Patents

Literature

1425 results about "Intermediate stage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An intermediate stage, level, or position is one that occurs between two other stages, levels, or positions. You should consider breaking the journey with intermediate stopovers at airport hotels. Intermediate learners of something have some knowledge or skill but are not yet advanced .

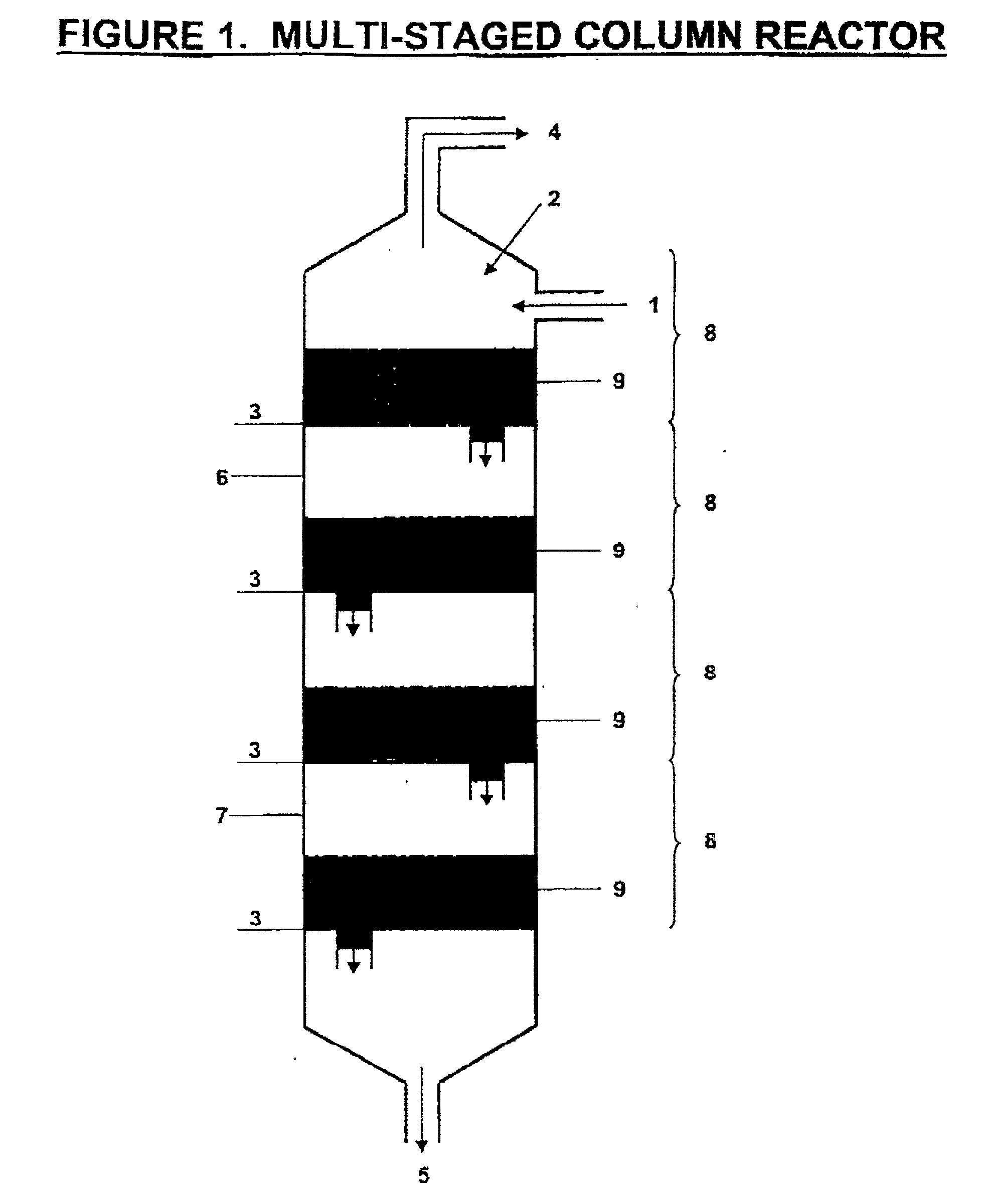

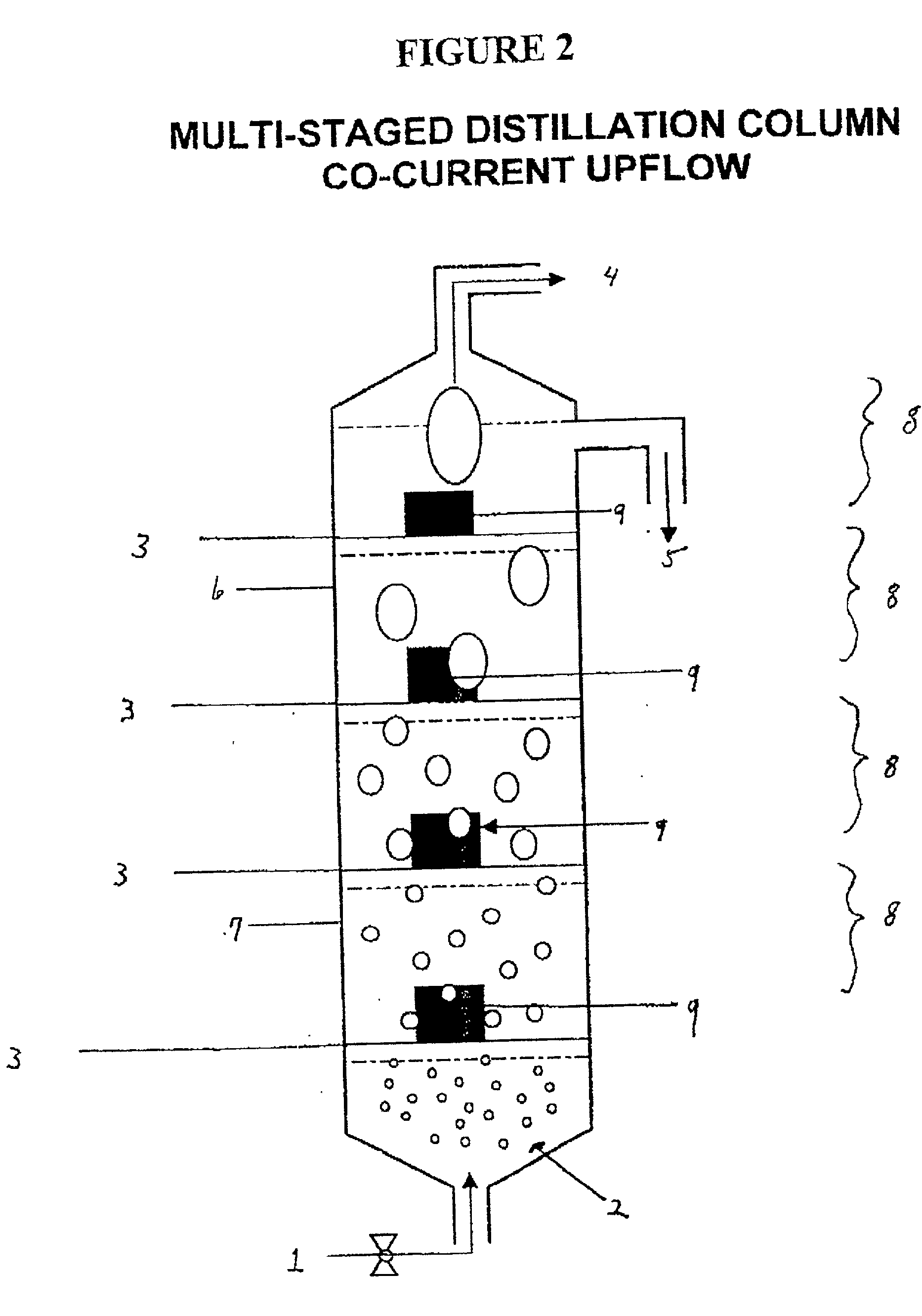

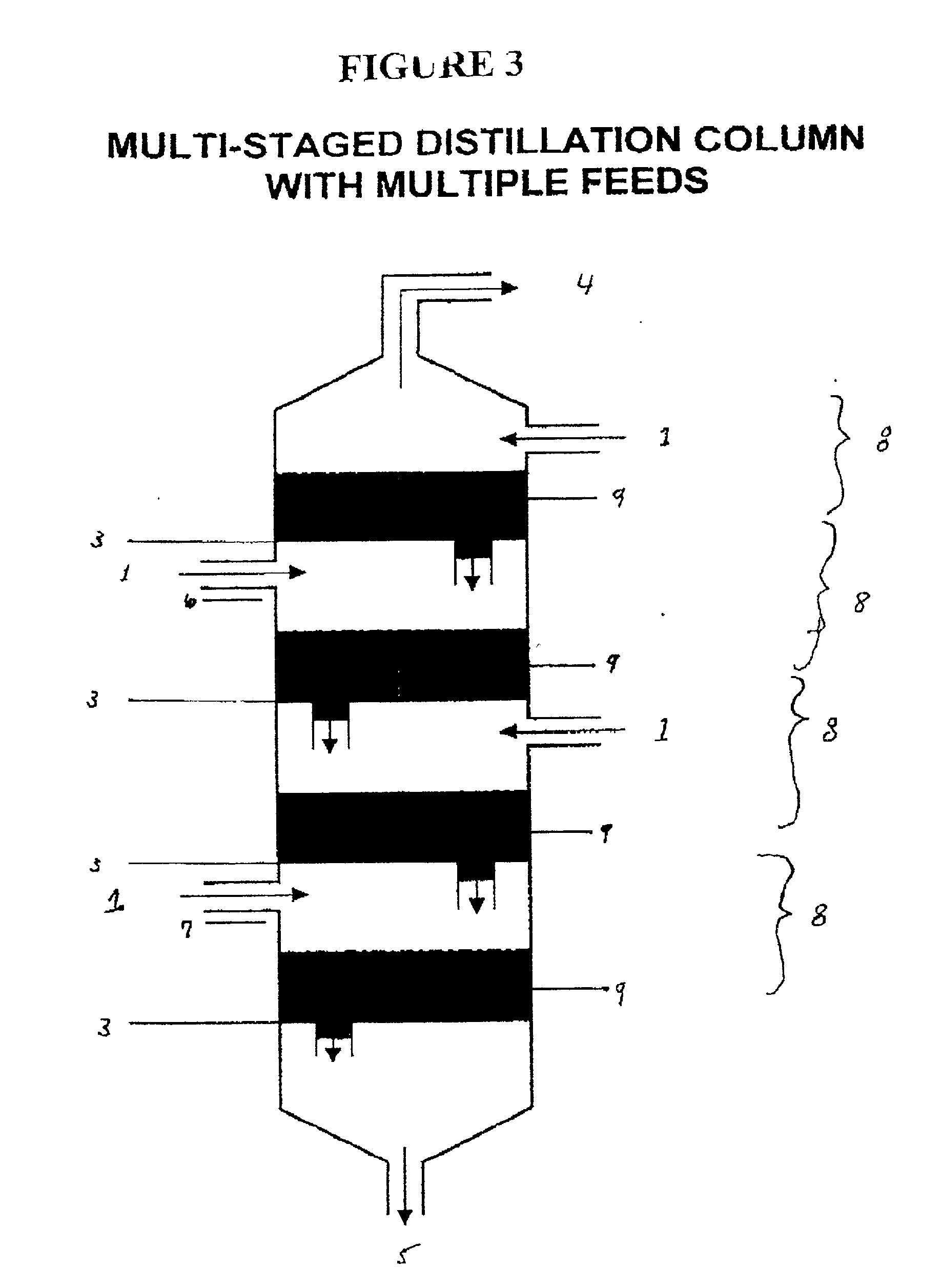

Continuous process for the preparation of polytrimethylene ether glycol

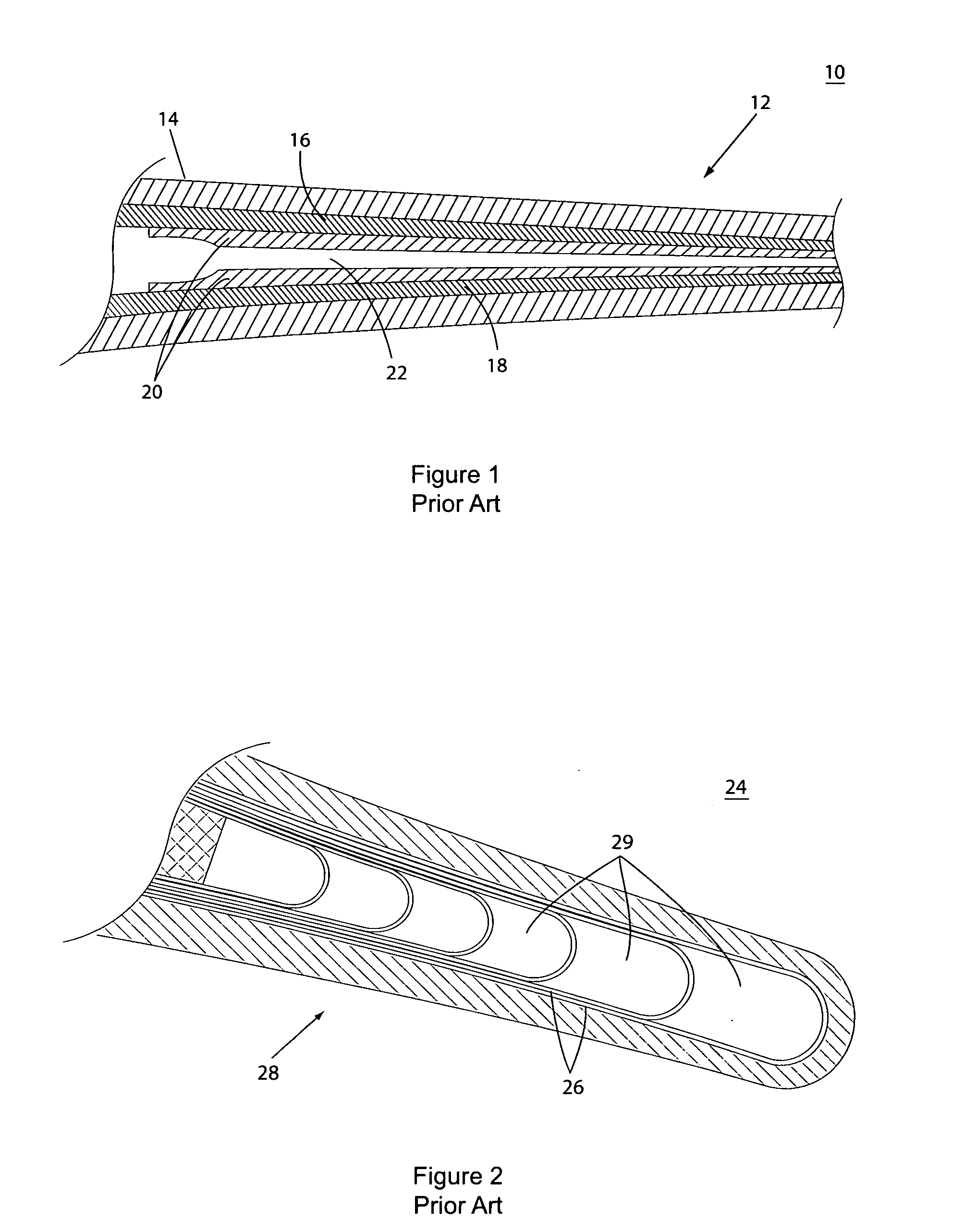

InactiveUS6720459B2Liquid-gas reaction as foam/aerosol/bubblesOrganic compound preparationGas phaseEther

