Patents

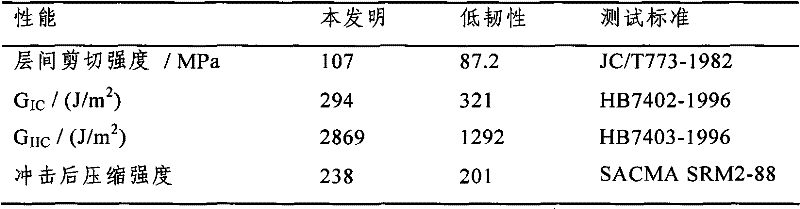

Literature

3646 results about "Resin-Based Composite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A dental restorative material made up of disparate or separate parts (e.g., resin and quartz particles).

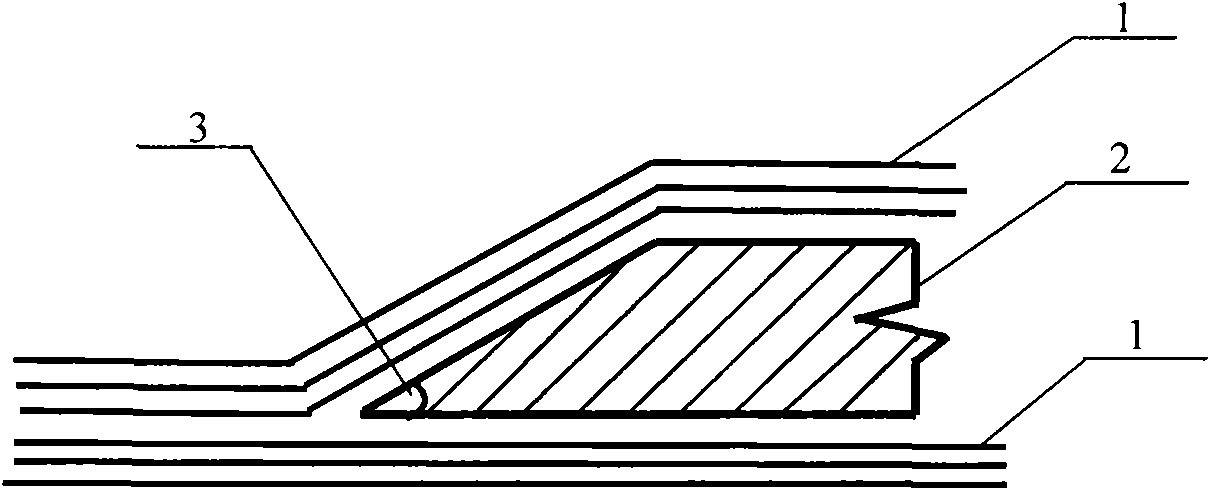

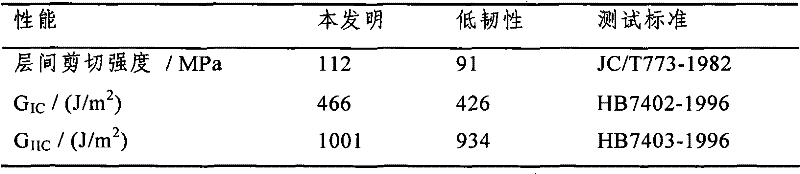

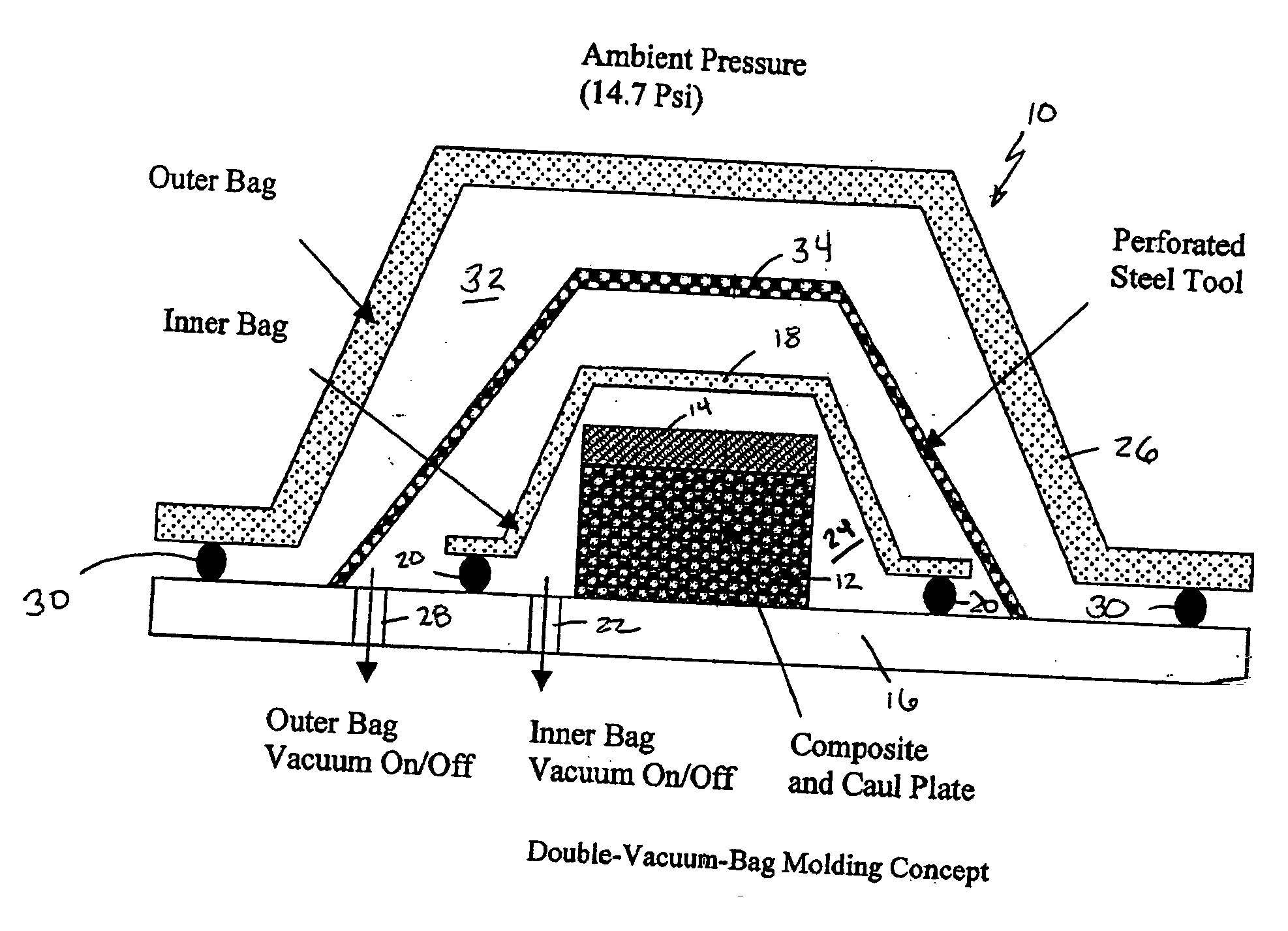

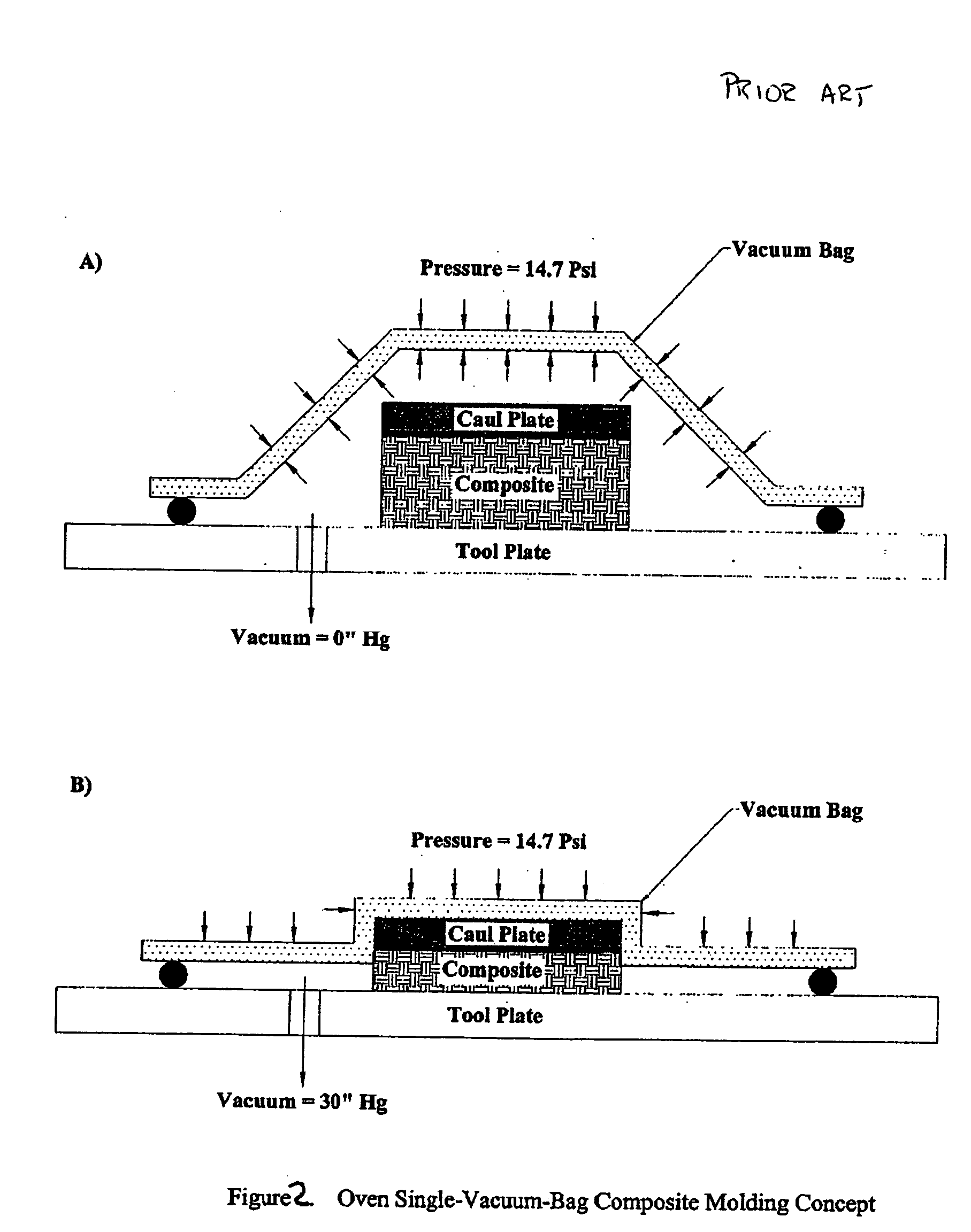

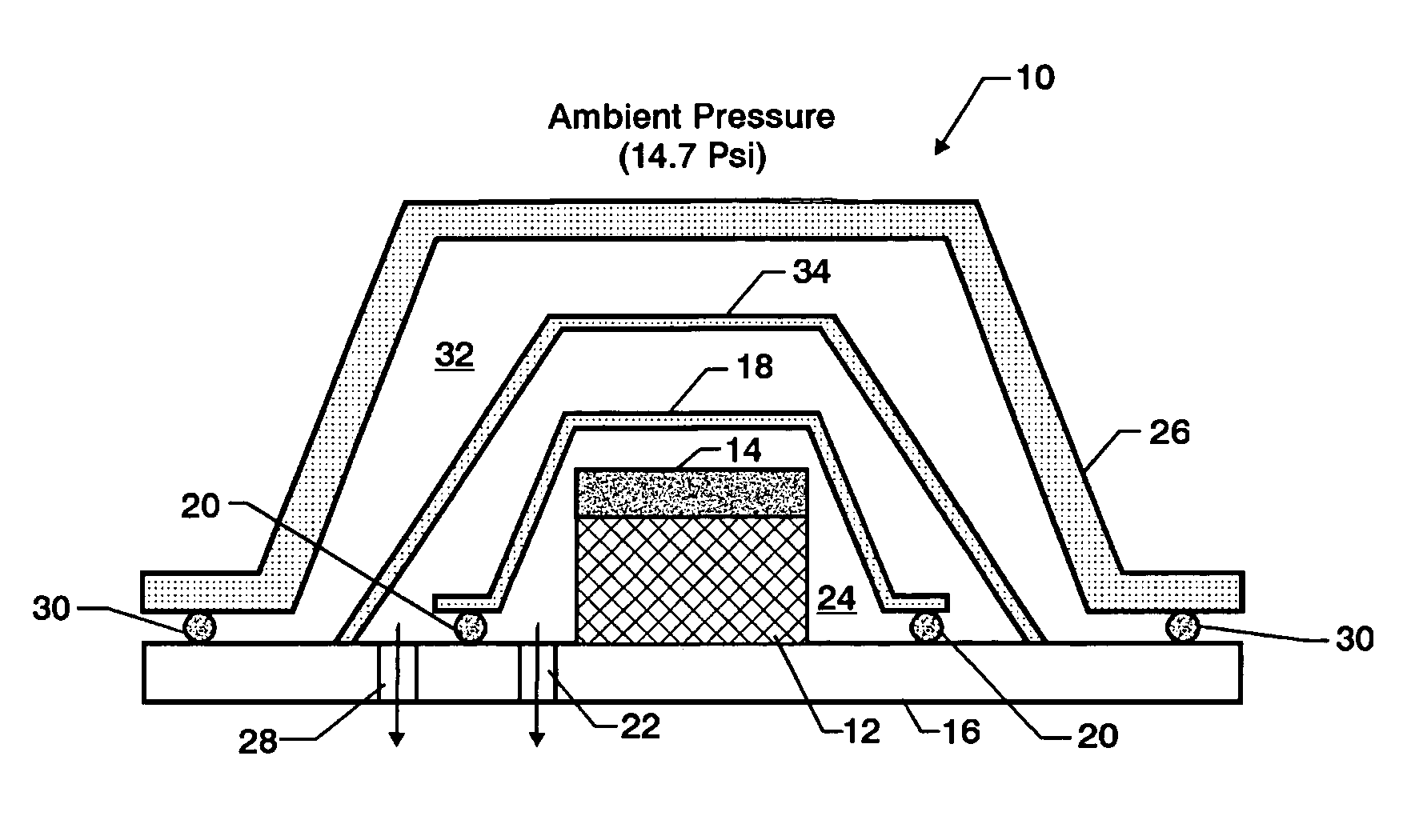

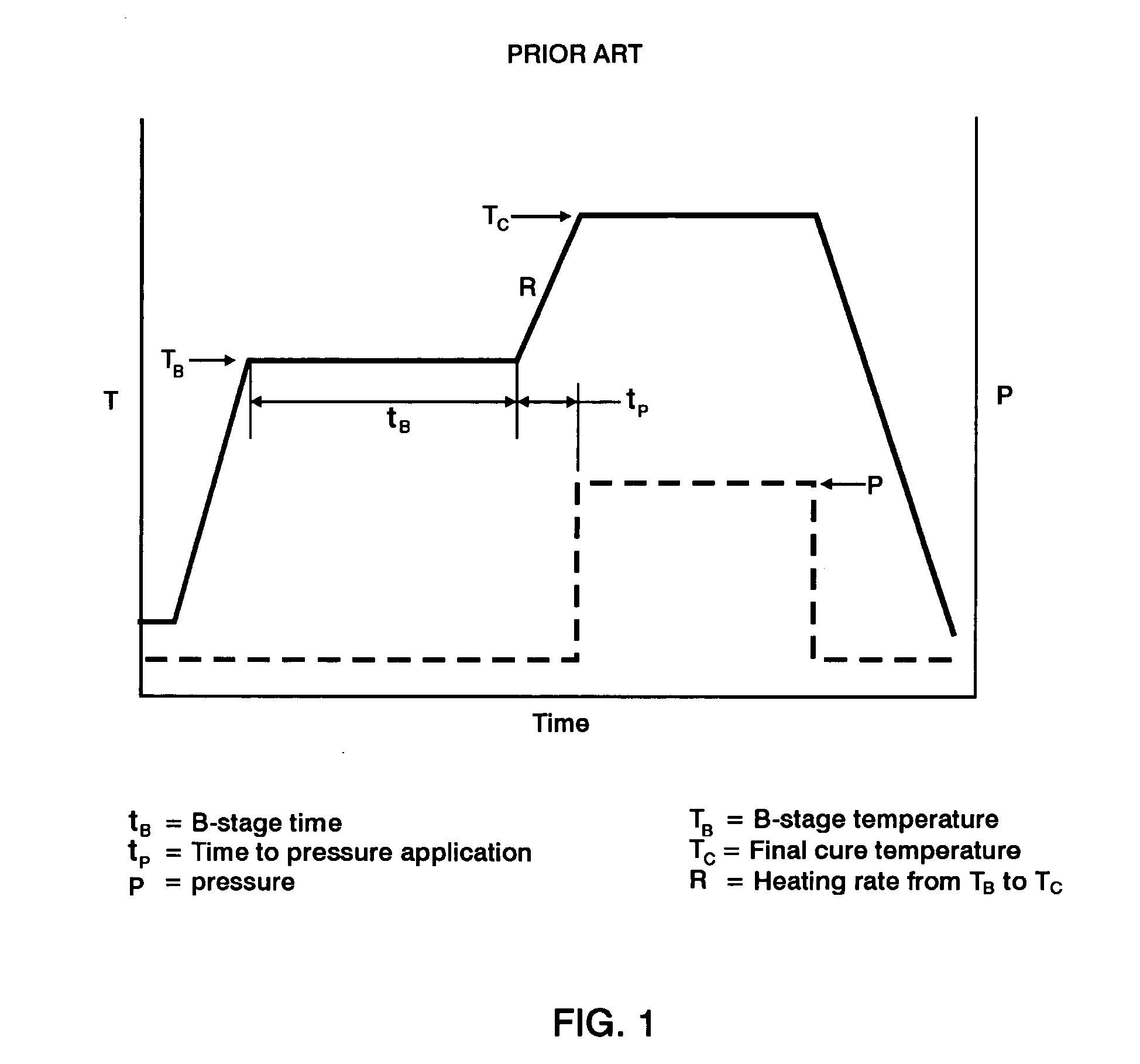

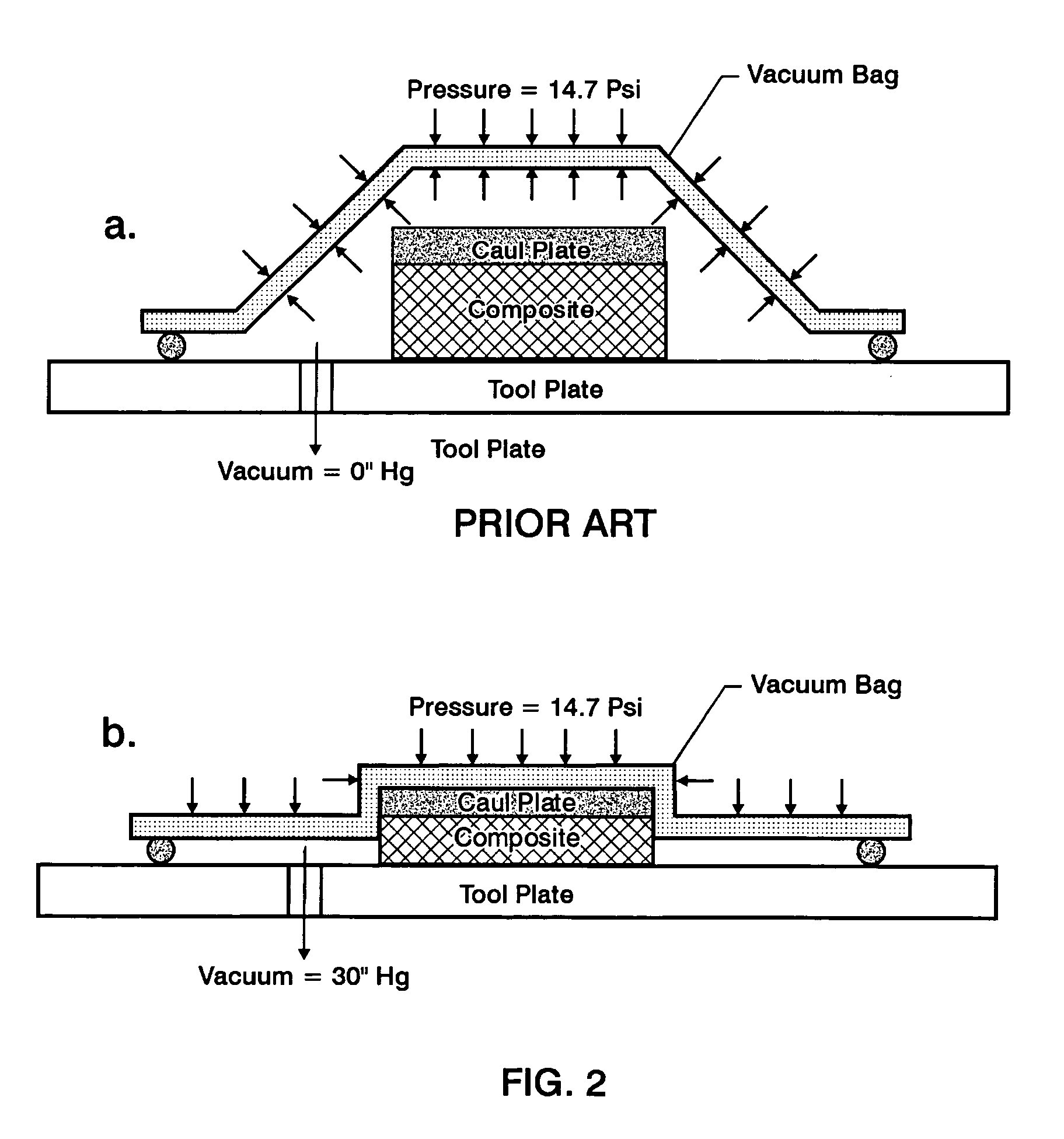

Double vacuum bag process for resin matrix composite manufacturing

InactiveUS20050253309A1Improve performanceImprove propertiesLaminationLamination apparatusRelative pressureResin matrix

A double vacuum bag molding assembly with improved void management and laminate net shape control which provides a double vacuum environment for use in fabricating composites from prepregs containing air and / or volatiles such as reactive resin matrix composites or composites from solvent containing prepregs with non-reactive resins matrices. By using two vacuum environments during the curing process, a vacuum can be drawn during a B-stage of a two-step cycle without placing the composite under significant relative pressure. During the final cure stage, a significant pressure can be applied by releasing the vacuum in one of the two environments. Inner and outer bags are useful for creating the two vacuum environments with a perforated tool intermediate the two. The composite is placed intermediate a tool plate and a caul plate in the first environment with the inner bag and tool plate defining the first environment. The second environment is characterized by the outer bag which is placed over the inner bag and the tool plate.

