Patents

Literature

94 results about "Dental mold" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

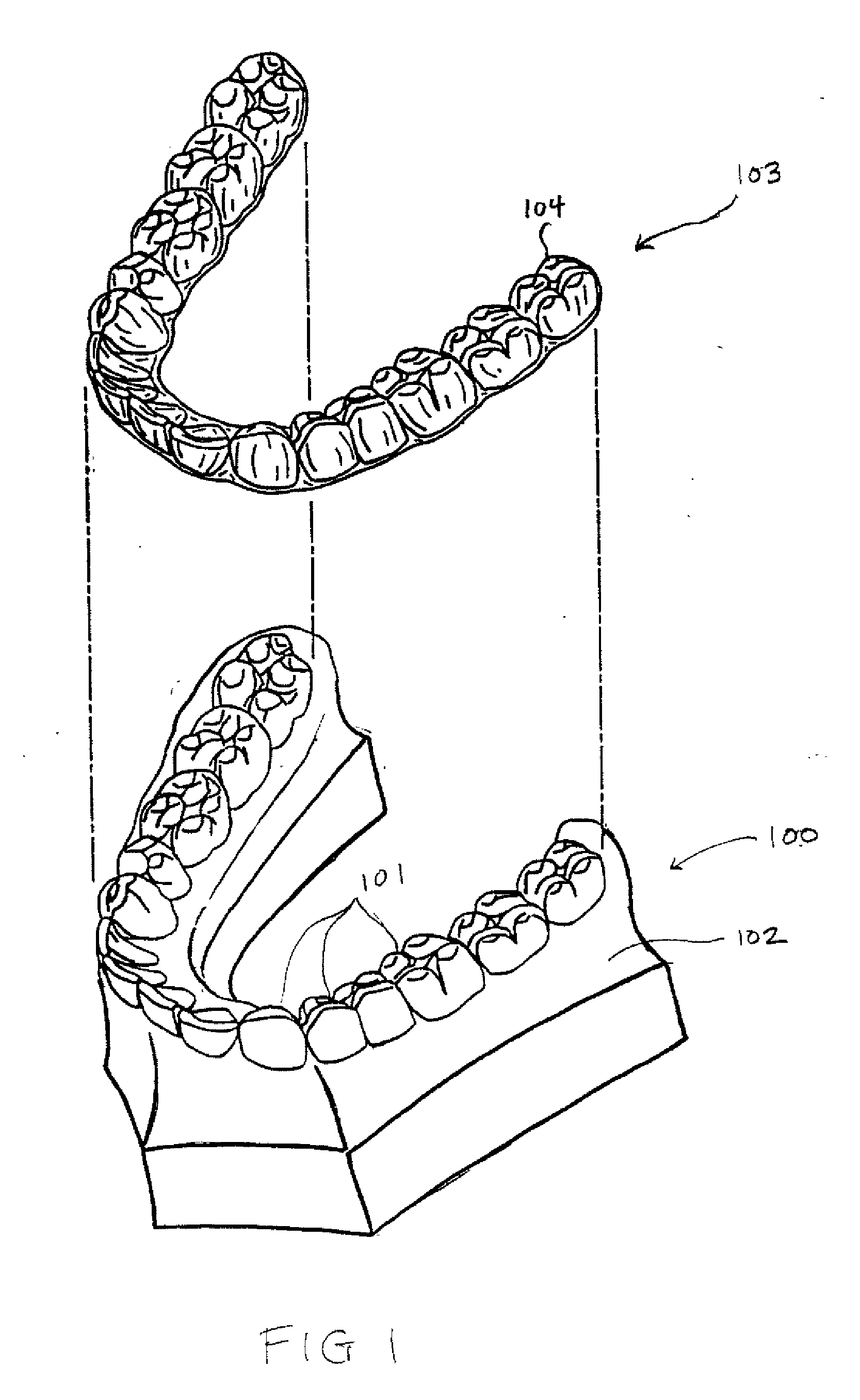

Methods for correcting tooth movements midcourse in treatment

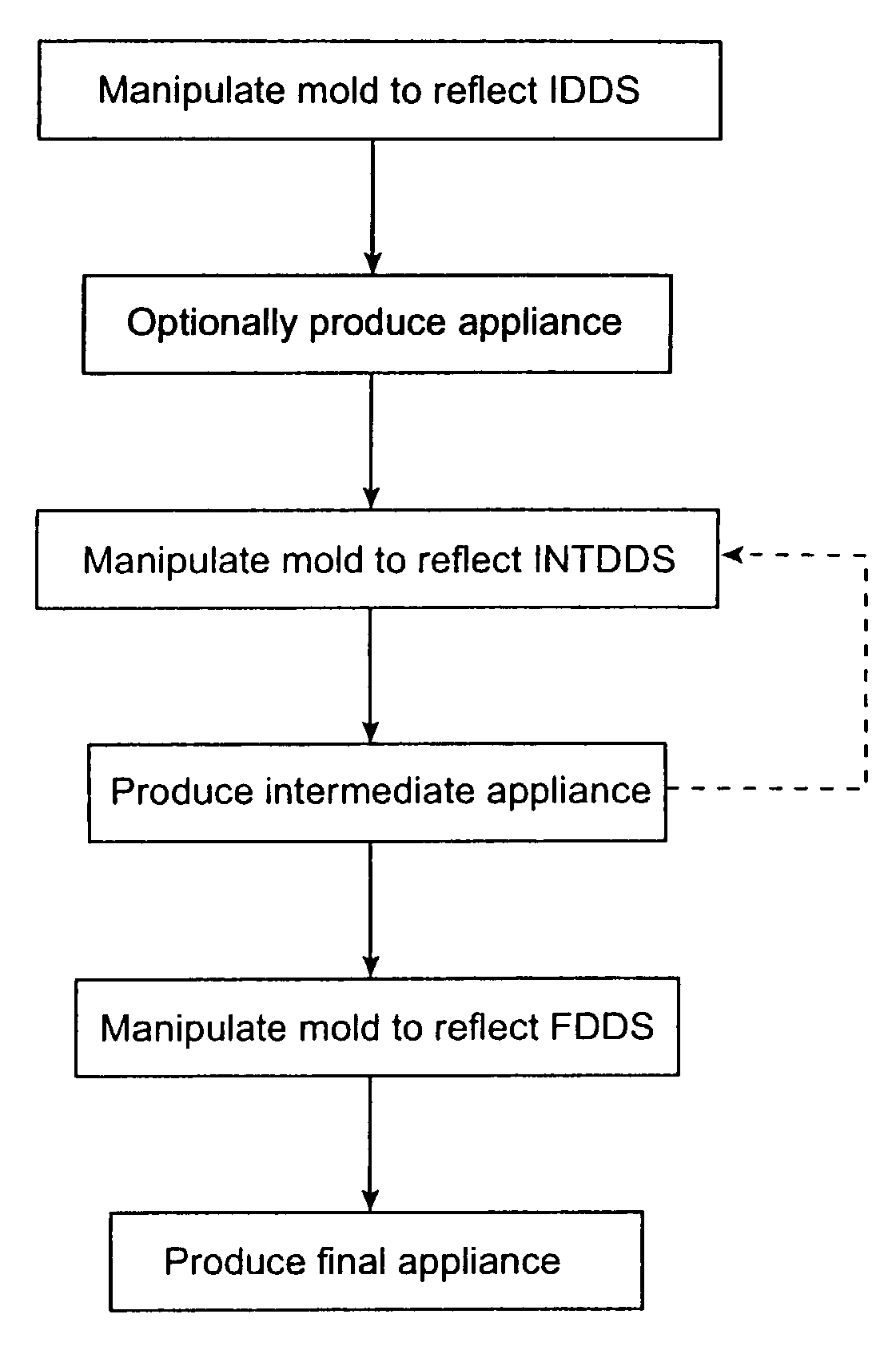

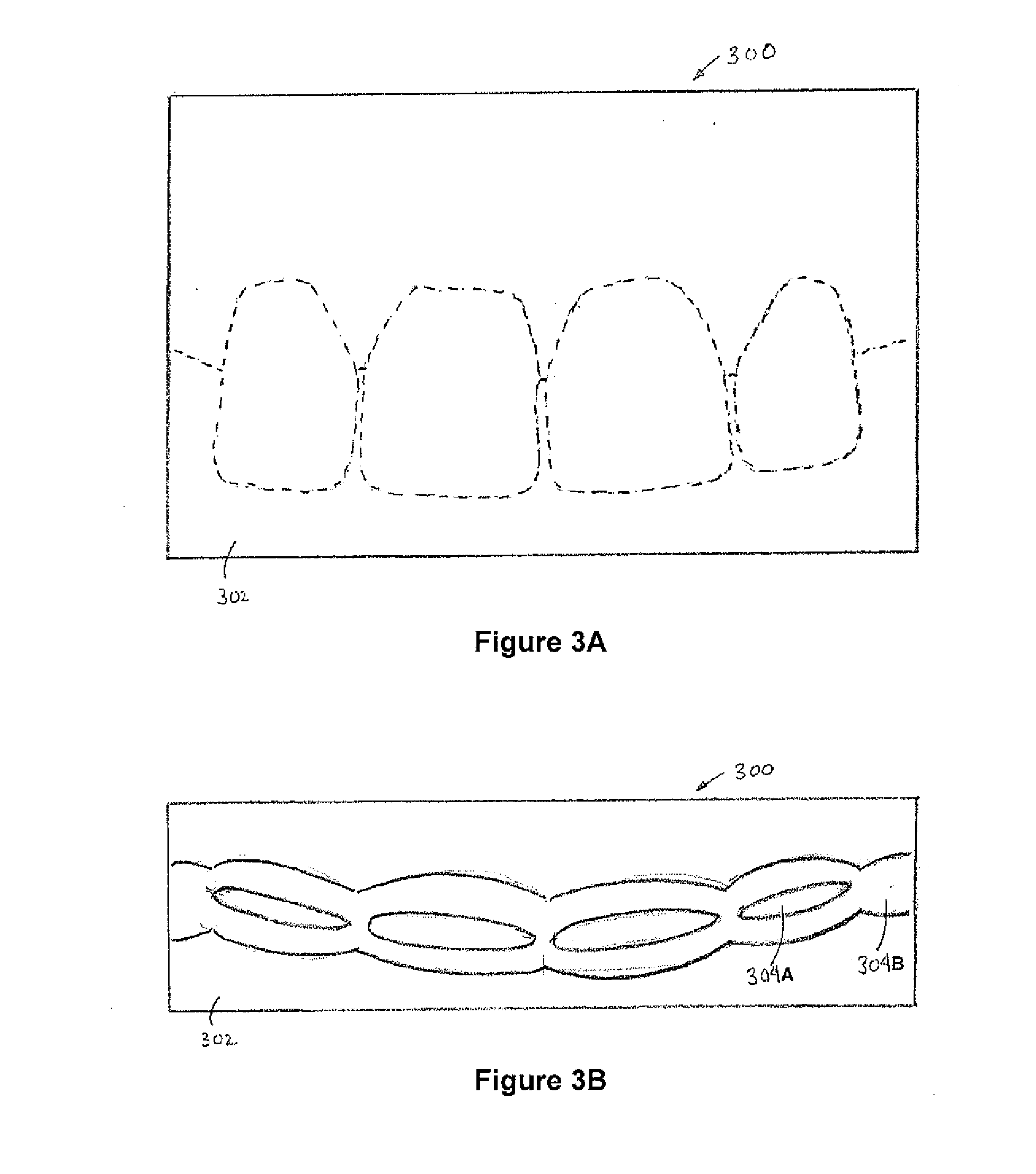

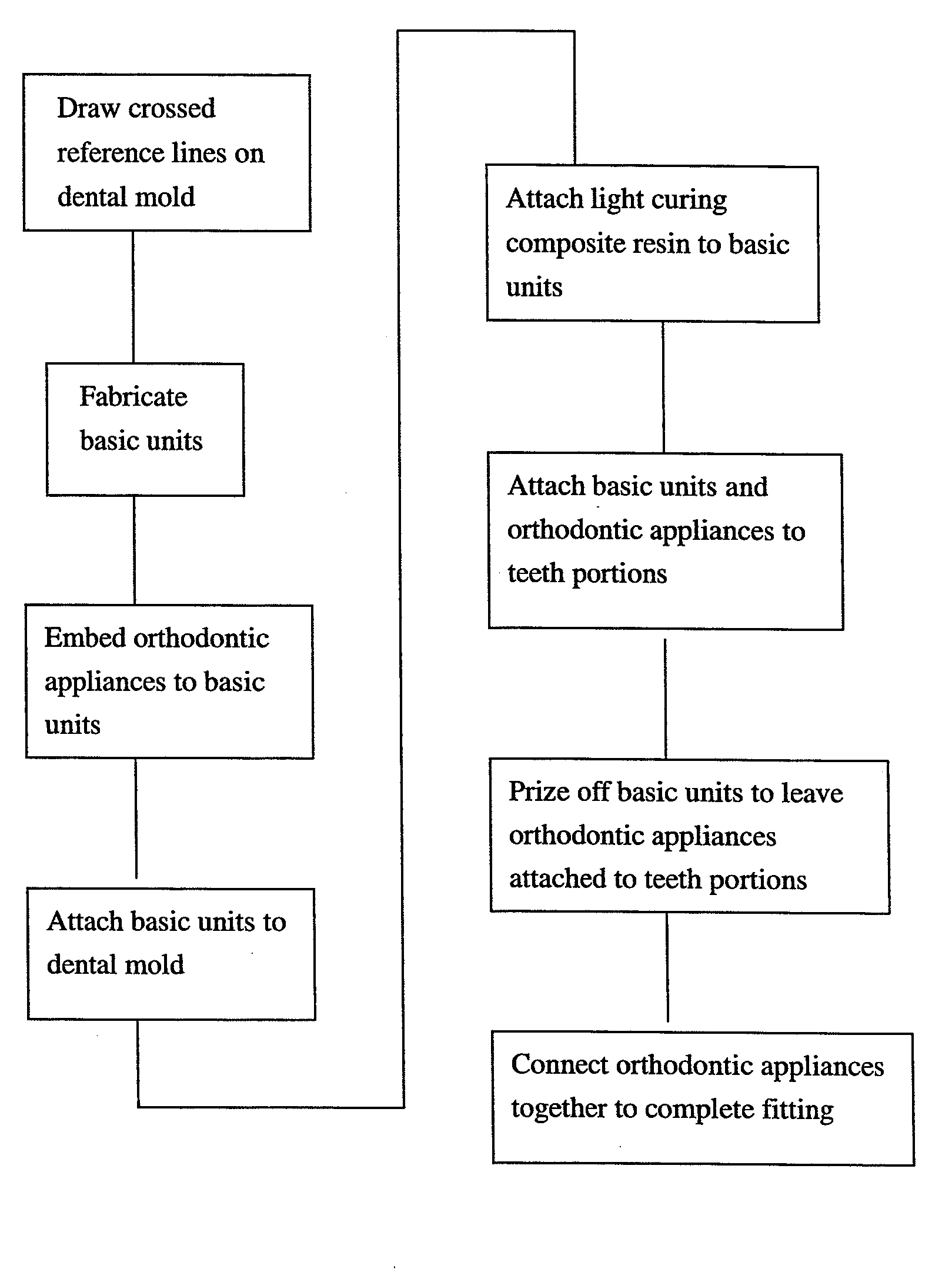

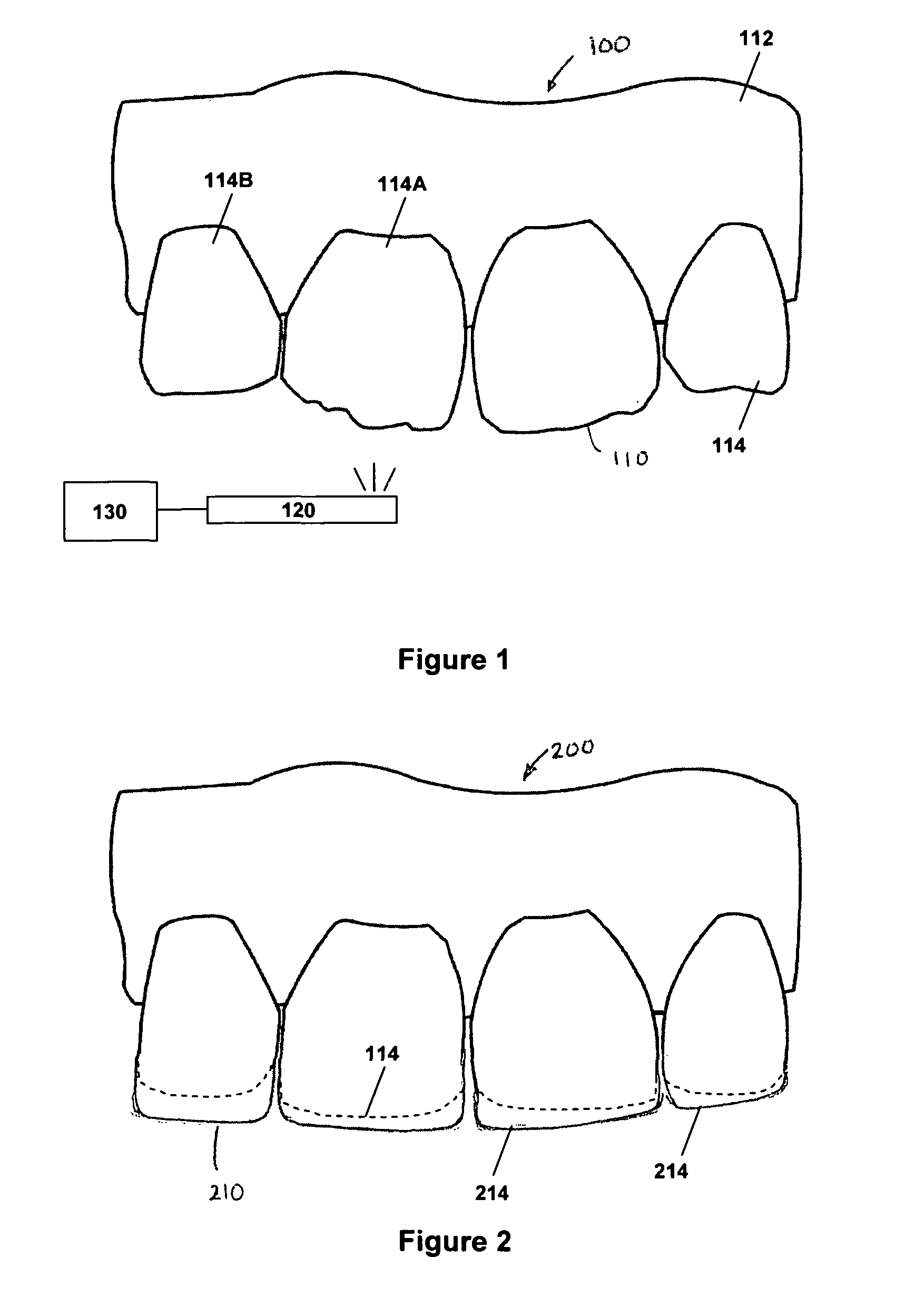

Appliances are made using a dental mold representing a patient's dental configuration. In particular, thermoformable plastic positioning appliances which fit over the patient's teeth may be formed over a three-dimensional mold of the patient's dentition. An apparatus and methods which employ a manipulable or reconfigurable mold to model patient dentition and gingiva at each stage of treatment. The apparatus and methods are particularly useful for performing midcourse corrections during orthodontic procedures using a plurality of such appliances in sequence.

Owner:ALIGN TECH

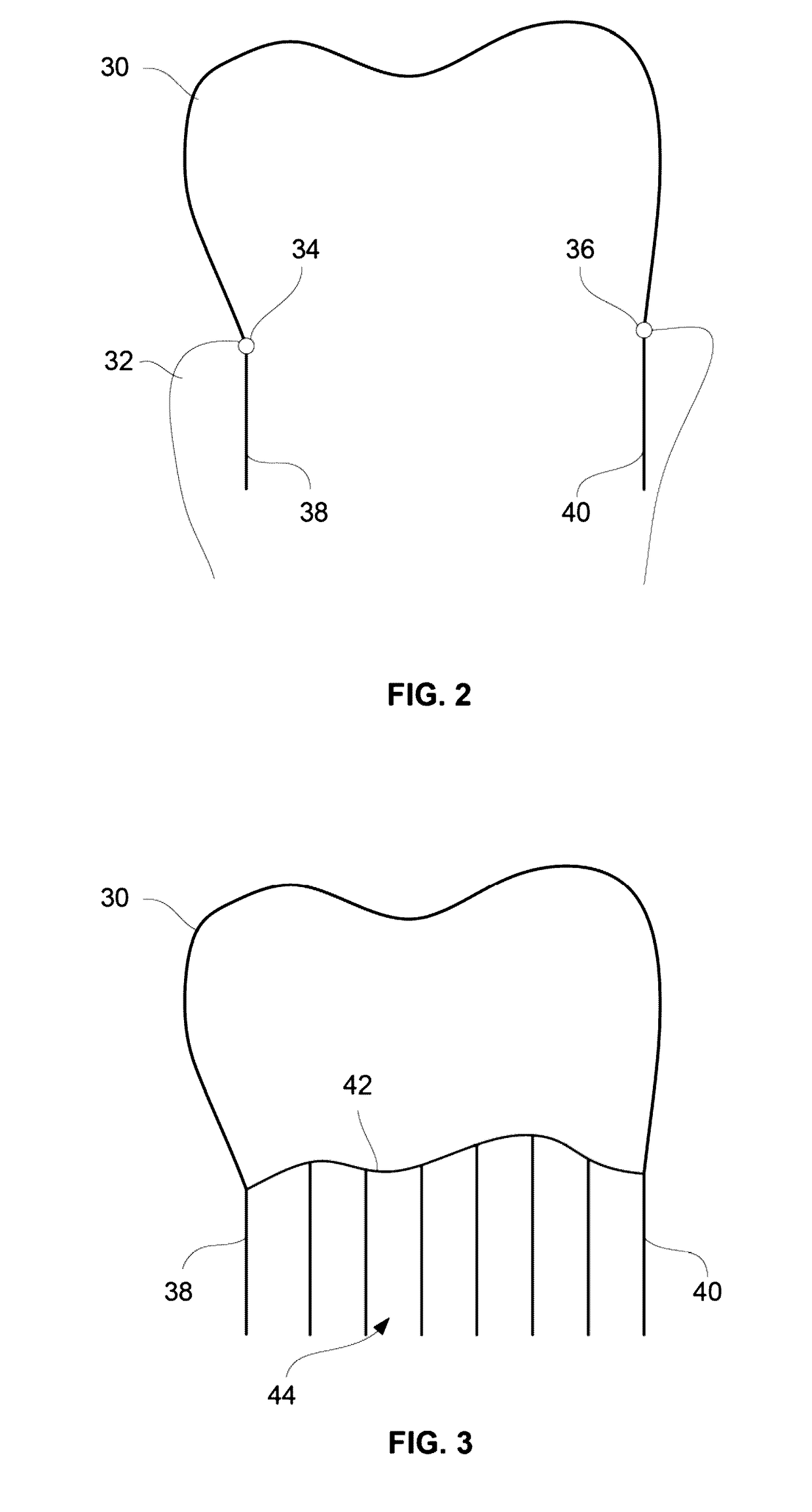

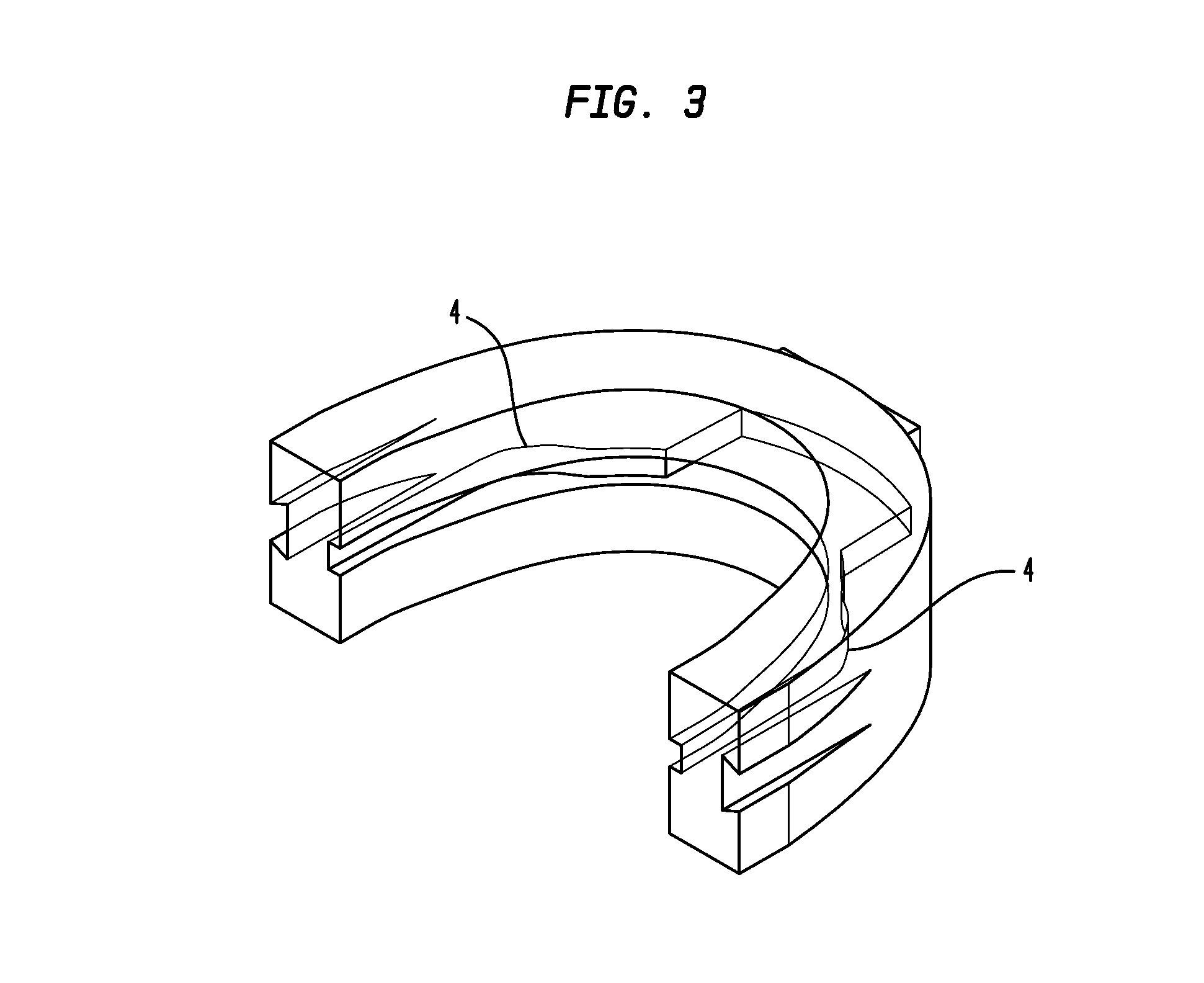

Method for dental restoration and related kit

The disclosure generally relates to a method for forming a dental mold. The method generally includes: (a) scanning an existing dental structure to generate a three-dimensional first digital model of the existing dental structure, (b) modifying the first digital model of the existing dental structure to generate a three-dimensional second digital model of a planned dental structure; (c) generating a three-dimensional third digital model corresponding to a negative of the second digital model; (d) digitally sectioning the third digital model into at least one buccal model portion and at least one lingual model portion of the third digital model; and (e) creating a dental mold comprising at least one buccal mold portion and at least one lingual mold portion based on the sectioned third digital model. The disclosure also relates to (a) methods of assembling the dental mold over a tooth and a gum of a patient having an existing dental structure in need of dental restoration, (b) methods of performing a dental restoration on the existing dental structure of the patient using the dental mold, and (c) kits including components for forming the dental mold and / or for performing the dental restoration using the dental mold.

Owner:VUILLEMOT WILLIAM C

Method for dental restoration and related kit

The disclosure generally relates to a method for forming a dental mold. The method generally includes: (a) scanning an existing dental structure to generate a three-dimensional first digital model of the existing dental structure, (b) modifying the first digital model of the existing dental structure to generate a three-dimensional second digital model of a planned dental structure; (c) generating a three-dimensional third digital model corresponding to a negative of the second digital model; (d) digitally sectioning the third digital model into at least one buccal model portion and at least one lingual model portion of the third digital model; and (e) creating a dental mold comprising at least one buccal mold portion and at least one lingual mold portion based on the sectioned third digital model. The disclosure also relates to (a) methods of assembling the dental mold over a tooth and a gum of a patient having an existing dental structure in need of dental restoration, (b) methods of performing a dental restoration on the existing dental structure of the patient using the dental mold, and (c) kits including components for forming the dental mold and / or for performing the dental restoration using the dental mold.

Owner:VUILLEMOT WILLIAM C

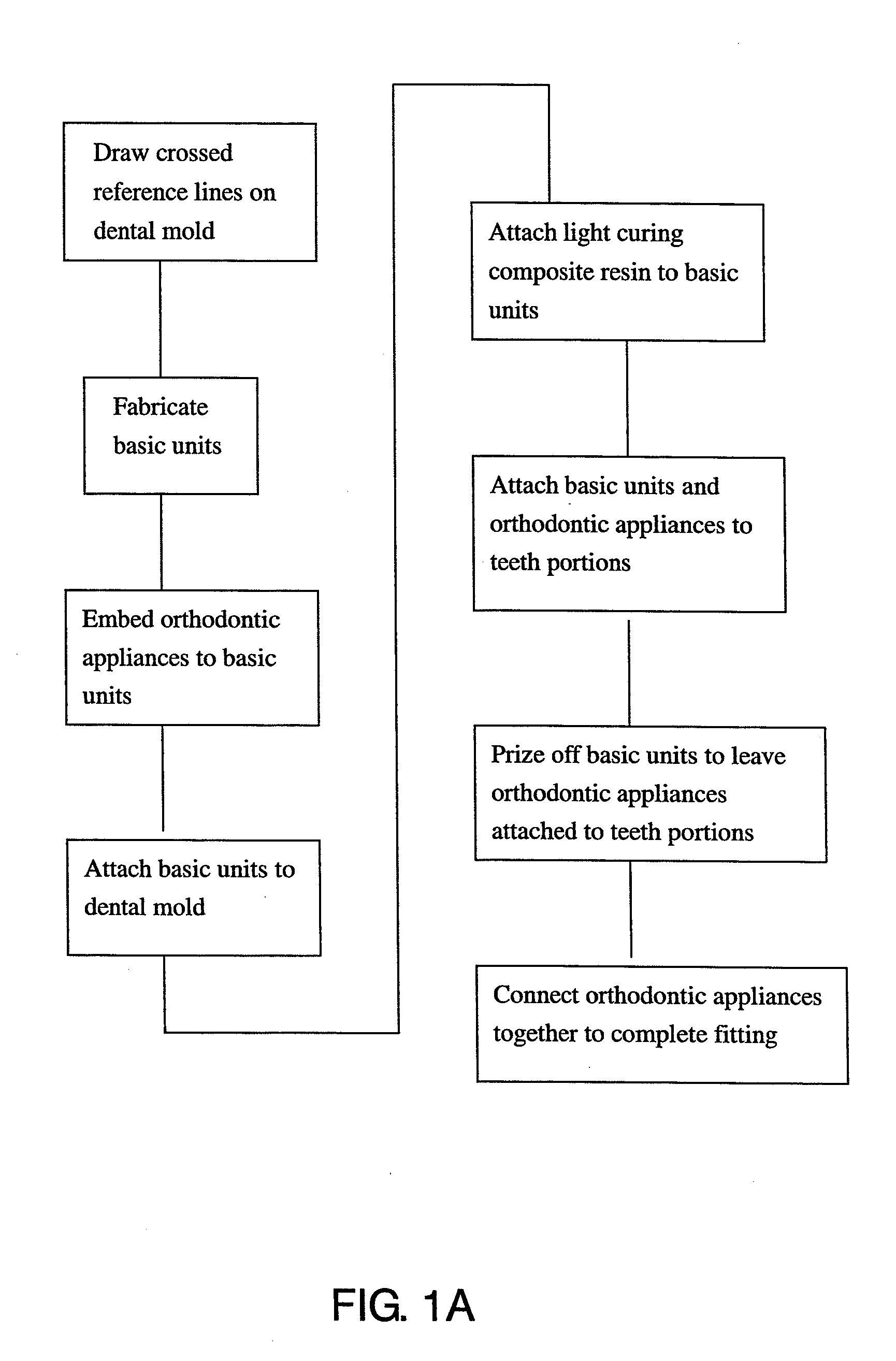

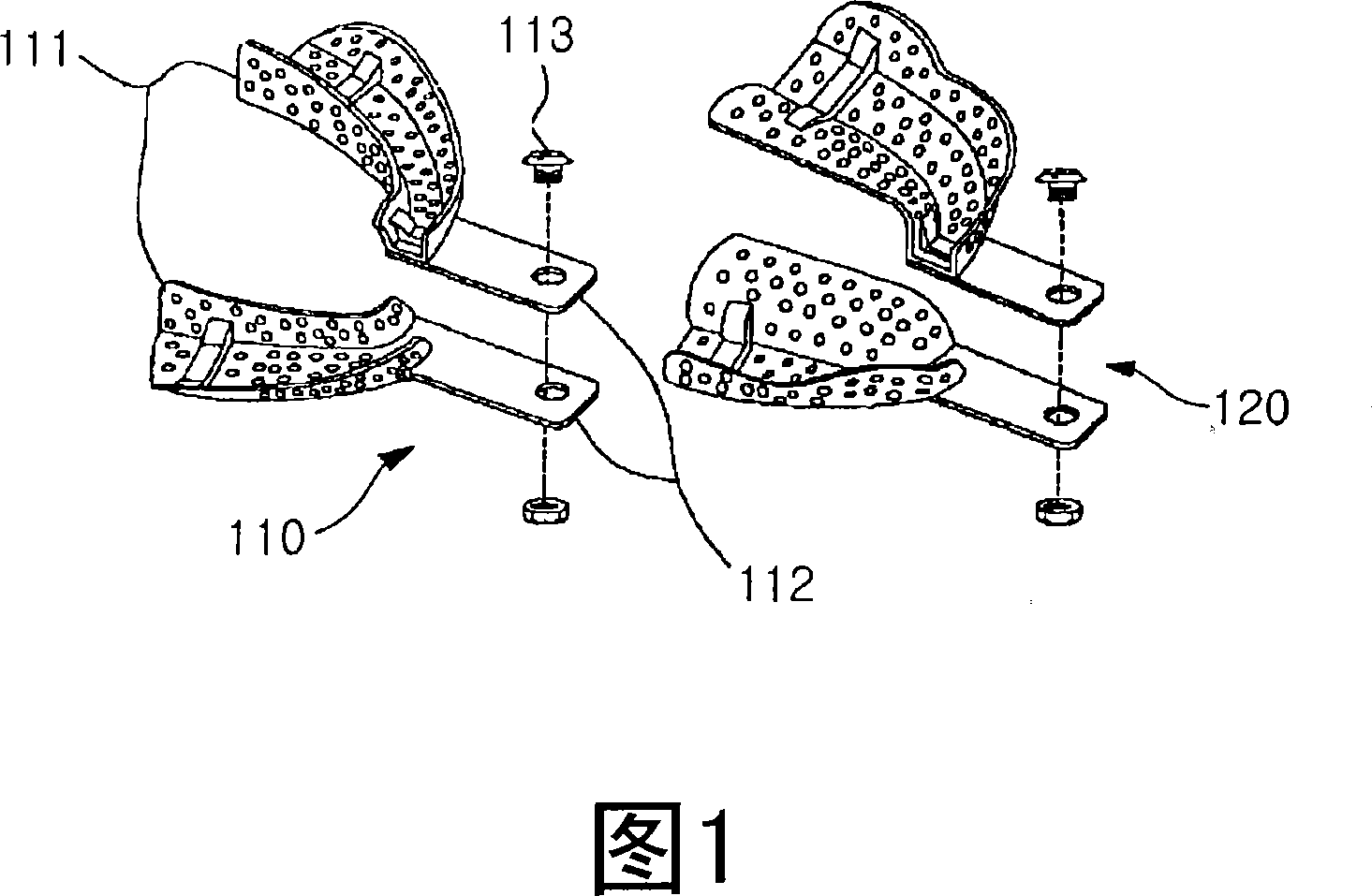

Positioning method for orthodontic appliance and structure thereof

A positioning method for orthodontic appliance and structure, mainly provided with base units molded by plastic injection. During the fabricating process, a crossed reference line is first drawn on a dental mold of the patient, after heating, the orthodontic appliance is embedded to the base unit, and a flexible member is used to bind and fixedly position the orthodontic appliance. Each of the aforementioned base units together with the orthodontic appliance is attached to the dental mold, and then light curing composite resin is attached to each of the base units. Accordingly, after applying an adhesive layer to each of the orthodontic appliances, each of the series connected base units together with the orthodontic appliances bound to the base units is directly attached to the respective teeth portion of the patient requiring straightening, thereby enabling fitting of orthodontic appliances to be more convenient and providing a more efficient fabricating process.

