Patents

Literature

116 results about "Dicyclohexyl phthalate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

To do this, concentrations of eight phthalates (dimethyl phthalate (DMP), diethyl phthalate (DEP), diisobutyl phthalate , di-n-butyl phthalate , benzylbutyl phthalate (BBP), dicyclohexyl phthalate (DCHP), di(2-ethylhexyl) phthalate and di-n-octyl phthalate ) were determined in 591 foods and 30 packaging materials.

Hot melt adhesive

InactiveCN102653665ASuitable for production process requirementsReasonable formula designMacromolecular adhesive additivesEpoxyPolyolefin

The invention discloses a hot melt adhesive which comprises the following components in parts by mass: 5-10 parts of EVA (ethylene-co-vinyl acetate), 2-6 parts of tackifier, 5-10 parts of diluent, 0.5-1.5 parts of antioxidant and 0.5-1.5 parts of plasticizer. The tackifier is one of rosin resin, petroleum resin, terpene resin, phenolic resin and epoxy resin; the diluent includes one or both of wax and low-molecular polyolefin; the antioxidant is phenolic antioxidant; and the plasticizer is DCHP (Dicyclohexyl phthalate). The EVA contains 20-30% of vinyl acetate monomer; and the wax is microcrystalline wax with molecular weight of 3,000-4,000 and melting point of 65-85 DEG C.

Owner:成都鑫三洋科技发展有限公司

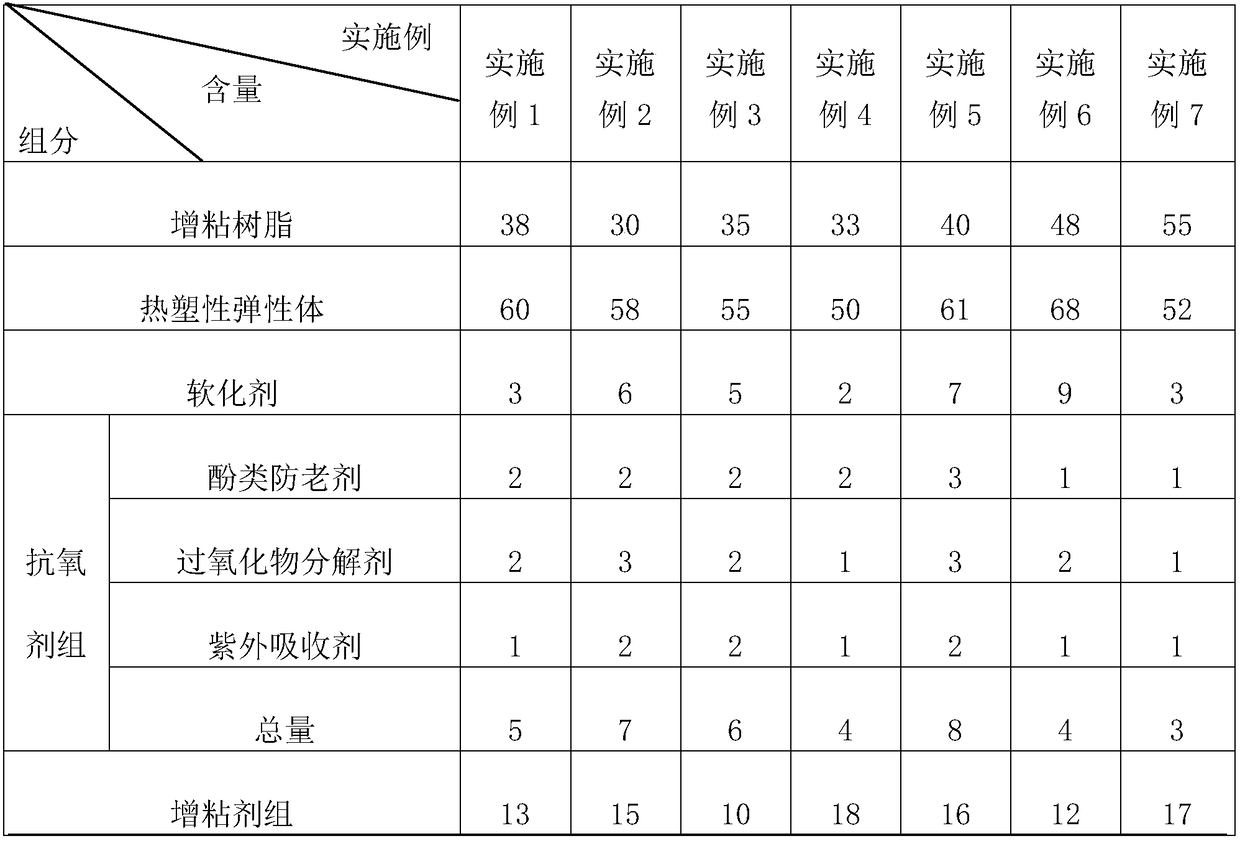

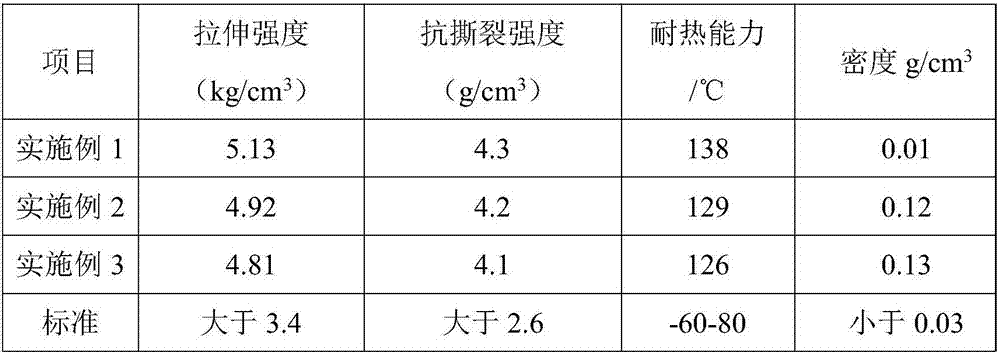

Anti-oxidation medical hot-melt pressure-sensitive adhesive and preparation method thereof

InactiveCN108587532AImprove adhesionNo stimulationNon-macromolecular adhesive additivesMacromolecular adhesive additivesMicrocrystalline waxIrritation

The invention discloses an anti-oxidation medical hot-melt pressure-sensitive adhesive and a preparation method thereof. The anti-oxidation medical hot-melt pressure-sensitive adhesive comprises the following components: tackifying resin, a thermoplastic elastomer, a softening agent, an antioxidant group and a tackifier group, wherein the tackifying resin is hydrogenated petroleum resin, the thermoplastic elastomer is SBS / SIS, the antioxidant group comprises a phenolic anti-aging agent, a peroxide decomposing agent and an ultraviolet absorbent, and the tackifier group comprises at least one selected from rosin modified resin, terpene resin, a maleic anhydride grafted compatilizer, microcrystalline wax, dicyclohexyl phthalate and polyisobutene. According to the invention, harm is not causedto skins during peeling while the adhesive force of the product is further improved, and all the components are nontoxic and harmless, have no irritation to the skins, and have low allergenicity. Inaddition, the oxidation resistance of the product is greatly improved, the application range of the product is expanded, and the bonding reliability is further ensured.

