Patents

Literature

3571 results about "Liquid product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pre-passivation process for a continuous reforming apparatus, and passivation process for a continuous reforming apparatus during the initial reacation

ActiveUS20100282645A1Reduce operational riskReduce contentThermal non-catalytic crackingPhysical/chemical process catalystsLiquid productReaction temperature

The present invention relates to a pre-passivation process for a continuous reforming apparatus prior to the reaction, or a passivation process for a continuous reforming apparatus during the initial reaction, comprising loading a reforming catalyst into the continuous reforming apparatus, starting the gas circulation and raising the temperature of a reactor, injecting sulfide into the gas at a reactor temperature ranging from 100-650° C., controlling the sulfur amount in the recycle gas within a range of 0.5-100×10−6 L / L so as to passivate the apparatus.The process of the present invention may also comprise the following steps:(1) loading a reforming catalyst into the continuous reforming apparatus, starting the gas circulation and raising the temperature of a reactor, feeding the reforming feedstock into the reaction system when the temperature of the reactor is increased to 300-460° C., introducing sulfide into the reaction system while or after the reforming feedstock is fed, controlling the ratio of the total sulfur amount introduced into the system to the reforming feedstock within the range of 0.5 μg / g-50 μg / g, reducing the content of sulfide introduced into the system when hydrogen sulfide concentration in the recycle gas reaches to 2.0 μL / L˜30 μL / L; and(2) maintaining the reforming reactor at a temperature of 460-490° C., controlling the ratio of the total sulfur amount introduced into the system to the reforming feedstock within the range of 0.2 μg / g-0.5 μg / g, adjusting the amount of the reforming feedstock to the design value of the apparatus, increasing the reforming reaction temperature to 490-545° C. according to the requirements on the octane number of the liquid product, and letting the reforming apparatus run under normal operating conditions.

Owner:CHINA PETROCHEMICAL CORP +1

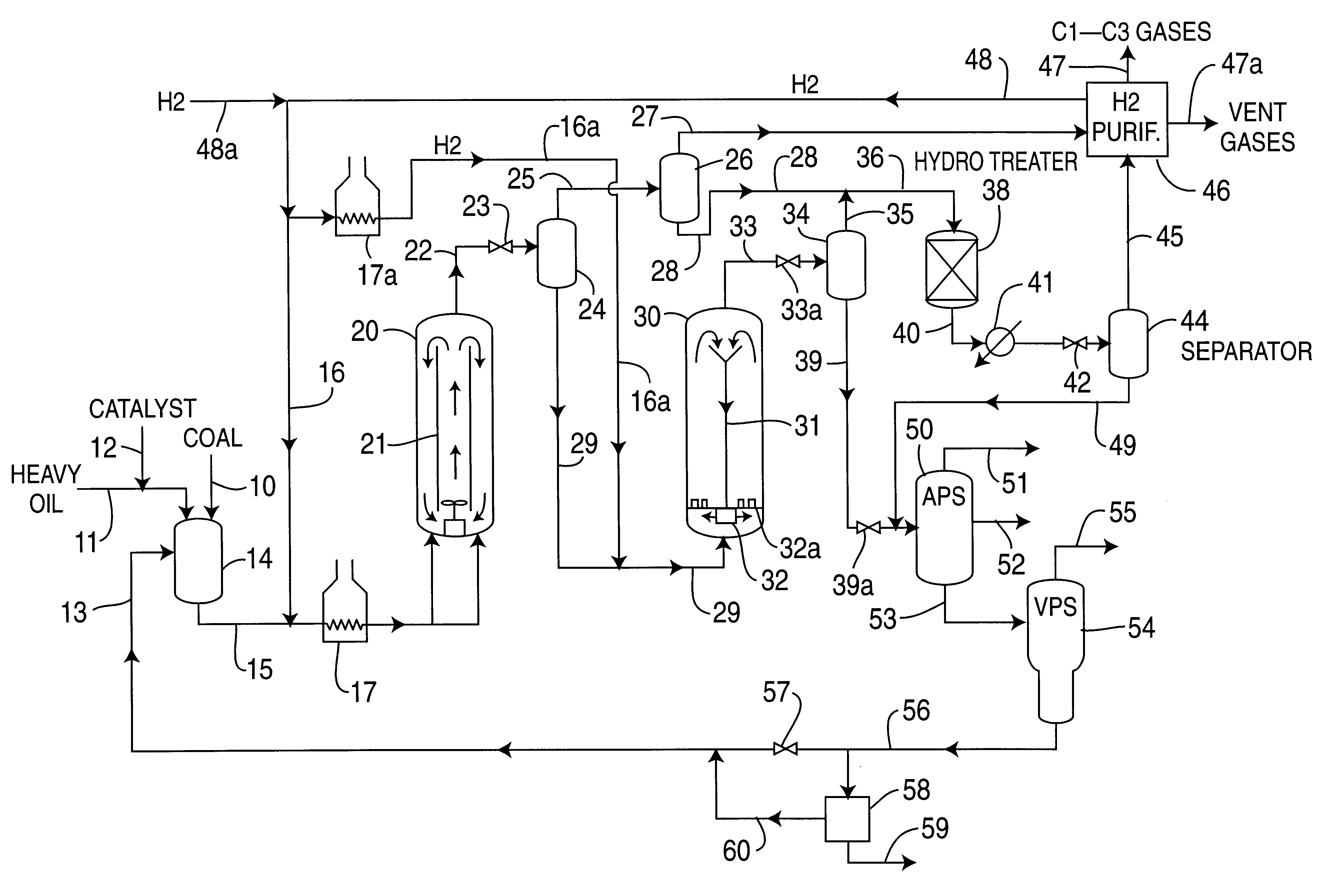

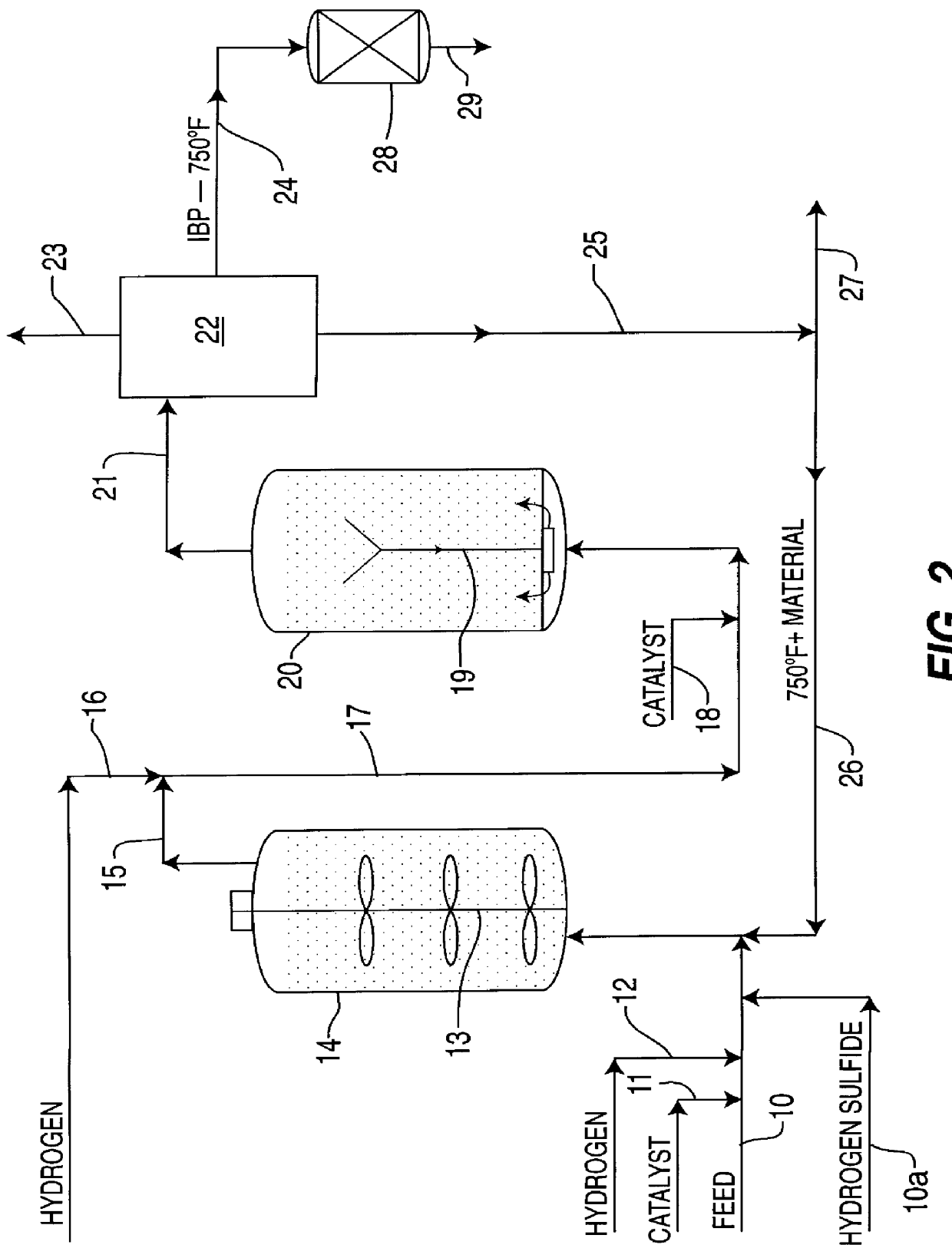

Catalytic multi-stage process for hydroconversion and refining hydrocarbon feeds

InactiveUS6190542B1Improve distillation yieldQuality improvementCatalyst activation/preparationLiquid hydrocarbon mixture productionLiquid productDistillates petroleum

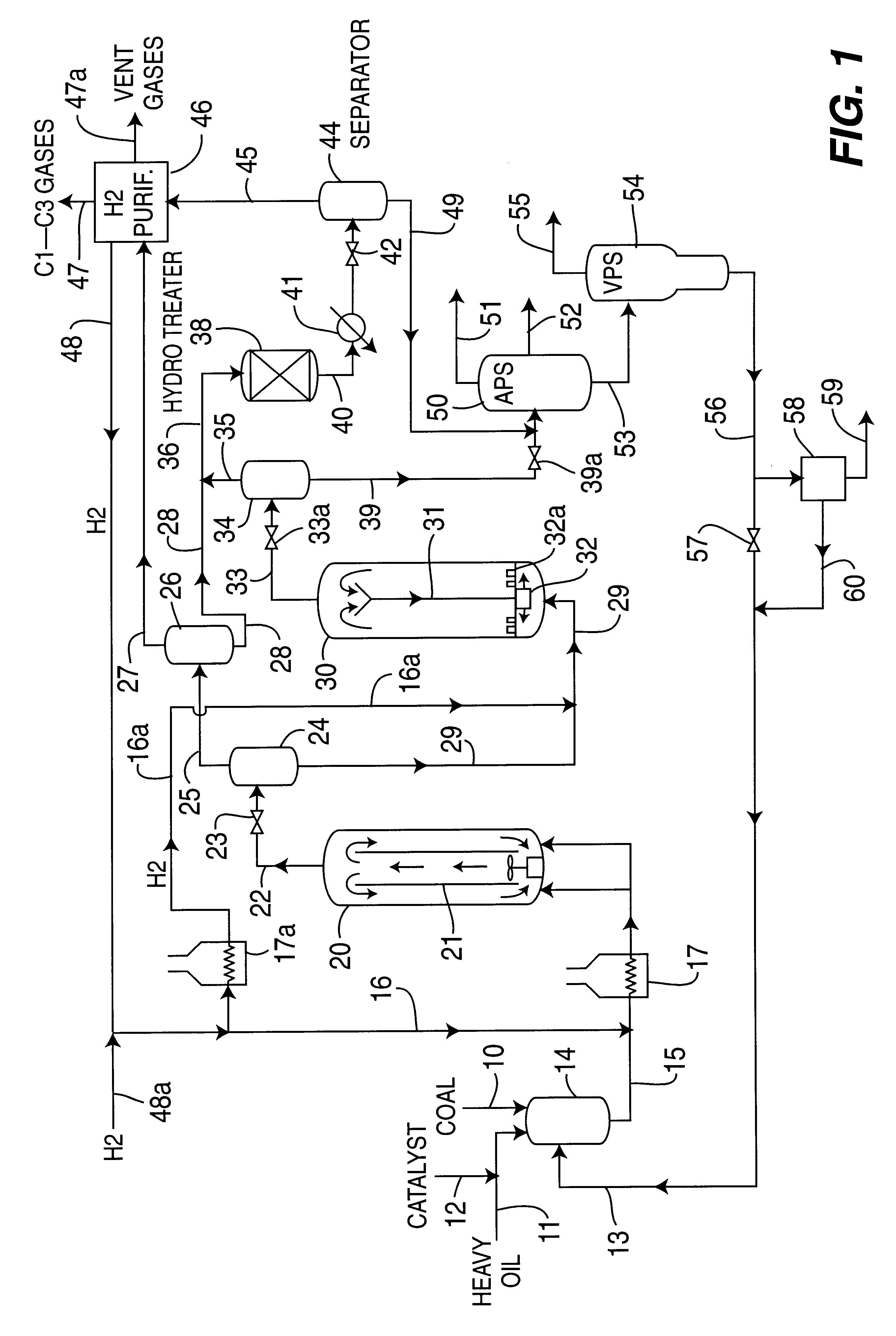

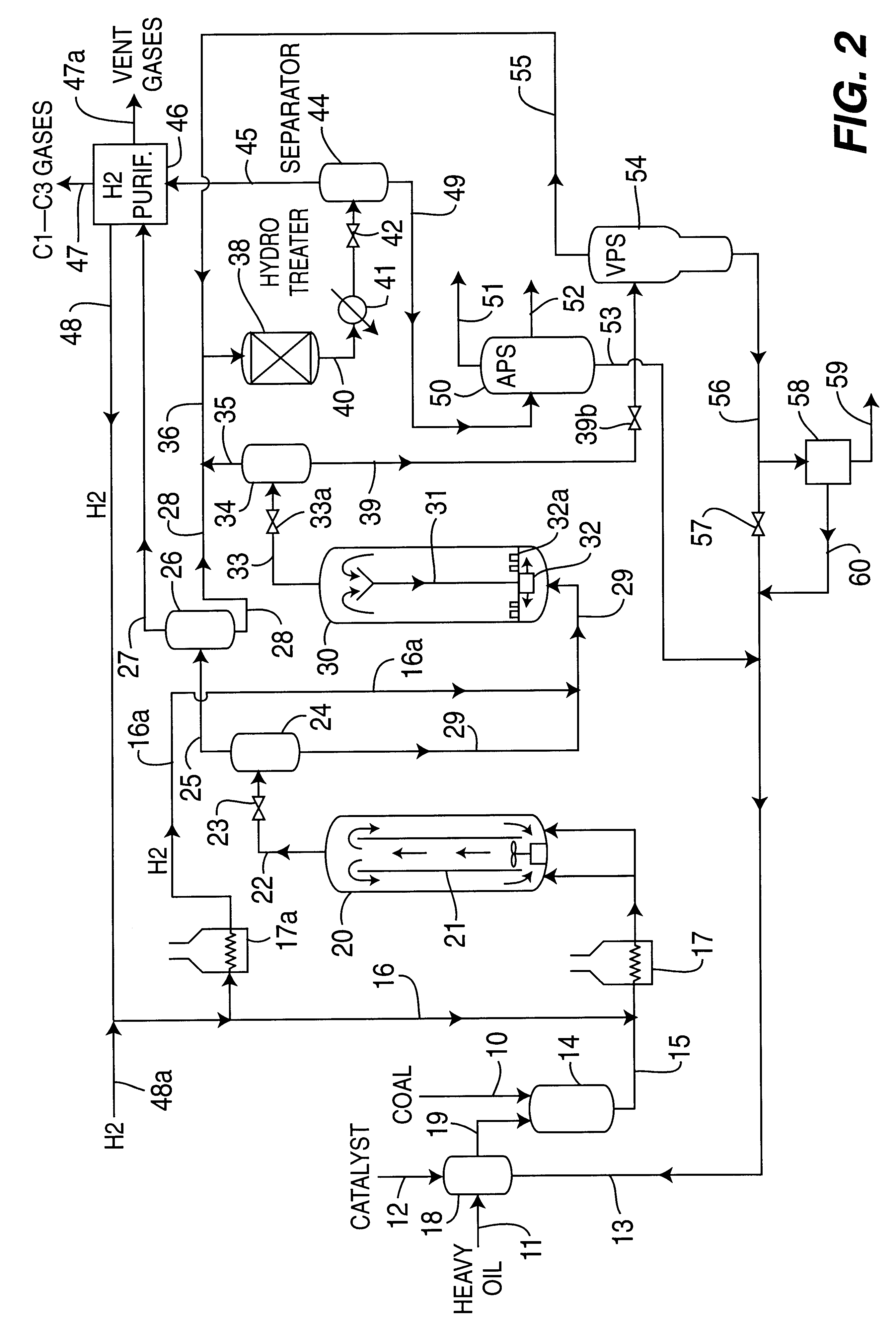

A multi-stage catalytic hydrogenation and hydroconversion process for heavy hydrocarbon feed materials such as coal, heavy petroleum fractions, and plastic waste materials. In the process, the feedstock is reacted in a first-stage, back-mixed catalytic reactor with a highly dispersed iron-based catalyst having a powder, gel or liquid form. The reactor effluent is pressure-reduced, vapors and light distillate fractions are removed overhead, and the heavier liquid fraction is fed to a second stage back-mixed catalytic reactor. The first and second stage catalytic reactors are operated at 700-850.degree. F. temperature, 1000-3500 psig hydrogen partial pressure and 20-80 lb. / hr per ft.sup.3 reactor space velocity. The vapor and light distillates liquid fractions removed from both the first and second stage reactor effluent streams are combined and passed to an in-line, fixed-bed catalytic hydrotreater for heteroatom removal and for producing high quality naphtha and mid-distillate or a full-range distillate product. The remaining separator bottoms liquid fractions are distilled at successive atmospheric and vacuum pressures, low and intermediate-boiling hydrocarbon liquid products are withdrawn, and heavier distillate fractions are recycled and further upgraded to provide additional low-boiling hydrocarbon liquid products. This catalytic multistage hydrogenation process provides improved flexibility for hydroprocessing the various carbonaceous feedstocks and adjusting to desired product structures and for improved economy of operations.

Owner:HEADWATERS CTL

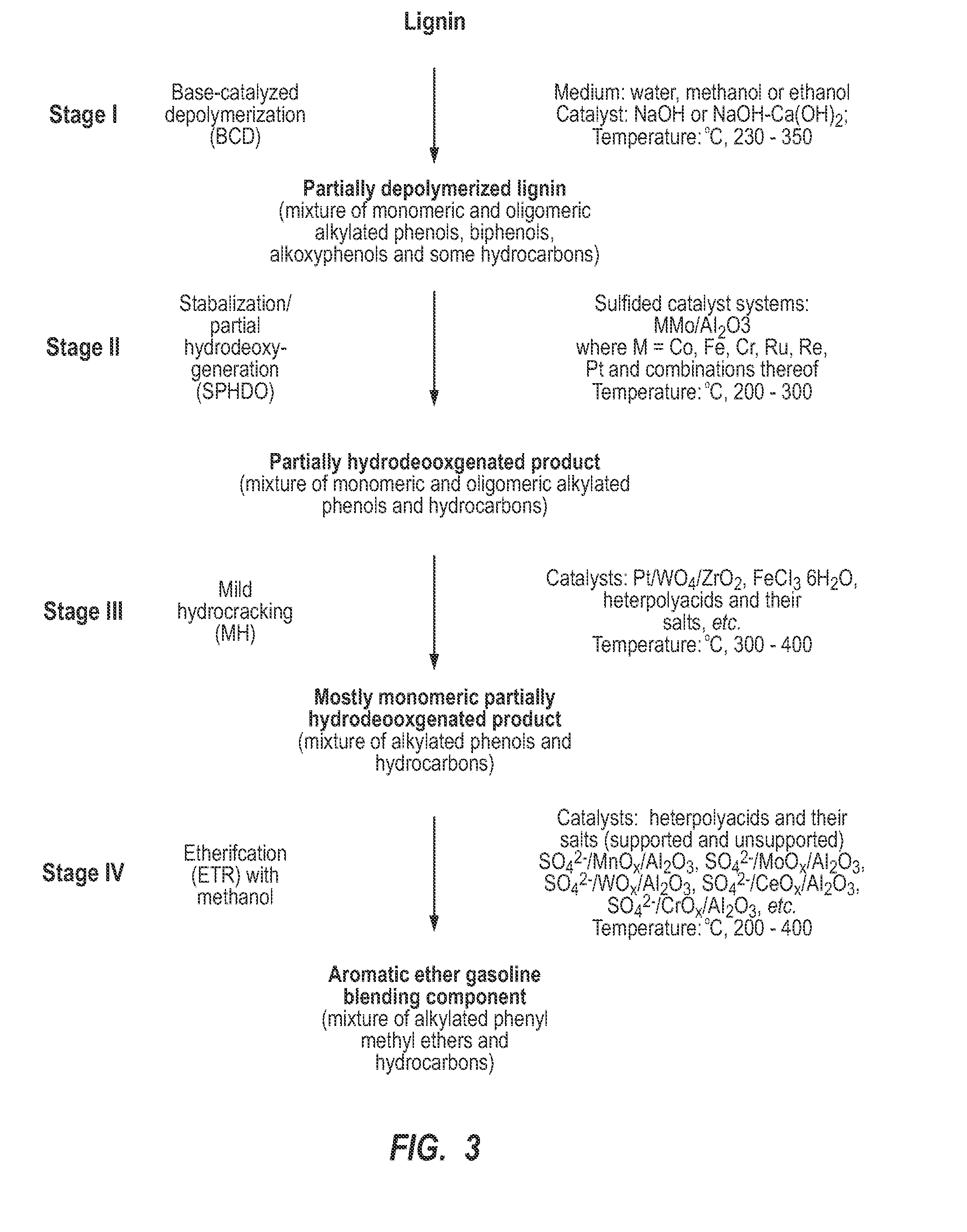

Processes for catalytic conversion of lignin to liquid bio-fuels and novel bio-fuels

InactiveUS20080050792A1Increase productionAcceptable processing conditionBiofuelsSolid fuelsLiquid productLignin degradation

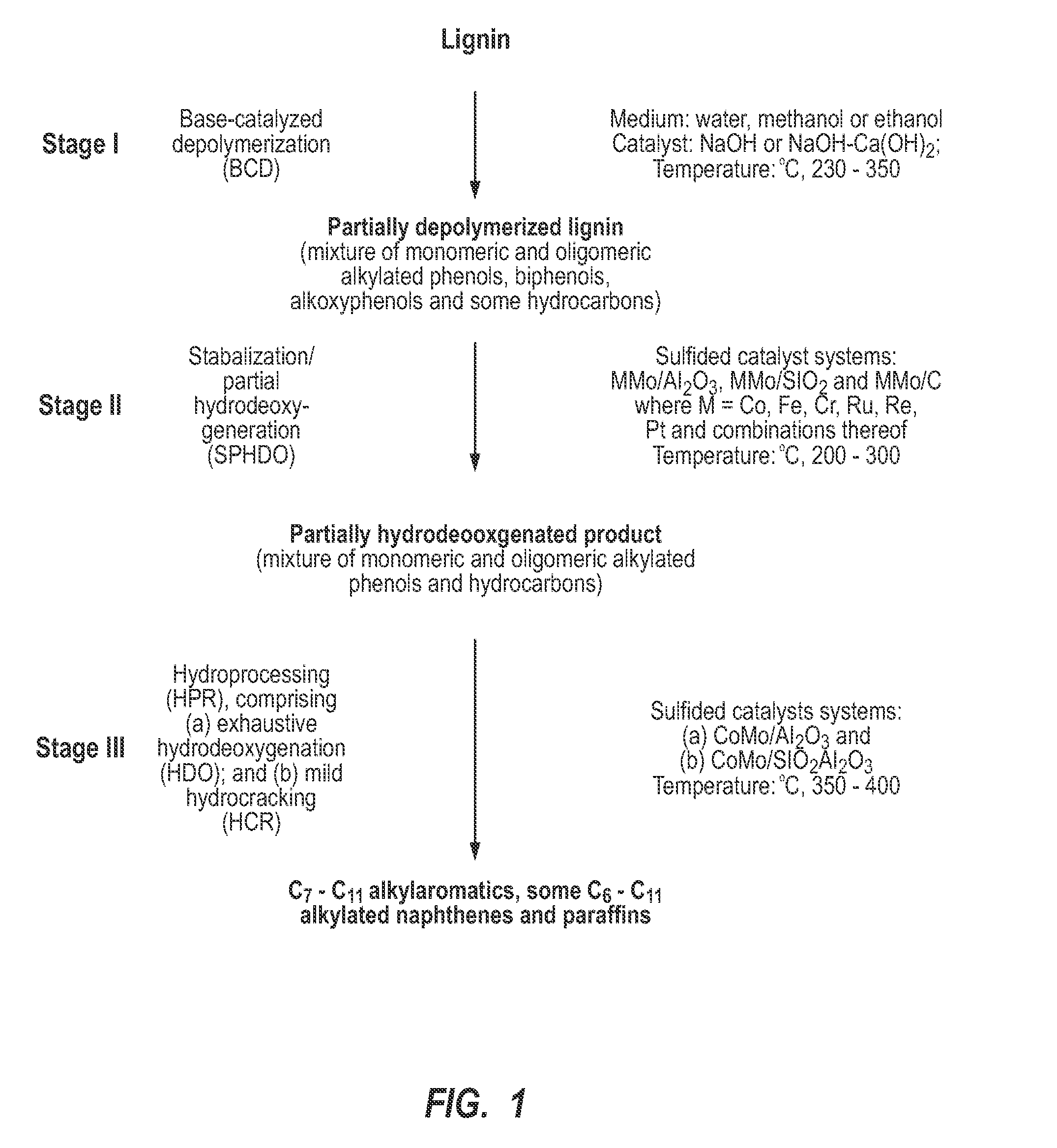

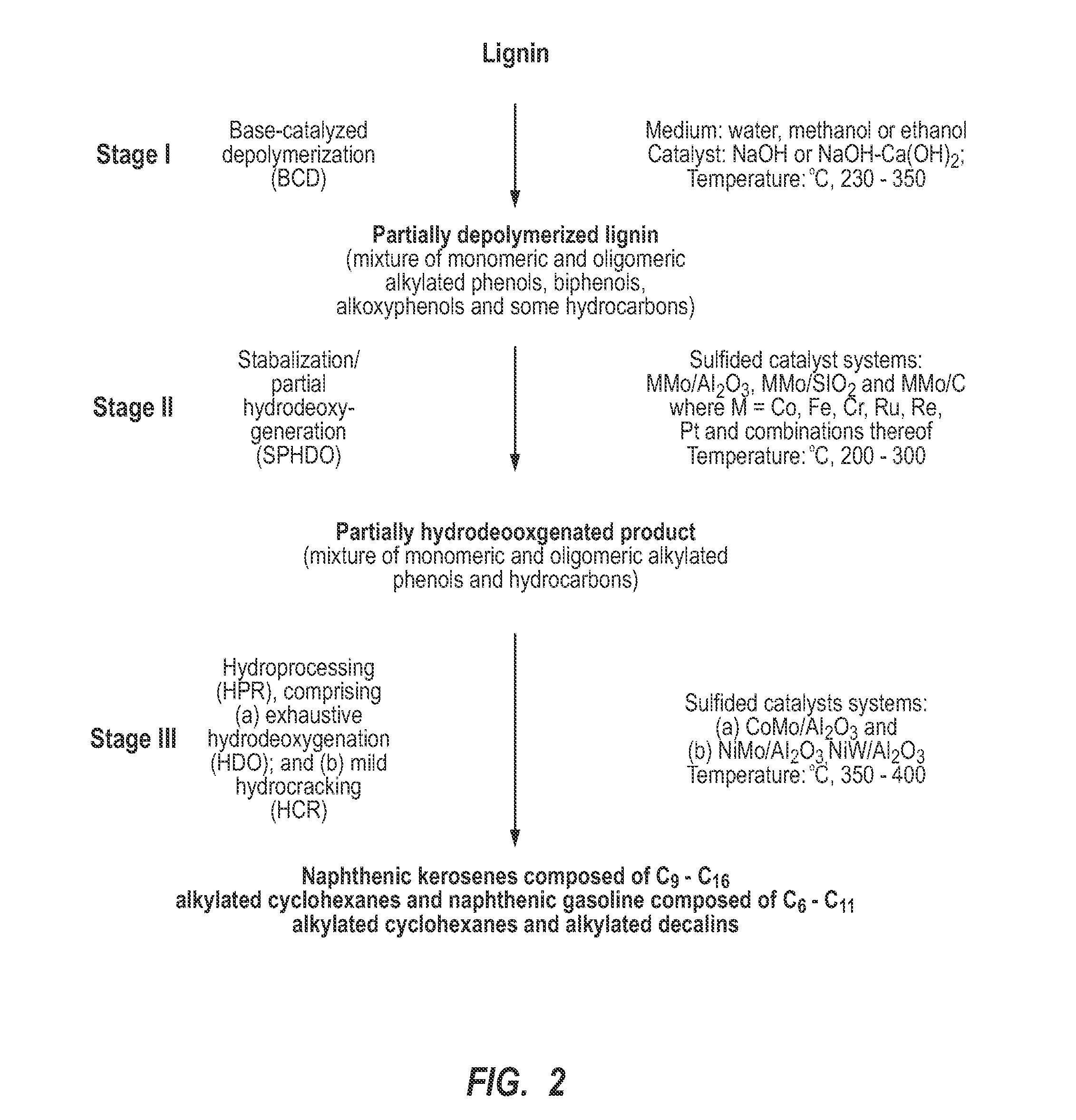

Processes for conversion of lignin to liquid products such as bio-fuels and fuel additives are disclosed and described. A process for conversion of a lignin material to bio-fuels can include subjecting the lignin material to a base catalyzed depolymerization reaction to produce a partially depolymerized lignin. The partially depolymerized lignin can then be subjected to a stabilization / partial hydrodeoxygenation reaction to form a partially hydrodeoxygenated product. Following partial hydrodeoxygenation, the partially hydrodeoxygenated product can be reacted in a hydroprocessing step to form a bio-fuel. Each of these reaction steps can be performed in single or multiple steps, depending on the design of the process. The production of an intermediate partially hydrodeoxygenation product and subsequent reaction thereof can significantly reduce or eliminate reactor plugging and catalyst coking. A variety of useful bio-fuels such as fuels, fuel additives, and the like, including gasoline and jet or rocket fuels are describe which can be readily produced from renewable lignin materials in an improved conversion process.

Owner:UNIV OF UTAH RES FOUND

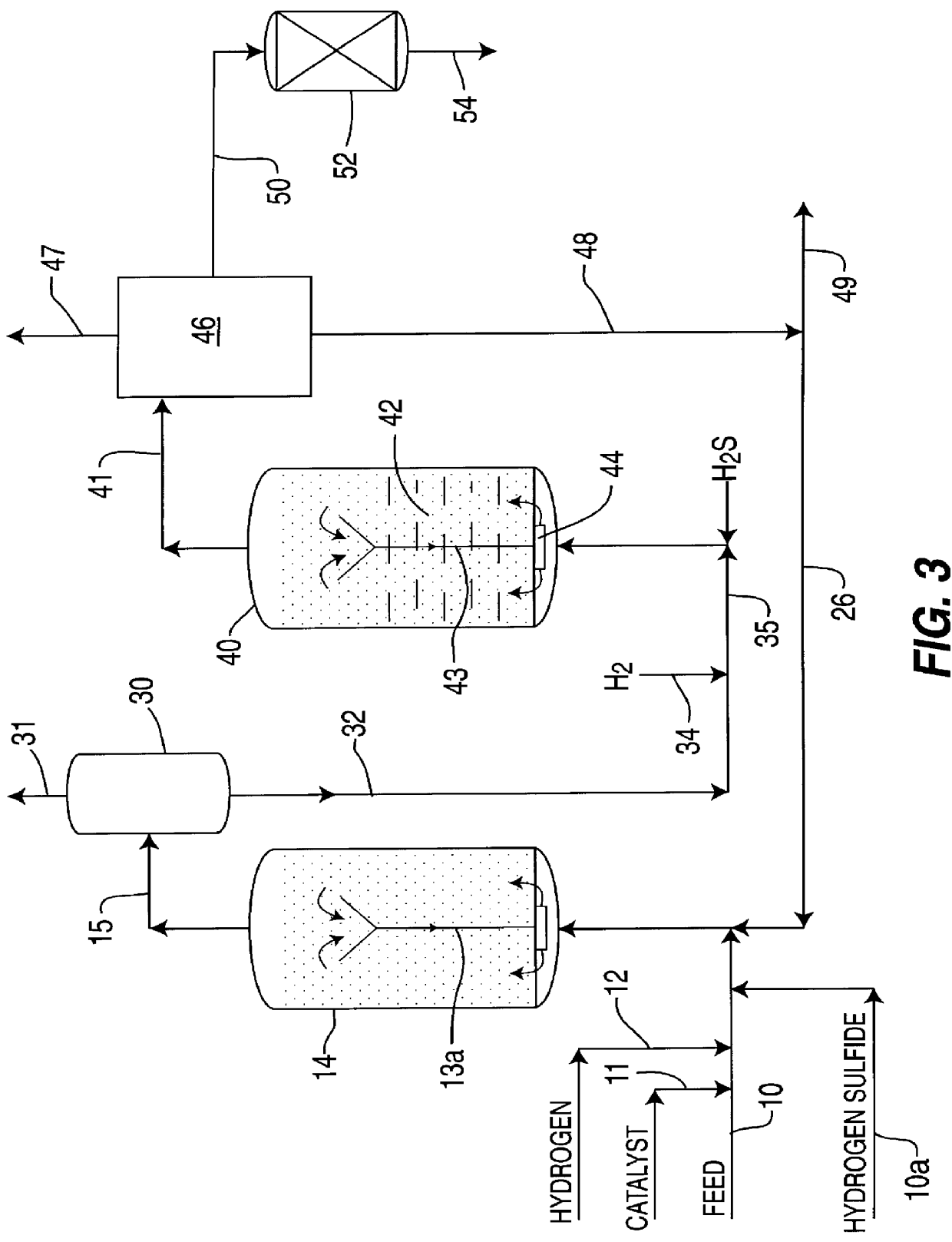

Two stage process for hydrodesulfurizing distillates using bulk multimetallic catalyst

InactiveUS6929738B1Preparation by oxo-reaction and reductionOrganic compound preparationLiquid productHydrogen

A two stage hydrodesulfurizing process for producing low sulfur distillates. A distillate boiling range feedstock containing in excess of about 3,000 wppm sulfur is hydrodesulfurized in a first hydrodesulfurizing stage containing one or more reaction zones in the presence of hydrogen and a hydrodesulfurizing catalyst. The liquid product stream thereof is passed to a first separation stage wherein a vapor phase product stream and a liquid product stream are produced. The liquid product stream, which has a substantially lower sulfur and nitrogen content then the original feedstream is passed to a second hydrodesulfurizing stage also containing one or more reaction zones where it is reacted in the presence of hydrogen and a second hydrodesulfurizing catalyst at hydrodesulfurizing conditions. The catalyst in any one or more reaction zones is a bulk multimetallic catalyst comprised of at least one Group VIII non-noble metal and at least two Group VIB metals.