Owner:EZBOND DIGITAL CO LTD

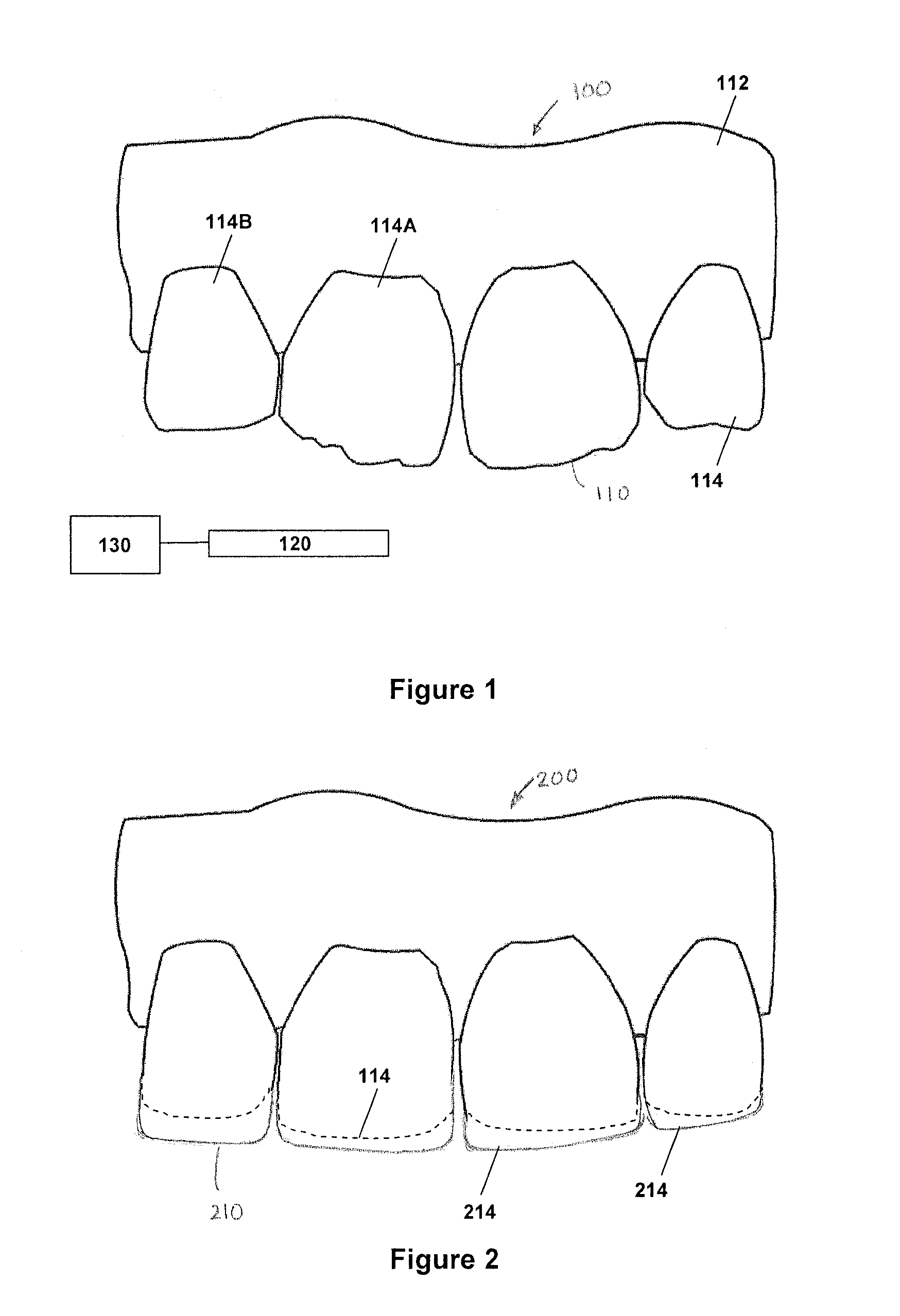

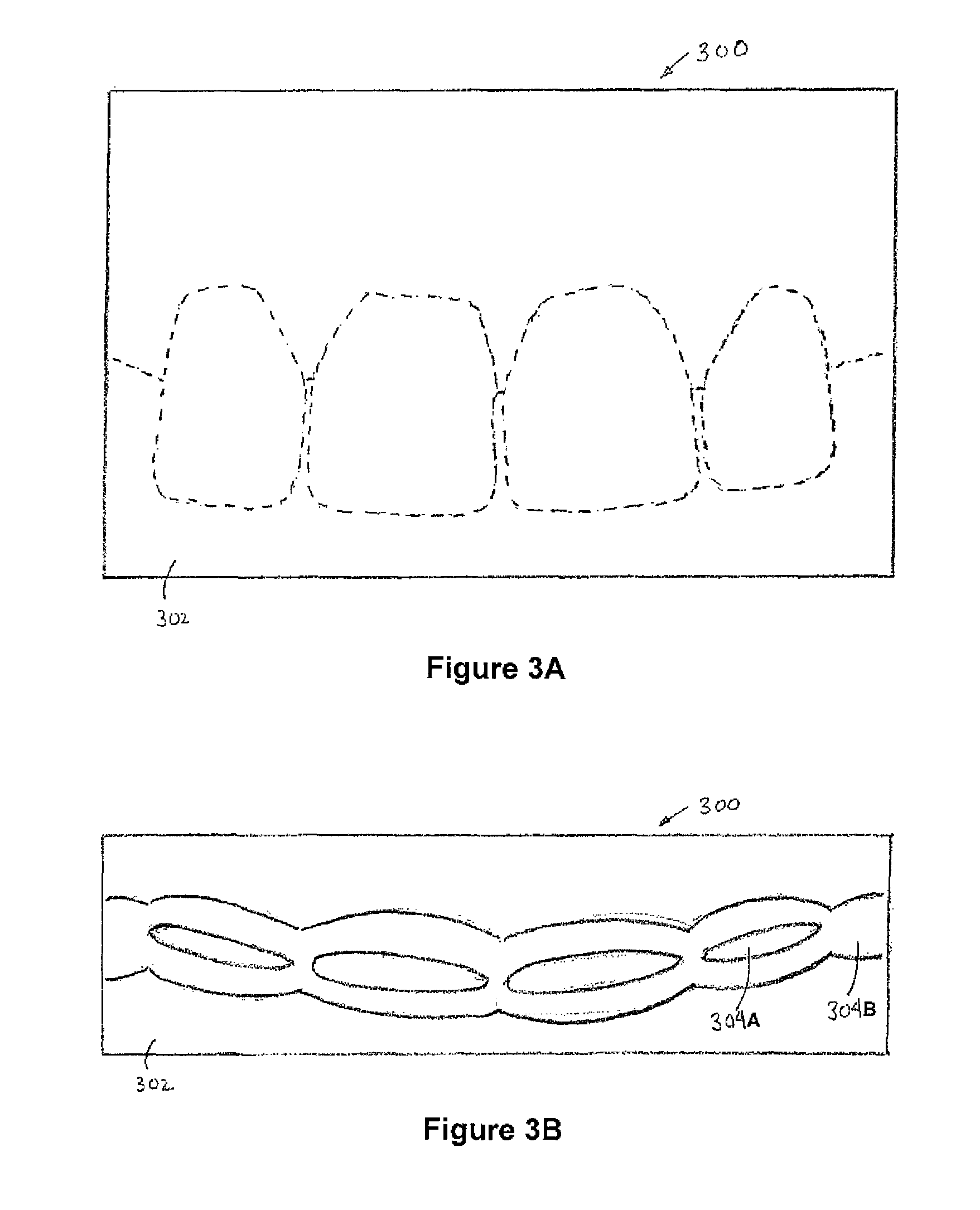

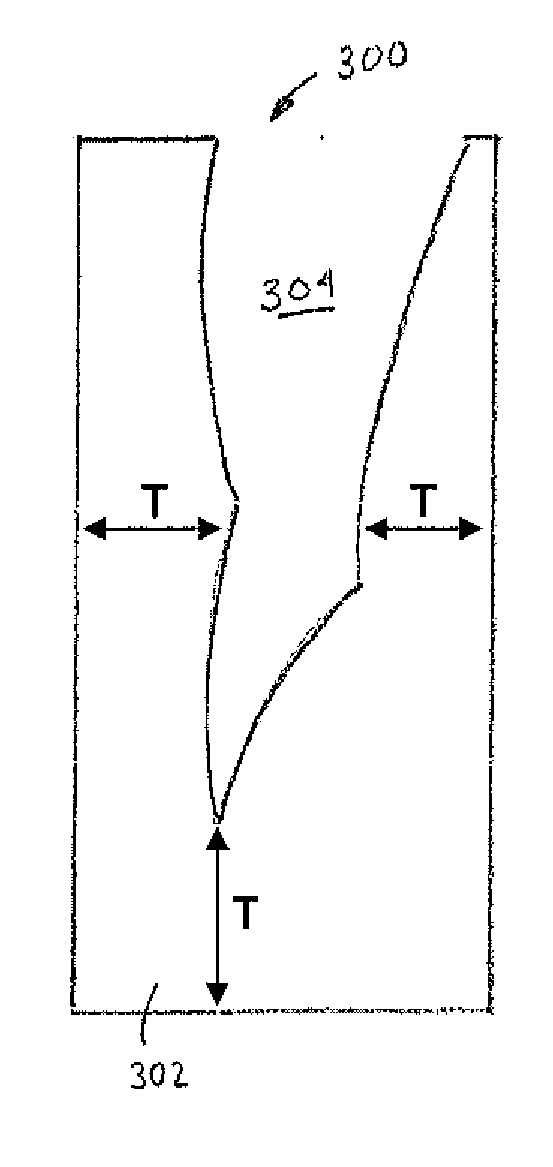

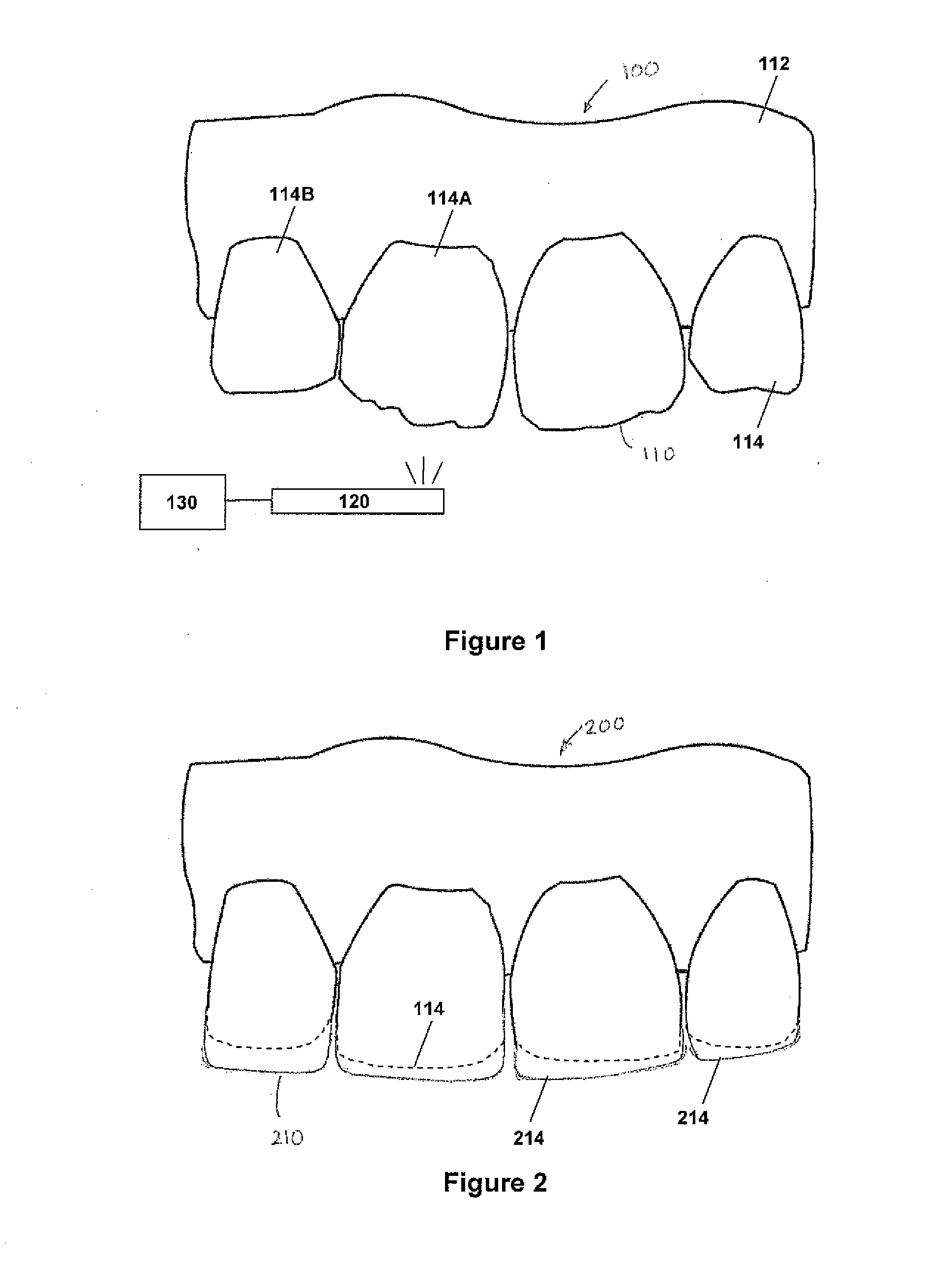

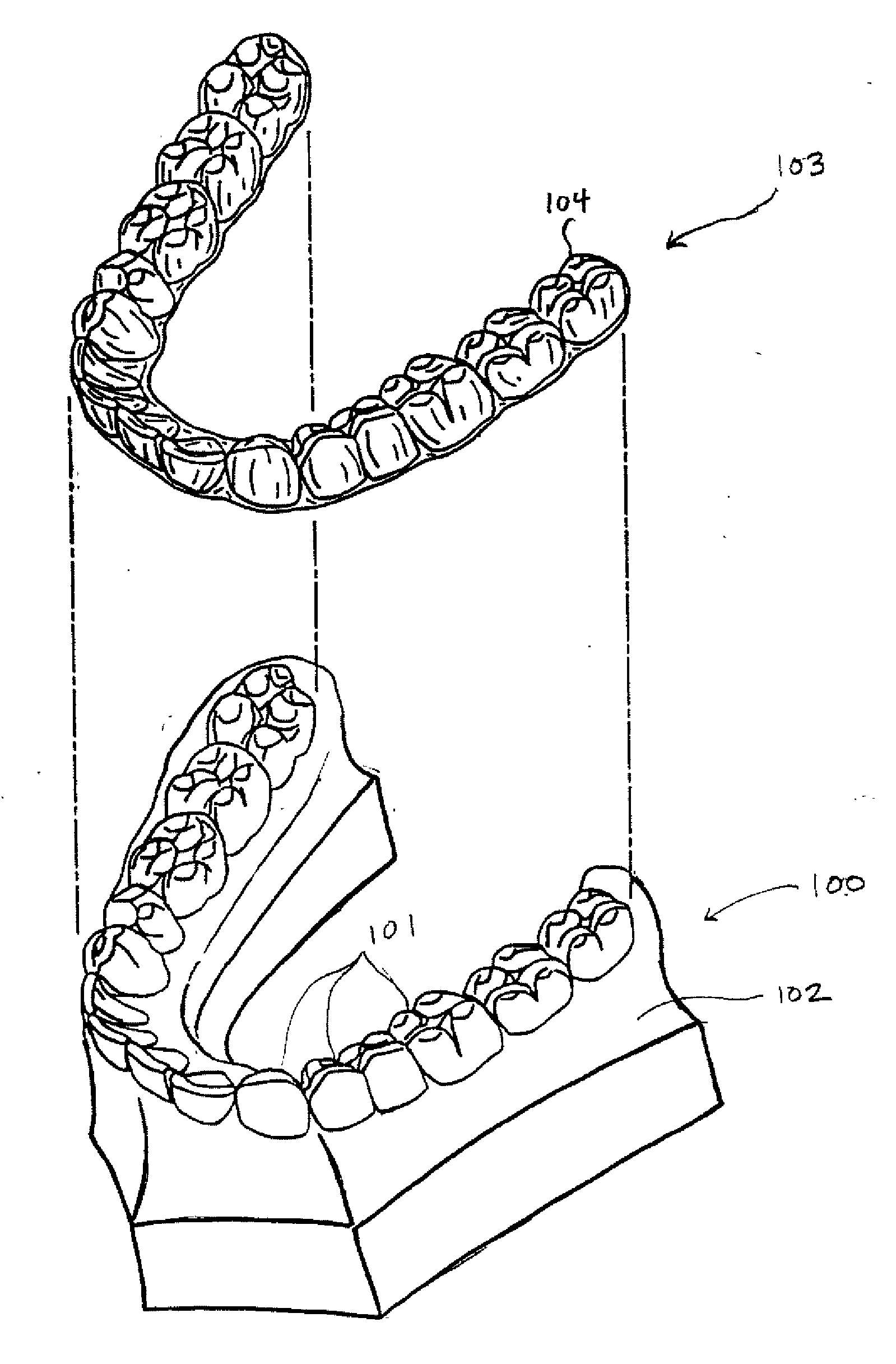

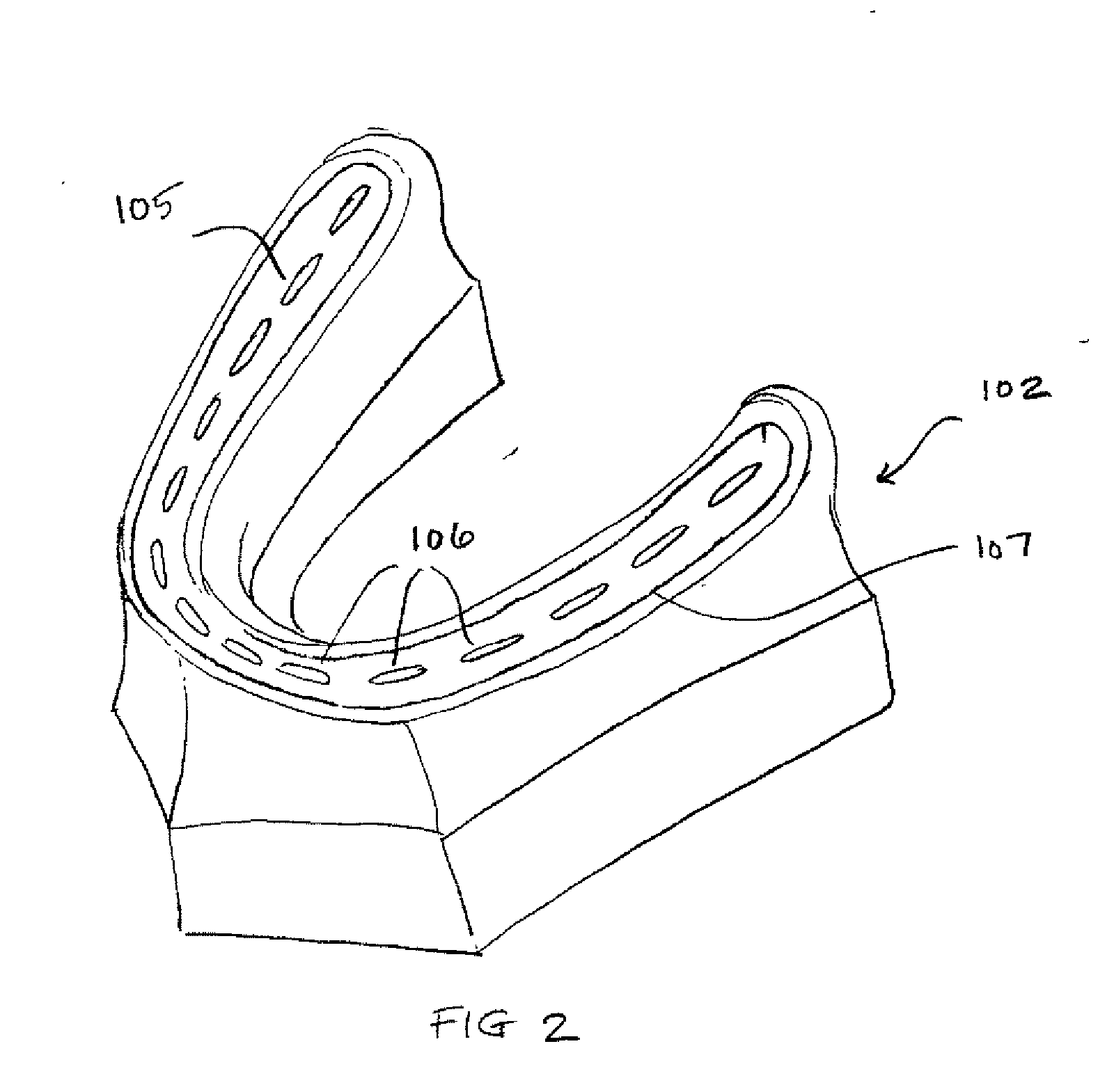

Modified tooth positioning appliances and methods and systems for their manufacture

InactiveUS7037111B2Eliminate timeFree laborImpression capsAdditive manufacturing apparatusGingival tissueRapid prototyping

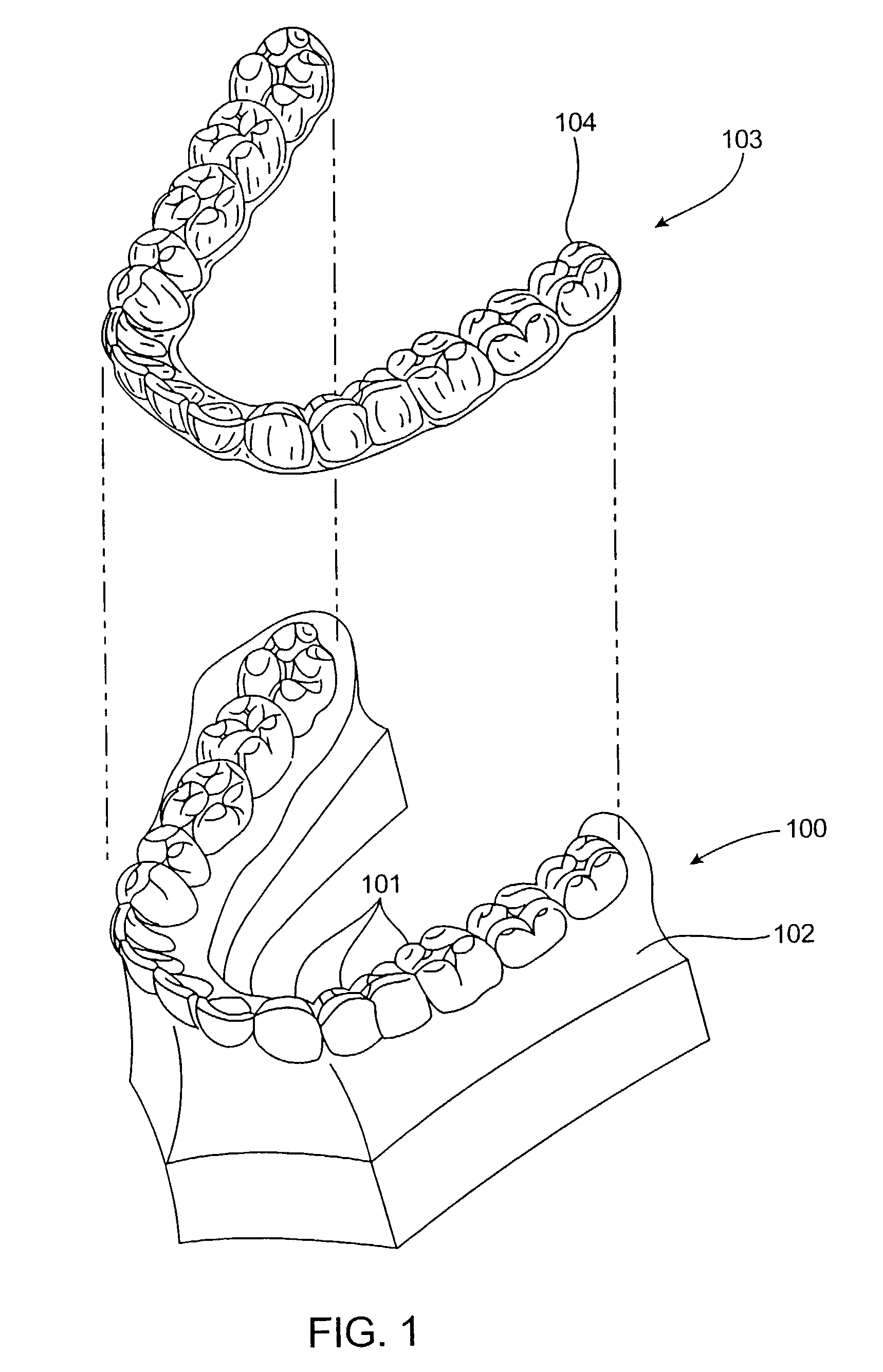

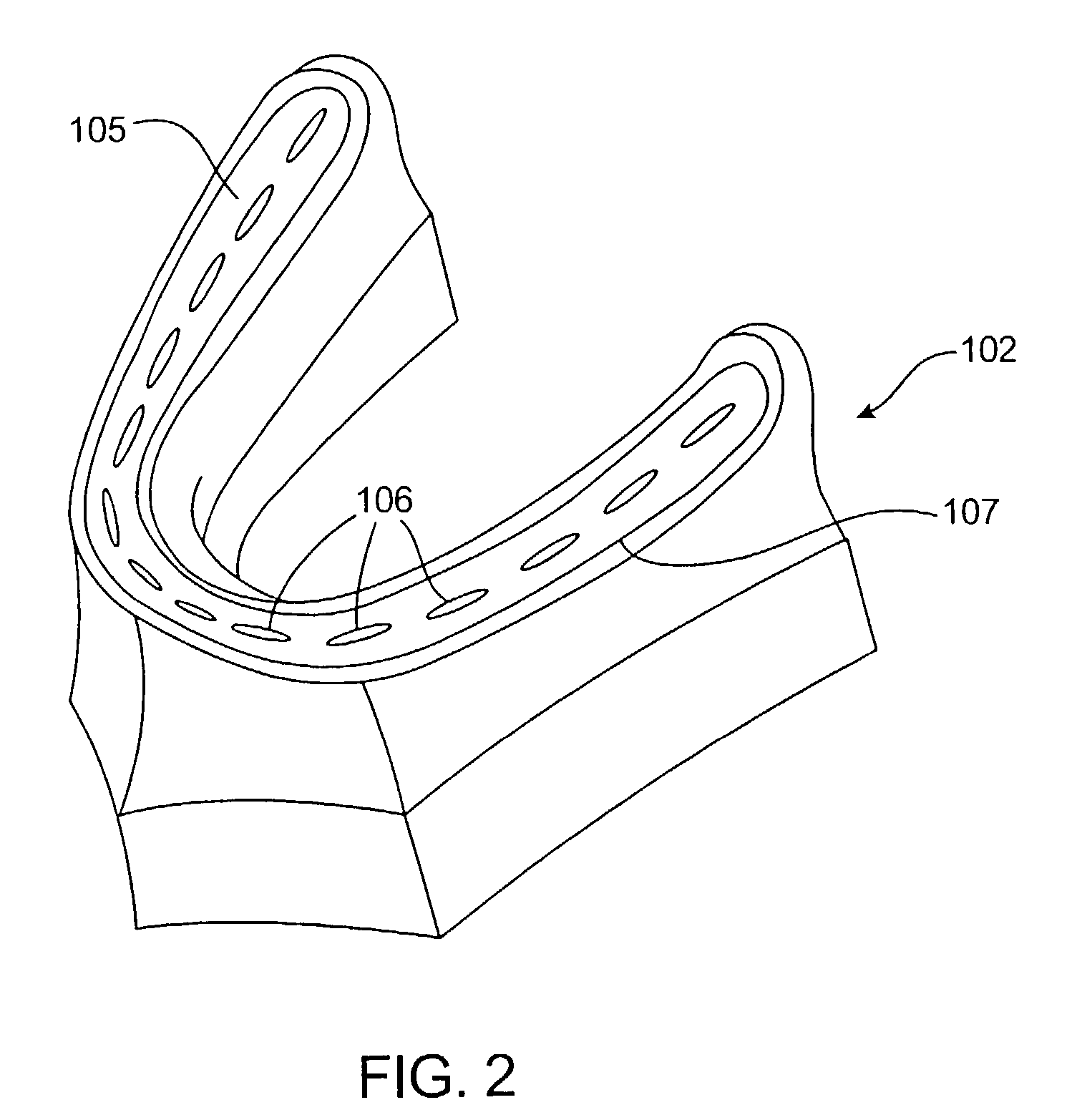

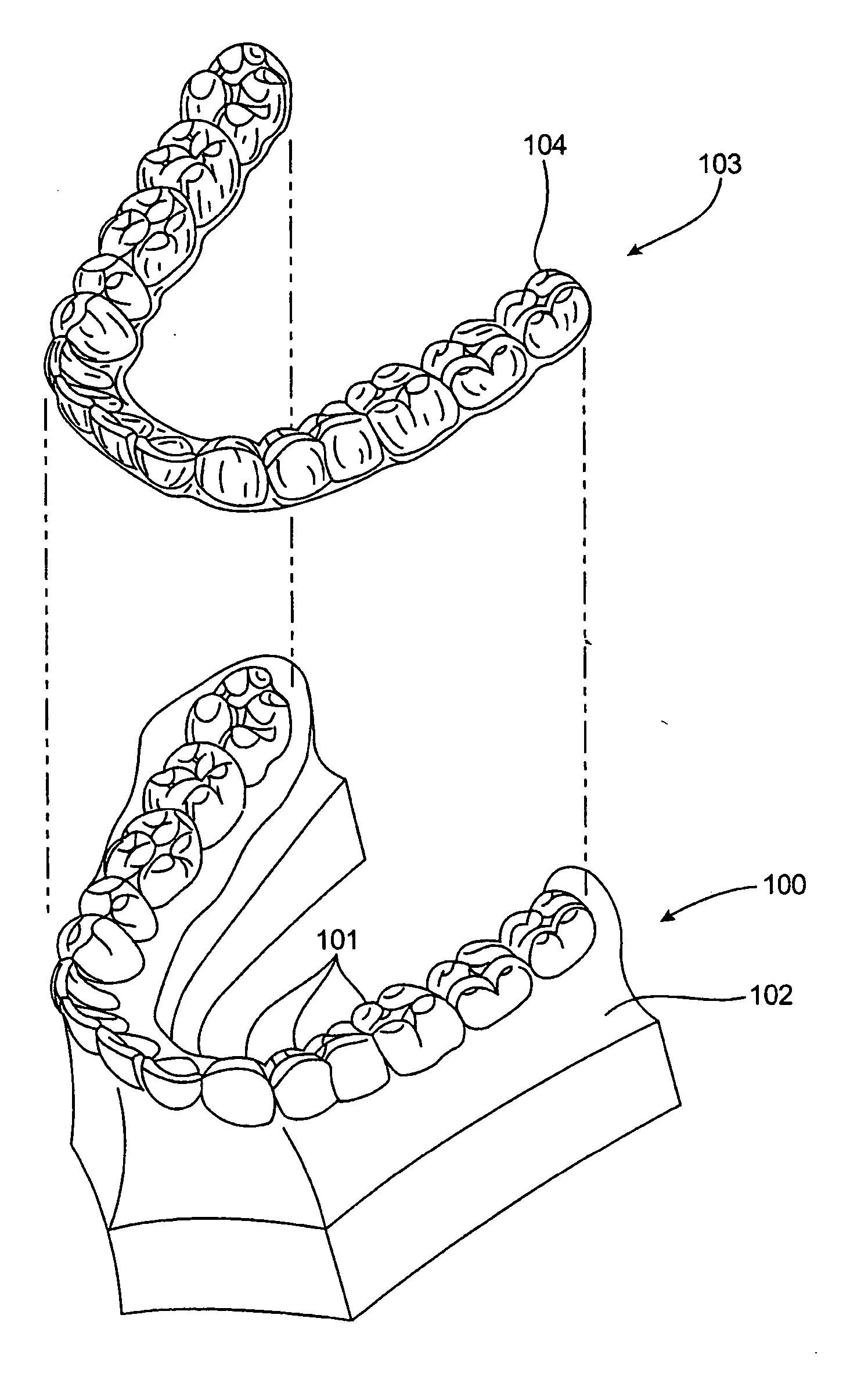

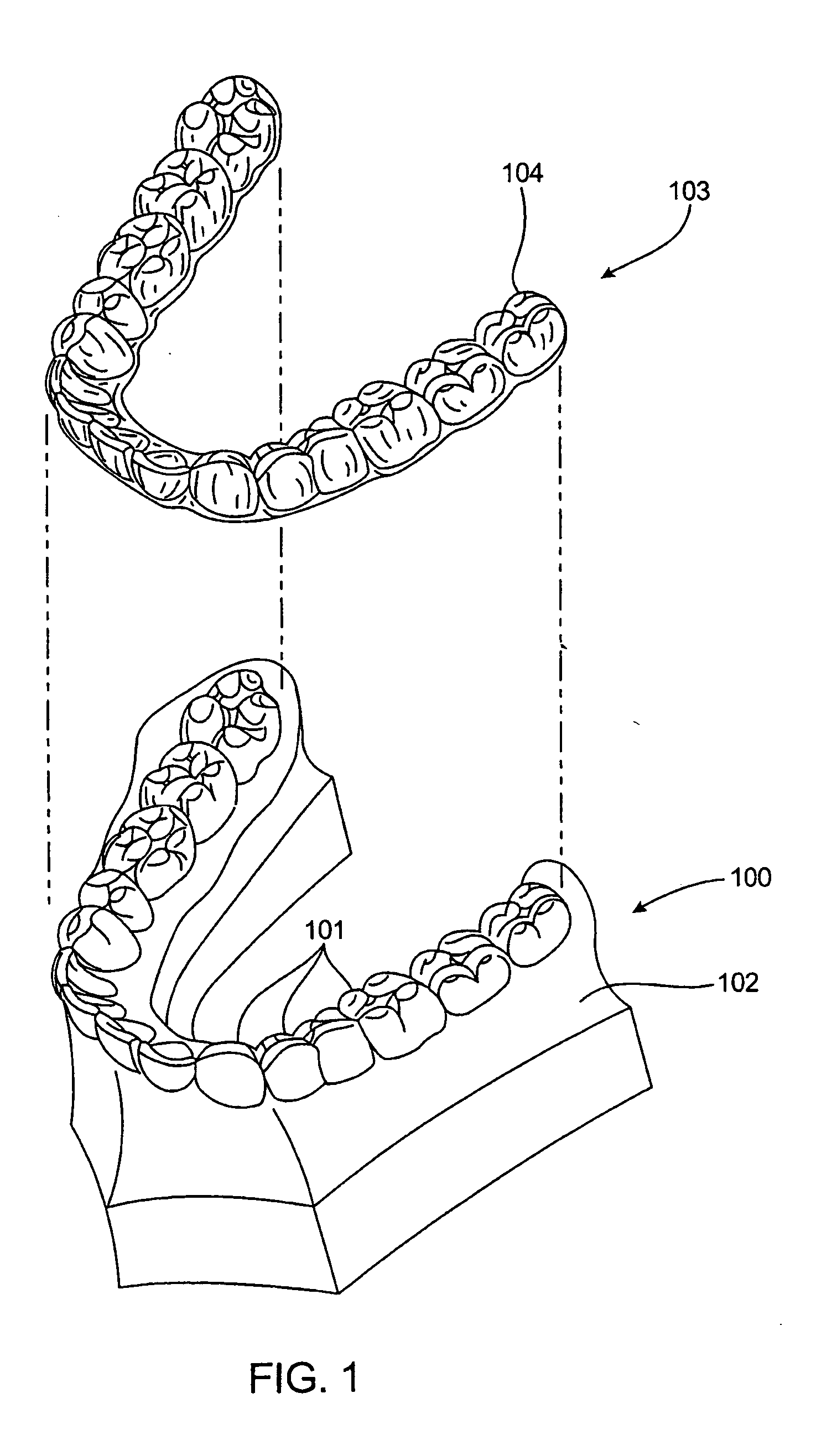

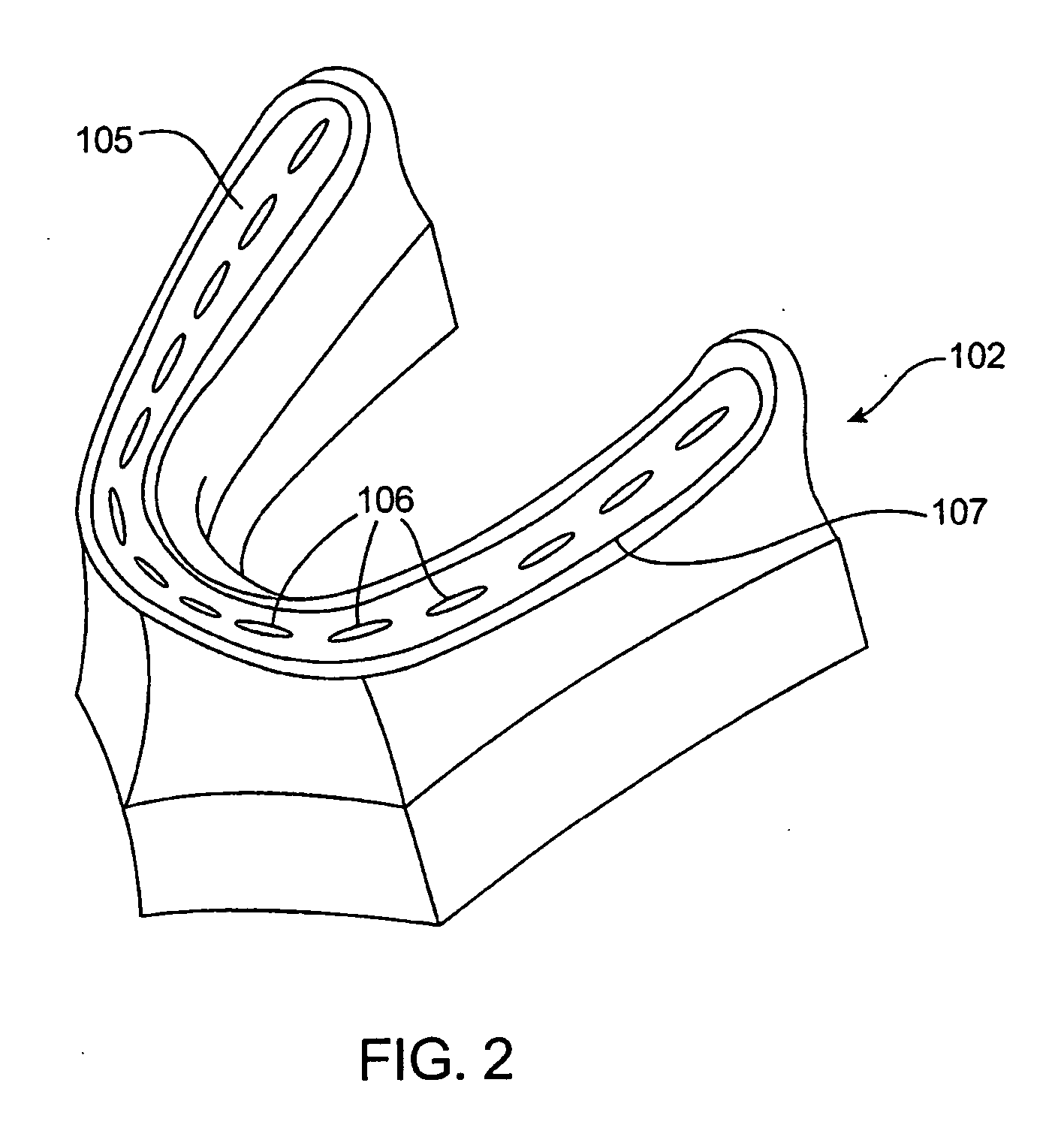

The present invention provides improved devices, systems and methods for producing dental molds, each having portions representing a patient's oral soft tissue and a desired tooth configuration. These molds are designed for use in the fabrication of appliances used in orthodontic treatment, particularly, elastic repositioning appliances. However, they may also be used in the fabrication of traditional appliances, such as retainers and positioners, used, for example in the final or finishing stages of an otherwise conventional treatment. The dental molds are comprised of a mold or relief of the patient's soft tissue, such as a palate, facial gingival tissue and / or lingual gingival tissue, and a separate or separable mold or relief of the patient's dental arch having teeth in a desired tooth configuration. Since, the tooth configuration will change as a patient progresses through orthodontic treatment, the relief of the dental arch will be fabricated separately from the relief of the oral soft tissue. Typically, the dental arch relief will be fabricated using rapid prototyping methods. The soft tissue relief may also be fabricated using rapid prototyping, however it may also be fabricated using traditional mold making methods, i.e., casting with plaster or other mold making materials. In either case, the resulting dental mold with be comprised of a “split-mold” having fixedly or removably joined arch and soft tissue reliefs.

Owner:ALIGN TECH

Method for dental restoration and related kit

The disclosure generally relates to a method for forming a dental mold. The method generally includes: (a) scanning an existing dental structure to generate a three-dimensional first digital model of the existing dental structure, (b) modifying the first digital model of the existing dental structure to generate a three-dimensional second digital model of a planned dental structure; (c) generating a three-dimensional third digital model corresponding to a negative of the second digital model; (d) digitally sectioning the third digital model into at least one buccal model portion and at least one lingual model portion of the third digital model; and (e) creating a dental mold comprising at least one buccal mold portion and at least one lingual mold portion based on the sectioned third digital model. The disclosure also relates to (a) methods of assembling the dental mold over a tooth and a gum of a patient having an existing dental structure in need of dental restoration, (b) methods of performing a dental restoration on the existing dental structure of the patient using the dental mold, and (c) kits including components for forming the dental mold and / or for performing the dental restoration using the dental mold.

