Patents

Literature

116results about "Mangesium aluminates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

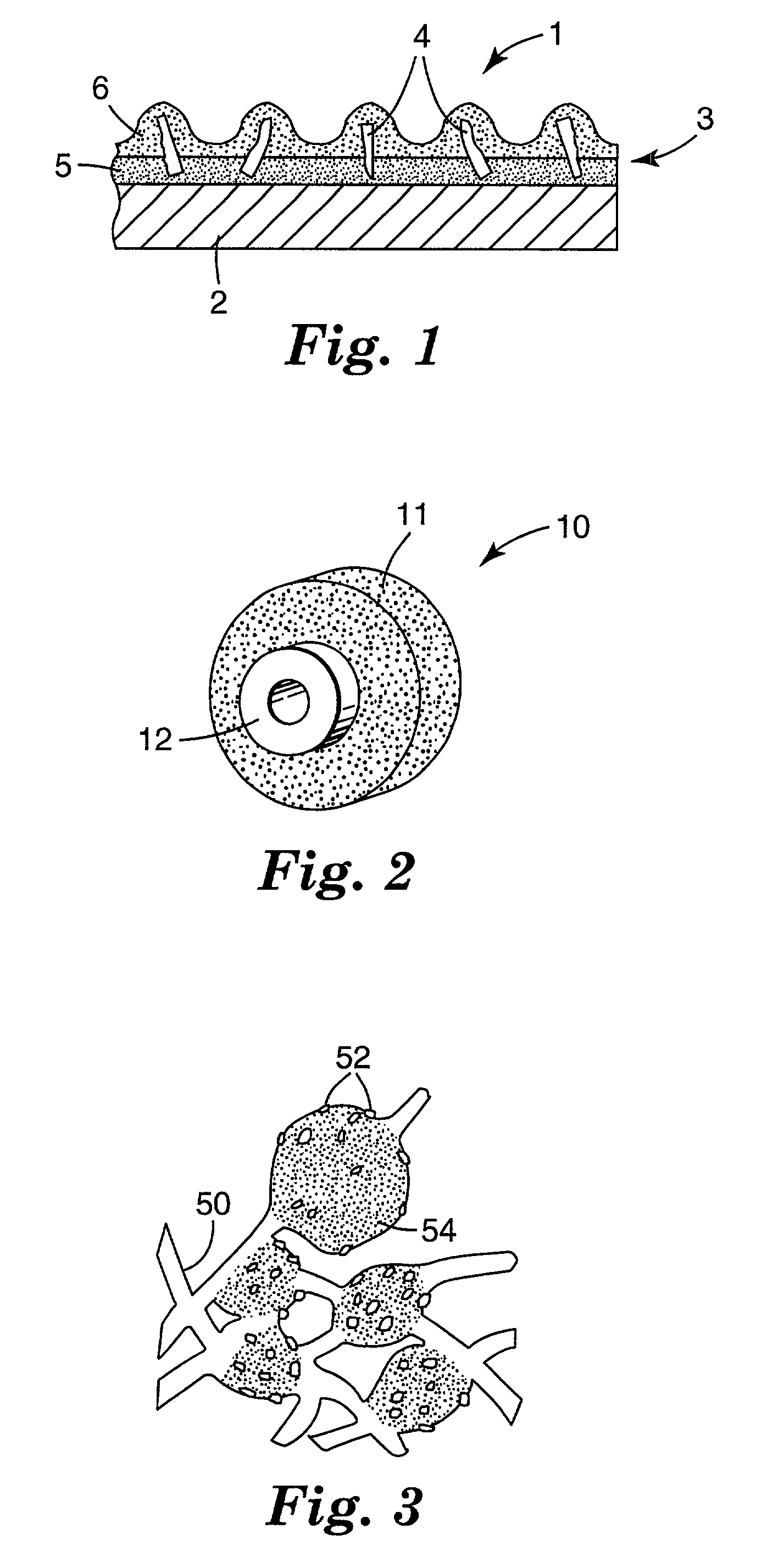

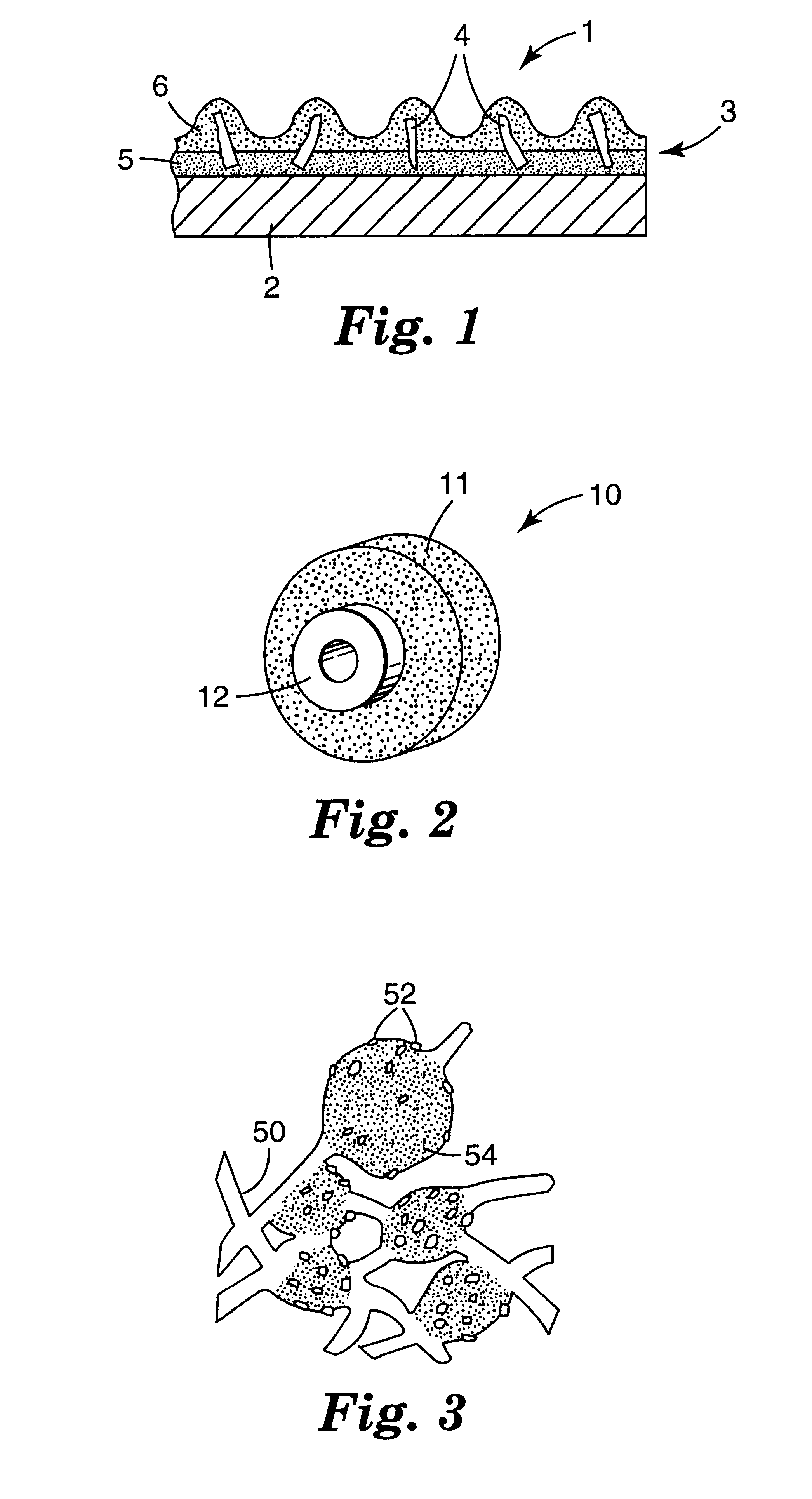

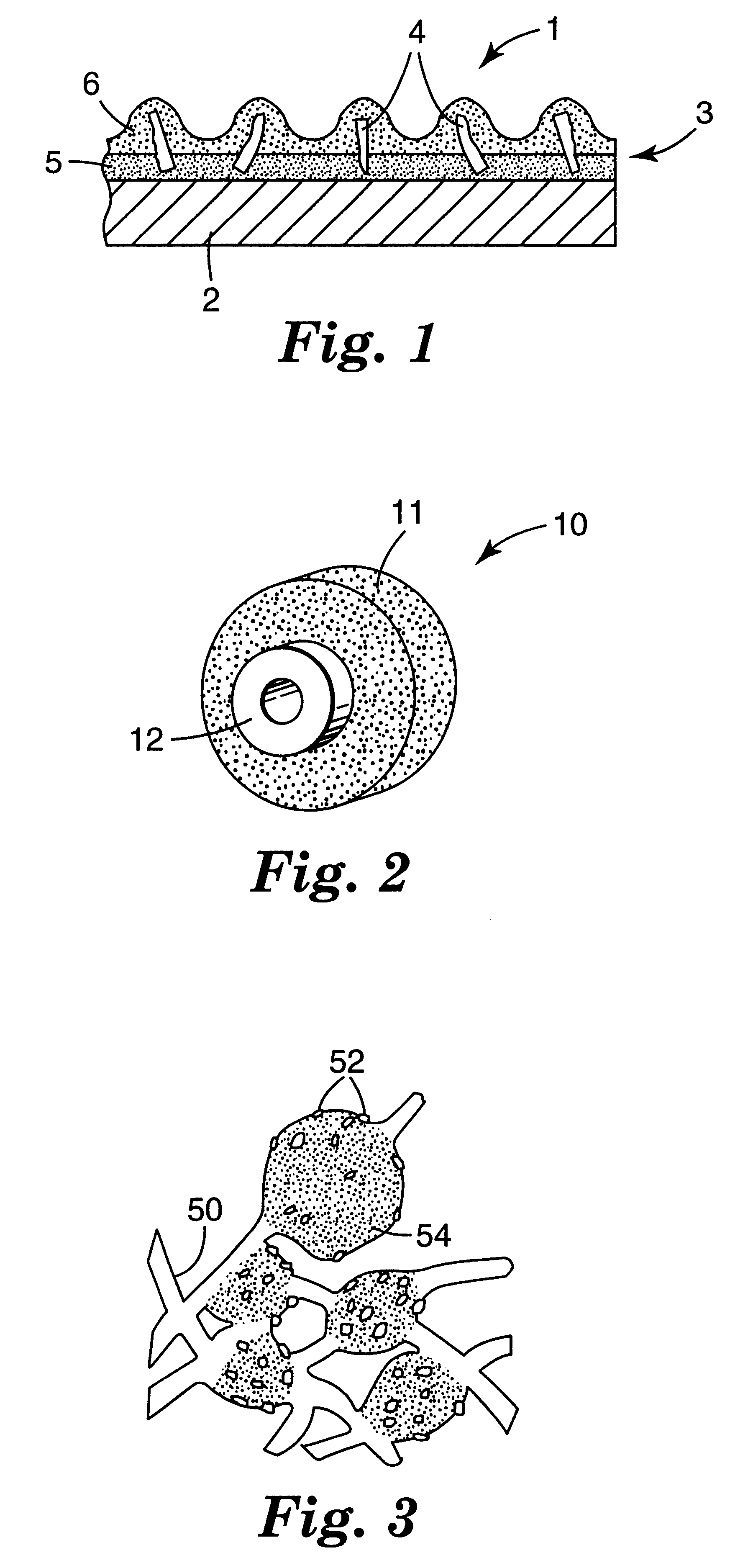

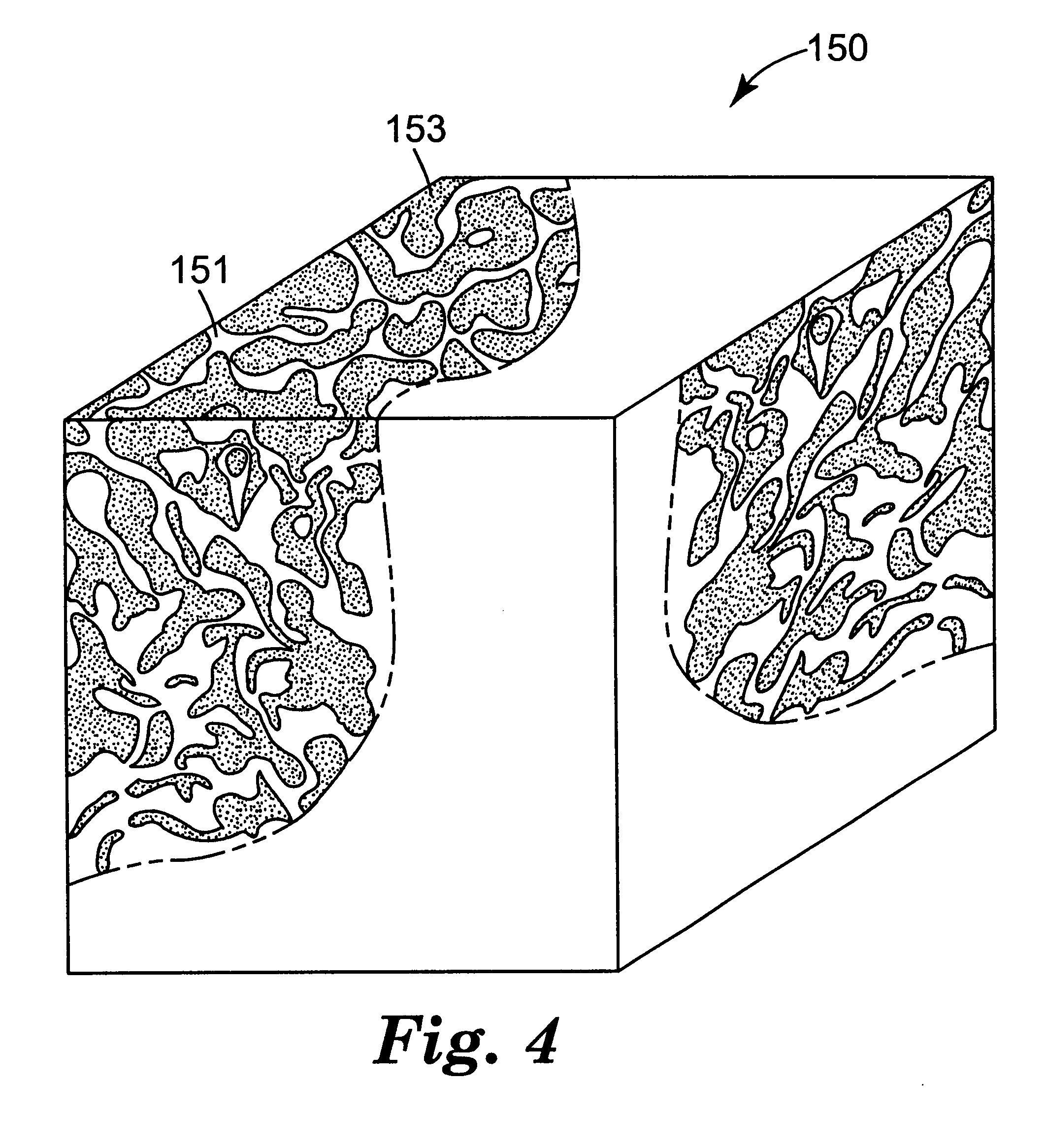

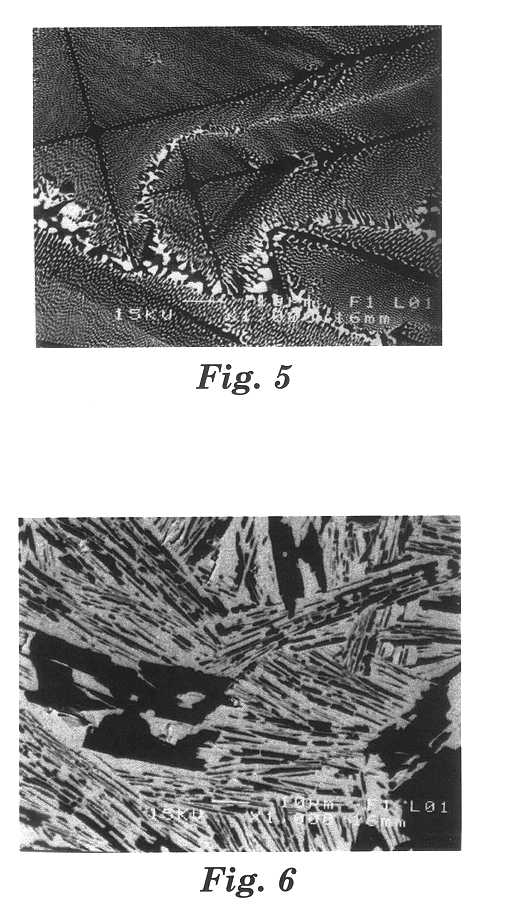

Fused Al2O3-MgO-rare earth oxide eutectic abrasive particles, abrasive articles, and methods of making and using the same

InactiveUS20010027623A1Improve grinding performanceLower performance requirementsPigmenting treatmentMangesium aluminatesRare earthAbrasive

Owner:3M INNOVATIVE PROPERTIES CO

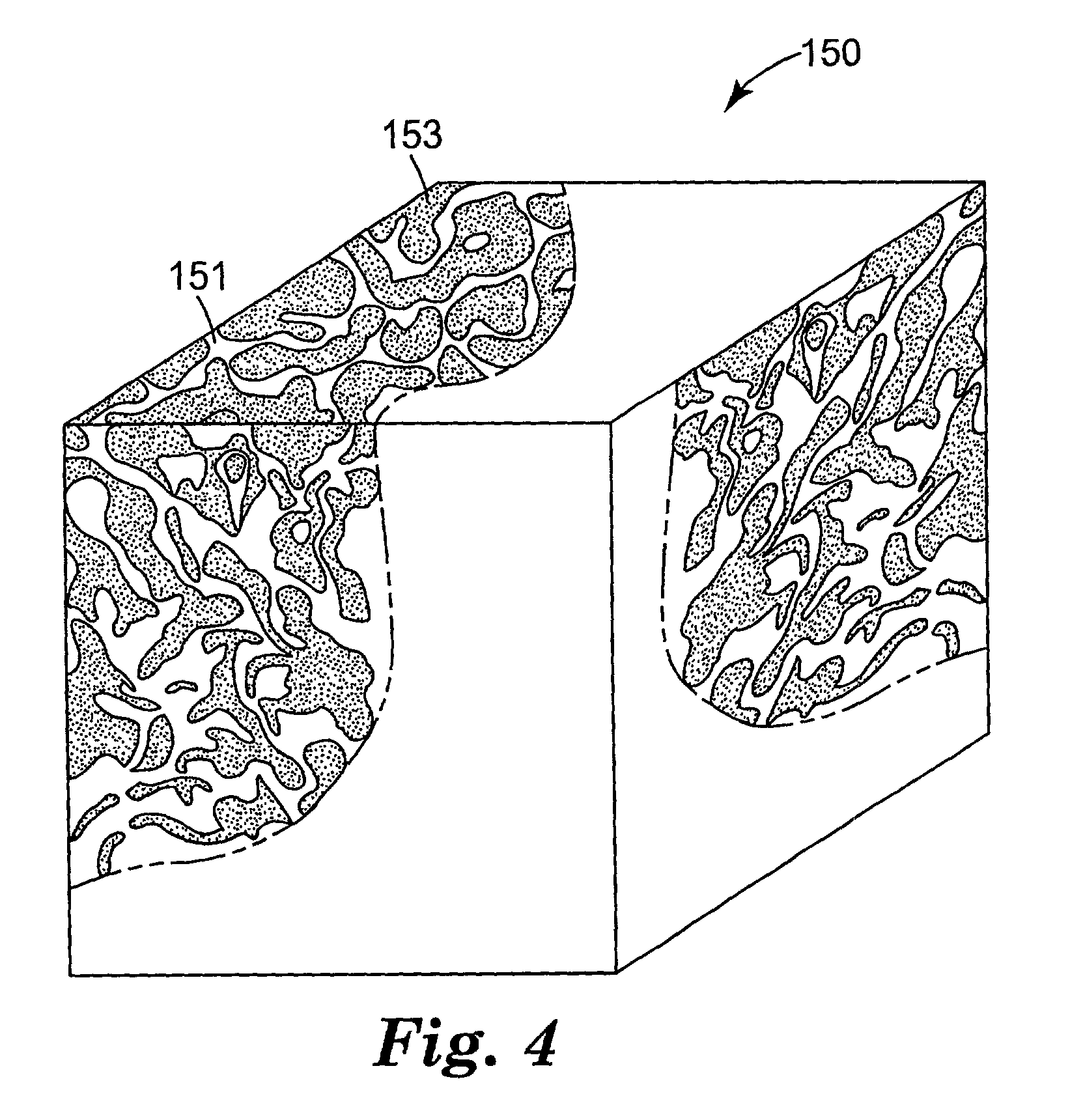

Fused Al2O3-Y2O3 eutectic abrasive particles, abrasive articles, and methods of making and using the same

InactiveUS6592640B1Improve grinding performanceLower performance requirementsPigmenting treatmentMangesium aluminatesMaterials scienceAbrasive

Owner:3M INNOVATIVE PROPERTIES CO

Fused-Al2O3-MgO-Y2O3 eutectic abrasive particles, abrasive articles, and methods of making and using the same

InactiveUS6706083B1Improve grinding performanceLower performance requirementsPigmenting treatmentMangesium aluminatesAbrasive