Owner:浙江精华科技有限公司

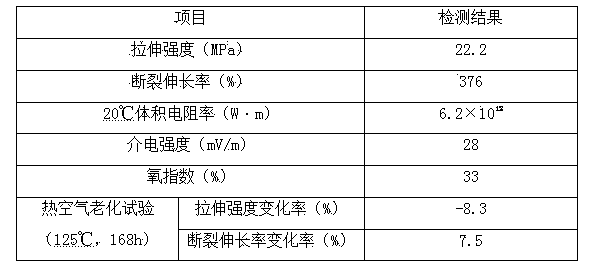

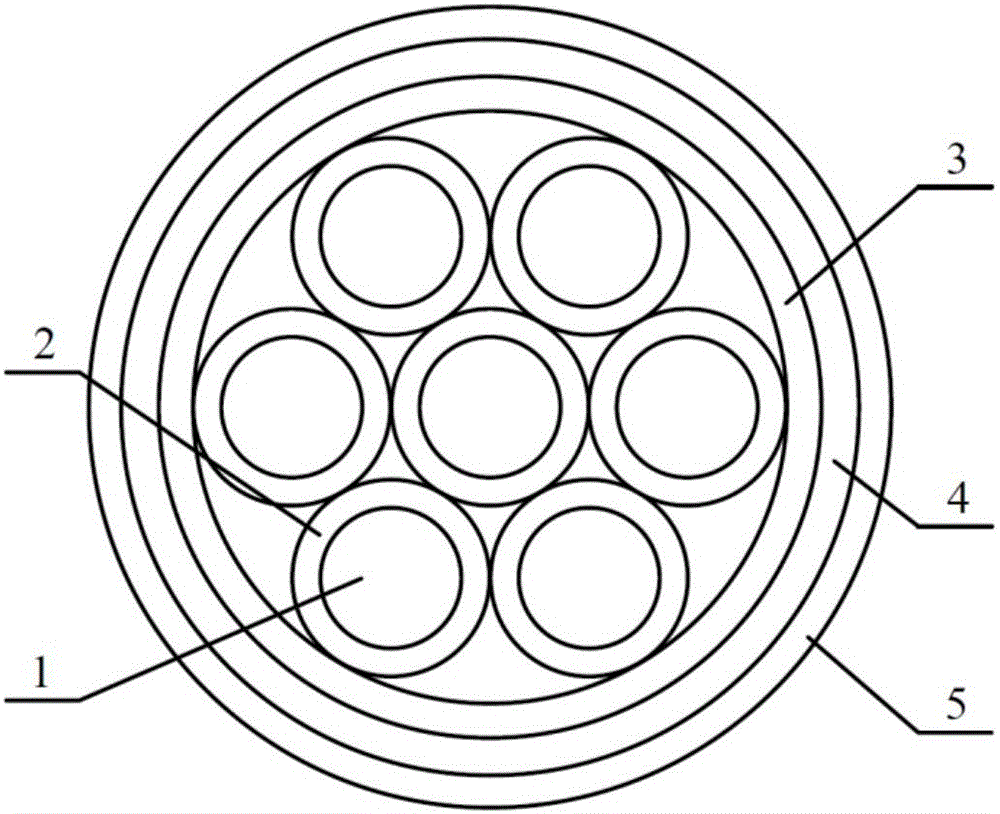

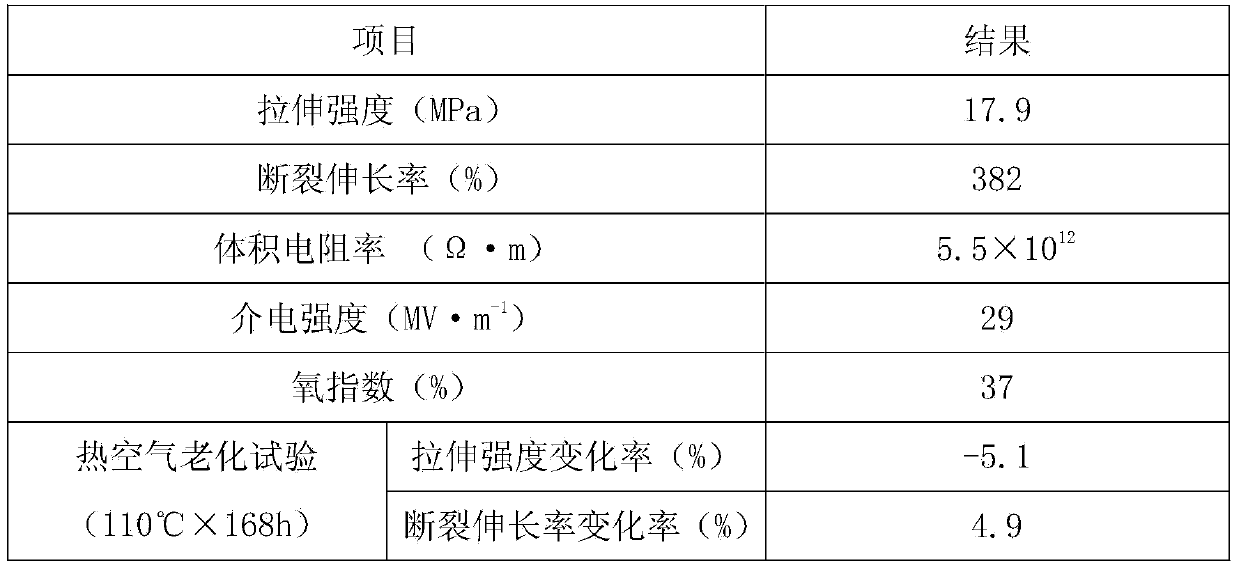

EVA (ethylene-vinyl acetate) elastomer sheath material for wind power generation torsion-resistant flexible cables and preparation method thereof

ActiveCN103122098AGood dispersionImprove heat aging resistancePlastic/resin/waxes insulatorsInsulated cablesElastomerEngineering

The invention discloses an EVA (ethylene-vinyl acetate) elastomer sheath material for wind power generation torsion-resistant flexible cables and a preparation method thereof. The EVA elastomer sheath material for wind power generation torsion-resistant flexible cables comprises the following components in parts by weight: 60-70 parts of EVA, 30-40 parts of CPE (chlorinated polyethylene), 20-25 parts of acetylene smoke, 10-15 parts of modified nano SiO2, 30-50 parts of talcum powder, 5-10 parts of antimony pentoxide, 1-2 parts of polytrimethyldihydroquinoline, 10-15 parts of dicyclohexyl phthalate, 2-3 parts of lead stearate, 3-5 parts of disalt-base lead phthalate, 1-2 parts of vinyltriethoxysilane and 6-8 parts of DCP (dicumyl peroxide). The sheath material disclosed by the invention has the advantages of excellent physical and mechanical properties, favorable high / low temperature resistance, favorable oil resistance, favorable solvent resistance, favorable wear resistance, favorable ozone resistance, favorable aging resistance, favorable flame retardancy, low smoke, high flexibility, torsion resistance and the like, is very durable, environment-friendly and pollution-free, and can completely satisfy the requirements for wind power generation flexible cables.

Owner:ANHUI HUAJIN CABLE GROUP

Wear-resisting rubber material for tires

The invention discloses a wear-resisting rubber material for tires. The wear-resisting rubber material comprises the following raw materials in parts by weight: 45-50 parts of butadiene styrene rubber, 10-15 parts of butadiene rubber, 10-15 parts of natural rubber, 20-25 parts of isoprene rubber, 0.5-0.8 part of sulfur powder, 2-3 parts of accelerant nonanoyloxybenzene sulfonate (NOBS), 1.3-1.7 parts of accelerant DM, 0.5-0.9 part of accelerant tetramethyl thiuram monosulfide (TMTM), 10-15 parts of nano-cellulose whisker, 10-15 parts of barite powder, 20-23 parts of calcite powder, 7-9 parts of brucite powder, 5-8 parts of aluminium nitride, 30-35 parts of carbon black N234, 1-1.2 parts of single alkoxy titanate coupling agent, 1-1.2 parts of plasticizer dicyclohexyl phthalate (DCHP), 3-7 parts of octyl epoxy stearate, 0.3-1.2 parts of anti-aging agent 264, and 1-2 parts of anti-aging agent MB. The wear-resisting rubber material for the tires has excellent wear-resisting and ageing-resistant properties, so that the wear-resisting rubber material can adapt to the service environment of the tires, and the cost is also reduced.