Owner:VUILLEMOT WILLIAM C

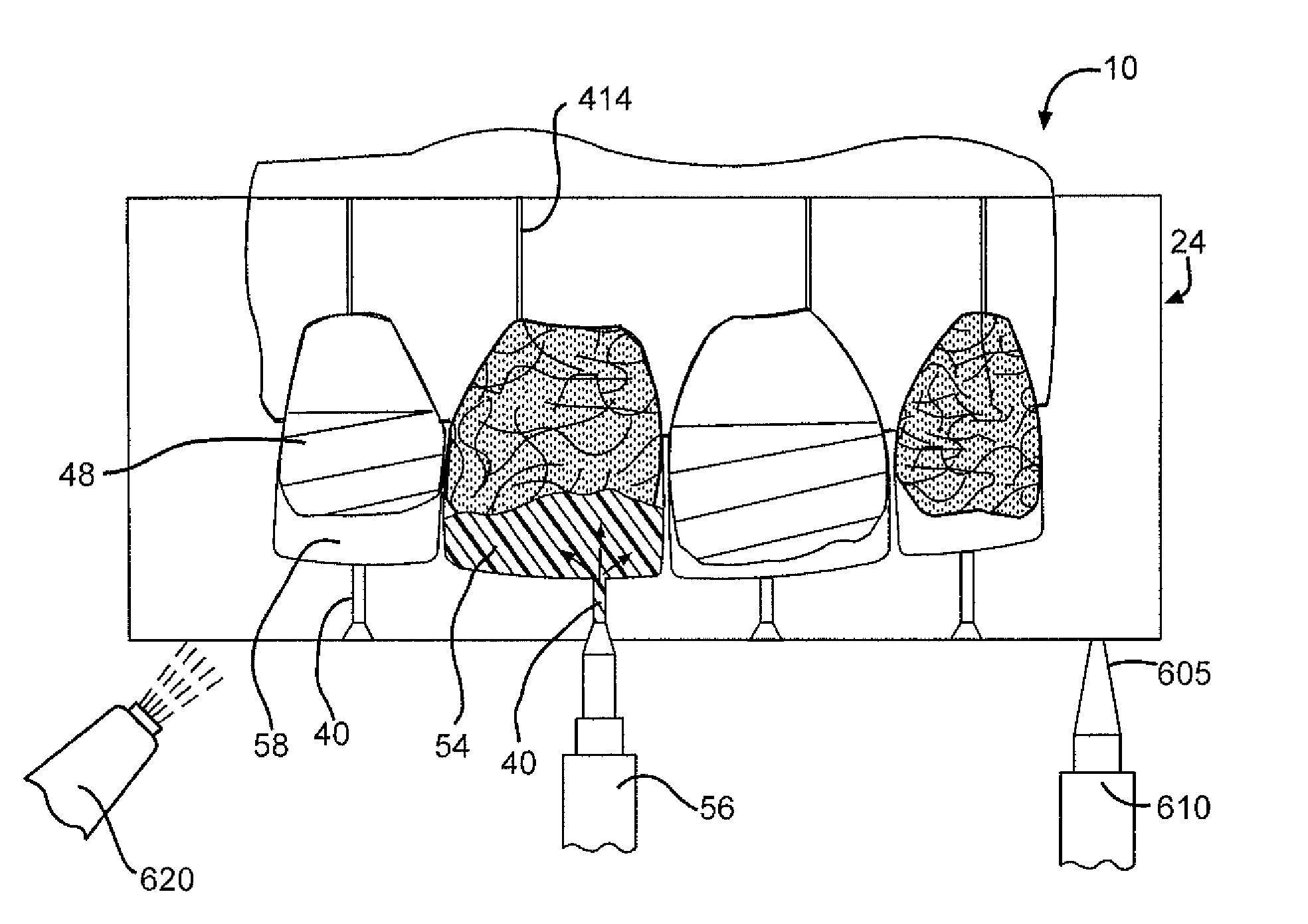

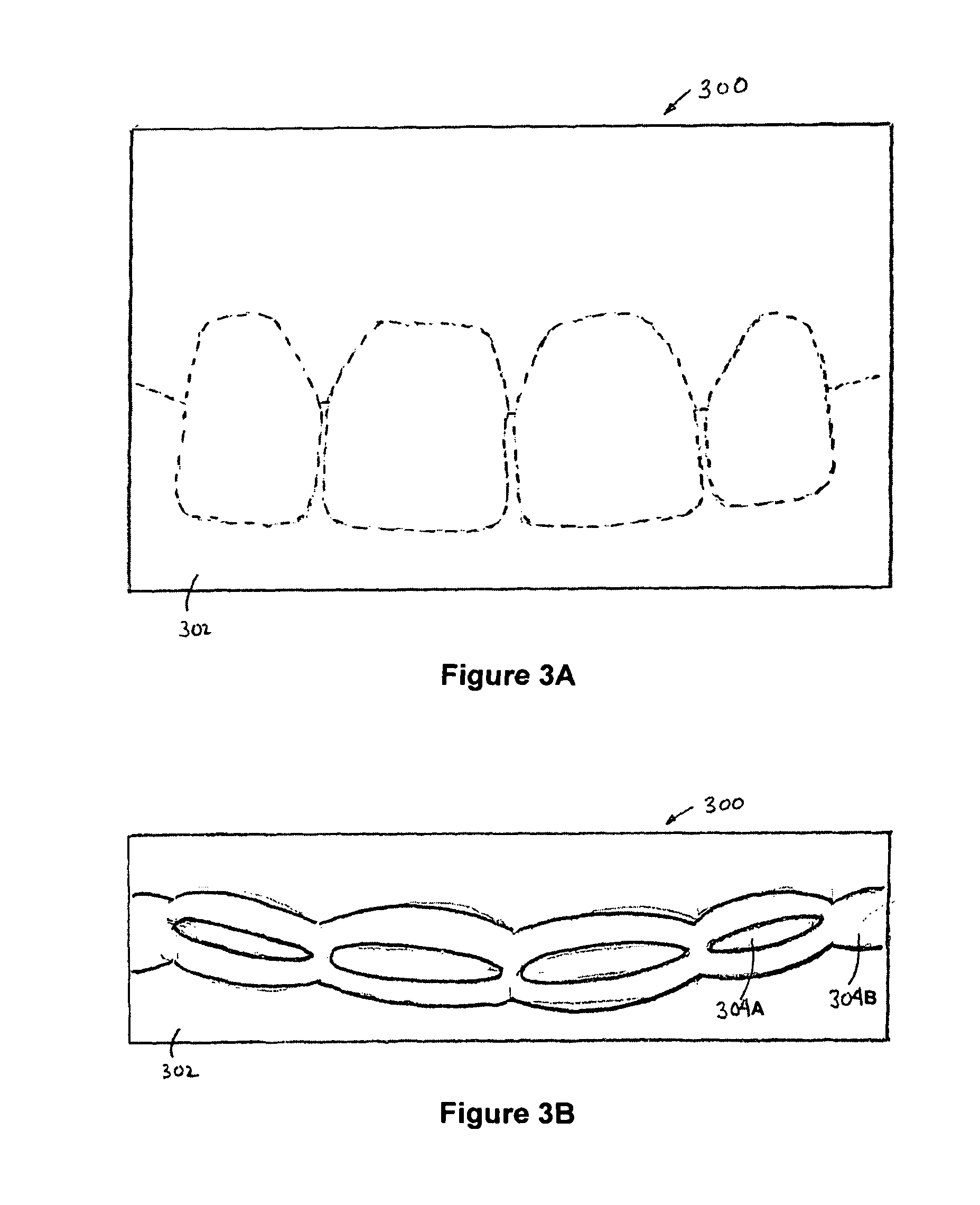

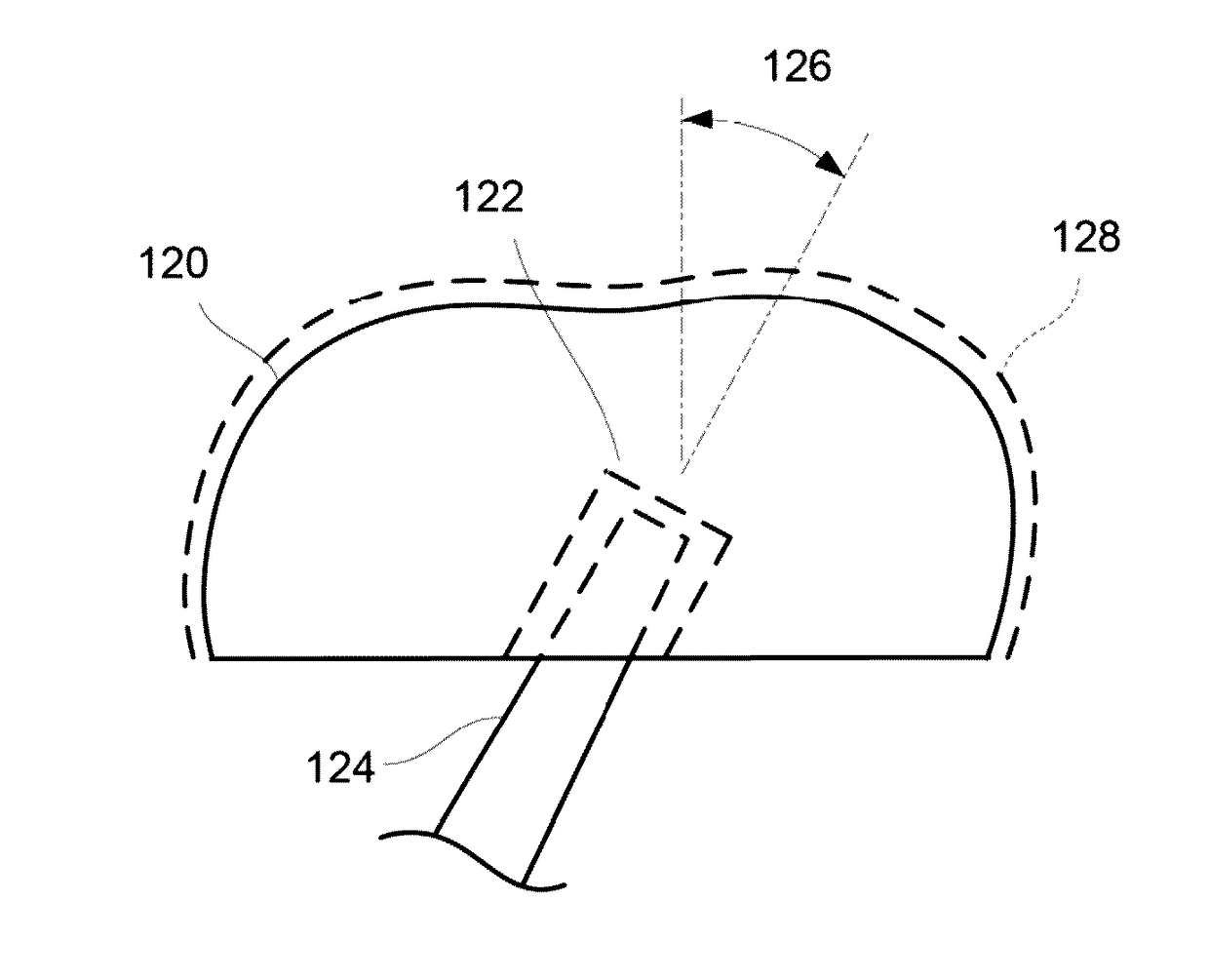

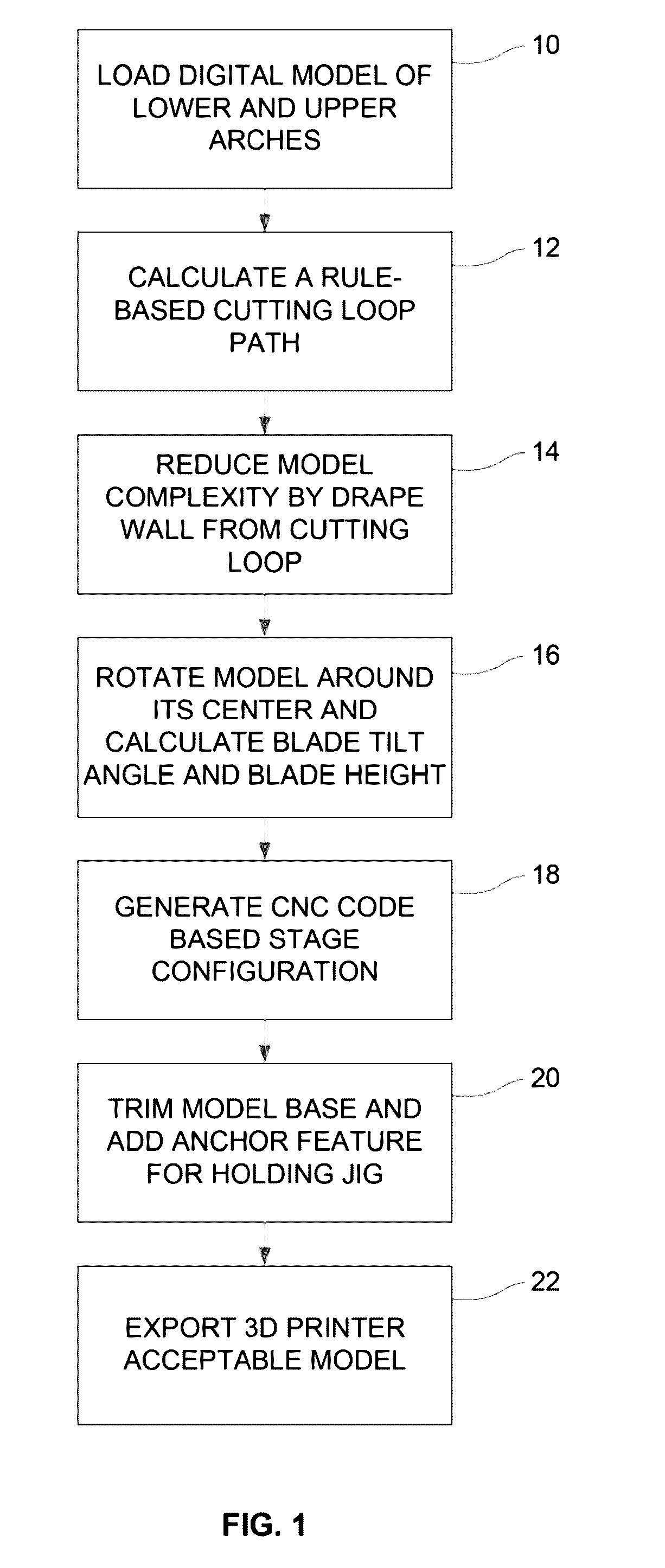

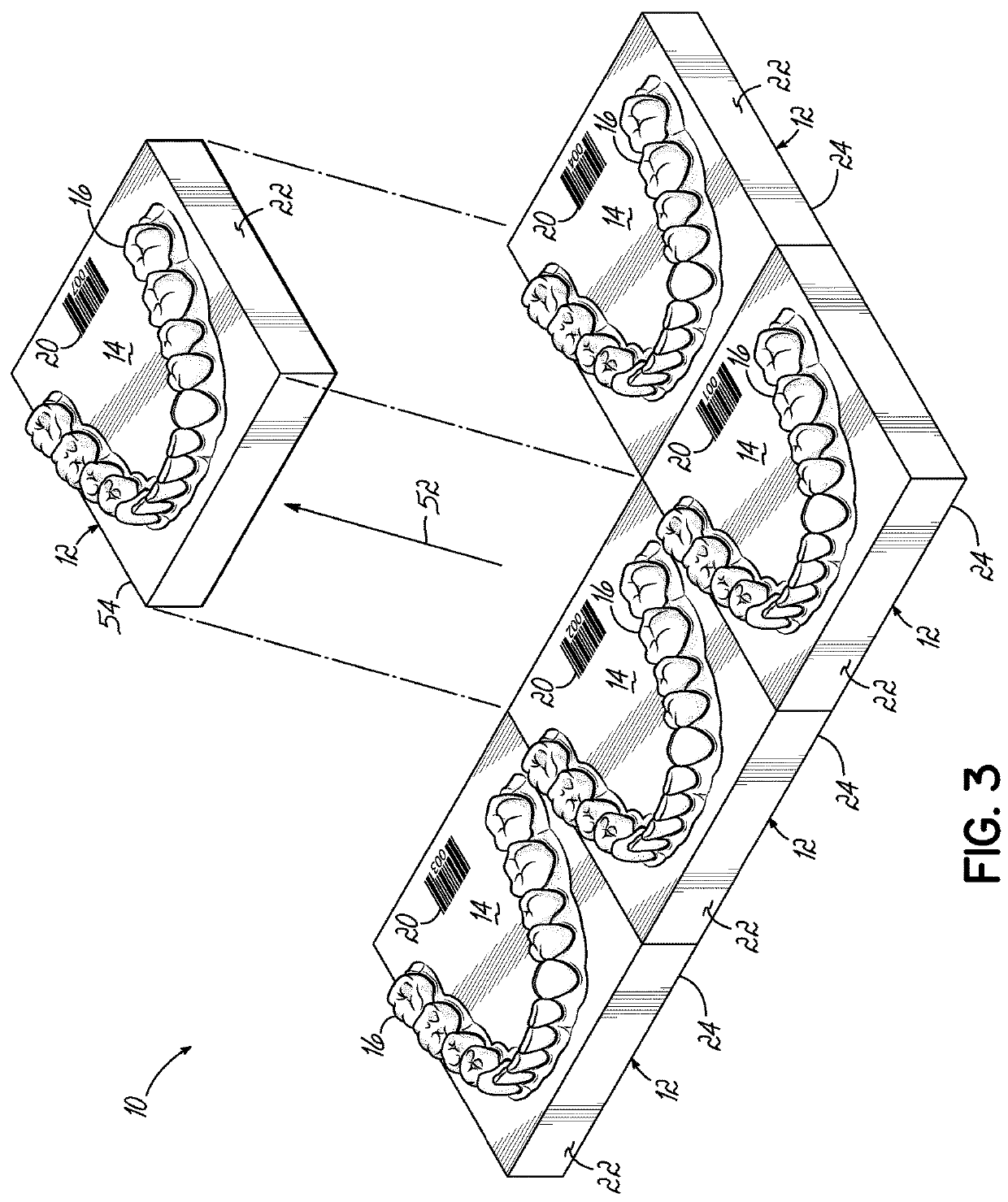

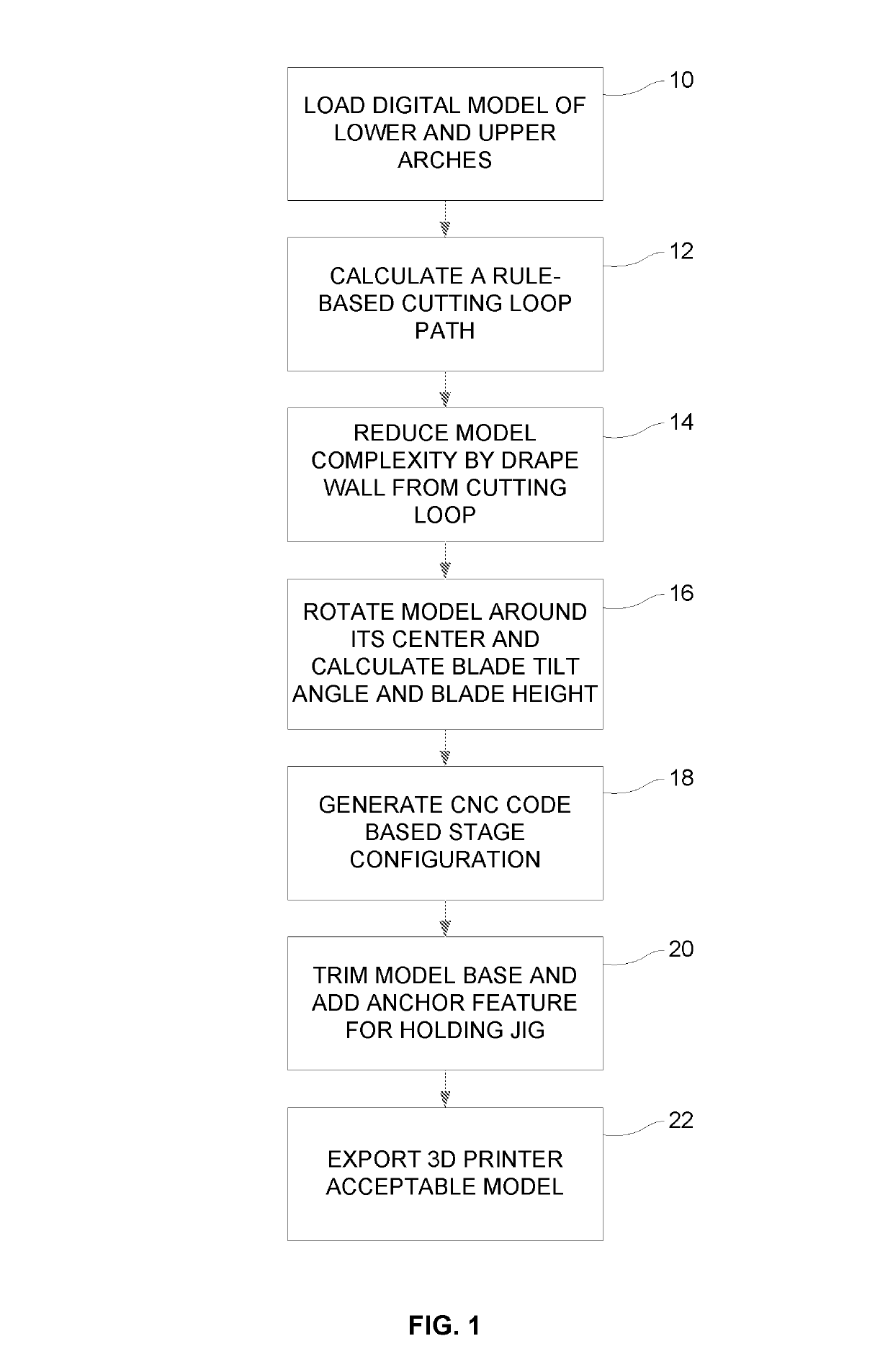

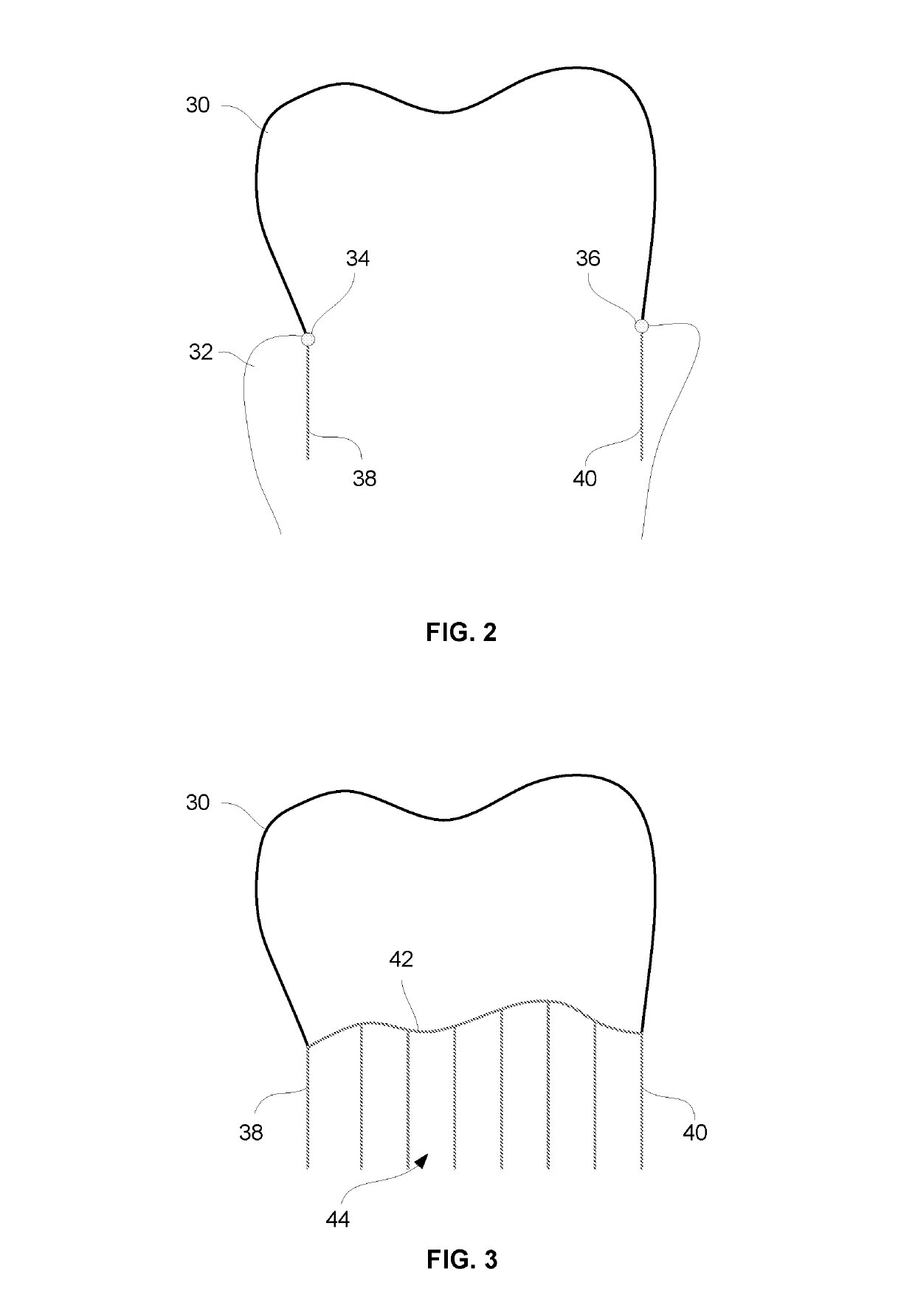

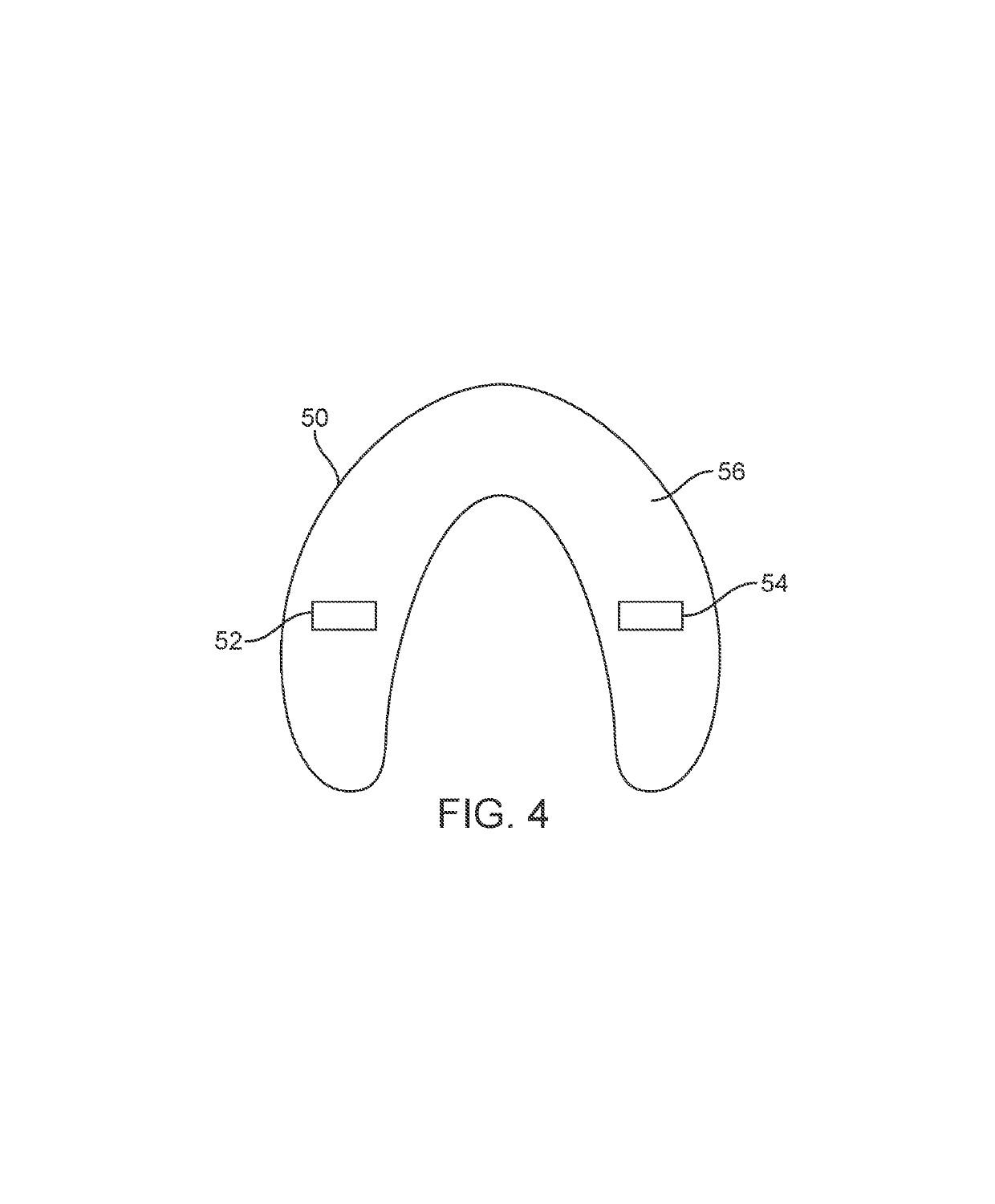

Systems and methods for fabricating dental appliances or shells

Systems and methods are disclosed for cutting and trimming dental molds and oral appliances by receiving a digital model of teeth, determining a cutting loop path and applying a drape wall to the cutting loop to generate a simplified tooth base in a dental mold having an inner arch curve and an outer arch curve. The oral appliance may be formed on the dental mold and a cutter may be applied using a sweeping motion across the inner and outer arch curves.

