Patents

Literature

1036 results about "Pyrolysis oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pyrolysis oil, sometimes also known as biocrude or bio-oil, is a synthetic fuel under investigation as substitute for petroleum. It is obtained by heating dried biomass without oxygen in a reactor at a temperature of about 500 °C with subsequent cooling. Pyrolytic oil (or bio-oil) is a kind of tar and normally contains levels of oxygen too high to be considered a hydrocarbon. This high oxygen content results in non-volatility, corrosiveness, immiscibity with fossil fuels, thermal instability, and a tendency to polymerize when exposed to air. As such, it is distinctly different from petroleum products. Removing oxygen from bio-oil or nitrogen from algal bio-oil is called upgrading.

Production of Blended Fuel from Renewable Feedstocks

ActiveUS20090301930A1Minimize the numberReduce the amount requiredRefining to change hydrocarbon structural skeletonBiofuelsParaffin waxEngineering

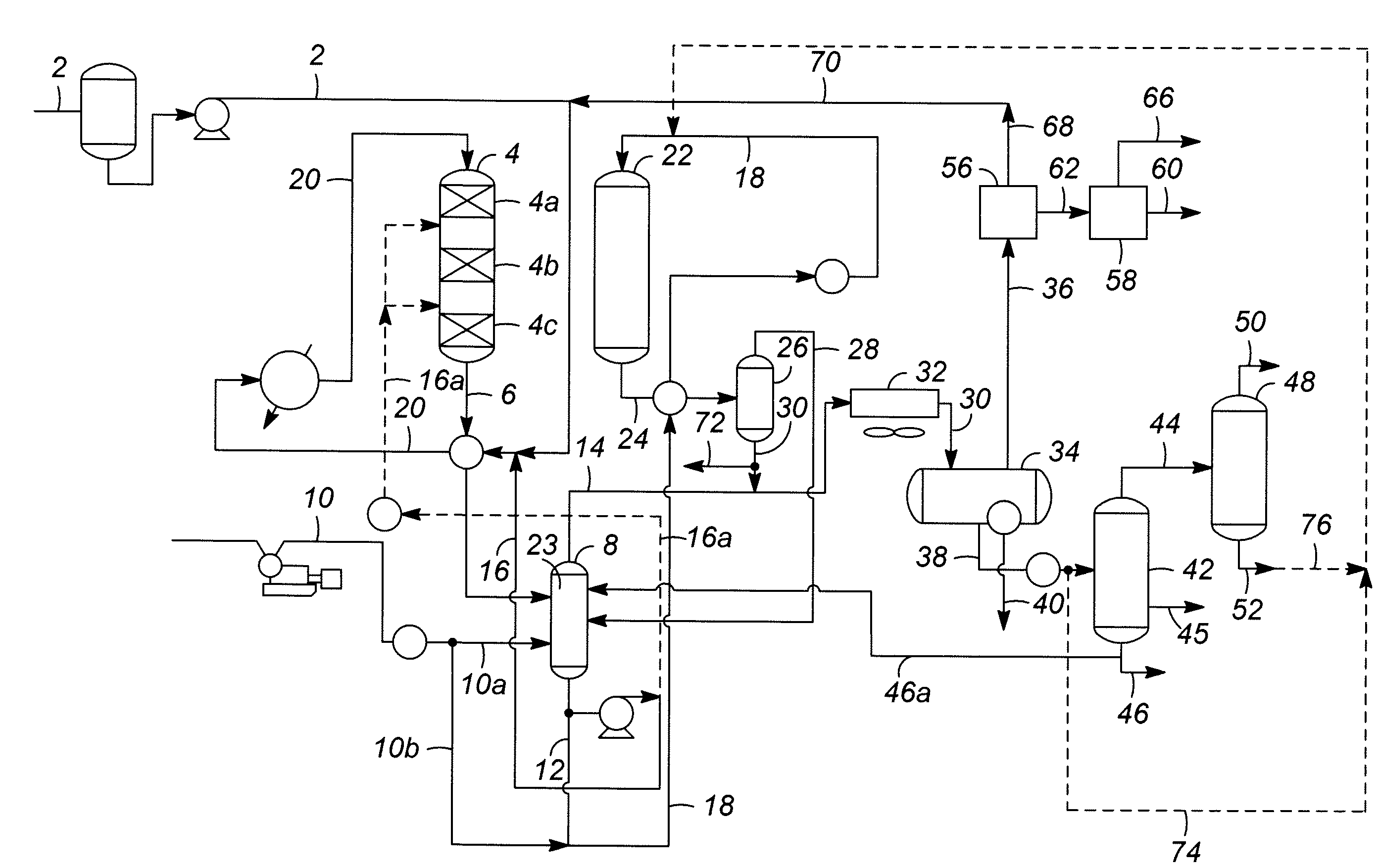

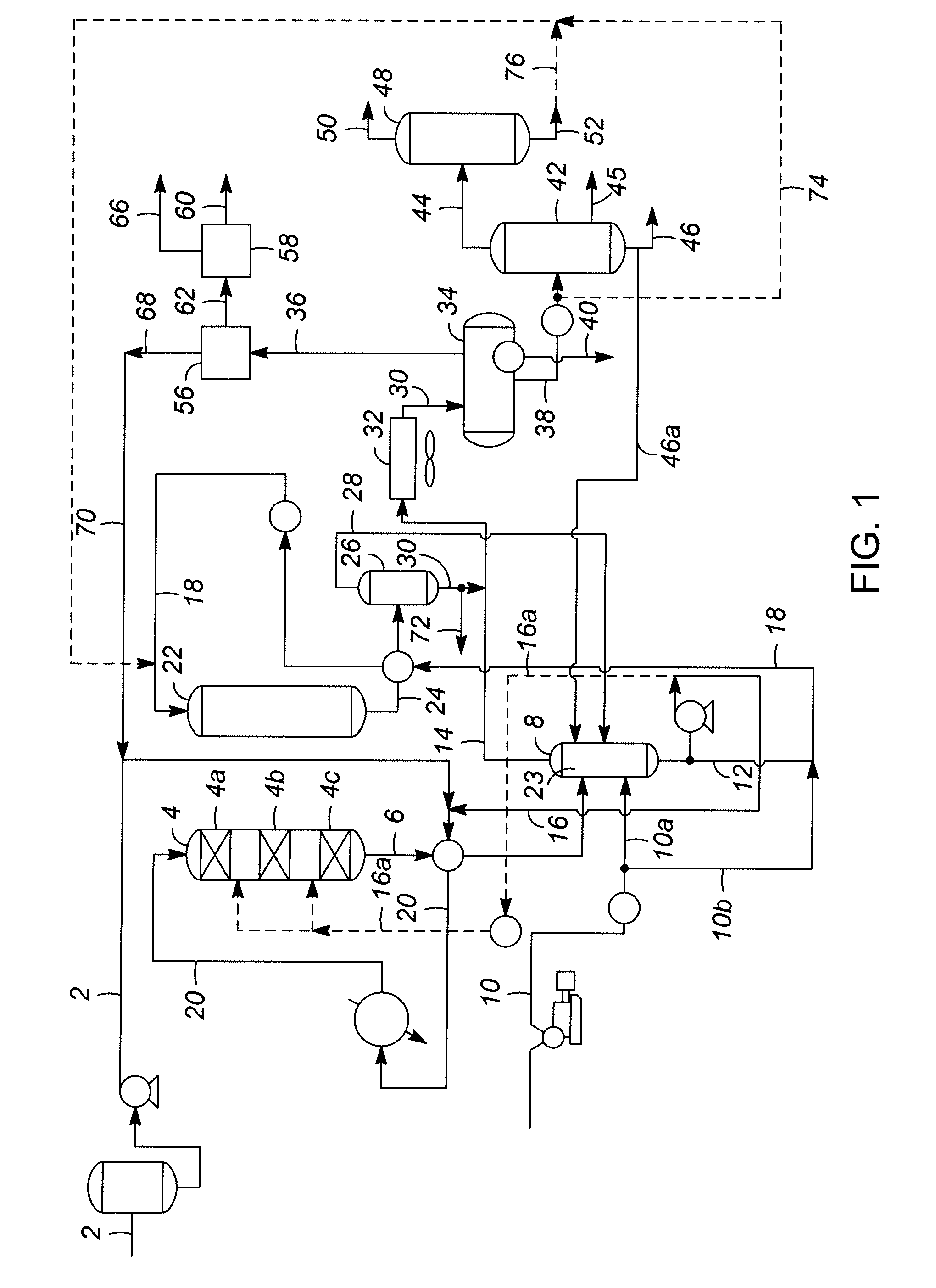

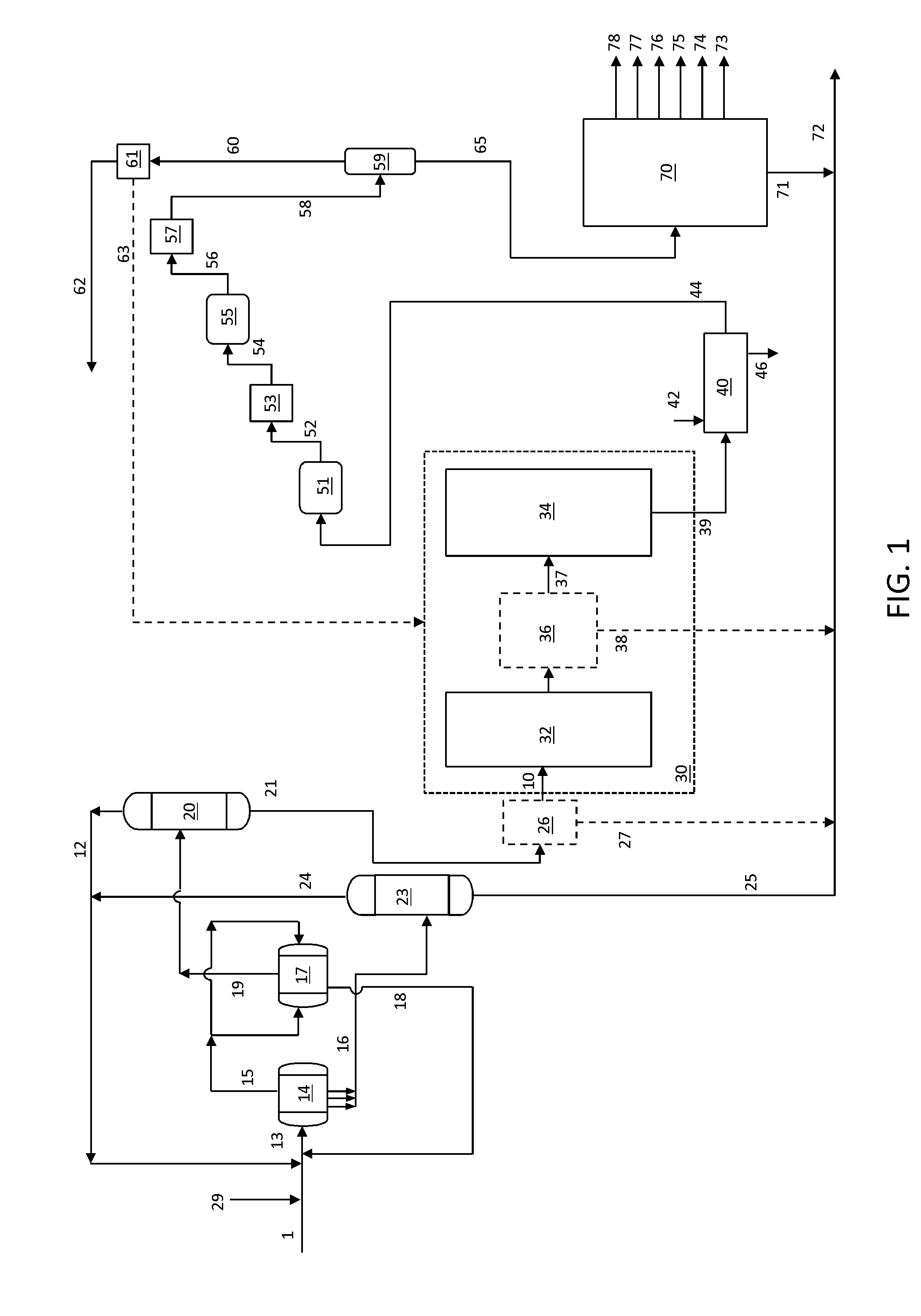

A process for producing a blended fuel from a paraffin rich component and a cyclic rich component, where each of the components are generated from a renewable feedstock, is presented. The paraffin rich component is generated from glycerides and free fatty acids in feedstocks such as plant and animal oils. The cyclic rich component is generated from biomass derived pyrolysis oil. The source of the animal or plant oil and the biomass may be the same renewable source.

Owner:UOP LLC

Process for catalytic hydrotreatment of a pyrolysis oil

ActiveUS20110119994A1Reduces coke formationLiquid carbonaceous fuelsLiquid hydrocarbon mixture productionCellulosePyrolysis oil