Owner:3M INNOVATIVE PROPERTIES CO

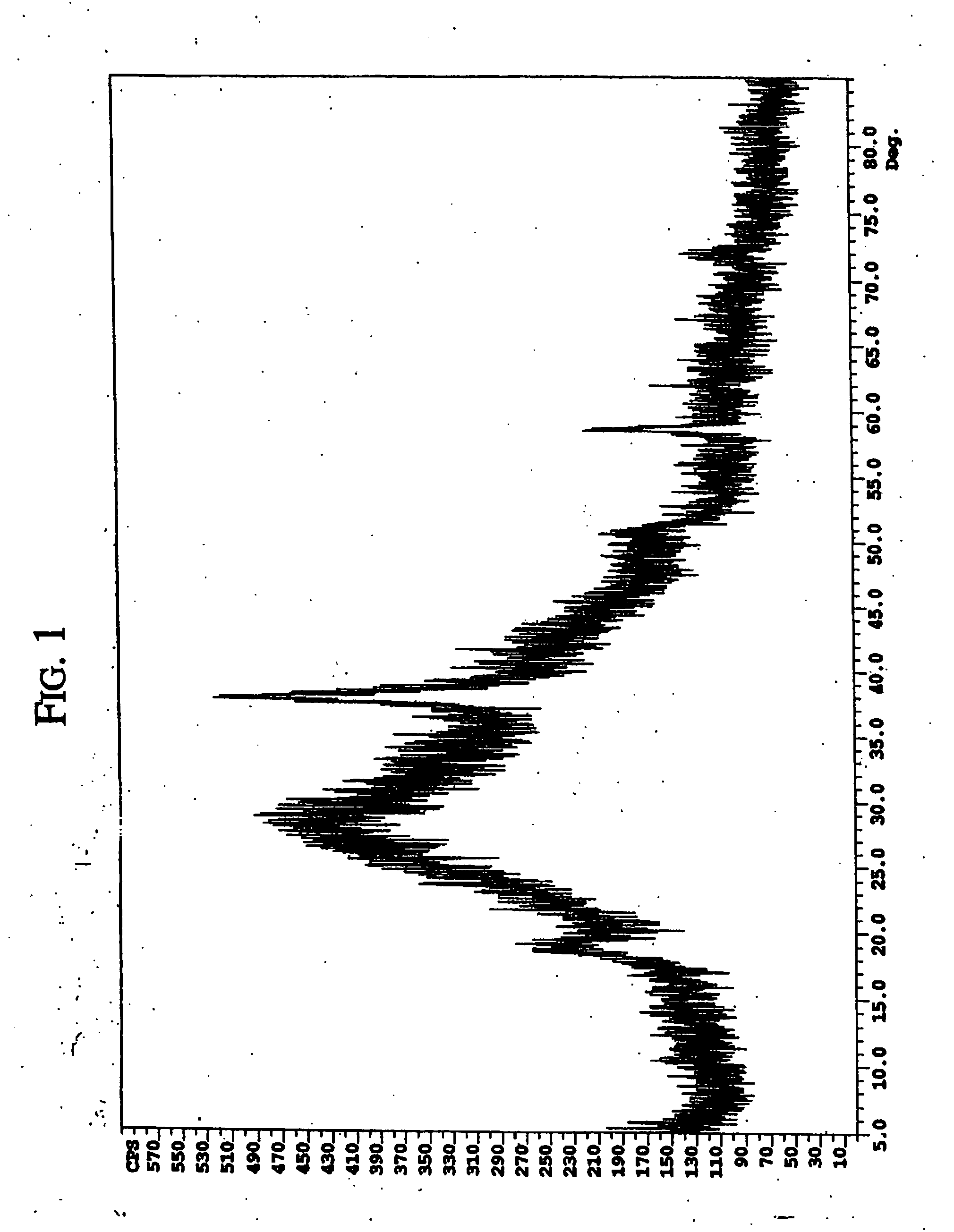

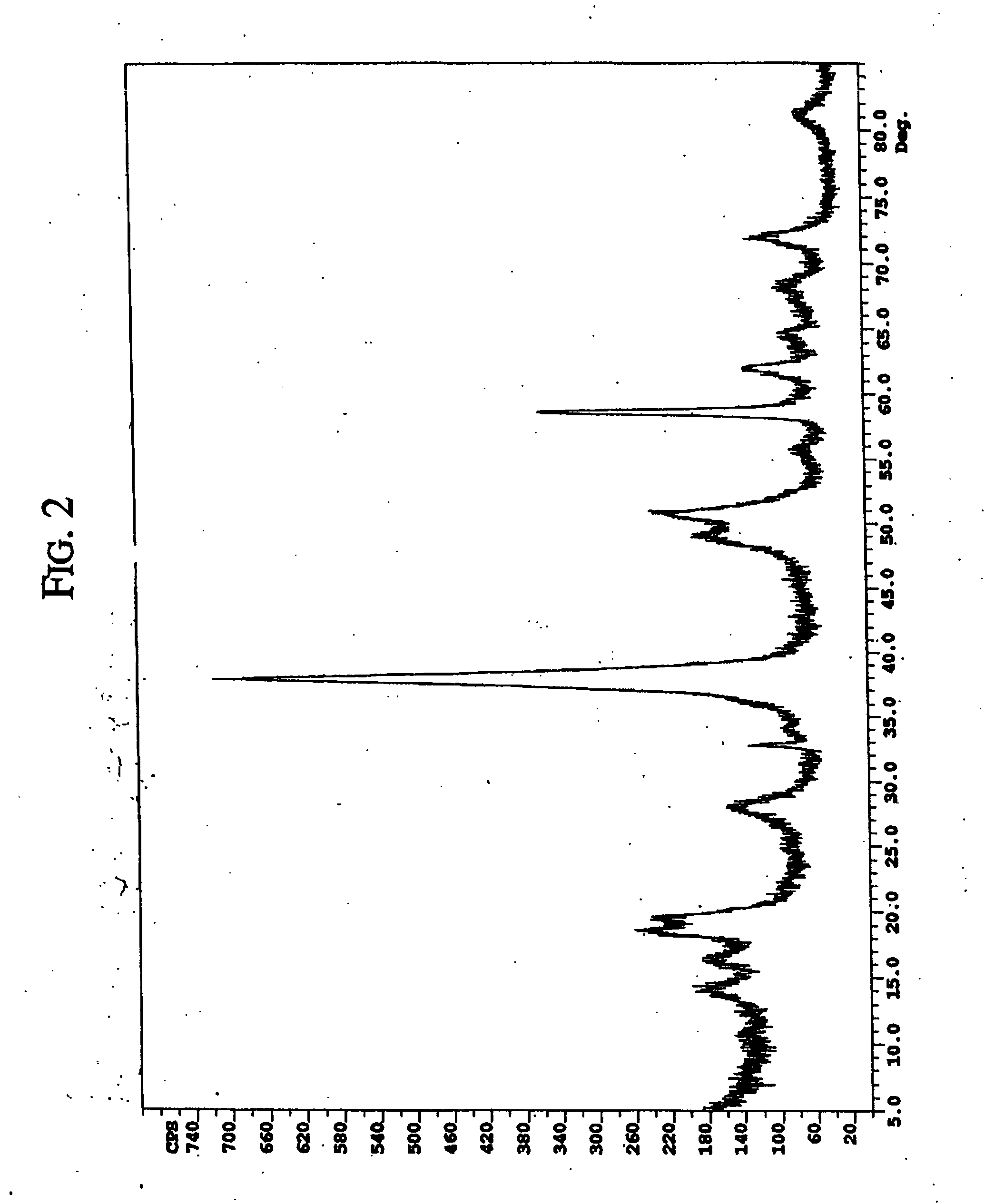

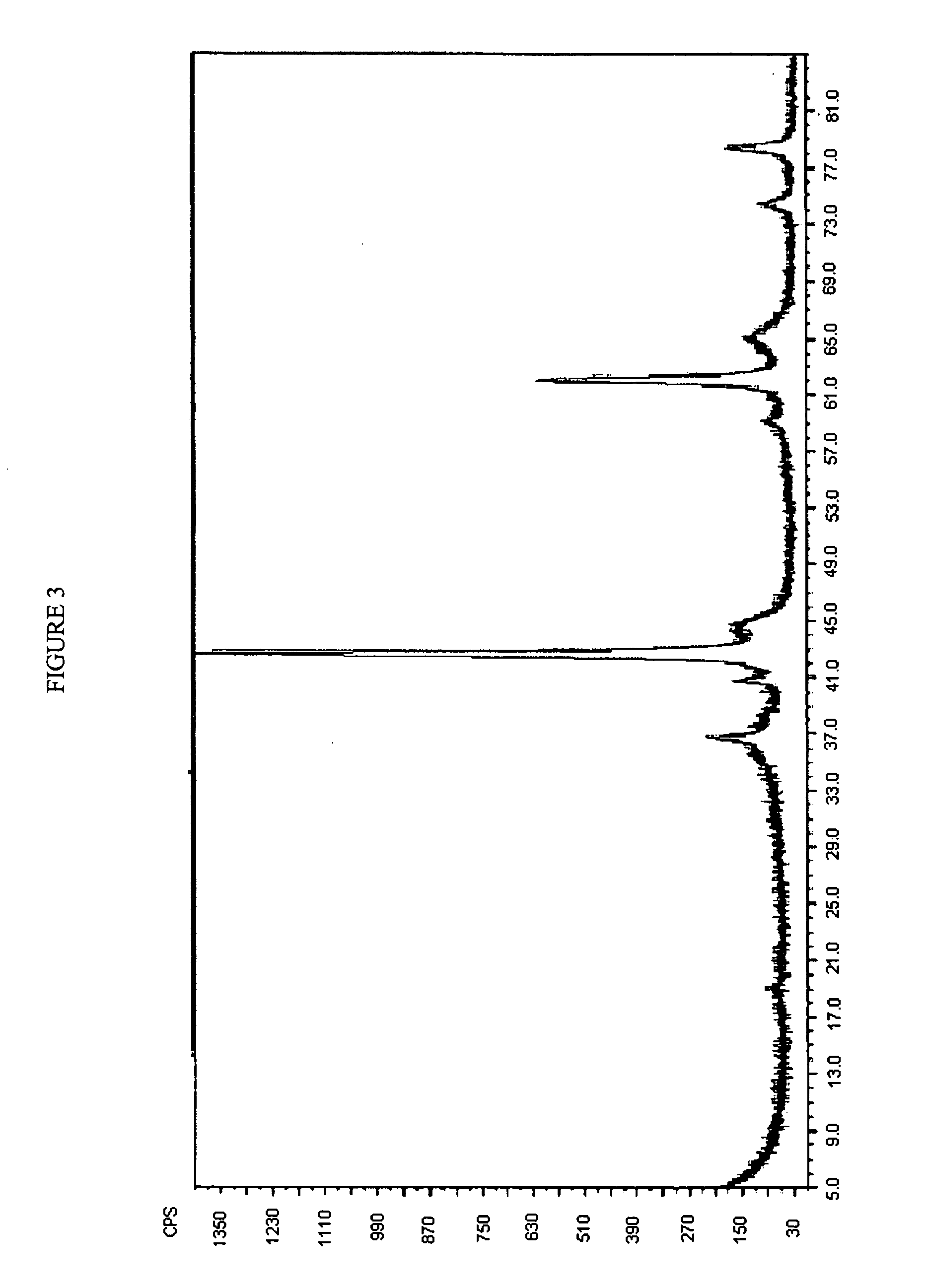

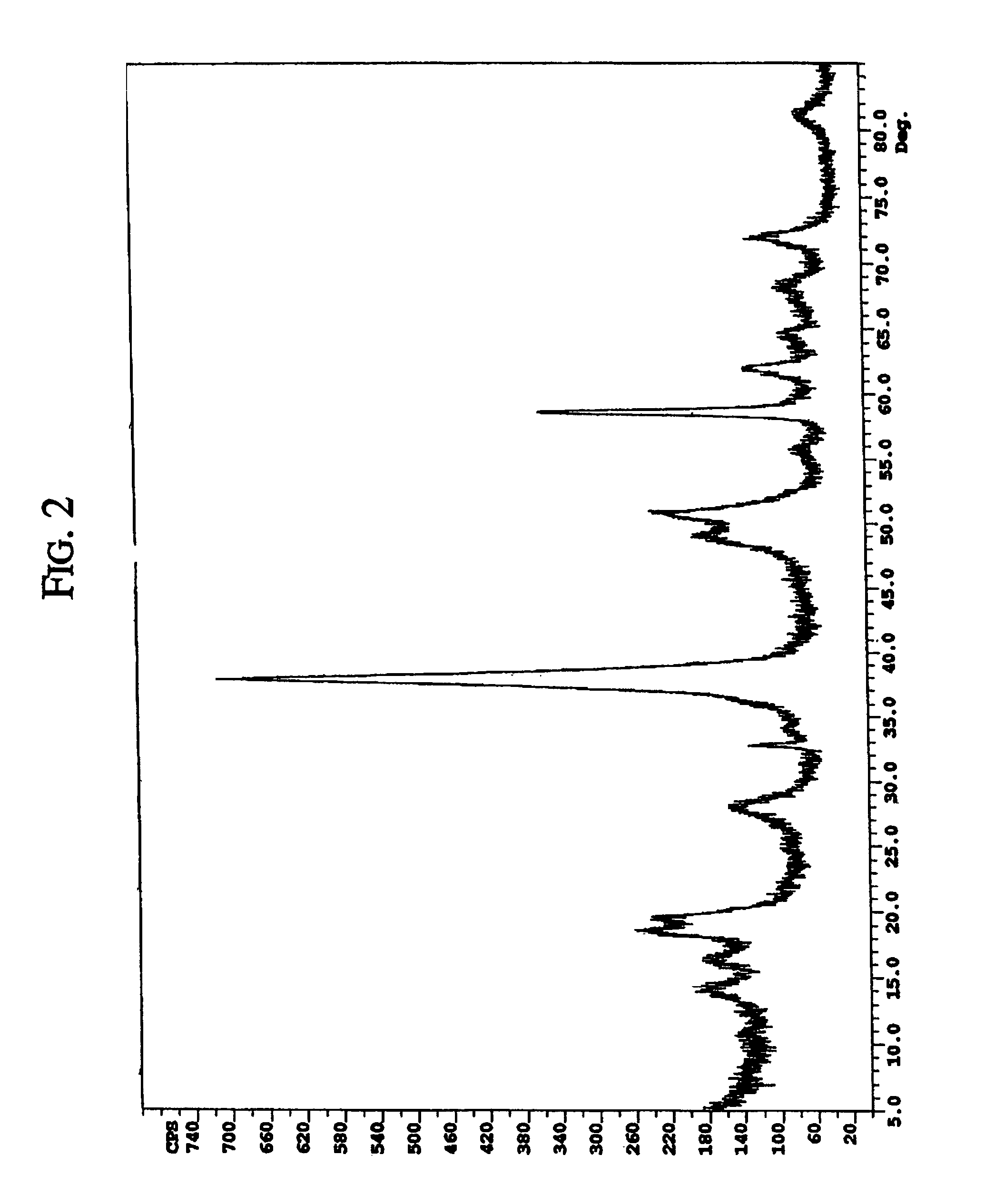

Mixed metal oxide sorbents

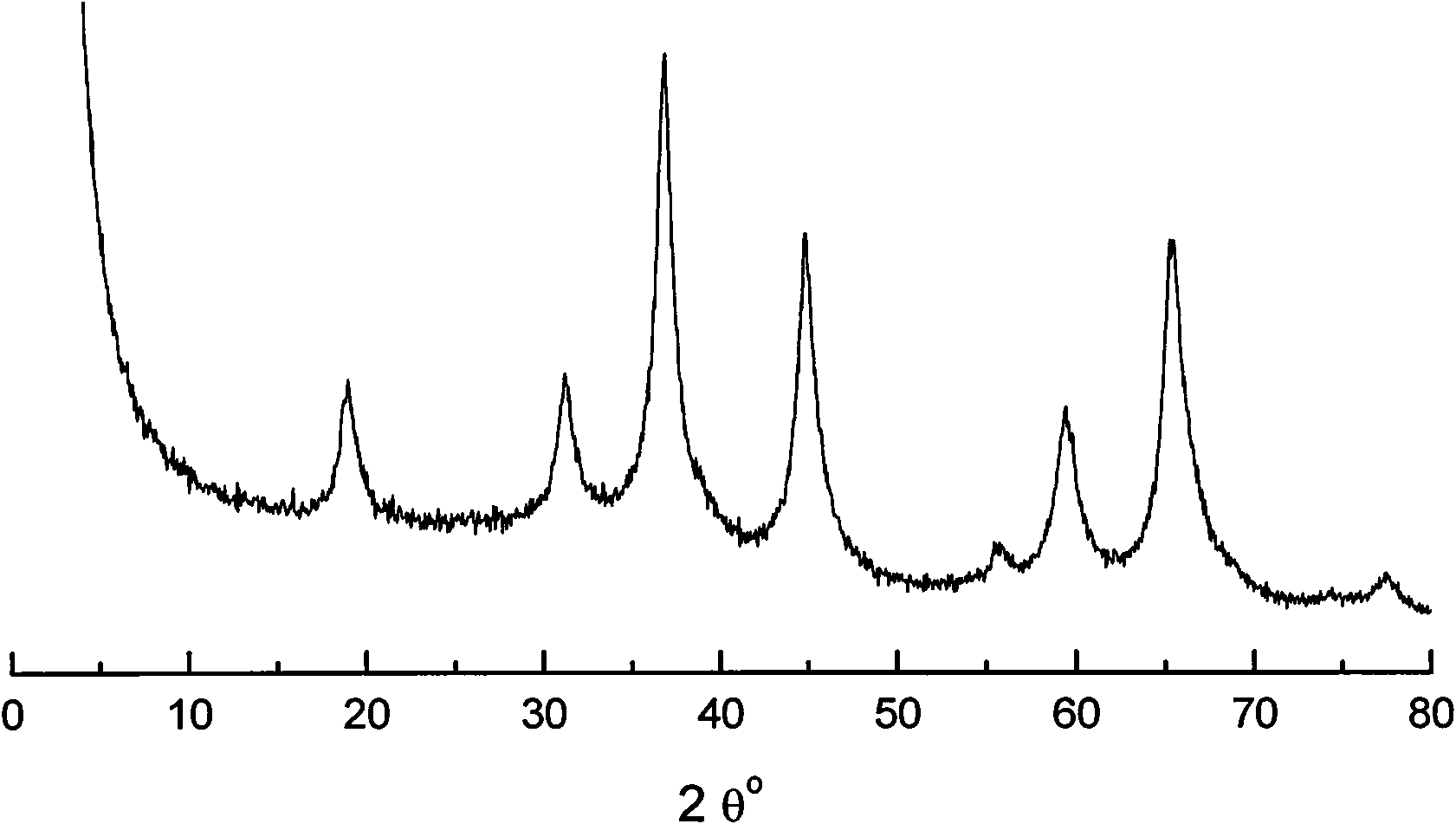

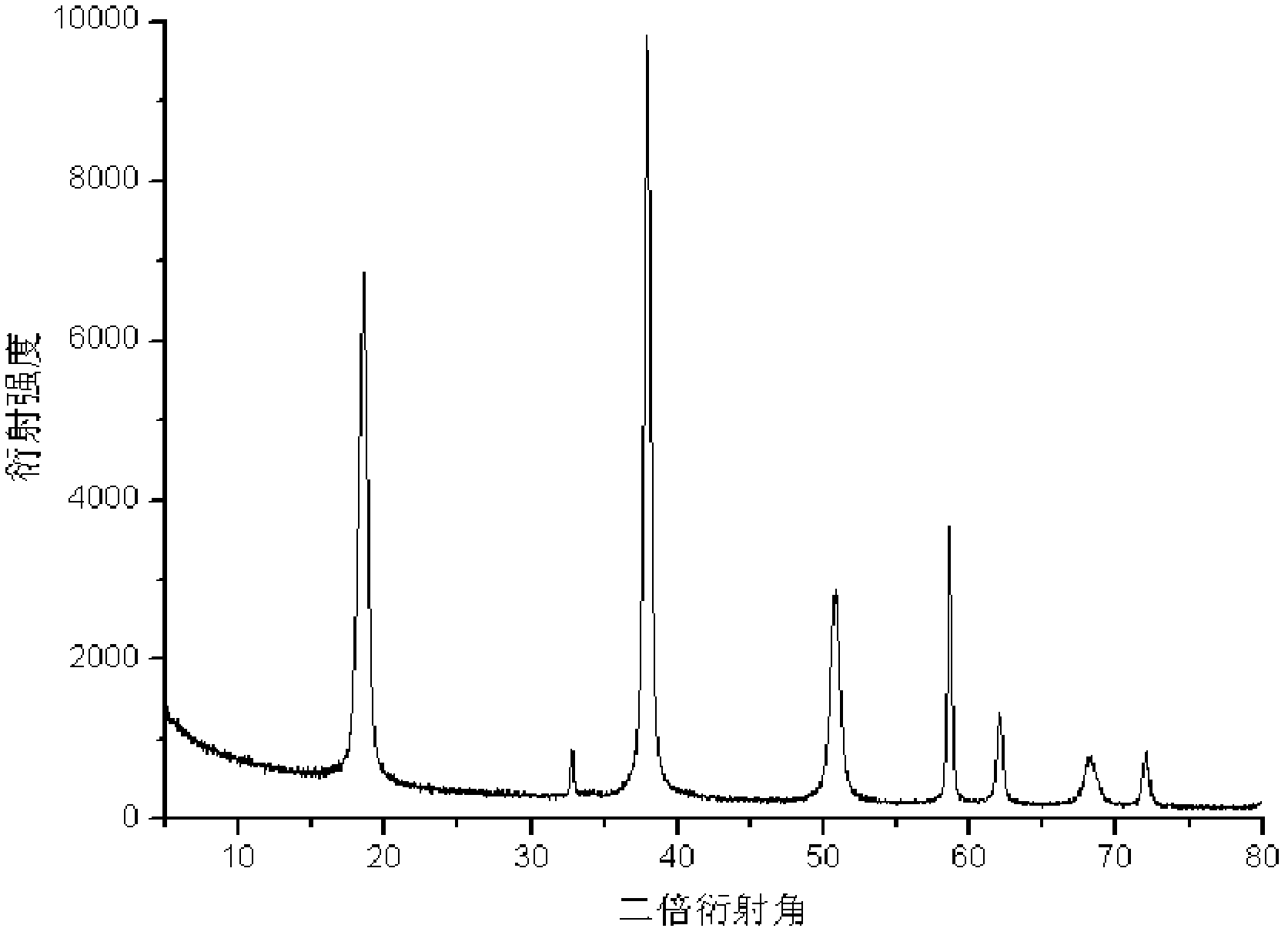

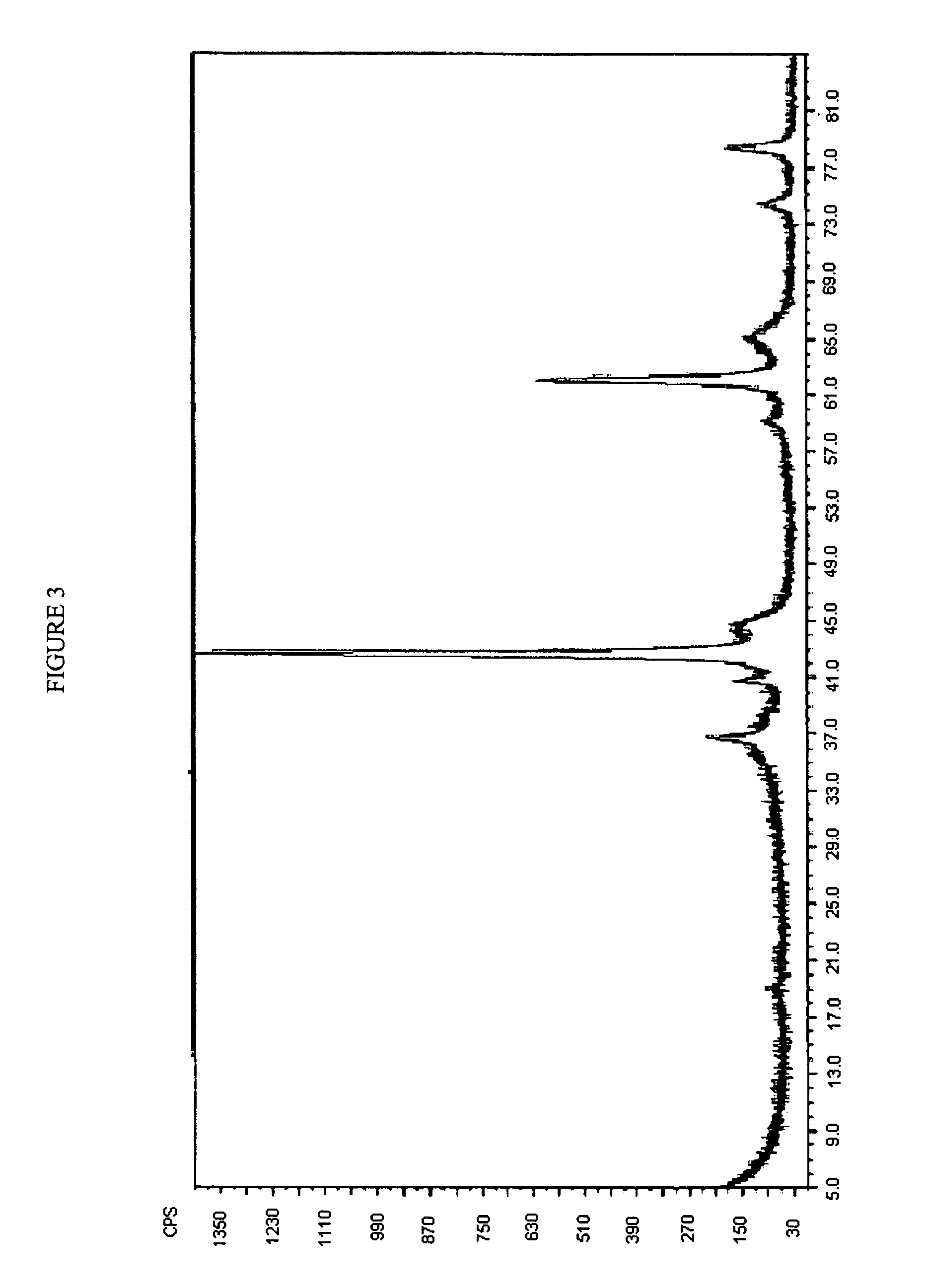

The present invention is directed to methods for reducing SOx, NOx, and CO emissions from a fluid stream comprising contacting said fluid stream with a compound comprising magnesium and aluminum and having an X-ray diffraction pattern displaying at least a reflection at a two theta peak position at about 43 degrees and about 62 degrees, wherein the ratio of magnesium to aluminum in the compound is from about 1:1 to about 10:1. In one embodiment, the ratio of magnesium to aluminum in the compound is from about 1:1 to about 6:1. In one embodiment, the ratio of magnesium to aluminum in the compound is from about 1.5:1 to about 10:1. In another embodiment, the invention is directed to methods wherein the ratio of magnesium to aluminum in the compound is from about 1.5:1 to about 6:1.

Owner:JOHNSON MATTHEY PROCESS TECH

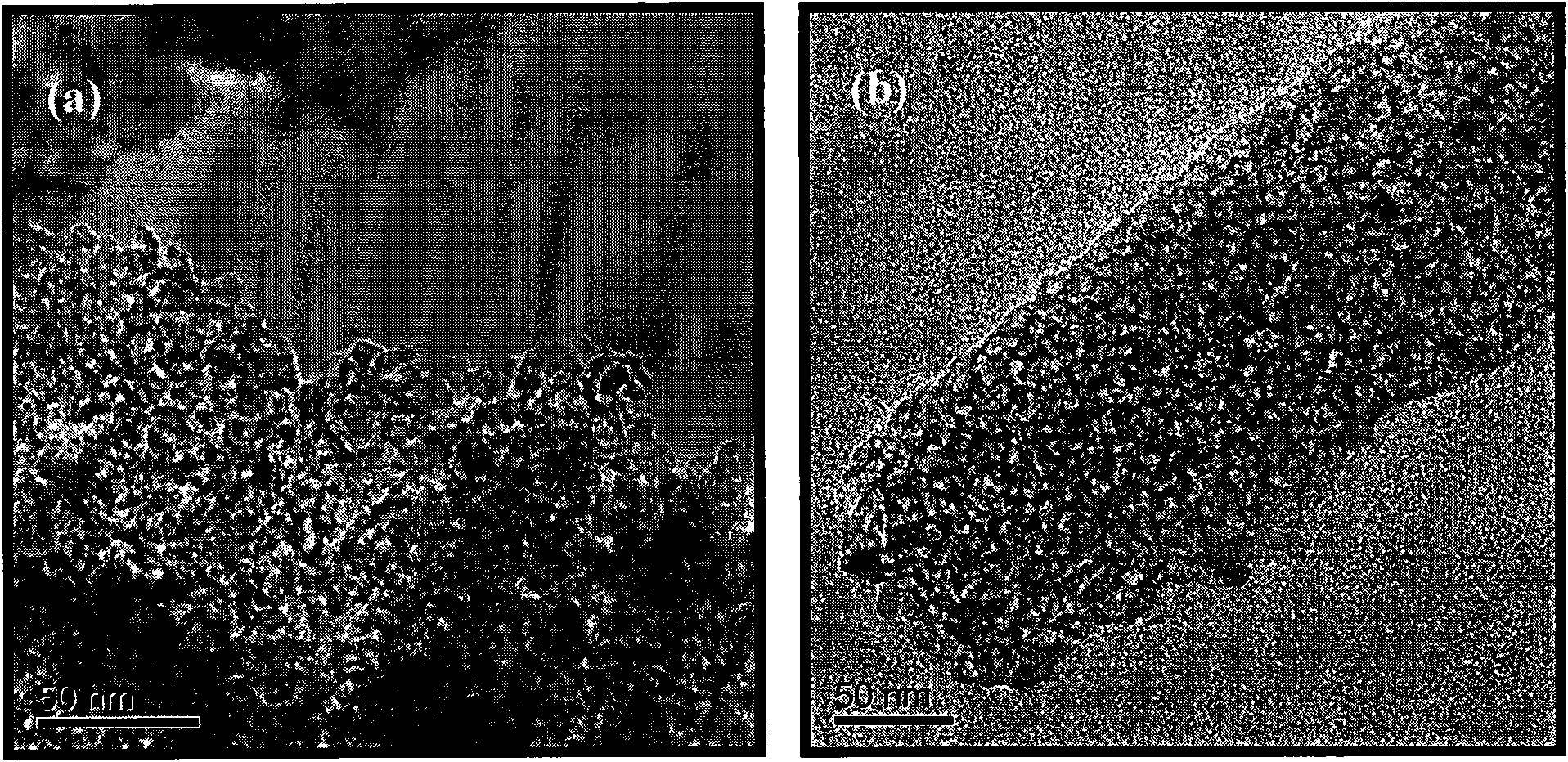

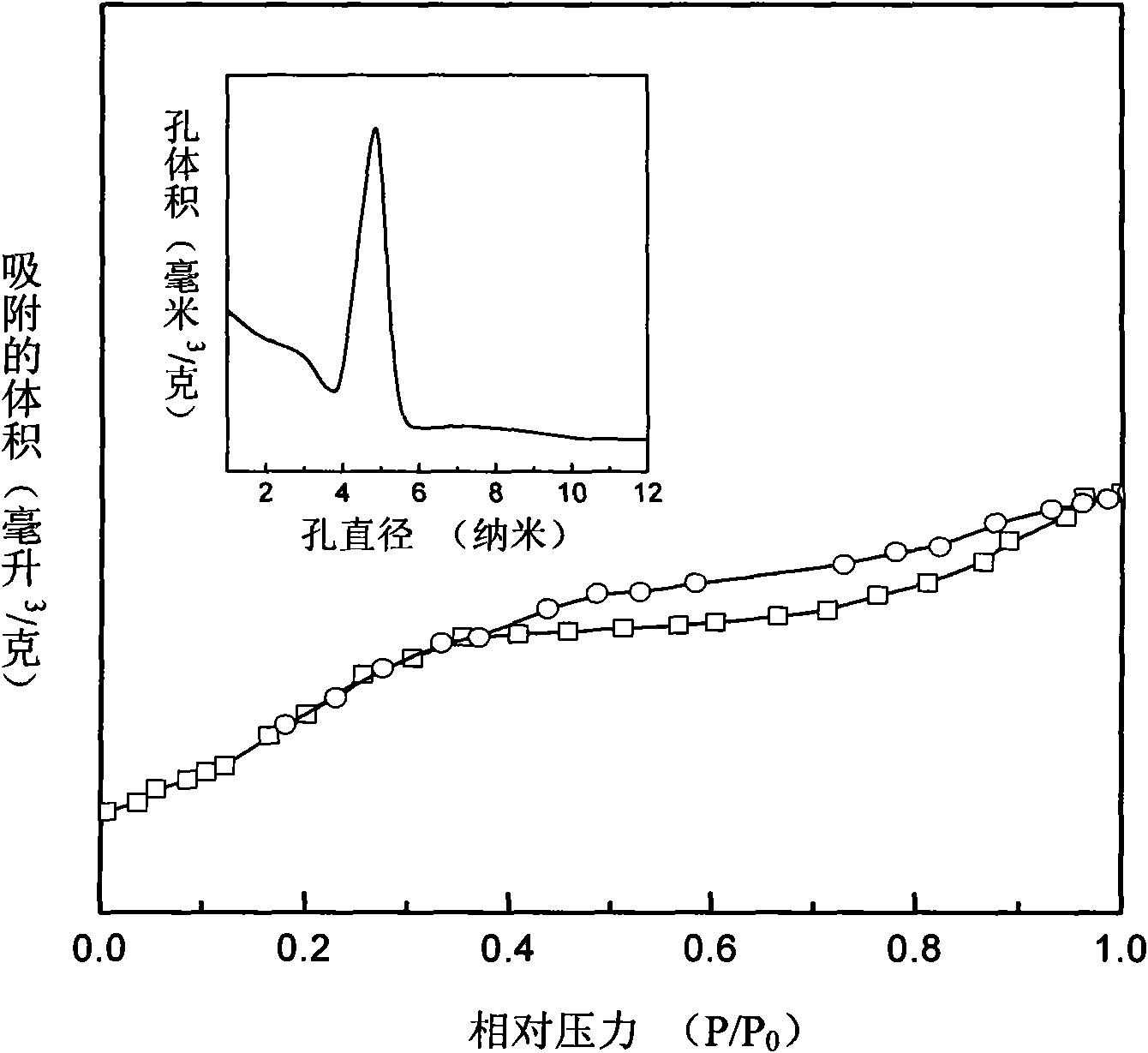

Method for preparing superfine mesoporous magnesium aluminate spinel

The invention discloses a method for preparing a superfine mesoporous magnesium aluminate spinel, which comprises the following steps: (1) adding an alkaline solution into a mixed solution of a soluble aluminum salt and a magnesium salt, and adding a surfactant into the mixture; (2) performing hydrothermal crystallization on the mixture after ageing at a temperature of between 120 and 180 DEG C for 4 to 72 hours; and (3) separating the mixture to obtain a solid product, and washing, filtering and drying the solid product to obtain magnesium aluminate spinel powder without baking or after baking at a temperature of between 500 and 700 DEG C for 4 to 6 hours. The particle size of the magnesium aluminate spinel prepared by the method is less than 100 nanometers, the specific surface area is between 200 and 400 m / gram, the pore volume is between 0.20 and 0.55 cm / gram, and the most probable pore diameter is between 3 and 6 nanometers.

Owner:NORTHWEST UNIV(CN)

Fused AL2O3-MgO-rare earth oxide eutectic abrasive particles, abrasive articles, and methods of making and using the same

InactiveUS6596041B2Improve grinding performanceLower performance requirementsPigmenting treatmentMangesium aluminatesNonwoven fabricComposite material

