Patents

Literature

569results about How to "Less energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

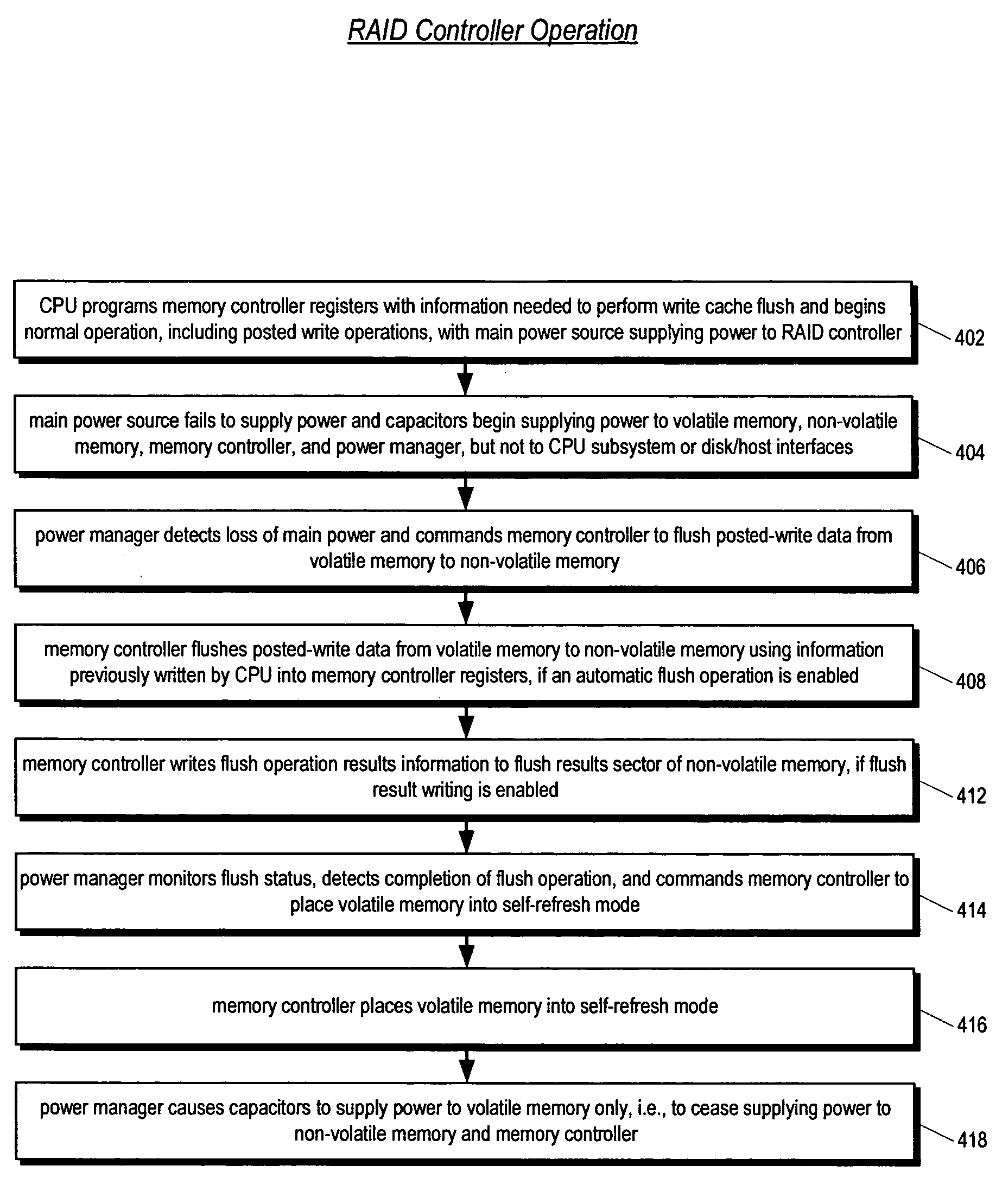

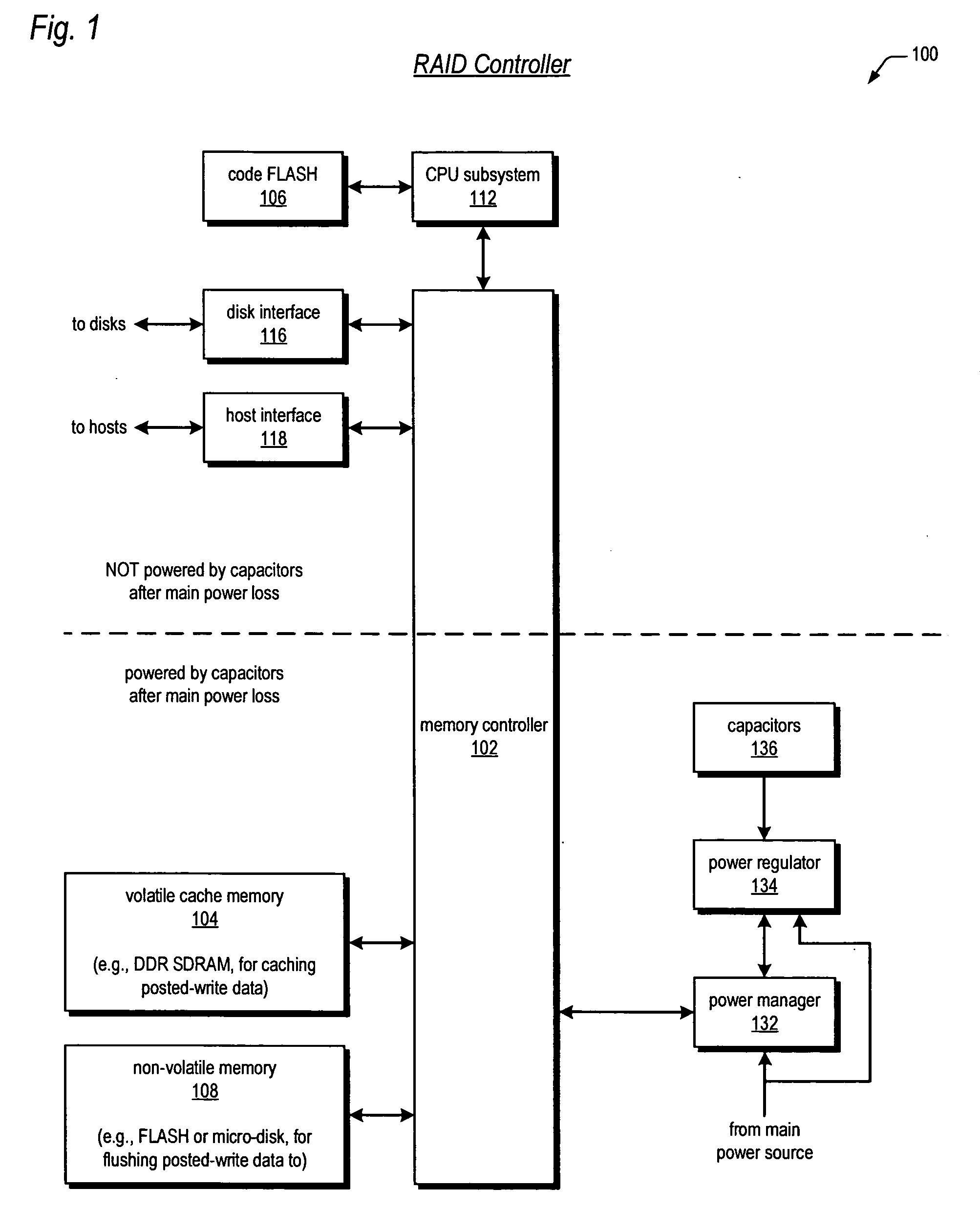

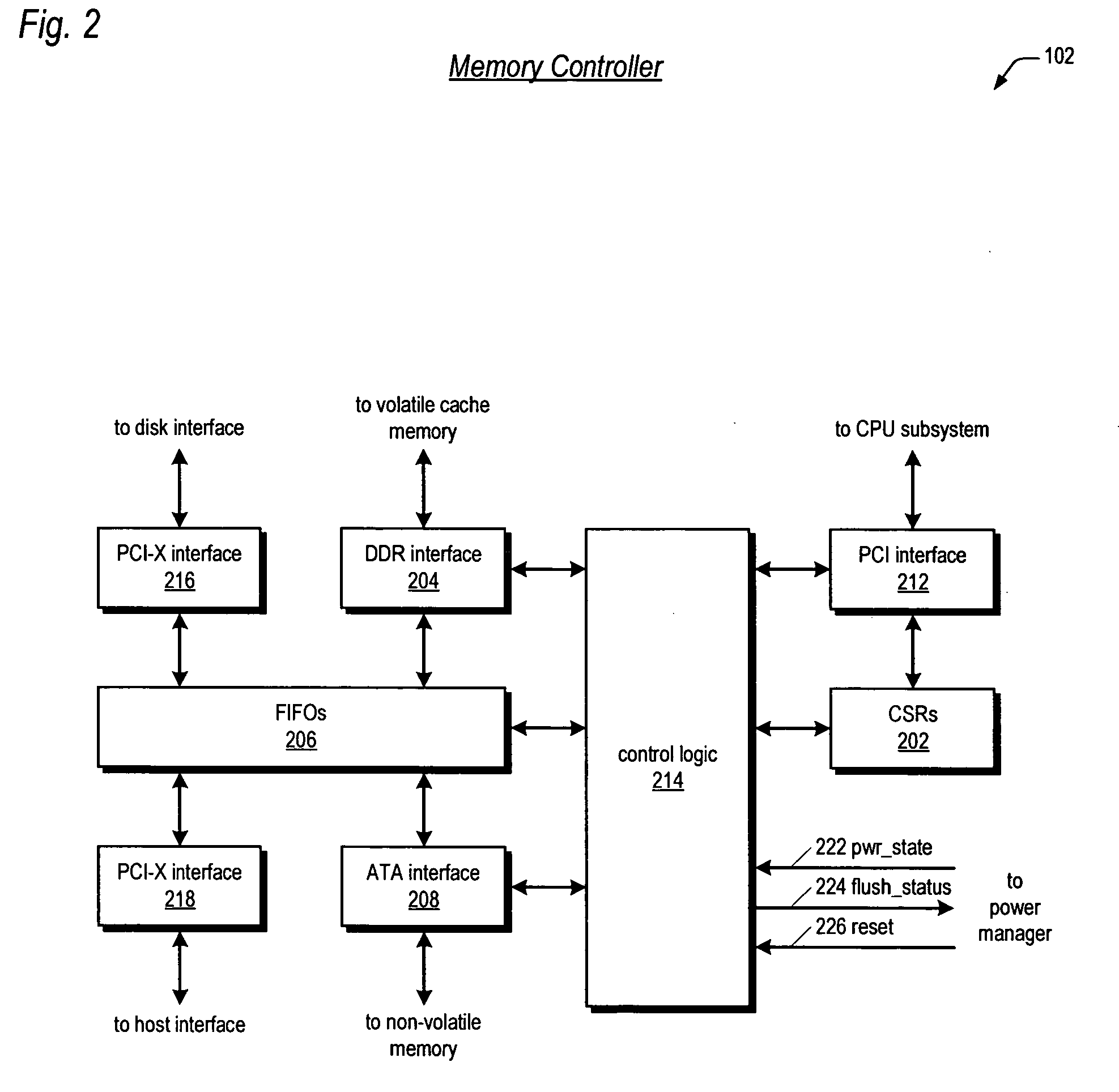

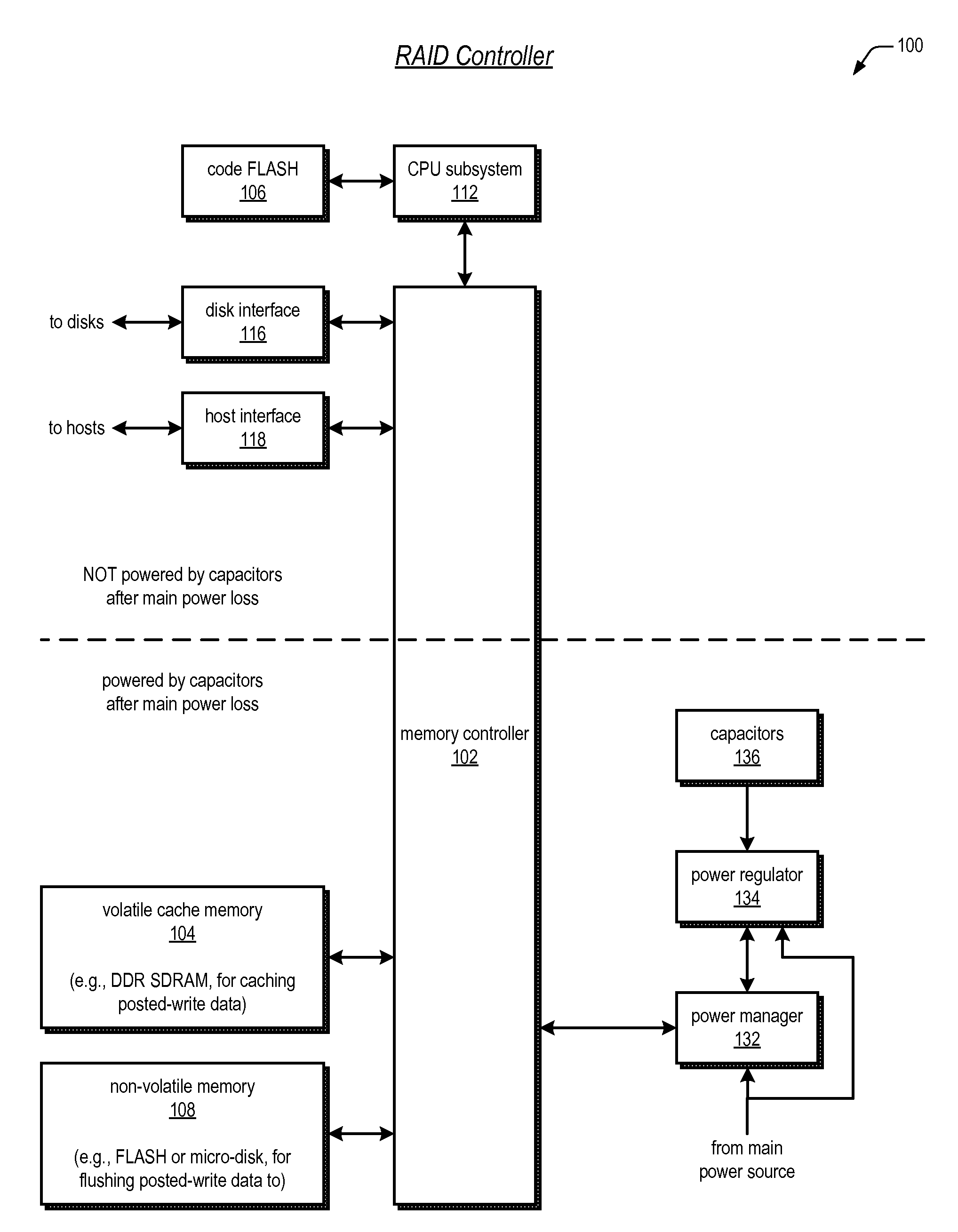

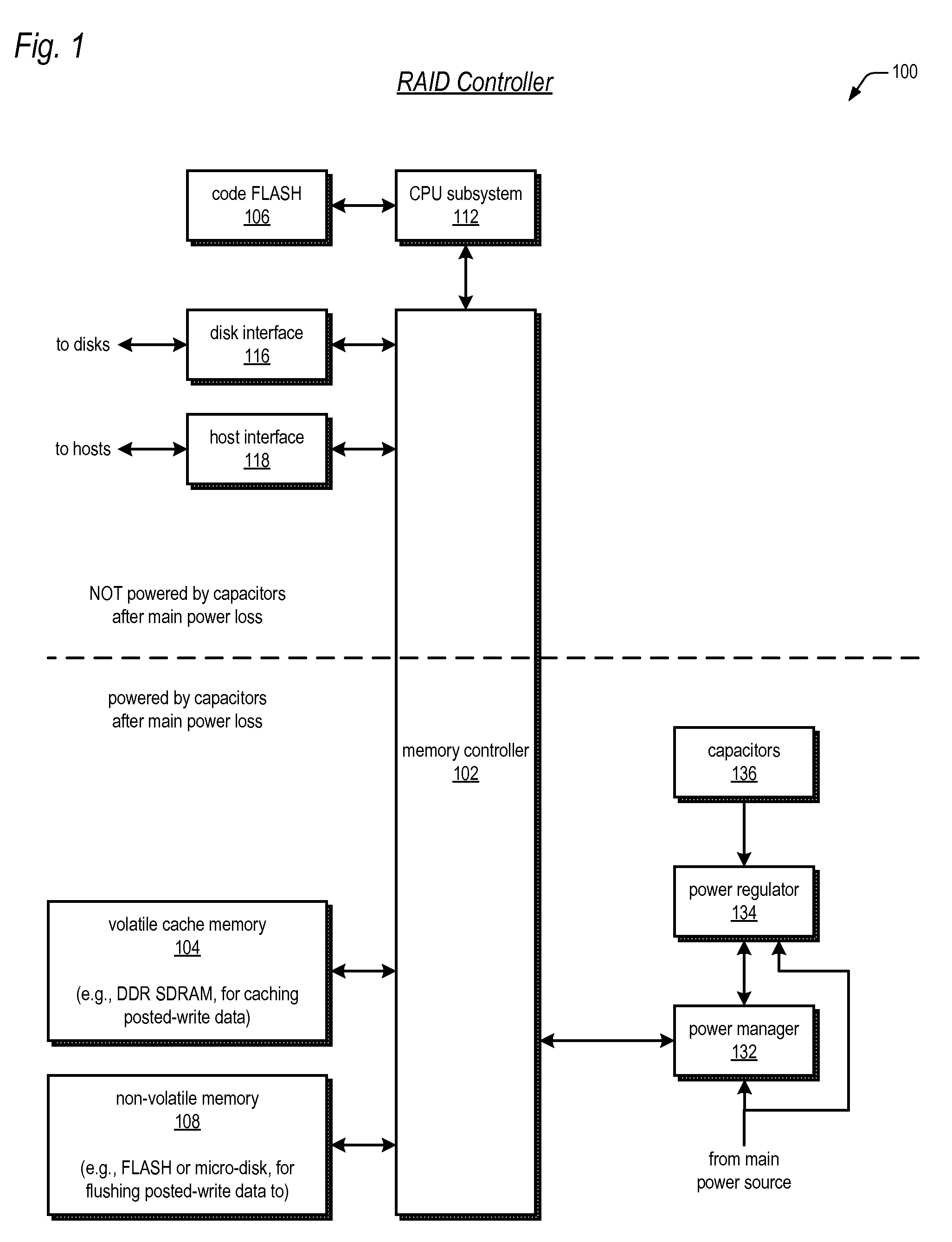

Raid controller using capacitor energy source to flush volatile cache data to non-volatile memory during main power outage

InactiveUS20060015683A1Reduces amount of energy storage capacity requirementLess expensiveEnergy efficient ICTMemory loss protectionRAIDStored energy

A write-caching RAID controller is disclosed. The controller includes a CPU that manages transfers of posted-write data from host computers to a volatile memory and transfers of the posted-write data from the volatile memory to storage devices when a main power source is supplying power to the RAID controller. A memory controller flushes the posted-write data from the volatile memory to the non-volatile memory when main power fails, during which time capacitors provide power to the memory controller, volatile memory, and non-volatile memory, but not to the CPU, in order to reduce the energy storage requirements of the capacitors. During main power provision, the CPU programs the memory controller with information needed to perform the flush operation, such as the location and size of the posted-write data in the volatile memory and various flush operation characteristics.