Owner:ZHAOQING JUNHONG CO LTD

Conducting silver aluminum slurry containing dicyclohexyl phthalate

ActiveCN103021505AImprove photoelectric conversion efficiencyImprove conductivityNon-conductive material with dispersed conductive materialCable/conductor manufactureEnvironmental resistanceSlurry

The invention discloses conducting silver aluminum slurry containing dicyclohexyl phthalate. The conducting silver aluminum slurry comprises, by weight, 50-52.4 parts of A material, 10-15 parts of B material, 1-2 parts of silane coupling agent KH540, 0.5-1 part of tributyl phosphate, 1-2 parts of organosilicon flatting agent, 0.3-0.5 part of castor oil, 0.2-0.4 part of sodium dodecyl sulfate and 0.4-0.6 part of dicyclohexyl phthalate. The conducting slurry does not contain lead, completely meets the environment-friendly requirements, is applied to solar battery production and can be high in adhesion when formed on the surface of a solar battery, photoelectric conversion efficiency of the battery is high, silver powder of different grain diameters and the like are selected and used simultaneously, the contact area between grains is increased, and accordingly the conducting capability of the silver slurry is improved.

Owner:浙江极铝科技有限公司

Nano high-air-tightness compressive film and preparation method thereof

The invention discloses a nanometer high-air-tightness compressive film, which consists of the following components: PVC (Polyvinyl Chloride) resin, DOP (Dioctyl Phthalate), DBP (Dibutyl Phthalate), DCHP (Dicyclohexyl Phthalate), a stabilizer, modified nanometer kaolin, calcium carbonate and other aids. The nanometer high-air-tightness compressive film is prepared by performing a calendaring process, an attaching process, a cooling step and a coiling step on each component. The nanometer high-air-tightness compressive film has the advantages that: a DOP-DBP-DCHP compound plasticizer is adopted, so that PVC resin is fully plasticized; the DCHP plays a role in plasticizing, and contributes to making a PVC film structure denser and enhancing the air tightness of the compressive film; the air tightness of the compressive is further improved by adopting the modified nanometer kaolin, and superior physical and mechanical performance of the compressive film is achieved simultaneously; and high-strength industrial polyester screen cloth is taken as an intermediate reinforcing material, so that compressive film provided by the invention has extremely high compressive strength.

Owner:FUJIAN SIJIA ENVIRONMENTAL PROTECTION MATERIAL TECH

EPE pearl wool and preparation method thereof

InactiveCN107880347AEasy to operateShorten the timeLow-density polyethyleneLinear low-density polyethylene

The invention provides EPE pearl wool. The EPE pearl wool is prepared from the following raw materials in parts by weight: 70-80 parts of low density polyethylene, 30-40 parts of high density polyethylene, 10-15 parts of an ethylene-vinyl acetate copolymer, 12-16 parts of azodicarbonamide, 3-5 parts of dicumyl peroxide, 3-5 parts of zinc oxide, 20-30 parts of titanate modified calcium carbonate, 5-7 parts of isobutyl triethoxysilane, 1-2 parts of magnesium stearate, 4-6 parts of butyl stearate, 4-5 parts of hexamethylenetetramine, 3-5 parts of polycarbonate, 5-7 parts of aluminum hydroxide, 8-9 parts of bamboo charcoal powder, 6-8 parts of dioctyl adipate, 3-5 parts of ethanol amine, 8-9 parts of dicyclohexyl phthalate and 7-9 parts of kaolin. The EPE pearl wool provided by the invention has good elasticity, buffering capability, thermal stability and mechanical properties. The invention also provides a preparation method of the EPE pearl wool.

Owner:HEFEI LANGSHENG NOVEL MATERIAL CO LTD

Modified nitrile rubber sheathing material for cable for oil well

InactiveCN104788758AGood dispersionGood compatibilityInsulated cablesInsulated conductorsPyrophosphateButadiene-styrene rubber

The invention discloses a modified nitrile rubber sheathing material for a cable for an oil well. The modified nitrile rubber sheathing material comprises raw materials in parts by weight as follows: 32-35 parts of nitrile rubber, 25-28 parts of a modified montmorillonite compound nylon / polypropylene composite material, 10-13 parts of butadiene styrene rubber, 7-10 parts of a polyurethane elastomer, 13-16 parts of inorganic filler, 1-1.3 parts of sulphur powder, 2-4 parts of an accelerator DM, 0.5-0.8 parts of an antioxidant 168, 0.3-0.6 parts of an antioxidant 1010, 1.1-1.4 parts of a DCHP (plasticizer dicyclohexyl phthalate), 1-3 parts of a mono-alkoxy pyrophosphate type titanate coupling agent and 4-7 parts of epoxy ethylhexyl stearate. The modified nitrile rubber sheathing material has excellent oil-resistant and flame-retardant performance, good mechanical performance such as tensile strength, stress at definite elongation, tearing resistance, extrusion and rolling and the like as well as good storage stability.

Owner:ANHUI WUZHOU SPECIAL CABLE GRP

Formula of foamed polyethylene plastic

The invention discloses a formula of foamed polyethylene plastic. The foamed polyethylene plastic comprises polyethylene plastic and additives, wherein the additives comprise fatty alcohol-polyoxyethylene ether sodium sulfate serving as a foaming agent, liquid polysulfide rubber serving as a softening agent, acrylate copolymer serving as a toughening agent, dicyclohexyl phthalate serving as a plasticizer, benzoyl peroxide serving as a cross-linking agent and vinyltriethoxysilane serving as a coupling agent. After the foaming agent and various auxiliary aids are added into the polyethylene plastic, the mechanical properties such as softness, toughness, tear resistance and plasticity of the foamed polyethylene plastic are greatly improved, and the service life of the foamed polyethylene plastic is prolonged; and the reaction rate of polyethylene in the production process can be improved, so that production cost is greatly reduced.

Owner:SUZHOU XINGWU ENG PLASTIC

Mould-prevention polyethylene water supply tubular product and preparation method thereof

InactiveCN104098823AImprove antibacterial propertiesImprove mechanical propertiesGlycerolMechanical property

The invention discloses a mould-prevention polyethylene water supply tubular product and a preparation method thereof. The mould-prevention polyethylene water supply tubular product is prepared from the following raw materials in parts by weight: 50-70 parts of medium density polyethylene, 25-45 parts of metallocene linear low density polyethylene, 20-30 parts of nylon 12, 15-20 parts of dimethyl fumarate, 4-8 parts of perfluorinated polyether lubricating grease, 3-6 parts of liquid paraffin, 1-2 parts of protocatechuic acid ethyl ester, 2-3 parts of propylparaben, 1.5-2.5 parts of trichlamide, 2.5-4.5 parts of antimony sulfate, 5-10 parts of jade powder, 15-20 parts of calcining loess, 2-3 parts of dodecanoic acid monoester with triglycerol, 1-2 parts of zinc undecylenate, 5-10 parts of epoxidized soybean oil, 1-2 parts of calcium stearate, 1-2 parts of barium stearate, 20-25 parts of filling master batch, 10-15 parts of dicyclohexyl phthalate, 2-3 parts of N,N'-Bis(1-methylpropyl)-1,4-phenylenediamine and 1.5-2.5 parts of chlorotributyltin. The mould-prevention polyethylene water supply tubular product has excellent antibacterial property, can effectively restrain and prevent attachment and breeding of mould, prevents mould from corroding the tubular product, has excellent mechanical property, ageing resistance, heat resistance and processability, and is long in service life and wide in application prospect.

Owner:ANHUI DINGYUAN ZHENYUN PLASTIC

High-elasticity vibration-resistant expanded polyethylene plate and method for manufacturing same

The invention discloses a high-elasticity vibration-resistant expanded polyethylene plate and a method for manufacturing the same. The high-elasticity vibration-resistant expanded polyethylene plate comprises, by weight, 120-140 parts of polyethylene, 20-30 parts of ethylene-vinyl acetate copolymers, 10-14 parts of p-toluenesulfonhydrazide, 5-8 parts of dichlorotetrafluoroethane, 3-5 parts of dicumyl peroxide, 7-9 parts of zinc oxide, 40-50 parts of titanate-modified calcium carbonate, 8-10 parts of leucite powder, 5-7 parts of dynasylan ibteo, 6-9 parts of magnesium stearate, 4-6 parts of butyl stearate, 4-5 parts of hexamethylenetetramine, 3-5 parts of polycarbonate, 10-14 parts of aluminum hydroxide, 7-9 parts of titanium nitride whiskers, 6-8 parts of dioctyl adipate, 3-5 parts of 2-aminoethanol, 8-9 parts of dicyclohexyl phthalate, 7-9 parts of magnesium diboride and 4-6 parts of jade powder. The high-elasticity vibration-resistant expanded polyethylene plate and the method have the advantages that the polyethylene plate manufactured by the aid of the method not only is excellent in vibration-resistant and buffer performance, but also is high in mechanical strength and good in ageing resistant, and good flame-retardant effects can be realized.