Owner:3M INNOVATIVE PROPERTIES CO

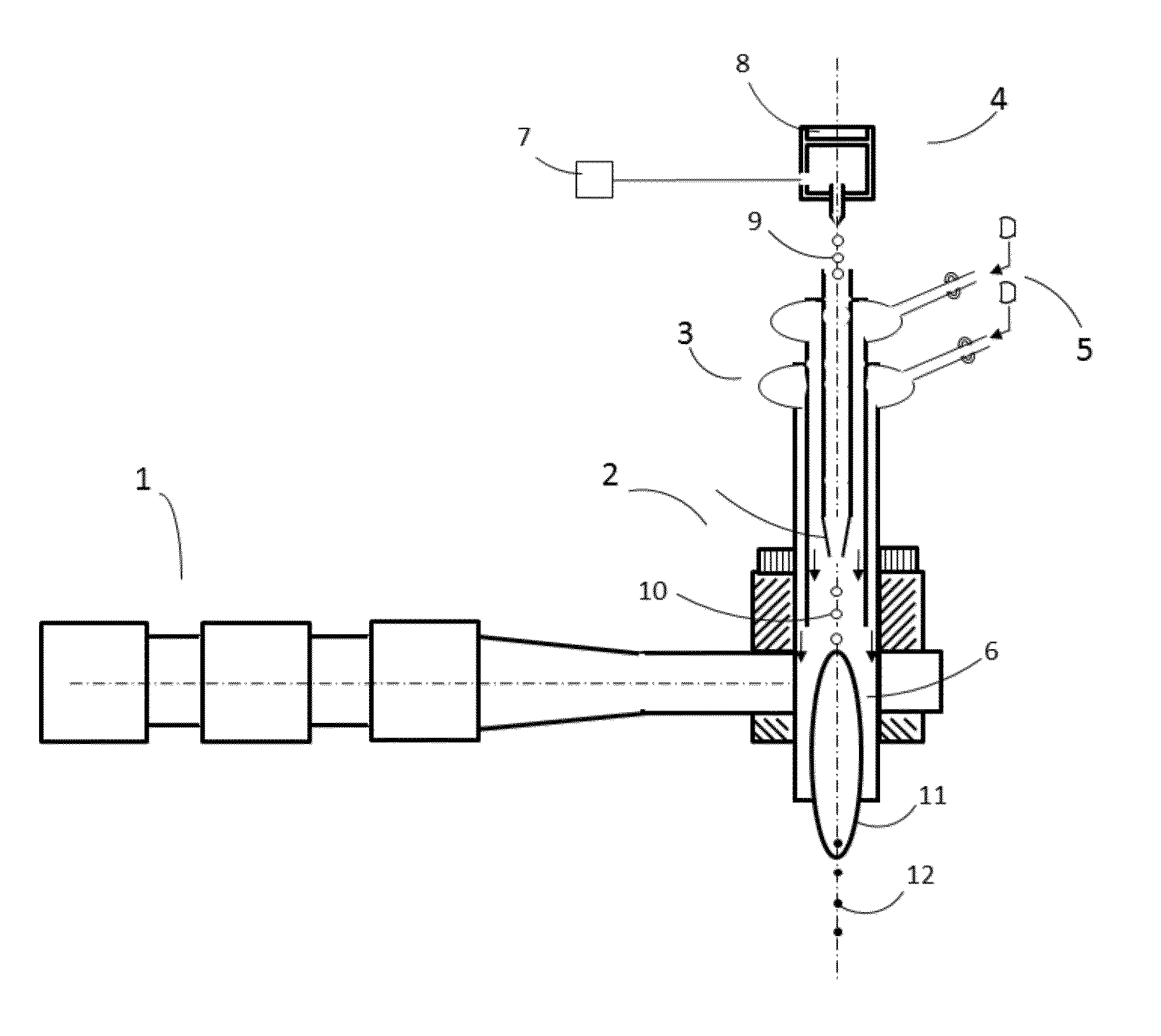

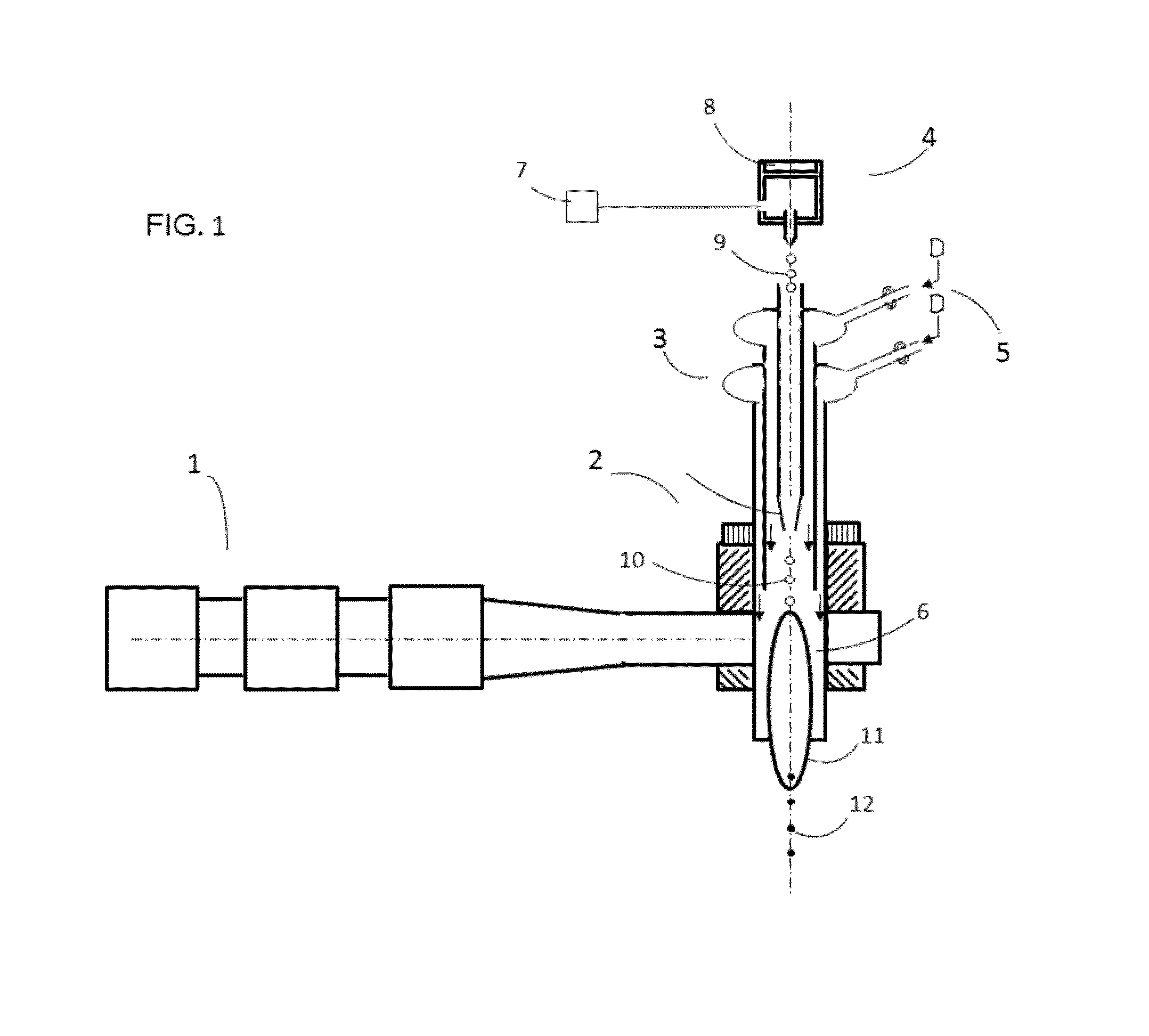

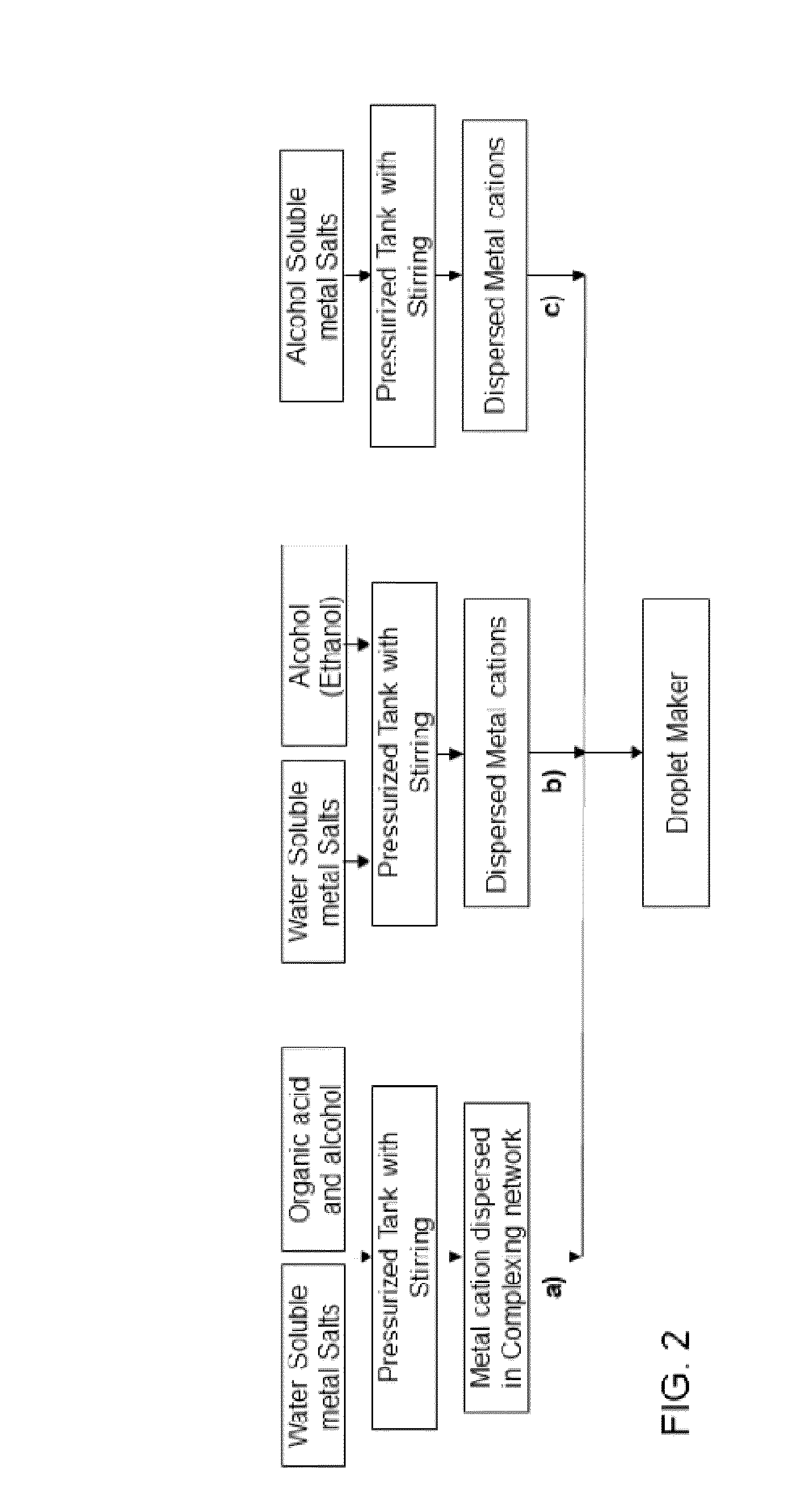

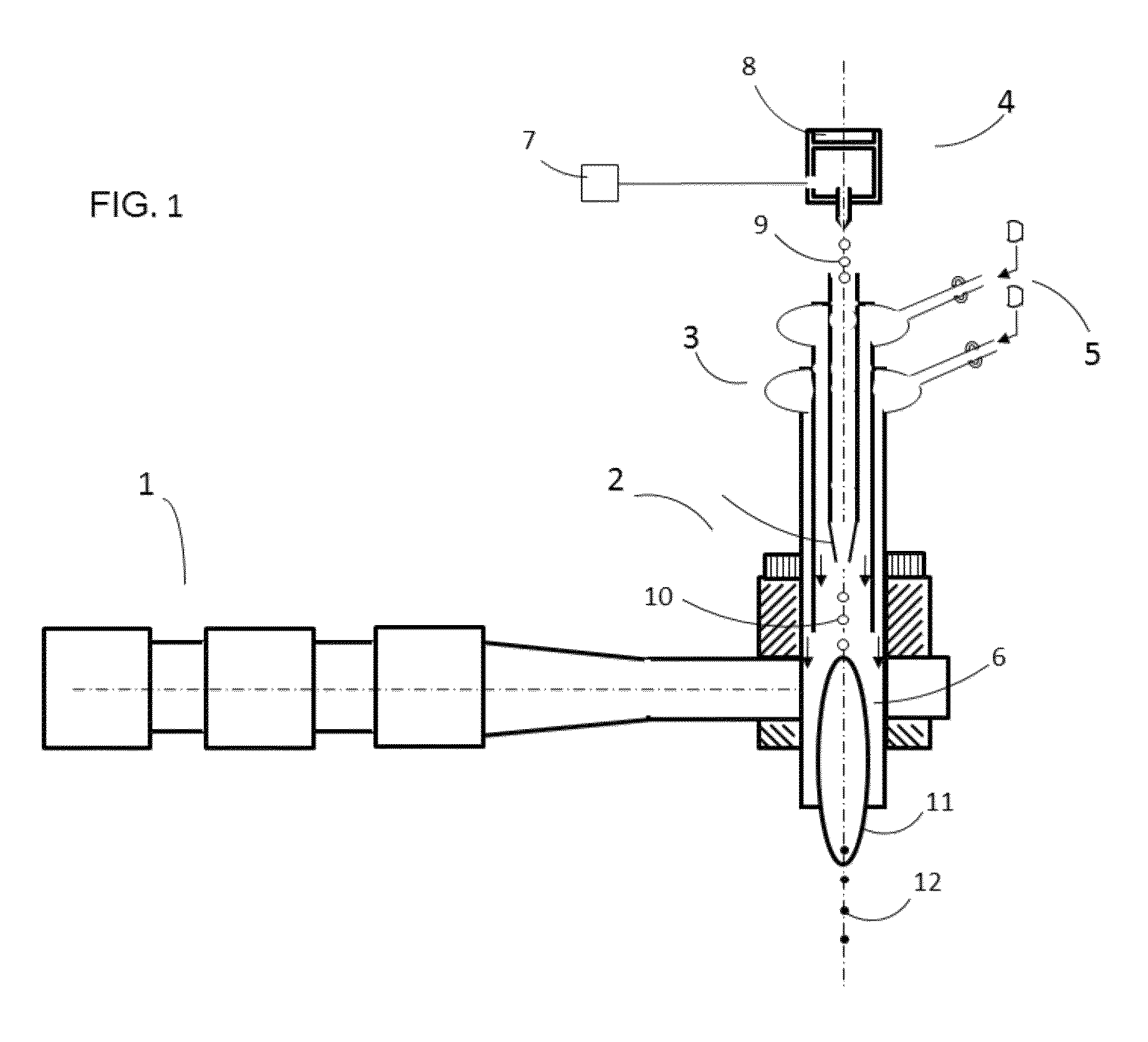

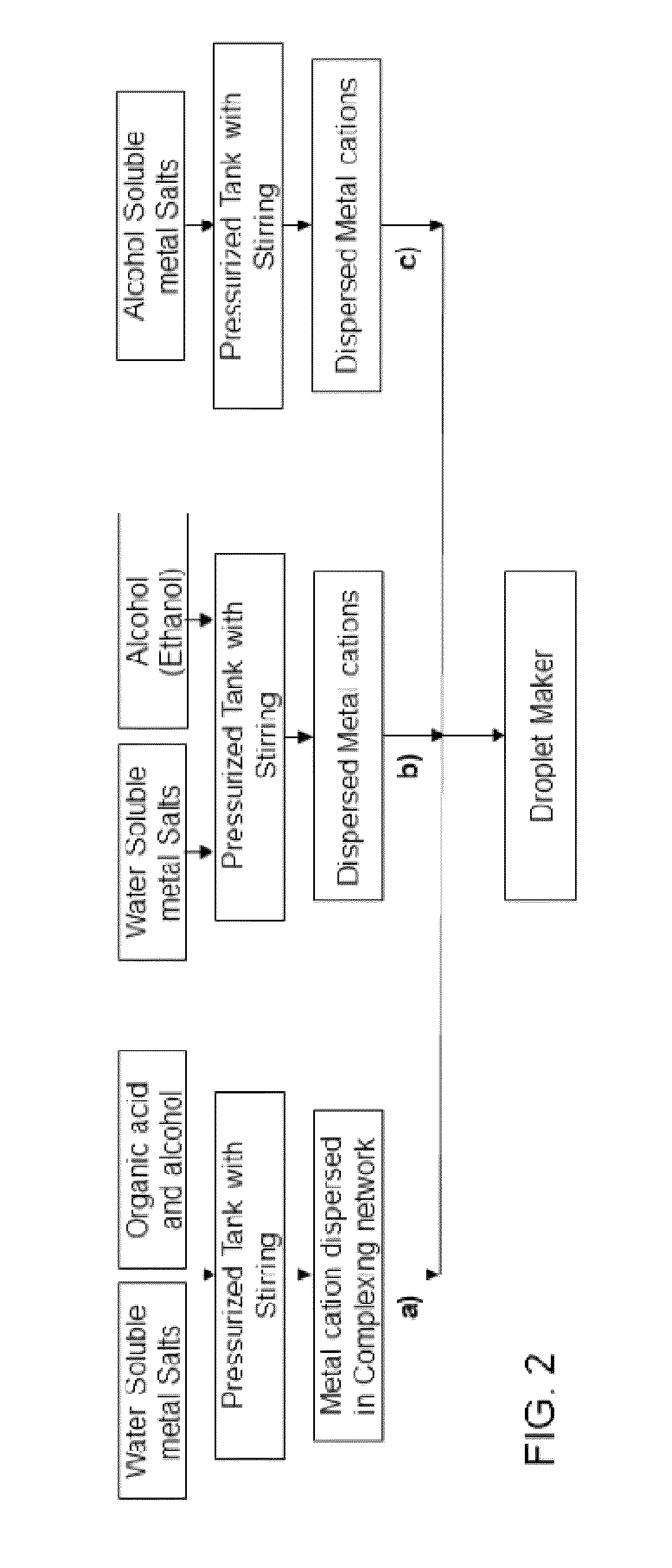

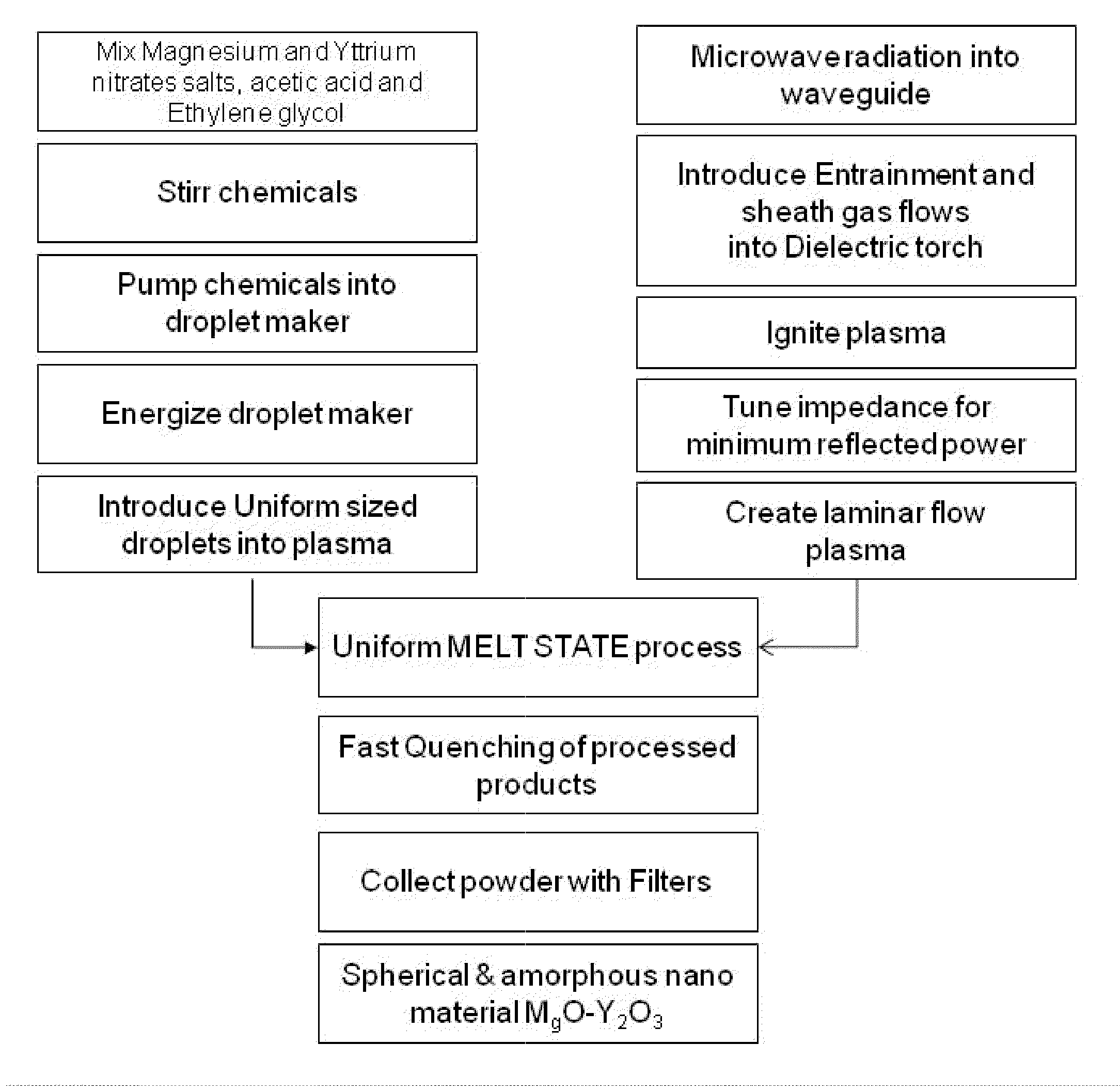

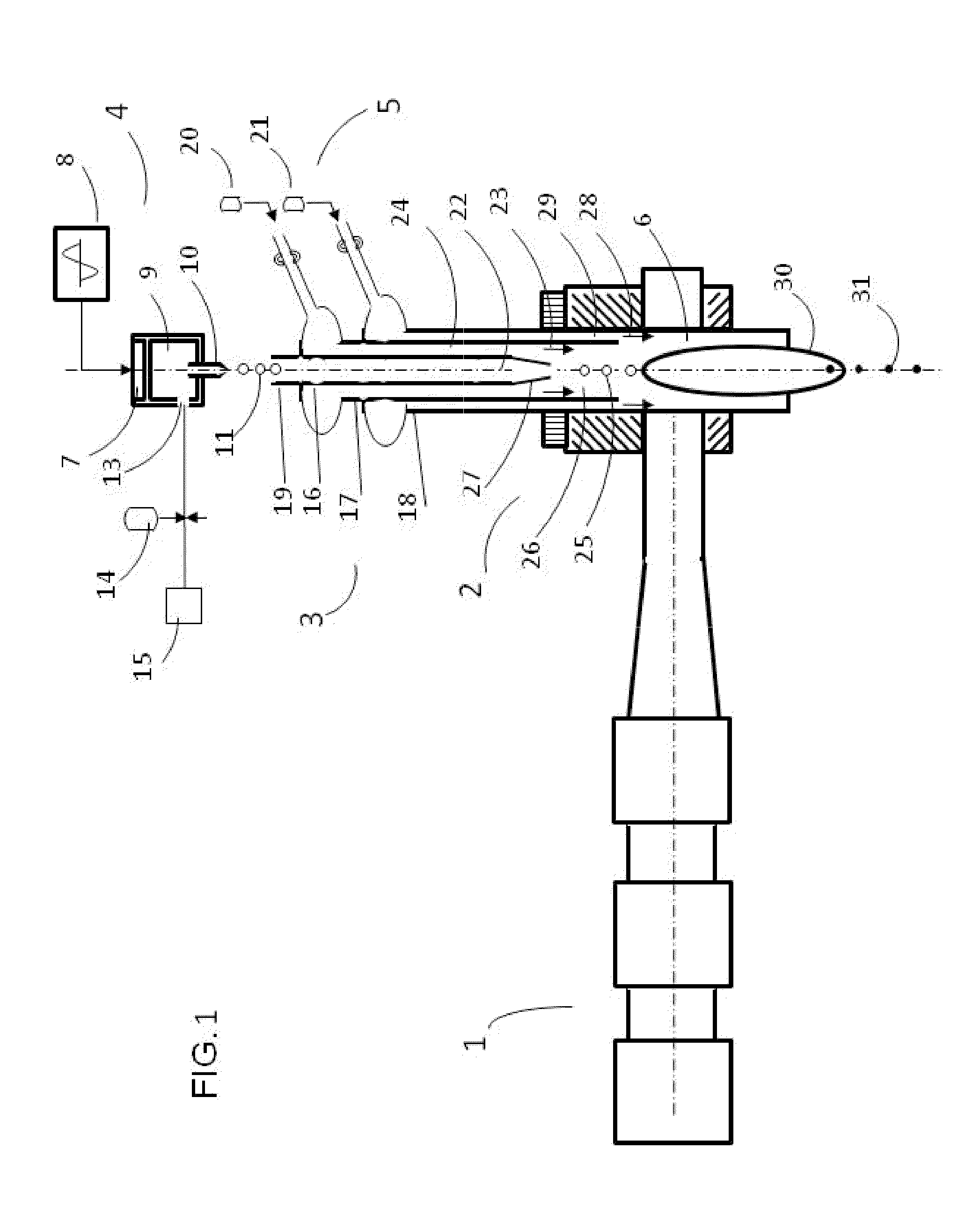

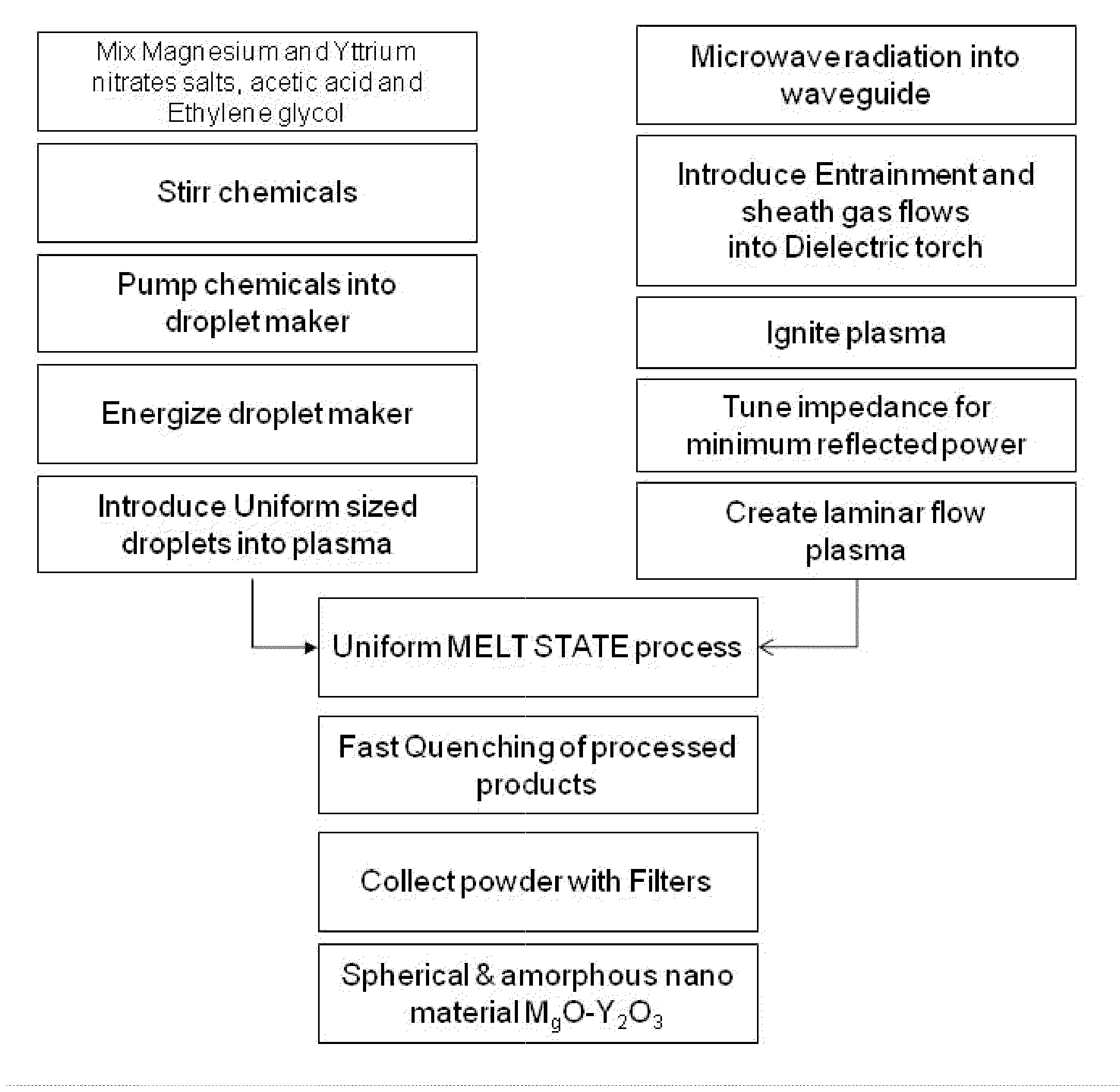

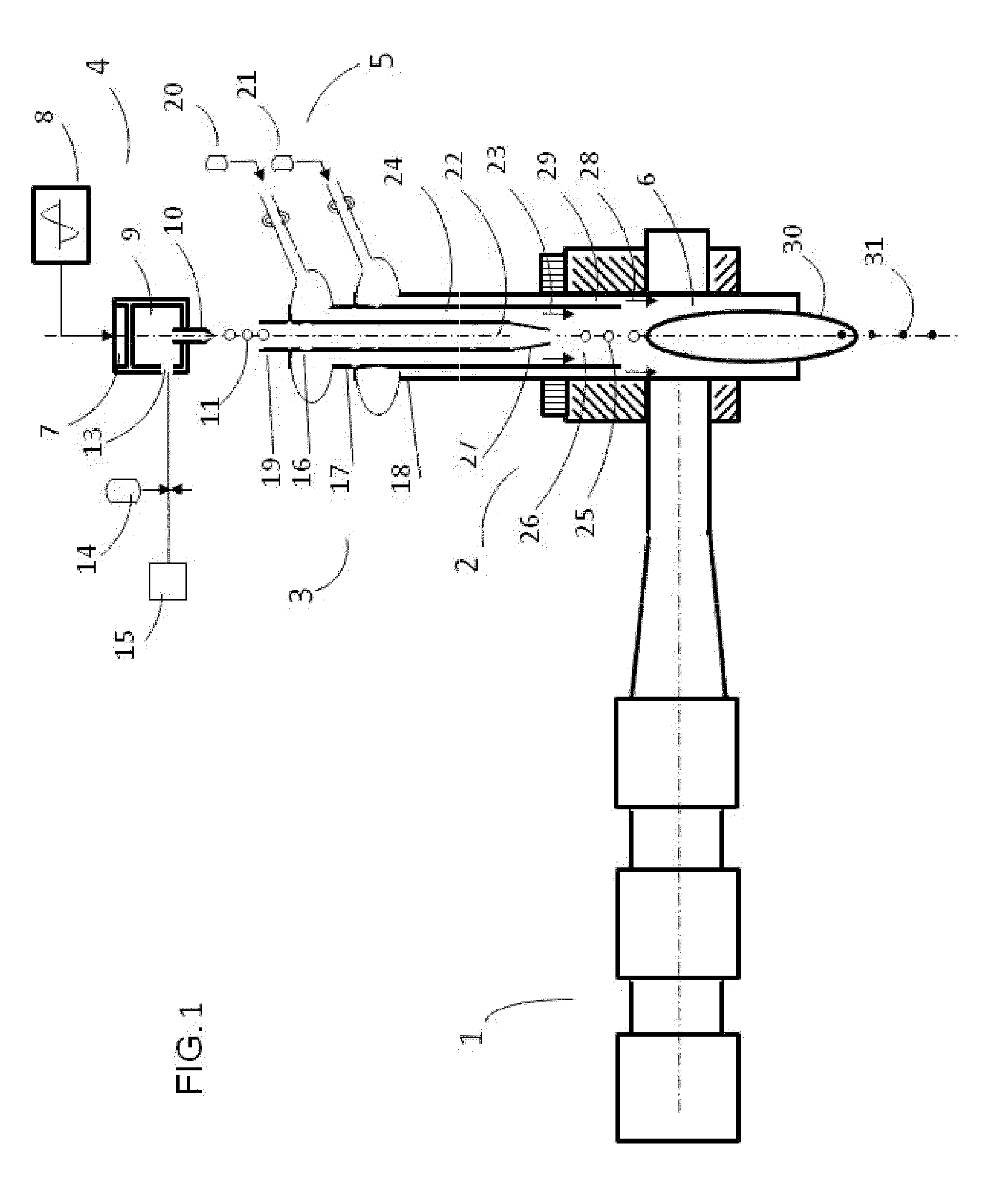

Method for the production of multiphase composite materials using microwave plasma process

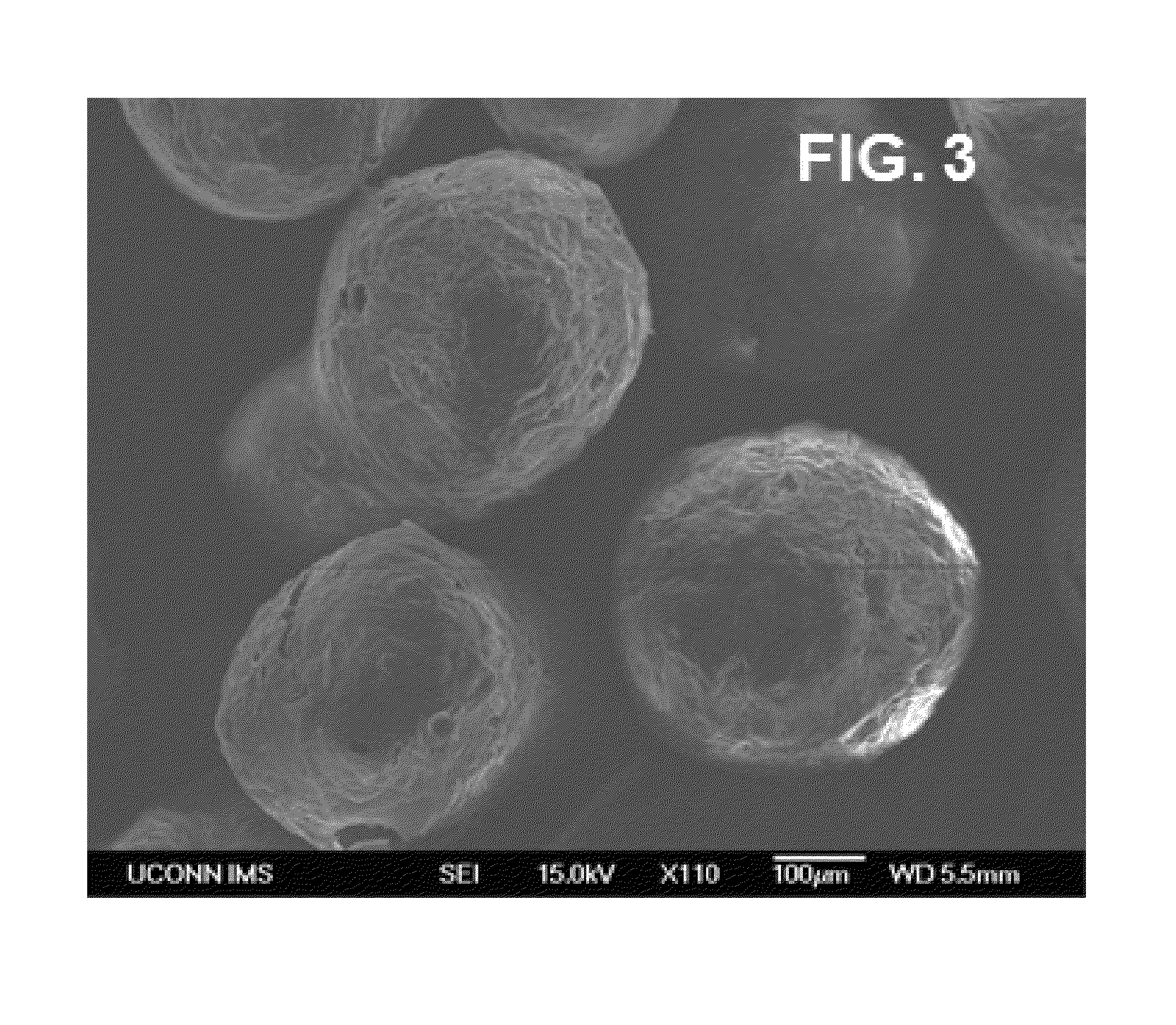

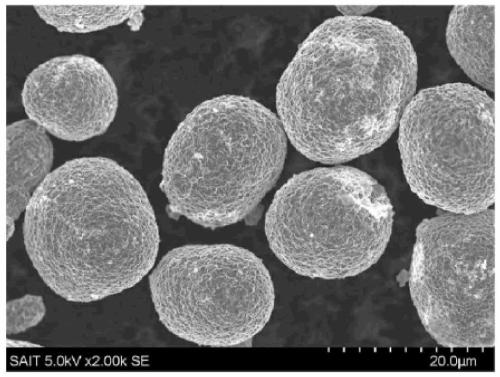

Disclosed herein is a method to produce multiphase composite materials directly from solution precursor droplets by a fast pyrolysis process using a microwave plasma embodiment containing a microwave generating source, a dielectric plasma torch, and a droplet maker. Here, using homogenous solution precursors, droplets are generated with a narrow size distribution, and are injected and introduced into the microwave plasma torch with generally uniform thermal path. The generally uniform thermal path in the torch is achieved by axial injection of droplets into an axisymmetric hot zone with laminar flows. Upon exposing to high temperature within the plasma with controlled residence time, the droplets are pyrolyzed and converted into particles by quenching with a controlled rate of the exhaust gas in a gas chamber. The particles generated have generally uniform sizes and uniform thermal history, and can be used for a variety of applications.

Owner:6K INC

Method for the production of multiphase composite materials using microwave plasma process

Disclosed herein is a method to produce multiphase composite materials directly from solution precursor droplets by a fast pyrolysis process using a microwave plasma embodiment containing a microwave generating source, a dielectric plasma torch, and a droplet maker. Here, using homogenous solution precursors, droplets are generated with a narrow size distribution, and are injected and introduced into the microwave plasma torch with generally uniform thermal path. The generally uniform thermal path in the torch is achieved by axial injection of droplets into an axisymmetric hot zone with laminar flows. Upon exposing to high temperature within the plasma with controlled residence time, the droplets are pyrolyzed and converted into particles by quenching with a controlled rate of the exhaust gas in a gas chamber. The particles generated have generally uniform sizes and uniform thermal history, and can be used for a variety of applications.

Owner:6K INC

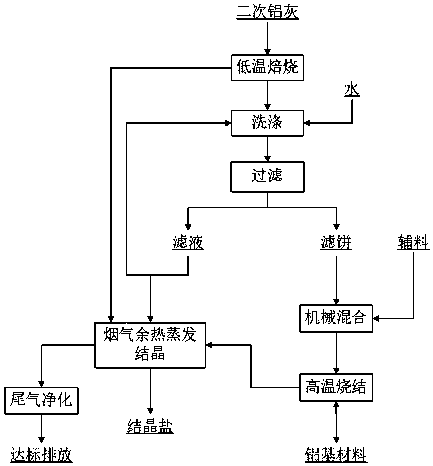

High-efficiency clean resource utilization method for quadratic aluminum dust

ActiveCN109179464AClean and efficient treatmentRealize high-value utilizationHuman health protectionCalcium aluminatesResource utilizationPotassium

The invention discloses a high-efficiency clean resource utilization method for quadratic aluminum dust. The method comprises the following steps: performing low-temperature roasting treatment on quadratic aluminum dust, removing harmful elements such as nitrogen, carbon and fluorine, pulping, washing, desalting and dehydrating the quadratic aluminum dust, removing sodium salt, potassium salt andother impurity components, washing brine and evaporating and crystallizing by utilizing flue gas waste heat. The purified quadratic aluminum dust can serve as a raw material to be directly utilized, and after the quadratic aluminum dust is mechanically mixed with auxiliary materials (calcium-based, silicon-based and magnesium-based), an aluminum based inorganic material is prepared at a high temperature, and the sintering exhaust gas realizes up-to-standard discharge by virtue of dust removal and dry defluorinated purification. According to the technology in the invention, the quadratic aluminum dust can be safely, cleanly and efficiently treated and converted into the high-value aluminum based inorganic material to the greatest degree, and environmental-friendly treatment and high-value resource utilization of the quadratic aluminum dust can be realized.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

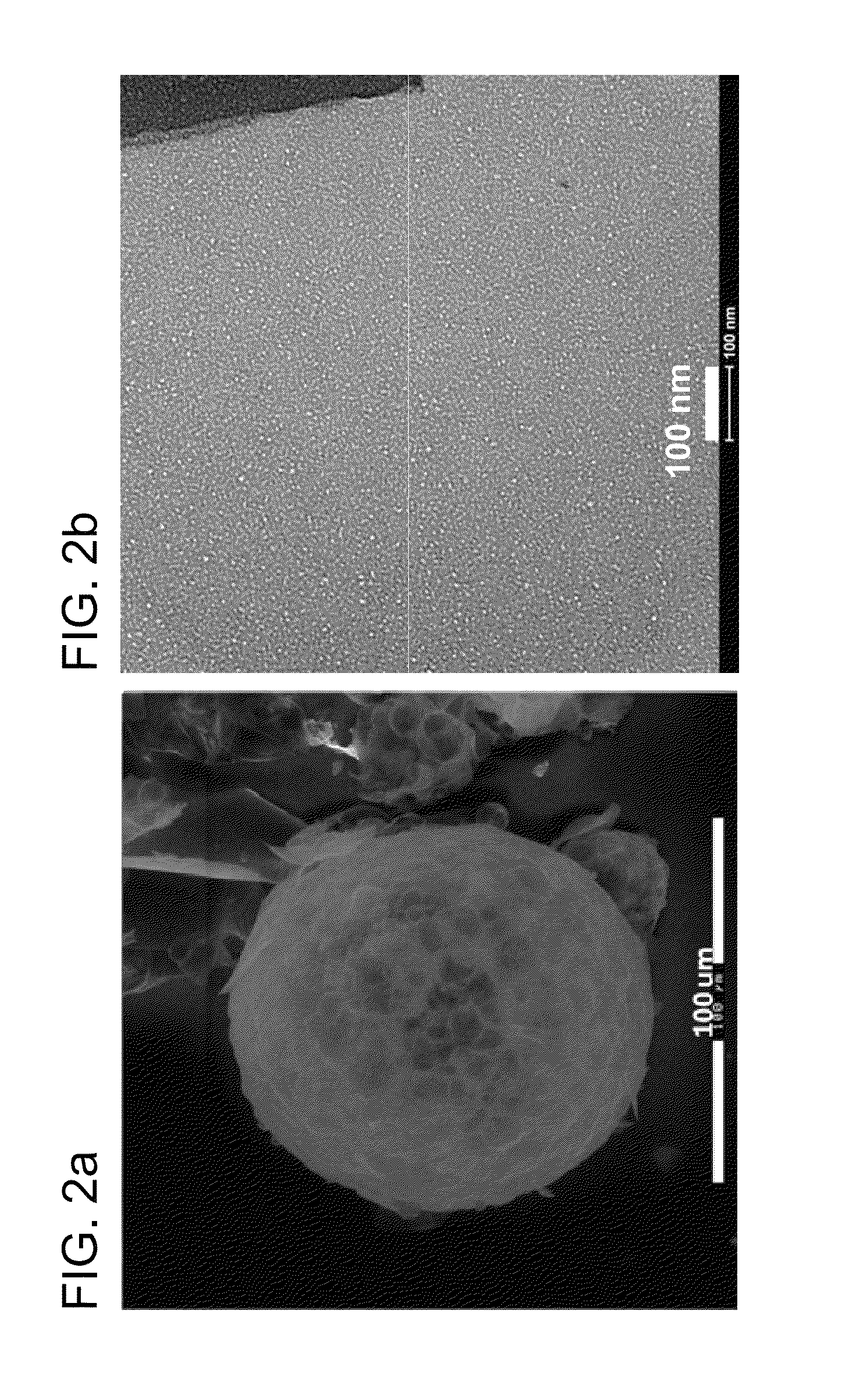

Method for making amorphous particles using a uniform melt-state in a microwave generated plasma torch

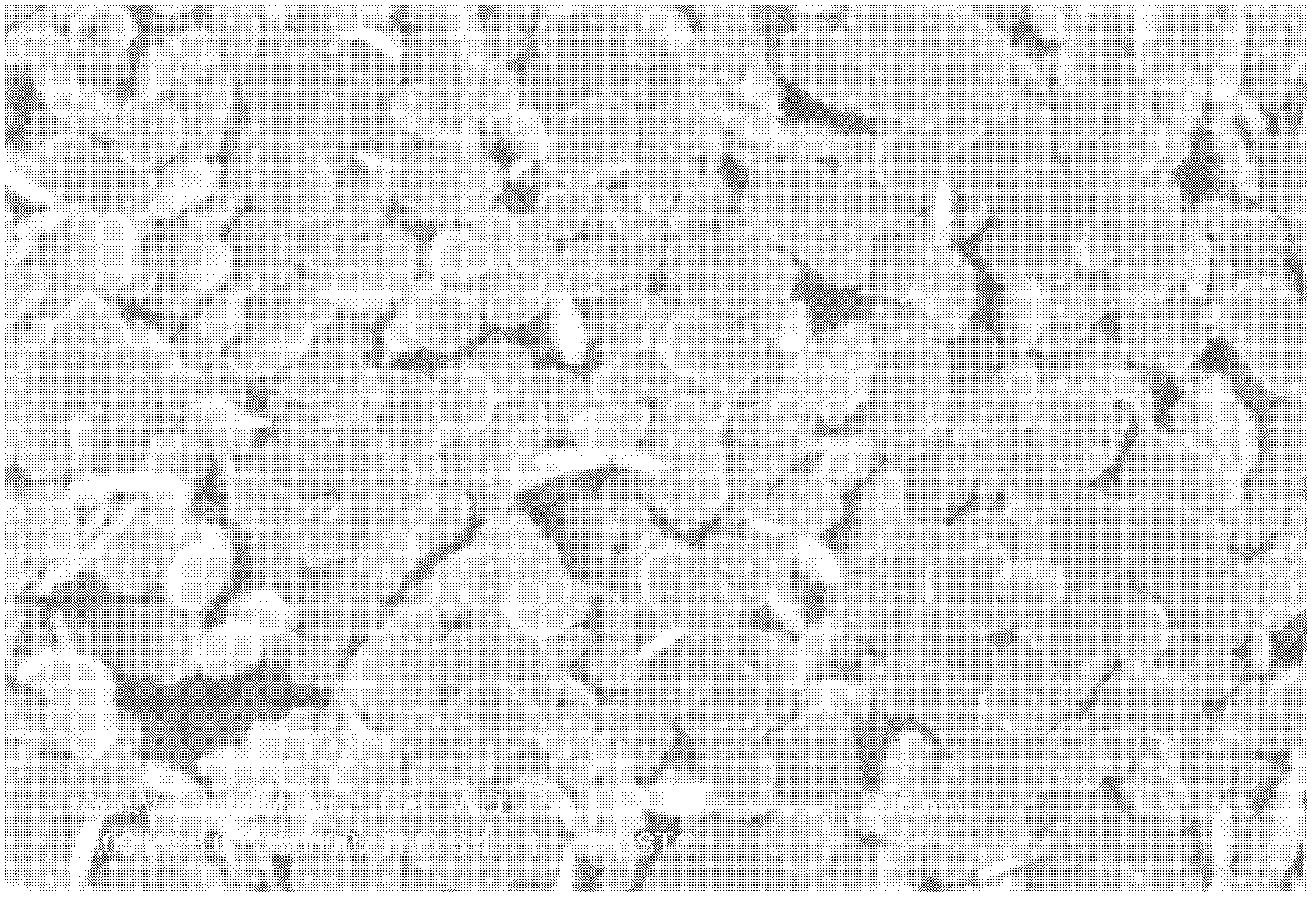

ActiveUS8951496B2Improve thermal performanceImprove toleranceCyanogen compoundsNitrogen compoundsMolten stateNon oxide ceramics

Feed material comprising uniform solution precursor droplets is processed in a uniform melt state using microwave generated plasma. The plasma torch employed is capable of generating laminar gas flows and providing a uniform temperature profile within the plasma. Plasma exhaust products are quenched at high rates to yield amorphous products. Products of this process include spherical, highly porous and amorphous oxide ceramic particles such as magnesia-yttria (MgO—Y2O3). The present invention can also be used to produce amorphous non oxide ceramic particles comprised of Boron, Carbon, and Nitrogen which can be subsequently consolidated into super hard materials.