Owner:ULAB SYST INC

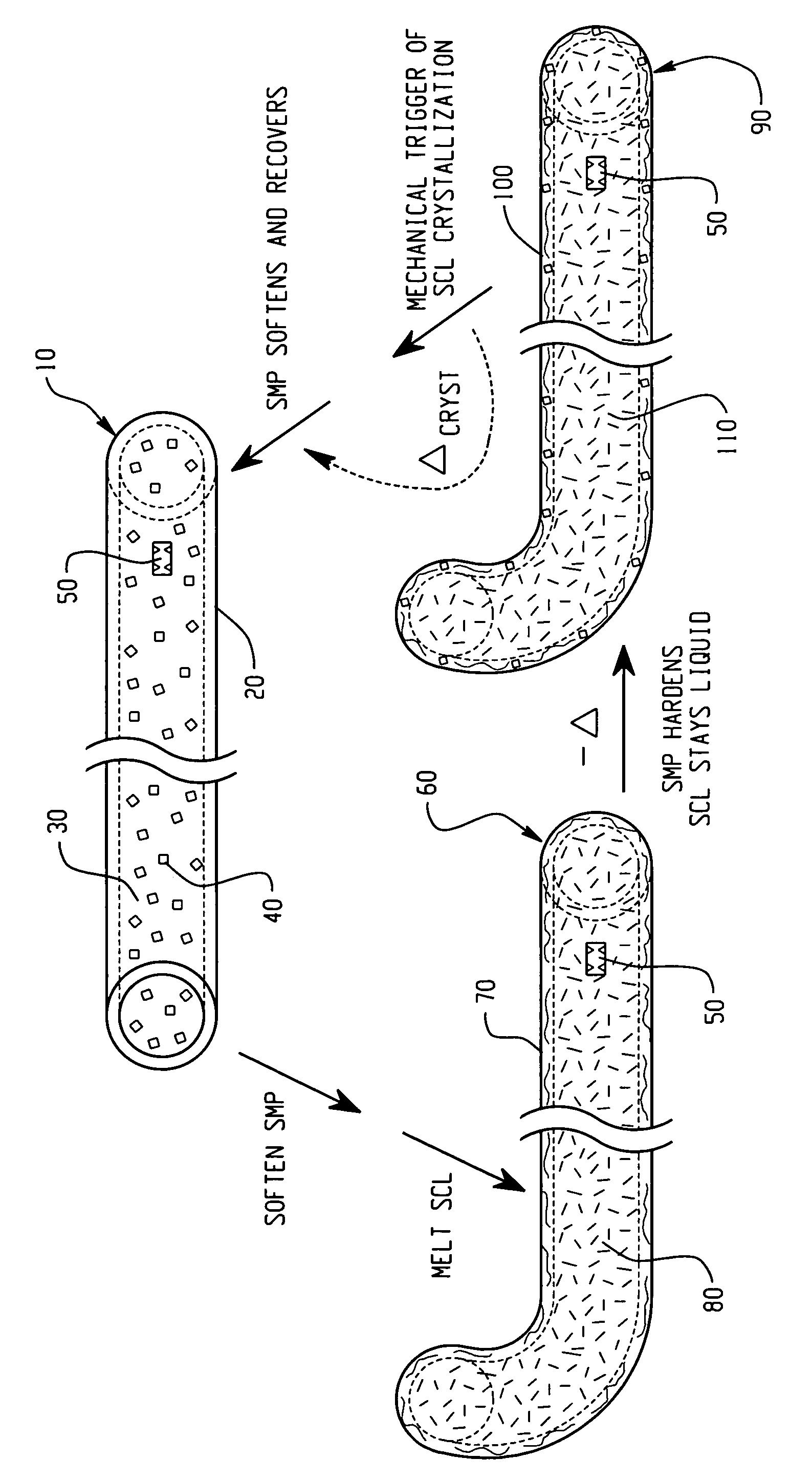

Mechanically activated shape memory device

Owner:UNIV OF CONNECTICUT

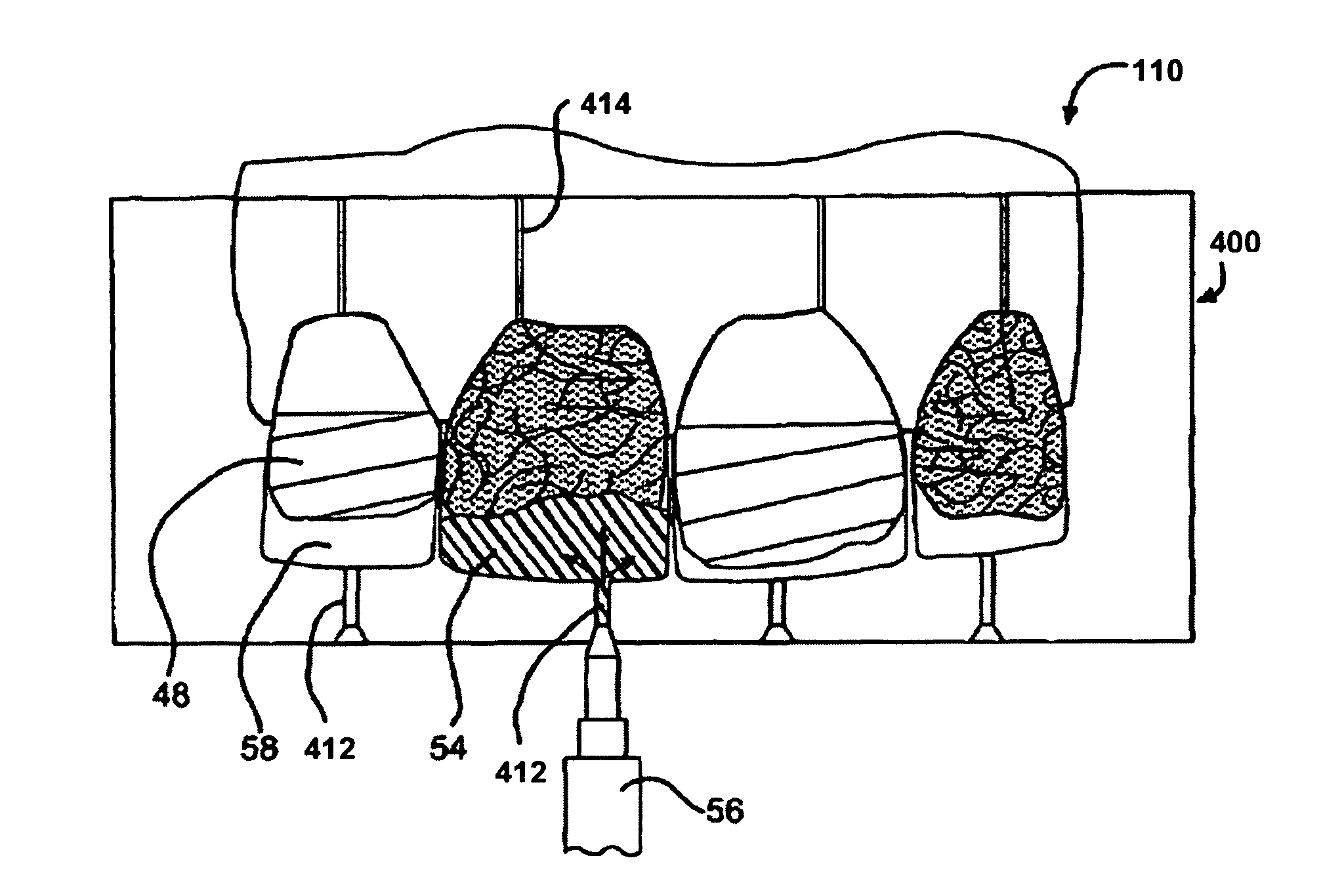

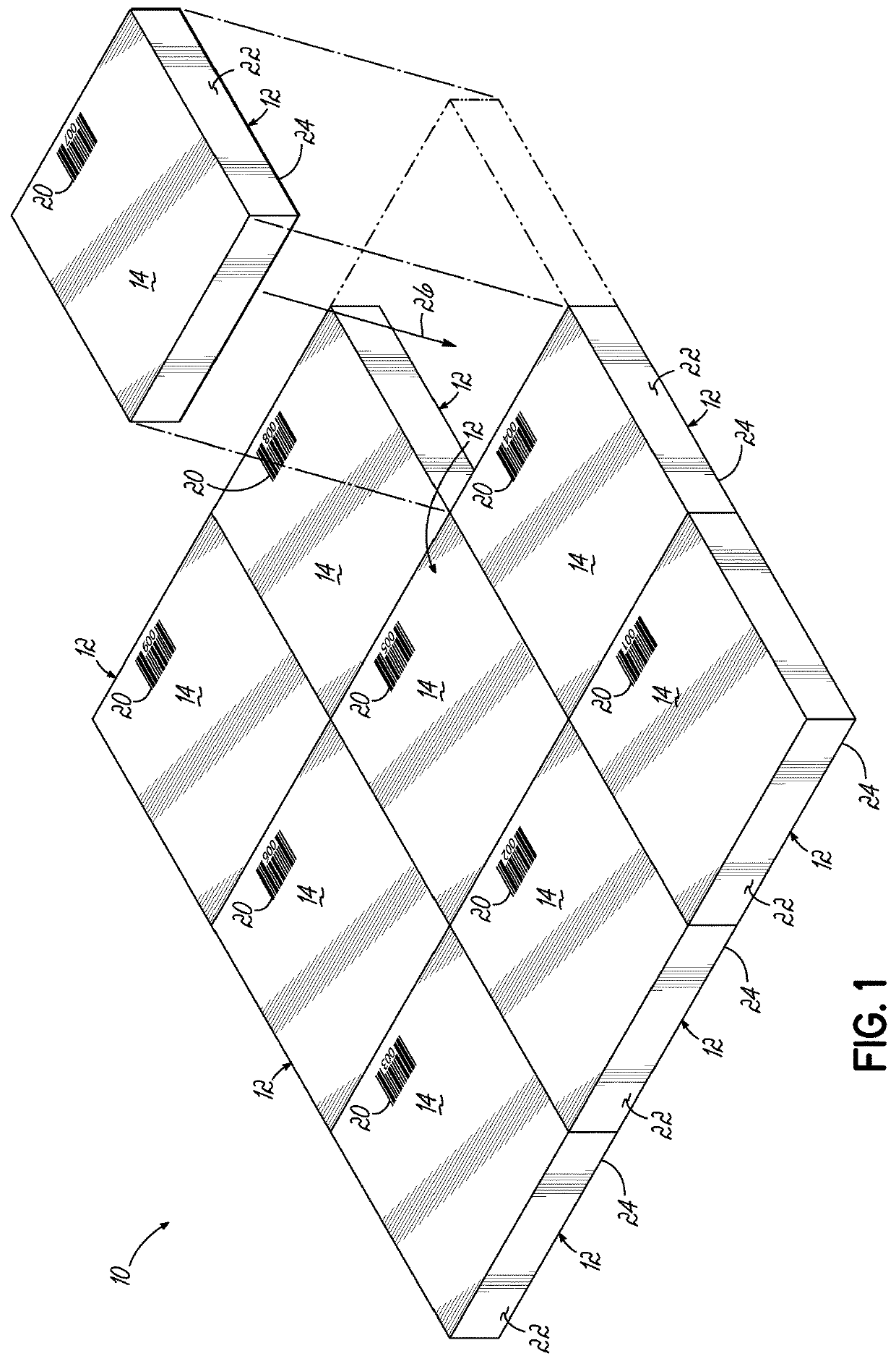

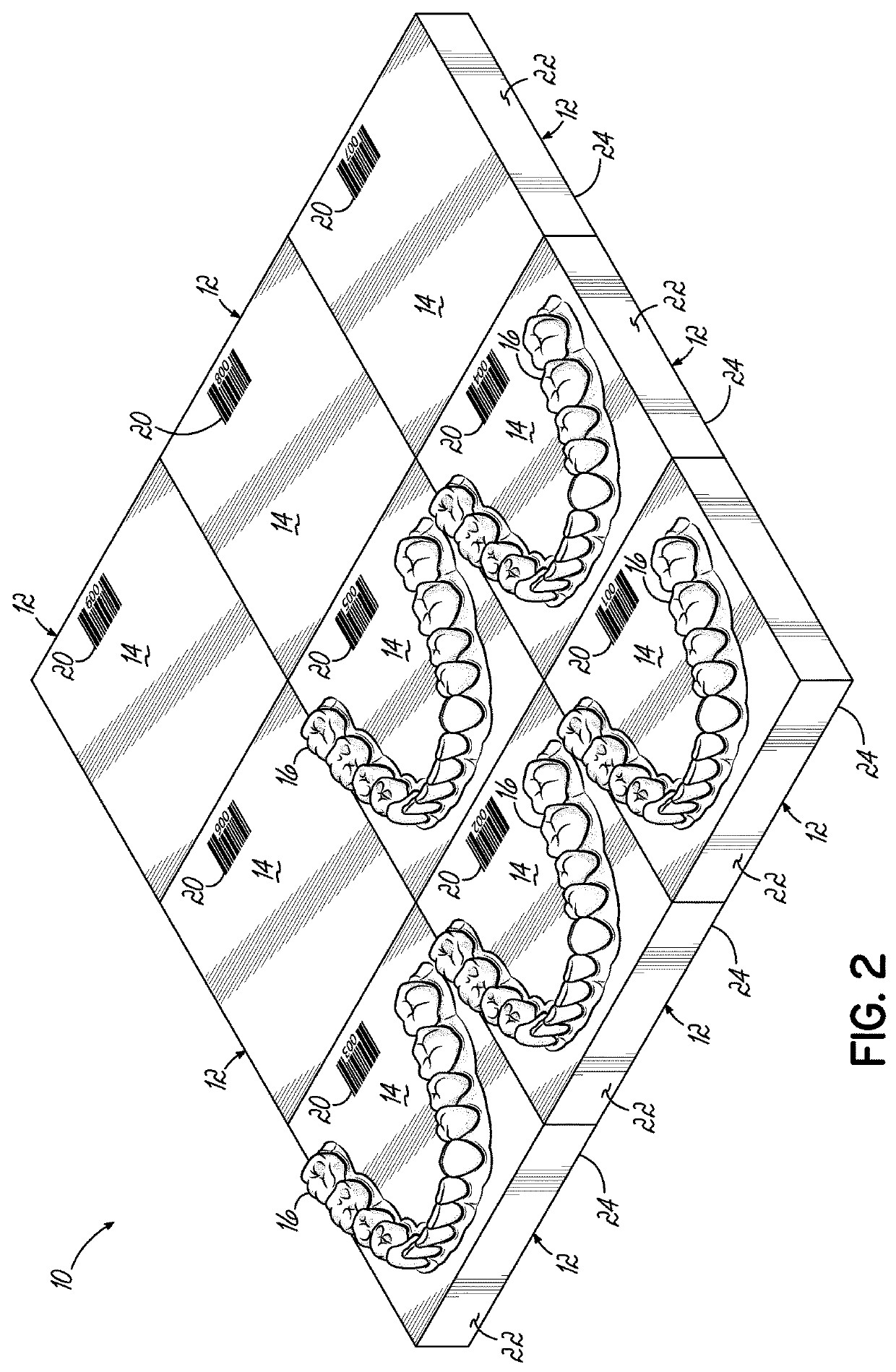

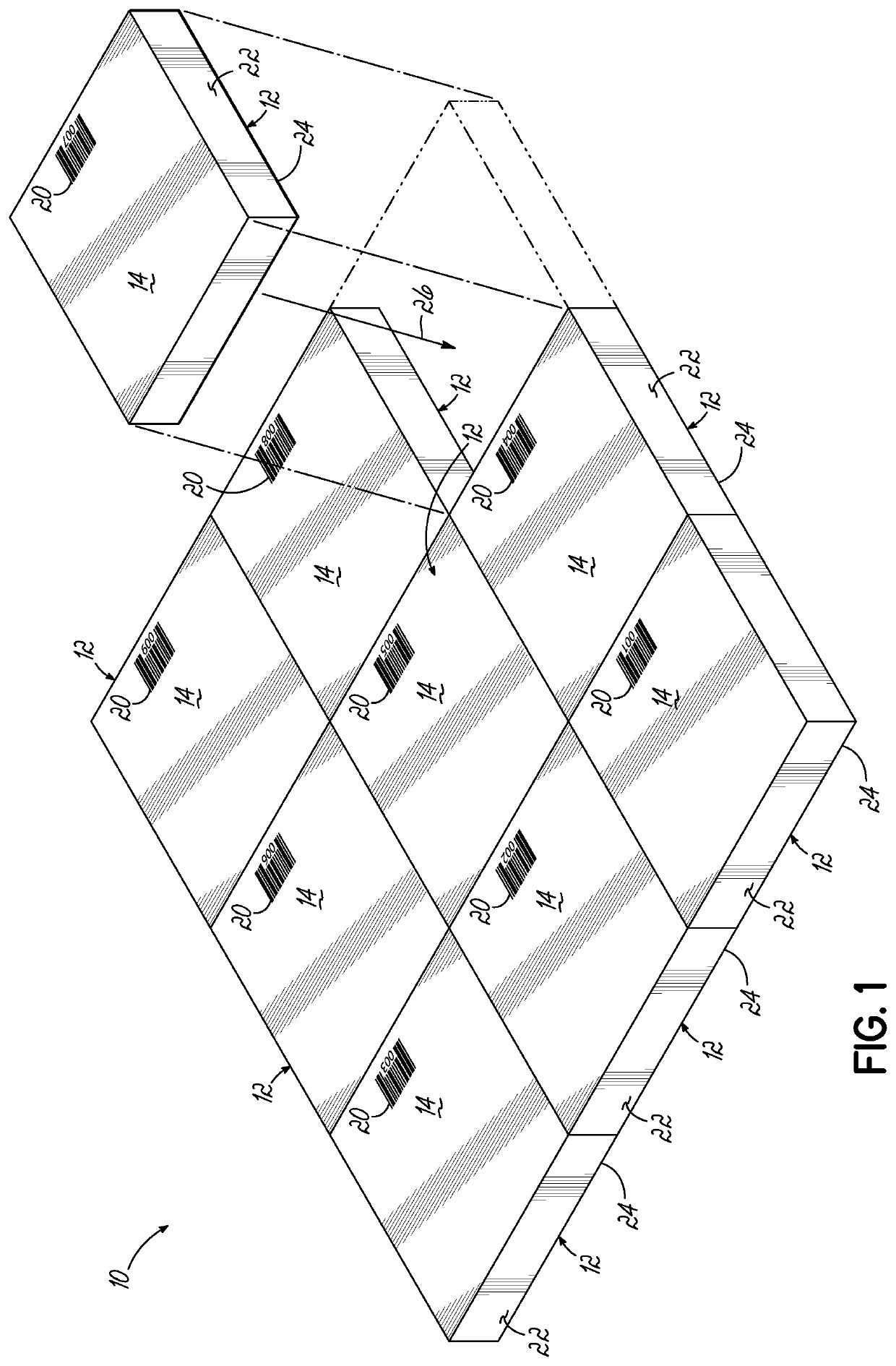

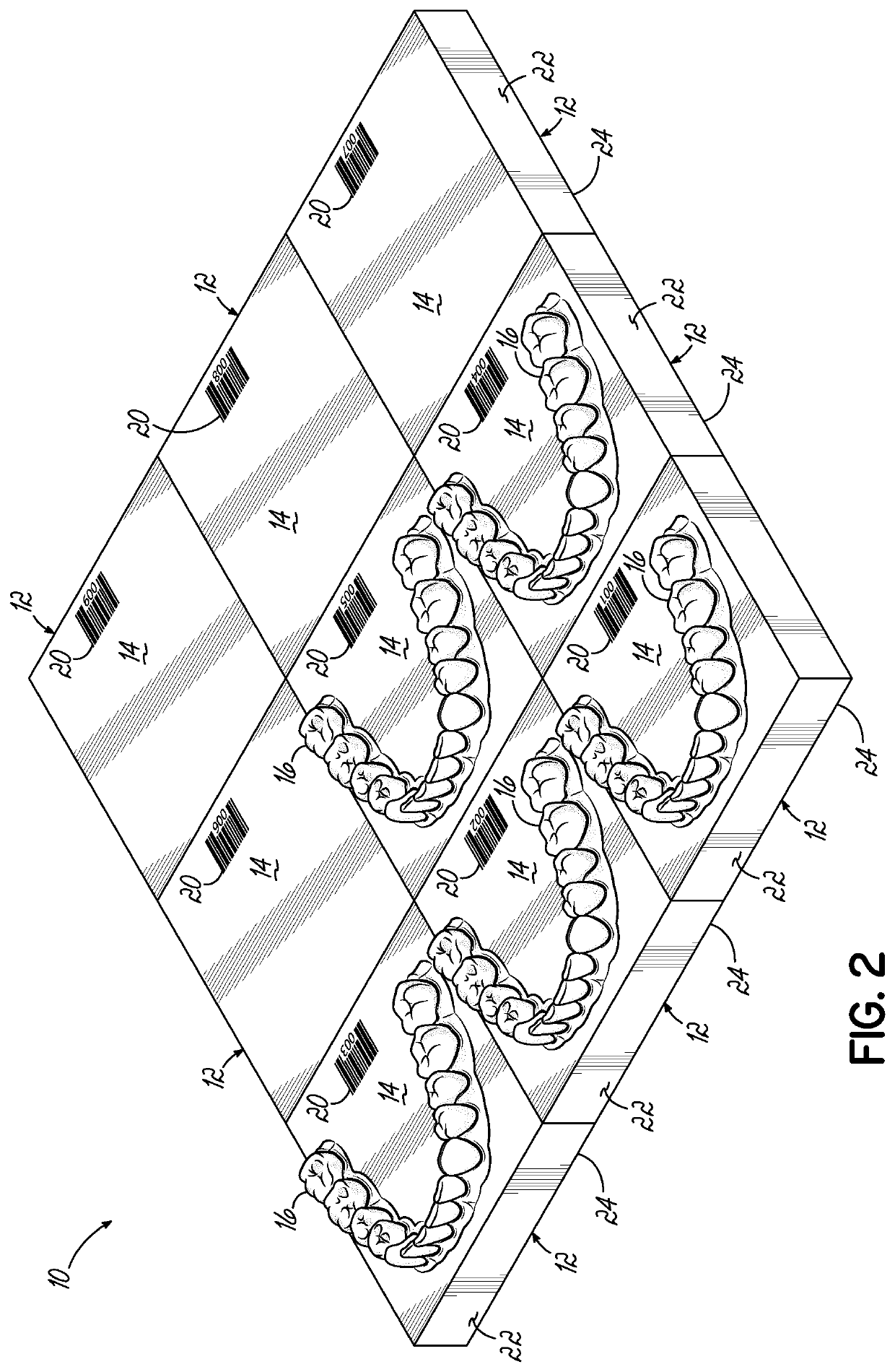

Systems and methods of identifying and tracking dental molds in automated aligner fabrication systems

An aligner fabrication system combines design data and material to form a plurality of dental molds with which a plurality of aligners are formed. The aligner fabrication system includes a build assembly that defines a build surface on which the dental molds are formed. The build assembly is constructed of a plurality of individual build platforms that are removably coupled together. Each individual build platform is associated with an identification entity. The dental molds are formed on the build surface. One dental mold is formed on one individual build platform. The design data associated with the one dental mold is linkable to the identification entity on the one individual build platform.

Owner:ORMCO CORP

Systems and methods for fabricating dental appliances or shells

Systems and methods are disclosed for cutting and trimming dental molds and oral appliances by receiving a digital model of teeth, determining a cutting loop path and applying a drape wall to the cutting loop to generate a simplified tooth base in a dental mold having an inner arch curve and an outer arch curve. The oral appliance may be formed on the dental mold and a cutter may be applied using a sweeping motion across the inner and outer arch curves.

Owner:ULAB SYST INC

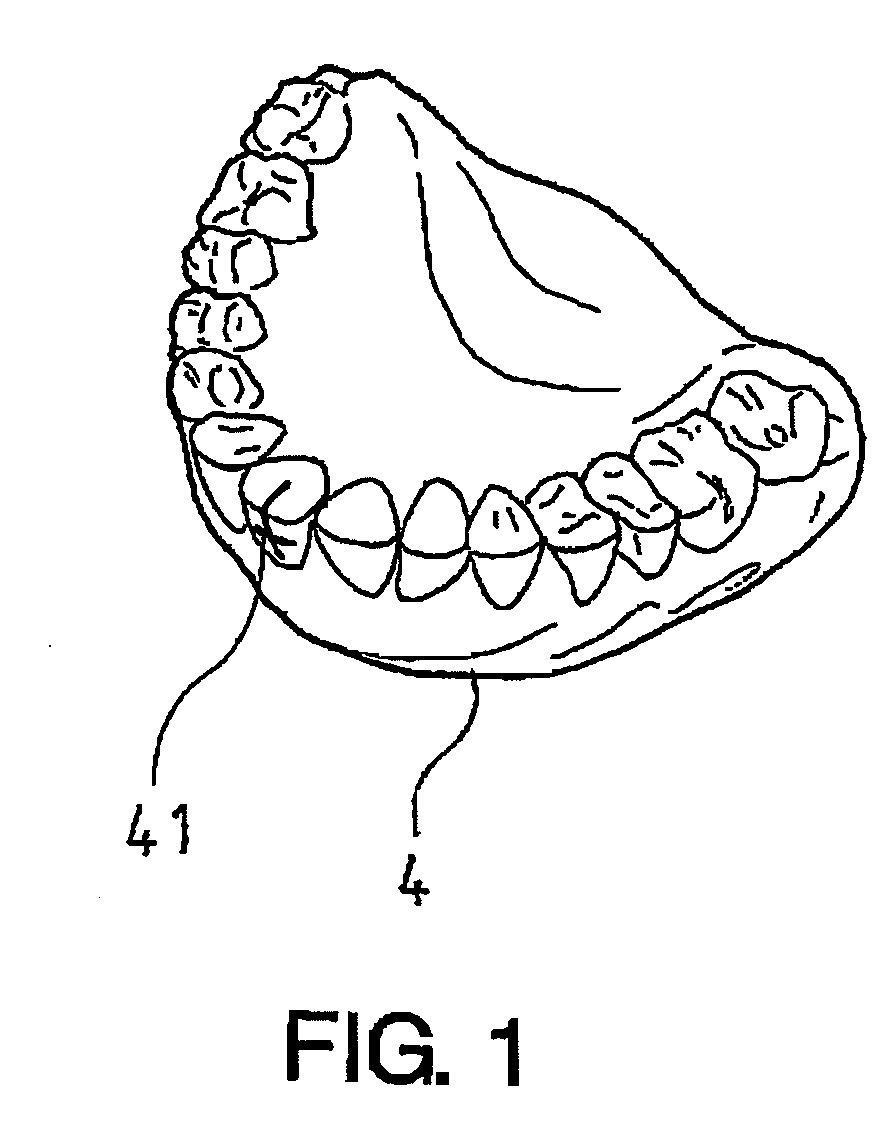

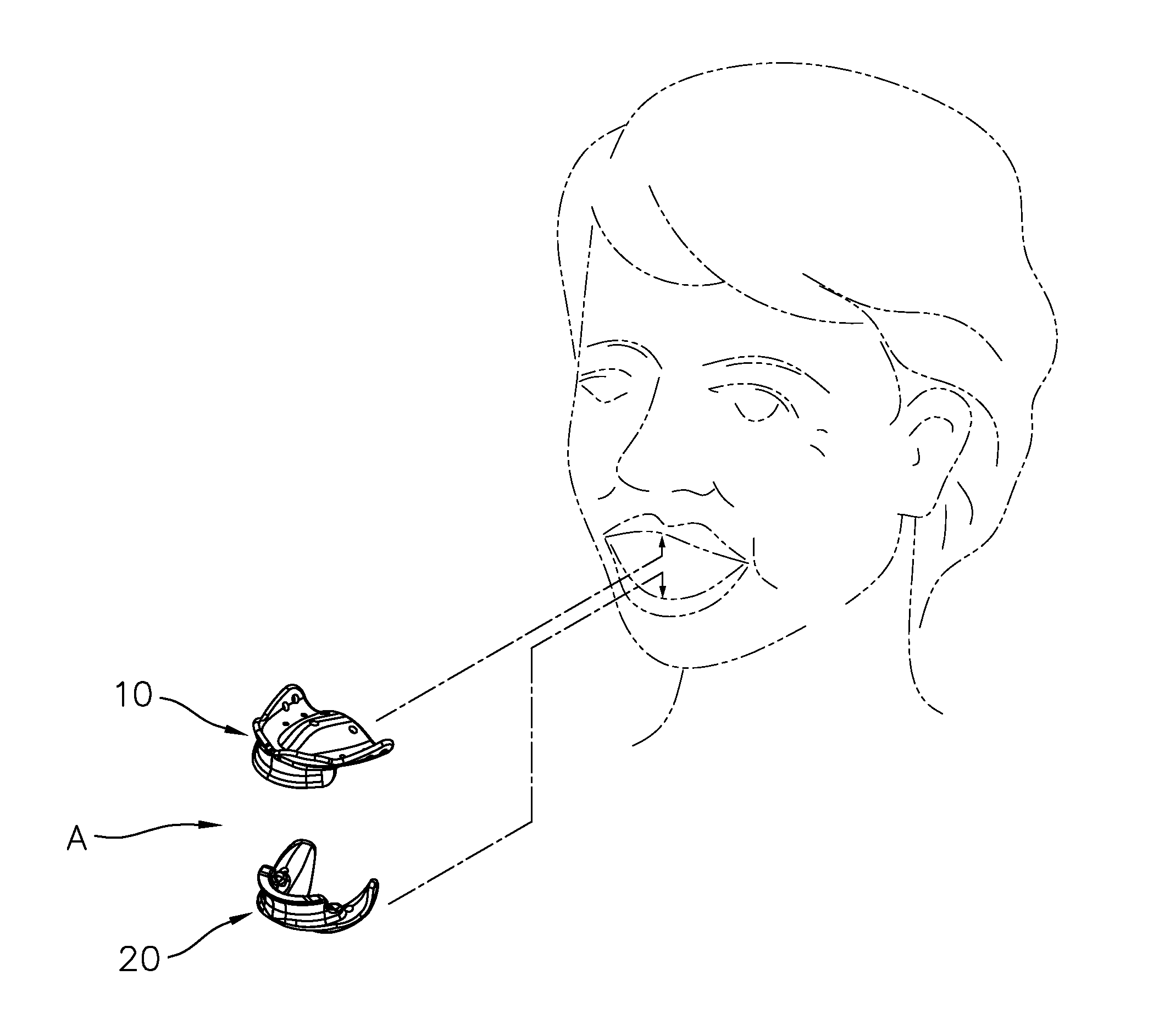

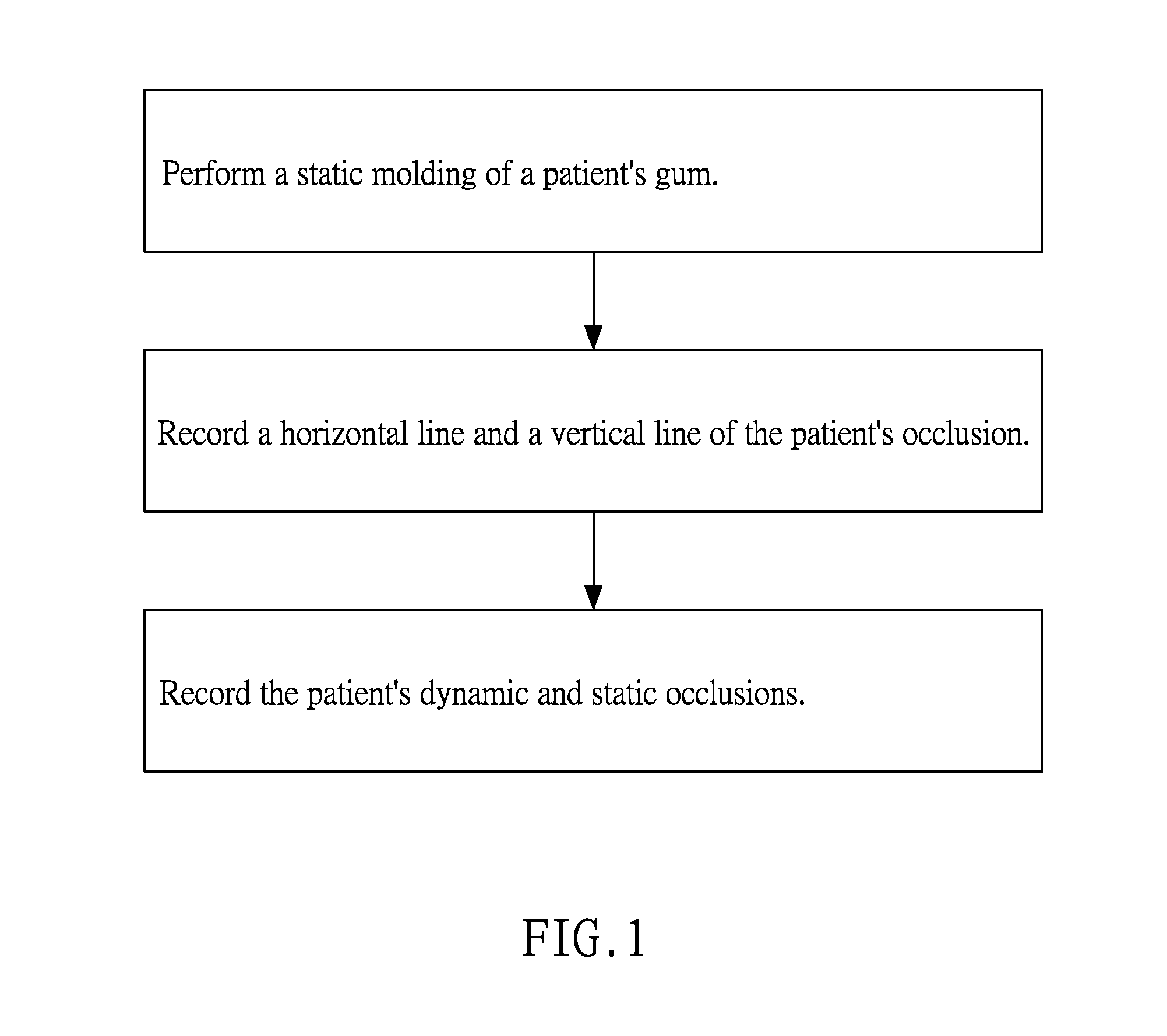

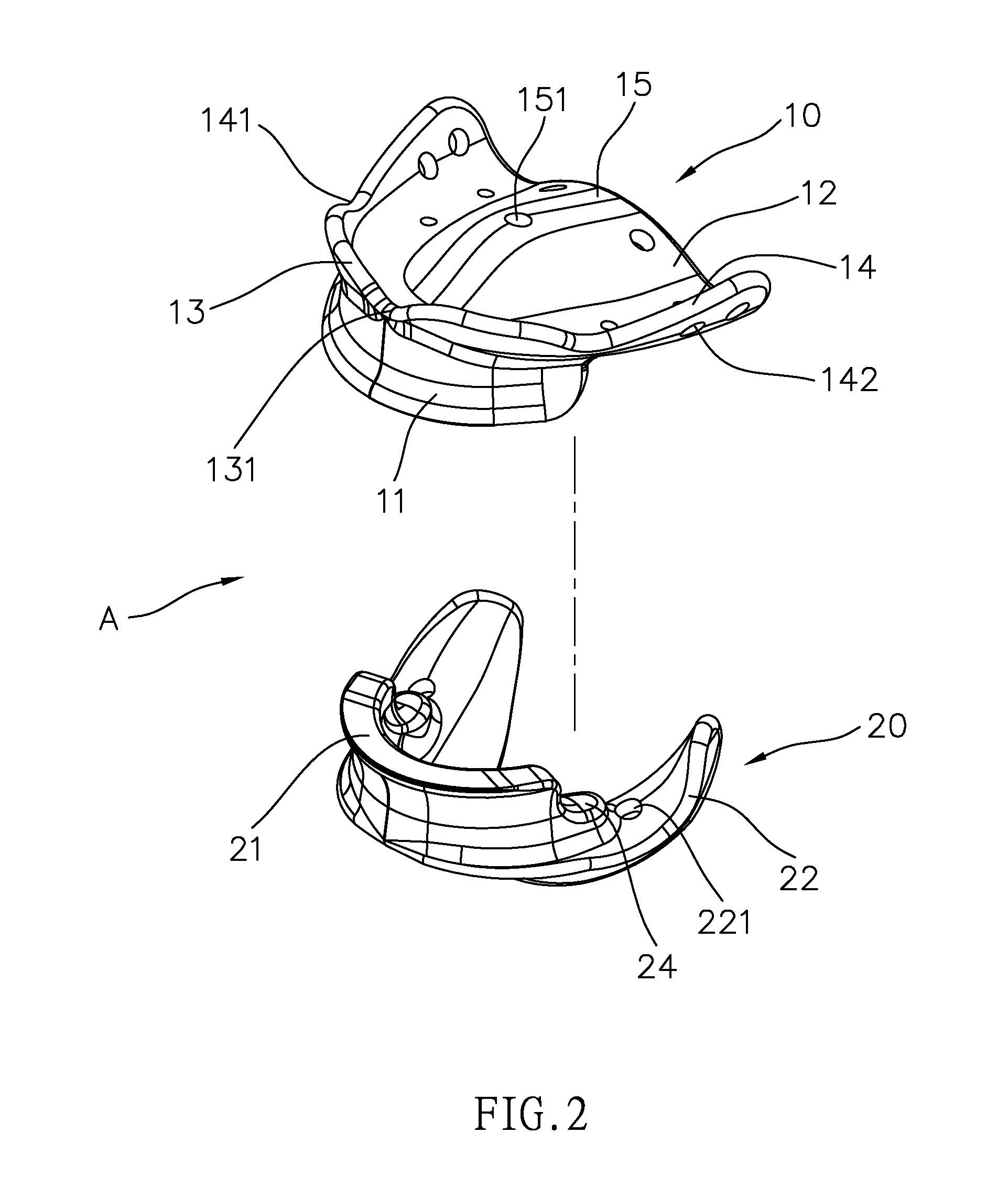

Method and apparatus of full mouth reconstruction

A full mouth reconstruction method and apparatus includes a denture molding structure mounted onto a patient's maxilla and mandible after being filled with an impression material, so that a static molding of the patient's gum can be performed based on the patient's occlusion. Important reference data including the vertical height of occlusion, facial midline, horizontal occlusion line, connecting line between two pupils and nose-ear horizontal line are recorded for facial and oral reconstructions while the patient is biting a first recording device, and the facial movements of the patient's chewing and speaking are recorded quickly while the patient is biting a second recording device. Records of a metal calibration are applied to obtain data of a patient's front-and-rear, left-and-right, and up-and-down maxillary and mandibular movements through facial movements of a patient's chewing and speaking, and these data are provided to a dental mold technician for producing the denture.

Owner:CHIOU WEN HSIN +1

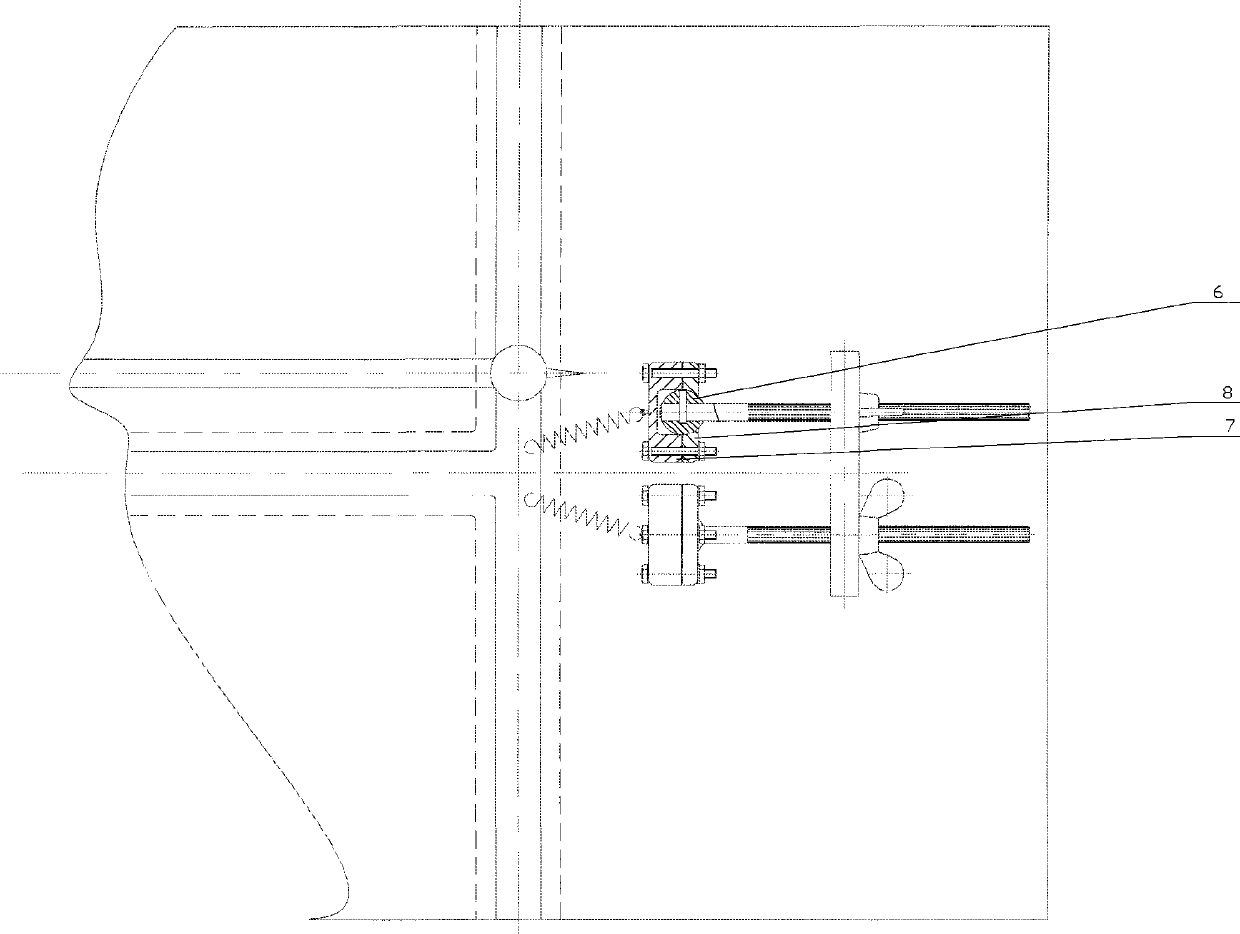

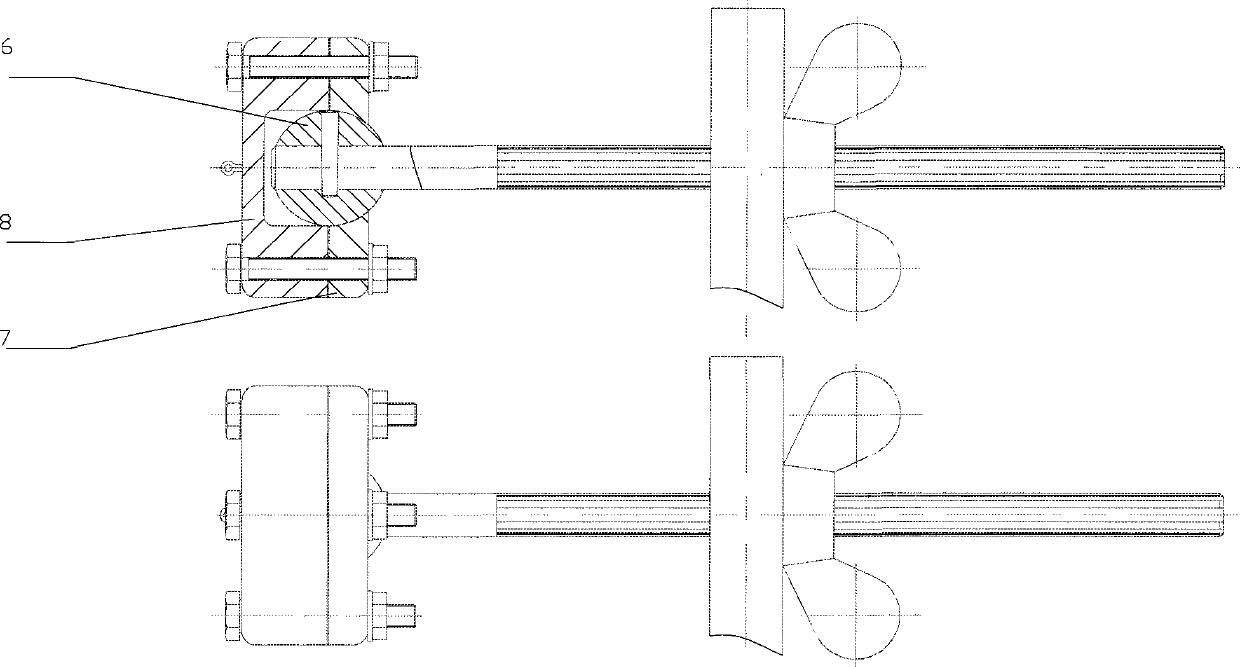

Device and method for measuring orthodontic force of oral cavity in vitro

InactiveCN101411647AReal-time measurementSmall structure sizeDentistryMuscle exercising devicesIn vivoDental mold

The invention provides a device and a method based on combination of in vivo impression taking and in vitro impression measurement, and belongs to the technical field of force measurement, in particular to measurement of the orthodontic force of an oral cavity. The device for in vitro measurement of the orthodontic force of the oral cavity comprises a model clamping and positioning device, a marking and positioning device, a force measuring device and a coordinate measuring device. The measuring system has the characteristics of simple structure, convenient operation, and capability of conveniently obtaining the orthodontic force at any moment during the orthodontic process, predicting movement of teeth and providing guidance for orthodontic clinics.

Owner:SOUTHEAST UNIV

Dental articulator

A dental modeling system for forming a dental model from a mold of at least a portion of a person's opposed upper and lower teeth. The modeling system includes dental articulator features that are integrated with opposing bases and dental model bases configured to receive removable tapered pins. The system also includes pin locators for improved alignment of teeth of the dental mold when creating the dental model. The pin locator can also include removable tapered pins for use in aligning with specific teeth of the dental mold.