Owner:DOT HILL SYST

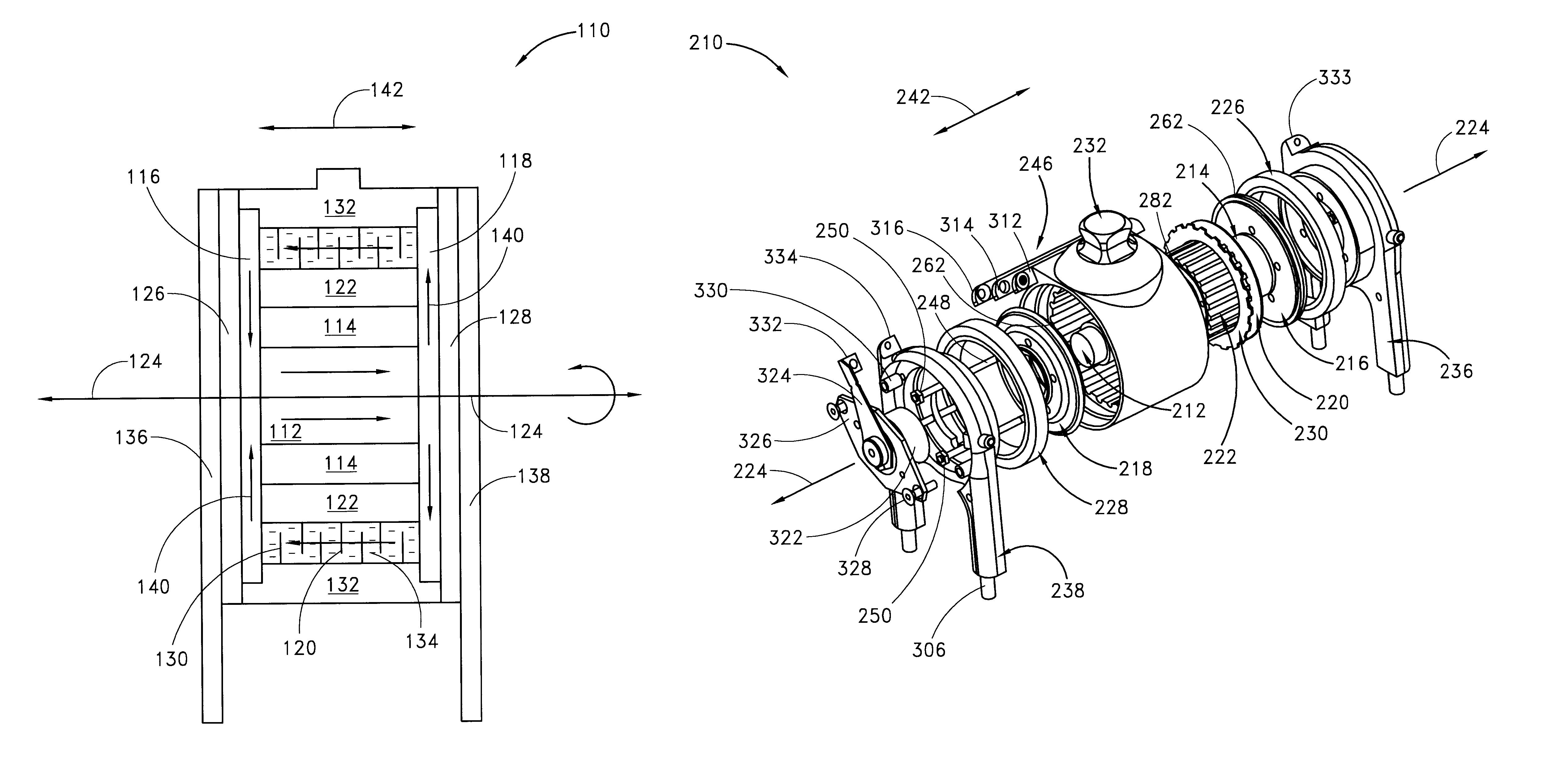

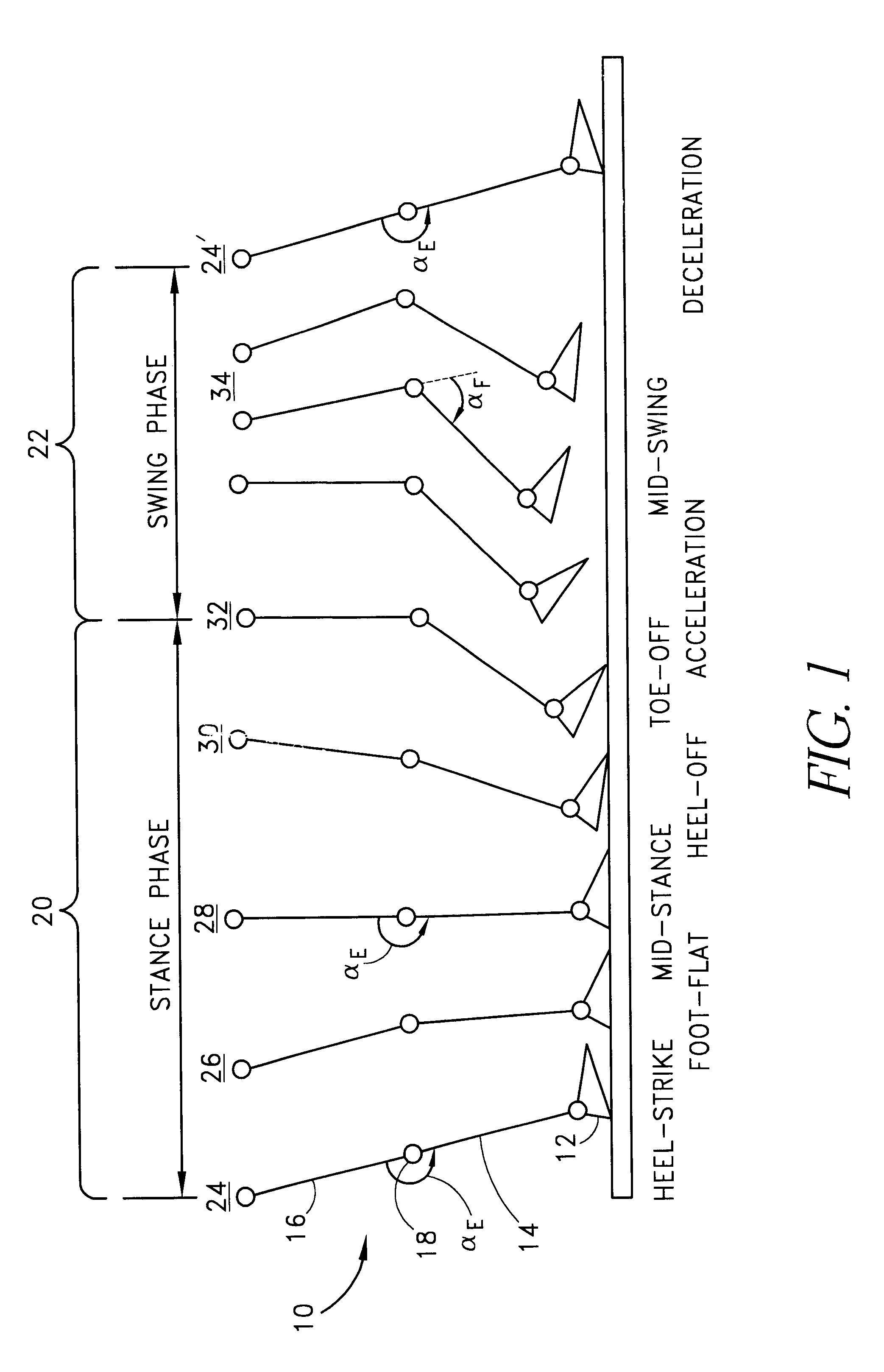

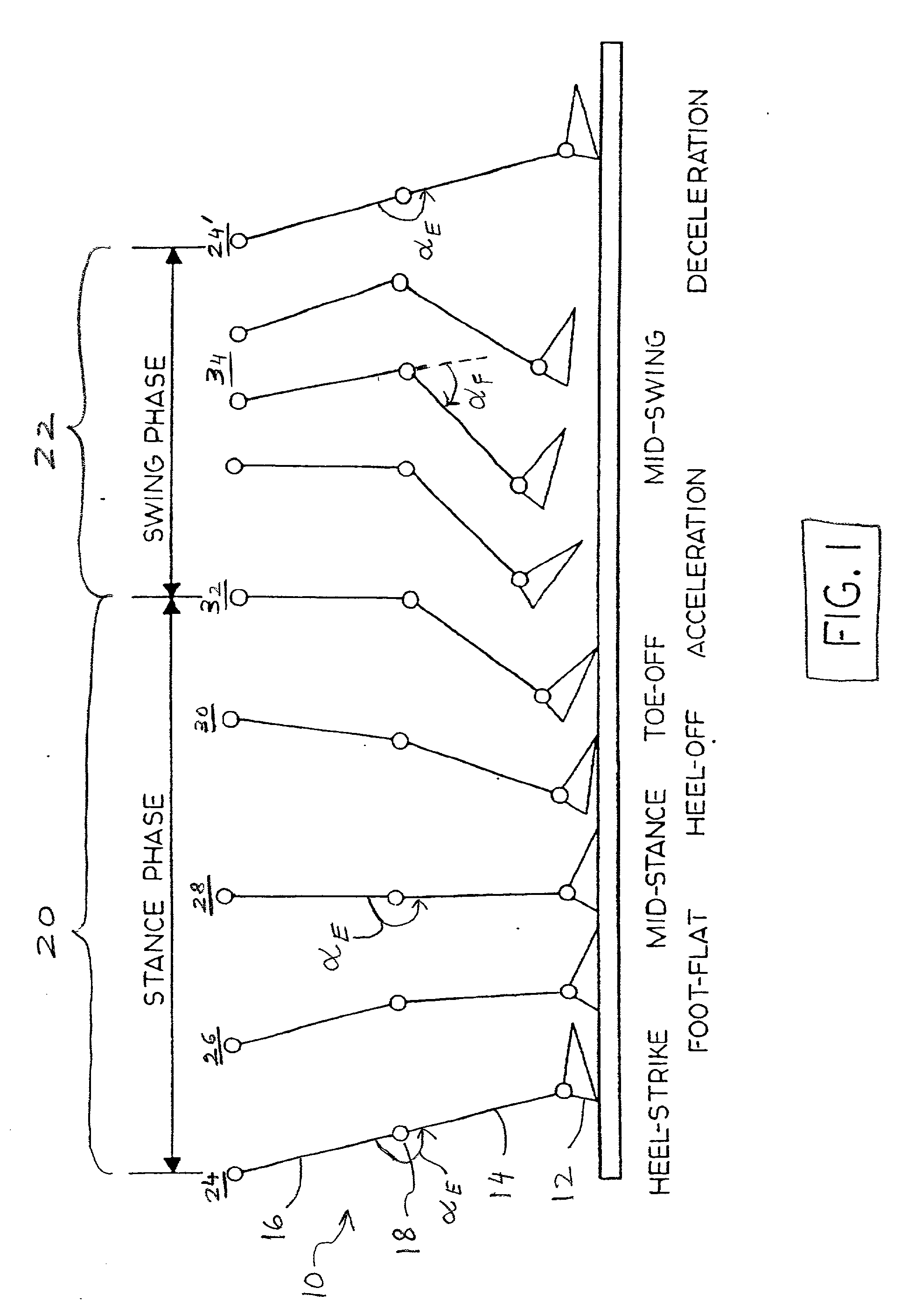

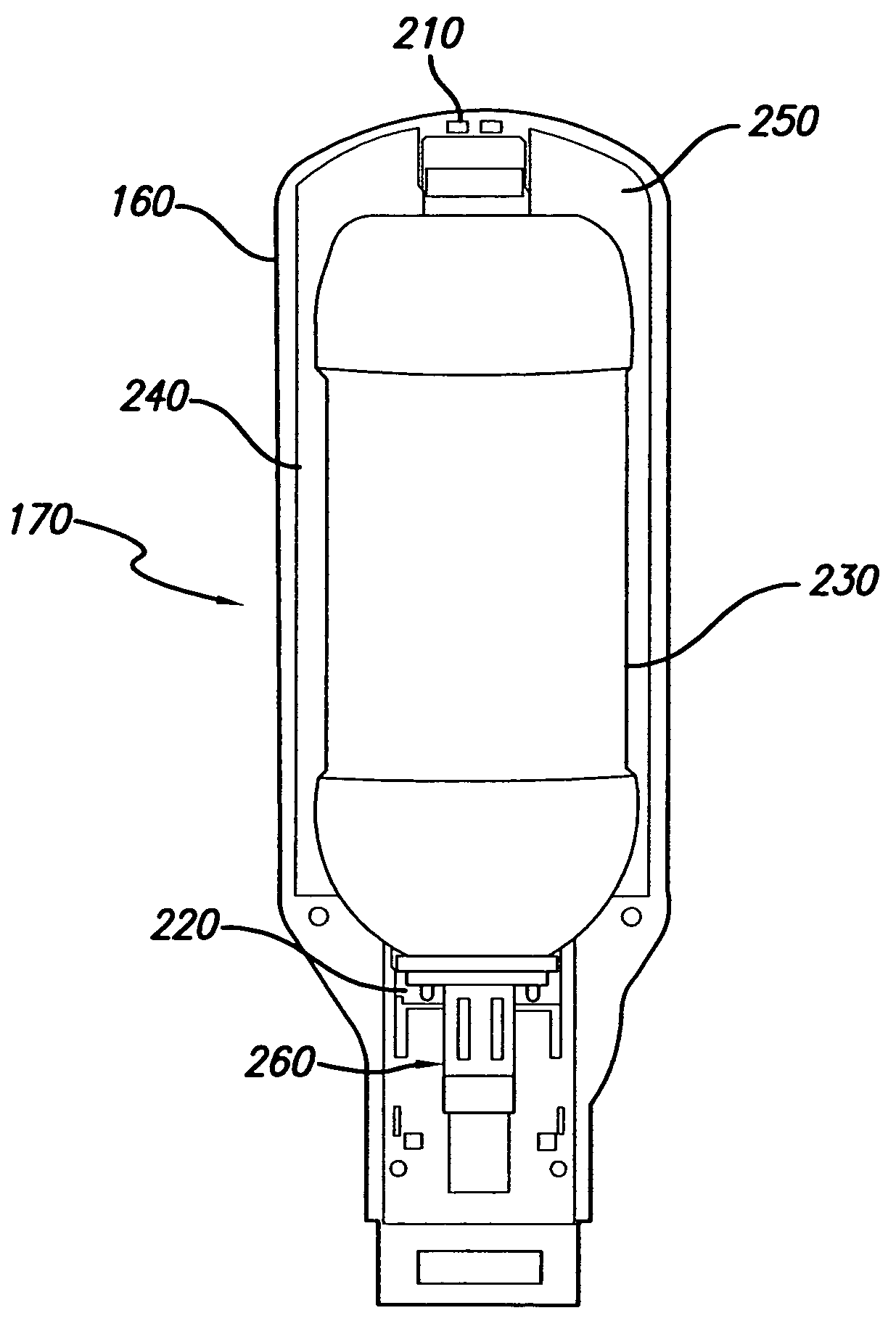

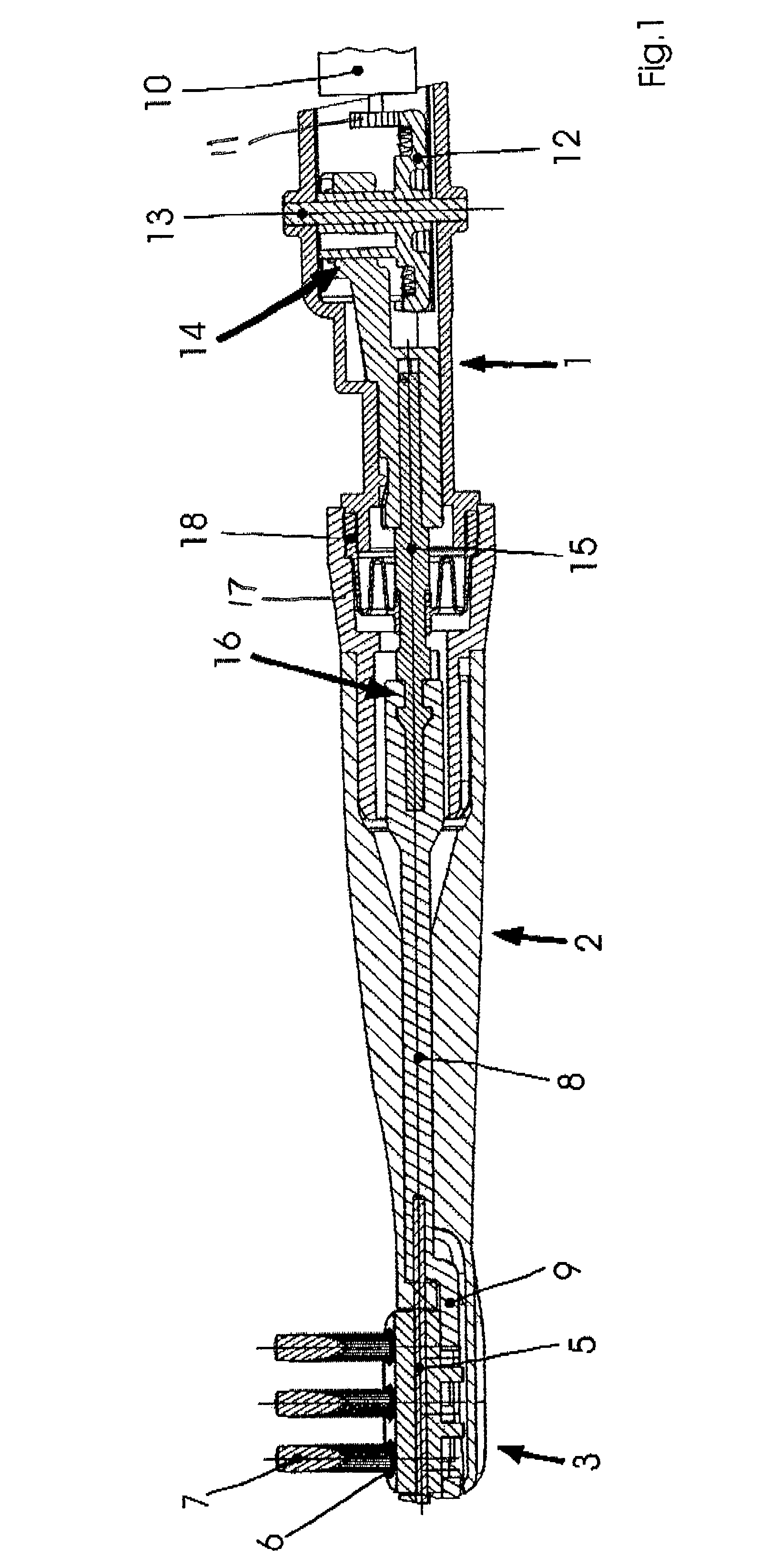

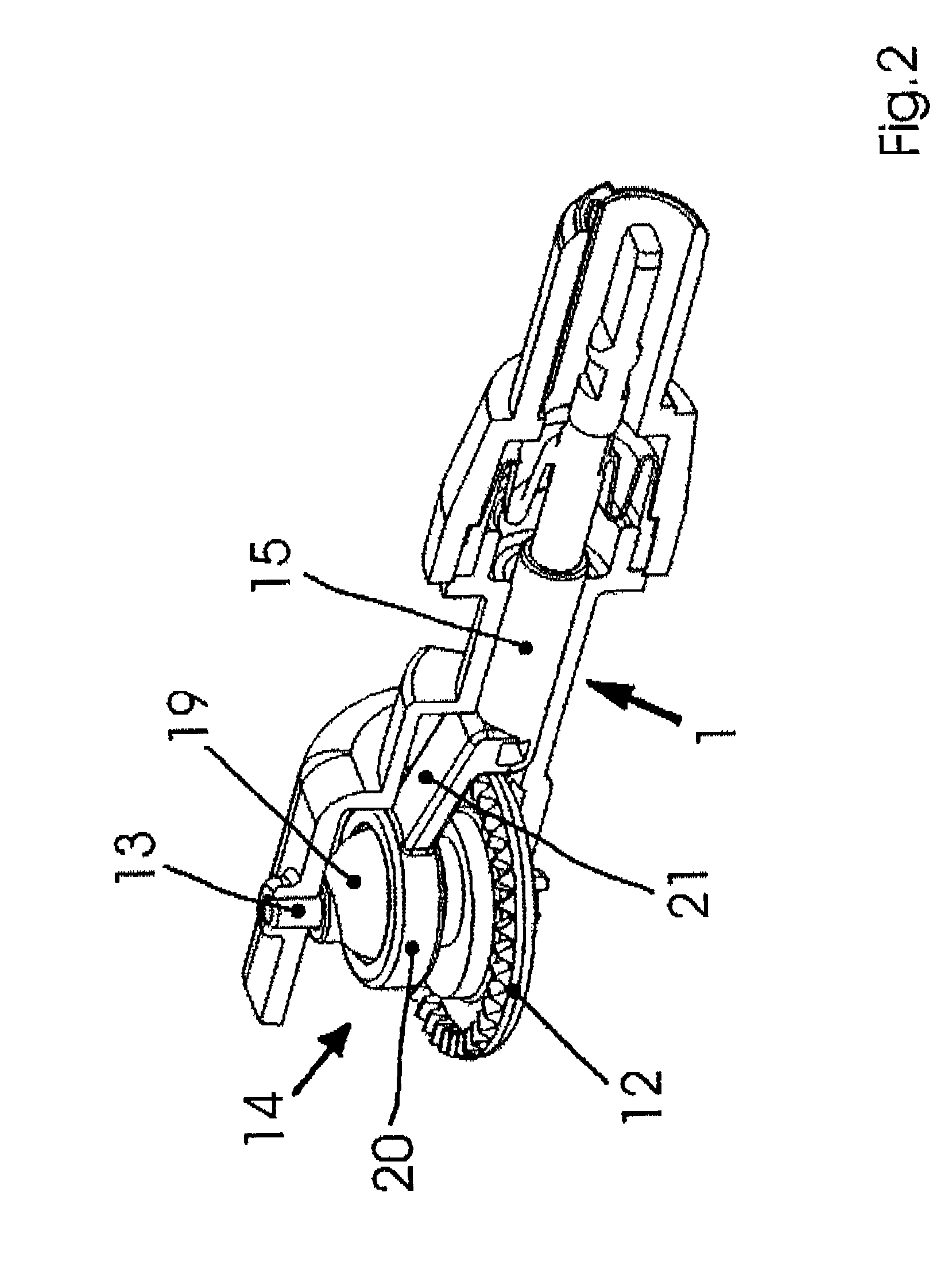

Electronically controlled prosthetic knee

InactiveUS6764520B2Improve efficiencyImprove practicalitySpringsNon-rotating vibration suppressionLow speedMagnetorheological fluid

The present invention relates to a variable-torque magnetorheologically actuated prosthetic knee which utilizes a plurality of interspersed and alternating rotors and stators to shear magnetorheological fluid in gaps formed therebetween. Advantageously, by operating in the "shear mode" there is substantially no or negligible fluid pressure buildup or change. Moreover, the multiple MR fluid gaps or flux interfaces desirably allow for the production of a large torque at low speed-eliminating the need for a transmission-and also for a wide dynamic torque range. One embodiment of the invention allows the rotors and / or stators to close the gaps therebetween to create a frictional torque component, thereby forming a "hybrid" braking system which provides a total torque or damping which is a combination of viscous torque and frictional torque.

Owner:MASSACHUSETTS INST OF TECH

Electronically controlled prosthetic knee

InactiveUS20010029400A1Move and/or adapt comfortably and safelyImprove efficiencySpringsNon-rotating vibration suppressionFriction torqueMagnetorheological fluid

The present invention relates to a variable-torque magnetorheologically actuated prosthetic knee which utilizes a plurality of interspersed and alternating rotors and stators to shear magnetorheological fluid in gaps formed therebetween. Advantageously, by operating in the "shear mode" there is substantially no or negligible fluid pressure buildup or change. Moreover, the multiple MR fluid gaps or flux interfaces desirably allow for the production of a large torque at low speed-eliminating the need for a transmission-and also for a wide dynamic torque range. One embodiment of the invention allows the rotors and / or stators to close the gaps therebetween to create a frictional torque component, thereby forming a "hybrid" braking system which provides a total torque or damping which is a combination of viscous torque and frictional torque.

Owner:MASSACHUSETTS INST OF TECH

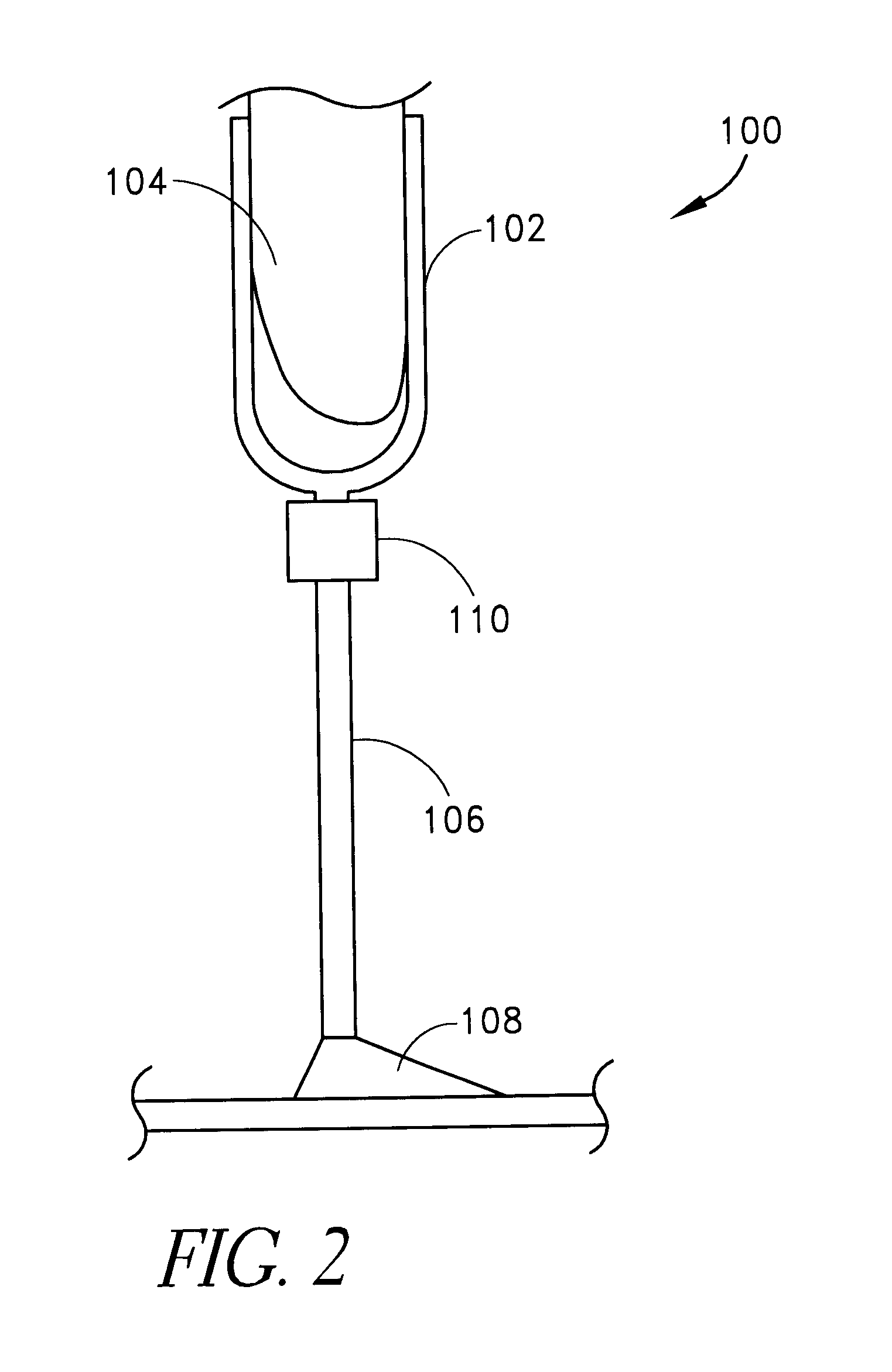

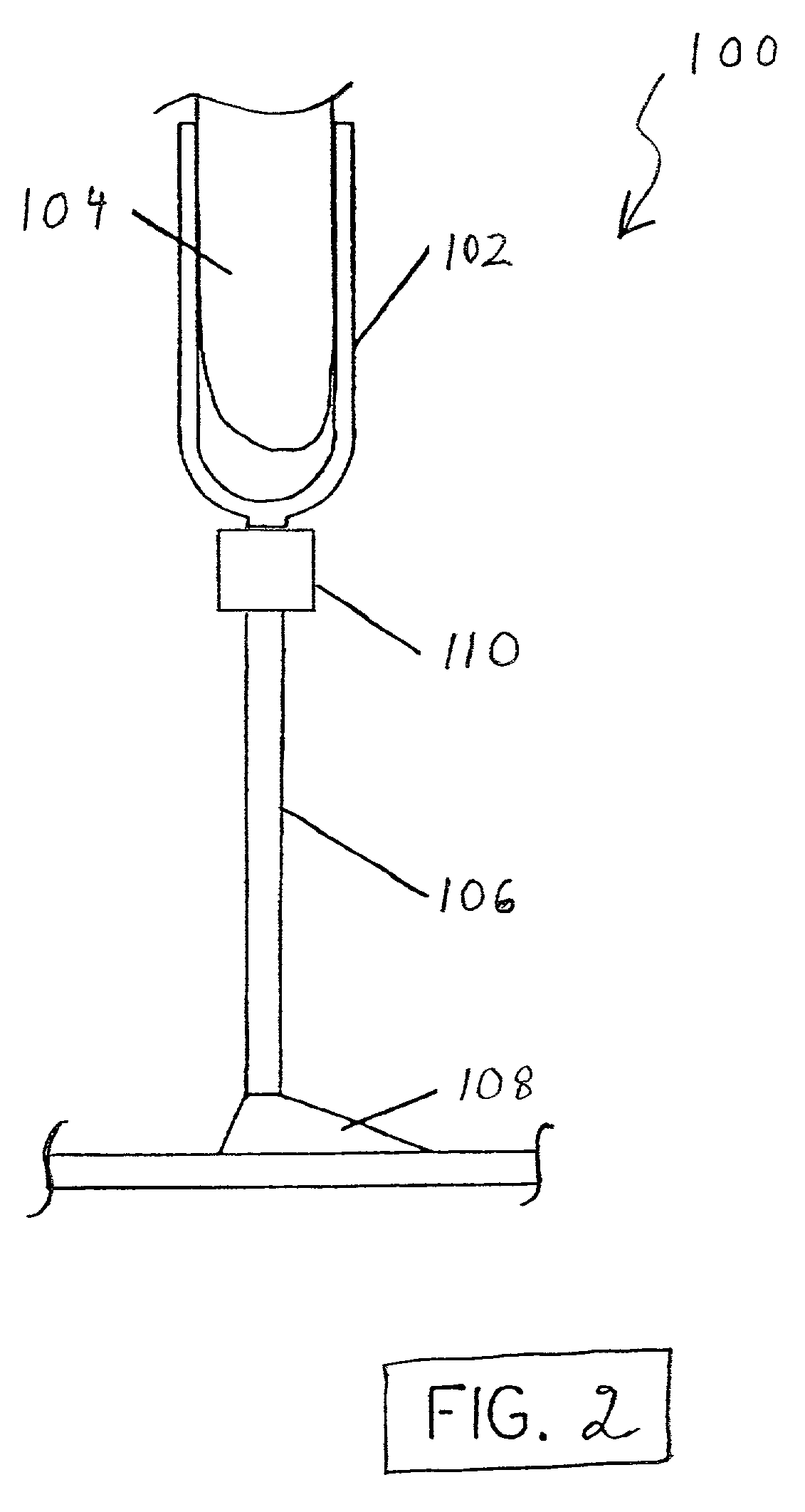

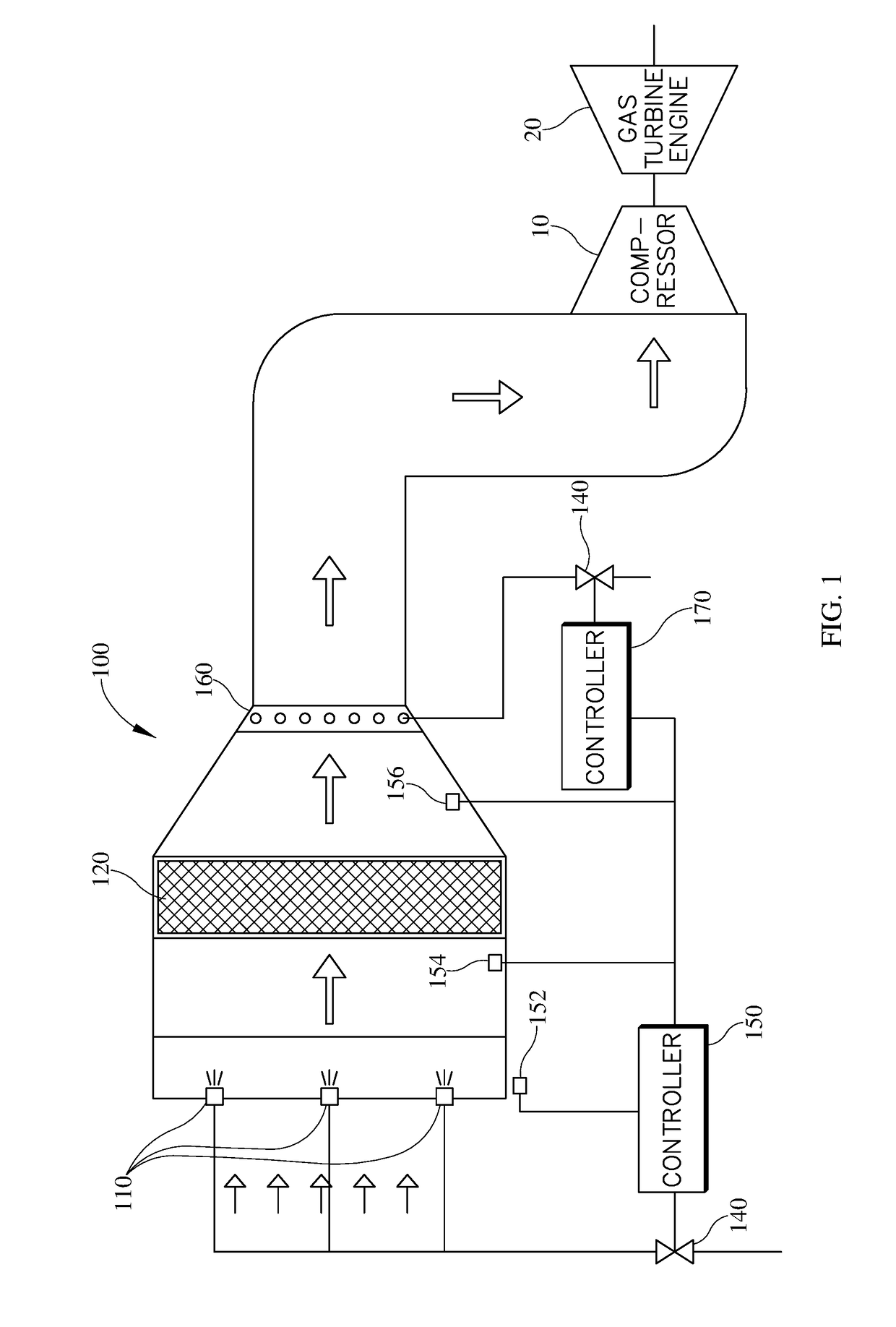

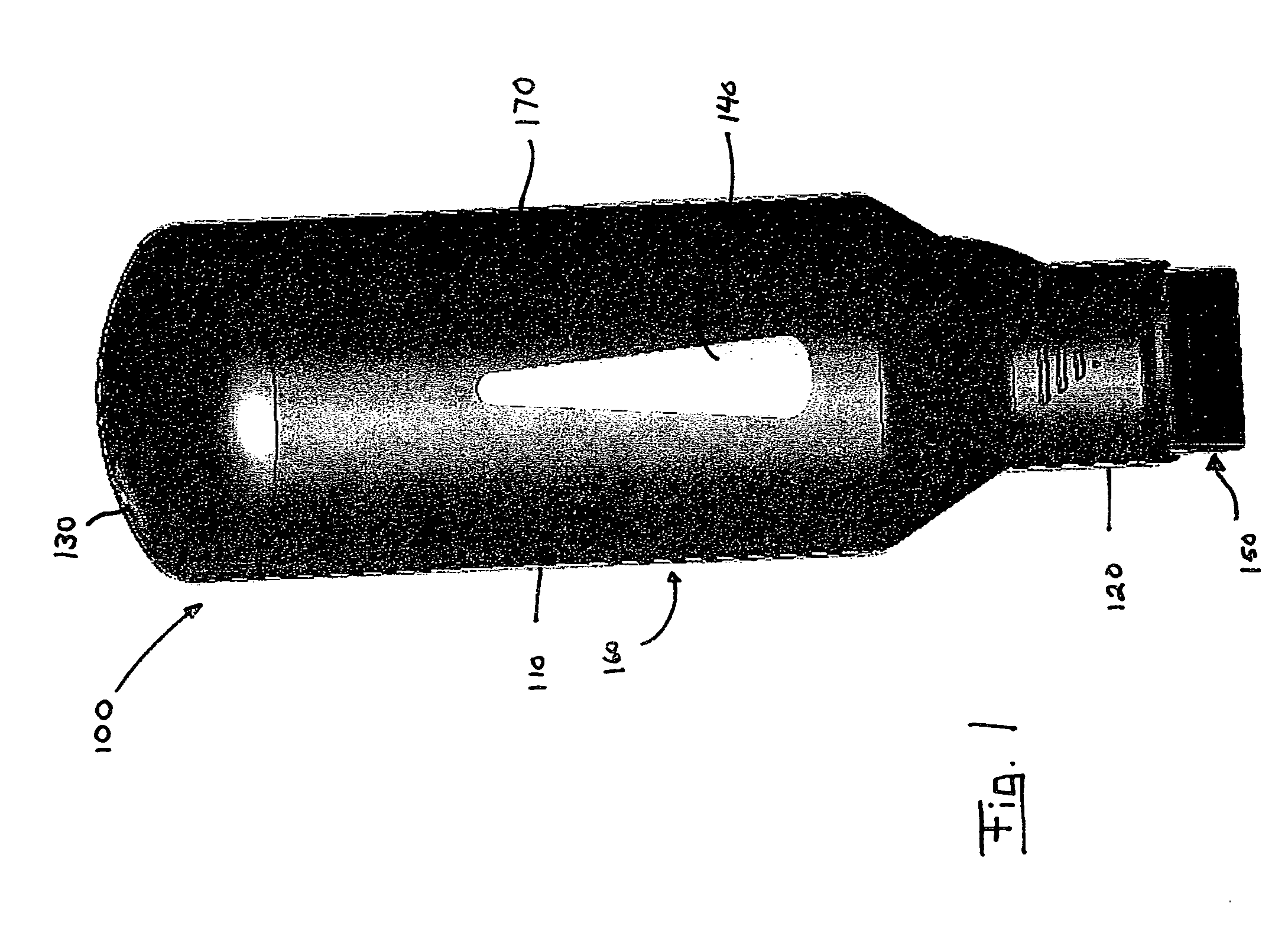

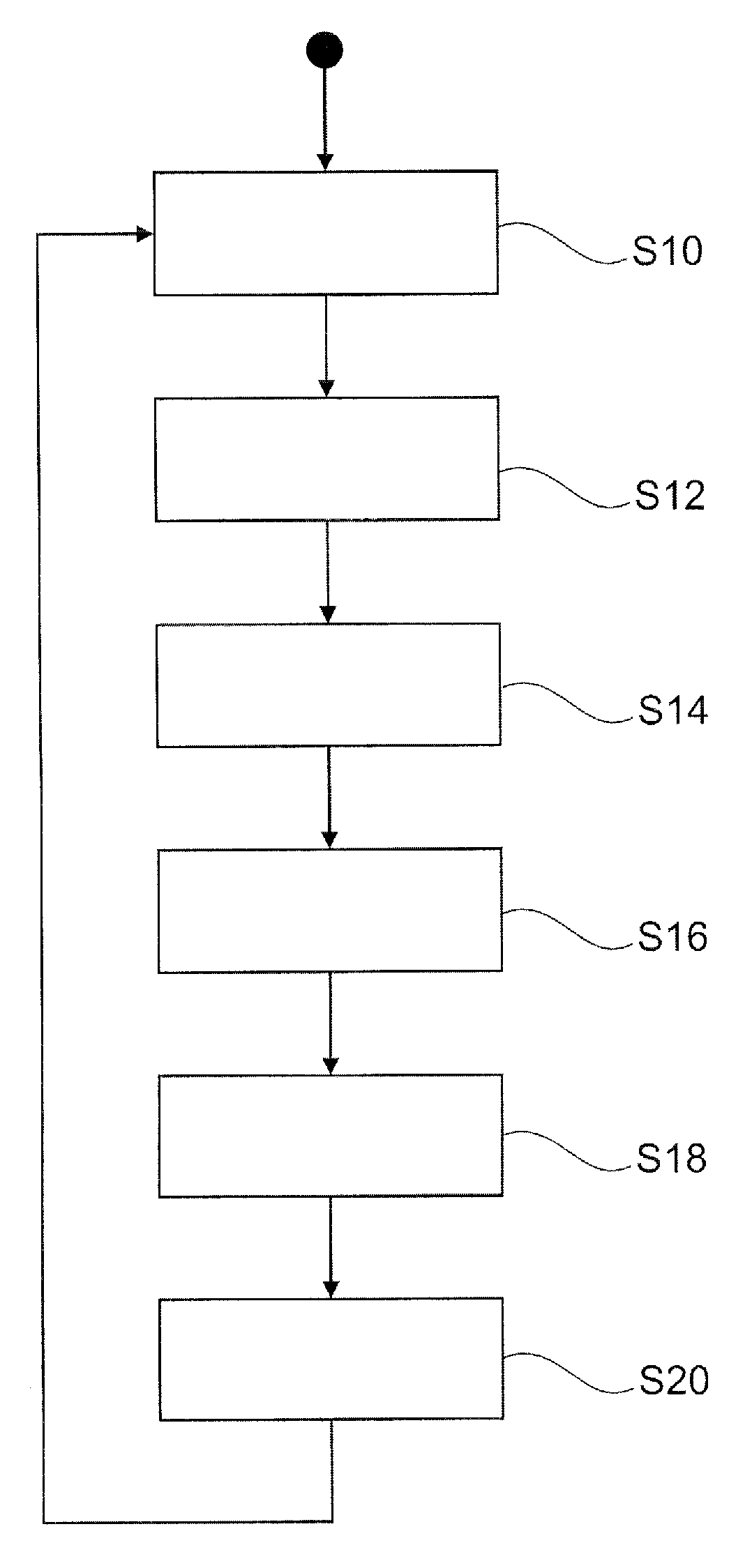

System for reducing inlet air temperature of a device

ActiveUS20180172294A1Reduce device temperatureSimple nozzle designCoolant flow controlLighting and heating apparatusBiomedical engineeringAir temperature

The present embodiments disclose a system (100) for reducing inlet air temperature of a device, comprising: a fogging system that provides air cooling, wherein the fogging system comprises at least one low pressure atomiser (110).

Owner:AAF LTD

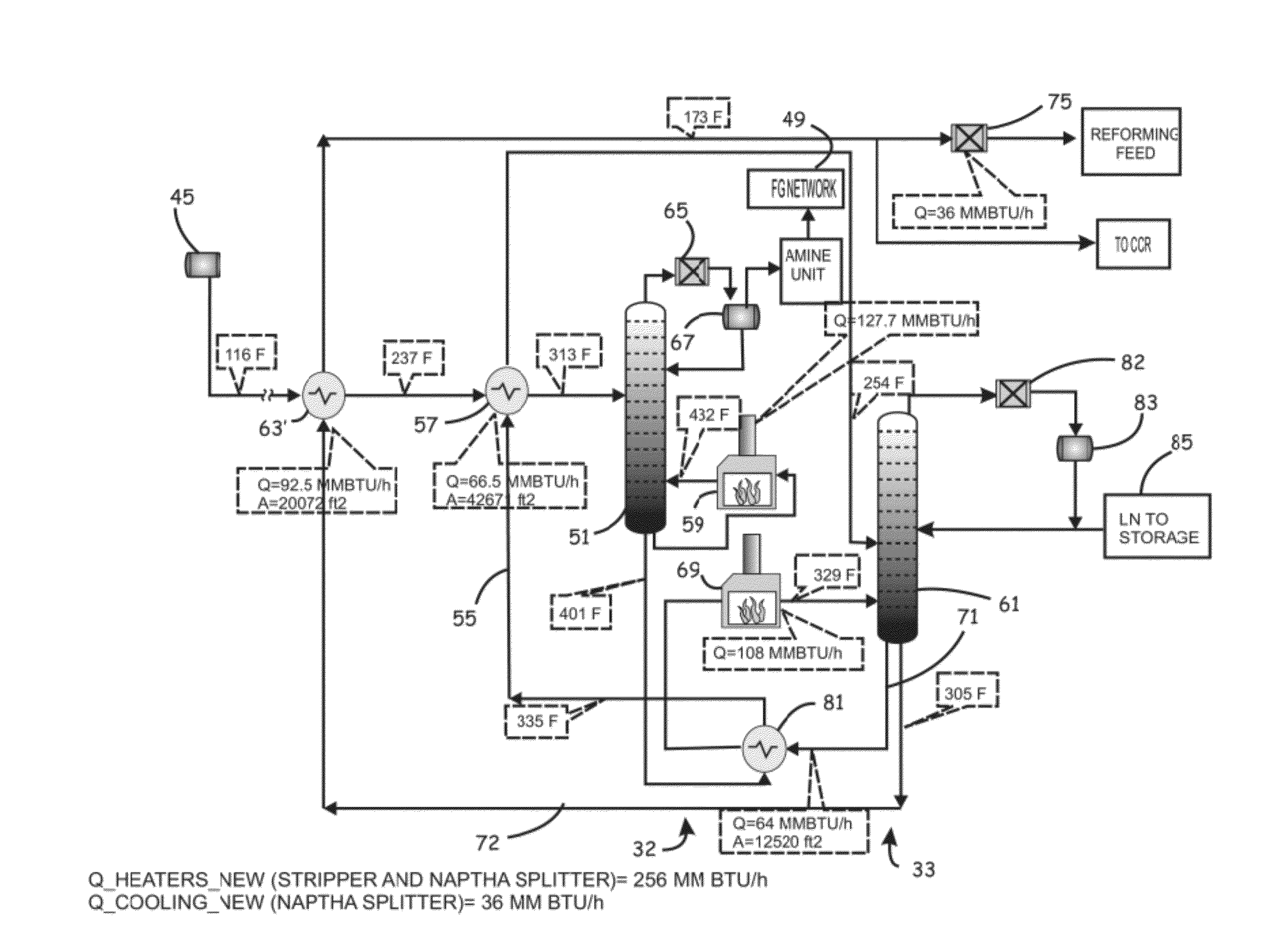

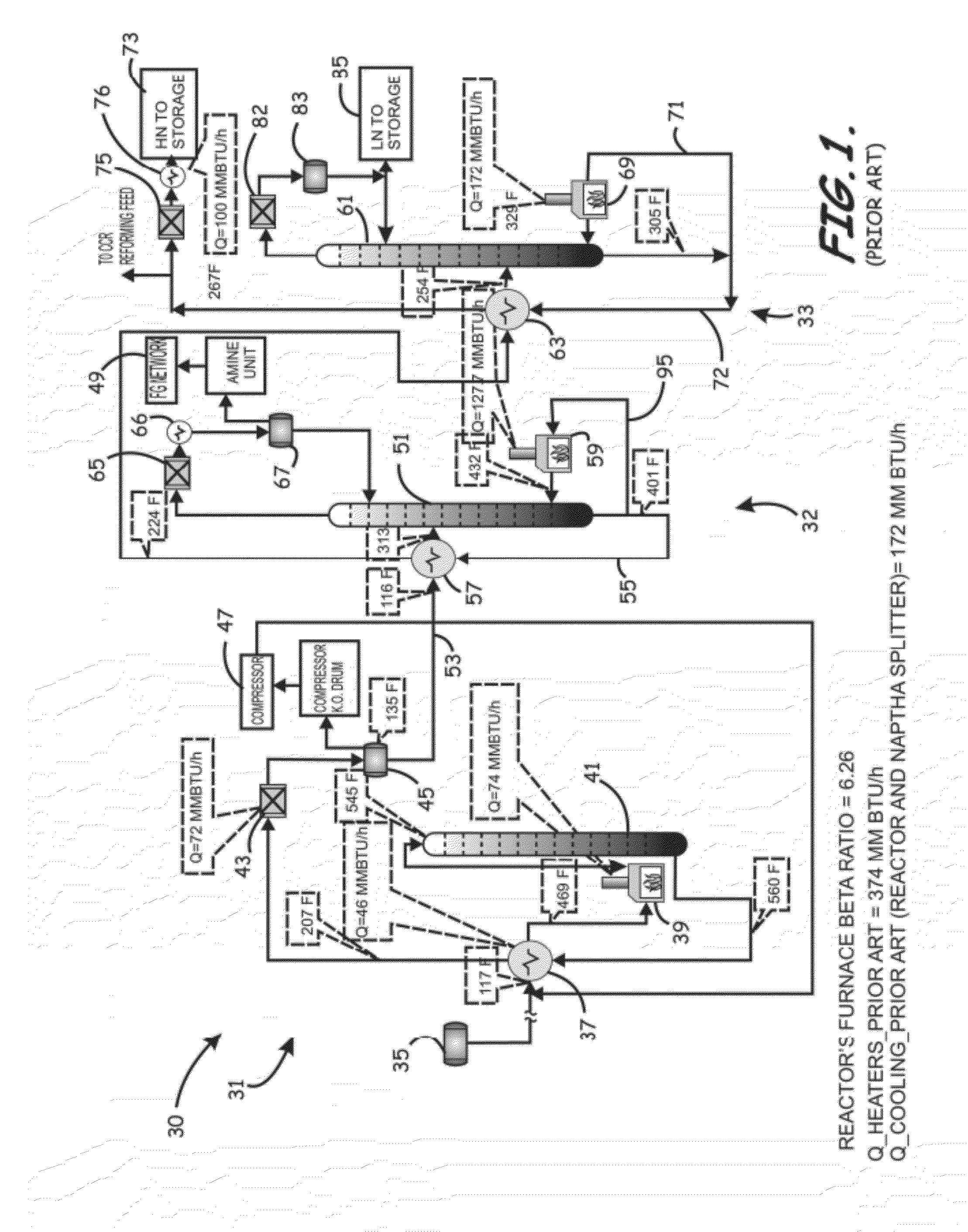

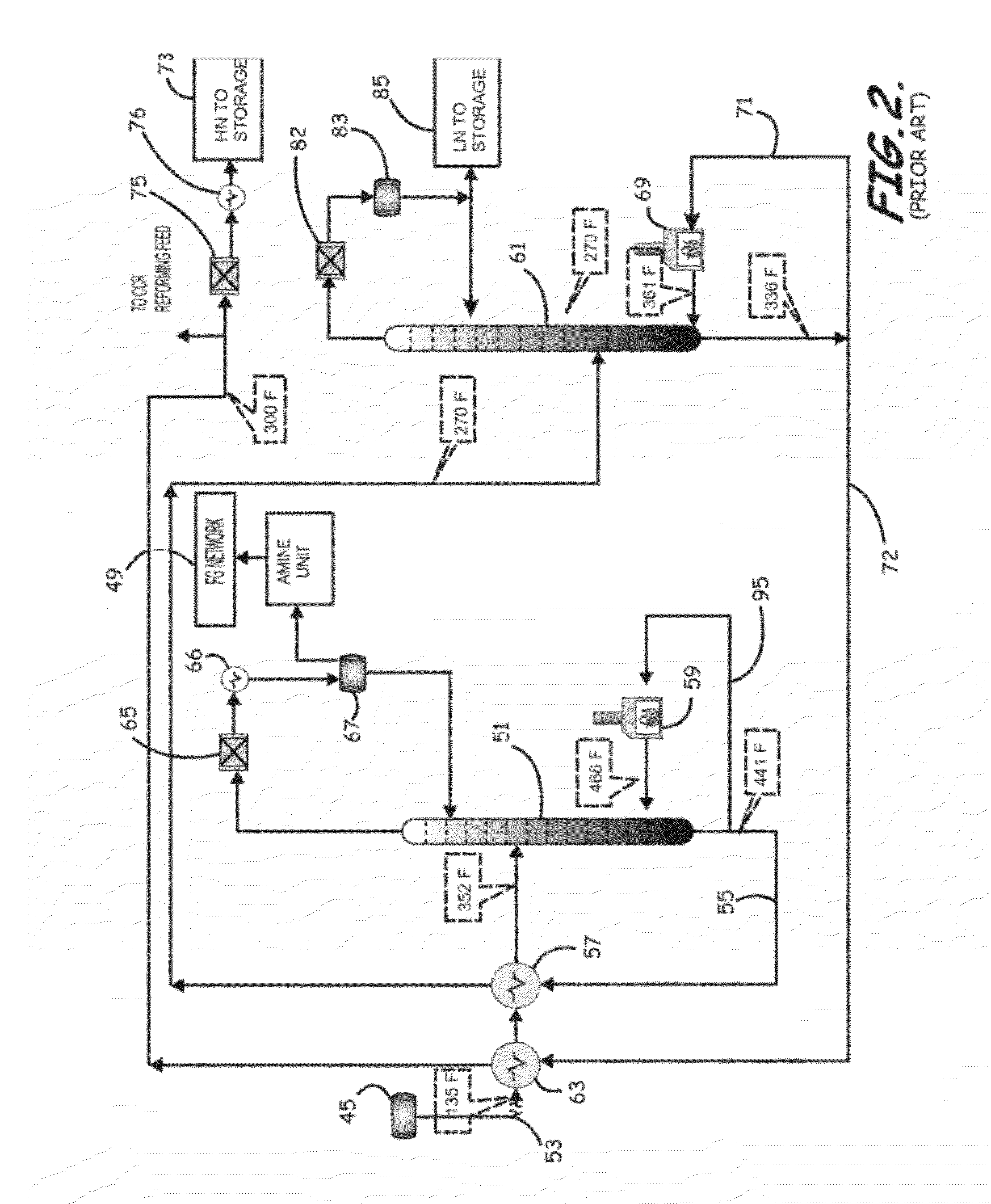

Energy-Efficient and Environmentally Advanced Configurations For Naptha Hydrotreating Process

ActiveUS20120279900A1Less emissionsLower ratioRecuperative heat exchangersThermal naphtha reformingProcess systemsNaphtha

Systems and methods of hydrotreating different naphtha feed stocks destined for a refining reforming unit and other applications with less energy consumption than conventionally possible, while producing less greenhouse gas emissions, and / or using a lesser number of heaters and correspondingly less capital investment in such heaters, air coolers, and water coolers, are provided. According to the more examples of such systems and methods, such reductions are accomplished by directly integrating a naphtha stripping process section with a naphtha splitting process section. Additional reductions can also be accomplished through directly integrating a naphtha hydrotreat reaction process section with the naphtha stripping process section.