Owner:周诗慧

Heat conducting flame-retardant control cable

InactiveCN105199225AFacilitate cross-linkingImprove thermal conductivityInsulated cablesInsulated conductorsFiberAntioxidant

The invention discloses a heat conducting flame-retardant control cable which comprises a core, an insulating layer, a shielding layer and a sheath layer. The insulating layer wraps the core, the shielding layer wraps the insulating layer, and the sheath layer wraps the shielding layer; the insulating layer is made of low-smoke halogen-free polyolefin materials, the low-smoke halogen-free polyolefin materials comprise, by weight, polypropylene, methylvinyl silicone rubber, ethylene-vinyl acetate copolymers, tetra propyl ammonium phenylsulfonyl, isopropyl tri-(iso-stearoyl) titanate, caprolactam, magnesium oxide, 2, 5-dimethyl-2, 5-tert butyl peroxy-3-hexyne, alkylated diphenylamines, 2-mercapto benzimidazole zinc salt, dicyclohexyl phthalate, kaolin, cerium dioxide, polyacrylonitrile fibers, anti-aging agents and antioxidants. The heat conducting flame-retardant control cable has the advantages of good heat conductivity and excellent flame-retardant property.

Owner:ANHUI LAND GRP

Anti-aging PE film for packaging and preparation method thereof

InactiveCN105440400AConducive to protecting the appearance qualityImprove appearance qualityMicrocrystalline waxPack material

Owner:李嘉

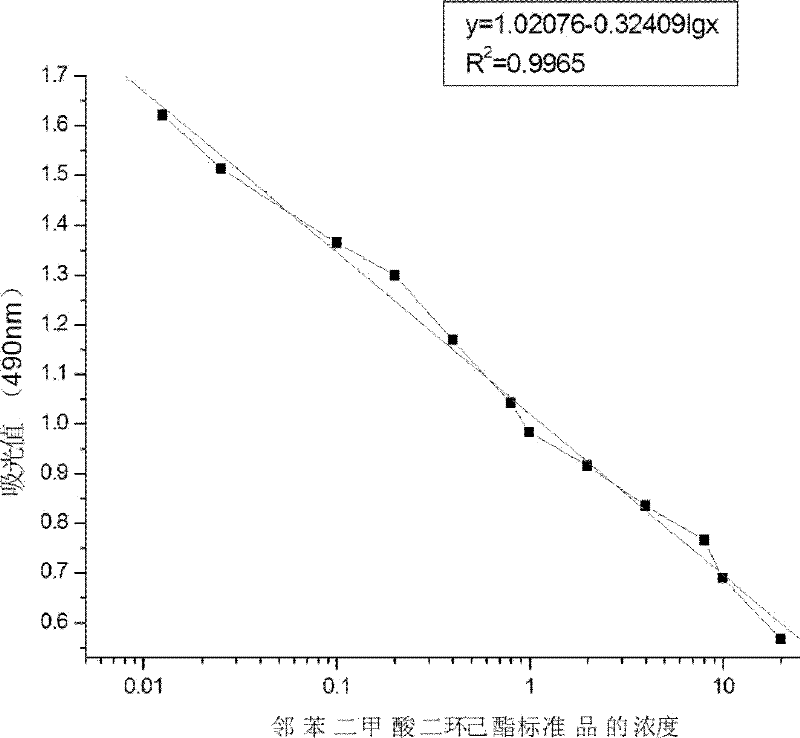

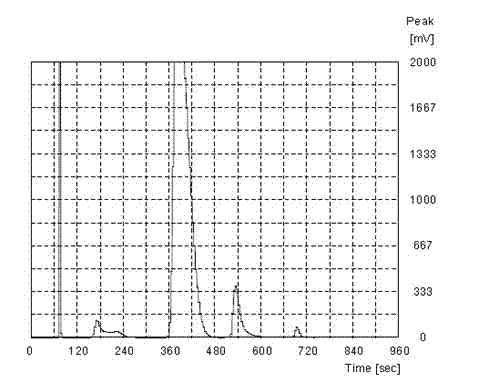

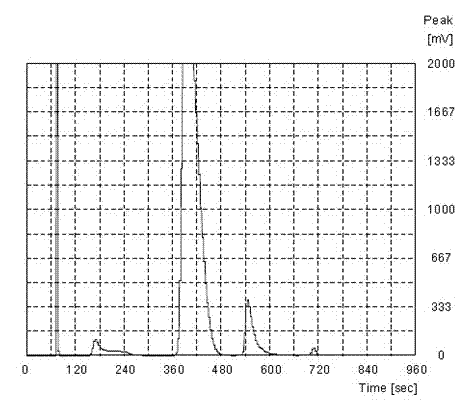

Method for detecting dicyclohexyl phthalate in environmental water sample

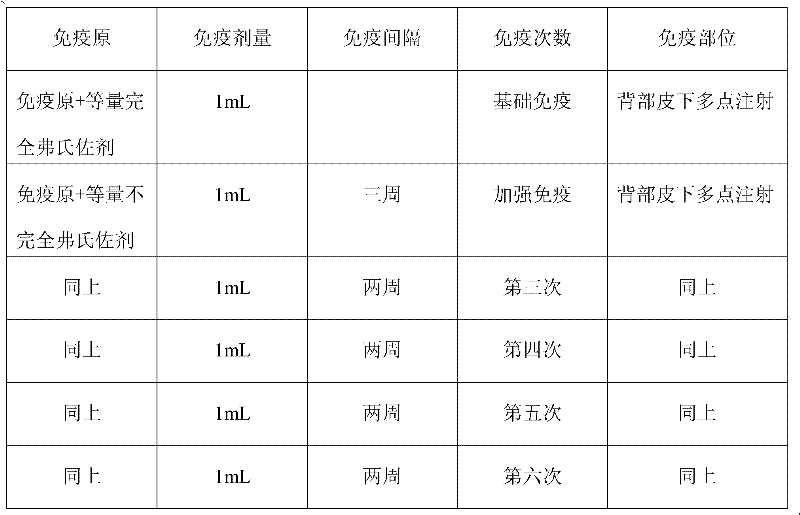

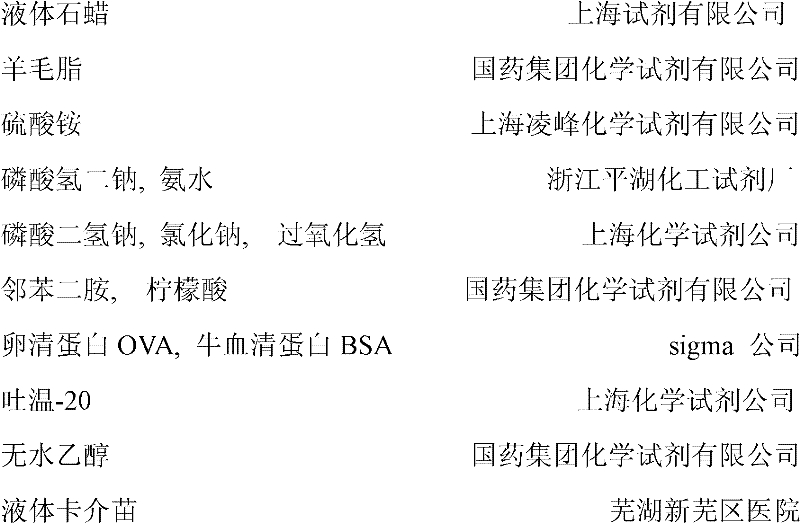

InactiveCN102539744AStrong specificityAmplify the measurement signalMaterial analysisHorse radish peroxidaseAnalysis method

The invention discloses a method for detecting dicyclohexyl phthalate in an environmental water sample, and the method comprises the following steps: a, an establishment step of a standard curve, and b, a detection step of the sample. Compared with the prior art, the method not only has the selectivity of an antigen and an antibody of the dicyclohexyl phthalate, but also a measured signal can be amplified by an enzymatic reaction, the sensitivity is improved, and simultaneously, a horse radish peroxidase is ordinary on the market, is cheap and is suitable for popularization. Therefore, by using such an analyzing method with the advantages of simpleness, quickness, low cost, strong specificity and the like, the convenience is provided for the micro monitoring of a dicyclohexyl phthalate pollutant in a proper environment.