Owner:HUFFMAN RONALD E

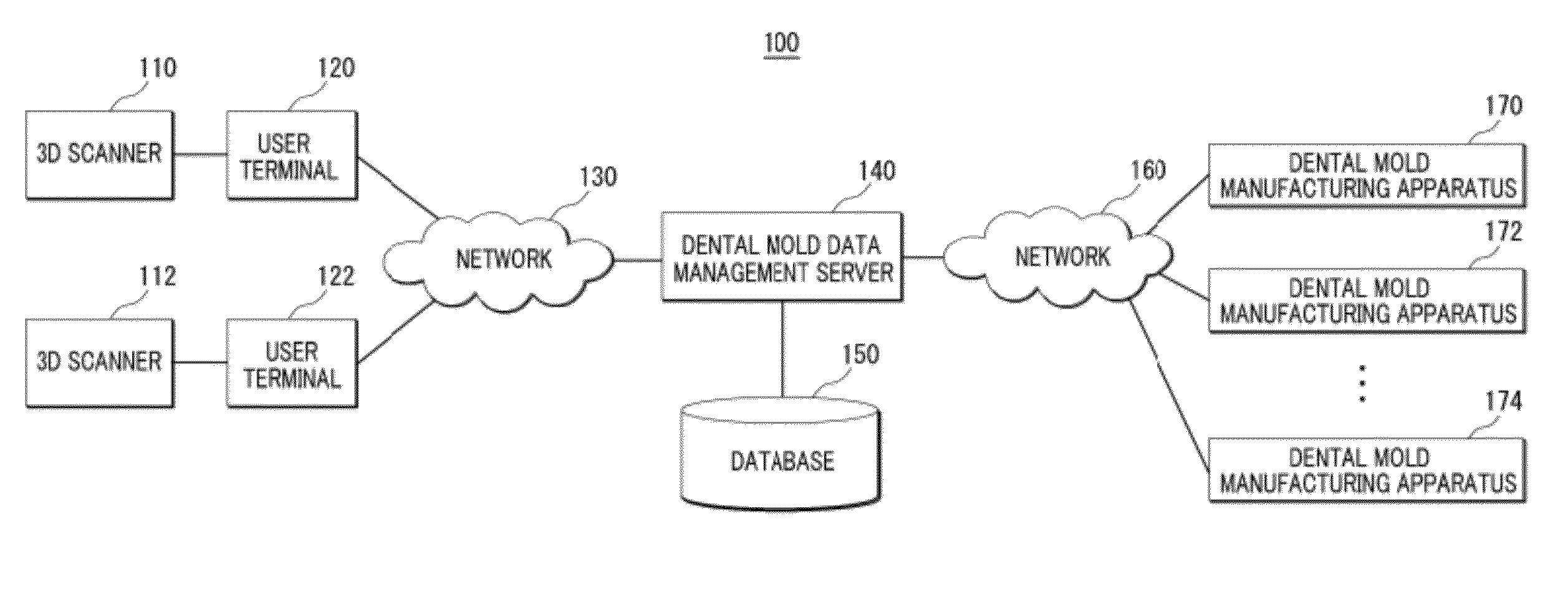

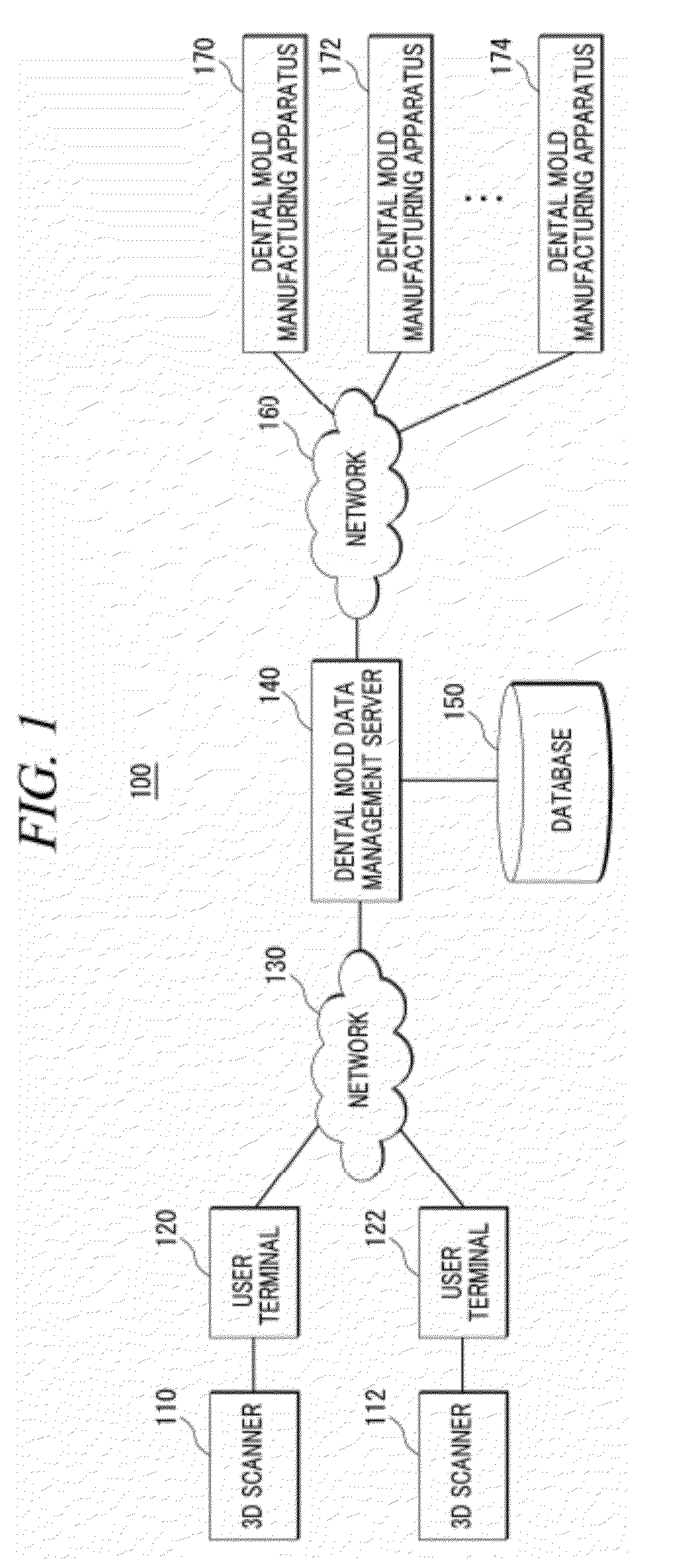

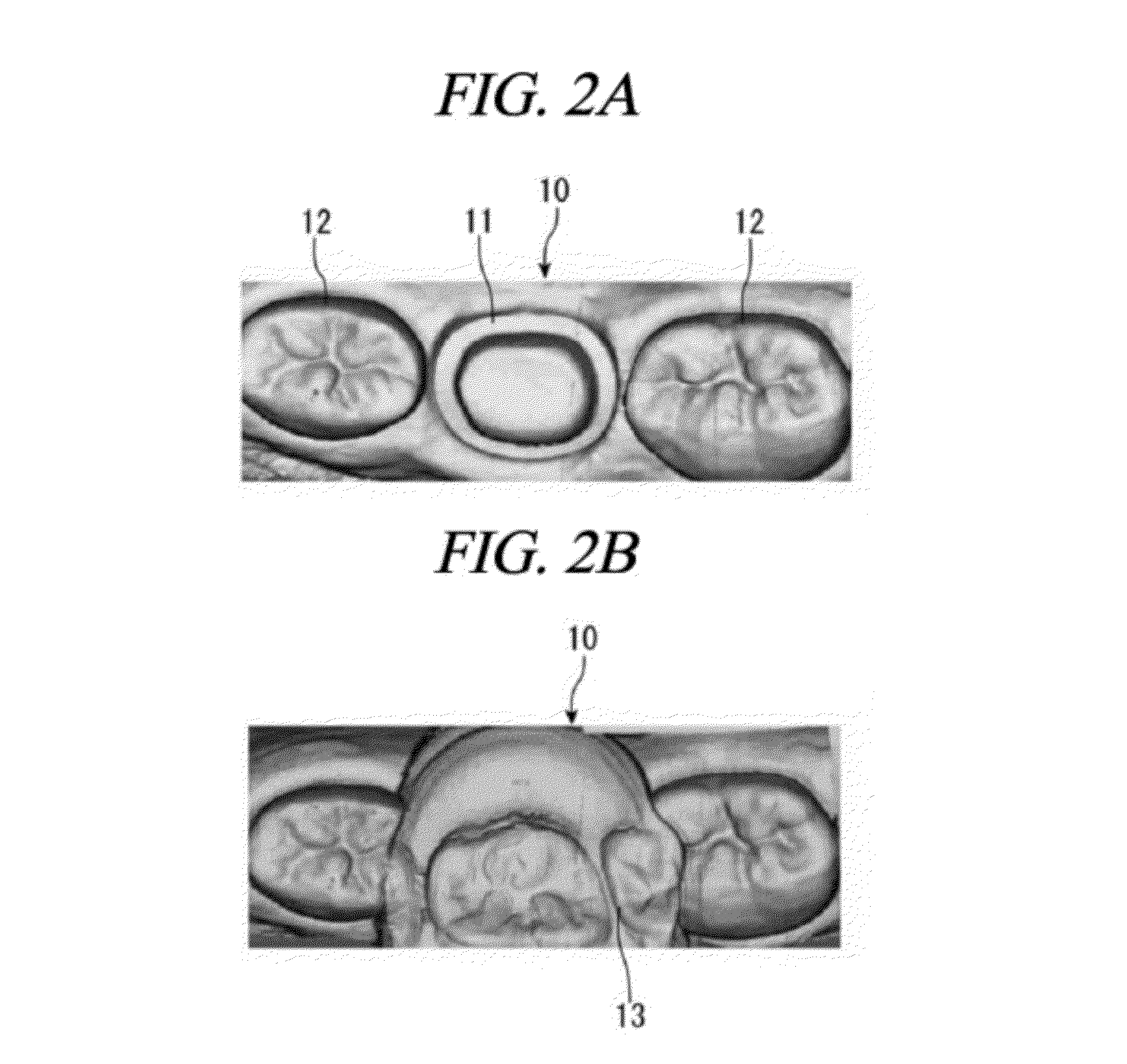

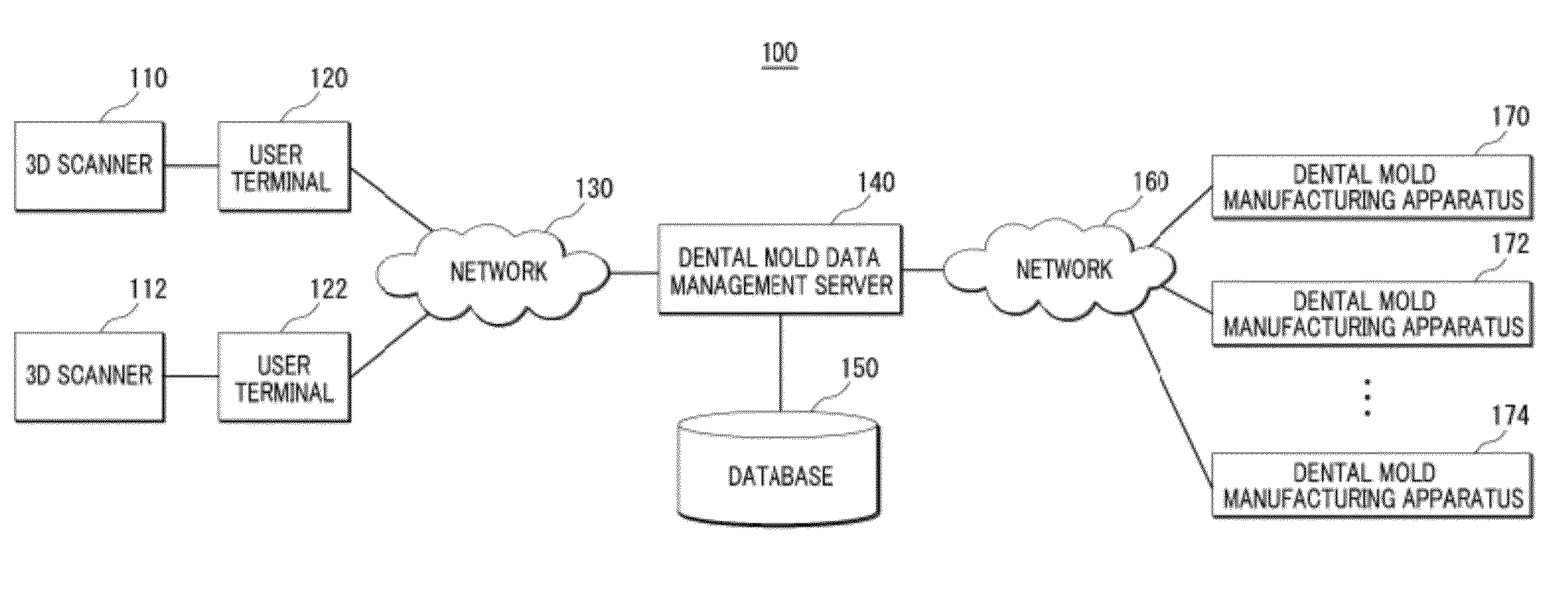

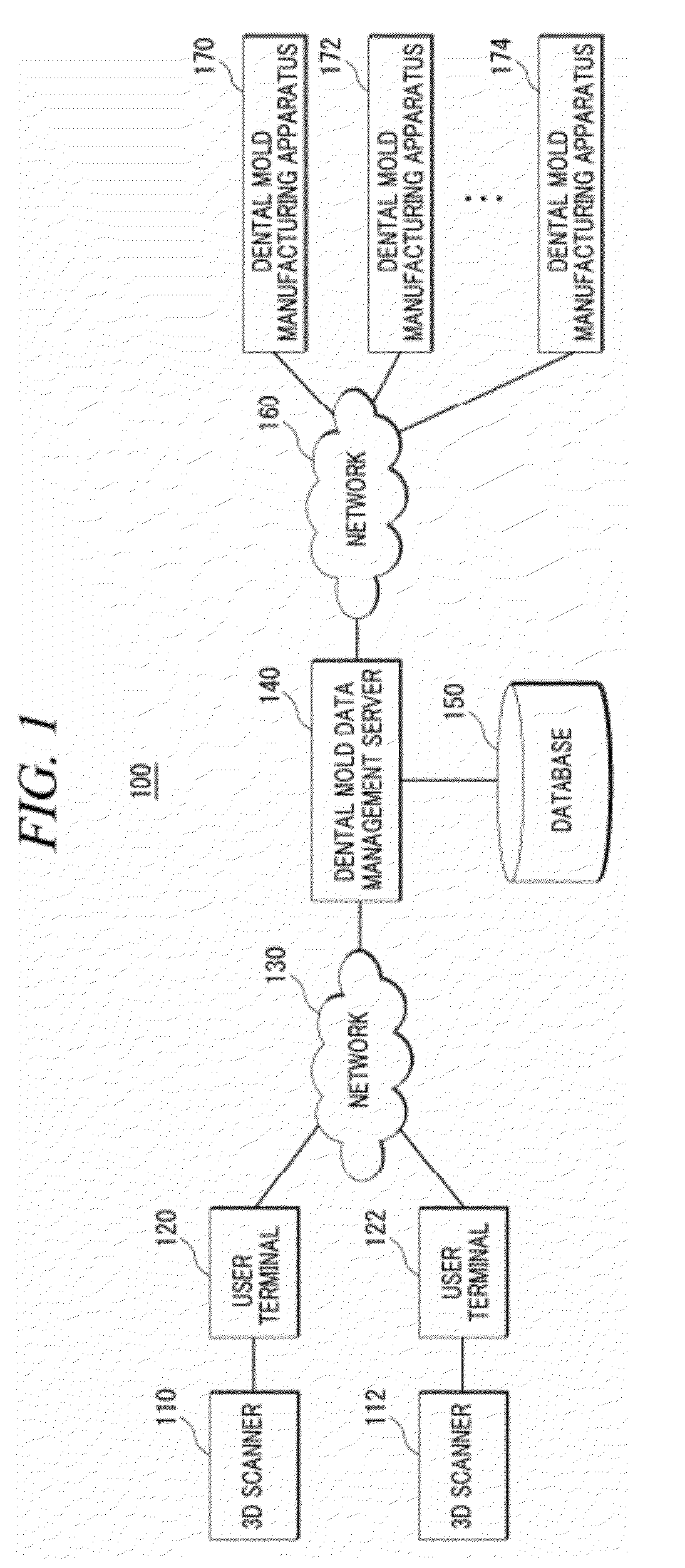

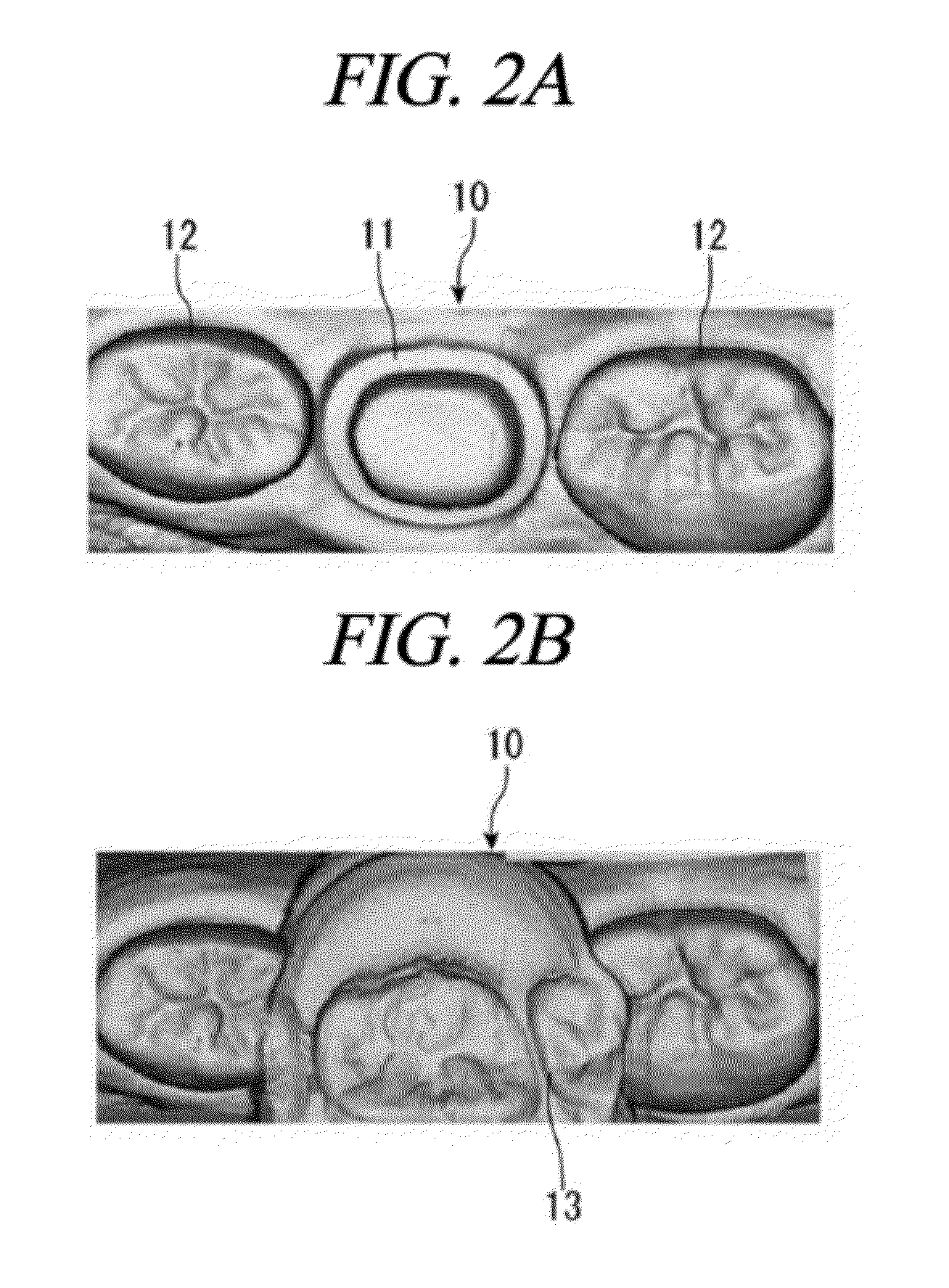

On-line system for manufacturing a dental mold

An on-line system for manufacturing a dental mold is provided. In one embodiment, An on-line system for manufacturing a dental mold may comprise a user terminal configured to receive graphic data of a damaged tooth, a tooth adjacent to the damaged tooth and a tooth occluded with the damaged tooth, which are obtained by a 3D scanner, and to generate graphic data of a restoration tooth based on the received graphic data; a dental mold data management server configured to receive the graphic data of the restoration tooth from the user terminal; and one or more dental mold manufacturing apparatuses configured to receive the graphic data of the restoration tooth from the dental mold data management server and to manufacture the dental mold corresponding to the graphic data of the restoration tooth.

Owner:KIM JIN HWAN

On-line system for manufacturing a dental mold

An on-line system for manufacturing a dental mold is provided. In one embodiment, An on-line system for manufacturing a dental mold may comprise a user terminal configured to receive graphic data of a damaged tooth, a tooth adjacent to the damaged tooth and a tooth occluded with the damaged tooth, which are obtained by a 3D scanner, and to generate graphic data of a restoration tooth based on the received graphic data; a dental mold data management server configured to receive the graphic data of the restoration tooth from the user terminal; and one or more dental mold manufacturing apparatuses configured to receive the graphic data of the restoration tooth from the dental mold data management server and to manufacture the dental mold corresponding to the graphic data of the restoration tooth.

Owner:KIM JIN HWAN

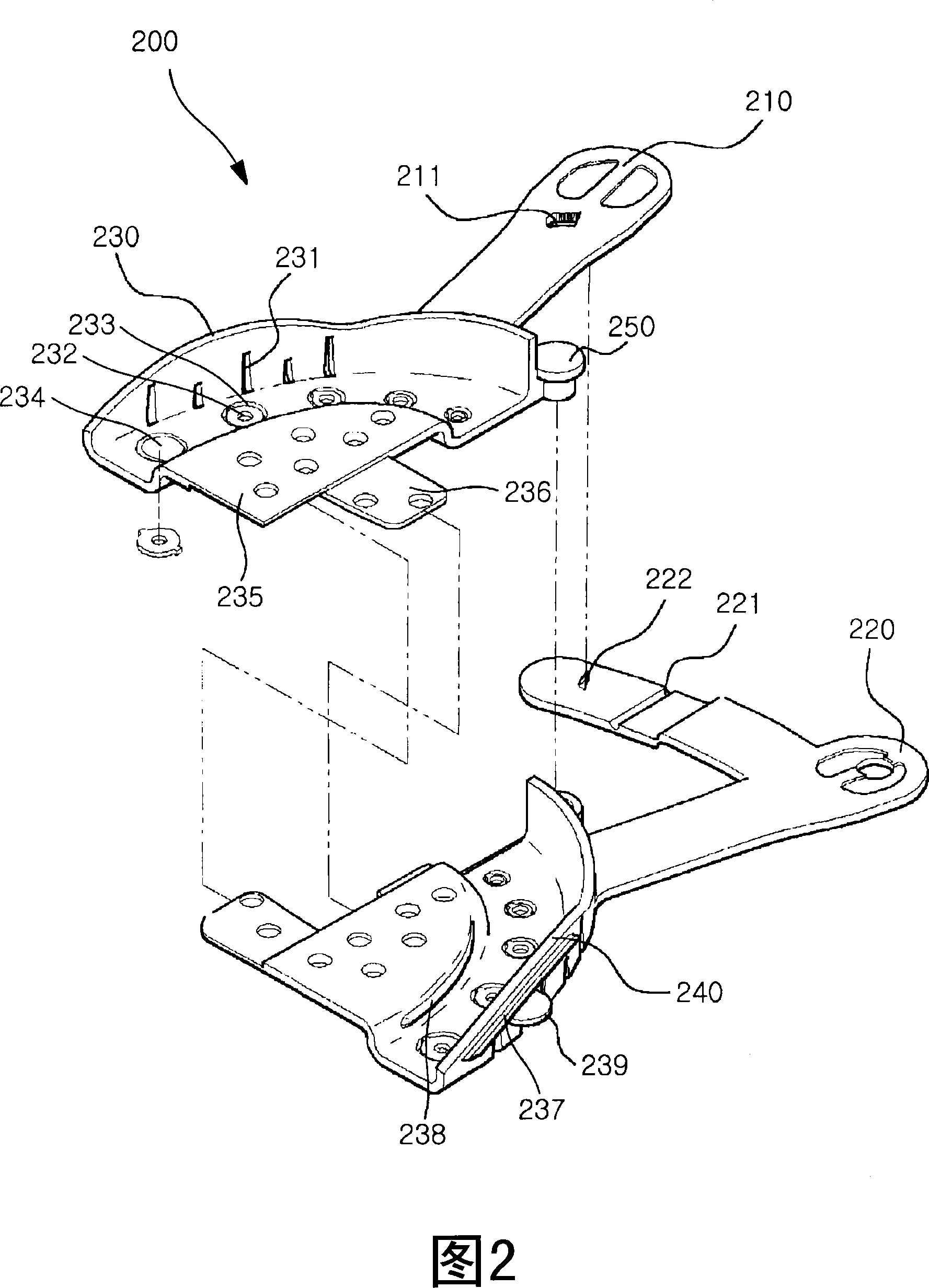

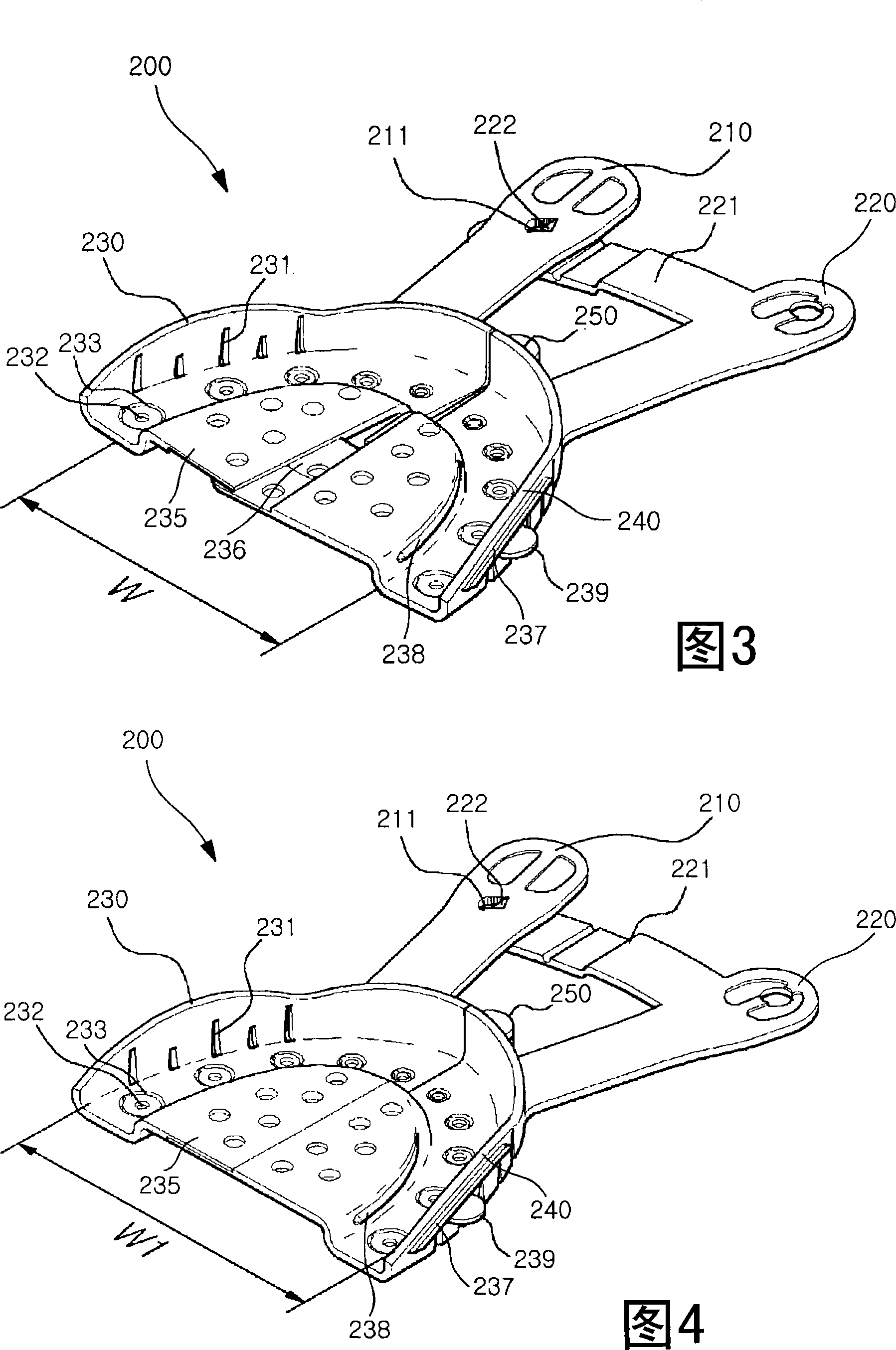

Tooth stamper disc

The invention discloses a dental print mold palte realizing width of the dental print mold matching with dental arch of sufferer with different size, and keeping regulated width of the dental print mold steadily during obtain the dental print mold plate of the sufferer. The the dental print mold includes: a first and second holding part for holding print mold material, the first and second holding part are formed corresponding to dental arch of sufferer and separatedly each other; a pivotal part for pivoting reserve part of the first and second holding part and rotating with thereof to reguale width between the first and second holding part; and a handle part extending from the holding part and grasped by the manipulater when regulating width between the first and second holding part, and a locking device for locking the first and second holding part steadily on corresponding to position of regulated width. Thereby, the invention can regulate the width of the print mold to match with dental arch size of sufferer, dental arch size of sufferer for dental cavity and teeth of sufferer is different, so the mold can suit for all sufferers. Moreover, the regulted width of the mold can be kept steadily during obtaining dental mold of sufferers, so can obtain right dental print mold quickly.