Owner:NASA

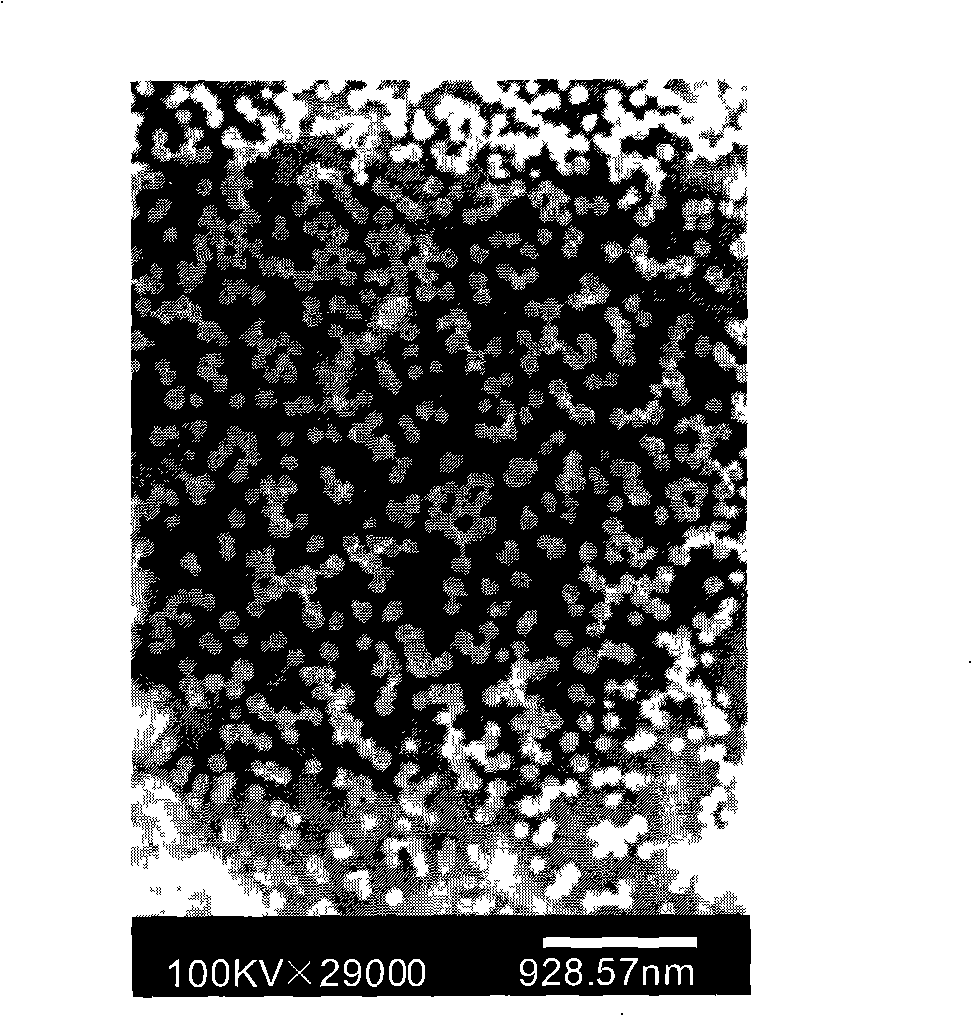

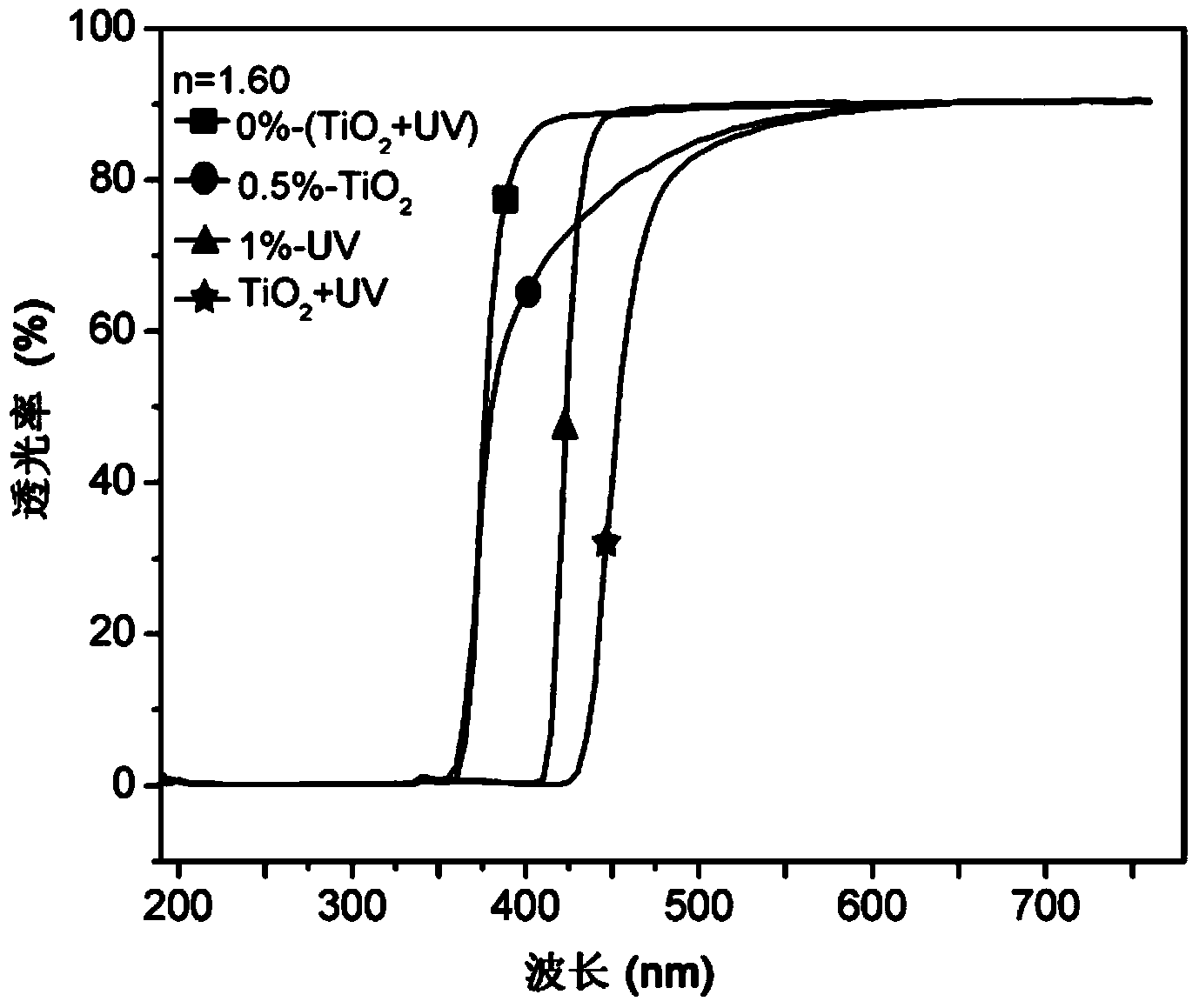

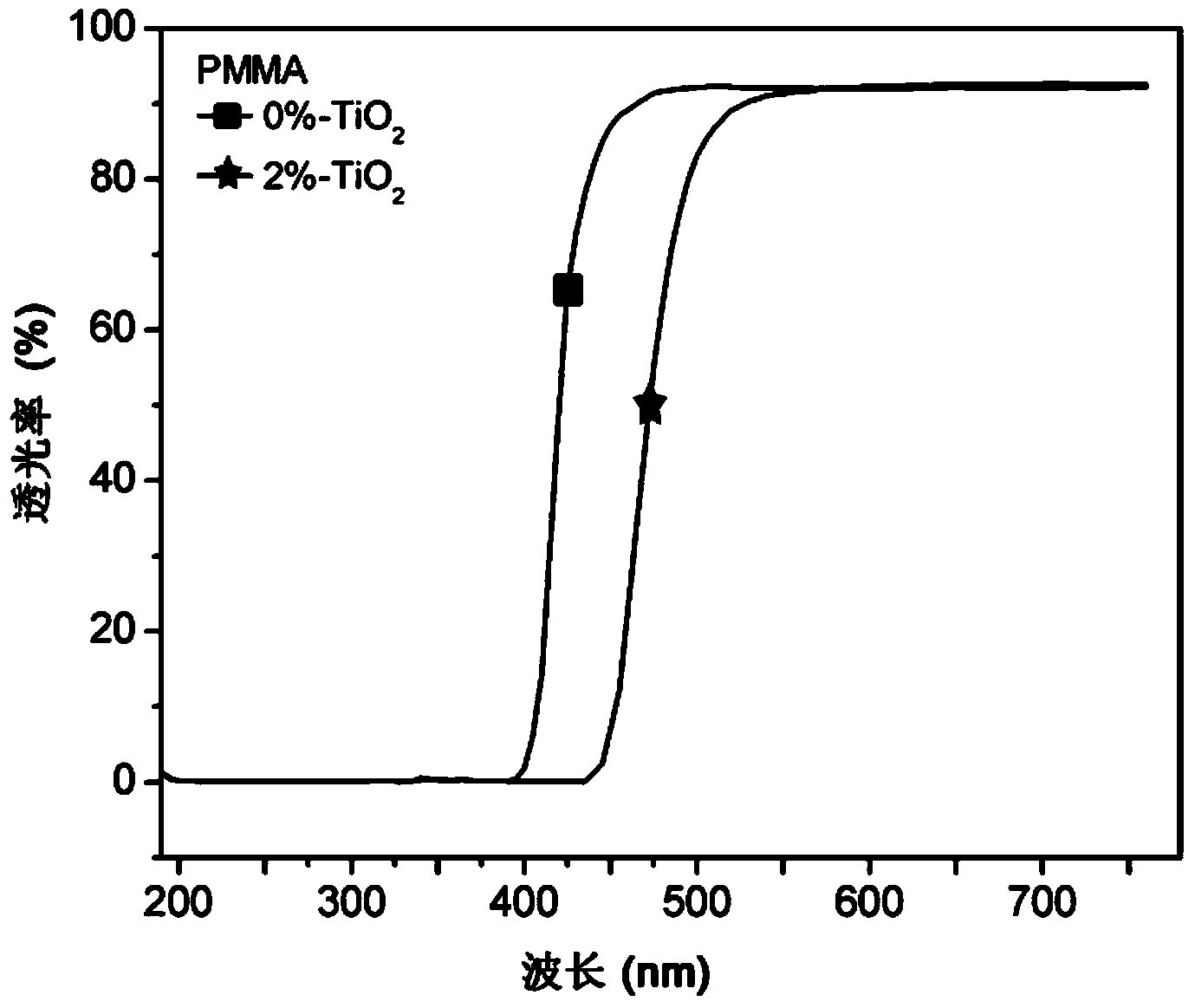

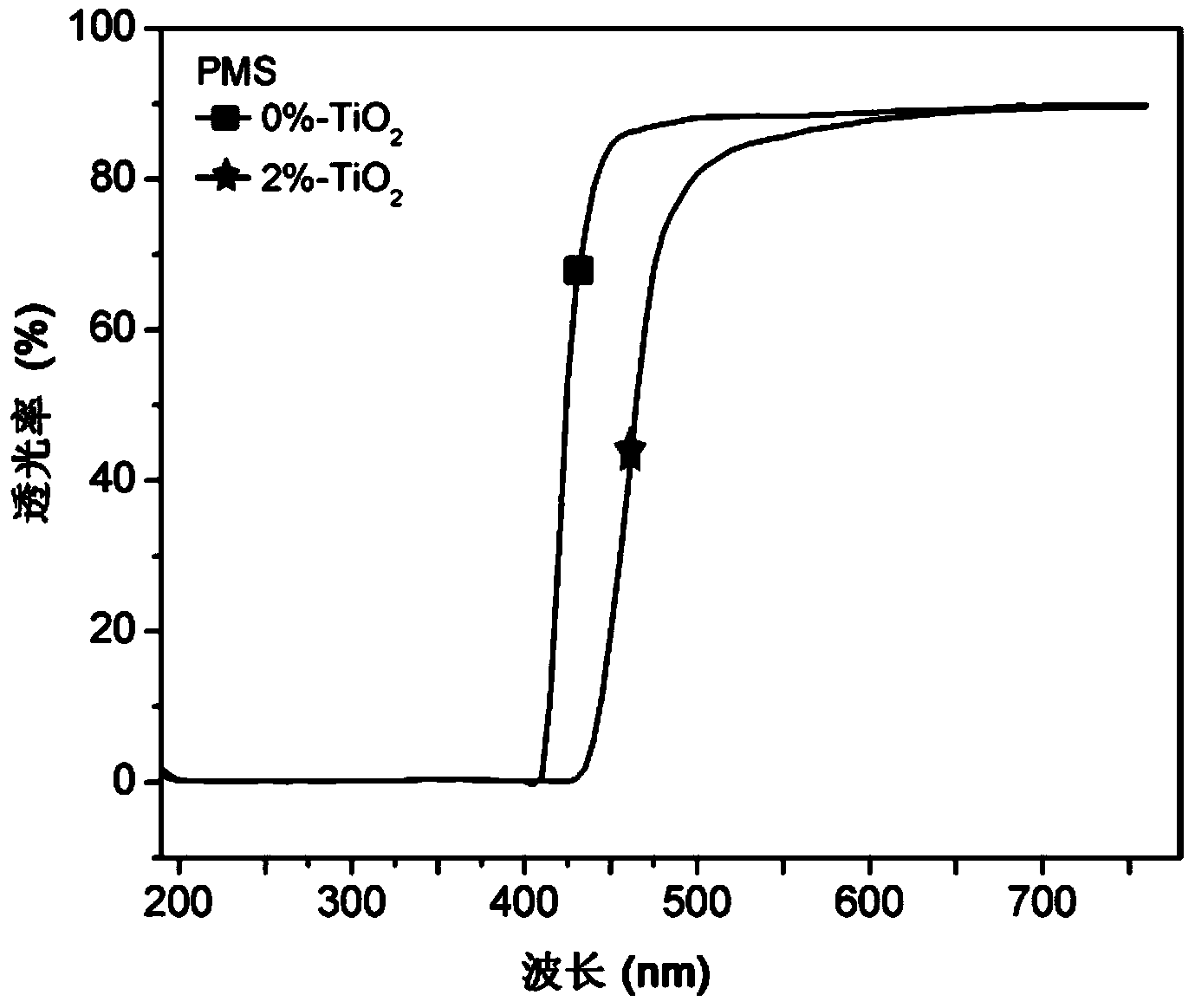

Blue light cut nano compound resin material, lens and preparation method thereof

ActiveCN103980643AEvenly dispersedComprehensive and excellent comprehensive performanceOptical partsHigh energyUltraviolet lights

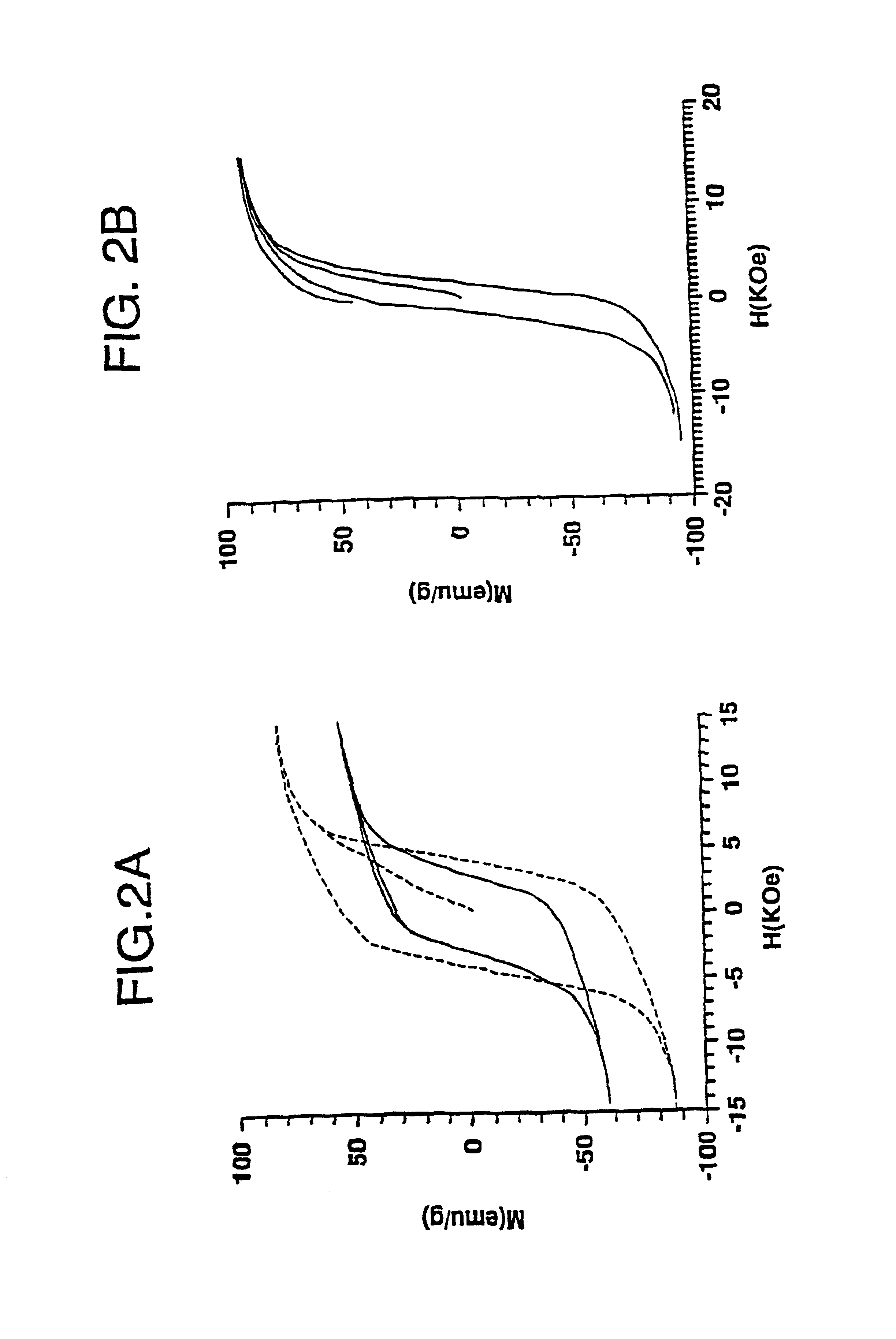

The invention relates to a blue light cut nano compound resin material and lens and a manufacturing method thereof. The blue light cut nano compound resin material comprises macromolecule resin as well as core-shell type transition metal oxide nano particles and an ultraviolet light absorber which are dispersed in the macromolecule resin, wherein the core-shell type transition metal oxide nano particles account for 0.2-2% of the total weight of the resin, and the ultraviolet light absorber accounts for 0.5-5% of the total weight of the resin; particle size of nano particles is 20-50nm; the shell is a surface active agent, and thickness is 3-10nm; the nano particles and the ultraviolet light absorber are fully dispersed in a macromolecule monomer, and a prepolymerization and secondary polymerization technological process is carried out, so that the blue light cut compound resin material is obtained. The manufacturing method of the blue light cut compound resin material is simple in technology and good in reproducibility, the manufactured resin material and lens can efficiently and permanently shield high energy harmful blue light and ultraviolet light with wavelength within the range of 380-450nm, vision is clear and colour vision is soft under strong and weak light environments respectively, and the blue light cut compound resin material has excellent overall performance.

Owner:JIANGSU SHIKEXINCAI CO LTD

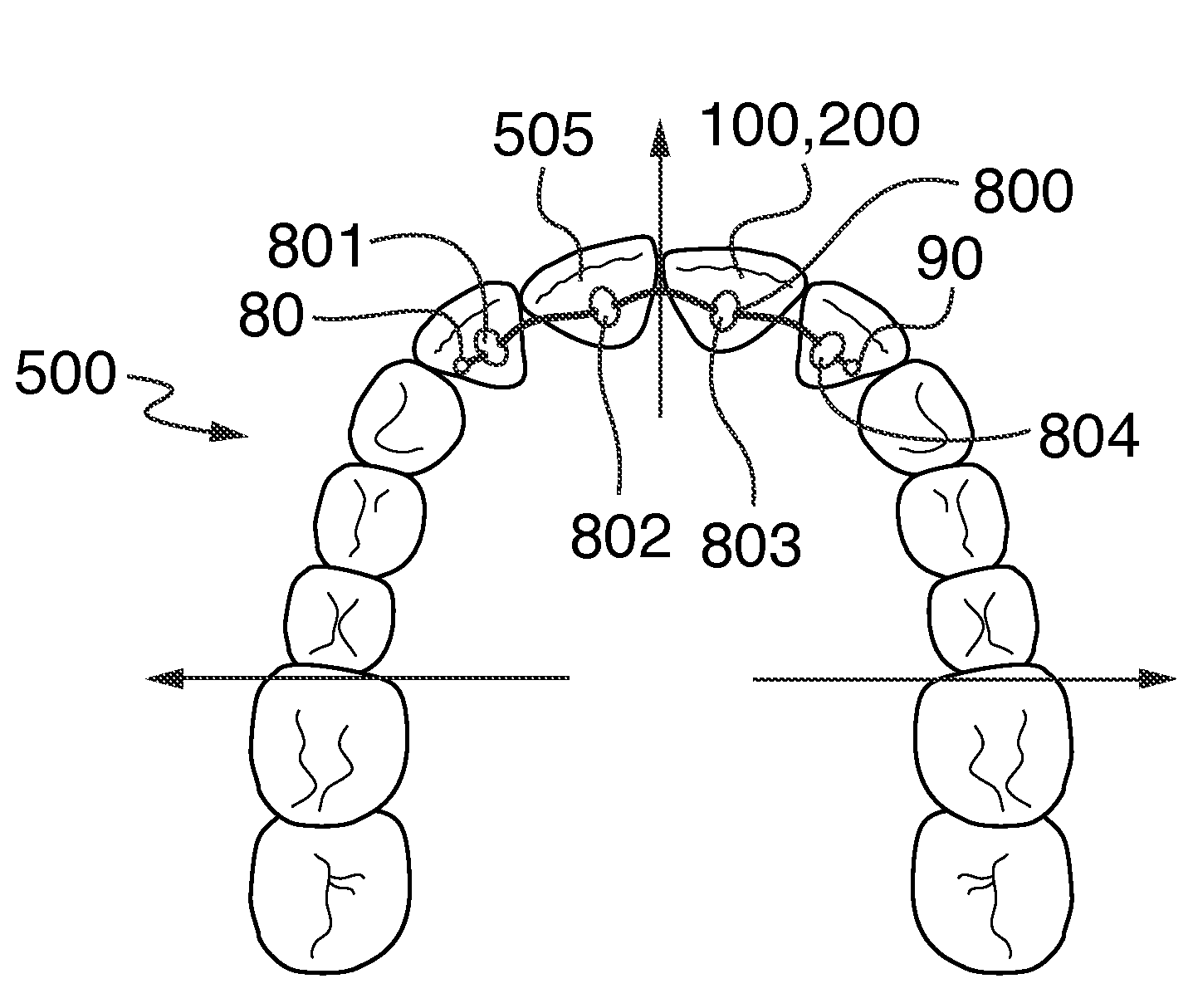

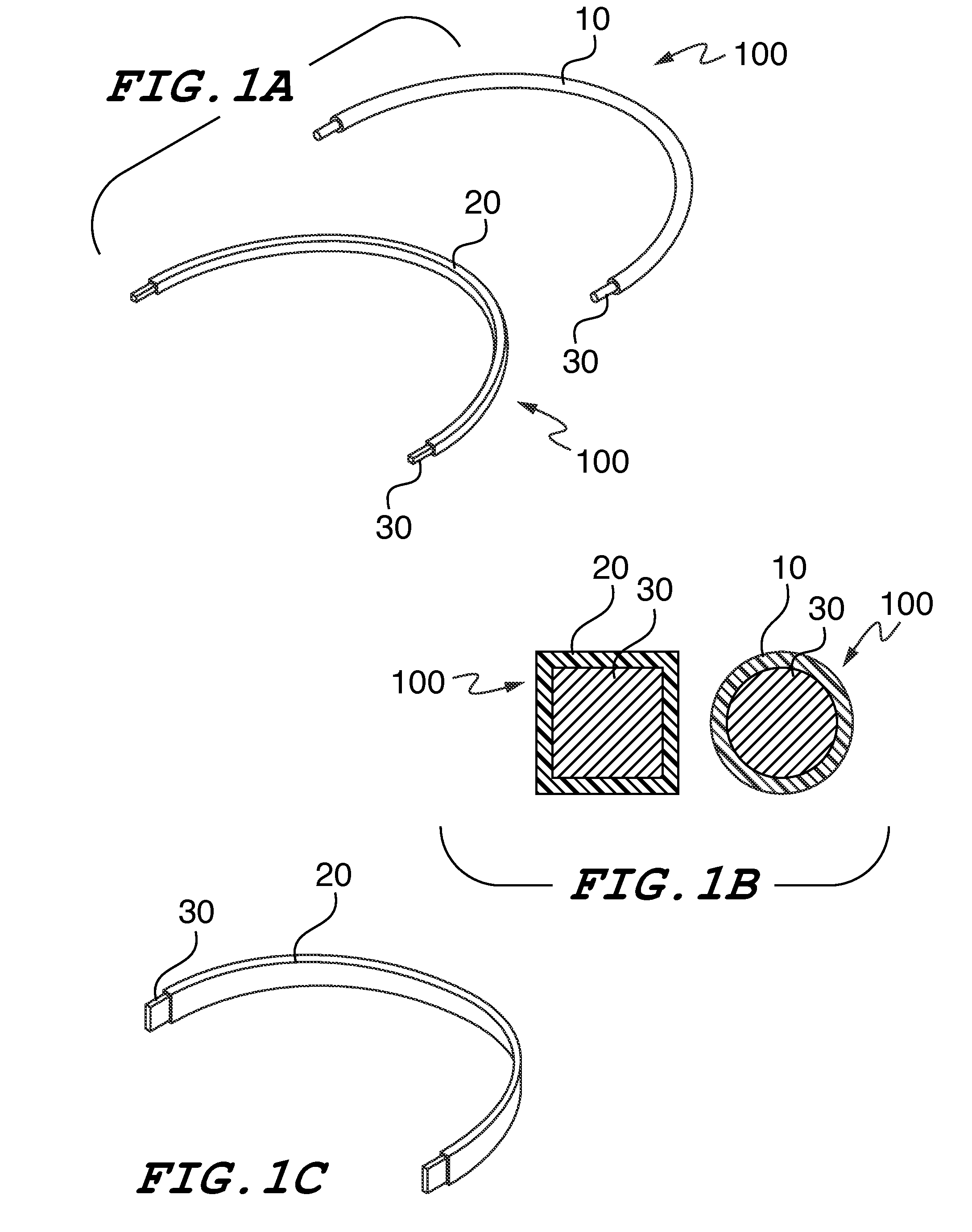

Orthodontic Wire Alignment System and Method

ActiveUS20140302448A1Minimize contaminationPrecise positioningArch wiresBracketsLingual surfaceResin-Based Composite

Disclosed is a system and method for treating mal-alignment of teeth using super-elastic nickel titanium, heat activated nickel titanium coated or uncoated orthodontic wires with composite resins in order to effectuate desired tooth alignment. The composite resin is formed into beads that hold the wire in place preferably on the lingual surface of the teeth. Alternate embodiments using composite brackets are disclosed. The overall purpose of this invention is to provide a close contact, low profile orthodontic system, in particular, a lingual orthodontic system that is significantly more comfortable than existing orthodontic systems, completely concealed and effective.

Owner:ALTA SMILES LLC

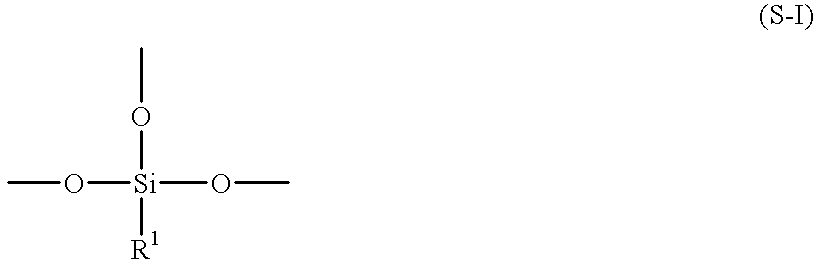

Process for preparing aqueous resin, aqueous curable resin composition, aqueous paint, and method for formation of coating therefrom

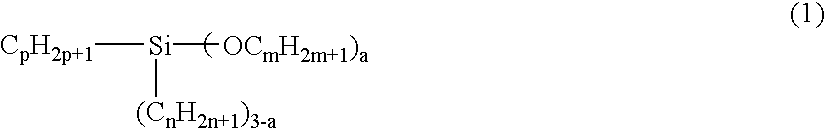

InactiveUS6268440B1Good storage stabilityImprove curing effectGroup 4/14 element organic compoundsFibre treatmentWater basedCarbon number

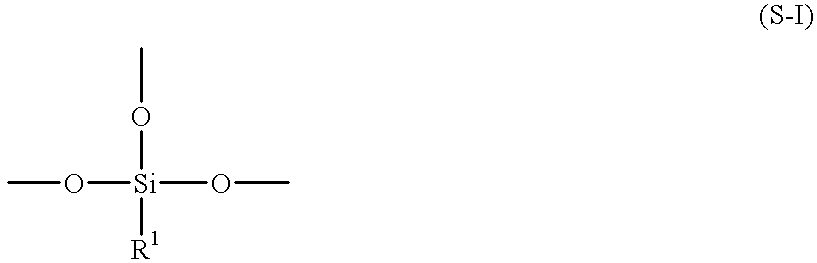

A water-base resin has both excellent storage stability and excellent curability at room temperature, the water base resin being obtained by mixing a composite resin (C) and a polysiloxane (D), bringing about a condensation reaction partially between them if necessary, and thereafter dispersing or dissolving the resulting mixture or partially condensed product into a water-base medium, wherein the composite resin (C) comprises a polysiloxane segment (A) and a polymer segment (B), the polysiloxane segment (A) having at least one silicon atom selected from the group consisting of a silicon atom bearing at least one organic group having a total carbon number of at least 3 together with at least one hydrolyzable group and / or at least one hydroxyl group, a silicon atom bearing one hydrolyzable group or one hydroxyl group together with two groups selected from the group consisting of methyl groups and ethyl groups, and a silicon atom bearing at least one triorganosiloxy group together with at least one hydrolyzable group and / or at least one hydroxyl group, and the polymer segment (B) having at least one type of hydrophilic group selected from the group consisting of an anionic group, a cationic group, and a non-ionic group, and wherein the polysiloxane (D) has a hydrolyzable group bonded to a silicon atom and / or a hydroxyl group bonded to a silicon atom, the polysiloxane (D) having a structure represented by the following structural formula (S-I) as an essential structural unit:(wherein R1 in the formula denotes a methyl group or an ethyl group). A water-base curable resin composition comprising the water-base resin as an essential component produces a cured material which possesses excellent resistance stain during outdoor exposure as well as excellent durability such as acid rain resistance and gloss retention during outdoor exposure.

