Waterproof paint for automobile and preparation method of waterproof paint

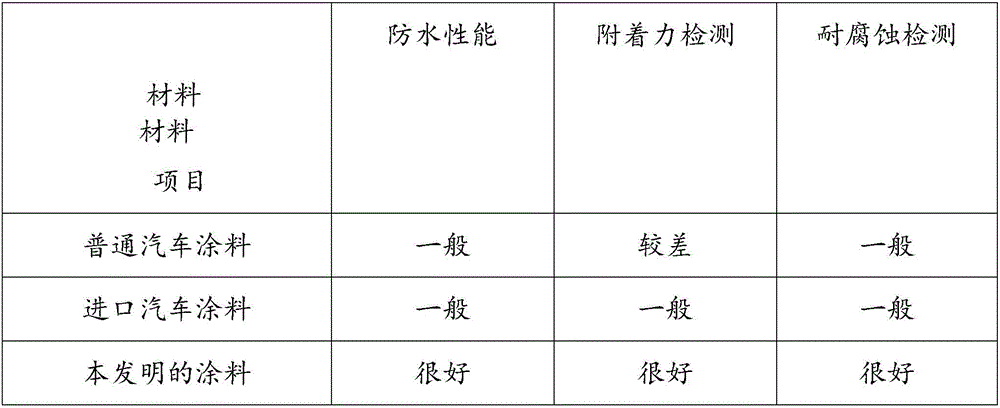

A technology for waterproof coatings and automobiles, applied in anti-corrosion coatings, coatings, etc., can solve the problems of weak adhesion, automobile coatings have no waterproof effect, no corrosion resistance effect, etc., and achieve the effect of maintaining corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A kind of waterproof coating for automobiles, made of the following materials in parts by weight, including 18 parts of potassium silicate, 25 parts of nano silicon dioxide, 33 parts of polyvinyl acetate, 16 parts of styrene-butadiene rubber emulsion, 22 parts of isocyanate, 16 parts of dicyclohexyl phthalate, 22 parts of dibutyl phthalate, 25 parts of propylene glycol fatty acid ester, 14 parts of magnesite gel, 23 parts of fatty acid polyethylene glycol ester, 12 parts of simethicone , 7 parts of triethoxysilane, 6 parts of rosin modified phenolic resin, 16 parts of iron oxide red, 18 parts of water glass, 6 parts of polyether glycol and 17 parts of tartaric acid.

[0019] A preparation method for automobile waterproof paint, comprising the following steps:

[0020] 1) Will, including 18 parts of potassium silicate, 25 parts of nano silicon dioxide, 33 parts of polyvinyl acetate, 16 parts of styrene-butadiene rubber emulsion, 22 parts of isocyanate, 16 parts of dicycl...

Embodiment 2

[0026] A kind of waterproof coating for automobiles, made of the following materials in parts by weight, including 19 parts of potassium silicate, 27.5 parts of nano silicon dioxide, 34 parts of polyvinyl acetate, 16-20 parts of styrene-butadiene rubber emulsion, 22 parts of isocyanate -24 parts, 16-20 parts of dicyclohexyl phthalate, 24 parts of dibutyl phthalate, 27.5 parts of propylene glycol fatty acid ester, 16 parts of magnesite gel, 24.5 parts of fatty acid polyethylene glycol ester, 13 parts of simethicone, 9 parts of triethoxysilane, 8 parts of rosin modified phenolic resin, 17 parts of iron oxide red, 19 parts of water glass, 7.5 parts of polyether glycol and 19.5 parts of tartaric acid.

[0027] A preparation method for automobile waterproof paint, comprising the following steps:

[0028] 1) 19 parts of potassium silicate, 27.5 parts of nano silicon dioxide, 34 parts of polyvinyl acetate, 16-20 parts of styrene-butadiene rubber emulsion, 22-24 parts of isocyanate, 1...

Embodiment 3

[0034] A kind of waterproof coating for automobiles, made of the following materials in parts by weight, including 20 parts of potassium silicate, 30 parts of nano silicon dioxide, 35 parts of polyvinyl acetate, 20 parts of styrene-butadiene rubber emulsion, 24 parts of isocyanate, 20 parts of dicyclohexyl phthalate, 26 parts of dibutyl phthalate, 30 parts of propylene glycol fatty acid ester, 18 parts of magnesite gel, 26 parts of fatty acid polyethylene glycol ester, 14 parts of simethicone , 11 parts of triethoxysilane, 10 parts of rosin modified phenolic resin, 18 parts of iron oxide red, 20 parts of water glass, 9 parts of polyether glycol and 22 parts of tartaric acid.

[0035] A preparation method for automobile waterproof paint, comprising the following steps:

[0036] 1) Mix 20 parts of potassium silicate, 30 parts of nano silicon dioxide, 35 parts of polyvinyl acetate, 20 parts of styrene-butadiene rubber emulsion, 24 parts of isocyanate, 20 parts of dicyclohexyl pht...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com