Owner:ORAL BIOTECH

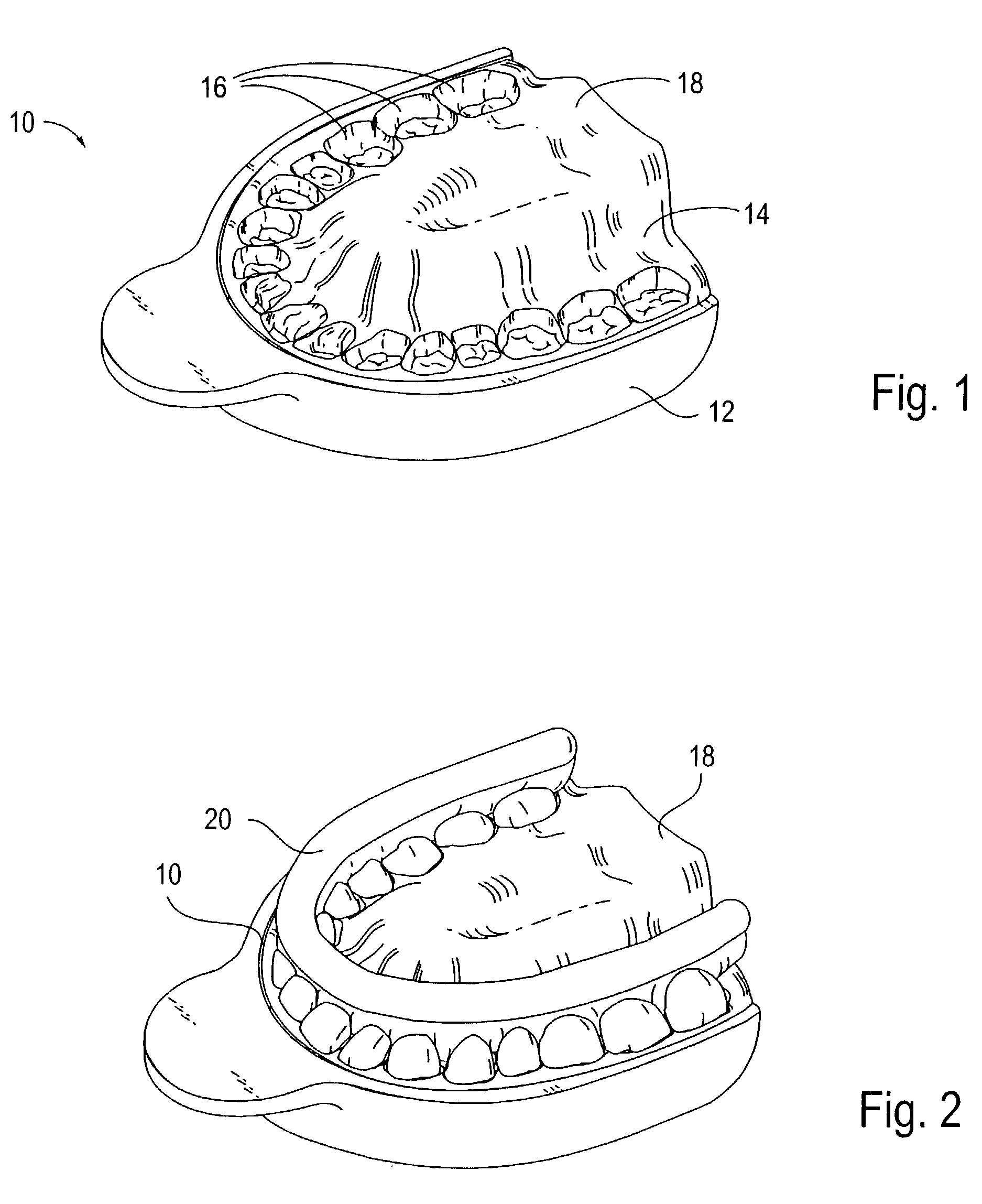

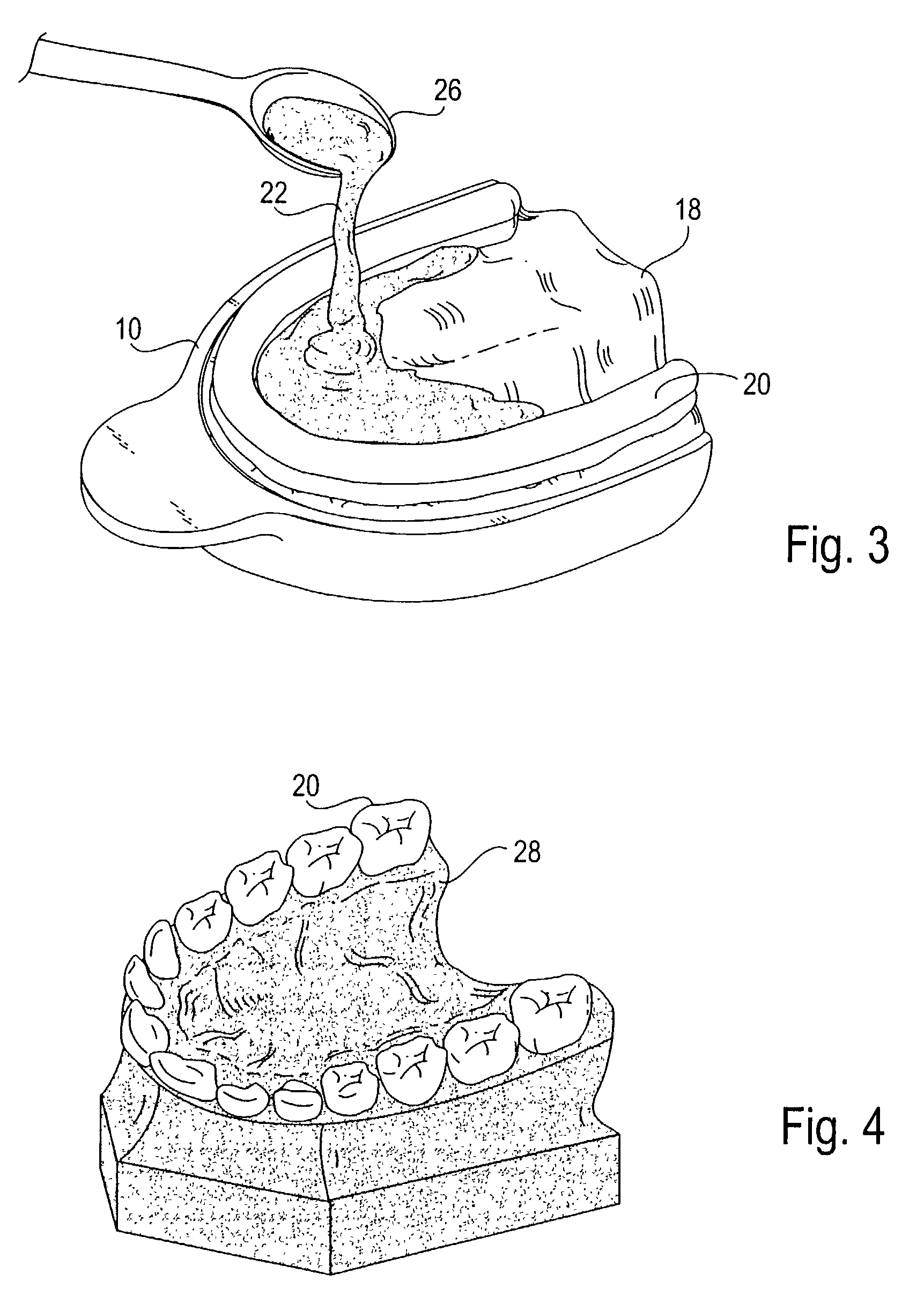

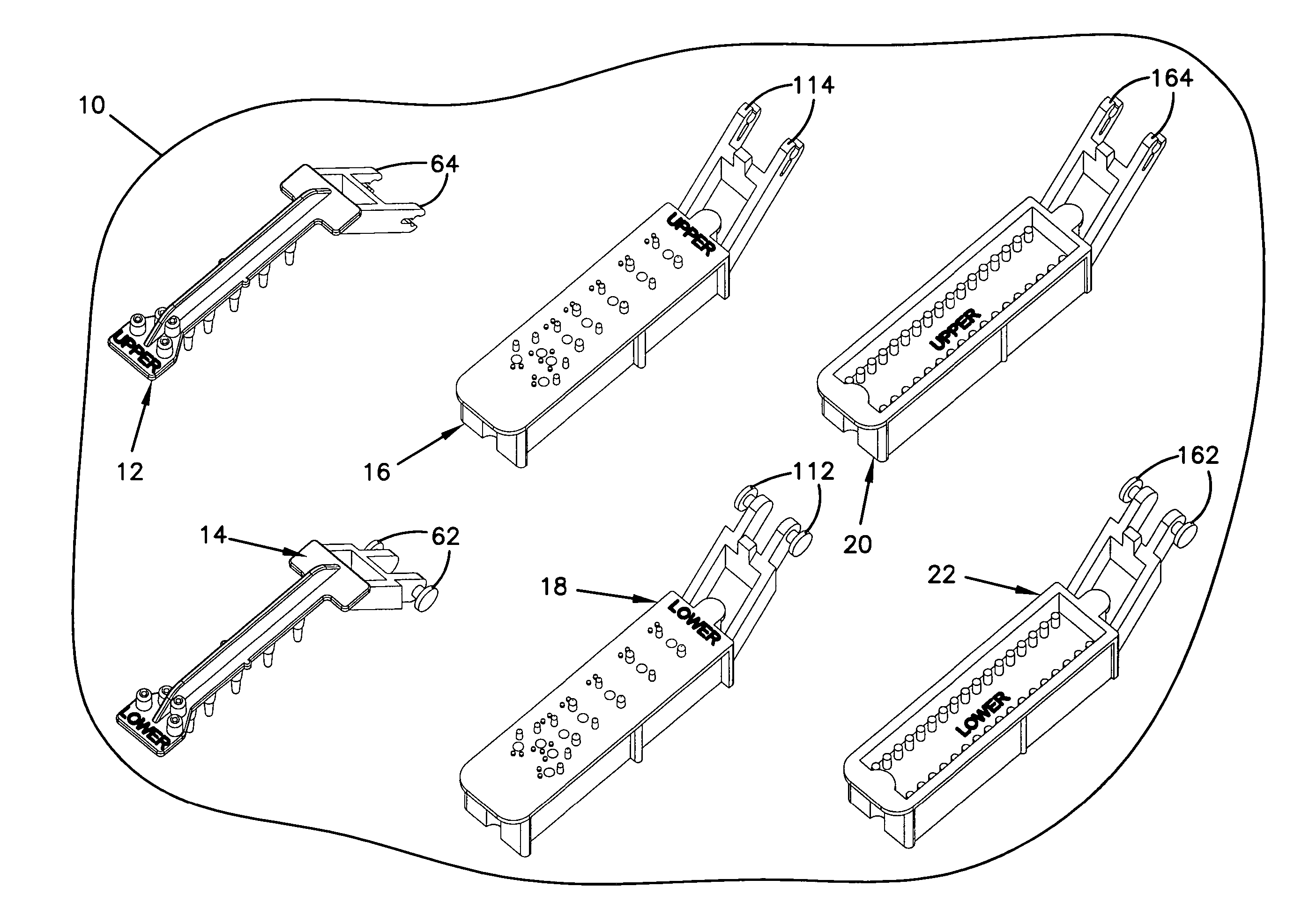

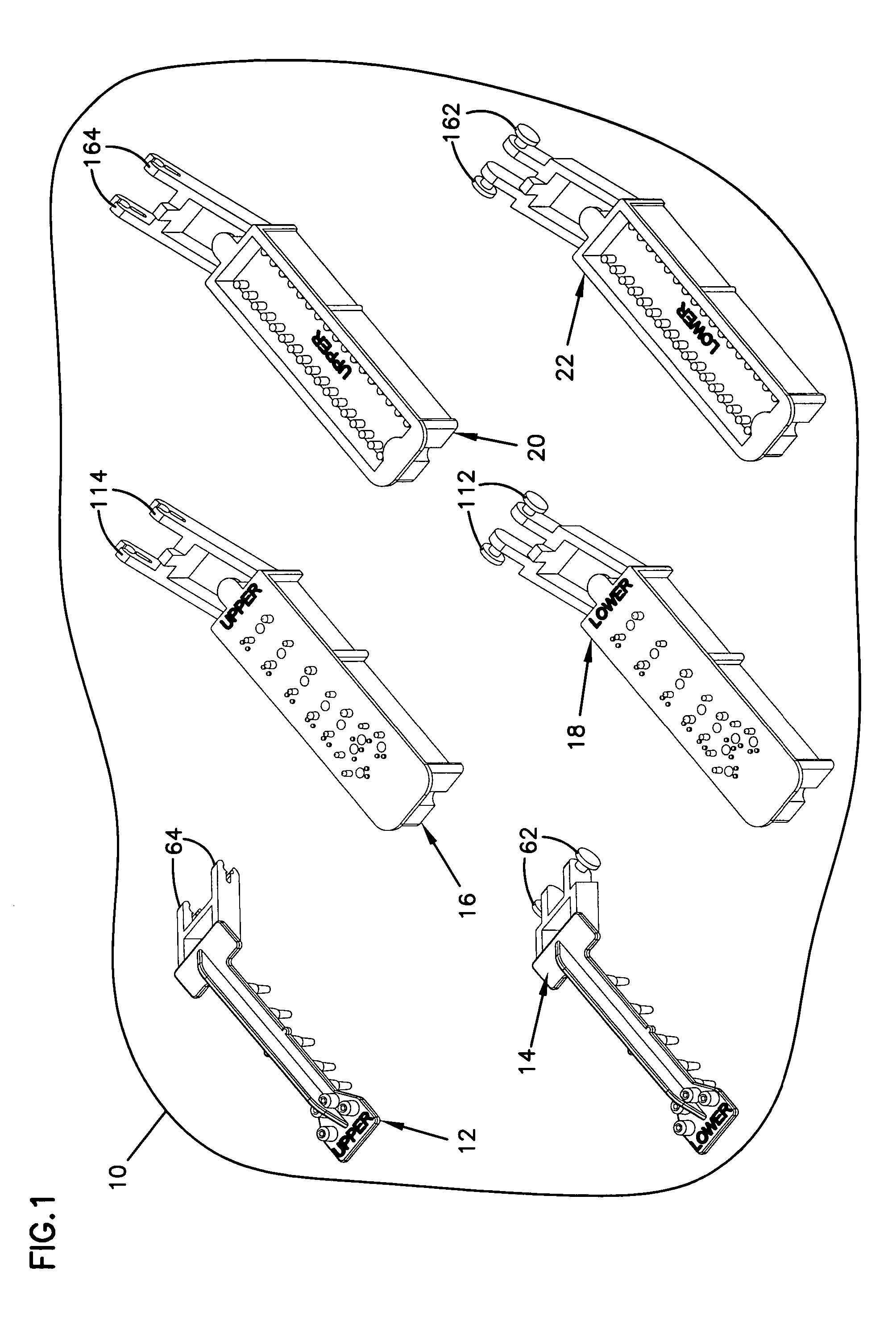

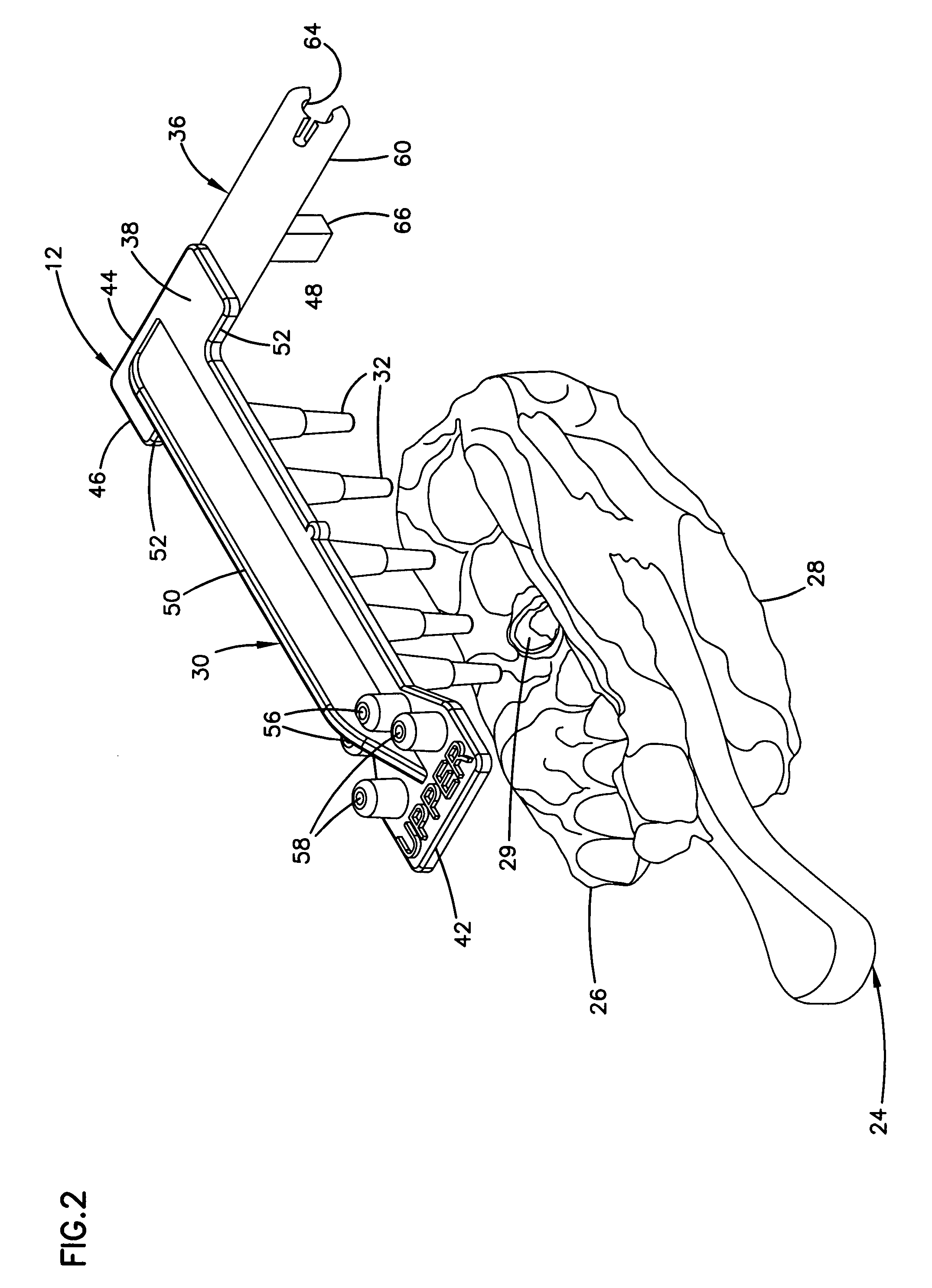

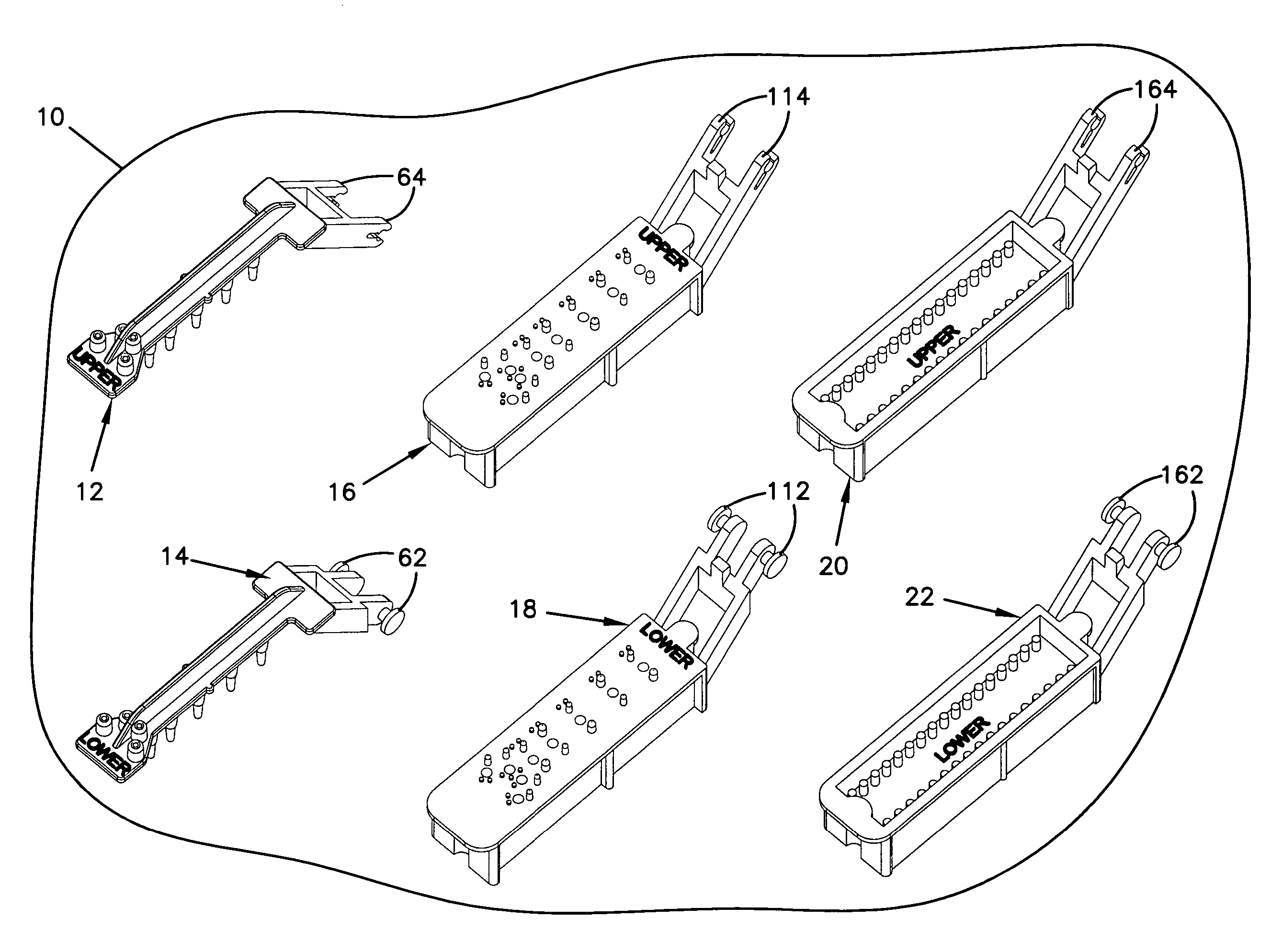

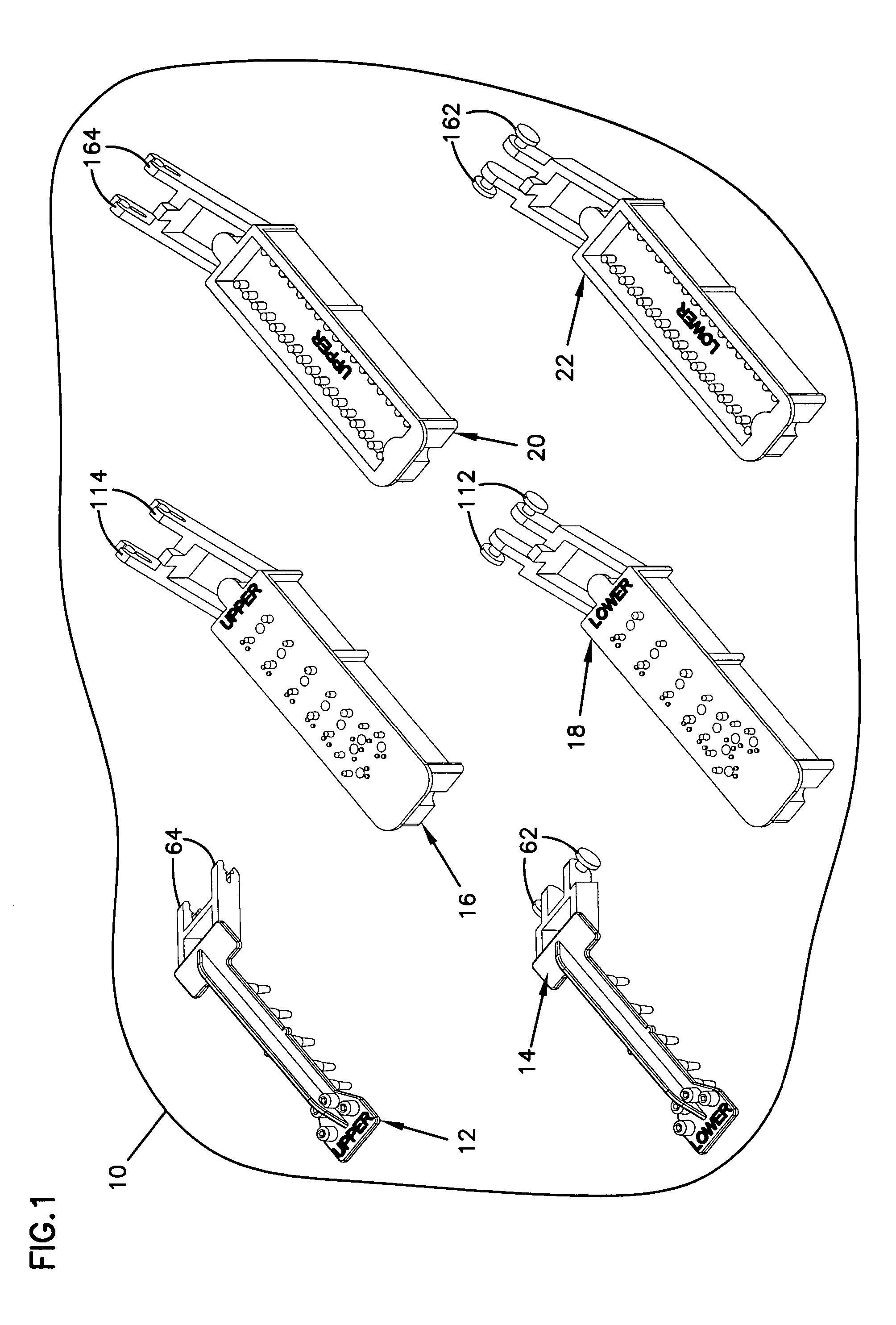

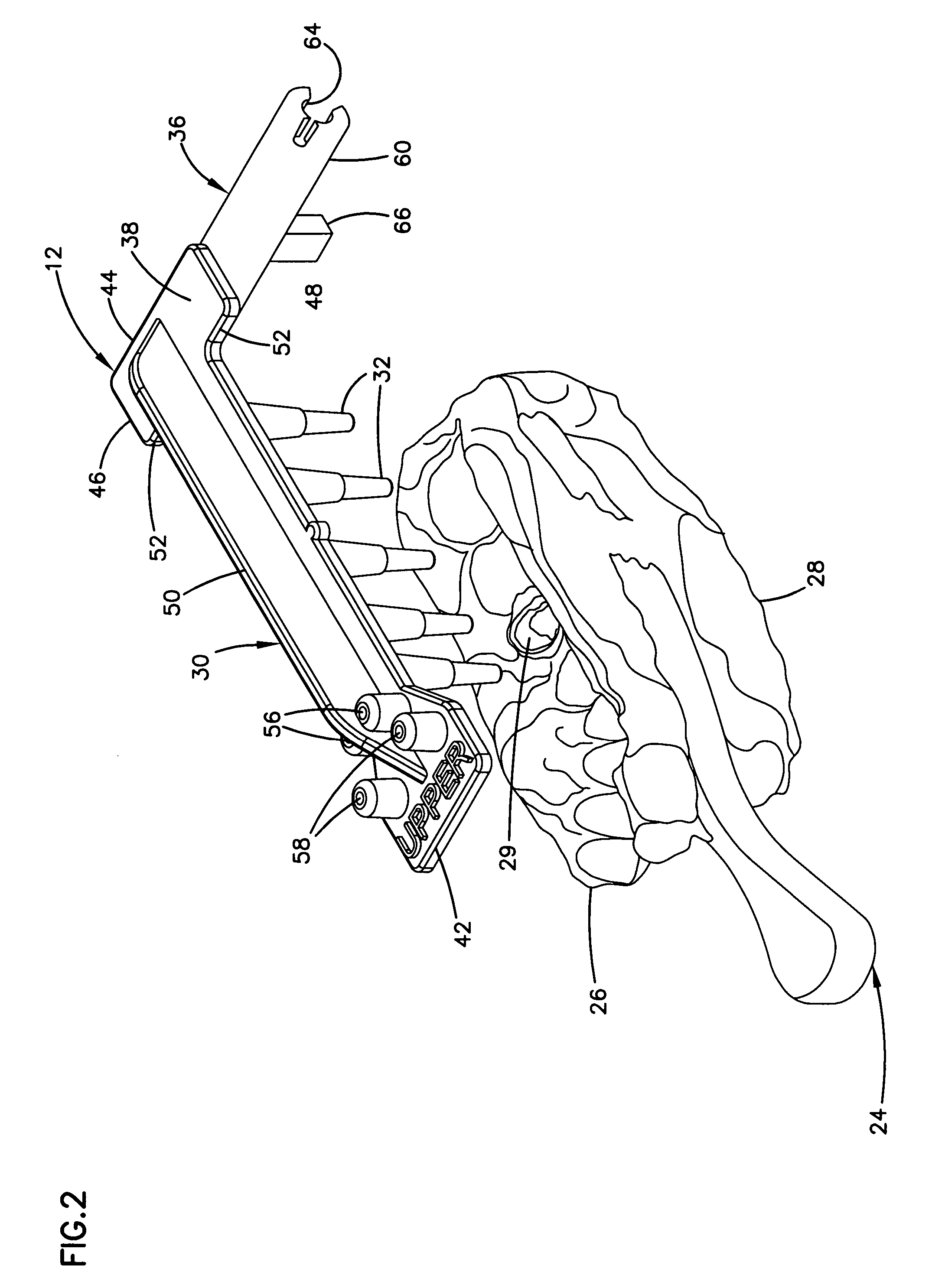

Dental Impression Model System, Apparatus, and Method

ActiveUS20160250004A1Reduces chance distortionReduce operating errorsImpression capsImpression traysModel system

Embodiments of this invention provide predictability and standardization in the field creating dental models. Embodiments of the invention are capable of accommodating multiple variations and goals of dental impressions, including but not limited to creating dental models for study models, mouth guards, night guards, whitening trays, sleep apnea / snoring devices, etc. Embodiments may incorporate single arch and dual arch impression trays, as well as base model formers and articulators, among other devices of varying shapes, dimensions, sizes and manufacturers. Embodiments of the invention use standard dimensions for accommodating various components. To adapt embodiments of the invention for multiple purposes, and to standardize the process, embodiments of the invention include a shell that allows for standardized dental models to be suspended in the shell during the process of creating dental molds, creating a reservoir for the dental mold. Embodiments allow for a trimming process where impressions are standardized by cutting away lateral excess impression material by running a knife along the lateral portion of upper and lower impression tray walls, and then by trimming away vertical excess by placing the tray into the vertical excess trimming device.In these embodiments, dental impressions and embodiments of a predetermined shell allow dental models to be created, including articulated models, in a simplified process.The present invention thus allows dental professionals to easily pour up single and double arch dental impressions, create base models, and, optionally, articulate models in fewer steps than currently available, allowing less waste, material, and use of time than traditional and current methods.

Owner:DIMARINO JAMES C

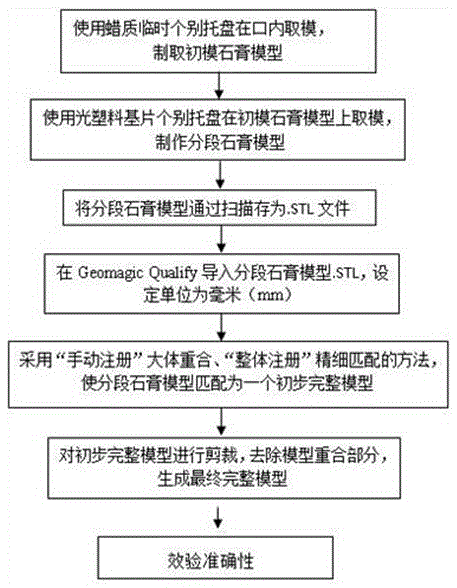

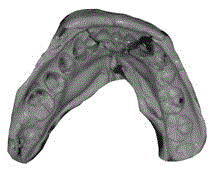

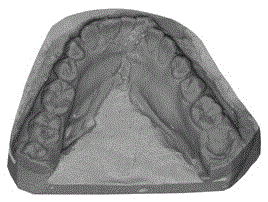

Method for acquisition of complete dentition model by computer rectification combination by sectionally taking model

ActiveCN105596106AShorten the timeConvenient for clinical model takingDentistryOriginal dataDimensional modeling

A method for acquisition of a complete dentition model by computer rectification combination by sectionally taking the model comprises the following steps: 1) a tooth position is selected, 2) a dental mold is made, 3) each segment of dentition gypsum model is scanned to obtain original data, and the original data is respectively stored as an STL file, 4) reverse engineering software-Geomagic Qualify is used for segmented dentition matching by use of a computer, 5) software initial parameters are set, the STL file in the step 4 is selected, a three-dimensional modeling view is formed in the software, then sectional dentition gypsum model three-dimensional views are respectively matched with segmented models, and overlapping parts of the models can be removed by operation cutting to obtain a the complete dentition model, and 6) accuracy is verified, and according to the method, dentitions of mouth-opening-limitation other patients excluding patients with complete limitation of mouth opening (trismus) and some severe limitation of mouth opening can be collected, and reliable data can be provided for follow-up treatment and operations.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

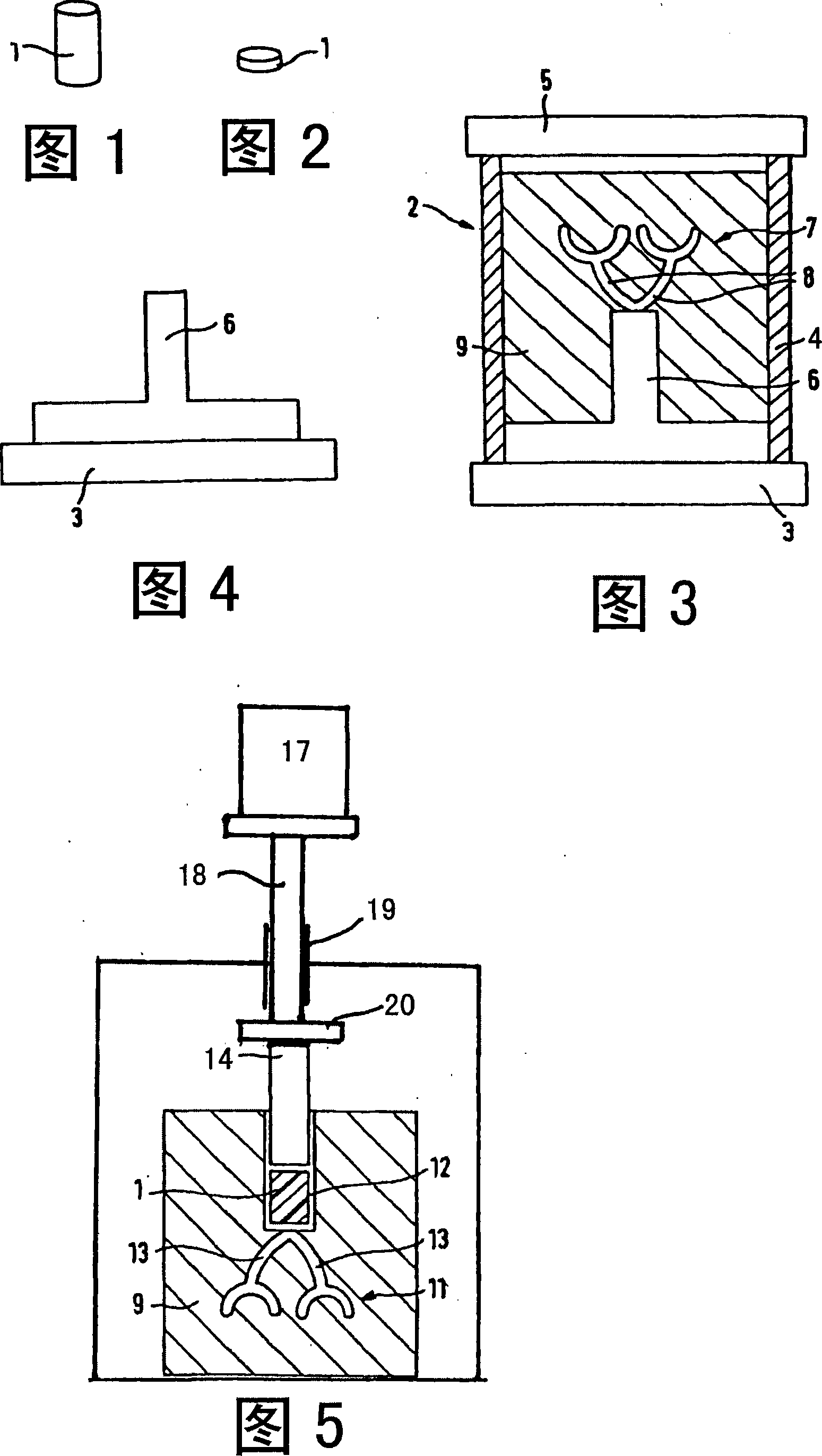

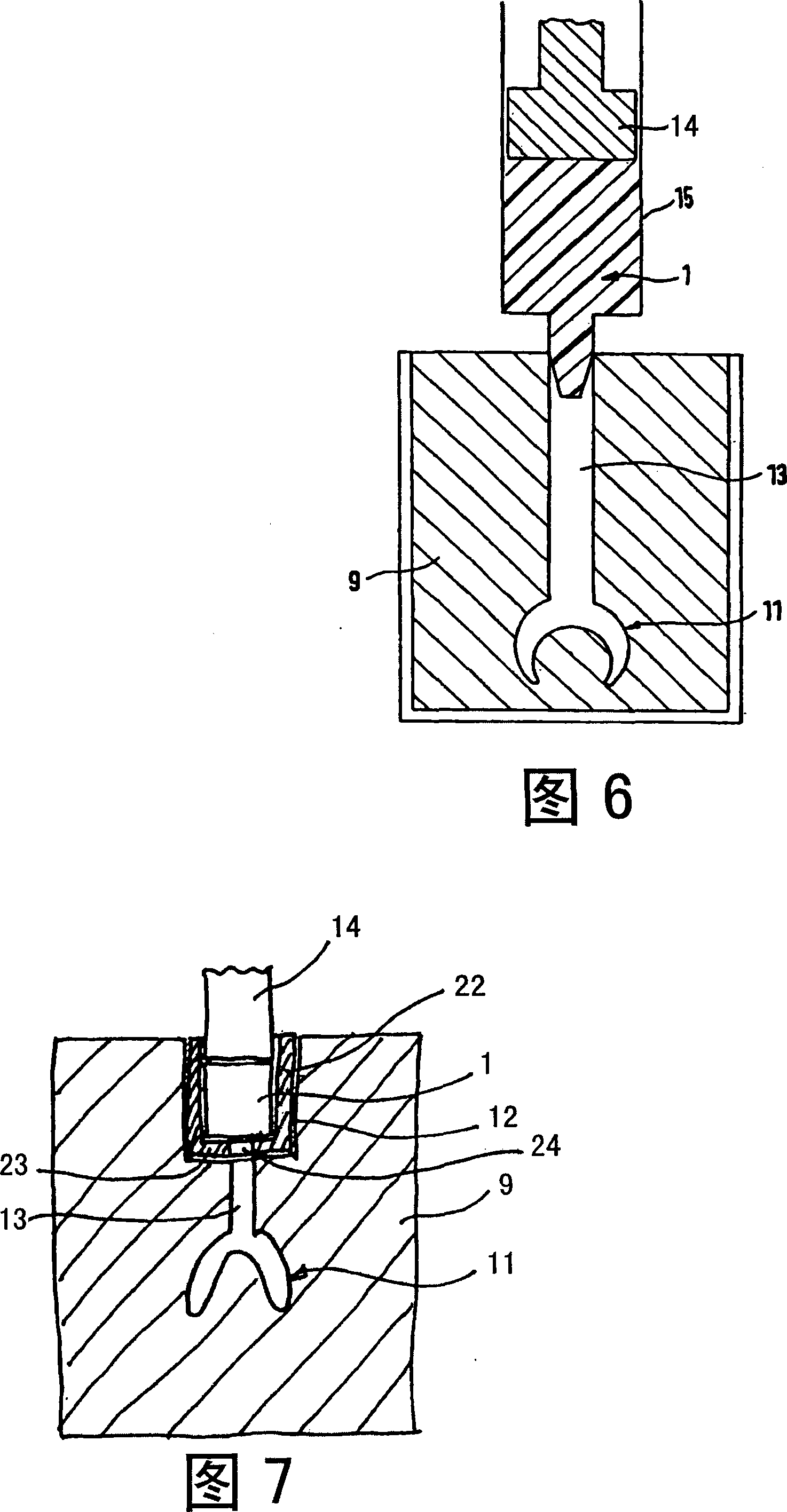

Method for producing dental molded parts

In order to produce dental molded parts for a dental prosthesis, a shaping model (7) of the desired dental molded part is made, for example, from wax. The model is embedded in a heat-resistant molding compound (9). The molding compound (9) is subsequently hardened, and the wax model (7) is melted in order to form a mold cavity (11) that corresponds to the negative of the desired dental molded part. The thermoplastic heated to the processing temperature is introduced with pressure into the formed mold cavity (11) in the molding compound (9), and the thermoplastic, which forms the desired dental molded part, is removed from the mold once the molding compound (9) is solidified. The molding compound (9) has a temperature of at least 150 DEG C at the point in time at which the thermoplastic is introduced.

Owner:F·韦科雷

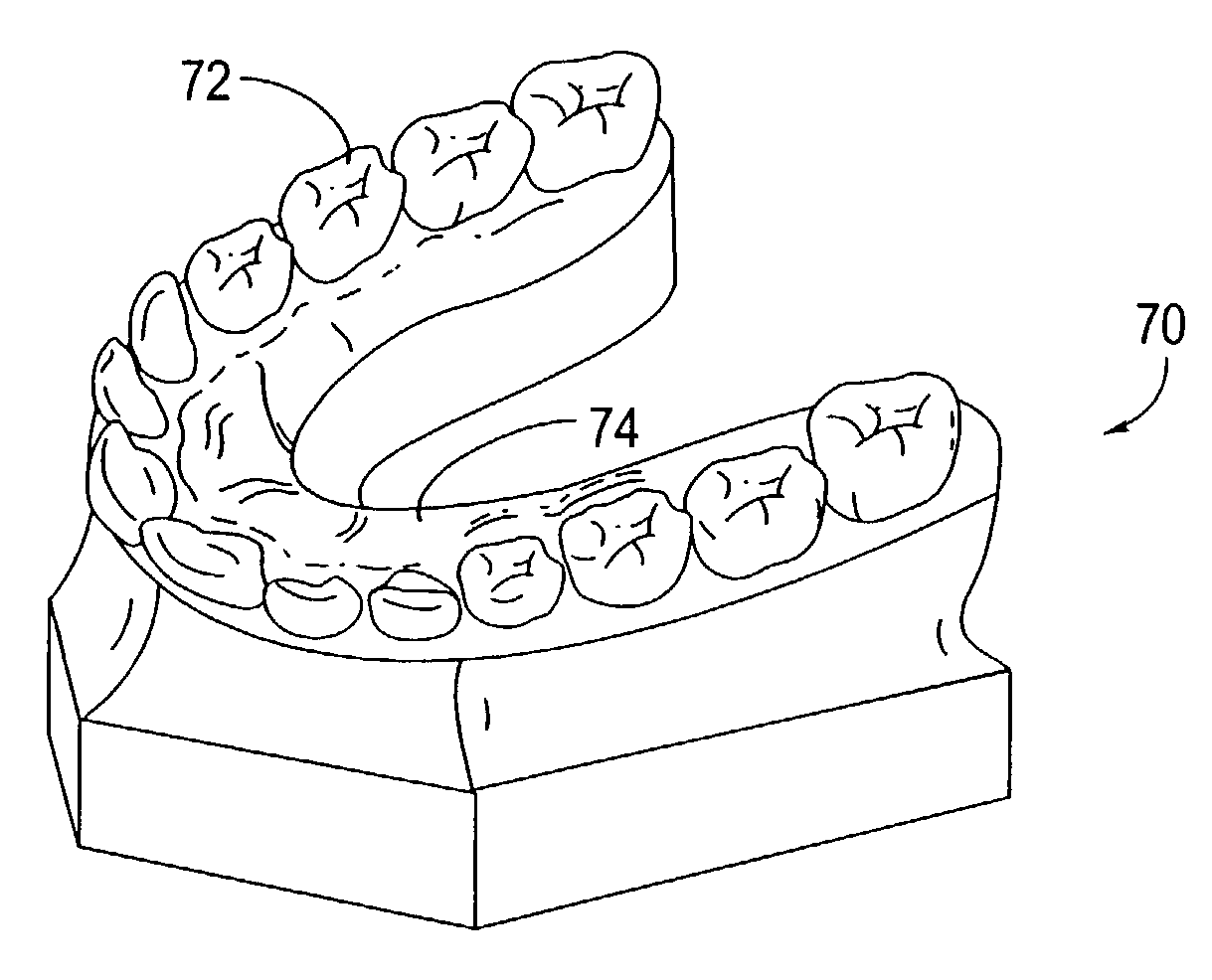

Reconfigurable dental model system for fabrication of dental appliances

The present invention provides a manipulable or reconfigurable dental model system and methods for its use to model a series of tooth configurations corresponding to sequential tooth movements during an orthodontic treatment. When a patient undergoes orthodontic treatment, teeth and bite configurations are realigned in a series of stages. Each stage represents a new pattern or dental configuration that will eventually lead to a proper final positioning of the entire dentition. Progress from the initial configuration, through the intermediate stages and finally to the final configuration may be accomplished using any one or a combination of different dental appliances. Of particular interest to the present invention, many of these appliances may be made using a dental mold representing the patient's dental configuration. In particular, thermoformable plastic positioning appliances which fit over the patient's teeth may be formed over a three-dimensional mold of the patient's dentition. When successive appliances are used throughout treatment to reposition the teeth from initial to final configuration, a new mold has typically been produced to fabricate the appliance for each stage. The present invention provides an apparatus and methods which employ a manipulable or reconfigurable mold to model patient dentition and gingiva at each stage of treatment.