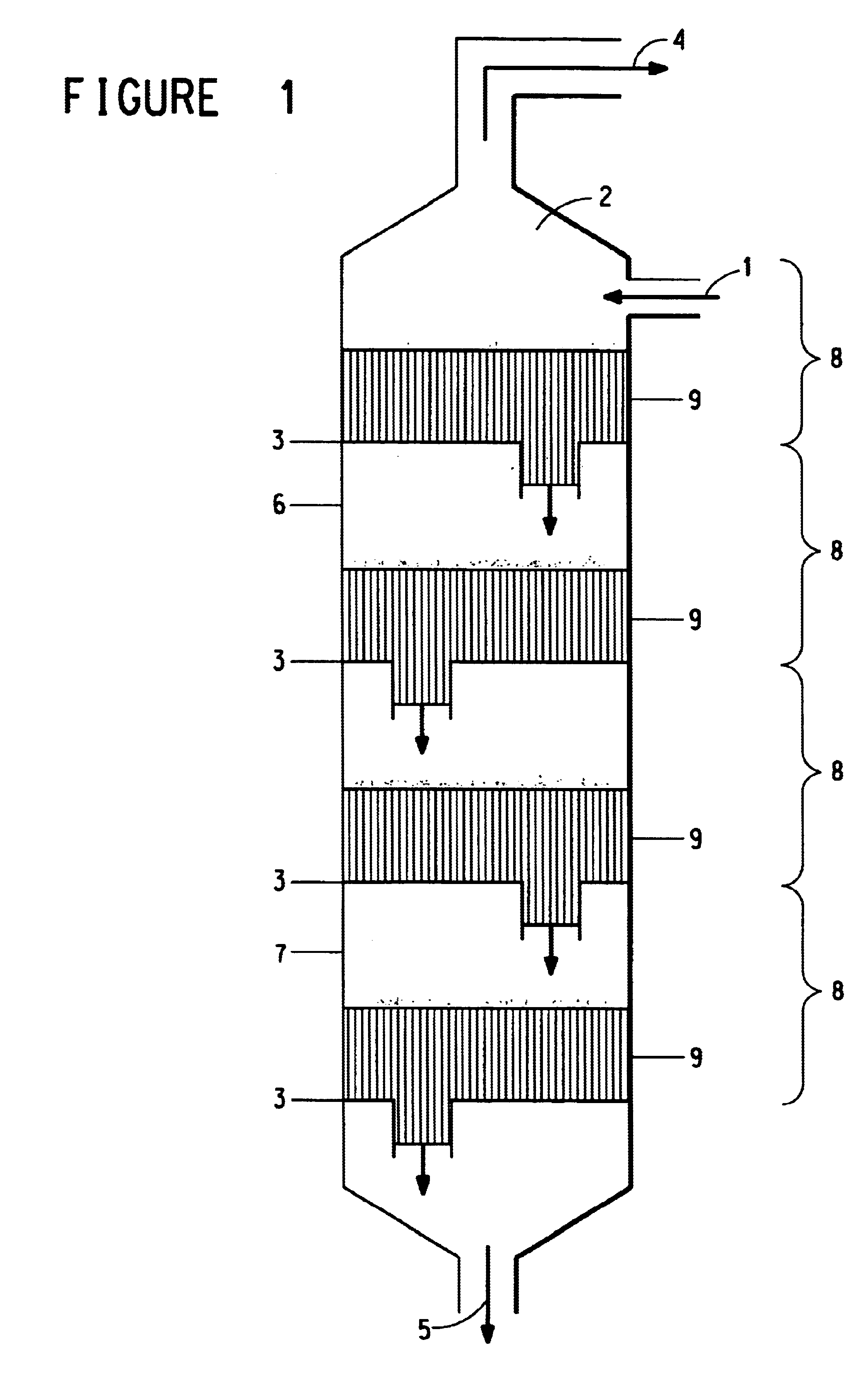

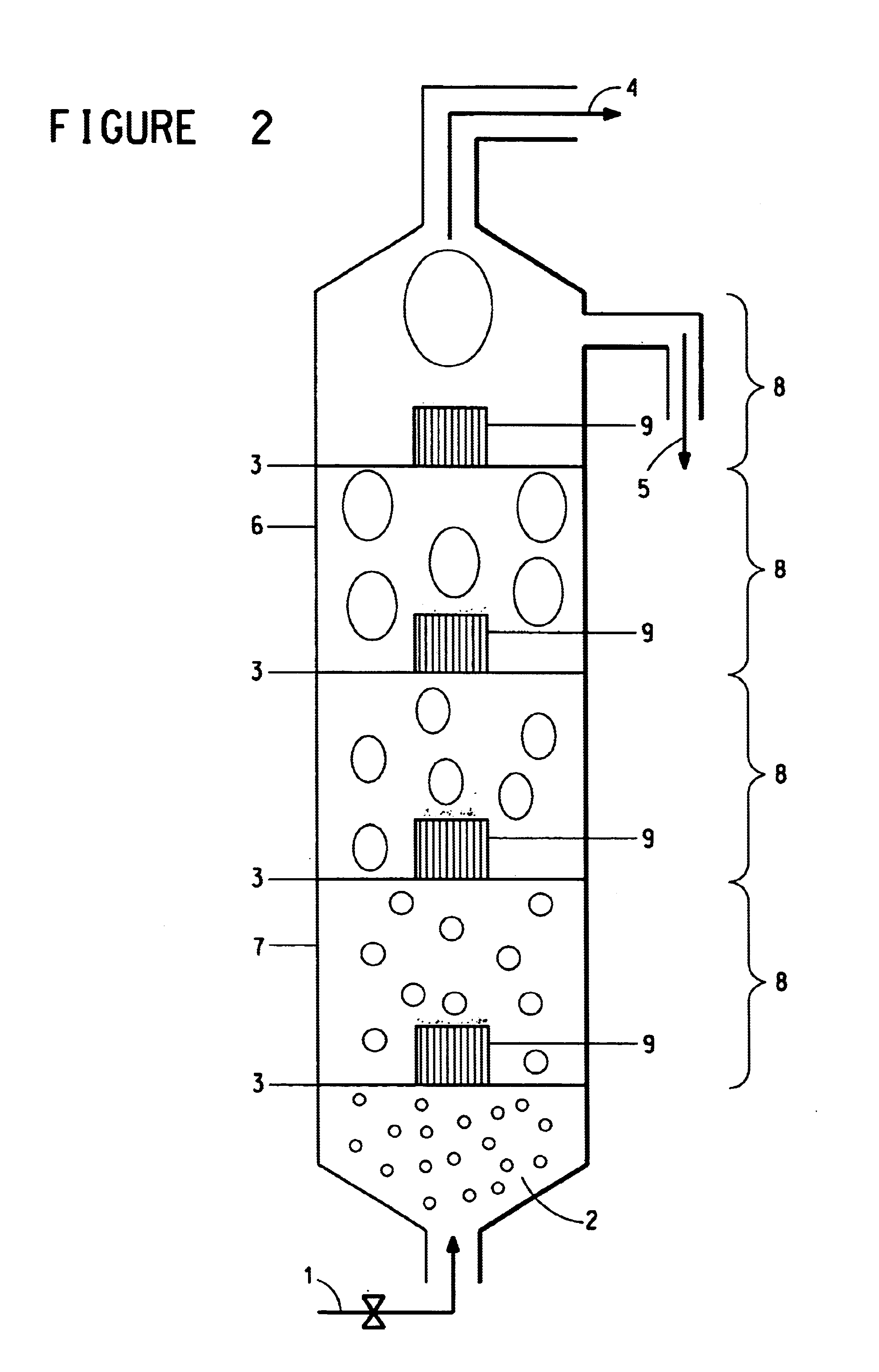

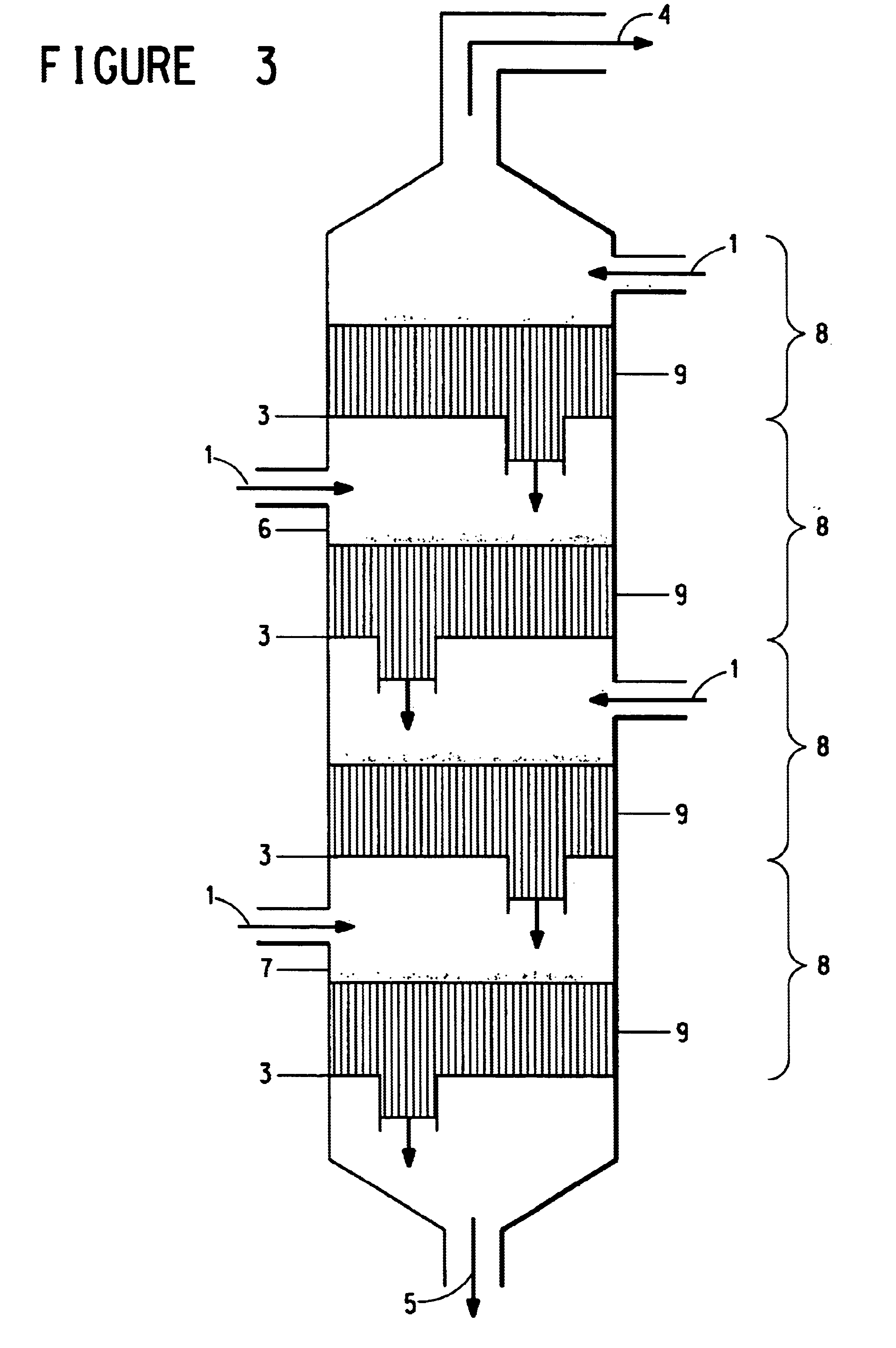

The invention is a continuous process for the preparation of polytrimethylene ether glycol from 1,3-propanediol reactant. In addition, the invention is directed to a continuous multi-stage process comprising reacting at least one reactant in a liquid phase in an up-flow column reactor, and forming a gas or vapor phase by-product wherein the gas or vapor phase by-product is continuously removed at the top and at least one intermediate stage.

Owner:DUPONT CA +1

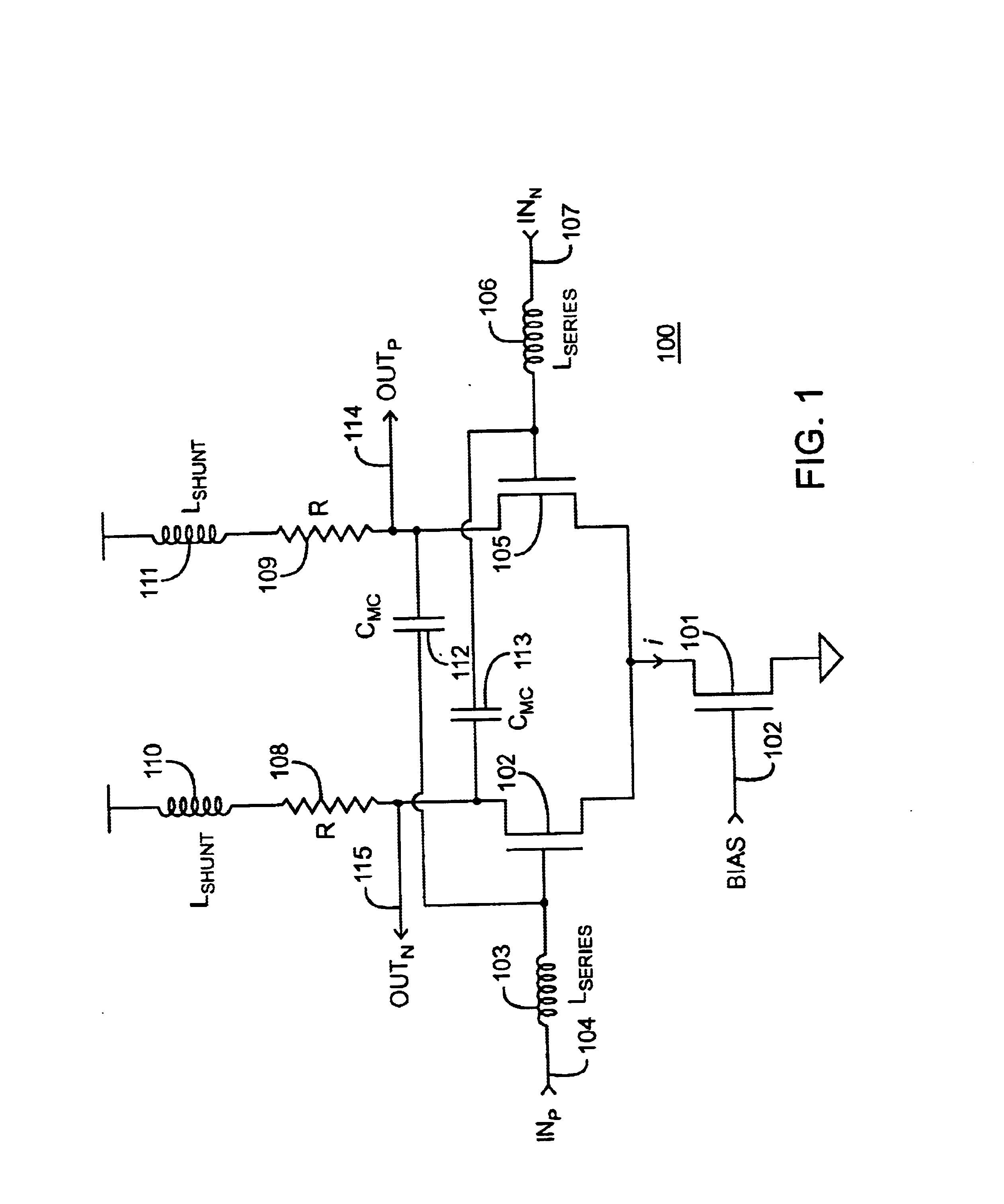

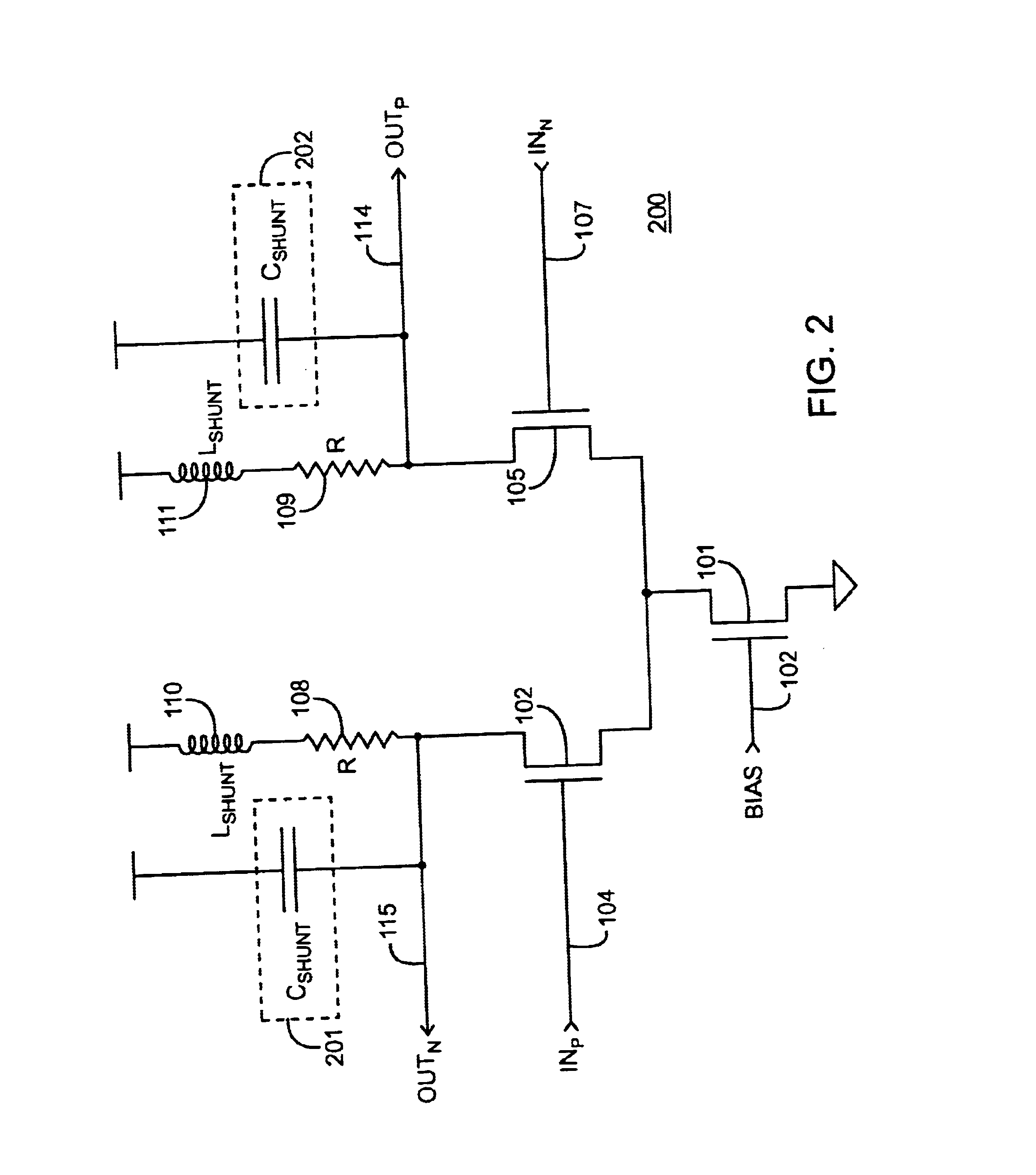

Current-controlled CMOS wideband data amplifier circuits

InactiveUS6624699B2Maximum bandwidth expansionReduced Miller CapacitanceAmplifier combinationsAmplifier modifications to reduce detrimental impedenceCapacitanceCMOS

