Patents

Literature

1110 results about "Animal oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production of diesel fuel from vegetable and animal oils

A process for producing a fuel composition from vegetable and / or animal oil comprises hydrodeoxygenating and hydroisomerizing the oil in a single step. The fuel composition has acceptable lubricity and comprises a mixture of C14 to C18 paraffins having a ratio of iso to normal paraffins of 2 to 8 and less than 5 ppm sulfur.

Owner:BEN GURION UNIVERSITY OF THE NEGEV

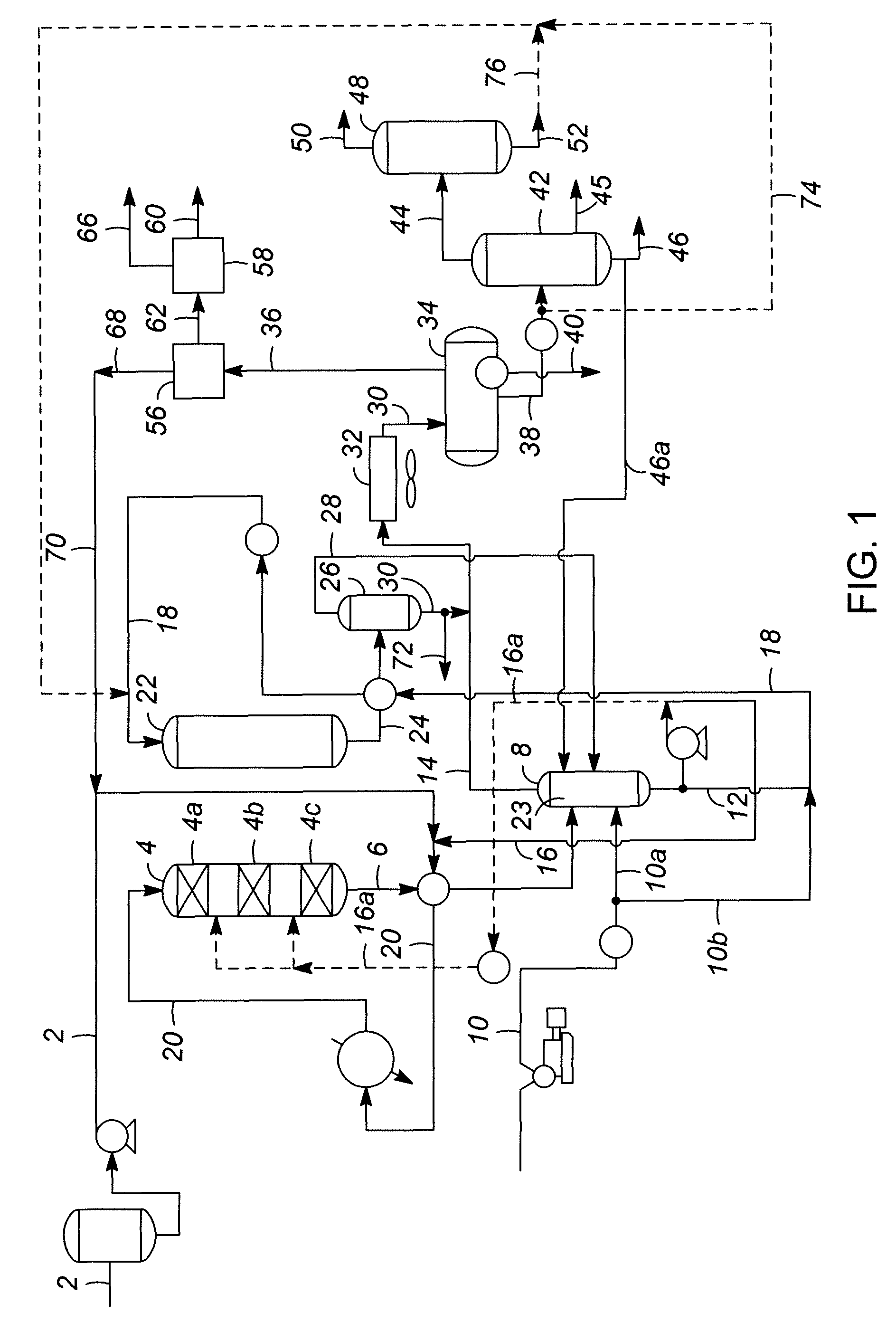

Production of Blended Fuel from Renewable Feedstocks

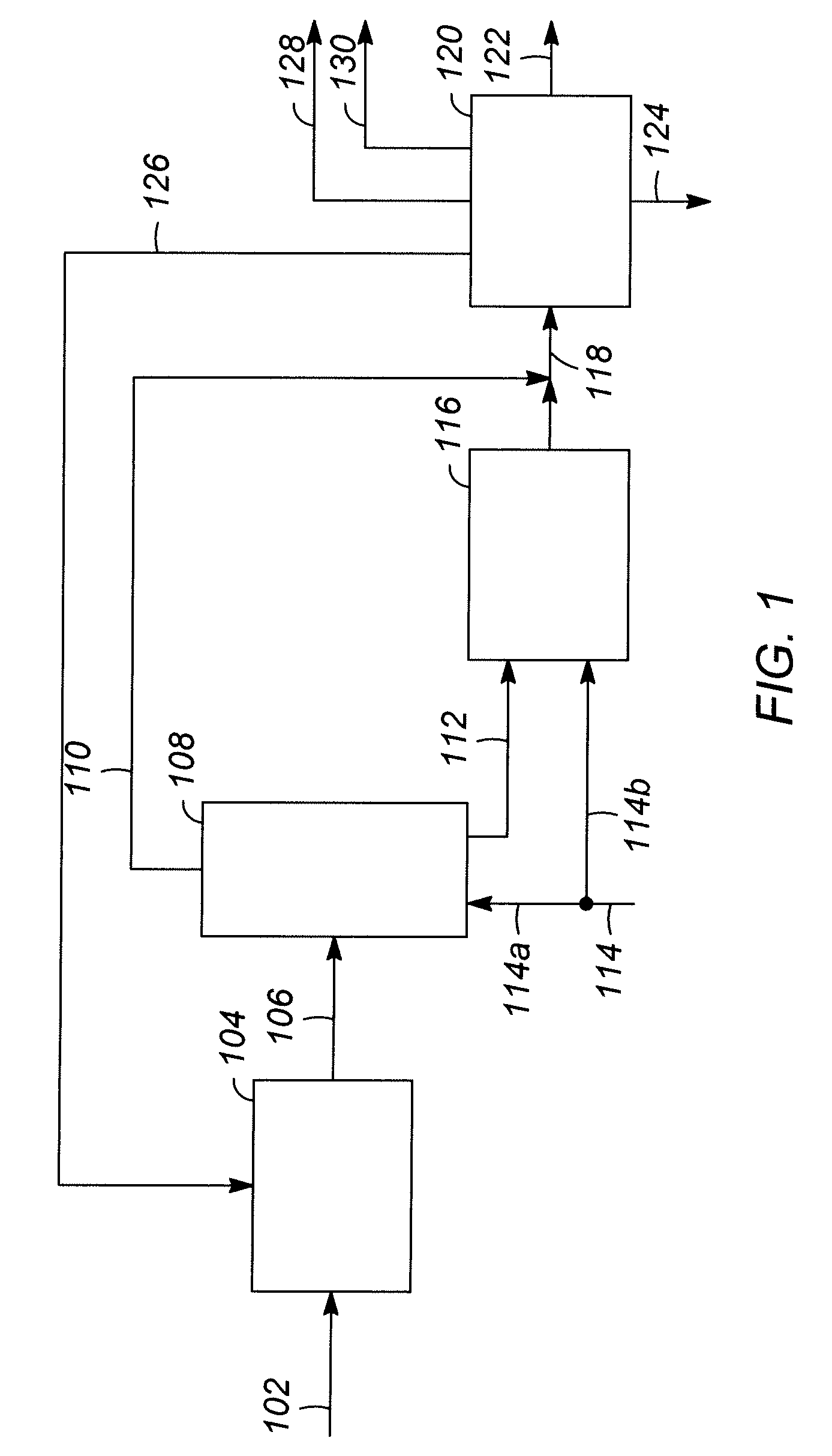

ActiveUS20090301930A1Minimize the numberReduce the amount requiredRefining to change hydrocarbon structural skeletonBiofuelsParaffin waxEngineering

A process for producing a blended fuel from a paraffin rich component and a cyclic rich component, where each of the components are generated from a renewable feedstock, is presented. The paraffin rich component is generated from glycerides and free fatty acids in feedstocks such as plant and animal oils. The cyclic rich component is generated from biomass derived pyrolysis oil. The source of the animal or plant oil and the biomass may be the same renewable source.