Owner:EXXON RES & ENG CO

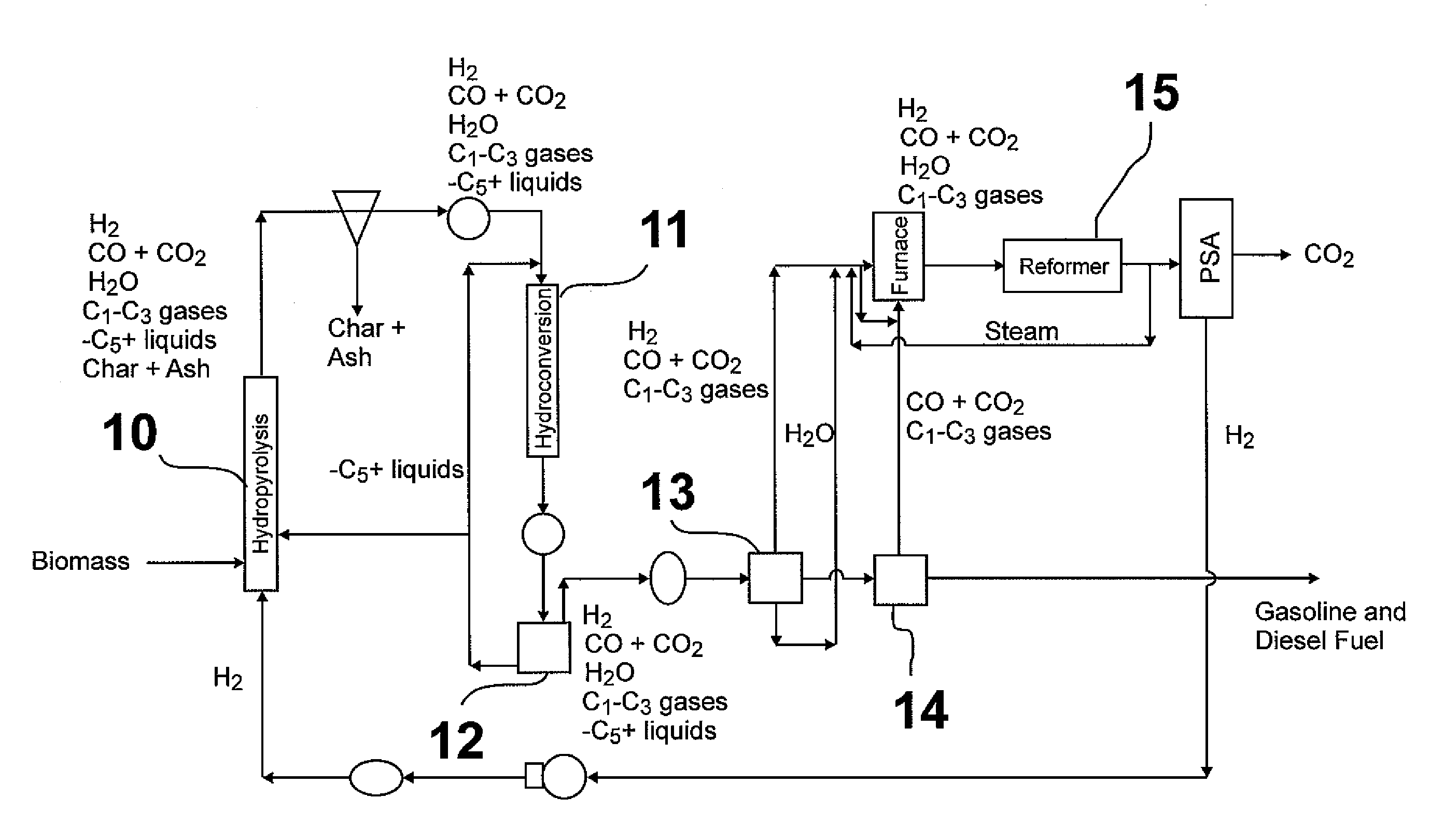

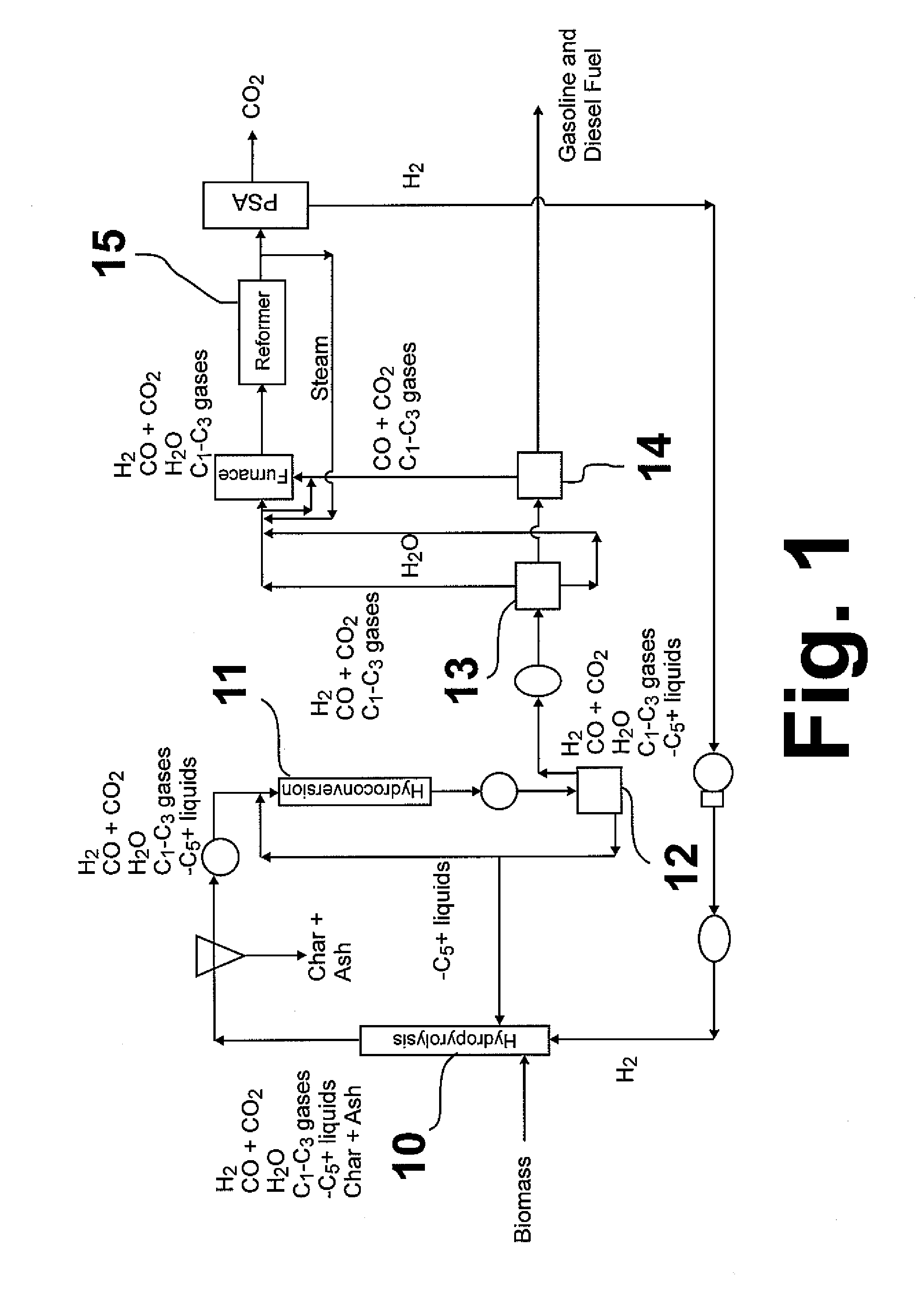

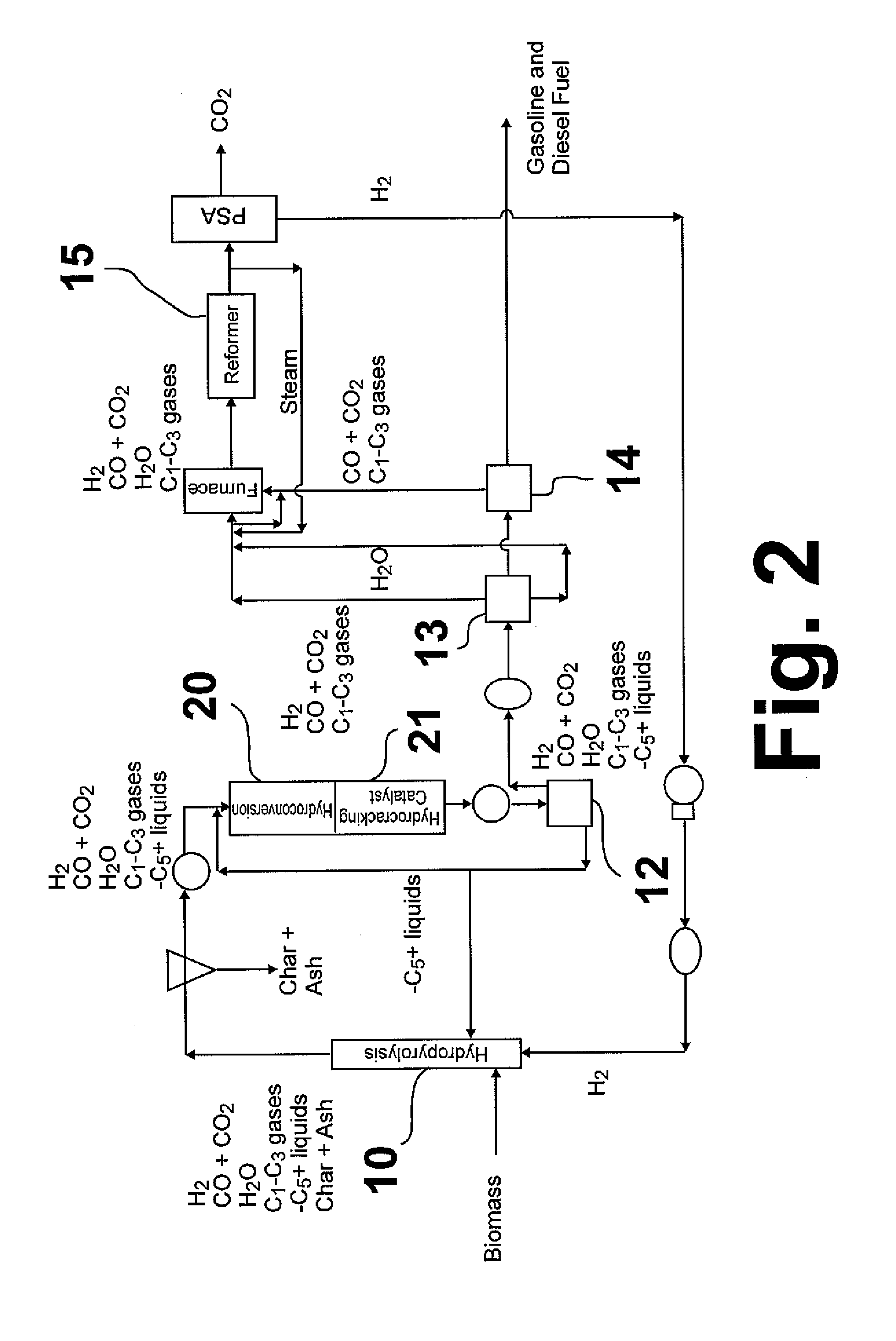

Hydropyrolysis of biomass for producing high quality liquid fuels

A self-sustaining process for producing high quality liquid fuels from biomass in which the biomass is hydropyrolyzed in a reactor vessel containing molecular hydrogen and a deoxygenating catalyst, producing a partially deoxygenated hydropyrolysis liquid, which is hydrogenated using a hydroconversion catalyst, producing a substantially fully deoxygenated hydrocarbon liquid and a gaseous mixture comprising CO and light hydrocarbon gases (C1-C3). The gaseous mixture is reformed in a steam reformer, producing reformed molecular hydrogen, which is then introduced into the reactor vessel for hydropyrolizing the biomass. The deoxygenated hydrocarbon liquid product is further separated to produce diesel fuel, gasoline, or blending components for gasoline and diesel fuel.

Owner:GAS TECH INST

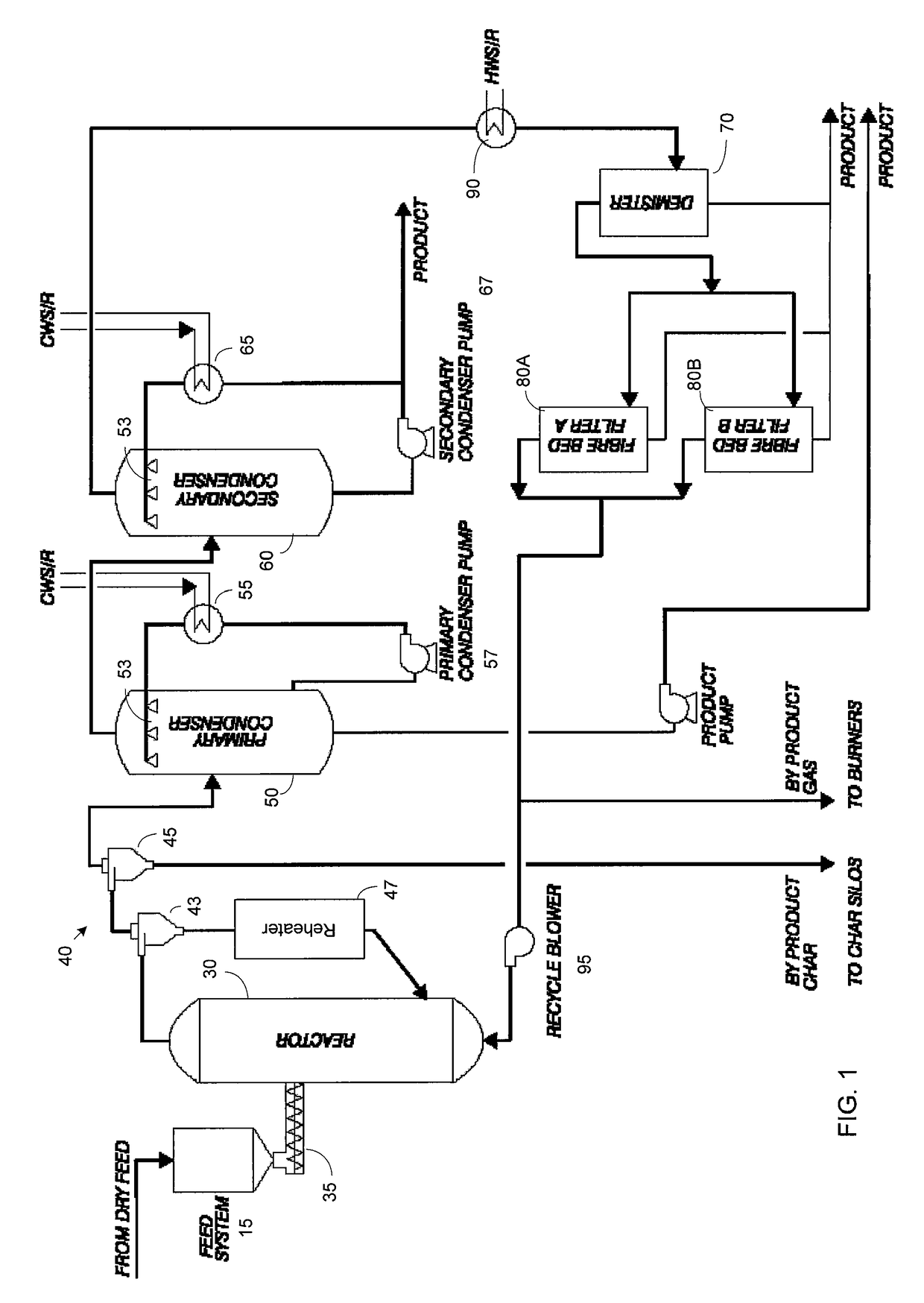

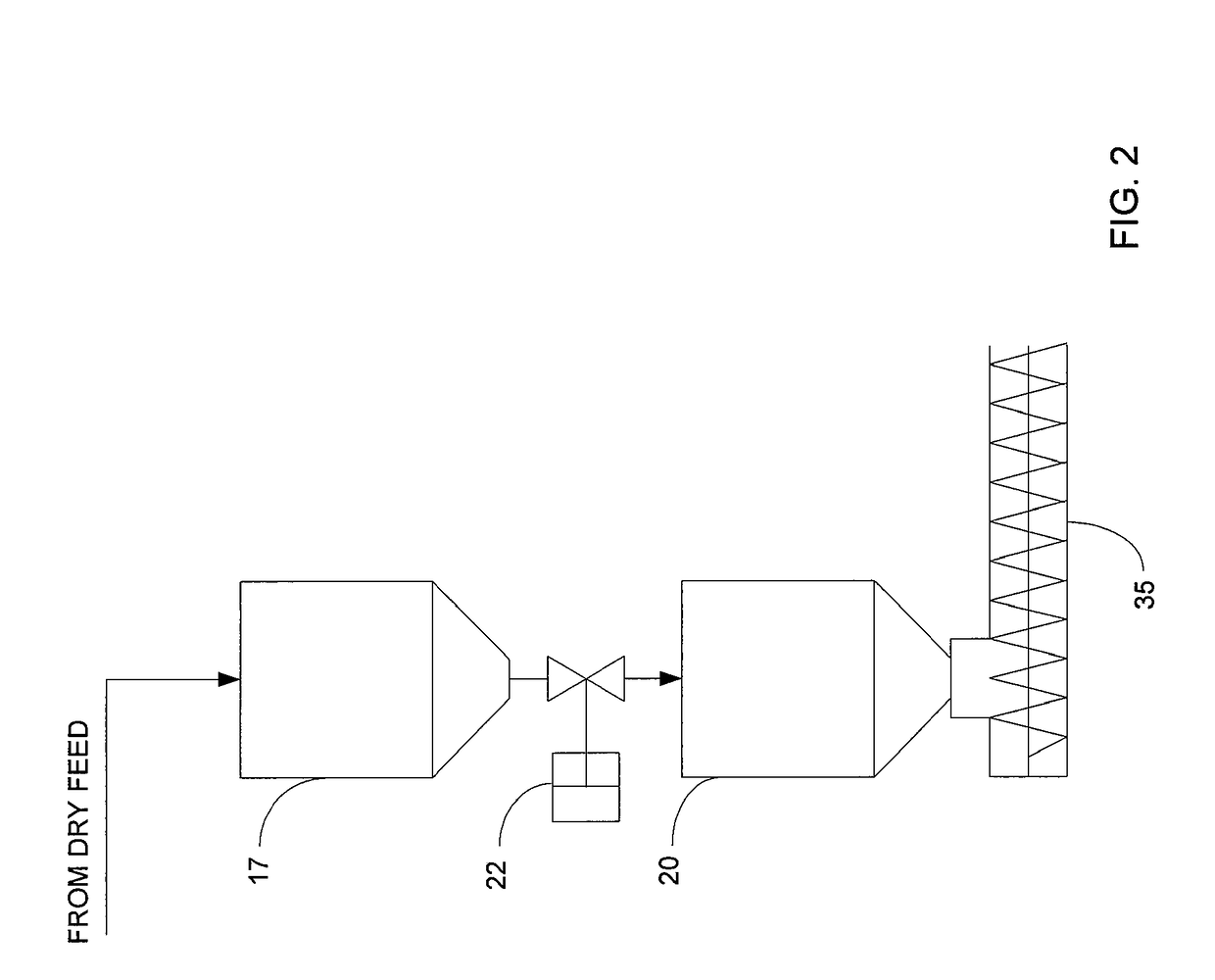

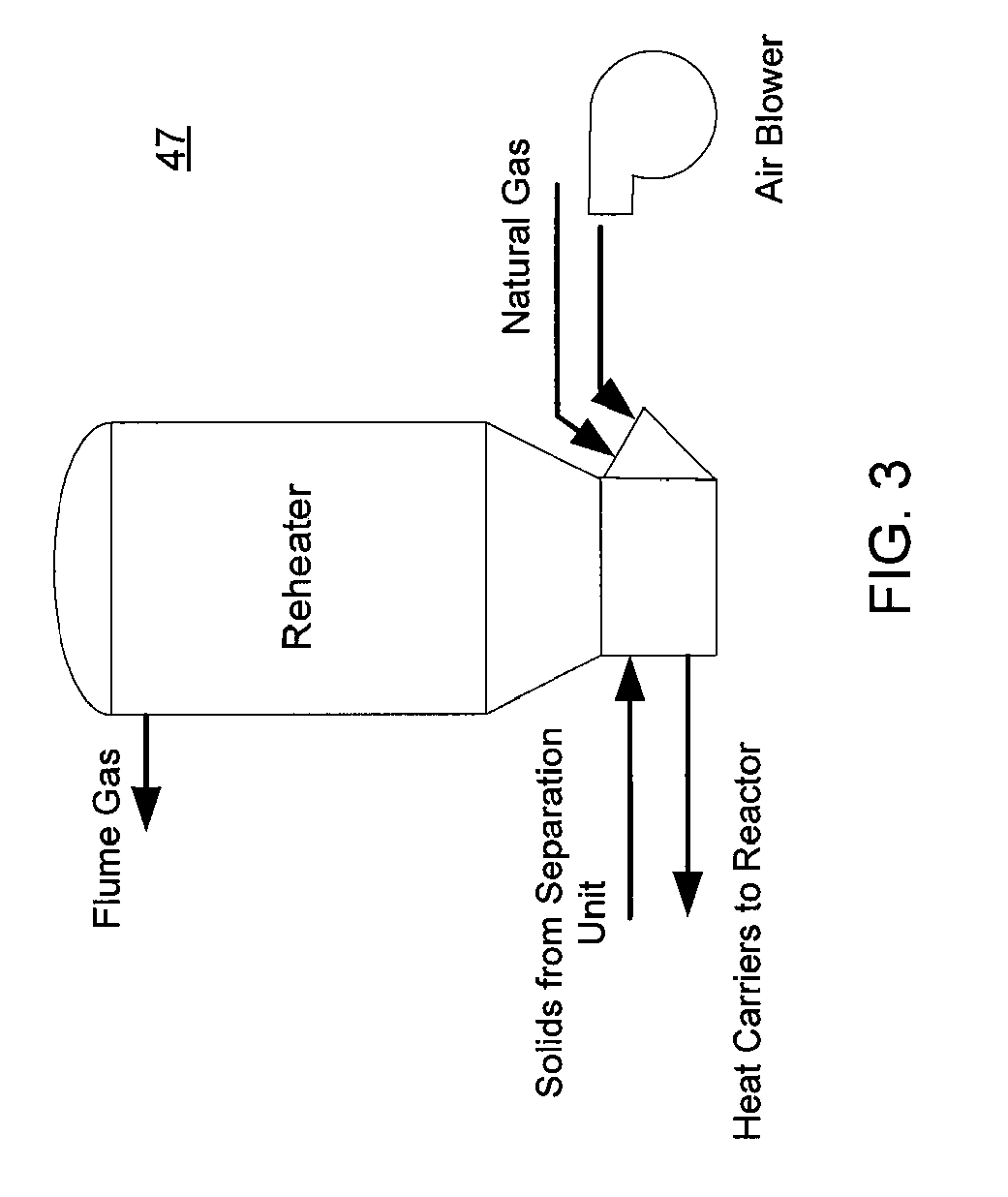

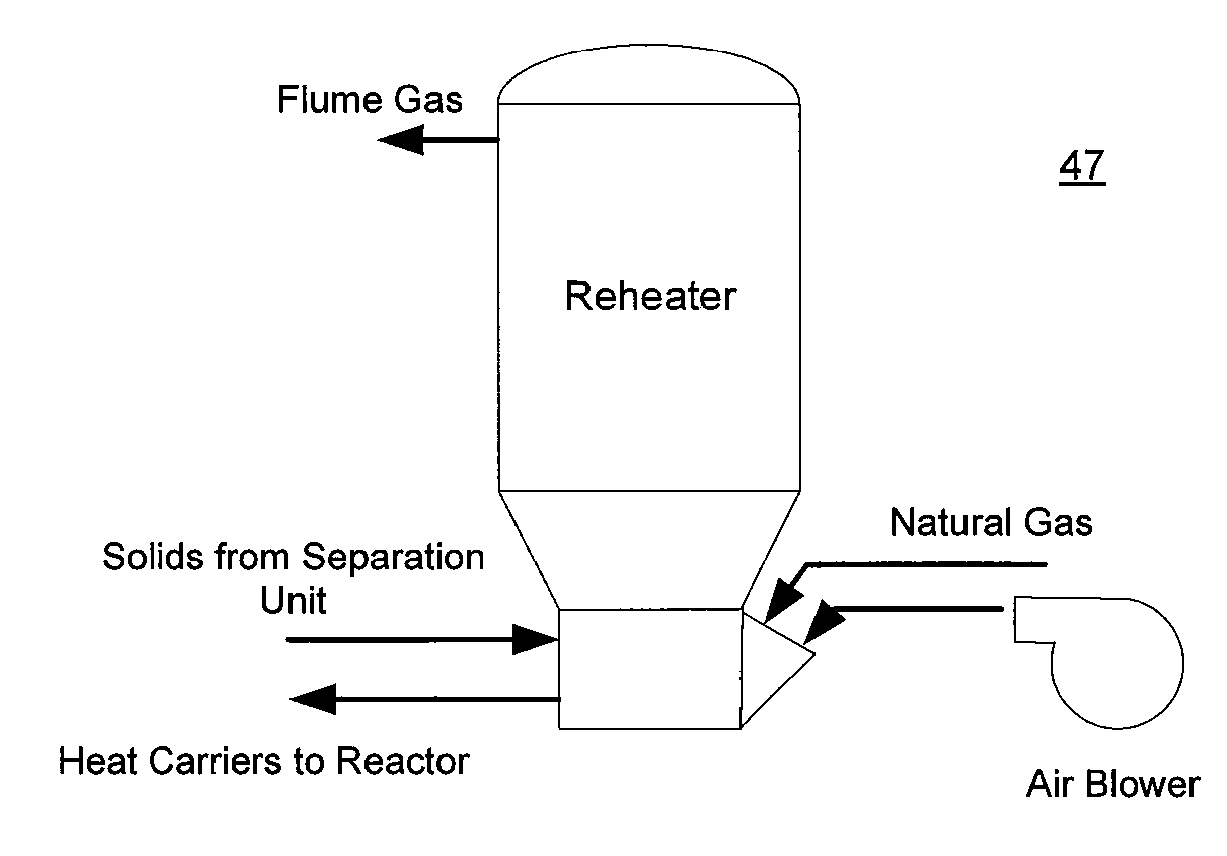

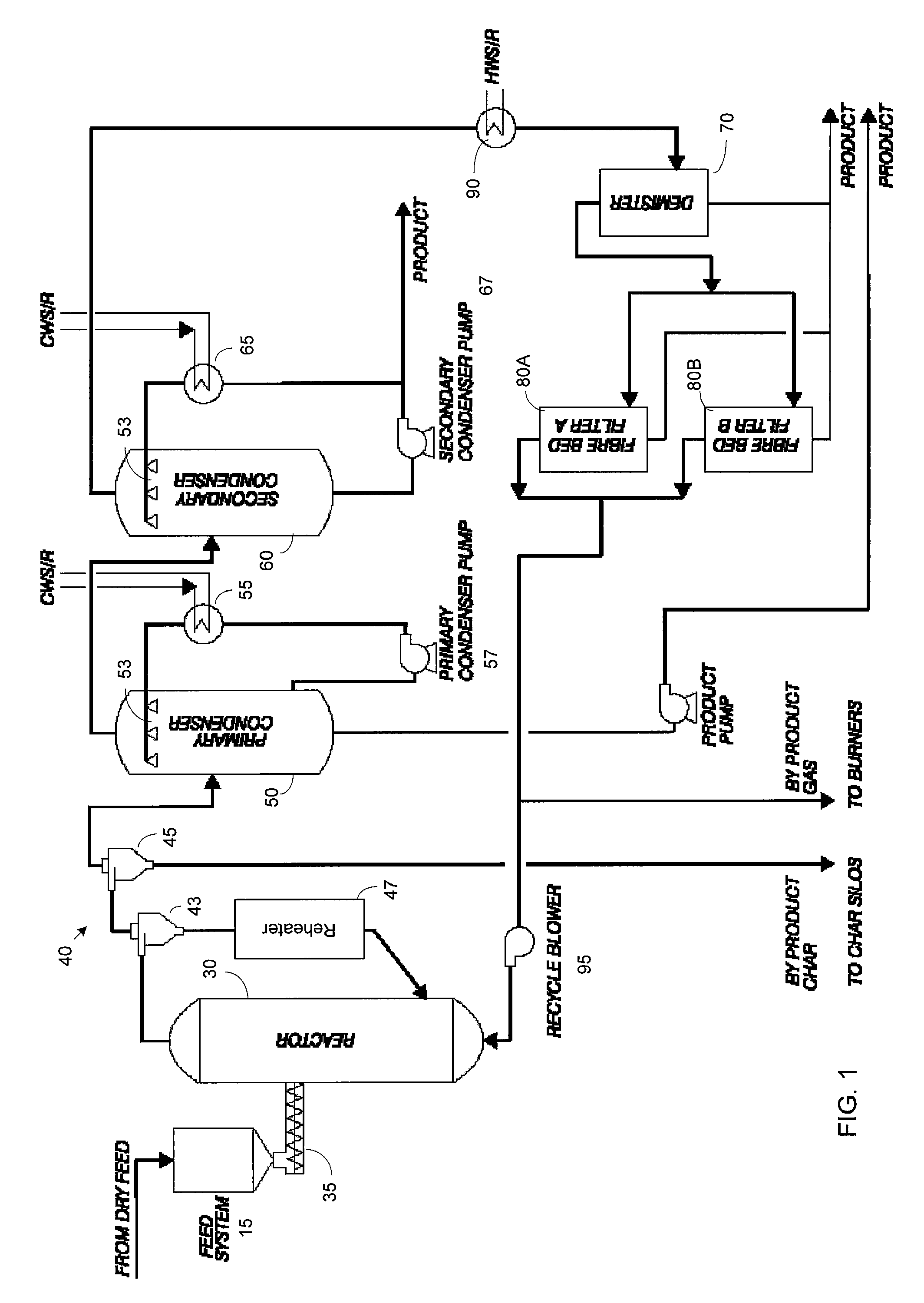

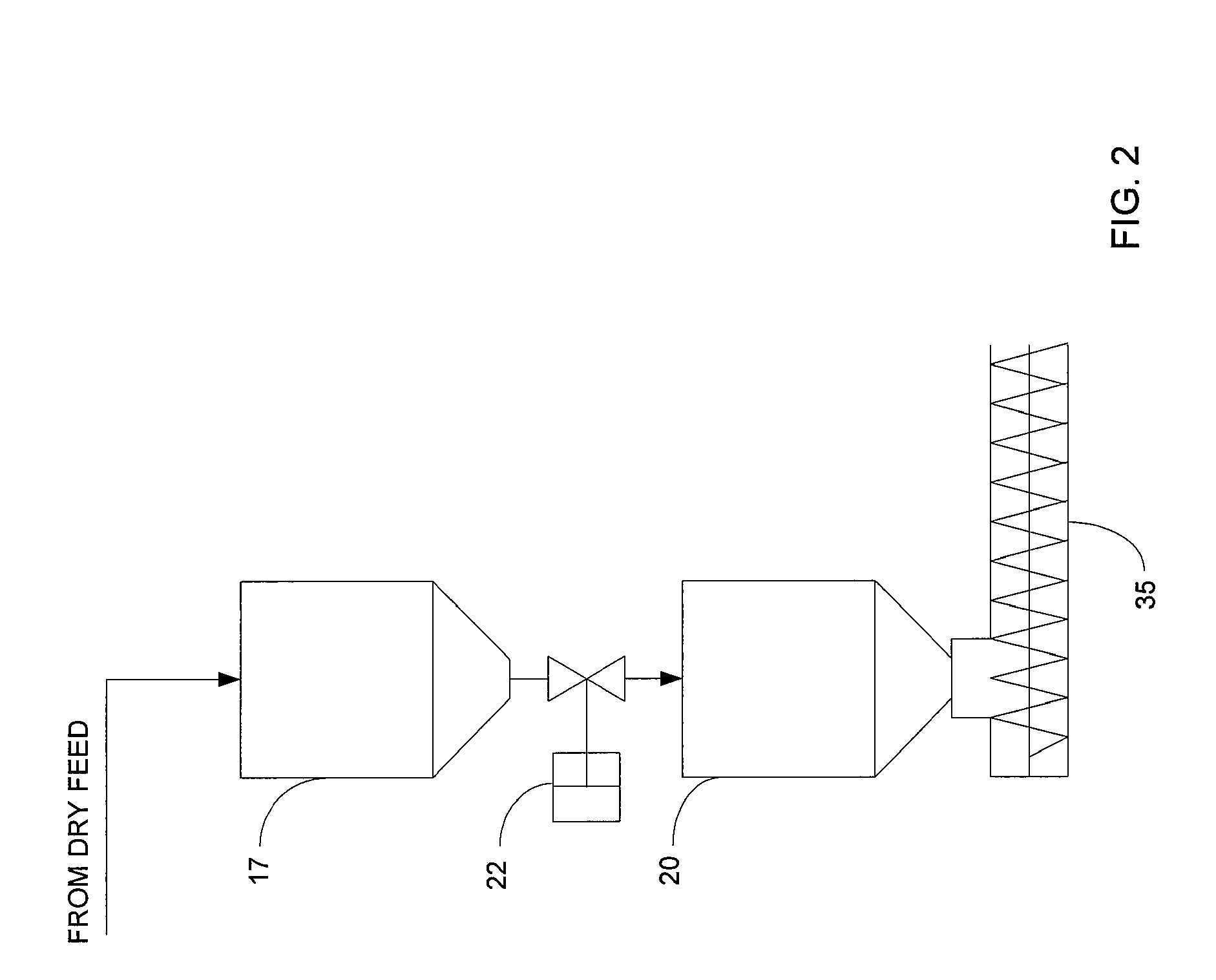

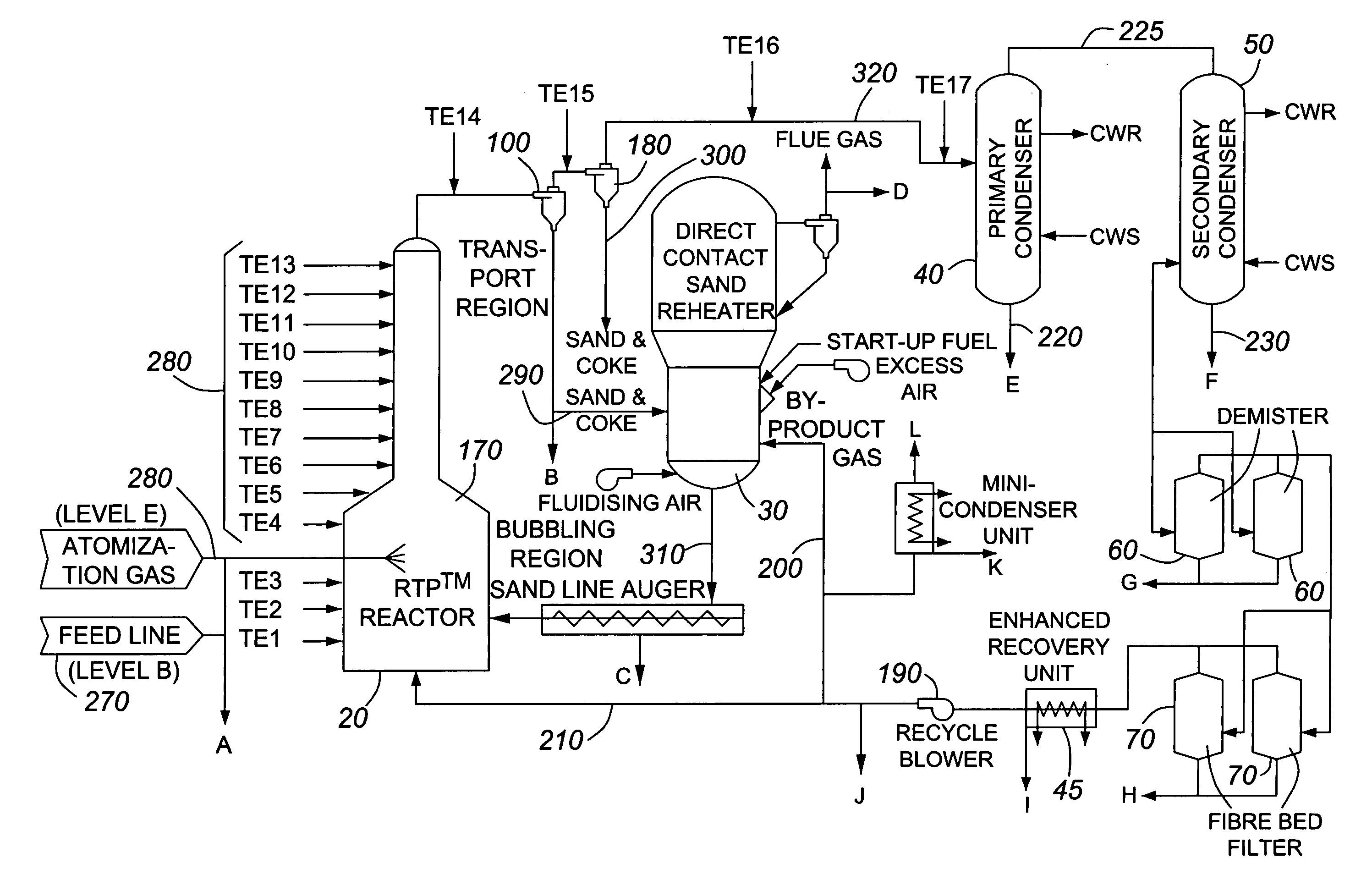

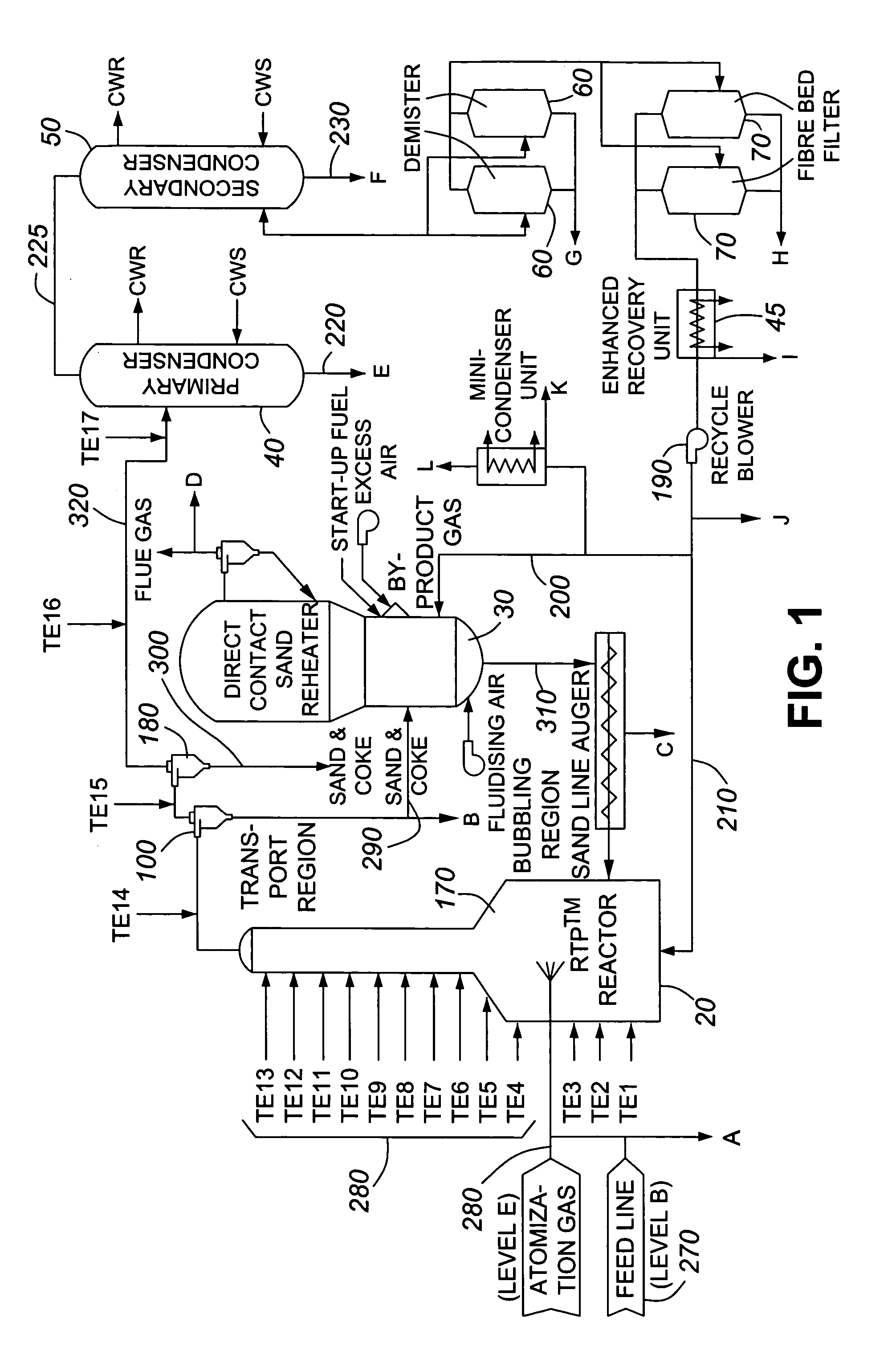

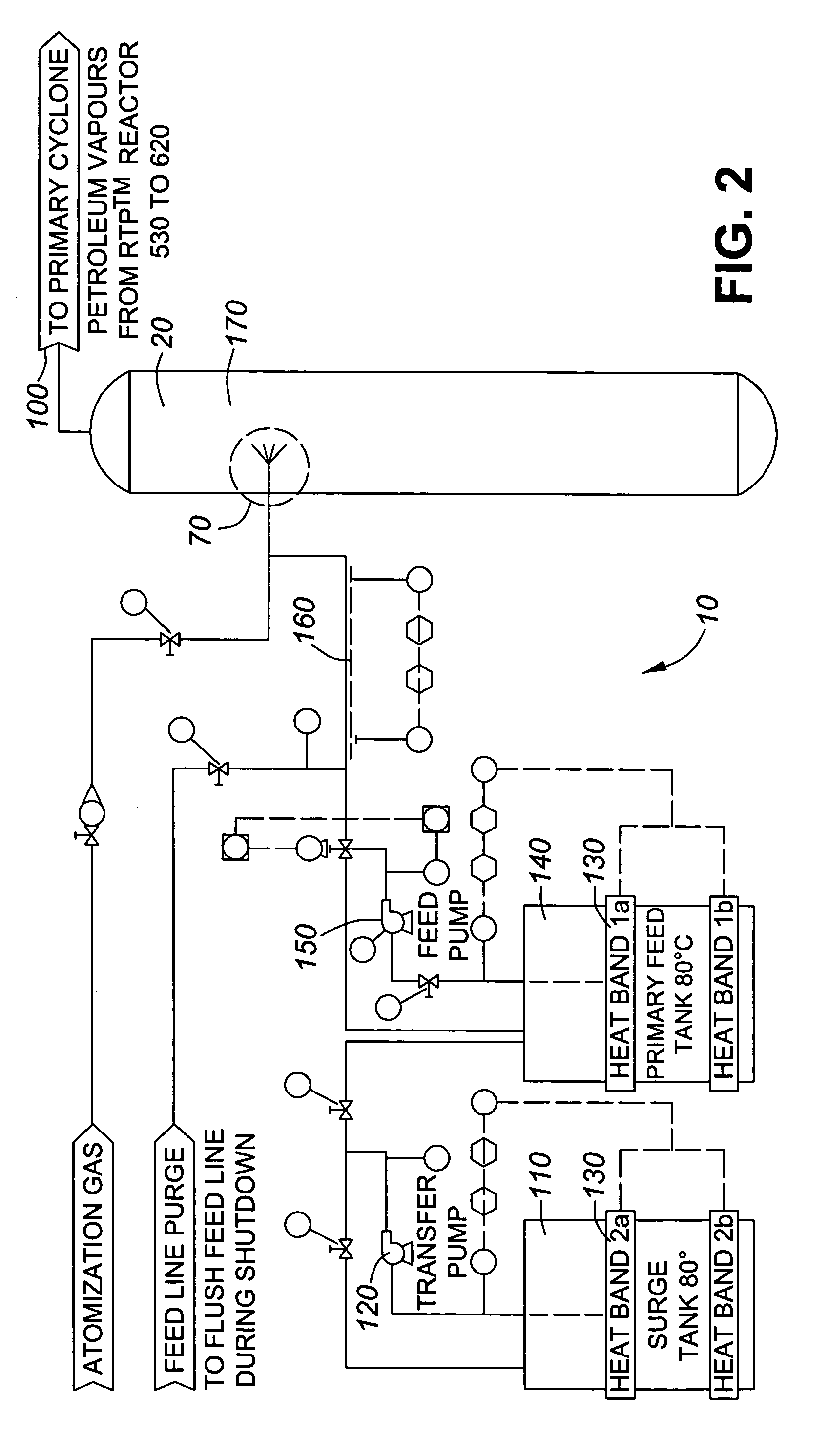

Rapid thermal conversion of biomass

ActiveUS7905990B2Improved rapid thermal conversion processEffective recoveryThermal non-catalytic crackingSolid waste disposalLiquid productHeat carrier

A rapid thermal conversion process for efficiently converting wood, other biomass materials, and other carbonaceous feedstock (including hydrocarbons) into high yields of valuable liquid product, e.g., bio-oil, on a large scale production. Biomass material, e.g., wood, is feed to a conversion system where the biomass material is mixed with an upward stream of hot heat carriers, e.g., sand, that thermally convert the biomass into a hot vapor stream. The hot vapor stream is rapidly quenched with quench media in one or more condensing chambers located downstream of the conversion system. The rapid quenching condenses the vapor stream into liquid product, which is collected from the condensing chambers as a valuable liquid product. The liquid product may itself be used as the quench media.

