Patents

Literature

672 results about "Brucite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Brucite is the mineral form of magnesium hydroxide, with the chemical formula Mg(OH)₂. It is a common alteration product of periclase in marble; a low-temperature hydrothermal vein mineral in metamorphosed limestones and chlorite schists; and formed during serpentinization of dunites. Brucite is often found in association with serpentine, calcite, aragonite, dolomite, magnesite, hydromagnesite, artinite, talc and chrysotile.

Reduction of coal-fired combustion emissions

ActiveUS20060034743A1Efficiently and economically capturedReduce in quantityUsing liquid separation agentSolid fuel pretreatmentBruciteMagnesite

A process for mitigation of fouling deposits within a combustion zone, capturing of toxic metal emissions, and reduction of visible sulfur emissions attributable to sulfuric acid mist during coal combustion. SO3 formed during coal combustion is reduced by the addition to the coal of raw, unprocessed magnesium-containing minerals such as magnesite ore or brucite ore. The minerals are pulverized to a fine particle size and combined with pulverized coal to provide a mixture of the particles. The mixture is combusted and the ore particles calcine and decrepitate to very fine magnesium oxide particles that have a significant particle surface area. The magnesium oxide particles react with the SO3 produced during combustion of the coal and also capture toxic metals to reduce the quantity of undesirable stack discharge components.

Owner:PREMIER MAGNESIA

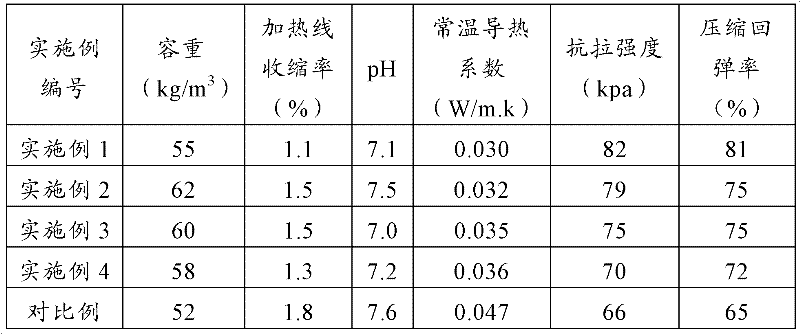

Composite heat-insulating material and preparation method thereof

The invention relates to a composite heat-insulating material, comprising the following ingredients: 0.4-10 wt% of sepiolite, 0-5 wt% of brucite, 0-15 wt% of alumina silicate fiber, 5-10 wt% of asbestos fiber, 0.5-8 wt% of aerogel, 0-12 wt% of diatomite, 0-3 wt% of bentonite, 1-5 wt% of perlite, 0.5-5 wt% of dispersant, 0.1-1 wt% of polyvinyl alcohol, 0-1 wt% of soluble glass, 0-0.015 wt% of sodium cetanesulfonate, and the balance consisting of clear water. The invention also discloses a preparation method of the composite heat-insulating material. The composite heat-insulating material disclosed herein has low heat-insulating coefficient, good flexibility, and high tensile strength, and is difficult to pulverization. In addition, the method has the advantages of simple process, high production efficiency, and low energy consumption.

Owner:张永武

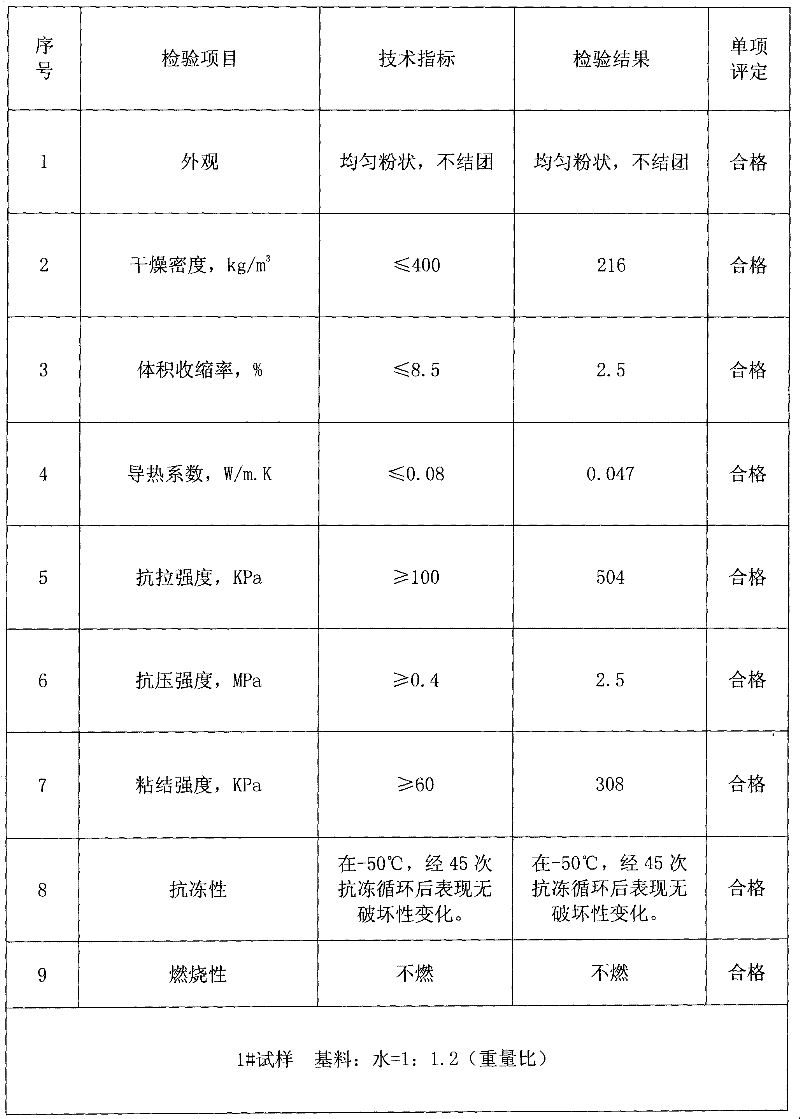

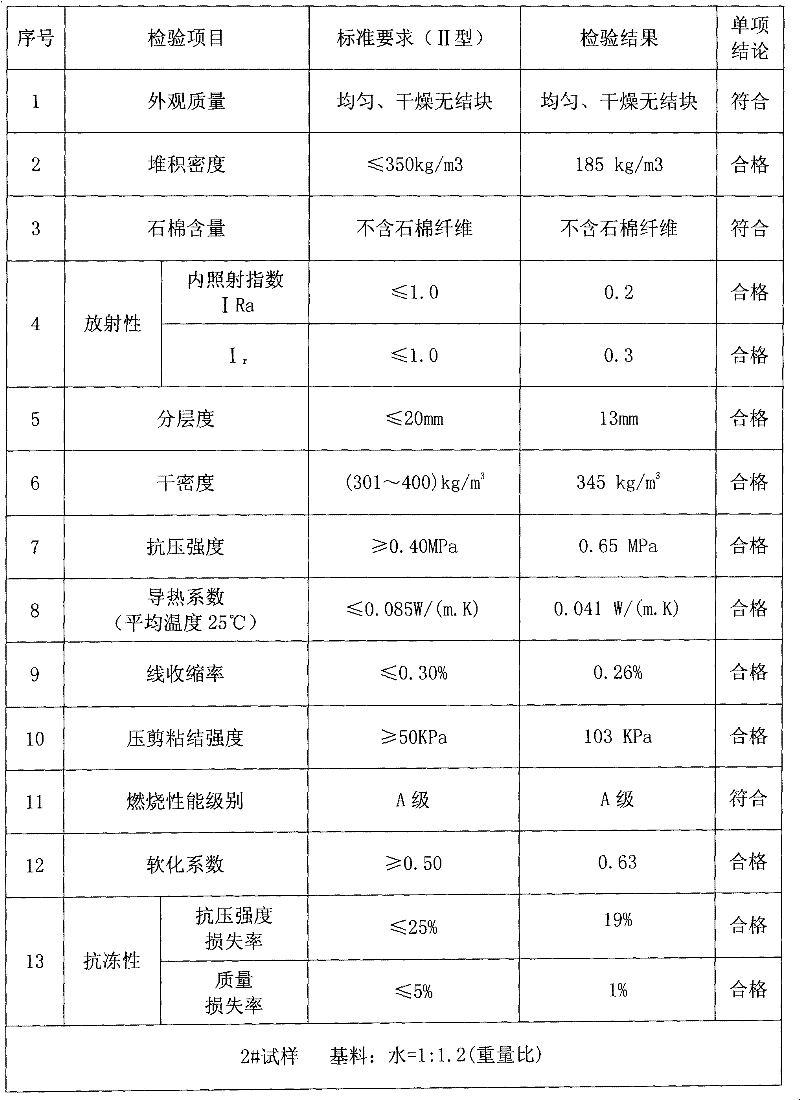

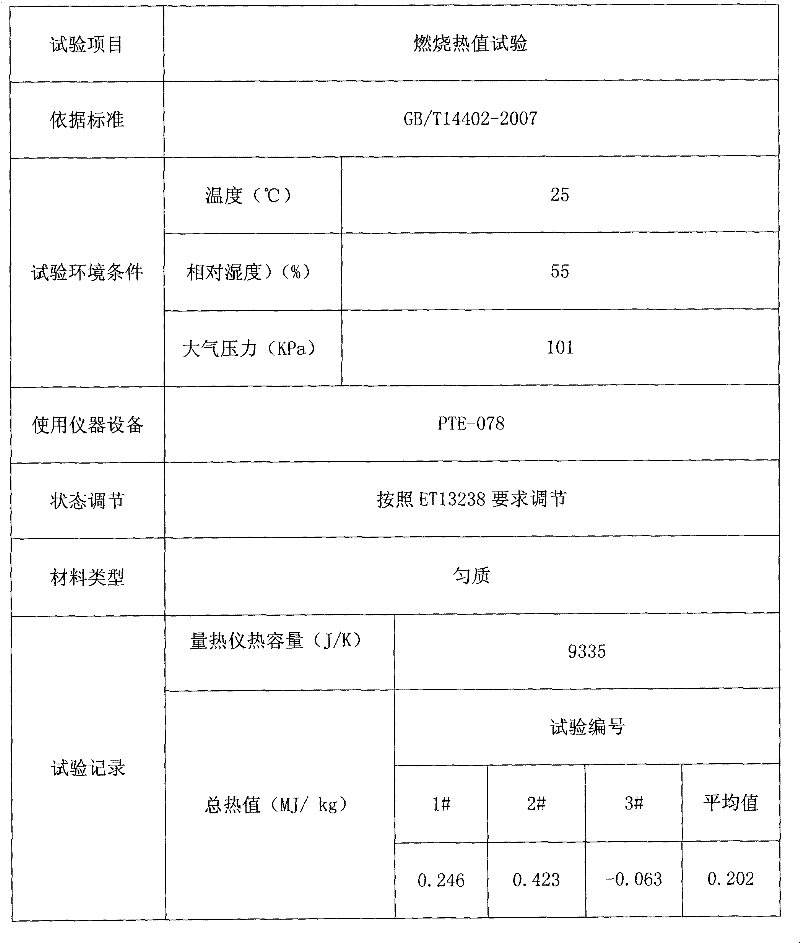

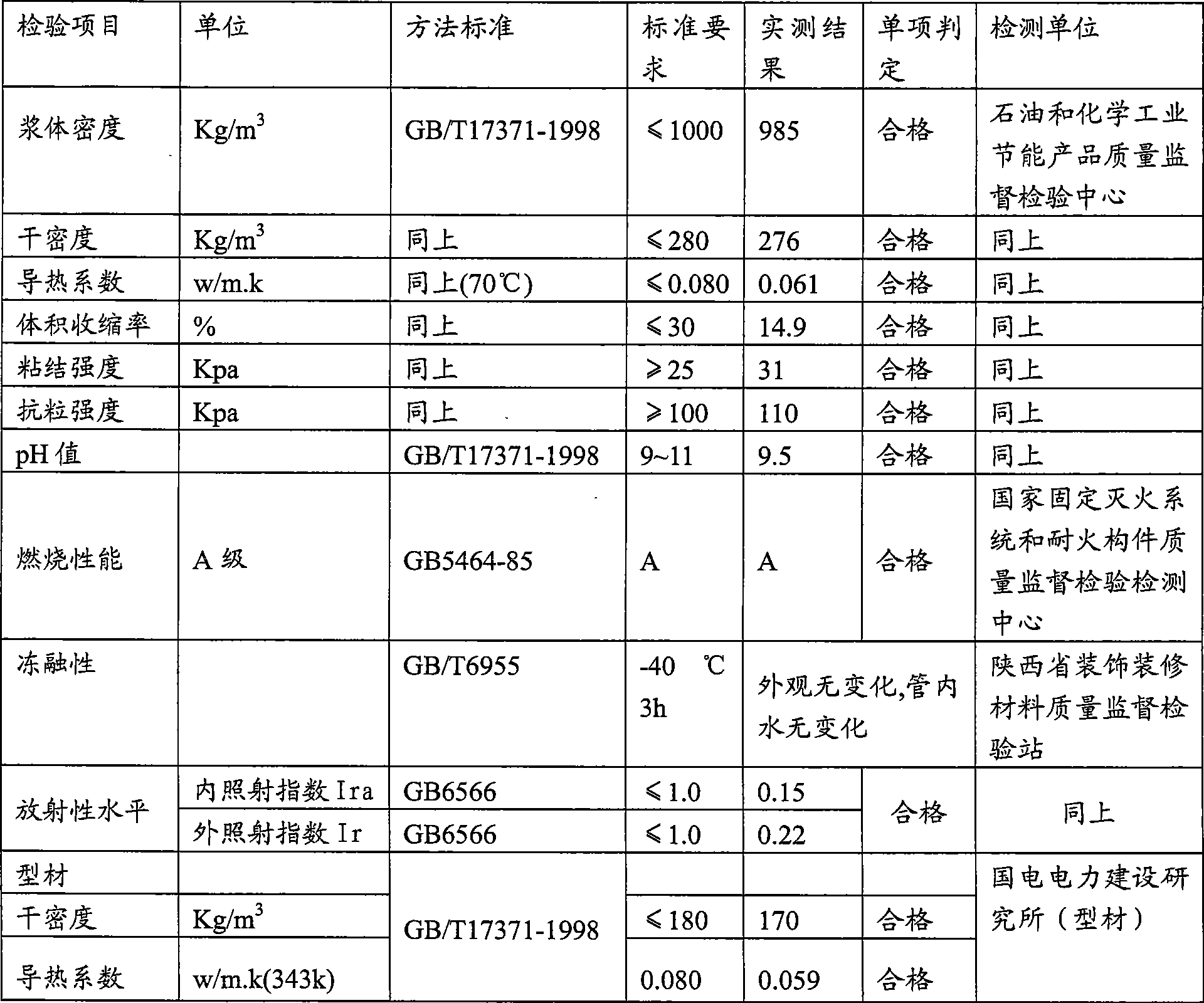

Siliceous heat-insulation composite material for wall

The invention relates to a siliceous heat-insulation composite material for a wall, which comprises base materials and water. The base materials mainly comprise closed-cell expanded perlite, cement, building gypsum, inorganic mineral substance fibers, high-viscosity attapulgite clay, redispersible rubber powder, hydroxypropyl methyl cellulose auxiliaries and a water repellent, wherein the inorganic mineral substance fibers comprise alumina silicate fibers, brucite fibers, mineral cotton fibers and the like, and when the material is used, the weight ratio of the base materials to the water is 1:1.2-1.3. The material as an amorphous powdery heat-insulation material is excellent in energy conservation, heat insulation, sound absorption, flame retardance reaching level A1, fireproofing, seismic resistance, crack control, flexibility and weatherability, does not chemically react with the wall, is high in strength and ageing resistance, avoids deformation, crack, hollowing, shedding and is the same as the wall in service life in use. The material is green, environment-friendly and non-toxic, is applicable to heat insulation of an inner wall and an outer wall made of various wall base materials, a splitting wall and heat-insulation energy-saving projects such as roofs, basements, garages, stairs, corridors, fire-fighting accesses and the like.

