Patents

Literature

9826 results about "Rosin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

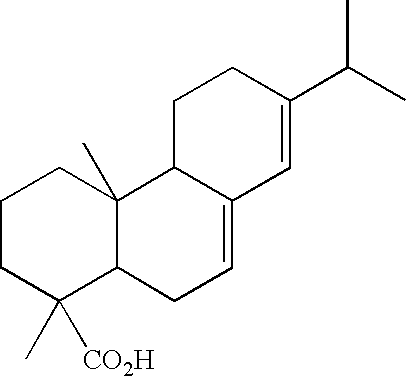

Rosin, also called colophony or Greek pitch (Latin: pix græca), is a solid form of resin obtained from pines and some other plants, mostly conifers, produced by heating fresh liquid resin to vaporize the volatile liquid terpene components. It is semi-transparent and varies in color from yellow to black. At room temperature rosin is brittle, but it melts at stove-top temperature. It chiefly consists of various resin acids, especially abietic acid. The term "colophony" comes from colophonia resina, Latin for "resin from Colophon", an ancient Ionic city.

Hydrogenation process for hydrocarbon resins

InactiveUS20030150778A1Improve productivityIncrease volumePreparation by oxo-reaction and reductionCatalyst activation/preparationProduction rateHalogen

This invention provides a process for hydrotreating hydrocarbon resins, which process comprises contacting a feedstock comprising a hydrocarbon resin or rosin, under suitable hydrotreating conditions, with a bulk multimetallic catalyst comprised of at least one Group VIII non-noble metal and at least two Group VIB metals and wherein the ratio of Group VIB metal to Group VIII non-noble metal is from about 10:1 to about 1:10. The process accord invention can achieve increased hydrocarbon resin productivity through increase in throughput volumes and effective catalyst lifetimes. The process of the invention is desirably practiced with a bulk catalyst consisting of only the combination of the metal species with the active metal components. The absence of carrier substrates largely removes the possibility of halogen accumulation on substrate surfaces that, in turn, can acidify metal catalysts such that additional, progressive cracking of the hydrocarbon resin molecules occurs.

Owner:EXXONMOBIL CHEM PAT INC

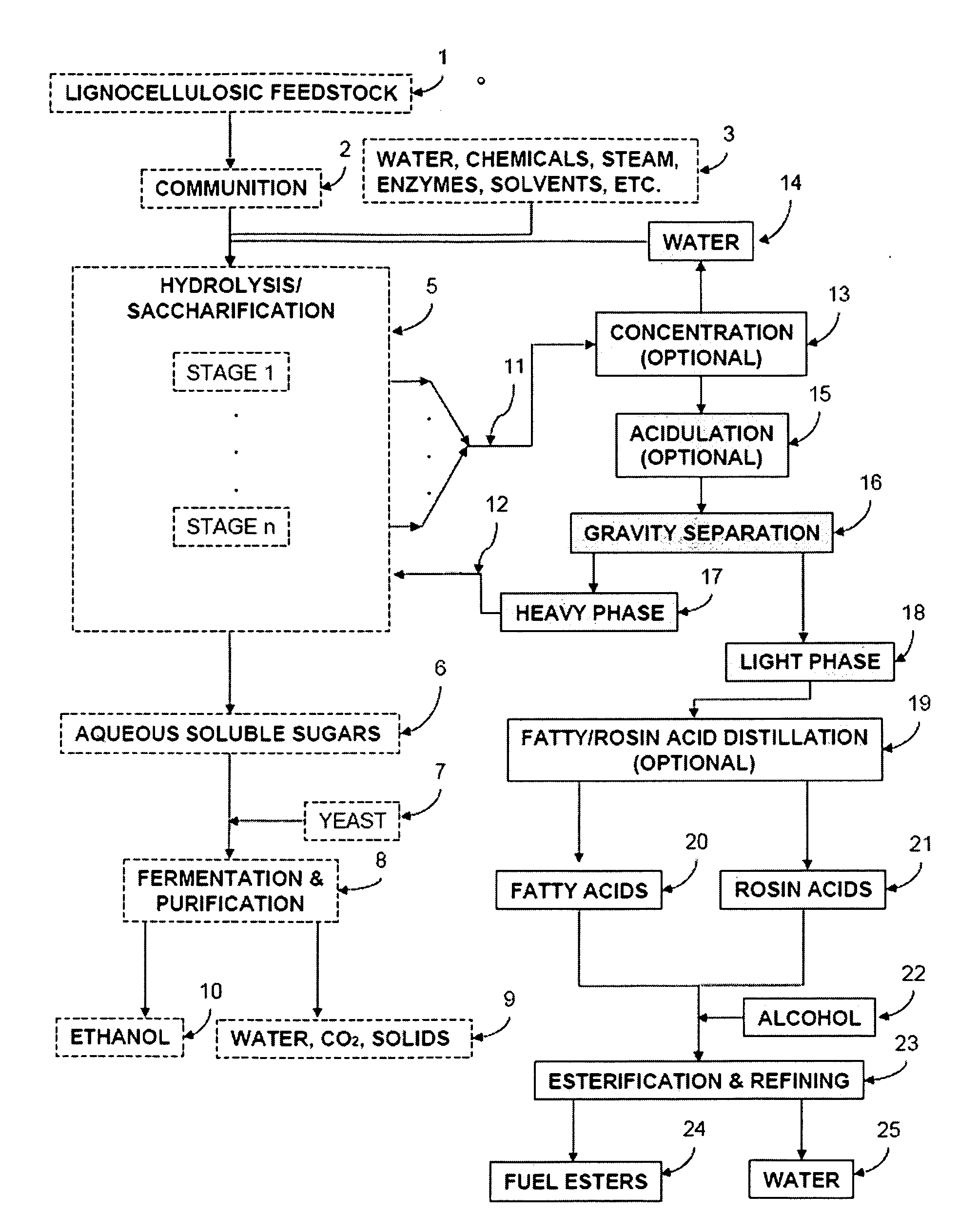

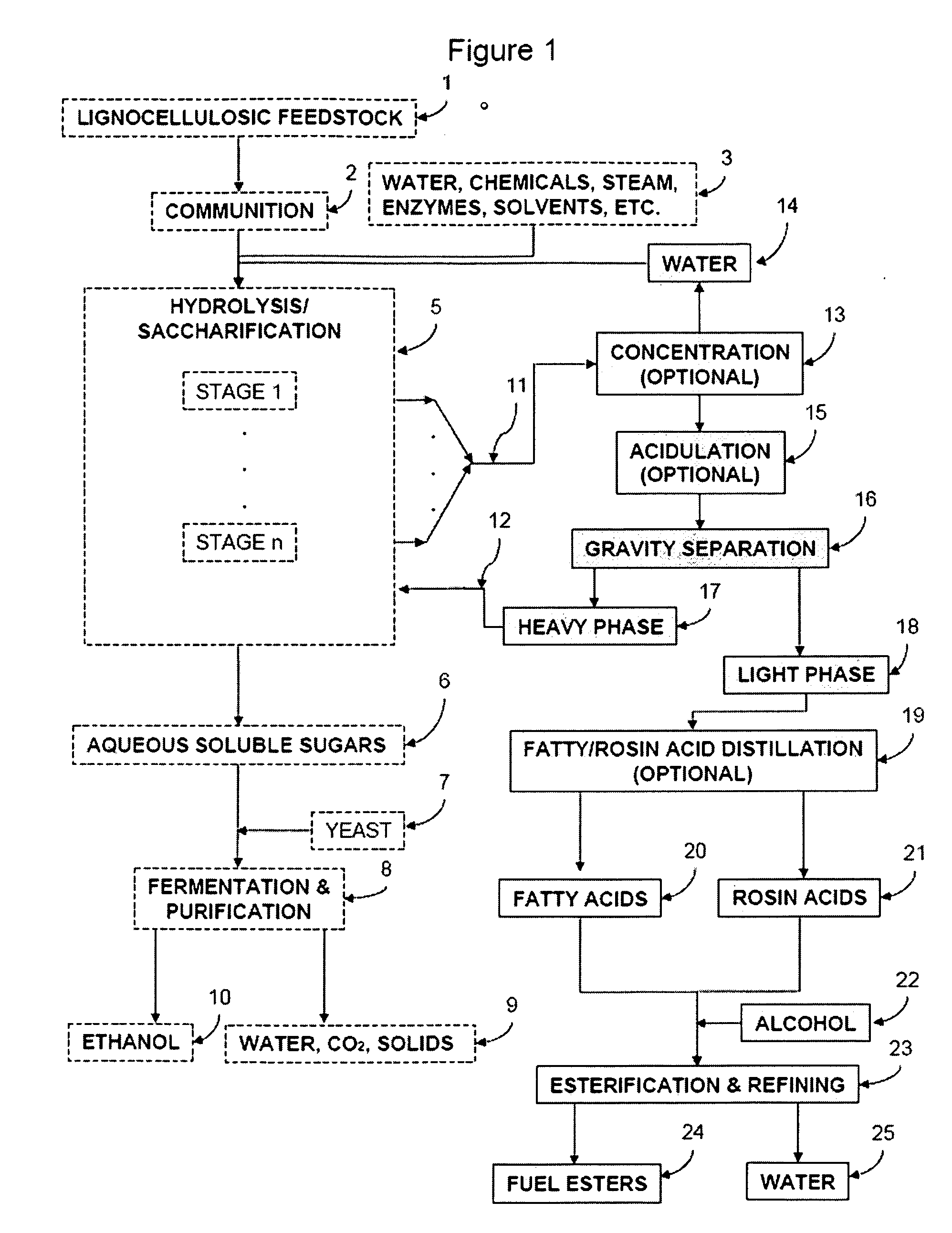

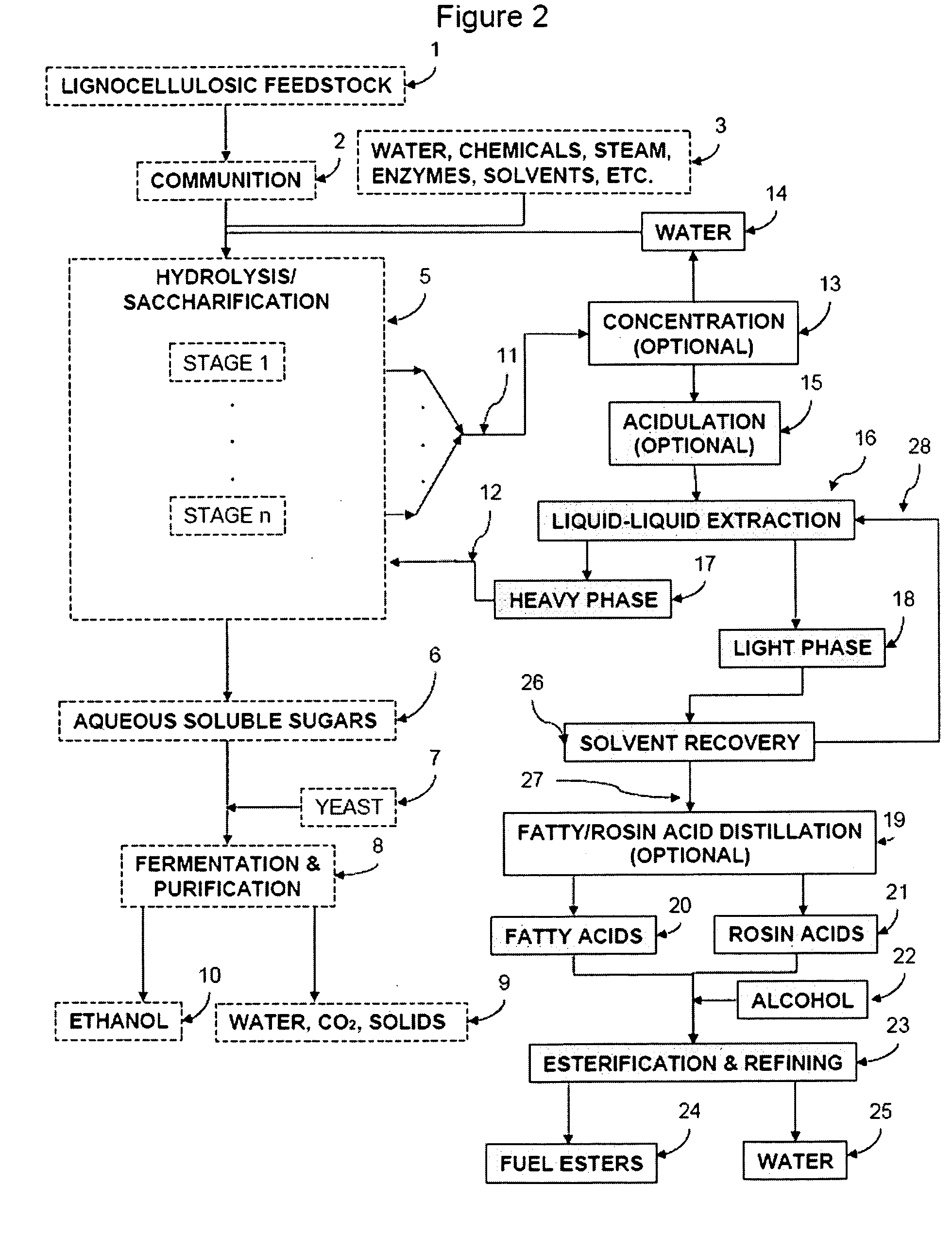

Production of Ester-based Fuels Such As Biodiesel From Renewable Starting Materials

ActiveUS20090056201A1Fatty oils/acids recovery from wasteFatty acid esterificationCelluloseBiodiesel

Production of ester-based fuels such as biodiesel or jet fuel from renewable starting materials such as lignocellulosic material or algae is disclosed. Pulping and saccharification of the renewable starting materials produces carboxylic acids such as fatty acids or rosin acids, which are esterified via a gas sparged, slurry form of heterogeneous reactive distillation to yield ester-based fuels.

