Patents

Literature

586 results about "Chromite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chromite is a mineral that is an iron chromium oxide. It has a chemical formula of FeCr₂O₄. It is an oxide mineral belonging to the spinel group. The element magnesium can substitute for iron in variable amounts as it forms a solid solution with magnesiochromite(MgCr₂O₄). A substitution of the element aluminium can also occur, leading to hercynite (FeAl₂O₄). Chromite today is mined particularly to make stainless steel through the production of ferrochrome (FeCr), which is an iron-chromium alloy.

Thermal protective coating for ceramic surfaces

ActiveUS6921431B2Extended shelf lifeConvenience to workFireproof paintsOther chemical processesColloidal silicaSodium Bentonite

A coating admixture, method of coating and substrates coated thereby, wherein the coating contains colloidal silica, colloidal alumina, or combinations thereof; a filler such as silicon dioxide, aluminum oxide, titanium dioxide, magnesium oxide, calcium oxide and boron oxide; and one or more emissivity agents such as silicon hexaboride, carbon tetraboride, silicon tetraboride, silicon carbide, molybdenum disilicide, tungsten disilicide, zirconium diboride, cupric chromite, or metallic oxides such as iron oxides, magnesium oxides, manganese oxides, chromium oxides, copper chromium oxides, cerium oxides, terbium oxides, and derivatives thereof. In a coating solution, an admixture of the coating contains water. A stabilizer such as bentonite, kaolin, magnesium alumina silicon clay, tabular alumina and stabilized zirconium oxide is also added.