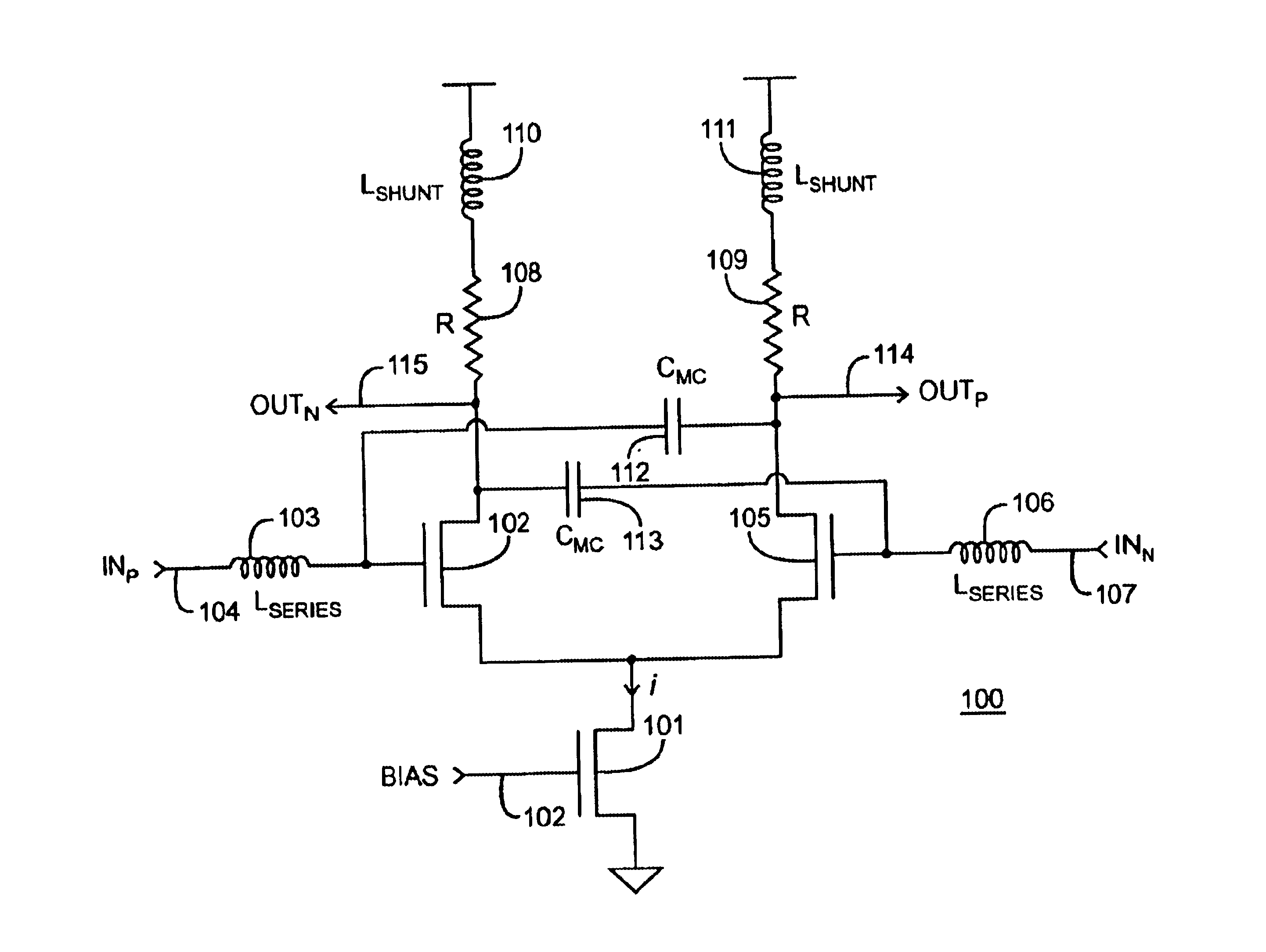

Expansion of the bandwidth of a wideband CMOS data amplifier is accomplished using various combinations of shunt peaking, series peaking, and miller capacitance cancellation. These various combinations are employed in any of the amplifier input stage, in intermediate stages, or in the last stage.