Owner:SHELL USA INC

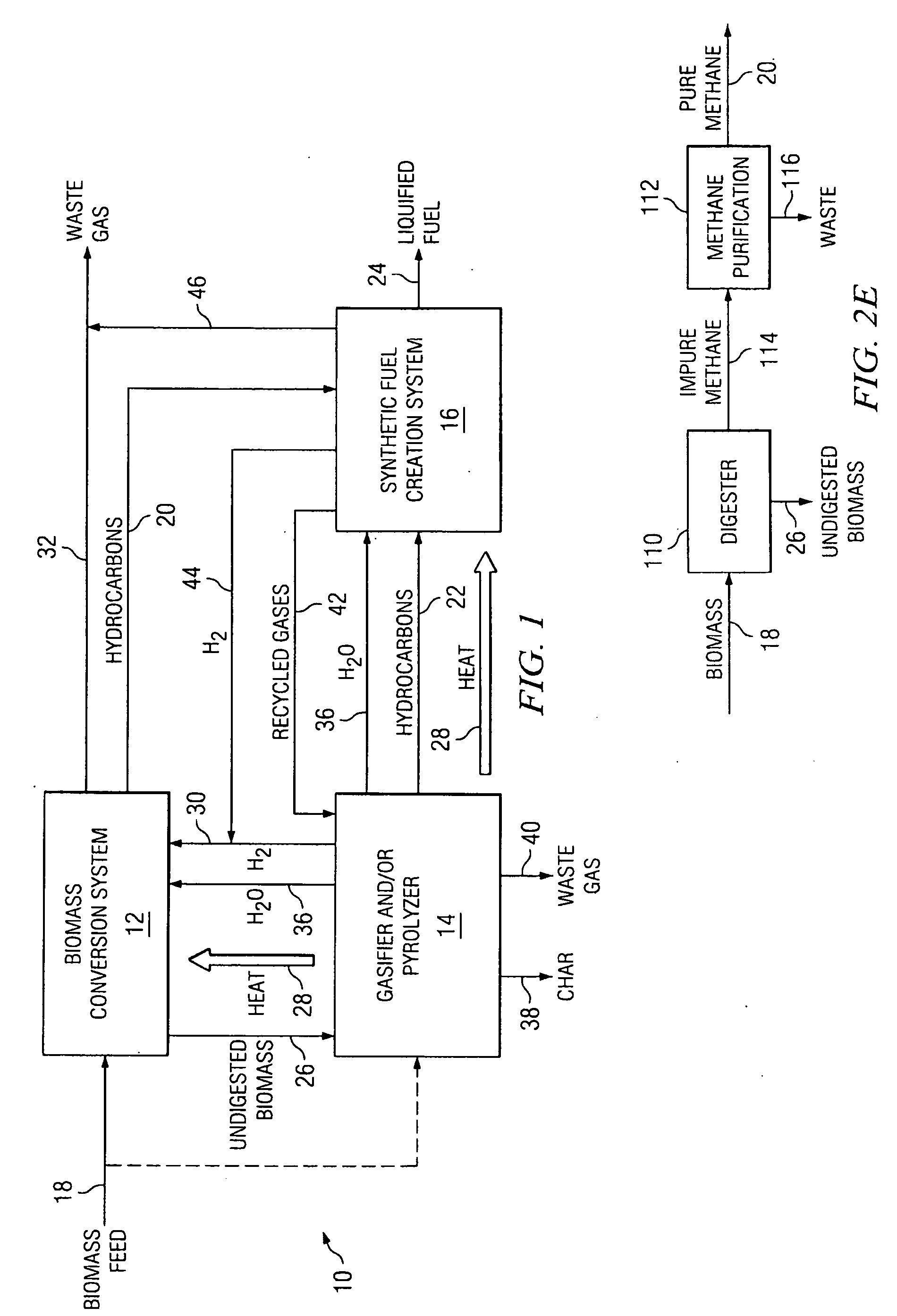

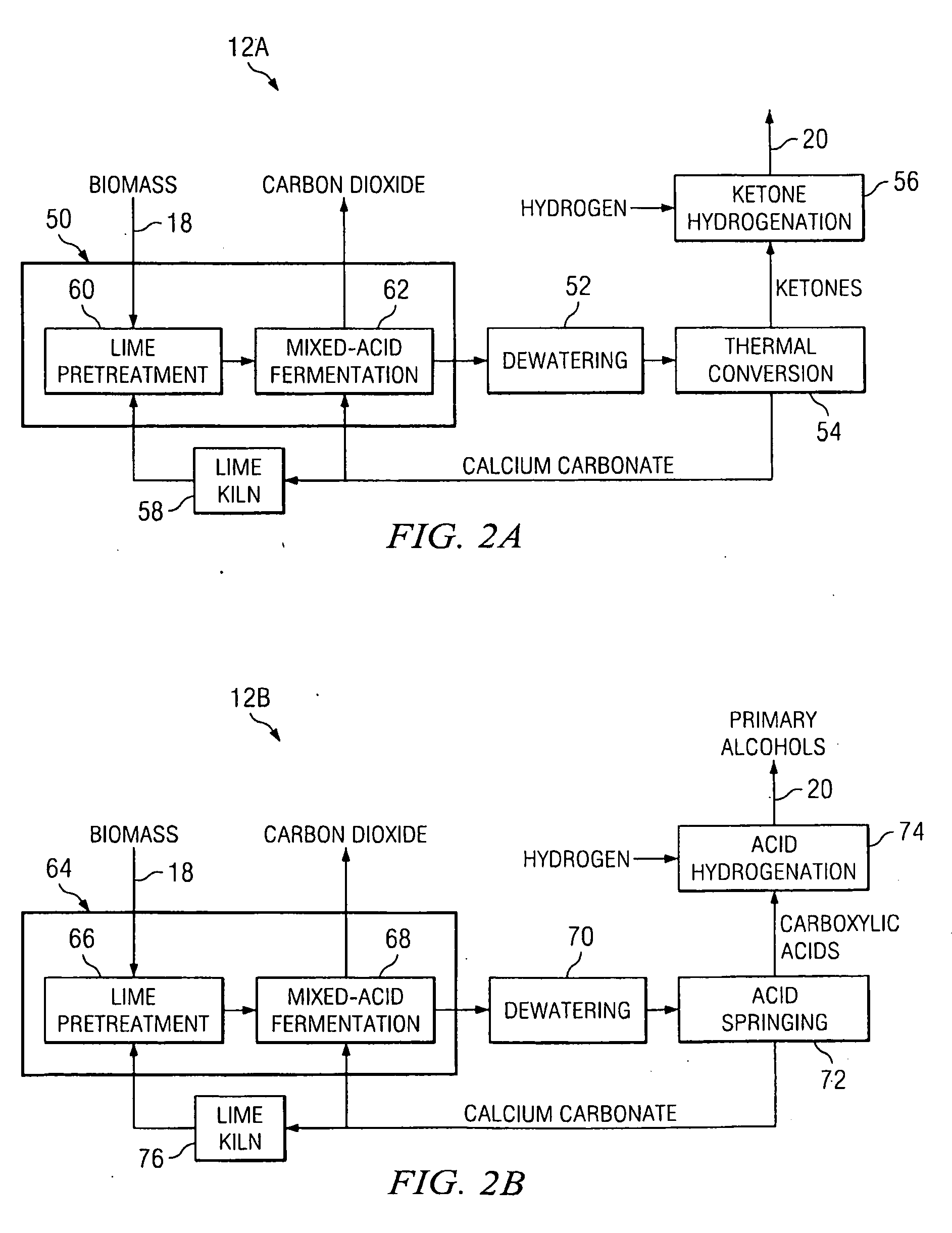

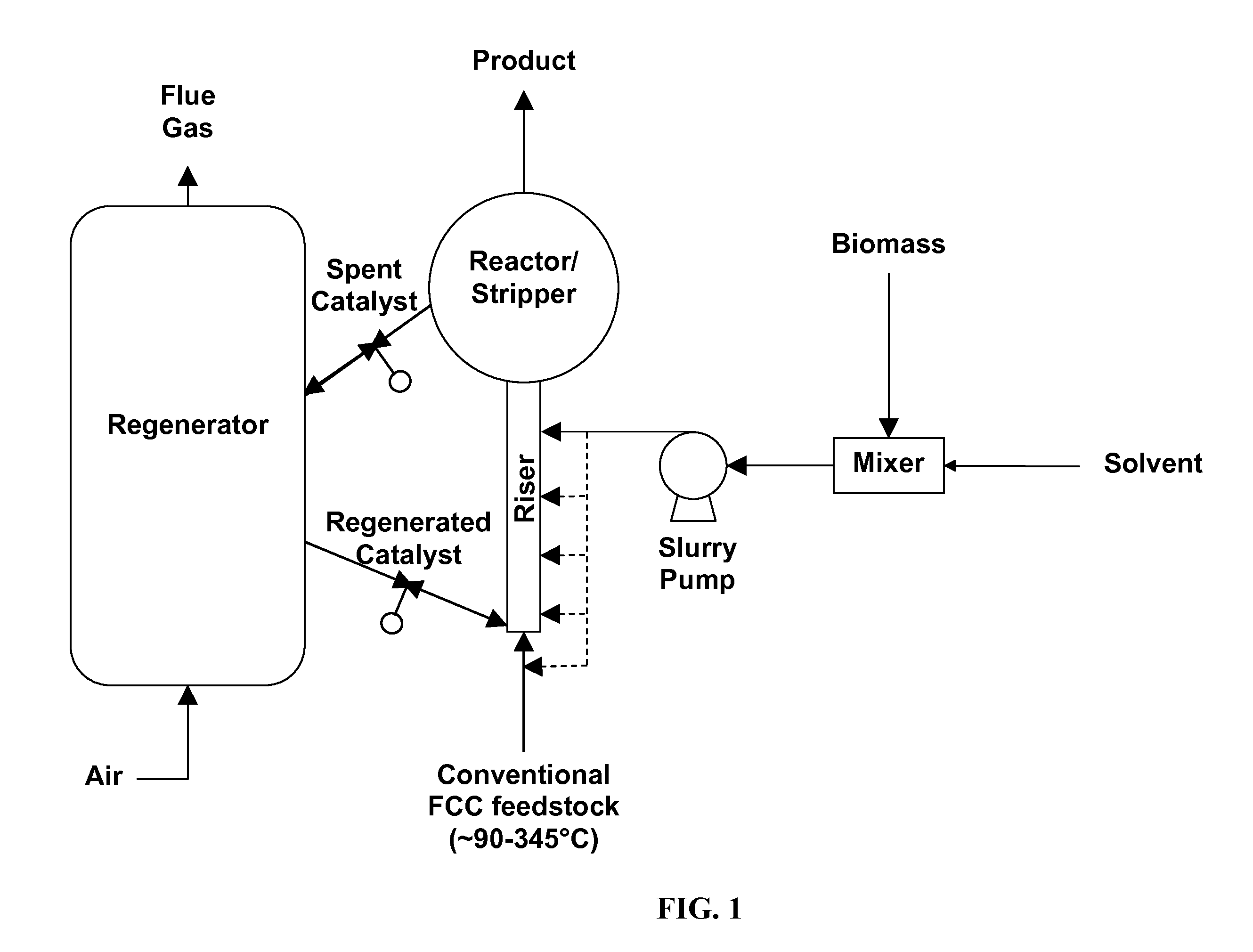

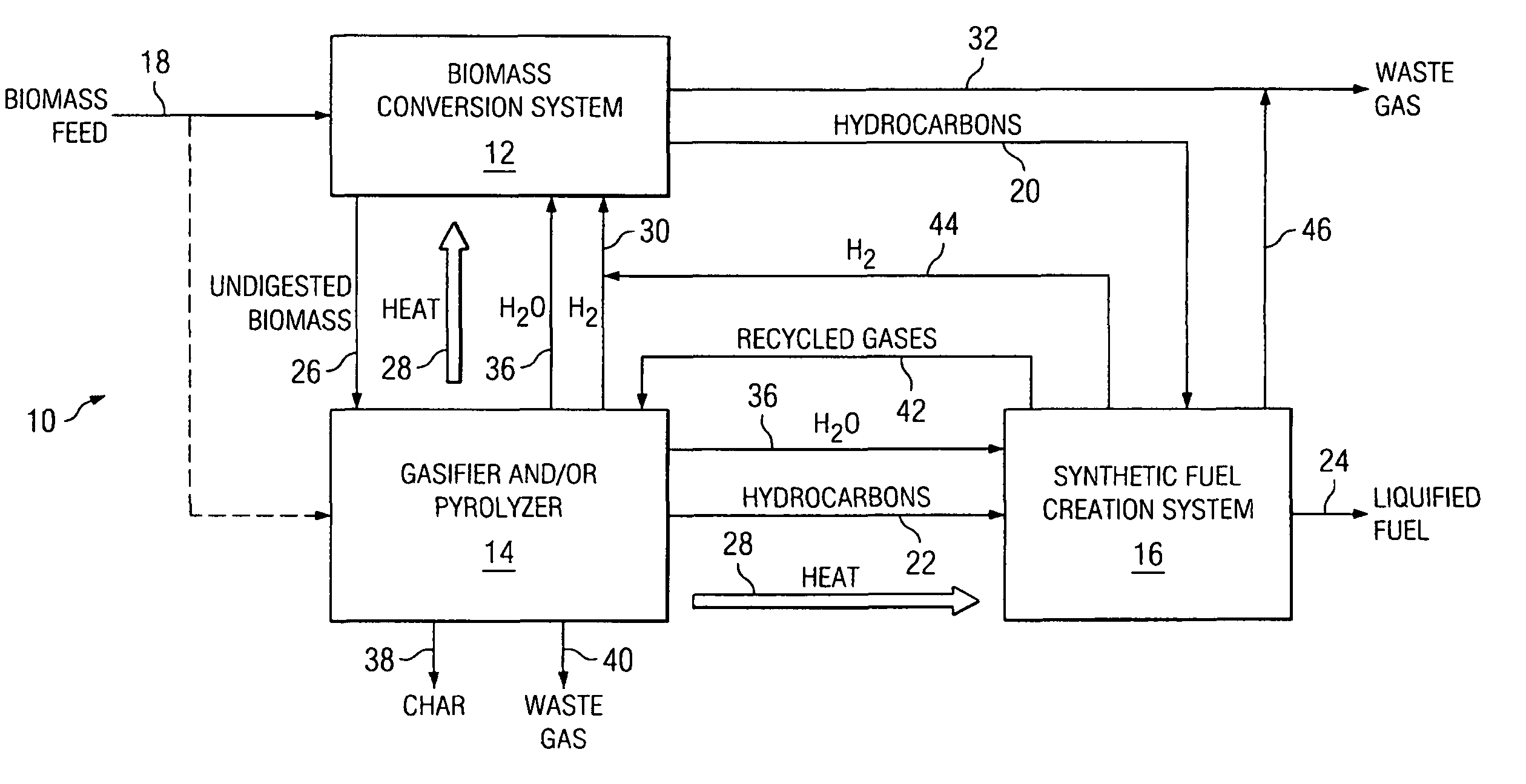

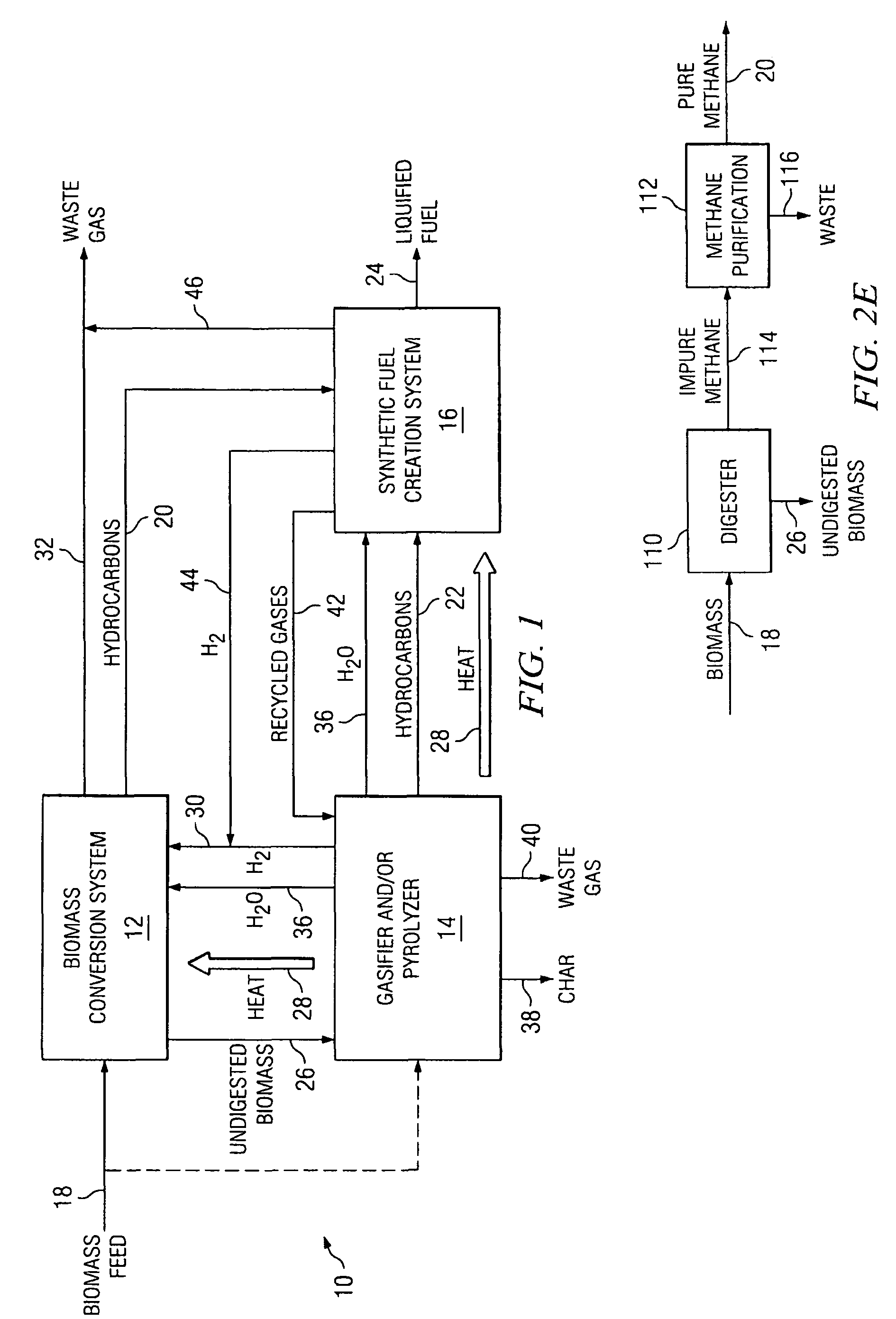

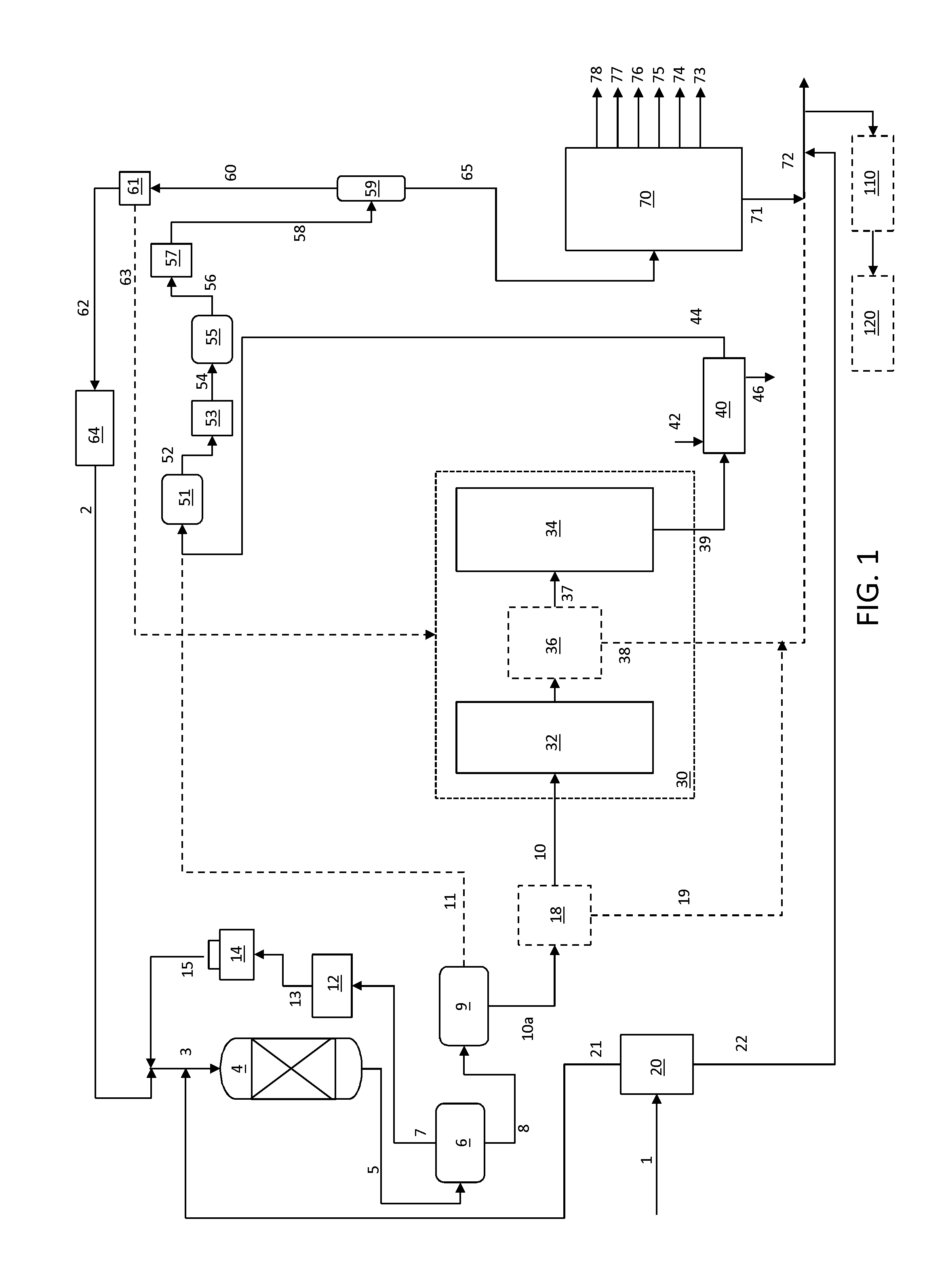

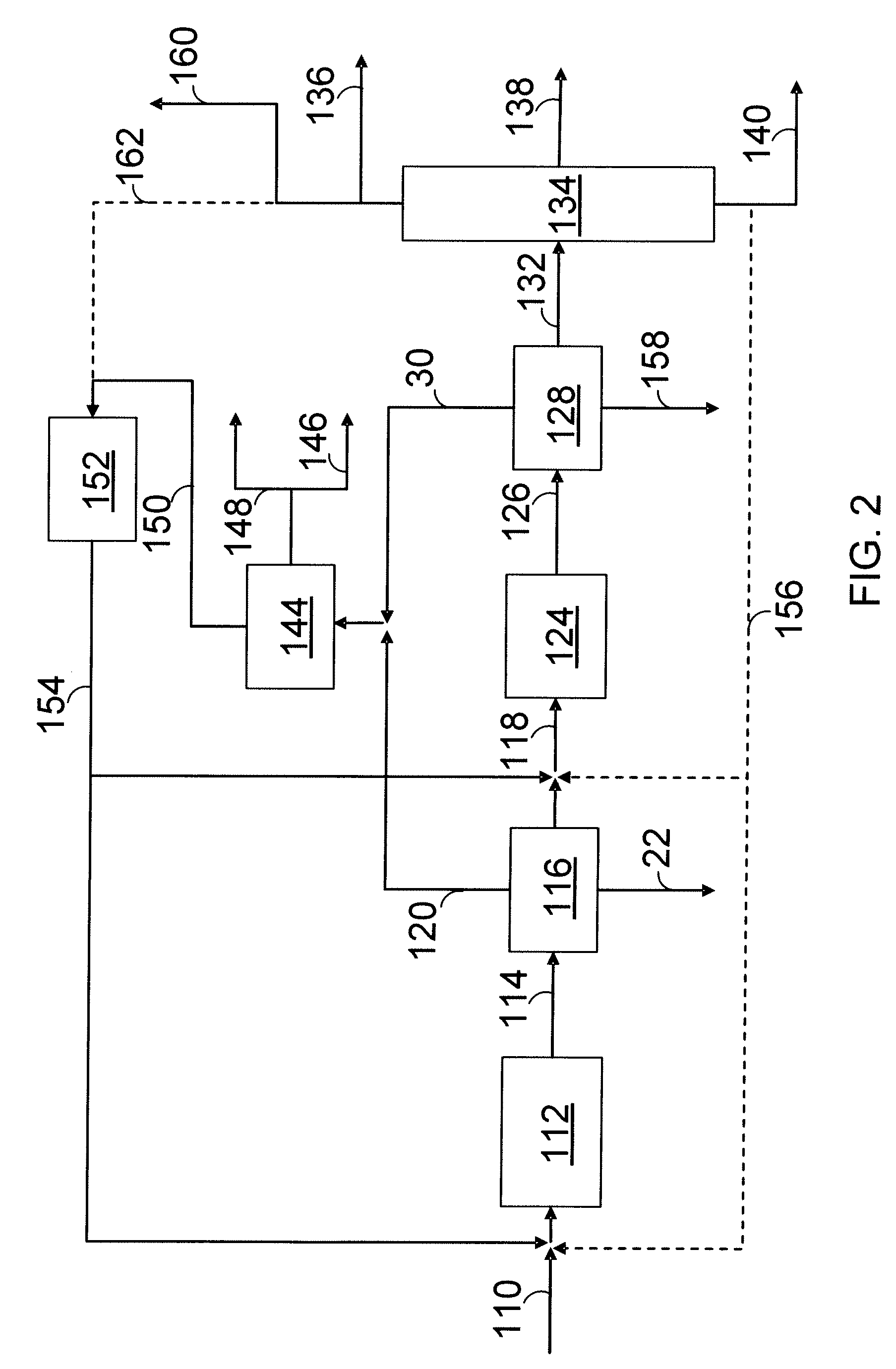

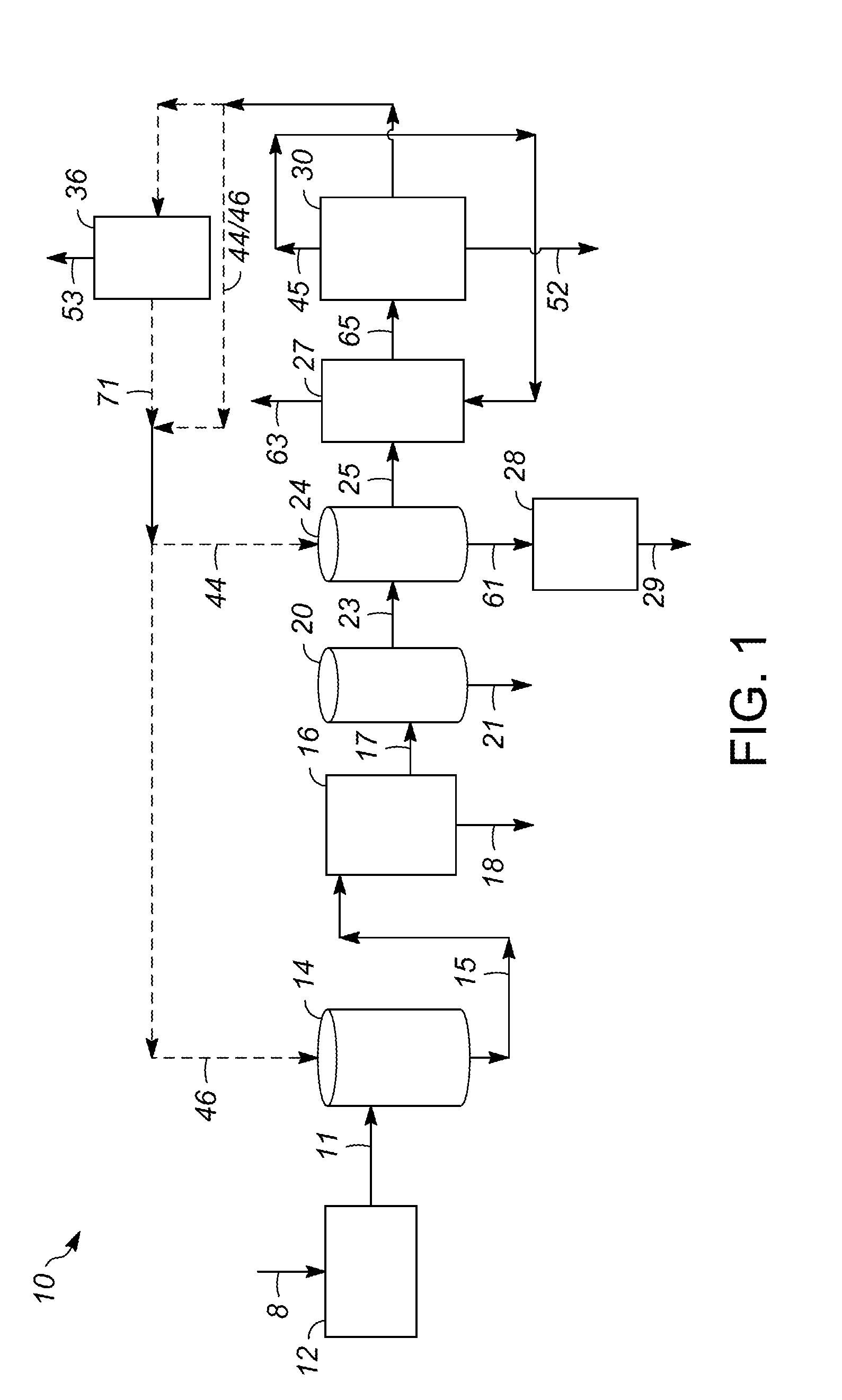

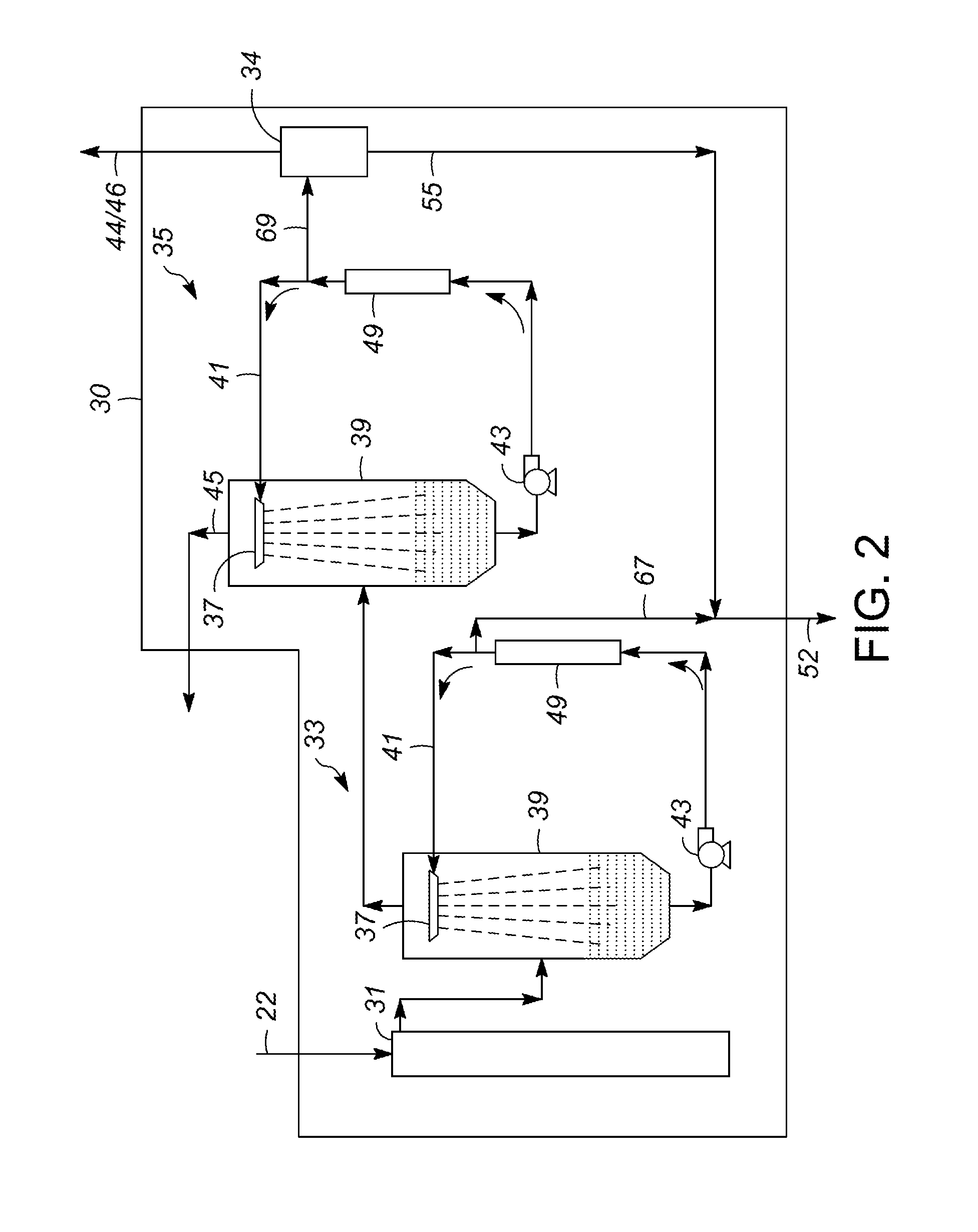

Integrated Biofuel Production System

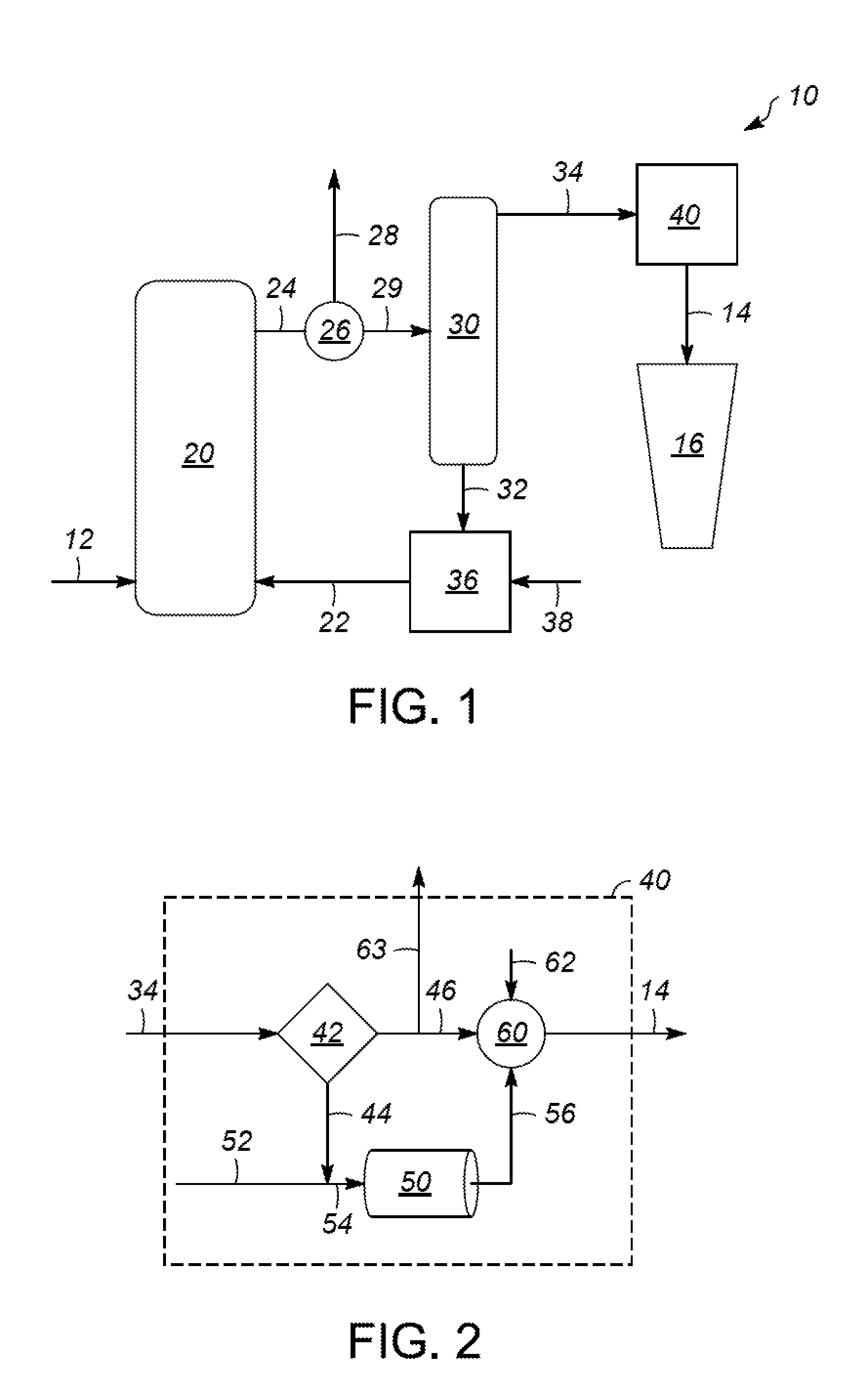

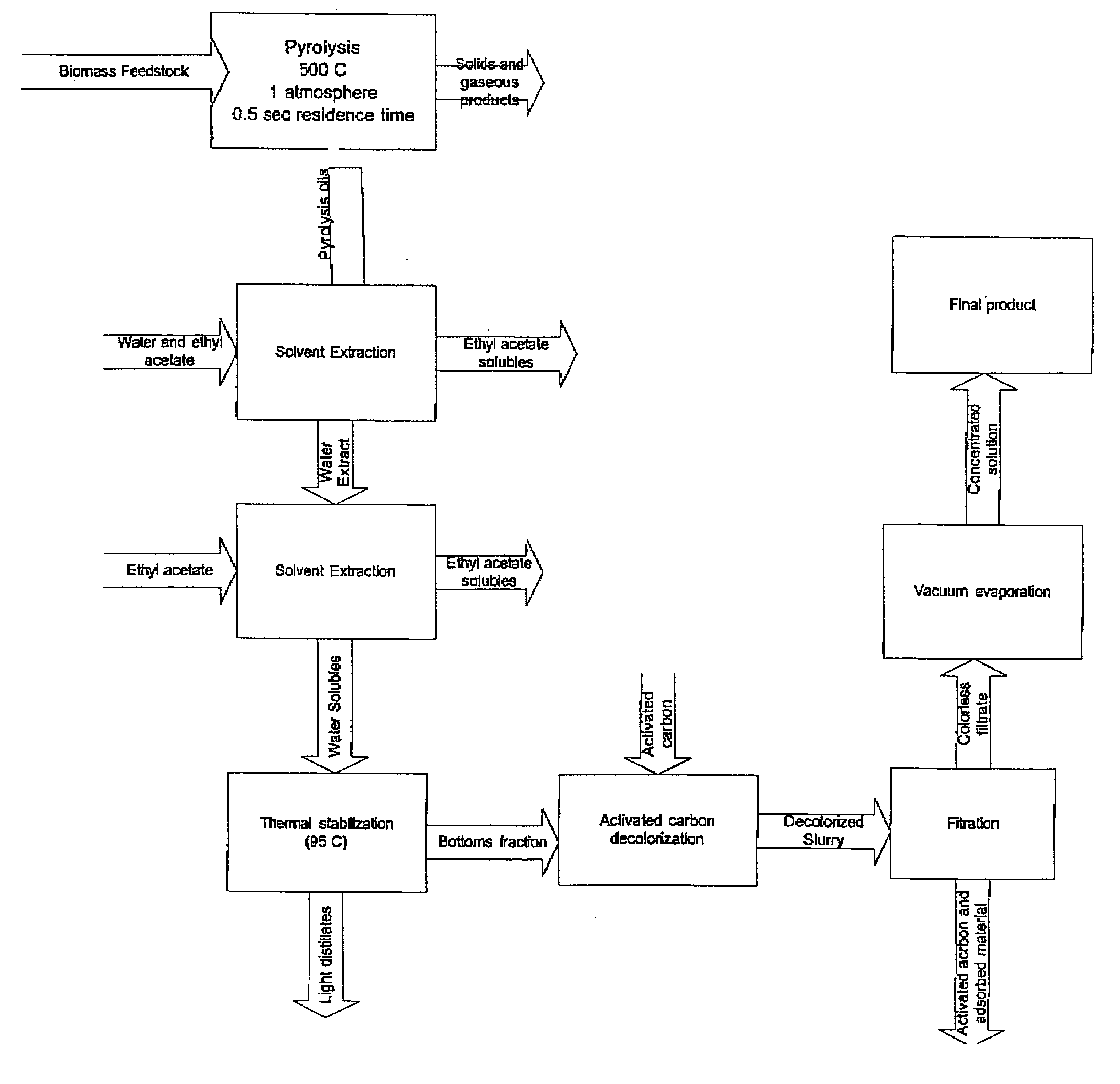

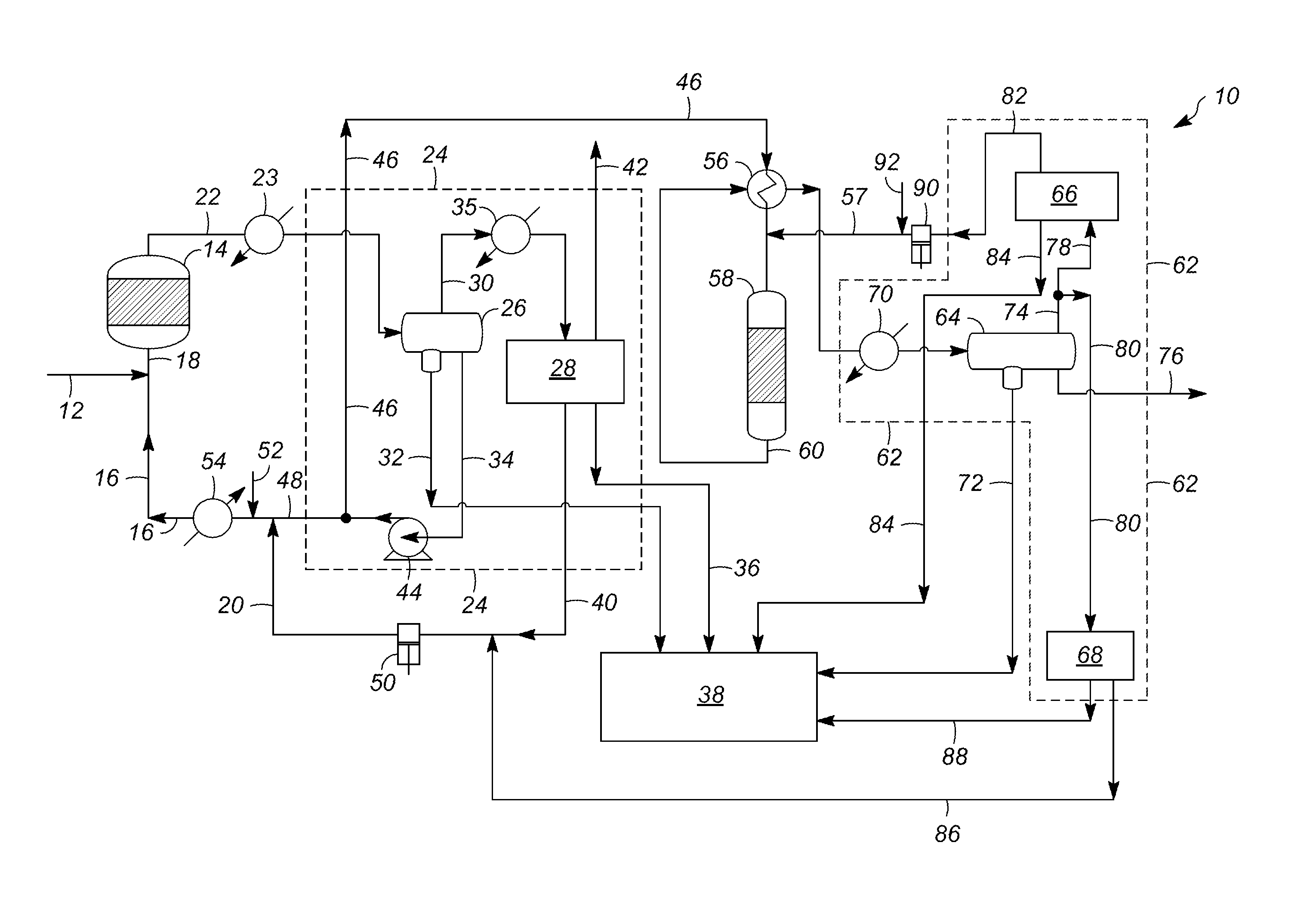

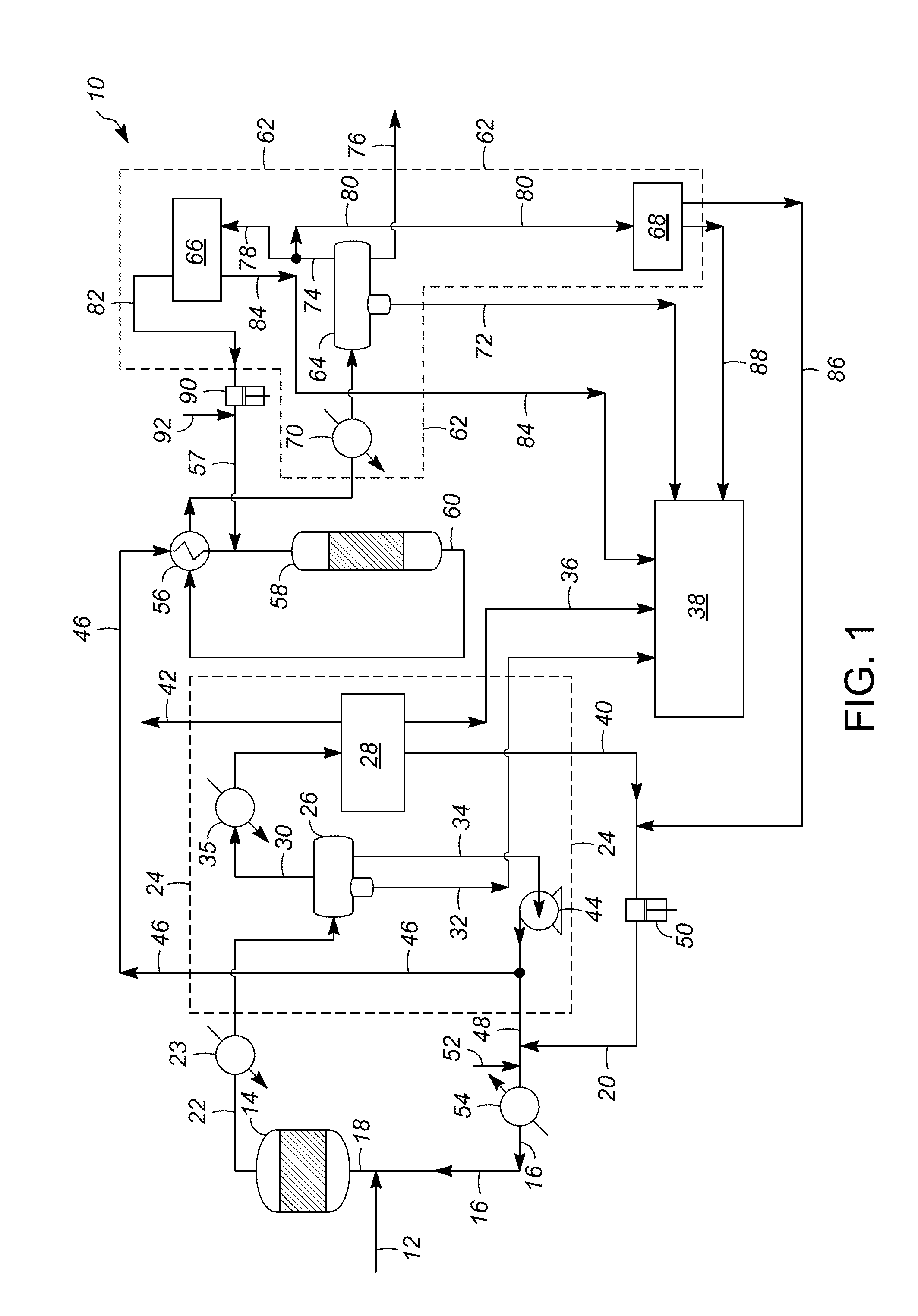

InactiveUS20090239279A1Increase energy densityImprove conversion efficiencyWaste based fuelSedimentation separationThermal energyResidual biomass

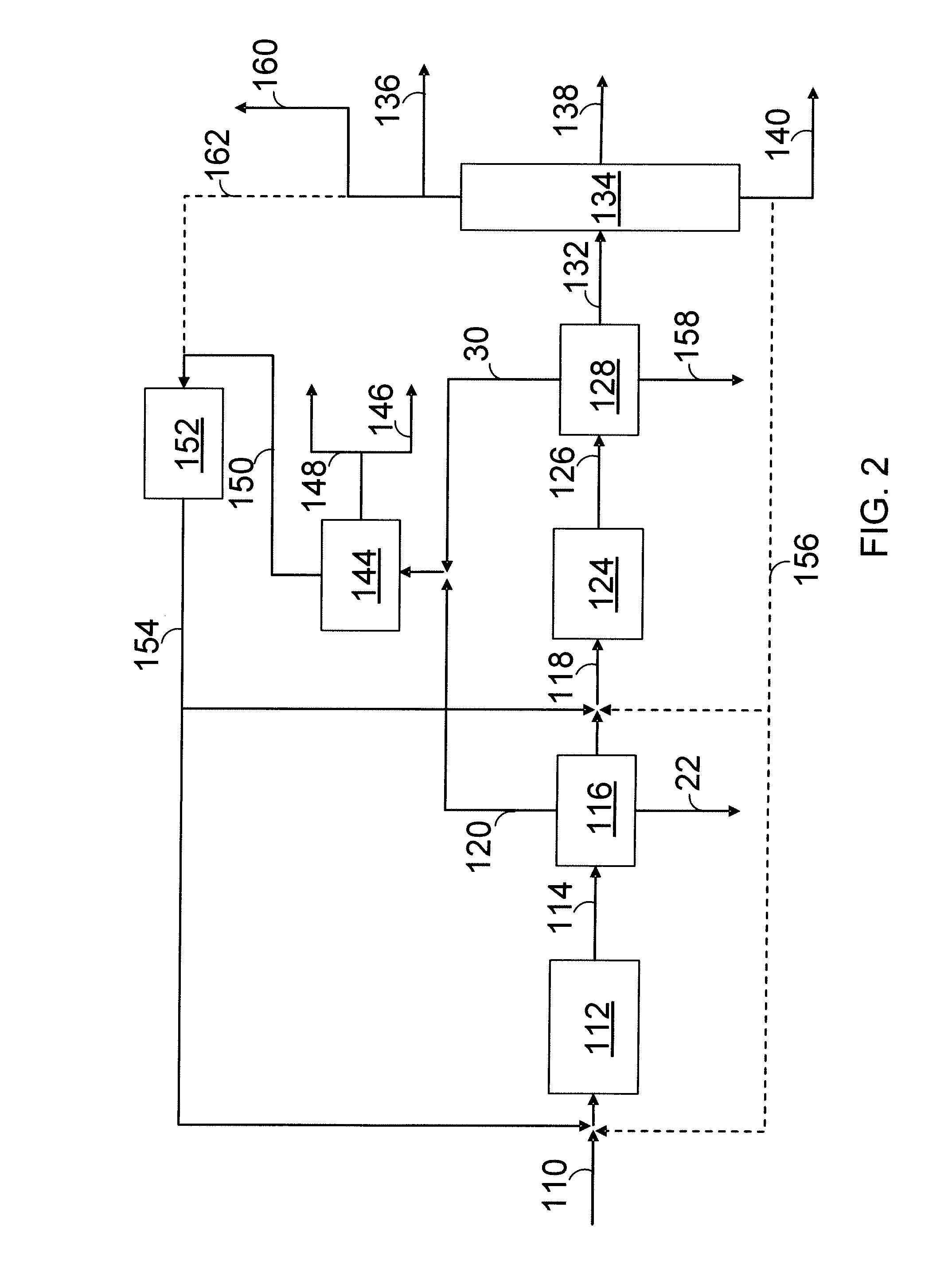

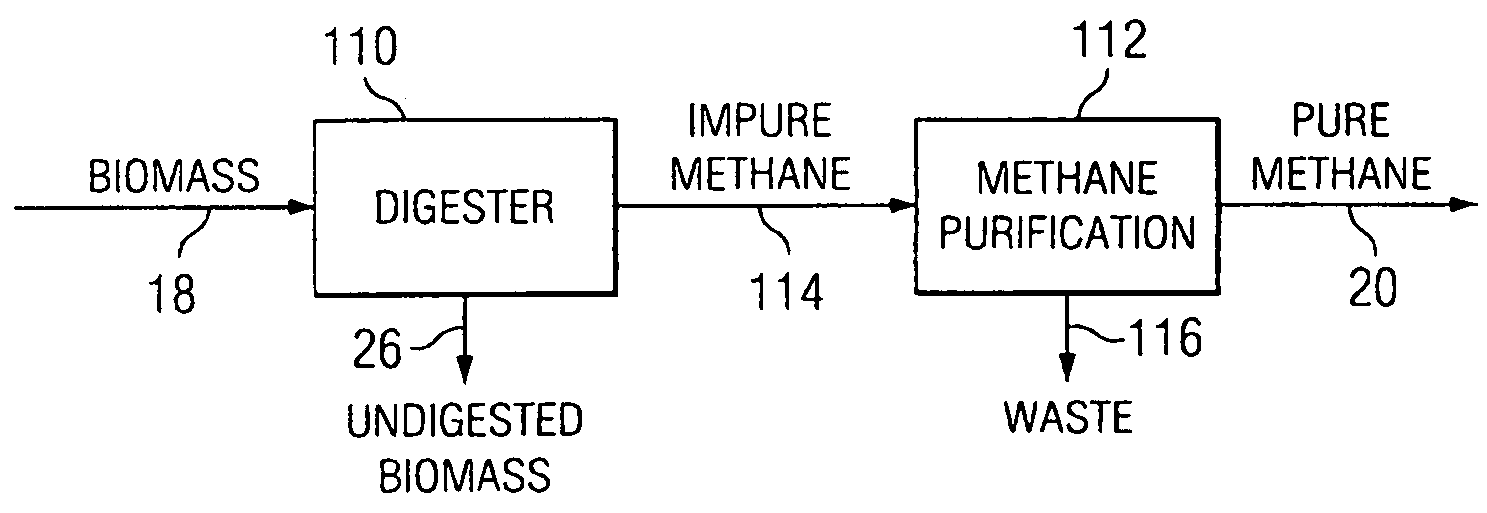

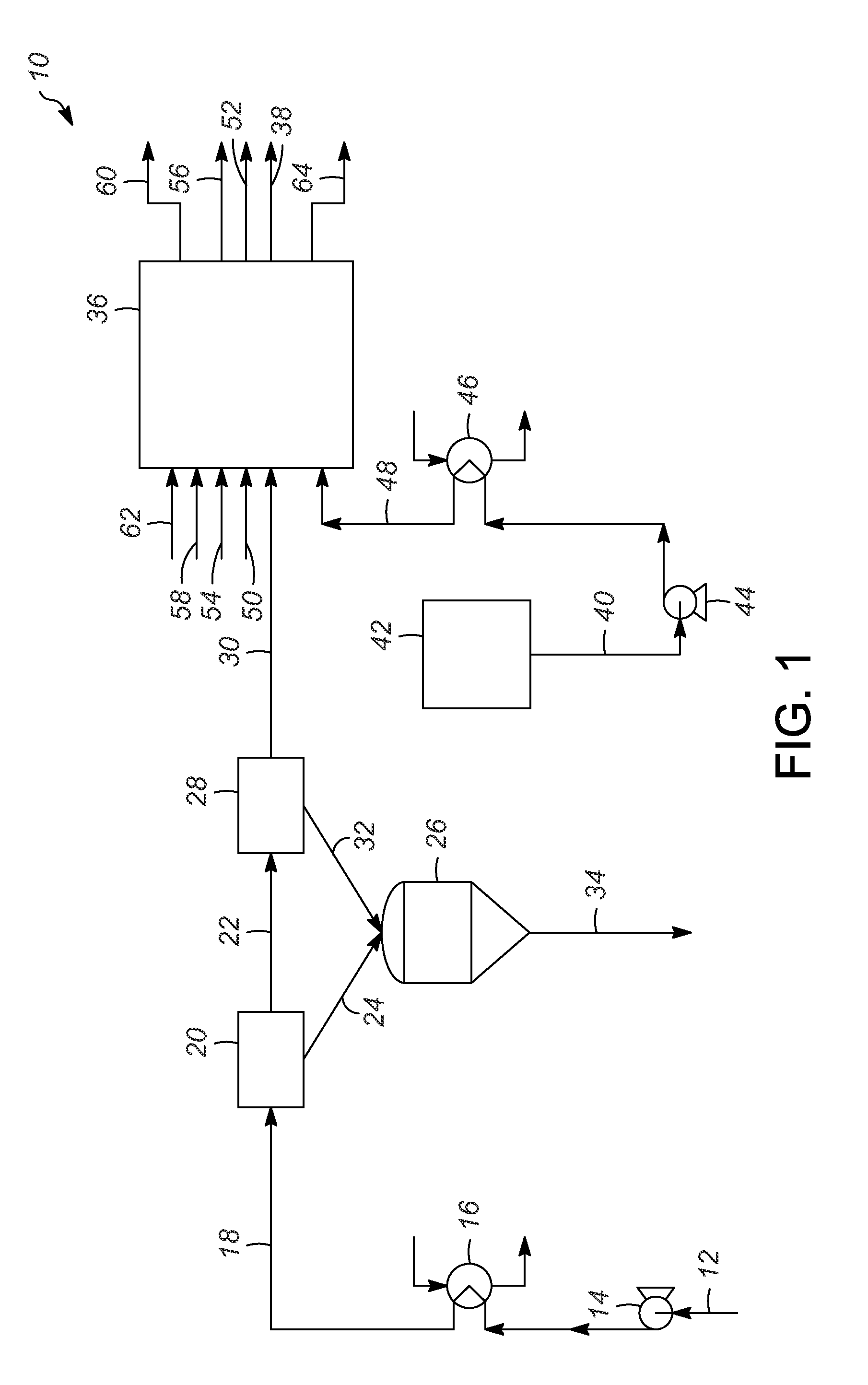

According to an embodiment, a biomass conversion subsystem produces methane and / or alcohol and residual biomass. A pyrolysis or a gasification subsystem is used to produce thermal energy and / or process gasses. The thermal energy may be stored thermal energy in the form of a pyrolysis oil. A fuel conversion subsystem produces liquid hydrocarbon fuels from the methane and / or alcohol using thermal energy and / or process gasses produced by the gasification or pyrolysis subsystem. Because the biomass production system integrates the residual products from biomass conversion and the residual thermal energy from pyrolysis or gasification, the overall efficiency of the integrated biomass production system is greatly enhanced.

