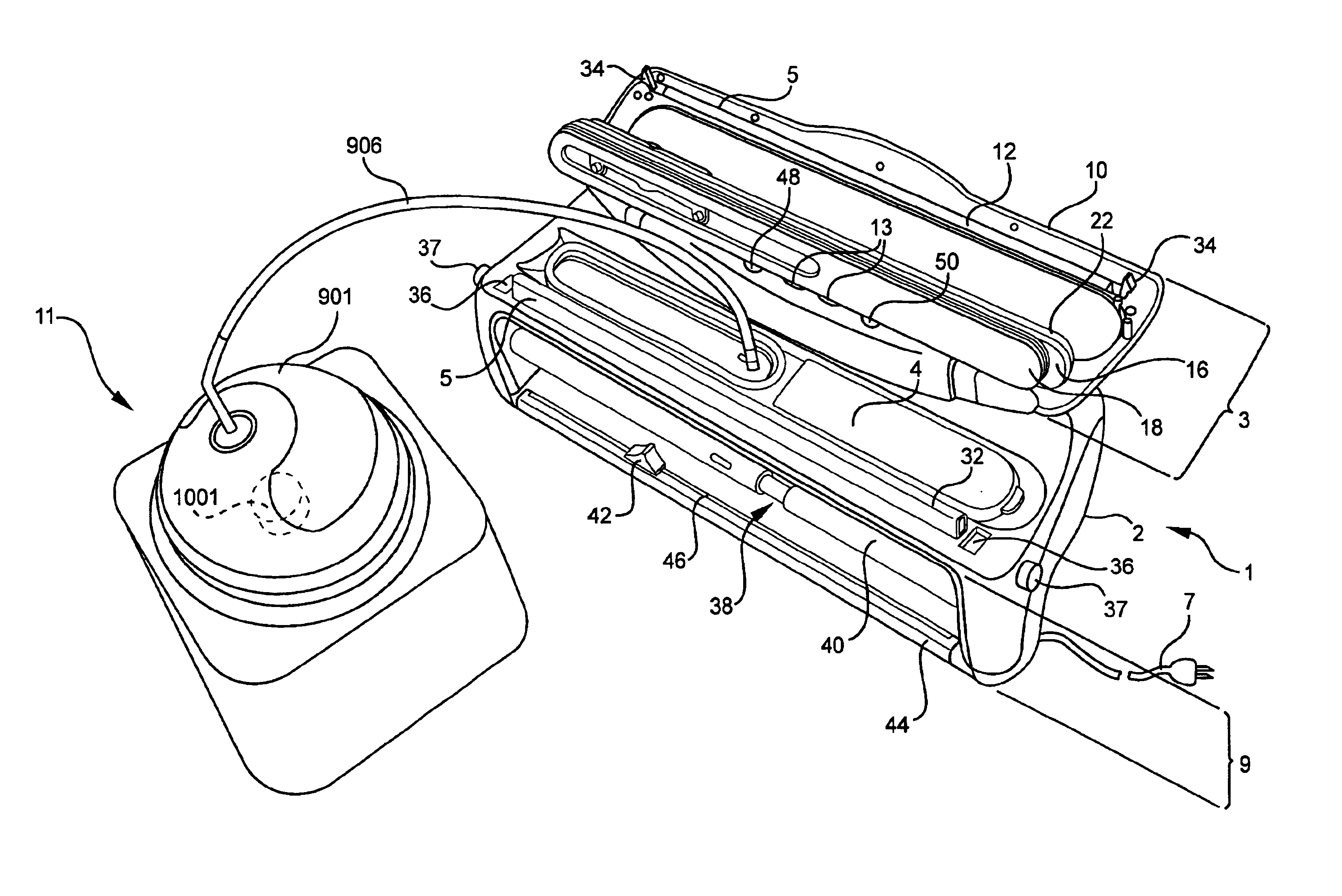

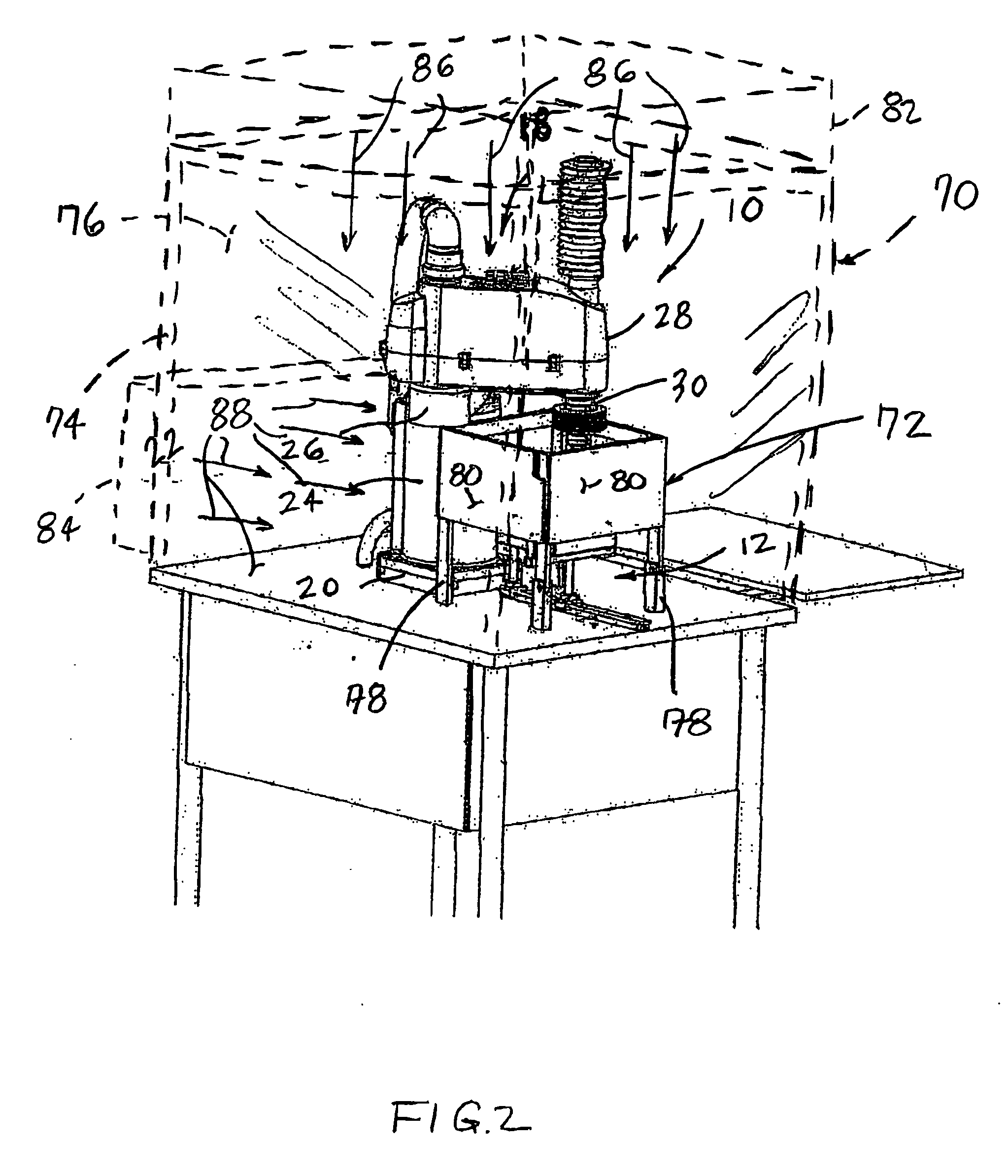

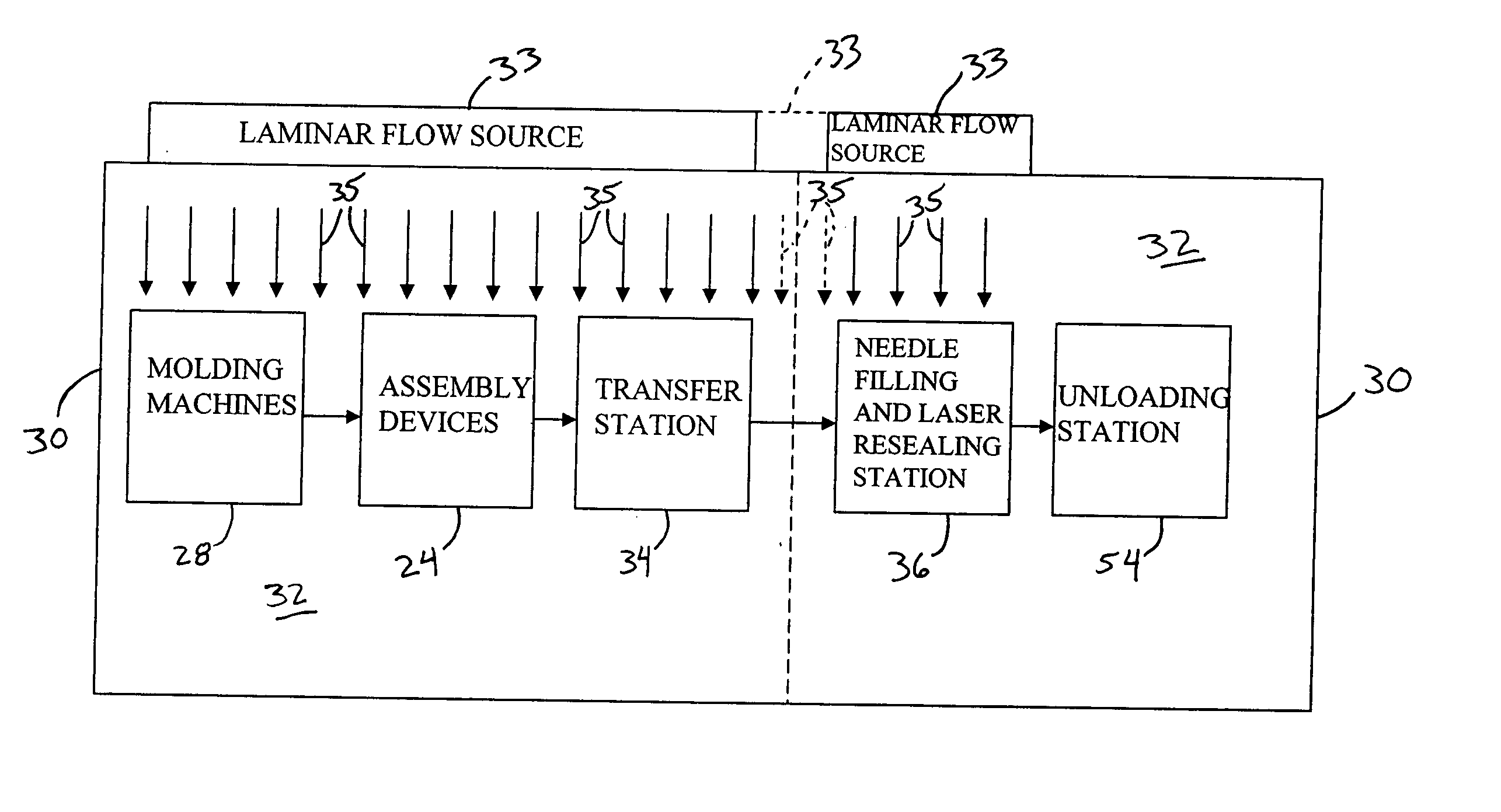

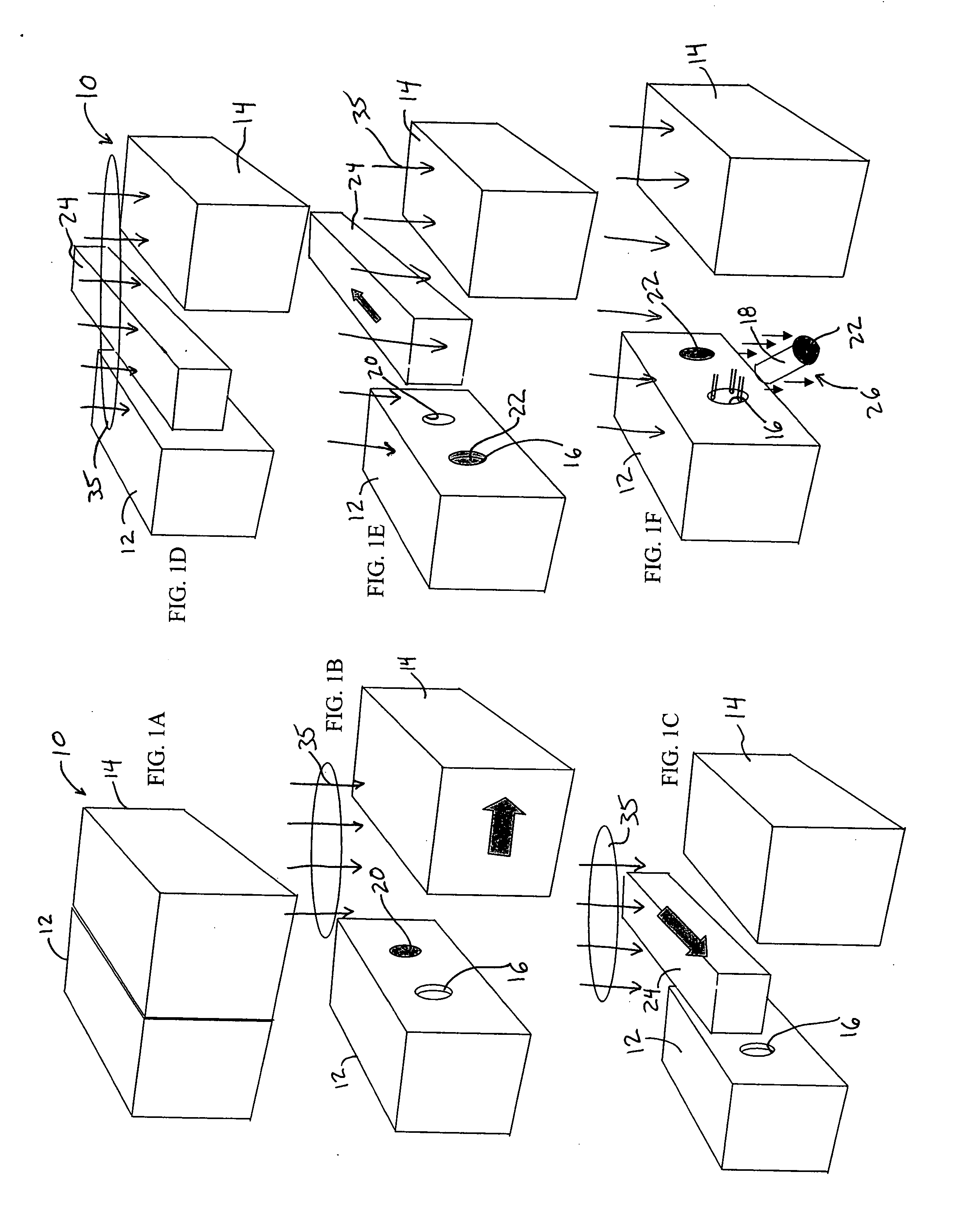

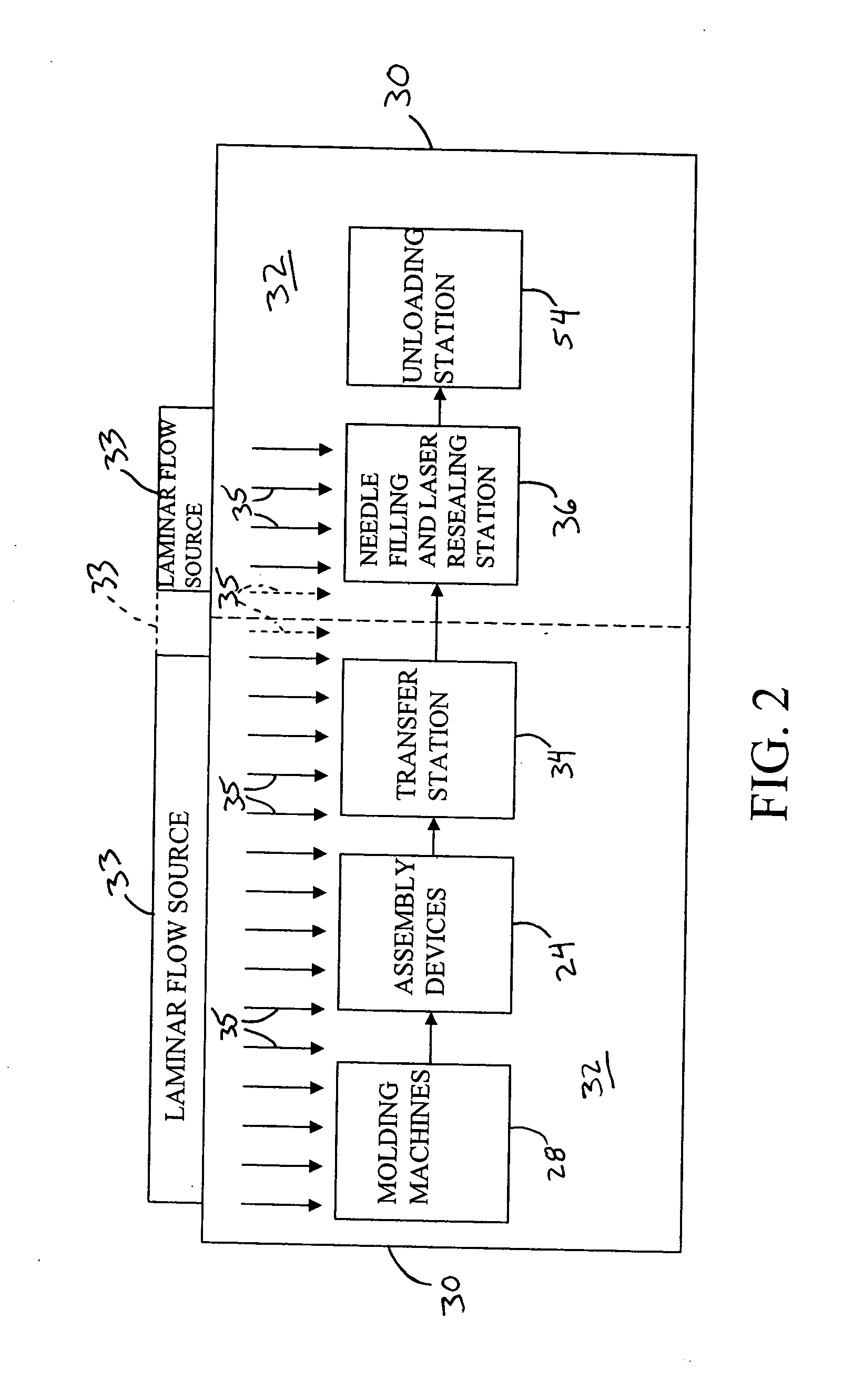

Apparatus and method for needle filling and laser resealing

ActiveUS7096896B2Rapidly and efficiently needle fill and laser resealCost efficientPackage sterilisationWrapper twisting/gatheringMedicineRobotic arm