Owner:DAINIPPON INK & CHEM INC

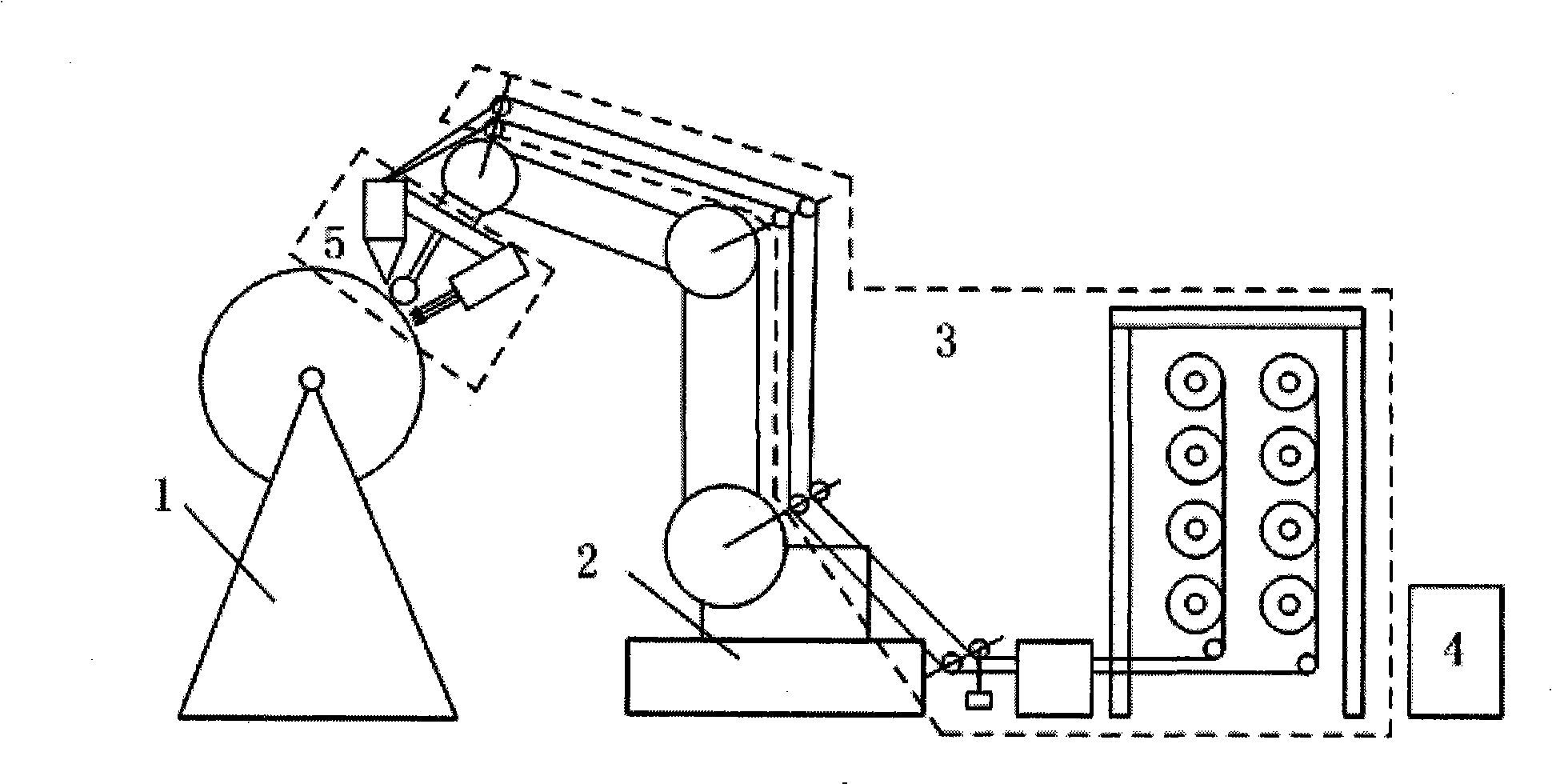

Multi-degree-of-freedom 3D printer of fiber reinforced composite material and printing method thereof

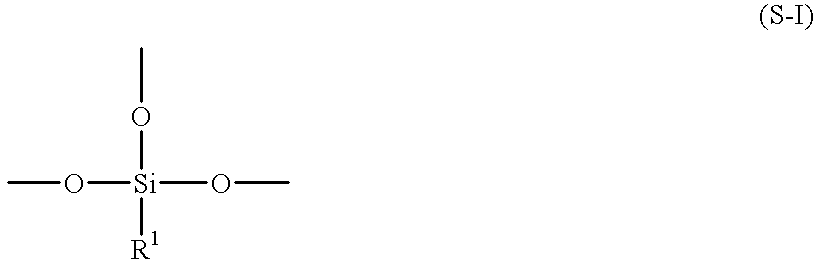

The invention discloses a multi-degree-of-freedom 3D printer of a fiber reinforced composite material and a printing method thereof. The 3D printing can be performed with any angle and any movement locus by making use of the flexibility of a manipulator; and a 3D printing head mounted on the multi-degree-of-freedom 3D printer can perform the 3D printing of a high-strength short fiber reinforced composite material, and can perform the splicing and the weaving of continuous resin-based long fiber to produce a structural body of a continuous fiber reinforced resin-based composite material. The multi-degree-of-freedom 3D printer can precisely control the orientation of reinforced fiber in a composite material part in the 3D printing process, and can realize the quick production of the composite material part with specific mechanical, electric and thermal performances and a complex structure. Meanwhile, a mold customized beforehand and a pretreated fiber prepreg tape are not needed in the process; and the multi-degree-of-freedom 3D printer is not only suitable for the production of large parts, but also suitable for the large-batch production of small parts, so that the production cost and the production period are largely reduced, and the wide application of the composite material parts is further promoted.

Owner:XI AN JIAOTONG UNIV

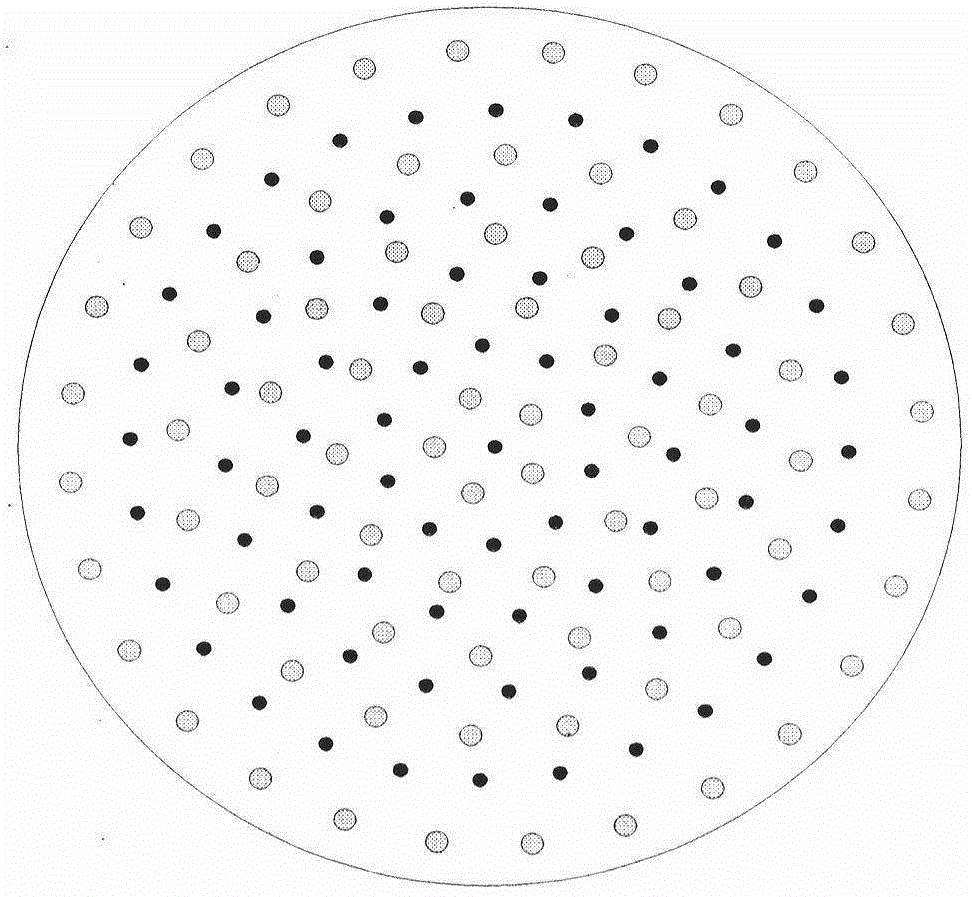

Composite particle for dielectrics, ultramicroparticulate composite resin particle, composition for forming dielectrics and use thereof

InactiveUS20030151032A1High dielectric constantSmall dielectric loss tangentSemiconductor/solid-state device detailsSolid-state devicesInorganic particleResin-Based Composite

The dielectric-forming composition according to the invention is characterized by consisting of: composite particles for dielectrics in which part or all of the surfaces of inorganic particles with permittivity of 30 or greater are coated with a conductive metal or a compound thereof, or a conductive organic compound or a conductive inorganic material; and (B) a resin component constituted of at least one of a polymerizable compound and a polymer. In addition, another dielectric-forming composition according to the invention is characterized by containing: ultrafine particle-resin composite particles composed of (J) inorganic ultra fine particles with the average particle size of 0.1 mum or smaller, and (B) a resin component constituted of at least one of a polymerizable compound and a polymer, wherein part or all of the surfaces of the inorganic ultrafine particles (J) are coated with the resin component (B), and the ultrafine particle-resin composite particles contain 20% by weight or more of the inorganic ultrafine particles (J); and inorganic particles with the average particle size of 0.1 to 2 mum and permittivity of 30 or greater, or inorganic composite particles in which a conductive metal or a compound thereof, or a conductive organic compound or a conductive inorganic material is deposited on the part or all of the surfaces of the inorganic particles.

Owner:JSR CORPORATIOON

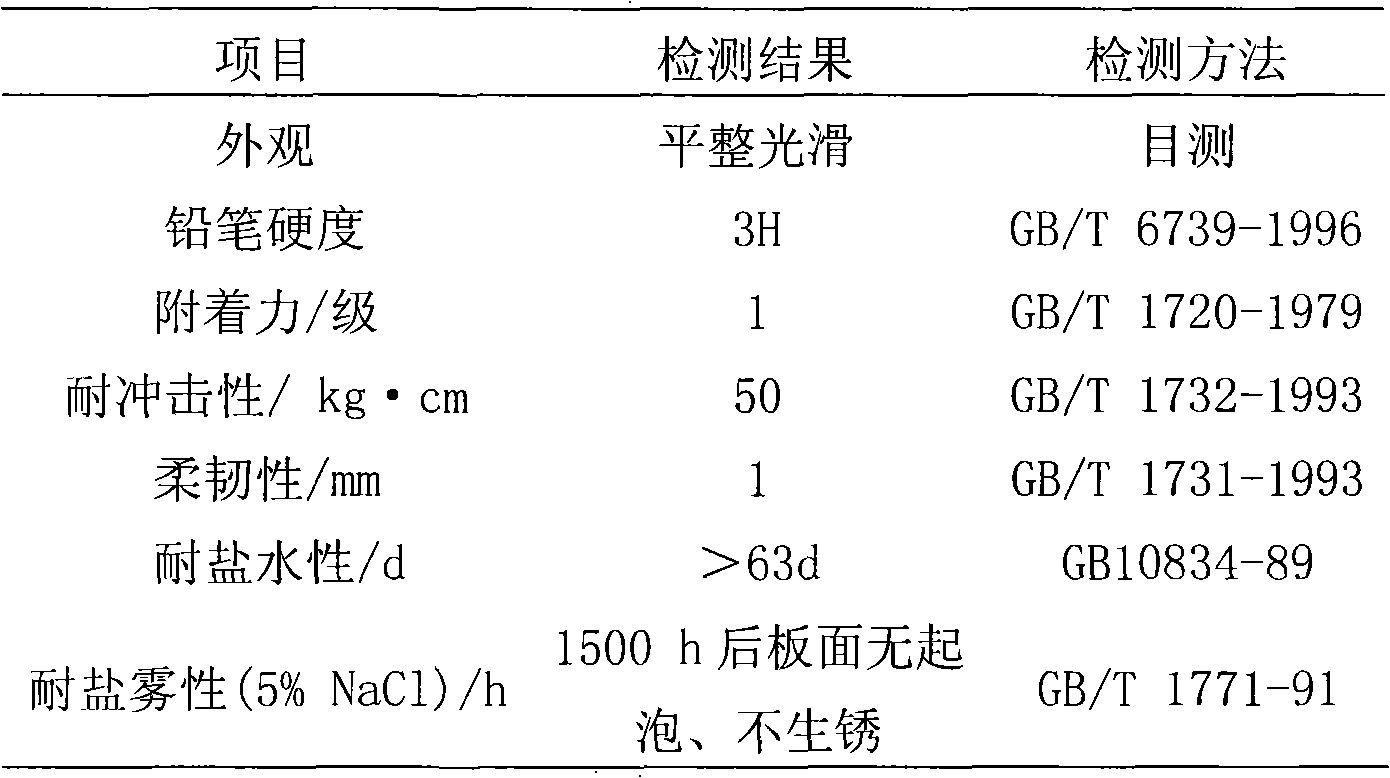

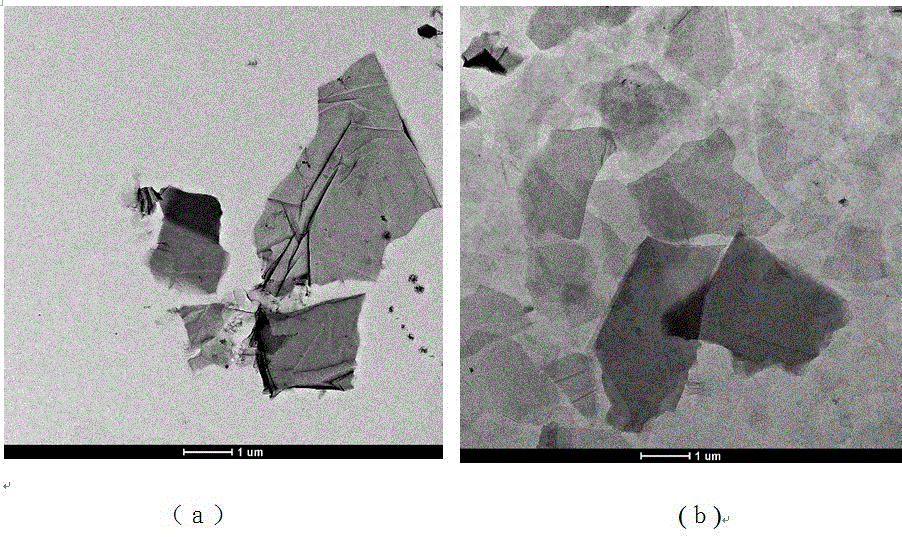

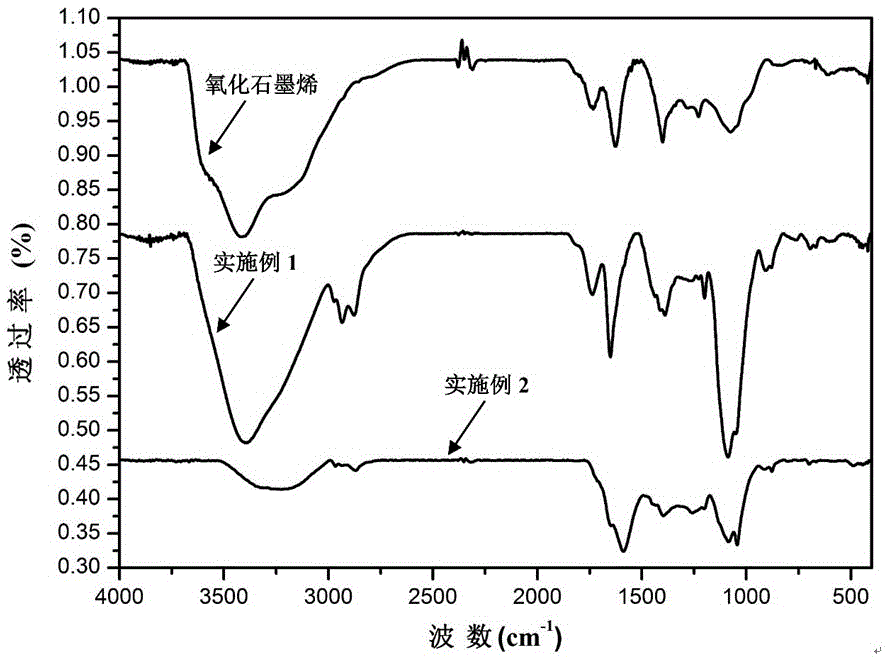

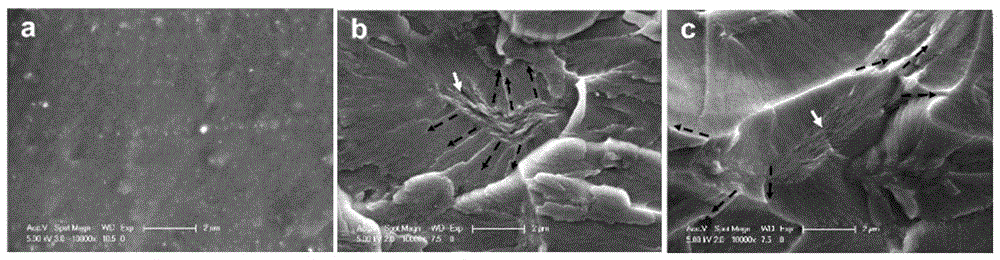

Graphene/polysiloxane composite coating material and preparation method thereof

ActiveCN106752926AImprove scratch resistanceImprove wear resistanceFireproof paintsAnti-corrosive paintsEpoxyResin-Based Composite

The invention provides a graphene / polysiloxane composite coating material and a preparation method thereof. The method comprises the following steps: modifying the graphene surface with active groups by a chemical modification technique to obtain modified graphene, mixing the modified graphene with a silane compound, a dispersion medium, a non-essential comonomer and a non-essential accelerator, and carrying out hydrolytic condensation or hydrolytic condensation-free radical polymerization to generate a graphene / polysiloxane composite resin in situ; and mixing the resin with a non-essential blend resin, a non-essential curing agent, a non-essential solvent, a non-essential pigment and filler and a non-essential aid, and carrying out physical blending, amino epoxy addition reaction, Michael addition reaction and the like to form a film, thereby obtaining the graphene / polysiloxane composite coating material. The uniformly dispersed graphene lamellae and polysiloxane have strong interface effects, also have the gas / liquid barrier and heat shielding effects, and endow the coating with excellent corrosion resistance, flame retardancy and the like, thereby greatly enhancing the mechanical properties, corrosion resistance, scratch resistance, wear resistance and the like of the coating.

