Patents

Literature

788 results about "Capital investment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

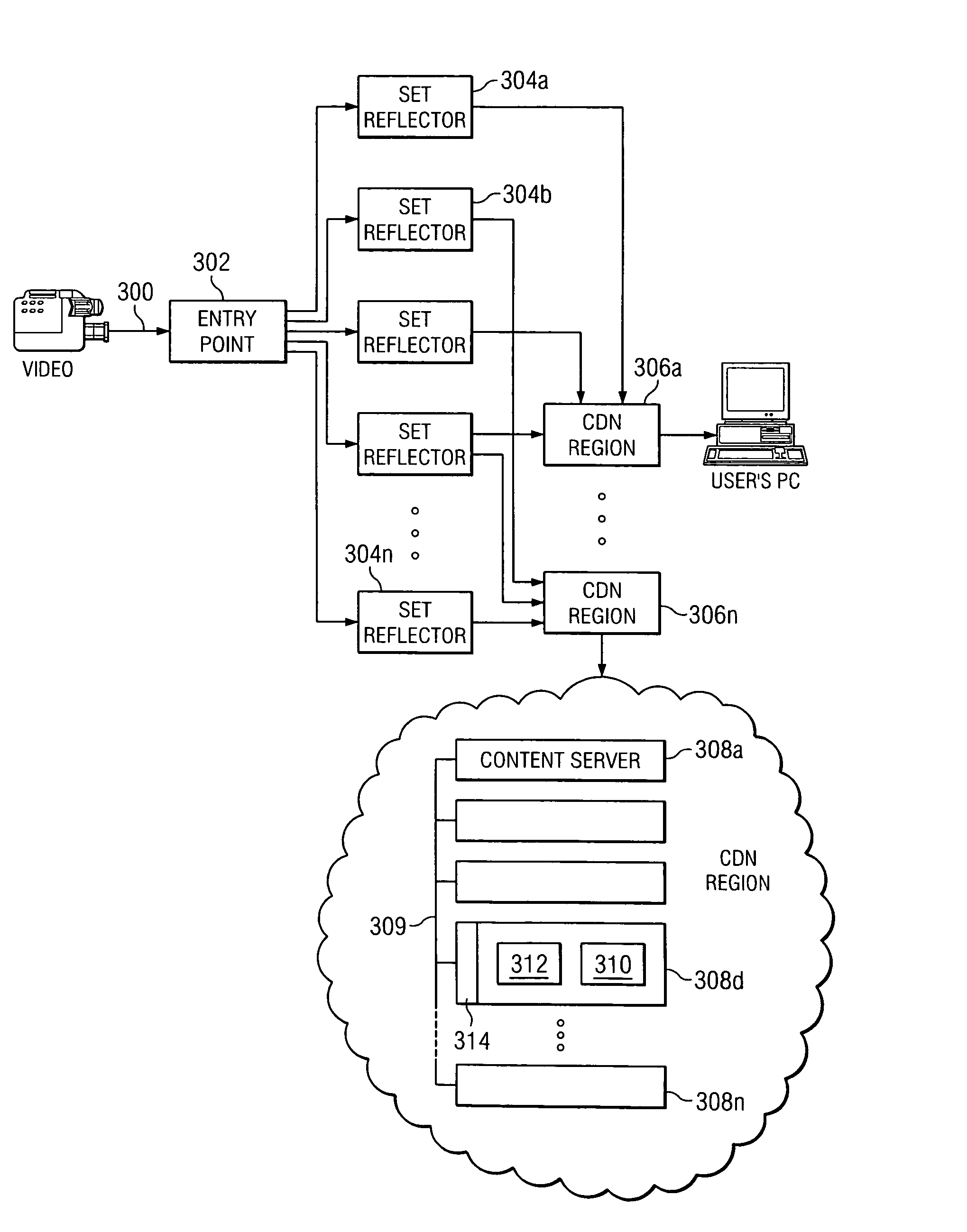

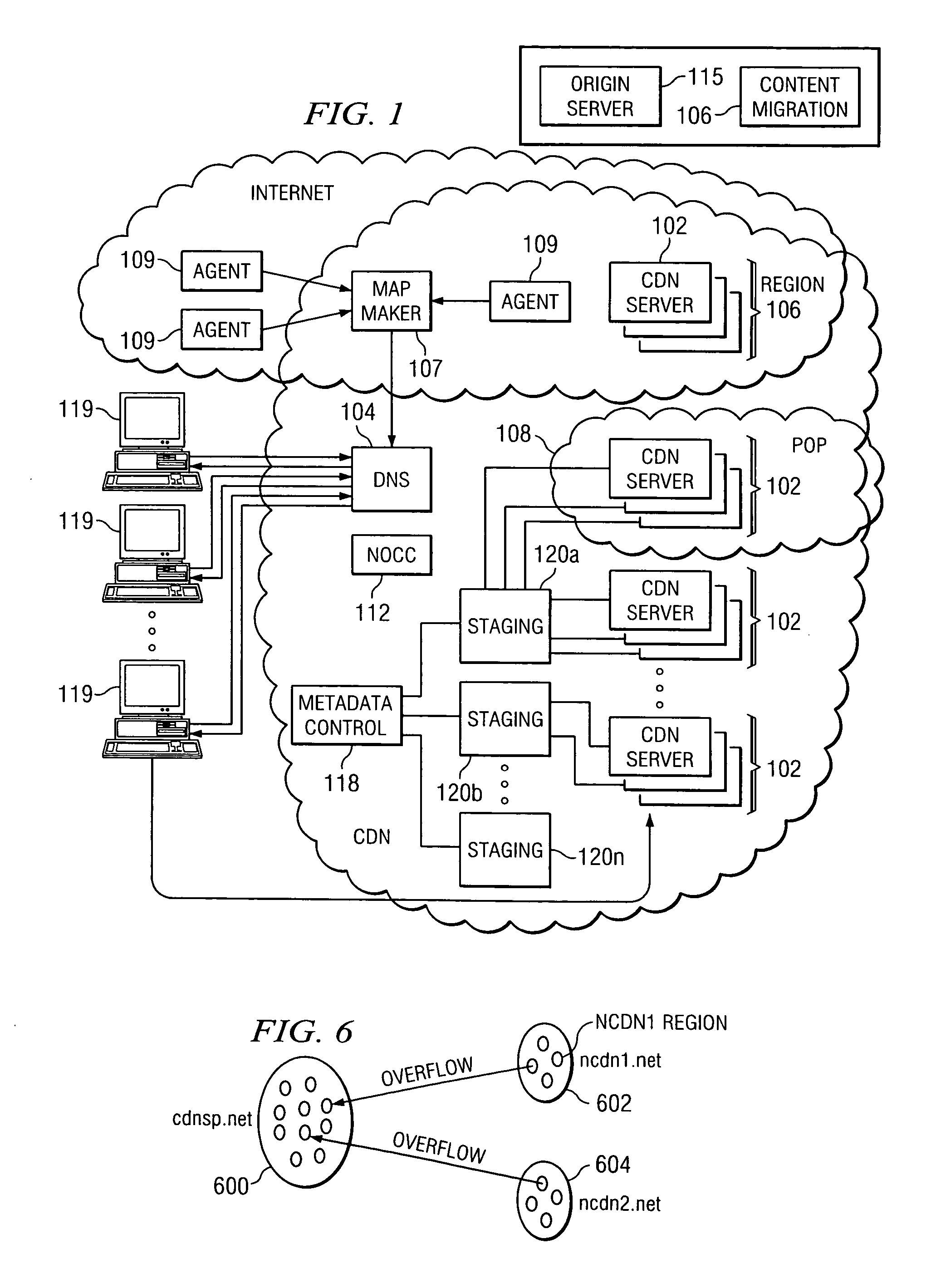

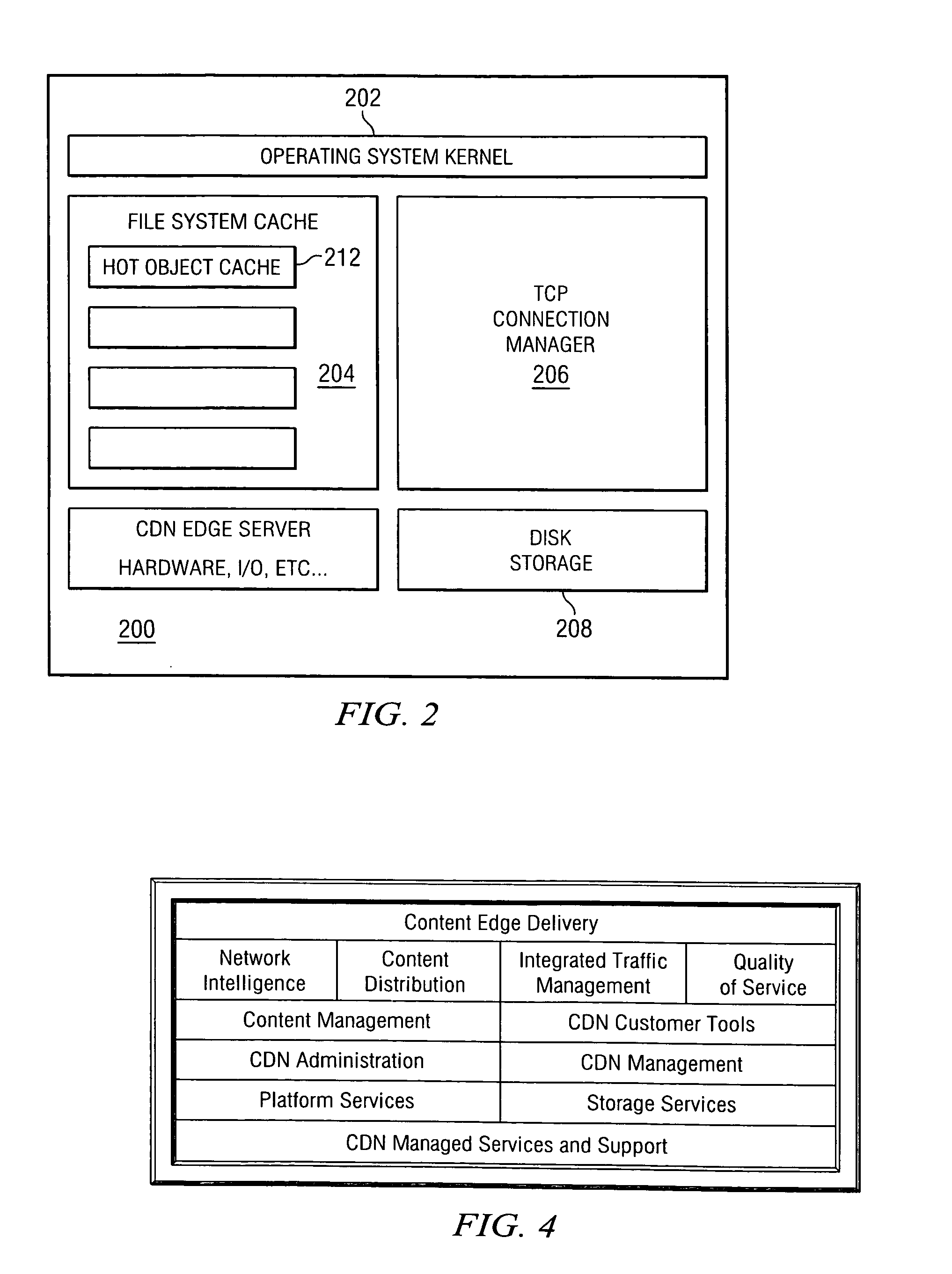

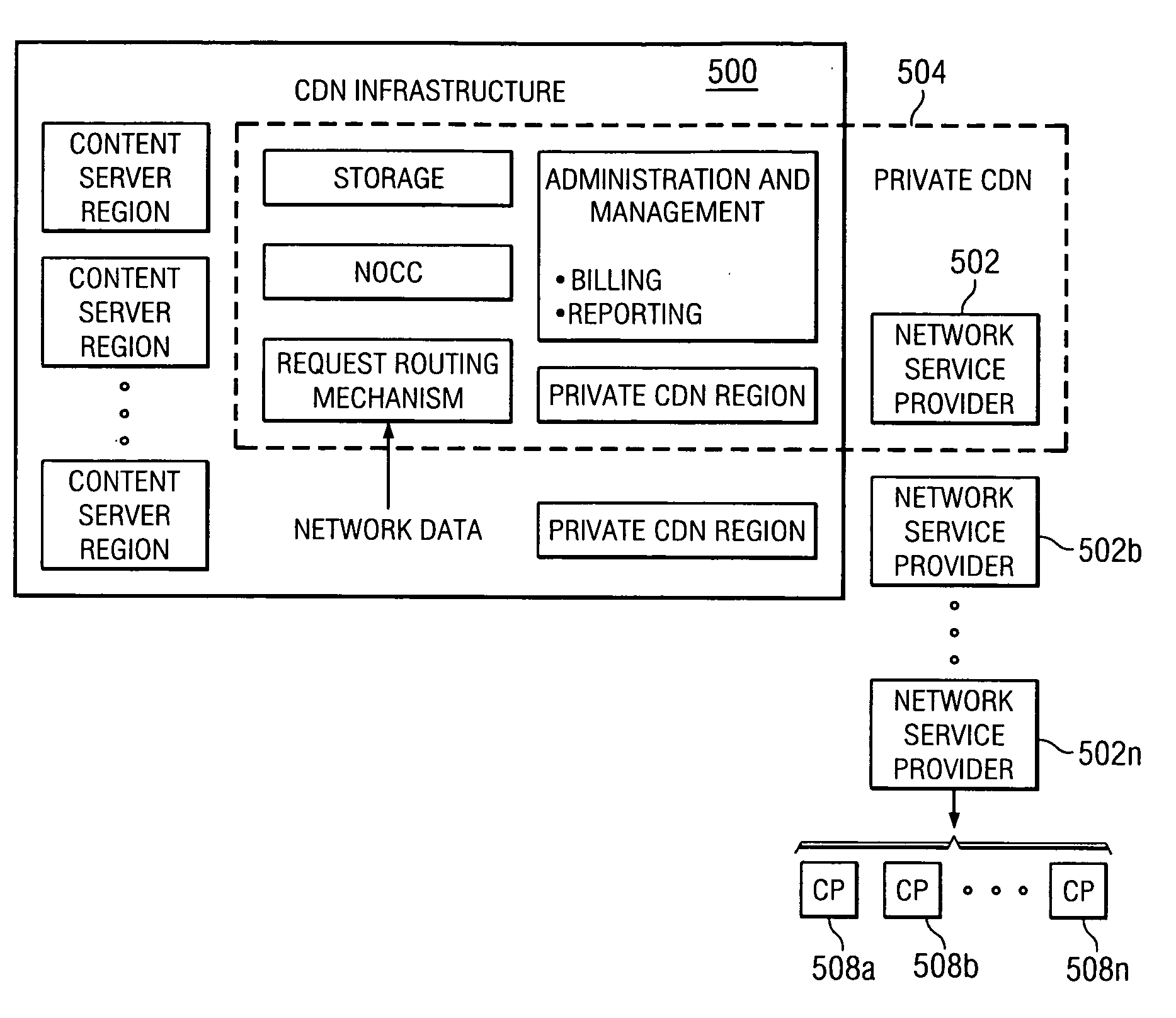

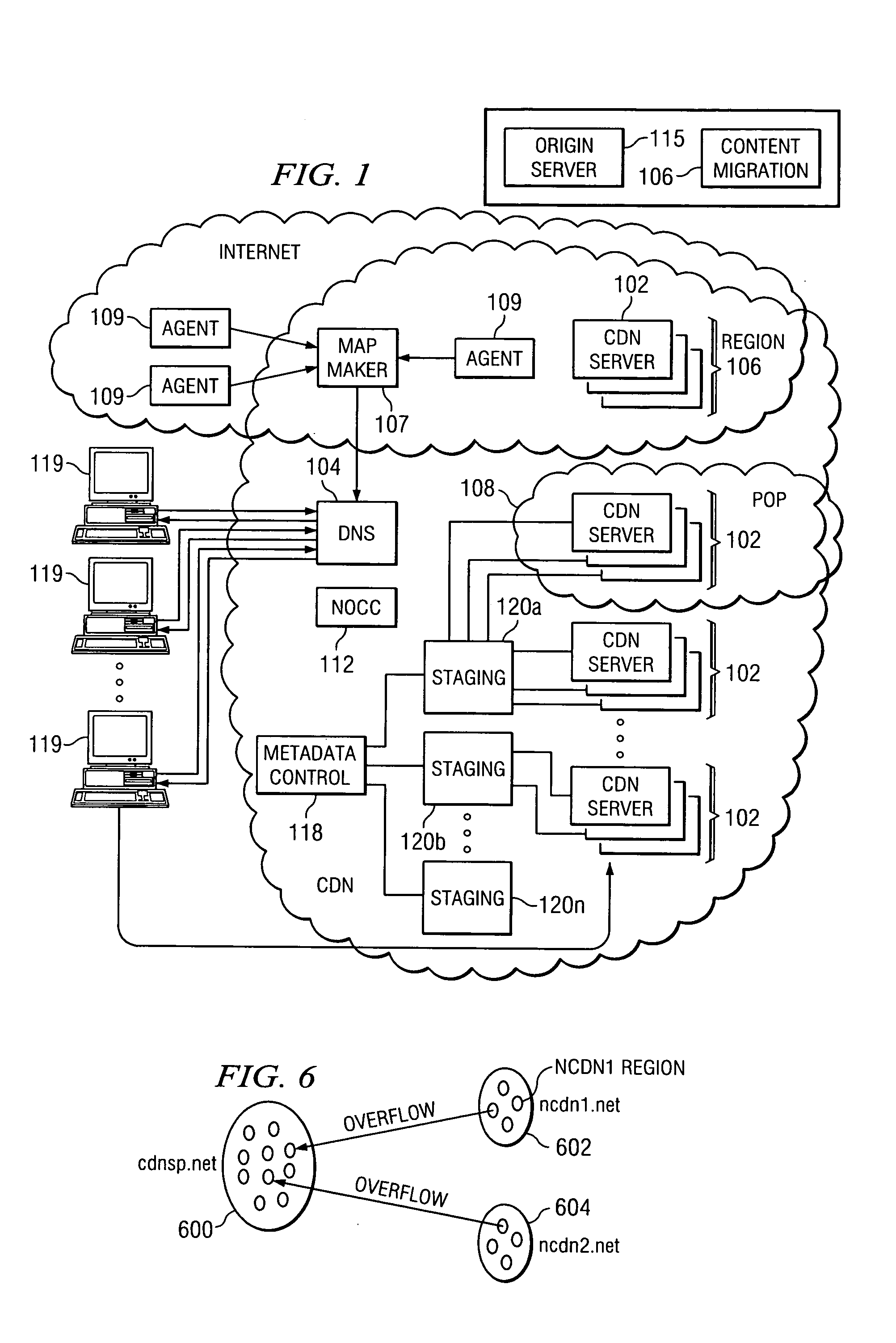

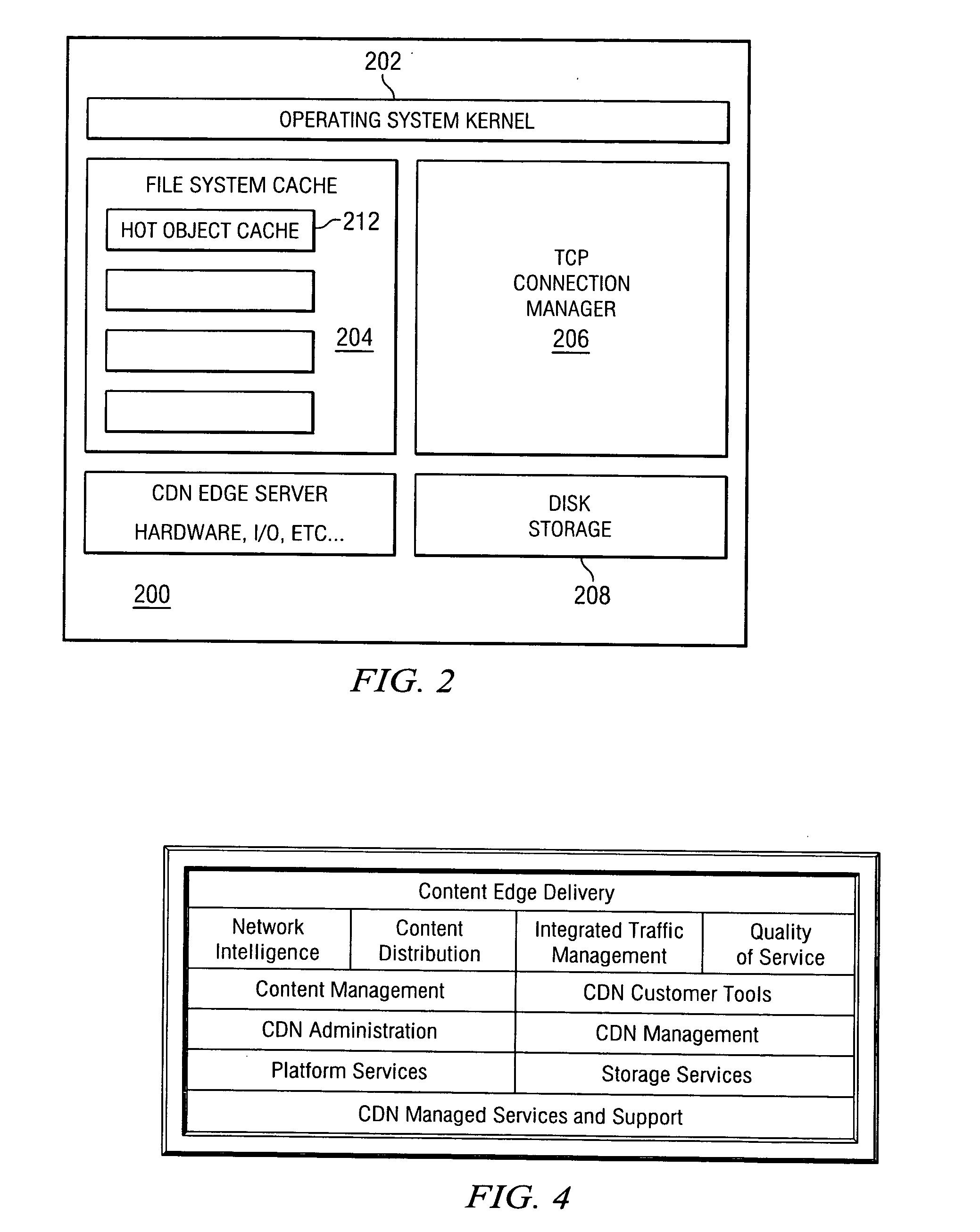

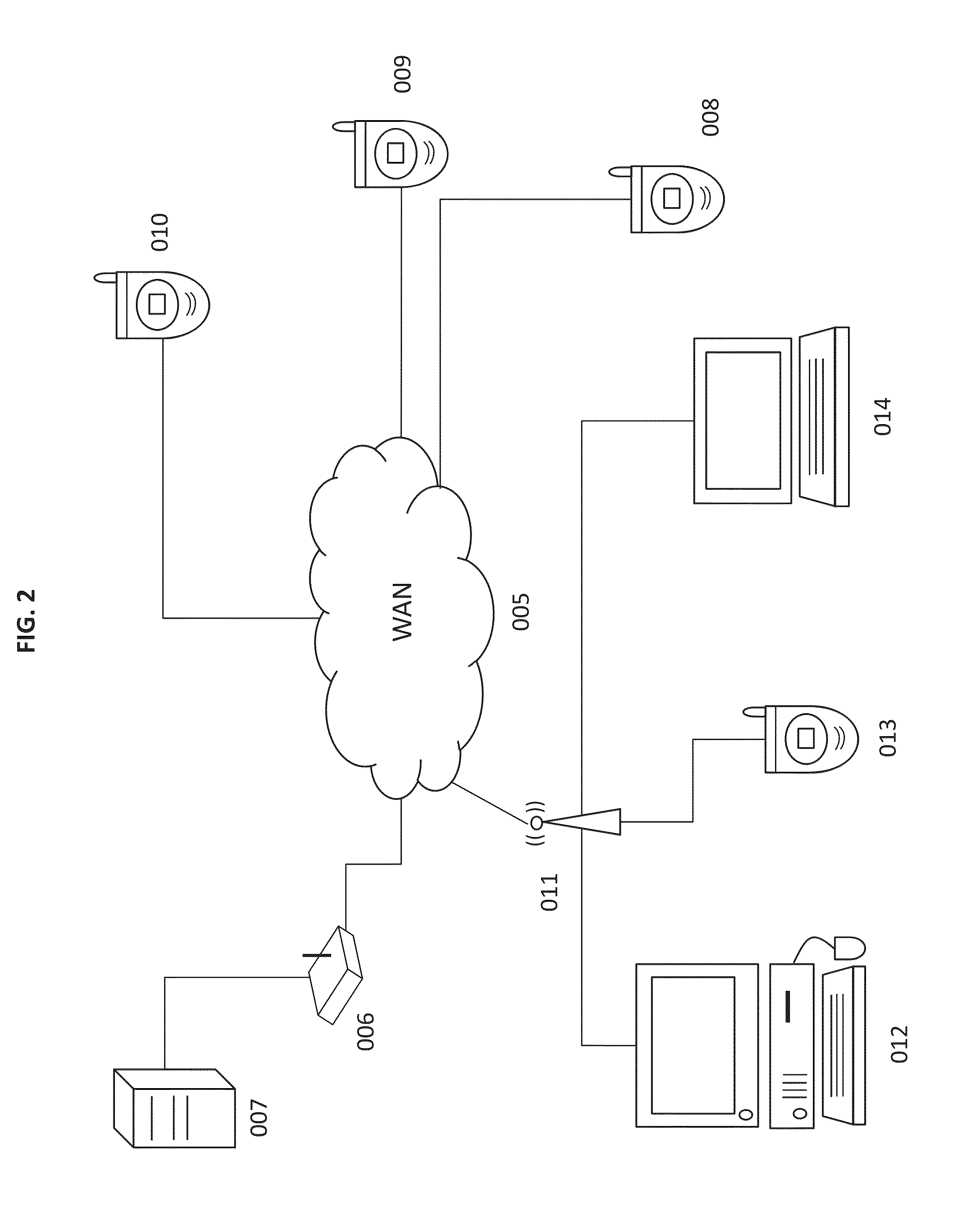

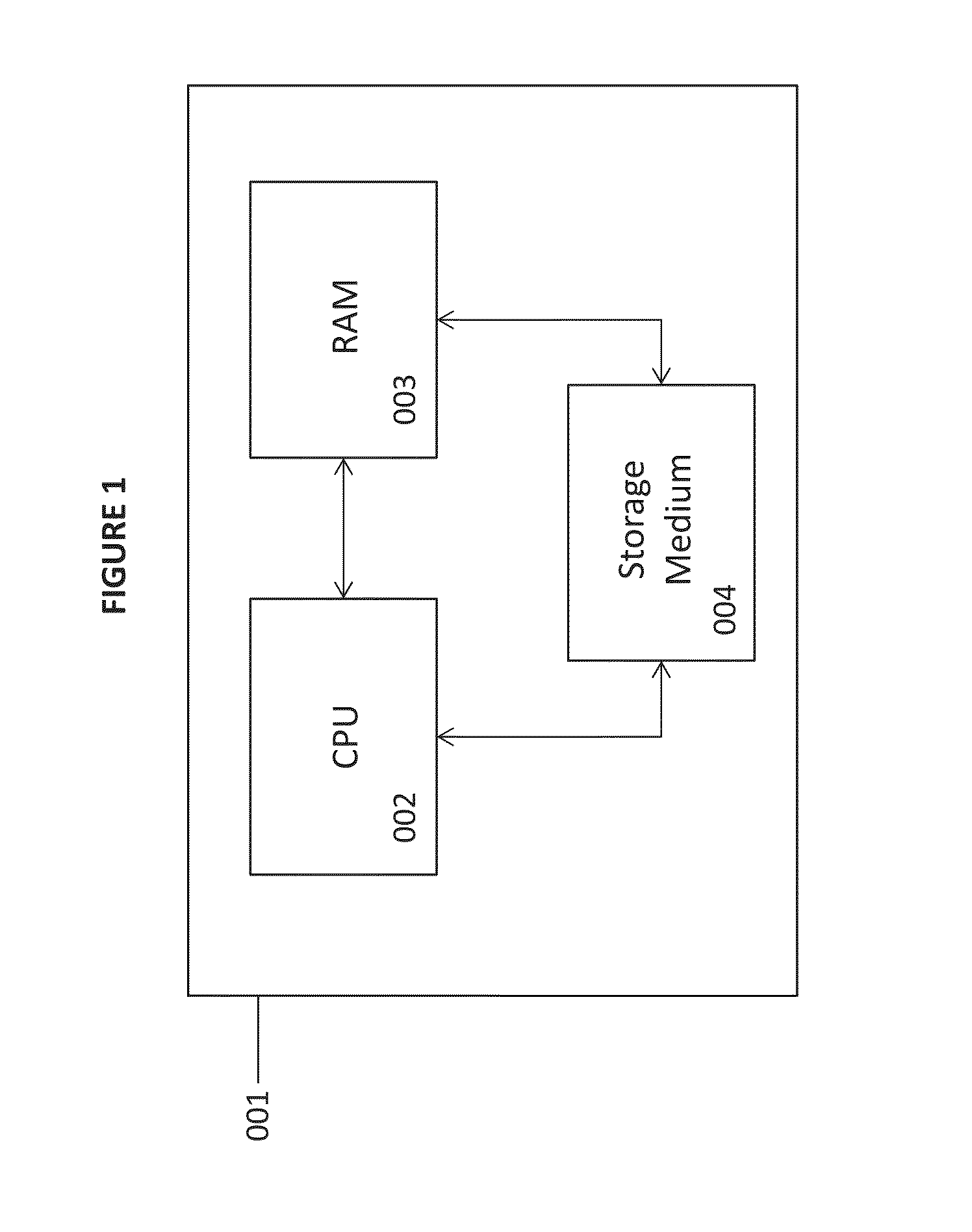

Content delivery network service provider (CDNSP)-managed content delivery network (CDN) for network service provider (NSP)

InactiveUS20070168517A1FinanceData switching by path configurationSchema for Object-Oriented XMLDistributed computing

A CDN service provider shares its CDN infrastructure with a network to enable a network service provider (NSP) to offer a private-labeled network content delivery network (NCDN or “private CDN”) to participating content providers. The CDNSP preferably provides the hardware, software and services required to build, deploy, operate and manage the CDN for the NCDN customer. Thus, the NCDN customer has access to and can make available to participating content providers one or more of the content delivery services (e.g., HTTP delivery, streaming media delivery, application delivery, and the like) available from the global CDN without having to provide the large capital investment, R&D expense and labor necessary to successfully deploy and operate the network itself. Rather, the global CDN service provider simply operates the private CDN for the network as a managed service.

