Patents

Literature

2795 results about "Petroleum resin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrocarbon resin is a C5/C9 aromatic hydrocarbon used in industrial applications. It has a tackifying effect and is suitable for use in paint, printing ink, adhesives, rubber and other areas where tackiness is required.

Eva recycling method

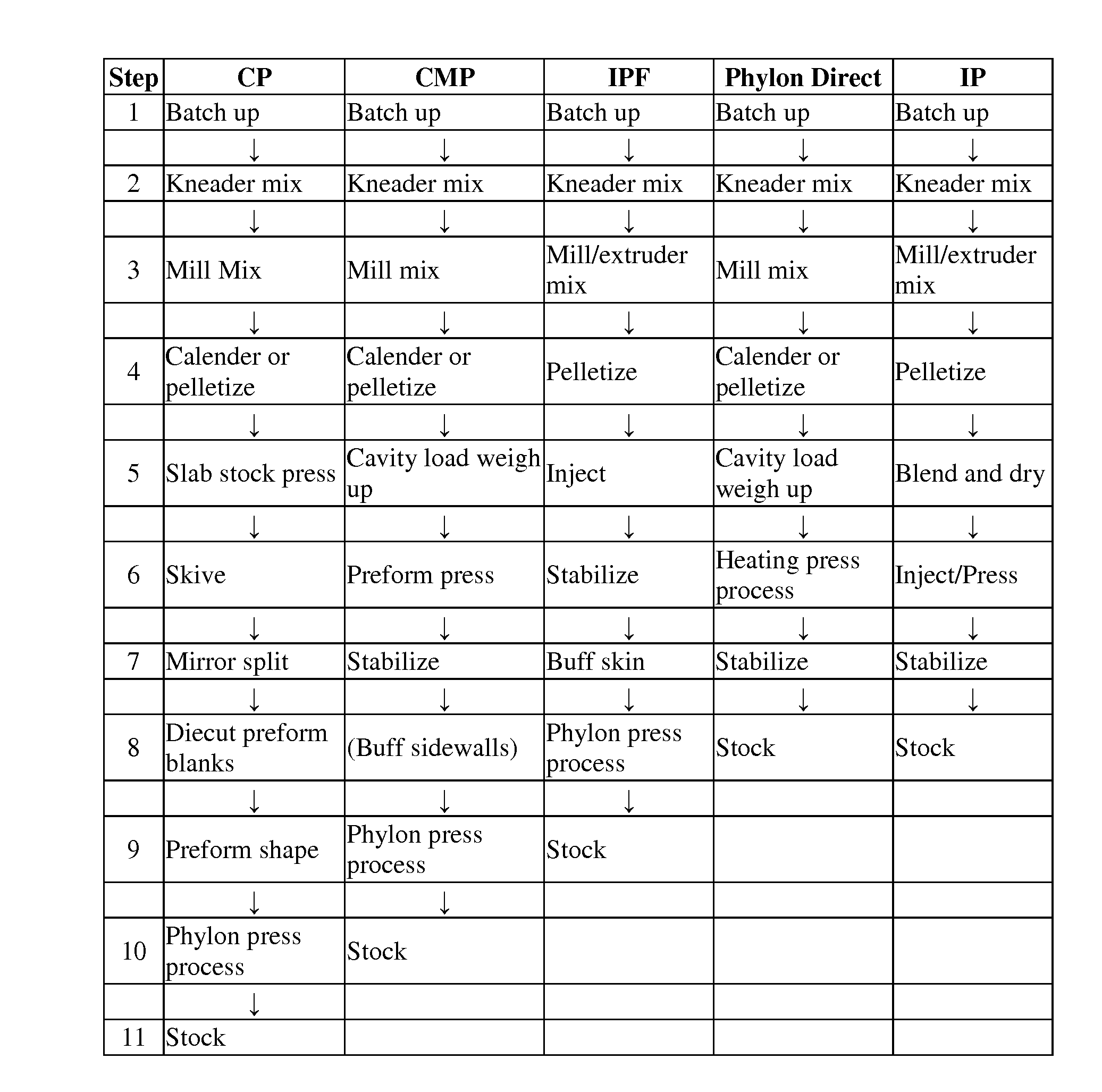

ActiveUS20140066530A1Good physical propertiesMore rubberySolesPlastic recyclingFoaming agentPetroleum resin

A method of recycling scrap ethylene-vinyl acetate (EVA) foam involves foaming and crosslinking a blend containing virgin EVA resin and scrap EVA foam, as well as a crosslinking agent and blowing agent for the EVA resin. The blend further contains a compatibilizer, which is a hydrogenated petroleum resin.

Owner:NIKE INTERNATIONAL LTD

Rubber composition for tire and pneumatic tire using the same

A rubber composition for a tire, in which a specific tackifier is compounded, and tackiness and various physical properties are improved, compared with compounding a petroleum resin or a terpene resin, is provided. The rubber composition for a tire comprising an alkyd resin and a pneumatic tire using the same. It is preferable that a material derived from a resource other than petroleum, particularly, a material derived from animal and / or vegetable, and more particularly, a material derived from an animal oil and / or a vegetable oil is contained in the alkyd resin, and it is preferable that unsaturated polybasic acid is contained in the alkyd resin.

Owner:SUMITOMO RUBBER IND LTD

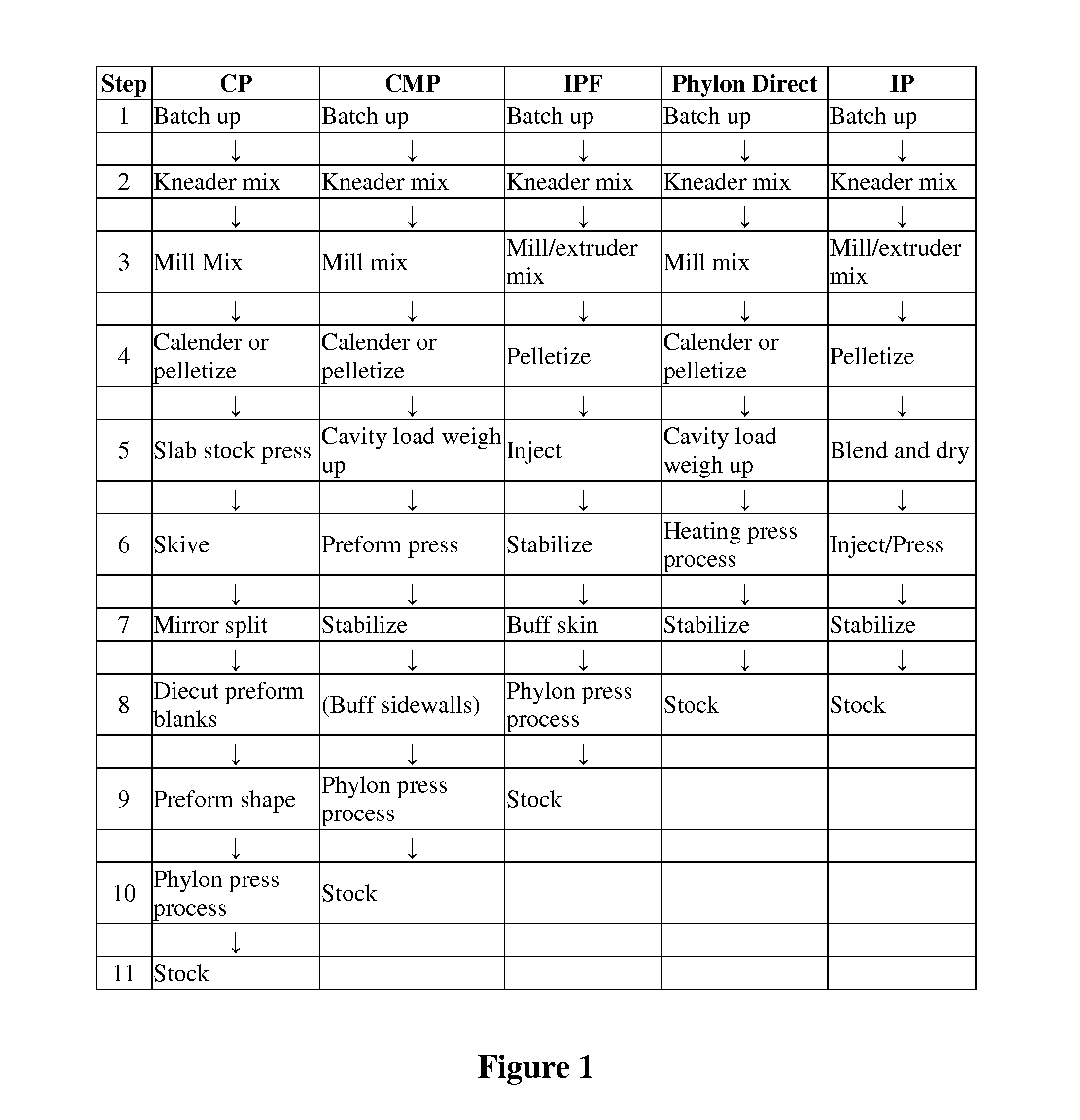

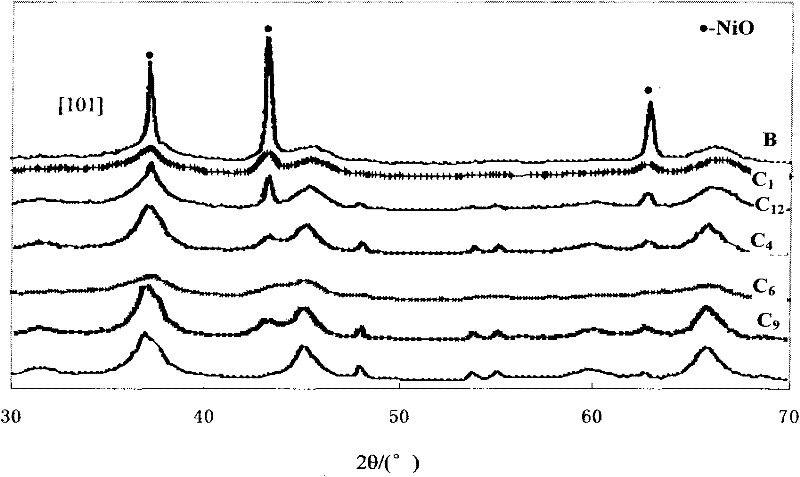

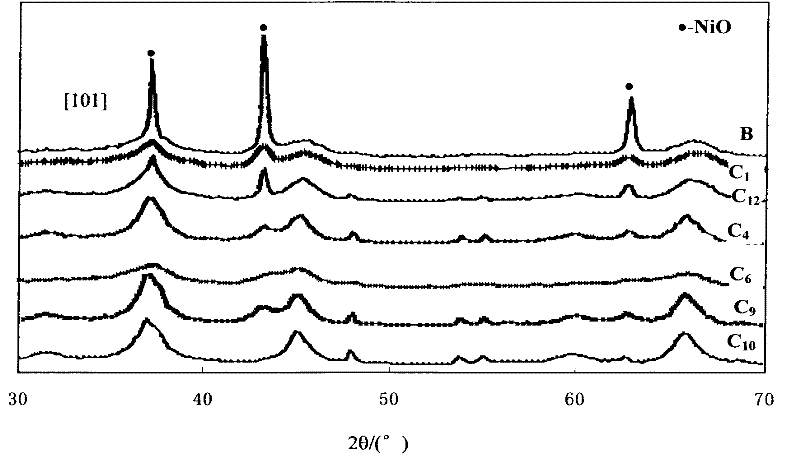

Preparation method of nickel-based hydrogenation catalyst

ActiveCN102451691AUniform precipitationEvenly dispersedMetal/metal-oxides/metal-hydroxide catalystsPetroleum resinSilicon oxide

The invention discloses a preparation method of a nickel-based hydrogenation catalyst. The preparation method comprises the following steps that carrier alumina and / or silicon oxide, an active metal ingredient and an auxiliary agent ingredient are prepared into slurry; the slurry and a precipitator are added into a reactor in a parallel flow way and are prepared into a catalyst precursor; and the catalyst precursor, a peptizing agent and water are mixed, kneaded, molded, dried and calcined to form the nickel-based hydrogenation catalyst. Through the preparation method, the active metal ingredient can uniformly precipitate on the carrier so that high-uniformity uniformity of the active metal ingredient on the carrier is guaranteed. Through the parallel flow way for precipitation, a uniform precipitation environment in precipitation is obtained so precipitates having the same shape and size are obtained. The nickel-based hydrogenation catalyst obtained by the preparation method can be utilized for hydrogenation decoloration of C5 petroleum resin, C9 petroleum resin and C5-C9 mixed petroleum resin.