Owner:FUDAN UNIV

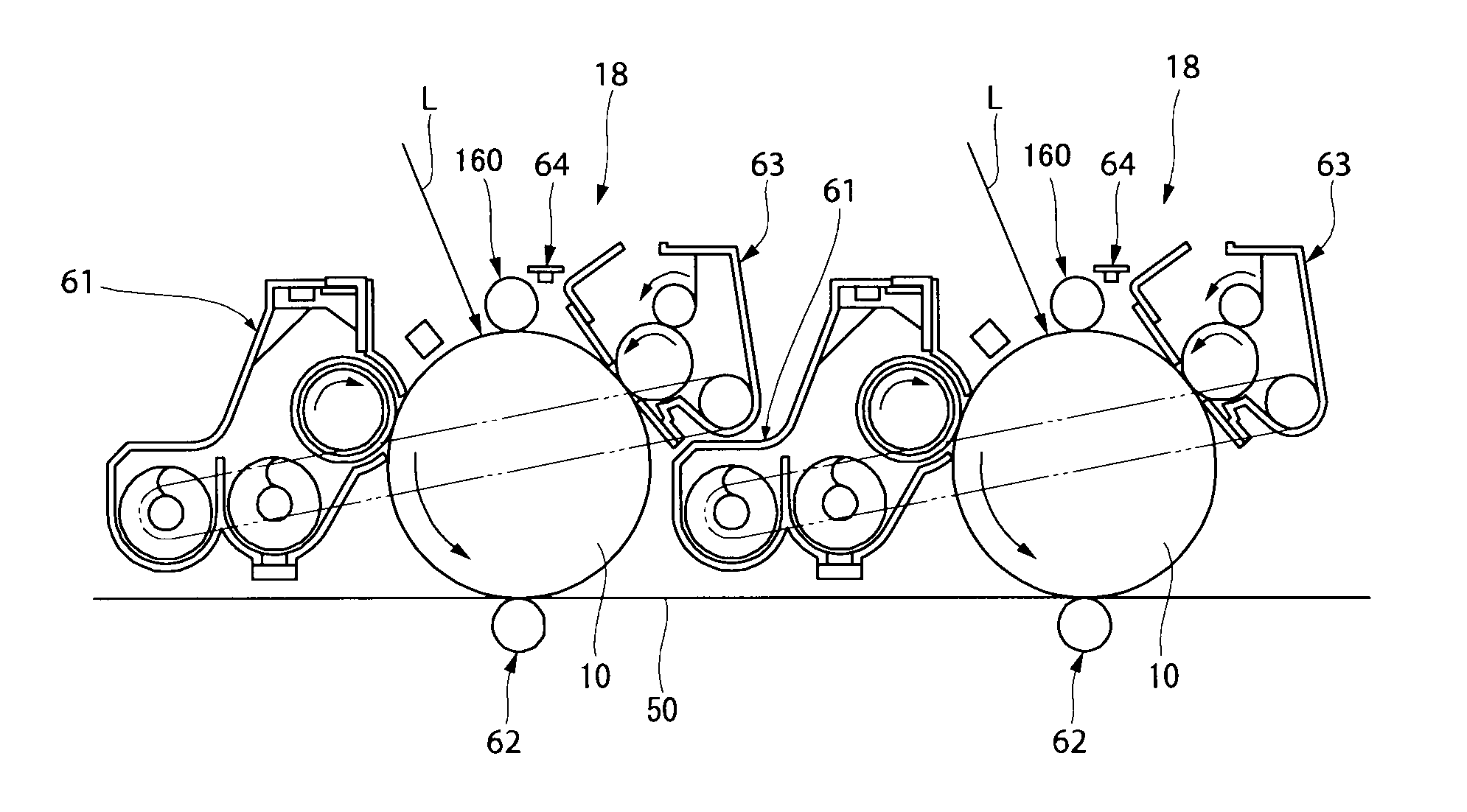

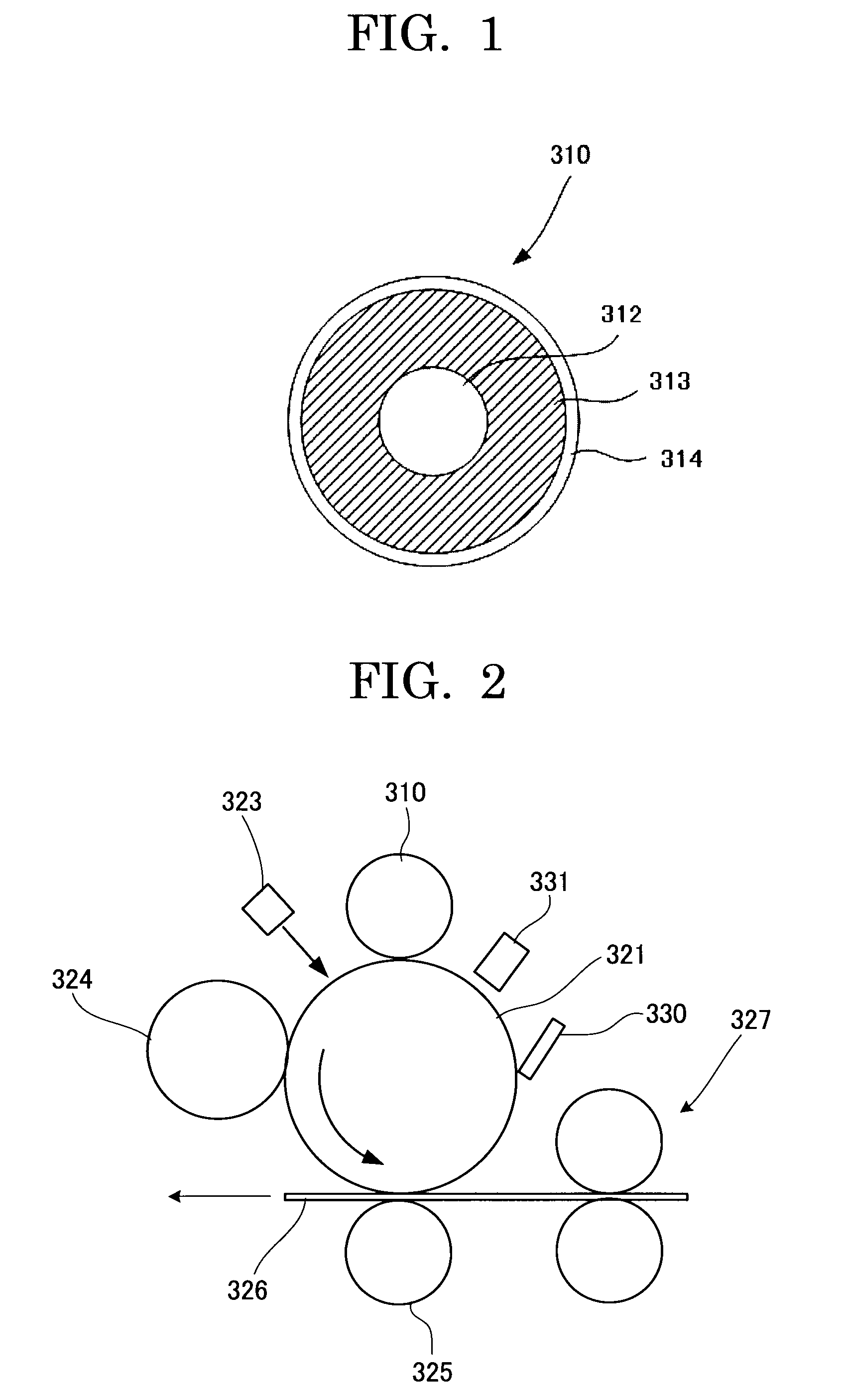

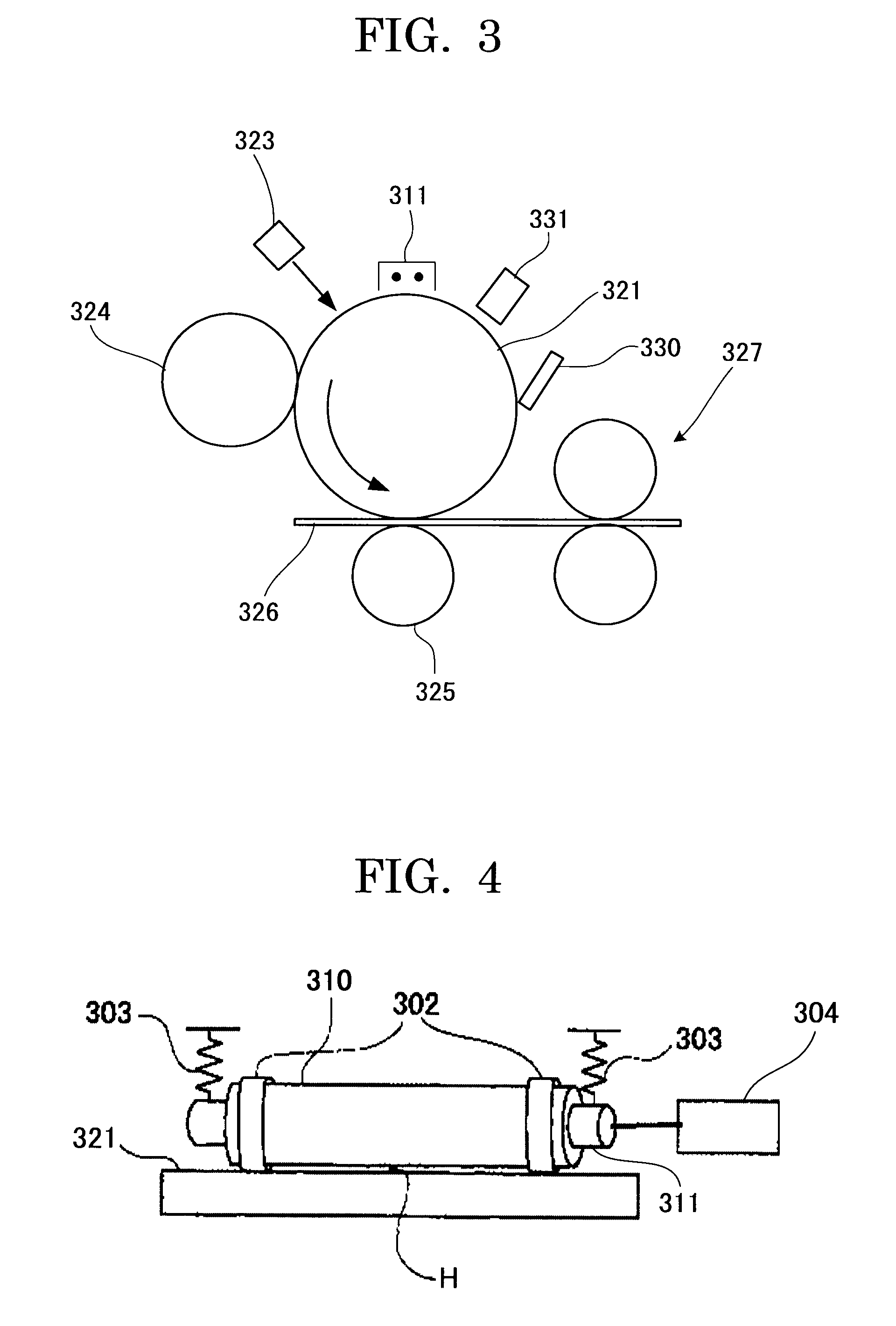

Toner, image forming apparatus, image forming method, and process cartridge using the toner

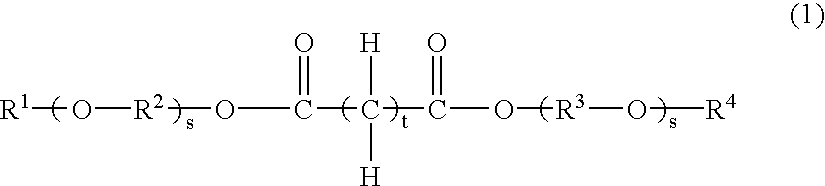

ActiveUS20080280219A1High quality imagingDecrease in image densityDevelopersElectrographic processes using charge patternImage formationCarboxylic acid

The present invention provides a toner containing at least a binder resin, a releasing agent, and a colorant, wherein the binder resin contains at least a polyester resin (A) having a softening point Tm(A) of 120° C. to 160° C., a polyester resin (B) having a softening point Tm(B) of 80° C. or more and less than 120° C. and a composite resin (C) containing a condensation polymerization monomer and an addition polymerization monomer, at least any one of the polyester resins (A) and (B) is a polyester resin prepared by condensation-polymerizing an alcohol component substantially composed of only aliphatic alcohol with a carboxylic acid component, and 65% or more of the alcohol component is 1,2-propanediol.

Owner:RICOH KK

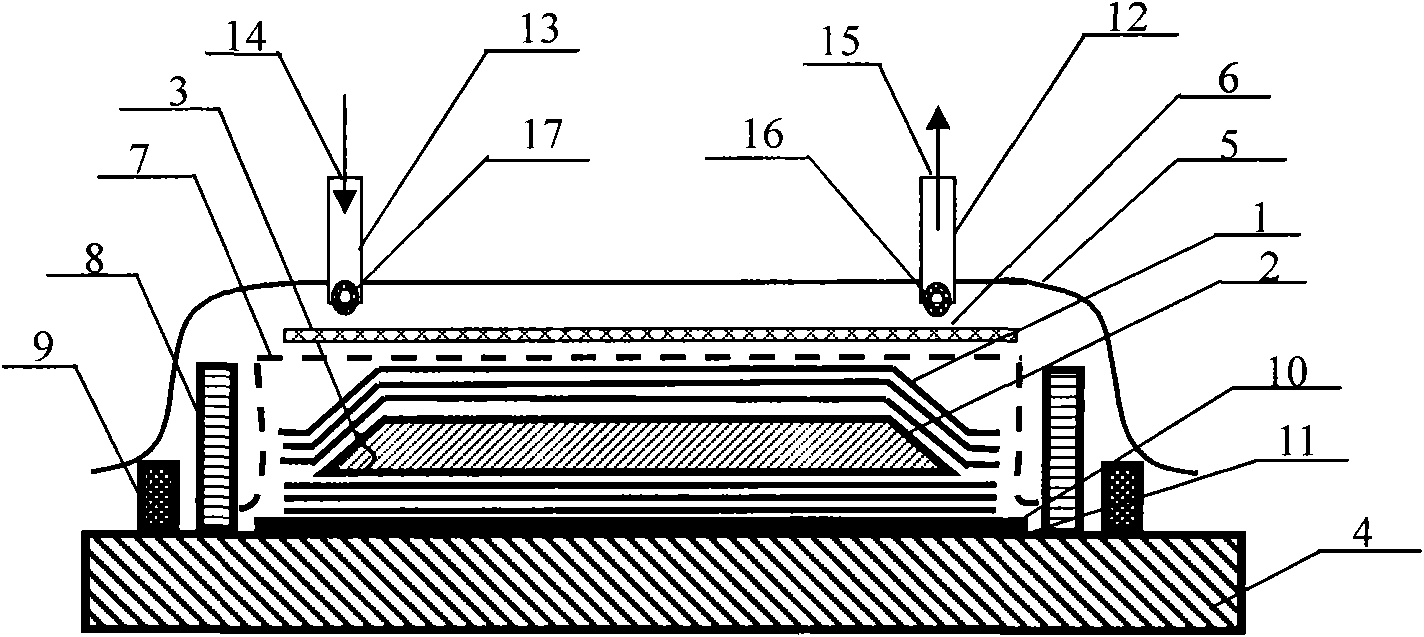

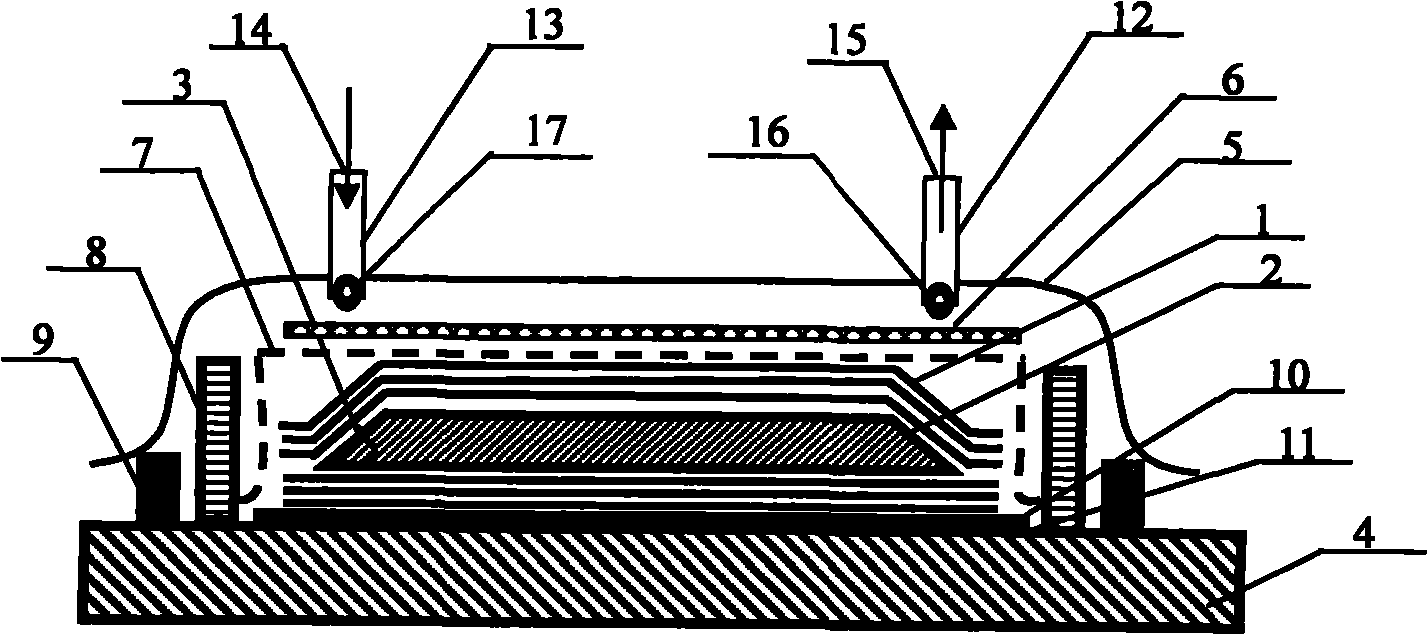

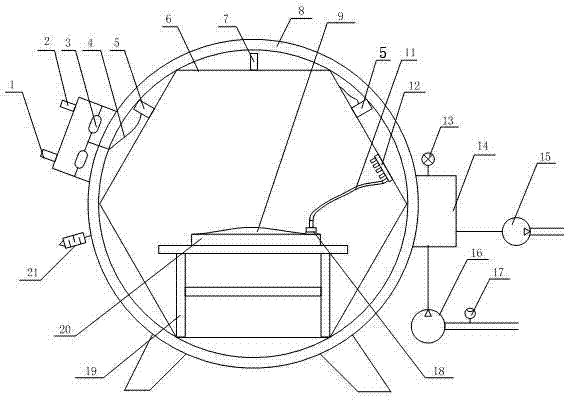

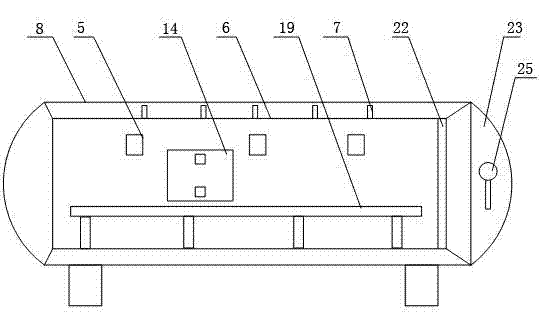

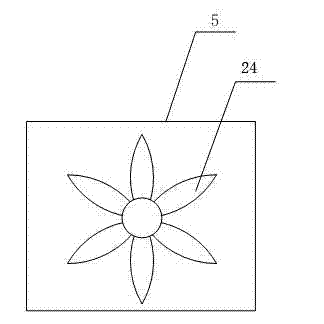

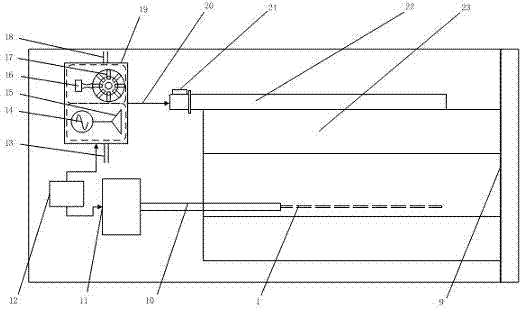

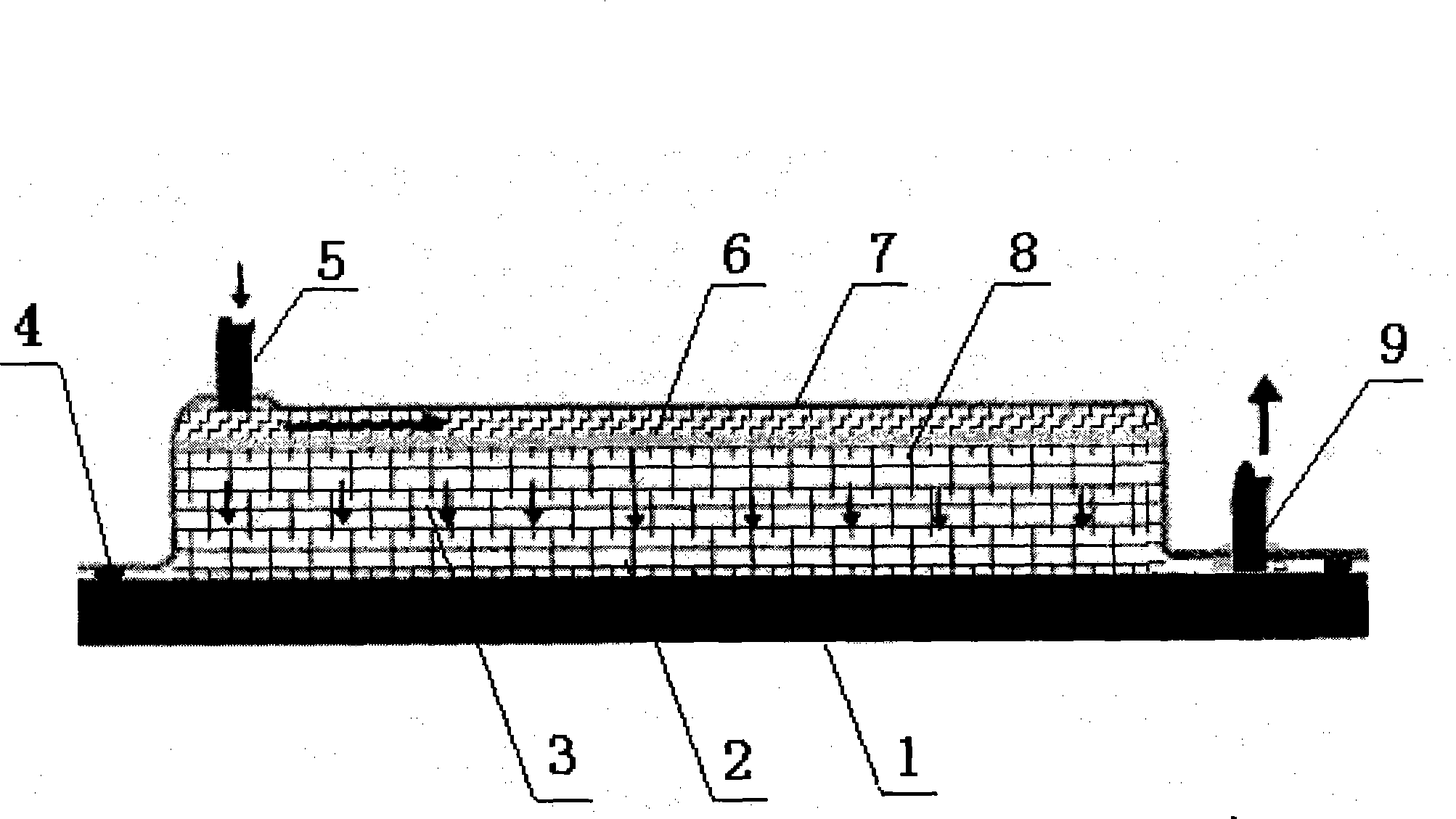

Method and device for curing fiber-reinforced resin-based composite material component by utilizing microwaves

ActiveCN103587130ASolve for uniformitySolve power problemsResin-Based CompositeFiber-reinforced composite

The invention relates to a method and a device for curing a fiber-reinforced resin-based composite material component by utilizing microwaves. The microwaves which are generated by a microwave source with linearly-adjustable power are guided into a resonant cavity, and the microwaves penetrate through and heat the composite material, so that the composite material can be quickly cured and formed. By adopting the advanced octagonal microwave-mode resonant cavity, the uniformity of an electromagnetic field inside the device can be realized; the interference of the reflection wave on the microwave source can be reduced by adopting an automatic impedance matching system, so that the optimal transmission of the microwave power can be realized. A vacuum pipe connector and a temperature sensor are arranged on the inner side wall of the octagonal multi-mode resonant cavity, a glass worktable is arranged inside the resonant cavity, and the rotation of a ball screw is controlled through a stepper motor to control the back-forth movement of the worktable. A choking groove is adopted to prevent the leakage of the microwave. By adopting the method and the device, the problems of the traditional autoclave forming method that the time for manufacturing the fiber-reinforced composite material is long, the energy consumption is high and the heat is non-uniform can be solved, the curing time can be saved, and the quality and performance of the composite material component can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

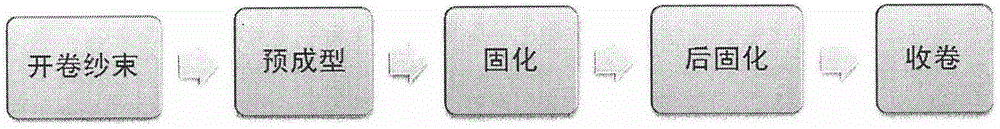

Fiber-reinforced resin-based composite material core and preparation method thereof

InactiveCN104672782AImprove promotion effectPromote the stability of the effectGlass fiberResin-Based Composite

The invention provides a fiber-reinforced resin-based composite material core. The composite material core is prepared from a fiber-reinforced composite material core in the inner part and an insulating layer on the outer layer, wherein the insulating layer is a glass fiber layer and has the thickness of 0.2-2mm. According to the fiber-reinforced resin-based composite material core, the internal structure is uniform, a layering phenomenon difficultly occurs, the strength is high, the toughness is high, and the cost is reduced.

Owner:STATE GRID CORP OF CHINA +3

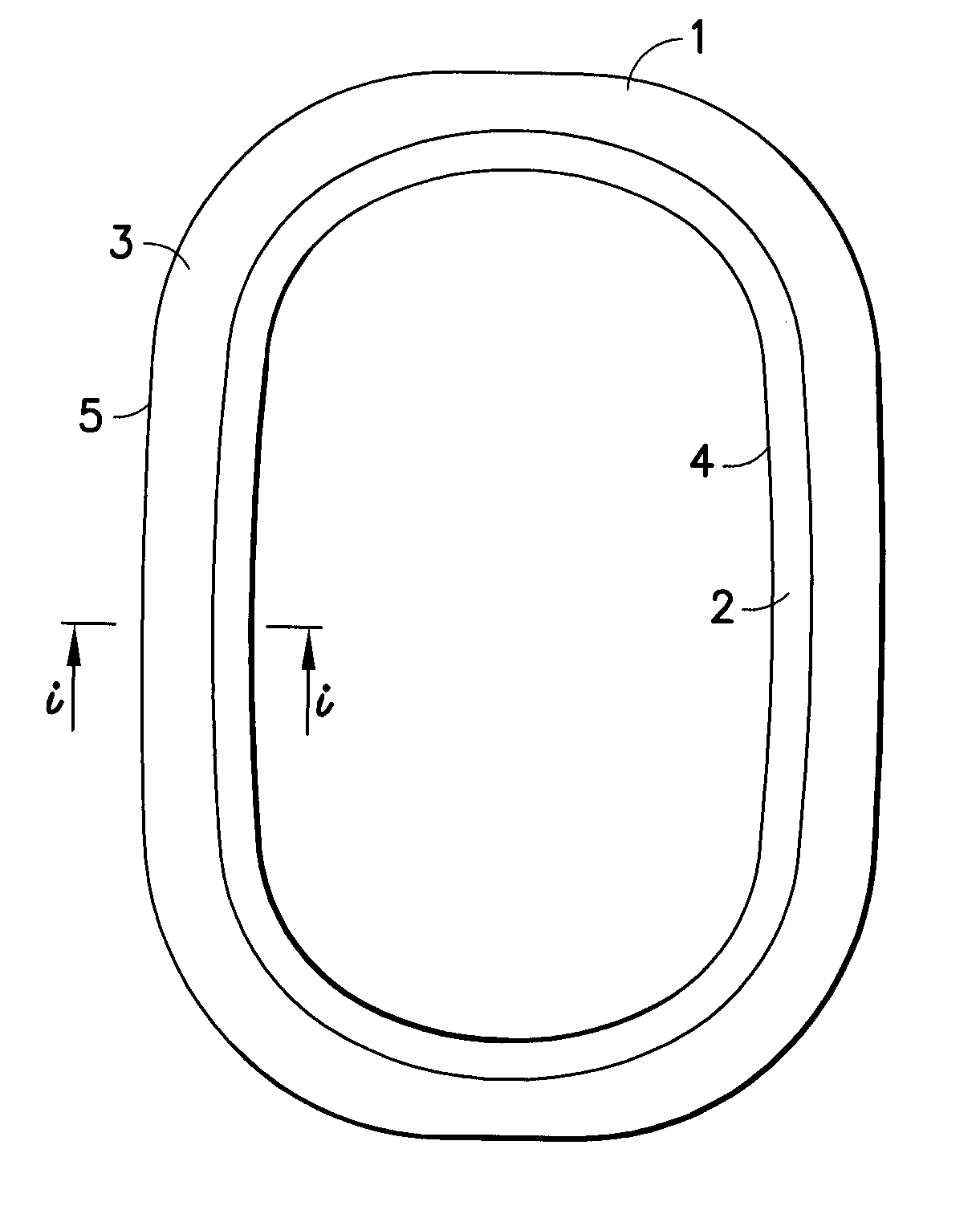

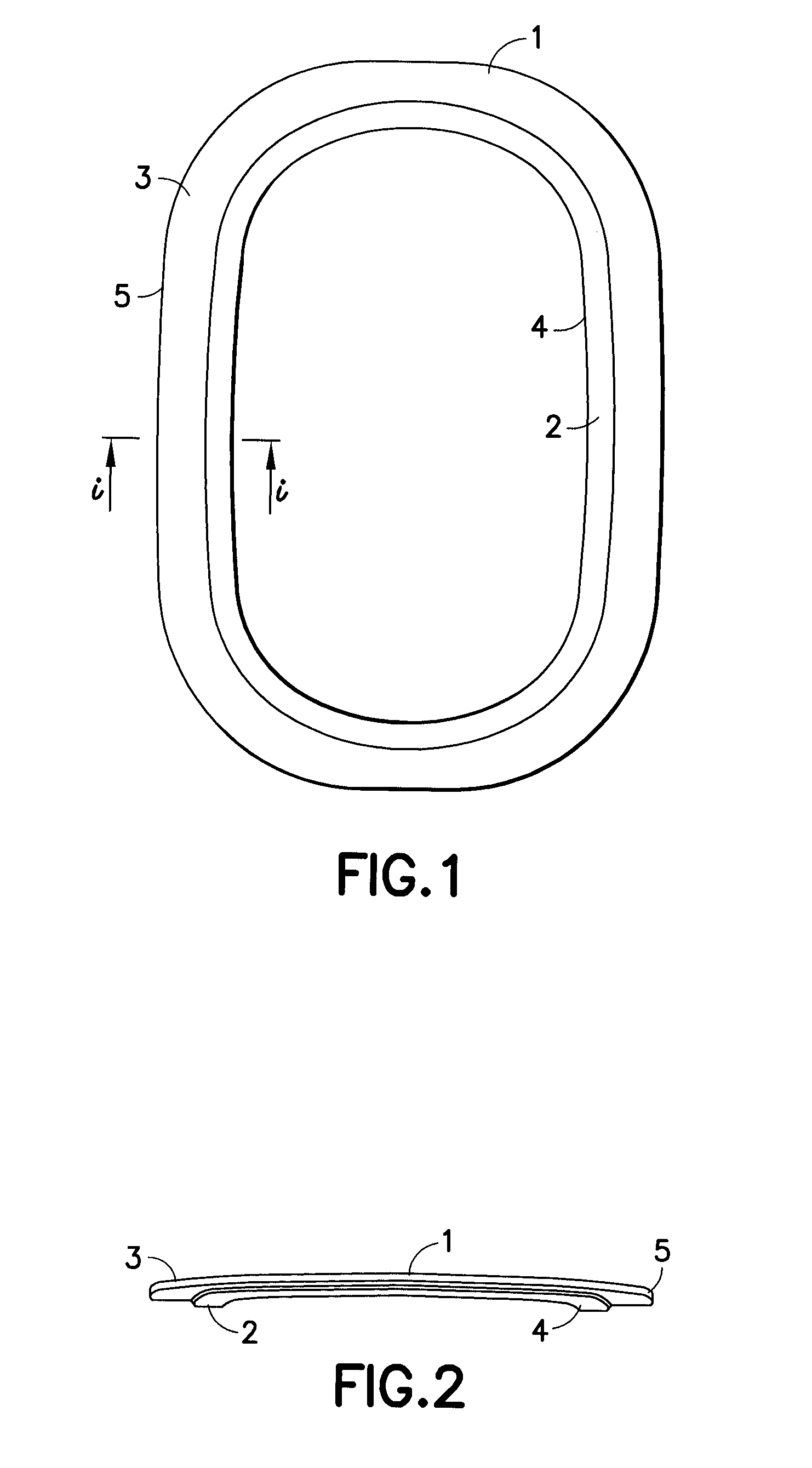

Composite resin window frame constructions for airplanes

InactiveUS20080078876A1Easy to fabricateEasy to installDoors/windowsEfficient propulsion technologiesResin-Based CompositeUltimate tensile strength

A composite resin window frame for installation in a composite resin airplane fuselage has an inner flange for receiving and securely affixing an aircraft window transparency and an outer flange adapted for connection to the airplane fuselage structure. The frame has a generally flat configuration which does not require any additional strength enhancing member such as an additional flange perpendicular to the structure. The composite resin window frame has sufficient strength to securely affix a window transparency to a composite resin fuselage.