Owner:6K INC

Doped anionic clays

The present invention is directed to a process for the preparation of a doped anionic clay. In said process a trivalent metal source is reacted with a divalent metal source, at least one of the metal sources being either doped boehmite, doped MgO or doped brucite, to obtain a doped anionic clay. Suitable dopants are compounds containing elements selected from the group of alkaline earth metals (for instance Ca and Ba), alkaline metals, transition metals (for example Co, Mn, Fe, Ti, Zr, Cu, Ni, Zn, Mo, W, V, Sn), actinides, rare earth metals such as La, Ce, and Nd, noble metals such as Pt and Pd, silicon, gallium, boron, titanium, and phosphorus.

Owner:AKZO NOBEL NV +1

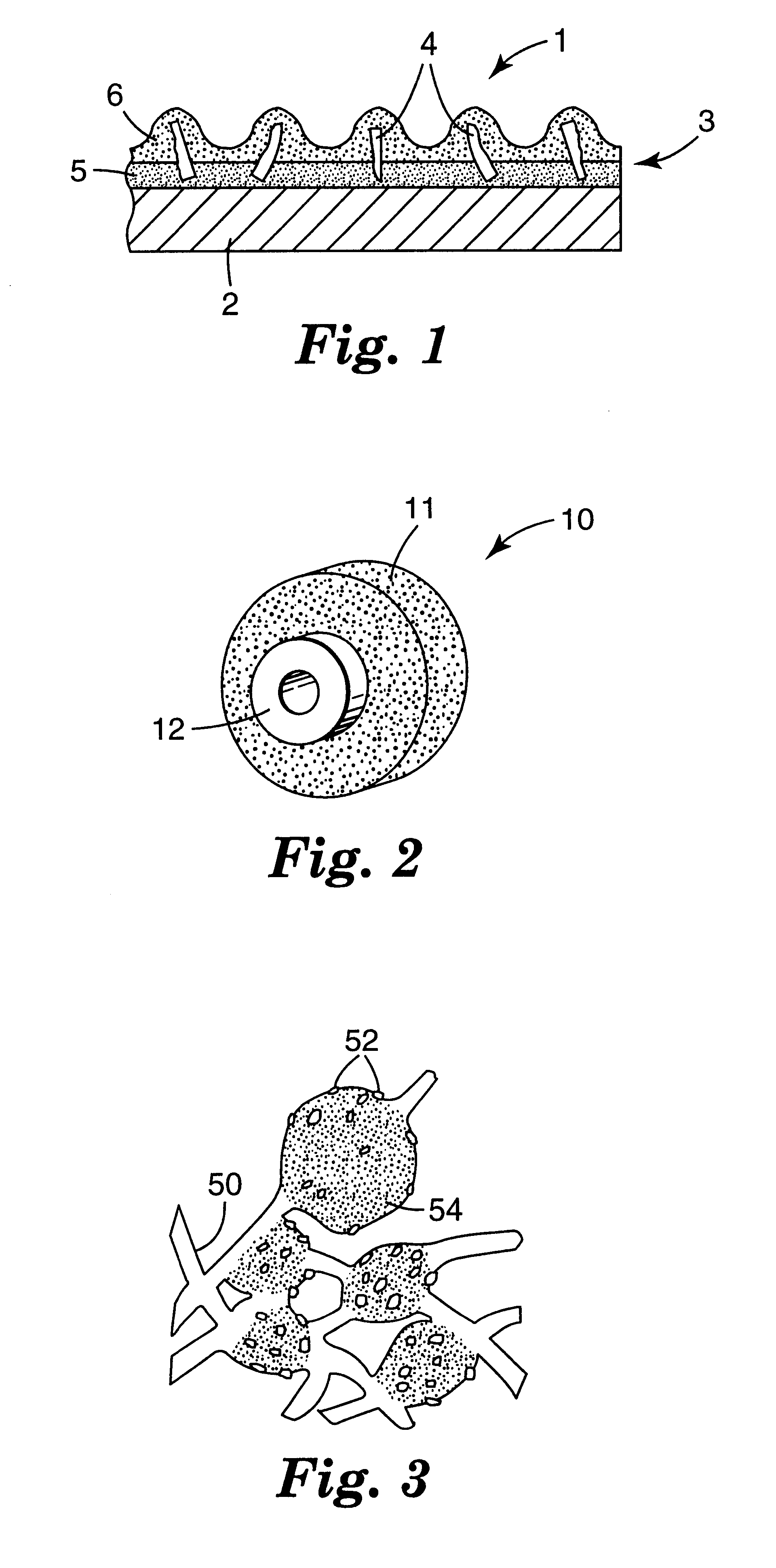

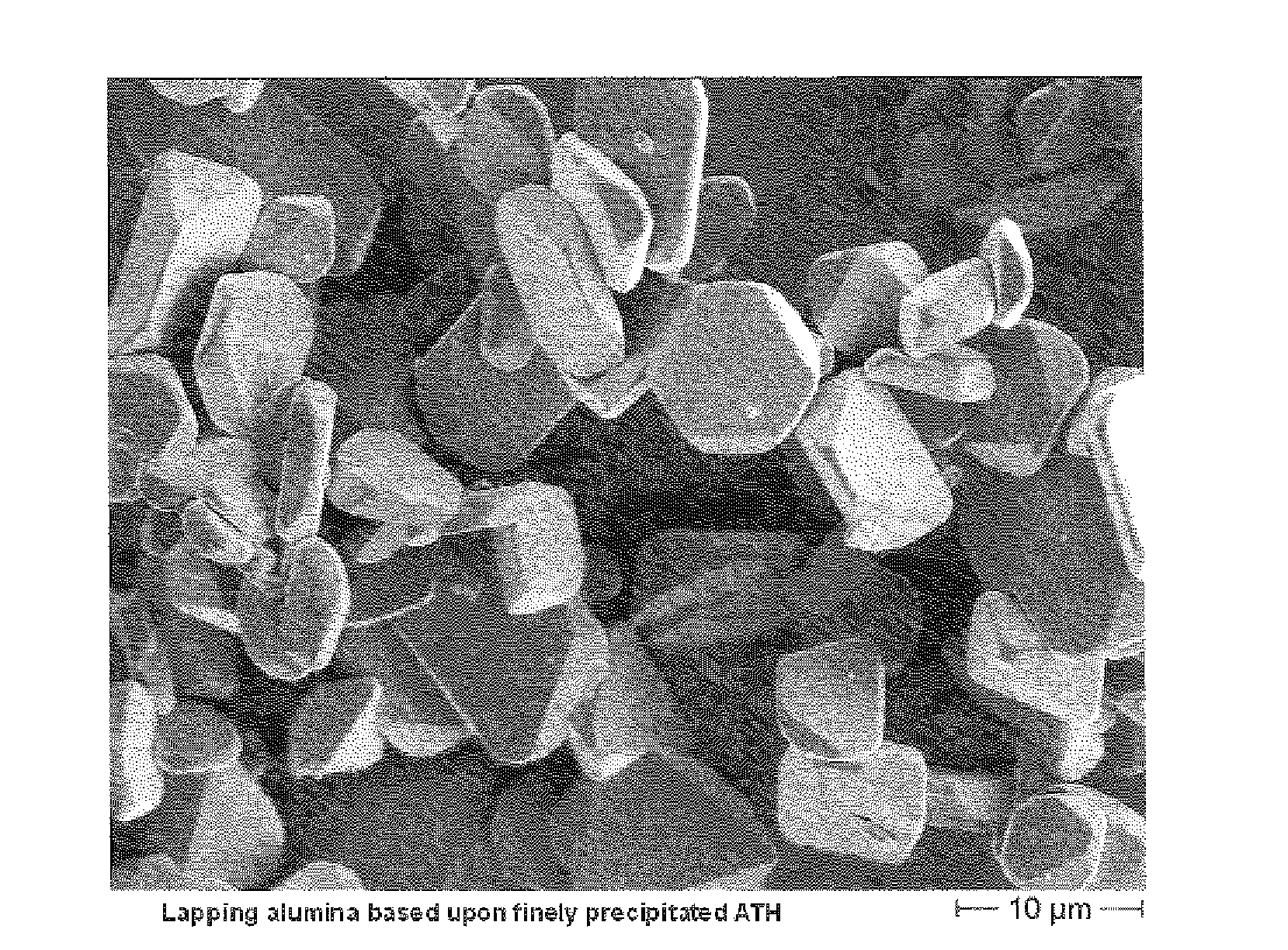

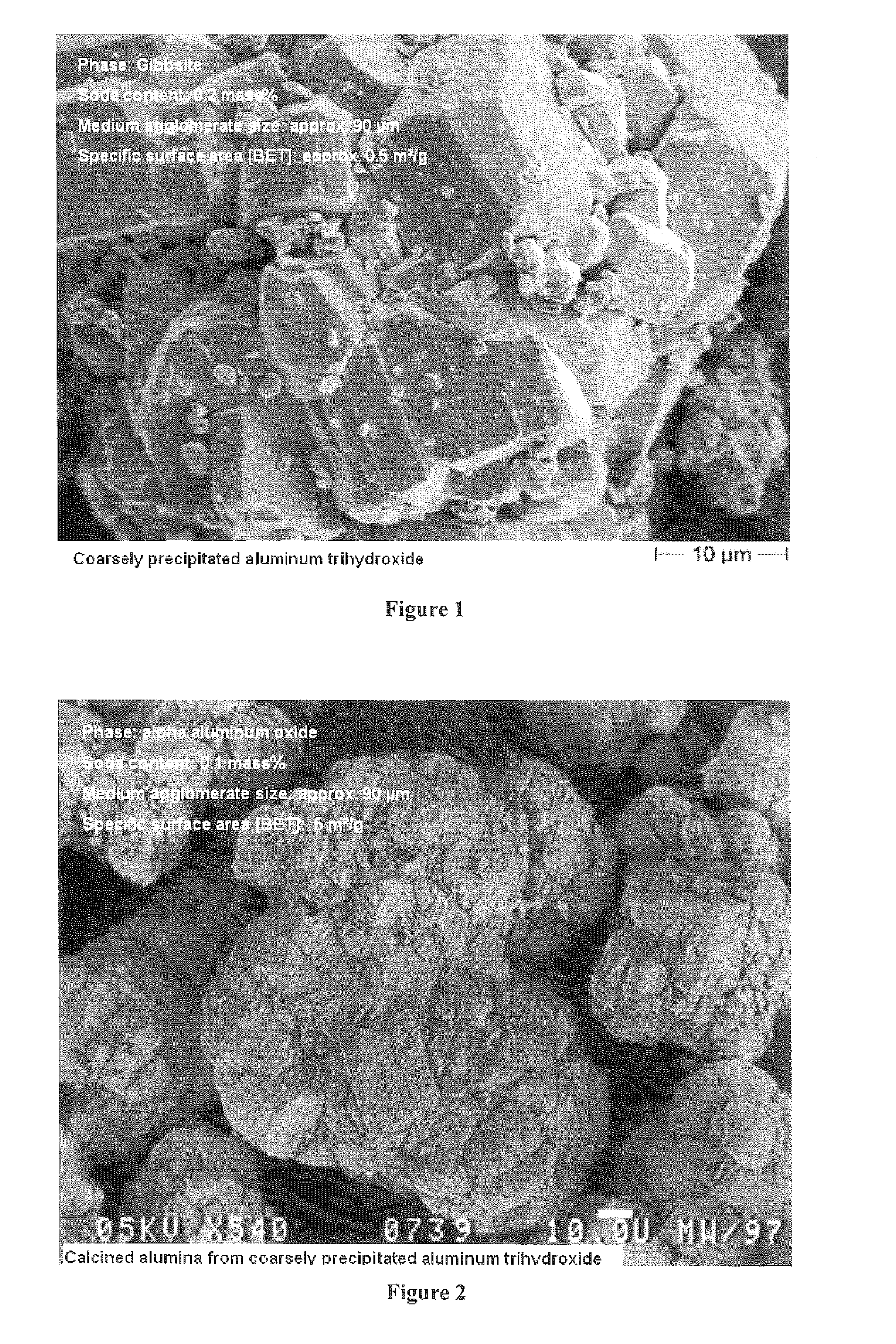

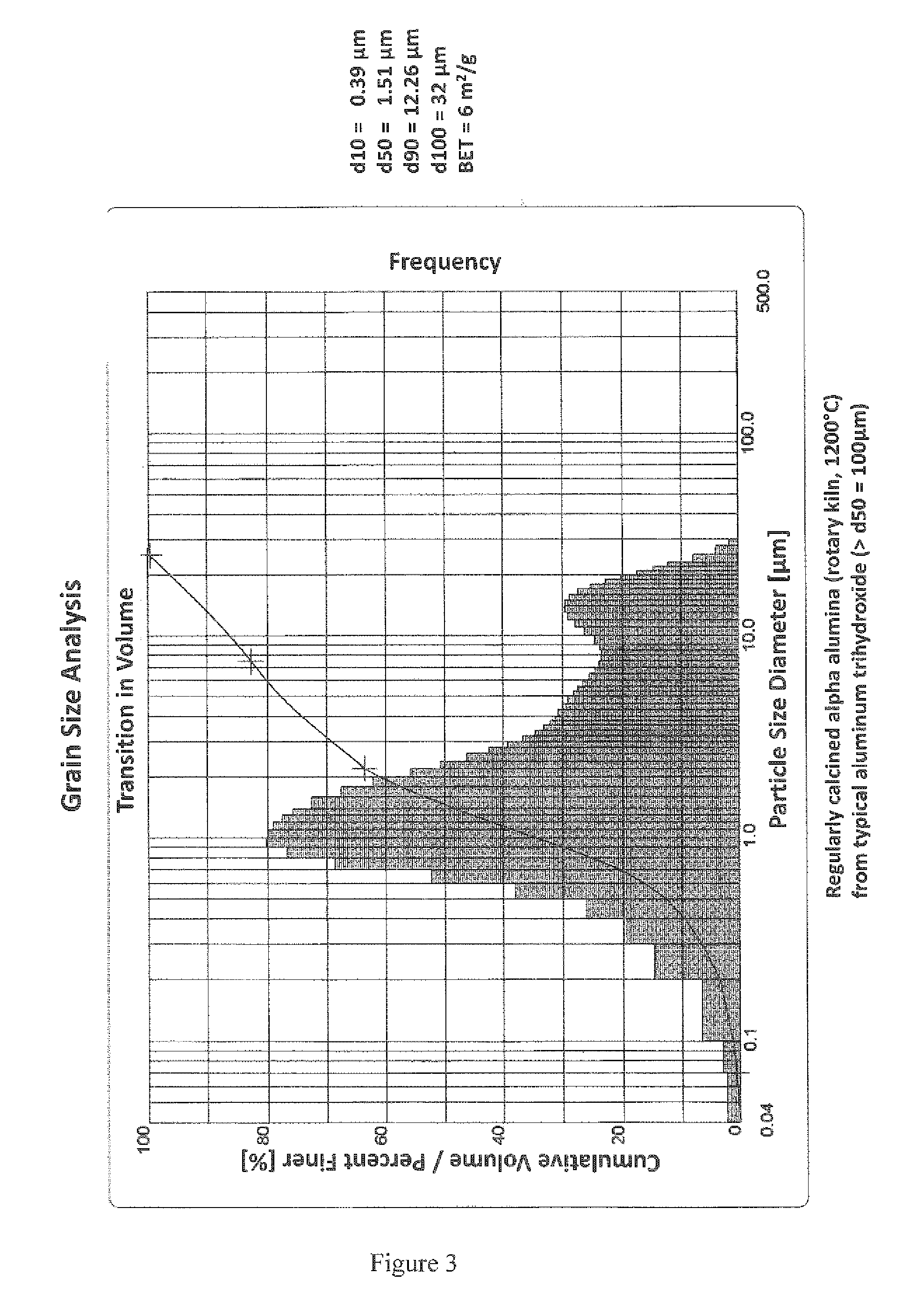

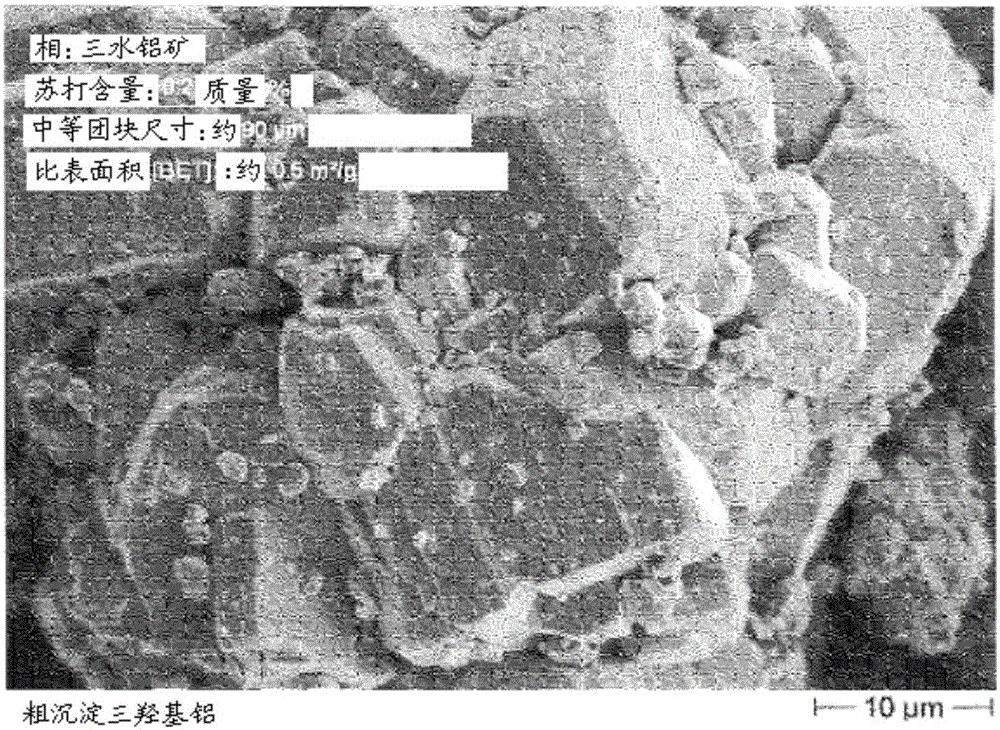

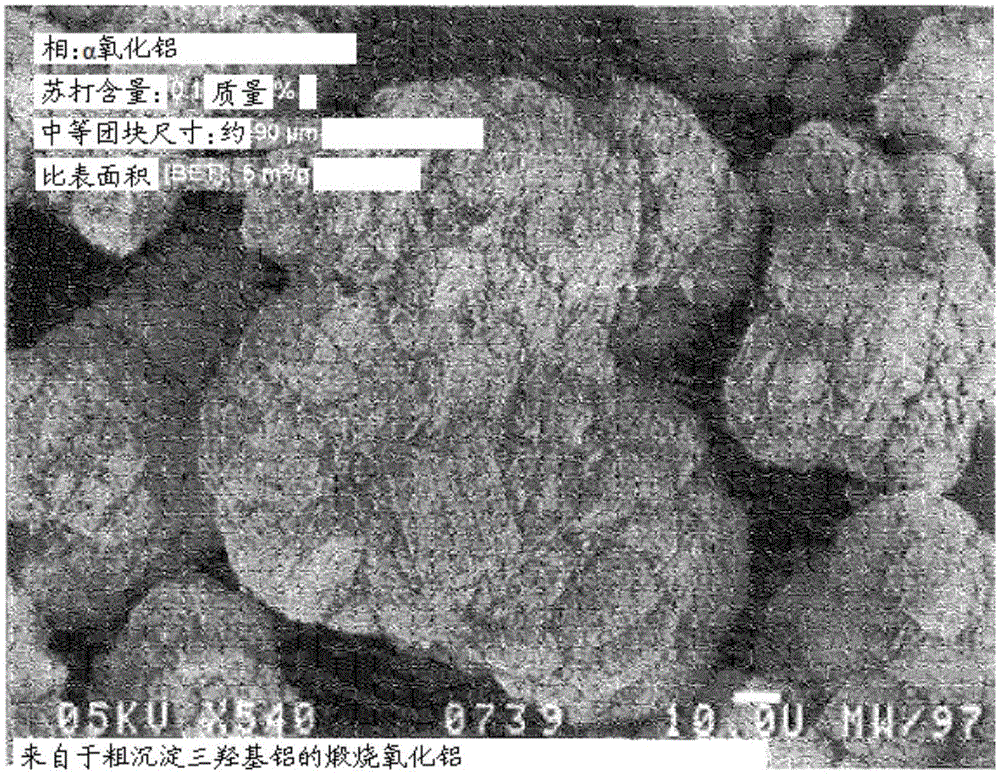

Production Method of a Novel Polishing Alumina

InactiveUS20150315442A1Minimize presenceLess energy expenditurePigmenting treatmentAlkaline earth titanatesParticulatesCombustion

Provided is a method for the formation of particulate compounds of selectable size characteristics, which method includes supporting a slurried particulate precursor on a porous support; heating the support such that aggregates of the particulate compound are formed, and desagglomerating the aggregates into their component particulate. In a preferred embodiment, an aqueous slurry of alumina particulate which has not undergone the alpha transition is contacted with a porous support having defined pore and cavity sizes, such that the slurry occupies at least some of the interstices of the porous support. The slurry and support are heated such that the alumina precursor slurry undergoes the alpha transition. The alpha alumina product is then particulated. The support is of such a material that it is either lost through combustion during heating or otherwise removable after heating, such as during or after particulation, without destroying the particle characteristics imparted by the porous support. Additionally, in a further embodiment, co-components are added to the slurry in order to impart desired properties to the particulated product.

Owner:ALBEMARLE EURO

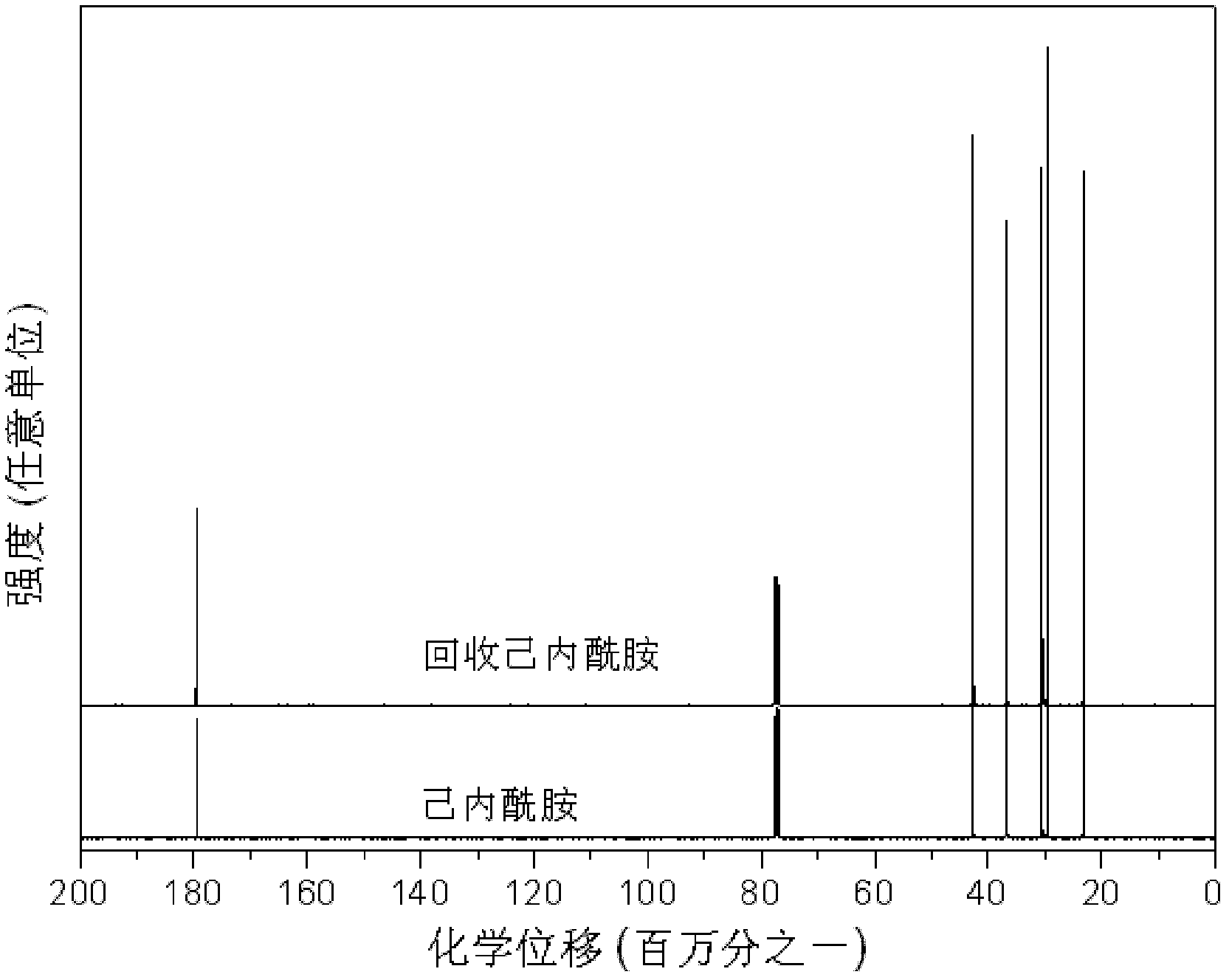

Application of lactam as solvent in nano-grade material preparation

ActiveCN103204525AIncrease added valueMeet the requirements of green environmental protectionMaterial nanotechnologySilicaSolventMacromolecule

Disclosed is an application of lactam as a solvent in nanomaterial preparation. The preparation method comprises a precipitation method, a sol-gel method or a high-temperature pyrolysis method. The method achieves recycling utilization of the lactam solvent, which meets the requirements of environmental protection.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Method for making amorphous particles using a uniform melt-state in a microwave generated plasma torch

ActiveUS20140155249A1Improve thermal performanceImprove toleranceCyanogen compoundsNitrogen compoundsNon oxide ceramicsMolten state

Feed material comprising uniform solution precursor droplets is processed in a uniform melt state using microwave generated plasma. The plasma torch employed is capable of generating laminar gas flows and providing a uniform temperature profile within the plasma. Plasma exhaust products are quenched at high rates to yield amorphous products. Products of this process include spherical, highly porous and amorphous oxide ceramic particles such as magnesia-yttria (MgO—Y2O3). The present invention can also be used to produce amorphous non oxide ceramic particles comprised of Boron, Carbon, and Nitrogen which can be subsequently consolidated into super hard materials.