Owner:SAUDI ARABIAN OIL CO

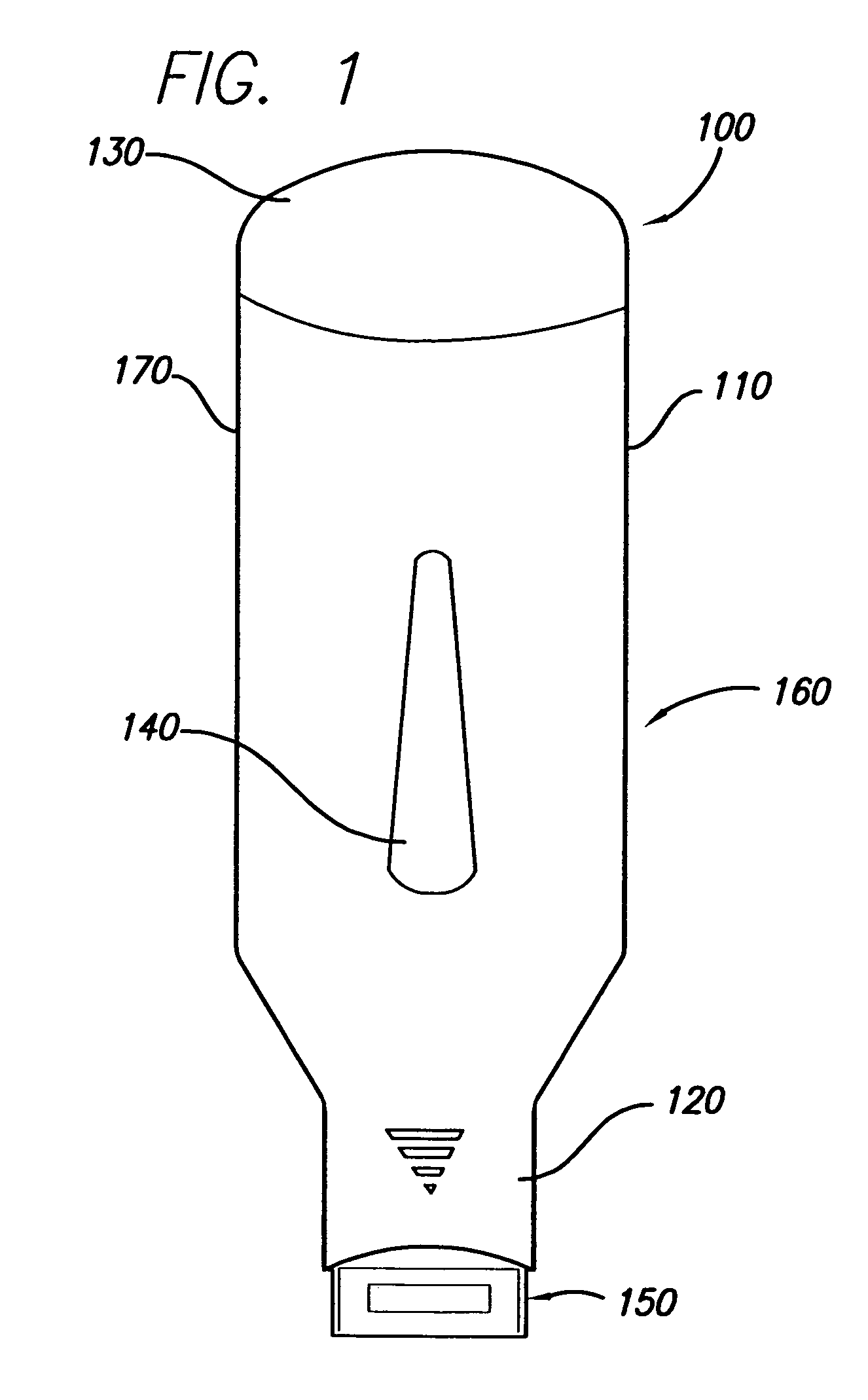

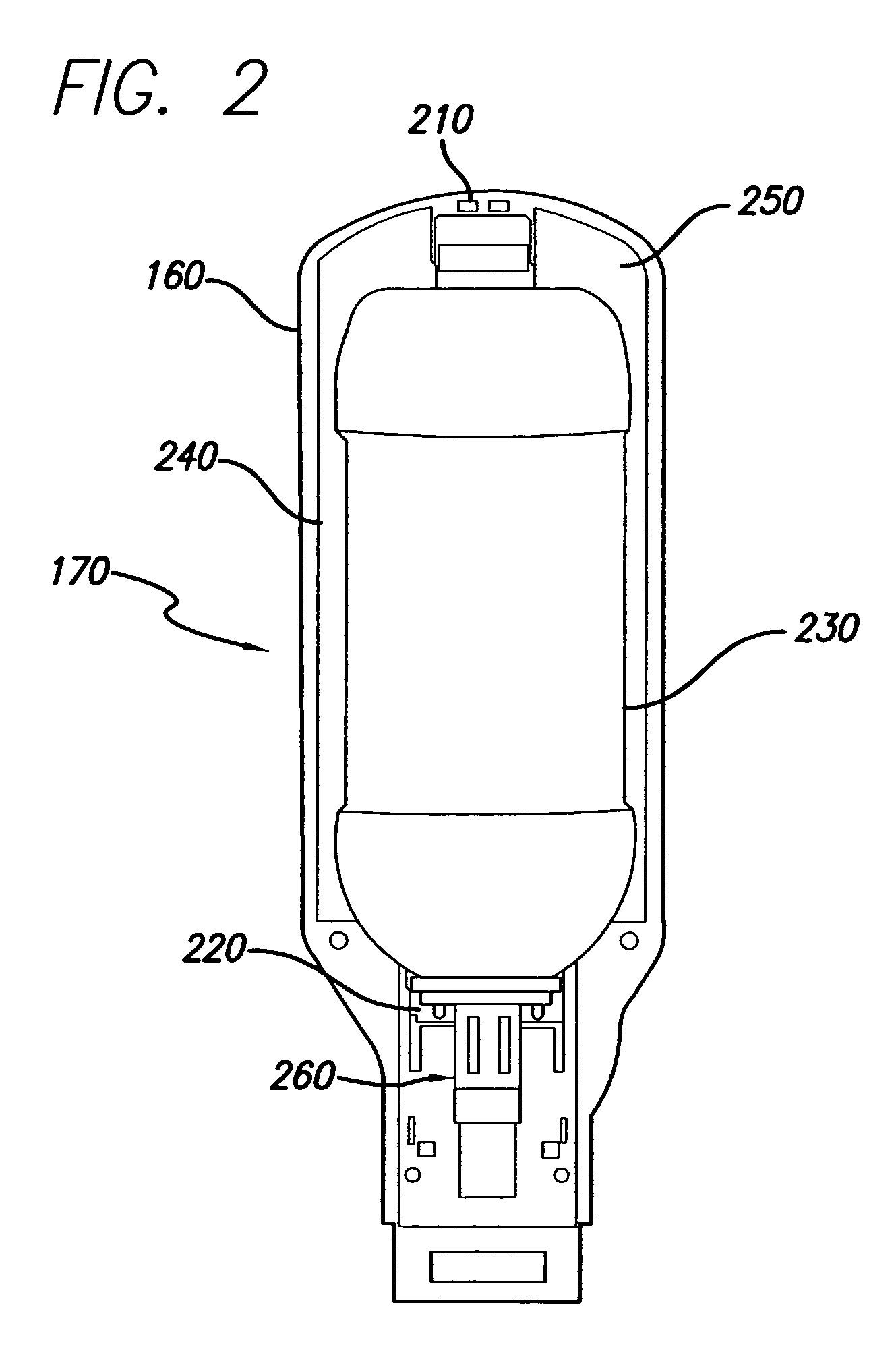

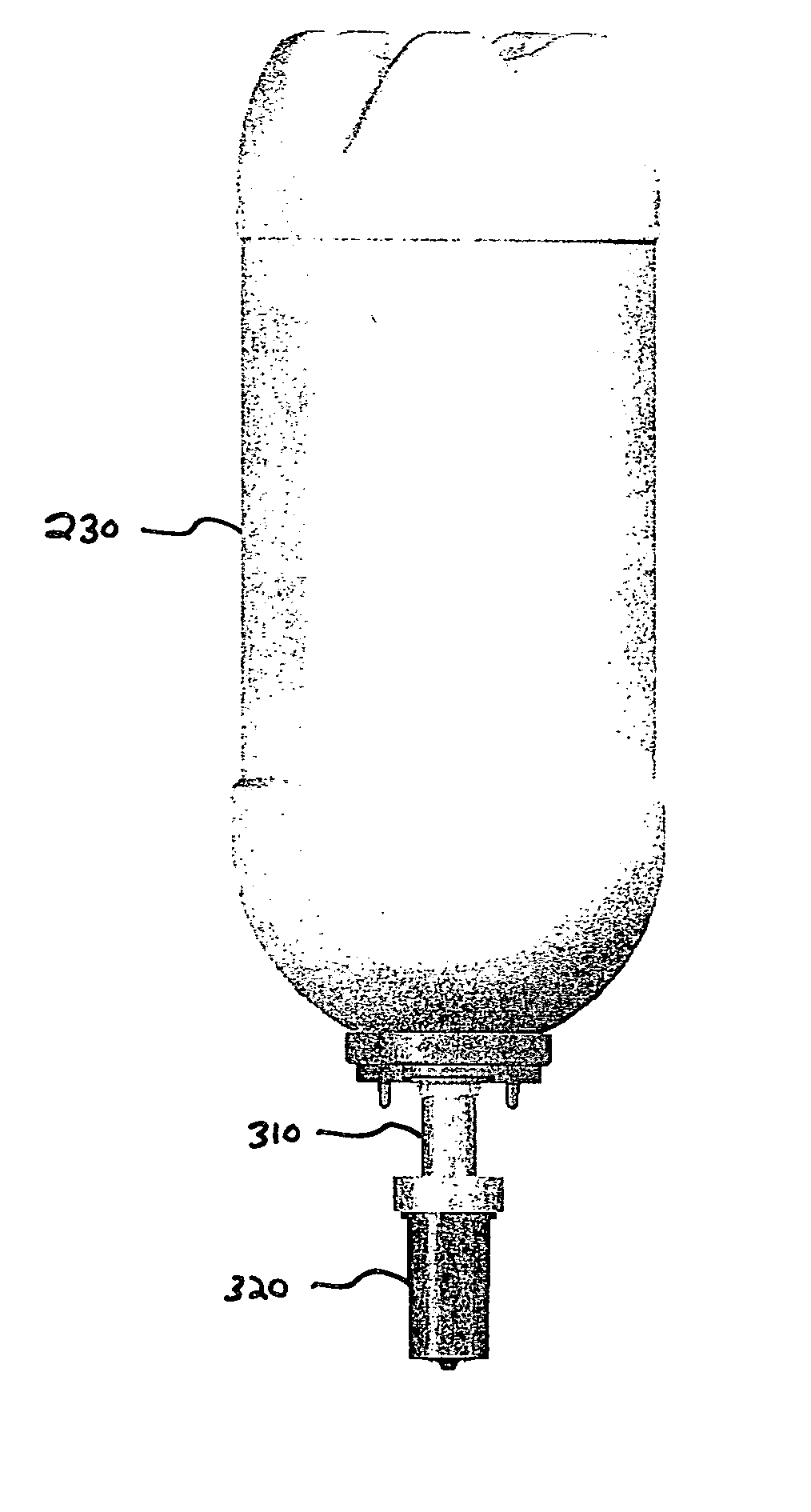

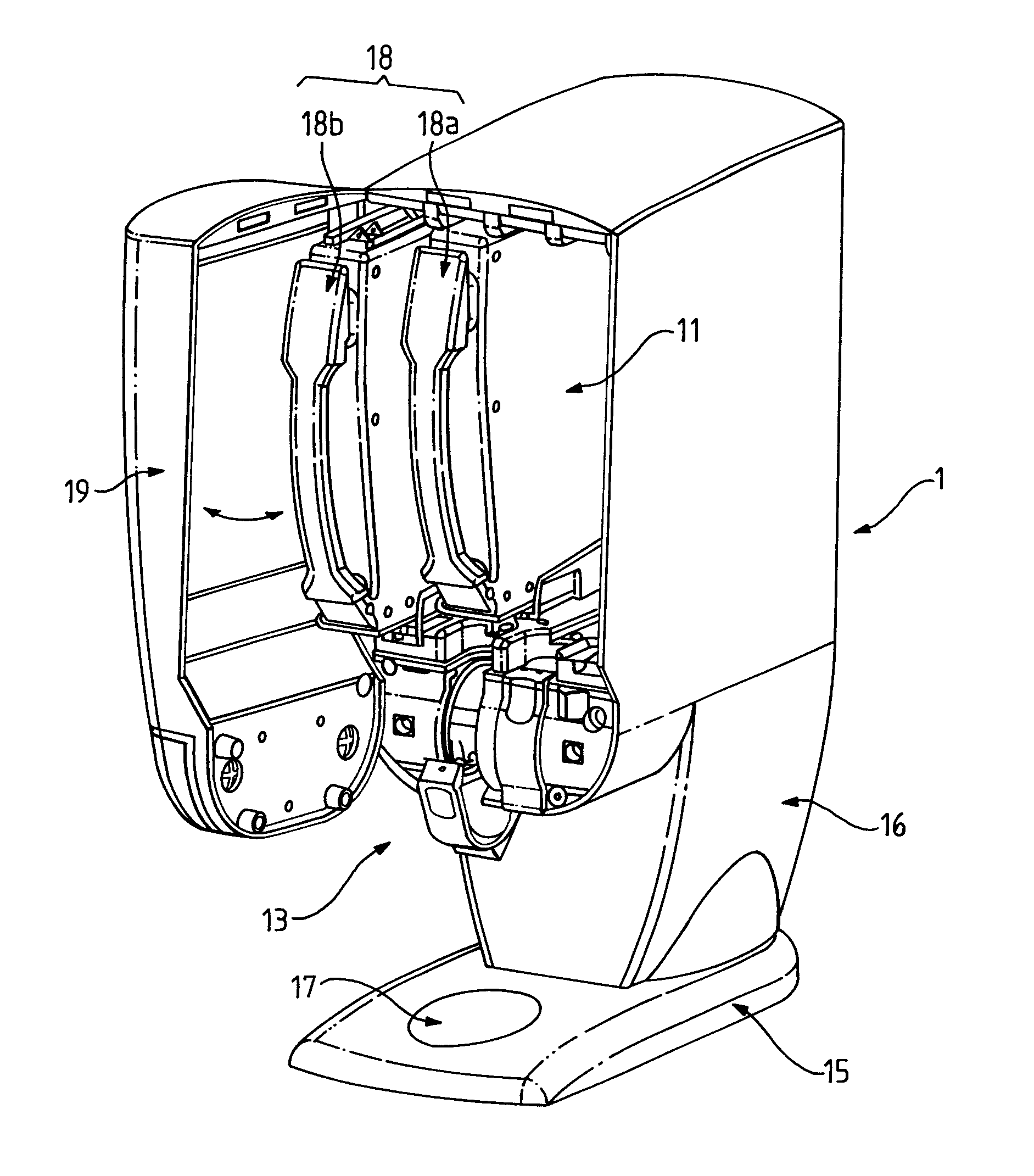

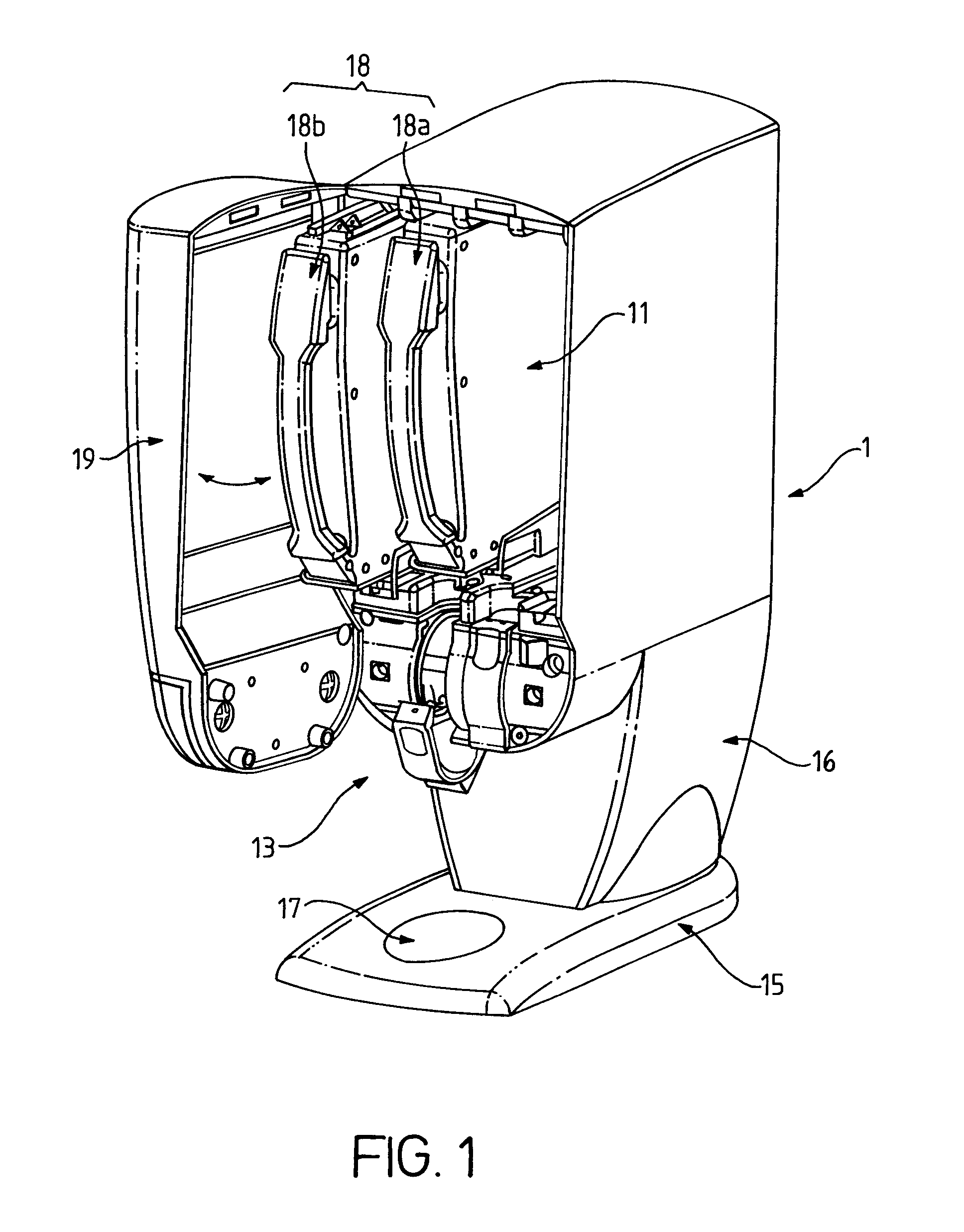

Apparatus and method for dispensing post-foaming gel soap

ActiveUS7540397B2More efficientLess expensiveOperating means/releasing devices for valvesLarge containersActuatorSOAP

Owner:RUBBERMAID COMMERCIAL PRODUCTS

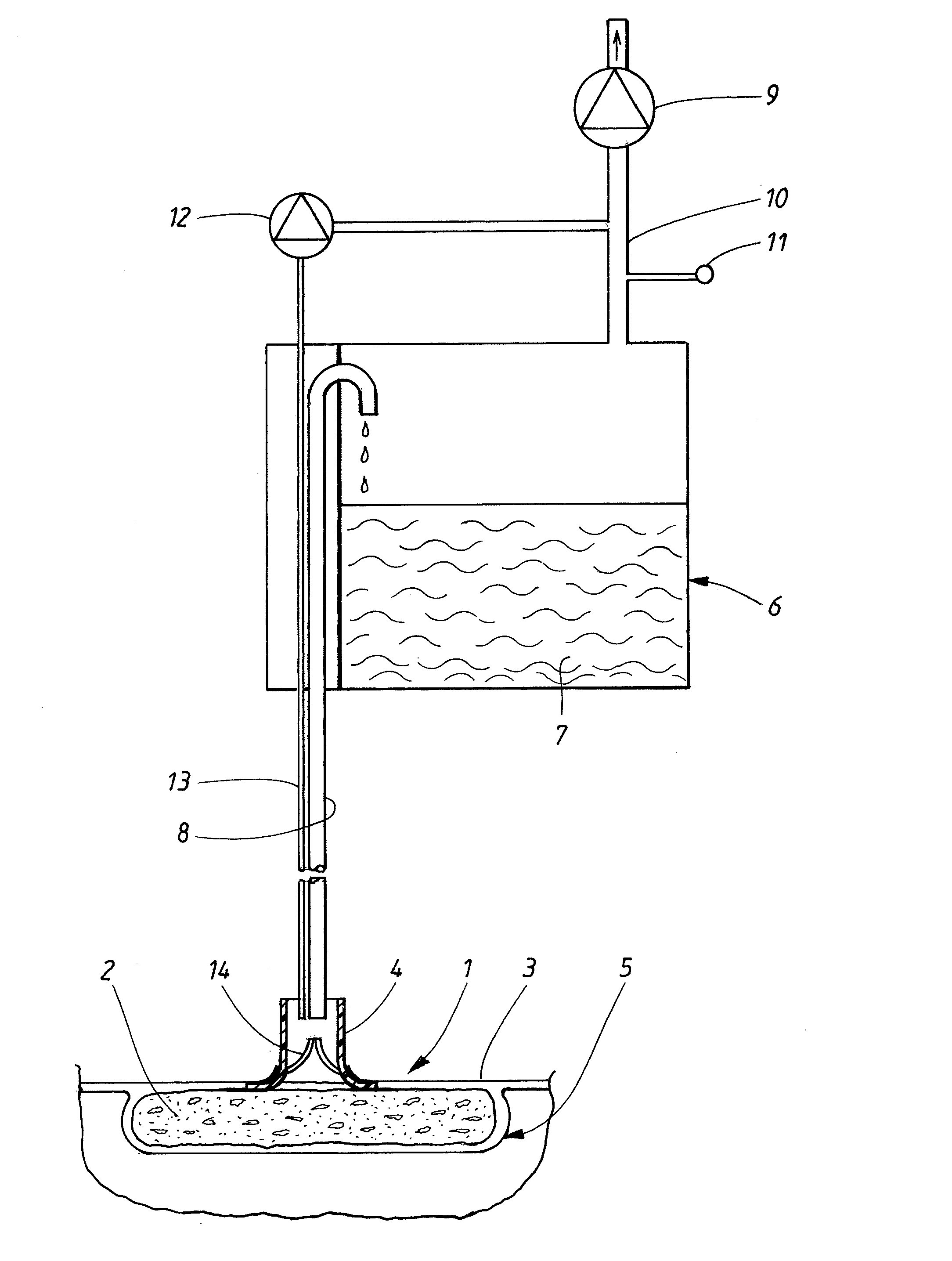

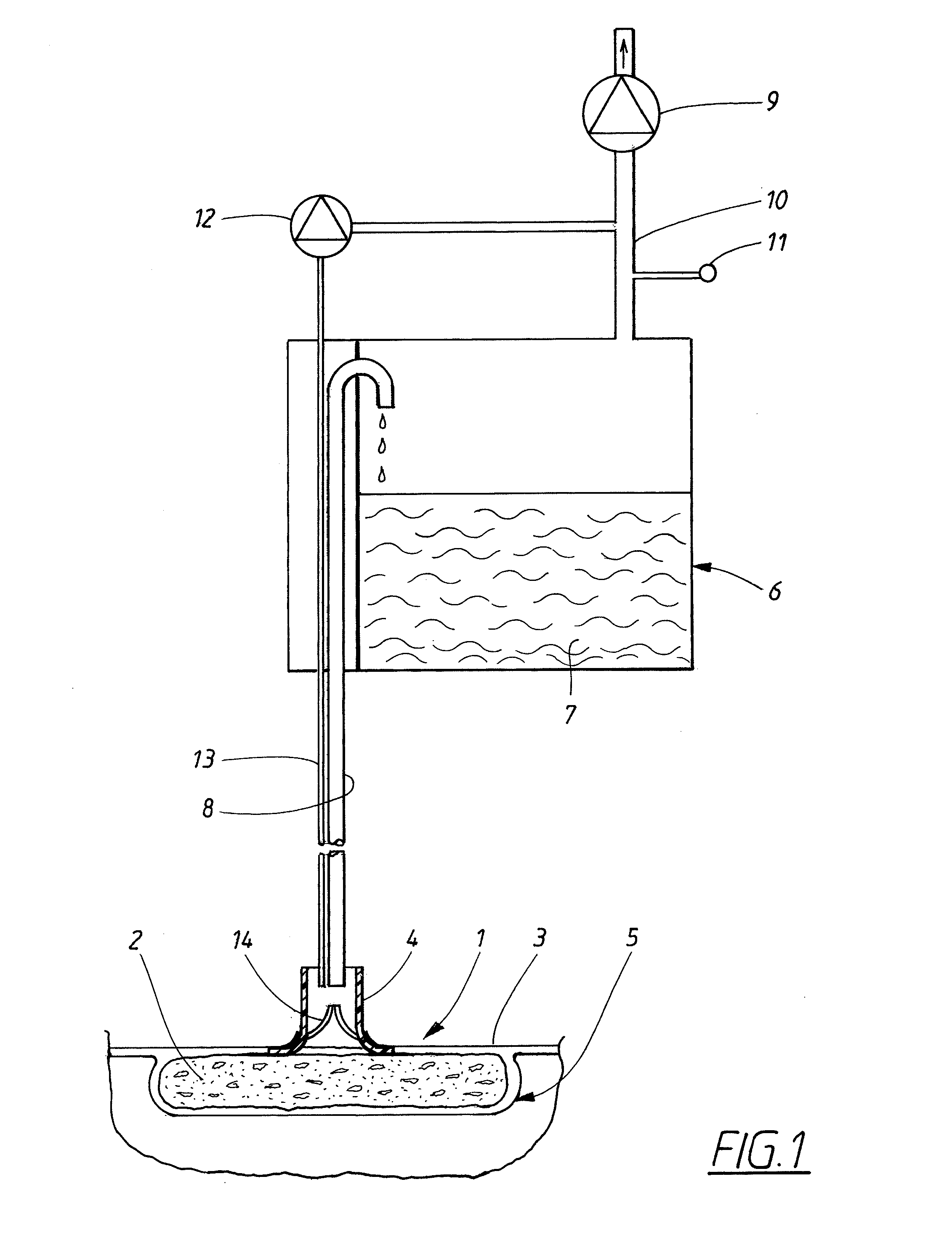

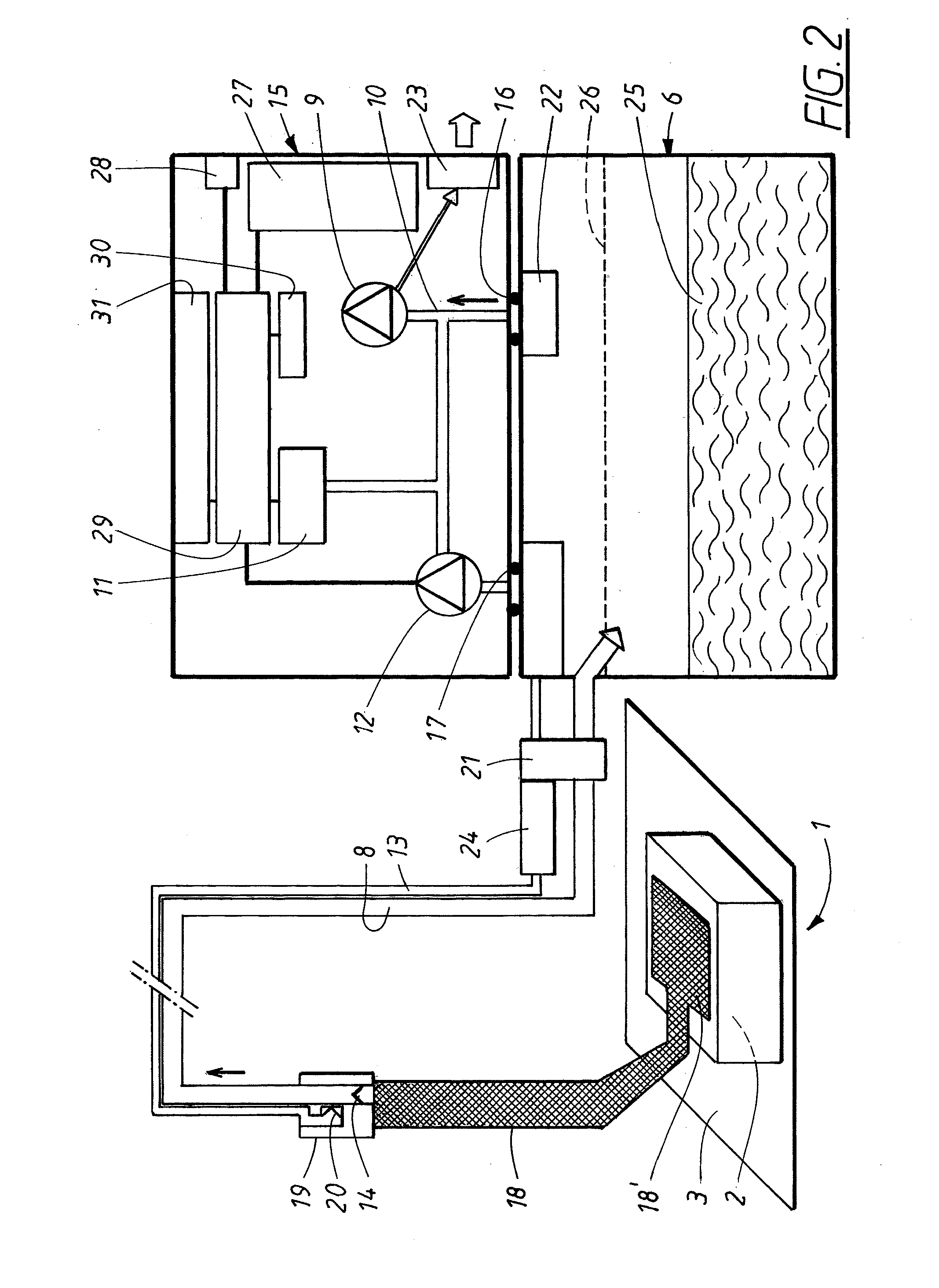

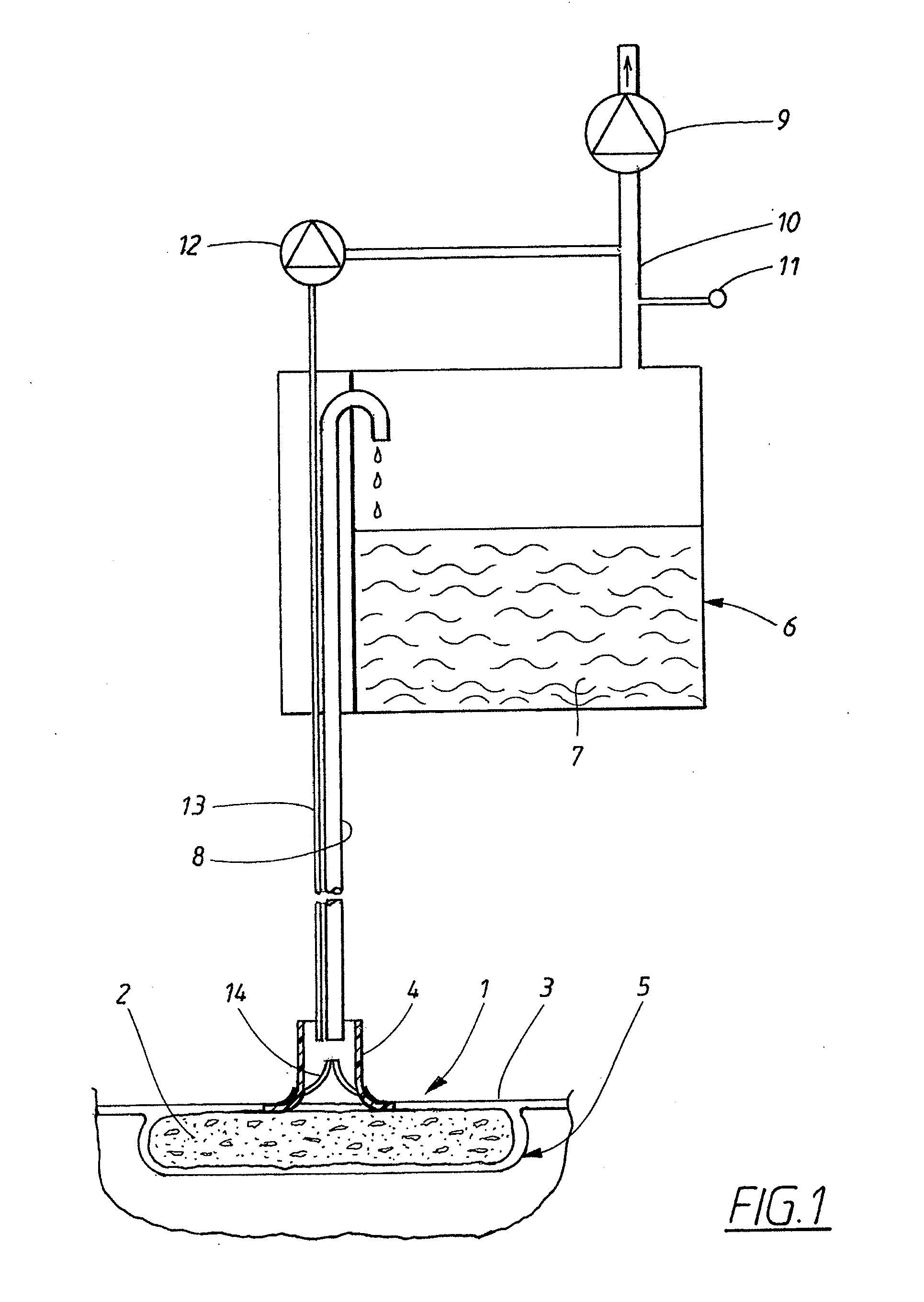

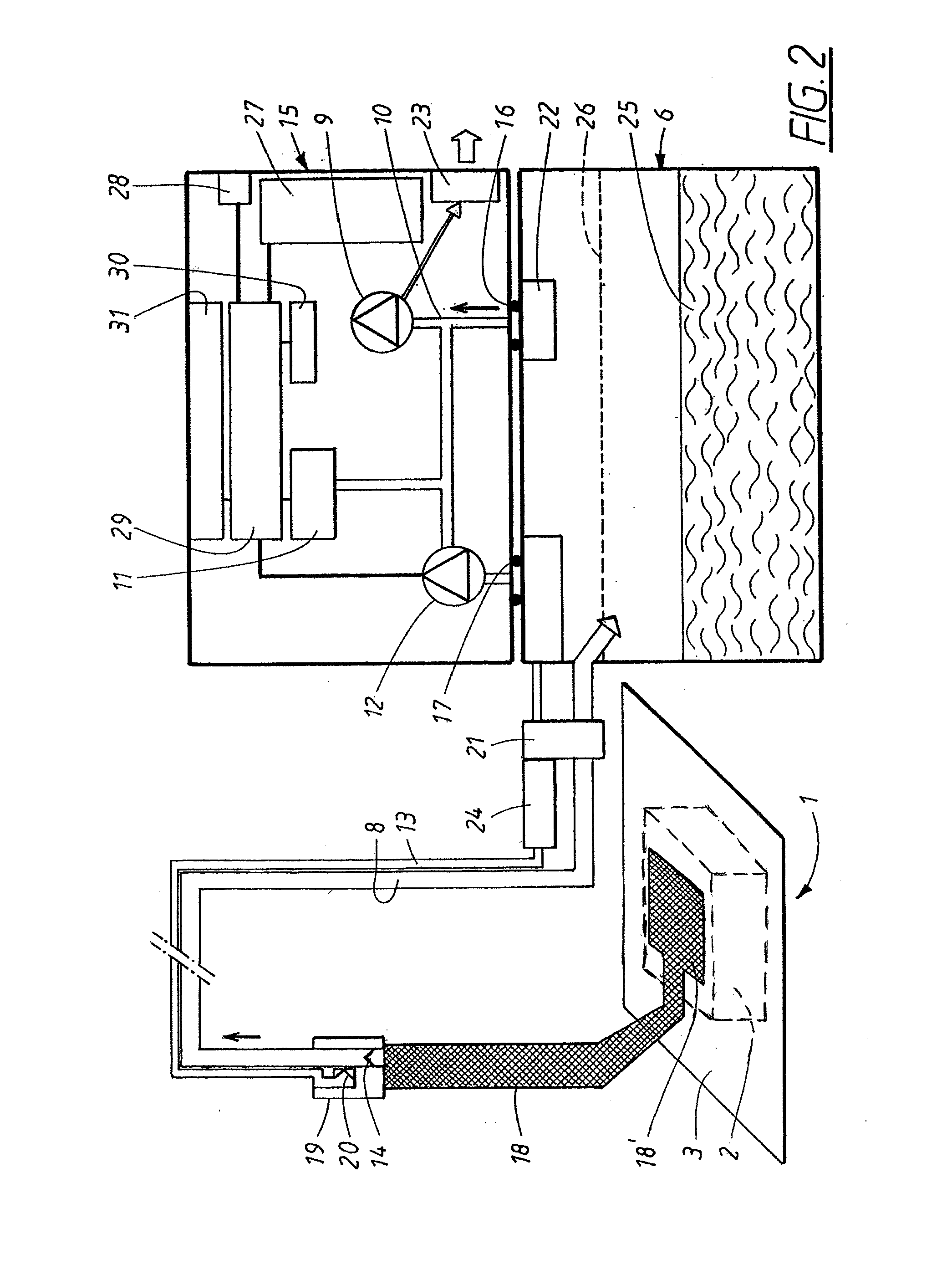

Apparatus and method for controlling the negative pressure in a wound

ActiveUS20120046625A1Sufficient energyRapid battery consumptionWound drainsIntravenous devicesBiomedical engineeringCatheter