Owner:AKAMAI TECH INC

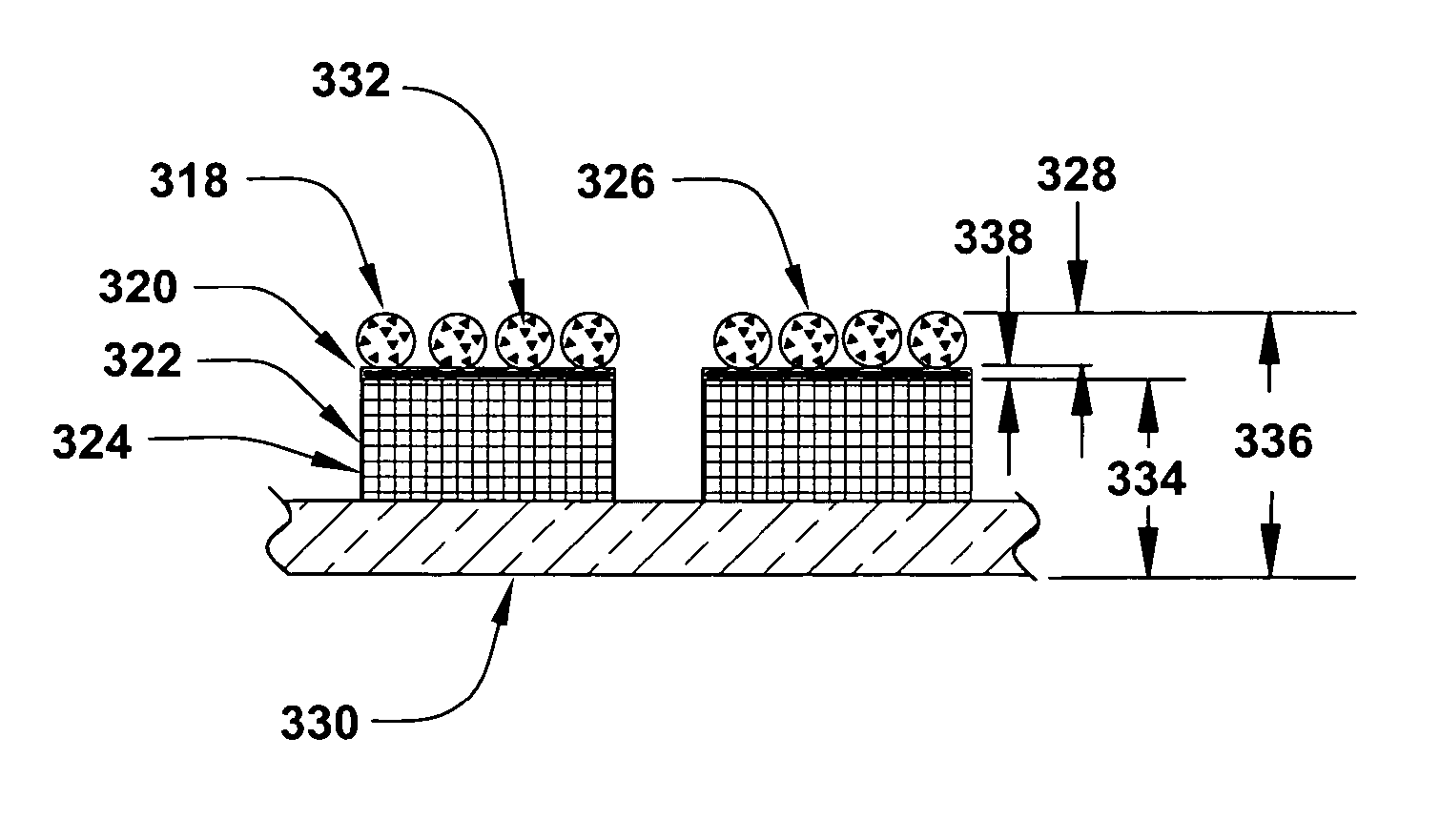

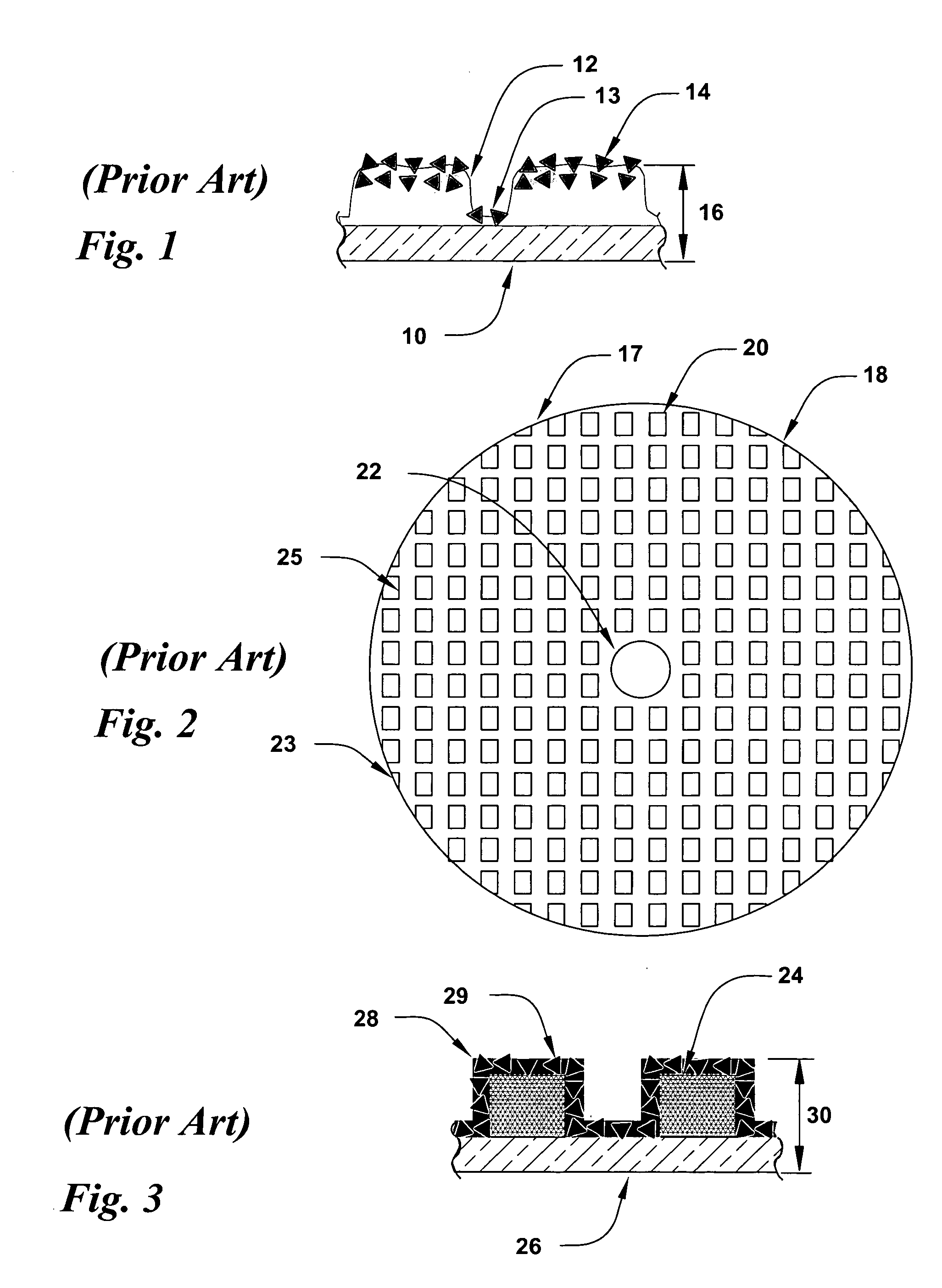

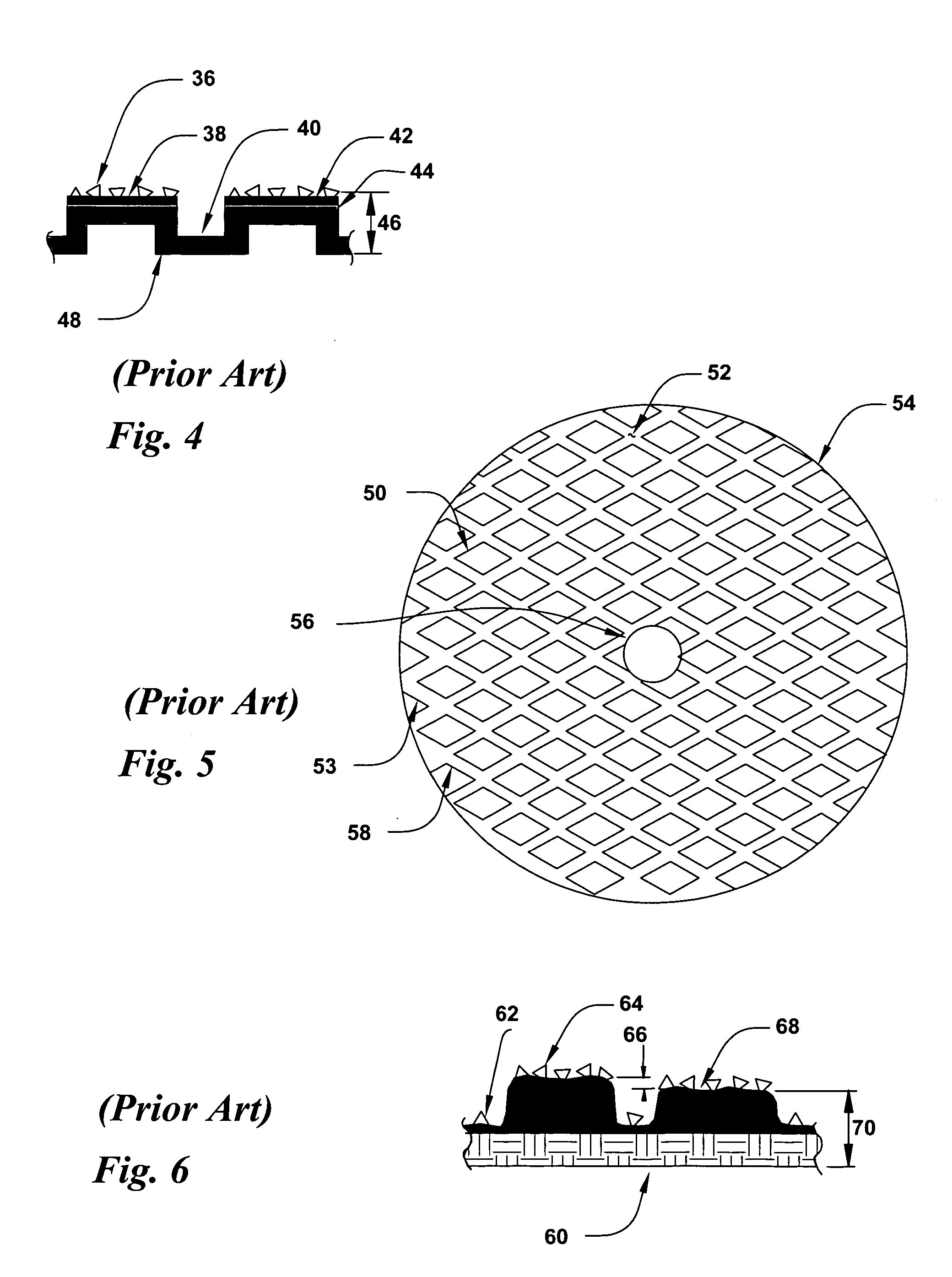

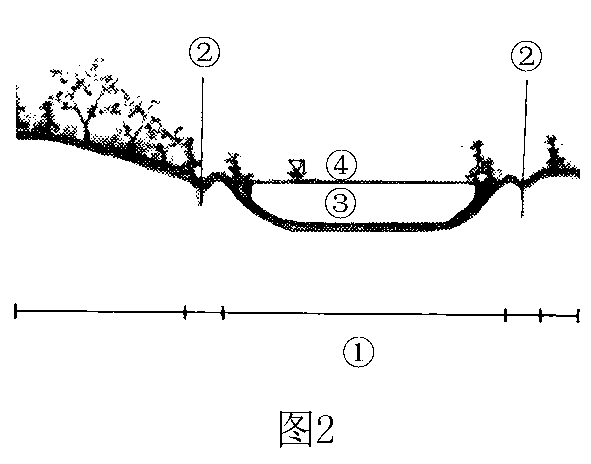

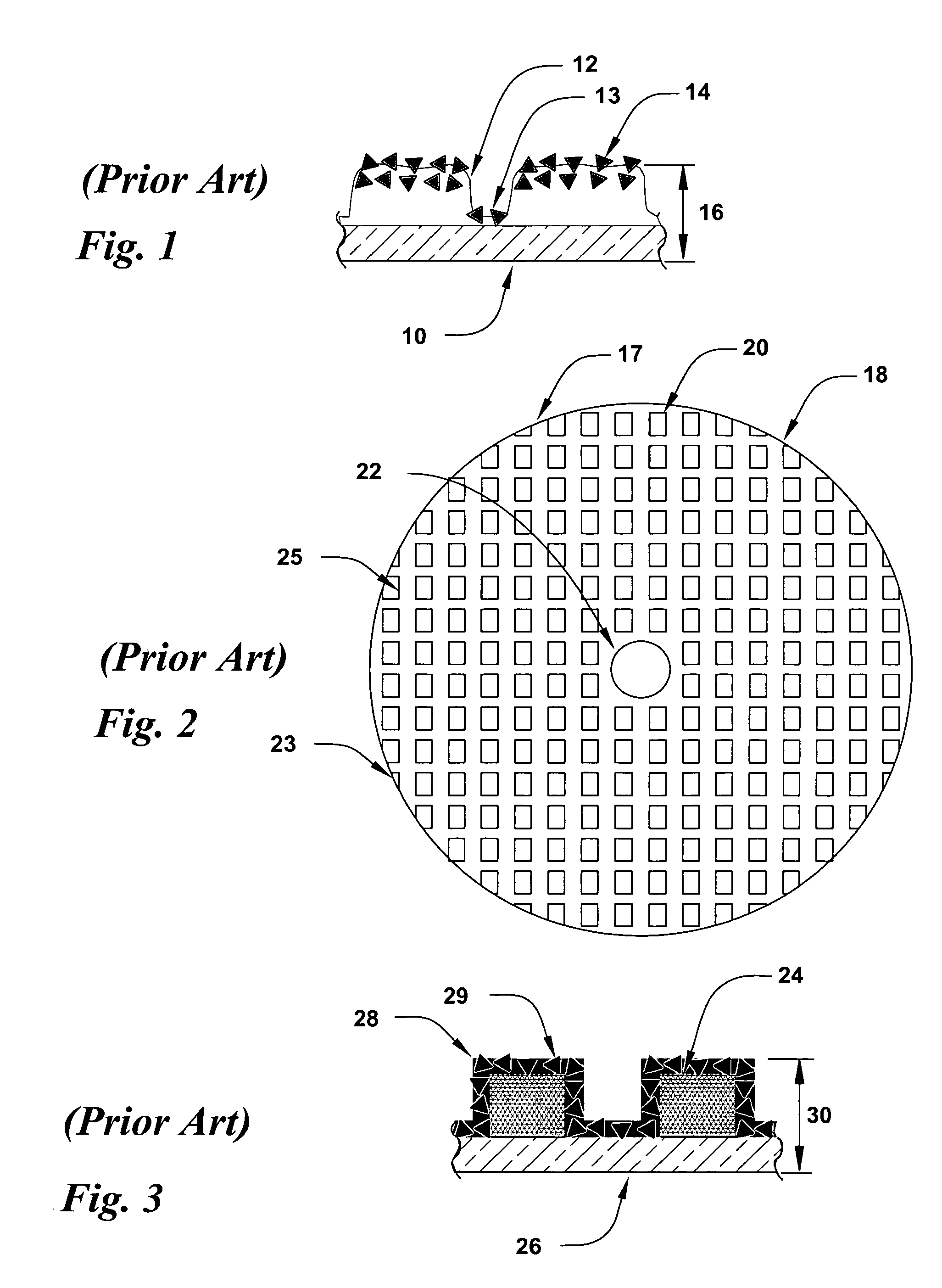

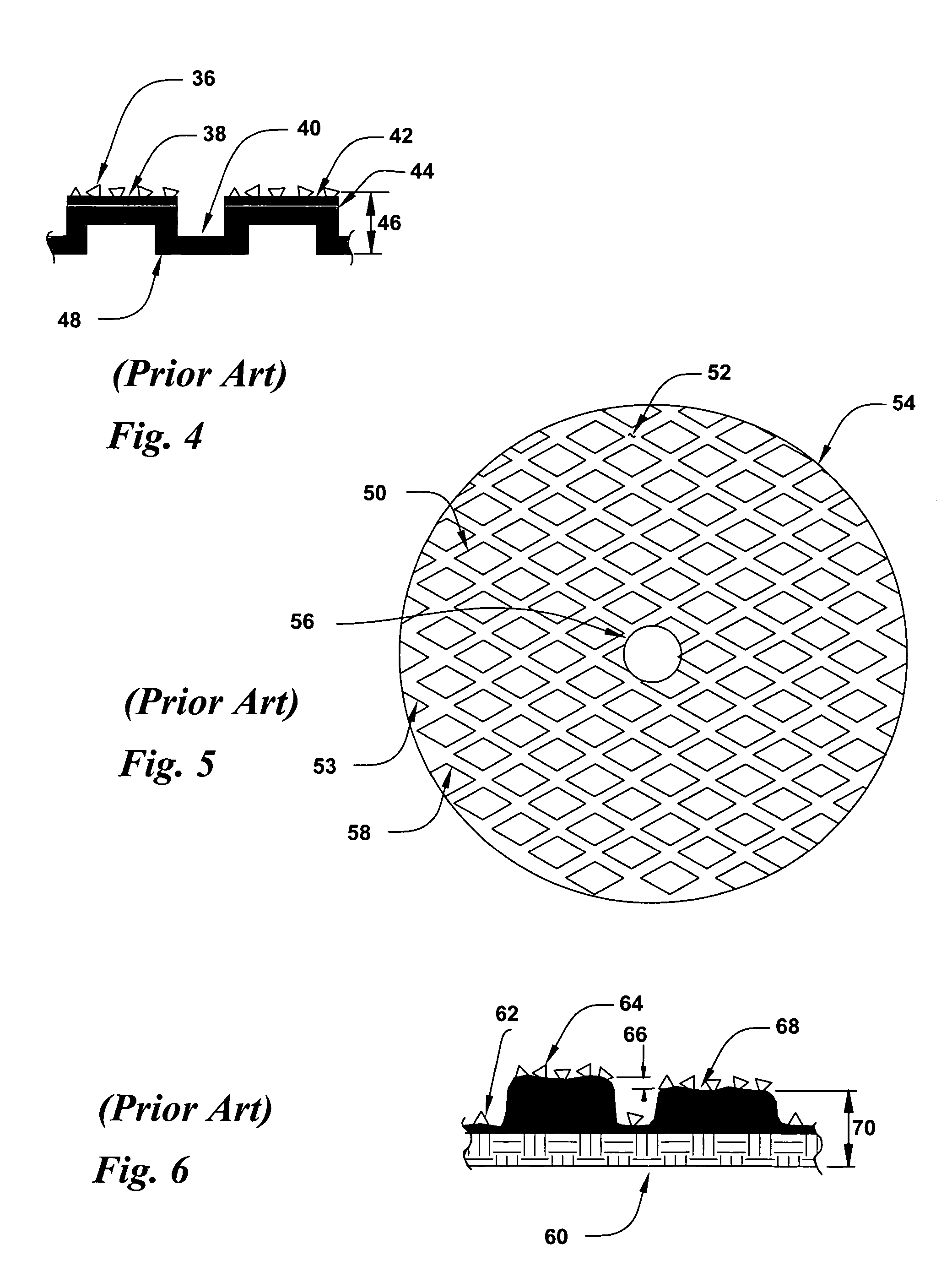

Abrasive bead coated sheet and island articles

InactiveUS20050118939A1Simple processReduce investmentPigmenting treatmentOther chemical processesWater basedSlurry

Flexible abrasive sheet articles having precision thickness flat-topped raised island structures that are coated with a monolayer of equal sized abrasive agglomerate are described. Methods of producing high quality equal-sized spherical shaped composite abrasive agglomerate beads containing small diamond abrasive particles are described. Beads are produced by level-filling fine mesh screens or perforated sheets with a water based metal oxide slurry containing abrasive particles and then using a fluid jet to eject the abrasive slurry lumps from the individual screen cells into a dehydrating environment. Surface tension forces form the ejected liquid lumps into spheres that are solidified and then heated in a furnace to form ceramic beads. These porous ceramic abrasive beads can be bonded directly onto the flat planar surface of a flexible backing material or they can be bonded onto raised island surfaces to form rectangular or disk abrasive sheet articles. Abrasive articles having equal sized abrasive beads are particularly suited for lapping and raised island articles are suited for high speed lapping. Non-abrasive equal-sized beads can also be formed using this simple bead manufacturing process, which requires only a very low capital investment.