Owner:CHINA PETROLEUM & CHEM CORP +1

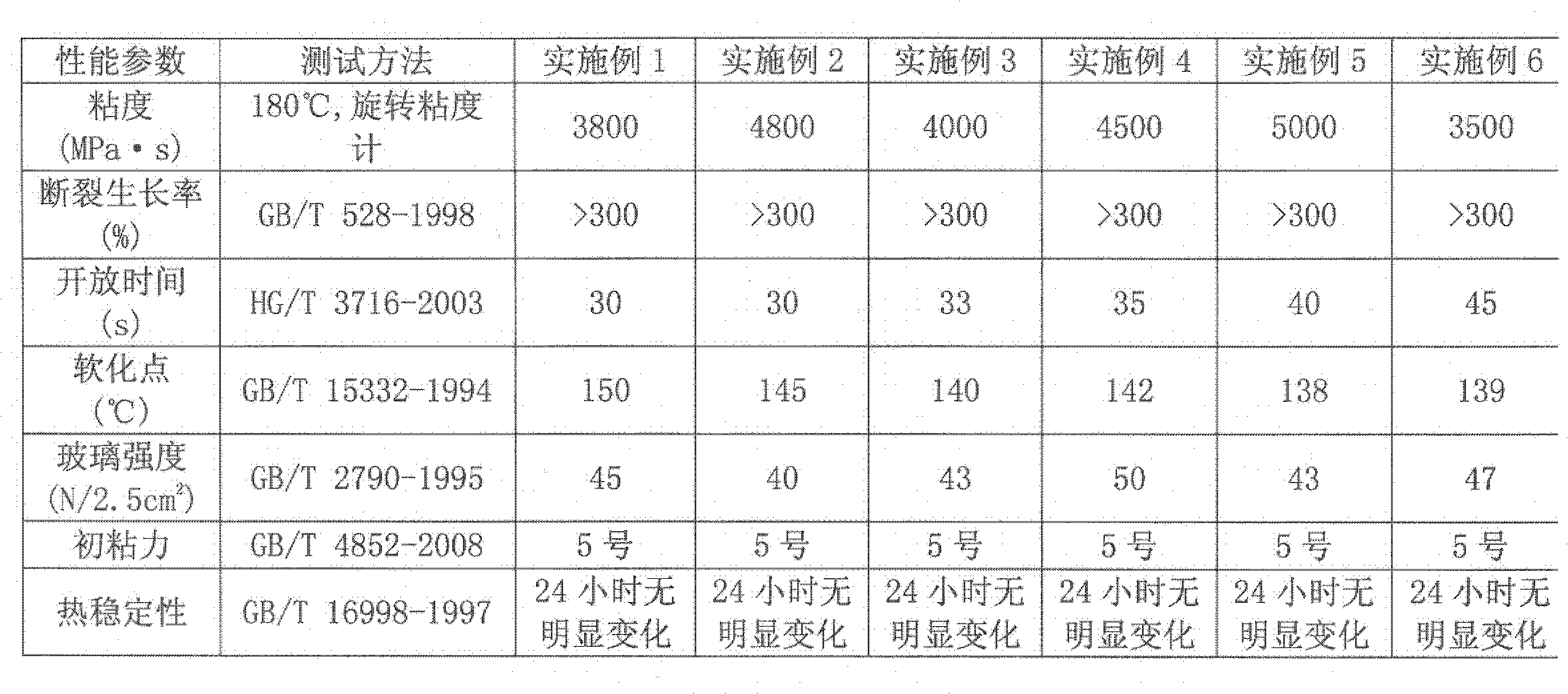

Hot melt adhesive

InactiveCN102653665ASuitable for production process requirementsReasonable formula designMacromolecular adhesive additivesEpoxyPolyolefin

The invention discloses a hot melt adhesive which comprises the following components in parts by mass: 5-10 parts of EVA (ethylene-co-vinyl acetate), 2-6 parts of tackifier, 5-10 parts of diluent, 0.5-1.5 parts of antioxidant and 0.5-1.5 parts of plasticizer. The tackifier is one of rosin resin, petroleum resin, terpene resin, phenolic resin and epoxy resin; the diluent includes one or both of wax and low-molecular polyolefin; the antioxidant is phenolic antioxidant; and the plasticizer is DCHP (Dicyclohexyl phthalate). The EVA contains 20-30% of vinyl acetate monomer; and the wax is microcrystalline wax with molecular weight of 3,000-4,000 and melting point of 65-85 DEG C.

Owner:成都鑫三洋科技发展有限公司

Preparation method for C9 hydrogenation petroleum resin

InactiveCN102924659AWide adaptabilityImprove performanceMetal/metal-oxides/metal-hydroxide catalystsHydrodesulfurizationSolvent

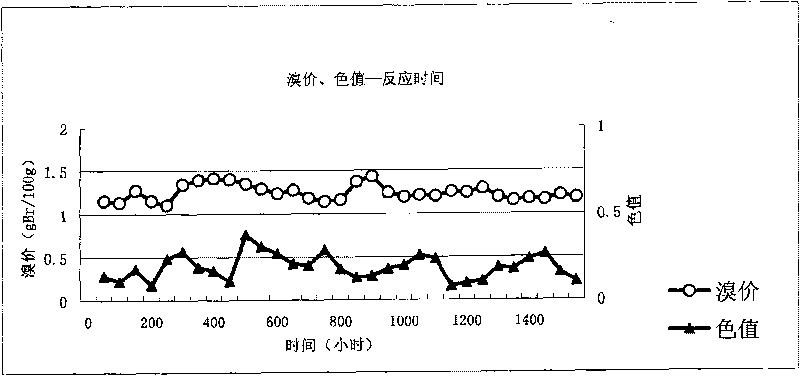

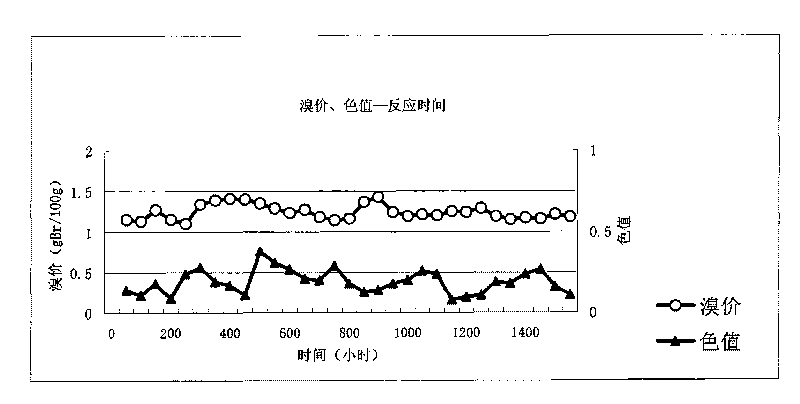

The invention relates to a preparation method for C9 hydrogenation petroleum resin. The C9 hydrogenation petroleum resin is dissolved in organic solvent, and the concentration of the C9 hydrogenation petroleum resin is 5wt %-30wt%. The C9 hydrogenation petroleum resin is filtered to remove undissolved substances, then subjected to a first section of hydrodesulfurization process and a second section of hydrogenation decoloration process, and finally subjected to the process of decompression rectification and solvent recovery to obtain C9 hydrogenation petroleum resin products. The preparation method adopts two-section hydrogenation, improves reaction activity, selectivity and impurity resistant capability, is wide in adaptability of C9 petroleum resin raw materials, and obtains C9 petroleum resin through adoption of thermal polymerization or catalytic polymerization. No matter impurity content in resin solution is high or low, particularly, when sulphur content is high in the resin solution, the two-step hydrogenation process can be carried out through the preparation method, and the C9 hydrogenation petroleum resin with high performance is obtained. Through the first section of hydrodesulfurization, hydrogenation noble metal catalyst in the second section is effectively protected. Service life of catalyst is greatly prolonged. Reaction pressure of the two-section hydrogenation is quite low, and industrial production cost is little.

Owner:CHINA PETROLEUM & CHEM CORP

Hot-melt pressure-sensitive adhesive type matrix for medical use and its preparation

InactiveCN1800289AImprove anti-agingOxidative decomposition is goodSurgical adhesivesFilm/foil adhesivesPetroleum resinThermoplastic elastomer

The invention relates to a medical used hot melt pressure-sensitive adhesive type base material and its preparing method which provides a hot melt pressure-sensitive adhesive and an adhesive used paste preparation. The main element of the hot melt pressure-sensitive adhesive is styrenic thermoplastic elastomer SIS (phenylethene -isoprene -phenylethene three block copolymers) with adhesive resin (such as petroleum resin, terpenes polymer, polyisobutylene), flexing oil (such as liquid petrolatum) and aging retarder (such as propyl gallate, BZ) and so on.

Owner:SHANGHAI ARIBA ELECTRIC

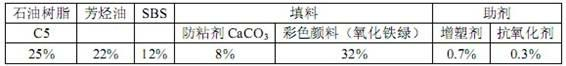

Color asphalt binder capable of being directly applied and preparation method thereof

ActiveCN101928465AEasy to prepareAdapt to use requirementsIn situ pavingsBuilding insulationsButadiene DioxideRoad engineering

The invention belongs to the technical field of road engineering, in particular to a color asphalt binder capable of being directly applied and a preparation method thereof. The binder consists of 25 to 38 percent of petroleum resin, 12 to 22 percent of aromatic oil, 8 to 15 percent of styrene-butadiene triblock copolymer (SBS), 28 to 32 percent of color pigment, 5 to 10 percent of abherent, 0.05 to 1 percent of plasticizer, and 0.05 to 1 percent of antioxidant. The binder has a simple preparation method, can meet the technical index requirements of various building asphalts by adjusting the content of the petroleum resin, the content of the aromatic oil and the content of the styrene-butadiene triblock copolymer. Color asphalt binders in red, yellow, blue and other colors can be produced by regulating the color pigment. Furthermore, in the process of transporting the color asphalt binder, heating transportation is not required, and a special tanker for transportation is not required, so that the problems of low transportation efficiency and difficult operation of the color asphalt are solved. Meantime, the storage time of the solid particular color asphalt binder is greatly prolonged, and the color asphalt binder is convenient to apply, and has positive effect on popularization and application of color asphalt pavements.

Owner:SHANGHAI PUDONG ROAD & BRIDGE CONSTR

Hot melt adhesive used for automotive interiors, and preparation method of hot melt adhesive

InactiveCN102618211AHarmless to healthHigh bonding strengthWax adhesivesNatural resin adhesivesPolyethylene vinyl acetateParaffin wax

The invention discloses a hot melt adhesive used for automotive interiors, and a preparation method of the hot melt adhesive. The hot melt adhesive used for automotive interiors is characterized by comprising a proportion of paraffin, polyethylene wax, a thermoplastic elastic body SBS, random polyolefin, polyethylene vinyl acetate, C5 petroleum resin, rosin pentaerythritol ester, antioxygen, coupling agent and filler. The preparation method comprising the following steps: heating a stirring kettle to 140 to 160 DEG C, and adding the paraffin and the polyethylene wax; adding the thermoplastic elastic body SBS, vacuum-pumping and keeping warm, adding HMW(high molecular weight) random polyolefin I, HMW random polyolefin II and the antioxygen; adding the coupling agent and the filler; cooling, and adding polyethylene vinyl acetate I and polyethylene vinyl acetate II; cooling and adding the C5 petroleum resin; adding the rosin pentaerythritol ester and keeping warm; and emptying the stirring kettle, pressurizing, discharging and forming. No pollution or poison is produced during the production process of the hot melt adhesive; and the hot melt adhesive has the advantages of high adhesion strength, long opening time, good temperature resistance, strong ageing resistance, good tenacity, strong waterproofness and the like.