Owner:建平县德鑫外墙保温材料有限责任公司

Cordierite nucleated glass prepared by using flyash and its preparation method

The present invention relates to an iolite pyroceram prepared by using flyash as main raw material and its preparation method. Its composition includes (wt%) 45-77% of flyash, 5-15% of alumina powder of bauxite, 10-25% of basic magnesium carbonate or magnesite or brucite or magnesium oxide powder, 3-10% of methyl cellulose and 3-30% of water.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Roasting method for producing sodium chromate using chrome iron ore as raw material

InactiveCN1418823AAvoid scaringSolve the pollution of the environmentChromates/bichromatesBrucitePericlase

The method for preparing sodium chromate by calcining chromite includes the following steps: pulverizing chromite and sieving with 200 mesh sieve, adding sodium carbonate whose added amount is 80-150% of chromite amount, and adding magnesite, baudisserite, periclase, brucite or synthetic magnesium oxide, magnesium hydroxide and magnesium carbonate and calcining them at 1000-1200 deg.c for 10-60 min. under the condition of oxidation atmosphere, then extracting clinker and dissolving sodium chromate so as to obtain the goal of preparing sodium chromate. The conversion rate of chromite can be upto 97-99.5%.

Owner:TIANJIN CHEM RES & DESIGN INST

Anti-backflow leak-stopping agent, preparation method and applications thereof

ActiveCN103087687AImprove anti-reflux abilityImprove anti-reverse discharge abilityDrilling compositionEpoxyFiber

The present invention relates to an anti-backflow leak-stopping agent, a preparation method and applications thereof. The anti-backflow leak-stopping agent comprises the following components, by weight, 20-30 parts of modified self-emulsifying epoxy resin wrapped sand, 10-20 parts of ultrafine calcium carbonate, 15-25 parts of fiber brucite, and 35-55 parts of a non-penetrant NPL-2. According to the anti-backflow leak-stopping agent, a leak stopping effect is significant, anti-backflow capability of the blocking layer can be effectively improved, the anti-backflow leak-stopping agent can be subjected to compatibility use with any drilling fluid systems, use environment requirements are low, economic cost is moderate, and a characteristic of easy generalization and application is provided.

Owner:CHINA PETROLEUM & CHEM CORP +1

Novel thermal insulation composite material composition and method of making the same

ActiveCN101391872AOvercoming the defect of loss of thermal insulation propertiesReduced insulation performanceFiberMicro bubble

The invention relates to a novel thermal insulation and heat preservation composite material composition, which is characterized by comprising the following components: fiber materials such as aluminum silicate fiber, glass cotton, sepiolite, brucite and the like, dispersants such as rapid T and / or sodium hexametaphosphate, expanded vitrified micro bubbles, various special additives and the like. Calculated according to 1m<3> finished product, the content ranges of the components of the thermal insulation and heat preservation composite material composition are: 90-110kg of fiber materials, 8-12kg of dispersants, 90-110kg of expanded vitrified micro bubbles and 5-8kg of other additives. The other additives can be catalyst, gelling agent, curing agent, accelerating agent, reinforcing agent and the like. The invention also relates to a manufacturing method of the thermal insulation and heat preservation composite material composition.

Owner:谢文丁

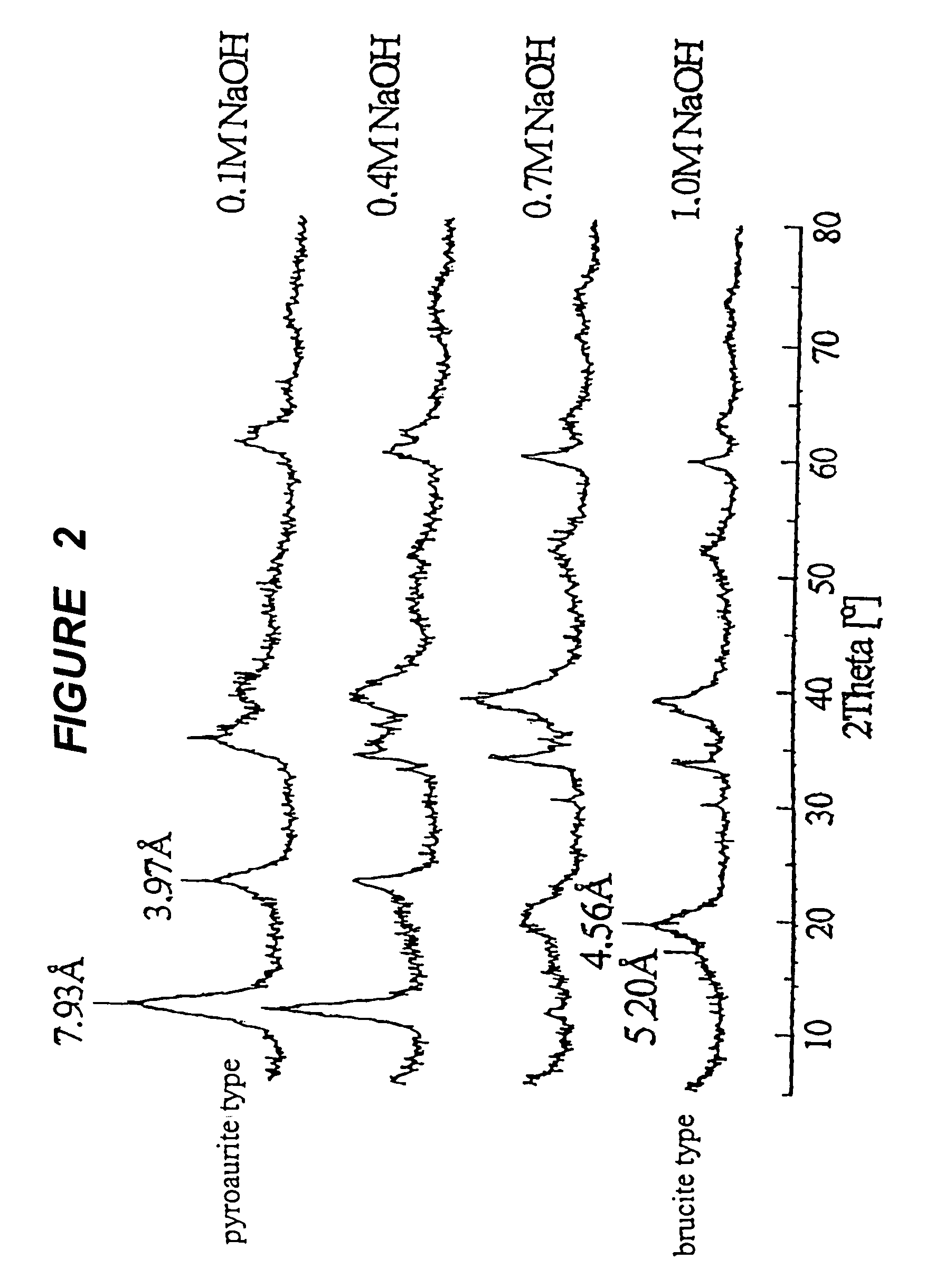

Doped anionic clays

The present invention is directed to a process for the preparation of a doped anionic clay. In said process a trivalent metal source is reacted with a divalent metal source, at least one of the metal sources being either doped boehmite, doped MgO or doped brucite, to obtain a doped anionic clay. Suitable dopants are compounds containing elements selected from the group of alkaline earth metals (for instance Ca and Ba), alkaline metals, transition metals (for example Co, Mn, Fe, Ti, Zr, Cu, Ni, Zn, Mo, W, V, Sn), actinides, rare earth metals such as La, Ce, and Nd, noble metals such as Pt and Pd, silicon, gallium, boron, titanium, and phosphorus.

Owner:AKZO NOBEL NV +1

Reduction of coal-fired combustion emissions

ActiveUS7276217B2Efficiently and economically capturedReduce in quantityUsing liquid separation agentEmission preventionSulfurBrucite

A process for mitigation of fouling deposits within a combustion zone, capturing of toxic metal emissions, and reduction of visible sulfur emissions attributable to sulfuric acid mist during coal combustion. SO3 formed during coal combustion is reduced by the addition to the coal of raw, unprocessed magnesium-containing minerals such as magnesite ore or brucite ore. The minerals are pulverized to a fine particle size and combined with pulverized coal to provide a mixture of the particles. The mixture is combusted and the ore particles calcine and decrepitate to very fine magnesium oxide particles that have a significant particle surface area. The magnesium oxide particles react with the SO3 produced during combustion of the coal and also capture toxic metals to reduce the quantity of undesirable stack discharge components.

Owner:PREMIER MAGNESIA

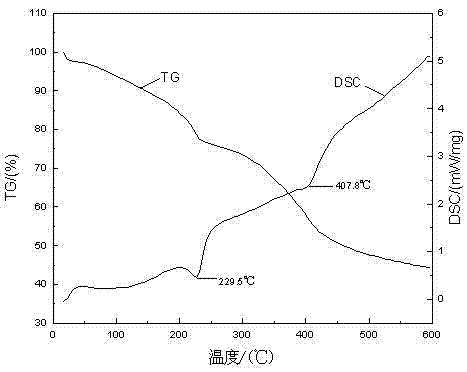

Method for making cable-material flame-retardant of natural brucite magnesium hydrate

InactiveCN1814698ALow modification costSettle the priceInsulated cablesInsulated conductorsEngineeringPre treatment

This invention relates to a method for preparing a fire retardant agent for natural brucite Mg(OH)2 cables including: selecting sheet-like natural brucite, 2, pre-processing the natural brucite, 3, getting superfine micro-particles of Mg(OH)2 after entering into the gas flow to be collided, crushed and magnetized, 4, putting the micro-particles into a modifying machine, then dropping or spraying the magnetized modifier into the modifying machine to get the fire retardant agent of Mg(OH)2 of natural brucite.

Owner:吕世发

Clean preparation method for basic magnesium carbonate

InactiveCN101935059ASave waterTypical Atom Economy ReactionMagnesium carbonatesSynthesis methodsWater source

The invention relates to a clean preparation method for basic magnesium carbonate, which prepares the basic magnesium carbonate by taking natural mineral brucite or synthesized magnesium hydroxide as raw materials and by performing the atom economic reaction of the raw material and CO2. All atoms in the raw materials participate in the reaction, and a target product is generated; the economical efficiency of the atoms is 100 percent; and thus, the reaction is a typical atom economic reaction. A reaction process avoids using raw materials such as dolomite, magnesite or brine, and sodium carbonate which are usually used by the conventional synthesis method, so that a product has no impurities, the pure product can be directly obtained without drying, a washing link is removed, a great amount of water source is saved, and the environment is protected.

