Patents

Literature

4343 results about "Catalytic hydrogenation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

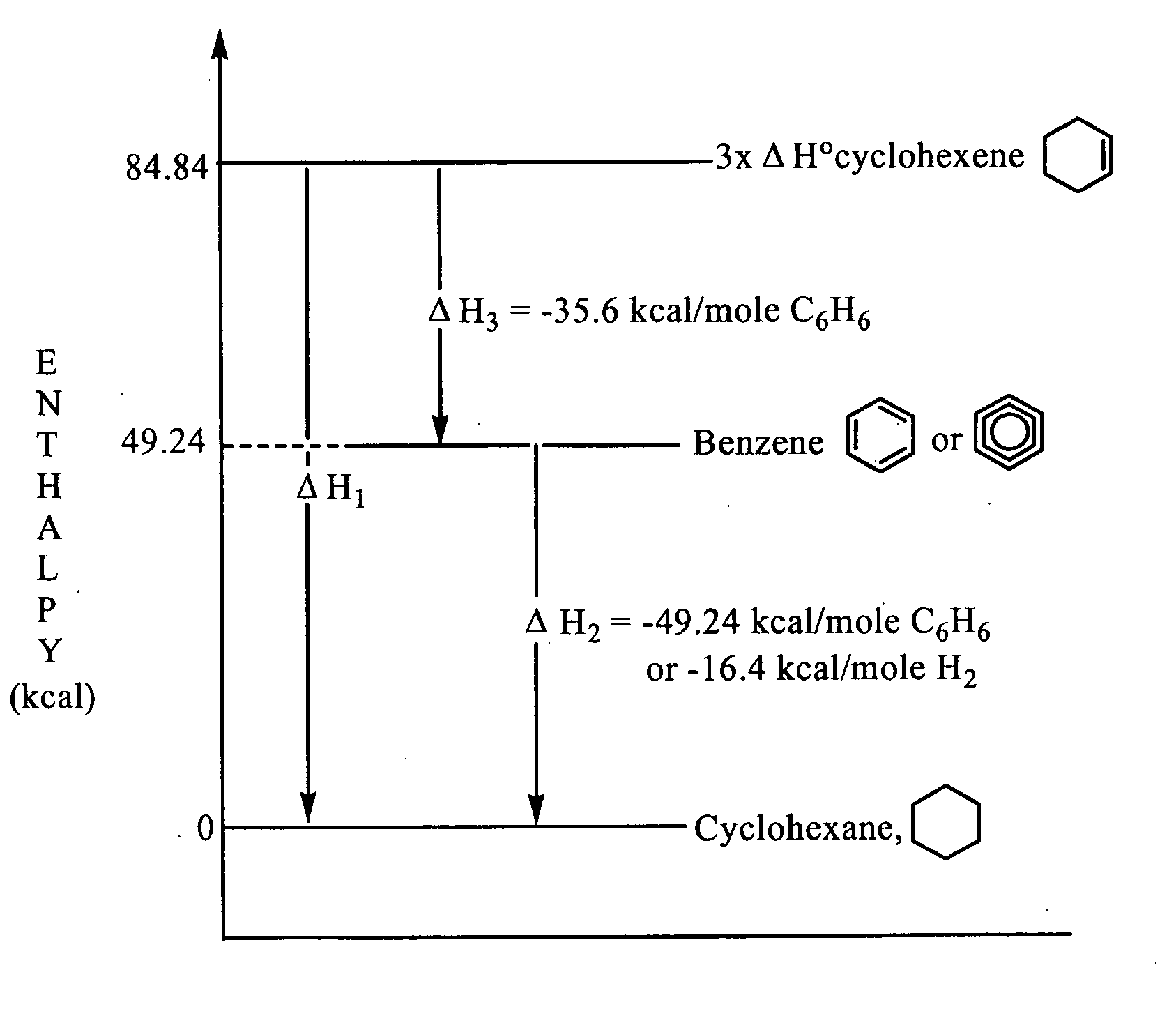

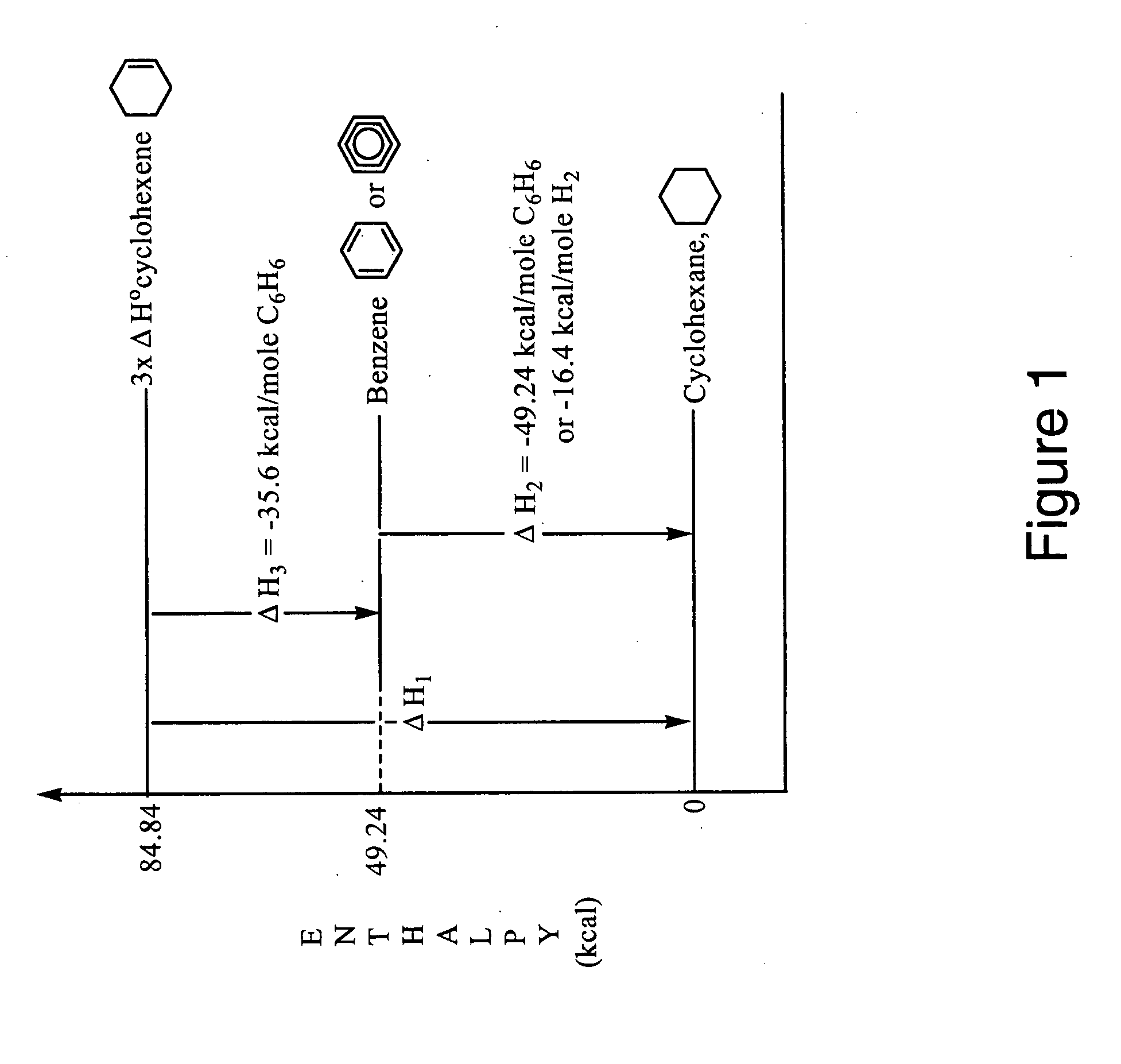

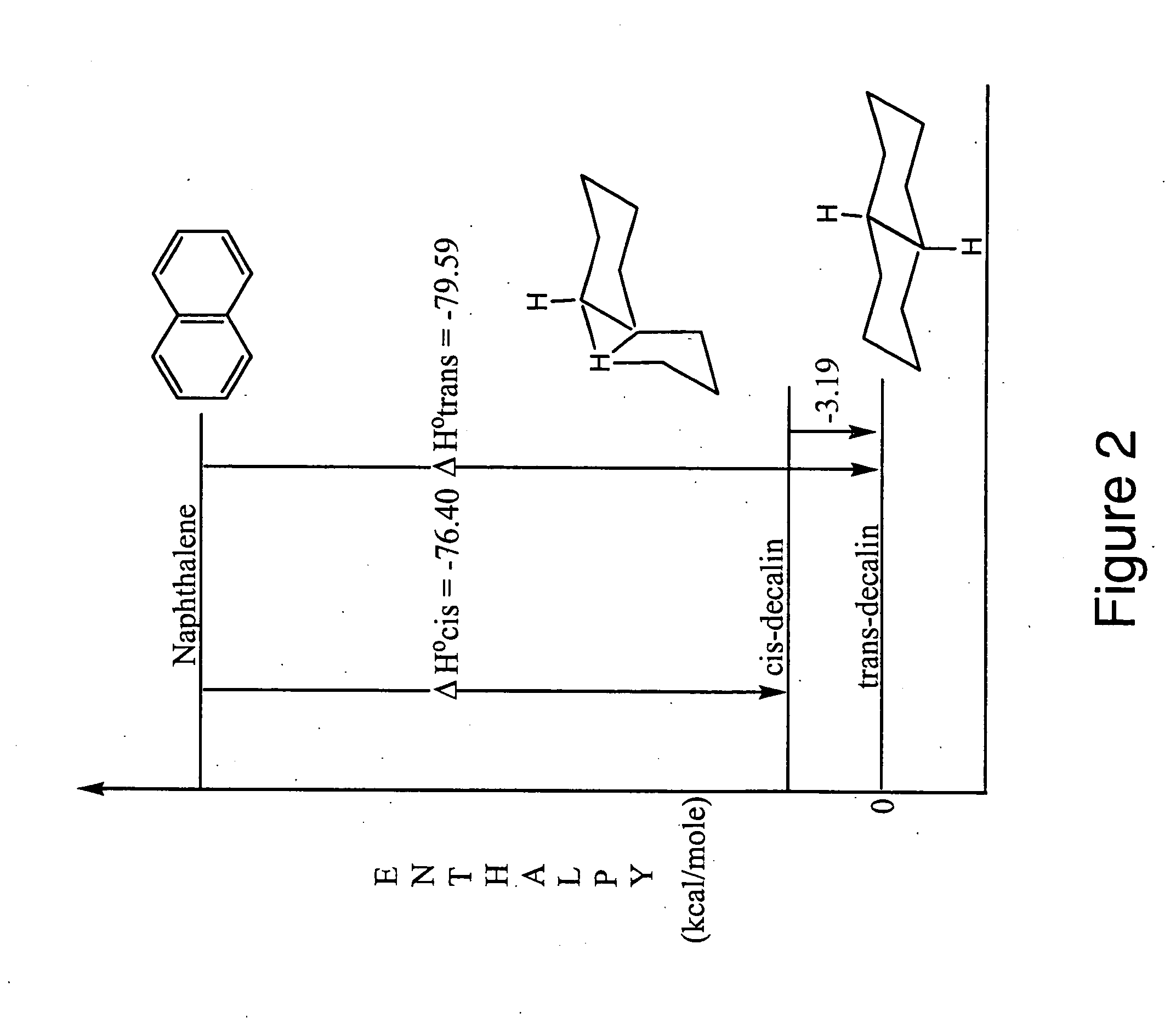

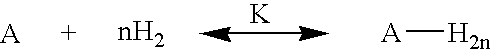

Catalytic hydrogenation is hydrogenation in presence of catalysts. Addition of hydrogen to alkenes is an exothermic (releasing heat energy) reaction, requiring the use of a transition metal catalyst due to the high energy barriers to direct the reaction between alkenes and hydrogen gas.

