Patents

Literature

3147 results about "Solid product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solid Products aims to improve your business operations with a line of high-caliber Manufacturing Solutions for unexpected hard-to-machine parts and materials resulting in reduced rough cycle times, extended tool life, decreased tool breakage, controlled machine load and overall optimized manufacturing productivity.

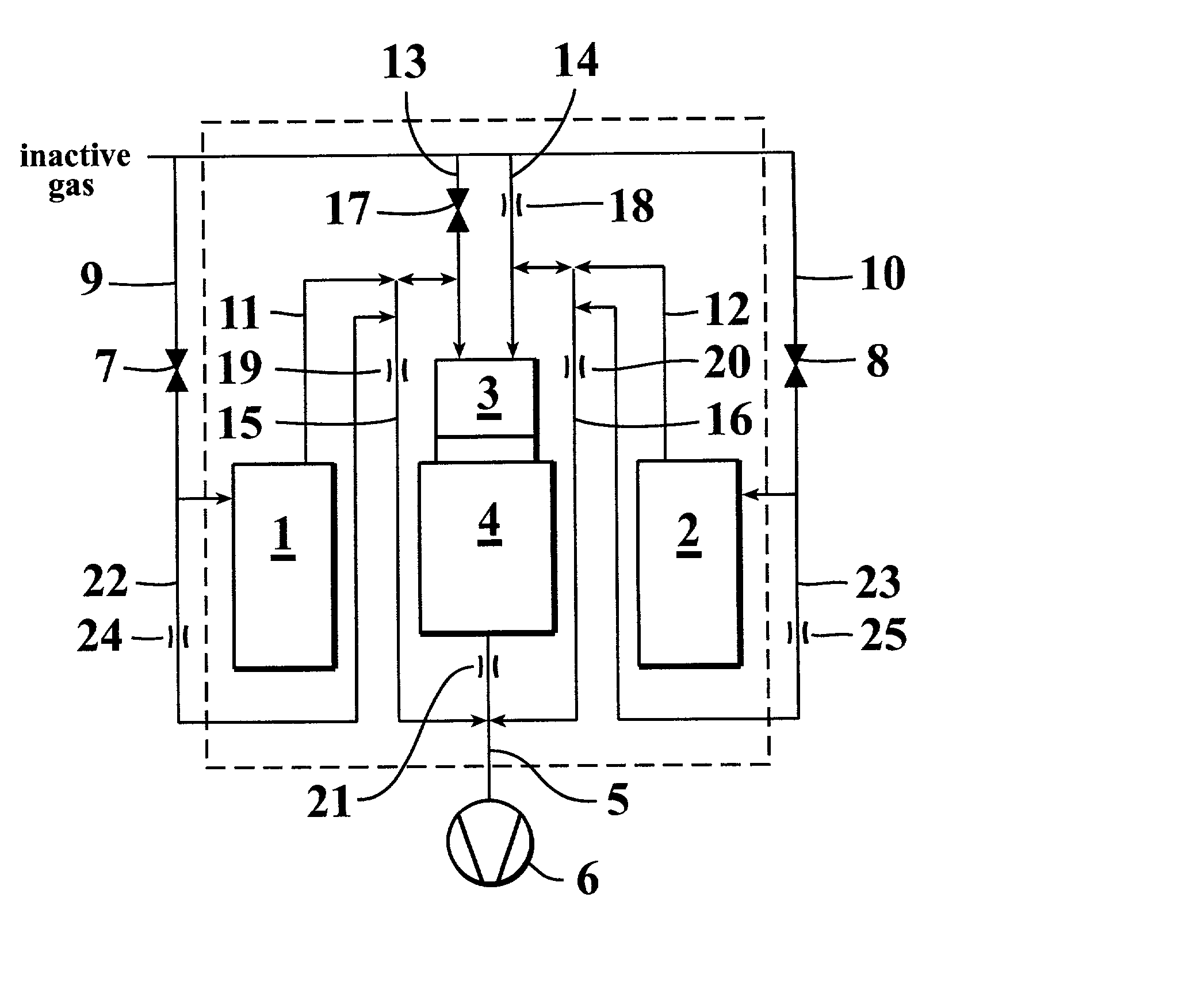

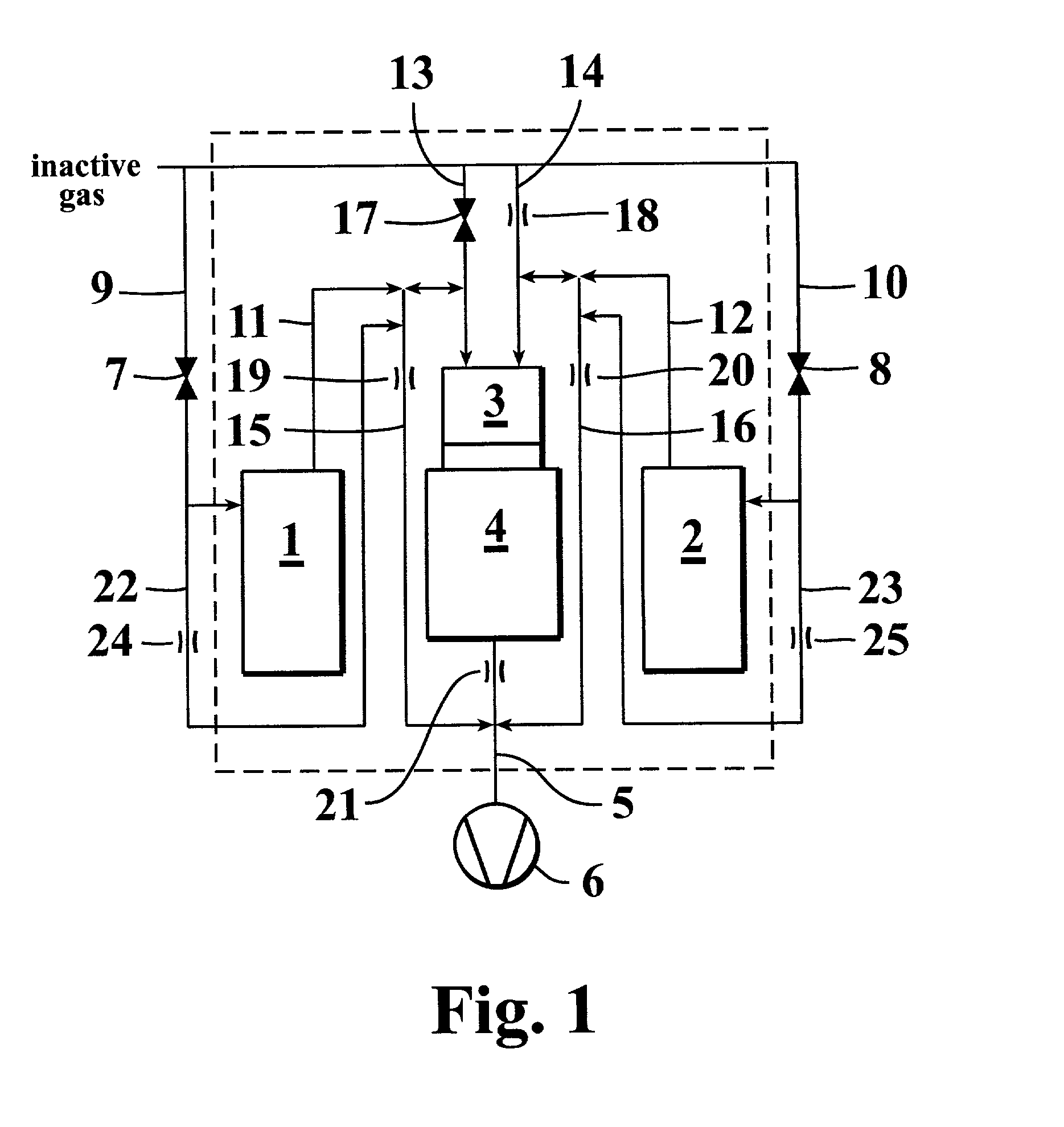

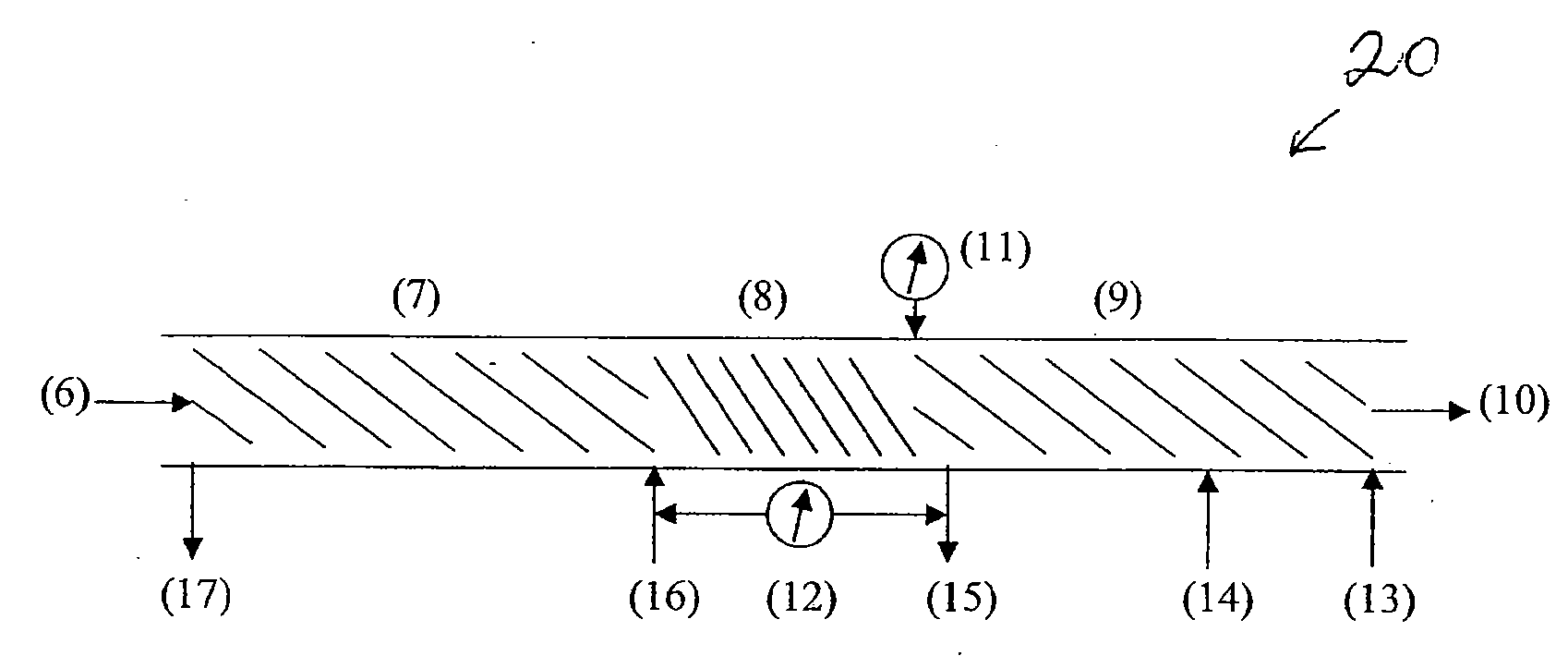

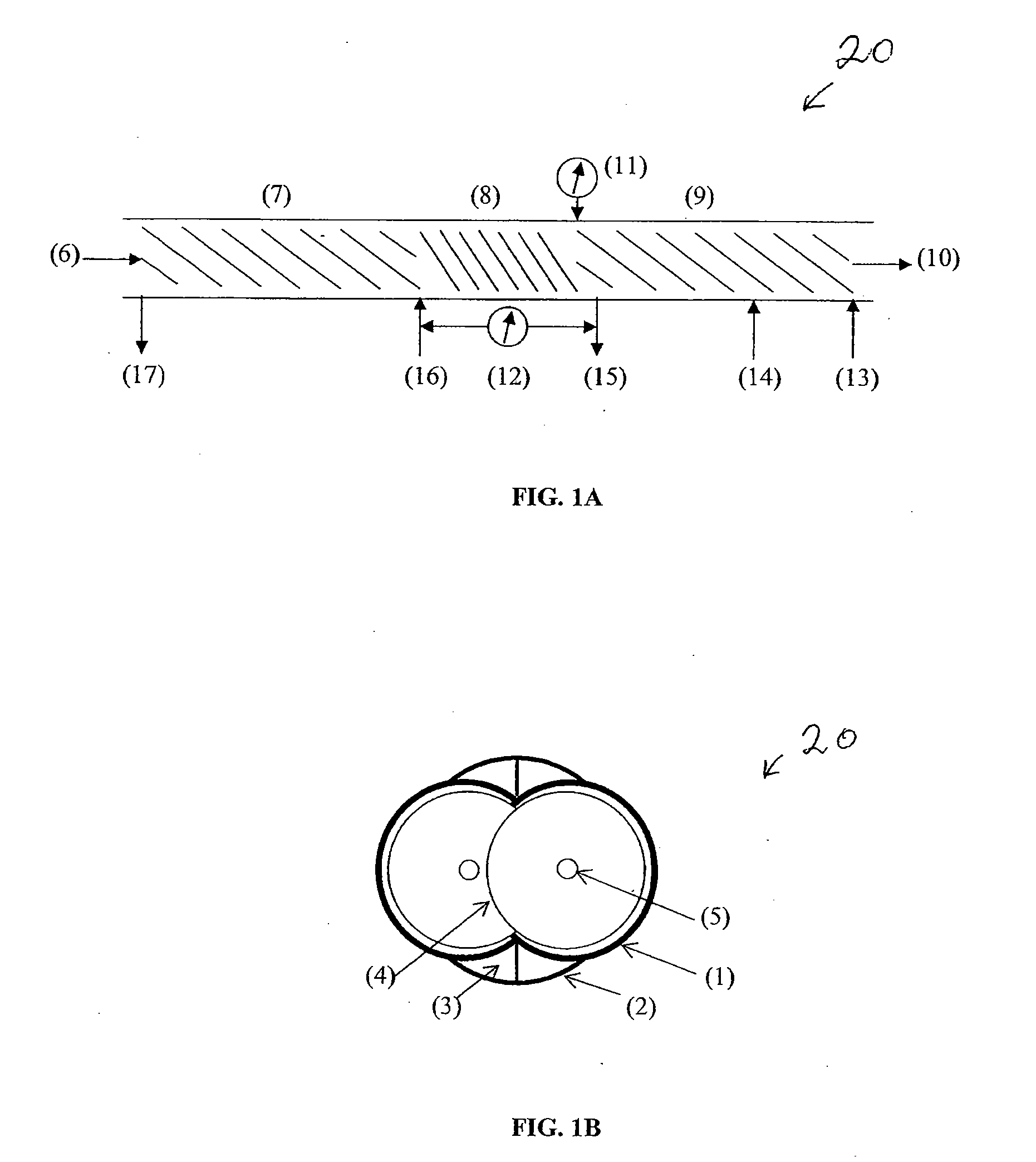

Method and apparatus of growing a thin film onto a substrate

InactiveUS20020108570A1Good film uniformitySimple and efficientPolycrystalline material growthSemiconductor/solid-state device manufacturingInlet channelGas phase

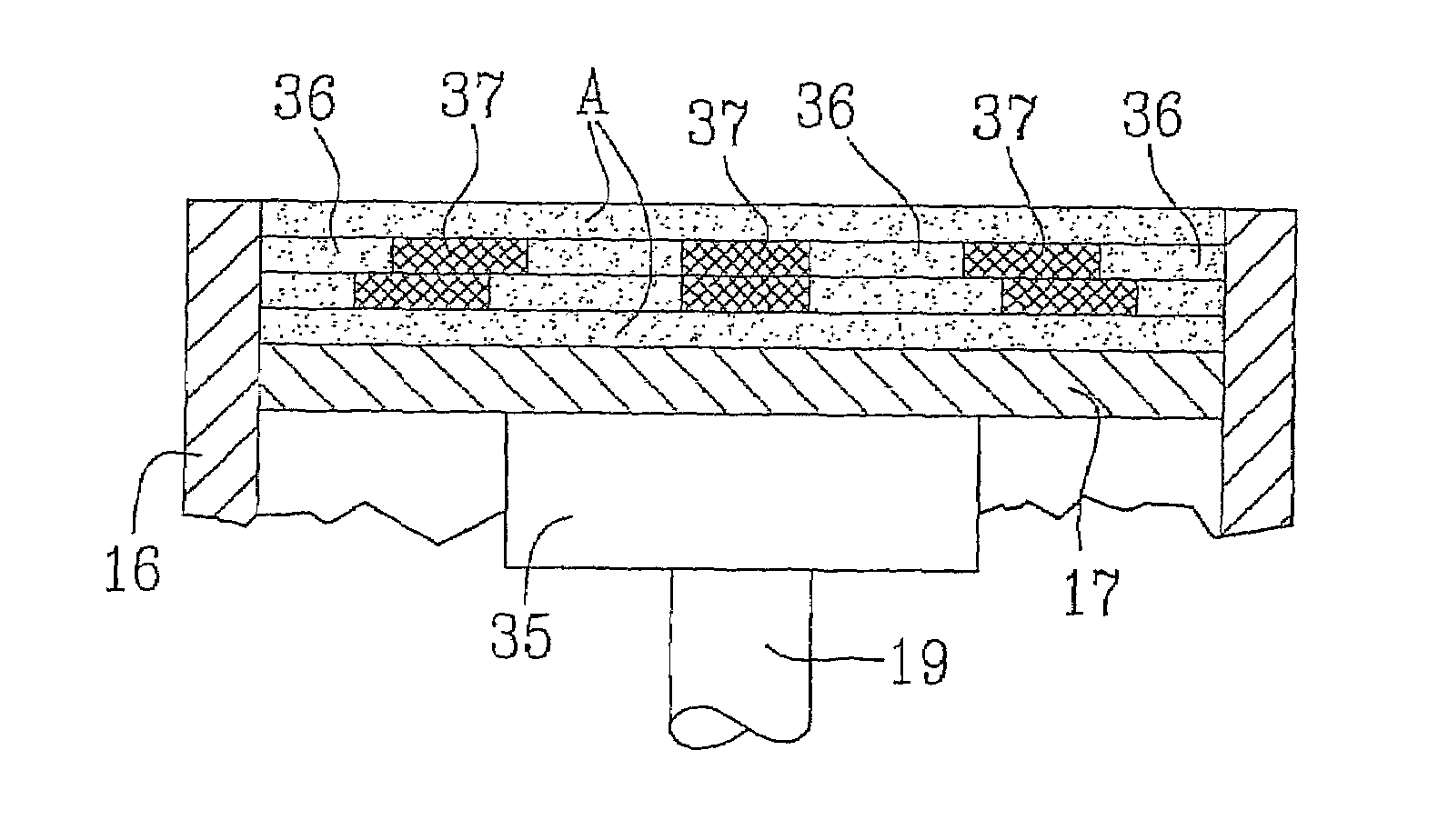

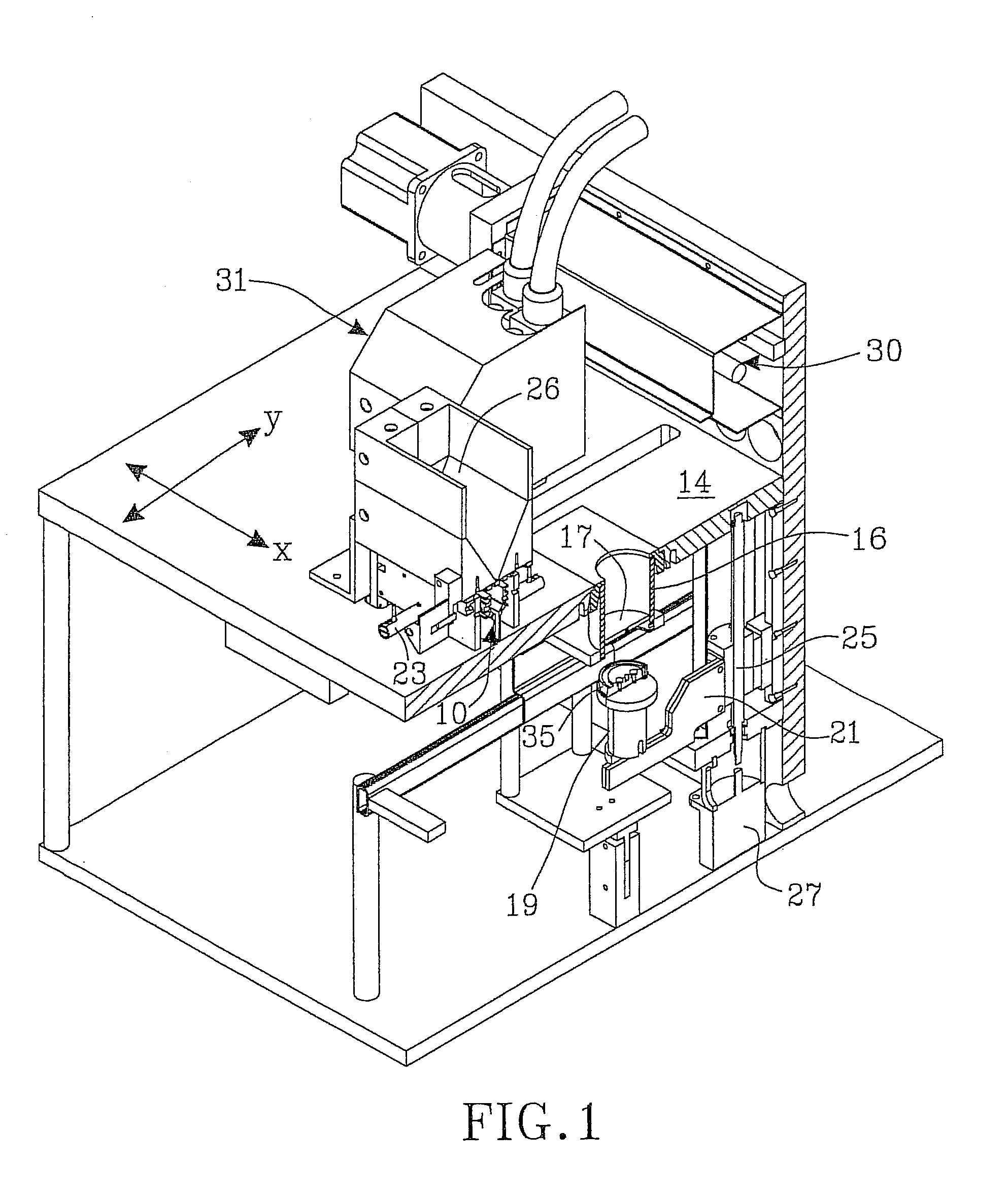

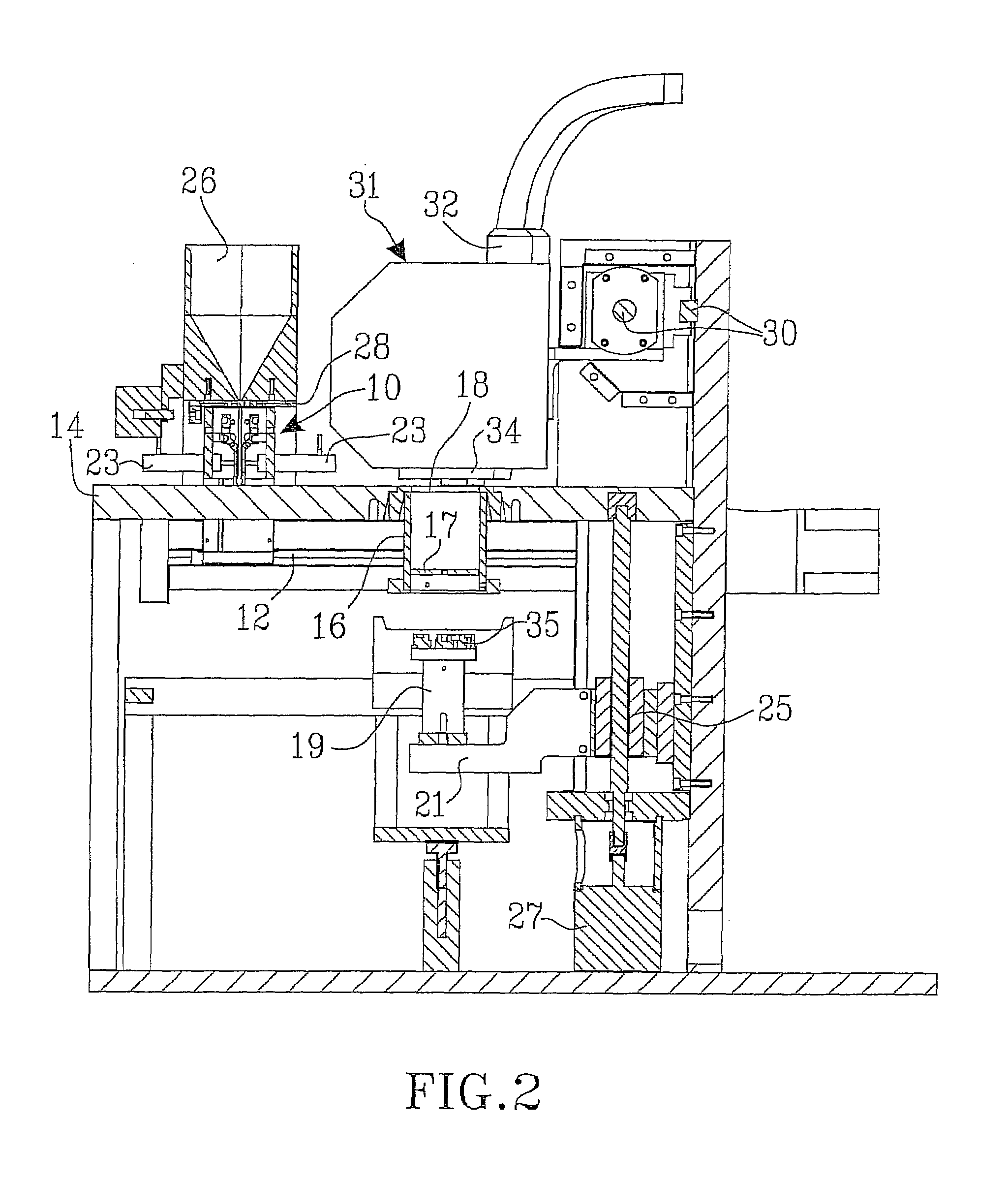

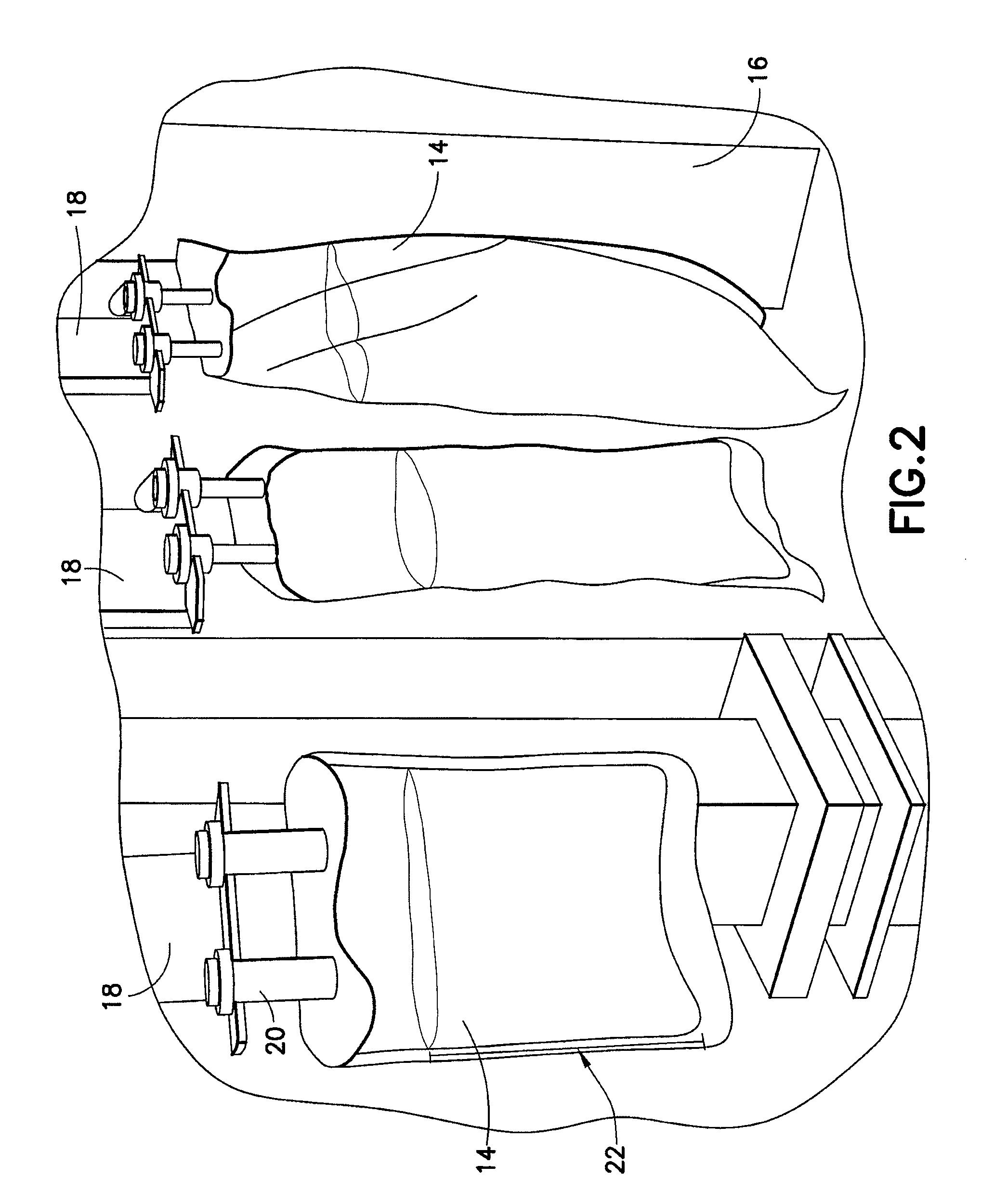

A method and an apparatus for growing a thin film onto a substrate by the ALD process. The apparatus comprises a reaction chamber into which the substrate can be disposed; a plurality of inlet channels communicating with said reaction chamber, said inlet channels being suited for feeding the reactants employed in a thin-film growth process in the form of vapor-phase pulses into said reaction chamber; at least one outlet channel communicating with said reaction chamber, said outlet channel being suited for the outflow of reaction products and excess amounts of reactants from said reaction space; and a pre-reaction chamber arranged immediately upstream of the reaction chamber, said pre-reaction chamber forming a first reaction zone, in which the reactants of successive vapor-phase pulses can be reacted with each other in the vapor phase to form a solid product, whereas said reaction chamber forming a second reaction zone can be operated under conditions conducive to ALD growth of a thin film.