Owner:浙江固特新材料科技股份有限公司

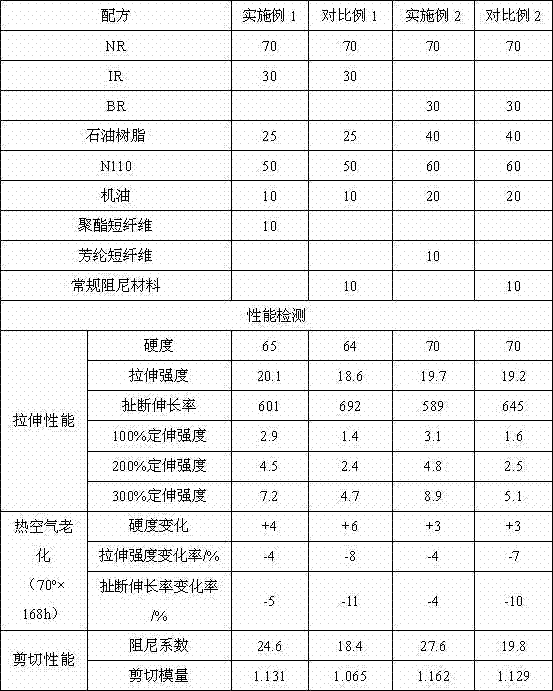

Ultra-high damping rubber composite material and preparation process of rubber composite material

The invention belongs to the technical field of rubber and discloses an ultra-high damping rubber composite material and a preparation process of the rubber composite material. The preparation process disclosed by the invention is mainly technically characterized by comprising the following steps of: adding short fibers, carbon black, petroleum resin, a plasticizer, a vulcanizing agent, an active agent, an accelerant and an anti-aging agent in rubber; and mixing the components in an internal mixer and then vulcanizing in a flat vulcanizing machine. According to the ultra-high damping rubber composite material disclosed by the invention, a predetermined amount of short fibers, carbon black and petroleum resin are uniformly dispersed in a rubber matrix; compared with the common high-damping material, the damping coefficient of the ultra-high damping rubber composite material disclosed by the invention is increased by more than 20%; and the ultra-high damping rubber composite material disclosed by the invention has the advantages of being strong in energy consumption property and ductility and obvious in damping and shock insulating effects, effectively controlling the earthquake response of shock insulating structures, and being environment-friendly and stable in property. The stretching strength is greater under the condition with the same hardness, so that a rubber bearing prepared by the ultra-high damping rubber composite material disclosed by the invention is greater in bearing force; the whole size of the bearing is smaller than the size of the traditional high-damping rubber bearing; and the rubber bearing has the advantages of saving the use space, being convenient to construct and more excellent in resistance to fatigue performance.

Owner:HENGSHUI ZHONGTIEJIAN ENG RUBBER +1

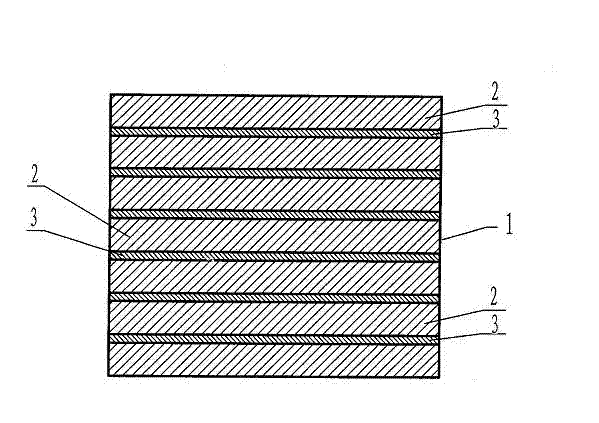

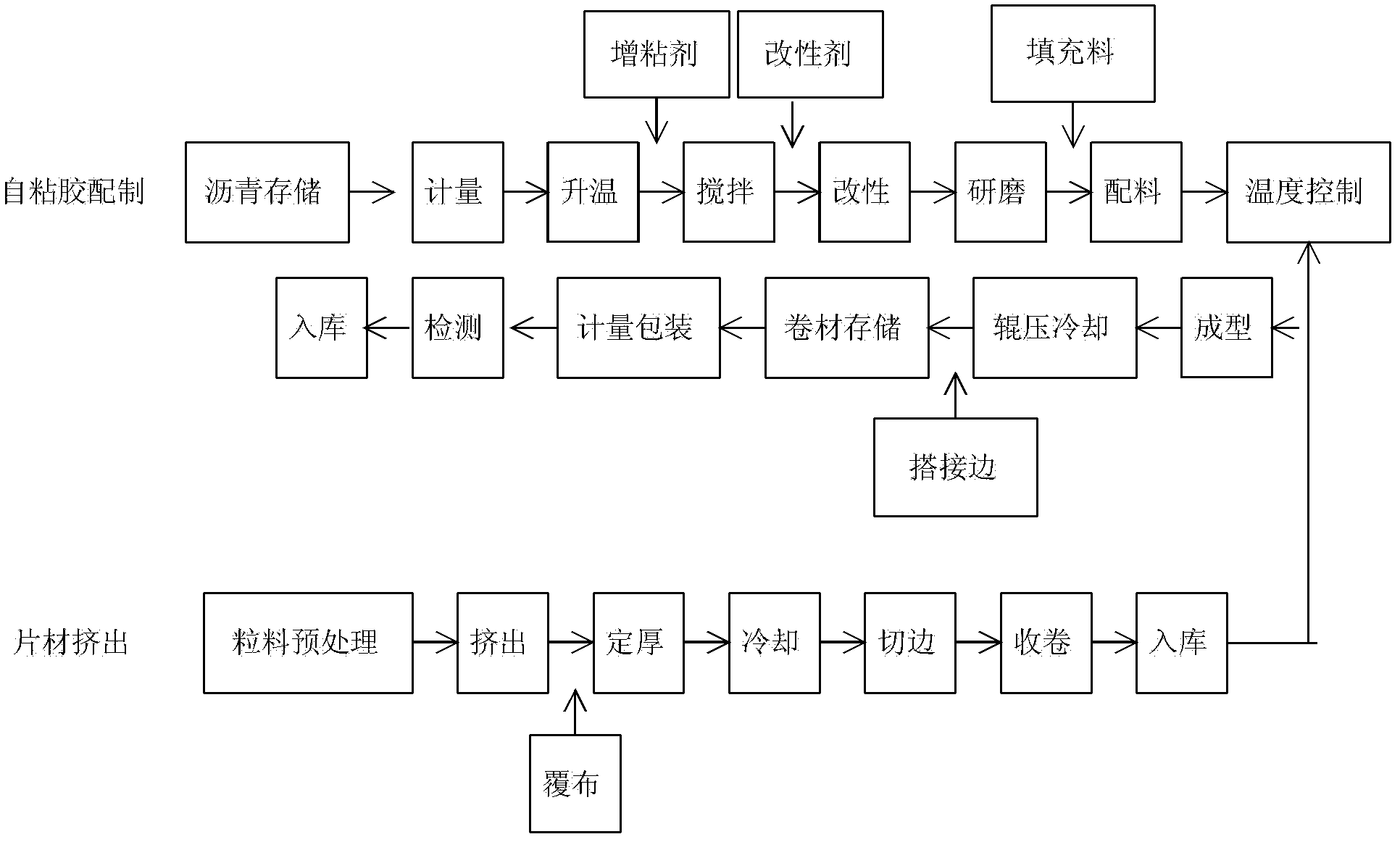

Asphalt self-adhesive and high-polymer self-adhesion rubber waterproof coiled material prepared from asphalt self-adhesive

InactiveCN102559135AGood compatibilityHigh composite strengthMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesUltimate tensile strengthButadiene-styrene rubber