Owner:ENSYN RENEWABLES

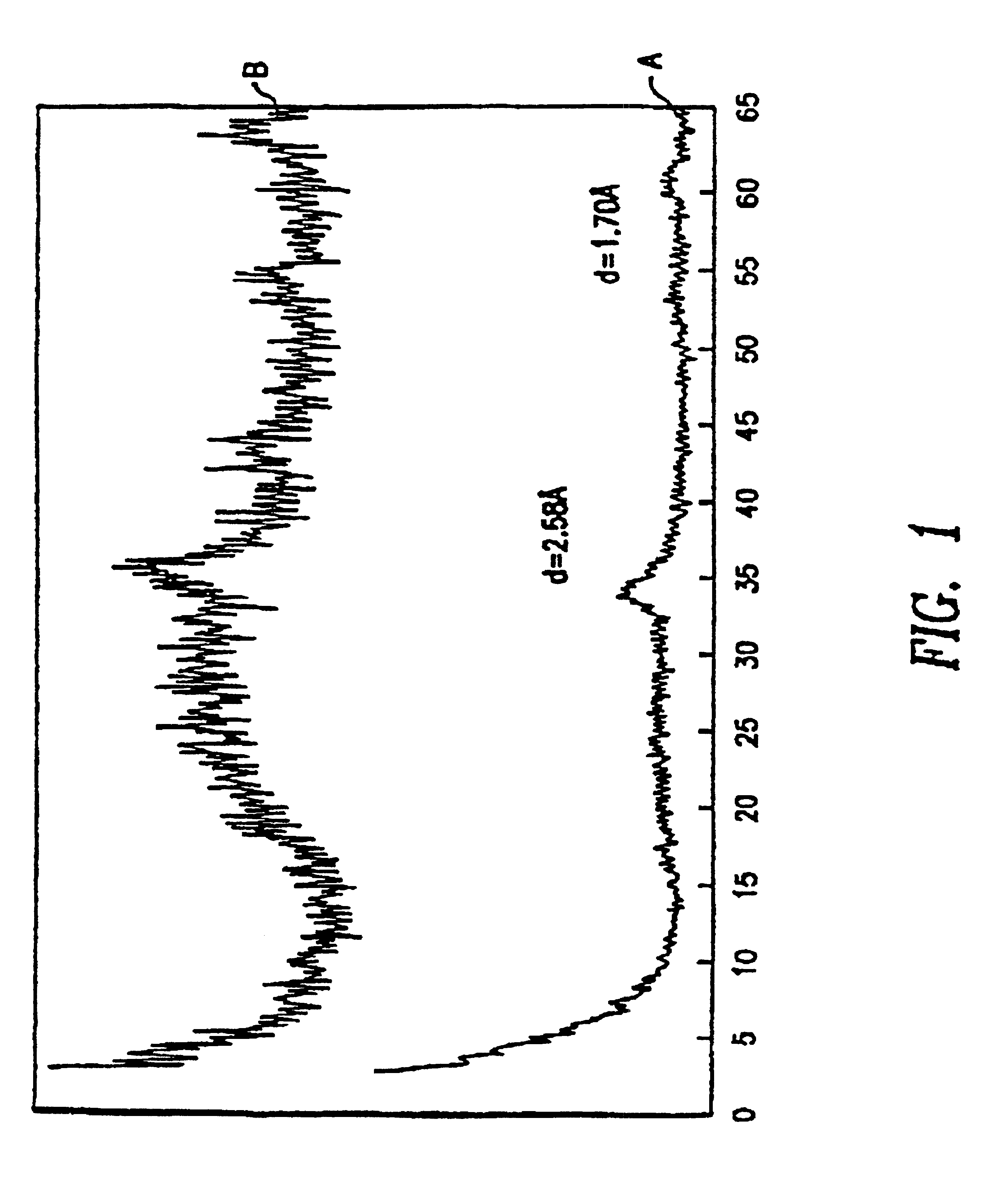

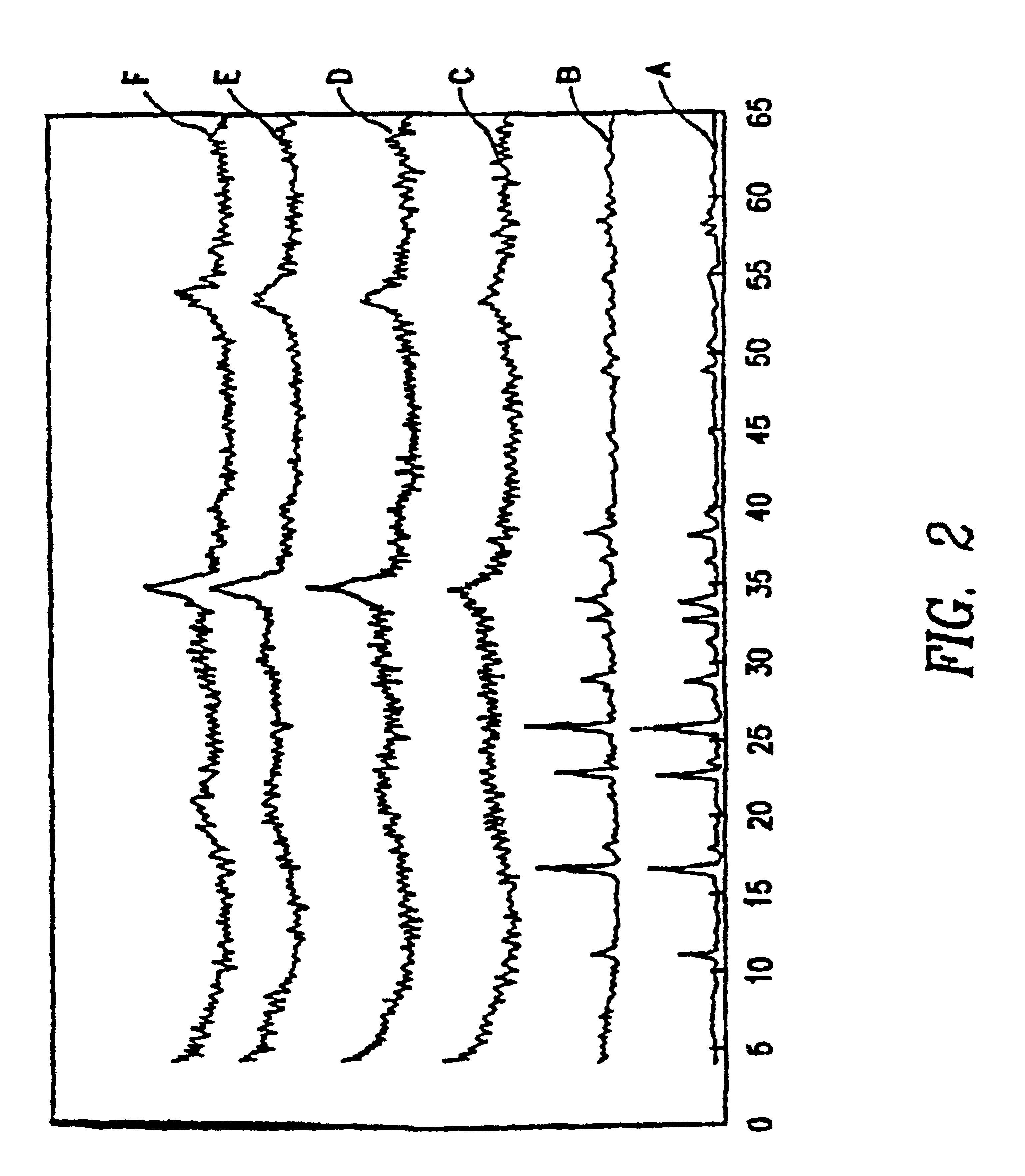

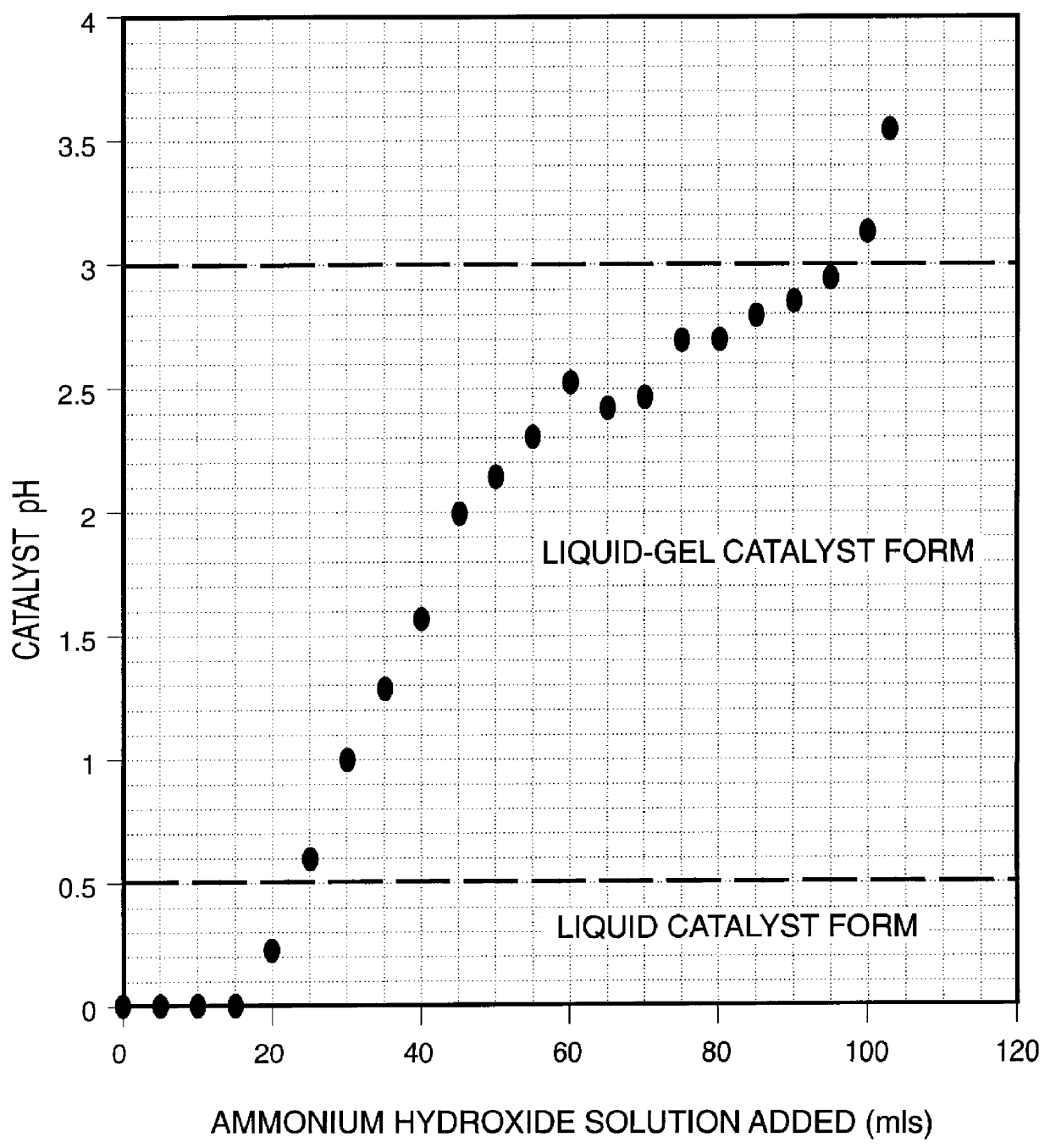

Iron-based ionic liquid catalysts for hydroprocessing carbonaceous feeds

InactiveUS6139723AIncrease hydrocracking ability of catalystIndirect and direct heating destructive distillationCatalyst activation/preparationLiquid productIron salts

A highly dispersed iron-based ionic liquid or liquid-gel catalyst which may be anion-modified and metals-promoted has high catalytic activity, and is useful for hydrocracking / hydrogenation reactions for carbonaceous feed materials. The catalyst is produced by aqueous precipitation from saturated iron salt solutions such as ferric sulfate and ferric alum, and may be modified during preparation with anionic sulfate (SO42-) and promoted with small percentages of at least one active metal such as cobalt, molybdenum, palladium, platinum, nickel, or tungsten or mixtures thereof. The resulting catalyst may be used in a preferred ionic liquid form or in a liquid-gel form, and either fluidic form can be easily mixed and reacted with carbonaceous feed materials such as coal, heavy petroleum fractions, mixed plastic waste, or mixtures thereof. The invention includes methods for making the ionic liquid or liquid-gel catalyst, and processes for using the fluidic catalysts for hydroprocessing the carbonaceous feed materials to produce desirable low-boiling hydrocarbon liquid products.

Owner:HEADWATERS CTL

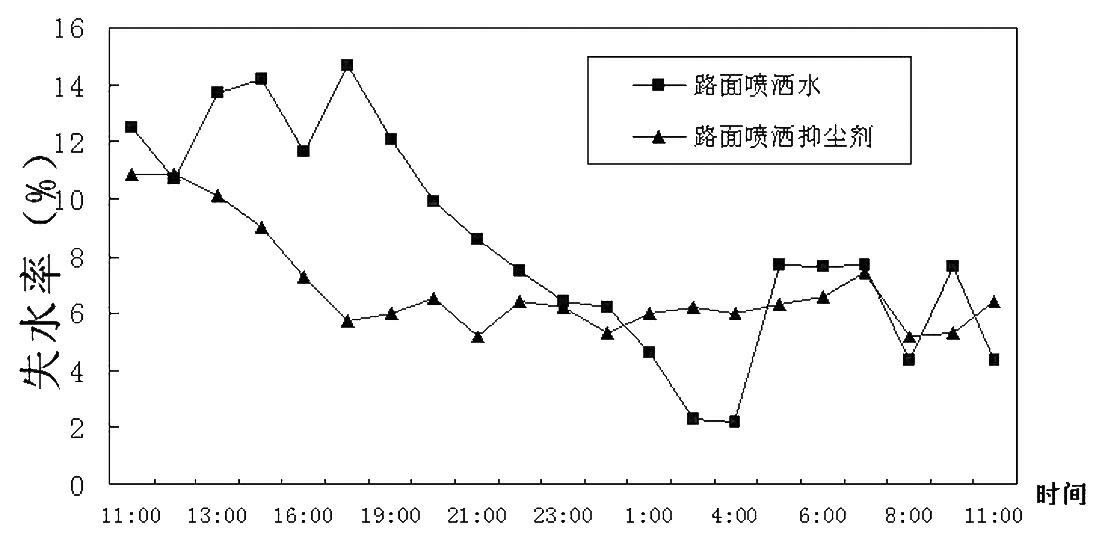

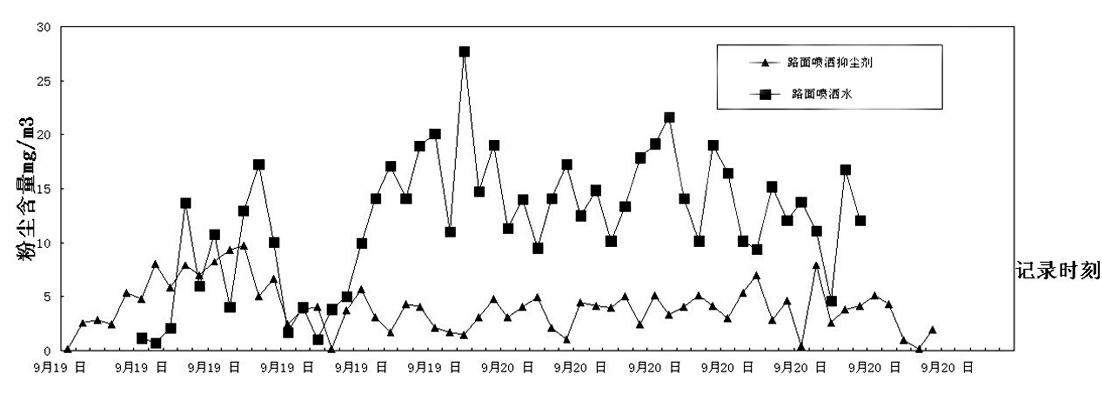

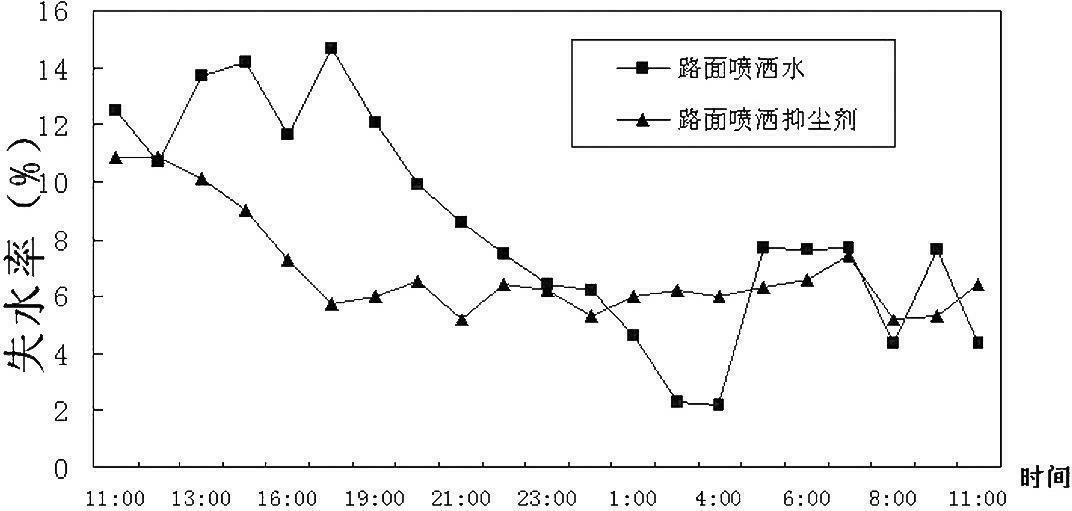

Road dust suppressant

ActiveCN102660227AStrong anti-pressure functionLarge particle sizeOther chemical processesLiquid productEvaporation

The invention discloses a road dust suppressant, which is prepared by mixing and blending 0.1-2.0% of water-soluble high molecular polymer, 20-50% of moisture absorption humectant, 1.0-5.0% of preservative, 0.5-5.0% of penetrating agent and the balance water. The road dust suppressant is a dynamic dust-proof and dust-suppressing liquid product which combines functions of wetting, bonding, permeating, adsorbing moisture and the like into a whole and has extremely strong pressurization-resistant function. The road dust suppressant has the advantages of obvious anti-evaporation performance and good water retention hygroscopicity, and dust on the road surface can be coagulated and is unlikely to fly. The road dust suppressant disclosed by the invention not only can be applied to road dust suppressing but also can be simultaneously used for the aspects, such as the mine exploration and transportation environment, storage yards of coal ash, coal and other ores, and the treatments of municipal construction earthwork dust raise.

Owner:山西兴源盛科技有限公司

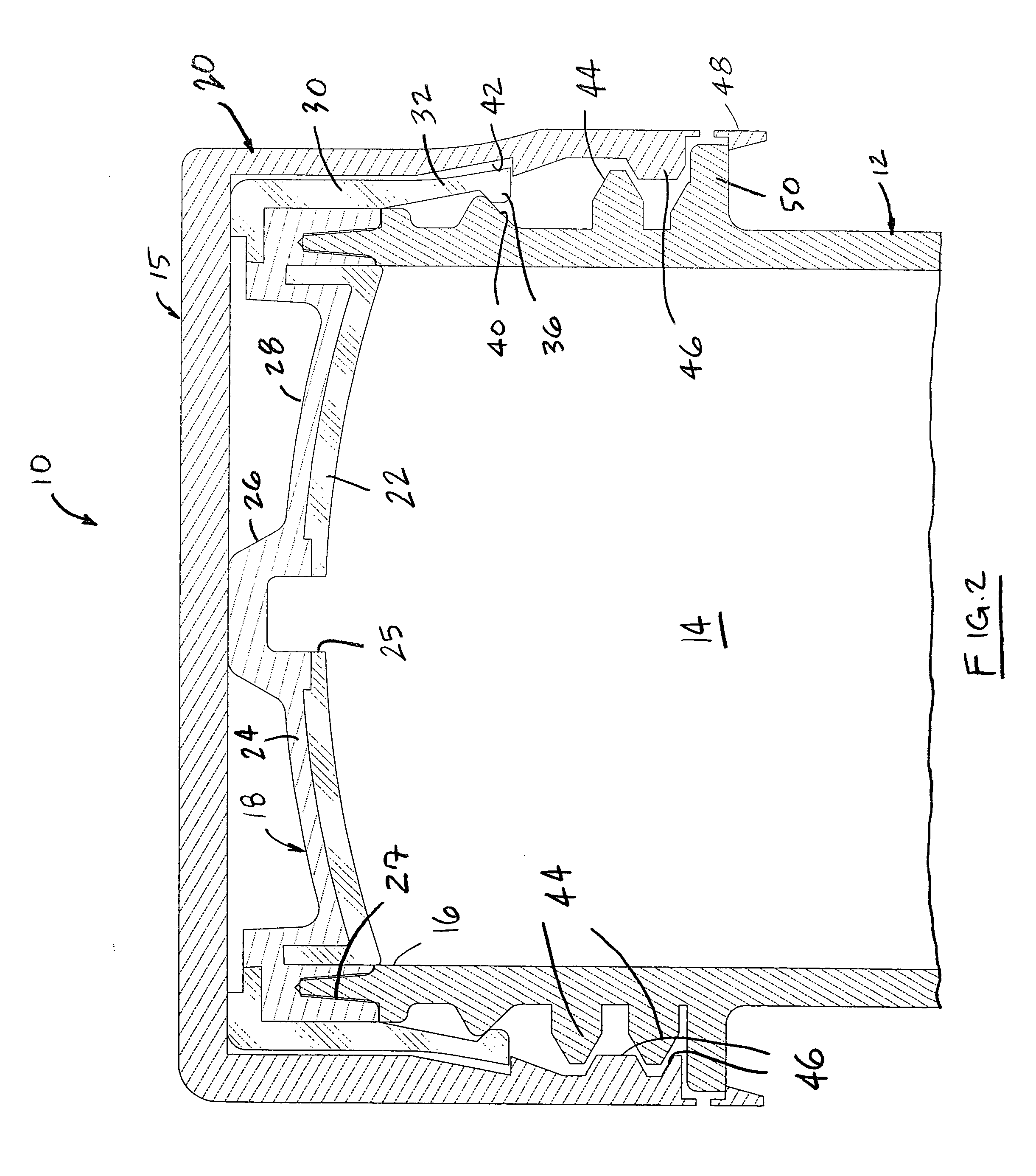

Container closure with overlying needle penetrable and thermally resealable portion and underlying portion compatible with fat containing liquid product, and related method

InactiveUS20060231519A1Avoiding seal integrity problemGood product containmentCapsLiquid fillingLiquid productFormulary

A container and method are provided for storing fat containing liquid products, such as infant or baby formula, or other milk-based products. The container includes a body defining a storage chamber for receiving the aseptic fat containing liquid product, and a first aperture in fluid communication with the storage chamber. The body does not leach more than a predetermined amount of leachables into the fat containing liquid product and does not undesirably alter a taste profile of the fat containing liquid product. A container closure assembly includes a stopper receivable within the first aperture for hermetically sealing the storage chamber. The stopper includes a first material portion defining an internal surface in fluid communication with the storage chamber forming at least most of the surface area of the container closure that can contact any fat containing liquid product within the storage chamber and that does not leach more than a predetermined amount of leachables into the fat containing liquid product or undesirably alter a taste profile of the fat containing liquid product. A second material portion of the stopper either (i) overlies the first material portion and cannot contact any product within the storage chamber, or (ii) forms a substantially lesser surface area of the container closure that can contact any product within the storage chamber in comparison to the first material portion. The second material portion is needle penetrable for filling the storage chamber with product, and a resulting needle aperture formed in the second material portion is thermally resealable such as by the application of laser energy to seal the product within the storage chamber. A sealing portion of the container closure is engageable with the body prior to needle filling the storage chamber to thereby form a substantially dry hermetic seal between the container closure and body.

Owner:MEDINSTILL DEV

Rapid thermal conversion of biomass

ActiveUS20090139851A1Improved rapid thermal conversion processEffective recoveryThermal non-catalytic crackingCoke quenchingLiquid productHeat carrier

The present invent provides improved rapid thermal conversion processes for efficiently converting wood, other biomass materials, and other carbonaceous feedstock (including hydrocarbons) into high yields of valuable liquid product, e.g., bio-oil, on a large scale production. In an embodiment, biomass material, e.g., wood, is feed to a conversion system where the biomass material is mixed with an upward stream of hot heat carriers, e.g., sand, that thermally convert the biomass into a hot vapor stream. The hot vapor stream is rapidly quenched with quench media in one or more condensing chambers located downstream of the conversion system. The rapid quenching condenses the vapor stream into liquid product, which is collected from the condensing chambers as a valuable liquid product. In one embodiment, the liquid product itself is used as the quench media.

Owner:ENSYN RENEWABLES

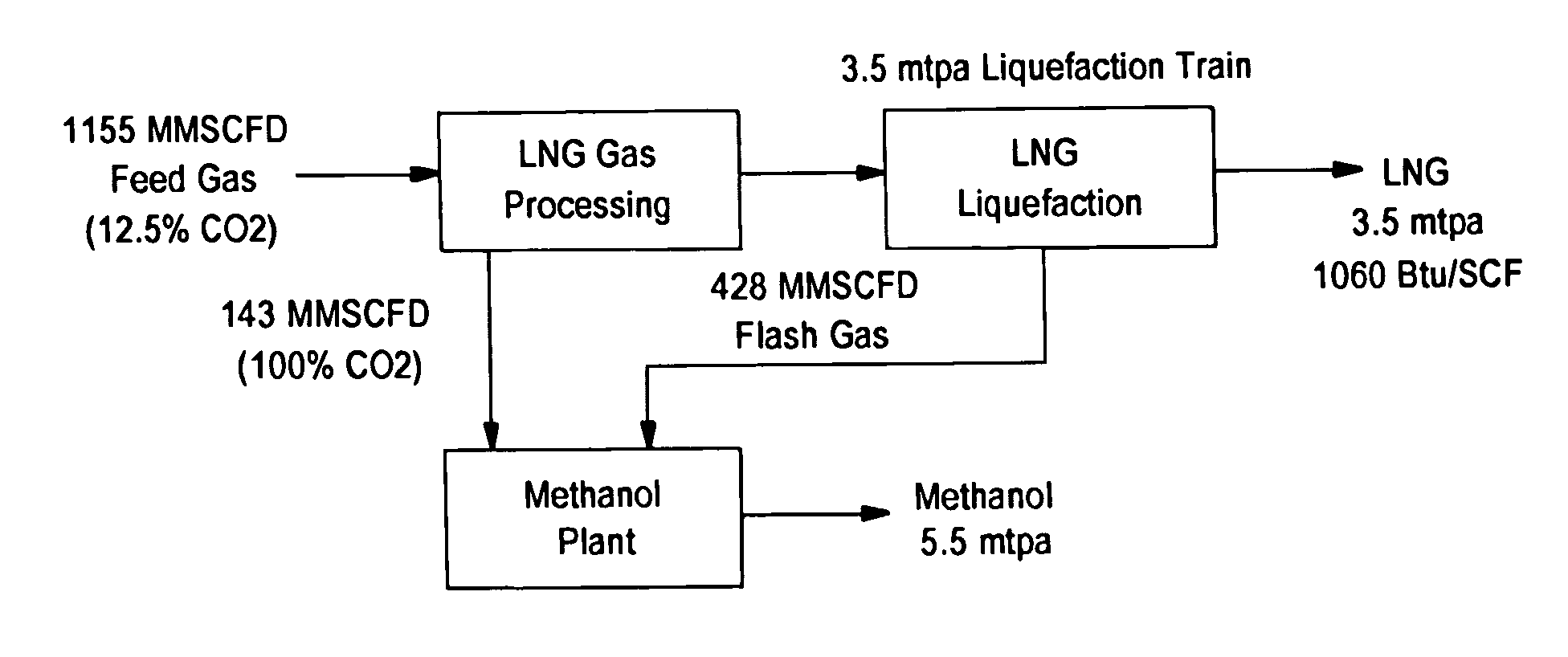

Integrated processing of natural gas into liquid products

ActiveUS7168265B2Effectively integrating the LNG and GTL phases and processing stepsHydrogenSolidificationLiquid productProcess engineering

An integrated process for producing LNG and GTL products is provided, wherein a CO2-containing natural gas feed to an LNG production zone is first pre-treated to separate at least a portion of the CO2 therefrom, and the resulting CO2 stream obtained thereby is then directed to a GTL production zone and utilized to make GTL products that include methanol and / or methanol derivatives.

Owner:BP CORP NORTH AMERICA INC

Modified thermal processing of heavy hydrocarbon feedstocks

InactiveUS7572362B2Quick upgradeReducing H2S contentThermal non-catalytic crackingTreatment with plural serial cracking stages onlyLiquid productParticulates

The present invention is directed to the upgrading of heavy petroleum oils of high viscosity and low API gravity that are typically not suitable for pipelining without the use of diluents. It utilizes a short residence-time pyrolytic reactor operating under conditions that result in a rapid pyrolytic distillation with coke formation. Both physical and chemical changes taking place lead to an overall molecular weight reduction in the liquid product and rejection of certain components with the byproduct coke. The liquid product is upgraded primarily because of its substantially reduced viscosity, increased API gravity, and the content of middle and light distillate fractions. While maximizing the overall liquid yield, the improvements in viscosity and API gravity can render the liquid product suitable for pipelining without the use of diluents. This invention particularly relates to reducing sulfur emissions during the combustion of byproduct coke (or coke and gas), to reducing the total acid number (TAN) of the liquid product, and to reducing the hydrogen sulfide content of one, or more than one component of the product stream. The method comprises introducing a particulate heat carrier into an up-flow reactor, introducing the feedstock at a location above the entry of the particulate heat carrier, allowing the heavy hydrocarbon feedstock to interact with the heat carrier for a short time, separating the vapors of the product stream from the particulate heat carrier and liquid and byproduct solid matter, regenerating the particulate heat carrier in the presence of the calcium compound, and collecting a gaseous and liquid product from the product stream.

Owner:IVANHOE HTL GASOLINEEUM

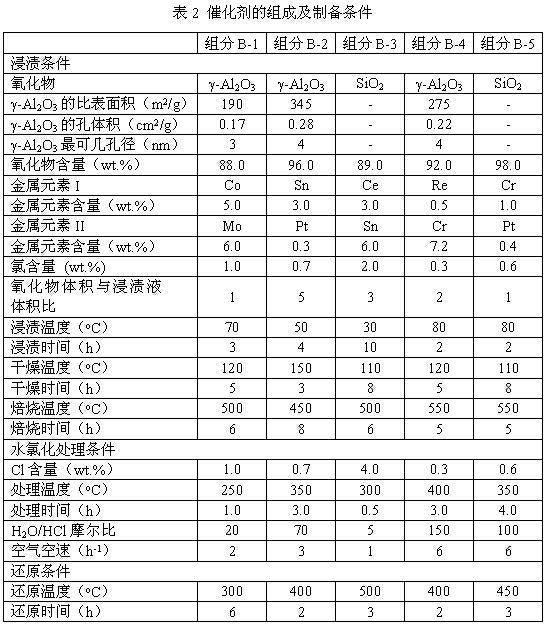

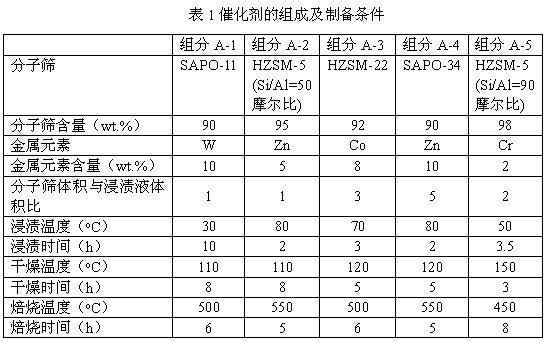

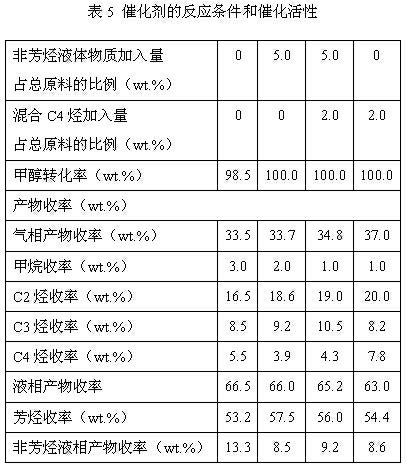

Catalyst for preparing aromatic hydrocarbon through methanol conversion as well as preparation method and application thereof

InactiveCN102416342AHigh yieldHigh activityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsLiquid productGas phase

The invention discloses a catalyst for preparing aromatic hydrocarbon through methanol conversion. The catalyst comprises a component A and components B, wherein the mass ratio of component A to components B is 0.25-4; the component A is a modified zeolite molecular sieve and comprises 80-99wt% of molecular sieves and 1-20wt% of molecular sieve modifiers; the components B are oxide loaded metallic elements and halogen and comprise 85-95wt% of oxide, 0.5-10wt% of total metallic elements and 0.1-5wt% of halogen; and the component A and the components B are formed through squashing or extruding after being mixed uniformly. The catalyst has the following characteristics that: (1) the total recovery of benzene, toluene and xylene is higher and selectivity is high; (2) the raw material treatment capacity is large; (3) the non-aromatic hydrocarbon liquid product can serve as the solvent oil or gasoline component; (4) C4 hydrocarbon and non-aromatic hydrocarbon liquid phase products in the gas phase product can circularly enter into the catalyst bed layer, thus not only balancing the reaction heat but also improving the total recovery of the aromatic hydrocarbon; and (5) the catalyst has high activity and long life.

