Composite pressure container

A composite material and pressure vessel technology, which is applied in the field of pressure vessels, can solve the problems of no prestressed winding, etc., and achieve the effects of small welding deformation, weight reduction, and stress concentration reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

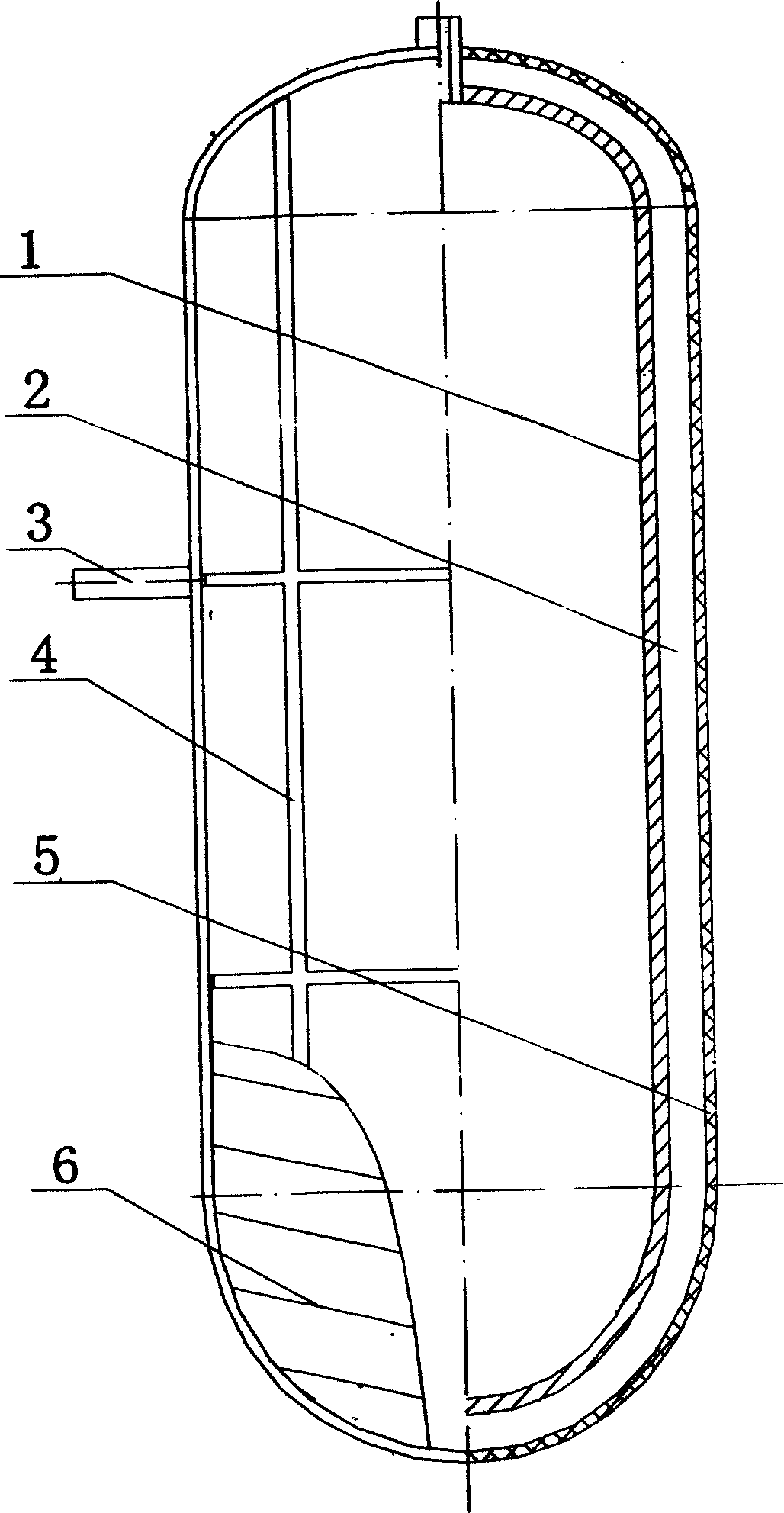

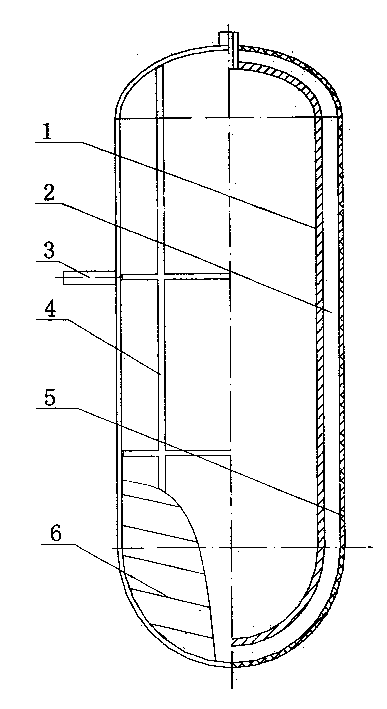

[0013] As shown in the accompanying drawings, the left half of the figure is cut on the composite material layer 2, and the lower left part shows a schematic diagram of the composite material layer 2 being formed by the oblique composite material winding tape 6; the right half is a cross-sectional view. In the present invention, it is an inner container 1 made of a high-strength aluminum alloy thin-wall inner lining or a plastic thin-wall inner lining, and a prestressed inclination angle is used to wind a high-strength fiber-impregnated epoxy resin-based composite material winding tape 6 outside the inner container 1. The outer surface of the material layer 2 and the composite material layer 2 is provided with a vertically and horizontally connected small groove 4, which is covered with an airtight outer protective layer 5, and the leak-picking holes on the airtight outer protective layer 5 are connected vertically and horizontally with the small grooves on the outer surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com