Owner:BEIJING UNIV OF CHEM TECH

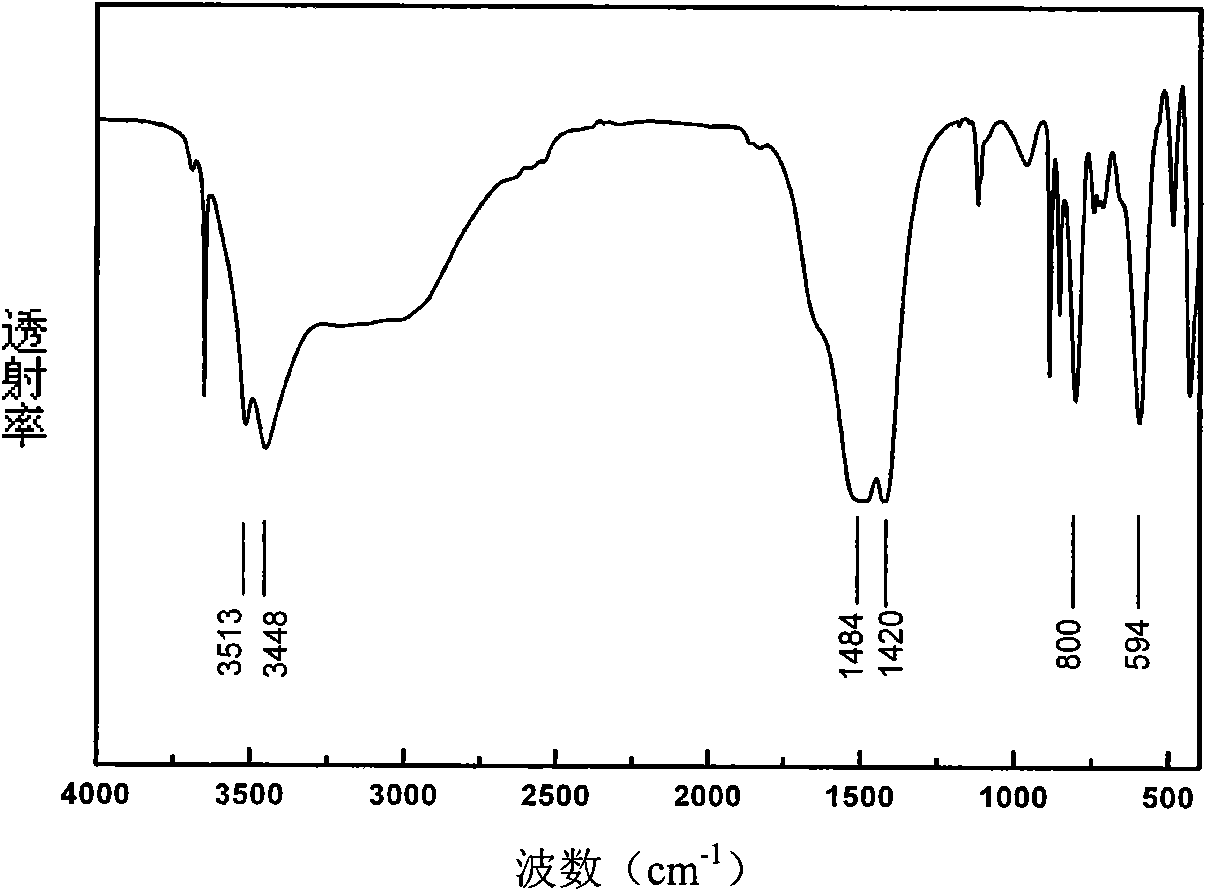

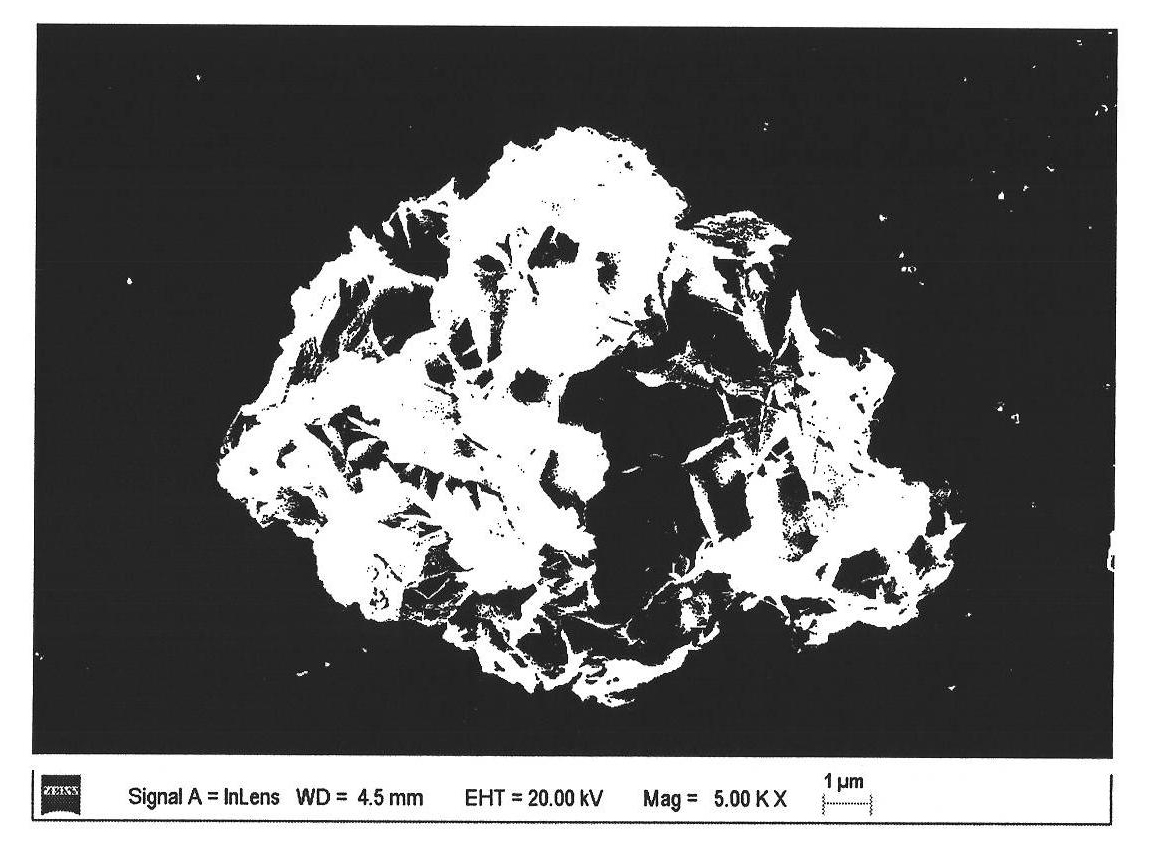

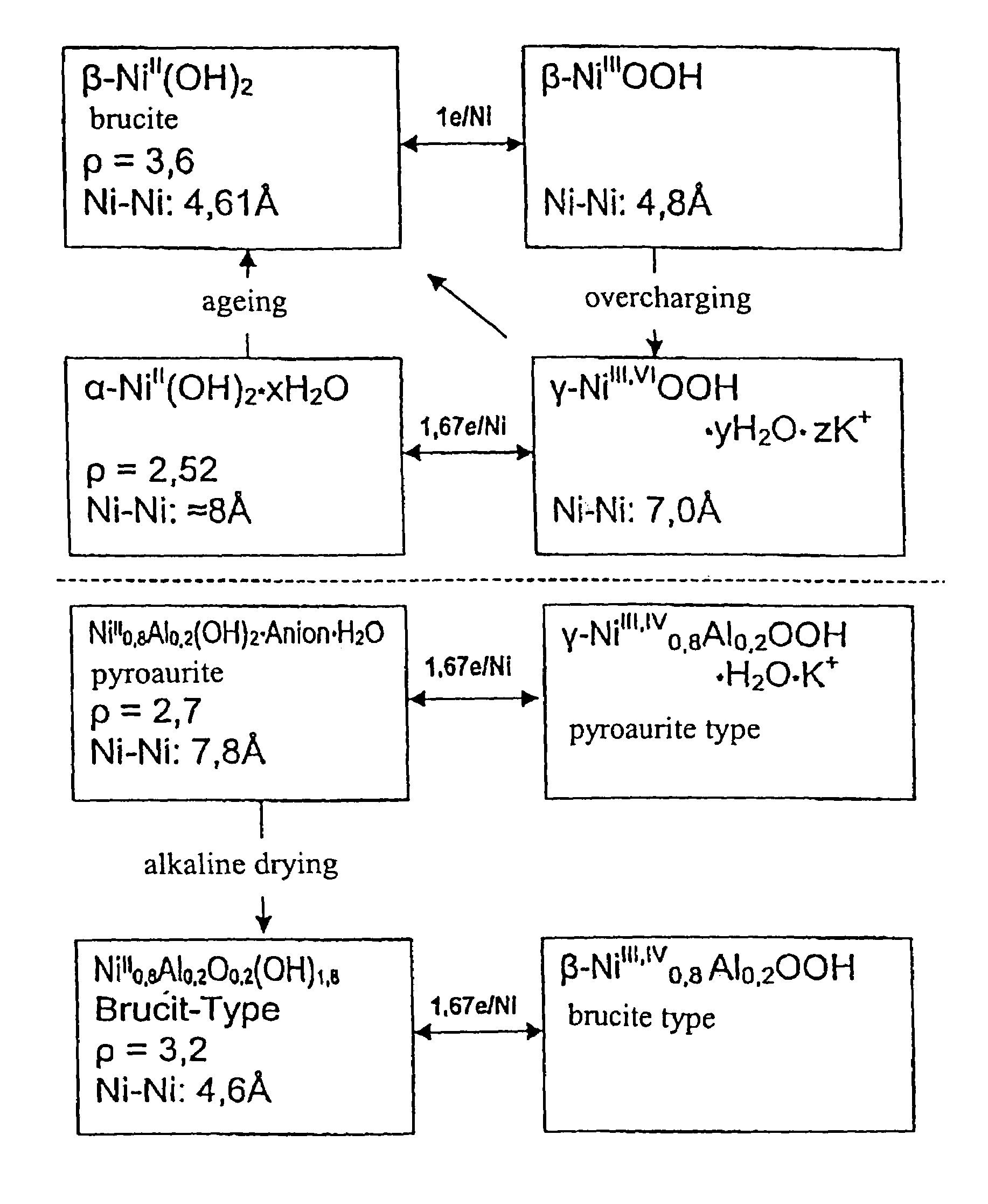

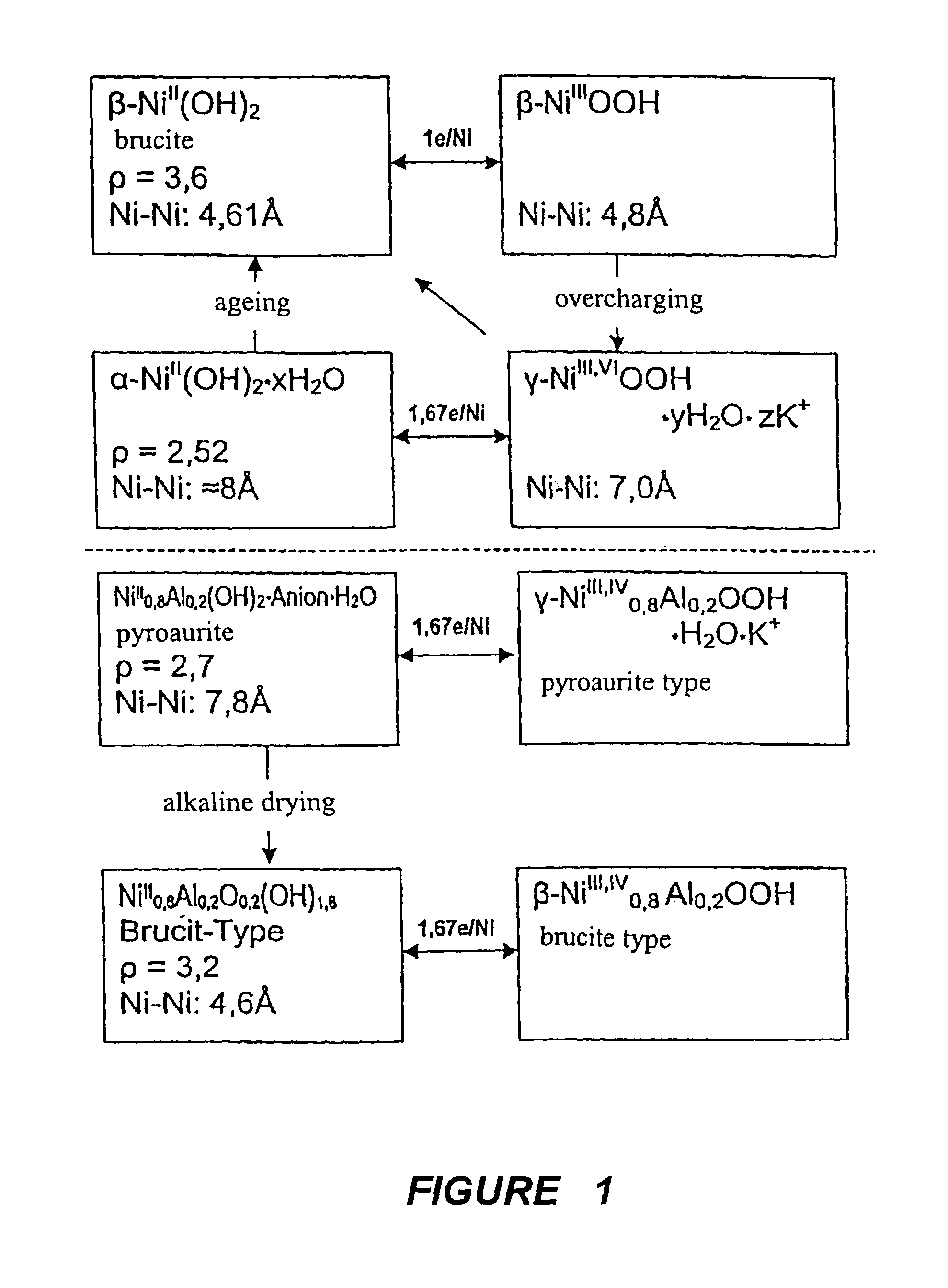

Active material for rechargeable batteries

InactiveUS6958139B1Reduce spacingImprove storage densityNickel carbonylsAlkaline accumulator electrodesElectrical batteryNickel oxide hydroxide

A mixed metal hydroxide with brucite structure is described, which contains nickel hydroxide as its main component and at least one trivalent metal selected from the group consisting of Co, Fe, Al, Ga, In, Sc, Y and La in an amount of from about 12 to about 30 atom % relative to the sum of the metal components including Ni. The invention also relates to a rechargeable battery containing a mixed metal hydroxide according to the invention as an electrochemically active material as well as a secondary batter containing the mixed metal hydroxide. The invention also relates to a process for producing a mixed metal hydroxide having a brucite structure.

Owner:TODA IND

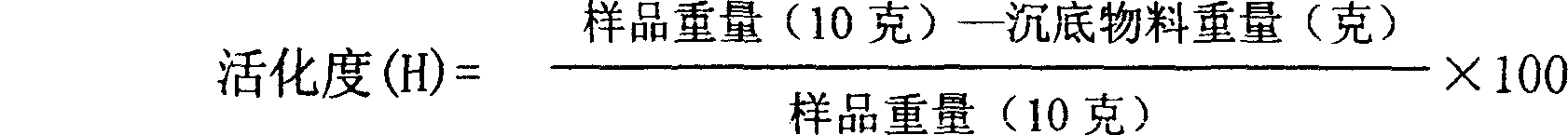

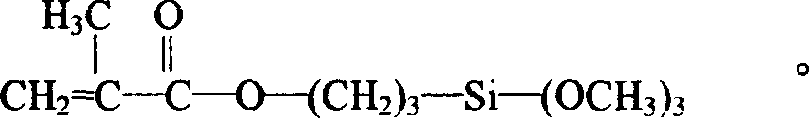

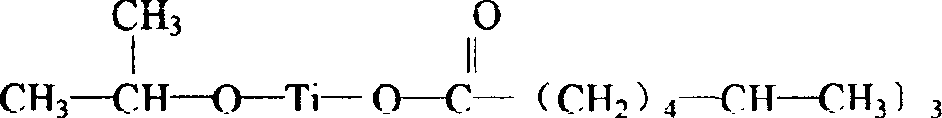

Surface treating coupling agent for natural magnesium hydroxide organic flame-retardant powder

InactiveCN1492005AGood dispersionGood compatibilityPigment treatment with non-polymer organic compoundsDispersityStearic acid

The present invention belongs to the field of green flame retardant surface treating technology, and is especially surface treating coupling agent for natural magnesium hydroxide inorganic flame retardant powder. The surface treating coupling agent consists of: silane or alkali metal salt of higher fatty acid as anionic surfactant including alkyl sulfate and sulfonated succinate in 0.5-4 wt%, stearic acid in 0.2-3 wt%, or gamma-methyl propyl acrylate trimethoxy silane 0.1-0.2 wt%. The present invention solves the technological problems in surface treatment of natural brucite, and composite coupling agent is used to raise the dispersity and compatibility of brucite in polymer material and improve the mechanical performance of flame retardant material. Low molecular weight organosilicon compound with special structure has outstanding effect of improving the strength and heat resistance of stuffing material.