Owner:NORTHWEST UNIV

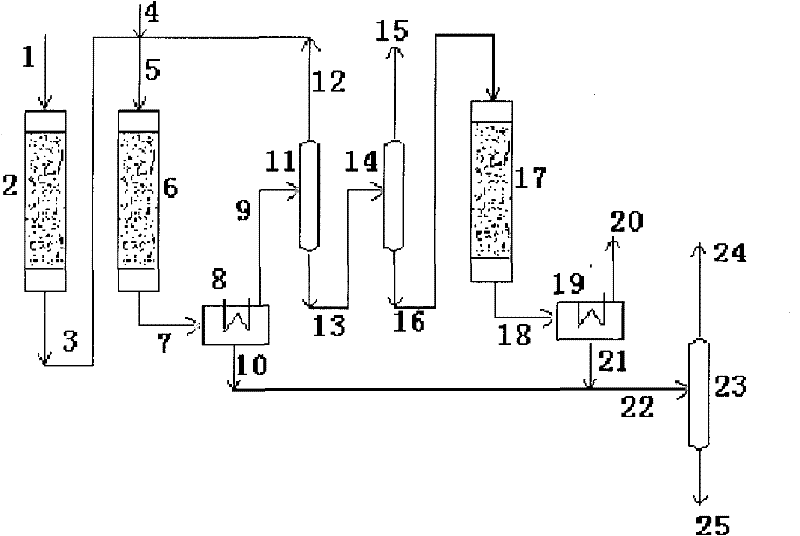

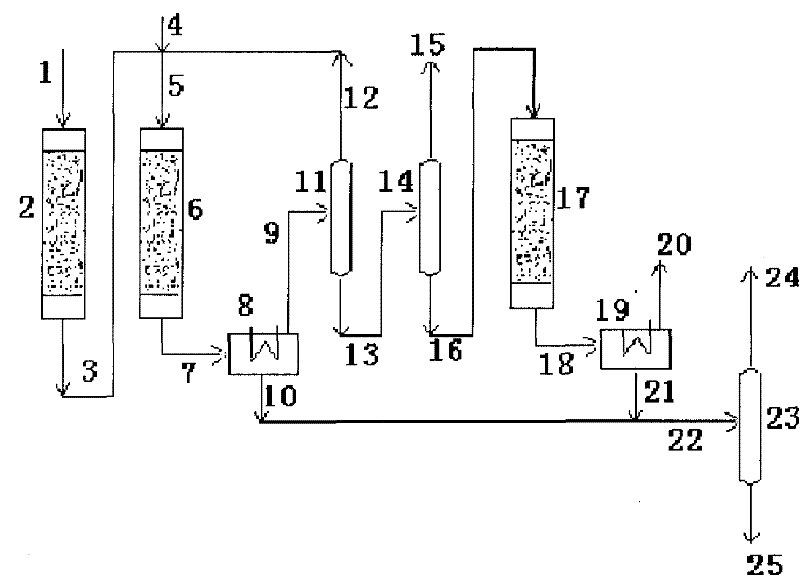

Method for preparing propylene and aromatic hydrocarbon by virtue of conversion of methanol

ActiveCN102190546AHigh yieldHydrocarbon from oxygen organic compoundsEthylene productionLiquid productGas phase

The invention relates to a method for preparing propylene and aromatic hydrocarbon by virtue of conversion of methanol, and the method is mainly used for solving the problem that the methanol is just converted into propylene and the aromatic hydrocarbon can not be co-produced in the prior art. The method comprises the following steps: 1) converting above 80% of methanol into dimethyl ether by virtue of pre-reaction; 2) feeding the generated diamethyl ether and residual methanol into a device for producing propylene from the methanol for reaction so as to obtain a material flow I which mainly comprises the propylene, ethylene and C4, C5, C6 and over-C6 hydrocarbons; 3) after the material flow I is separated, returning the ethylene back to the device for producing the propylene from the methanol for cycling reaction, and feeding C4 and C5 hydrocarbons into an aromatizing device for reaction so as to obtain a material flow II containing aromatic hydrocarbon; and 4) cooling the material flow II, separating a gas-phase product low-carbon hydrocarbons from a liquid-phase product, and separating the liquid product from the material flow I so as to obtain C6 and over-C6 hydrocarbons, mixing, extracting and separating so as to obtain the aromatic hydrocarbon and non-aromatic hydrocarbon. By using the technical scheme, the problem is well solved; and the method can be used in industrialproduction for preparing the ethylene and the aromatic hydrocarbon by virtue of conversion of methanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

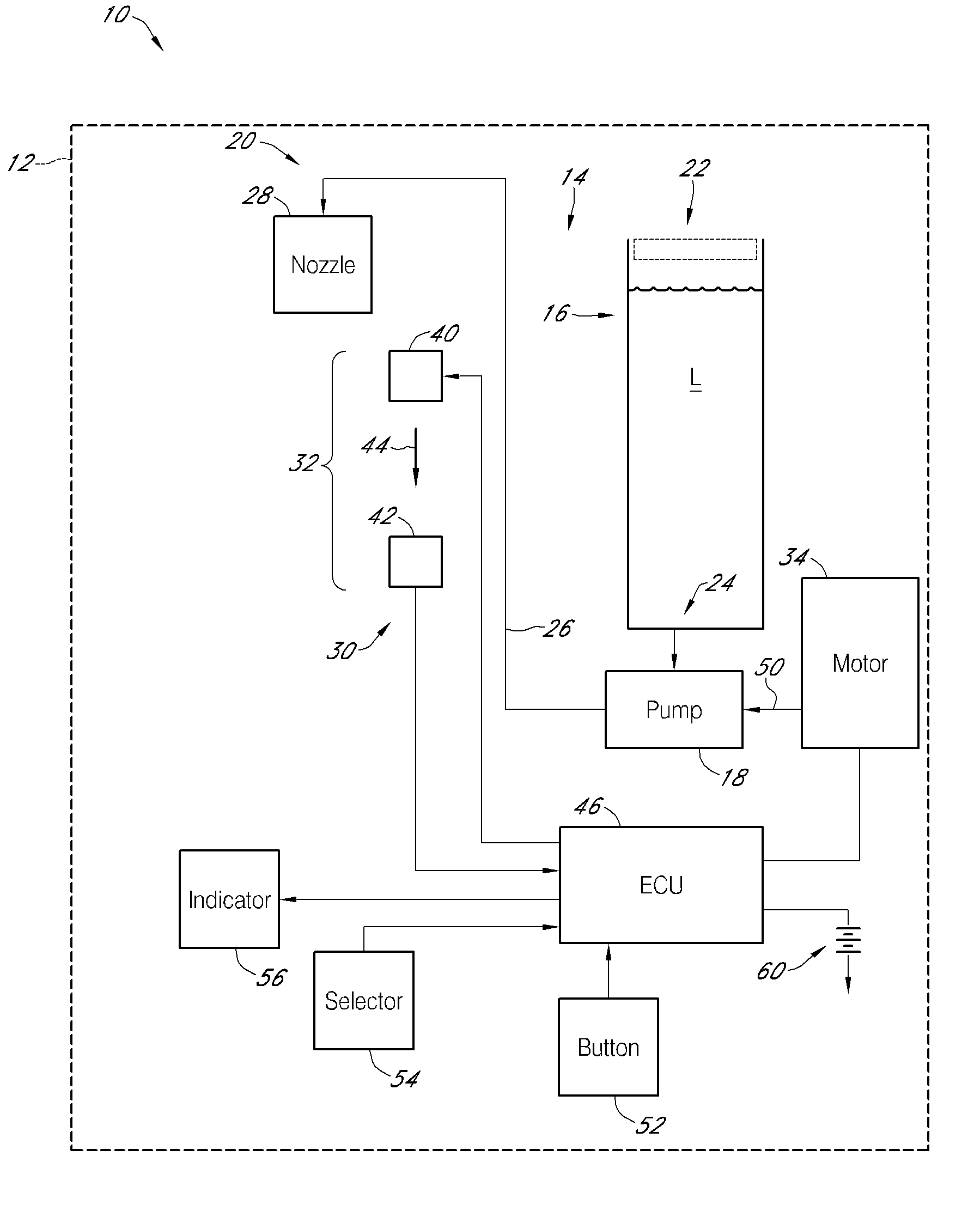

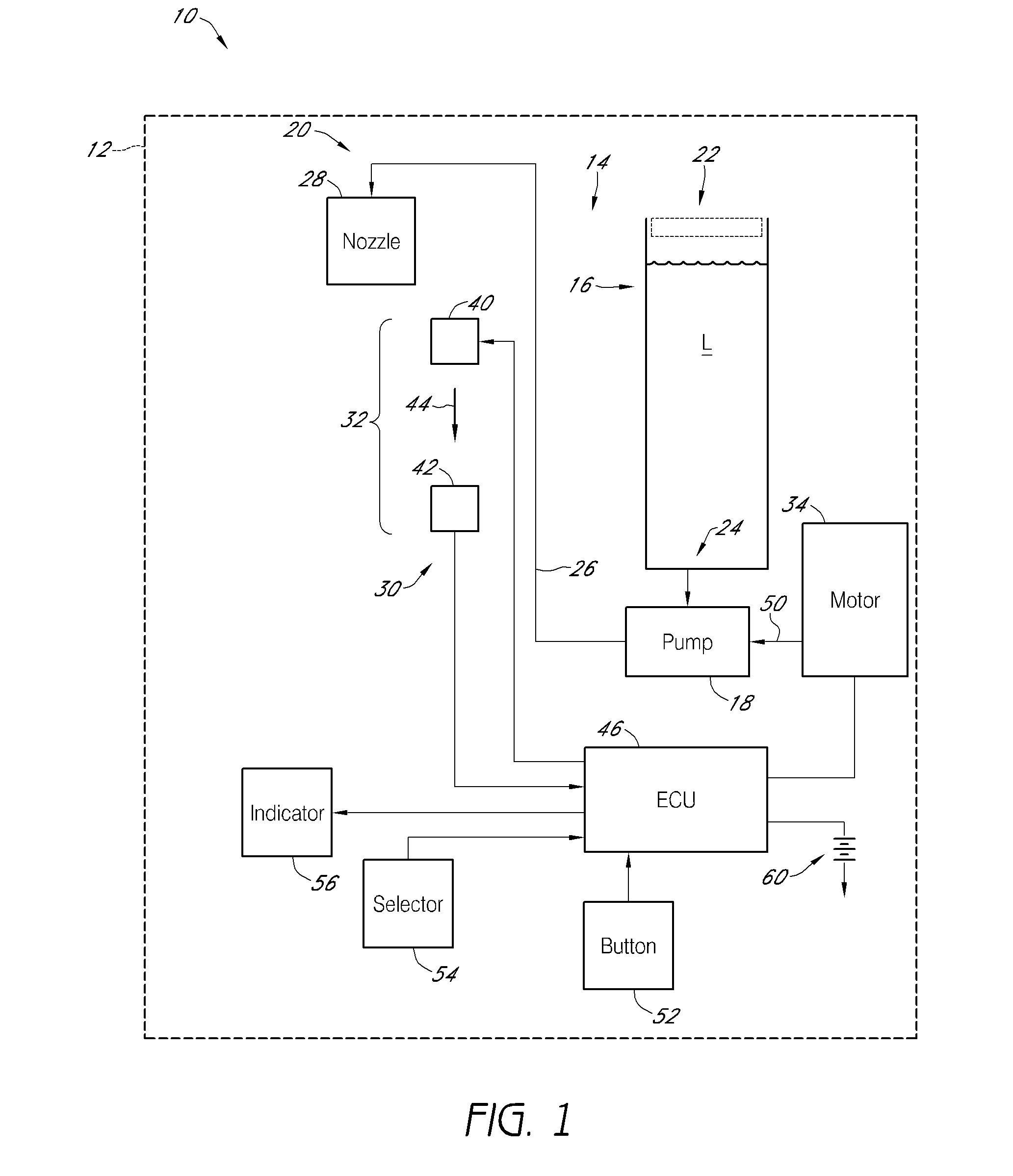

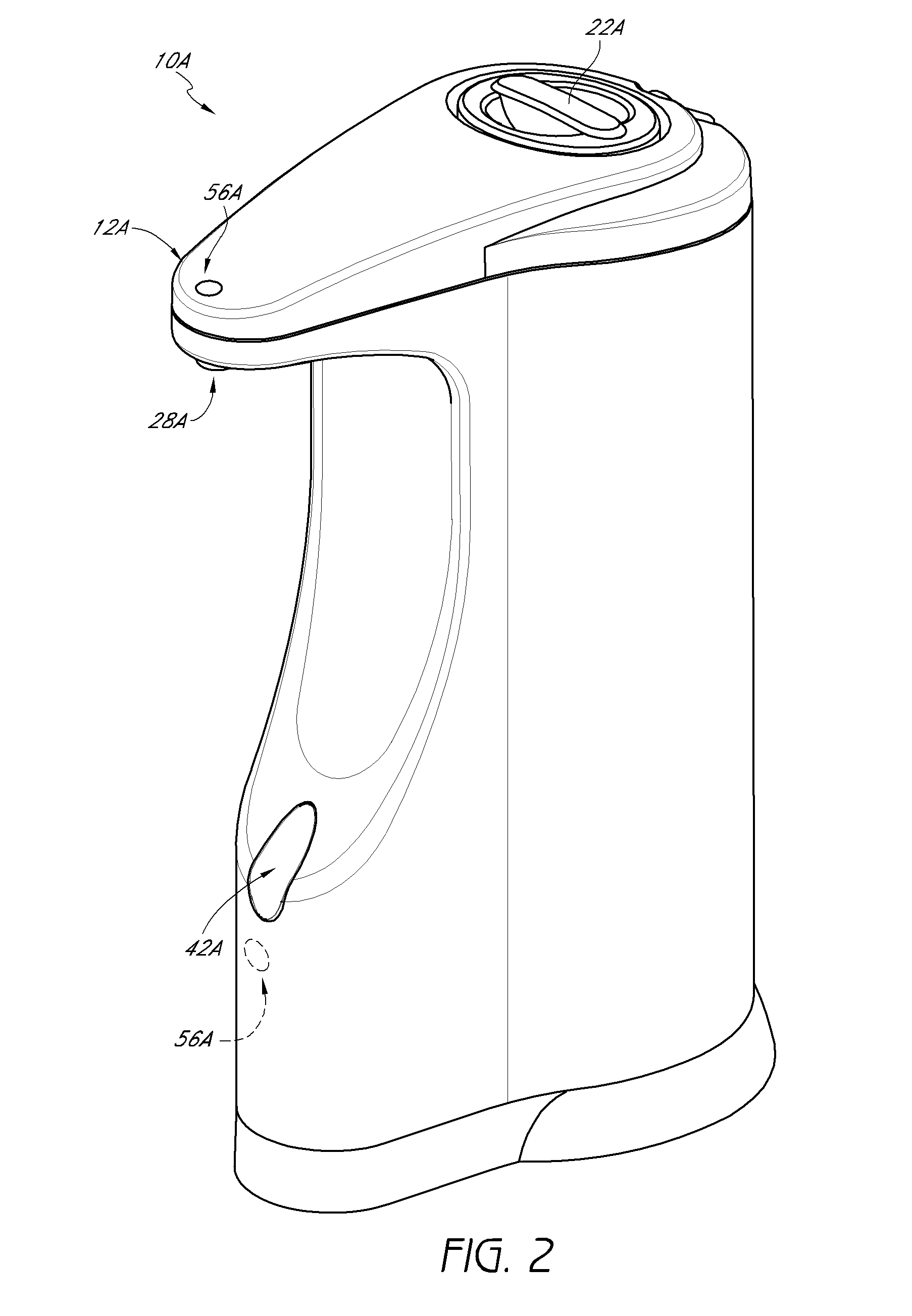

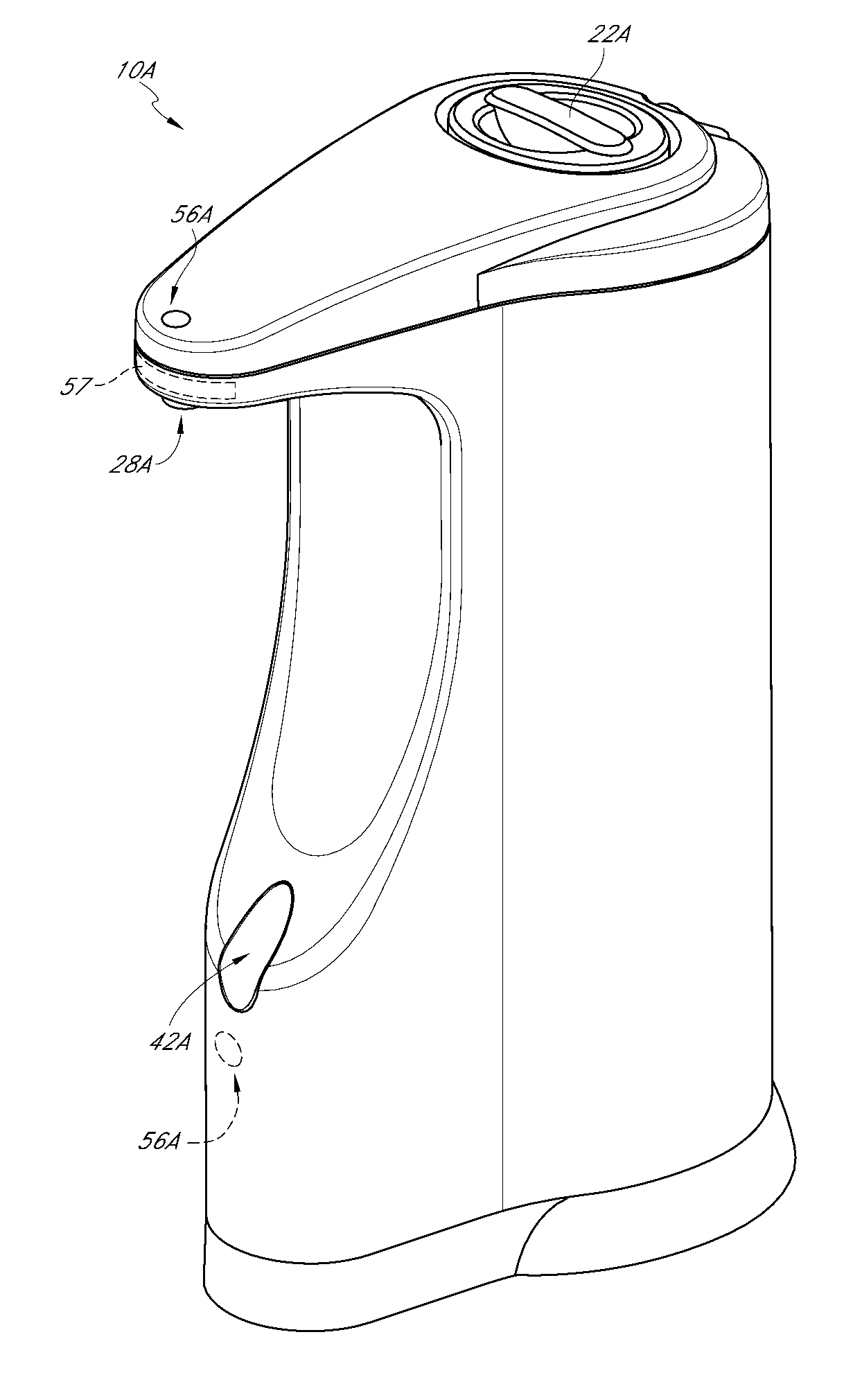

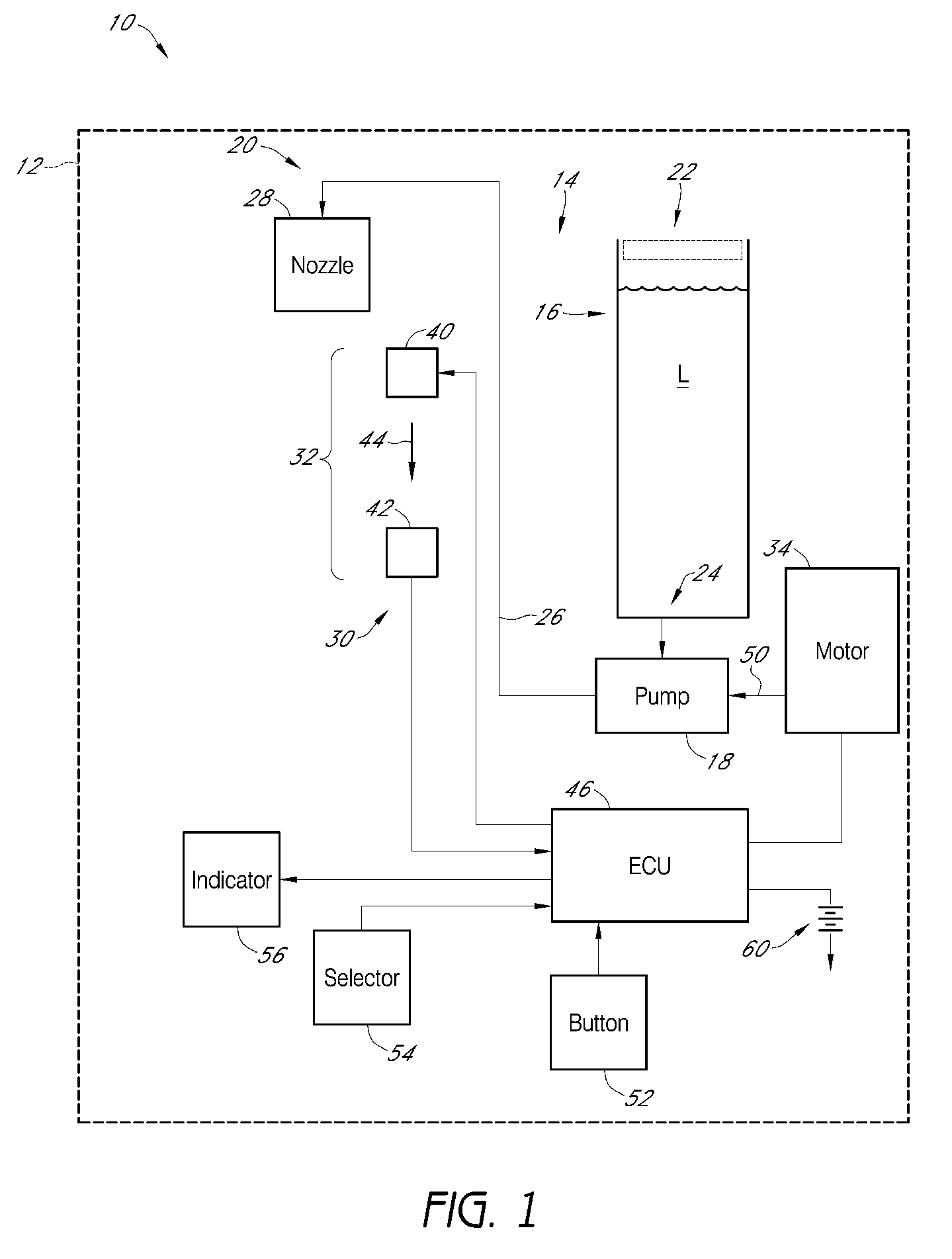

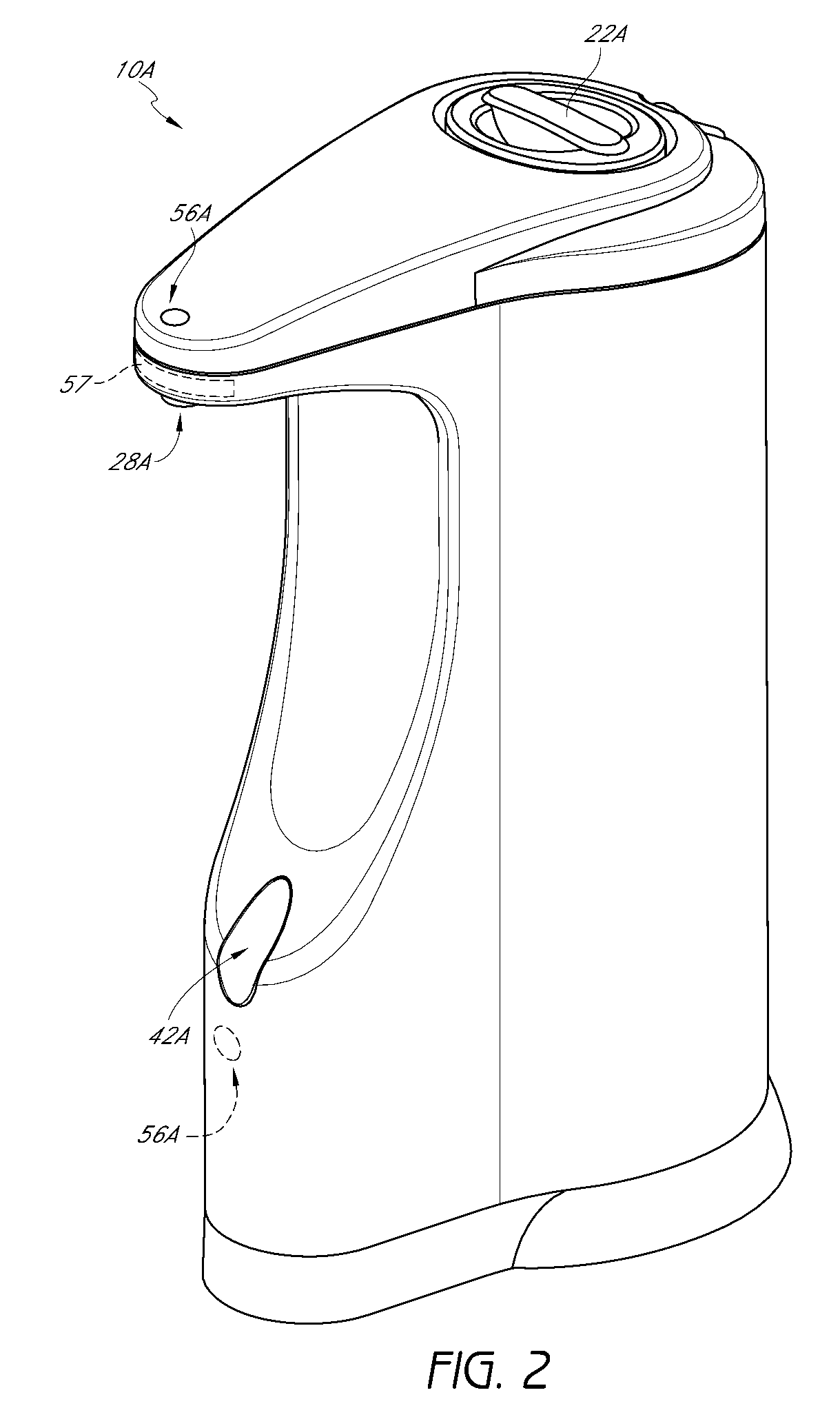

Electric soap dispenser

An electric soap dispenser that includes sensors for detecting the presence of an object. The dispenser can be configured to dispense an amount of liquid soap, for example, upon detecting the presence of an object. The dispenser can include various features for enhancing the performance thereof. For example, the dispenser can include an additional button for manual operation of the pump. Additionally, the dispenser can detect the voltage of a power supply and compensate for a drop in voltage of the power supply so as to produce more uniform dispensations of the liquid product.

Owner:SIMPLEHUMAN

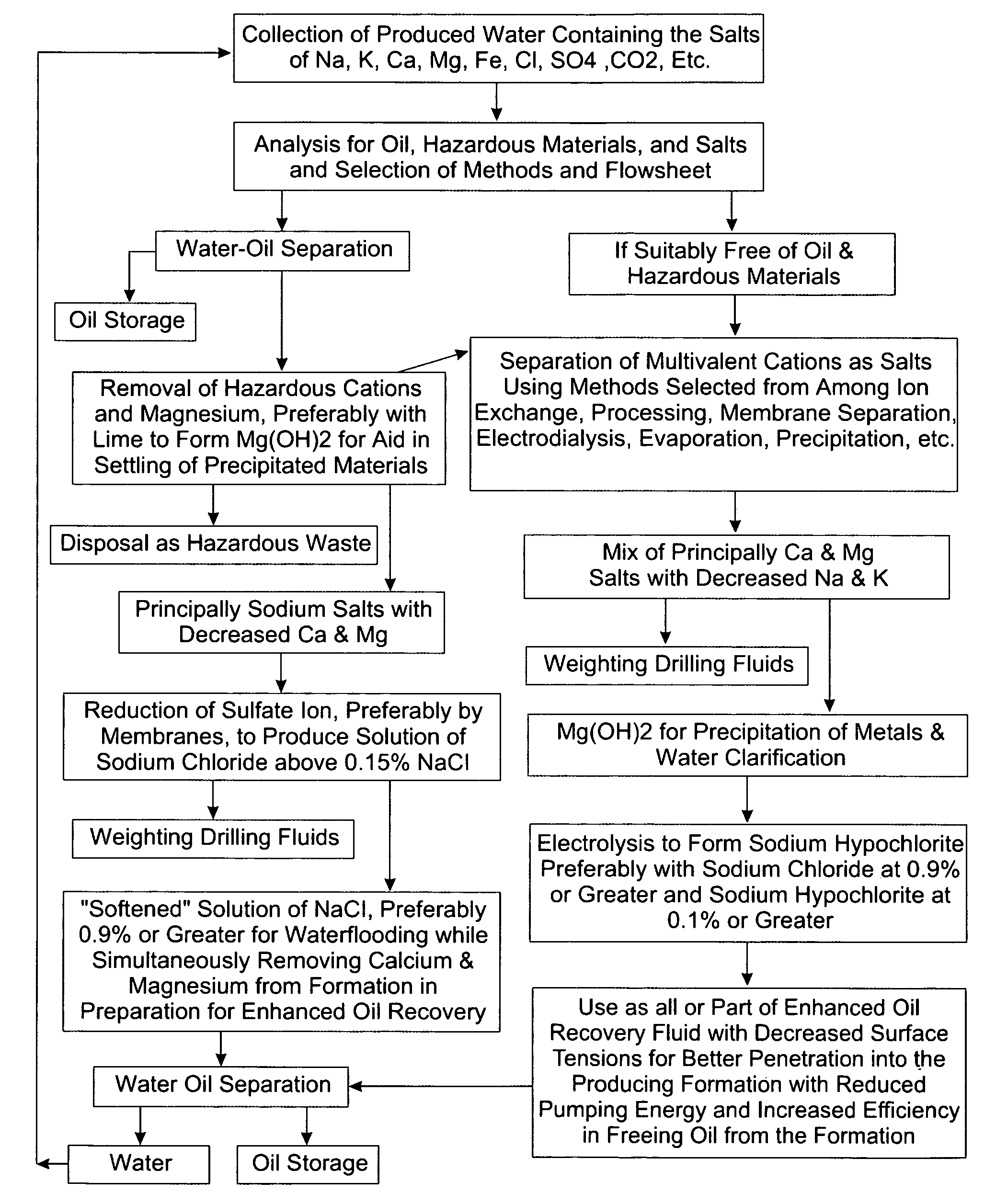

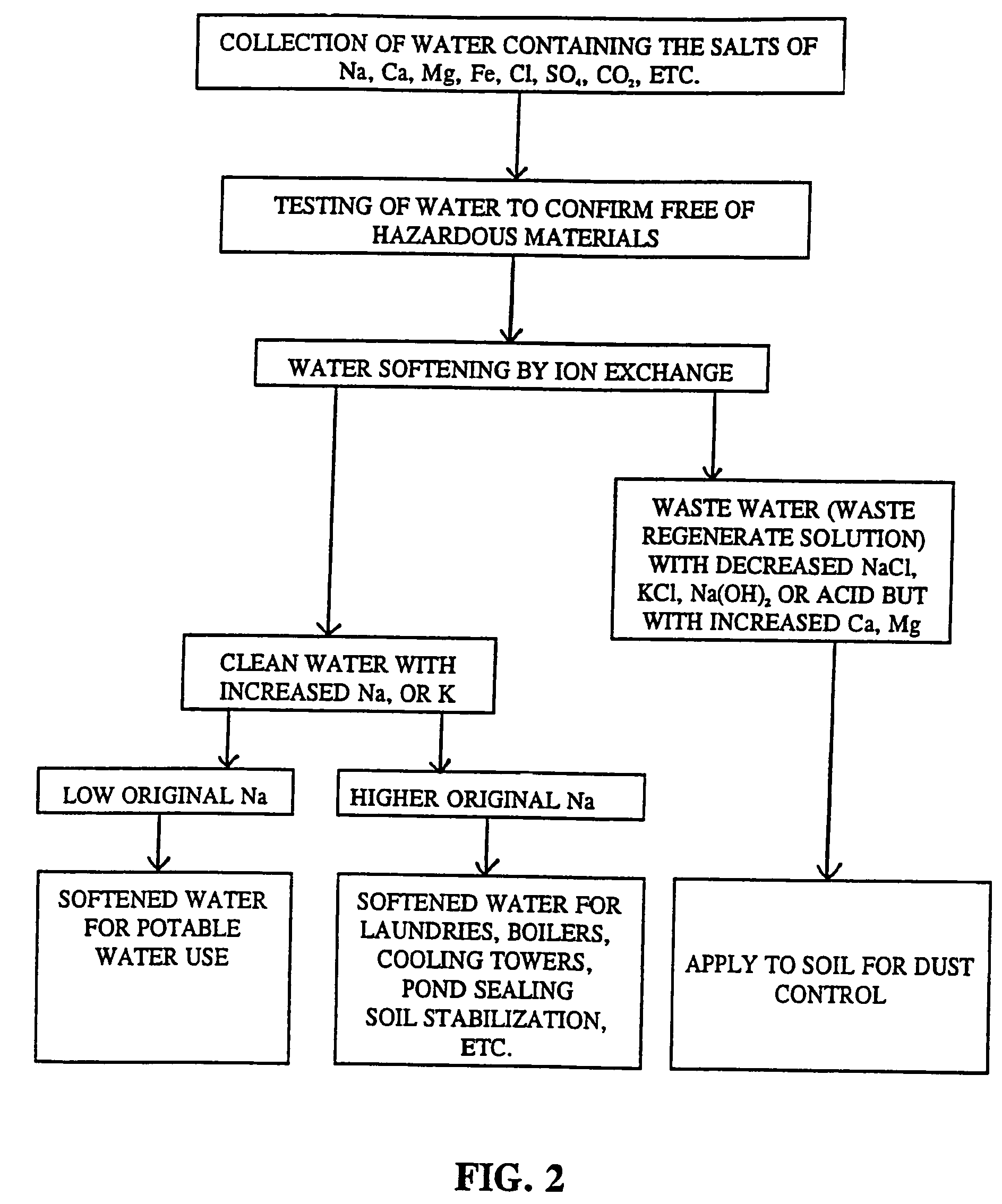

Methods of improving oil or gas production with recycled, increased sodium water

InactiveUS7717173B2Reduction tendencySpecific water treatment objectivesScale removal and water softeningLiquid productEnvironmental engineering

A method of improving oil or gas well production has the steps of (a) collecting contaminated water having 0.15% or more by weight of the salts of Na, Ca, Mg, K, Cl, SO4 or CO3 or combinations thereof (b) separation processing the contaminated water to produce i.) a first separated liquid product having increased sodium chloride and decreased magnesium chloride and calcium chloride or combinations thereof than the collected water, and ii) a second solid or liquid product having decreased sodium chloride and increased magnesium chloride and calcium chloride or combinations thereof than the collected water, and (c) injecting the first liquid product into an oil or gas well formation to improve production.