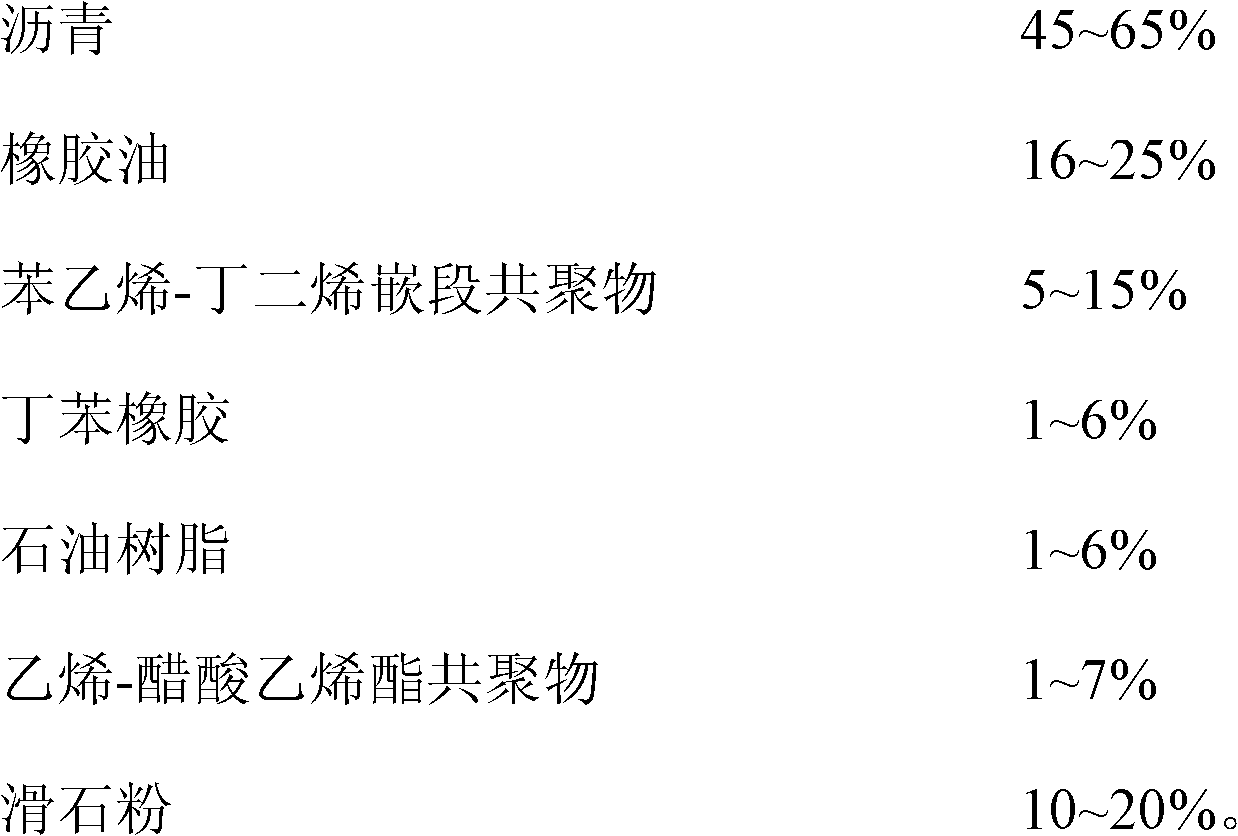

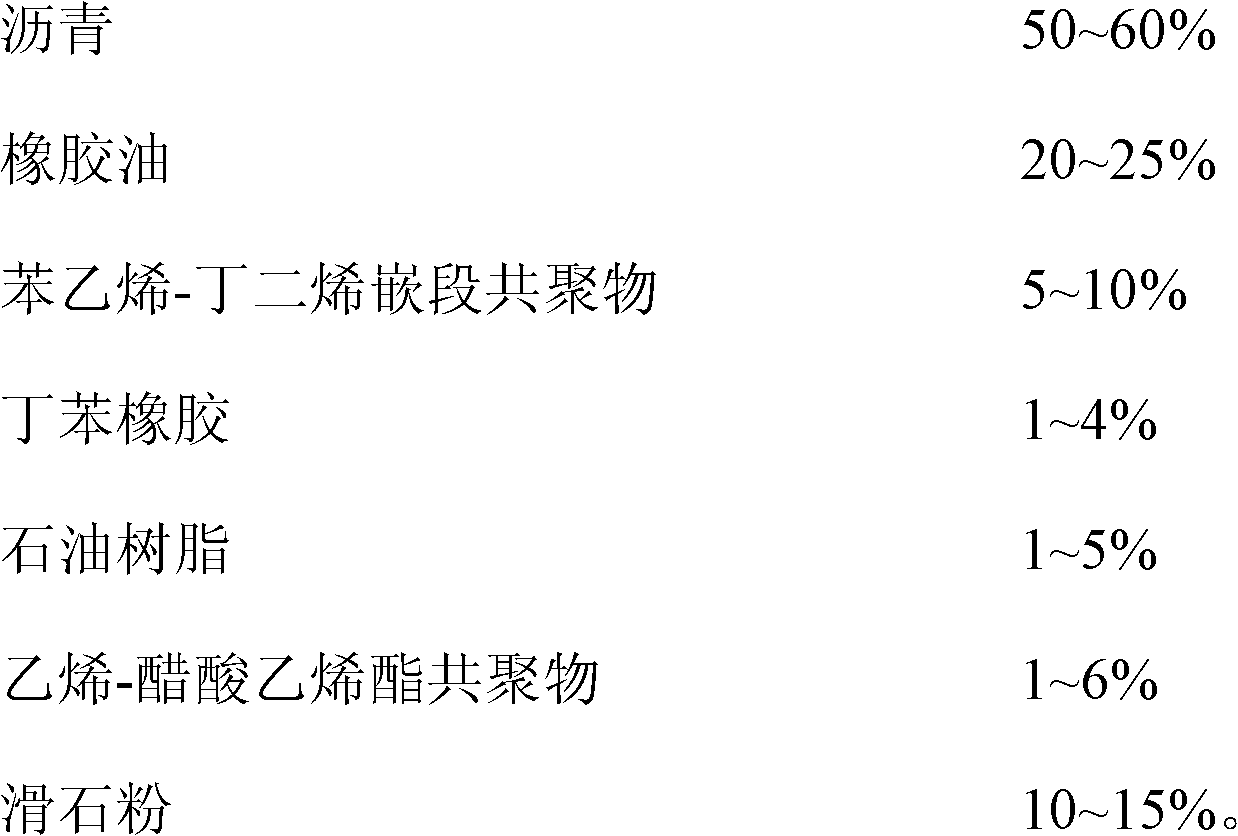

The invention discloses asphalt self-adhesive. The asphalt self-adhesive comprises the following components in percentage by weight: 45 to 65 percent of asphalt, 16 to 25 percent of rubber oil, 5 to 15 percent of styrene butadiene styrene (SBS), 1 to 6 percent of styrene butadiene rubber (SBR), 1 to 6 percent of petroleum resin, 1 to 7 percent of ethylene vinyl acetate (EVA), and 10 to 20 percent of talcpowder. The invention also provides a high-polymer self-adhesion rubber waterproof coiled material which comprises a non-woven fabric coating, a high-polymer sheet coating, and an asphalt self-adhesive coating which consists of the asphalt self-adhesive from bottom to top. Two ends of the waterproof coiled material are provided with joint sides. The asphalt self-adhesive contains EVA, so the compatibility of the self-adhesive and a high-polymer sheet is improved, and compounding intensity of the high-polymer sheet coating is improved. The problem that the high-polymer sheets cannot be jointed reliably in a self-adhesion joint process is solved, so the coiled materials are jointed by the adhesive; and the coiled materials can be adhered firmly and reliably, and adjusted freely and flexibly.

Owner:SHENZHEN ZHUOBAO TECH

Preparation of hydrogenation catalyst and use thereof

ActiveCN101700494ACatalyst carriersCatalyst activation/preparationRare-earth elementHydrogenation reaction

The invention provides a preparation method of a hydrogenation catalyst suitable for the hydrogenation reaction of C5 petroleum resin. The method comprises the steps of: taking aluminium hydroxide, kieselguhr, pore-expanding agent and rare earth element-modified aluminium oxide as a carrier; loading bi-component noble metal on the carrier; and adjusting the catalytic activity with the rare earth element to obtain the hydrogenation catalyst with high activity and long service life. The catalyst is particularly suitable for the hydrogenation of the perchloride-containing C5 petroleum resin, thereby being capable of preparing hydrogenated petroleum resin with light hue and high softening point.

Owner:CHINA PETROLEUM & CHEM CORP

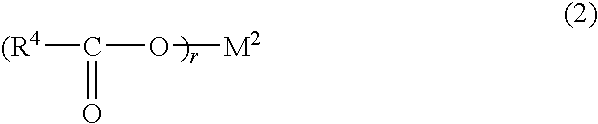

Resin composition, laminate using the same, and molded body using the laminate

InactiveUS8114522B2Improve adhesionSynthetic resin layered productsDomestic containersPolyolefinPetroleum resin

Disclosed is a resin composition forming an adhesive layer between a polylactic acid resin substrate layer and a polyolefin resin substrate layer. The resin composition includes a modified polyolefin resin (A) and a terpene resin (B), and the mass ratio (A) / (B) between the both resins (A) and (B) is 20 / 80 to 99 / 1. Alternatively, the resin composition may be a resin composition including 10 to 90% by mass of a polylactic acid resin (C), 5 to 89% by mass of the modified polyolefin resin (A) and 1 to 80% by mass of a hydrogenated petroleum resin (D), with the total amount of these resins constrained to be 100% by mass.

Owner:UNITIKA LTD

Preparation method for Carbon 5/Carbon 9 hydrogenated petroleum resin

The invention discloses a preparation method for Carbon 5 / Carbon 9 hydrogenated petroleum resin. In the existing preparation methods, certain methods have extremely high requirements on devices and high cost, and catalysts used by certain methods are not ideal for aromatic ring hydrogenation effect or easily cause intoxication. The preparation method comprises the following steps: firstly dissolving Carbon 5 / Carbon 9 petroleum resin by a dissolvent, then carrying out centrifugal sedimentation on the carbon 5 / Carbon 9 petroleum resin so as to remove most insoluble gel and asphaltenes, filtering the carbon 5 / Carbon 9 petroleum resin in an absorption tower filled with fillers so as to remove remained insoluble gel, asphaltenes and heavy metals; carrying out medium pressure hydrogenation reaction on liquid obtained through filtration in a static bed filled with secondary hydrogenation catalyst; and finally, carrying out flash evaporation and steam stripping so as to remove solvent in the product. The preparation method adopts a macroporous catalyst carrier; fluids are not easily blocked in holes, thereby greatly reducing fluid pressure drop and increasing effective catalytic area; and secondary hydrogenation can be completed in medium pressure, thereby greatly reducing requirements on devices and investment cost of the devices and obtaining hydrogenated petroleum resin with high quality.

Owner:杭州腾王网络科技有限公司

Process for producting petruleum resin by hot polymerizing

InactiveCN100999564ASolve the difficulty of not being able to produce low-color petroleum resinRetention timePetroleum resin

The present invention relates to hot polymerization process of producing petroleum resin, especially with C9 fraction as the side product of ethylene production. The C9 fraction material is first cut into three fraction sections including styrene resin oil, dicyclopentadiene resin oil and indene resin oil; and the three fraction sections are added into hot polymerization reaction kettle according to the requirement of the product for polymerizing, with the hot polymerization reaction kettle comprising four serially connected kettles with separate regulation on temperature, pressure, material retention time and other parameters. The product obtained through polymerization in the four serially connected kettles is distilled to eliminate solvent so as to obtain the petroleum resin product.

Owner:天津天大天海化工新技术有限公司 +1

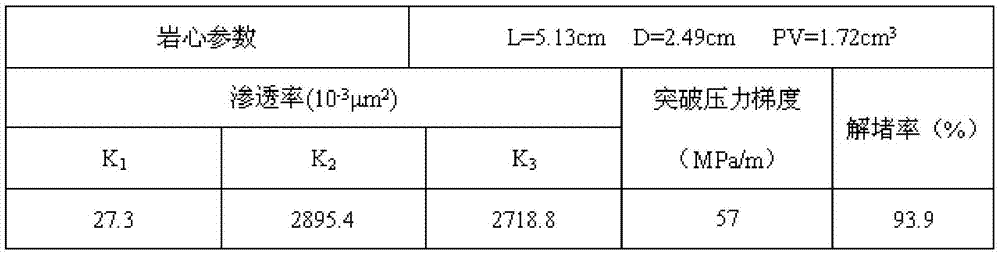

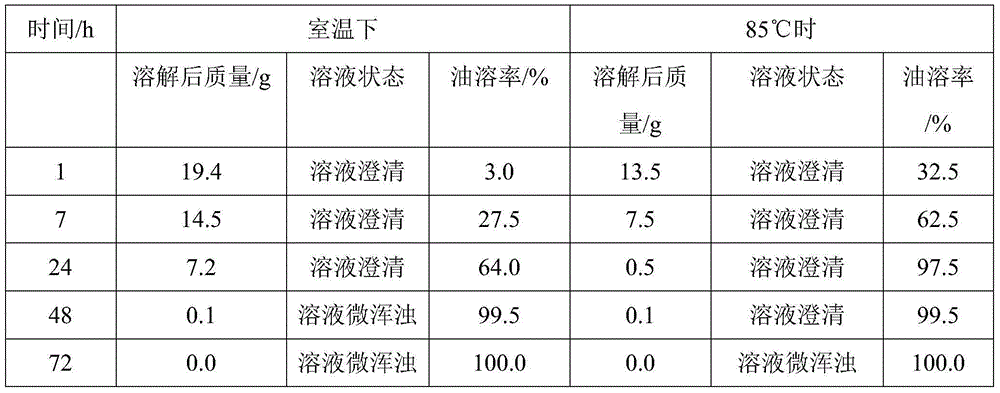

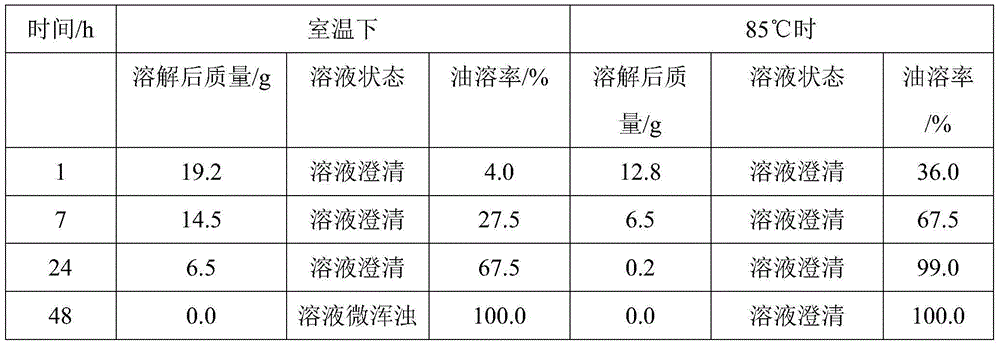

Oil-soluble hydraulic fracture temporary plugging reorientation agent and preparation method thereof

ActiveCN105441047AStrong temporary blocking abilityWide softening point rangeDrilling compositionSolubilityAdhesive

The invention provides an oil-soluble hydraulic fracture temporary plugging reorientation agent with the breakthrough pressure gradient higher than 50 MPa / m. The oil-soluble hydraulic fracture temporary plugging reorientation agent comprises a fluidity regulator, a toughener, a heat stabilizer, a colorant and the balance of an oil-soluble adhesive, wherein the oil-soluble adhesive has an adhesion function, can deform under the actions of the formation temperature and pressure and be adhered to crack and rock surfaces to realize plugging, particularly adopts one or two of rosin modified pentaerythritol resin, rosin modified phenolic resin, p-tert-butylphenol-formaldehyde resin and petroleum resin. The invention further provides a preparation method of the oil-soluble hydraulic fracture temporary plugging reorientation agent. The fracture temporary plugging reorientation agent has the characteristics of good oil solubility, adjustable softening point and applicability to deflection fracturing modification of a low-permeability reservoir oil well at different temperatures.