Owner:DUESCHER WAYNE O

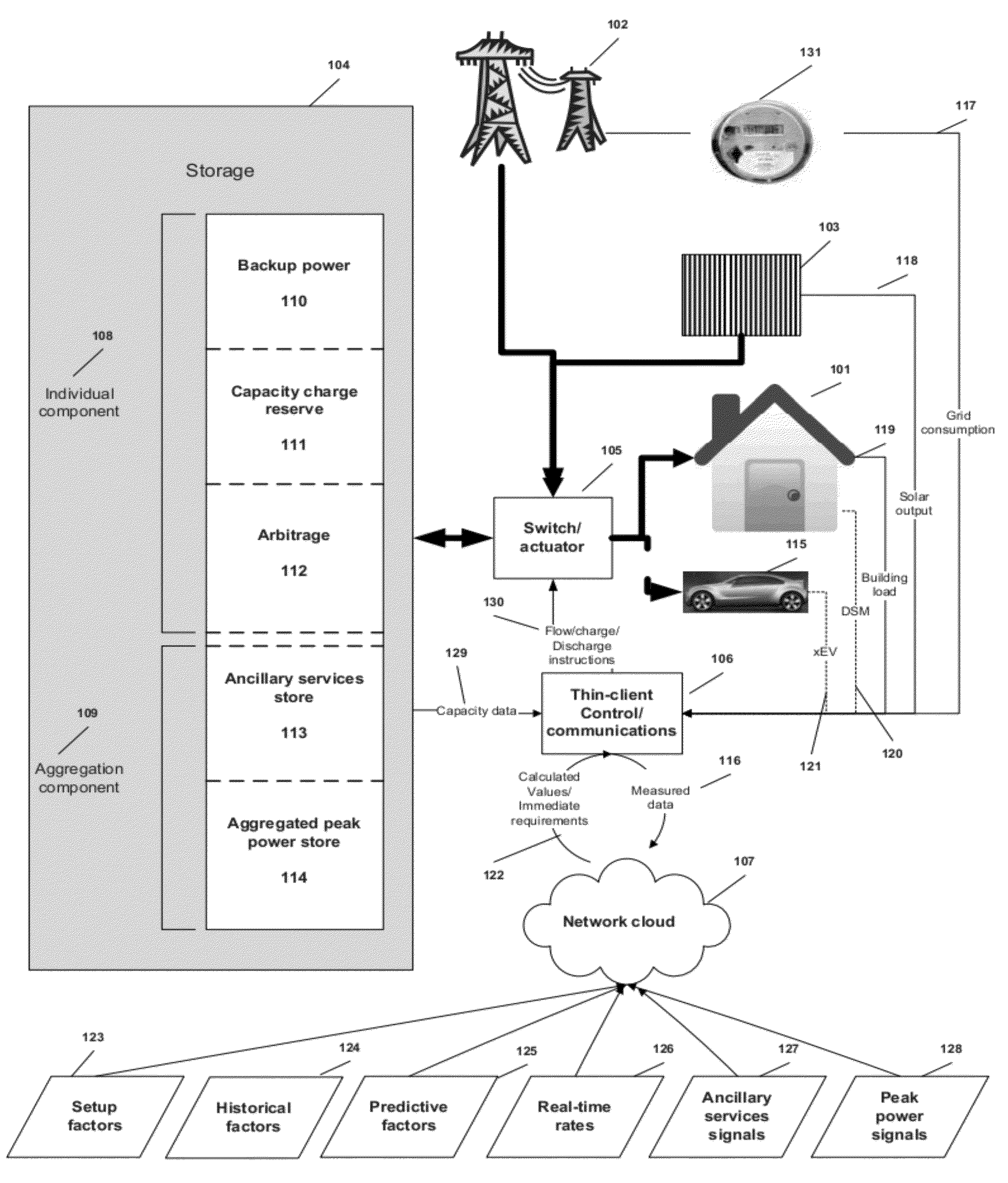

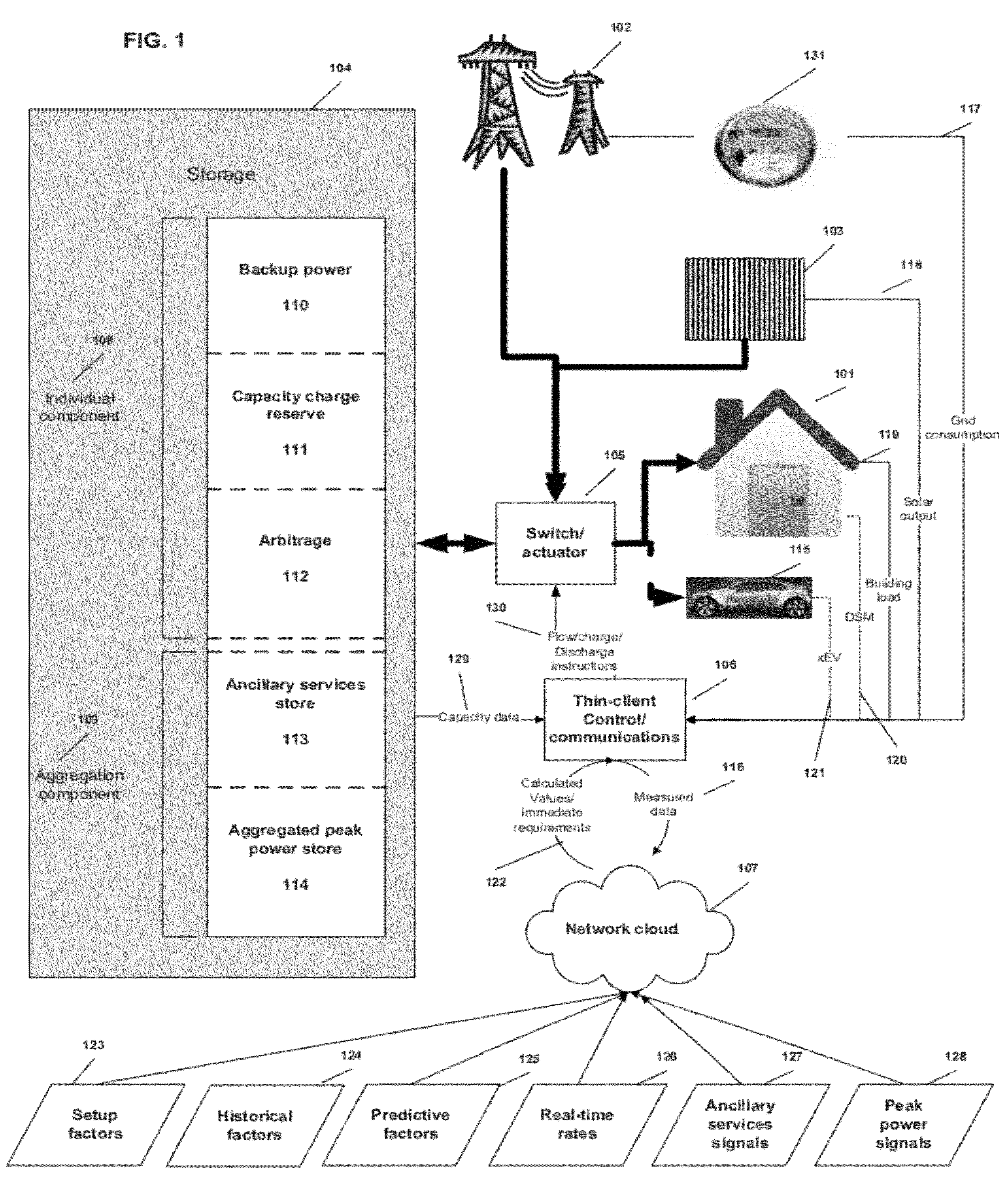

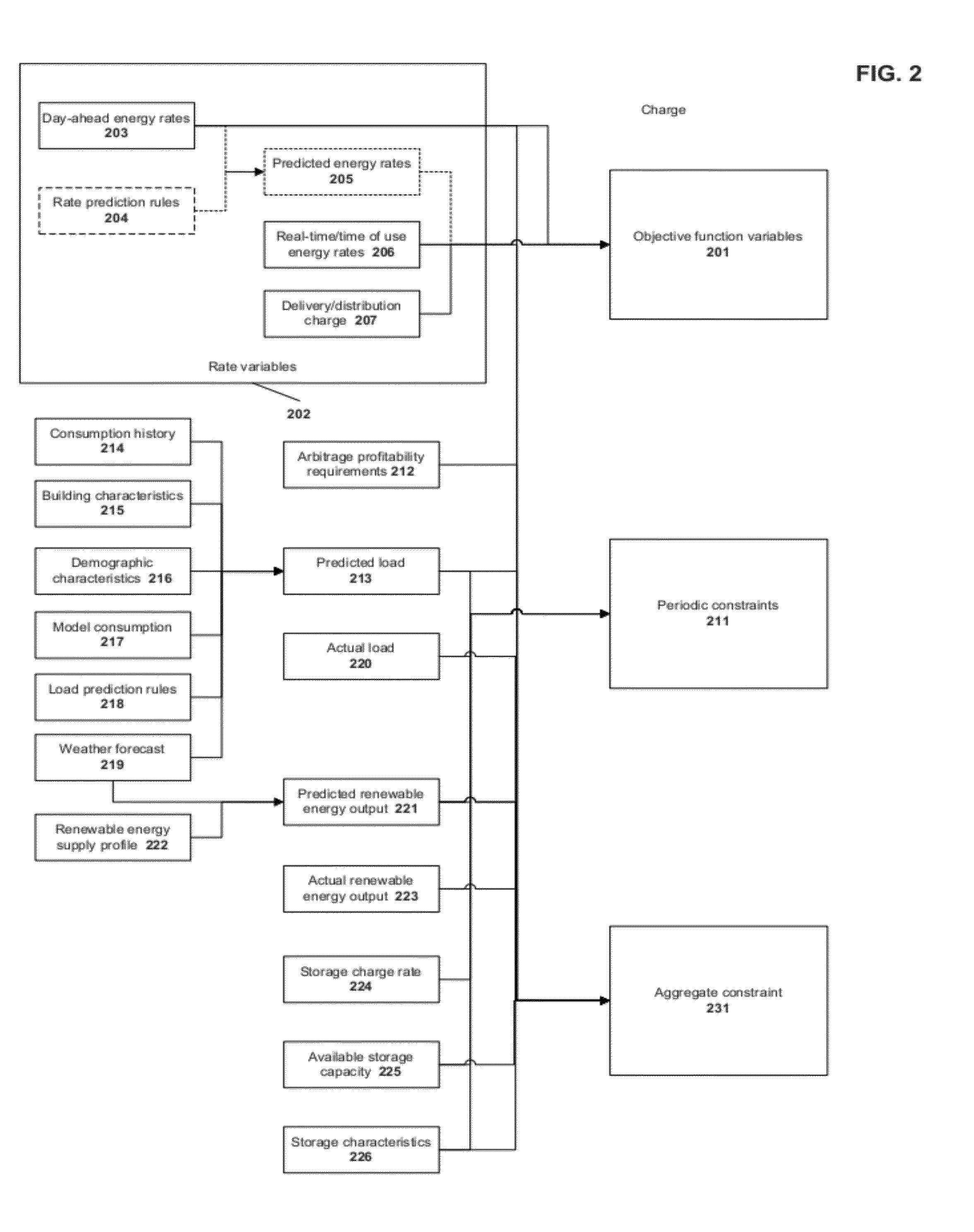

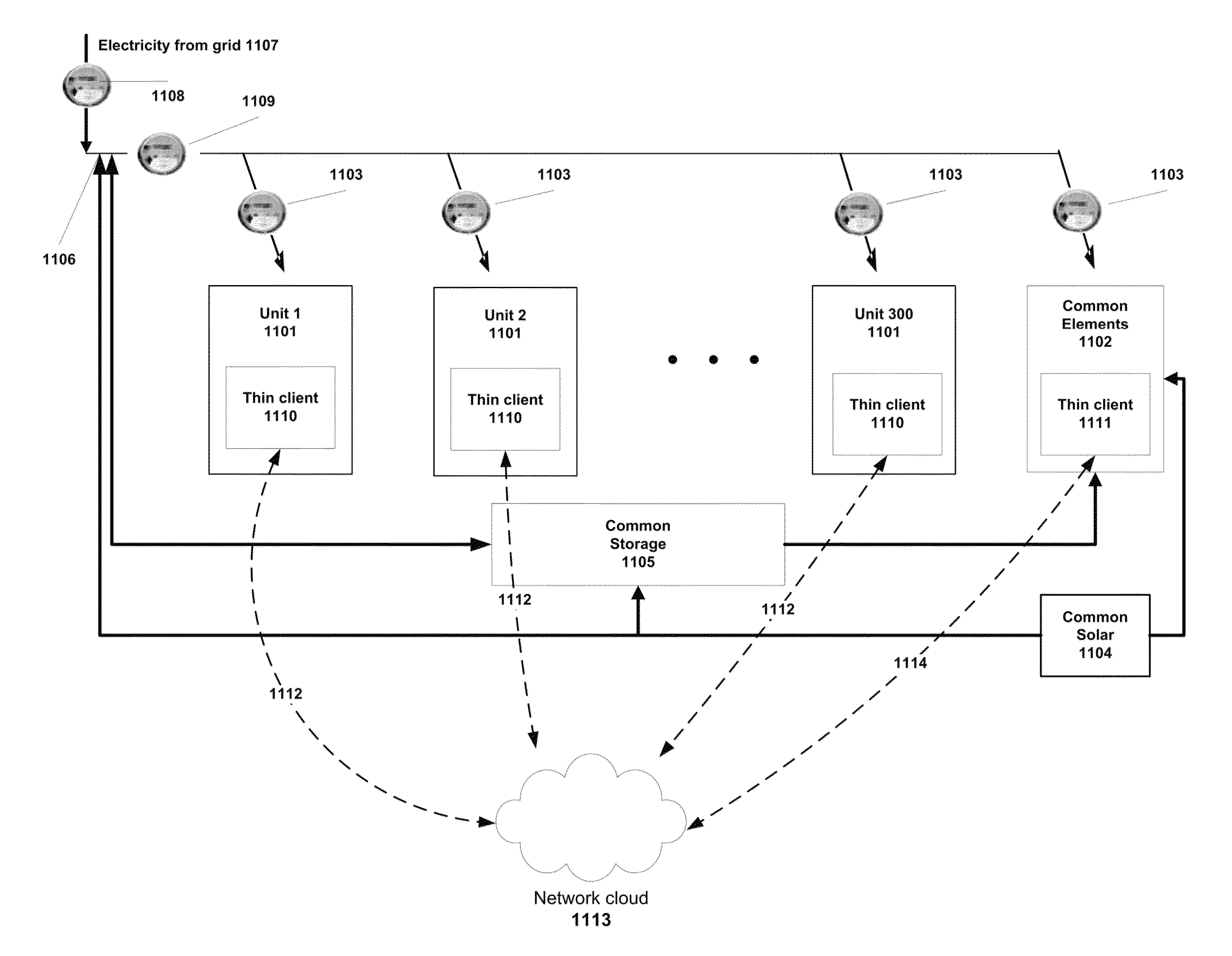

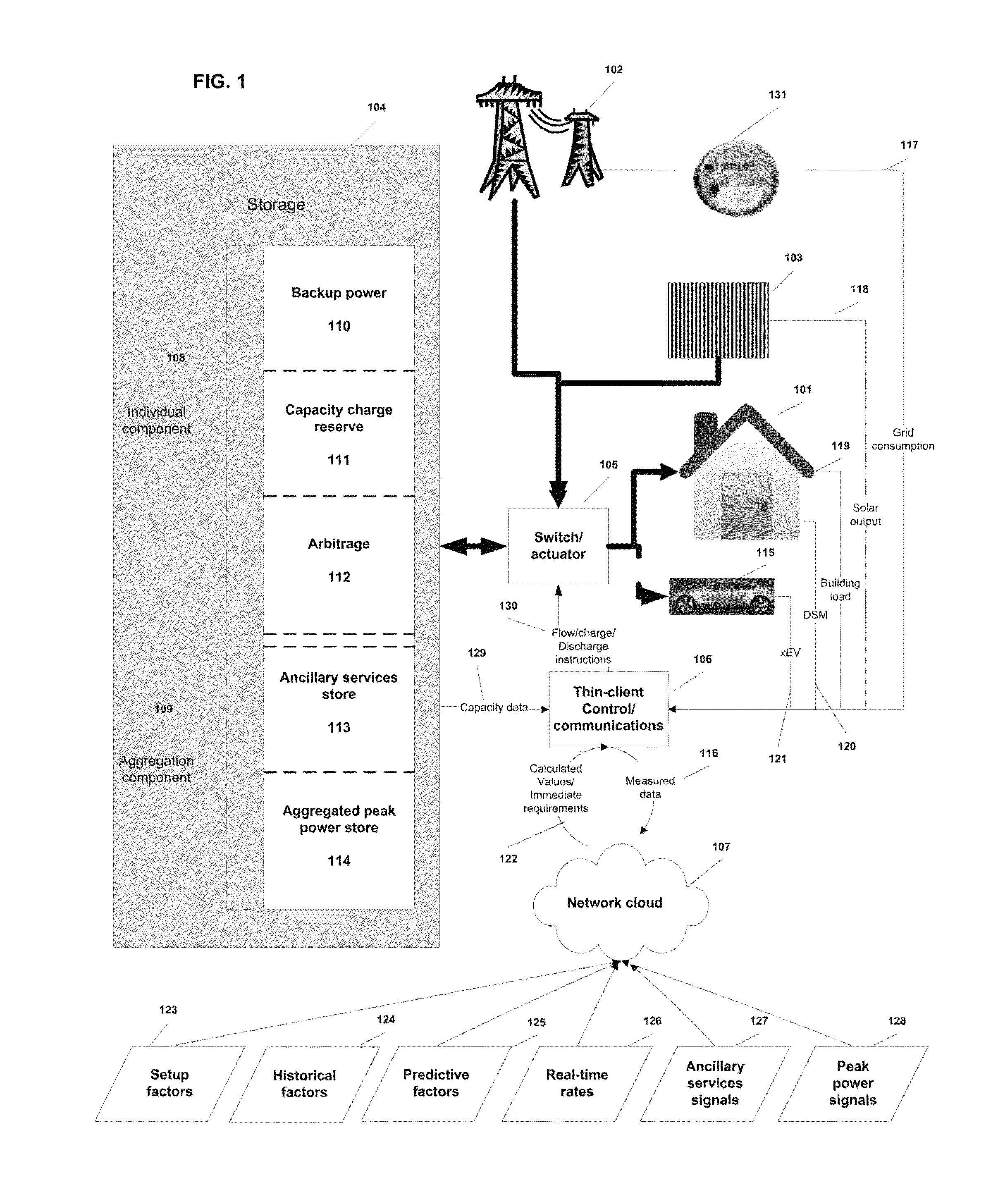

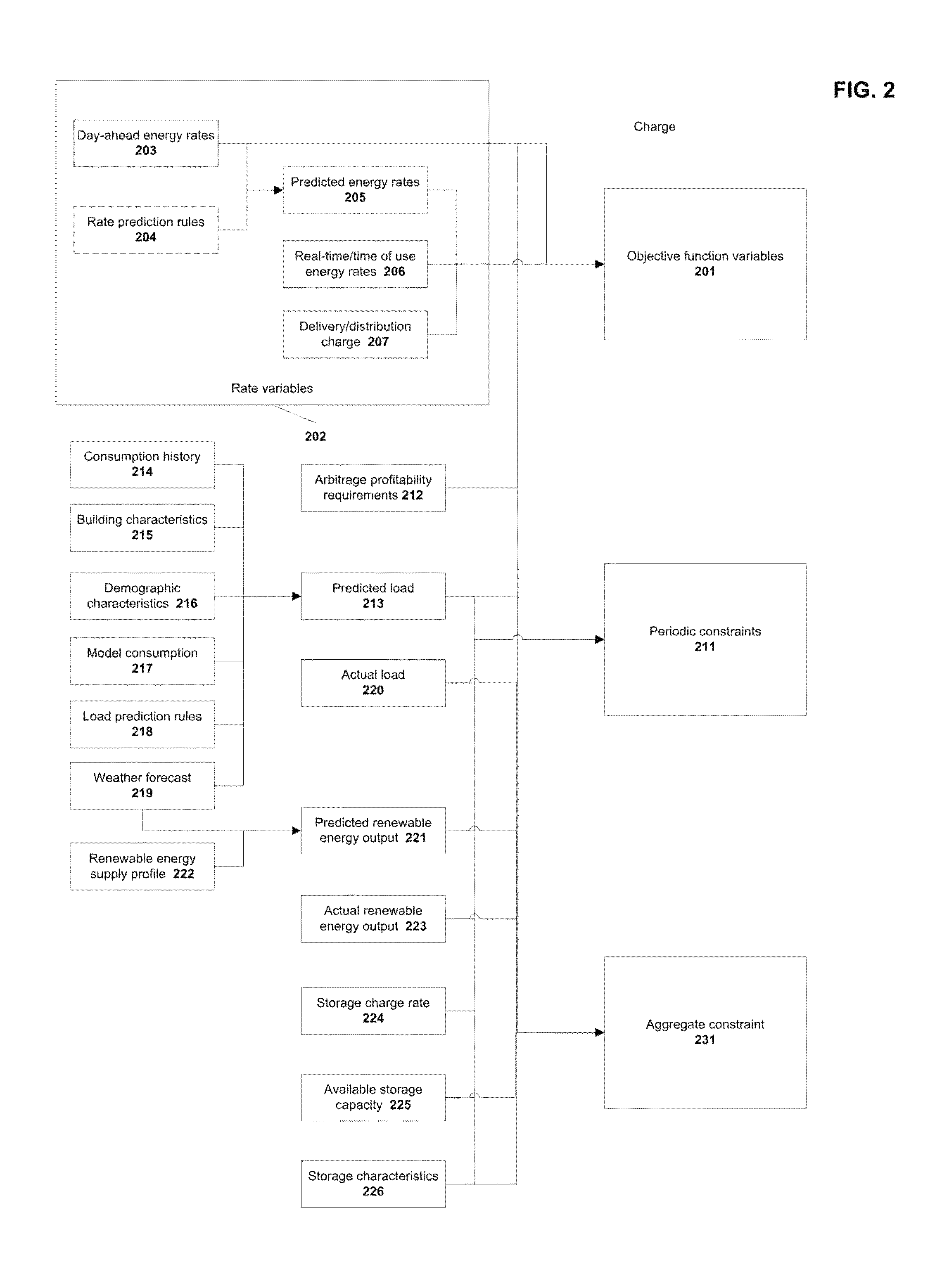

Virtual power plant system and method incorporating renewal energy, storage and scalable value-based optimization

ActiveUS20120130556A1Effective distributionLow costLevel controlWind energy generationCapital investmentPredictive factor

Methods and systems provided for creating a scalable building block for a virtual power plant, where individual buildings can incorporate on-site renewable energy assets and energy storage and optimize the acquisition, storage and consumption of energy in accordance with a value hierarchy. Each building block can be aggregated into a virtual power plant, in which centralized control of load shifting in selected buildings, based on predictive factors or price signals, can provide bulk power for ancillary services or peak demand situations. Aggregation can occur at multiple levels, including developments consisting of both individual and common renewable energy and storage assets. The methods used to optimize the system can also be applied to “right size” the amount of renewable energy and storage capacity at each site to maximize return on the capital investment.

Owner:INTELLIGENT GENERATION

Content delivery network service provider (CDNSP)-managed content delivery network (CDN) for network service provider (NSP)

ActiveUS7149797B1Large capital investmentSimple configurationFinanceMultiprogramming arrangementsComputer scienceWeb content

A CDN service provider shares its CDN infrastructure with a network to enable a network service provider (NSP) to offer a private-labeled network content delivery network (NCDN or “private CDN”) to participating content providers. The CDNSP preferably provides the hardware, software and services required to build, deploy, operate and manage the CDN for the NCDN customer. Thus, the NCDN customer has access to and can make available to participating content providers one or more of the content delivery services (e.g., HTTP delivery, streaming media delivery, application delivery, and the like) available from the global CDN without having to provide the large capital investment, R&D expense and labor necessary to successfully deploy and operate the network itself. Rather, the global CDN service provider simply operates the private CDN for the network as a managed service.

Owner:AKAMAI TECH INC

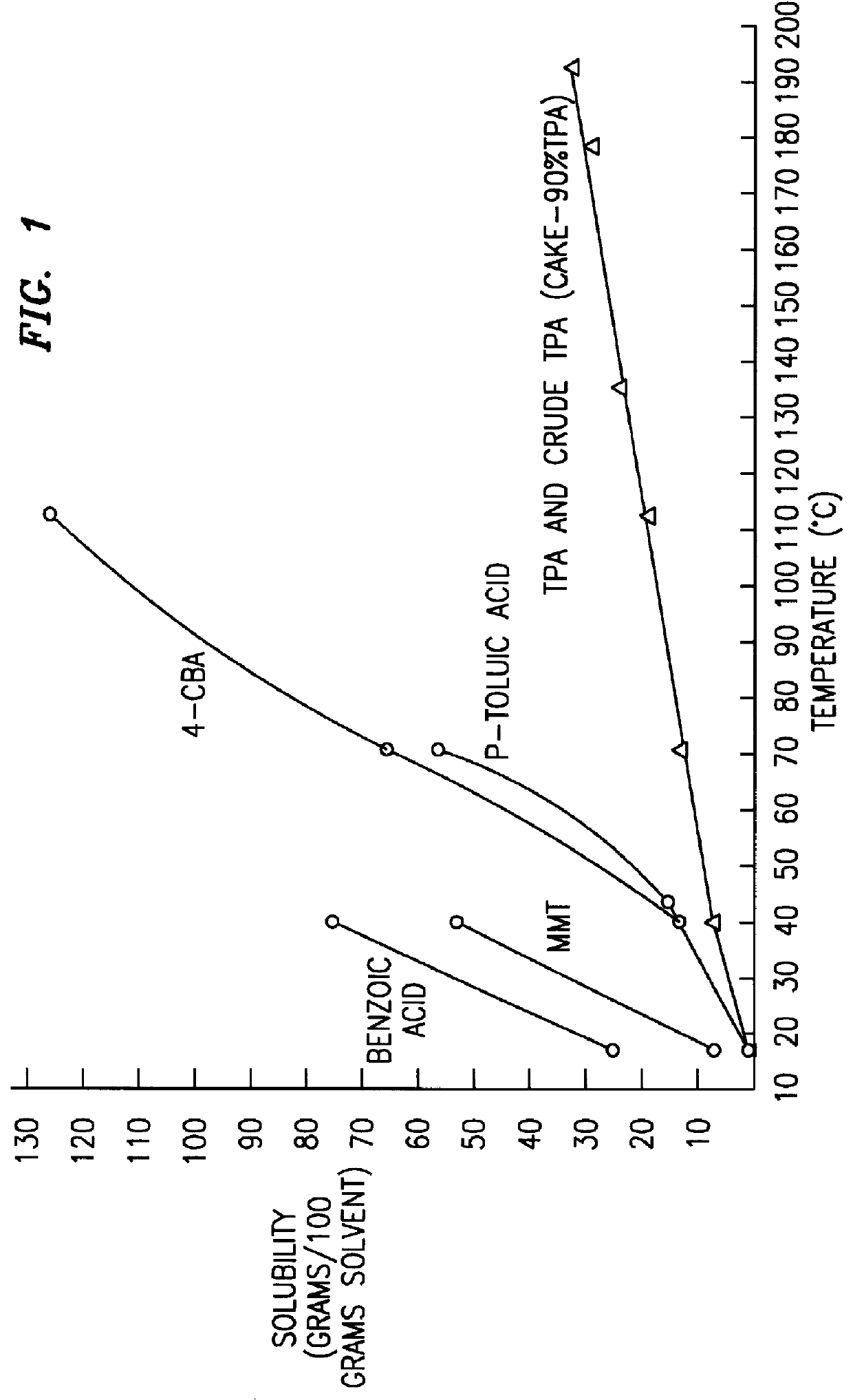

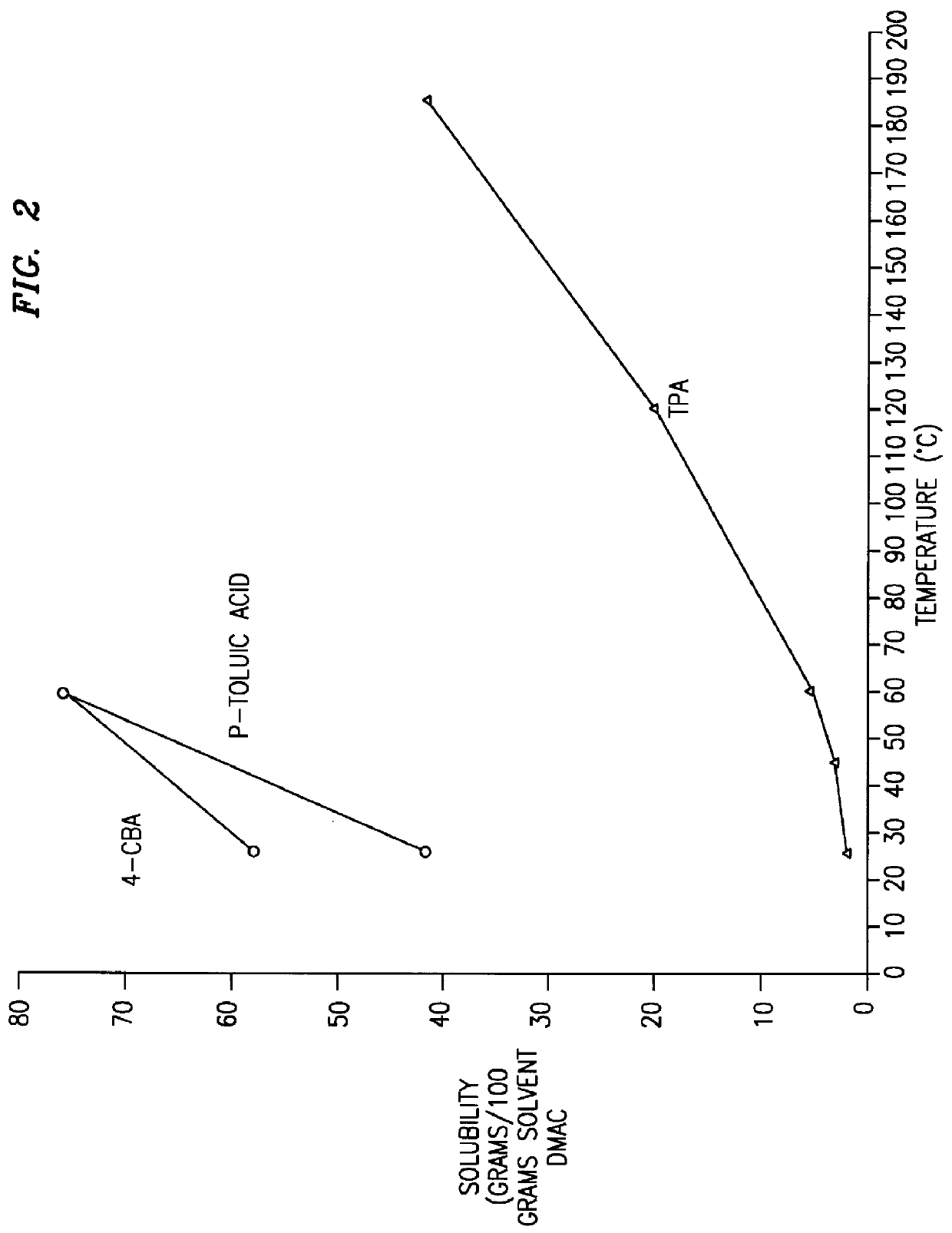

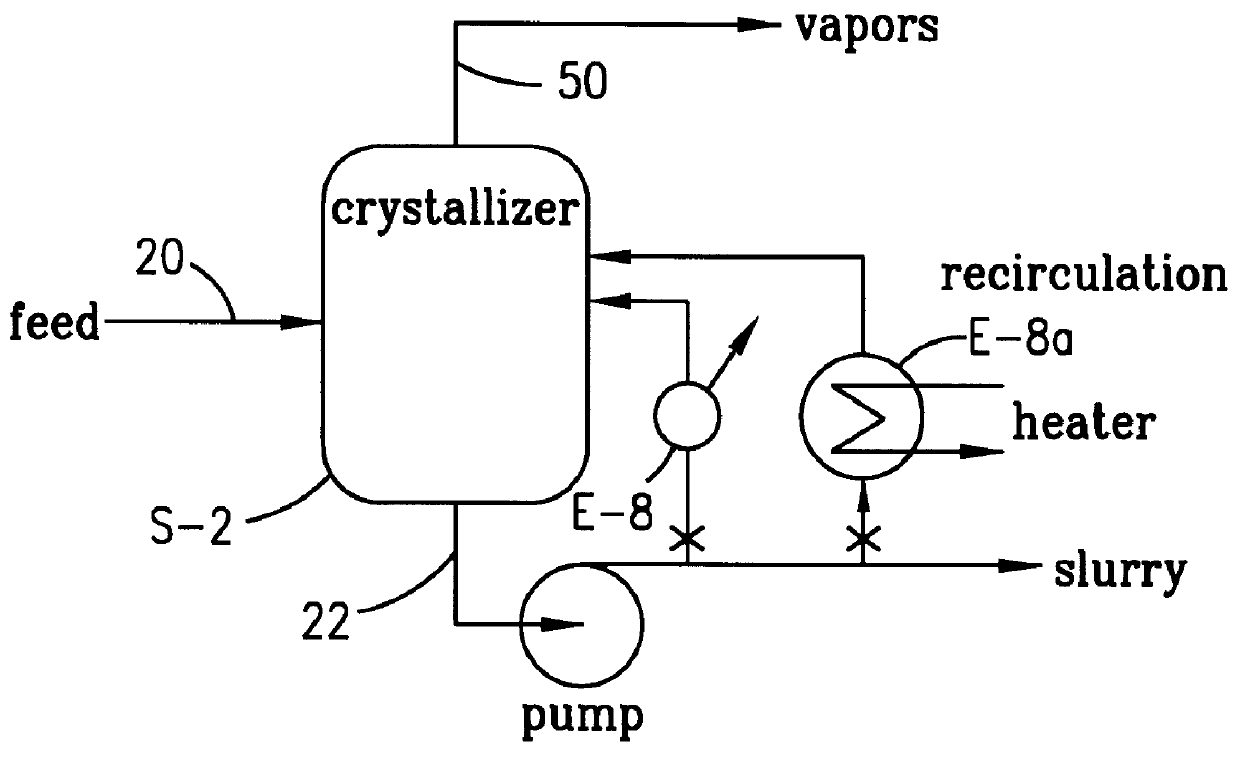

Method and apparatus for preparing purified terephthalic acid

InactiveUS6013835AOrganic compound preparationCarboxylic preparation by oxidationPolyester resinSide reaction

A method and apparatus for purifying crude terephthalic acid from a liquid dispersion thereof also containing impurities selected from unreacted starting materials, solvents, products of side reactions and / or other undesired materials is provided. The method comprises the steps of filtering the dispersion to form a crude terephthalic acid filter cake, dissolving the filter cake in a selective crystallization solvent at an elevated temperature to form a solution, crystallizing purified terephthalic acid from the solution in the crystallization solvent by reducing the pressure and temperature of the solution, and separating the crystallized purified terephthalic acid from the solution. According to the invention, the selective crystallization solvent is non-aqueous, non-corrosive and essentially non-reactive with terephthalic acid. Preferably, the selective crystallization solvent is N-methyl pyrrolidone. The method and apparatus produces purified terephthalic acid having a purity desired for use in forming polyester resin and other products at an economically attractive rate and at operating conditions of reduced severity which require a lower capital investment and simplified processing.

Owner:GTC TECHNOLOGY INC

Qualitative and quantitative modeling of enterprise risk management and risk registers

The present invention is applicable in the field of corporate finance, corporate capital investments, economics, math, business risk analysis, simulation, decision analysis, qualitative risk analysis, risk management, quantitative risk analysis, and business statistics, and relates to the modeling and valuation of investment decisions under uncertainty and risk within all companies, allowing these firms to properly identify, assess, quantify, value, diversify, and hedge their corporate capital investment decisions and their associated risks. Specifically, the present invention looks at starting from a comprehensive qualitative risk register and moving the analysis into the realms of quantitative risk modeling, simulation, and optimization.