Owner:THE BOEING CO

Temperature-controlled induction heating of polymeric materials

Owner:TAS ACQUISITION CO

Implant prosthodontics and methods of preparing and seating the same

InactiveUS7758346B1Maximize efficiencyMinimize disruptionDental implantsImpression capsDenturesProsthodontics

Owner:LETCHER WILLIAM F

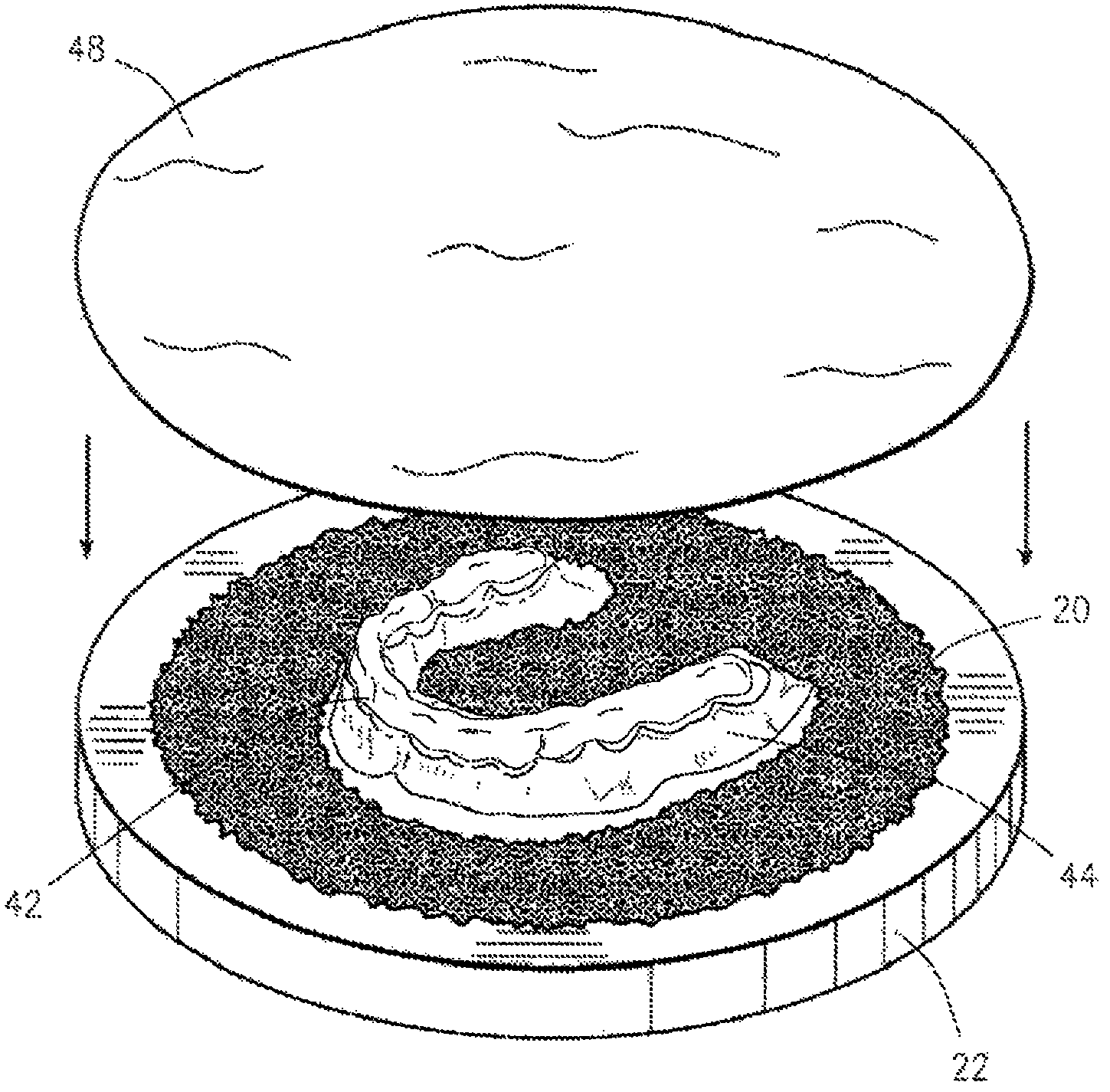

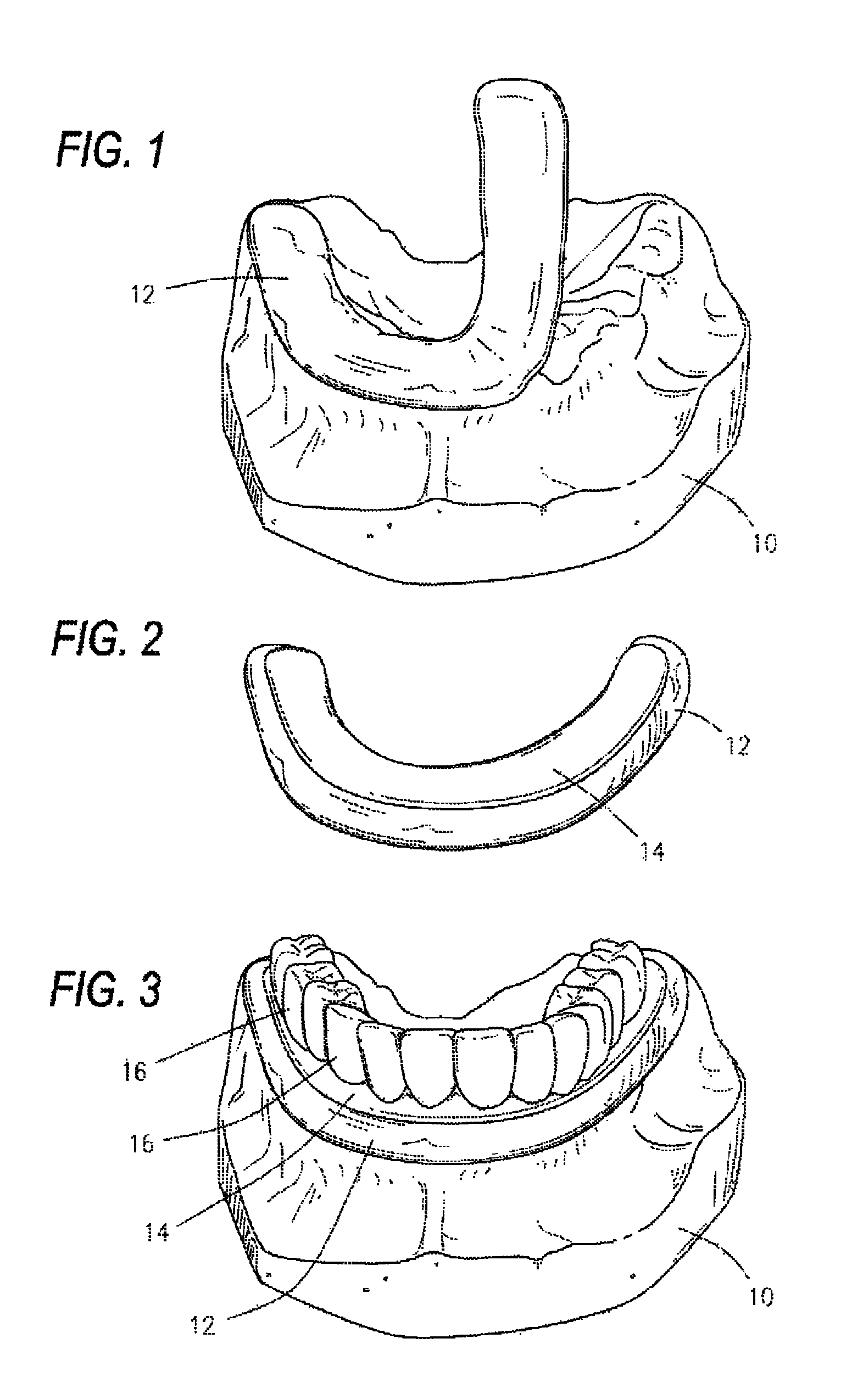

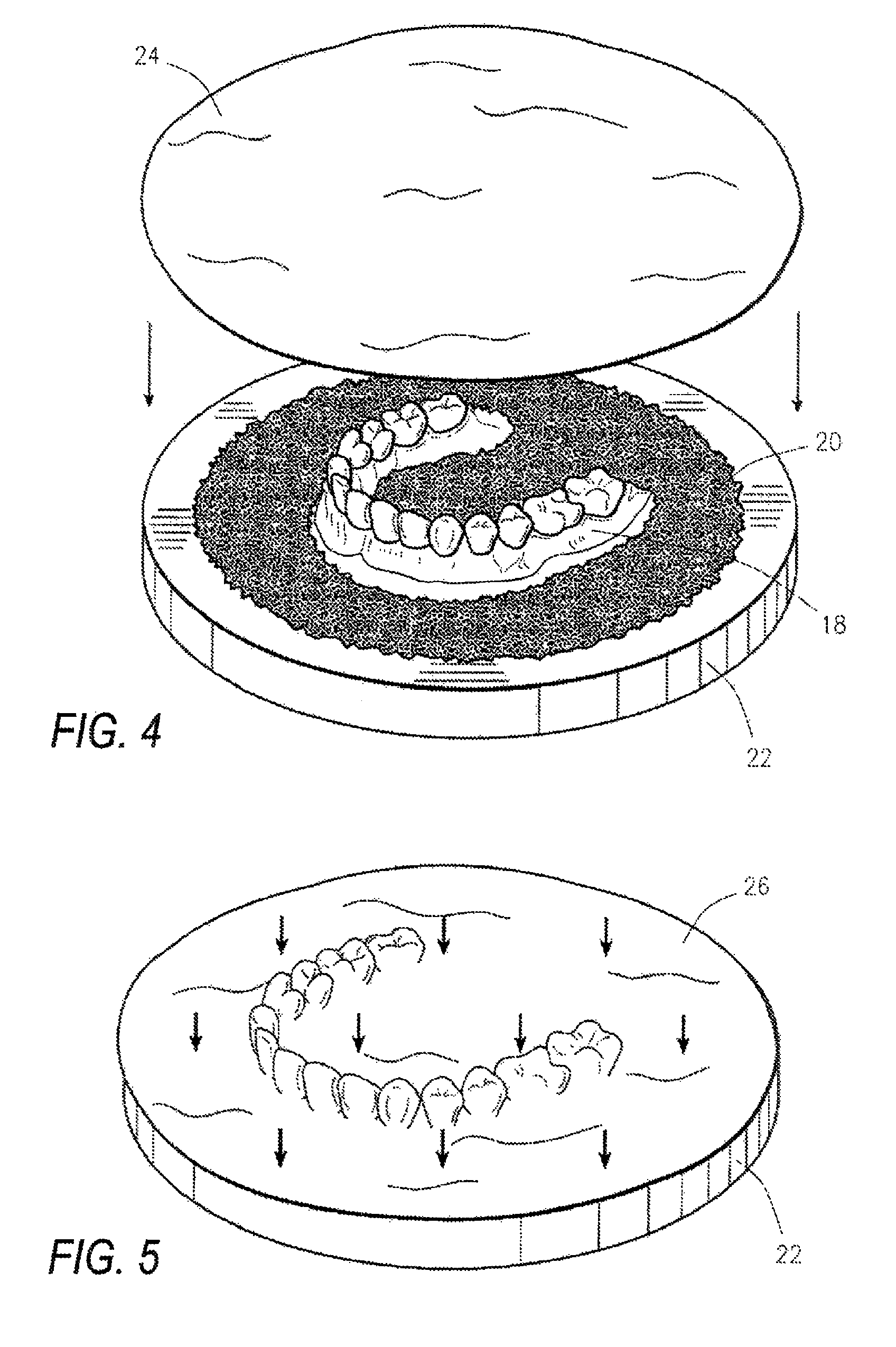

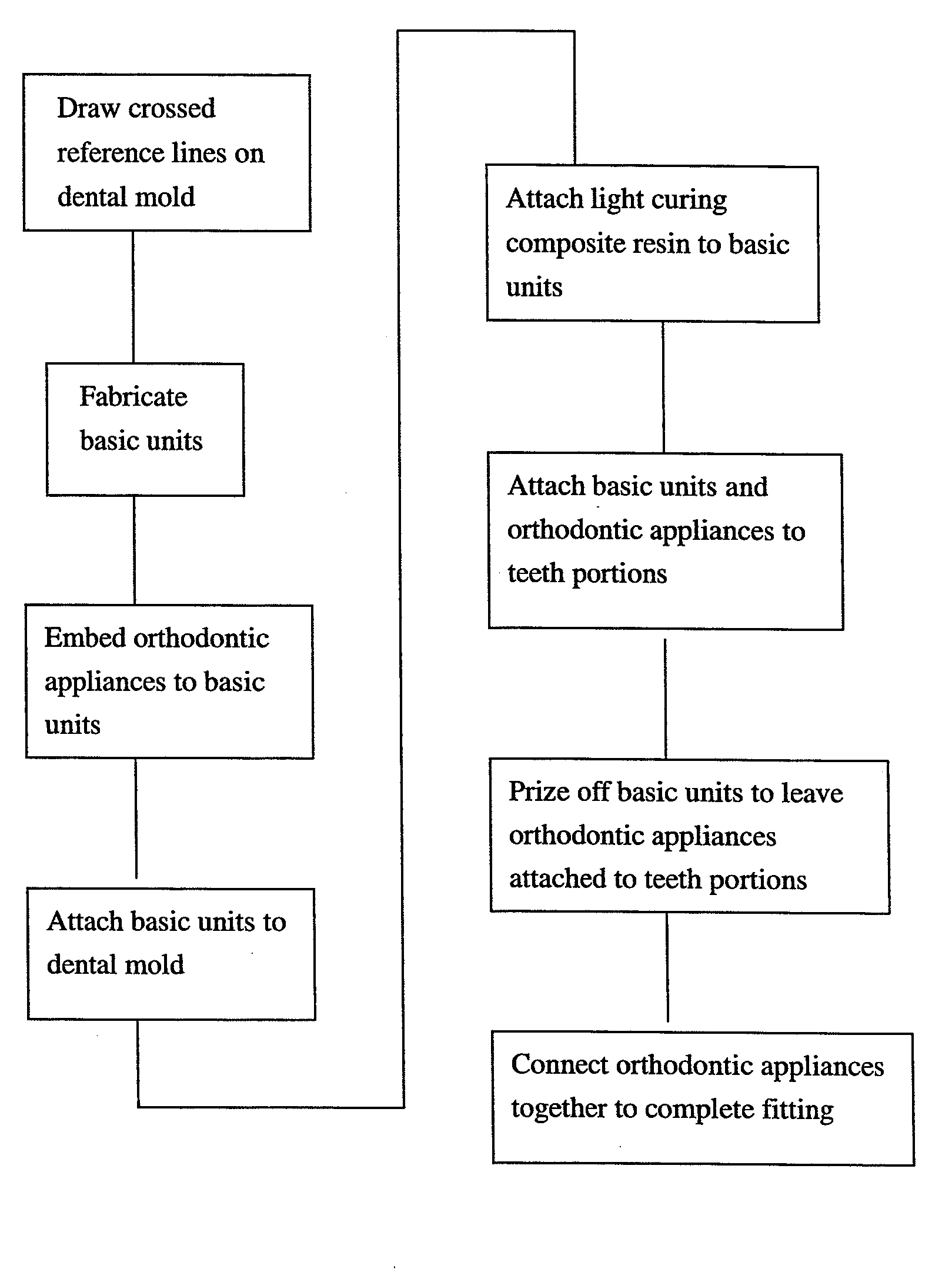

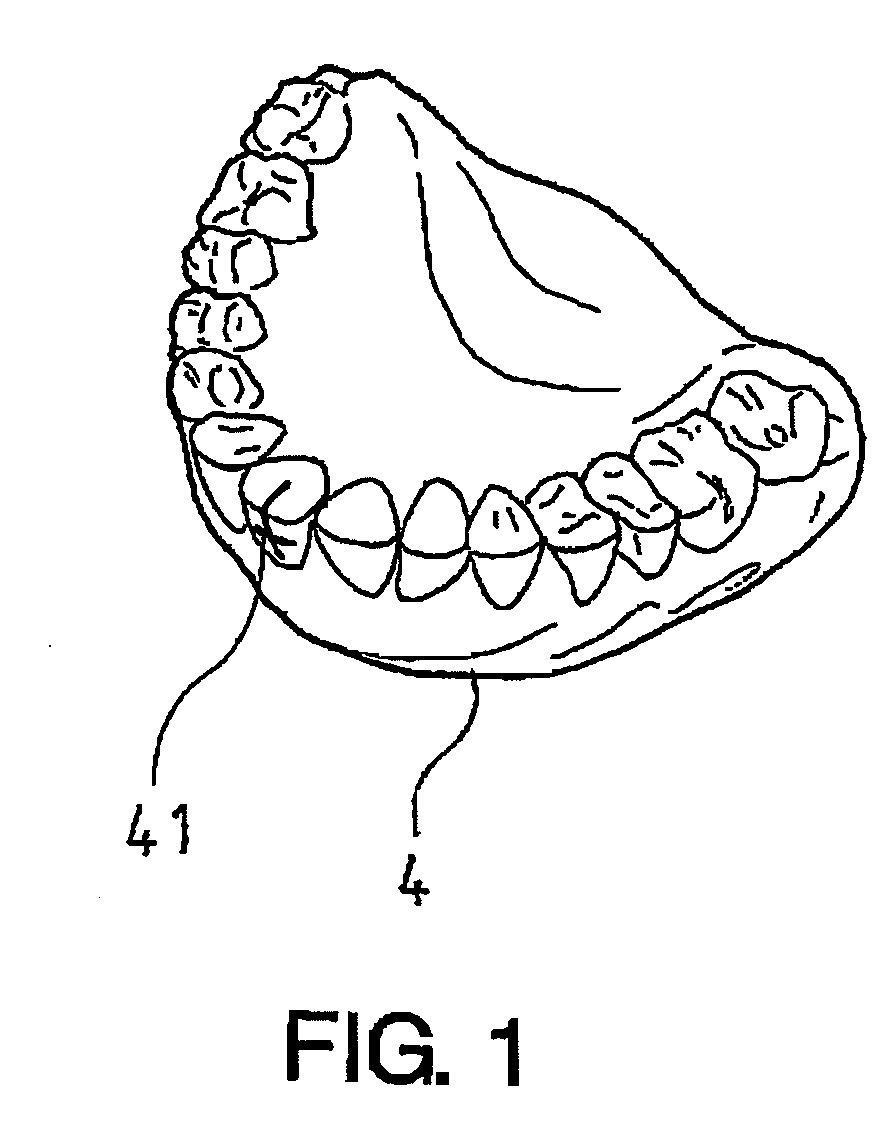

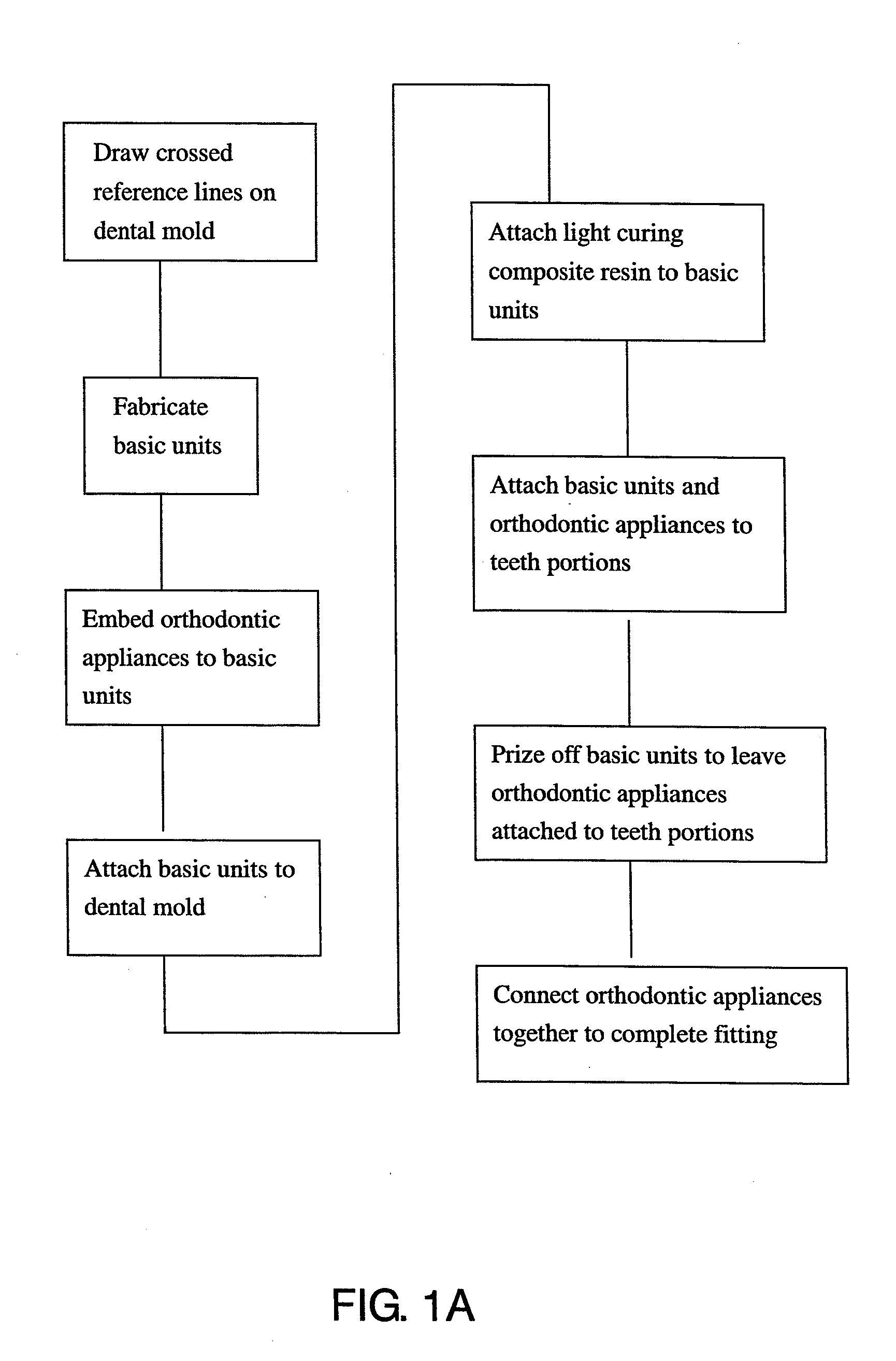

Positioning method for orthodontic appliance and structure thereof

A positioning method for orthodontic appliance and structure, mainly provided with base units molded by plastic injection. During the fabricating process, a crossed reference line is first drawn on a dental mold of the patient, after heating, the orthodontic appliance is embedded to the base unit, and a flexible member is used to bind and fixedly position the orthodontic appliance. Each of the aforementioned base units together with the orthodontic appliance is attached to the dental mold, and then light curing composite resin is attached to each of the base units. Accordingly, after applying an adhesive layer to each of the orthodontic appliances, each of the series connected base units together with the orthodontic appliances bound to the base units is directly attached to the respective teeth portion of the patient requiring straightening, thereby enabling fitting of orthodontic appliances to be more convenient and providing a more efficient fabricating process.