Owner:UOP LLC

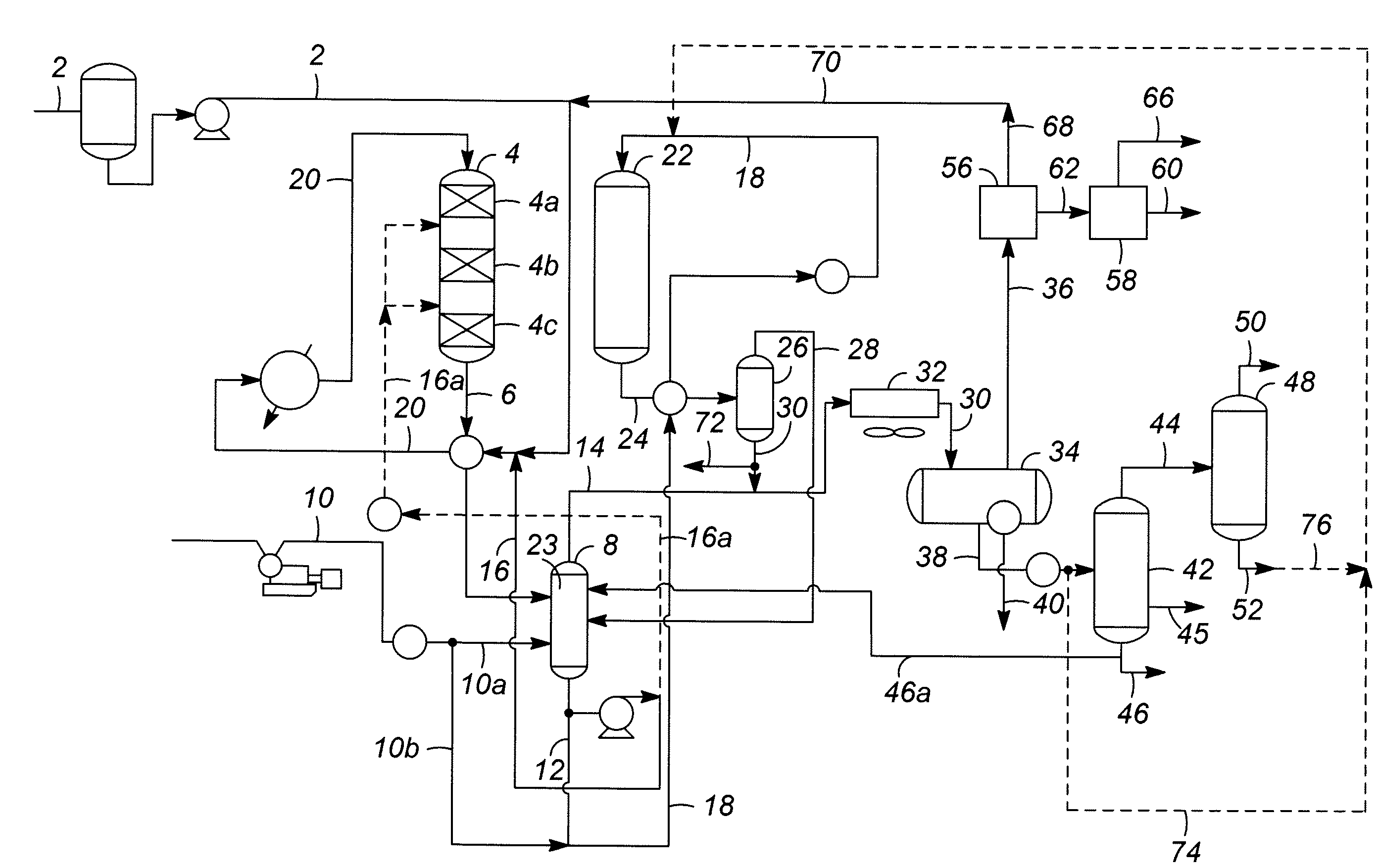

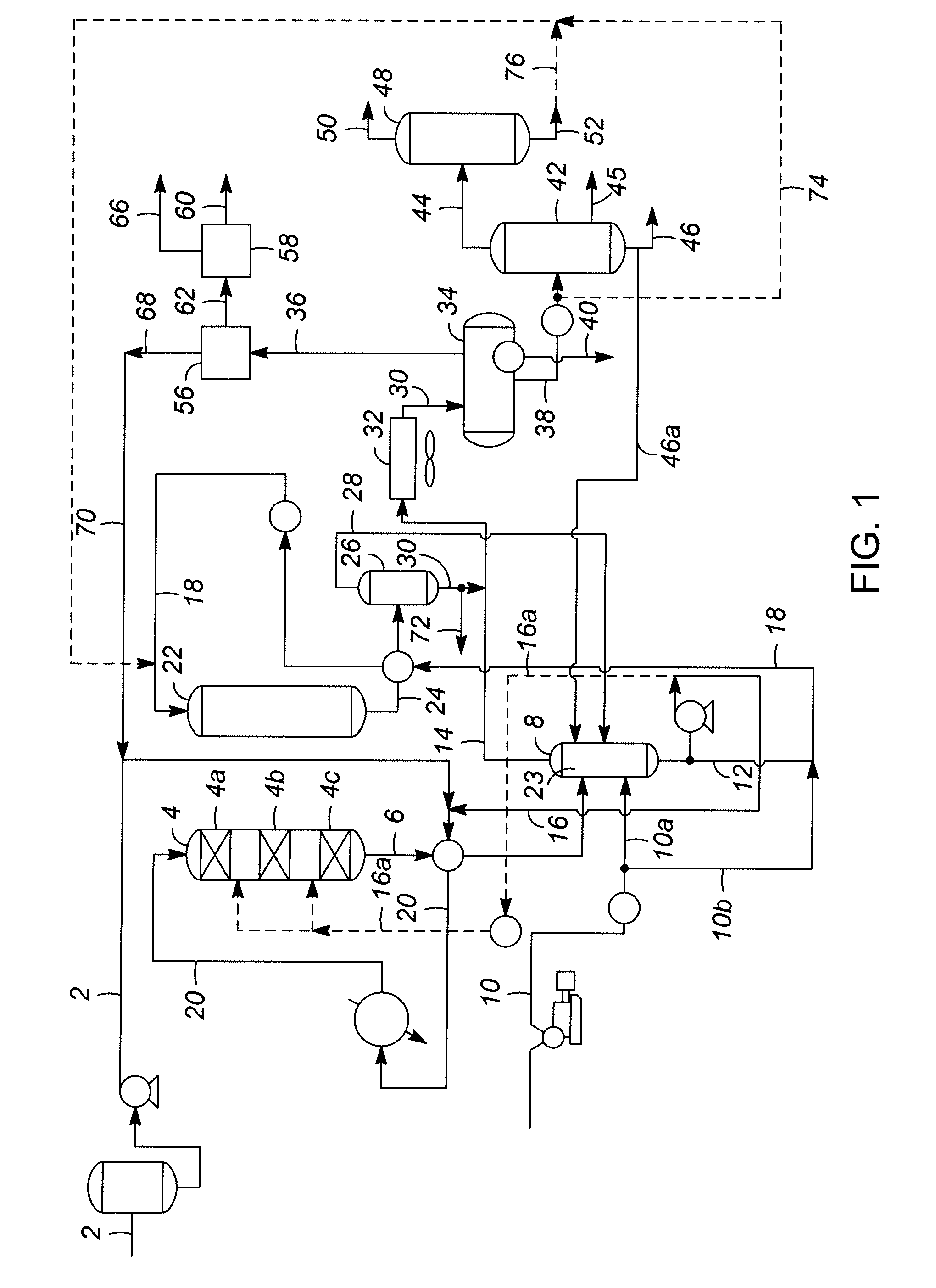

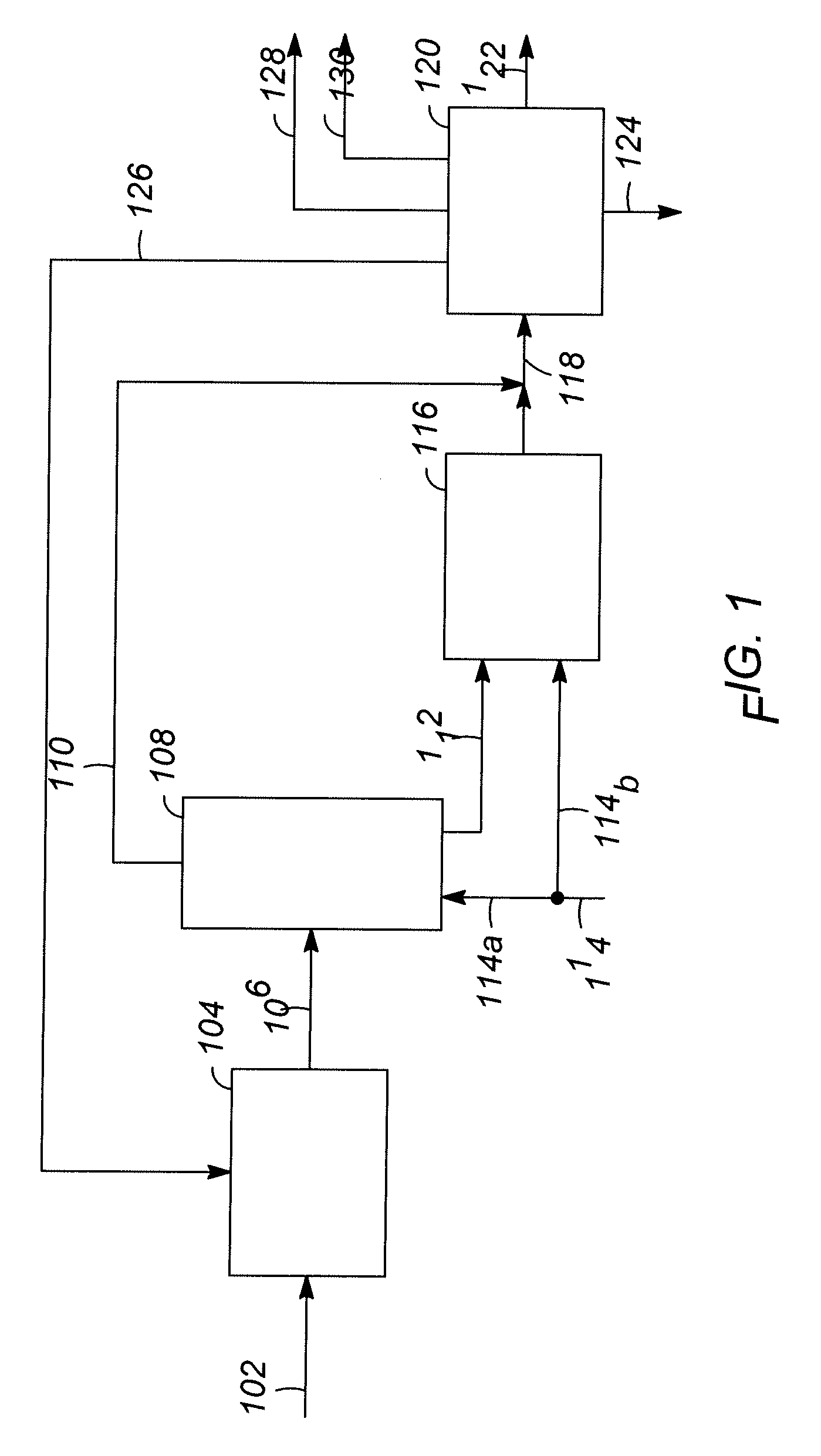

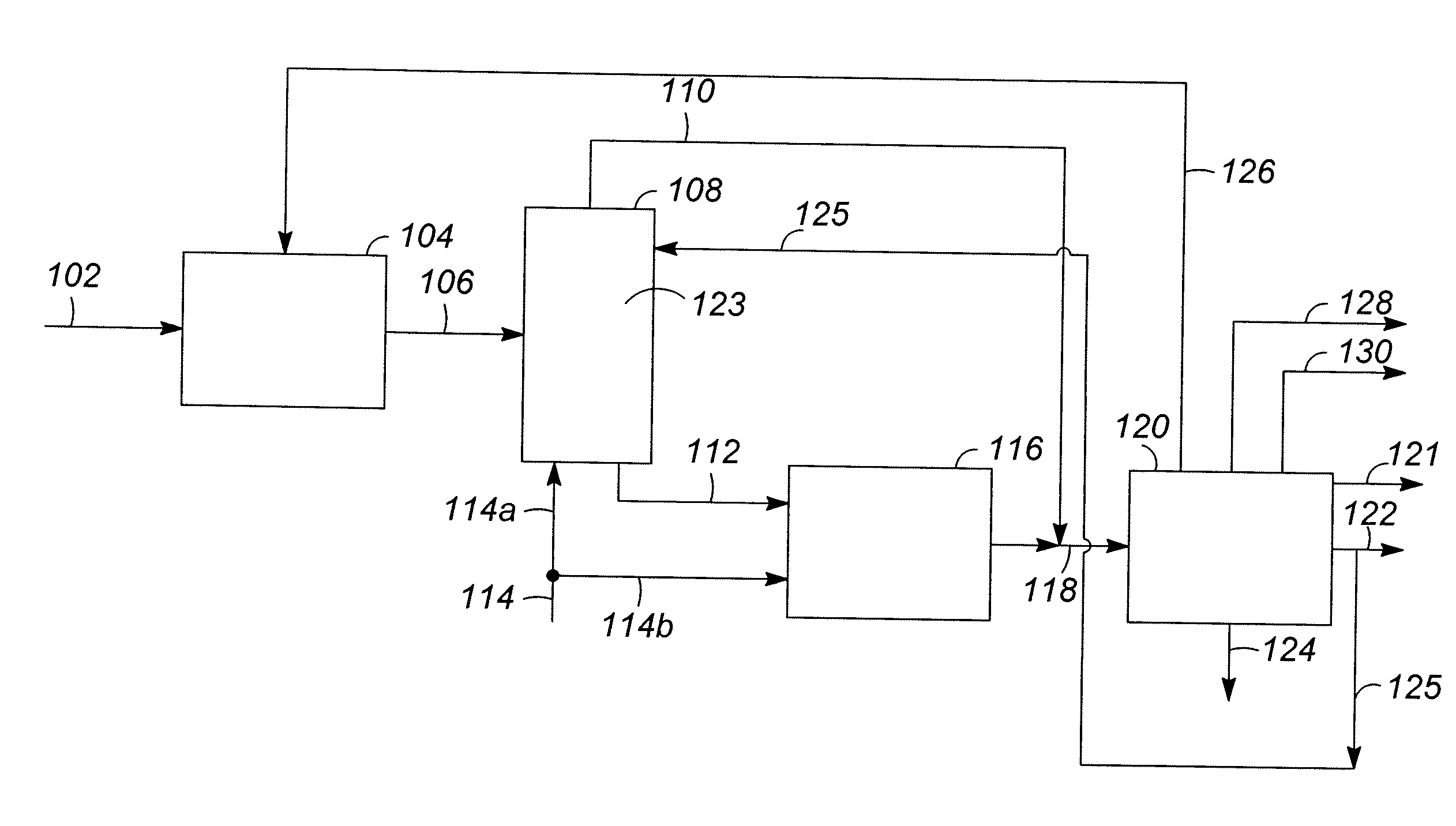

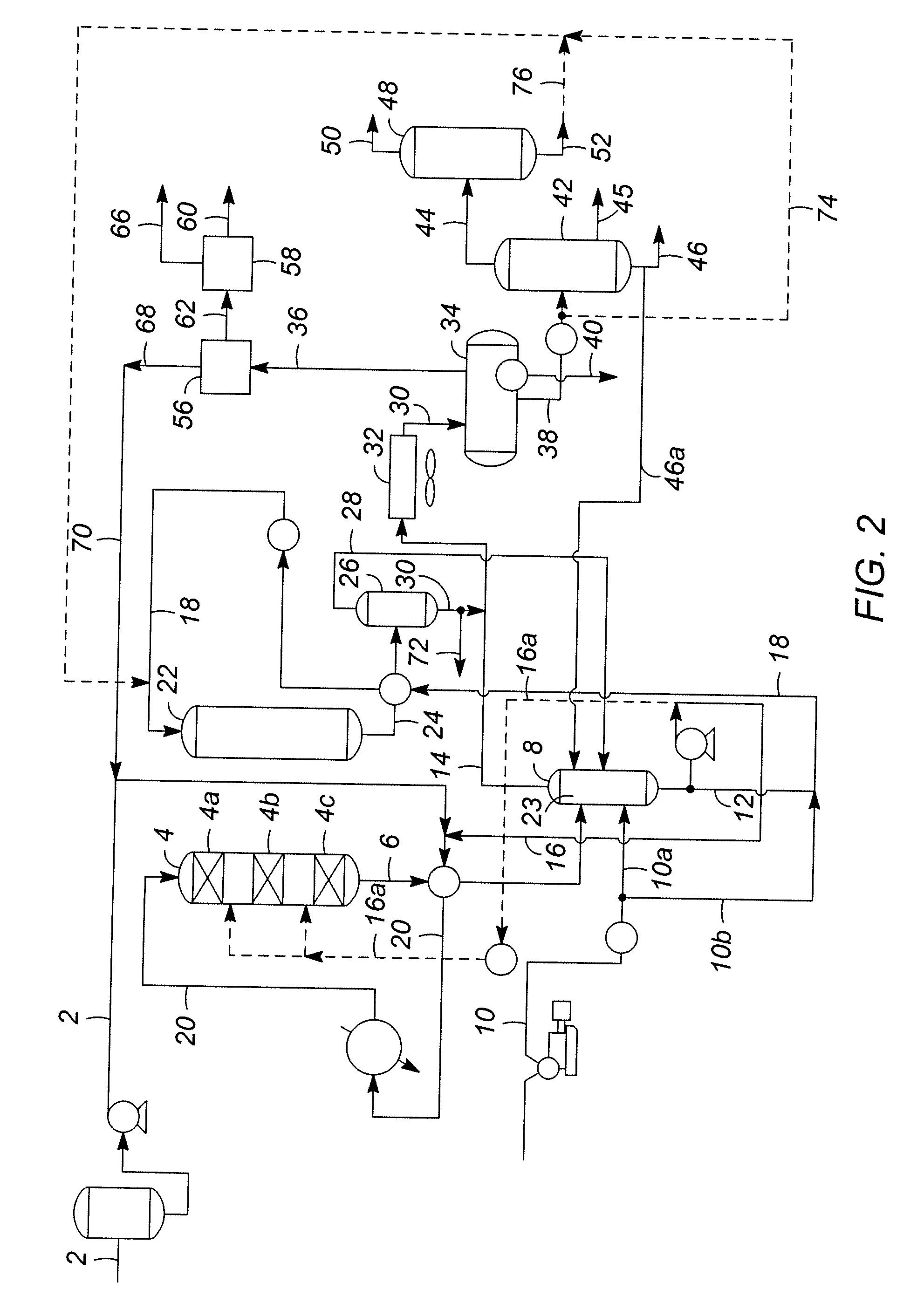

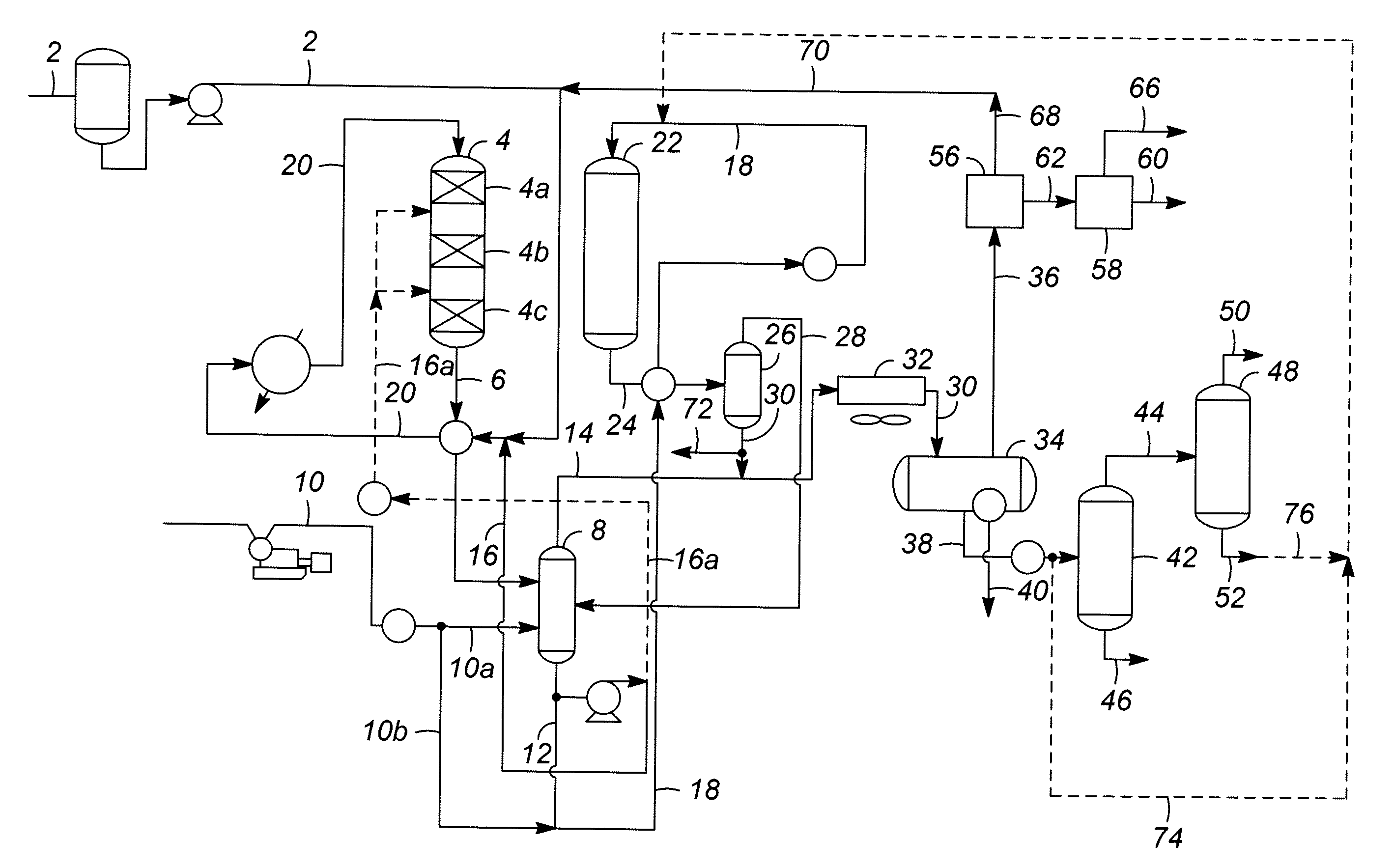

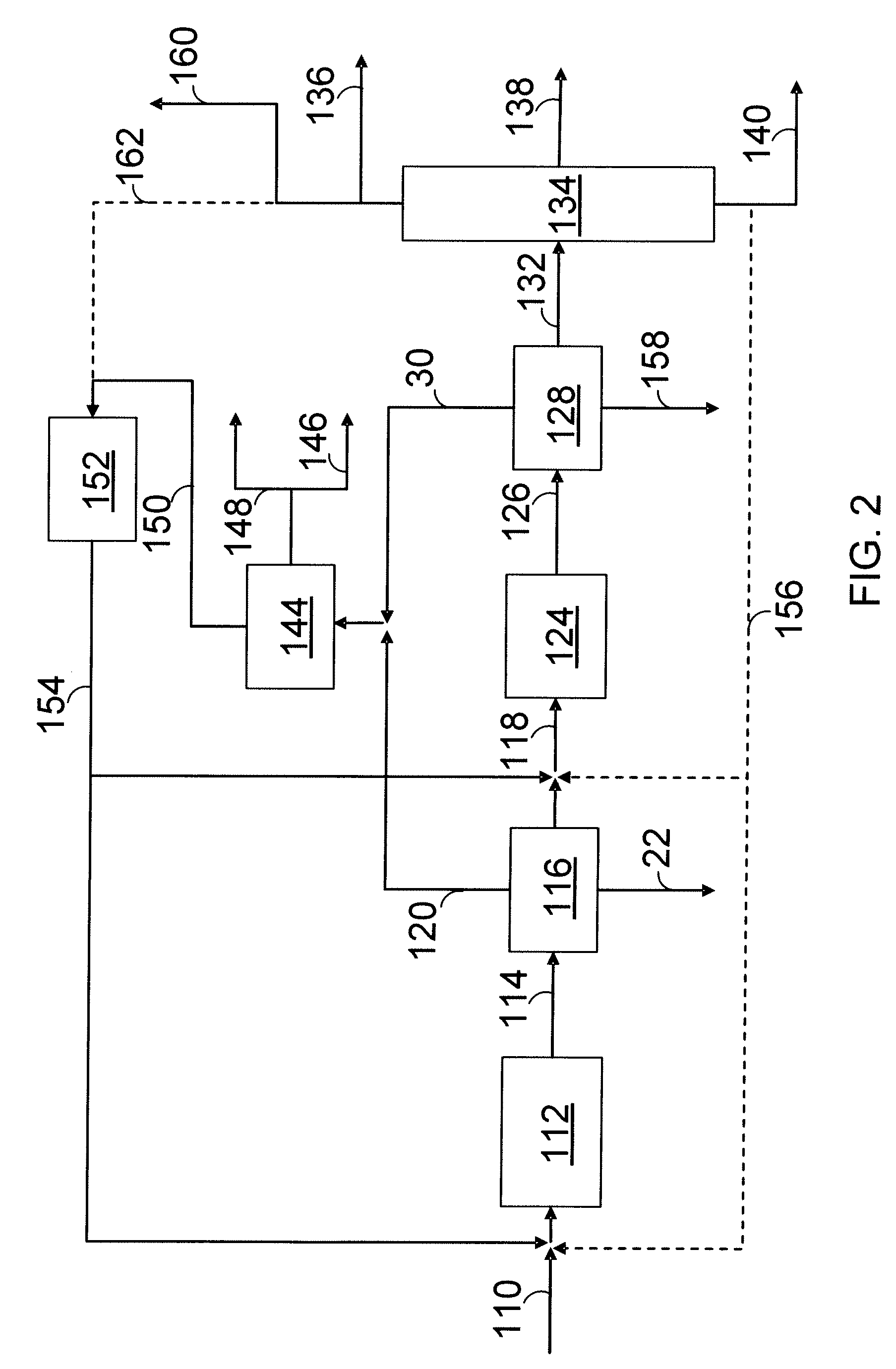

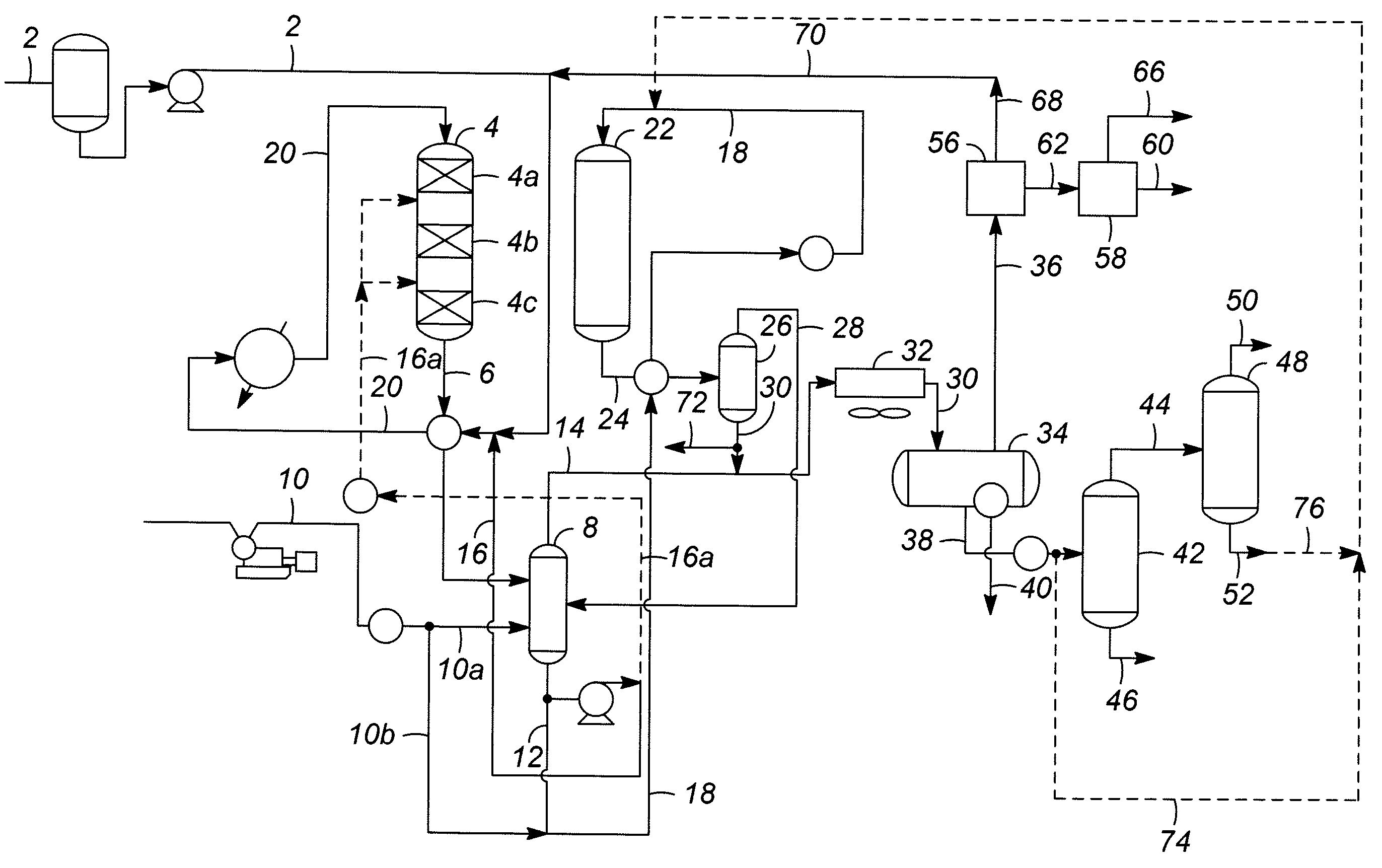

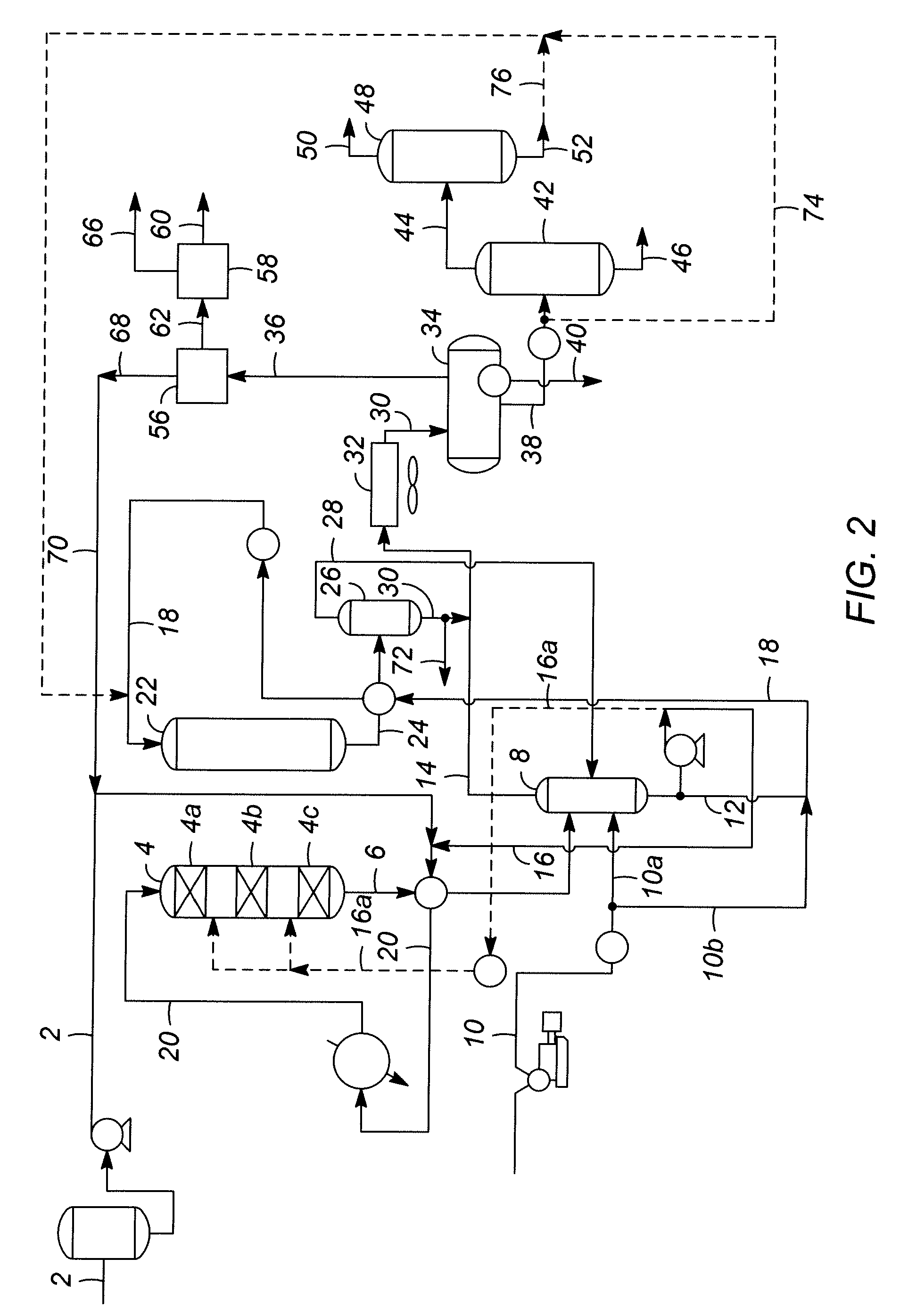

Production of Aviation Fuel from Renewable Feedstocks

ActiveUS20090283442A1Improve solubilityMinimize severityTreatment with plural serial cracking stages onlyRefining to change hydrocarbon structural skeletonIsomerizationBoiling point

A hydrocarbon product stream having hydrocarbons with boiling points in the aviation fuel range is produced from renewable feedstocks such as plant and animal oils. The process involves treating a renewable feedstock by hydrogenating, deoxygenating, isomerization, and selectively hydrocracking the feedstock to produce paraffinic hydrocarbons having from about 9 to about 16 carbon atoms and a high iso / normal ratio in a single reaction zone containing a multifunctional catalyst, or set of catalysts, having hydrogenation, deoxygenation, isomerization and selective hydrocracking functions.