Owner:WESSEX

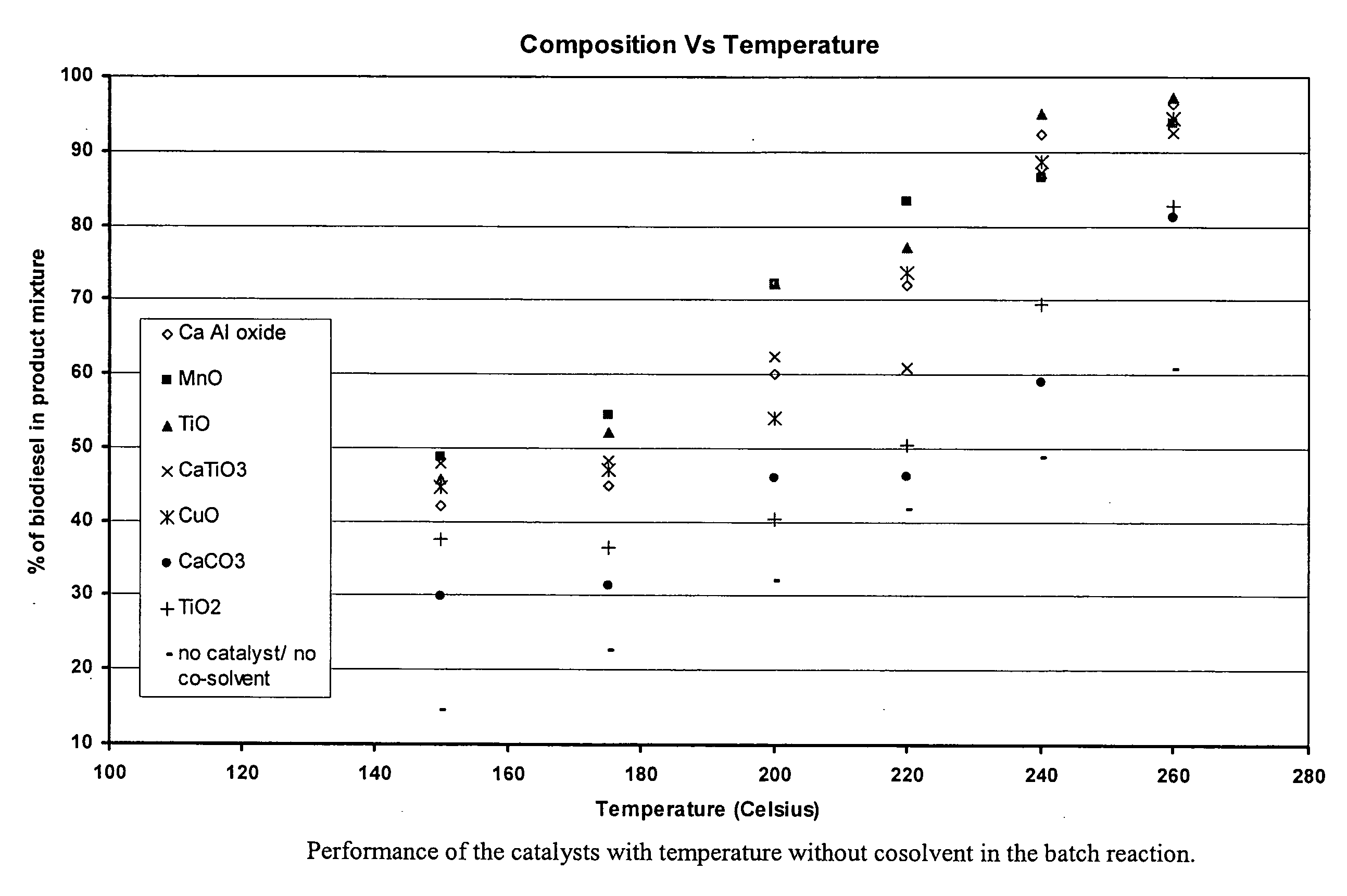

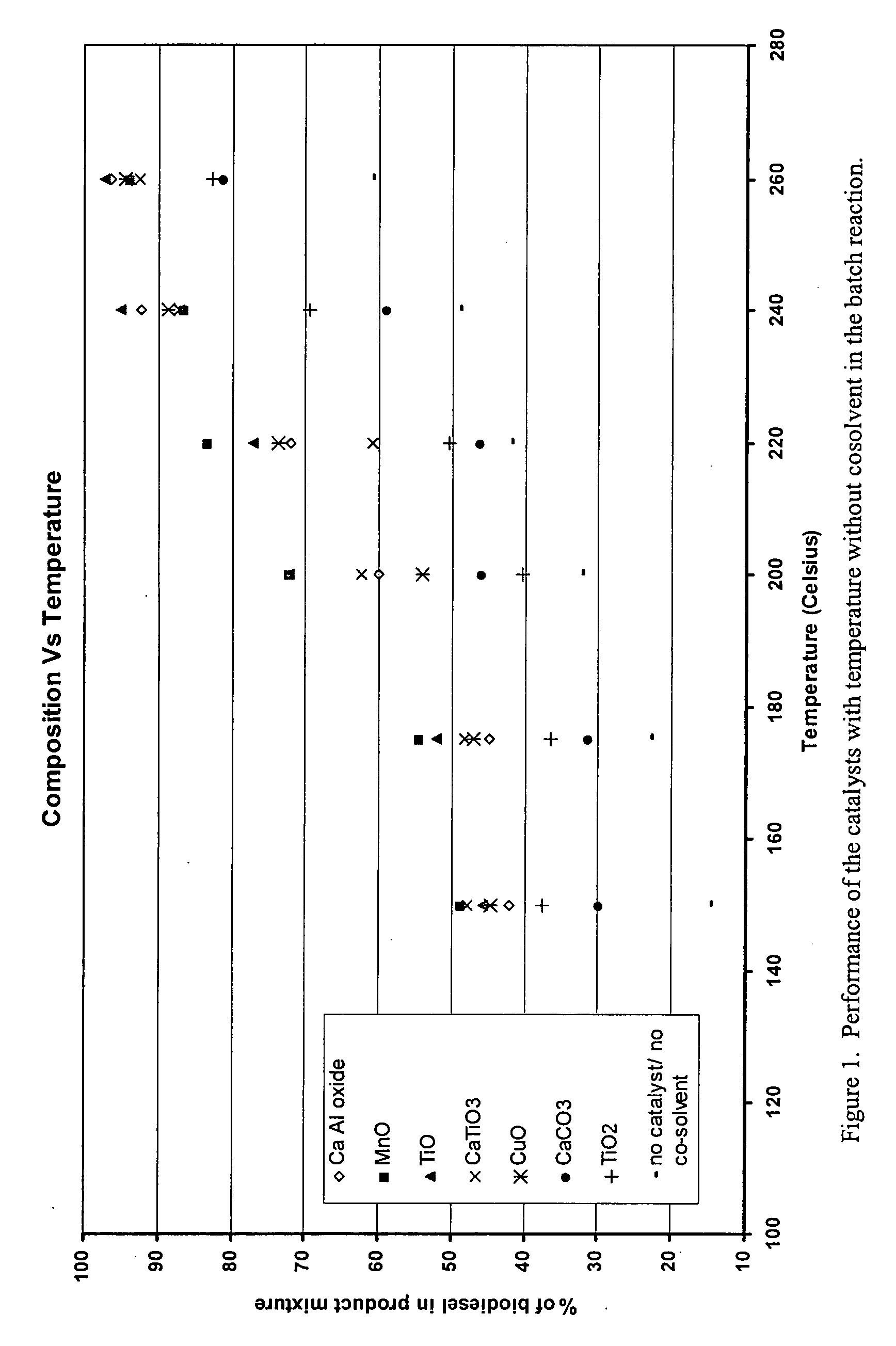

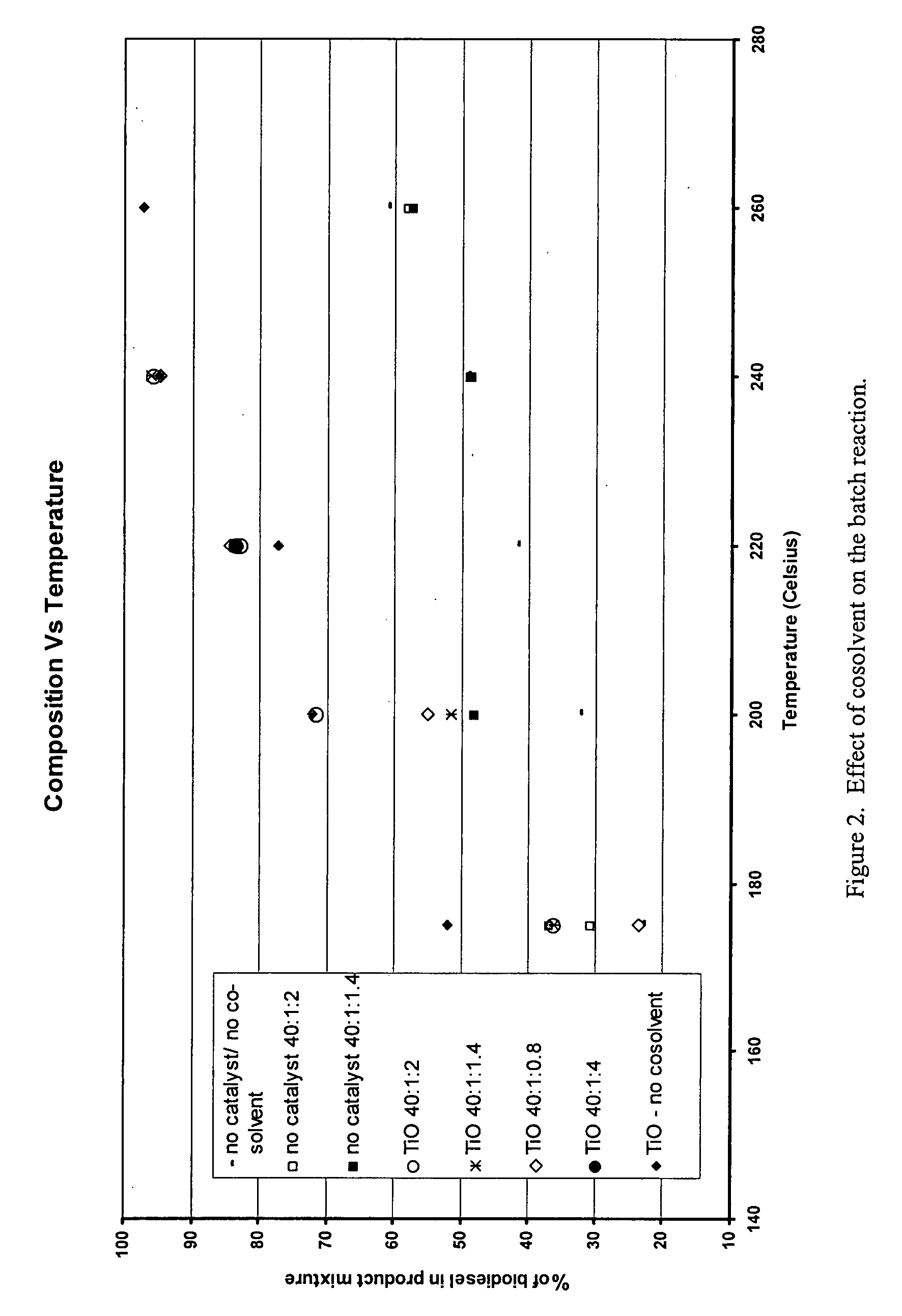

Green biodiesel

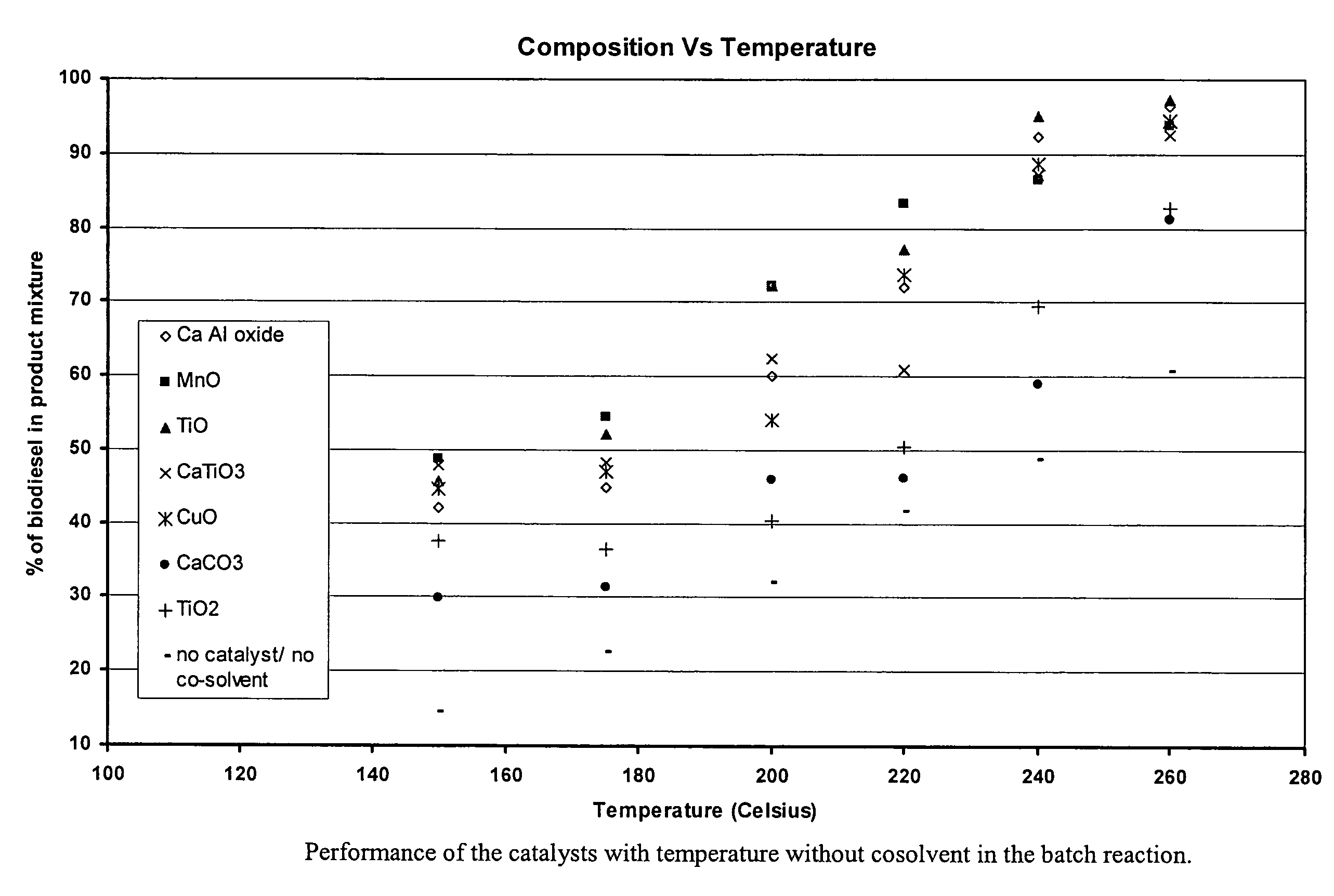

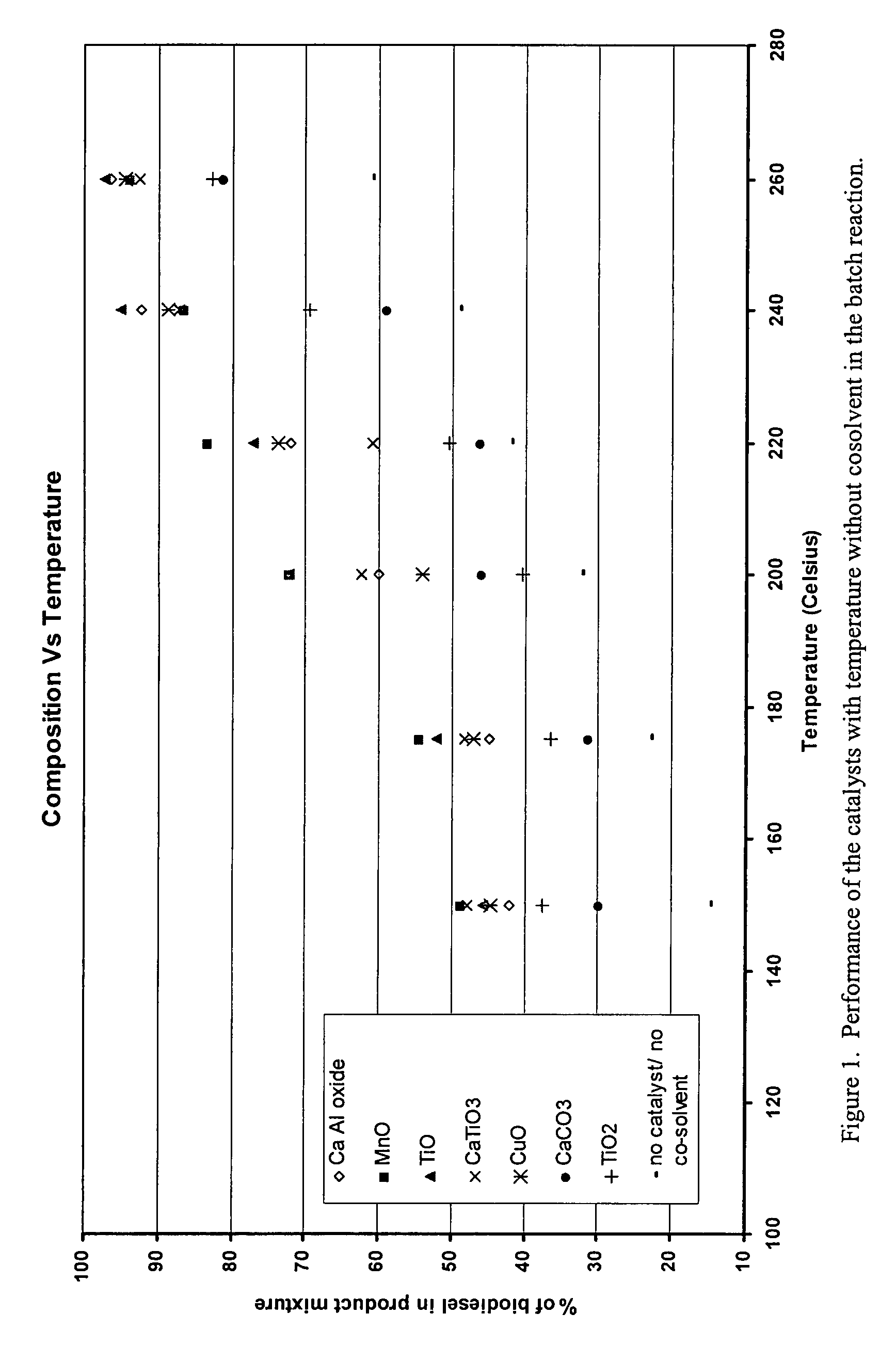

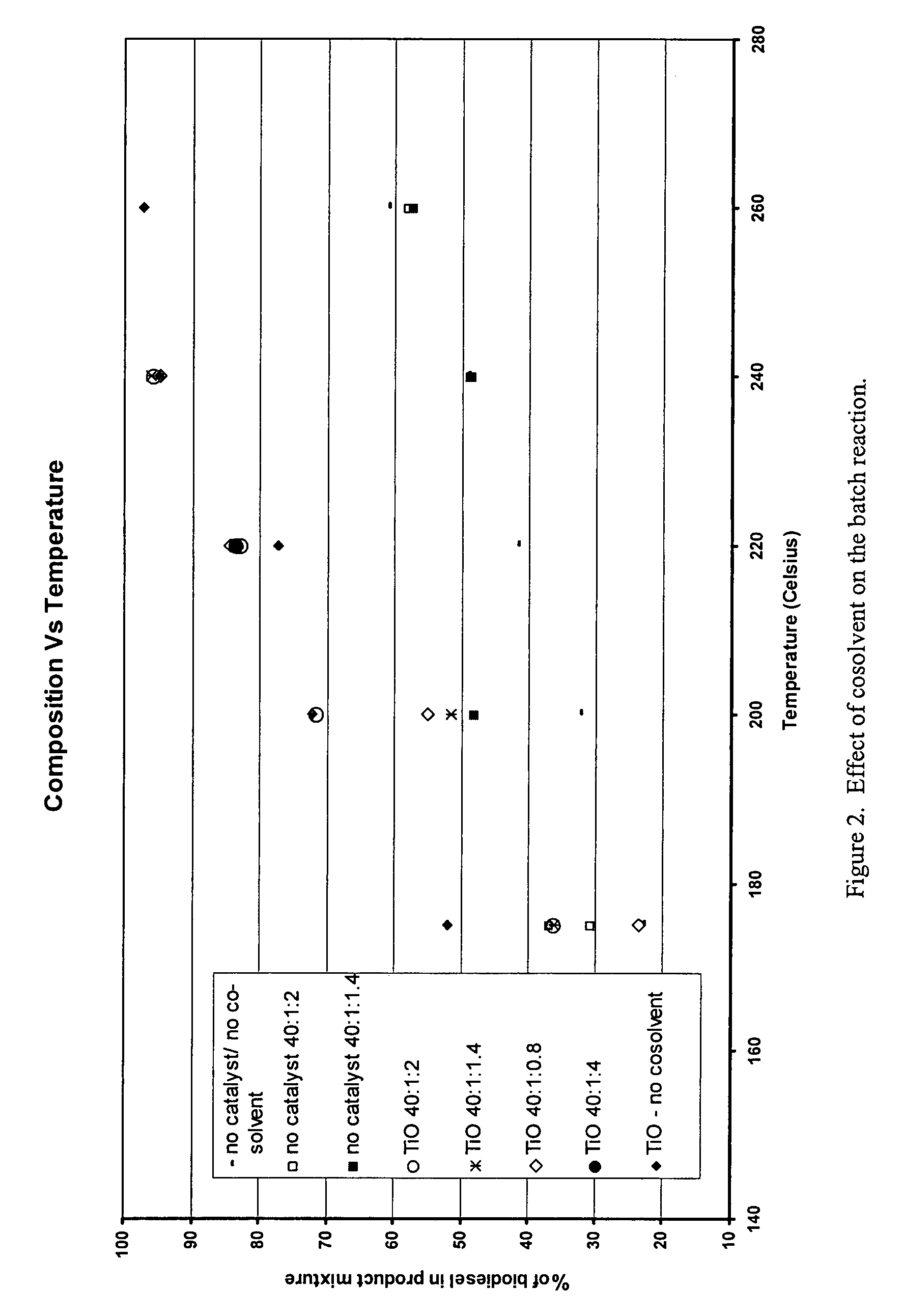

InactiveUS7563915B2Reduce wasteSignificant energyFatty oils/acids recovery from wasteFatty acid esterificationCalcium silicateBiodiesel

Methods for improved manufacture of green biodiesel focus on the selection and use of one or more solid metallic oxide base catalyst(s) selected from the group consisting of calcium oxide (CaO), calcium aluminum oxide (CaO—Al2O3), calcium titanate (CaTiO3), barium titanate (BaTiO3), magnesium aluminum oxide (MgO—Al2O3), zinc oxide (ZnO), copper (II) oxide (CuO), nickel oxide (NiO), manganese oxide (MnO), titanium oxide (TiO), vanadium oxide (VO), cobalt oxide (CoO), iron oxide (FeO), chromite (FeCr2O4), hydrotalcite (Mg6Al2(CO3)(OH)16.4(H2O), magnetite (Fe3O4), magnesium silicate and calcium silicate.