Owner:6K INC

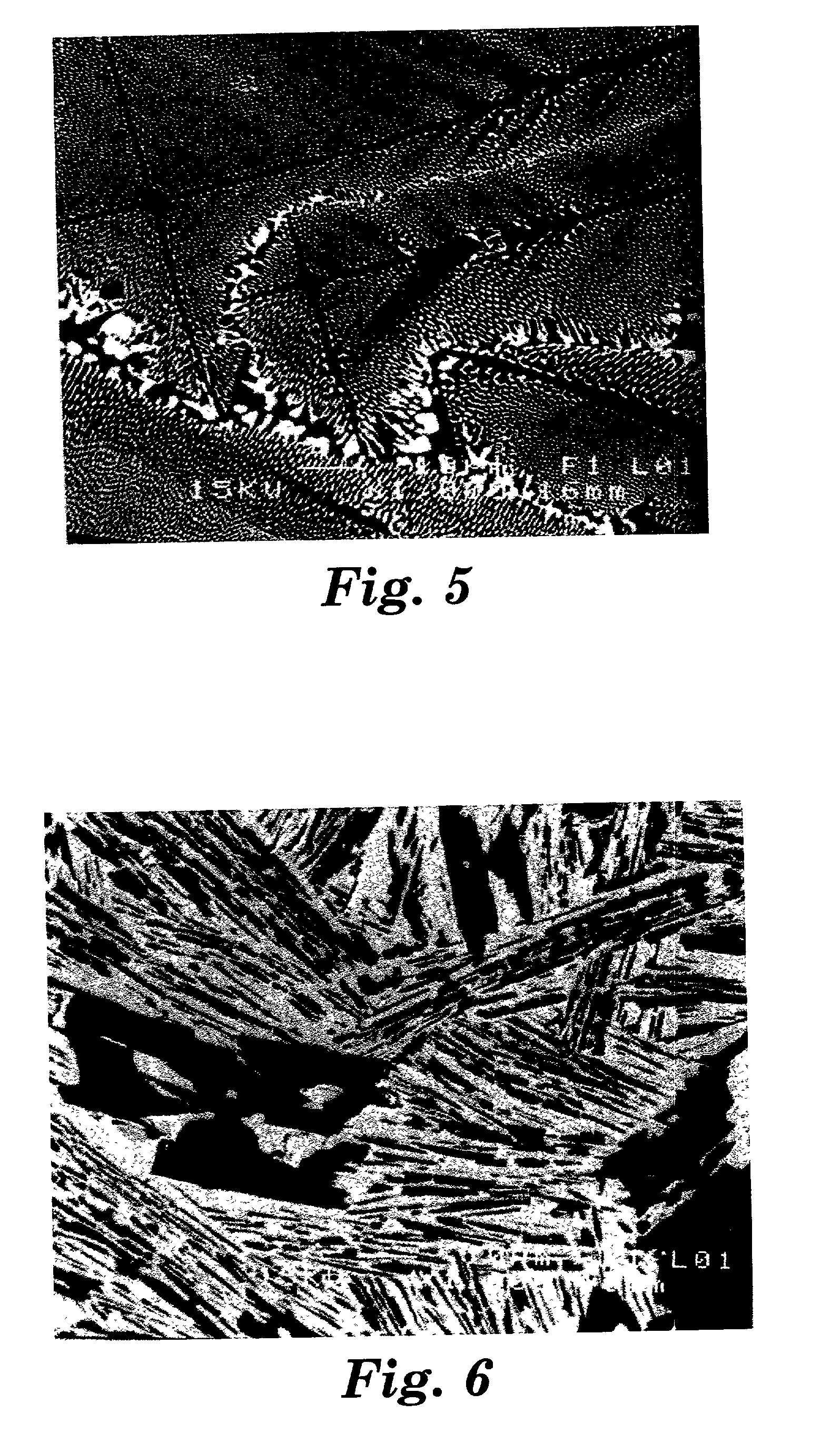

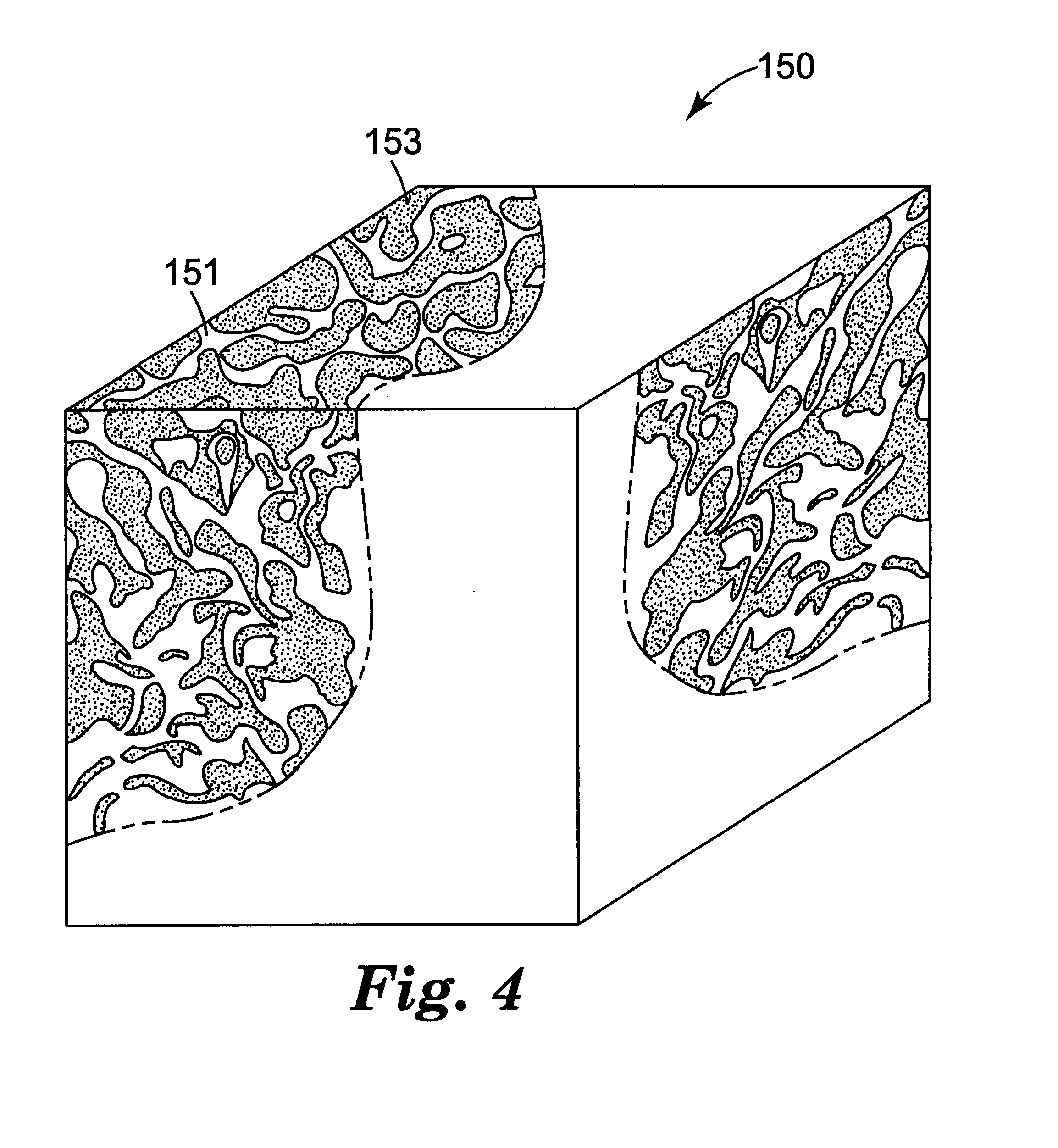

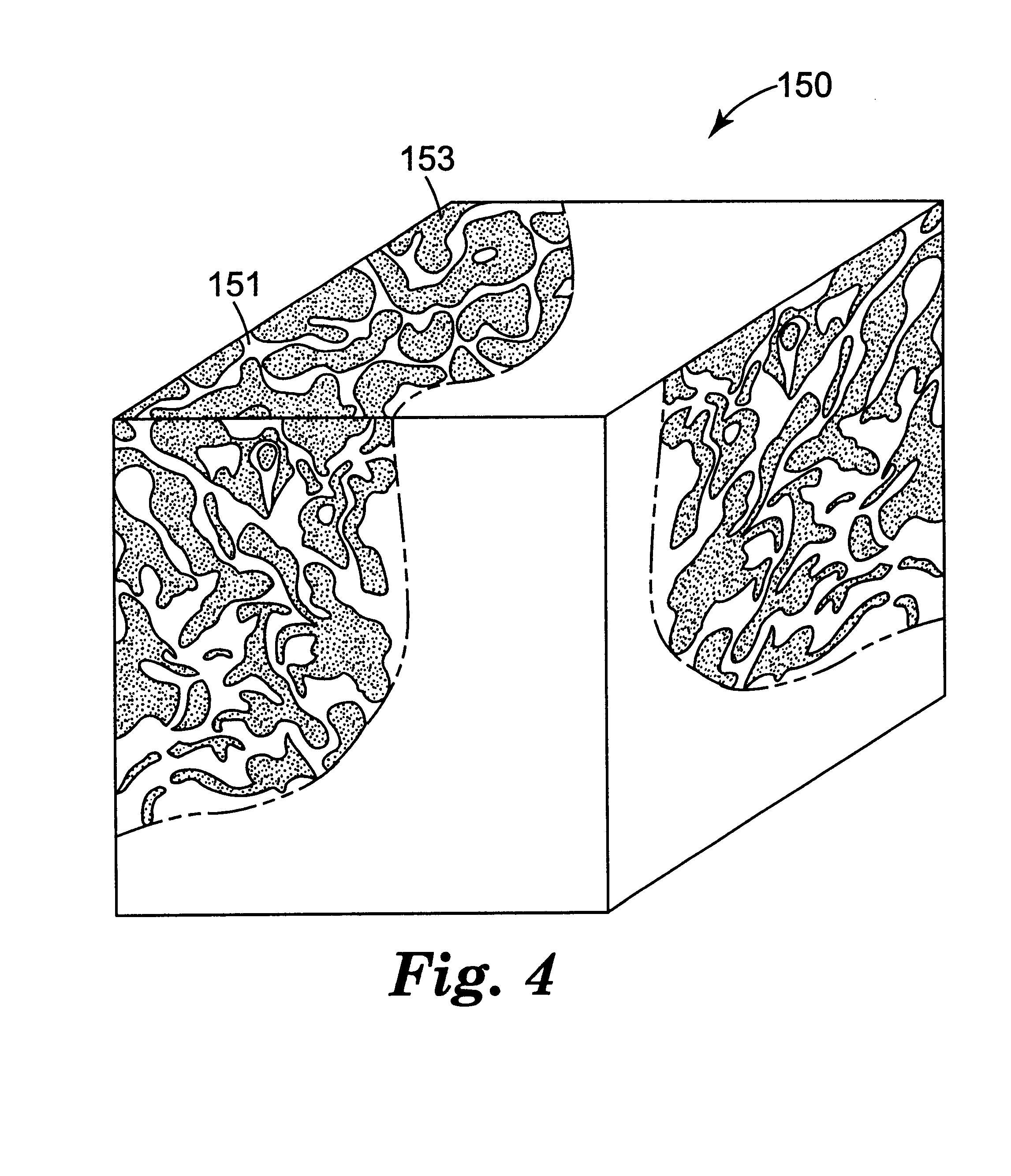

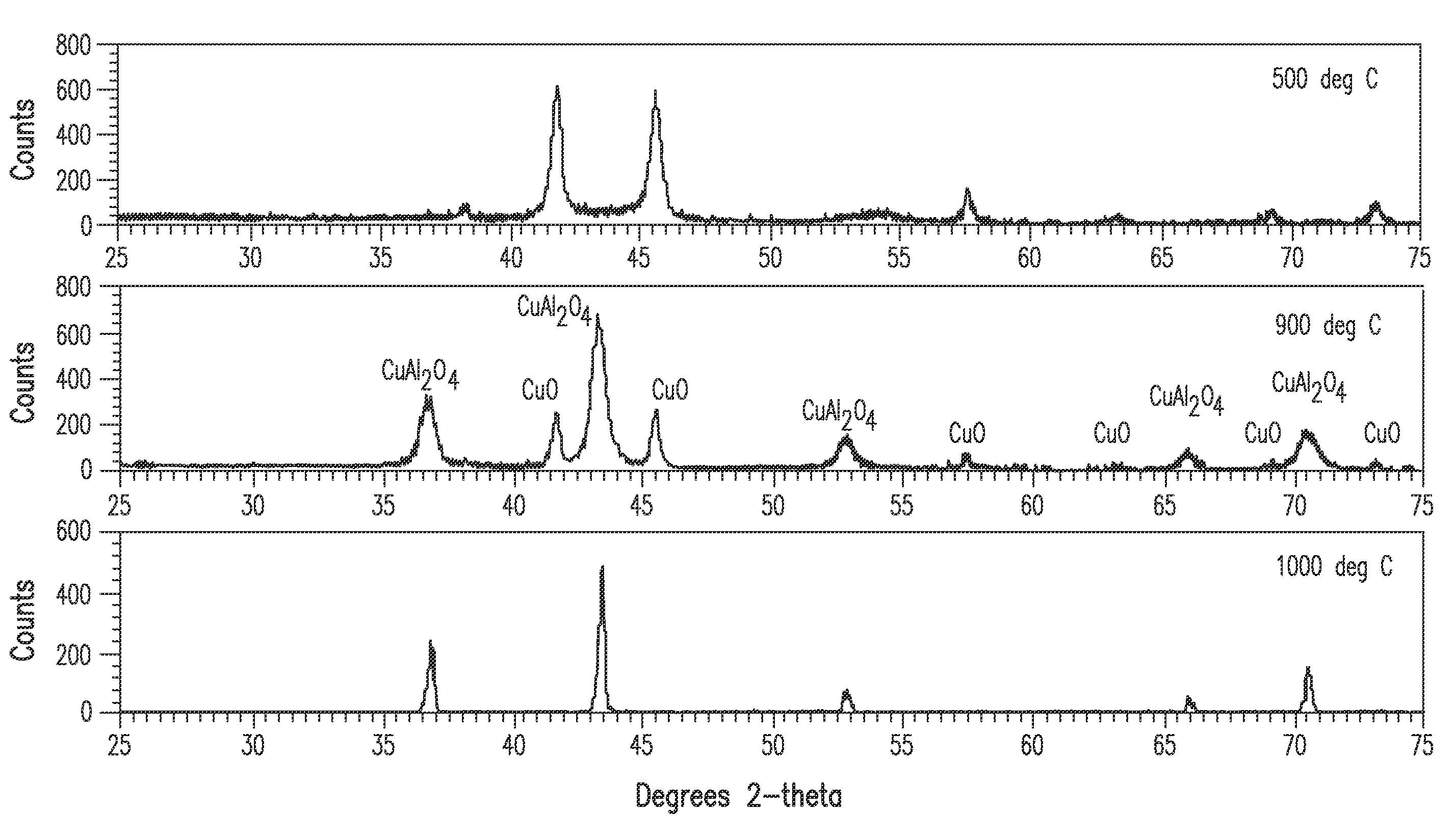

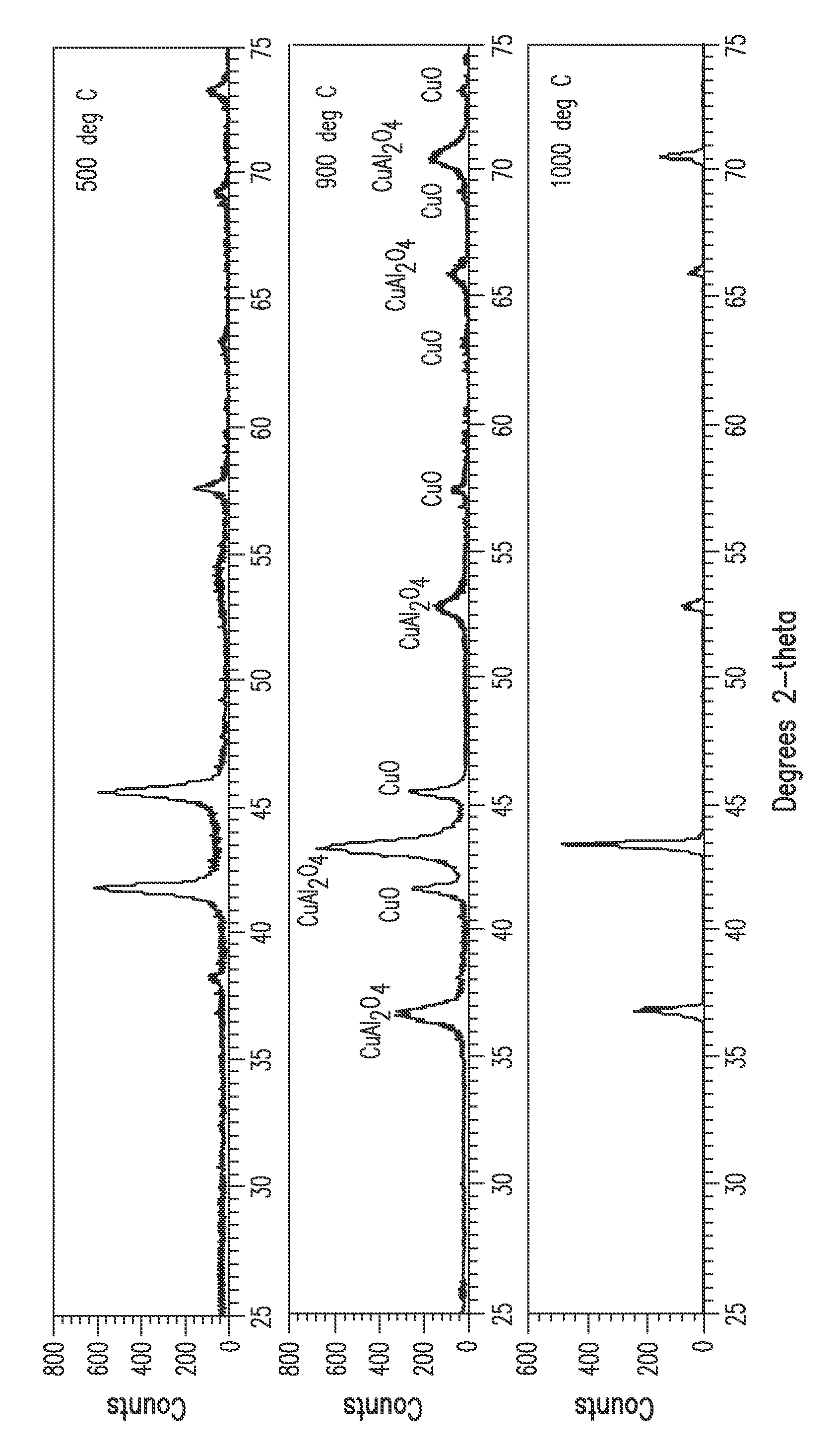

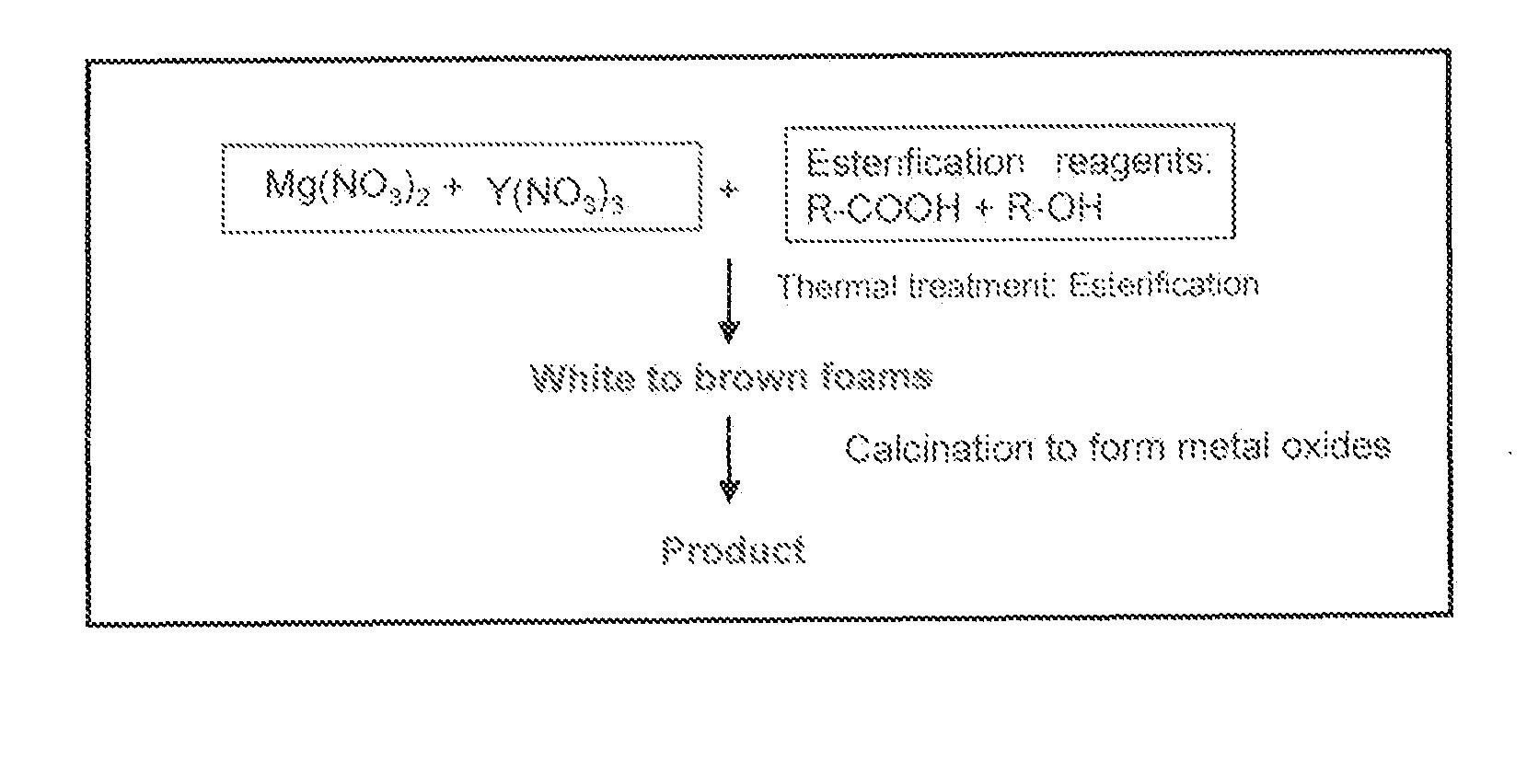

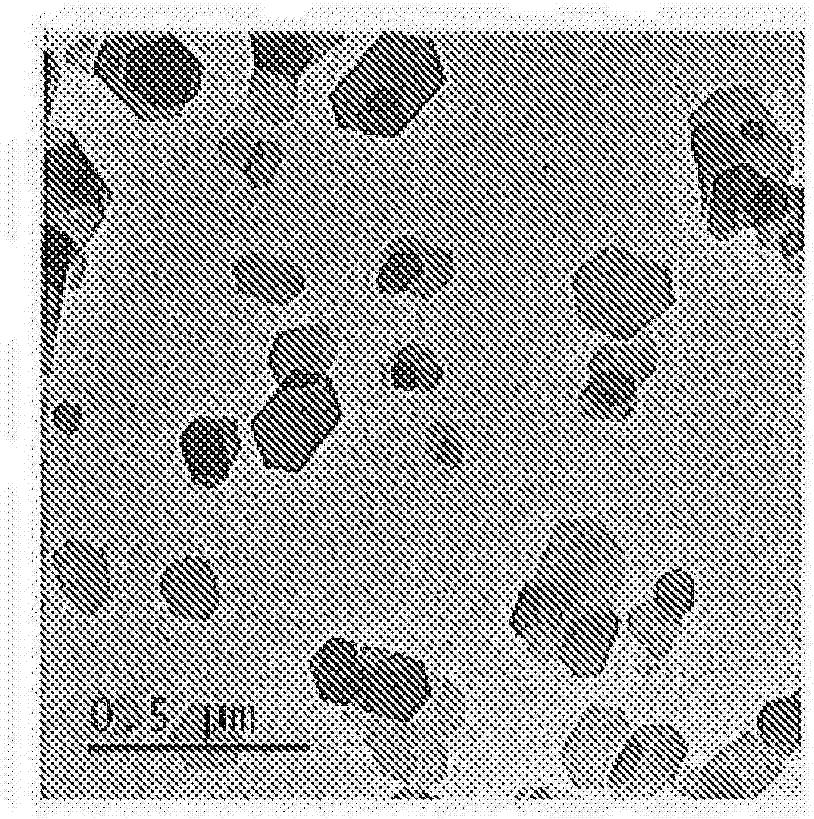

Method of synthesizing multi-iphase oxide ceramics with small phase domain sizes

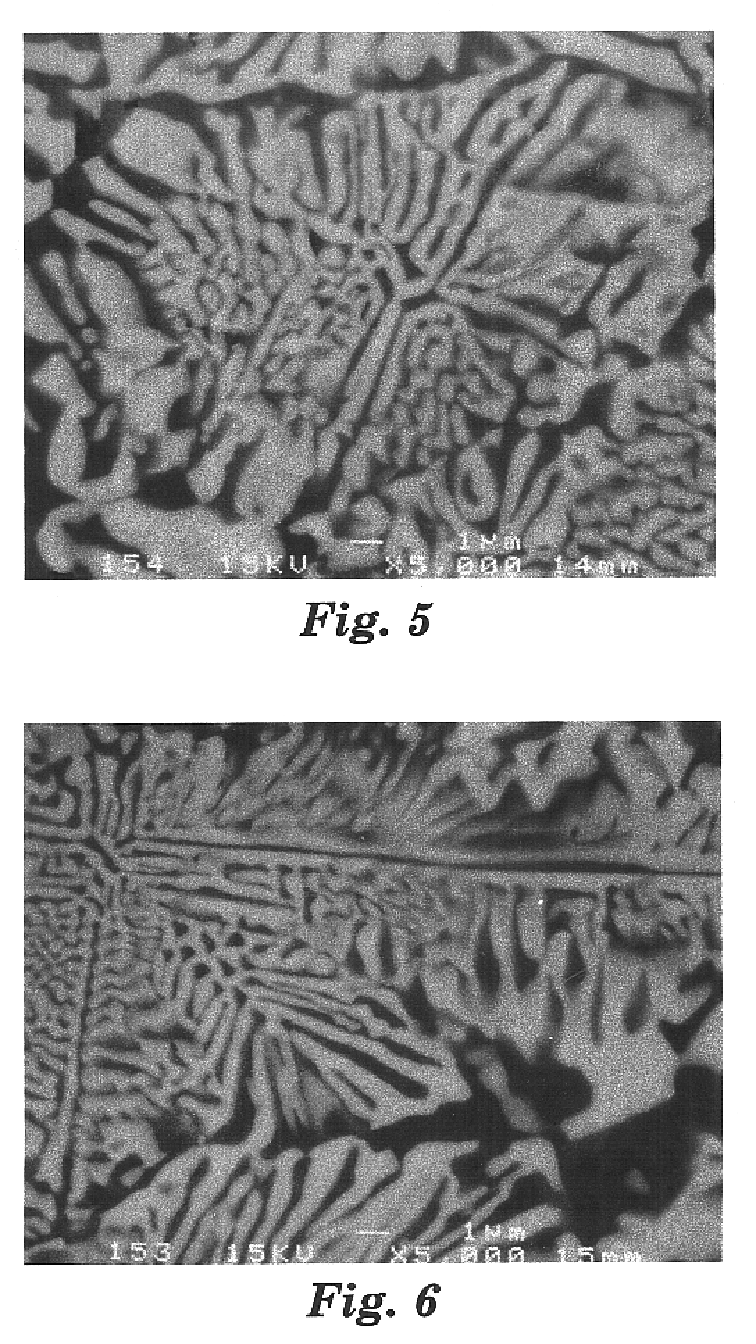

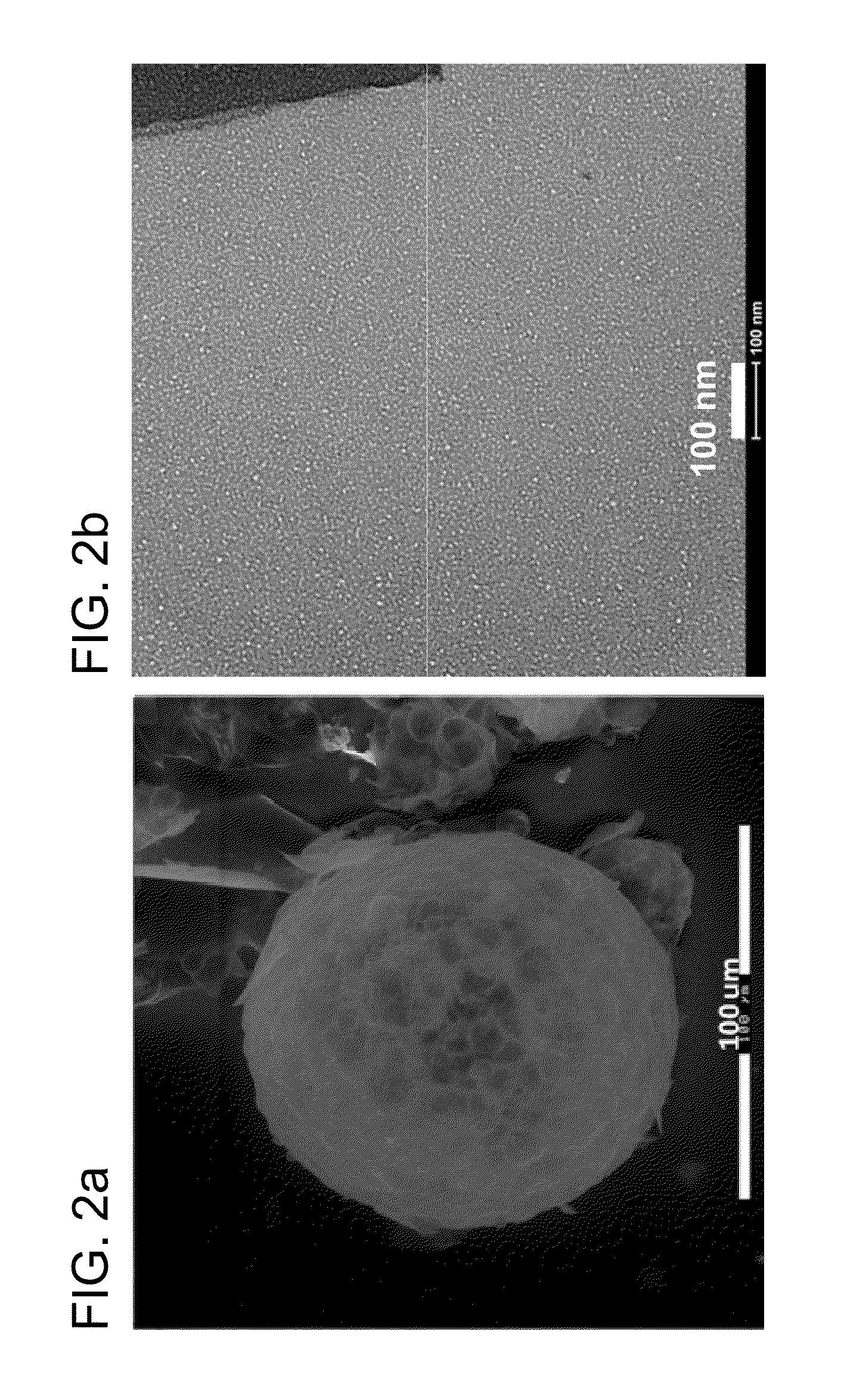

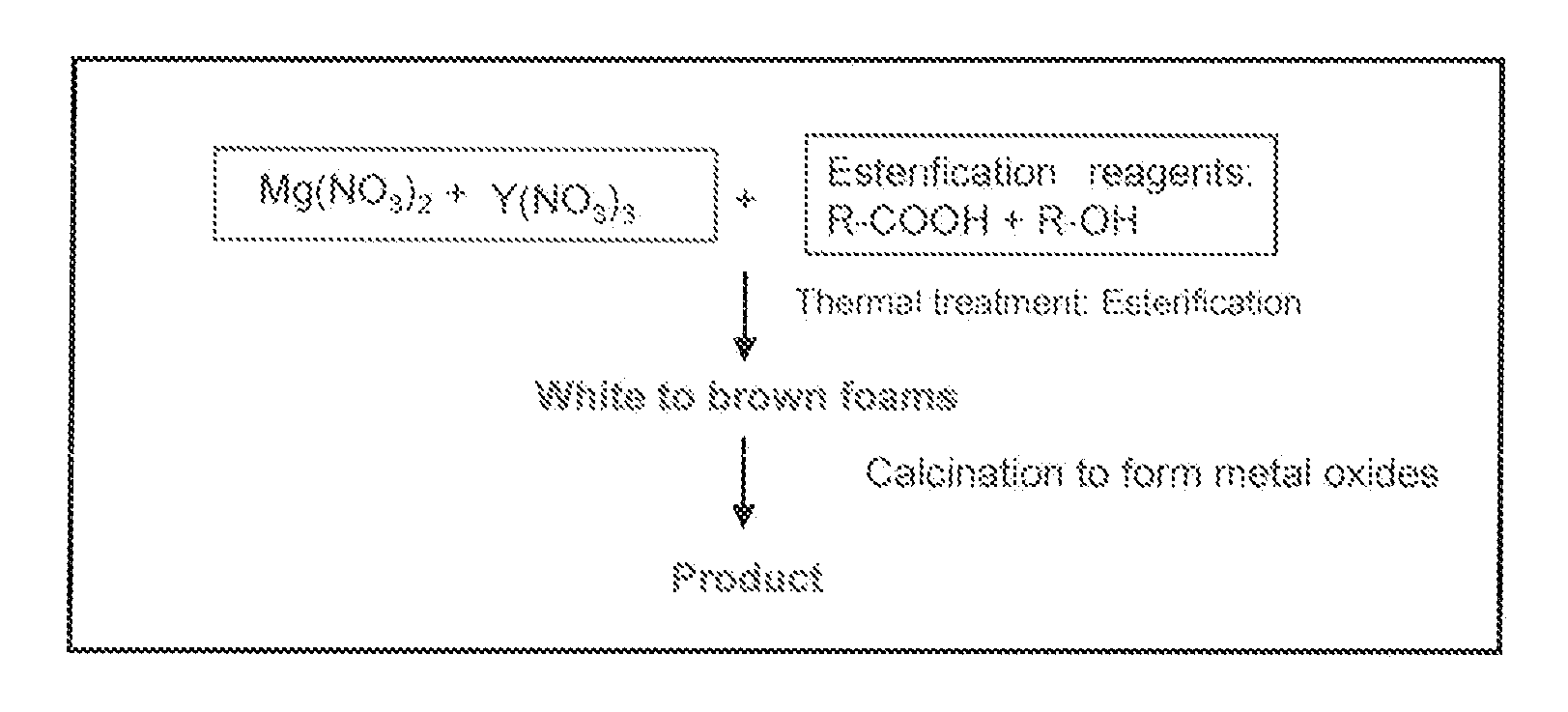

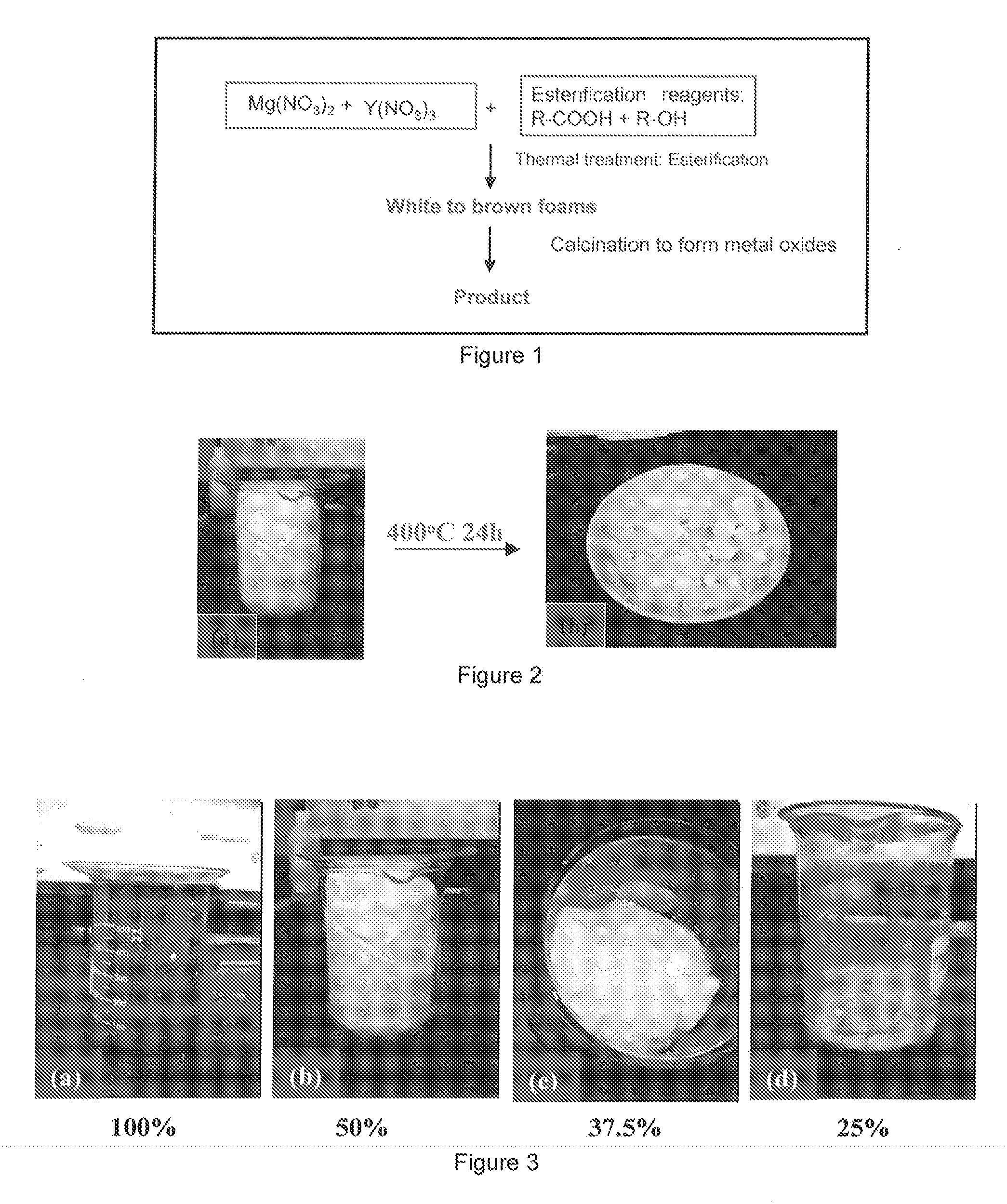

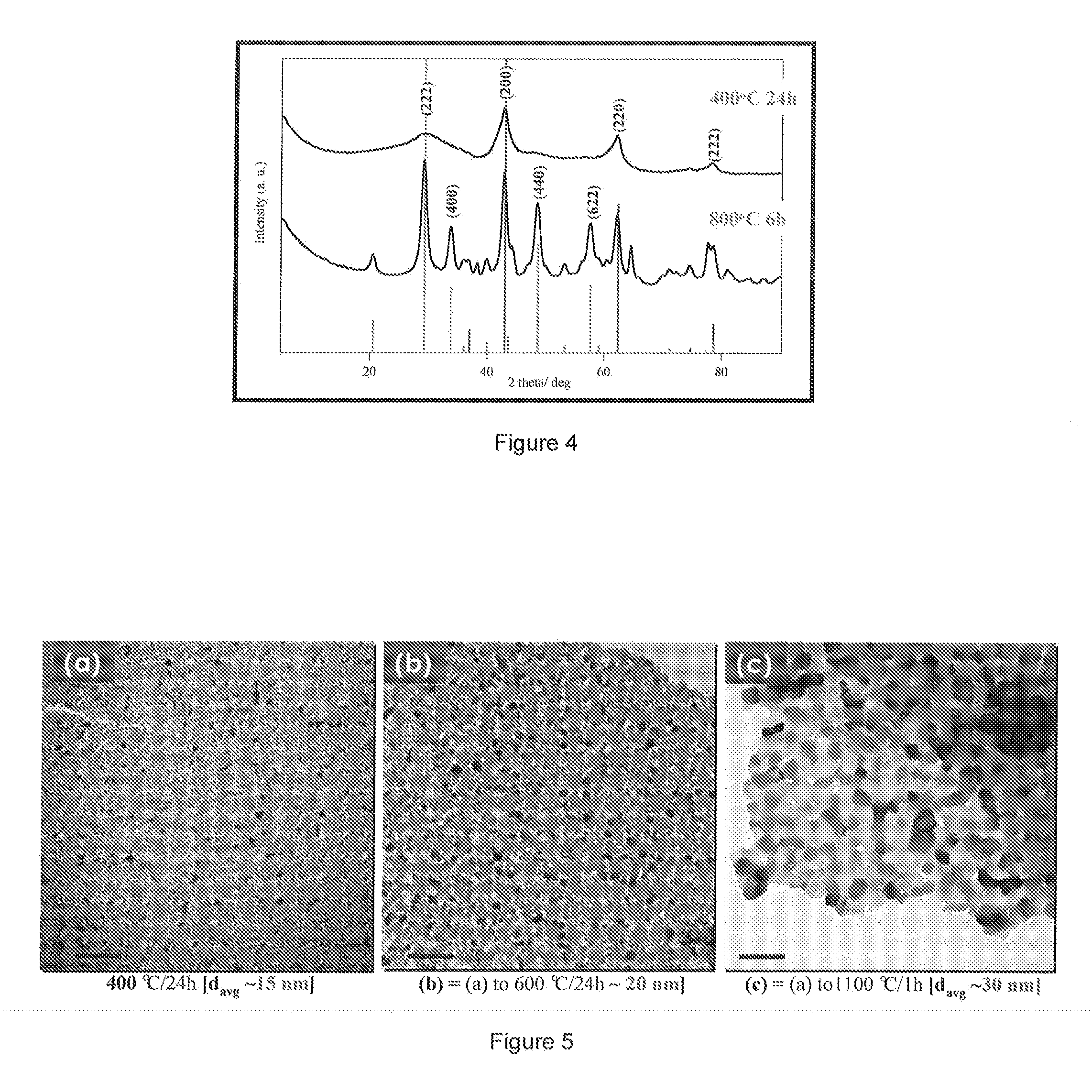

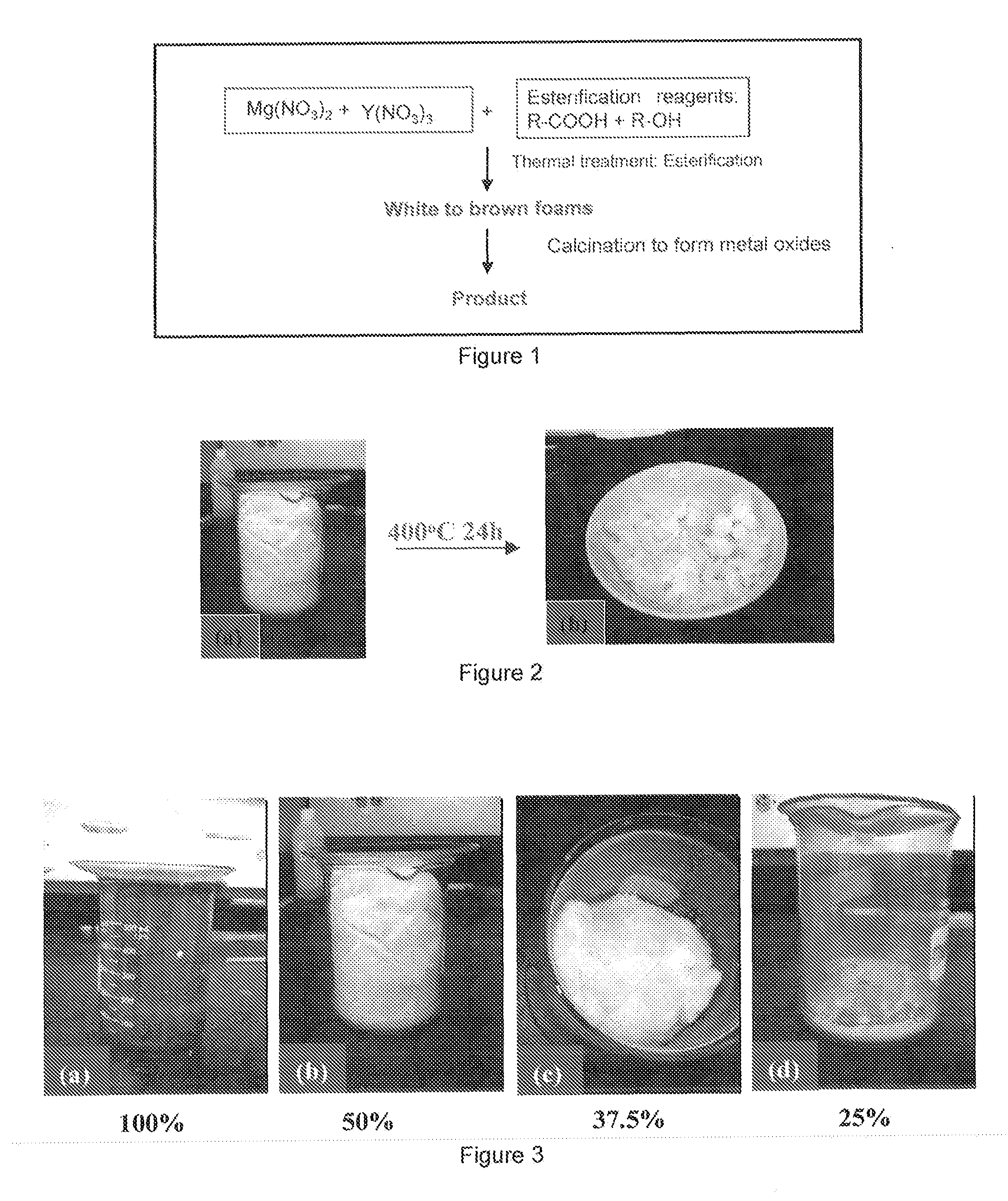

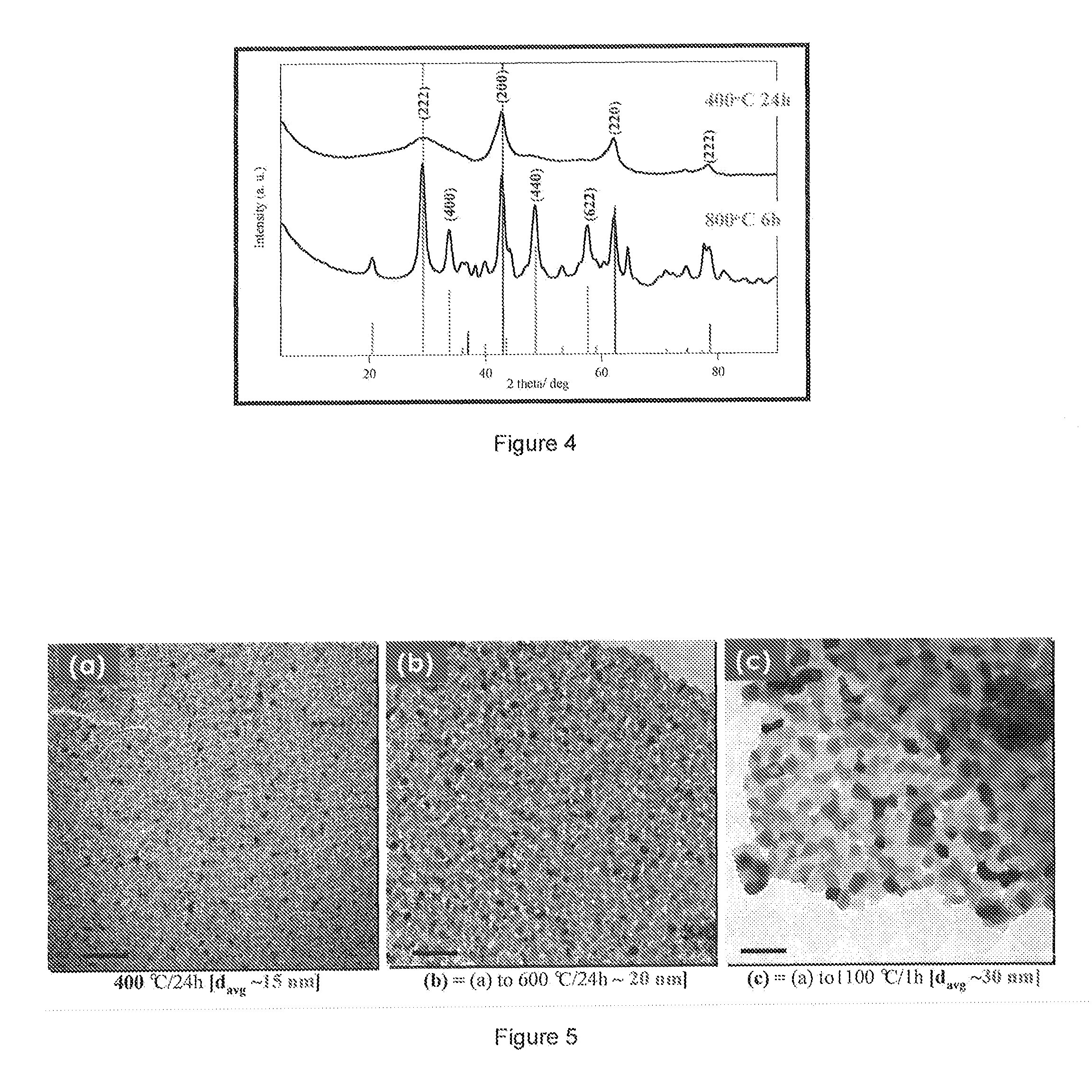

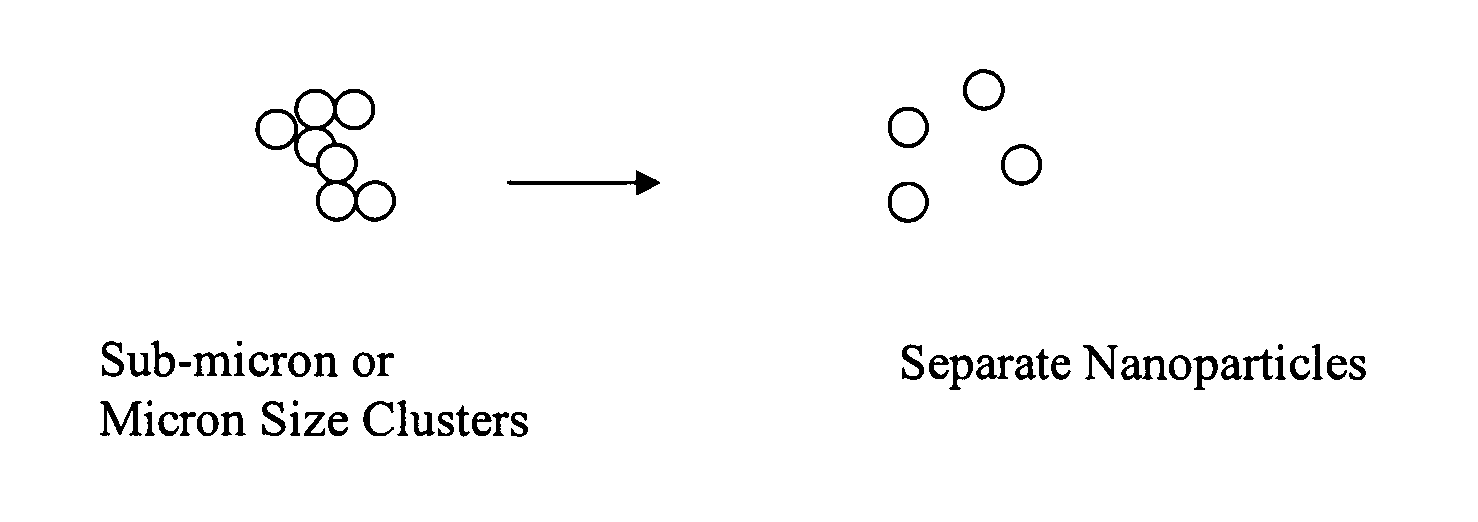

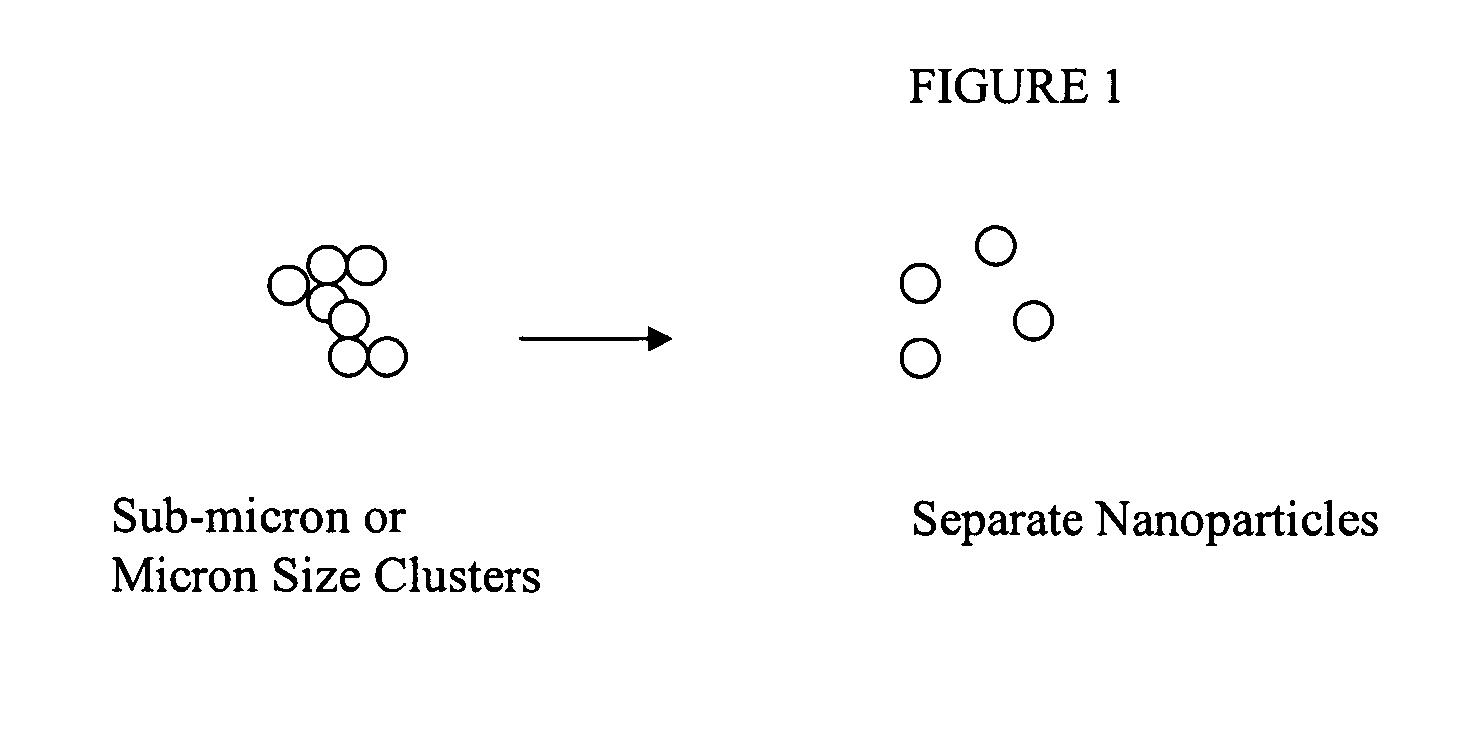

InactiveUS20120322645A1Inhibit aggregationPrevent precipitationMaterial nanotechnologyOxide/hydroxide preparationOxide ceramicsMicroscopic scale

Nanocomposites of multi-phase metal oxide ceramics have been produced from water soluble salts of the resulting metal oxides by a foaming esterification sol-gel method. The evolution of volatile gases at elevated temperature during the esterification reaction causes the formation of a foam product. Nanocomposites of multi-phase metal oxide ceramics have also been produced by a cation polymer precursor method. In this second method, the metal cations are chelated by the polymer and the resulting