Owner:ANHUI NORMAL UNIV

Polyurethane anticorrosive wearable coating and preparation method thereof

InactiveCN108456484AImprove adhesionImprove wear resistanceFireproof paintsAntifouling/underwater paintsPhosphateAluminium hydroxide

The invention discloses a polyurethane anticorrosive wearable coating and a preparation method thereof, and relates to the technical field of anticorrosive coatings. The polyurethane anticorrosive wearable coating is prepared from, by weight, 34-43 parts of poly-adipic acid-gylcol ester-glycol, 80-100 parts of polyether N210, 17-24 parts of polyether N330, 60-80 parts of isophorone diisocyanate, 0.5-2 parts of triethylene diamine, 5-10 parts of 2-methyl-1,3-propylene glycol, 1-2 parts of trimethylolpropane, 4-10 parts of modified organosilicon, 4-7 parts of fumed silica, 10-17 parts of kaolin,25-35 parts of titanium dioxide, 0.5-2 parts of ethyl cellulose, 3-7 parts of propylene glycol, 0.2-1 part of aluminium hydroxide, 0.5-2 parts of 3(2-chlorin isopropyl) organic phosphate, 1-3 parts of dicyclohexyl phthalate, 0.5-2 parts of defoaming agent, 0.5-2 parts of anti-aging agent and 4-8 parts of coalescing agent. The polyurethane anticorrosive wearable coating and the preparation methodthereof have the advantages that the acid, alkali and salt-spray corrosion resistant performance is excellent, the wear resistance and antibacterial property are good, the adhesive force to the base material is high, the impact resistance and glossiness are good, and the mechanical property is better.

Owner:安徽大松树脂有限公司

Special material for protective casing for preventing pests and rats from biting communication cable and preparation method of special material

InactiveCN104371191AImprove the anti-pest performanceAvoid infringementPlastic/resin/waxes insulatorsInsulated cablesAdjuvantPhosphate

The invention discloses a special material for a protective casing for preventing pests and rats from biting a communication cable and a preparation method of the special material. The special material is prepared from the following raw materials in parts by weight: 52-76 parts of polypropylene, 31-43 parts of ethylene-trifluorochlor oethylene copolymer, 3-6 parts of benzyl benzoate, 4-6 parts of diethylene glycol bis(allylcarbonate), 2-4 parts of cycloheximide, 3-5 parts of tetrabasic lead sulfate, 10-15 parts of dicyclohexyl phthalate, 16-22 parts of spherical silica sand, 2-4 parts of triphenyltin acetate, 1.5-2.5 parts of m-chloroaniline, 5-10 parts of dibutyl azelate, 2-3 parts of phenyl diisodecyl phosphate, 4-8 parts of chlorinated paraffin, 8-14 parts of barium metatitanate, 5-10 parts of encapsulated red phosphorous, 1-2 parts of phenylethyl resorcinol and 4.5-6.5 parts of an adjuvant. The substances such as benzyl benzoate, triphenyltin acetate and m-chloroaniline are added to the special material for the protective casing disclosed by the invention, so that the pest and rat bite preventing property of the protective casing can be greatly improved; the damage to the protective casing caused by pests and rats is effectively prevented; the safety and normal operation of an optical cable are ensured; and meanwhile, the special material has excellent abrasive resistance, weather fastness, corrosion resistance and temperature tolerance, long service life and wide application range.

Owner:安徽电信器材贸易工业有限责任公司

Pulverized Anthracite modifying agent and coal blending and coking method using same

The invention relates to a pulverized anthracite modifying agent and a coal blending and coking method using the same. The pulverized anthracite modifying agent comprises the components in percentage by weight: 30-60 percent of boric acid, 0.5-25 percent of malonic acid or azelaic acid or alpha-alanine or a mixture of the malonic acid or the azelaic acid or the alpha-alanine, 0.5-25 percent of dodecyl dimethyl benzyl ammonium chloride or cationic cellulose polymer or stearic acid sodium lactate or a mixture of two or three of the dodecyl dimethyl benzyl ammonium chloride or the cationic cellulose polymer or the stearic acid sodium lactate, and 0.5-25 percent of dicyclohexyl phthalate or triphenyl phosphate or a mixture of the dicyclohexyl phthalate or the triphenyl phosphate. The coal blending and coking method comprises the steps of: step 1. modifying anthracite; and step 2. weighing the modified anthracite and coking coal according to 1-50 percent of the mass of coking mixed coal, and blending the coal for coking according to a conventional production technology. The coal blending and coking method has the advantages that the proportion of the anthracite in the coking mixed coal is obviously increased, and the coking cost is substantially reduced. The coal blending and coking method provides a new approach for coking by using the anthracite and expands the resources of the coking coal.