Owner:MEDINSTILL DEV

Appliance for vacuum sealing food containers

A system for evacuating containers. The system includes a base housing defining a recess having a vacuum inlet port in communication with a vacuum source. An inner door is hinged to the base housing and is sized to cover the recess when in a closed position, and an outer door having a sealing member is hinged to close over the inner door. A vacuum nozzle extends at least partially between the inner and outer doors and is in communication with the recess. The inner and outer doors cooperate to retain a flexible container therebetween and around the nozzle so that the nozzle is positioned for fluid communication with an inside of the container. A removable drip pan is positioned to retain fluids drawn by the nozzle.

Owner:HOLMES GRP THE

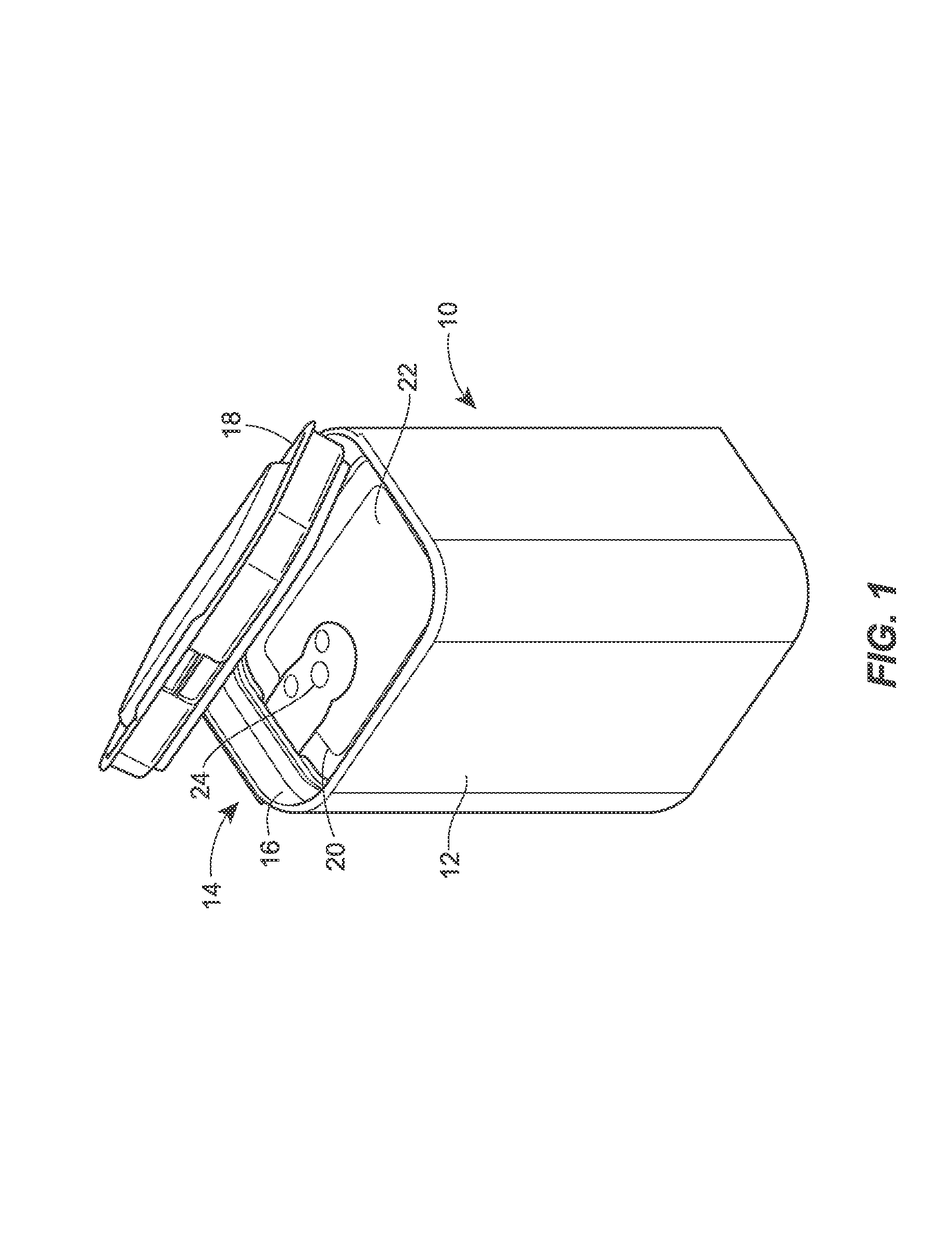

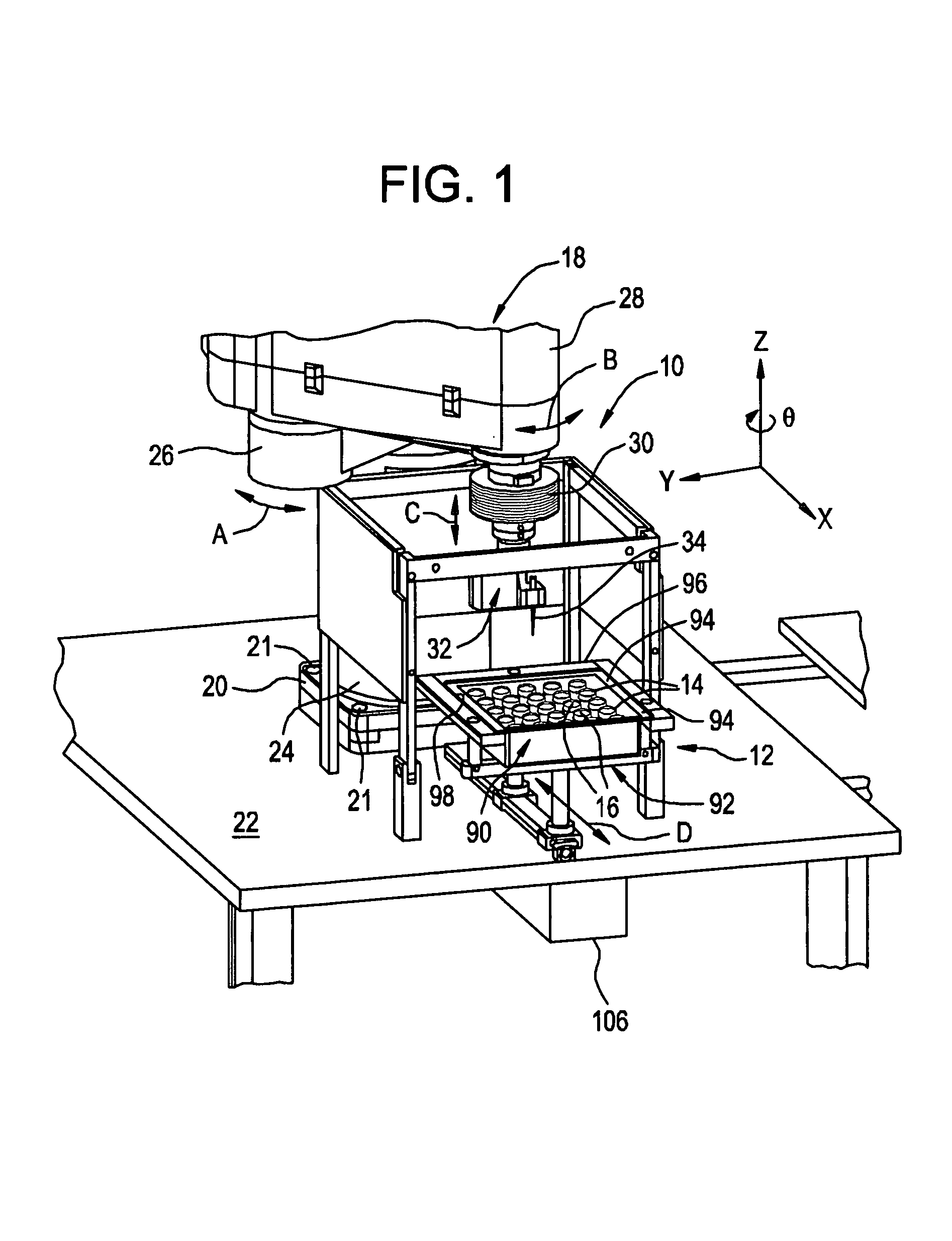

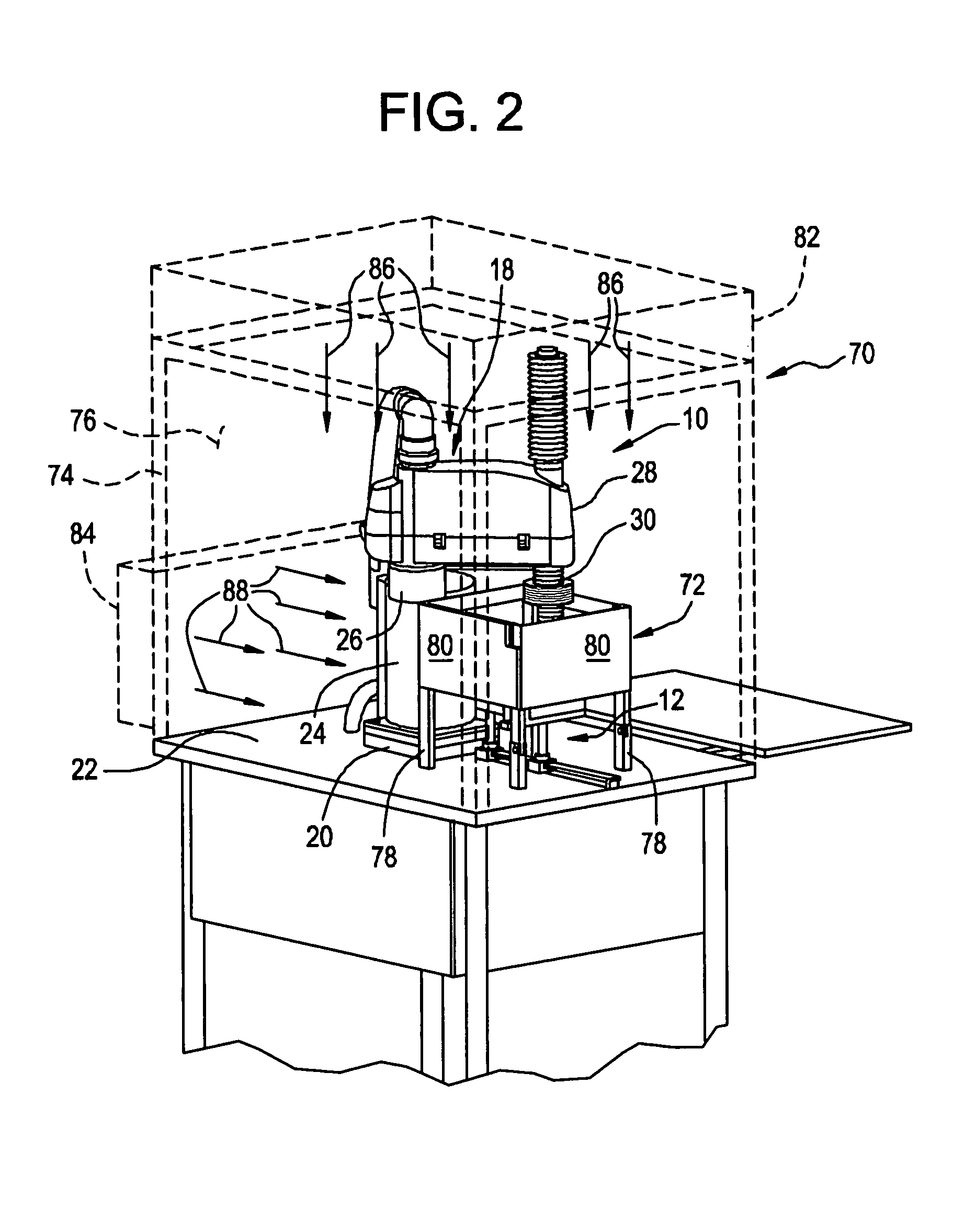

Apparatus and method for needle filling and laser resealing

ActiveUS20050194059A1Rapidly and efficiently needle fillCost efficientPackage sterilisationWrapper twisting/gatheringSyringe needleFixed position

An apparatus is provided for needle filling and thermally resealing containers having stoppers that are needle penetrable for filling the containers with a substance, and are thermally resealable for thermally sealing a needle hole in the stopper upon withdrawal of a needle therefrom. A container support of the apparatus supports at least one container having a resealable stopper in a substantially fixed position during needle filling and thermally resealing a needle hole in the stopper upon withdrawal of a needle therefrom. A robotic arm of the apparatus is drivingly mounted adjacent to the container support and movable relative thereto. A manifold is drivingly mounted on the robotic arm and includes (1) a needle for penetrating the resealable stopper and introducing a substance through the needle and into the container; (2) a laser optic assembly for heating a needle penetrated region of the stopper and, in turn, sealing a needle hole in the stopper; and (3) a temperature sensor for sensing the temperate of a needle penetrated region of the stopper to determine whether a needle hole therein is sealed. The manifold is movable laterally relative to the container on the container support to position the manifold relative to a needle penetrable region of the stopper of the container.

Owner:MEDINSTILL DEV

Method for molding and assembling containers with stoppers and filling same

A stopper and container body are molded in the same molding machine. An assembly device, such as a pick and place robot, transfers the stopper from one mold cavity into the opening in the container body located within another mold cavity, or vice versa, to assemble the stopper and container body. Then, the assembled container body and stopper are removed from the molding machine and transported to a needle filling and laser resealing station for filling and laser resealing. A laminar flow source directs a substantially laminar flow of air or sterile gas over the mold surfaces, stoppers and container bodies, and assembly device, to prevent contamination during assembly.