Owner:PENN STATE RES FOUND

Thermal protective coating for ceramic surfaces

ActiveUS20050051057A1Extend working lifeReduce surface temperatureFireproof paintsOther chemical processesColloidal silicaSodium Bentonite

A coating admixture, method of coating and substrates coated thereby, wherein the coating contains colloidal silica, colloidal alumina, or combinations thereof; a filler such as silicon dioxide, aluminum oxide, titanium dioxide, magnesium oxide, calcium oxide and boron oxide; and one or more emissivity agents such as silicon hexaboride, carbon tetraboride, silicon tetraboride, silicon carbide, molybdenum disilicide, tungsten disilicide, zirconium diboride, cupric chromite, or metallic oxides such as iron oxides, magnesium oxides, manganese oxides, chromium oxides, copper chromium oxides, cerium oxides, terbium oxides, and derivatives thereof. In a coating solution, an admixture of the coating contains water. A stabilizer such as bentonite, kaolin, magnesium alumina silicon clay, tabular alumina and stabilized zirconium oxide is also added.

Owner:WESSEX

Thermal protective coating

ActiveUS7105047B2Extended shelf lifeReduce weightAlkali metal silicate coatingsPretreated surfacesCalcium silicateSodium Bentonite

A coating, method of coating and substrates coated thereby, wherein the coating contains an inorganic adhesive such as an alkali / alkaline earth metal silicate such as sodium silicate, potassium silicate, calcium silicate, and magnesium silicate; a filler such as a metal oxide for example silicon dioxide, aluminum oxide, titanium dioxide, magnesium oxide, calcium oxide and boron oxide; and one or more emissivity agents such as silicon hexaboride, carbon tetraboride, silicon tetraboride, silicon carbide, molybdenum disilicide, tungsten disilicide, zirconium diboride, cupric chromite, or metallic oxides such as iron oxides, magnesium oxides, manganese oxides, chromium oxides and copper chromium oxides, and derivatives thereof. In a coating solution, an admixture of the coating contains water. A stabilizer such as bentonite, kaolin, magnesium alumina silicon clay, tabular alumina and stabilized zirconium oxide may be added.

Owner:WESSEX

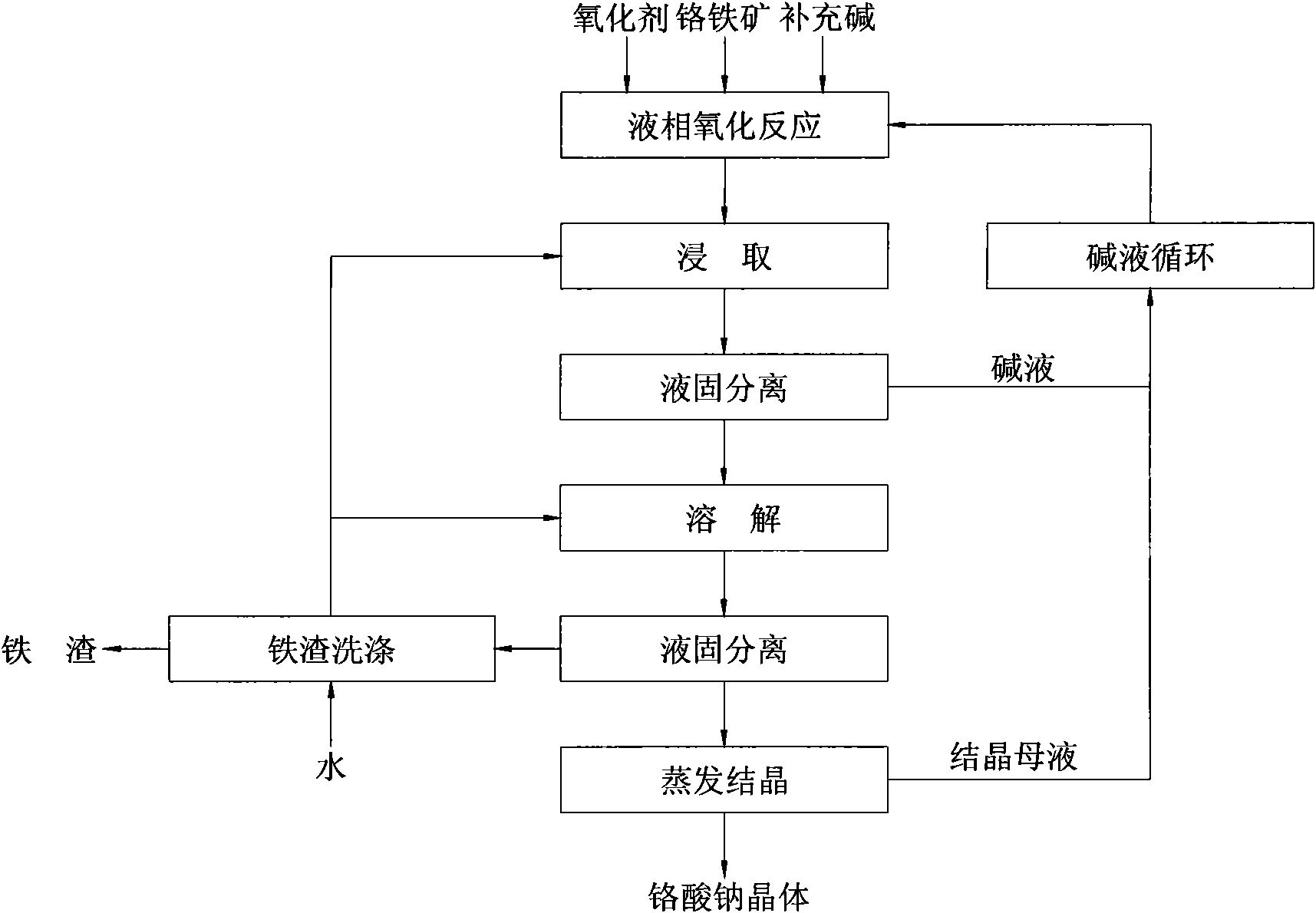

Clean production method for preparing sodium chromate from chromite

InactiveCN101659444AObvious superiorityLow reaction temperatureChromates/bichromatesSlagSodium nitrate

The invention relates to a clean production method for preparing sodium chromate from chromite, which comprises the following steps of: reacting the chromite with an oxidizing gas in a medium of NaOH-NaNO3-H2O, wherein sodium nitrate serves as a catalytic medium and is not consumed in the reaction; obtaining a mixed reaction product of an alkali liquor, the sodium chromate and iron slag after thereaction; leaching the mixed reaction product, performing liquid-solid separation of the alkali liquor and a crystal slag mixture (a mixture of a sodium chromate crystal and the iron slag), dissolvingthe mixture of the iron slag and the sodium chromate crystal, performing liquid-solid separation of the solution of the iron slag and the sodium chromate crystal, performing evaporative crystallization of the sodium chromate solution, rinsing and drying the obtained sodium chromate solution, obtaining qualified sodium chromate products; and circulating the crystallized mother liquor and the alkali liquor together to decompose the chromite. In the method, the chromium conversion ratio is above 99 percent and the chromium content ratio in the slag is less than 0.5 percent.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

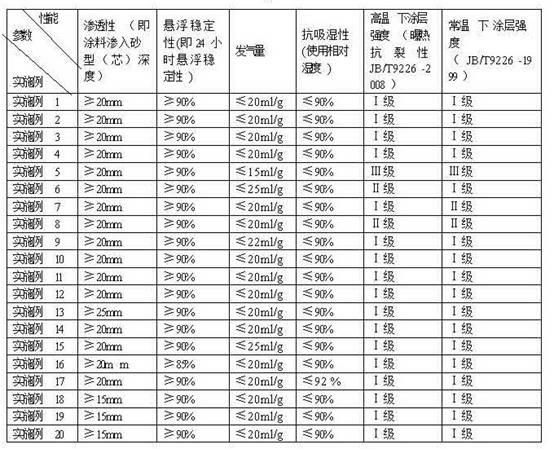

High-permeability sand-burning-preventing paint for casting and preparation method thereof

InactiveCN102139342AImprove permeabilityImprove high temperature strengthFoundry mouldsFoundry coresAlkylphenolSuspending Agents

The invention discloses high-permeability sand-burning-preventing paint for casting and a preparation method thereof. The high-permeability sand-burning-preventing paint is prepared from the following raw materials: refractory aggregate, a binding agent, an activating agent, a thickening agent, a suspending agent, a defoaming agent and a carrier, wherein the masses of the binding agent, the activating agent, the thickening agent, the suspending agent, the defoaming agent and the carrier respectively account for 0.5-2.5 percent, 0.01-0.05 percent, 0.1-0.5 percent, 1.5-5.0 percent, 0.01-0.1 percent and 40-220 percent of the mass of the refractory aggregate; the refractory aggregate is a mixture of one or two of zircon powder and chromite fines in any proportion; the binding agent is phenolic resin or a mixture of the phenolic resin and one or more than two of oxidized rosin and ethyl silicate; the activating agent is alkylphenol ethoxylates; the carrier is ethanol; the thickening agent is polyvinyl butyral; the suspending agent is lithium bentonite; and the defoaming agent is normal butanol.