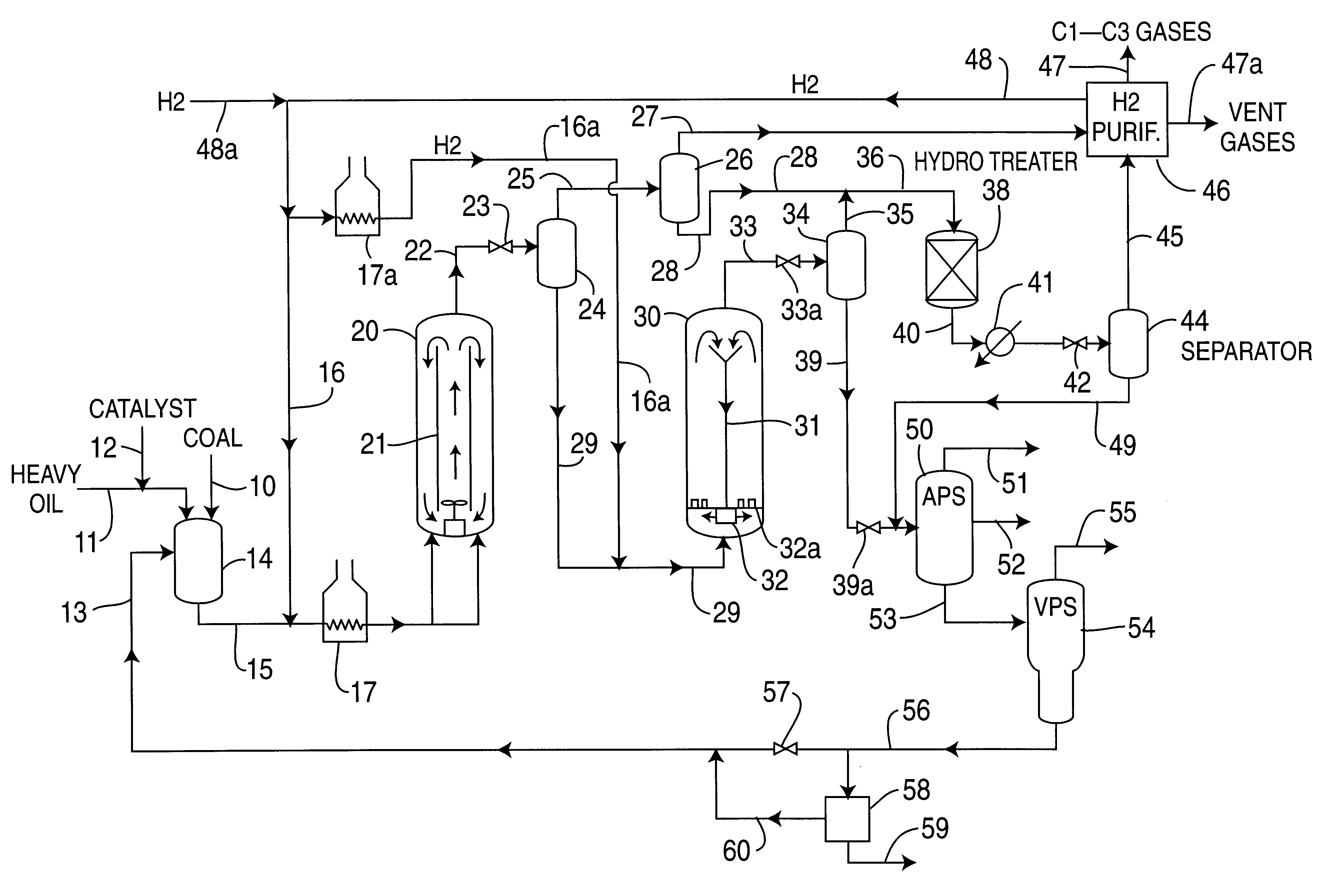

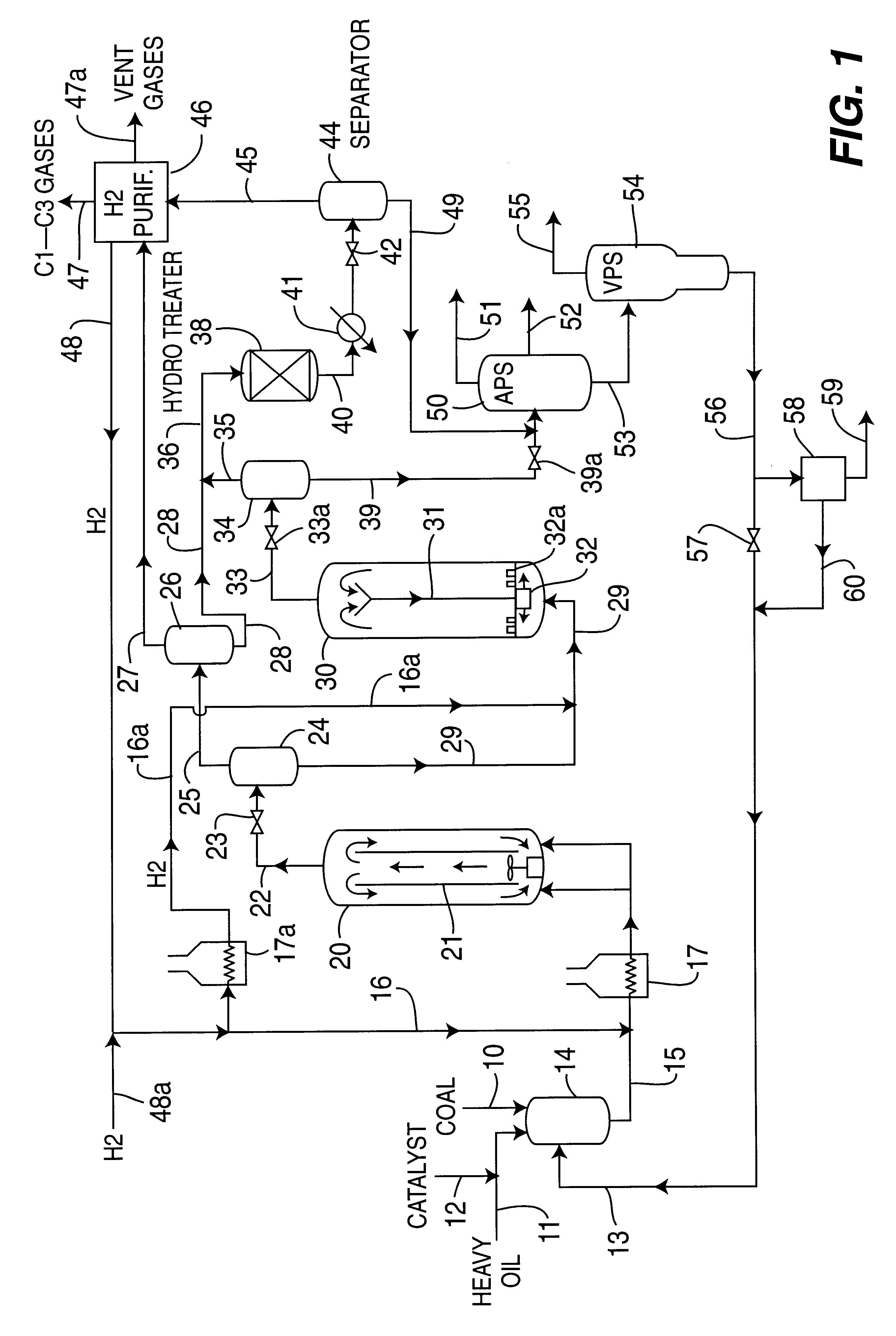

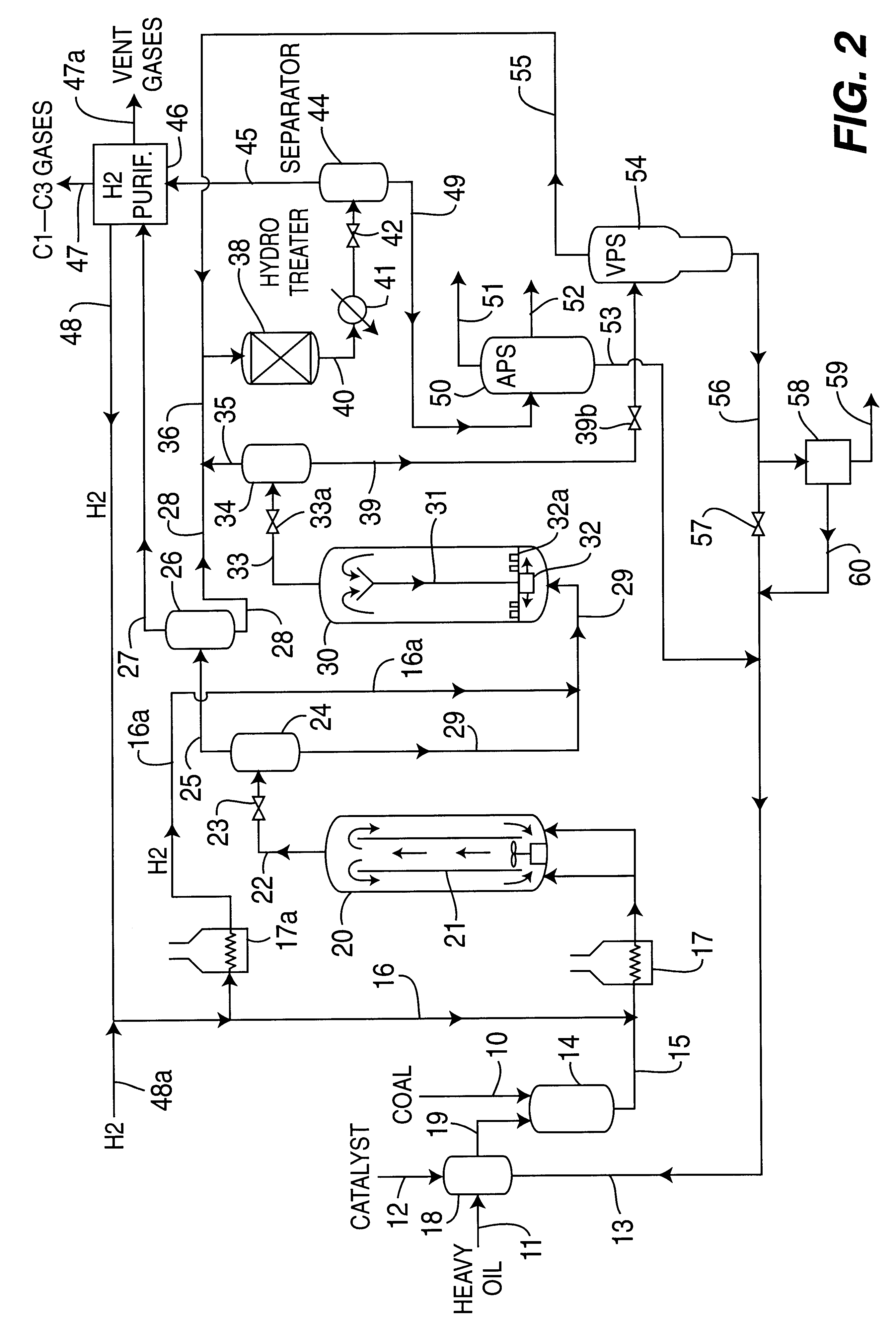

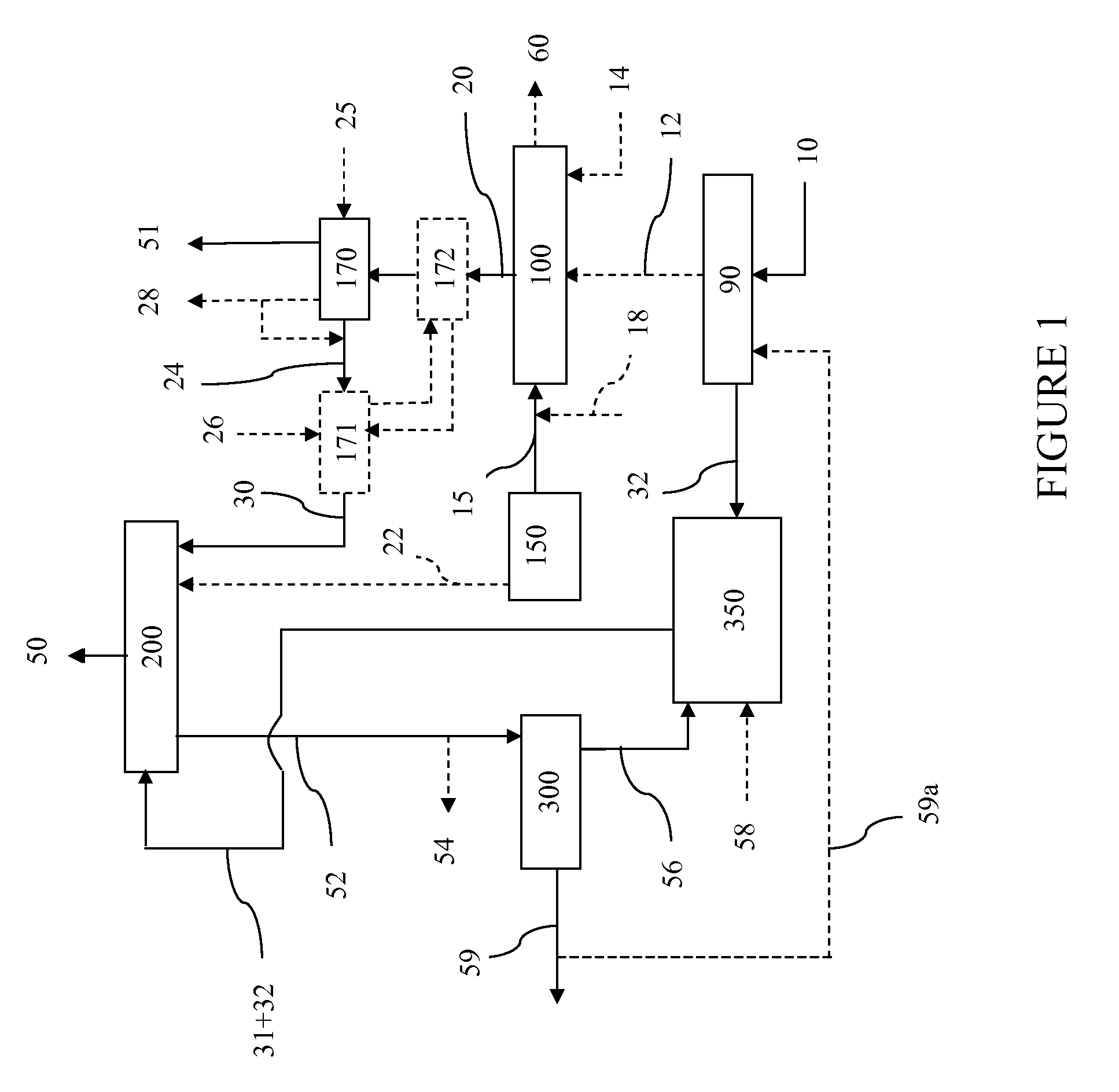

Catalytic multi-stage process for hydroconversion and refining hydrocarbon feeds

InactiveUS6190542B1Improve distillation yieldQuality improvementCatalyst activation/preparationLiquid hydrocarbon mixture productionLiquid productDistillates petroleum

A multi-stage catalytic hydrogenation and hydroconversion process for heavy hydrocarbon feed materials such as coal, heavy petroleum fractions, and plastic waste materials. In the process, the feedstock is reacted in a first-stage, back-mixed catalytic reactor with a highly dispersed iron-based catalyst having a powder, gel or liquid form. The reactor effluent is pressure-reduced, vapors and light distillate fractions are removed overhead, and the heavier liquid fraction is fed to a second stage back-mixed catalytic reactor. The first and second stage catalytic reactors are operated at 700-850.degree. F. temperature, 1000-3500 psig hydrogen partial pressure and 20-80 lb. / hr per ft.sup.3 reactor space velocity. The vapor and light distillates liquid fractions removed from both the first and second stage reactor effluent streams are combined and passed to an in-line, fixed-bed catalytic hydrotreater for heteroatom removal and for producing high quality naphtha and mid-distillate or a full-range distillate product. The remaining separator bottoms liquid fractions are distilled at successive atmospheric and vacuum pressures, low and intermediate-boiling hydrocarbon liquid products are withdrawn, and heavier distillate fractions are recycled and further upgraded to provide additional low-boiling hydrocarbon liquid products. This catalytic multistage hydrogenation process provides improved flexibility for hydroprocessing the various carbonaceous feedstocks and adjusting to desired product structures and for improved economy of operations.

Owner:HEADWATERS CTL

Method for producing alcohols by hydrogenation of carbonyl compounds

InactiveUS6486366B1Less amountHigh strengthSugar derivativesOrganic compound preparationCobaltPt element

A method for preparation of alcohols by catalytic hydrogenation of carbonyl compounds with hydrogen or hydrogen-containing gases in the presence of a hydrogenation catalyst of Raney type, where the catalyst is used in the form of hollow bodies, Preferred as catalytically active components are nickel, cobalt, copper, iron, platinum, palladium or ruthenium.

Owner:DEGUSSA AG

Method for the hydro-processing of a gas oil feedstock, and corresponding hydro-refining unit

InactiveCN101517038AShort stayReduce volumeLiquid hydrocarbon mixture productionEthylene productionFixed bedPetroleum

The invention relates to a method for the catalytic hydro-processing of a petroleum feedstock of the gas oil type and of a biological feedstock containing vegetal oils and / or animal fats, in a catalytic fixed-bed hydro-processing unit, said method being characterised in that the petroleum feedstock is introduced into the reactor upstream from the biological feedstock. The invention also relates to a catalytic hydro-processing unit for implementing said method, and to a corresponding hydro-refining unit.