Owner:TEXAS A&M UNIVERSITY

Method and system for capturing carbon dioxide from biomass pyrolysis process

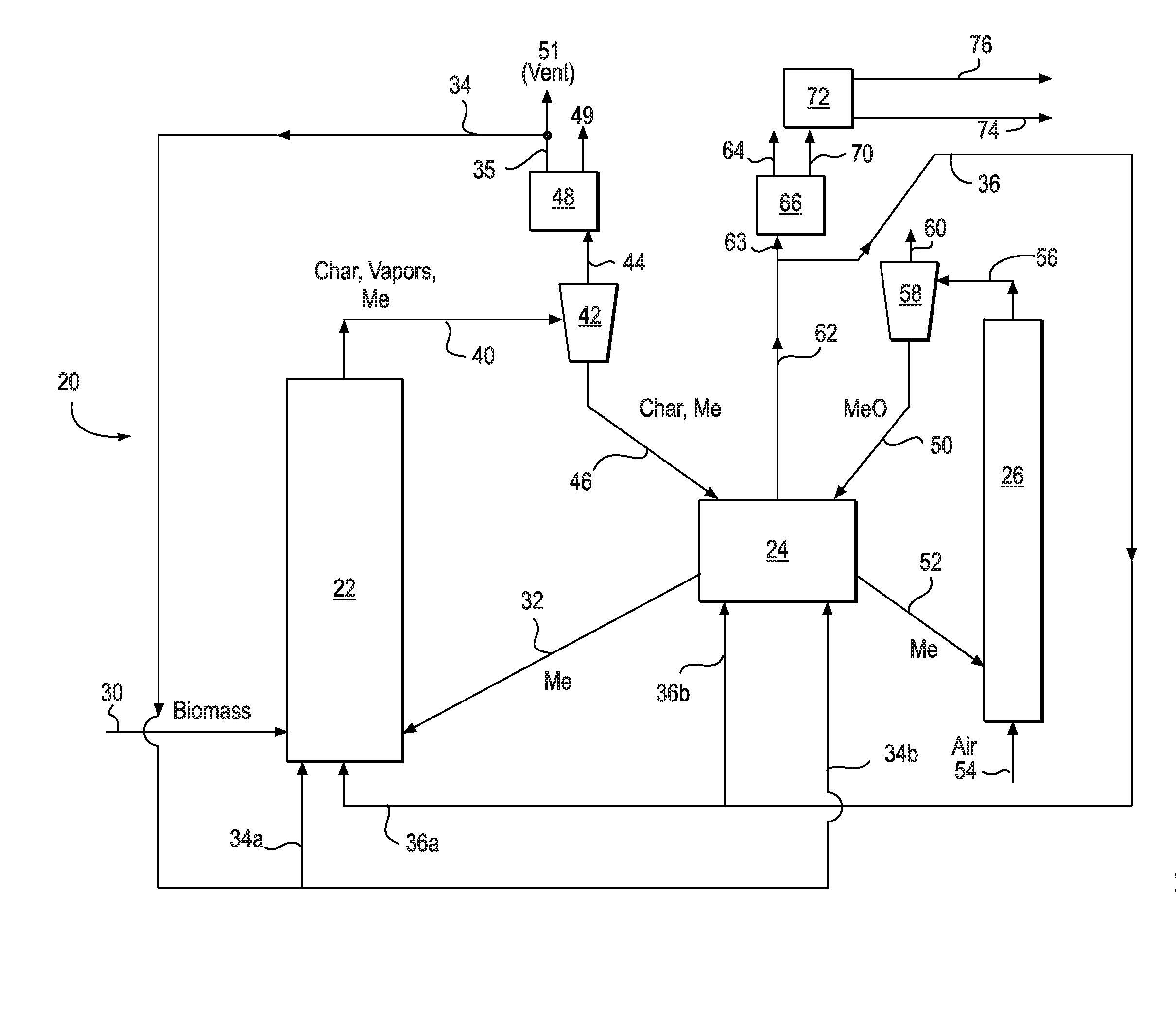

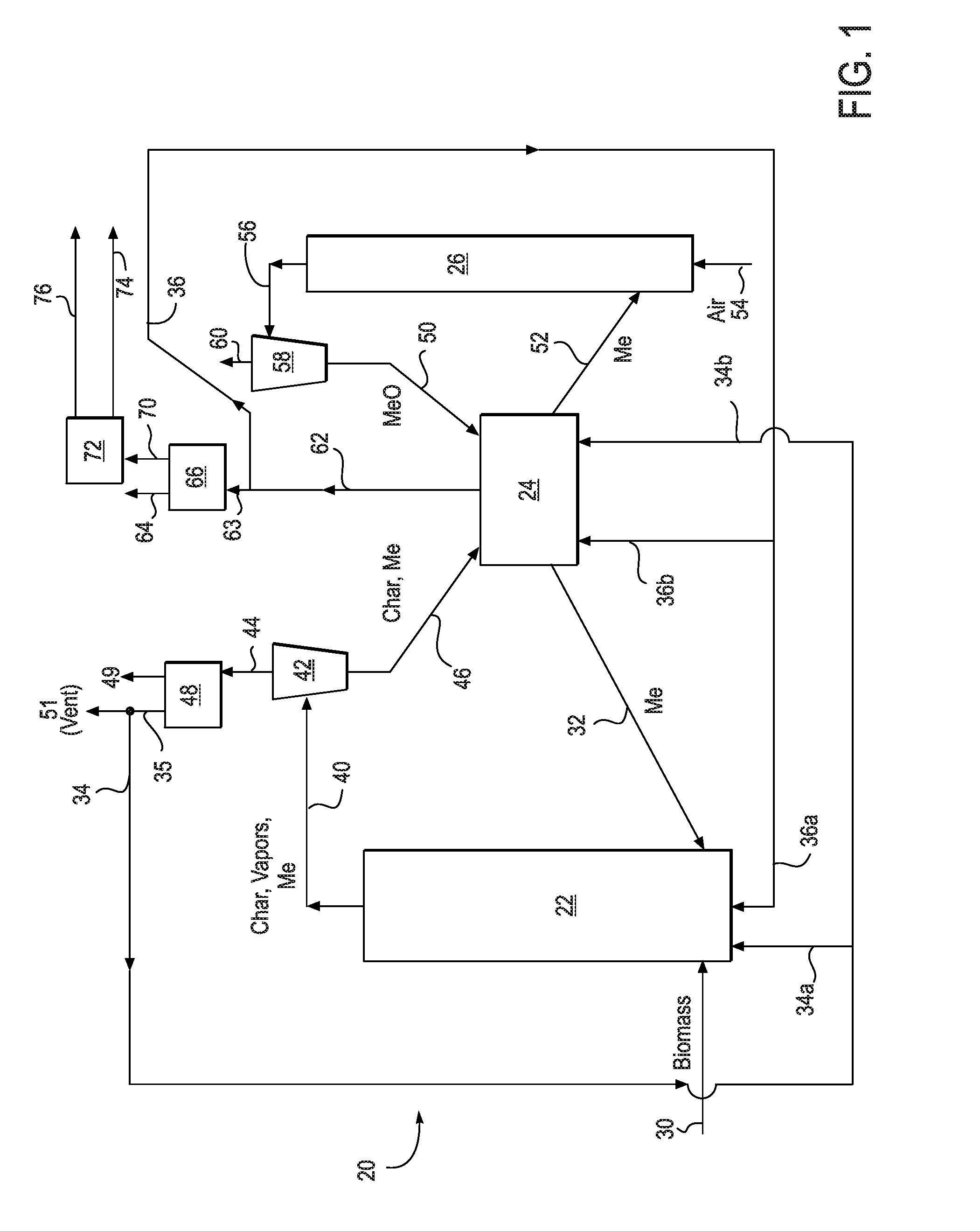

A system and method for biomass pyrolysis utilizing chemical looping combustion of a produced char to capture carbon dioxide is disclosed. The system includes a biomass pyrolysis reactor, a char combustor, and oxidation reactor and a separator for separating carbon dioxide from flue gas produced by the char combustion. The pyrolysis reactor pyrolyzes biomass in the presence of reduced metal oxide sorbents producing char and pyrolysis oil vapor. The char is separated and combusted in the char combustor, in the presence of oxidized metal oxide sorbents, into a gaseous stream of carbon dioxide and water vapor. The carbon dioxide and water are separated so that a stream of carbon dioxide may be captured. The oxidation reactor oxidizes, in the presence of air, a portion of reduced metal oxide sorbents into oxidized metal oxide sorbents that are looped back to the char combustor to provide oxygen for combustion. A second portion of the reduced metal oxide sorbents is recycled from the char combustor to the pyrolysis reactor to provide heat to drive the pyrolysis. Pyrolysis oil upgrading catalyst particles may be used in addition to the metal oxide sorbents as heat energy carrier particles to improve the quality of the pyrolysis oil vapors produced in the pyrolysis reactor. Also, the metal oxide sorbents may have metals incorporated therein which serve to upgrade the pyrolysis vapors produced during pyrolysis. Non-limiting examples of such metals include Ni, Mo, Co, Cr, W, Rh, Ir, Re, and Ru.

Owner:CHEVROU USA INC

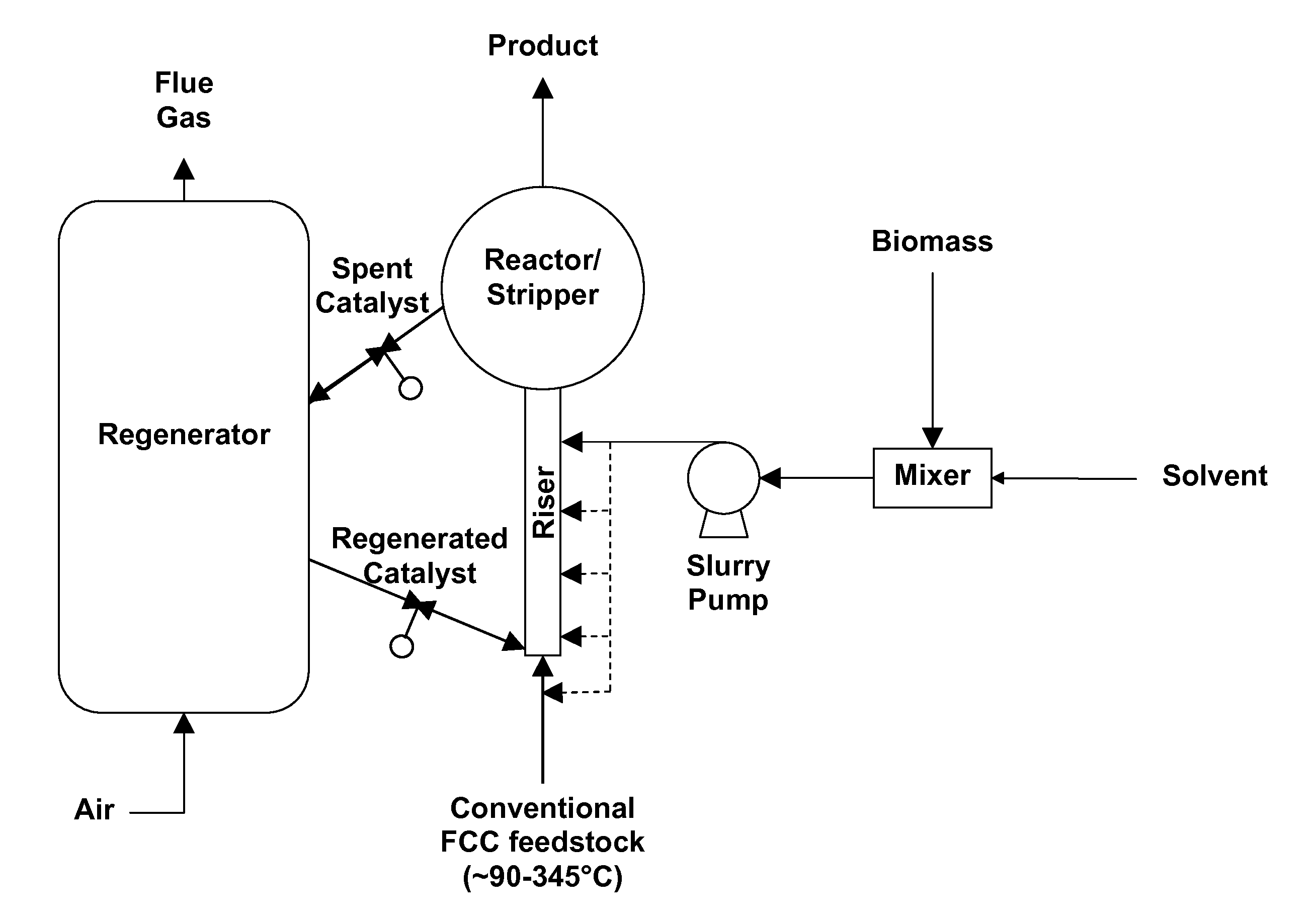

Integrated fcc biomass pyrolysis/upgrading

Owner:PHILLIPS 66 CO

Integrated biofuel production system

InactiveUS8153850B2Improve efficiencyIncrease energy densityGas production bioreactorsWaste based fuelThermal energySystem integration

According to an embodiment, a biomass conversion subsystem produces methane and / or alcohol and residual biomass. A pyrolysis or a gasification subsystem is used to produce thermal energy and / or process gasses. The thermal energy may be stored thermal energy in the form of a pyrolysis oil. A fuel conversion subsystem produces liquid hydrocarbon fuels from the methane and / or alcohol using thermal energy and / or process gasses produced by the gasification or pyrolysis subsystem. Because the biomass production system integrates the residual products from biomass conversion and the residual thermal energy from pyrolysis or gasification, the overall efficiency of the integrated biomass production system is greatly enhanced.

Owner:TEXAS A&M UNIVERSITY

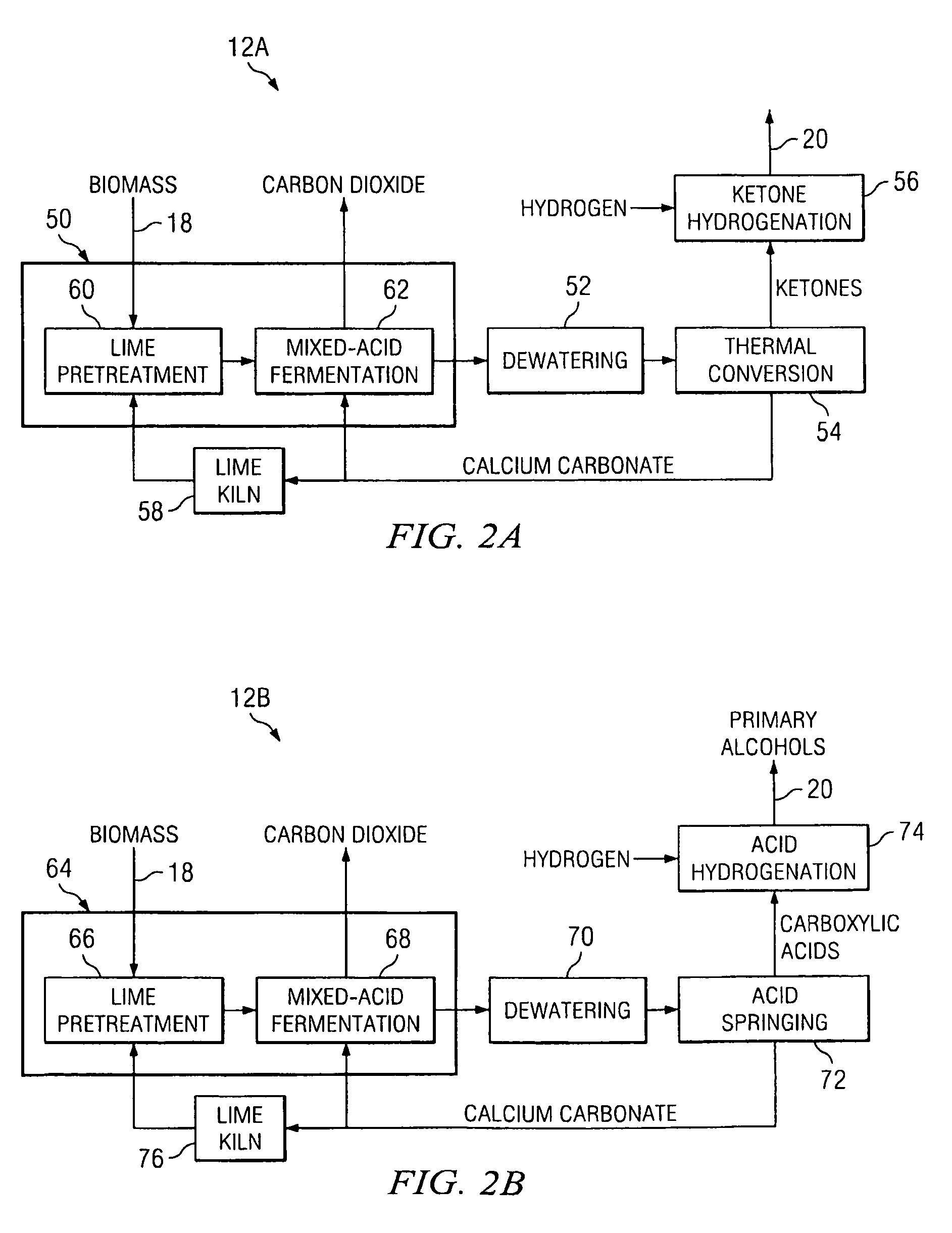

Systems and methods for producing fuels from biomass

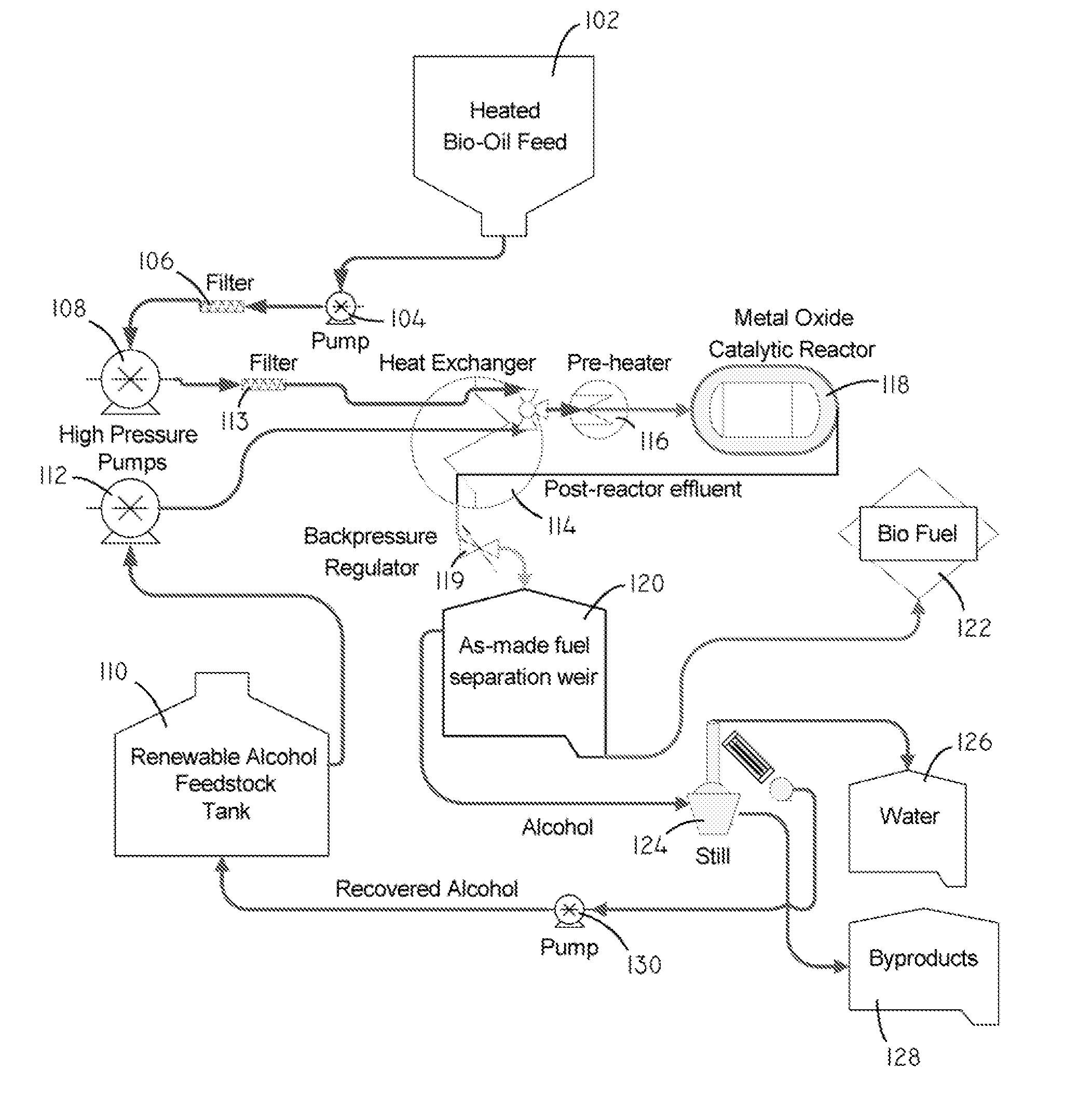

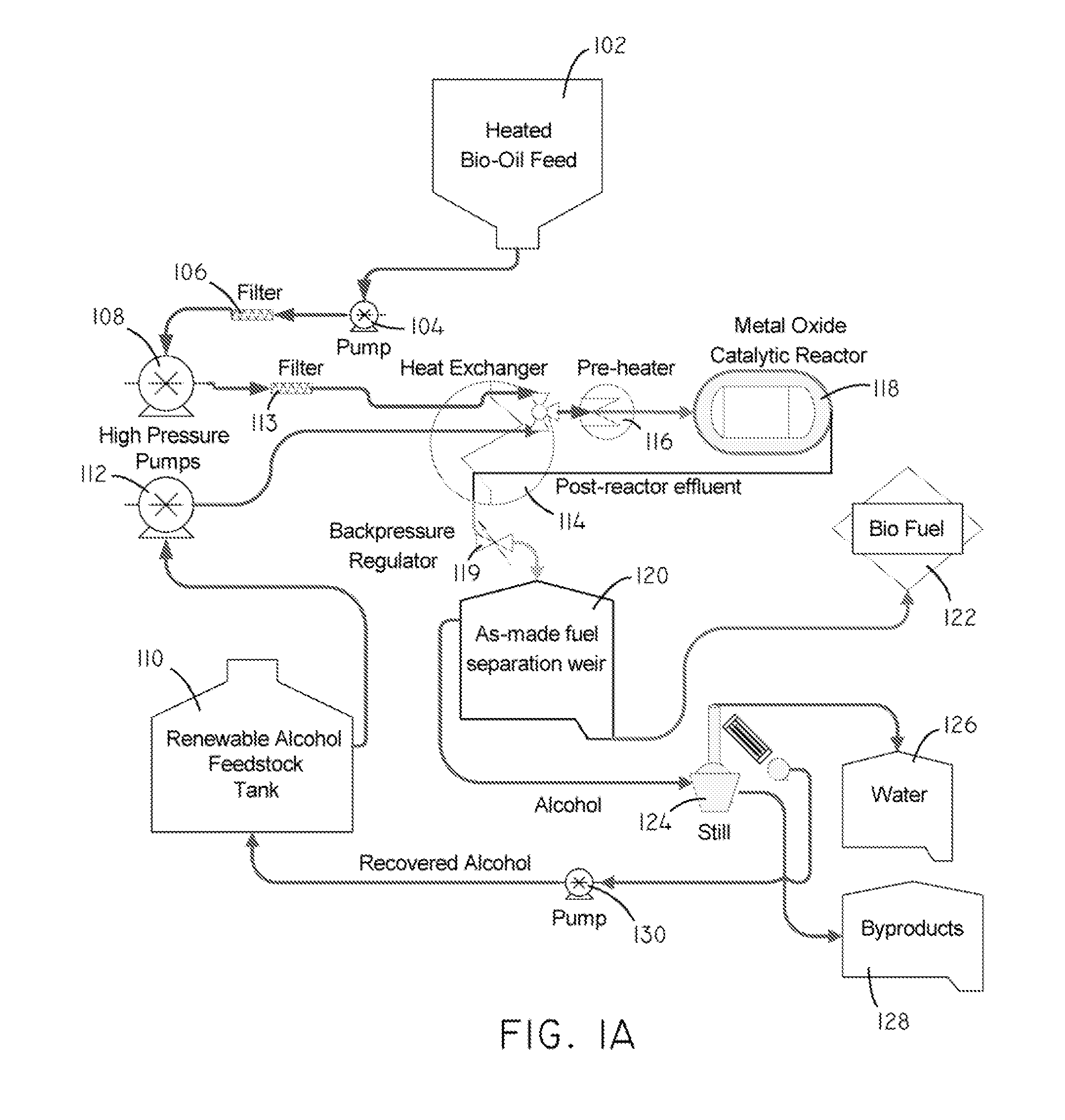

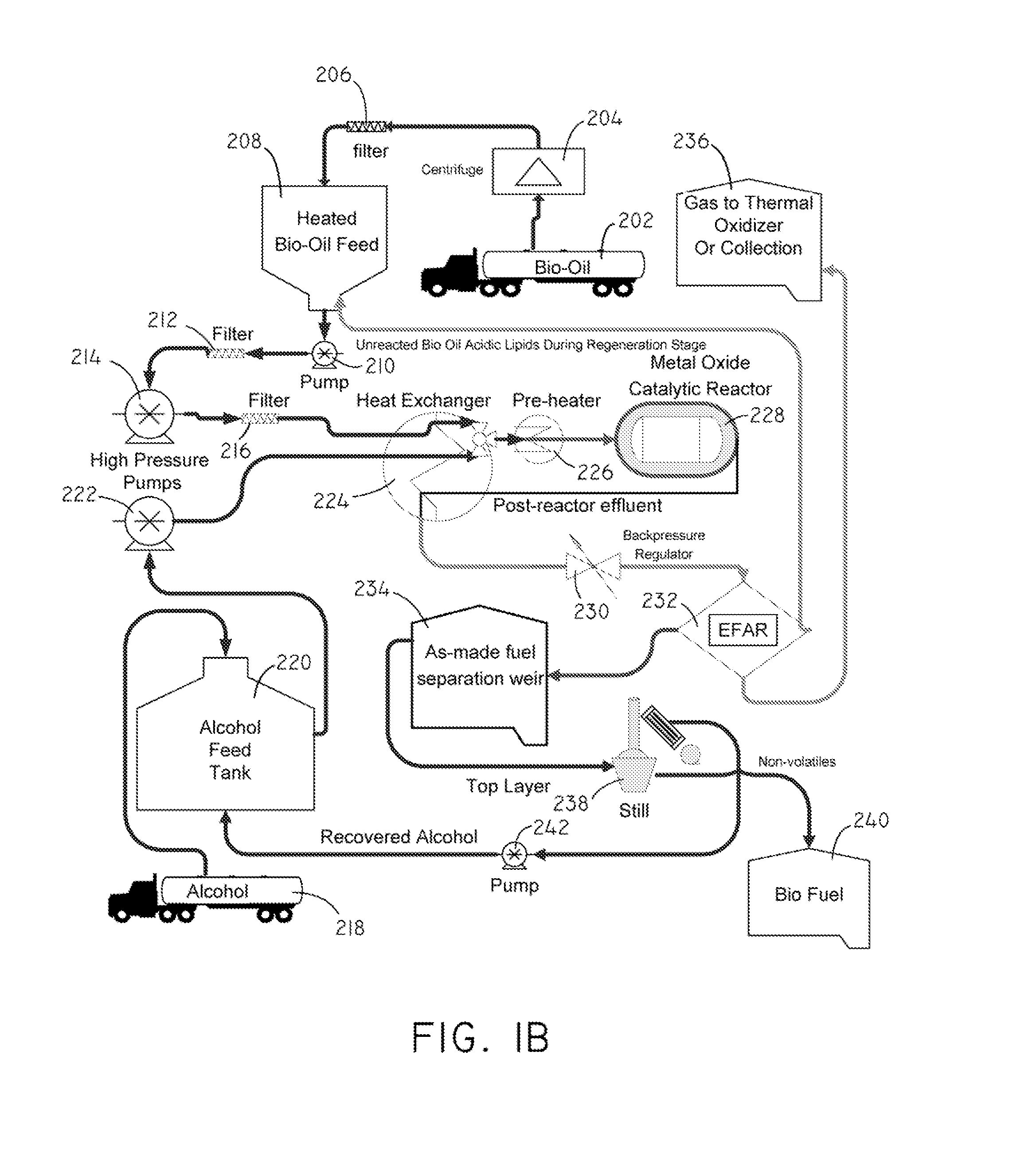

The present invention relates to systems and methods for producing fuels. In an embodiment, the invention includes a method of producing a diesel-equivalent fuel, including pyrolyzing biomass to form a pyrolysis oil and contacting the pyrolysis oil and an alcohol with a metal oxide catalyst at a temperature of greater than about 60 degrees Celsius. In an embodiment, the invention includes a method of refining pyrolysis oil including contacting pyrolysis oil and an alcohol with a metal oxide catalyst at a temperature of greater than about 60 degrees Celsius. In an embodiment, the invention includes a system for processing biomass into fuel including a pyrolysis chamber defining an interior volume; a first heating element configured to heat the pyrolysis chamber; a refining chamber in selective fluid communication with the pyrolysis chamber, the refining chamber defining an interior volume, a metal oxide catalyst disposed within the interior volume; and a second heating element configured to heat the refining chamber. Other embodiments are also described herein.