Owner:MOLNLYCKE HEALTH CARE AB

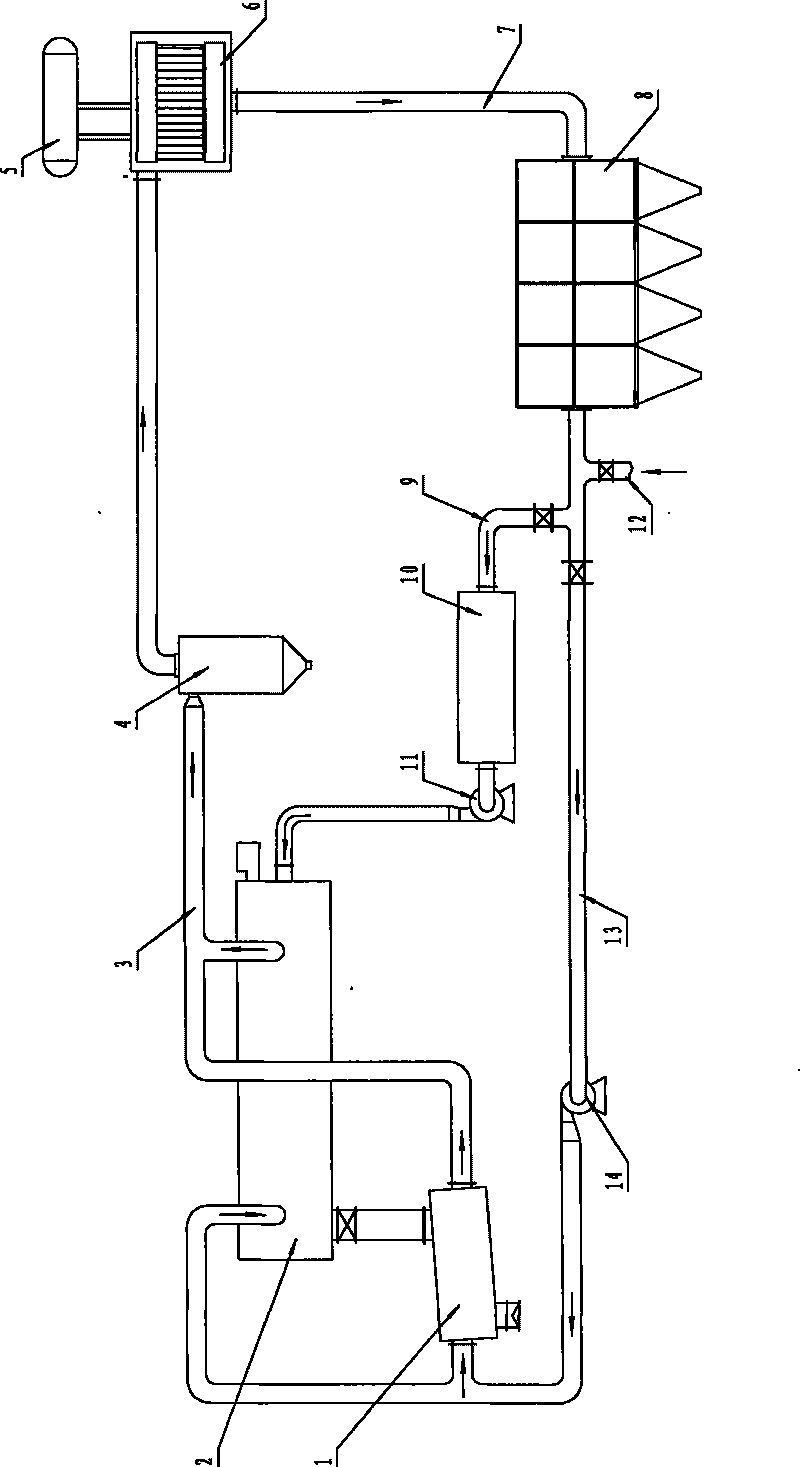

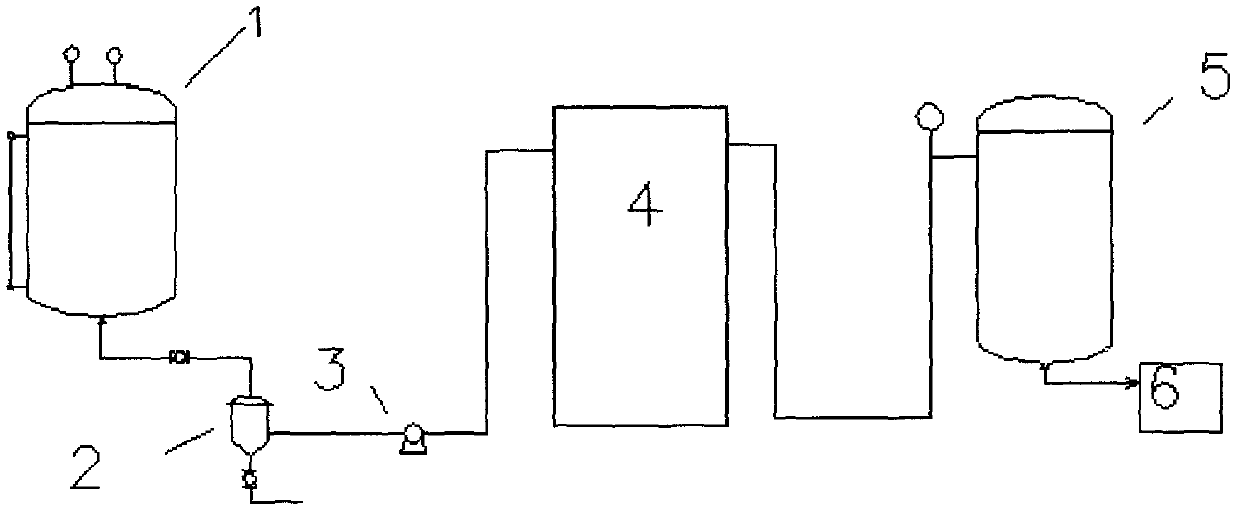

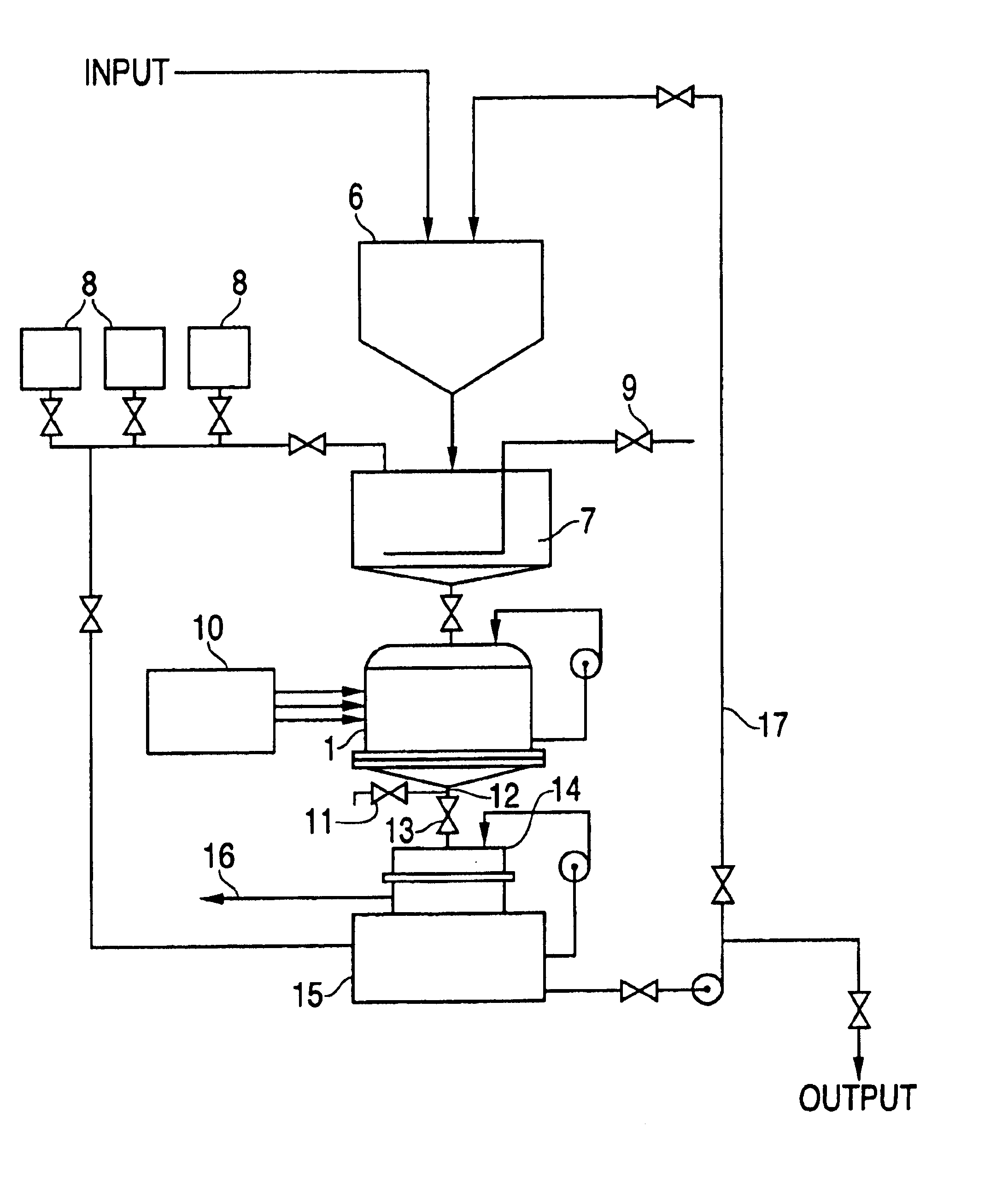

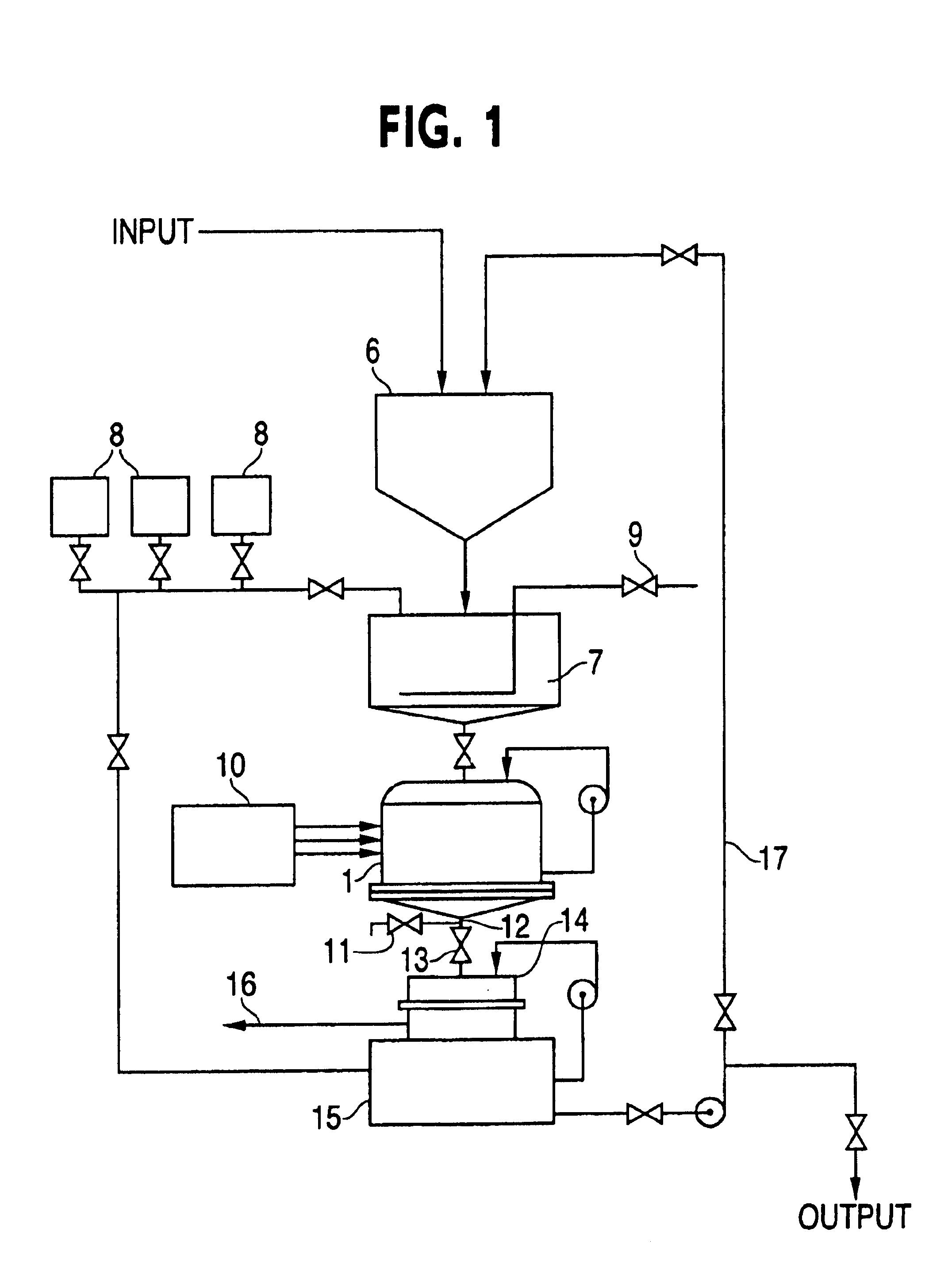

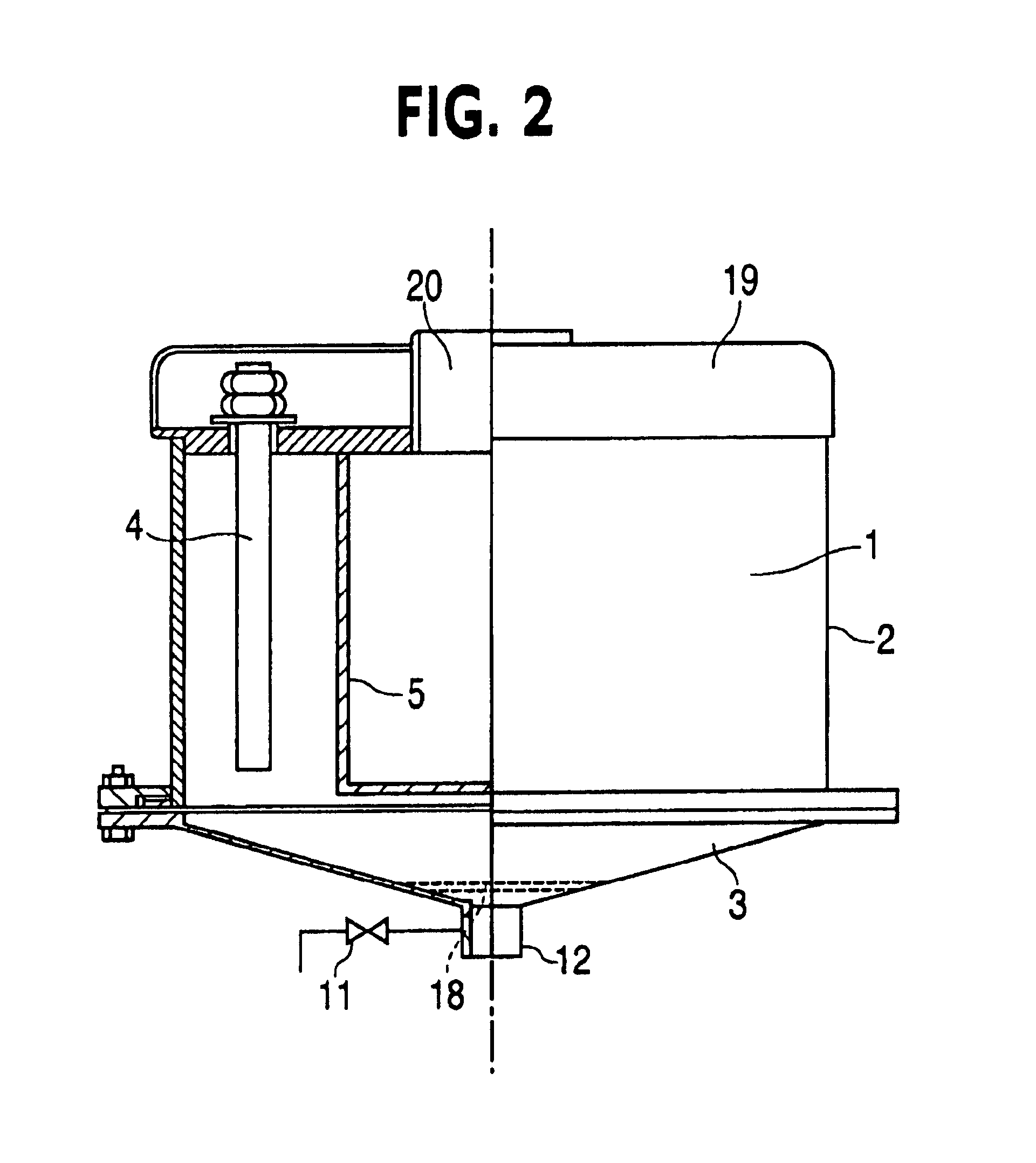

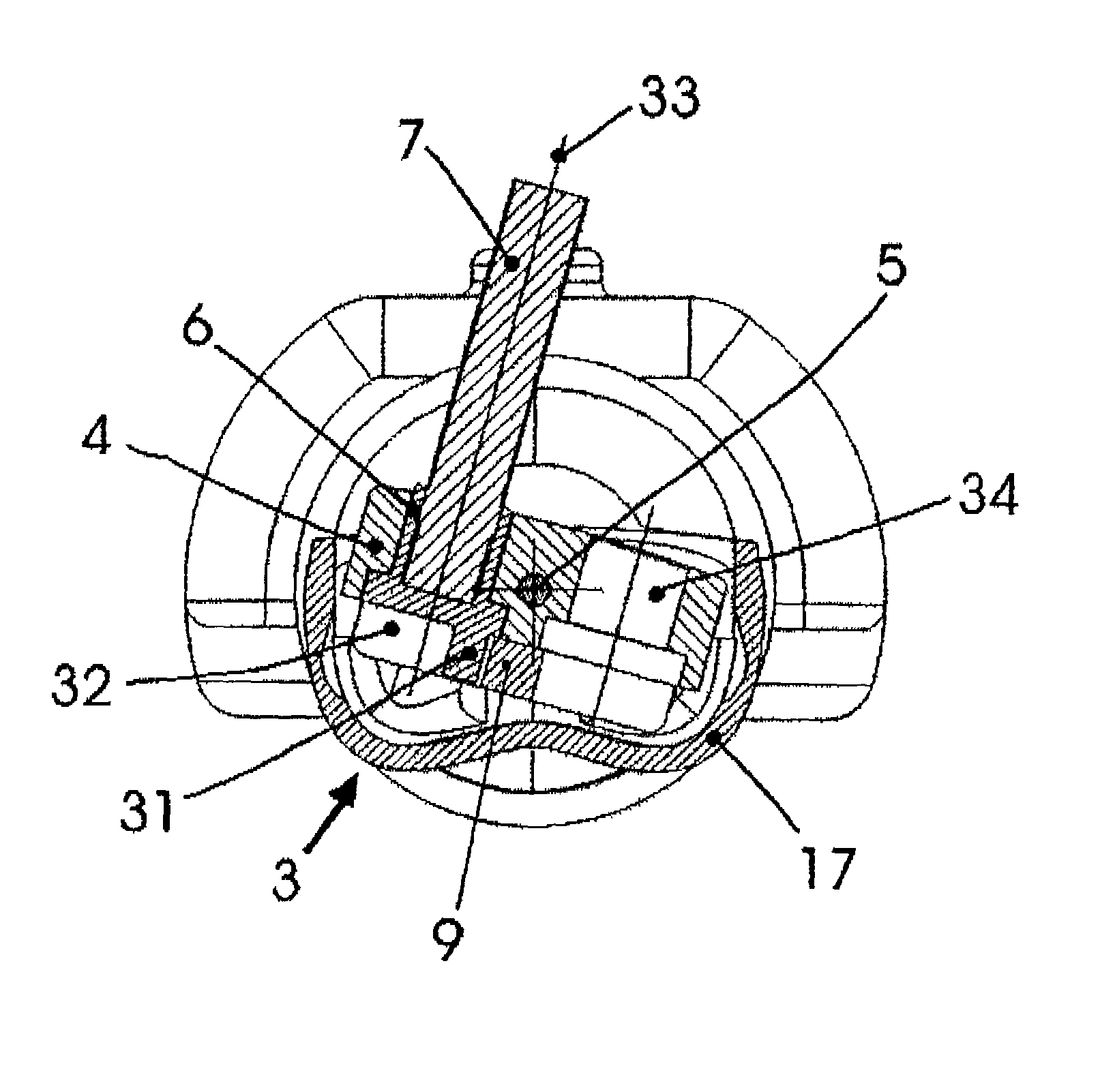

Process and device for processing liquid steel slag

ActiveCN101691620AImprove economic efficiencyReduce dust pollutionRecycling and recovery technologiesProcess efficiency improvementSlagLiquid steel

The invention provides a process and device for processing liquid steel slag, belonging to the technical field of the metallurgical equipment and aiming at solving the problems of liquid steel slag granulation and liquid steel slag sensible heat recovery. The process for processing the liquid steel slag comprises the following steps: a, granulating the liquid steel slag by quenching gas; b, cooling the high-temperature liquid solid steel slag; c, recovering liquid steel slag sensible heat; and d, reusing cooling gas. The invention also provides a device for processing liquid steel slag. The invention is mainly characterized in that firstly, the liquid steel slag is granulated in a sealed granulating tank, the liquid steel slag is small and uniform, the pure Fe in the liquid steel slag can not be oxidized and the economic benefit of the liquid steel slag processing process is improved; secondly, the liquid solid steel slag is cooled in a sealed cooling tank, less cooling gas leaks, the dust pollution is reduced, and less cooling gas is supplemented; and thirdly, the inert gas is used as the cooling gas in the granulating tank and the cooling tank, and the cooling gas inversely exchanges heat with the liquid steel slag, thus the efficiency of exchanging heat between the liquid steel slag and the cooling gas is improved, the temperature of the cooling gas at the outlet is increased, and the liquid steel slag sensible heat is recovered.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

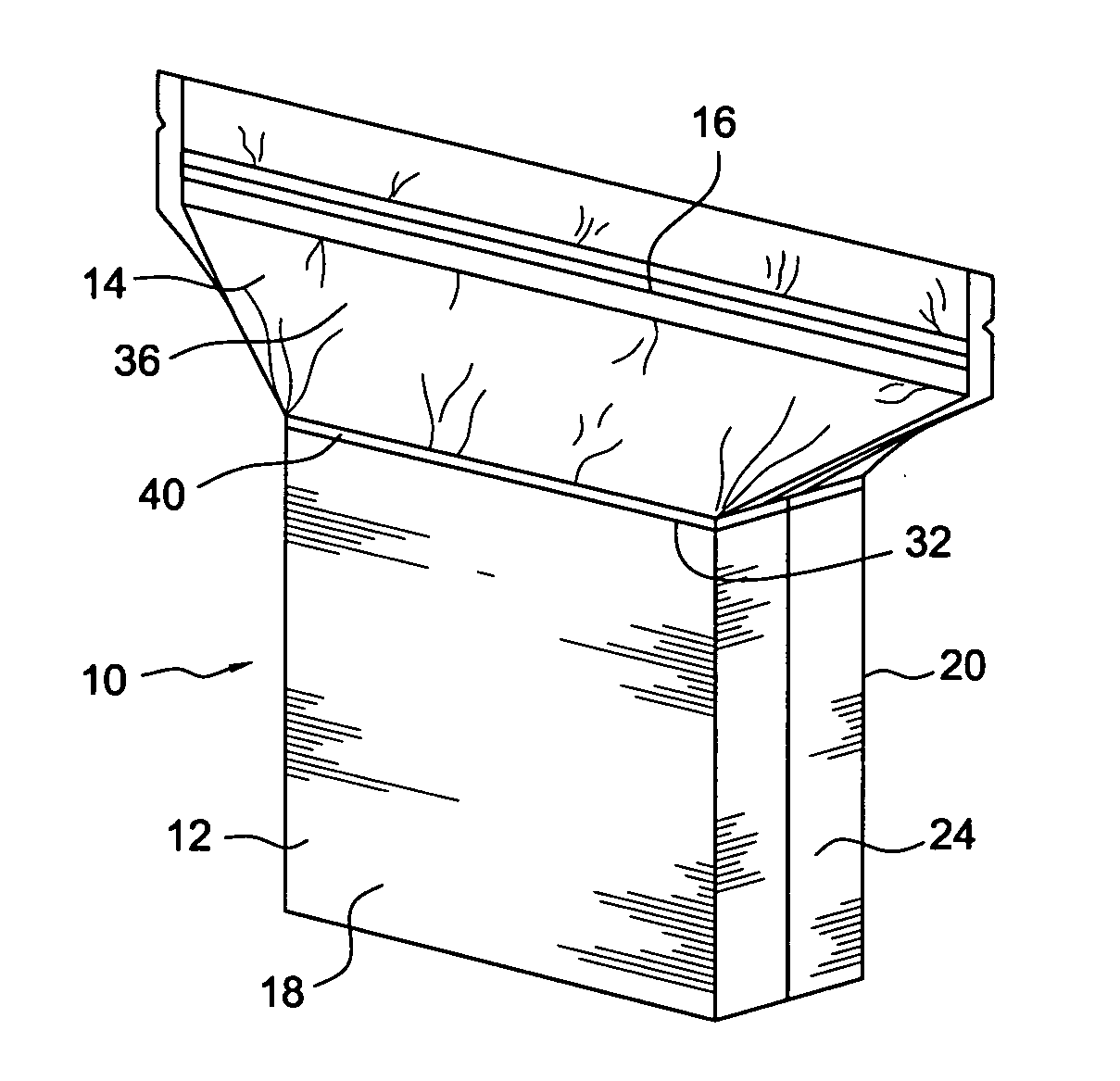

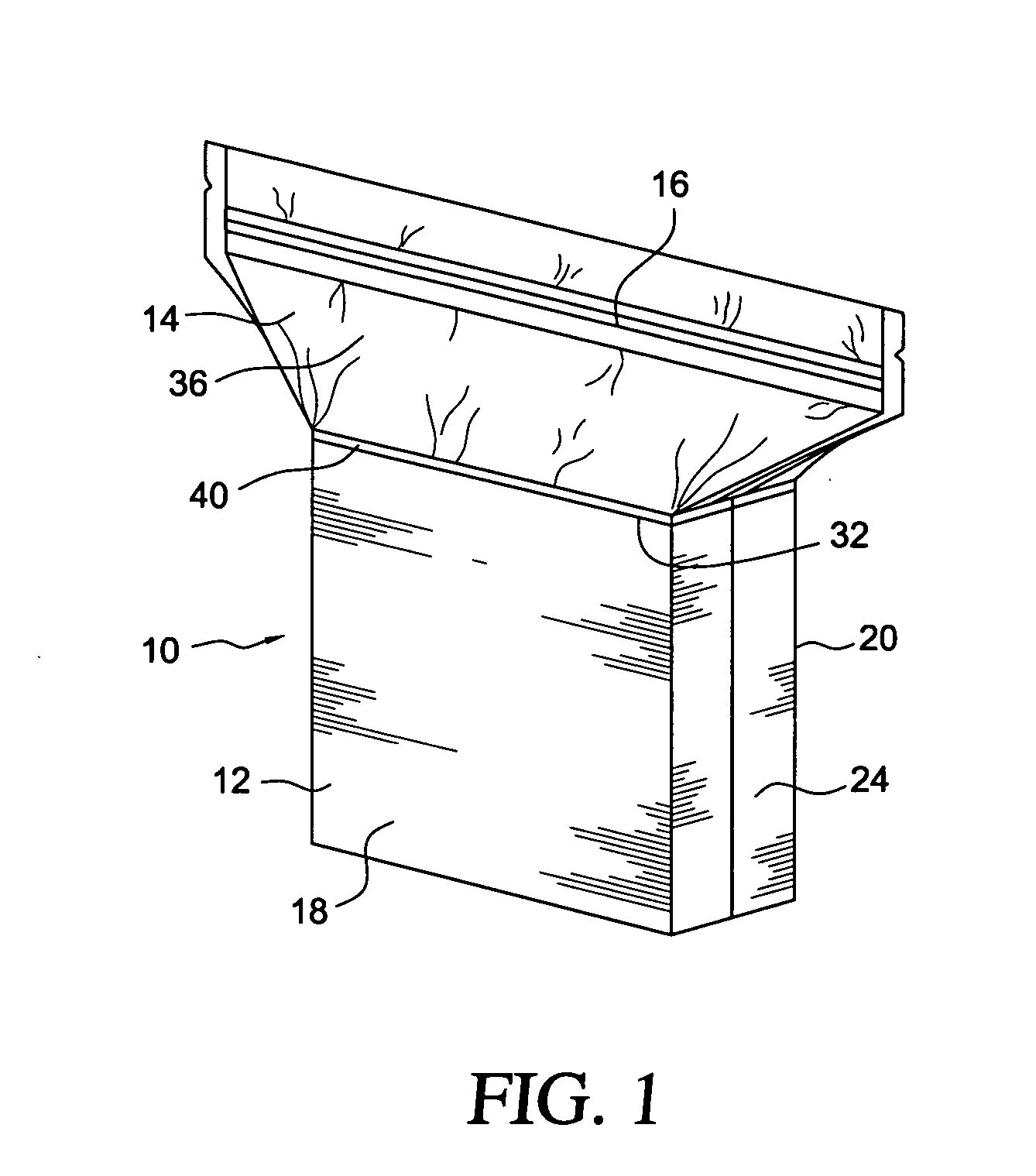

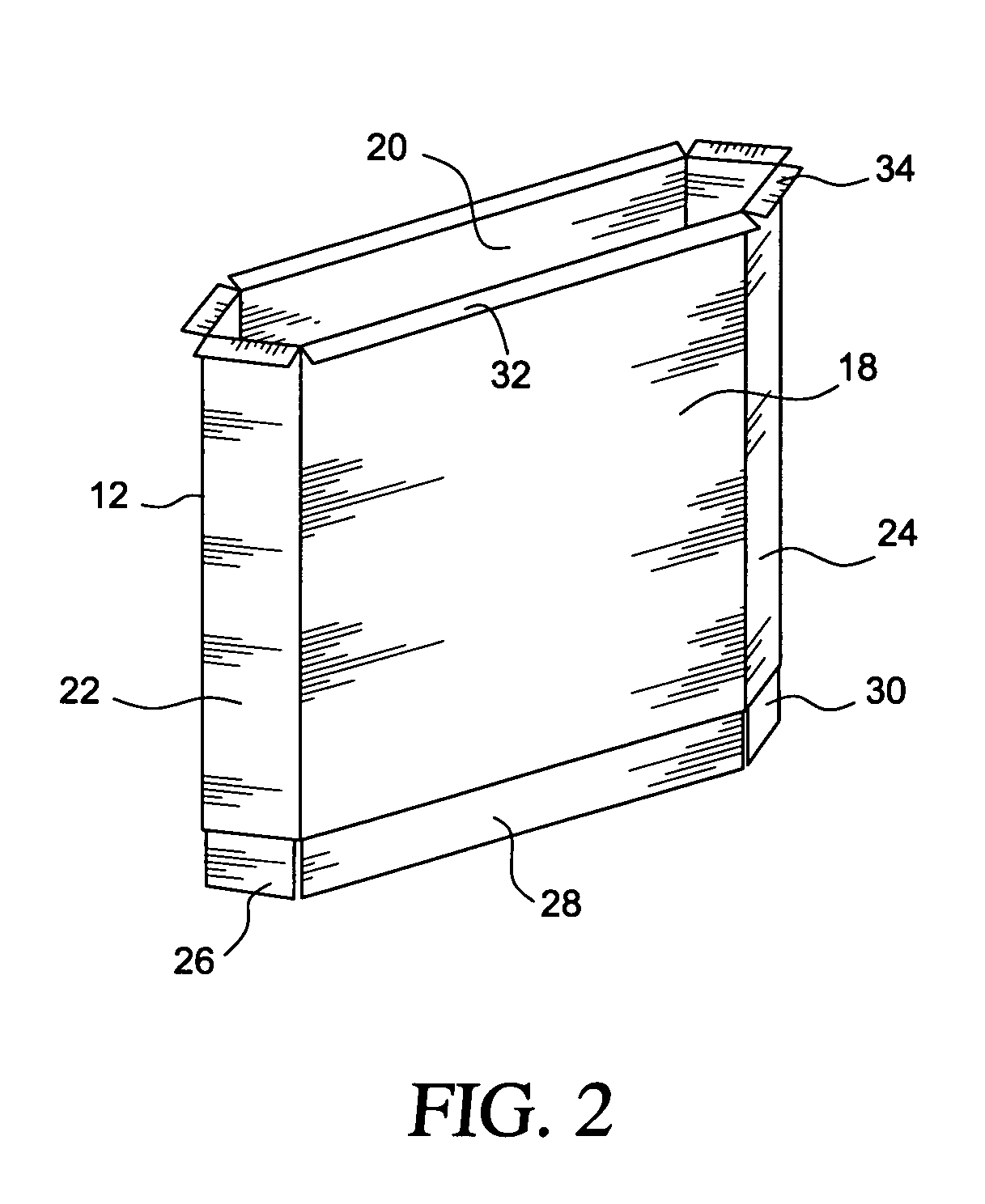

Combination container and bag

InactiveUS20110017812A1Many solutionsLess energy consumptionBoxes/cartons making machineryBag making operationsPaperboardCoating

Bag-on-container assemblies and bag-in-container assemblies are disclosed. The container may include a paperboard box having a front wall, a rear wall, a pair of opposed side walls, a plurality of flaps capable of forming a bottom wall and a plurality of flaps capable of forming a top wall. The inside surfaces of the box walls, including the outwardly facing strips, may have a thermal plastic coating thereon. The bag component of each type of assembly may include a closure member for to enable resealing of the bag component.