Owner:衡阳中钢衡重铸锻有限公司

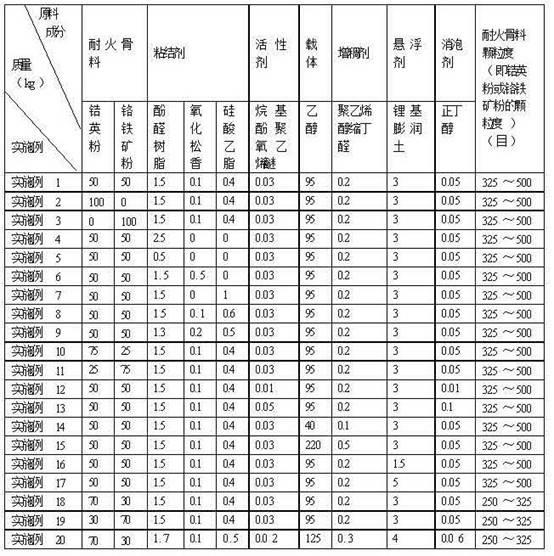

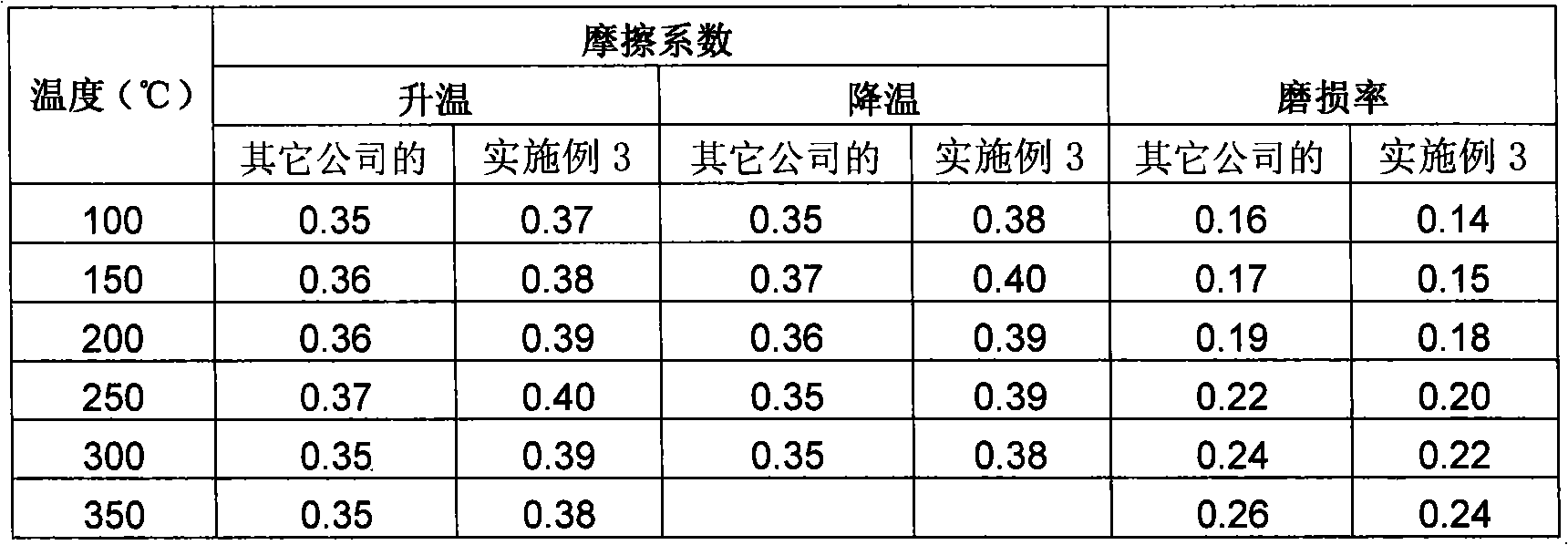

High-performance semi-metallic brake pad

ActiveCN101555915ASensitive brakesReduce brake noiseFriction liningGraphite particleAluminium silicate

A high-performance semi-metallic brake pad comprises the following components according to weight percentages: 4-6% of nitrile rubber powder, 2-4% of tyre powder, 3-5% of crystalline flake graphite, 6-9% of foam iron powder, 9-13% of boron containing phenolic resin, 8-12% of chopped steel fibre, 2-4% of alumina fibre, 8-11% of red copper fibre, 2-5% of cashew nut oil friction powder, 2-3% of graphite particle, 2-3% of calcined petroleum coke, 7-13% of barite, 3-4% of chromite, 2-3% of magnetite, 2-4% of diatomite, 7-10% of glued aluminium silicate fibre, 3-5% of flake aluminium powder, 2-4% of molybdenum disulfide, 0.2-0.5% of zinc stearate, 0.7-1% of antimony sulphide, 0.5-1% of copper sulphide, and 0.3-0.5% of tungsten carbide. After the brake pad is used, the car brake is sensitive, brake noise is low and comfort performance is good. The brake drum or brake disc has no damage in long-term use.

Owner:摩擦一号制动科技(仙桃)有限公司

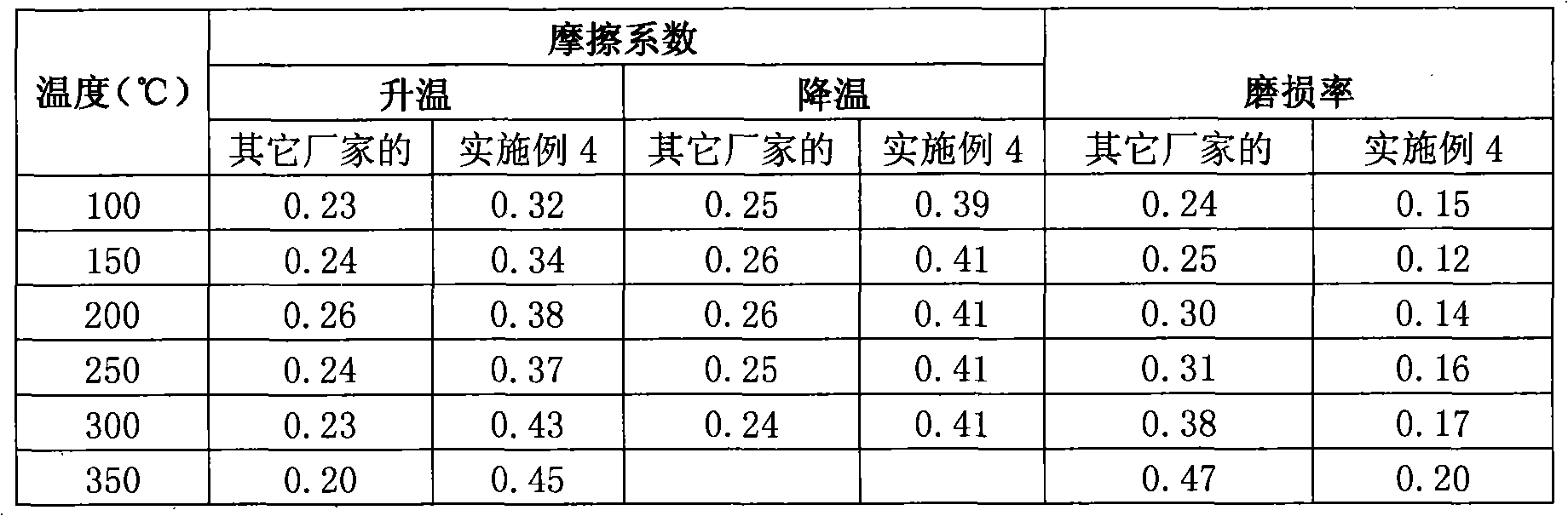

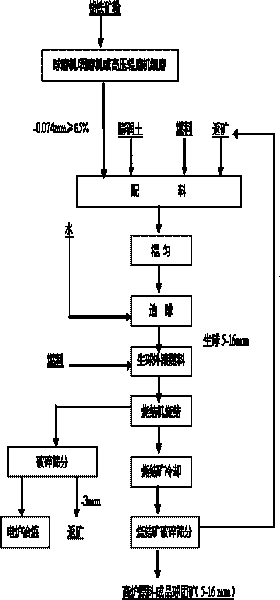

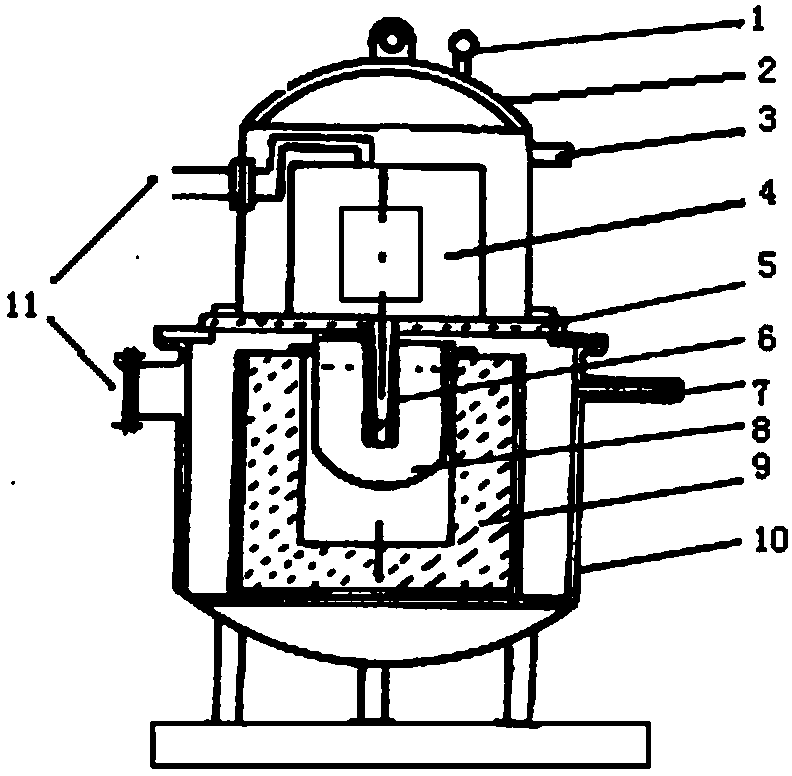

Method for pollution-free production of sodium chromate by pressure leaching of chromite

ActiveCN101817561AObvious superioritySimple ingredientsChromates/bichromatesReaction temperatureHydrometallurgy

The invention belongs to the field of chromite hydrometallurgy and chromium chemical industry, and in particular relates to a method for the pollution-free production of sodium chromate by pressure leaching of chromite. The method comprises the following steps of: 1) reacting the chromite with oxidizing gas in solution of NaOH; 2) diluting the product obtained by the step 1) and making subcrystalline sodium chromate to fully enter a liquid phase; 3) performing solid-liquid separation on the solid-liquid mixed slurry obtained by the step 2); 4) adding calcium oxide into the obtained diluent for removing impurities; and 5) evaporating and crystallizing the obtained solution without the impurities to obtain a sodium chromate crystal and crystallization mother solution; after the solid-liquid separation, rinsing the sodium chromate crystal by using saturated solution of sodium chromate; and drying to obtain a qualified sodium chromate product. The method has the advantages of simple reaction system component, no difficultly separated phase introduced in the system, contribution to high-efficiency separation of the sodium chromate, great reduction in reaction temperature, low energy consumption, effective reduction in production cost of the sodium chromate, and high chromium leaching yield.

Owner:HUBEI ZHENHUA CHEMICAL CO LTD

Colorized reflection heat insulation coating and color card thereof

ActiveCN102181217AModulation shortcutHigh Solar ReflectanceReflecting/signal paintsMulticolor effect coatingsHigh reflectivityMaterials science

The invention discloses a colorized reflection heat insulation coating. Carbon black, iron oxide red, organic yellow, phthalocyanine green, phthalocyanine blue, and other conventional common pigments are replaced by the pigments, namely nickel iron chromite black, nickel iron chromite red, cobalt blue, titanium yellow and cobalt green, so that the colorized reflection heat insulation coating can meet the demand of the external wall decoration on colors and has high reflectivity to solar energy and a good heat insulation effect. The invention also provides a color card by which a colorized coating is formed by mixing the nickel iron chromite black, the nickel iron chromite red, the cobalt blue, the titanium yellow and the cobalt green, a user can quickly mix the coating of the corresponding colors according to the pigment formula corresponding to each color in the color card, and the color card is convenient to use.

Owner:NIPPON PAINT GUANGZHOU

Thermal protective coating

ActiveUS20060156958A1Extended shelf lifeExcellent optical propertiesAlkali metal silicate coatingsPretreated surfacesCalcium silicateSodium Bentonite

A coating, method of coating and substrates coated thereby, wherein the coating contains an inorganic adhesive such as an alkali / alkaline earth metal silicate such as sodium silicate, potassium silicate, calcium silicate, and magnesium silicate; a filler such as a metal oxide for example silicon dioxide, aluminum oxide, titanium dioxide, magnesium oxide, calcium oxide and boron oxide; and one or more emissivity agents such as silicon hexaboride, carbon tetraboride, silicon tetraboride, silicon carbide, molybdenum disilicide, tungsten disilicide, zirconium diboride, cupric chromite, or metallic oxides such as iron oxides, magnesium oxides, manganese oxides, chromium oxides and copper chromium oxides, and derivatives thereof. In a coating solution, an admixture of the coating contains water. A stabilizer such as bentonite, kaolin, magnesium alumina silicon clay, tabular alumina and stabilized zirconium oxide may be added.