Owner:AVAGO TECH INT SALES PTE LTD

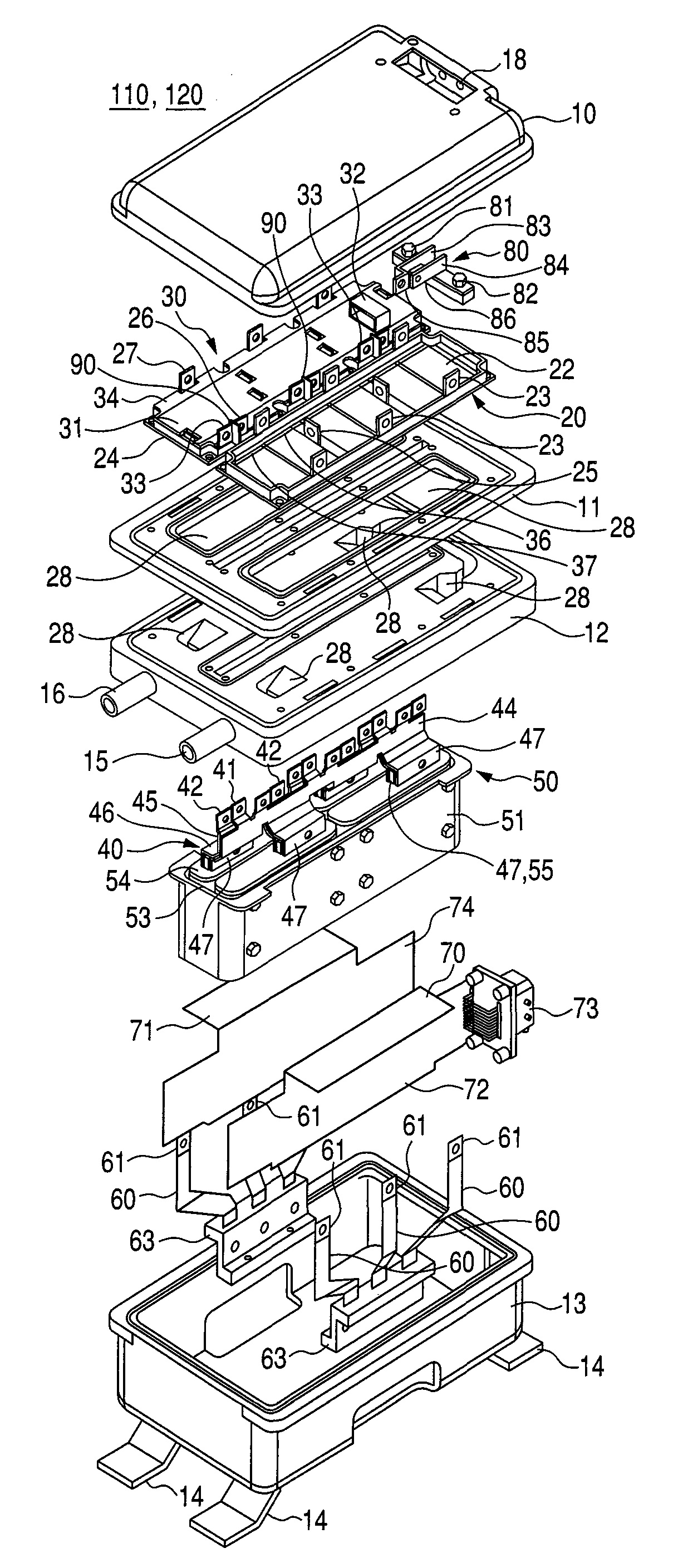

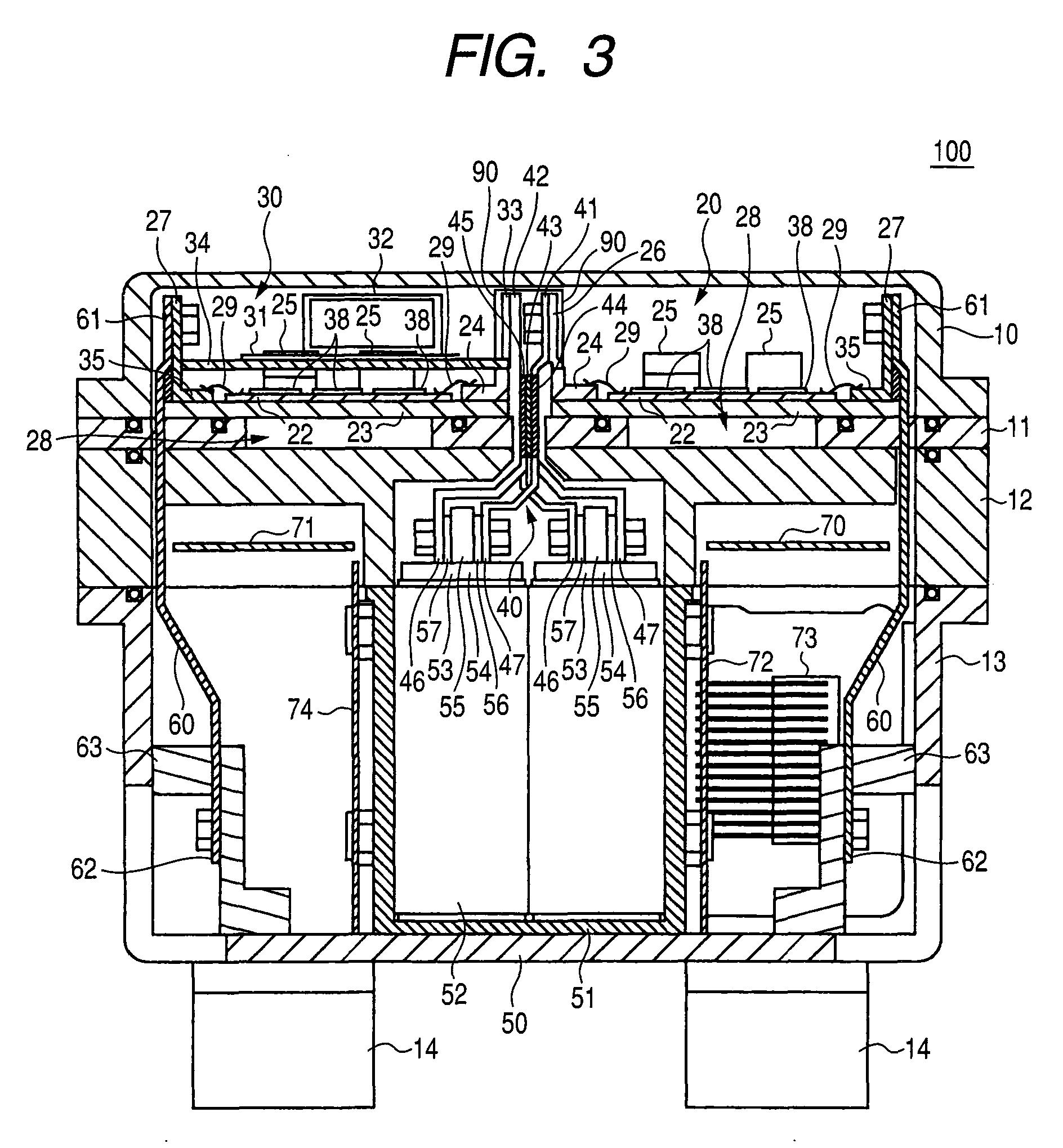

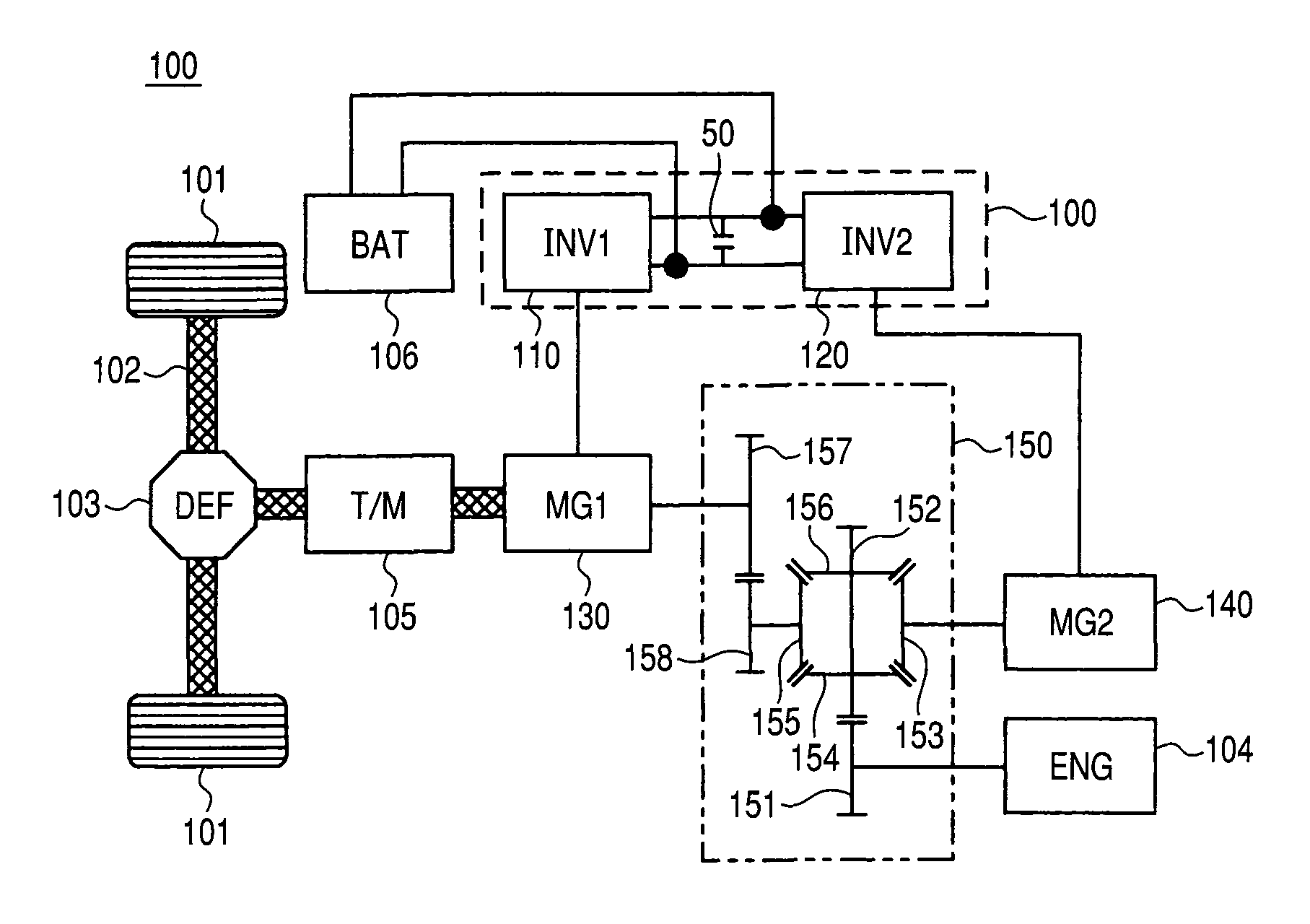

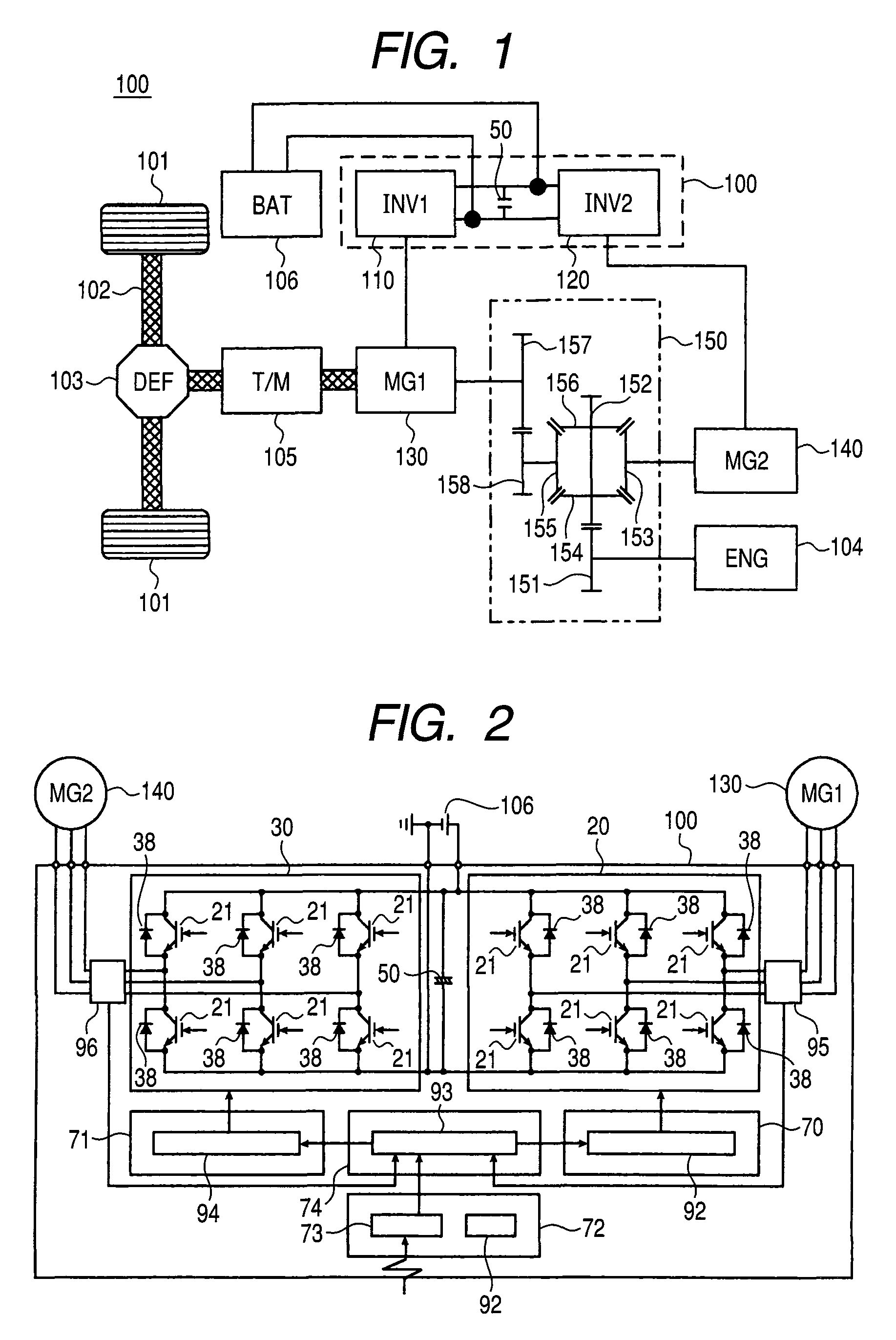

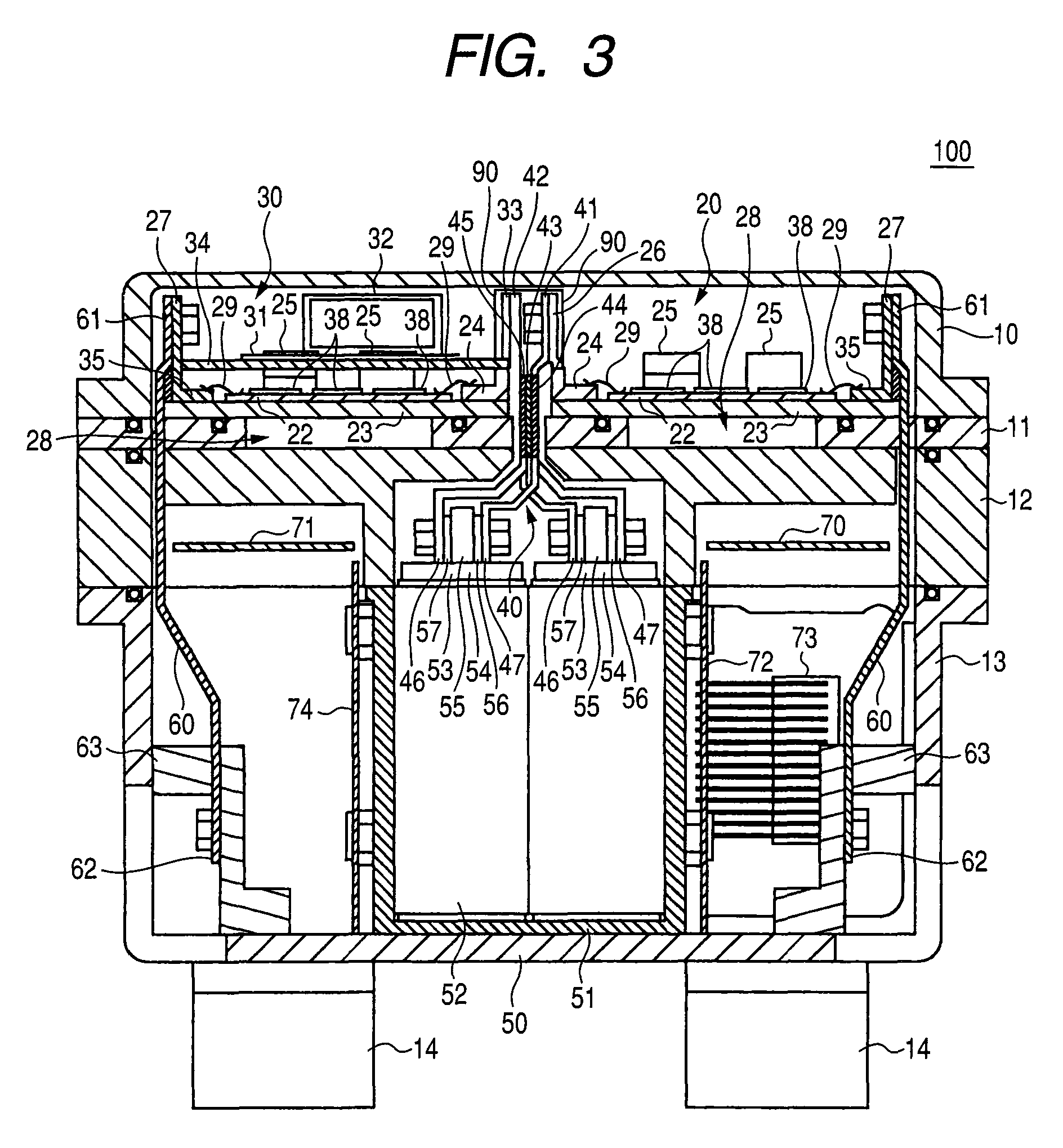

Power Converter

ActiveUS20080130223A1Avoid excessive volumeIncrease productionConversion constructional detailsSolid-state devicesIntermediate stageSemiconductor

First and second bases and composing a coolant path structure are arranged at the middle stage of the power converter, and semiconductor modules and a capacitor are arranged on both surfaces of the coolant path structure. Furthermore, through-holes are formed in the first and second bases, and cables of DC and AC circuits are laid via the through-holes.

Owner:HITACHI ASTEMO LTD

Continuous process for the preparation of polytrimethylene ether glycol

The invention is a continuous process for the preparation of polytrimethylene ether glycol from 1,3-propanediol reactant. In addition, the invention is directed to a continuous multi-stage process comprising reacting at least one reactant in a liquid phase in an up-flow column reactor, and forming a gas or vapor phase by-product wherein the gas or vapor phase by-product is continuously removed at the top and at least one intermediate stage.

Owner:DUPONT CA +1

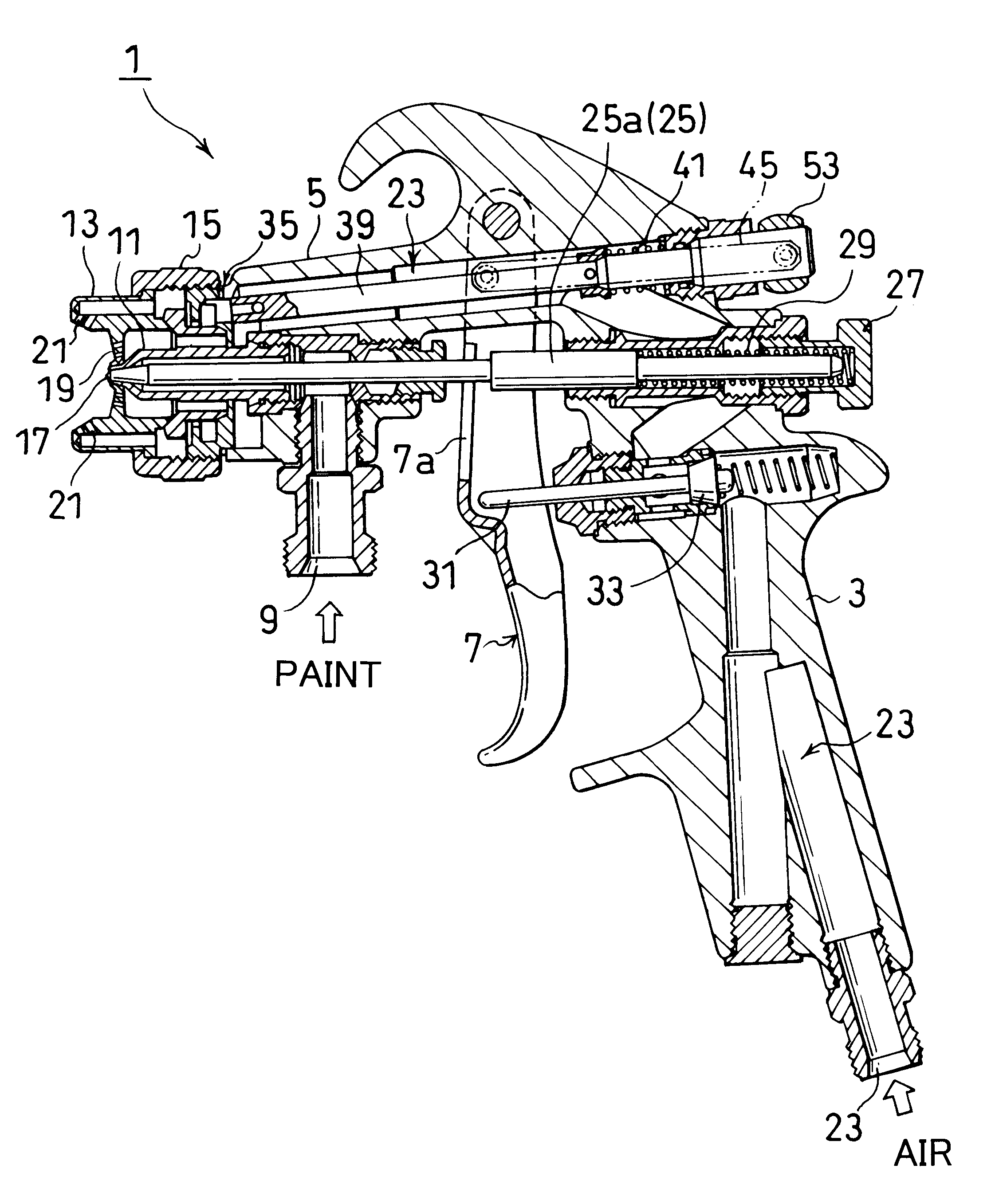

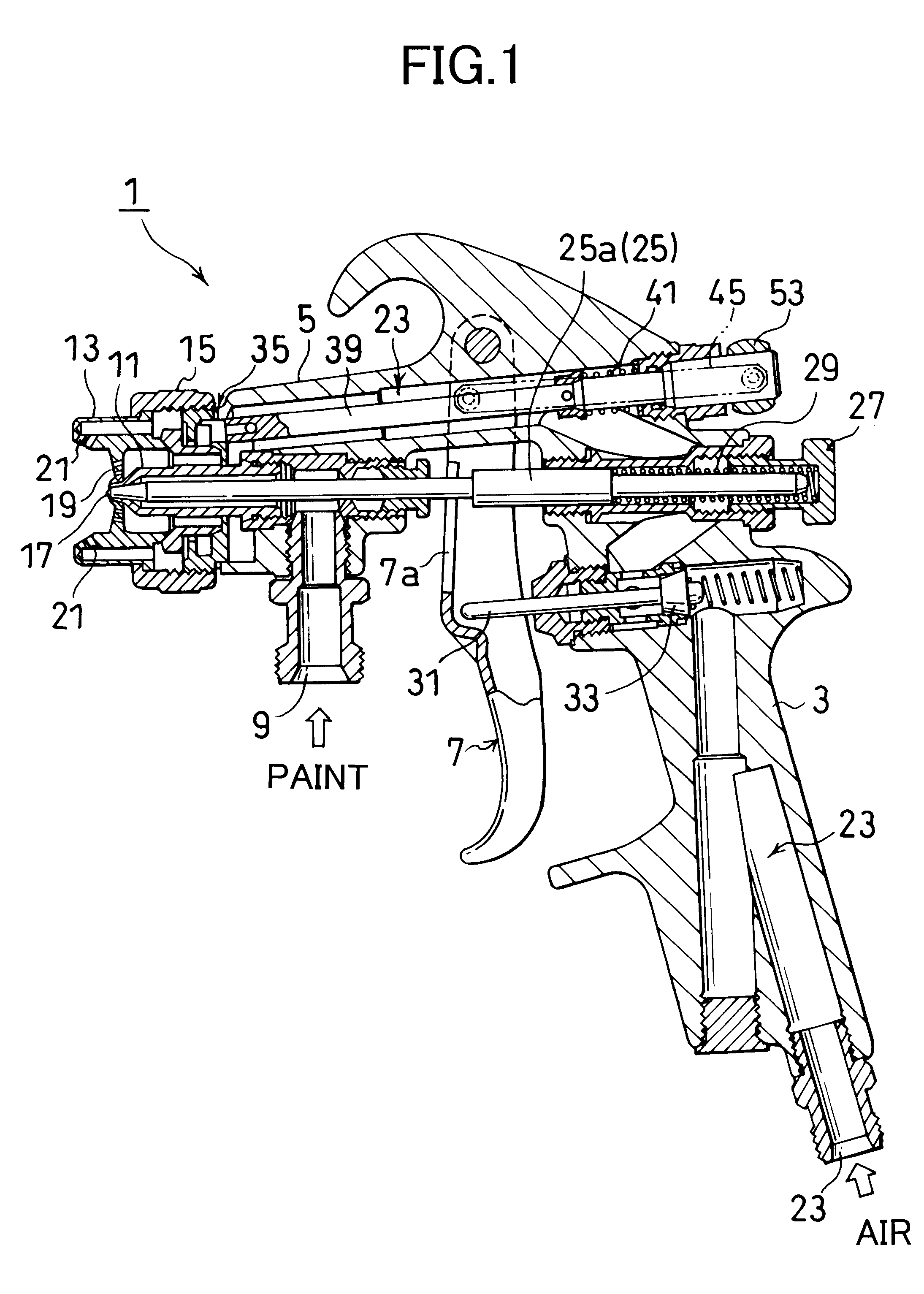

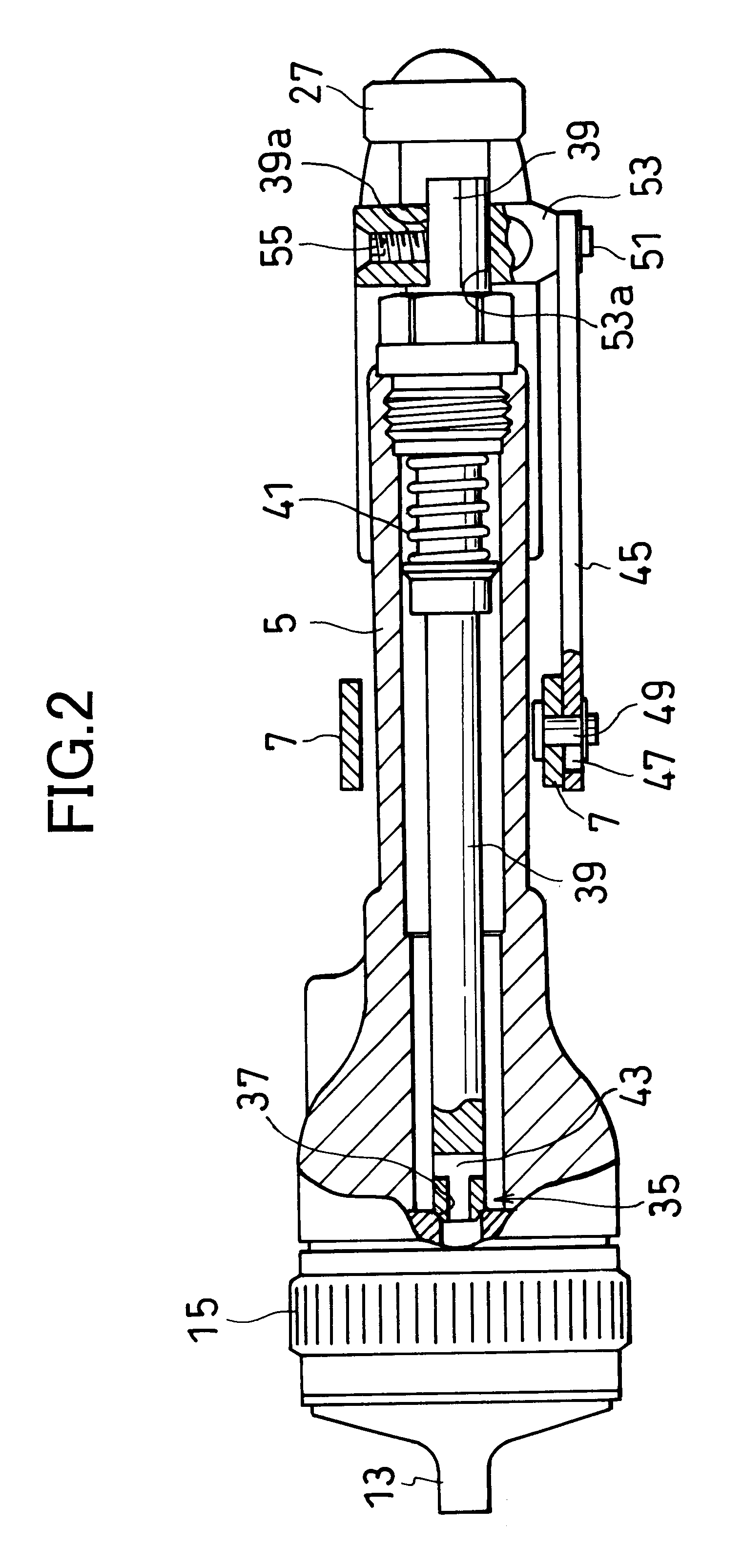

Aerosol spray gun

InactiveUS6402058B2Reduce in quantityLiquid spraying apparatusGaseous fuel burnerAerosol sprayCoupling