Owner:SHAANXI XINGYOU TECH DEV CO LTD

Heat-conduction and electric-conduction hot melt glue and preparation method thereof

InactiveCN103540280AGood compatibilityReduce the amount addedNon-macromolecular adhesive additivesElectrically-conducting adhesivesThermoplasticPolymer science

The invention relates to a heat-conduction and electric-conduction hot melt glue and a preparation method thereof. The hot melt glue is high in heat-conduction and electric-conduction properties under a precondition that the elasticity and bonding strength of the original hot melt glue; the heat conduction coefficient reaches more than 2.0w / m.k. According to the hot melt glue, base materials comprise styrene thermoplastic elastomers (SEBS) and styrene-butadiene-styrene thermoplastic elastomers (ESBS) modified by epoxidation; a thickening agent comprises two of hydrogenated rosin, terpene resin and C9 petroleum resin; a filler is graphene solid powder with heat-conduction and electric-conduction functions; the addition amount of the base materials accounts for 30-40%; the addition amount of thickening resin accounts for 30-50%; the addition amount of the solid graphene powder accounts for 1.5-3.5%; the addition amount of the other accessory ingredient naphthenic oil accounts for 15-18%; the addition amount of an antioxidant accounts for 1-2%; the heat-conduction and electric-conduction hot melt glue is prepared from the components of the hot melt glue through a melt blending method.

Owner:SHENYANG JIANZHU UNIVERSITY

Cold mixing color asphalt mixture and preparation method

The invention discloses a cold mixing color asphalt mixture and a preparation method. The preparation method comprises the following steps: selecting aromatic hydrocarbon oil, rubber oil, petroleum resin, epoxy resin, a modifier, a plasticizer, a diluent, diatomite, a pigment and stabilizers, and mixing the materials according to the mass proportion, thus obtaining color asphalt cement; selecting an emulsifier, the stabilizers and a defoamer, and mixing the three materials with the color asphalt cement in proportion, thus obtaining emulsified color asphalt cement; and selecting an aggregate, a filler, cement, a waterborne curing agent, an expansive agent and the emulsified color asphalt cement, and mixing the materials in proportion, thus obtaining the cold mixing color asphalt mixture.