product is gelled and foamed. Calcination of the resulting foams gives nanocomposite powders with extremely fine, uniform grains and phase domains. These microstructures are remarkably stable both under post-calcination heat treatment and during consolidation by hot-pressing.

Owner:UNIV OF CONNECTICUT CENT FOR SCI & TECH COMMLIZATION

Heat-insulating material

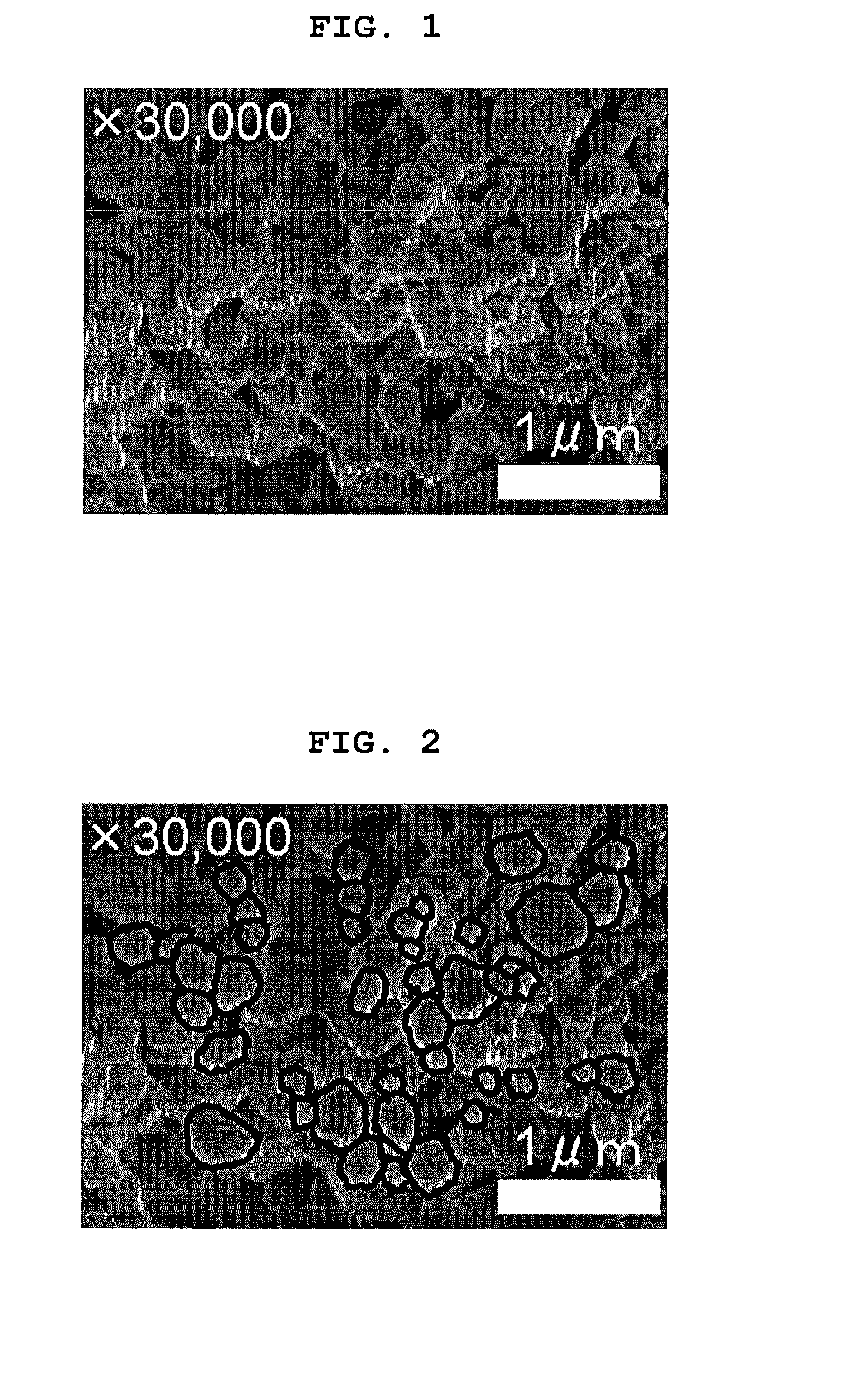

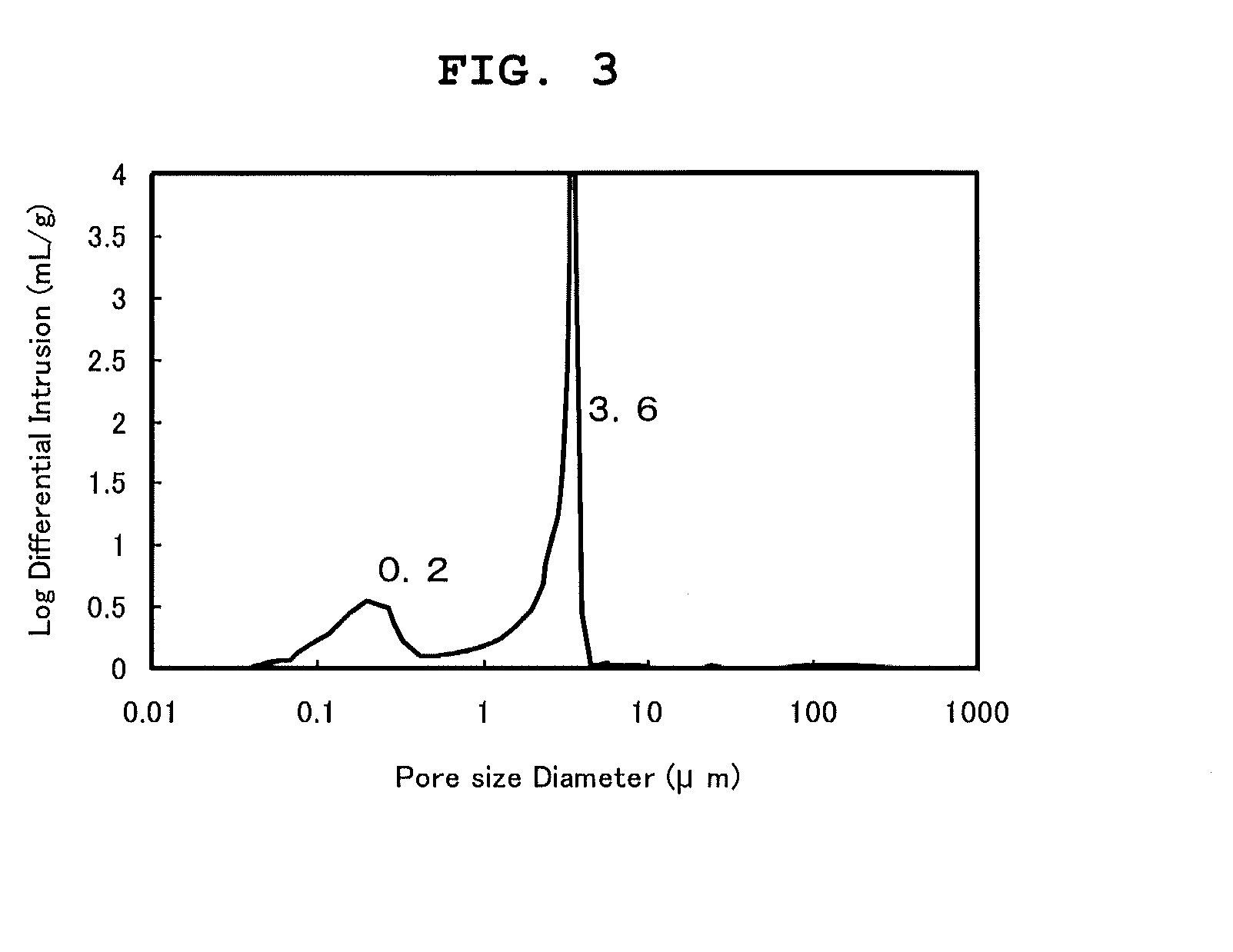

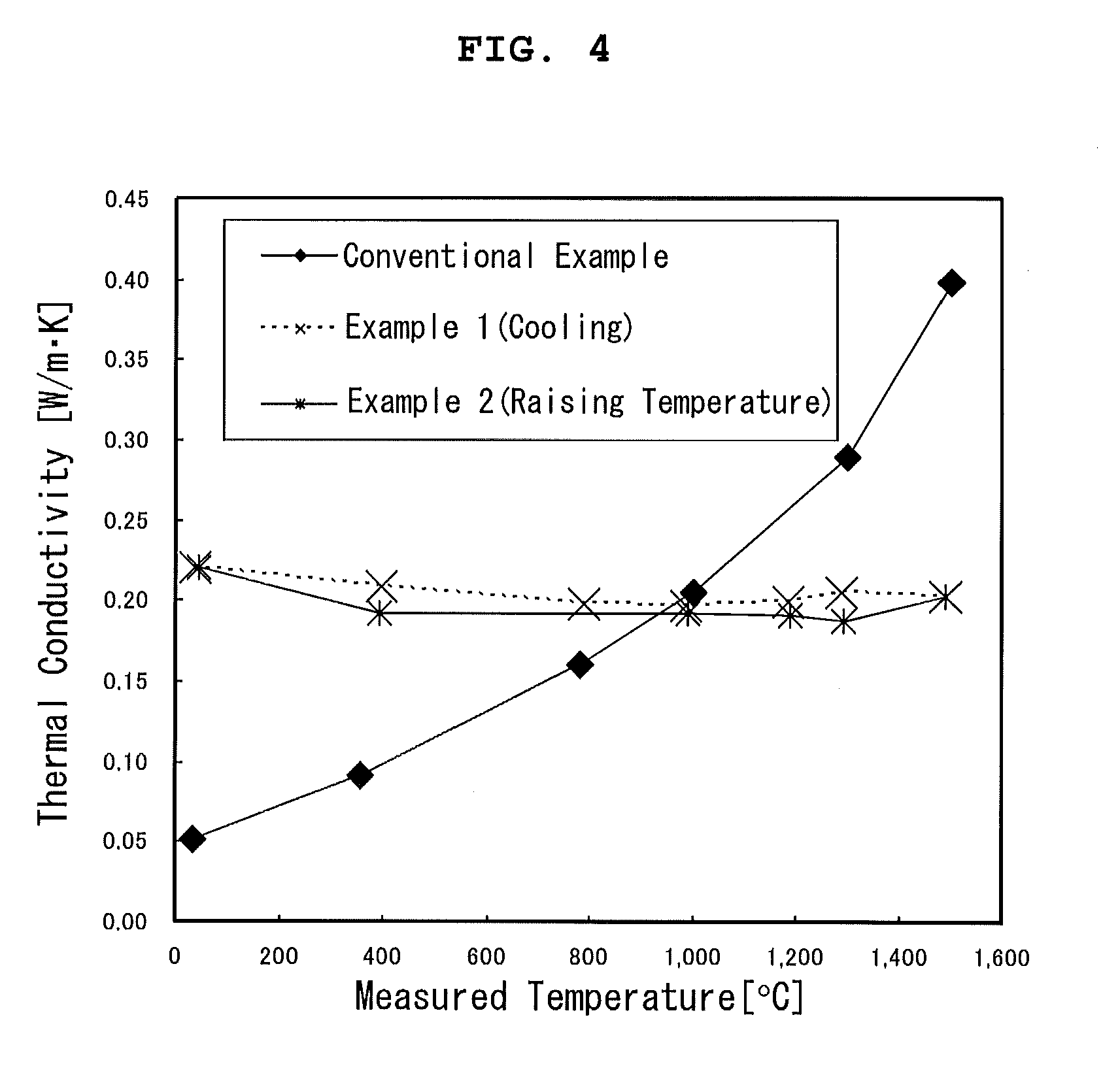

ActiveUS20140112861A1Reduce in quantityLess energy supplyMangesium aluminatesCeramicwareMetallurgyPore diameter

A heat-insulating material is provided in which thermal conductivity is controlled not to increase and good insulation properties are held even in a high temperature range. The heat-insulating material is formed of a spinel porous sintered body having a porosity of 65 to 90 vol. % and represented by a chemical formula XAl2O4 (X═Zn, Fe, Mg, Ni, or Mn) which is arranged such that large pores having a diameter of greater than 1000 μm occupy 25 vol. % or less of the total pore volume, fine pores having a diameter of 0.45 μm or less occupy 5 to 40 vol. % of the volume of the pores having a diameter of 1000 μm or less, at least one pore-diameter distribution peak is within a range of 0.14 to 10 μm, and is formed of sintered particles having a calculated average particle diameter of 0.04 to 1 μm.