Owner:CHONGQING LUNIU TECH

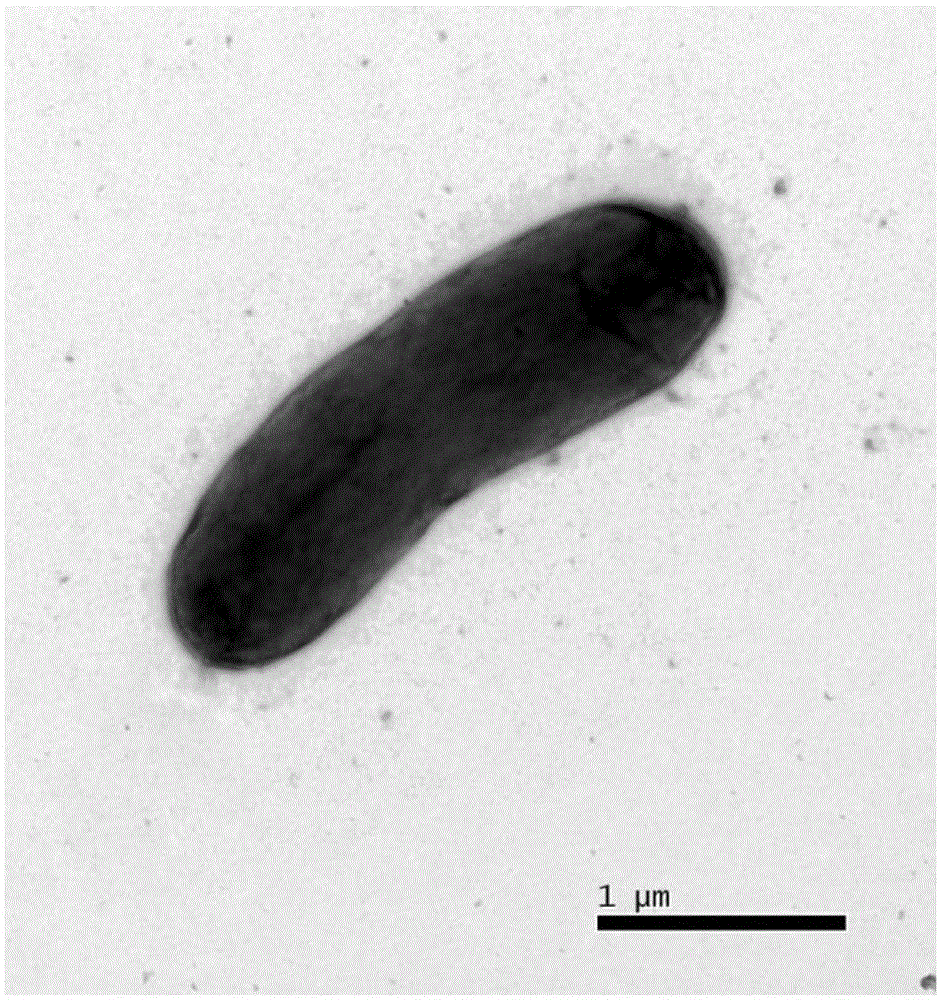

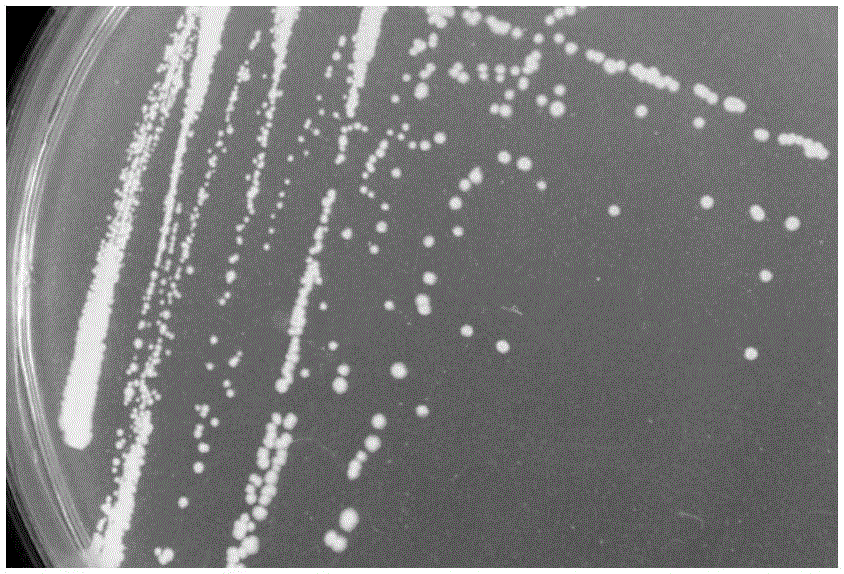

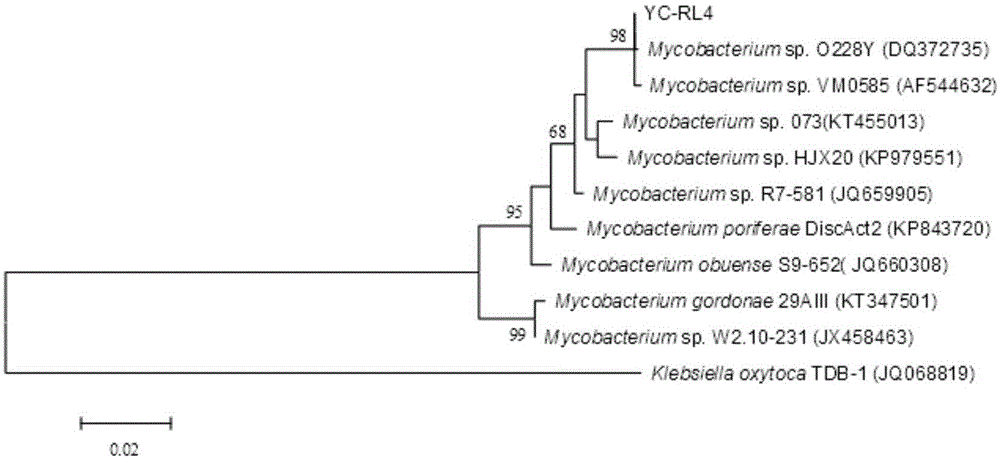

Mycobacterium YC-RL4 and application thereof

ActiveCN105154365AEfficient degradationNo pollution in the processBacteriaWater contaminantsBioremediationAcid substances

The invention provides a mycobacterium YC-RL4 capable of degrading various phthalate acid substances. The preserving number of the mycobacterium YC-RL4 is CGMCC No.10993. Within five days, the bacterium can perform 100% degradation on 100 mg / L di-2-ethylhexyl phthalate (DEHP), dicyclohexyl phthalate (DCHP), dimethyl phthalate (DMP), di-n-butyl ortho-phthalate (DBP) and diethyl phthalate (DEP) contained in an inorganic salt culture medium. In addition, the bacterium is wide in range of tolerance to salt ion concentration, pH and temperature. The mycobacterium YC-RL4 can be applied to bio-remediation of phthalate substance environmental pollution, has good application potentials for treating high-salt high-alkali industrial production wastewater of pollutants and has good economical value and application prospects.

Owner:中国农业科学院研究生院

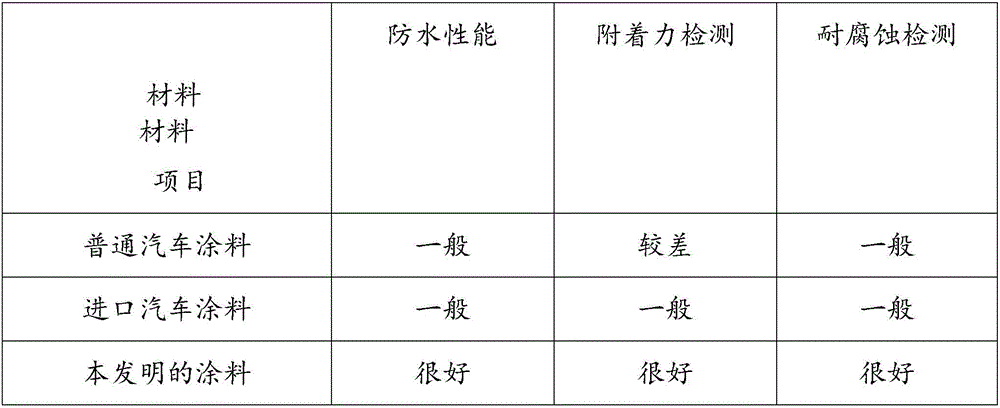

Waterproof paint for automobile and preparation method of waterproof paint

InactiveCN106700765AWith waterproof effectStrong adhesionConjugated diene hydrocarbon coatingsAnti-corrosive paintsMetasilicatePotassium

The invention discloses a waterproof paint for an automobile. The waterproof paint for the automobile is prepared from the following materials by weights: 18-20 parts of potassium metasilicate, 25-30 parts of nano-silica, 33-35 parts of polyvinyl acetate, 16-20 parts of butadiene styrene rubber emulsion, 22-24 parts of isocyanate, 16-20 parts of dicyclohexyl phthalate, 22-26 parts of dibutyl phthalate, 25-30 parts of propylene glycol esters of fatty acid, 14-18 parts of magnesite cement, 23-26 parts of fatty acid polyglycol ester, 12-14 parts of simethicone, 7-11 parts of triethoxysilane, 6-10 parts of rosin modified phenolic resin, 16-18 parts of iron oxide red, 18-20 parts of sodium silicate, 6-9 parts of polyether glycol, and 17-22 parts of tartaric acid. The waterproof paint for the automobile has an excellent waterproof effect, is strong in adhesive force, and has an effect of corrosion resistance at the same time.