Owner:SHENZHEN TRAFFIC CONSTR ENG TEST & DETECTION CENT

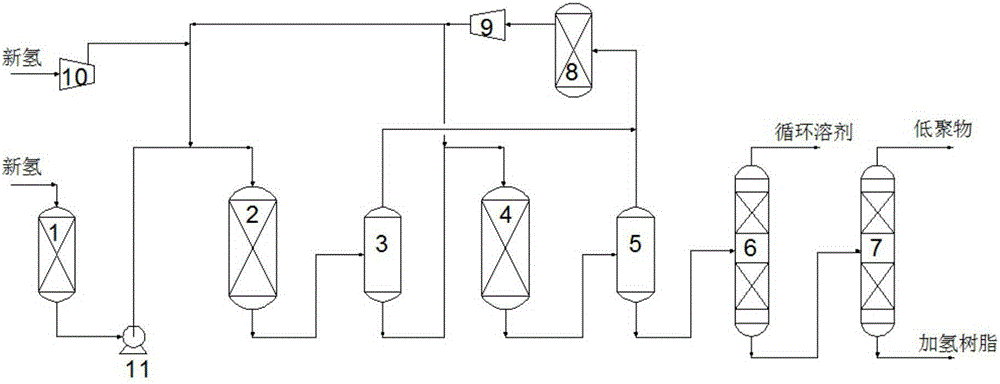

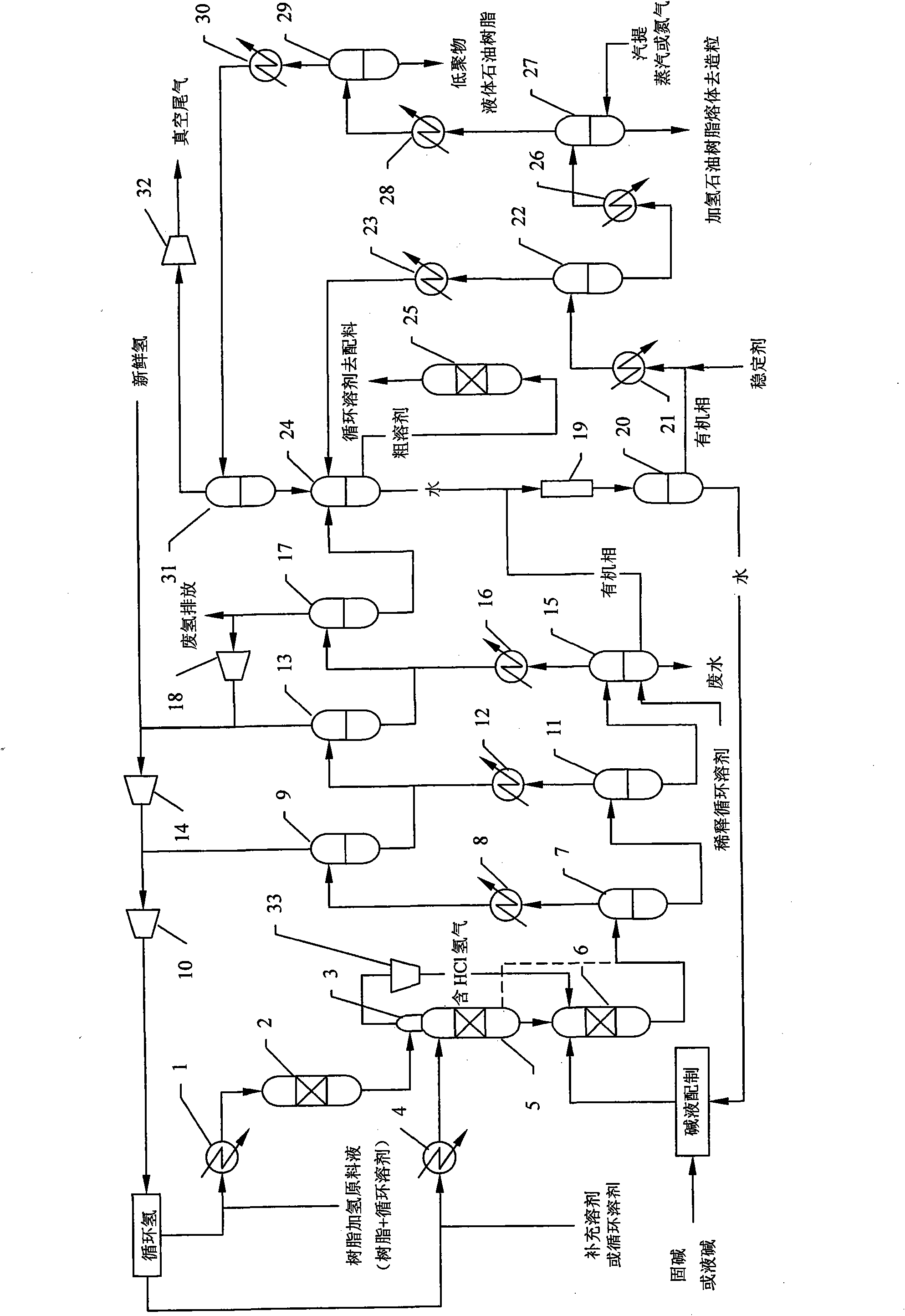

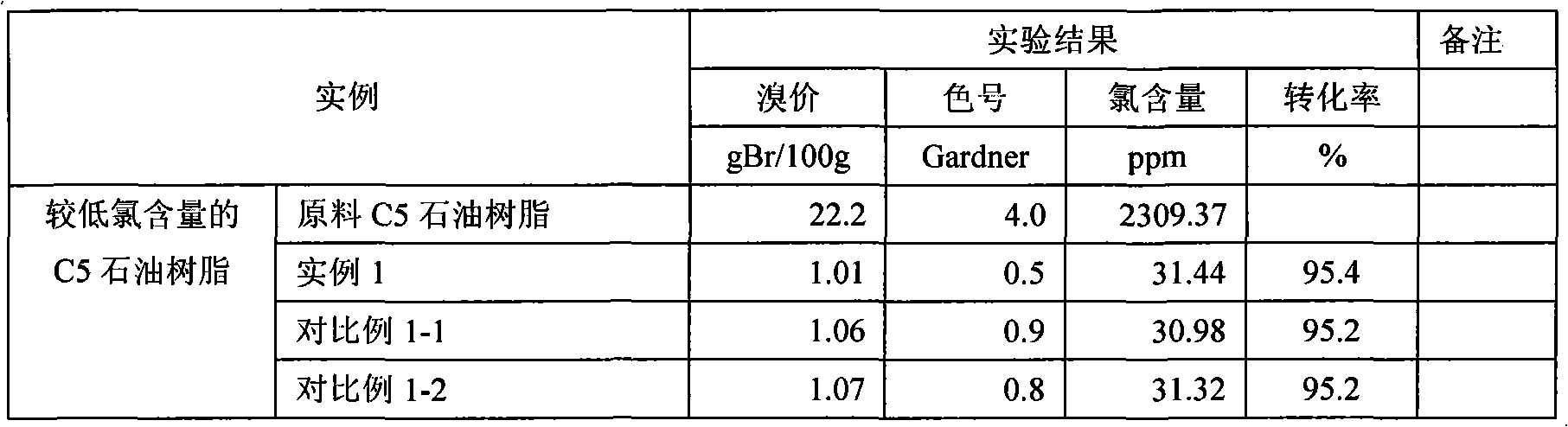

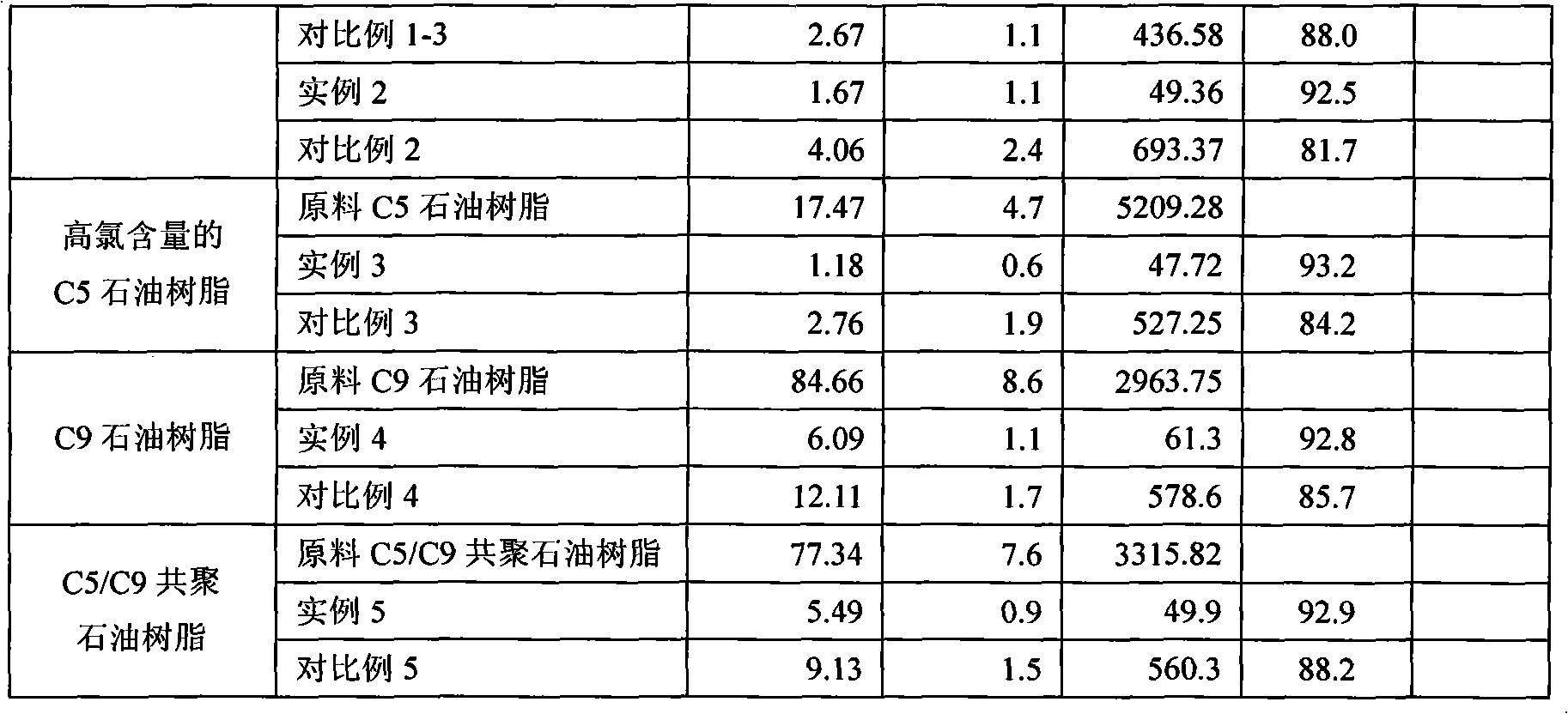

Combined hydrotreatment method and hydrotreatment system for petroleum resin

The invention relates to a combined hydrotreatment method for petroleum resin. The combined hydrotreatment method comprises the following steps of firstly, mixing raw materials of the petroleum resin with a recycled solvent; after a mixture is subjected to high-temperature treatment, adsorbing the mixture by using an adsorbing material to obtain refined petroleum resin; secondly, introducing the refined petroleum resin into a hydrogenation fixed bed which is used at the first stage and is filled with a hydrogenation catalyst, reacting the refined petroleum resin with hydrogen at a volume ratio of 1:500 to 1,000 under the conditions of 5 to 20MPa and 150 to 200DEG C, and removing toxic gases containing hydrogen chloride and hydrogen sulfide to collect liquid phase components; thirdly, introducing the liquid phase components into a hydrogenation fixed bed which is used at the second stage and is filled with the hydrogenation catalyst, reacting the liquid phase components with the hydrogen under the conditions of 10 to 20MPa and 220 to 280DEG C, performing flash evaporation on reactants to remove the recycled solvent, and collecting products to obtain the petroleum resin. The invention also provides a combined hydrotreatment system for the petroleum resin. By adopting the method and the system provided by the invention, hydrogenated petroleum resin with the advantages of No.0 chromaticity, good thermal stability and accordance with domestic standard requirements can be produced.

Owner:朗盈科技(北京)有限公司

High-temperature oil-soluble temporary plugging agent and preparation method thereof

The invention relates to a high-temperature oil-soluble temporary blocking agent. The high-temperature oil-soluble temporary blocking agent is characterized by comprising the following components in percent by weight: 10-40% of asphalt, 20-50% of C9 petroleum resin, 15-50% of coumarone resin, 5-15% of a surfactant, 2-15% of a polymer fiber and 1-10% of a softening-point additive. The preparation procedures of the high-temperature oil-soluble temporary blocking agent are as follows: firstly, adding the asphalt into a reactor, heating to melt the asphalt, adding the C9 petroleum resin and the coumarone resin into the reactor, stirring continuously until the substances in the reactor are fully melted, continuously adding the surfactant, the polymer fiber and the softening-point additive into the reactor, stirring for 30 minutes to mix uniformly, stopping heating a mixture, cooling, then collecting particles, washing, and screening to obtain the high-temperature oil-soluble temporary blocking agent with different particle sizes. The high-temperature oil-soluble temporary blocking agent provided by the invention overcomes the defect that the traditional oil-soluble temporary blocking agent can not resist high temperature. The high-temperature oil-soluble temporary blocking agent has good oil solubility, acid and salt resistance and high-temperature degradation resistance. The added softening-point additive is capable of regulating the range of the softening point, and thus an oil layer can be protected.

Owner:TIANJIN DAGANG OILFIELD BINGANG GRP BOHONG PETROLEUM CHEM

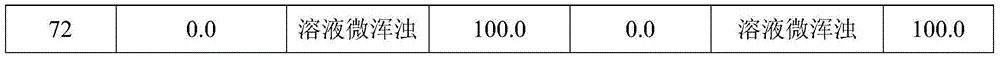

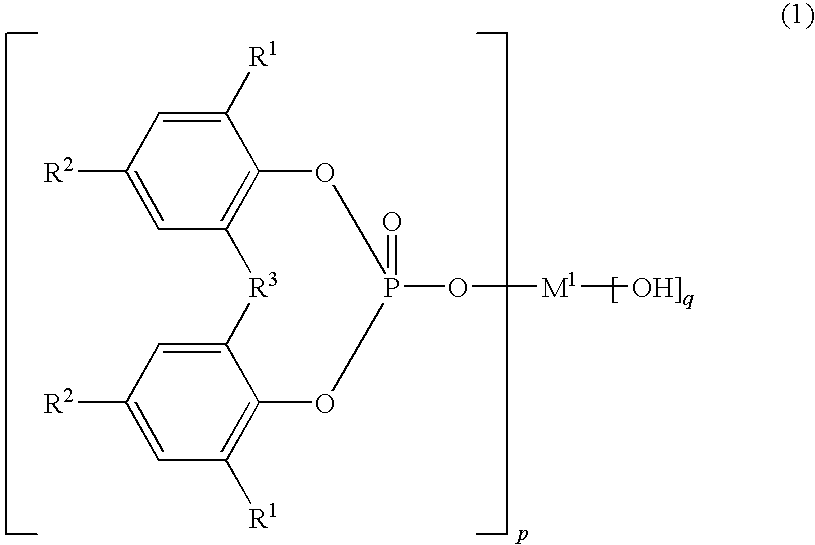

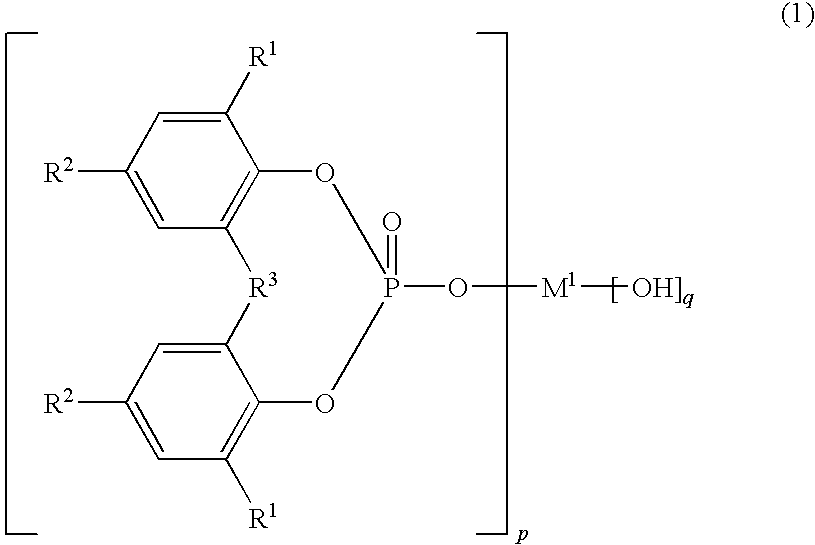

Nucleating agent masterbatch for polyolefin resin

ActiveUS20100204374A1Improve propertiesHigh transparencyGroup 5/15 element organic compoundsMasterbatchPolymer science

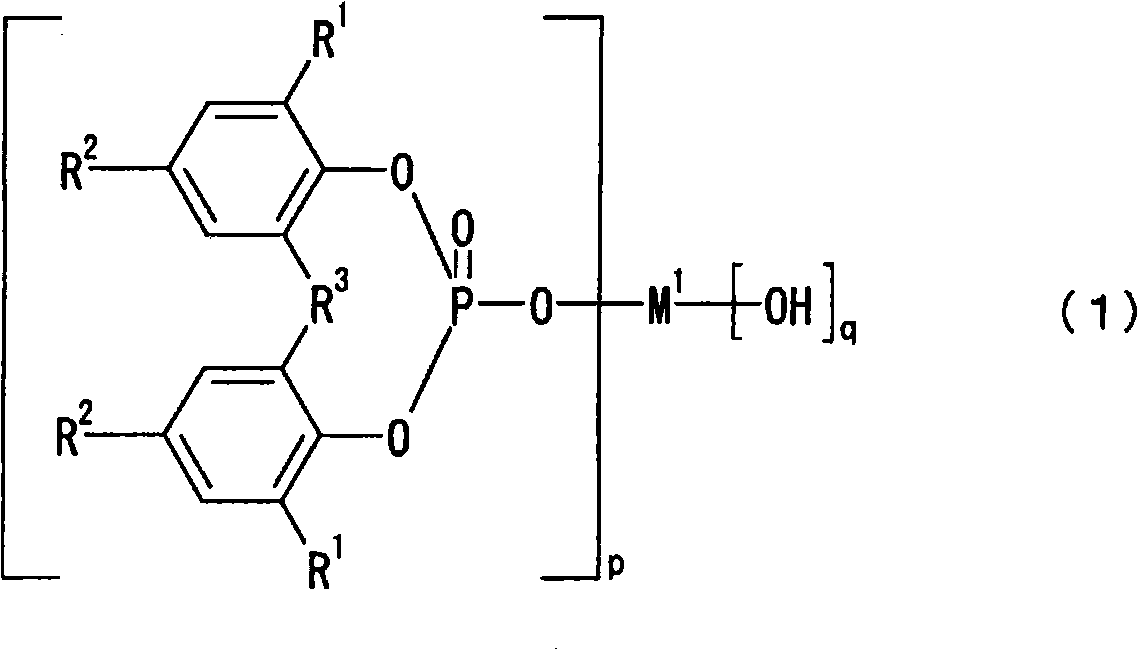

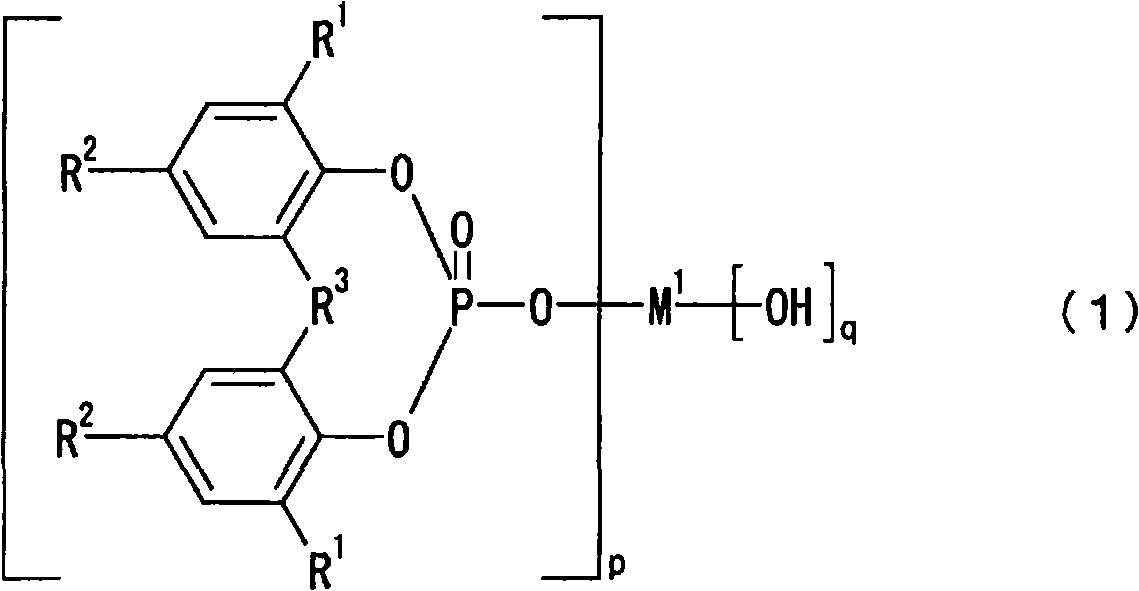

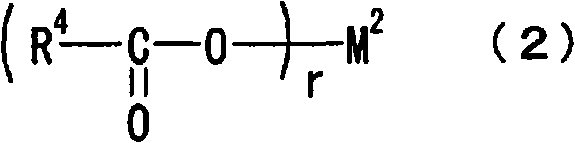

Provided is a nucleating agent masterbatch for polyolefin resin excellent in dispersibility into a polyolefin resin, which nucleating agent masterbatch is capable of improving transparency and mechanical strength of the polyolefin resin, which is a crystalline polymer, which nucleating agent masterbatch is further excellent in resistance to heat coloring; and a polyolefin resin composition using the masterbatch. Specifically, provided is a nucleating agent masterbatch for polyolefin resin, wherein, based on 100 parts by mass of a fully hydrogenated petroleum resin (A) having a softening point of not lower than 100° C., 3 to 150 parts by mass of an aromatic phosphate metal salt (B) represented by the following general formula (1):