Owner:COORSTEK INC

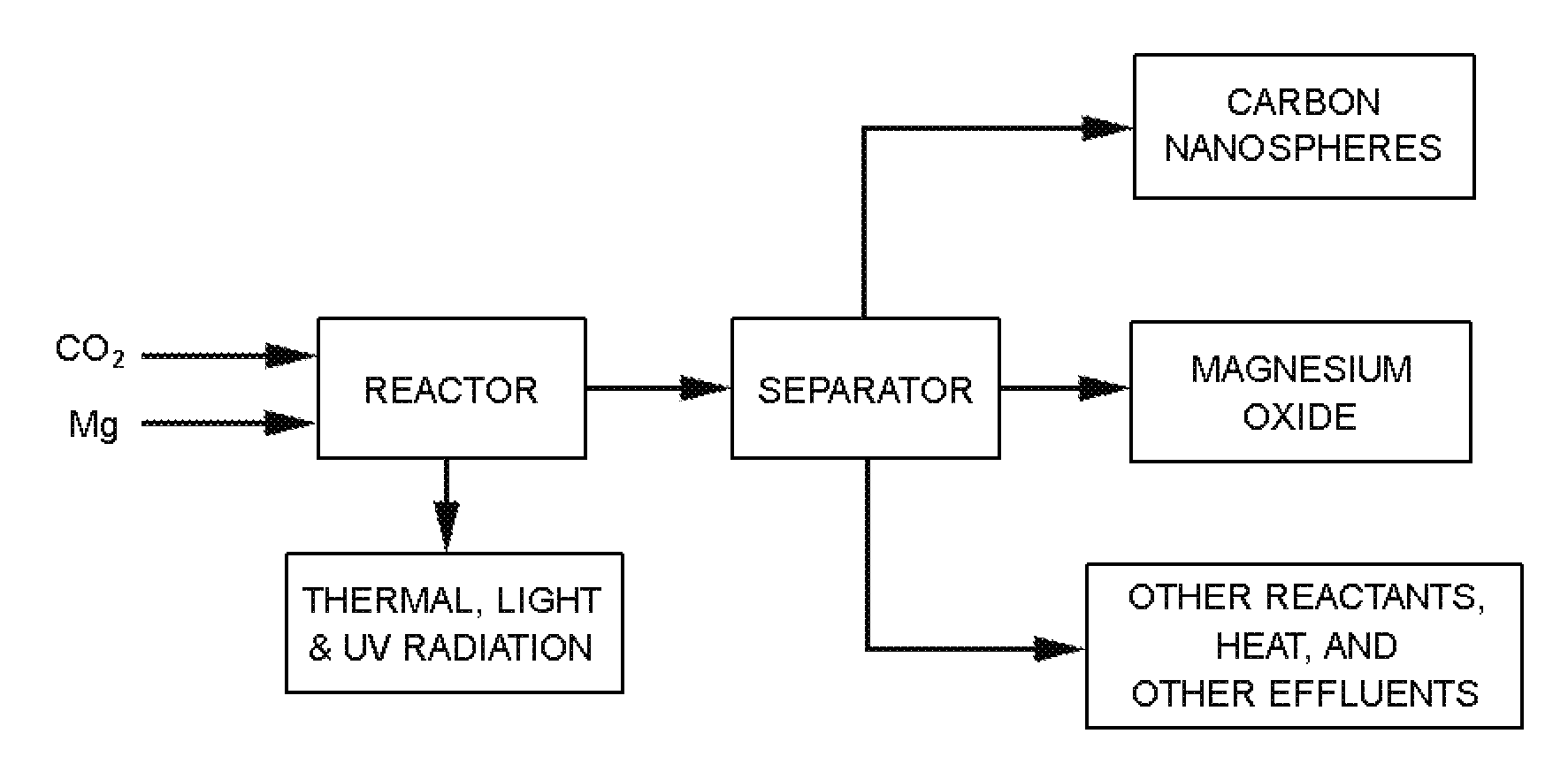

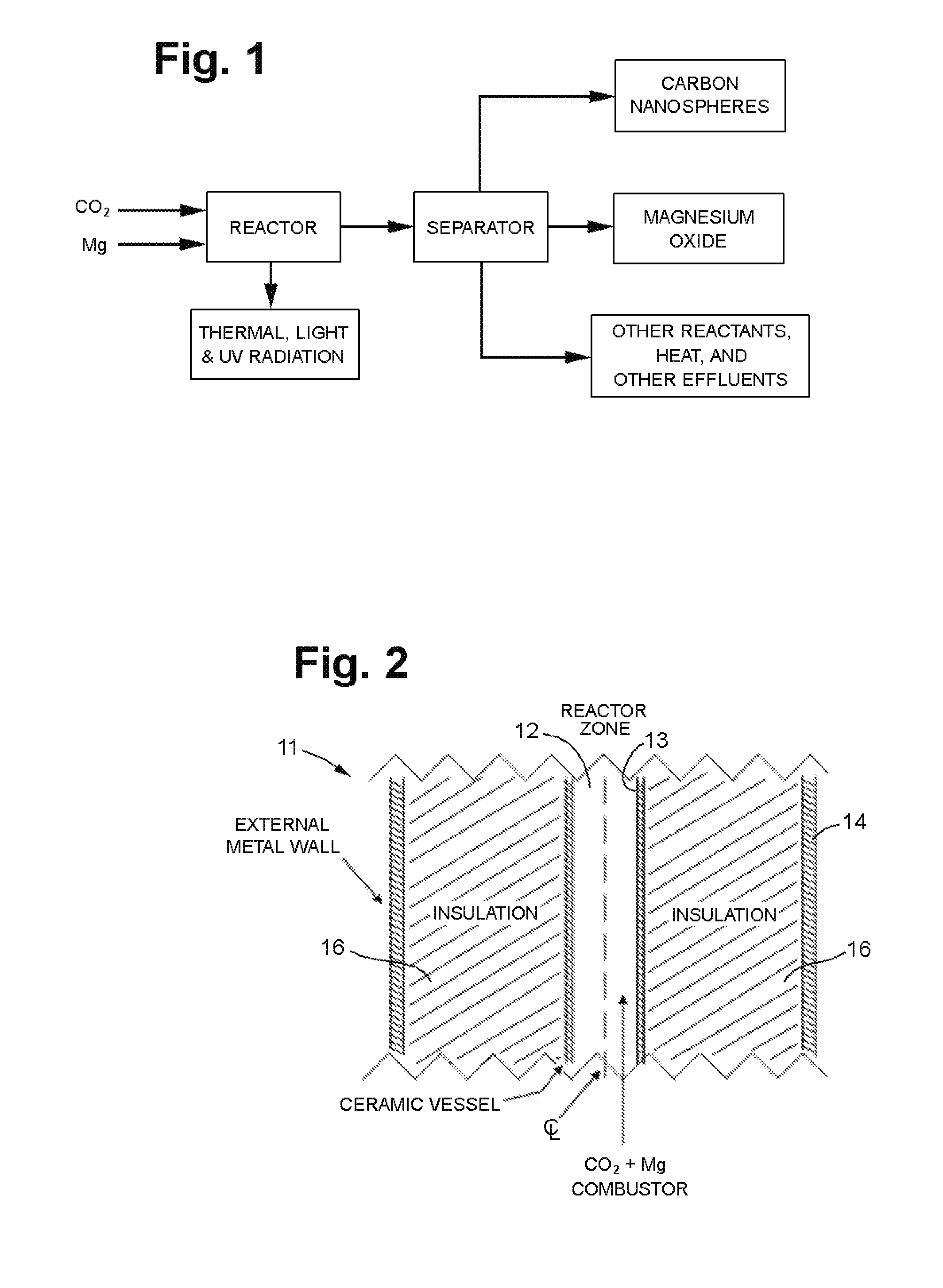

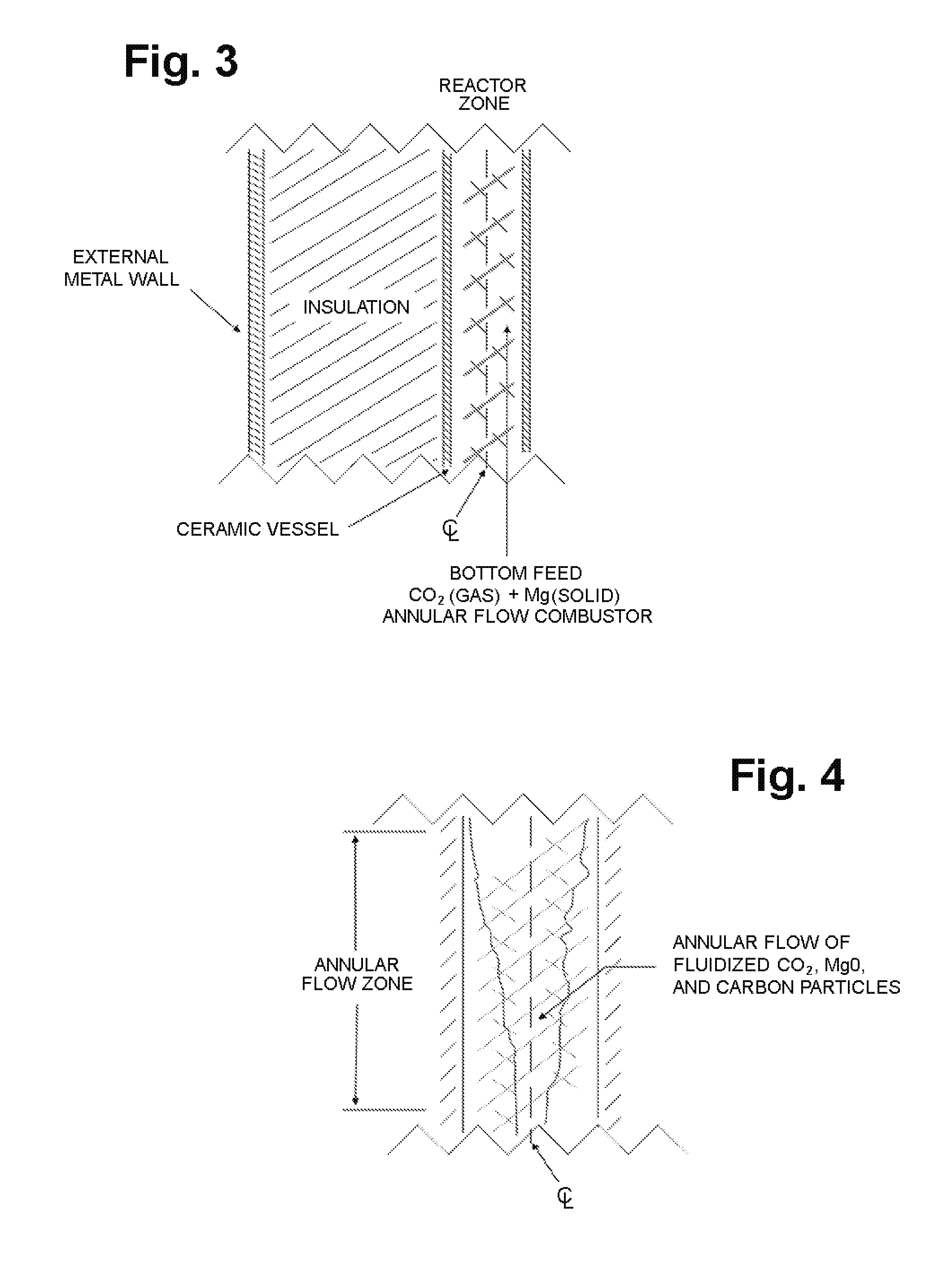

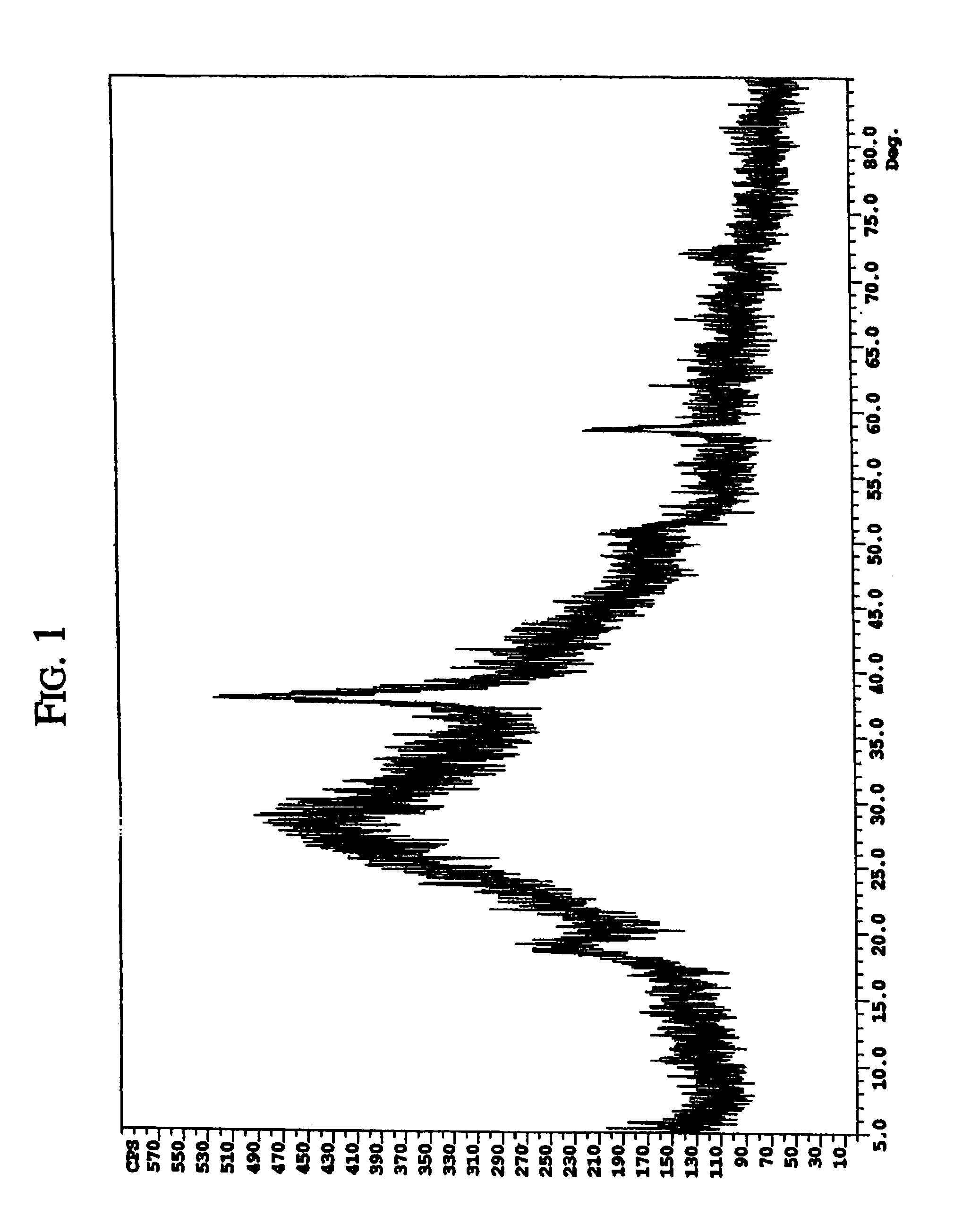

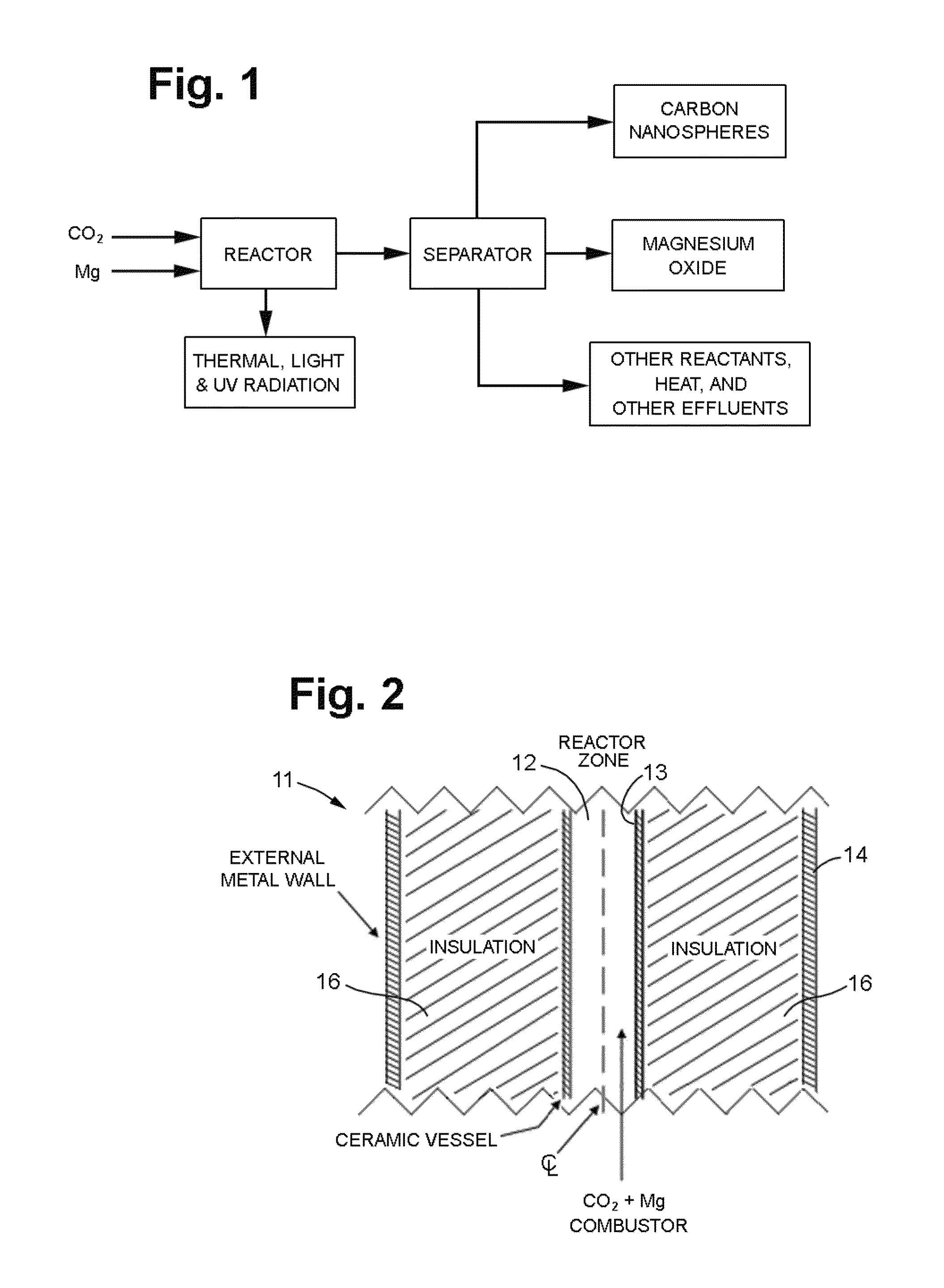

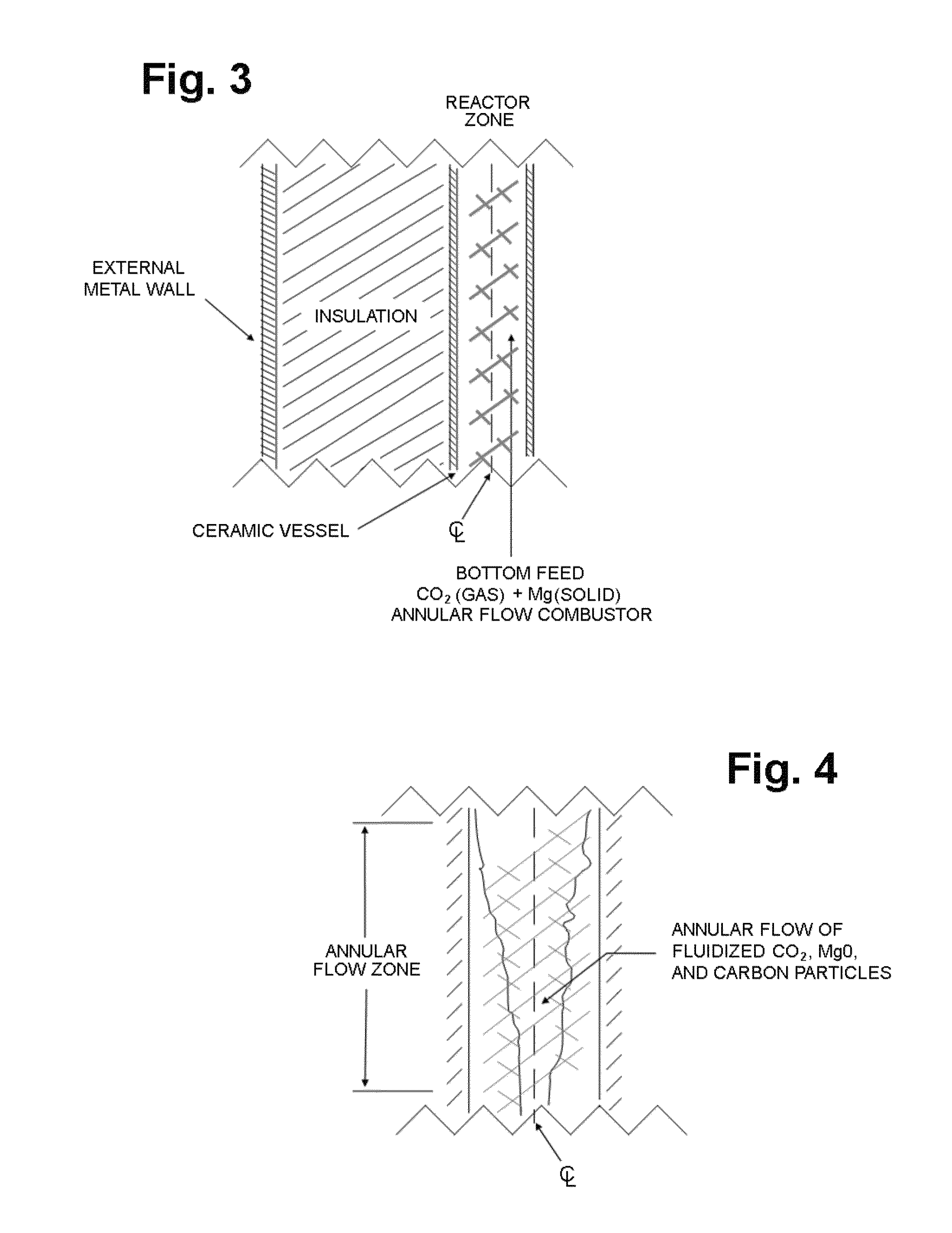

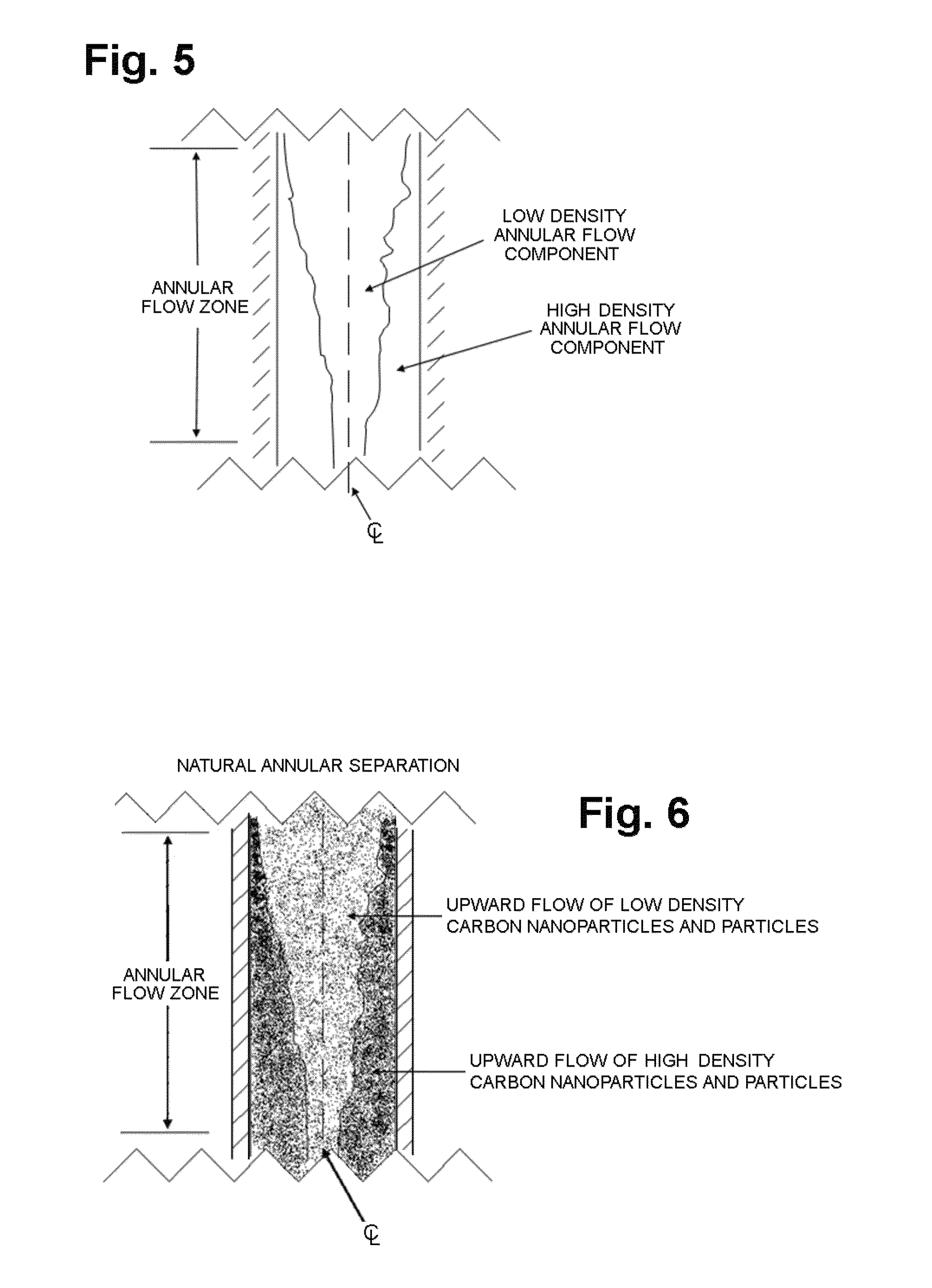

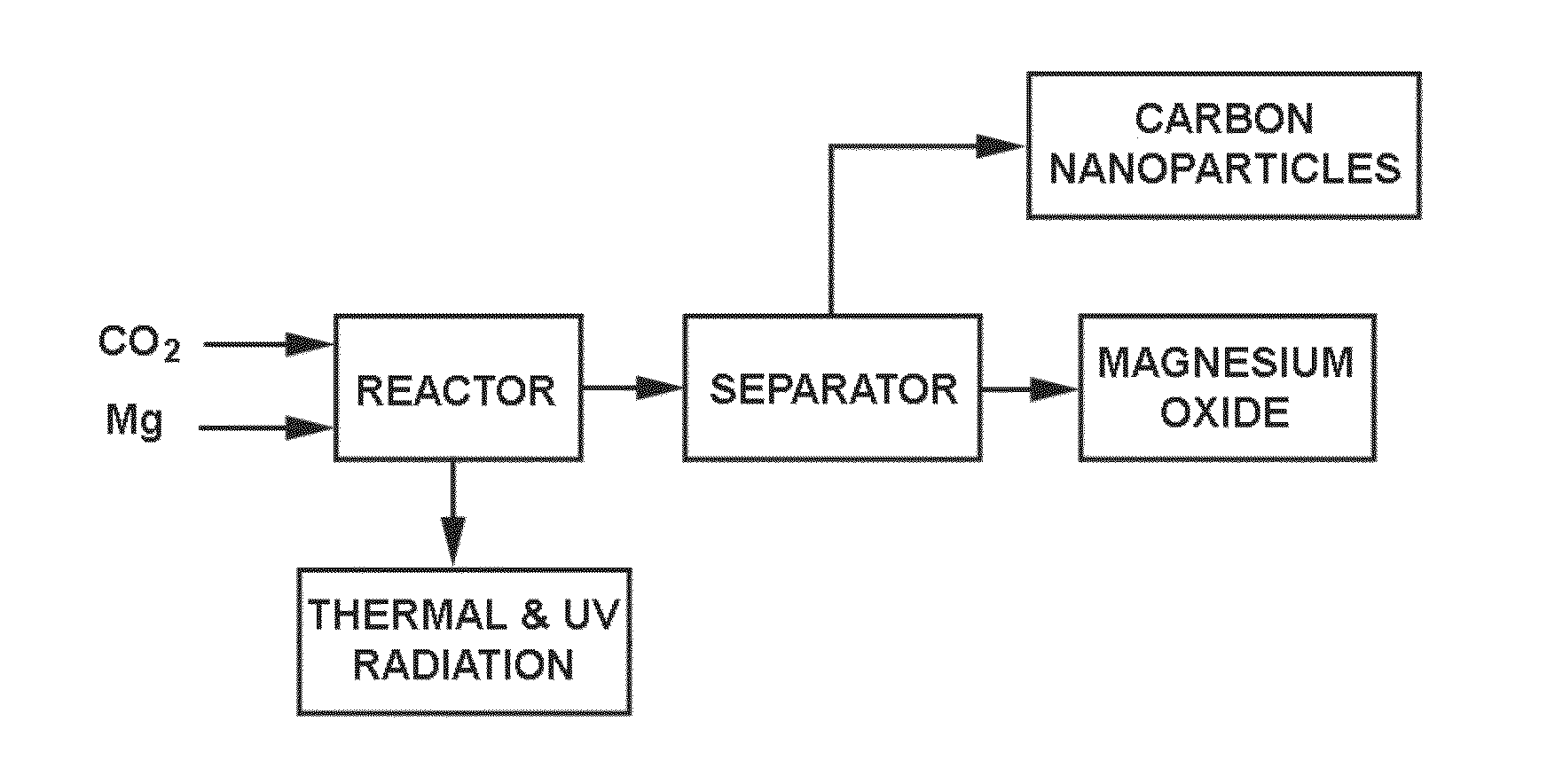

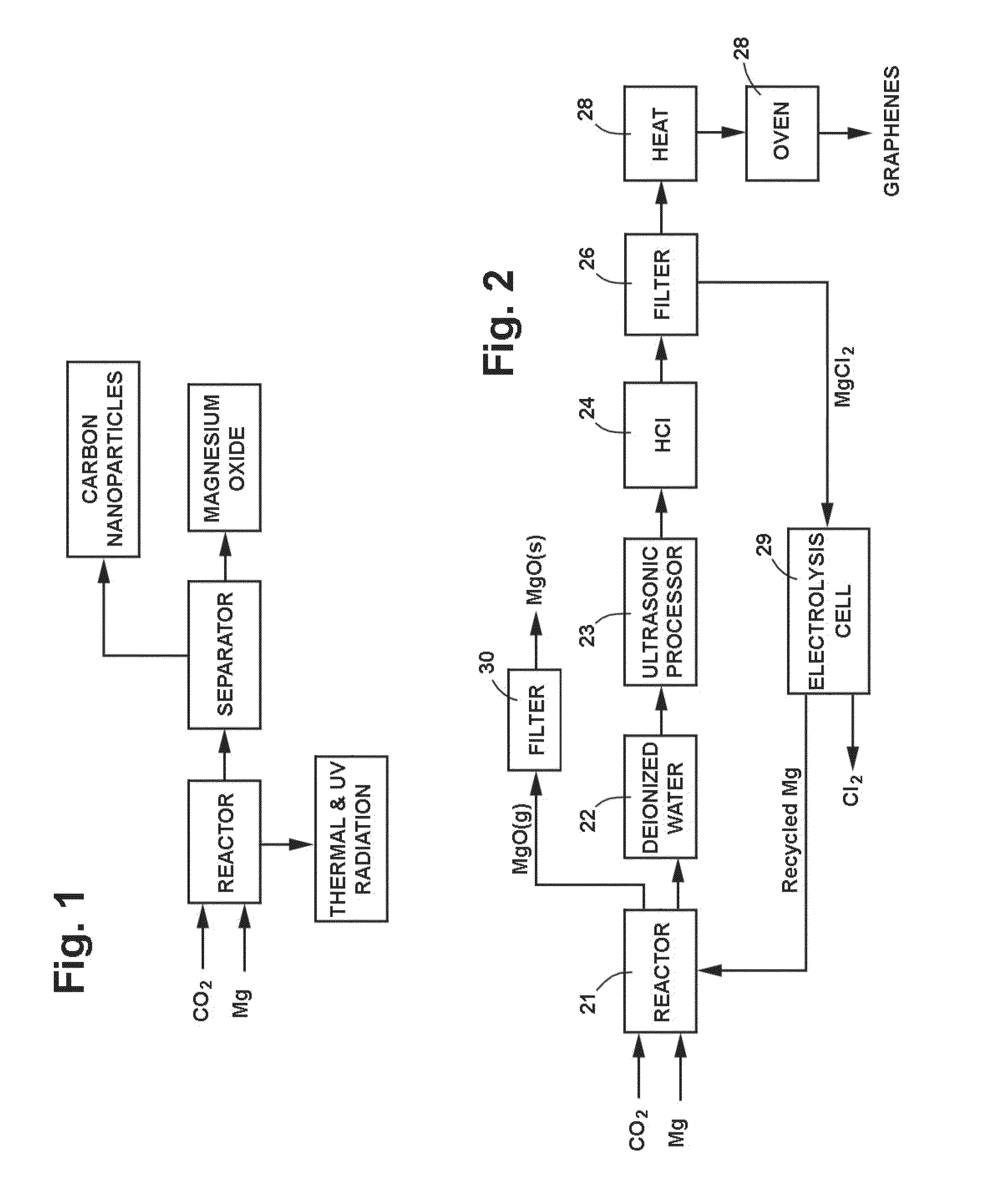

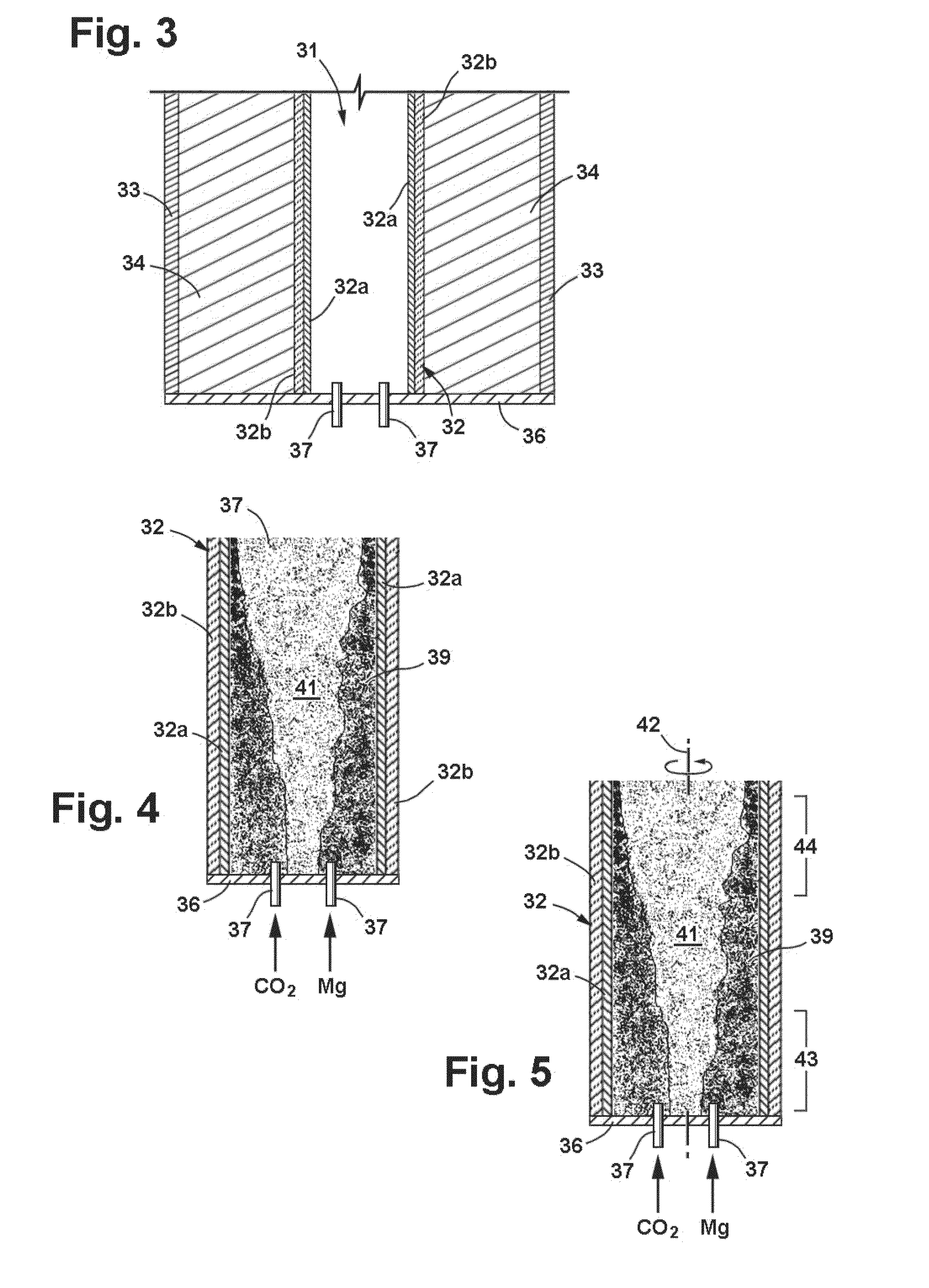

Process for the Production of Carbon Nanospheres and Sequestration of Carbon

InactiveUS20110256049A1Mass productionControlled morphologyMaterial nanotechnologyMangesium aluminatesReaction temperatureCarbon nanotube

Process for producing carbon nanospheres and other nano materials with carbon dioxide and magnesium. The carbon dioxide and magnesium are combusted together in a reactor to produce carbon nanospheres and magnesium oxide, which are then separated to provide the individual reaction products. The reaction occurs at a very high temperature, e.g. 2000° F.-5000° F. and also produces large amounts of useful energy in the form of heat and light, including infrared and ultraviolet radiation. Other oxidizing agents such as aluminum can be combined with the magnesium, and the metal oxides produced by the reaction can be recycled to provide additional oxidizing agents for combustion with the carbon dioxide. By varying the reaction temperature, the morphology of the carbon products can be controlled.