Owner:MUN JOHNATHAN

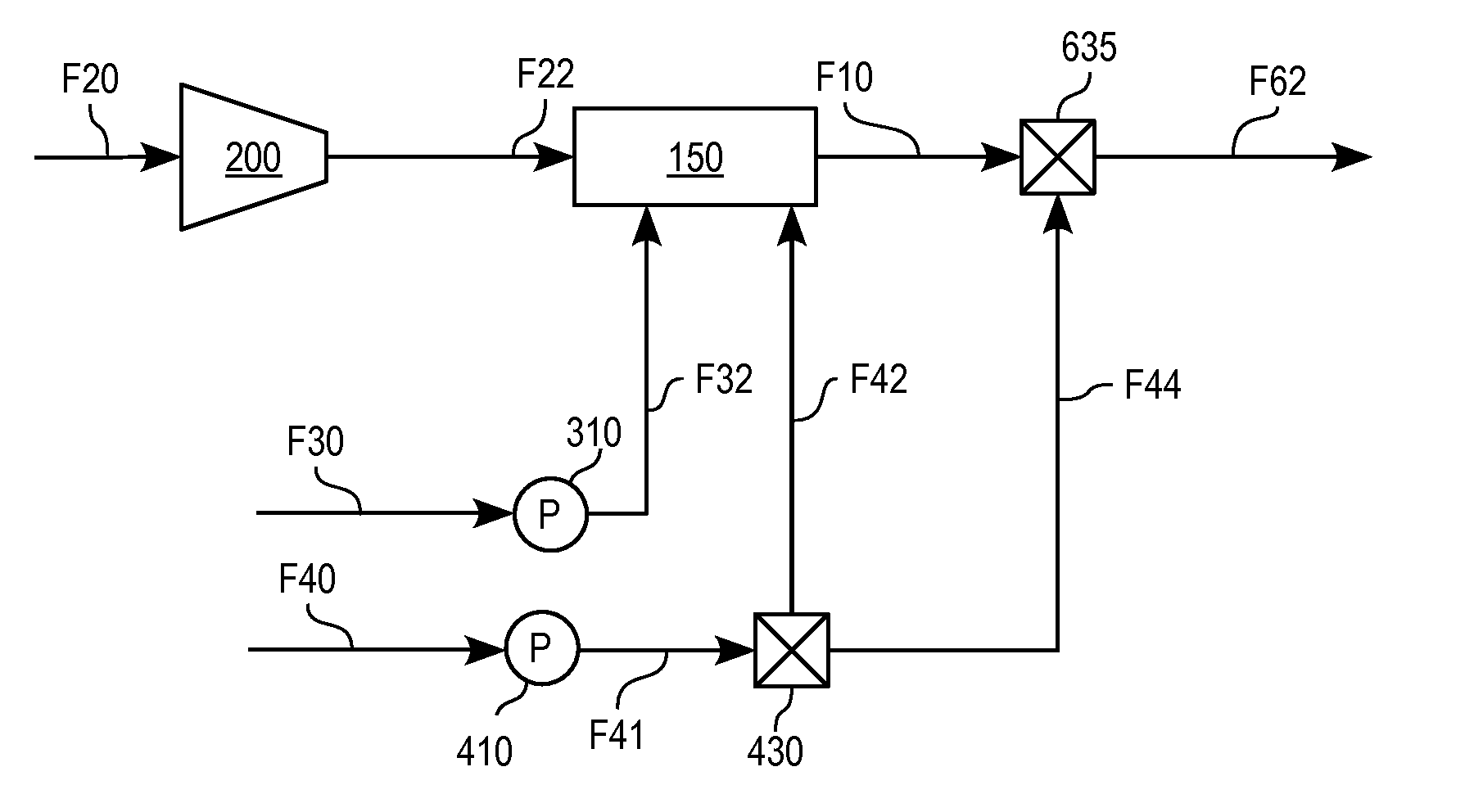

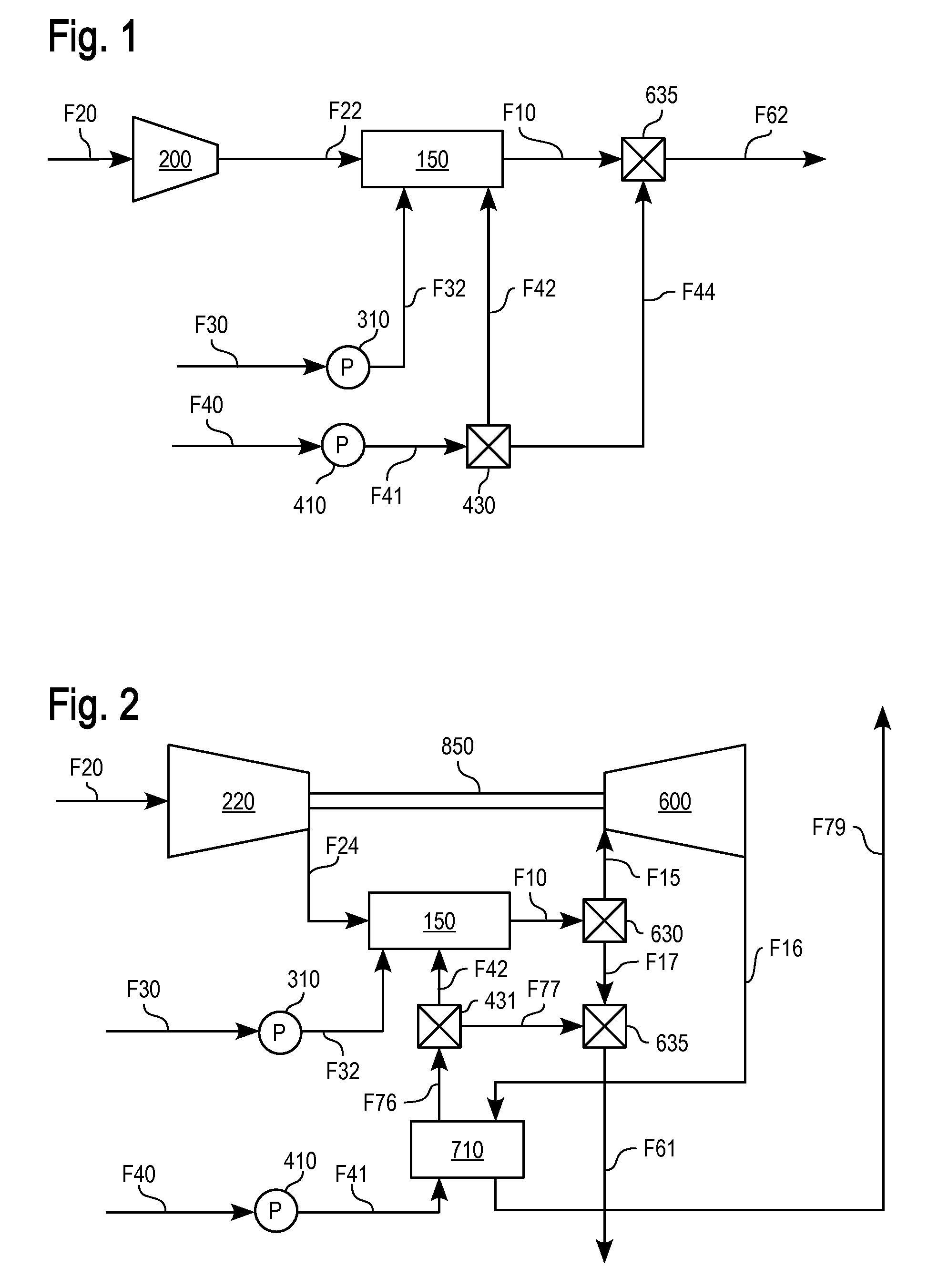

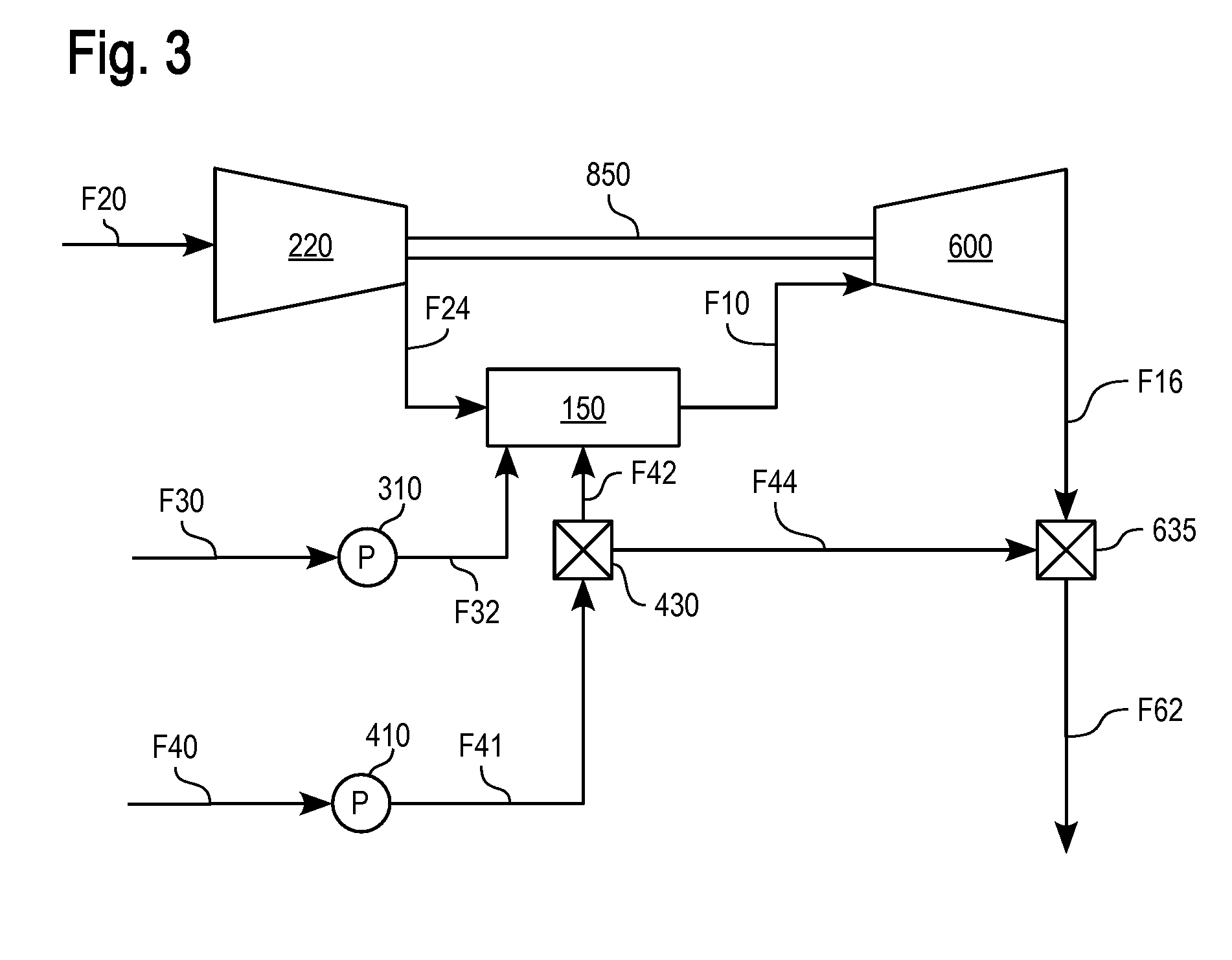

Heavy oil recovery with fluid water and carbon dioxide

ActiveUS20090071648A1Improves hydrocarbon extraction efficiencySpeed up the extraction processFluid removalFuel oilInjection well

Diluted wet combustion forms a hot process fluid or VASTgas comprising carbon dioxide (CO2) and fluid water which is delivered geologic formations and / or from surface mined materials to reduce the viscosity and / or increase hydrocarbon extraction. This may improve thermal efficiency and / or increases heat delivery for a given combustor or per capital investment. High water and / or CO2 content is achieved by reducing non-aqueous diluent and / or adding or recycling CO2. Power recovered from expanding the VASTgas may be pressurize the VASTgas for delivery by partial expansion through a Direct VAST cycle, and / or by diverting compressed oxidant through a parallel thermogenerator in a Diverted VAST cycle. Pressurized VASTgas may be injected into well within the hydrocarbon formation or with mined material into a heavy hydrocarbon separator vessel to heat, mobilize, solubilize and / or extract heavy hydrocarbons. Light hydrocarbons may be mixed in with the hot process fluid to enhance hydrocarbon mobilization and recovery. Microwaves may further heat the VASTgas and / or hydrocarbon. Sulfur oxidation, calcining limestone and / or recycling may increase CO2. Oxygen enrichment may increase the specific power. VASTgas may be delivered through and back injection wells and / or production wells, and / or between sequential injection wells in alternating and / or paired zigzag formations with multiple wells per VAST combined heat and power recovery system.

Owner:VAST HLDG LLC

Project economics analysis tool

ActiveUS20130103615A1Facilitate business risk analysisFinanceForecastingRisk profilingAnalysis tools

The present invention is applicable in the field of corporate finance, corporate capital investments, economics, math, risk analysis, simulation, decision analysis, and business statistics, and relates to the modeling and valuation of investment decisions under uncertainty and risk within all companies, allowing these firms to properly identify, assess, quantify, value, diversify, and hedge their corporate capital investment decisions and their associated risks