Owner:UOP LLC

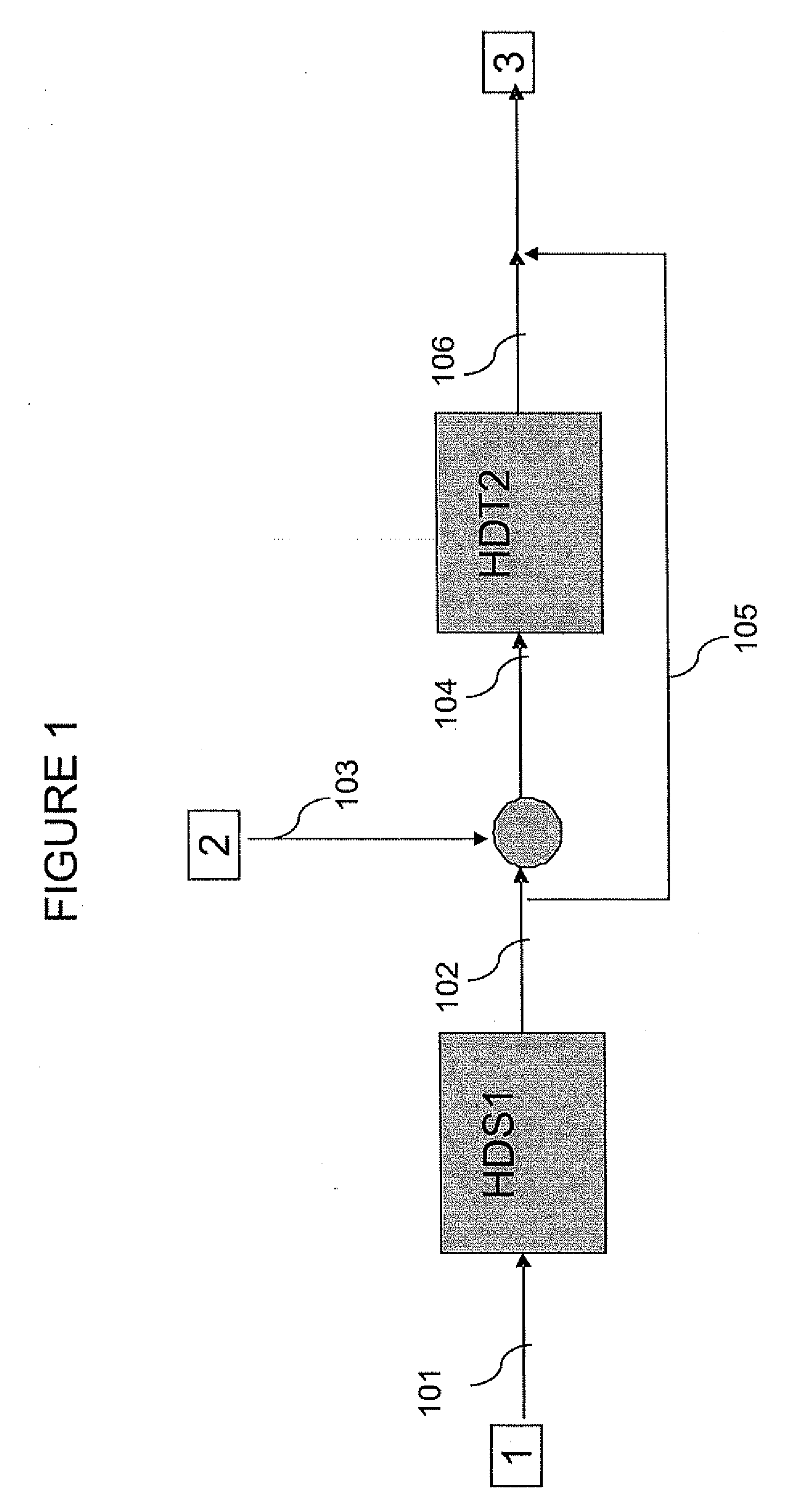

Methods of hydrotreating a mixture made up of oils of animal or vegetable origin and of petroleum cuts with quench injection of the oils on the last catalyst bed

ActiveUS20080173570A1Low costReduce use costCatalytic crackingHydrocarbon oil crackingDistillates petroleumVegetable oil

A hydrotreating method uses two catalyst beds with the introduction, on the last catalyst bed, of oils of animal or vegetable origin for co-treating a mixture made up of oils of vegetable or animal origin and of petroleum cuts (gas oil cuts (GO) and middle distillates) in order to produce gas oil effluents meeting specifications with an improved cetane number. The first catalyst bed is dedicated to only the deep desulfurization reactions (HDS1) of a petroleum type feed. The effluents of the first catalyst bed having an effluent sulfur content below or equal to 50 mg / kg are separated into two streams. The first stream, which is predominant, is sent to the gas oil pool. The second stream is mixed with oils of vegetable or animal origin. The resultant oil-petroleum cut mixture is then subjected to a milder hydrotreatment (HDT2). The effluents obtained at the outlet of the second catalyst bed can optionally be mixed with the predominant stream from the first bed. The process economy, the tolerance to the specifications relative to oils of animal or vegetable origin and the quality of the products obtained are thus greatly improved.