Owner:GRAPHENE TECH

Mixed metal oxide sorbents

The present invention is directed to methods for reducing SOx, NOx, and CO emissions from a fluid stream comprising contacting said fluid stream with a compound comprising magnesium and aluminum and having an X-ray diffraction pattern displaying at least a reflection at a two theta peak position at about 43 degrees and about 62 degrees, wherein the ratio of magnesium to aluminum in the compound is from about 1:1 to about 10:1. In one embodiment, the ratio of magnesium to aluminum in the compound is from about 1:1 to about 6:1. In one embodiment, the ratio of magnesium to aluminum in the compound is from about 1.5:1 to about 10:1. In another embodiment, the invention is directed to methods wherein the ratio of magnesium to aluminum in the compound is from about 1.5:1 to about 6:1.

Owner:JOHNSON MATTHEY PROCESS TECH

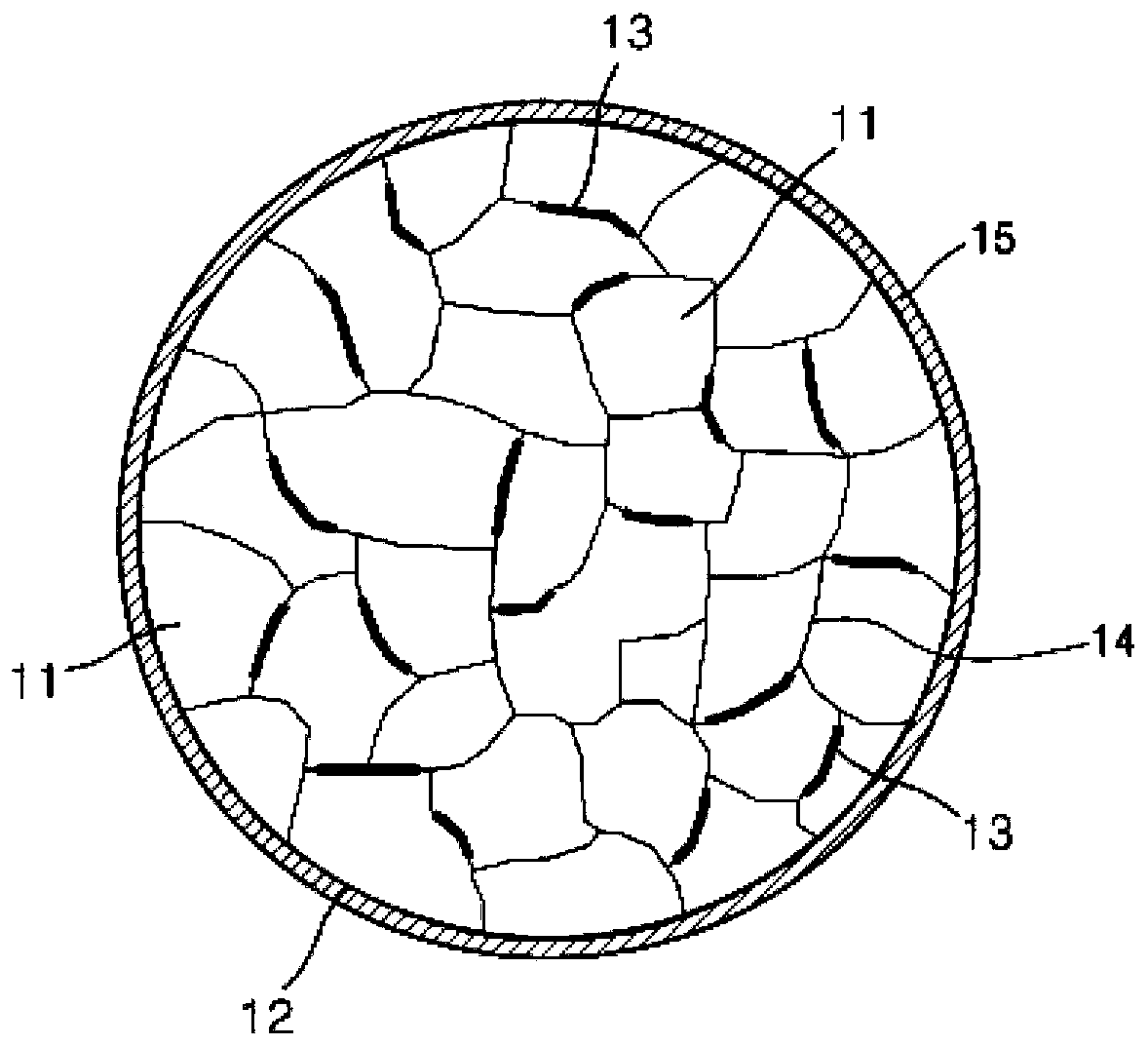

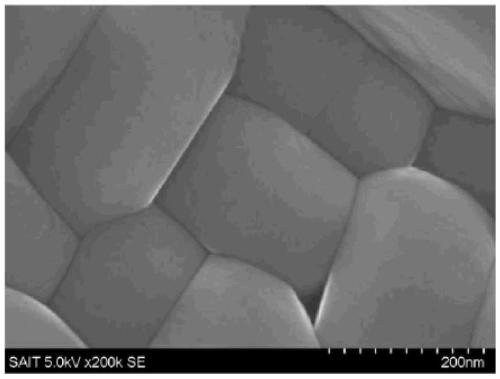

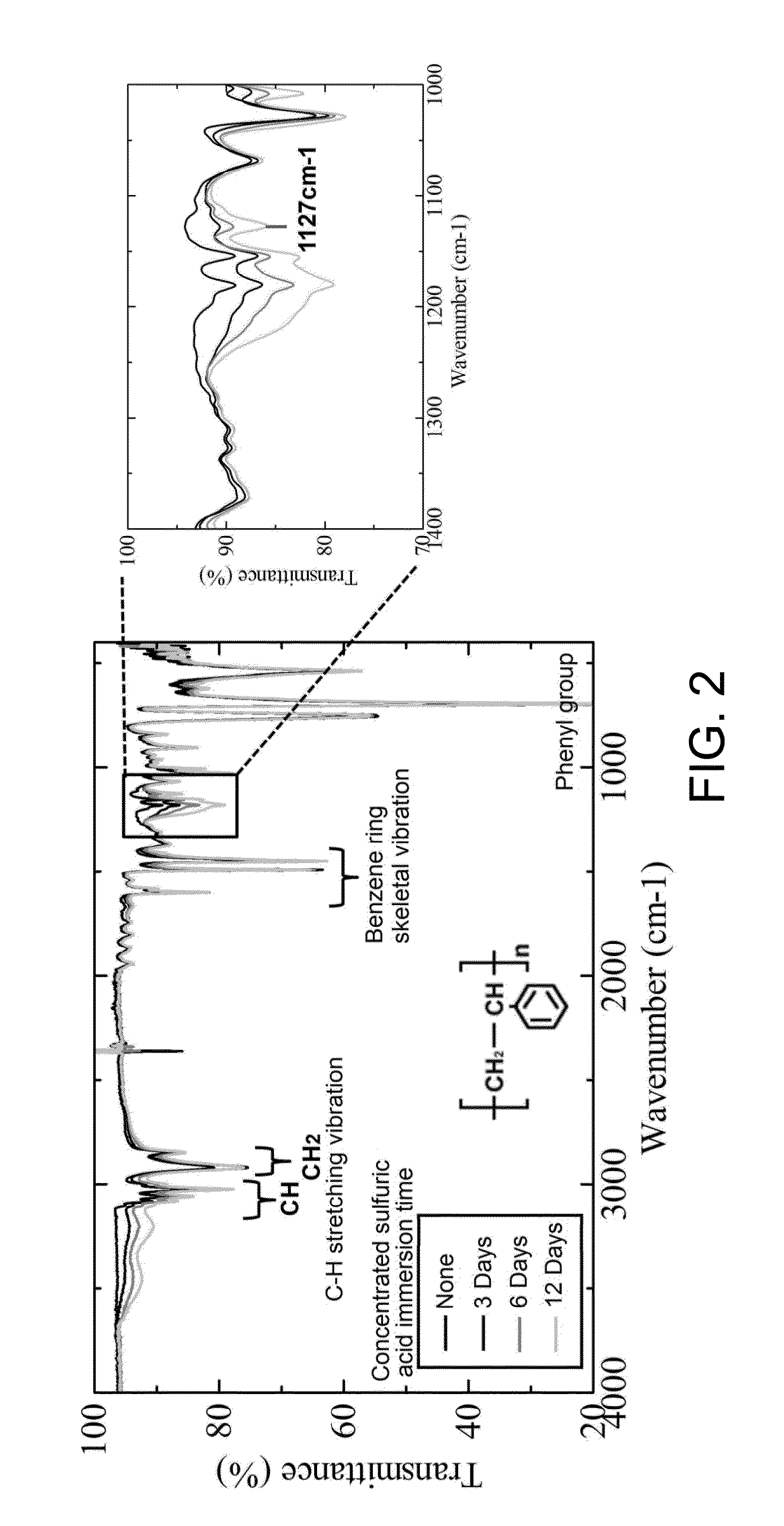

Composite cathode active material, cathode and lithium battery each including the same, and method of preparing composite cathode active material

PendingCN111106328AMangesium aluminatesElectrode thermal treatmentLamellar crystalsComposite cathode

The invention relates to a composite cathode active material, a cathode and a lithium battery each including the same, and a method of preparing the composite cathode active material. The composite cathode active material includes a secondary particle; and a coating on a surface of the secondary particle, wherein the secondary particle comprises a plurality of primary particles, and the pluralityof primary particles include a lithium nickel transition metal oxide having a layered crystal structure; and a grain boundary between primary particles of the plurality of primary particles, the grainboundary including a lithium metal oxide having a crystal structure different from the lithium nickel transition metal oxide having a layered crystal structure, wherein the coating on the surface ofthe secondary particle includes a metal oxide including cobalt, and a Group 2 element, a Group 12 element, a Group 13 element, or a combination thereof

Owner:SAMSUNG ELECTRONICS CO LTD +1

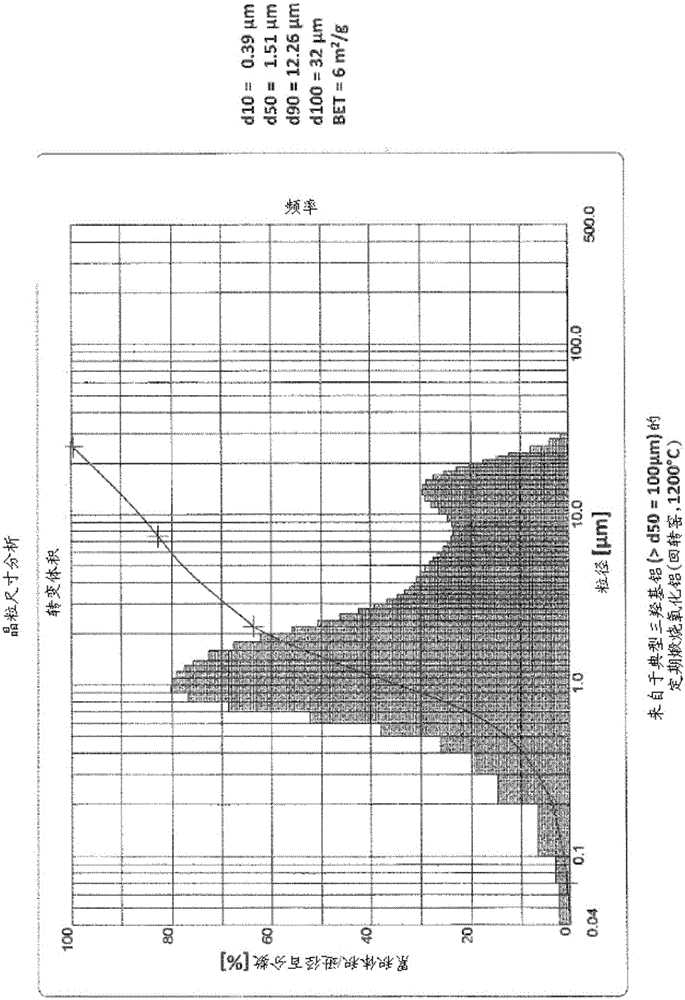

Method for producing fine-grained particles

ActiveUS7727909B2High porosityEasy to combineMaterial nanotechnologyOxygen/ozone/oxide/hydroxideNanometreMetal

Owner:VERY SMALL PARTICLE CO LTD

Production method of a novel polishing alumina

InactiveCN105026315AImprove productivityImprove thermal conductivityAlkaline earth titanatesAlkali metal silicate coatingsParticulatesCombustion

Provided is a method for the formation of particulate compounds of selectable size characteristics, which method includes supporting a slurried particulate precursor on a porous support; heating the support such that aggregates of the particulate compound are formed, and desagglomerating the aggregates into their component particulate. In a preferred embodiment, an aqueous slurry of alumina particulate which has not undergone the alpha transition is contacted with a porous support having defined pore and cavity sizes, such that the slurry occupies at least some of the interstices of the porous support. The slurry and support are heated such that the alumina precursor slurry undergoes the alpha transition. The alpha alumina product is then particulated. The support is of such a material that it is either lost through combustion during heating or otherwise removable after heating, such as during or after particulation, without destroying the particle characteristics imparted by the porous support. Additionally, in a further embodiment, co-components are added to the slurry in order to impart desired properties to the particulated product.

Owner:ALBEMARLE EURO

Process for the production of carbon nanoparticles and sequestration of carbon

InactiveUS8377408B2Increase in sizeLow costMaterial nanotechnologyNanostructure manufactureReaction temperatureMaterials science

Process for producing carbon nanospheres and other nano materials with carbon dioxide and magnesium. The carbon dioxide and magnesium are combusted together in a reactor to produce carbon nanospheres and magnesium oxide, which are then separated to provide the individual reaction products. The reaction occurs at a very high temperature, e.g. 2000° F.-5000° F. and also produces large amounts of useful energy in the form of heat and light, including infrared and ultraviolet radiation. Other oxidizing agents such as aluminum can be combined with the magnesium, and the metal oxides produced by the reaction can be recycled to provide additional oxidizing agents for combustion with the carbon dioxide. By varying the reaction temperature, the morphology of the carbon products can be controlled.

Owner:GRAPHENE TECH

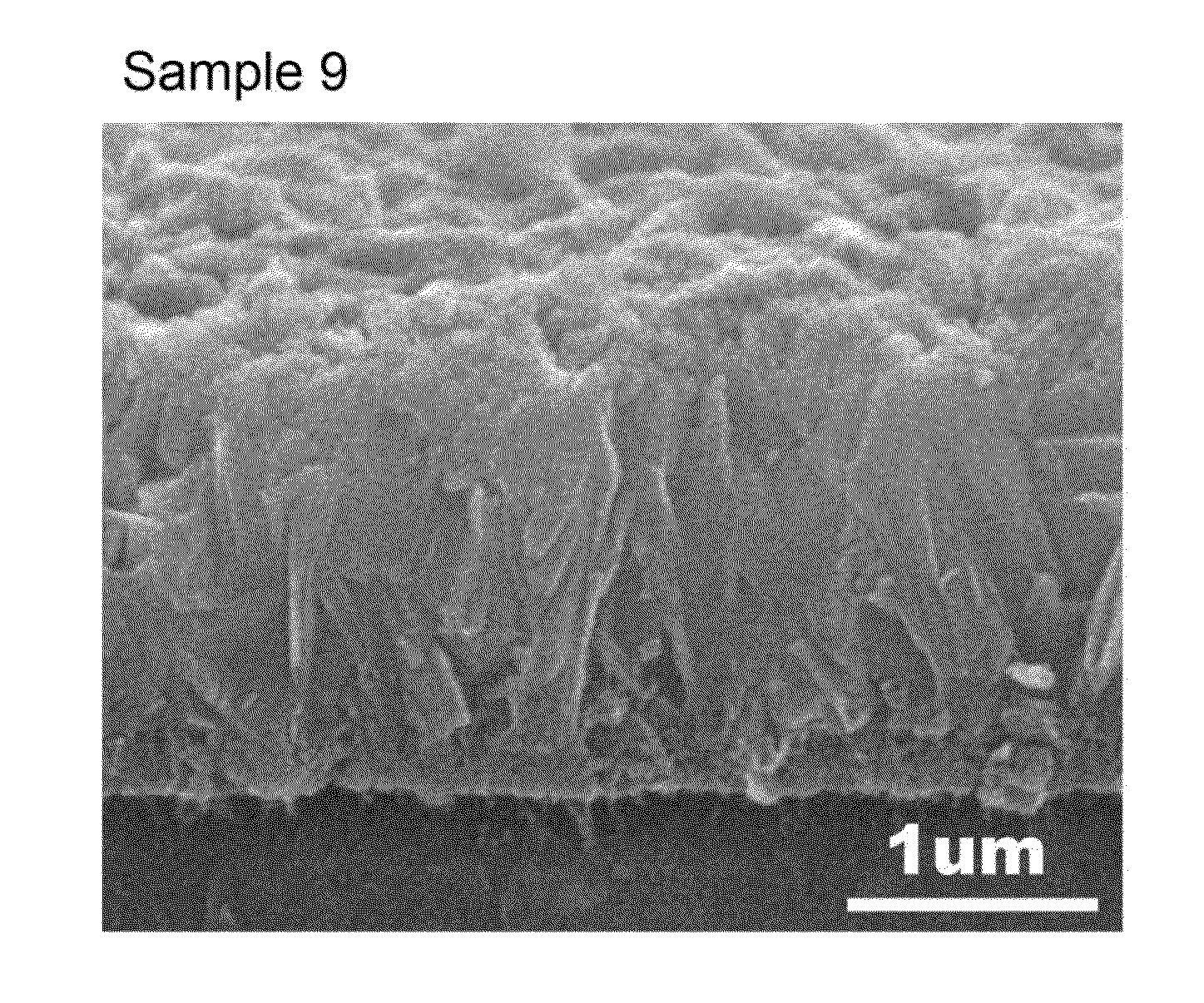

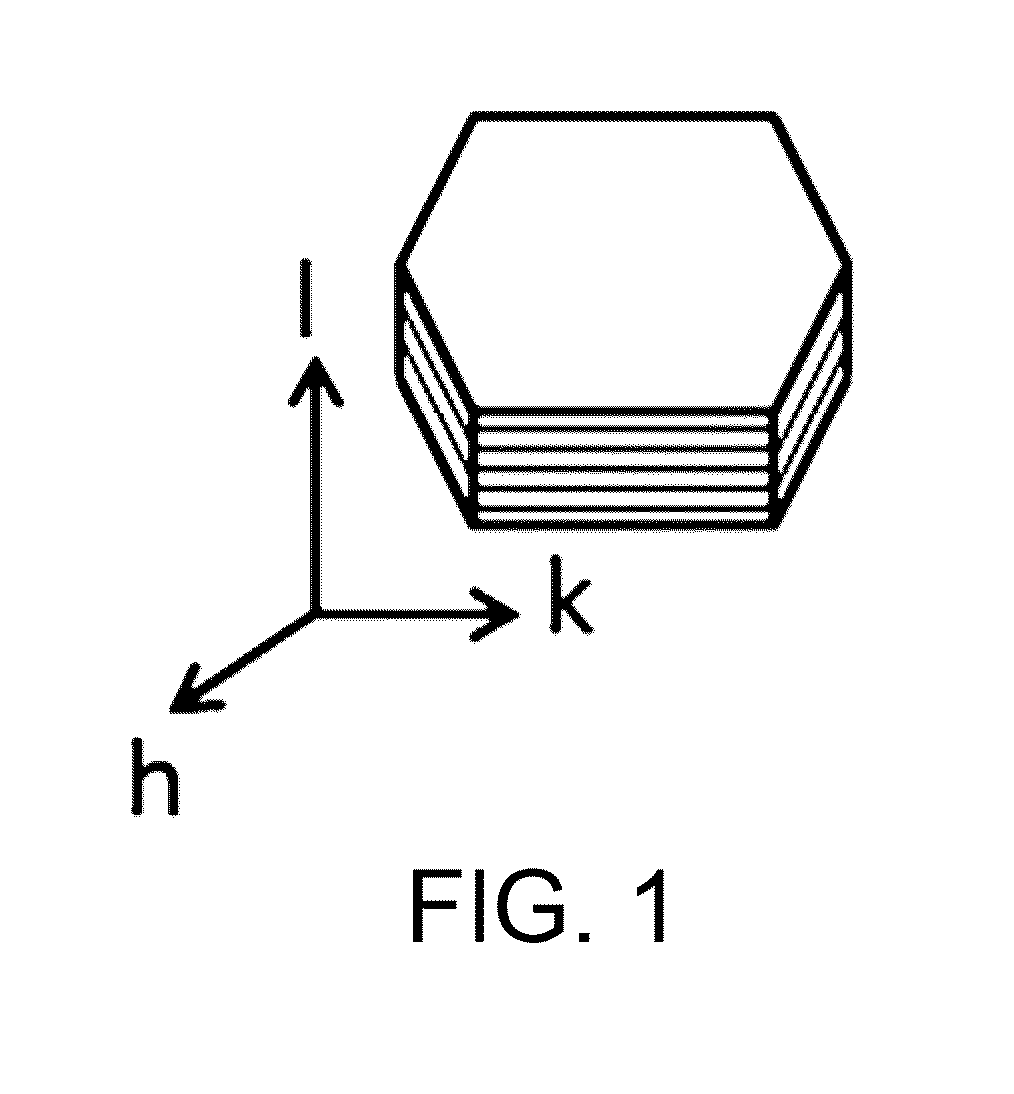

Layered-double-hydroxide-oriented film and method for producing same

ActiveUS20150340680A1Improve conductivityReduce resistanceFuel and primary cellsSolid electrolytesX-rayX-ray scattering techniques

Provided is a layered double hydroxide oriented membrane in which layered double hydroxide plate-like particles are highly oriented in the approximately perpendicular direction and which is also suitable for densification. The layered double hydroxide oriented membrane of the present invention is composed of a layered double hydroxide represented by the general formula: M2+1-xM3+x(OH)2An−x / n.mH2O wherein M2+ is a divalent cation, M3+ is a trivalent cation, An− is an anion having a valency of n, n is an integer of 1 or greater, x is 0.1 to 0.4, and m is 0 or greater, wherein when a surface of the oriented membrane is measured by X-ray diffractometry, a peak of a (003) plane is not substantially detected or is detected to be smaller than a peak of a (012) plane.

Owner:NGK INSULATORS LTD

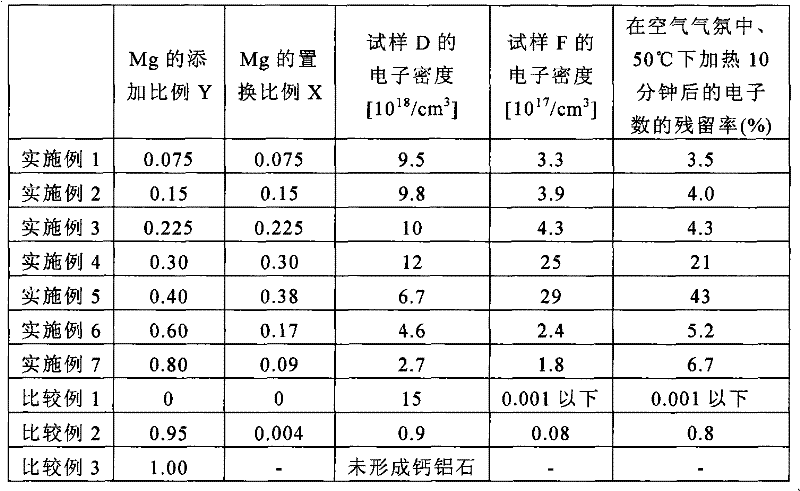

Mayenite-type compound and process for production of same

InactiveCN102131735AChemically stableImprove productivityCalcium aluminatesGas-filled discharge tubesCrystal structureOxygen

The present invention relates to a mayenite-type compound containing Ca, Al and oxygen, wherein part of the Ca atoms are replaced by at least one kind of atoms (M) selected from the group consisting of Be, Mg and Sr. The M / (Ca+M) atomic ratio is 0.01 to 0.50, and at least part of the free oxide ions contained in the mayenite-type crystal structure are replaced with anions of an element having an electron affinity smaller than that of oxygen.

Owner:ASAHI GLASS CO LTD

Nanomaterials and Process for Making the Same

ActiveUS20130295000A1Low costAvoid insufficient purityMaterial nanotechnologyMangesium aluminatesMultiple layerMaterials science

Process for producing nanomaterials such as graphenes, graphene composites, magnesium oxide, magnesium hydroxides and other nanomaterials by high heat vaporization and rapid cooling. In some of the preferred embodiments, the high heat is produced by an oxidation-reduction reaction of carbon dioxide and magnesium as the primary reactants, although additional materials such as reaction catalysts, control agents, or composite materials can be included in the reaction, if desired. The reaction also produces nanomaterials from a variety of other input materials, and by varying the process parameters, the type and morphology of the carbon nanoproducts and other nanoproducts can be controlled. The reaction products include novel nanocrystals of MgO (percilase) and MgAl2O4 (spinels) as well as composites of these nanocrystals with multiple layers of graphene deposited on or intercalated with them.

Owner:GRAPHENE TECH

Method of synthesizing multi-phase oxide ceramics with small phase domain sizes

InactiveUS8877119B2Inhibit aggregationPrevent precipitationMaterial nanotechnologyOxide/hydroxide preparationOxide ceramicCalcination

Nanocomposites of multi-phase metal oxide ceramics have been produced from water soluble salts of the resulting metal oxides by a foaming esterification sol-gel method. The evolution of volatile gases at elevated temperature during the esterification reaction causes the formation of a foam product. Nanocomposites of multi-phase metal oxide ceramics have also been produced by a cation polymer precursor method. In this second method, the metal cations are chelated by the polymer and the resulting product is gelled and foamed. Calcination of the resulting foams gives nanocomposite powders with extremely fine, uniform grains and phase domains. These microstructures are remarkably stable both under post-calcination heat treatment and during consolidation by hot-pressing.

Owner:UNIV OF CONNECTICUT CENT FOR SCI & TECH COMMLIZATION

Method for preparing aluminum oxide from aluminum ash in slag-free manner

ActiveCN112093814AImprove removal efficiencyEfficient removalMangesium aluminatesAmmonium sulfatesSlagSeed crystal

The invention discloses a method for preparing aluminum oxide from aluminum ash in a slag-free manner, which comprises the following steps: proportionally introducing chlorine into aluminum ash, controlling the reaction temperature and time, introducing water vapor after completing primary denitrification, removing residual nitrogen, fluorine and chlorine to obtain impurity-removed aluminum ash and adsorption steam, and condensing the adsorption steam to form an adsorption solution; adding a corresponding amount of lime into the adsorption solution, reacting to obtain a defluorination solution, adding SO2 for neutralization to obtain an ammonium sulfate solution, and concentrating the solution to obtain an ammonium sulfate product; adding alkali liquor at a corresponding proportion to conduct alkali dissolution treatment on the impurity-removed aluminum ash, thus preparing a liquid phase and a slag phase; and additionally mixing a Bayer process solution with an alkali solution, and carrying out seed crystal decomposition and roasting to obtain the aluminum oxide product. According to the method, a two-stage steam impurity removal mode is adopted, so that the removal efficiency of nitrogen in the aluminum ash is greatly improved, fluorine residues are effectively removed, the aluminum ash is subjected to impurity removal through alkali dissolution treatment, corrosion to equipment is small, and implementation is easy.

Owner:中铝东南材料院(福建)科技有限公司 +2

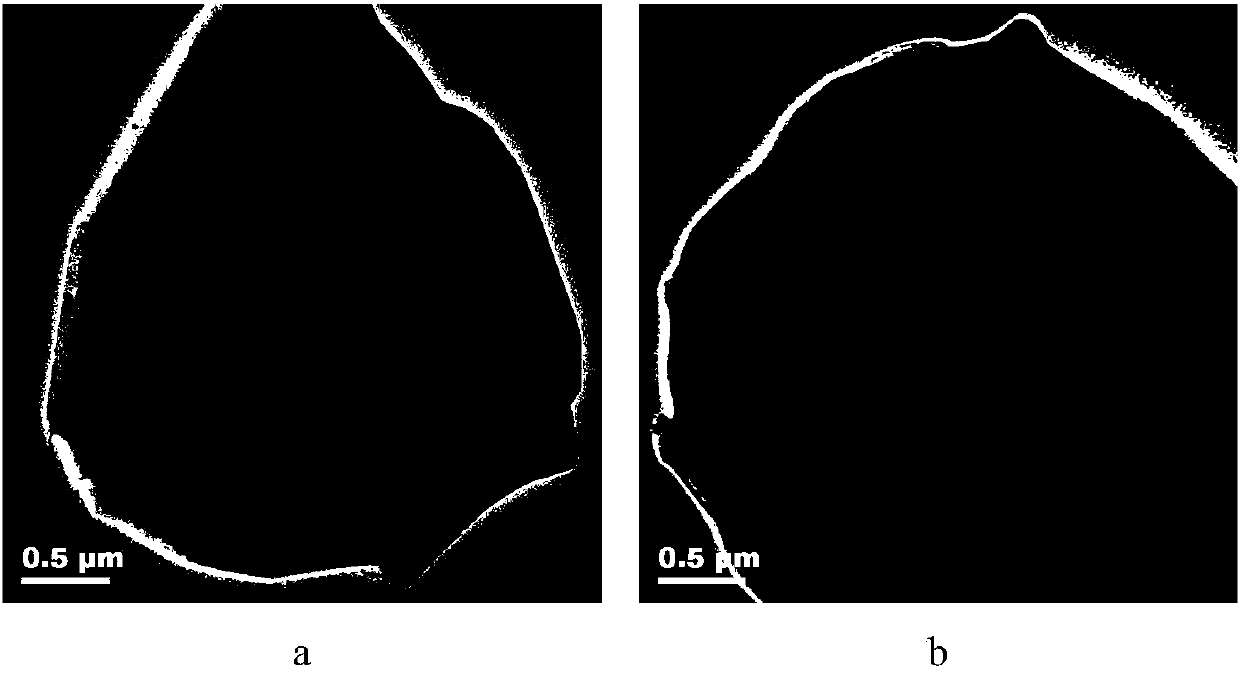

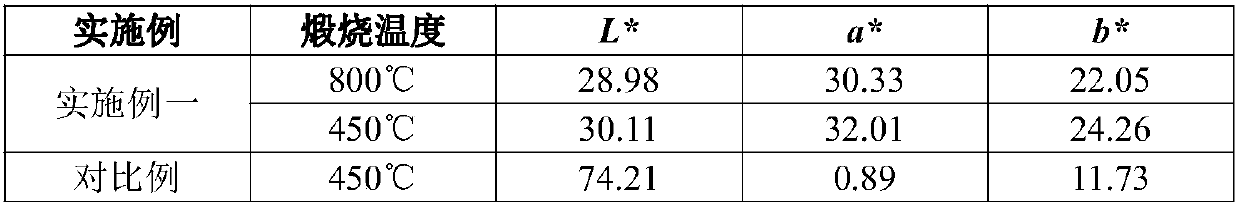

Magnesium aluminum spinel wrapping type gamma-Ce2S3 red pigment and preparation method thereof

ActiveCN108033477AImprove high temperature stabilityImprove corrosion resistanceRare earth metal sulfidesMangesium aluminatesVulcanizationSpinel

The invention discloses magnesium aluminum spinel wrapping type gamma-Ce2S3 red pigment. The magnesium aluminum spinel wrapping type gamma-Ce2S3 red pigment comprises a gamma-Ce2S3 color body servingas an inner core as well as a magnesium aluminum spinel shell wrapping the color body inner core. In addition, the invention also discloses a preparation method of the wrapping type gamma-Ce2S3 red pigment. The preparation method comprises the following steps: preparing a CeO2 precursor which is jointly wrapped by aluminum hydroxide and magnesium hydroxide by a liquid phase method and then performing high-temperature vulcanization treatment further through vulcanization atmosphere and inert atmosphere to prepare the magnesium aluminum spinel wrapping type gamma-Ce2S3 red pigment. Through wrapping by the magnesium aluminum spinel, the gamma-Ce2S3 is effectively stabilized, the high-temperature stability of the wrapped and modified pigment is greatly improved and the application field is greatly expanded; furthermore, the process is simple, the reaction is easy to control, the preparation process and the product performance are more stable and reliable, so that industrialized popularization and application are facilitated.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Process for preparing small size layered double hydroxide particles

InactiveCN107531503AWithout compromising purityCalcium aluminatesMaterial nanotechnologyPtru catalystSorbent

A process for preparing particles of a layered double hydroxide of the general formula [Mp z+ M'q y+ (OH)2]a+(Xn-)a / n.bH2O (I) wherein Mz+ and M'y+ are metal cations or mixtures of metal cations, z =1 or 2; y = 3 or 4; p + q = 1; b = 0 to 10, Xn- is an anion, n is 1 to 5 and a is determined by p, q, y and z such that a = zp+yq-2 comprises (a) mixing, in aqueous solution, Mz+ cations, M'y+ cationsand Xn- anions, with a base; and (b) allowing the layered double hydroxide of formula (I) to precipitate from the solution mixed in step (a). Preferably, M is Li, Mg, Zn, Fe, Ni, Co, Cu, Ca, or a mixture of two or more. Preferably, y is 3 and M' is Al, Ga, In, Fe or a mixture of two or more thereof. Also provided are particles obtainable by the process, especially wherein M is Ca, M' is Al and Xn- is NO3-. Particles of a layered double hydroxide wherein the particles have a particle size of not greater than 2000 nm, preferably not greater than 300 nm and especially not greater than 100 nm, are also provided. The layered double hydroxides according to the invention are useful in certain applications, for example, as adsorbents, coatings and catalyst supports.

Owner:SCG CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com