An aerosol spray gun used selectively in two spraying modes of small and large patterns is provided. The aerosol spray gun has a throttle valve, an air duct, and a coupling link. The throttle valve has an internal air duct for supplying pressurized air to a patterning air outlet which shapes a paint spraying stream jetted out from the aerosol spray gun, and has a movable valve element to which a compressed spring applies force to open the valve. The air duct created at the tip of the movable valve element supplies a small volume of air from the internal air duct to the patterning air outlet while the movable valve element seats on a valve seat. The coupling link, coupling the movable valve element to the trigger, has an elongated hole to disconnect the trigger from the movable valve element without cooperative relation between them from an initial stage where an operator begins to squeeze the trigger to an intermediate stage before the operator fully squeezes the trigger.

Owner:CARLISLE FLUID TECH RANSBURG JAPAN KK

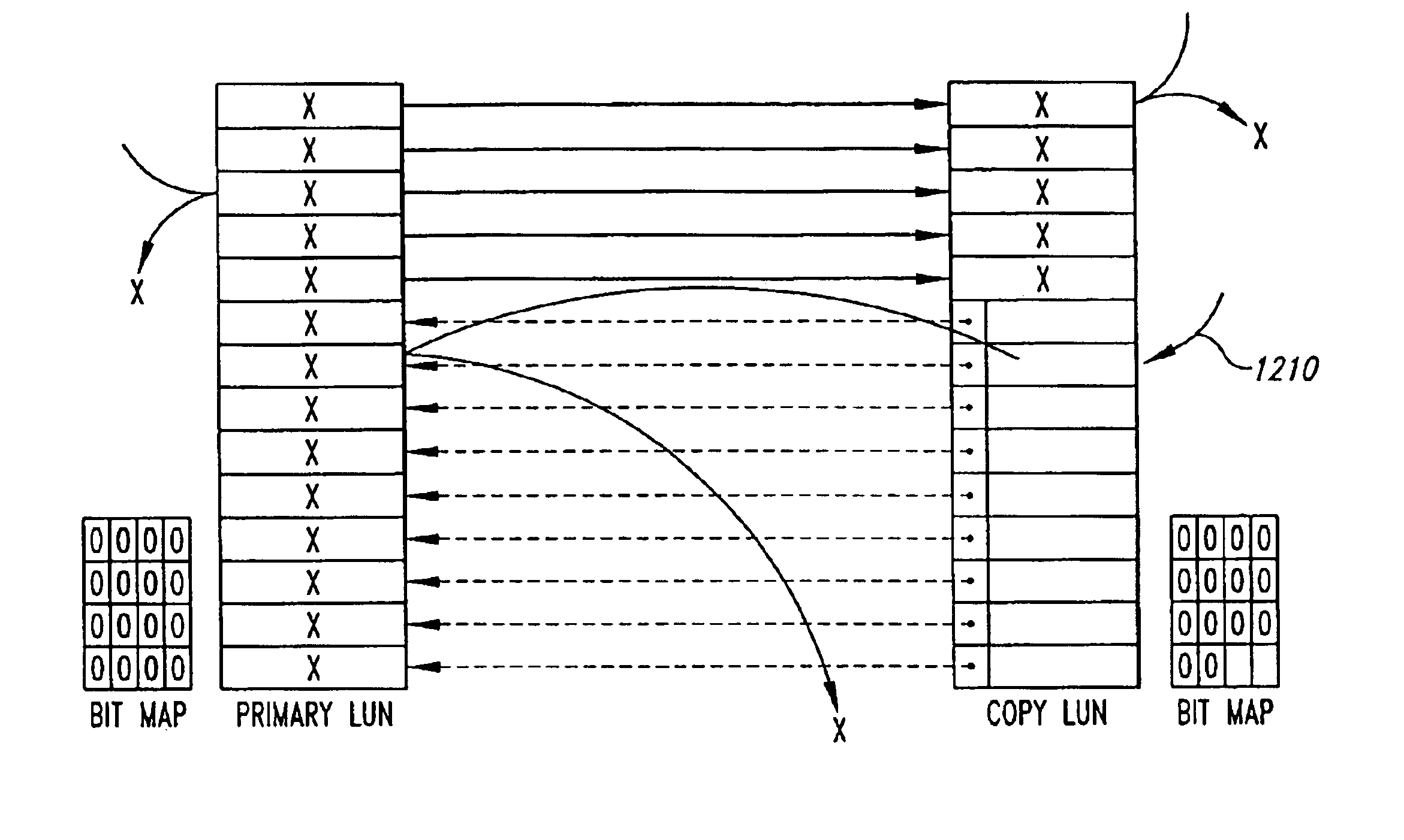

Immediately available, statically allocated, full-logical-unit copy with a transient, snapshot-copy-like intermediate stage

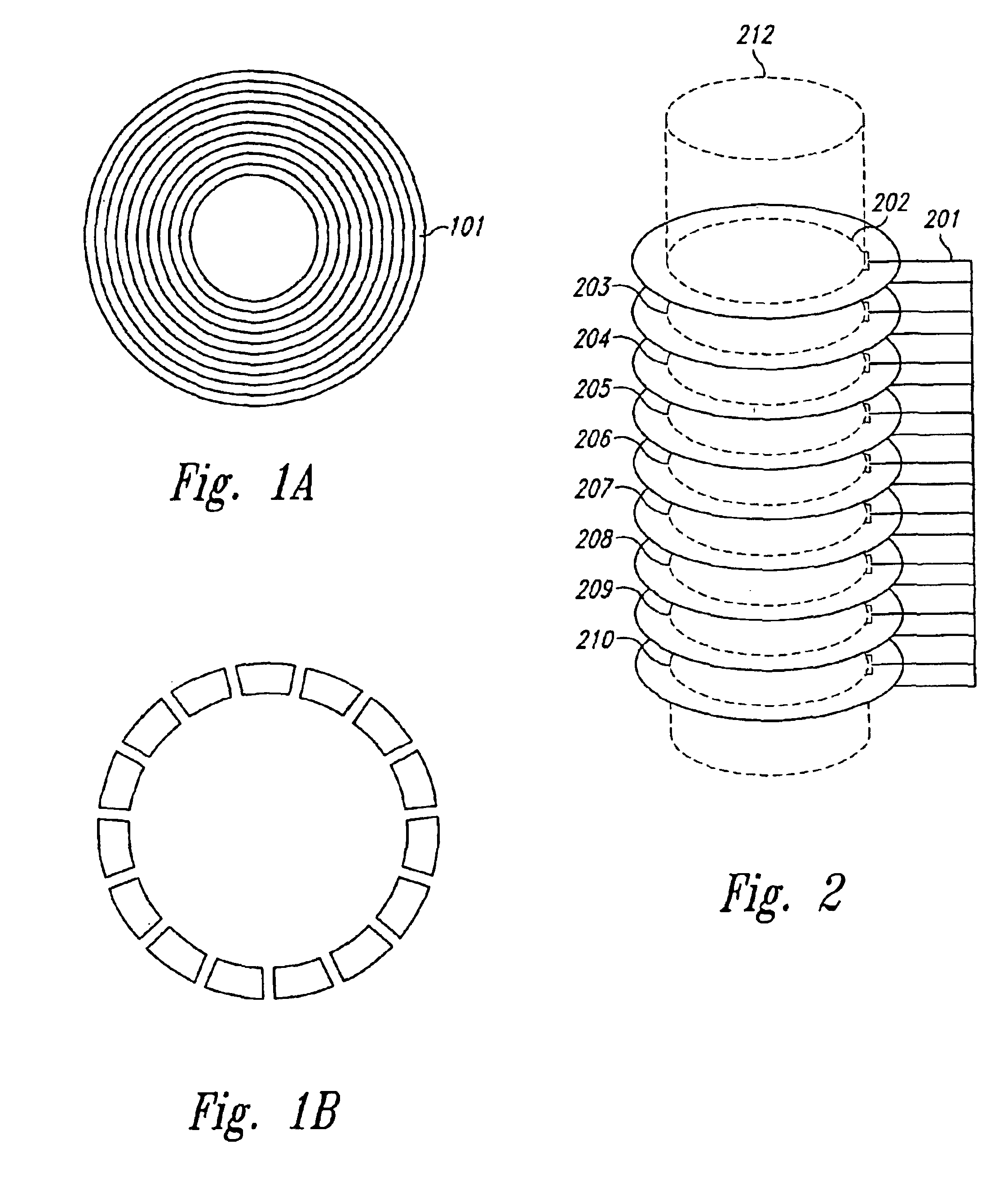

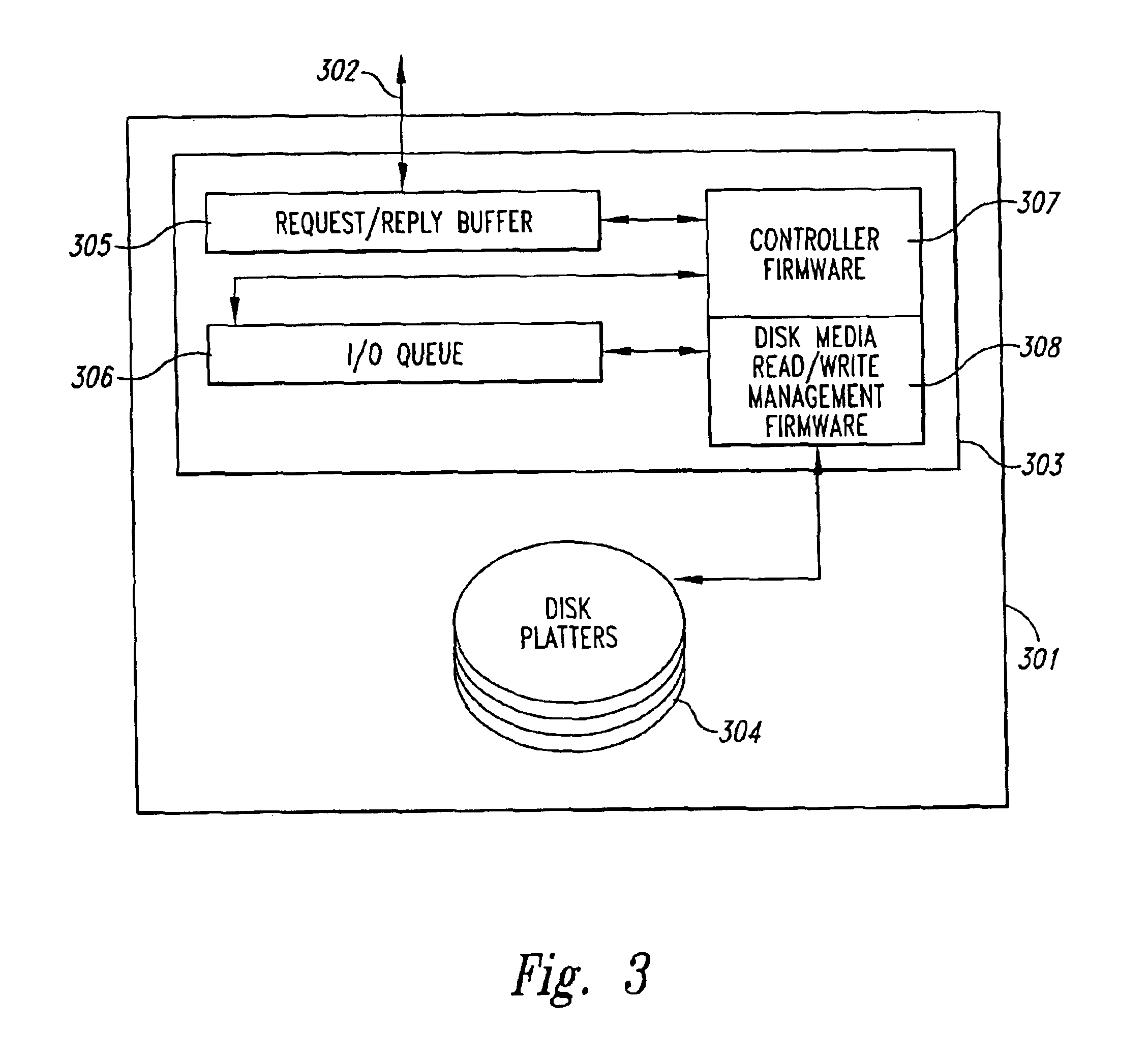

InactiveUS6907505B2Data processing applicationsInput/output to record carriersComputer hardwareIntermediate stage

A hybrid LUN copy operation that ultimately produces a full LUN copy, but involves a transient snapshot-copy-like intermediate stage. In one embodiment, a statically pre-allocated copy LUN is initialized with references pointing back to the primary LUN. Over time, the sectors, blocks, or other data-storage units of the primary LUN are copied to the copy LUN, so that, in the end, a full copy LUN in completed. In a second, alternative embodiment, both the primary LUN and copy LUN are READ and WRITE accessible immediately following the nearly instantaneous initialization of the copy LUN. In both embodiments, the copy LUN may be statically allocated. The immediate-full-LUN-copy operations provided by the present invention further enable rotatable copy-LUN groups, each copy LUN within a copy-LUN group representing a full, robust copy LUN.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