Owner:INST FR DU PETROLE

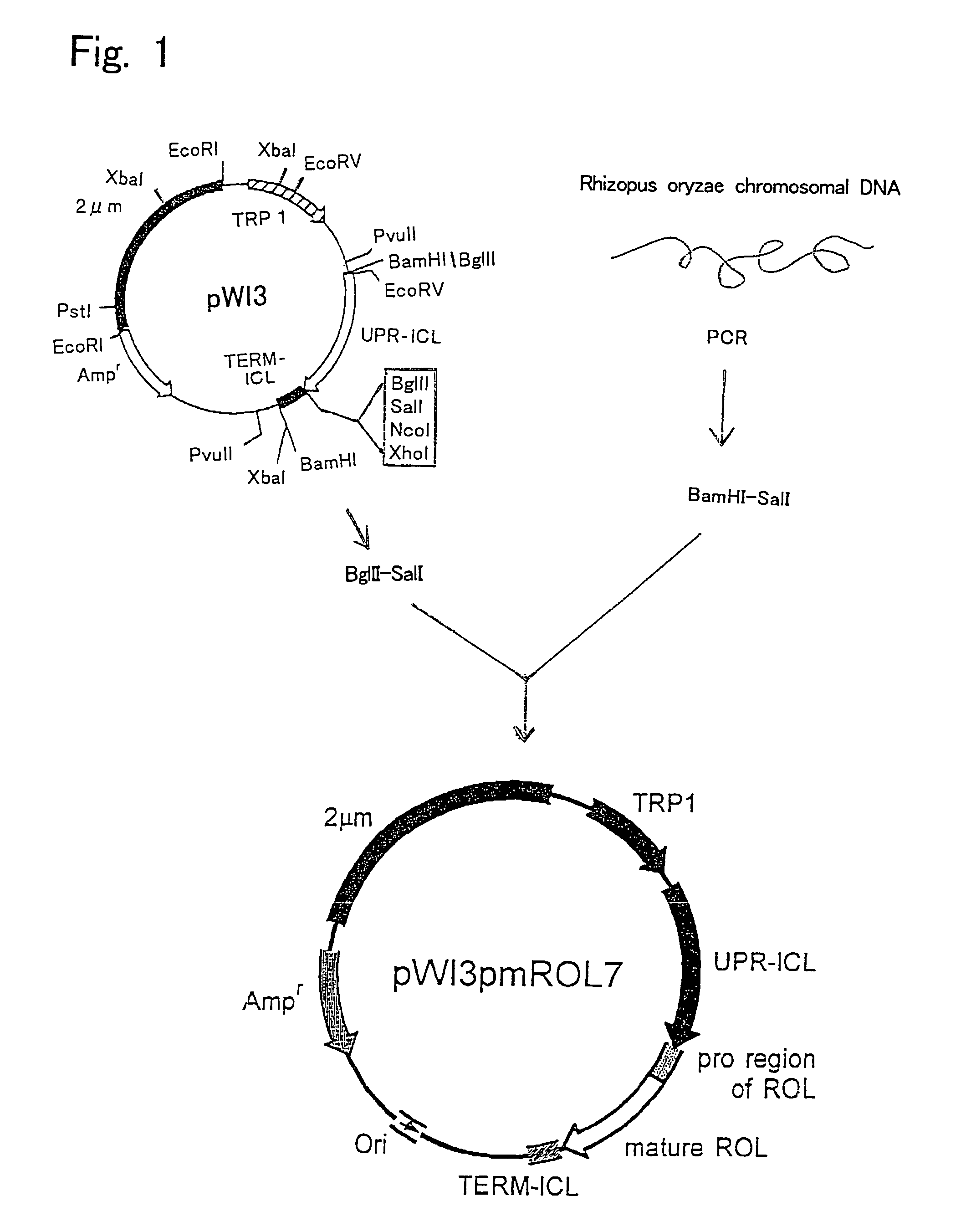

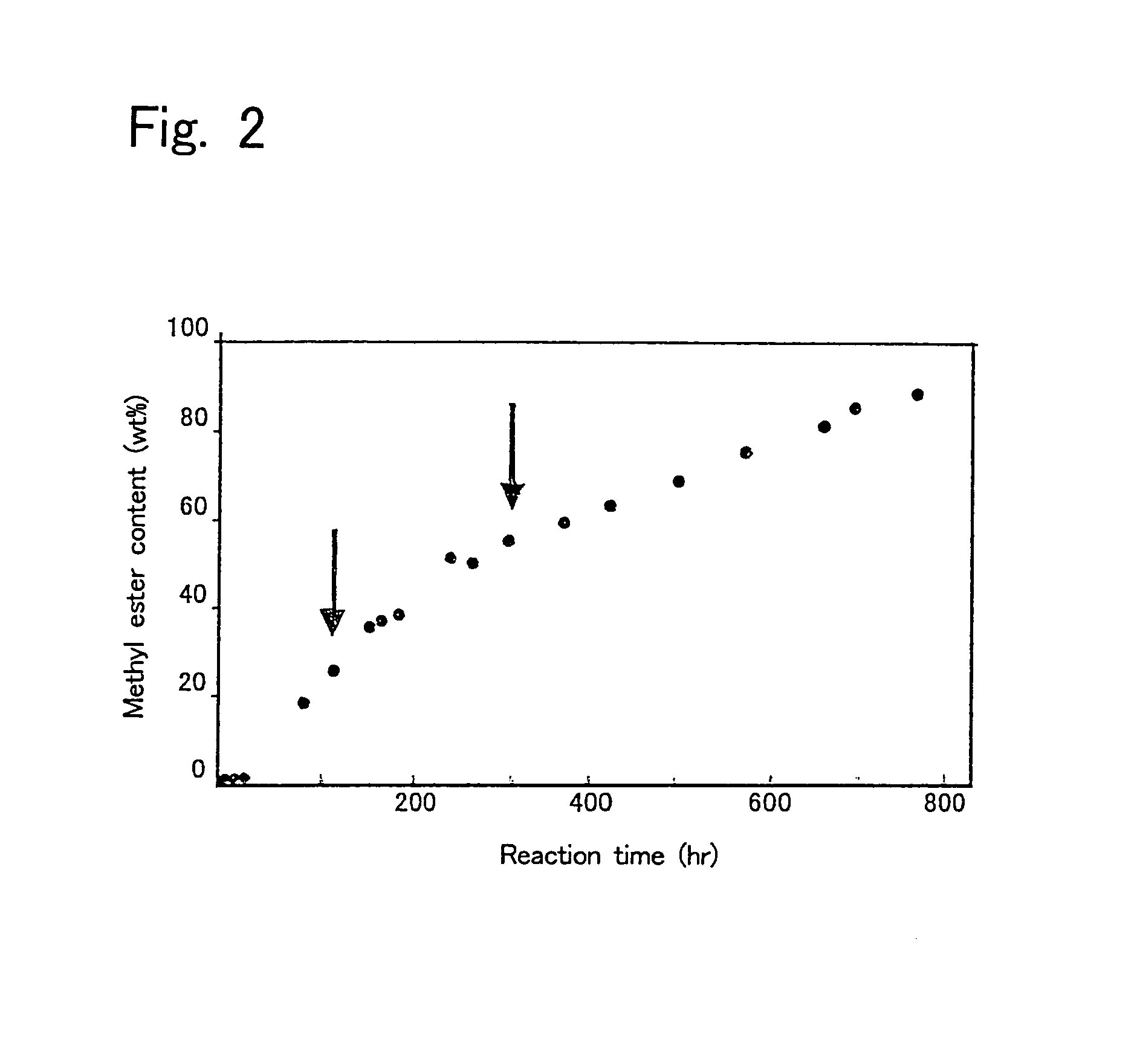

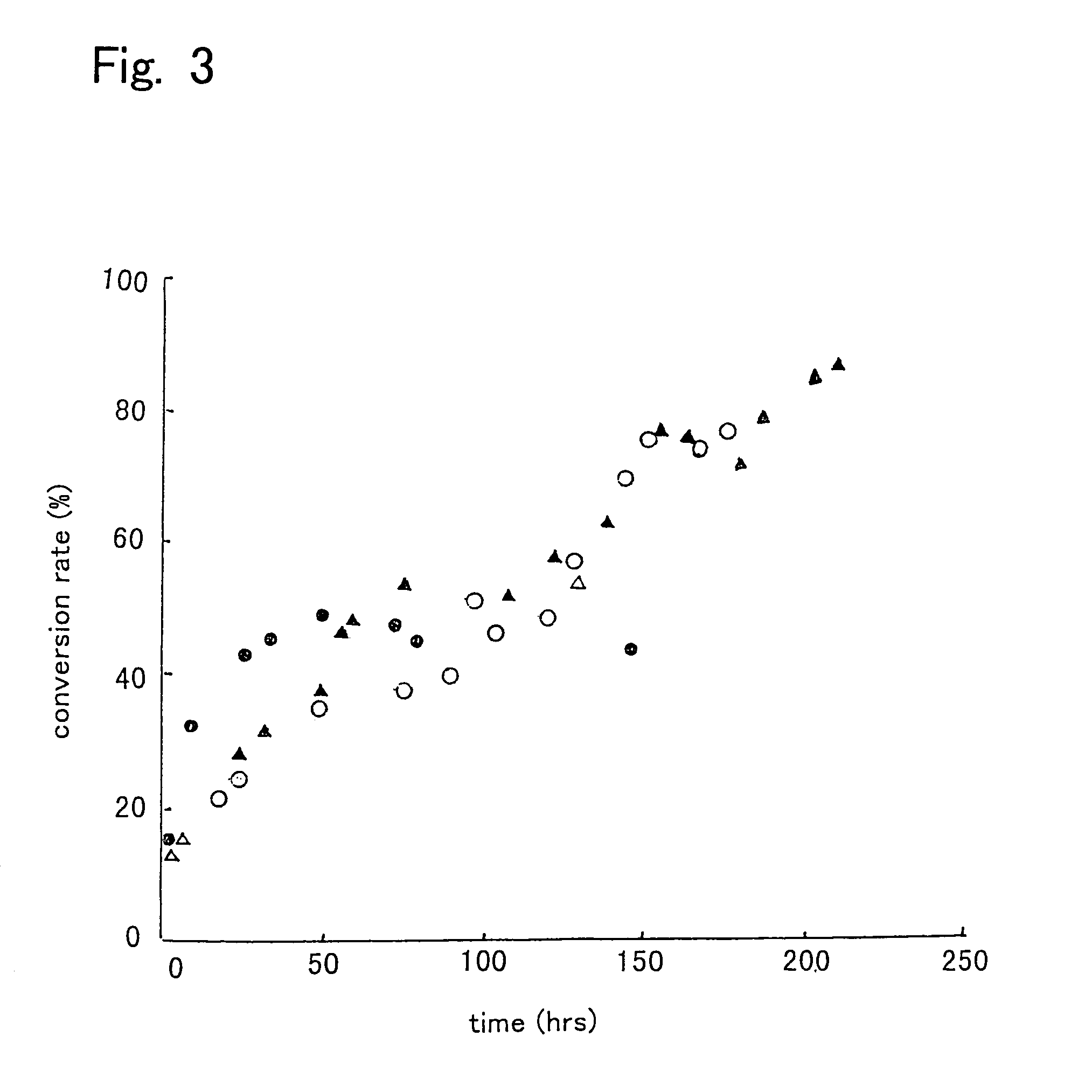

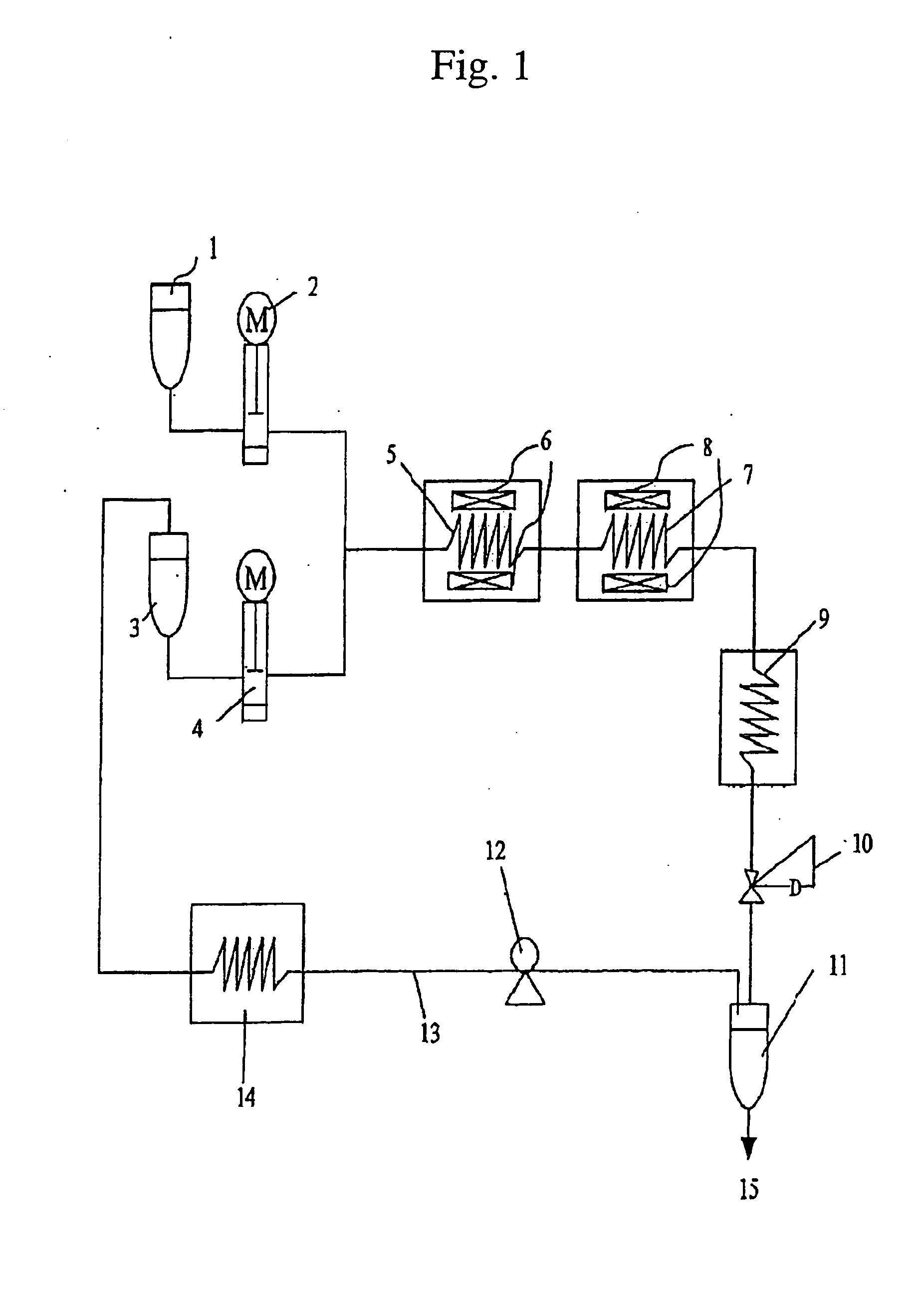

Process for producing fatty acid lower alcohol ester

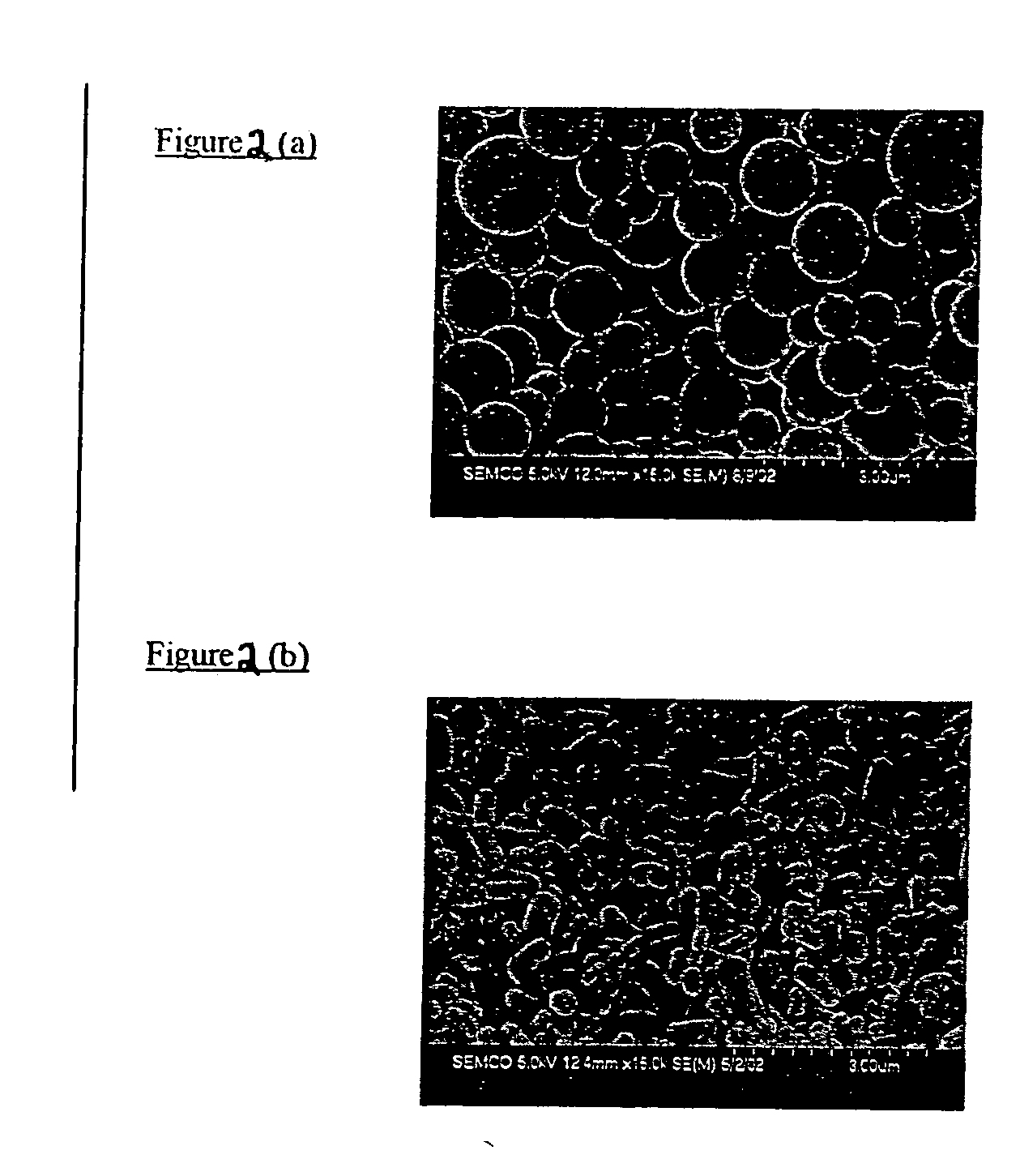

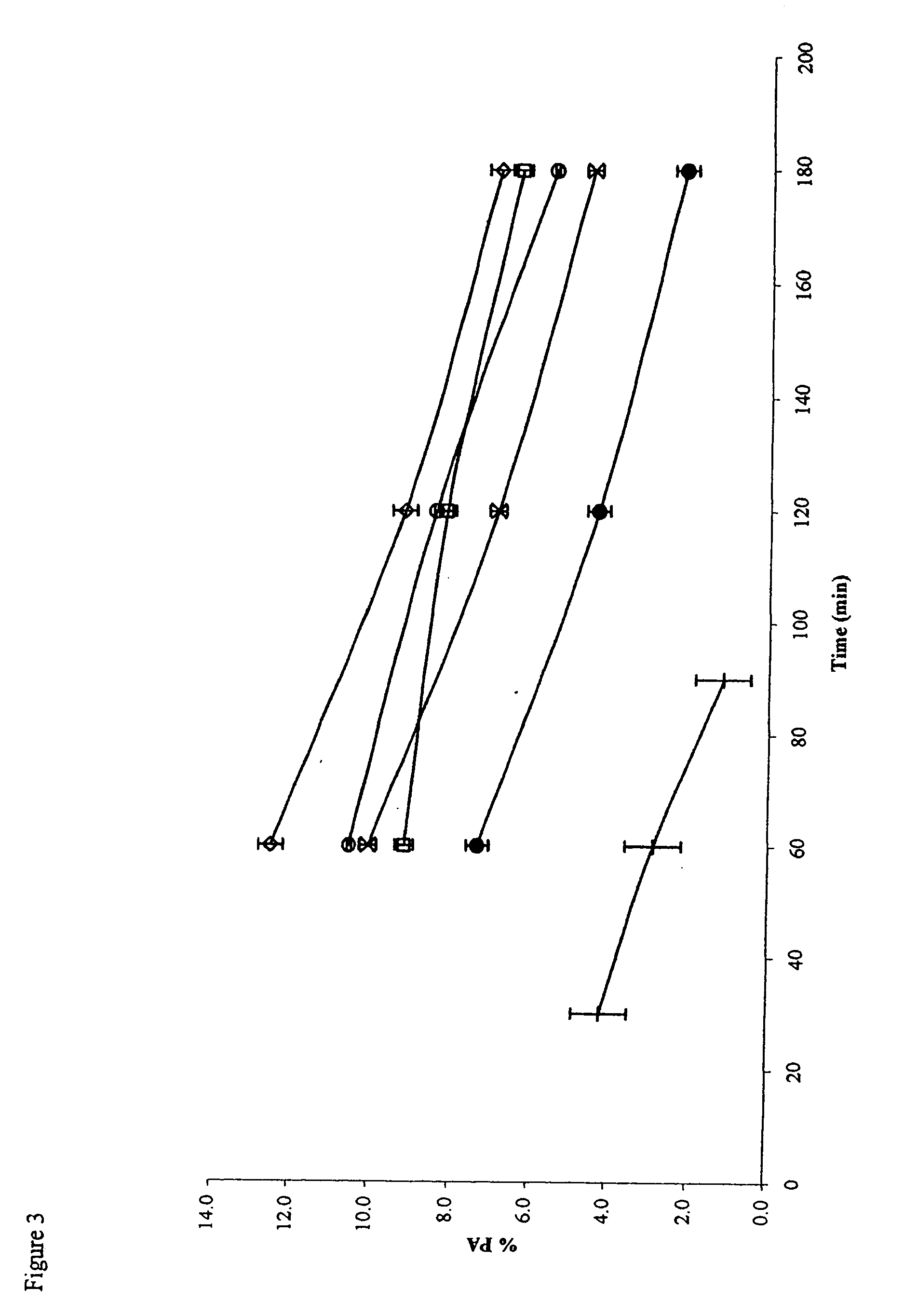

InactiveUS6982155B1Efficient productionImprove permeabilityFatty acid chemical modificationOrganic compound preparationOil and greaseMicroorganism

The present invention provides a method for producing a fatty acid ester inexpensively and efficiently by reacting a lipase or an intact mircroorganism containing a lipase, an oil and fat, and a linear lower alcohol in a system containing little or no solvent in the presence of water. The intact microorganism has not been treated with a solvent or the like, and is used as such, so that a fatty acid ester can be prepared in a simple manner. An oil and fat, a natural oil and fat such as a vegetable oil and fat, an animal oil and fat, as well as a waste oil thereof can be used. According to the method of the present invention, a reaction proceeds even in the presence of water, so that waste oils containing a large amount of water can be used as a raw material. Therefore, the waste oil to be dumped into the environment can be recycled, and a biodiesel fuel, which hardly pollutes the environment, can be provided at the same time.