Owner:ADEKA CORP

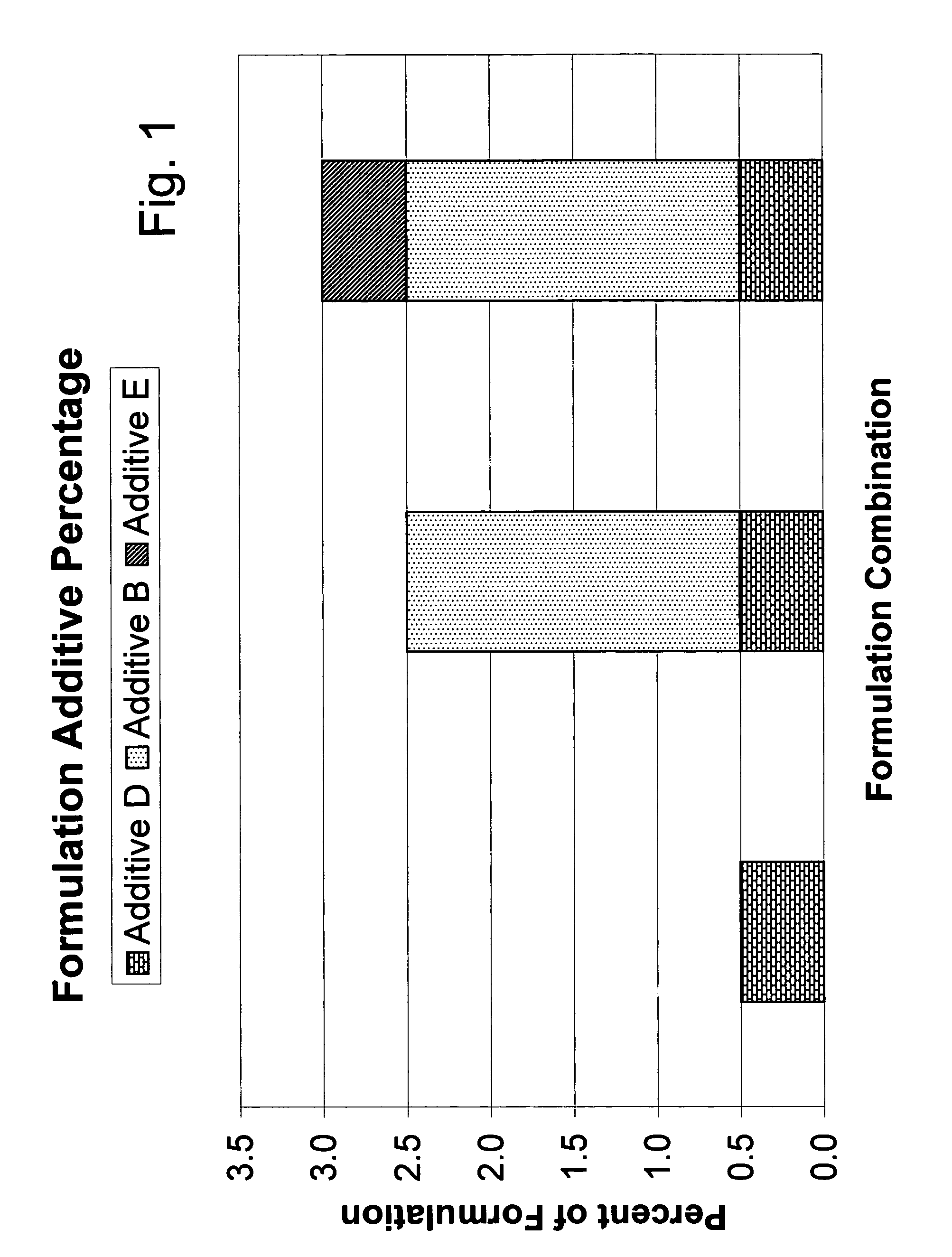

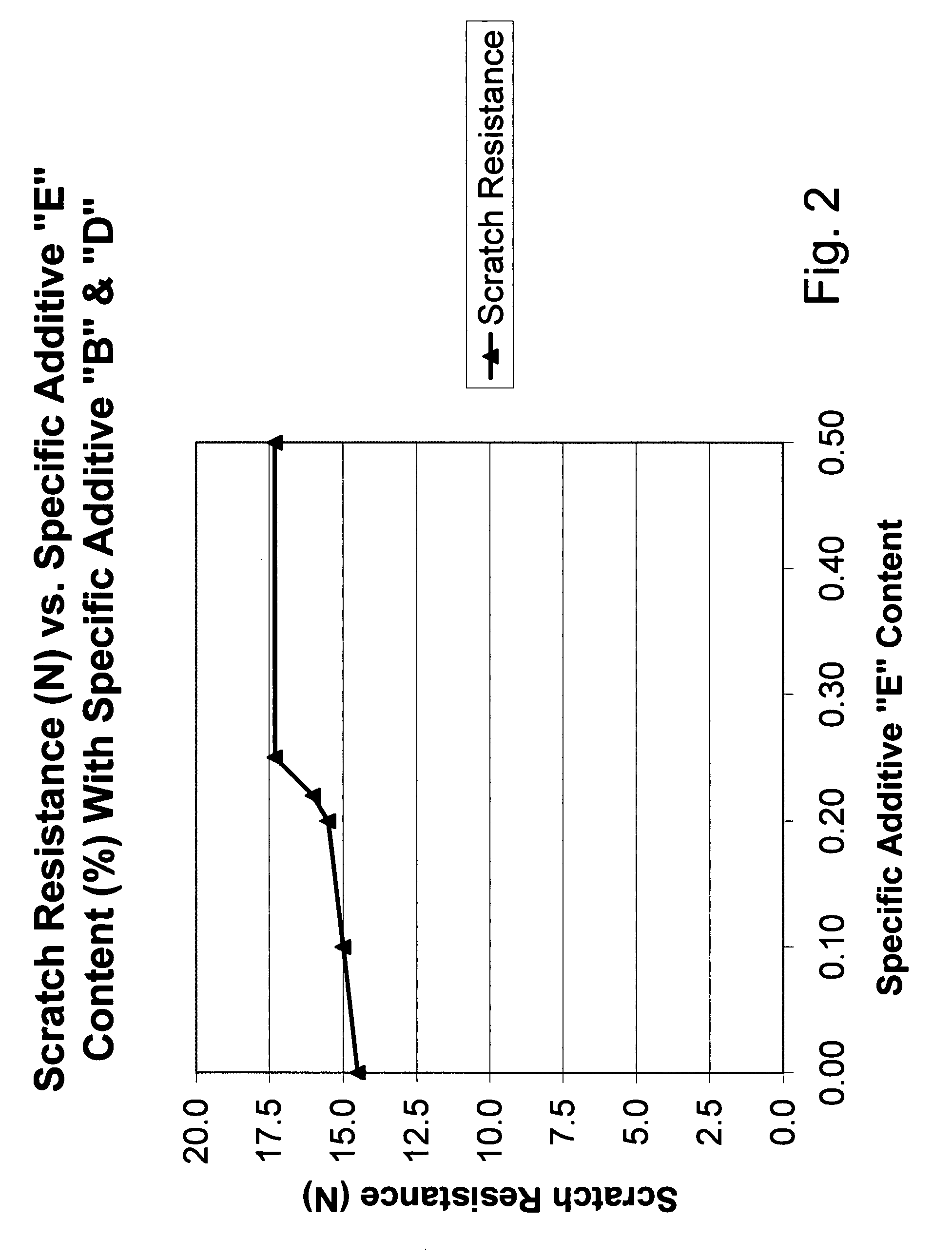

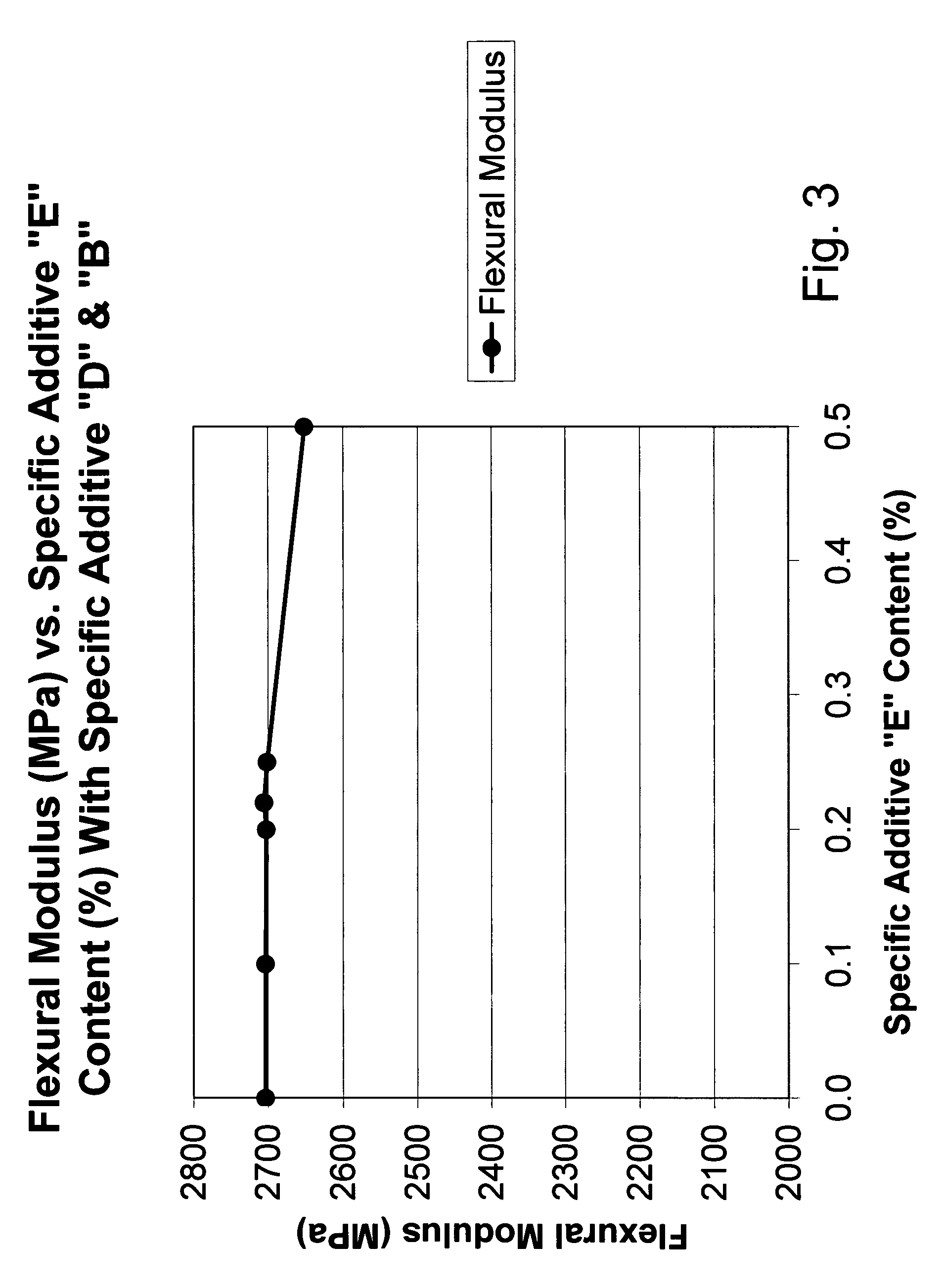

Scratch-resistant polypropylene composition

The invention relates to polypropylene compositions, methods of preparing the polypropylene compositions, and methods of producing molded or extruded articles of the polypropylene composition. In one embodiment, the polypropylene composition contains: (a) about 60 to about 65 wt. % of a polypropylene resin; (b) about 10 to about 15 wt. % of an ethylene-alpha-olefin copolymer rubber; (c) about 20 to about 25 wt. % talc; (d) about 0.5 to about 3.0 wt. % of a grafted polypropylene resin; (e) about 0.2 to about 0.5 wt. % of an unsaturated fatty acid amide; and (f) about 0.2 to about 0.5 wt. % scratch-resistant agent, all based on the weight of the polypropylene composition. The scratch-resistant agent contains about 30 to about 50 wt. % of an ethylene vinyl acetate, and about 50 to about 70 wt. % of an aliphatic petroleum resin, based on the weight of the scratch-resistant agent. In another aspect, the invention relates to a process for preparing the polypropylene composition described above. In a further aspect, the invention involves a method of molding or extruding the polypropylene composition described above. In yet a further aspect, the invention includes molded or extruded articles of the polypropylene composition described above. The polypropylene compositions of the invention are especially useful in the preparation of molded objects and articles requiring superior scratch resistance.