Owner:杨治富

Fire-retardant and thermal-insulation mortar

InactiveCN103787631AImprove fire resistanceImprove flame retardant performanceCrack resistanceThermal insulation

The invention discloses fire-retardant and thermal-insulation mortar. The mortar consists of the following raw materials in parts by weight: 30-40 parts of high-alumina cement, 40-50 parts of glass bead, 10-15 parts of carborundum, 0.5-1 part of hydroxypropyl methyl cellulose, 2-4 parts of viny acetateethylene emulsion (VAE) re-dispersible emulsion powder, 1-3 parts of polypropylene fiber, 0.5-1.5 parts of wood fiber, 5-10 parts of heavy calcium powder, 3-6 parts of seaweed powder, 4-8 parts of brucite powder, 3-5 parts of mica powder, 8-12 parts of kaolin, 5-10 parts of gypsum, 0.3-0.5 part of polycarboxylic water reducer and 4-6 parts of thermal insulation particles. The fire-retardant and thermal-insulation mortar disclosed by the invention is excellent in fire retardant performance, good in flame retardant property, good in thermal insulation and heat preservation performance, high in binding strength, strong in adhesive force, excellent in crack resistance and weather fastness, low in cost and wide in application prospect and is convenient to construct, and fire retarding grade reaches A grade.

Owner:青岛中科菲力工程技术研发有限公司

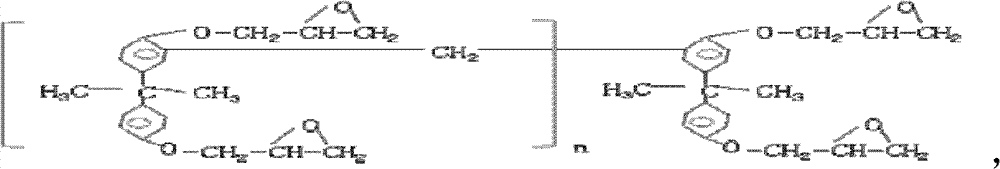

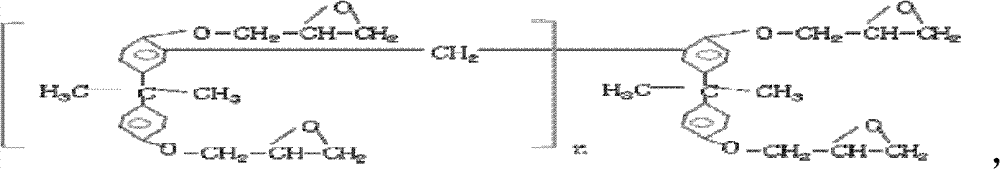

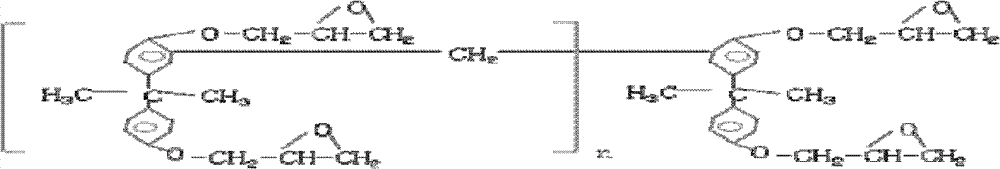

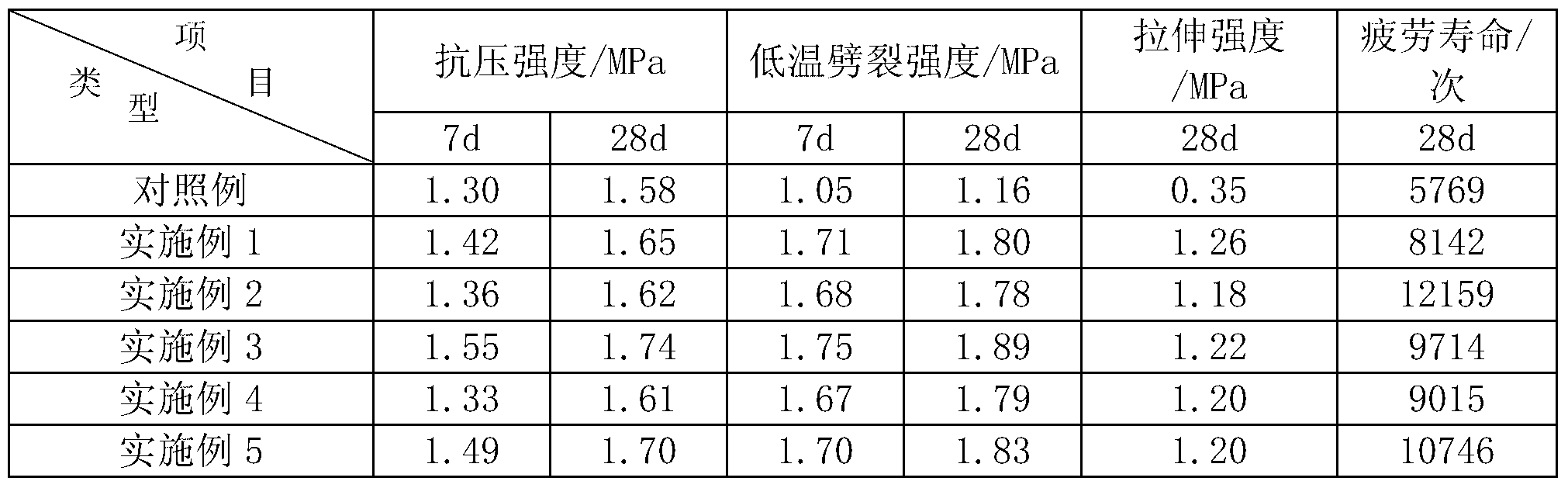

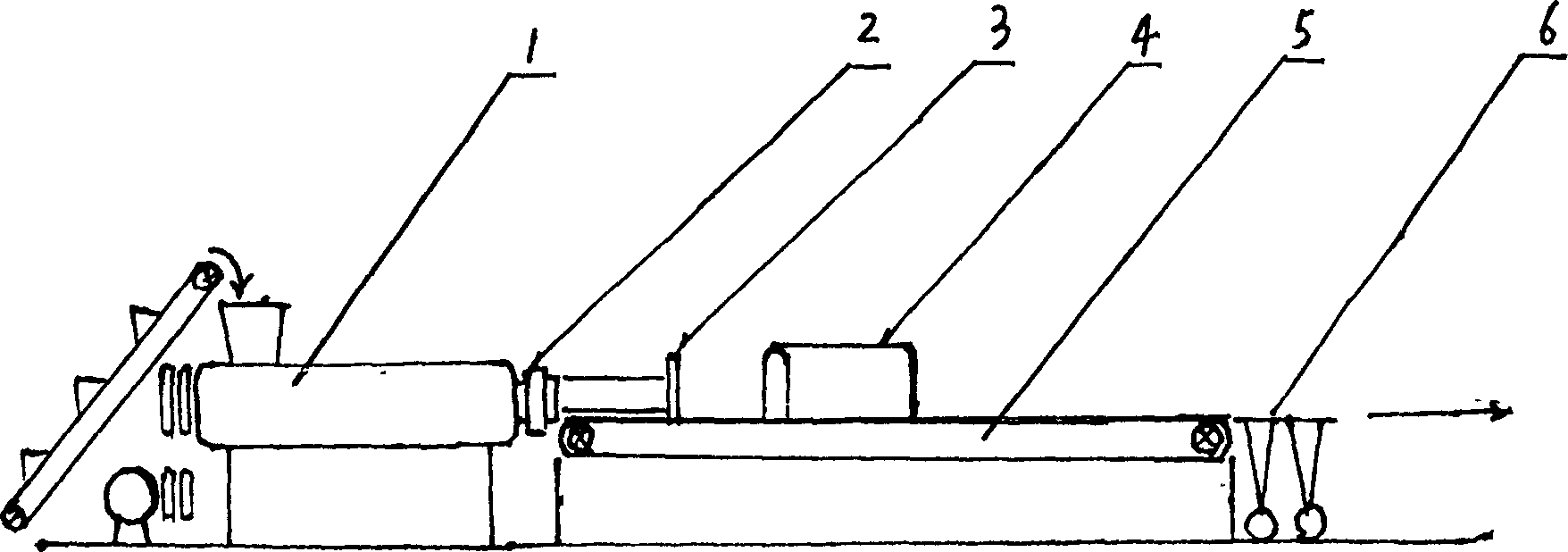

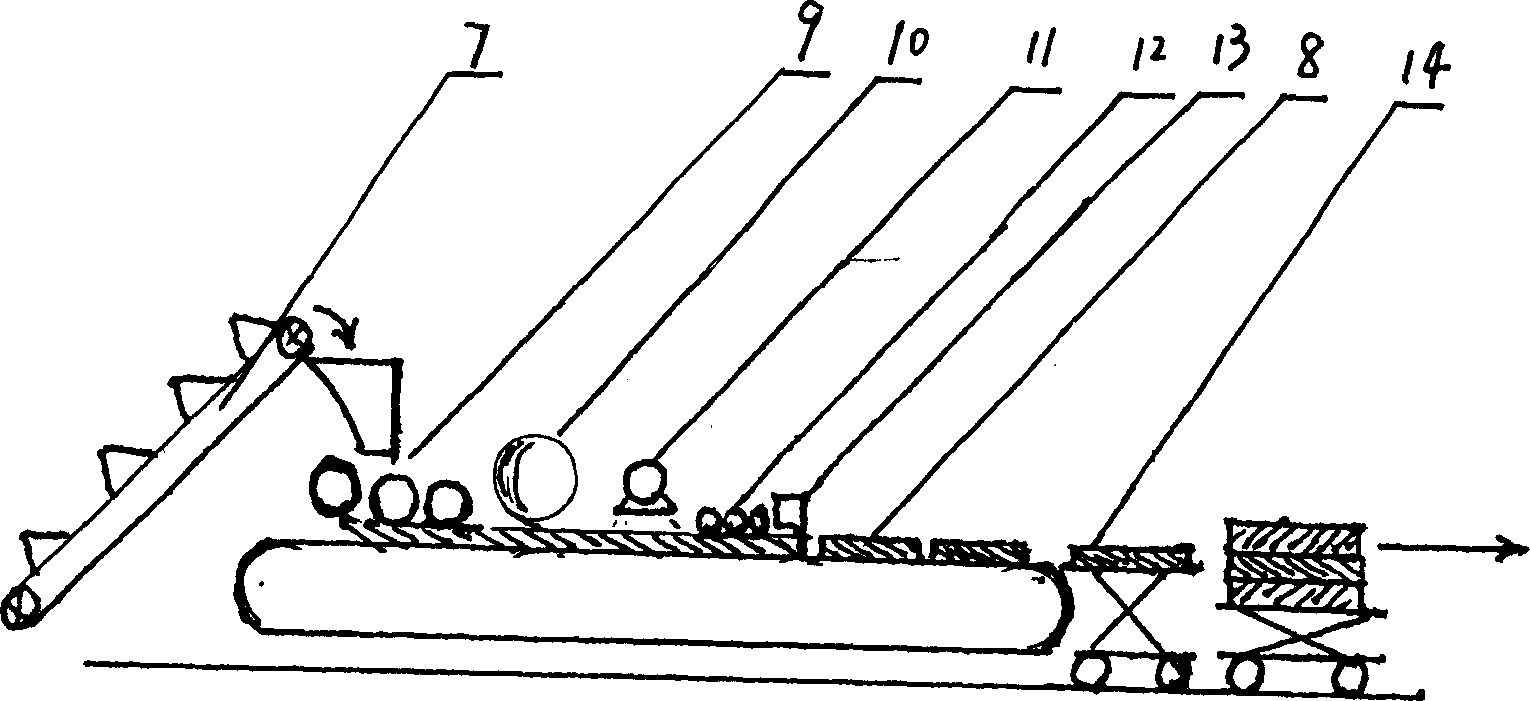

Fiber-toughened cement-emulsified asphalt-based mixture and preparation method thereof

The invention relates to the field of preparation of highway asphalt pavement materials, and particularly relates to a fiber-toughened cement-emulsified asphalt-based mixture and a preparation method thereof. The fiber-toughened cement-emulsified asphalt-based mixture comprises the following ingredients in parts by weight: 0.1-0.6 part of brucite mineral fiber, 1-5 parts of cement, 1-10 parts of emulsified asphalt, 0.5-2.0 parts of bisphenol A-type epoxy resin, 0.2-0.6 part of diethylenetriamine and 81.4-95.0 parts of aggregate. The method comprises the following steps of: adding the brucite mineral fiber into aggregate and performing dry mixing in a room-temperature condition; adding a proper amount of water, and mixing again; sequentially adding the emulsified asphalt, the bisphenol A-type epoxy resin and the diethylenetriamine, and mixing; and finally, adding the cement and uniformly mixing to obtain the fiber-toughened cement-emulsified asphalt-based mixture. The fiber-toughened cement-emulsified asphalt-based mixture provided by the invention can improve the tensile deformation ability, low-temperature crack resistance and fatigue rupture resistance of the cement emulsified-asphalt mixture and prolong the service life of pavement; and the construction process is simple to operate and economical and environment-friendly.

