Patents

Literature

33617 results about "Sulfur" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sulfur (in British English, sulphur) is a chemical element with the symbol S and atomic number 16. It is abundant, multivalent, and nonmetallic. Under normal conditions, sulfur atoms form cyclic octatomic molecules with a chemical formula S₈. Elemental sulfur is a bright yellow, crystalline solid at room temperature.

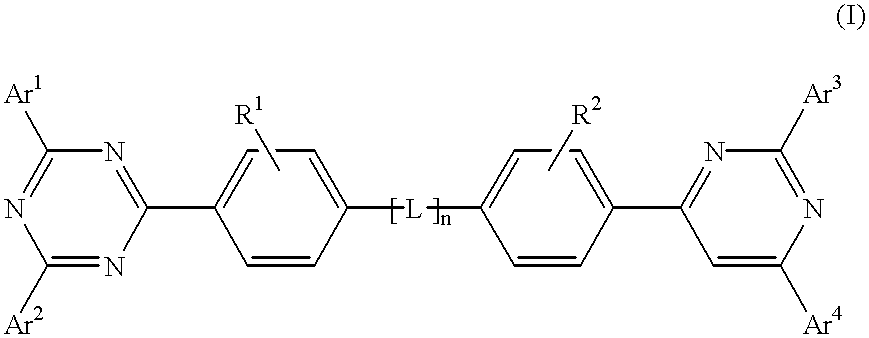

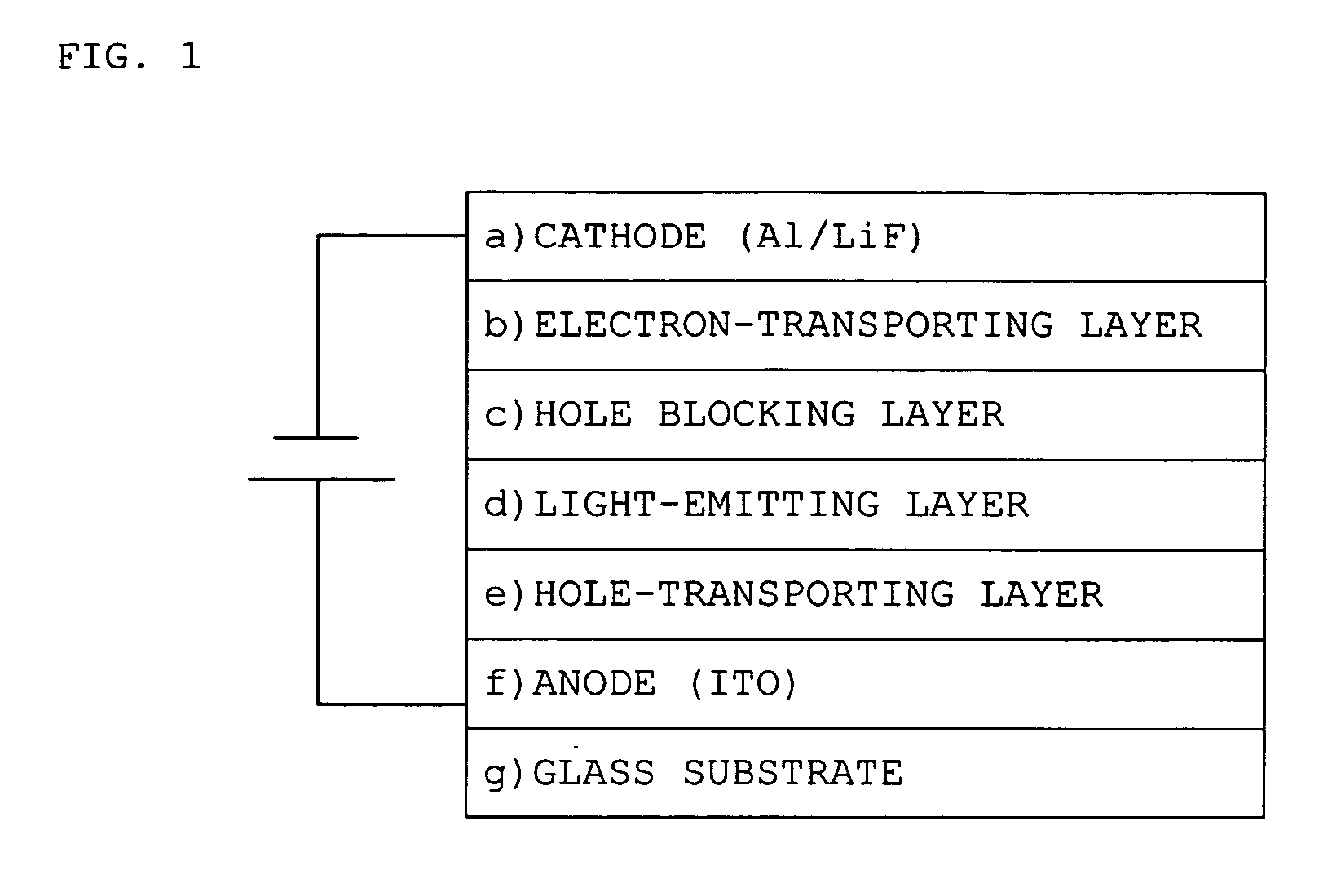

Electroluminescent (EL) devices

InactiveUS6225467B1Improve efficiencyIncreased durabilitySilicon organic compoundsElectroluminescent light sourcesArylHalogen

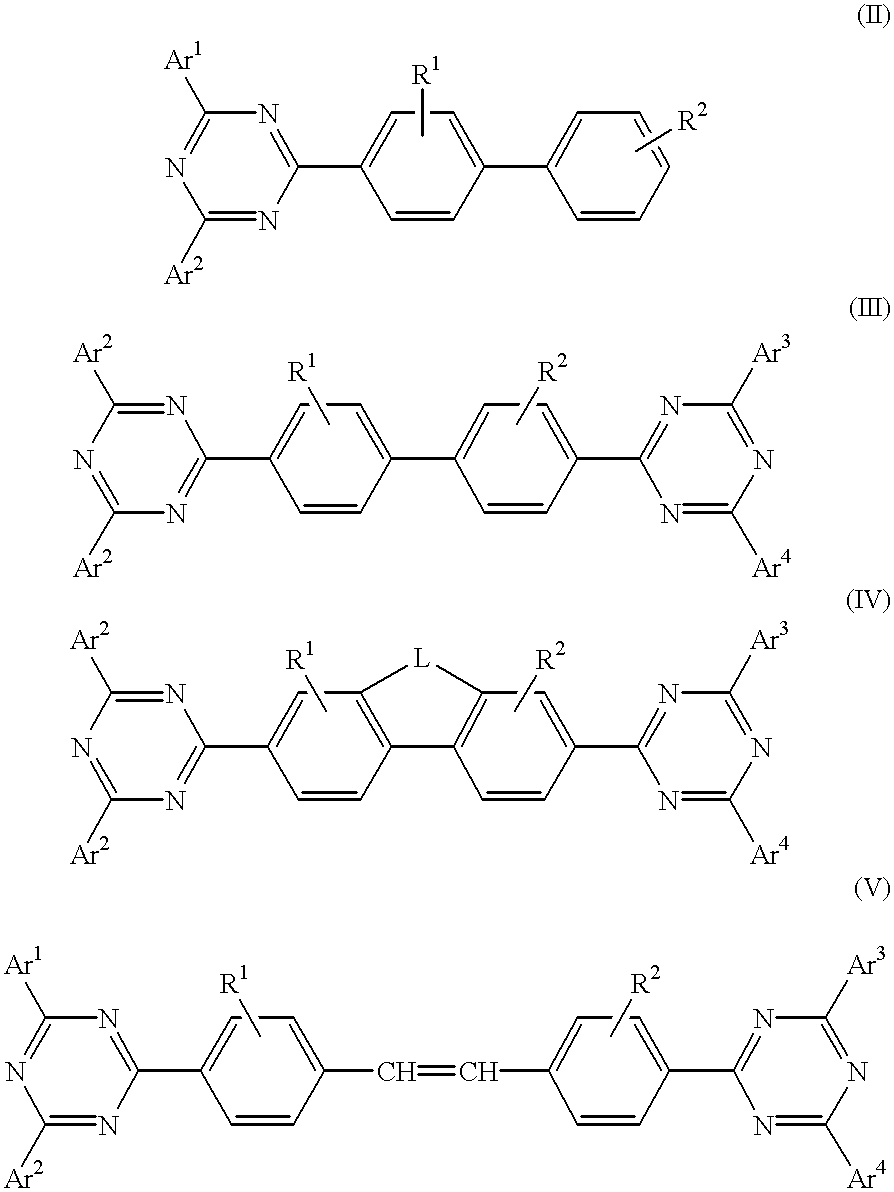

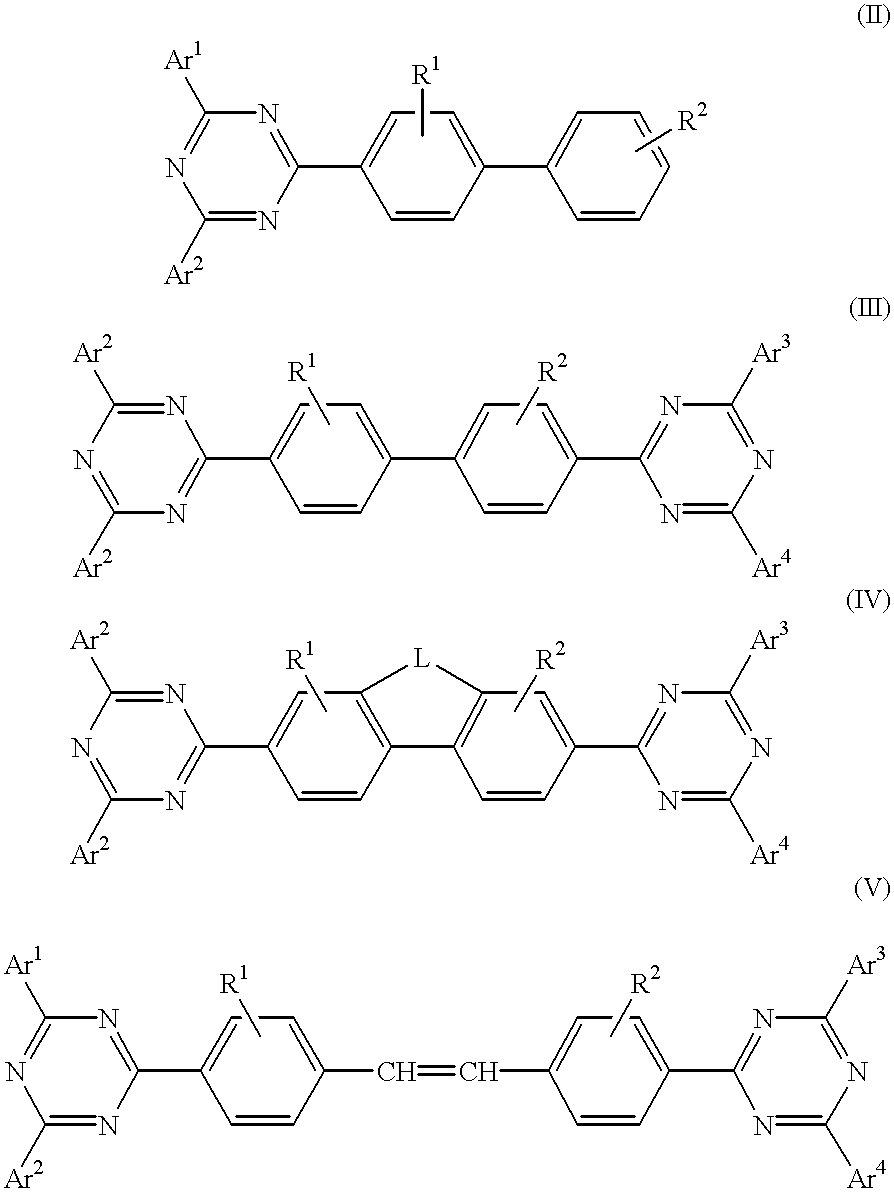

The triazinewherein Ar1, Ar2, Ar3, and Ar4 are each independently an aryl; R1 and R2 are substituents selected from the group consisting of hydrogen, an alkyl, an aryl, an alkoxy, a halogen atom, and a cyano; R3 and R4 are each a divalent group L selected from the group consisting of -C(R'R'')-, alkylene, an oxygen atom, a sulfur atom, and -Si(R'R'')-, wherein R' and R'' are selected from the group consisting of hydrogen, alkyl, alkoxy, and aryl.

Owner:LG DISPLAY CO LTD

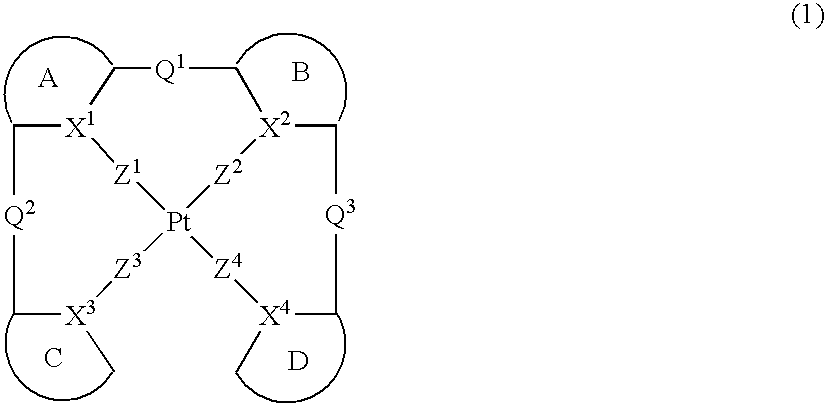

Platinum complex and light emitting device

ActiveUS20070103060A1Enhanced glowSolve low luminous efficiencyDischarge tube luminescnet screensElectroluminescent light sourcesOxygenLight emission

Provision of a novel platinum complex which is useful as a material for a light-emitting device of good light emission characteristic and light emission efficiency, and a novel light-emitting material that may be utilized in various fields. A platinum complex represented by the following general formula (1): (in which two rings of ring A, ring B, ring C, and ring D represent nitrogen-containing heterocyclic rings which may have a substituent and the remaining two rings of them represent aryl rings or hetero aryl rings which may have a substituent, the ring A and the ring B, the ring A and the ring C or / and the ring B and the rind D may form condensed rings. Two of X1, X2, X3, and X4 represent nitrogen atoms coordination bonded to a platinum atom and the remaining two of them represent carbon atoms or nitrogen atoms. Q1, Q2, and Q3 each represents a bond, oxygen atom, sulfur atom or bivalent group, two of Z1, Z2, Z3, and Z4 represent coordination bonds, and the remaining two of them represent covalent bonds, oxygen atoms or sulfur atoms), and a light-emitting device containing the platinum complex.

Owner:TAKASAGO INTERNATIONAL CORPORATION

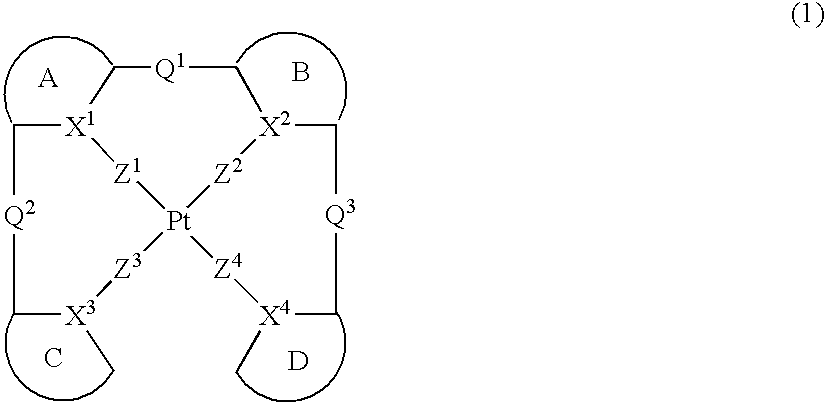

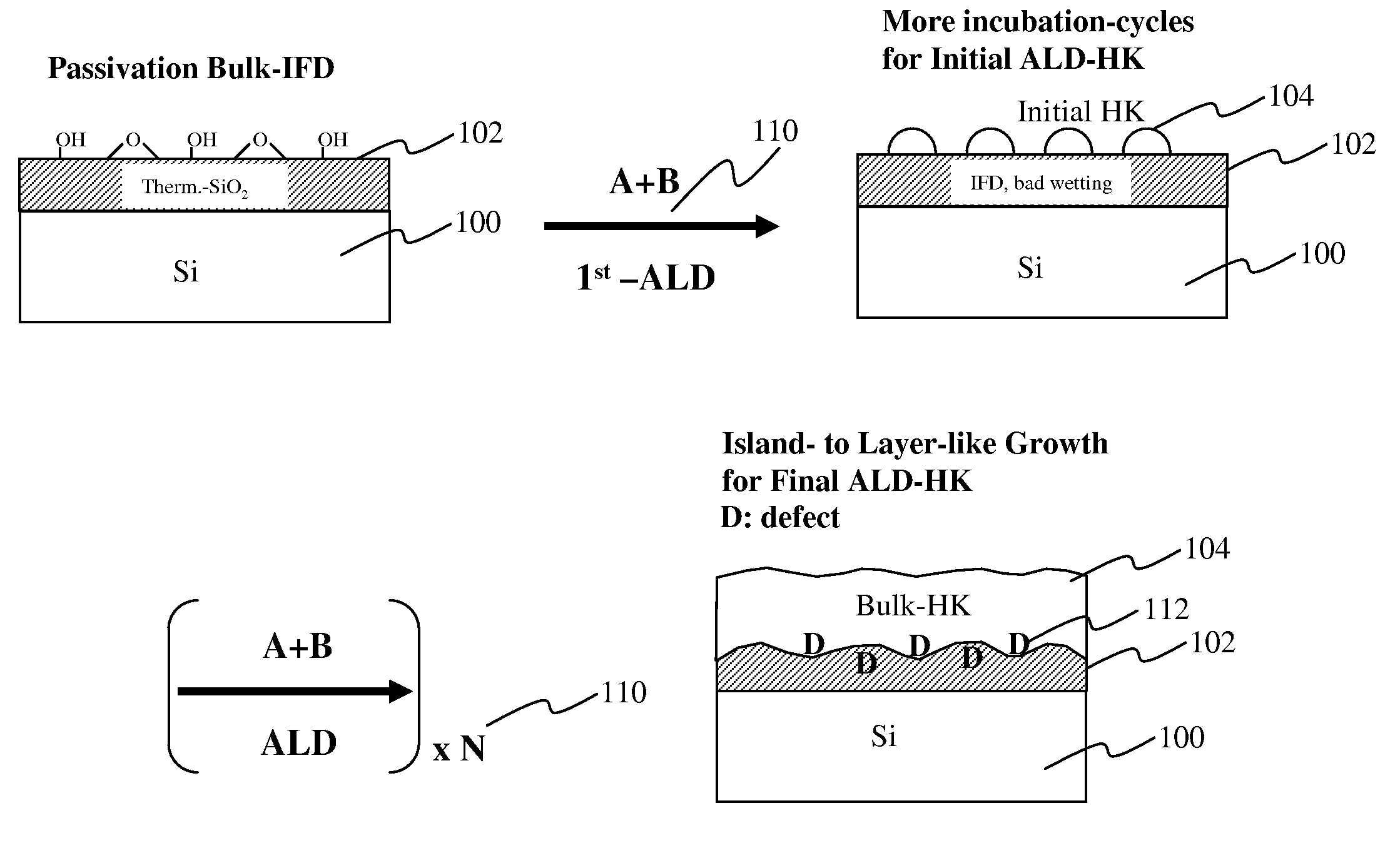

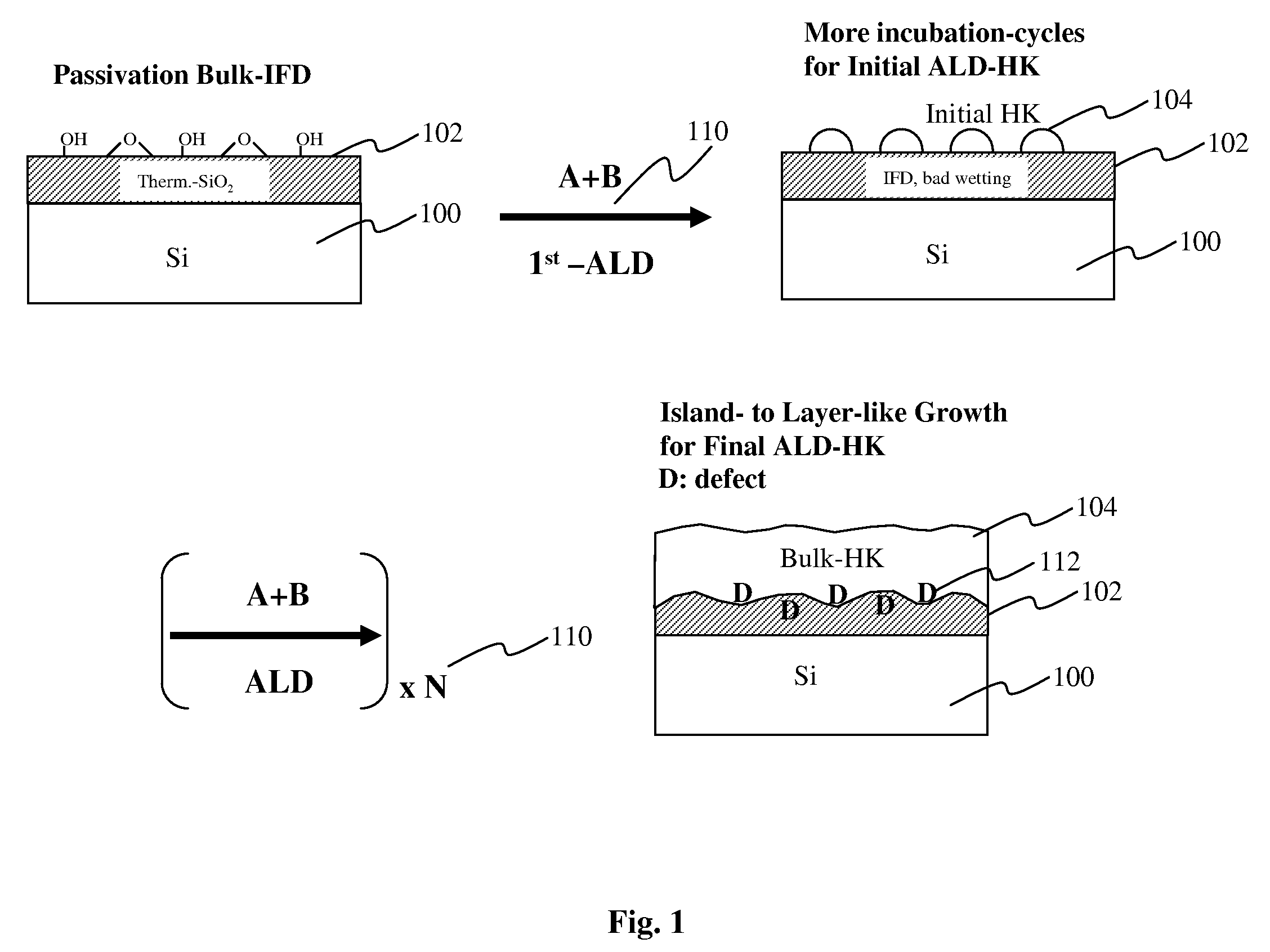

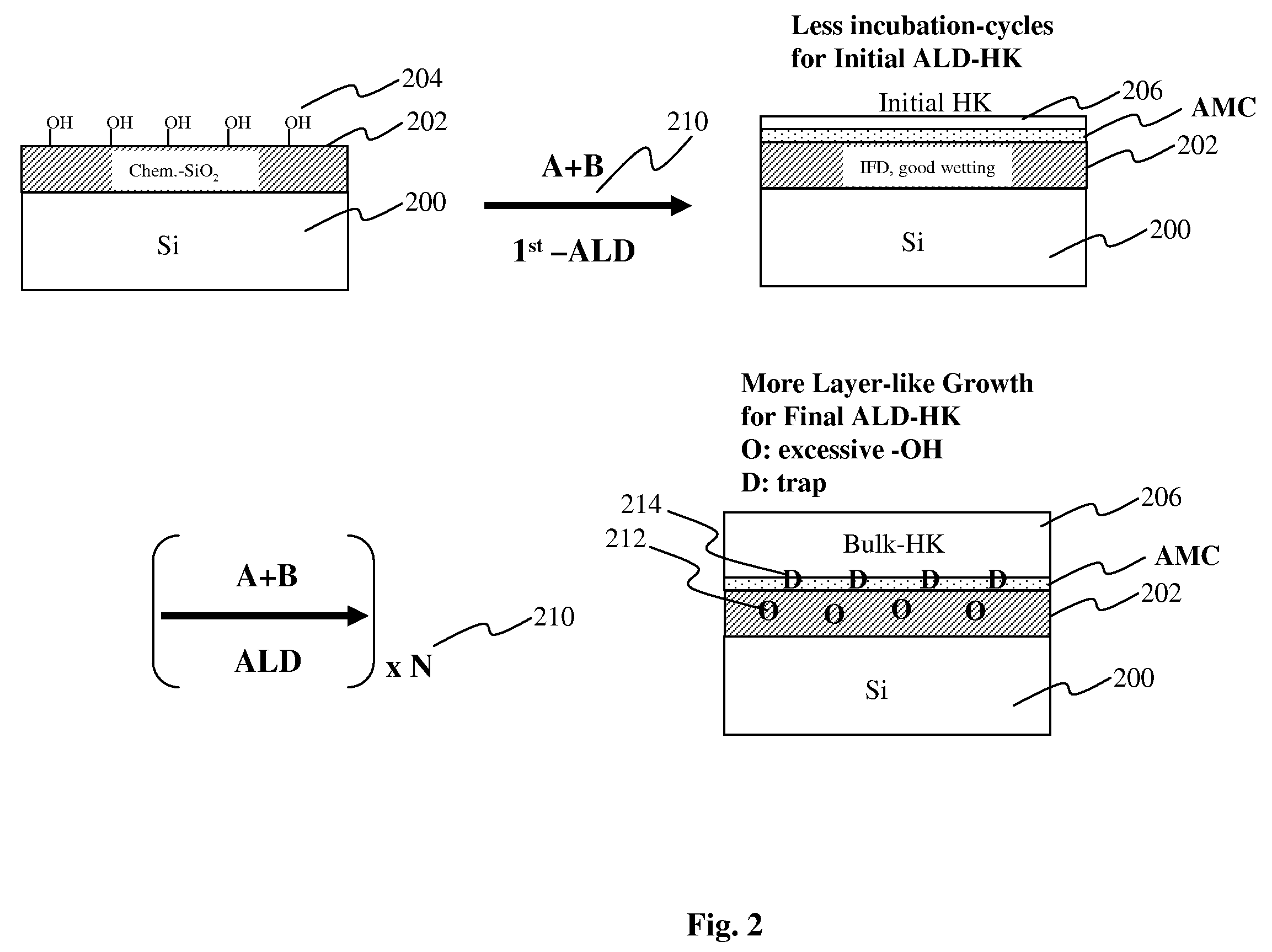

Method of Fabricating a Gate Dielectric for High-K Metal Gate Devices

ActiveUS20100075507A1Facilitate formation of the high-k dielectric layerImprove electrical performanceSemiconductor/solid-state device manufacturingChemical vapor deposition coatingGate dielectricSulfur

The present disclosure provides a method of fabricating a semiconductor device. The method includes providing a substrate, forming an interfacial layer on the substrate by treating the substrate with radicals, and forming a high-k dielectric layer on the interfacial layer. The radicals are selected from the group consisting of hydrous radicals, nitrogen / hydrogen radicals, and sulfur / hydrogen radicals.

Owner:TAIWAN SEMICON MFG CO LTD

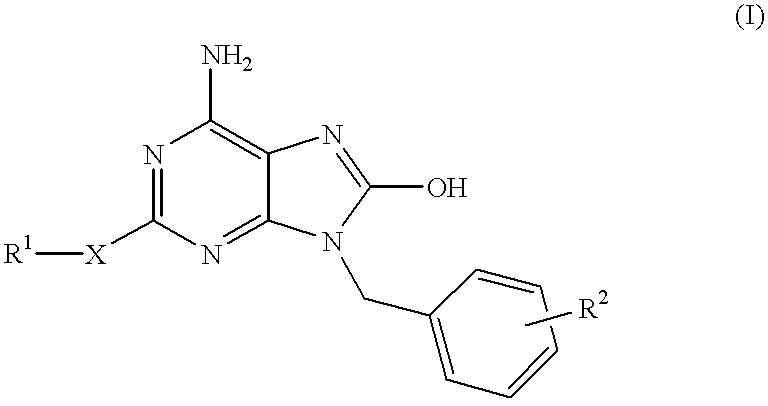

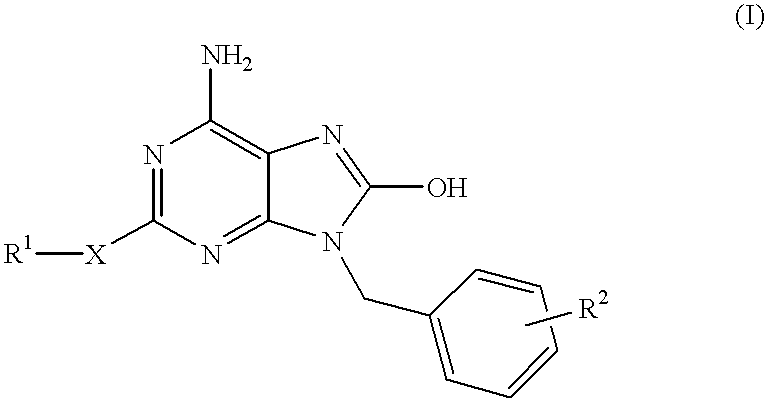

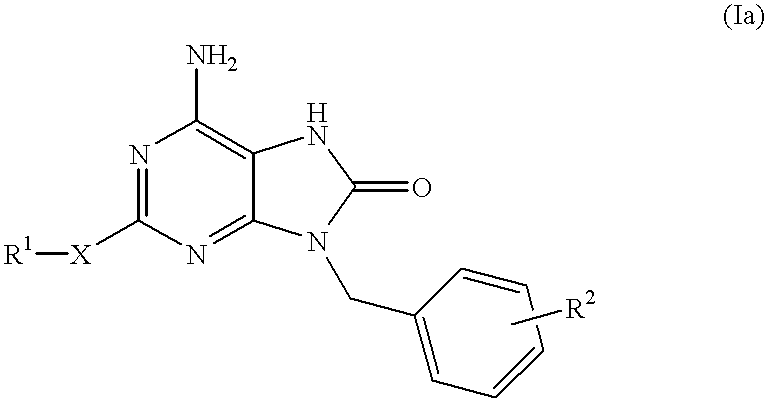

Heterocyclic compounds

InactiveUS6329381B1Excellent interferon biosynthesis inducing activityInhibition thicknessAntibacterial agentsBiocideBULK ACTIVE INGREDIENTInterferon inducer

The present invention relates to a heterocyclic compound of the following general formula (I):wherein X is sulfur atom, oxygen atom or -NR3- (R3 may form a heterocyclic ring or a substituted heterocyclic ring with R1 via the nitrogen atom),R1 is alkyl group, substituted alkyl group, aryl group, substituted aryl group, heterocyclic group or substituted heterocyclic group, andR2 is hydrogen atom, halogen atom etc.;or its pharmaceutically acceptable salt and interferon inducers, antiviral agents, anticancer agents and therapeutic agents for immunologic diseases comprising the compound (I) or its pharmaceutically acceptable salt as active ingredients.