Owner:TOTAL RAFFINAGE MARKETING

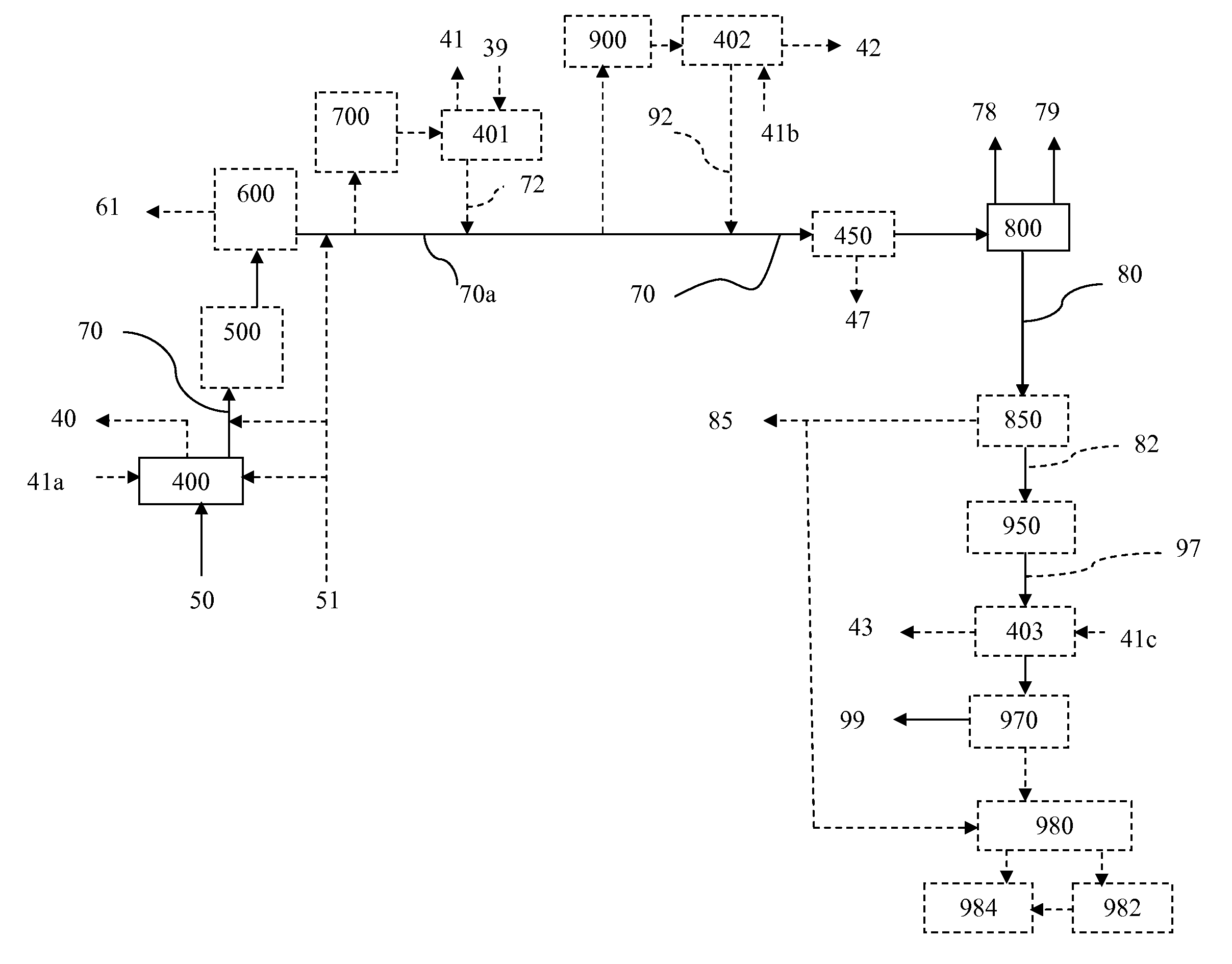

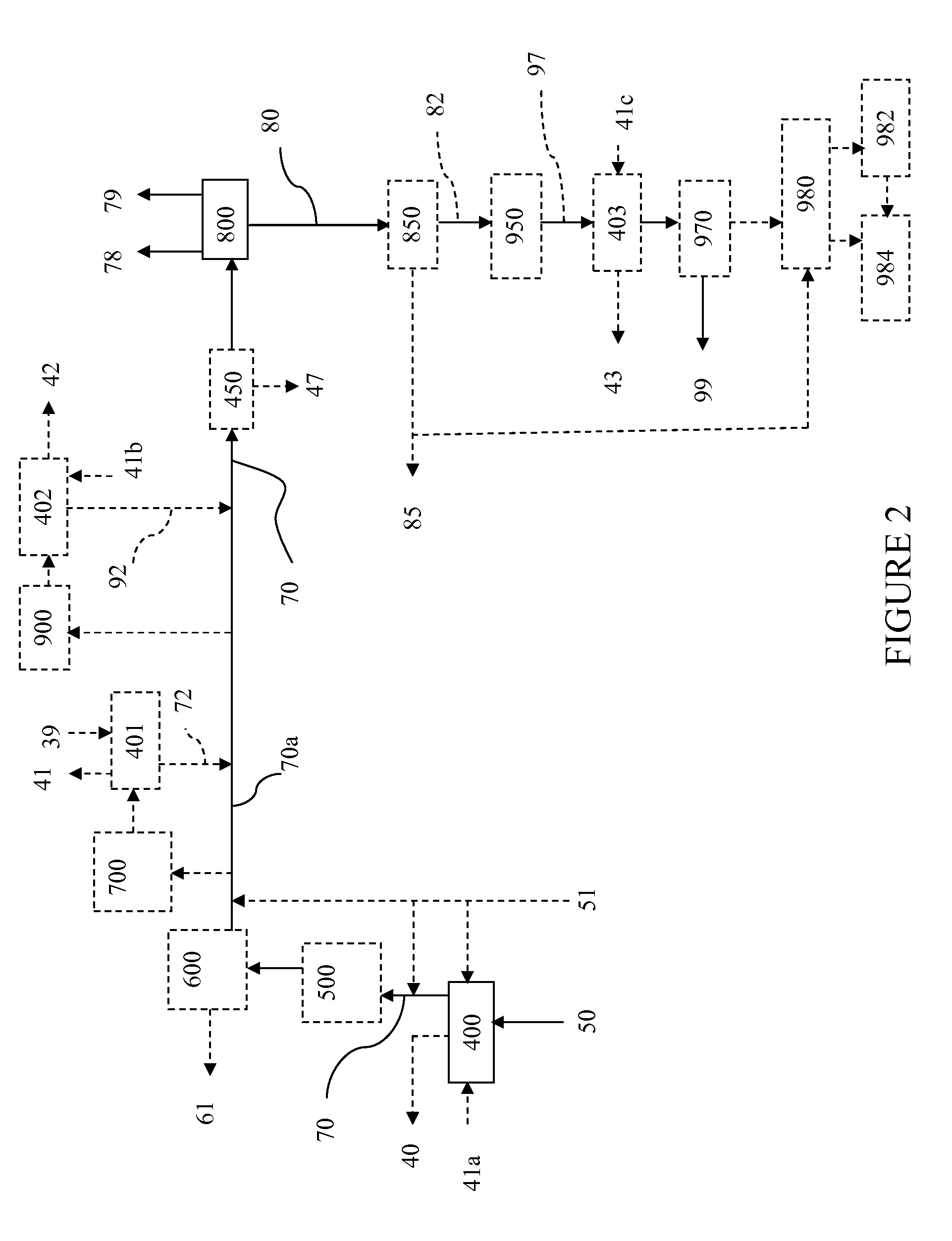

Processes for hydromethanation of a carbonaceous feedstock

InactiveUS20110062012A1Combustible gas chemical modificationCoke ovensMethanationCatalytic hydrogenation

The present invention relates to processes for preparing gaseous products, and in particular methane and / other value added gases such as hydrogen, via the catalytic hydromethanation of a carbonaceous feedstock in the presence of steam and syngas, wherein a hydromethanation reactor is combined with a syngas generator in a particular combination.

Owner:SURE CHAMPION INVESTMENT LTD

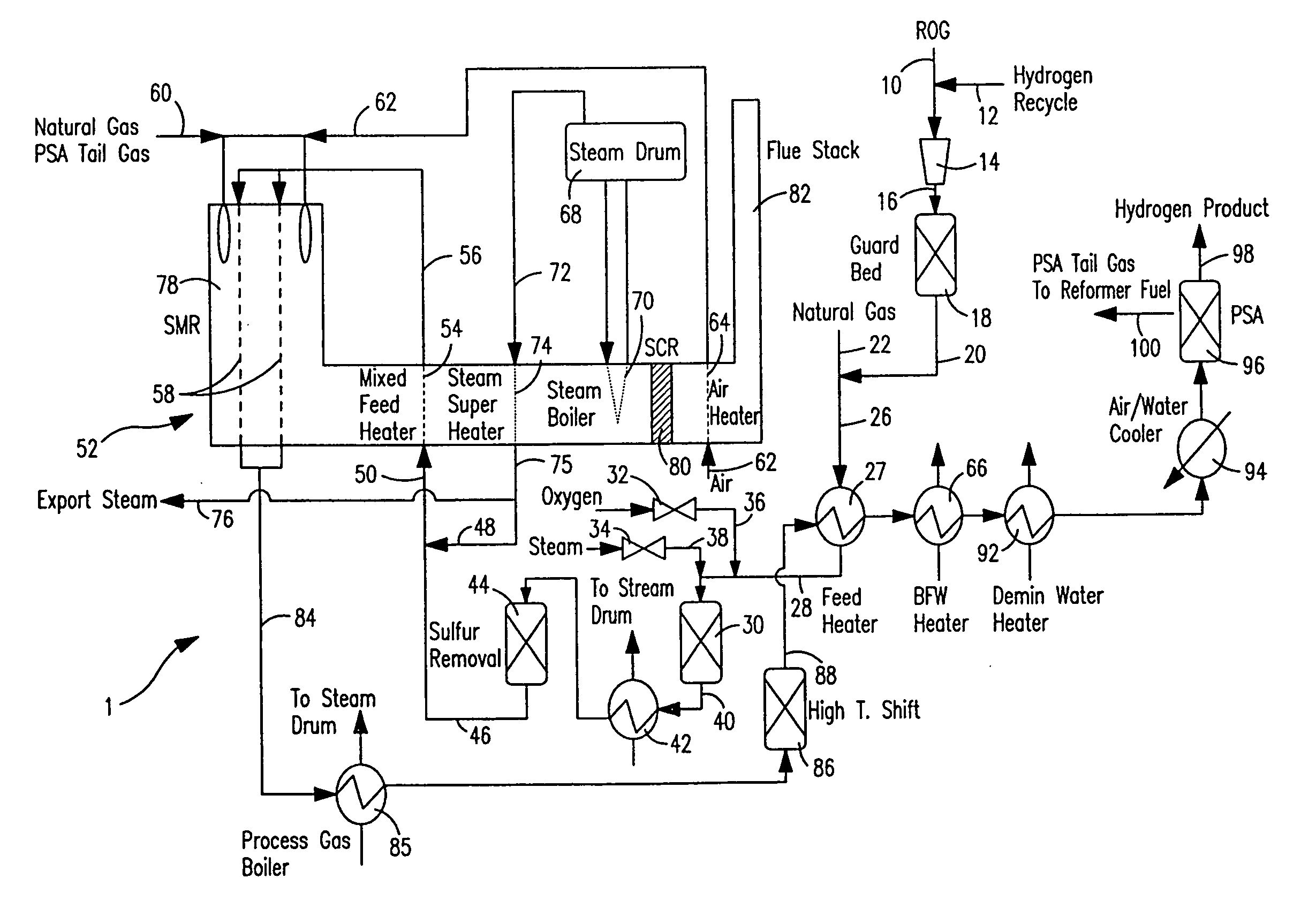

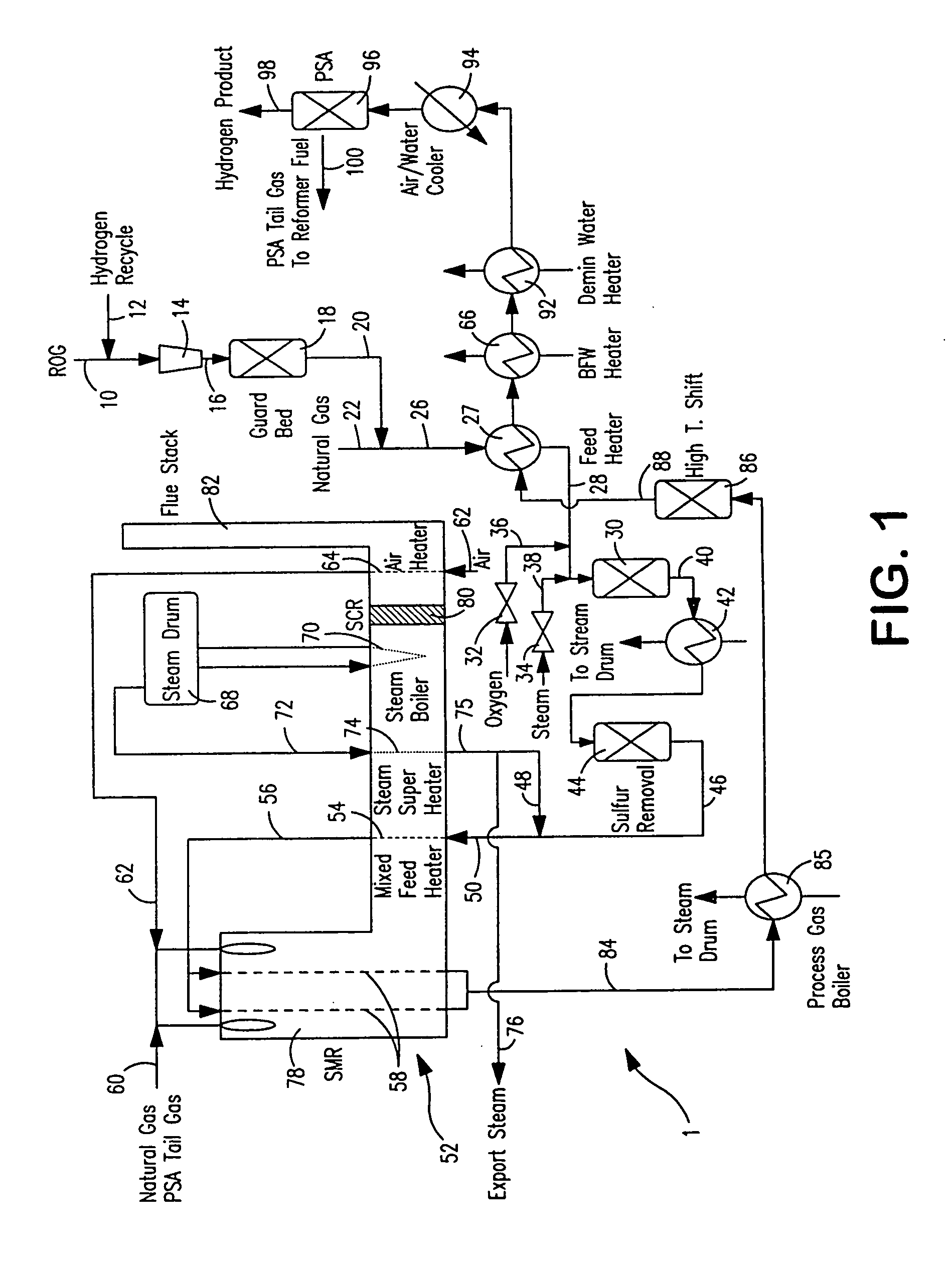

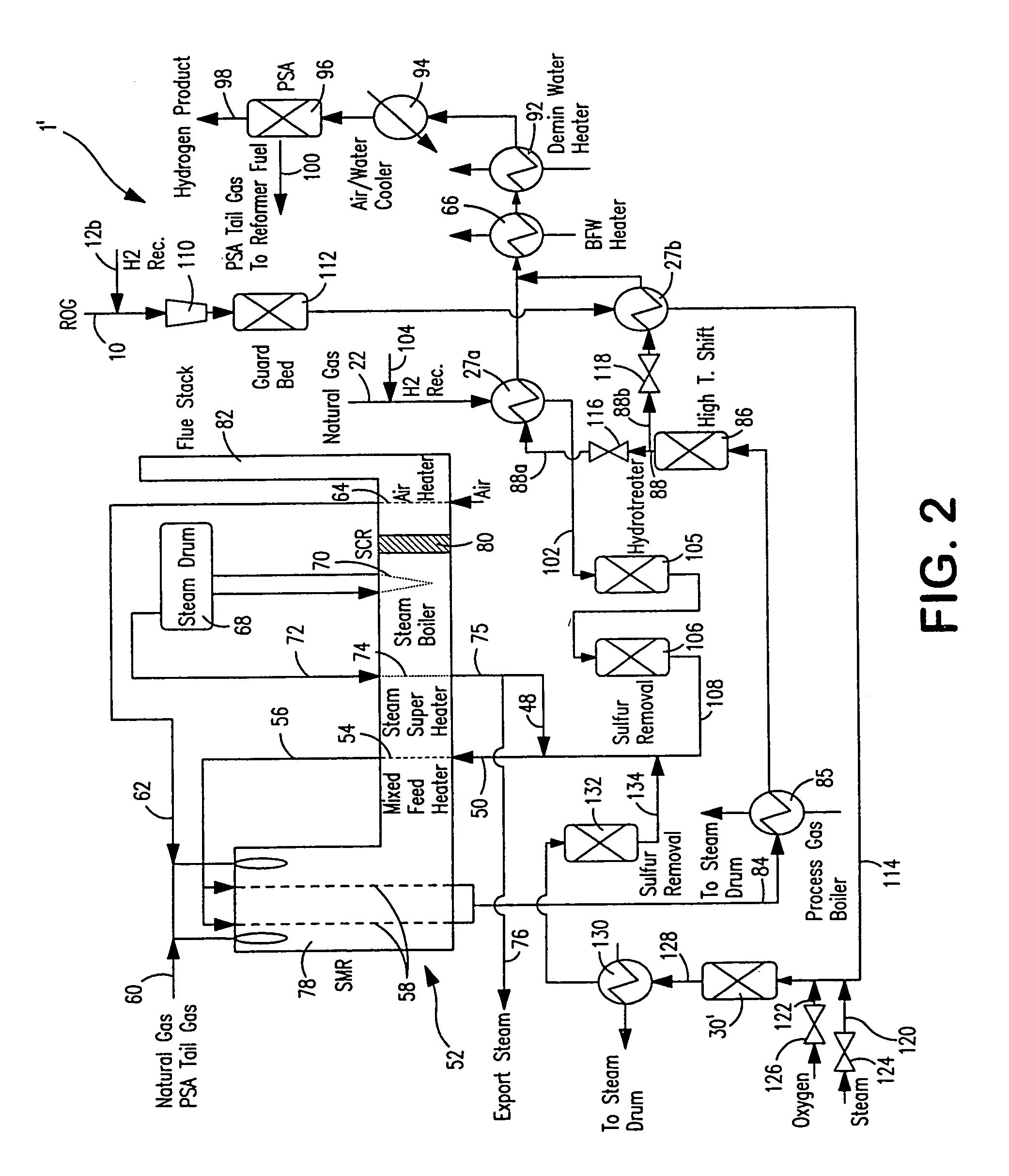

Steam methane reforming method

ActiveUS7037485B1Reduce fuel usageReduce firing rateHydrocarbon from carbon oxidesHydrogen separation using solid contactMethane reformerAlkane

A steam methane reforming method in which a feed stream is treated in a reactor containing a catalyst that is capable of promoting both hydrogenation and partial oxidation reactions. The reactor is either operated in a catalytic hydrogenation mode to convert olefins into saturated hydrocarbons and / or to chemically reduce sulfur species to hydrogen sulfide or a catalytic oxidative mode utilizing oxygen and steam to prereform the feed and thus, increase the hydrogen content of a synthesis gas produced by a steam methane reformer. The method is applicable to the treatment of feed streams containing at least 15% by volume of hydrocarbons with two or more carbon atoms and / or 3% by volume of olefins, such as a refinery off-gas. In such case, the catalytic oxidative mode is conducted with a steam to carbon ratio of less than 0.5, an oxygen to carbon ratio of less than 0.25 and a reaction temperature of between about 500° C. and about 860° C. to limit the feed to the steam methane reformer to volumetric dry concentrations of less than about 0.5% for the olefins and less than about 10% for alkanes with two or more carbon atoms.

Owner:PRAXAIR TECH INC

Processes For Hydromethanation Of A Carbonaceous Feedstock

ActiveUS20100292350A1Increase oxygenIncrease the amount of carbonOrganic compound preparationCombustible gas catalytic treatmentPhysical chemistryProcess engineering

The present invention relates to processes for preparing gaseous products, and in particular methane, via the catalytic hydromethanation of a carbonaceous feedstock in the presence of steam, syngas and an oxygen-rich gas stream.

Owner:SURE CHAMPION INVESTMENT LTD

Hydroprocessing using bulk bimetallic catalysts

ActiveUS20070090024A1Catalyst activation/preparationTreatment with hydrotreatment processesPtru catalystPhysical chemistry

The invention relates to a process for upgrading hydrocarbonaceous feedstreams by hydroprocessing using bulk bimetallic catalysts. More particularly, the invention relates to a catalytic hydrotreating process for the removal of sulfur and nitrogen from a hydrocarbon feed such as a fuel or a lubricating oil feed. The catalyst is a bulk catalyst containing a Group VIII metal and a Group VIB metal.