Owner:ENDICOTT BIOFUELS II

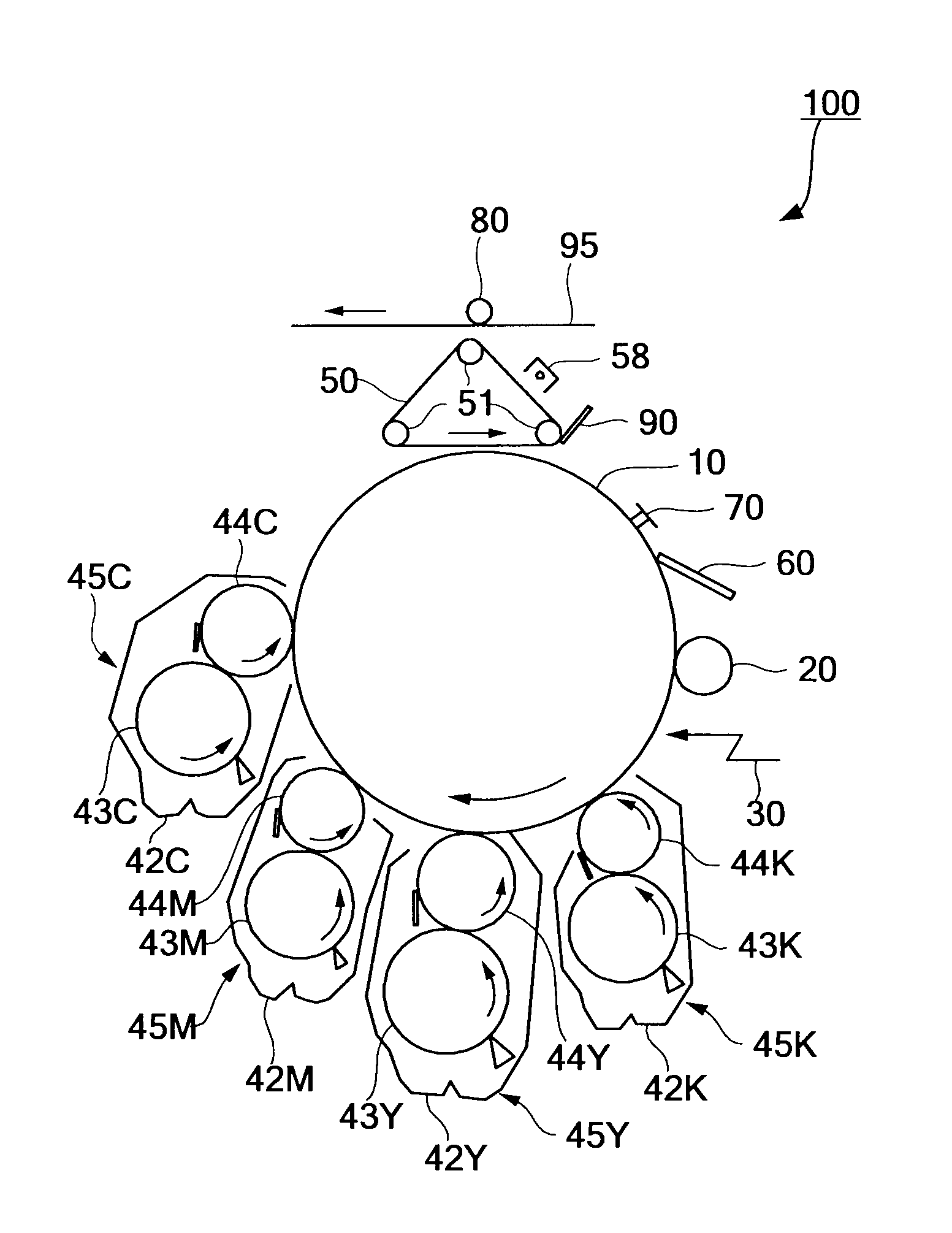

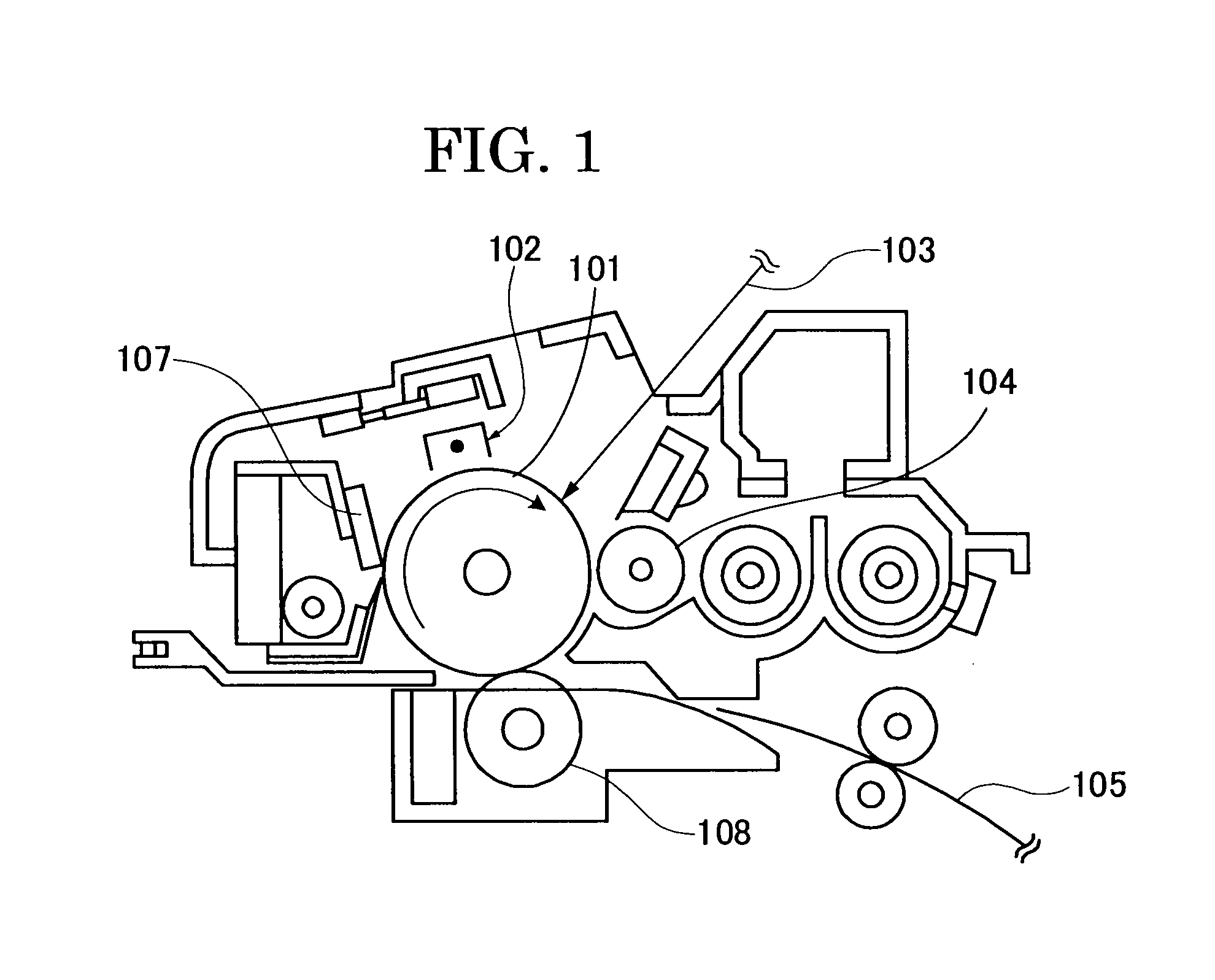

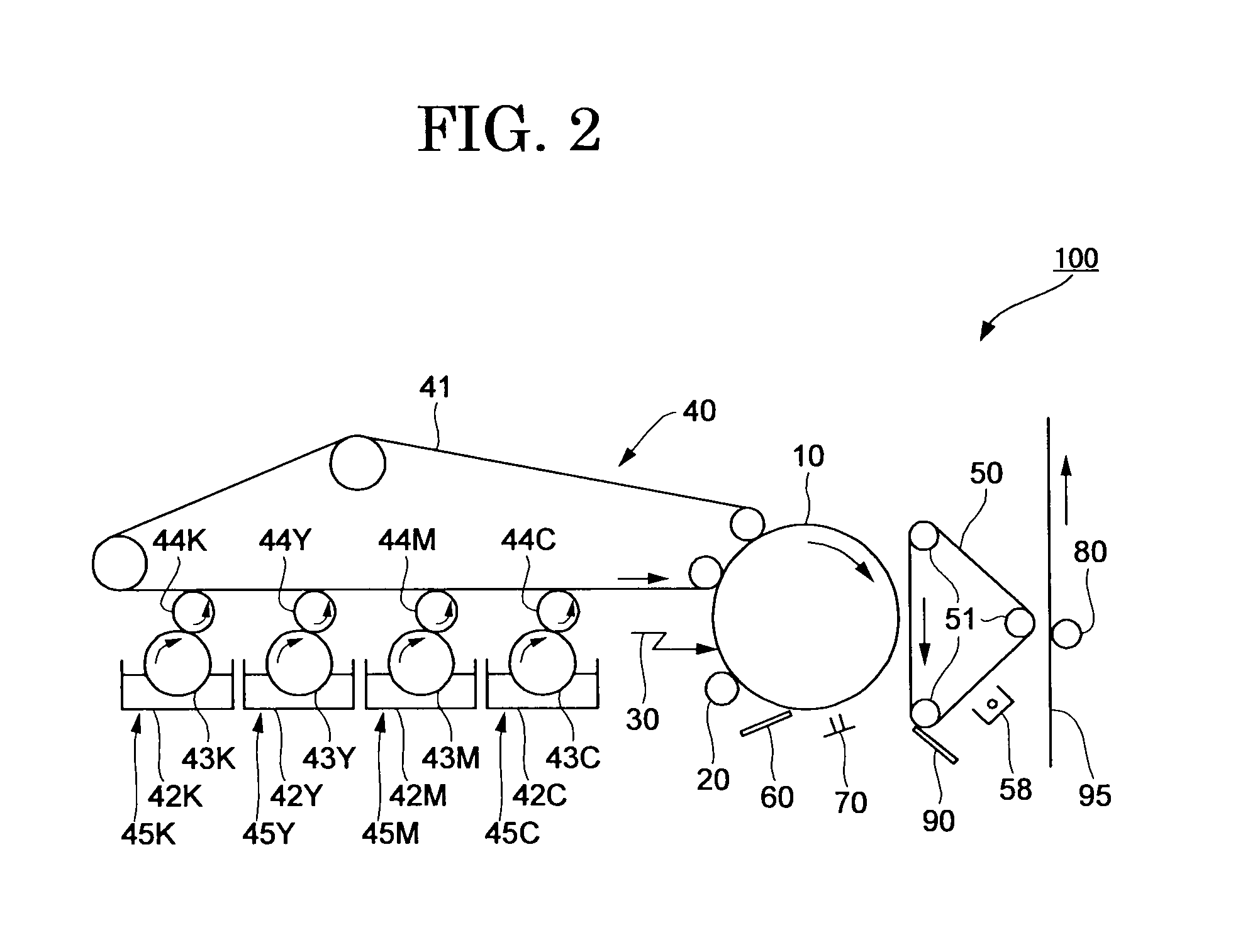

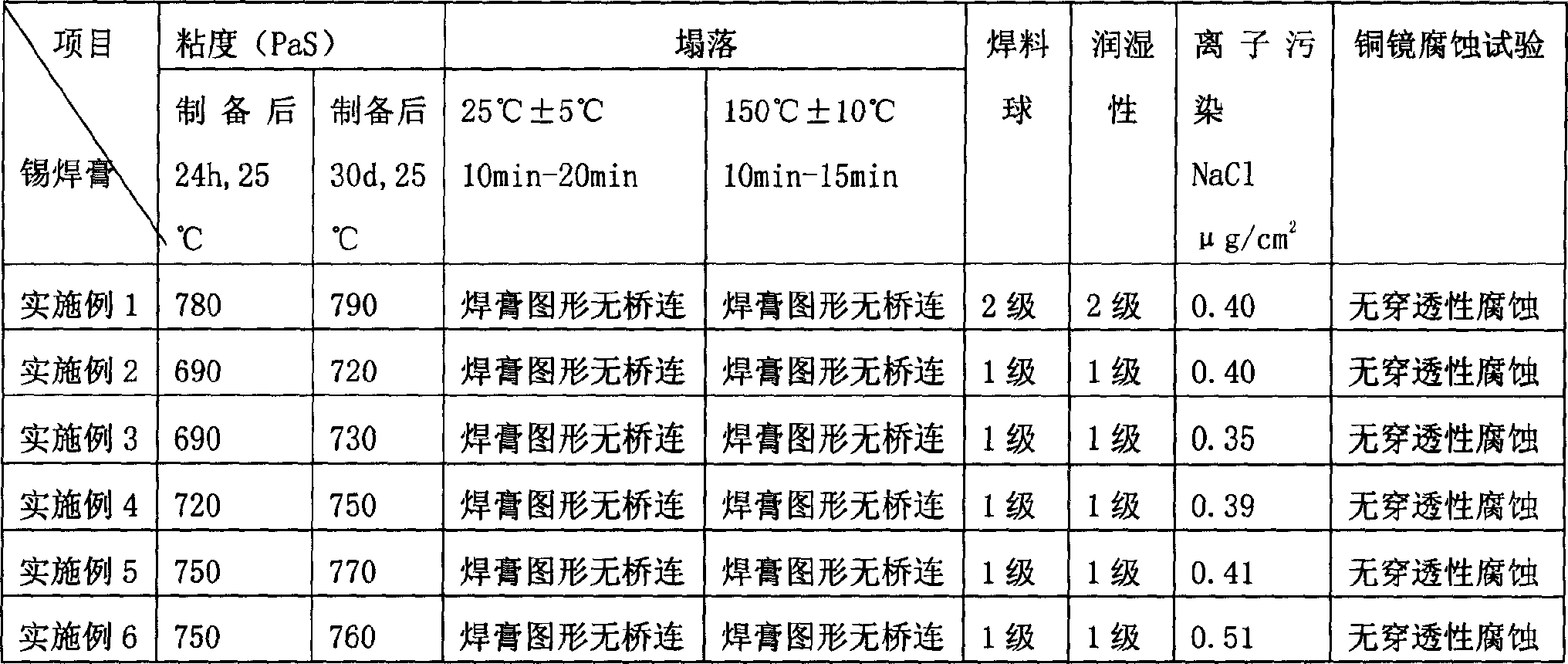

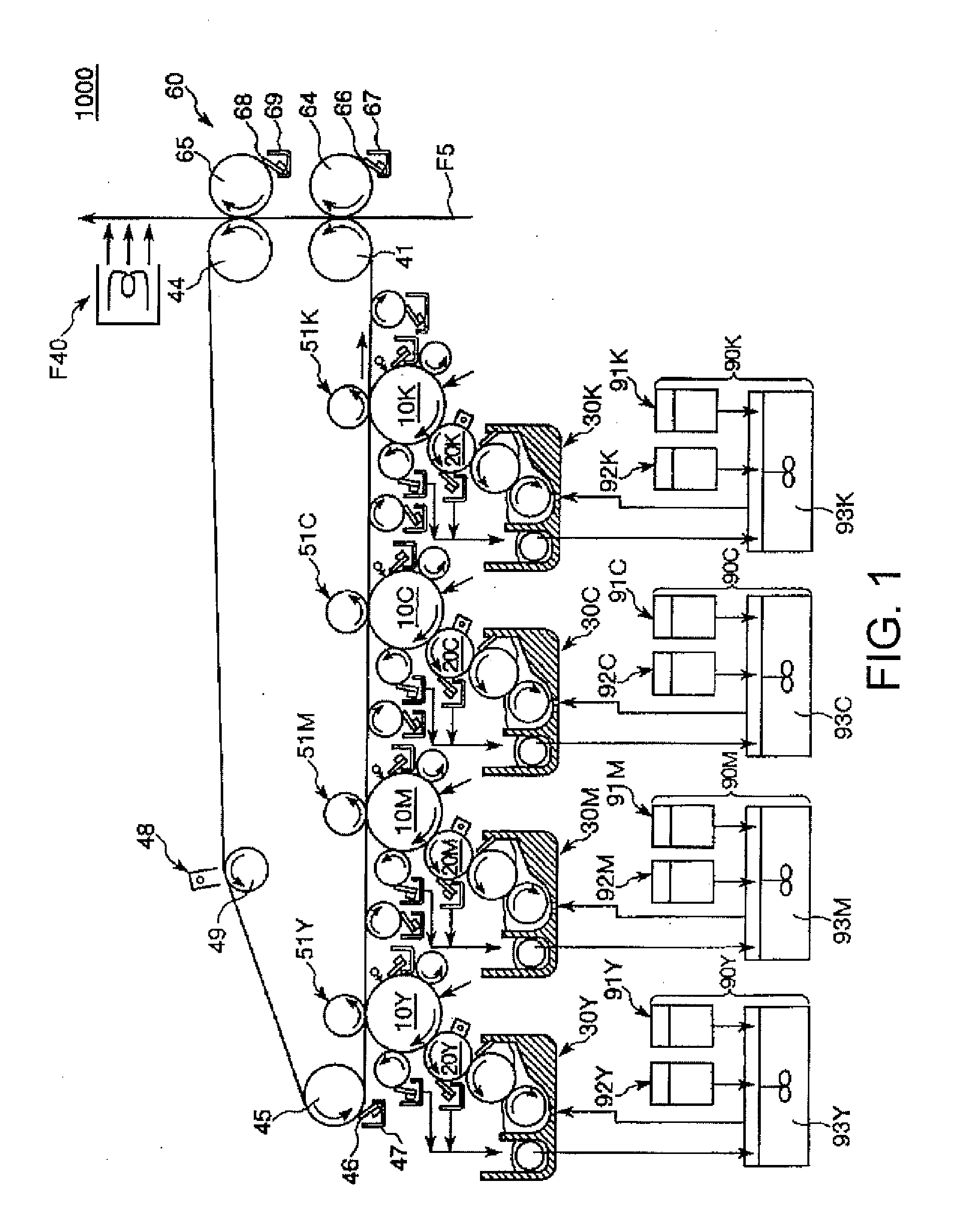

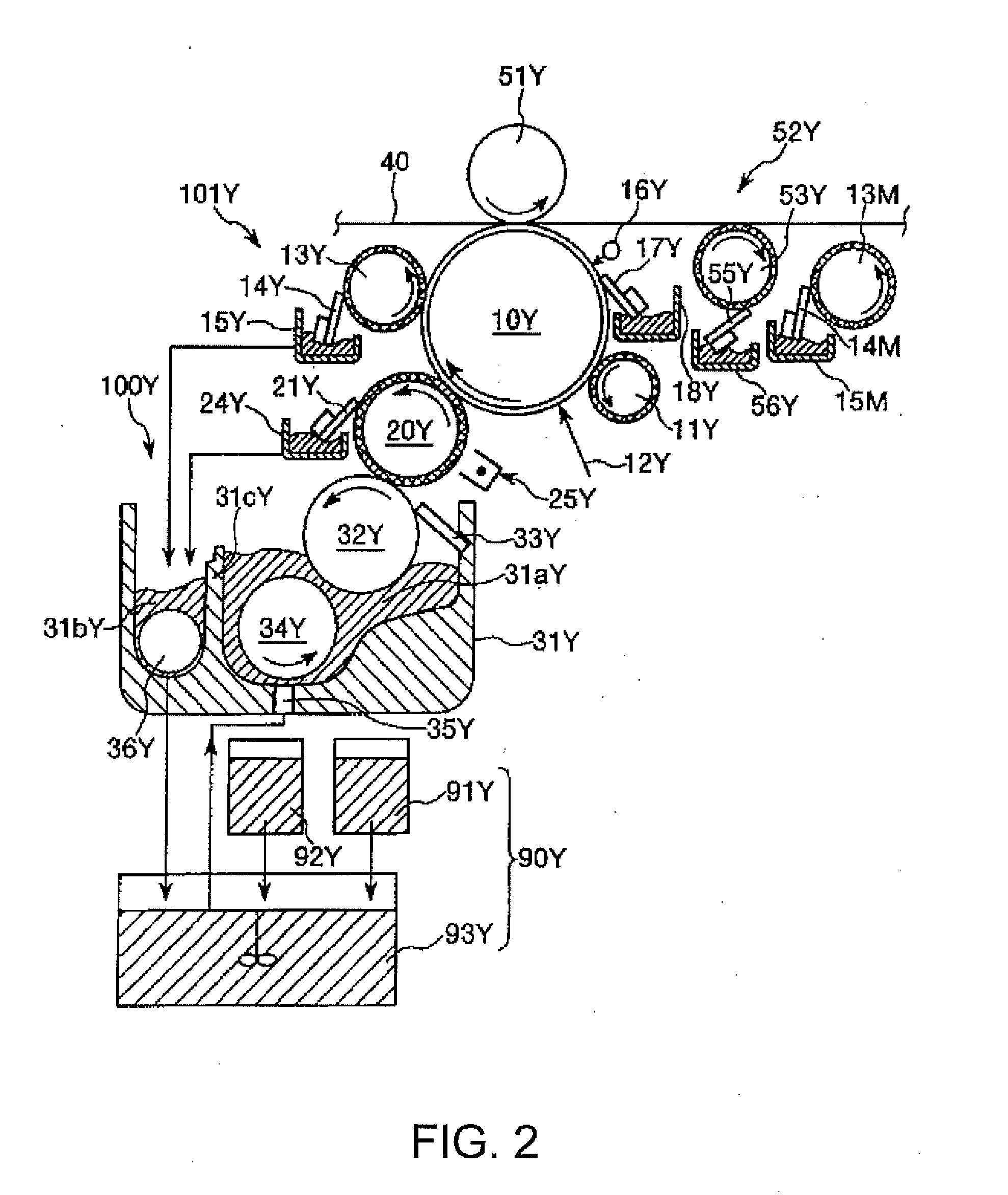

Toner, as well as image forming apparatus and image forming method using the same

ActiveUS20080280218A1Good storage stabilityLow temperature-fixing propertyDevelopersElectrographic process apparatusCarboxylic acidPropanediol

To provide a toner produced by emulsifying or dispersing in an aqueous medium particles containing at least polyester resin particles and by aggregating the polyester resin particles, wherein the polyester resin particles contain a polyester resin, the polyester resin is produced by condensation polymerization of an alcohol component containing 65 mol % or more 1,2-propanediol in a dihydroxy alcohol component and a carboxylic acid component containing purified rosin, and the softening point of the polyester resin is 80° C. or more and less than 120° C., and wherein the toner comprises a colorant and a releasing agent.

Owner:RICOH KK

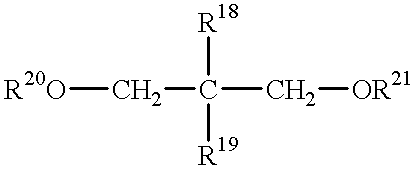

Solid catalyst component for alpha-olefin polymerization, catalyst for alpha-olefin polymerization, and process for producing alpha-olefin polymer

InactiveUS6187883B1High catalytic activityNarrow particle size distributionOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationOrganic acidEther

The present invention relates to a solid catalyst component for alpha-olefin polymerization having a narrow particle size distribution of not less than 6.0 in terms of the value of N in a Rosin-Rammler function of particle size distribution and giving a catalytic activity of not less than 10,000 ((g-polymer produced / g-solid catalyst component) / hour) in polymerization. The catalyst component is obtained by a process which comprises reducing a titanium compound with an organomagnesium compound in the presence of an organosilicon compound and an ester to obtain a solid product, then treating the solid product with: (a) a mixture of titanium tetrachloride and an ether, (b) an organic acid halide, and (c) a mixture of titanium tetrachloride and an ether optionally containing an ester.