Owner:SUMITOMO DAINIPPON PHARMA CO LTD

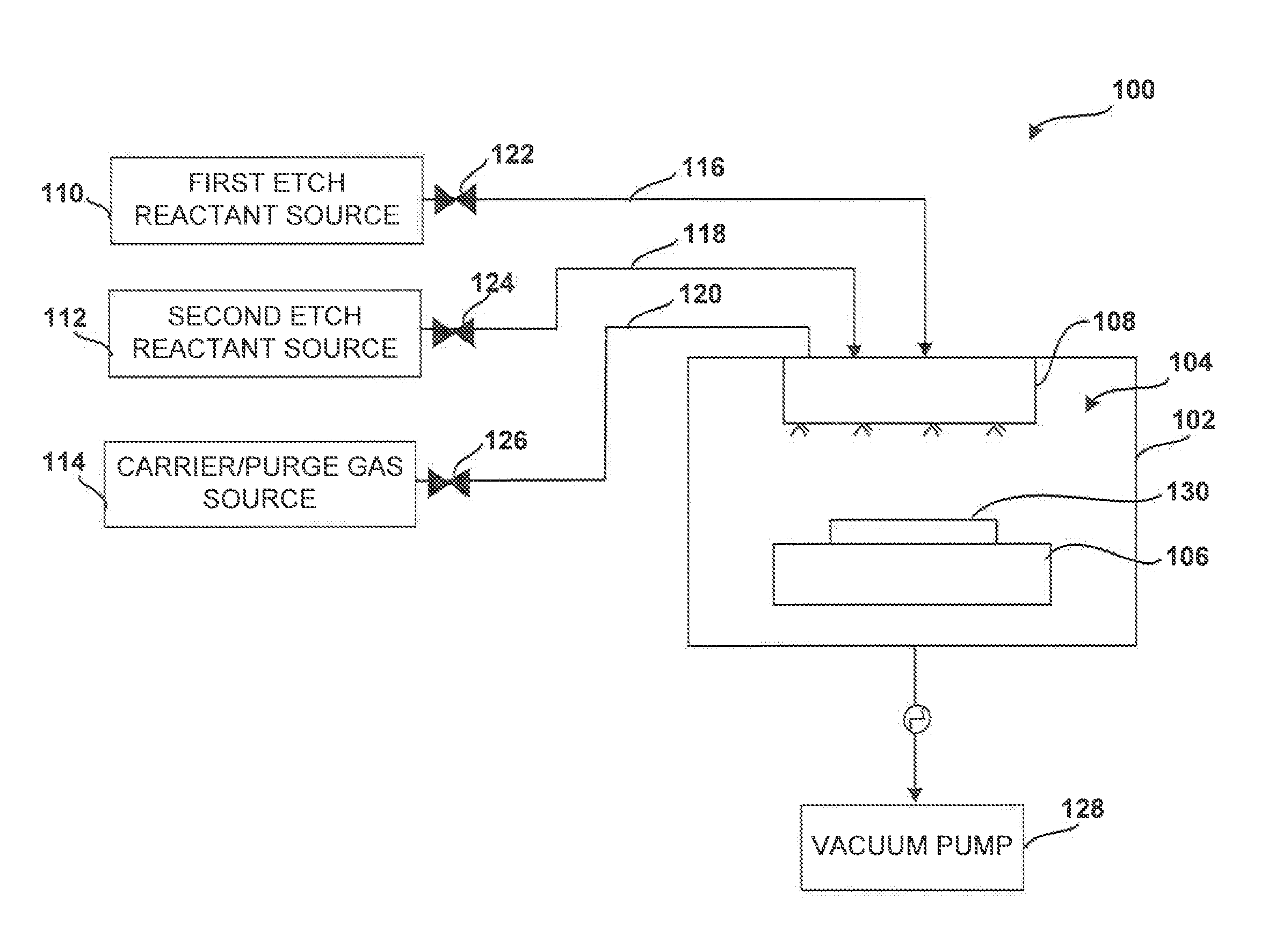

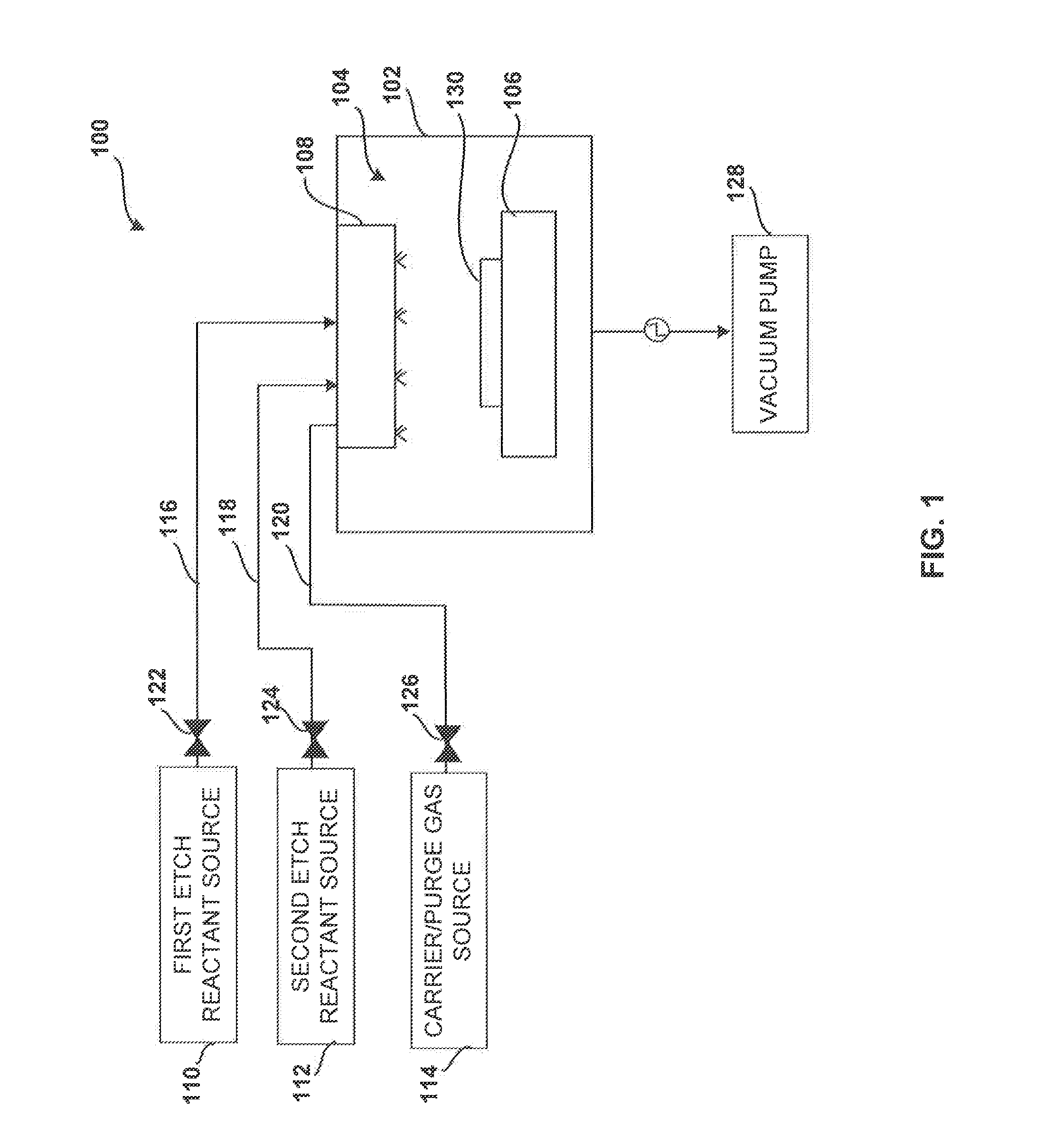

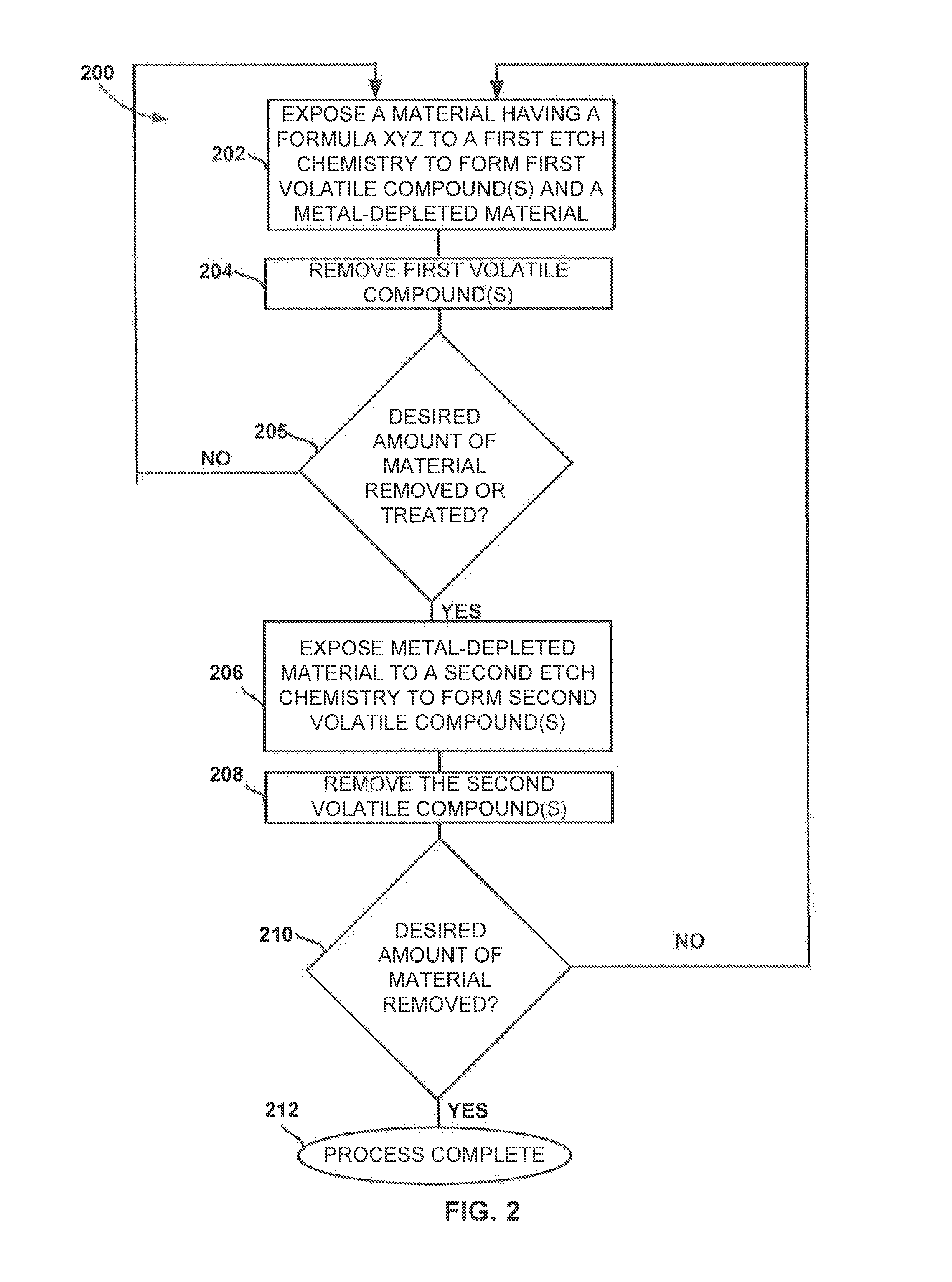

Multi-step method and apparatus for etching compounds containing a metal

ActiveUS20140217065A1Reduce harmReduce formationDecorative surface effectsSemiconductor/solid-state device manufacturingSulfurChemical compound

A system and method for etching a material, including a compound having a formulation of XYZ, wherein X and Y are one or more metals and Z is selected from one or more Group 13-16 elements, such as carbon, nitrogen, boron, silicon, sulfur, selenium, and tellurium, are disclosed. The method includes a first etch process to form one or more first volatile compounds and a metal-depleted layer and a second etch process to remove at least a portion of the metal-depleted layer.

Owner:ASM IP HLDG BV

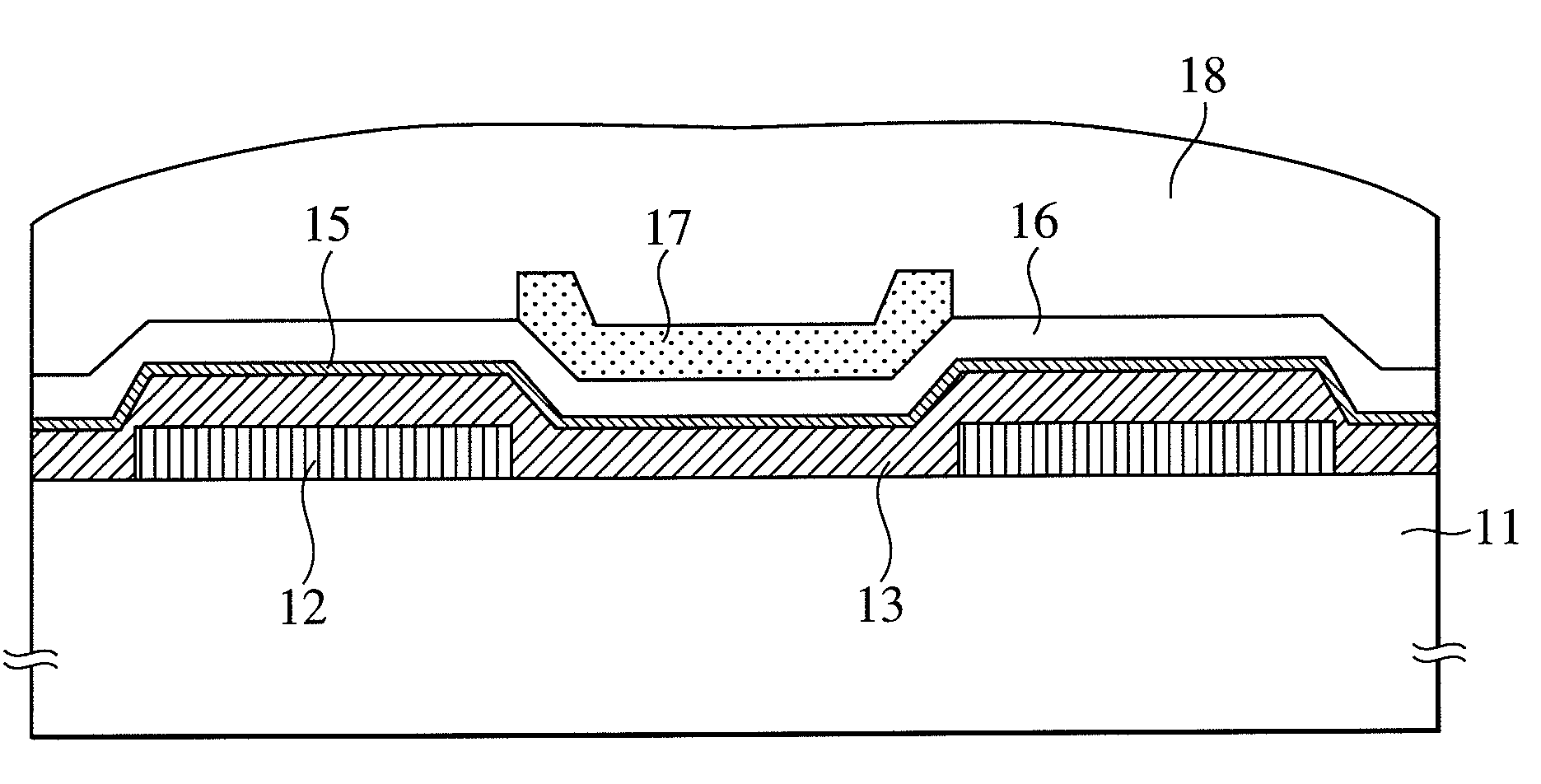

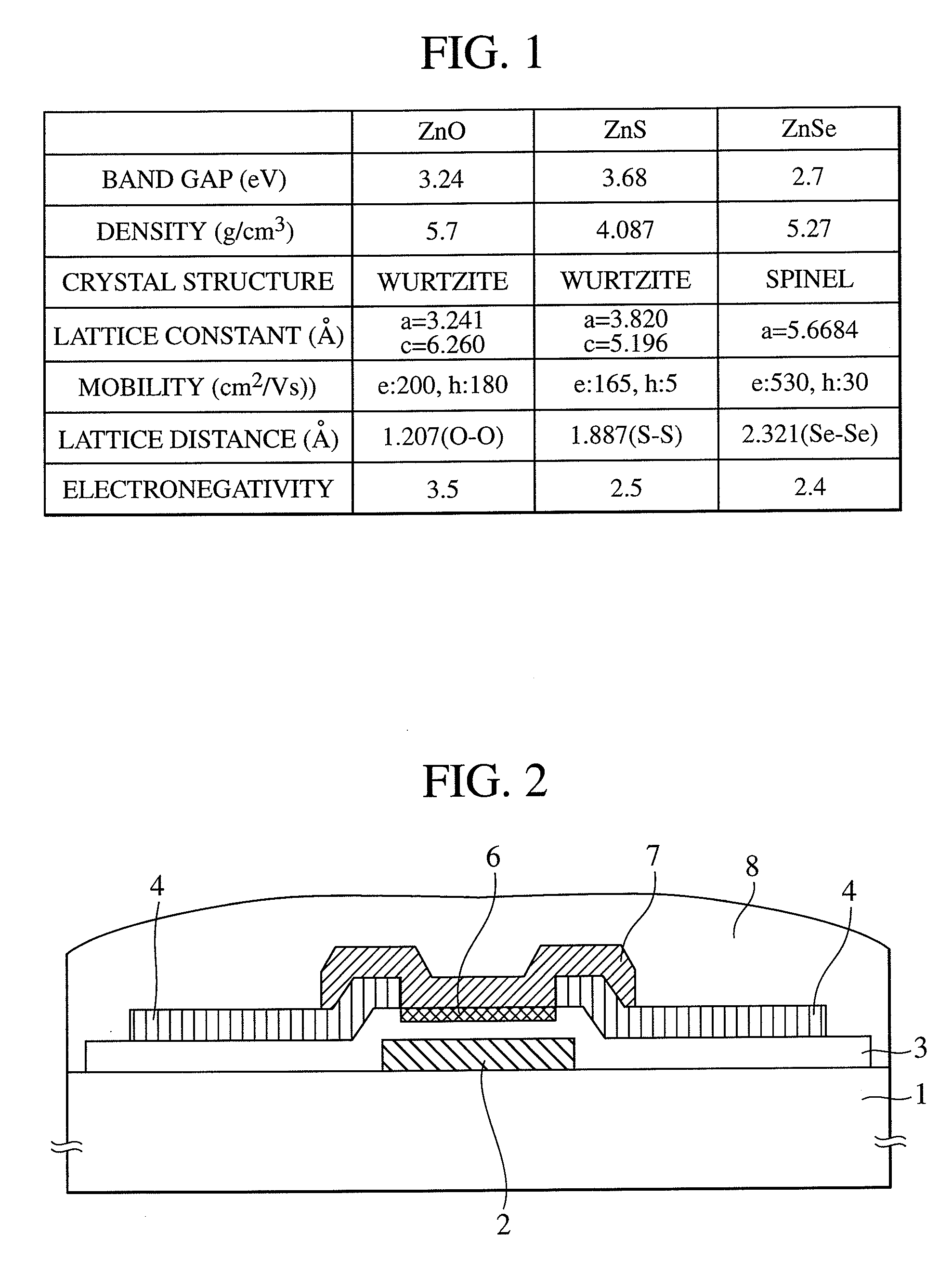

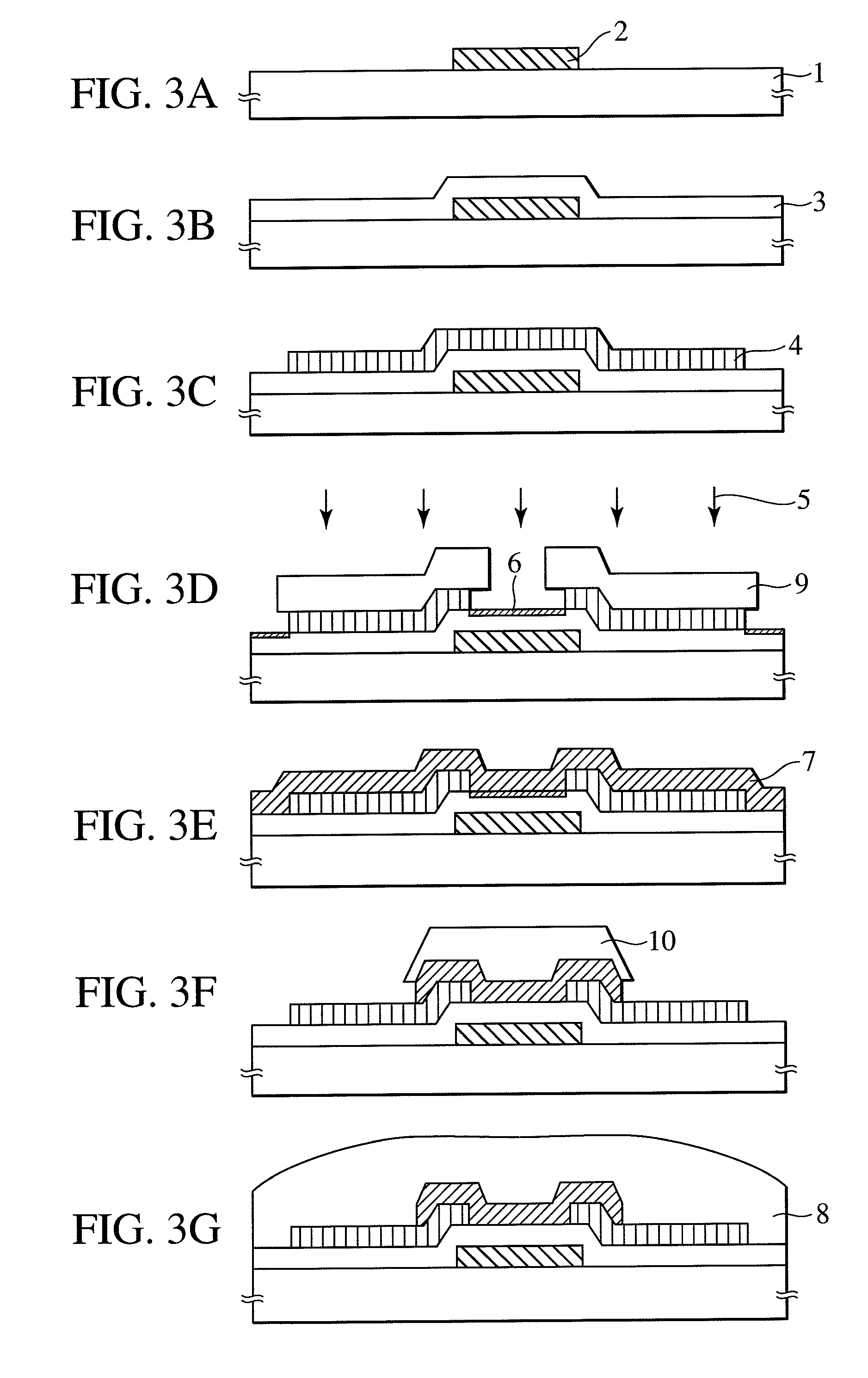

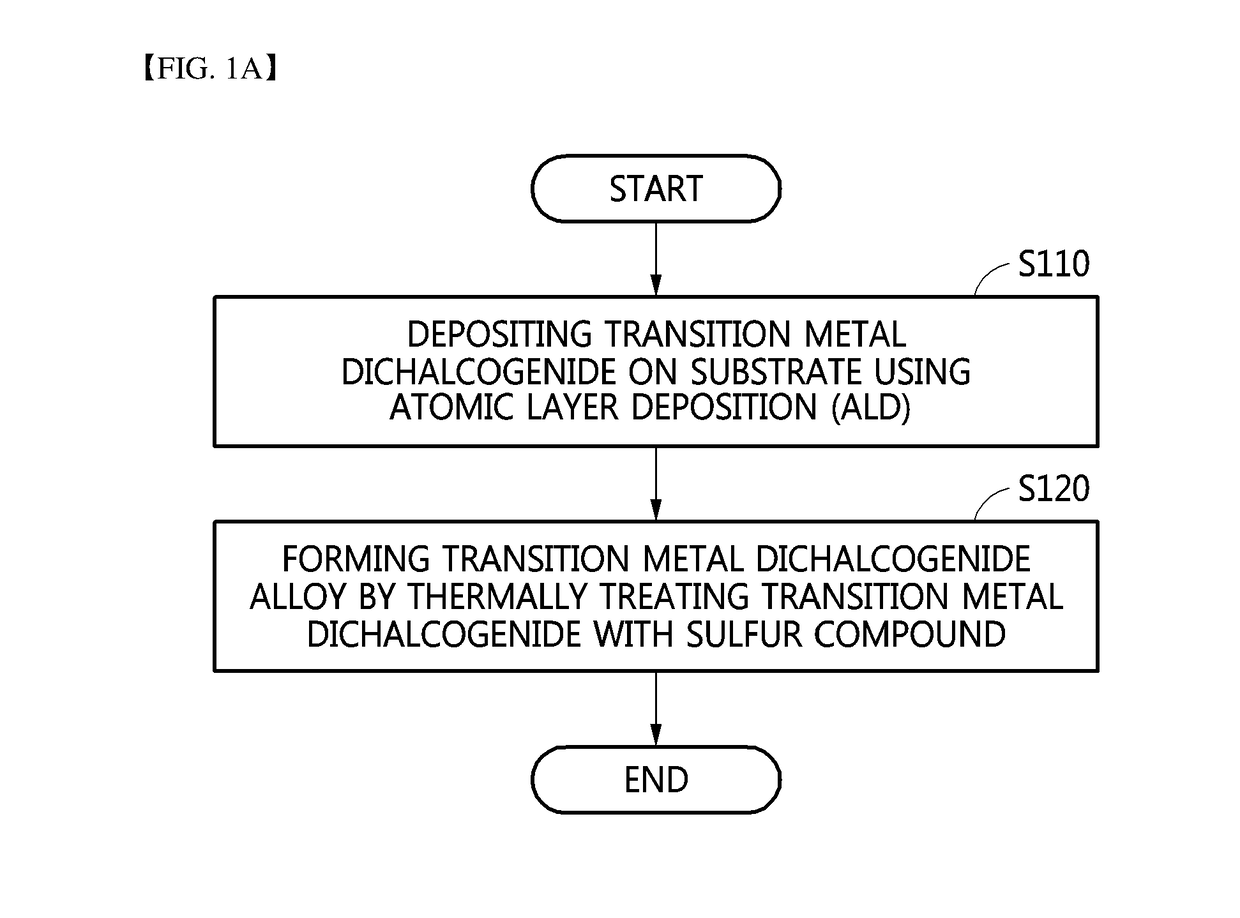

Oxide semiconductor device and surface treatment method of oxide semiconductor

InactiveUS20090166616A1Effectively suppressing the threshold potential shift and occurrence of leak currentPhysical property is lessSolid-state devicesSemiconductor/solid-state device manufacturingGas phaseThreshold potential

Oxygen defects formed at the boundary between the zinc oxide type oxide semiconductor and the gate insulator are terminated by a surface treatment using sulfur or selenium as an oxygen group element or a compound thereof, the oxygen group element scarcely occurring physical property value change. Sulfur or selenium atoms effectively substitute oxygen defects to prevent occurrence of electron supplemental sites by merely applying a gas phase or liquid phase treatment to an oxide semiconductor or gate insulator with no remarkable change on the manufacturing process. As a result, this can attain the suppression of the threshold potential shift and the leak current in the characteristics of a thin film transistor.

Owner:HITACHI LTD

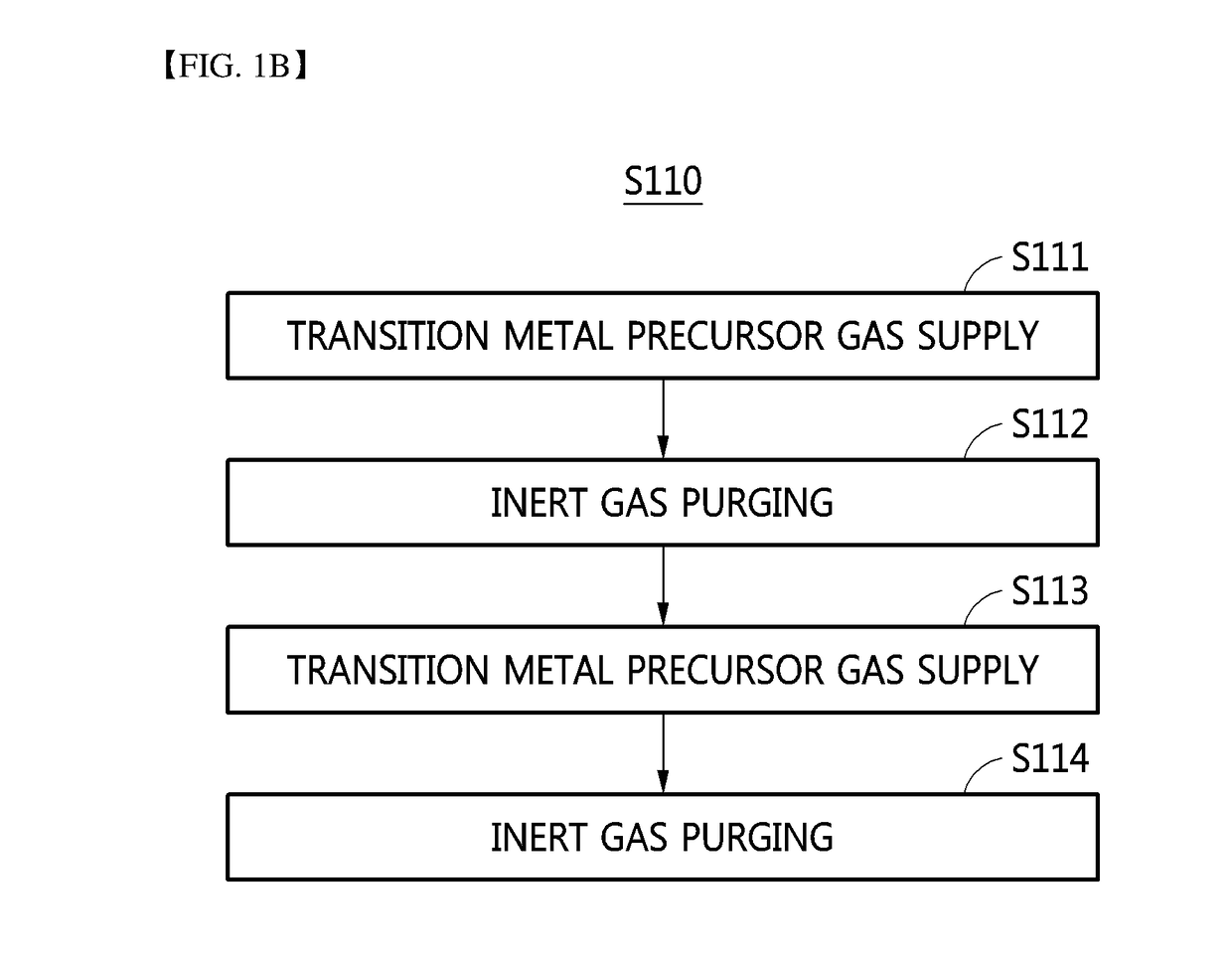

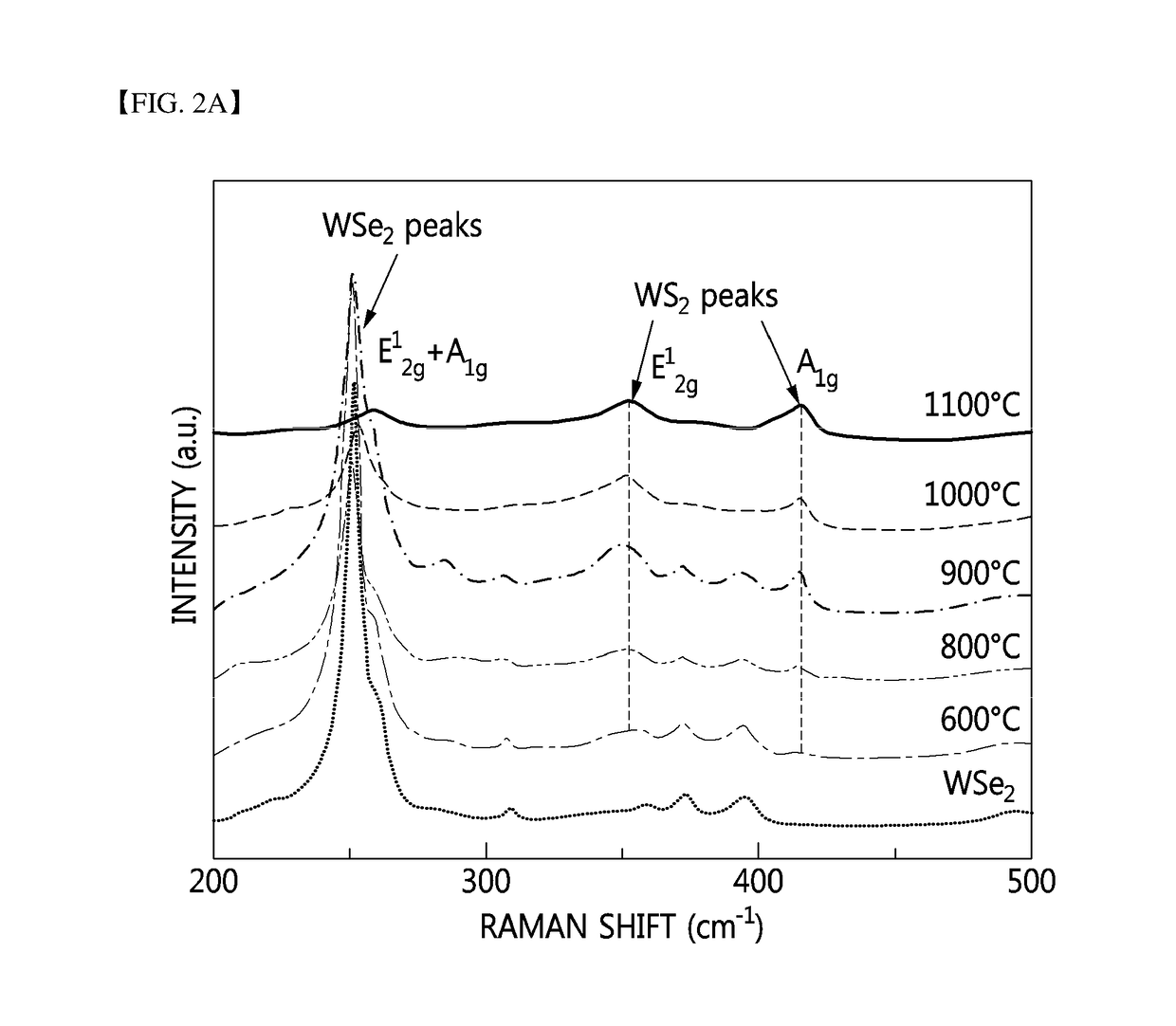

Transition metal dichalcogenide alloy and method of manufacturing the same

ActiveUS20170267527A1Semiconductor/solid-state device manufacturingSelenium/tellurium compounds with other elementsSulfurAlloy

Disclosed are a transition metal dichalcogenide alloy and a method of manufacturing the same. A method of manufacturing a transition metal dichalcogenide alloy according to an embodiment of the present disclosure includes a step of depositing transition metal dichalcogenide on a substrate using atomic layer deposition (ALD); and a step of forming a transition metal dichalcogenide alloy by thermally treating the transition metal dichalcogenide with a sulfur compound.