Owner:ASM INTERNATIONAL

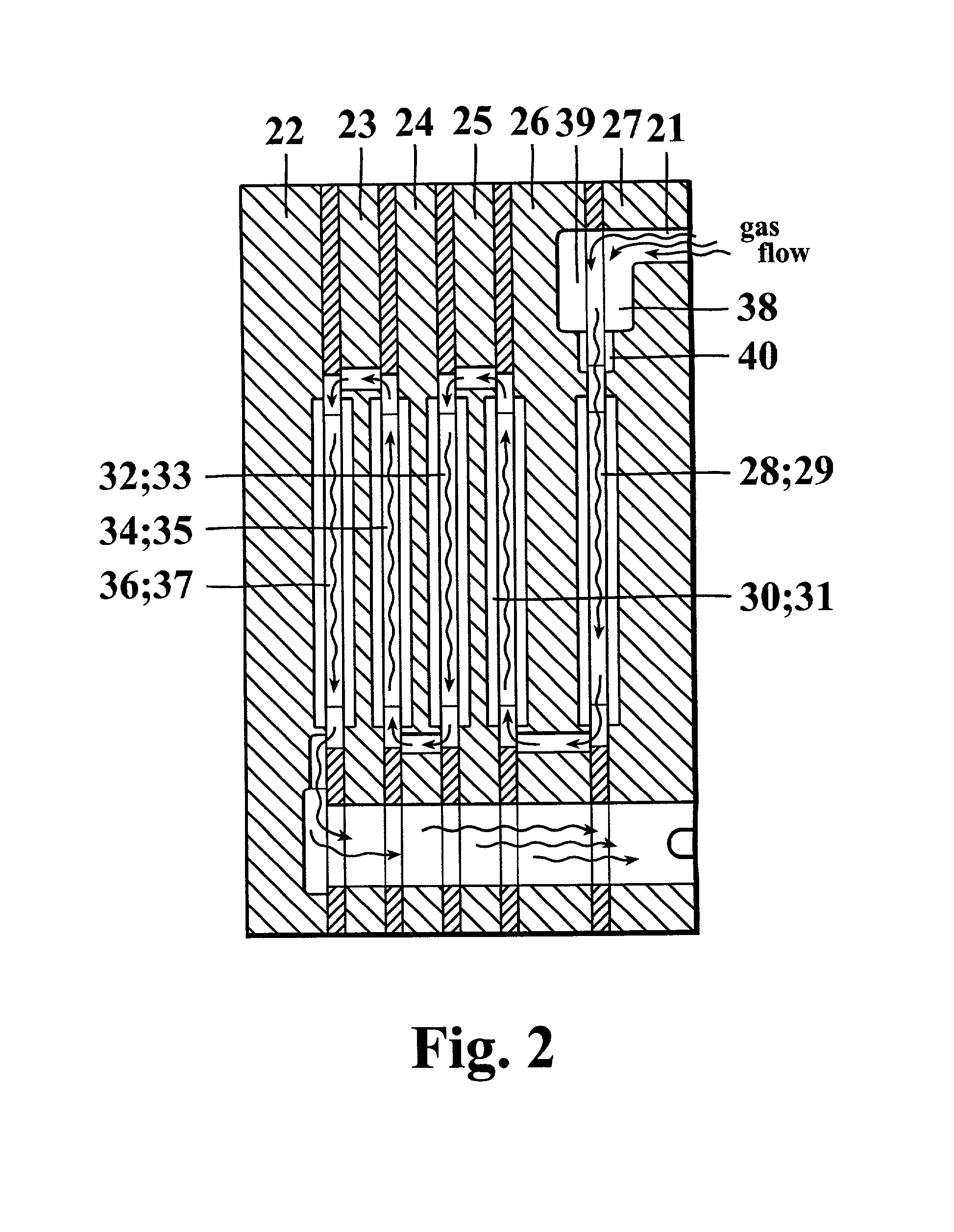

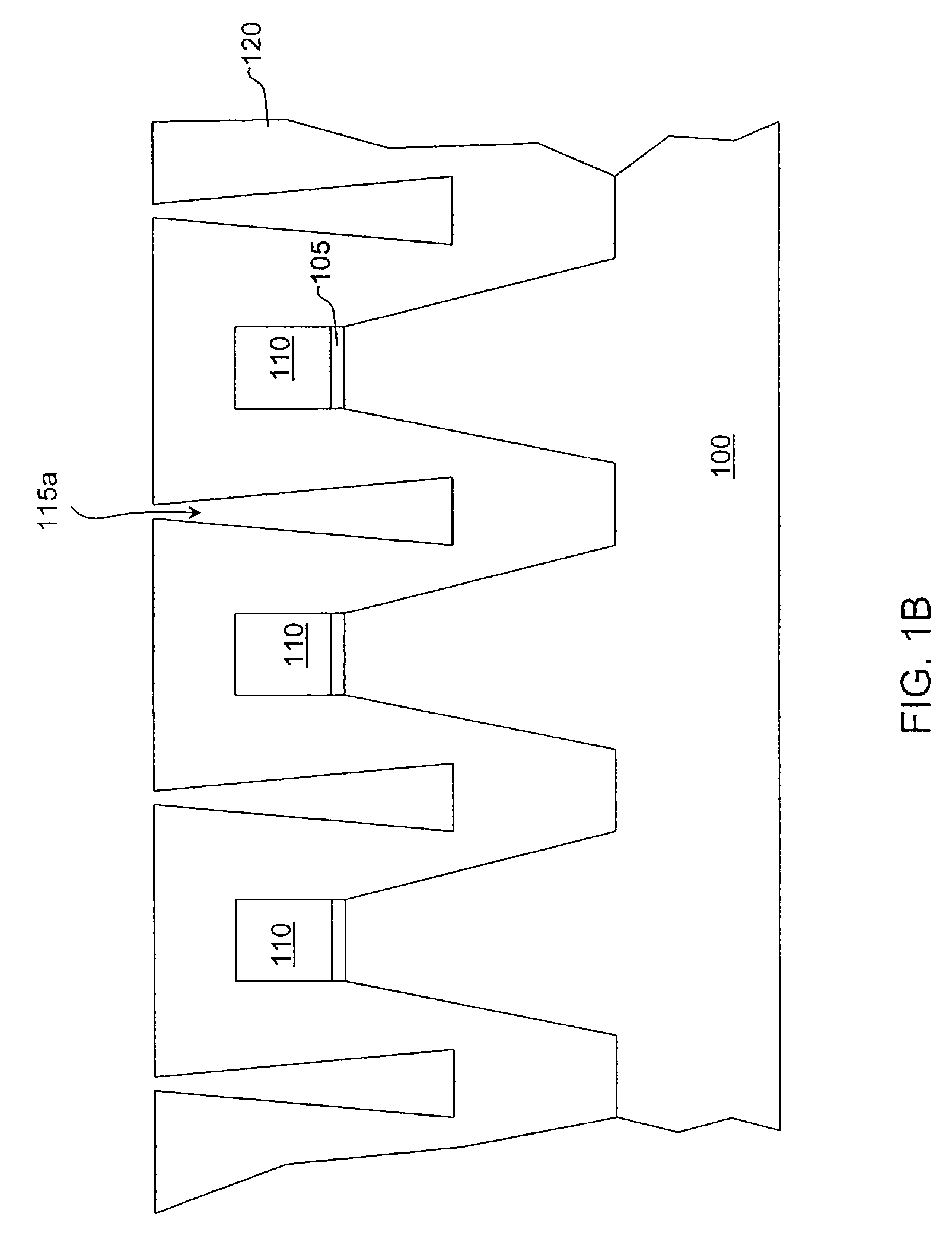

Methods of thin film process

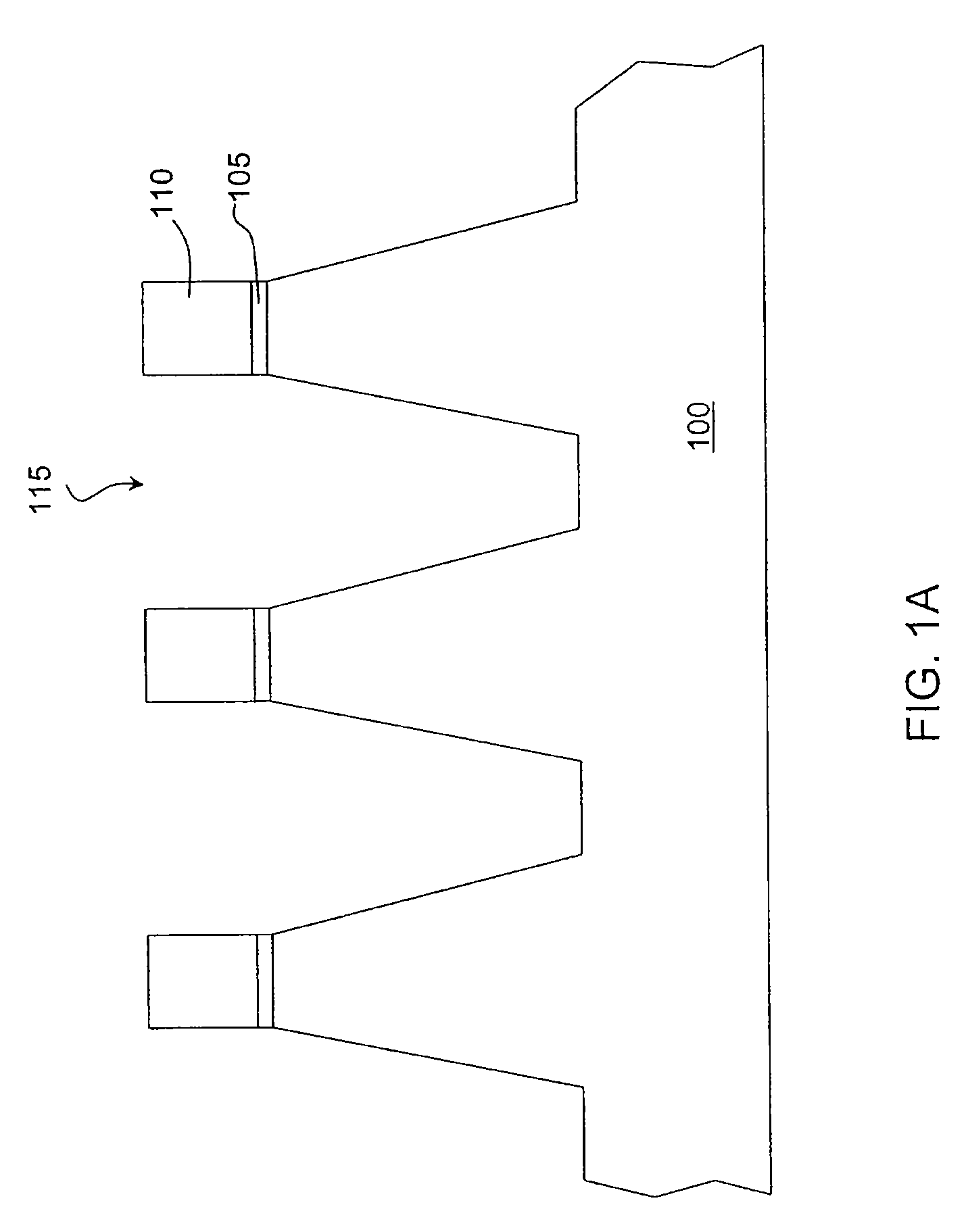

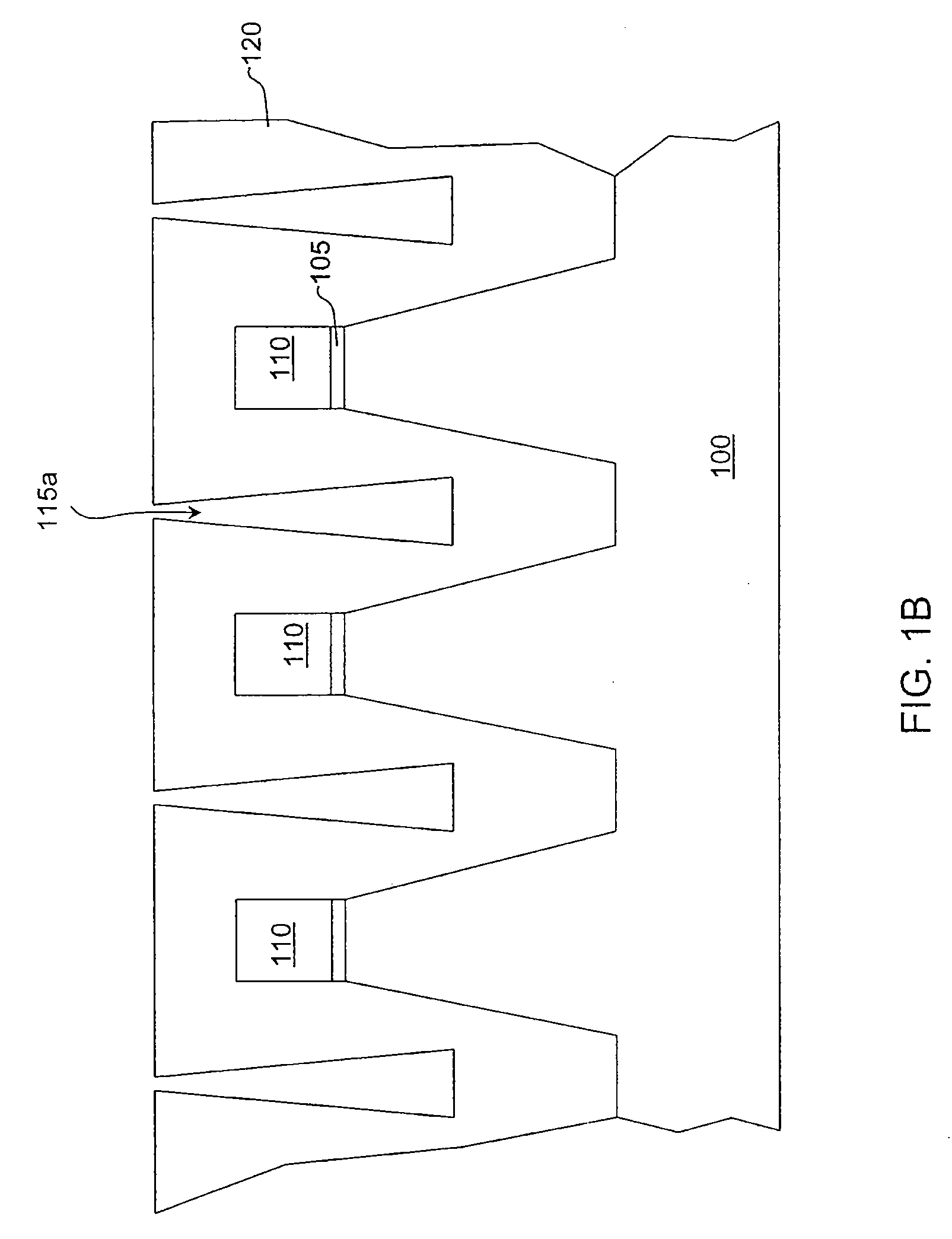

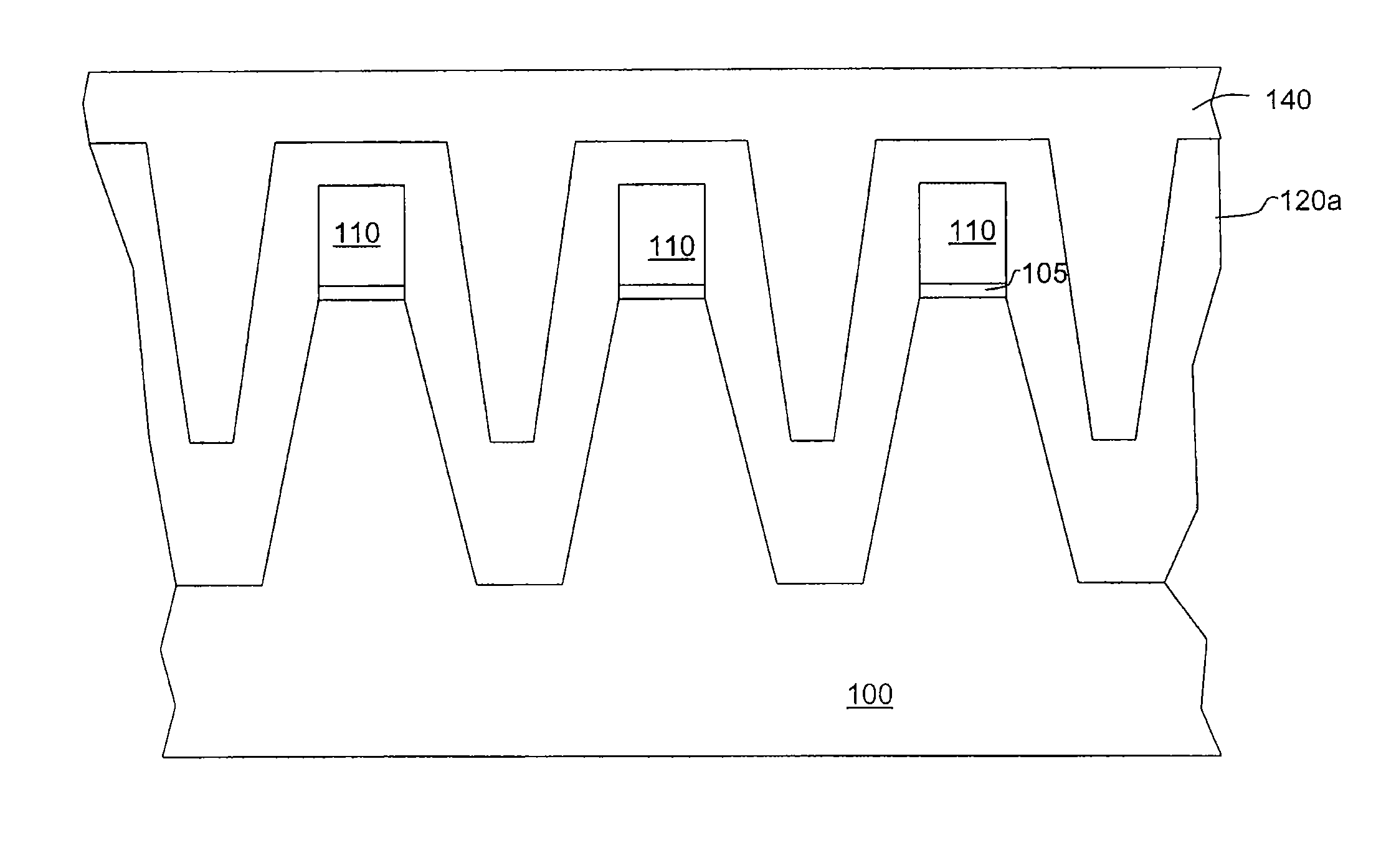

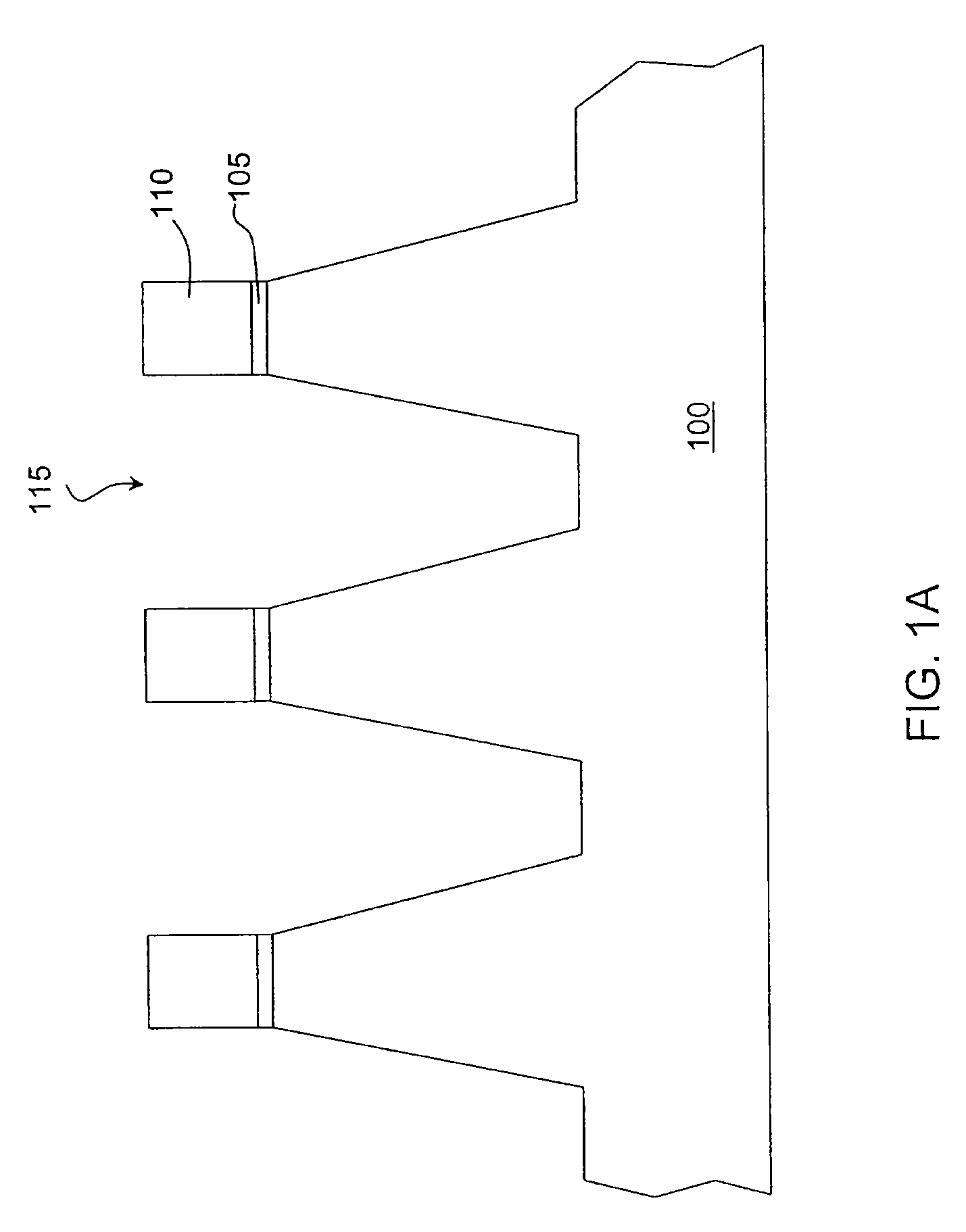

A method for forming a semiconductor structure includes forming a plurality of features across a surface of a substrate, with at least one space being between two adjacent features. A first dielectric layer is formed on the features and within the at least one space. A portion of the first dielectric layer interacts with a reactant derived from a first precursor and a second precursor to form a first solid product. The first solid product is decomposed to substantially remove the portion of the first dielectric layer. A second dielectric layer is formed to substantially fill the at least one space.

Owner:APPLIED MATERIALS INC

Methods of thin film process

A method for forming a semiconductor structure includes forming a plurality of features across a surface of a substrate, with at least one space being between two adjacent features. A first dielectric layer is formed on the features and within the at least one space. A portion of the first dielectric layer interacts with a reactant derived from a first precursor and a second precursor to form a first solid product. The first solid product is decomposed to substantially remove the portion of the first dielectric layer. A second dielectric layer is formed to substantially fill the at least one space.

Owner:APPLIED MATERIALS INC

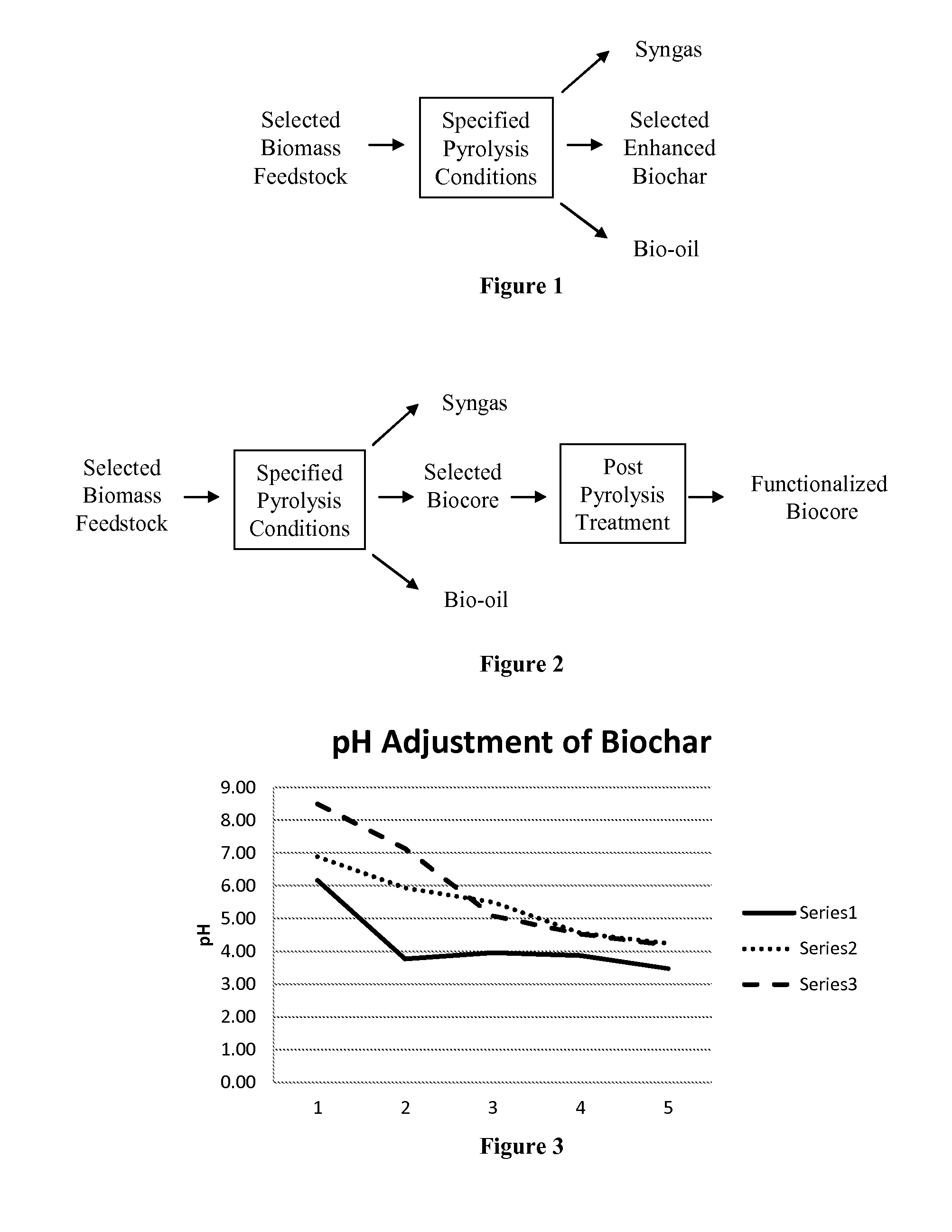

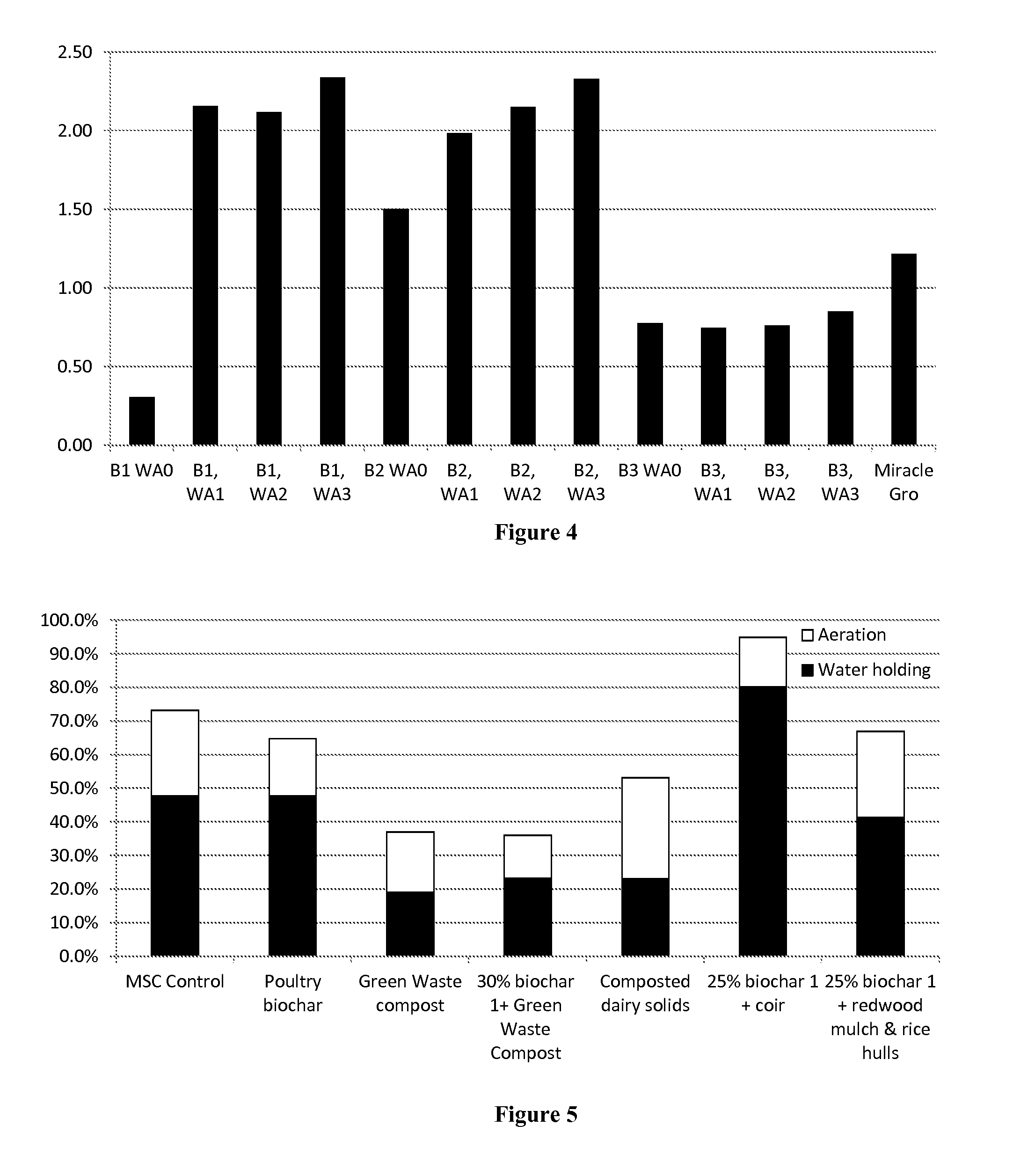

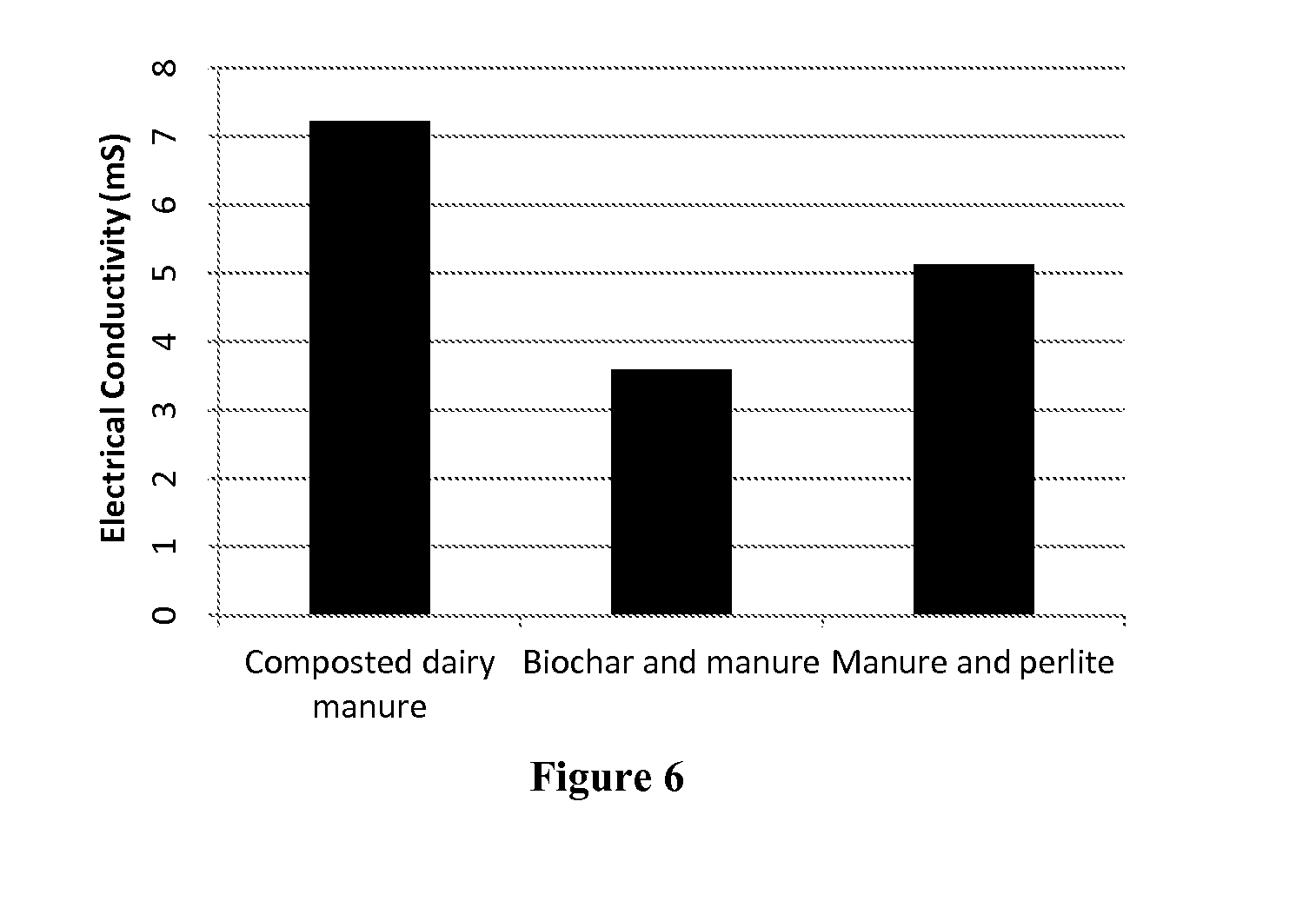

Biochar

ActiveUS8361186B1Enhanced and functionalizedCalcareous fertilisersMagnesium fertilisersForming gasBiological activation