Owner:EZBOND DIGITAL CO LTD

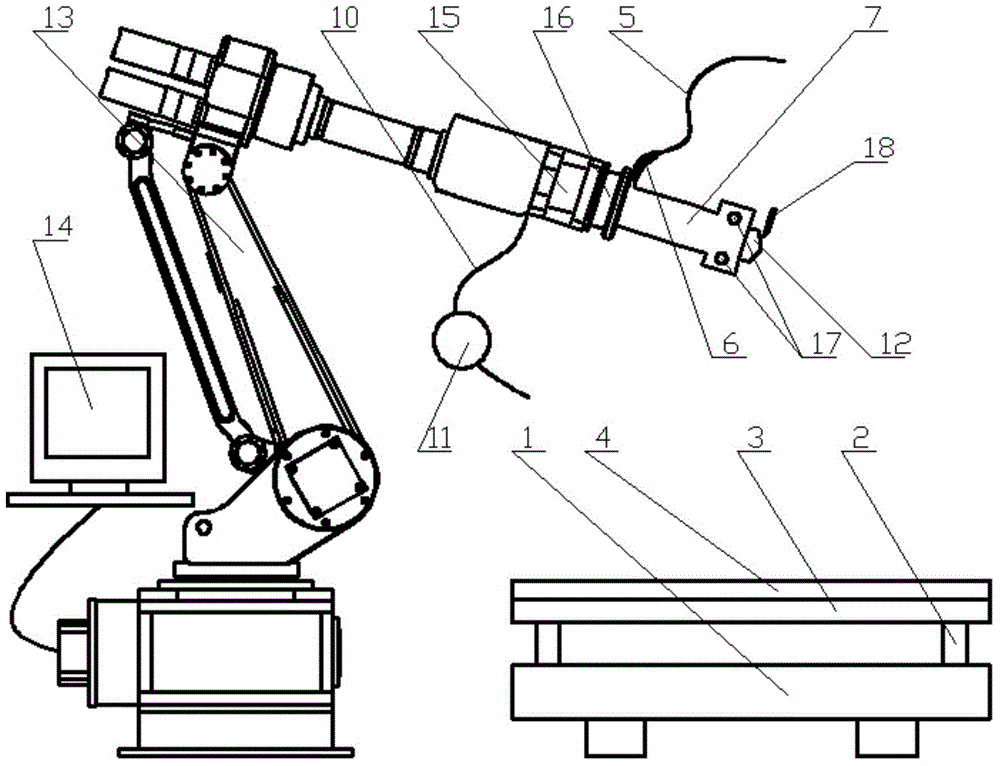

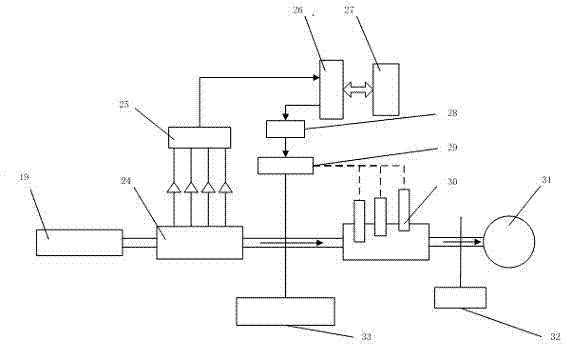

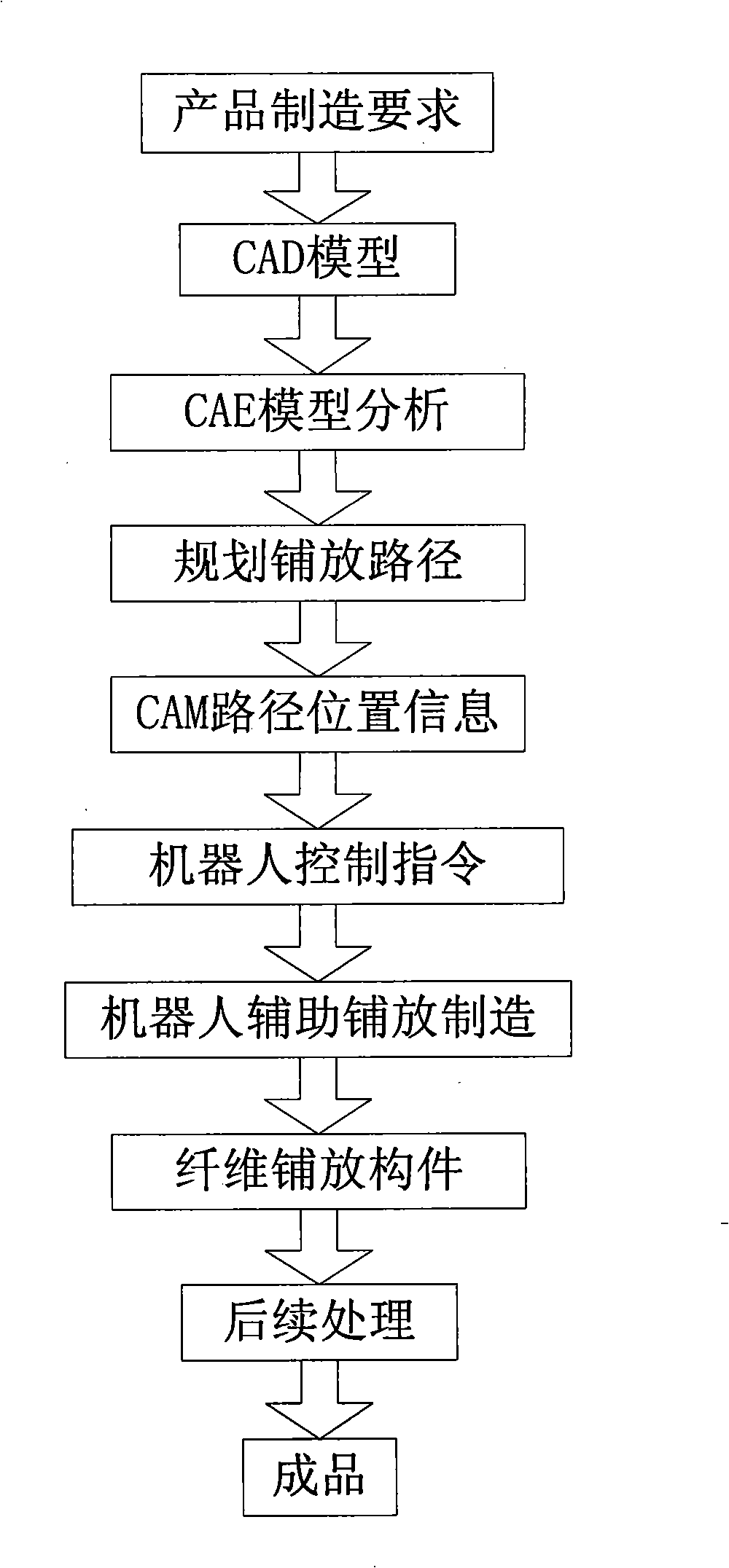

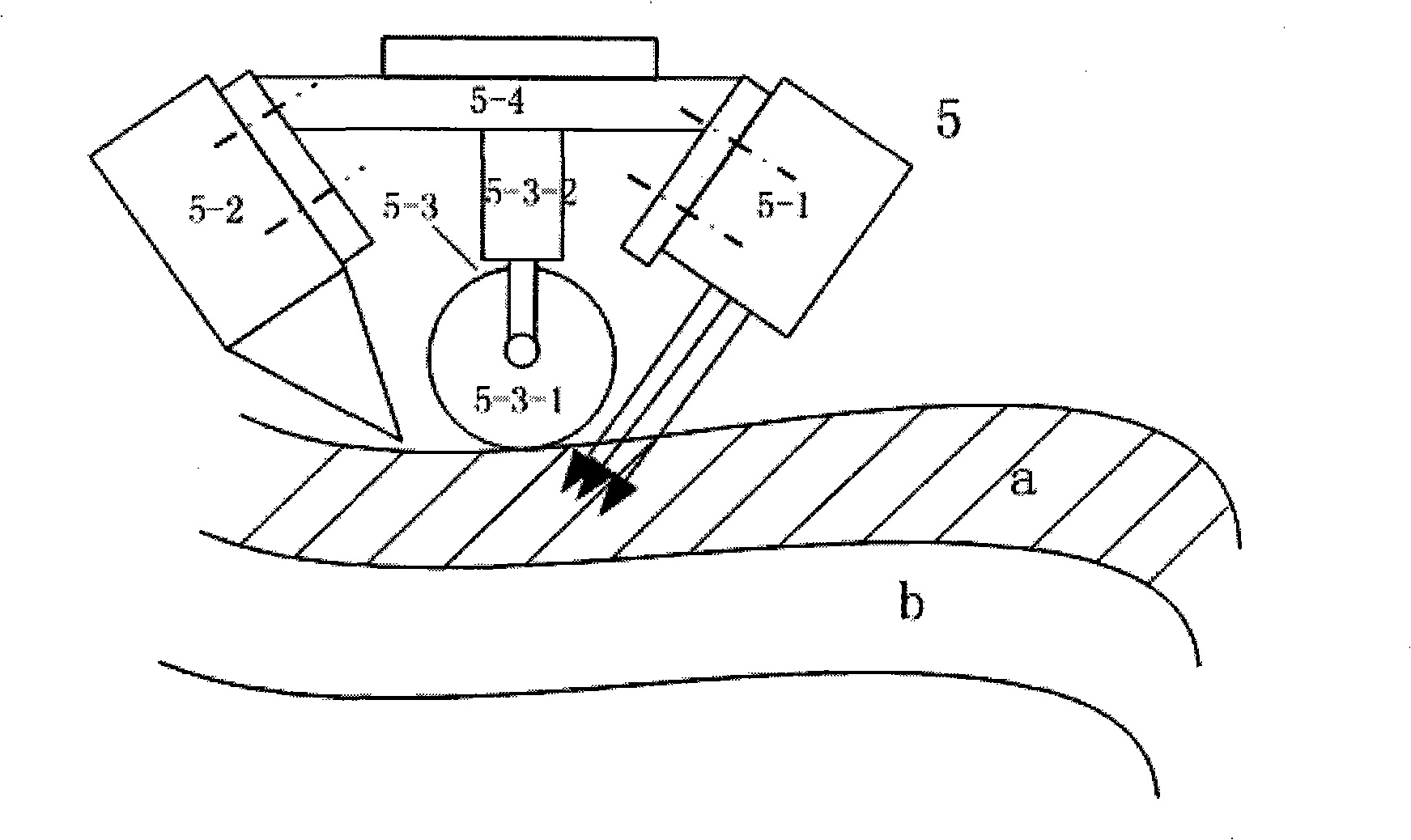

In-situ consolidation fibre laying method and device for producing resin-based compound material component

InactiveCN101254652ASimple manufacturing processShorten the manufacturing cycleCrazingThermal deformation

The invention discloses a method and a device for manufacturing resin-based composite material component by using fiber placement technology. By adopting fiber placement technology, the method and the device can place a fiber placement layer on the surface of a core die by a compaction mechanism to solve the problem of conventional winding equipment that is incapable of manufacturing surface component with negative curvature and non-gyrorotor component. Meanwhile, in-situ instantaneous stratified radiation curing is adopted to eliminate the influence of a tensile force in the fiber placement layer on the shape of the product and to solve the problems and disadvantages of large thermal deformation and easy generation of cracks due to autoclave curing treatment, the restriction of the autoclave volume on the component size, high production cost, and long production period. Based on industrial robot as the manufacture body, the device can improve the problems of prior placement equipment such as the deficiency of the flexibility in manufacturing more complex surface and complex structure.

Owner:XI AN JIAOTONG UNIV

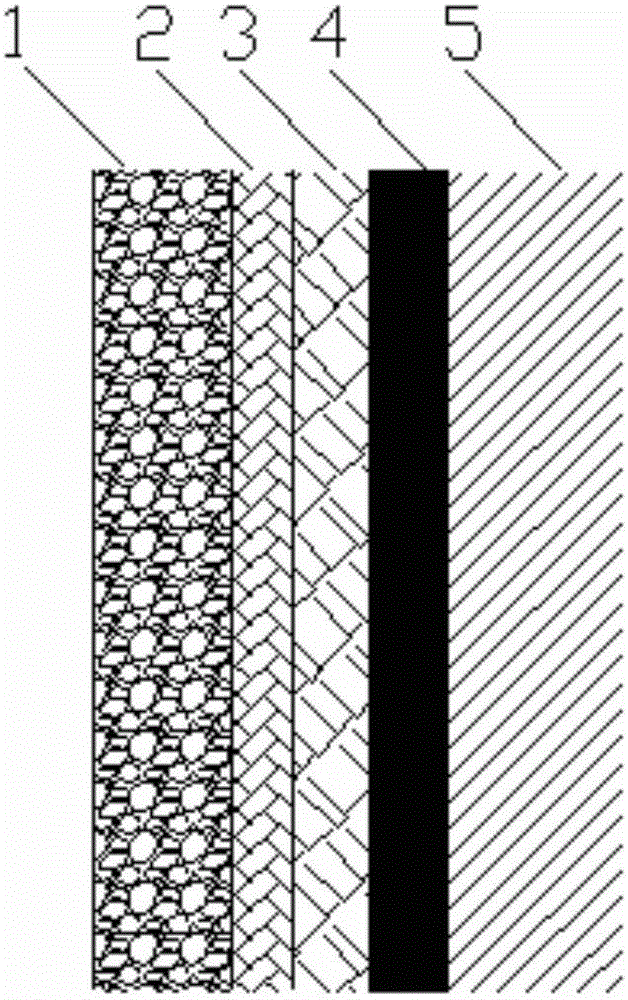

Broadband wave-absorbing force bearing composite material and preparing method thereof

ActiveCN105196638AAbsorbing frequency band is wideImprove electrical performanceLamination ancillary operationsSynthetic resin layered productsCarbon fibersResin matrix

The invention belongs to the technical field of manufacturing radar stealth materials for military aircrafts and particularly relates to a broadband wave-absorbing force bearing composite material adopting a secondary curing process and a preparing method thereof. The material is composed of a wave-transparent foam layer, a wave-transparent skin layer, an electrical loss wave-absorbing layer and a shielding bottom layer. The wave-transparent foam layer is made of an on-sale closed-hole hard organic foam material with the thickness of 2 mm-20 mm; the wave-transparent skin layer is made of a continuous wave-transparent fiber enhancing resin matrix composite material with the thickness of 0.1 mm-4 mm; the electrical loss wave-absorbing layer is made of a wave-transparent fiber cloth enhancing composite material which contains carbon black and is 0.5 mm-5 mm thick; the shielding bottom layer is made of a carbon fiber woven cloth material. According to the broadband wave-absorbing force bearing composite material adopting the second curing process, the wave-absorbing frequency band is wider, electrical performance is stable, and the composite material can be applied to various military targets and used for manufacturing stealth structural members with high broadband stealth performance.

Owner:BEIJING RES INST OF MECHANICAL & ELECTRICAL TECH

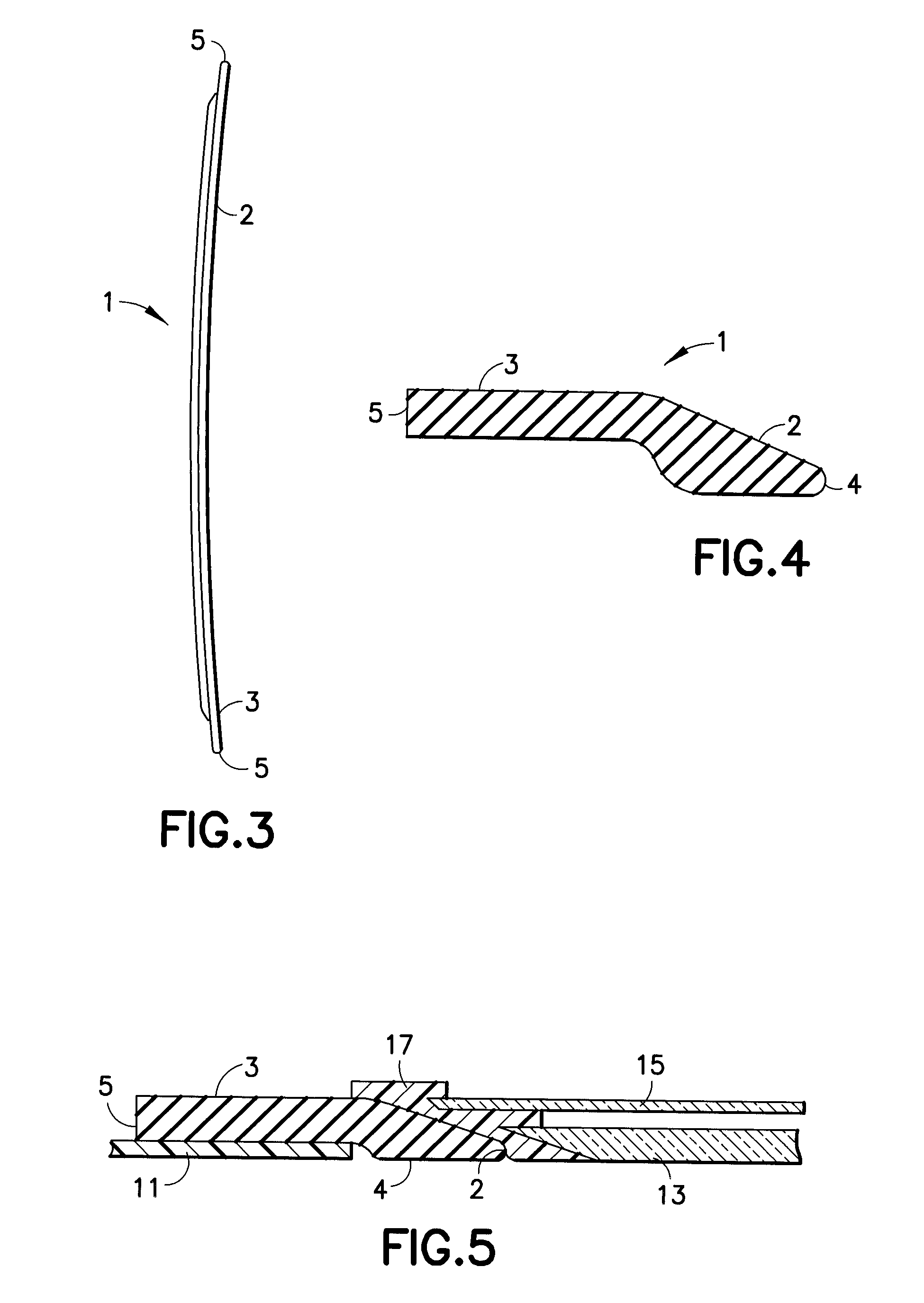

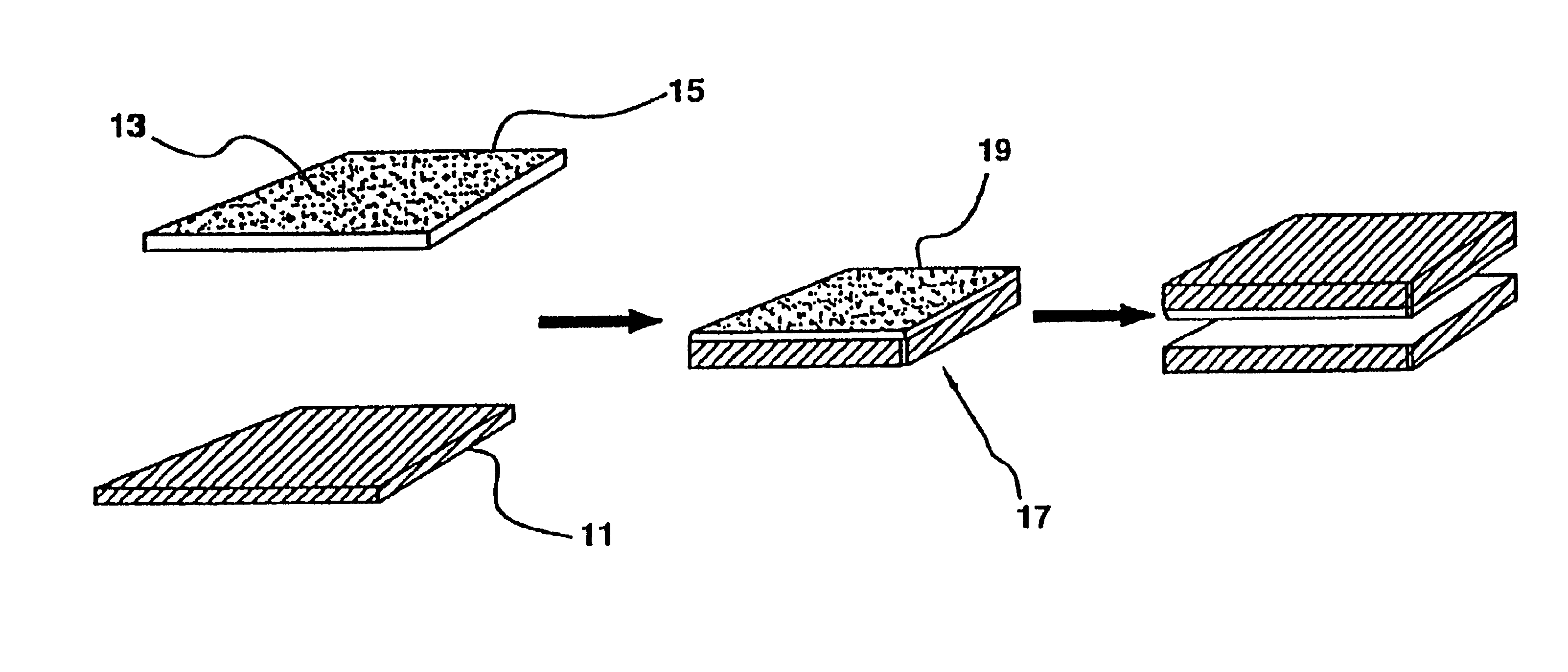

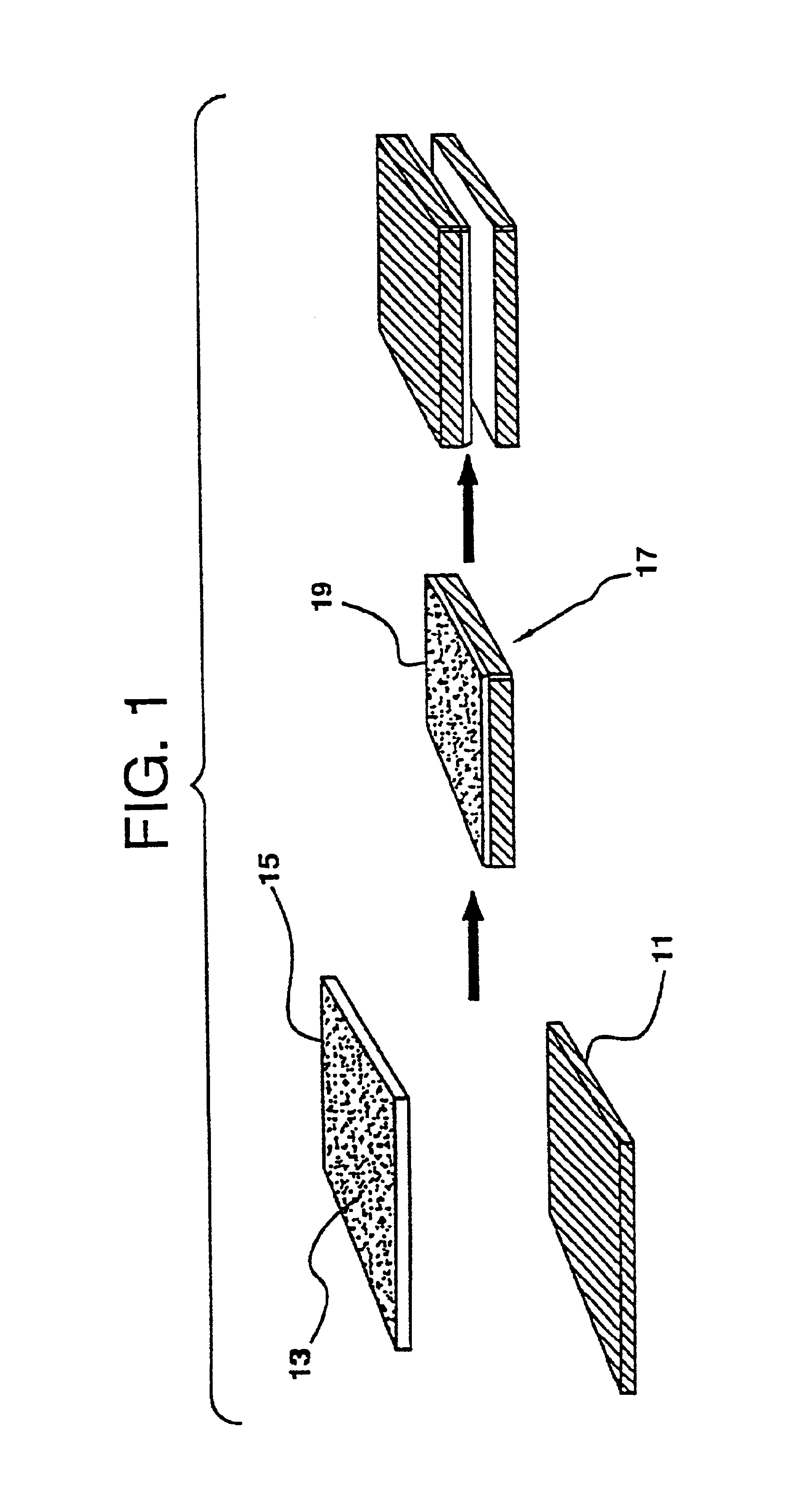

Double vacuum bag process for resin matrix composite manufacturing

InactiveUS7186367B2Improve performanceImprove propertiesLaminationLamination apparatusRelative pressureResin matrix

A double vacuum bag molding assembly with improved void management and laminate net shape control which provides a double vacuum environment for use in fabricating composites from prepregs containing air and / or volatiles such as reactive resin matrix composites or composites from solvent containing prepregs with non-reactive resins matrices. By using two vacuum environments during the curing process, a vacuum can be drawn during a B-stage of a two-step cycle without placing the composite under significant relative pressure. During the final cure stage, a significant pressure can be applied by releasing the vacuum in one of the two environments. Inner and outer bags are useful for creating the two vacuum environments with a perforated tool intermediate the two. The composite is placed intermediate a tool plate and a caul plate in the first environment with the inner bag and tool plate defining the first environment. The second environment is characterized by the outer bag which is placed over the inner bag and the tool plate.

Owner:NASA

Epoxy resin combination, composite material and preparation method thereof

The application discloses an epoxy resin composition, a composite material and a preparation method thereof. The epoxy resin composition provided by the application comprises epoxy resin, small molecular compounds with one or a plurality of epoxy groups, as well as amine curing agents. The application has the advantages that high-performance epoxy resin is prepared by a method of blending and modifying common epoxy resin and adding additives, and a high-performance epoxy resin-based composite material is prepared by compounding epoxy resin with reinforcing material through a liquid composite molding process. The composite material has the advantages of simple preparation process and low price, and is beneficial to large amounts of popularization and industrialization. In addition, the composite material can also be used in automobile, ship, wind power blade and other civil composite material fields, can greatly reduce manufacturing cost, and can promote technical and industrial upgrading.