Owner:SUMITOMO CHEM CO LTD

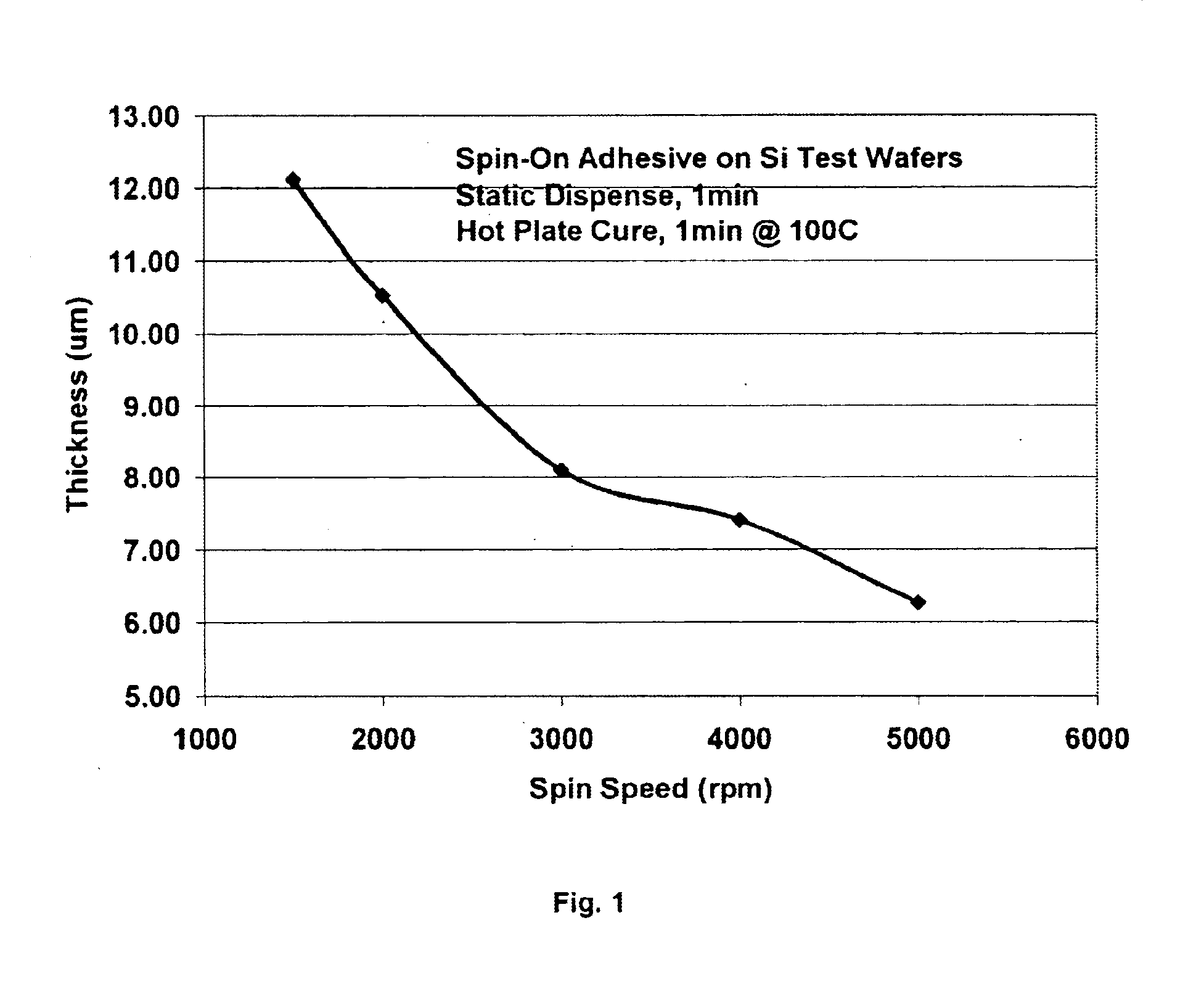

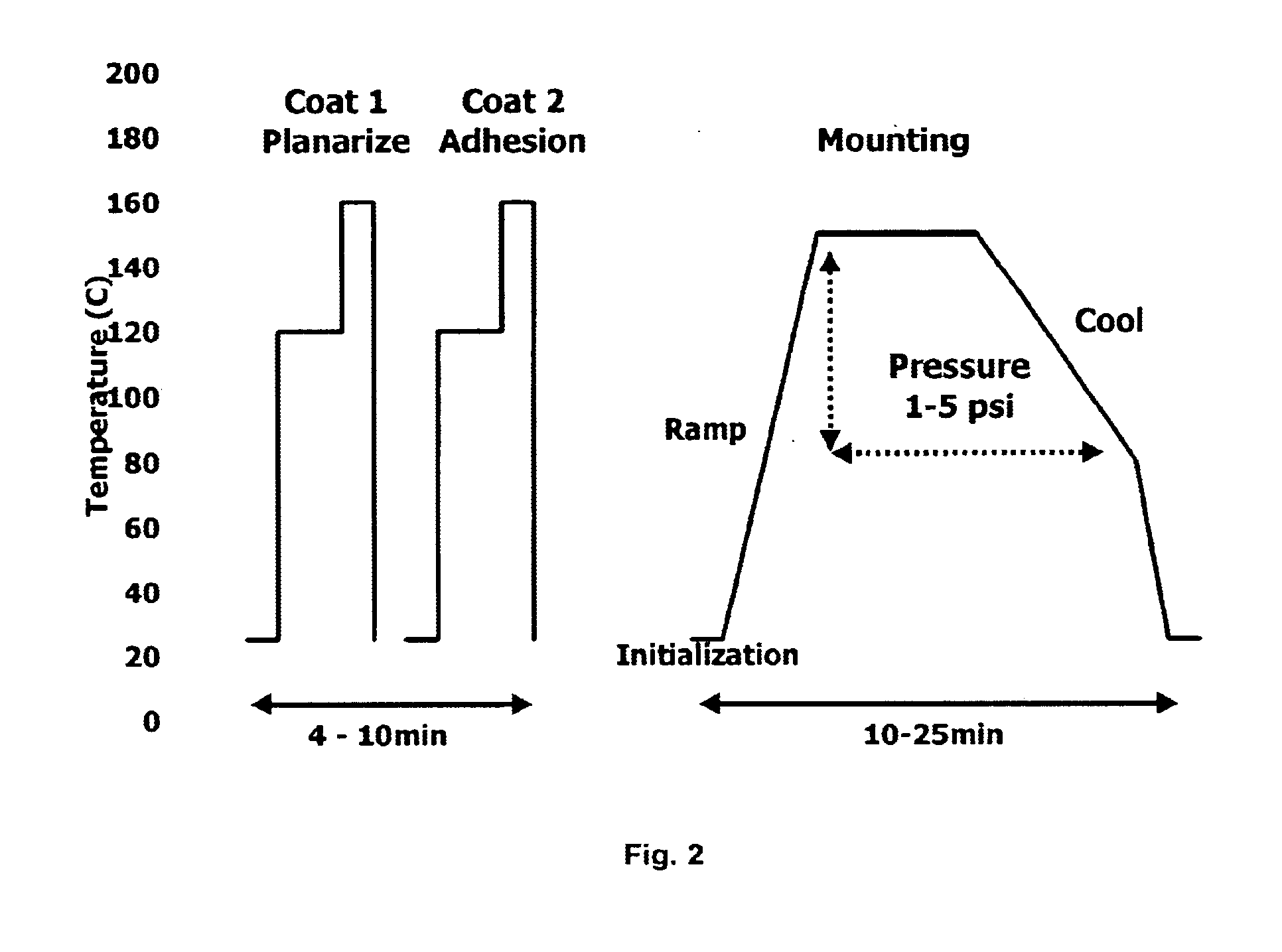

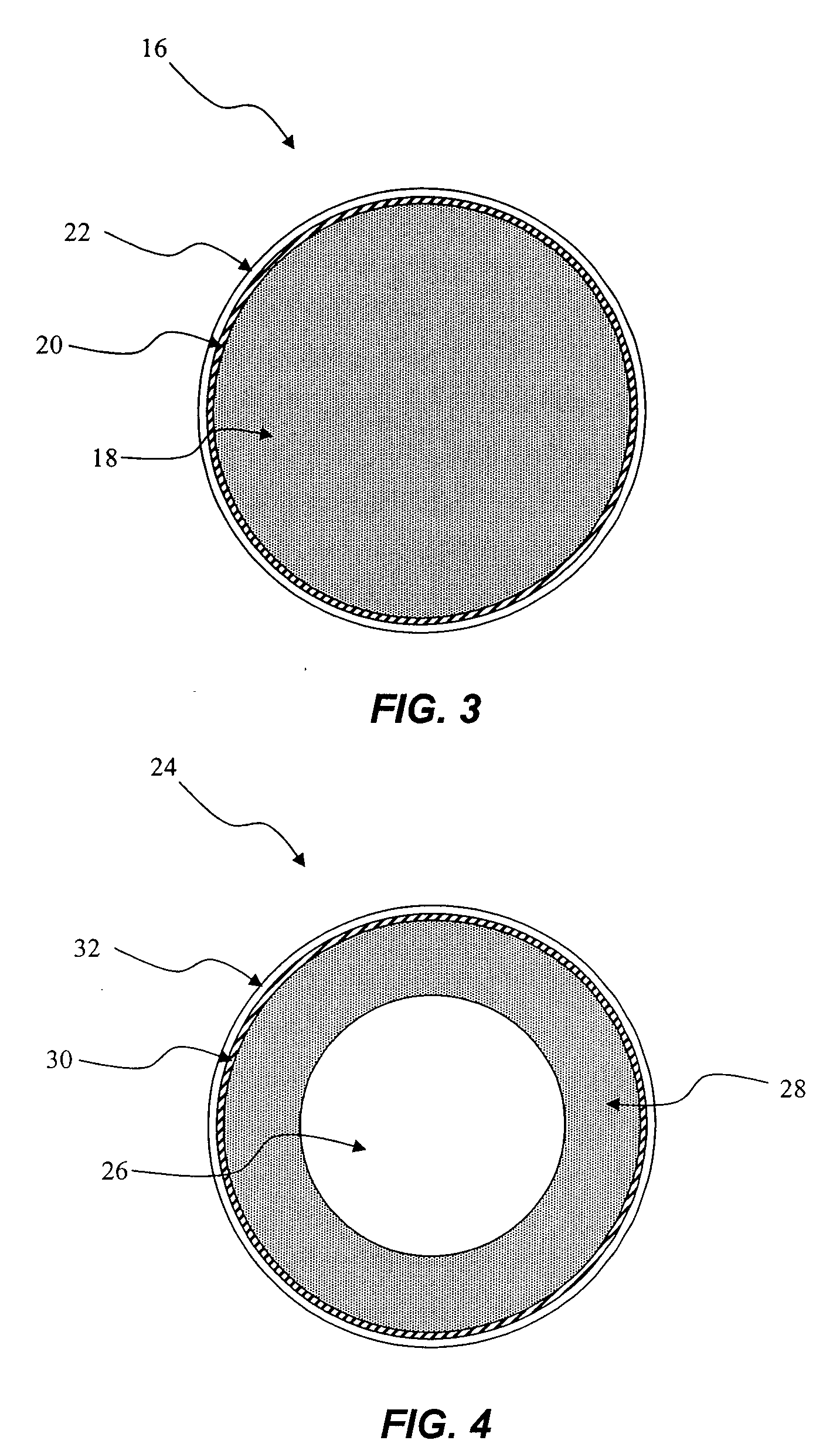

Spin-on adhesive for temporary wafer coating and mounting to support wafer thinning and backside processing

InactiveUS6869894B2Semiconductor/solid-state device testing/measurementSynthetic resin layered productsAdhesiveFluorescence

A liquid form adhesive system is provided for spin-coating on wafers and mounting to rigid carrier substrates to support thinning and backside processing. The liquid adhesive comprises about 30-35% of a rosin, between 5-10% of a thermoplastic urethane, a nonionic surfactant present between 1-3%, and a trace of an ultraviolet fluorescing dye. The entire system is dissolved in 50-65%, by weight, of a dual solvent mixture composed of dimethylacetamide and propylene glycol monomethyl ether. When the mixture is made to a specific viscosity, filtered, applied by a spin-coating method to the wafer frontside surface, and cured, the result is a uniform and smooth surface of defined thickness. When the coated wafer is mounted to a rigid substrate, it may be mechanically thinned to thicknesses down to and beyond 25 um, depending upon the wafer composition, diameter, and process. Once thinned, the adhesive is safe for backside processing and is dissolved away at completion to provide a thinned wafer that is clean and ready for final dicing or chipping operations.

Owner:GENERAL CHEM CORP +1

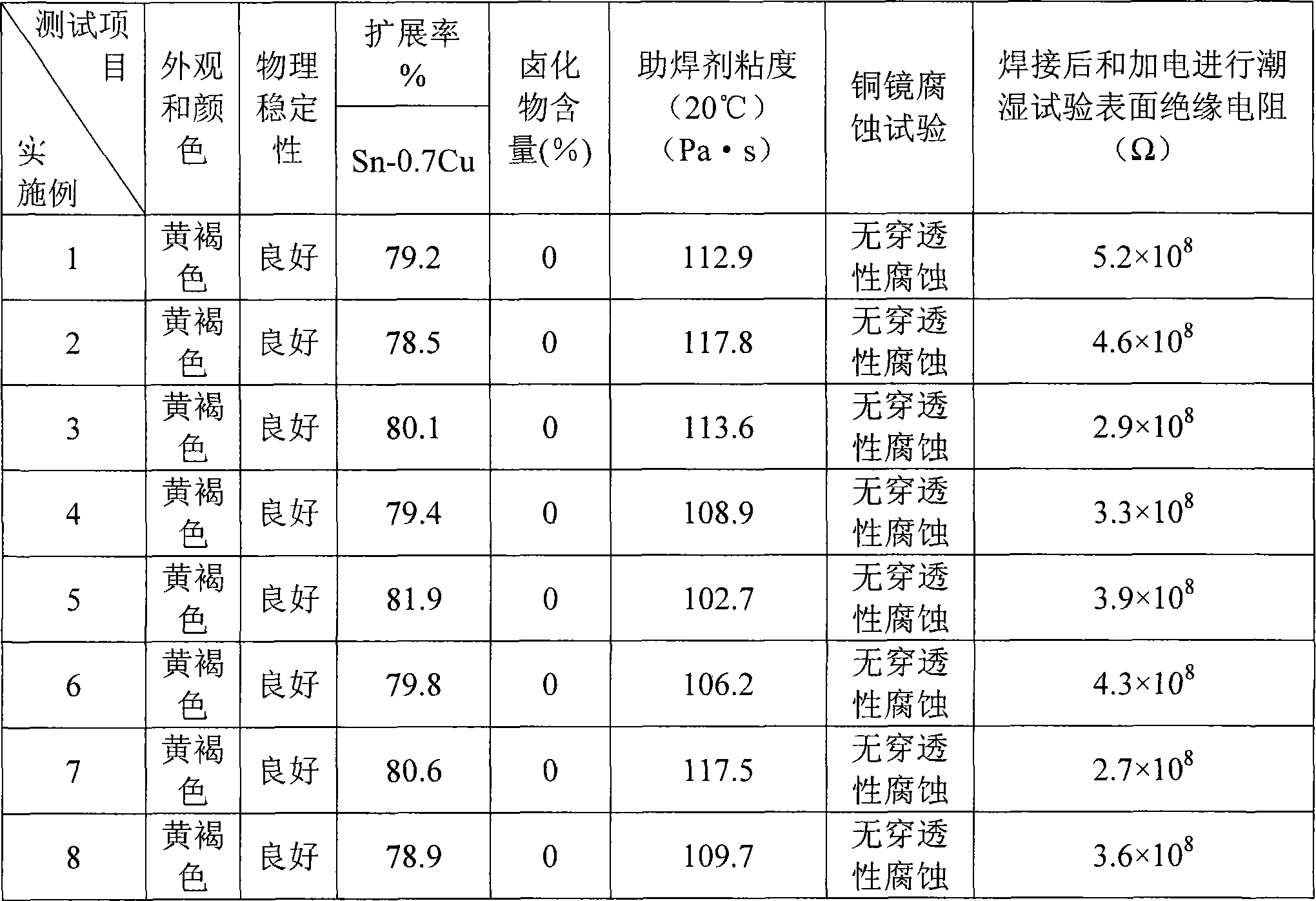

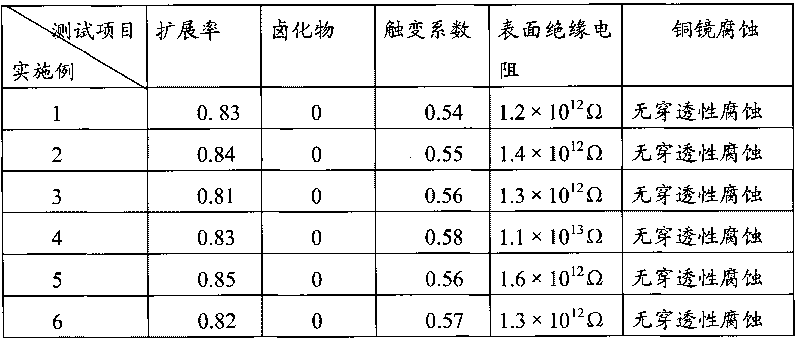

Low-rosin and cleaning-free welding accessory without halogen for lead-free welding grease

InactiveCN101073862AGood print shapeNo viscosity requirementWelding/cutting media/materialsSoldering mediaSolventSolder paste

The invention is concerned with low rosin type halogen-free and cleaning-free flux using for lead-free solder paste, belonging to flux field. About the existing rosin type flux, the leftover after welding is high and the leavings with halogen has cauterization. The matter of this invention is 5 to 20 wt percent of organic acid activator, 10 to 29 wt percent of modified rosin, 1 to 10 wt percent of binder, 0.5 to 6 wt percent of stabilizer, 1 to 6 wt percent of surfactant, 1 to 8 wt percent of corrosion inhibitor, 1 to 10 wt percent of thickener, and the rest is solvent with high boiling point. The copper mirror after welding is not penetration, and this invention without halogen has high insulation resistance and good assistant jointing capability. The viscosity of matched solder paste is advisable to solve the high content of rosin in the flux and great smoke. The leftover after welding is colorless and transparent film and it dose not absorb water with the normal temperature without clearing to fit for the welding demand of common production.