Owner:EXXON RES & ENG CO

Process for catalytic hydrotreatment of a pyrolysis oil

ActiveUS20110119994A1Reduces coke formationLiquid carbonaceous fuelsLiquid hydrocarbon mixture productionCellulosePyrolysis oil

Owner:SHELL USA INC

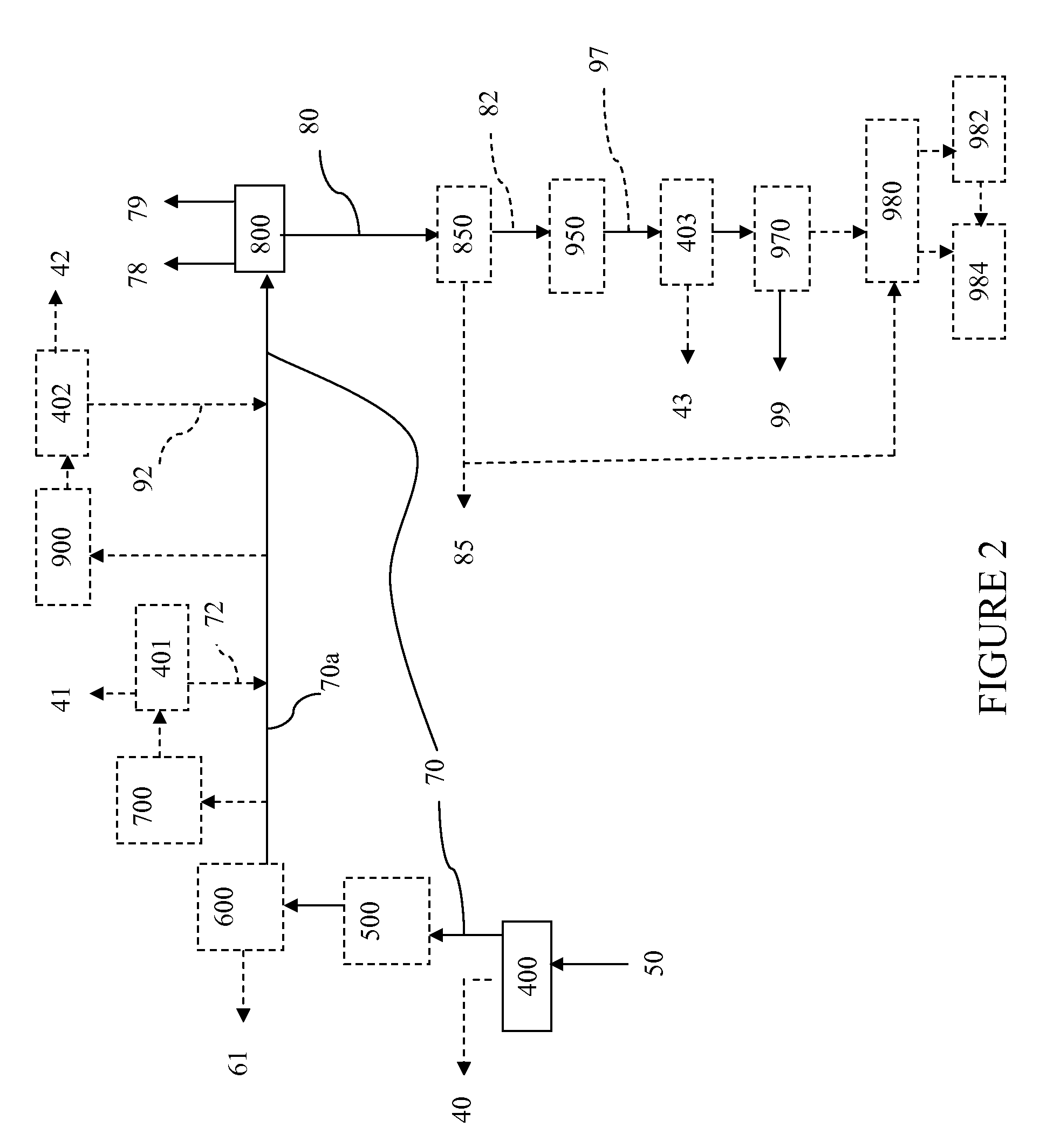

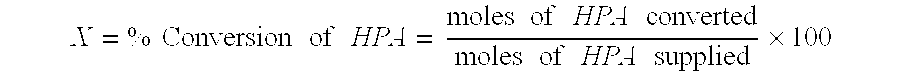

Catalytic hydrogenation of 3-hydroxypropanal to 1,3-propanediol

InactiveUS6342646B1Improves performance and lifetimeImprove hydrogenation activityOrganic compound preparationOxygen compounds preparation by reductionAsymmetric hydrogenation1,3-Propanediol

The present invention provides an improved process for the hydrogenation of 3-hydroxypropanal to 1,3-propanediol which comprises purifying an aqueous solution of 3-hydroxypropanal by contacting said aqueous solution with a purifying agent prior to hydrogenation.

Owner:EI DU PONT DE NEMOURS & CO

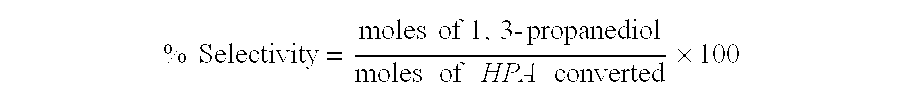

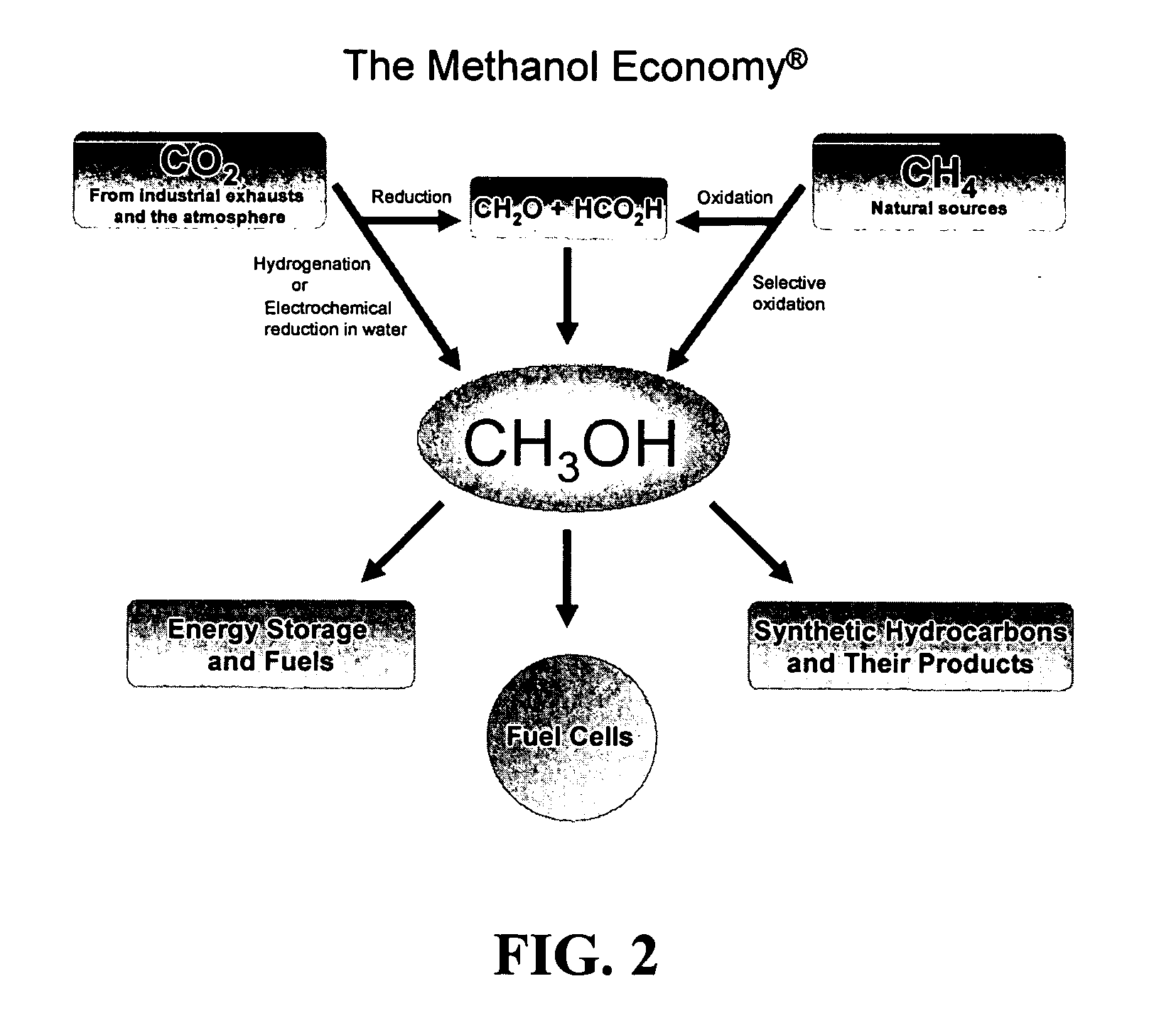

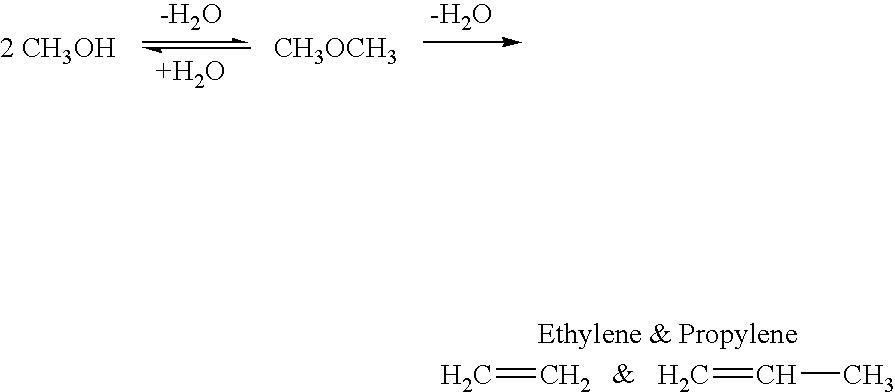

Selective oxidative conversion of methane to methanol, dimethyl ether and derived products

ActiveUS20060235088A1Minimize or eliminate the disadvantages or dangers inherentPreparation by oxidation reactionsElectrolysis componentsFormate EstersDimethyl ether

The present invention relates to a method of producing methanol from a methane source by oxidizing methane under conditions sufficient to a mixture of methanol and formaldehyde while minimizing the formation of formic acid and carbon dioxide. The oxidation step is followed by treatment step in which formaldehyde is converted into methanol and formic acid which itself can further be converted into methanol via catalytic hydrogenation of intermediately formed methyl formate.