Owner:UNIVERSAL SYNERGETICS

Apparatus and method for controlling the negative pressure in a wound

ActiveUS20120184930A1Clear instructionsSufficient energyWound drainsMedical devicesPressure curveCirculating pump

An apparatus and method are provided for treating wound with negative pressure. The apparatus includes a wound cover, a first pump for providing said negative pressure at a chosen pressure level to the wound, a canister, a first conduit between the wound cover and the canister, first means for measuring the pressure within the canister, and a second conduit which connects the canister with the first pump. A circulating pump is arranged to intermittently transport a gas volume from the canister to the wound region via a third conduit and back to the canister via the first conduit in order to press out possible exudates from the first conduit to the canister. A second means analyzes the pressure curve over time of said pressure in the canister and a third means indicates by alarm when said pressure curve differs from a normal cyclical form.

Owner:MOLNLYCKE HEALTH CARE AB

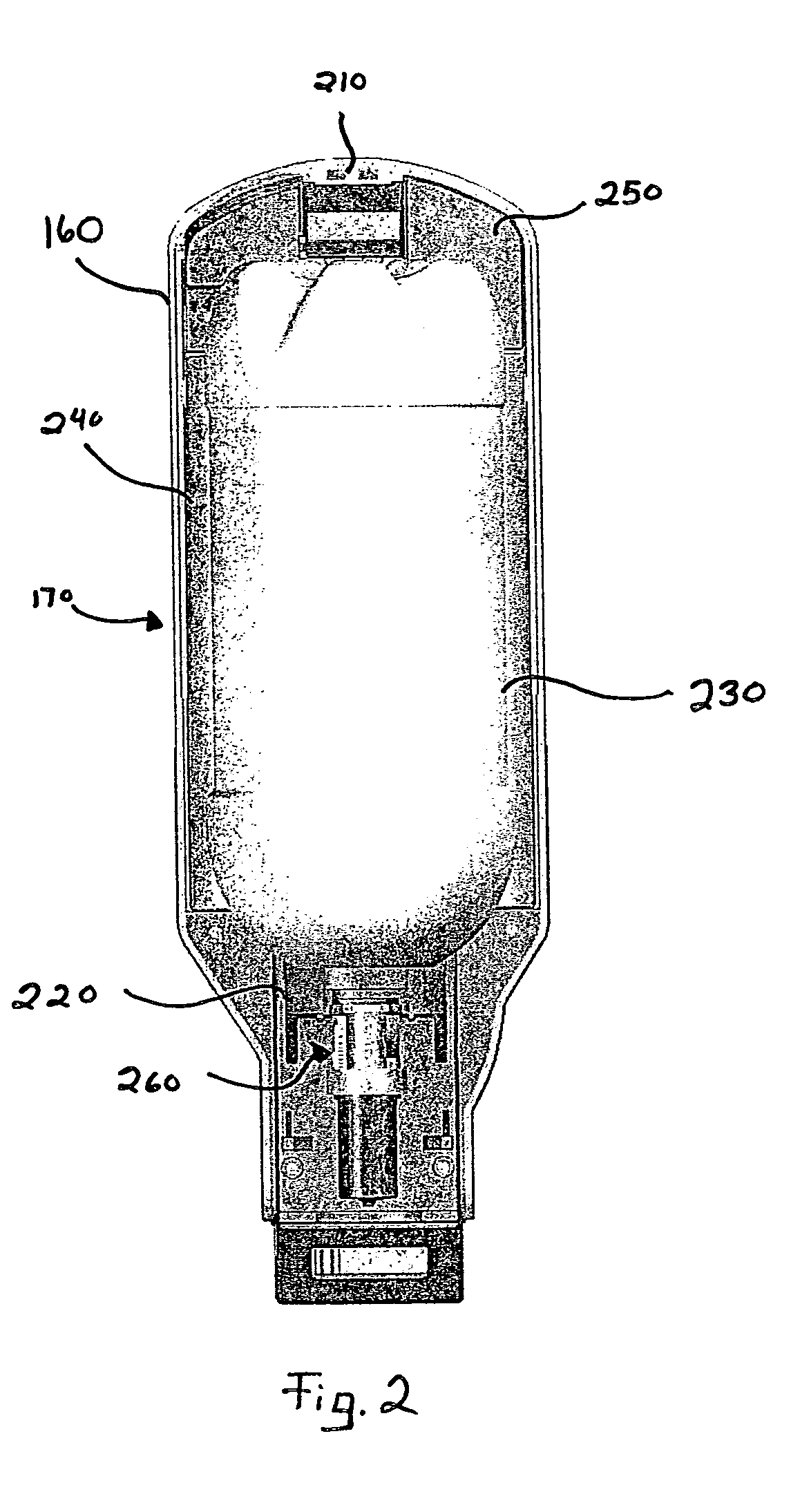

Apparatus and method for dispensing post-foaming gel soap

ActiveUS20050247735A1Less energy consumptionReduce supplyLarge containersHolders and dispensersPistonProduct gas

An apparatus for dispensing a post-foaming gel soap is disclosed. The dispenser includes a housing containing a first actuator and a second actuator. A motor is operatively connected to said first and second actuator. A circuit is connected to said motor, as well as a sensor assembly and a power supply. In operation, said first and second actuator moves a stem valve and a cylindrical pump located on a reservoir containing a gel soap and an inert propellant gas. The cylindrical pump operates on a piston principle and also closes to prevent any dripping after use. Further disclosed are various methods of accurately dispensing a consistent dose of gel soap.

Owner:RUBBERMAID COMMERCIAL PRODUCTS

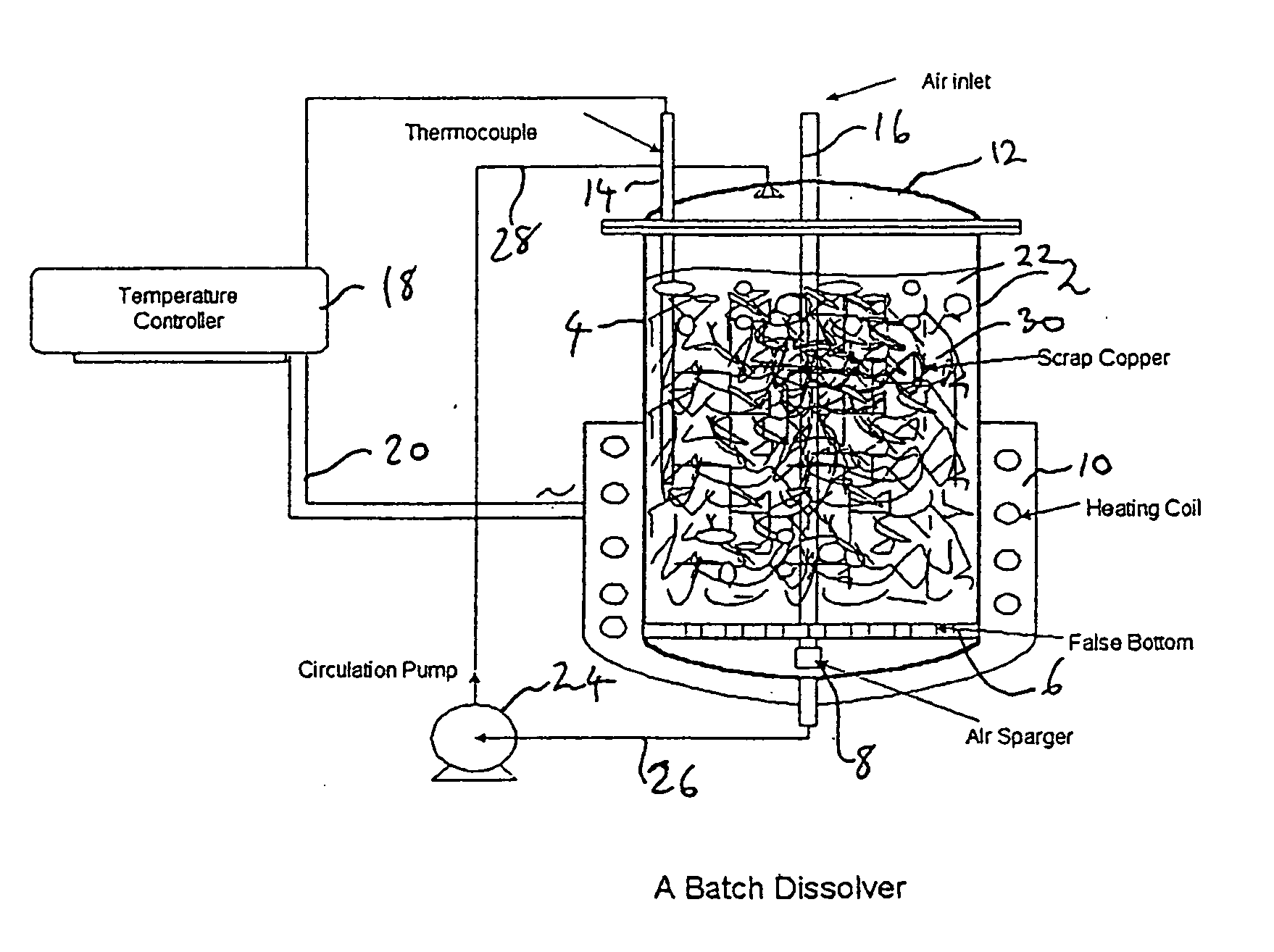

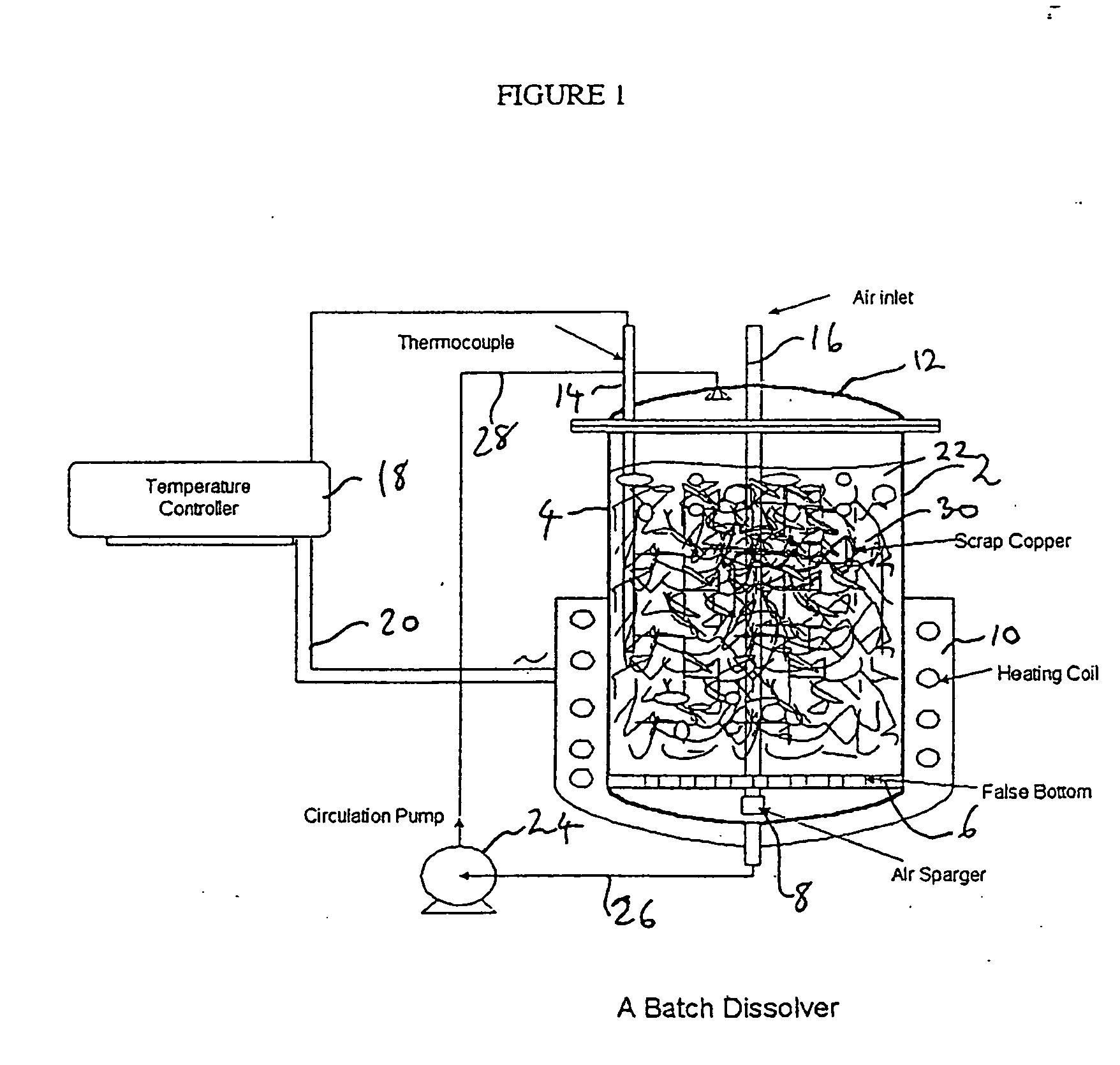

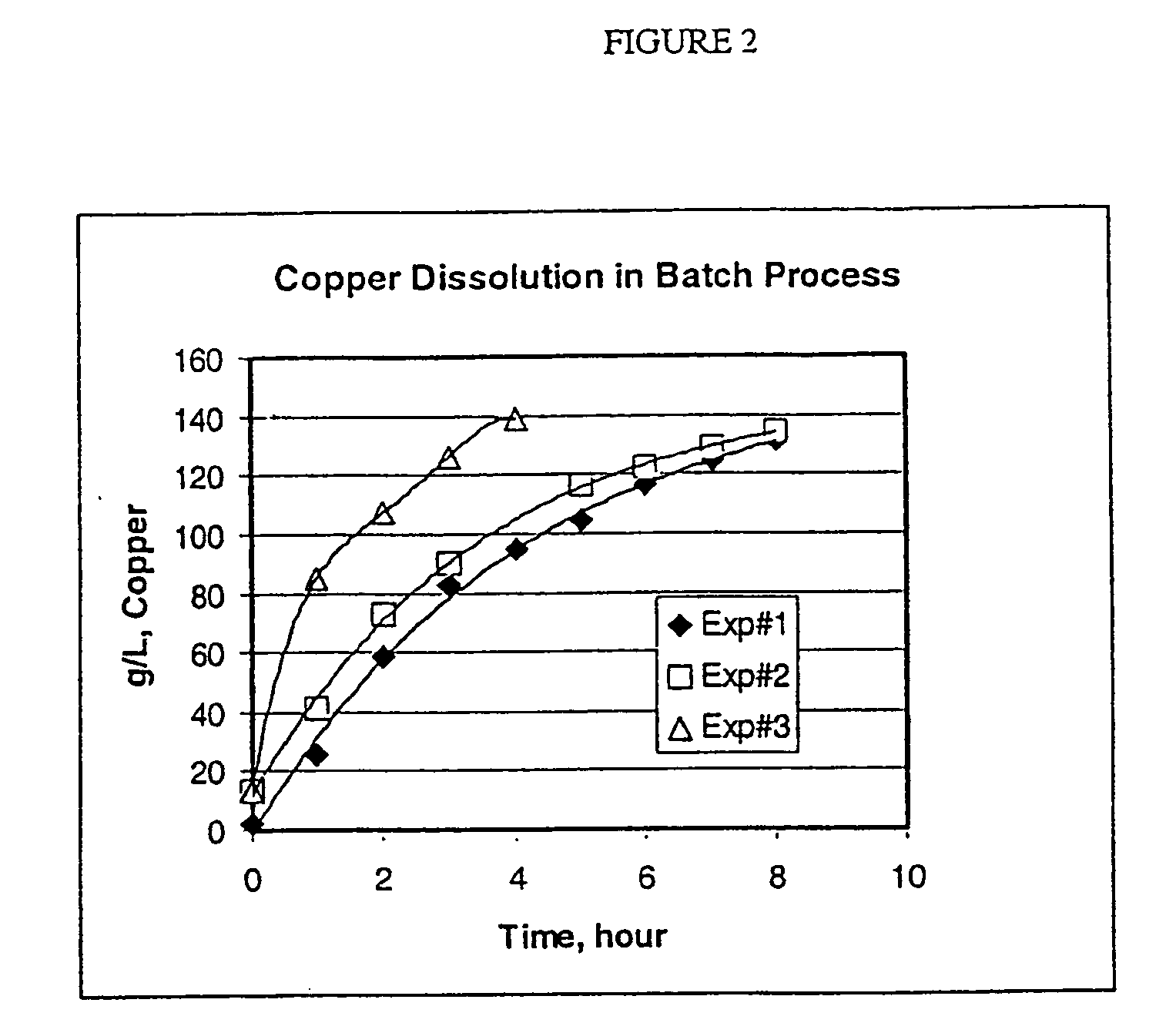

Process for the dissolution of copper metal

ActiveUS20050130866A1High initial dissolution rateShorten the timeGroup 1/11 element organic compoundsSolvent extractionGramEquivalent weight

Process for producing a copper-containing aqueous solution, in which a copper mass is dissolved in the presence of air in an aqueous leach liquor containing monoethanolamine and an acid, wherein the amount of acid equivalents is between 0.05 and about 0.7 times the equivalents of monoethanolamine, and wherein the rate of copper dissolution into the aqueous leach liquor is greater than about 4.3 grams of copper per liter of leach liquor per hour until a product having at least about 80 grams per liter is obtained.

Owner:KOPPERS PERFORMANCE CHEM

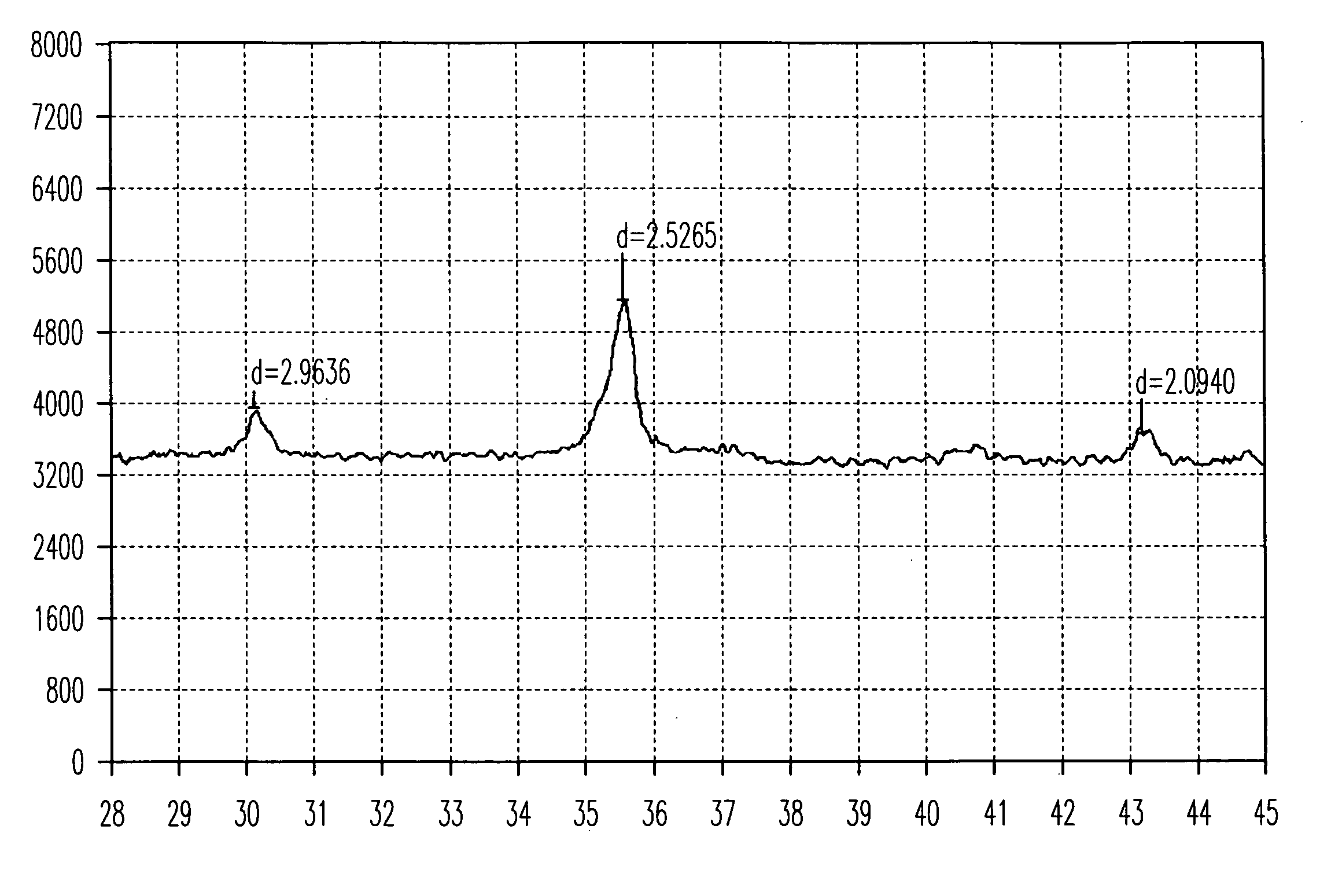

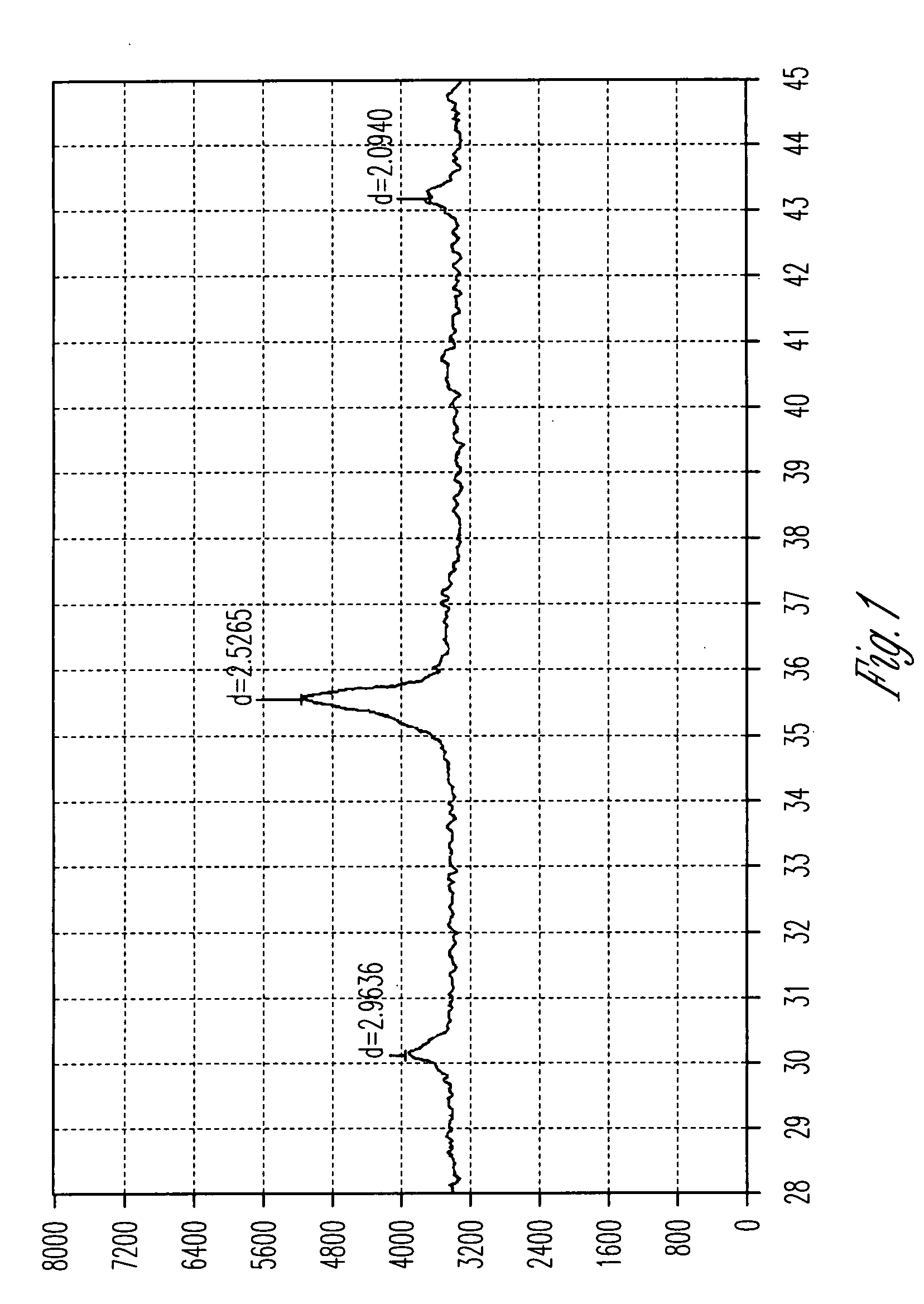

Composition for a desulfurizer with a high sulfur capacity and the process of making the same

ActiveUS20080047395A1Quality improvementEasy to operateGas treatmentBlast furnace componentsActive componentLiquid state

The present invention discloses a composition for a desulfurizer with a high sulfur capacity and a process for making the same. The composition comprises the active components of three kinds of iron oxides and is used in the desulfurizer to remove hydrogen sulfide from the gaseous and liquid state feed stocks. The above-mentioned composition comprises cubic ferroferric oxide in the form of crystalline phase (Fe3O4), amorphous ferric oxide (Fe2O3) and amorphous ferric oxide monohydrate (Fe2O3.H2O). The composition has a sulfur capacity of at least 40%. The process for preparing the composition comprises the following steps: (1) mixing a solid ferrous compound with a solid hydroxide at a molar ratio of iron to hydroxyl being in the range from 1:2 to 1:3; (2) kneading the mixture feeds obtained in step (1) and making them react completely; (3) drying the products obtained in step (2) in the air; (4) washing and filtering the feeds obtained in the step (3); (5) naturally drying or baking the solids obtained in step (4) to form a composition for a desulfurizer with a high sulfur capacity. The process of the present invention is simple and easy to operate, consumes less energy and produces the products with a stable quality.

Owner:BEIJING HAIXIN ENERGY TECH CO LTD

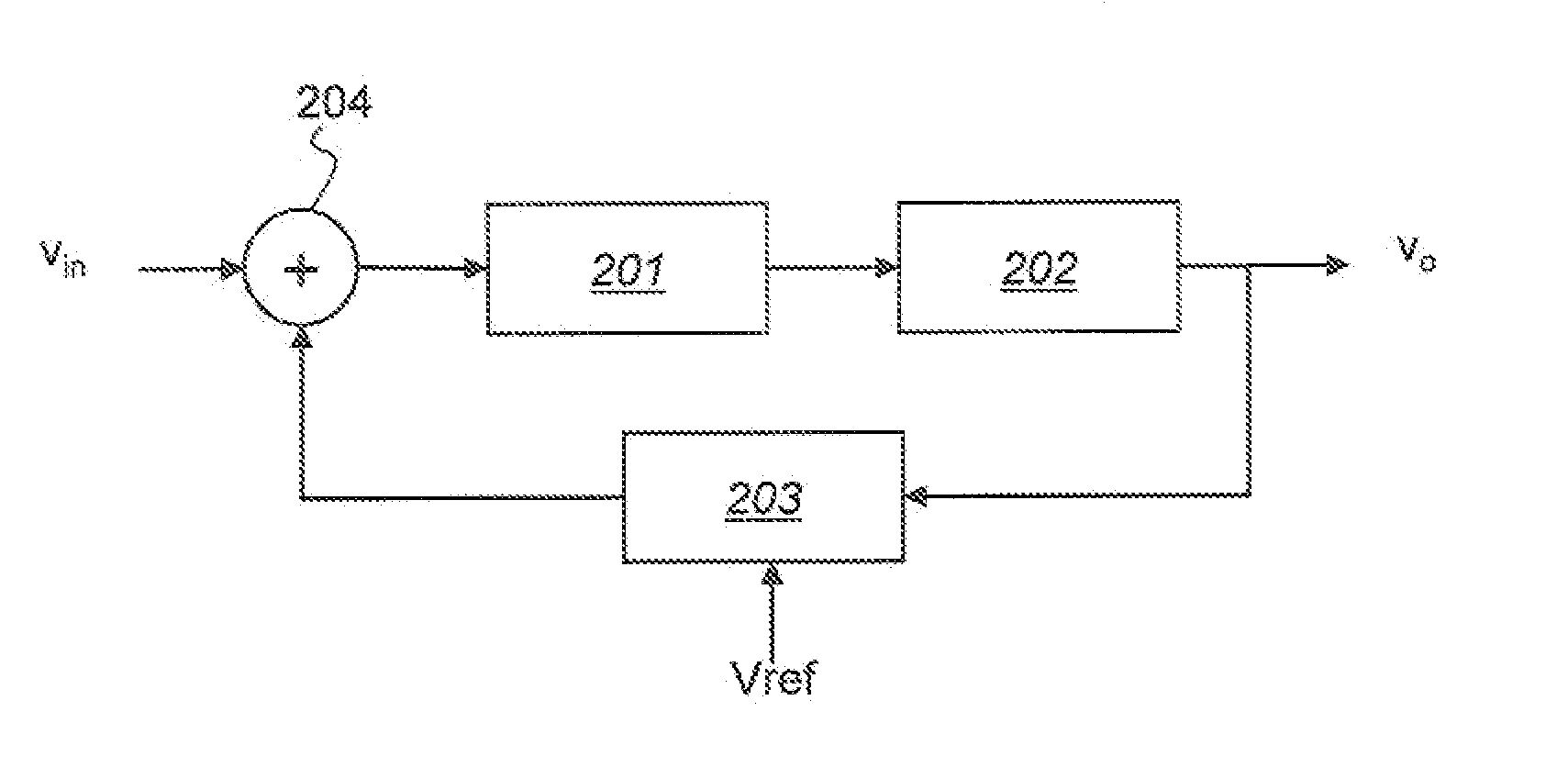

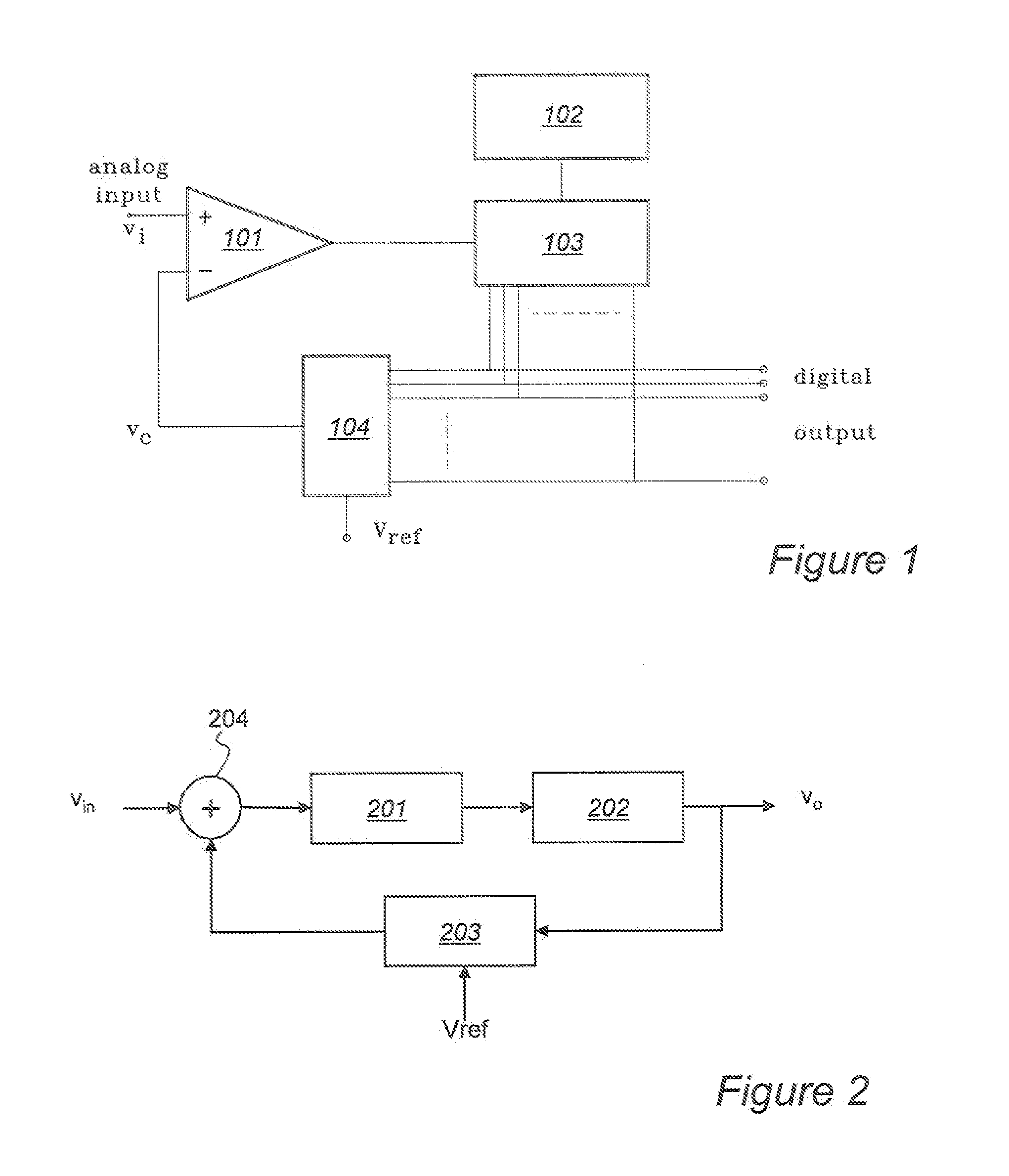

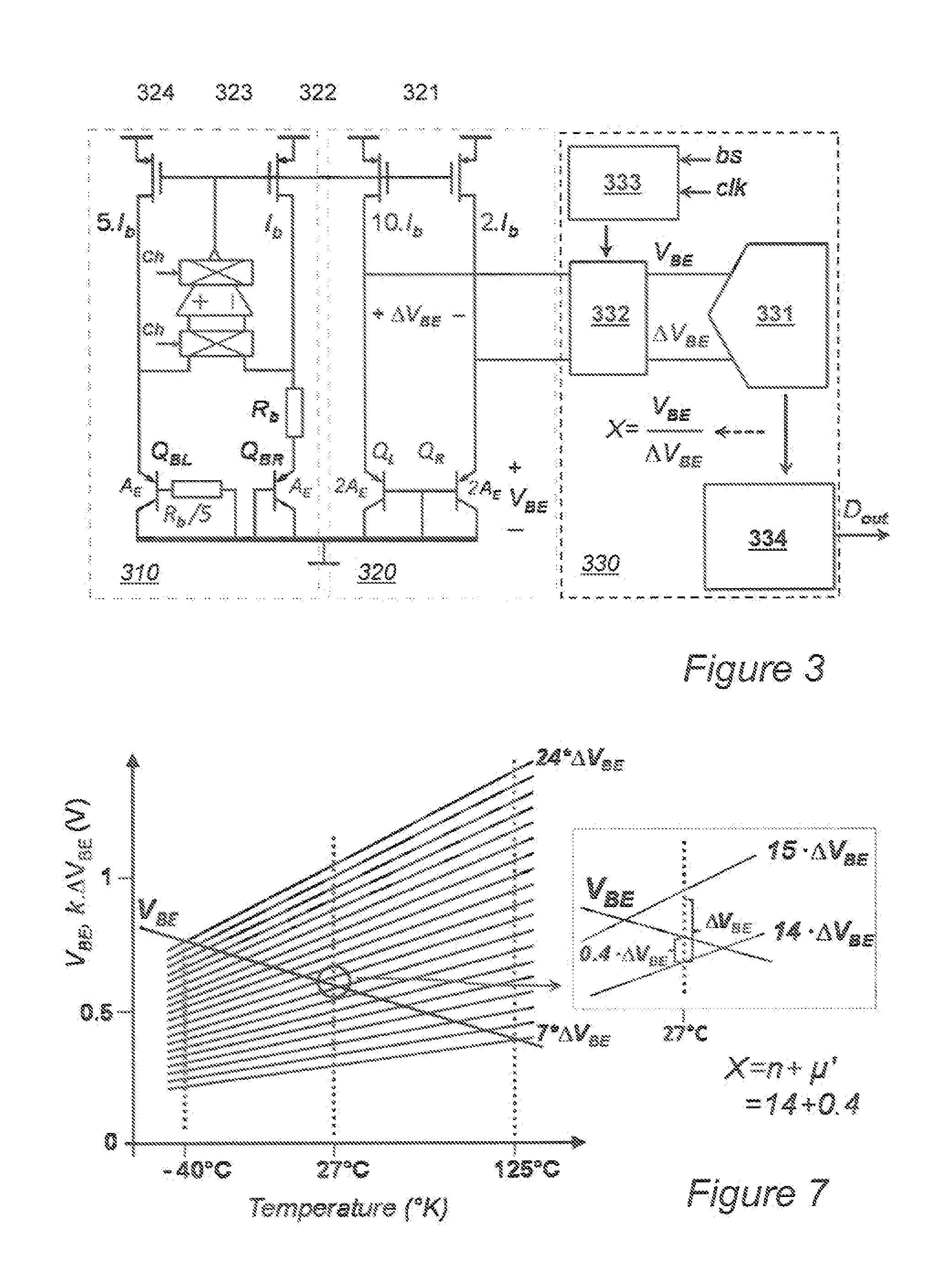

Adc, a temperature sensor, a non-contact transponder, and a method of converting analog signals to digital signals

ActiveUS20110200070A1Small coverageWithout an undue burden of time (and thus energy)Thermometer detailsThermometer with A/D convertersVIT signalsGreek letter sigma

An ADC is disclosed which has, as a first stage, a successive approximation converter, or other compensated, direct comparison converter, followed by a sigma delta modulation converter as a second stage. The sigma delta converter may beneficially be a first order modulator. The resulting ADC combines accuracy with low power consumption per conversion, and thus is particularly suited for use in temperature sensors for applications such as RFID transponders. Such a temperature sensor and an RFID transponder are also disclosed. There is also disclosed a method of analog-to-digital conversion, comprising a first successive approximation register or other compensated, direct comparison conversion stage followed by a sigma delta modulation stage, which, further, may be combined with providing a proportional-to-absolute-temperature (PTAT) signal, for low-power, accurate temperature sensing.