Owner:WESSEX

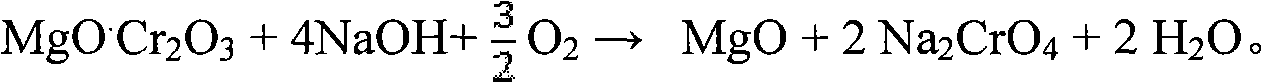

Sintering technology of ferrochrome mineral powder

Owner:CENT SOUTH UNIV

Process for simultaneous recovery of chromium and iron from Chromite Ore Processing Residue

InactiveUS20040086438A1Simple eco-friendlySolvent extractionMolybdeum compoundsIron saltsChromate salt

The present invention relates to a process for simultaneous recovery of chromium and iron from Chromite Ore Processing Residue (COPR) and more particularly, the present invention relates to an economical and environment-friendly process for recovering chromium as a chromate salt and iron as an iron salt from non-leachable Chromite Ore Processing Residue and avoids landfilling of toxic metals.

Owner:COUNCIL OF SCI & IND RES

Manufacturing process of pump body casting of super duplex stainless steel centrifugal pump

InactiveCN102626769AReduce manufacturing costReduce maintenance costsFoundry mouldsFoundry coresFuranTemperature control

The invention provides a manufacturing process of a pump body casting of a super duplex stainless steel centrifugal pump. The manufacturing process comprises steps of sand mould prefabricating, material smelting, casting, sand shakeout and heat treatment, wherein a runner core in a sand mould is composed of chromite furan resin sand of which the outer layer is filled with quartz furan resin sand;in material smelting, super duplex stainless steel material ZG00Cr25Ni7Mo4N is used, the chemical composition, ferrite content and PREN (Pitting Resistance Equivalent) value of molten steel are undercontrol and the casting temperature is from 1540 DEG C to1560 DEG C; after sand shakeout, forced air cooling is carried out, spray cooling is further carried out on the thick and large part of the casting, and after a casting system and a dead head are removed, the heat treatment is carried out. The pump body casting of a super duplex stainless steel centrifugal pump, which is manufactured by using the manufacturing method, has the advantages that the manufacturing and maintenance cost is reduced, abrasion resistance and pitting resistance are improved and the service life is prolonged.

Owner:遵义拓特铸锻有限公司

Method and device for electroextraction of heavy metals from technological solutions and wastewater

InactiveUS6887368B2Reduced heavy metal levelLess energy consumptionFrom normal temperature solutionsLiquid separation by electricityConductive materialsMaterials science

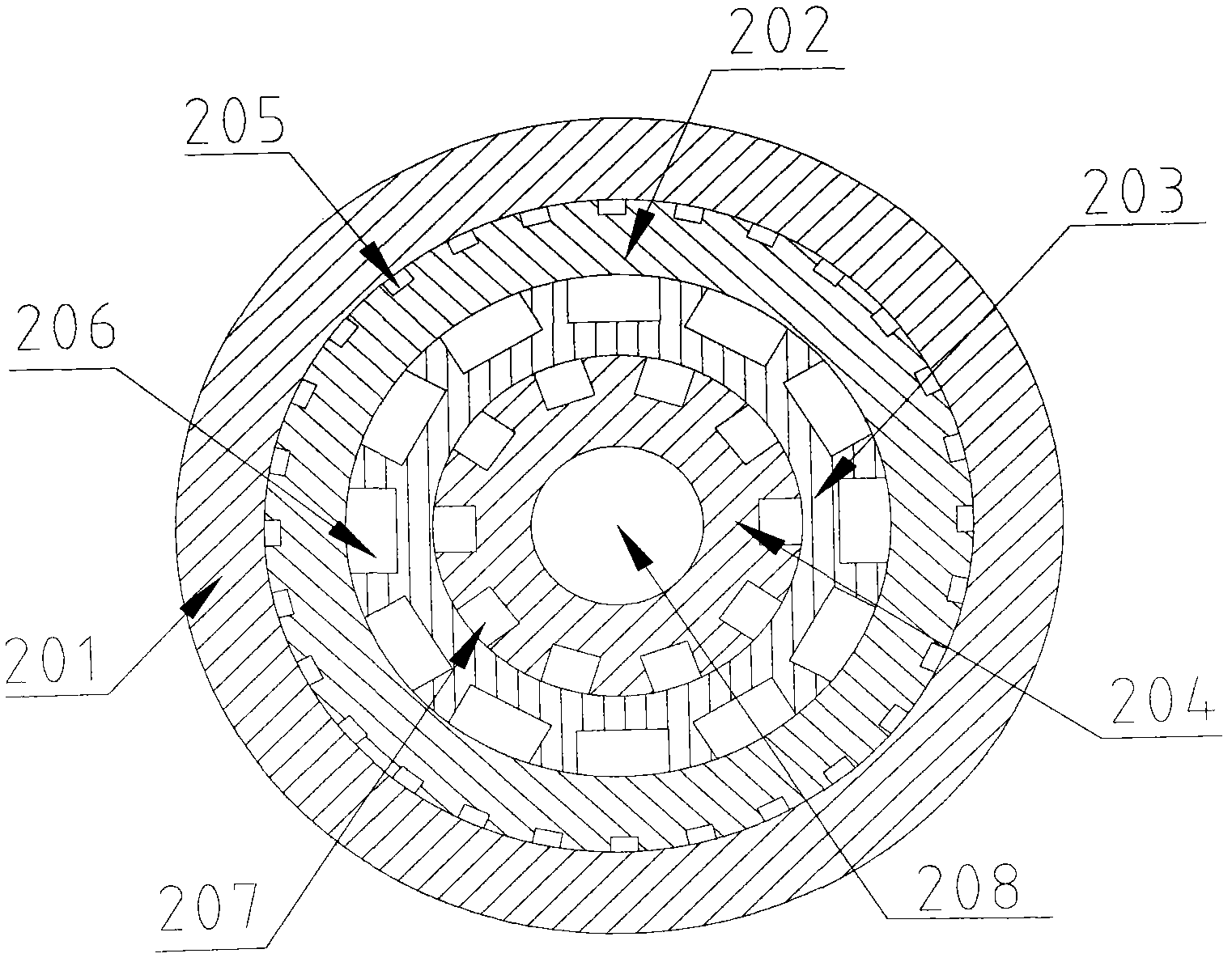

The basic principles of the method for heavy metals electroextraction from technological solutions and wastewater includes pretreating to remove Chromium-6 and high concentrations of heavy metals and periodically treating in a six-electrode bipolar cylindrical electroreactor made of non-conducting material to achieve lower accepted levels of impurities. Six cylindrical steel electrodes form two triode stacks and are fed with three-phase alternating current of commercial frequency (50-60 Hz), which can be pulsed. Each phase of the three-phase current is connected to three electrodes of one triode stack or in parallel to two triode stacks. The parallel connection of three-phase current to two triode stacks is performed so that the same phase of the three phase current is connected in parallel with each two opposite electrodes of six electrodes located along the periphery, or with two adjacent electrodes. A bipolar stationary aluminum electrode is situated in the inter-electrode space. In one of the embodiments, the bipolar electrode is made of a perforated heat-resistant plastic container filled with secondary aluminum and duralumin scrap. In another embodiment, the bipolar electrode of aluminum or duralumin scrap may be made without a perforated container and is placed in the inter-electrode space as a bulk scrap. In this case, to prevent shorts, each of six steel electrodes is placed in isolated perforated plastic shell with holes of 5 mm in diameter. Non-ferrous metals are extracted in a form of ferrite-chromites, and aluminates as well as hydroxyl salts deposited in the inter-electrode space without electrolysis deposits on electrodes. Deposits are separated from solution by known methods of filtration.