Owner:KANSAI CHEM ENG CO LTD

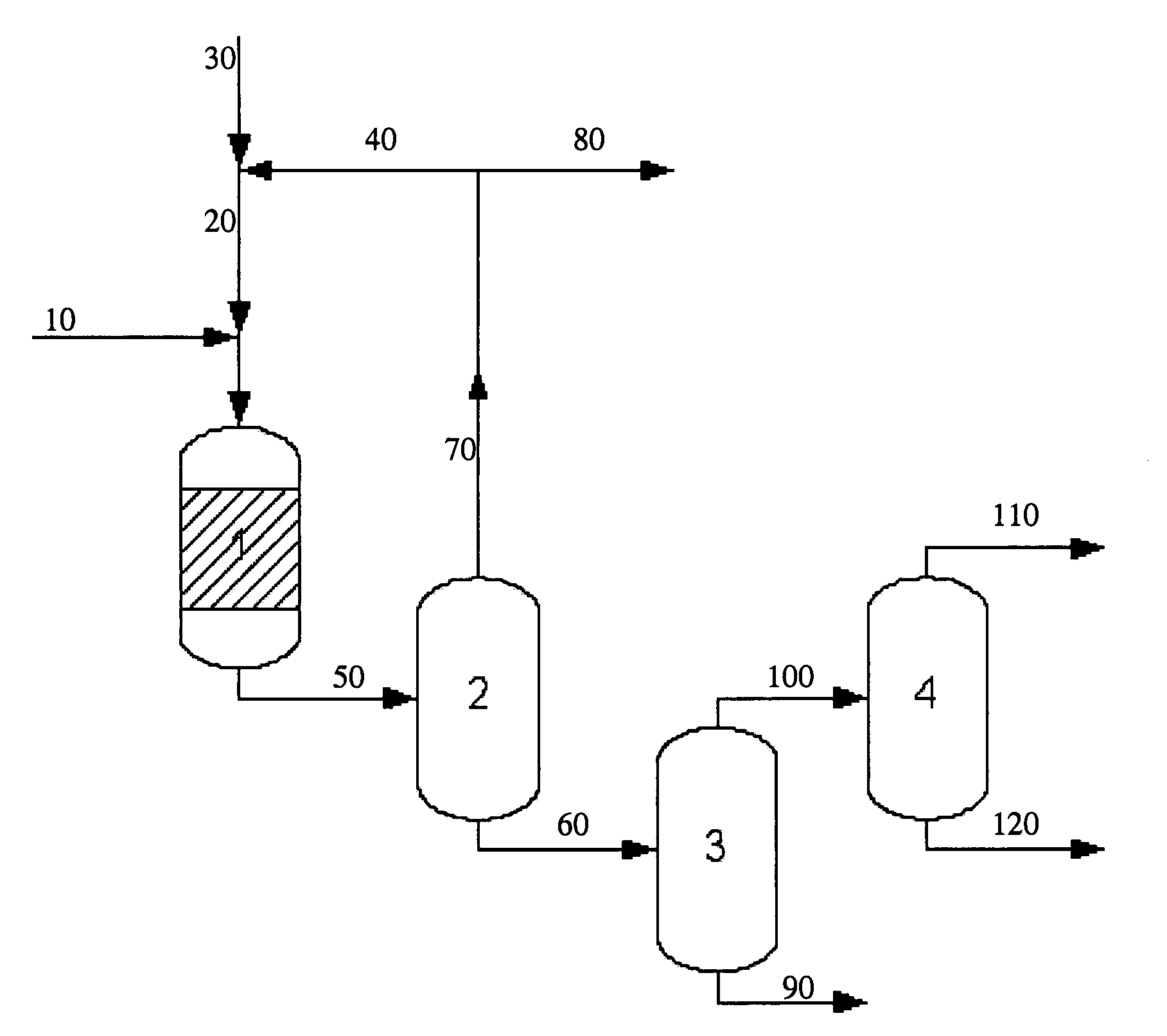

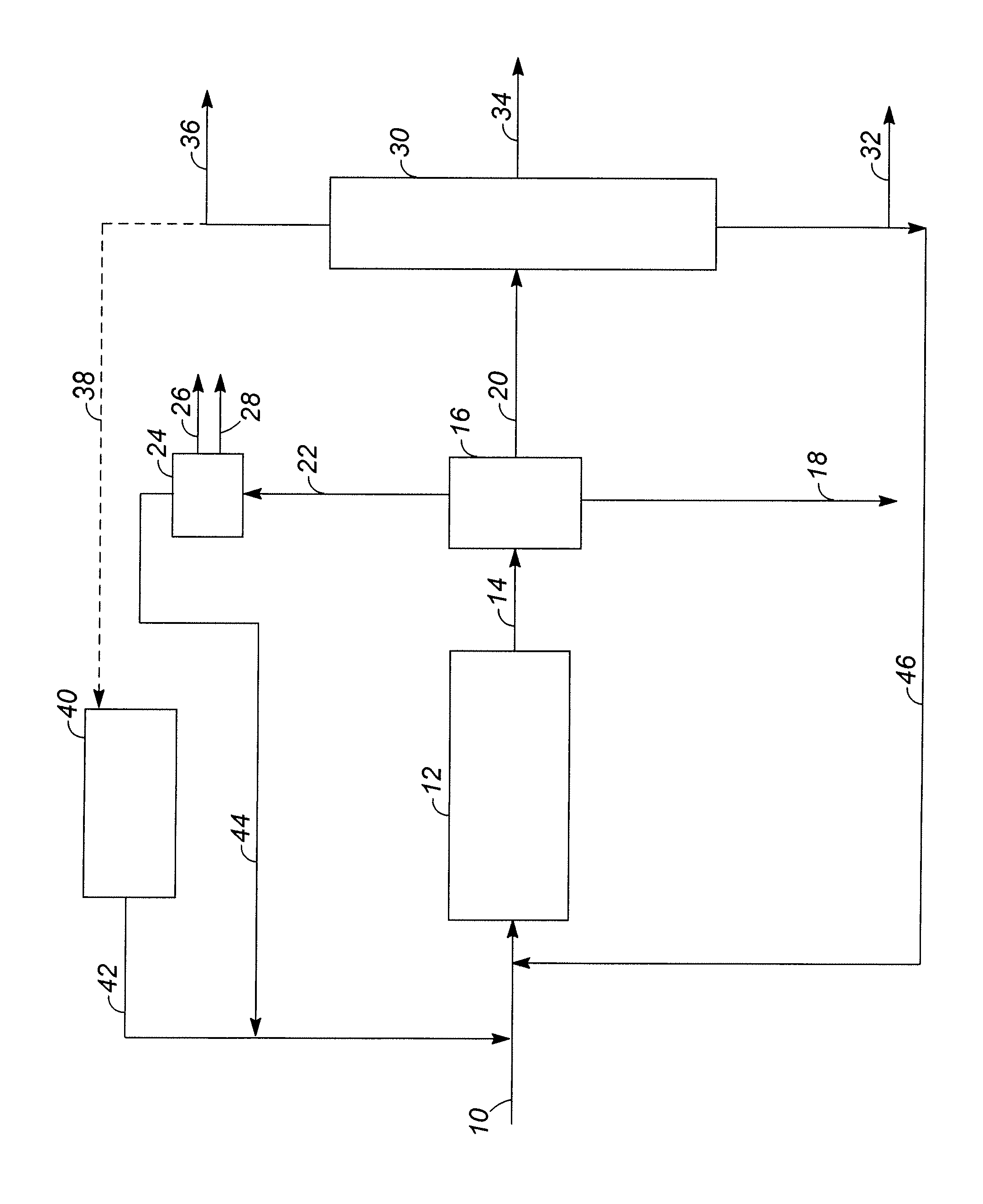

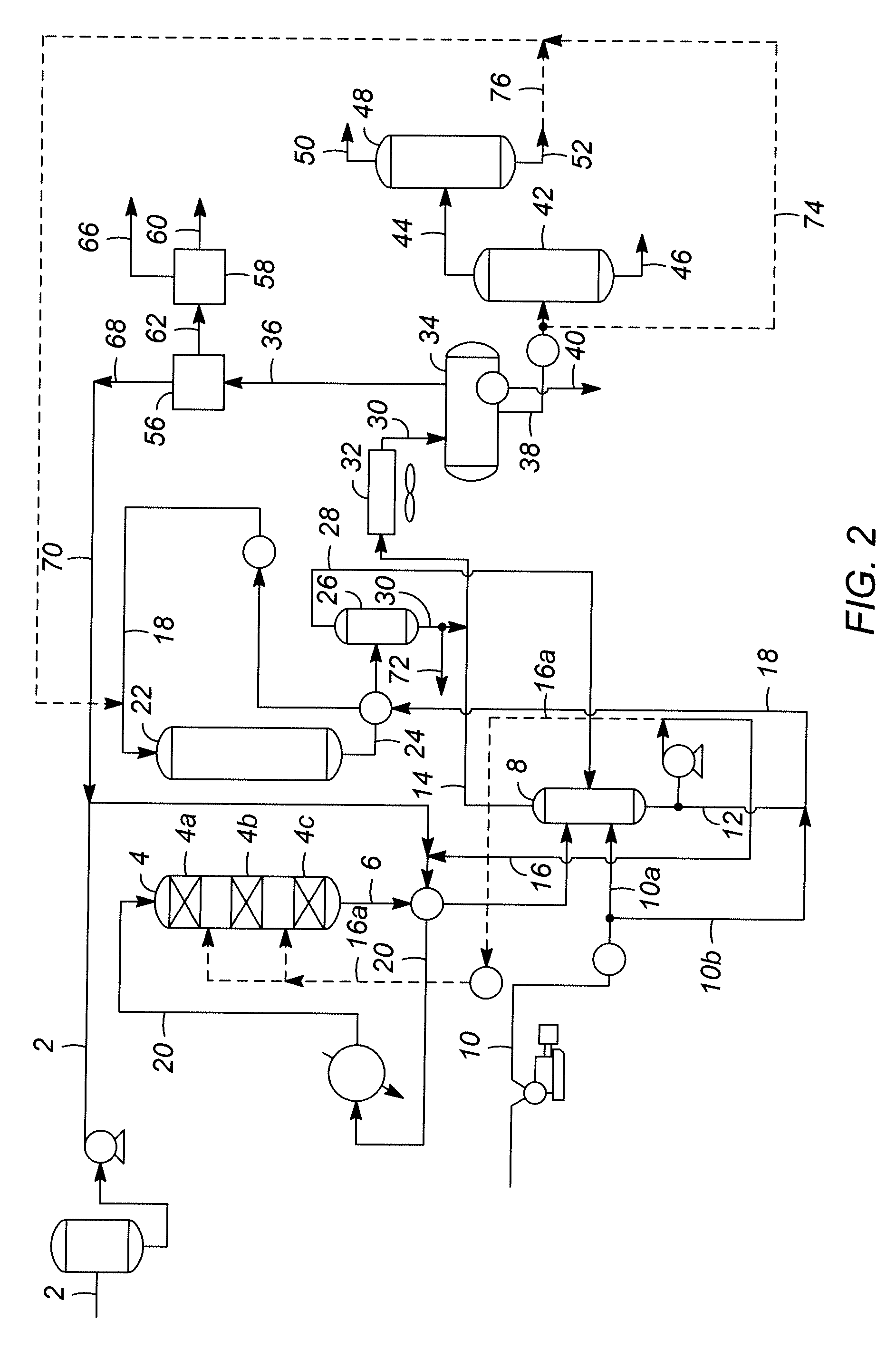

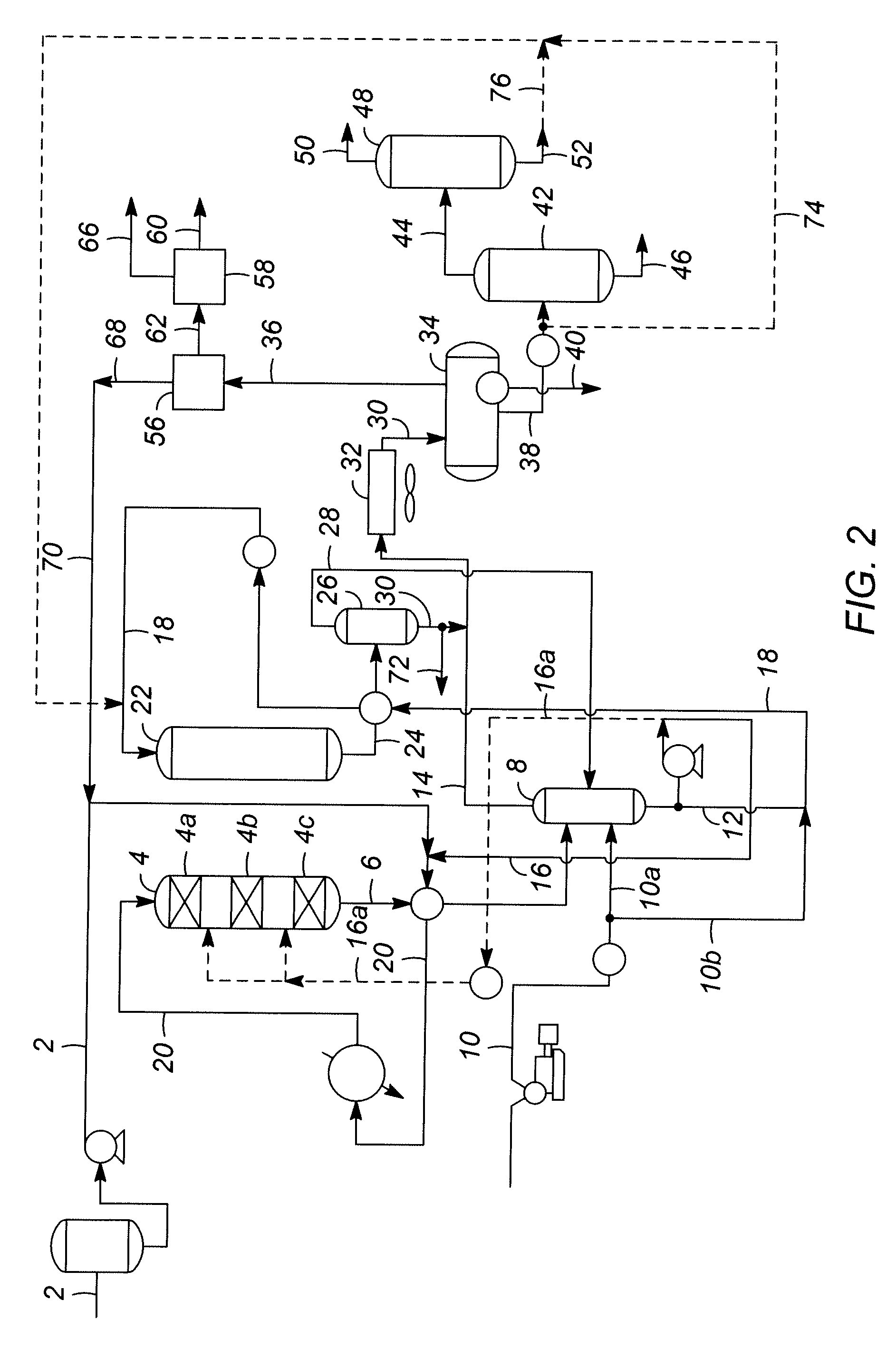

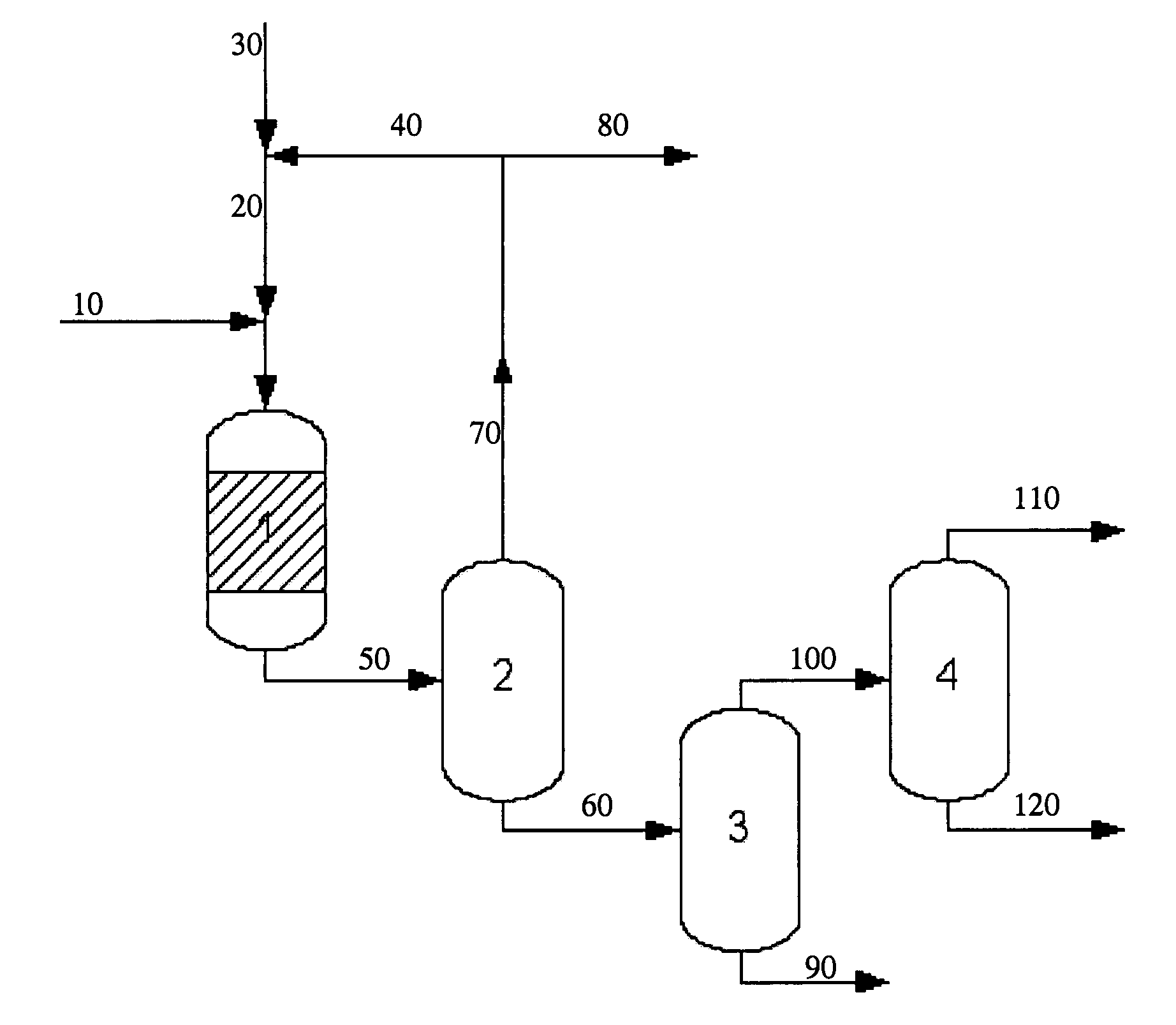

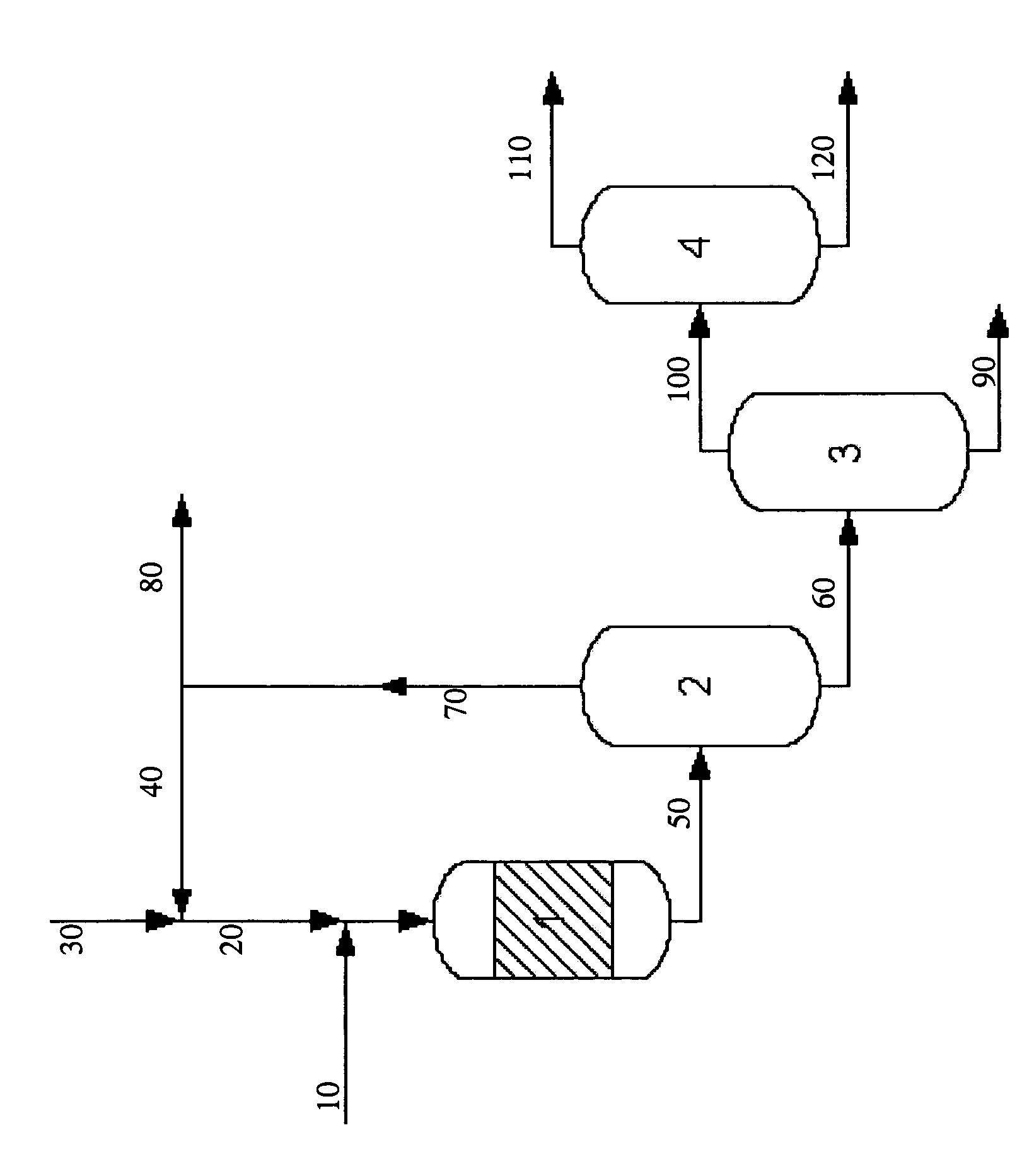

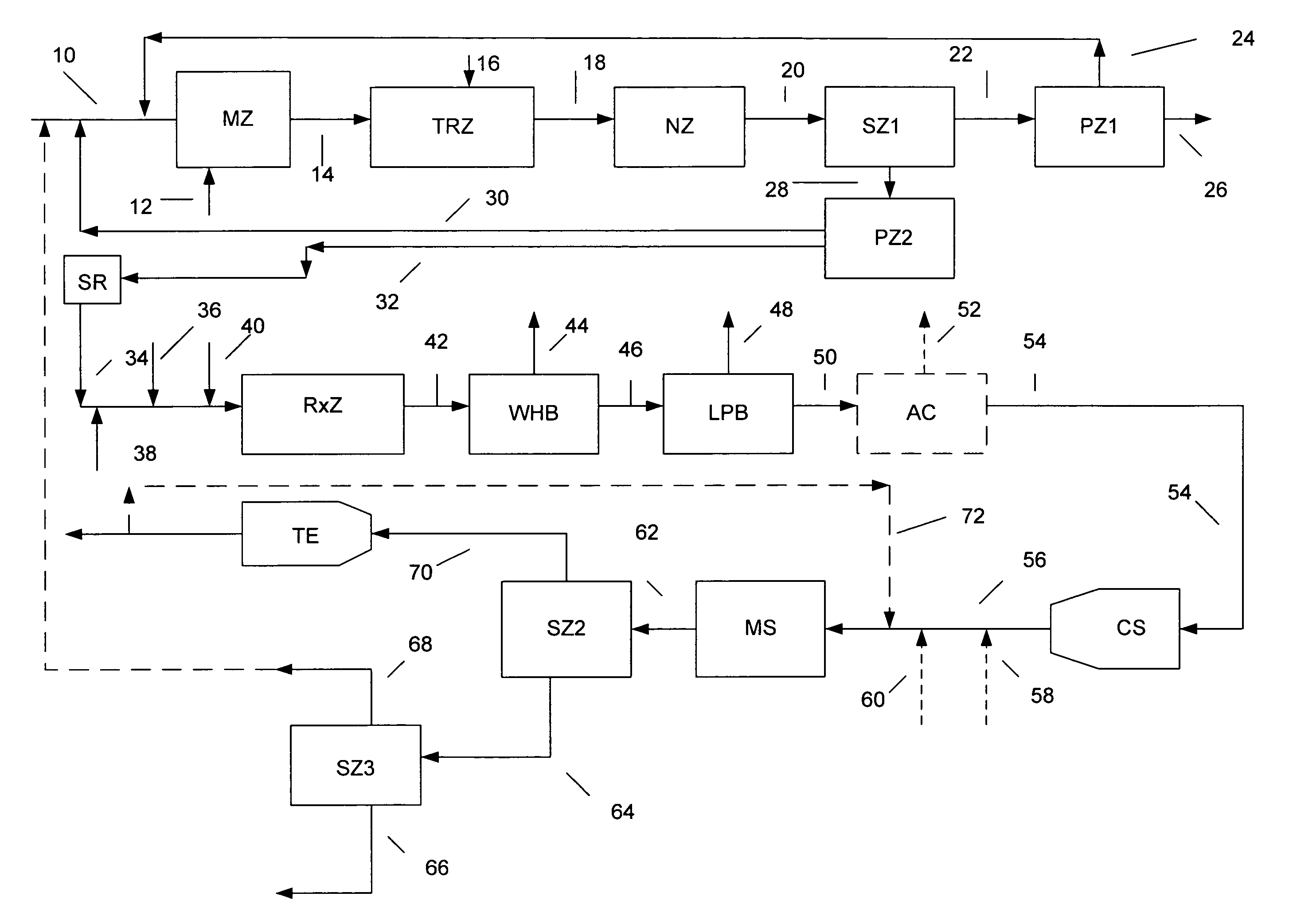

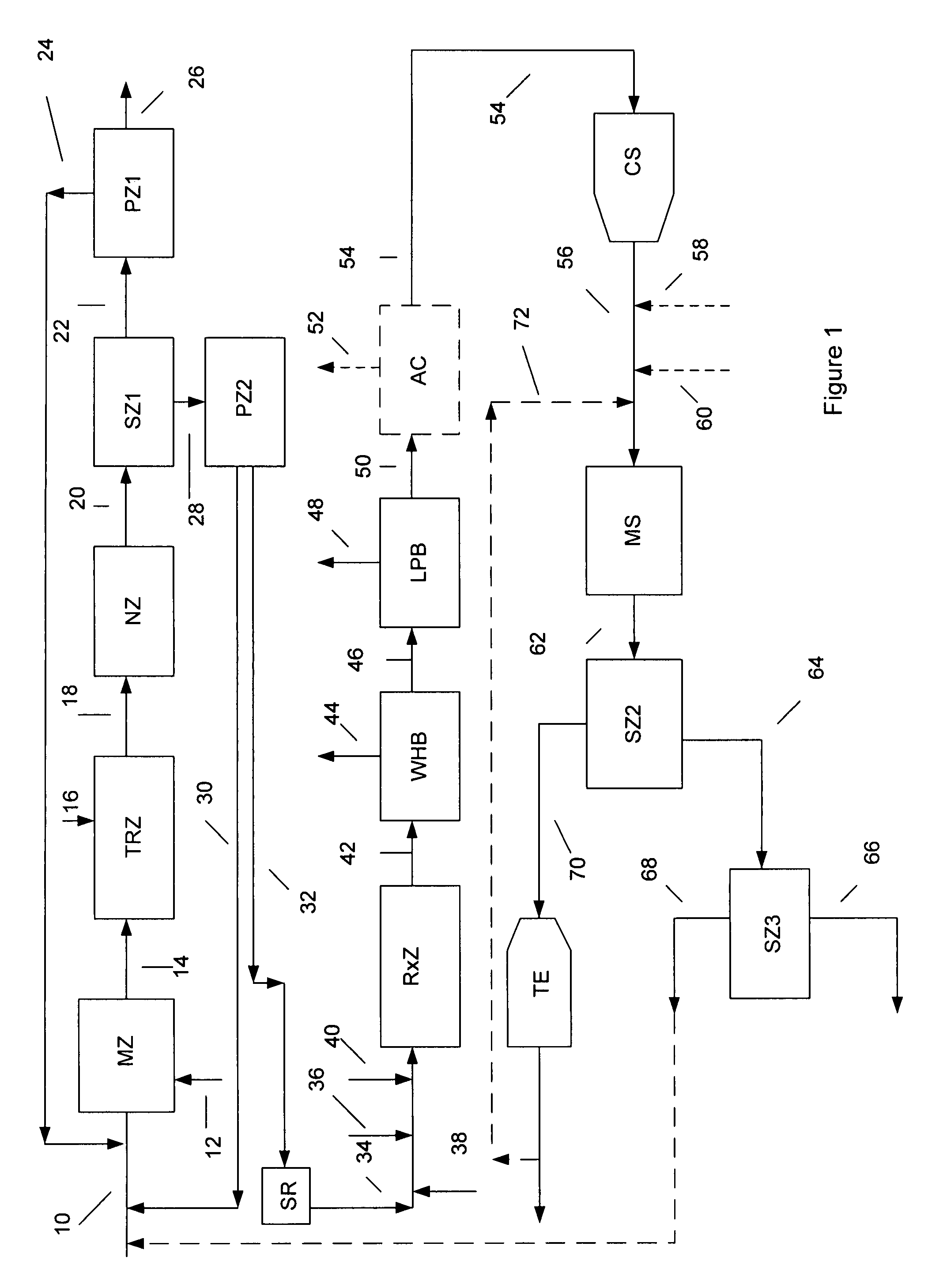

Production of Diesel Fuel from Biorenewable Feedstocks

ActiveUS20090077866A1Refining to change hydrocarbon structural skeletonHydrocarbon by hydrogenationSolubilityHydrogen

A process has been developed for producing diesel boiling range fuel from renewable feedstocks such as plant oils and animal oils, fats, and greases. The process involves treating a renewable feedstock by hydrogenating and deoxygenating i.e. decarboxylating, decarbonylating, and / or hydrodeoxygenating to provide a hydrocarbon fraction useful as a diesel boiling range fuel or diesel boiling range fuel blending component. If desired, the hydrocarbon fraction can be isomerized to improve cold flow properties. A portion of the hydrogenated and deoxygenated feedstock is selectively separated and then recycled to the treatment zone to increase the hydrogen solubility of the reaction mixture.

Owner:UOP LLC

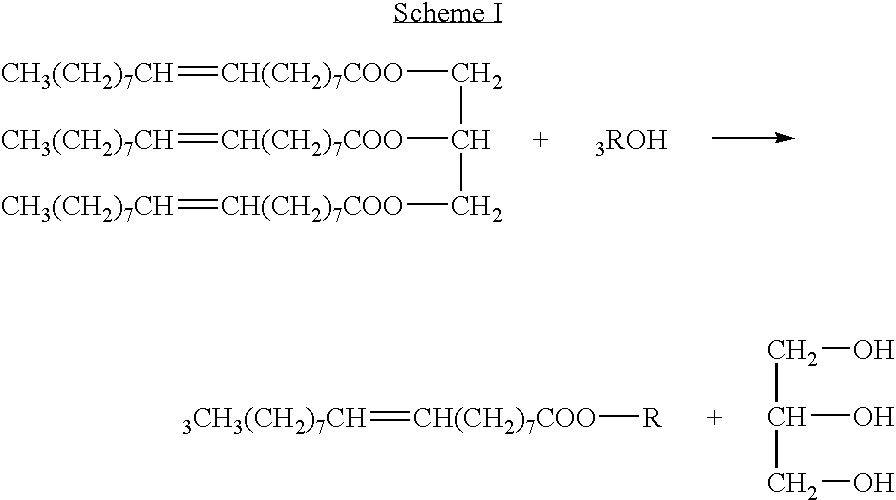

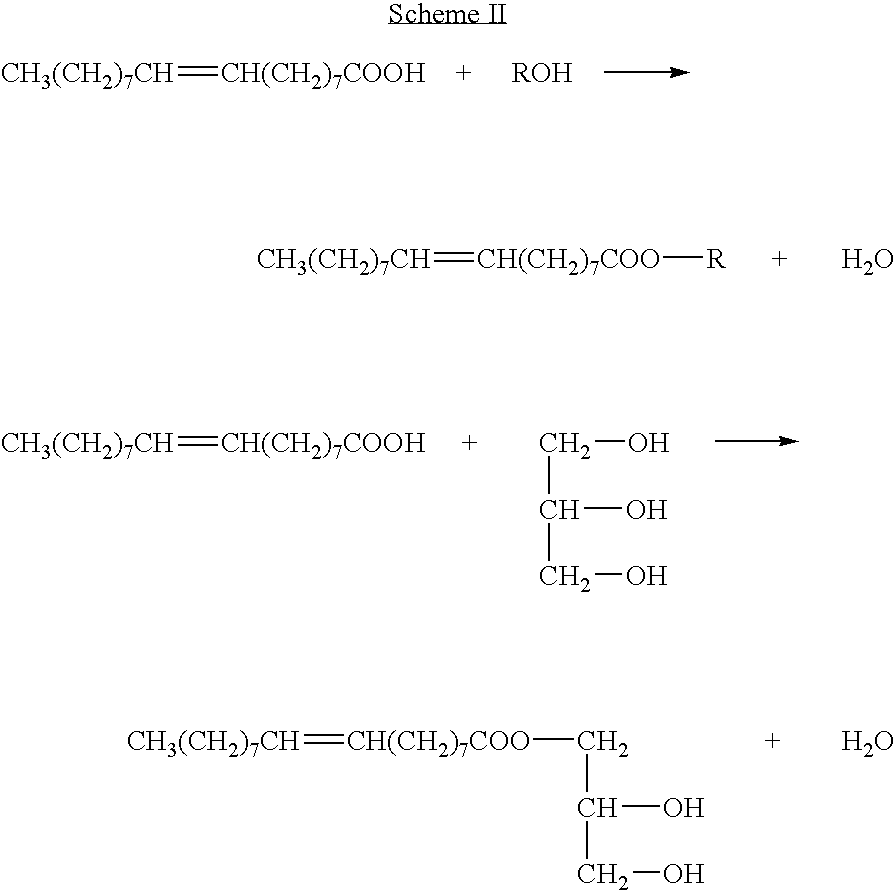

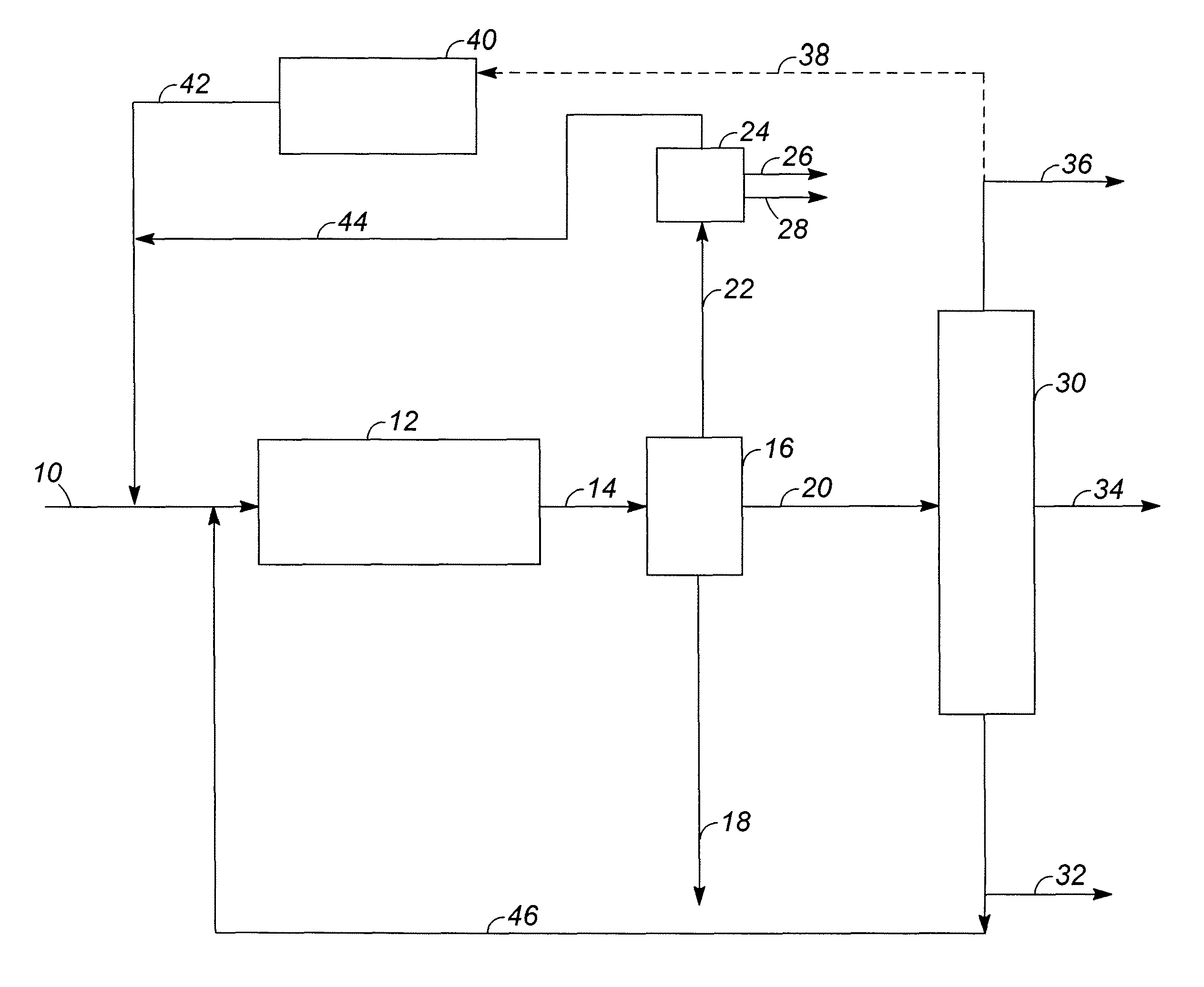

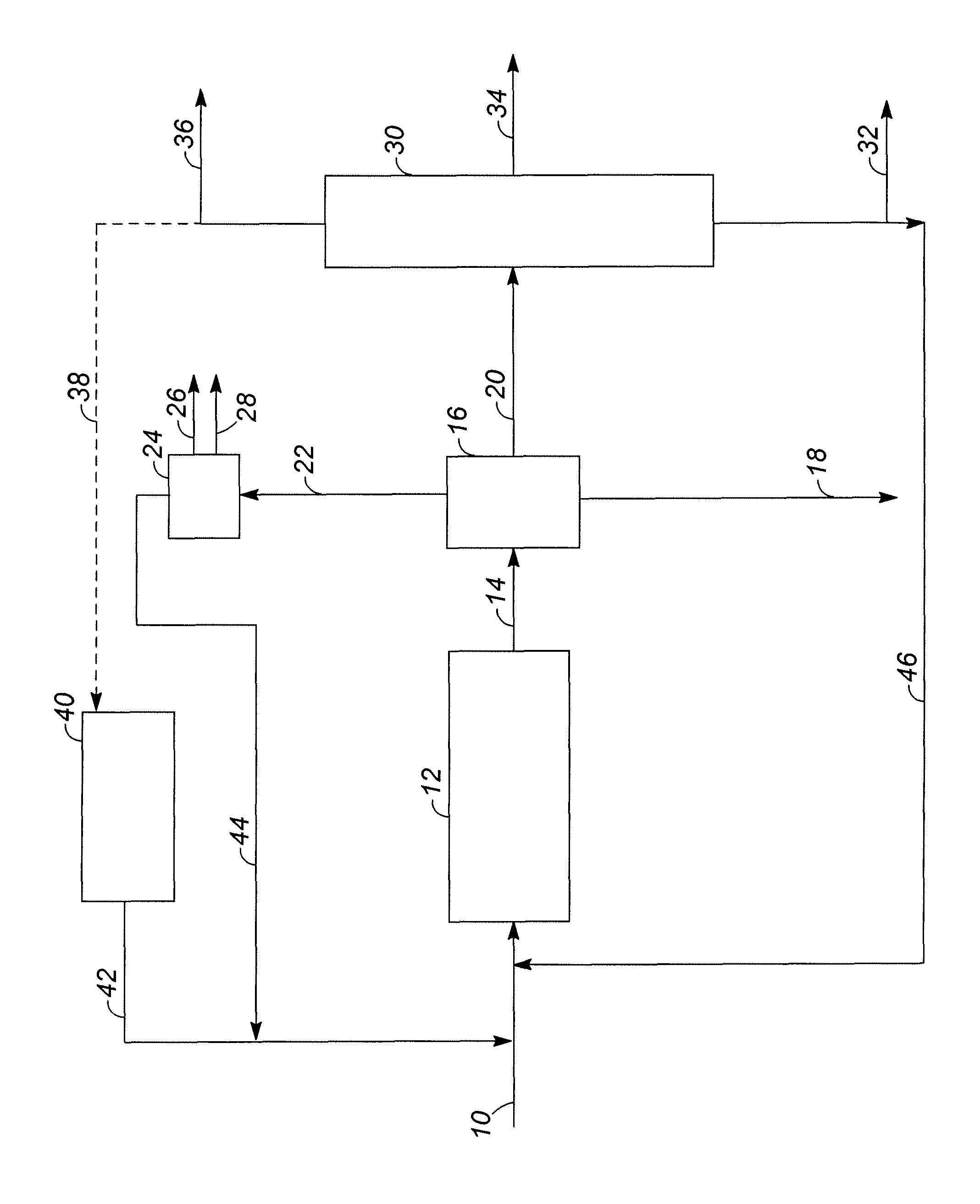

Process for producing alkyl esters from a vegetable or animal oil and an aliphatic monoalcohol