Owner:CHANGAN UNIV

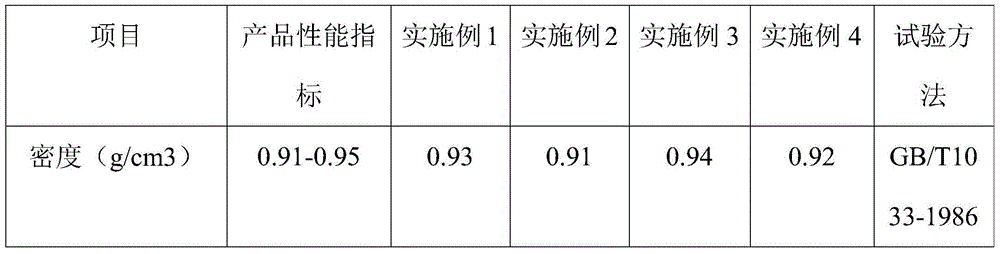

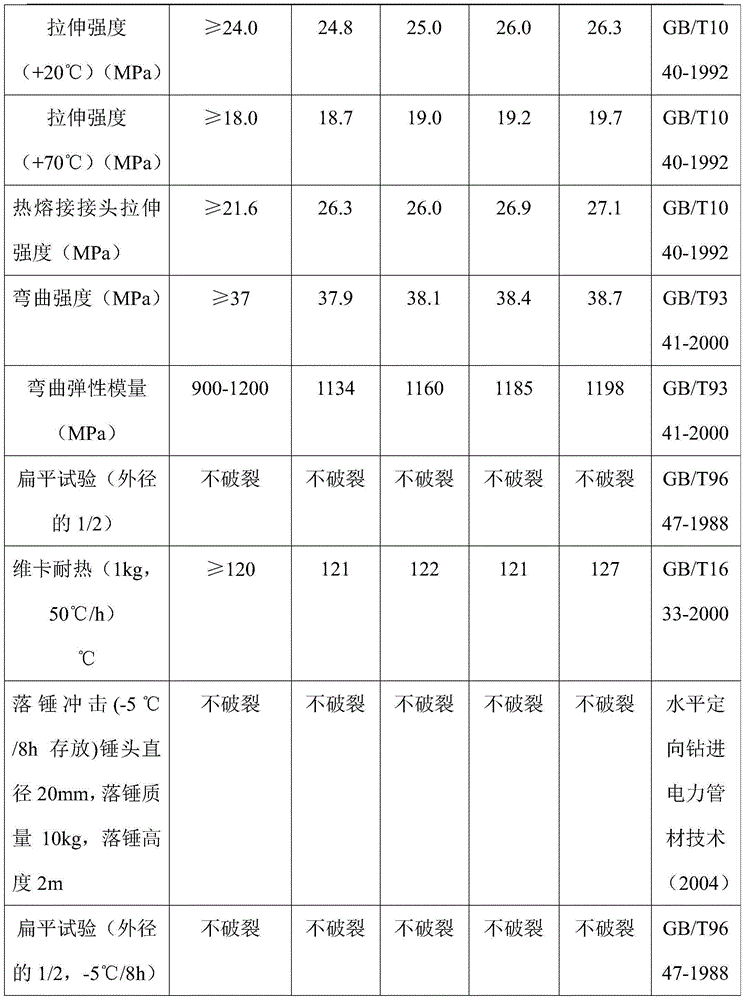

Anti-impact MPP (molypermalloy powder core) electric protection tube

The invention discloses an anti-impact MPP (molypermalloy powder core) electric protection tube. The anti-impact MPP electric protection tube is prepared from the following raw materials in parts by weight: 90-110 parts of polypropylene, 5-15 parts of ethylene-propylene-diene monomer, 10-25 parts of talcum powder, 3-10 parts of brucite powder, 5-12 parts of modified micro silicon powder, 0.8-2 parts of colouring agent, 5-15 parts of nano mica, 0.5-2 parts of antioxidant, 0.5-2 parts of polytetrafluoroethylene, 10-25 parts of modified shell powder, 5-15 parts of modified hectorite, 5-25 parts of novel organic montmorillonite, 5-18 parts of melamine cyanurate, 10-25 parts of modified crystal whisker, 15-30 parts of long glass fiber, 3-8 parts of expandable graphite and 5-20 parts of intumescent flame retardants. The anti-impact MPP electric protection tube has excellent impact resistance, flame retardance, ageing resistance, cold resistance and heat resistance.

Owner:安徽宁国市高新管业有限公司

High-strength ice crack type ceramic product and preparation technology thereof

The invention relates to the technical field of preparation of ceramics, in particular to a high-strength ice crack type ceramic product and a preparation technology thereof. The high-strength ice crack type ceramic product comprises a blank and a glaze, wherein the blank comprises 58 parts of kaolin, 24 parts of potassium feldspar, 13 parts of quartz, 17 parts of clay, 2 parts of talcum, 15 partsof melting additive, 20 parts of wollastonite, 14 parts of brucite, 10 parts of sodium feldspar, 8 parts of calcium silicate, 8 parts of barium sulfate, and 6 parts of sepiolite; the glaze comprises45 parts of potassium feldspar, 16 parts of montmorillonite, 26 parts of quartz, 39 parts of sodium feldspar, 3 parts of color oxide, 2 parts of sodium hexametaphosphate, 5 parts of talcum, and 20 parts of calcium carbonate. The preparation technology comprises the following steps of S1, preparing of the materials; S2, drawing of the blank; S3, plain firing; S4, glaze applying; S5, firing. The high-strength ice crack type ceramic product prepared by the preparation technology has the advantages that the mechanical strength is high, the color is transparent and clear, and the cracks are fine and regular.

Owner:福建省泉州市契合工贸有限公司

Composite efficient energy-saving heat-insulating material, and its manufacturing method and special apparatus

InactiveCN1470471AGood vacuum insulation effectGood heat insulationThermal insulationPipe protection by thermal insulationFiberSodium Bentonite

The composite high-effective energy-saving heat-insulating material comprises the following components: aluminium silicate fibre, glass fibre, quick T, sepiolite, brucite, expansive pearlite, piaozhuor diatomite, bentonite, catalyst and adhesive. Its production method includes the following steps: placing the soaked aluminium silicate fibre, glass fibre and quick T into stirring machine to obtain slurry material, adding sepiolite and brucite, then adding expansive pearlite and piaozhu, adding bentonite, catalyst and adhesive, stirring them to obtain paste-like finished product, pipe blank and wall plate blank material respectively.

Owner:谢文丁

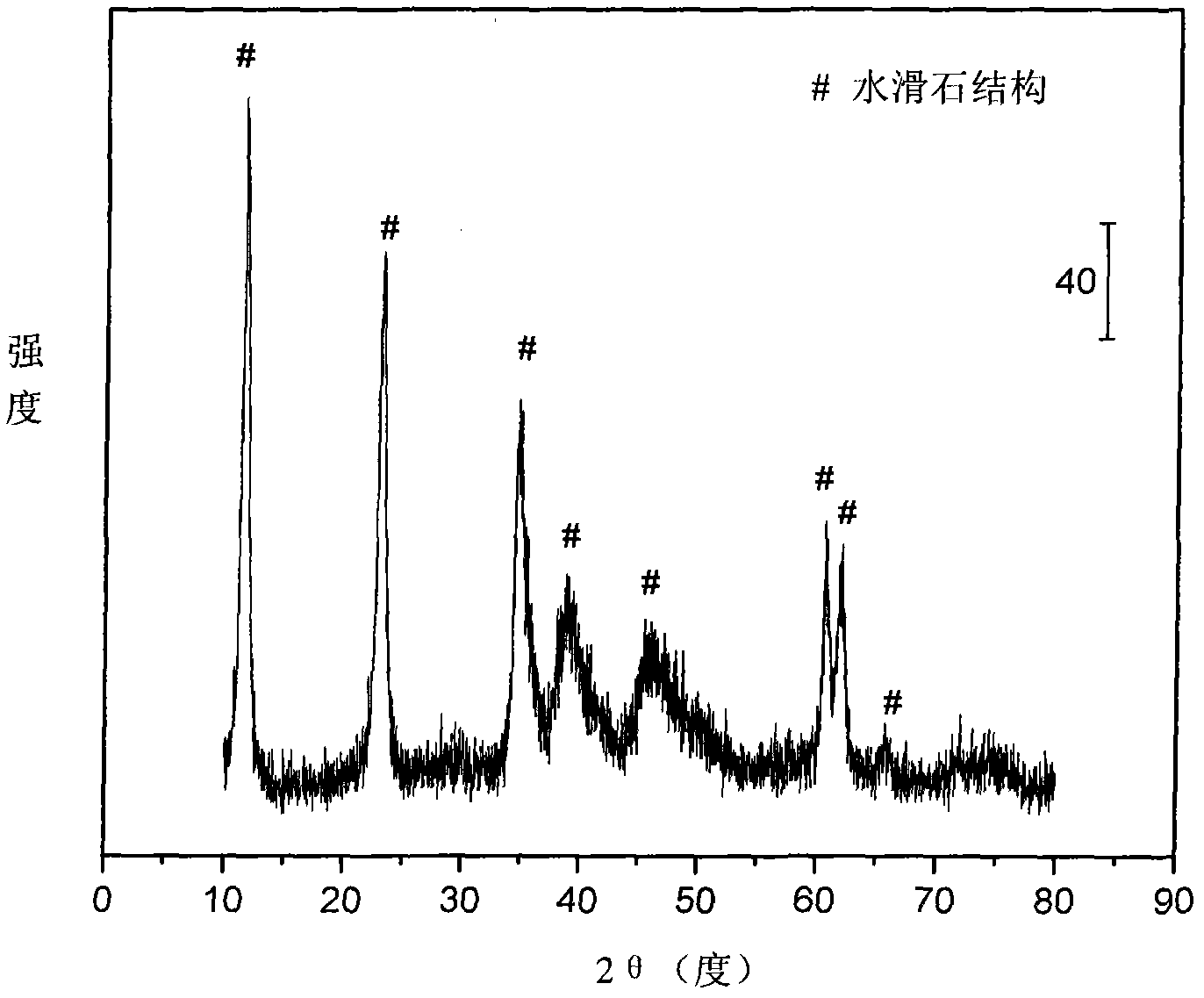

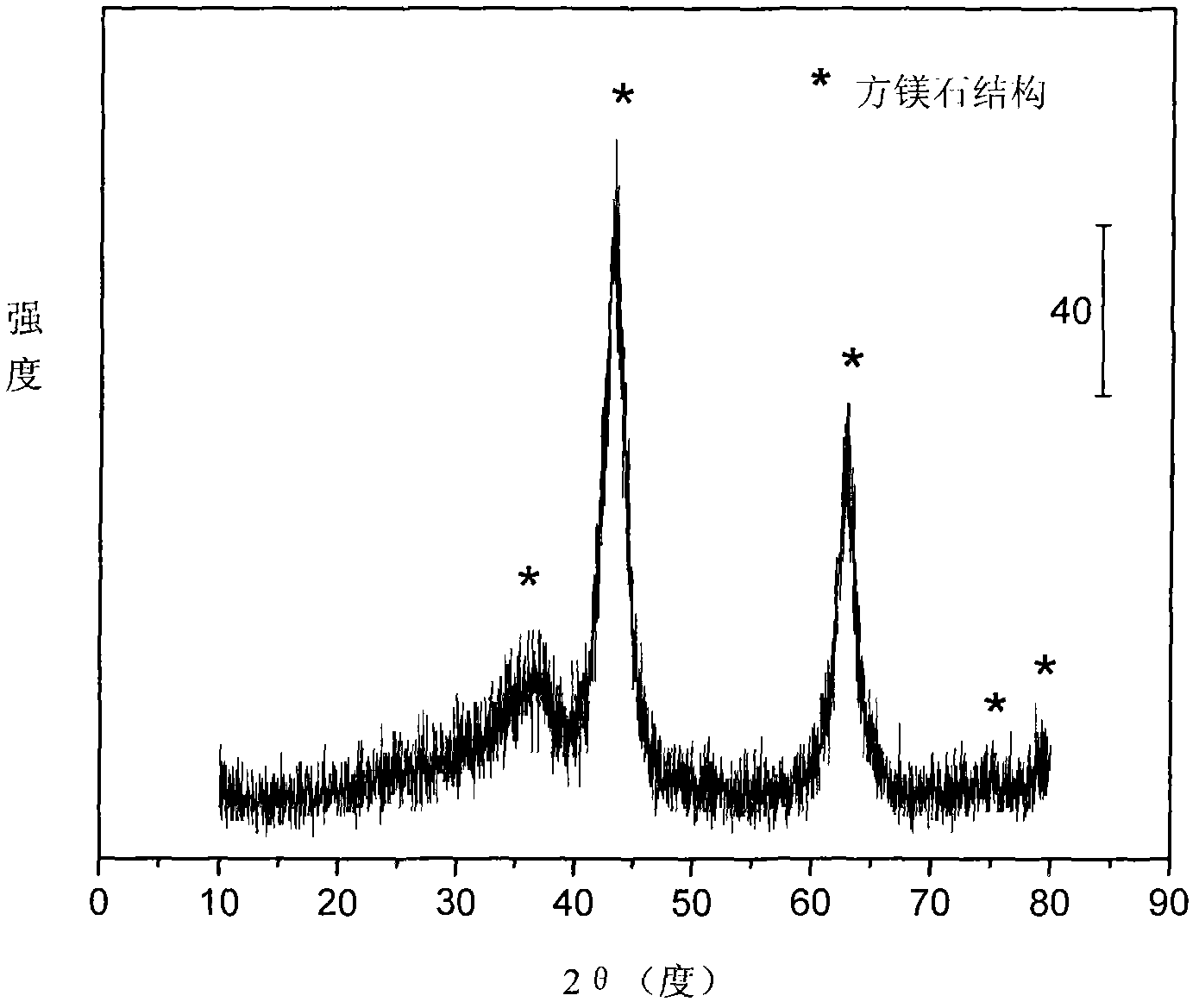

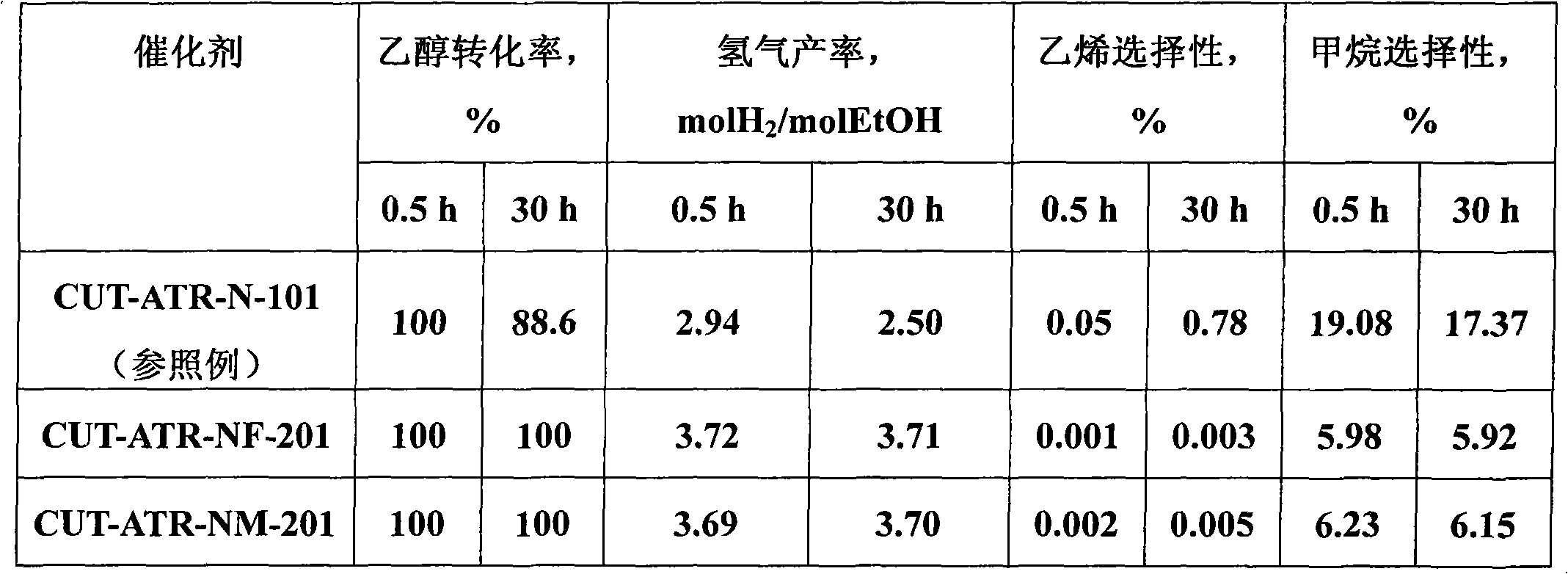

Nickel-base catalyst used for autothermal reforming of ethanol for producing hydrogen and preparation method thereof