Owner:SARTEC

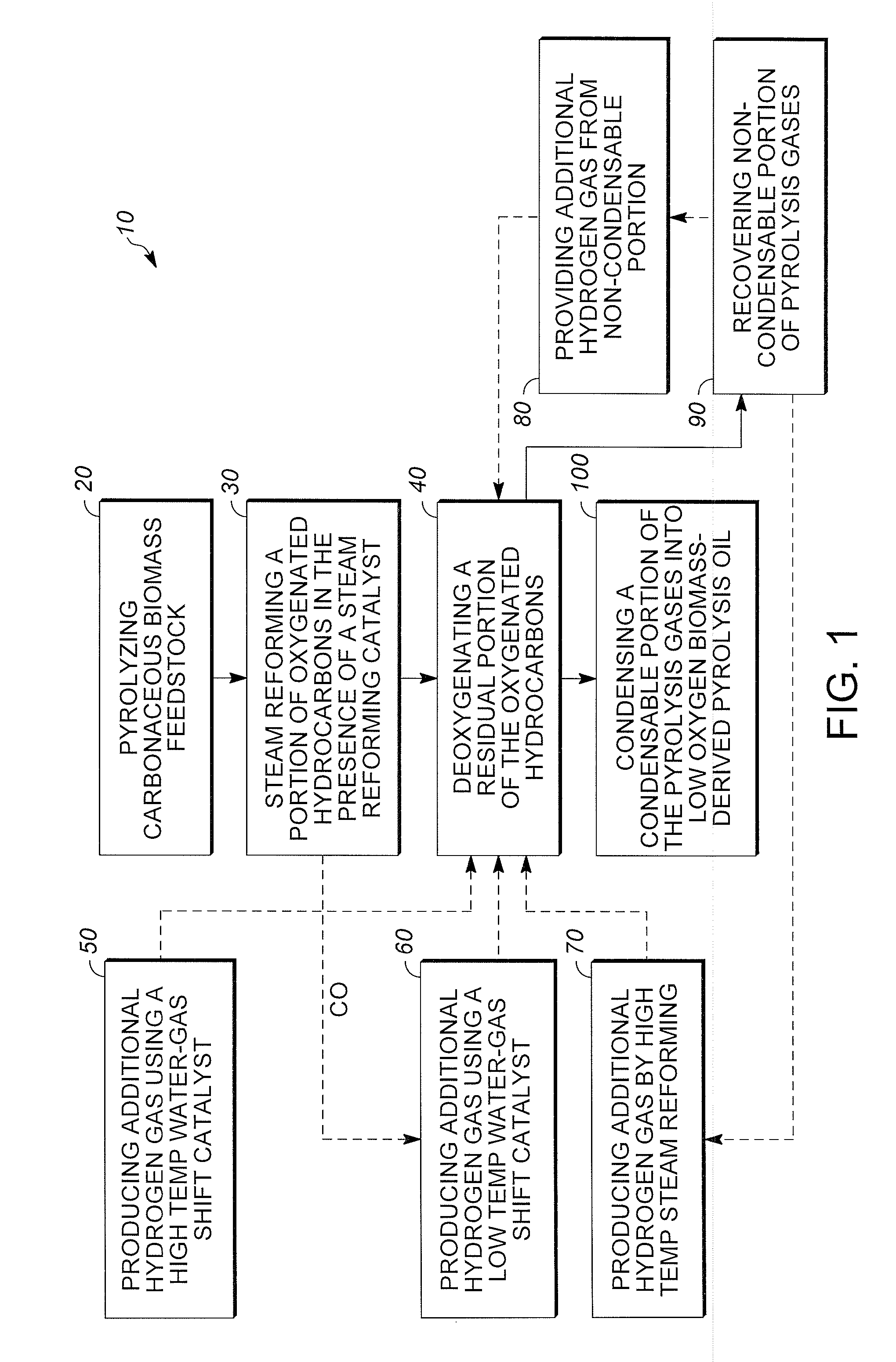

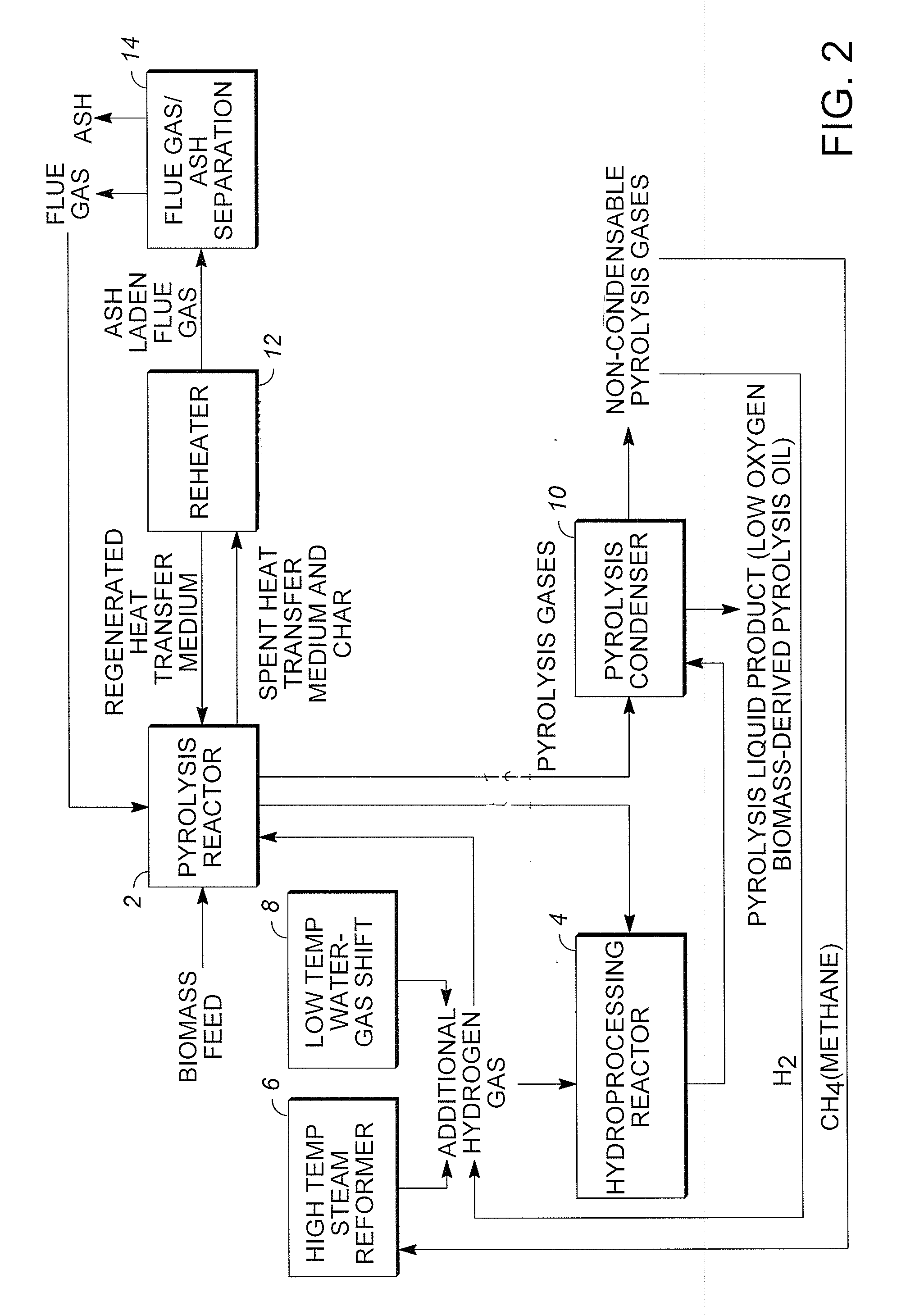

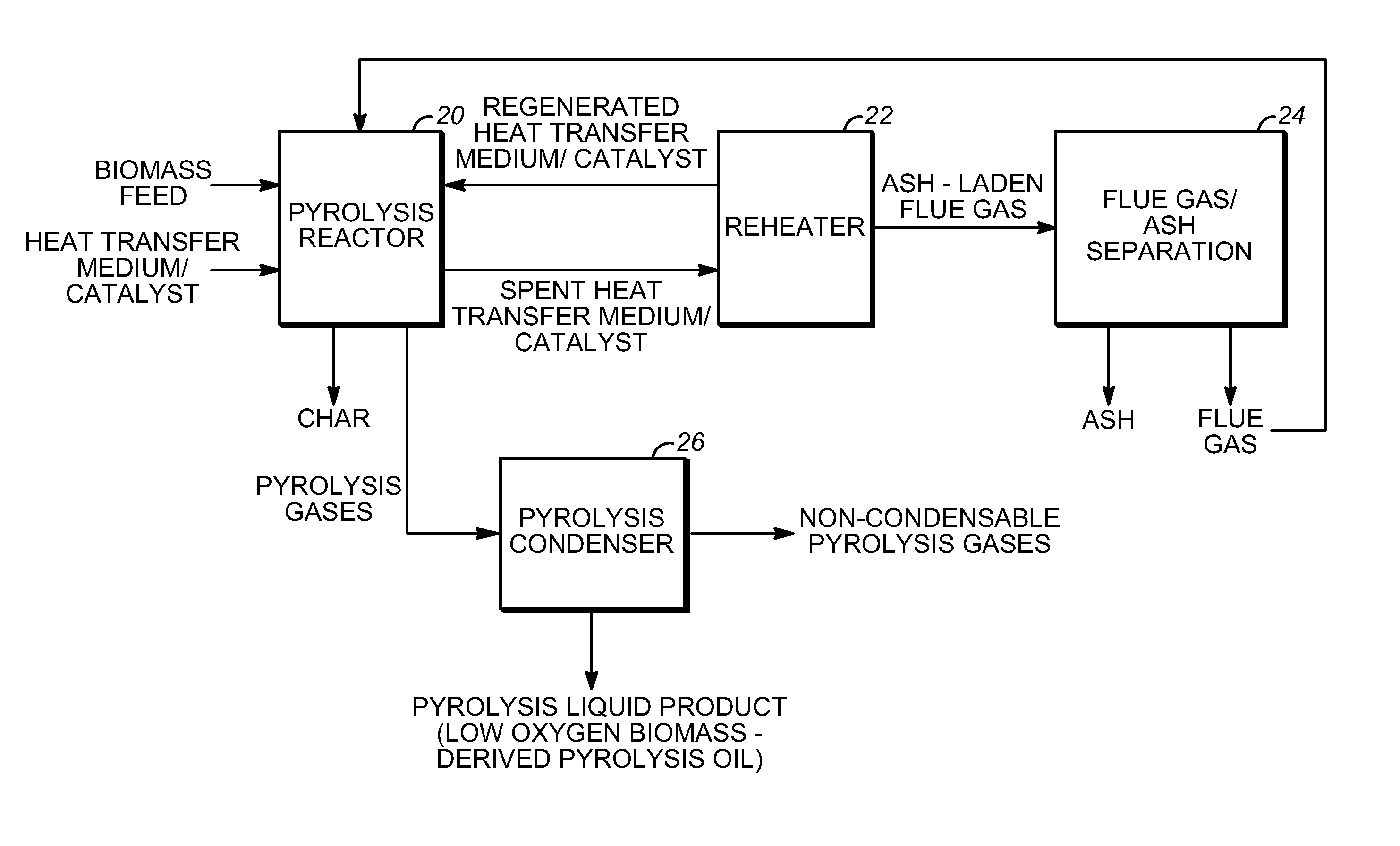

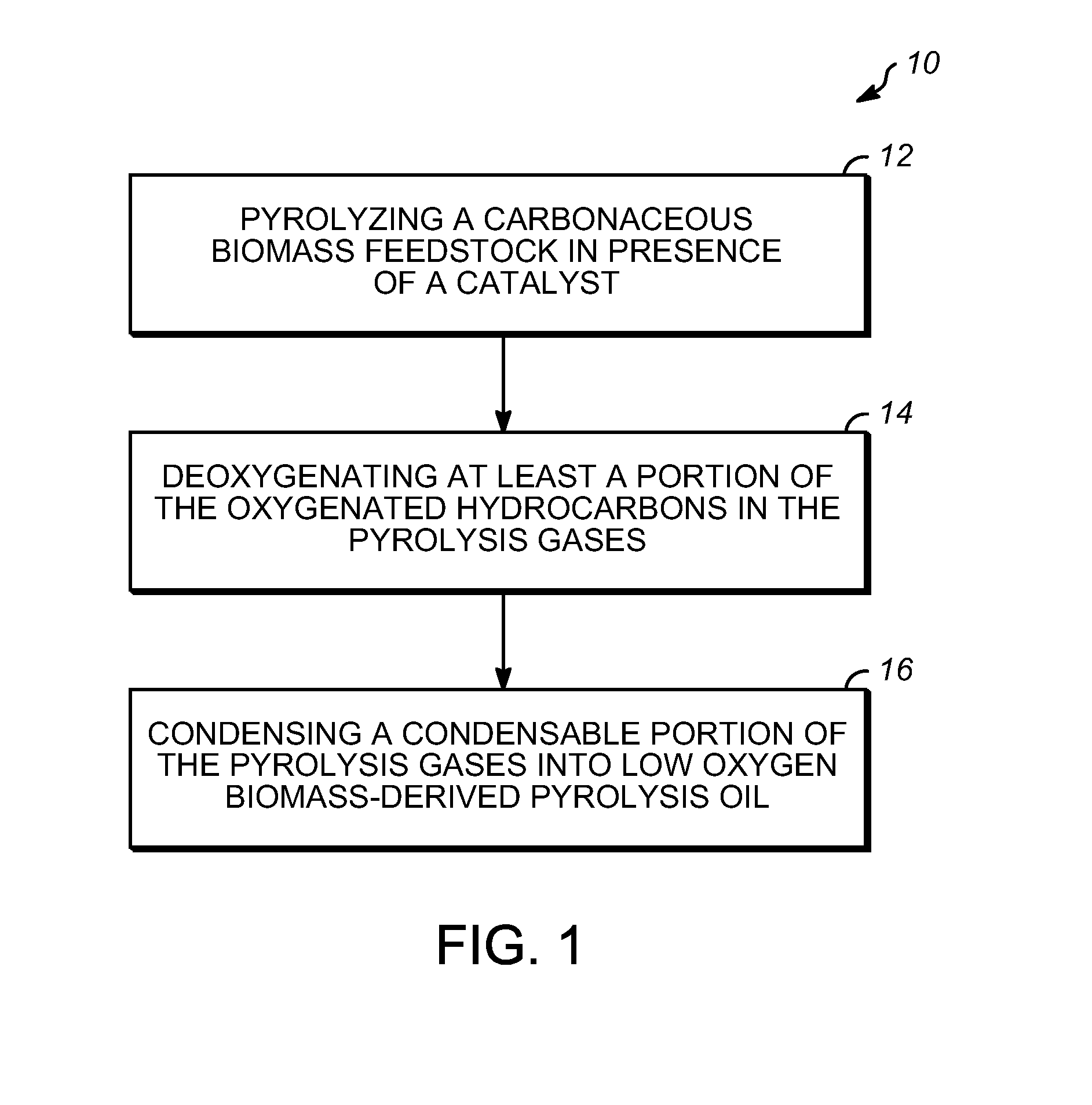

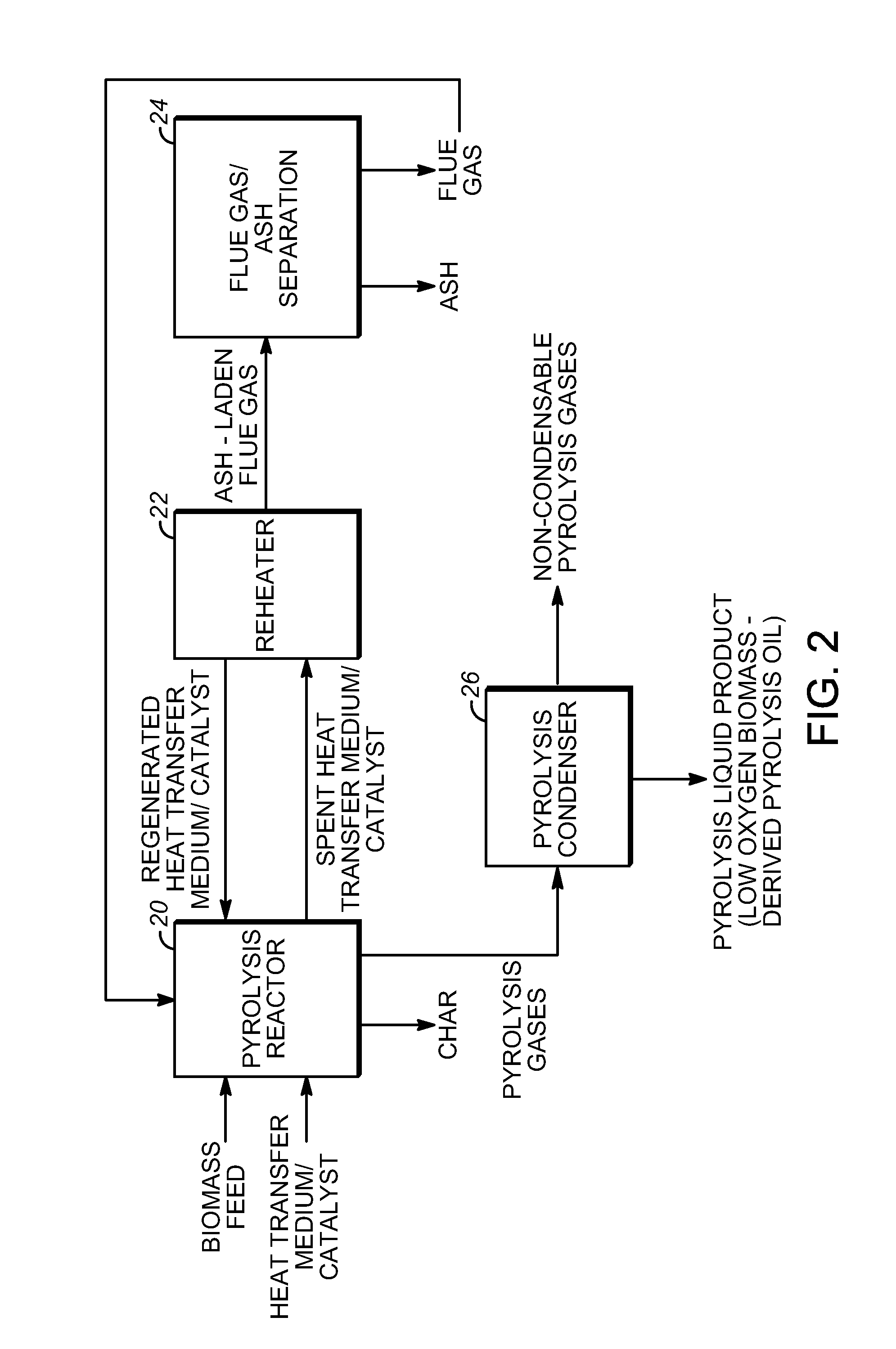

Low oxygen biomass-derived pyrolysis oils and methods for producing the same

InactiveUS20110201854A1Direct heating destructive distillationBiofuelsSteam reformingPartial oxidation

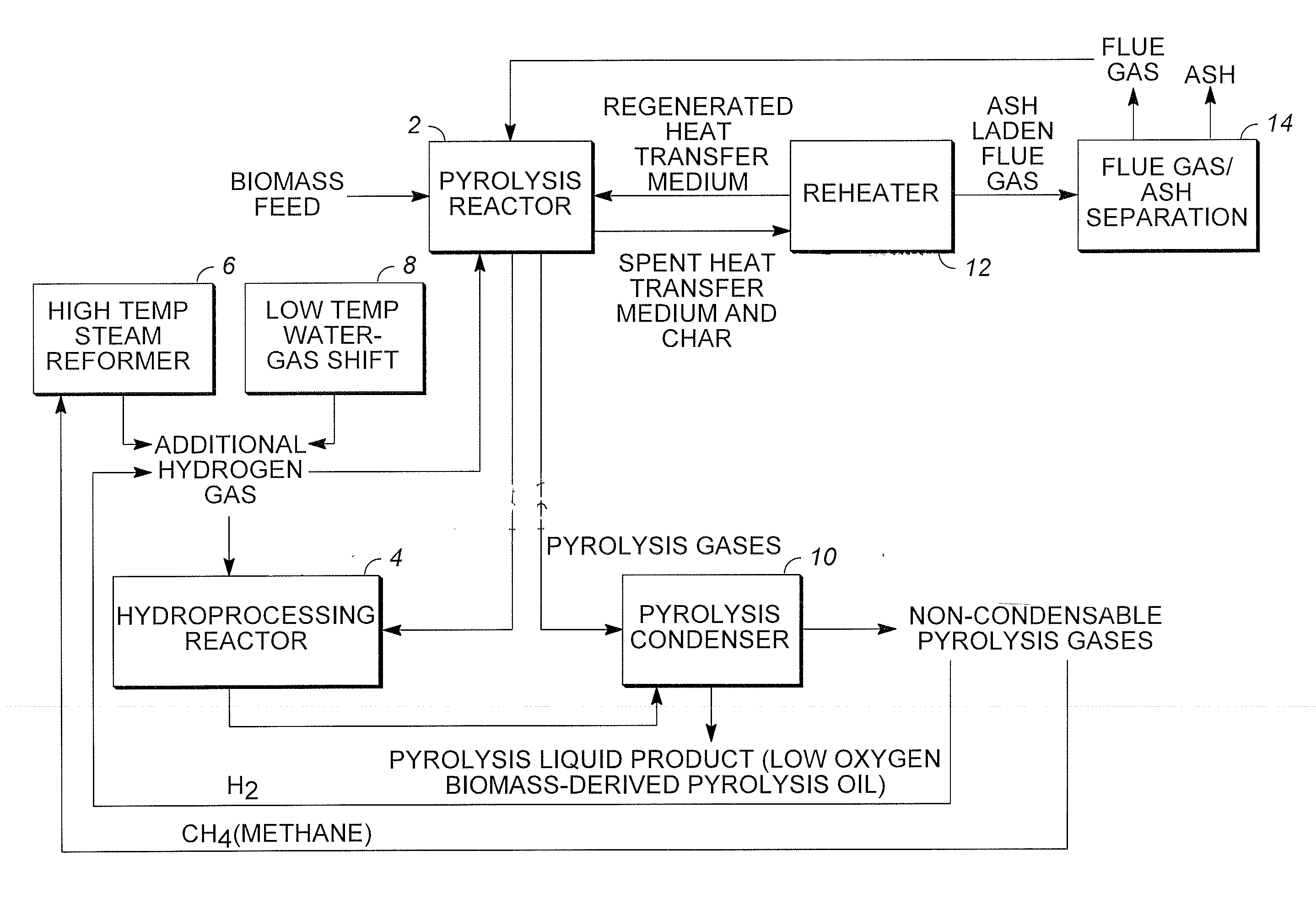

Methods are provided for producing low oxygen biomass-derived pyrolysis oil from carbonaceous biomass feedstock. The carbonaceous biomass feedstock is pyrolyzed in the presence of a steam reforming catalyst to produce char and pyrolysis gases. During pyrolysis, a portion of the oxygenated hydrocarbons in the pyrolysis gases is converted into hydrocarbons by steam reforming also yielding carbon oxides and hydrogen gas. The hydrogen gas at least partially deoxygenates a residual portion of the oxygenated hydrocarbons. Additional hydrogen gas may also be produced by water-gas shift reactions to deoxygenate the residual portion of the oxygenated hydrocarbons in the pyrolysis gases. Deoxygenation may occur in the presence of a hydroprocessing catalyst. A condensable portion of the pyrolysis gases is condensed to form low oxygen biomass-derived pyrolysis oil.

Owner:UOP LLC

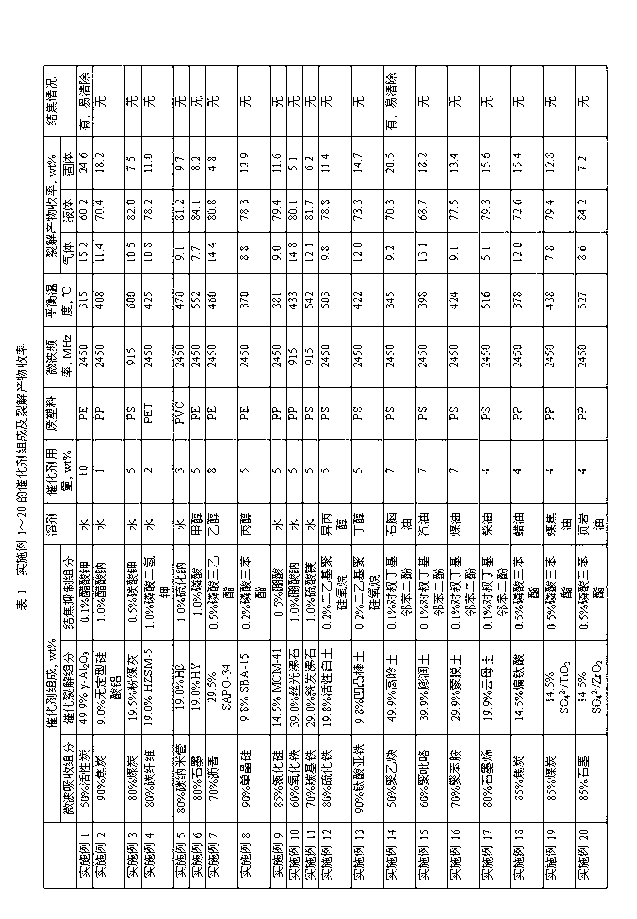

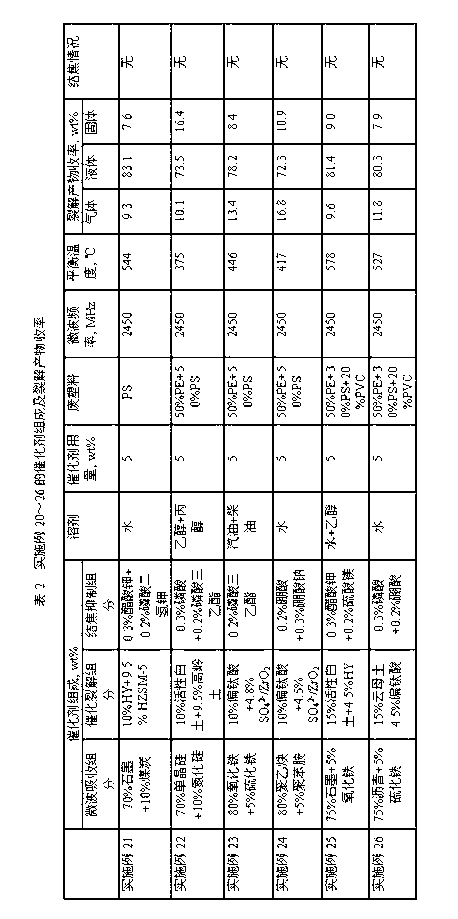

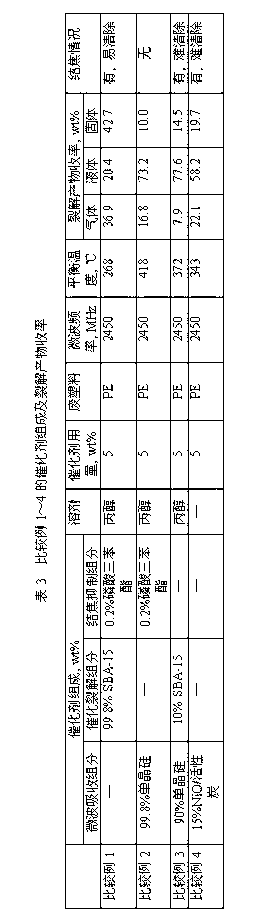

Catalyst for waste plastic microwave pyrolysis and preparation method thereof

InactiveCN103252226AEasy to prepareHigh yieldMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsMicrowave pyrolysisPtru catalyst

The invention discloses a catalyst for waste plastic microwave pyrolysis and a preparation method thereof. The catalyst comprises the following components by mass percent: 50.0-90.0% of a microwave absorption component, 9.0-49.9% of a catalytic cracking component, and 0.1-1.0% of a coking inhibiting component. The invention also discloses the preparation method of the catalyst. Compared with the prior art, the catalyst has the advantages that firstly, the catalyst has multiple functions, can effectively convert the microwave electromagnetic energy into heat, provides necessary energy for waste plastic pyrolysis and catalytic cracking, and can reach high equilibrium temperature in action; secondly, the yield of liquid pyrolysis oil is high, no coke is generated in the pyrolysis or the coke is loose and is easy to clear away; and thirdly, the preparation method of the catalyst is simple and is applicable to industrial production.

Owner:王文平 +2

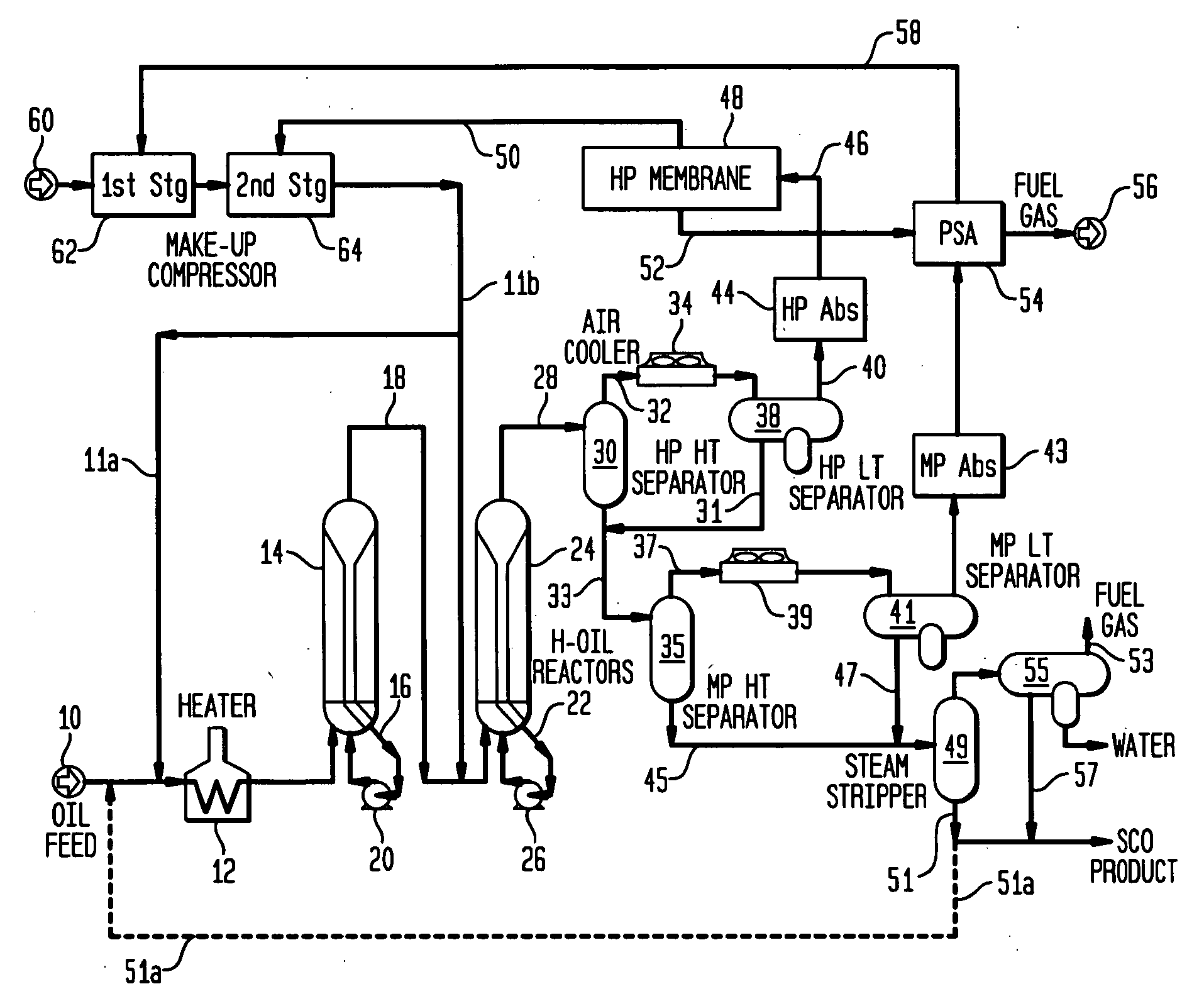

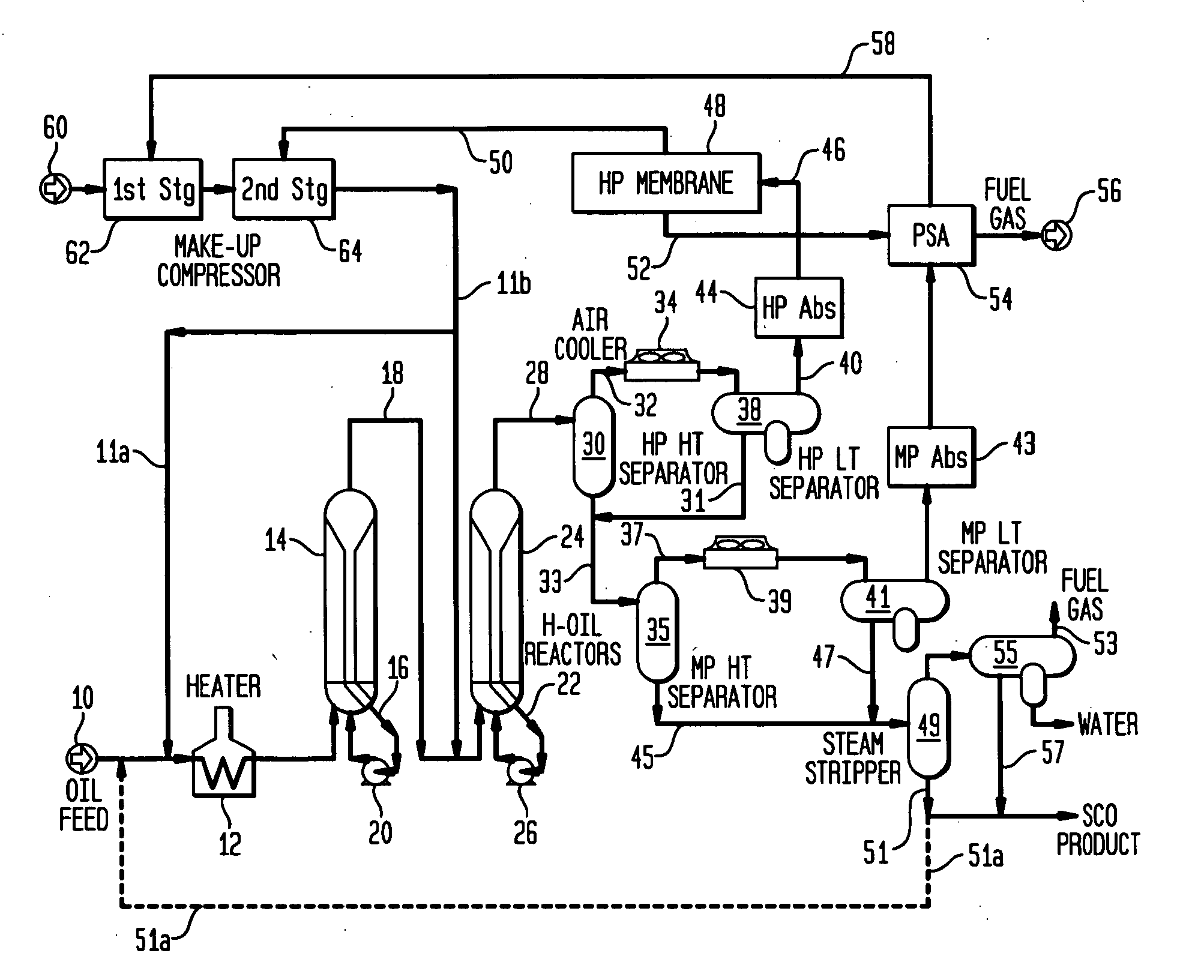

Process for upgrading coal pyrolysis oils

ActiveUS20100147743A1Reduce and eliminate needMinimize feedstock foulingLiquid hydrocarbon mixture productionHydrocarbon oil crackingOxygen contaminationPtru catalyst

This invention utilizes a novel method and set of operating conditions to efficiently and economically process a potentially very fouling hydrocarbon feedstock. A multi-stage catalytic process for the upgrading of coal pyrolysis oils is developed. Coal Pyrolysis Oils are highly aromatic, olefinic, unstable, contain objectionable sulfur, nitrogen, and oxygen contaminants, and,may contain coal solids which will plug fixed-bed reactors. The pyrolysis oil is fed with hydrogen to a multi-stage ebullated-bed hydrotreater and hydrocracker containing a hydrogenation or hydrocracking catalyst to first stabilize the feed at low temperature and is then fed to downstream reactor(s) at higher temperatures to further treat and hydrocrack the pyrolysis oils to a more valuable syncrude or to finished distillate products. The relatively high heat of reaction is used to provide the energy necessary to increase the temperature of the subsequent stage thus eliminating the need for additional external heat input. A refined heavy oil product stream is recycled to the fresh feed to minimize feedstock fouling of heat exchangers and feed heaters.

Owner:MACARTHUR JAMES B +2

Integrated solvent deasphalting and steam pyrolysis process for direct processing of a crude oil

ActiveUS9284497B2Thermal non-catalytic crackingTreatment with plural serial stages onlyFuel oilSteam pyrolysis

A process is provided that is directed to a steam pyrolysis zone integrated with a solvent deasphalting zone to permit direct processing of crude oil feedstocks to produce petrochemicals including olefins and aromatics. The integrated solvent deasphalting and steam pyrolysis process for the direct processing of a crude oil to produce olefinic and aromatic petrochemicals comprises charging the crude oil to a solvent deasphalting zone with an effective amount of solvent to produce a deasphalted and demetalized oil stream and a bottom asphalt phase; thermally cracking the deasphalted and demetalized oil stream in the presence of steam to produce a mixed product stream; separating the mixed product stream; recovering olefins and aromatics from the separated mixed product stream; and recovering pyrolysis fuel oil from the separated mixed product stream.