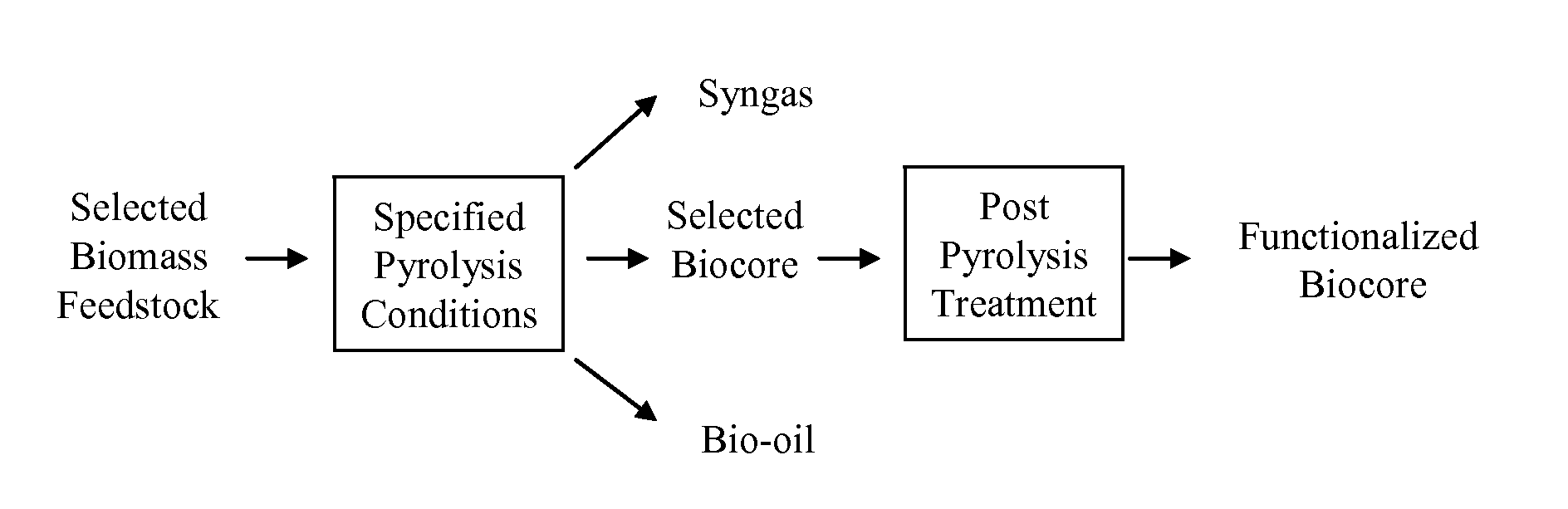

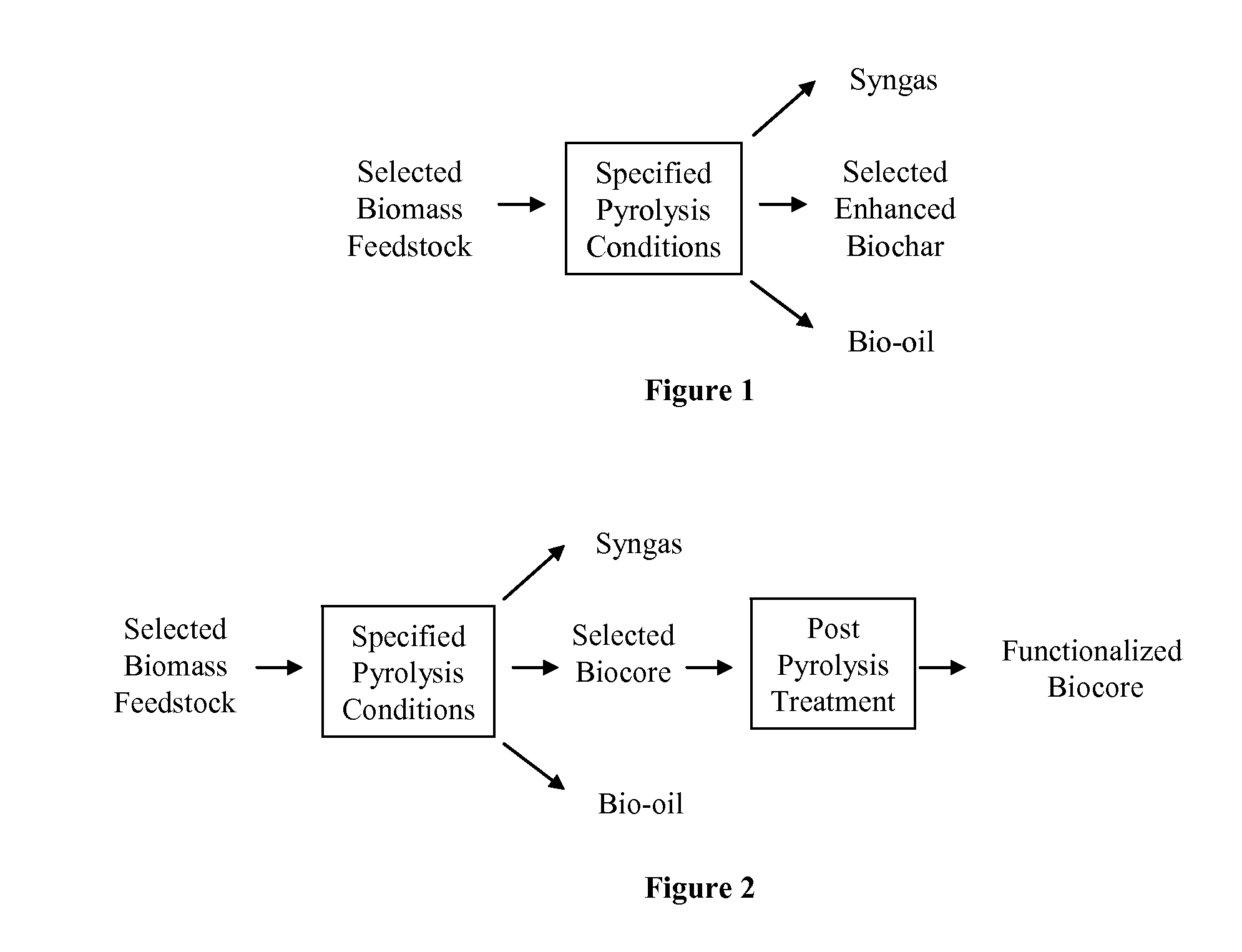

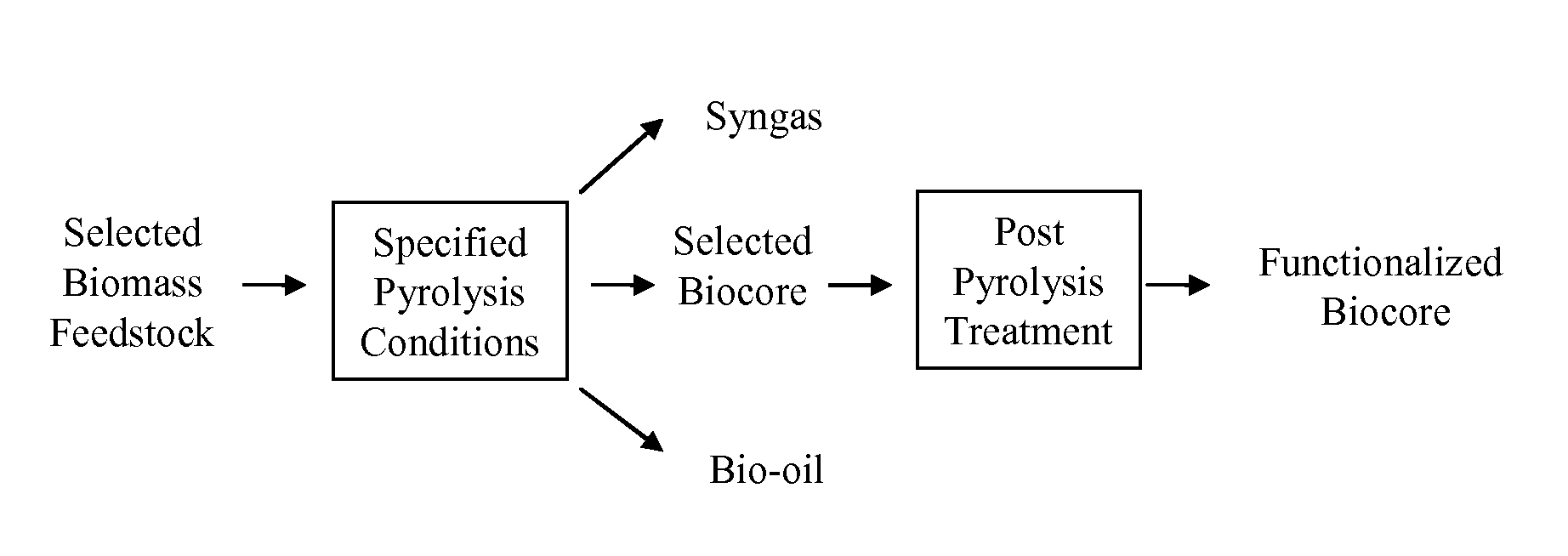

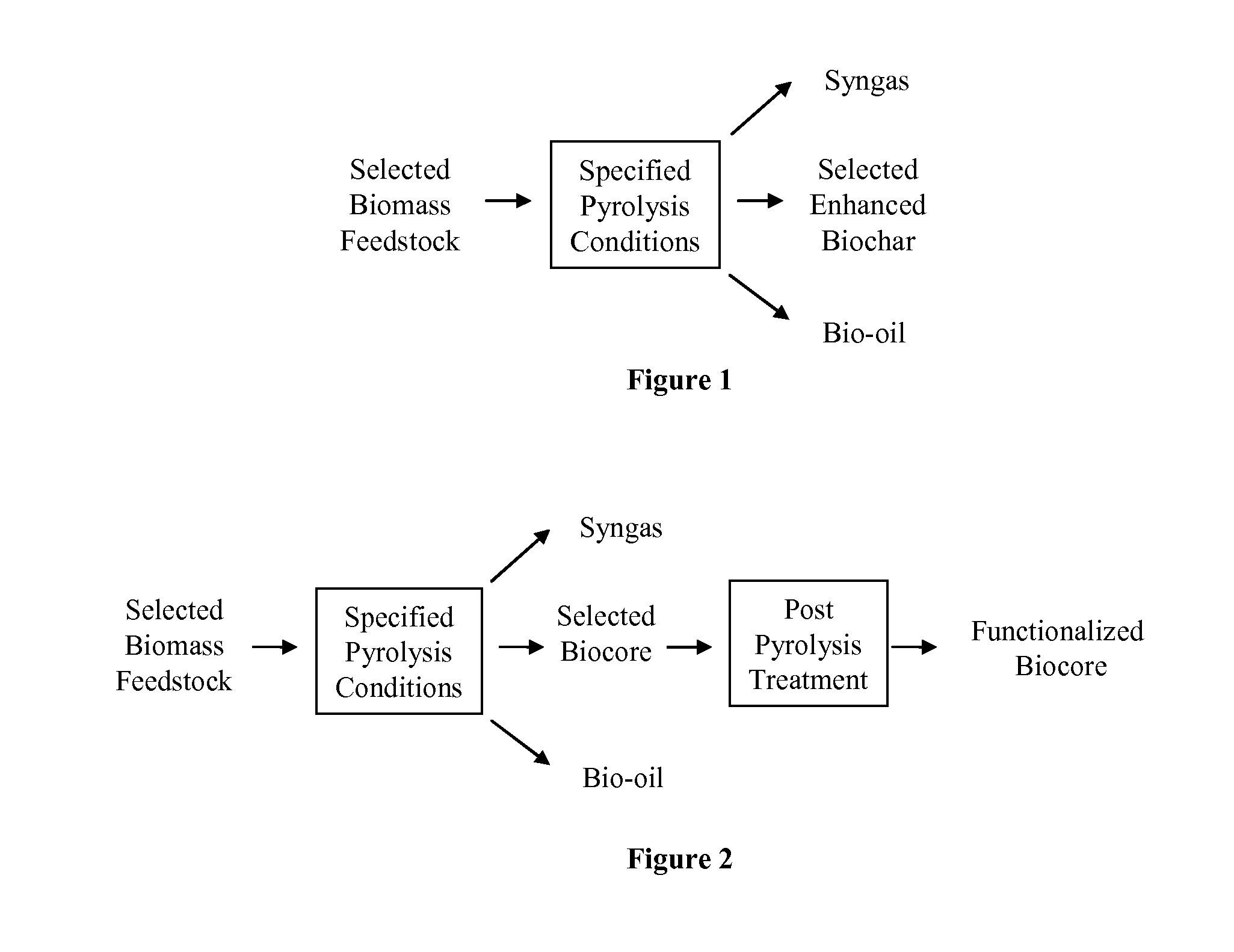

The invention provides for methods, devices, and systems for pyrolyzing biomass. A pyrolysis unit can be used for the pyrolysis of biomass to form gas, liquid, and solid products. The biomass materials can be selected such that an enhanced biochar is formed after pyrolysis. The biomass can be pyrolyzed under specified conditions such that a selected biochar core is formed. The pyrolysis process can form a stable biochar core that is inert and / or resistant to degradation. The biochar or biochar core can be functionalized to form a functionalized biochar or functionalized biochar core. Functionalization can include post-pyrolysis treatments such as supplementation with microbes or physical transformations including annealing and / or activation.

Owner:FULL CIRCLE BIOCHAR

Moving bed biomass fractionation system and method

InactiveUS20080029233A1Improve production yieldIncrease pressureWashing/displacing pulp-treating liquorsDigestersChemical reactionFiltration

Countercurrent extraction of lignocellulosic biomass such as trees, grasses, shrubs, and agricultural residues or waste involves the separation of cellulose fibers from other constituents, for subsequent use in the manufacture of paper, plastics, ethanol, and other industrial chemicals. Systems and methods involve continuous, multiple processing steps that may include chemical reactions with mixing at elevated temperature and / or pressure, efficient reagent or solvent utilization, filtration at elevated temperature and / or pressure, controlled discharge of liquid and solid products, and energy recuperation.