InactiveCN101972656AEasy to introduceLarge specific surface areaHydrogenMetal/metal-oxides/metal-hydroxide catalystsManganeseCarbon deposit

The invention relates to a nickel-based catalyst used for the autothermal reforming of ethanol for producing hydrogen and a preparation method thereof. Aiming at the problems of structural change, oxidation and sintering of active ingredients and deactivation of the conventional catalyst during the autothermal reforming of the ethanol, the invention provides a novel catalyst with a stable structure, sintering resistance, carbon deposit resistance, oxidation resistance and high activity. The chemical formula of the catalyst is NiaMgbAlcXdO4.5+ / -delta, wherein X is an auxiliary agent Fe or Mn, a is 0.25 to 0.40, b is 2.6 to 2.75, c is 0.1 to 0.8 and d is 0.2 to 0.9. A brucite-based (Mg(OH)2.mH2O) hydrotalcite structure is taken as a precursor, so that the active ingredient nickel and the auxiliary agent heteroion component are introduced into a laminated structure and a position between laminated structures; meanwhile, the auxiliary agent iron or magnesium is introduced, so the reducibility and stability of the active ingredients of the catalyst are improved, and the yield of the hydrogen is obviously improved and remains stable.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Process for smelting magnesium by alumino-thermic reduction of magnesia

The invention relates to an extraction method of nonferrous metal magnesium, in which dolostone(MgCO3, CaCO3), brucite (Mg(OH)2) and giobertite (MgOCO3) are chosen as raw material, metal aluminum as reducer. At first, said three raw materials are calcined respectively to produce magnesia. Magnesia reacts with reducer aluminum with chemical reaction formula: 21MgO+12CaO+14Al=12CaO.7Al2O3+21Mg, in which weight of each raw material accords to reaction formula. Raw materials are mixed, forced to ball and then added into reduction jar. Reduction jar is added into reduction furnace. Advantages of the invention: saving 20-50% of energy cost and increasing service life of reduction jar; reducing periodic time of reduction from 12h to 7-8h so as to increase output of single jar; increasing 30-90% of magnesium production; decreasing racial of raw material and magnesium; furnace slag having multiple use and reducing cost of magnesium manufacture.

Owner:NORTHEASTERN UNIV

Method for preparing laminated composite metal hydroxide

InactiveCN101905869AOvercome costsOvercoming productivityOxide/hydroxide preparationAcid waterHydrogen

The invention discloses a method for preparing a laminated composite metal hydroxide, comprising the following steps of: mixing M(OH)2 and N(OH)3 according to the molar ratio of 2-4:1; and subjecting the mixture and an acid water solution to a reaction for 0.1-10 days at 100-300DEG C under the stirring condition, wherein the consumption of the acid water solution is 1-1,000 parts by weight, on the basis of the total weight of M(OH)2 and N(OH)3 as 1 part by weight, the molar ratio of acid in the acid water solution to N in the N(OH)3 is (n-1):1 to (n+1):1 and n expresses the number of nitrogen in each molecule of acid. When the laminated composite metal hydroxide is prepared from the method, various components in raw materials participate in the reaction to generate a target product or water molecule, no side product is generated in the process, water resources are saved and the environment is protected. In addition, in the method, by using brucite and pseudo-boehmite with low price as raw materials, the invention overcomes the defects that the clean preparation method in the prior art requires raw materials with high cost and is difficult to be applied to industrial production.

Owner:BEIJING UNIV OF CHEM TECH

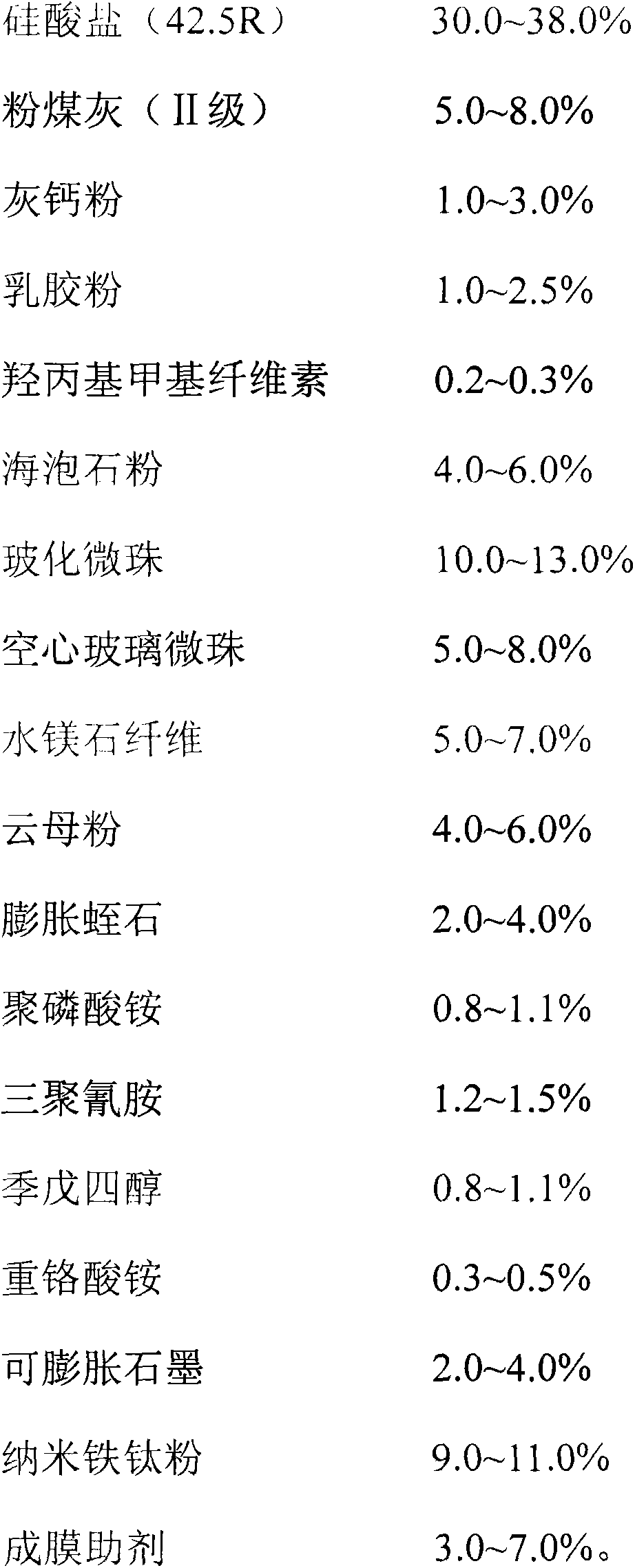

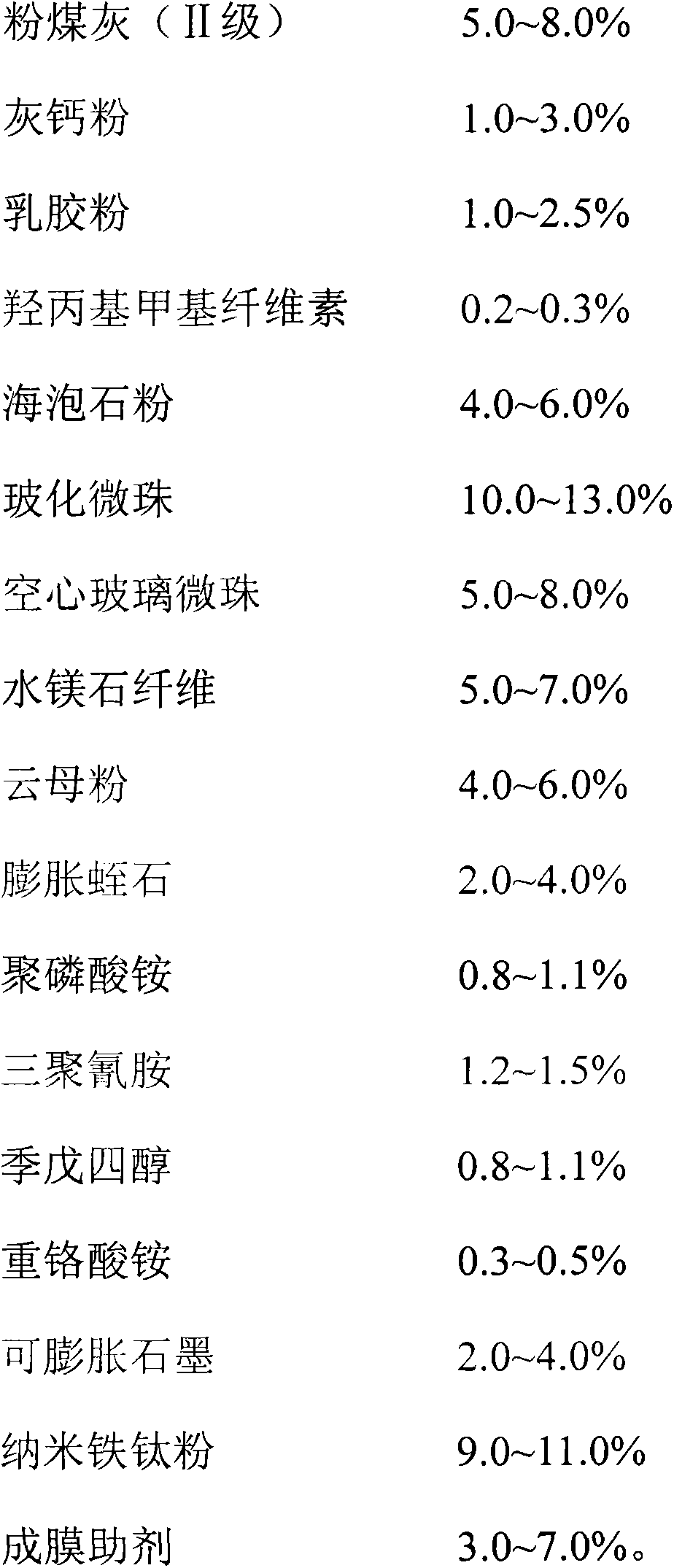

Hydrocarbon-resistant outdoor thick fireproofing coating for steel structures

ActiveCN103450716ALow thermal conductivityImprove fire and corrosion resistanceFireproof paintsAnti-corrosive paintsFiberFireproofing

The invention provides a hydrocarbon-resistant outdoor thick fireproofing coating for steel structures, wherein the fireproofing coating is prepared from the following raw materials in percentage by weight: 30.0-38.0% of silicate (42.5R), 5.0-8.0% of coal ash (II-grade), 1.0-3.0% of ash calcium powder, 1.0-2.5% of latex powder, 0.2-0.3% of hydroxypropyl methyl cellulose, 4.0-6.0% of sepiolite powder, 10.0-13.0% of glass beads, 5.0-8.0% of hollow glass beads, 5.0-7.0% of brucite fiber, 4.0-6.0% of mica powder, 2.0-4.0% of expanded vermiculite, 0.8-1.1% of ammonium polyphosphate, 1.2-1.5% of melamine, 0.8-1.1% of pentaerythritol, 0.3-0.5% of ammonium dichromate, 2.0-4.0% of expansible graphite, 9.0-11.0% of nano iron-titanium powder and 3-7% of a coalescing agent. The hydrocarbon-resistant outdoor thick fireproofing coating has binding strength, good water resistance and acid-base resistance property, and is safe and non-toxic, little in smoke, thermocycling resistant, excellent in corrosion resistance, and hydrocarbon fire resistant; the fireproofing coating can be widely used for fireproofing and anti-corrosion coating protection of indoor and outdoor steel structures.