Owner:MUN JOHNATHAN

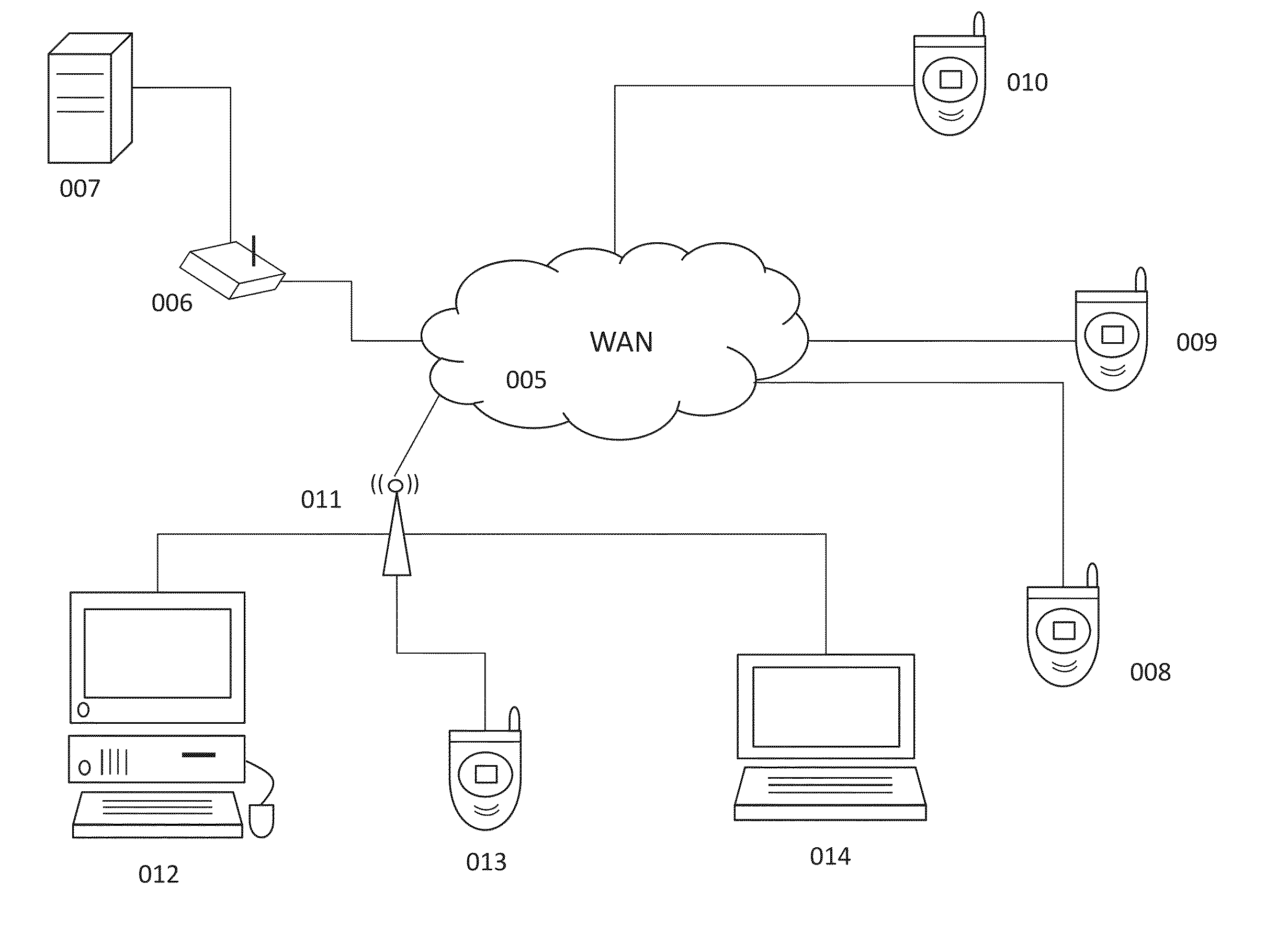

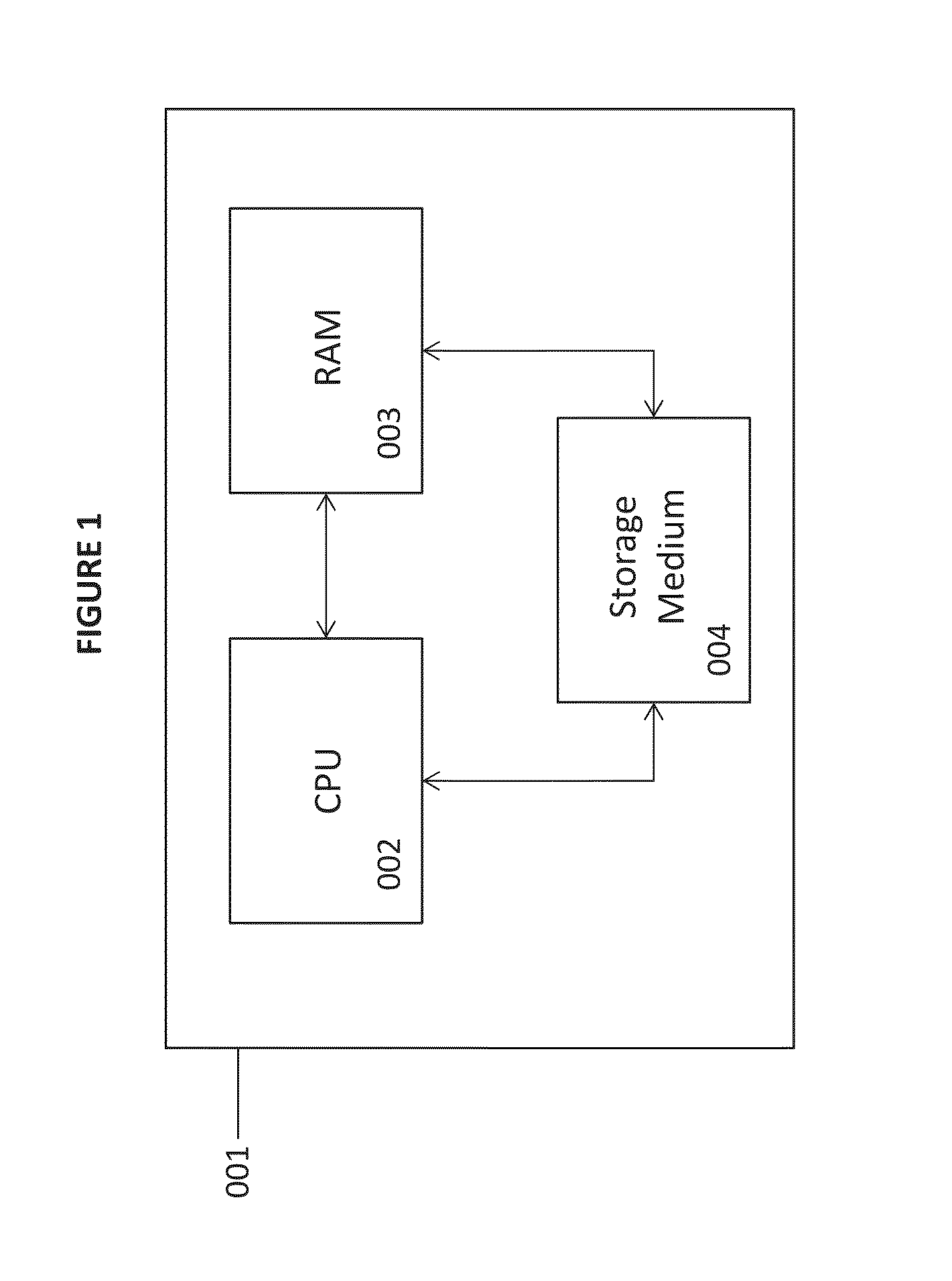

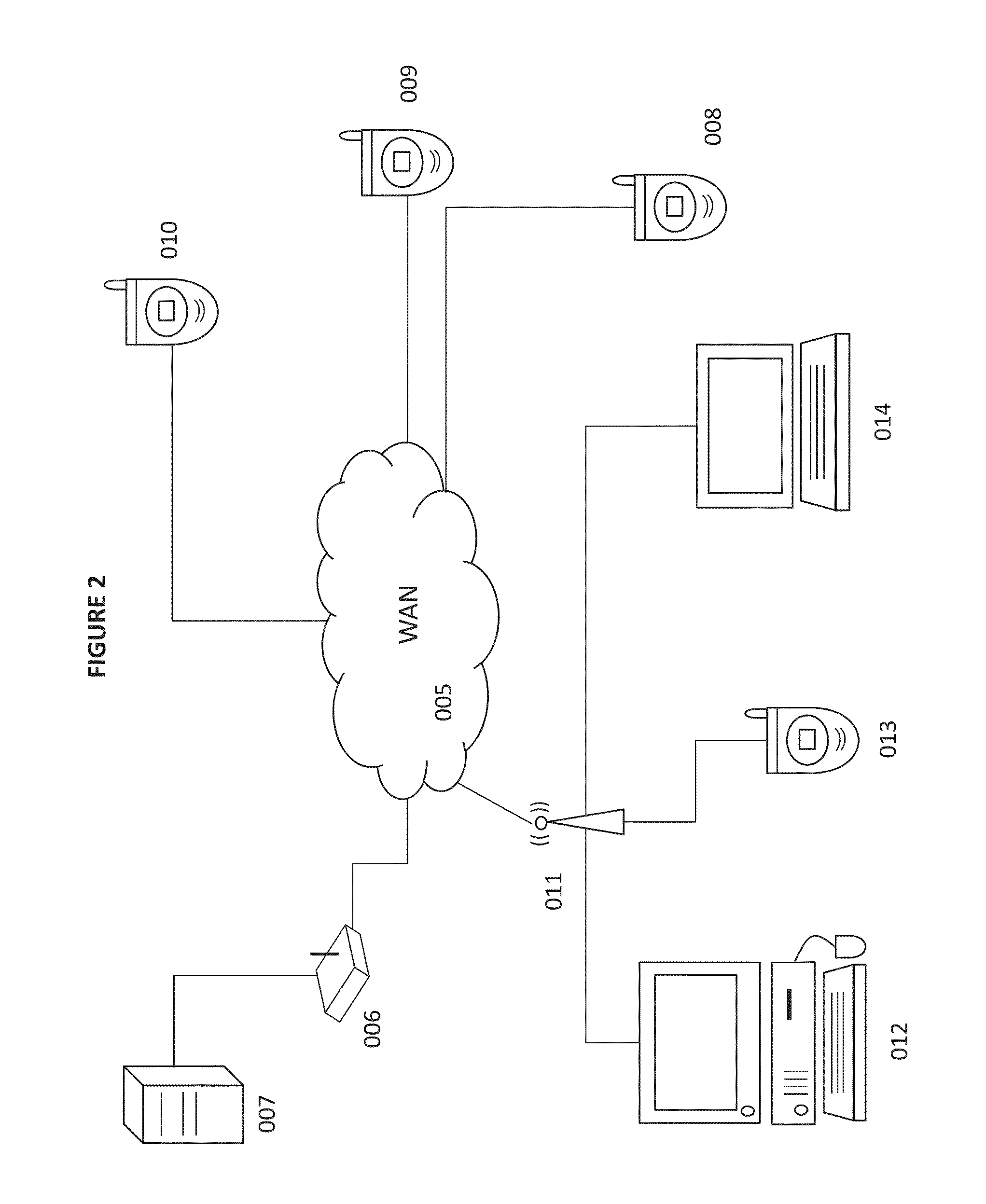

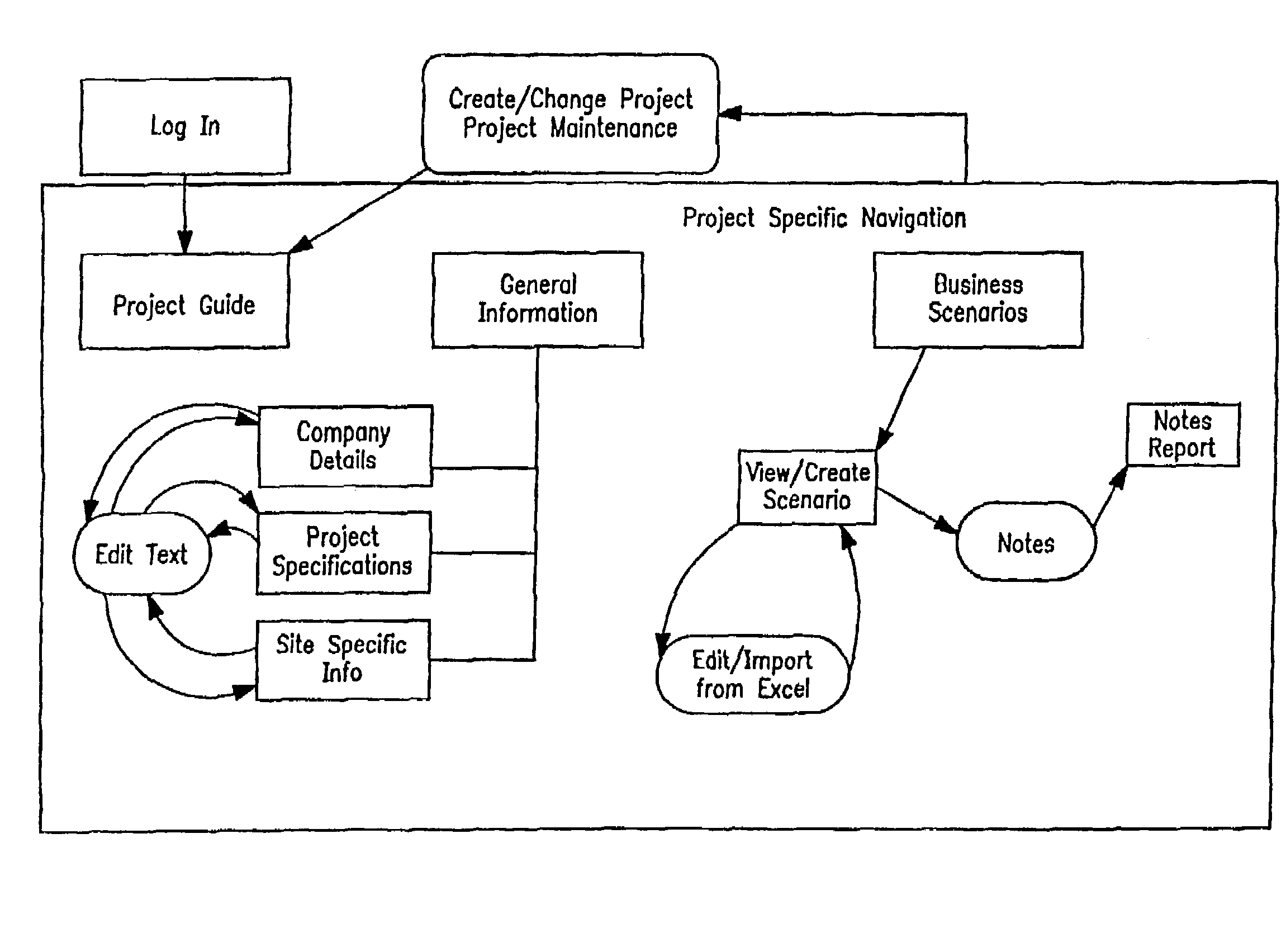

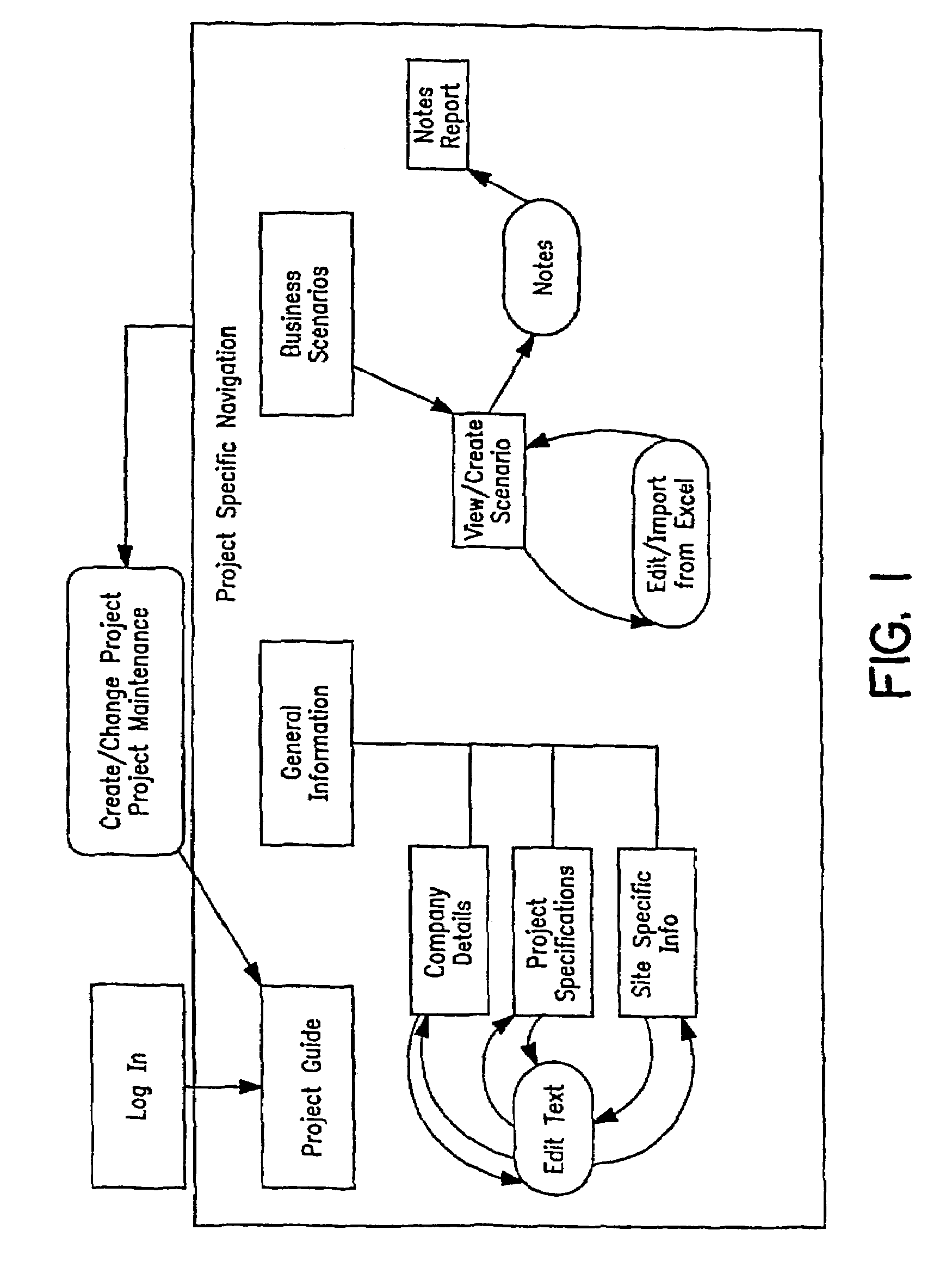

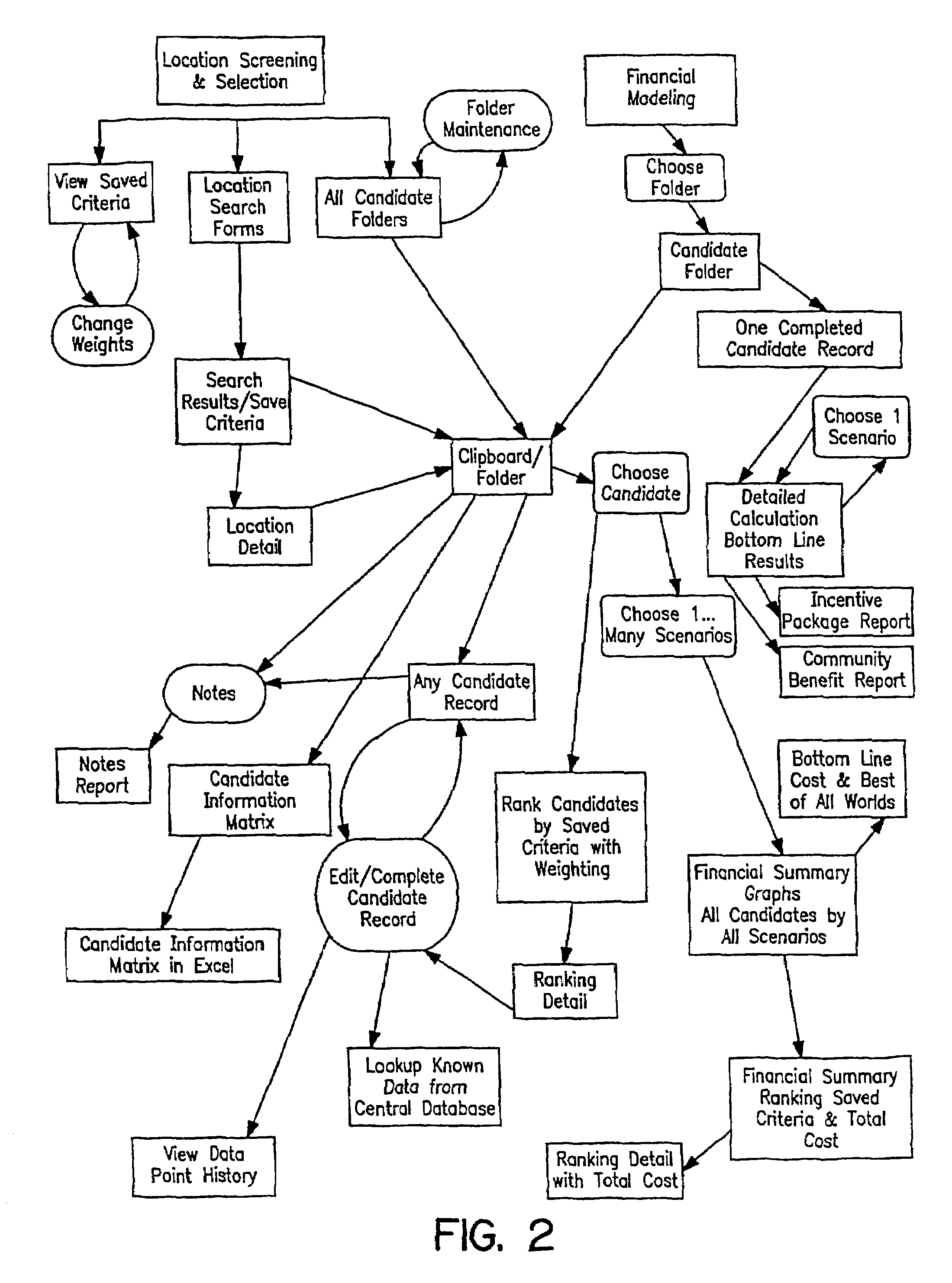

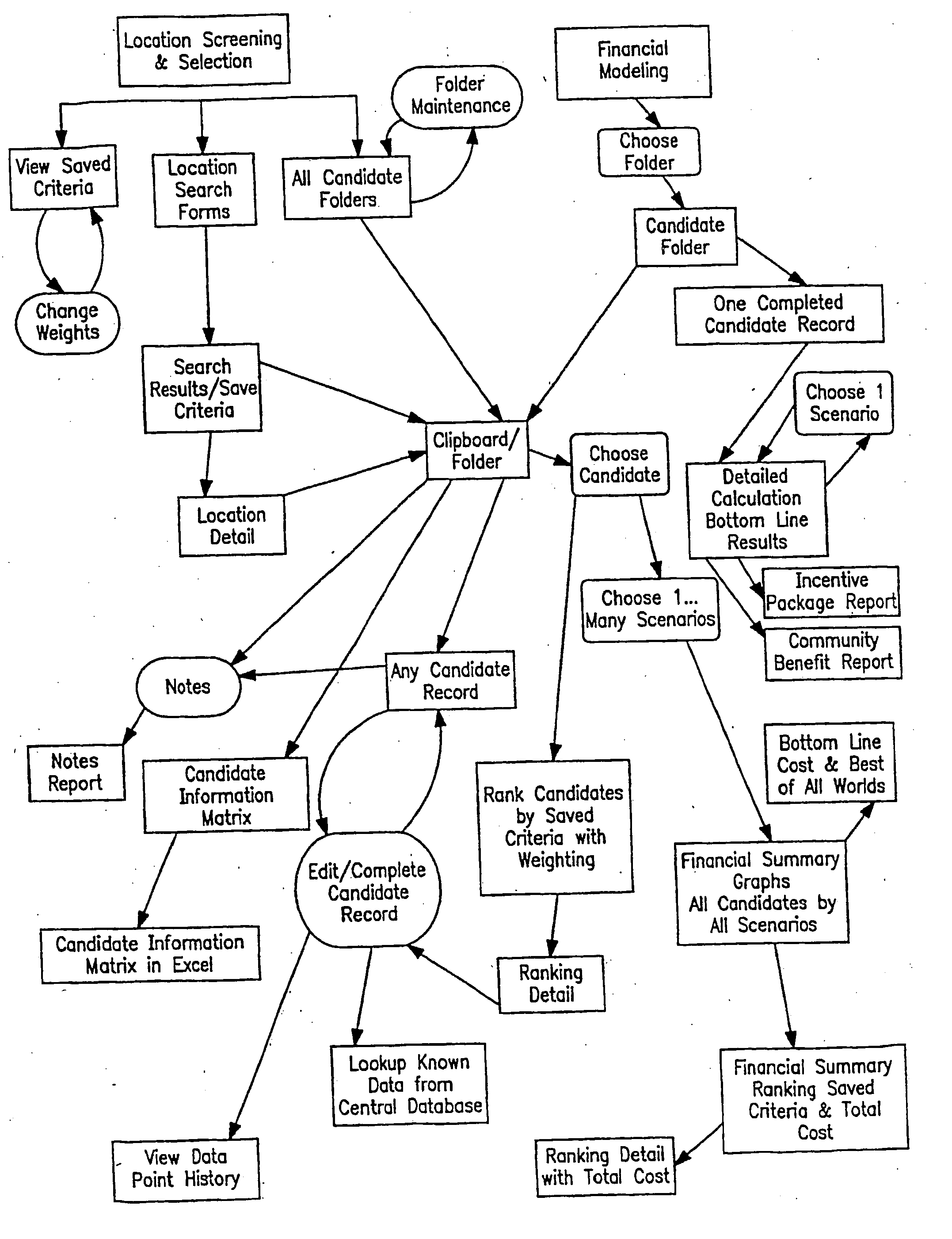

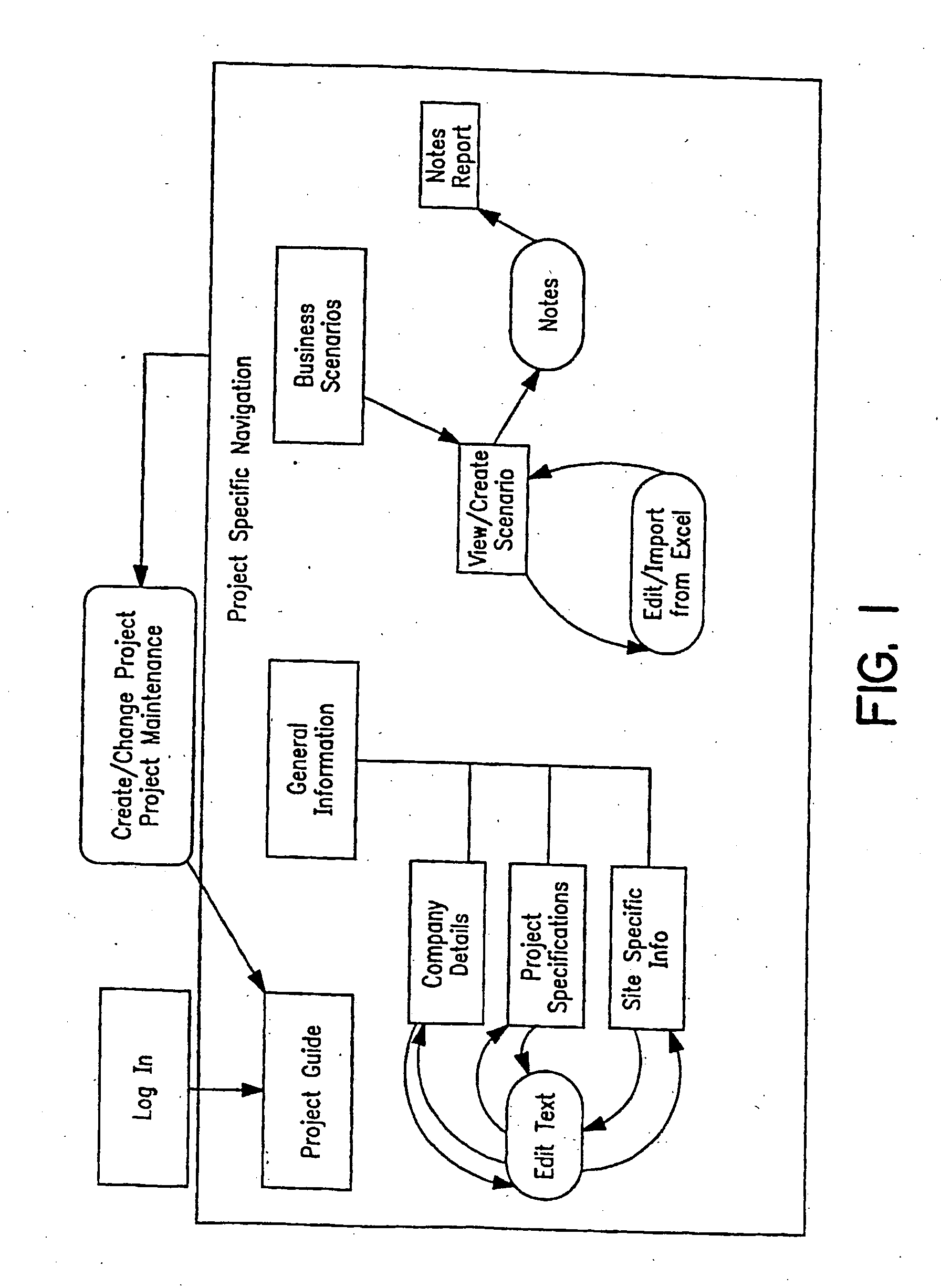

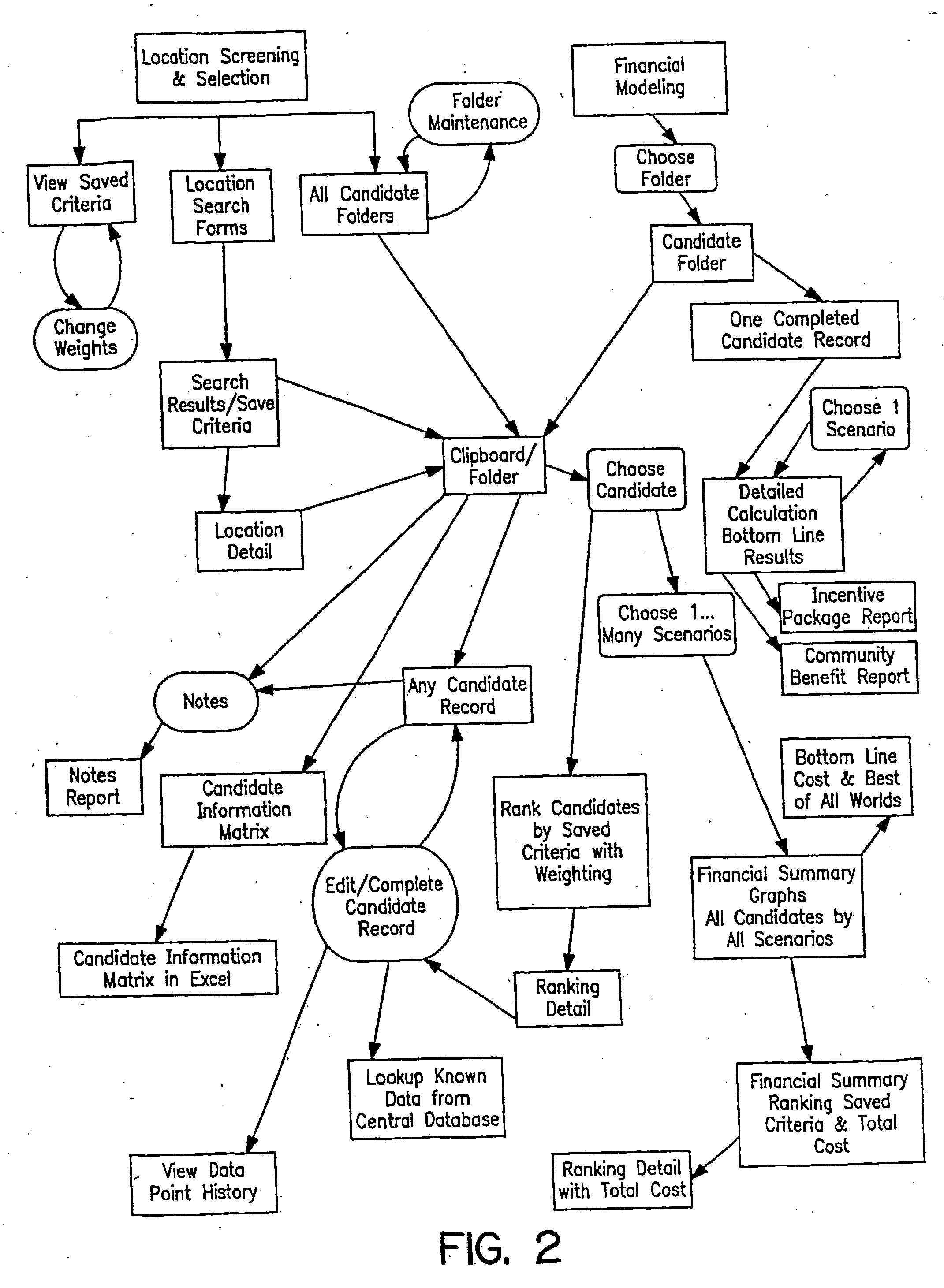

Method of making capital investment decisions concerning locations for business operations and/or facilities

ActiveUS7640196B2Quick and efficientQuickly and efficiently providesFinanceMarketingDemographic AccountingBusiness enterprise

The present invention relates to methods for facilitating capital investment decisions and transactions concerning development, expansion, consolidation, location, relocation, merger, acquisition, and / or disposition of business operations and / or facilities using computer interface inquiries. The inventive method allows a user to select and compare business locations based on demographic and / or economic criteria and to optionally determine financial factors associated with operating a business in selected locations. In particular, the invention is directed to a method for deciding whether, where, and to what extent to invest capital for the development, expansion, consolidation, location, or relocation of a business, business operation, or business facility. For example, the invention provides a method for selecting locations for expansion or relocation of a business operation or business facility.

Owner:WEISS RHETT L

Method of making capital investment decisions concerning locations for business operations and/or facilities

ActiveUS20050171877A1Quick and efficientQuickly and efficiently providesFinanceSpecial data processing applicationsKnowledge managementCapital investment

The present invention relates to methods for facilitating capital investment decisions and transactions concerning development, expansion, consolidation, location, relocation, merger, acquisition, and / or disposition of business operations and / or facilities using computer interface inquiries. The inventive method allows a user to select and compare business locations based on demographic and / or economic criteria and to optionally determine financial factors associated with operating a business in selected locations. In particular, the invention is directed to a method for deciding whether, where, and to what extent to invest capital for the development, expansion, consolidation, location, or relocation of a business, business operation, or business facility. For example, the invention provides a method for selecting locations for expansion or relocation of a business operation or business facility.

Owner:WEISS RHETT L

Qualitative and quantitative analytical modeling of sales performance and sales goals

InactiveUS20140324521A1Facilitate business risk analysisFinanceForecastingRisk profilingDecision taking

The present invention is applicable in the field of sales performance management coupled with corporate finance, corporate capital investments, economics, math, business risk analysis, simulation, decision analysis, qualitative risk analysis, risk management, quantitative risk analysis, and business statistics, and relates to the modeling and valuation of investment decisions and sales performance management and analysis under uncertainty and risk within all companies, allowing these firms to properly identify, assess, quantify, value, diversify, and hedge their corporate capital investment and sales management decisions and their associated risks. Specifically, the present invention looks at starting from comprehensive qualitative sales performance management and moving the analysis into the realms of quantitative risk-based sales performance modeling, simulation, and optimization.

Owner:MUN JOHNATHAN

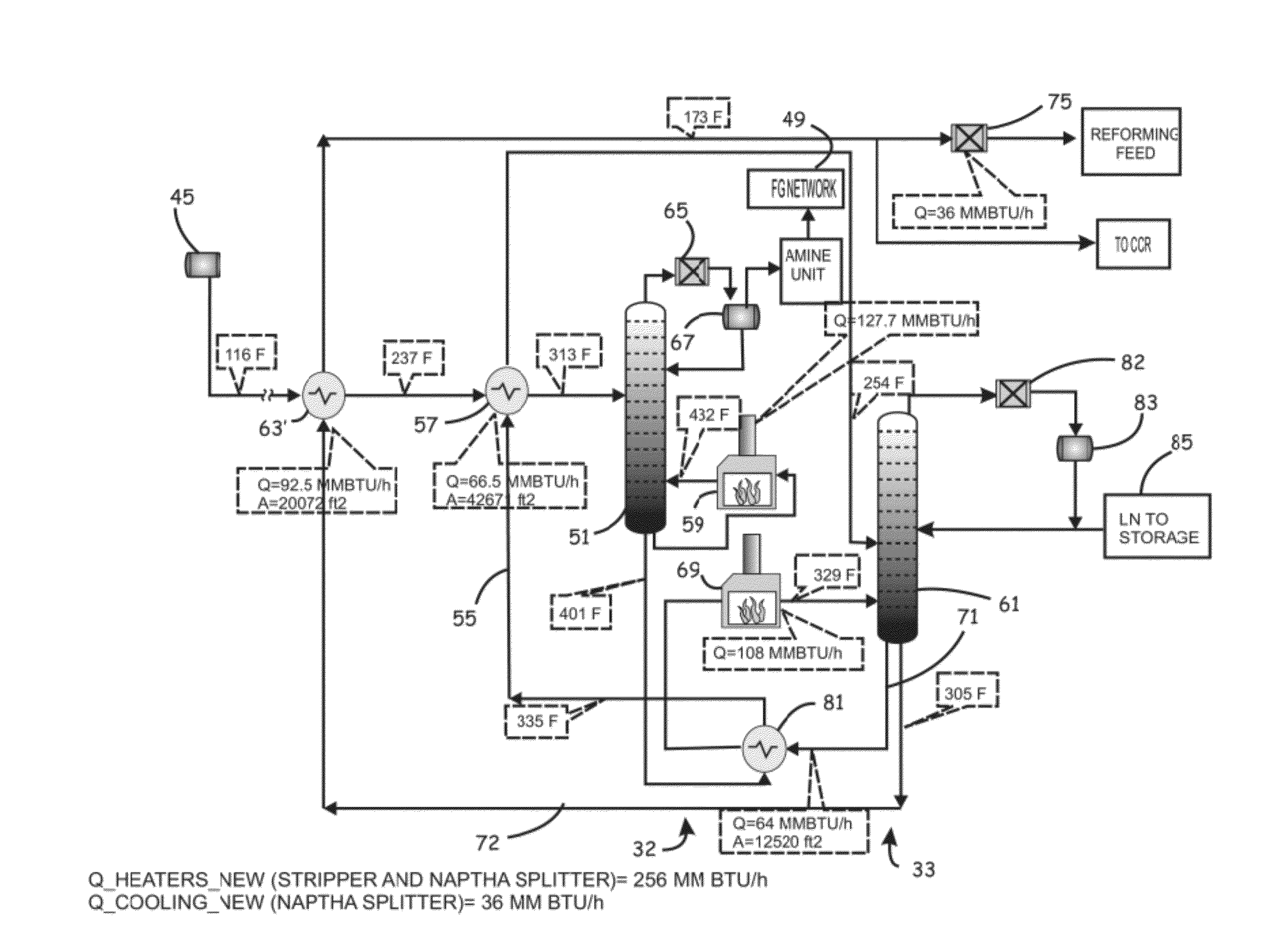

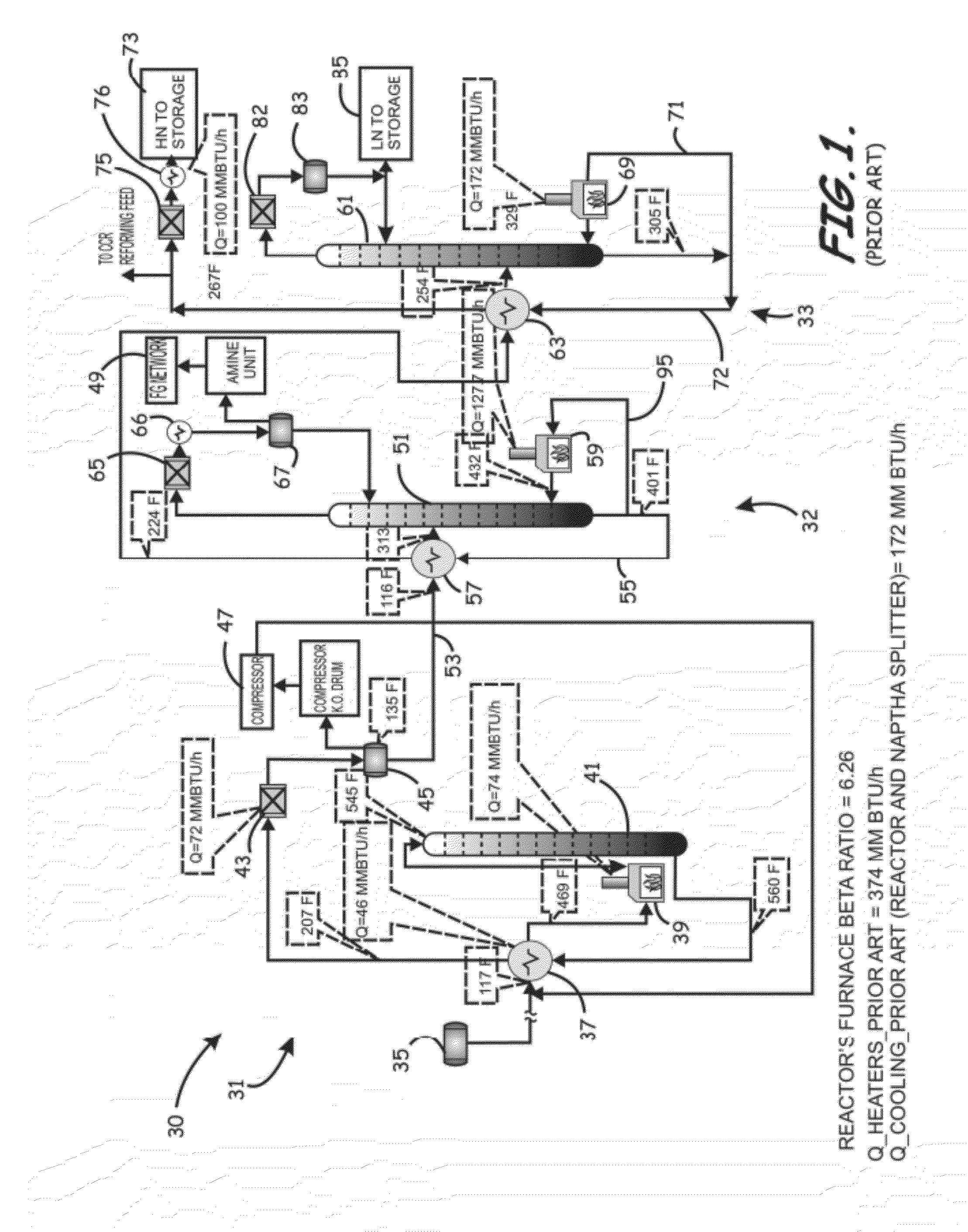

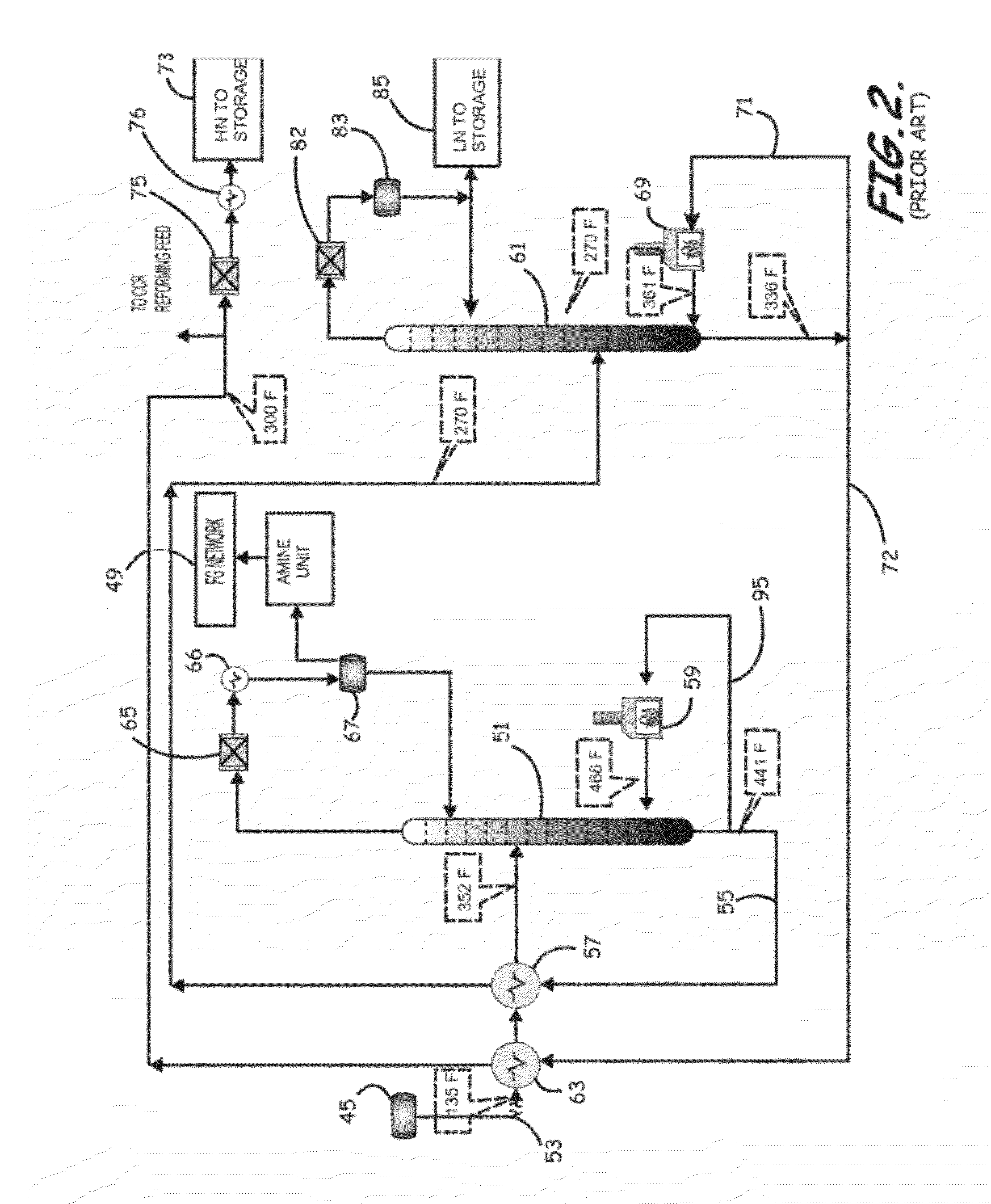

Energy-Efficient and Environmentally Advanced Configurations For Naptha Hydrotreating Process

ActiveUS20120279900A1Less emissionsLower ratioRecuperative heat exchangersThermal naphtha reformingProcess systemsNaphtha

Systems and methods of hydrotreating different naphtha feed stocks destined for a refining reforming unit and other applications with less energy consumption than conventionally possible, while producing less greenhouse gas emissions, and / or using a lesser number of heaters and correspondingly less capital investment in such heaters, air coolers, and water coolers, are provided. According to the more examples of such systems and methods, such reductions are accomplished by directly integrating a naphtha stripping process section with a naphtha splitting process section. Additional reductions can also be accomplished through directly integrating a naphtha hydrotreat reaction process section with the naphtha stripping process section.

Owner:SAUDI ARABIAN OIL CO

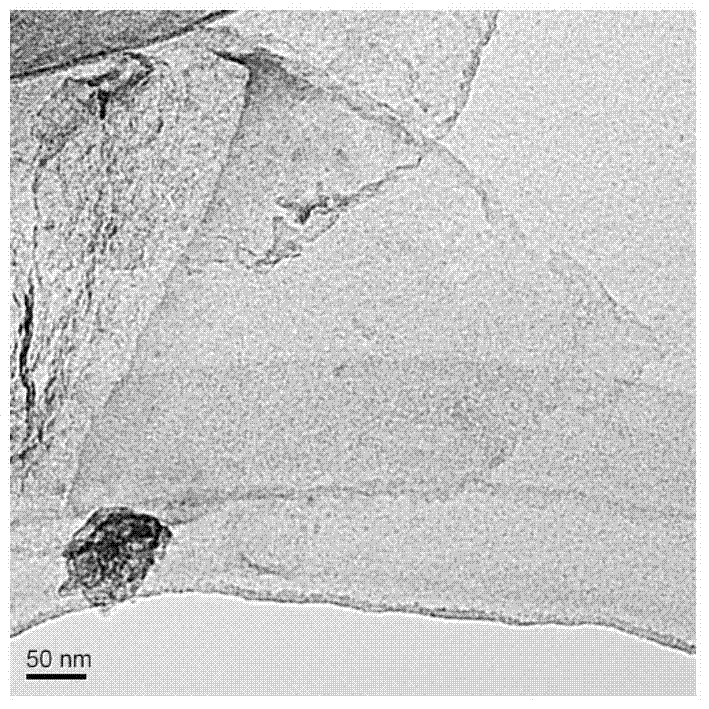

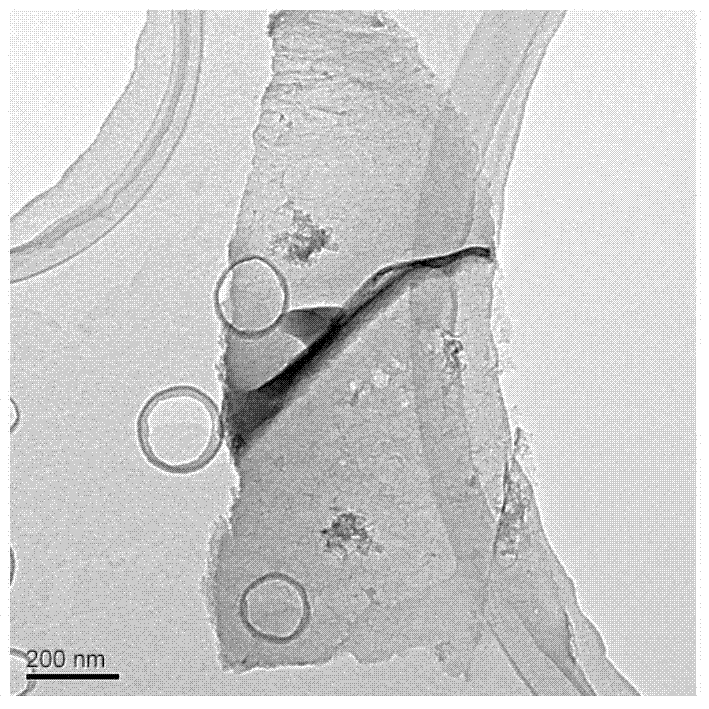

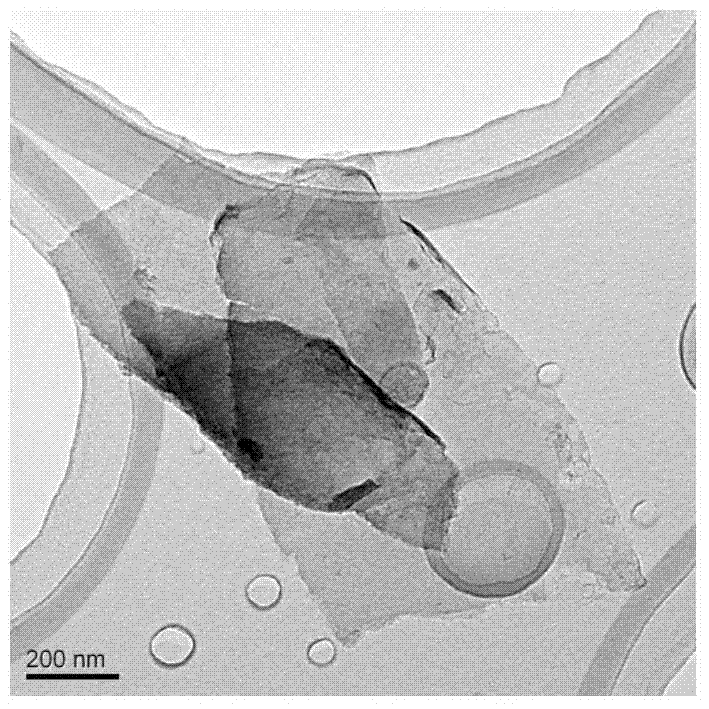

Method for preparing graphene by taking biomass as raw material

InactiveCN104724696AMitigate post-processing issuesEfficient strippingMaterial nanotechnologyOrganic solventCvd graphene

The invention discloses a method for preparing graphene by taking biomass as a raw material. The method comprises the following steps: dipping the biomass in an organic solvent for 1-5 hours, centrifuging, drying, calcining for 1-24 hours at the temperature of 600-1600 DEG C in the presence of inert gas, and cooling, thus obtaining graphene. The method for preparing the graphene by taking the biomass as the raw material has the advantages that cheap and easily available biomass is taken as the raw material, the problem of aftertreatment of dried-up herbaceous plants is effectively solved, and an effective path is provided for high value-added utilization of the herbaceous plants; a preparation technology in each step is controllable and is high in repeatability, the prepared graphene is obvious in exfoliation, and the minimum lamellar thickness is 3nm only; and the method is simple and environmentally friendly, low in capital investment and suitable for large-scale industrial production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Project economics analysis tool

The present invention is applicable in the field of corporate finance, corporate capital investments, economics, math, risk analysis, simulation, decision analysis, and business statistics, and relates to the modeling and valuation of investment decisions under uncertainty and risk within all companies, allowing these firms to properly identify, assess, quantify, value, diversify, and hedge their corporate capital investment decisions and their associated risks

Owner:MUN JOHNATHAN

Virtual power plant system and method incorporating renewal energy, storage and scalable value-based optimization

ActiveUS9300141B2Efficiently distributedLow costLevel controlWind energy generationOperating energyEngineering

Methods and systems provided for creating a scalable building block for a virtual power plant, where individual buildings can incorporate on-site renewable energy assets and energy storage and optimize the acquisition, storage and consumption of energy in accordance with a value hierarchy. Each building block can be aggregated into a virtual power plant, in which centralized control of load shifting in selected buildings, based on predictive factors or price signals, can provide bulk power for ancillary services or peak demand situations. Aggregation can occur at multiple levels, including developments consisting of both individual and common renewable energy and storage assets. The methods used to optimize the system can also be applied to “right size” the amount of renewable energy and storage capacity at each site to maximize return on the capital investment.