Owner:NXP BV

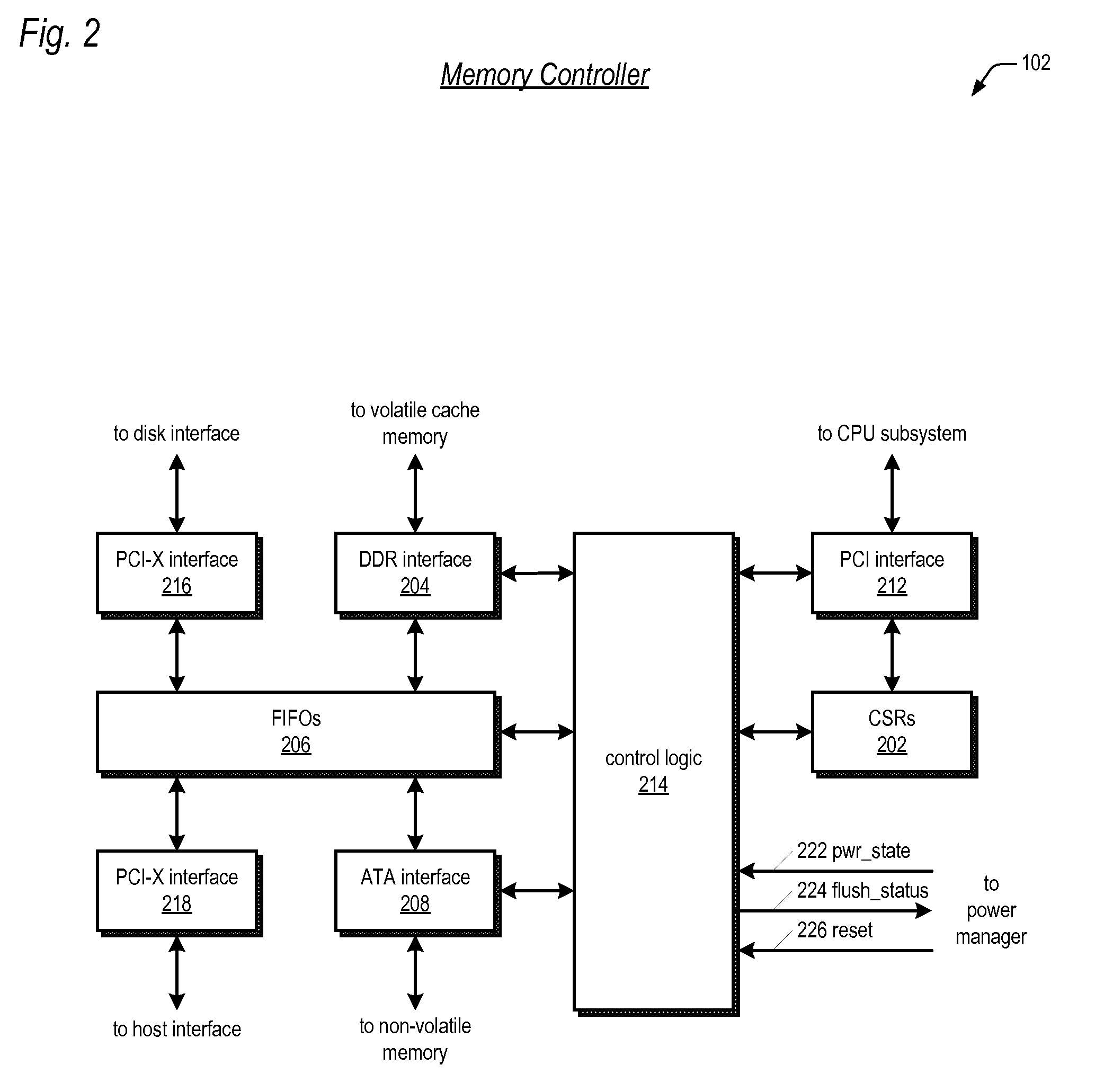

Raid controller using capacitor energy source to flush volatile cache data to non-volatile memory during main power outage

ActiveUS20080215808A1Reduces amount of energy storage capacity requirementLess expensiveEnergy efficient ICTError detection/correctionRAIDMemory controller

A write-caching RAID controller includes a CPU that manages transfers of posted-write data from host computers to a volatile memory and transfers of the posted-write data from the volatile memory to a redundant array of storage devices when a main power source is supplying power to the RAID controller. A memory controller transfers the posted-write data received from the host computers to the volatile memory and transfers the posted-write data from the volatile memory for transfer to the redundant array of storage devices as managed by the CPU. The memory controller flushes the posted-write data from the volatile memory to the non-volatile memory when main power fails, during which time capacitors provide power to the memory controller, volatile memory, and non-volatile memory, but not to the CPU, in order to reduce the energy storage requirements of the capacitors. During main power provision, the CPU programs the memory controller with information needed to perform the flush operation, such as the location and size of the posted-write data in the volatile memory and various flush operation characteristics.

Owner:DOT HILL SYST

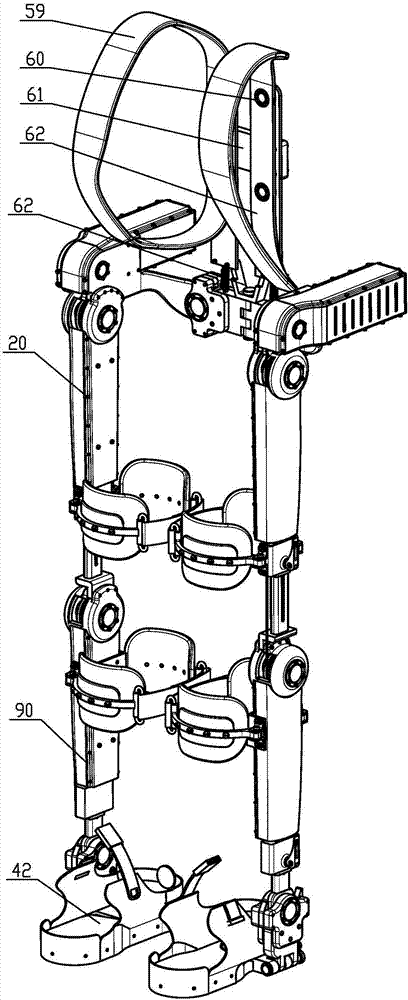

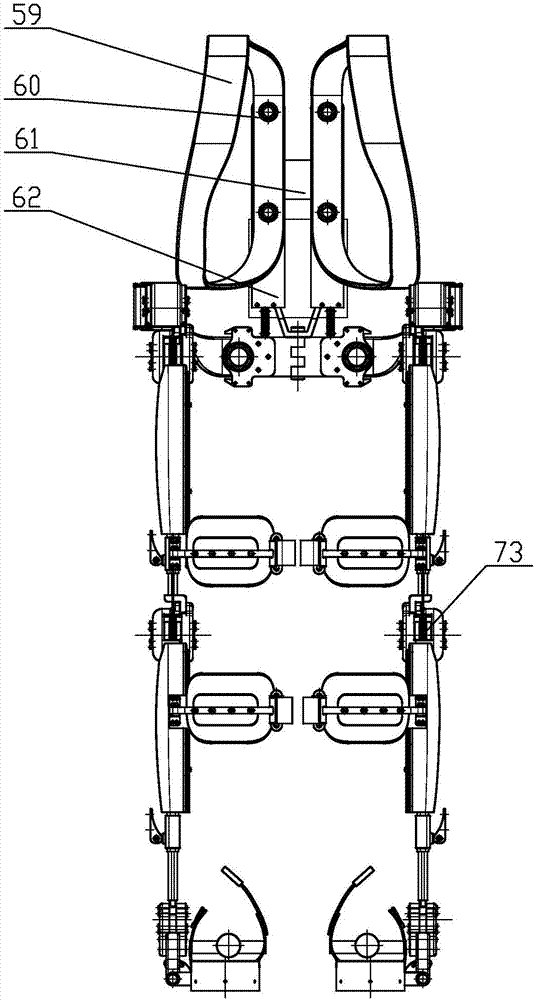

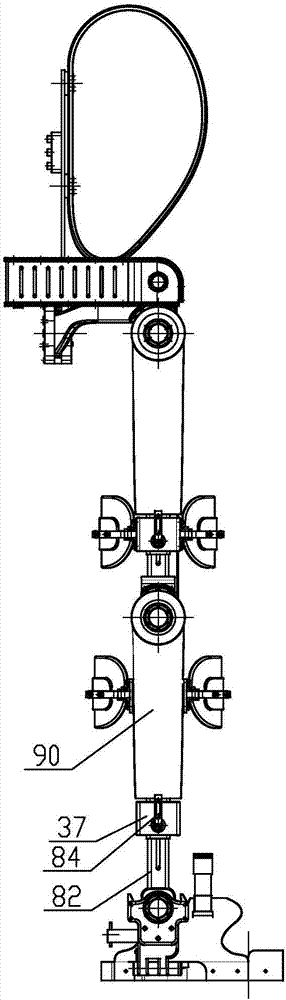

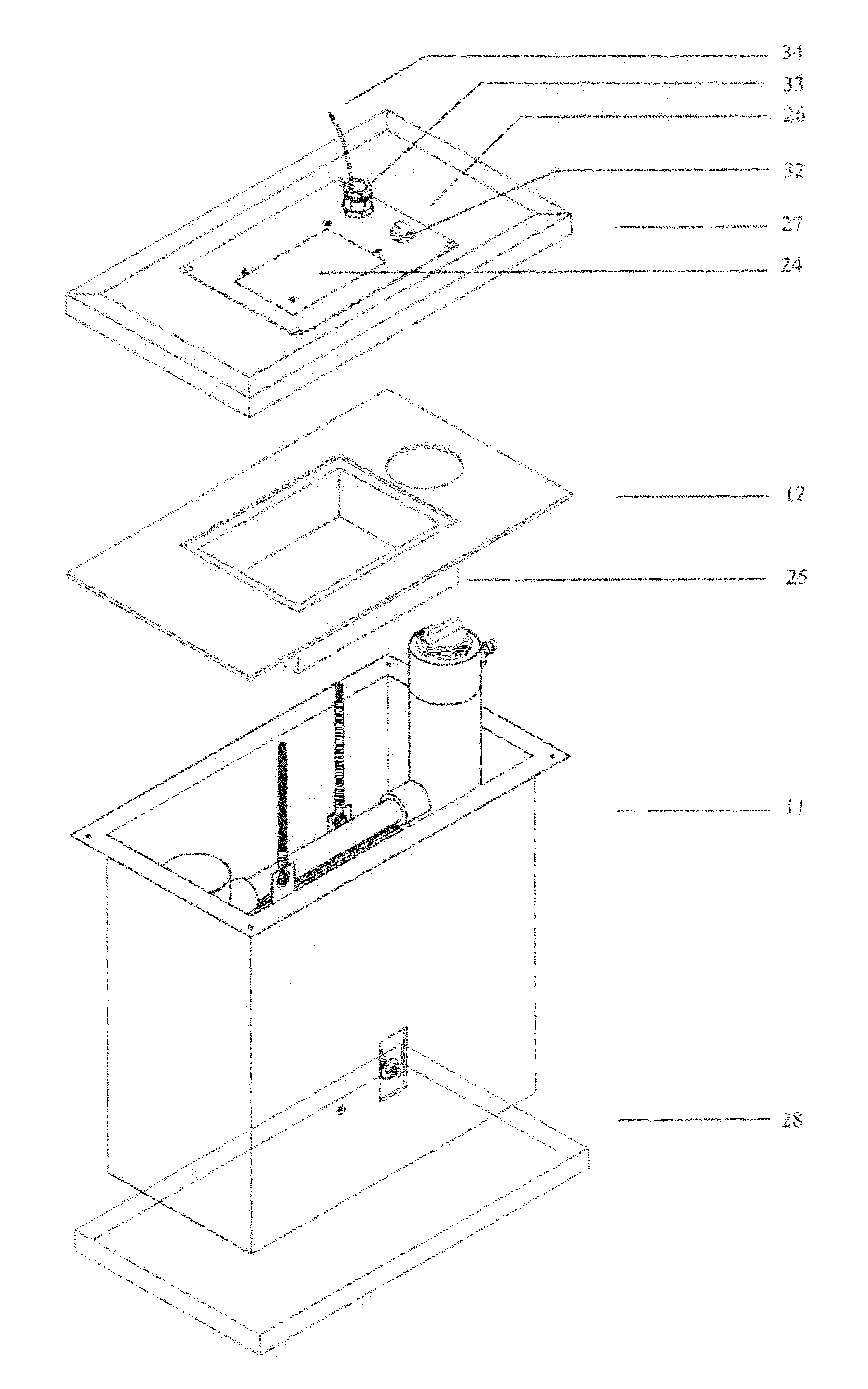

Underactuated lower limb assistance exoskeleton robot based on rope-pulley mechanism

ActiveCN107137207AReduce consumptionReduce the numberProgramme-controlled manipulatorChiropractic devicesExoskeleton robotCoxal joint

The invention provides an underactuated lower limb assistance exoskeleton robot based on a rope-pulley mechanism, and relates to an underactuated lower limb assistance exoskeleton robot. The robot aims to solve the problems that a prior active joint-driving exoskeleton has large self-mass, large drive energy consumption, and a passive joint exoskeleton cannot provide effective assistance. The robot comprises a harness device, a drive control power system, two thigh bar devices, two leg bar devices, two ankle devices, two drive devices and two strings; wherein each drive device includes a motor shell bracket, a first motor shell, a waist frame, a planetary reducer, a second motor shell, a servo motor, a third motor shell, a hip joint spline shaft, a drive pulley, an elastic actuator, a first shaft sleeve, a small bevel gear, a large bevel gear, a second shaft sleeve, a fourth motor shell, a fifth motor shell, a sixth motor shell, a fixing plate and two first bearing end covers with bearings. The underactuated lower limb assistance exoskeleton robot based on the rope-pulley mechanism is used for the field of assistance exoskeleton robots.

Owner:HARBIN INST OF TECH

On demand hydrogen enhancement system for internal and external combustion engine

InactiveUS20100206721A1Increased flame speedImprove performanceCellsInternal combustion piston enginesExternal combustion engineInternal combustion engine

The objective of this invention, on demand hydrogen enhancement system for internal and external combustion engine, is to develop a continuous non pressurized water electrolyzer from clean water (not pure water or distil water) generator system. The mixed hydrogen gas and oxygen gas called “Oxyhydrogen”. Oxyhydrogen use as catalyse for internal and external combustion engine to increase fuel flame speed. It can use with variety fuels such as Ethanol, Methanol, Gasohol, Gasoline, Diesel, Bio Diesel, LPG, CNG, and LNG. This system can reduce fuel consumption, increase fuel efficiency, increase torque, reduce emissions, and reduce engine temperatures. The system required no cooling fan and electrolytic solution circulating pump. The system has less heat loss and very low electrical consumption. Oxyhydrogen will produce on demand as the engine RPM and load of generator. The control unit detects signal frequency from the alternator. Gas production rate low at low RPM and use less current and gas production will high at high RPM and use higher current. This can save lot of energy for the electrolysis process. In the past, water electrolysis use direct current (D.C.). In this invention the inventor uses D.C. with Frequency Modulate (FM) pulse width modulator (PWM) instead of Amplitude Modulator (AM) to control the electrolyzer (FMPWM). This circuit had current detector for automatic current adjustment and over current protection.