Owner:北京玻钢院复合材料有限公司

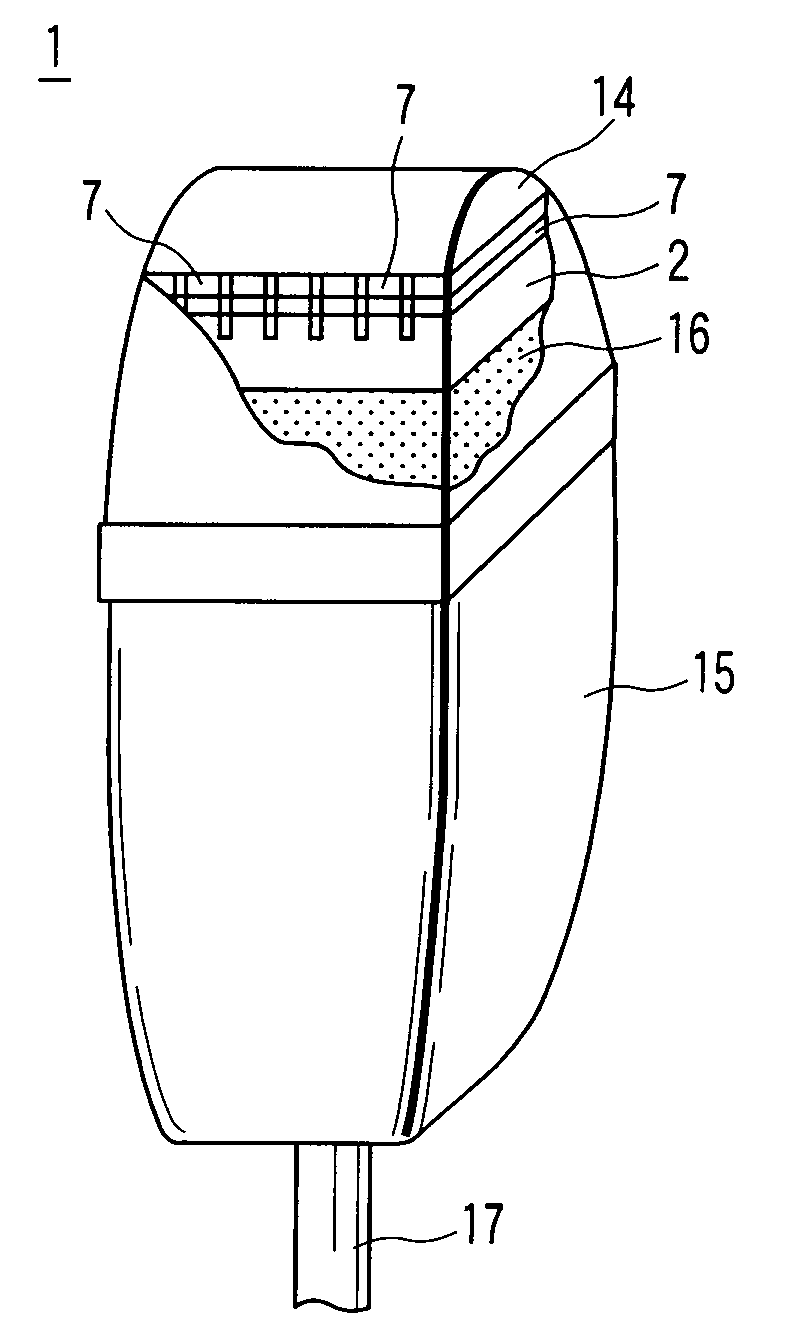

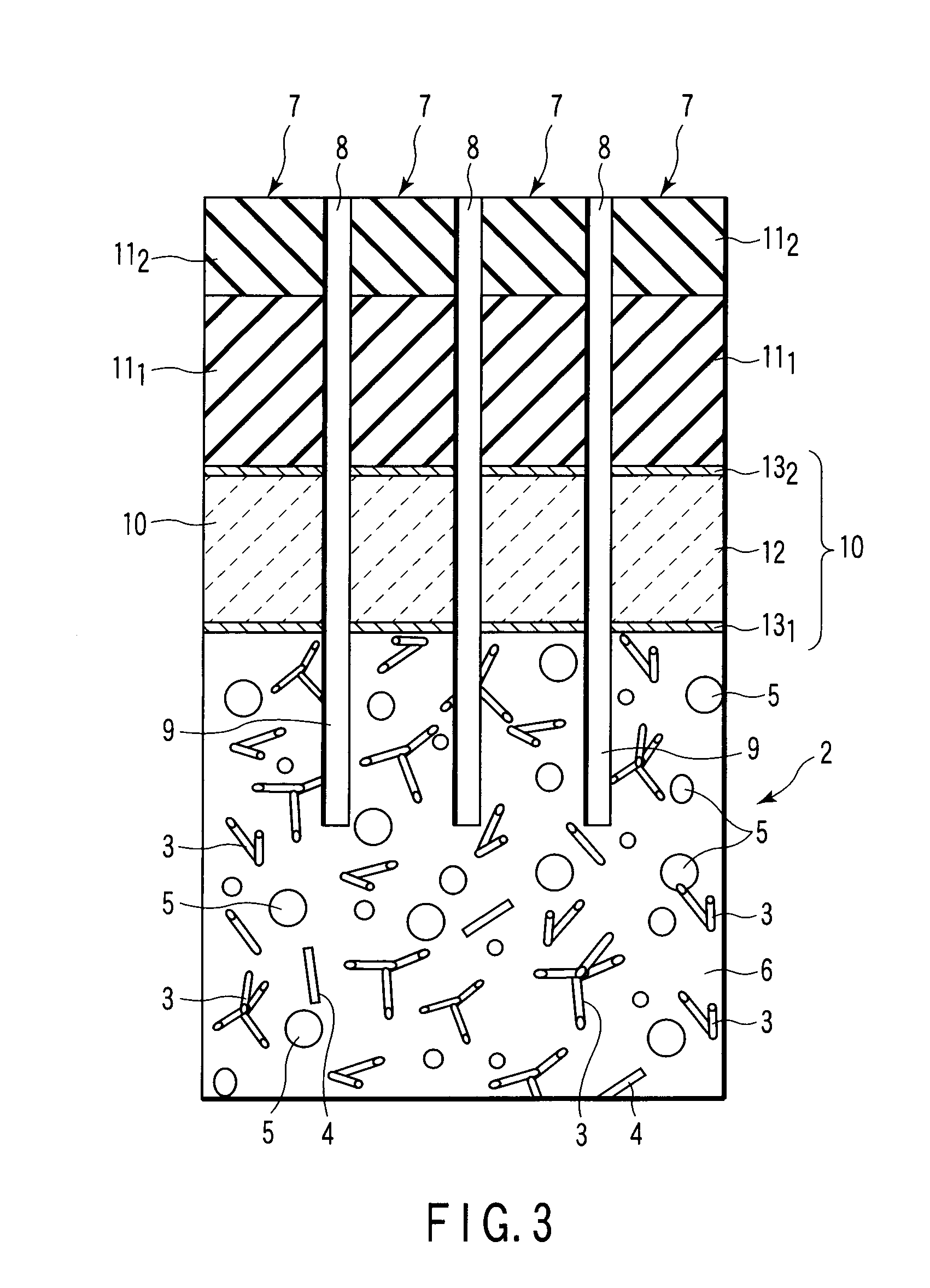

Ultrasonic probe and ultrasonic diagnostic apparatus

InactiveUS20080098816A1Ultrasonic/sonic/infrasonic diagnosticsMultiple-port networksResin-Based CompositeZinc

An ultrasonic probe comprises an acoustic backing layer made of a composite resin material including a resin and a plurality of bonded fibers contained the resin, each of the bonded fibers being formed of a plurality of zinc oxide fibers bonded to each other at one edge portions and extending in different directions in the other edge portions, the composite resin material exhibiting an acoustic impedance of 1.3 to 6 MRayls at 25° C., a plurality of channels arranged on the acoustic backing layer with space, each channel having a piezoelectric element and an acoustic matching layer formed on the piezoelectric element, and an acoustic lens formed to cover at least the surface of the acoustic matching layer of each channel.

Owner:KK TOSHIBA

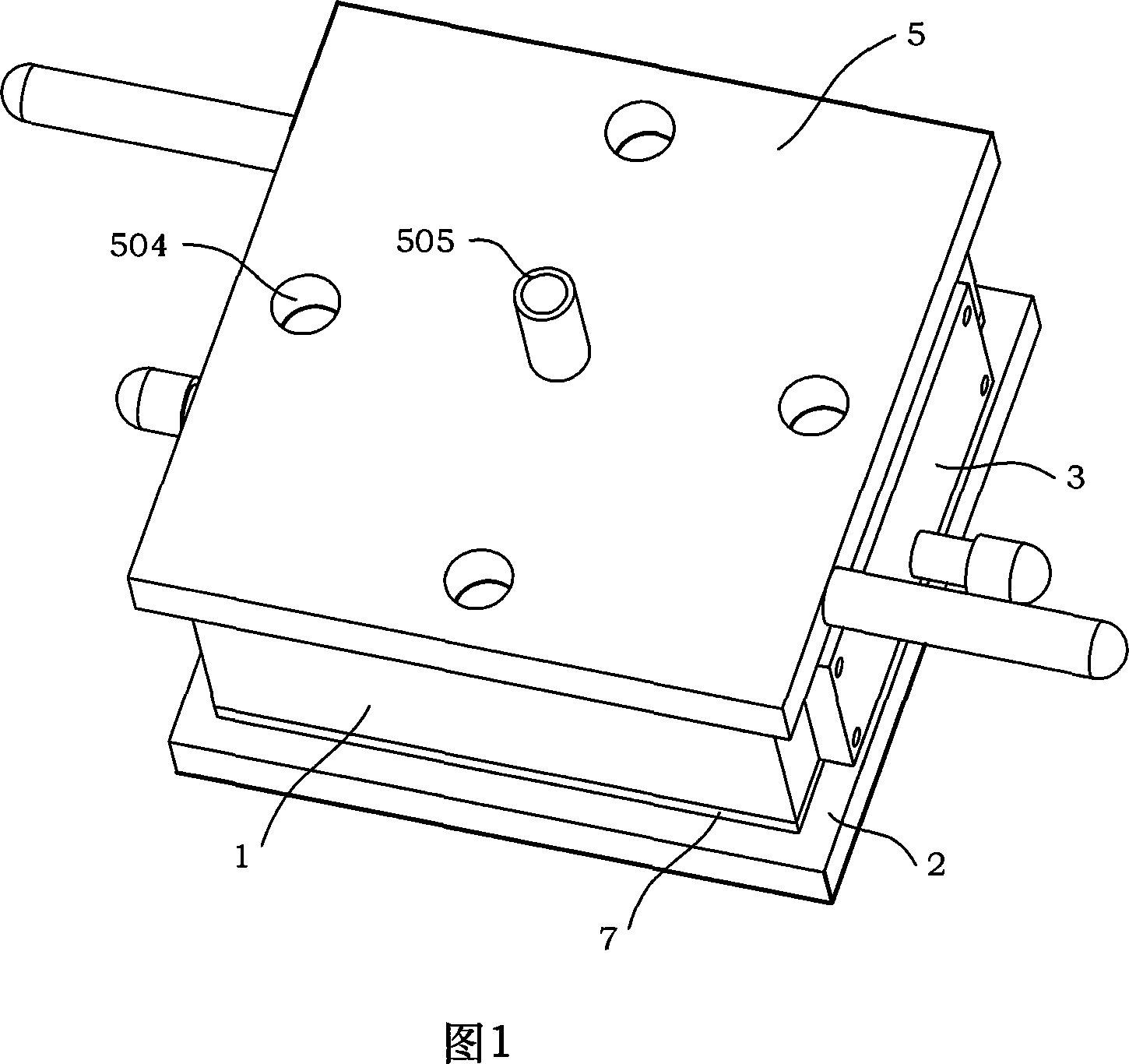

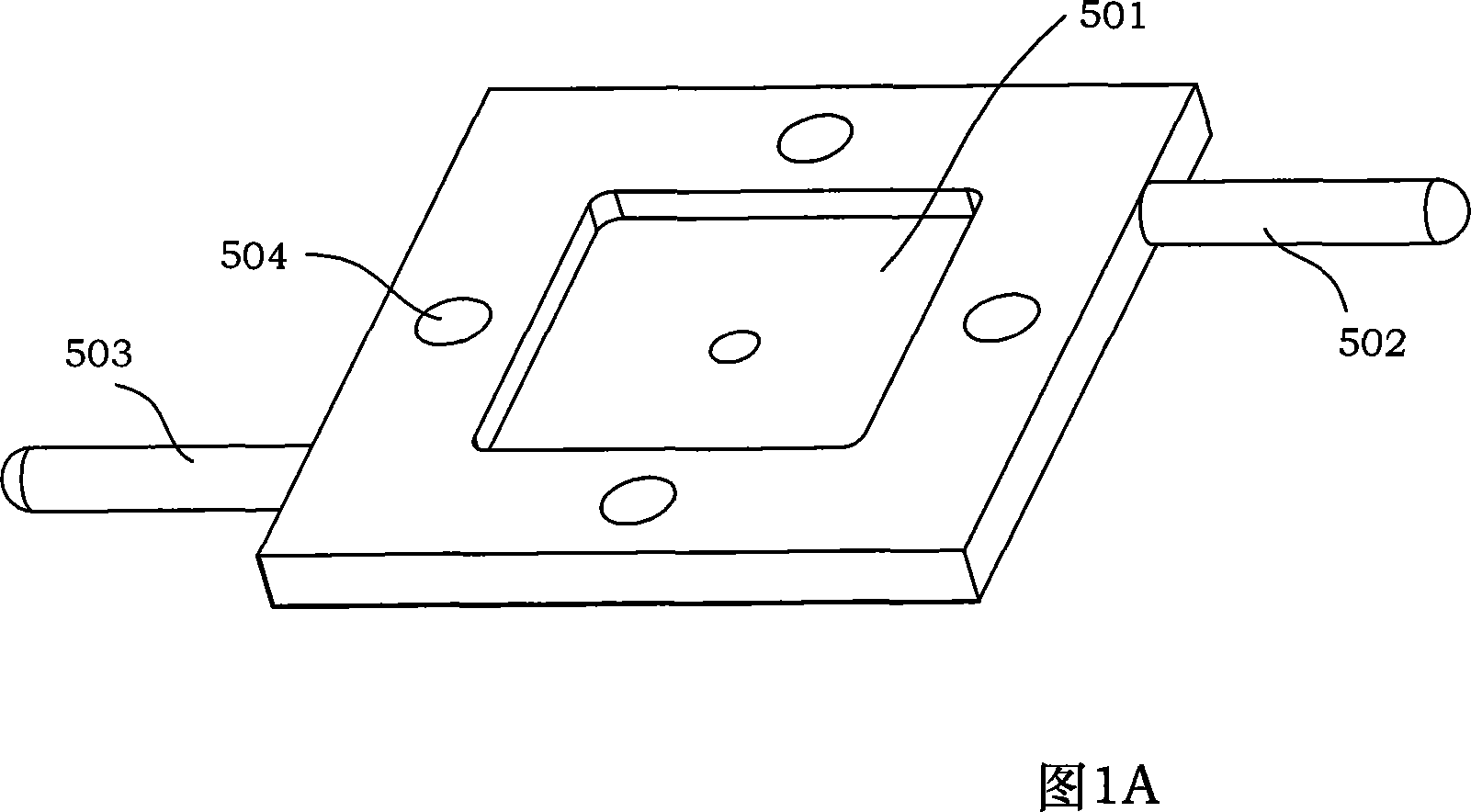

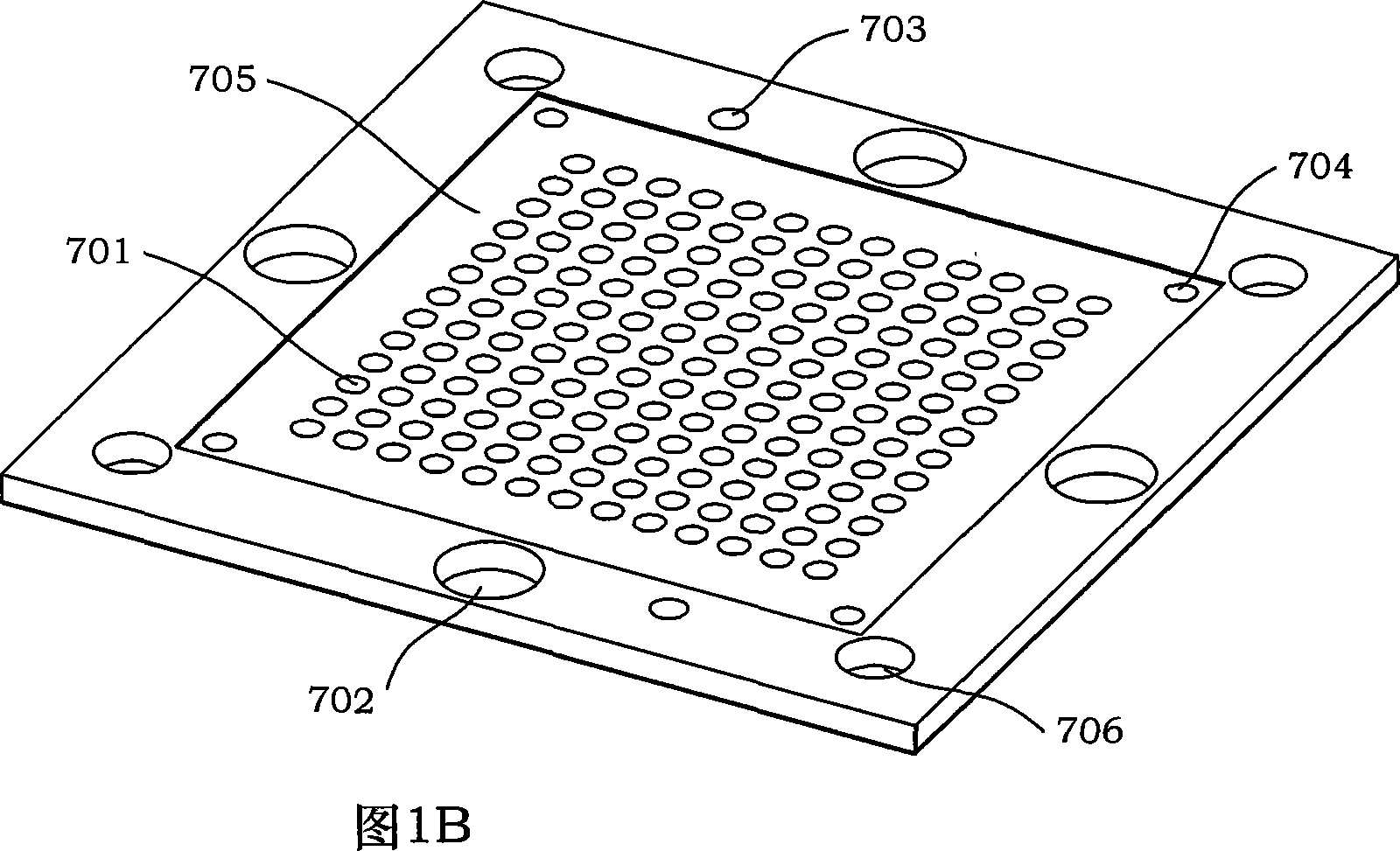

Permeability detecting device and saturated permeability detecting method fiber spread layer surface and thickness direction

InactiveCN101051019AImprove reliabilityGood repeatabilityPermeability/surface area analysisSpecial data processing applicationsGraduated cylinderNetwork structure

A method for determining saturated penetration coefficient at thickness and inner surface directions of fiber fabric includes laying presoaked fiber fabric in test mould utilizing flow-dividing plate and four edge of mould cavity to fix network structure of fiber fabric, using solvent to remove off resin in presoaked fiber fabric, exerting pressure on fiber fabric to vary volume friction of fiber, erecting various accessories on said test mould to form different flow channels, using stopwatch and measuring cylinder to record relevant data and combining measured data with Darcy law for calculation out saturated penetration coefficient at thickness and inner surface direction on fiber fabric.

Owner:BEIHANG UNIV

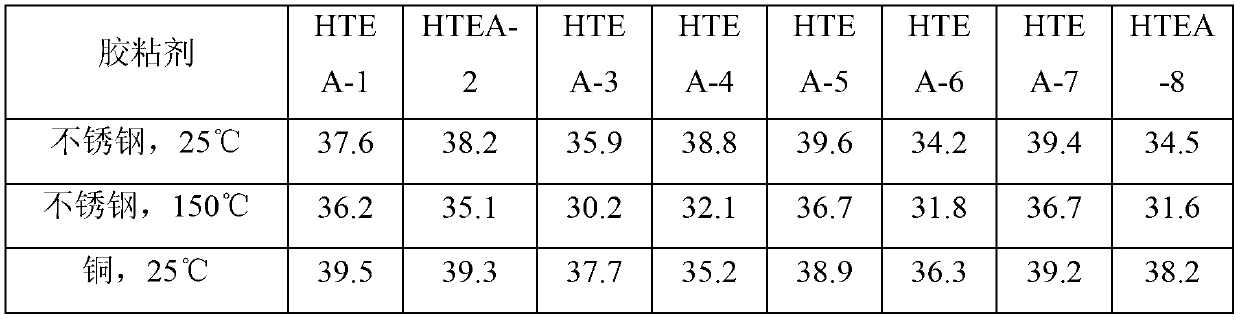

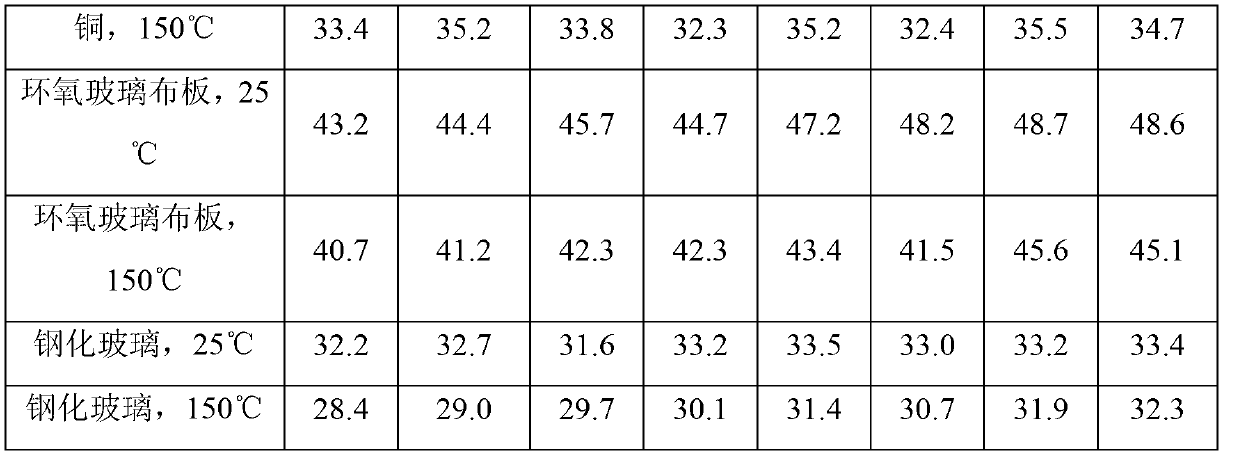

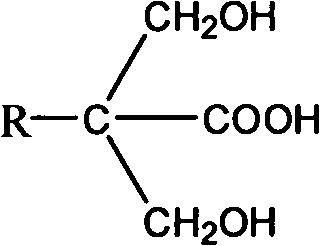

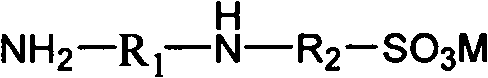

2,2-bis[4-(2,4-diamidophenoxy)phenyl]hexafluoropropane high-temperature-resistant epoxy adhesive and preparation method thereof

InactiveCN103146330AGood adhesionGood viscosity controllabilityMacromolecular adhesive additivesEpoxynovolac adhesivesResin-Based CompositePhenyl group

The invention relates to a 2,2-bis[4-(2,4-diamidophenoxy)phenyl]hexafluoropropane high-temperature-resistant epoxy adhesive and a preparation method thereof. The 2,2-bis[4-(2,4-diamidophenoxy)phenyl]hexafluoropropane high-temperature-resistant epoxy adhesive is composed of a component A and a component B, wherein the component A is a copolymer prepared by reacting 2,2-bis[4-(2,4-diamidophenoxy)phenyl]hexafluoropropane and epoxy resin; and the component B is a homogeneous transparent solution with the solid content of 15-30%, which is prepared by reacting 2,2-bis[4-(2,4-diamidophenoxy)phenyl]hexafluoropropane and aromatic dibasic acid anhydride in a strong-polarity non-proton organic solvent and toluene. The preparation method comprises the following step: evenly mixing the component A and the component B in a mass ratio of 1:(1-2) at room temperature. The preparation technique is simple; and the adhesive has excellent comprehensive properties, can be widely used for bonding steel, copper, aluminum or any other metal with ceramic, glass, resin-base composite material or any other substrate, and has favorable industrialization prospects.

Owner:DONGHUA UNIV +1

4,4'-bis(2,4-diamidophenoxy)diphenylsulphone high-temperature-resistant epoxy adhesive and preparation method thereof

InactiveCN103131369AGood adhesionGood viscosity controllabilityMacromolecular adhesive additivesEpoxynovolac adhesivesOrganic solventRoom temperature

The invention relates to a 4,4'-bis(2,4-diamidophenoxy)diphenylsulphone high-temperature-resistant epoxy adhesive and a preparation method thereof. The 4,4'-bis(2,4-diamidophenoxy)diphenylsulphone high-temperature-resistant epoxy adhesive is composed of a component A and a component B in a mass ratio of 1:(1-2), wherein the component A is a copolymer prepared by reacting 4,4'-bis(2,4-diamido phenoxy)diphenylsulphone and epoxy resin; and the component B is a homogeneous-phase transparent solution with the solid content of 15-30%, which is prepared by reacting 4,4'-bis(2,4-diamidophenoxy)diphenylsulphone and aromatic dibasic acid anhydride in a strong-polarity non-proton organic solvent and diphenylsulphone. The preparation method comprises the following step: evenly mixing the component A and the component B in a mass ratio of 1:(1-2) at room temperature. The preparation technique is simple; and the adhesive has excellent comprehensive properties, can be widely used for bonding steel, copper, aluminum or any other metal with ceramic, glass, resin-base composite material or any other substrate, and has favorable industrialization prospects.