Owner:BEIJING UNIV OF TECH

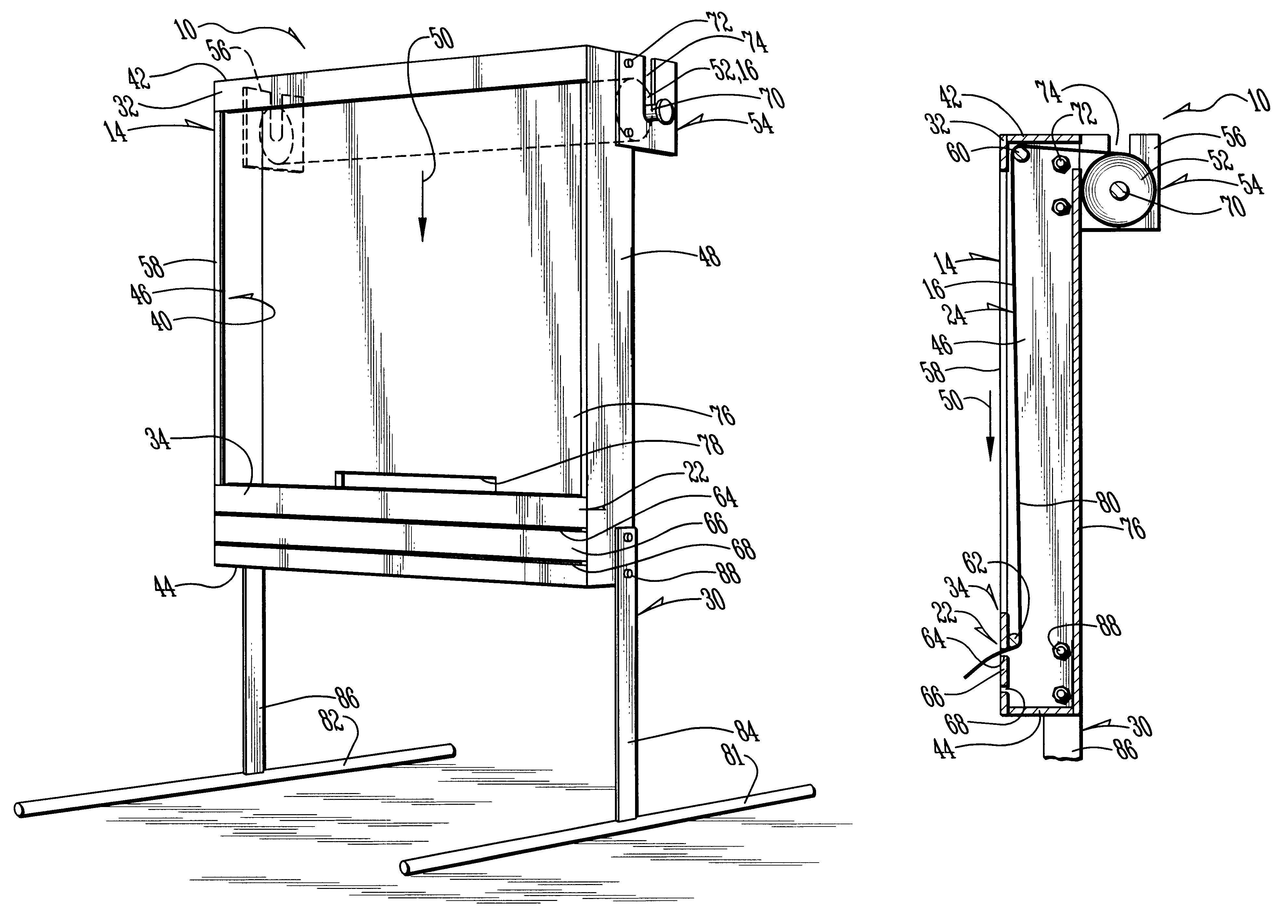

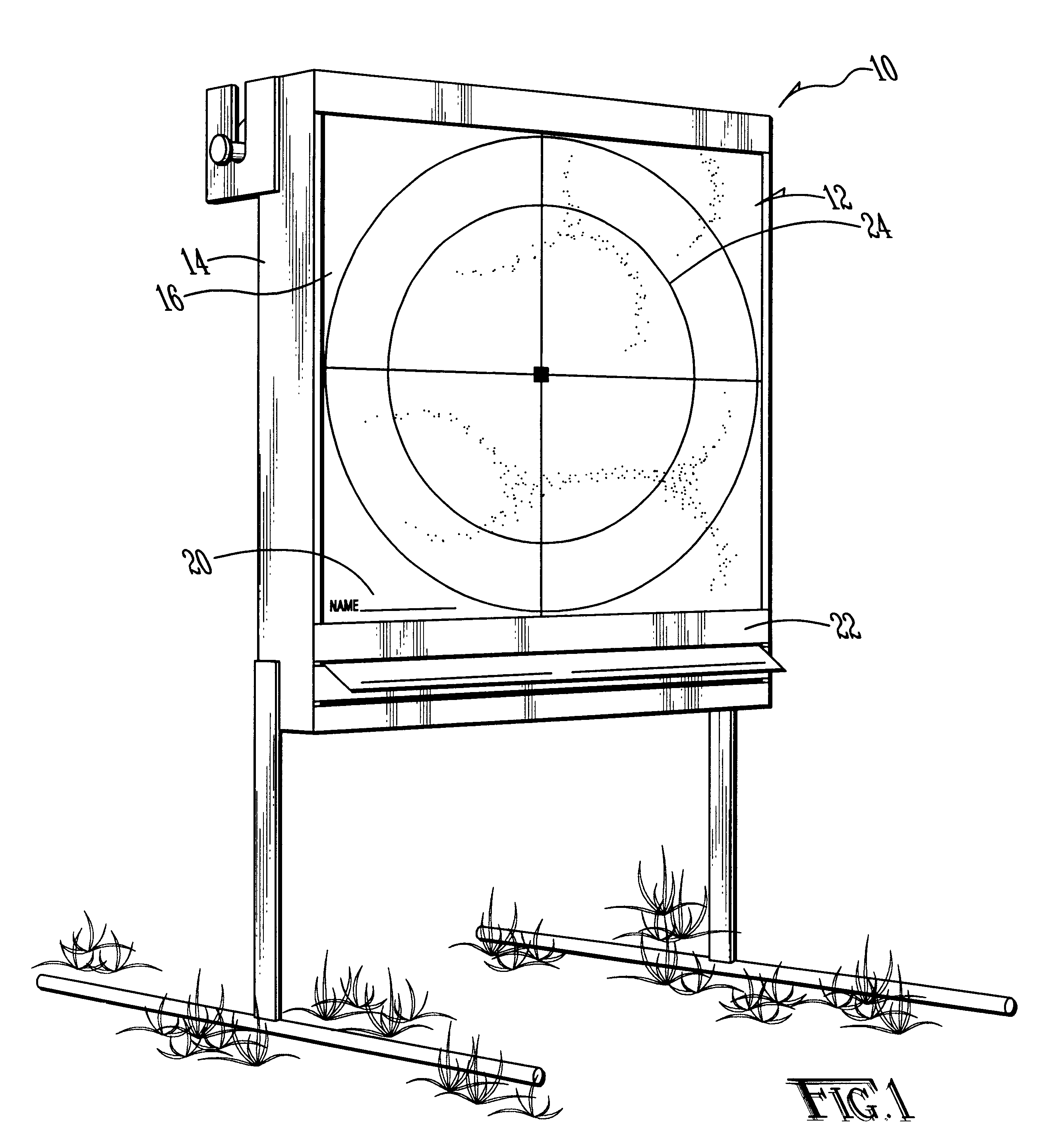

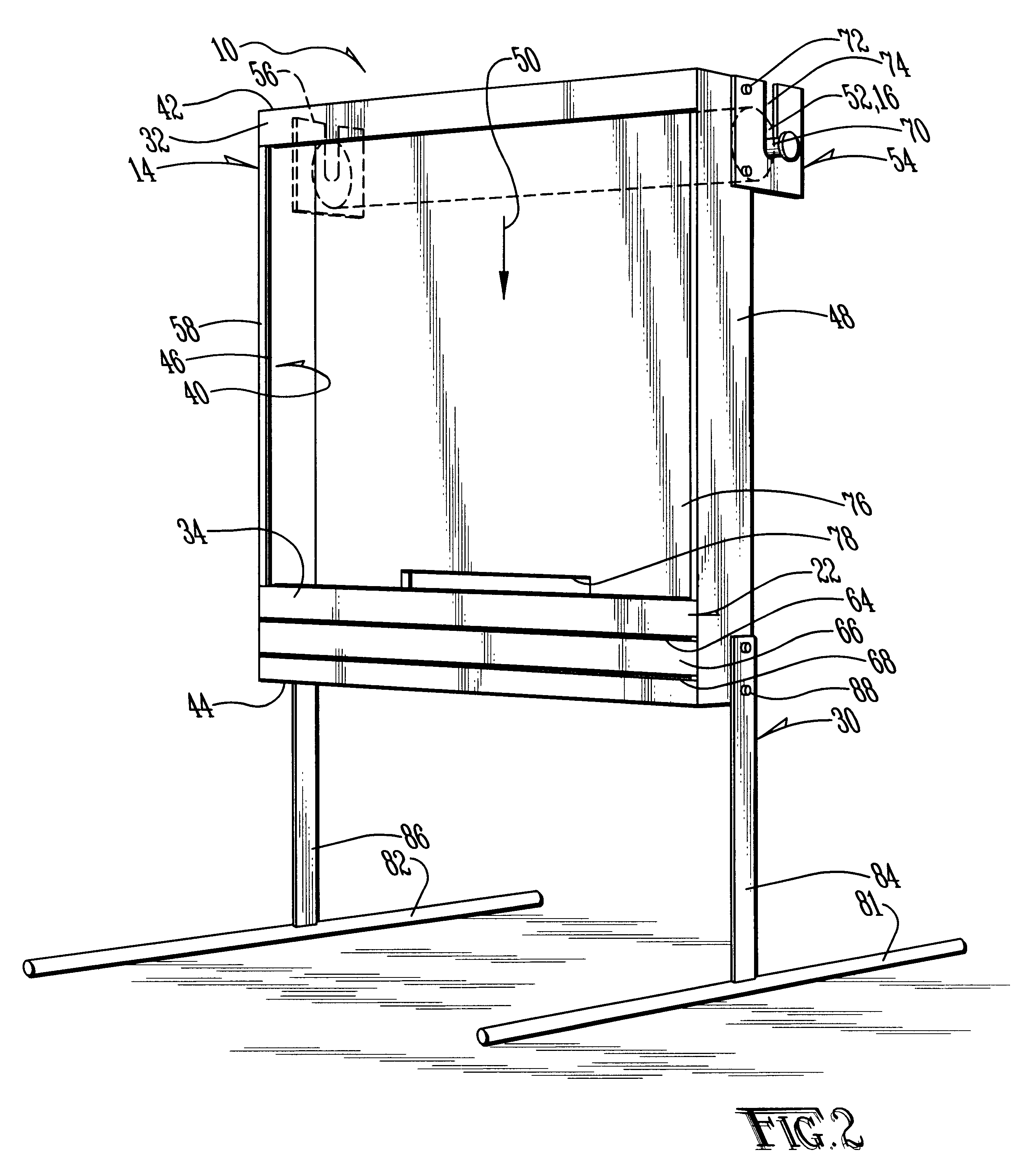

Paper roll target apparatus

A target assembly includes special paper on which a target is imprinted and which is stored on a feeder roll in a frame and which is moved past a target area in the frame to either a take-up roll or to an exit slot. If the paper passes through the exit slot, it can be moved past a cutting slot and cut off using a knife or the like. The paper is a special rosin sized sheathing, such as forty pound wax paper, which retains the desired orientation during a target shoot, as well as makes clean, precise holes when impacted by shot whereby a precise record of a shot is made. An area on the paper adjacent to each target can be used to record data pertinent to the shoot whereby a firearm can be sighted in or a load adjusted.

Owner:BAKER JON ELLIS

Rosin cation asphalt emulgent

InactiveCN1861721AReduce manufacturing costGood emulsificationTransportation and packagingMixingRosinAsphalt

The invention relates to a rosin cationic bitumen emulsifier. The rosin intermediate is reacted by the rosin and the polyethylene polyamine, then to condensate with the different types of the quaternary ammonium salt to get the emulsifier. The emulsifier can be used to produce the normal cationic emulsifying asphalt or the SBR modified emulsifying asphalt for the road priming oil and the felting oil. The character of the invention is to use the nature resin rosin as the material, so the cost has decreased and it meets the environment need. The emulsifying asphalt can reach the need of the standard of the China ministry of communications and the America ASTMD2397.