Owner:芜湖天鸿汽车零部件有限公司

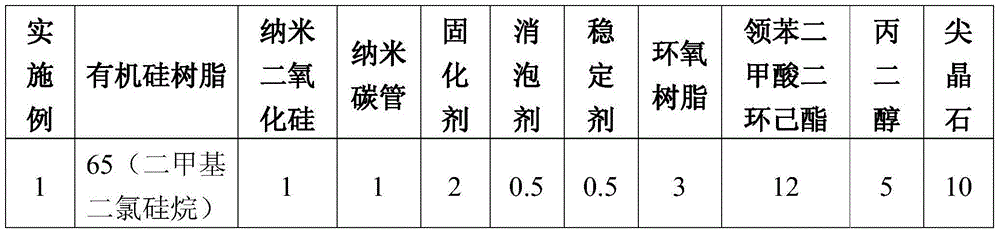

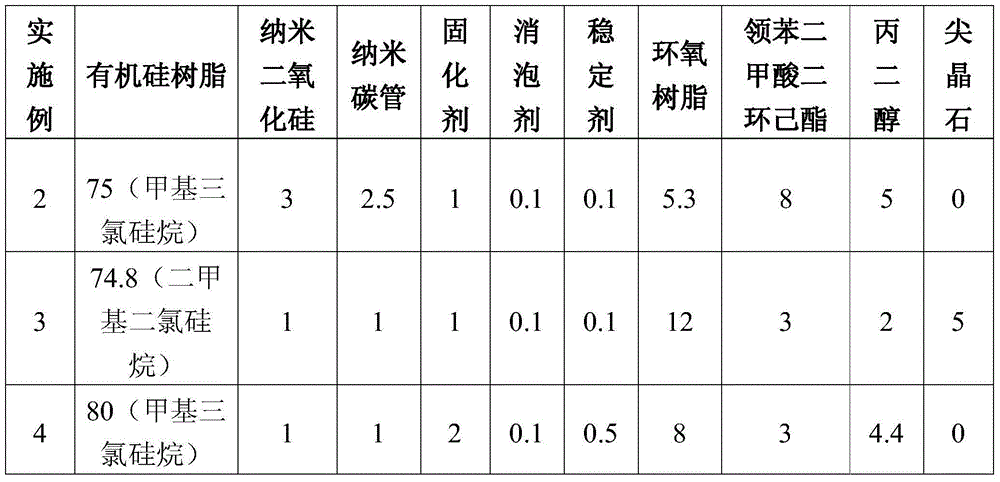

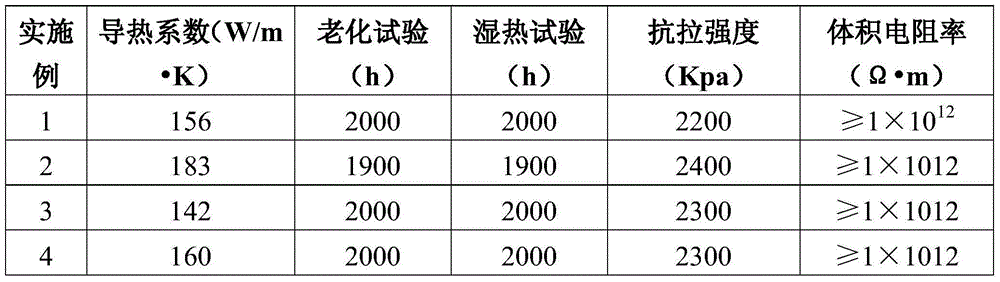

Heat-dissipating coating for LED lamp and preparation method thereof

The invention relates to a heat-dissipating coating for an LED lamp. The heat-dissipating coating for the LED lamp comprises 65-80 parts of organic silicon resin, 1-3 parts of nano silica, 1-2.5 parts of carbon nano-tubes, 1-2 parts of curing agents, 0.1-0.5 part of antifoaming agent, 0.1-0.5 part of stabilizing agent, 3-12 parts of epoxy resin, 3-12 parts of dicyclohexyl phthalate and 2-5 parts of propylene glycol. A preparation method of the heat-dissipating coating comprises the steps that (1) the components in the formula are weighed according to the parts in weight, then the carbon nano-tubes are added to the propylene glycol to form a solution, and the solution is stirred to be uniform at the temperature ranging from 55 DEG C to 65 DEG C; (2) after the organic silicon resin, the nano silica, the epoxy resin, the dicyclohexyl phthalate, the curing agents and the antifoaming agents are uniformly mixed to form a solution, the solution is stirred for 1-1.5 hours at the speed ranging from 550r / min to 650r / min; (3) the solution in the step (1) and the solution in the step (2) are mixed, then the stabilizing agent is added to the mixture, and the mixture is stirred to be uniform.

Owner:FOSHAN HECAI TECH SERVICE

Cold-resistant seal ring based on graphene/polymer composite material and preparation method

InactiveCN106751233AImprove cold resistanceGuaranteed sizeDomestic articlesAqueous alcoholPolymer composites

The invention discloses a cold-resistant seal ring based on a graphene / polymer composite material. The composite material utilizes a polymer as a matrix and graphene as filler. The cold-resistant seal ring is prepared through steps as follows: (1), graphene is poured into an alcoholic solution, a suspension containing graphene and the alcoholic solution in a mass ratio being 1:10-1:50 is prepared, and a uniform graphene solution is prepared by an ultrasonic disperser; (2), fluororubber, a plasticizer dicyclohexyl phthalate and the like are added to a grinding machine and ground for 25-36 h; (3), a mixture obtained through grinding is added to the graphene solution obtained in the step (1), and a mixed solution is obtained; (4), the mixed solution obtained in the step (3) is mixed in a closed rubber mixing mill for 2 min, then the plasticizer dicyclohexyl phthalate, an anti-aging agent octylated diphenylamine and the like are sequentially added, the mixing temperature is 85-105 DEG C, the mixing time is 2 h, then the temperature is increased to 185-200 DEG C at a speed of 10 DEG C / min, and a piece is formed through stamping and cooled naturally. The problem of poor cold resistance of the cold-resistant seal ring prepared from a fluororubber seal ring as a main material is solved simply and reasonably.

Owner:南京润屹电子科技有限公司

Fire extinguishing material suitable for extinguishing electric vehicle fire

The invention relates to the technical field of fire extinguishing materials. The fire extinguishing material comprises the following raw material components: a fire extinguishing enhancer, a stabilizer, an antifreeze agent, a thickener, perfluoro(2-methyl-3-pentanone) and water, wherein the fire extinguishing enhancer is a mixture composed of sodium silicate, silicon dioxide and slaked lime powder, and dicyclohexyl phthalate is selected as the stabilizer. The prepared fire extinguishing material is suitable for extinguishing the fire of an electric vehicle, a thickener component is sprayed into fire, a large amount of heat is consumed due to the dehydration of colloid slurry, the perfluoro(2-methyl-3-pentanone) in a water-based component absorbs heat and is vaporized, and the sodium silicate, the silicon dioxide and the slaked lime which are used as a flame retardant are combined to take away heat generated by the combustion reaction of a battery, so that the battery of the electric vehicle is effectively prevented from continuing to combust, a quick fire extinguishing effect is achieved, and the fire extinguishing material is simple in raw material and low in cost.

Owner:厦门市兆泰云智能科技有限公司

High heat-resistant cable

InactiveCN105131352AHigh strengthImprove heat resistanceInsulated cablesInsulated conductorsElectrical conductorCarbon nanotube

The invention discloses a high heat-resistant cable. The high heat-resistant cable comprises a cable core; the cable core comprises conductors arranged at the middle part, and insulating layers used for coating the conductors; the cable core is coated with an inter sheath layer; the inter sheath layer is coated with a steel belt armour layer; the steel belt armour layer is coated with an outer sheath layer; the outer sheath layer is made of a modified natural rubber material; and the modified natural rubber material comprises following raw materials: natural rubber, fluororubber, carbon nano tube, nanometer aluminium oxide, modified attapulgite, stearic acid, zinc oxide, sulphur, 4,4-dithiodimorpholine, antioxidant 4010NA, lanthanum stearate, accelerant M, accelerant DM, accelerant TMTD, dicyclohexyl phthalate, and dioctyl phthalate. The high heat-resistant cable is excellent in heat resistance, high in strength, excellent in aging resistance, small in compression set, and long in service life.

Owner:合肥市再德高分子材料有限公司

One-component polyurethane textile machine coating and preparation method thereof

InactiveCN104263231AWidely producedRosin coatingsPolyurea/polyurethane coatingsCellulosePolymer science

The invention discloses a one-component polyurethane textile machine coating and a preparation method thereof. The preparation method comprises the following steps of weighing castor oil, citric acid, pentaerythritol, rosin water, toluene diisocynate, titanium dioxide, butanol, a delustering agent, diatomite, bentonite, cellulose nitrate, tricresyl phosphate, dicyclohexyl phthalate and pigment; pouring the castor oil into a reaction kettle, adding pentaerythritol after heating, and reacting while heating; adding citric acid and the rosin water, and reacting while keeping the temperature of 225-235 DEG C; after cooling, adding toluene diisocynate, heating to 85-100 DEG C after stirring, and reacting while keeping the temperature; adding butanol and the rest raw materials; and dispersing in a sand mill, and discharging. The one-component polyurethane textile machine coating has the fineness of 25-35mu m, the hardness of 0.5-0.7, the impact strength of 50-60cm, the adhesive force of 1 and the flexibility of 1mm; the flow-out time of the one-component polyurethane textile machine coating is 50-60 seconds, the surface dry time is 1-3 hours, and the hard dry time is 7-9 hours; and the one-component polyurethane textile machine coating does not blister or fall off after being soaked into 30-DEG C distilled water for 4-6 days.