Owner:PUREVISION TECH

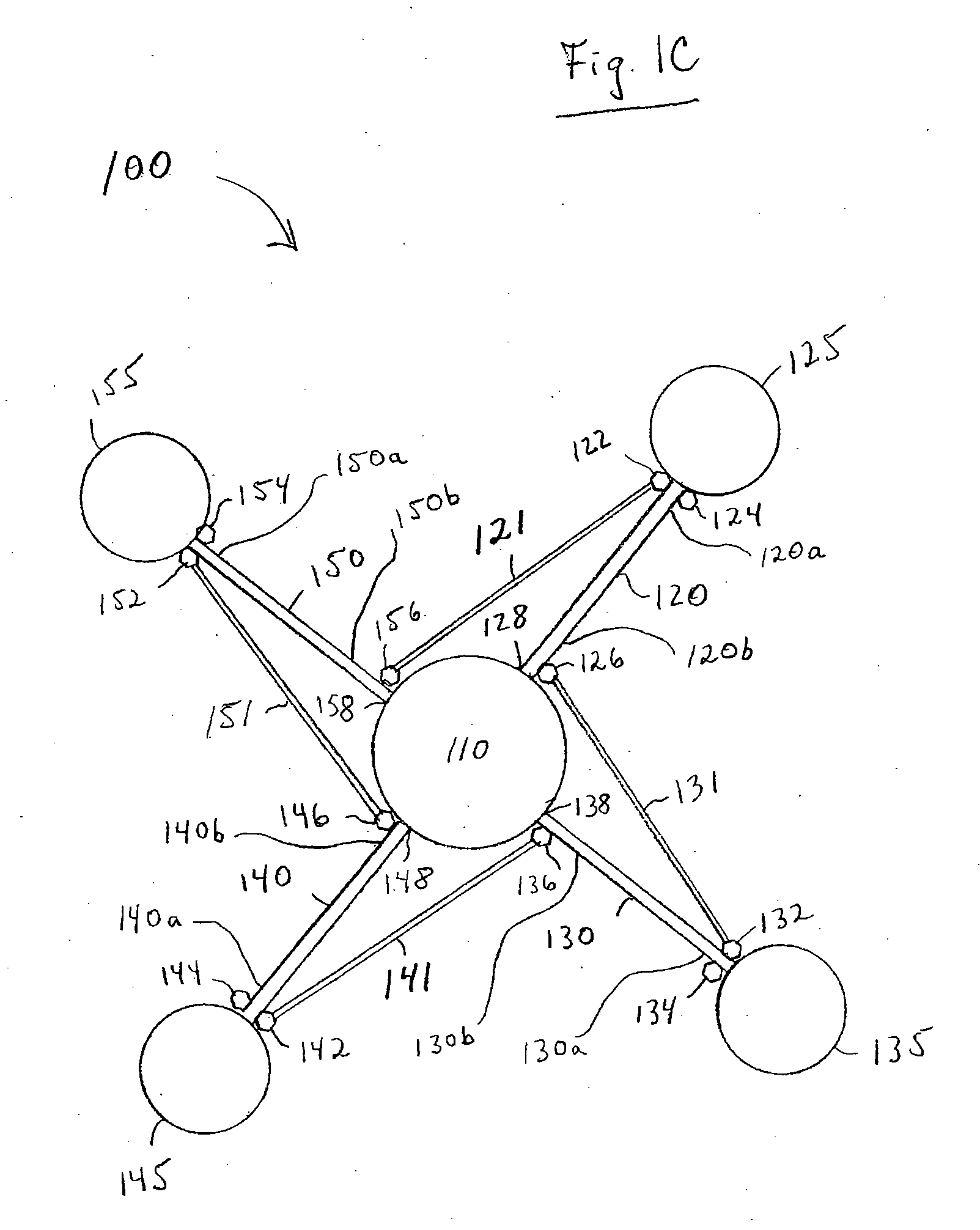

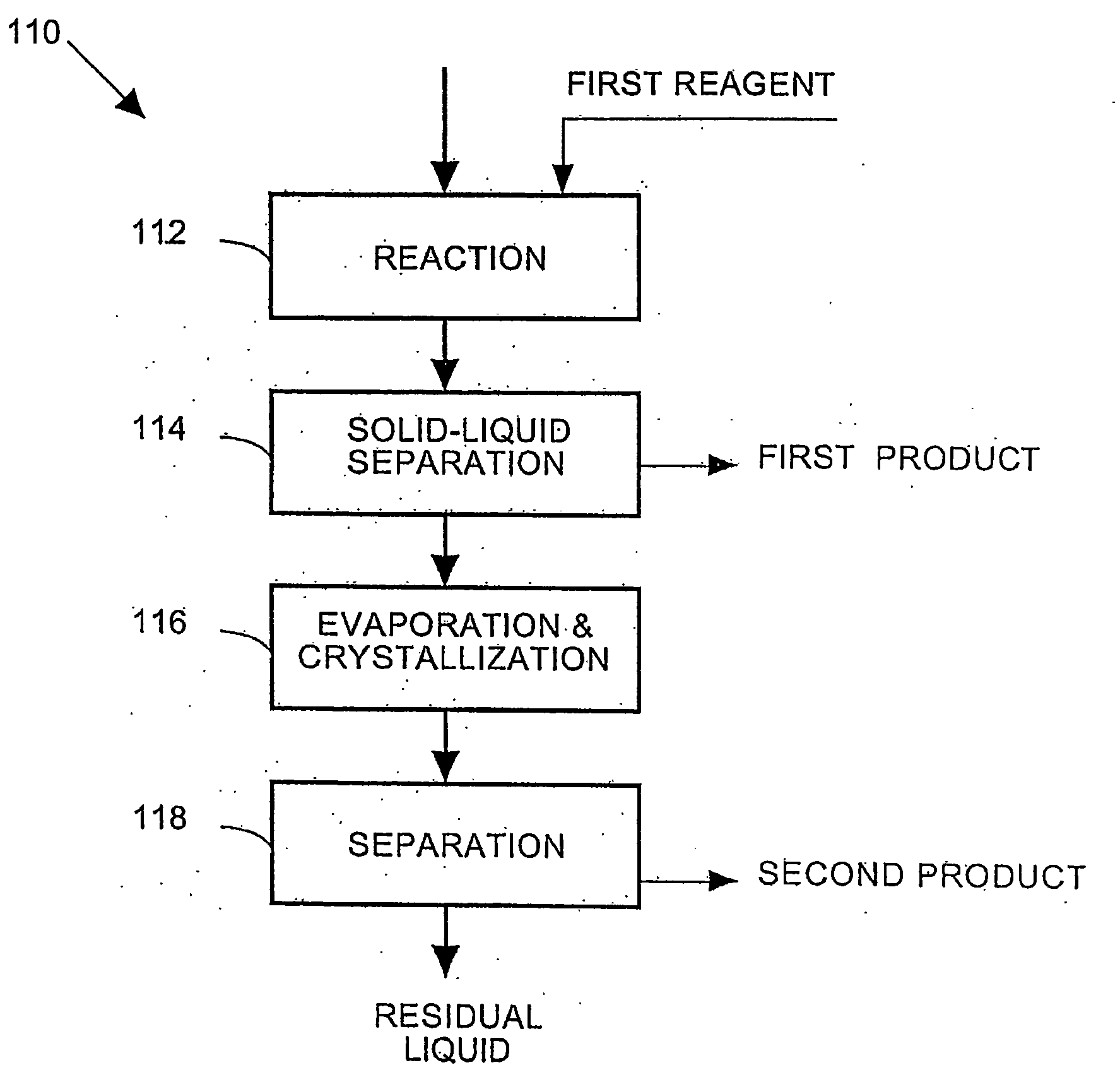

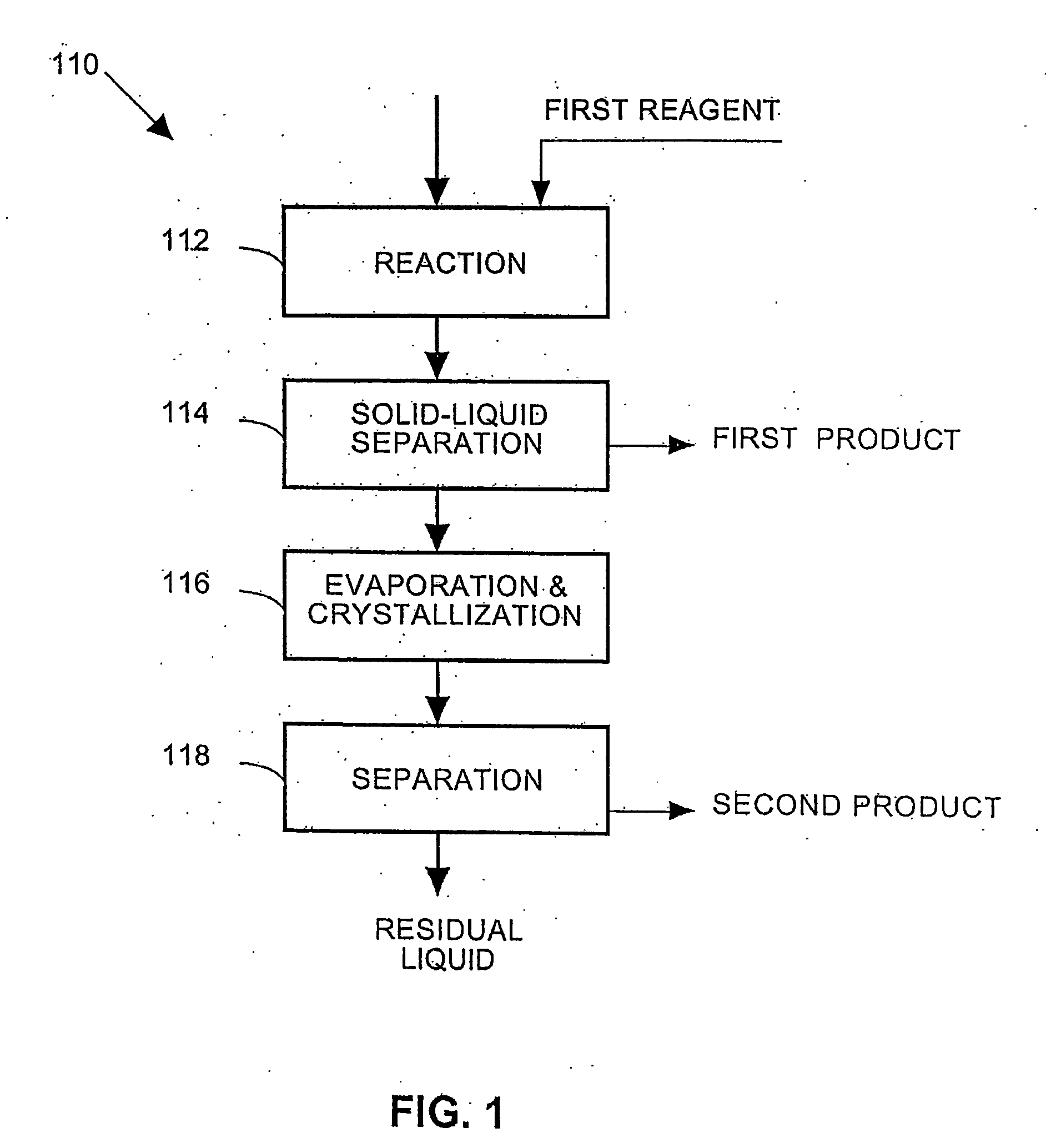

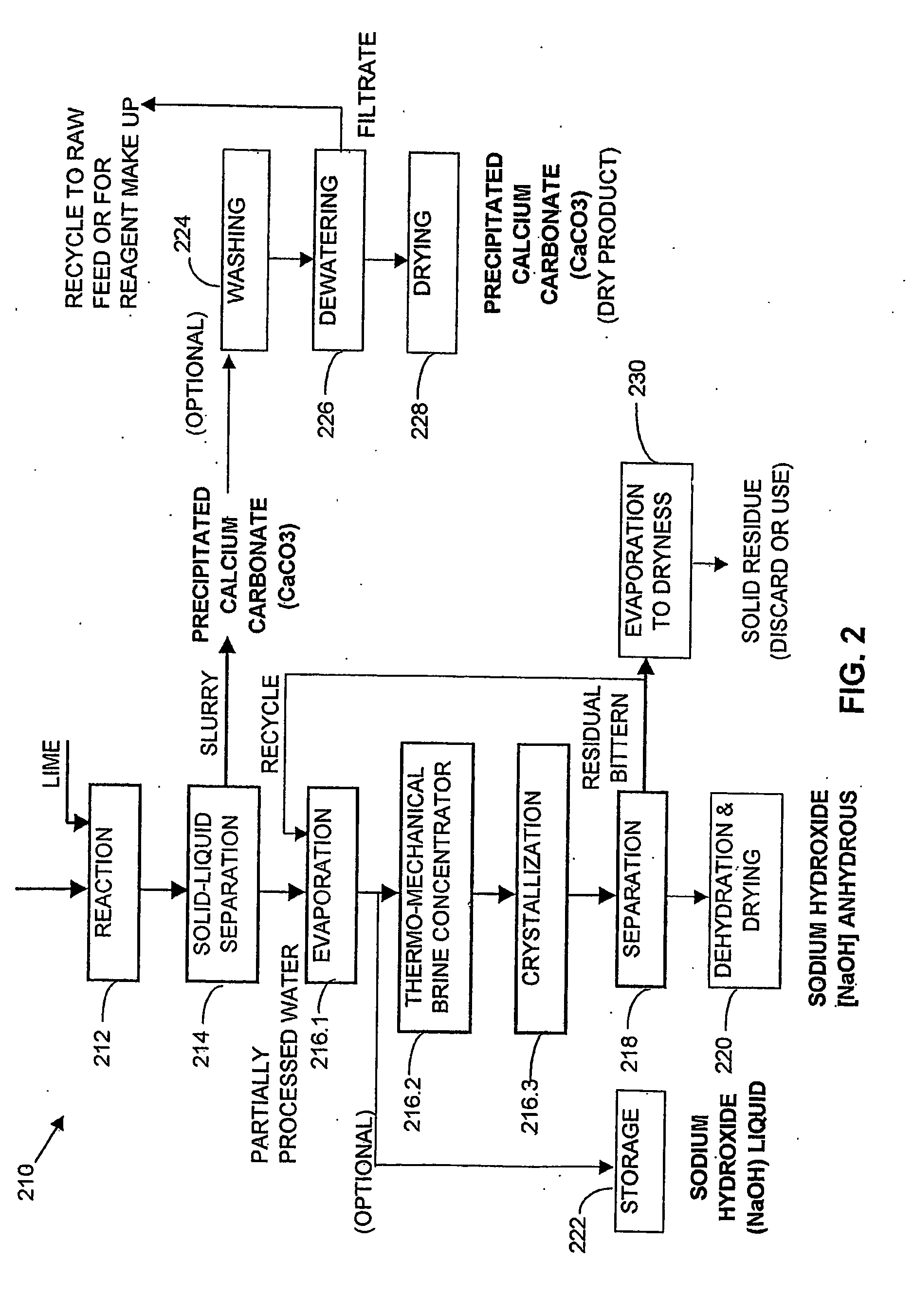

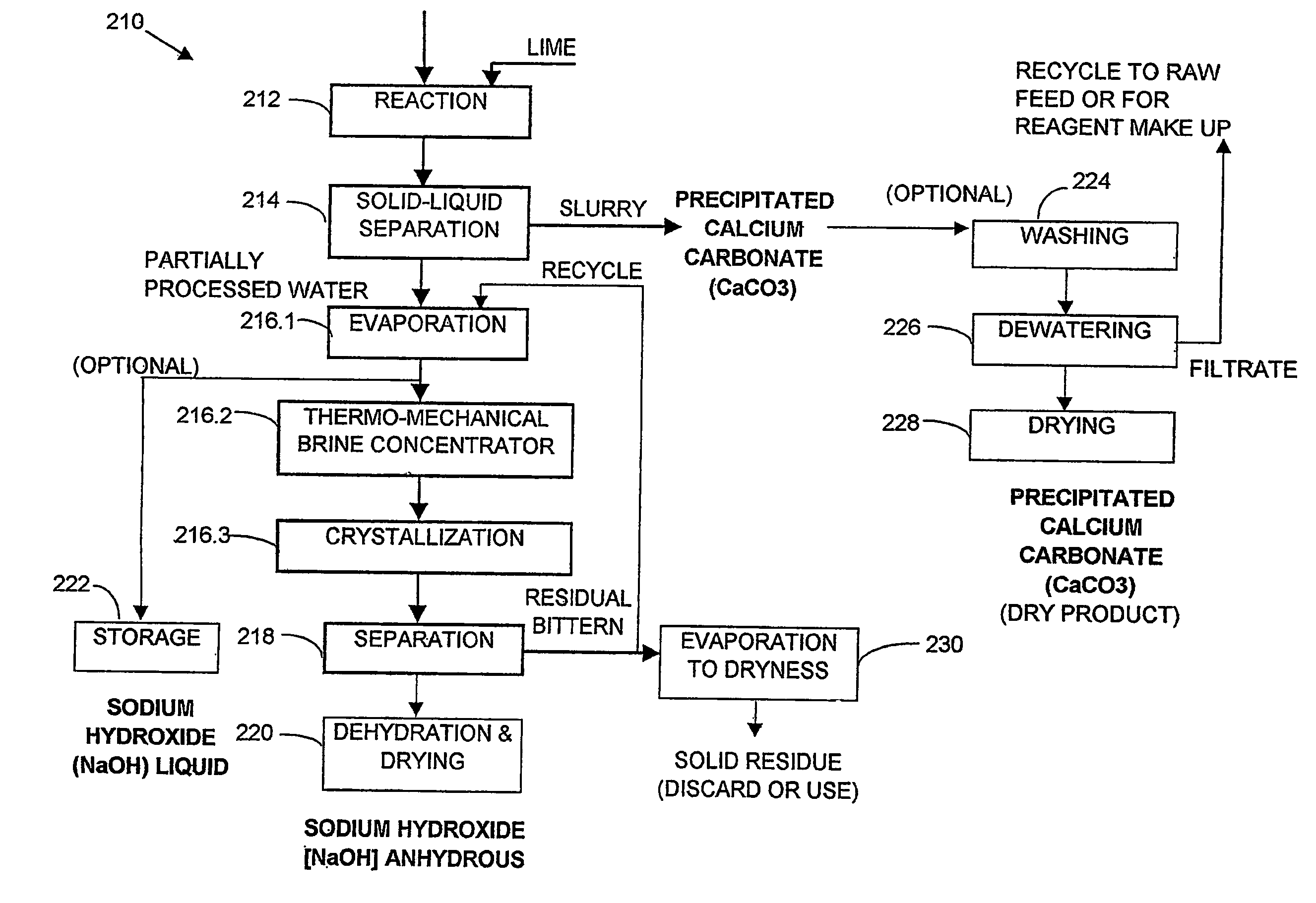

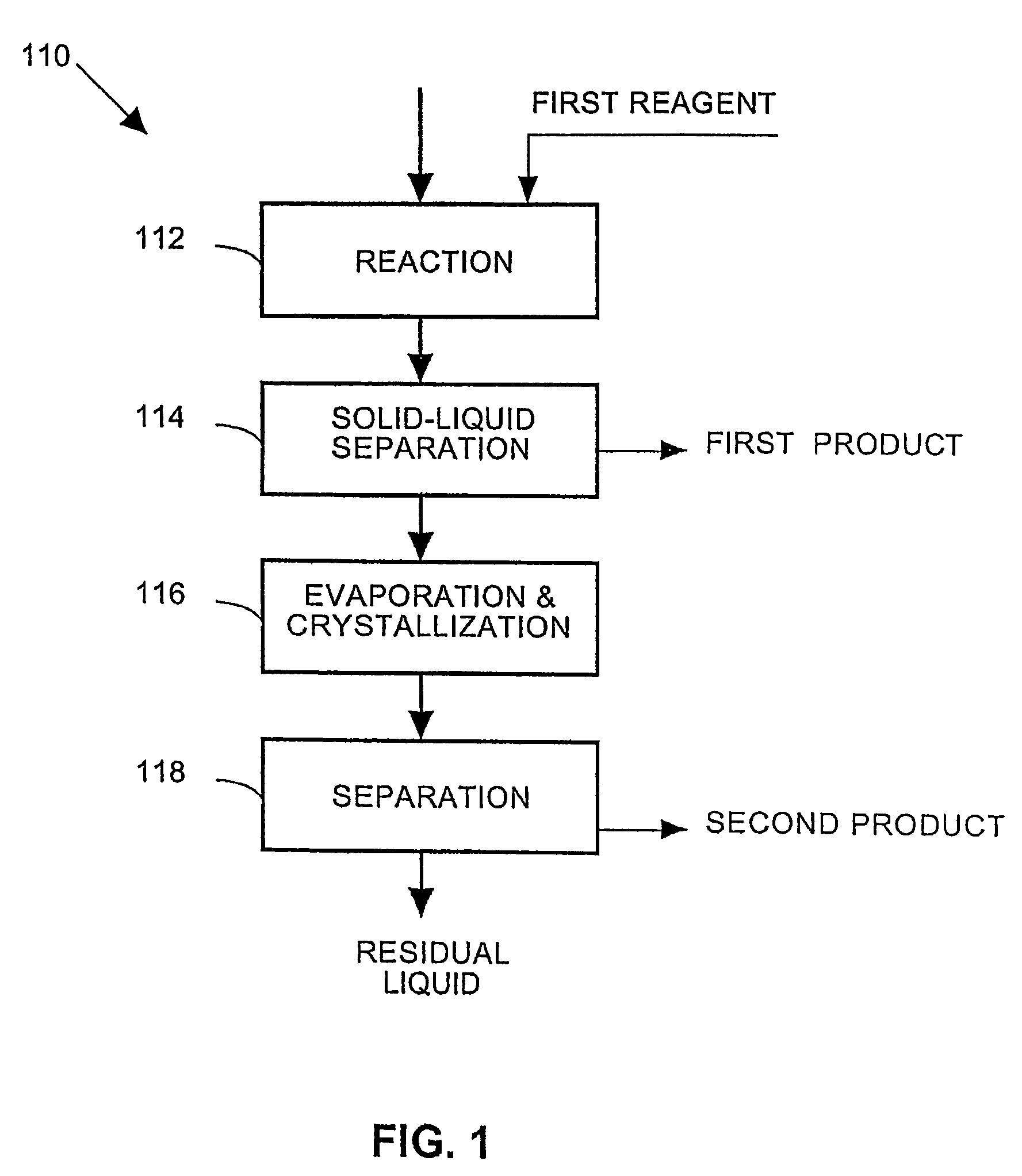

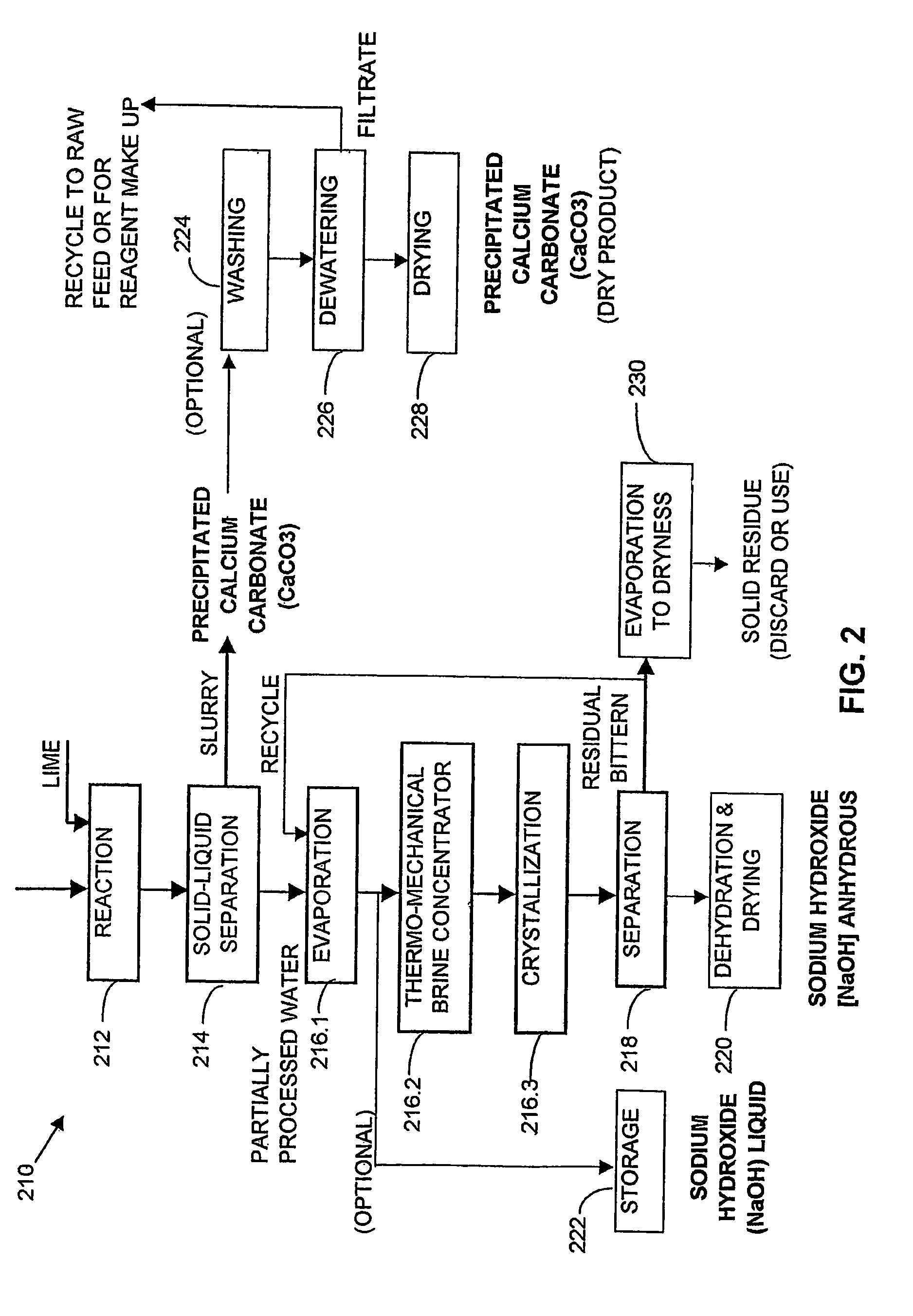

Process and apparatus for the treatment of saline water

InactiveUS20060196836A1Reduce ZLD costReduce loadWaste water treatment from quariesGeneral water supply conservationTotal dissolved solidsEvaporation

A process and an apparatus are described for treating seven types of saline waters each having a concentration of total dissolved solids exceeding 1 g / L, wherein the concentration of total dissolved solids, the ratio of the chloride ion concentration to the bicarbonate ion concentration and the ratio of the chloride ion concentration to the sulphate ion concentration of each of the water types are as indicated in Table 1. The process includes the steps of contacting the water with a first reagent comprising a source of calcium ions selected from calcium oxide and calcium hydroxide to form a first solid product which is recovered. The process includes a further step of subjecting at least a portion of the partially processed water to at least partial evaporation so as to promote the formation of a precipitate and a mother liquor. The precipitate is recovered as a second product.