Owner:INTELLIGENT GENERATION

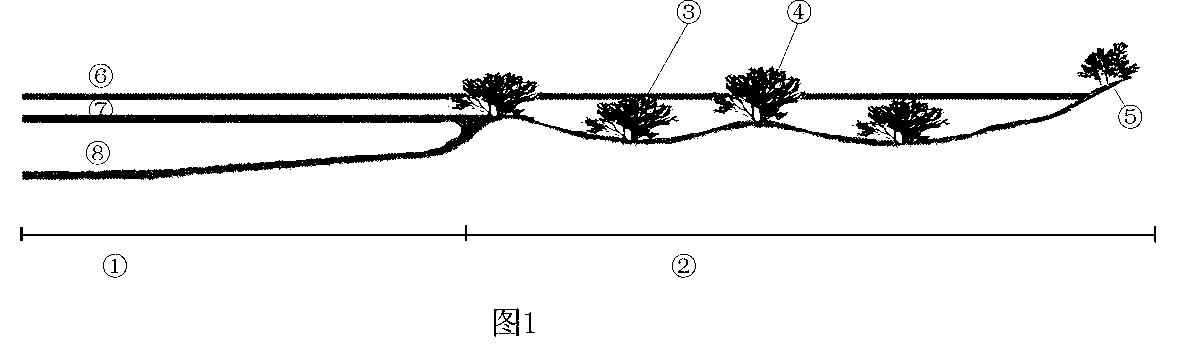

Micro-reformation and vegetation restoration method for degraded plateau and lake wetlands

ActiveCN103314763AAccelerate the speed of recovery successionImprove water qualityClimate change adaptationHorticultureRevegetationRestoration method

The invention belongs to the technical field of environmental protection and ecological engineering, relates to topological micro-reformation and vegetation restoration, and discloses a vegetation restoration method applicable to degraded plateau and lake wetlands. The vegetation restoration method is low in personnel and capital investment and mainly includes stages of background evaluation, selective enclosure and livestock reduction, topological micro-reformation for the wetlands and construction of screened plant communities or plant zones. The vegetation restoration method has the advantages that plateau wetland vegetation restoration is accelerated, wetland vegetation ecosystems are constructed, and the environmental quality of the degraded wetlands is improved.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

Method of forming a flexible abrasive sheet article

InactiveUS8545583B2Simple processReduce investmentPigmenting treatmentOther chemical processesWater basedPrill

Flexible abrasive sheet articles having precision thickness flat-topped raised island structures that are coated with a monolayer of equal sized abrasive agglomerate are described. Methods of producing high quality equal-sized spherical shaped composite abrasive agglomerate beads containing small diamond abrasive particles are described. Beads are produced by level-filling fine mesh screens or perforated sheets with a water based metal oxide slurry containing abrasive particles and then using a fluid jet to eject the abrasive slurry lumps from the individual screen cells into a dehydrating environment. Surface tension forces form the ejected liquid lumps into spheres that are solidified and then heated in a furnace to form ceramic beads. These porous ceramic abrasive beads can be bonded directly onto the flat planar surface of a flexible backing material or they can be bonded onto raised island surfaces to form rectangular or disk abrasive sheet articles. Abrasive articles having equal sized abrasive beads are particularly suited for lapping and raised island articles are suited for high speed lapping. Non-abrasive equal-sized beads can also be formed using this simple bead manufacturing process, which requires only a very low capital investment.

Owner:DUESCHER WAYNE O

Edge drop control method of cold-rolled non-oriented silicon steel

ActiveCN103464469ARealize closed-loop controlHigh control precisionRoll mill control devicesMetal rolling arrangementsEffect functionEngineering

The invention provides an edge drop control method of cold-rolled non-oriented silicon steel. The edge drop control method includes that a cold rolling five frame and all six roller rolling mill is utilized as an object; an objective function is that the horizontal thickness difference of the non-oriented silicon steel is minimum; the complete set of working roller forecast and feedback and working roller bending compensation control method for edge thinning control of the non-oriented silicon steel is established through introduction of an efficiency effected function array. According to the edge drop control method of the cold-rolled non-oriented silicon steel, the original control device is fully utilized; the maintenance is easy; the technology import capital investment is saved; meanwhile the influence on the flatness control accuracy can be effectively reduced and the horizontal thickness control accuracy of the non-oriented silicon steel can be improved to enable the horizontal thickness difference to decrease from 25 microns to 8 microns below and accordingly the laminated rate of the non-oriented silicon steel finished product and the qualified rate of the quality of the finished product are improved and a new solution is provided to adapt to the edge drop control presetting and feedback of industrial application.

Owner:ANGANG STEEL CO LTD

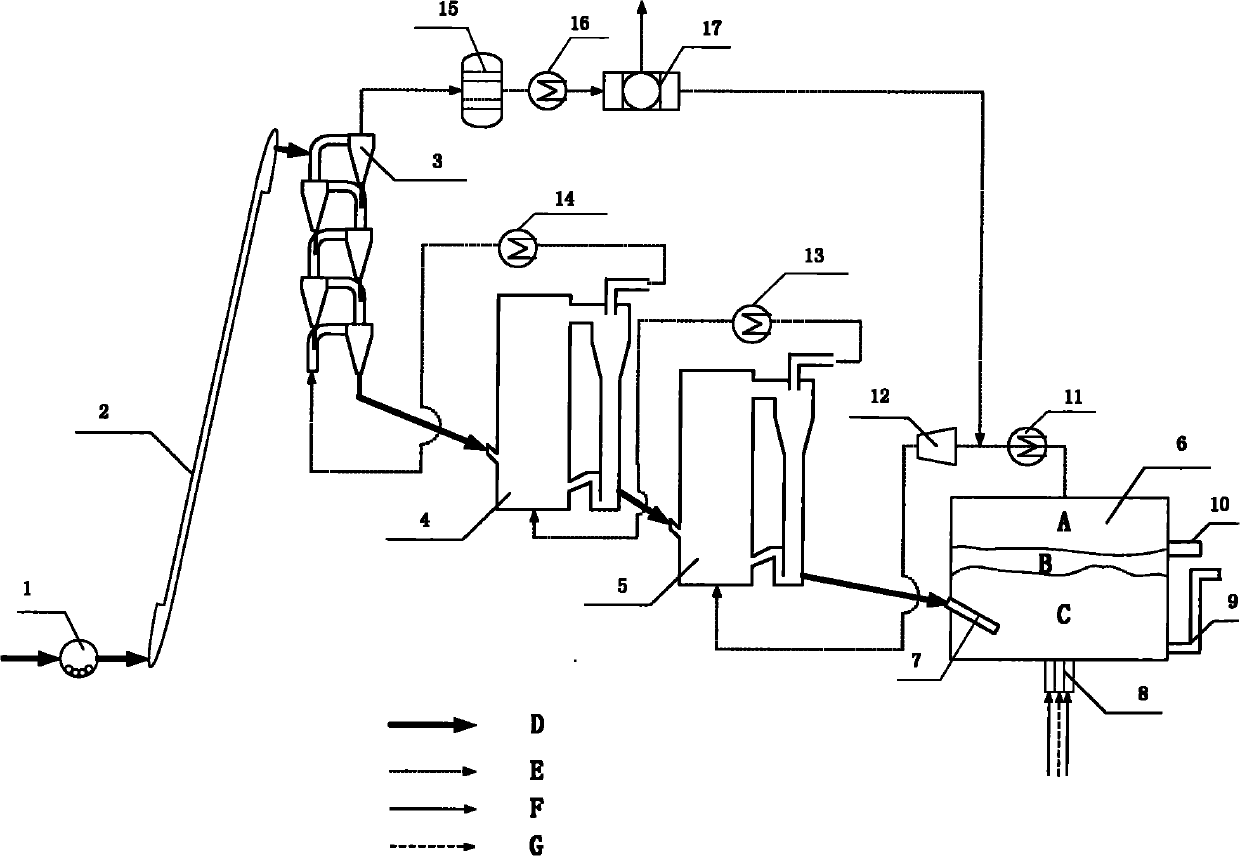

Direct steelmaking process by using fine ores, coal and oxygen

The invention discloses a direct steelmaking process by using fine ores, coal and oxygen. Coal dust and oxygen are blown into a high-temperature melt to produce reducing gas; by utilizing the advantages of gas phase suspension preheating of fine iron ore and high speed and high efficiency of gas phase reduction, the fine iron ore is preheated and reduced respectively in a cyclonic preheater and a recirculating fluidized bed; and the obtained pre-reduced fine iron ore with the metallization rate of over 90 percent is blown into the high-temperature melt to form molten steel. Due to the reduction at lower temperature, the generated pre-reduced fine iron ore achieves less carburization, and less decarbonization is achieved when the finished product molten steel is obtained. The direct steelmaking process simplifies the steelmaking production flow essentially. The direct steelmaking process has the advantages of high productivity, low energy consumption for each ton of steel, equipment and capital investment conservation, full simplification of physical distribution, no temperature loss in the molten iron transporting process, and easy implementation of production continuity and automatic control.

Owner:LAIWU IRON & STEEL GRP

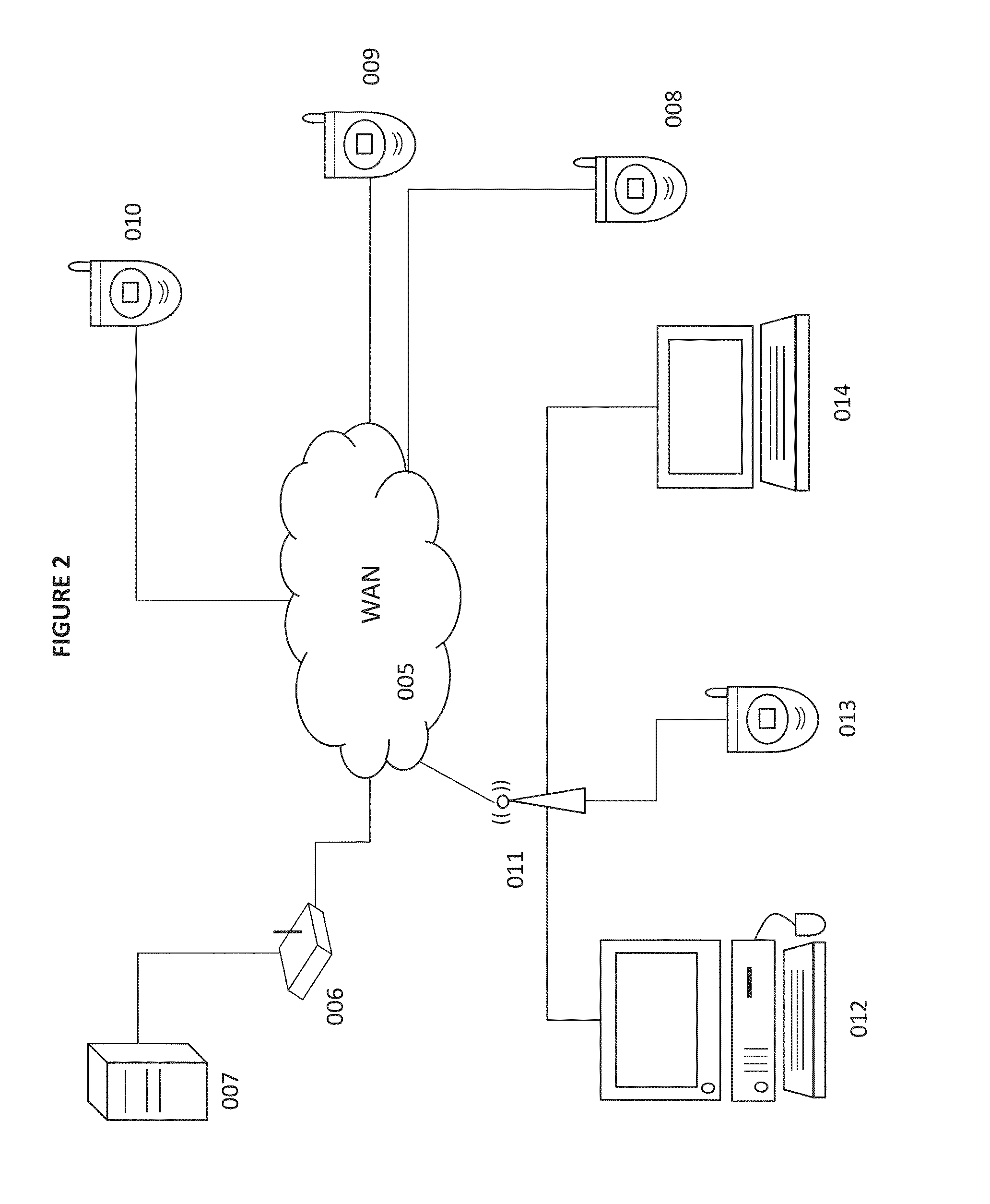

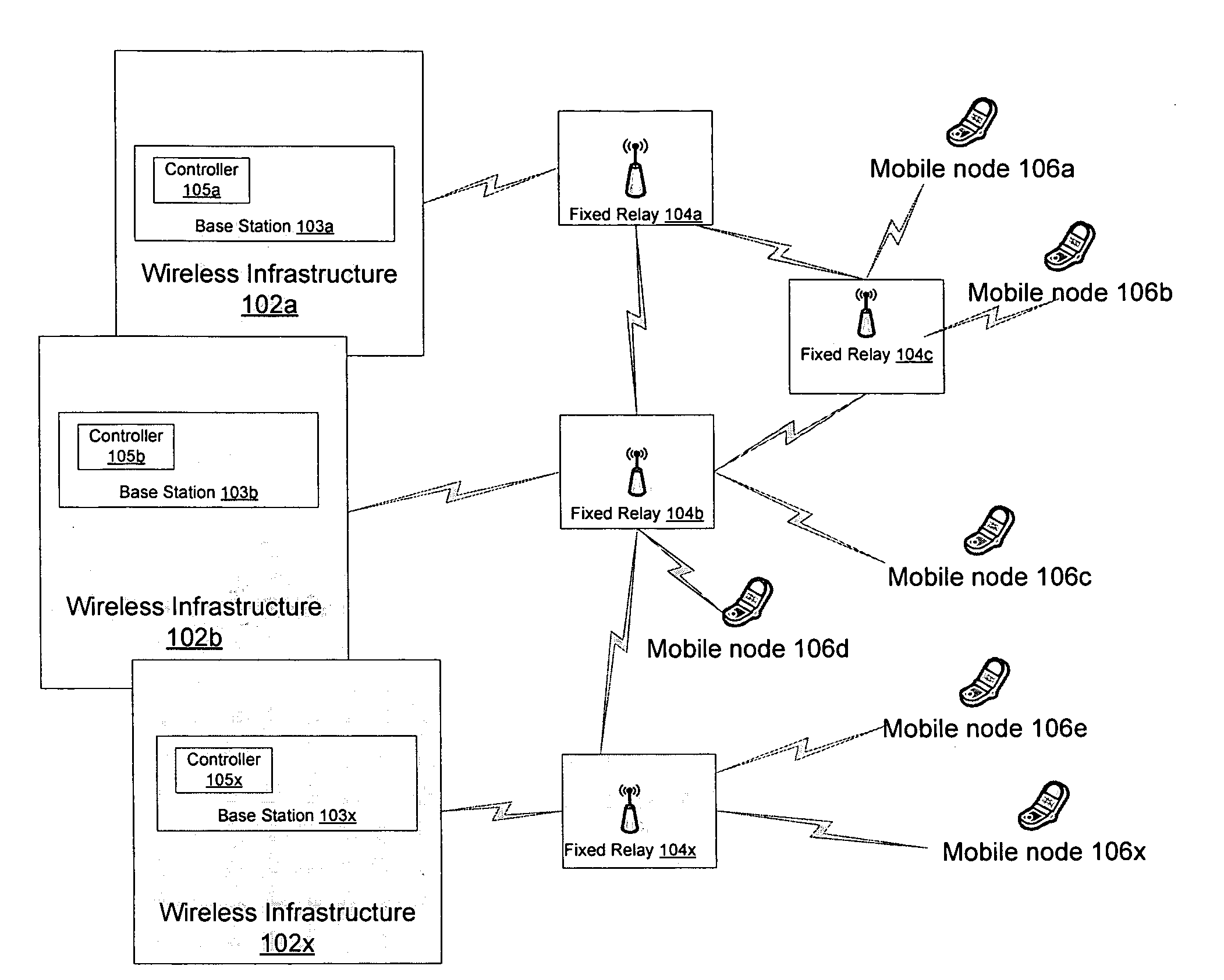

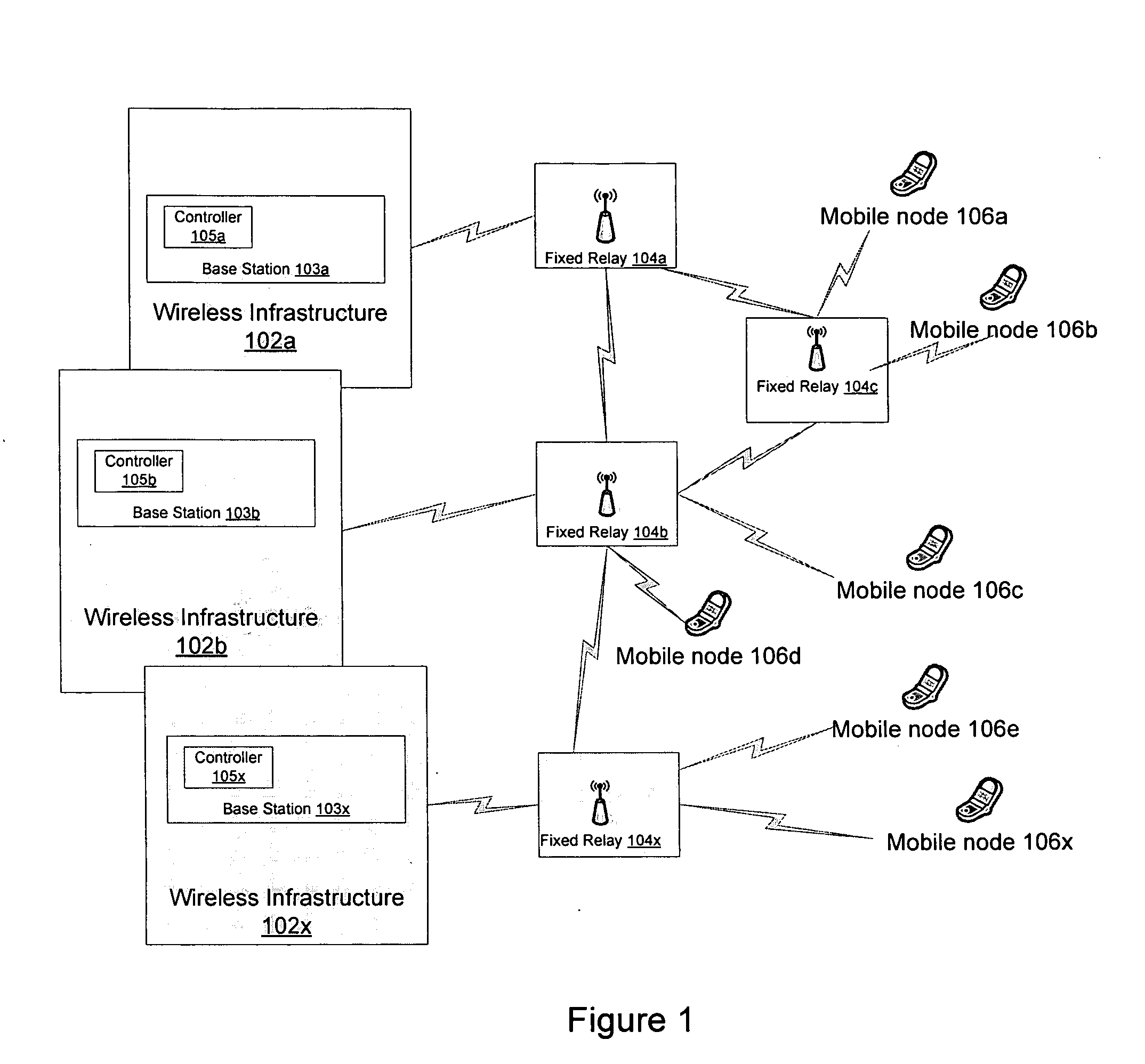

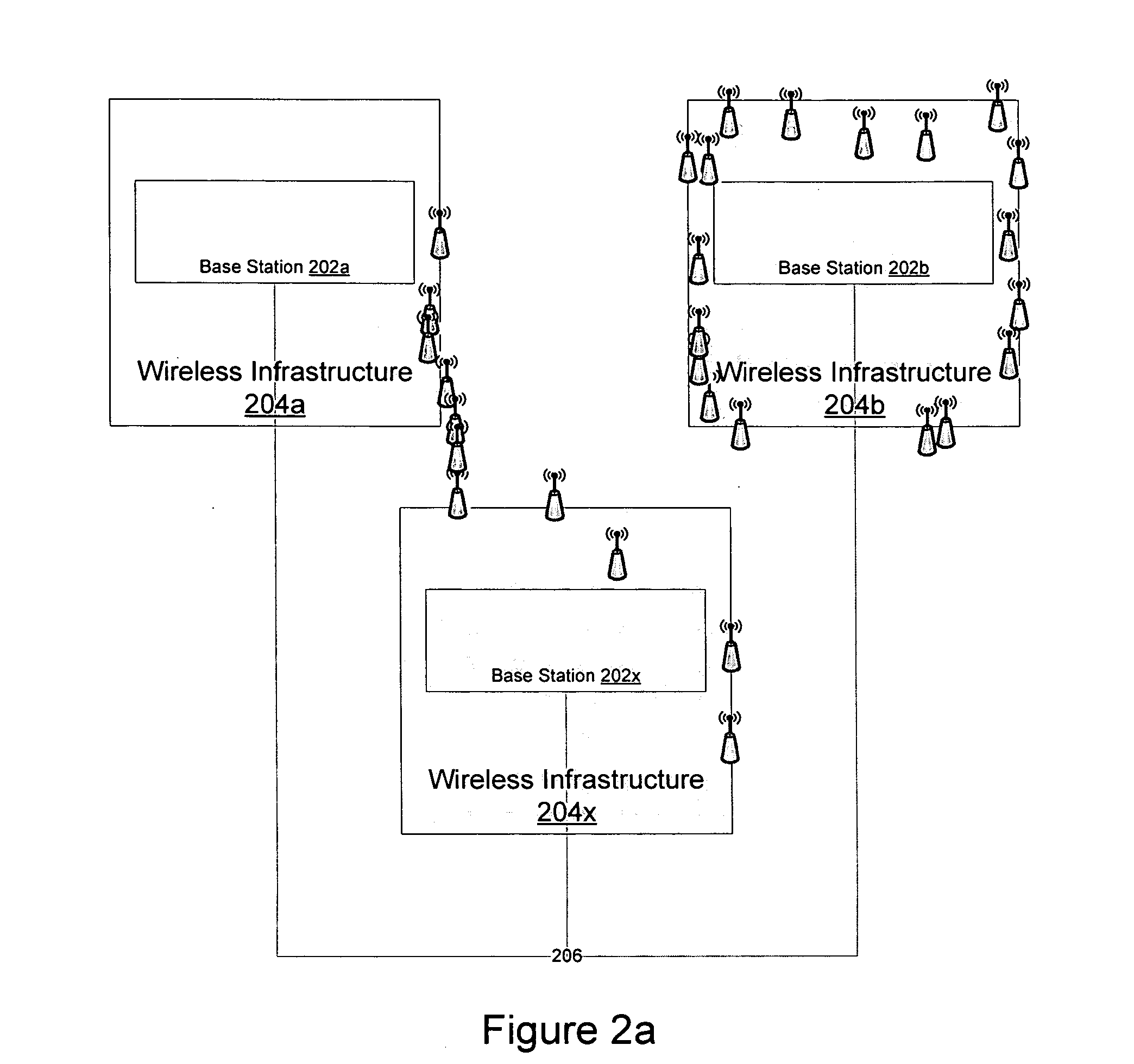

Method and apparatus for scale-free topology generation in relay based wireless networks

InactiveUS20070291663A1Data switching by path configurationNetwork connectionsWireless mesh networkAverage path length

A method of placing nodes in an area that requires coverage, the method includes the step of creating a network topology such that the average path length is kept to a minimum number of hops at the time of placement of a new node, wherein a limit is placed on a number of neighbors at the time of placement of the new node, the number being a parameter that impacts the average path length, resiliency and capital investment. The new node is connected to at least one node in the network.