Owner:MILLER ROSS +1

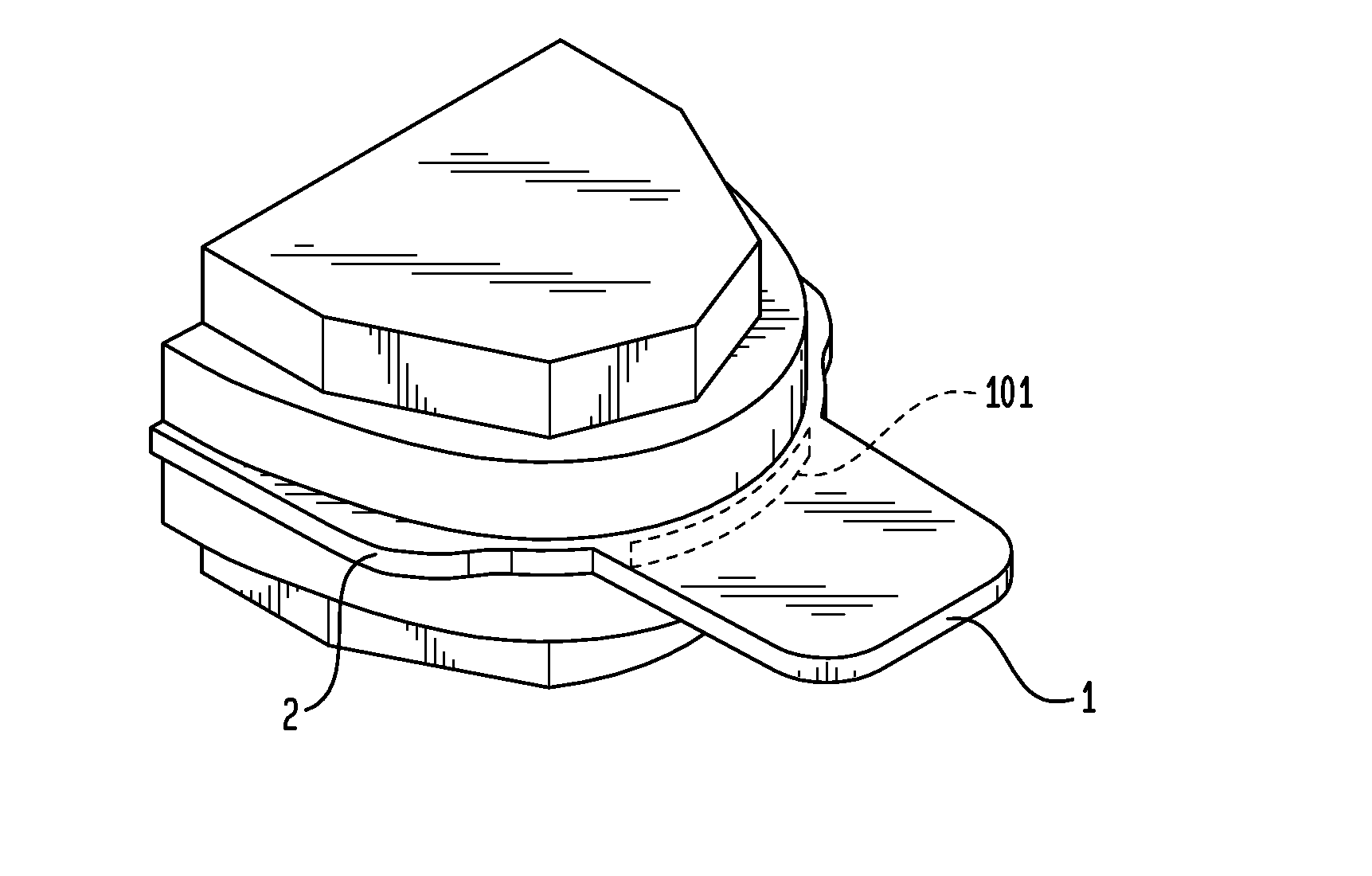

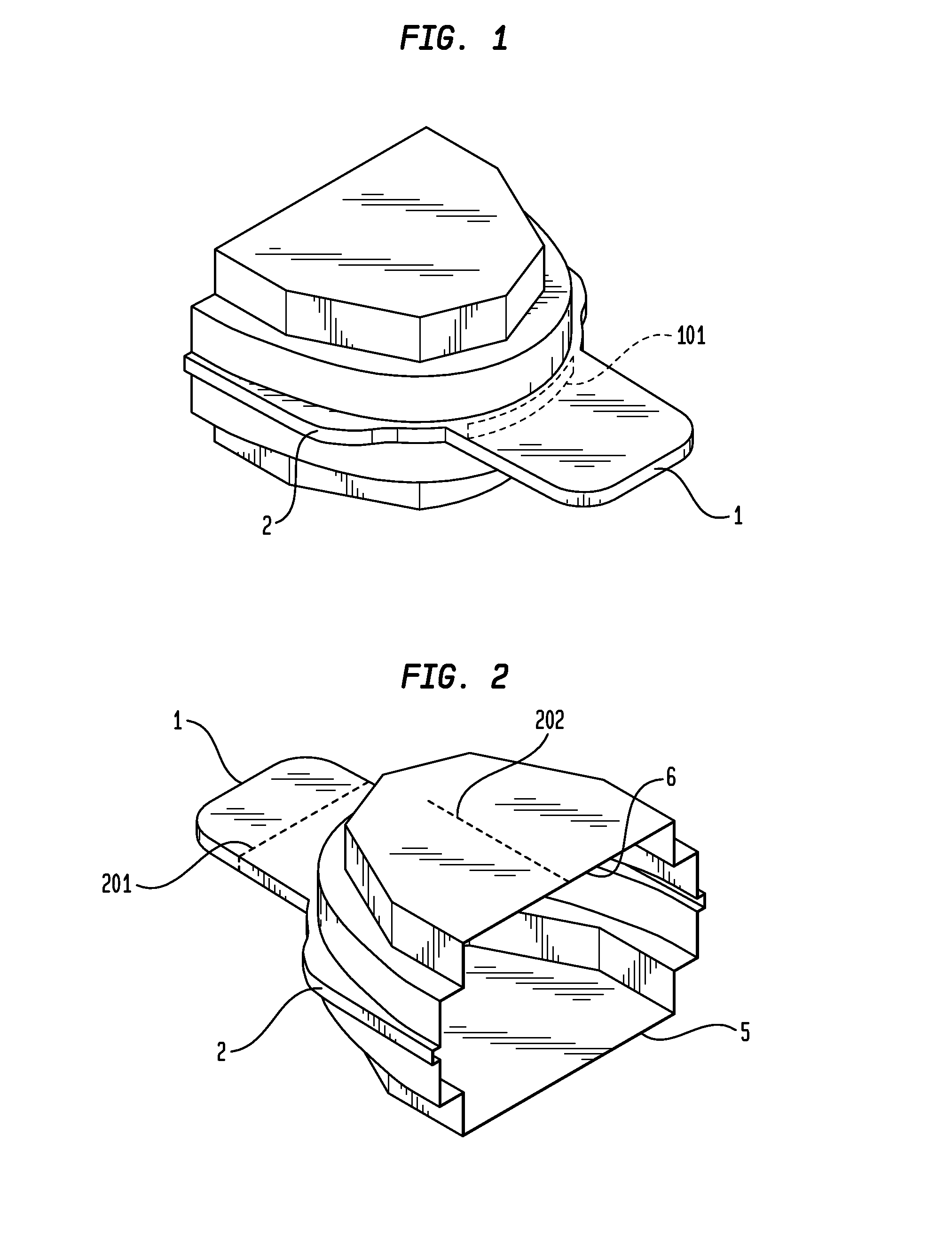

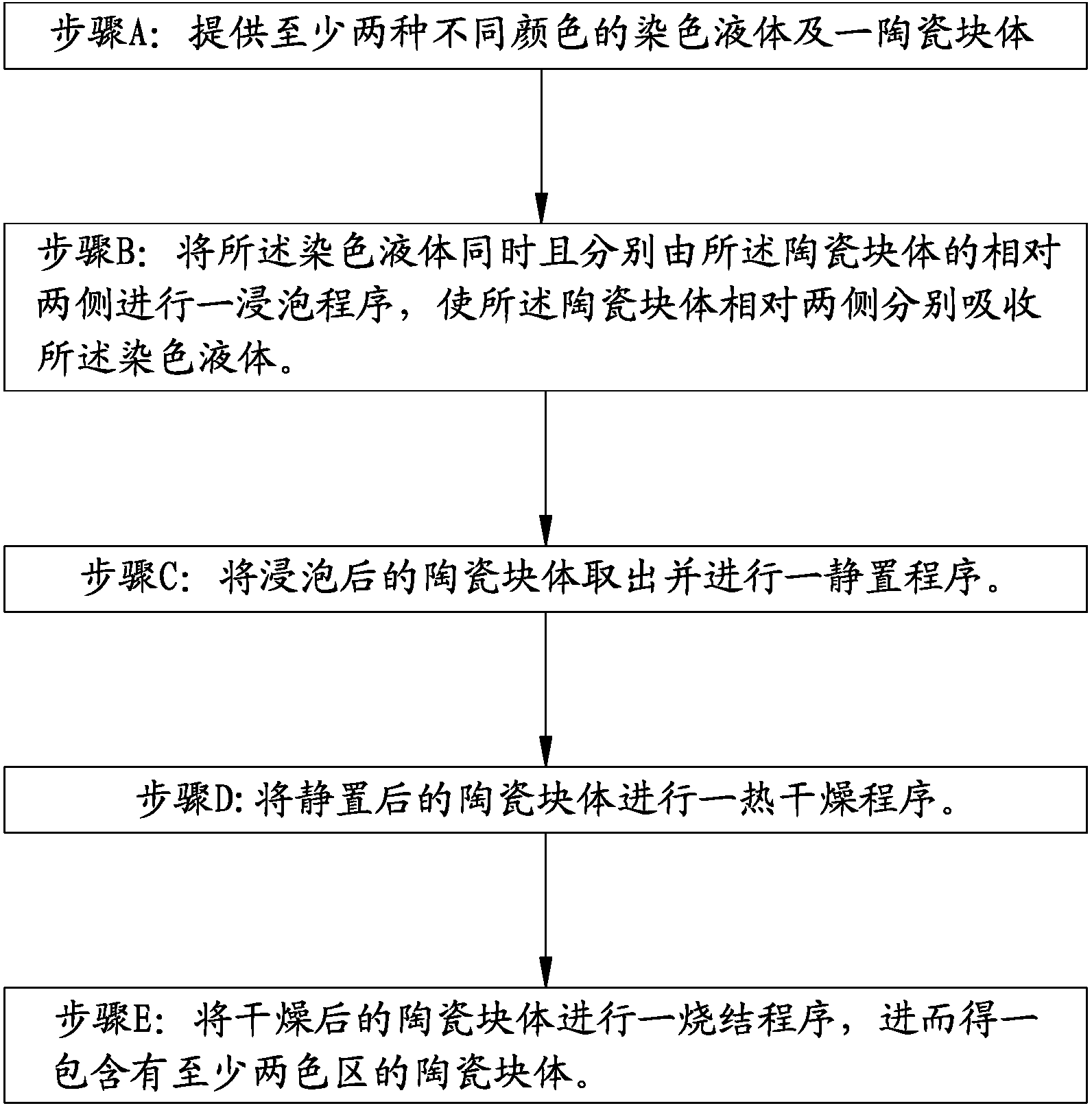

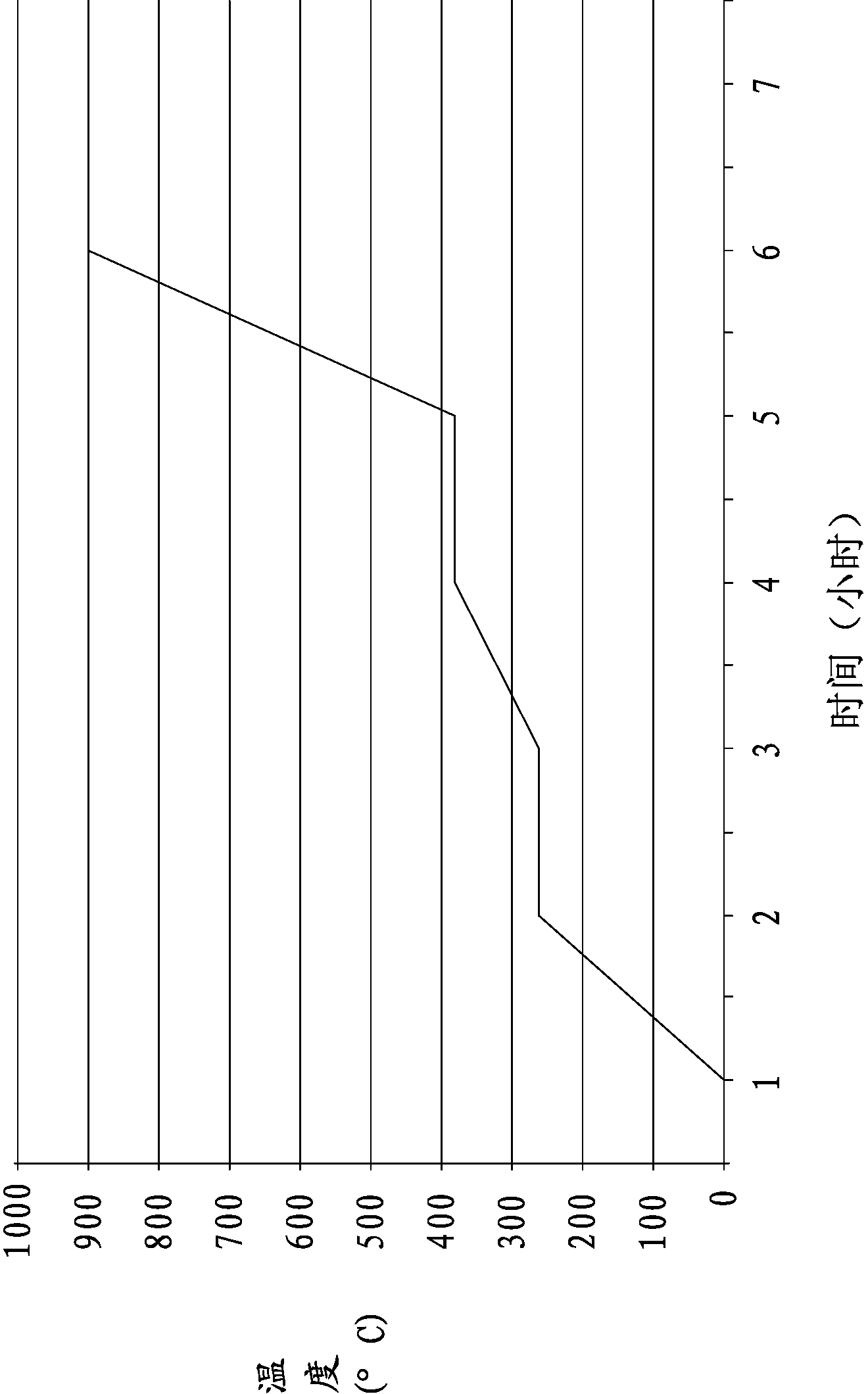

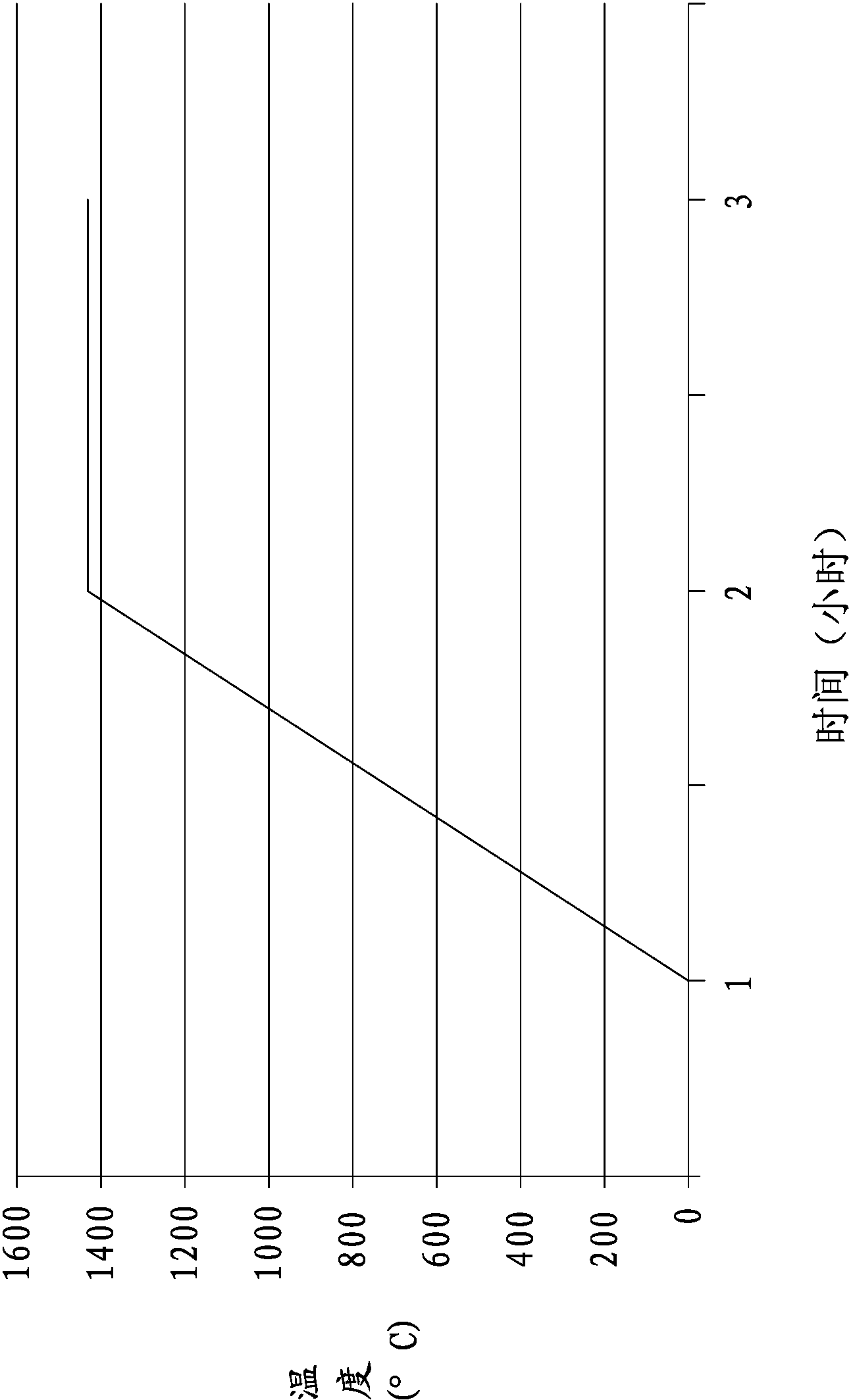

Dental model gradational-layer ceramic block and manufacture method thereof

InactiveCN104337586AHigh strengthImprove reliabilityTooth crownsArtificial teethMetallurgyDental mold

The present invention discloses a dental mold gradational-layer ceramic block and a manufacture method thereof. The dental mold gradational-layer ceramic block comprises a ceramic block, wherein one end of the ceramic block contains a first color zone, the other end of the ceramic block contains a second color zone, and the gradational colors exist between the first color zone and the second color zone. The manufacture method comprises: A. providing at least two dyeing liquids with different colors and a ceramic block, B. concurrently soaking the opposite both sides of the ceramic block respectively with the two dyeing liquids so as to make the opposite both sides of the ceramic block respectively absorb the dyeing liquids, C. taking the soaked ceramic block, and standing, D. carrying out heat drying on the standing ceramic block, and E. sintering the dried ceramic block so as to obtain the ceramic block containing at least the two color zones and having the gradational colors. With the structure and the steps, the dental mold gradational-layer ceramic block has the gradational colors, and meets the aesthetic requirement of the people on the teeth.

Owner:COALITION TECH

Method of manufacturing surgical template positioning device

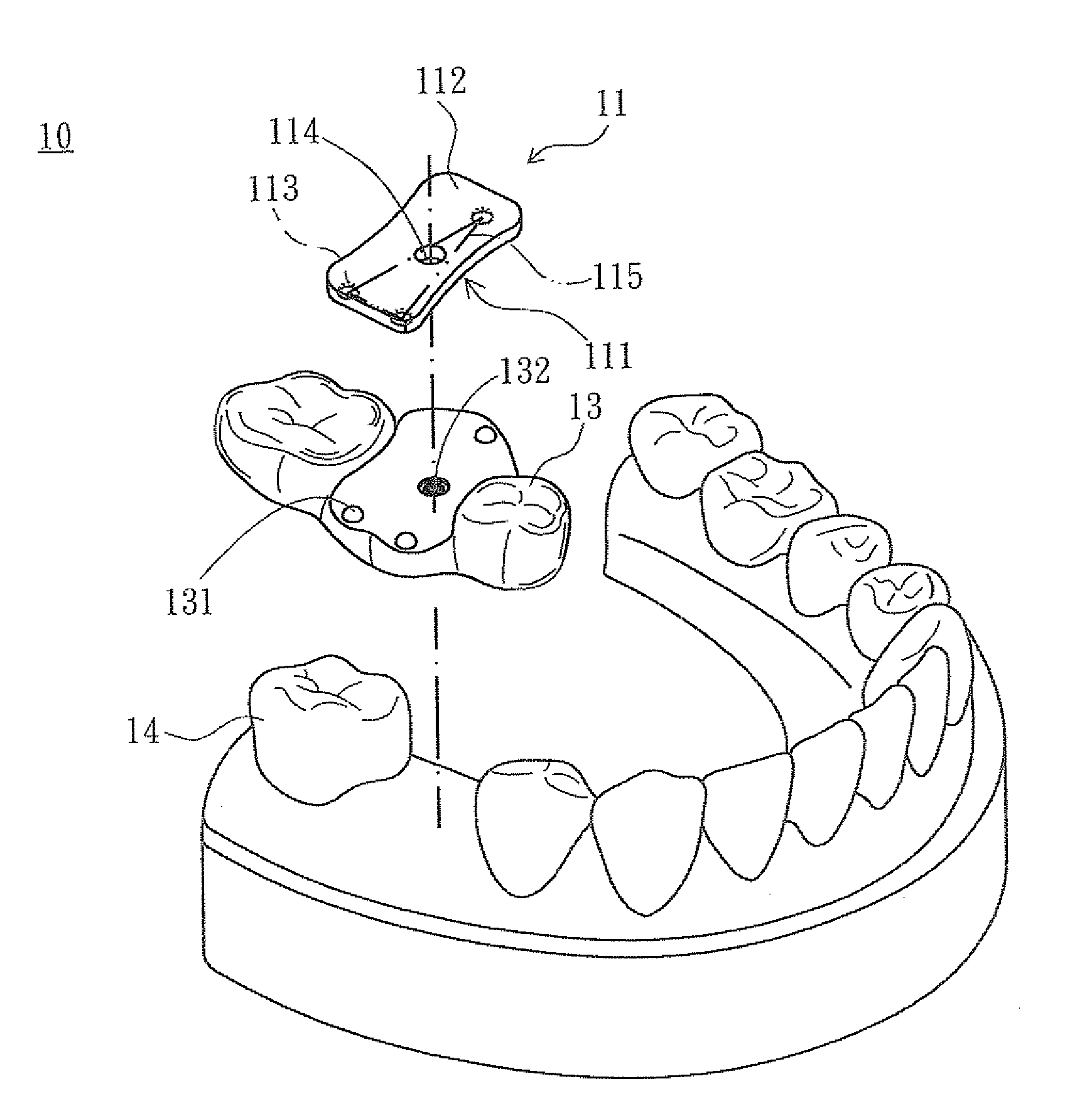

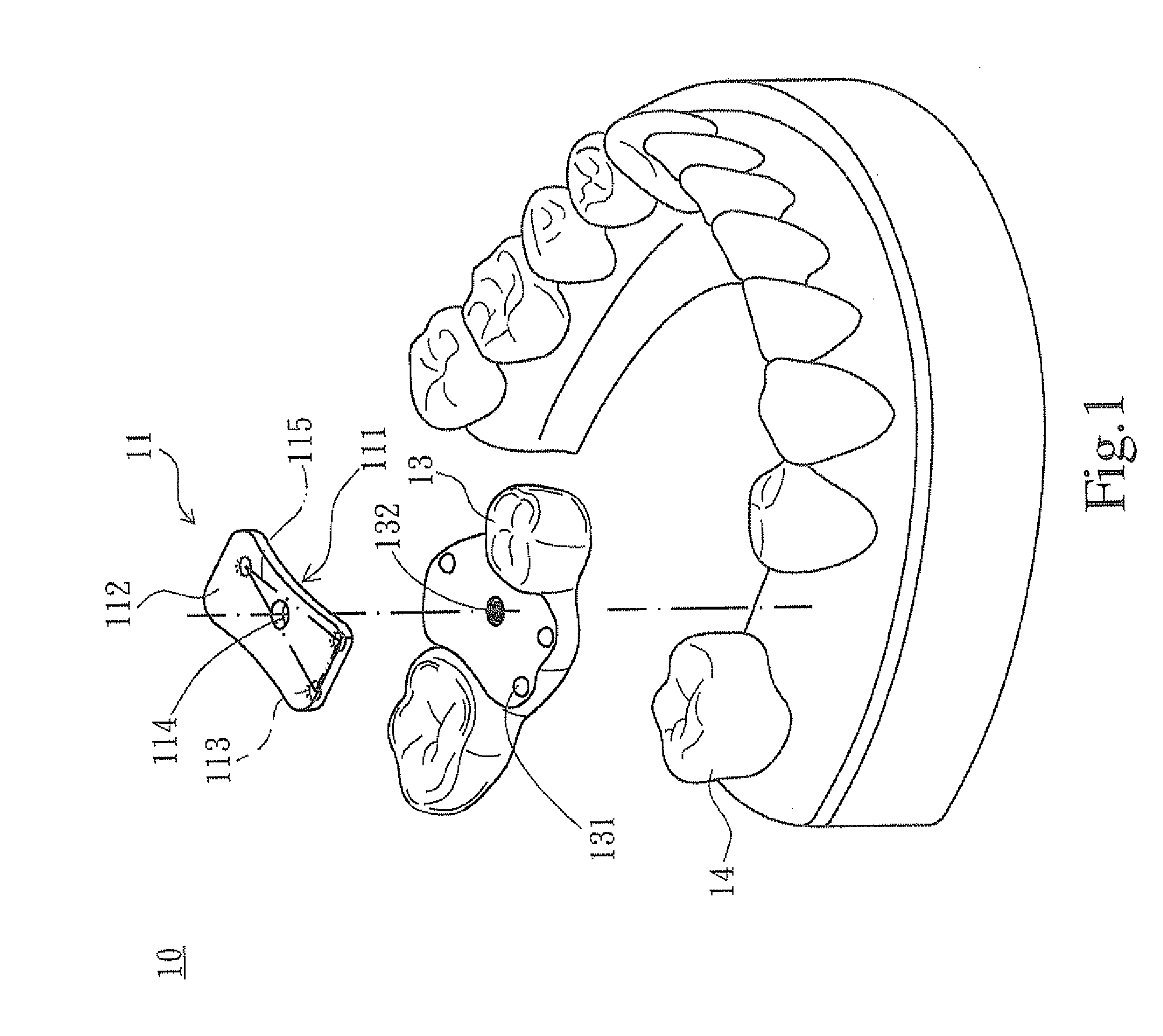

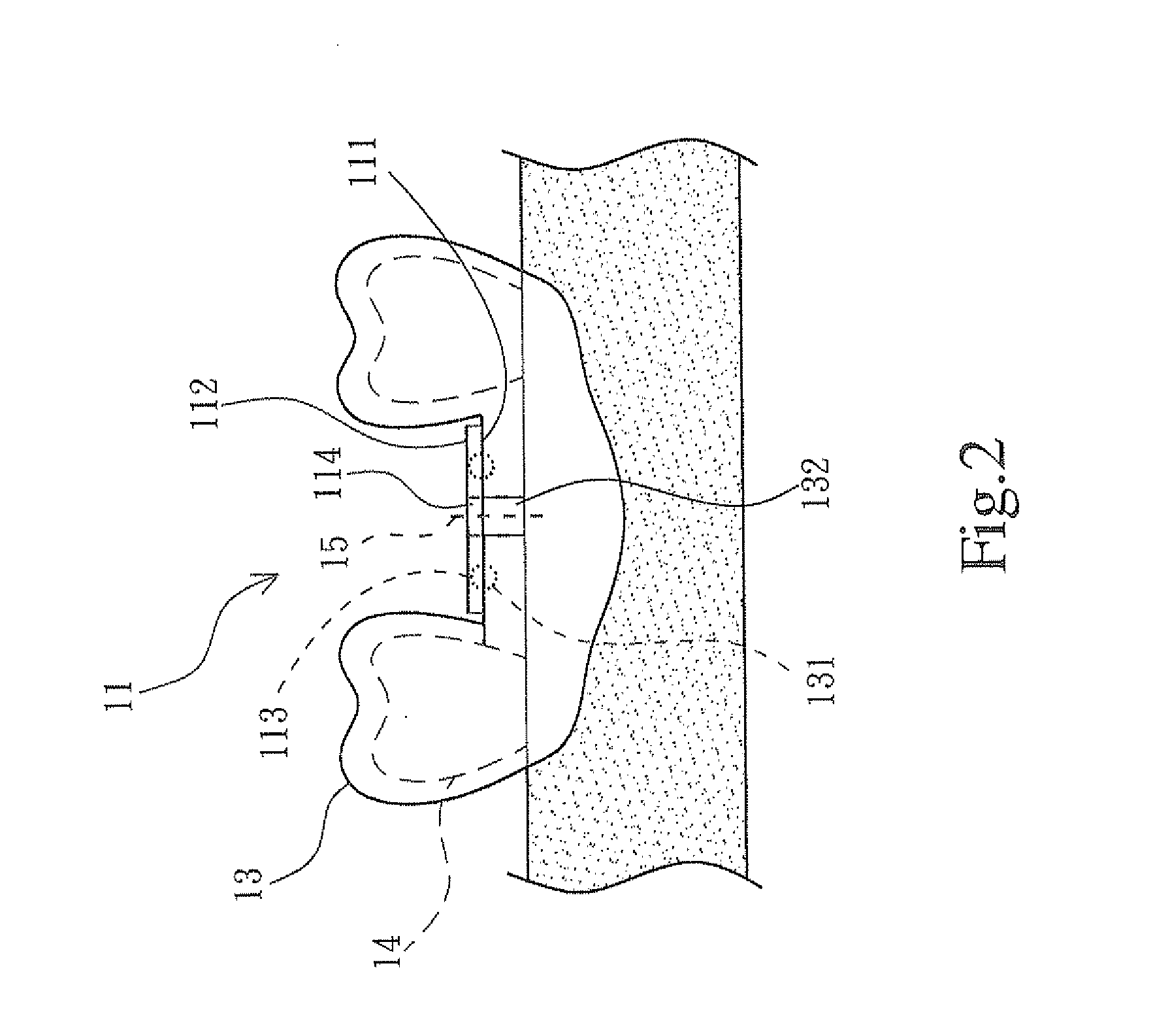

ActiveUS20150099241A1Reduce biasLess discomfortBoring toolsRadiation diagnostics for dentistrySurgical operationEngineering

A surgical template positioning device is provided, and has a template and a dental mold. The template has a first surface formed with at least three spherical recesses, a second surface, and a guiding hole. The dental mold has at least three spherical portions partially embedded in the at least three spherical recesses and an implanted hole having an axis the same as the guiding hole. The at least three spherical recesses have three spherical centers as being three vertices of a triangle, the axis passes through the triangle, and the at least three spherical portions have spherical centers corresponding with the three vertices of the triangle. A method of manufacturing the surgical positioning device is also provided.

Owner:TAIWAN IMPLANT TECH

Dental articulator

A dental modeling system for forming a dental model from a mold of at least a portion of a person's opposed upper and lower teeth. The modeling system includes dental articulator features that are integrated with opposing bases and dental model bases configured to receive removable tapered pins. The system also includes pin locators for improved alignment of teeth of the dental mold when creating the dental model. The pin locator can also include removable tapered pins for use in aligning with specific teeth of the dental mold.