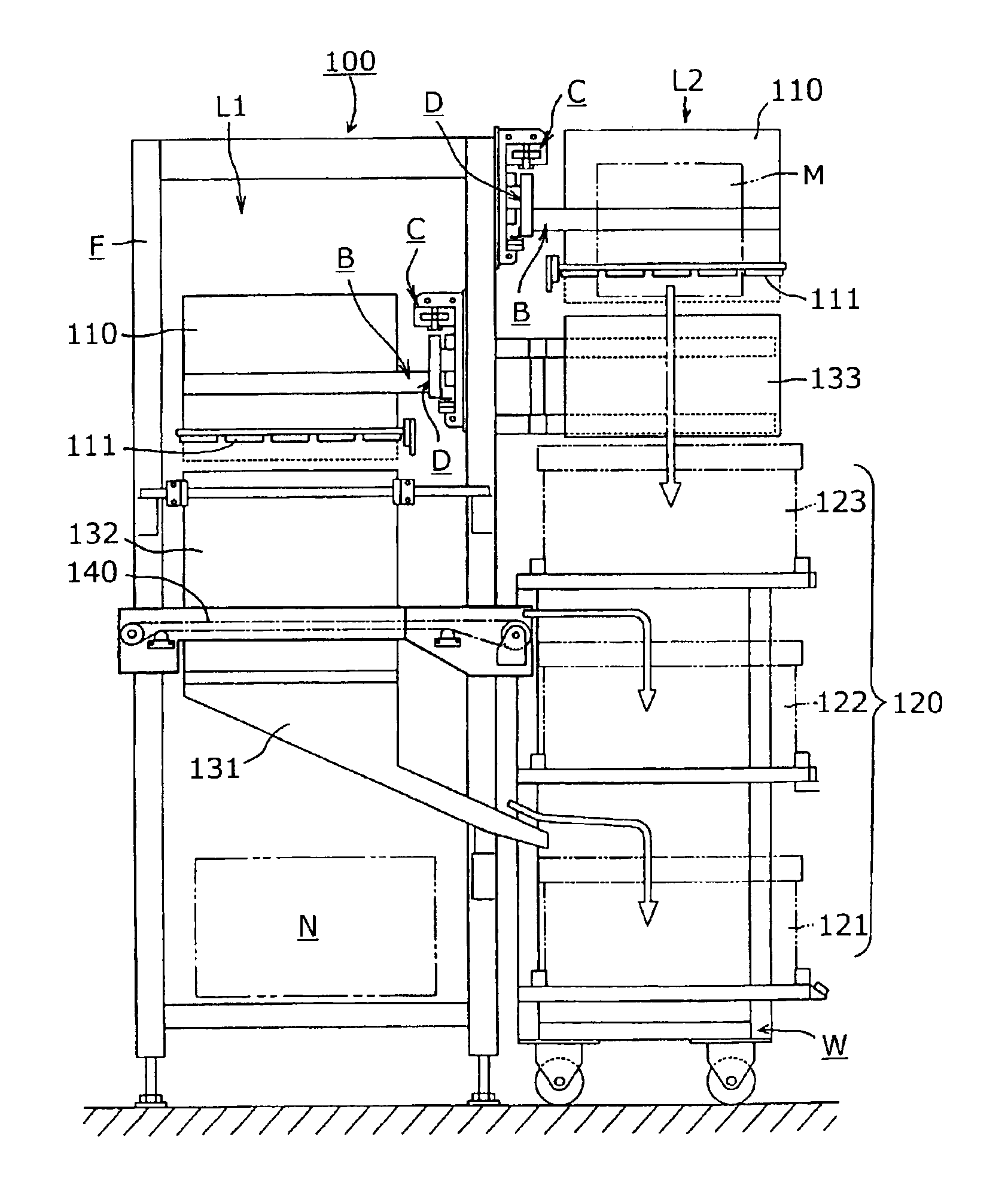

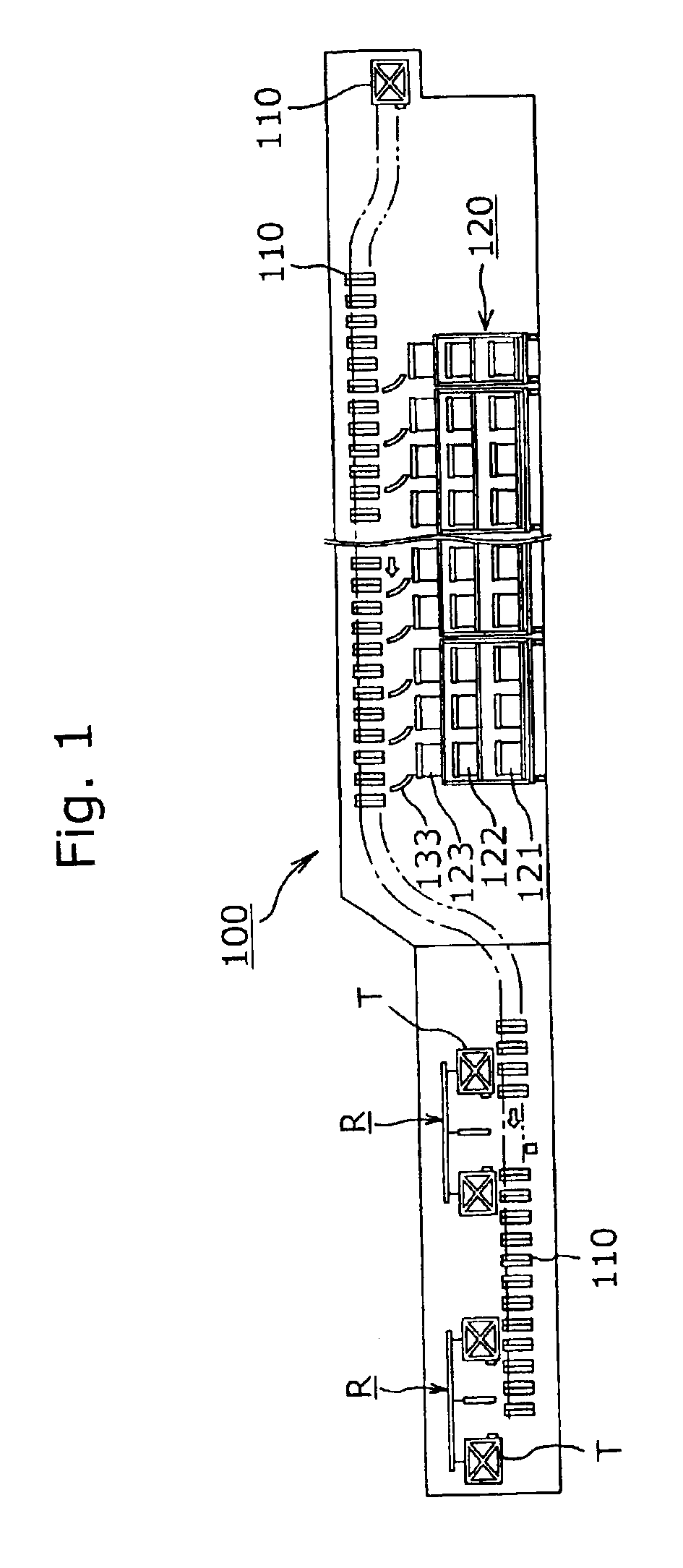

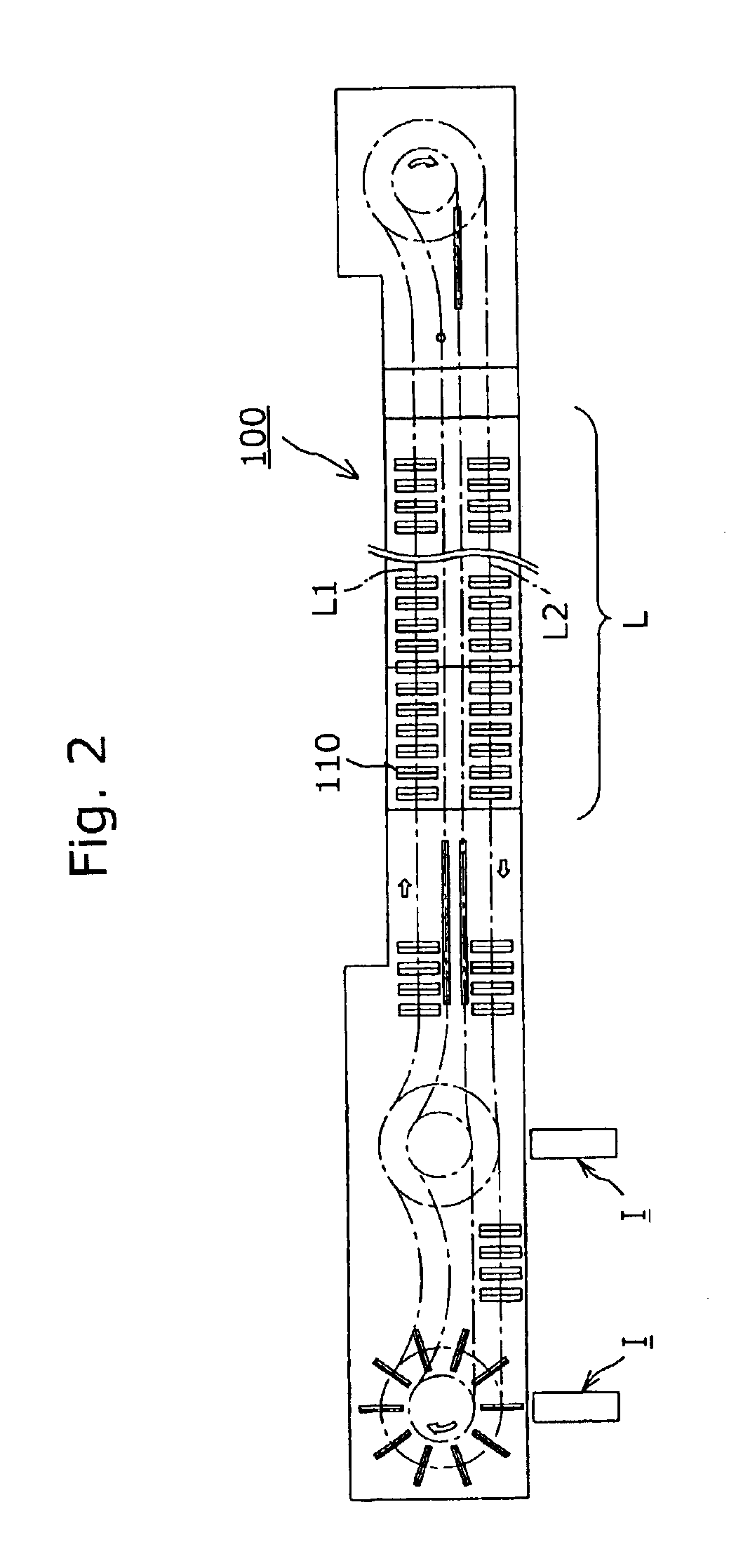

Mail sorter

InactiveUS6897395B2Reliable sortingAvoid damageSeparation devicesCharacter and pattern recognitionEngineeringIntermediate stage

A mail sorter, which can reliably sort mail while avoiding the breakage and the recovery mistake of mail released from conveyor baskets, which move on the mail sorting line in circulation. The mail sorter has a conveyor line with a conveying forward run and a conveying return run closely arranged back to back with each, and layered mail recovery box groups are disposed along a lower region of the conveying return run in parallel to each other. The mail recovery box groups comprise lowest stage boxes for recovering mail M released from conveyor baskets on the conveying forward run through a transverse deflection chute, middle stage boxes for recovering mail M released from the conveyor baskets on the conveying forward run through a discharge chute, and uppermost stage boxes for recovering mail M released from the conveying baskets on the conveying return run through a buffer chute.