Owner:ECYCLING

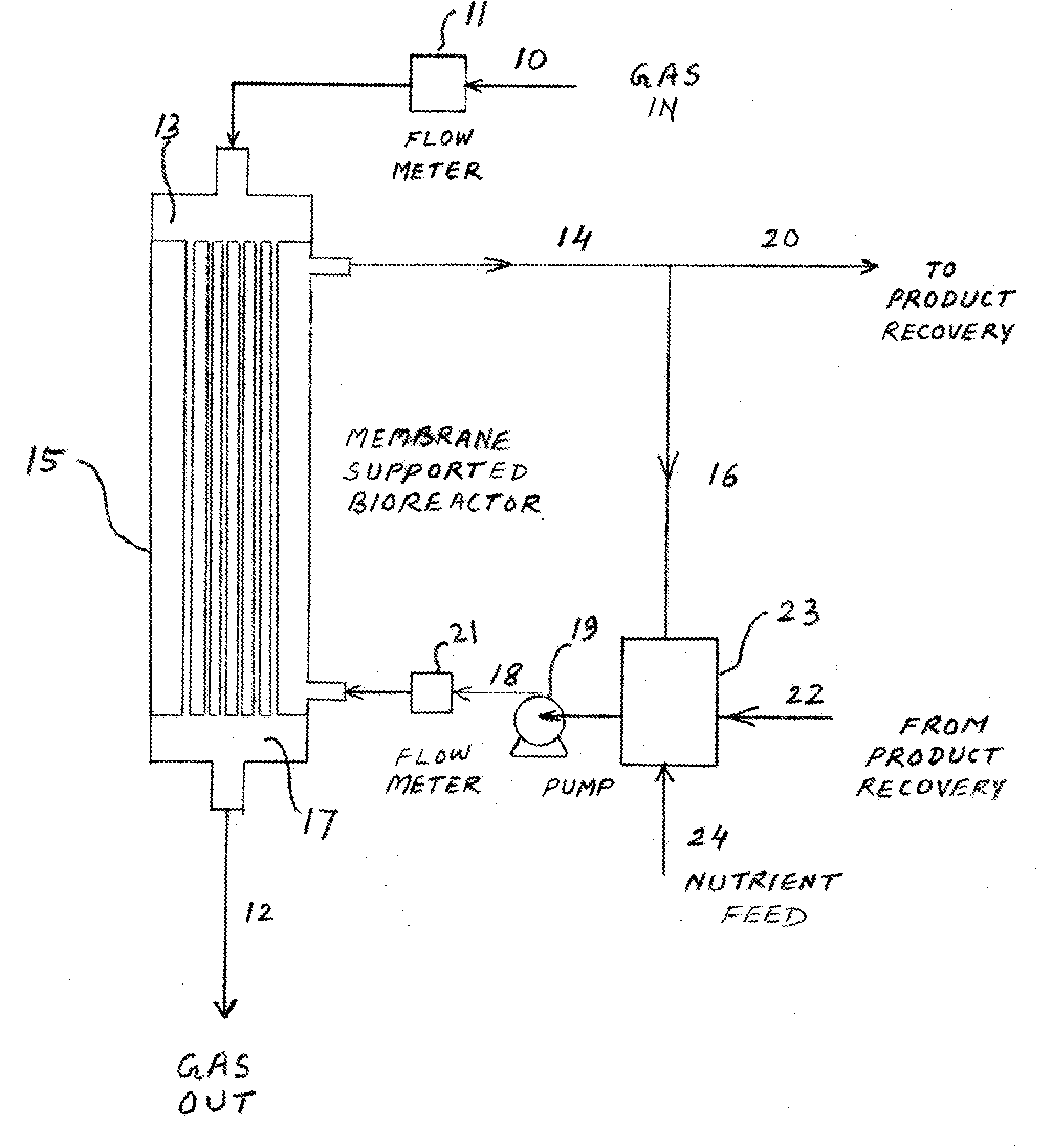

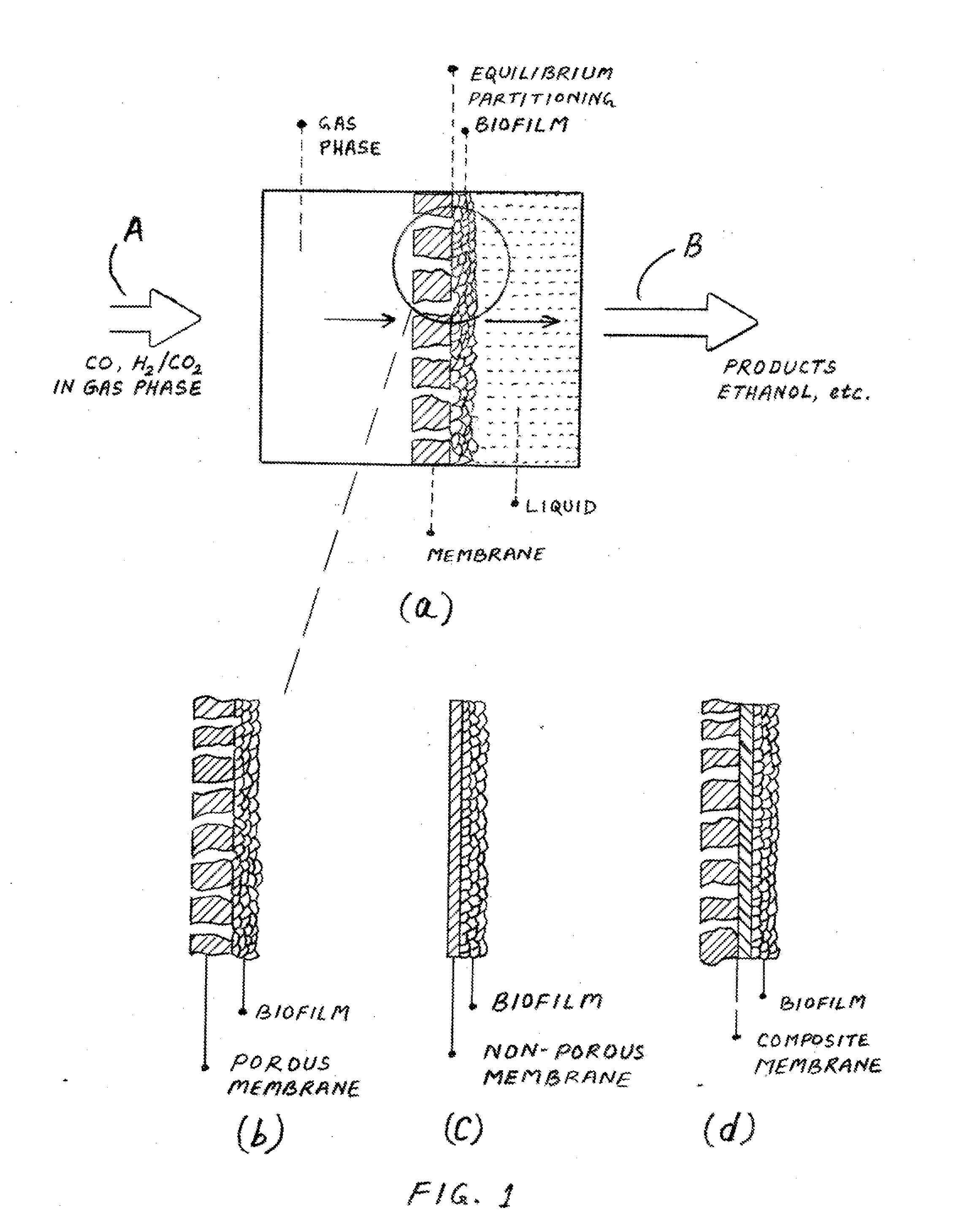

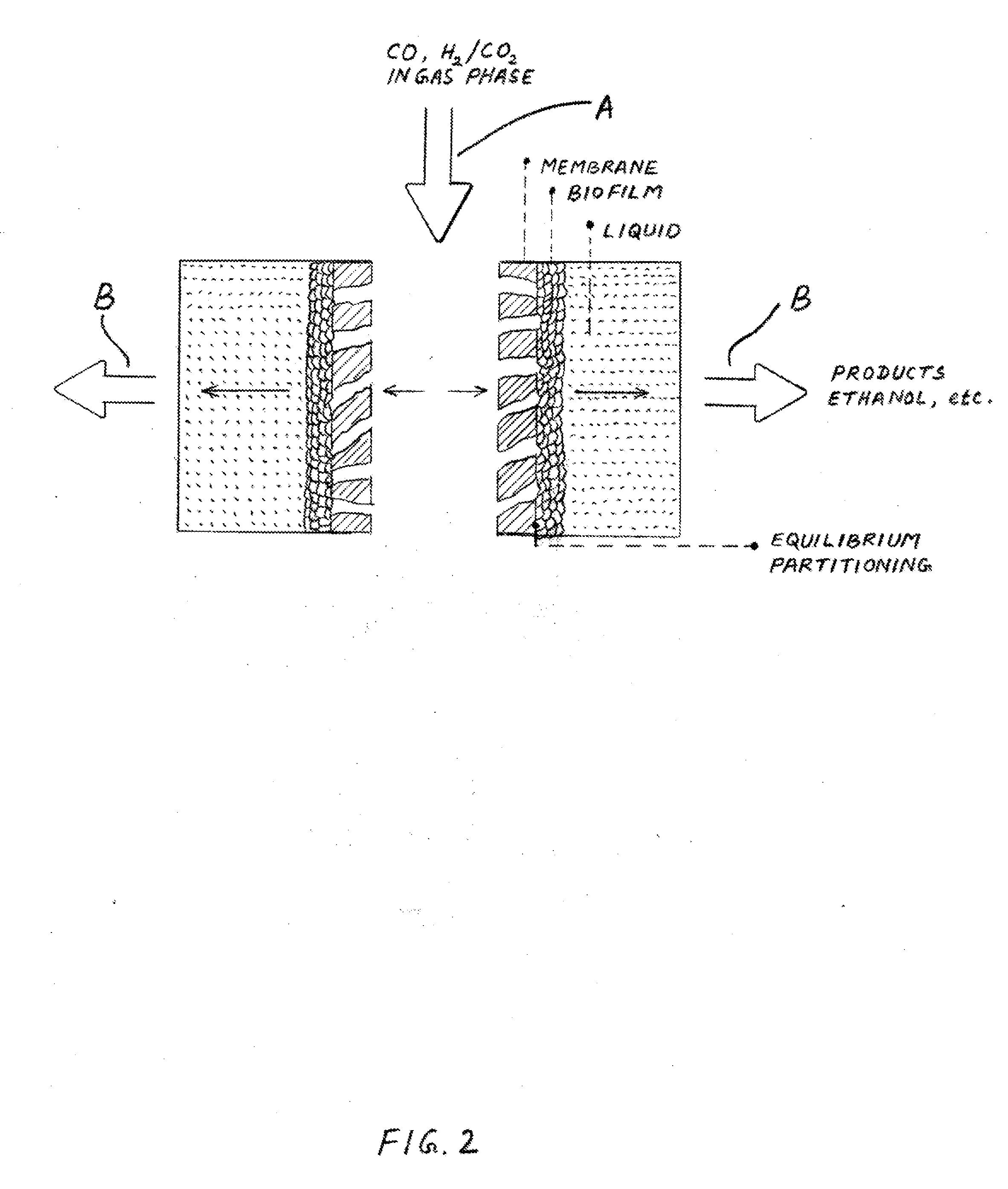

Membrane supported bioreactor for conversion of syngas components to liquid products

InactiveUS20080305539A1Guaranteed economic efficiencyEasy to controlBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid productBiofilm

Ethanol and other liquid products are produced by contacting syngas components such as CO or a mixture of CO2 and H2 with a surface of a membrane and transferring these components in contact with a biofilm on the opposite side of the membrane. These steps provide a stable system for producing liquid products such as ethanol, butanol and other chemicals. The gas fed on the membrane's gas contact side transports through the membrane to form a biofilm of anaerobic microorganisms that converted the syngas to desired liquid products. The system can sustain production with a variety of microorganisms and membrane configurations.

Owner:COSKATA INC

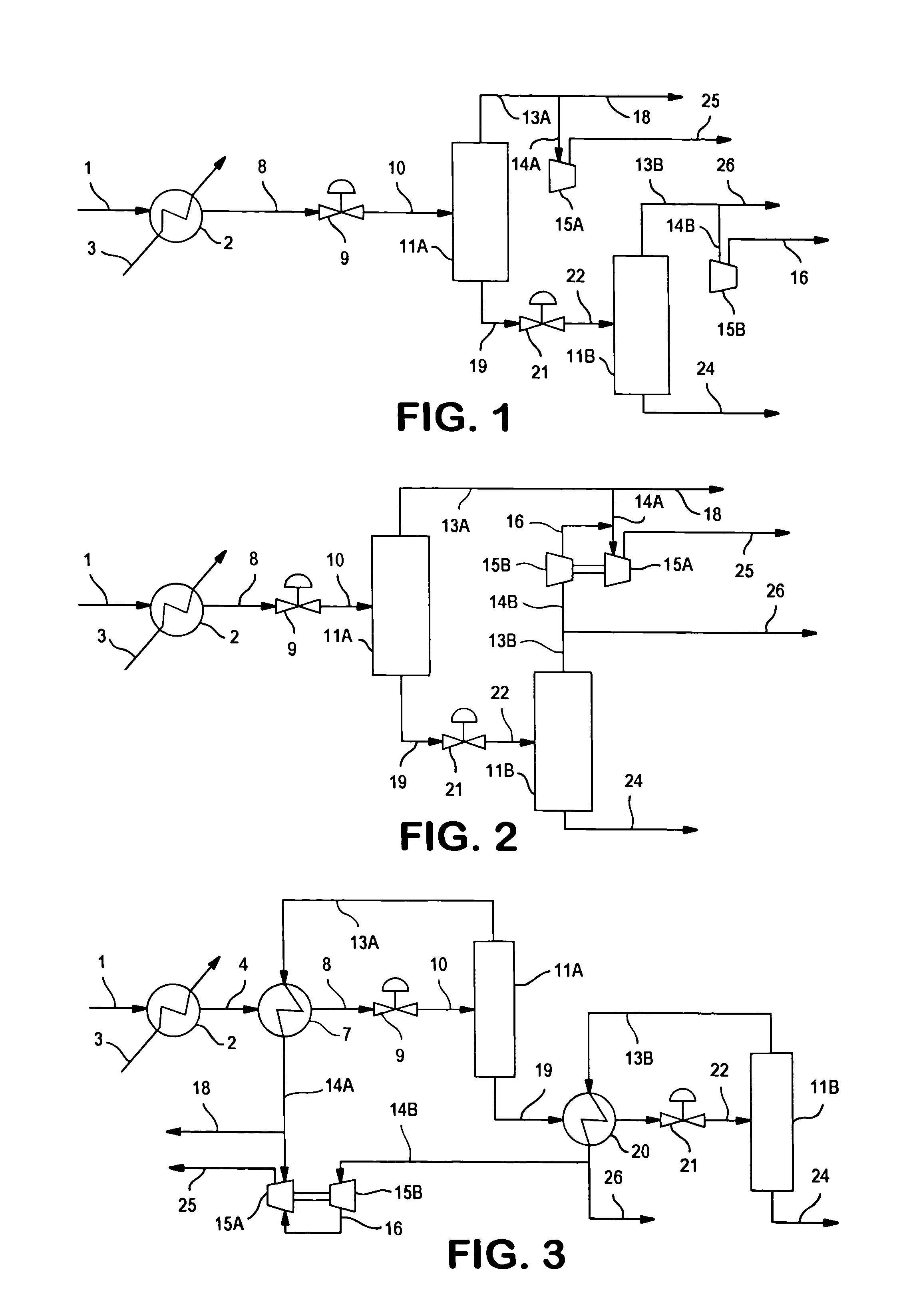

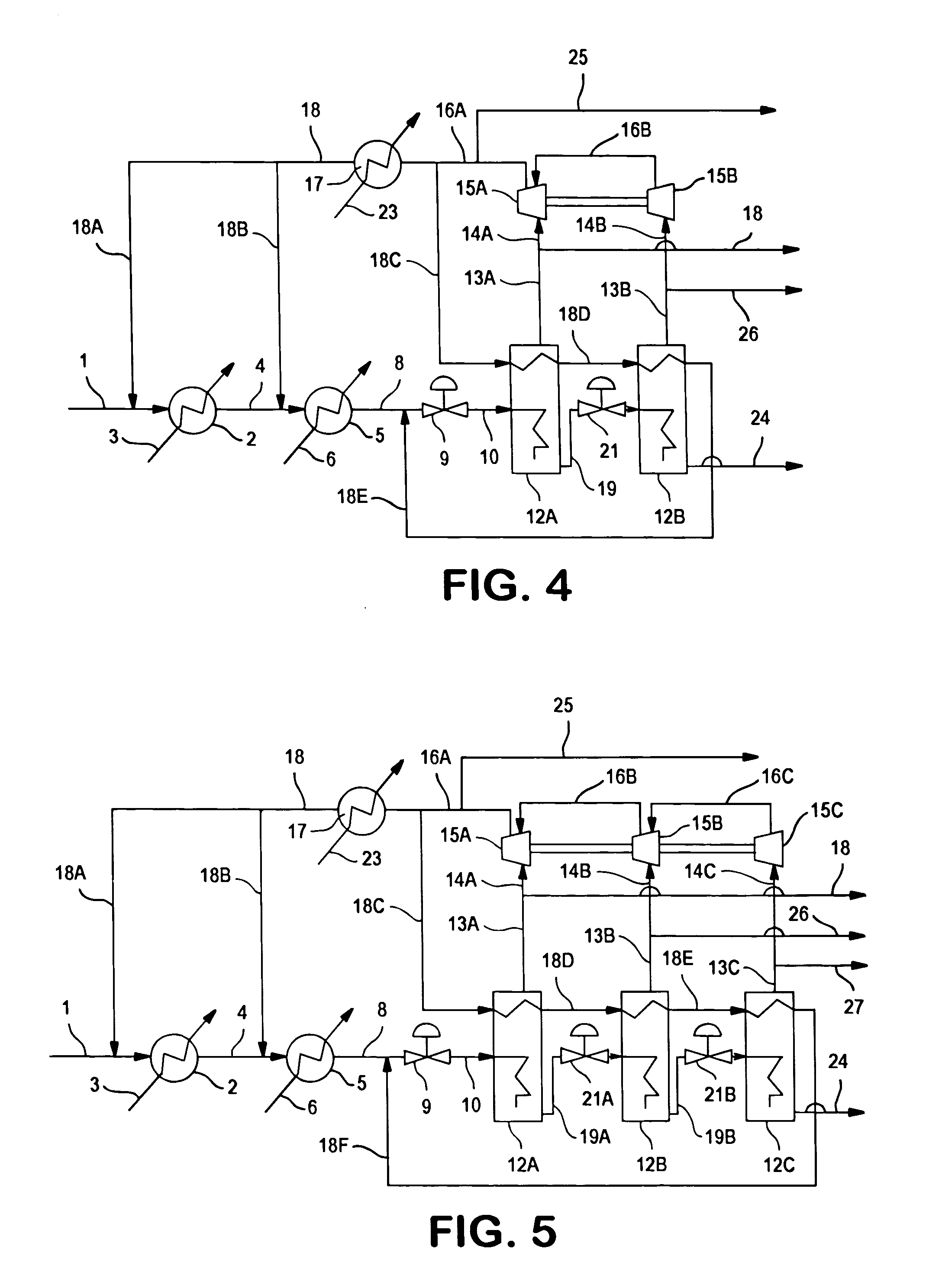

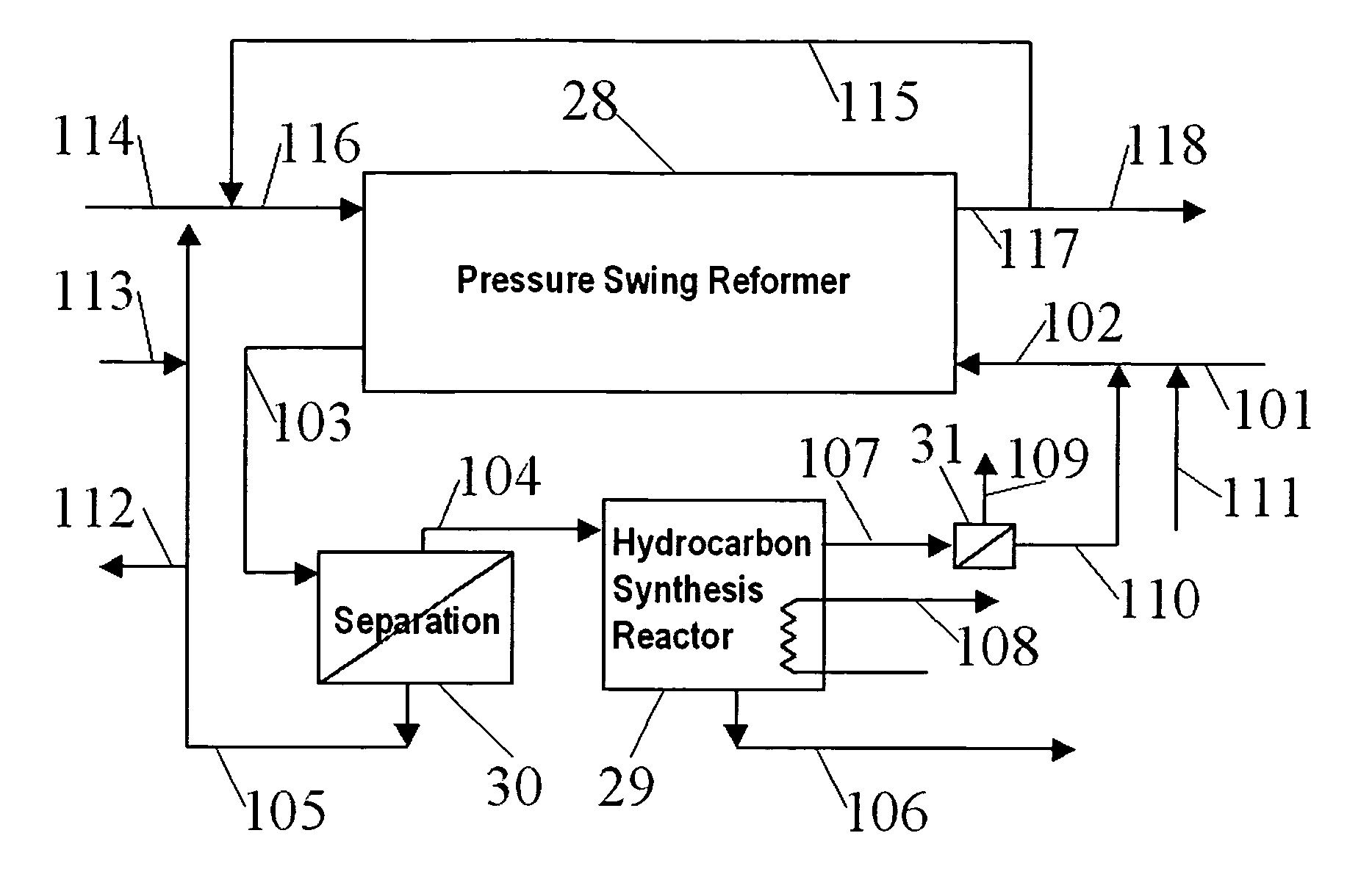

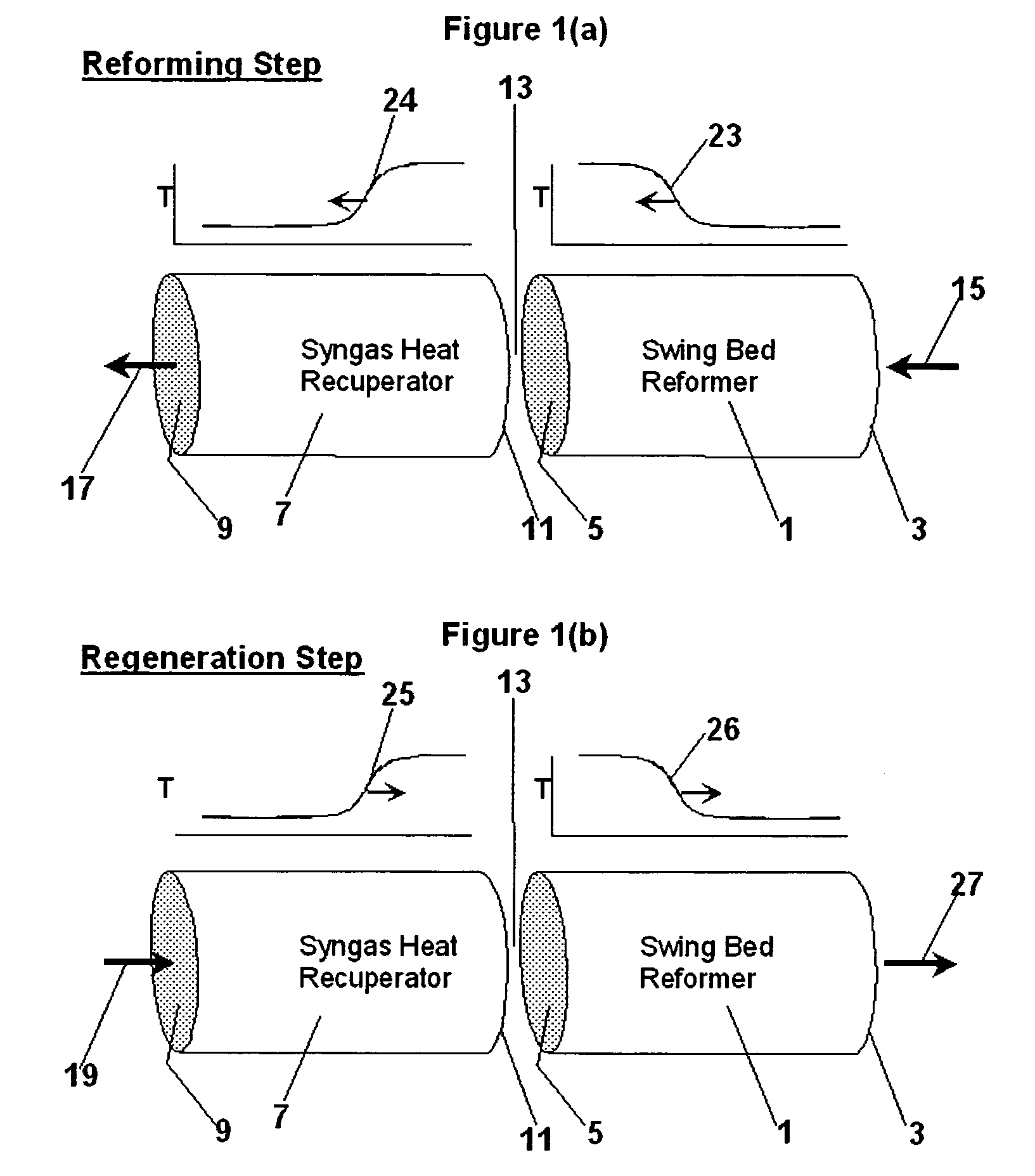

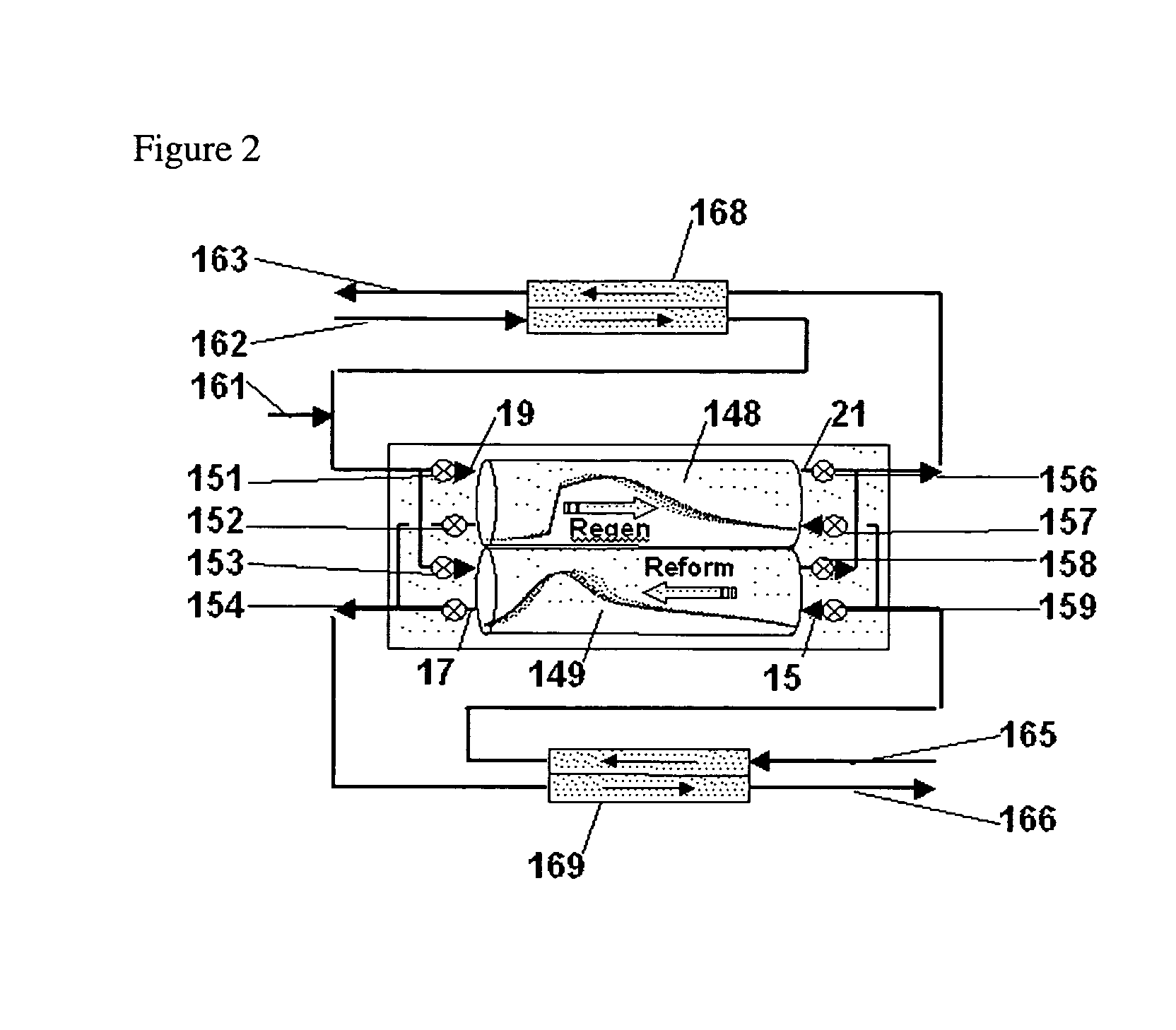

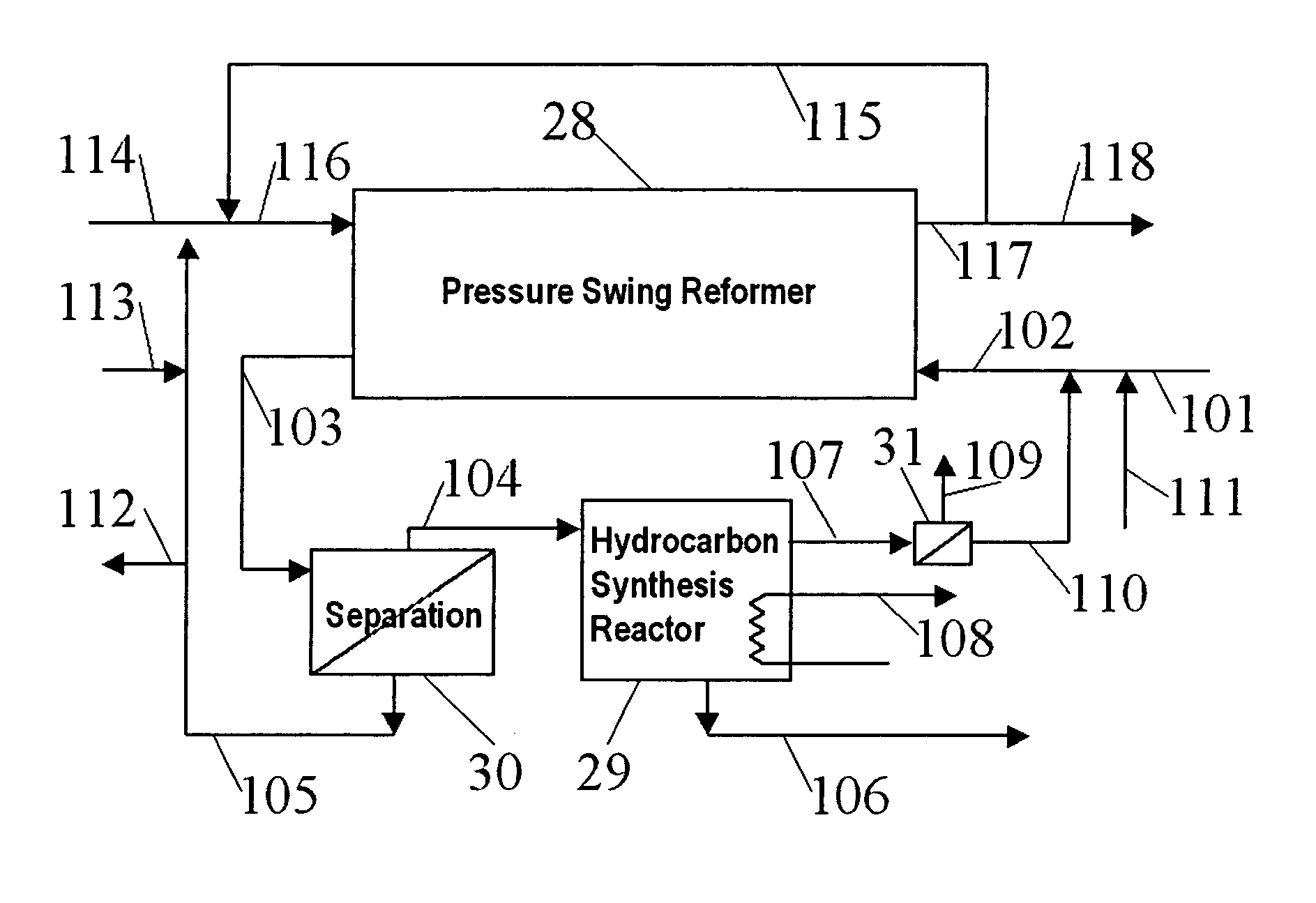

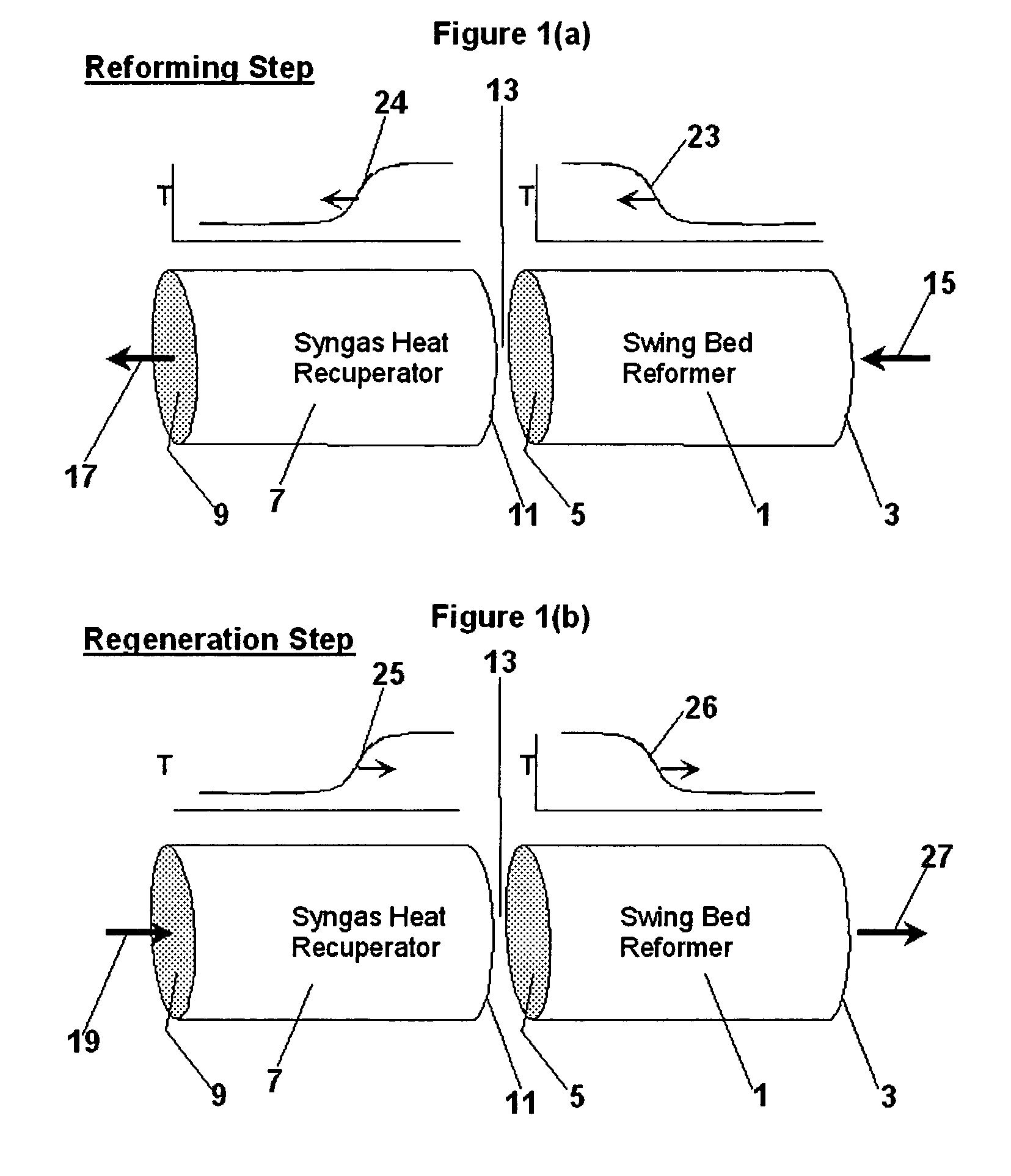

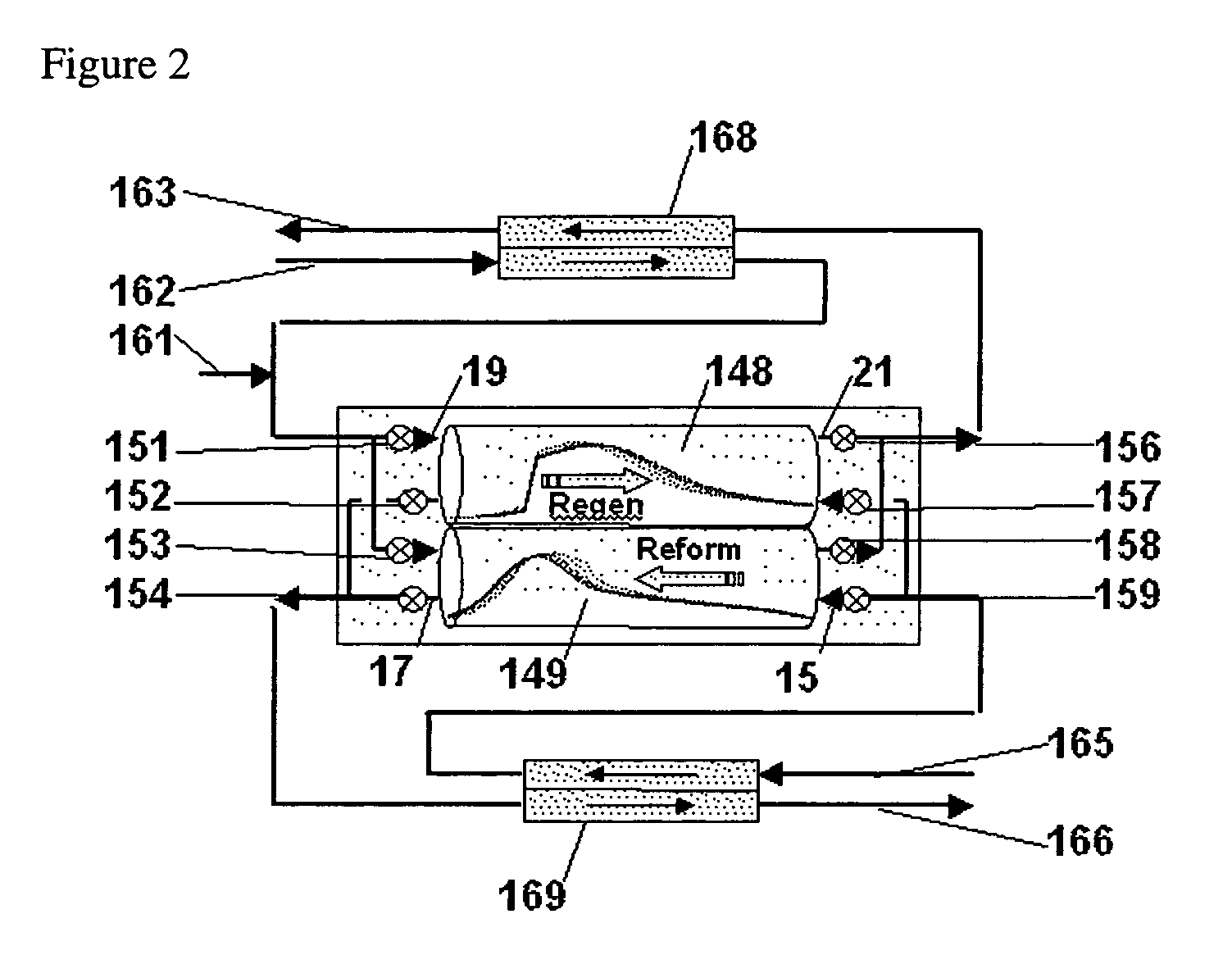

Hydrocarbon synthesis process using pressure swing reforming

ActiveUS7045553B2Material efficiencyAccelerates synthesis processOrganic compounds purification/separation/stabilisationHydrogenLiquid productSyngas

The invention provides a method for producing liquid hydrocarbons by first generating in a pressure swing reformer a synthesis gas stream having a mole ratio of H2:CO greater than 2:1. Then, a portion of the hydrogen is separated to produce a synthesis gas stream having a mole ratio of H2:CO of about 2:1 which steam is then introduced into a hydrocarbon synthesis reactor for conversion to liquid products.