Owner:MEDINSTILL DEV

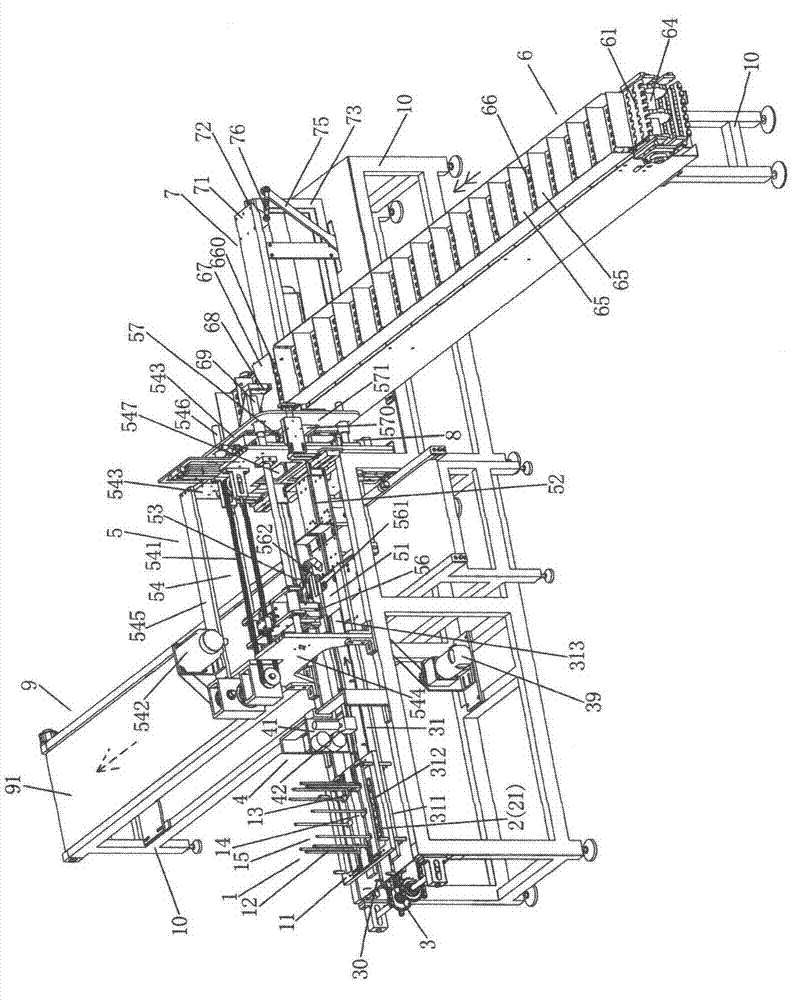

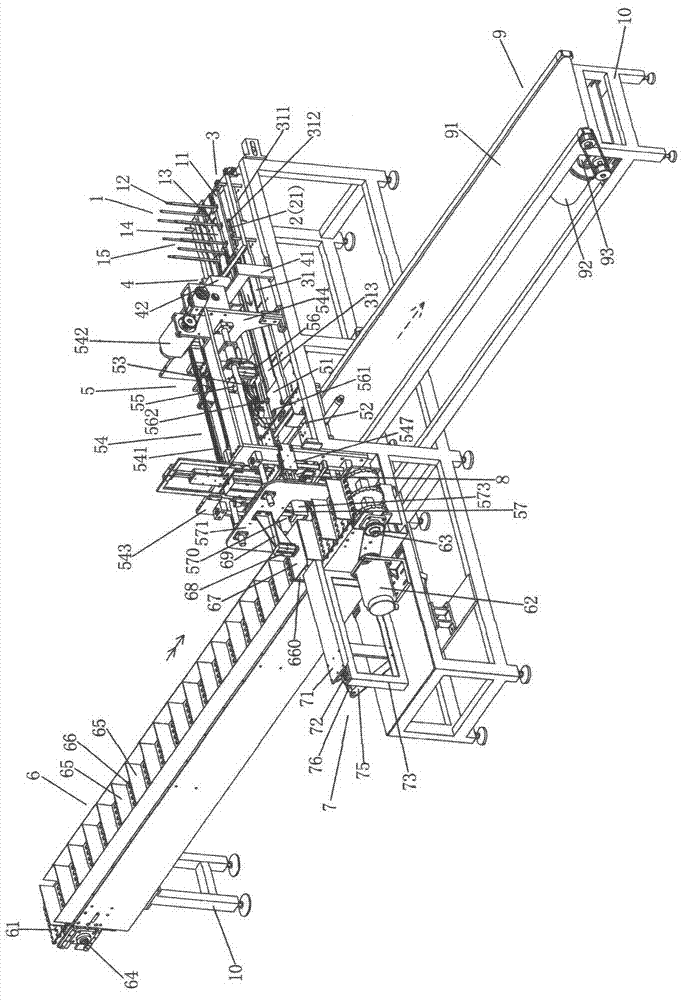

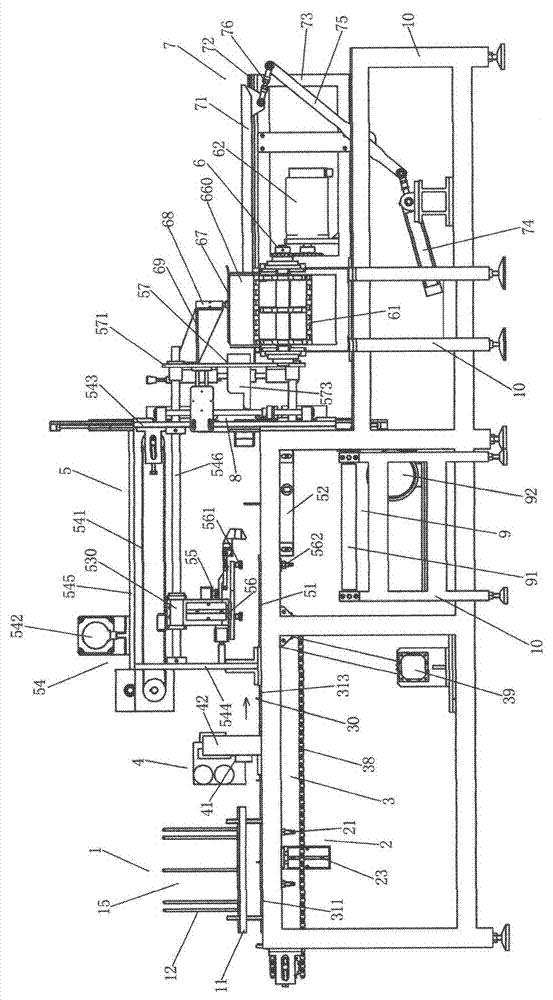

Bag-feeding pillow type packaging machine

ActiveCN103241409AHigh degree of automationIncrease productivityPackaging by pressurising/gasifyingWrapper twisting/gatheringEngineeringPackaging machine

Disclosed is a bag-feeding pillow type packaging machine. A horizontal bag conveyor is disposed between a bag feeder and a horizontal bag opener. A feeding part of the horizontal bag conveyor is located below the bag feeder. A discharge part of the horizontal bag conveyor is connected with the rear end of the horizontal bag opener. A bag picker is located below the horizontal bag conveyor. The bag picker extends into the bag feeder through the feeding part of the horizontal bag conveyor. The horizontal bag opener is disposed on the conveying direction of the horizontal bag conveyor, a conveying device is disposed in front of the horizontal bag opener, the conveying direction of the conveying device is perpendicular to that of the horizontal bag conveyor, a horizontal feeding device is disposed on one side of the conveying device and located on the conveying direction of the horizontal bag conveyor, a motion direction of the horizontal feeding device is perpendicular to the conveying direction of the conveying device, a sealing device is disposed on the horizontal bag opener, a finished product output device is disposed below the horizontal bag opener, and the conveying direction of the finished product output device is perpendicular to that of the horizontal bag conveyor.

Owner:广东宏川环宇智能装备有限公司

Standup bag and method of manufacturing same

InactiveUS6957915B2Eliminate needFacilitate opening and pouringFlexible coversWrappersMechanical engineeringMaterial Perforation

A standup bag for granular products or the like and a method of manufacturing the bag. The standup bag is manufactured from an extruded heat sealable material and includes both an integral handle and a perforation to facilitate opening and pouring out the contents of the bag.

Owner:HB CREATIVE LLC

Tea bag packer

ActiveCN101992868AInhibit sheddingExtended sealing lengthWrapper twisting/gatheringPackaging foodstuffsReciprocating motionEngineering

The invention discloses a tea bag packer. A hanging wire coil component thereof comprises a central shaft, wherein one end of the central shaft is fixedly connected to a frame; a shaft sleeve is assembled on the periphery of the central shaft by rotating the shaft; a hanging wire coil is coaxially fixed with an external end face of the shaft sleeve away from the frame along the radial direction; hanging wire claws extending along radial direction are uniformly distributed on the periphery of the hanging wire coil; a support rod for supporting cotton wires is slidingly penetrated through each hanging wire claw along the radial direction of the hanging wire coil; a cam connecting rod transmission mechanism which is in transmission connection with each support rod and drives the support rod to have linear reciprocating motion along the axis thereof is sleeved on the periphery of the shaft sleeve close to the hanging wire coil; and the cam is fixedly connected to the frame. Through the structure of the invention, the cotton wire can avoid the non-heat-seal area on the tea bag when the cotton wire is heat-sealed with the tea bag, so as to prolong the sealing length between the cotton wire and the tea bag, enhance the connecting strength between the cotton wire and the tea bag and avoid the phenomenon in the prior art that the cotton wire drops off.

