Automatic non-standard steel welding production line

A welding production line and automatic welding technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of not meeting production needs, low degree of automation, inconvenient production work, etc., and achieve small space occupation and capital investment Less, better product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below with reference to the drawings and embodiments.

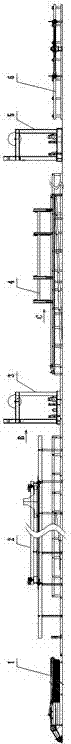

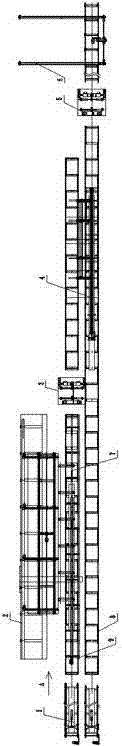

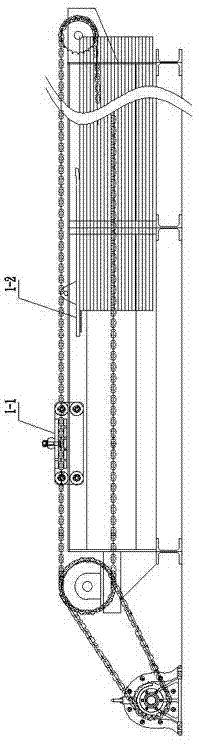

[0039] See attached Figure 1-2 The automatic non-standard section steel welding production line disclosed in the present invention manufactures the plate into predetermined section steel through the steps of conveying, blanking, feeding, rotating, positioning, welding, and conveying. The production line includes wing plate automatic pushing system 1, wing plate conveying system, web automatic cutting and feeding system 2, section steel welding system, T-shaped steel automatic turning system 4, finished product automatic conveying system 6, web automatic conveying system 7, The wing plate conveying system includes a lower wing plate conveying system 8 and an upper wing plate conveying system 9. The section steel welding system includes a T-shaped steel automatic welding system and an H-shaped steel automatic welding system. Wing plate conveying system and web automatic b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com