Owner:EXXON RES & ENG CO

Hydrocarbon synthesis process using pressure swing reforming

ActiveUS7053128B2HydrogenOrganic compounds purification/separation/stabilisationLiquid productHydrogen

The invention provides a method for producing liquid hydrocarbons by first generating in a pressure swing reformer a synthesis gas stream having a mole ratio of H2:CO greater than 2:1. Then, a portion of the hydrogen is separated to produce a synthesis gas stream having a mole ratio of H2:CO of about 2:1 which steam is then introduced into a hydrocarbon synthesis reactor for conversion to liquid products.

Owner:EXXON RES & ENG CO

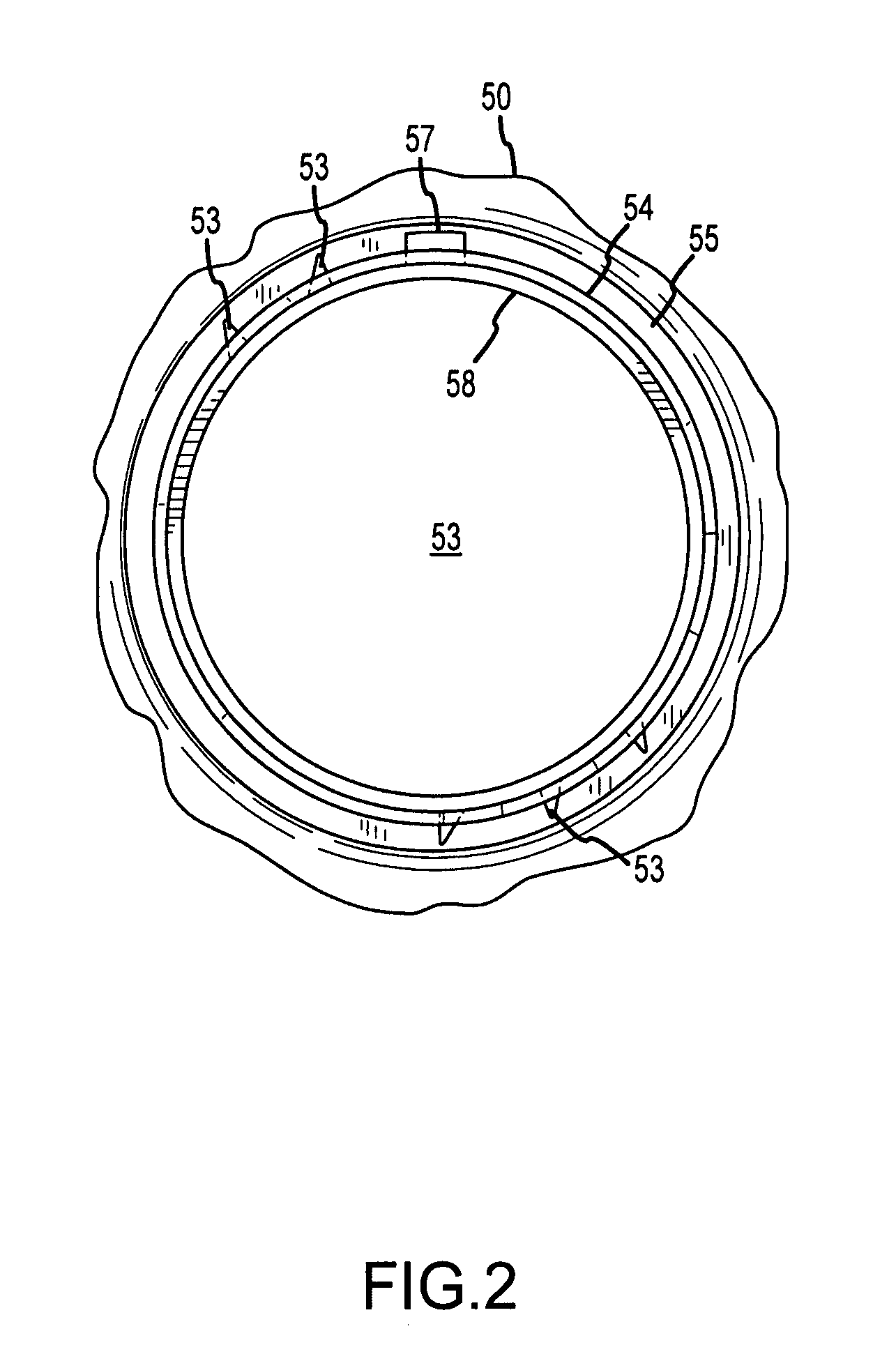

Liquid product pouring and measuring package with drain-back spout fitment and tight-sealing measuring cup assembly

An improved dispensing package for liquids is described comprising a combination pouring spout fitment, a closure that functions as a measuring cup when removed and inverted, and a bottle. The improved liquid seal between the closure and the fitment is made possible through mismatched bevels on the closure and fitment respectively wherein the sharper angled bevel on one of the parts buries into the wider angled bevel of the other part. The applied torque is prevented from loosening prematurely through a thread configuration form that allows the closure to seat securely into the spout fitment with the closure threads pushing back up against the bottom surfaces of the fitment threads in a “locked” arrangement. The correct alignment of the fitment on the bottle is made possible through the coordination of a thread stop on the fitment and corresponding locking lug on the neck of the bottle. Lastly, an indicia means is used on the outside of the fitment skirt to verify that the spout fitment and closure subassembly has been correctly orientated on the bottle even through the direction of the spout is obscured when the closure is in place.

Owner:HENKEL KGAA

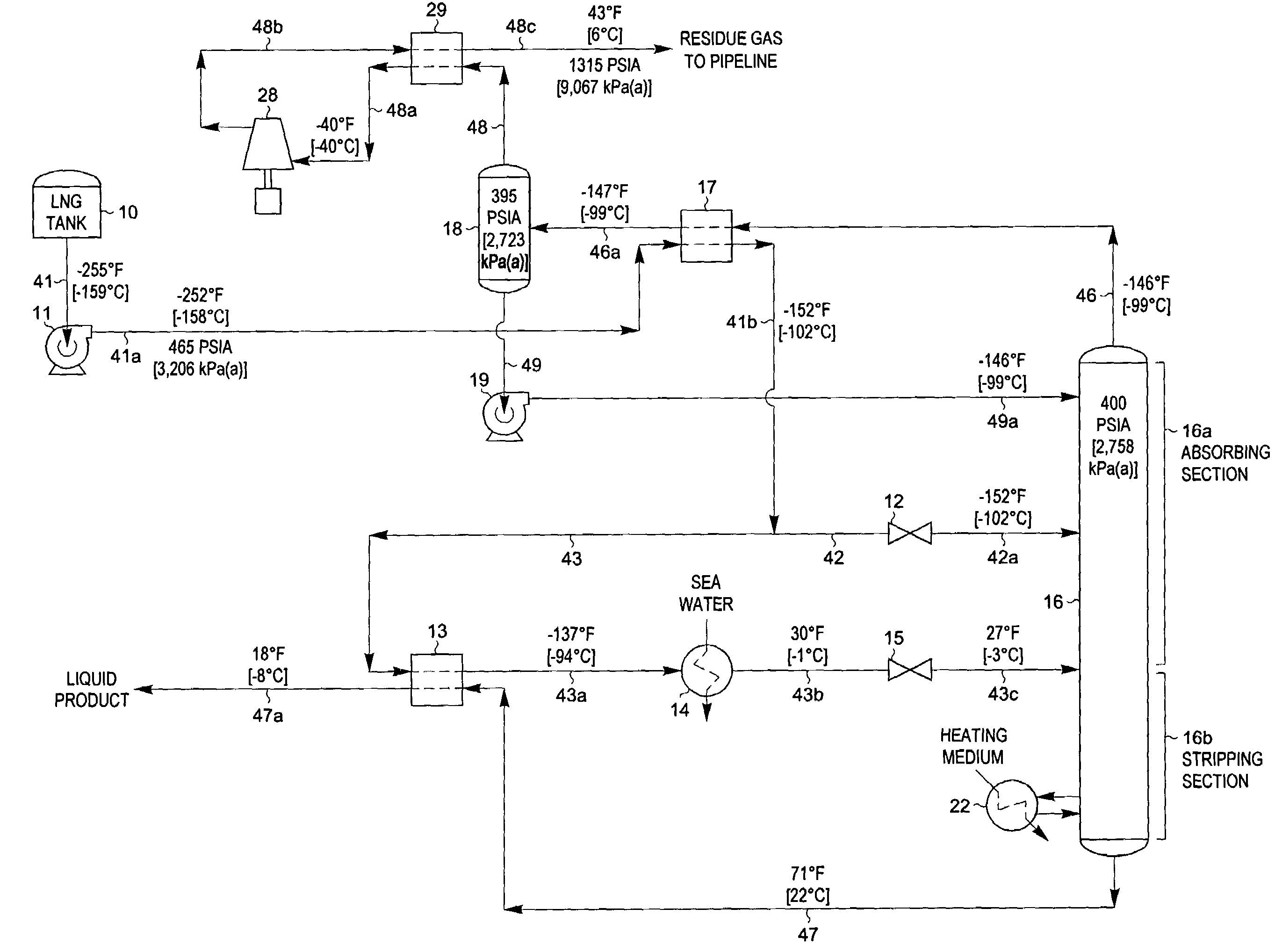

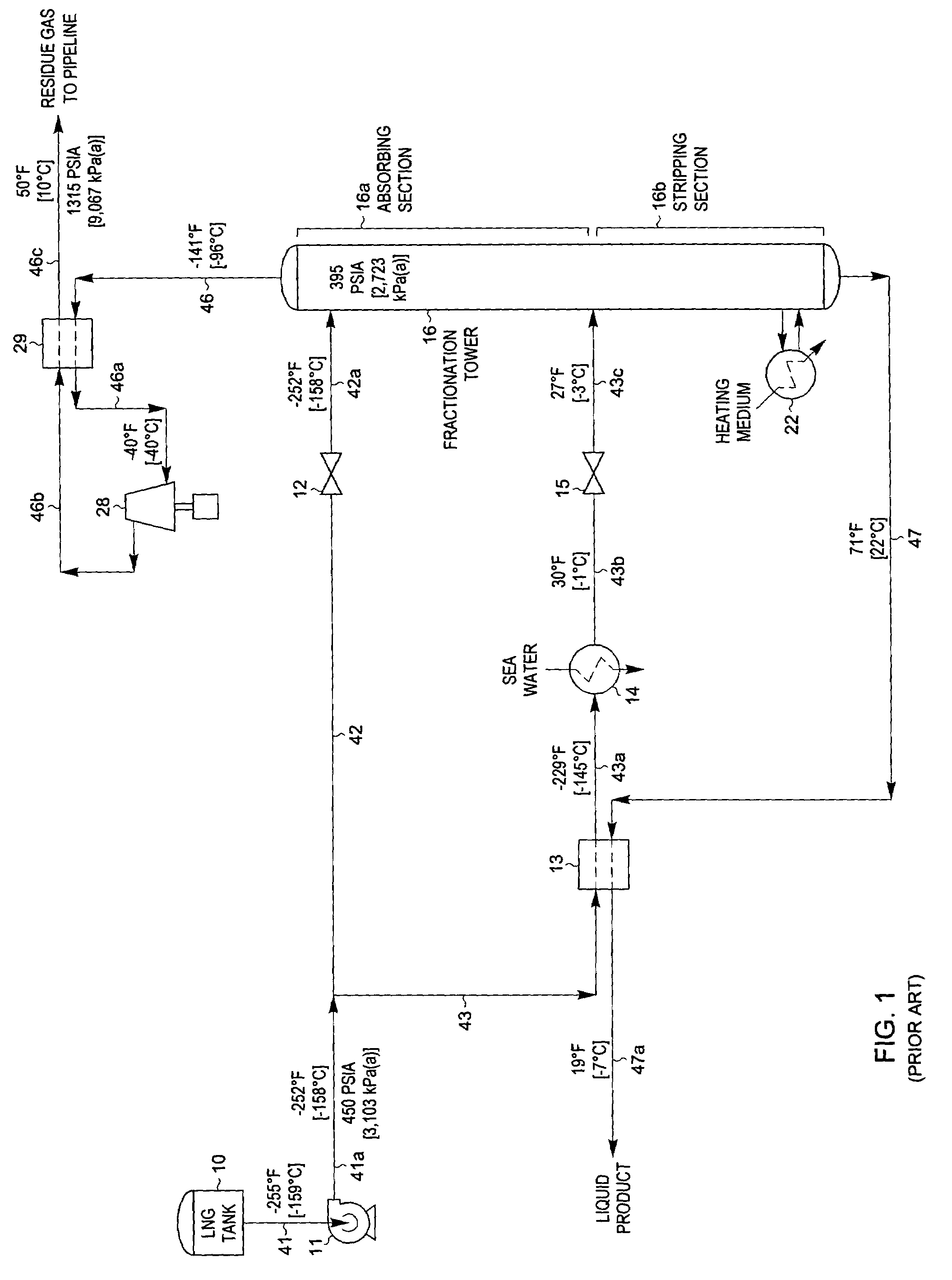

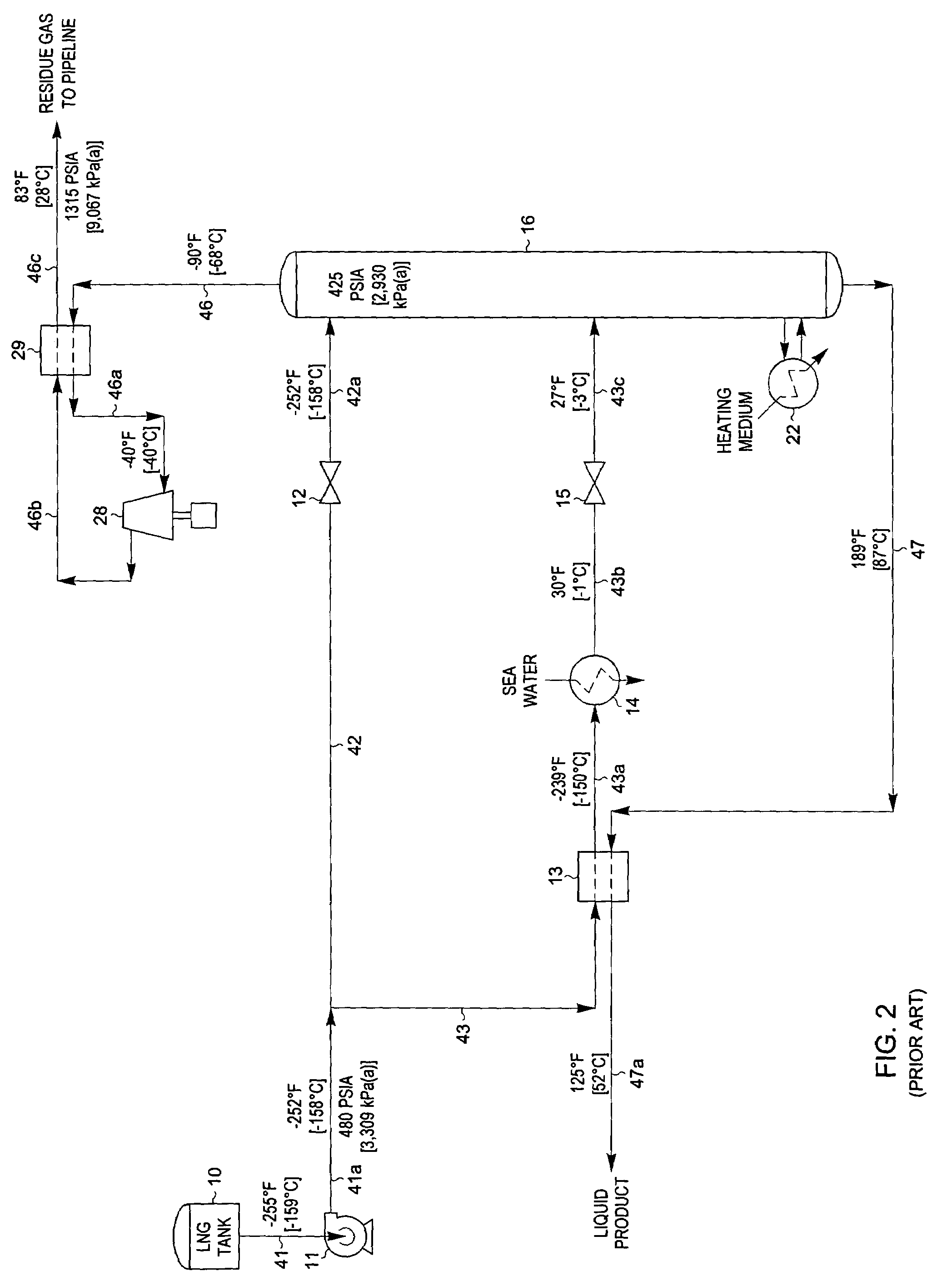

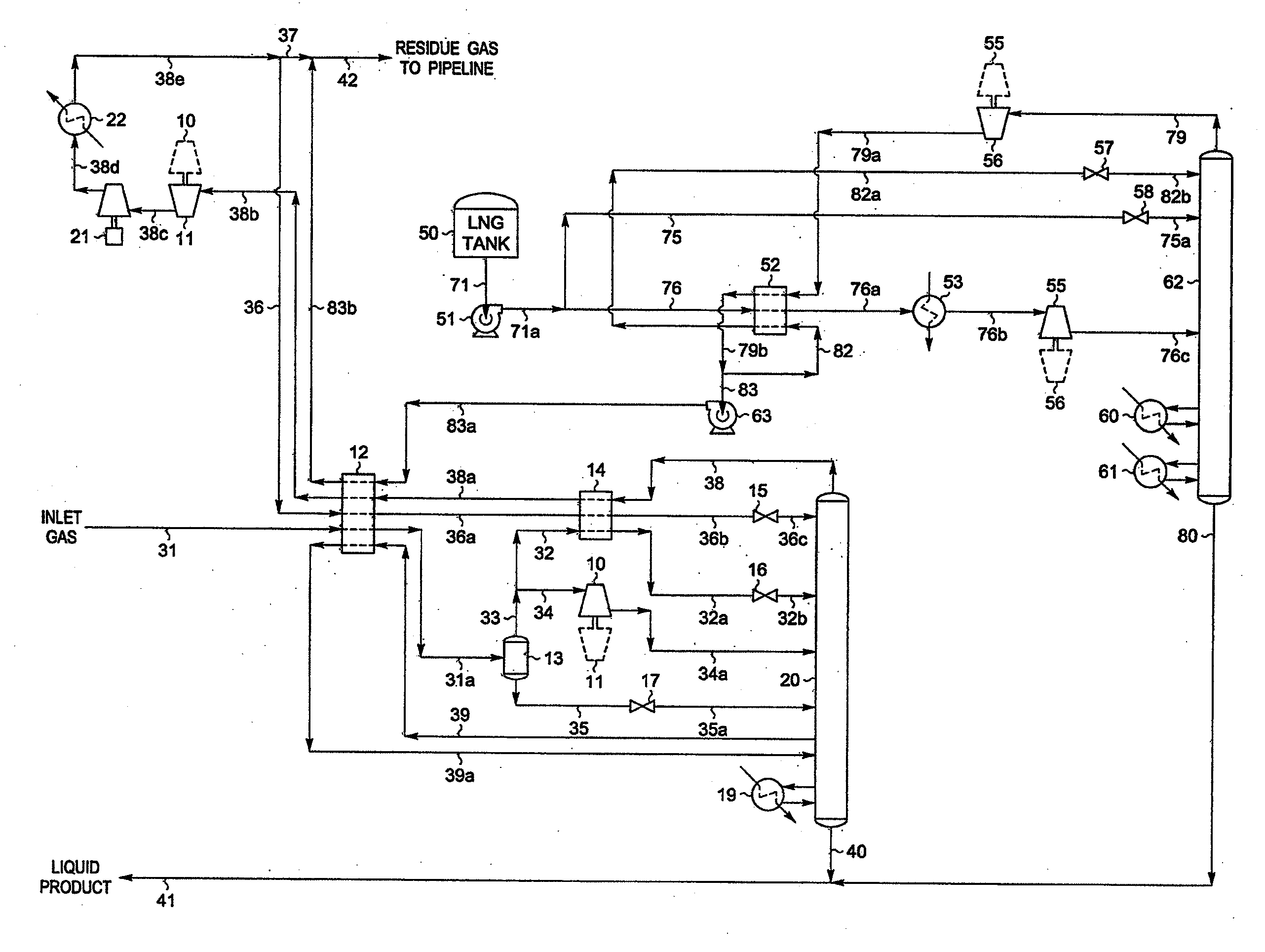

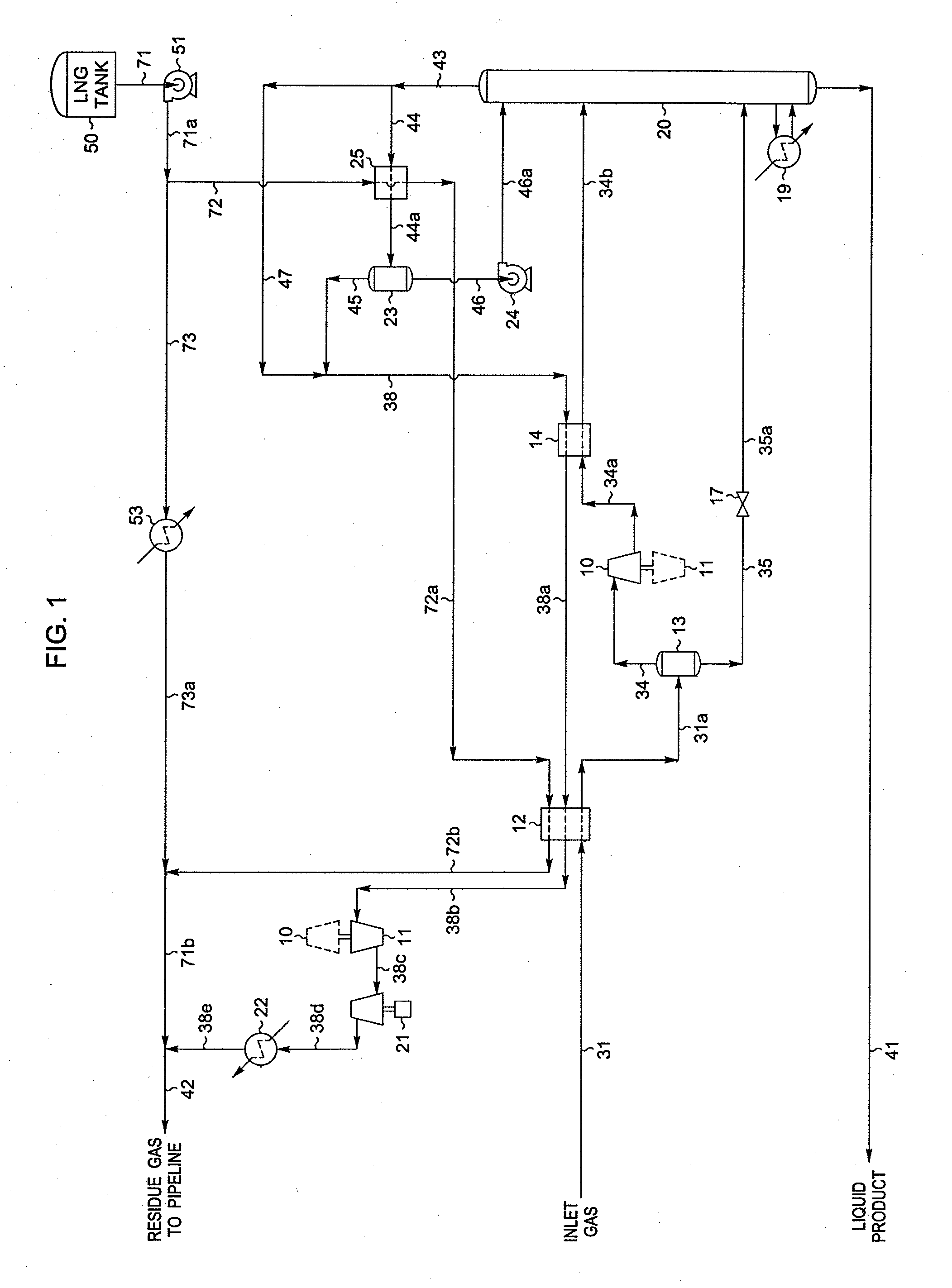

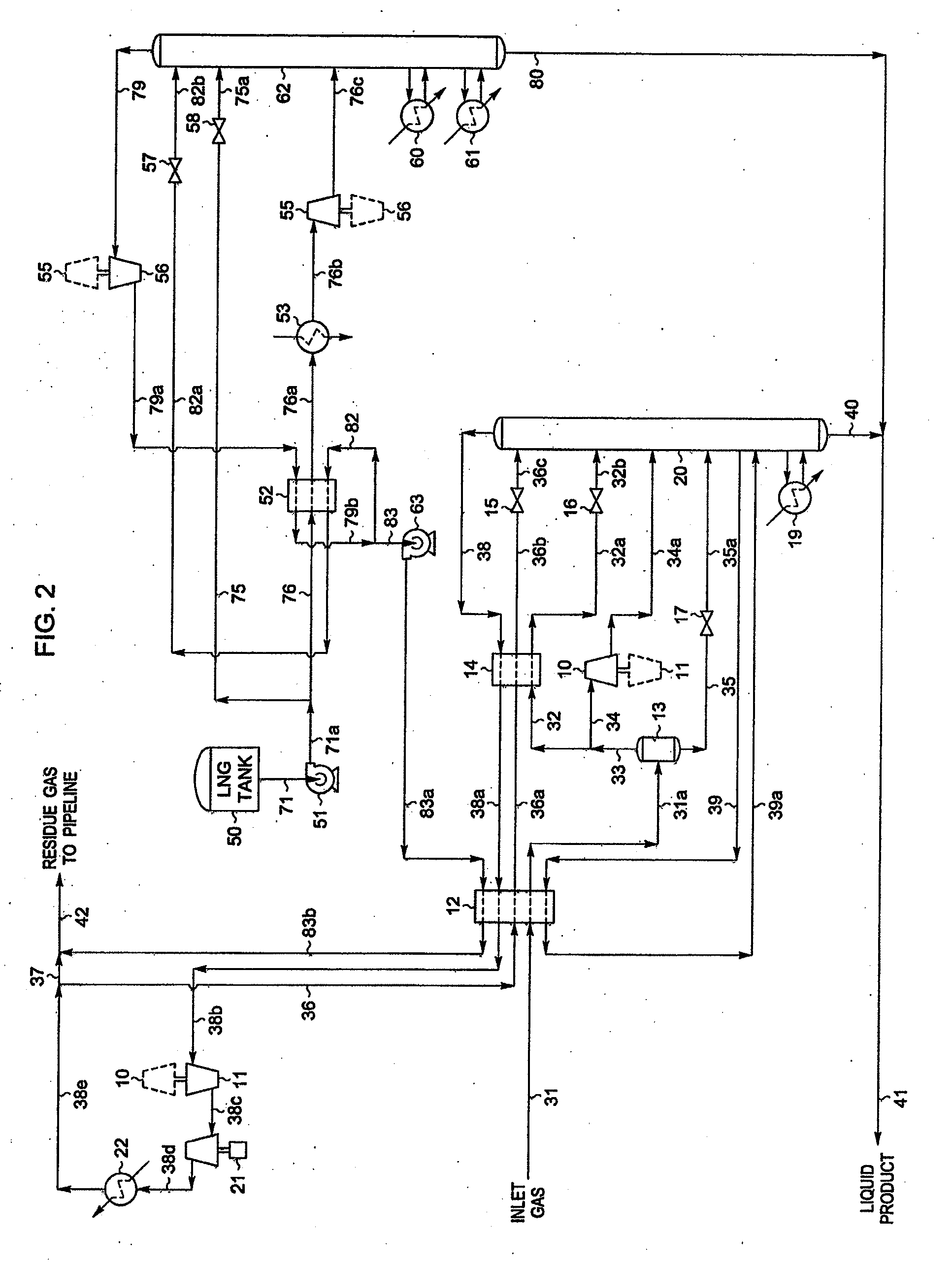

Liquefied natural gas processing

Owner:UOP LLC +1

Liquefied Natural Gas and Hydrocarbon Gas Processing

A process for the recovery of ethane, ethylene, propane, propylene, and heavier hydrocarbons from a liquefied natural gas (LNG) stream and a hydrocarbon gas stream is disclosed. The LNG feed stream is divided into two portions. The first portion is supplied to a fractionation column at a first upper mid-column feed point. The second portion is directed in heat exchange relation with a first portion of a warmer distillation stream rising from the fractionation stages of the column, whereby the LNG feed stream is partially heated and the distillation stream is totally condensed. The condensed distillation stream is divided into a “lean” LNG stream and a reflux stream, whereupon the reflux stream is supplied to the column at a top column feed position. The second portion of the LNG feed stream is heated further to partially or totally vaporize it and thereafter supplied to the column at a first lower mid-column feed position. The gas stream is divided into two portions. The second portion is expanded to the operating pressure of the column, then both portions are directed in heat exchange relation with the lean LNG stream and the second portion of the warmer distillation stream, whereby both portions of the gas stream are cooled, the lean LNG stream is vaporized, and the second portion of the distillation stream is heated. The first portion of the gas stream, which has been cooled to substantial condensation, is supplied to the column at a second upper mid-column feed point, and the second portion is supplied to the column at a second lower mid-column feed point. The quantities and temperatures of the feeds to the column are effective to maintain the column overhead temperature at a temperature whereby the major portion of the desired components is recovered in the bottom liquid product from the column.

Owner:ORTLOFF ENGINEERS

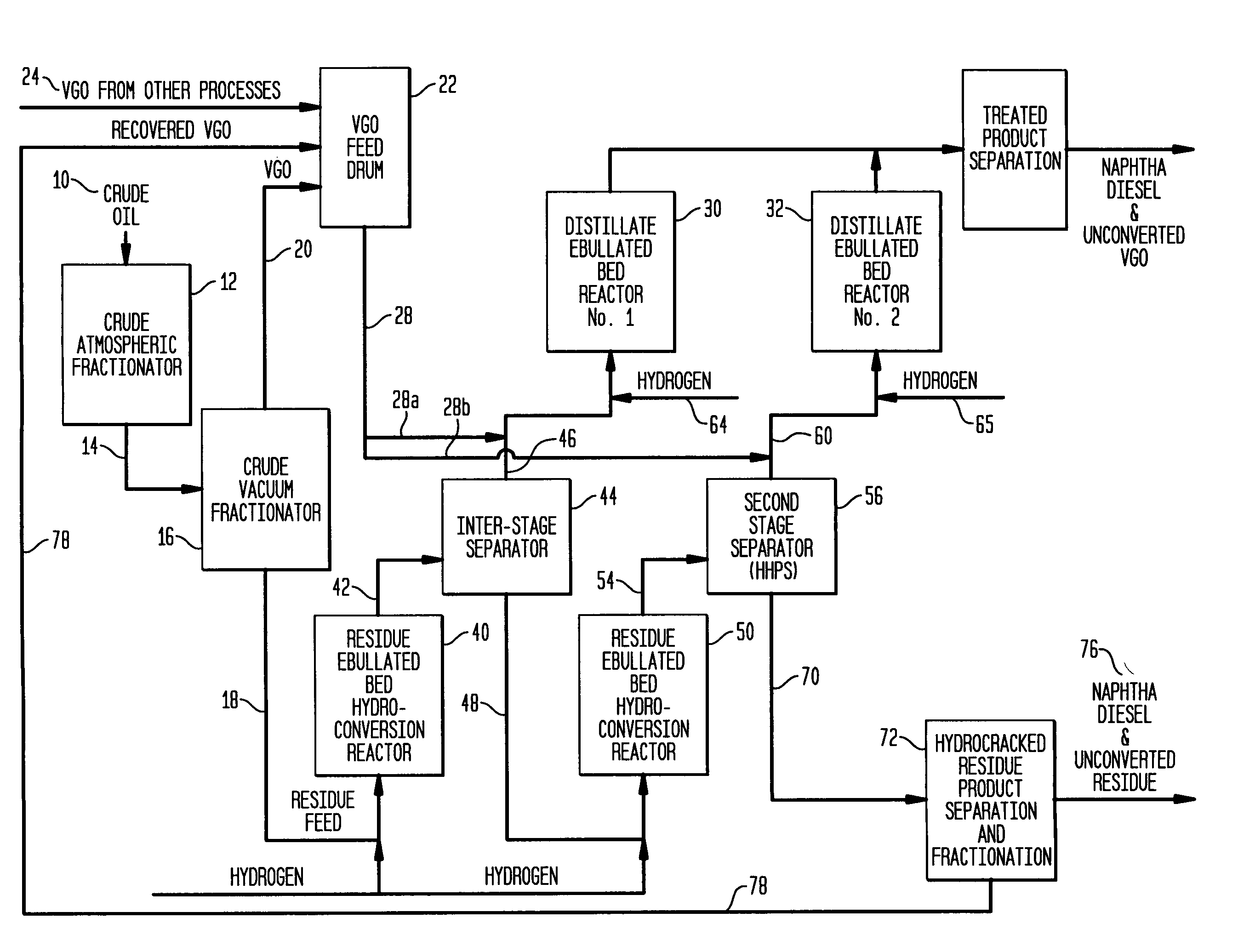

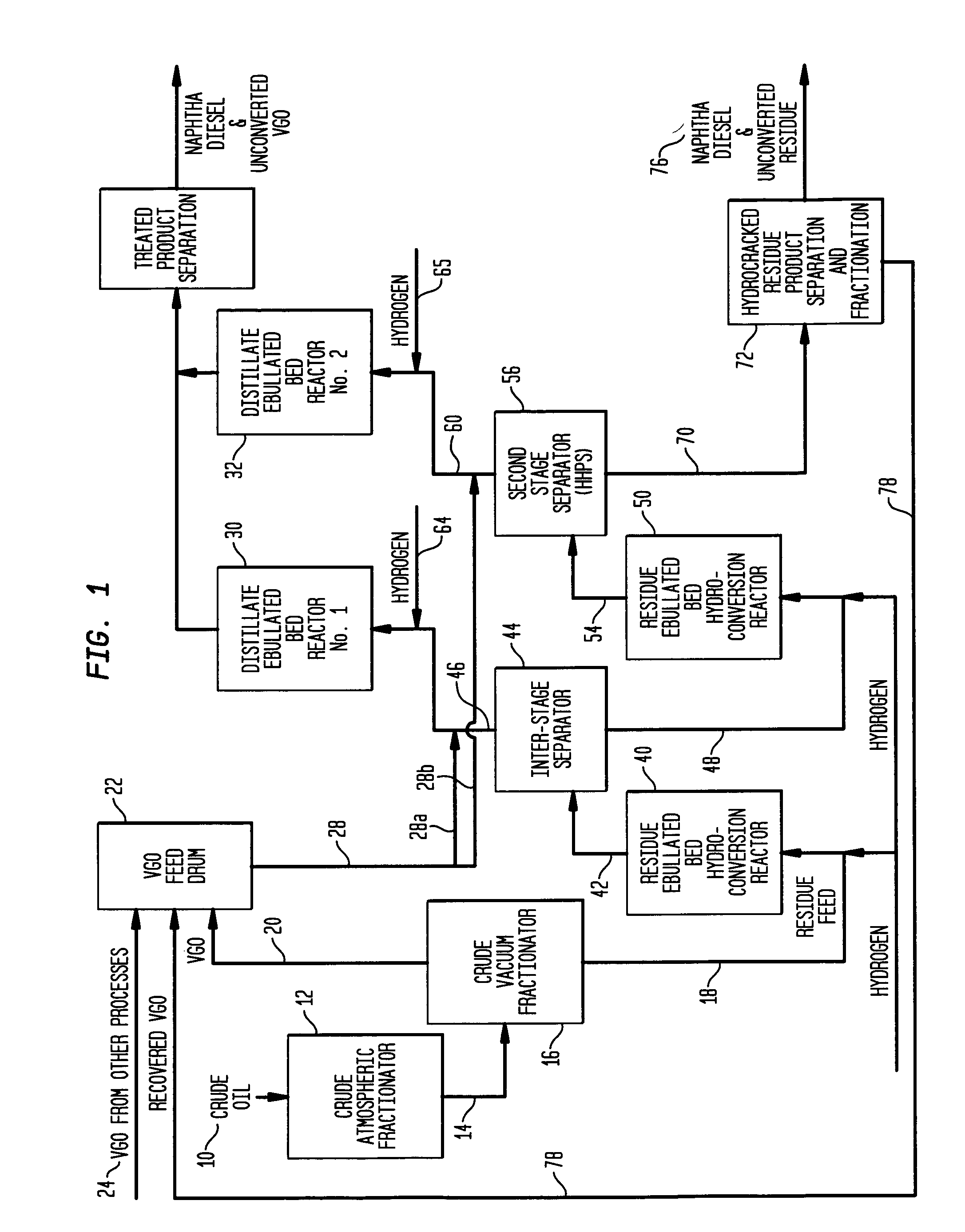

Process for multistage residue hydroconversion integrated with straight-run and conversion gasoils hydroconversion steps

InactiveUS7938952B2Improve throughputMitigate issueTreatment with plural serial cracking stages onlyMolecular sieve catalystsVapor liquidLiquid product

This invention relates to a novel integrated hydroconversion process for converting heavy atmospheric or vacuum residue feeds and also converting and reducing impurities in the vacuum gas oil liquid product. This is accomplished by utilizing two residue hydroconversion reaction stages, two vapor-liquid separators, and at least two additional distillate ebullated-bed hydrocracking / hydrotreating reaction stages to provide a high conversion rate of the residue feedstocks.