Owner:NOKIA CORP

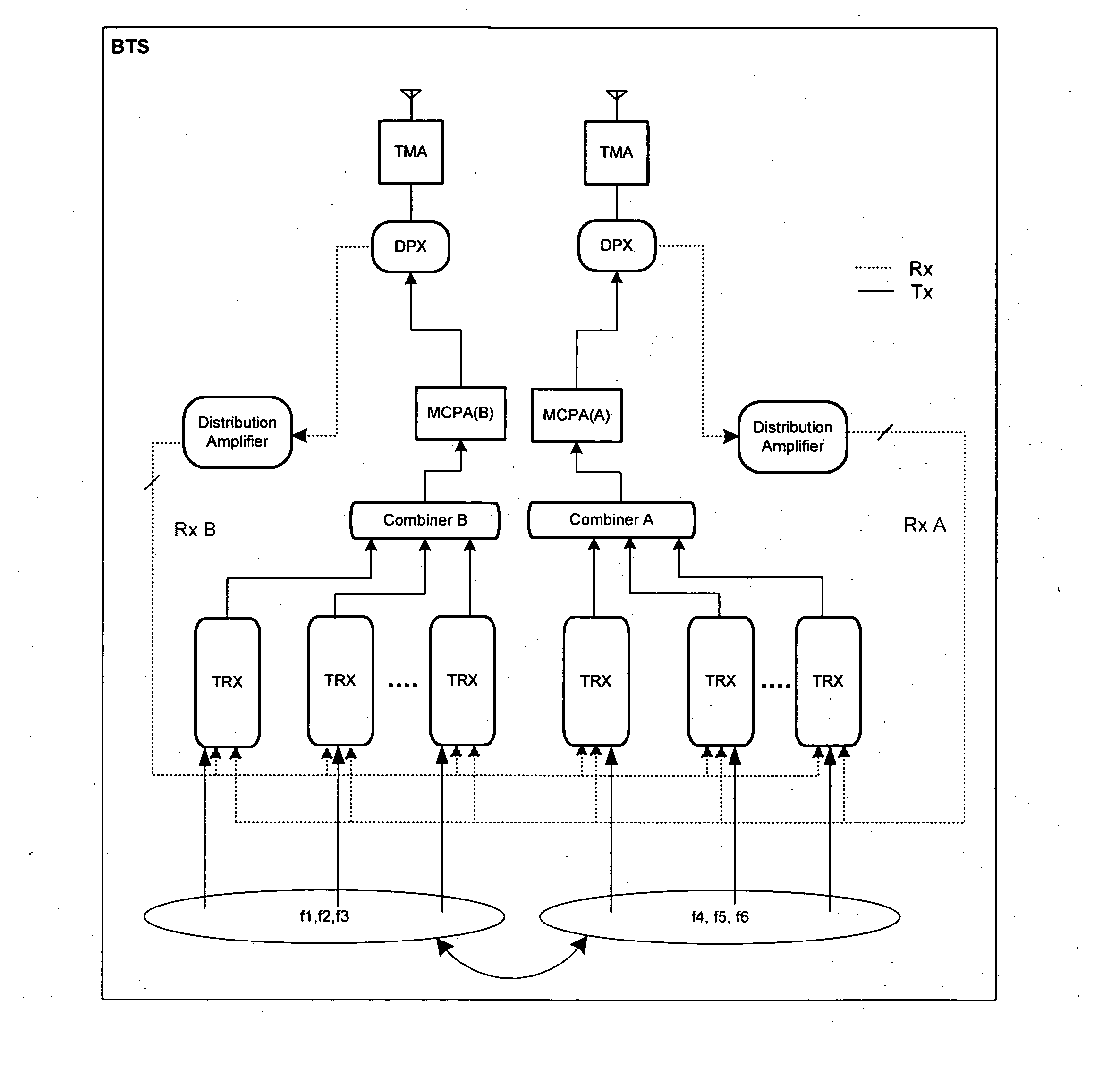

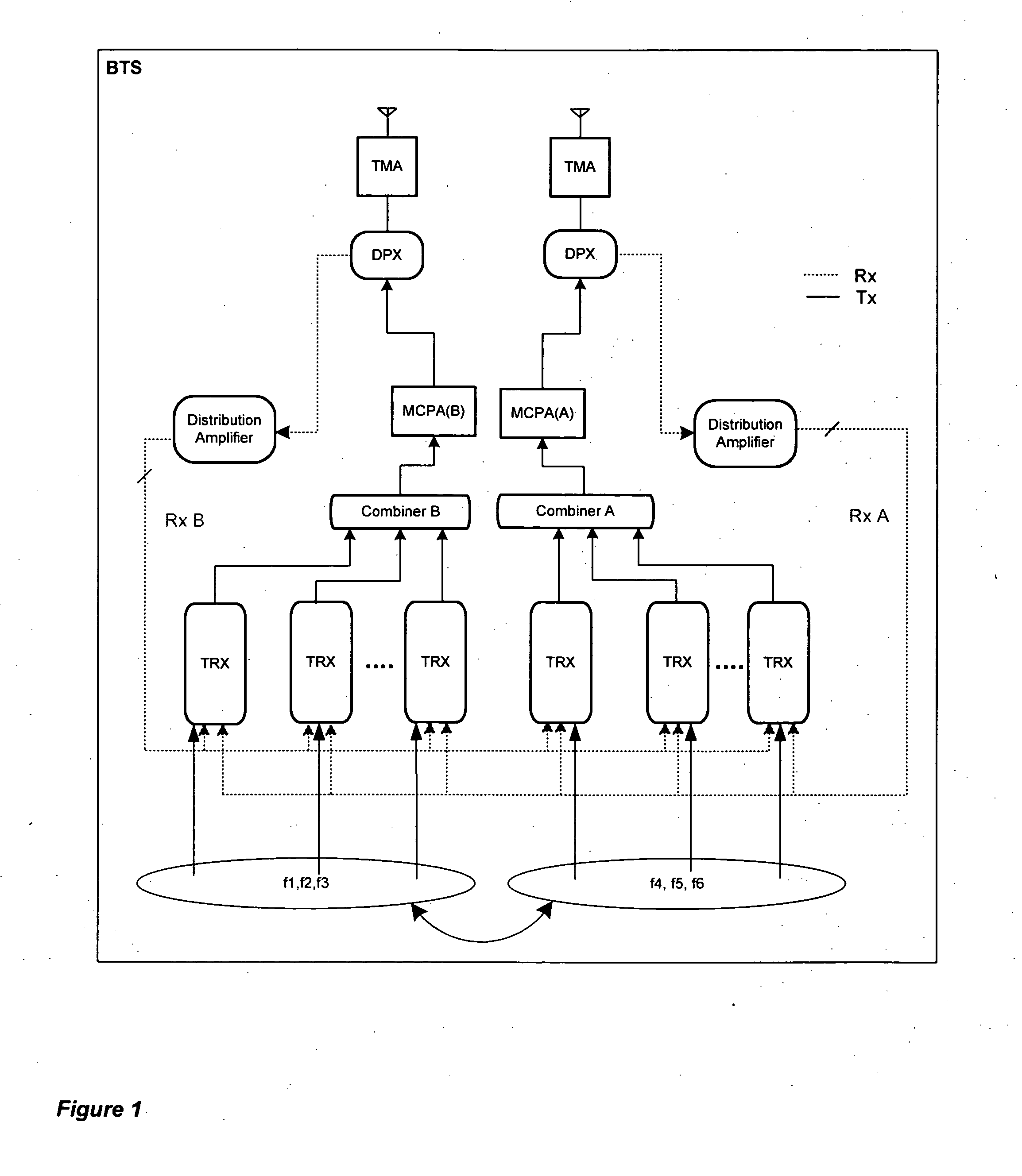

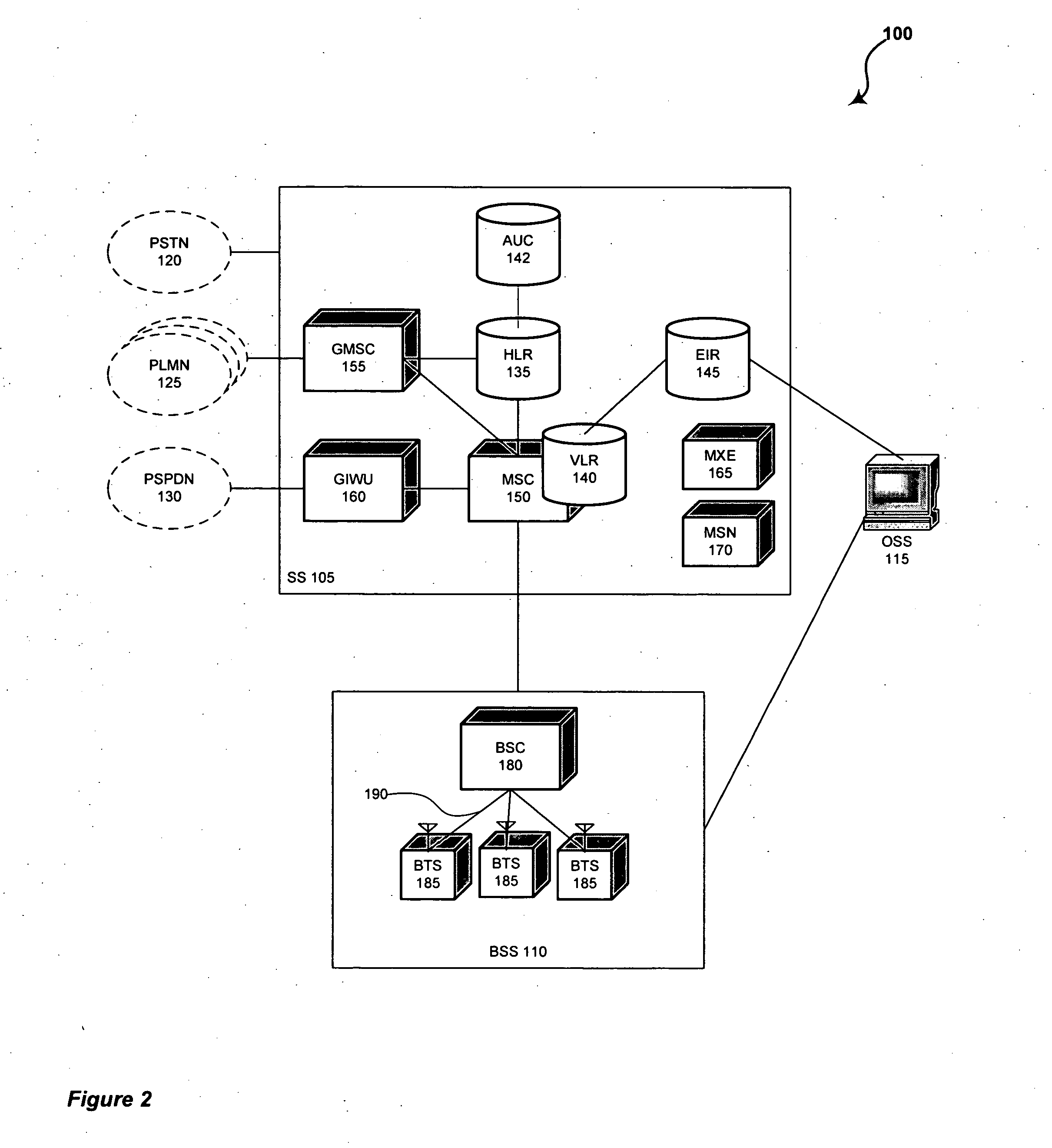

Systems and methods for implementing fully redundant antenna hopping with multi-carrier power amplifiers and combining schemes within a base station

ActiveUS20040214608A1Transmitters monitoringSpatial transmit diversityCarrier signalDiversity scheme

A Transmit Diversity Redundancy controller dynamically mediates implementation of diversity and antenna hopping by detecting and remediating faults on antenna branches while minimizing the capital investment required. The controller monitors the equipment along the antenna branches. If a fault occurs, the controller determines the appropriate fault remediation measures to implement based on default settings, or relays an indicator to an external processor (e.g., a BTS or BSC CPU) and awaits instructions. If traffic on the BTS is high, the external processor instructs the TDR controller to combine the signals carried by the downed branch with the signals carried by the active branches, and the combined carrier signals are transmitted over the active branches. Otherwise, the external processor instructs the controller to allow signals carried by the downed antenna branch to be dropped, and notifies the BSC to suspend assignment of calls to the dropped carriers until the branch is restored.

Owner:CINGULAR WIRELESS II LLC

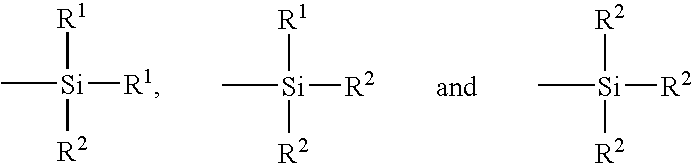

Process for preparing a silica rubber blend

InactiveUS20050022915A1Efficiently and effectively disperseEnhanced interactionSpecial tyresOrganic dyesPolymer scienceEnd-group

The present invention relates to a technique to efficiently and effectively disperse silica throughout a rubbery polymer. By utilizing this technique mechanical mixing procedures that are energy intensive and require large capital investments in mixing equipment can be significantly reduced. By reducing the amount of shearing forces to which the rubber is subjected polymer degradation is also significantly reduced. The utilization of the technique of this invention also results in a uniform blend of the silica throughout the rubber and consequently better interaction between the silica and the rubber. This results in better physical properties, such as higher modulus. The subject invention more specifically discloses a process for preparing a silica / rubber blend which comprises dispersing silica, a silica coupling agent, and a low molecular weight end-group functionalized diene rubber throughout a cement of a conventional rubbery polymer, and subsequently recovering the silica / rubber blend from the organic solvent. The present invention further reveals a tire which is comprised of a generally toroidal-shaped carcass with an outer circumferential tread, two spaced beads, at least one ply extending from bead to bead and sidewalls extending radially from and connecting said tread to said beads, wherein said tread is adapted to be ground-contacting, and wherein said tread is comprised of the silica / rubber blend made by dispersing silica, a silica coupling agent, and a low molecular weight end-group functionalized diene rubber throughout a cement of a conventional rubbery polymer, and subsequently recovering the silica / rubber blend from the organic solvent.

Owner:THE GOODYEAR TIRE & RUBBER CO

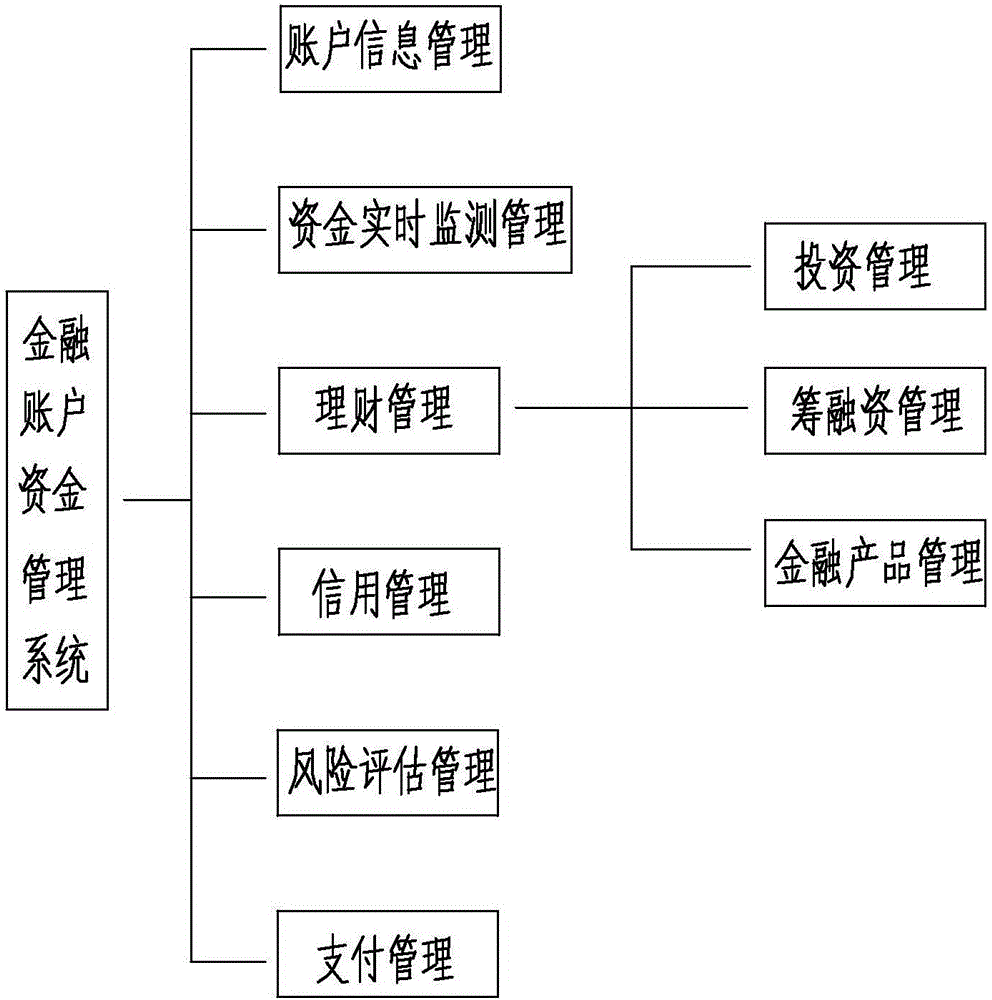

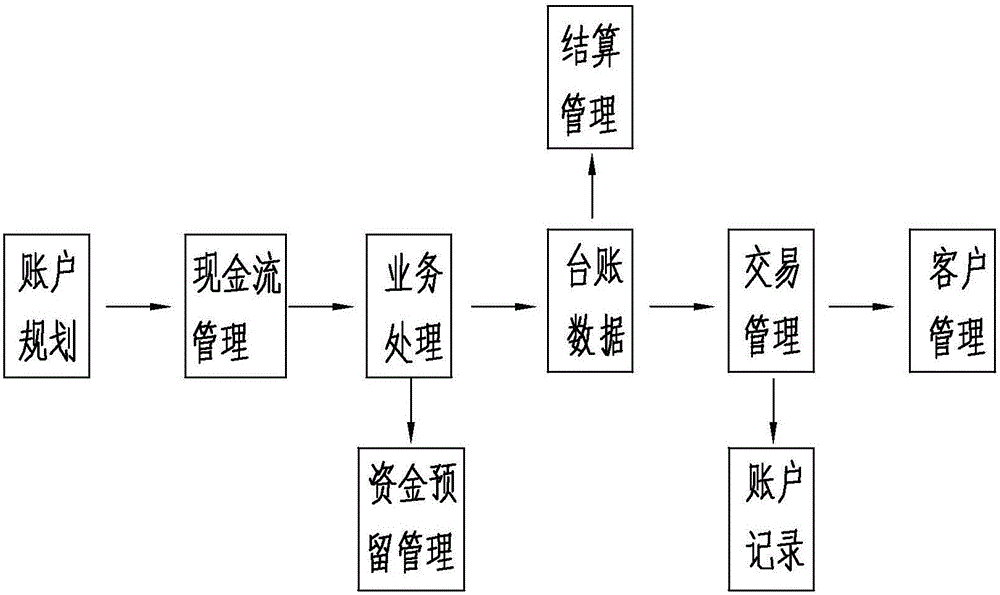

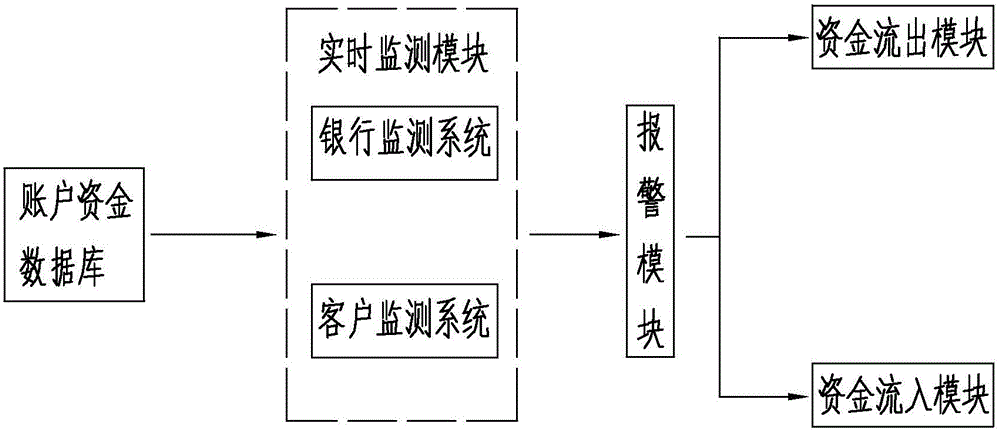

Financial account capital management system and method

InactiveCN105894376AImprove securityPrevent illegal diversionFinanceFinancial tradingCapital investment

The invention discloses a financial account capital management system and method. The system comprises account information management, capital real-time monitoring management, financial management, credit management, risk assessment management and payment management. The capital real-time monitoring management comprises an account capital database, a real-time monitoring module, an alarm module, a capital outflow module and a capital inflow module. The account capital database is connected with the alarm module through the real-time monitoring module; the alarm module is connected with the capital outflow module and the capital inflow module; and the real-time monitoring module comprises a bank monitoring system and a client monitoring system. The system is simple in structure and high in practicability; conventional financial transactions can be realized, and through real-time monitoring management of an account, safety of financial transactions is improved; and selected investment products are subjected to quota allocation according to credit rating, risk tolerance grade and risk tolerance period of a user, thereby reducing capital investment risk and improving risk management and control capability of the whole account.

Owner:浙江爱贷金融服务外包股份有限公司

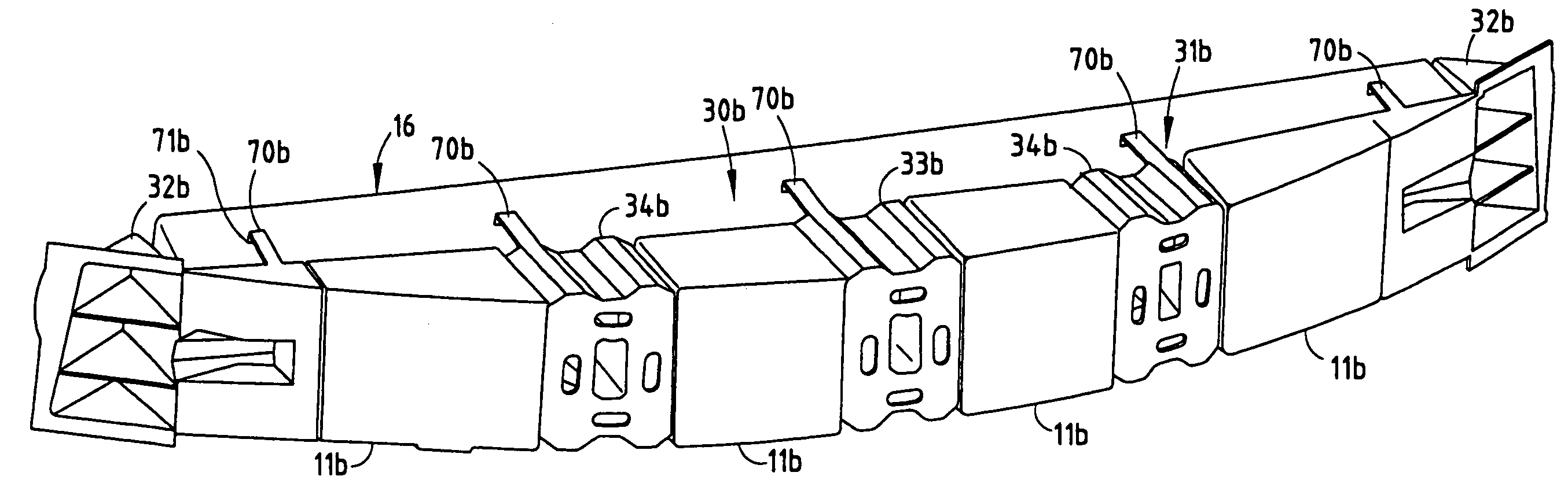

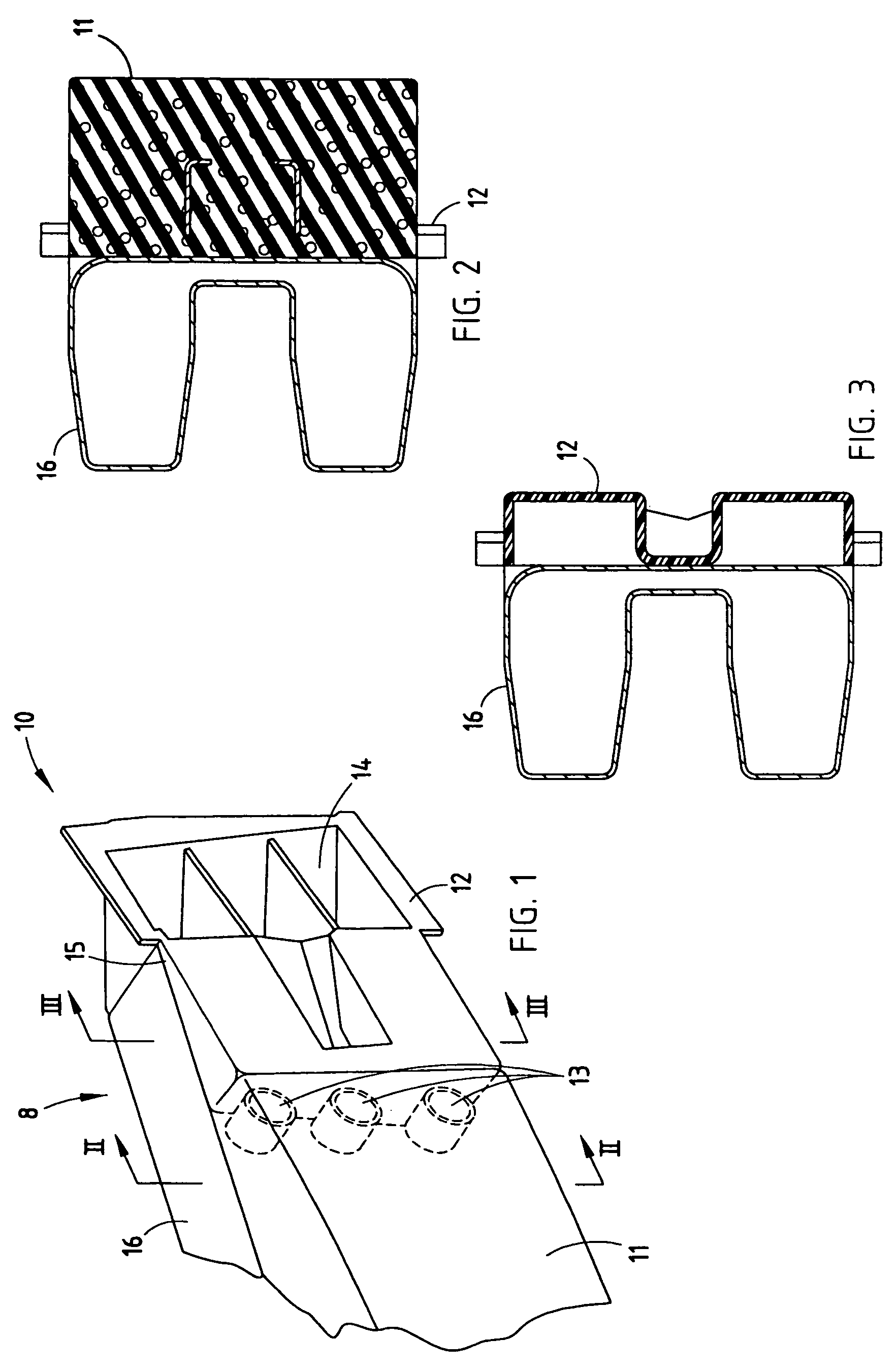

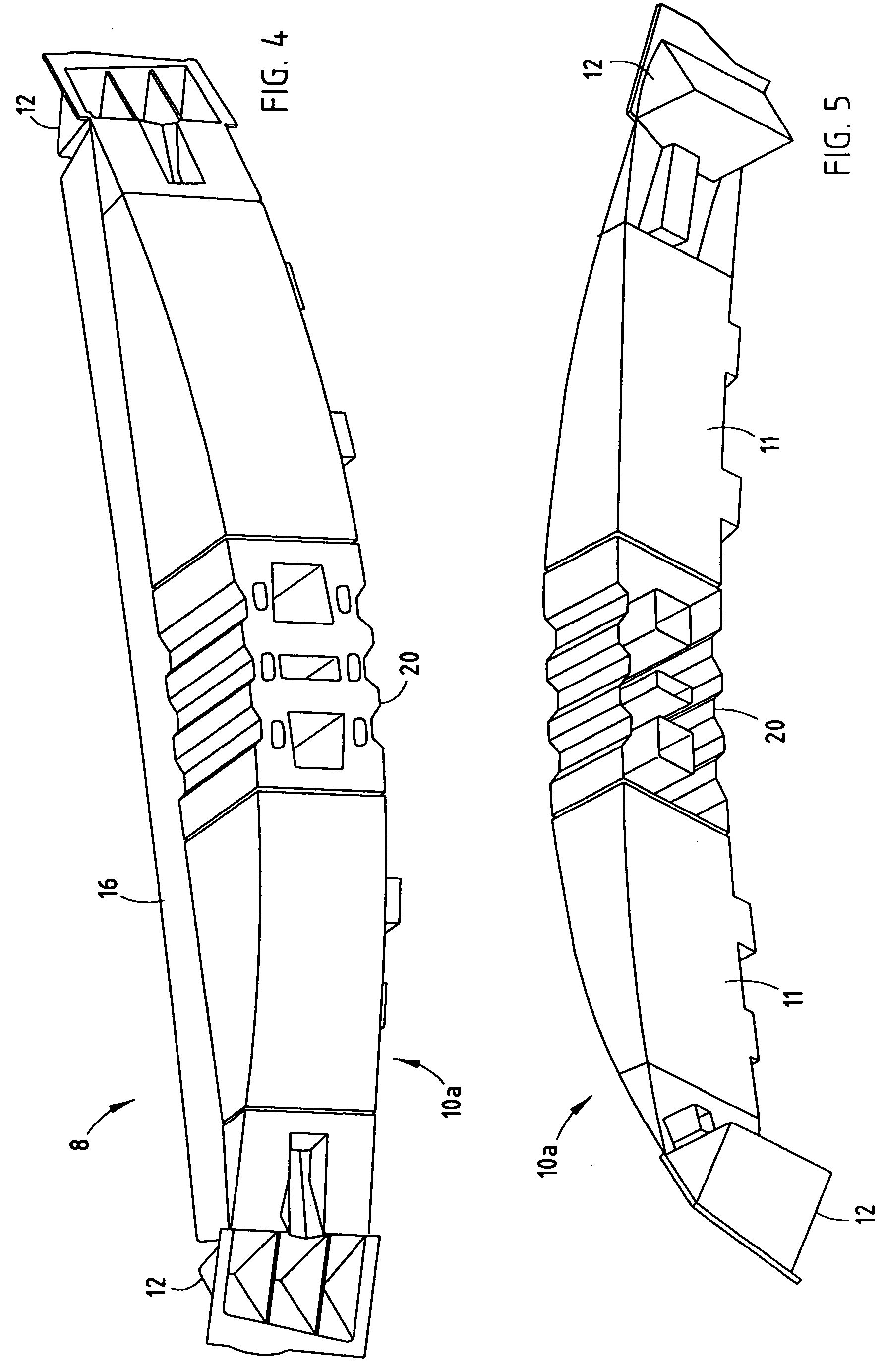

Bumper system with energy absorber

A bumper system includes a bumper beam having a face and ends, and an energy absorber mounted on the face. The energy absorber has a one-piece injection-molded non-foam piece with box sections and interconnecting straps, and a one-piece or multi-piece foam component securely insert-molded onto the injection-molded non-foam piece. Different foam molds can be used to form differently shaped front surfaces on the foam component. By this arrangement, different energy absorbing systems are provided for vehicles, such as to satisfy the need for different styling and shapes, while still using the same non-foam piece. By this arrangement, the energy absorber is a single unit that can be handled and attached to the bumper beam. At the same time, capital investment in molding dies and tooling is reduced.

Owner:NETSHAPE INT LLC

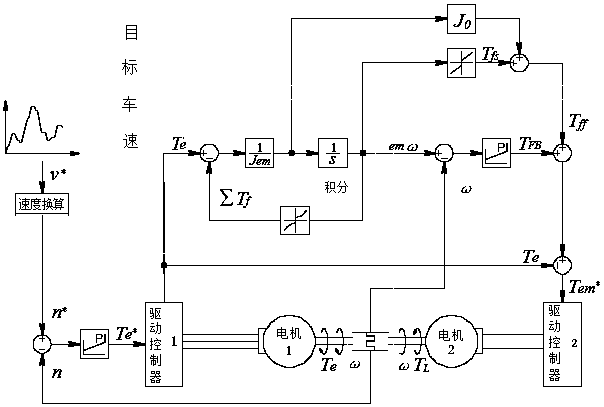

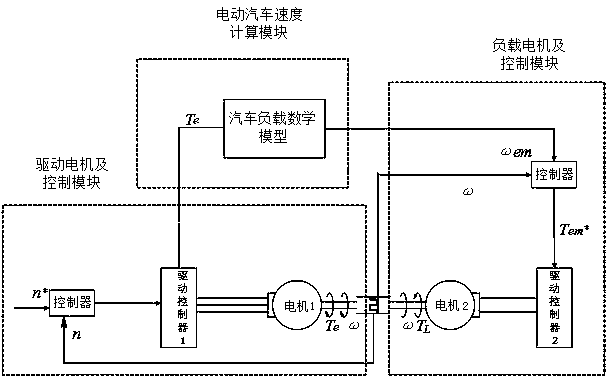

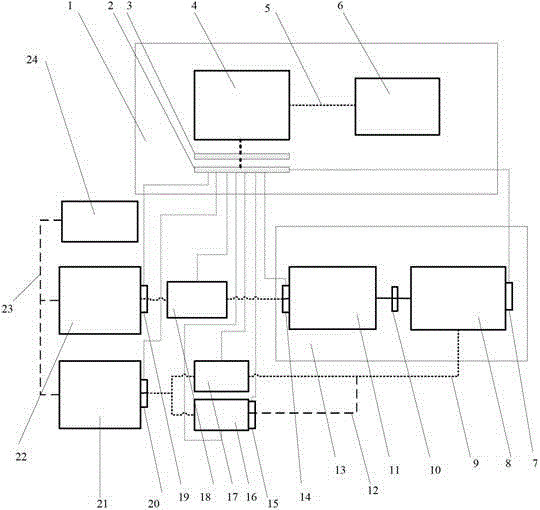

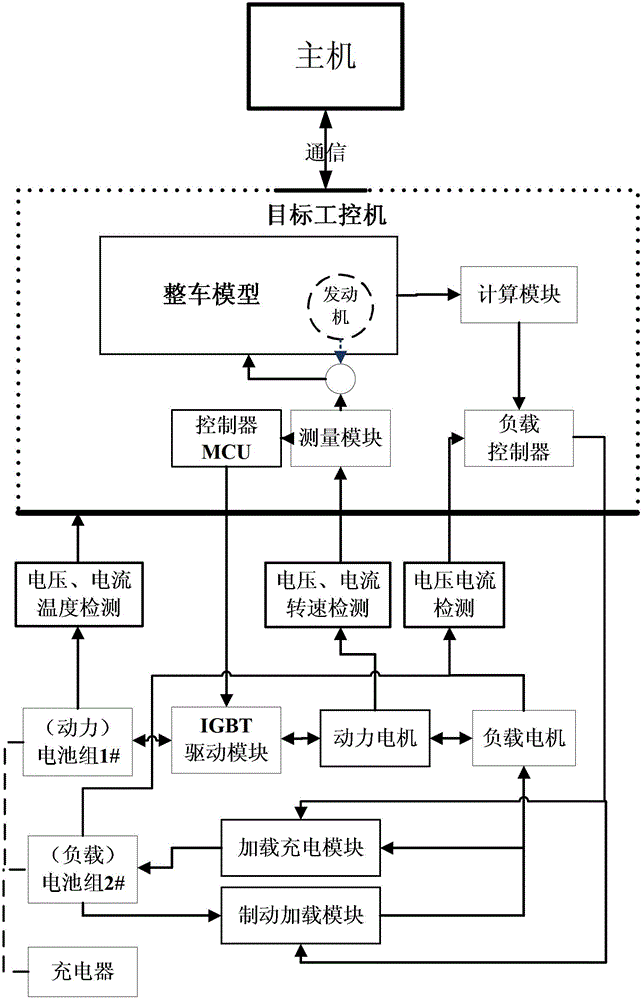

Load simulation device used for electric power test and control method for system thereof

InactiveCN108303875ASolve the accuracy problemSolve the problem that the eddy current dynamometer cannot reverse the drag force system limitVehicle testingAdaptive controlElectric machineLoad model

The invention discloses a load simulation device used for electric power test and a control method for a system thereof. The load simulation device comprises a drive motor and a control module, an electric vehicle speed control module, and a load motor and a control module. The electric vehicle speed control module is a vehicle load mathematical model. The drive motor is a permanent magnet synchronous motor. The load motor is a direct current motor. The load simulation system calculates the target simulation speed of the system based on the drive torque of the electric vehicle drive motor andthe load model of a vehicle. The target simulation speed is used as the target rotation speed of the load motor coupled to the drive motor to control the speed of the load motor. According to the invention, the control precision is high; outdoor driving is not affected by the weather environment; the research and development test level of a pure power vehicle powertrain and key technologies thereof is improved; the development cycle of the powertrain and related components thereof can be greatly shortened; and capital investment is reduced.