Owner:ADVANCED COMPOSITES +1

Preparation method for medical use hydrocolloid dressing

The invention discloses a preparation method for medical hydrocolloid dressing. The preparation method comprises the following steps:,1, dissolving styrene-butadiene-styrene block copolymer, then adding aliphatic series petroleum resins, carrying out the reaction, slowly adding cyclane oil, raising the temperature, then adding N.N-dibutyl dithio amido formic acid, and keeping the temperature to form a component A; 2, mixing anhydrosorbitol fatty acid ester and a polyoxyethylene sorbitan fatty ester condensation compound at normal temperature to form a liquid state component B; 3, taking sodium carboxymethyl cellulose, carboxymethyl chitosan, calcium alginate fibers and solid silver corpuscles, crushing the calcium alginate fibers into short fibers, mixing the substances at normal temperature to form a component C; and 4, adding the component B into the component A, raising the temperature, slowly stirring the mixture evenly and then adding the component C, stirring and cooling down the mixture, carrying out the debubbling in the vacuum, reducing the temperature, forming the dressing onto antiseize paper through injection moulding, and covering a PU film on the surface of the hydrocolloid to form a finished product.

Owner:褚加冕

Highly effective pour depressant for thermodynamic oil extraction process

ActiveCN101210173AImprove applicabilityStrong pouring capacityDrilling compositionWater basedDepressant

A high-efficiency pour point depressant for thermal recovery process comprises (1) biphenyl, polycyclic aromatic hydrocarbons or polycyclic aromatic hydrocarbon derivatives free of chlorine and sulfur elements; (2) liquid petroleum products containing arene larger than 5%, petroleum resin in liquid state at normal temperature or natural hydrocarbon aggregates in particle state at normal temperature; (3) surfactant; (4) fusel oil; (5) alcohol ethers having a closed cup flash point larger than 20 DEG C; and (6) oil-soluble or water-soluble polymers respectively having a nonpolar section eutectic with paraffin molecule and a polar section for twisting crystal form of wax crystal on a main chain and / or a branch chain. The high-efficiency pour point depressant of the invention performs all functions of both water-base pour point depressant and oil-base pour point depressant, and can efficiently assist the prior various thermal recovery processes in exploring high pour-point oil and heavy oil reservoirs, with the advantages of greatly reduced exploitation cost, prolonged production cycle of the oil well, increased output of the oil well, increased ultimate recovery of the oil reservoir,as well as significant economic benefit.

Owner:盘锦河升大地石油科技有限公司

Grinding material for precision casting

The invention relates to a precise casting mold material, which comprises: petroleum wax, petroleum resin, high polymer, mineral wax and animal-plant wax. This product has high bending strength, superficial hardness, small linear shrinkage and ash, and well other properties, overcomes opposite in prior art, and fits to manufacture large-scale thin-wall integral fine-casting structure part.

Owner:CHINA PETROLEUM & CHEM CORP +1

Colour asphalt and its preparation method

The present invention discloses a color asphalt and its preparation method. Its composite includes petroleum asphalt 90# 40-44%, petroleum resin 120# 26-30%, petroleum resin 90# 3-5%, extractive oil 4-6%, xylene 2-4%, santobrite salt 5-7%, 99% chromium 2-4%, iron oxide 30# 3-5%, rosen 3-4% and titanium oxide 1-3% and proper quantity of pigment. Said invention adopts the following processes: reduced pressure distillation for extracting asphaltene, splitting by splitter tower, adding resin material, titanium and pigment, then making high-temp. synthesis. It is a new type builidng material, can be used for laying pavement, etc.

Owner:周英久

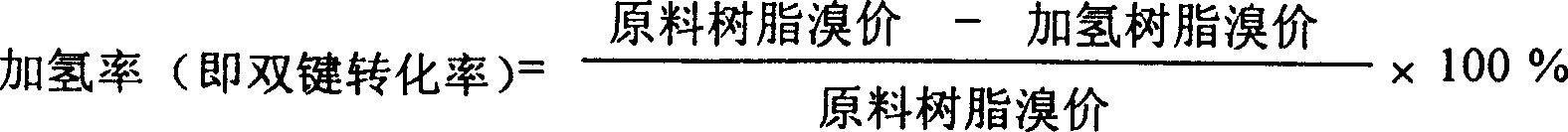

Industrial manufacture method for hydrogenated petroleum resin

ActiveCN102382259ASimplify the caustic cleaning processReduce corrosionPetroleum resinHydrogenation reaction

The invention relates to an industrial manufacture method for hydrogenated petroleum resin, which comprises the following steps of: generating hydrogenation reaction on petroleum resin which is obtained by polymerizing cracking C5 and C9 fractions under the proper condition of the existence of hydrogenation catalyst and solvents by adopting the processes of two-section hydrogenation and combination alkaline cleaning neutralization; hydrogenating the unsaturated component in the petroleum resin to reduce double-bond content; hydrogenating a non-ferrous perssad to fade; hydrogenating to remove chlorine retained in the polymerization process; and carrying out alkaline cleaning, water cleaning, stabilizer injection and solvent removal to obtain light or colourless hydrogenated petroleum resin. The method further simplifies the process through the organic combination of unit operation, and the industrial manufacture method for the hydrogenated petroleum resin, which has the advantages of wide adaptability on hydrogenated raw materials, less corrosion on system equipment, high product quality and high production capability is formed.

Owner:CHINA PETROLEUM & CHEM CORP

Highly effective viscosity-reducing agent for thermodynamic oil extraction process

ActiveCN101235279ASolve the problem of emulsification blockageImprove timelinessDrilling compositionSolubilityPetroleum product

High efficiency viscosity-reducing agent which is used on THE thermal oil extraction technology, which is formed by the following raw materials with percentage by weight, firstly phenyl benzene, fused ring aromatic hydrocarbon or fused ring aromatic hydrocarbon derivative which does not contain chlorine element and sulfur element, secondly liquid petroleum product whose aromatic hydrocarbons content is no more than 5%, petroleum resin which is liquid state under the constant temperature or hydrocarbons natural aggregation which is particle state under the constant temperature, thirdly water-soluble anionic surface active agent, water-soluble non-ionic surface active agent, oil solubility anionic surface active agent or oil solubility non-ionic surface active agent, fourthly fusel oil, fifthly alcohol ether, sixthly oil solubility or water-soluble polymer which respectively has nonpolar portion which has eutectic crystal with ceresin wax molecular and polar portion which can make wax crystal system twisty on main chain and or branch chain, seventhly hyperoxide, eighthly carbamide, ammonium carbonate, ammonium acid carbonate or ammonium nitrite and ninthly ketone. The high efficiency viscosity-reducing agent has strong suitability, strong viscosity-reducing ability, safety and reliability, can largely reduce extract cost and increase the yield of oil pump, and increases the final recovery efficiency of oil reservoir.

Owner:盘锦河升大地石油科技有限公司

Process for preparing hydrogenated C5/C9 copolymerized petroleum resin

The invention discloses a preparing method of hydrogenated C5 / C9 copolymerized oil resin, which comprises the following steps: dissolving C5 / C9 copolymer oil resin in the hydrogenation solvent; decoloring through adsorbing agent to proceed catalytic hydrogenating reaction with hydrogen in the fixed bed reactor at 220-270 Deg C under 2.0-8.0Mpa; setting the bulk air-speed at 0.1-1.0h-1 and hydrogen and oil rate at 300-3000:1; allocating the catalyst as load-patterned nickel catalyst with 35-50% Ni; adopting gamma-Al2O3 as carrier with specific area at 150-300m2 / g and hole conpacitance at 0.2-0.4ml / g; decompressing hydrogenated product; distilling to recycle solvent to obtain the product.

Owner:SINOPEC YANGZI PETROCHEM

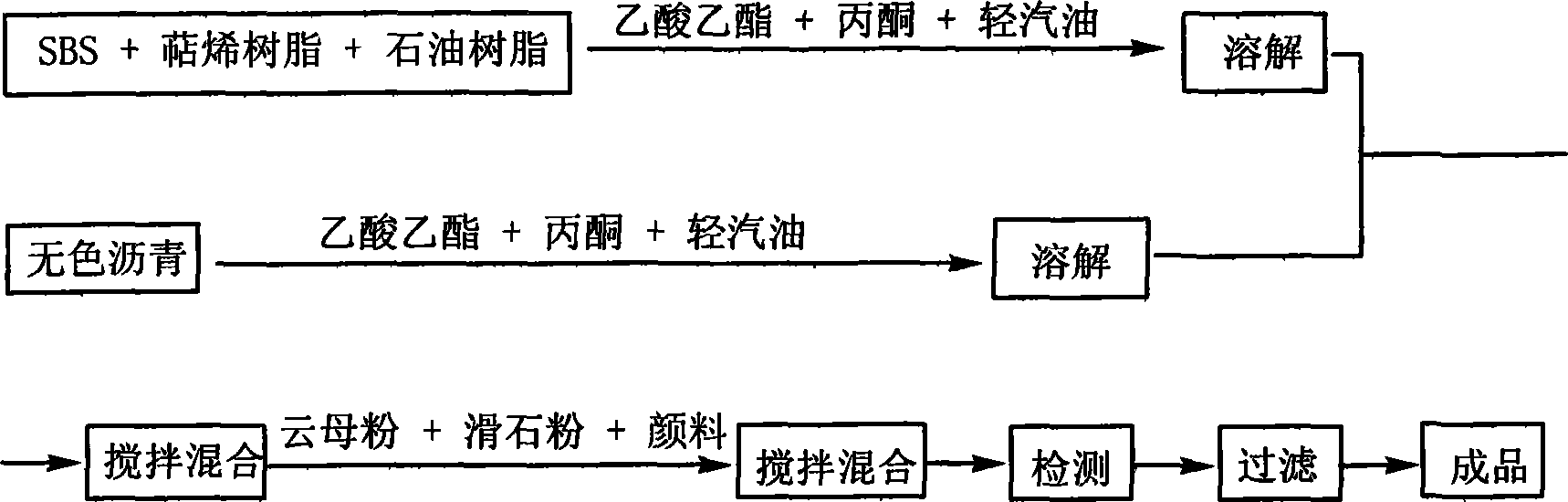

Color SBS modified waterproof asphalt material

InactiveCN101074345ASave energySimple and fast operationAntifouling/underwater paintsPaints with biocidesExtensibilityBituminous waterproofing

A color SBS modified asphalt waterproof coating with colorless asphalt as main filming substance is cheap and convenient. It adopts diamylene resin and petroleum resin as viscosity increaser and acetic ether as solvent. It saves resources, It's non-toxic, has no environmental pollution and excellent heat, freezing, ageing, water and weather resistances, has better extensibility and adhesive strength. It can be used for roof of architectures, toilet, gain depot, dam, oil depot, pipeline, swimming pool and tunnel.

Owner:ZHENGZHOU UNIV

Nucleator masterbatch for polyolefin resin

Disclosed is a nucleator masterbatch for polyolefin resins, which is excellent in dispersibility in polyolefin resins and resistance to thermal coloration. This nucleator masterbatch for polyolefin resins enables to improve transparency and mechanical strength of a polyolefin resin which is a crystalline polymer. Also disclosed is a polyolefin resin composition using such a nucleator masterbatch for polyolefin resins. Specifically disclosed is a nucleator masterbatch for polyolefin resins, which is characterized by being obtained by adding 3-150 parts by mass of an aromatic metal phosphate salt (B) represented by the general formula (1) below to 100 parts by mass of a completely hydrogenated petroleum resin (A) having a softening point of not less than 100 DEG C.

Owner:ADEKA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com