Owner:DALIAN UNIV OF TECH

Modified hydrocarbon cleaning agent

The invention relates to the technical field of the cleaning agent, in particular to a modified hydrocarbon cleaning agent. The main technical scheme in the invention is as follows: additives are added in the hydrocarbon cleaning agent which contains solvent without aromatic hydrocarbons, solvent with low aromatic hydrocarbons and C10-13 normal paraffin or isoparaffin, namely alcohol additive, ester additive and ether additive are added in the hydrocarbon cleaning agent D40, D60, D65 and D80 and the hydrocarbon cleaning agent C10, C11, C12 and C13 to ensure that the modified hydrocarbon cleaning agent has high cleaning capability, high KB value, low aniline point, low cost, little odor and high recovery rate, can be used to clean macromolecular pollutants such as wax, resin, printing ink and rosin and can be heated for cleaning in a special device.

Owner:广东新球清洗科技股份有限公司

Non-halide cleaning-free welding flux for leadless solder

InactiveCN101062536AImprove solderabilityHigh insulation resistanceWelding/cutting media/materialsSoldering mediaSurface-active agentsAmino acid

The invention relates to a lead free soldering clean free soldering flux with the mass percentage of organic acid activating agent 1. 5-3. 5%, surface active agent 0. 04-0. 6%, organic amine and derivant 2. 0-5. 0%, with the rest being film forming matter. The said organic acid could be one or more of the aliphatic acid mono acid or bi-acid, aromatic acid, or amino acid. The said surface active agent is one or more of the nonion surface active agent, and the said organic amine and the derivant being ethanediamine, tetramethylenediamine, diethyl ethanolamine and so on, with the said film forming material being diethyl ethanolamine or resin. The soldering flux does not have halogen, being environmental protective, good in welding, welding spot being full and luminous, without residue, no corrosion, high in isolation resistance.

Owner:CENT SOUTH UNIV

Primer coating for enhancing adhesion of liquid toner to polymeric substrates

ActiveUS7470736B2Improve adhesionImprove coating adhesionSpecial tyresInksWater basedPolyvinyl chloride

A primer coating is provided for use on polymeric substrates to enhance adhesion of liquid toner to the substrates for printing in an electrophotographic printing device. The primer coating is water-based and includes a dispersion of a copolymer of ethylene and acrylic or methacrylic acid, and a compatible adhesion enhancer selected from an aliphatic polyurethane dispersion, a hydrogenated hydrocarbon rosin or rosin ester dispersion, and an amorphous acrylic polymer dispersion. The coating may also include additives such as wetting agents, antiblocking agents, matting agents, and waxes. The primer coating may be applied to a variety of polymeric substrates including polypropylene, biaxially oriented polpypropylene, polyethylene terephthalate, and polyvinyl chloride.

Owner:MICHELMAN INC

Detumescent and analgesic ointment for curing rheumatism and contusion and preparation method thereof

InactiveCN102000302AHeavy metal active ingredientsHydroxy compound active ingredientsInjury causeRheumatism

The invention discloses detumescent and analgesic ointment for curing rheumatism and contusion and a preparation method thereof. The ointment is a pure herbal pharmaceutics, which is composed of monarch drugs, ministerial drugs, adjuvant drugs and conductant drugs. The preparation method comprises the following steps: placing 5kg of tung oil in a pan; grinding all traditional Chinese bug bulk pharmaceutical chemicals (BPC) into refined powder, wrapping the adjuvant drugs and the conductant drugs with gauzes, and placing into a frying pan for boiling; boiling with charcoal fire for 90min, putting the powder in to the frying pan after generating smokes, and boiling the mixture to obtain semi-creamy mixture; placing the ministerial drugs into the pan for even stirring to obtain semi-creamy mixture; taking the pan away from the fire and putting the monarch drugs into ointment for even stirring; placing 2.5kg of rosin into the ointment and evenly stirring to obtain the ointment, and pasting the ointment on kraft papers with 11 centimeters; and pressing the ointment on the kraft papers by a 6-centimeter iron module to obtain the ointment with diameter of 6 centimeters, and placing the obtained ointment on fixed patches. The detumescent and analgesic ointment for curing rheumatism and contusion can be used for stimulating the circulation of the blood and causing the muscles and joints to relax, relieving bruises and pains, and curing traumatic injuries and rheumatoid arthritis.

Owner:吴兴保

Composition useful for healing and protecting skin

The present invention relates to a formulation of herbal cream for cracked heels and palms. Since the components in the formulation are from herbal sources it is very safe and eco-friendly and does not produce any harmful effects on the skin. It is comprised of a natural wax as an emulsifier, extract of curcuma and the gum of Acacia or Colophonium or Shorea. The gum gives a synergistic effect in binding and healing the skin with natural wound healing herbal extract selected from the aqueous extracts of curcuma, neem and allantonin. This is combined with a wound healing fragrant oil. The natural wound healing herbal extract acts as a humectant and the gum gives an synergistic effect in binding the skin thereby reducing water loss from the skin. The cream spreads evenly and smoothly when applied on the affected parts, and quickens healing, restores natural suppleness and softness and also serves as an antiseptic.

Owner:COUNCIL OF SCI & IND RES

Halogen-free tin-bismuth-copper soldering paste and preparation method thereof

InactiveCN101695794AExtended shelf lifeExtended service lifeWelding/cutting media/materialsSoldering mediaAntioxidantExpansion rate

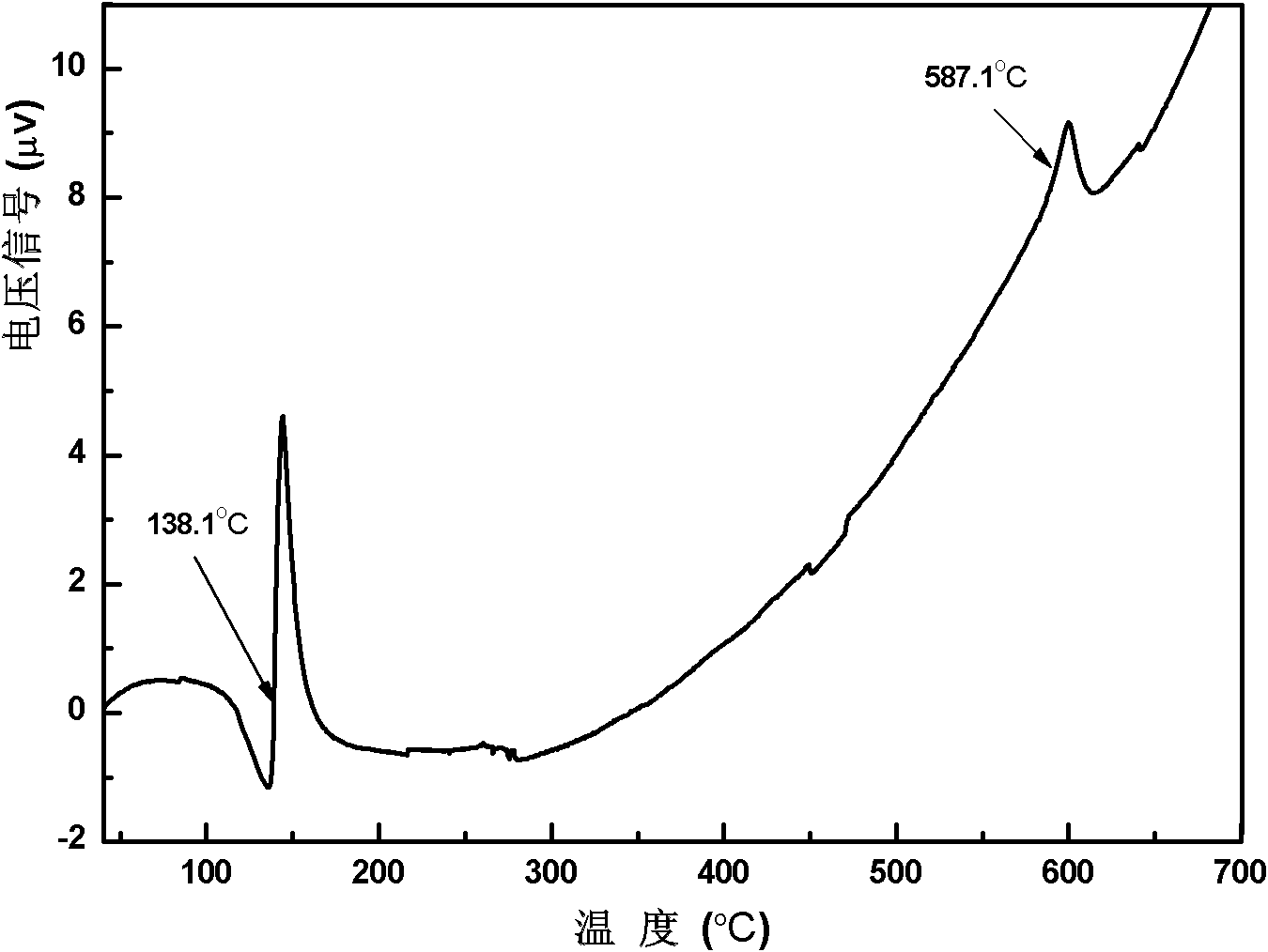

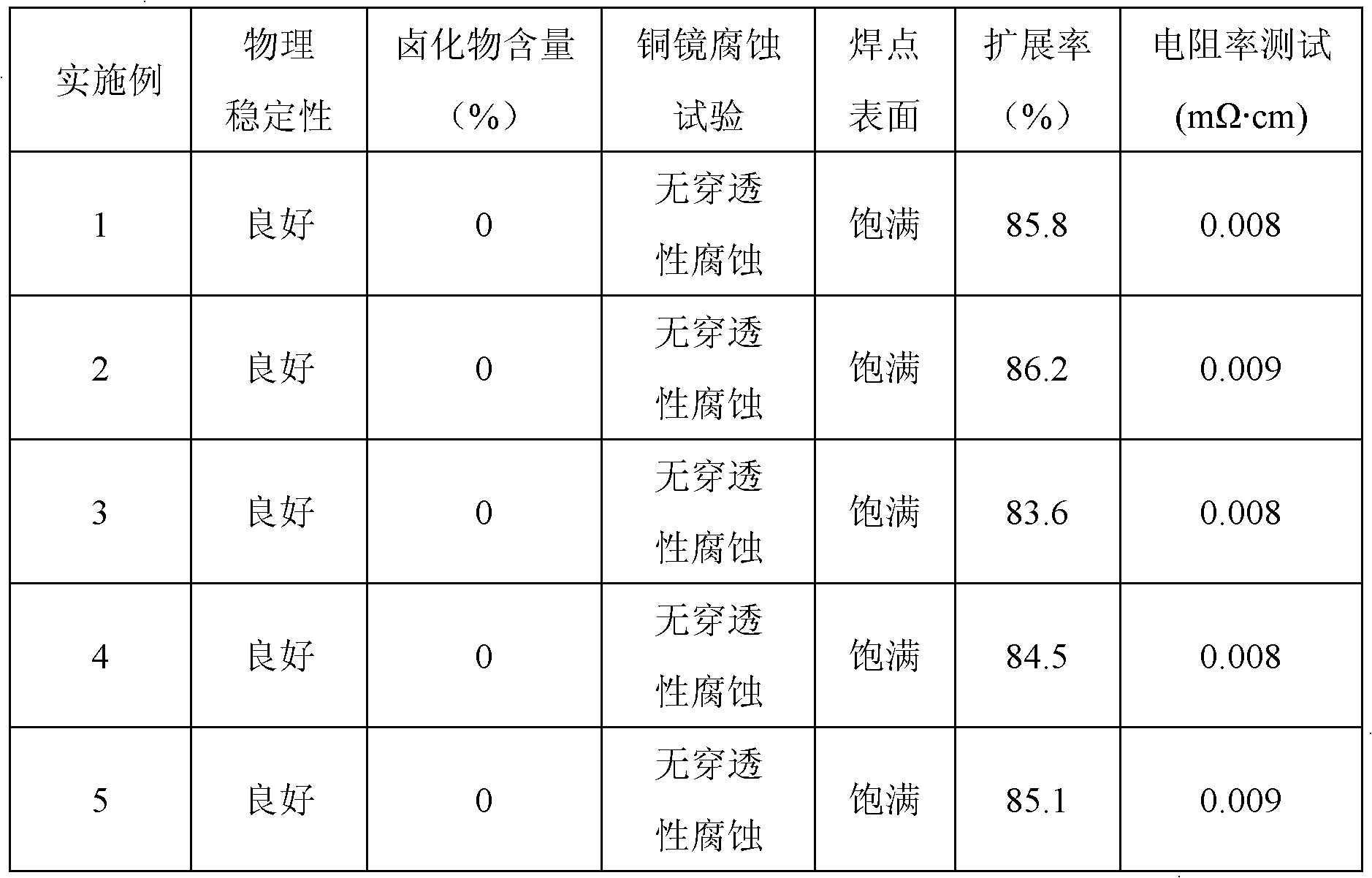

The invention relates to the technical field of soldering pastes, in particular to a halogen-free tin-bismuth-copper soldering paste and a preparation method thereof. A soldering flux of the halogen-free tin-bismuth-copper soldering paste consists of the following components in percentage by weight: 20 to 40 percent of polymerized rosin, 1 to 6 percent of rosin amine, 4 to 8 percent of thixotropic agent, 5 to 10 percent of organic acid, 5 to 10 percent of organic amine, 1 to 5 percent of antioxidant, 0.5 to 3 percent of surfactant and an organic solvent. The halogen-free tin-bismuth-copper soldering paste is mainly characterized by adopting the organic acid and the organic amine serving as activating agents and comprising no halogens at all, so not only the solderability is not reduced, but also the expansion rate and the insulation resistance value of the soldering paste are improved, and simultaneously the corrosivity of residues after soldering to a base material is reduced and the service life of the soldering paste is prolonged; and particularly, the peak temperature of the soldering paste during soldering is lower in favor of reducing the thermal damages to electronic components.