Owner:HUNAN VICRUNS ELECTRIC TECH +1

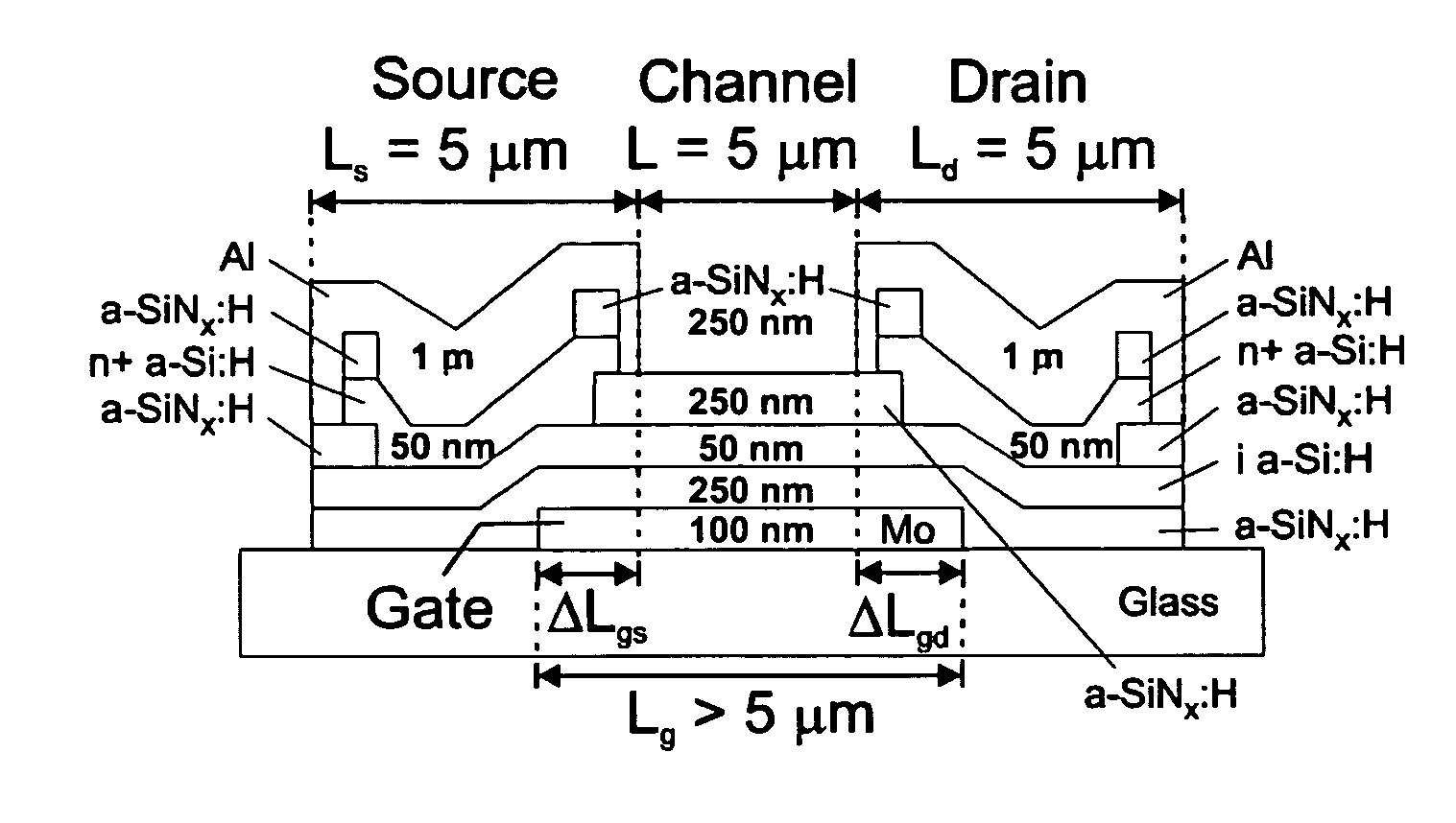

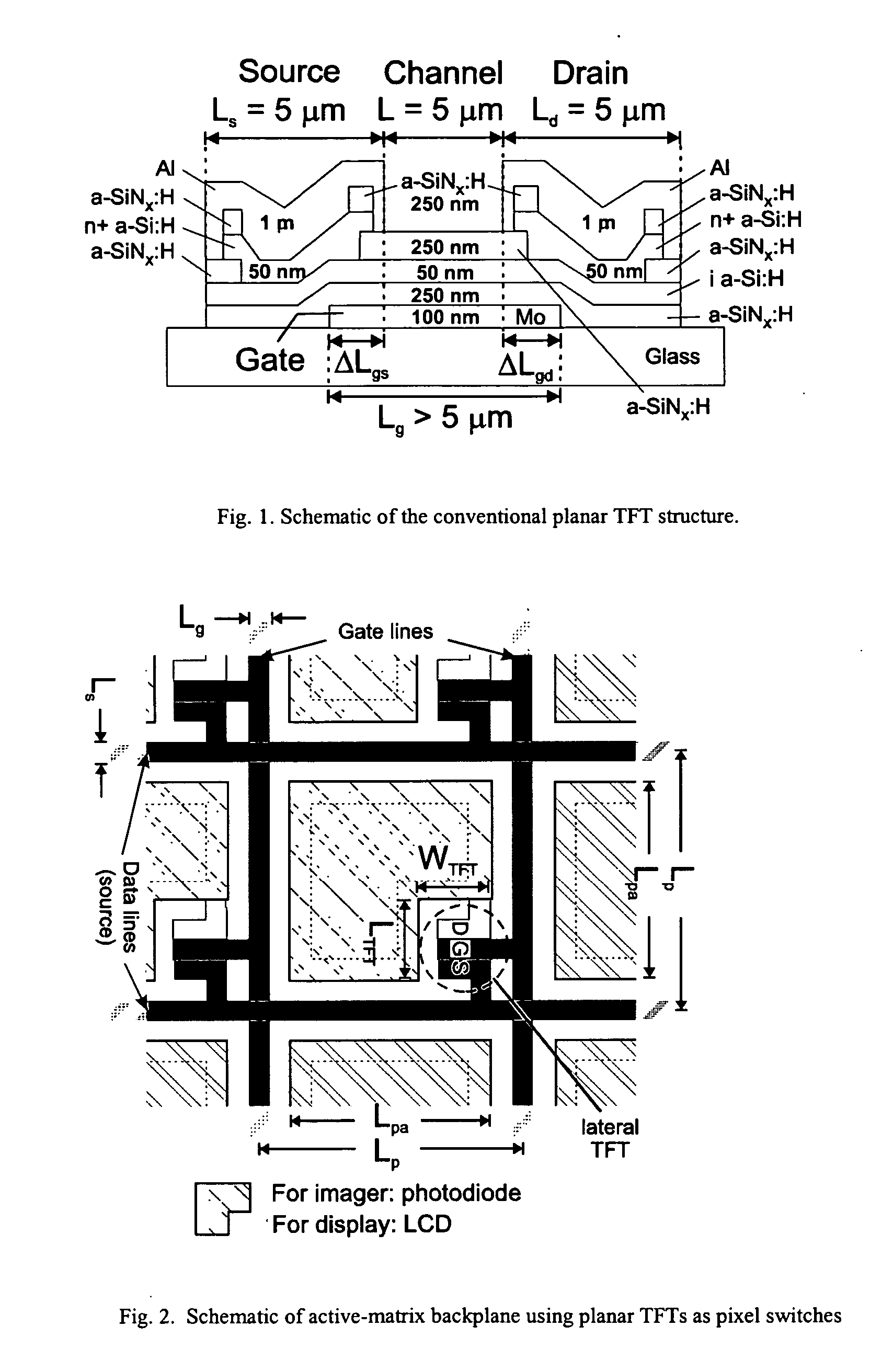

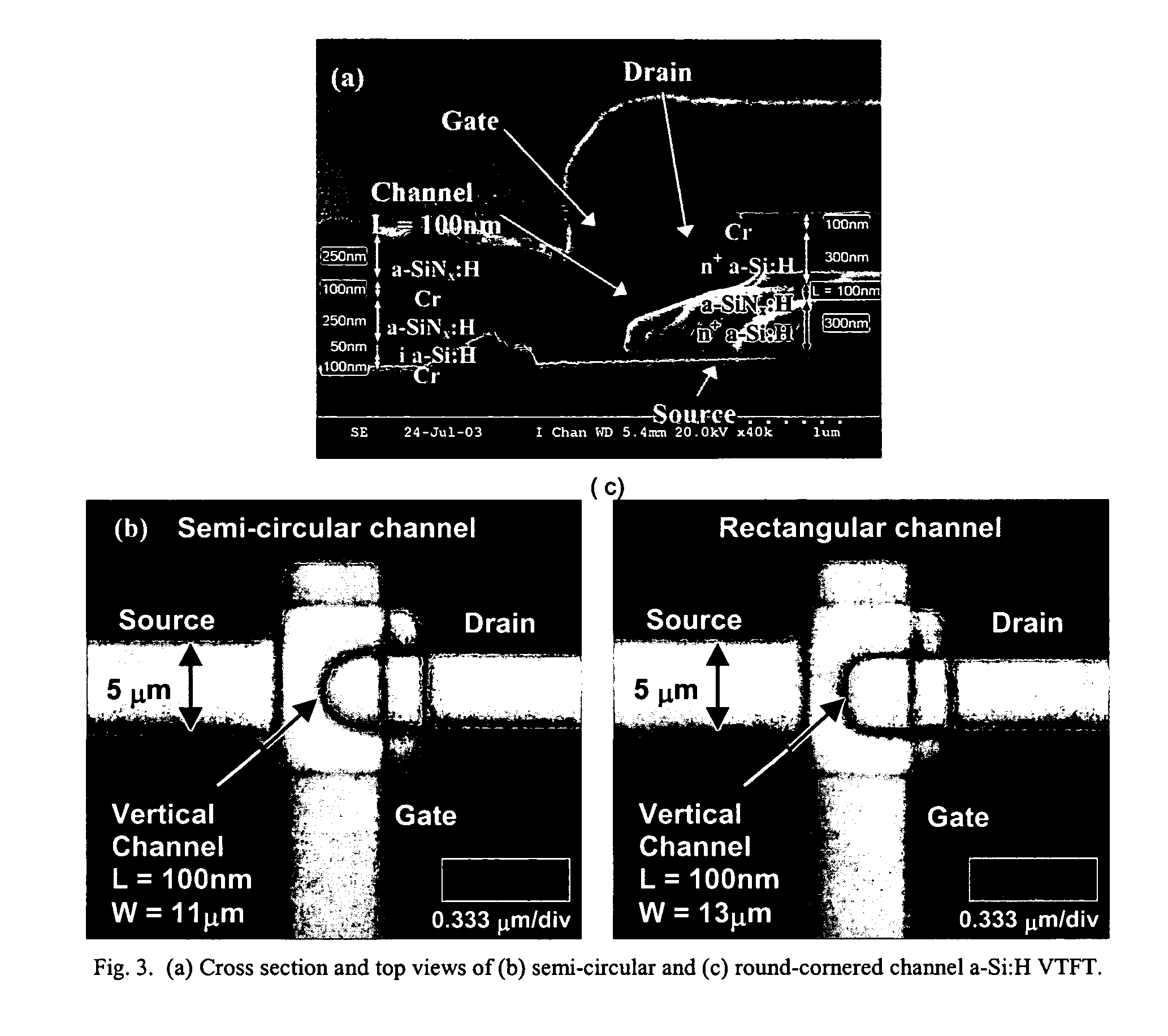

Vertical thin film transistor electronics

InactiveUS20050258427A1Reduce leakage currentAvoid high gate leakage currentTransistorSolid-state devicesProcess equipmentAmorphous silicon

Disclosed here is the design of a new vertical thin film transistor (VTFT) using hydrogenated amorphous silicon (a-Si:H) technology. This design allows the channel length to be scaled down to nanometer-scale (100 nm and beyond) as well as the smallest possible TFT size on glass, plastic, or other common types of substrates, based on the standard photo-etching and thin film deposition processes. The emphasis of using the standard processes for the new VTFTs has a strong implication that no additional process equipment and capital investments are required for technological advancements and gains in performance.

Owner:CHAN ISAAC WING TAK +1

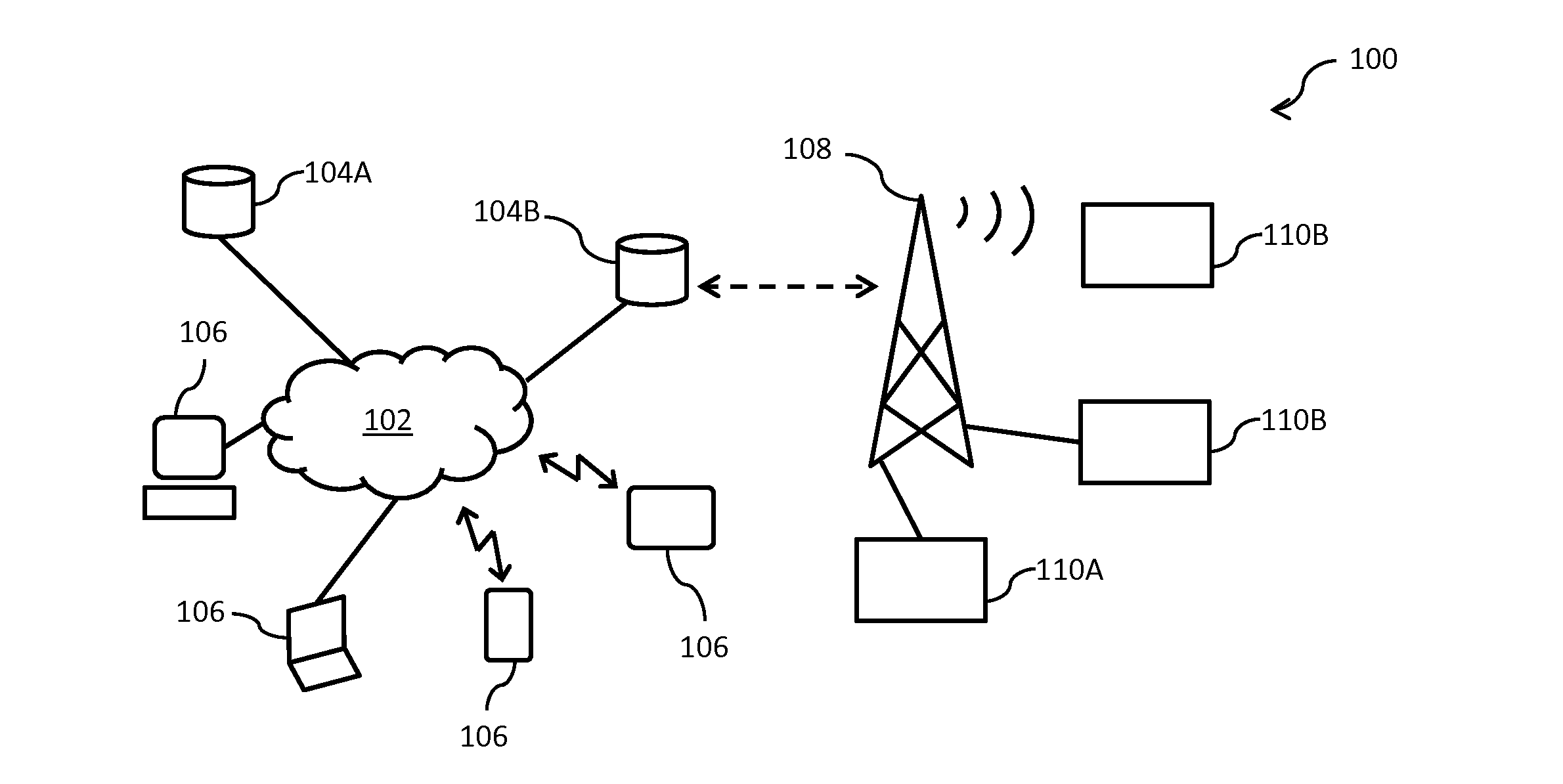

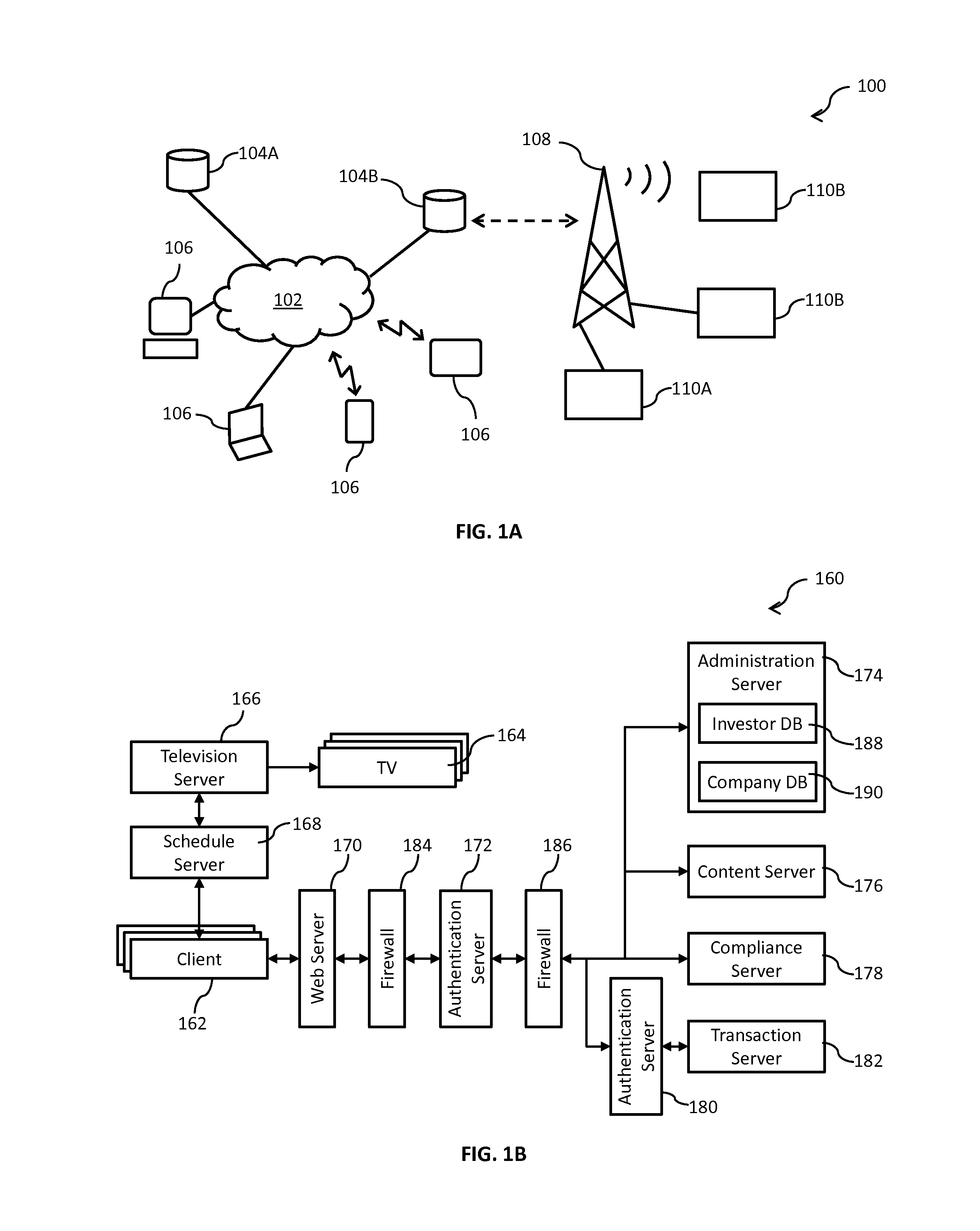

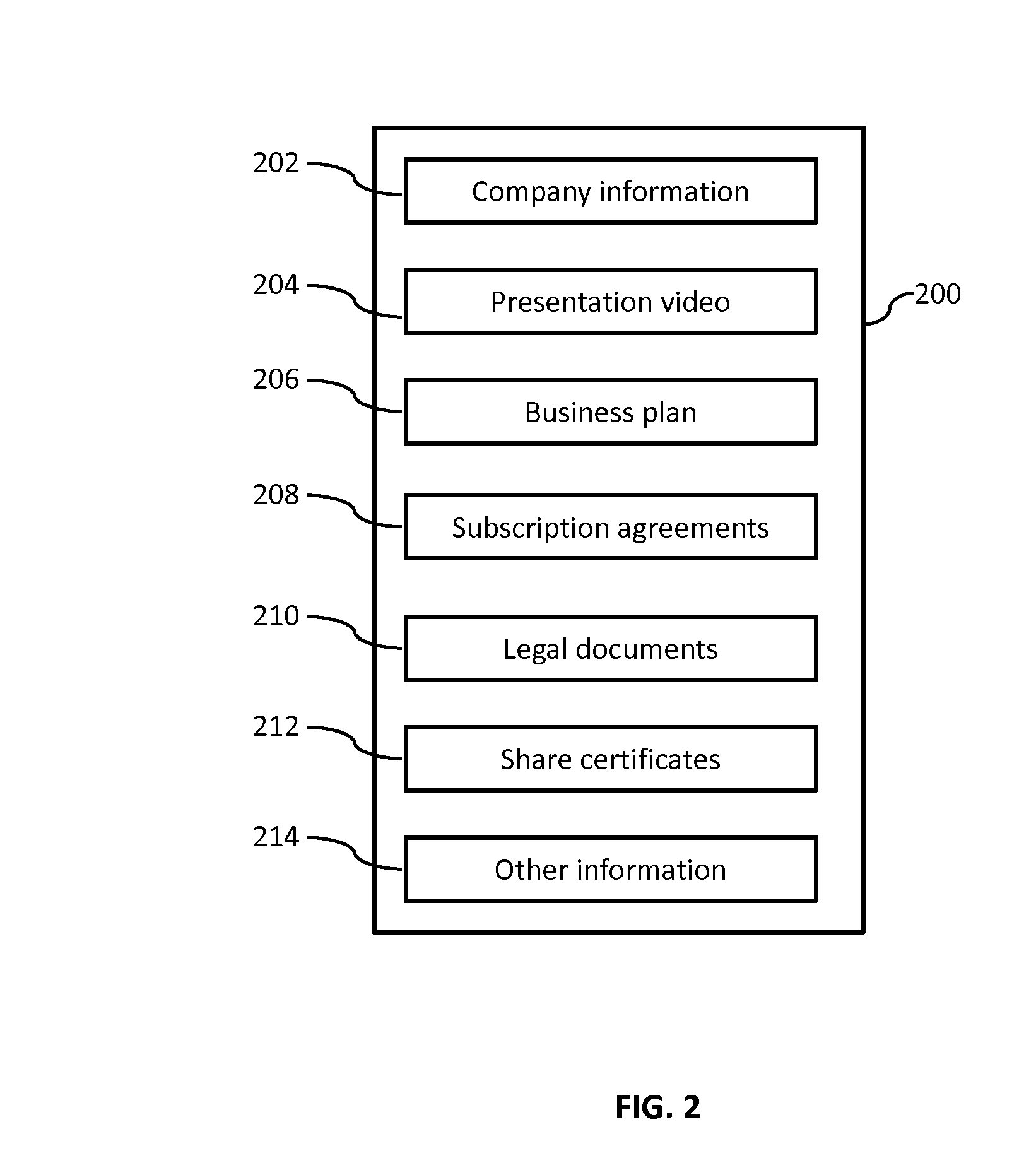

Method for establishing investment transactions using second screen technology and a computer network system employing same

InactiveUS20140143120A1Easy to buySimple processFinanceFundraising managementNetworked systemDistributed computing

A method and a computer network system for establishing a transaction for transferring security shares in exchange of capital investment via the use of second screen technology is disclosed. The system synchronizes a plurality of client computing devices by periodically sending thereto a notification regarding a television program about a fund-seeking company currently in broadcast. An investment user registered with the system may use the client computing device to obtain further information regarding the fund-seeking company while watching the television program, and complete a transaction to acquire shares thereof.

Owner:BUSINESS INSTINCTS GRP

Hybrid power/electric vehicle drive motor system hardware-in-loop algorithm verification test bed

InactiveCN102749583ALow costReduce investmentElectric testing/monitoringDynamo-electric machine testingElectrical batteryEnergy recovery

The invention relates to a hybrid power / electric vehicle power motor / battery hardware-in-loop test bed, in particular to a motor control and braking energy recovery strategy test system under energy-saving hybrid power / electric vehicle-mounted power motor / battery hardware-in-loop vehicle running whole-environmental simulation. A simulation test bed is constructed by using physical objects such as a power motor, a battery pack, power drivers such as IGBT (Insulated Gate Bipolar Transistor) and the like. Power motor control strategies, braking energy recovery strategies and overall vehicle control effects of various vehicle models under whole environment can be quickly verified by cooperating high-quality simulation environment through parameter setting in the established semi-physical simulation system, and the verifications of vehicle motor control strategies and braking energy recovery strategies are dynamically integrated. When energy is saved, the capital investment to real vehicle tests can be reduced, the development cost is saved, the development period is shortened, and the times and the dangerousness of real vehicle tests are reduced.

Owner:JILIN UNIV

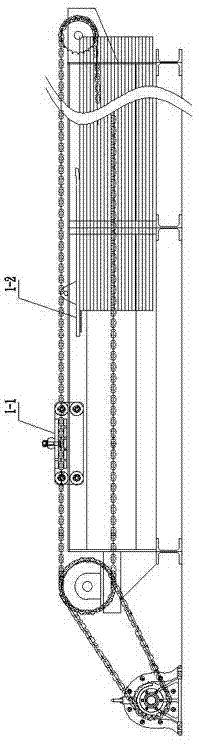

Automatic non-standard steel welding production line

ActiveCN104842083ARealize continuous automatic welding productionReduce welding distortionWelding/cutting auxillary devicesAuxillary welding devicesProduction lineEngineering

An automatic non-standard steel welding production line comprises an automatic wing plate pushing system, wing plate conveying systems, an automatic web discharging and feeding system, an automatic T-steel welding system, an automatic T-steel turnover system, an automatic H-steel welding system and an automatic finished product conveying system. The wing plate conveying systems include an upper wing plate conveying system and a lower wing plate conveying system, and the wing plate conveying systems and the automatic web discharging and feeding system are arranged vertically. In the automatic non-standard steel welding production line, all the devices are simple in structure, easy to operate, stable in mutual connection, continuous automatic welding production of non-standard steel can be realized, weld seams on two sides of a plate are welded at the same time, and the automatic non-standard steel welding production line is small in distortion, less in capital investment, small in space occupation, suitable for non-standard steel manufactures with various scales, timesaving, laborsaving, manpower saving, high in working efficiency and good in product quality.

Owner:LUANXIAN ZHONGXING STEEL STRUCTURE

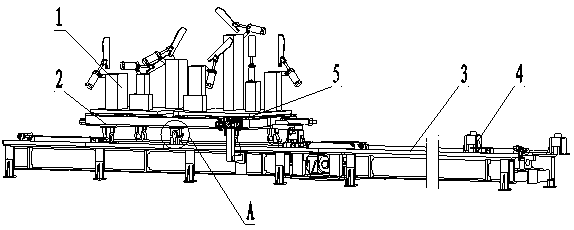

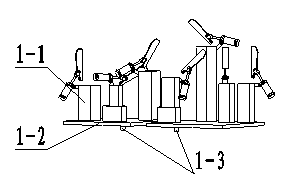

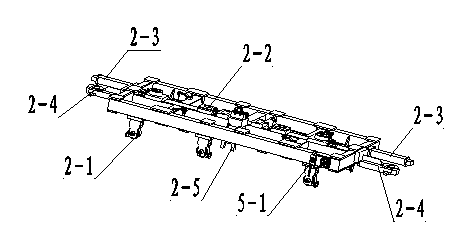

Flexible welding production line for side wall plate of automobile

ActiveCN102699585AImprove flexible production capacityImproved flexible production capacityWelding/cutting auxillary devicesAuxillary welding devicesProduction lineProgrammable logic controller

The invention relates to a flexible welding production line for a side wall plate of an automobile, which is used for improving the flexible production capacity of an autobody welding line body, and comprises a clamp body, a trolley, a frame, a drive mechanism and a PLC (programmable logic controller) control system. The clamp body is installed on the trolley which is connected with the drive mechanism. The trolley is controlled by the PLC control system and dragged by the drive mechanism to reciprocate on a track of the frame to convey the clamp and workpiece of the welding line body. The drive mechanism is arranged on the frame which is fixed on the level ground. The flexible welding production line for the side wall plate of the automobile provided by the invention has the advantages of stable performance, strong universality and high degree of automation, and according to the flexible welding production line, not only is the work efficiency of the welding operation improved remarkably and the production pace of the factory is ensured, but also the flexible production capacity of the welding line body is improved, the capital investment on devices is lowered, the period of new products in batch production is shortened, and large economic benefits is brought for enterprises.

Owner:长城汽车股份有限公司平湖分公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com