Owner:IND ACADEMIC CORP FOUND YONSEI UNIV

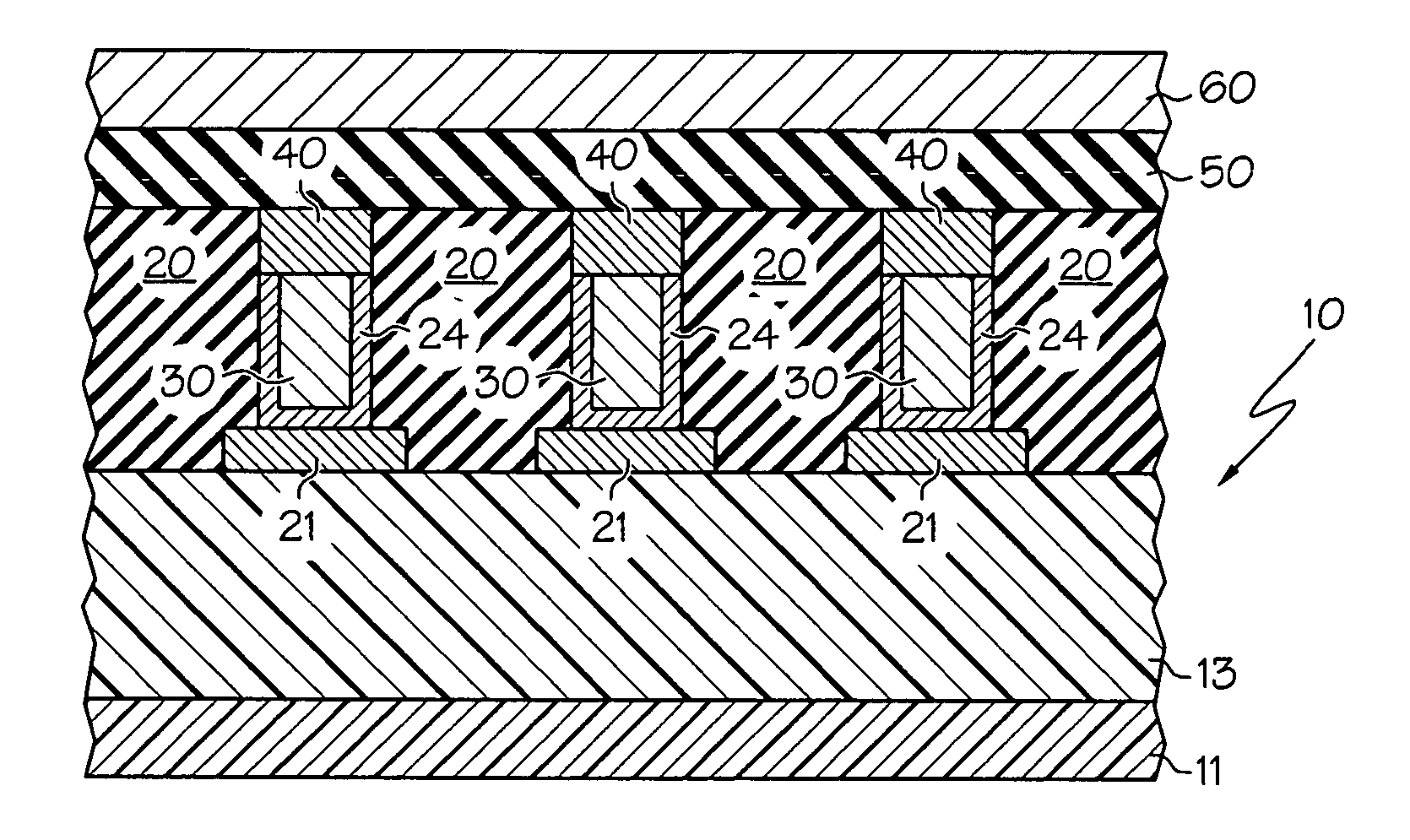

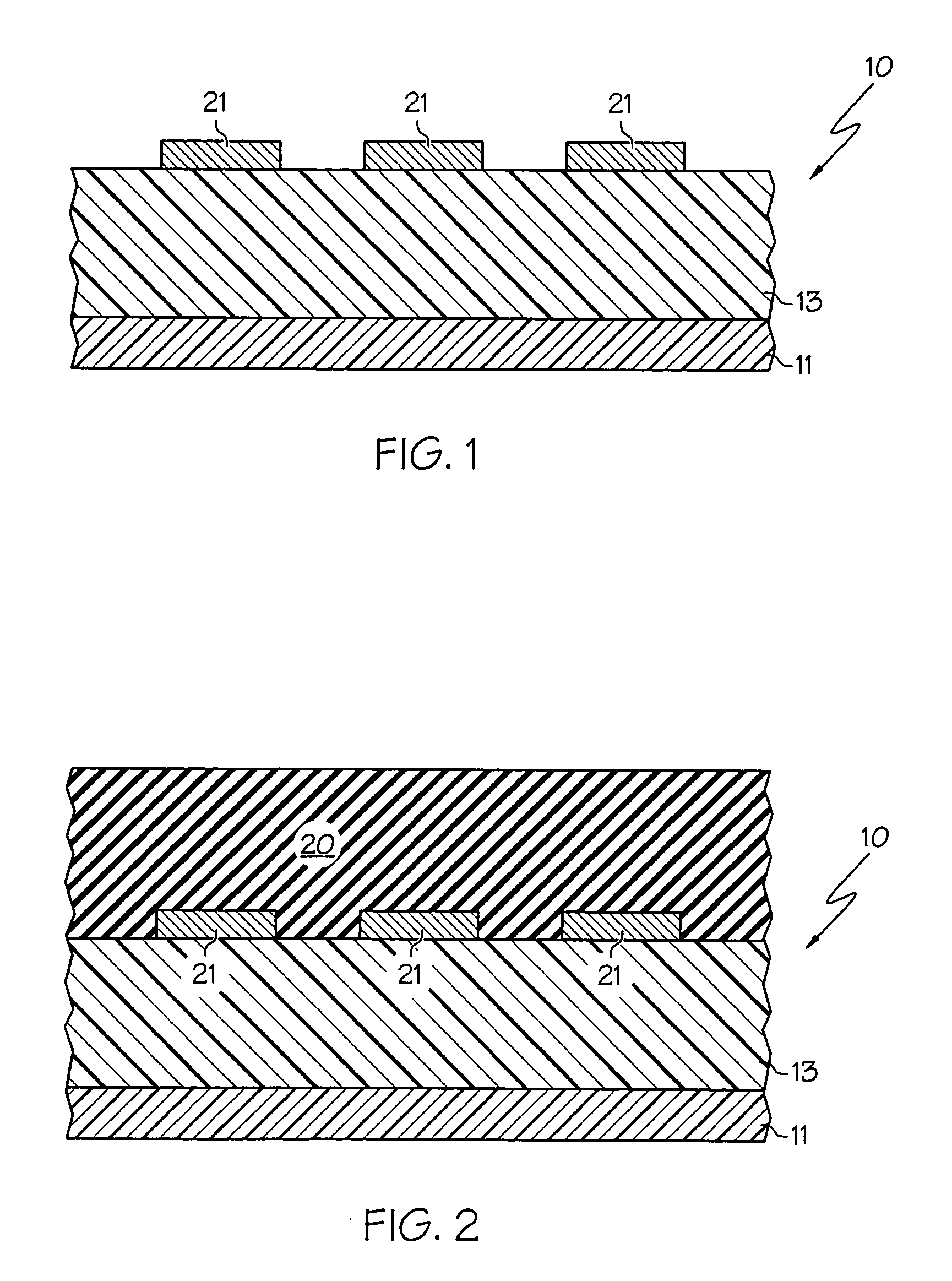

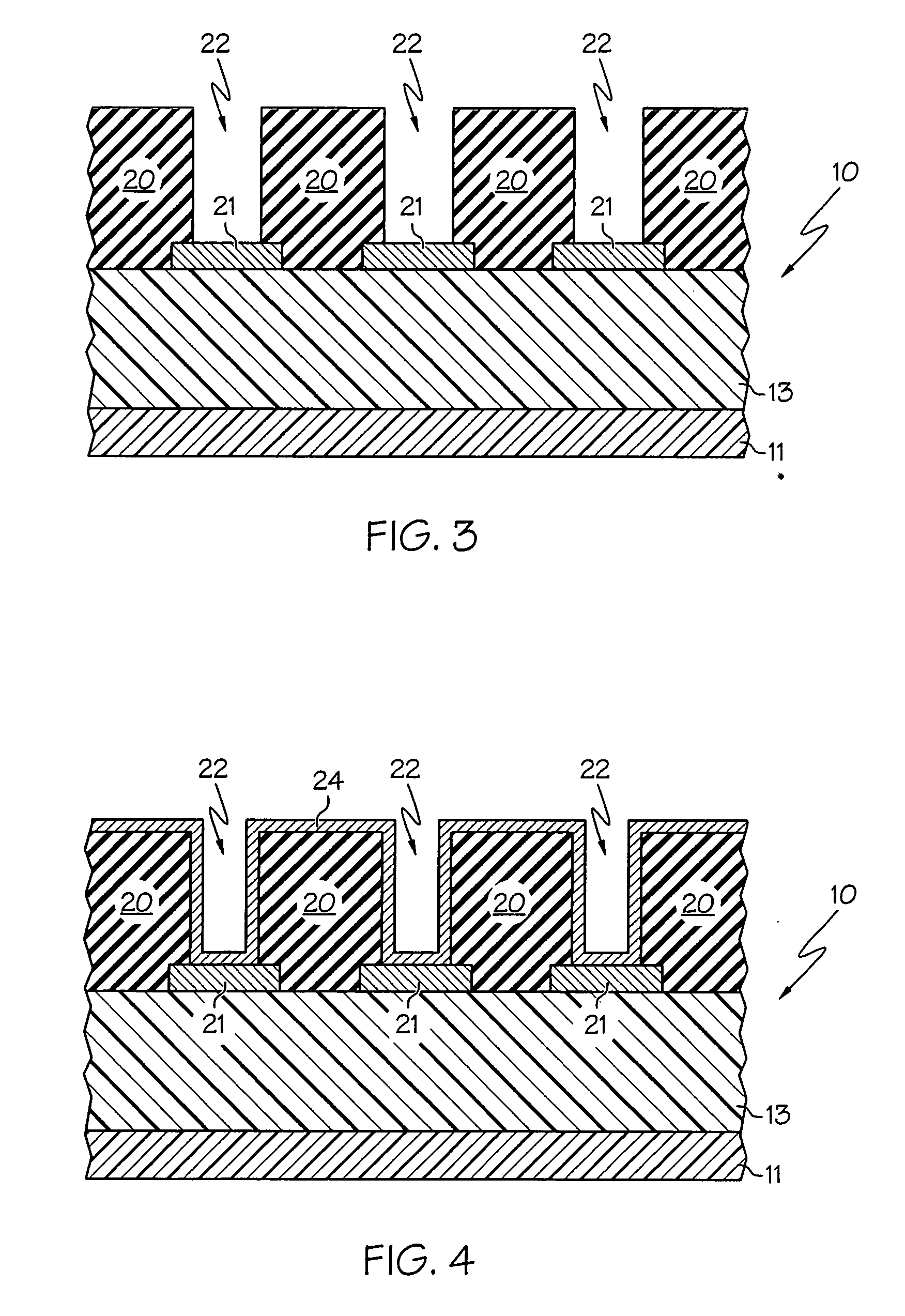

Electroless plating of metal caps for chalcogenide-based memory devices

InactiveUS20060094236A1Good electrical contactSemiconductor/solid-state device manufacturingPlatinumSulfur

A method of forming a metal cap over a conductive interconnect in a chalcogenide-based memory device is provided and includes, forming a layer of a first conductive material over a substrate, depositing an insulating layer over the first conductive material and the substrate, forming an opening in the insulating layer to expose at least a portion of the first conductive material, depositing a second conductive material over the insulating layer and within the opening, removing portions of the second conductive material to form a conductive area within the opening, recessing the conductive area within the opening to a level below an upper surface of the insulating layer, forming a cap of a third conductive material over the recessed conductive area within the opening, the third conductive material selected from the group consisting of cobalt, silver, gold, copper, nickel, palladium, platinum, and alloys thereof, depositing a stack of a chalcogenide based memory cell material over the cap, and depositing a conductive material over the chalcogenide stack.

Owner:MICRON TECH INC

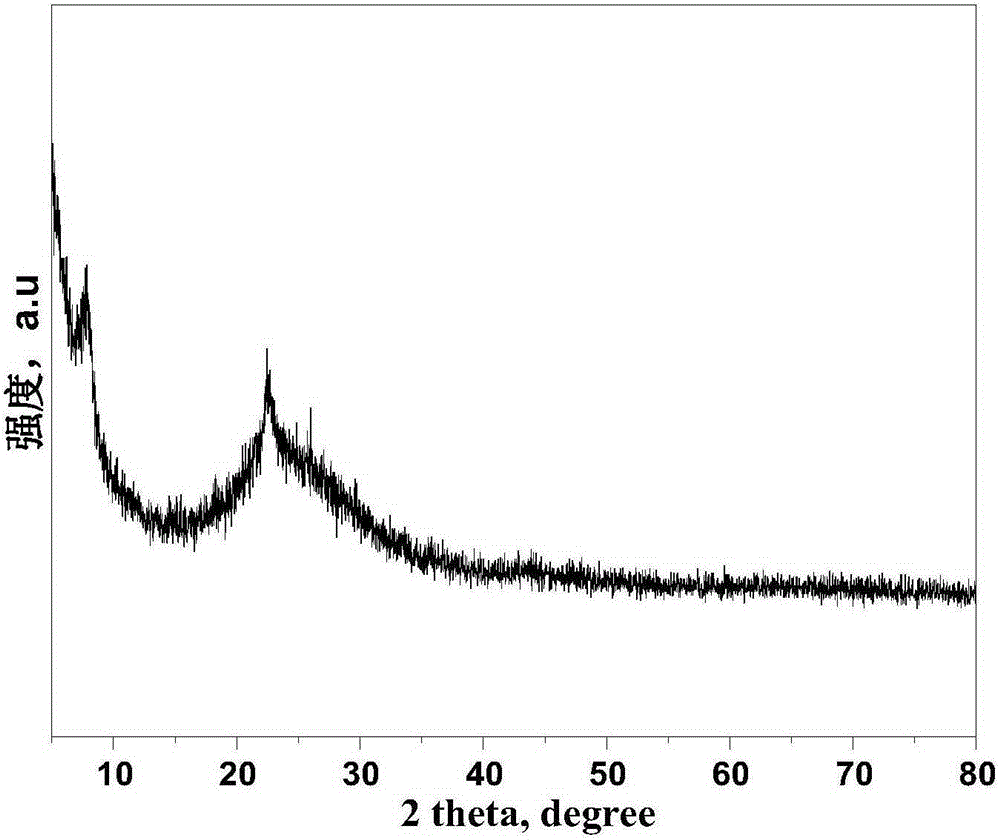

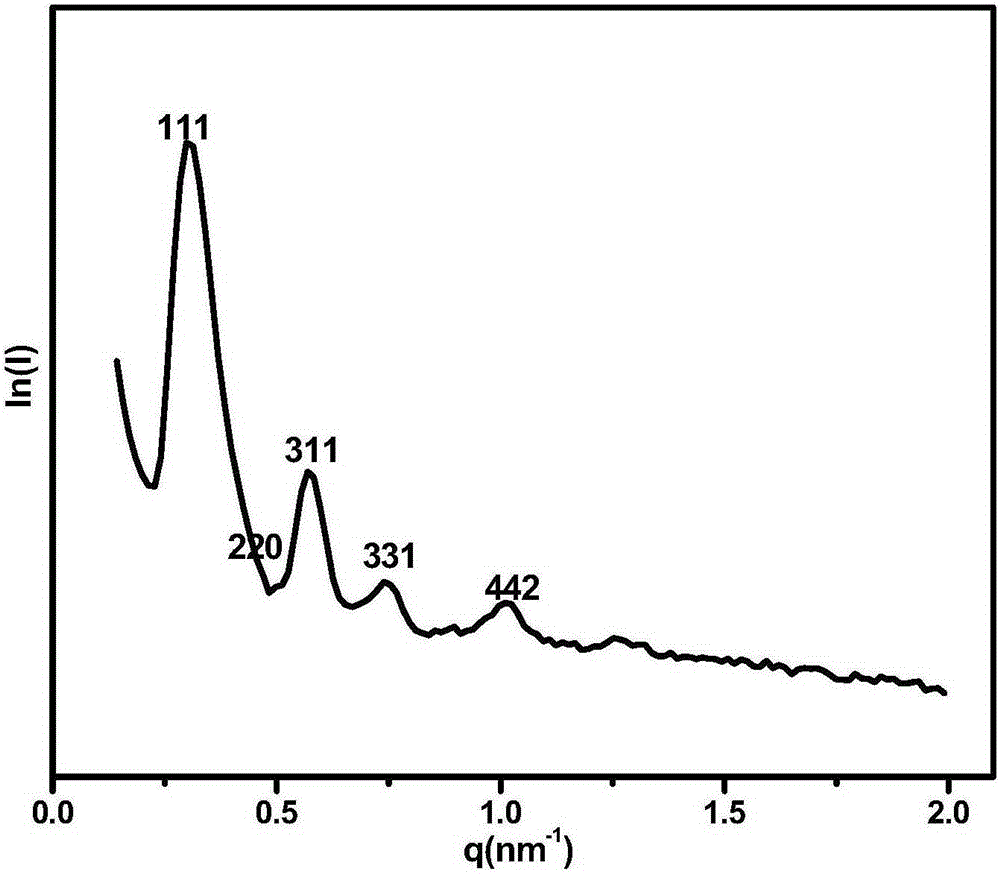

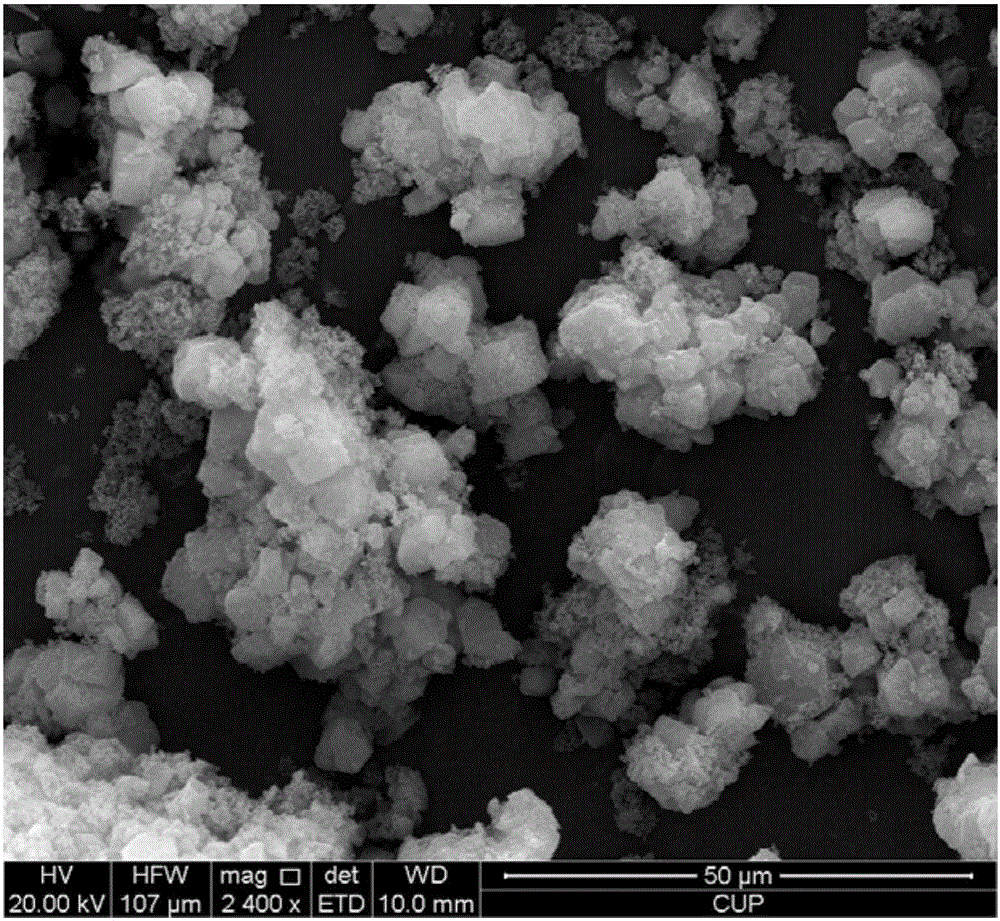

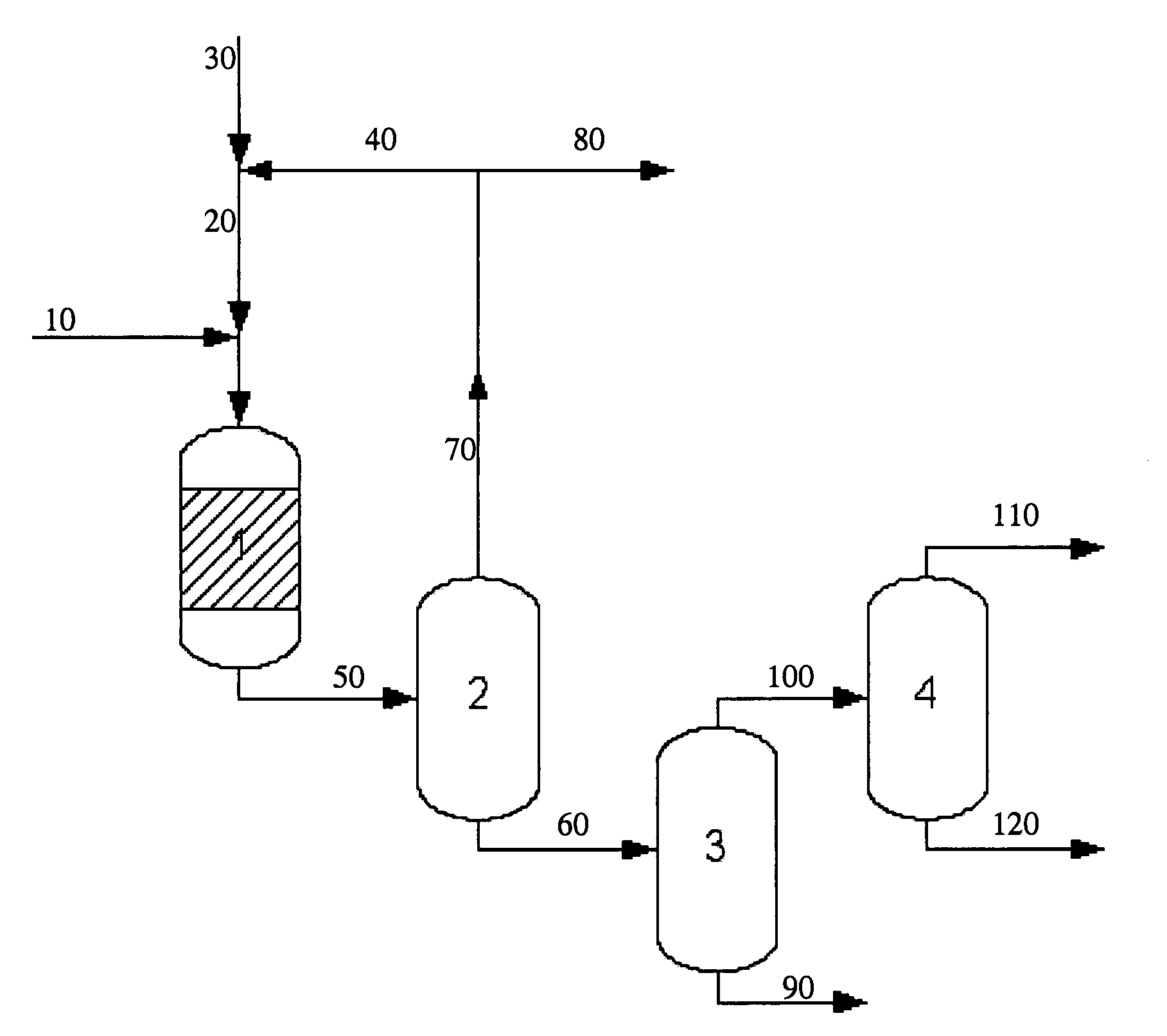

Composite molecular sieve and hydrodesulfurization catalyst prepared with composite molecular sieve as carrier

ActiveCN105251527AGood dispersionModerate dispersionMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveSulfur

The invention provides a composite molecular sieve and a hydrodesulfurization catalyst prepared with the composite molecular sieve as a carrier. According to the composite molecular sieve and the hydrodesulfurization catalyst, the Beta-FDU-12 composite molecular sieve is of a bimodal porous structure, namely a Beta micropore and an FDU-12 mesoporous, the superficial area of the composite molecular sieve is 800-1000m<2>.g<-1>, the pore diameter is 14-25 nm, and the pore volume is 0.4-0.9 cm<3>.g<-1>.The hydrodesulfurization catalyst prepared with the Beta-FDU-12 composite molecular sieve as the carrier is outstanding in performance, the yield of FCC diesel oil can be higher than 99%, the denitrification percent can be higher than 98%, and the sulphur content is lower than 10 ppm.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Production of diesel fuel from vegetable and animal oils

A process for producing a fuel composition from vegetable and / or animal oil comprises hydrodeoxygenating and hydroisomerizing the oil in a single step. The fuel composition has acceptable lubricity and comprises a mixture of C14 to C18 paraffins having a ratio of iso to normal paraffins of 2 to 8 and less than 5 ppm sulfur.

Owner:BEN GURION UNIVERSITY OF THE NEGEV

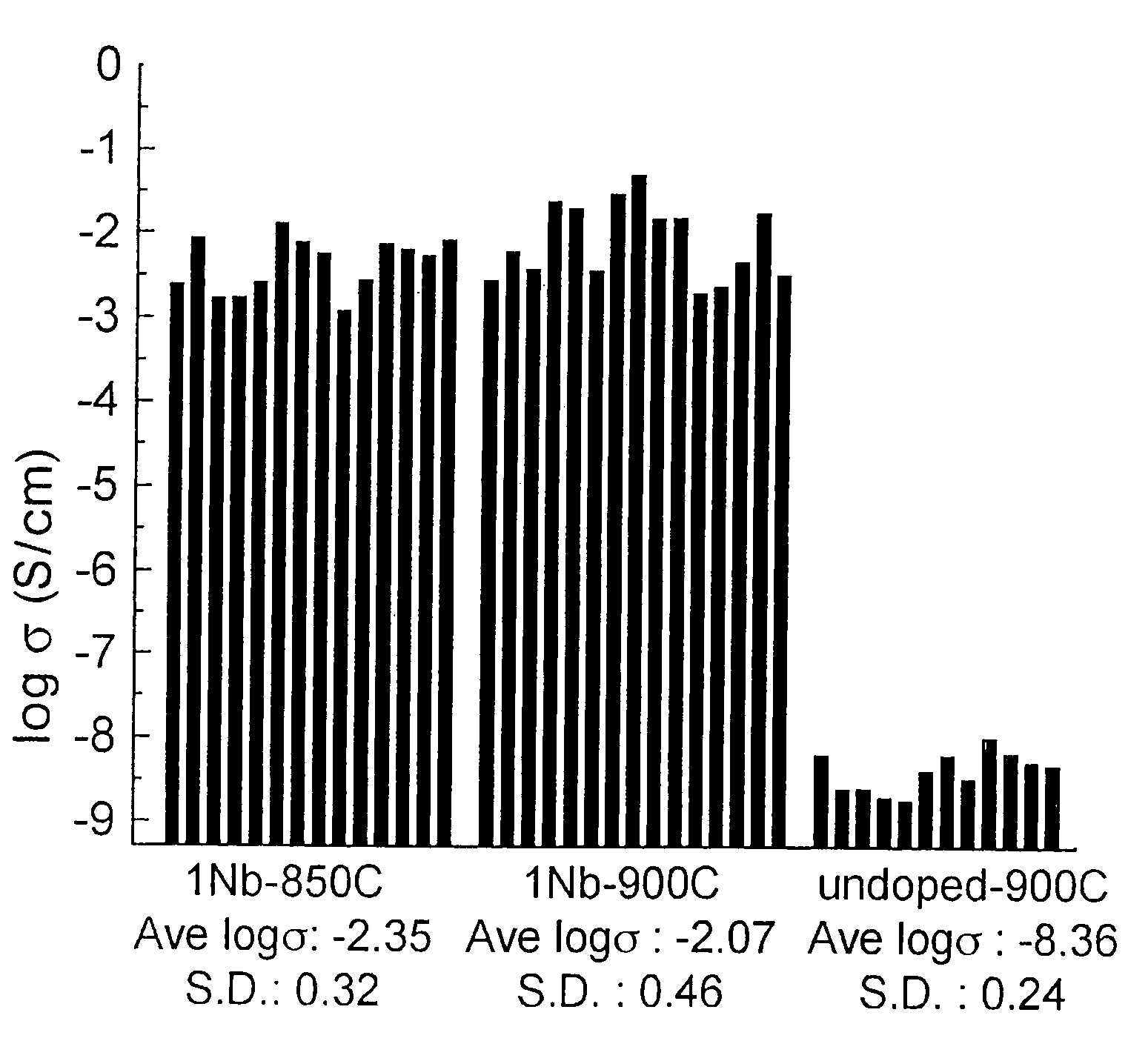

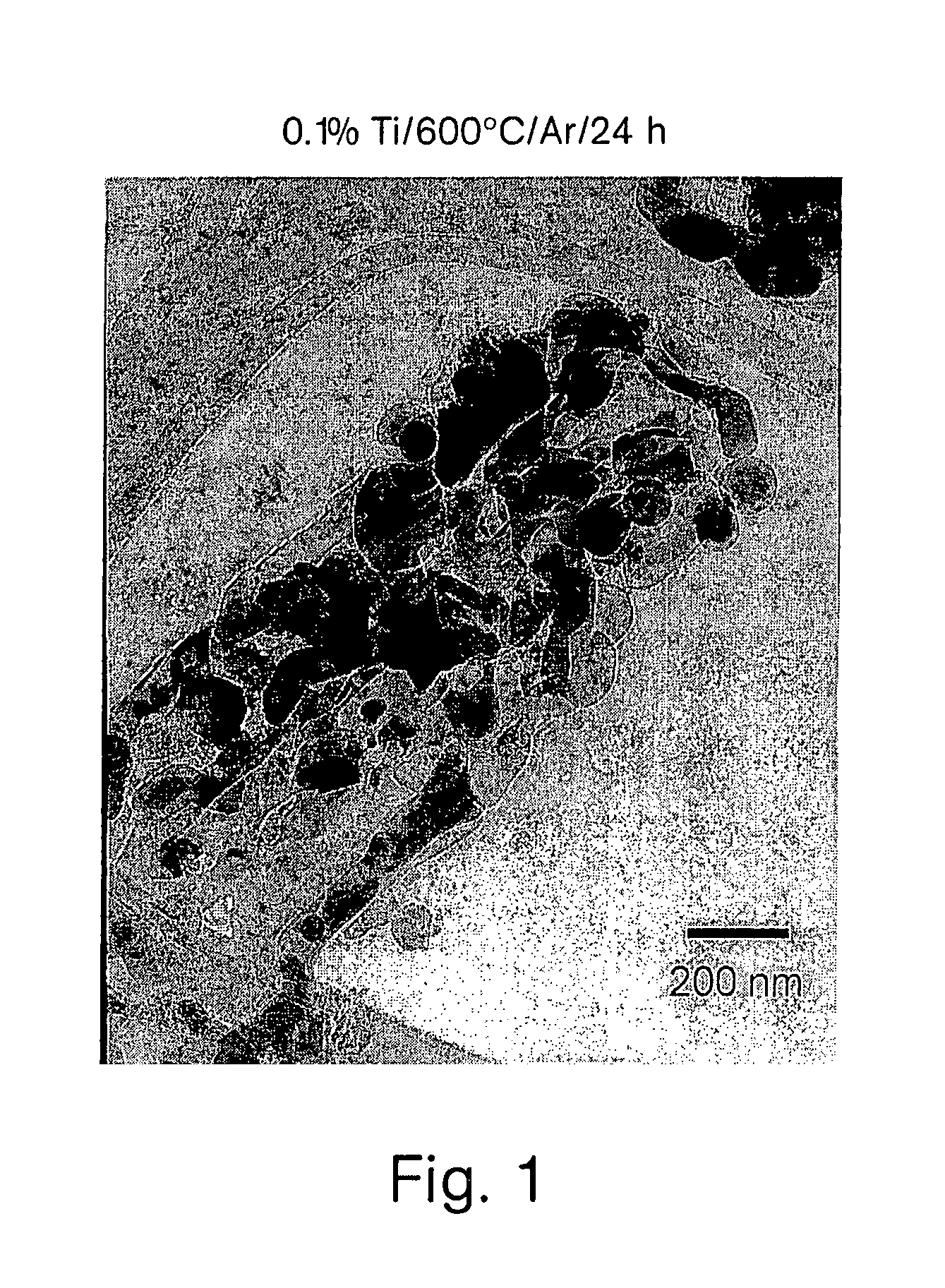

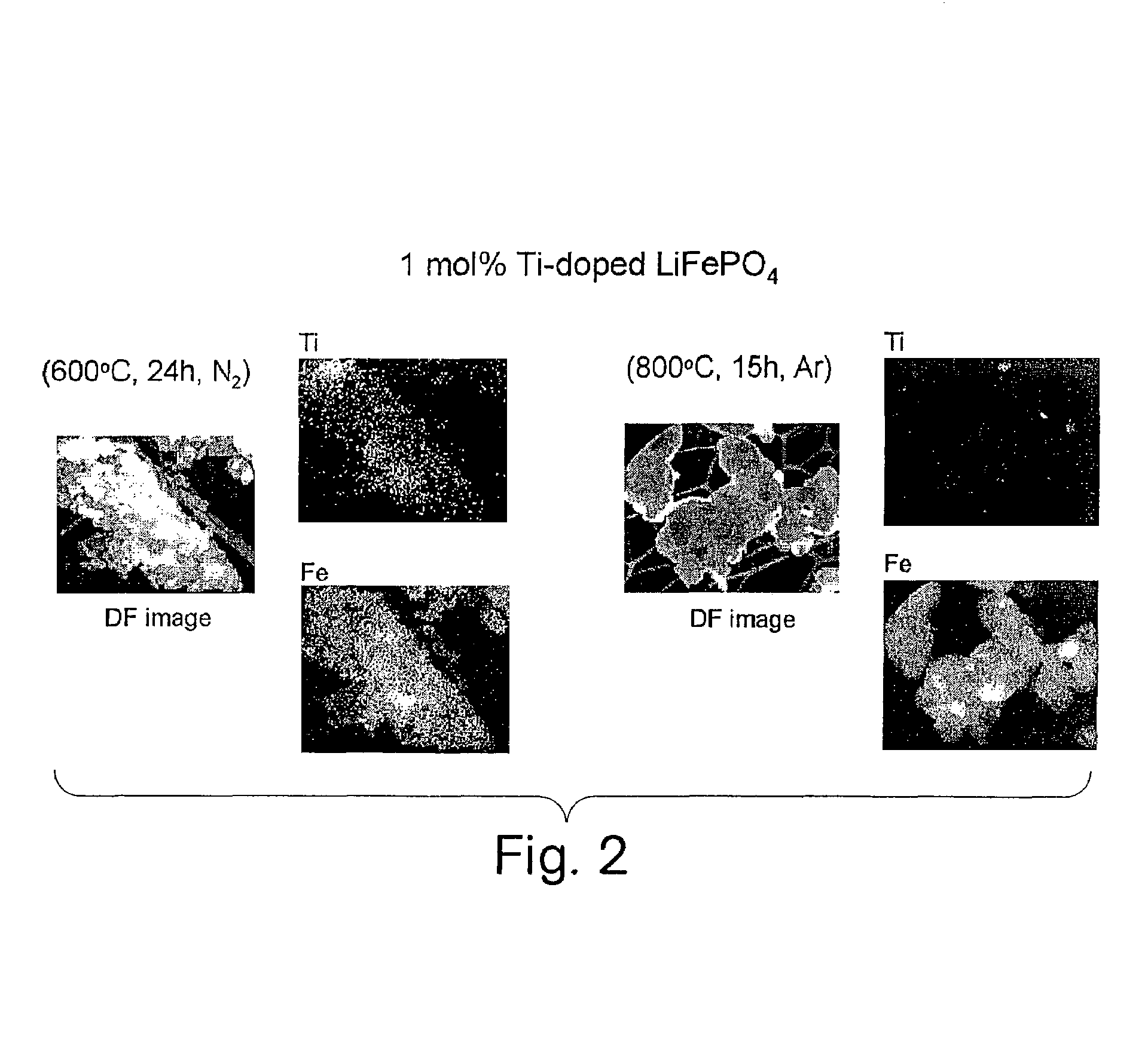

Conductive lithium storage electrode

A compound comprising a composition Ax(M′1-aM″a)y(XD4)z, Ax(M′1-aM″a)y(DXD4)z, or Ax(M′1-aM″a)y(X2D7)z, and have values such that x, plus y(1-a) times a formal valence or valences of M′, plus ya times a formal valence or valence of M″, is equal to z times a formal valence of the XD4, X2D7, or DXD4 group; or a compound comprising a composition (A1-aM″a)xM′y(XD4)z, (A1-aM″a)xM′y(DXD4)z(A1-aM″a)xM′y(X2D7)z and have values such that (1-a)x plus the quantity ax times the formal valence or valences of M″ plus y times the formal valence or valences of M′ is equal to z times the formal valence of the XD4, X2D7 or DXD4 group. In the compound, A is at least one of an alkali metal and hydrogen, M′ is a first-row transition metal, X is at least one of phosphorus, sulfur, arsenic, molybdenum, and tungsten, M″ any of a Group IIA, IIIA, IVA, VA, VIA, VIIA, VIIIA, IB, IIB, IIIB, IVB, VB, and VIB metal, D is at least one of oxygen, nitrogen, carbon, or a halogen, 0.0001<a≦0.1, and x, y, and z are greater than zero. The compound can have a conductivity at 27° C. of at least about 10−8 S / cm. The compound can be a doped lithium phosphate that can intercalate lithium or hydrogen. The compound can be used in an electrochemical device including electrodes and storage batteries and can have a gravimetric capacity of at least about 80 mAh / g while being charged / discharged at greater than about C rate of the compound.