Owner:东莞市特尔佳电子有限公司

Environment protecting wood wax oil

InactiveCN101550316ANo pollution in the processMeet environmental protection requirementsCoatingsWood impregnation detailsWaxVegetable oil

The present invention relates to an environment protecting wood wax oil which comprises the following main components by weight: 75-85 parts of vegetable oil, 0.1-1 part of vegetable wax or animal wax, 11-22 parts of rosin resin, 1-2 parts of drier and 0.1-1 part of cosolvent. The preparing method of the wood wax oil comprises the following steps: heating and melting the vegetable oil and wax mixing system, reducing the temperature and adding other materials, and mixing to uniform for obtaining the wood wax oil. The wood wax oil related to the invention can totally penetrate into the wood. The wood wax oil of the invention is remarkably different with the traditional paint with the existence of paint skin. The surface of wood wax oil has an open texture effect. The different woods can represent different real tactile sensation. Furthermore the wood with the environment protecting wood wax oil can be partially restored and retrofitted without mark. The wood wax oil can preserve various excellent performances of wood and effectively prevent the seasoning cracking of wood. The wood is caused to possess the excellent performances of ventilation, drying, corrosion resistance, worm resistance, flame resistance, etc. The using quality of wood can be increased comprehensively.

Owner:TIANJIN XIANDAIREN RE EMPLOYMENT SERVICE

Lead-free halogen-free tinol and preparation process

ActiveCN1876311AImprove compatibilityImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaOrganic acidHalogen

The invention discloses a leadless and no-halogen tonal, comprising following components with percent by weight: alloy powder 80-98 and welding flux 2-20; said alloy powder is one of SnAgCu, SnAgNi, SnAgBiCu, SnAgBiSb, SnCu and SnAg; said welding flux concludes following components with percent by weight: modified resin antioxidant 30-60, organic acid activating agent 5-15, thixotropic agent 4-14, plasticizing agent 2-6, plasticizing agent 0.4-2, inhibitor 0.1-0.5 and organic solvent 20-40; said modified resin antioxidant comprises following components with percent by weight: modified rosin resin 80-90, anti-oxidant 2-8, and reducer 2-8. The tonal is characterized by good thixotropic behavior, no oxidation, no dry welding and no short circuit.

Owner:BEIJING XINLI MACHINERY

Thermosetting flux and solder paste

InactiveUS20050056687A1Improve bindingBonded firmlyPrinted circuit assemblingPrinted circuit aspectsRosinSolder paste

The invention aims to provide a thermosetting flux suitable for solder bonding of a semiconductor element and an electronic part and making solder bonding with a high bonding strength and a high heat resistant strength at a high temperature possible and a paste containing the flux and a non-lead type solder paste and with respect to the thermosetting flux, an epoxy resin, a hardening agent, and at least one of rosin derivatives having functional groups reactive on the epoxy resin and selected from maleic acid-modified rosin, a fumaric acid-modified rosin, and acrylic acid-modified rosin are used. The flux can be used in form of a solder paste while being mixed and kneaded with the non-lead type solder alloy powder.

Owner:KK TOSHIBA

Water-soluble soldering flux dedicated for lead-free solder

InactiveCN1836825AImprove solderabilityImprove performanceWelding/cutting media/materialsSoldering mediaOrganic acidWater soluble

The water soluble soldering flux specially for lead-free soldering material consists of boric acid and organic acid activator 5.0-10.0 wt%, non-ionic surfactant or cationic surfactant 0.1-1.0 wt%, co-solvent 8.0-20.0 wt%, filming agent 0.1-1.0 wt%, corrosion retardant 0.1-0.5 wt%, except deionized water. The compounding process includes the following steps: mixing co-solvent and partial deionized water, adding filming agent under stirring, adding the rest deionized water, activator and surfactant after dissolving, adding corrosion retardant while stirring to dissolve, stilling, and filtering to obtain the filtrate as the soldering flux. The water soluble soldering flux has excellent soldering assisting performance on lead-free soldering material, environment friendship and other advantages.

Owner:BEIJING UNIV OF TECH

Hot melt adhesive

InactiveCN102653665ASuitable for production process requirementsReasonable formula designMacromolecular adhesive additivesEpoxyPolyolefin

The invention discloses a hot melt adhesive which comprises the following components in parts by mass: 5-10 parts of EVA (ethylene-co-vinyl acetate), 2-6 parts of tackifier, 5-10 parts of diluent, 0.5-1.5 parts of antioxidant and 0.5-1.5 parts of plasticizer. The tackifier is one of rosin resin, petroleum resin, terpene resin, phenolic resin and epoxy resin; the diluent includes one or both of wax and low-molecular polyolefin; the antioxidant is phenolic antioxidant; and the plasticizer is DCHP (Dicyclohexyl phthalate). The EVA contains 20-30% of vinyl acetate monomer; and the wax is microcrystalline wax with molecular weight of 3,000-4,000 and melting point of 65-85 DEG C.

Owner:成都鑫三洋科技发展有限公司

Liquid Developer and Image Forming Method

InactiveUS20100055602A1Easy to fixExcellent in long-term dispersion stability of toner particlesElectrographic process apparatusDevelopersRosinAnalytical chemistry

Owner:SEIKO EPSON CORP

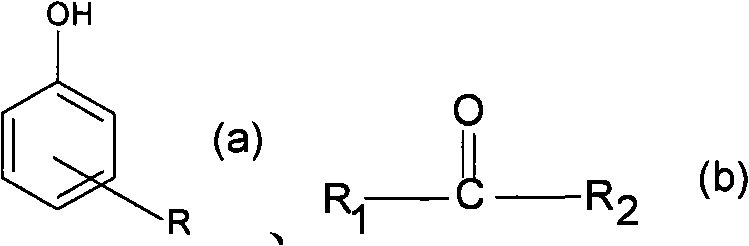

Halogen-free cleaning-free rosin flux, and preparation and application thereof

ActiveCN102513732ALess corrosiveSlow growth rateWelding/cutting media/materialsSoldering mediaSolventSolder paste

The invention discloses a halogen-free cleaning-free rosin flux, and preparation and application thereof, and particularly relates to a flux suitable for surface mount lead-free welding paste, preparation of the flux and application of the flux. The flux comprises 20-50% (mass fraction, the same below) of rosin, 5-25% of film-forming agent, 30-50% of high boiling solvent, 3-8% of activator and 2-5% of thixotropic agent, and the flux does not contain any halogen. In order to control growth of interface IMC (intermediate compound) during welding, 0.3-1% of combined inhibitor is added. The welding paste prepared with the flux and lead-free tin-silver-copper powder has the advantages of excellent printing performance, fine weldability, less post-weld residue, thin and even welding spot interface IMC and excellent mechanical property, and is capable of meeting the requirement of high-end electronic products on packaging.

Owner:CENT SOUTH UNIV

Low-VOC additives for extending wet edge and open times of coatings

A low VOC coating additive employing a water-dispersible rosin, a high glass transition temperature water-dispersible polymer, and optionally an amphiphilic component. The additive can be added to a coating to improve the performance characteristics of the coating, such as wiped wet edge time, open time, block resistance, gloss, scrub resistance, tack-free time, dry-to-touch time, and yellowing.

Owner:EASTMAN CHEM CO

Primer coating for enhancing adhesion of liquid toner to polymeric substrates

ActiveUS20050245651A1Enhanced liquid toner adhesionImprove adhesionSpecial tyresInksWater basedPolymer science

A primer coating is provided for use on polymeric substrates to enhance adhesion of liquid toner to the substrates for printing in an electrophotographic printing device. The primer coating is water-based and includes a dispersion of a copolymer of ethylene and acrylic or methacrylic acid, and a compatible adhesion enhancer selected from an aliphatic polyurethane dispersion, a hydrogenated hydrocarbon rosin or rosin ester dispersion, and an amorphous acrylic polymer dispersion. The coating may also include additives such as wetting agents, antiblocking agents, matting agents, and waxes. The primer coating may be applied to a variety of polymeric substrates including polypropylene, biaxially oriented polpypropylene, polyethylene terephthalate, and polyvinyl chloride.

Owner:MICHELMAN INC

Thermal- and chemical-resistant acid protection coating material and spin-on thermoplastic adhesive

New compositions for use as protective coatings and / or adhesives are provided. The compositions comprise a hydrocarbon resin (e.g., terpene rosin) and a rubber (e.g., EPDM) dispersed or dissolved in a solvent system. The solvent system is preferably a single-solvent system, and the compositions are preferably free of surfactants, dyes, and chromophores. The compositions can be cured or dried to form layers or films that are chemically and thermally resistant, but that can be readily dissolved and removed at the appropriate stage in the fabrication process.

Owner:BREWER SCI

Composite waterproof plate, ad its manufacturing method and use

InactiveCN1640640AImprove waterproof performanceImprove corrosion resistanceWood working apparatusDomestic articlesPolymer scienceAdhesive

The present invention relates to a composite water-proof material. It is made up by using (by weight portion) 20-70 portions of plant fibre, 10-60 portions of flyash and 5-40 portions of adhesive through the processes of mixing them, die-pressing and polymerization. The described adhesive is formed from maleic anhydride, phthalic anhydride, polyalcohol, styrene or mixture of their homologous compounds, also can include trimeric cyanamide, acrylic acid or rosin and dicyclopentadiene. Its raw material composition also can include 10-40 portions of new and old plastics. Said plate material has strong strength and good water-proof property, so that it has extensive application range.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

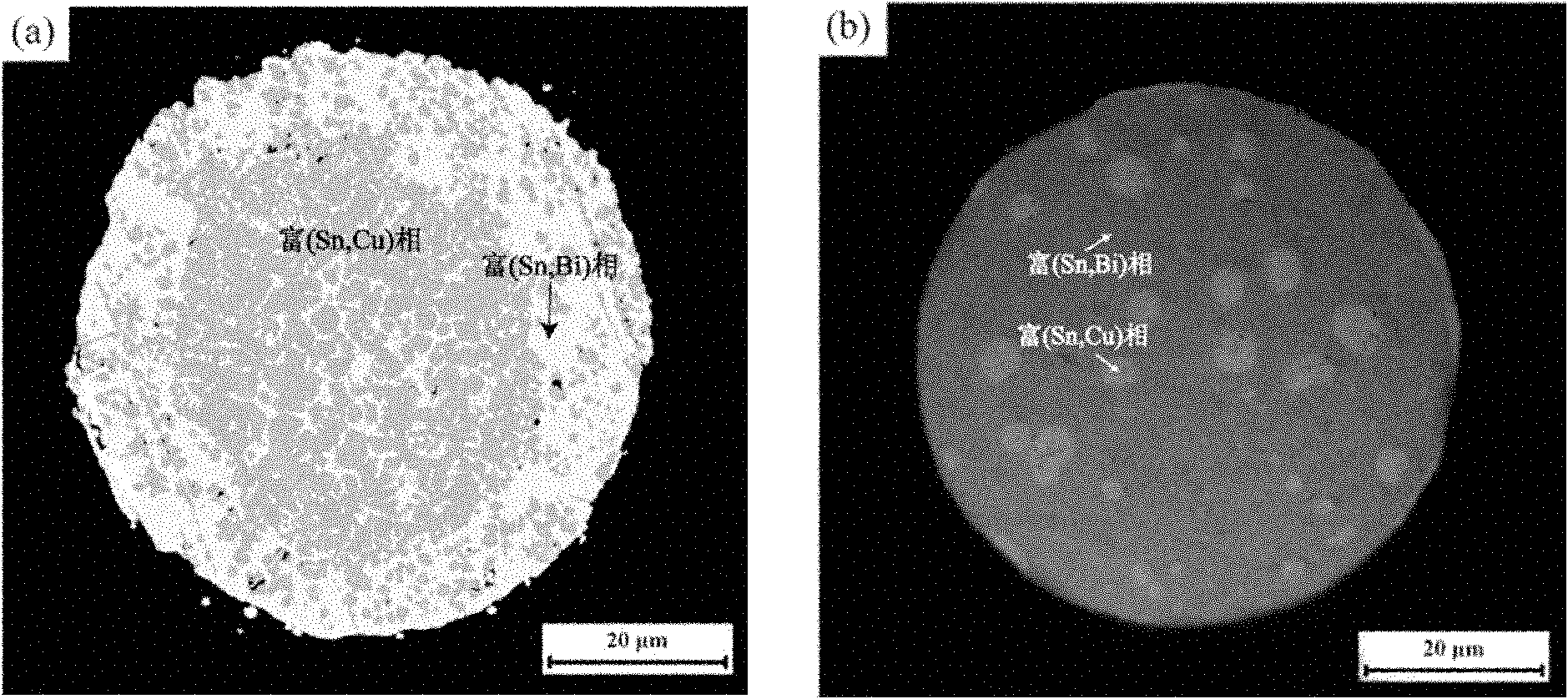

Soldering paste of Sn-Bi-Cu self-packed composite powder and preparation method thereof

The invention provides a soldering paste of Sn-Bi-Cu self-packed composite powder and a preparation method thereof, and relates to a soldering paste. The soldering paste of Sn-Bi-Cu self-packed composite powder comprises the following components by weight percent: 88-90% of Sn-Bi-Cu self-packed composite powder and the balance of pasty scaling powder. The preparation method of the Sn-Bi-Cu self-packed composite powder comprises the steps: adding rosin and an activating agent into a dissolvent to be dissolved, adding a corrosion inhibitor, a surface active agent and a thixotropic agent, and cooling to be pasty after the mixture is completely dissolved; and mixing the Sn-Bi-Cu self-packed composite powder with the pasty scaling powder to obtain the soldering paste of the Sn-Bi-Cu self-packed composite powder. The soldering paste is free of lead and halogen, and is good in soldering performance, so that the problem of the influence to the overall performance caused by the bad electrical conductivity or bad thermal conductivity of a soldering point can be solved if the soldering paste is applied to an electric encapsulating field, and the maintenance cost and the repair coast of some precise instruments can be greatly reduced.