InactiveUS6878837B2High purityImpact on overall process costFatty oils/acids recovery from wasteFatty acid esterificationAluminateTransesterification

Alkyl esters of fatty acids, and high purity glycerin, are produced using a process comprising a set of transesterification reactions between a vegetable or animal oil and an aliphatic monoalcohol employing a heterogeneous catalyst, for example based on zinc aluminate, the water content in the reaction medium being controlled to a value that is below a given limiting value.

Owner:INST FR DU PETROLE

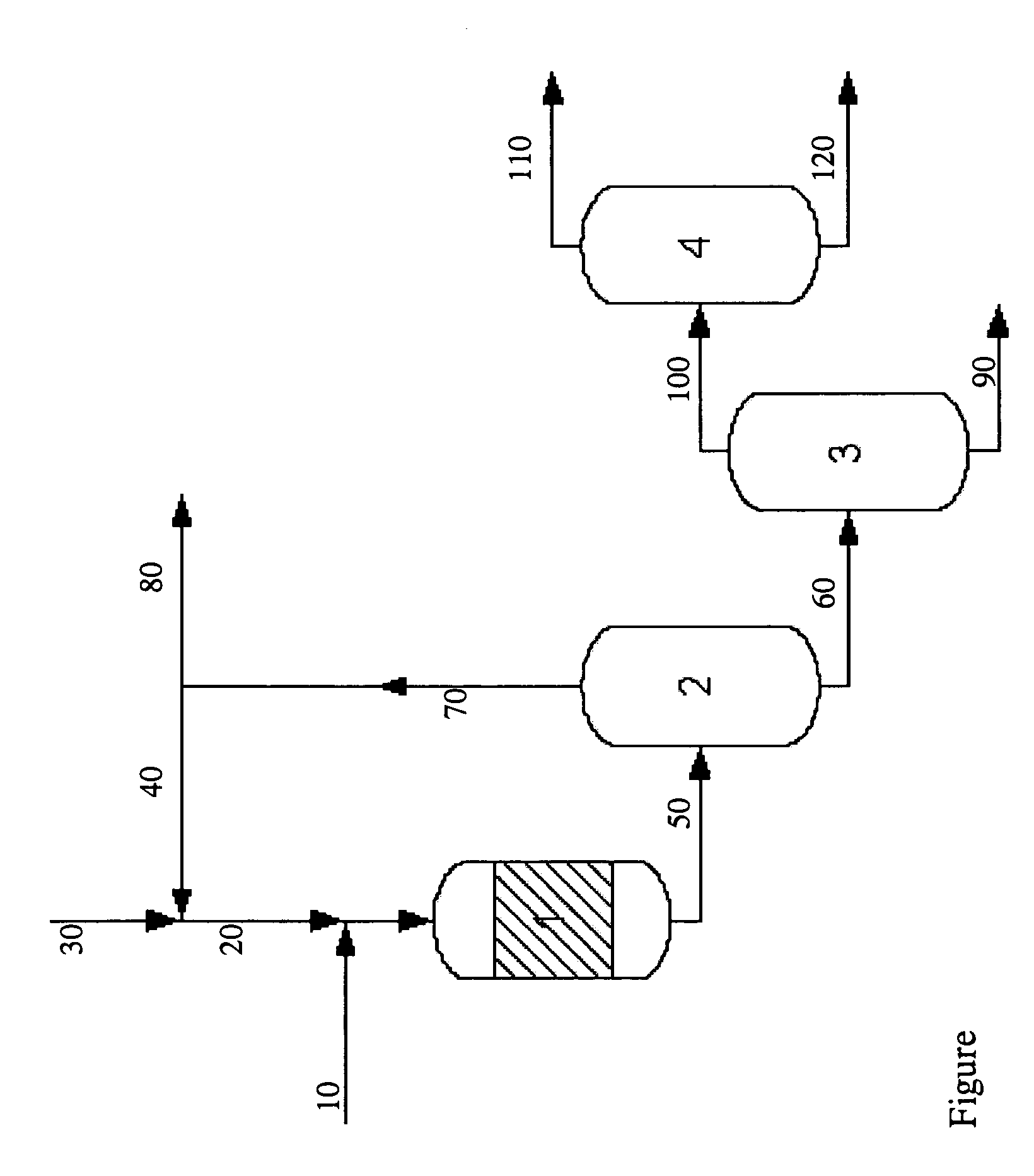

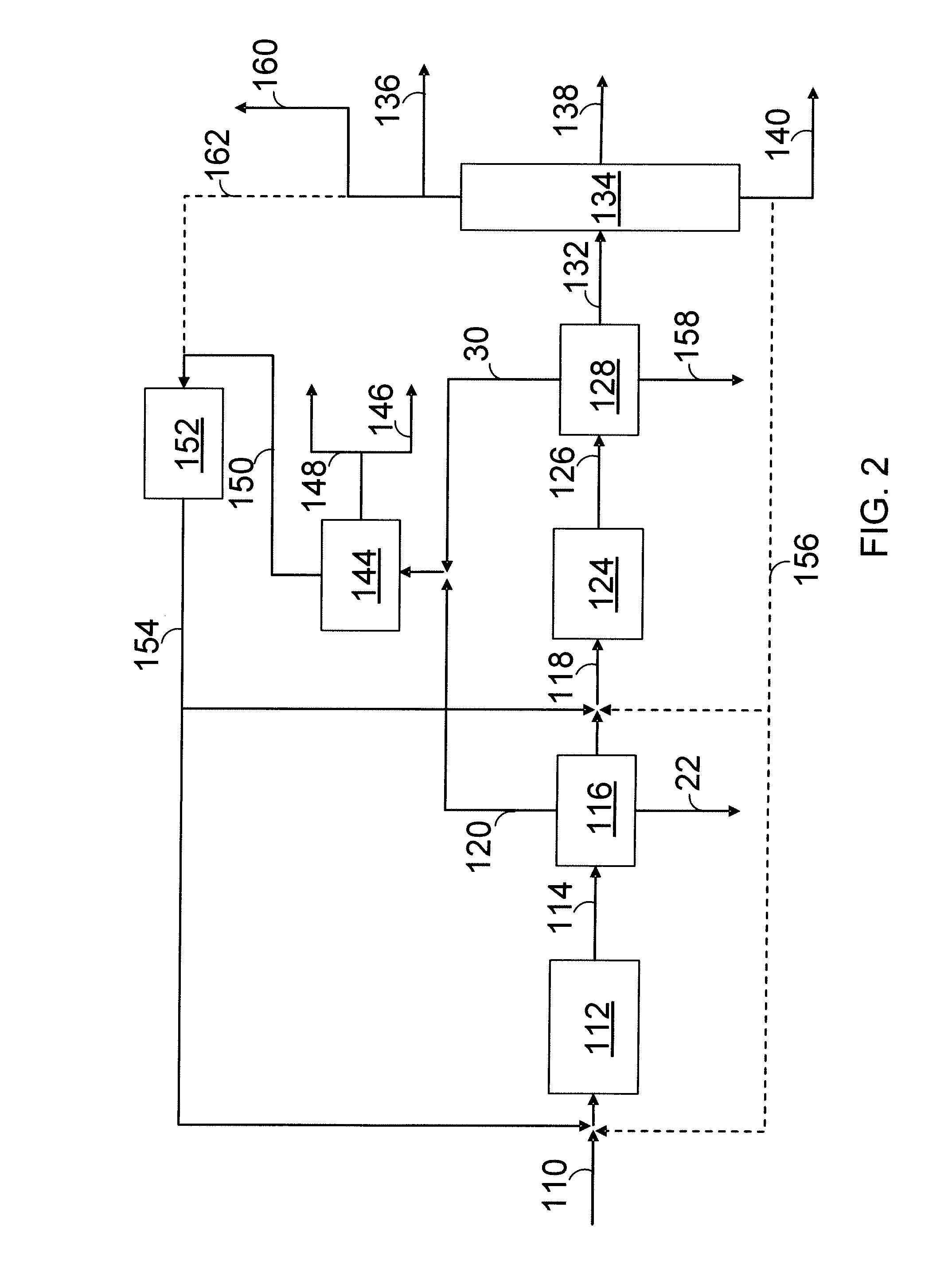

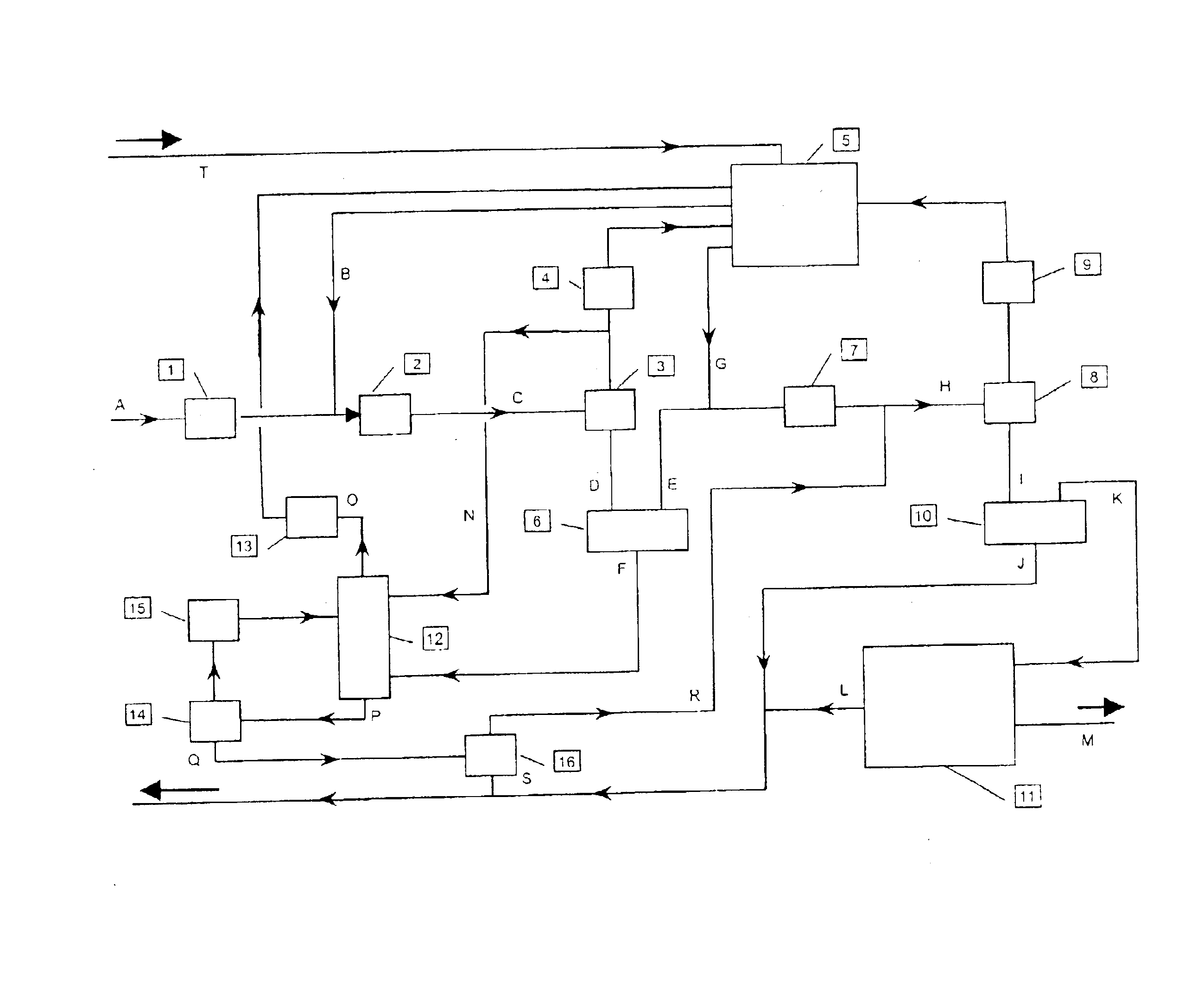

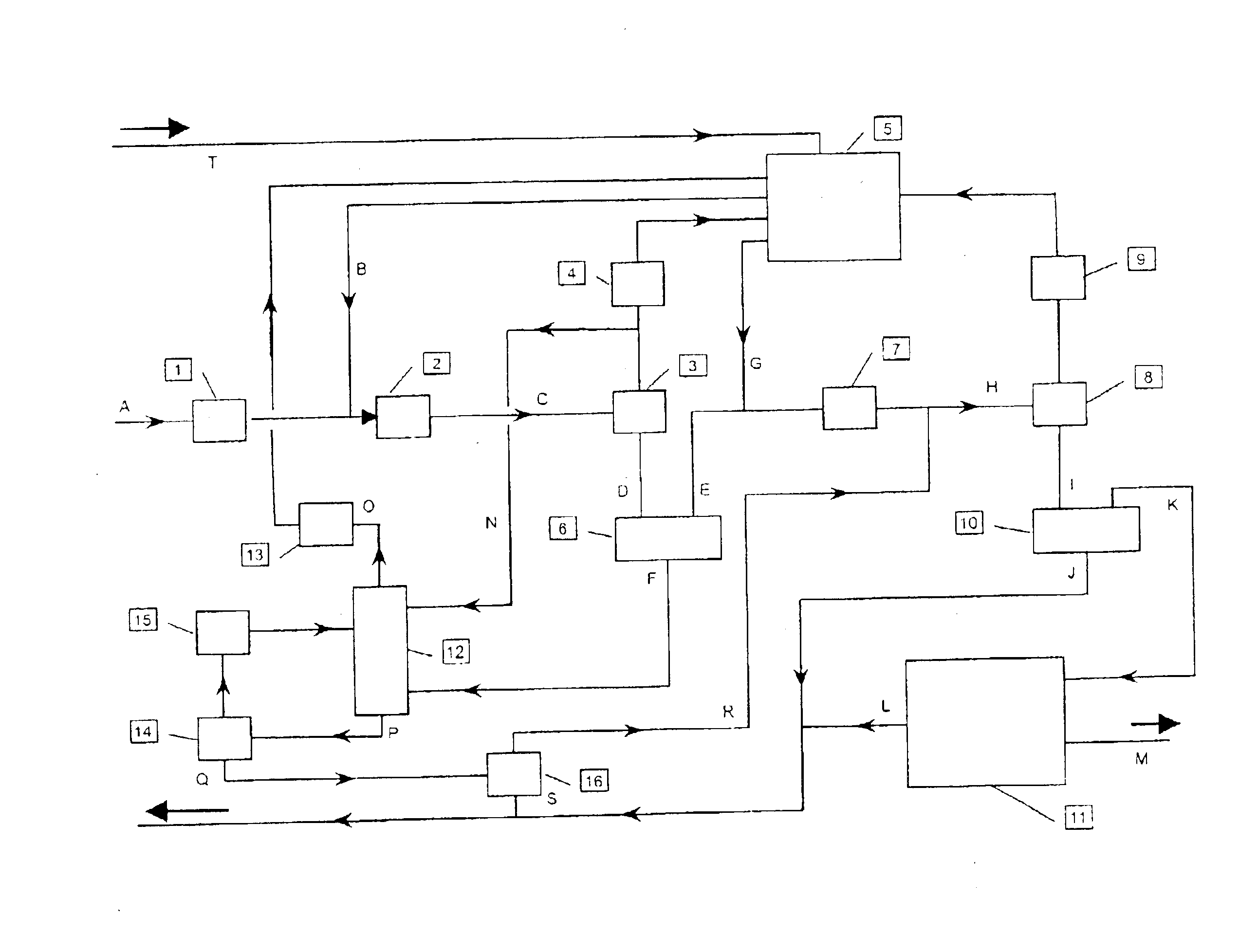

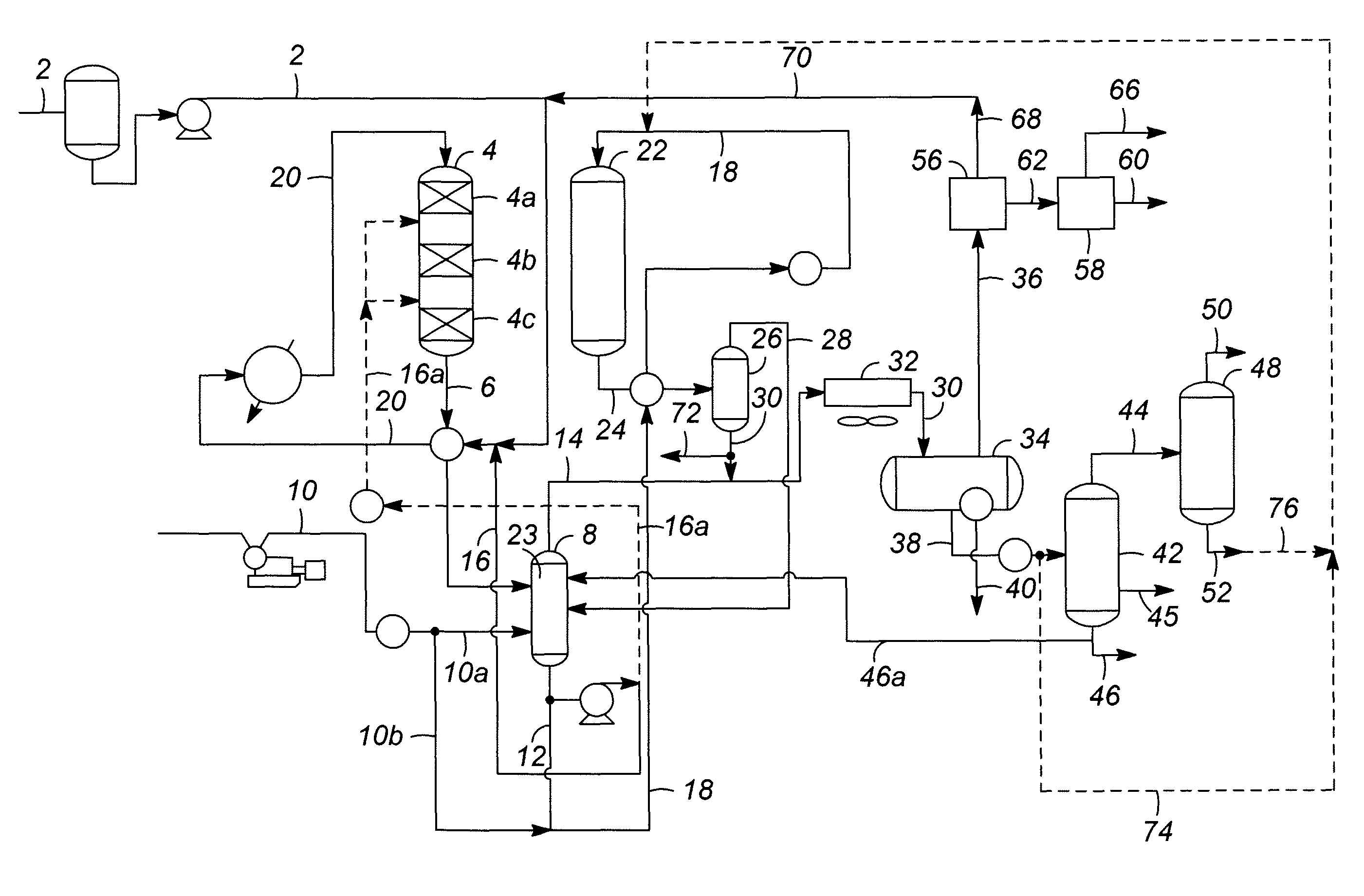

Production of Transportation Fuel from Renewable Feedstocks

ActiveUS20090229172A1Reduce first amountMinimize the numberBiofuelsLiquid hydrocarbon mixture productionNaphthaHigh pressure hydrogen

A process has been developed for producing a diesel boiling point range product and an aviation boiling point range product from renewable feedstocks such as plant and animal oils. The process involves treating a renewable feedstock by hydrogenating and deoxygenating to provide a hydrocarbon fraction which is then isomerized and selectively cracked to form the diesel boiling point range product and the aviation boiling point range product. A portion of the diesel boiling point range product, aviation boiling point range product, naphtha product, LPG, or any combination thereof can be optionally used as a rectification agent in the selective hot high pressure hydrogen stripper to decrease the amount of product carried in the stripper overhead.