Owner:UNIV OF SOUTHERN CALIFORNIA

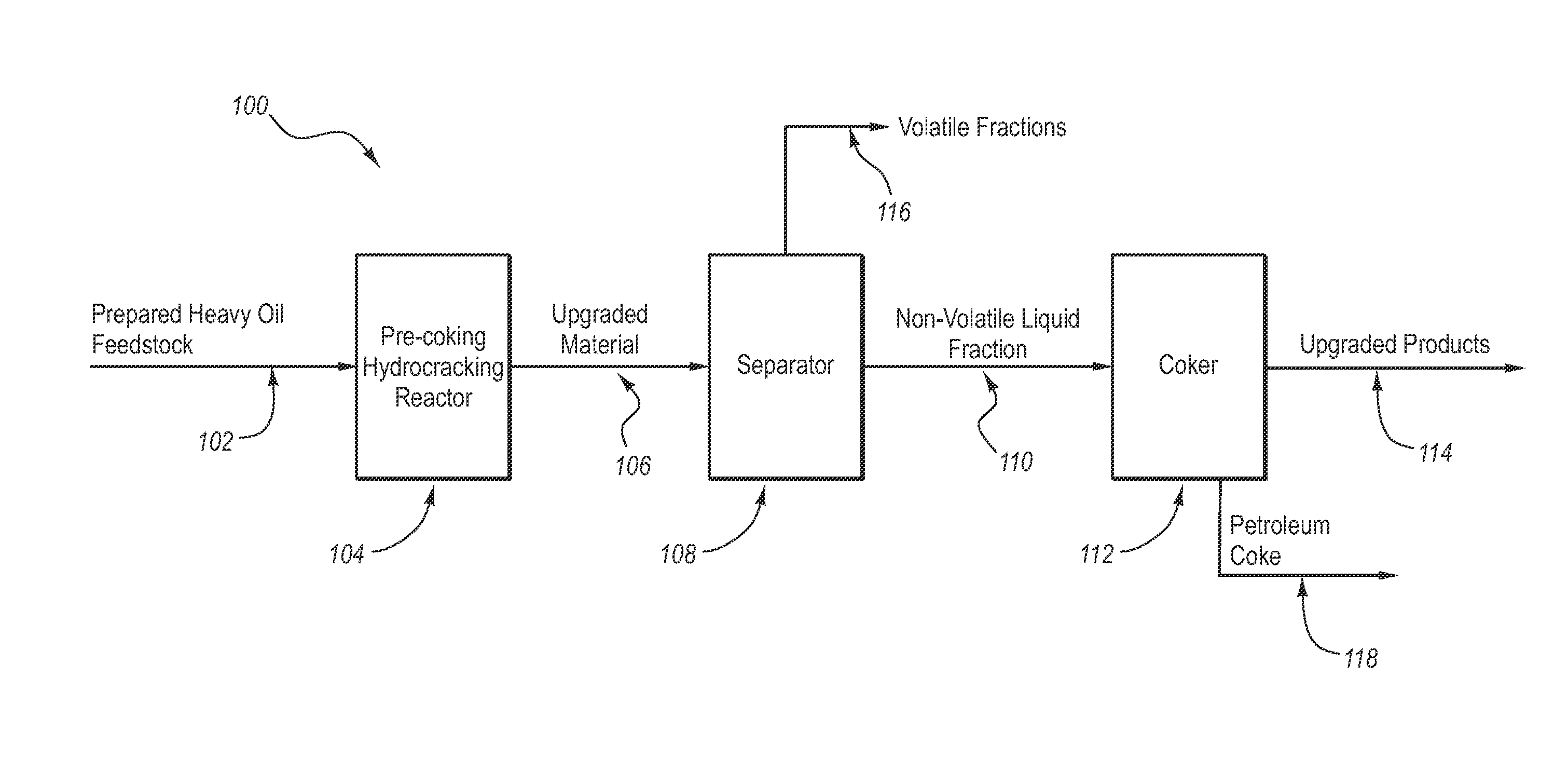

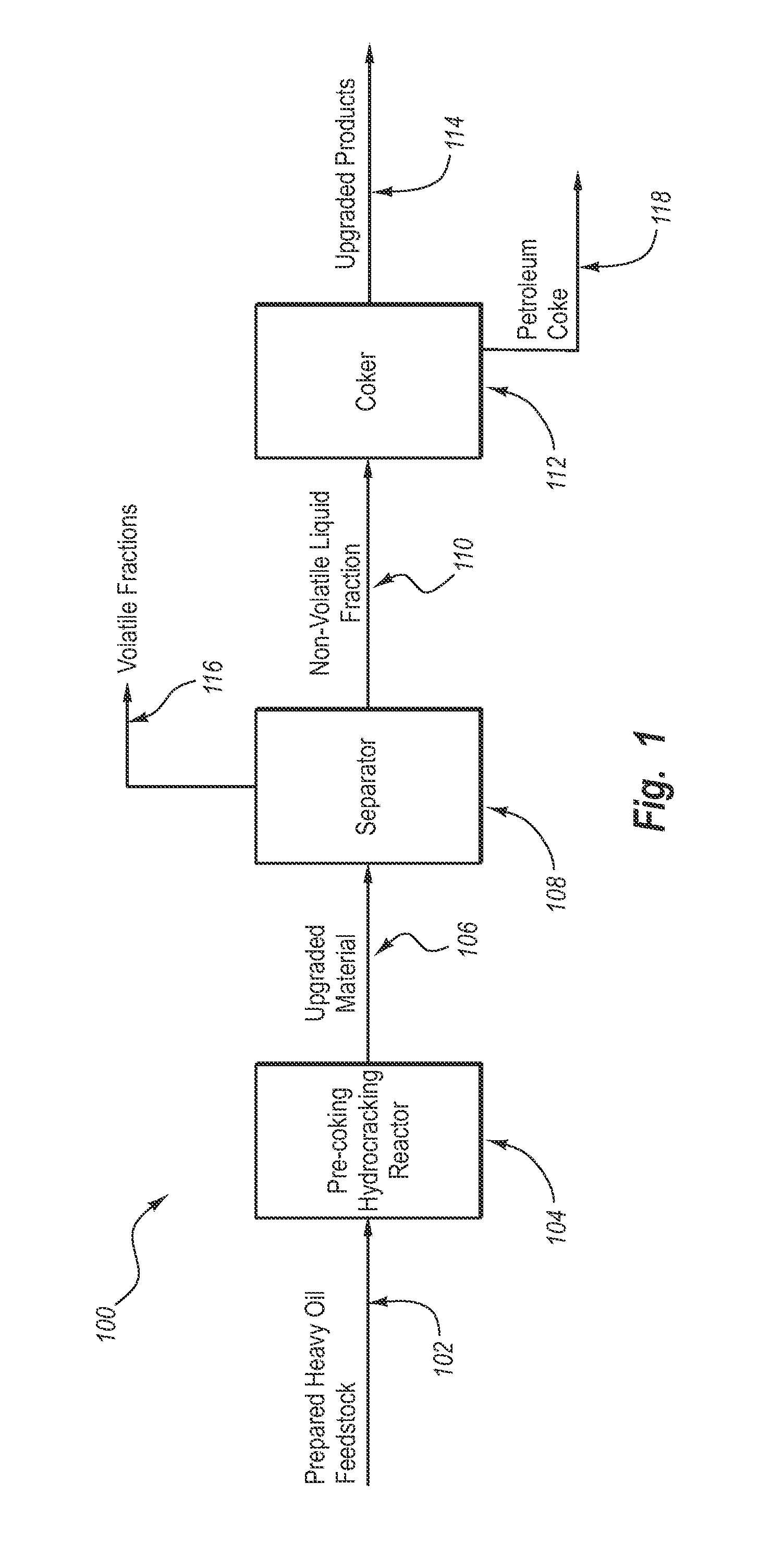

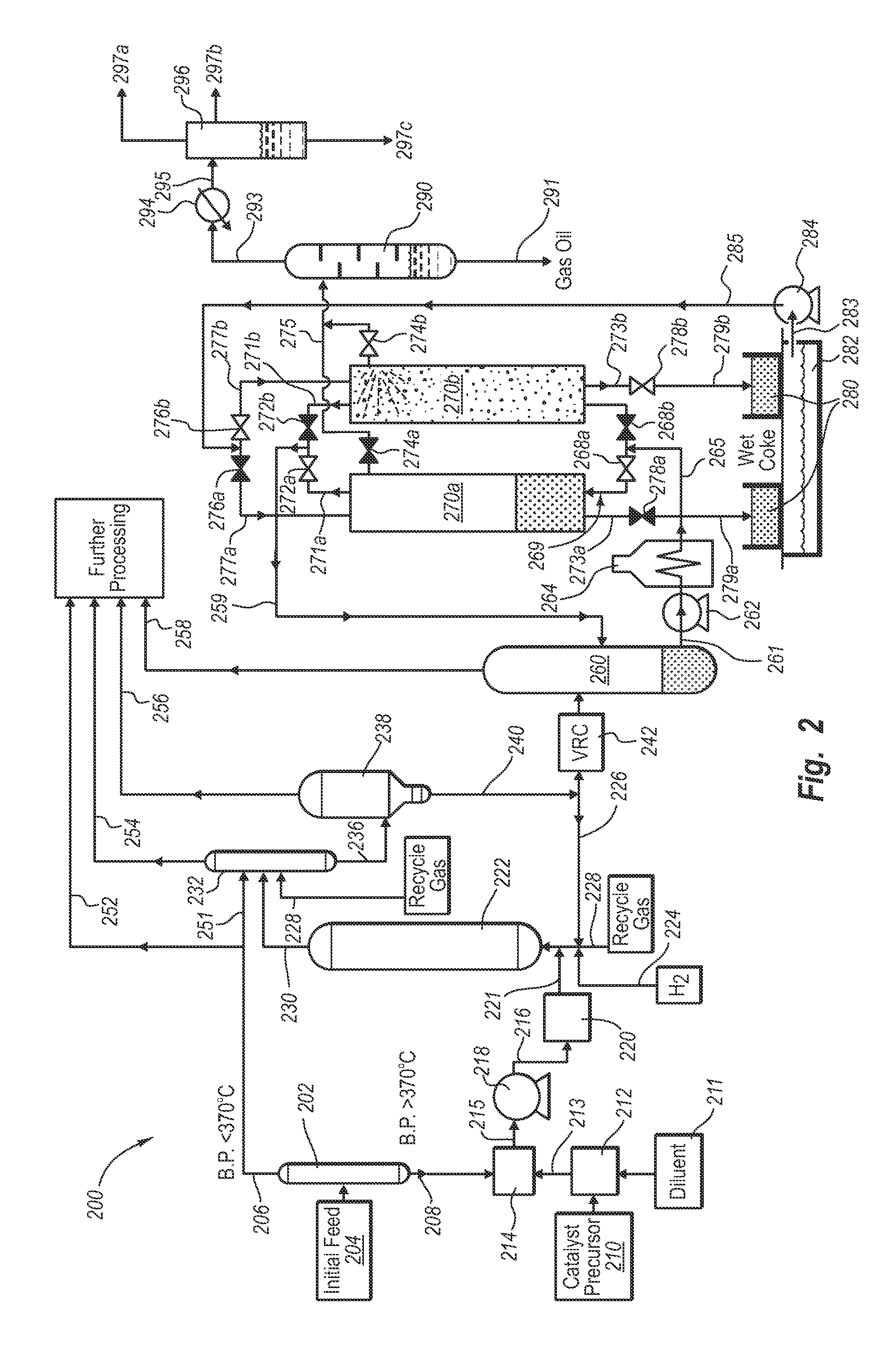

Methods and systems for upgrading heavy oil using catalytic hydrocracking and thermal coking

ActiveUS20140027344A1Speed up the conversion processImprove distillation yieldThermal non-catalytic crackingCatalyst activation/preparationHydrogenBoiling point

Methods and systems for hydroprocessing heavy oil feedstocks to form upgraded material use a colloidal or molecular catalyst dispersed within heavy oil feedstock, pre-coking hydrocracking reactor, separator, and coking reactor. The colloidal or molecular catalyst promotes upgrading reactions that reduce the quantity of asphaltenes or other coke forming precursors in the feedstock, increase hydrogen to carbon ratio in the upgraded material, and decrease boiling points of hydrocarbons in the upgraded material. The methods and systems can be used to upgrade vacuum tower bottoms and other low grade heavy oil feedstocks. The result is one or more of increased conversion level and yield, improved quality of upgraded hydrocarbons, reduced coke formation, reduced equipment fouling, processing of a wider range of lower quality feedstocks, and more efficient use of supported catalyst if used with the colloidal or molecular catalyst, as compared to a conventional hydrocracking process or a conventional thermal coking process.

Owner:HEADWATERS TECH INNOVATION LLC

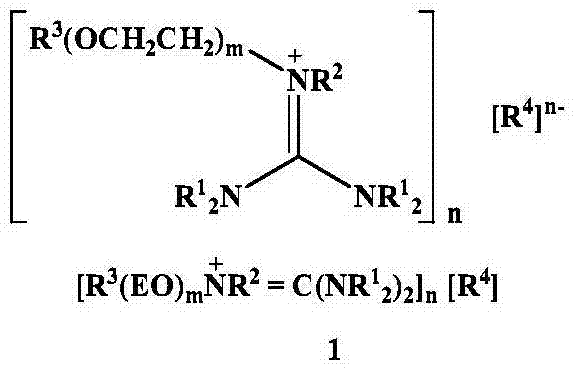

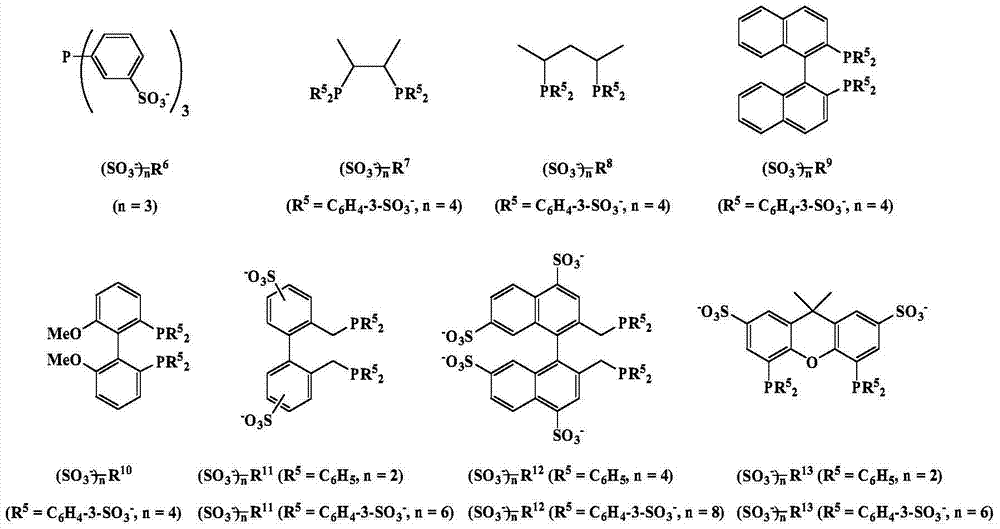

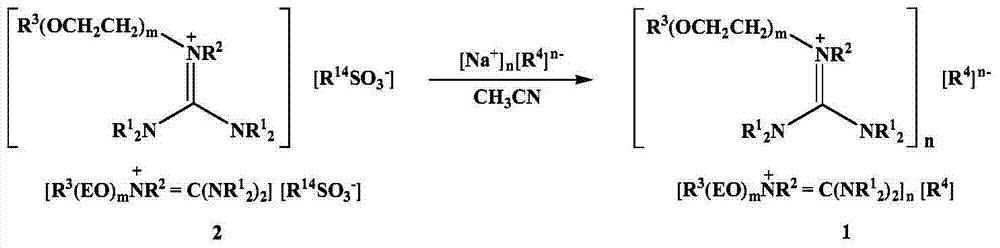

Preparation method of first-class phosphorus functionalized ionic liquid and application of ionic liquid in hydroformylation

ActiveCN103483381AEasy to synthesizeThe synthetic method is matureOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsIon exchangeOrganic reaction

The invention relates to synthesis of first-class phosphorus functionalized polyether alkyl guanidinium ionic liquid, and an application of the first-class phosphorus functionalized polyether alkyl guanidinium ionic liquid in a homogeneous catalytic reaction. The functionalized ionic liquid of such class can be easily prepared by an ion exchange reaction between the polyether alkyl guanidinium ionic liquid and sulfonic acid type water soluble phosphine ligand. The designed phosphorus functionalized ionic liquid can be applied to organic reactions, including hydroformylation, hydroesterification, hydrocarboxylation and catalytic hydrogenation under the catalyzing of a transition metal; the dosage of the ionic liquid used in the catalytic reaction can be decreased; the activity of the catalytic reaction can be improved; a catalyst can be separated and cycled simply and conveniently.

Owner:QINGDAO UNIV OF SCI & TECH

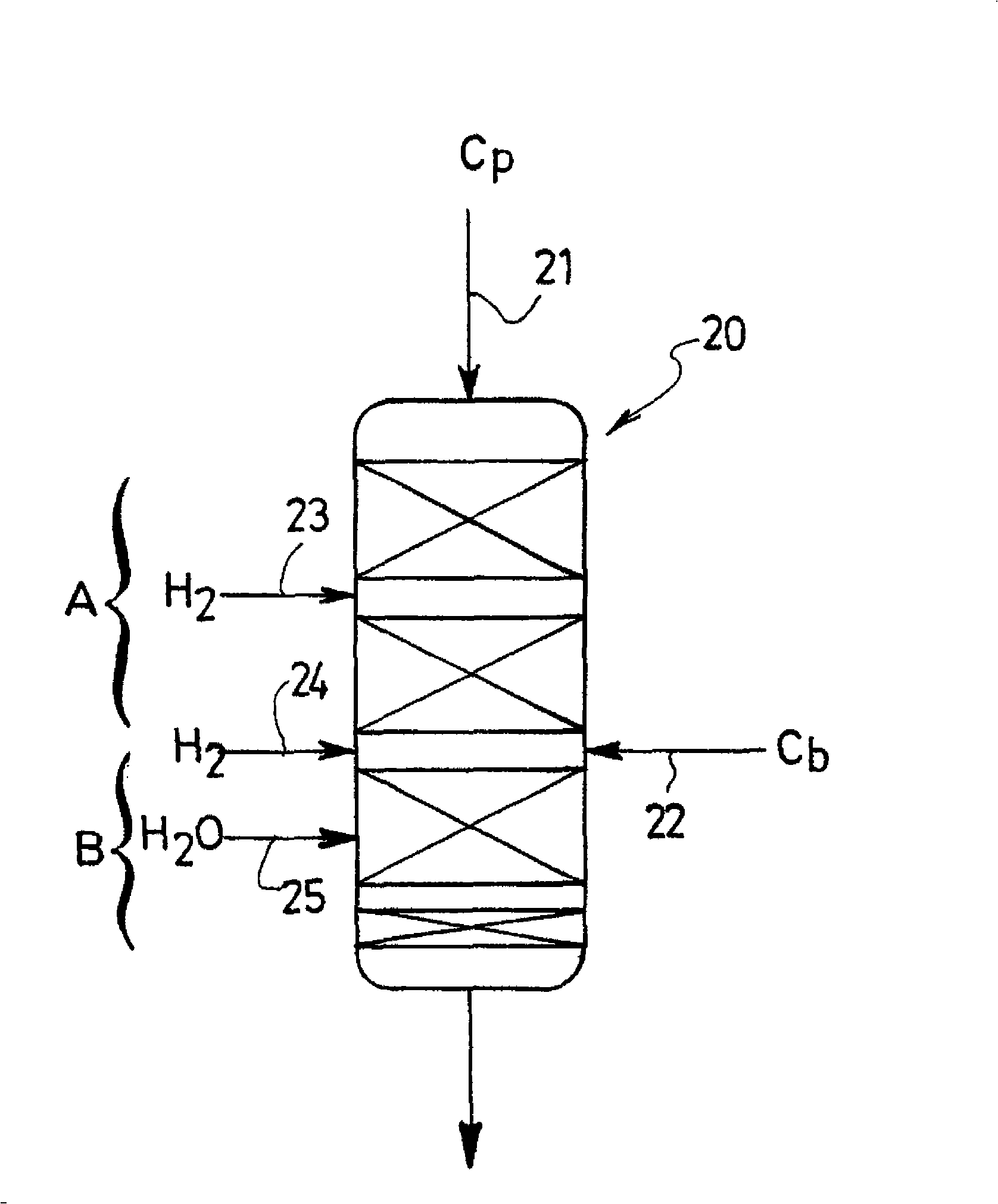

Catalytic selective hydrogenation

ActiveCN1895766AHigh selectivityControl selection of hydrogenation depthChemical/physical/physico-chemical stationary reactorsHydrocarbon oils refiningChemistryCatalytic hydrogenation

A selective catalytic hydrogenation process able the control the hydroselectivity includes such steps as fixing the selective hydrocatalyst to the rotator of a super-gravitational rotary-bed reactor, rotating to form a rotating catalyst bed, and making the hydrocarbon material and H2 pass through the rotating catalyst bed in parallel mode or opposite mode. Controlling the rotation speed and radial thickness of rotator can control the hydroselectivity.

Owner:CHINA PETROLEUM & CHEM CORP

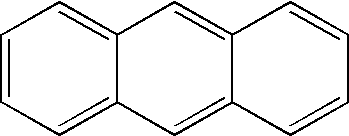

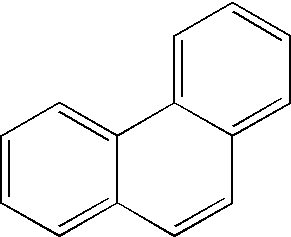

Hydrogen storage by reversible hydrogenation of pi-conjugated substrates

ActiveUS20050002857A1Less energy expenditureEasy to separateCatalytic naphtha reformingVariable capacity gas holdersPartial hydrogenationDehydrogenation

Processes are provided for the storage and release of hydrogen by means of a substantially reversible catalytic hydrogenation of extended pi-conjugated substrates which include large polycyclic aromatic hydrocarbons, polycyclic aromatic hydrocarbons with nitrogen heteroatoms, polycyclic aromatic hydrocarbons with oxygen heteroatoms, polycyclic aromatic hydrocarbons with alkyl, alkoxy, nitrile, ketone, ether or polyether substituents, pi-conjugated molecules comprising 5 membered rings, pi-conjugated molecules comprising six and five membered rings with nitrogen or oxygen hetero atoms, and extended pi-conjugated organic polymers. The hydrogen, contained in the at least partially hydrogenated form of the extended pi-conjugated system, can be facilely released for use by a catalytic dehydrogenation of the latter in the presence of a dehydrogenation catalyst which can be effected by lowering the hydrogen gas pressure, generally to pressures greater than 0.1 bar or raising the temperature to less than 250° C. or less, or by a combination of these two process parameters.