Owner:GEO PROCESSORS

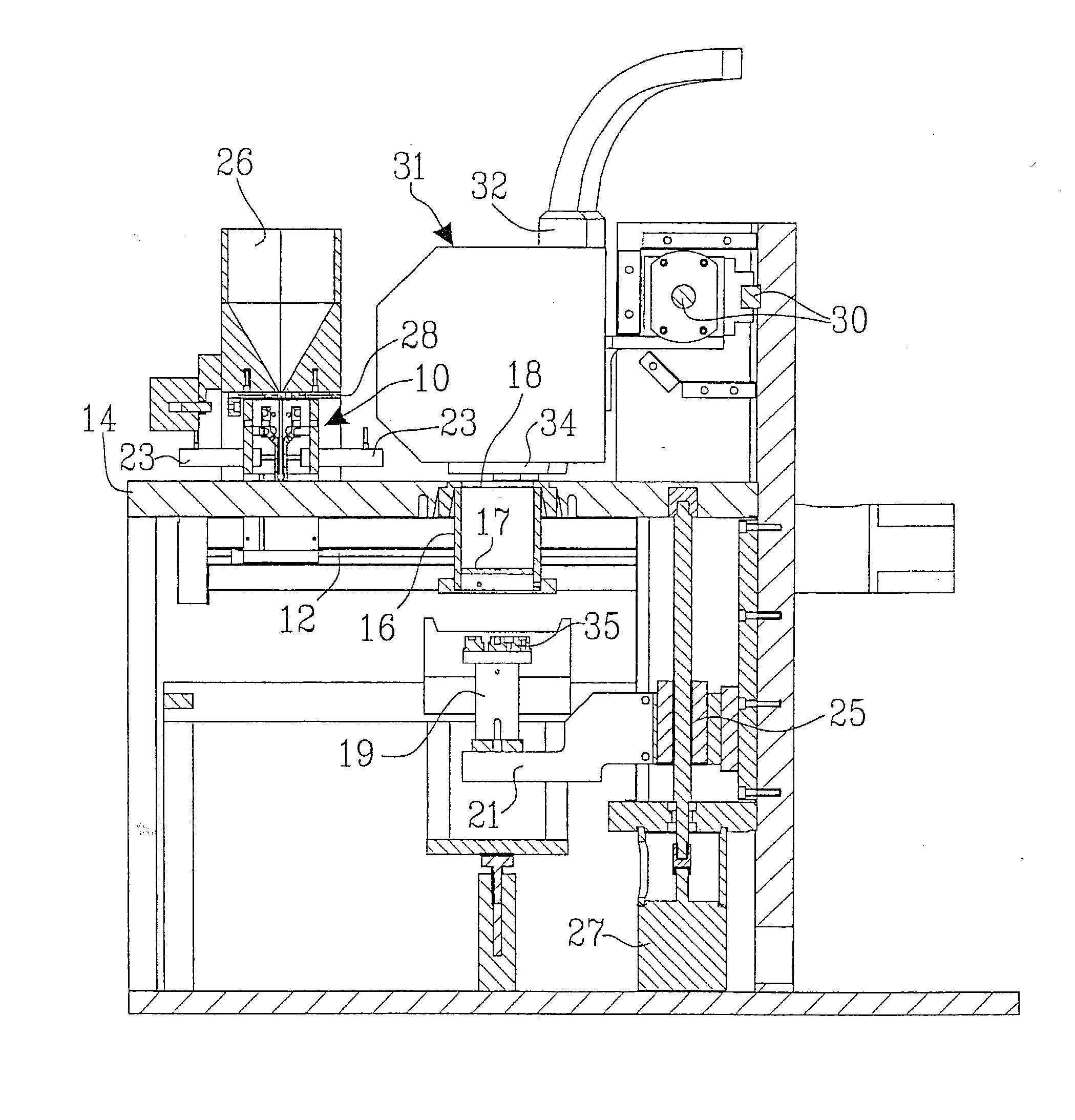

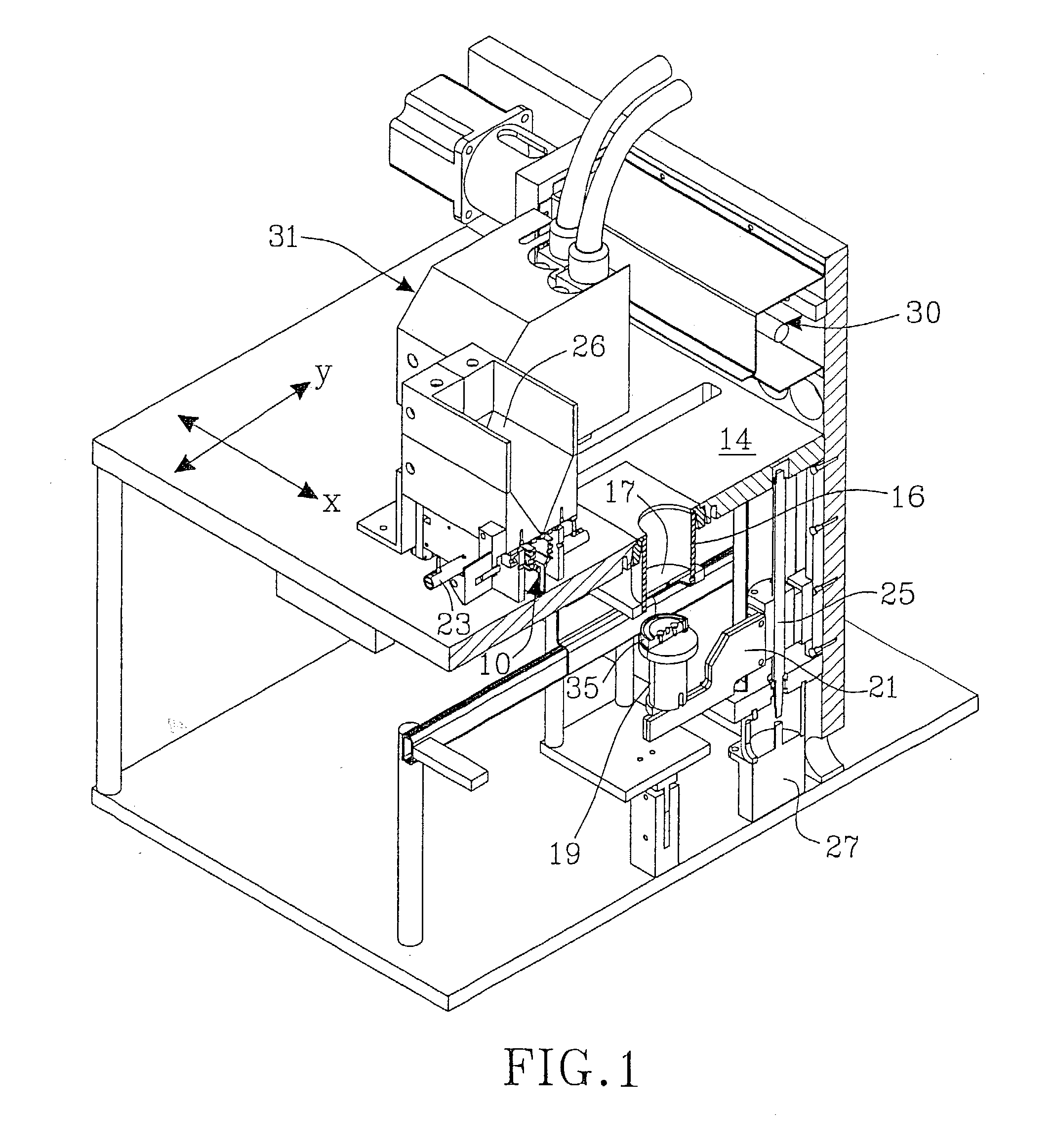

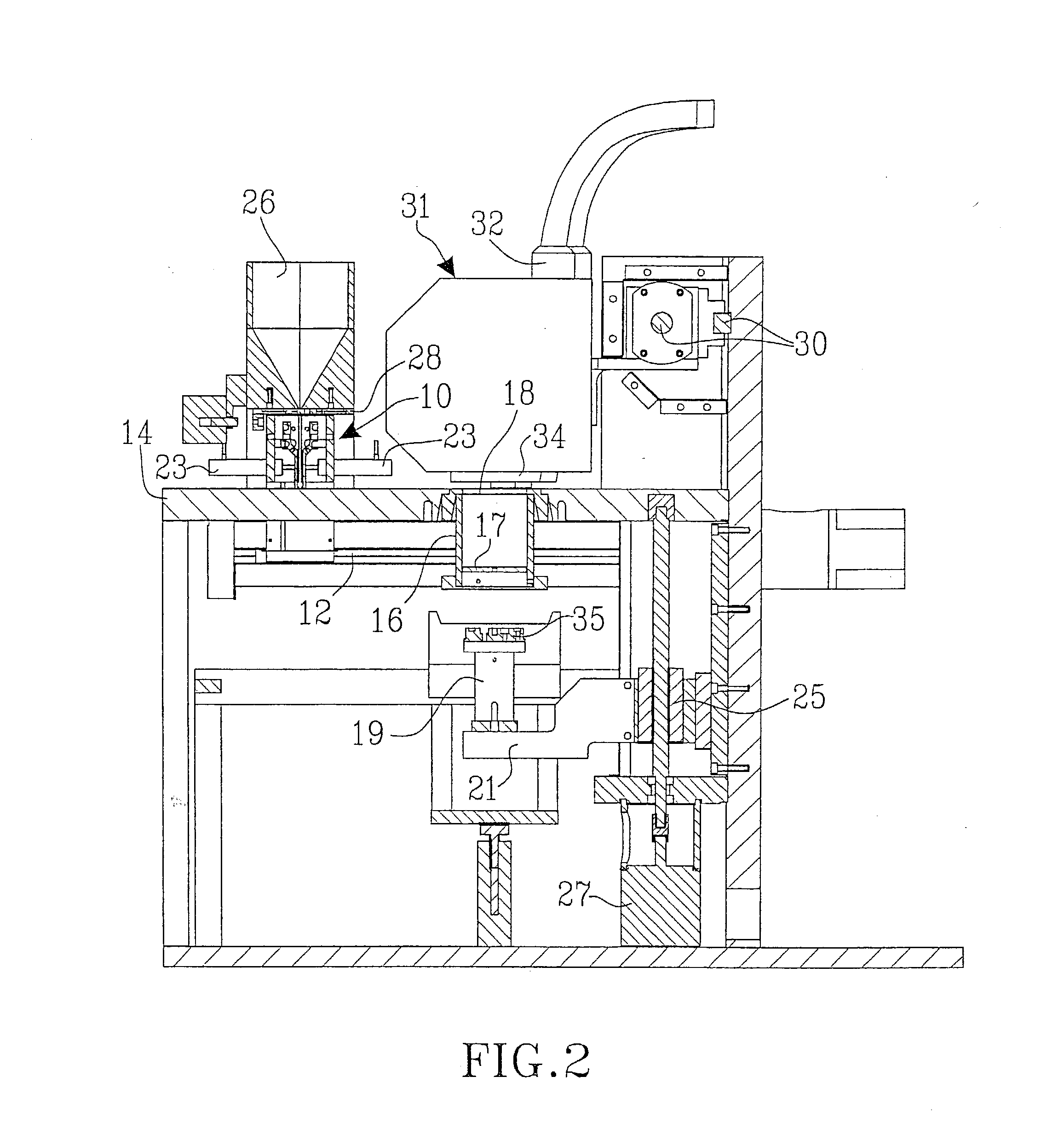

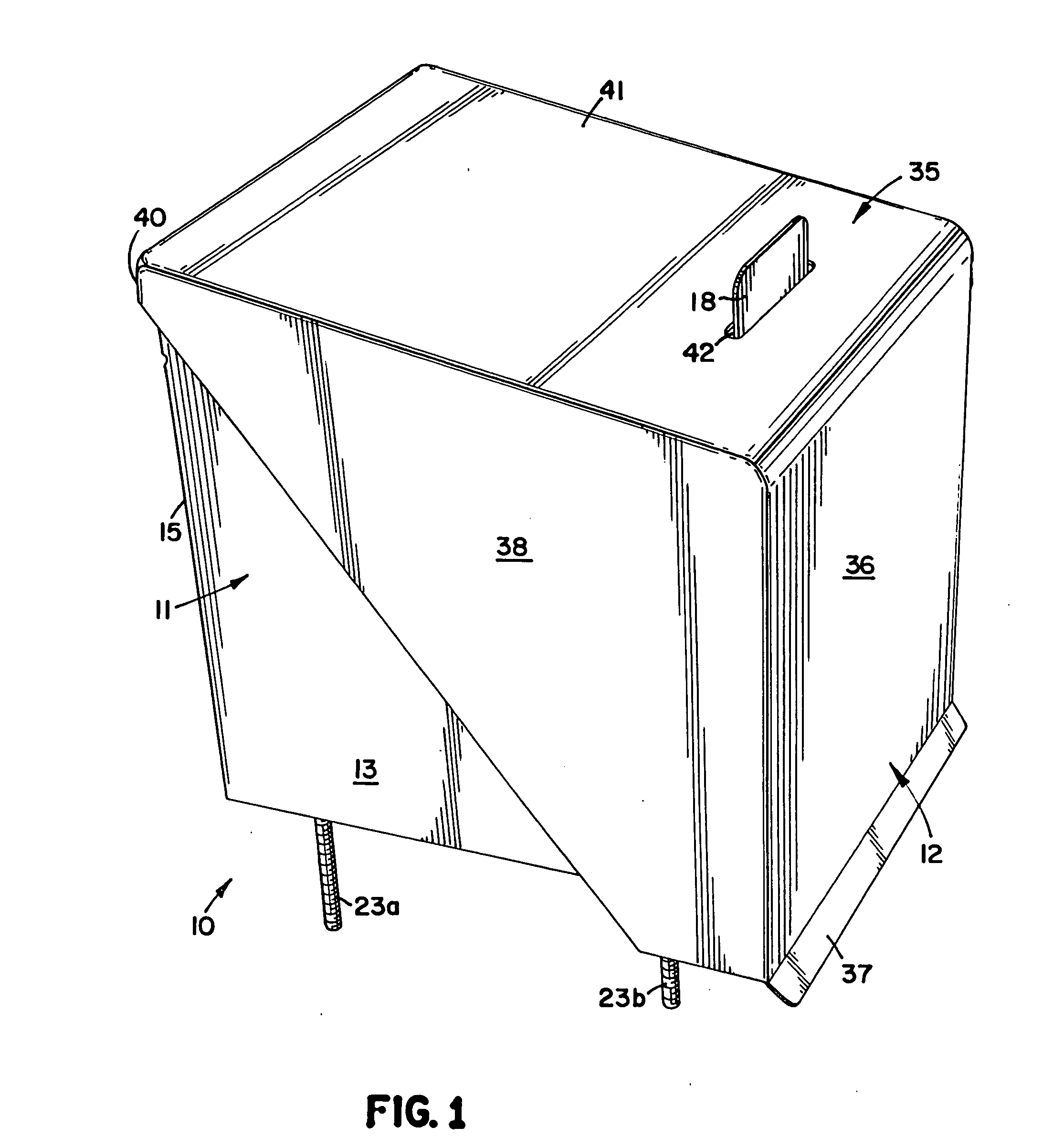

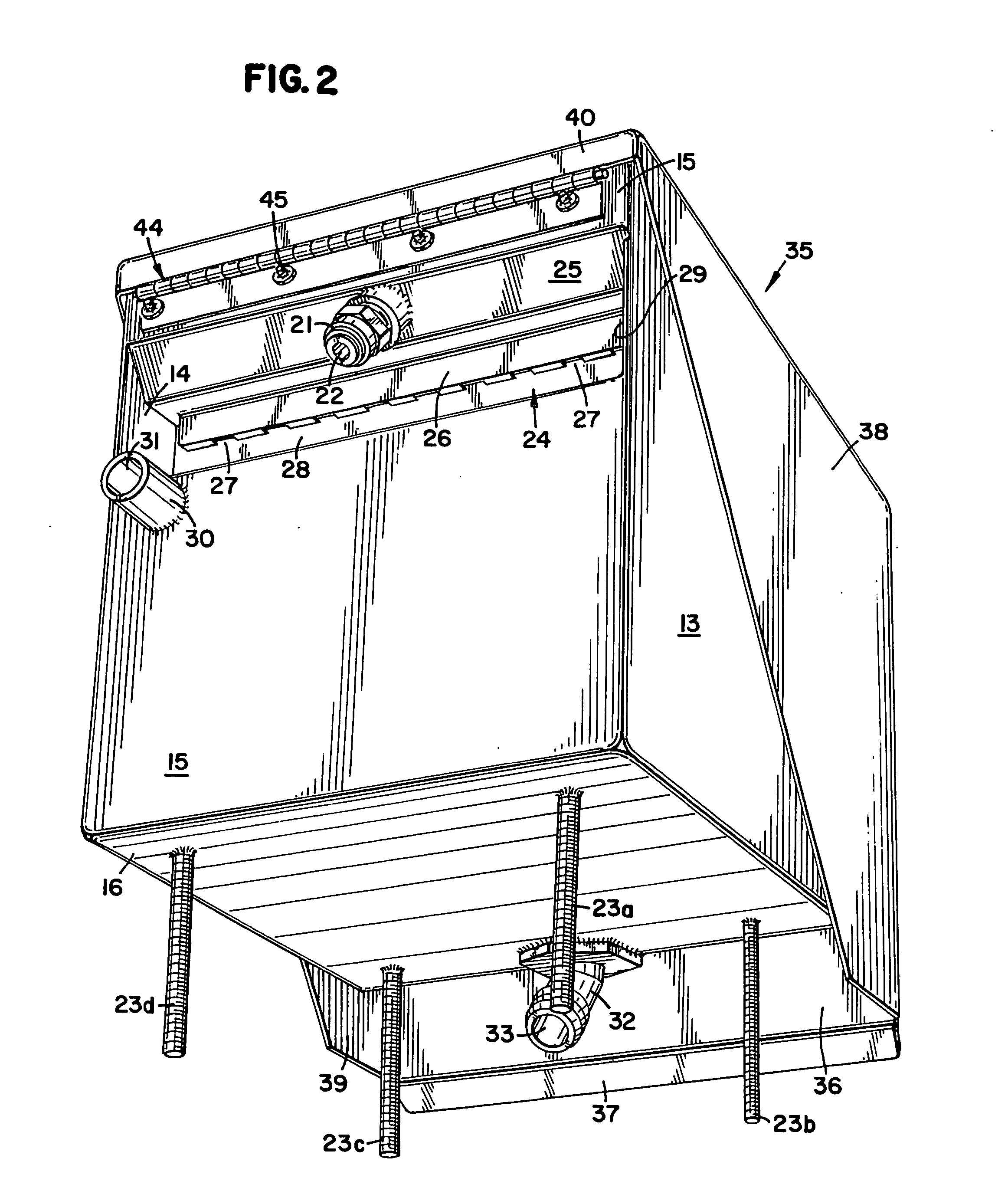

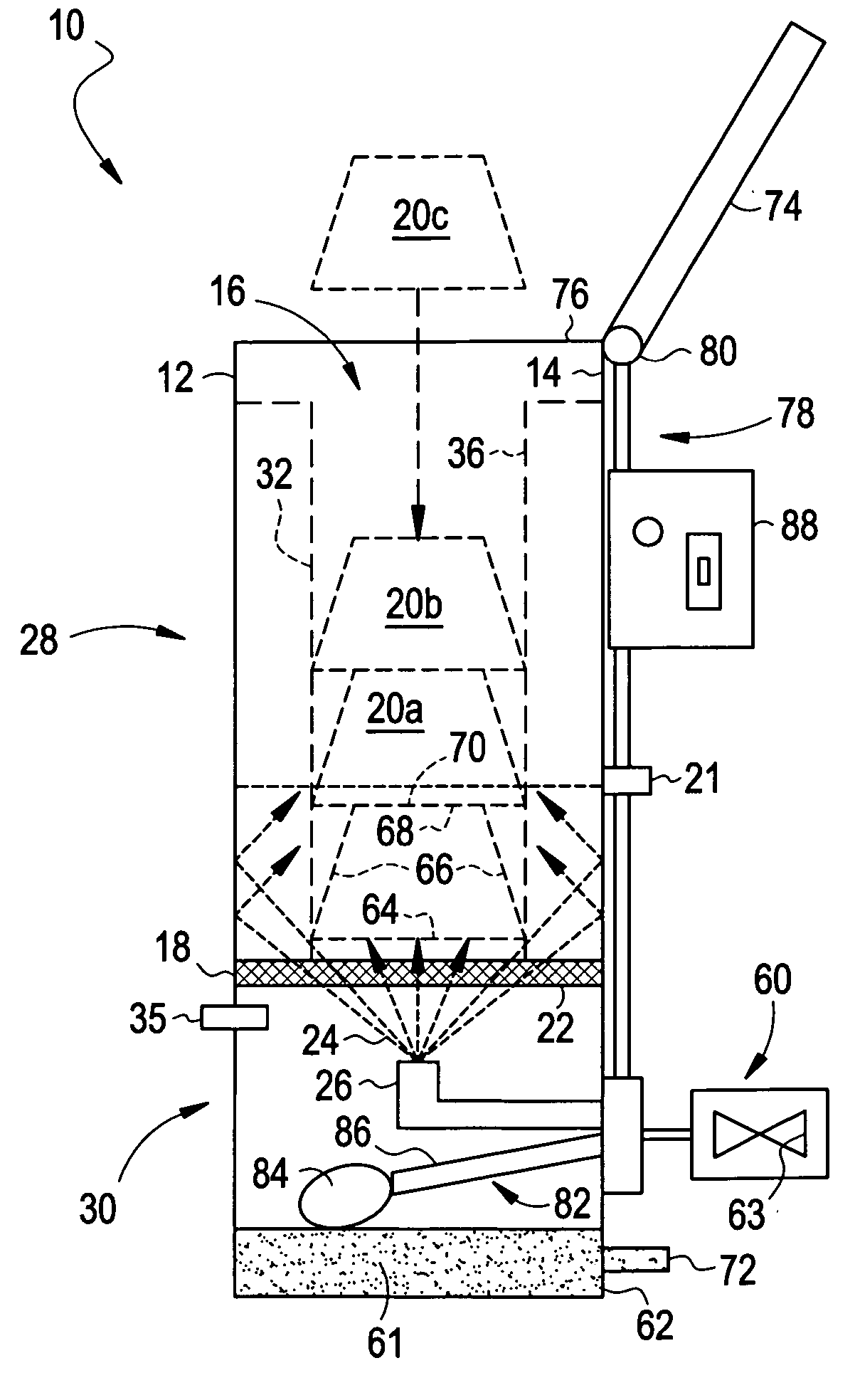

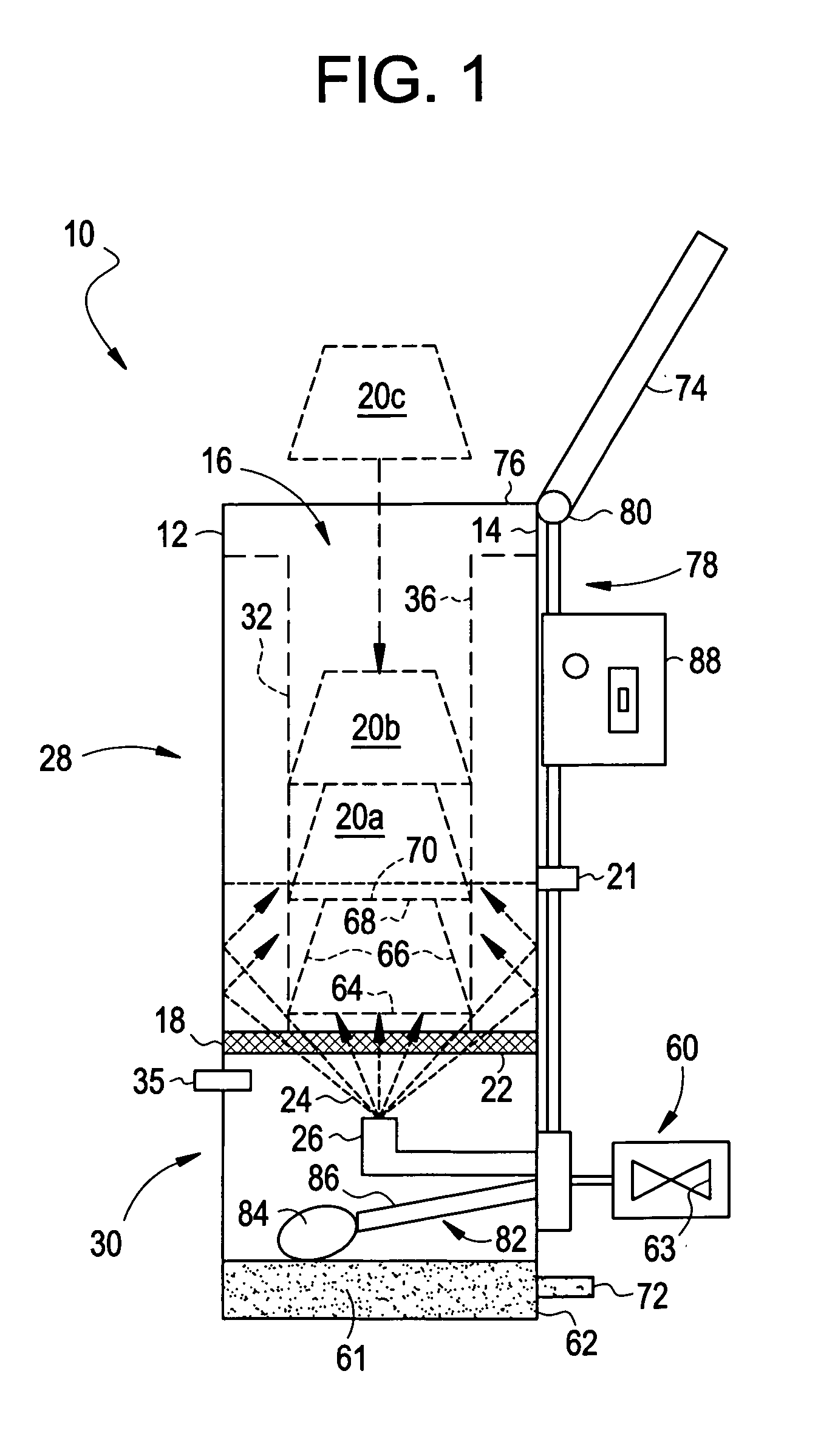

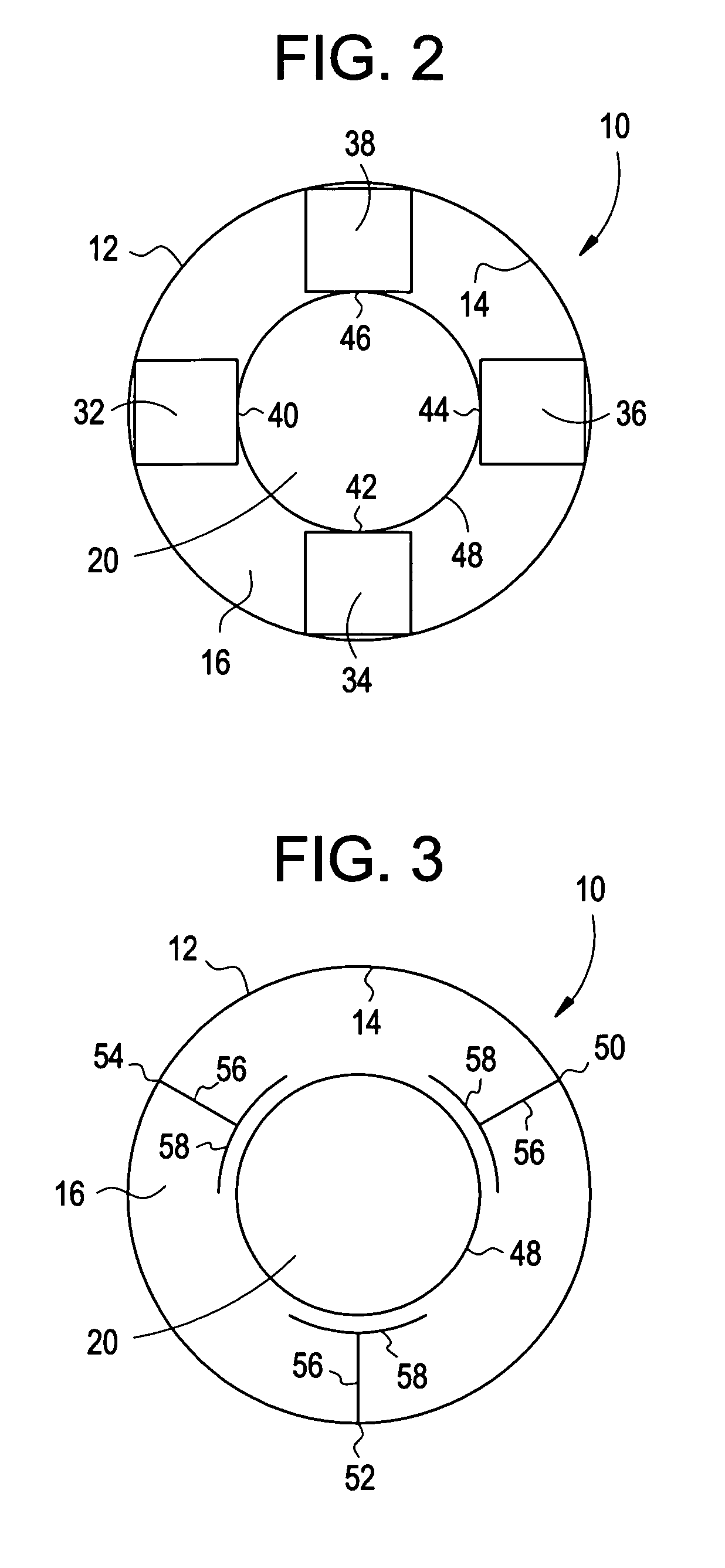

Solid rinse additive dispenser

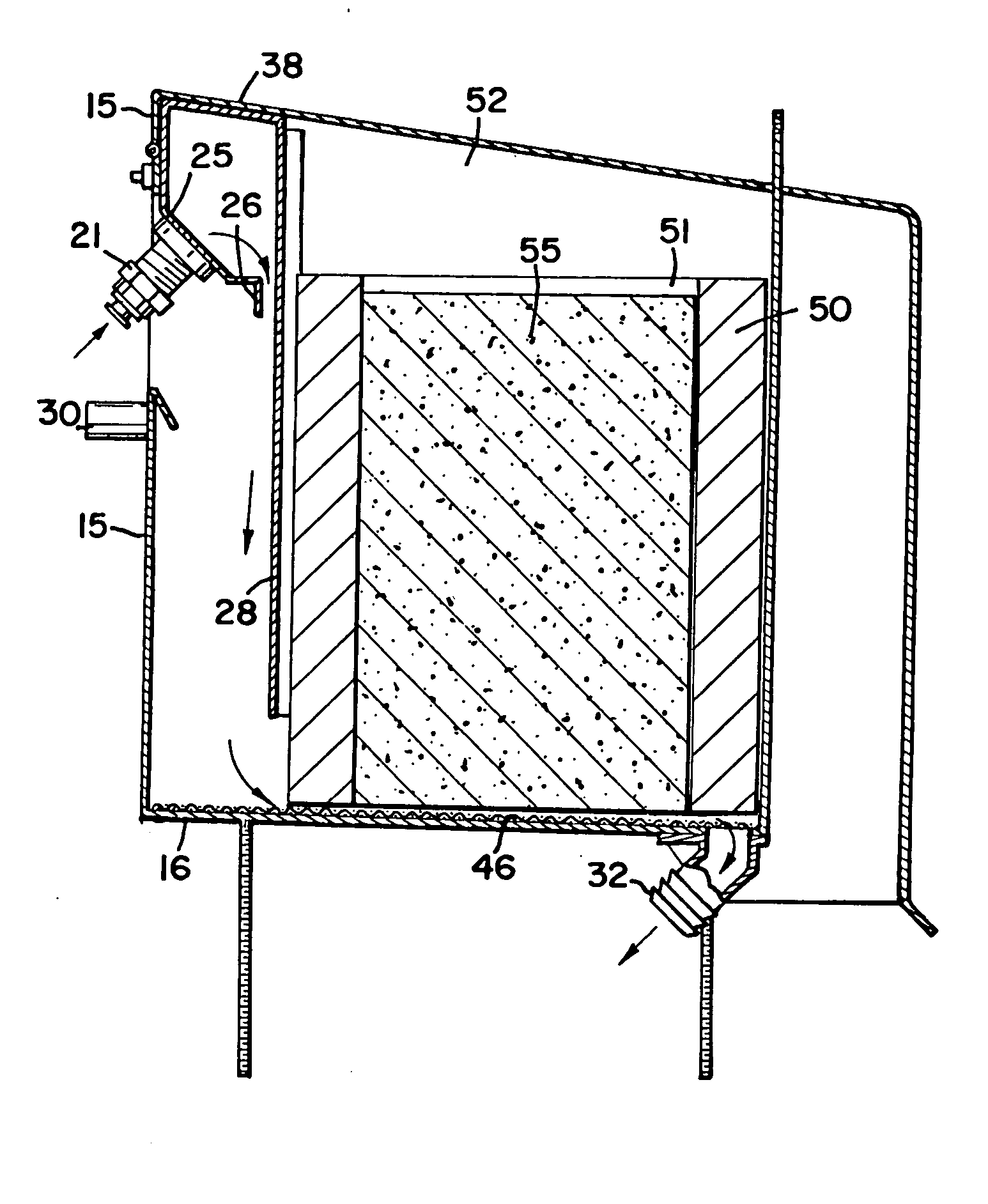

A product dispenser (10) for dispensing a use solution from a solid product includes a chamber (11) having a front (12), a back (15), and a bottom (16). The chamber (11) defines a cavity (20) configured and arranged to receive a solid product and a diluent. An inlet (21) proximate the back (15) of the chamber (11) is configured and arranged to receive the diluent, and an outlet portion (26) is in fluid communication with the inlet (21). The outlet portion (26) spans a length of the back (15) and includes a plurality of apertures (27) along the length of the back (15). The plurality of apertures (27) allows diluent to fan out along the back (15), flow down the back (15), and cascade evenly with relatively even pressure from proximate the back (15) toward proximate the front (12) of the chamber (11). A use solution outlet (32) proximate the bottom (16) and the front (12) of the chamber (11) allows diluent and a use solution to exit the chamber (11).

Owner:ECOLAB USA INC

Blackthorn pear fruit-juice solid product and its production

The invention is concerned with the solid product of roxburgh rose juice and the preparation method, it is: prepares the roxburgh rose juice or combined roxburgh rose juice to be granule, tablet, capsule or effervesce agent in order to improve the stability of vitamin C, vitamin p and superoxide dismutase in it, and reduce the nutritive value loss of roxburgh rose juice. The preparation method is: 1) prepares clear roxburgh rose juice; 2) prepares roxburgh rose condensing juice; 3) adds 1% -50% accessories into the clear roxburgh rose juice or roxburgh rose condensing juice; 4) gets grains by wet-process, or makes instant powder of roxburgh rose then gets grains by wet-process; 5) the above grains dry at the temperature of 30 centigrade - 70 centigrade in order to get the solid products.

Owner:SHANGHAI NORMAL UNIVERSITY

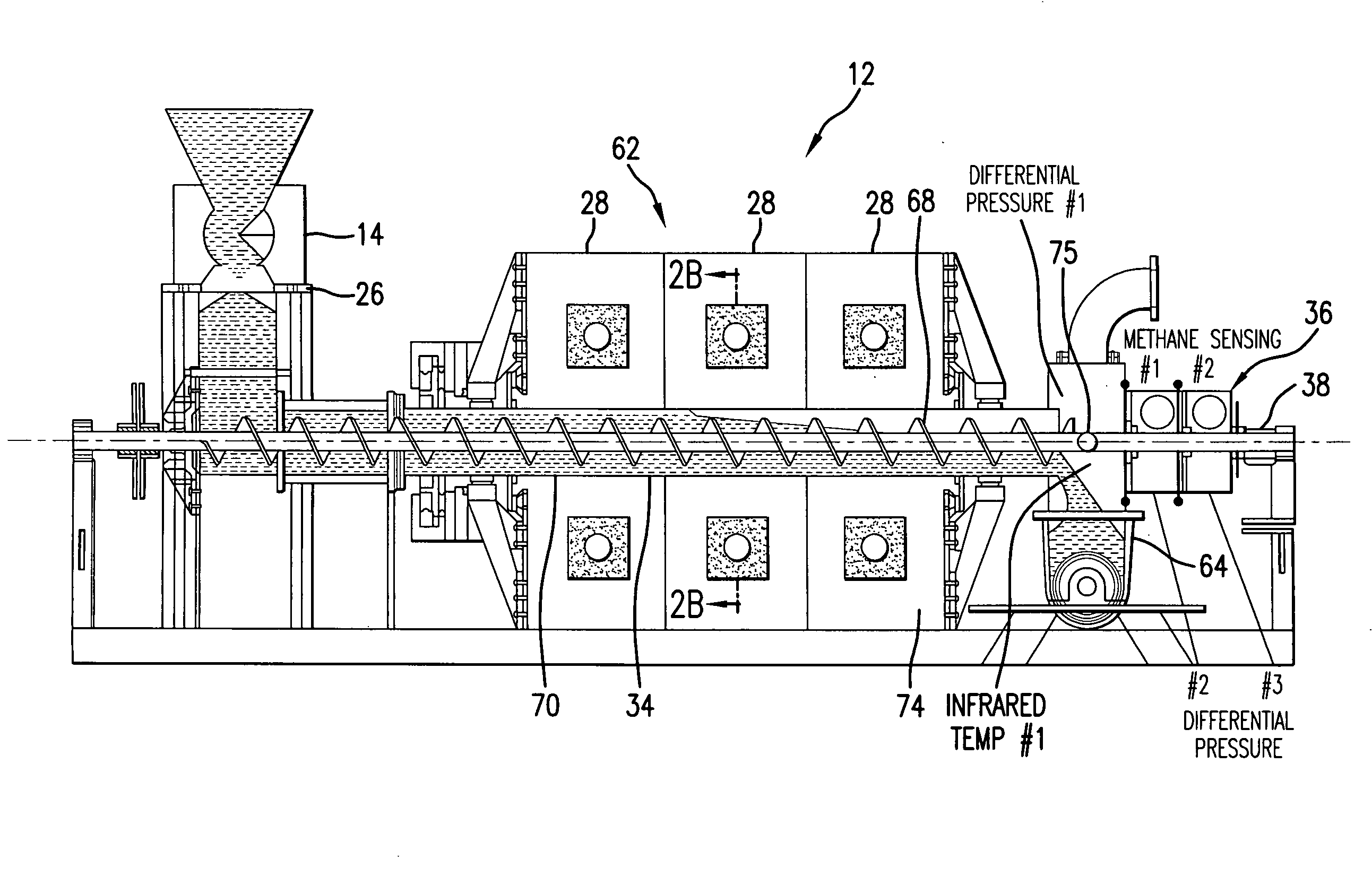

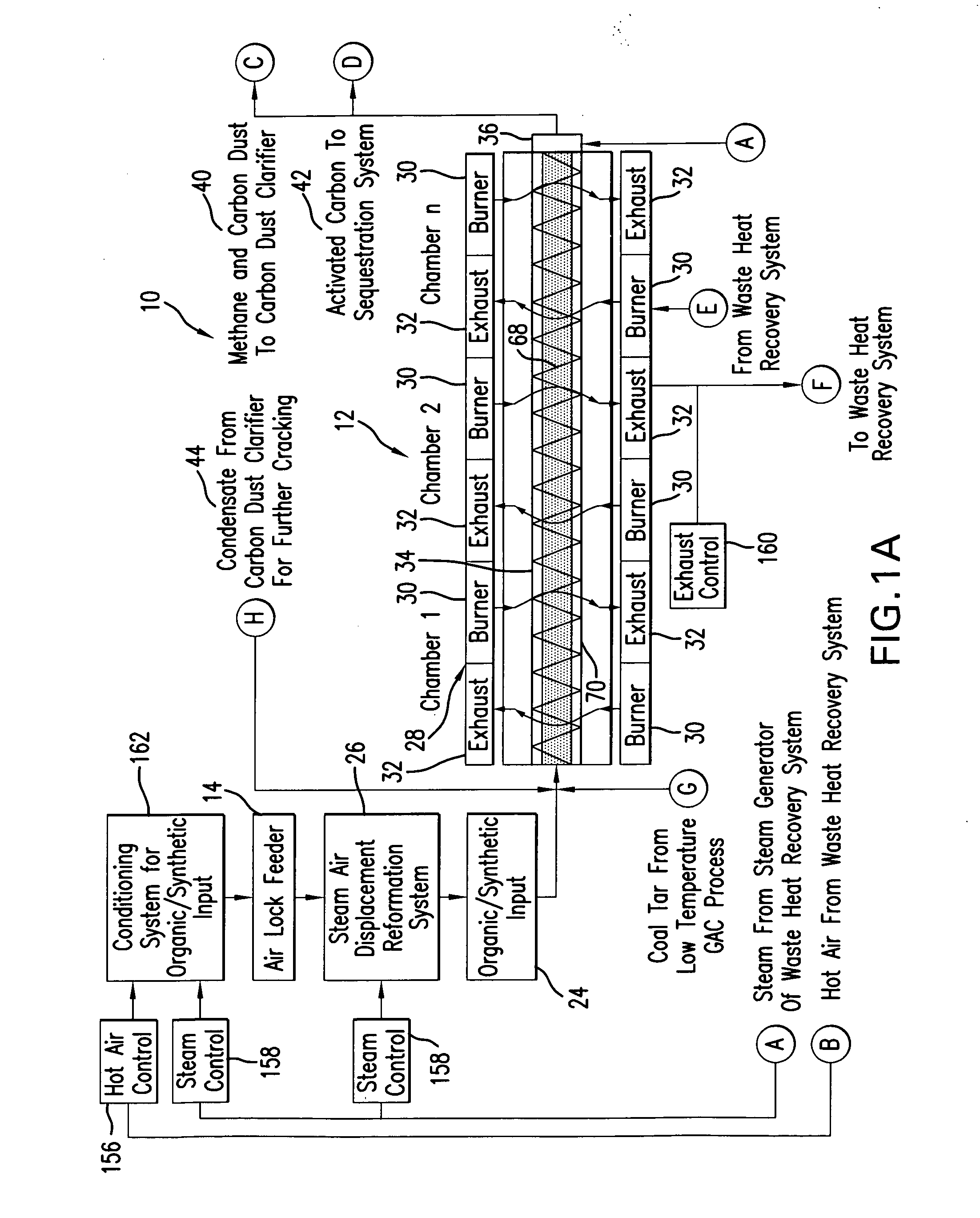

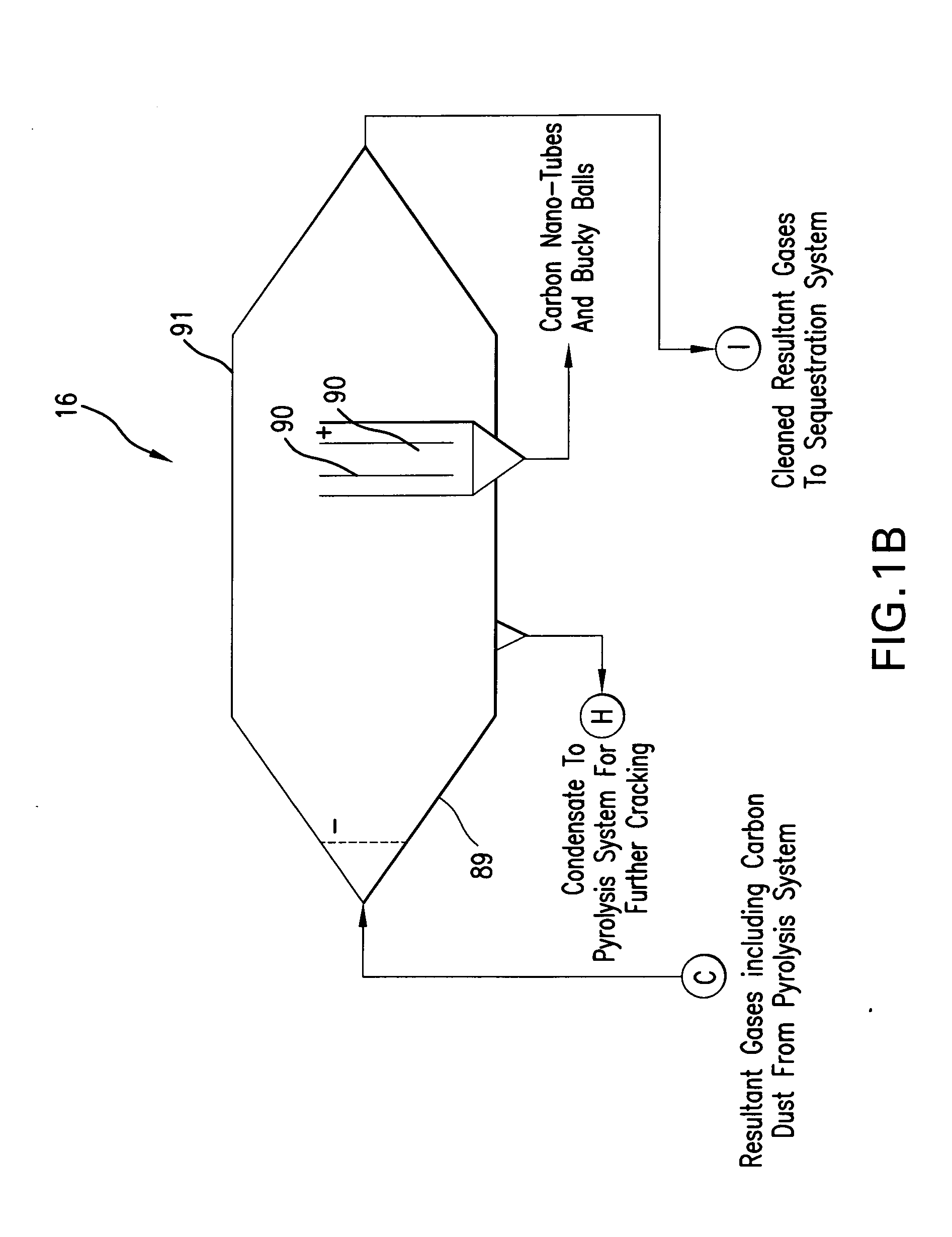

Pyrolysis Systems, Methods, and Resultants Derived Therefrom

ActiveUS20080286557A1Fit closelyWithout undesired degradation of communication system performanceLayered productsUsing liquid separation agentActivated carbon filtrationSilicon dioxide

A system and process for gasification of a carbonaceous feedstock uses pyrolysis to produce a gas product, which may include methane, ethane, and other desirable hydrocarbon gases, and a solids product, which includes activated carbon or carbon. The gas product may then be filtered using at least a portion of the activated carbon from the solids product as a filtering medium. In an embodiment, at least some of the noxious chemicals are sequestered or removed from the gas product in one or more filtering steps using the activated carbon as a filtering medium. In a further embodiment, the filtering steps are performed in stages using activated carbon at different temperatures. A high-temperature pyrolysis system that produces activated carbon may be combined with another high-temperature pyrolysis system that does not produce activated carbon to provide filtering of noxious compounds using activated carbon from the first high-temperature pyrolysis system. A high-temperature pyrolysis system may be combined with one or more low-temperature feedstock conversion processes such that waste heat from the high-temperature pyrolysis system is used to operate the low-temperature process. A novel non-wetting carbon having pores fused with silica can be produced from using the system and process.

Owner:TUCKER RICHARD D

Solid catalyst component for alpha-olefin polymerization, catalyst for alpha-olefin polymerization, and process for producing alpha-olefin polymer

InactiveUS6187883B1High catalytic activityNarrow particle size distributionOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationOrganic acidEther

The present invention relates to a solid catalyst component for alpha-olefin polymerization having a narrow particle size distribution of not less than 6.0 in terms of the value of N in a Rosin-Rammler function of particle size distribution and giving a catalytic activity of not less than 10,000 ((g-polymer produced / g-solid catalyst component) / hour) in polymerization. The catalyst component is obtained by a process which comprises reducing a titanium compound with an organomagnesium compound in the presence of an organosilicon compound and an ester to obtain a solid product, then treating the solid product with: (a) a mixture of titanium tetrachloride and an ether, (b) an organic acid halide, and (c) a mixture of titanium tetrachloride and an ether optionally containing an ester.