Owner:MASSACHUSETTS INST OF TECH

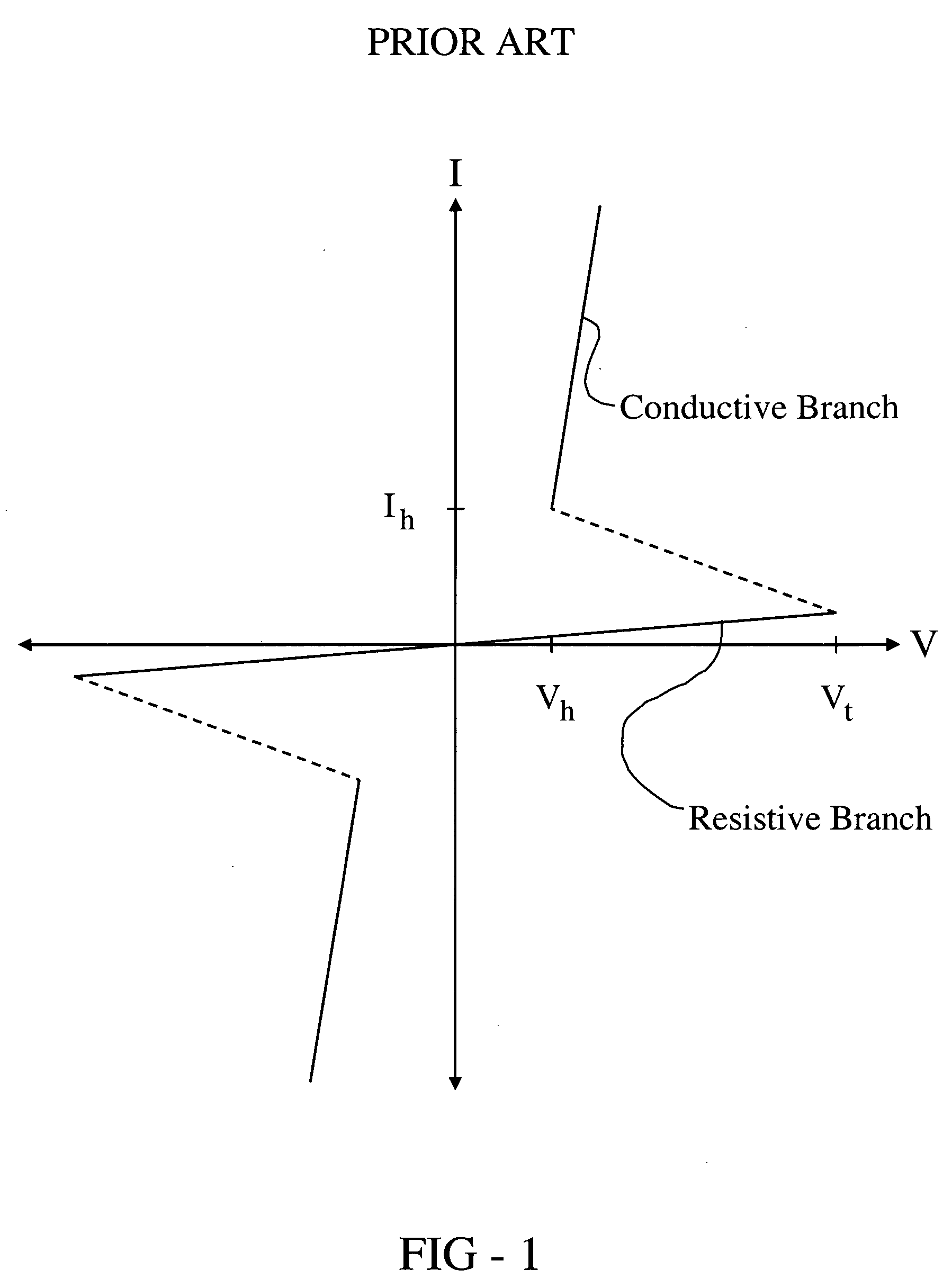

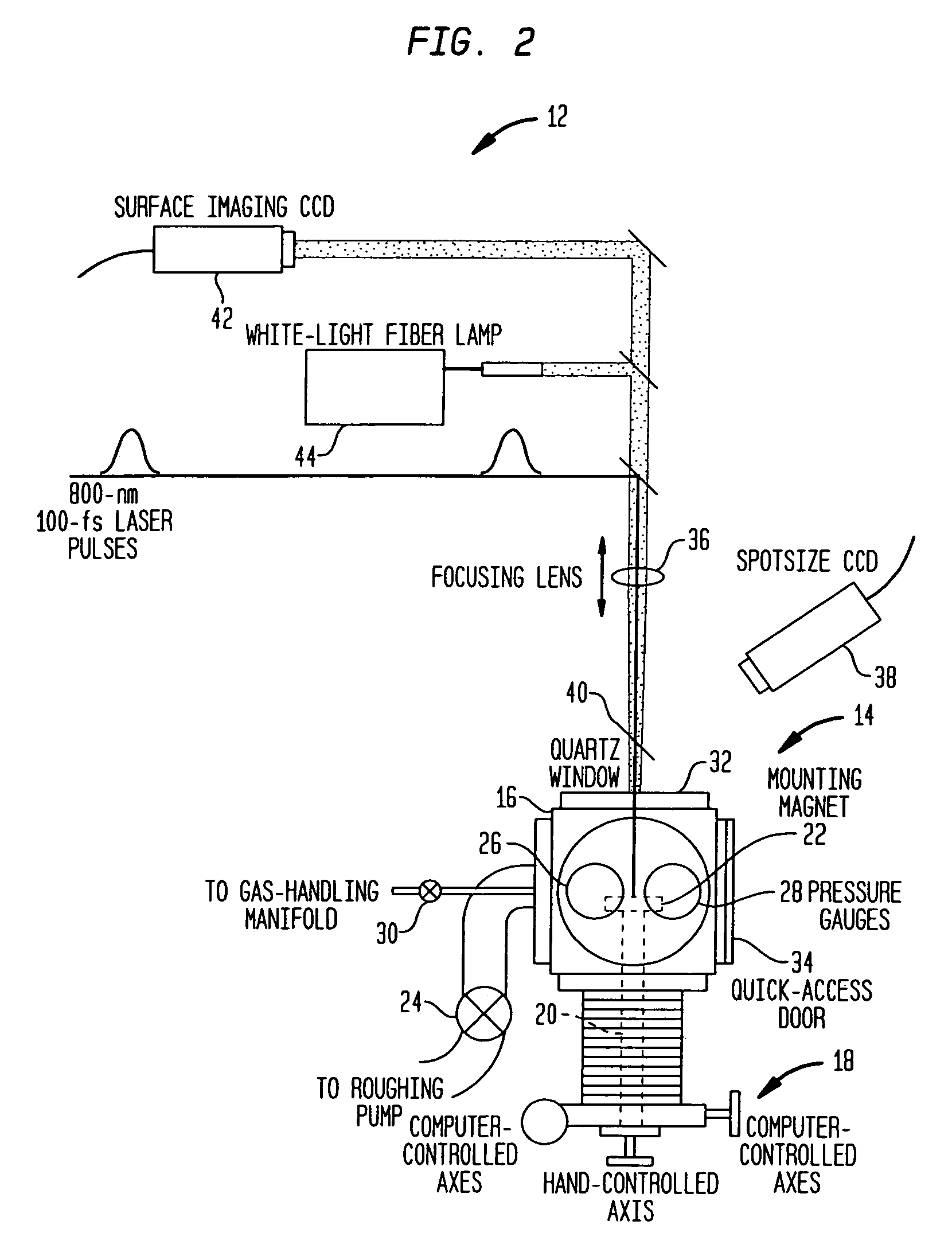

Silicon-based visible and near-infrared optoelectric devices

InactiveUS7057256B2Promote generationFinal product manufactureSemiconductor/solid-state device manufacturingPhotovoltaic detectorsSurface layer

In one aspect, the present invention provides a silicon photodetector having a surface layer that is doped with sulfur inclusions with an average concentration in a range of about 0.5 atom percent to about 1.5 atom percent. The surface layer forms a diode junction with an underlying portion of the substrate. A plurality of electrical contacts allow application of a reverse bias voltage to the junction in order to facilitate generation of an electrical signal, e.g., a photocurrent, in response to irradiation of the surface layer. The photodetector exhibits a responsivity greater than about 1 A / W for incident wavelengths in a range of about 250 nm to about 1050 nm, and a responsivity greater than about 0.1 A / W for longer wavelengths, e.g., up to about 3.5 microns.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

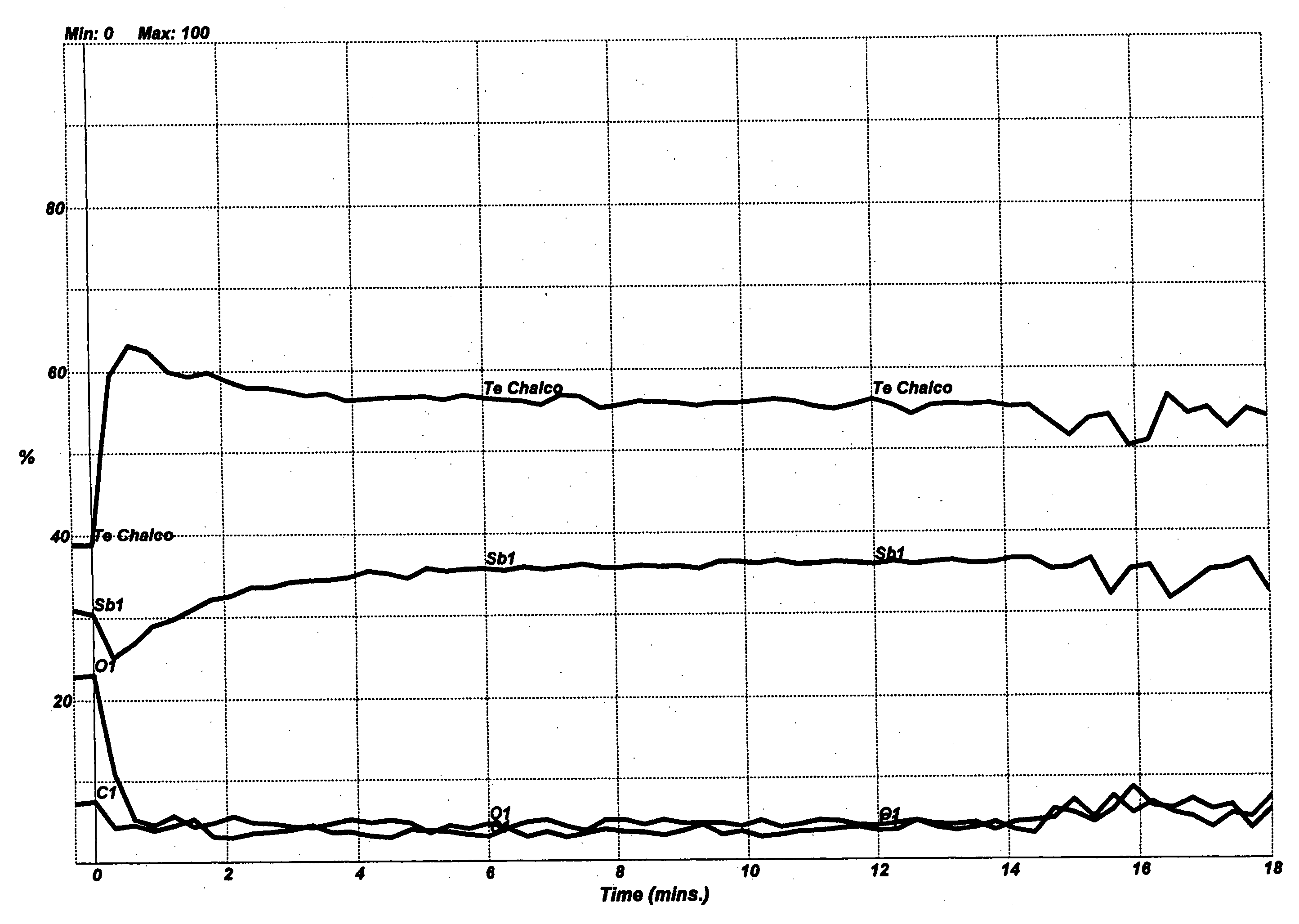

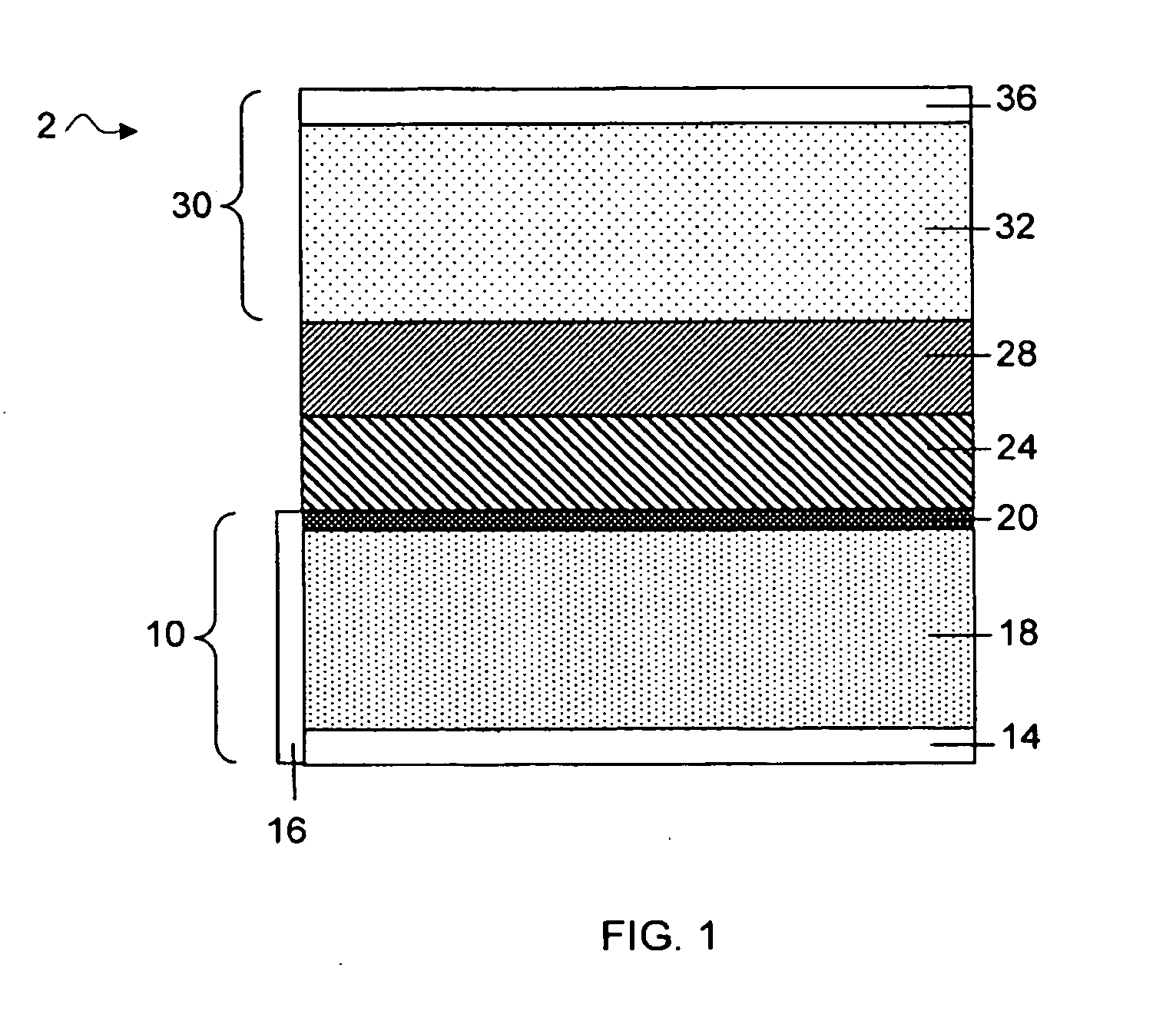

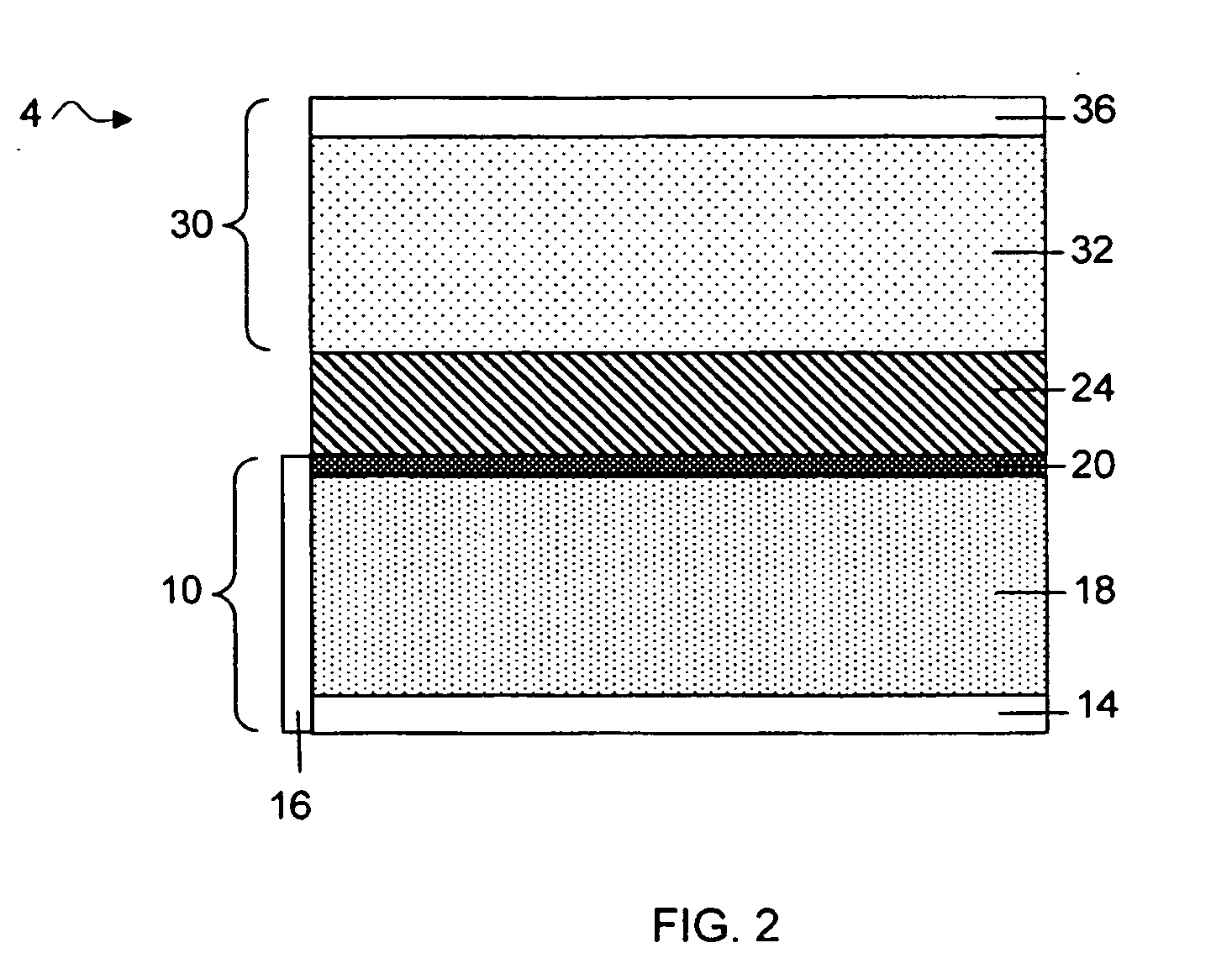

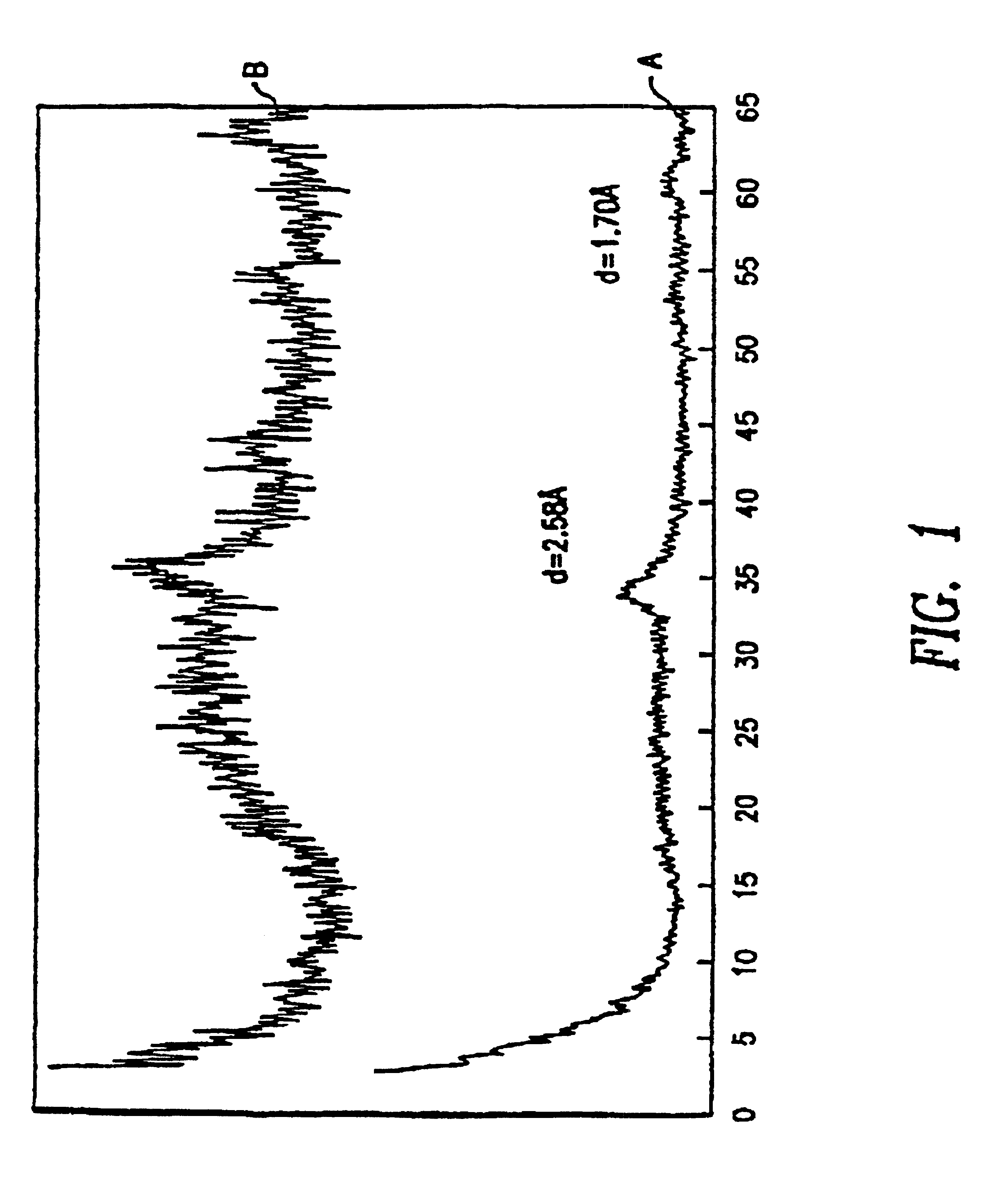

Chemical vapor deposition of chalcogenide materials

A chemical vapor deposition (CVD) process for preparing electrical and optical chalcogenide materials. In a preferred embodiment, the instant CVD-deposited materials exhibit one or more of the following properties: electrical switching, accumulation, setting, reversible multistate behavior, resetting, cognitive functionality, and reversible amorphous-crystalline transformations. In one embodiment, a multilayer structure, including at least one layer containing a chalcogen element, is deposited by CVD and subjected to post-deposition application of energy to produce a chalcogenide material having properties in accordance with the instant invention. In another embodiment, a single layer chalcogenide material having properties in accordance with the instant invention is formed from a CVD deposition process including three or more deposition precursors, at least one of which is a chalcogen element precursor. Preferred materials are those that include the chalcogen Te along with Ge and / or Sb.