Owner:石家庄雅致化工有限公司

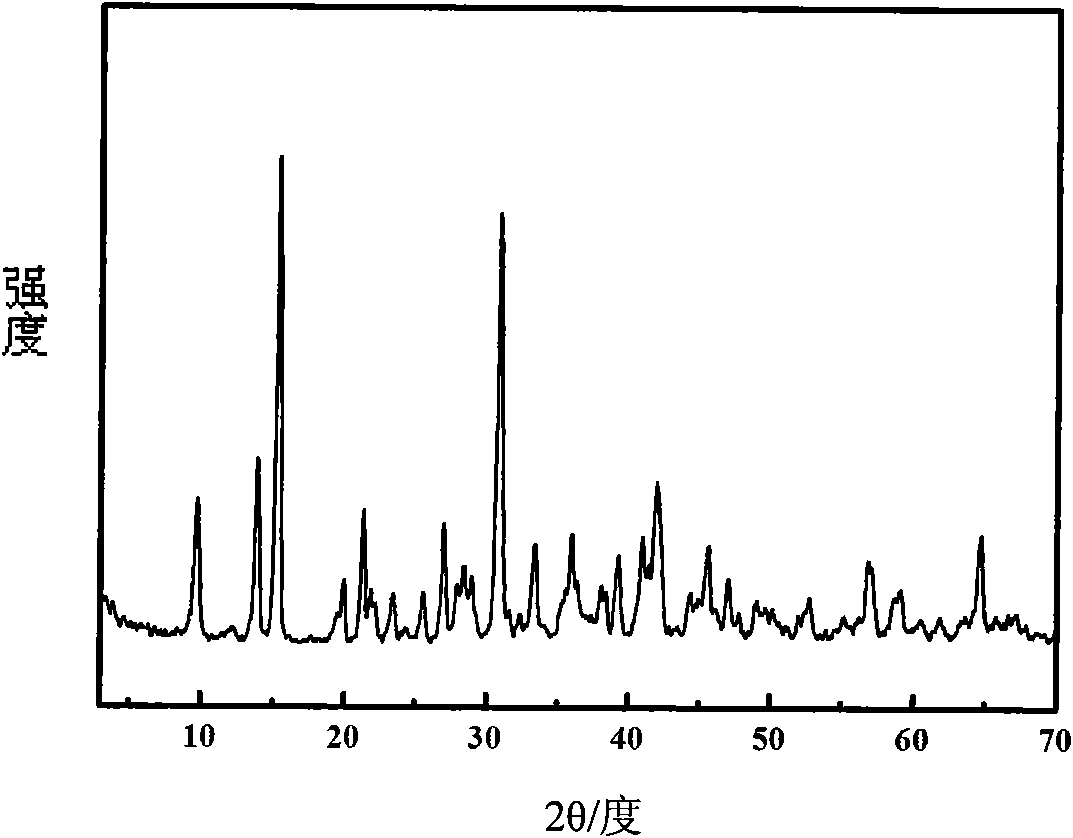

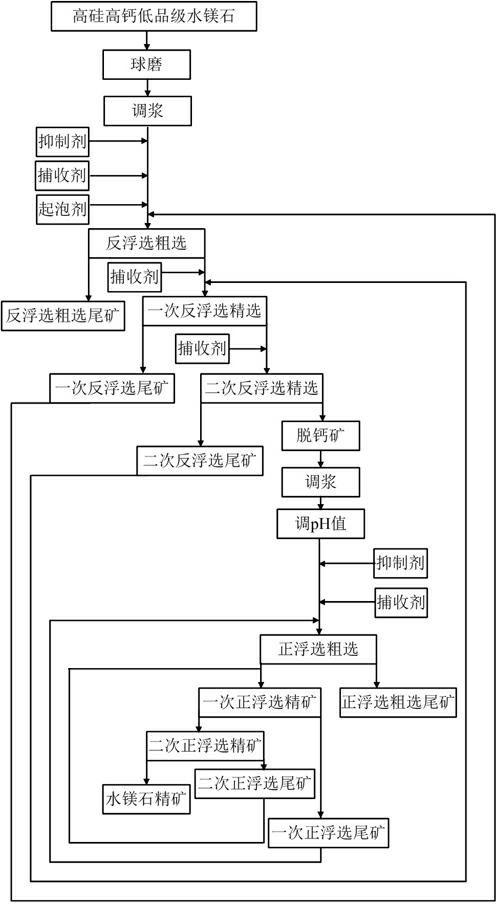

Step-by-step flotation method for high-silicon high-calcium low-grade brucite

InactiveCN102527520AImprove flotation environmentProcess runs smoothlyFlotationFoaming agentHydrogen

The invention belongs to the technical field of mineral processing, and particularly relates to a step-by-step flotation method for high-silicon high-calcium low-grade brucite, which includes the steps: adding water into the ball-milled high-silicon high-calcium low-grade brucite to prepare raw ore pulp, feeding the raw ore pulp into flotation equipment, adding inhibitors, collecting agents and foaming agents into the raw ore pulp in a stirring manner to perform reverse rougher flotation, and performing reverse cleaner flotation for obtained raw finished ores for 0-2 times to obtain desiliconized ores; and adding water into the desiliconized ores to prepare ore pulp, adjusting the pH (potential of hydrogen) value of the ore pulp, adding inhibitors into the ore pulp in a stirring manner, stirring collecting agents to perform direct rougher flotation, and performing direct cleaner flotation for obtained decalcified finished ores for 0-2 times to obtain finished brucite ores. The ores treated by the step-by-step flotation method are low in grade, the obtained finished brucite ores are high in purity, and the step-by-step flotation method is fine in flotation effect and low in cost.

Owner:NORTHEASTERN UNIV +1

Preparation method for magnetism-containing modified corundum composite material

The invention relates to a preparation method for a magnetism-containing modified corundum composite material. The composite material comprises the following main chemical components (wt): more than 95% of Al2O3 and less than 5% of MgO (Al2O3+MgO>99%); a main phase is a spinel-corundum phase. The preparation method comprises the following steps: taking industrial Al2O3, alpha-Al2O3 and Al(OH)3 as aluminum sources and magnesium salts such as brucite, light-burned MgO, dead burnt magnesite and magnesite as magnesium sources, adding 0.5-5% of alumina sol as a bonding agent or a combustion supporting agent, uniformly mixing through a gap-type or continuous-type ball mill, finely grinding, grading powder through air separation, forming the powder through a process of balling, pressing or the like, finally quickly sintering in a vertical kiln or a rotary kiln at 1,700-1,950 DEG C, crushing, grading, and deironing to obtain the magnetism-containing modified corundum composite material. According to the method, a high-quality refractory material for a liner of a high-temperature kiln is obtained, is low in expansion, high in strength, good in stability in a high-temperature reduction atmosphere and good in alkali resistance and slag corrosion resistance, and is a conventional sintered corundum upgrade product.

Owner:JIANGSU JINGXIN NEW MATERIAL

High-elasticity wear-resisting flame-retardant rubber material

The invention discloses a high-elasticity wear-resisting flame-retardant rubber material. The high-elasticity wear-resisting flame-retardant rubber material is prepared from the following raw materials in parts by weight: 40-45 parts of butadiene styrene rubber, 30-36 parts of polyurethane elastomer, 10-18 parts of chloroprene rubber, 2-3 parts of vulcanizing agent BPO (benzoyl peroxide), 1.2-1.8 parts of sulphur, 2-4 parts of accelerant DM (2,2'-dibenzothiazoledisulfde), 20-25 parts of modified titanium dioxide, 10-14 parts of calcite powder, 6-10 parts of brucite powder, 4-9 parts of aluminum nitride, 14-15 parts of carbon black N660, 2-5 parts of quartz powder, 5-8 parts of zinc oxide, 9-12 parts of magnesium hydrate, 1-4 parts of single alkoxyl pyrophosphate titanate coupling agent, 2-5 parts of diphenyl phosphate, 1-4 parts of melamine, 1-3 parts of stearic acid, 1-1.3 parts of anti-aging agent 264, and 2-4 parts of anti-aging agent MB (2-mercaptobenzimidazole). The high-elasticity wear-resisting flame-retardant rubber material has high elasticity, good abrasion resistance and excellent flame retardant effect.

Owner:ANHUI HONGYI CABLE GROUP

Method for preparing silica aerogel by doped brucite fiber and titanium dioxide powder

The invention provides a method for preparing silica aerogel by doped brucite fiber and titanium dioxide powder. The raw materials are available and non-toxic, the doped brucite fiber is used for enhancing the strength of the aerogel, brucite fiber is the only one environmentally friendly fiber which is not cancerogenic at present, fusing point thereof is as high as 1960 DEG C, and the brucite fiber can resist higher temperature compared with glass fiber and the like; the titanium dioxide powder is added, so that the defect of high temperature infrared transparence is avoided and heat conductivity at high temperature can be reduced; and supercritical technology is adopted to prepare aerogel composite material block without crack, the density thereof is 0.13-0.3g / cm<3>, heat conductivity at900K can be reduced to 0.045W.m<-1>.K<-1>, and breaking strength can reach 1.08MPa.