Owner:SAUDI ARABIAN OIL CO

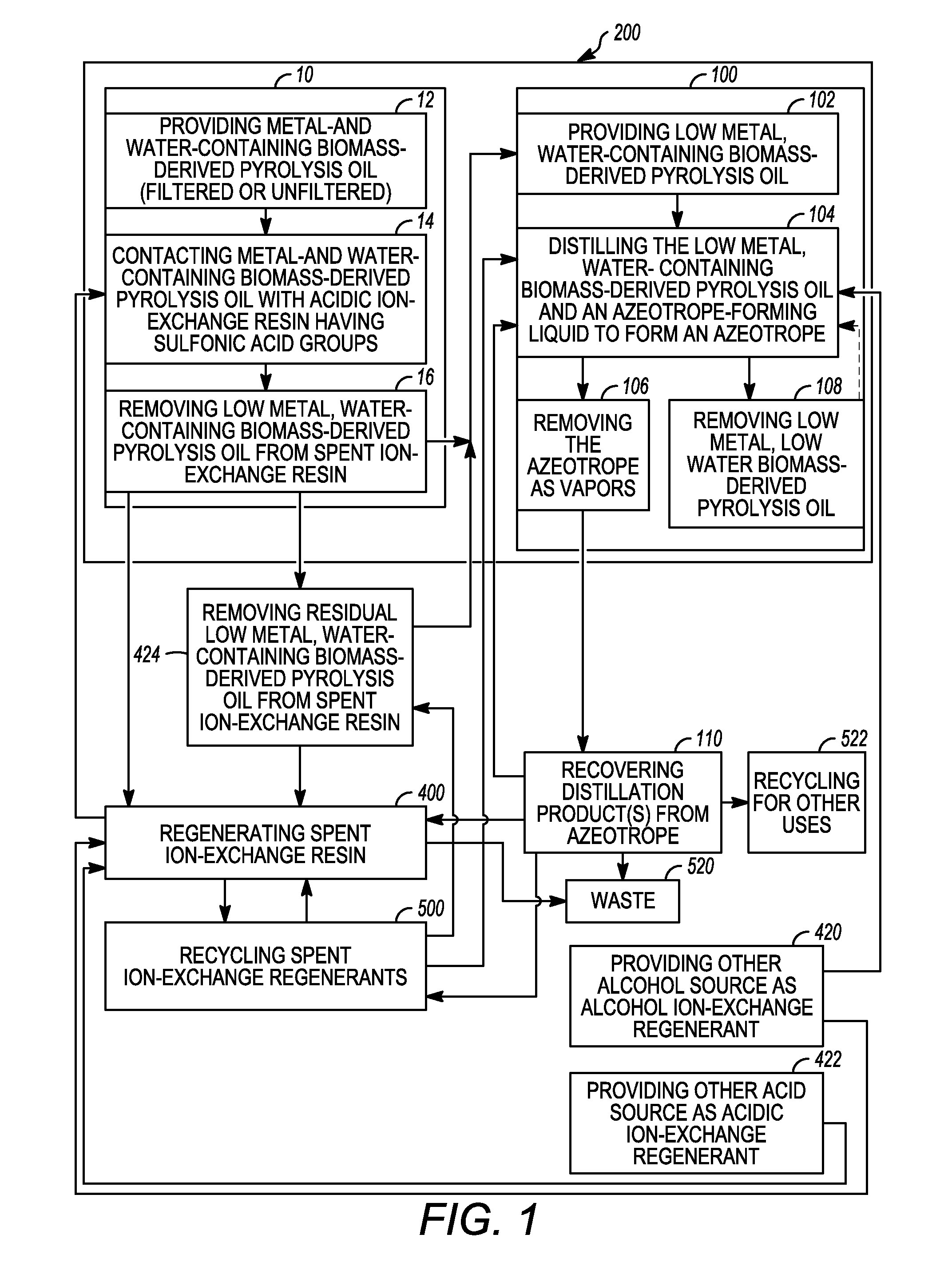

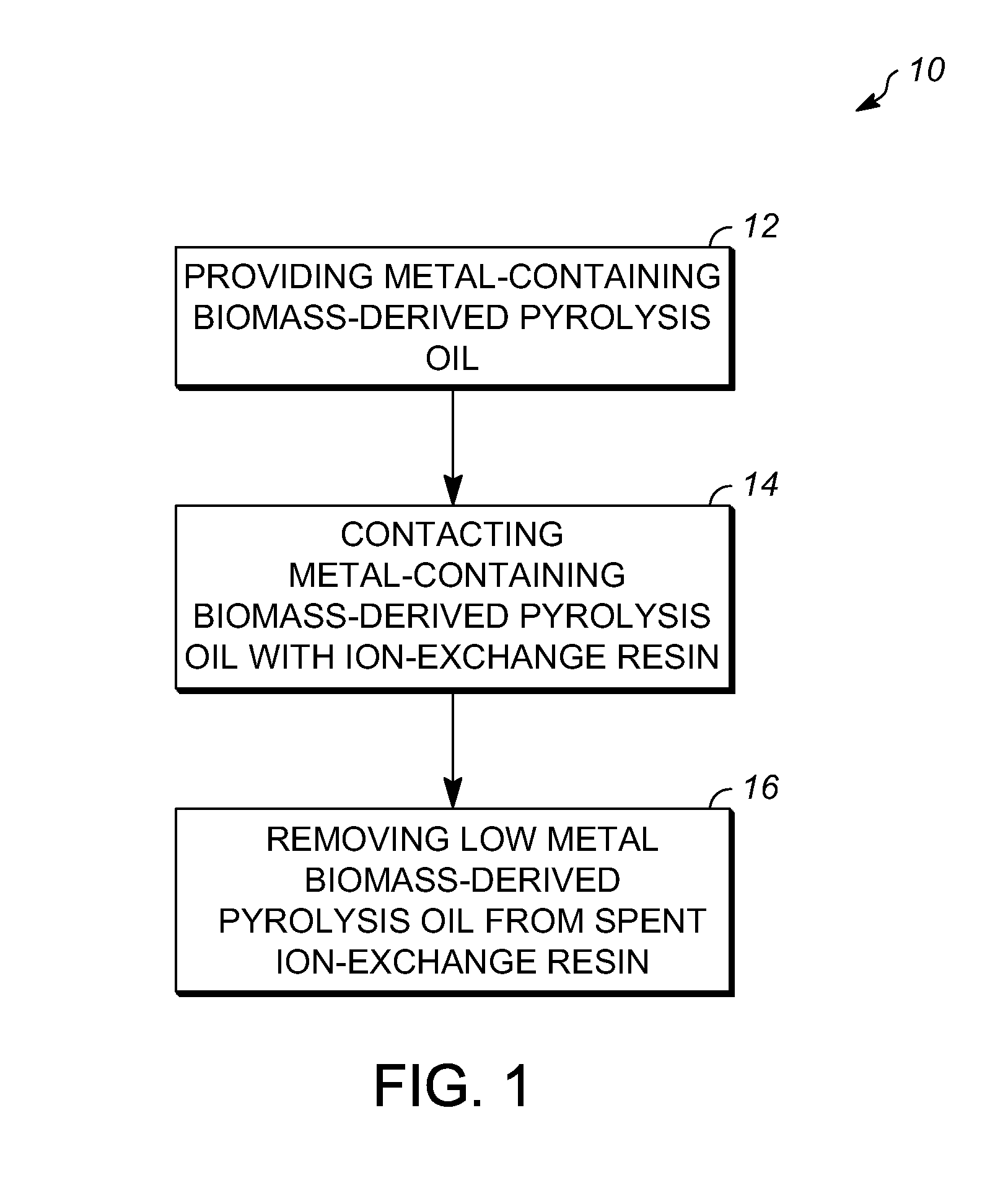

Low metal, low water biomass-derived pyrolysis oils and methods for producing the same

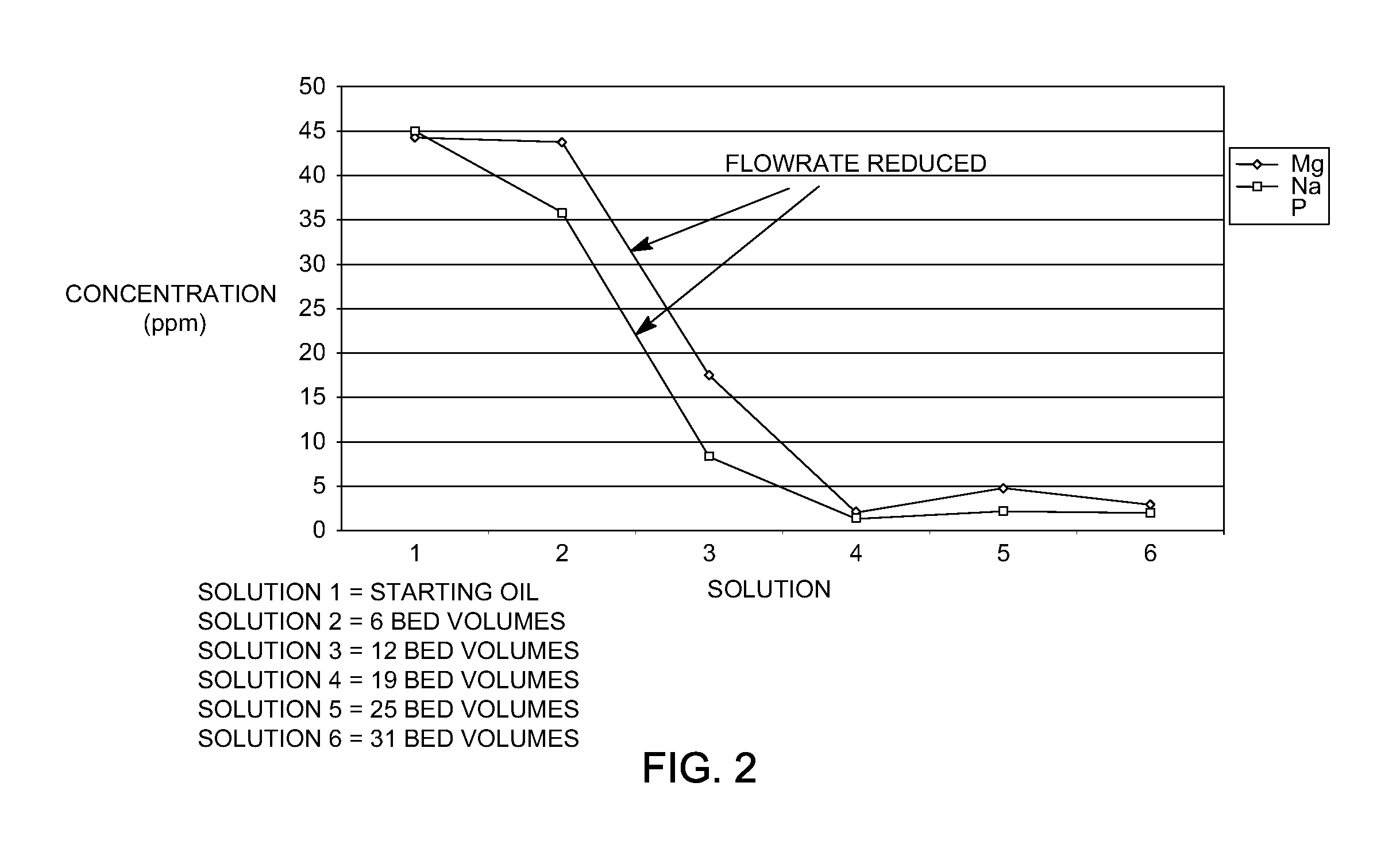

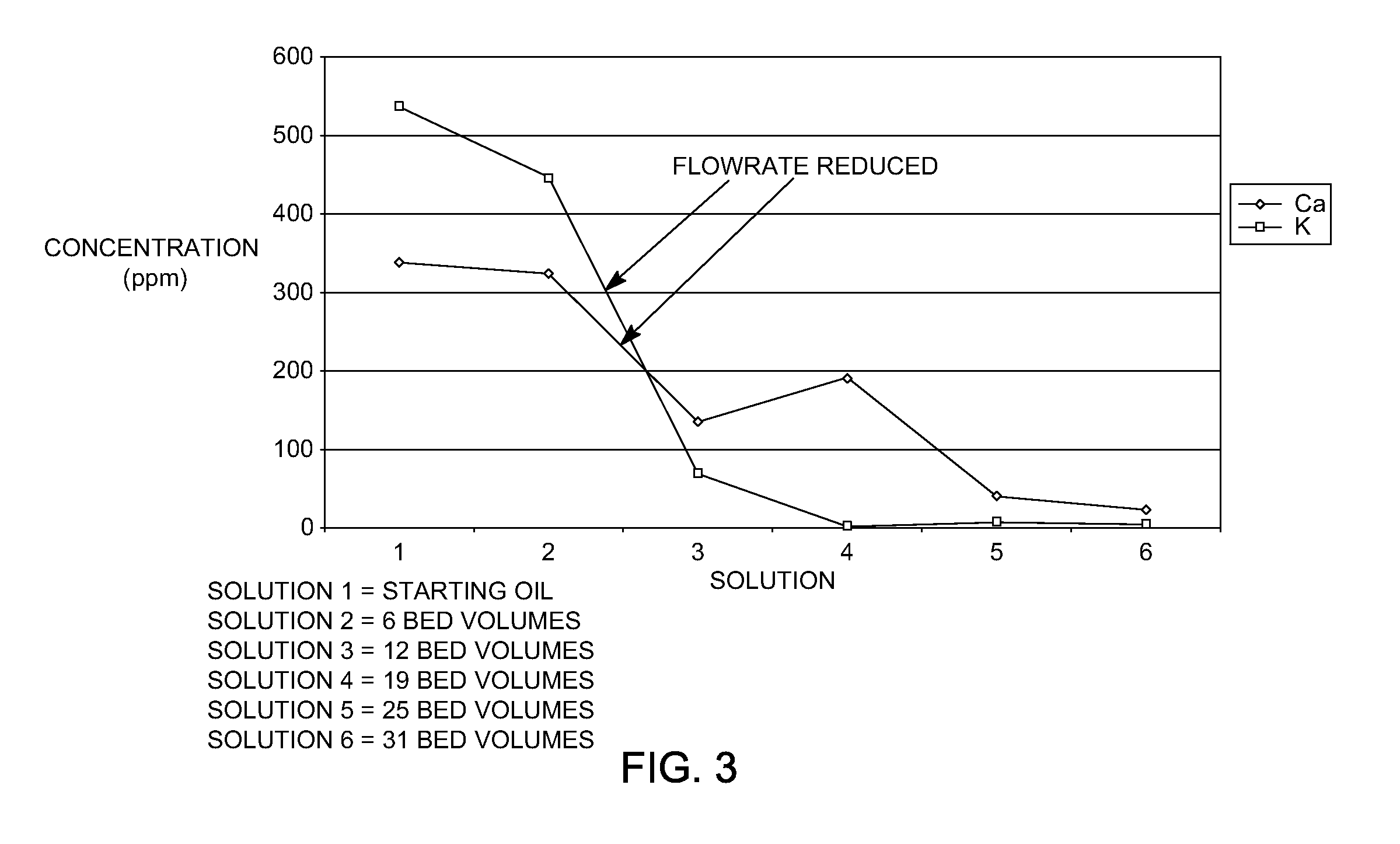

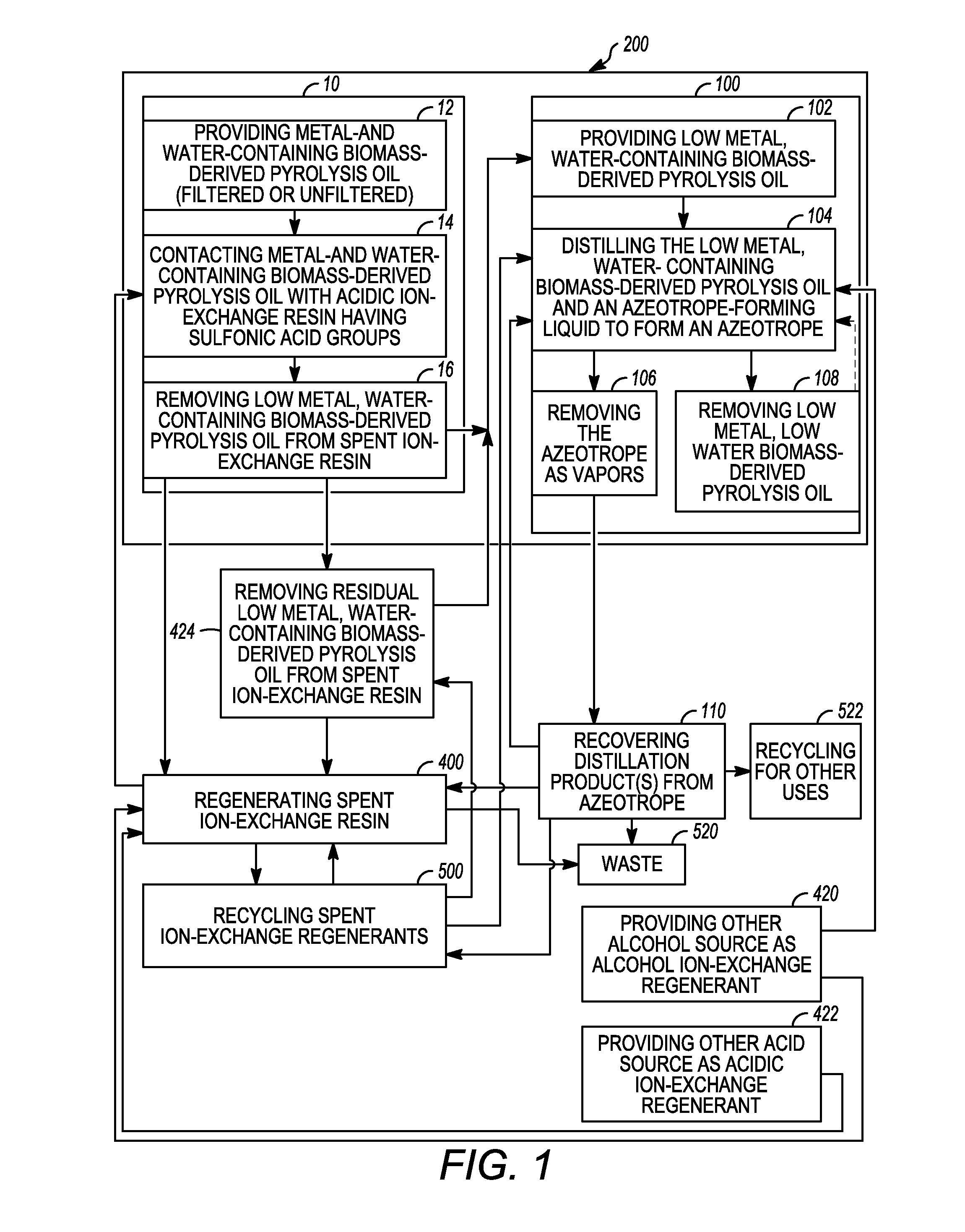

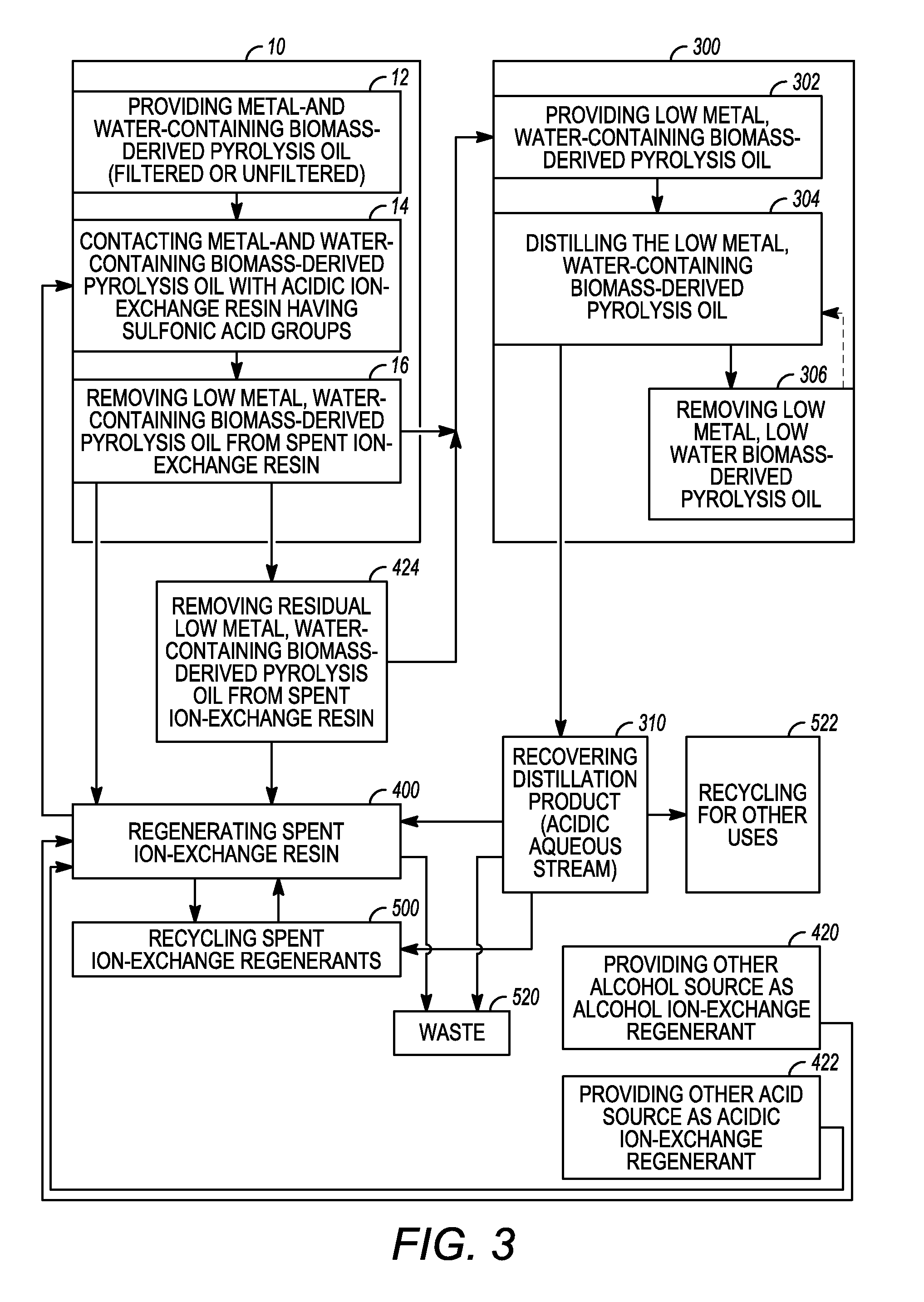

Low metal, low water biomass-derived pyrolysis oils and methods for producing the same are provided. Metal- and water-containing biomass-derived pyrolysis oil is contacted with an acidic ion-exchange resin having sulfonic acid groups to produce a low metal, water-containing biomass-derived pyrolysis oil. The low metal, water-containing biomass-derived pyrolysis oil is removed from the spent ion-exchange resin after ion-exchange. The low metal, water-containing biomass-derived pyrolysis oil is distilled to produce a low metal, low water biomass-derived pyrolysis oil and a distillation product. The distillation product comprises one or both of an alcohol ion-exchange regenerant and an acidic ion-exchange regenerant which may be used to regenerate the spent ion-exchange resin. The regenerated acidic ion-exchange resin may be recycled. The spent alcohol and acid ion-exchange regenerants may be recovered and recycled.

Owner:UOP LLC

Low water biomass-derived pyrolysis oil and processes for preparing the same

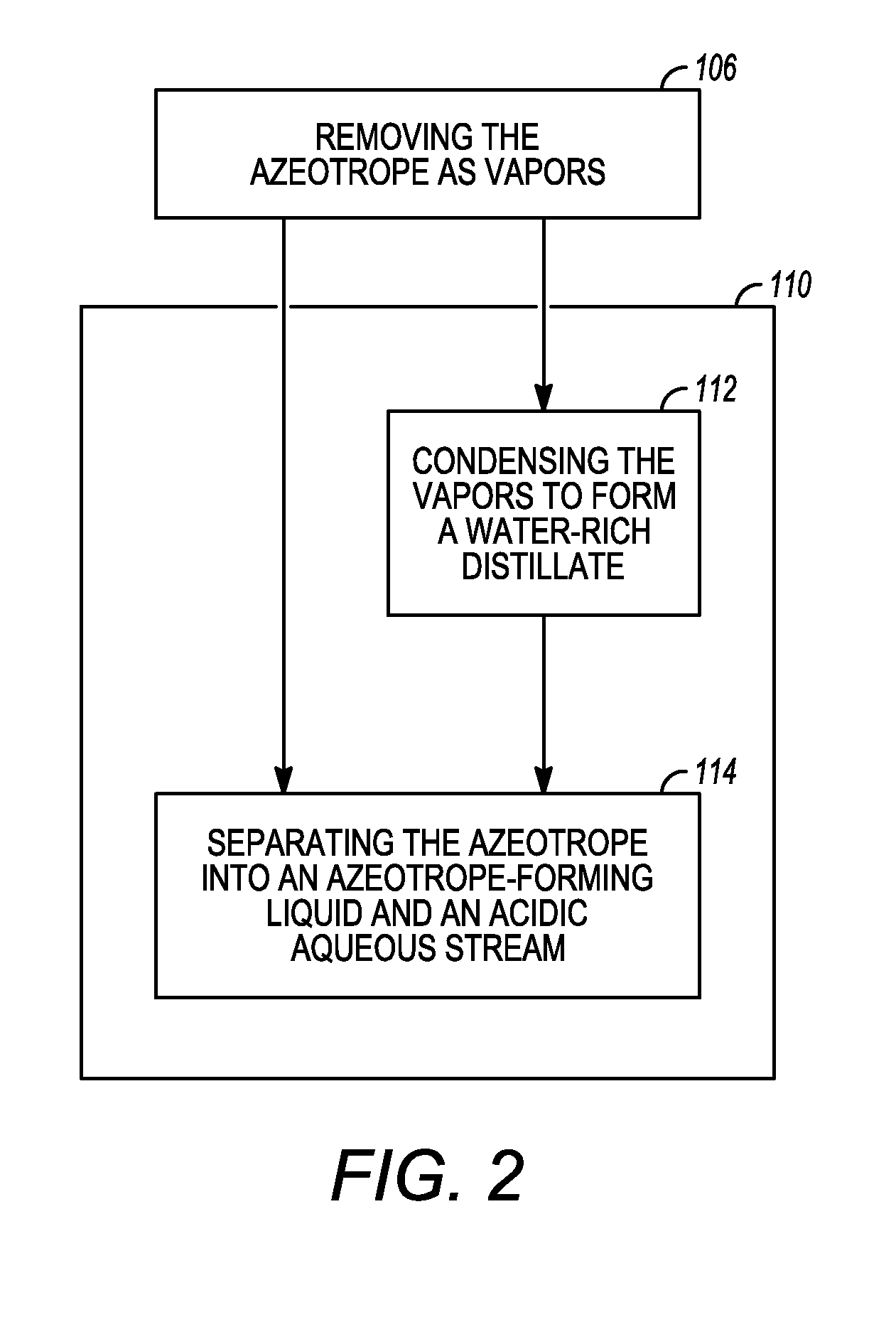

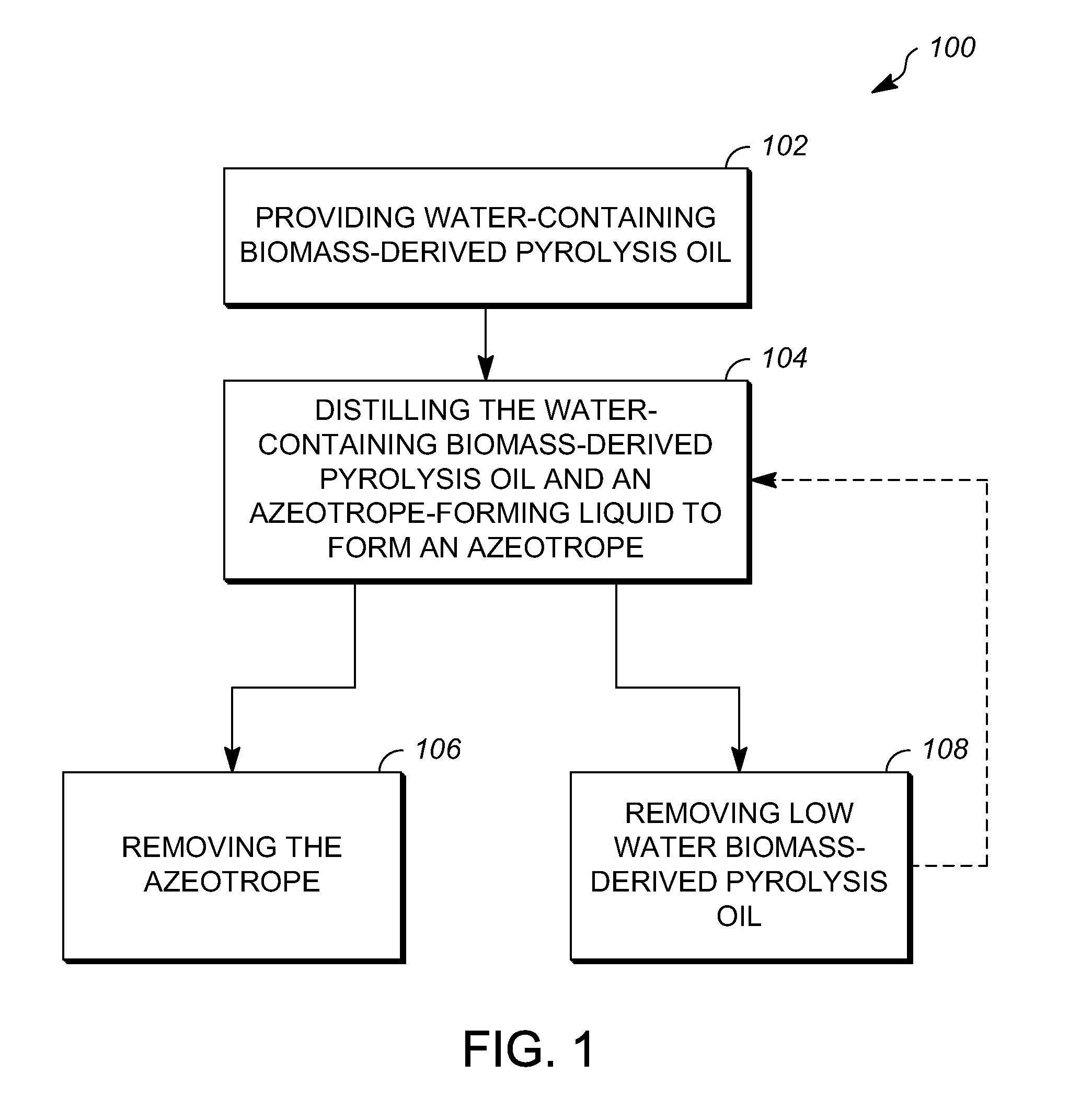

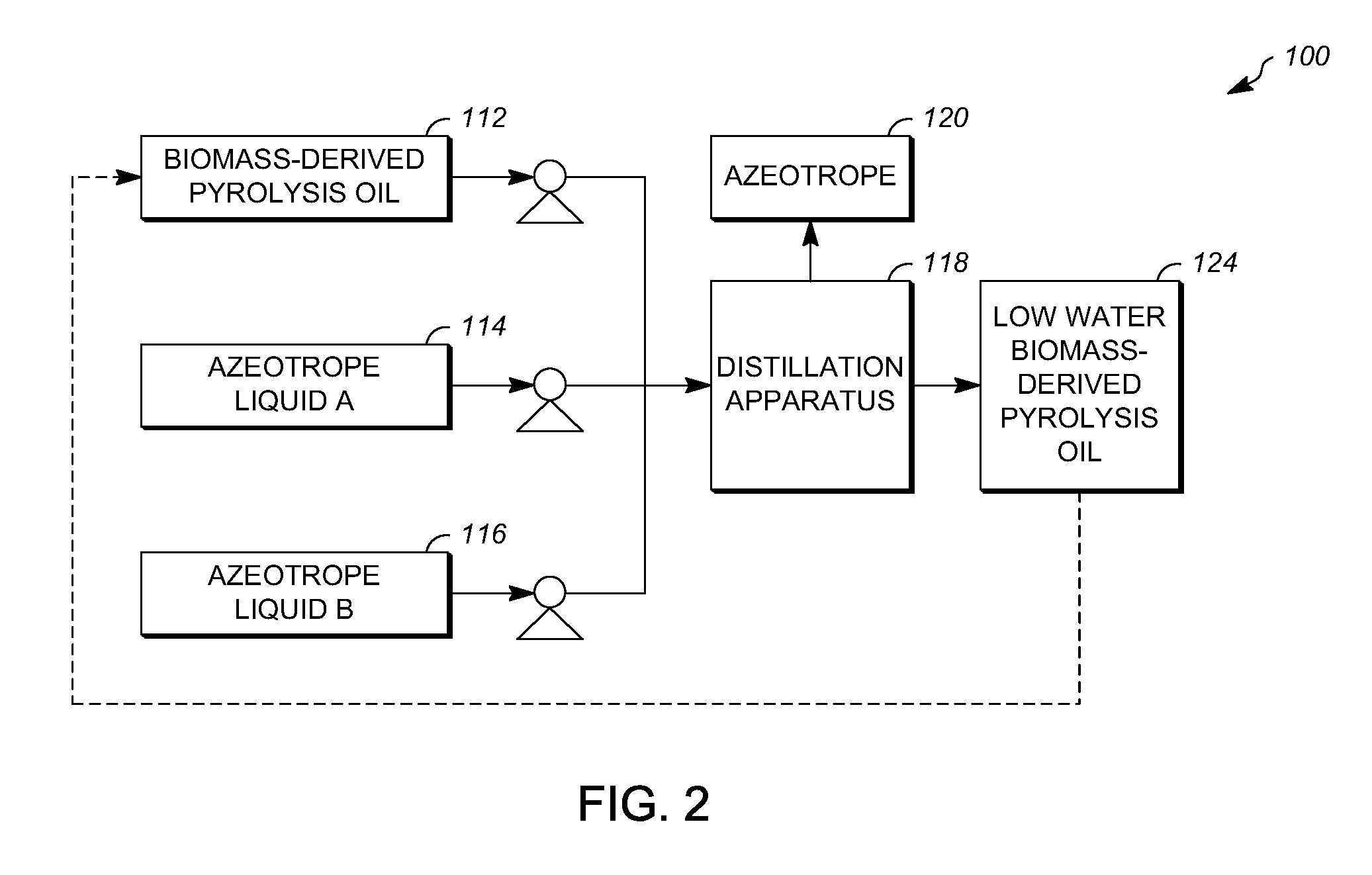

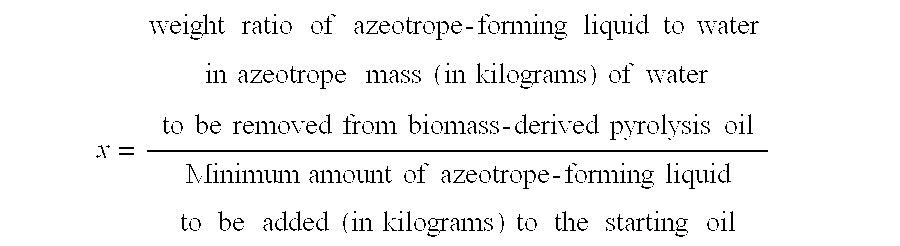

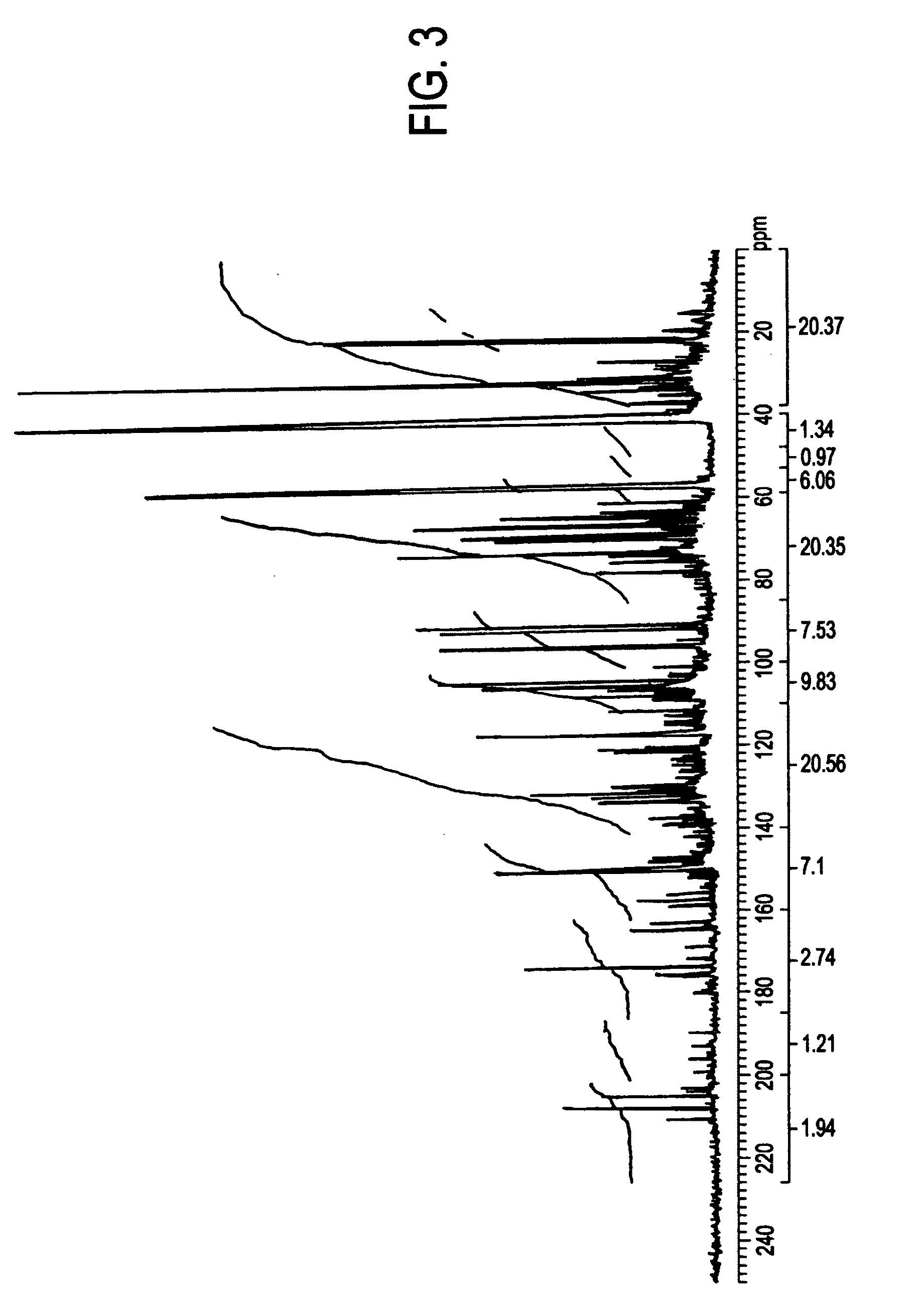

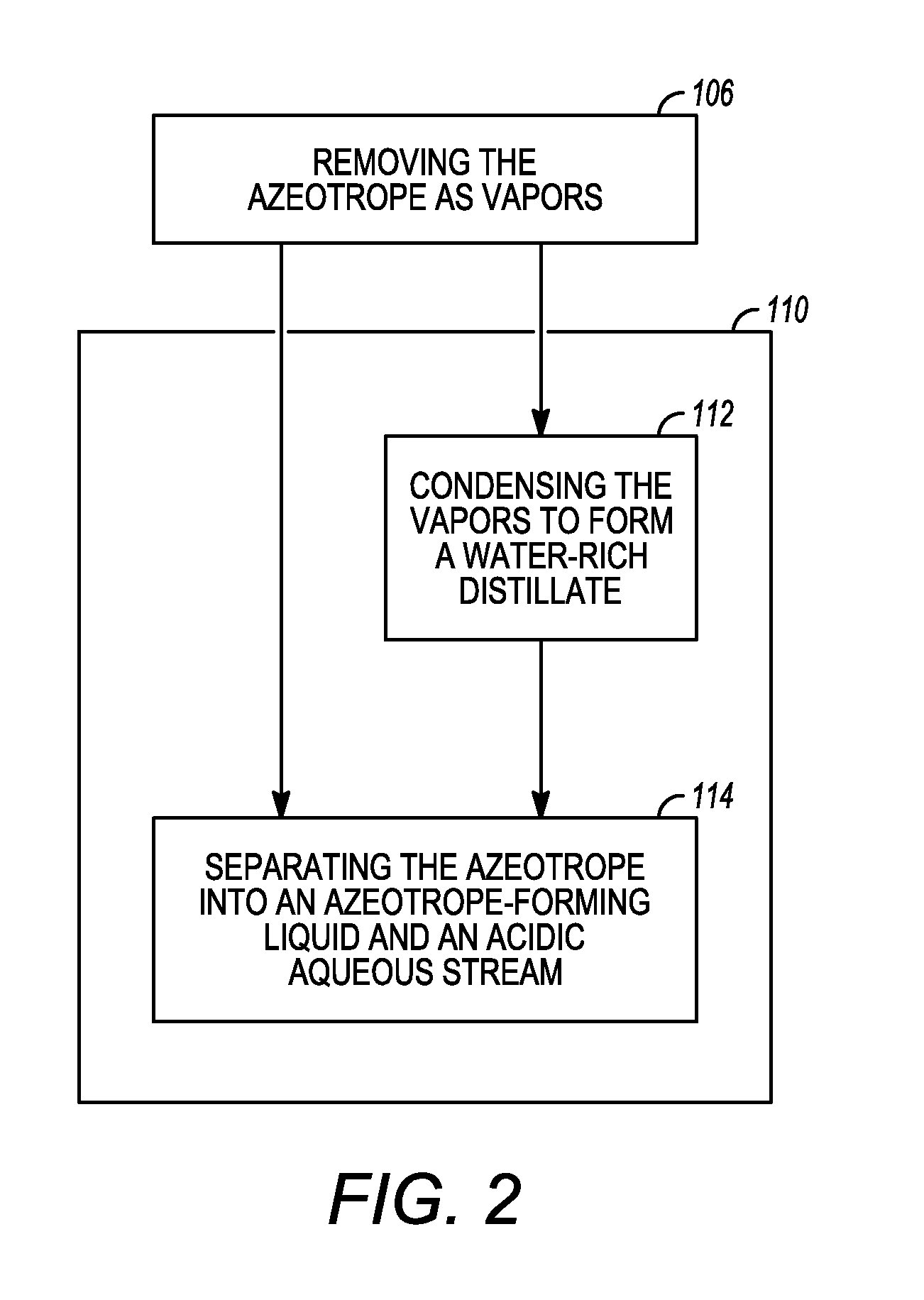

InactiveUS20110146140A1Reduce wateringLiquid carbonaceous fuelsAzeotropic distillationBoiling pointAzeotrope

Low water-containing biomass-derived pyrolysis oils and processes for preparing them are provided. Water-containing biomass-derived pyrolysis oil is distilled in the presence of an azeotrope-forming liquid to form an azeotrope. The azeotrope is removed at or above the boiling point of the azeotrope and low water biomass-derived pyrolysis oil is obtained.