Owner:UOP LLC

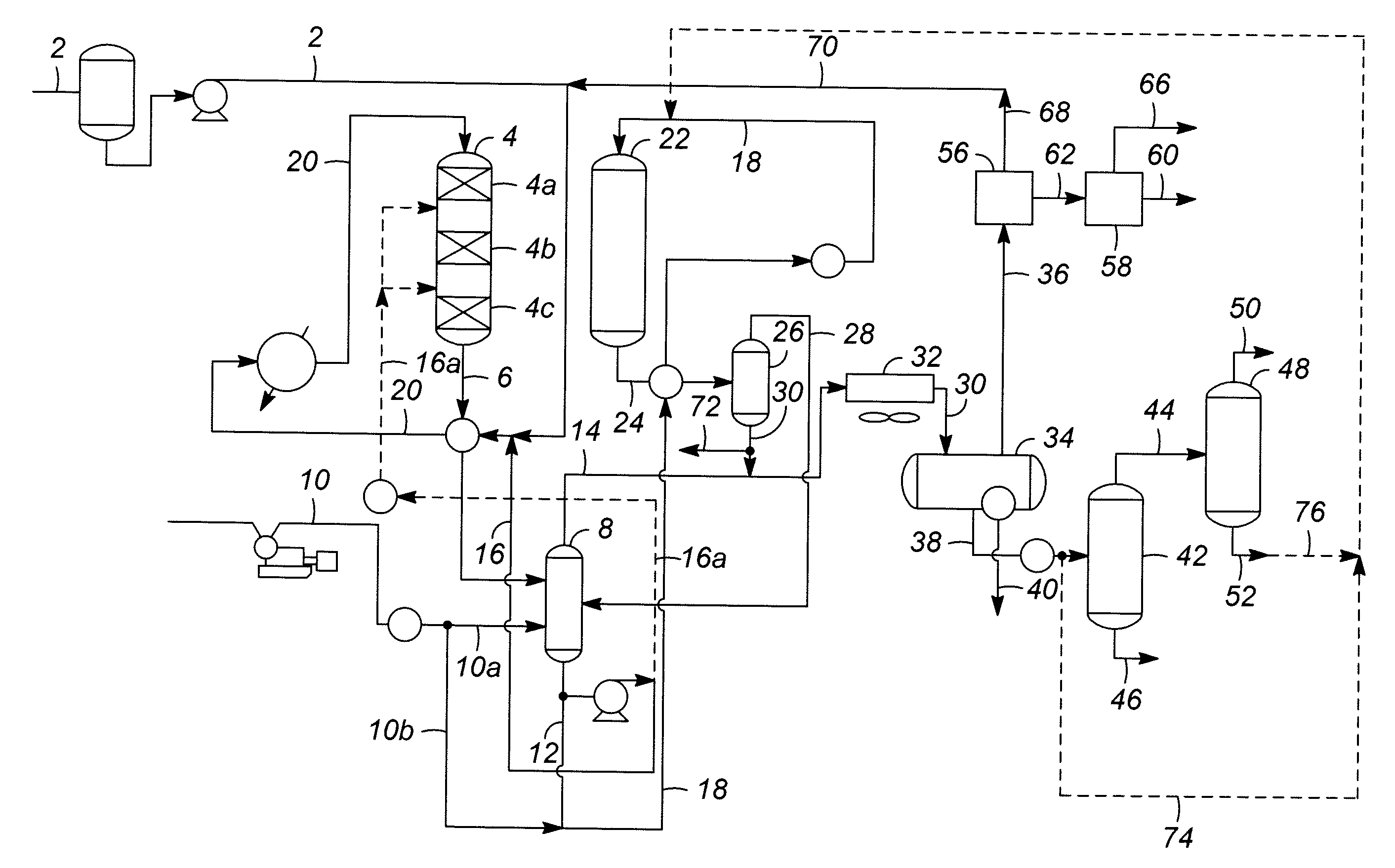

Production of diesel fuel from biorenewable feedstocks

ActiveUS7999142B2Refining to change hydrocarbon structural skeletonHydrocarbon by hydrogenationSolubilityHydrogen

A process has been developed for producing diesel boiling range fuel from renewable feedstocks such as plant oils and animal oils, fats, and greases. The process involves treating a renewable feedstock by hydrogenating and deoxygenating i.e. decarboxylating, decarbonylating, and / or hydrodeoxygenating to provide a hydrocarbon fraction useful as a diesel boiling range fuel or diesel boiling range fuel blending component. If desired, the hydrocarbon fraction can be isomerized to improve cold flow properties. A portion of the hydrogenated and deoxygenated feedstock is selectively separated and then recycled to the treatment zone to increase the hydrogen solubility of the reaction mixture.

Owner:UOP LLC

Process for preparing biological diesel oil from waste animal and plant oil

InactiveCN1382762AEliminate emissionsSimple production processLiquid hydrocarbon mixture productionBio-feedstockOil and greaseBiodiesel

A process for preparing biologic diesel oil from waste plant or animal oil includes alcoholysis and esterifying reactions under the existance of acidic catalyst, separating out the excessive non-product part to obtain coarse product, adding saturated equeous solution of edible salt containing sodium carbonate (10%), neutralizing reaction, adding industrial sodium carbonat4e, heating distillation and collecting the gas-phase fraction at 22-320 deg.C to obtain biologic diesel oil. Its advantages are high performance no pollution, and simple preparing process.

Owner:叶活动 +1

Production of blended fuel from renewable feedstocks

ActiveUS8329967B2Minimize the numberReduce the amount requiredRefining to change hydrocarbon structural skeletonBiofuelsParaffin waxEngineering

A process for producing a blended fuel from a paraffin rich component and a cyclic rich component, where each of the components are generated from a renewable feedstock, is presented. The paraffin rich component is generated from glycerides and free fatty acids in feedstocks such as plant and animal oils. The cyclic rich component is generated from biomass derived pyrolysis oil. The source of the animal or plant oil and the biomass may be the same renewable source.

Owner:UOP LLC

High temperature biobased lubricant compositions from boron nitride

InactiveUS20100105583A1Improve the lubrication effectEnhanced anti-wearBase-materialsBoron nitrideAlpha-olefin

This present invention discloses a method for the preparation of an improved high temperature engine lubricant composition comprising the steps of: 1) providing at least one biobased natural oil or biobased synthetic oil selected from the group consisting of natural or synthetic vegetable oil, natural or synthetic animal oil, genetically modified vegetable oil, genetically modified synthetic vegetable oil, natural or synthetic tree oil, and mixtures thereof; 2) providing at least one boron nitride; and 3) optionally, providing at least one base oil selected from the group consisting of a synthetic ester, solvent refined petroleum oil, a hydrocracked petroleum white oil, an all hydroprocessed synthetic oil, Fischer Tropsch oil, petroleum oil group I, group II, group III, a polyalphaolefin (PAO), and mixtures thereof; 4) optionally, providing at least one additive or combination of additives selected from the group consisting of anti-oxidant(s), corrosion inhibitor(s), metal deactivator(s), viscosity modifier(s), anti-wear inhibitor(s), friction modifier(s), and extreme pressure agent(s); 5) blending 1), 2), 3), and 4) in any sequence to form said composition.

Owner:RENEWABLE LUBRICANTS INC

Rubber composition for tire and pneumatic tire using the same

A rubber composition for a tire, in which a specific tackifier is compounded, and tackiness and various physical properties are improved, compared with compounding a petroleum resin or a terpene resin, is provided. The rubber composition for a tire comprising an alkyd resin and a pneumatic tire using the same. It is preferable that a material derived from a resource other than petroleum, particularly, a material derived from animal and / or vegetable, and more particularly, a material derived from an animal oil and / or a vegetable oil is contained in the alkyd resin, and it is preferable that unsaturated polybasic acid is contained in the alkyd resin.

Owner:SUMITOMO RUBBER IND LTD

Production of diesel fuel from renewable feedstocks containing phosphorus

InactiveUS20090321311A1Refining to change hydrocarbon structural skeletonCatalytic naphtha reformingSolubilityHydrogen

A process has been developed for producing diesel fuel from renewable feedstocks such as plant oils, animal oils and greases. The process involves treating a renewable feedstock by hydrogenating and deoxygenating to provide a diesel boiling range fuel hydrocarbon product. If desired, the hydrocarbon product can be isomerized to improve cold flow properties. A portion of the hydrocarbon product is recycled to the treatment zone to increase the hydrogen solubility of the reaction mixture. The renewable feedstock comprises from about 1 to about 20 wt. ppm phosphorus measured as elemental phosphorus.

Owner:UOP LLC +1

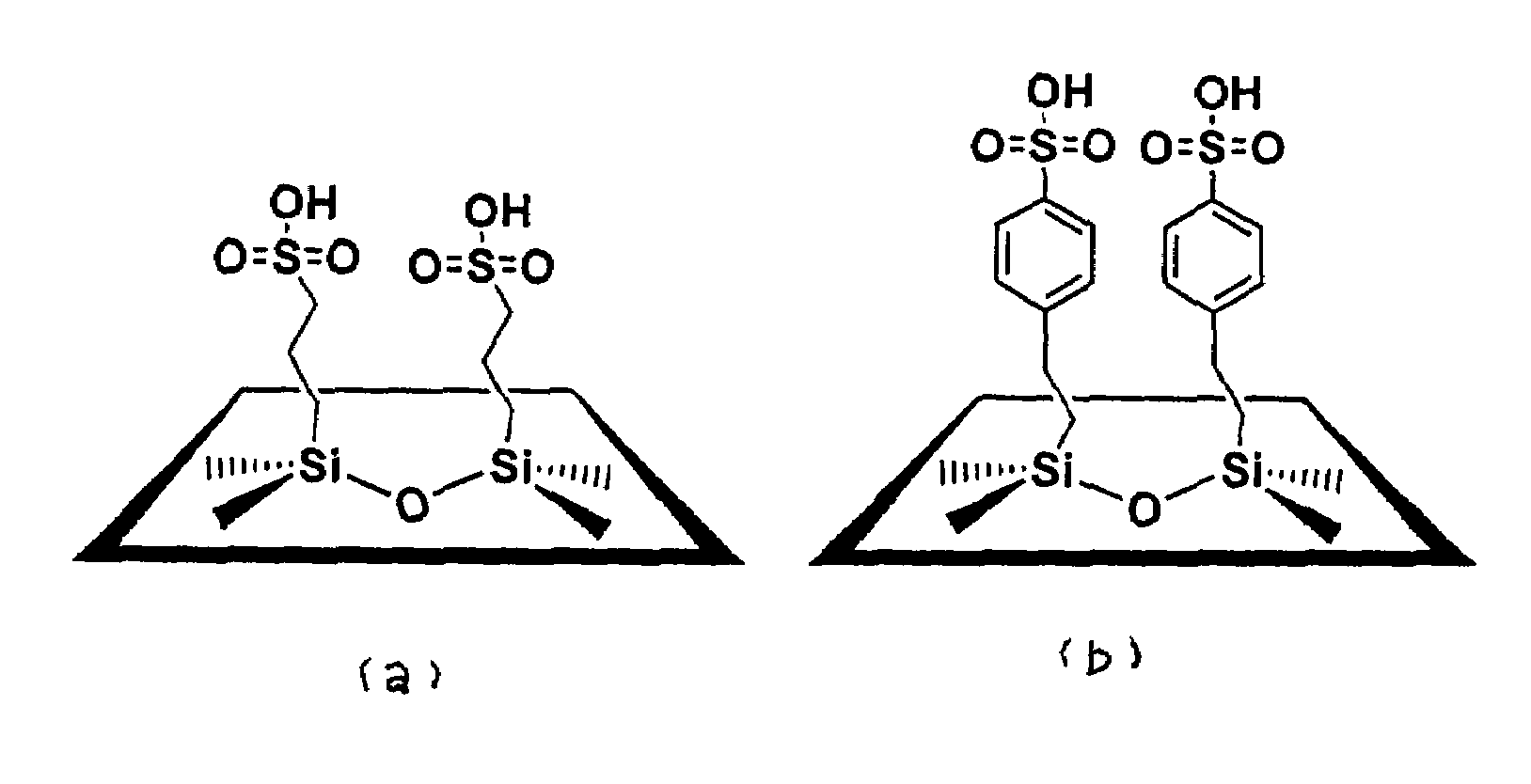

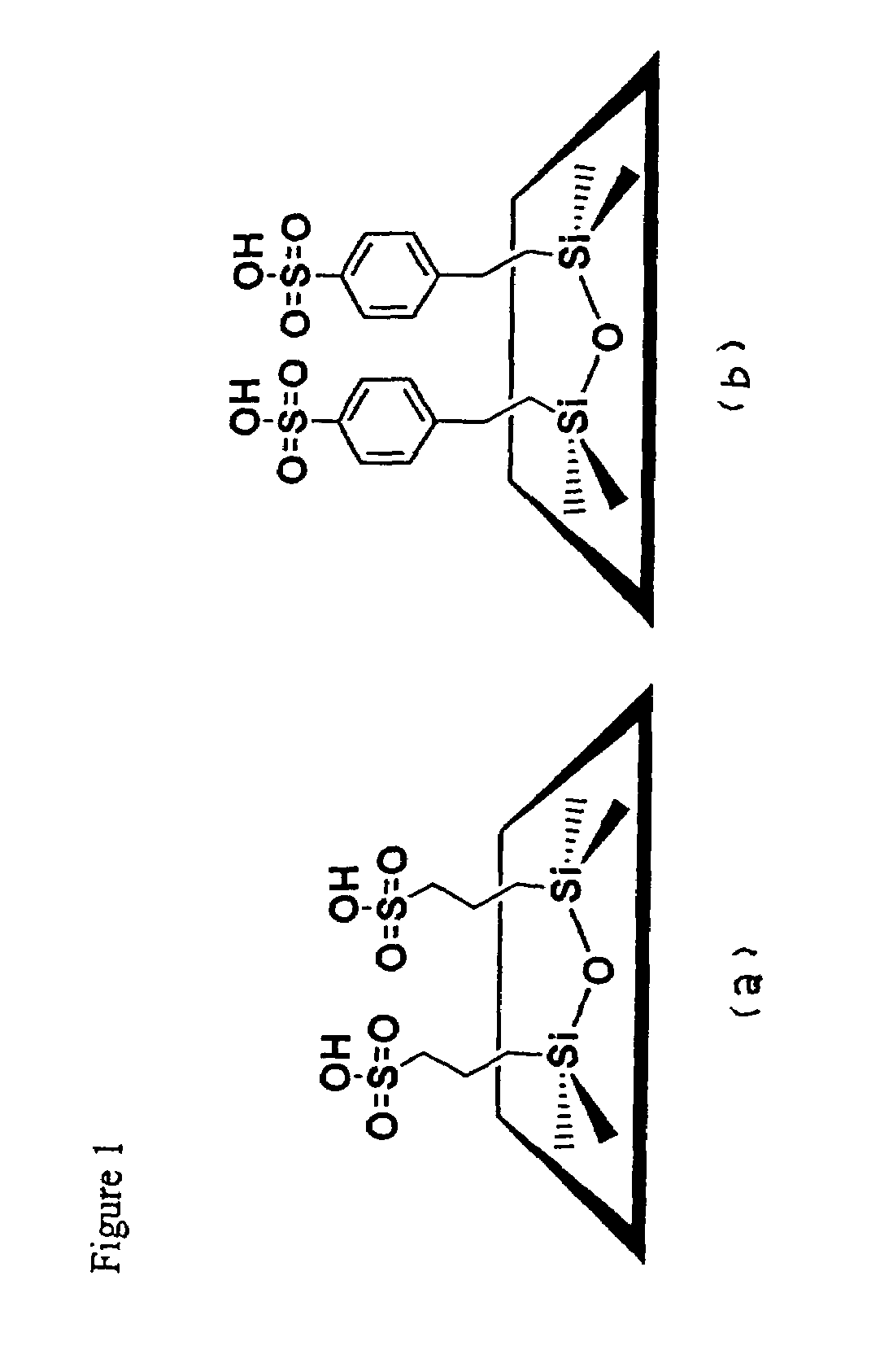

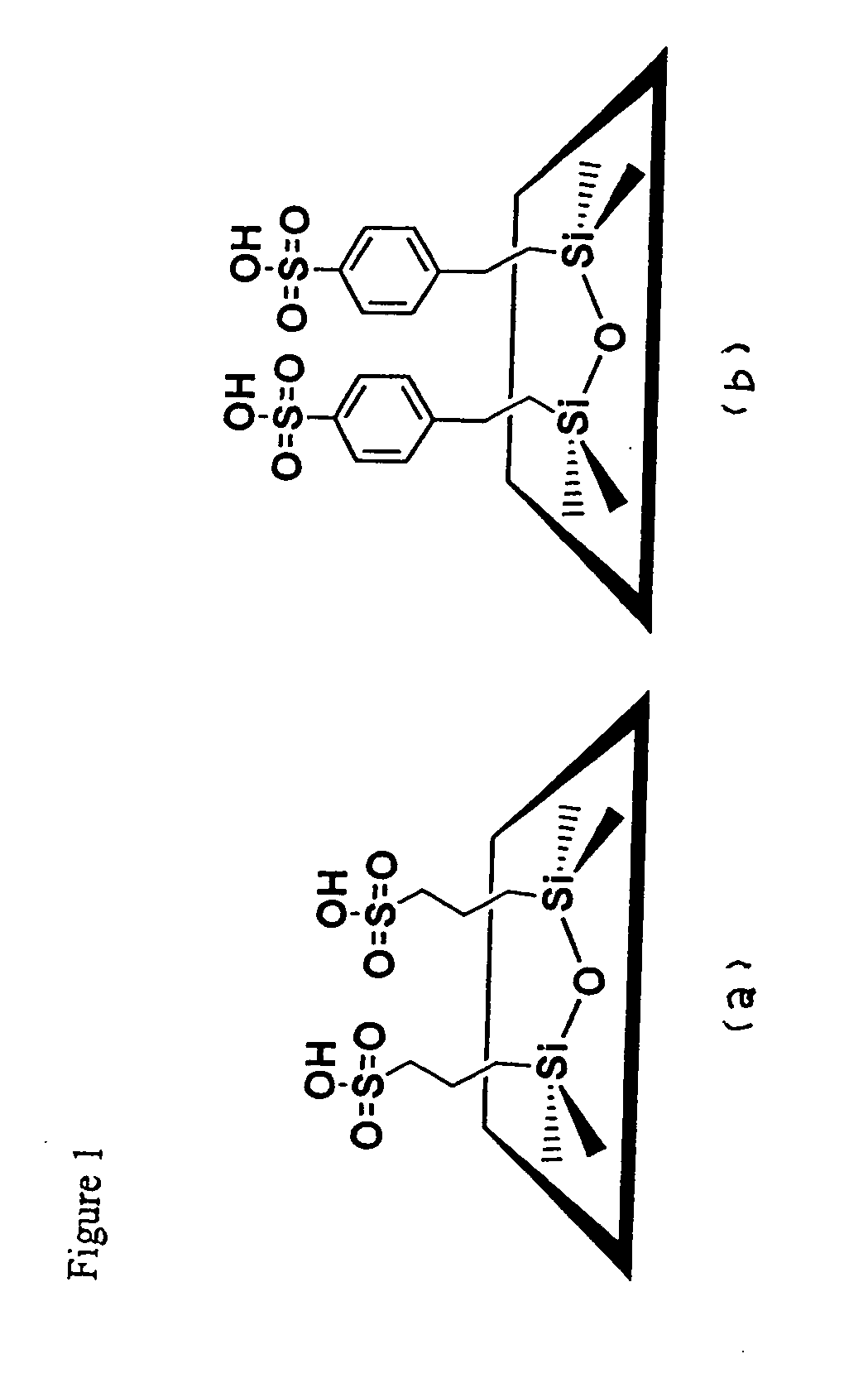

Use of functionalized mesoporous silicates to esterify fatty acids and transesterify oils

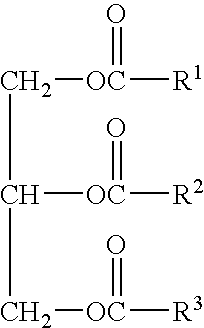

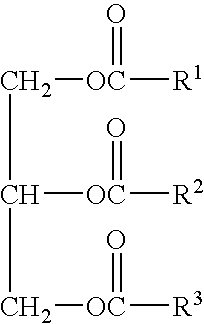

InactiveUS7122688B2Permit releaseEasy to separateFatty oils/acids recovery from wasteFatty acid chemical modificationIodo fatty acidMonoglyceride

The present invention provides a method to prepare a fatty acid lower alkyl esters from a feedstock, such as a vegetable or an animal oil, comprising one or more fatty acid glycerol esters such as mono-, di- or tri-glycerides, and free fatty acids, comprising combining the feedstock, a lower alcohol and an acidic mesoporous silicate under conditions wherein the mesoporous silicate catalyzes the formation of the corresponding fatty acid lower alkyl ester of the free fatty acids an optionally glycerol.