Owner:AIR PROD & CHEM INC

Process for catalytic hydrotreating of sour crude oils

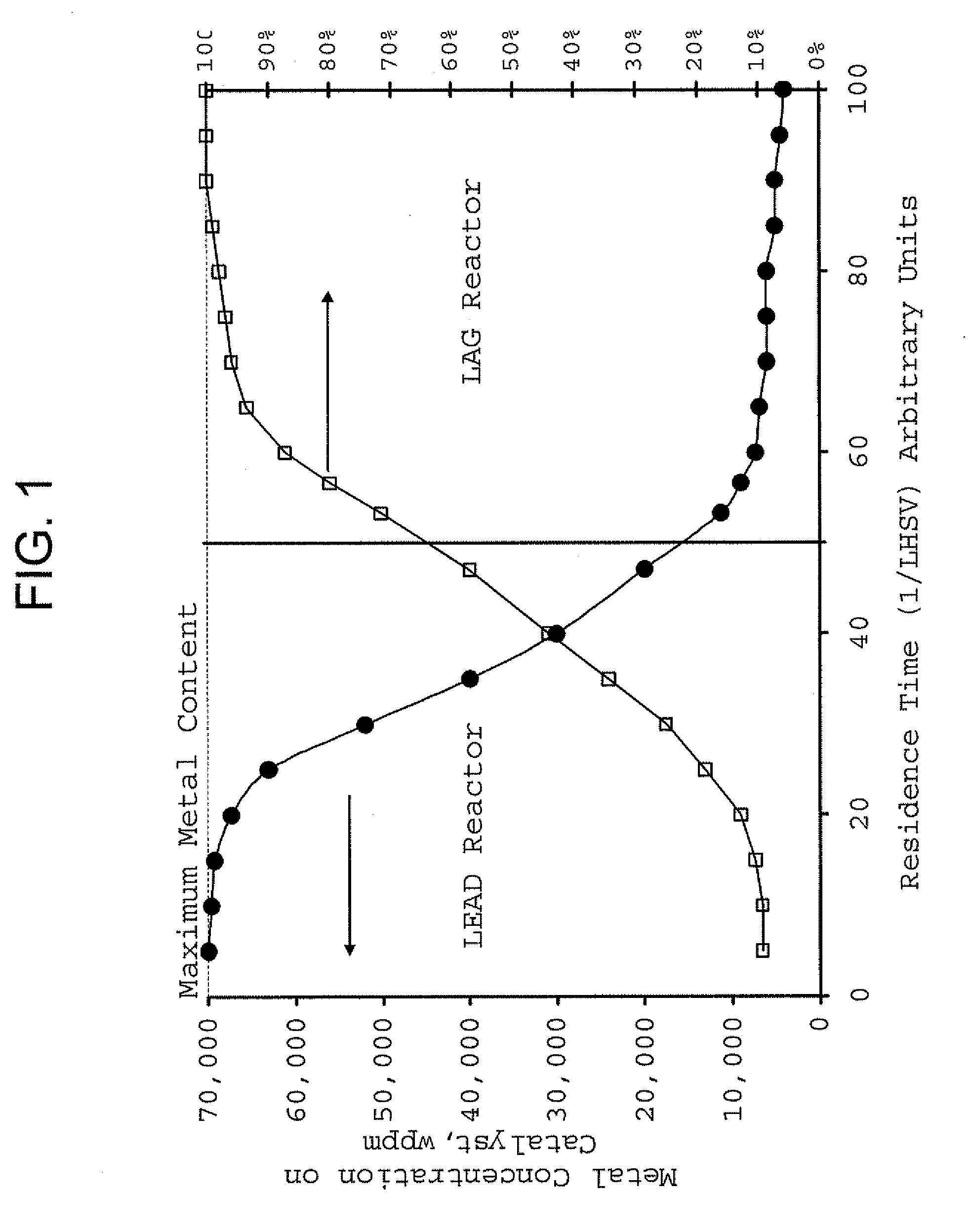

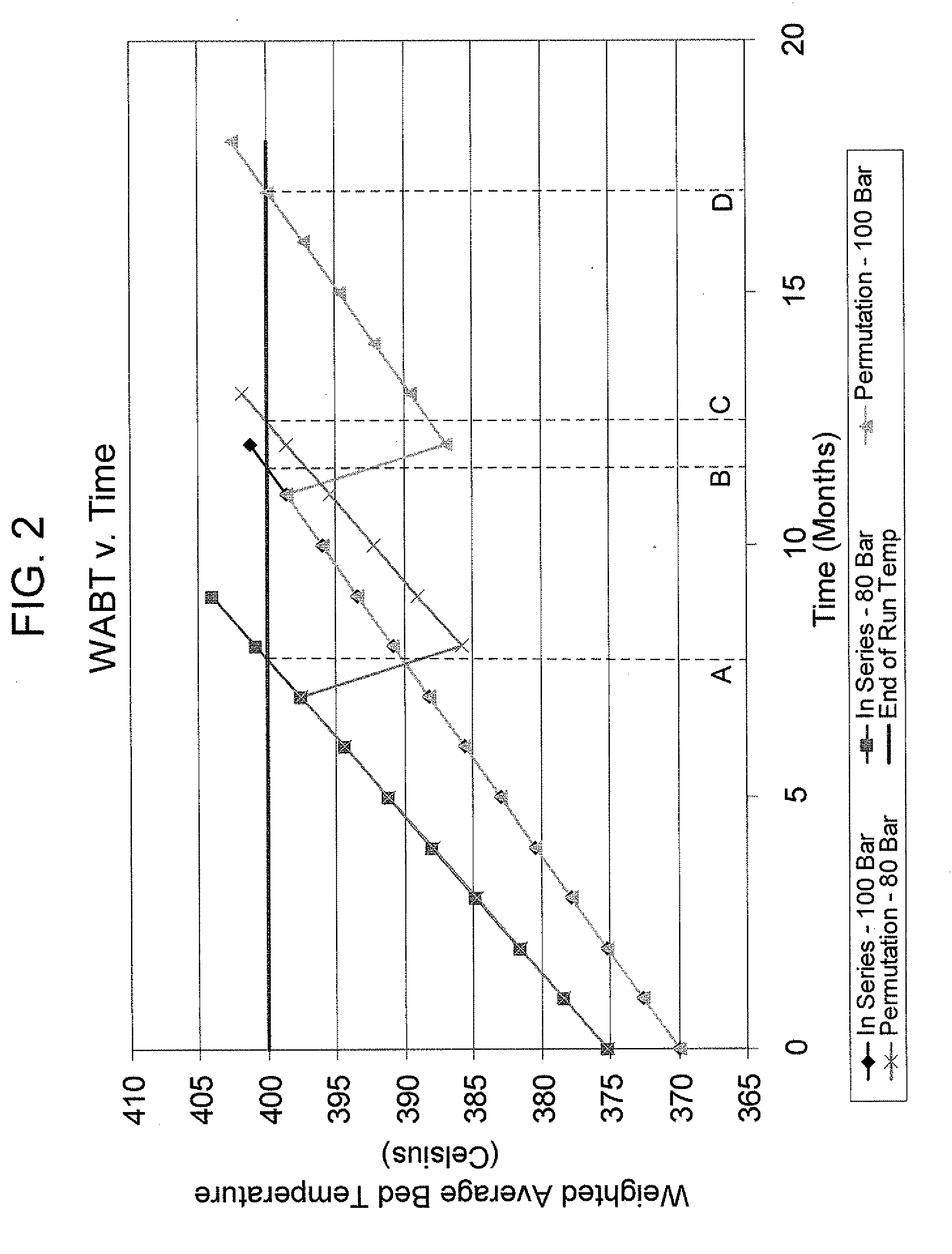

ActiveUS20090139902A1Improve catalyst utilizationImproves HDS activityTreatment with hydrotreatment processesFilter regenerationHydrodesulfurizationSulfur

A continuous process for upgrading sour crude oil by treating the sour crude oil in a two step process that includes a hydro-demetallization section and a hydro-desulfurization section, both of which are constructed in a permutable fashion so as to optimize the operating conditions and catalyst lifespan to produce a high value crude oil having low sulfur and low organometallic impurities.

Owner:SAUDI ARABIAN OIL CO

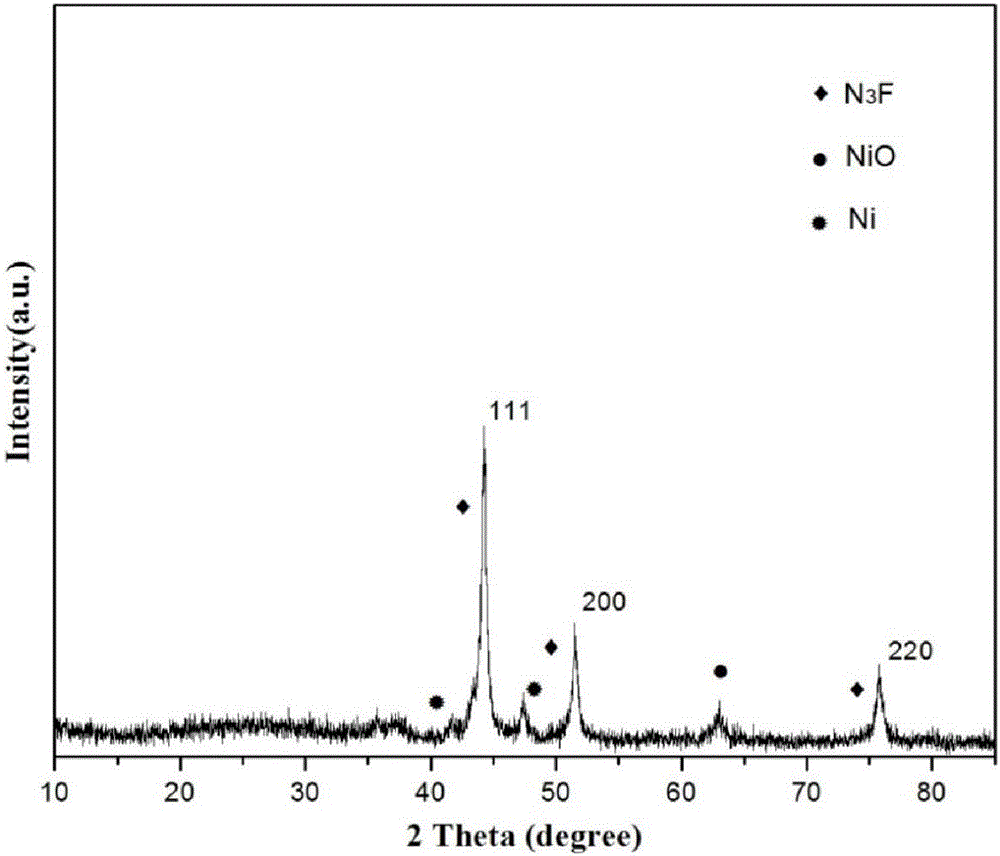

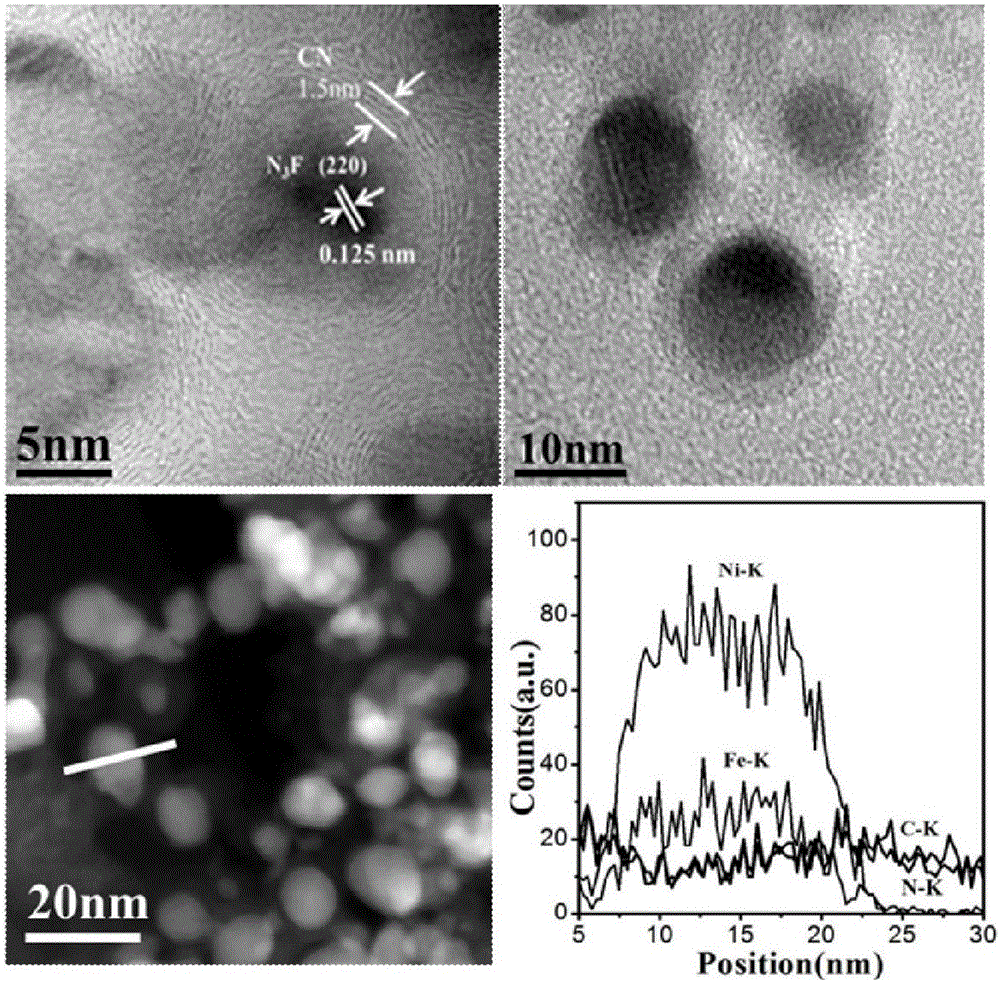

Preparation of nitrogen doped carbon-encapsulated core-shell structure ferro-nickel nano-catalyst and application thereof in catalyzing o-chloronitrobenzene hydrogenation reaction

ActiveCN106732733AMaterial nanotechnologyPhysical/chemical process catalystsNano catalystNitro compound

The invention provides a preparation method of a nitrogen doped carbon-encapsulated core-shell structure ferro-nickel nano-catalyst and the application of the nitrogen doped carbon-encapsulated core-shell structure ferro-nickel nano-catalyst in catalyzing an o-chloronitrobenzene hydrogenation reaction. According to the method, the novel nitrogen doped carbon-encapsulated core-shell structure ferro-nickel nano-catalyst is prepared by synthesizing a ferronickel layered doubled hydroxide precursor with small grain size and high surface energy through a nucleation crystallization isolation method, evenly mixing the ferronickel layered doubled hydroxide precursor with a melamine and dicyandiamide mixed carbon material precursor, and finally self-reducing at high temperature. The nitrogen doped carbon-encapsulated core-shell structure ferro-nickel nano-catalyst is efficiently applied to the reaction where halogenated aniline is generated through catalytic hydrogenation of a nitro-halogen compound, and the conversion rate of o-chloronitrobenzene and the selectivity of o-chloroaniline are respectively up to 95-100% and 98-100%. The structure of the novel nitrogen doped carbon-encapsulated core-shell structure ferro-nickel nano-catalyst is unique and novel, the process is green and energy-saving, the structure of the catalyst is stable, and the catalyst has a broad application prospect.

Owner:BEIJING UNIV OF CHEM TECH

Catalyzer for oxalic ester hydrogenation synthesizing of glycolate and method of preparing the same

ActiveCN101138730AHigh reactivitySolving problems with Cr/Cu catalystsOrganic compound preparationCarboxylic acid esters preparationOxalatePore distribution

A catalyst for hydrogenated synthesis of glycollate with oxalate and a preparation method for the catalyst belong to the glycollate preparation technical field. The catalyst of the present invention uses the copper metal as the main active component, and silver as the promoter, and is manufactured with the method of immersion. A carrier of the catalyst is the modified silica sol. The select content of the copper metal is 5 to 45 percent of the carrier weight, and the optimal content of the copper metal is 10 to 40 percent. The content of silver metal is 0.1 to 15 percent of the carrier weight, and the optimal content of silver metal is 1 to 8.0 percent. The select carrier is the silica sol with a double peak pore distribution structure and the specific surface area of the carrier is 100-300m2 / g; and the optimal specific surface area of the carrier is 120-240m2 / g. The present invention settles the problem of applying a Cr / Cu catalyst in the oxalate gas-phase catalytic hydrogenation. Proven by experiments, the catalyst is provided with the very high reaction activity and glycollate selectivity in the reaction to synthesize glycollate with oxalate and hydrogen Moreover, the catalyst is provided with the long usable life and the stable reaction performance, and can be easily controlled.