Owner:INST FR DU PETROLE

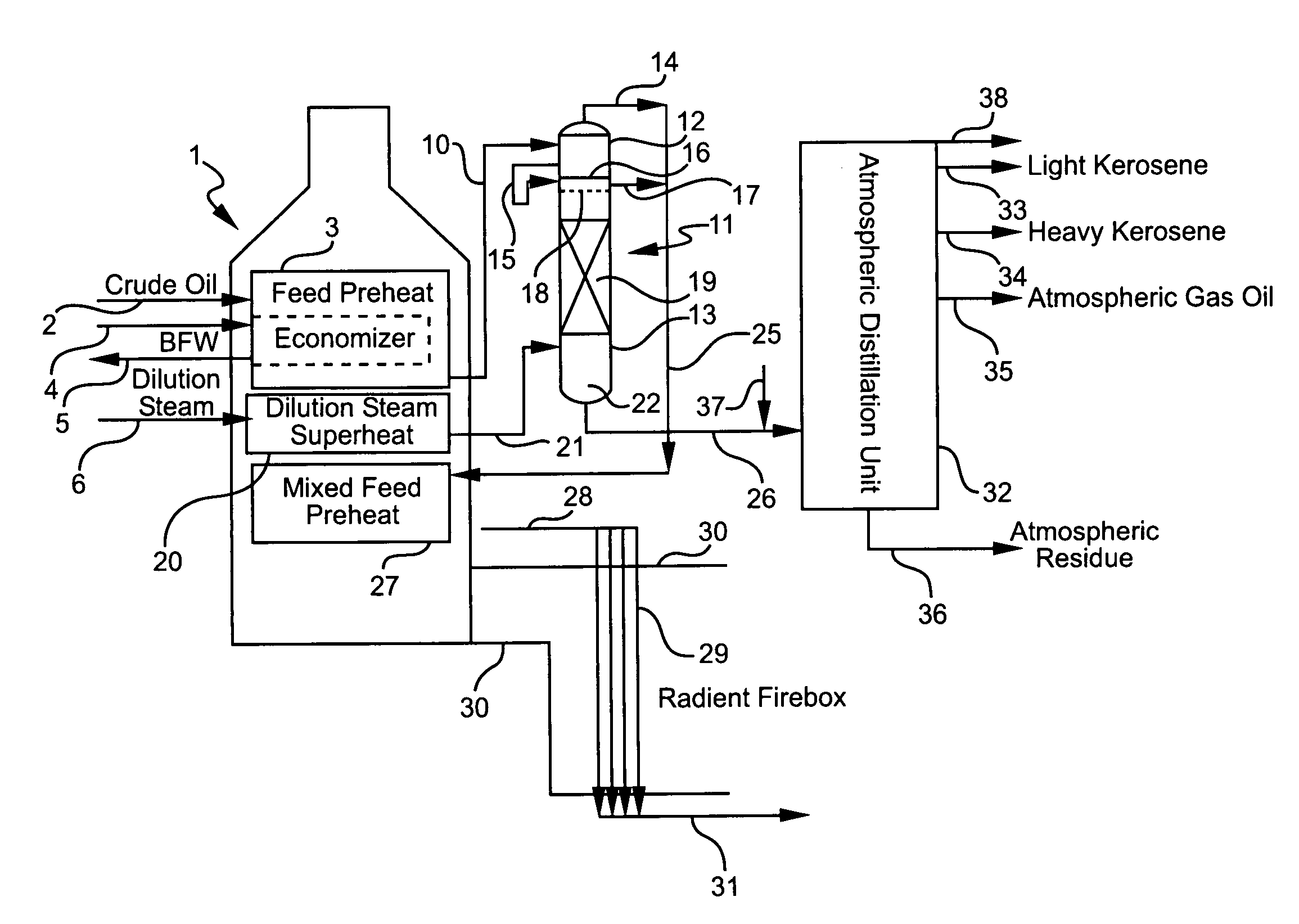

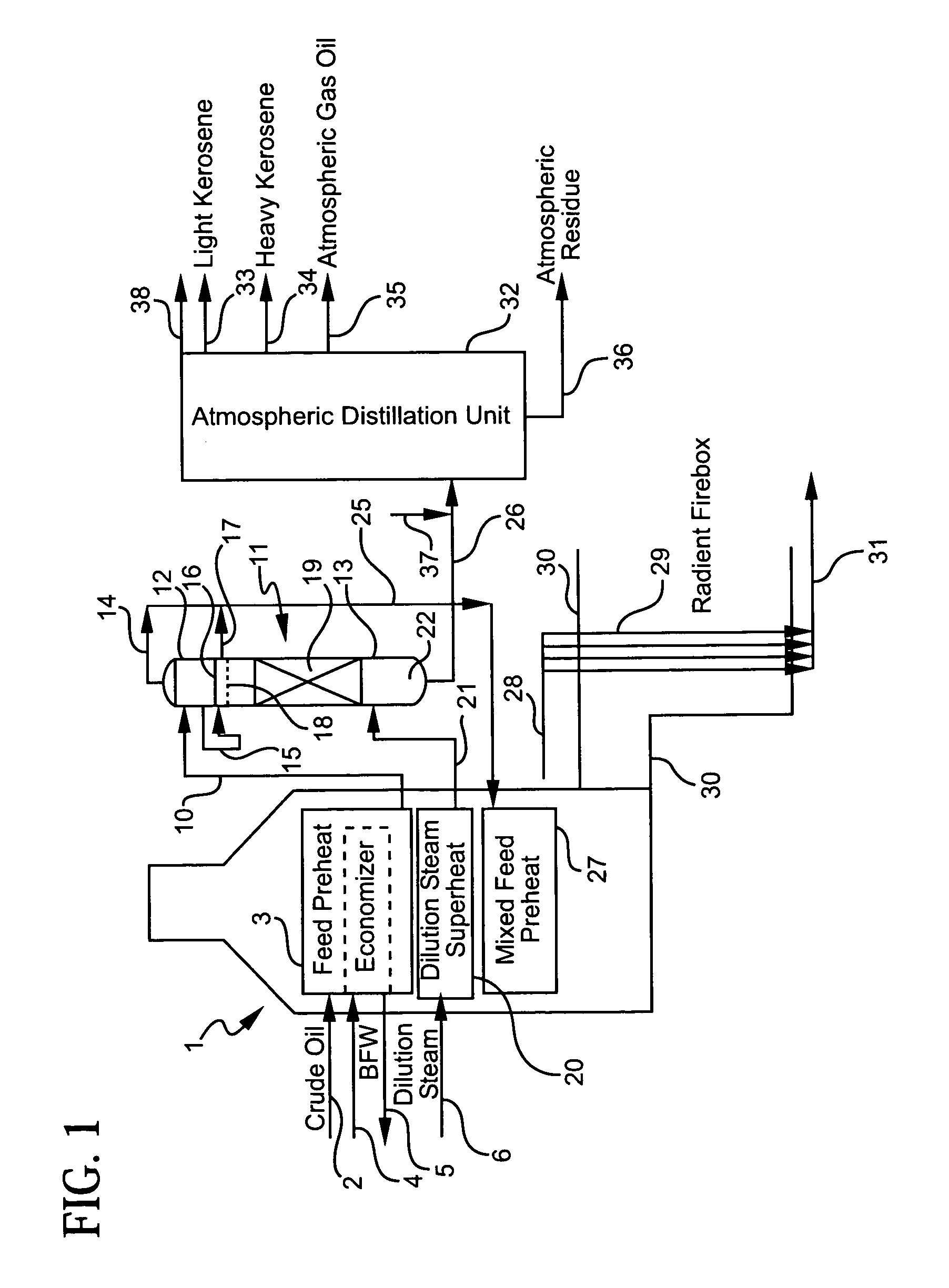

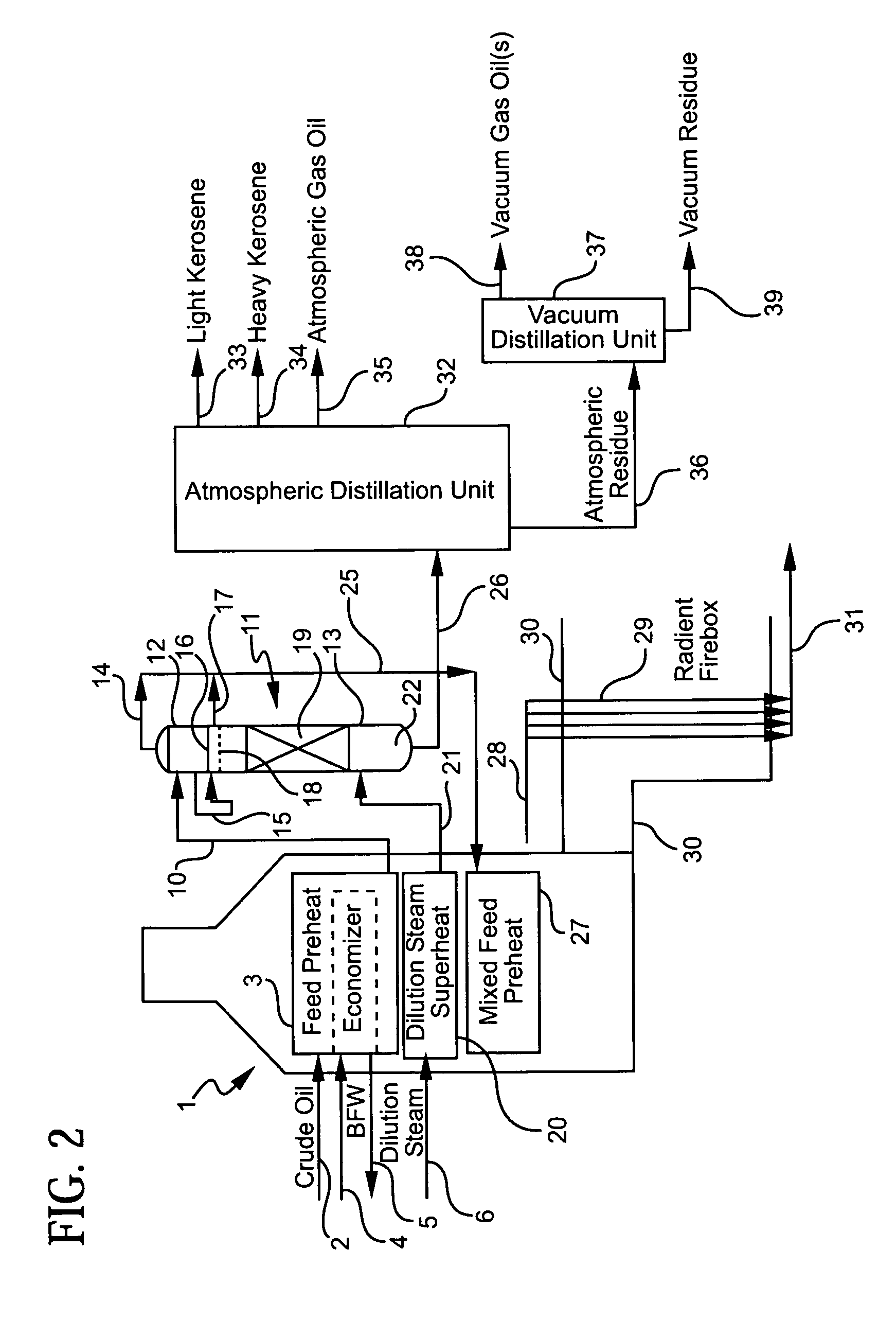

Olefin production utilizing whole crude oil/condensate feedstock with enhanced distillate production

InactiveUS7550642B2Maximize recoveryThermal non-catalytic crackingTreatment with plural serial stages onlyLiquid productNatural-gas condensate

A method processing a liquid crude and / or natural gas condensate feed comprising subjecting the feed to a vaporization step to form a vaporous product and a liquid product, subjecting the vaporous product to severe thermal cracking, and subjecting the liquid product to crude oil refinery processing.

Owner:EQUSR CHEM LP

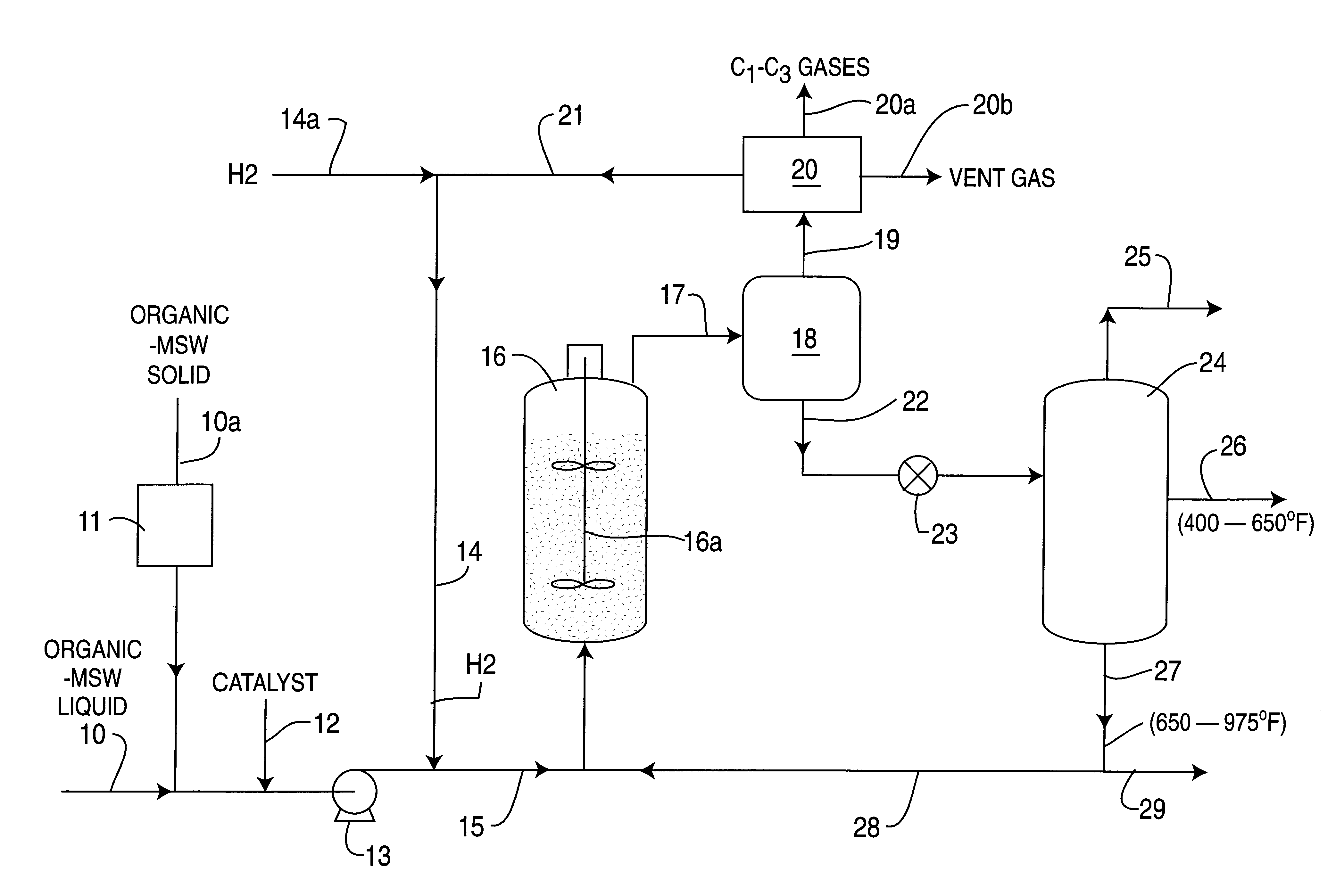

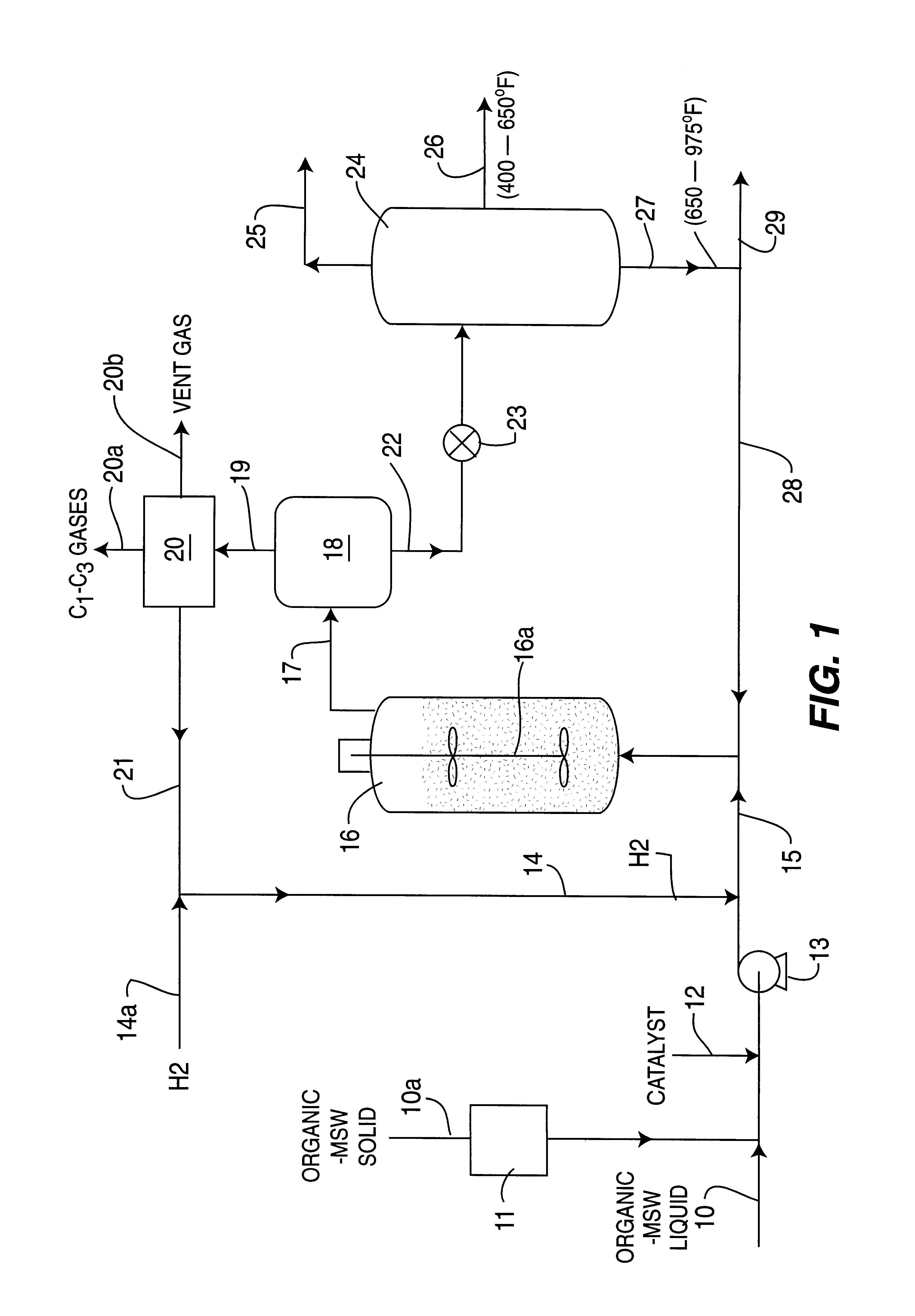

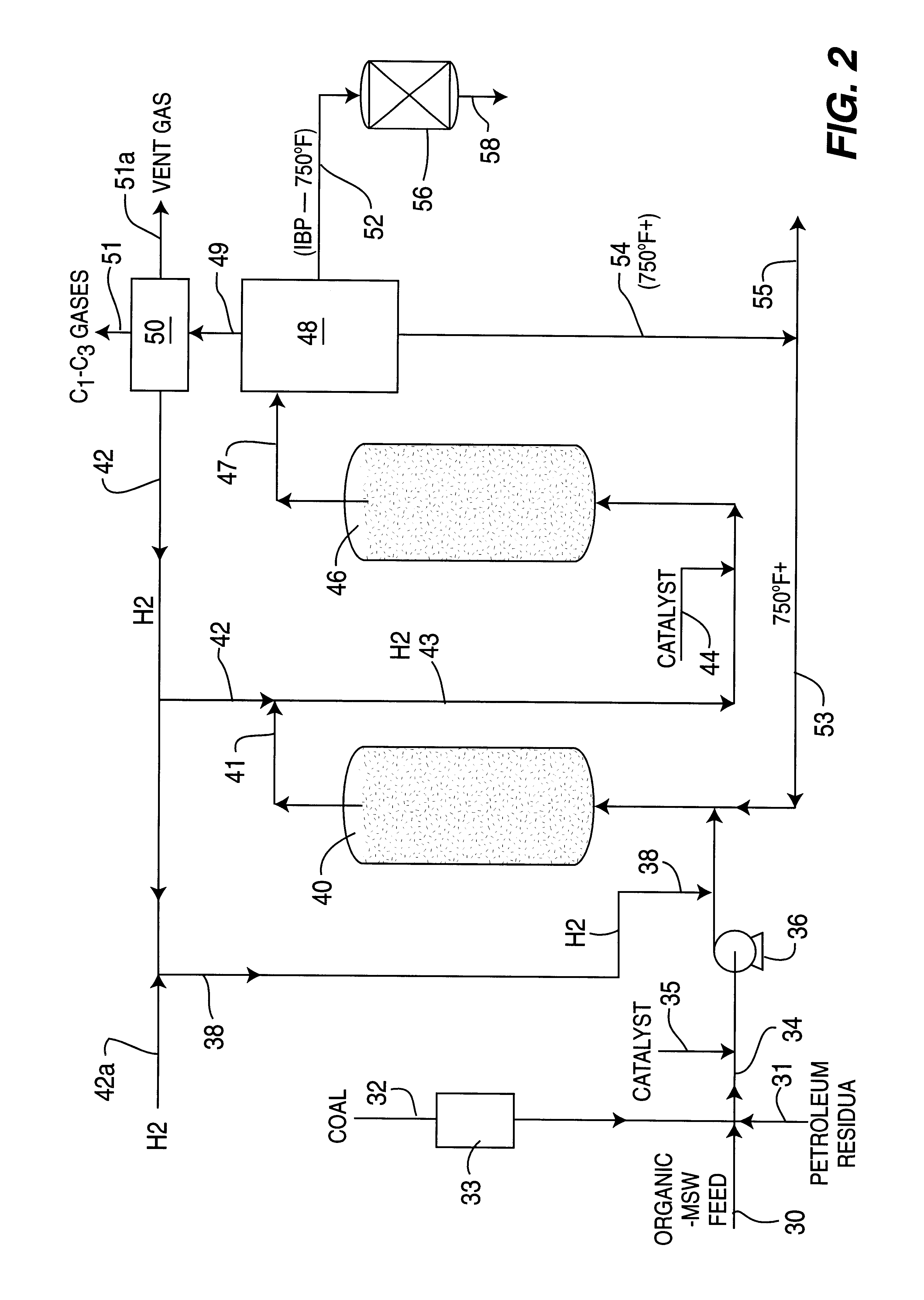

Catalytic hydroconversion of chemically digested organic municipal solid waste materials

InactiveUS6270655B1Increase surface areaReduce total nitrogenLiquid hydrocarbon mixture productionHydrocarbon oil crackingParticulatesLiquid product

A hydrocarbon liquid feedstock containing at least 50 wt. % chemically digested organic-MSW material is catalytically hydroconverted utilizing either a single stage or two-stage catalytic reaction process to produce desirable lower-boiling hydrocarbon liquid products. The catalyst can be either a particulate supported type catalyst such as containing cobalt and / or molybdenum and / or nickel on alumina support, or a dispersed slurry type catalyst containing mainly iron oxide with anions of molybdate, phosphate, sulfate or tungstate, and combinations thereof. Broad useful reaction conditions are 600-860° F. (315-460° C.) temperature, 1000-3000 psi hydrogen partial pressure, and fresh feed rate of 20-60 pounds / hr / ft3 reactor volume. Effluent material from the final stage catalytic reactor is phase separated and the resulting liquid portion is fractionated to produce the desired low-boiling hydrocarbon liquid products particularly useful as transportation fuels. If desired, the chemically digested organic-MSW feedstock can be blended with petroleum residua and / or particulate coal and / or mixed waste plastics and the blended feed material processed in catalytic two-stage reactors to produce similar desirable low-boiling hydrocarbon liquid products.