Owner:CHANGCHUN UNIV OF SCI & TECH

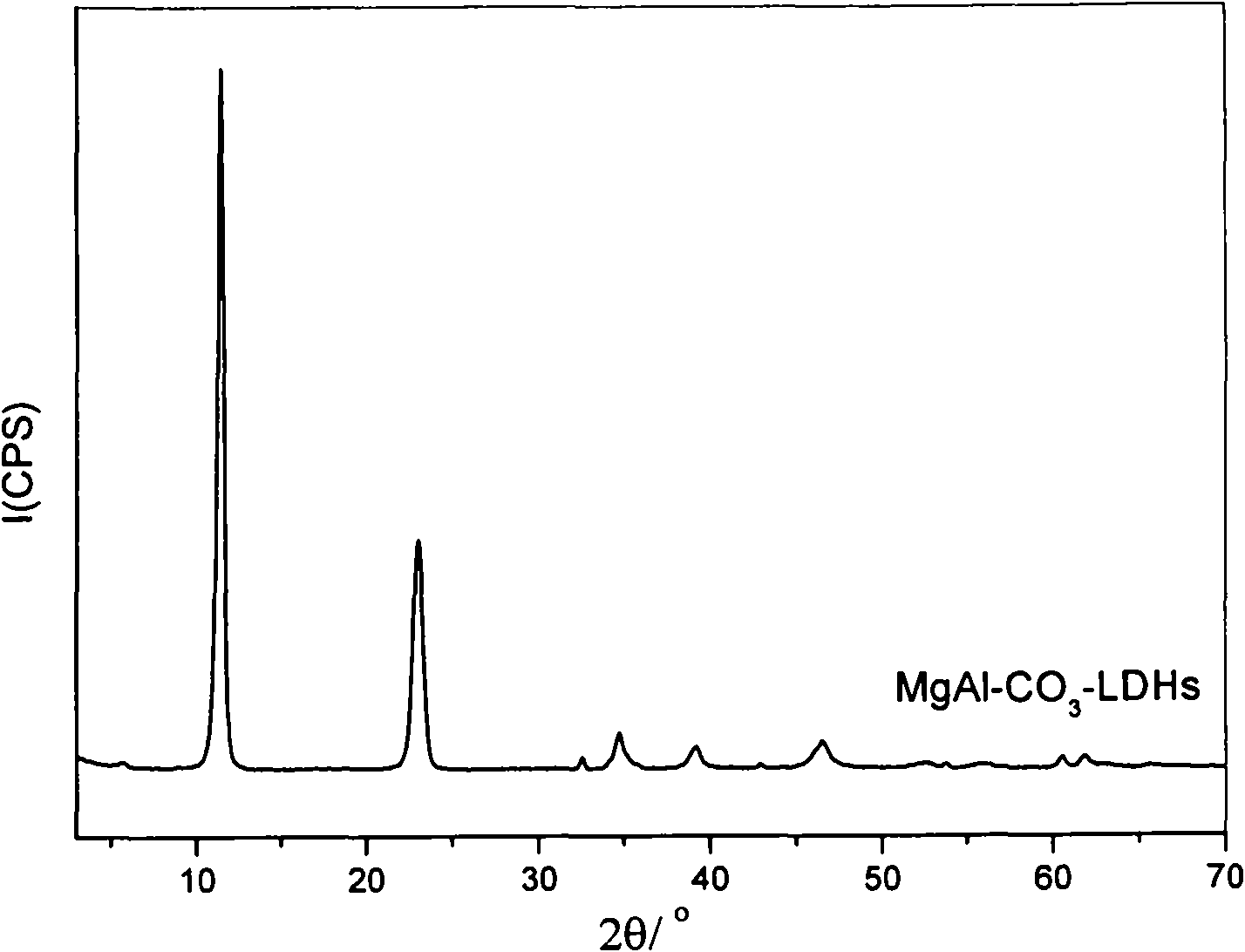

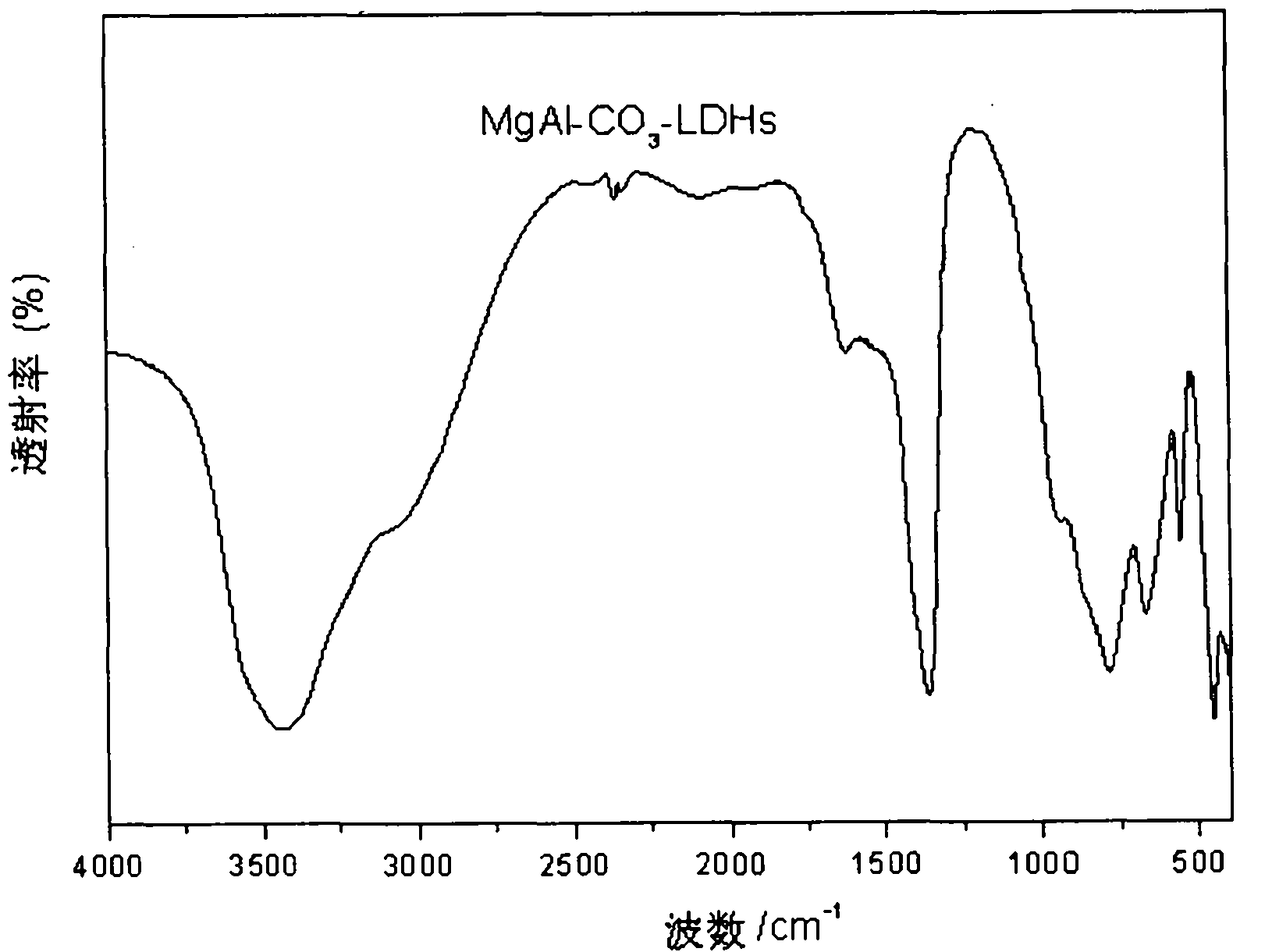

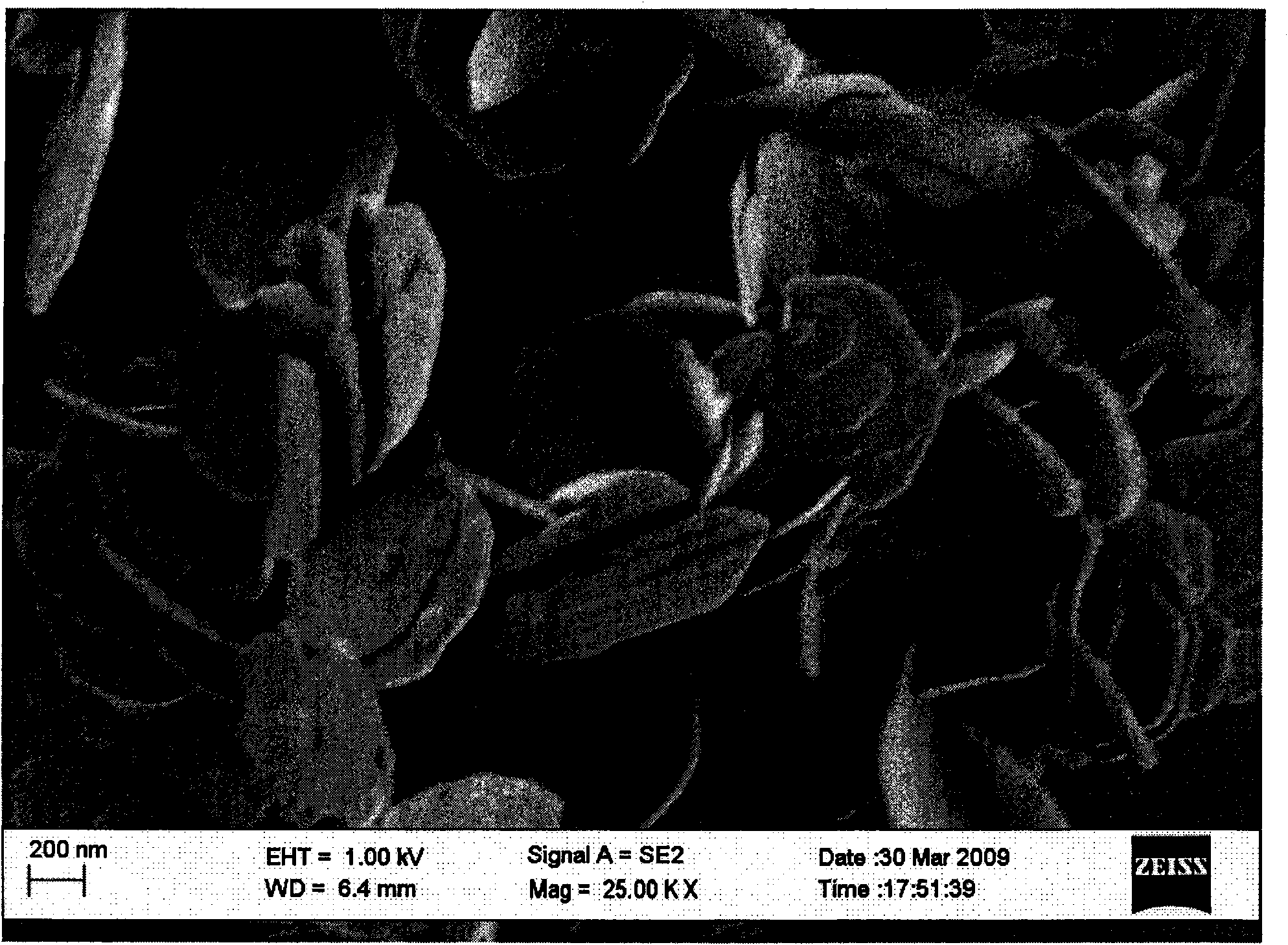

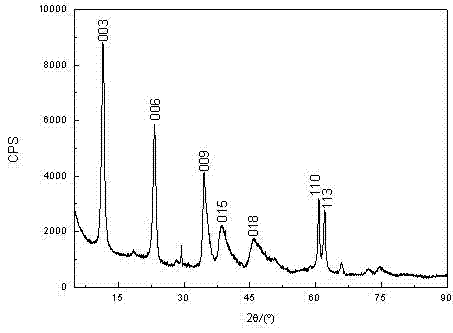

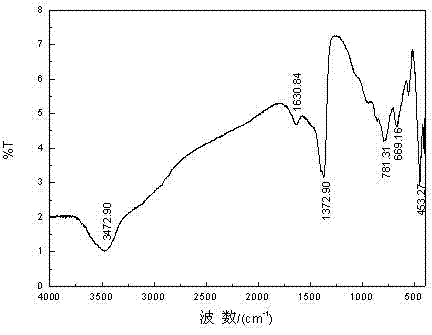

Method for preparing hydrotalcite by adopting brucite

InactiveCN102219248AWide variety of sourcesAbundant resource reservesAluminium oxides/hydroxidesWater bathsAluminium hydroxide

The invention relates to the technical field of hydrotalcite preparation, in particular to a method for preparing hydrotalcite by adopting brucite. In the method, brucite is adopted as a magnesium source, aluminum hydroxide is adopted as an aluminum source, and two main process steps of de-crystallization of brucite and aluminum hydroxide and recrystallization of de-crystallization substances areadopted. The method comprises the following steps: combining the brucite with the aluminum hydroxide according to the mole ratio of magnesium to aluminum being 2:4 to obtain mixture, mixing the mixture with zirconium oxide balls uniformly according to the ball-material ratio being 50:1, arranging the mixture and the zirconium oxide balls into a zirconium oxide ball milling tank for ball milling, then adding deionized water accounting for 10-20% of the total amount of brucite and aluminum hydroxide for ball milling continuously; mixing the material after ball milling and sodium carbonate solution according to the mole ratio being Mg2+:CO32-=1.5-6, stirring and crystallizing the mixture for 1-5h under water bath with the temperature being 60-80 DEG C, and the stirring rotation speed being 500r / min, and finally washing and drying to obtain the final product hydrotalcate.

Owner:NORTHEASTERN UNIV +1

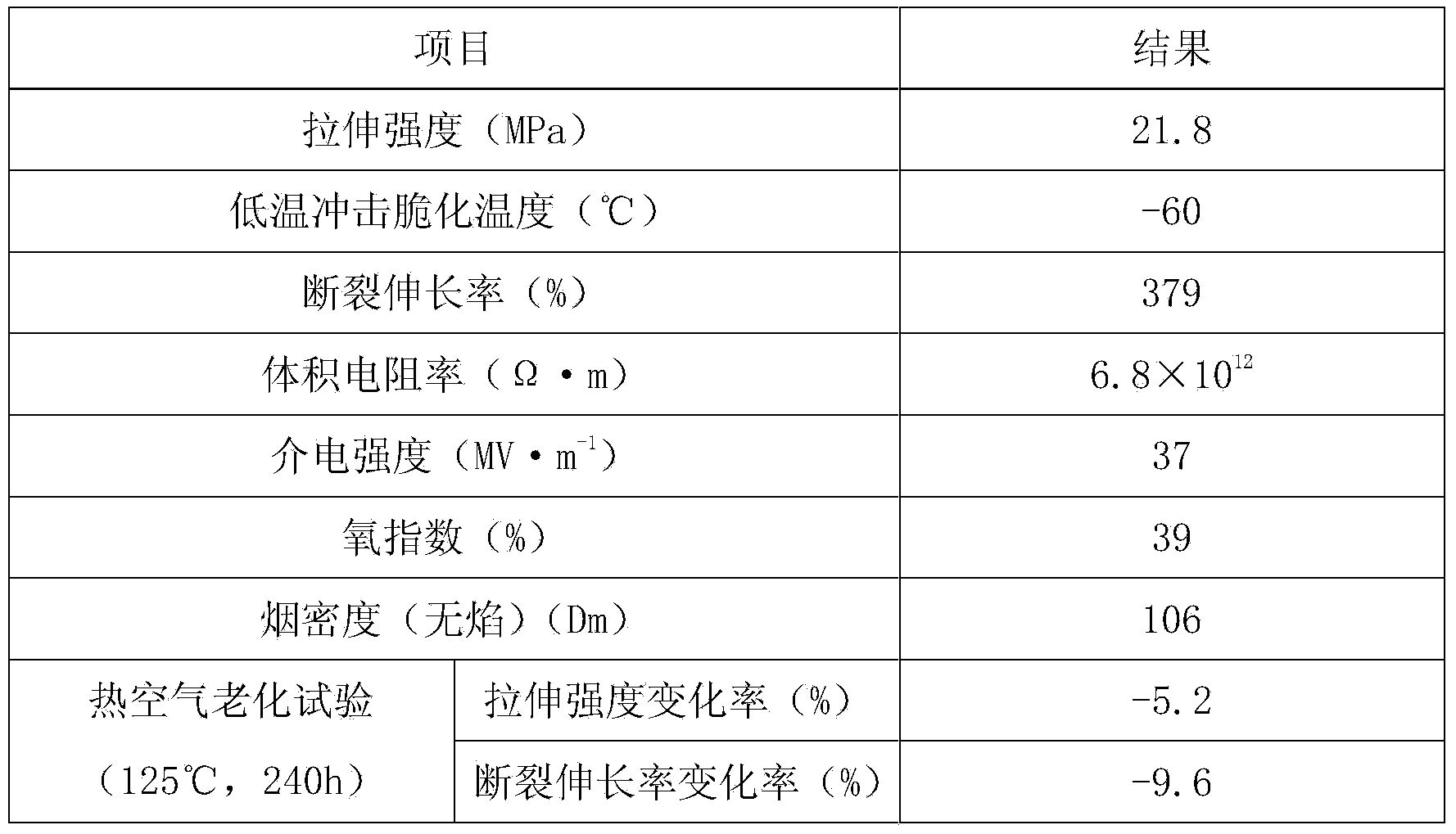

High and low temperature-resistant insulating sheath material for transformer and preparation method thereof

ActiveCN103509353AGood high and low temperature resistanceImprove insulation performanceRubber insulatorsInsulated cablesTransformerBrucite

The invention discloses a high and low temperature-resistant insulating sheath material for a transformer and a preparation method thereof. The high and low temperature-resistant insulating sheath material is prepared from 70-90 weight parts of fluorosilicone rubber, 20-30 weight parts of SG-3-type PVC, 10-15 weight parts of dioctyl maleate, 5-10 weight parts of nylon acid diisobutyl ester, 15-20 weight parts of magnesium hydroxide, 10-15 weight parts of ammonium polyphosphate, 4-8 weight parts of molybdenum trioxide, 30-40 weight parts of fumed silica, 4-6 weight parts of zinc oxide, 2-3 weight parts of stearic acid, 1-2 weight parts of nano-cerium oxide, 1-2 weight parts of bis(P,P-bis-ethylhexyl diphosphato)ethanediolato titanate, 3-6 weight parts of oxidized polyethylene wax, 10-15 weight parts of brucite powder, 15-20 weight parts of nano-barite, 8-12 weight parts of nano-wollastonite and 4-6 weight parts of a composite filling material. The high and low temperature-resistant insulating sheath material has excellent high and low temperature resistance, good insulating properties, good physical and mechanical properties, good weathering aging resistance, acid and alkali resistance, radiation resistance and oil resistance, can be used in a temperature range of -60-180 DEG C for a long time, does not deform, embrittle and crack, and is durable.

Owner:ANHUI KELIN ELECTRONICS

Flame retardant composite board and manufacture method thereof

InactiveCN104552488AHigh mechanical strengthGood nail gripWood veneer joiningDomestic articlesBruciteComposite plate

The invention provides a flame retardant composite board. The flame retardant composite board comprises a homogeneous naked panel and a facing layer arranged on at least one surface of the homogeneous naked panel, wherein the homogeneous naked panel is prepared from raw materials of, based on weight parts, 65-98.5 parts of plant straw particles, 3-10 parts of binder and 3-10 parts of fire retardant, wherein the fire retardant is prepared from raw materials of magnesium oxide, calcium sulfate, aluminum hydroxide, brucite, zinc molybdate and zinc borate. The flame retardant composite board has good chemical properties of fire retarding, water prevention, insect prevention and the like, and good physical and mechanical properties, can replace wood artificial boards, and is used in various fields. The invention further provides a manufacture method of the flame retardant composite board. The manufacture method of the flame retardant composite board mainly adopts a normal temperature cold press molding technology to solidify and shape the raw materials of the naked panel, not only greatly saves energy, but also improves product performance, enables the flame retardant composite board to have water prevention and fire prevention functions, and simultaneously can substantially reduce equipment cost, achieves a whole green production process, and does not cause pollution during the whole production process.

Owner:信阳美丽真好秸秆新材科技有限公司

Preparation method for superfine active brucite composite modified material

The invention discloses a preparation method for superfine brucite, and particularly discloses a composite modifying method for preparing the brucite into active brucite. The specific technological process is implemented through the steps of grinding, pulping, filtering, drying and smashing, modifying and the like. Through the technological method provided by the invention, the active brucite of which the surface is covered with a long carbon chain anionic surfactant is prepared, the surface of magnesium hydrate is provided with a long-chain radical (-C15-20H30-40), and alcohol radicals possibly generated after the hydrolysis of a coupling reagent and residual hydroxide radicals on the surface of the magnesium hydrate are subjected to condensation reaction to form automatic polymerization , as a result, an organic radical with high surface activity is grafted on the surface of the brucite; as the organic radical has good hydrophobicity, the possibility of aggregation among small particles of the brucite is reduced, and the dispersion in plastic is facilitated; the interface interaction between the active brucite and matters like plastic and resin is enhanced, and the flame retardant property of polymers is improved. Therefore, the superfine active brucite provided by the invention can be used in plastic and resin industries.

Owner:丹东亿龙高科技材料有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com