Owner:OVONYX

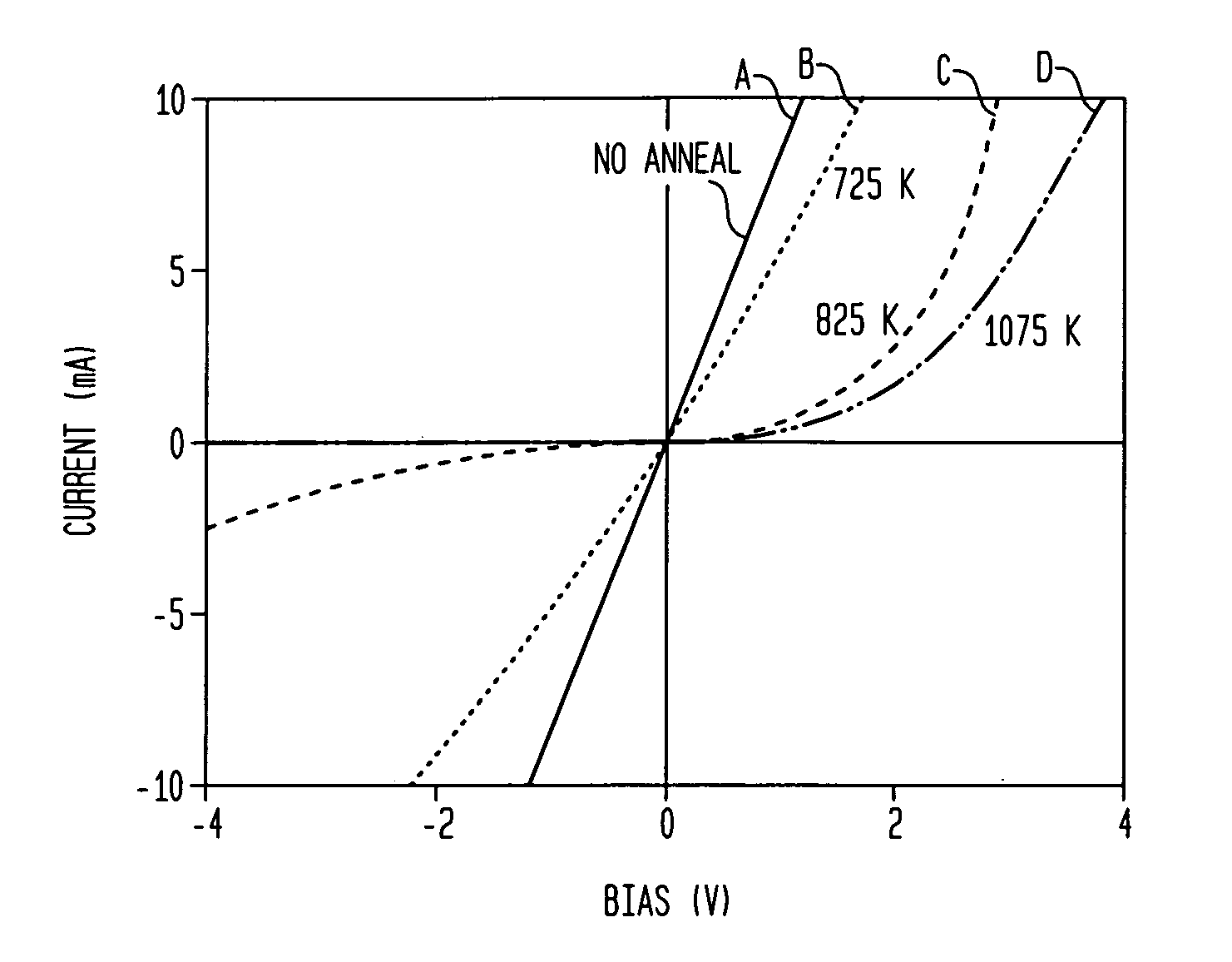

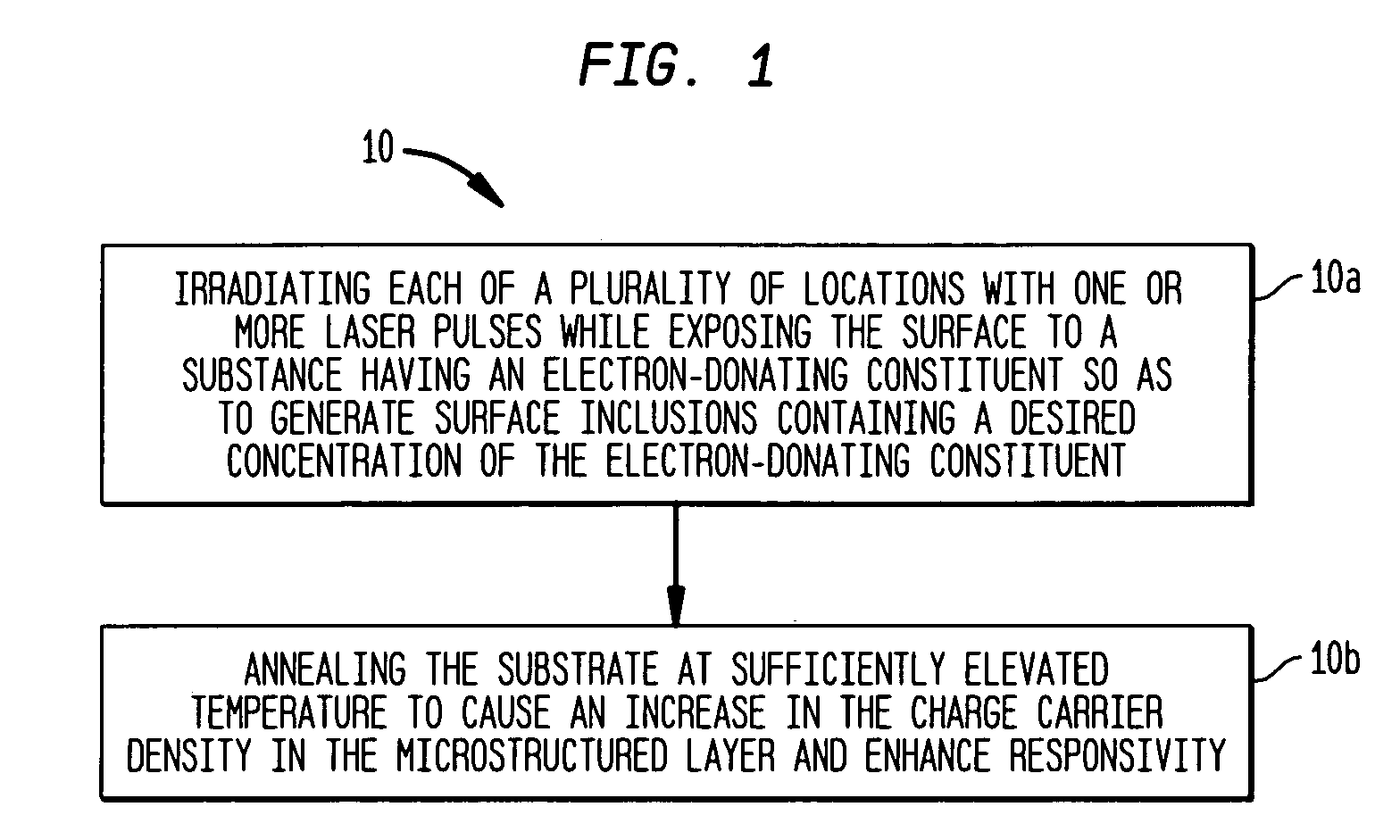

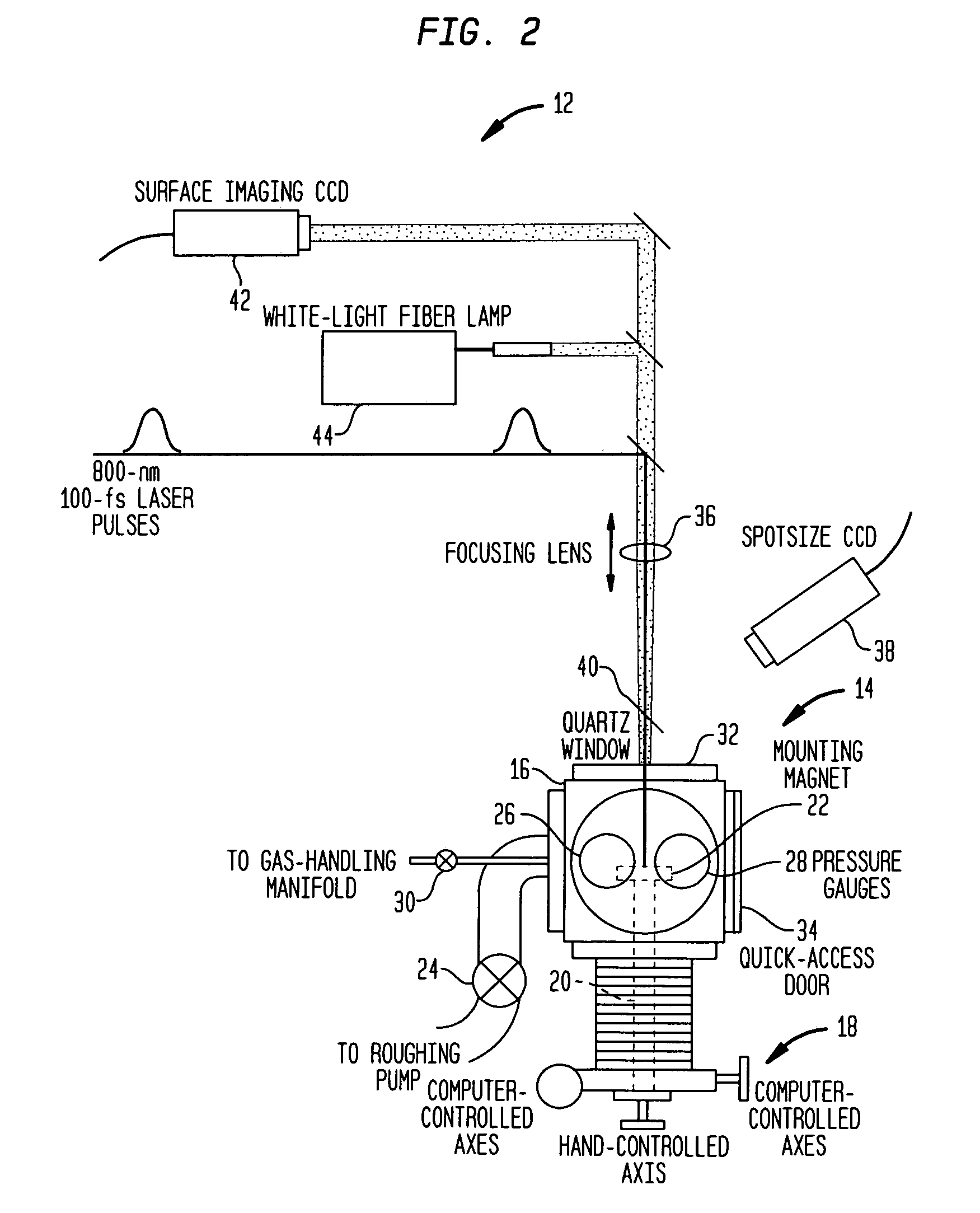

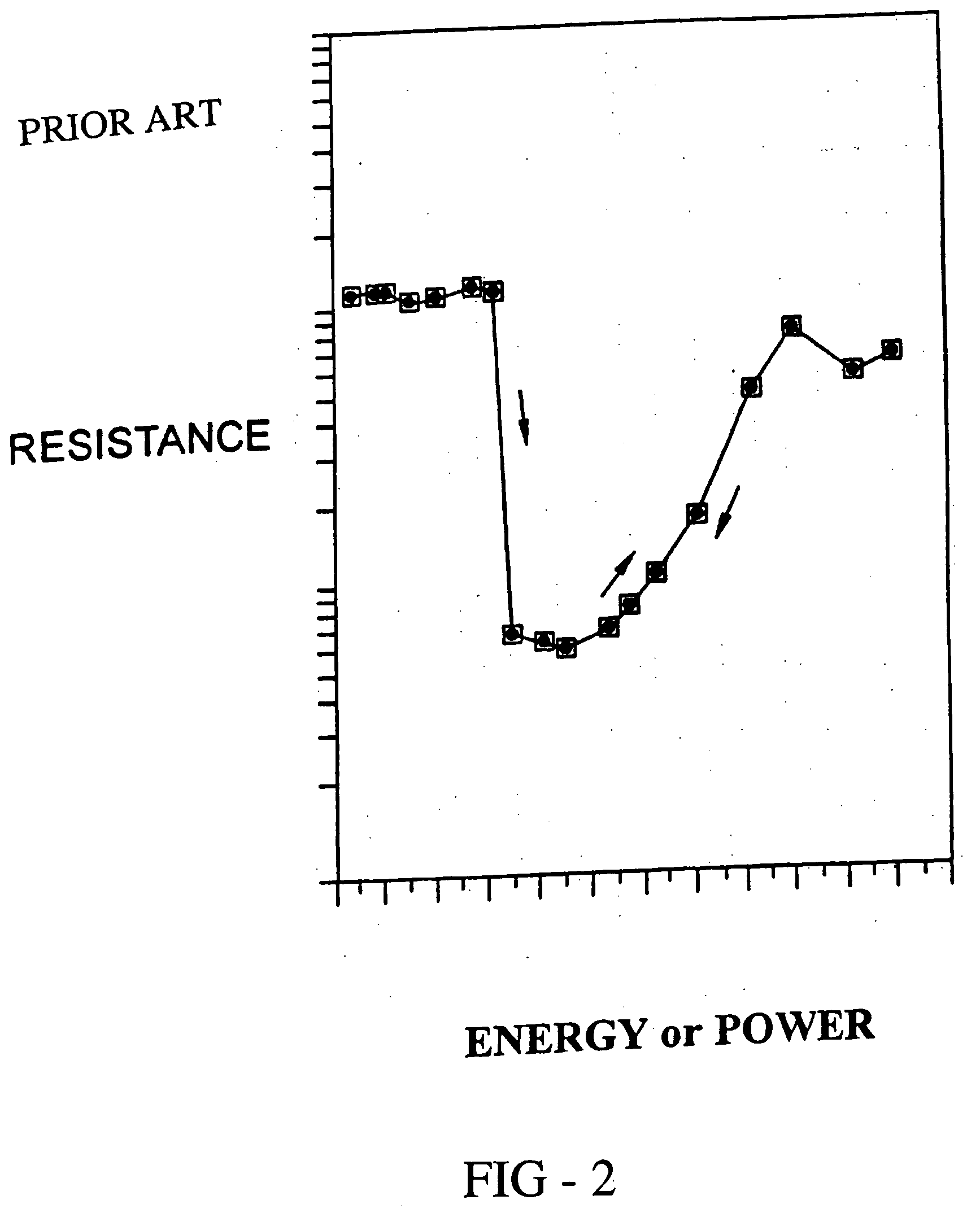

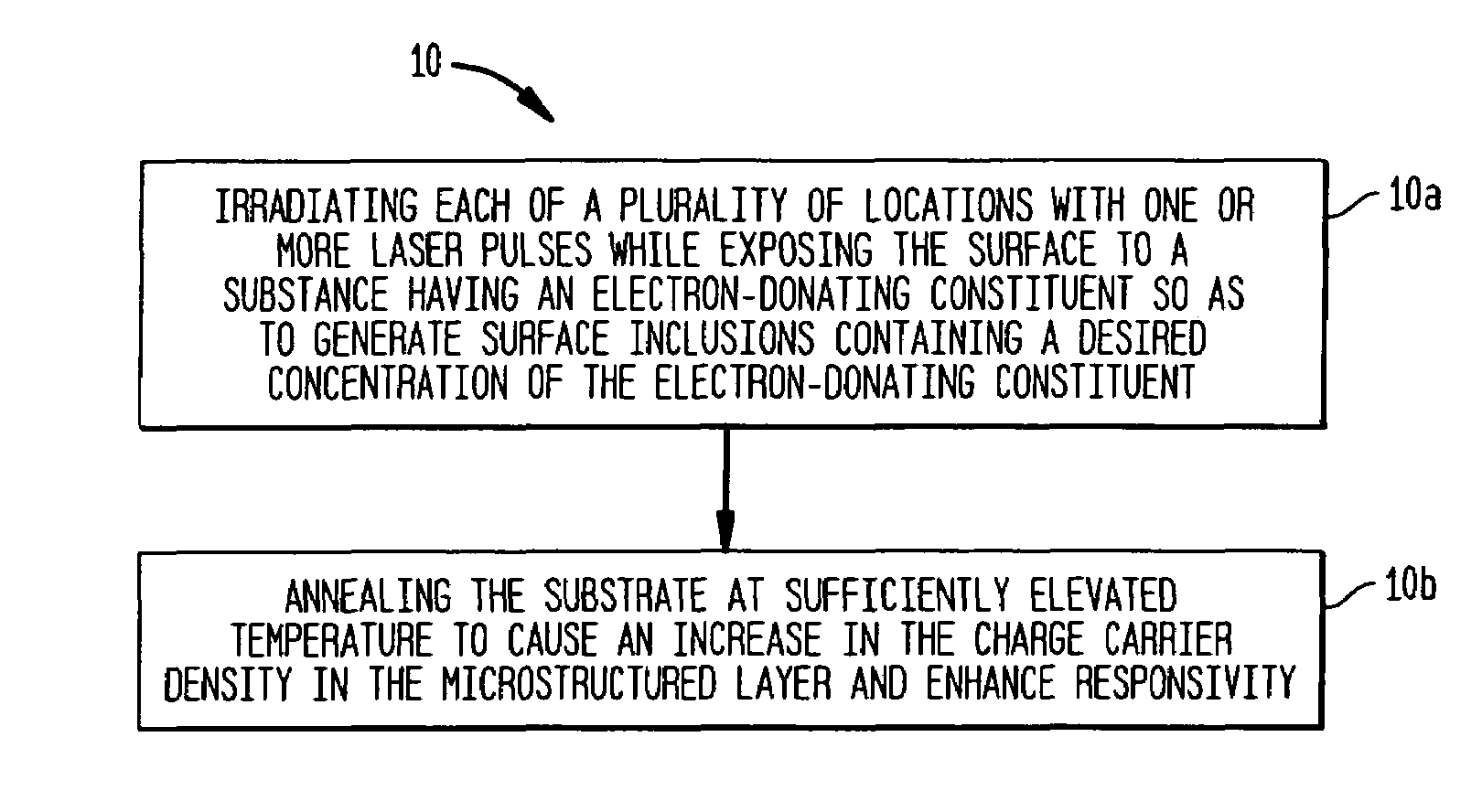

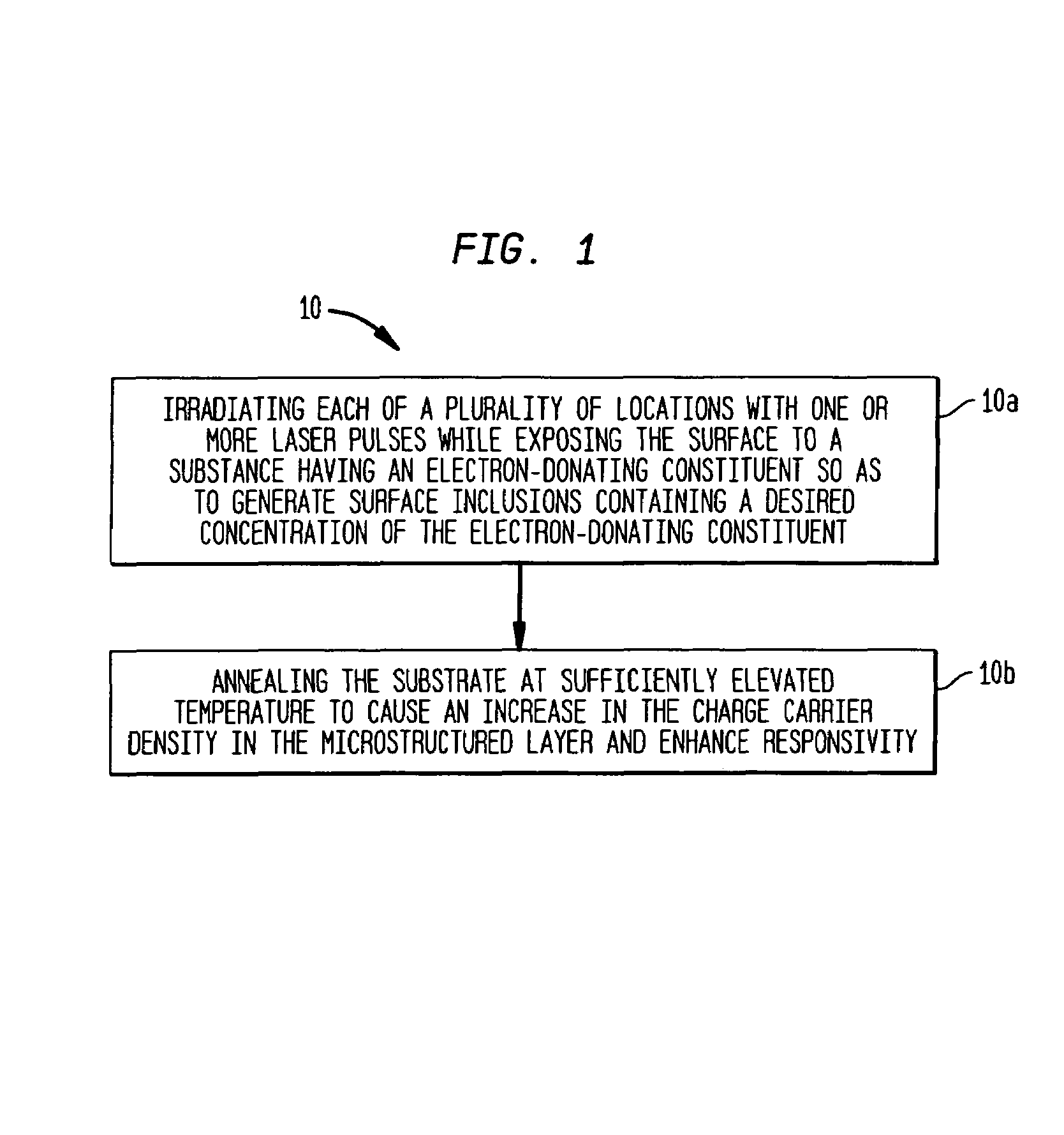

Manufacture of silicon-based devices having disordered sulfur-doped surface layers

InactiveUS7354792B2Final product manufactureSemiconductor/solid-state device manufacturingSurface layerCharge-carrier density

The present invention provides methods of fabricating a radiation-absorbing semiconductor wafer by irradiating at least one surface location of a silicon substrate, e.g., an n-doped crystalline silicon, by a plurality of temporally short laser pulses, e.g., femtosecond pulses, while exposing that location to a substance, e.g., SF6, having an electron-donating constituent so as to generate a substantially disordered surface layer (i.e., a microstructured layer) that incorporates a concentration of that electron-donating constituent, e.g., sulfur. The substrate is also annealed at an elevated temperature and for a duration selected to enhance the charge carrier density in the surface layer. For example, the substrate can be annealed at a temperature in a range of about 700 K to about 900 K.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

Additive formulation for lubricating oils

InactiveUS7285516B2Reduce the amount requiredOrganic chemistryOrganic compound preparationSulfurPhosphorus

Lubricating oils containing an additive formulation including at least one sulphonate, saligenin and salixarate detergent provide improved wear performance and decreased sulphur and phosphorus emissions.

Owner:THE LUBRIZOL CORP

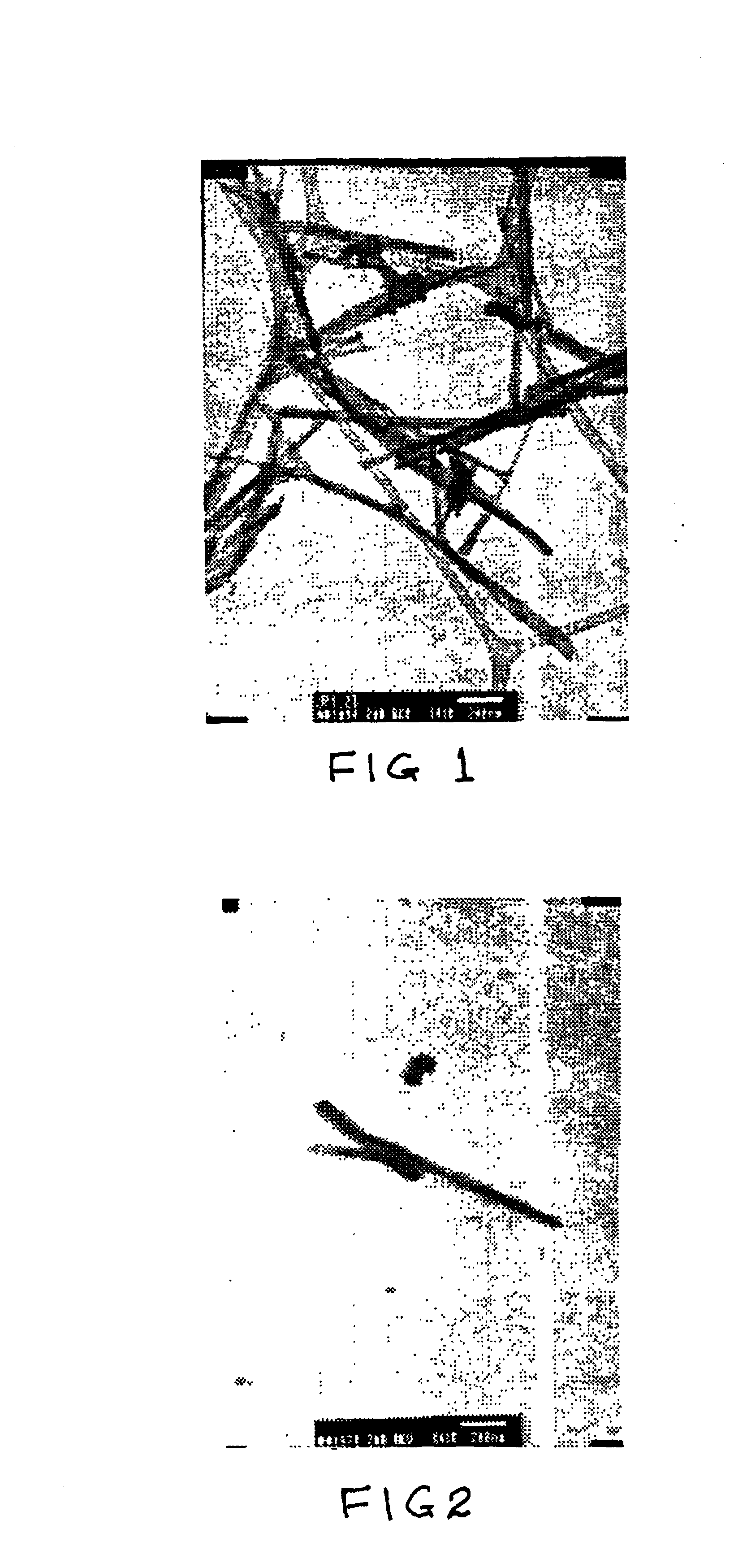

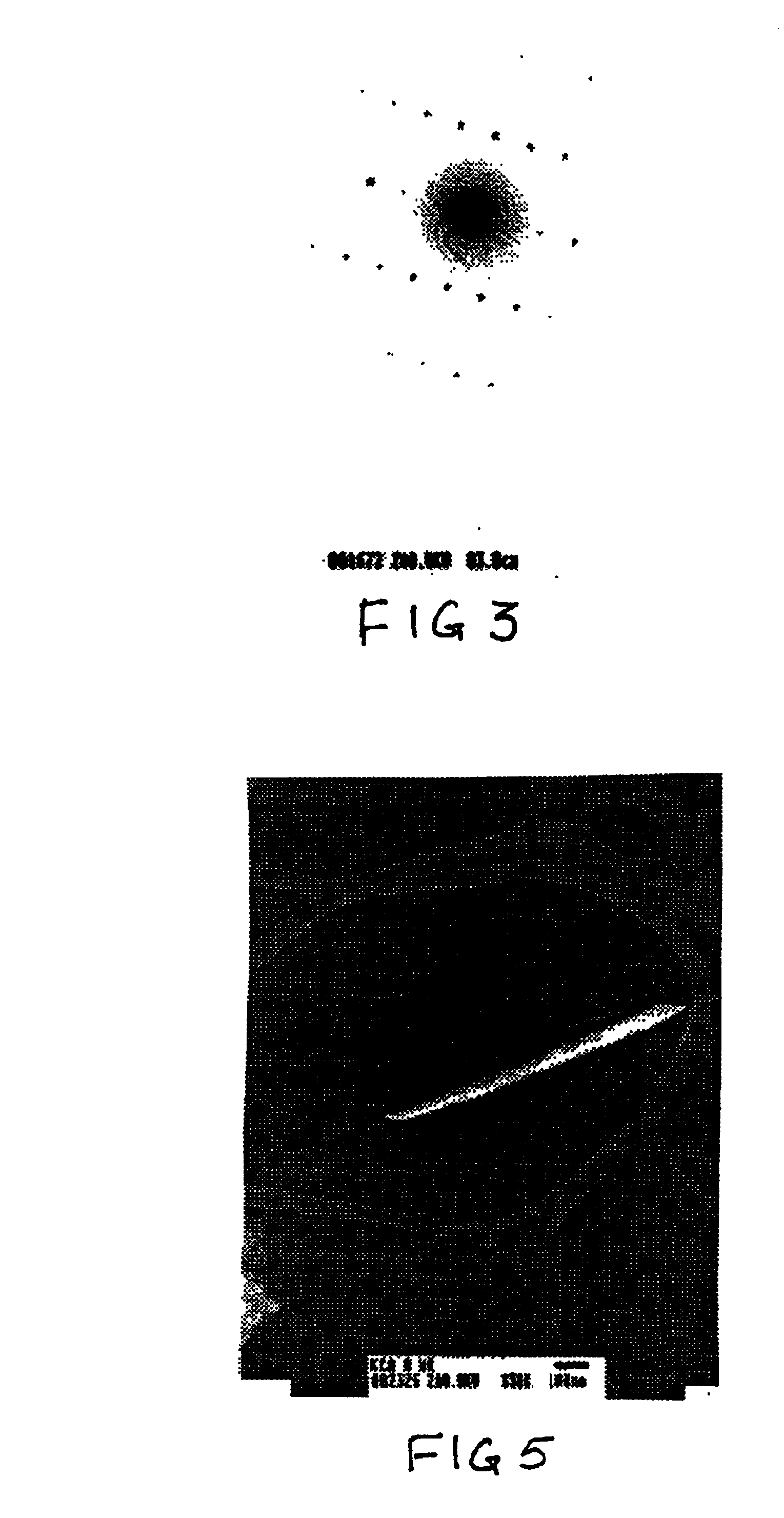

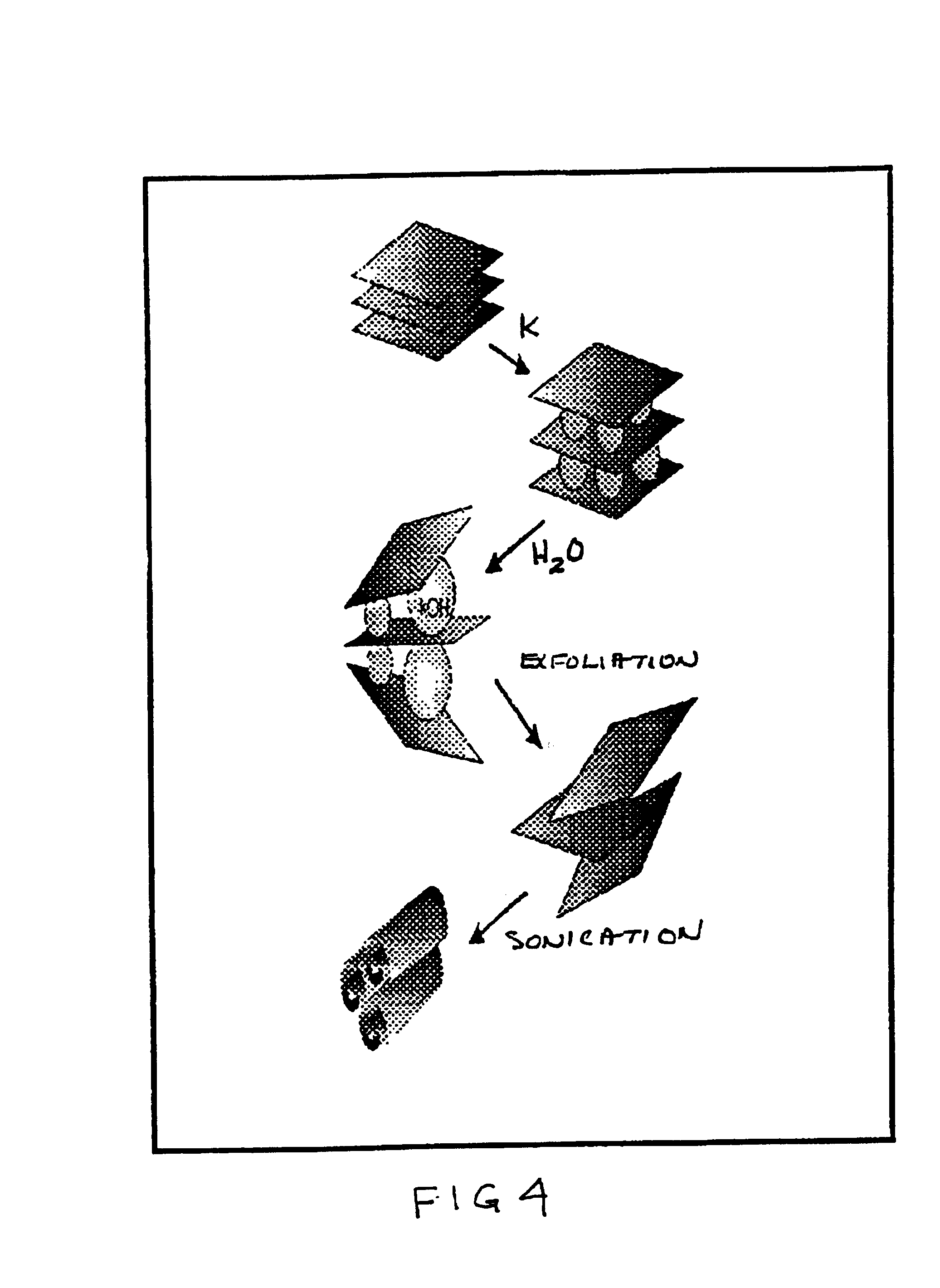

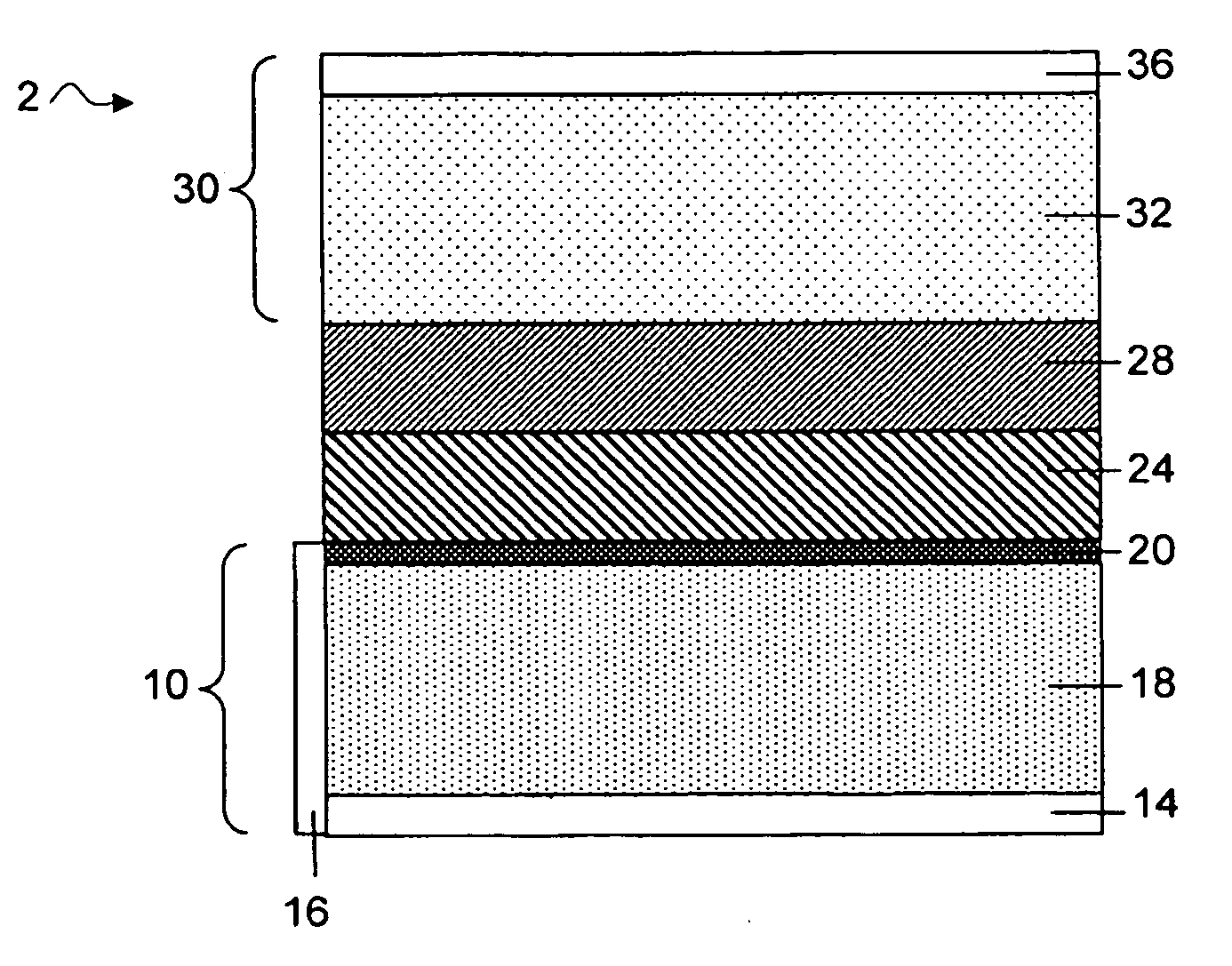

Chemical manufacture of nanostructured materials

InactiveUS6872330B2High strengthIncrease volumeMaterial nanotechnologyOxide/hydroxide preparationInorganic compoundTe element

A low temperature chemical route to efficiently produce nanomaterials is described. The nanomaterials are synthesized by intercalating ions into layered compounds, exfoliating to create individual layers and then sonicating to produce nanotubes, nanorods, nanoscrolls and / or nanosheets. It is applicable to various different layered inorganic compounds (for example, bismuth selenides / tellurides, graphite, and other metal complexes, particularly transition metal dichalcogenides compounds including oxygen, sulfur, tellurium or selenium).

Owner:RGT UNIV OF CALIFORNIA

Separation of electrolytes

Methods and articles relating to separation of electrolyte compositions within lithium batteries are provided. The lithium batteries described herein may include an anode having lithium as the active anode species and a cathode having sulfur as the active cathode species. Suitable electrolytes for the lithium batteries can comprise a heterogeneous electrolyte including a first electrolyte solvent (e.g., dioxolane (DOL)) that partitions towards the anode and is favorable towards the anode (referred to herein as an “anode-side electrolyte solvent”) and a second electrolyte solvent (e.g., 1,2-dimethoxyethane (DME)) that partitions towards the cathode and is favorable towards the cathode (and referred to herein as an “cathode-side electrolyte solvent”). By separating the electrolyte solvents during operation of the battery such that the anode-side electrolyte solvent is present disproportionately at the anode and the cathode-side electrolyte solvent is present disproportionately at the cathode, the battery can benefit from desirable characteristics of both electrolyte solvents (e.g., relatively low lithium reactivity of the anode-side electrolyte solvent and relatively high polysulfide solubility of the cathode-side electrolyte solvent).