Owner:UOP LLC

Pyrolysis fuels and methods for processing pyrolysis fuels

Pyrolysis fuels and methods for processing pyrolysis fuel are provided. In one embodiment, a method of processing pyrolysis fuel converts biomass to pyrolysis fuel including pyrolysis oil and char particles. Also, the method includes resizing a portion of the char particles so that substantially all resized char particles have a largest dimension no greater than about 5 microns.

Owner:UOP LLC

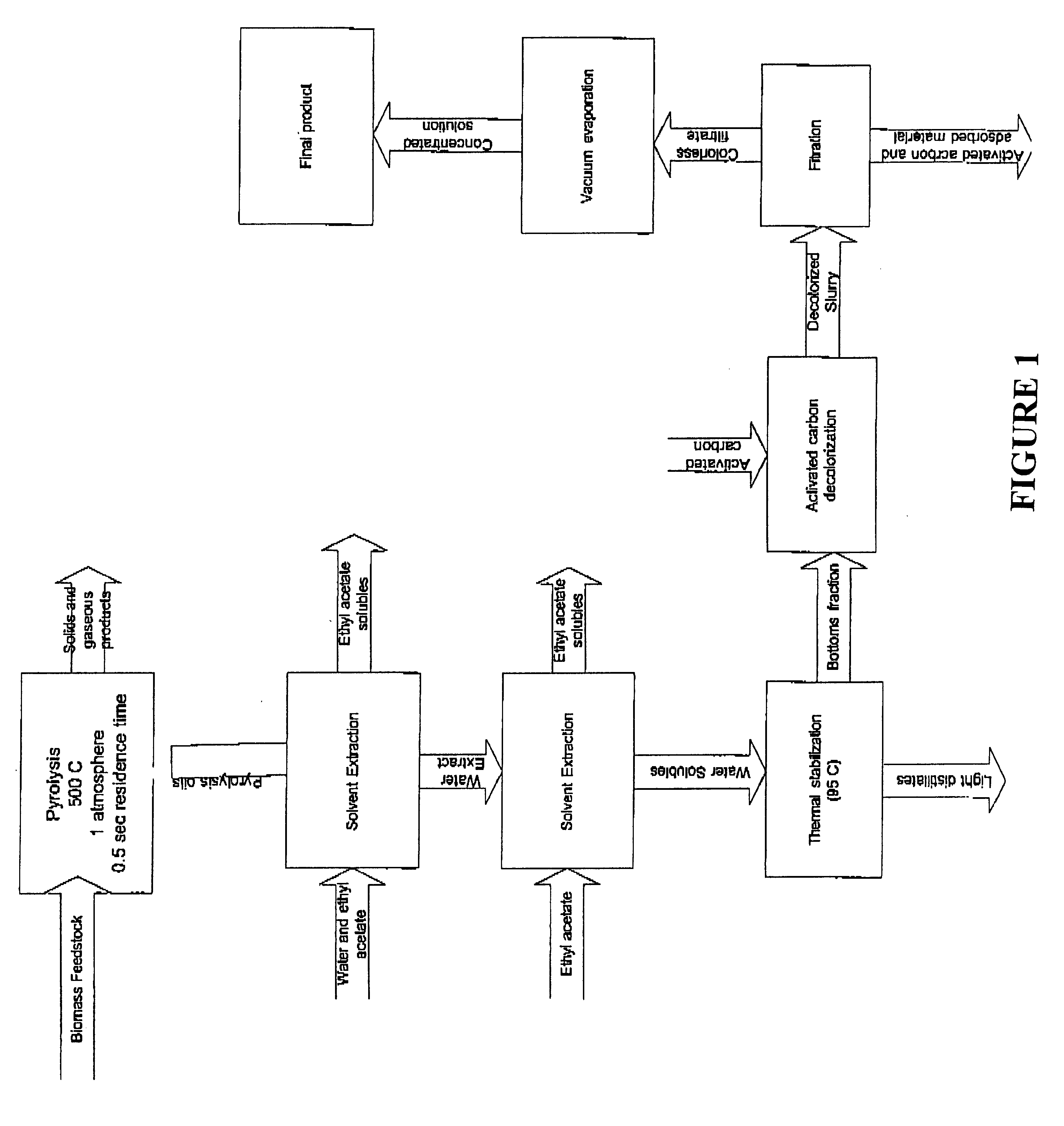

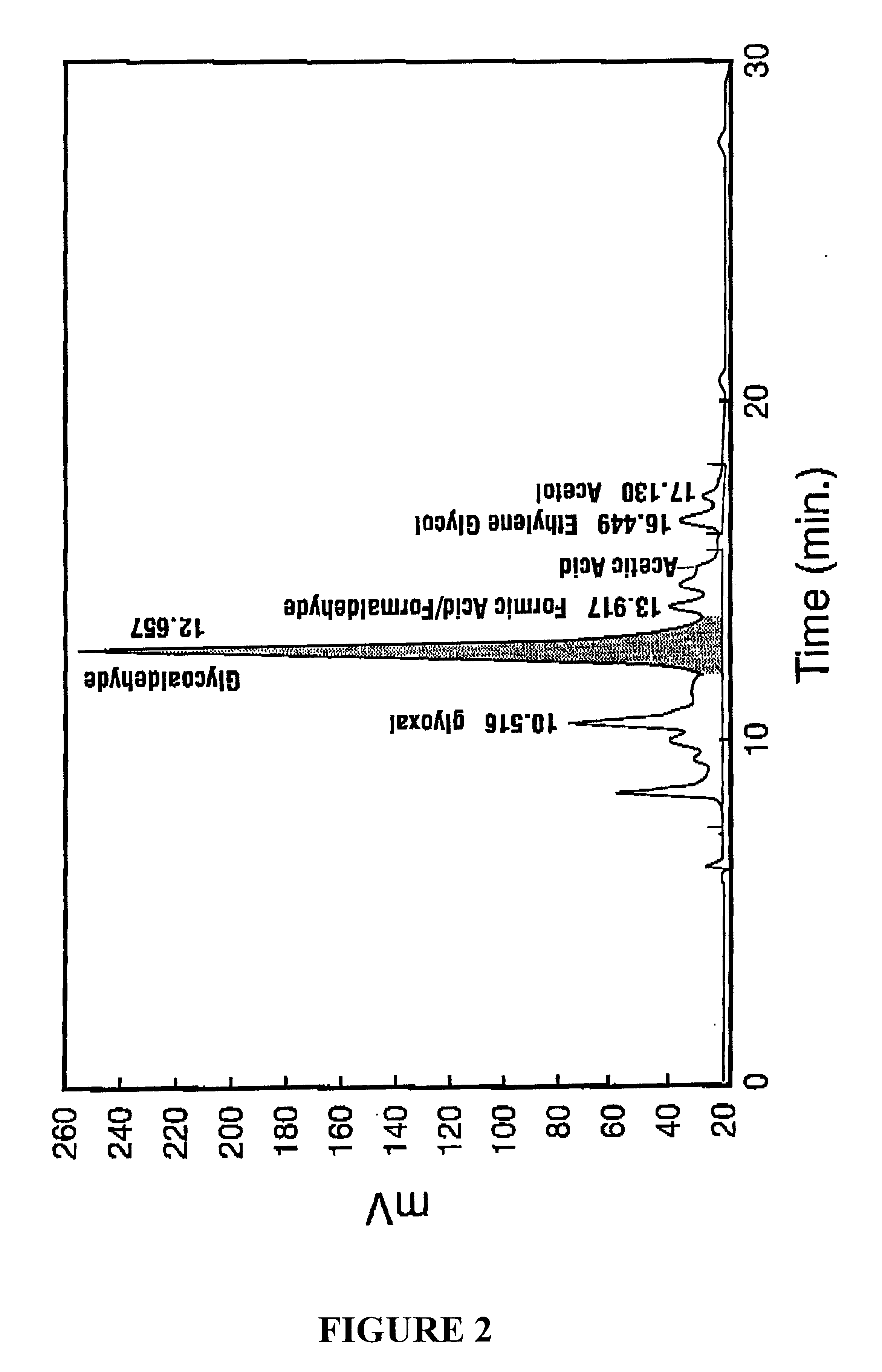

Preparation of brightness stabilization agent for lignin containing pulp from biomass pyrolysis oils

A process for producing a brightness stabilization mixture of water-soluble organic compounds from biomass pyrolysis oils comprising:a) size-reducing biomass material and pyrolyzing the size-reduced biomass material in a fluidized bed reactor;b) separating a char / ash component while maintaining char-pot temperatures to avoid condensation of pyrolysis vapors;c) condensing pyrolysis gases and vapors, and recovering pyrolysis oils by mixing the oils with acetone to obtain an oil-acetone mixture;d) evaporating acetone and recovering pyrolysis oils;e) extracting the pyrolysis oils with water to obtain a water extract;f) slurrying the water extract with carbon while stirring, and filtering the slurry to obtain a colorless filtrate;g) cooling the solution and stabilizing the solution against thermally-induced gelling and solidification by extraction with ethyl acetate to form an aqueous phase lower layer and an organic phase upper layer;h) discarding the upper organic layer and extracting the aqueous layer with ethyl acetate, and discarding the ethyl acetate fraction to obtain a brown-colored solution not susceptible to gelling or solidification upon heating;i) heating the solution to distill off water and other light components and concentrating a bottoms fraction comprising hydroxyacetaldehyde and other non-volatile components having high boiling points; andj) decolorizing the stabilized brown solution with activated carbon to obtain a colorless solution.

Owner:MIDWEST RES INST

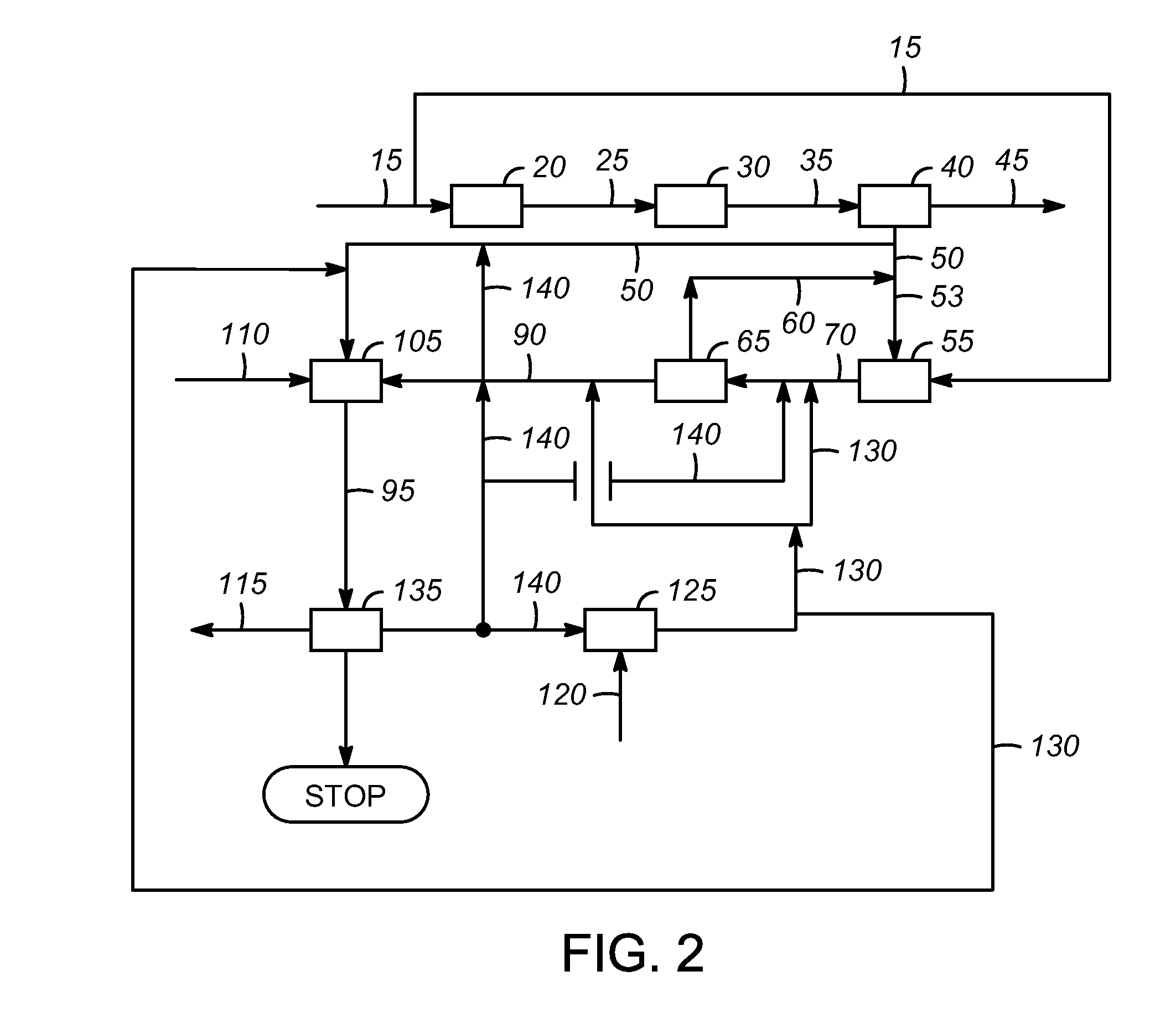

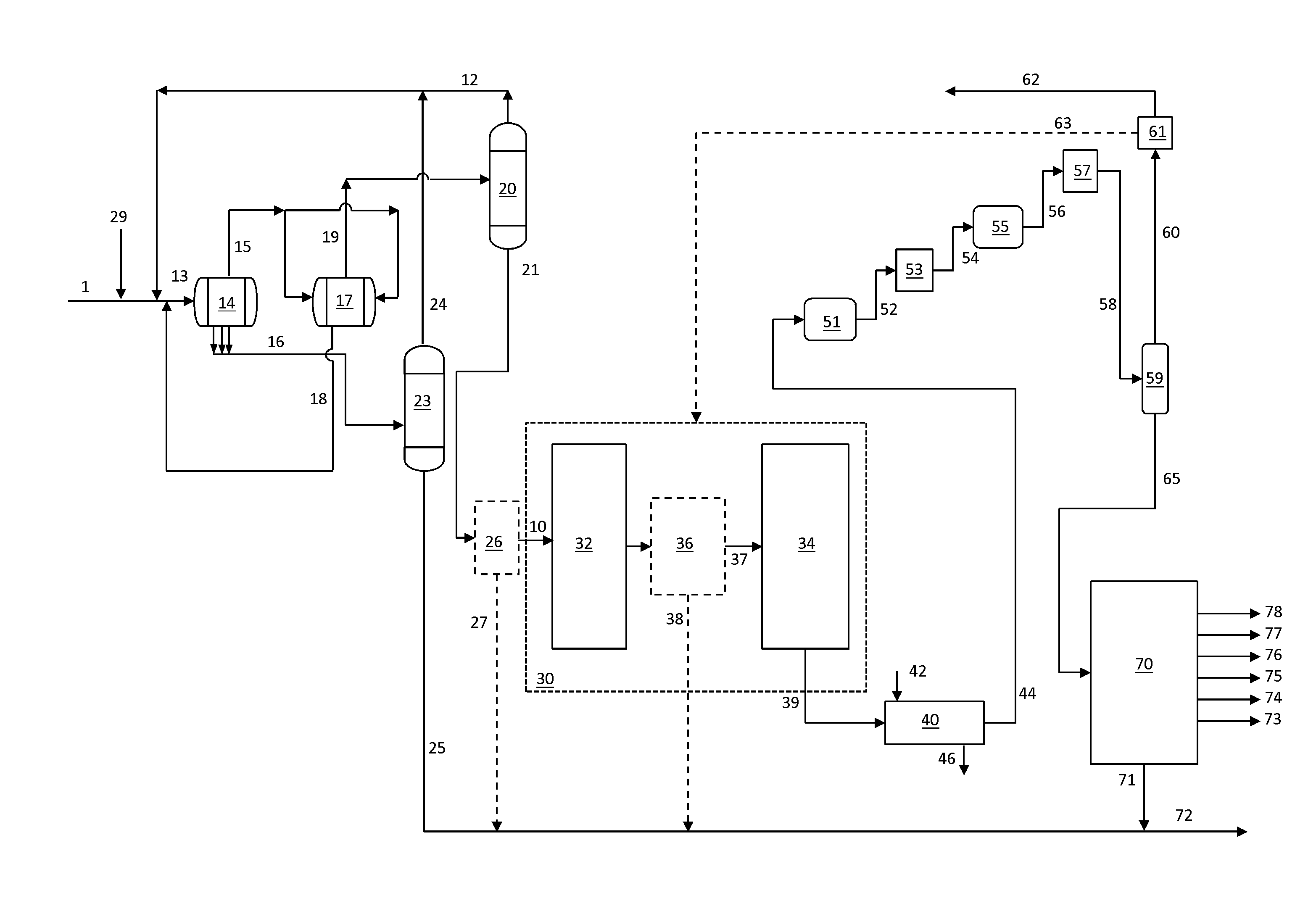

Integrated hydrotreating and steam pyrolysis process including residual bypass for direct processing of a crude oil

ActiveUS9296961B2Thermal non-catalytic crackingTreatment with plural serial cracking stages onlySteam pyrolysisFuel oil

A process is provided that is directed to a steam pyrolysis zone integrated with a hydroprocessing zone including residual bypass to permit direct processing of crude oil feedstocks to produce petrochemicals including olefins and aromatics. The integrated hydrotreating and steam pyrolysis process for the direct processing of a crude oil to produce olefinic and aromatic petrochemicals comprises separating the crude oil into light components and heavy components; charging the light components and hydrogen to a hydroprocessing zone operating under conditions effective to produce a hydroprocessed effluent reduced having a reduced content of contaminants, an increased paraffinicity, reduced Bureau of Mines Correlation Index, and an increased American Petroleum Institute gravity; thermally cracking the hydroprocessed effluent in the presence of steam to produce a mixed product stream; separating the mixed product stream; purifying hydrogen recovered from the mixed product stream and recycling it to the hydroprocessing zone; recovering olefins and aromatics from the separated mixed product stream; and recovering a combined stream of pyrolysis fuel oil from the separated mixed product stream and heavy components from step (a) as a fuel oil blend.

Owner:SAUDI ARABIAN OIL CO

Low metal biomass-derived pyrolysis oils and processes for producing the same

Low metal biomass-derived pyrolysis oils and processes for producing the same are provided. Low metal biomass-derived pyrolysis oil is produced by a process of contacting metal-containing biomass-derived pyrolysis oil with an acidic ion-exchange resin having sulfonic acid groups. Low metal biomass-derived pyrolysis oil is removed from spent acidic ion-exchange resin after ion-exchange.

Owner:UOP LLC

Production of stable biomass pyrolysis oils using fractional catalytic pyrolysis

ActiveUS20100212215A1Eliminate needImprove stabilityMolecular sieve catalystsMultiple metal hydridesCatalytic pyrolysisReactive gas

Methods for fractional catalytic pyrolysis which allow for conversion of biomass into a slate of desired products without the need for post-pyrolysis separation are described. The methods involve use of a fluid catalytic bed which is maintained at a suitable pyrolysis temperature. Biomass is added to the catalytic bed, preferably while entrained in a non-reactive gas such as nitrogen, causing the biomass to become pyrolyzed and forming the desired products in vapor and gas forms, allowing the desired products to be easily separated.

Owner:VIRGINIA TECH INTPROP INC

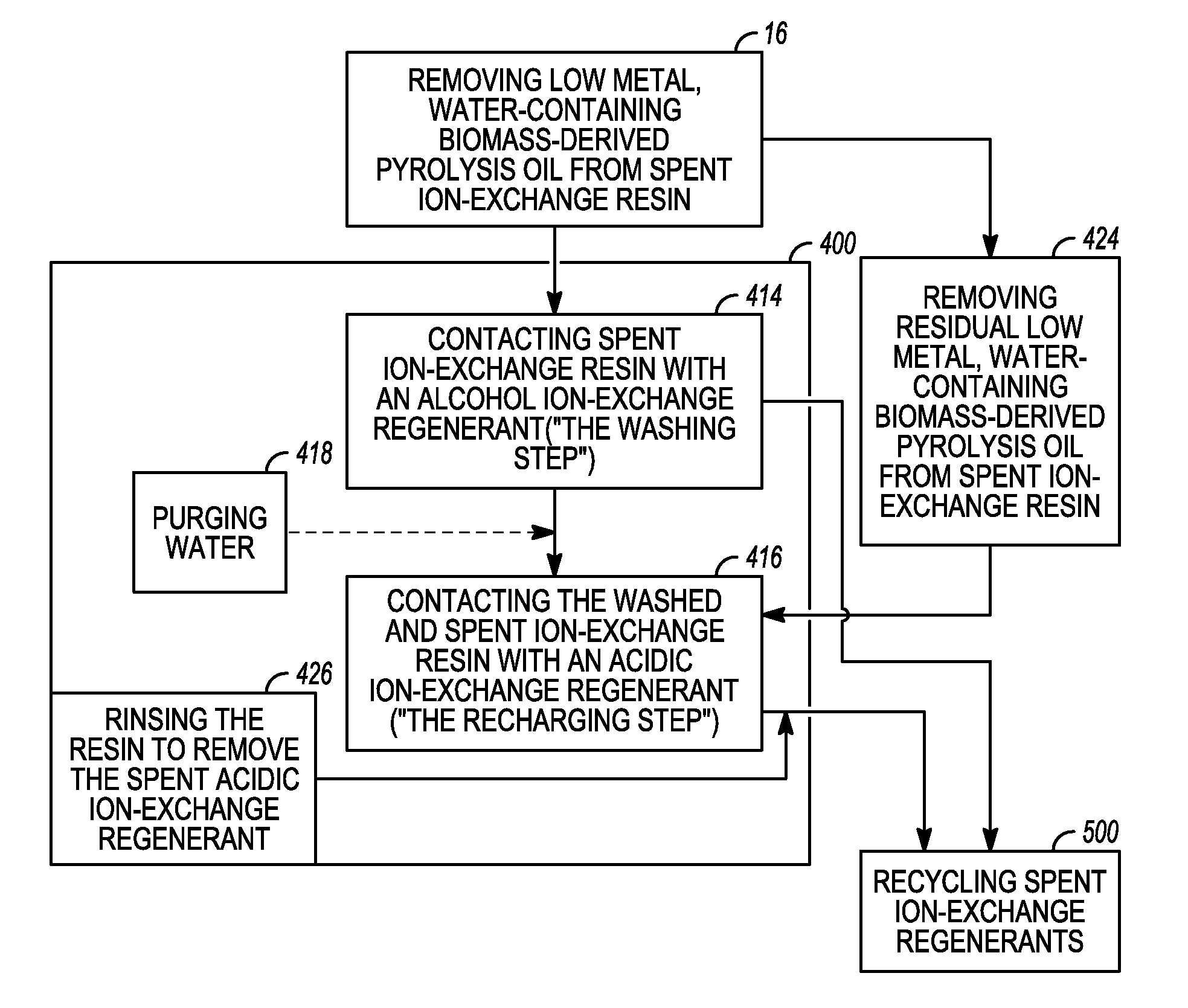

Methods for regenerating acidic ion-exchange resins and reusing regenerants in such methods

ActiveUS20110146145A1High phase stabilityComponent separationIon-exchanger regenerationAlcoholIon exchange

Methods for regenerating acidic ion-exchange resins and reusing regenerants in such methods are provided. A spent ion-exchange resin is contacted with an alcohol ion-exchange regenerant. The spent ion-exchange resin is thereafter contacted with an acidic ion-exchange regenerant to recharge the acidic ion-exchange resin to produce a regenerated acidic ion-exchange resin. Metal- and water-containing biomass-derived pyrolysis oil is then contacted with the regenerated acidic ion-exchange resin to produce low metal, water-containing biomass-derived pyrolysis oil. The regenerated acidic ion-exchange resin may be recycled. The spent alcohol and acid ion-exchange regenerants may be recovered and recycled.

Owner:UOP LLC

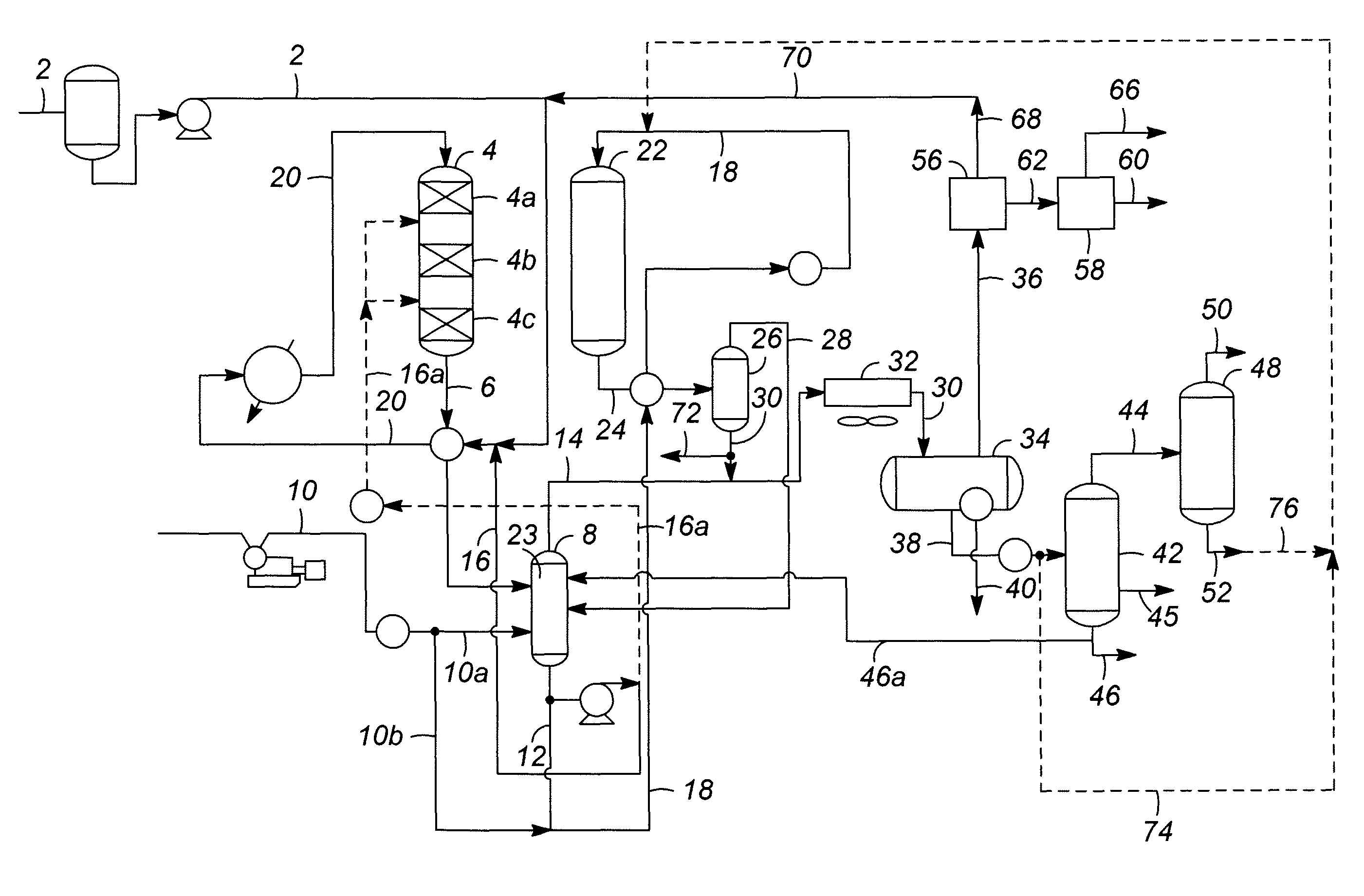

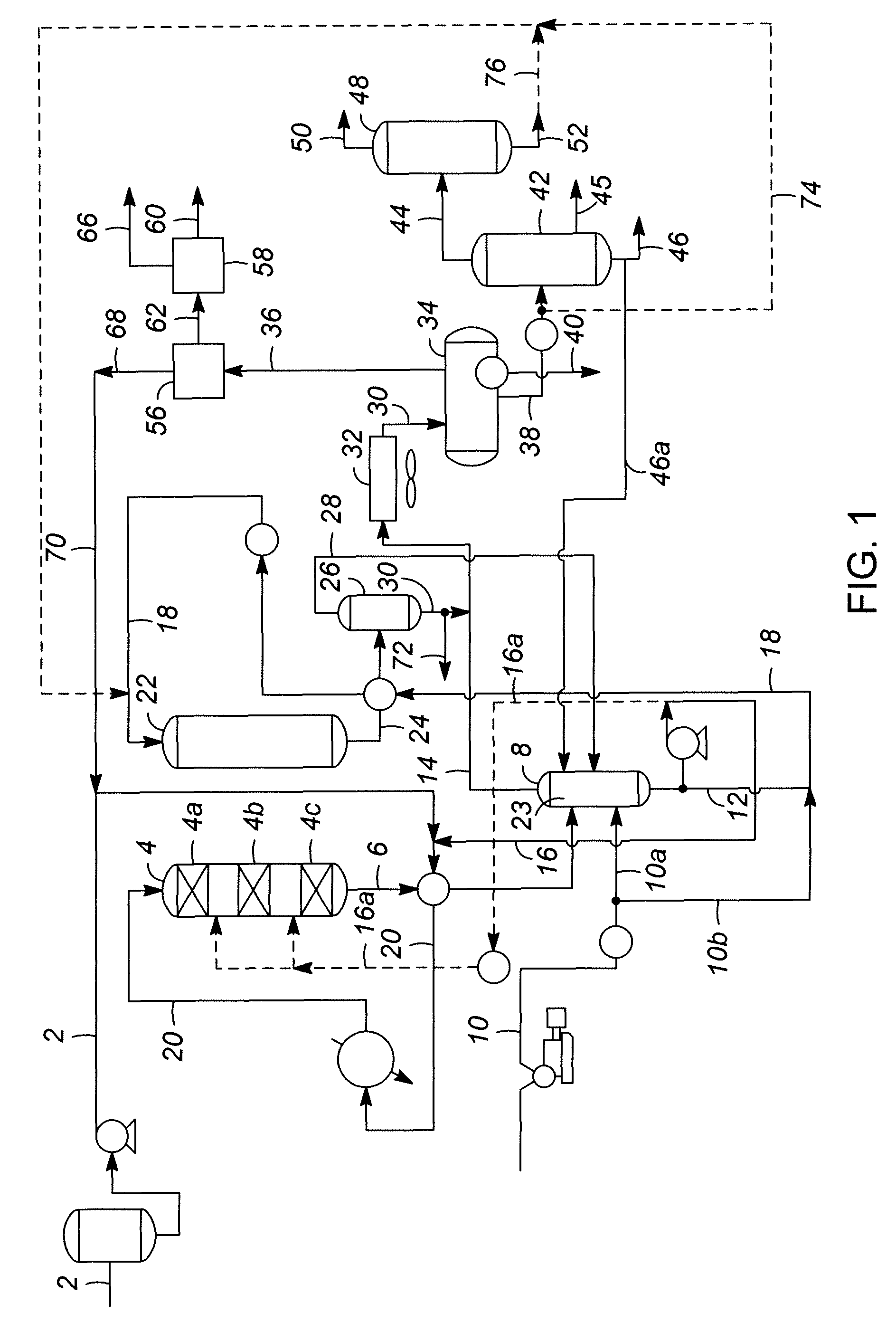

Production of blended fuel from renewable feedstocks

ActiveUS8329967B2Minimize the numberReduce the amount requiredRefining to change hydrocarbon structural skeletonBiofuelsParaffin waxEngineering

A process for producing a blended fuel from a paraffin rich component and a cyclic rich component, where each of the components are generated from a renewable feedstock, is presented. The paraffin rich component is generated from glycerides and free fatty acids in feedstocks such as plant and animal oils. The cyclic rich component is generated from biomass derived pyrolysis oil. The source of the animal or plant oil and the biomass may be the same renewable source.