Owner:SUMITOMO CHEM CO LTD

Biochar Compositions and Methods of Use Thereof

ActiveUS20150128672A1Enhanced and functionalizedNitrogenous fertilisersOrganic fertilisersForming gasBiological activation

The invention provides for methods, devices, and systems for pyrolyzing biomass. A pyrolysis unit can be used for the pyrolysis of biomass to form gas, liquid, and solid products. The biomass materials can be selected such that an enhanced biochar is formed after pyrolysis. The biomass can be pyrolyzed under specified conditions such that a selected biochar core is formed. The pyrolysis process can form a stable biochar core that is inert and / or resistant to degradation. The biochar or biochar core can be functionalized to form a functionalized biochar or functionalized biochar core. Functionalized can include post-pyrolysis treatments such as supplementation with microbes or physical transformations including annealing and / or activation.

Owner:FULL CIRCLE BIOCHAR

Process for the treatment of saline water

InactiveUS7595001B2Waste water treatment from quariesGeneral water supply conservationTotal dissolved solidsEvaporation

A process and an apparatus are described for treating seven types of saline waters each having a concentration of total dissolved solids exceeding 1 g / L, wherein the concentration of total dissolved solids, the ratio of the chloride ion concentration to the bicarbonate ion concentration and the ratio of the chloride ion concentration to the sulphate ion concentration of each of the water types are as indicated in Table 1. The process includes the steps of contacting the water with a first reagent comprising a source of calcium ions selected from calcium oxide and calcium hydroxide to form a first solid product which is recovered. The process includes a further step of subjecting at least a portion of the partially processed water to at least partial evaporation so as to promote the formation of a precipitate and a mother liquor. The precipitate is recovered as a second product.

Owner:GEO PROCESSORS

Method performing microwave pyrolysis on garbage

InactiveCN102585860AGuaranteed uptimeContinuous Industrialization ImplementationSolid waste disposalSpecial form destructive distillationMicrowave pyrolysisResource utilization

The invention discloses a method for performing microwave pyrolysis on garbage. The method comprises the following steps of: 1) pretreating the garbage to obtain structured garbage which is suitable for microwave pyrolysis; 2) performing microwave pyrolysis on the garbage, namely introducing pyrolysis gas out of a pyrolysis gas outlet of a microwave pyrolysis device, continuously outputting pyrolysis solid products from a pyrolysis solid residue discharge port on the microwave pyrolysis device, sealing the rest parts of the microwave pyrolysis device except a garbage inlet, the pyrolysis solid residue discharge port and a pyrolysis gas outlet to prevent the pyrolysis gas from being leaked and preventing external air from entering the microwave pyrolysis device to ensure that the pyrolysis gas is used as protective gas for pyrolysis reaction; and 3) recovering pyrolysis products, namely treating according to the pyrolysis products. The method has the characteristics of rapidness and high efficiency, low energy consumption, low cost, high resource utilization rate, simplicity in operation, high garbage volume reduction rate, capacity of obviously reducing damage of garbage to environment and the like; and by the method, innocent treatment of the garbage can be realized really.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING +1

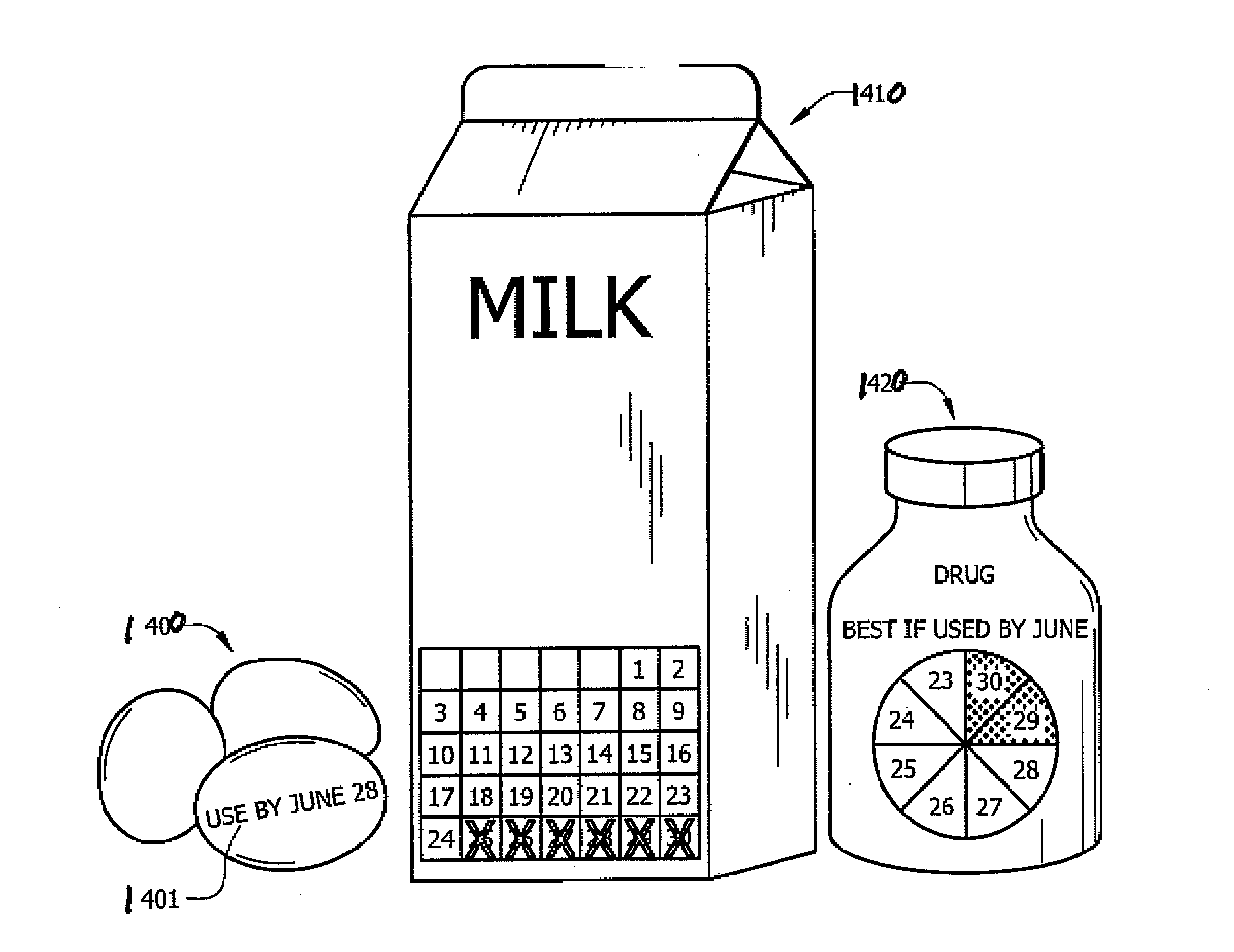

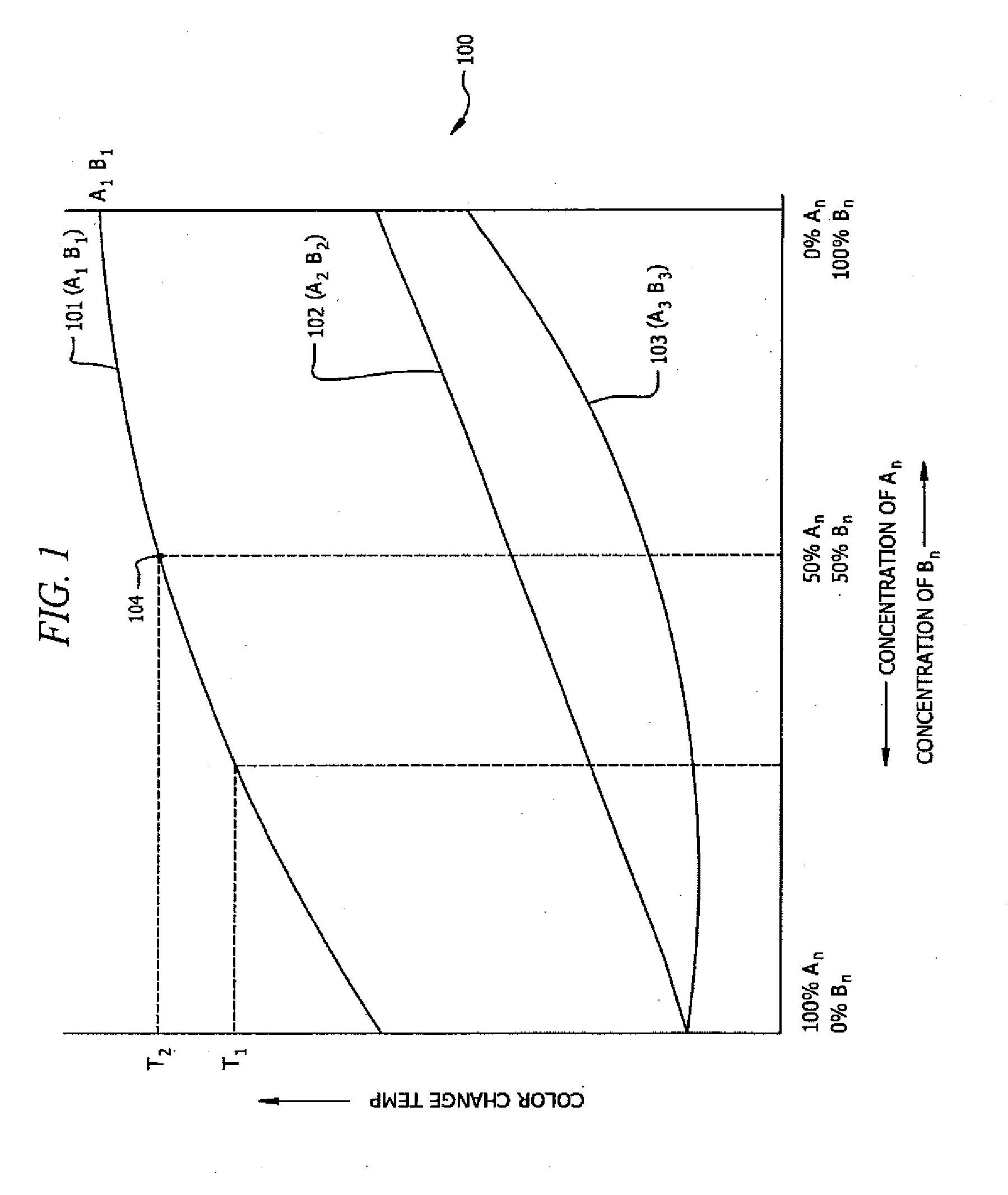

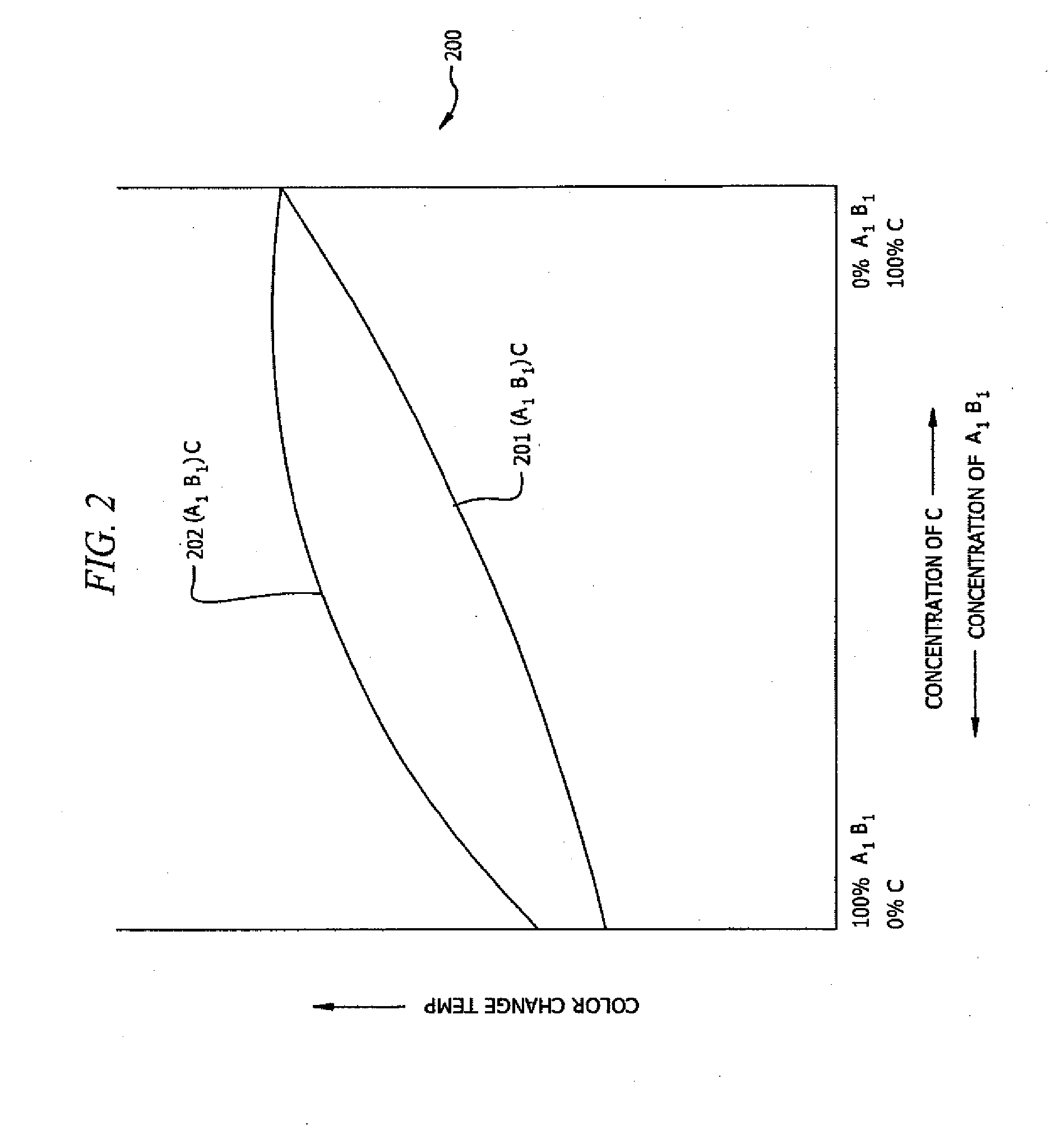

Co-topo-polymeric compositions, devices and systems for controlling threshold and delay activation sensitivities

ActiveUS20100012018A1Liquid crystal compositionsThermometer detailsBiological activationColor changes

Co-topo-polymeric indicator compositions and methods for making and using the same are provided. Indicator compositions of the invention include a polymer and undergo a color change, which may be reversible or irreversible, in response to an applied stimulus, e.g., temperature. Aspects of methods of producing the compositions include setting a fluid co-topo-polymeric precursor composition into a solid product and then subjecting the solid product (either immediately or after a delay period) to polymerizing conditions to produce the desired indicator composition. Also provided are indicator devices that include the indicator compositions of the invention. The compositions of the invention find use in a variety of different applications.

Owner:SEGAN INDS

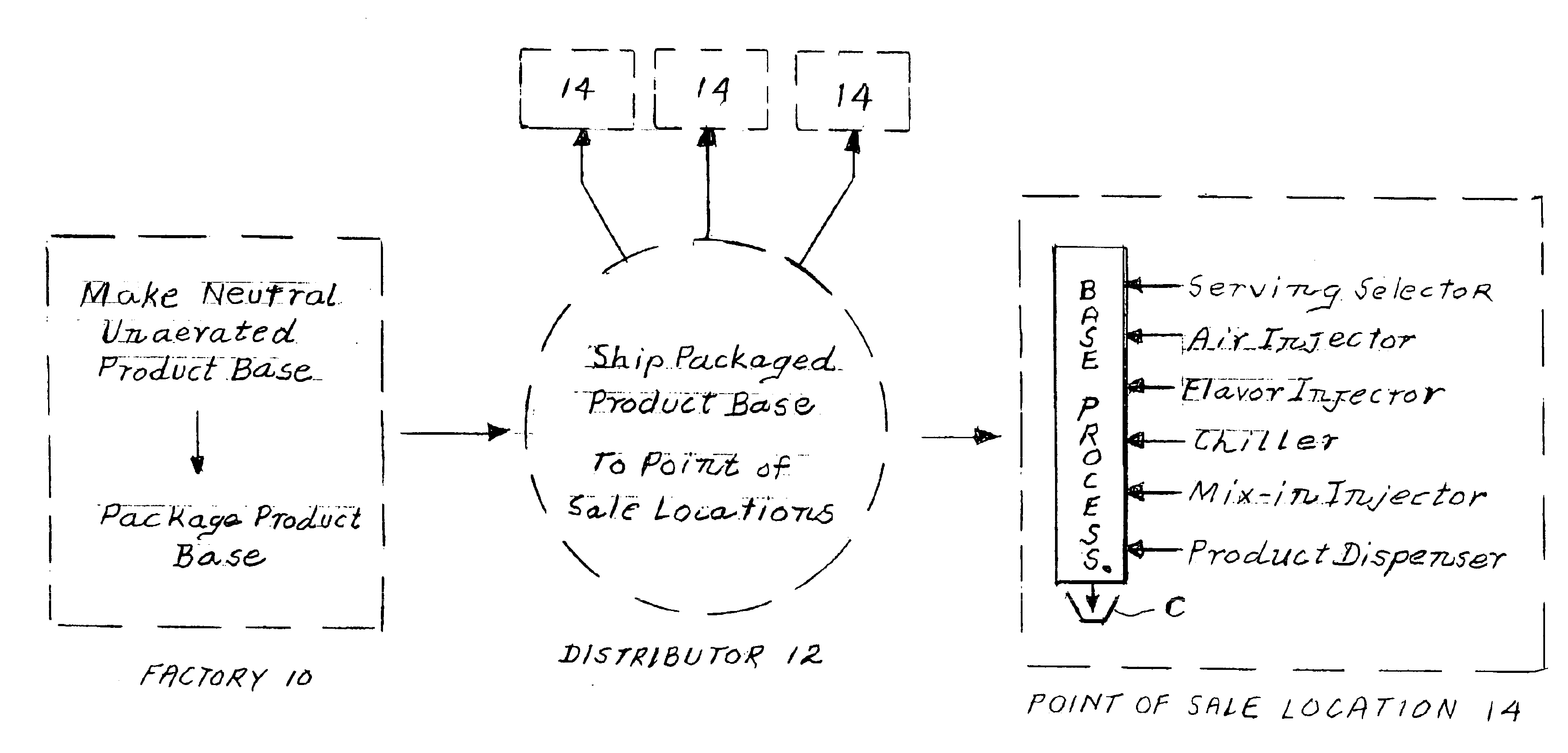

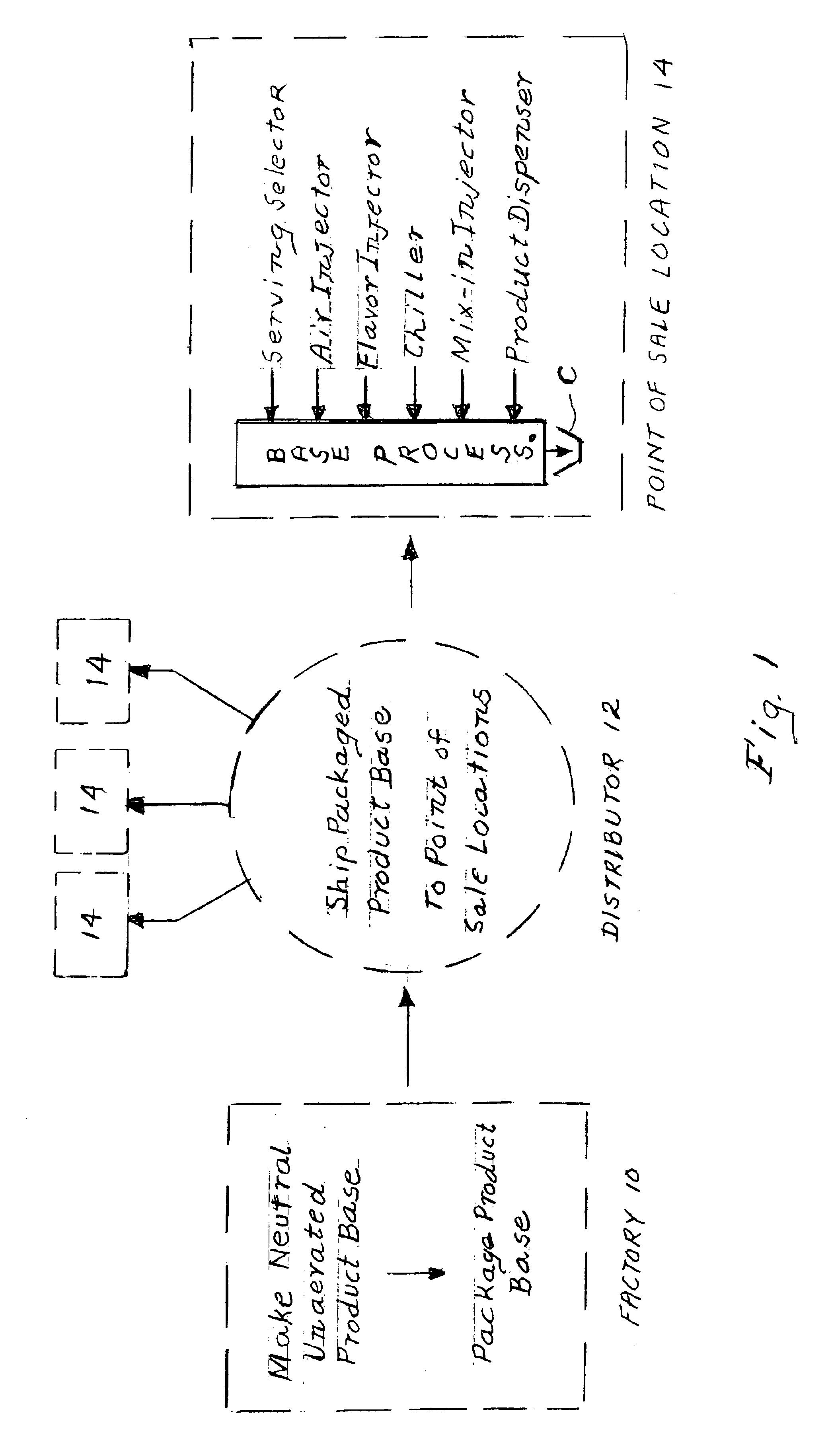

Efficient manufacture and distribution of chilled solid food products

InactiveUS6941858B2Lower requirementImprove production efficiencyMilk preservationMilk treatmentDistribution systemCommon carrier

An efficient manufacturing and distribution system for food products that are normally served at temperatures well below ambient uses a two stage manufacturing process. In the first stage, a neutral base product is prepared in bulk and is shipped to point of sale at ambient temperatures by common carrier, private trucking, parcel express, mail, etc. At the point of sale, a user selected quantity of it is finished to the specification of the user by aerating it, adding flavorings, mix-ins, etc. as desired, chilling it, and delivering it to the consumer.

Owner:MOOBELLA ACQUISITION +1

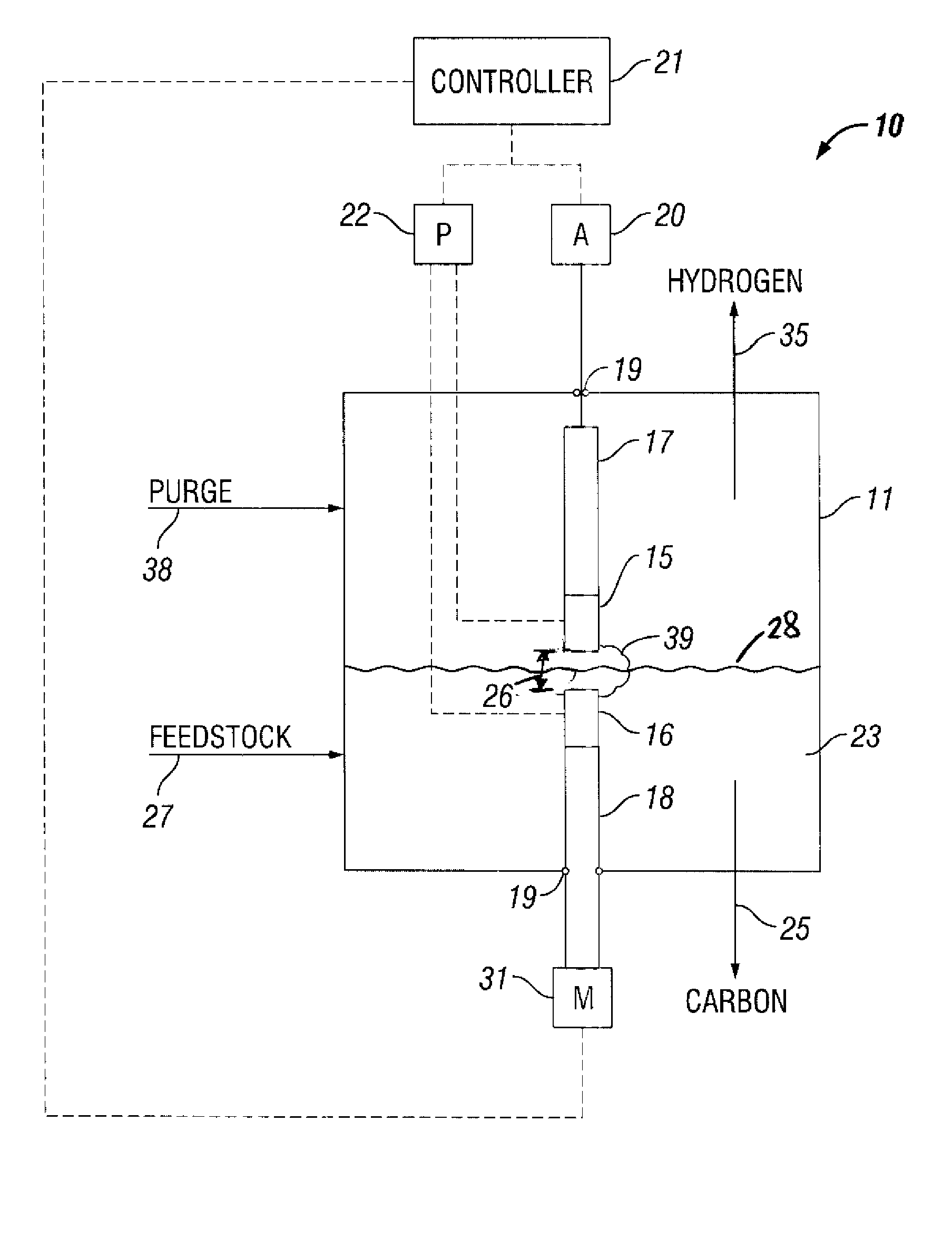

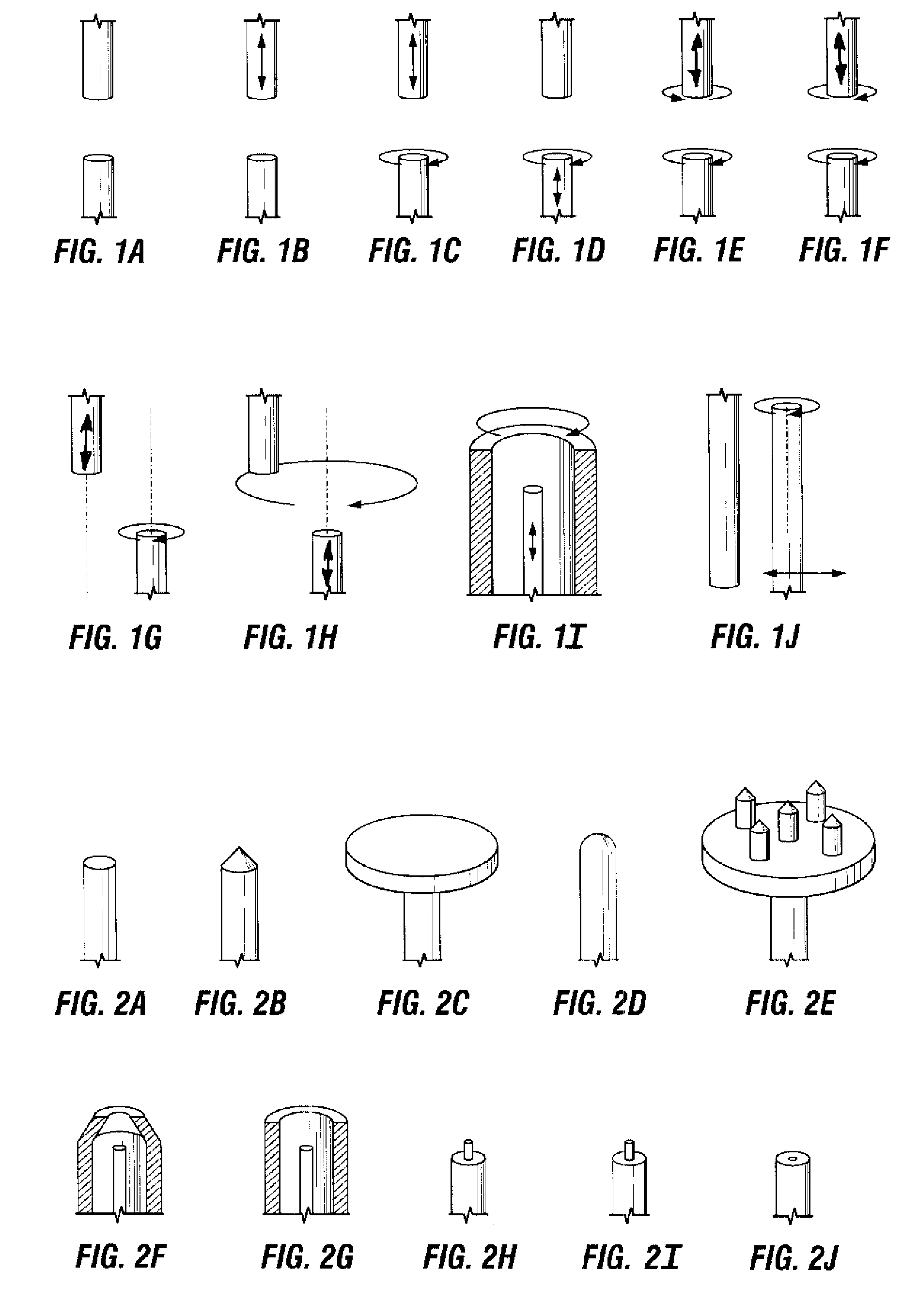

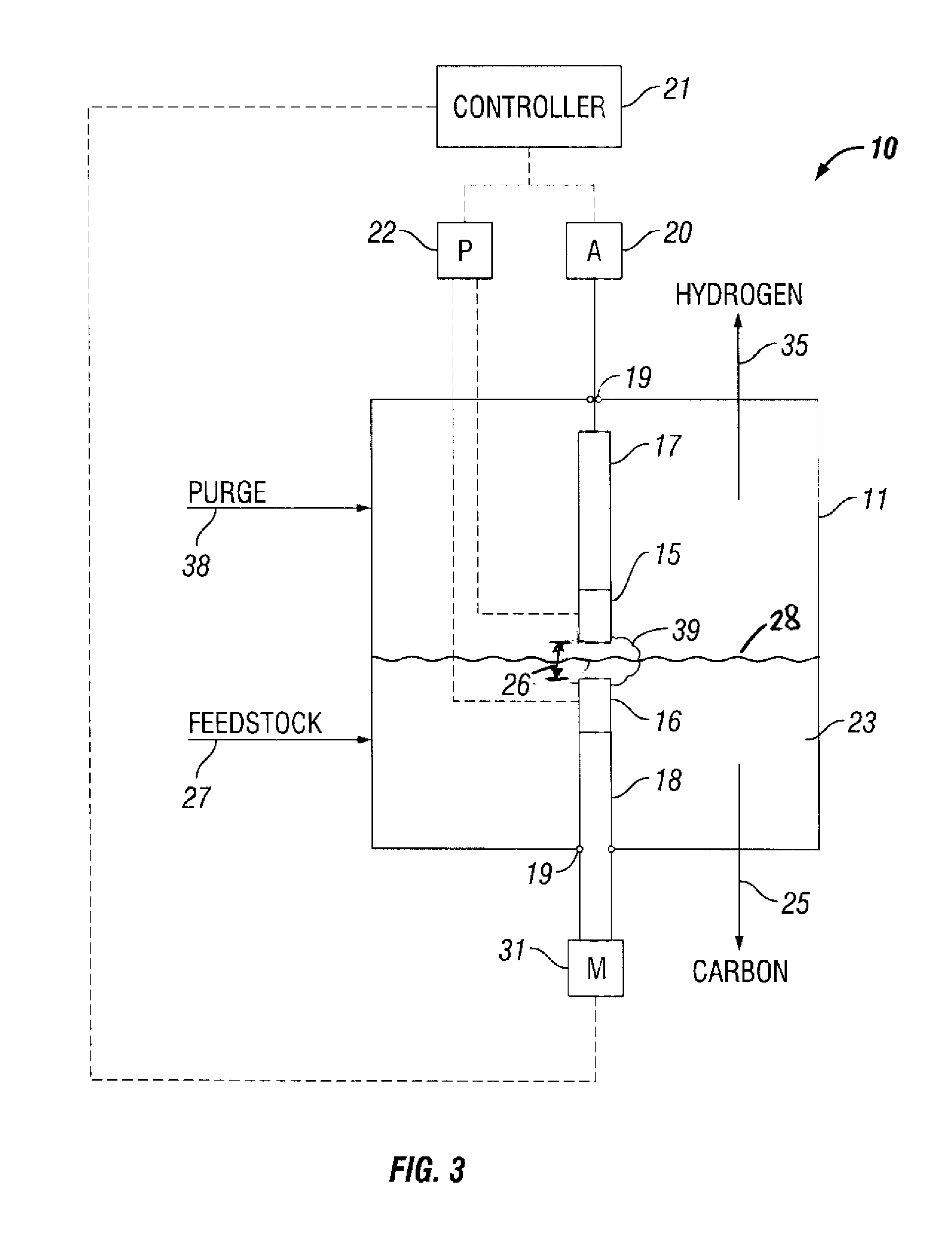

Hydrogen production using plasma- based reformation

Hydrogen gas production includes supplying a hydrocarbon fluid to a gap between a pair of electrodes, applying a voltage across the electrodes to induce an electrical arc, wherein the electrical arc contacts the hydrocarbon to form a plasma and produces a gaseous product comprising hydrogen gas and a solid product comprising carbon, and dynamically adjusting the gap length to control at least one parameter of the plasma. Preferably, the gap length is decreased during plasma initiation or reformation and increased to increase the hydrogen gas production rate. The method preferably includes dynamically adjusting the spatial separation of the electrodes and rotating at least one electrode while generating hydrogen gas to reduce adherence of solids to the electrodes. Furthermore, the polarity of the electrodes may be periodically reversed, primarily to reduce adherence of solids. If the hydrocarbon fluid is a liquid, the method may include controlling the level of the hydrocarbon liquid relative to the pair of electrodes.