Owner:XIAMEN UNIV

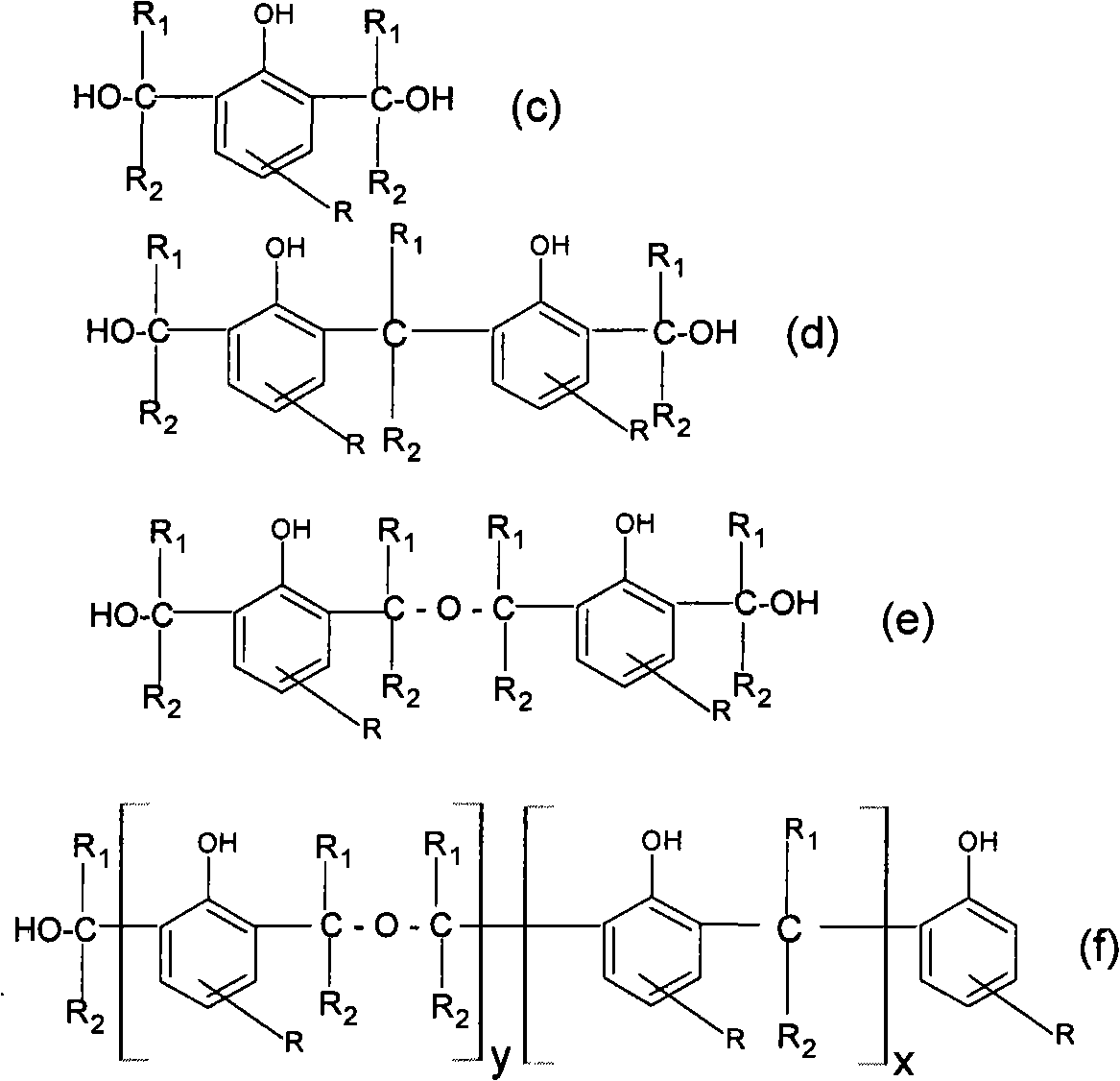

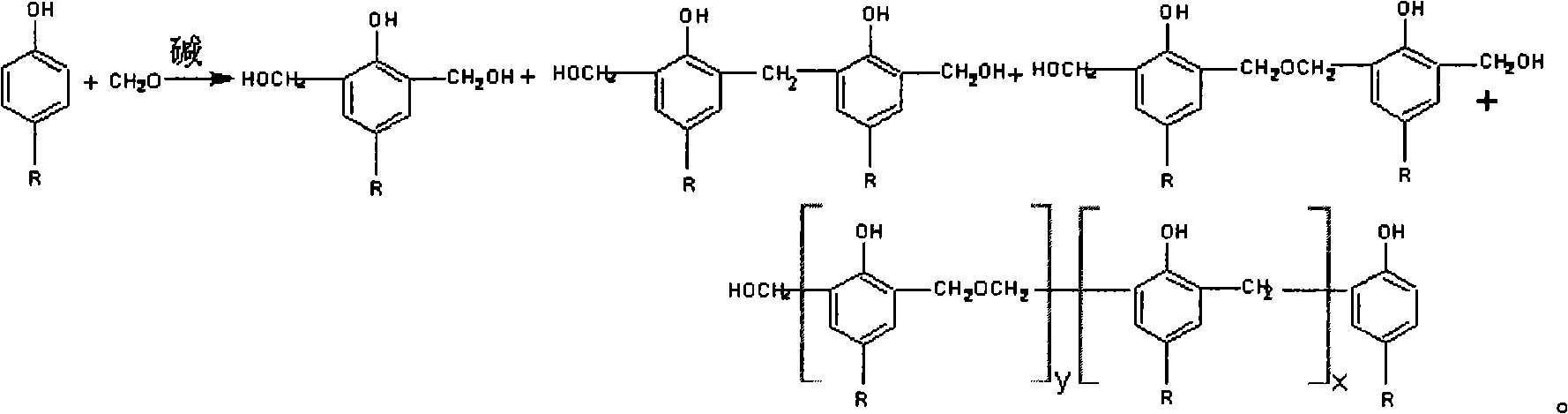

Modified phenolic tackifying resins for rubber compounding applications

This invention is related to modified alkylphenol aldehyde resins and a method for preparing them from the reactions of alkylphenols, aldehydes, amines, rosins and fatty acids. When used in rubber compounds, these modified alkylphenol aldehyde resins provide much improved tack properties.

Owner:SINO LEGEND CHINA CHEM

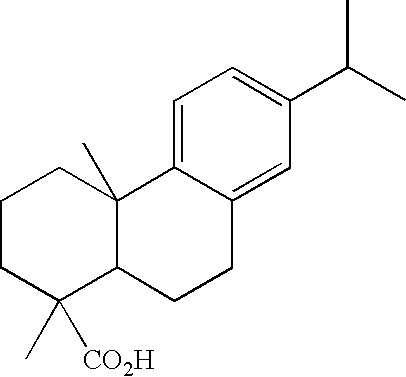

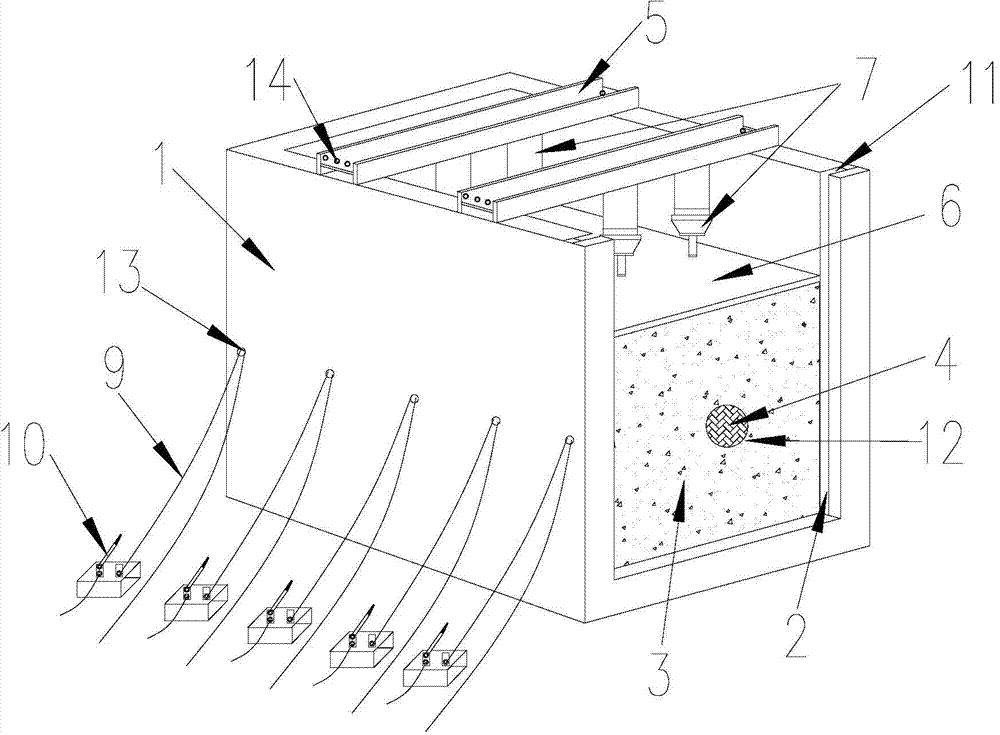

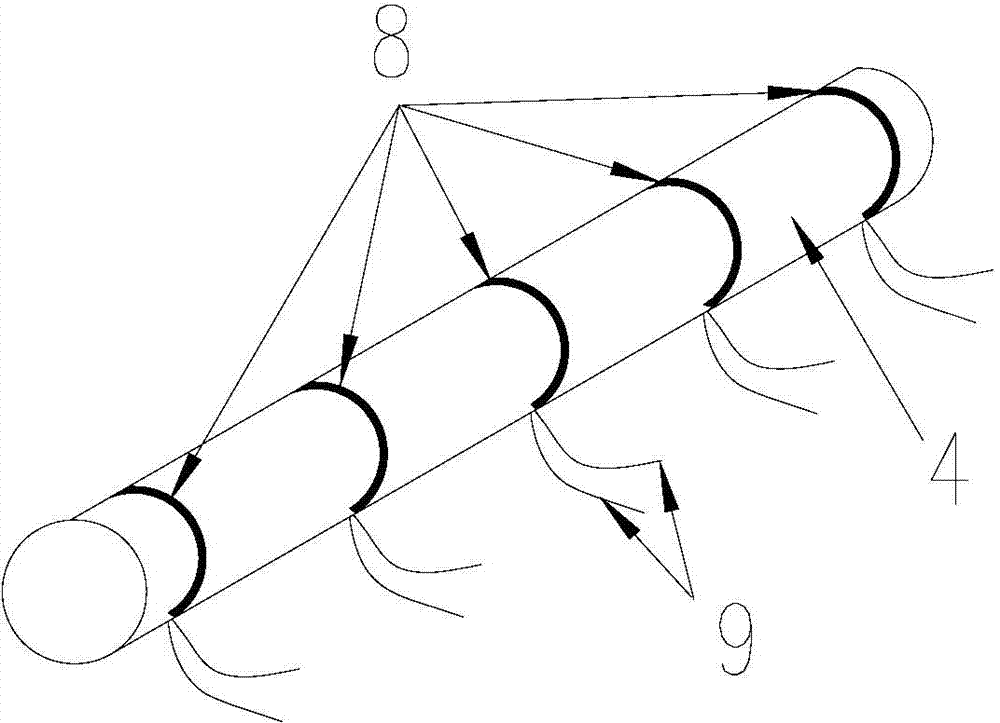

Laboratory model testing device for tunnel excavation

InactiveCN103616287AHigh simulationAvoid the influence of surrounding fillersMaterial strength using tensile/compressive forcesModel testingEngineering

Owner:HUNAN UNIV

Hot melt adhesive used for automotive interiors, and preparation method of hot melt adhesive

InactiveCN102618211AHarmless to healthHigh bonding strengthWax adhesivesNatural resin adhesivesPolyethylene vinyl acetateParaffin wax

The invention discloses a hot melt adhesive used for automotive interiors, and a preparation method of the hot melt adhesive. The hot melt adhesive used for automotive interiors is characterized by comprising a proportion of paraffin, polyethylene wax, a thermoplastic elastic body SBS, random polyolefin, polyethylene vinyl acetate, C5 petroleum resin, rosin pentaerythritol ester, antioxygen, coupling agent and filler. The preparation method comprising the following steps: heating a stirring kettle to 140 to 160 DEG C, and adding the paraffin and the polyethylene wax; adding the thermoplastic elastic body SBS, vacuum-pumping and keeping warm, adding HMW(high molecular weight) random polyolefin I, HMW random polyolefin II and the antioxygen; adding the coupling agent and the filler; cooling, and adding polyethylene vinyl acetate I and polyethylene vinyl acetate II; cooling and adding the C5 petroleum resin; adding the rosin pentaerythritol ester and keeping warm; and emptying the stirring kettle, pressurizing, discharging and forming. No pollution or poison is produced during the production process of the hot melt adhesive; and the hot melt adhesive has the advantages of high adhesion strength, long opening time, good temperature resistance, strong ageing resistance, good tenacity, strong waterproofness and the like.

Owner:浙江固特新材料科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com