Owner:SION POWER CORP

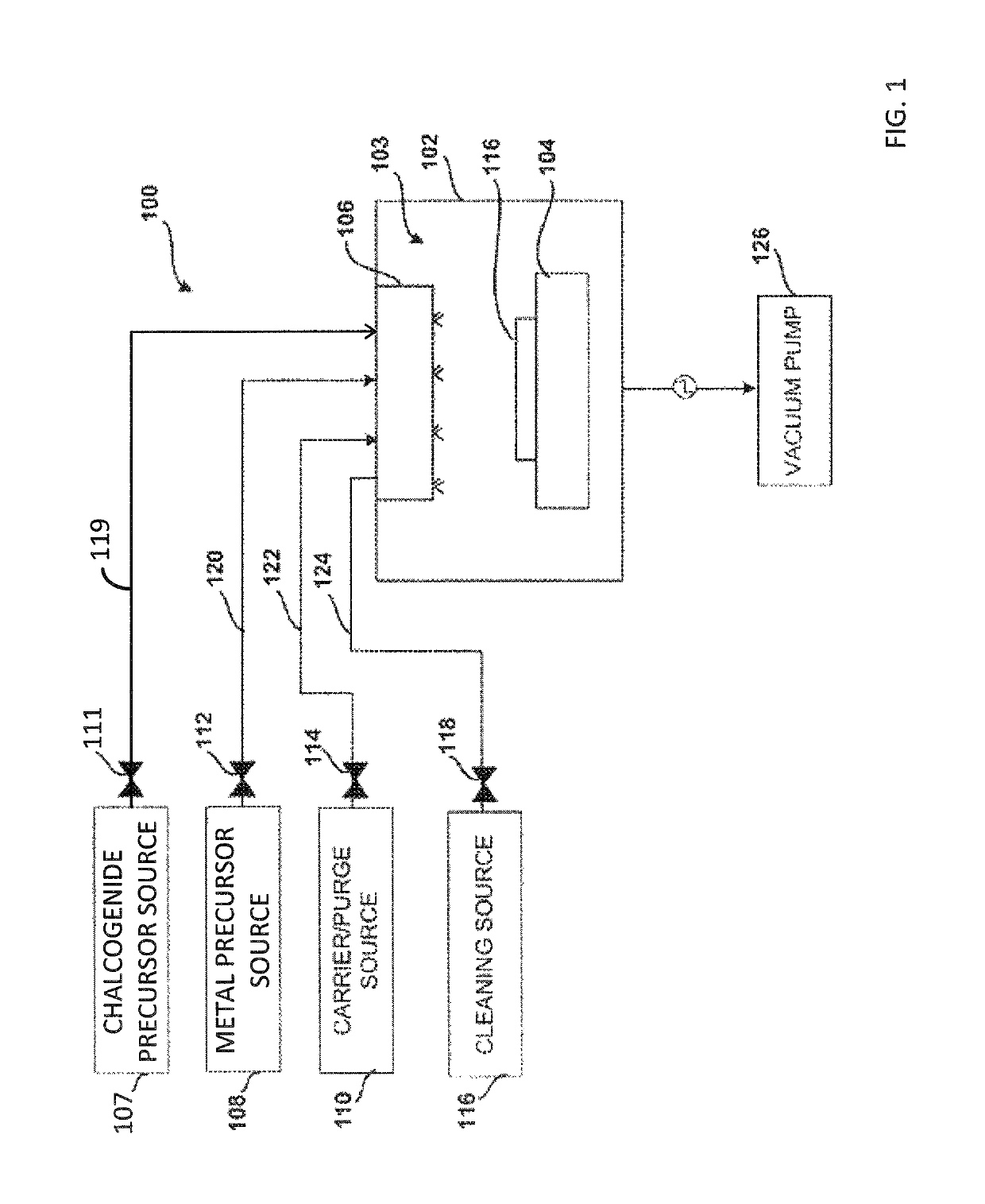

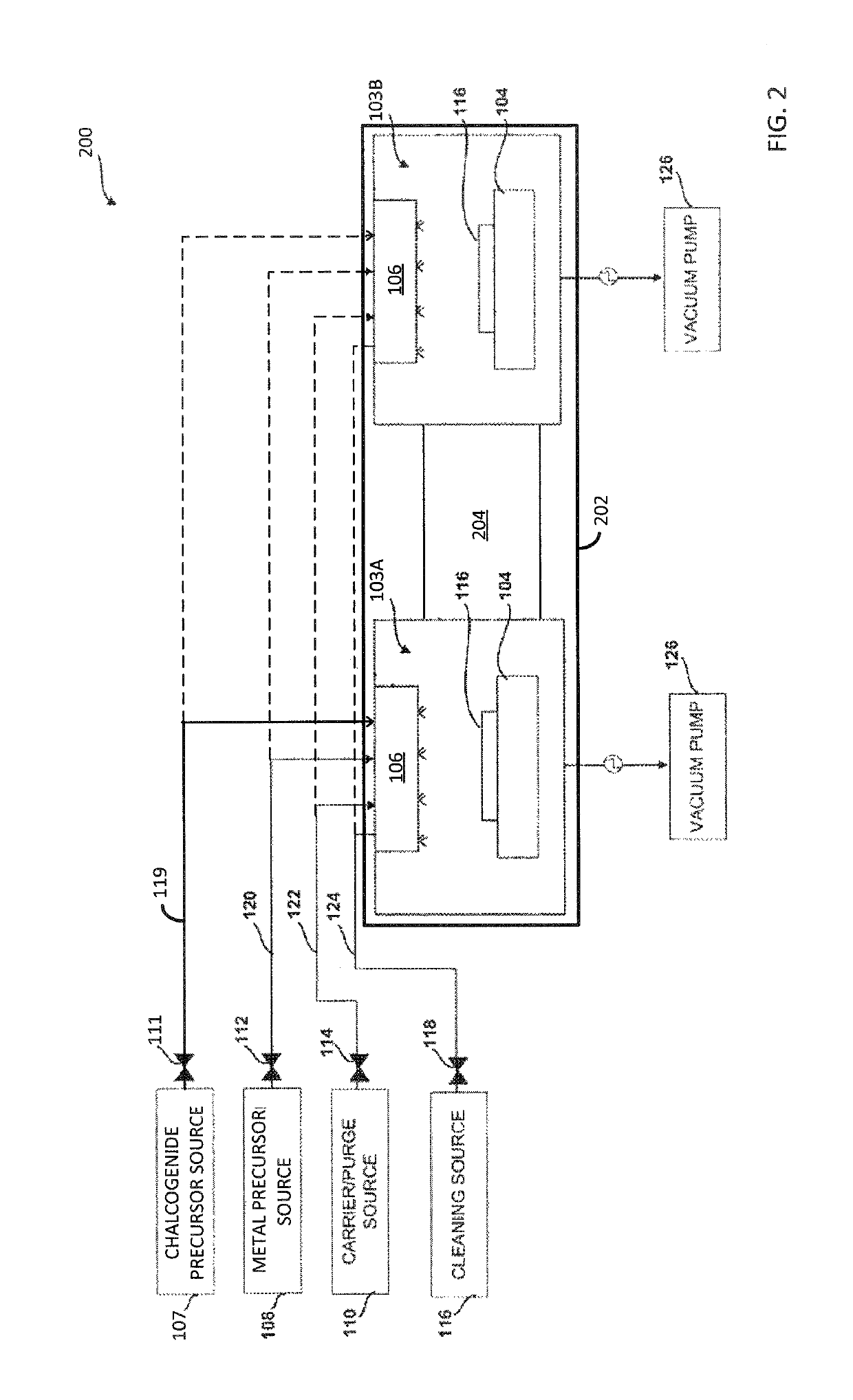

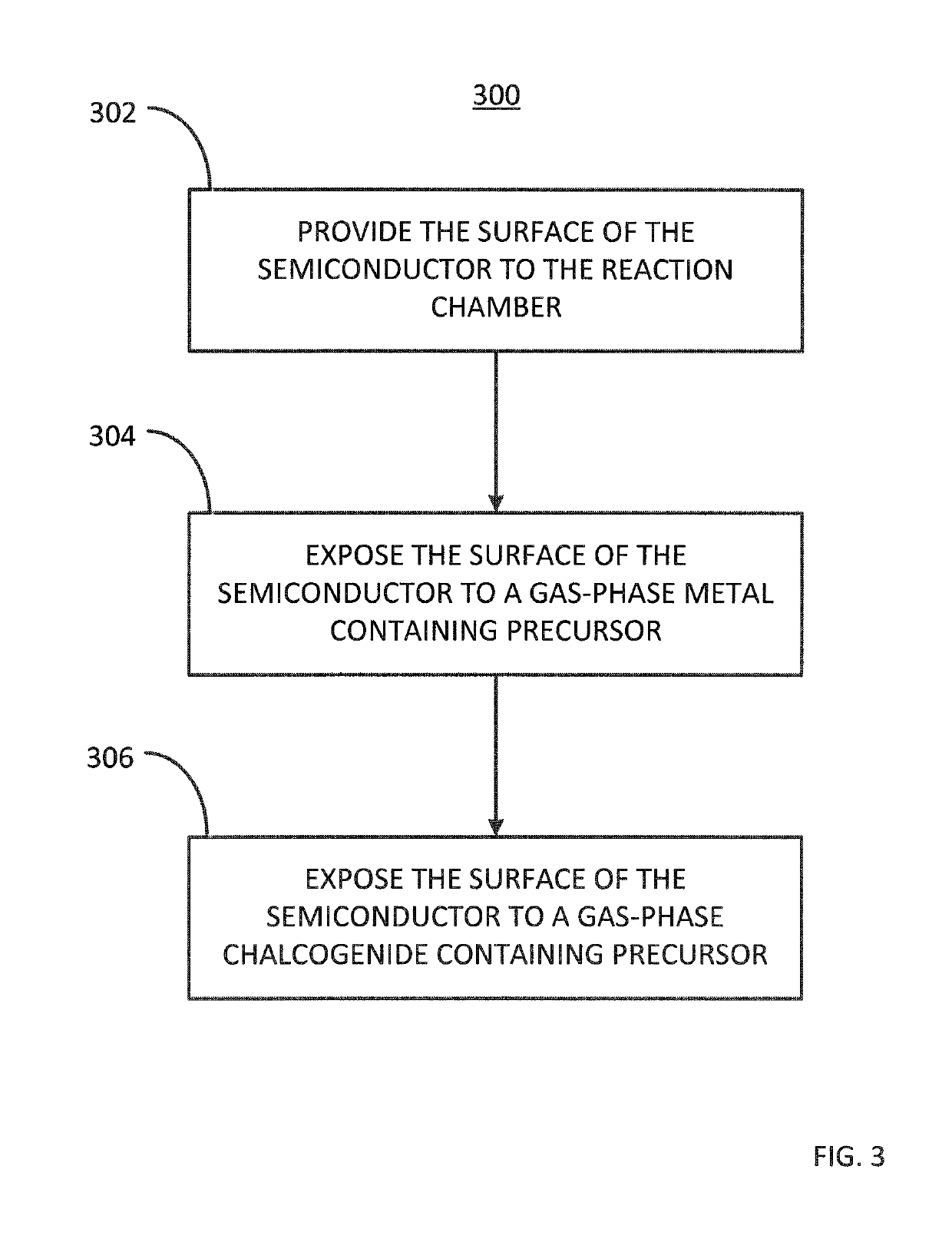

Method for passivating a surface of a semiconductor and related systems

A system and a method for passivating a surface of a semiconductor. The method includes providing the surface of the semiconductor to a reaction chamber of a reactor, exposing the surface of the semiconductor to a gas-phase metal containing precursor in the reaction chamber and exposing the surface of the semiconductor to a gas-phase chalcogenide containing precursor. The methods also include passivating the surface of the semiconductor using the gas-phase metal containing precursor and the gas-phase chalcogenide containing precursor to form a passivated surface. The system for passivating a surface of a semiconductor may include a reactor, a metal containing precursor source fluidly coupled to the reactor, and a chalcogenide containing precursor source fluidly couple to the reactor, wherein the metal containing precursor source provides a gas-phase metal containing precursor to a reaction chamber of the reactor, and wherein the chalcogenide containing precursor source provides a gas-phase chalcogenide containing precursor to a reaction chamber of the reactor.

Owner:ASM IP HLDG BV

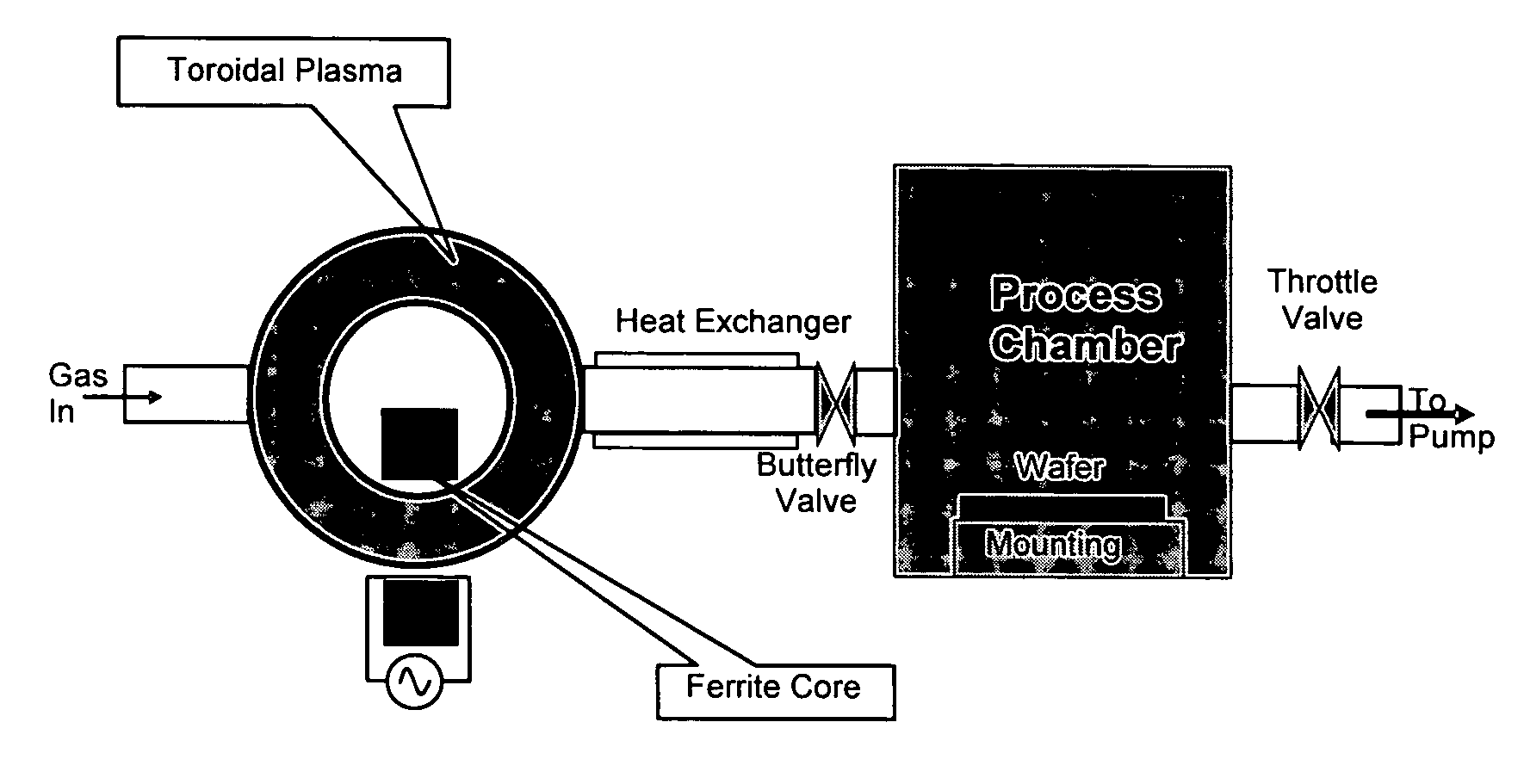

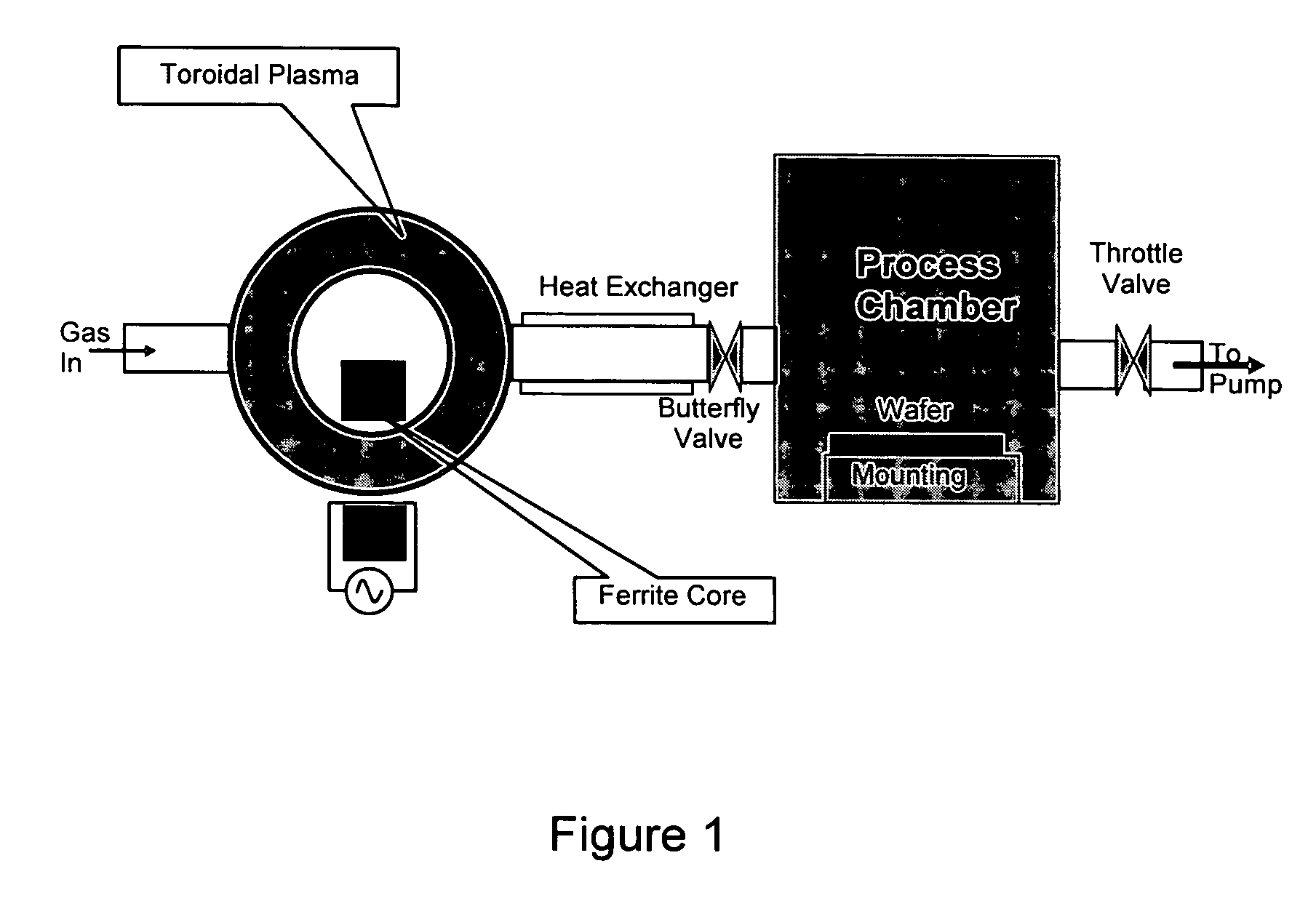

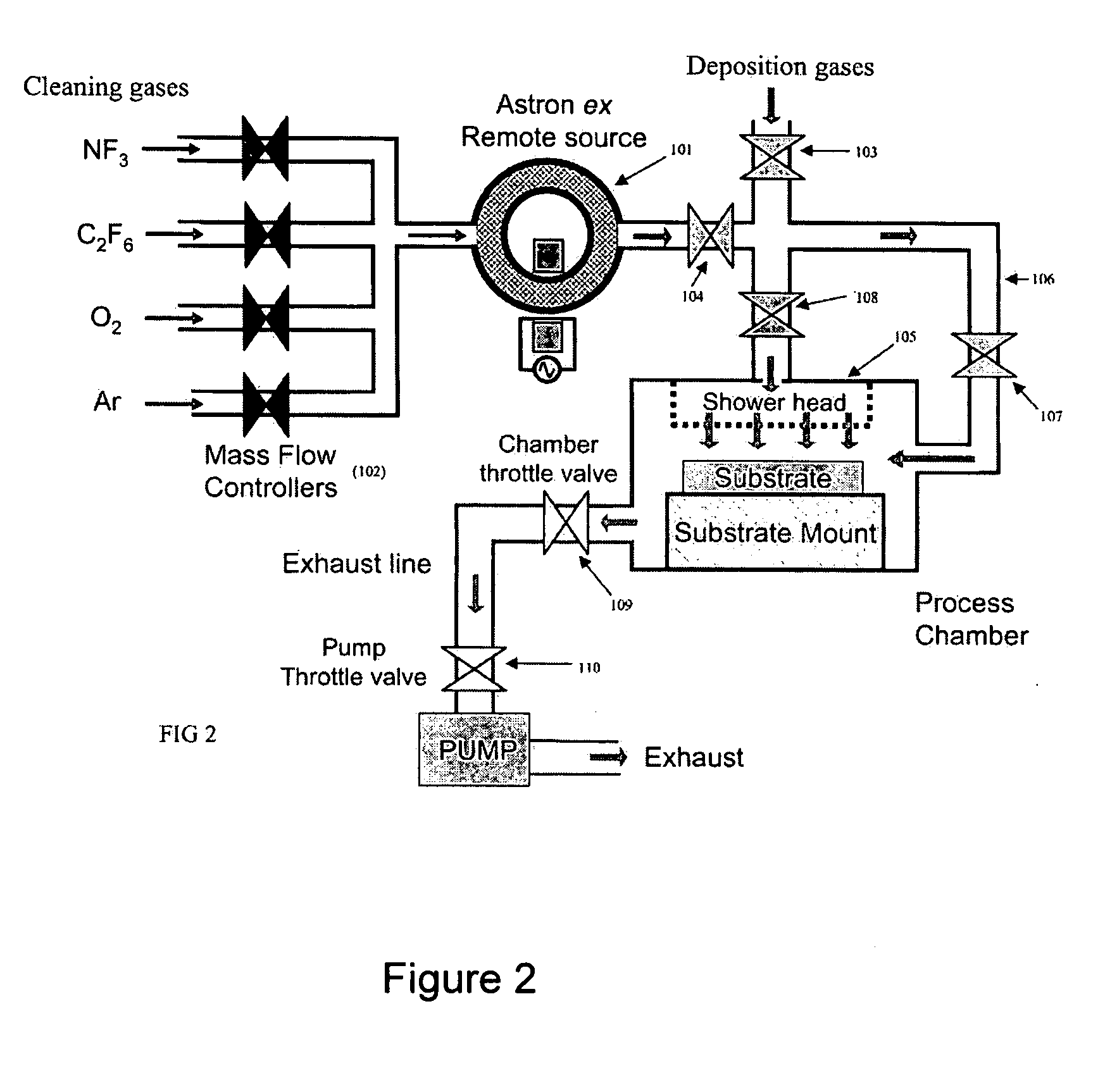

Method for removing surface deposits and passivating interior surfaces of the interior of a chemical vapor deposition reactor

InactiveUS20090047447A1Efficient removalInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsGas phaseSulfur

The present invention relates to plasma cleaning methods for removing surface deposits from a surface, such as the interior of a depositions chamber that is used in fabricating electronic devices. The present invention also provides gas mixtures and activated gas mixtures which provide superior performance in removing deposits from a surface. The methods involve activating a gas mixture comprising a carbon or sulfur source, NF3, and optionally, an oxygen source to form an activated gas, and contacting the activated gas mixture with surface deposits to remove the surface deposits wherein the activated gas mixture acts to passivate the interior surfaces of the apparatus to reduce the rate of surface recombination of gas phase species.

Owner:MASSACHUSETTS INST OF TECH

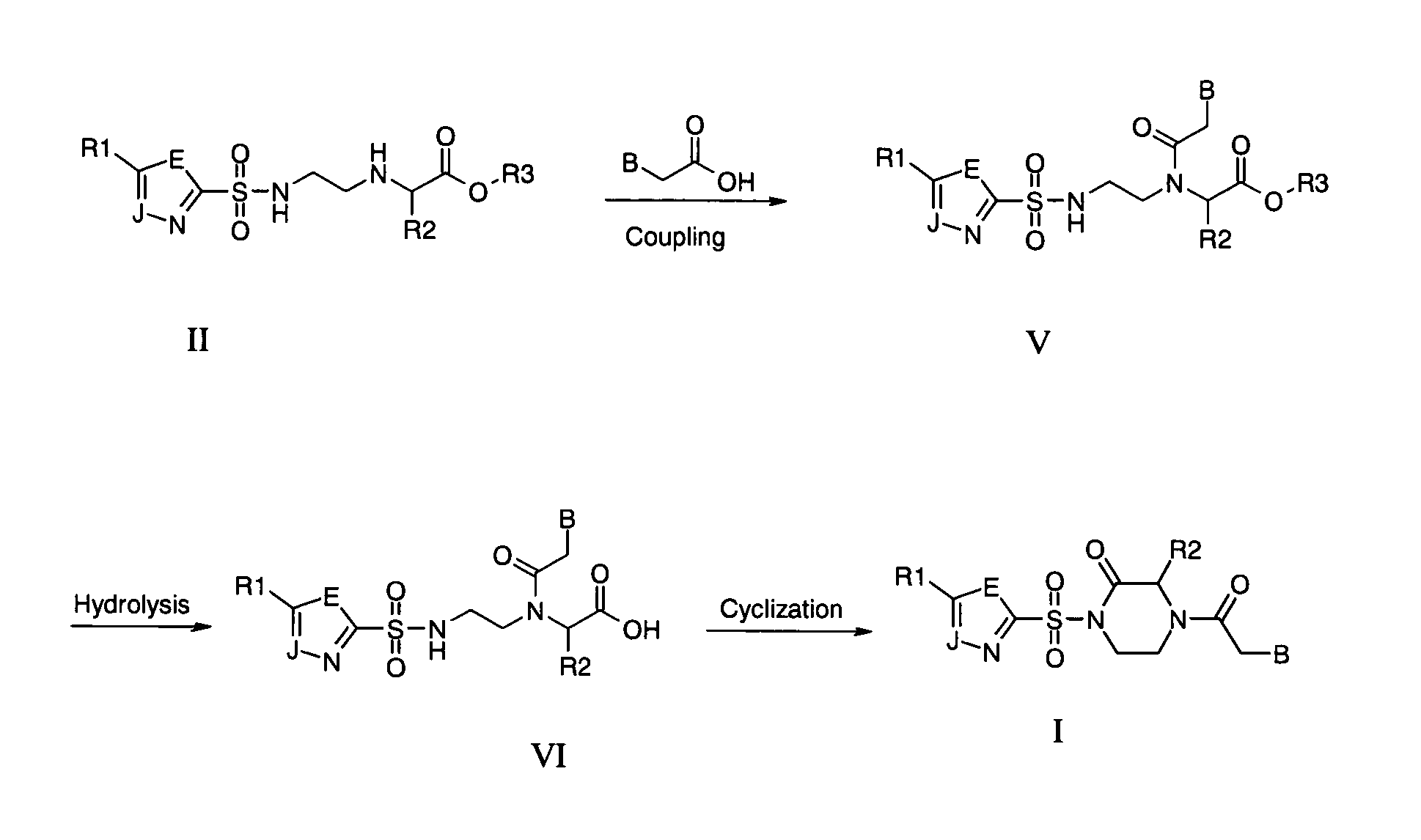

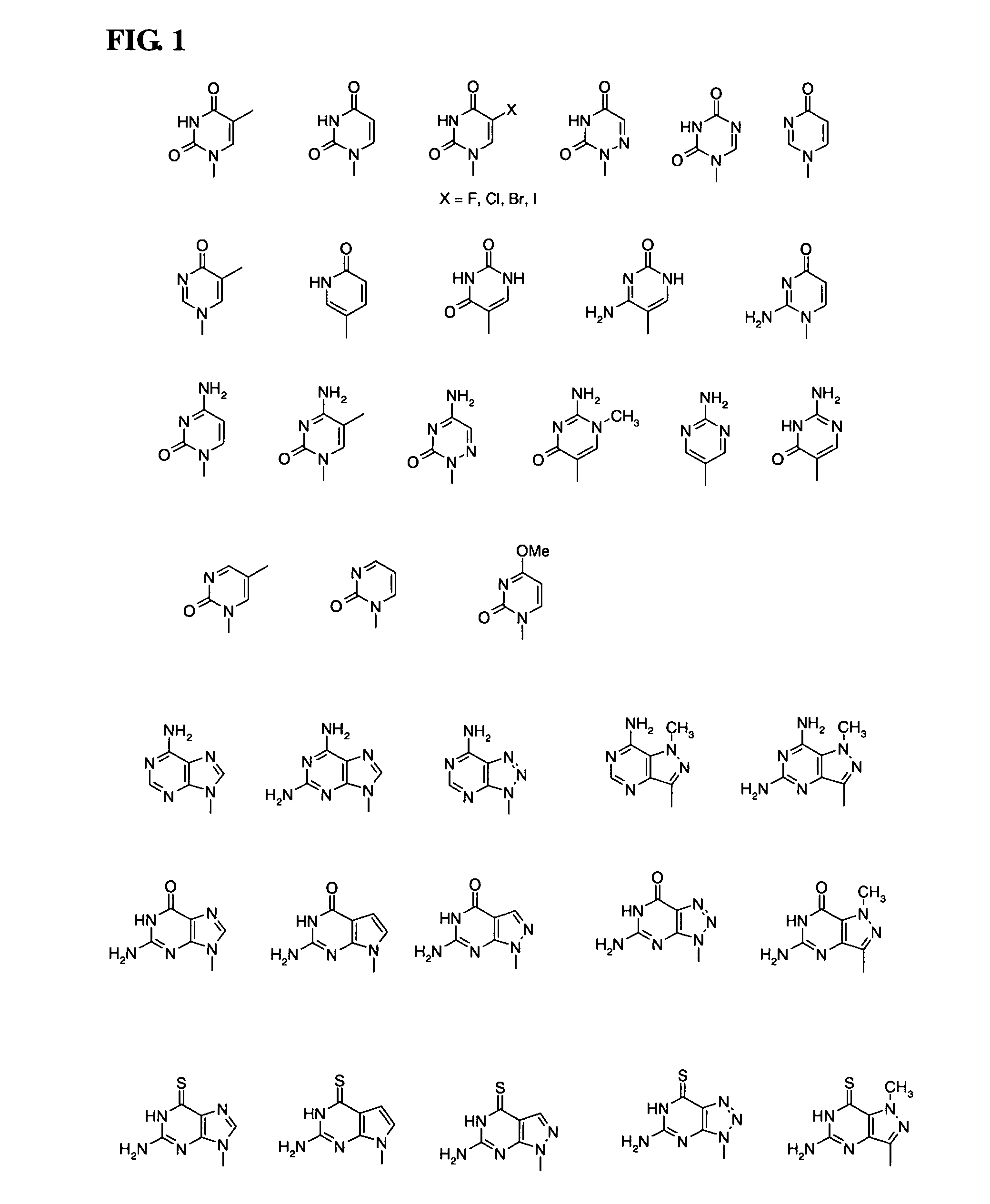

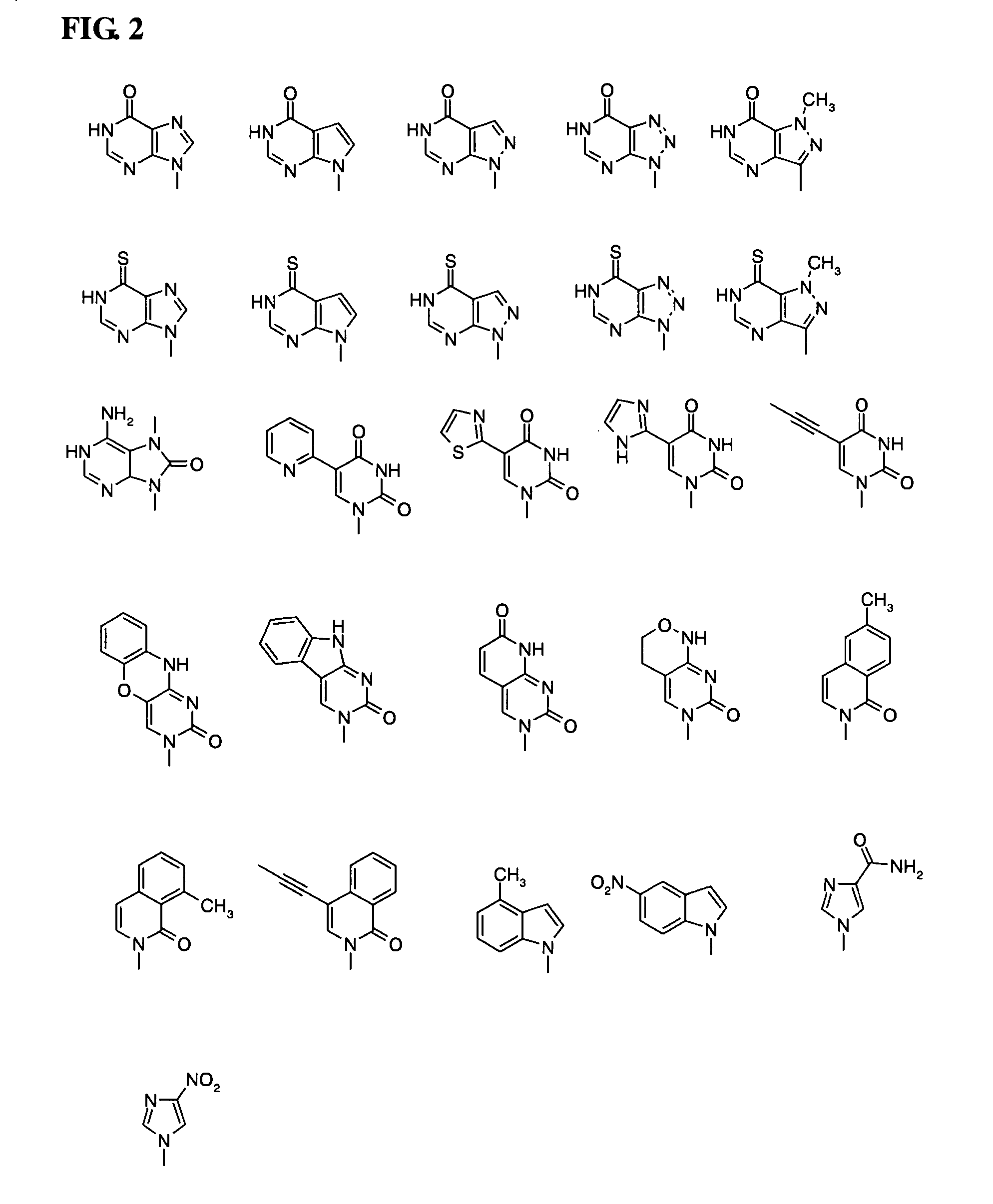

PNA monomer and precursor

ActiveUS7211668B2Improve efficiencyImprove convenienceOrganic active ingredientsSugar derivativesSide chainNucleobase