Owner:SNIDVONGS SURAVUT

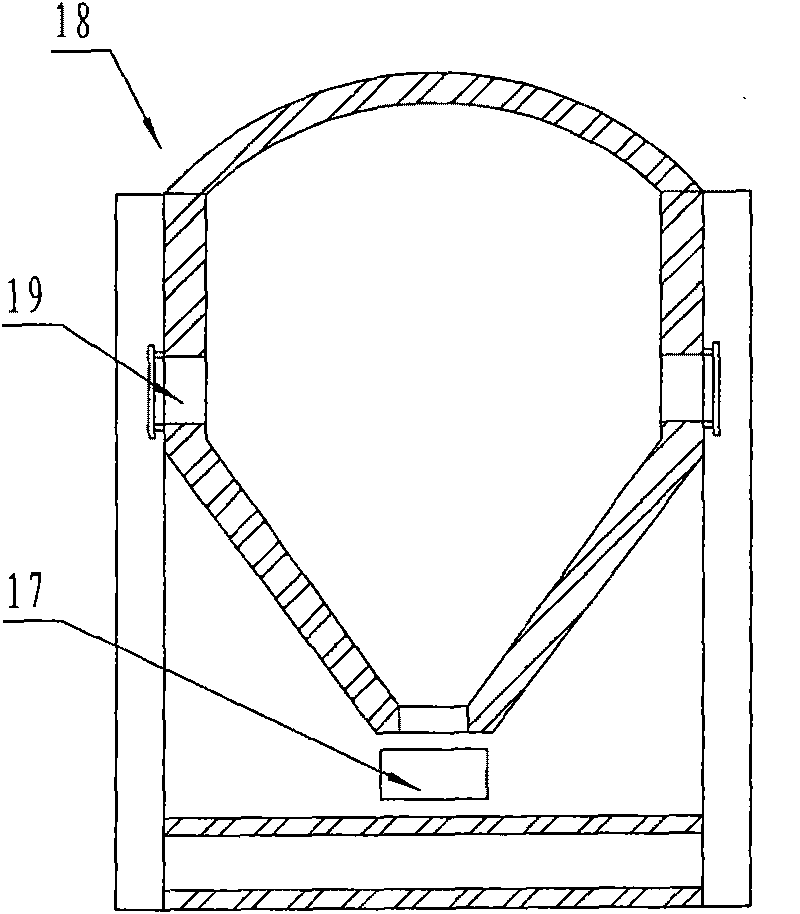

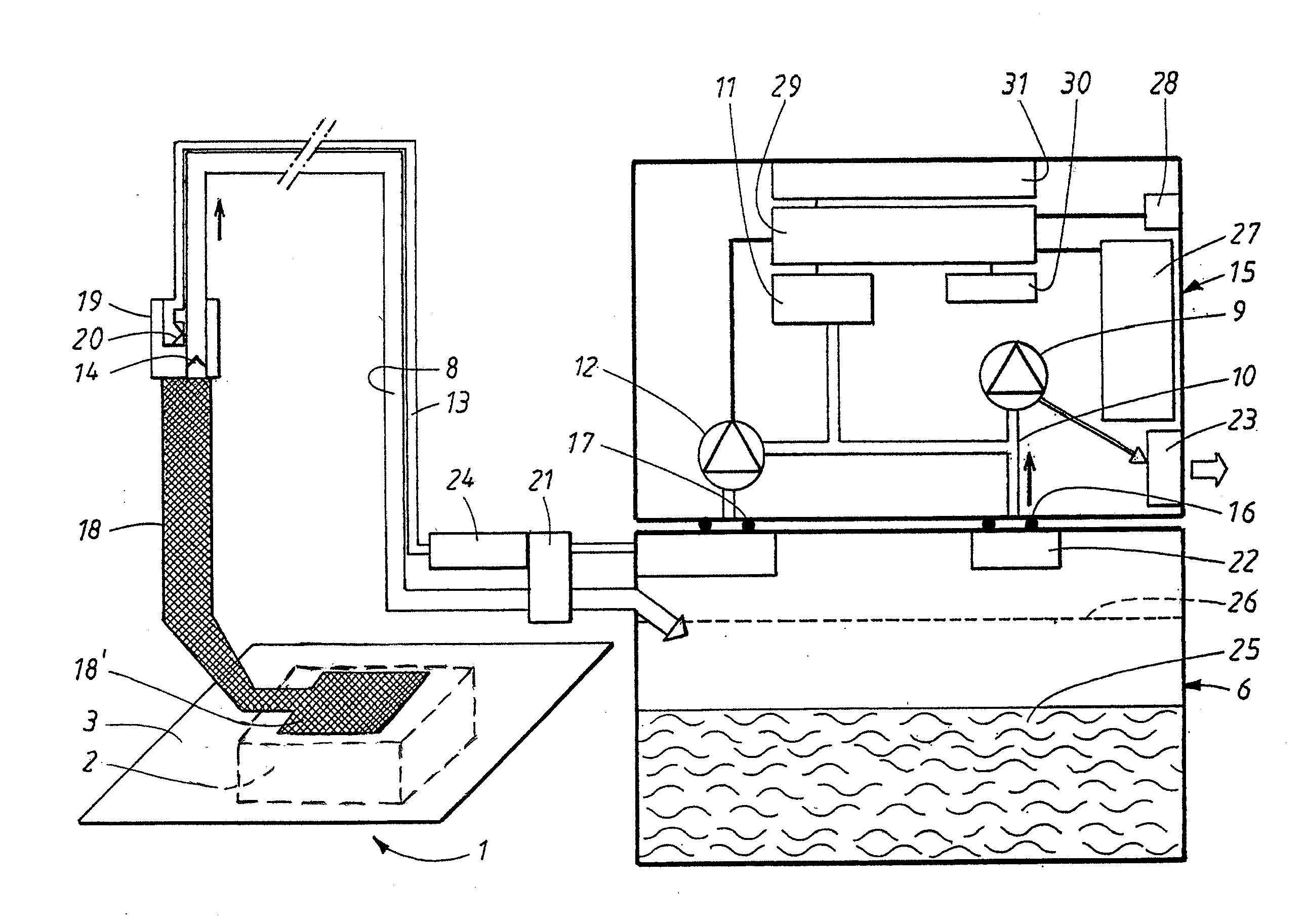

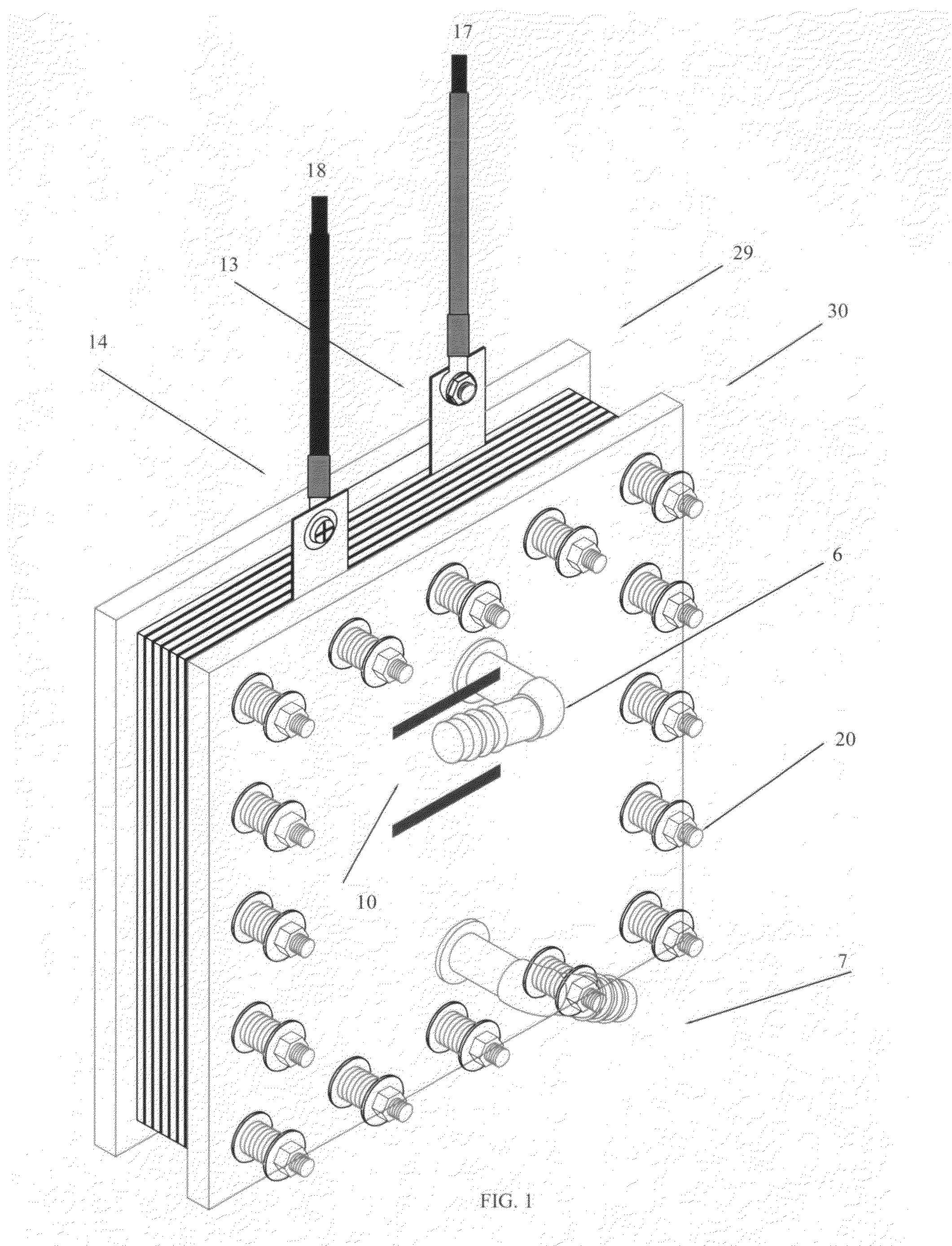

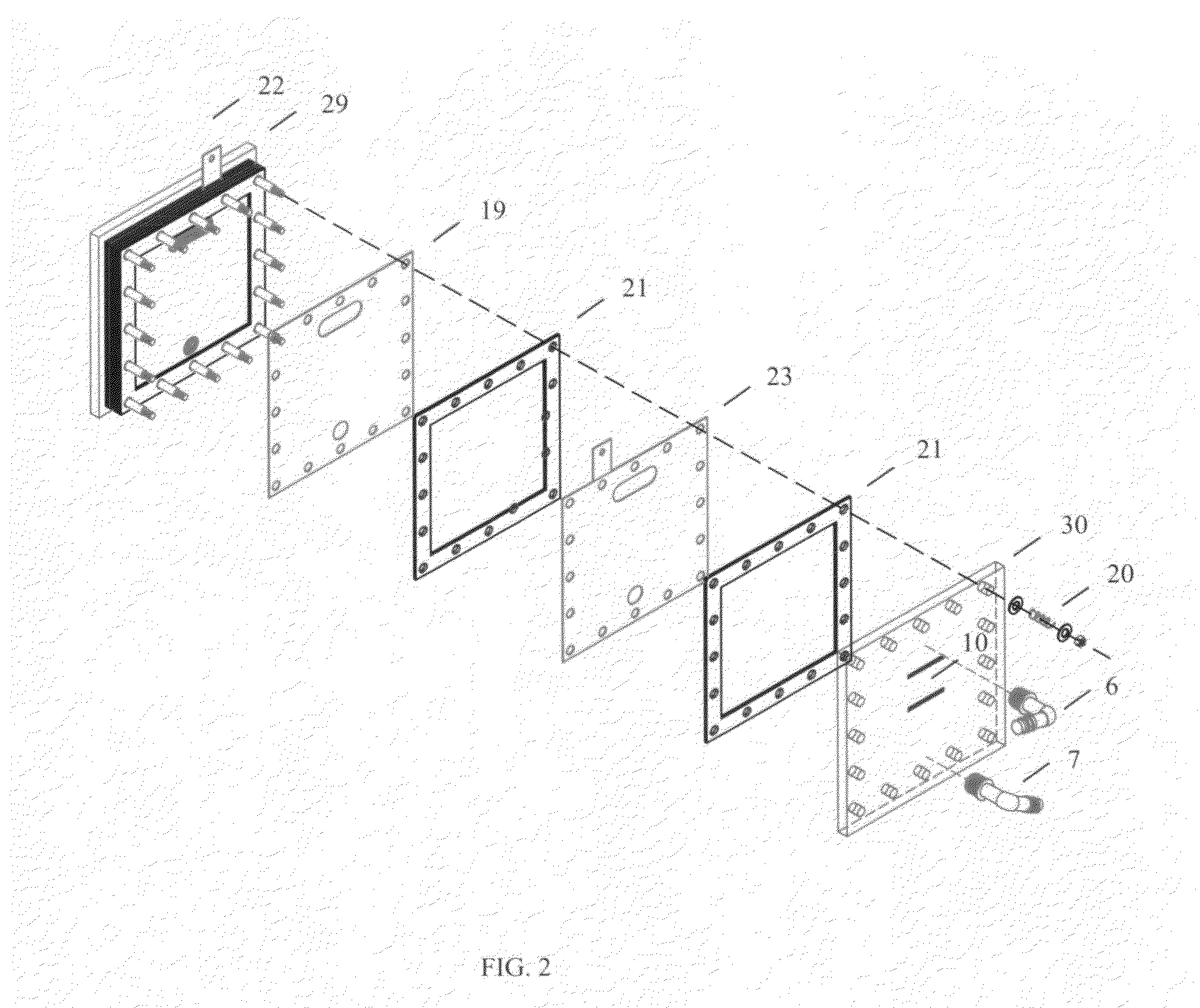

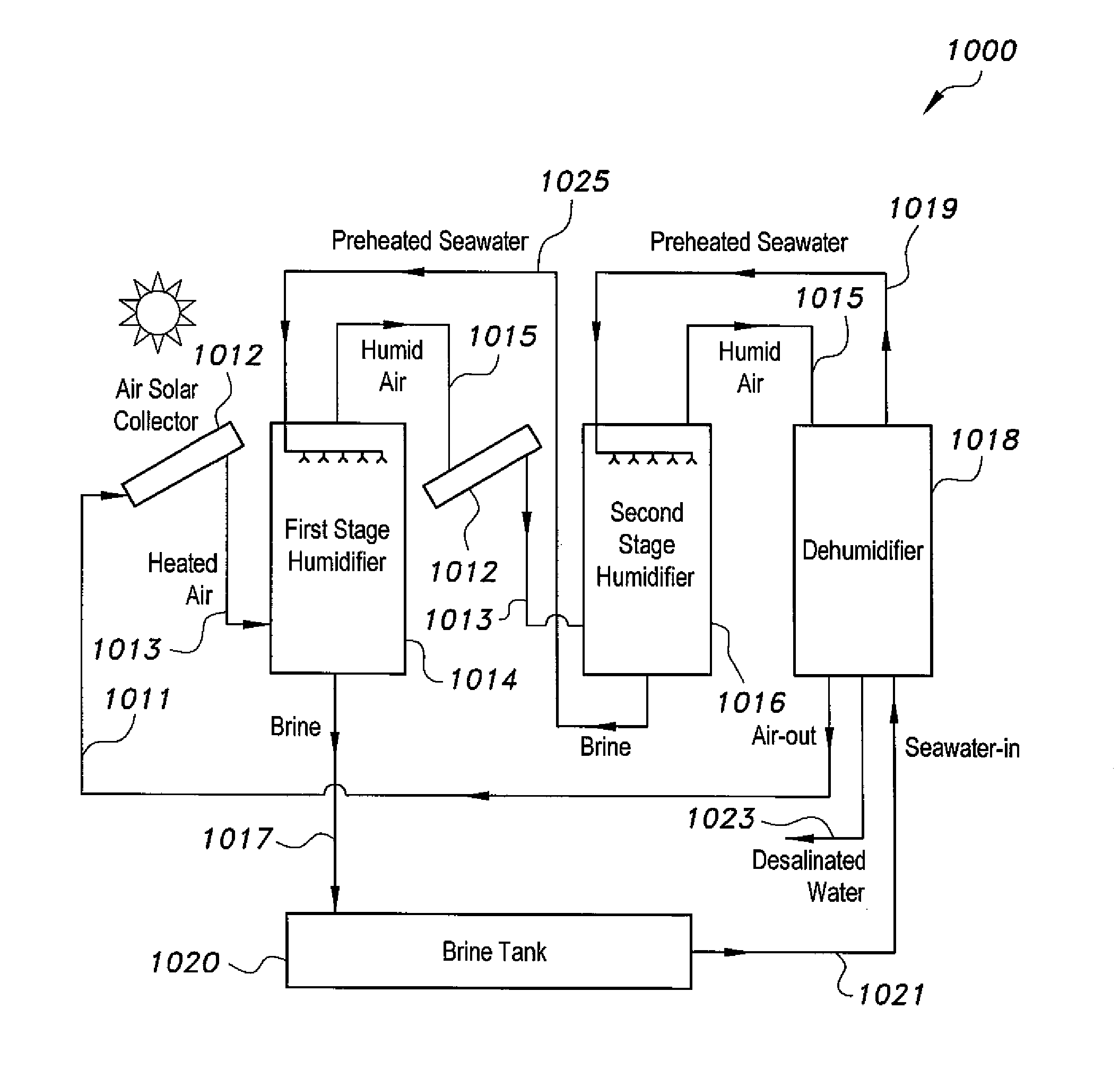

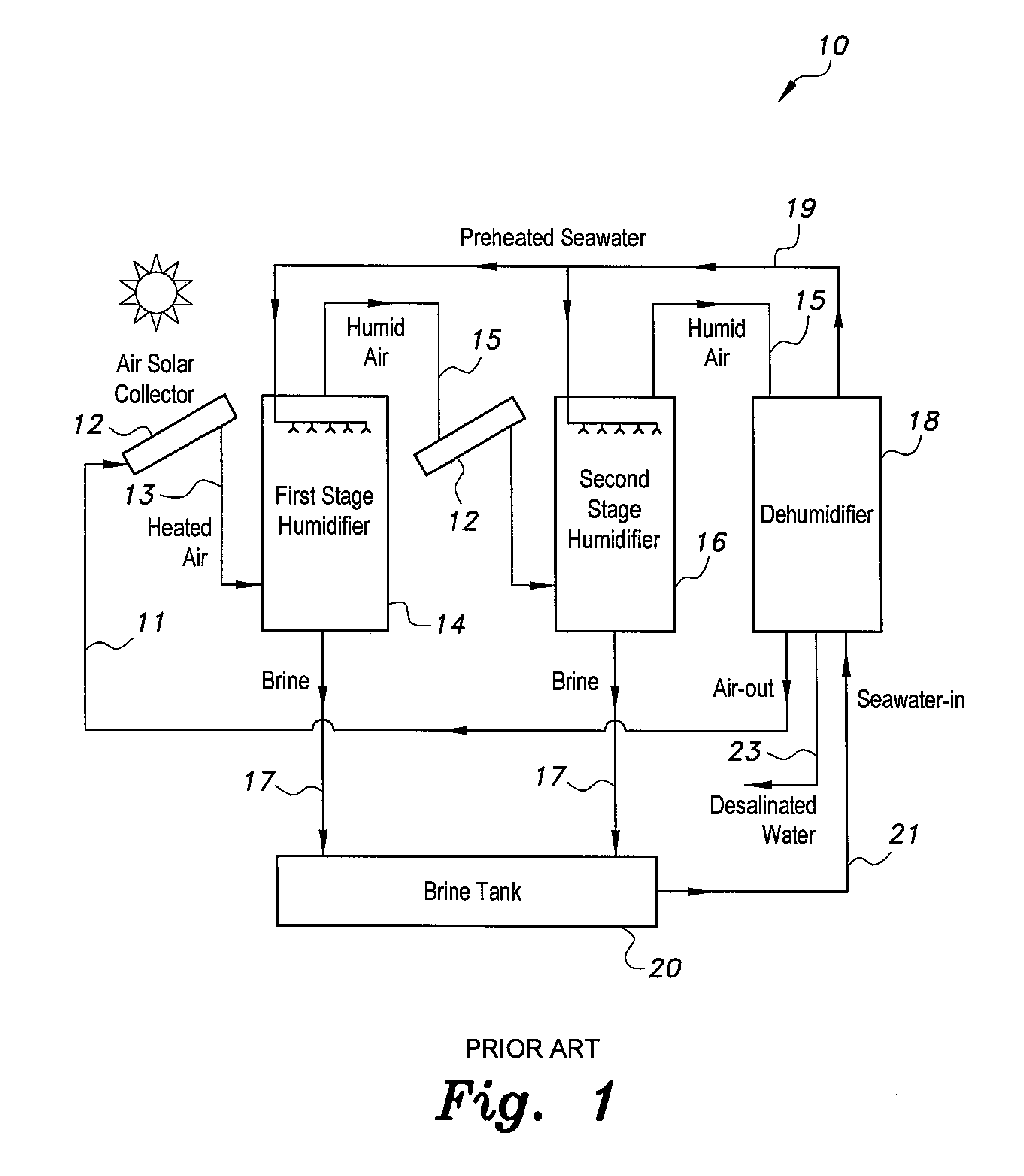

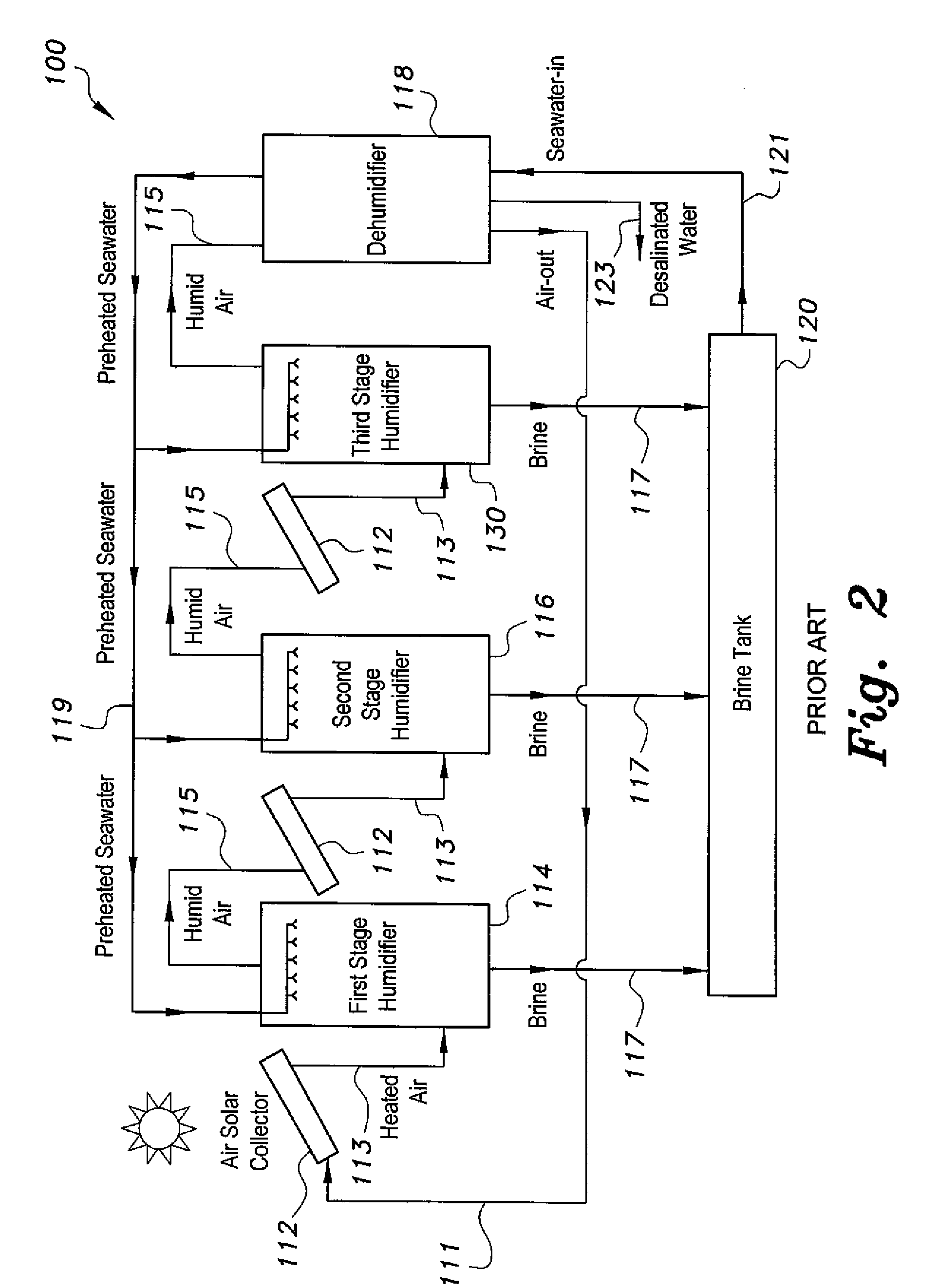

Solar-powered humidification-dehumidification desalination system

InactiveUS20140197022A1Efficient evaporationLess energy consumptionGeneral water supply conservationSeawater treatmentCondensation processSaline water

The solar-powered humidification-dehumidification desalination system includes a supply of saline / brackish water passing through a dehumidifier / condenser. The saline / brackish water is preheated in the dehumidifier / condenser due to the condensation process. A plurality of humidifying stages includes respective humidifiers and respective solar collectors. The solar collectors heat air, and the heated air passes through respective humidifiers to evaporate the preheated saline / brackish water, separating pure water from the brine. The humid air is reheated and recirculated through the humidifying stages and the dehumidifier, and the desalinated water from the dehumidifier via condensation is collected to and processed. The system recirculates the brine successively from each humidifier to the next for more efficient evaporation and less energy consumption.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS +1

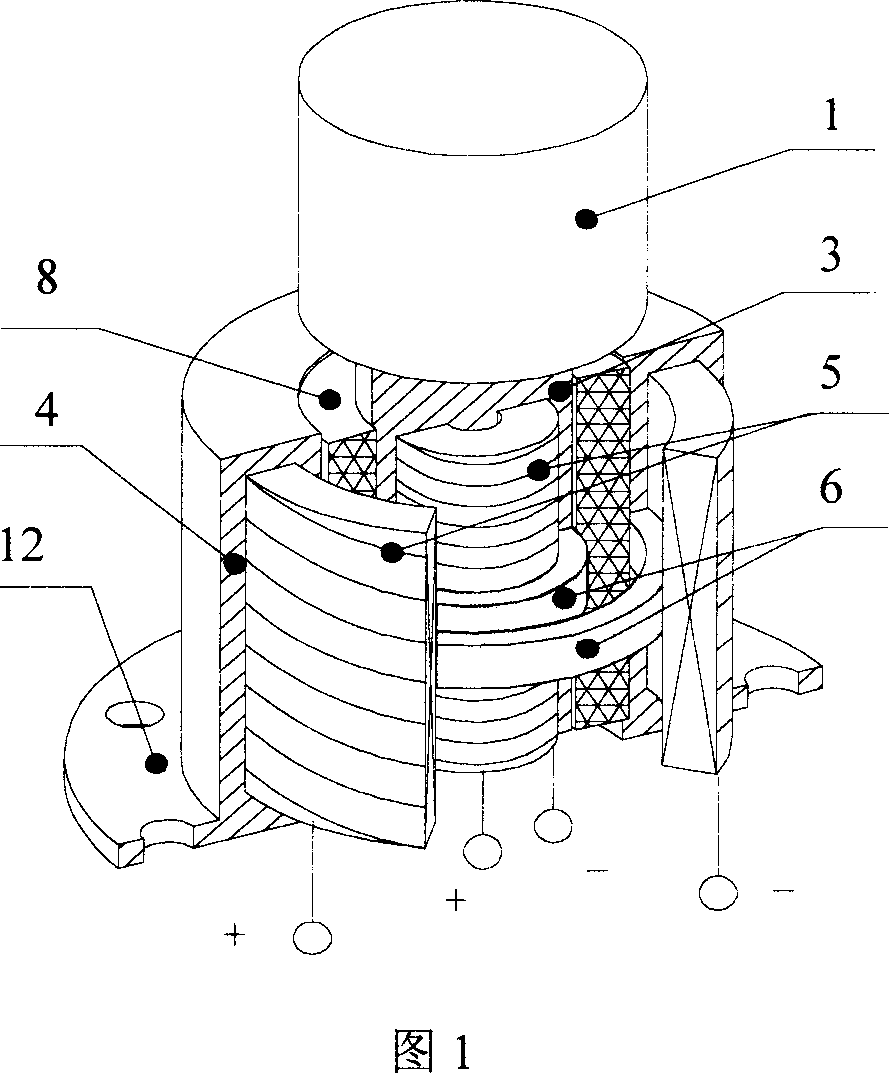

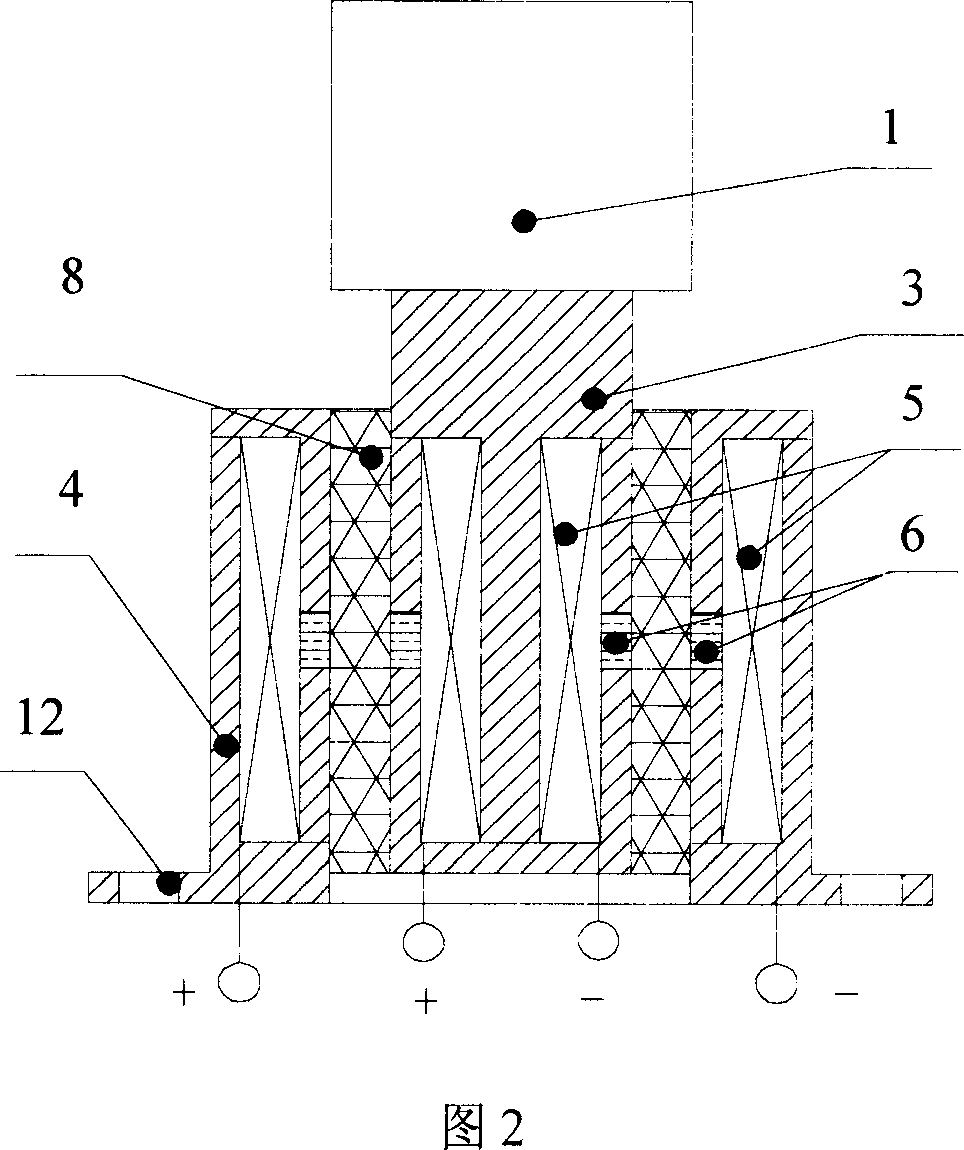

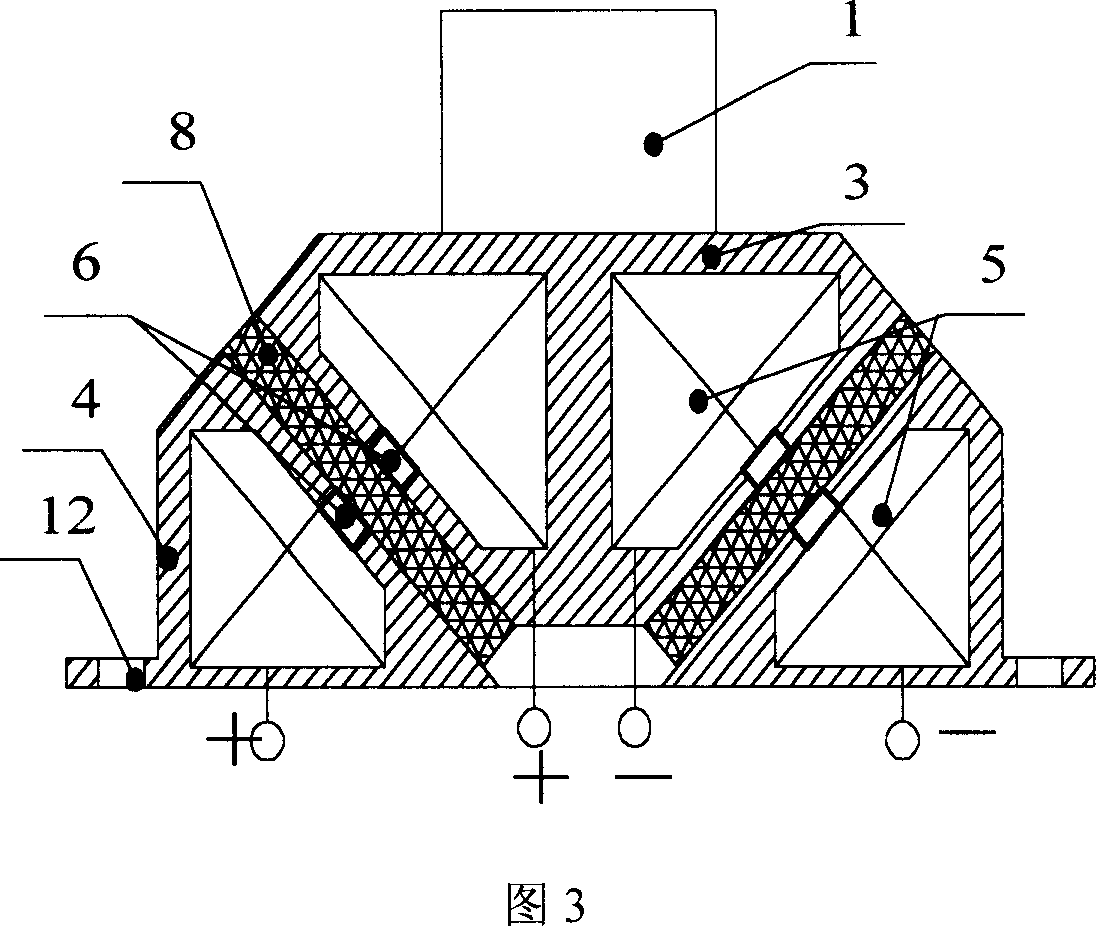

Magnetic flowing deformation elastomer frequency shift type attenuator and control method

InactiveCN1948781AAdjust the natural frequencyAdjust stiffnessNon-rotating vibration suppressionElastomerMagnetic current

The inventive vibration absorber comprises an execution unit, a control unit and a sensor. The execution unit consists of a magnetic inductor, a coil, a magnetic rheological elastic body, a vibration-absorbing mass block and a base. The above magnetic inductor consists of inner and outer sleeves, or a U-shaped iron-core and an armature or top and bottom plates and a column iron-core. Between inner and outer sleeves, the U-shaped iron-core and the armature or the top and bottom plates are filled the magnetic rheological elastic bodies. By regulating the voltage on the coil, the rigidity and the elasticity of the magnetic rheological elastic body are regulated to make its vibration frequency change, so as to make the vibration frequency of the vibration absorber execution unit is the same as that of the vibration-damping object.

Owner:UNIV OF SCI & TECH OF CHINA

Compartmentalized dispensing device and method for dispensing a flowable product therefrom

InactiveUS6871015B2Rapid and uniform heatingEfficient heatingOpening closed containersBottle/container closurePeristaltic pumpEngineering

The invention relates to a method for rapidly, efficiently heating and dispensing a flowable food product, using a device preferably of limited footprint whereby removable cassettes are provided for receiving a food-containing package. The cassettes at least include a direct conduction surface and an insulating coverage that substantially reduces radiant heat loss outside the cassettes. Preferably, there is provided peristaltic pumps, each one being adapted to engage a discharge tube of the food pouch wherein the pumps have their rotor plane oriented in alignment or parallel to the axial plane of the cassettes. Cassettes are heated by low power density generating heating members, such as a thin film heater or equivalent.

Owner:NESTEC SA

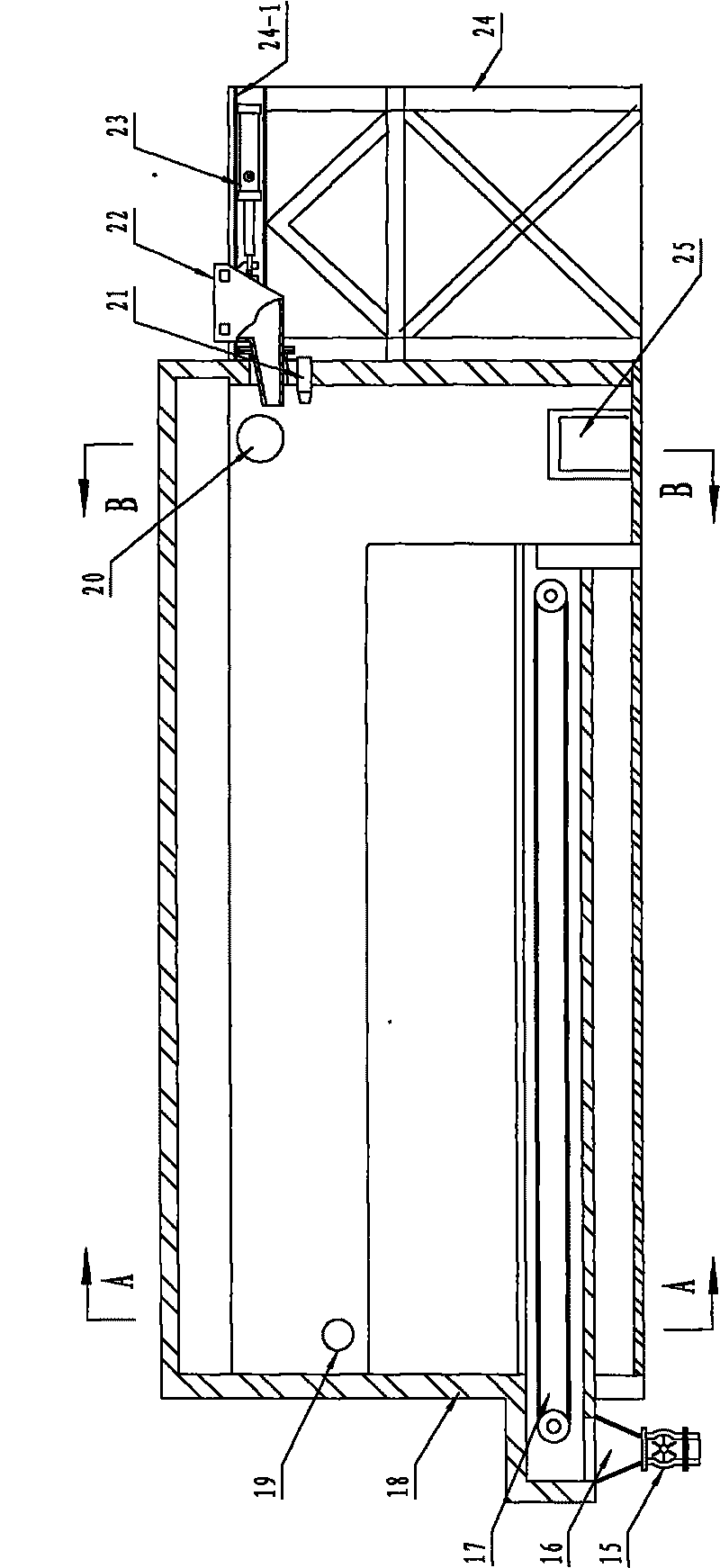

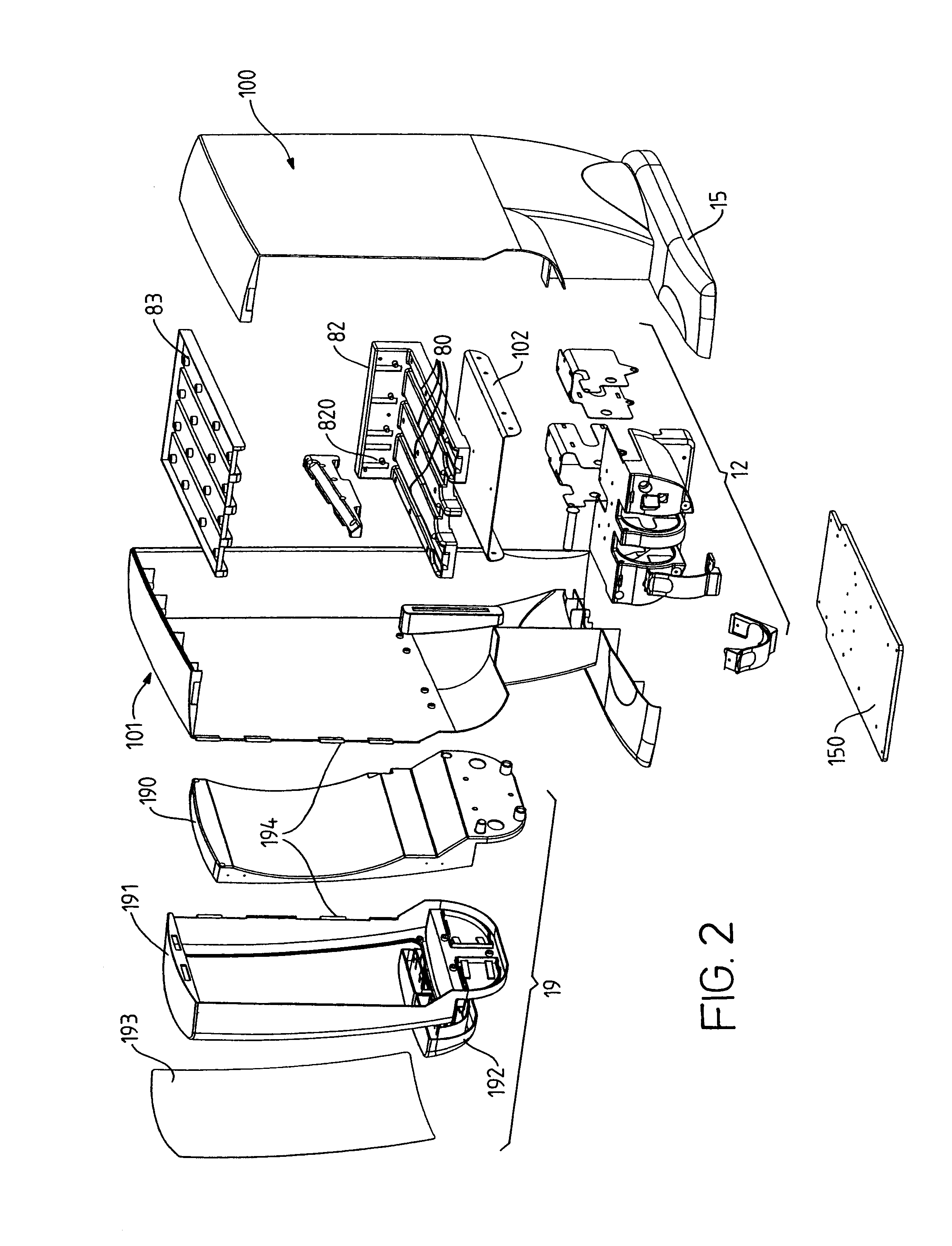

Livestock culture environment regulating device

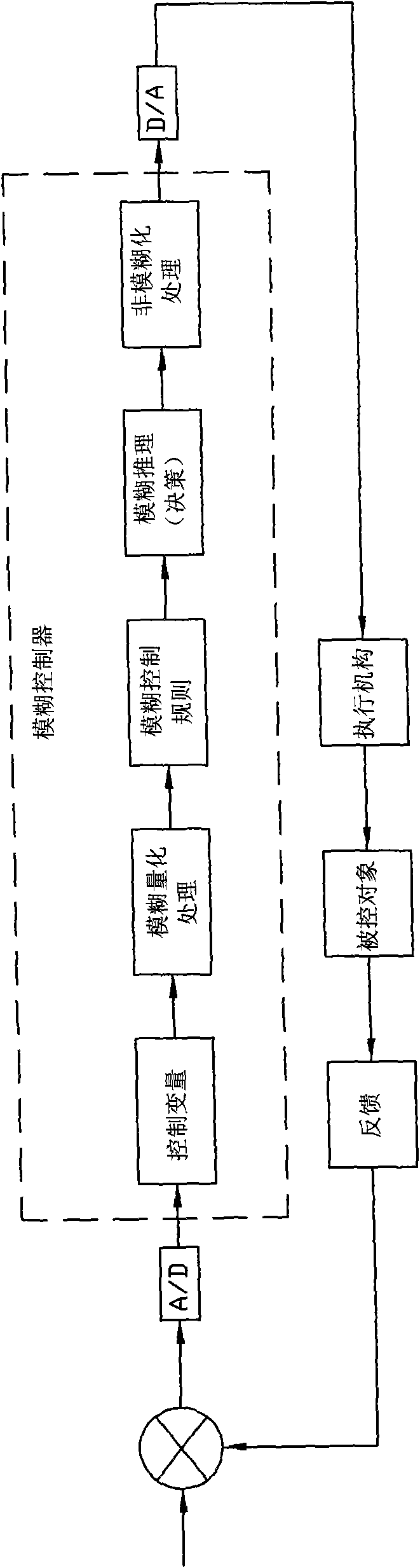

InactiveCN101650574ALess energy consumptionImprove cooling effectAnimal housingTemperature control using electric meansEngineeringAir blower

The invention discloses a livestock culture environment regulating device, comprising a measurement and control unit which comprises an intelligent measurement and control terminal. The intelligent measurement and control terminal comprises a microprocessor, a detector connected with the microprocessor and a control output which is connected with a control device; the detector comprises a temperature and humidity detector and an ammonia concentration detector; the control device comprises an air blower; the livestock culture environment regulating device is characterized in that the detector also comprises dust concentration monitoring, illuminance detection and wind speed detection; the control device also comprises a lighting device, an atomization device, a heating device and a sprayingdevice; when temperature reduction is required, the device performs temperature drop by adopting the mode of combining the air blower with atomization, namely, when the temperature is higher than theset value, temperature drop is carried out by adopting the mode of combining atomization with the air blower; and when the temperature is lower than the set temperature, temperature drop is carried out by adopting the air blower. The invention has the advantages of dropping temperature by combining the air blower with atomization, being capable of multifunctional detection and fuzzy control and the like.

Owner:柳平增

Method for providing a nanocellulose involving modifying cellulose fibers

ActiveUS20110036522A1Increases anionic charge densityReduce energy consumptionNanostructure manufacturePulp properties modificationAqueous electrolyteCellulose fiber

A method for the manufacturing of nanocellulose. The method includes a first modification of the cellulose material, where the cellulose fibres are treated with an aqueous electrolyte-containing solution of an amphoteric cellulose derivative. The modification is followed by a mechanical treatment. By using this method for manufacturing nanocellulose, clogging of the mechanical apparatus is avoided. Also the nanocellulose is manufactured in accordance with the method and uses of the cellulose.

Owner:INNVENTIA

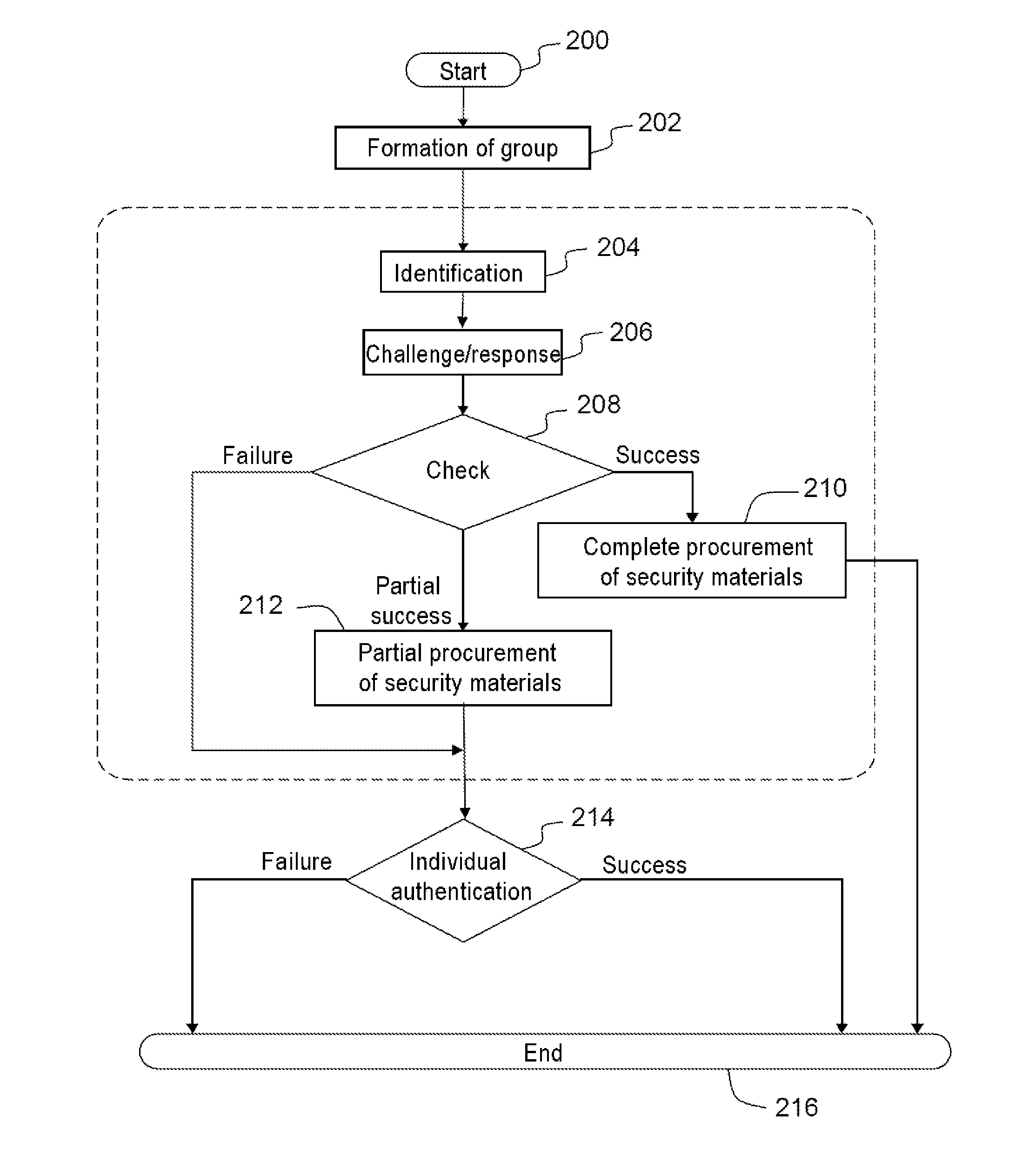

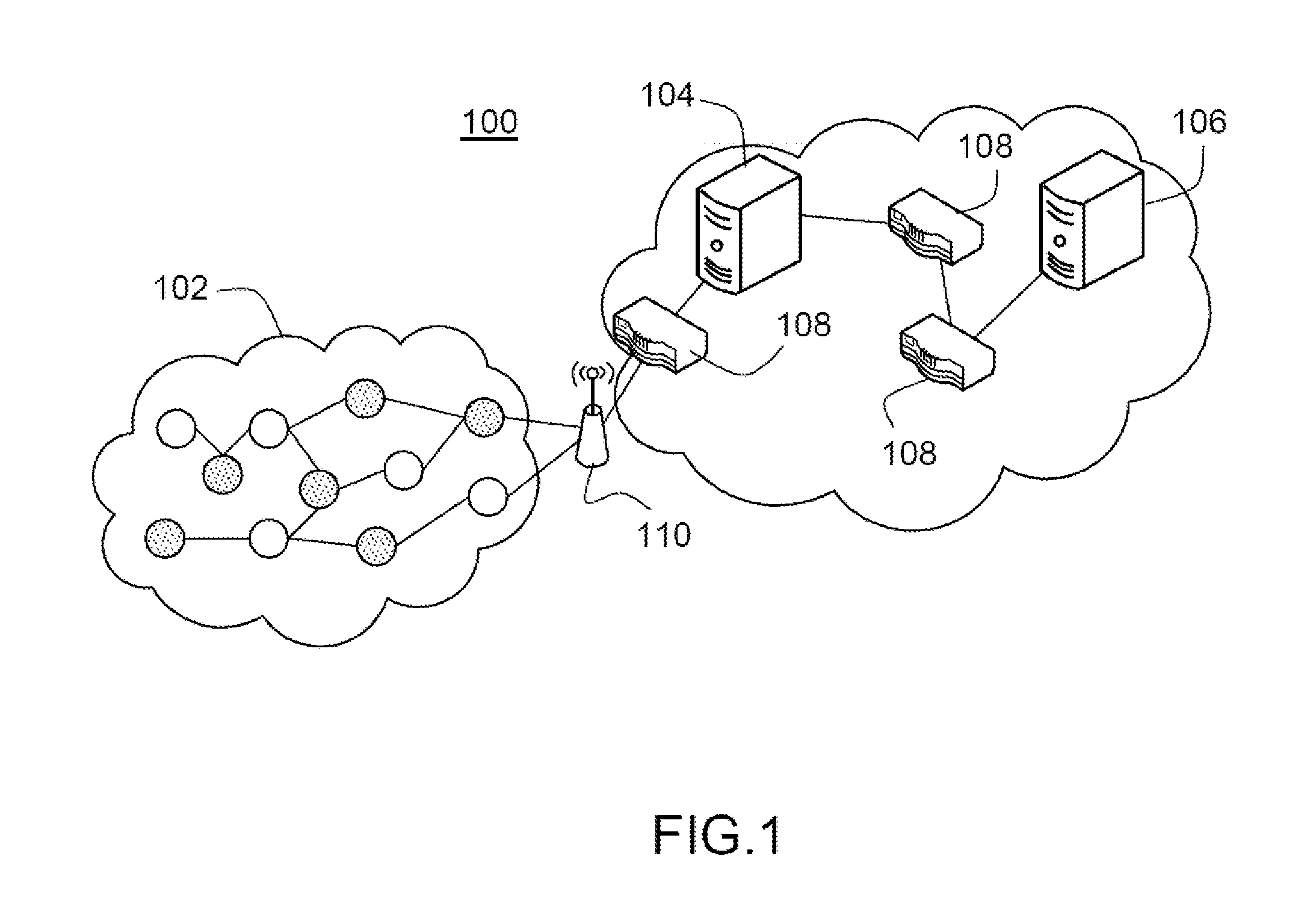

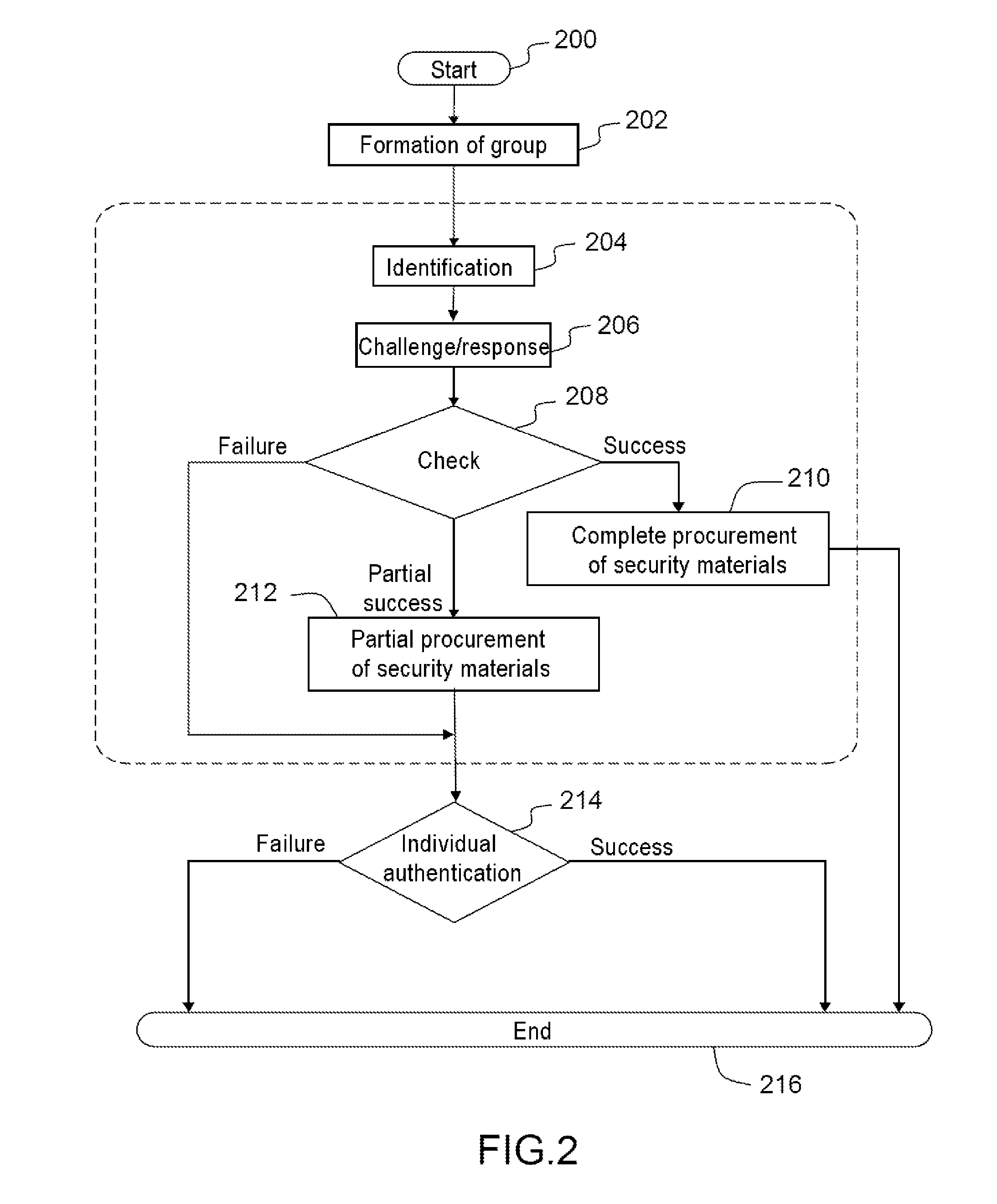

Method and system for authenticating the nodes of a network

InactiveUS20150149767A1Less overall consumptionLess energy consumptionDigital data processing detailsUser identity/authority verificationPersonalizationService provision