Owner:TIANJIN UNIV

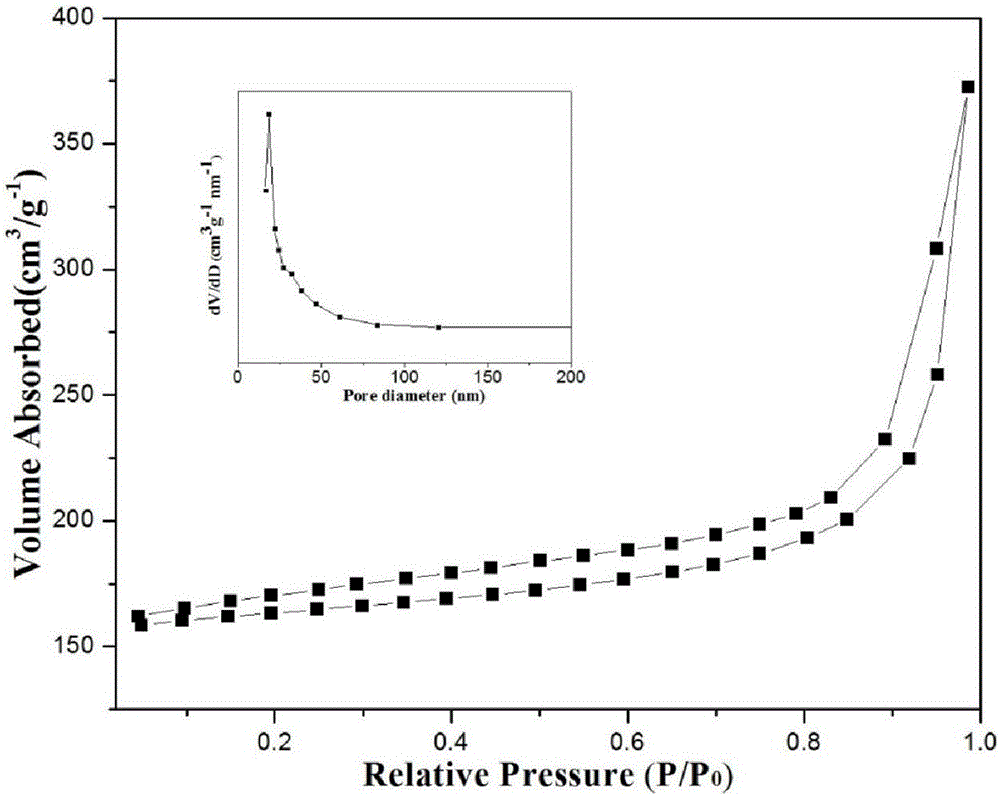

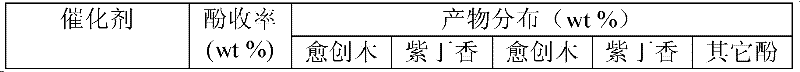

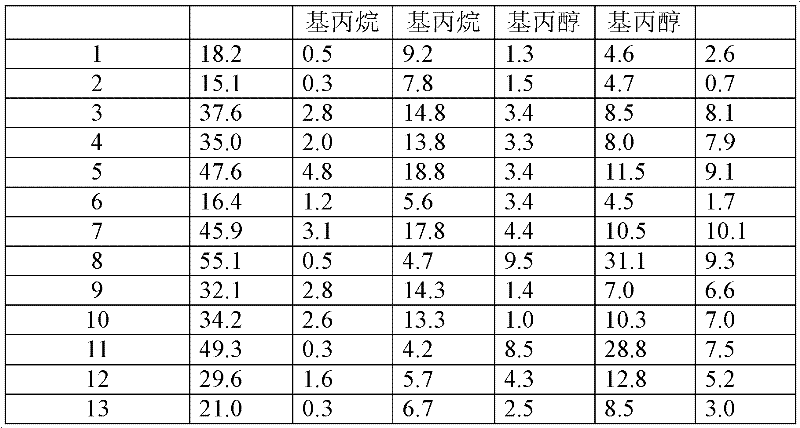

Application of tungsten-based catalyst in lignin catalytic hydrogenation for producing aromatic compound

ActiveCN102476980AWide variety of sourcesLow costCatalyst carriersOrganic compound preparationIridiumHydrogen pressure

The invention relates to hydrocracking of lignin, and specifically relates to a method for applying a tungsten-based catalyst to catalyze lignin hydrocracking for producing an aromatic compound. The catalyst comprises a main active component of non-zero-valent tungsten, and a second metal component of a small amount of one or more transition metals selected from zero-valent nickel, cobalt, ruthenium, iridium, palladium, platinum, iron, and copper. According to the method, raw materials such as lignin, biomass hydrolysis residue, lignosulfonate, and alkaline lignin are subject to catalytic hydrogenation under a hydrothermal condition with a temperature of 120 to 450 DEG C and a hydrogen pressure of 1 to 20MPa; the raw materials are cracked into C6-C9 phenolic compounds with high selectivity. A maximal phenol yield reaches 55.6%. Compared to existing technologies, according to the invention, renewable natural biomasses are adopted as raw materials, such that the raw materials are cheap, and have wide sources; inorganic acid and alkali are not required, such the production of a large amount of alkaline solution in traditional lignin catalysis is avoided; the tungsten-based catalyst is cheap; the reaction process is green, and has atom economical characteristics.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Hydrogen storage by reversible hydrogenation of pi-conjugated substrates

Processes are provided for the storage and release of hydrogen by means of a substantially reversible catalytic hydrogenation of extended pi-conjugated substrates which include large polycyclic aromatic hydrocarbons, polycyclic aromatic hydrocarbons with nitrogen heteroatoms, polycyclic aromatic hydrocarbons with oxygen heteroatoms, polycyclic aromatic hydrocarbons with alkyl, alkoxy, ketone, ether or polyether substituents, pi-conjugated molecules comprising 5 membered rings, pi-conjugated molecules comprising six and five membered rings with nitrogen or oxygen hetero atoms, and extended pi-conjugated organic polymers. The hydrogen, contained in the at least partially hydrogenated form of the extended pi-conjugated system, can be facilely released for use by a catalytic dehydrogenation of the latter in the presence of a dehydrogenation catalyst which can be effected by lowering the hydrogen gas pressure, generally to pressures greater than 0.1 bar or raising the temperature to less than 250° C. or less, or by a combination of these two process parameters.

Owner:AIR PROD & CHEM INC

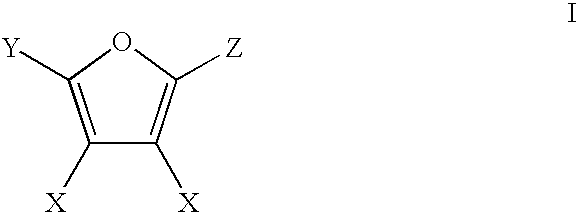

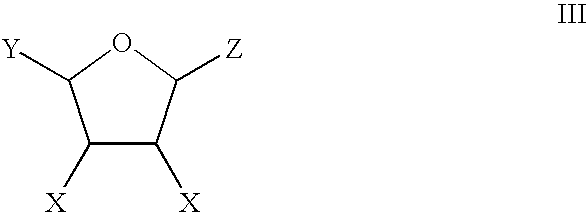

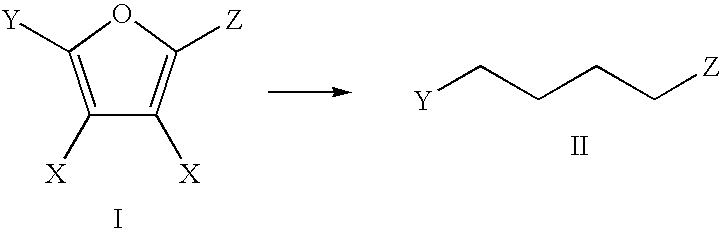

Production of Adipic Acid and Derivatives from Carbohydrate-Containing Materials

The present invention generally relates to processes for the chemocatalytic conversion of a carbohydrate source to an adipic acid product. The present invention includes processes for the conversion of a carbohydrate source to an adipic acid product via a furanic substrate, such as 2,5-furandicarboxylic acid or derivatives thereof. The present invention also includes processes for producing an adipic acid product comprising the catalytic hydrogenation of a furanic substrate to produce a tetrahydrofuranic substrate and the catalytic hydrodeoxygenation of at least a portion of the tetrahydrofuranic substrate to an adipic acid product. The present invention also includes products produced from adipic acid product and processes for the production thereof from such adipic acid product.

Owner:ARCHER DANIELS MIDLAND CO

Method for preparation of (substituted radical containted) aminophenol by catalytic hydrogenation of (substituted radical containted) nitrophenol

ActiveCN101041623AOvercoming pollutionSolve problems such as recycling difficultiesMolecular sieve catalystsOrganic compound preparationMolecular sieveNitrophenol

The invention discloses a making method of aminophenol with substituted group through hydrogenating nitrophenol with substituted group, which adopts Ni-A / X typed loaded catalyst, wherein A is one of Co, Mn, Cu, Cr, Mo, Ca, Zn, Fe and W; the carrier X is one of their composition of zeolite molecular sieve, Al2O3, SiO2, TiO2, MgO, active charcoal or amorphic aluminium silicate; the mass percentage of Ni in the catalyst is 2-45% and the mass percentage of component A is 1-40%.

Owner:SHANGHAI HUAYI NEW MATERIAL

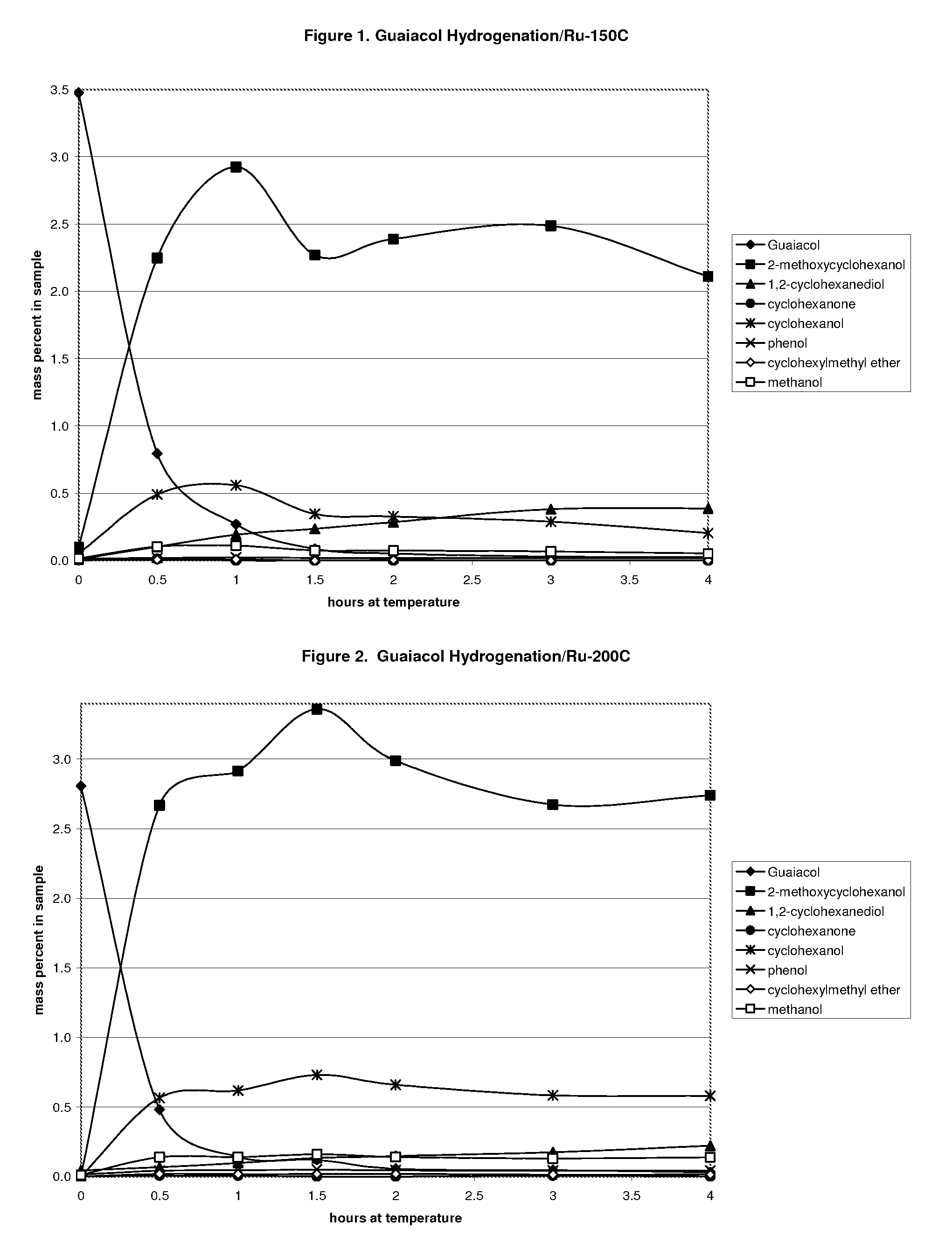

Method for preparing aromatic hydrocarbon by carrying out catalytic hydrodeoxygenation on lignin

InactiveCN104744204AWide variety of sourcesRaw materials are renewableHydrocarbon from oxygen organic compoundsEthylene productionIridiumPtru catalyst

The invention relates to a method for preparing aromatic hydrocarbon by carrying out catalytic hydrodeoxygenation on lignin. A catalyst used in the method provided by the invention comprises two active components, namely an acid site being one or combination of more than one of transition metal elements niobium, tantalum, zirconium, molybdenum, tungsten and rhenium and a hydrogenation or hydrogen transfer active site being one or more than one of ruthenium, platinum, palladium, iridium, iron, cobalt, nickel and copper. According to the method provided by the invention, a phenol group, a guaiacol group, a syringa phenolic group compound, natural lignin and industrial lignin are taken as raw materials, water is taken as a solvent, high selectivity catalytic hydrodeoxygenation is carried out at the temperature of 180-350 DEG C and hydrogen pressure of 0.1-5MPa or with methyl alcohol, isopropyl alcohol and formic acid as hydrogen sources, so that C6-C9 aromatic hydrocarbon is obtained, the highest mass yield of aromatic hydrocarbon is 10%, and content of aromatic hydrocarbon in product oil can be up to more than 75%. The method provided by the invention has the advantages that reproducible natural biomass can be used as a raw material, and the raw material is cheap and available; the water is taken as the solvent, so that a reaction process is environment-friendly; and content of aromatic hydrocarbon in the product is high, and reaction conditions are mild.

Owner:EAST CHINA UNIV OF SCI & TECH

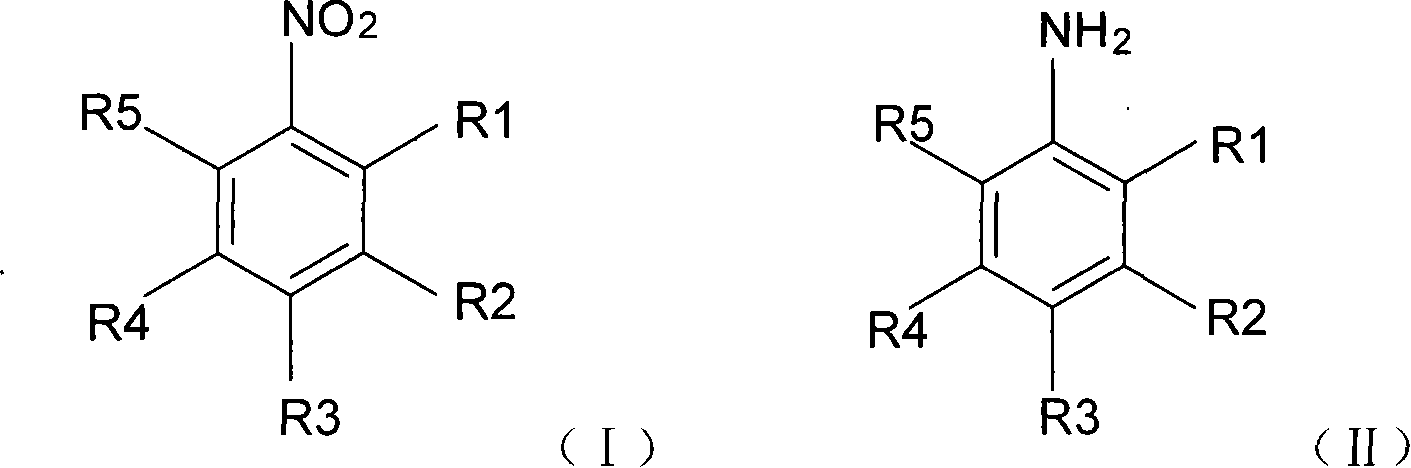

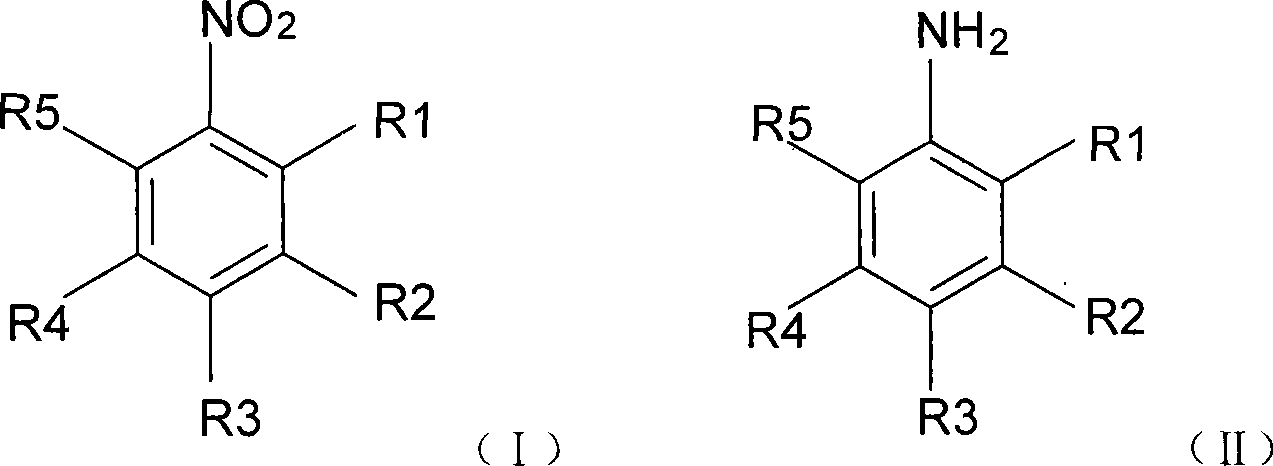

Production process of catalytically hydrogenating nitrobenzene halide to synthesize haloarylamine

InactiveCN1506348AInhibition of hydrodehalogenationHigh catalytic activityOrganic compound preparationAmino compound preparationHydrogenation reactionNitrobenzene

The production process is liquid phase catalytic hydrogenation reaction of nitrobenzene halide, such as o-chloronitrobenzene, p-chloronitrobenzene, 3, 4-dichloronitrobenzene and 3-chloro-4-fluoronitrobenzene, etc. with carbon nanotube carried Pd and Pt as hydrogenation catalyst to produce corresponding haloarylamine. The said production process can inhibit hydrodehalogenation, and has the advantages of high selectivity, high yield and high catalyst stability, etc. and thus high practical value.