Owner:PANAGENE INC

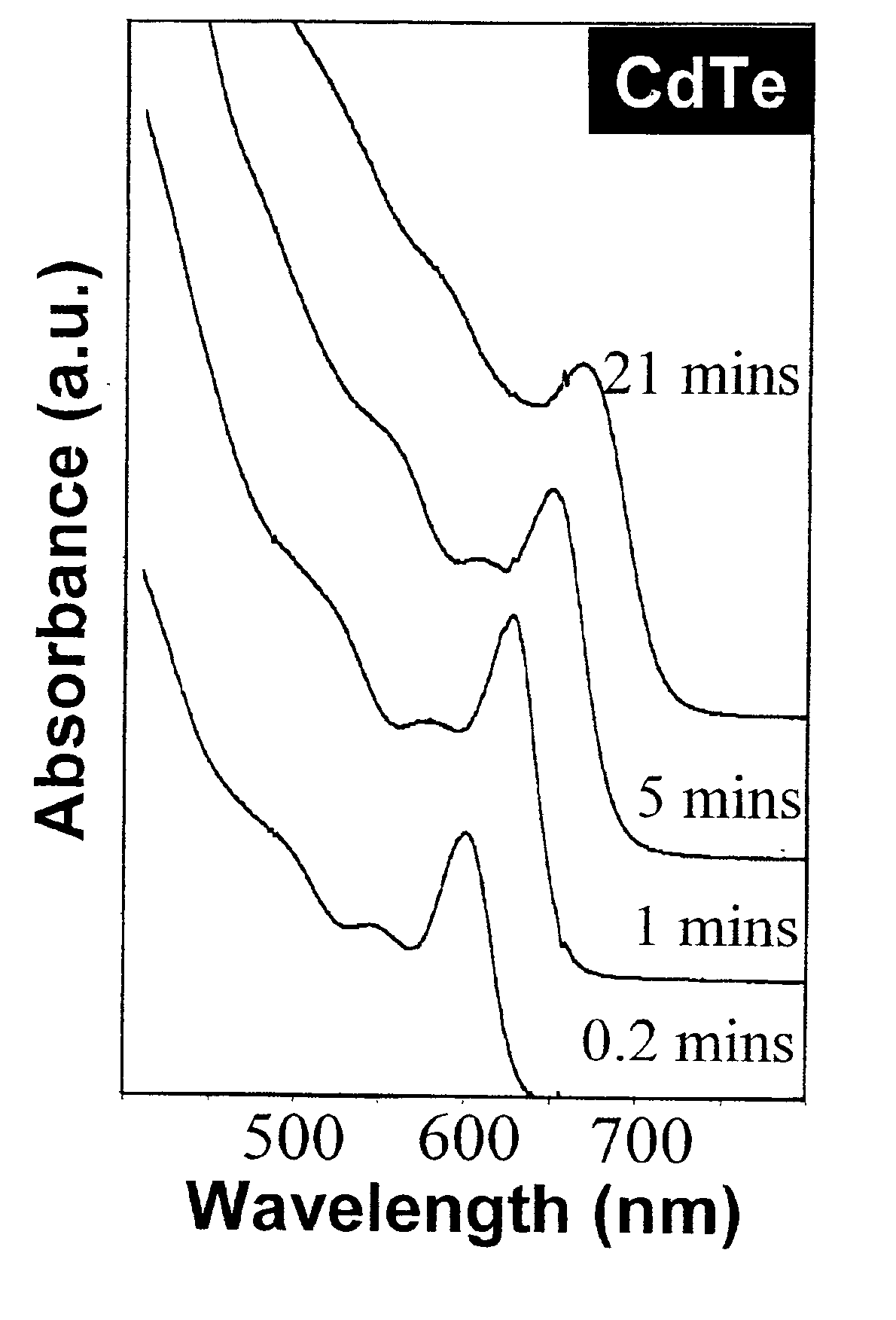

Synthesis of colloidal nanocrystals

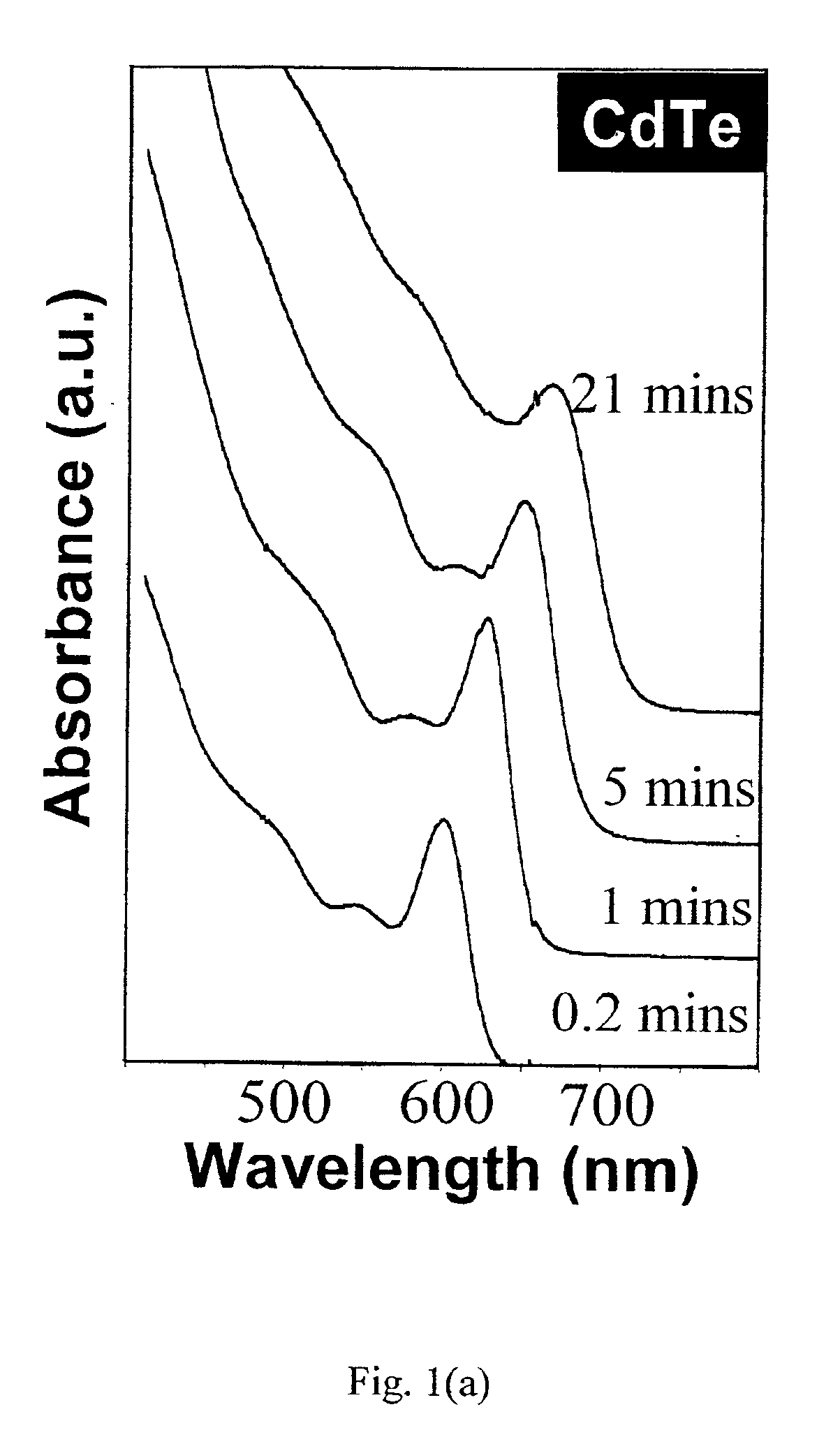

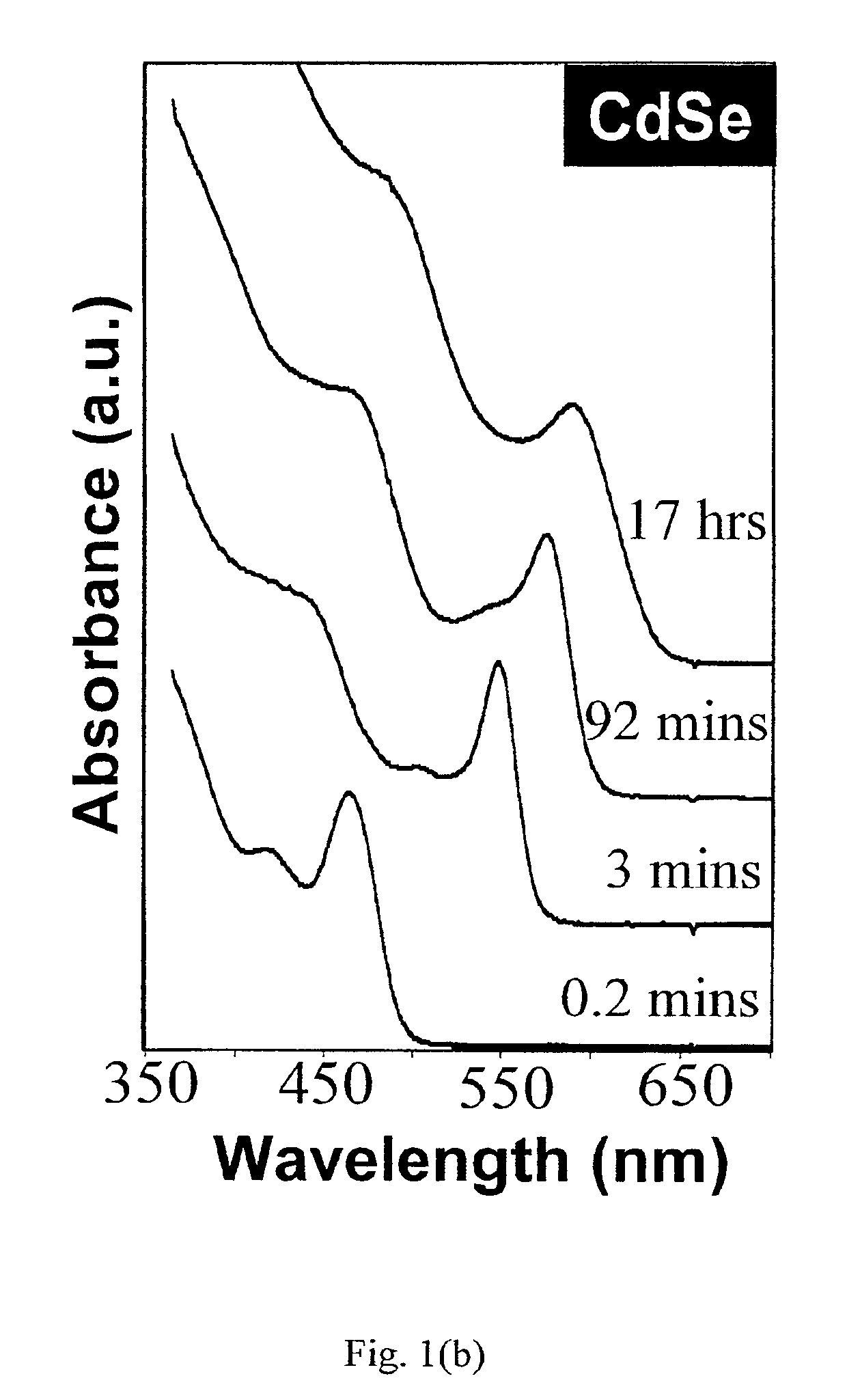

InactiveUS6872249B2High crystallinityGood monodispersityFrom gel stateMaterial nanotechnologyPresent methodSulfur

A method of synthesizing colloidal nanocrystals is disclosed using metal oxides or metal salts as a precursor. The metal oxides or metal salts are combined with a ligand and then heated in combination with a coordinating solvent. Upon heating, the metal oxides or salts are converted to stable soluble metal complexes. The metal complexes are formed by cationic species combining with the ligands and / or with the coordinating solvent. Finally, an elemental chalcogenic precursor, for example, Se, Te, or S, is introduced into the soluble metal complex to complete the formation of the nanocrystals at a controllable rate. High-quality CdSe, CdTe, and CdS nanocrystals are produced when CdO is used as the cadmium precursor. With the present method, the size, size distribution, and shape (dots or rods) of the resulting nanocrystals can be controlled during growth. For example, the resulting nanocrystals are nearly monodisperse without any size separation. Further, the method represents a major step towards a green chemistry approach for synthesizing high-quality semiconductor nanocrystals.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

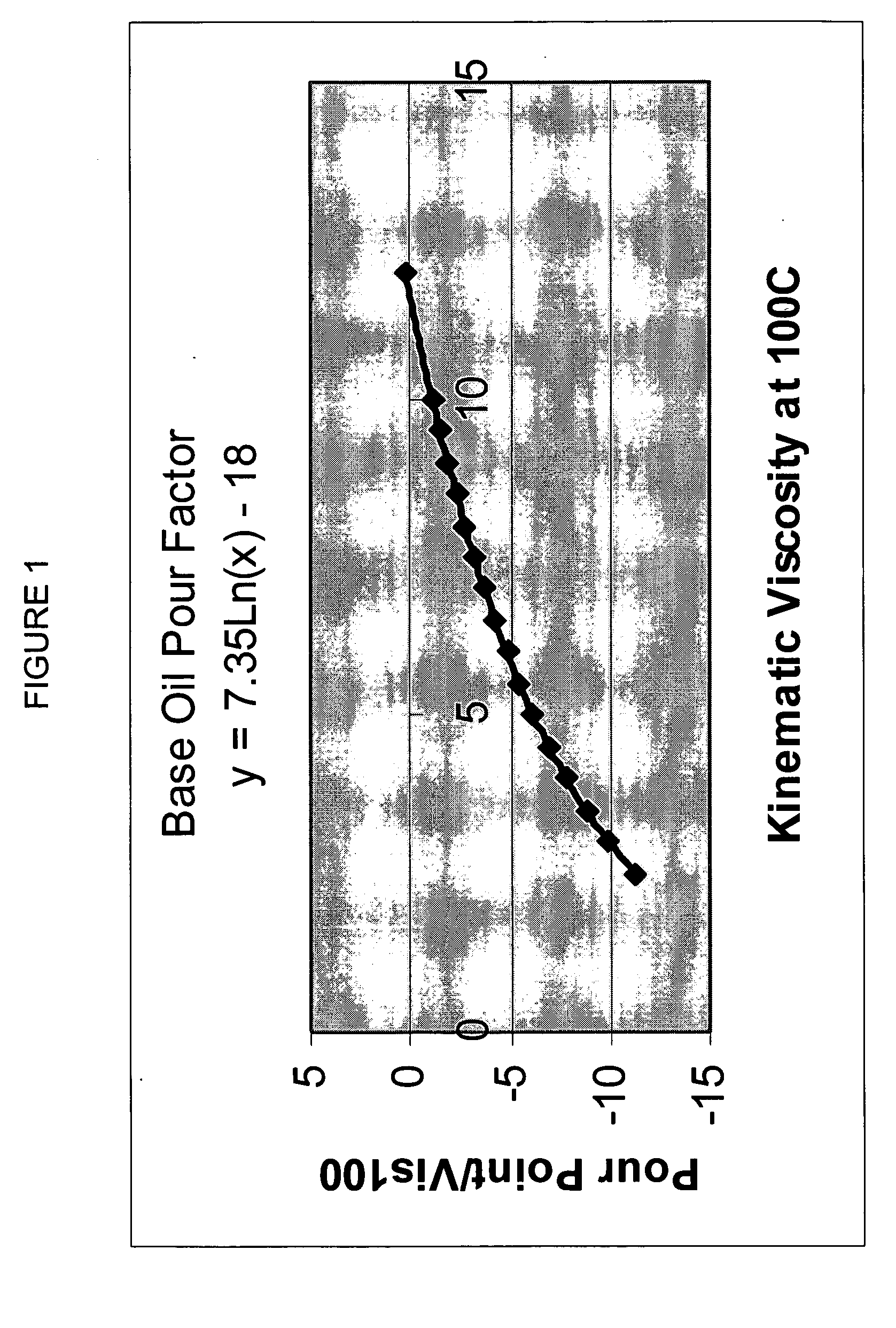

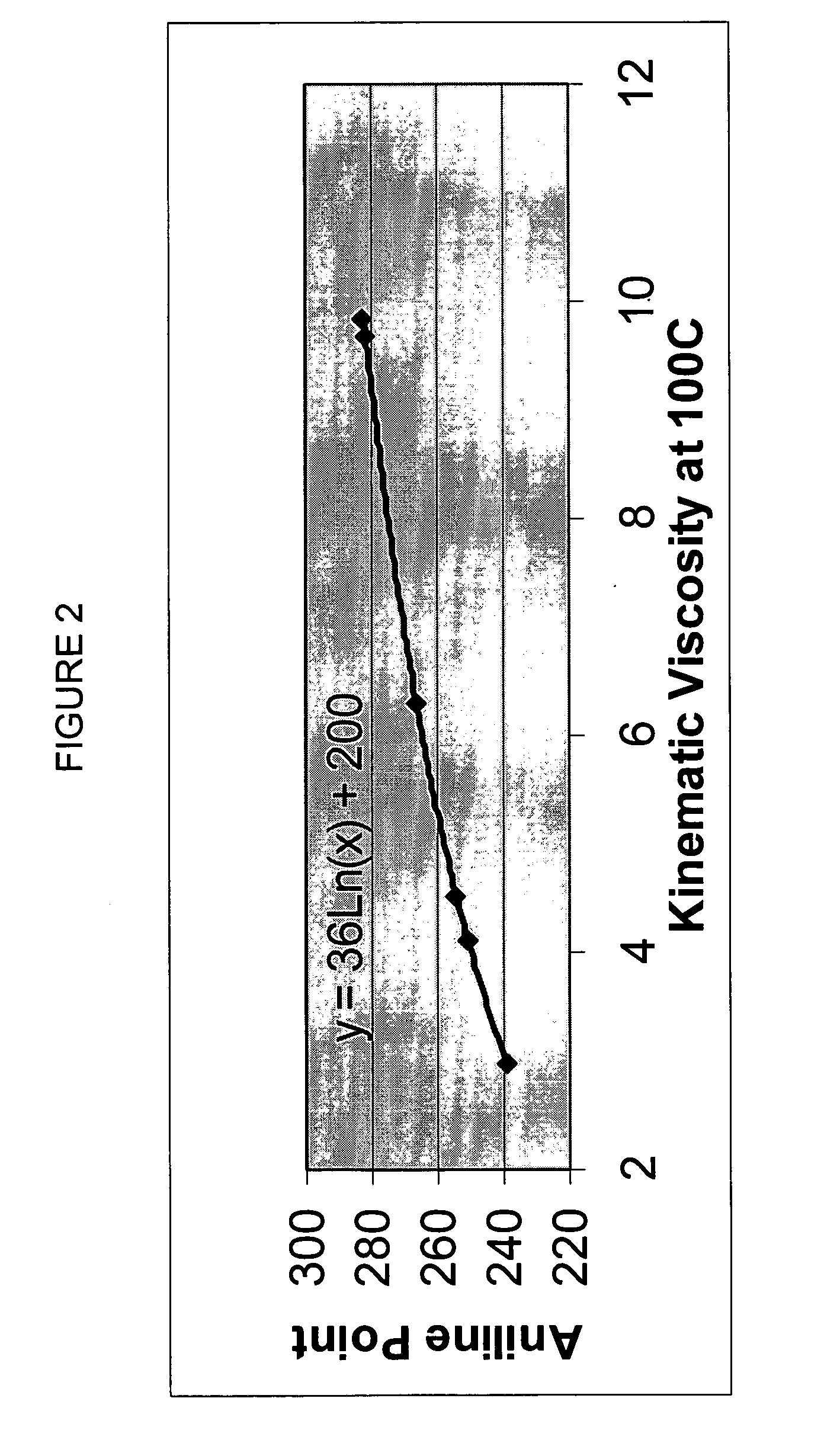

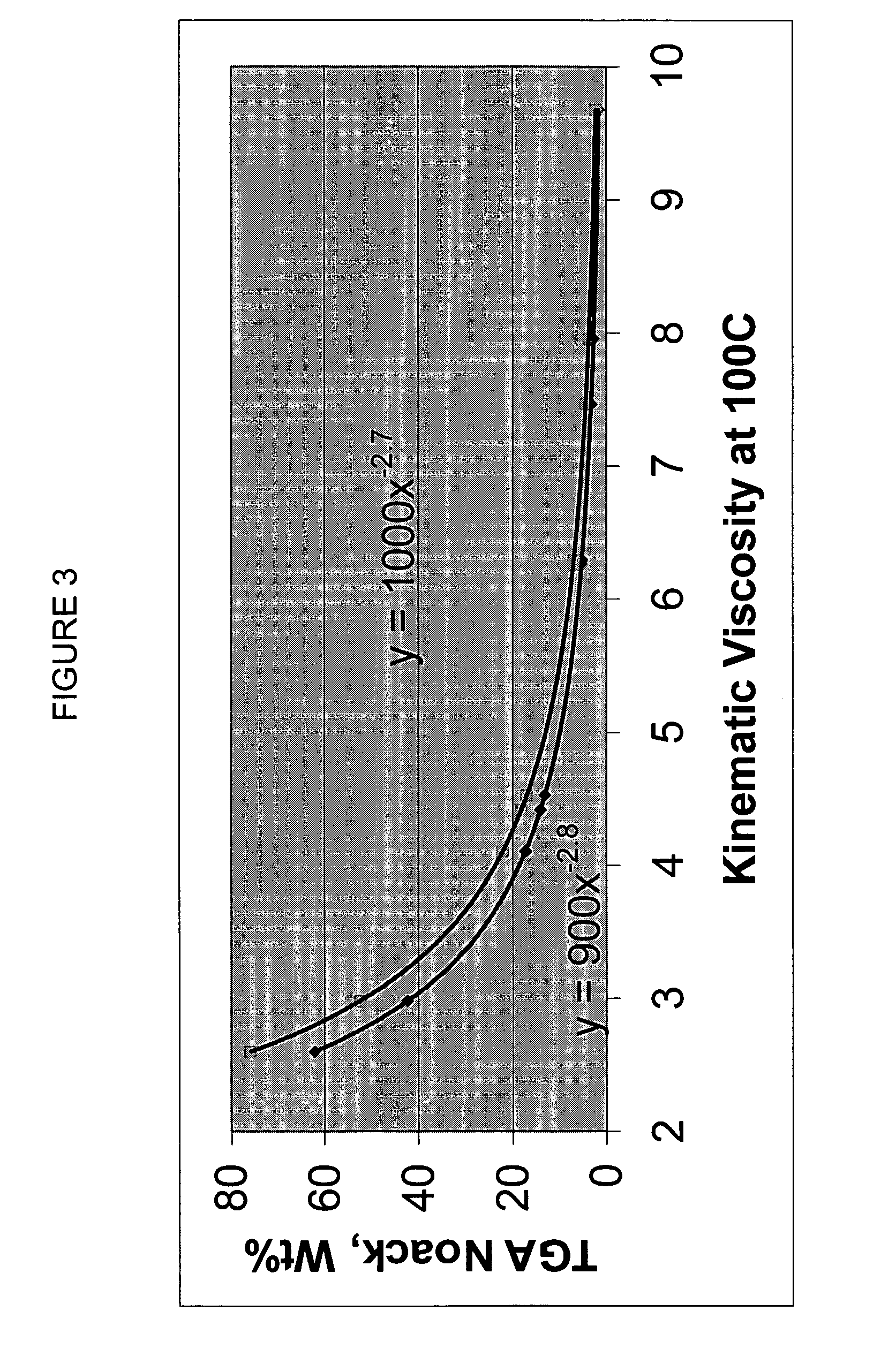

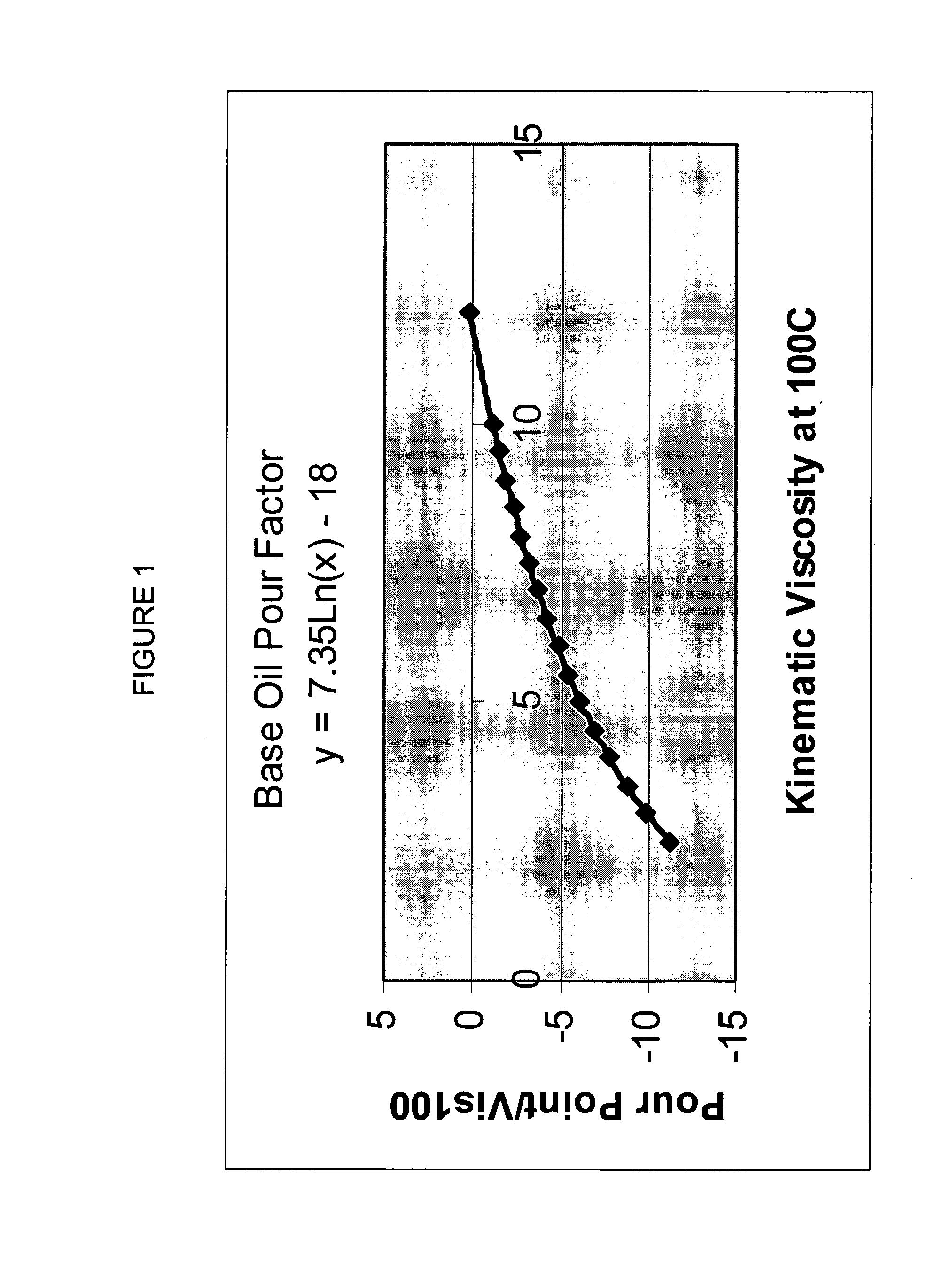

Process for manufacturing lubricating base oil with high monocycloparaffins and low multicycloparaffins

InactiveUS20050133409A1Improve Oxidation StabilityHigh viscosity indexTreatment with hydrotreatment processesAdditivesSyngasMolecular sieve

A process for manufacturing a lubricating base oil by: a) performing Fischer-Tropsch synthesis on syngas to provide a product stream; b) isolating from said product stream a substantially paraffinic wax feed having less than about 30 ppm total nitrogen and sulfur, and less than about 1 wt % oxygen; c) dewaxing said feed by hydroisomerization dewaxing using a shape selective intermediate pore size molecular sieve comprising a noble metal hydrogenation component, wherein the hydroisomerization temperature is between about 600° F. (315° C.) and about 750° F. (399° C.), to produce an is dimerized oil; and d) hydrofinishing said isomerized oil to produce a lubricating base oil having specific desired properties.

Owner:CHEVROU USA INC

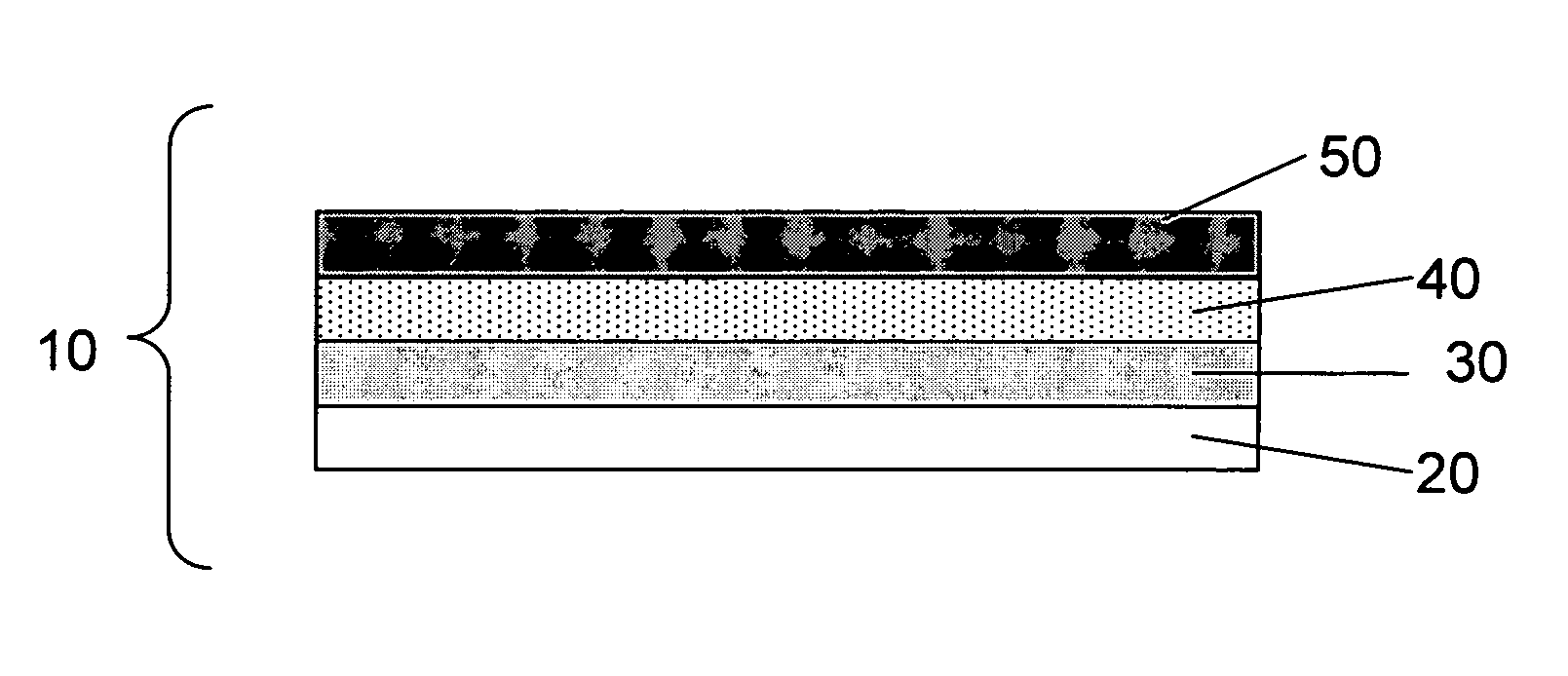

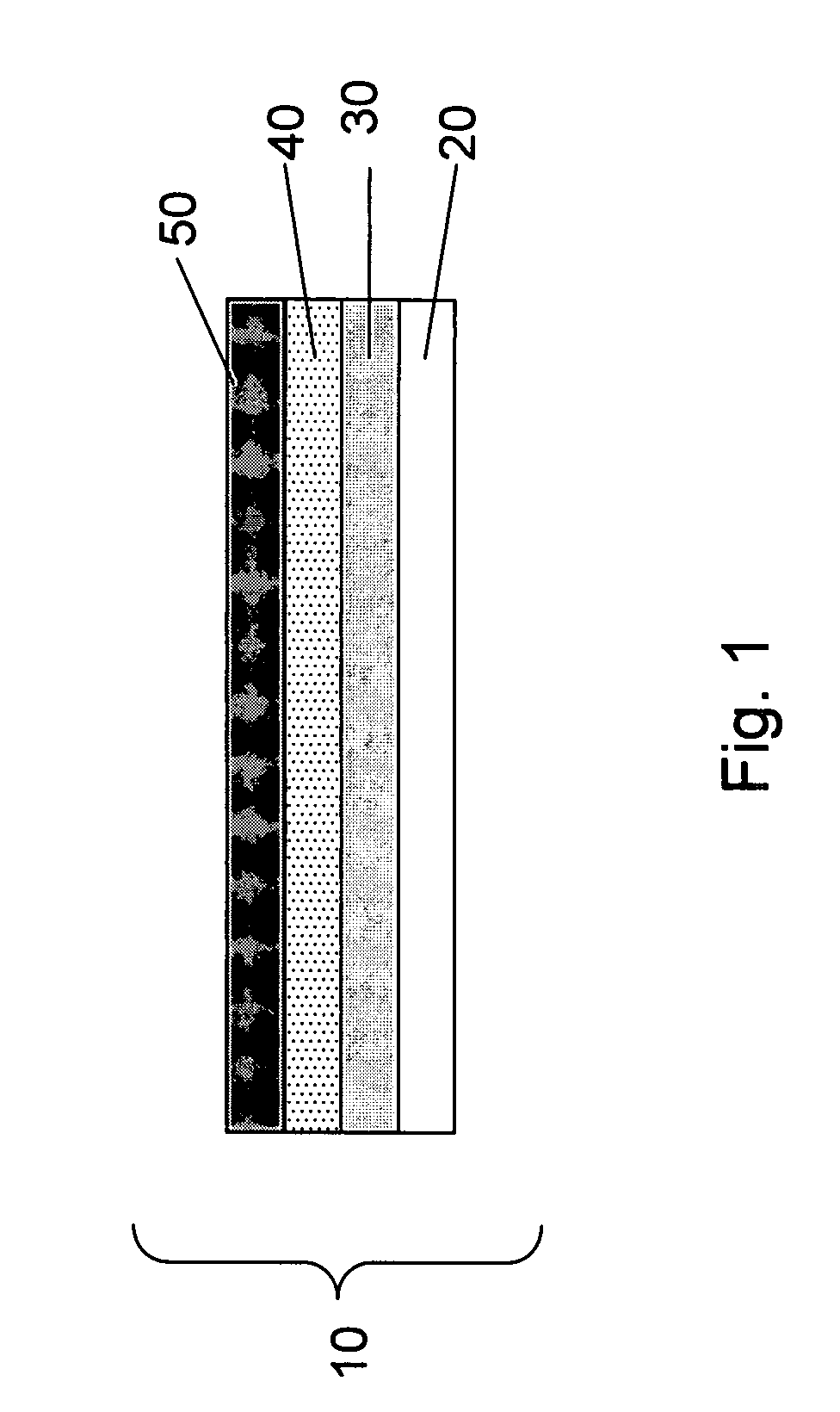

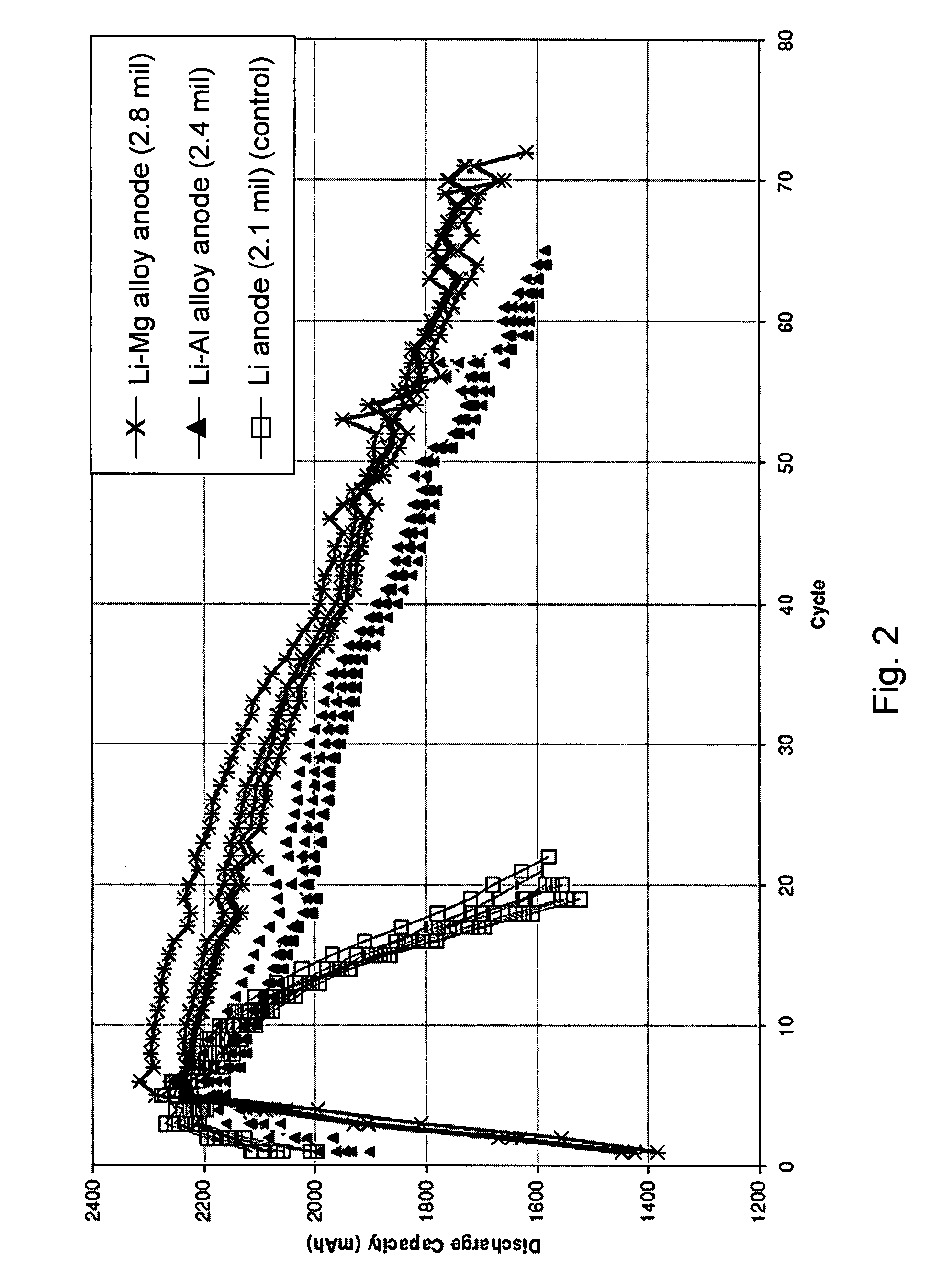

Lithium alloy/sulfur batteries

Electrochemical cells including anode compositions that may enhance charge-discharge cycling efficiency and uniformity are presented. In some embodiments, alloys are incorporated into one or more components of an electrochemical cell, which may enhance the performance of the cell. For example, an alloy may be incorporated into an electroactive component of the cell (e.g., electrodes) and may advantageously increase the efficiency of cell performance. Some electrochemical cells (e.g., rechargeable batteries) may undergo a charge / discharge cycle involving deposition of metal (e.g., lithium metal) on the surface of the anode upon charging and reaction of the metal on the anode surface, wherein the metal diffuses from the anode surface, upon discharging. In some cases, the efficiency and uniformity of such processes may affect cell performance. The use of materials such as alloys in an electroactive component of the cell have been found to increase the efficiency of such processes and to increase the cycling lifetime of the cell. For example, the use of alloys may reduce the formation of dendrites on the anode surface and / or limit surface development.