A system and a method are provided for authenticating the nodes of a communication network in order to access the services of a service provider, and includes a collective authentication of the nodes, performed in a single exchange between the nodes of the network declared in a group and an authentication server. Depending on the result of the authentication, the service provider is provided with cryptographic material in order to implement individualized controlled access to the resources or to the services offered for each node.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

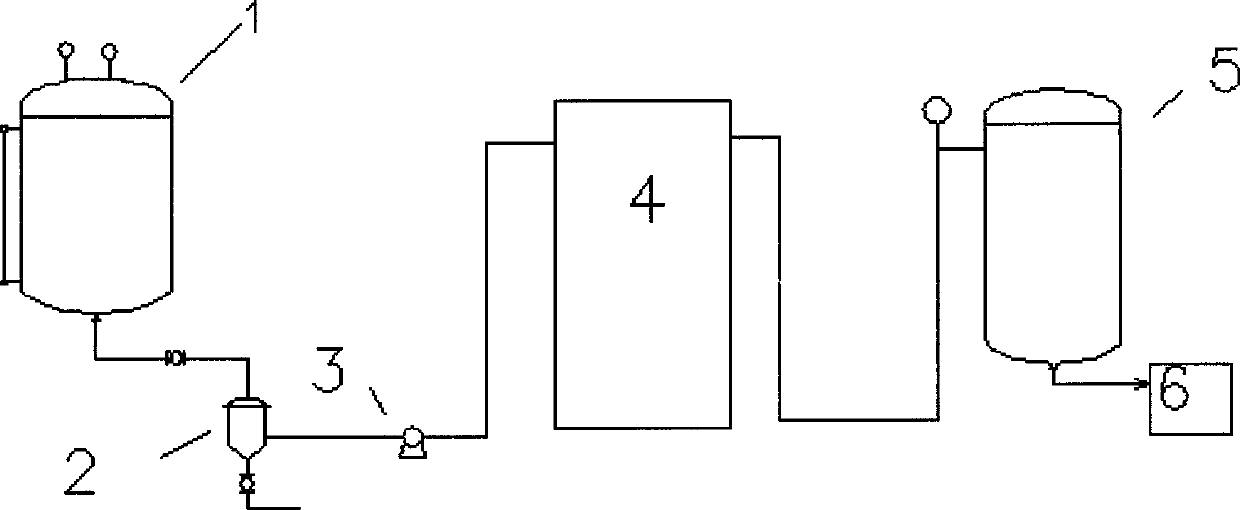

Device and method for continuously producing sodium methyl taurate in pipeline mode

InactiveCN102675160ALess energy consumptionStable concentrationSulfonic acids salts preparationHeat conductingDistillation

The invention relates to a device and a method for producing sodium methyl taurate, in particular to a device and a method for continuously producing sodium methyl taurate in a pipeline mode. The method comprises the following steps of: adding sodium hydroxyethyl sulfonate, water, methylamine and catalyst into a storage tank, pumping the materials into a continuous pipeline reactor through a boosting pipeline pump under the high pressure of 10 to 25MPa, heating to the temperature of between 150 and 300 DEG C through heat conducting oil, and reacting for 10 to 60 minutes in the pipeline reactor; and feeding the materials into an evaporator after reaction, performing multistage distillation, decolorizing, moisturizing, refining, and thus obtaining the qualified sodium methyl taurate. The device is simple and high in process safety, the reaction conditions are easy to control, continuous production is realized, the yield reaches over 90 percent, the sodium methyl taurate is stable in quality, and large-scale production can be realized with low investment in the industry.

Owner:HUANGGANG YONG AN PHARMA

Method for preparing sodium thiocyanate by using desulphurization waste liquid of coke oven gas

InactiveCN101597073AHigh purityHigh selectivityChemical industryThiocyanic acidLiquid wasteSodium thiocyanate

The invention discloses a method for preparing sodium thiocyanate by using desulphurization waste liquid of coke oven gas, and belongs to the technical field of utilization of desulphurization waste liquid of the coke oven gas. The method comprises the following steps: using the desulphurization waste liquid of the coke oven gas as a raw material, firstly, filtering the waste liquid in vacuum, using tributyl phosphate to extract thiocyanate radicals in the waste liquid, then using sodium hydroxide solution to back-extract the extract, and finally concentrating and crystallizing the extract, and washing and drying the crystals to obtain sodium thiocyanate crystals. The method uses the desulphurization waste liquid of the coke oven gas to prepare a sodium thiocyanate product with the purity as high as 93 to 95 percent so as to change waste into valuable and makes full use of waste resources; and the method is simple, saves energy, has no three-waste discharge, is favorable for environmental protection, has low production cost and good economic benefit, and develops a new path for the utilization of the desulphurization waste liquid resources of the coke oven gas. The sodium thiocyanate product prepared by the method can be widely applied in the industries of medicaments, textile, printing and dyeing, pesticide, chemistry and the like.

Owner:CHONGQING UNIV

Energy Saving Control for a Field Device

ActiveUS20100298999A1Reduce energy consumptionKeep energy smallMechanical power/torque controlLevel controlMonitor unitEngineering

A control for a field device comprises a monitoring unit that is separate from a control unit for controlling the field device which monitoring unit, when the control unit is in a sleep mode, waits for an activation signal in order to switch the control unit to the operating mode.

Owner:VEGA GRIESHABER GMBH & CO

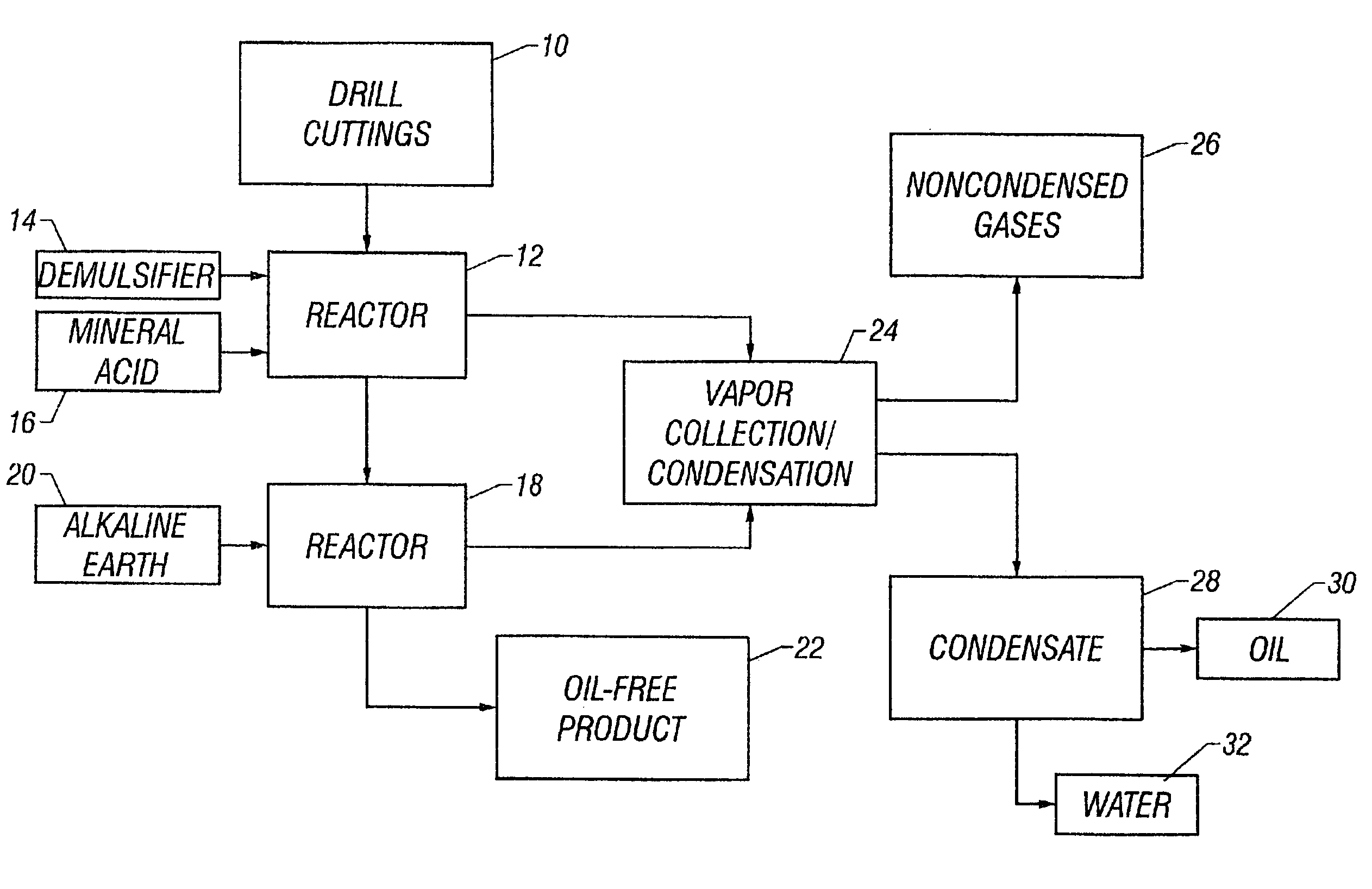

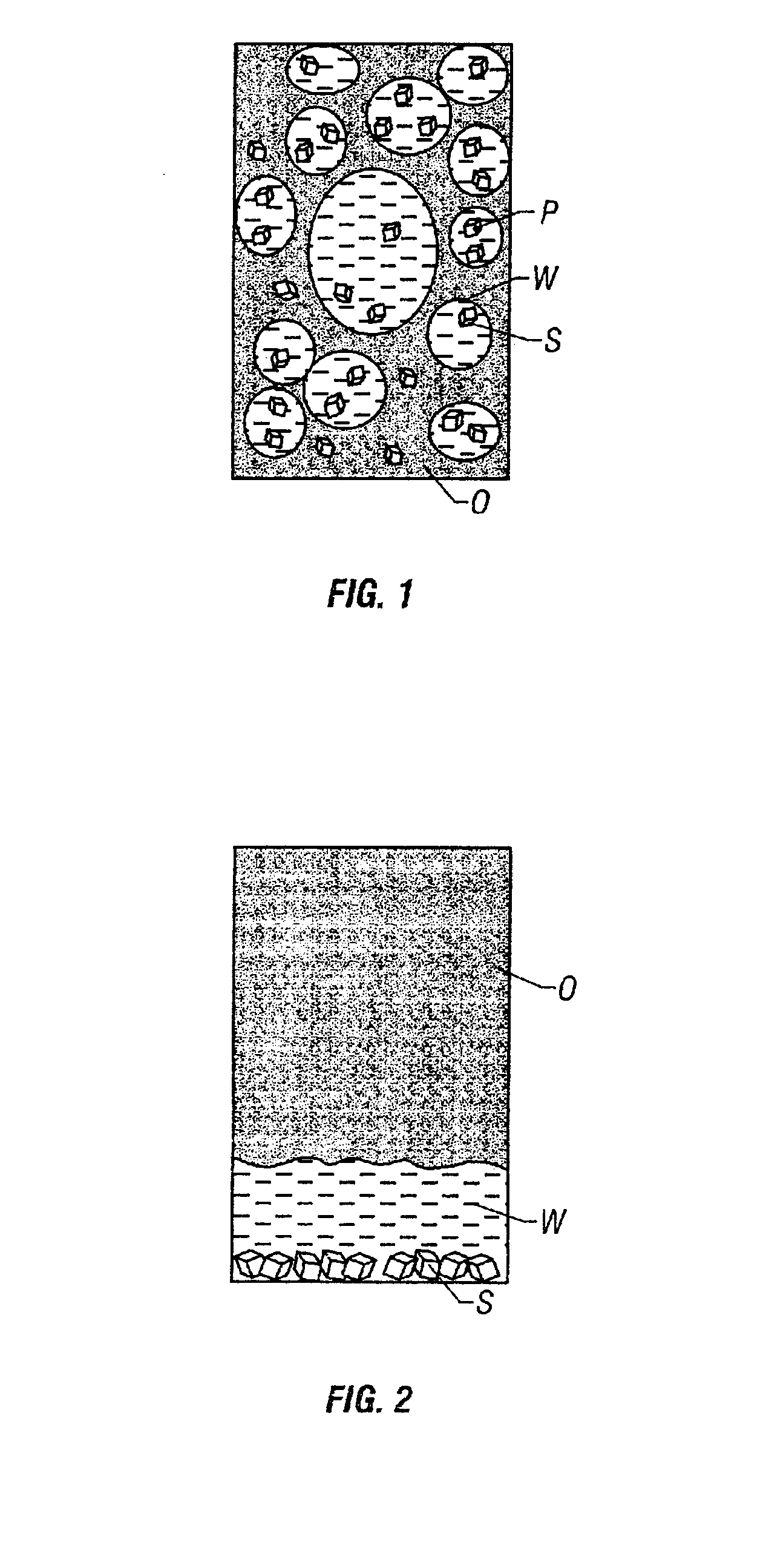

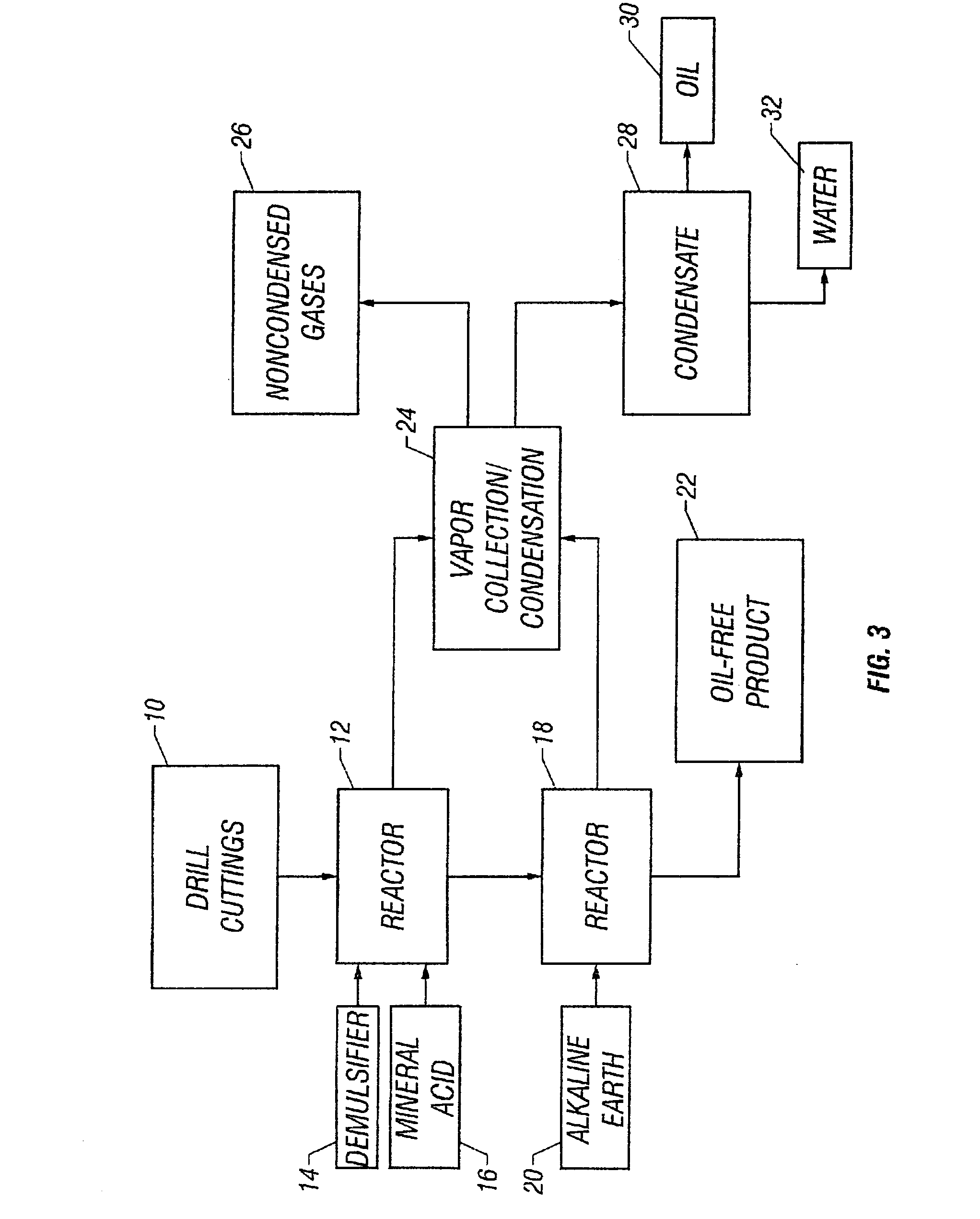

Drill cutting treatment method

InactiveUS6668947B2Easy to removeRapid and extensive and costsLighting and heating apparatusTransportation and packagingOrganic acidEmulsion

A method and apparatus for treating for disposal oil-contaminated clay substrates such as drill cuttings from drilling with an oil-based mud. If necessary, the substrate is pretreated with an aqueous emulsion breaker such as alkylbenzenesulfonic acid. The substrate is mixed under high shear conditions with a mineral acid such as sulfuric acid. This can be done in an agitated reactor with sequential addition of the organic and inorganic acids. The substrate is then mixed with alkaline earth such as lime in a second agitated reactor. The reactions between the acid(s), alkaline earth and substrate are exothermic and provide heat to vaporize the oil, reaction products and water. Recoverable constituents in the vapor can be condensed in a vapor collection system. The treated substrate is essentially free of oil and has a controlled water content.

Owner:RACIONAL ENERGY & ENVIRONMENT

Method and device for electroextraction of heavy metals from technological solutions and wastewater

InactiveUS6887368B2Reduced heavy metal levelLess energy consumptionFrom normal temperature solutionsLiquid separation by electricityConductive materialsMaterials science

The basic principles of the method for heavy metals electroextraction from technological solutions and wastewater includes pretreating to remove Chromium-6 and high concentrations of heavy metals and periodically treating in a six-electrode bipolar cylindrical electroreactor made of non-conducting material to achieve lower accepted levels of impurities. Six cylindrical steel electrodes form two triode stacks and are fed with three-phase alternating current of commercial frequency (50-60 Hz), which can be pulsed. Each phase of the three-phase current is connected to three electrodes of one triode stack or in parallel to two triode stacks. The parallel connection of three-phase current to two triode stacks is performed so that the same phase of the three phase current is connected in parallel with each two opposite electrodes of six electrodes located along the periphery, or with two adjacent electrodes. A bipolar stationary aluminum electrode is situated in the inter-electrode space. In one of the embodiments, the bipolar electrode is made of a perforated heat-resistant plastic container filled with secondary aluminum and duralumin scrap. In another embodiment, the bipolar electrode of aluminum or duralumin scrap may be made without a perforated container and is placed in the inter-electrode space as a bulk scrap. In this case, to prevent shorts, each of six steel electrodes is placed in isolated perforated plastic shell with holes of 5 mm in diameter. Non-ferrous metals are extracted in a form of ferrite-chromites, and aluminates as well as hydroxyl salts deposited in the inter-electrode space without electrolysis deposits on electrodes. Deposits are separated from solution by known methods of filtration.

Owner:URAL PROCESS ENG +2

Electric toothbrush

InactiveUS6973694B2Reduce manufacturing costEnhanced couplingCarpet cleanersKitchenware cleanersBristleTransverse groove

Owner:GIMELLI & CO AG

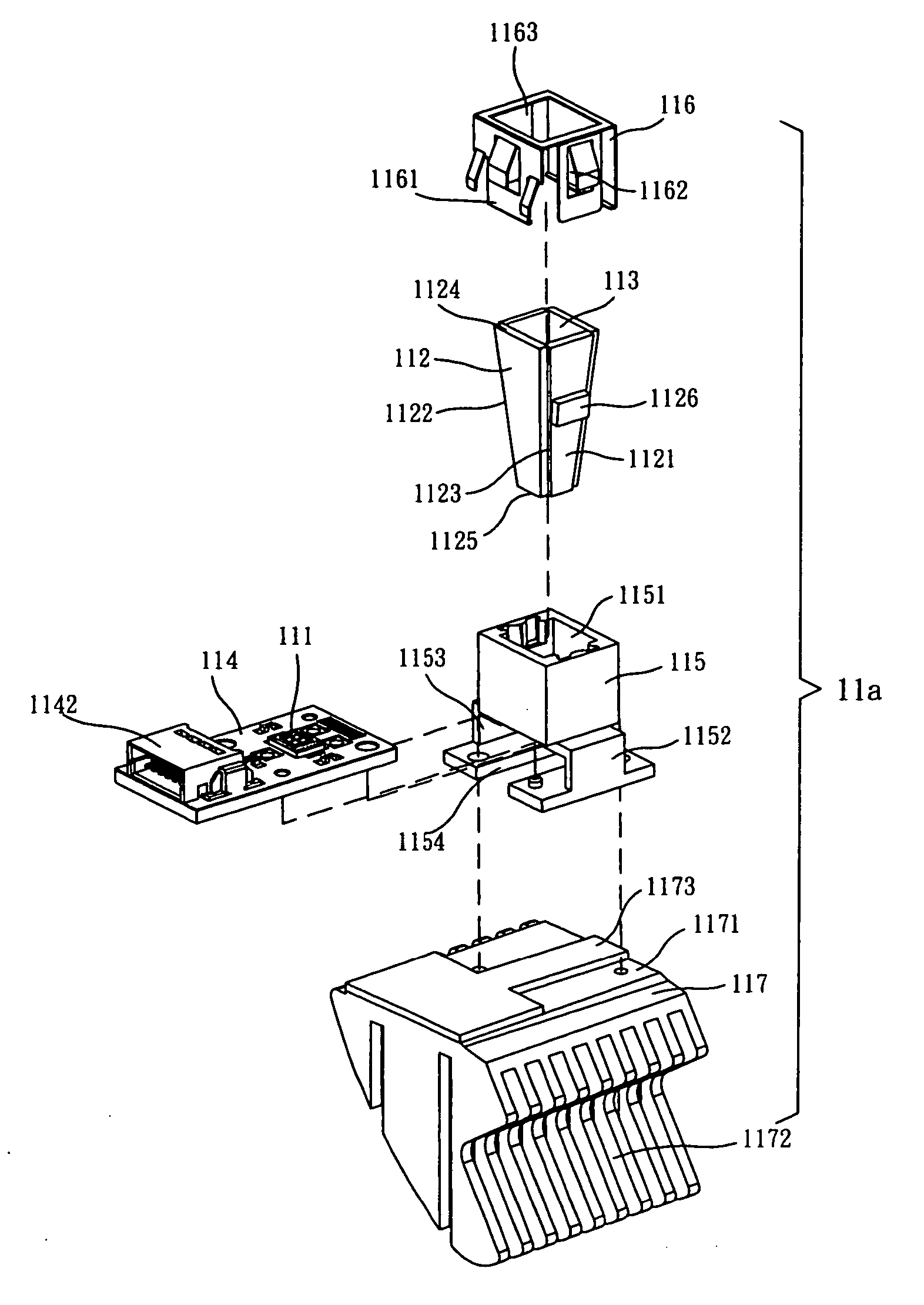

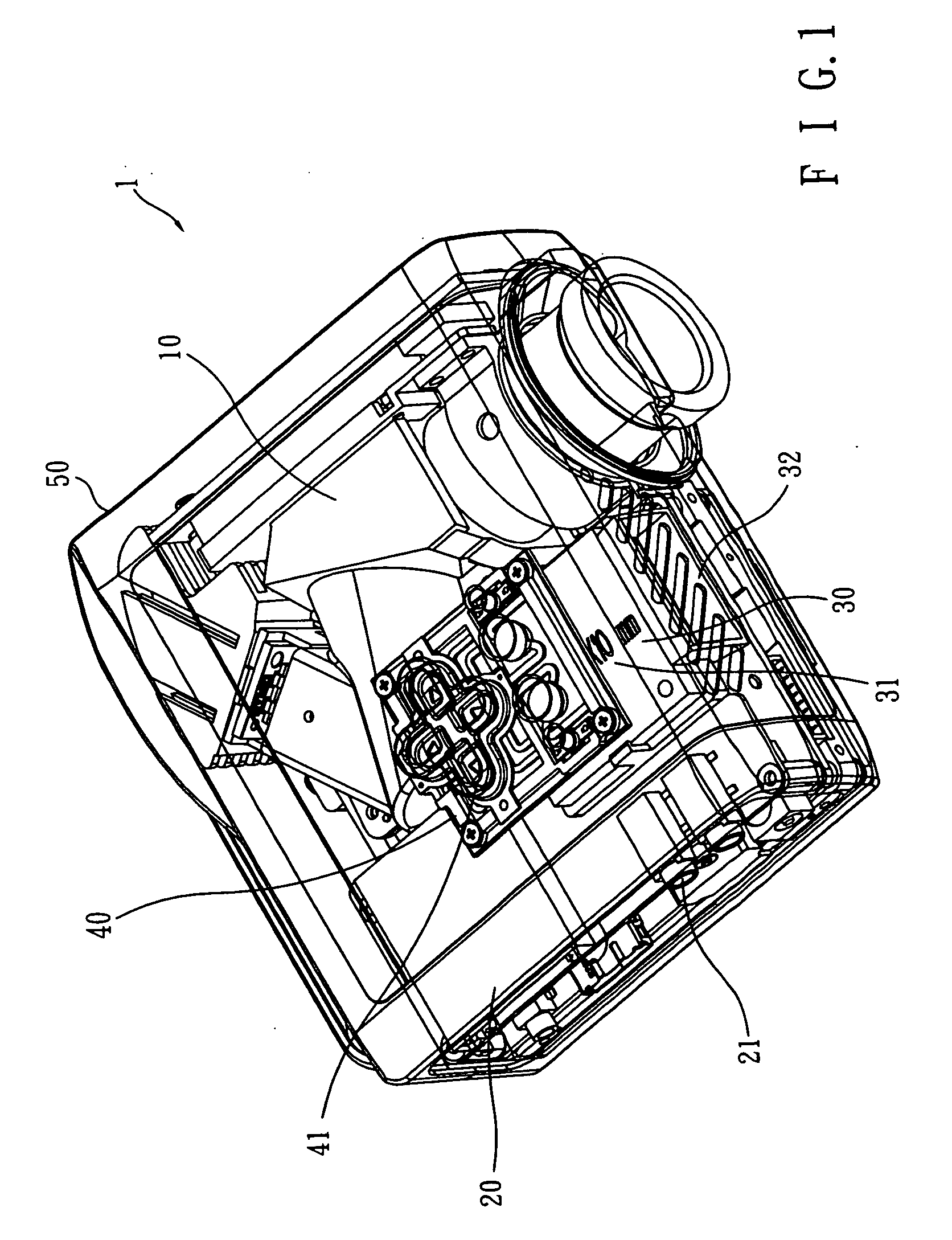

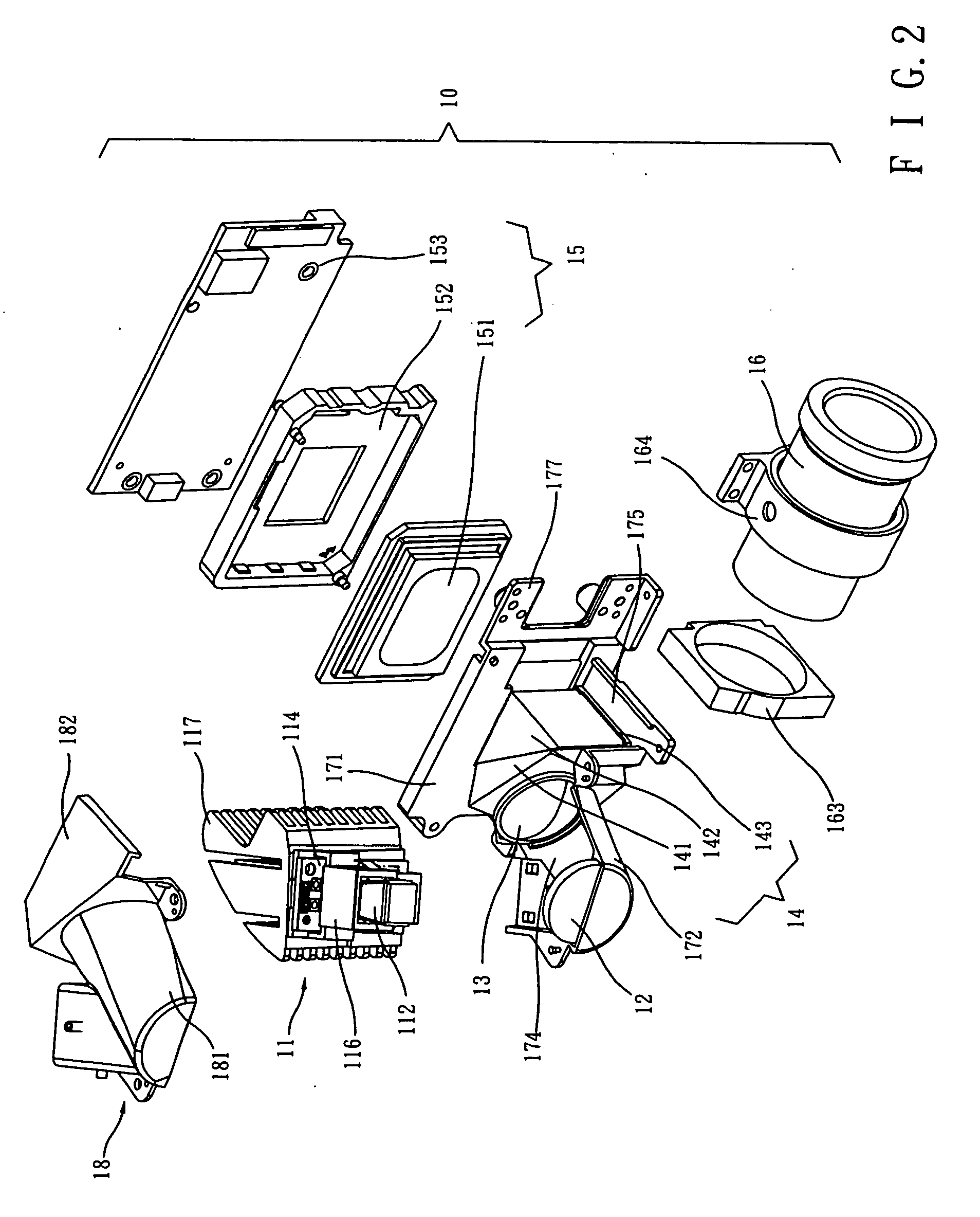

Optical engine and an image projector having the optical engine

InactiveUS20060078266A1Reduce dispersion angleIncrease brightnessColor television detailsOptical waveguide light guideRight triangleIncrease size

An optical engine for an image projector comprises a light source, a taper rod, at least one light condenser, a prism module, a Digital Micromirror Device (DMD) and a projection lens set. One end of the taper rod is adjacent to the light source. Light generated by the light source is guided by the taper rod following a light path. The taper rod has increasing sizes of cross-sections along the light path, so as to decrease the dispersion angle of light, make the light more uniform, and increase the brightness of light. The prism module includes a first prism having a right triangle cross-section and a second prism having a wedge cross-section. The prism module receives the light from the condenser, passes the light toward the DMD, receives the light reflected by the DMD, and then passes the reflected light toward the projection lens set. The projection lens set projects the light on an external projection plane.

Owner:PREMIER IMAGE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com