Owner:UOP LLC

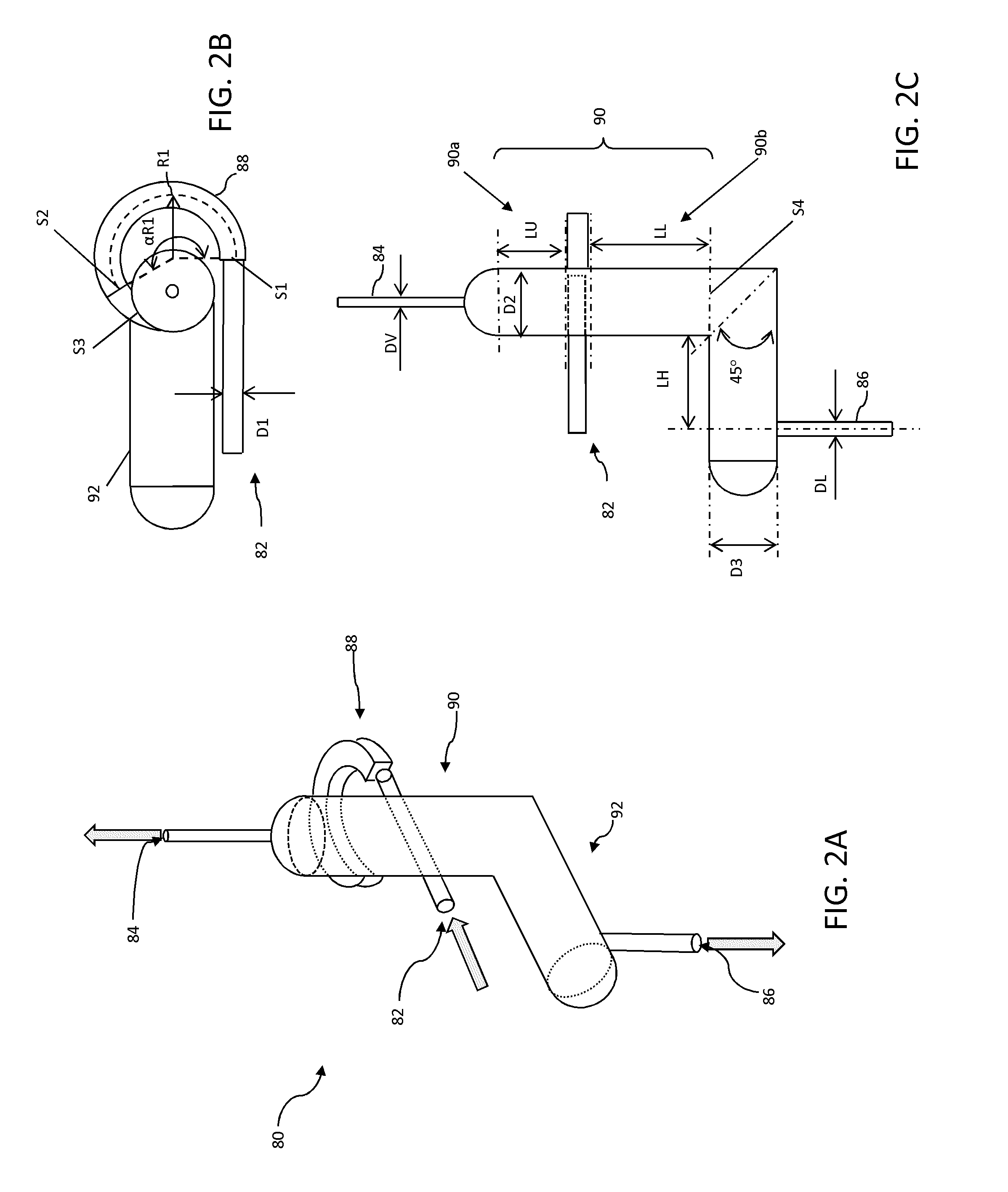

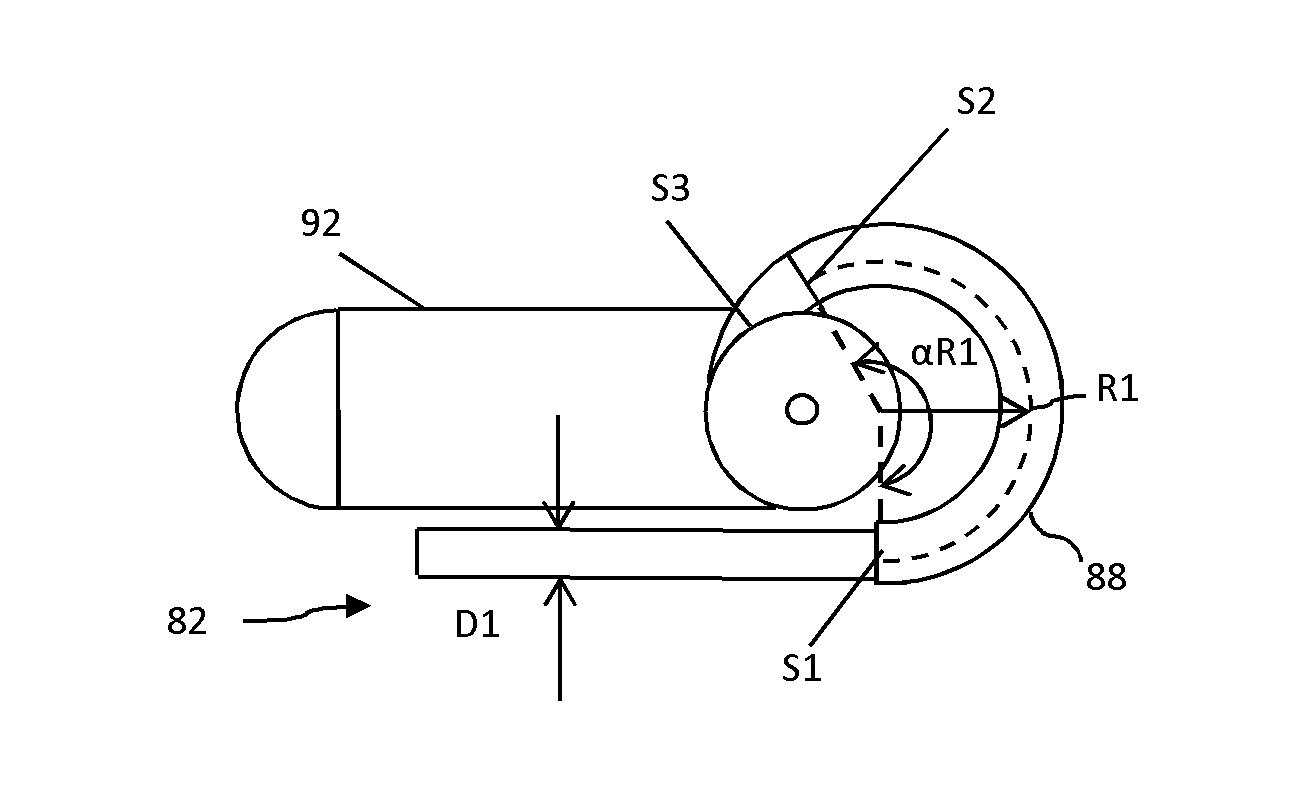

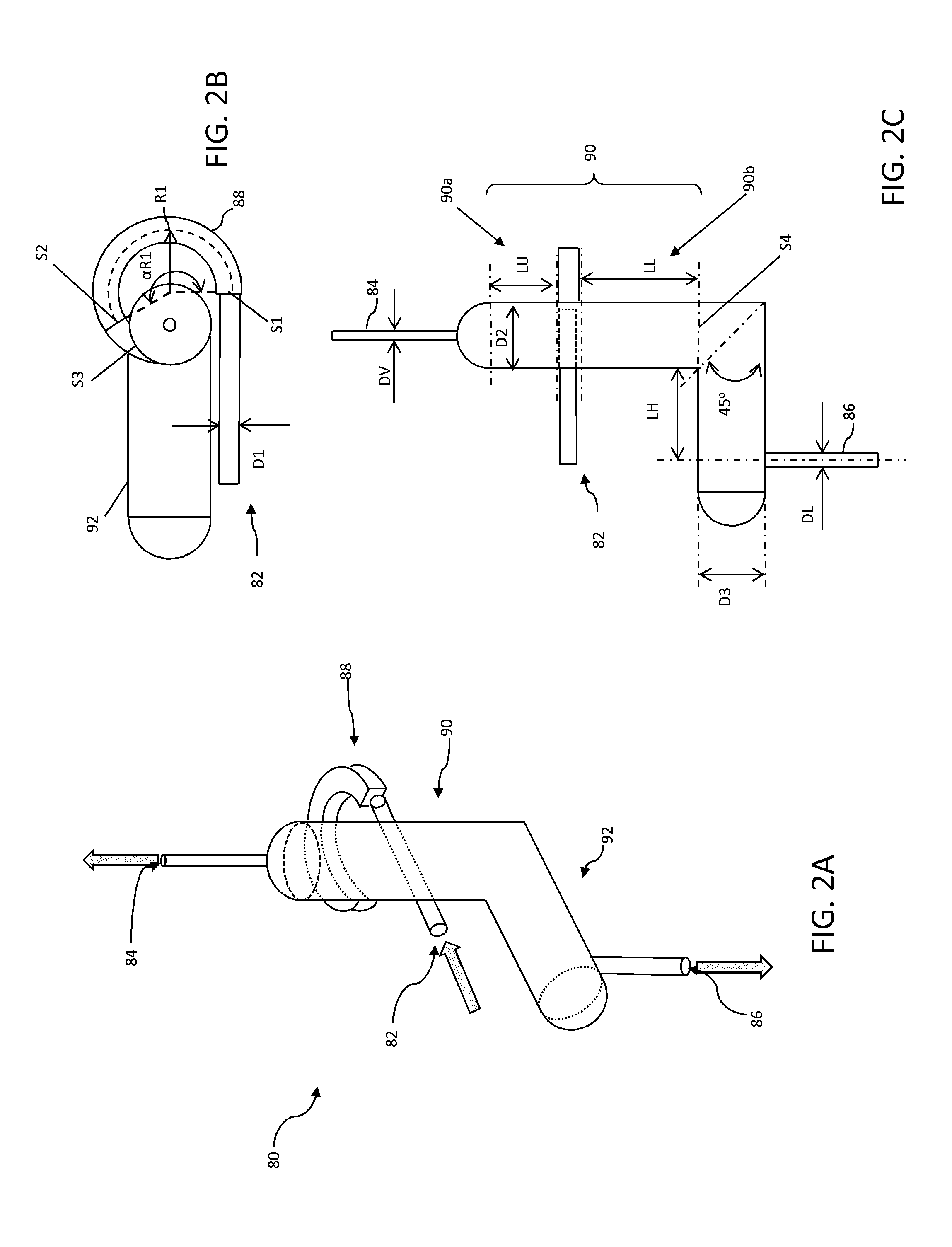

Methods and apparatuses for forming low-metal biomass-derived pyrolysis oil

Embodiments of methods and apparatuses for forming a low-metal biomass-derived pyrolysis oil are provided. The method comprises the steps of filtering a biomass-derived pyrolysis oil with a high flux rate filter arrangement having a flux rate of about 10 L / m2 / hr or greater to form a low-solids biomass-derived pyrolysis oil. The low-solids biomass-derived pyrolysis oil is filtered with a fine filter arrangement having a pore diameter of about 50 μm or less to form an ultralow-solids biomass-derived pyrolysis oil. The ultralow-solids biomass-derived pyrolysis oil is contacted with an ion-exchange resin to remove metal ions and form the low-metal biomass-derived pyrolysis oil.

Owner:UOP LLC

Thermally stable cocurrent gasification system and associated methods

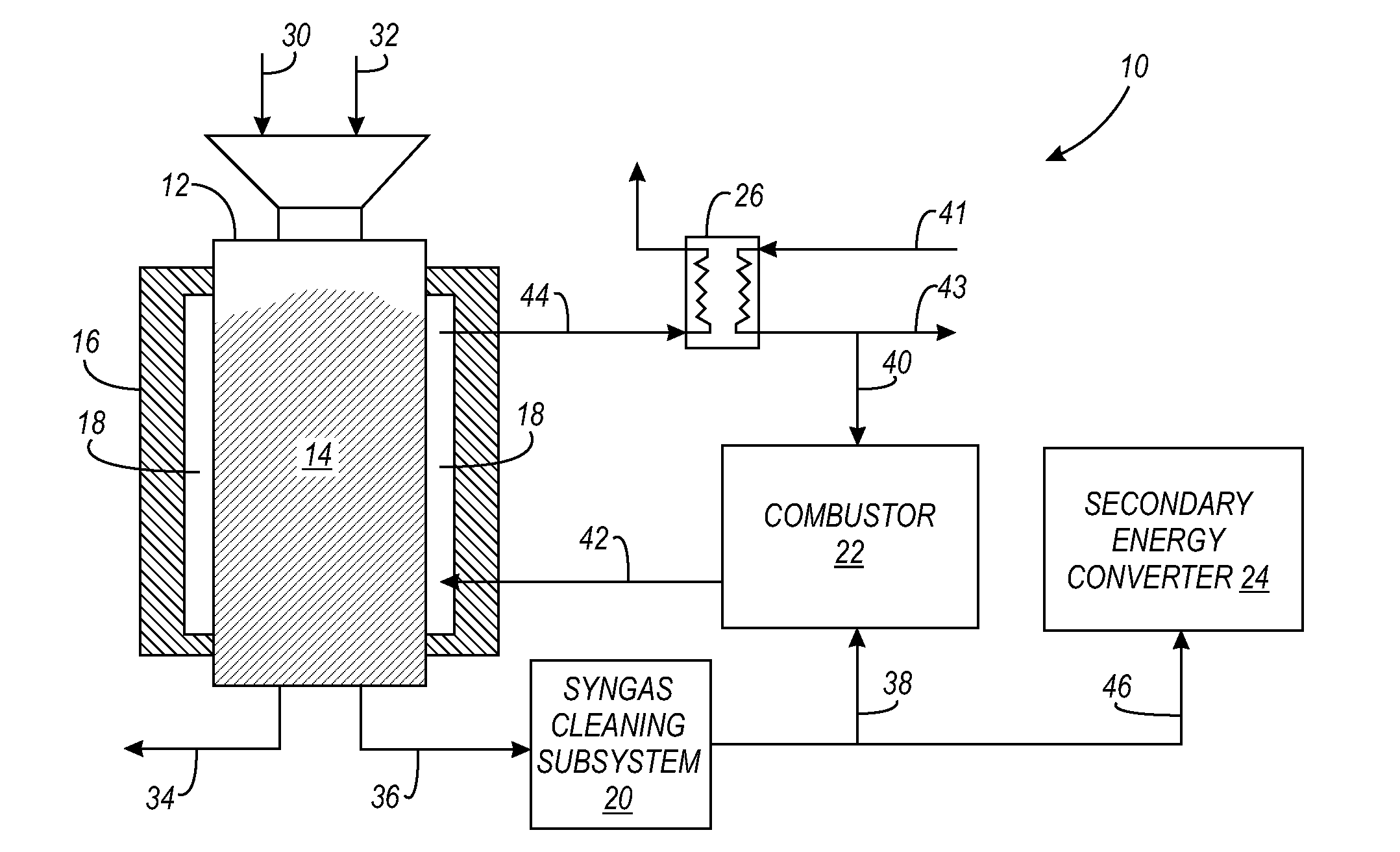

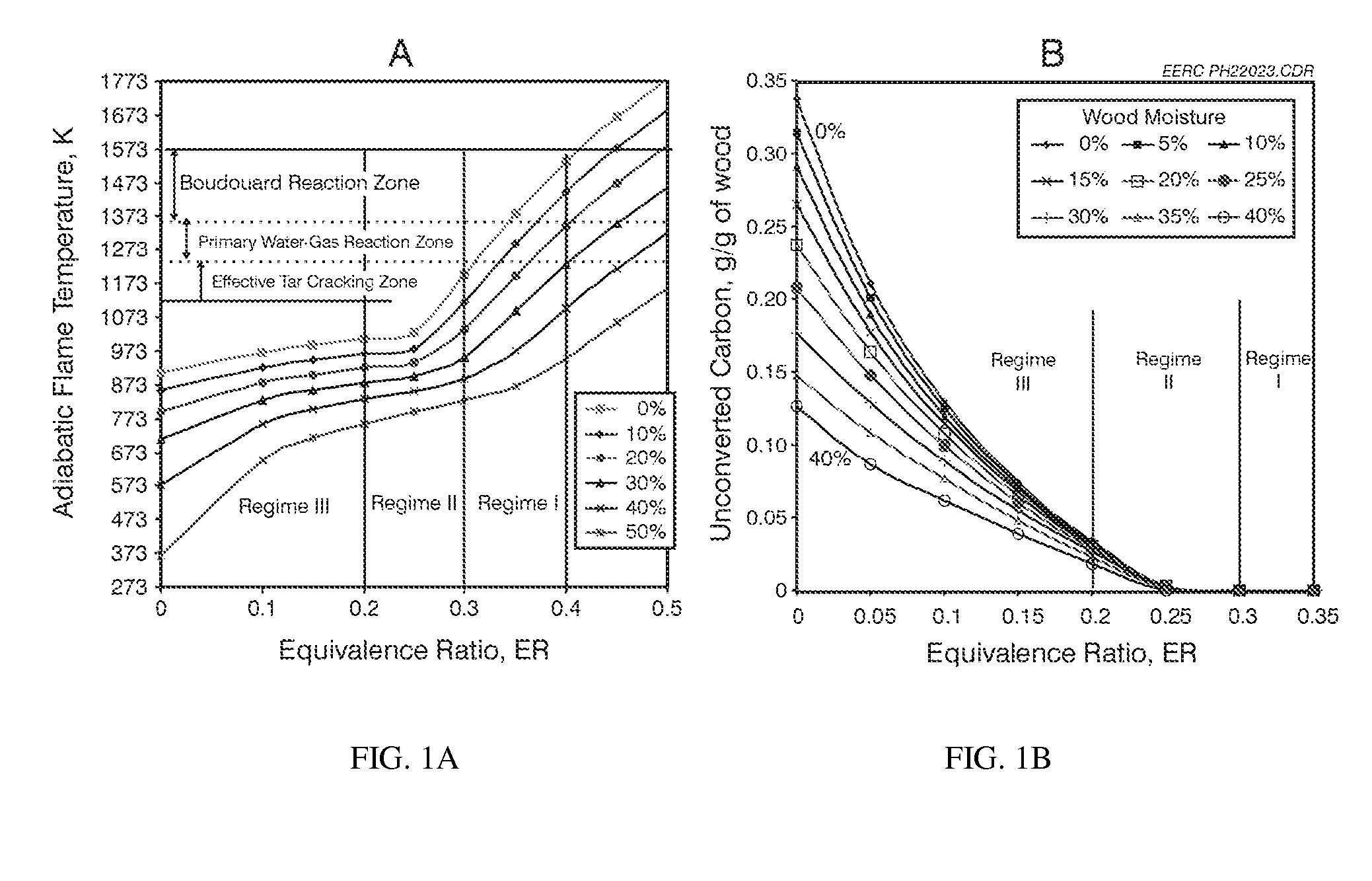

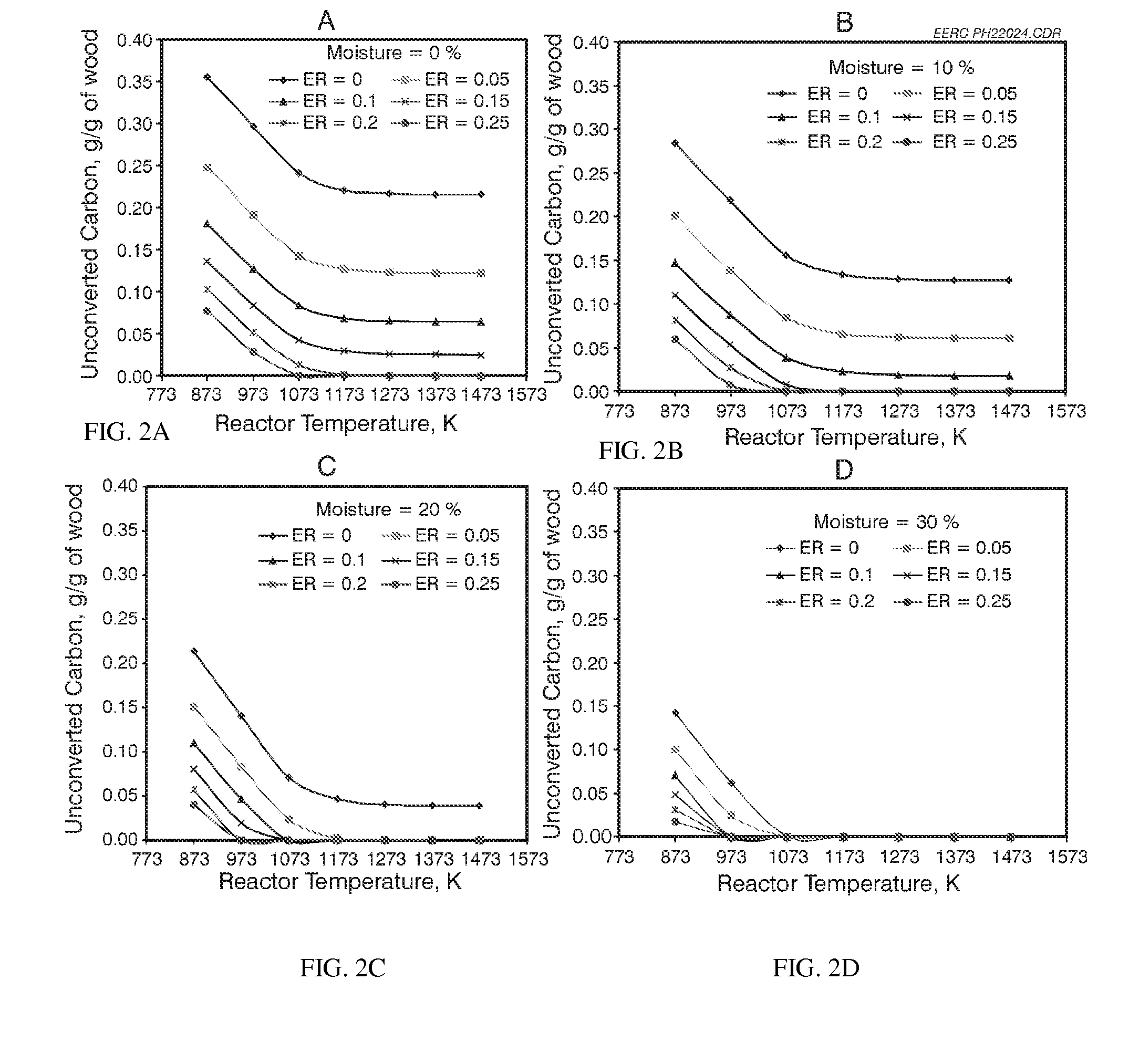

InactiveUS20080196308A1Reduce solid wasteGasification processes detailsCarburetting by solid carbonaceous material pyrolysisOperational costsHigh energy

A method and apparatus, in one example, relates to a system and method for the generation of very low-tar, high-energy synthesis gas from a large variety of carbonaceous feedstock, including those with higher moisture levels than conventional gasifiers. The system comprises a gasification reactor wherein a portion of the energy of the output syngas of the reactor is used to heat the gasification zone of the reactor via an annular space surrounding the gasification zone of the gasifier, to maintain a temperature condition above 800° C. The maintenance of a long, quasi-uniform high-temperature gasification zone reduces the amount of input air or oxygen, reduces bridging within the gasifier, cracks pyrolysis oils, increases the conversion of char, minimizes heat losses from the bed, and converts moisture within the packed bed into a gasification medium. This results in a very low tar synthesis gas with less nitrogen dilution and higher energy content than conventional gasifiers. The reduction in bridging reduces operating costs.

Owner:ENERGY & ENVIRONMENTAL RES CENT FOUNDATIO

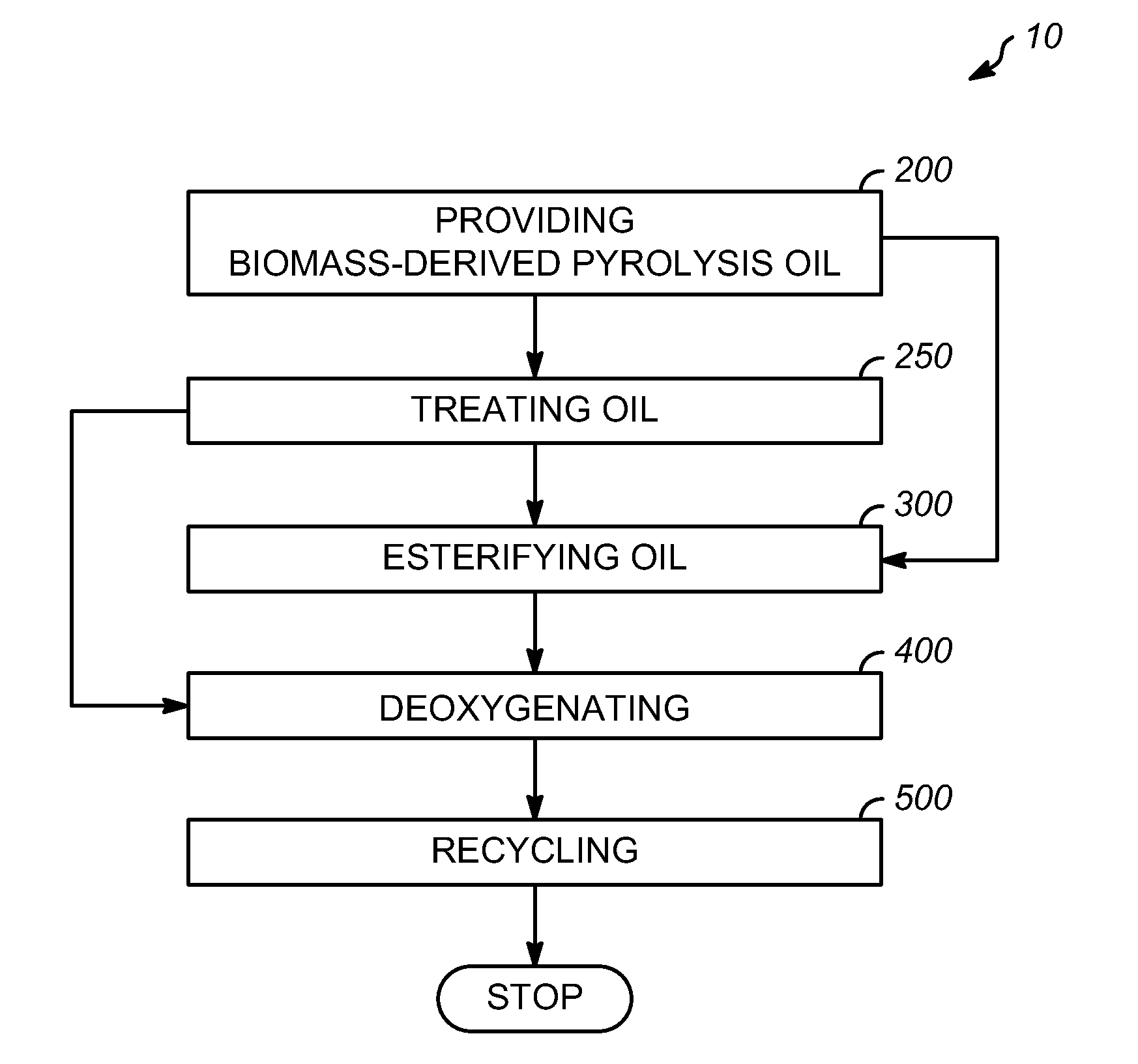

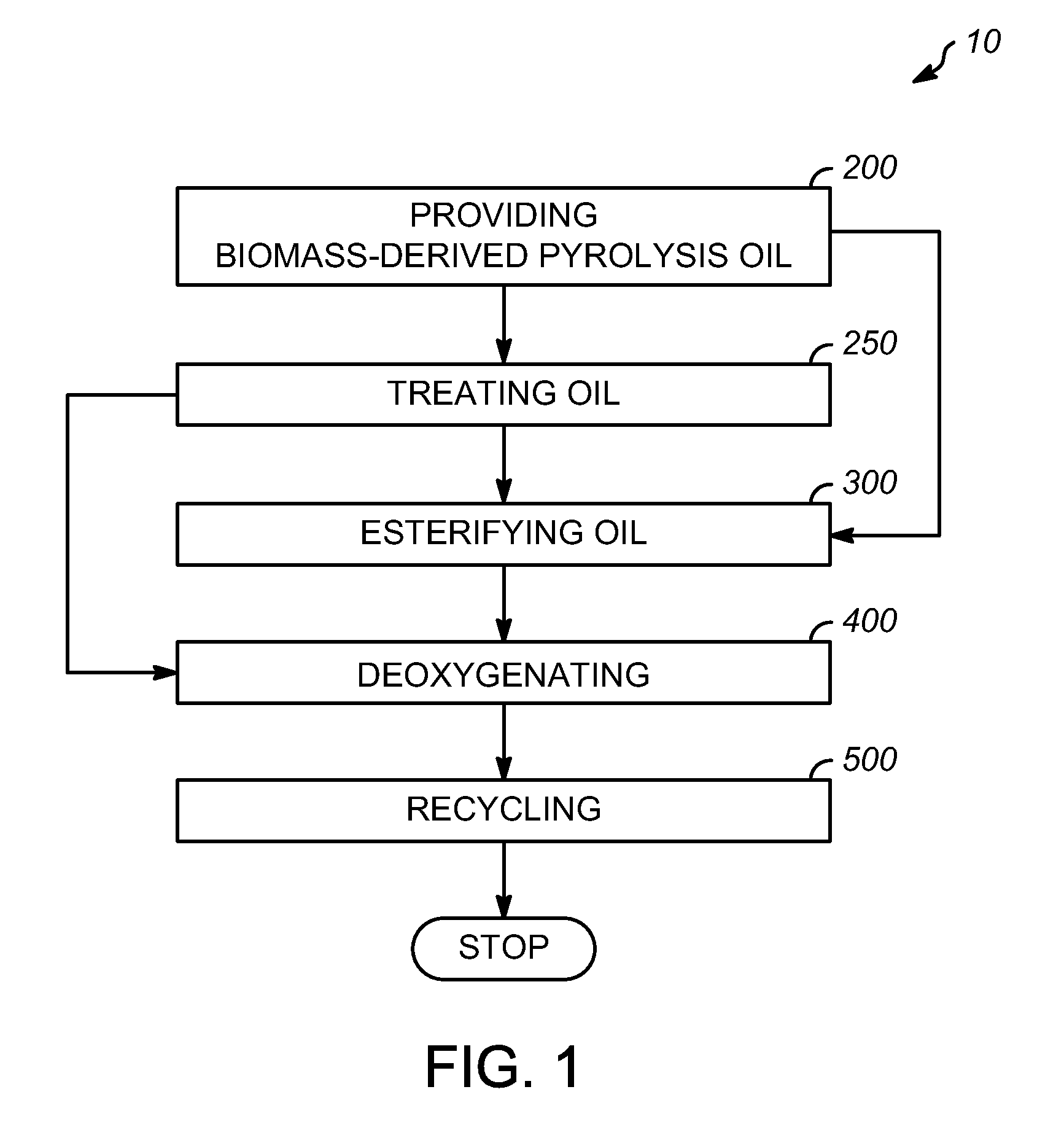

Methods for deoxygenating biomass-derived pyrolysis oil

Methods for deoxygenating a biomass-derived pyrolysis oil are provided. In an embodiment, a method for deoxygenating a biomass-derived pyrolysis oil comprises the steps of combining a biomass-derived pyrolysis oil stream with a heated low-oxygen-pyoil diluent recycle stream to form a heated diluted pyoil feed stream. The heated diluted pyoil feed stream has a feed temperature of about 150° C. or greater. The heated diluted pyoil feed stream is contacted with a first deoxygenating catalyst in the presence of hydrogen at first hydroprocessing conditions effective to form a low-oxygen biomass-derived pyrolysis oil effluent.