Owner:ZHEJIANG UNIV OF TECH

Effective catalyst used in hydrogenation of dimethyl oxalate to synthesizing ethylene glycol and production method thereof

InactiveCN101455976AGood dispersionHigh selectivityMolecular sieve catalystsOrganic compound preparationMolecular sieveNitrate

The invention provides an efficient catalyst used in glycol synthesis through dimethyl oxalate hydrogenation, and a preparation method thereof. A hexagonal mesoporous silicon molecular sieve is taken as a carrier which carries copper and additive metal, and the mass ratio of the copper to the additive metal to the hexagonal mesoporous silicon molecular sieve is 0.25-0.6:0.04-0.4:1. The preparation method comprises the following steps: soluble nitrates of the copper and the additive metal are compounded to be a metal ion solution with the total concentration between 0.5 and 2 M in water; the metal ion solution is slowly dripped into an aqueous solution containing the hexagonal mesoporous silicon molecular sieve; the adsorption temperature is between 20 and 90 DEG C; the solutions continue to be stirred at a constant temperature, so as to prepare a precursor; and the precursor is washed, dried, progressively heated to 250 to 950 DEG C and roasted, so as to obtain the powdered efficient catalyst. The catalyst has the advantages that the catalyst has a regular pore structure and high specific surface area, and can be better dispersed after an active copper species is stabilized by the additive metal and dispersed by the hexagonal mesoporous silicon molecular sieve, and the catalyst shows excellent hydrogenation activity and glycol selectivity in the reaction of synthesizing glycol through the catalytic hydrogenation of dimethyl oxalate.

Owner:SHANGHAI HUAYI ENERGY CHEM +1

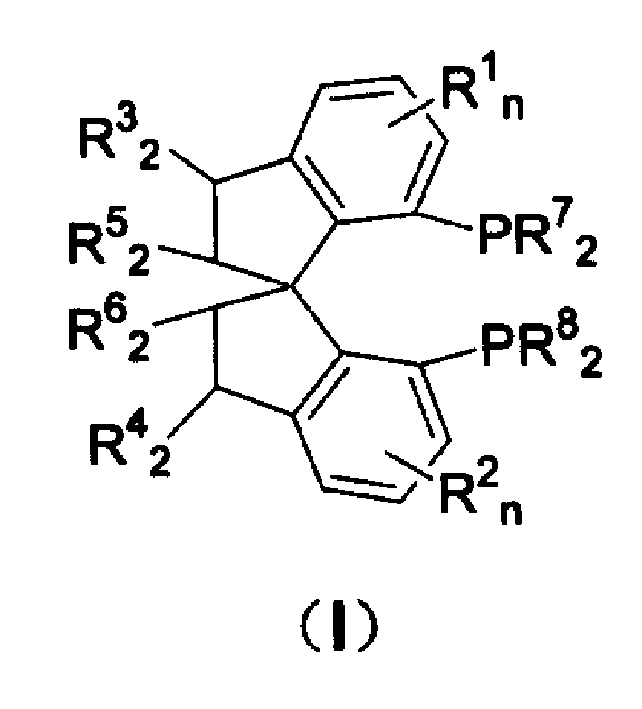

Spiro-diphosphine ligand

InactiveCN1439643AHigh stereoselectivityHigh enantioselectivityOrganic-compounds/hydrides/coordination-complexes catalystsGroup 5/15 element organic compoundsTrifluoromethanesulfonic anhydrideDiphosphines

A spirocyclo-biphosphine ligand is prepared from spirocyclo-biphenol through esterifying by trifluoro methylsulfonic acid anhydride, coupling with diaryloxyphosphine under catalysis of Pd, and reduction reacting on trichlorosilane. It includes d-and levo-spricyclo-biphosphine ligands, whose mixture is dl-spirocyclo-biphosphine ligand. It can be used for asymmetrical catalytic hydrogenation reaction of latent chiral ketone with high stereo selectivity and e.e. value up to 99.5%.

Owner:NANKAI UNIV

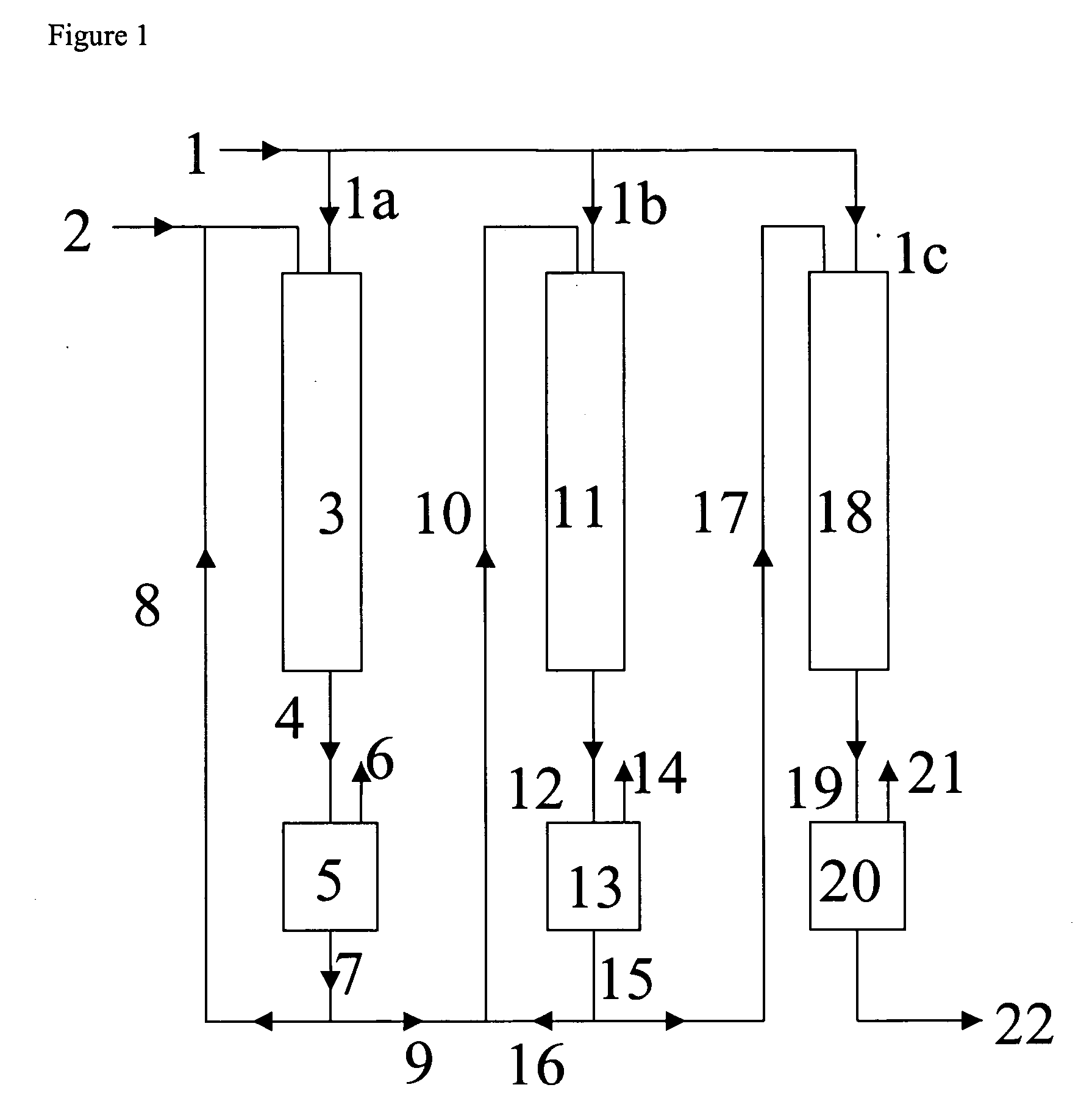

Method for continuous catalytic hydrogenation

InactiveUS20060161017A1Reduce procurement costsOrganic compound preparationCarboxylic acid esters preparationCarboxylic acidCatalytic hydrogenation

The invention relates to the preparation of alicyclic carboxylic acids or their derivatives by selective hydrogenation of the corresponding aromatic carboxylic acid (derivatives) in at least two series-connected reactors, at least one reactor being operated in loop operating mode. The catalyst volumes in the method are set in such a manner that the catalyst volume required, based on the conversion rate, is as low as possible.

Owner:EVONIK DEGUSSA GMBH

How to convert carbon dioxide into synthetic hydrocarbon through a process of catalytic hydrogenation called CO2hydrocarbonation

InactiveUS6987134B1Improve actionImprove standardizationOrganic compound preparationOxygen compounds preparation by reductionOxygenChemistry

This process uses two catalysts instead of one, converting CO2 into C8H18. Addition of a NaCl catalyst to a Ni catalyst improves the efficiency of Fischer's process because the salt catalyst retains humidity. Furthermore, chlorine opens chemical chains and sodium prevents crystals of oxygen from covering the Ni catalyst. If we are equipped to produce CO2 from biogas or smoke, we can recycle this CO2 and yield a useful liquid. In fact, recycling CO2 into a synthetic crude hydrocarbon, octane, contributes to clean air and to produce a valuable source of energy. Because CO2 is a renewable resource, this process favors a lasting economic development.

Owner:GAGNON ROBERT

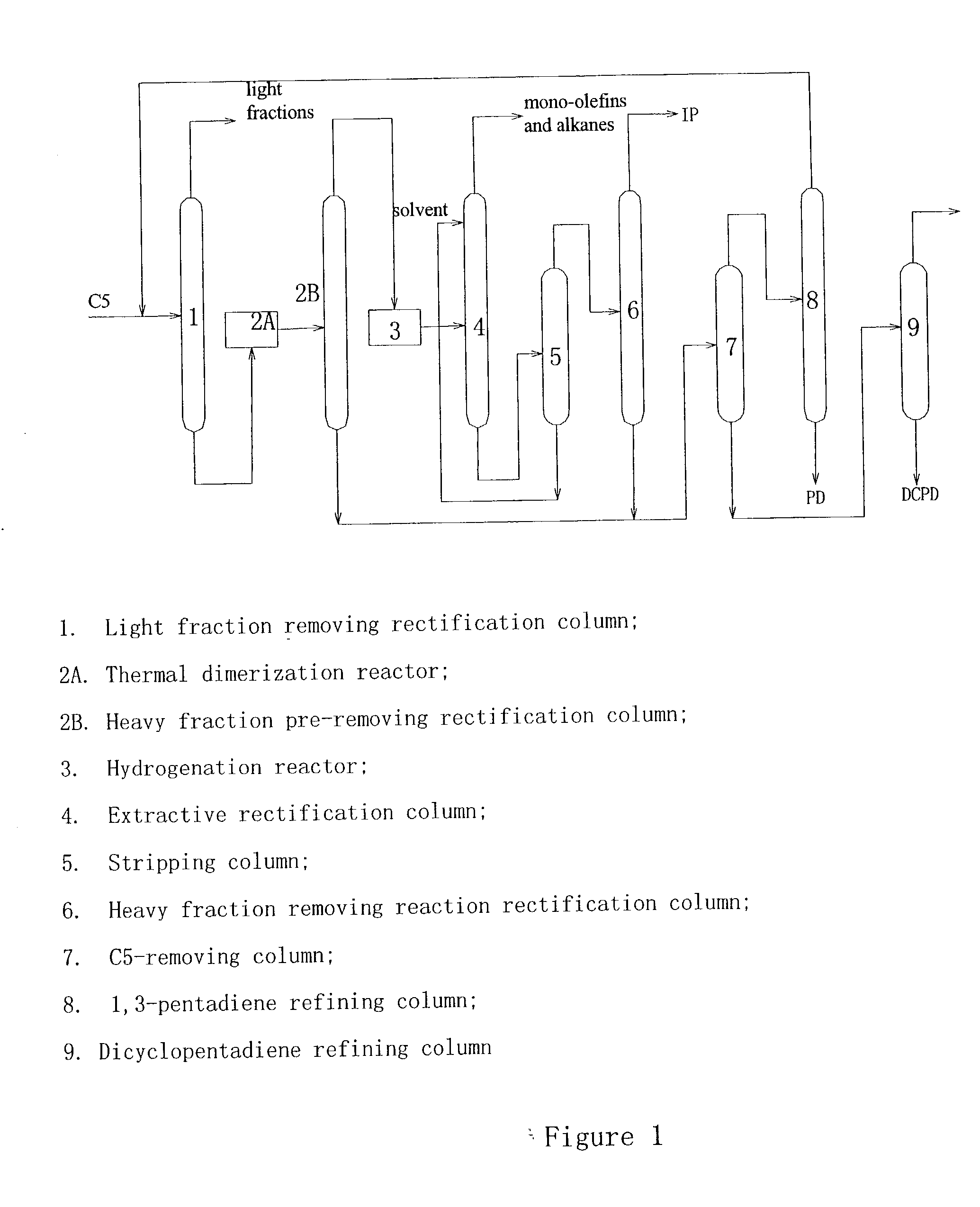

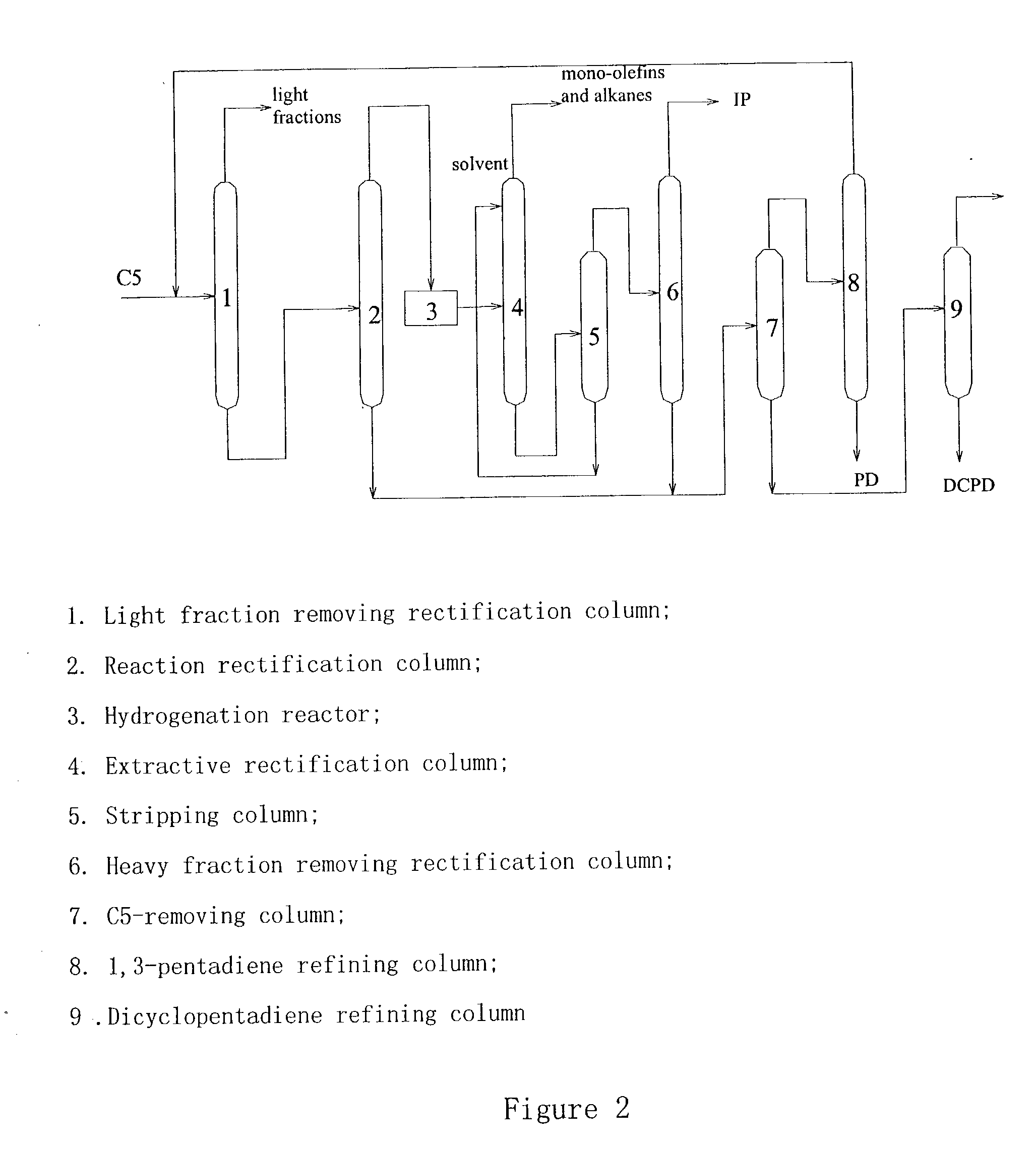

Process for separating C5 cuts obtained from a petroleum cracking process

ActiveUS20030100809A1Improve catalytic performanceHigh activityLiquid hydrocarbon mixtures productionDistillation purification/separationAlkyneSolvent

The present invention relates to a process for separating the isoprene, 1,3-pentadiene and dicyclopentadiene from a C5 cuts, comprising dimerization of the cyclopentadiene and selective catalytic hydrogenation. The second extractive rectification step can be omitted, because the alkynes are removed through selective catalytic hydrogenation prior to the extractive rectification. As a result, the solvent-recovering units can be simplified, and thus the process as a whole can be optimized. Correspondingly, the investment and energy consumption, the operation cost, and finally the production cost can be substantially reduced.

Owner:CHINA PETROCHEMICAL CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com