Owner:TSUBAKIMOTO CHAIN CO

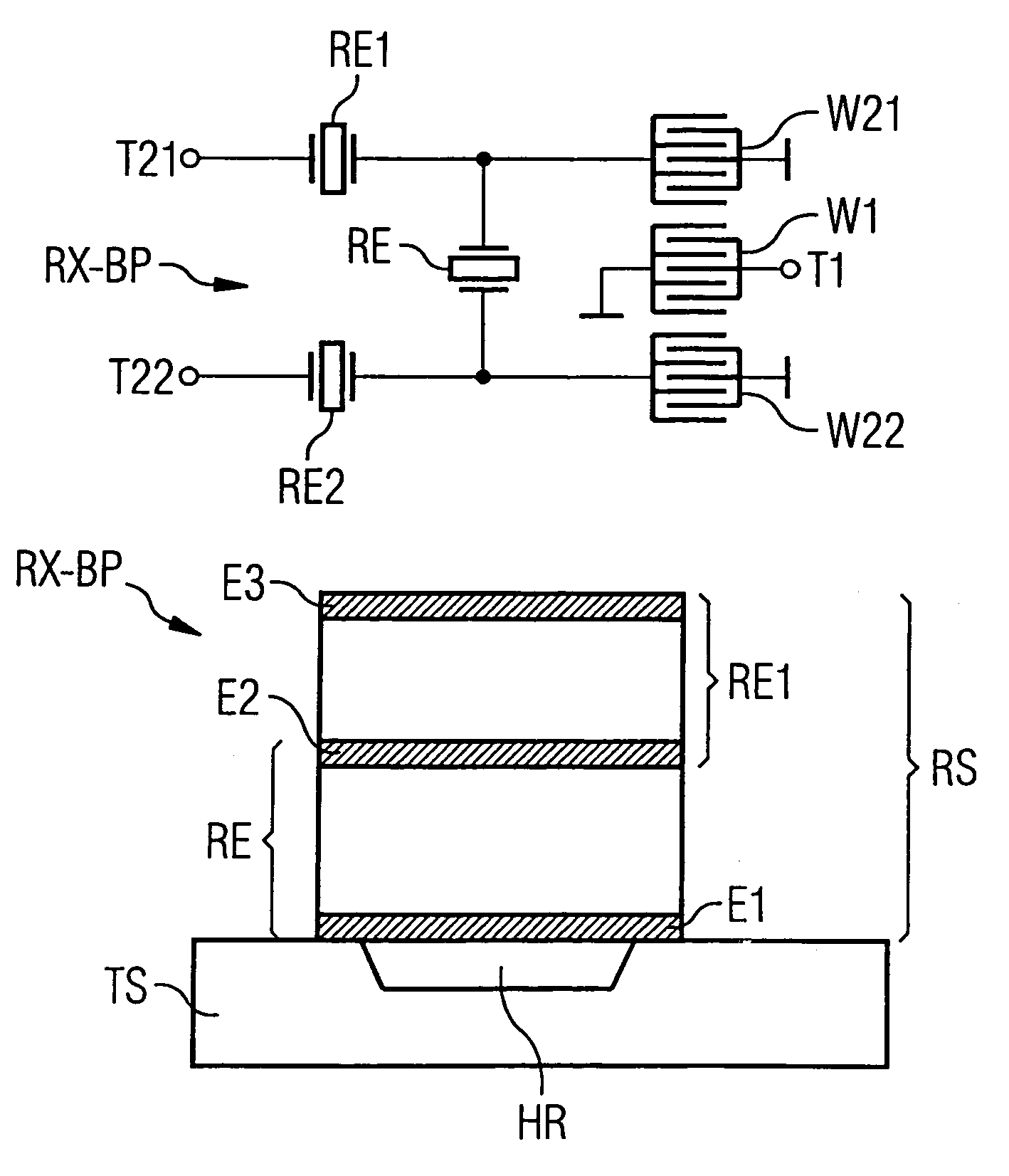

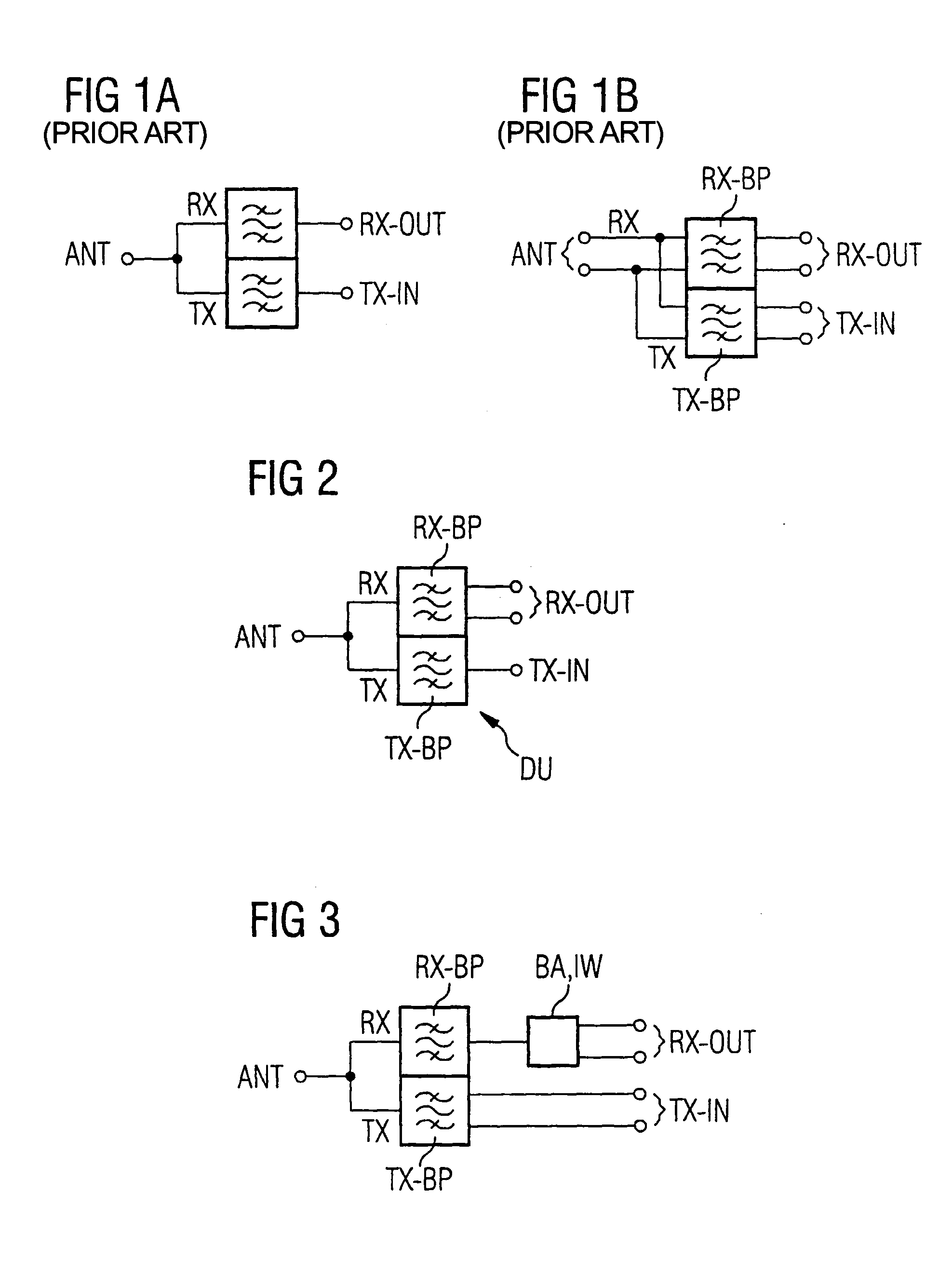

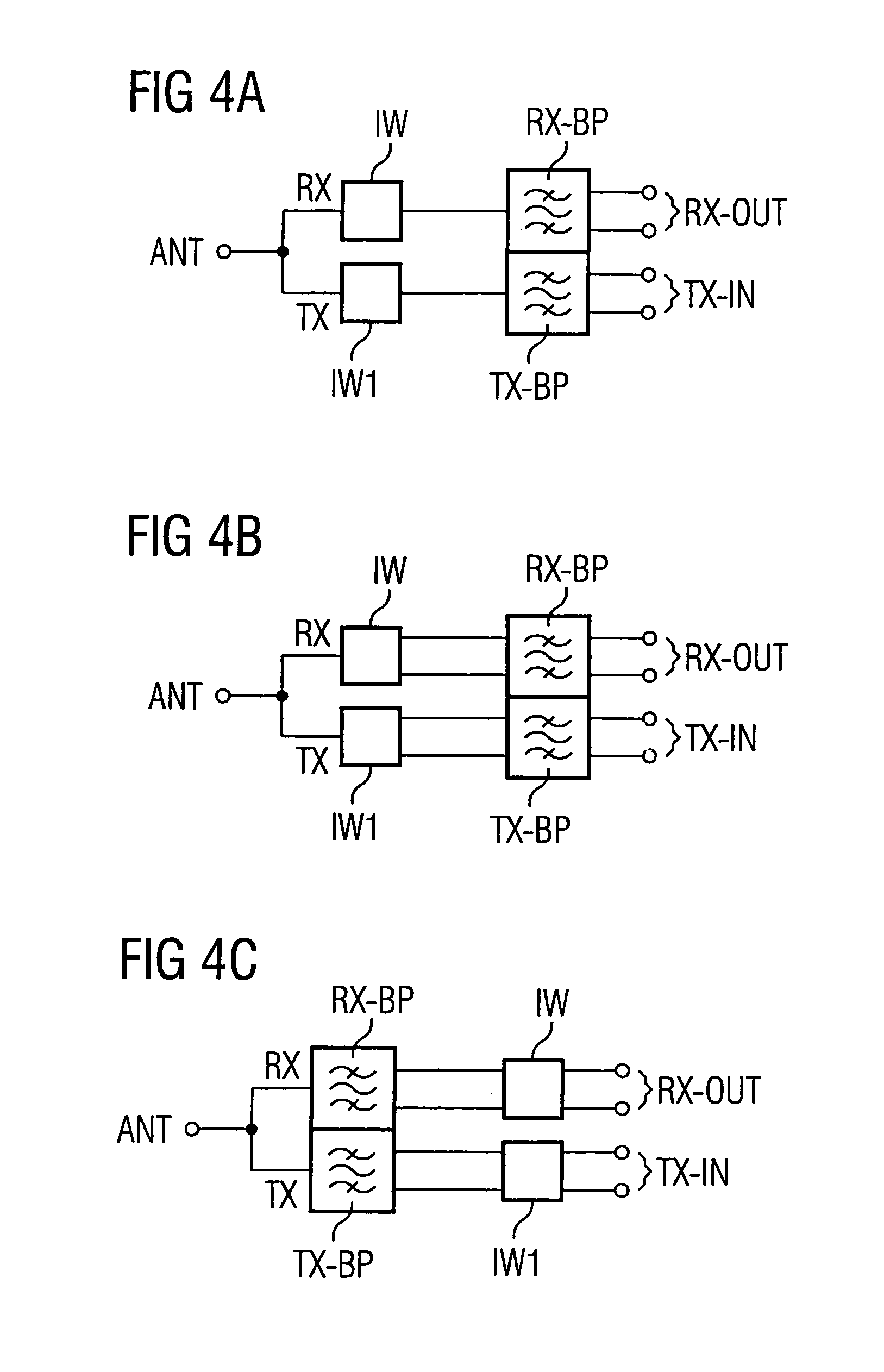

Duplexer with extended functionality

ActiveUS7102460B2Multiple-port networksPiezoelectric/electrostrictive/magnetostrictive devicesBandpass filteringAudio power amplifier

A duplexer has an asymmetrical antenna port and a symmetrical reception output, and therefore can be interconnected (without any intermediate stages) to an amplifier with a differential input. A reception bandpass filter is arranged in the reception path of the duplexer. The reception bandpass filter can have the functionality of a balun. The transmission input of the duplexer can be designed symmetrically, in which case a transmission bandpass filter arranged in the transmission path should be designed symmetrically on the input side. The impedance of the antenna port of the duplexer can differ from the impedance of the reception output or the transmission input. No intermediate stages (such as a balun or—in cases of impedances that differ between the duplexer and its corresponding amplifier—an impedance transformer) are required between the duplexer and the amplifier that is interconnected (whether before or after) in the transmission or reception path.

Owner:SNAPTRACK

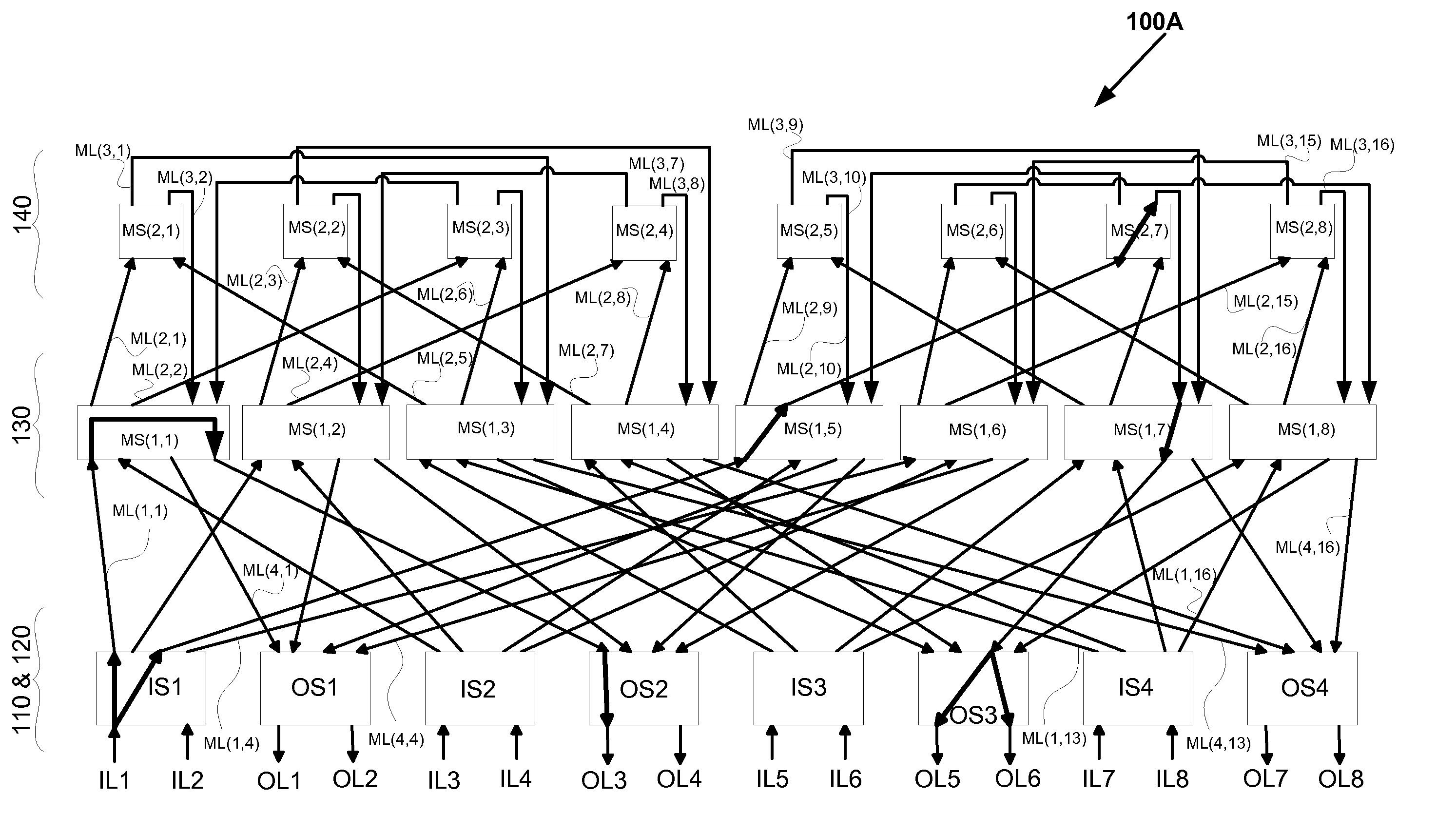

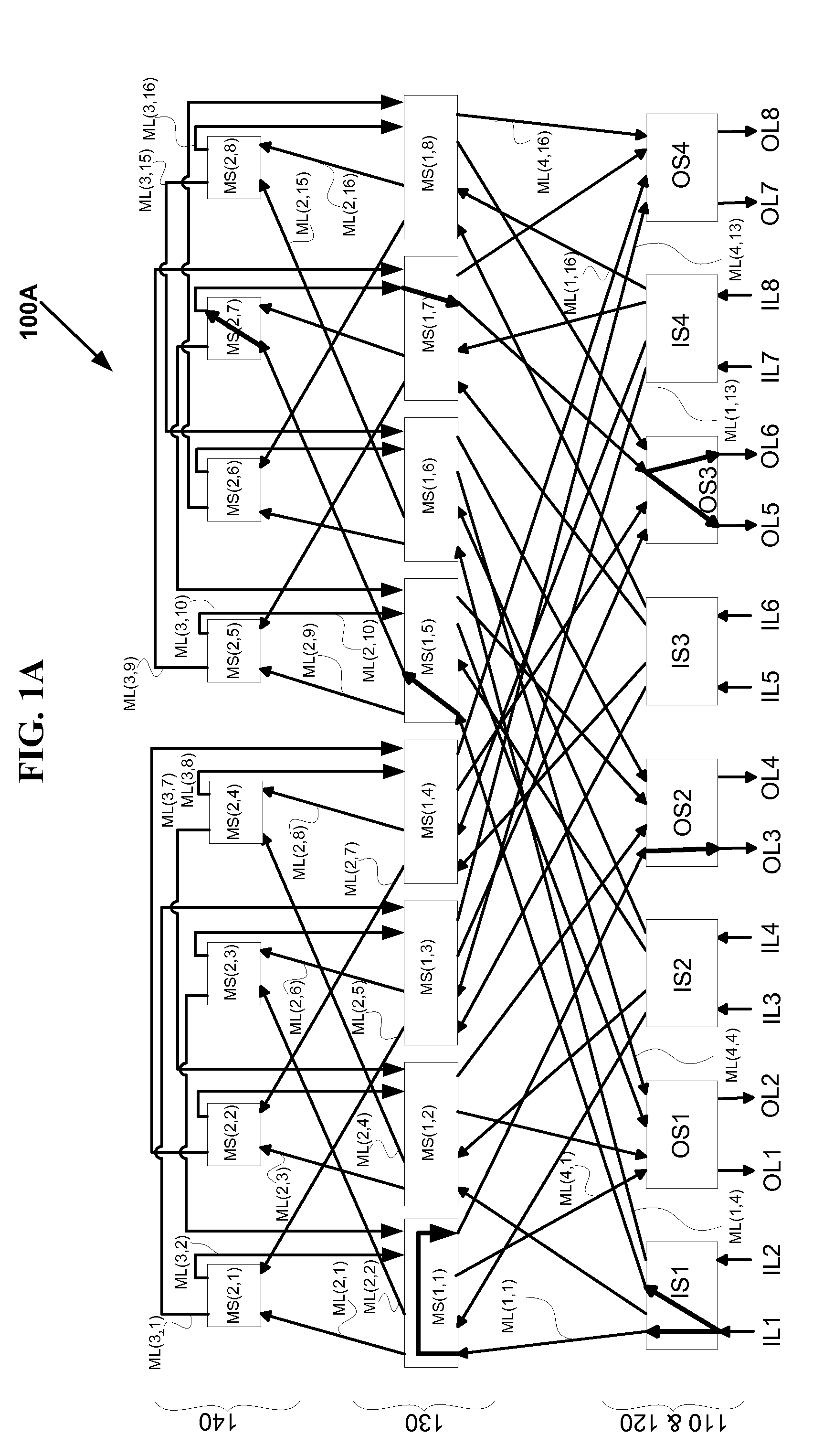

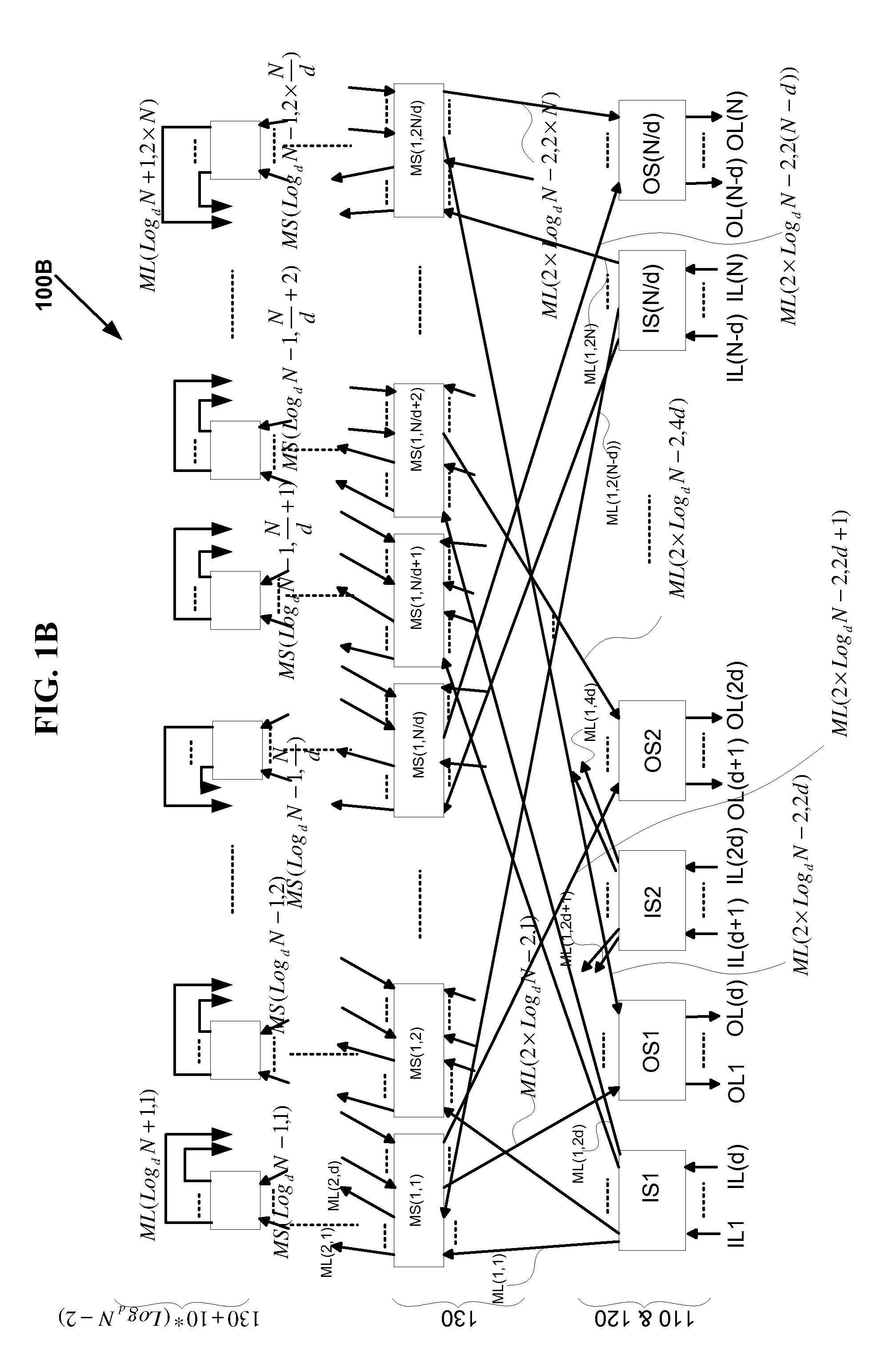

Fully connected generalized butterfly fat tree networks

ActiveUS8170040B2Electronic switchingData switching by path configurationIntermediate stageButterfly fat tree

A generalized butterfly fat tree network comprising (logd N) stages is operated in strictly nonblocking manner for unicast and in rearrangeably nonblocking manner for arbitrary fan-out multicast when s≧2, and is operated in strictly nonblocking manner for arbitrary fan-out multicast when s≧3, includes a leaf stage consisting of an input stage havingNdswitches with each of them having d inlet links and s×d outgoing links connecting to its immediate succeeding stage switches, and an output stage havingNdswitches with each of them having d outlet links and s×d incoming links connecting from switches in its immediate succeeding stage. The network also has (logd N)−1 middle stages with each middle stage, excepting the root stage, havings×Ndswitches, and each switch in the middle stage has d incoming links connecting from the switches in its immediate preceding stage, d incoming links connecting from the switches in its immediate succeeding stage, d outgoing links connecting to the switches in its immediate succeeding stage, d outgoing links connecting to the switches in its immediate preceding stage, and the root stage havings×Ndswitches, and each switch in the middle stage has d incoming links connecting from the switches in its immediate preceding stage and d outgoing links connecting to the switches in its immediate preceding stage.