Owner:HUFFMAN RONALD E

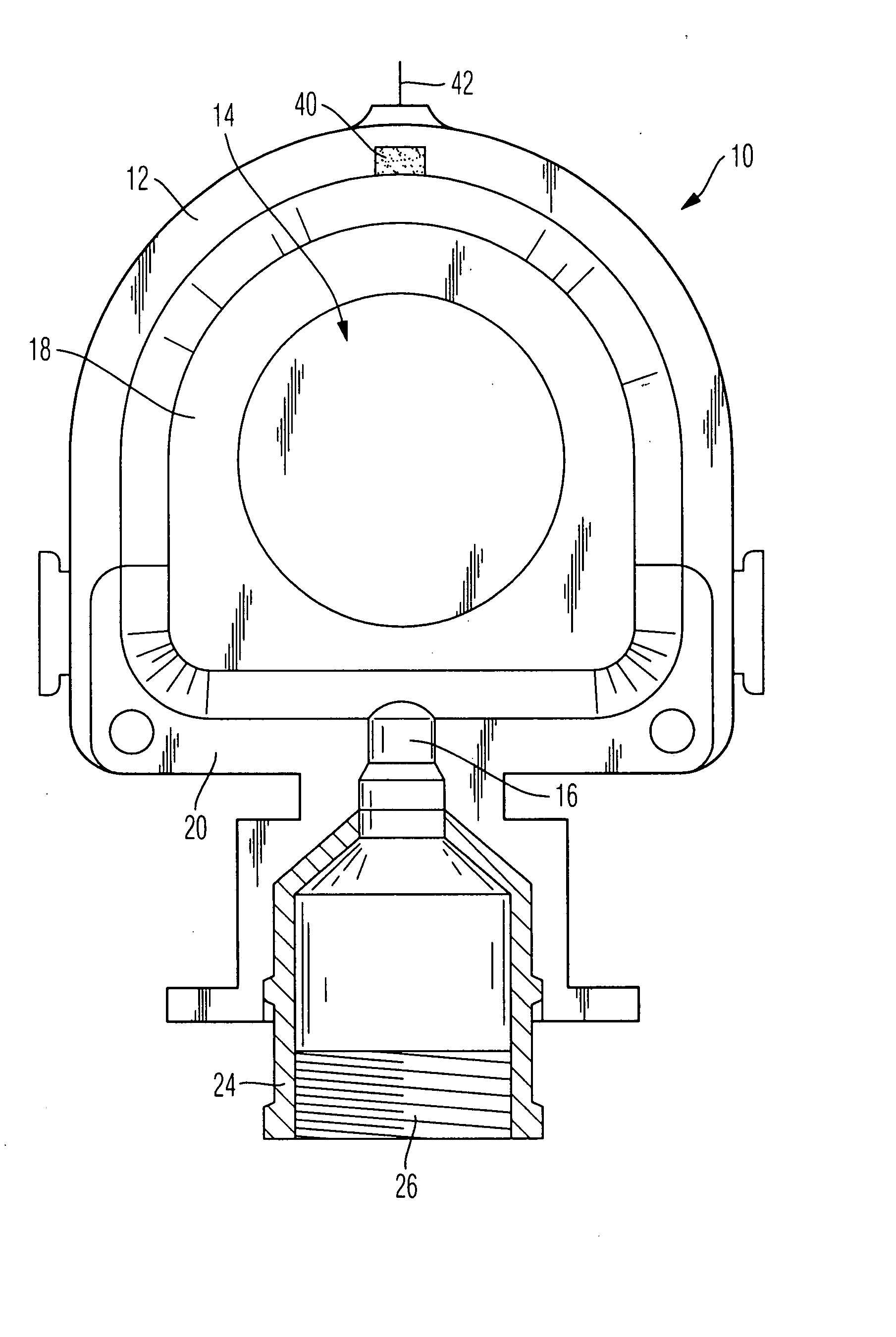

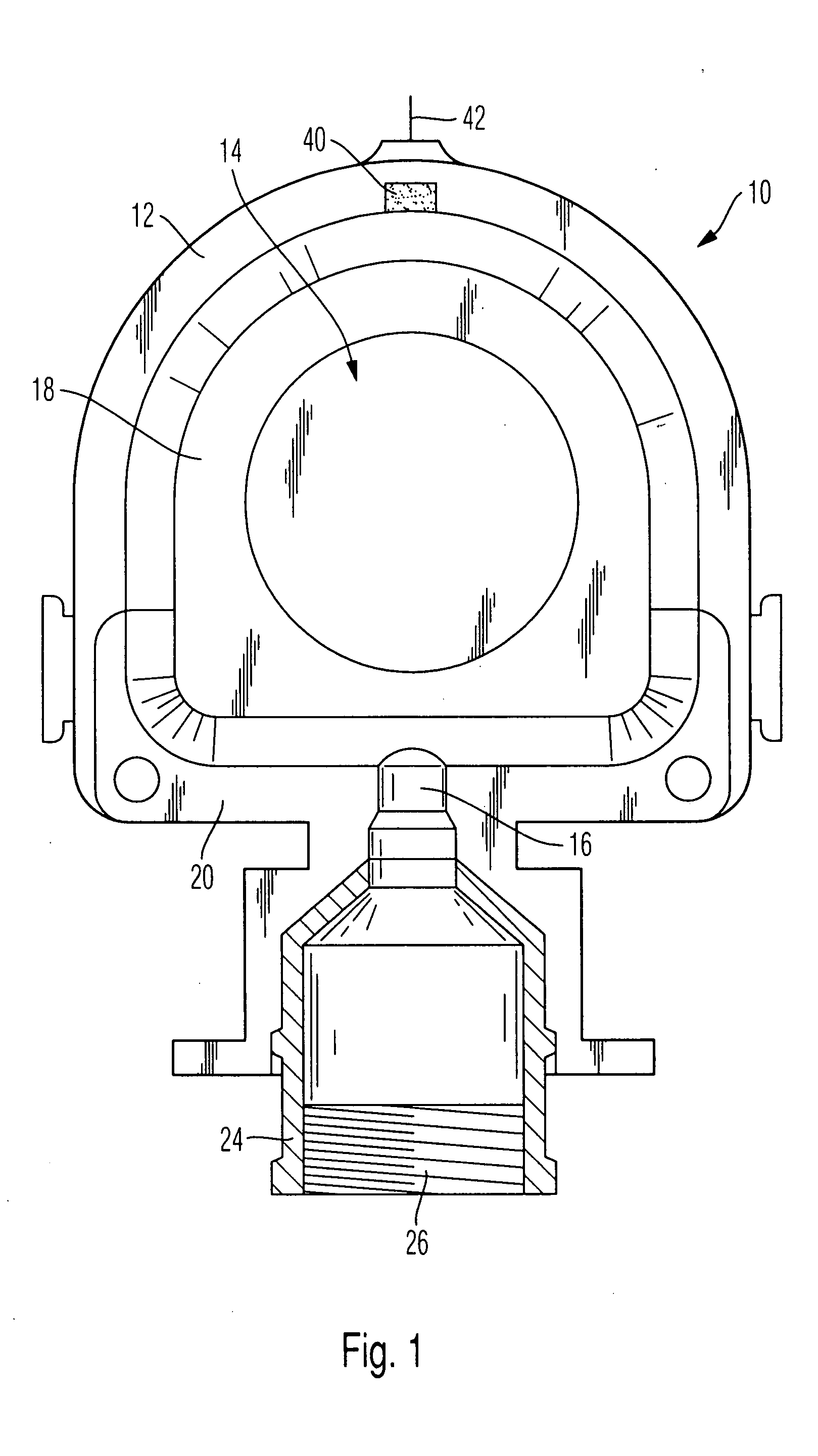

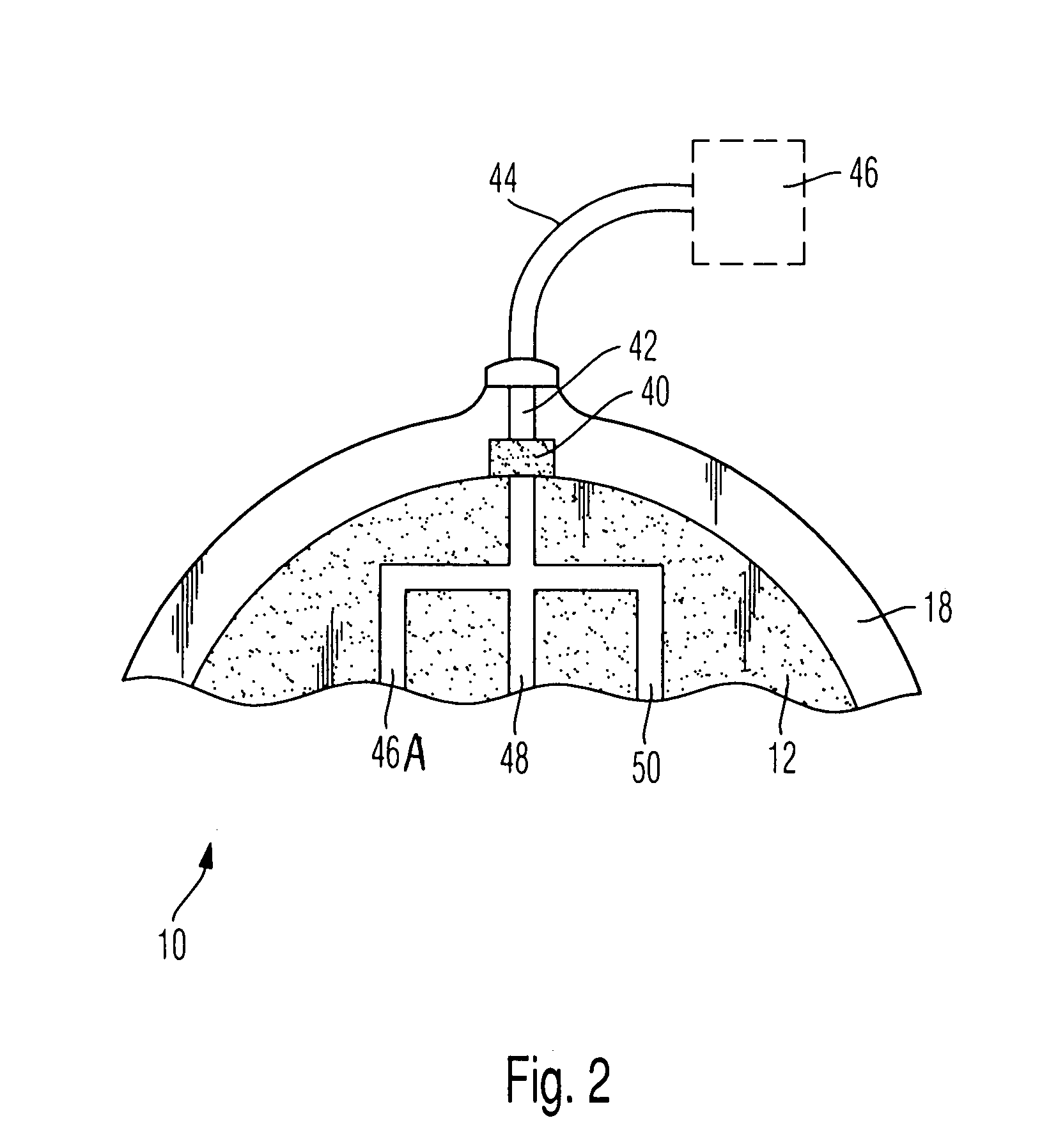

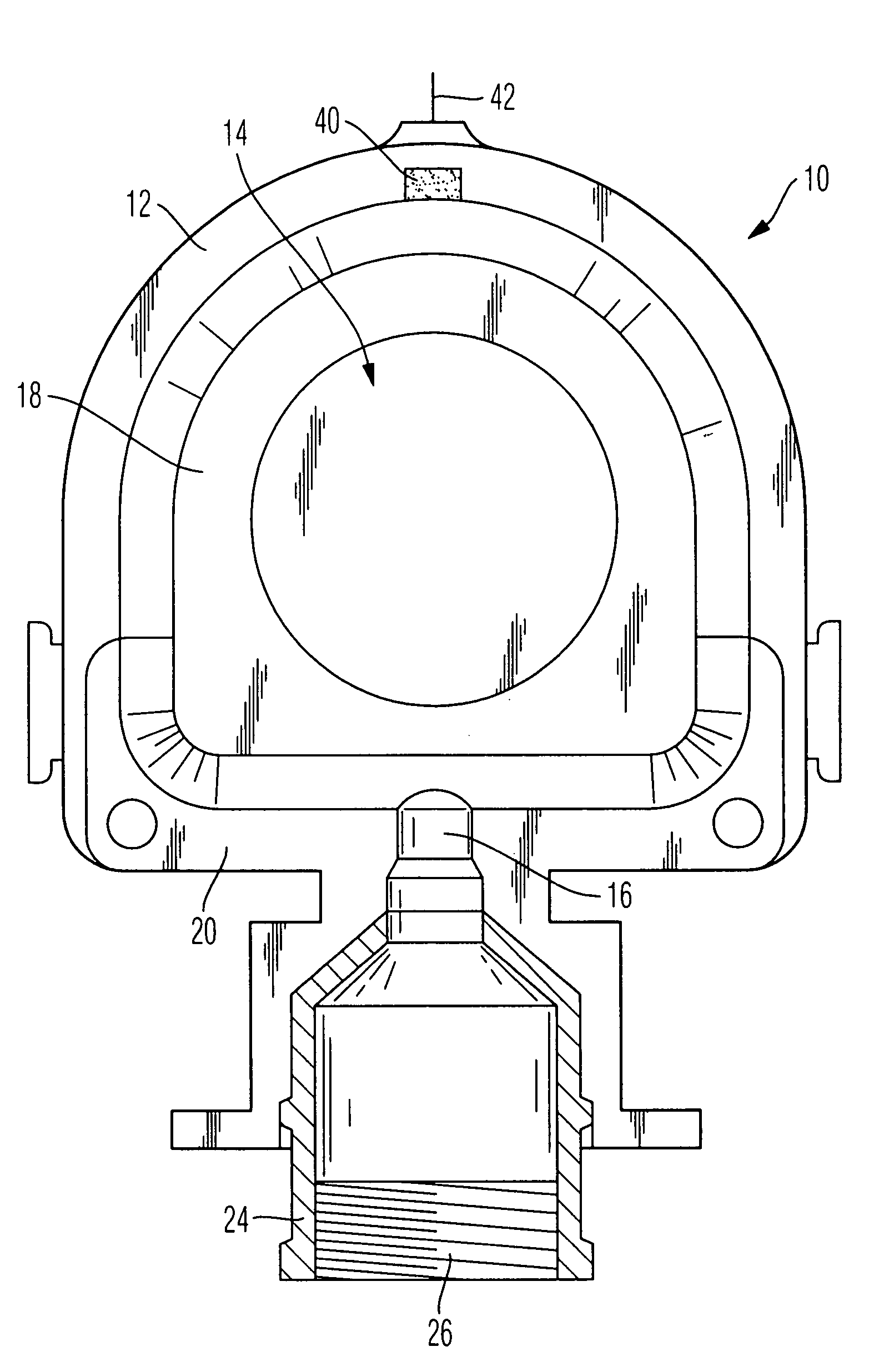

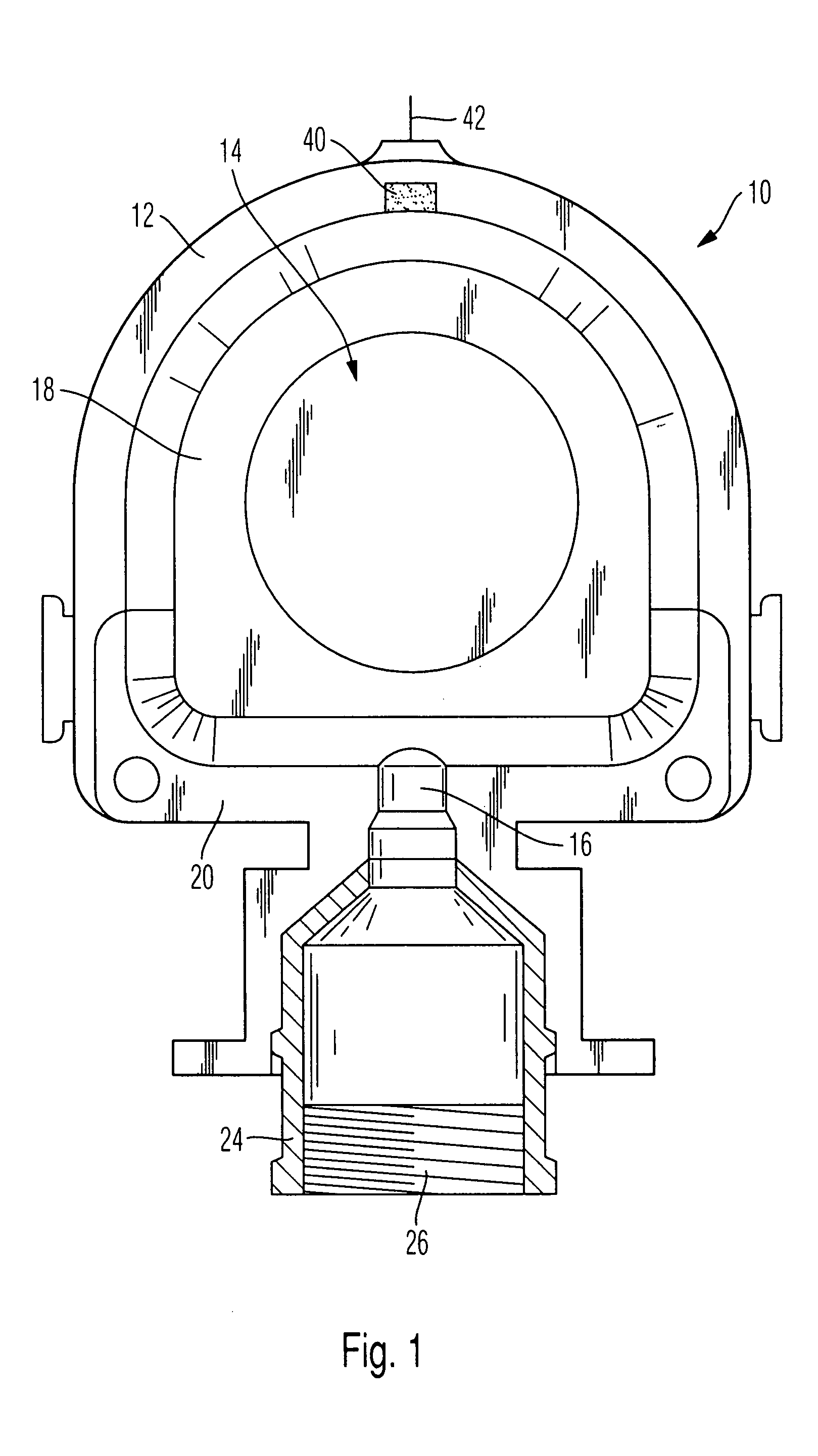

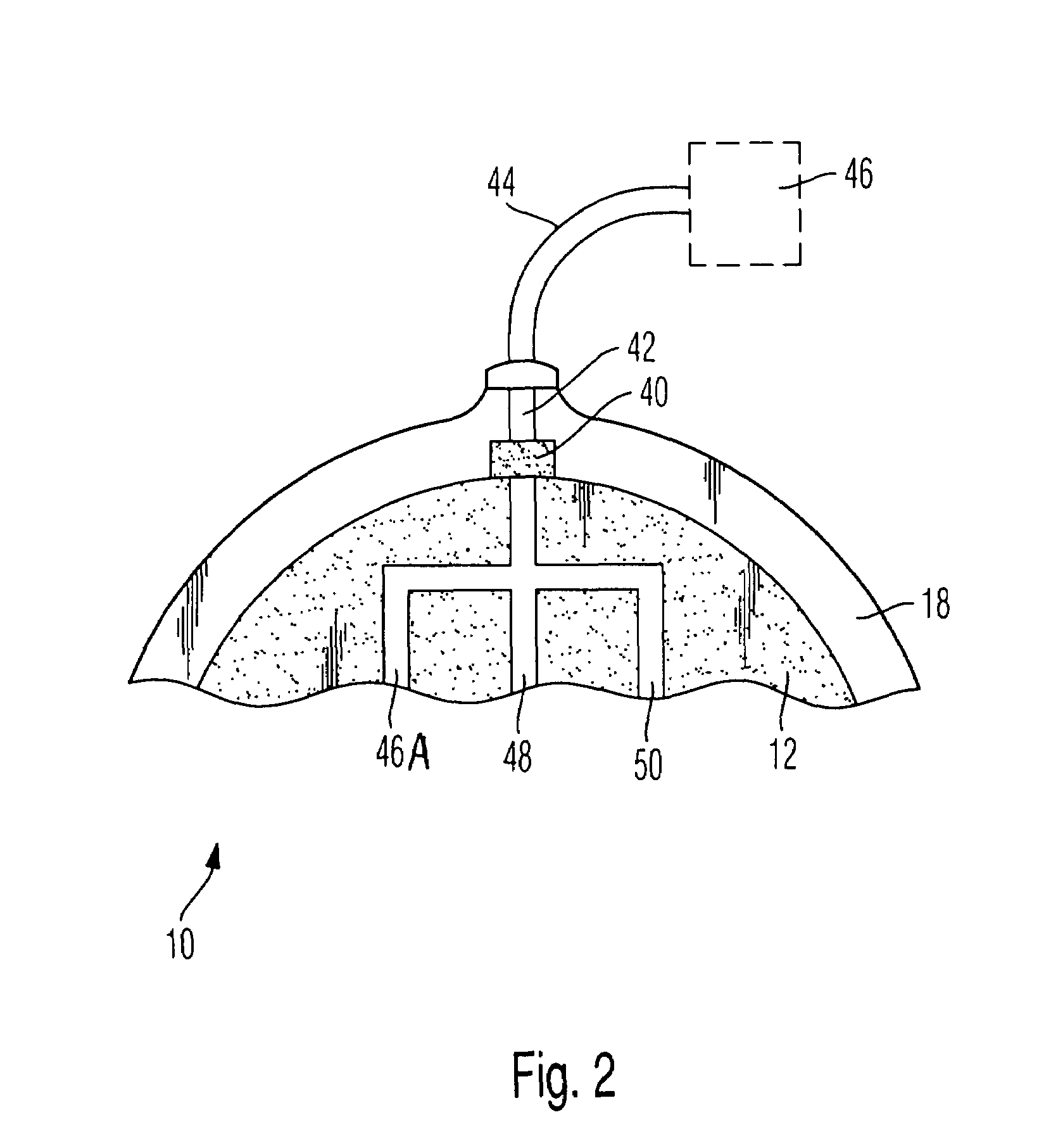

Dental mold flask

ActiveUS20080089966A1Easy to handleWide range of usesCeramic shaping apparatusLoose filtering material filtersEngineeringAir change

The invention relates to a dental mold flask (10) for production, in particular for injection molding, of dental molded parts, with at least two mold shells (12) via which a mold cavity (14) can be formed for introduction of polymerizable plastic through a filling channel (16), and with an air release channel (42) for the air that escapes during filling of the mold cavity (14). The air release channel (42) has a filter element (40) whose permeability for air changes automatically, in particular decreases, as soon as it comes into contact with the polymerizable plastic.

Owner:IVOCLAR VIVADENT AG

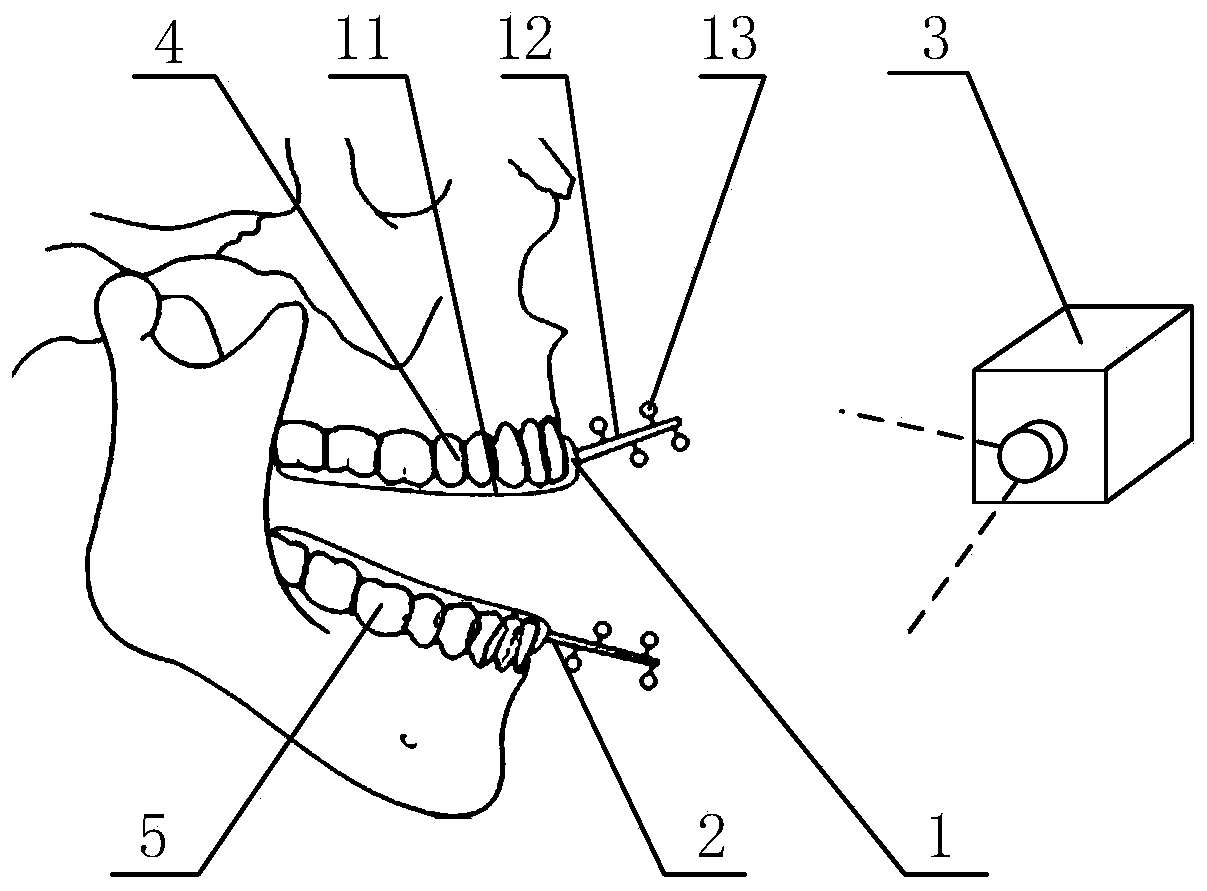

Positioning device for oral implant surgery and surgical path planning method

The invention relates to the technical field of oral treatment equipment, and discloses a positioning device for an oral implant surgery and a surgical path planning method. The positioning device includes an upper dentition positioning component, a lower dentition positioning component and a visual sensor; the upper dentition positioning component comprises a first dental mold sleeve plate and afirst visual marking member, the first dental mold sleeve plate is used for fitting the upper dentition, and the first visual marking member is connected to the first dental mold sleeve plate and protrudes the oral cavity; the lower dentition positioning component includes a second dental mold sleeve plate and a second visual marking member, the second dental mold sleeve plate is used for fittingthe lower dentition, and the second visual marking member is coupled to the second dental mold sleeve plate and protrudes the oral cavity; and a lens of the visual sensor is oriented towards a surgical field. The positioning device uses a machine vision system to convert a three-dimensional model in an occlusal state, performs preoperative measurement and intraoperative monitoring of the patient'sjaw position, and can improve the safety of the operation.

Owner:BEIJING YAKEBOT TECH CO LTD

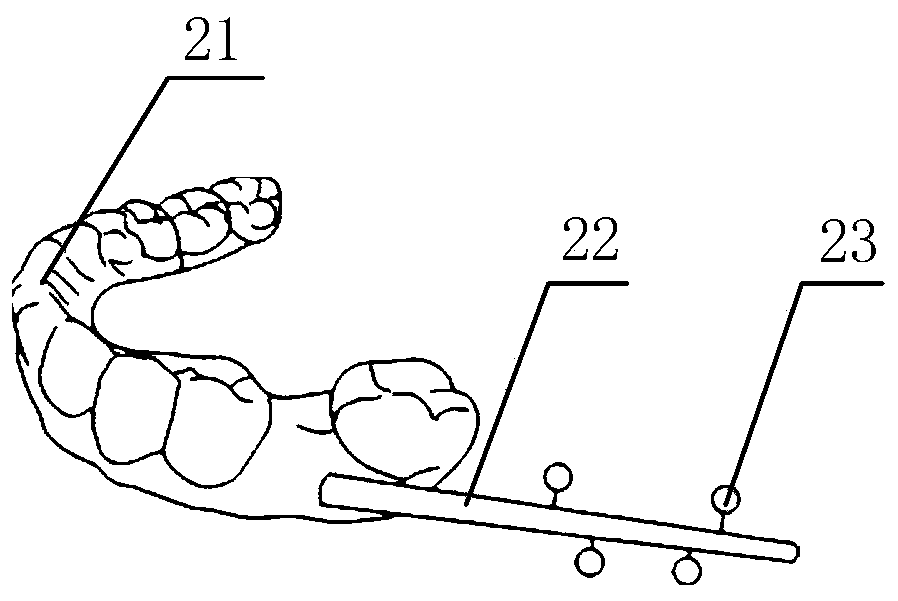

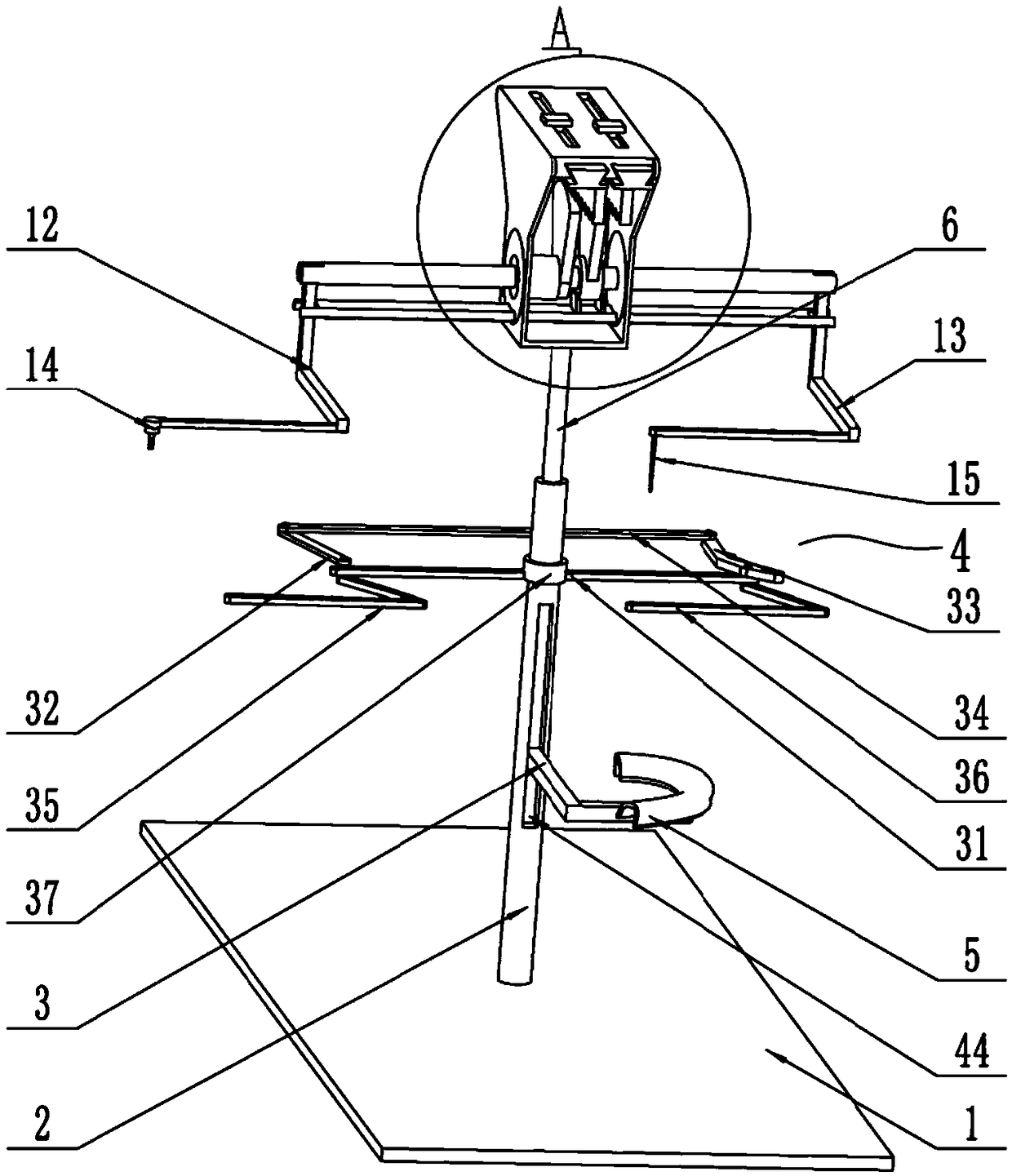

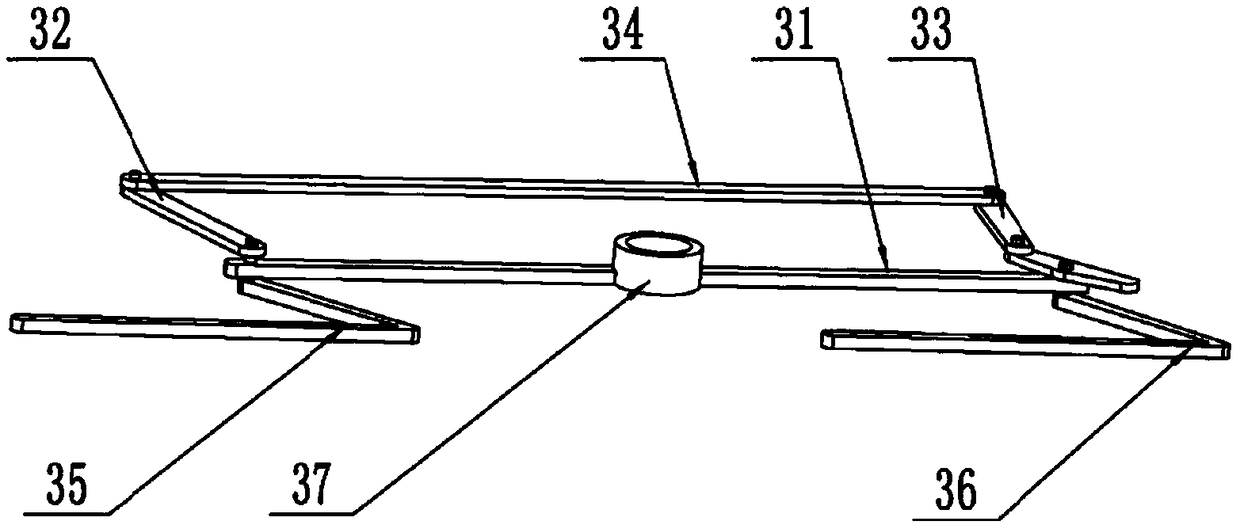

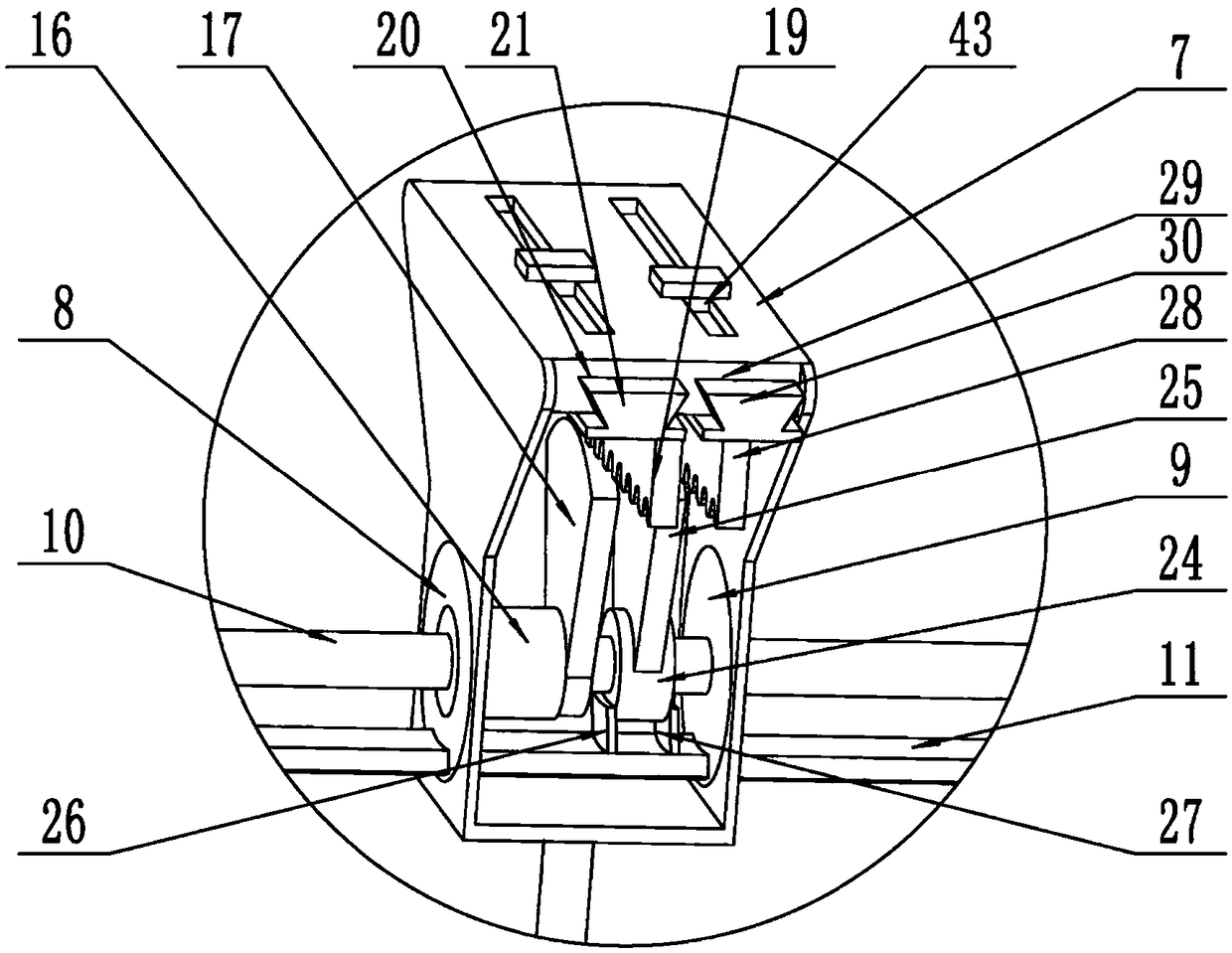

A guide plate positioner for implantation operation

ActiveCN109199616AAvoid unfavorable surgical conditionsReduced tactile sensitivityDental implantsEngineeringMouth opening

A guide plate positioner for implantation operation solves the problems that the implantation guide plate positioning implantation direction, the operation field of view is not wide enough in depth, the tactile sensitivity of an operator is reduced, and the mouth opening degree of some patients is insufficient, and the implantation guide plate positioner is used for positioning implantation direction. Including the base, a first support column is fixed on the base. A support frame is arranged on that first support column, a dental mold is arranged on the support frame, a positioning frame is arranged above the support frame, a second support column is vertically liftable in the first support column, a box body is fixed on the second support column, a first turntable is arranged on the boxbody, Second turntable, the first link and the second link, first connecting rod, the second connecting rod penetrates left and right through the first turntable and the second turntable. The left endof the first connecting rod is hinged with a first operating lever, the first operating lever is hinged with the left end of the second connecting rod, the right end of the second connecting rod is hinged with a second operating lever, the second operating lever is hinged with the right end of the second connecting rod, a drill bit is fixed on the first operating lever, and a guide needle is fixed on the second operating lever.

Owner:THE FIRST AFFILIATED HOSPITAL OF ZHENGZHOU UNIV

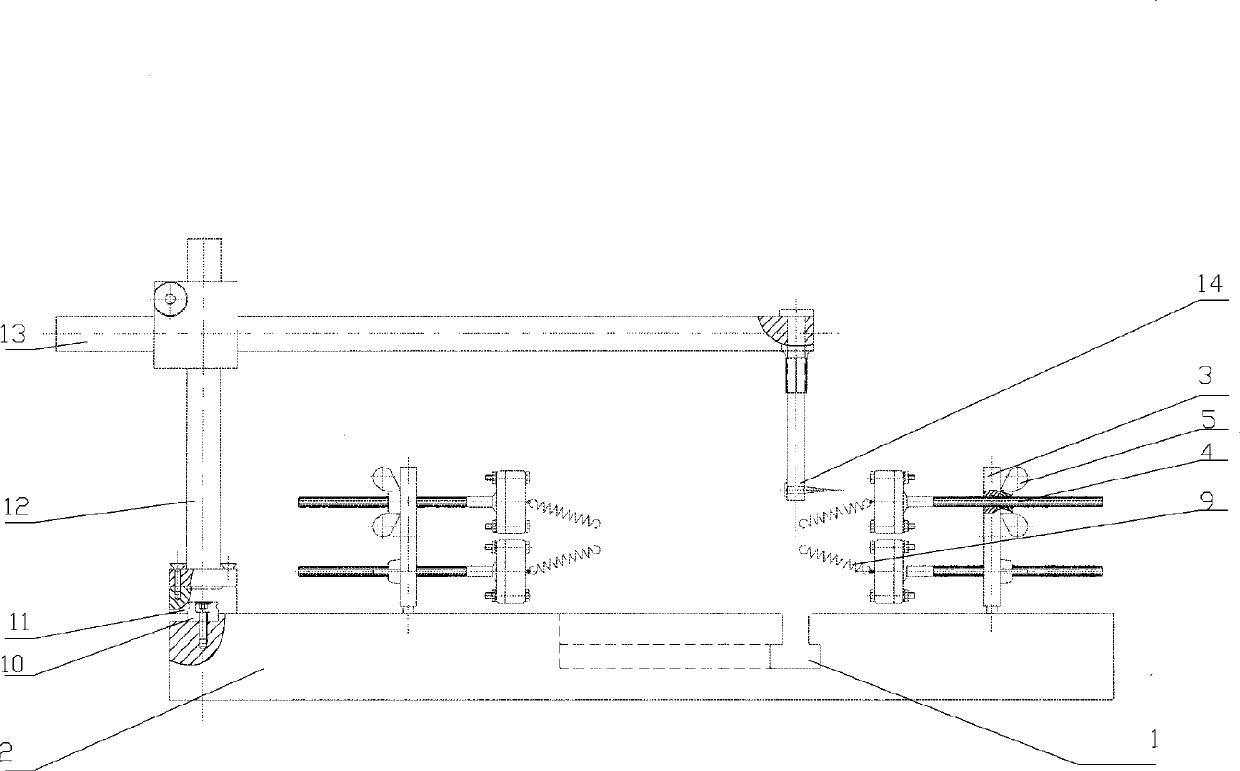

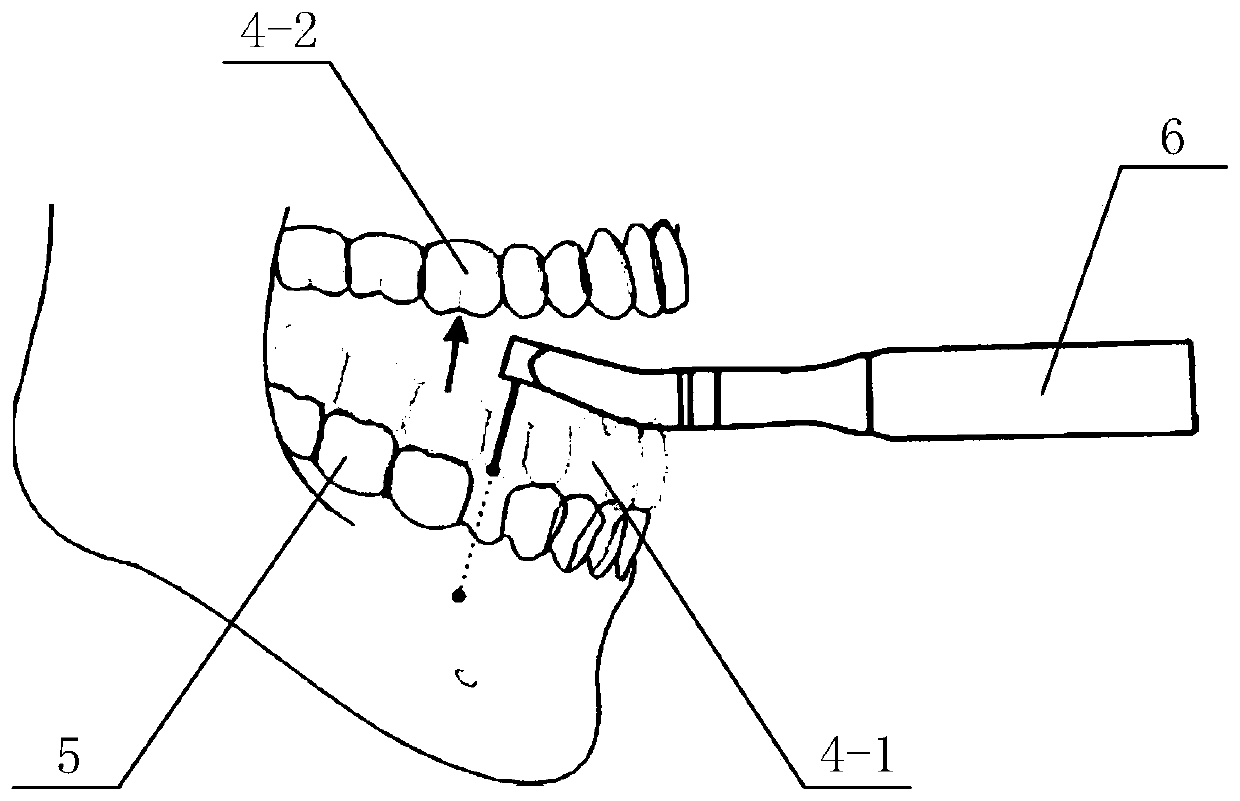

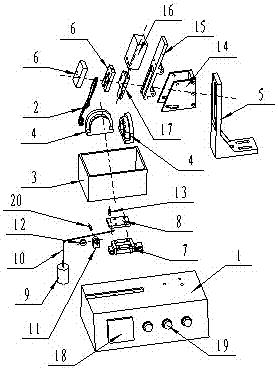

Tester for testing toothbrush bristles durability

ActiveCN104458458BEasy to operateEasy to useMaterial strength using repeated/pulsating forcesInvestigating abrasion/wear resistanceBristleWarm water

The invention discloses a tester for testing the durability of toothbrush bristles, which comprises a tester base 1, a toothbrush 2 and a dental mold warm water tank 3. A dental mold 4 is fixedly installed in the dental mold warm water tank. The test A horizontal counterweight device is provided on the base of the instrument, and the dental mold temperature water tank is fixedly installed on the horizontal counterweight device. A bracket 5 is also provided on the base of the tester, and an angle adjustment device is installed on the bracket. Clamp driving device is installed on the angle adjustment device, the clamp driving device is provided with toothbrush clamp 6, the toothbrush is fixedly clamped on the toothbrush clamp, and the bristles of the toothbrush stretch into the dental mold warm water tank and contact the dental mold. The invention has the beneficial effects of automatic testing, time saving and labor saving, and good testing effect.

Owner:GUANGDONG AITE ROLLER BRUSH TECH CO LTD

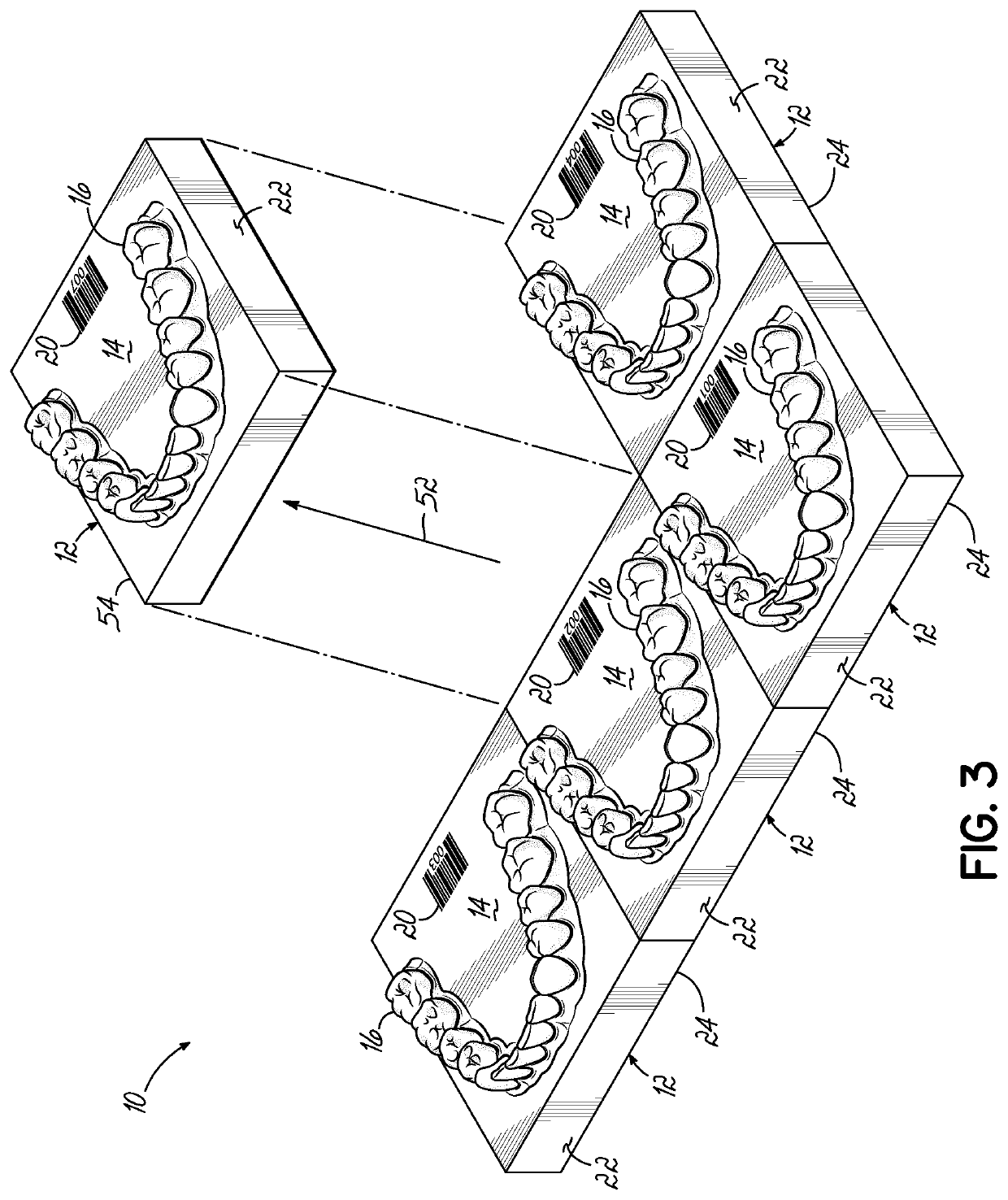

Systems and methods of identifying and tracking dental molds in automated aligner fabrication systems

An aligner fabrication system combines design data and material to form a plurality of dental molds with which a plurality of aligners are formed. The aligner fabrication system includes a build assembly that defines a build surface on which the dental molds are formed. The build assembly is constructed of a plurality of individual build platforms that are removably coupled together. Each individual build platform is associated with an identification entity. The dental molds are formed on the build surface. One dental mold is formed on one individual build platform. The design data associated with the one dental mold is linkable to the identification entity on the one individual build platform.

Owner:ORMCO CORP

Methods for correcting tooth movements midcourse in treatment

InactiveUS20060257814A1Additive manufacturing apparatusImpression capsORTHODONTIC PROCEDURESDentition

Owner:ALIGN TECH

Dental mold flask

ActiveUS7578667B2Easy to handleWide range of usesCeramic shaping apparatusLoose filtering material filtersEngineeringAir change

The invention relates to a dental mold flask (10) for production, in particular for injection molding, of dental molded parts, with at least two mold shells (12) via which a mold cavity (14) can be formed for introduction of polymerizable plastic through a filling channel (16), and with an air release channel (42) for the air that escapes during filling of the mold cavity (14). The air release channel (42) has a filter element (40) whose permeability for air changes automatically, in particular decreases, as soon as it comes into contact with the polymerizable plastic.

Owner:IVOCLAR VIVADENT AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com