Owner:CAMALUOYANGELECTROMECHANIC

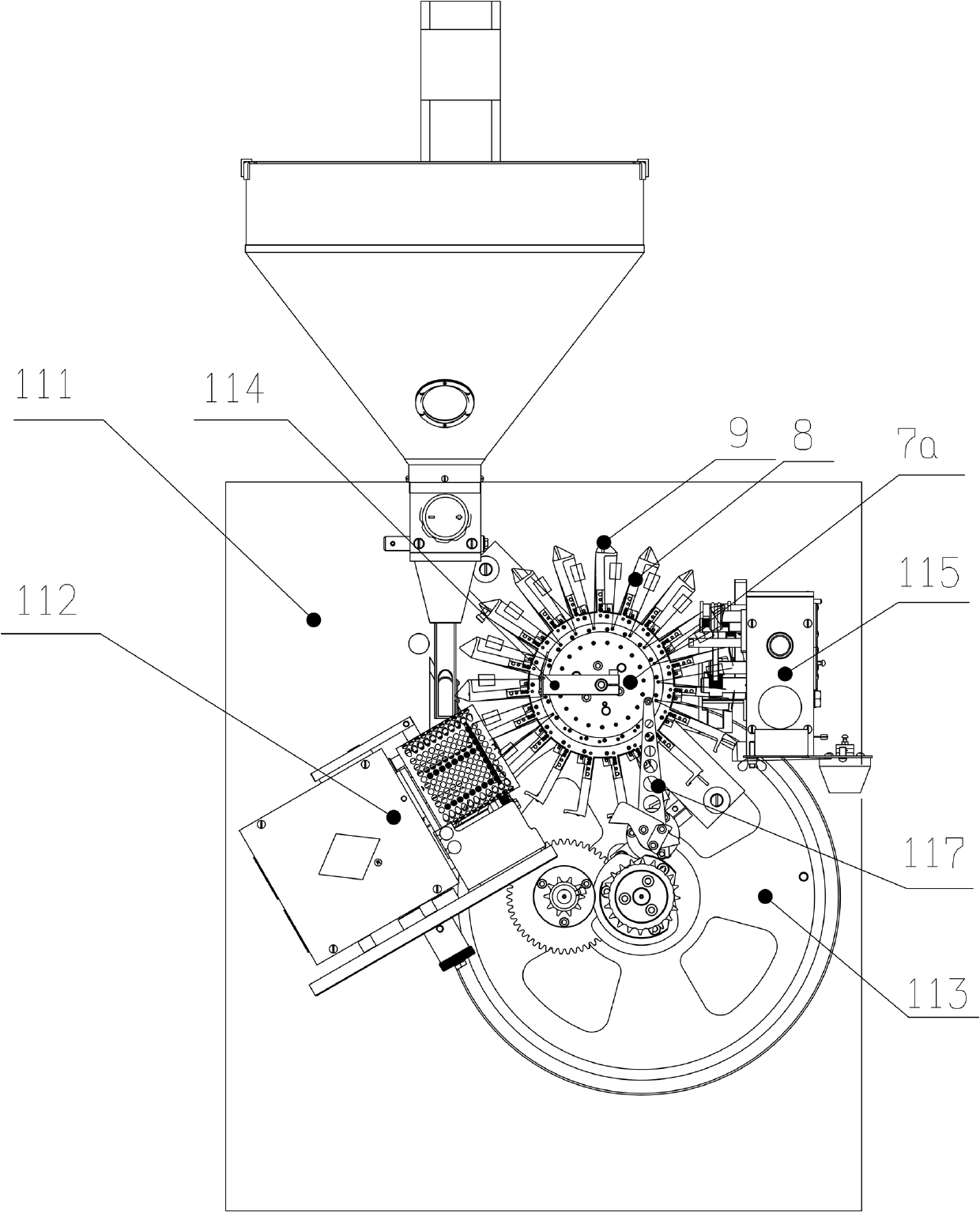

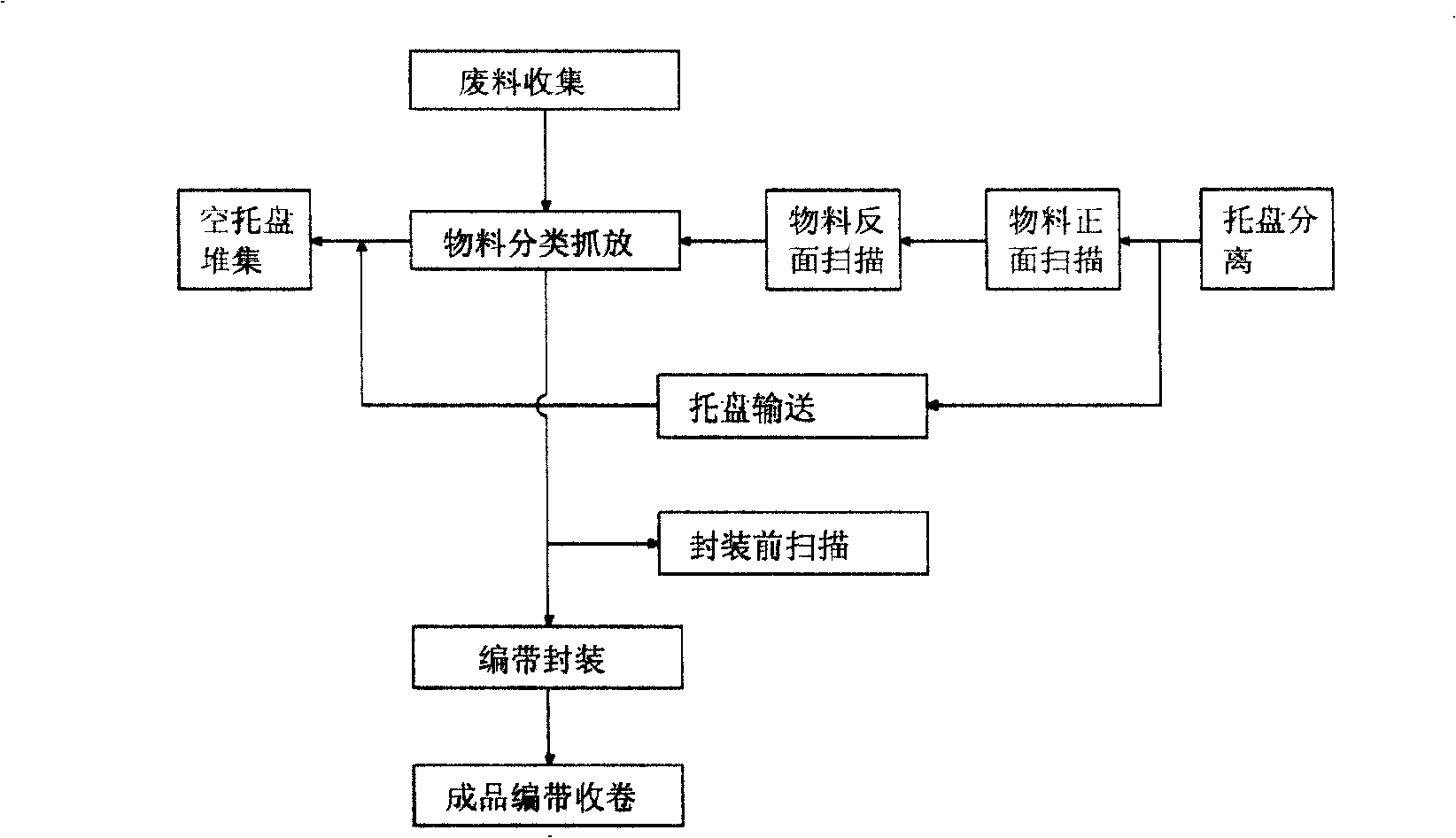

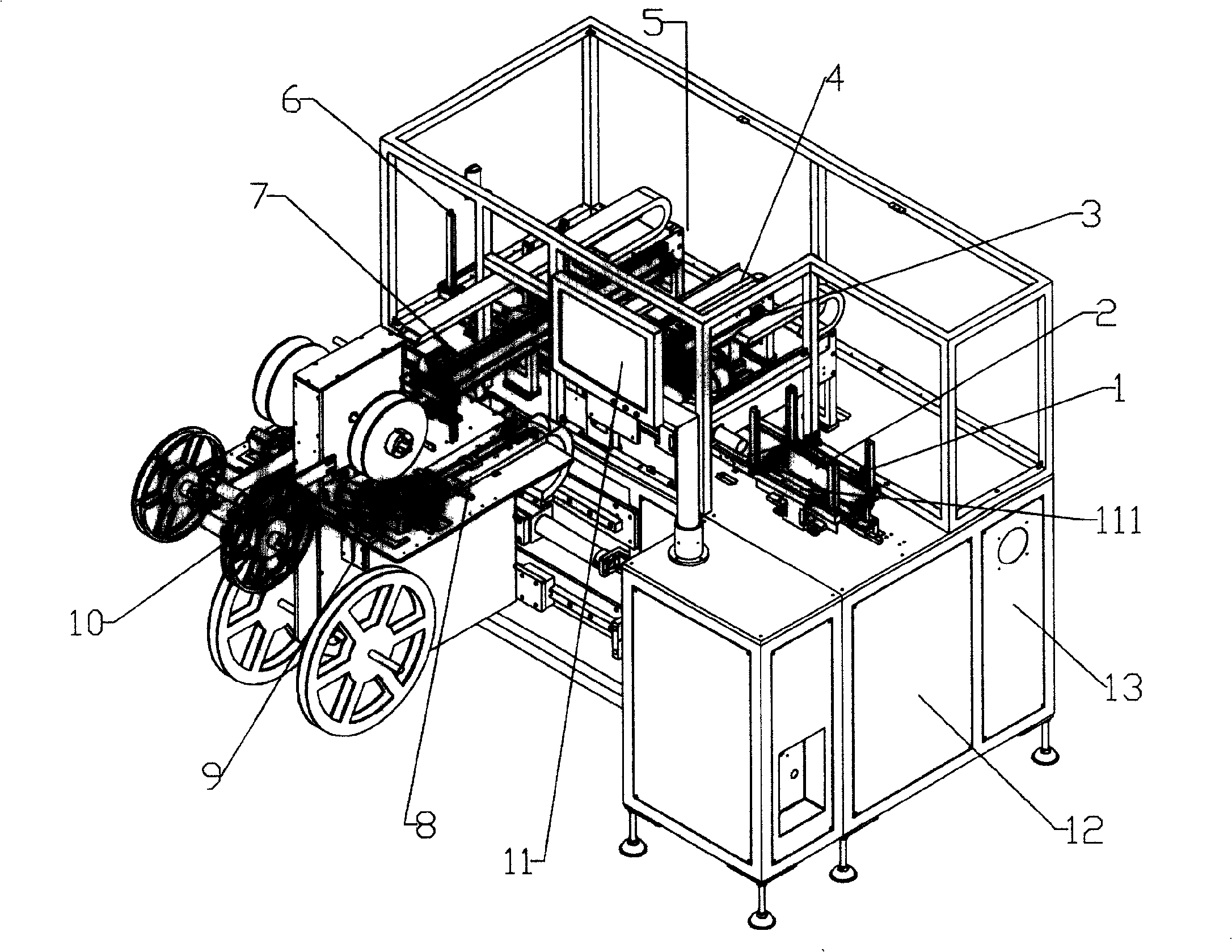

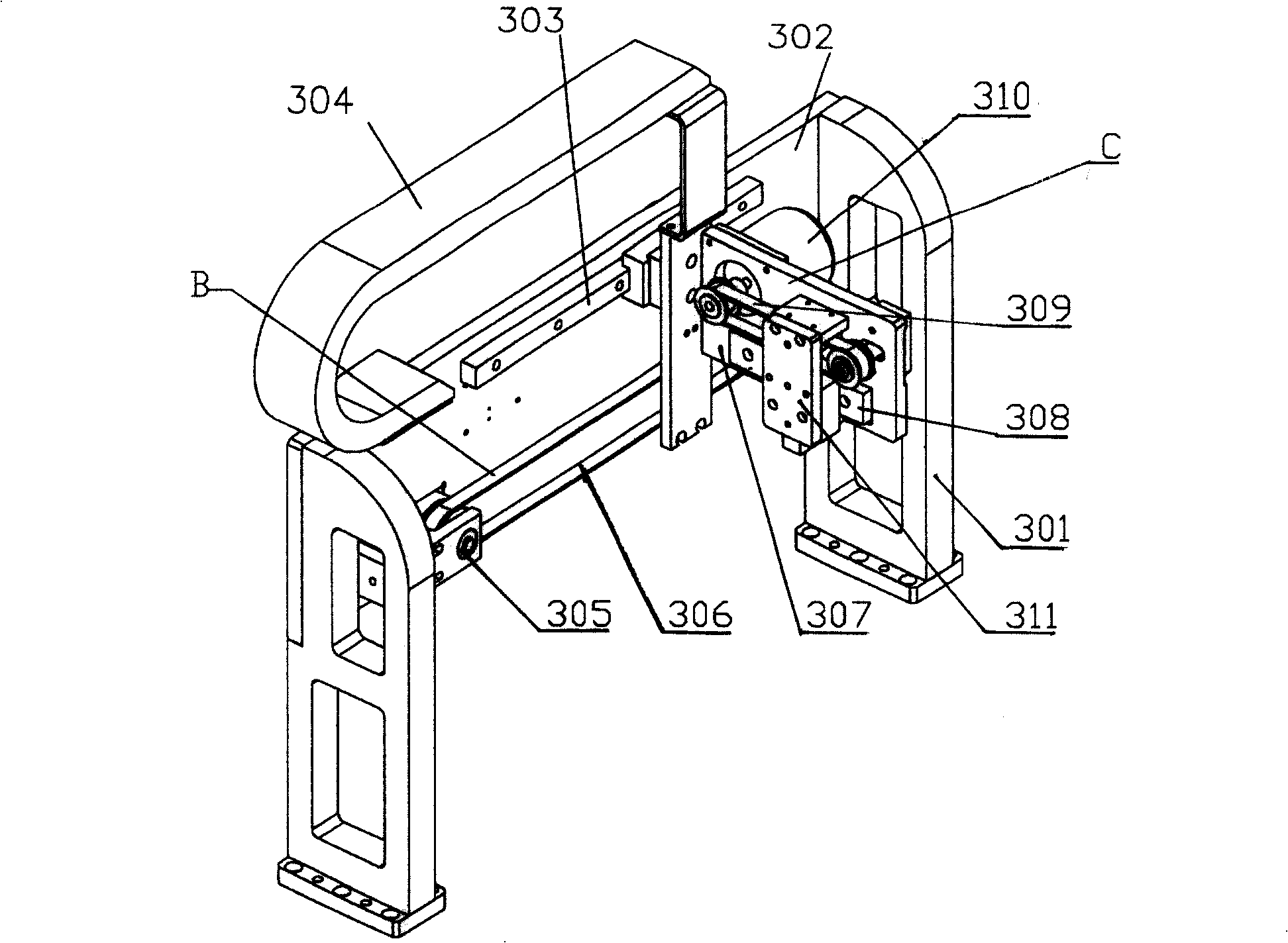

IC full-automatic method for testing brede and full-automatic holding tray type machine for testing brede

InactiveCN101244767AQuality assuranceAvoid lostSemiconductor/solid-state device testing/measurementOptically investigating flaws/contaminationElectricityControl system

The invention discloses an IC automatic detecting braiding method and an automatic pallet type detecting braiding machine, comprising a pallet-transport device, a braiding packing device, a waste materials collecting device. A PC control system and an electrical control system as well as a pallet-separate device are arranged on the front end of the pallet transport device and an empty pallet-collect device is arranged on the back end. The braiding lead direction of the braiding packing device is vertical to the pallet-transport direction of the pallet-transport device. A face side scan device and a back side device for detecting IC as well as a catch-and-put device for catching IC from the pallet are orderly arranged in the transportation range of the pallet-transport device. The catch-and-put device is electrically connected with the PC control system and the electrical control system and is a classification catch-and-put device which can classify the ICs according to the detecting results of the face side scan device and the back side device and then send the eligible ICs to the braiding packing device and the unqualified ICs to the waste materials collecting device. The braiding machine has the advantages of good accuracy and reliability for scanning and detecting, rapid speed for braiding and packing, low composite cost and high production efficiency.