Owner:LYNNTECH

Method for recovering carbon-fiber enhanced epoxy resin composite material

The invention relates to a method for recovering a carbon-fiber enhanced epoxy resin composite material. In the existing method, the requirement for equipment is high and the recovery cost is large. The method comprises the following steps of: cutting materials needing to be decomposed into blocks with the volume being 5cm<3>, putting the blocks in a backflow device containing acid liquor, heating for 5-20 minutes at the temperature of boiling point, cleaning and carrying out vacuum drying; then putting the obtained mixture into a reaction kettle, adding an organic solvent and an oxidizing agent, firstly heating, then cooling to normal temperature, and obtaining a primary product; and after cleaning, putting a solid product in the primary product into industrial acetone solution for dipping, obtaining recovered carbon fiber and carrying out pressure-reduced distillation on a liquid product to obtain phenol and derivatives thereof. In the method, reaction under low temperature and low pressure is realized and has the advantages of moderate reaction condition, easy control of reaction, fewer side products, no pollution basically and no corrosion to equipment and the like, so that the method is a green recovering method.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Solid product dissolver and method of use thereof

InactiveUS20050244315A1Easy to transportEasy to assembleWater treatment parameter controlDissolving using flow mixingIndustrial waterWater treatment

The present invention provides a device for producing a water treatment solution from a solid chemical block for distribution into a water system selected from the group comprising an institutional water system and an industrial water system. The device includes a housing to contain the solid chemical block. A fluid, preferably water at ambient temperature, is introduced into the housing to dissolve the block and form a liquid solution that may then be dispensed into either an institutional water system or an industrial water system. A method of dispensing the liquid solution with the device is also provided.

Owner:ECOLAB USA INC

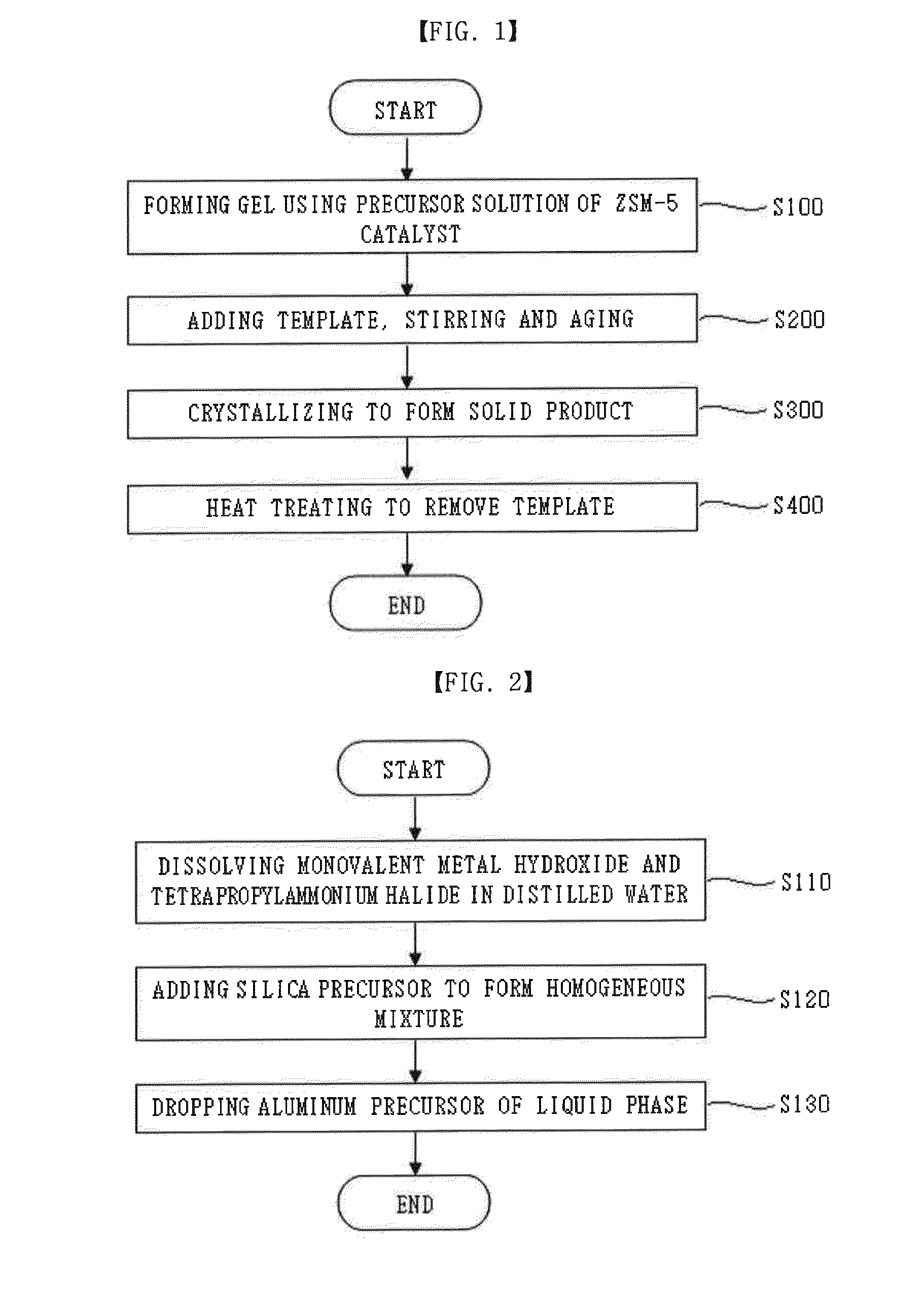

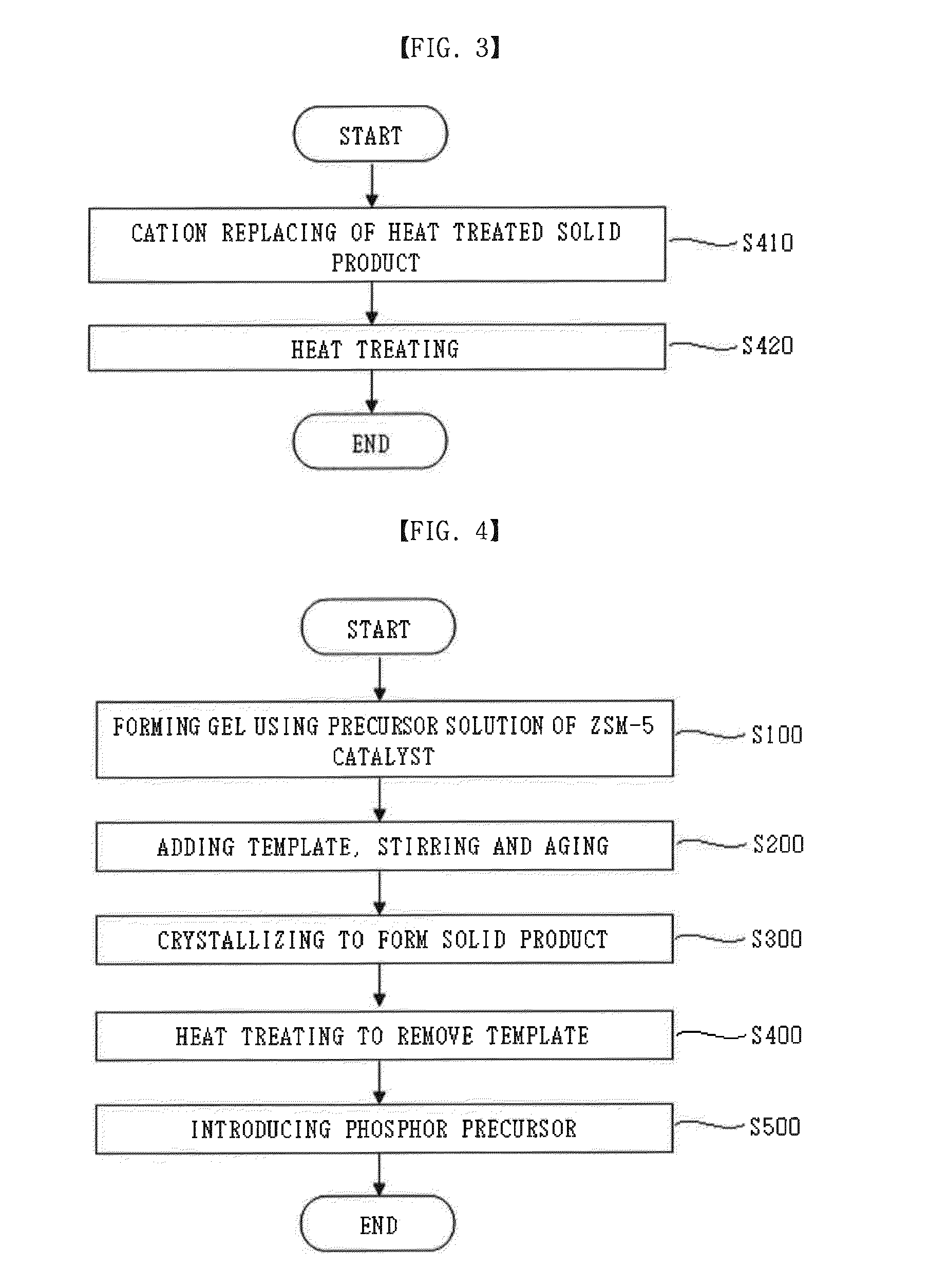

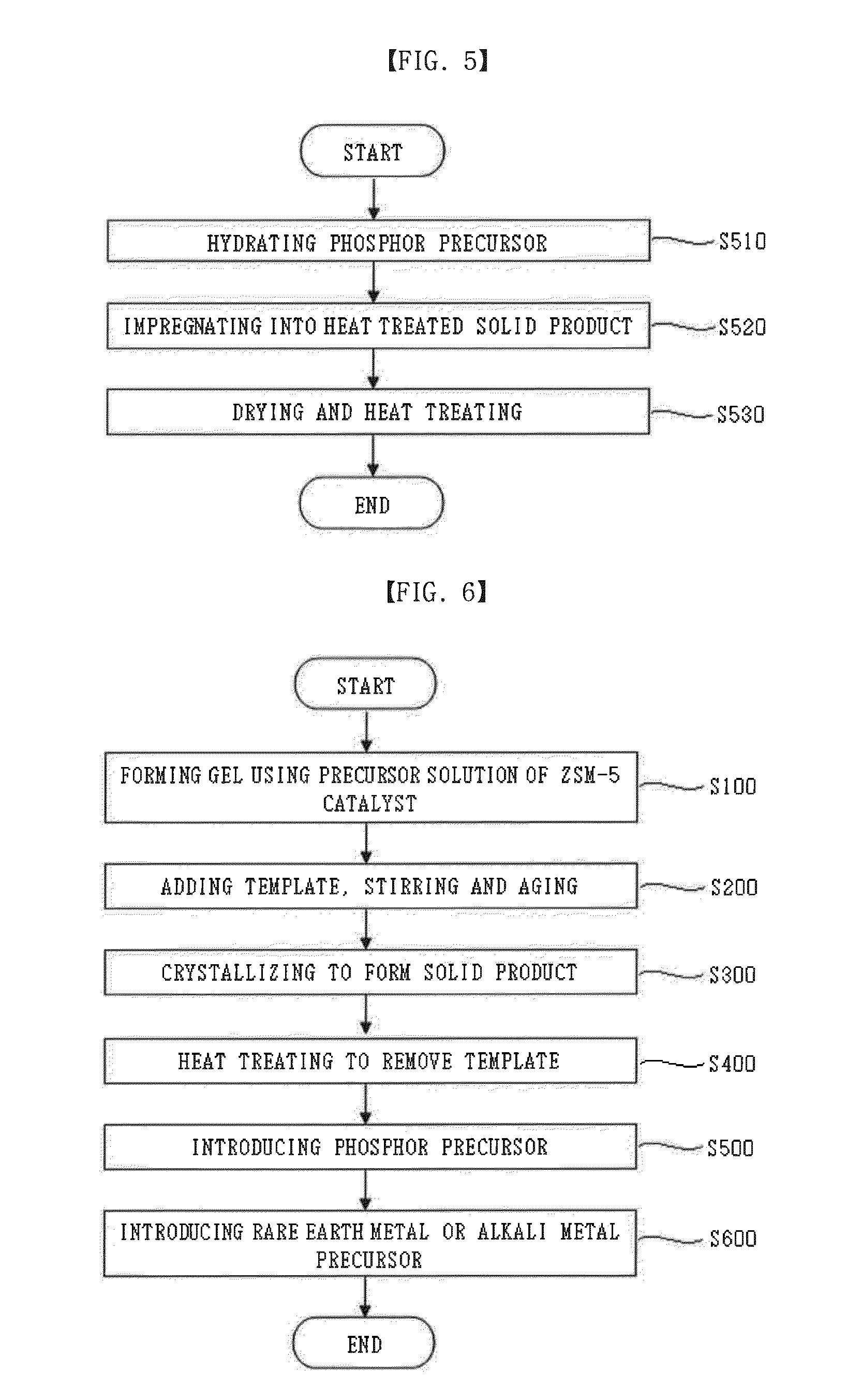

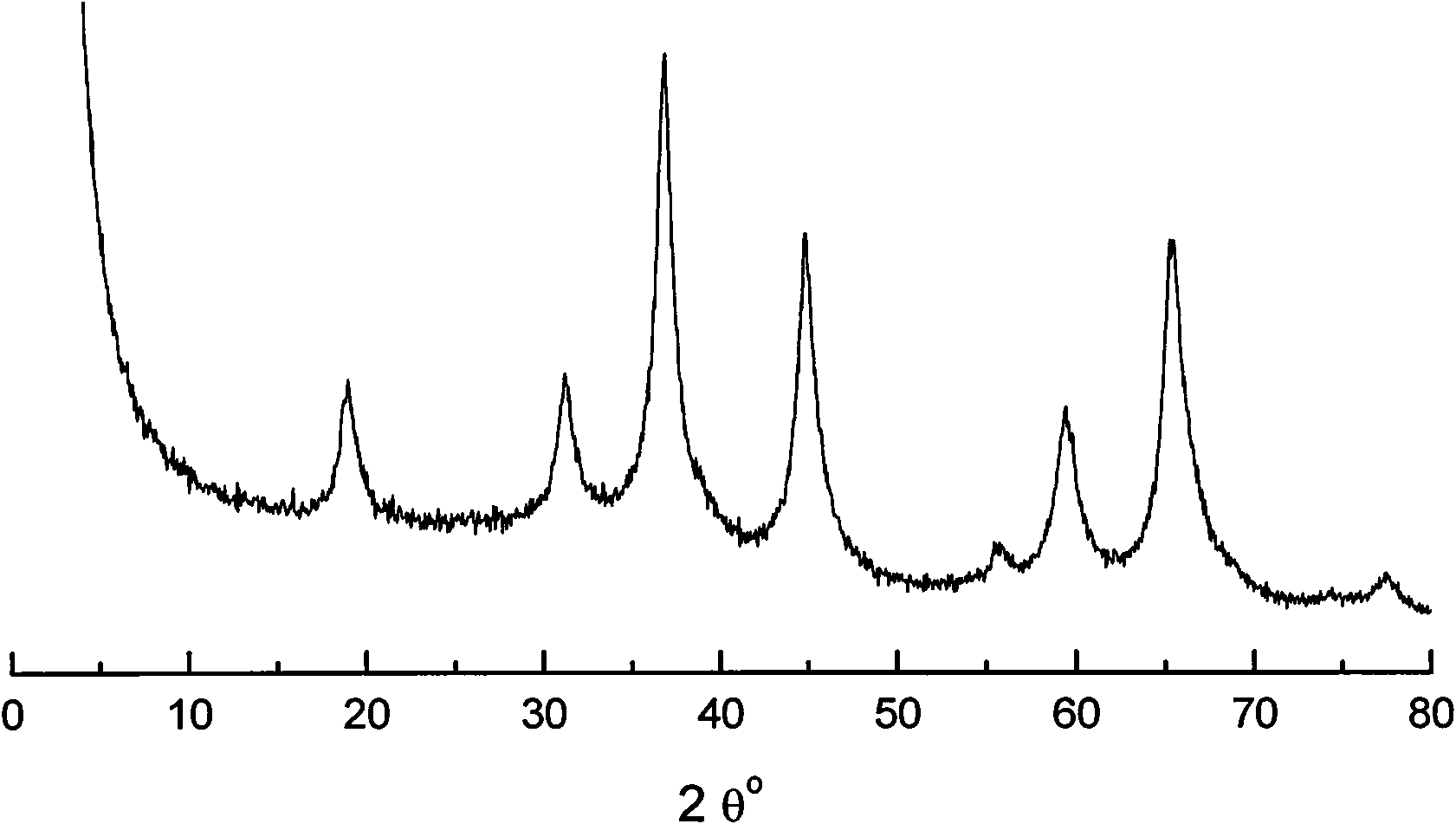

ZSM-5 catalyst with micropores and mesopores, preparation method thereof and production method of light olefins through catalytic cracking of hydrocarbons using the catalyst

InactiveUS20130085311A1Increase productionImprove featuresTreatment with plural serial cracking stages onlyCatalytic crackingHydrocarbon mixturesNaphtha

Provided is a method of preparing a ZSM-5 catalyst for preparing light olefins including ethylene and propylene through a catalytic cracking of a hydrocarbon mixture of C4 to C7 produced after a naphtha cracking. The method includes (a) forming a gel by aging a mixture solution including a silica precursor and an aluminum precursor; (b) adding a template possibly forming mesopores through a heat treatment, into the gel, stirring and then aging; (c) forming a solid product by crystallizing the aged mixture in step (b); and (d) heat treating the solid product to remove the template. The ZSM-5 catalyst may include micropores and mesopores and may have good physical and chemical properties along with a good pore property. The production yield of the light olefins may be increased.

Owner:HONAM PETROCHEM

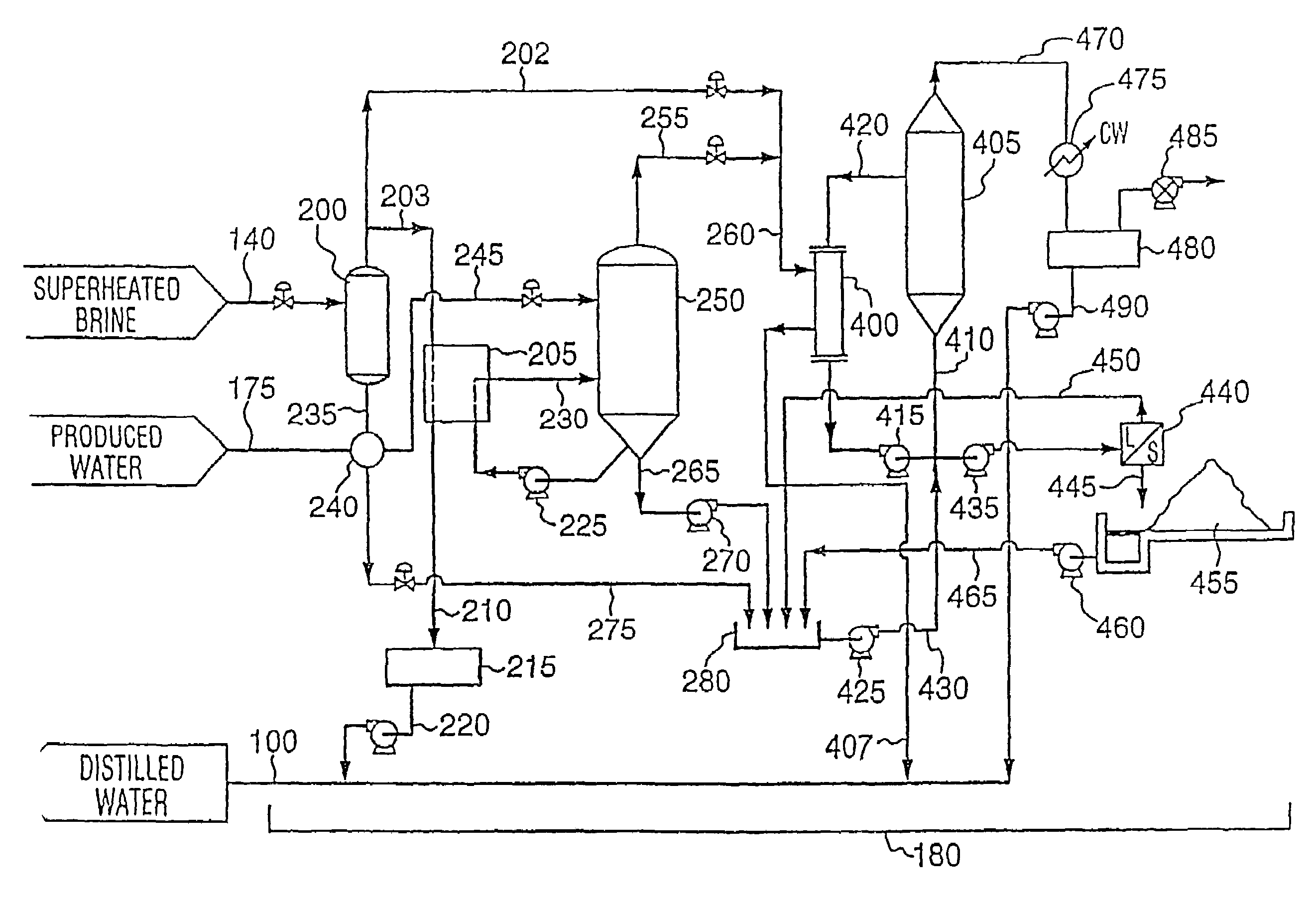

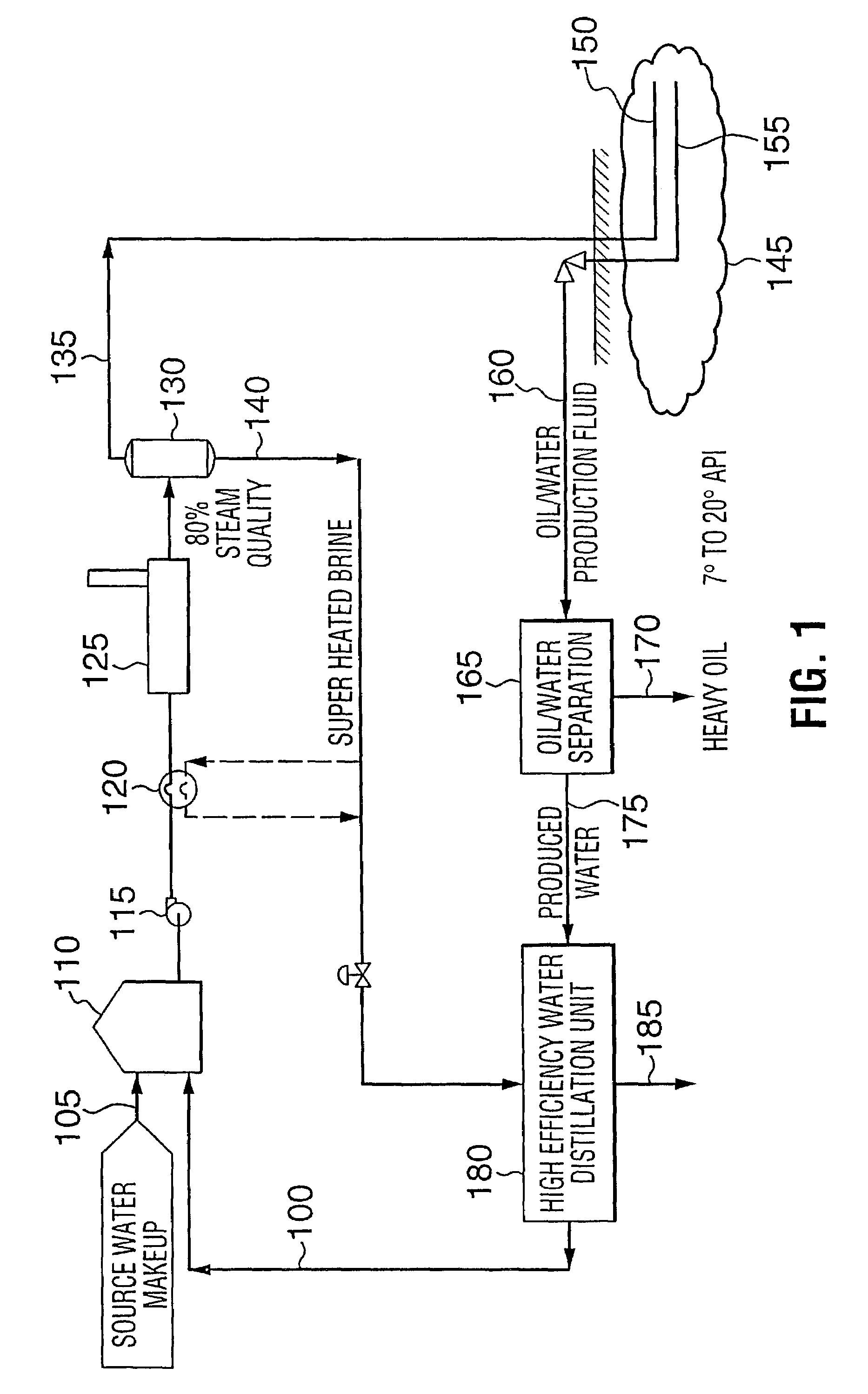

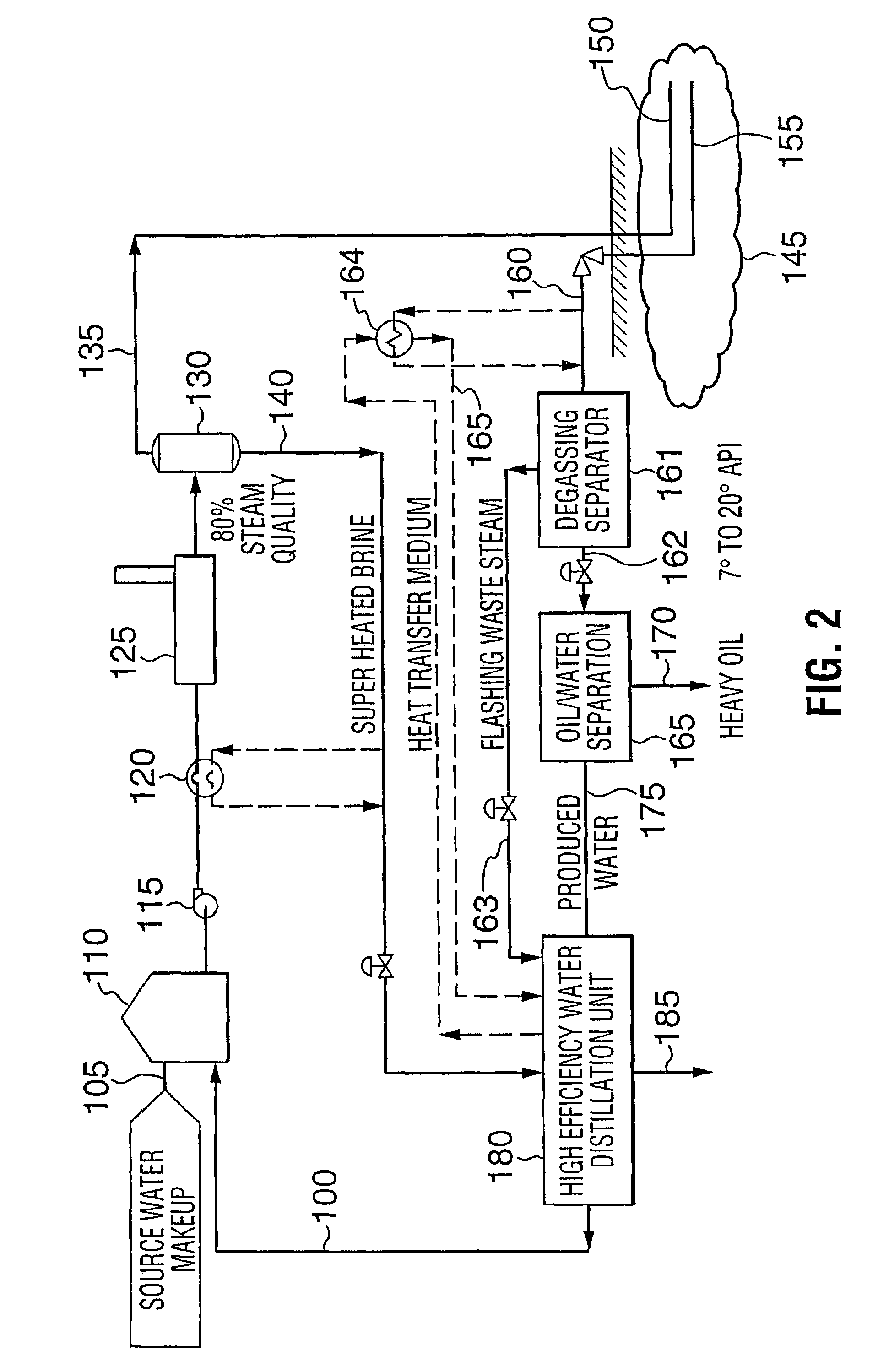

Water treatment process for thermal heavy oil recovery

There is disclosed a method and apparatus for treating produced water from a heavy oil thermal recovery unit to achieve water recovery and recycle levels of greater than 80% and as high as 100% to achieve zero discharge criteria. The method includes the initial steps of capturing the waste heat energy from the high pressure steam separator located downstream of the steam generators. Further, transferring the heat energy into a heated separator and reboiler exchanger to distill oil reservoir produced water and recover distilled water and a concentrated brine or solid product. The heated separator concentrated stream is circulated through the reboiler exchanger to maintain from 1% to about 50% mass vapour in the stream returning to the heated separator and prevent fouling and scaling. The apparatus includes a low pressure waste energy separator, heated separator and vapour compressor in combination with a forced circulation circuit to generate the distilled water.