Owner:SION POWER CORP

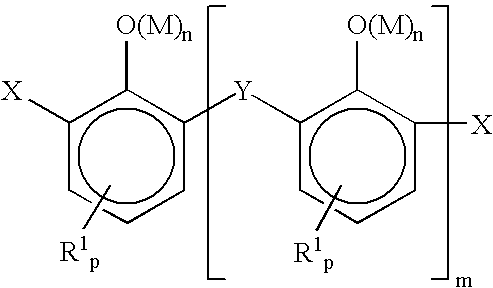

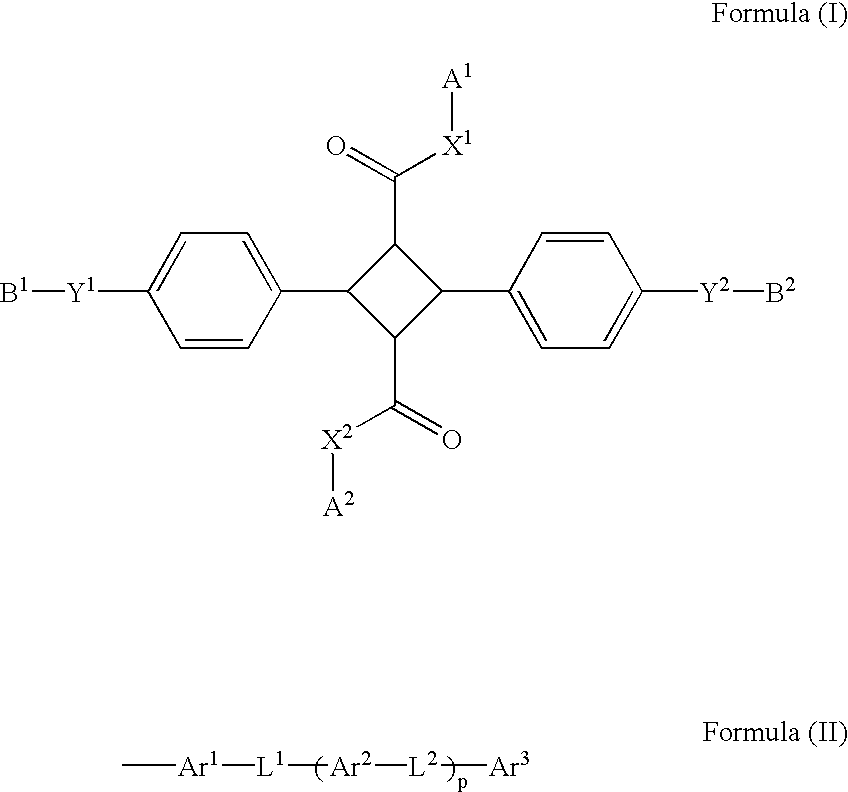

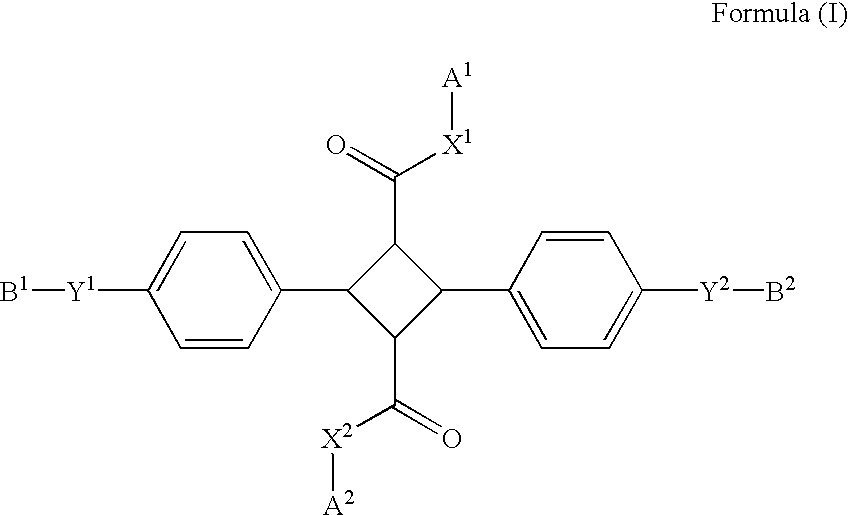

4-Membered ring compound and optical phase optical retardation plate using the same

InactiveUS20030102458A1Liquid crystal compositionsCarbamic acid derivatives preparationSulfurSingle bond

A 4-membered compound is represented by the following formula (I) is disclosed (in the formula, X1 and X2 each independently represent an oxygen atom, a sulfur atom or a substituted or unsubstituted imino group, Y1 and Y2 each independently represent a single bond, an oxygen atom or a substituted or unsubstituted imino group, B1 and B2 each independently represent an optionally substituted aliphatic, aliphatic carbonyl, aromatic or aromatic carbonyl group having 1-20 carbon atoms, and A1 and A2 each independently represent a group represented by the following formula (II) (Ar1, Ar2 and Ar3 each independently represent a cyclic group having 5-14 carbon atoms, L1 and L2 each independently represent a single bond or a divalent linking group, and p represents an integer of 0-2)). There is also disclosed a birefringence medium containing a 4-membered compound represented by the formula (I) and an optical element comprising the birefringence medium.

Owner:FUJIFILM CORP

Process to produce biofuels from biomass

Biofuels can be produced by: (i) providing a biomass containing celluloses, hemicelluloses, lignin, nitrogen compounds and sulfur compounds; (ii) contacting the biomass with a digestive solvent to form a pretreated biomass containing carbohydrates; (iii) contacting the pretreated biomass with hydrogen in the presence of a supported hydrogenolysis catalyst containing (a) sulfur, (b) Mo or W, and (c) Co and / or Ni incorporated into a suitable support to form a plurality of oxygenated intermediates, and (vi) processing at least a portion of the oxygenated intermediates to form a liquid fuel.

Owner:SHELL OIL CO

Finished lubricating comprising lubricating base oil with high monocycloparaffins and low multicycloparaffins

ActiveUS20050133407A1Improve Oxidation StabilityReduce wearRefining to change hydrocarbon structural skeletonLiquid hydrocarbon mixture productionMolecular sieveWax

A process for manufacturing a finished lubricant by: a) performing Fischer-Tropsch synthesis on syngas to provide a product stream; b) isolating from said product stream a substantially paraffinic wax feed having less than about 30 ppm total nitrogen and sulfur, and less than about 1 wt % oxygen; c) dewaxing said feed by hydroisomerization dewaxing using a shape selective intermediate pore size molecular sieve comprising a noble metal hydrogenation component, wherein the hydroisomerization temperature is between about 600° F. (315° C.) and about 750° F. (399° C.), to produce an isomerized oil; and d) hydrofinishing said isomerized oil, whereby a lubricating base oil is produced having specific desired properties; and e) blending the lubricating base oil with at least one lubricant additive.

Owner:CHEVROU USA INC

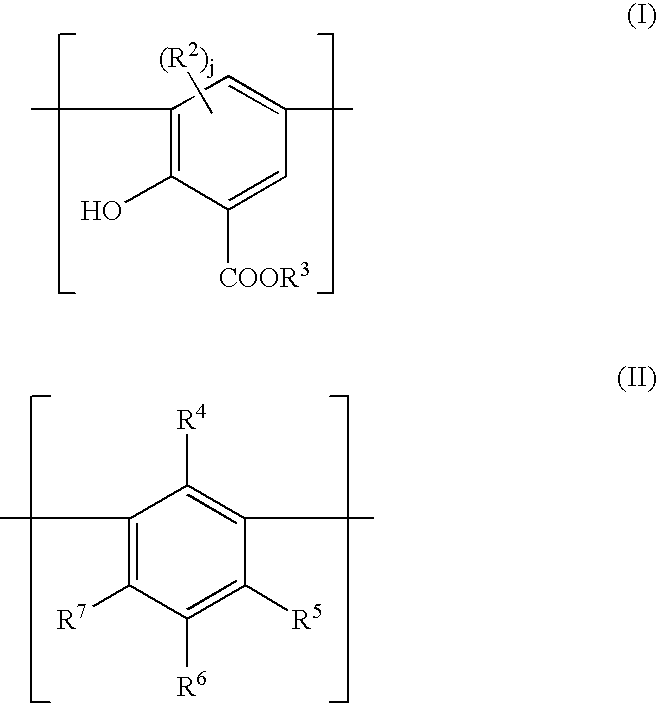

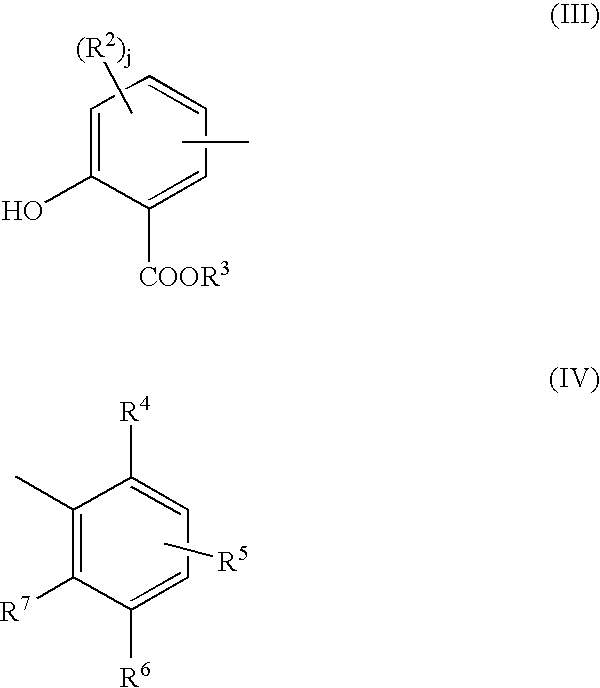

Photoelectric conversion device and method for producing same

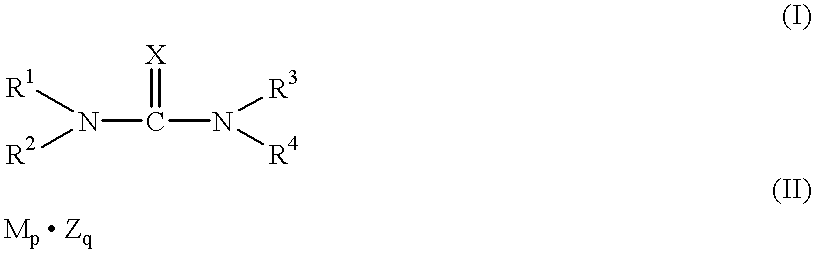

InactiveUS20020040728A1Promote conversionPrevent deterioration and volatilityLight-sensitive devicesDeferred-action cellsArylHydrogen atom

A method for producing a photoelectric conversion device comprising a conductive support and a photosensitive layer containing a semiconductor fine particle on which a dye is adsorbed, wherein the semiconductor fine particle is treated with a compound represented by the following general formula (I): wherein X represents an oxygen atom, a sulfur atom, a selenium atom or NY, in which Y represents a hydrogen atom, an aliphatic hydrocarbon group, a hydroxyl group or an alkoxy group; R1, R2, R3 and R4 independently represent a hydrogen atom, an aliphatic hydrocarbon group, an aryl group, a heterocyclic group, -N(R5)(R6), -C(=O)R7, -C(=S)R8, -SO2R9 or -OR10; R5 and R6 few independently have the same meaning as the R1, R2, R3 and R4; R7, R8 and R9 independently represent a hydrogen atom, an aliphatic hydrocarbon group, an aryl group, a heterocyclic group, -N(R5)(R6), -OR10 or -SR11; and R10 and R11 independently represent a hydrogen atom or an aliphatic hydrocarbon group.

Owner:FUJIFILM CORP

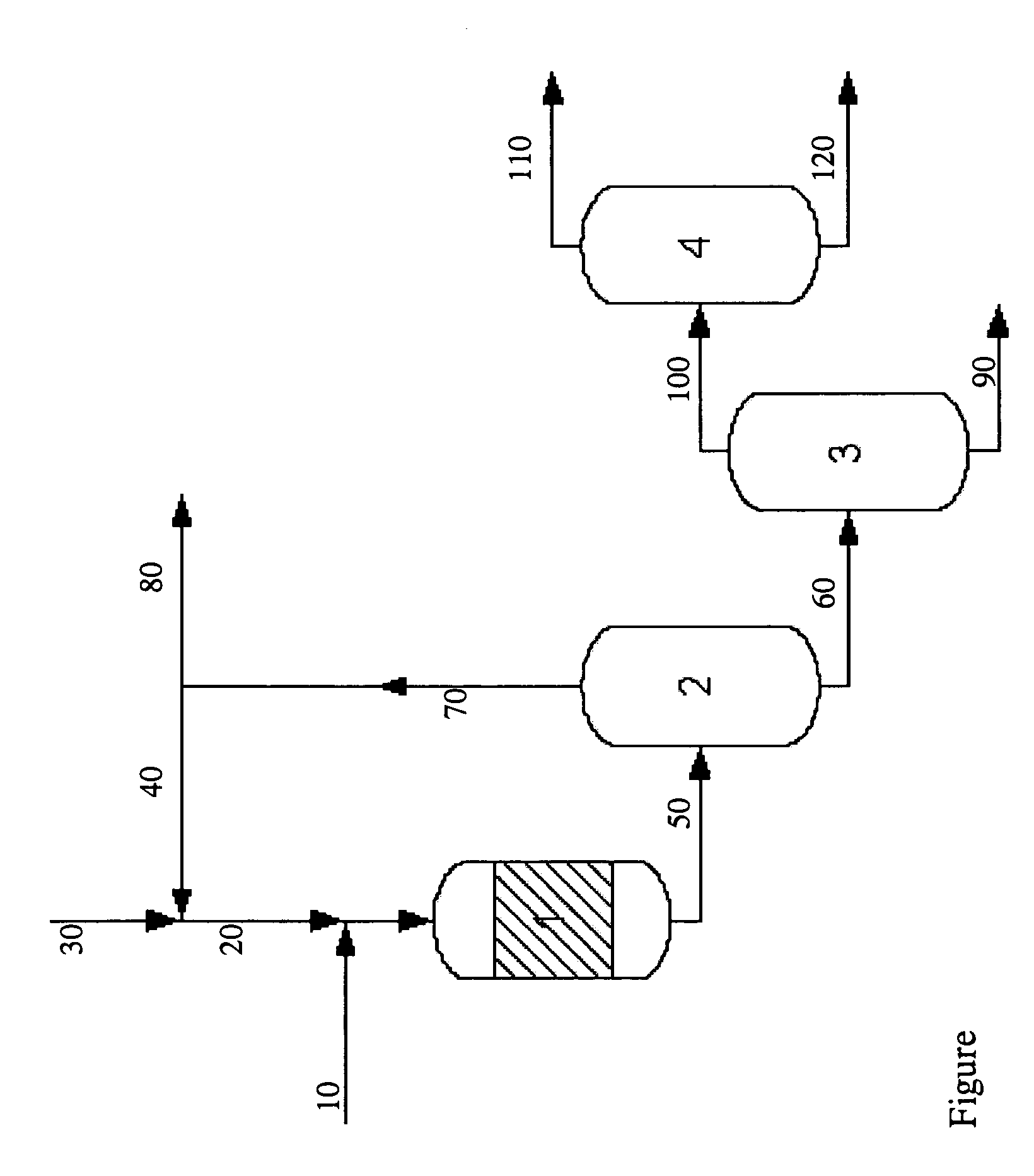

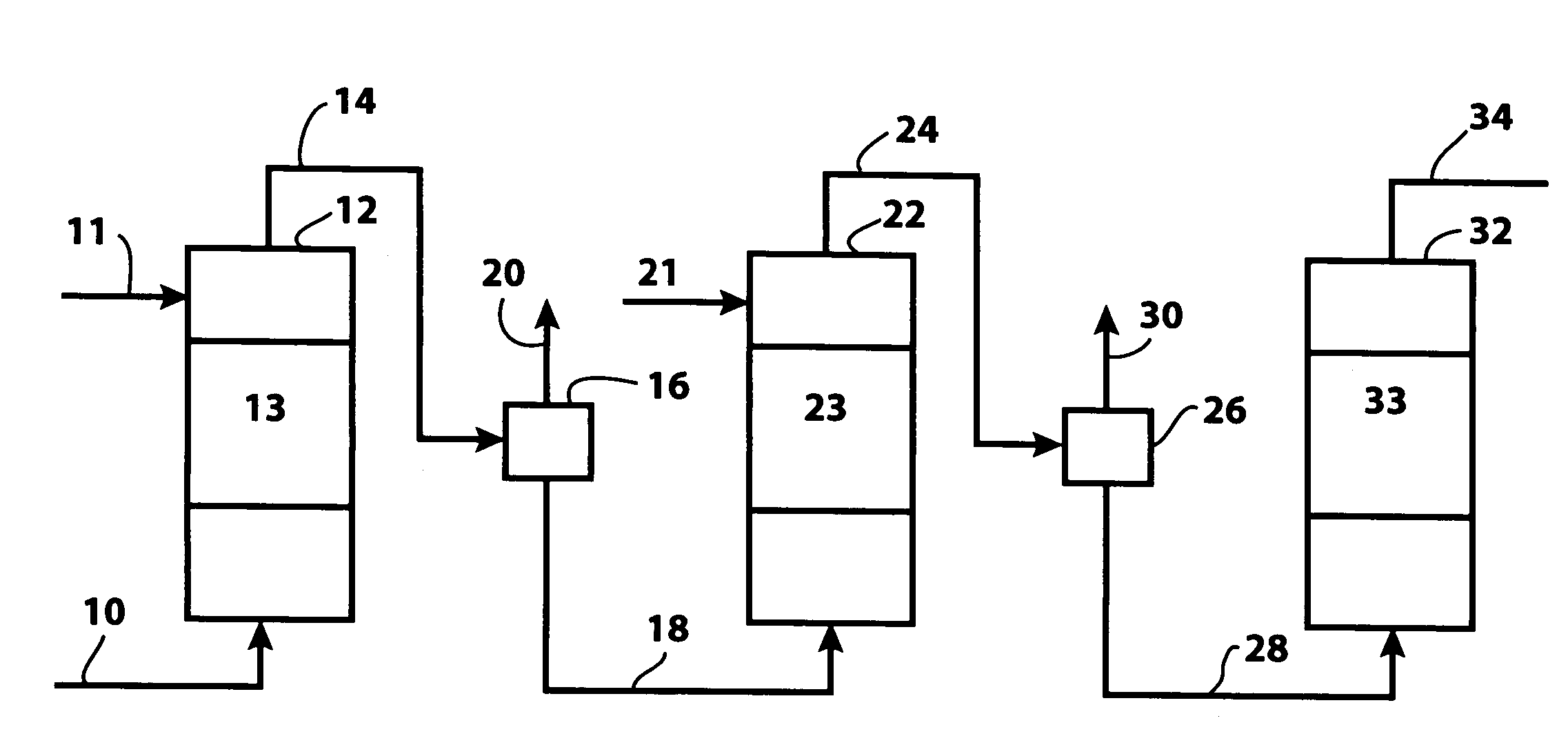

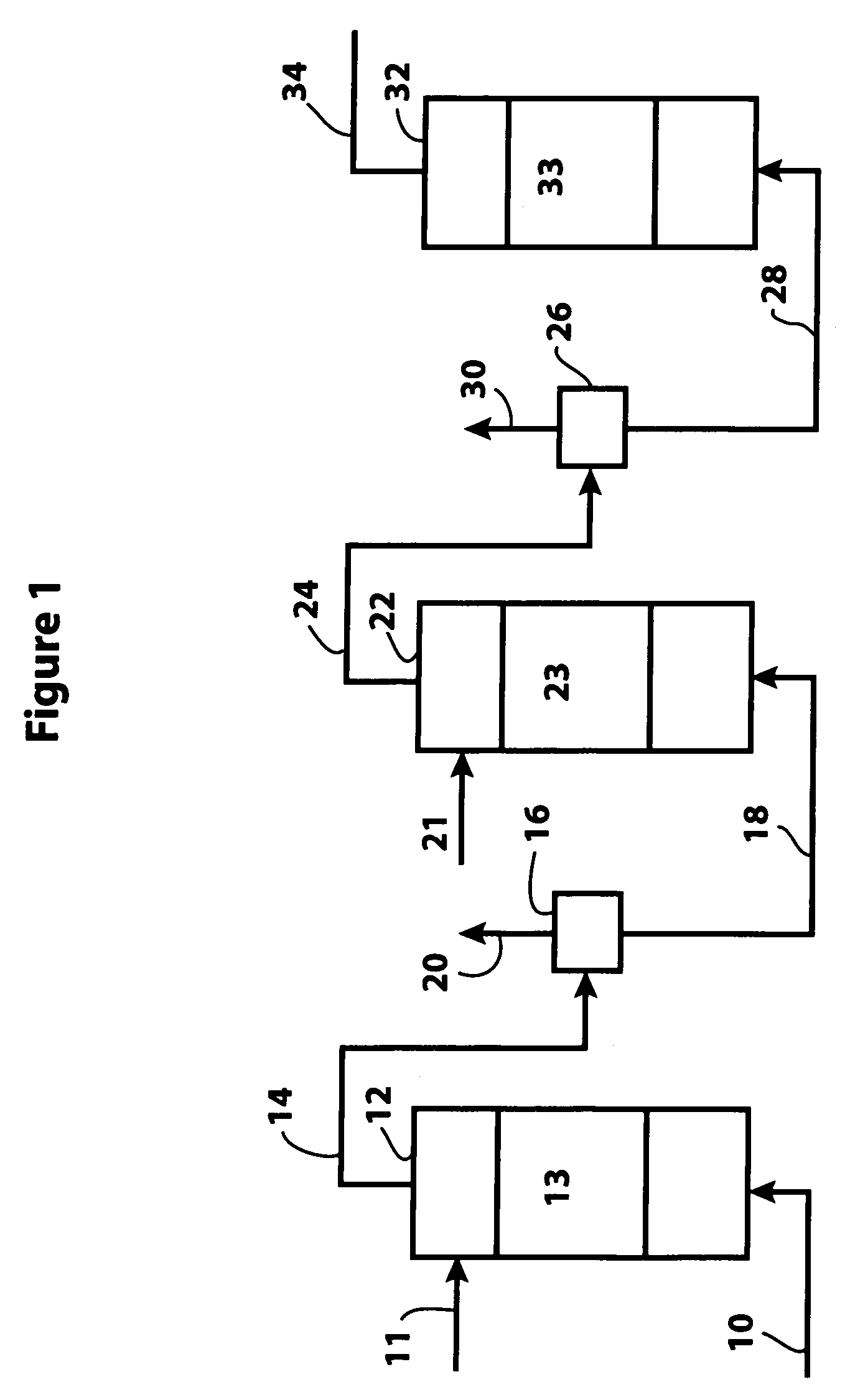

Two stage process for hydrodesulfurizing distillates using bulk multimetallic catalyst

InactiveUS6929738B1Preparation by oxo-reaction and reductionOrganic compound preparationLiquid productHydrogen

A two stage hydrodesulfurizing process for producing low sulfur distillates. A distillate boiling range feedstock containing in excess of about 3,000 wppm sulfur is hydrodesulfurized in a first hydrodesulfurizing stage containing one or more reaction zones in the presence of hydrogen and a hydrodesulfurizing catalyst. The liquid product stream thereof is passed to a first separation stage wherein a vapor phase product stream and a liquid product stream are produced. The liquid product stream, which has a substantially lower sulfur and nitrogen content then the original feedstream is passed to a second hydrodesulfurizing stage also containing one or more reaction zones where it is reacted in the presence of hydrogen and a second hydrodesulfurizing catalyst at hydrodesulfurizing conditions. The catalyst in any one or more reaction zones is a bulk multimetallic catalyst comprised of at least one Group VIII non-noble metal and at least two Group VIB metals.

Owner:EXXON RES & ENG CO

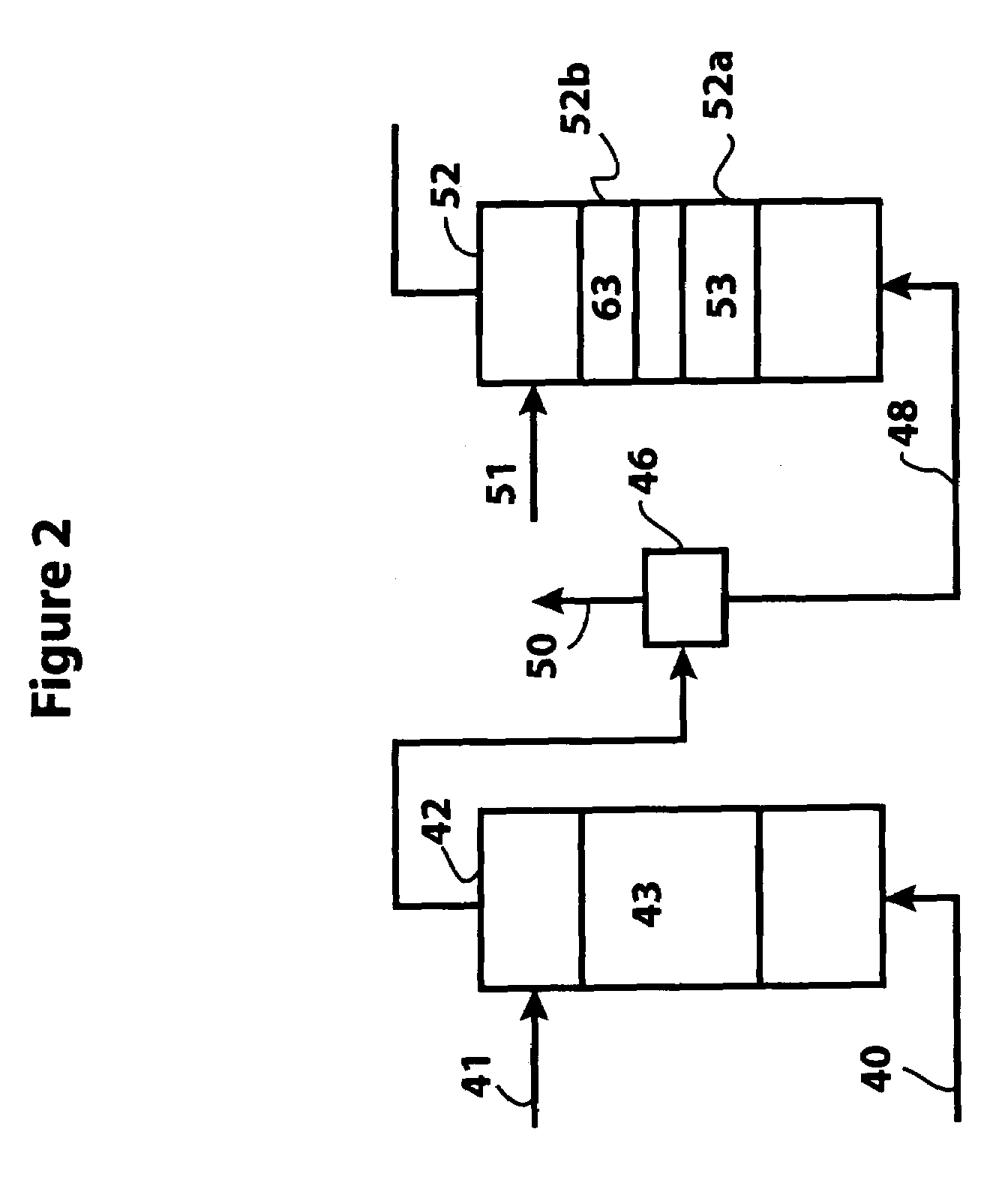

Process for upgrading naphtha

A method for upgrading a naphtha feed to a naphtha product containing less than about 10 wppm of nitrogen and less than about 15 wppm sulfur, the method comprising contacting said naphtha feed with hydrogen in the presence of a bulk multimetallic catalyst under effective reactor conditions to hydrodesulfurize and hydrodenitrogenize said naphtha feed to produce said naphtha product, wherein said bulk multimetallic catalyst comprises at least one Group VIII non-noble metal and at least two Group VIB metals.

Owner:EXXON RES & ENG CO

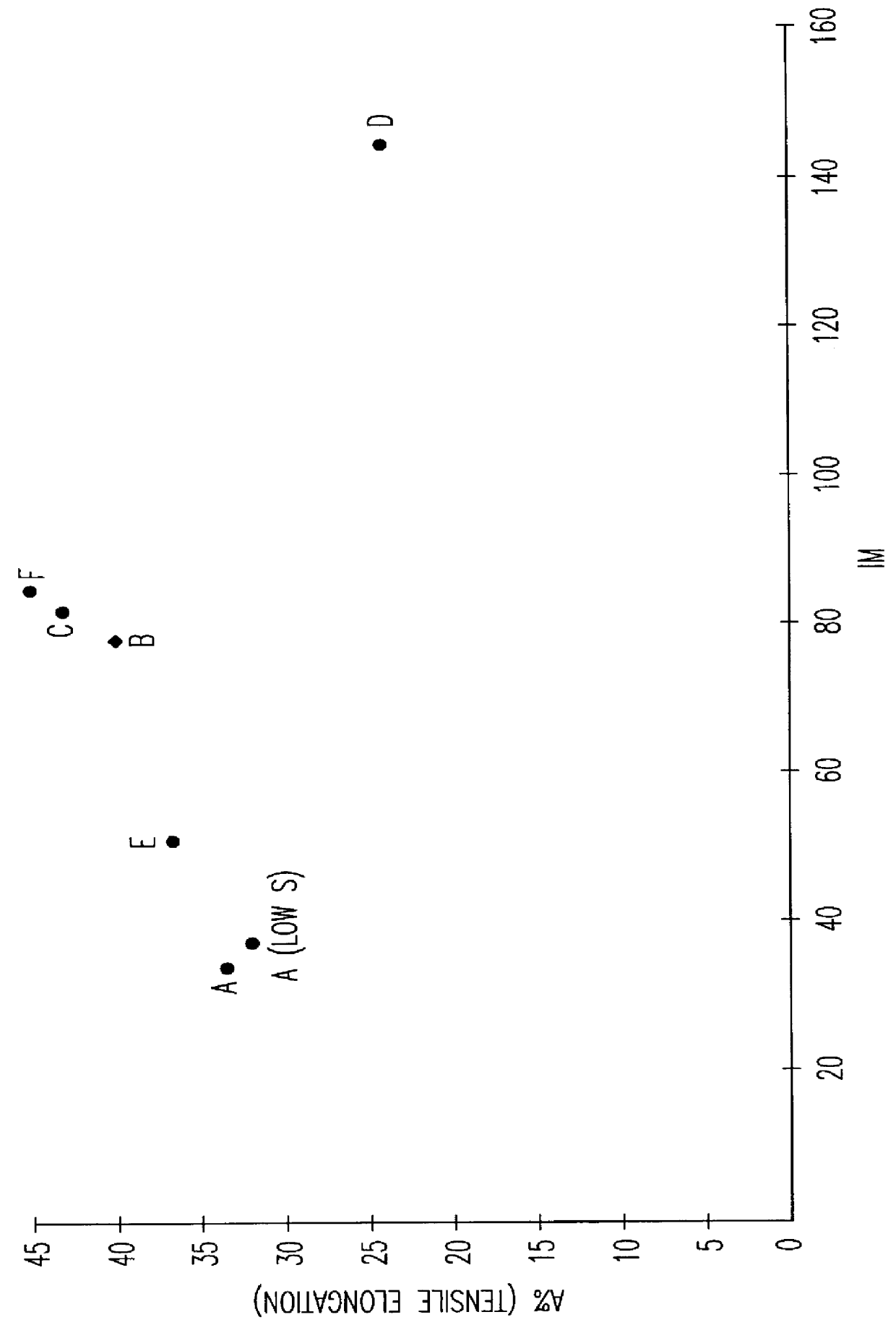

Austenoferritic stainless steel having a very low nickel content and a high tensile elongation

InactiveUS6096441ALow nickel contentImproved general propertyHeat treatment process controlElectric furnaceSulfurManganese

An austenoferritic stainless steel with high tensile elongation includes iron and the following elements in the indicated weight amounts based on total weight: carbon<0.04% 0.4%<silicon<1.2% 2%<manganese<4% 0.1%<nickel<1% 18%<chromium<22% 0.05%<copper<4% sulfur<0.03% phosphorus<0.1% 0.1%<nitrogen<0.3% molybdenum<3% the steel having a two-phase structure of austenite and ferrite and comprising between 30% and 70% of austenite, wherein Creq=Cr %+Mo %+1.5 Si % Nieq=Ni %+0.33 Cu %+0.5 Mn %+30 C %+30 N % and Creq / Nieq is from 2.3 to 2.75, and wherein IM=551-805(C+N)%-8.52 Si %-8.57 Mn %-12.51 Cr %-36 Ni %-34.5 Cu %-14 Mo %, IM being from 40 to 115.

Owner:UGITECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com