Owner:GRAND TECH SHENZHEN

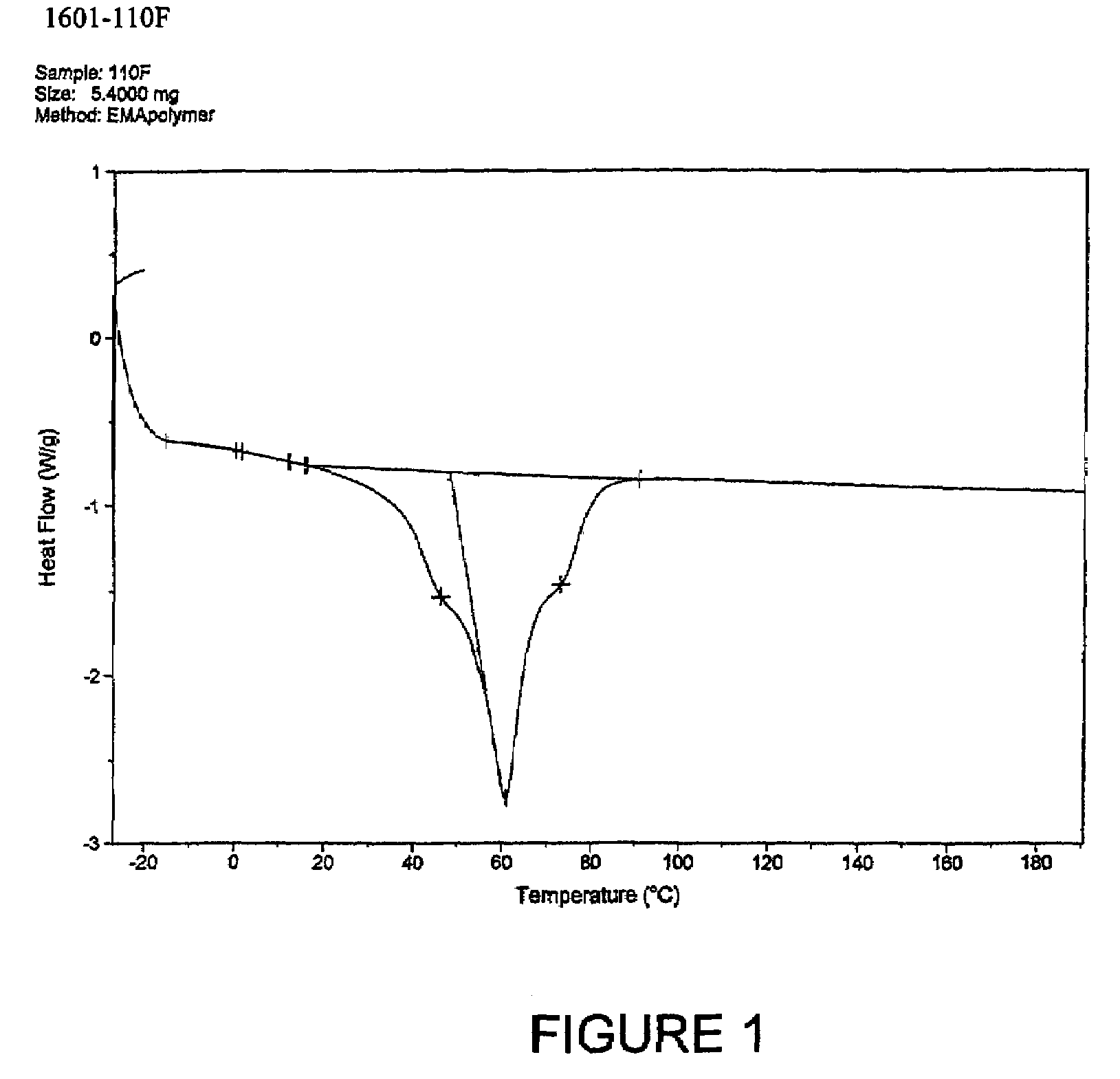

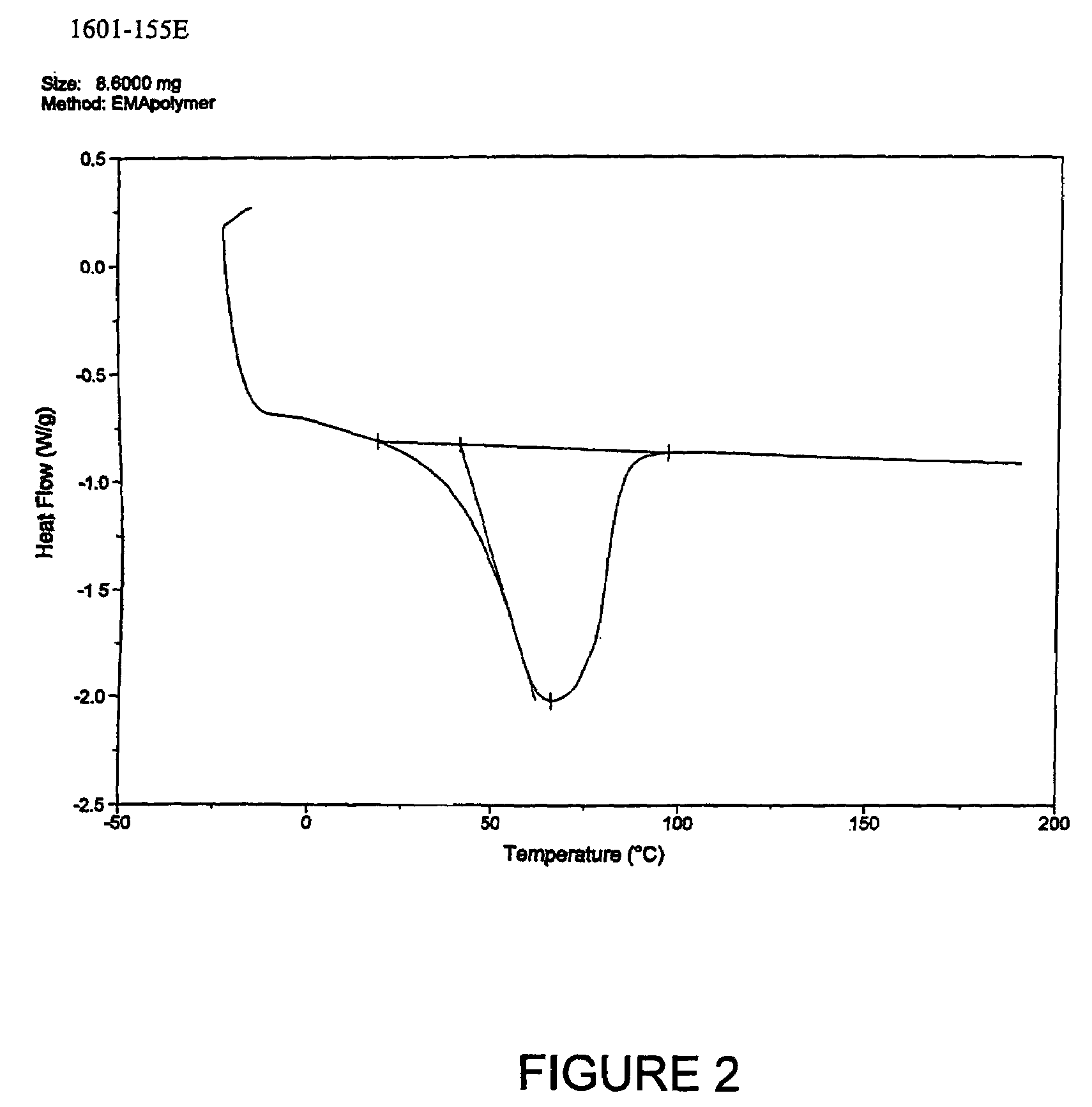

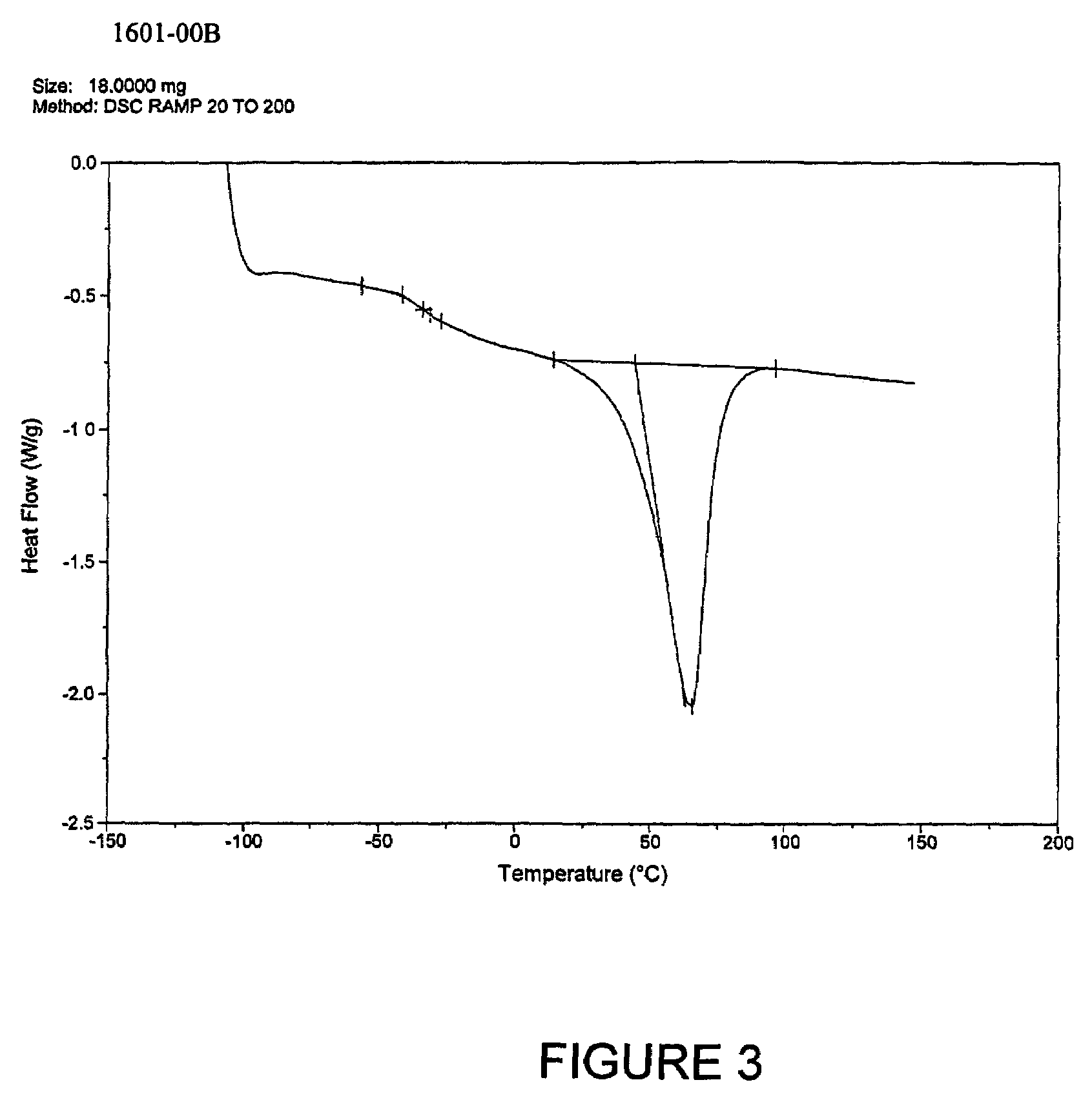

Process for packaging plastic materials like hot melt adhesives

A method for packaging plastic material using a film to surround the material, and more particularly to a method for packaging hot melt adhesives, the resulting package formed thereby, and the film composition used therein. The method is preferably a coextrusion process for packaging a pressure sensitive hot melt adhesive by extruding a hot melt adhesive through a die orifice, and coextruding a wax-based polymeric film to surround the hot melt adhesive. The coated adhesive may then be formed into individual packaged units having a finite size and shape. The polymeric film comprises a composition having at least 25% by weight of a wax material, an enthalpy of fusion of at least about 100 J / g, and an elongation value at break of at least about 100%. Any type of hot melt adhesive formulation can be packaged or surrounded by the polymeric film in the process. Also, the specific enthalpy of fusion desired and / or elongation value at break desired for the polymeric film can be obtained by blending an appropriate amount of partially crystalline ethylene-based polymer together with a thermoplastic elastomeric block copolymer and / or an ethylene based or propylene-based elastomer.

Owner:BOSTIK INC

Integrated cutting tool for waste disposal method and apparatus

Owner:EDGEWELL PERSONAL CARE BRANDS LLC +1

Flexible, Stackable Container and Method and System for Manufacturing Same

A flexible, stackable container for storing a quantity of a product may include a package formed from a single sheet of a lid fitment attached to a top side of the package. The top side of the package may have an outer first surface of the film and outwardly extending corner seals formed in the film at the edges of the top side and surrounding the top side of the package. The lid fitment may include a base having a central opening and a lid having a complimentary shape to the base to form a seal therebetween when the lid is closed down onto the base. The base may be sealed to one of the top surface of the top side, to the corner seals surrounding the top side, or to both, such that a portion of the top surface is accessible from the exterior of the container when the lid is separated from the base of the lid fitment. In other embodiments, the lid fitment may be attached at an open top end of the package, either directly or by a reinforcement ring, and may further include a cover attached to the lid fitment or the reinforcement ring to retain a quantity of a product in the container when the lid of the lid fitment is opened until the cover is punctured or removed.

Owner:PRIMAPAK LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com