Owner:DONGHUA UNIV +1

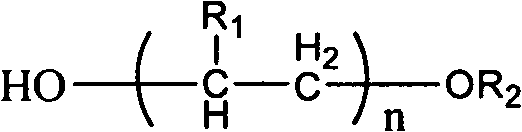

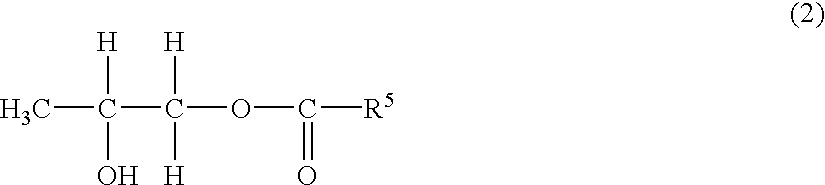

High-elasticity waterborne polyurethane-acrylate composite resin, and preparation method and application thereof

The invention relates to a high-elasticity waterborne polyurethane-acrylate composite resin which is prepared mainly from the following raw materials: 7 to 20 parts by mass of aliphatic polyisocyanates with highly symmetrical structure, 25 to 45 parts by mass of polyether polyol, 0 to 0.03 parts by mass of polyurethane catalyst, 0 to 2 parts by mass of low molecular weight alcohol chain extender, 1 to 6 parts by mass of hydrophilic chain extender, 0.4 to 1.5 parts by mass of low molecular weight amine chain extender, 1 to 4 parts by mass of organic amine neutralizer, 20 to 60 parts by mass of (methyl) acrylate monomer and 0.08 to 1.3 parts by mass of free radical initiator. The high-elasticity waterborne polyurethane-acrylate composite resin disclosed by the invention has good mechanical property at different using temperatures. A coating prepared from the high-elasticity waterborne polyurethane-acrylate composite resin not only has excellent mechanical property, but also has excellent water resistance, alkali resistance, stain resistance and ageing resistance, so the high-elasticity waterborne polyurethane-acrylate composite resin is very suitable for preparing the single-component elastic coating in the field of buildings.

Owner:WANHUA CHEM GUANGDONG

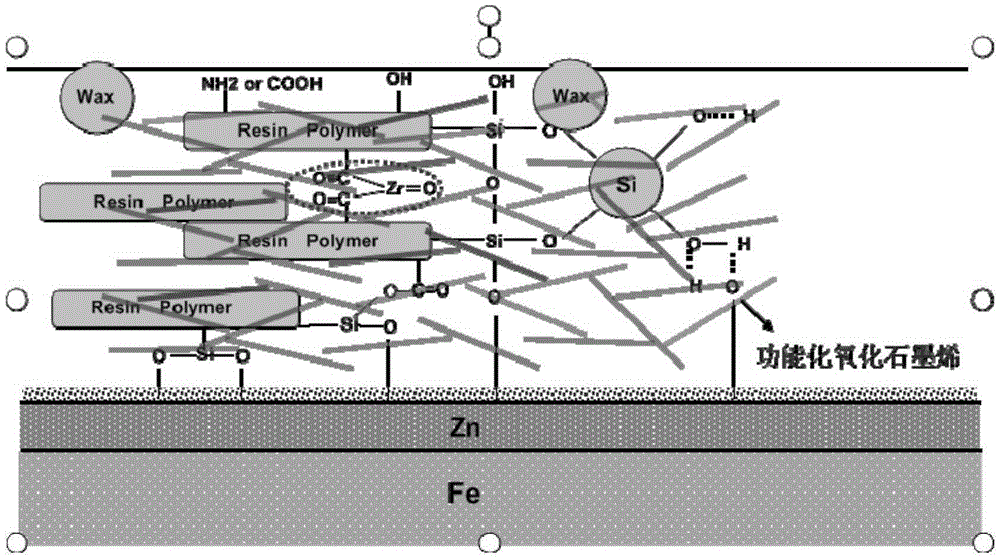

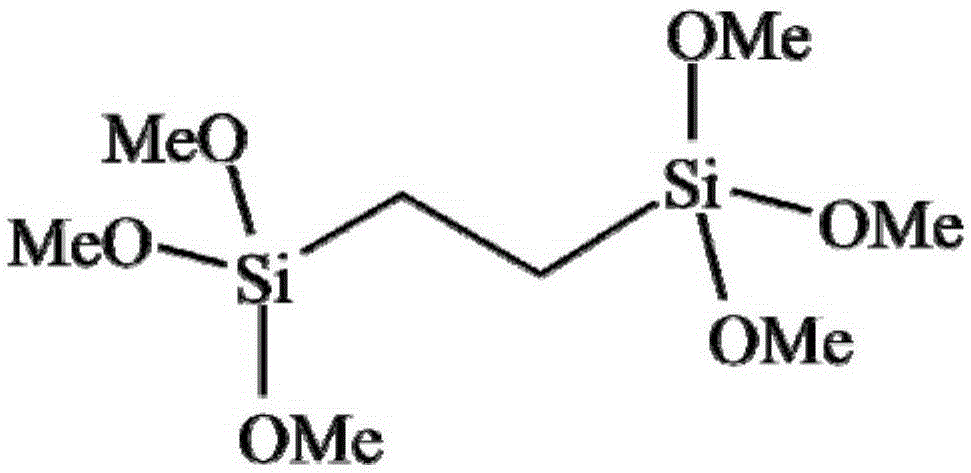

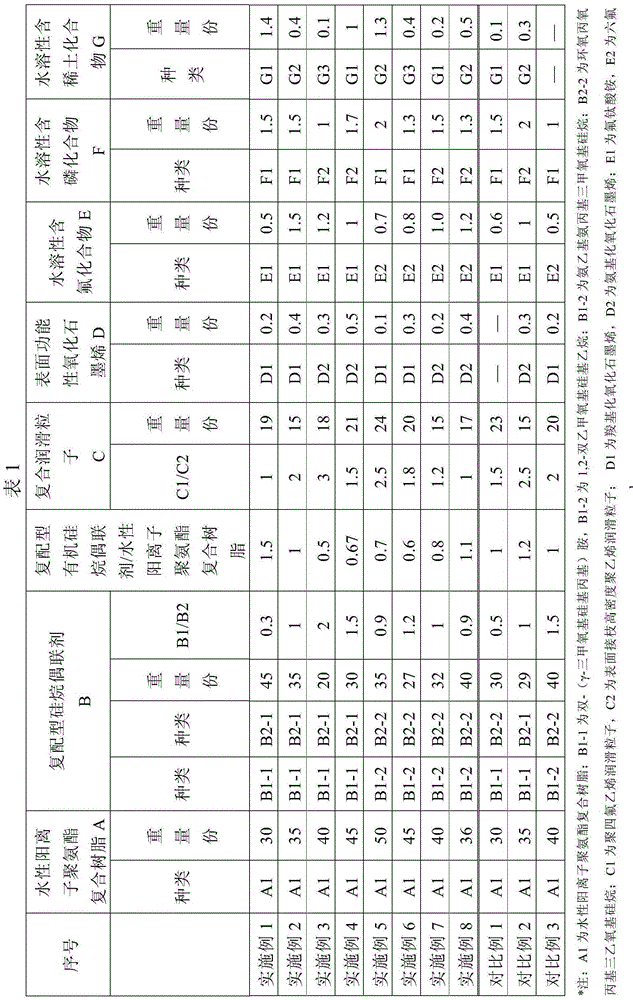

Galvanized steel sheet excellent in surface abrasion resistance, corrosion resistance and acid and base resistance and water-based surface treating agent

ActiveCN105255338AGood acid and alkali resistanceIncrease the degree of cross-linkingAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedCompound organic

The invention relates to a galvanized steel sheet excellent in surface abrasion resistance, corrosion resistance and acid and base resistance and a water-based surface treating agent. The surface of a galvanized steel sheet is coated with the surface treating agent in a solidified mode, wherein the surface treating agent includes water-based positive ion polyurethane composite resin, compound organic silane coupling agents containing bis-organic silane coupling agents and mono-organic silane coupling agents, compound lubrication particles containing teflon-surface modification high-density polyethylene particles, oxidized graphene, water-soluble fluorine-containing compounds, water-soluble phosphorous compounds, water-soluble rare earth salt compounds and other components, and therefore the surface treatment galvanized steel sheet excellent in surface abrasion resistance, corrosion resistance and acid and base resistance is obtained. Meanwhile, the surface treatment galvanized steel sheet has good resistance, such as solvent resistance, to all kinds of chemical media.

Owner:BAOSHAN IRON & STEEL CO LTD

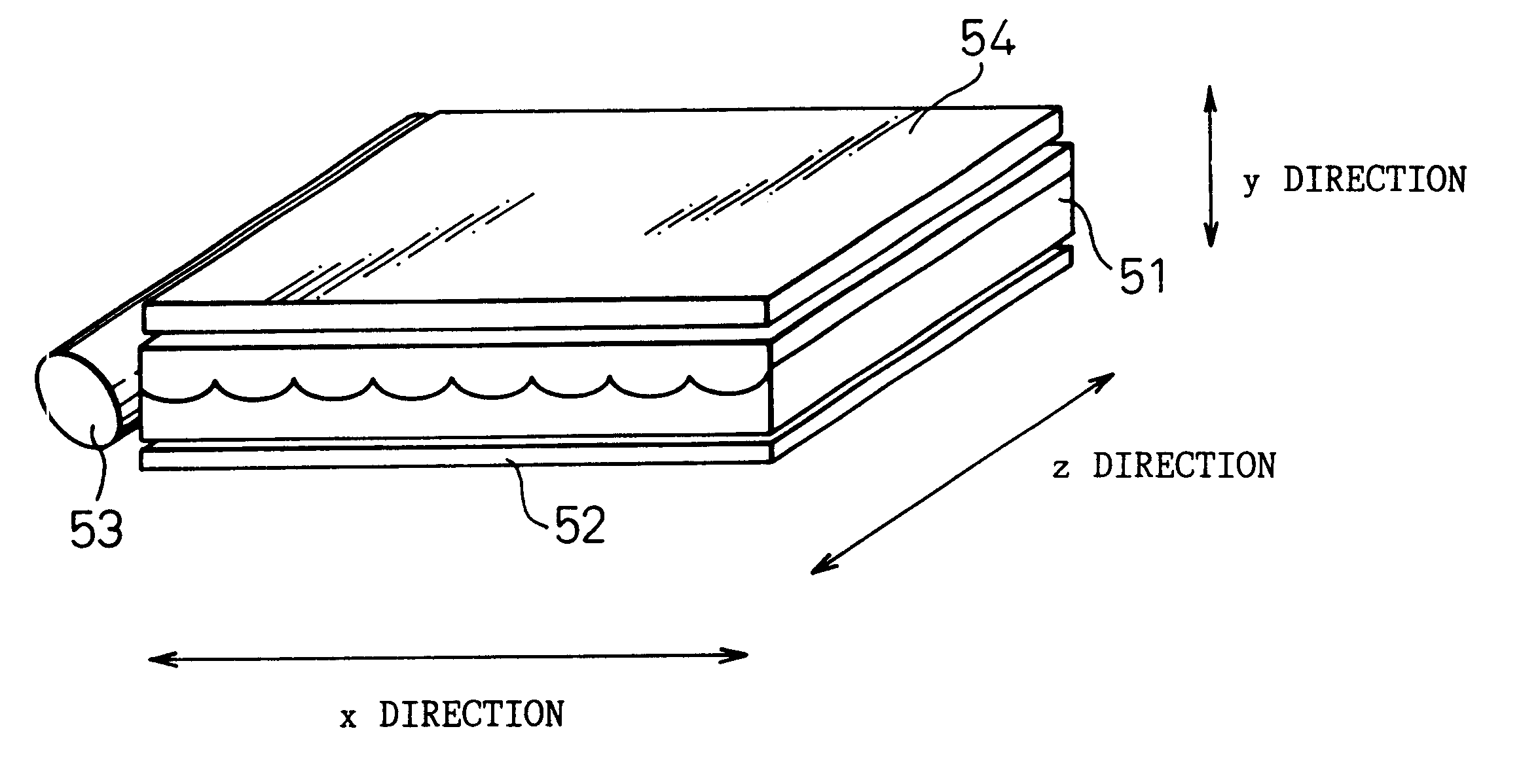

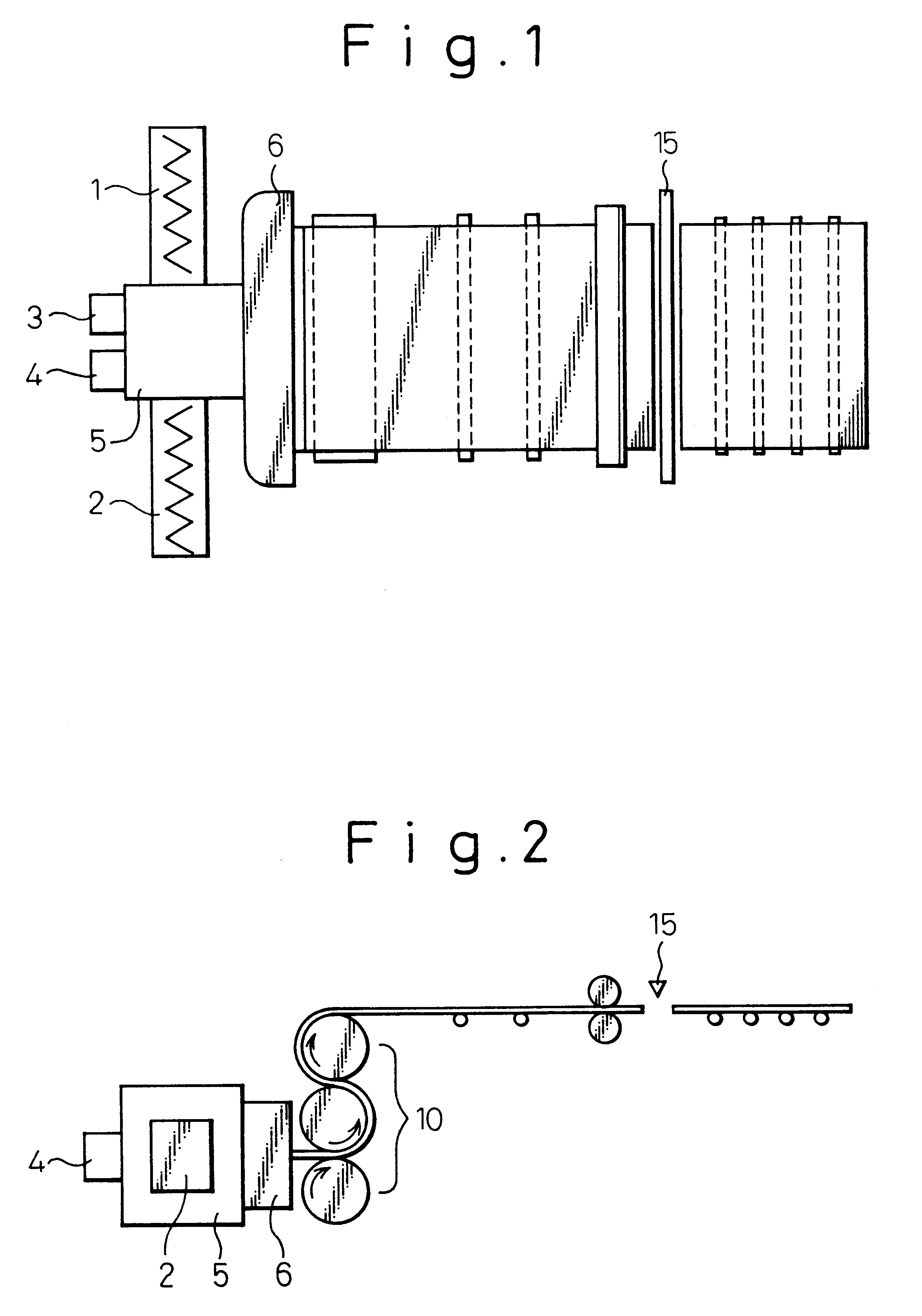

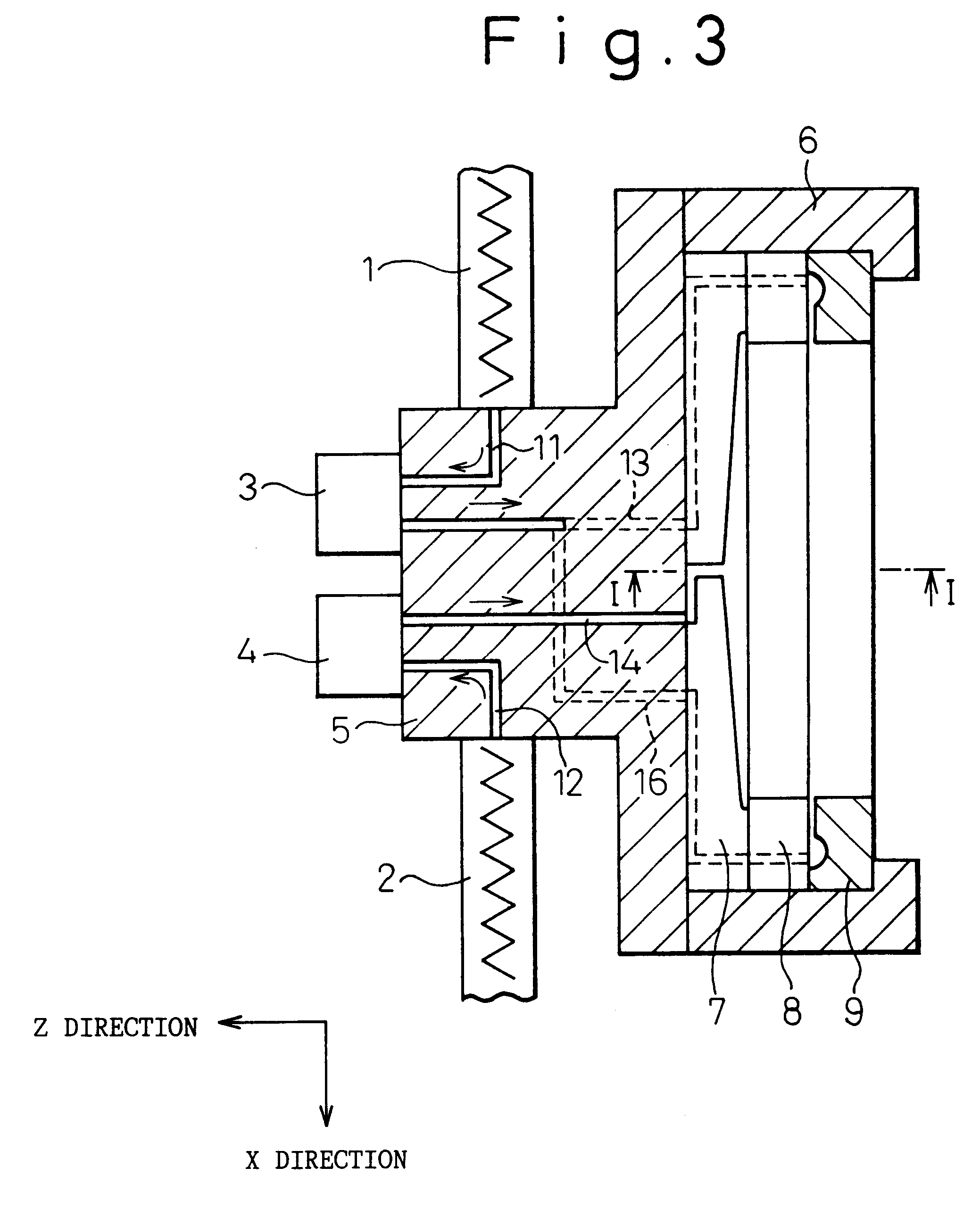

Resin sheet, process and apparatus for producing same, surface light source element and laminate

InactiveUS6312787B1Reduce the amount presentIncrease chanceMeasurement apparatus componentsDiffusing elementsLight guideRefractive index

A resin sheet having laminated transparent resin layers and a smooth outer surface, the refractive indexes of two resins of any adjacent two resin layers differing from each other, the interfaces among the resin layers having an uneven shape, is produced with an extrusion molding apparatus having such a structure that a plurality of transparent resins are extruded from respective separate flow passages into a composite resin flow passage to form a composite resin flow having a laminate structure with an uneven shape at the interfaces of the resin layers, and that the composite resin flow is extruded from an outlet of the composite resin flow passage. The resin sheet is used as a laminate, or a light guide of a surface light source element.

Owner:MITSUBISHI RAYON CO LTD

Technology of making automobile engine cover with carbon fiber reinforcement resin-based composite material

The invention discloses a technology of making automobile engine cover with carbon fiber reinforcement resin-based composite material, sequentially comprising: cleaning and preparing dies, coating sealant, gluing seal tape, coating mold lubricant, cutting carbon fabric and foam core material, paving and covering carbon fabric and foam core material, paving and covering auxiliary materials, sealing the vacuum section sealed by seal tape, absorbing and injecting resin, and solidifying, demolding and trimming. The making technology of the invention requires relatively short processing period and low labor cost, and is beneficial to both environmental protection and human health. Compared with conventional metal automobile engine covers, the automobile engine cover made of carbon fiber reinforcement resin-based composite material, with equal rigidity, is light in weight, stable in quality, and satisfactory in surface effects.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for preparing composite emulsion of epoxy resin-polyurethane

InactiveCN101270221AGood compatibilityIncrease crosslink densityPolyurea/polyurethane coatingsEpoxy resin coatingsEpoxyResin-Based Composite

The invention relates to a preparation method of epoxy resin-polyurethane composite latex. In the invention, firstly, polyisocyanate and oligomer diol are adopted to prepare linear amine ester prepolymer; cross-linking modification (small-molecule chain extender and large-molecule hydrophilic chain extender) and composite resin (linear amine ester prepolymer and epoxy resin)blend modification are integrated; the small-molecule chain extender and the large-molecule hydrophilic chain extender are used to extend the chain of the linear amine ester prepolymer, so that the linear amine ester prepolymer has a hydrophilic functional group and a branching structure, and the amine ester prepolymer with molecular internal cross-linking structure; and then liquid epoxy resin is added in, a neutralizer is added in to form salt and ionic water is added in to emulsificate, to prepare the epoxy resin-polyurethane composite latex. The composite latex of the invention has good stability with the grain size of about 140mm, consumes a small amount of curing agent, can improve the film performance and corrosion resistance, and is green and environment protective. The epoxy resin-polyurethane composite latex is applied in pigment concentrates to prepare two-component water-borne anti-corrosive coating.

Owner:WUHAN UNIV OF TECH

Method for deeply purifying minim phosphor in water with composite resin

ActiveCN101343093APhosphate content decreasedLarge amount of processingSpecific water treatment objectivesWater contaminantsFiltrationDesorption

The invention discloses a method for deeply purifying micro-phosphorus in water by composite resin. The pH value of water is firstly adjusted to between 5.0 and 9.0 for filtration, then the filtrate passes through an absorption tower filled with composite resin materials to make the micro-phosphorus in water be adsorbed on the composite resin; and the adsorption stops when the adsorption reaches the leakage point, a mixed solution of NaOH and NaCl serves as a desorption agent for desorption and regeneration, then a CO2 saturated solution is used to leach the absorption tower filled with composite resin materials for regenerating resin. The method takes composite resin of surface supported nano-hydrous ferric oxide or hydrous manganese oxide particles as an adsorbent to deeply purify micro-phosphorus in water. After the treatment by the method, the phosphate content (as P) in effluent can still be reduced to below 20ppb from 0.05-20ppm when the molar concentration of coexistent competing ions of Cl<->, HCO3<-> and SO4<2-> is far higher than that of phosphate ions. The method has large treatment capacity, and the materials are renewable and recyclable.

Owner:JIANGSU NJU ENVIRONMENTAL TECH

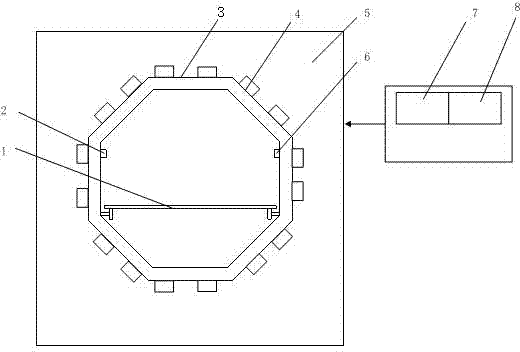

Processing apparatus and processing method for microwave cured fiber reinforced resin matrix composite

ActiveCN102729490AMeasure temperature in real timeEnsure controllabilityResin matrixResin-Based Composite

The invention relates to a processing apparatus and a processing method for a composite and especially to a processing apparatus and a processing method for a microwave cured fiber reinforced resin matrix composite. According to the invention, a polygonal multi-mode cavity is arranged in a tank; a microwave source water cooling interface and a microwave source electrical interface are connected with a magnetron; the magnetron is arranged at an outer side of the tank and connected with a rectangular waveguide tube through a magnetron antenna; the rectangular waveguide tube is arranged at an outer side of the polygonal multi-mode cavity; a vacuum pipe joint is arranged at an inside wall of the polygonal multi-mode cavity; a worktable is disposed in the polygonal multi-mode cavity; a die is disposed on the worktable; the composite is disposed in the die and a vacuum valve is arranged at the upper end of the die; and the vacuum valve is connected with the vacuum pipe joint through a vacuum pipe.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

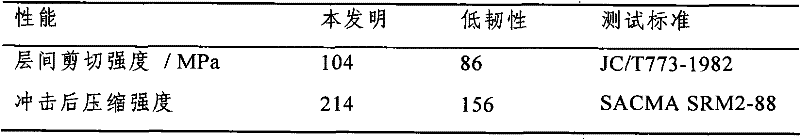

Preparation method for carbon nanotube non-woven fabric interlayer modified fiber reinforced composite materials

InactiveCN102516569AInhibition formationPrevent scalabilityCarbon nanotubeFiber-reinforced composite

The invention belongs to the advanced composite material preparing technology and relates to a preparation method for carbon nanotube non-woven fabric interlayer modified fiber reinforced composite materials. The method includes: enabling carbon nanotube non-woven fabric to enter resin rich areas of the layers of fiber reinforced thermosetting resin base composite materials in direct intercalation mode, using an autoclave molding process or a liquid forming process, and preparing interlayer the interlayer modified composite materials according to an original curing process of matrix resin. The carbon nanotube non-woven fabric can enter weak interlayer areas of the composite materials through direct intercalation mode, has no influence on flow of the resin in the curing process and a liquid forming process of the matrix resin, and simultaneously a network structure formed by carbon nanotubes in an interlayer can effectively prevent interlayer microcracks from being formed and extending, thereby improving strengthening-toughening performance of interlayer of the composite materials, obtaining high impact damage resistance and high damage tolerance, and covering a temperature range of typical aerospace composite structure application, in particular to a more than 300 DEG C high temperature range.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![2,2-bis[4-(2,4-diamidophenoxy)phenyl]hexafluoropropane high-temperature-resistant epoxy adhesive and preparation method thereof 2,2-bis[4-(2,4-diamidophenoxy)phenyl]hexafluoropropane high-temperature-resistant epoxy adhesive and preparation method thereof](https://images-eureka.patsnap.com/patent_img/c3dc5c5a-1b77-468c-bc0c-b8ed519f1fb6/BDA00002903323100091.PNG)