Owner:IOWA STATE UNIV RES FOUND

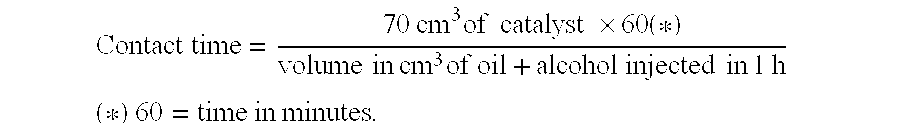

Process for producing fatty acid alkyl esters and glycerol of high-purity

InactiveUS20060014974A1Process economyFatty oils/acids recovery from wasteFatty acid esterificationAlcoholGlycerol

In a process for producing fatty acid alkyl esters and glycerol comprising at least one reaction stage in which a charge comprising a vegetable and / or animal oil and an alcohol are brought into contact, in the presence of a heterogeneous catalyst, so as to obtain an effluent comprising at least alkyl esters, glycerol and alcohol, and at least one separation stage during which a separation is carried out of at least one portion of the effluent so as to separate an alcohol-rich effluent and an alkyl esters-rich effluent, at least one separation stage consists of a membrane separation using at least one alcohol-permeable membrane.

Owner:INST FR DU PETROLE

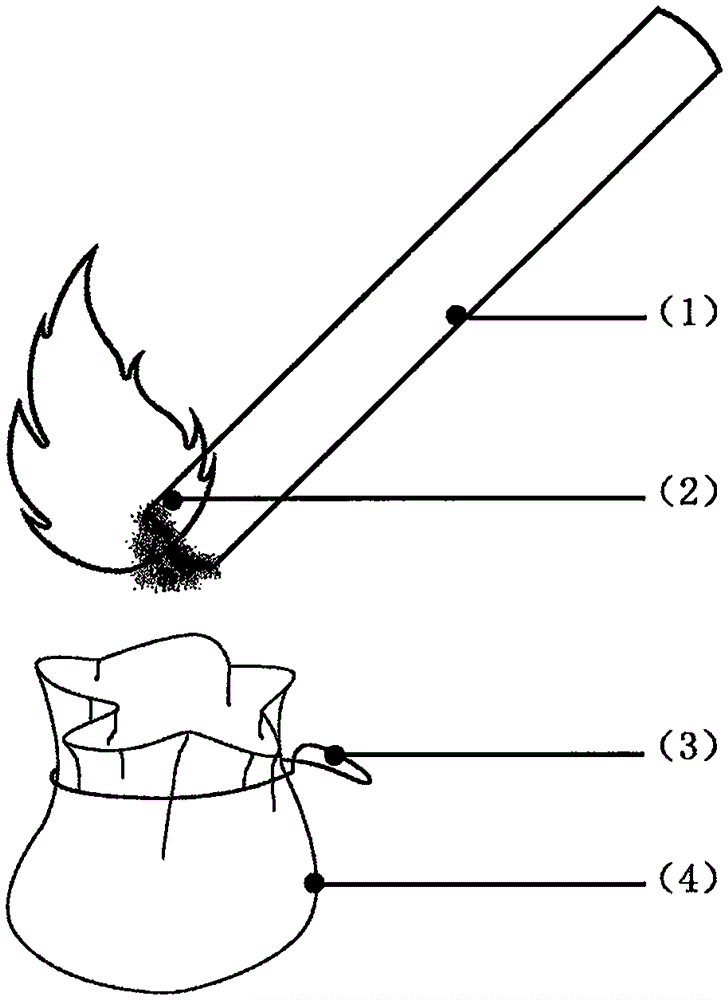

Pest-attracting plate, preparation method and application thereof

ActiveCN101617649AReduce manufacturing costSimple and fast operationInsect catchers and killersWaxVaseline

The invention provides a pest-attracting plate, a preparation method and application thereof, belonging to the field of plant protection. In the pest-attracting plate, pest gum and pest-attracting substances are coated on a carrier plate, wherein the pest-attracting substances are mixtures of pest attractant and dilacor which can be plant oil, honey, wax oil, glycerin, Vaseline and / or animal oil. Pests can be completely killed based on a tropism principle of pests to colour and smell with many killing types. The pest-attracting plate has durative and stable efficacy and low production cost, and is particularly suitable for promotion and popularization.

Owner:INST OF PLANT PROTECTION CHINESE ACAD OF AGRI SCI

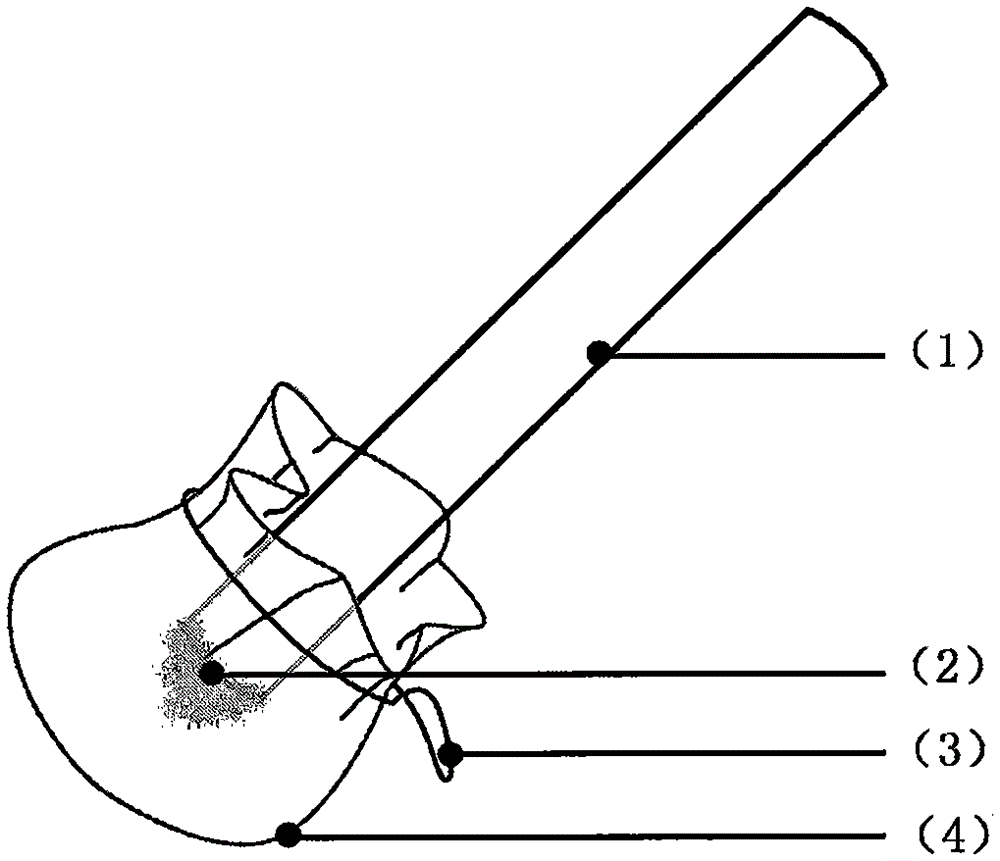

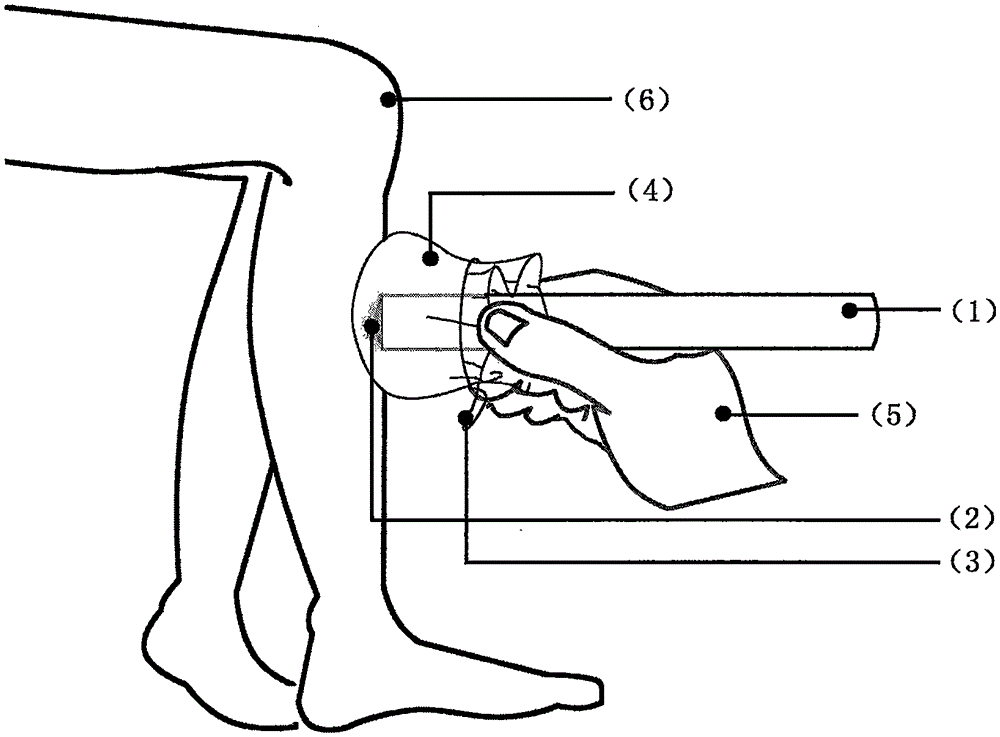

Moxa stick, moxa stick fabrication method and moxibustion device

ActiveCN105412938AEasy to useChange the way to add ingredients to medicinesDevices for heating/cooling reflex pointsDrug compositionsChemistryAnimal oil

The invention discloses a moxa stick. The moxa stick comprises wormwood processing objects, medicinal constituents and oil and fat; the wormwood processing objects absorb the oil and fat through contact; the oil and fat weight accounts for 10% and above the total weight of the moxa stick, and the oil and fat is vegetable oil and fat, animal oil and fat, vegetable oil and fat processing objects or animal oil and fat processing objects. A moxa stick fabrication method comprises the steps of getting the moxa stick to make contact with the oil, and getting the moxa stick to make contact with medicine. The medicinal constituents are added in the following one or more modes that: 1, the medicine is added to the moxa stick in the solid state; 2, the medicine is added to the moxa stick in the form of liquid medicine; 3, the medicine makes contact with the oil and fat, so that the medicine or the medicinal constituents are added to the moxa stick.

Owner:BEIJING XIAYANG INVESTMENT MANAGEMENT CO LTD

Production of diesel fuel from vegetable and animal oils

Owner:BEN GURION UNIVERSITY OF THE NEGEV

Process for non-catalytically producing biodiesel fuel without yielding by-product

InactiveUS20060288636A1Fatty oils/acids recovery from wasteFatty acid esterificationReaction temperatureFatty acid methyl ester

This invention provides a process for producing biodiesel fuel from vegetable or animal oils and fats or wastes thereof and methanol that does not use a catalyst and does not generate glycerin as a by-product. In this process, vegetable or animal oils and fats or wastes thereof are mixed with methanol, and a methanolysis reaction is carried out at a reaction temperature of between 370° C. and 500° C., a reaction pressure of between 20 MPa and 60 MPa, and a reaction period of between 4 minutes and 12 minutes without the use of a catalyst. This invention also provides biodiesel fuel that is mainly composed of fatty acid methyl esters, monoacylglycerol, and diacylglycerol.

Owner:INC ADMINISTRATIVE AGENCY NAT AGRI & BIO ORIENTED RES ORG

Integrated process for the manufacture of biodiesel

InactiveUS20070260078A1Fatty oils/acids recovery from wasteFatty acid esterificationTransesterificationAnimal oil

The present application describes an integrated process for the manufacture of biodiesel from vegetable or animal oils using a solid, transesterification catalyst and a solid, etherification catalyst.

Owner:MILLENNIUM RES LAB

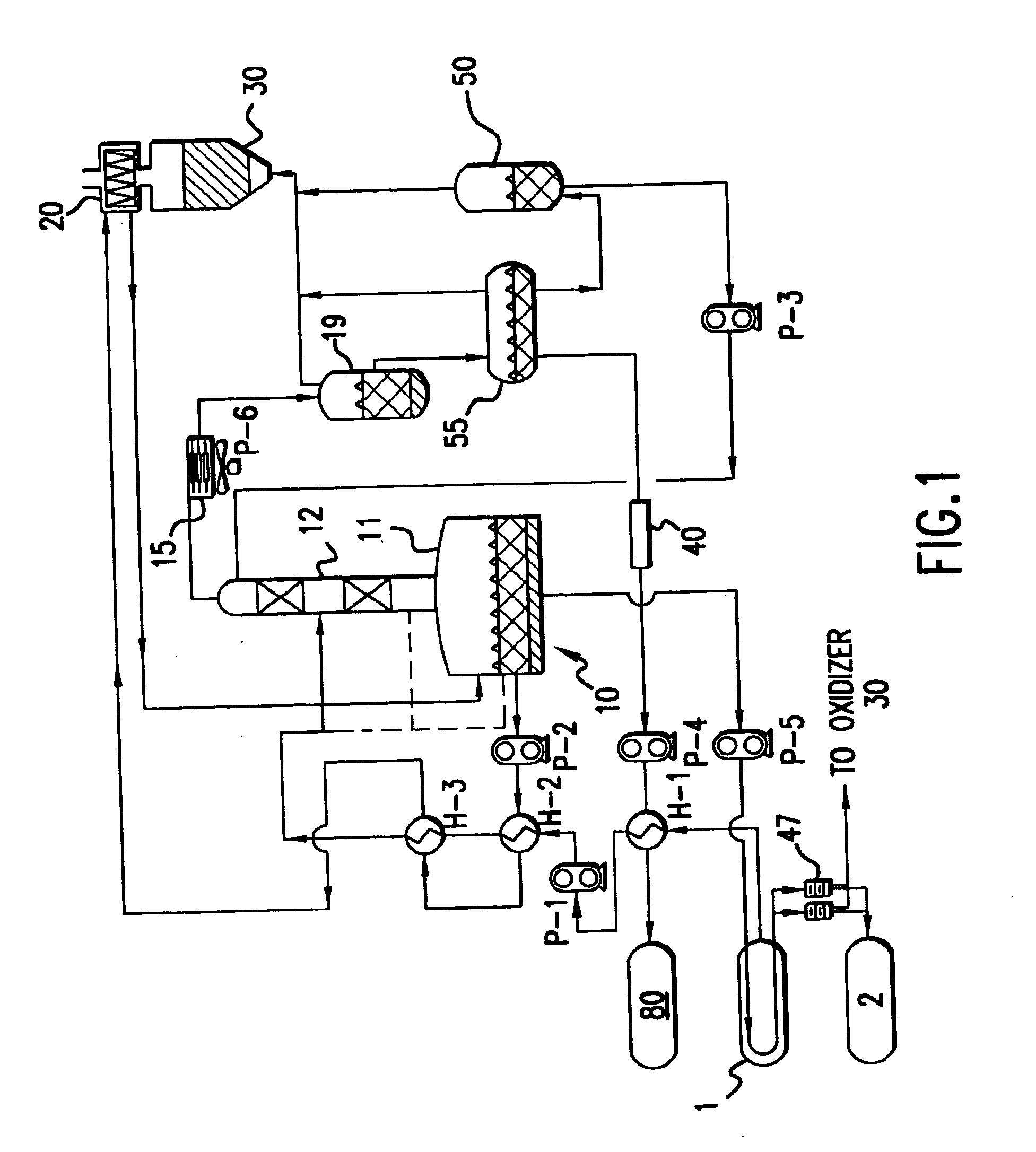

Process for converting tallow to diesel fuel

A process for thermally cracking virgin or waste animal oils (tallow) into a diesel fuel product is provided. The thermal cracking process uses low cracking temperatures from 625 to 725° F. with ambient pressure and no catalyst to generate a column distilled fraction of diesel fuel mixed with light ends, the light ends being flashed off to produce a high quality #2 diesel fuel suitable for road use. The oils to be distilled are exposed to a heat exchanger with a skin temperature of 1750° F. generated by hot air produced by a thermal oxidizer. This results in the processed product going from a liquid to a liguid / gas during the pump around residence time of 3 to 5 seconds before moving up a distillation column as a gas to the desired finished product.

Owner:G O E ENTERPRISES

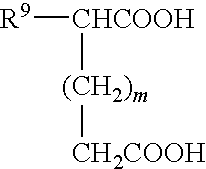

Process for transesterification of vegetable or animal oils using heterogeneous catalysts based on titanium, zirconium or antimony and aluminium

InactiveUS20050266139A1Possible formFatty acid esterificationPreparation by ester-hydroxy reactionHomogeneous catalysisTitanium oxide

A novel process is described for producing esters of linear monocarboxylic acids containing 6 to 26 carbon atoms, by reacting vegetable or animal oils, neutral or otherwise, with monoalcohols containing 1 to 18 carbon atoms in the presence of a catalyst selected from: mixtures of titanium oxide and alumina having formula: (TiOx)y(Al2O3)1-y where x has the value 1.5 to 2.2 and y, representing the weight ratio of the two oxides, has a value of 0.005 to 0.995; mixtures of zirconium oxide and alumina having formula: (ZrOx)y(Al2O3)1-y where x has the value 1.5 to 2.2 and y has a value of 0.005 to 0.995; and mixtures of antimony oxide and alumina having formula: (SbOx)y(Al2O3)1-y where x has the value 1.2 to 2.6 and y has a value of 0.005 to 0.995, in order to directly produce, in one or more steps, an ester for use as a fuel and a pure glycerin.

Owner:INST FR DU PETROLE

Biological organic inorganic compound fertilizer product and production method thereof

InactiveCN101468927AOvercoming pollutionOvercoming bactericidalBioloigcal waste fertilisersFertiliser formsLiquid wasteMicrobial agent

The invention relates to a chemical fertilizer and a production method thereof, in particular to a biological organic inorganic compound fertilizer product and a production method thereof. The biological organic inorganic compound fertilizer product comprises a fertilizer core and a coating in which the fertilizer core is wrapped, wherein the fertilizer core is a particle which is produced by adding humic acid and inorganic nitrogen-phosphorus-potassium raw materials to concentrated waste liquid rich in amino acid, organic matter and other nutrient components, guniting, coating and granulating; the concentrated waste liquid is obtained by treating wastewater of gourmet powder factories; and the coating at least comprises animal oil-fat, starch, bone glue and bacillus components. The product integrates quick, slow and long effects, and integrates organic, inorganic and biological materials. The production method takes the animal oil-fat, the starch and the bone glue which can provide lipid and other nutrients for microorganisms and are easy to degrade as carriers of a bacillus preparation, overcomes the phenomenon that the mixture of the bacillus preparation and other fertilizer components is easy to cause pollution to microbial agents and poison strains.

Owner:山东鲁虹农业科技股份有限公司

Production of aviation fuel from renewable feedstocks

ActiveUS8039682B2Improve solubilityMinimize severityRefining to change hydrocarbon structural skeletonHydrocarbon purification/separationIsomerizationBoiling point

A hydrocarbon product stream having hydrocarbons with boiling points in the aviation fuel range is produced from renewable feedstocks such as plant and animal oils. The process involves treating a renewable feedstock by hydrogenating, deoxygenating, isomerization, and selectively hydrocracking the feedstock to produce paraffinic hydrocarbons having from about 9 to about 16 carbon atoms and a high iso / normal ratio in a single reaction zone containing a multifunctional catalyst, or set of catalysts, having hydrogenation, deoxygenation, isomerization and selective hydrocracking functions.

Owner:UOP LLC

Concrete surface retarders

Surface retarder compositions of the invention comprise at least one surface retarder active suspended in a vegatable oil or derivative thereof, an animal oil or derivative thereof, or mixtures thereof. Methods involving use of the compositions are also described.

Owner:GCP APPL TECH INC

Use of functionalized mesoporous silicates to esterify fatty acids and transesterify oils

InactiveUS20050107624A1Valid conversionLarge specific surface areaFatty oils/acids recovery from wasteFatty acid chemical modificationAlcoholGlycerol

The present invention provides a method to prepare a fatty acid lower alkyl esters from a feedstock, such as a vegetable or an animal oil, comprising one or more fatty acid glycerol esters such as mono-, di- or tri-glycerides, and free fatty acids, comprising combining the feedstock, a lower alcohol and an acidic mesoporous silicate under conditions wherein the mesoporous silicate catalyzes the formation of the corresponding fatty acid lower alkyl ester of the free fatty acids an optionally glycerol.

Owner:IOWA STATE UNIV RES FOUND

Meat duck feed

InactiveCN102687817AReduce bile acid contentInhibit transformationAnimal feeding stuffSodium BentoniteAnimal science

The invention discloses a meat duck feed, belonging to the field of poultry feed. The meat duck feed contains the ingredients of 7 parts of corn, 46 parts of wheat, 11 parts of wheat middling, 10 parts of feed grade jujube powder, 2 parts of corn protein, 4 parts of cotton dregs, 4 parts of bean pulp, 2 parts of peanut meal, 4 parts of corn distillers, 2 parts of meat and bone meal, 2.9 parts of animal oil, 1.4 parts of mountain flour, 0.4 parts of calcium hydrophosphate, 0.7 parts of 70% lysine, 0.08 parts of methionine, 0.3 parts of chitosan, 0.05 parts of Chinese herbal medicine, 0.96 parts of bentonite, 0.25 parts of salt and 1 part of 1% premix, wherein the sum of the weight part percentages of the ingredients is 100%. The meat duck feed has the beneficial effects of reducing the in vivo bile acid of animals, preventing the cholesterol from being converted into cholesterol acid, increasing the feed intake quantity of the meat duck, improving the immunity and improving the carcassquality.

Owner:徐州金利饲料厂

Production of biodiesel and a side stream of crude glycerol which is converted to methanol

Owner:GD SPA

Process for converting feeds derived from renewable sources with pre-treatment of feeds by hot dephosphatation

InactiveUS20110138680A1Reduce lossesDifficult to operateBiofuelsFatty-oils/fats refiningPretreatment methodFixed bed

The invention concerns a process for the pre-treatment of an unrefined vegetable or animal oil, consisting of passing said oil through a reactor comprising at least one fixed bed of at least one adsorbent comprising a porous refractory oxide which is free of catalytic metals, at a temperature in the range 130° C. to 320° C., at a pressure in the range 0.1 to 7 MPa and with a residence time for said oil on said fixed bed in the range 0.1 to 1 hour. The invention concerns a process for pre-treatment of a semi-refined vegetable or animal oil, integrated upstream of a hydrotreatment step for the production of green gas oil.

Owner:INST FR DU PETROLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com