Owner:UOP LLC

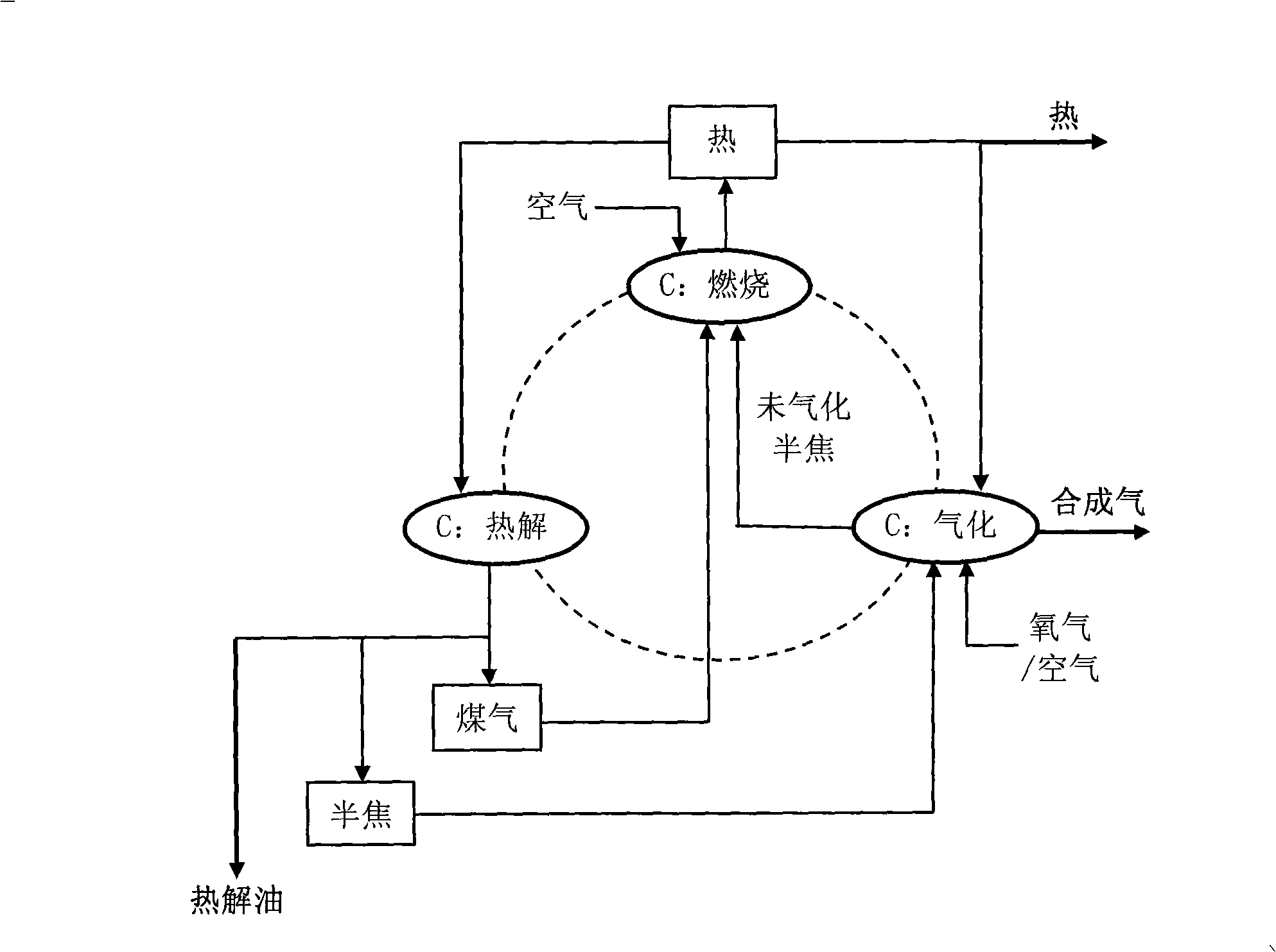

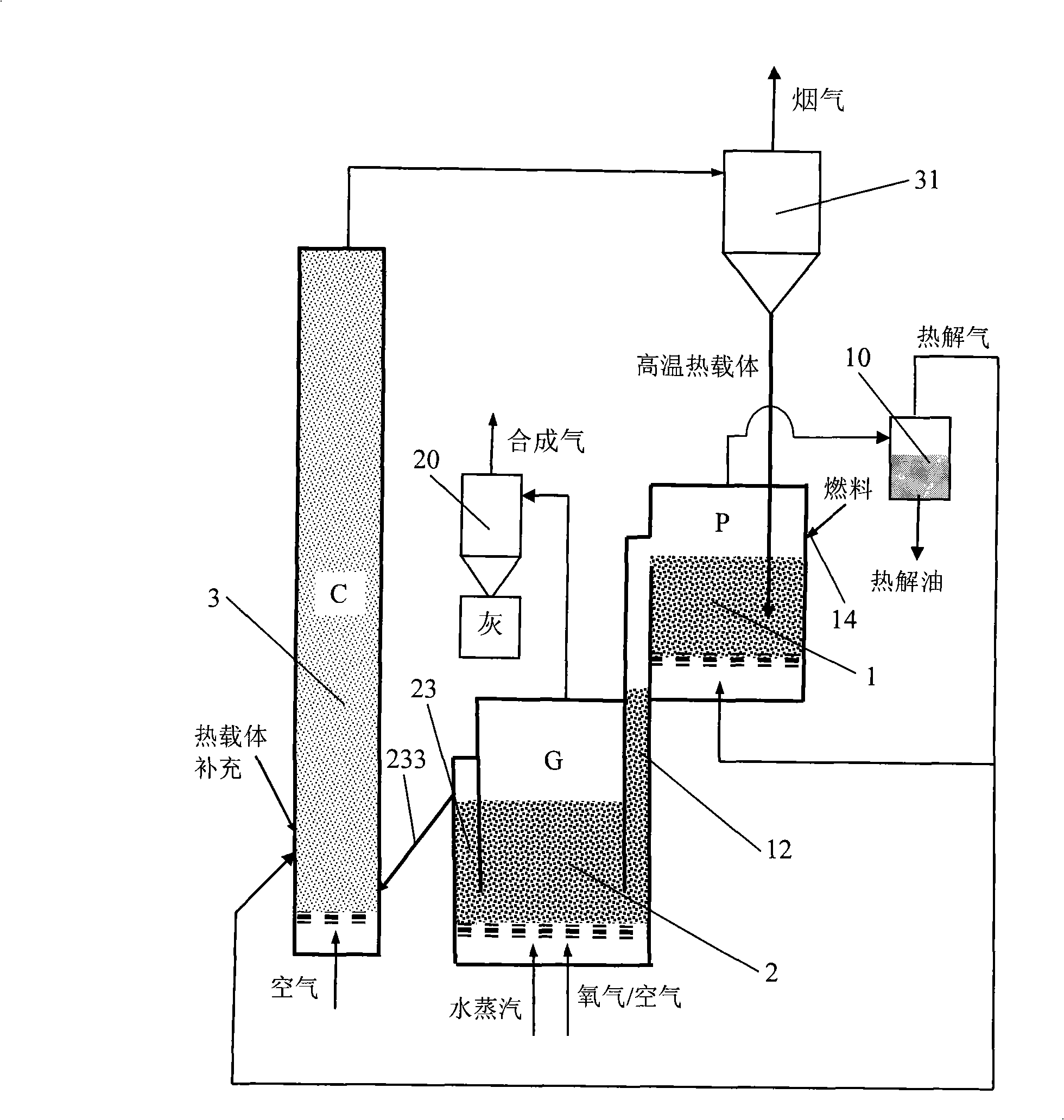

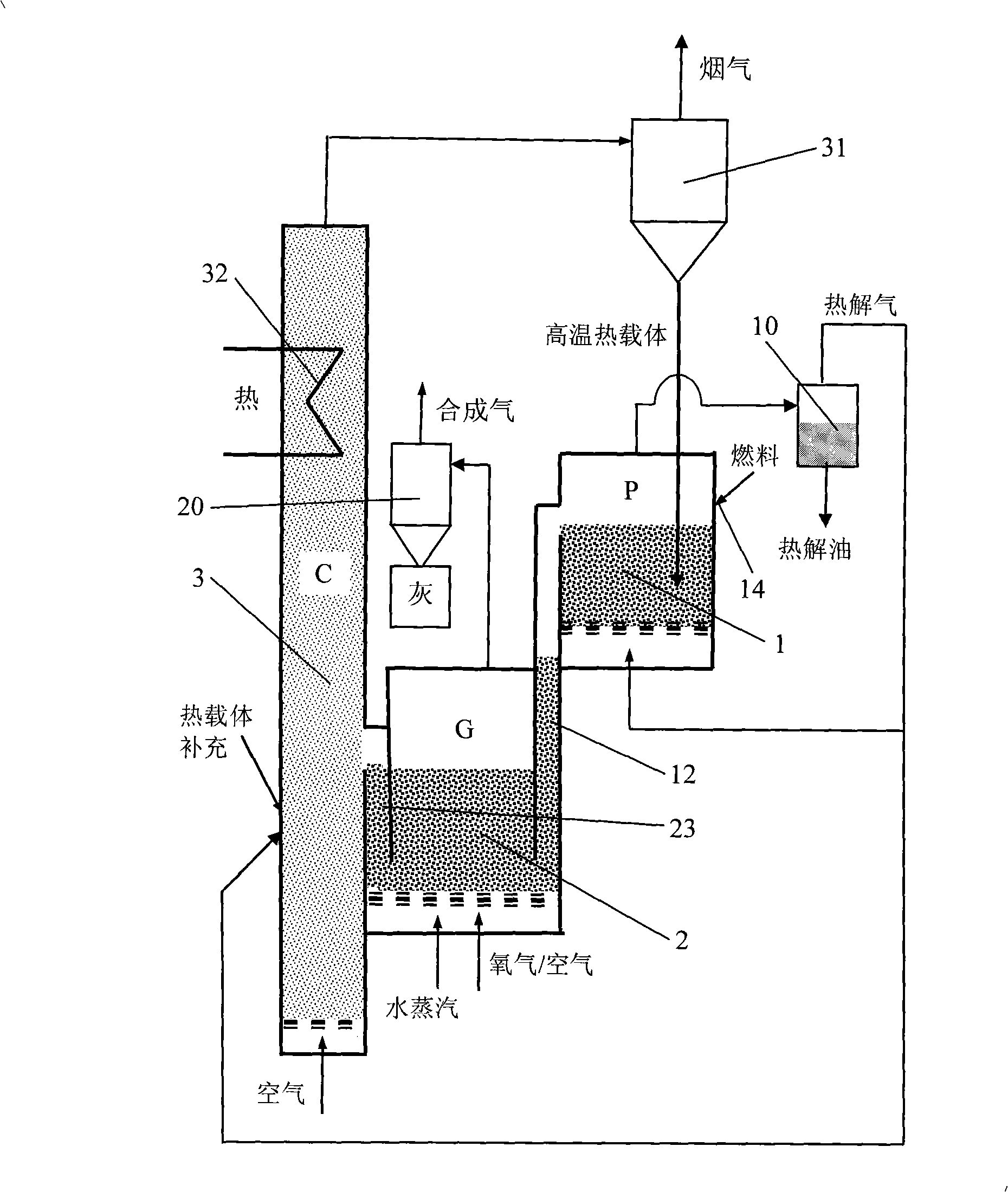

Combined thermal transition method and apparatus for solid fuel

InactiveCN101294092ARealize the value of "resources"Efficient productionLiquid hydrocarbon mixture productionCombined combustion mitigationBrown coalThermal transition

The invention relates to a thermal conversion method and a thermal conversion device of solid fuel, wherein the thermal conversion of the solid fuel is composed of three independent and association-controllable sub-processes of pyrolysis, gasification and burning by decoupling the integrated pyrolysis, gasification and burning reactions in the conventional thermal conversion process. A hot carrier substance is circulated among the sub-processes, so that the burning sub-process provides reactive heat to the pyrolysis and the gasification sub-processes and simultaneously provides oxygen to the gasification process to initiate internal burning so as to compensate for the gasification reaction heat that the hot carrier substance is unlikely to supply. Accordingly, the thermal conversion method can control the three thermochemical reactions of pyrolysis, gasification and burning by decoupling, recombination and association to achieve combined production of pyrolysis oil, synthesis gas and heat. Different from conventional single conversion devices for burning, gasification and pyrolysis, the thermal conversion method of the invention has the advantages of compact structure, high heat utilization efficiency and greatly reduced oxygen consumption for synthesis gas production, thus achieving high-value comprehensive conversion and utilization of solid fuels such as brown coal, bituminous coal and biomass.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Low oxygen biomass-derived pyrolysis oils and methods for producing the same

Low oxygen biomass-derived pyrolysis oils and methods for producing them from carbonaceous biomass feedstock are provided. The carbonaceous biomass feedstock is pyrolyzed in the presence of a catalyst comprising base metal-based catalysts, noble metal-based catalysts, treated zeolitic catalysts, or combinations thereof to produce pyrolysis gases. During pyrolysis, the catalyst catalyzes a deoxygenation reaction whereby at least a portion of the oxygenated hydrocarbons in the pyrolysis gases are converted into hydrocarbons. The oxygen is removed as carbon oxides and water. A condensable portion (the vapors) of the pyrolysis gases is condensed to low oxygen biomass-derived pyrolysis oil.

Owner:UOP LLC

Biomass quick cracked oil water vapour catforming hydrogen production method

InactiveCN101318622AExtended service lifeSolve the phenomenon of carbon depositionHydrogenCatalytic reformingGas phase

The invention discloses a method by adopting biomass fast pyrolysis oil which carries out two sections of fixed bed reactors and water vapor catalytic reforming for producing hydrogen; the two sections of fixed bed reactors are connected in series, the natural dolomite which is relatively cheap and easily available is taken as catalyst in water vapor reforming reaction at the first section of fixed bed reactor, while the second fixed bed reactor adopts Ni / Mgo as catalyst to further improve the purity and yield of the target product gas. Comparatively high temperature and comparatively high S / C (more than 12) are extremely important for the effective transformation of the biomass pyrolysis oil in the first fixed bed reactor. However, for any temperature point, low mass space velocity can facilitate the increasing of the yield of any gas product and the total gas phase transformation ratio of the biomass oil is increased accordingly. The Ni / MgO catalyst is extremely effective in the purification stage, when S / CH4 is not less than 2 and the temperature is not lower than 800 DEG C, the transformation ratio of methane can reach 100 %. Low mass space velocity can facilitate effective transformation of methane; when mass space velocity is not higher than 3600h<-1>, the potential hydrogen yield can reach 81.1%.

Owner:EAST CHINA UNIV OF SCI & TECH

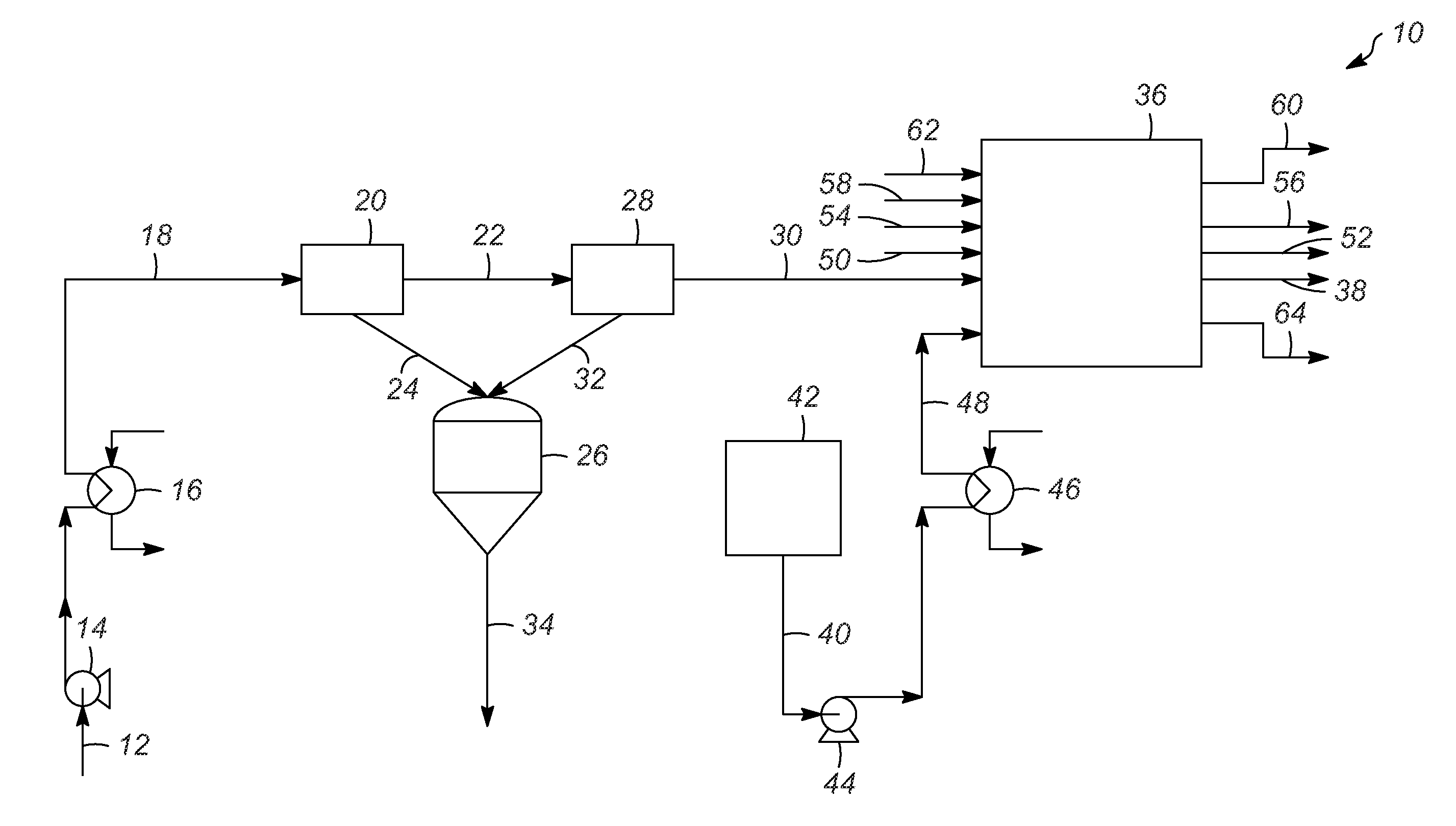

Methods and apparatuses for forming low-metal biomass-derived pyrolysis oil

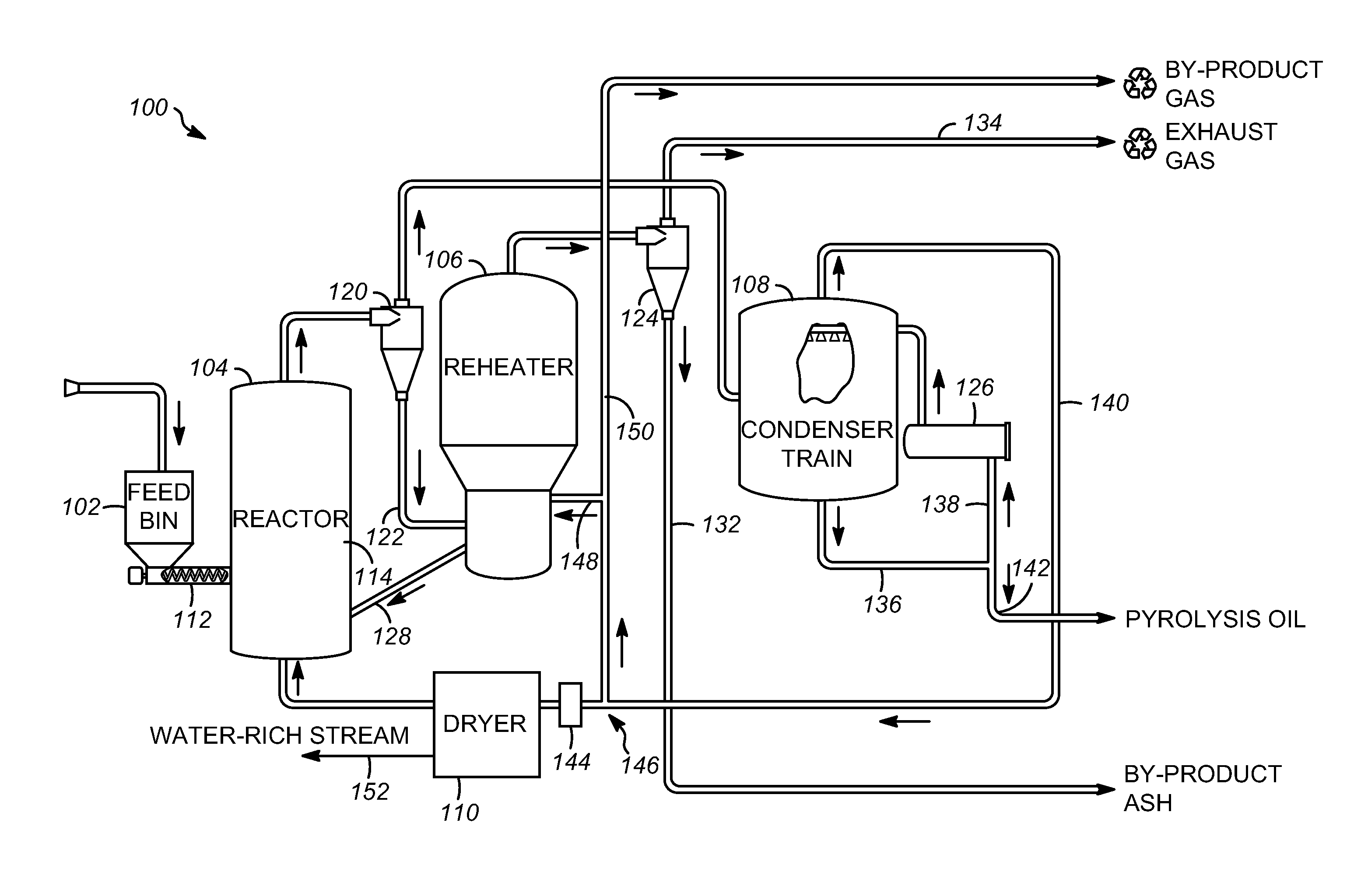

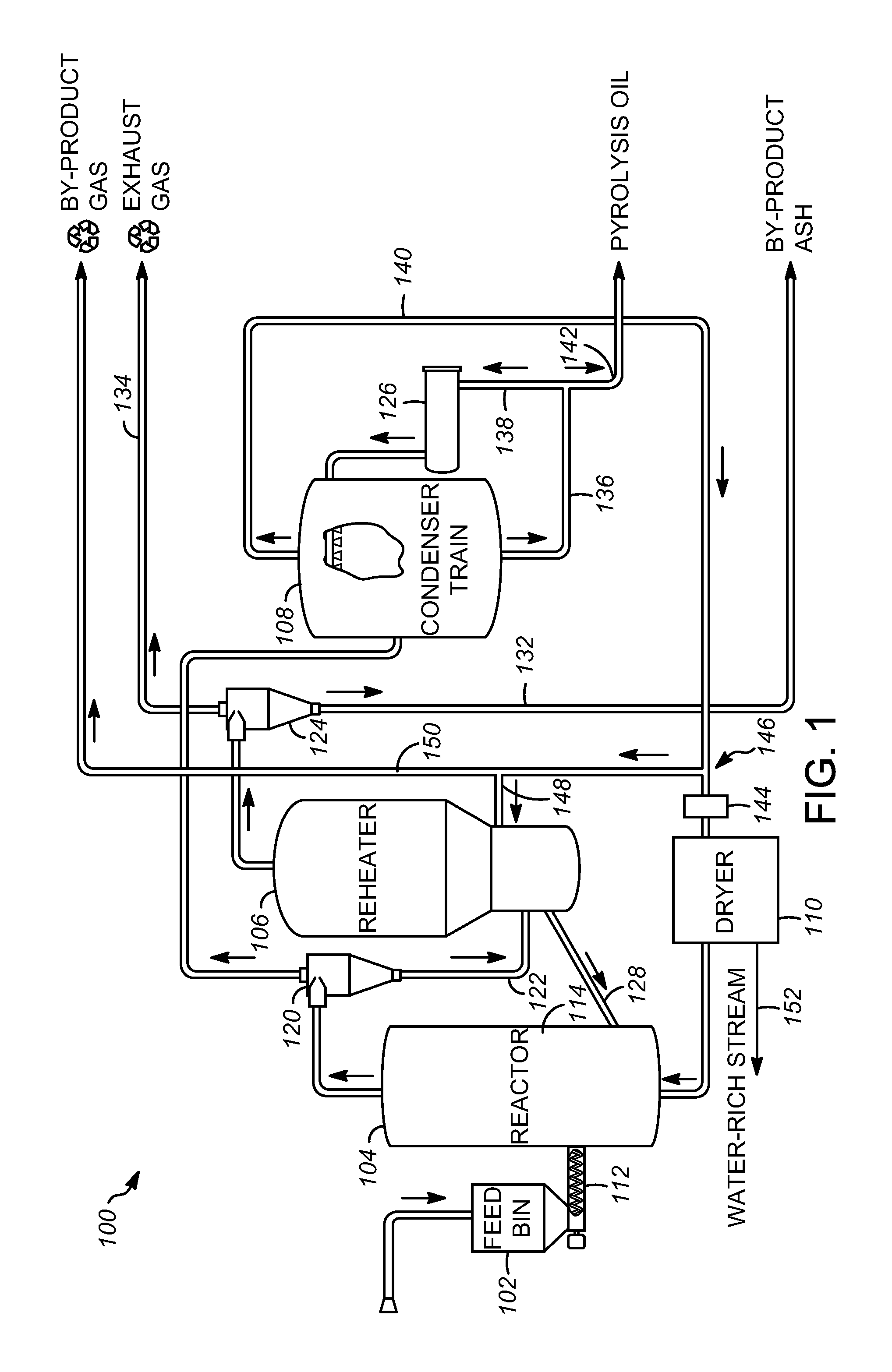

Methods and apparatuses for forming a low-metal biomass-derived pyrolysis oil are provided. In an embodiment, a method for forming a low-metal biomass-derived pyrolysis oil includes washing biomass comprising a water-soluble metal component therein with wash water that is substantially free of water-soluble metals. The washed biomass and water containing water-soluble metal are separated after washing the biomass. The washed biomass is pyrolyzed in a pyrolysis process to form a pyrolysis vapor stream. A portion of the pyrolysis vapor stream is condensed to form a condensate. The wash water is derived from the washed biomass. In an embodiment of an apparatus, the apparatus comprises a washing stage, a biomass dryer, a pyrolysis reactor, a quenching system comprising a primary condenser and a secondary condenser, and a return line that connects the quenching system to the washing stage.

Owner:UOP LLC

Low water biomass-derived pyrolysis oils and processes for producing the same

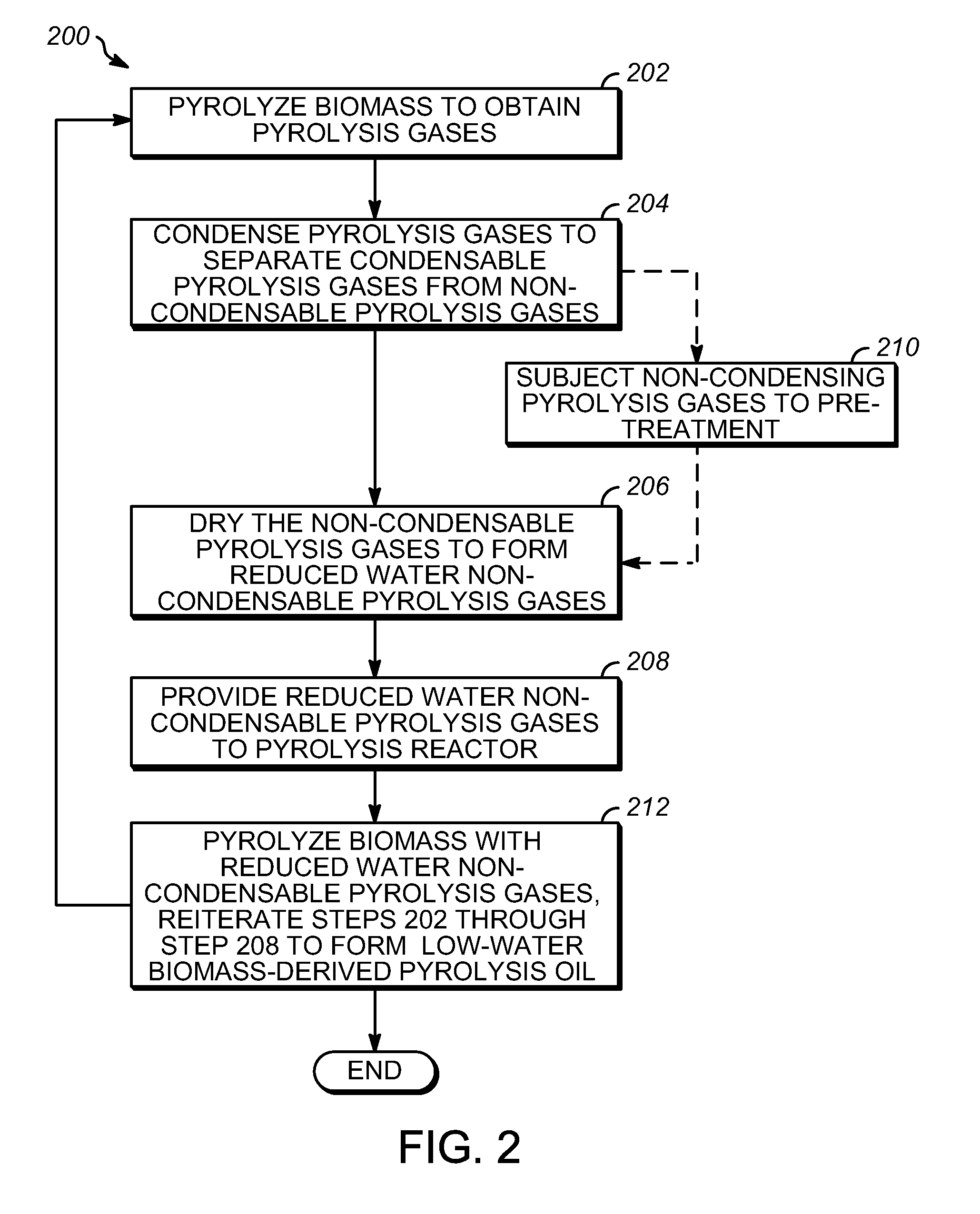

ActiveUS8519205B2Extensive contentReduce moistureDirect heating destructive distillationLiquid hydrocarbon mixture recoveryProduct gasWater content

Low water-containing biomass-derived pyrolysis oils and processes for producing them are provided. The process includes condensing pyrolysis gases including condensable pyrolysis gases and non-condensable gases to separate the condensable pyrolysis gases from the non-condensable gases, the non-condensable gases having a water content, drying the non-condensable pyrolysis gases to reduce the water content of the-non-condensable gases to form reduced-water non-condensable pyrolysis gases, and providing the reduced-water non-condensable pyrolysis gases to a pyrolysis reactor for forming the biomass-derived pyrolysis oil.

Owner:ENSYN RENEWABLES

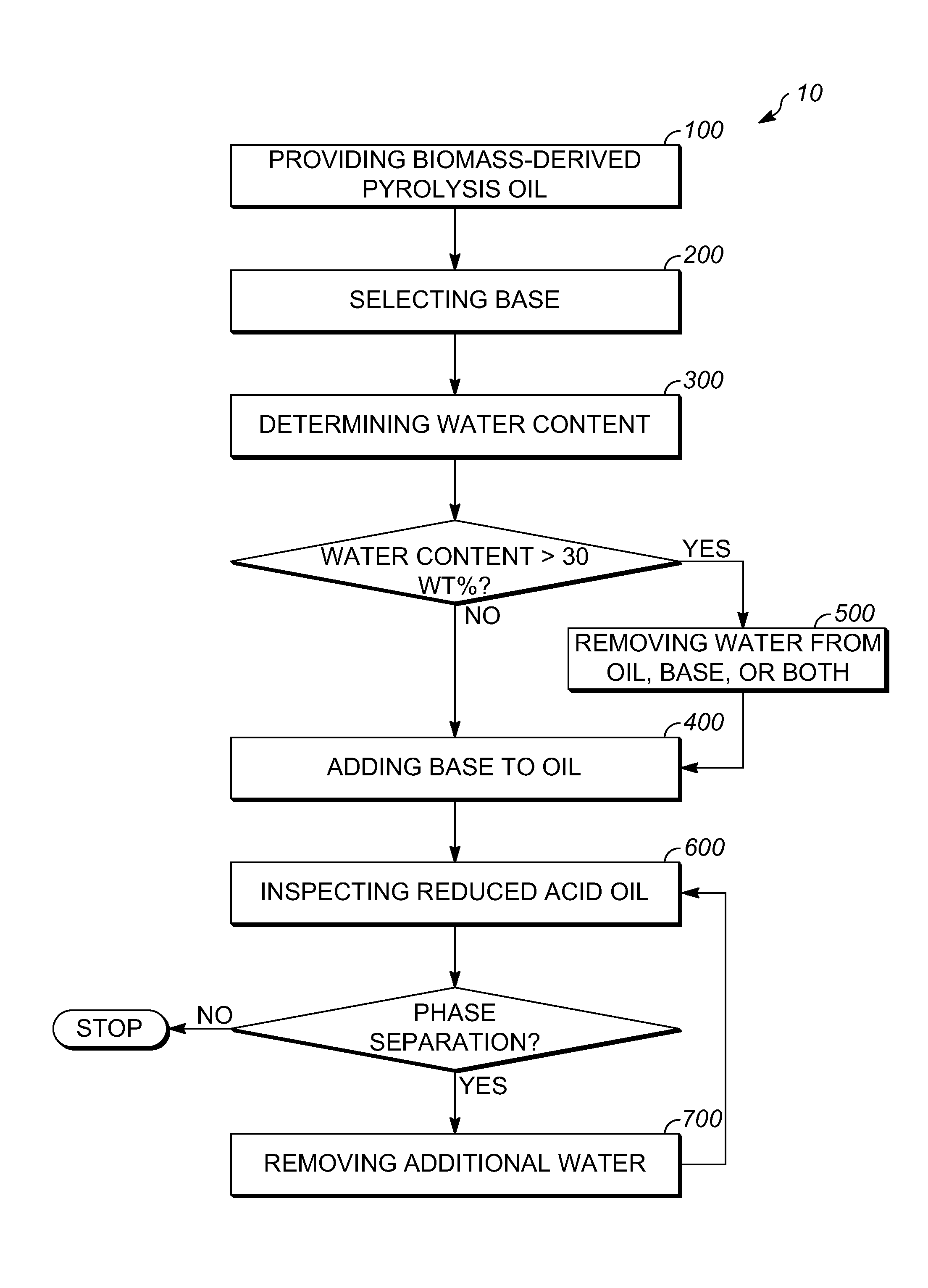

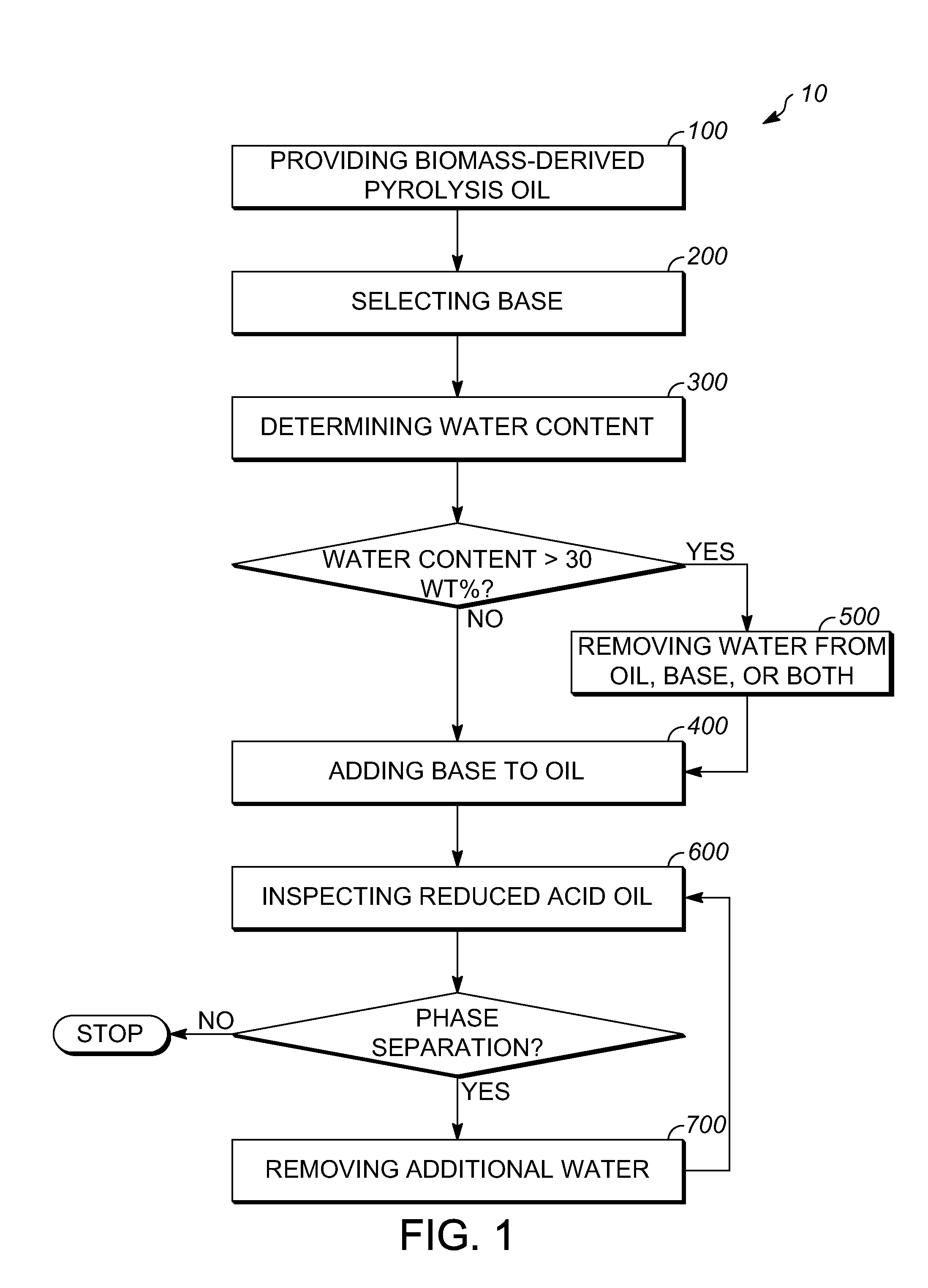

Methods for producing phase stable, reduced acid biomass-derived pyrolysis oils

Methods for producing phase stable, reduced acid biomass-derived pyrolysis oils are provided. Biomass-derived pyrolysis oil having a determined water content no greater than about 30% by weight is provided. A base is mixed with the biomass-derived pyrolysis oil to produce reduced acid biomass-derived pyrolysis oil. A base is selected from an inorganic base or a nitrogen-containing base.

Owner:UOP LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com