Owner:URAL PROCESS ENG +2

Molten liquid phase roasting method of chromite

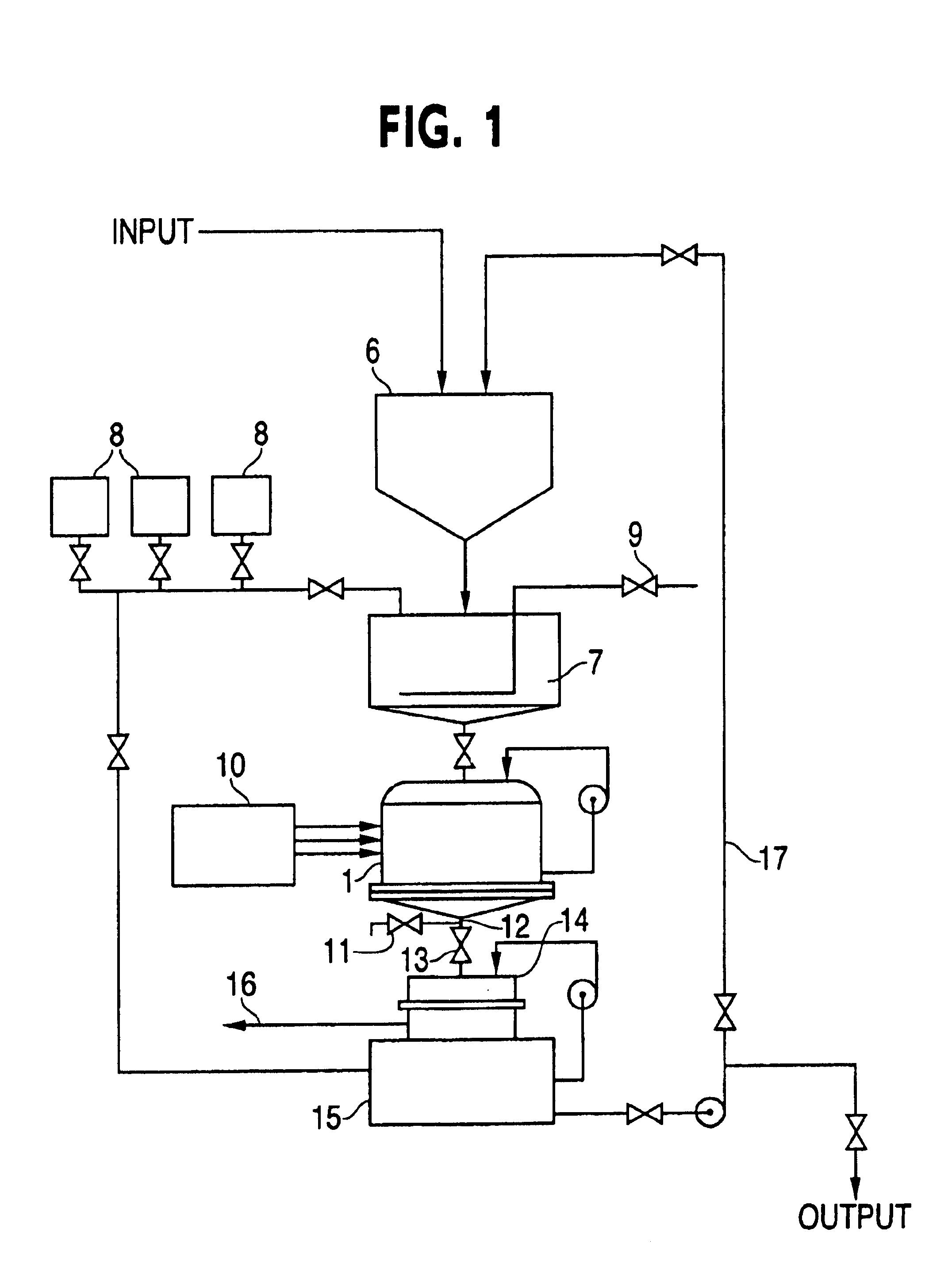

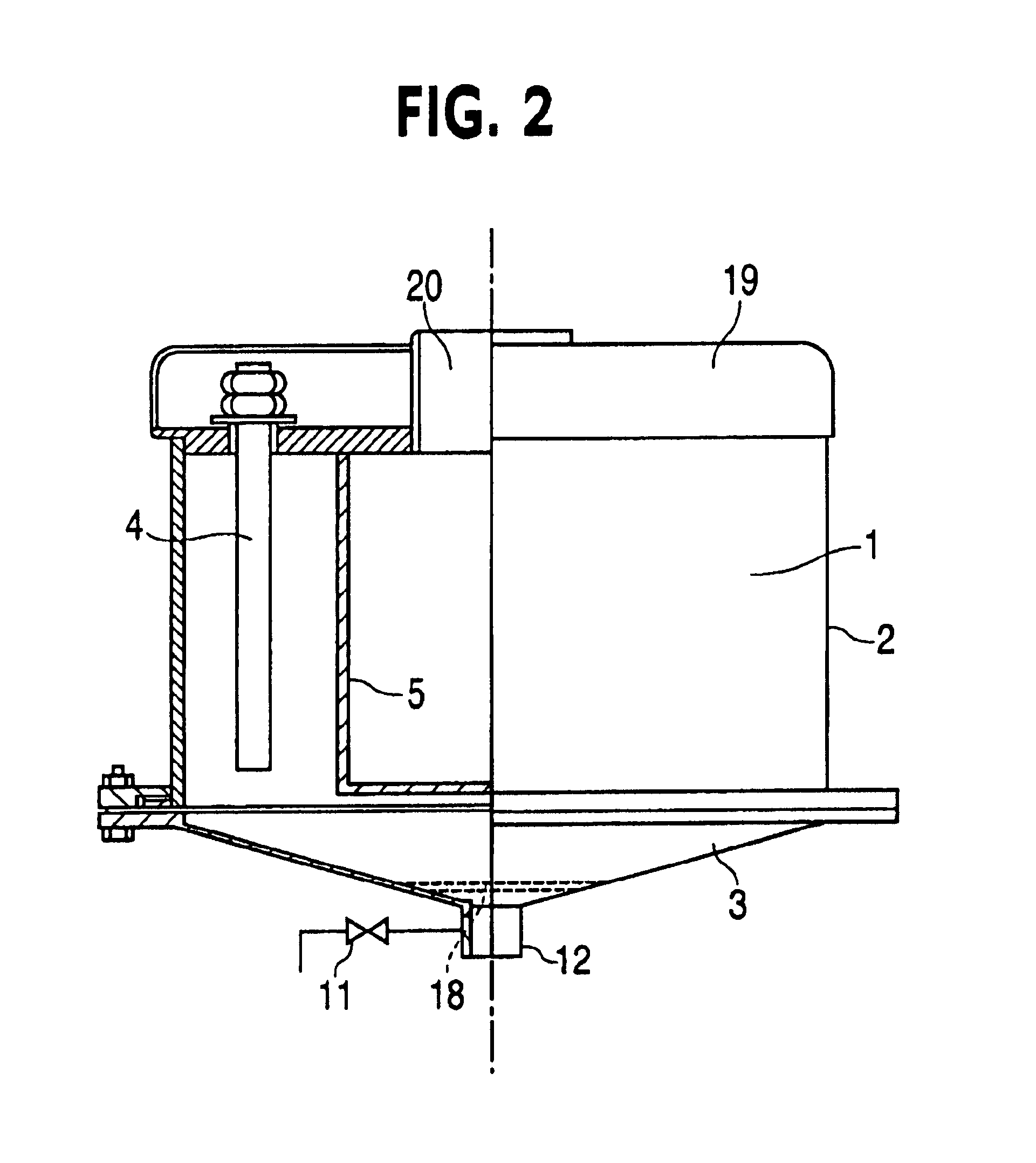

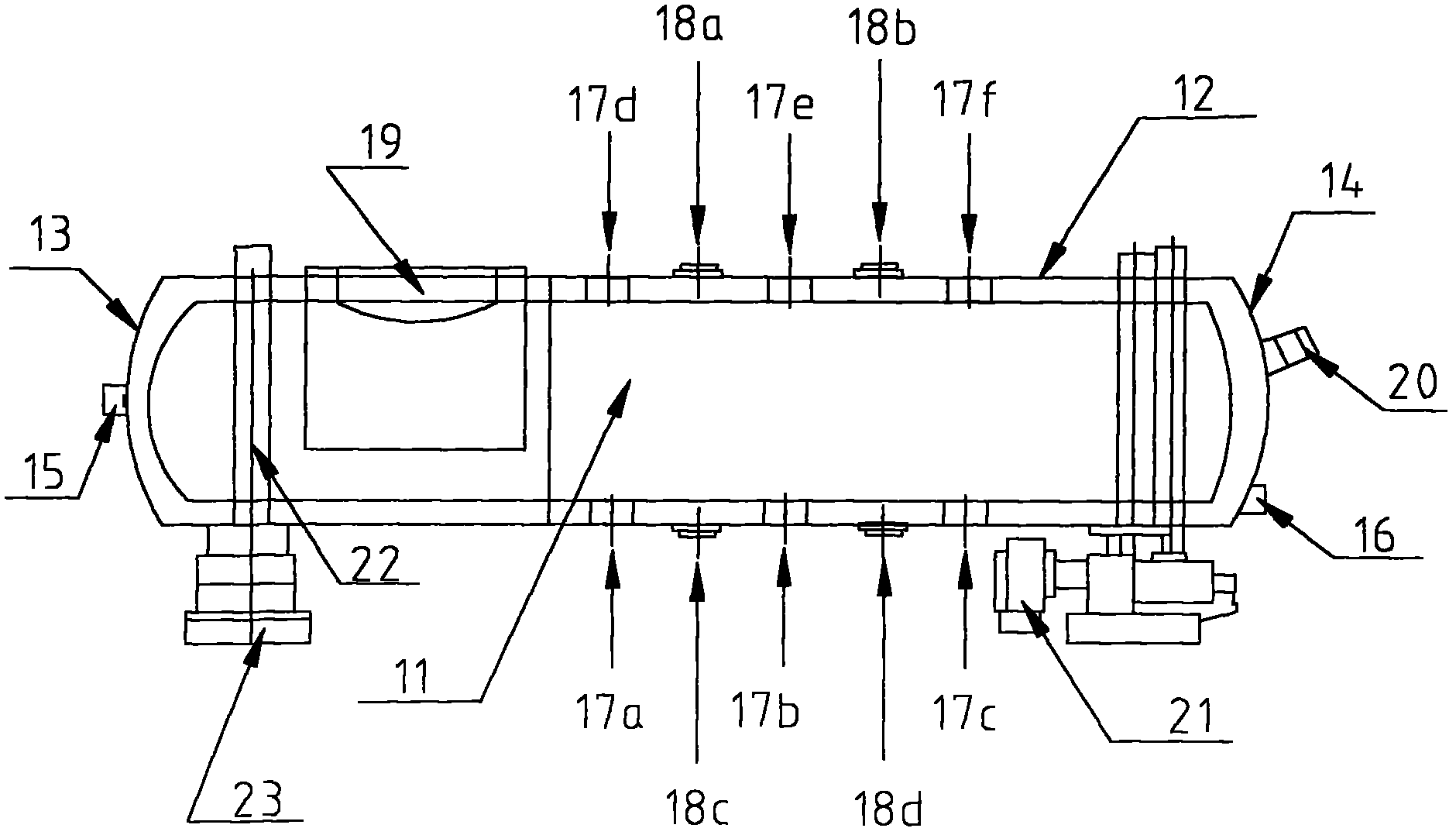

The invention relates to a molten liquid phase roasting method of chromite. The molten liquid phase roasting method comprises the following step of: performing molten liquid phase roasting on a mixture comprising chromite and optional sodium chromate in a horizontal rotary kiln in the presence of oxygen at 350-1,500 DEG C to obtain sodium chromate, wherein the mixture also comprises one or more of soda, sodium bicarbonate, sodium sulfate and sodium hydroxide; the horizontal rotary kiln comprises a kiln body and two end parts at the two ends of the kiln body; the two end parts are provided with a high-position liquid phase outlet and a low-position liquid phase outlet respectively; the kiln body is provided with an oxygen lance and a feed port; the oxygen lance and the feed port are arranged in a stagger way so as not to be on the same cross section of the kiln body; and a smoke outlet which is positioned on the kiln body is arranged between the high-position liquid phase outlet and one of the feed port and the oxygen lance closer to the high-position liquid phase outlet. According to the method, the chromite is in molten liquid phase in a molten salt system, so that the chromium conversion rate is greatly increased, the yield is increased, and the problem of high probability of wall attachment of a calcium-free roasting process is substantially solved.

Owner:SICHUAN YINHE CHEM

Production of large and super-critical steel-casting by using alkali phenolic aldehyde resin art

ActiveCN101003084ANo smellAvoid crackingFoundry mouldsFoundry coresChemical compositionSurface roughness

A technology using alkaline phenolic resin to cast large supercritical steel product with high quality includes such steps as supercritical smelting while strictly controlling the chemical components of steel, preparing sand mould from alkaline phenolic resin for sand core, the alkaline phenolic resin and chromite for surface sand, and alkaline phenolic resin and Si sand for back sand, filling argon gas in mould for 10-15 min, and immediately casting at 1580-1590 deg.C.

Owner:LIAONING FU-AN HEAVY INDUSTRY CO LTD

Clean production method for preparing potassium chromate from chromic iron

InactiveCN101481144AImprove liquidityReduced corrosion resistance requirementsChromates/bichromatesForeign matterPotassium nitrate

The invention belongs to the field of a method for producing chromic salt, in particular relates to a method for producing and cleaning potassium chromate. The method comprises the steps that chromite is reacted with oxidant with a chemical dose inside KOH-KNO3-H2O medium to obtain a mixed resultant of reaction containing alkali liquor, potassium chromate and slag after reaction, wherein the mass ratio of KOH and chromite is 1:1 to 2:1, and the mass ratio of KNO3 and chromite is 0.5:1 to 2:1. Through the leaching of the mixed resultant of reaction, the phases of potassium chromate macrocrystal-alkali liquor containing potassium nitrate-slag are separated, foreign matters in the solution are removed, the mixture is evaporated and crystallized, the obtained potassium chromate crystal is eluted and the pure product of potassium chromate is obtained. The percent conversion of chromium is higher than 99 percent and the rate of containing chromium in slag is less than 0.2 percent.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