Owner:FOUNTAIN QUAIL WATER MANAGEMENT LLC +1

Method for reclaiming carbon fiber reinforced epoxy resin composite material

ActiveCN102181071ARelieve stressImprove degradation efficiencyPlastic recyclingBulk chemical productionEpoxyPhosphomolybdic acid

The invention relates to a method for reclaiming a carbon fiber reinforced epoxy resin composite material. The conventional method is high in equipment requirement and high in reclamation cost. The method comprises the following steps of: adding a catalyst into an organic reagent to prepare supercritical CO2 composite solution; putting the carbon fiber reinforced epoxy resin composite material tobe decomposed into a reaction kettle, and adding the supercritical CO2 composite solution; and reacting for 1 to 24 hours at the temperature of between 100 and 250 DEG C under the pressure of 7.5 to 25.0MPa, cooling the product to normal temperature, washing and drying the solid product in the product to obtain carbon fibers, and performing reduced pressure distillation on the liquid product in the product to obtain phenol and derivatives thereof. The catalyst is one or two of liquid super acid, solid super acid, phosphotungstic acid, phosphomolybdic acid, acetic acid, formic acid, hydrochloric acid, sulfuric acid and nitric acid. The method has the advantages of high degradation efficiency, environmental friendliness, low cost and the like, and is a green method for reclaiming the waste and old carbon fiber reinforced epoxy resin composite material.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

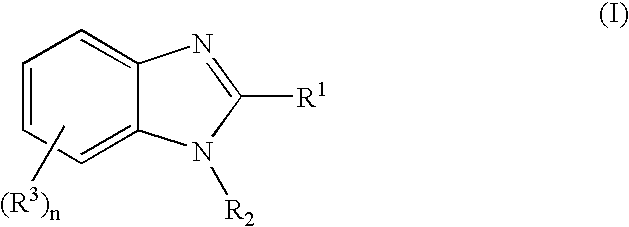

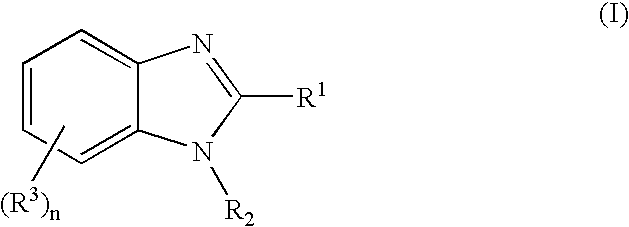

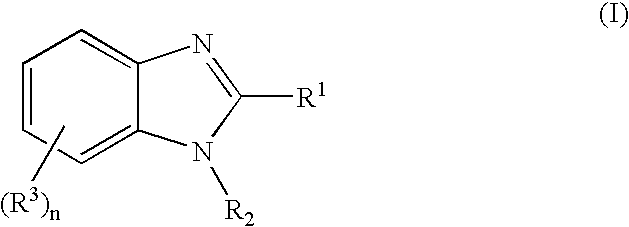

Wax emulsion preservative compositions and method of manufacture

An emulsion comprising water as the continuous phase, a wax as the discontinuous phase, an emulsifier and a preservative having the general structure:wherein R1 can be a heterocycle containing nitrogen and sulfur, such as thiazolyl, isothiazolyl, or thiadiazolyl, which can optionally be substituted with C1–C6 alkyl; R2 can be hydrogen or C1–C6 alkyl, specifically hydrogen; n is 0, 1, 2, or 3; each instance of R3 can independently be hydrogen, C1–C6 alkyl, phenoxy, C1–C6 alkoxy, halo, amino, C1–C6 alkylamino, di C1–C6 alkyl amino, imidazolyl, thiazolyl, isothiazolyl, thiadiazolyl, thienyl, furyl, pyrryl, naphthyl, phenyl, halophenyl, C1–C6 alkyl phenyl, or C1–C6 alkoxyphenyl. The preservative may be added to the emulsion after the emulsion is formed. The emulsion can be incorporated into a gypsum product such as gypsum board or gypsum wood fiber board. The gypsum product may be made by forming a slurry containing gypsum, water, and the emulsion into a solid product. A method for improving the water resistance of a lignocellulosic composite product prepared by mixing lignocellulosic material with a binder to form a mixture and solidifying the mixture in a selected configuration to form the composite product may include adding to the mixture an emulsion as described above.

Owner:MOMENTIVE SPECIALTY CHEMICALS

Biochar

The invention provides for methods, devices, and systems for pyrolyzing biomass. A pyrolysis unit can be used for the pyrolysis of biomass to form gas, liquid, and solid products. The biomass materials can be selected such that an enhanced biochar is formed after pyrolysis. The biomass can be pyrolyzed under specified conditions such that a selected biochar core is formed. The pyrolysis process can form a stable biochar core that is inert and / or resistant to degradation. The biochar or biochar core can be functionalized to form a functionalized biochar or functionalized biochar core. Functionalization can include post-pyrolysis treatments such as supplementation with microbes or physical transformations including annealing and / or activation.

Owner:FULL CIRCLE BIOCHAR

Methods, Systems and Apparatus For Monochromatic UV Light Sterilization

ActiveUS20100007492A1Minimize and eliminate shadowing effectShorten holding timeDough treatmentPackage sterilisationSolid massRegimen

The present disclosure provides for methods, systems and apparatus for monochromatic UV light sterilization of container systems and / or container-packaged products. More particularly, the present disclosure provides for improved methods, systems and apparatus for monochromatic UV light sterilization of liquid and / or solid products / solutions and / or packaging / container systems for liquid and / or solid products / solutions (e.g., parenteral pharmaceutical products / solutions and / or packaging / container systems for parenteral pharmaceutical products / solutions). In exemplary embodiments, the present disclosure provides for improved systems and methods for the sterilization of container systems and / or container-packaged products using monochromatic, continuous wave, high-intensity, incoherent light in multiple light source configurations, wherein such sterilization regimen achieves a desired sterilization level without negatively affecting the physical properties of the package / container systems and / or the efficacy of the underlying products / systems.

Owner:TRITON THALASSIC TECH

Method for producing wood fibre composite products

A process for producing a thermoformable fibre-plastics composite product comprising lignolcellulosic or natural fibres, particularly but not exclusively useful as an intermediate product in subsequent manufacture, comprises conveying the fibres in a dry or wet air stream and applying to the fibres a thermoplastic binding agent, and forming the fibres into a solid or semi-solid product such as a panel, which is thermoformable. In at least a preferred embodiment the process may be carried out in known plant for manufacture of medium density fibre board.

Owner:NEW ZEALAND FOREST RES INST

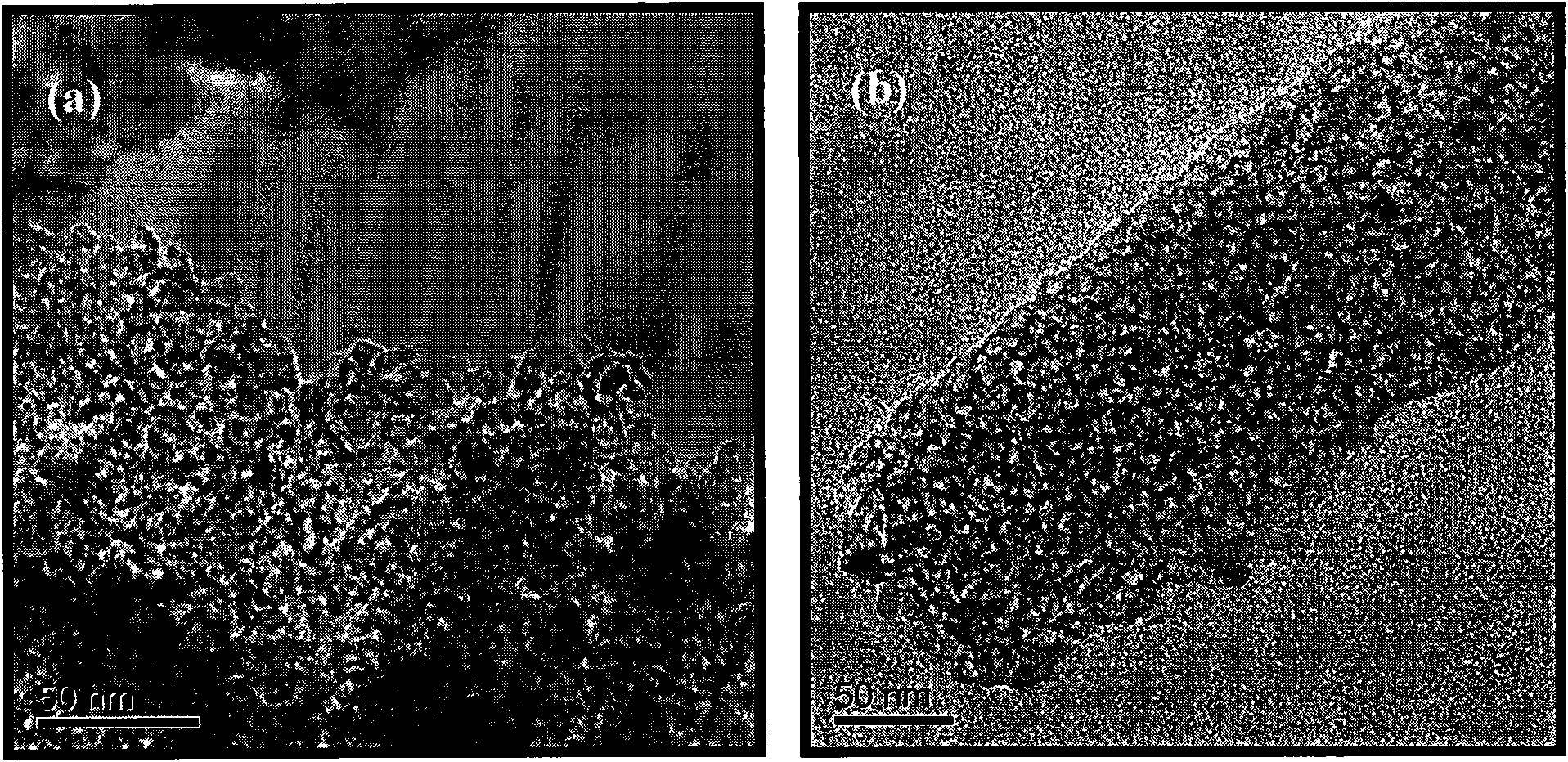

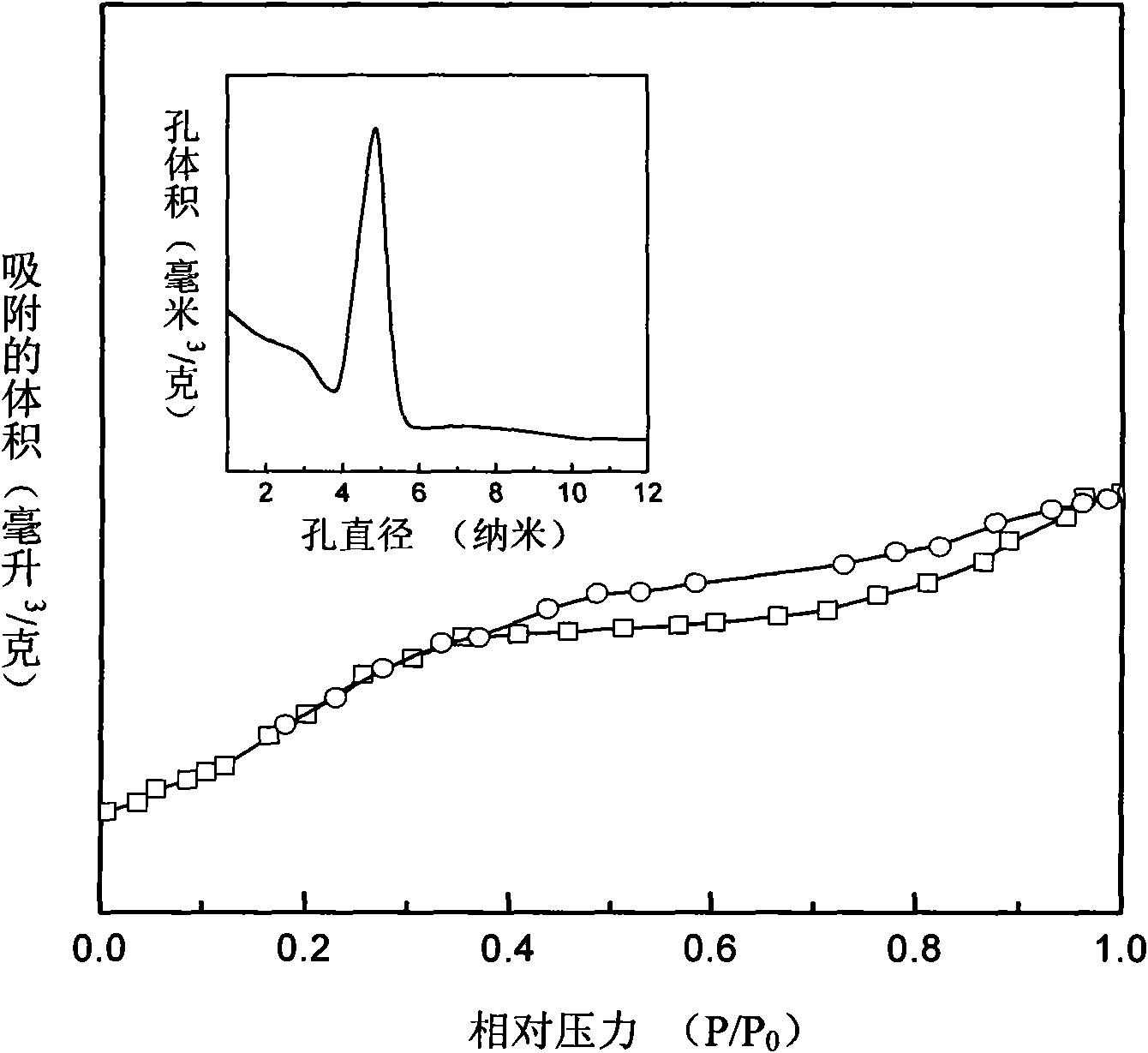

Method for preparing superfine mesoporous magnesium aluminate spinel

The invention discloses a method for preparing a superfine mesoporous magnesium aluminate spinel, which comprises the following steps: (1) adding an alkaline solution into a mixed solution of a soluble aluminum salt and a magnesium salt, and adding a surfactant into the mixture; (2) performing hydrothermal crystallization on the mixture after ageing at a temperature of between 120 and 180 DEG C for 4 to 72 hours; and (3) separating the mixture to obtain a solid product, and washing, filtering and drying the solid product to obtain magnesium aluminate spinel powder without baking or after baking at a temperature of between 500 and 700 DEG C for 4 to 6 hours. The particle size of the magnesium aluminate spinel prepared by the method is less than 100 nanometers, the specific surface area is between 200 and 400 m / gram, the pore volume is between 0.20 and 0.55 cm / gram, and the most probable pore diameter is between 3 and 6 nanometers.

Owner:NORTHWEST UNIV(CN)

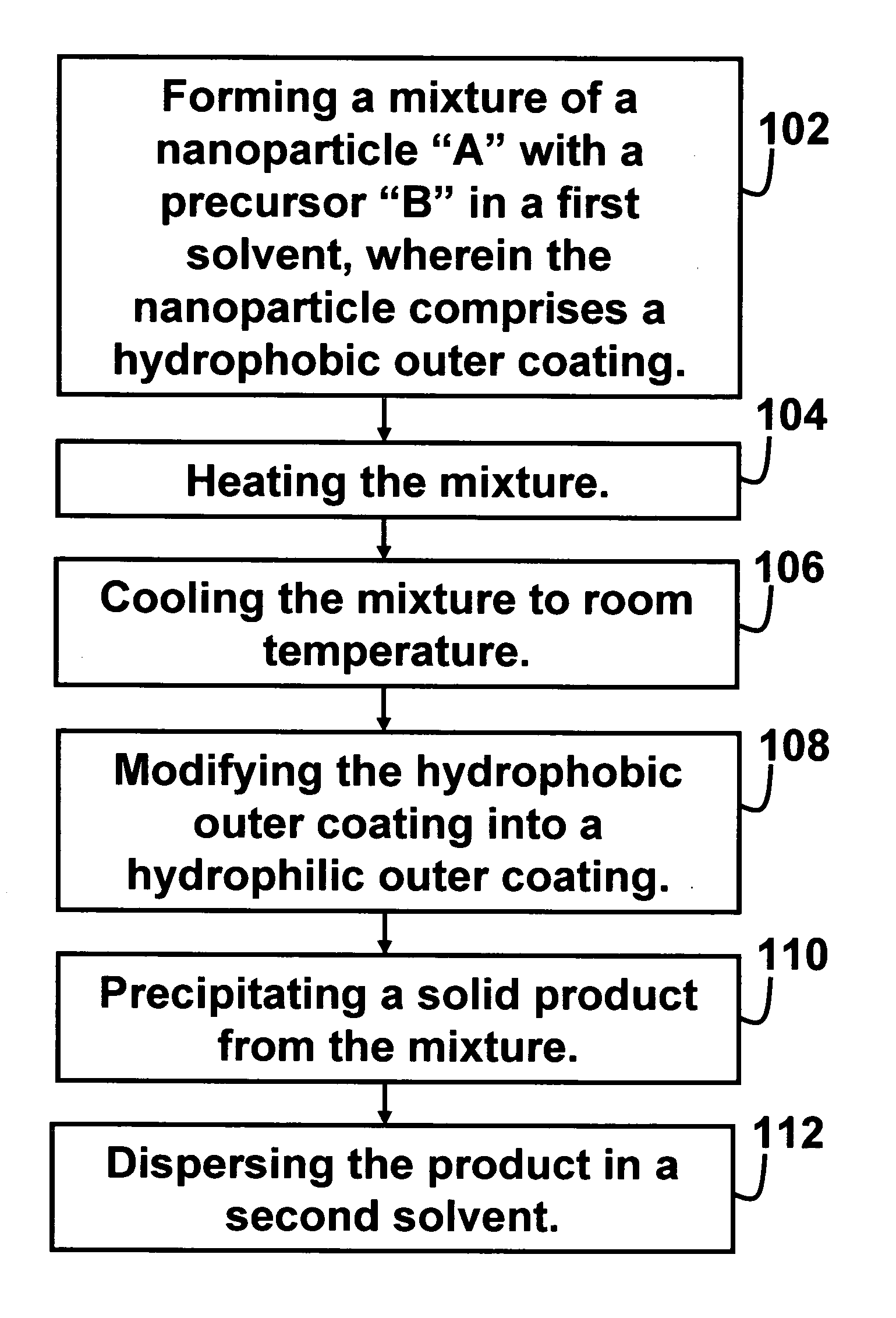

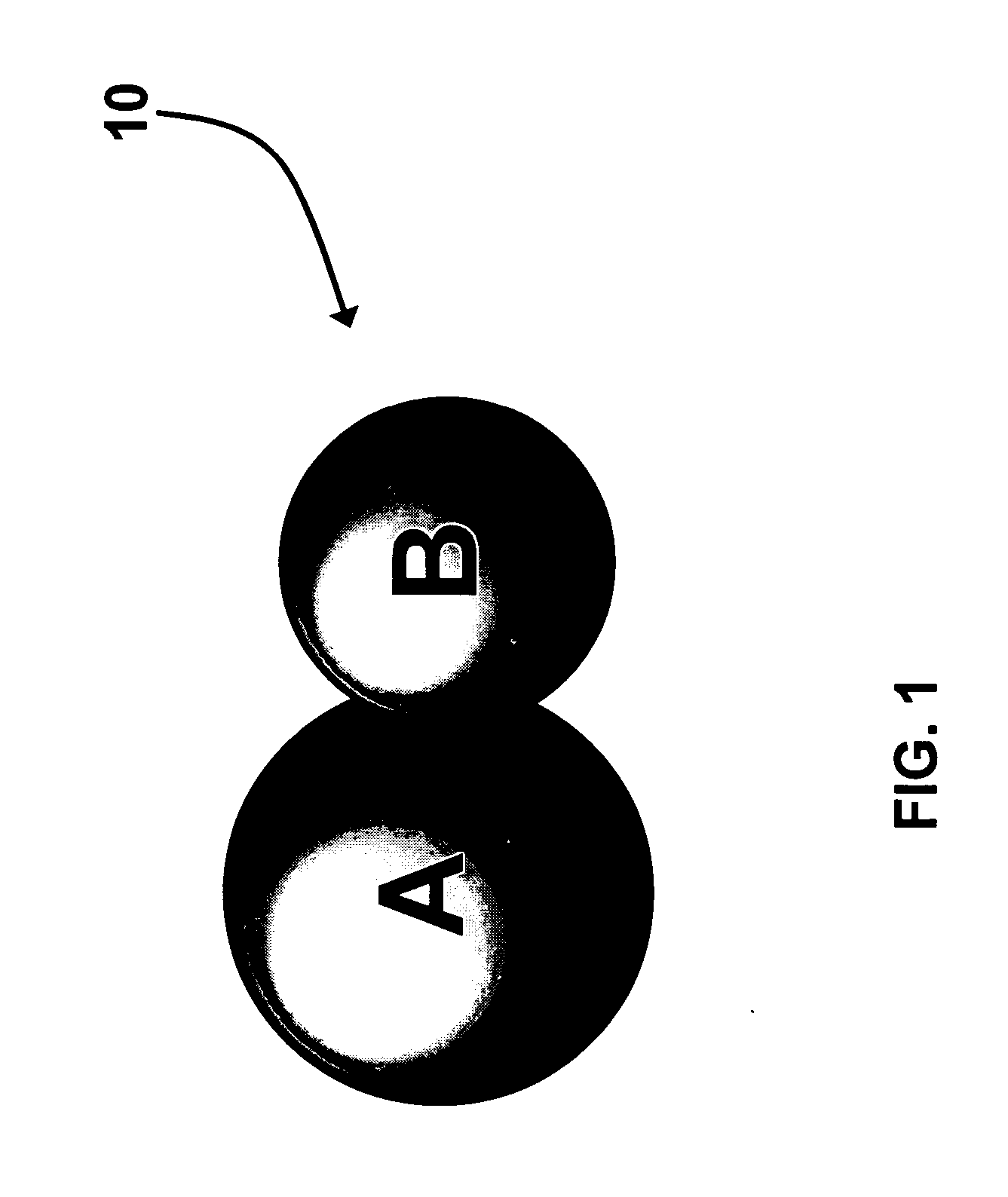

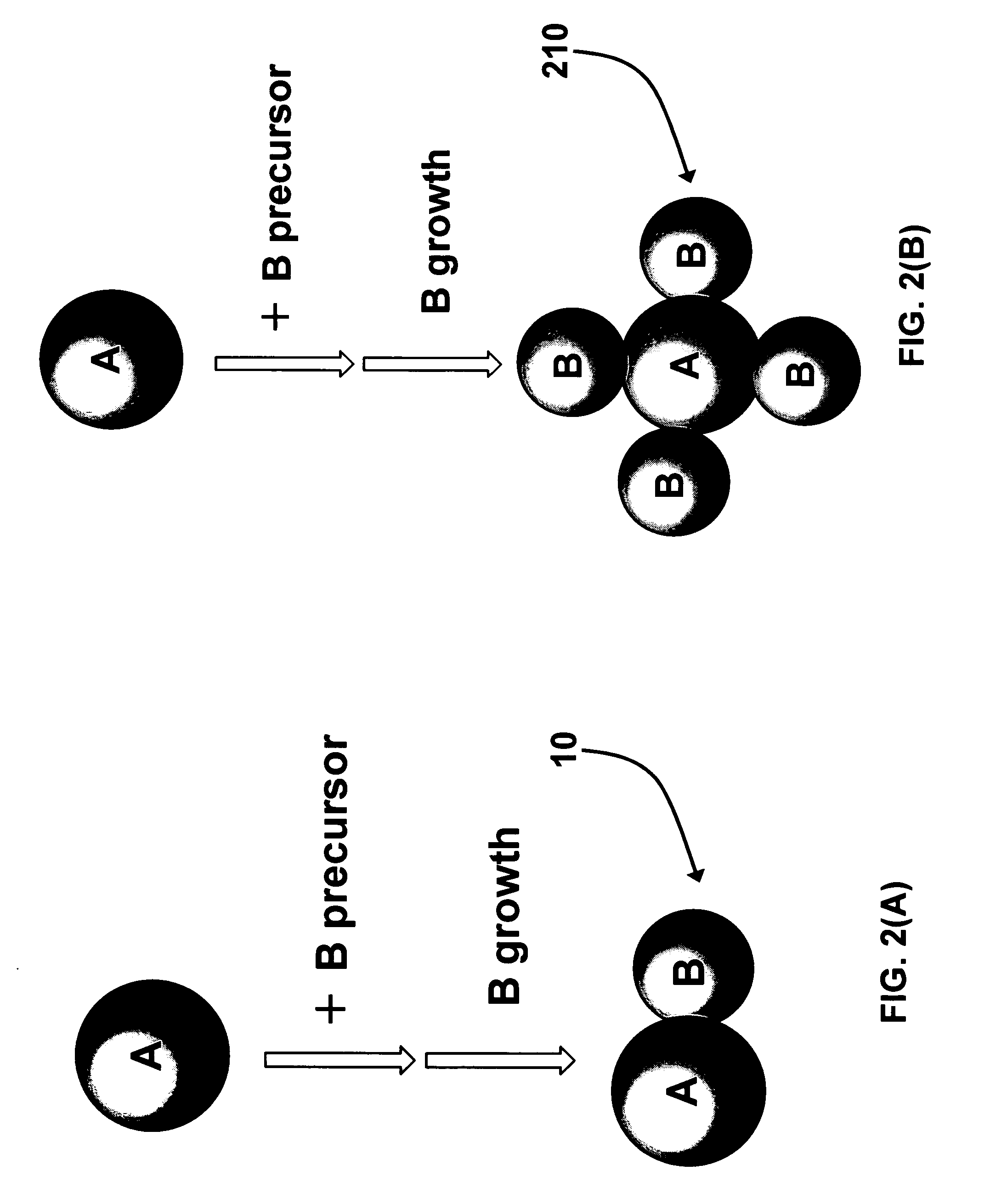

Dumbbell-like nanoparticles and a process of forming the same

InactiveUS20060053971A1Simple processGood signalMaterial nanotechnologyNanomagnetismAlkaneMetallic materials

Dumbbell-shaped or flower-shaped nanoparticles and a process of forming the same, wherein the process comprises forming a mixture of a nanoparticle with a precursor in a first solvent, wherein the nanoparticle comprises a hydrophobic outer coating; heating the mixture; cooling the mixture to room temperature; modifying the hydrophobic outer coating into a hydrophilic outer coating; precipitating a solid product from the mixture, and dispersing the product in a second solvent. The nanoparticles comprise any of a semiconducting, magnetic, and noble metallic material, wherein the nanoparticles comprise a first portion comprising any of PbSe, PbS, CdSe, CdS, ZnS, Au, Ag, Pd, and Pt, and wherein the precursor comprises any of a cationic, neutral or particulate Au, Ag, Pd, Pt, or transition metal (Fe, Co, Ni) precursors of Fe(CO)5, Co(CO)8, Ni(CO)4 or their analogues. The first and second solvents comprise any of alkanes, arenes, ethers, nitrites, ketones, and chlorinated hydrocarbons.

Owner:IBM CORP +1

Oil-containing solid product and process for producing the same

InactiveUS20090081292A1Reduce amountEliminate the problemPowder deliveryBiocideEmulsionWater soluble

An oil-containing solid in which liquid oil is contained in a large amount and from which oil seepage is slight; and a process for producing the same. The oil-containing solid is produced by impregnating a porous solid with a W / O emulsion. Further, use is made of the W / O emulsion having a water-soluble gellable substance incorporated in the water phase thereof. Consequently, the water-soluble gellable substance is converted to a gel in pores of the porous solid, thereby enhancing the liquid oil leakage preventing effect of the W / O emulsion.

Owner:MITSUBISHI CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com