Owner:JIANGSU KANG BAISI MECHANICAL TECH

High polymer material for pipeline and preparation method of high polymer material

The invention relates to a high polymer material for a pipeline and a preparation method of the high polymer material. The high polymer material comprises 4-8 parts of urea resin, 3-10 parts of polyisocyanurate, 2-6 parts of polyisobutene, 3-8 parts of brominated butyl rubber, 3-6 parts of dicyclohexyl phthalate, 2-5 parts of glass fiber, 4-7 parts of polytetrafluoroethylene, and 3-8 parts of furan resin. The preparation method comprises the following steps: step 1, taking all of the components, feeding the components in an agitator tank, and heating the agitator tank till the components are smelted; step 2, conducting twin-screw extrusion on the uniformly stirred material in the step 1 with a twin-screw extrusion machine, extruding out the material and granulating the material to obtain the high polymer material for the pipeline. The prepared high polymer material for the pipeline has the advantages of being high in tensile strength and shock strength.

Owner:苏州凯欧曼新材料科技有限公司

Method of preparing chloroethylene carbonate by adopting novel initiator

InactiveCN110698452AReduce bring inReduce moistureChlorine/hydrogen-chlorideOrganic chemistryBenzoyl peroxideWater chlorination

The invention discloses a method of preparing chloroethylene carbonate by adopting a novel initiator. The method comprises the following steps: 1) with ethylene carbonate and chlorine as reaction rawmaterials, controlling the temperature of a kettle to be 80-90 DEG C, taking a mixture of benzoyl peroxide and dicyclohexyl phthalate as a novel initiator, and carrying out a reaction under the actionof the novel initiator to generate chloroethylene carbonate; 2) absorbing hydrogen chloride and chlorine tail gas generated by a chlorination reaction with clear water and alkali liquor respectivelyto generate byproducts including concentrated hydrochloric acid with a content of greater than 30% and sodium hypochlorite with a content of greater than 10%; and 3) transferring a chloroethylene carbonate mixed solution into a deacidification kettle for deacidification treatment by using a transfer pump, controlling the temperature of the deacidification kettle to be 90-105 DEG C, performing vacuumizing while stirring, and carrying out deacidifying for 5 h to obtain chloroethylene carbonate with relatively low moisture and acidity. The preparation method provided by the invention can reduce water introduction, shorten reaction time and improve recovery efficiency, and is suitable for large-scale production in enterprises.

Owner:江苏瀚康新材料有限公司

Ageing resistant power line sheath material and preparation method thereof

InactiveCN103992539AStrong anti-agingGood chemical stabilityPlastic/resin/waxes insulatorsInsulated cablesPolybutylene terephthalateUltrahigh molecular weight polyethylene

The invention discloses an ageing resistant power line sheath material and a preparation method thereof. The ageing resistant power line sheath material is prepared by using the following raw materials, by weight, 45-65 parts of ultrahigh molecular weight polyethylene, 25-35 parts of chloroprene rubber, 10-20 parts of polybutylene terephthalate, 1.5-2.5 parts of vinyltrimethoxy silane, 2-3 parts of dicumyl peroxide, 4-8 parts of basic magnesium carbonate, 22-28 parts of nanometer kaolin, 14-26 parts of glass bead, 3-6 parts of glyceryl monoricinoleate, 10-15 parts of nylon acid dibutyl ester, 8-16 parts of dicyclohexyl phthalate, 5-10 parts of phosphoric trichloride, polymer with 1,3-benzenediol, phenyl ester, 5-10 parts of tris(2,3-dibromopropyl)isocyanurate, 1-2 parts of dibasic lead phosphite, 1-2 parts of calcium stearate, 1-2 parts of barium stearate, 4-6 parts of paraffin oil, 0.5-1.5 parts of tetramethylthiuranm monosulide, 1-2 parts of 2-mercaptobenzothiazole and 20-25 part of an assistant. The sheath material has the characteristics of strong ageing resistance, good chemical stability, high mechanical strength, wide use temperature, excellent flame resistance, excellent impact resistance, excellent wear resistance, excellent chemical corrosion resistance, durability, and wide application prospect.

Owner:TIANCHANG FUXIN ELECTRONICS

Waterproof underpad hot melt adhesive excellent in waterproof effect

InactiveCN108219720ADoes not affect viscosityMaintain bonding relationshipNon-macromolecular adhesive additivesMacromolecular adhesive additivesMicrocrystalline waxUrine production

The invention discloses a waterproof underpad hot melt adhesive excellent in waterproof effect. The waterproof underpad hot melt adhesive excellent in waterproof effect comprises an ethylene-vinyl acetate copolymer, a styrene-butadiene-styrene block copolymer, talcum powder, a tackifier, an anti-oxidant, naphthenic oil, paraffin oil, microcrystalline wax, liquid paraffin, and dicyclohexyl phthalate. The viscosity of the waterproof underpad hot melt adhesive is not influenced even the surface of the waterproof underpad is wetted by penetrated urine, the bonding effect among layers of the waterproof underpad is maintained, the raw materials are widely and easily available, and are cheap, and the safety is high.

Owner:苏州市苏宁床垫有限公司

High-impact-resistance automobile nylon composite and preparation method thereof

The invention discloses a high-impact-resistance automobile nylon composite and a preparation method thereof. The high-impact-resistance automobile nylon composite is prepared from the following raw materials by weight: 40 to 60 parts of nylon 12, 30 to 50 parts of nylon 6, 25 to 35 parts of poly(butyleneadipate-co-terephthalate), 15 to 20 parts of methacryIate-butadiene-styrene copolymer, 18 to 24 parts of spinel powder, 12 to 16 parts of boron mud, 10 to 15 parts of aluminum titanate fiber, 6 to 12 parts of cork powder, 1.5 to 2.5 parts of tetraisopropyl di(dioctylphosphate) titanate, 10 to 15 parts of C5 petroleum resin, 2 to 3 parts of magnesium oxide, 1.5 to 2.5 parts of calcium benzoate, 4 to 8 parts of coal tar pitch, 10 to 15 parts of octodecyl acyl tributyl citrate, 8 to 14 parts of dicyclohexyl phthalate, 2 to 3 parts of basic lead silicate, 1 to 2 parts of barium stearate, 1 to 2 parts of zinc stearate, 15 to 20 parts of modified kaolin and 1.5 to 2.5 parts of an antioxidant 3010. The nylon composite provided by the invention has greatly improved notch impact strength while maintaining high tensile strength and bending strength and has excellent shock resistance.

Owner:ANHUI ANLAN MOLD

Preparation method of stone-like furniture decorative coating

The invention discloses a preparation method of a stone-like furniture decorative coating. The preparation method comprises following steps: raw materials are subjected to pretreatment, wherein the raw materials such as shell powder are added according to a raw material mass ratio successively with stirring; auxiliary agents, such as 15 to 45 parts of an antifoaming agent, 15 to 45 parts of an anti-settling agent, are added, and a mixed solution is obtained via stirring; 55 to 75 parts of ethylene-vinyl acetate copolymerization emulsion adhesive, 10 to 50 parts of water-white rosin, 20 to 40 parts of polyacrylate water-retaining agent, 20 to 40 parts of polyurethane thickening agent, 20 to 40 part of dicyclohexyl phthalate plasticizer, and 40 to 70 parts of a color paste are added; an obtained mixed material is added into a material preparation tank slowly and uniformly, and the coating is obtained via continuous stirring; a substrate is coated with the coating; and finished products are obtained via drying and equilibrium of moisture. The stone-like furniture decorative coating prepared via the preparation method is green and friendly to the environment; no pollution is caused; adhesive force on the substrate, flexibility, and heat resistance are excellent; the stone-like furniture decorative coating is better than existing coatings, and application range is wide.

Owner:DALIAN FEIMA OFFICE FURNITURE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com