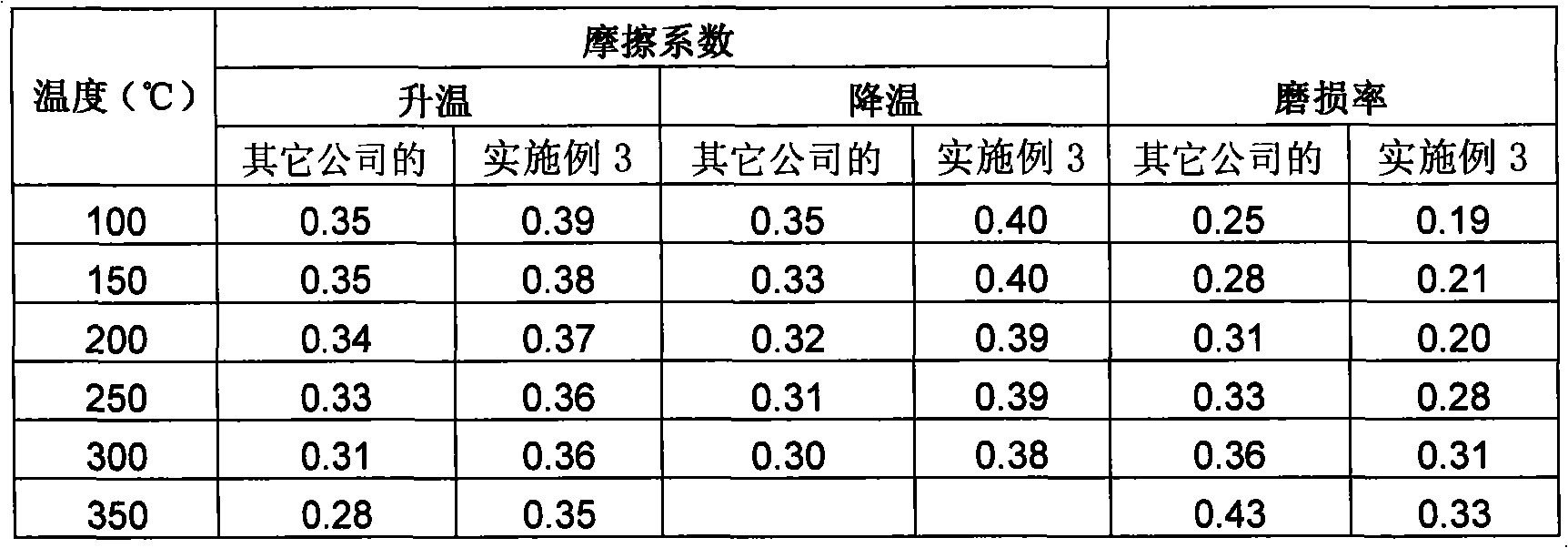

Ceramic brake pad of high-performing automobile

InactiveCN101555920AExtended service lifeImprove the lubrication effectFriction liningBoron nitrideCopper

A ceramic brake pad of high-performing automobile comprises the following components according to weight percentages: 7%-11% of ceramic fibre, 7-9% of glued aluminium silicate fibre, 5-8% of polyacrylonitrile fibre, 2-3% of aramid fibre 7-9% of red copper fibre, 7-10% of acicular aedelforsite fibre, 7-12% of barite, 7-9% of chromite, 1-2% of butyronitrile rubber, 7-11% of graphite particle, 0.2-0.5% of zinc oxide, 5-8.5% of calcined petroleum coke, 1-3% of expansion graphite, 6-10% of boron containing phenolic resin, 3-5% of magnetite, 1-1.5% of heavy-burned magnesia, 0.3-0.5% of modified whiten bead of resin acceptor, 3-5% of boron nitride and 0.3-0.5% of alumina; the invention can form excellent friction layer and transmission film in using process, thereby having good lubricating effect without damaging the couple plate; therefore, the service life of the friction material is greatly prolonged.

Owner:RUIYANG AUTOMOTIVE MATERIALS XIANTAO

Low-density ceramsite supporting agent and preparation method thereof

InactiveCN102876315AQuality improvementLight in massFluid removalSodium BentoniteExpanded clay aggregate

The invention discloses a low-density ceramsite supporting agent prepared by using bauxite tailings and a preparation method for the low-density ceramsite supporting agent. The low-density ceramsite supporting agent is prepared from the following raw materials in part by weight: 100 parts of calcined bauxite tailings, 1 to 2 parts of bentonite, 1 to 2 parts of chromite and 10 to 15 parts of non-calcined bauxite tailings. The production method comprises the following steps of: calcining and smashing the calcined bauxite tailings, smashing the bentonite, the bentonite and the non-calcined bauxite tailings, adding the materials into the calcined bauxite tailings, preparing ball materials, drying, and sintering to obtain the product. According to the method, the waste bauxite tailing is used as a main raw material, and the high-quality low-density ceramsite supporting agent can be produced by performing secondary sintering and rationally adding auxiliary materials; the preparation method is simple and low in production cost; and resources can be used to the greatest extent.

Owner:SHANXI FANGXING REFRACTORIES CO LTD

High-performance organic fibre brake pad

ActiveCN101555918AStable coefficient of frictionSmall thermal expansionFriction liningLow noiseCellulose

A high-performance organic fibre brake pad comprises the following components according to weight percentages: 5-9% of cashew nut oil friction powder, 4-8% of chromite, 7-10% of barite, 4-7% of calcined petroleum coke, 3-7% of crystalline flake graphite, 3-6% of sepiolite fibre, 4-7% of ceramic fibre, 1.5-3% of antimony sulphide, 4-7% of red copper fibre, 3-5% of glued aluminium silicate fibre, 1-2% of alumina fibre, 8-11% of vermiculite powder, 9-13% of organosilicone phenol-formaldehyde resin, 1-2% of carbon fibre, 5-7% of bastose, 1-2.5% of wood pulp cellulose, 3-6% of viscose fibre, 6-9% of bamboo carbon fibre, 3-5% of nitrile rubber and 0.3-0.5% of zinc oxide. The invention has the advantages of light weight, strong wear resistance, good flexibility, low noise and long service life, and the like, and the friction performance is stable at operating temperature between 100 DEG C and 450 DEG C.

Owner:摩擦一号制动科技(仙桃)有限公司

Manufacturing method for riveting-free type automobile clutch facing assembly

The present invention discloses a manufacturing method for a riveting-free type automobile clutch facing assembly. The method comprises the following steps: A, preparing a material: adding 18 kg of 2123 phenolic resin, 15 kg of tire rubber powder, 5 kg of glass fiber, 3 kg of emery grains, 5 kg of barite powder, 15 kg of precipitated barium sulfate, 5 kg of chromite powder, 4 kg of graphite flakes, 5 kg of petroleum coke, 10 kg of sepiolite fibers, and 15 kg of copper fibers to a stirring machine to uniformly stir to obtain 100 kg of the prepared material to provide a spare use; B, adding 1.5 kg of the stirred material to a mold, and placing a steel sheet in the mold; C, taking 1.5 kg of the stirred material on the steel sheet inside the mold; D, opening a press machine; E, carrying out pressing until the pressure is 35 MPa; F, carrying out electric heating until the temperature is 110-120 DEG C; and G, carrying out heat preservation and pressure keeping for 45 minutes, and then removing from the mold to obtain the riveting-free type automobile clutch facing assembly. With the method, the pressure plate surface and the fly wheel surface of the engine are not damaged; the clutch is not required to be manufactured separately; the facing and the steel sheet are subjected to one time hot pressing forming; hole drilling is not required, and riveting is not required.

Owner:TAIXING LONGPAN AUTO PARTS MFG

Plaster casting method for large-sized complex thin-walled magnesium alloy part

ActiveCN104209497ASolve Oxidation ProblemsImprove filling abilityFoundry mouldsFoundry coresVacuum castingMold filling

The invention relates to a plaster casting method for a large-sized complex thin-walled magnesium alloy part. The method comprises the following steps of coating the surface of an assembled form with a coating in situ, and arranging shapeless cold iron on a hot spot part, wherein a mixture for manufacturing the shapeless cold iron comprises the following components in percentage by mass: 1.25 percent of phenolic resin, 0.4 percent of toluenesulfonic acid, 1 to 1.5 percent of boric acid, 2 percent of bentonite and the balance of 70 to 140-mesh chromite sand; pouring a casting in an adjustable pressure casting device, arranging a plaster mold poured by the form at the casting position of the adjustable pressure casting device, filling a tank with dry air or a CO2 atmosphere with SF6 content of 0.1 to 1.0 percent, and performing vacuum casting and pressurized solidification, wherein the casting temperature is 710 to 750 DEG C, vacuum degree for primary mold filling is minus 0.6Mpa to minus 0.8Mpa, and the solidification pressure is 0.020 to 0.025Mpa. According to the method, oxidization can be prevented, the mold filling capability can be improved, shrinkage cavities and shrinkage porosities in the casting are reduced, and the obtained magnesium alloy casting is higher in density.

Owner:山西银光华盛镁业股份有限公司

Process for roasting chromite resources in ring kiln through pure oxygen by using low-temperature method and harmlessly and deeply utilizing chromium residue

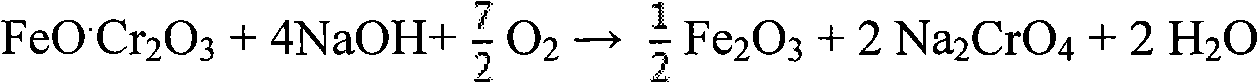

InactiveCN101824530AImprove resource conversion rateMagnesium carbonatesChromium trioxideSodium bicarbonateSlag

The invention belongs to the field of metallurgy and chemical engineering. The process comprises the following steps of: firstly, crushing chromite, adding sodium hydroxide and a catalyst to be oxidized and roasted by using a low-temperature pure oxygen method; diluting, cooling, extracting and filtering to obtain a sodium chromate crystal and ferrum-magnesium slag; adding an alkali washing solution into a sodium hydroxide solution to back extract to obtain the sodium hydroxide solution for recycling; adding water into the sodium chromate crystal and ferrum-magnesium slag to be dissolved and feeding filtrate into a carbonizer to decompose to extract aluminum; carbonizing, evaporating, condensing and crystallizing the extracted solution to obtain sodium chromate; and carbonizing ferrum-magnesium filter slag to generate sodium bicarbonate, reacting to generate a magnesium hydrogen carbonate solution, heating and cracking to generate a magnesium carbonate product and drying a filter cake to obtain ore refined powder; and secondly, crushing chromium residue, adding sodium bicarbonate in the ration of 1:8, adding a catalyst for calcination, cooling and adding water to soak; adding an aluminum hydroxide crystal into supernatant liquid, carbonizing and decomposing to remove aluminum in a reaction tank; filtering and washing an aluminum hydroxide product; adding a reducing agent into the filtrate to reduce hexavalent chromium to generate anhydrous chromium hydroxide and drying and roasting to obtain chromium sesquioxide; and returning the filtrate to a system for mixing after pyrolyzing and extracting to remove magnesium.

Owner:白向南 +2

Roasting method for producing sodium chromate using chrome iron ore as raw material

InactiveCN1418823AAvoid scaringSolve the pollution of the environmentChromates/bichromatesBrucitePericlase

The method for preparing sodium chromate by calcining chromite includes the following steps: pulverizing chromite and sieving with 200 mesh sieve, adding sodium carbonate whose added amount is 80-150% of chromite amount, and adding magnesite, baudisserite, periclase, brucite or synthetic magnesium oxide, magnesium hydroxide and magnesium carbonate and calcining them at 1000-1200 deg.c for 10-60 min. under the condition of oxidation atmosphere, then extracting clinker and dissolving sodium chromate so as to obtain the goal of preparing sodium chromate. The conversion rate of chromite can be upto 97-99.5%.

Owner:TIANJIN CHEM RES & DESIGN INST

Ceramsite sand for casting and preparation method thereof

ActiveCN107298584AImprove thermal conductivityHigh thermal expansionFoundry mouldsFoundry coresExpanded clay aggregateSilicon dioxide

The invention relates to a ceramsite sand for casting and a preparation method thereof. The ceramsite sand comprises the following chemical components in parts by weight: 35-65 parts of silicon dioxide, 30-50 parts of aluminum oxide, 1-10 parts of iron oxide, 1-4 parts of manganese dioxide and 2-8 parts of chromic oxide. The method comprises the following steps: performing grinding, and detecting the chemical composition and contents of the raw materials; and sequentially performing proportioning, ball making, screening, sintering and grading to obtain the finished product. The ceramsite sand prepared by the invention is high in thermal conductivity and refractoriness, conforms to the requirements for casting sand, can be used for casting and casting mold production instead of silica sand, chromite sand and the like, reduces the discharge amount of solid waste in the casting industry, and improves the quality of cast products.

Owner:NINGXIA KOCEL MOLD

Process for simultaneous recovery of chromium and iron from chromite ore processing residue

InactiveUS7220394B2Safe disposalSimple eco-friendly and cost-effectiveSolvent extractionMolybdeum compoundsIron saltsChromate salt

The present invention relates to a process for simultaneous recovery of chromium and iron from Chromite Ore Processing Residue (COPR) and more particularly, the present invention relates to an economical and environment-friendly process for recovering chromium as a chromate salt and iron as an iron salt from non-leachable Chromite Ore Processing Residue and avoids landfilling of toxic metals.