Owner:HYDROCARBON TECH

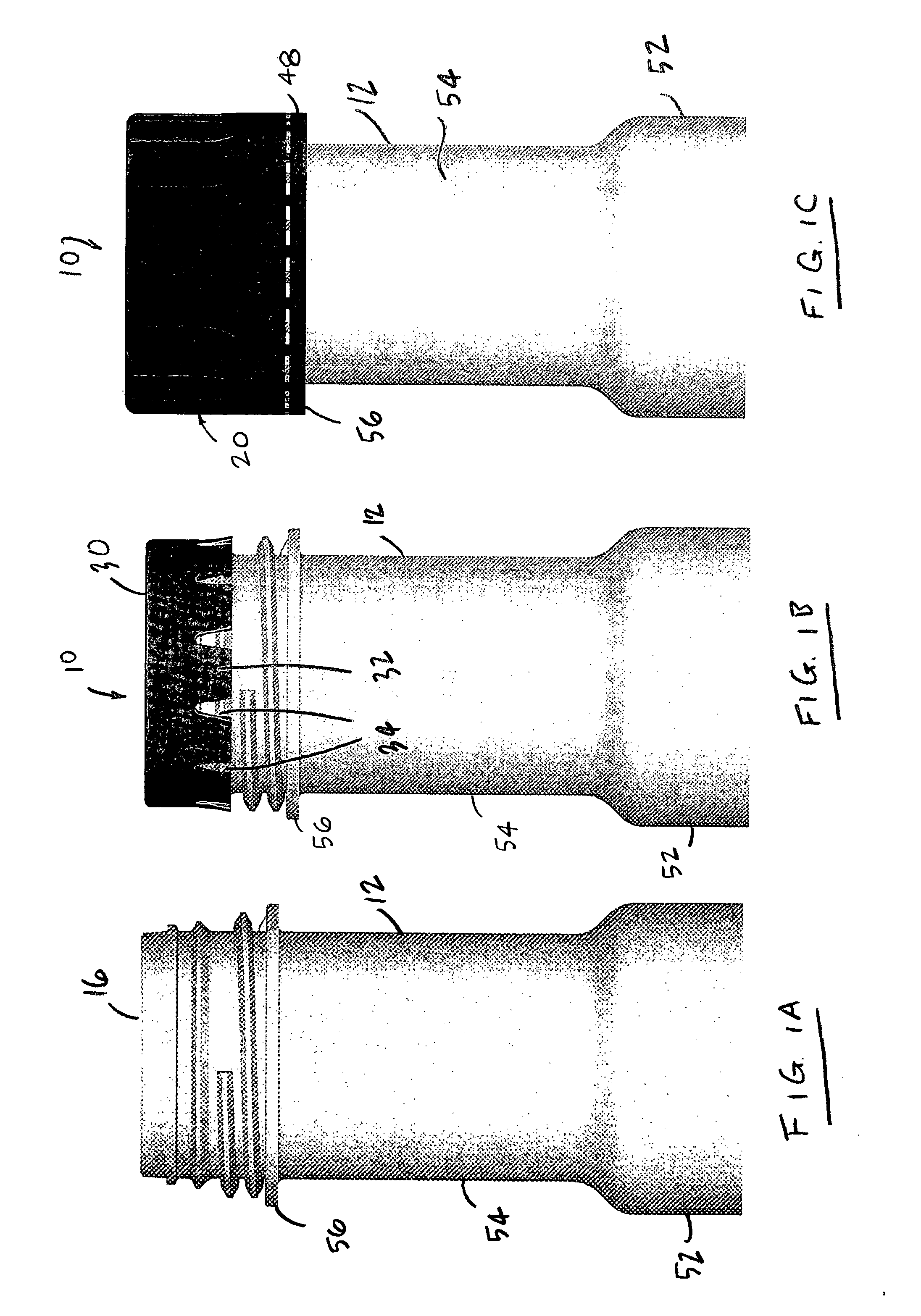

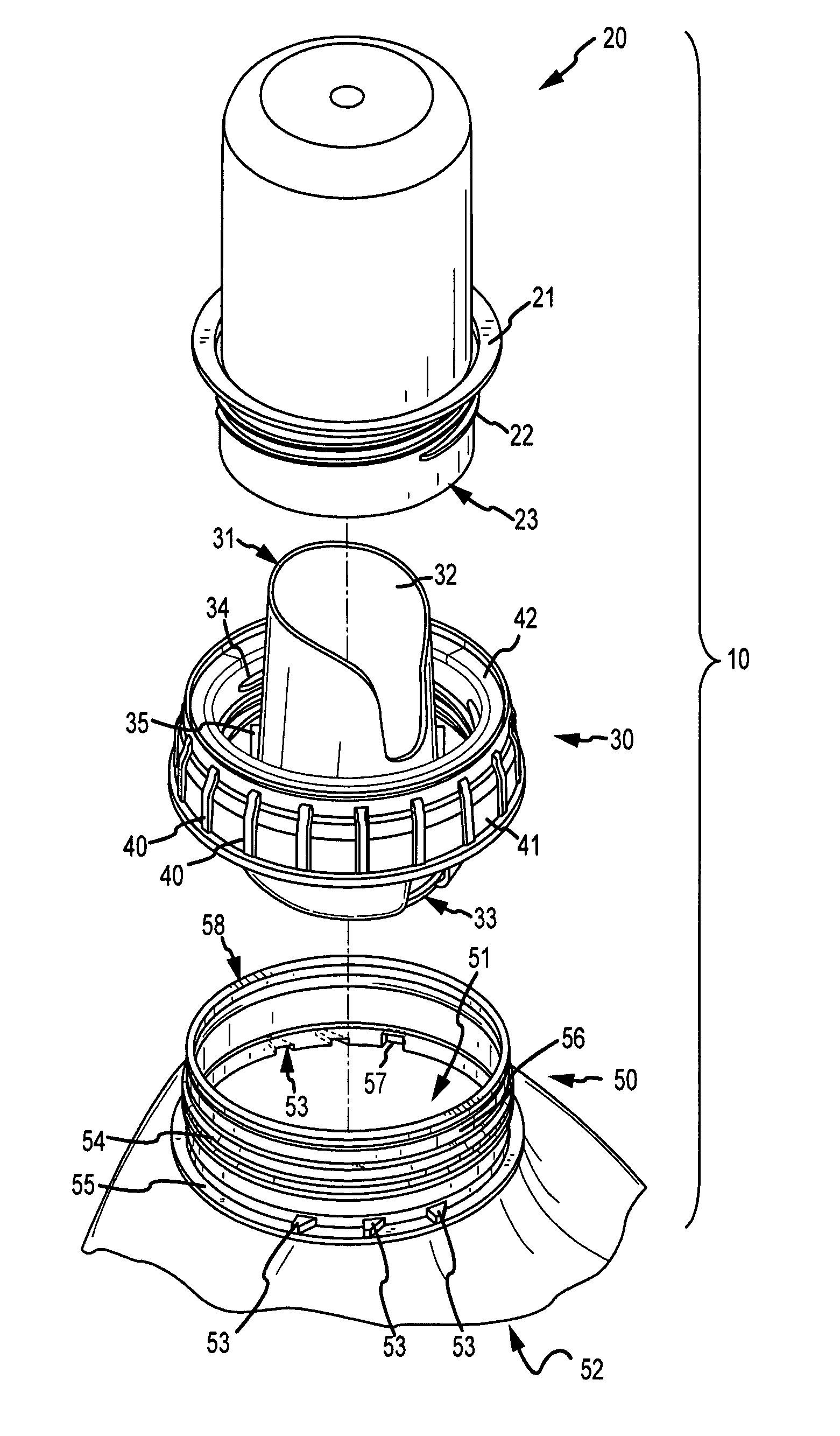

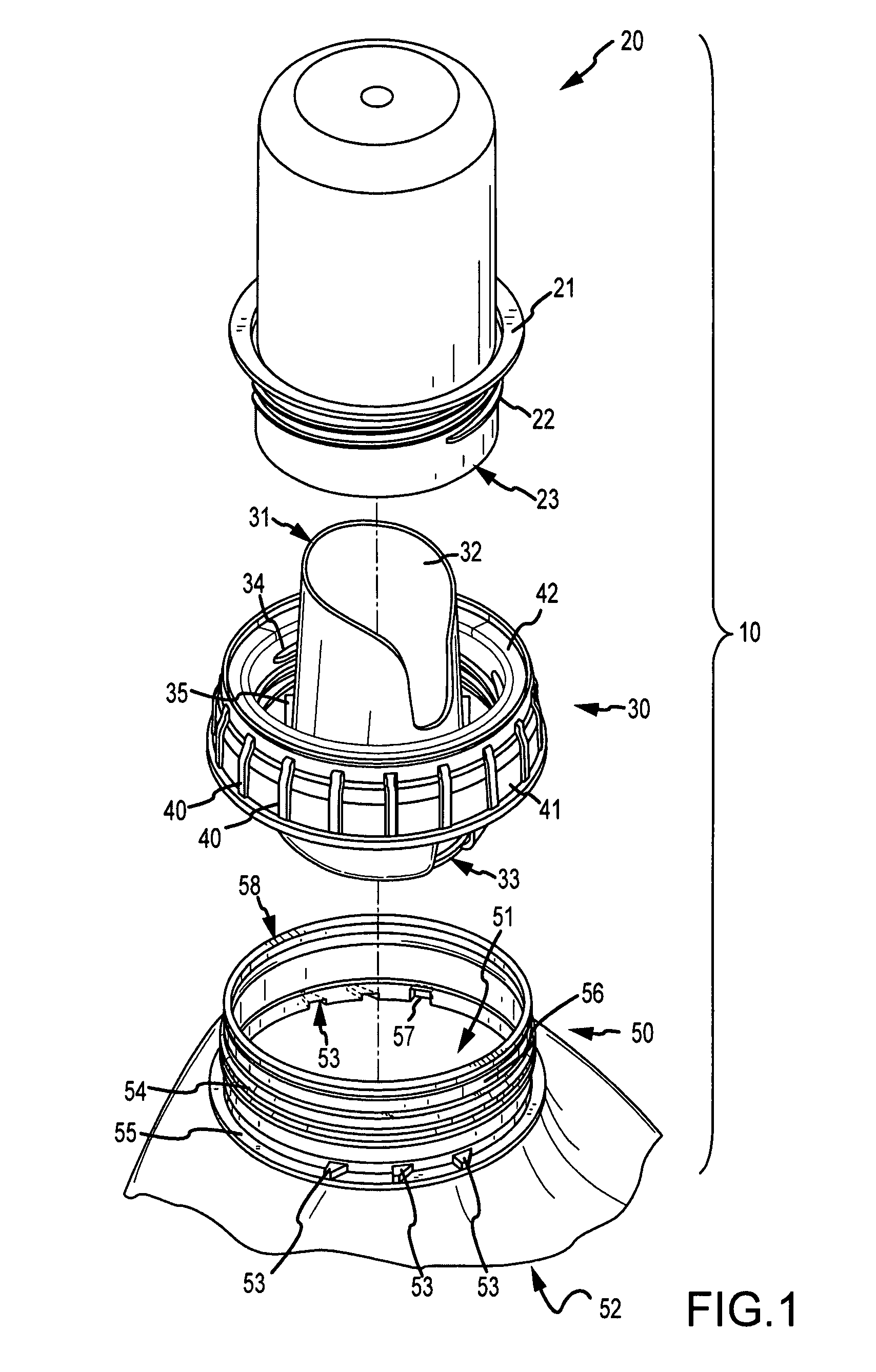

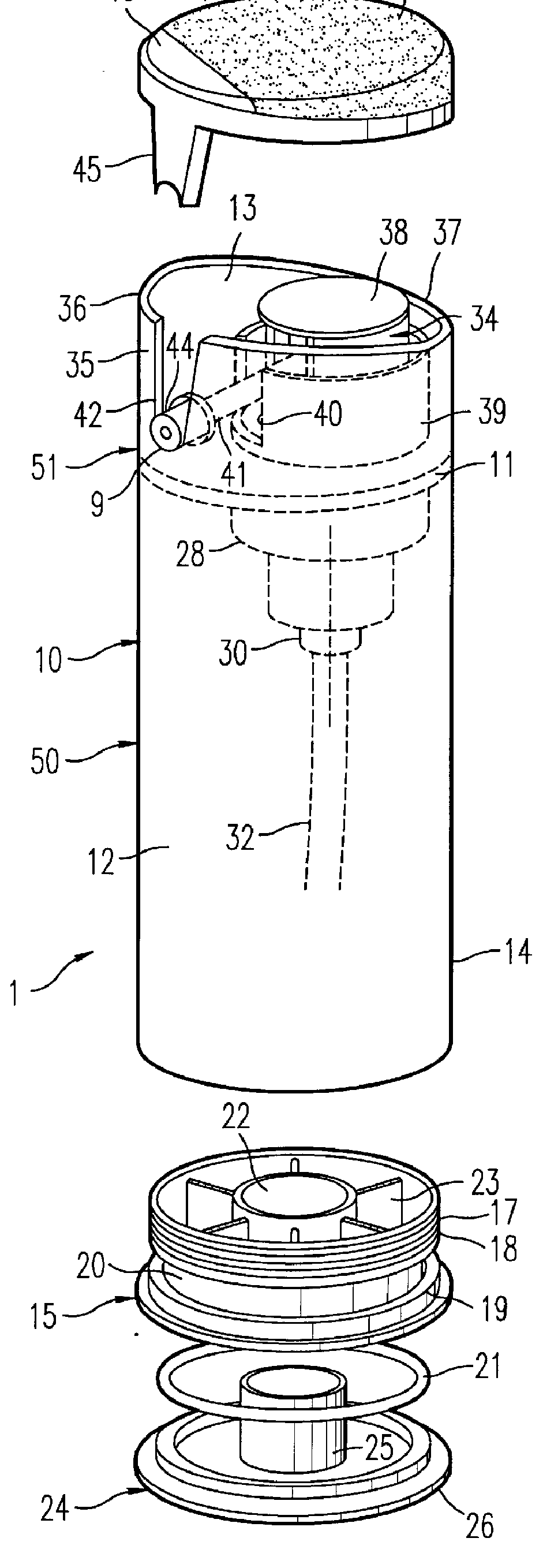

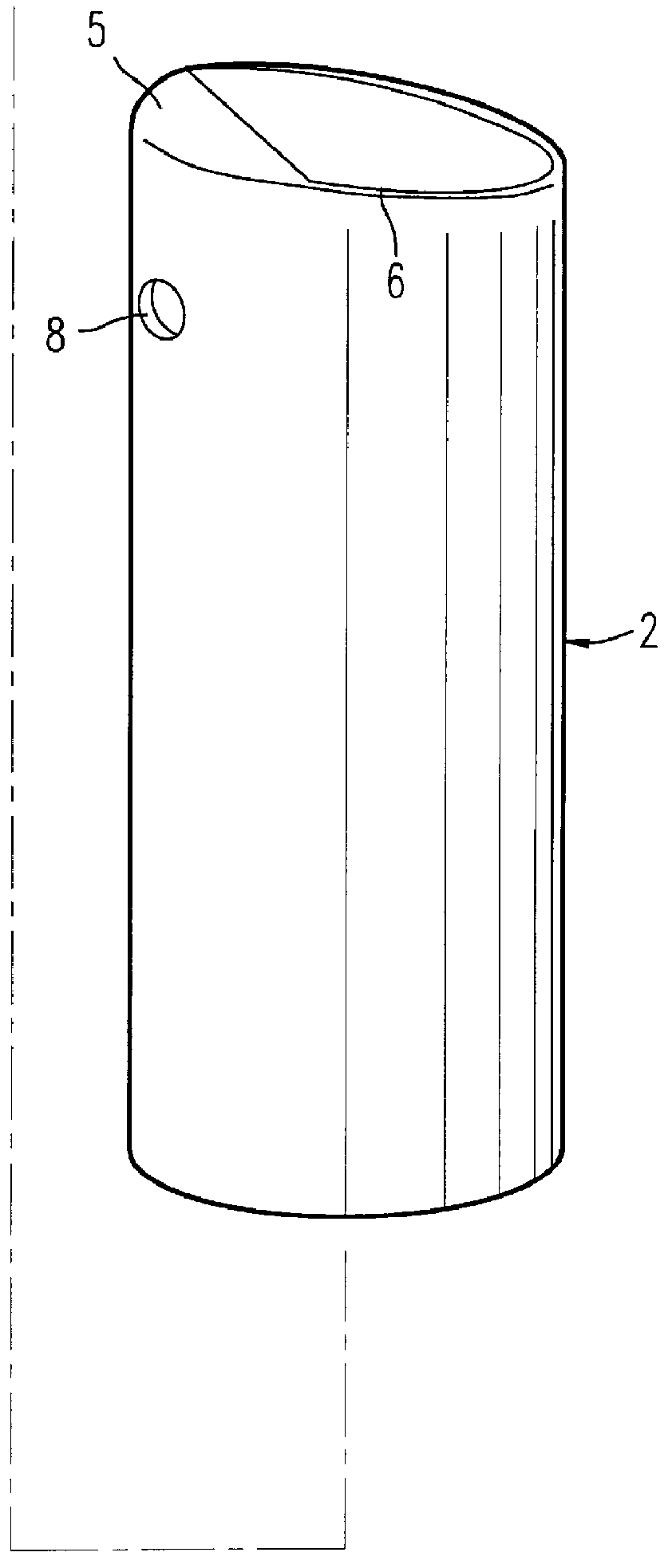

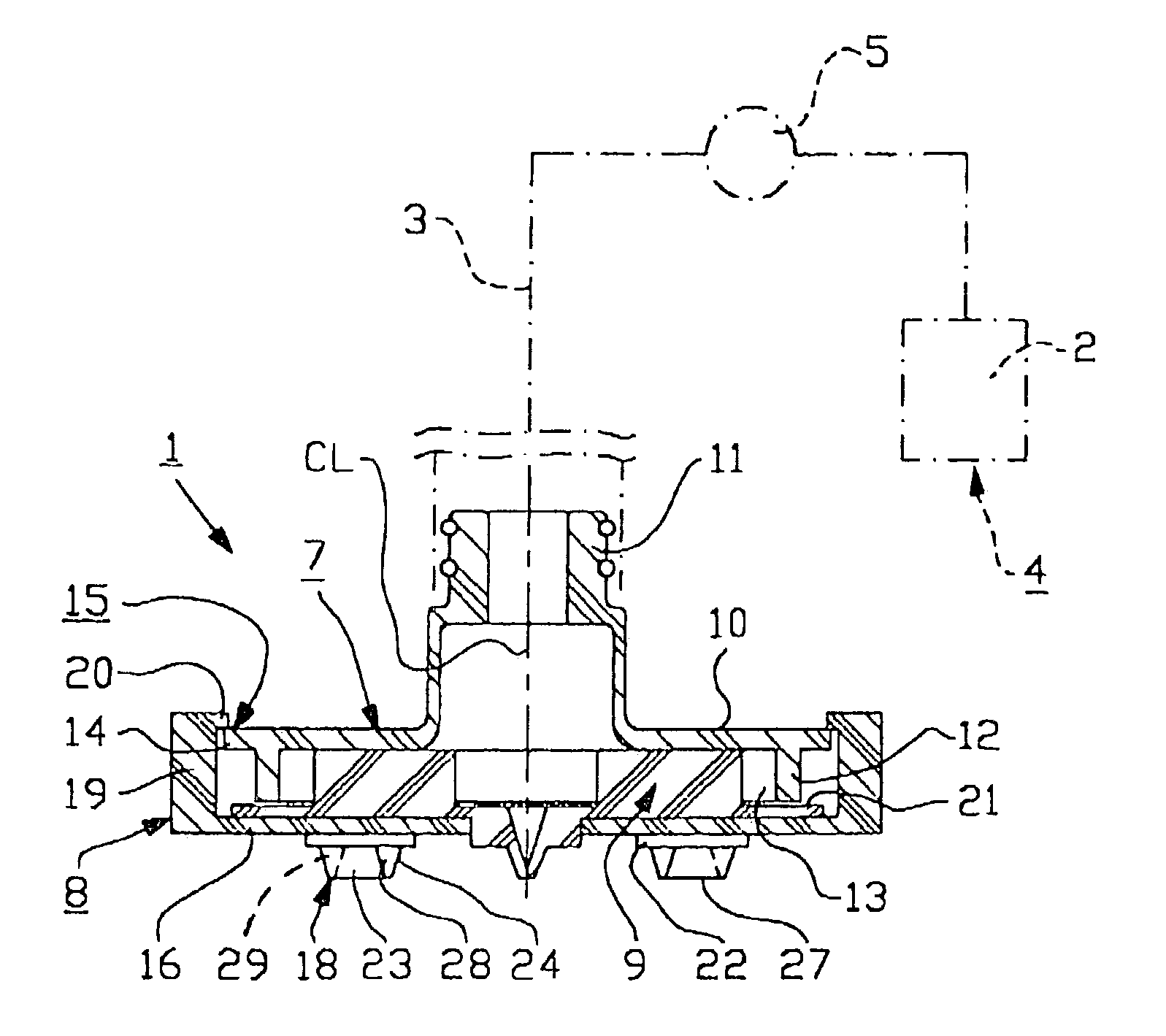

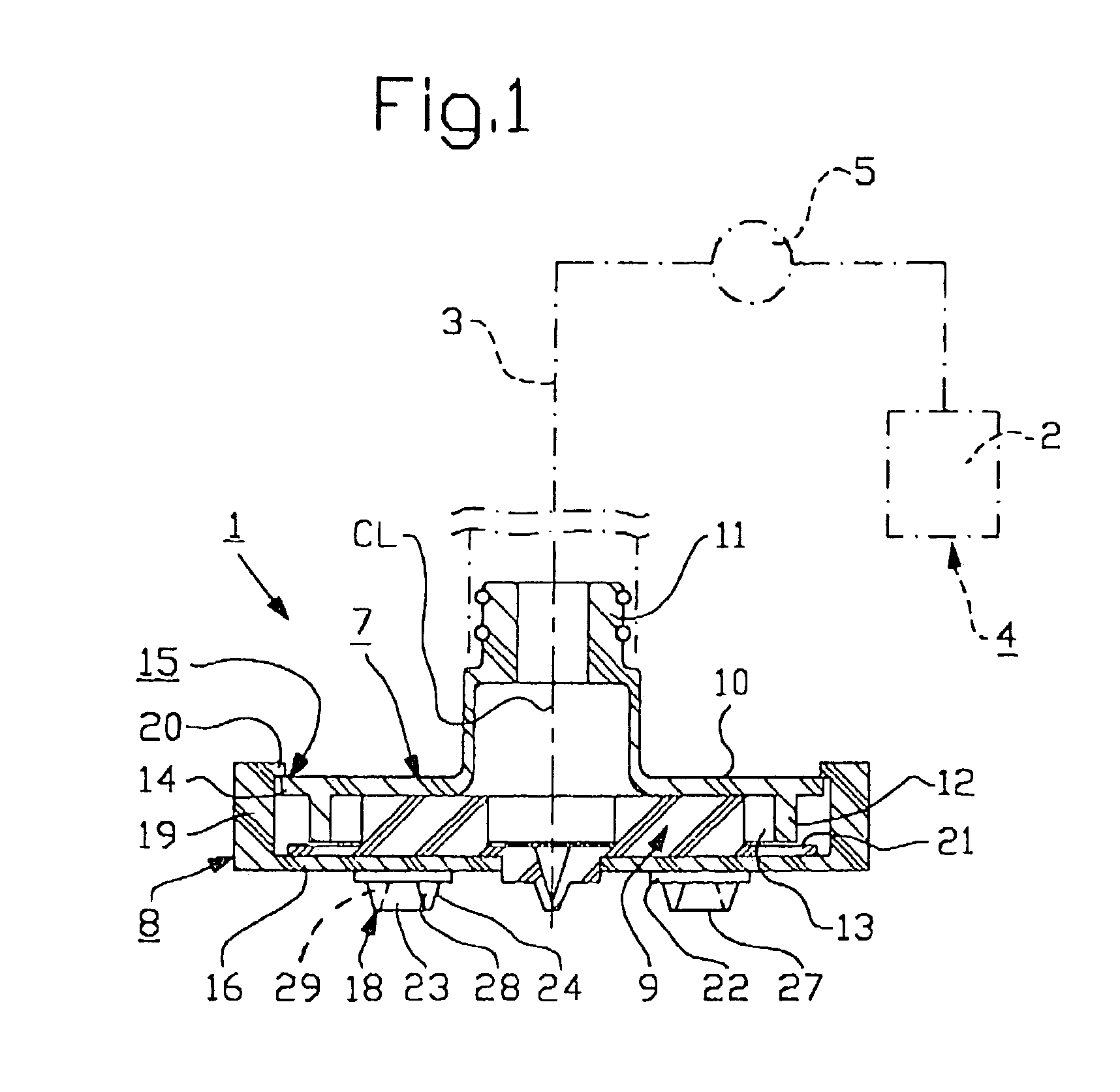

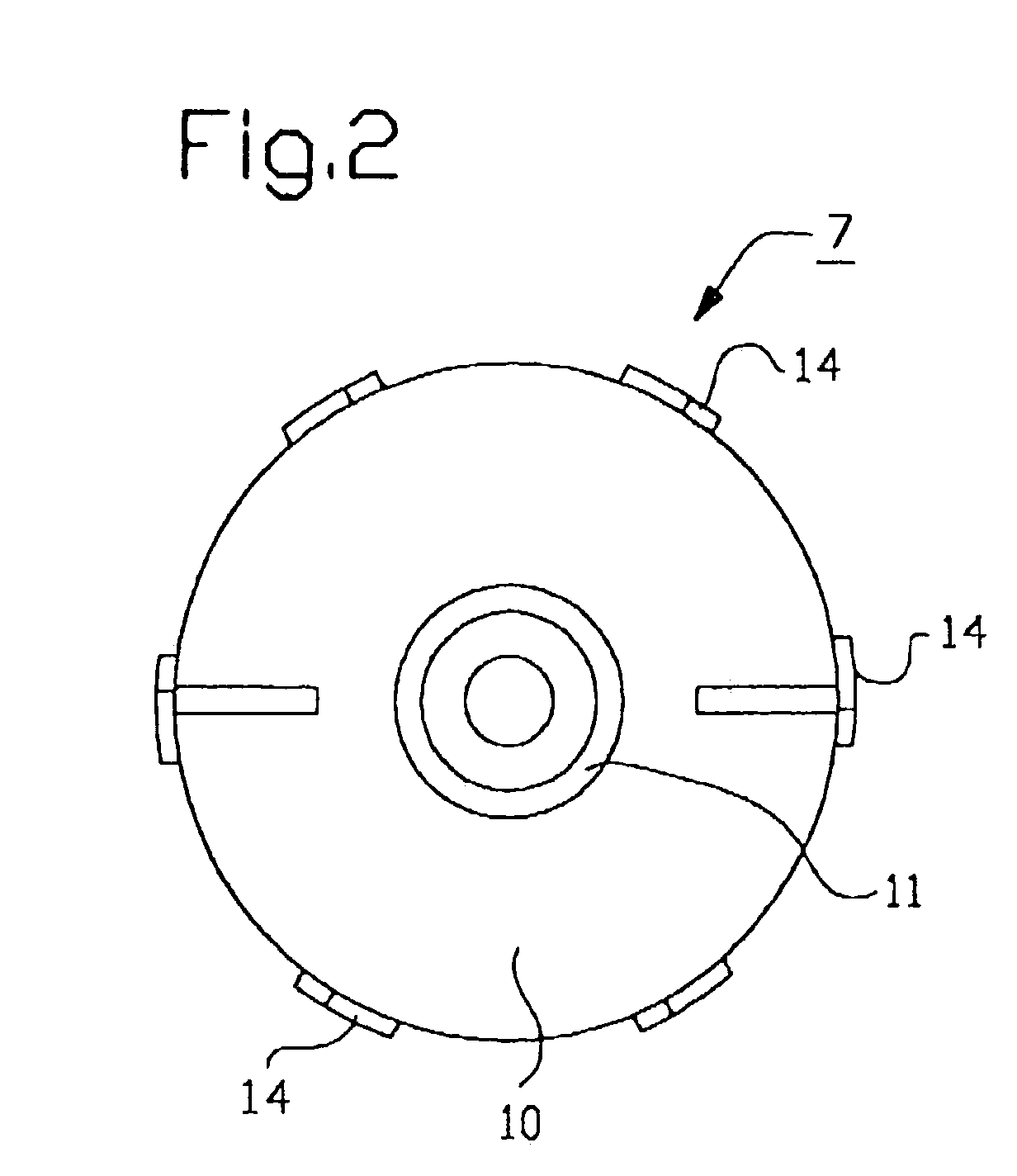

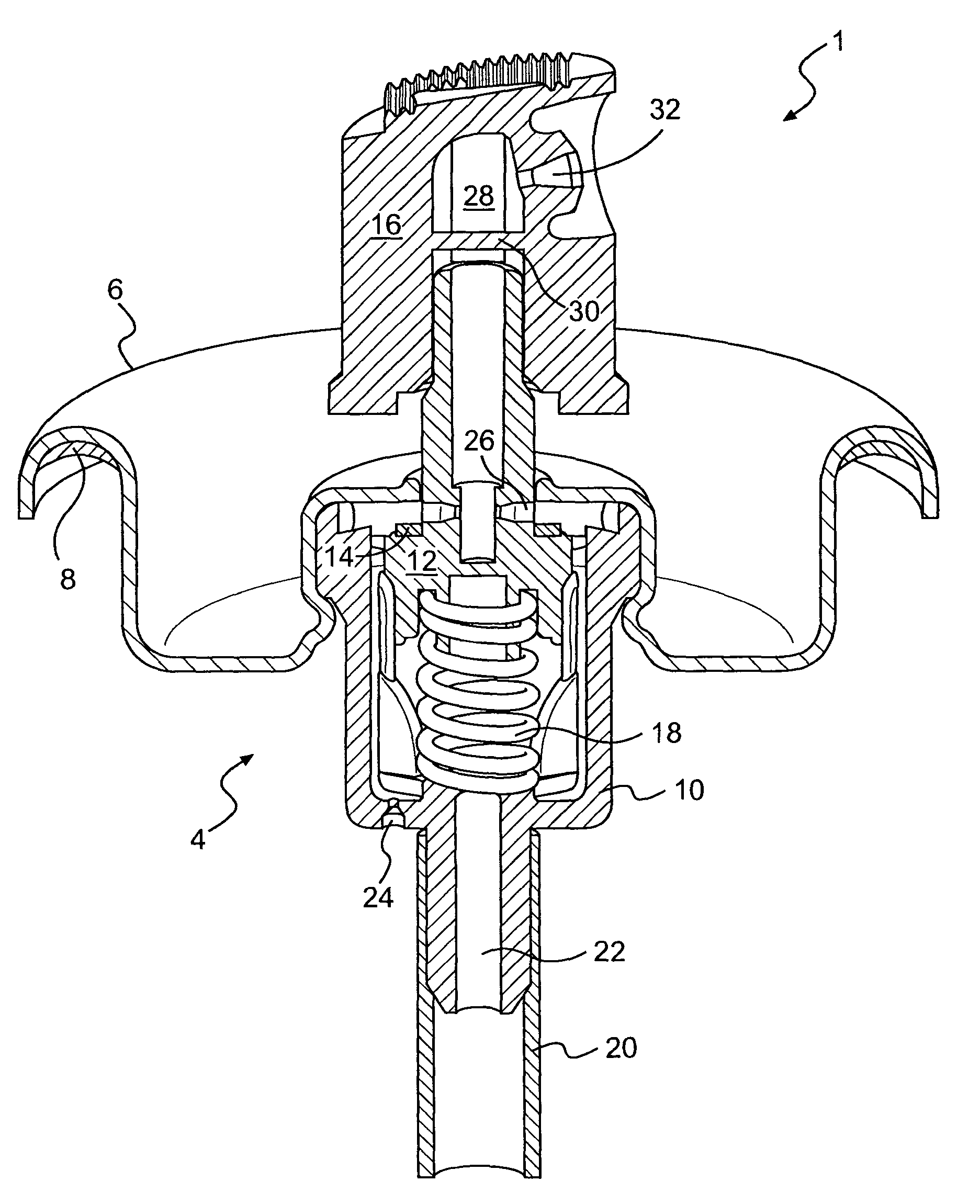

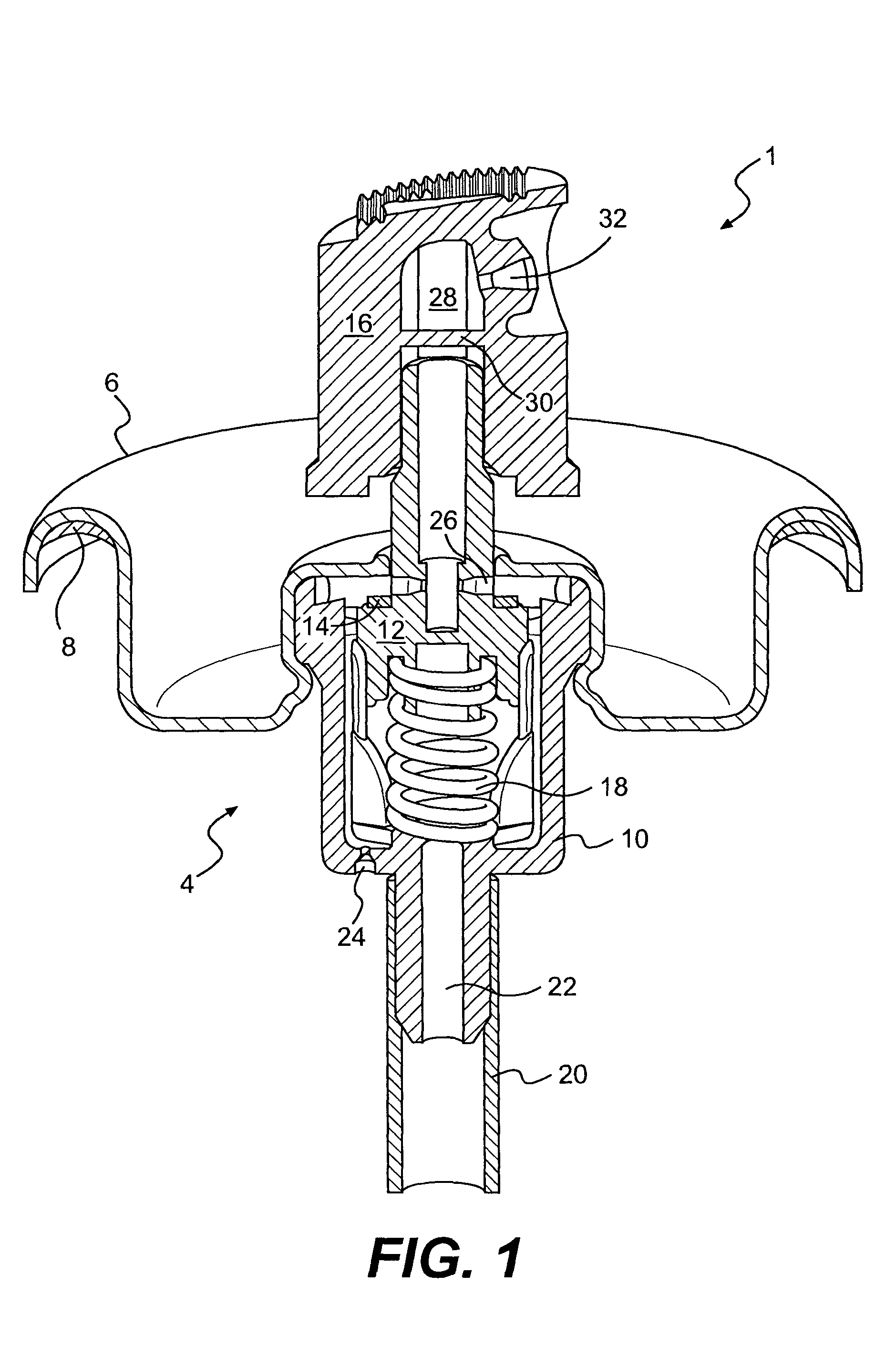

Pump-type packaging unit for a liquid or semi-liquid product

InactiveUS6089410AImprove aestheticsSimple and economic to obtain industriallyLarge containersLiquid transferring devicesLiquid productBiomedical engineering

A unit (1) for packaging and dispensing a liquid or semi-liquid product includes a body (10) with an axis X, forming a reservoir (12) for the liquid or semi-liquid product, the reservoir (12) being surmounted by a pump (30) actuable by an actuating element (34). The product emerges through at least one opening arranged in an outlet element (9) connected to the pump (30) by a conduit (41) forming a flexible connection. The outlet element (9) is held substantially immovably in position on a fixed portion (51) of the body (10) surmounting the reservoir (12), the actuating element (34) being independently mounted relative to the fixed portion (51) of the body (10).

Owner:LOREAL SA

Spray head

InactiveUS7040554B2Eliminate the problemEasy to disassembleLiquid surface applicatorsDust removalLiquid productCoupling

Owner:ASEPT INT

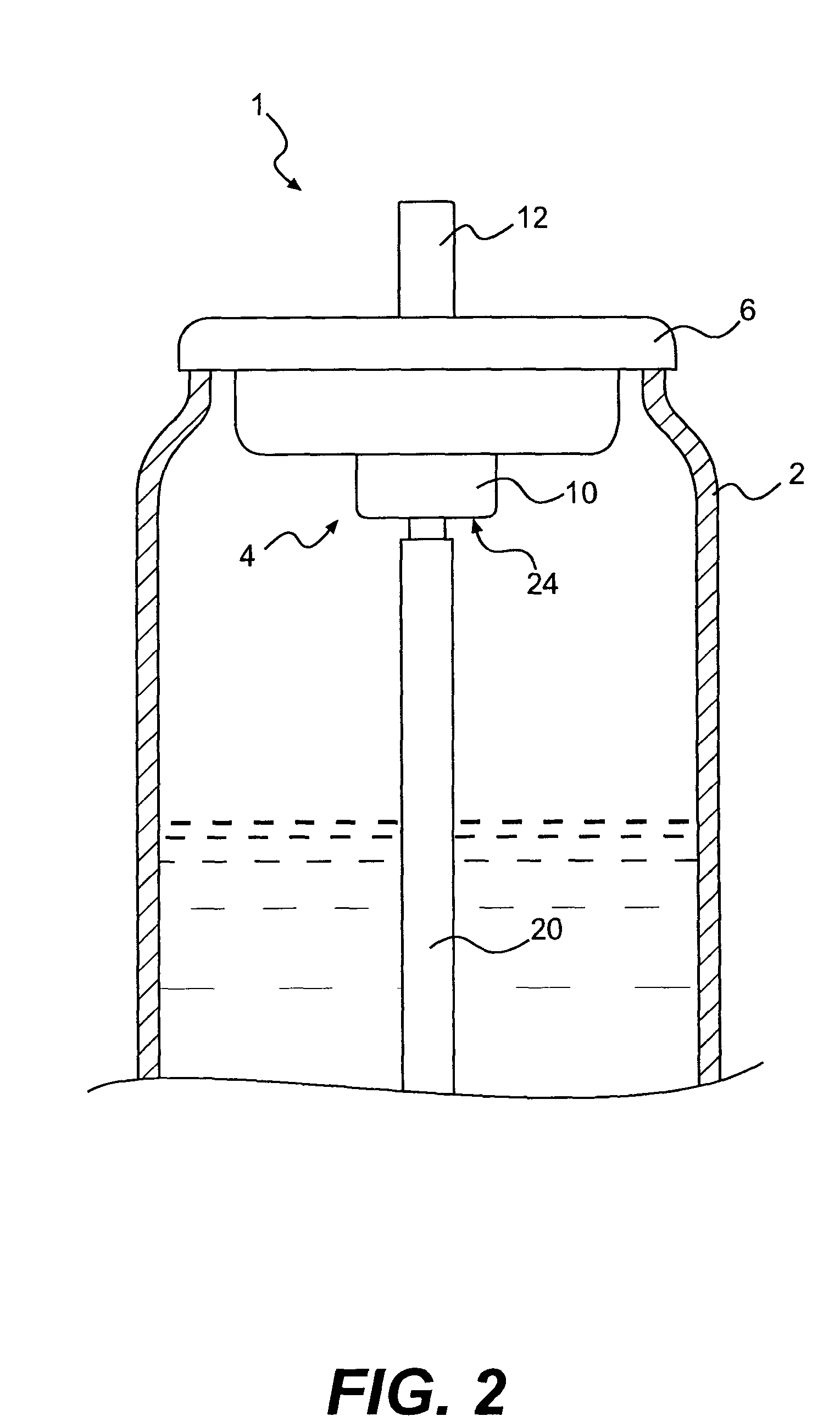

Aerosol dispenser assembly having low volatile organic compound (VOC) content

InactiveUS7014127B2Satisfactory particle sizeSatisfactory spray rateLiquid spraying apparatusLiquid dispensingLiquid productMechanical engineering

An aerosol dispenser assembly (1) has a container (2) holding a liquid product and a liquefied gas propellant for propelling the liquid product from the container, the propellant being present in a quantity of at most about 25% by weight of the contents of the container (2). A valve (4) is attached to the container (2) for selectively dispensing the liquid product from the container (2) as a mist. The assembly (1) is configured such that the mist has a small particle size, is dispensed at an expeditious rate, and very little product is retained in the container (2) when the propellant is depleted.

Owner:SC JOHNSON & SON INC

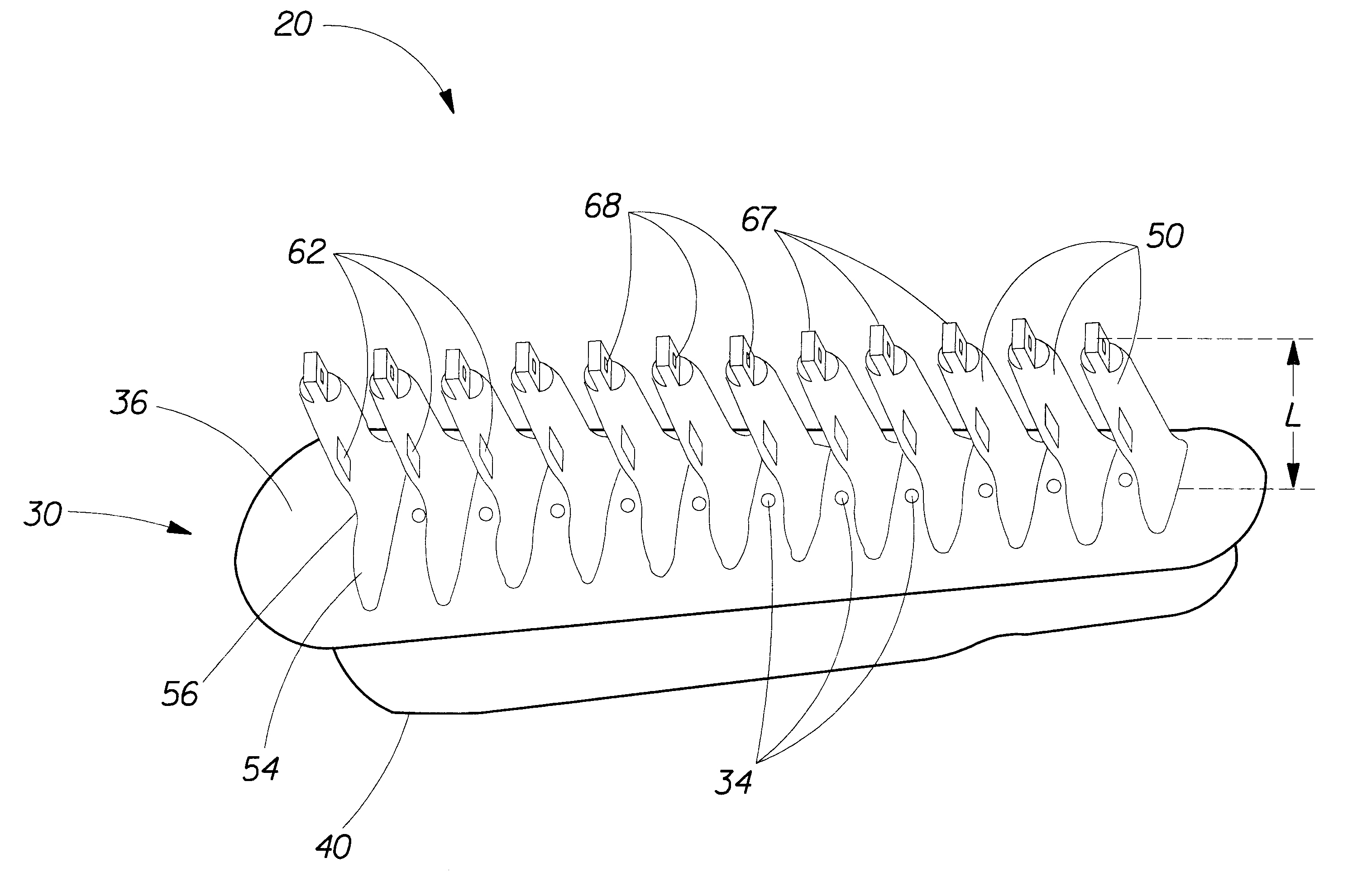

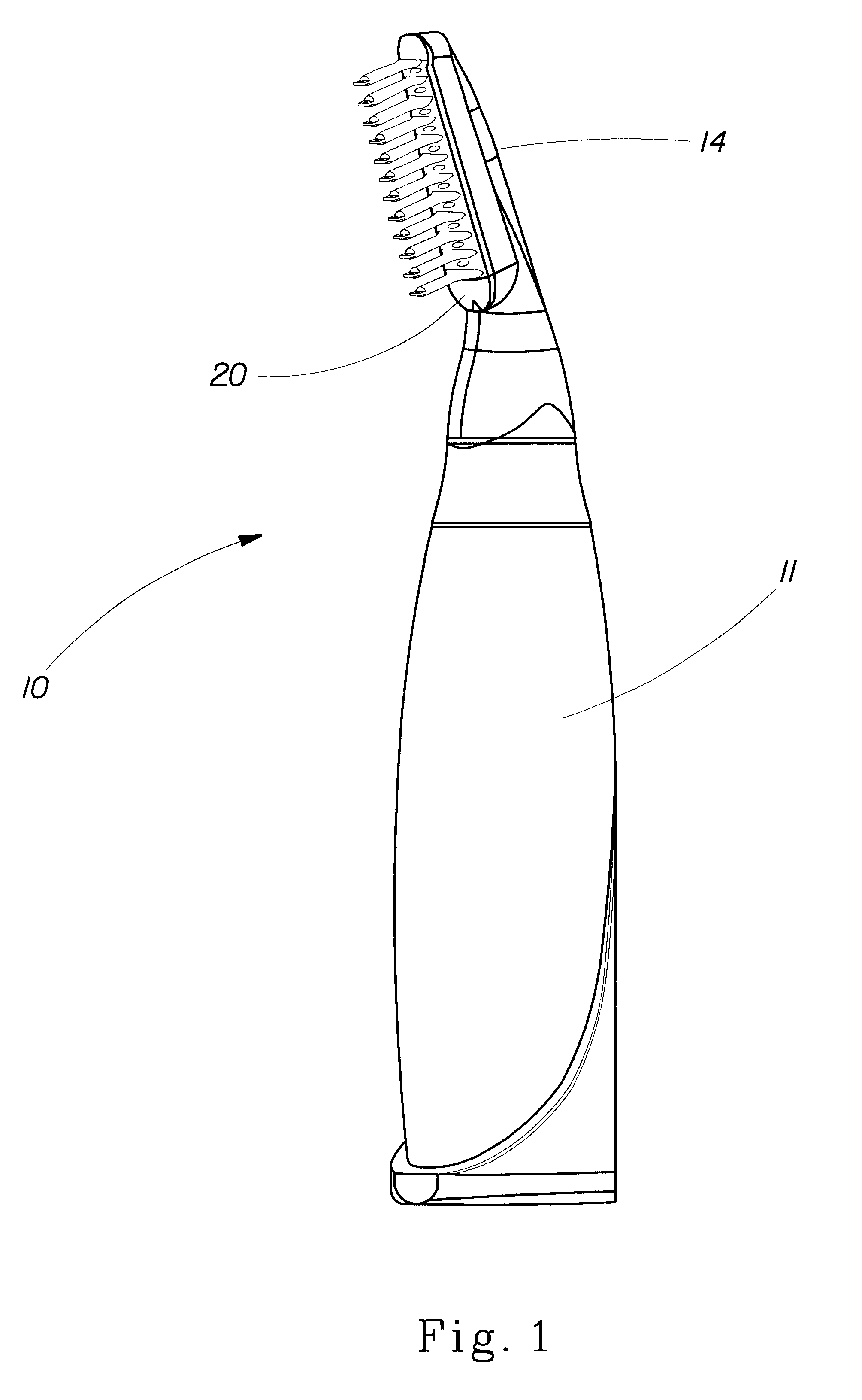

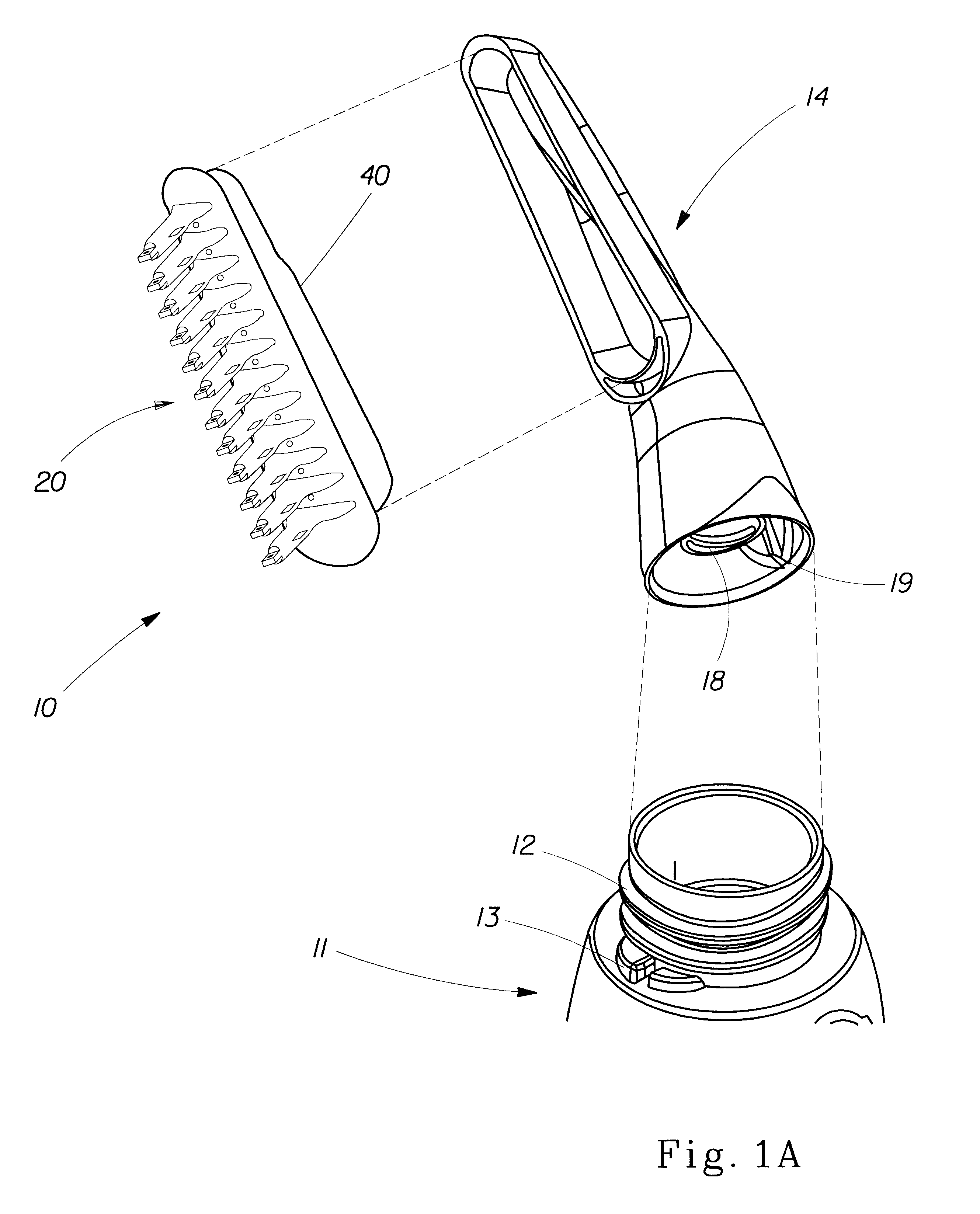

Applicator for applying liquid products to hair

Owner:WELLA OPERATIONS US LLC

Electric soap dispenser

ActiveUS8109411B2Convenient for userVolume measurement and fluid deliveryLarge containersLiquid productEngineering

An electric soap dispenser that includes sensors for detecting the presence of an object. The dispenser can be configured to dispense an amount of liquid soap, for example, upon detecting the presence of an object. The dispenser can include various features for enhancing the performance thereof. For example, the dispenser can include an additional button for manual operation of the pump. Additionally, the dispenser can detect the voltage of a power supply and compensate for a drop in voltage of the power supply so as to produce more uniform dispensations of the liquid product. Additionally, the dispenser can include a valve at its discharge end to prevent drips.

Owner:SIMPLEHUMAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com