Owner:COUNCIL OF SCI & IND RES

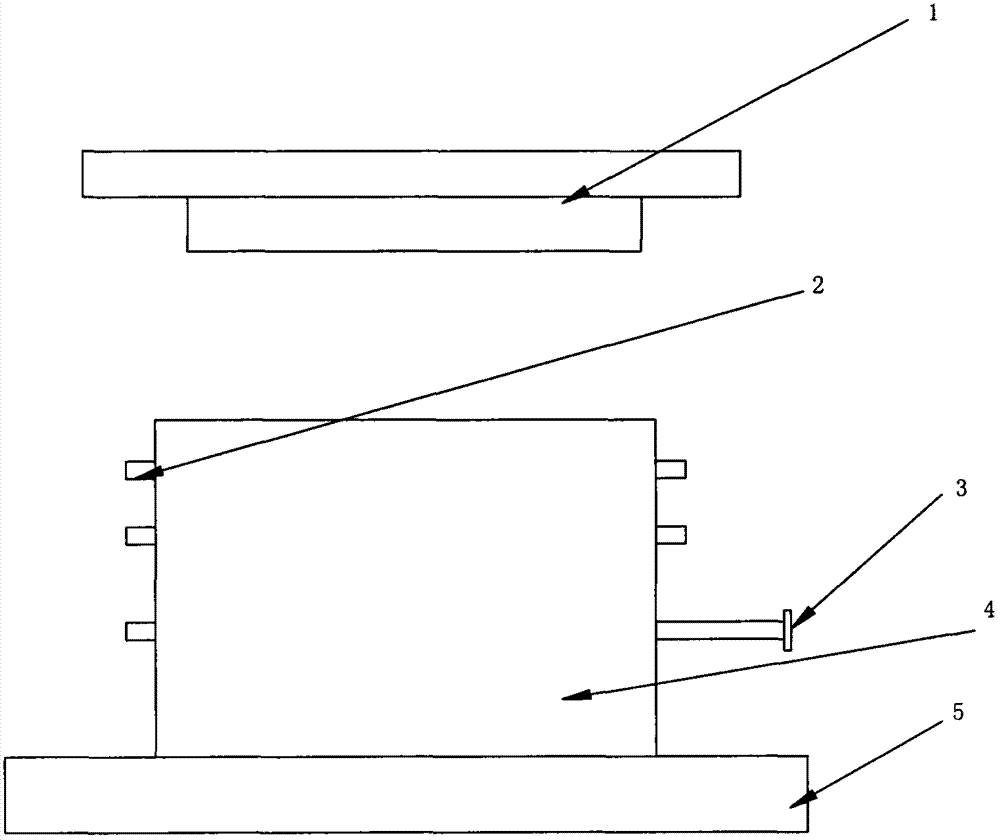

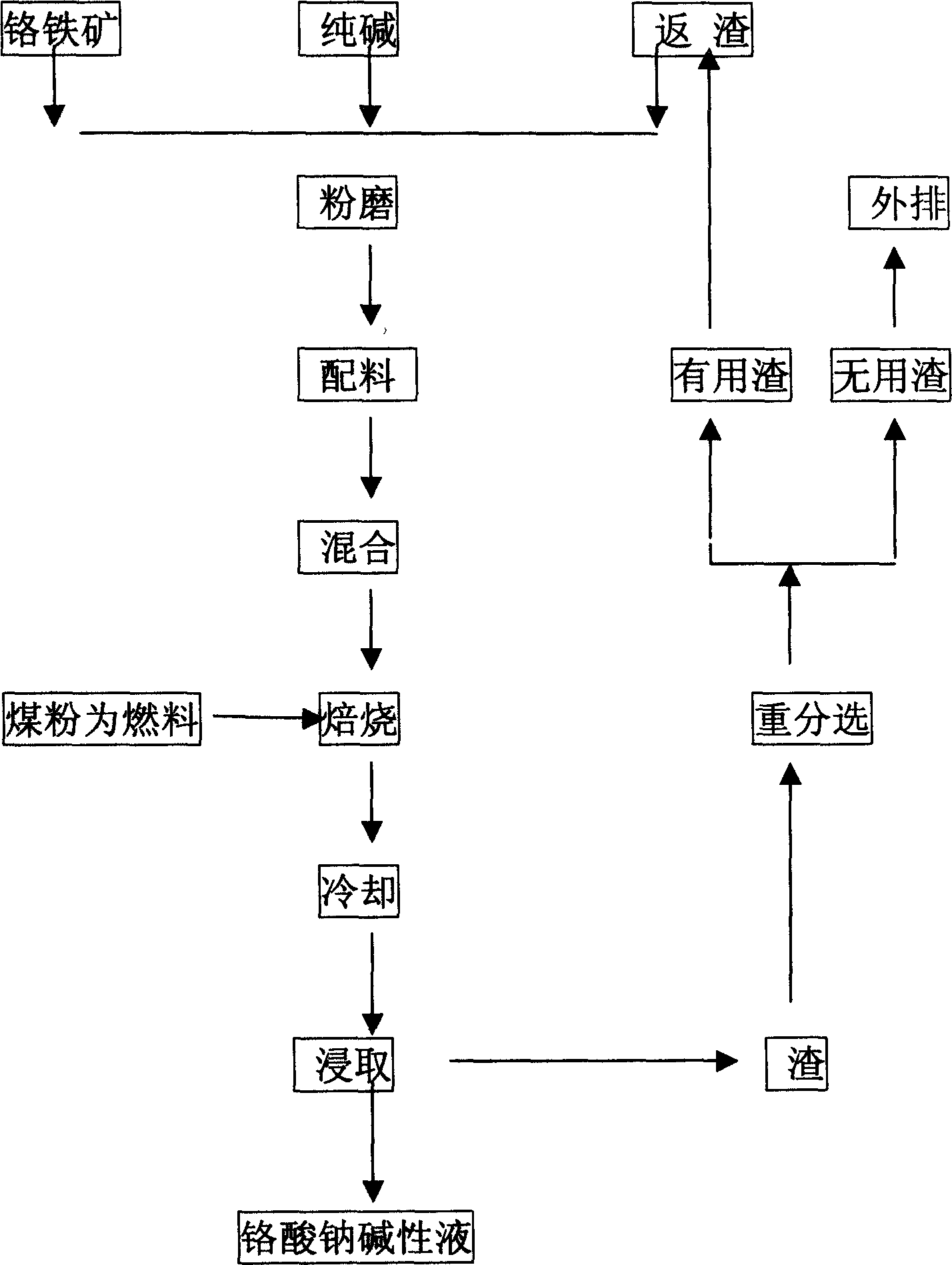

Process for producing sodium chromate by calcium-free calcination

The invention relates to a method to manufacture sodium chromate. It adopts non- calcium roasting technics to realize industrialized production. With chromite, soda and chrome dregs without calcium as charging after mixing evenly, coal dust as fuel, the steps are as follows: coal injection baking in burner, leaching clinker, gravity sorting chrome dregs without calcium and recycling useful dregs as filling. It is the first time that fillings are composed with iron ore, chromite and soda after baking. With shortening technics route and reducing equipment investment, the invention can reduce production cost. Without segregation and adhibiting wall, roasting heat is easy to control.

Owner:TIANJIN CHEM RES & DESIGN INST +1

Green Biodiesel

InactiveUS20070282119A1Significant energySignificant processing timeFatty oils/acids recovery from wasteFatty acid esterificationCalcium silicateBiodiesel

Methods for improved manufacture of green biodiesel focus on the selection and use of one or more solid metallic oxide base catalyst(s) selected from the group consisting of calcium oxide (CaO), calcium aluminum oxide (CaO—Al2O3), calcium titanate (CaTiO3), barium titanate (BaTiO3), magnesium aluminum oxide (MgO—Al2O3), zinc oxide (ZnO), copper (II) oxide (CuO), nickel oxide (NiO), manganese oxide (MnO), titanium oxide (TiO), vanadium oxide (VO), cobalt oxide (CoO), iron oxide (FeO), chromite (FeCr2O4), hydrotalcite (Mg6Al2(CO3)(OH)16.4(H2O), magnetite (Fe3O4), magnesium silicate and calcium silicate.

Owner:PENN STATE RES FOUND

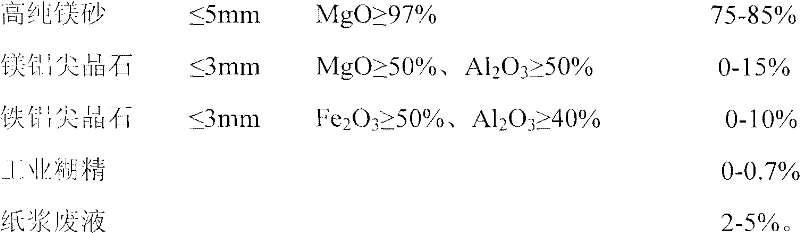

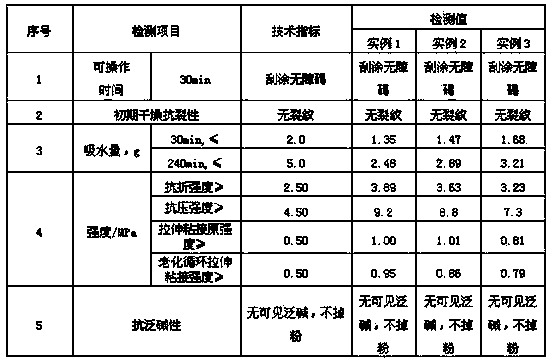

Magnesium-ferrum-aluminum composite spinel brick for large-scale cement kiln and preparation method thereof

The invention relates to a magnesium-ferrum-aluminum composite spinel brick for a large-scale cement kiln and a preparation method thereof, belonging to the field of refractory materials. The preparation method is characterized by comprising the following steps: by using high-purity magnesia, magnesia alumina spinel and hercynite as main raw materials and using pulp waste liquid and industrial dextrin as binders, mixing, pressing, drying, and firing at 1500-1700 DEG C to obtain the magnesium-ferrum-aluminum composite spinel brick. The product is applicable to firing zones and transition zones of cement kilns in all sizes, and can completely substitute magnesia-chromite bricks in the aspects of performance and cost, thereby implementing no chromium in the cement kiln refractory material. The product has obvious kiln skin adhesion effect, has the advantages of high heat and vibration stability, high temperature toughness and long running time (longer than 12 months), and performs very active functions on enhancing the running rate of the large-scale cement rotary kiln; and the fired magnesium-ferrum-aluminum composite spinel brick has the advantages of simple technique and low cost.

Owner:TONGDA REFRACTORY TECH CO LTD +1

Color thermal insulation mortar with heat reflection function for exterior wall

The invention provides a color thermal insulation mortar with a heat reflection function for an exterior wall. The color thermal insulation mortar comprises the following components by weight percent: 20-25% of white cement, 4-6% of early strength agent, 2-4% of active admixture, 10-20% of finer filler, 20-40% of light filling, 10-30% of fine sand, 1-3% of pigment and 4-6% of additive, wherein the early strength agent is white amorphous calcium aluminate of which the specific surface area is greater than or equal to 5,000m<2>kg; the light filling is a glass bead, which has a honeycomb mesh structure and of which the particle size is 0.09-0.60mm, the bulk density is 270-400Kg / m<3>, the cylinder compressive strength is greater than 2.0MPa, and the pigment is chromium titanium yellow, nickel titanate yellow, chromite-cobalt blue or ferrochromium black. The color thermal insulation mortar disclosed by the invention not only has the characteristics of being light in weight, strong in strength and low in water absorption rate by adding an inorganic composite pigment burnt at high temperature and the glass bead with a special structure, but also has high near infrared solar reflectance and low coefficient of thermal conductivity. Compared with the common mortar, the color thermal insulation mortar has better insulating and cooling effects, and is especially applicable to decoration of the exterior wall.

Owner:广东龙湖科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com