Owner:KONDA TECH

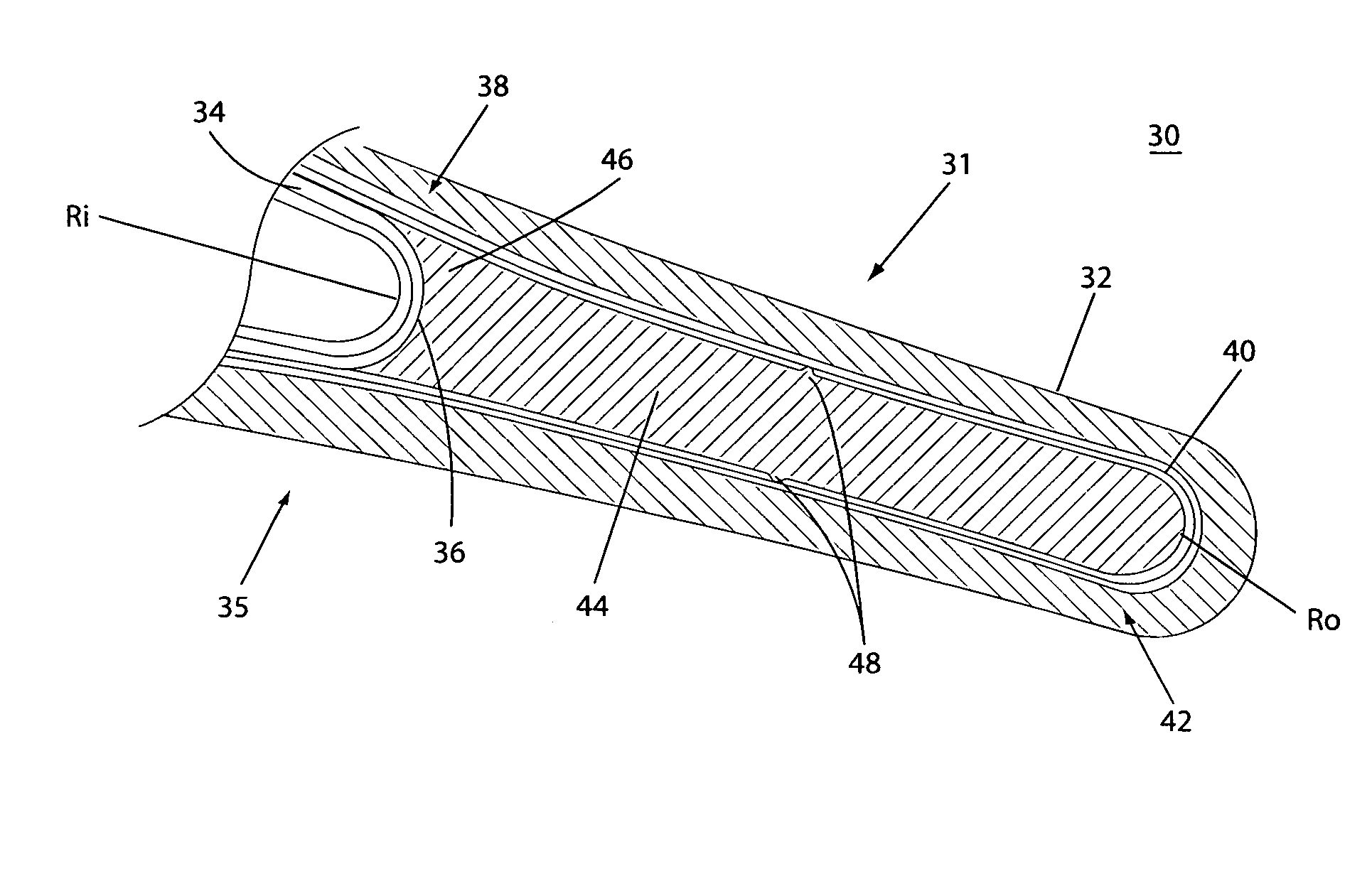

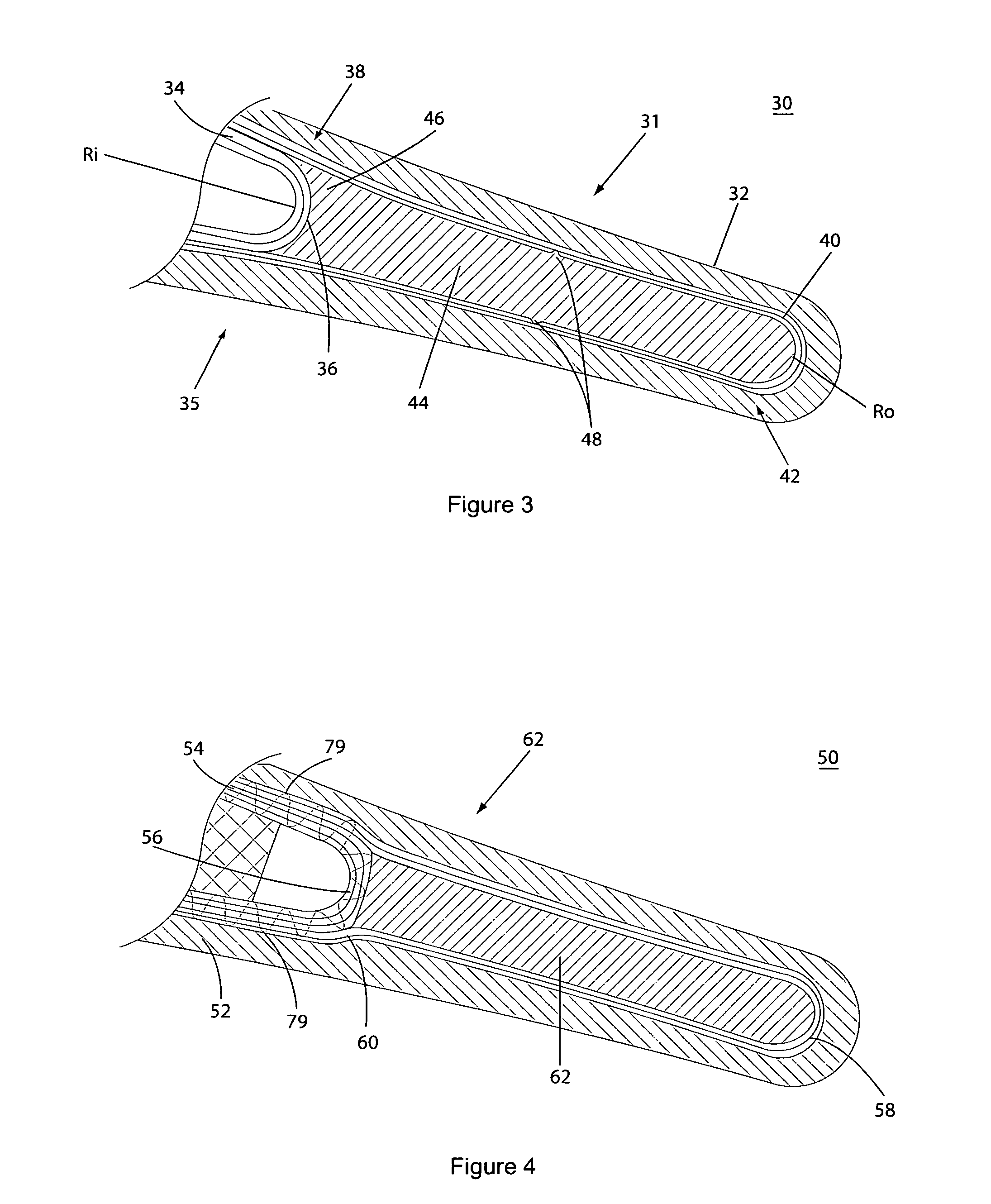

Ceramic matrix composite airfoil trailing edge arrangement

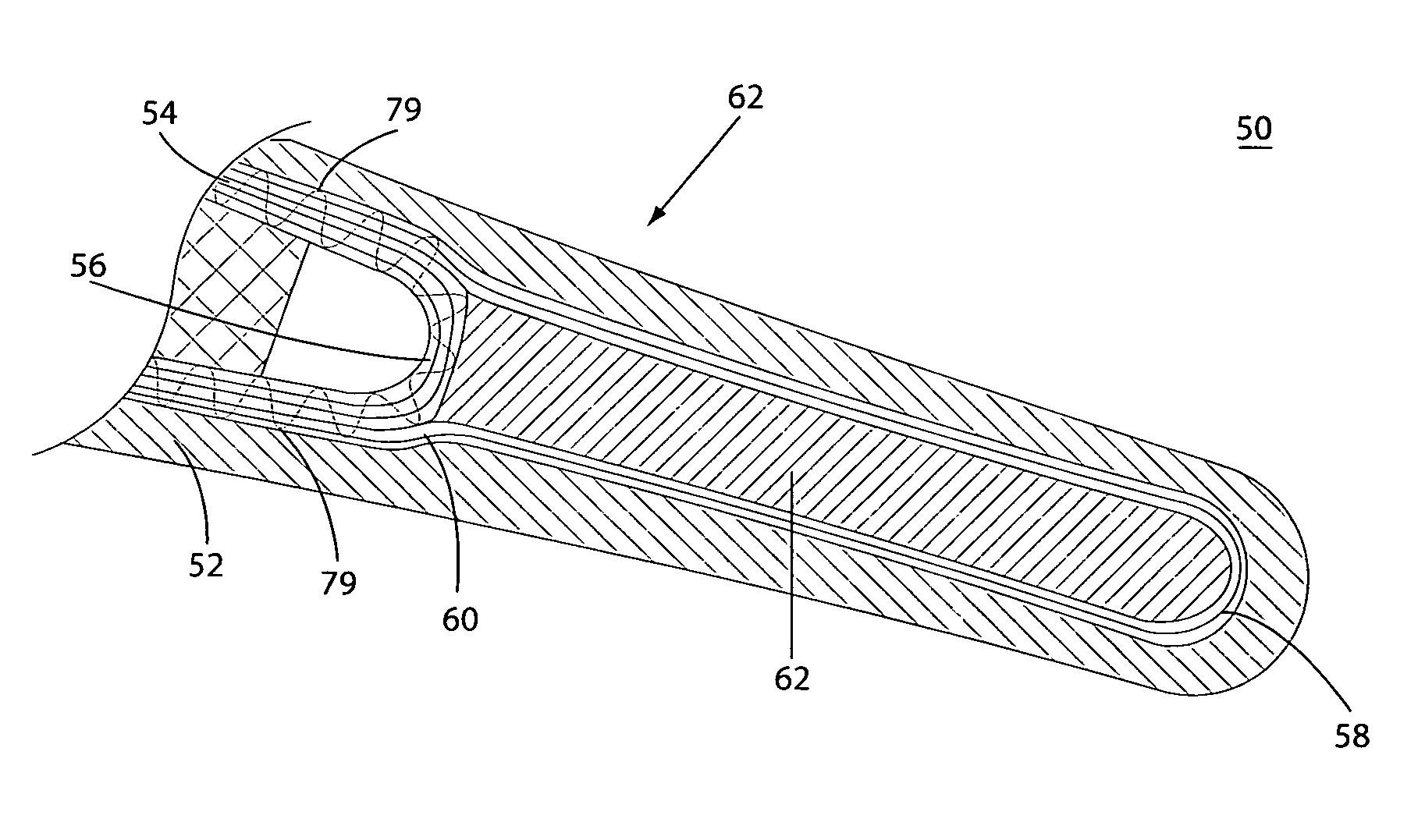

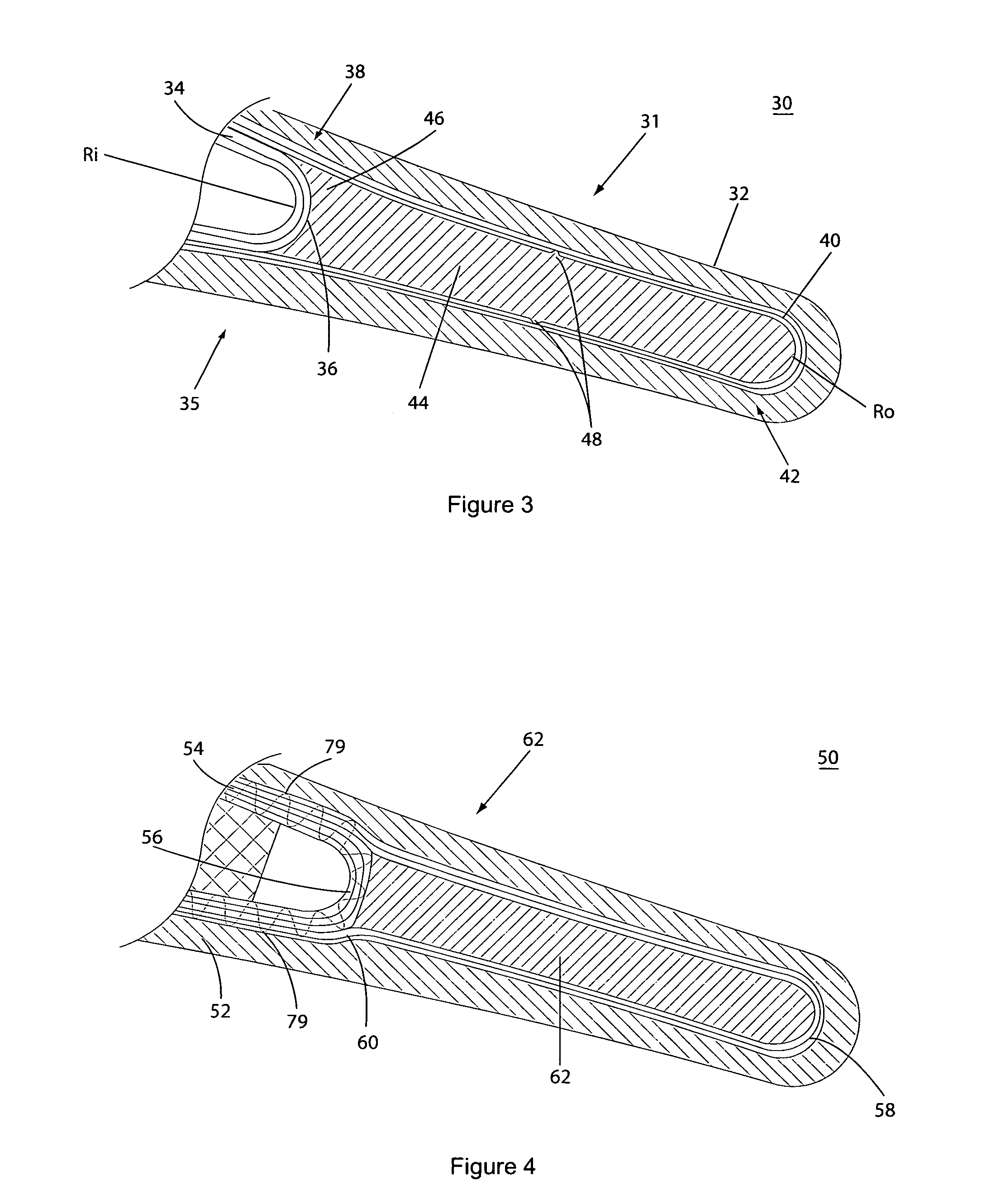

An airfoil (30) having a continuous layer of ceramic matrix composite (CMC) material (34) extending from a suction side (33) to a pressure side (35) around a trailing edge portion (31). The CMC material includes an inner wrap (36) extending around an inner trailing edge portion (38) and an outer wrap (40) extending around an outer trailing edge portion (42). A filler material (44) is disposed between the inner and outer wraps to substantially eliminate voids in the trailing edge portion. The filler material may be pre-processed to an intermediate stage and used as a mandrel for forming the outer trailing edge portion, and then co-processed with the inner and outer wraps to a final form. The filler material may be pre-processed to include a desired mechanical feature such as a cooling passage (22) or a protrusion (48). The filler material may include an upper layer (77) and a lower layer (78) separated by an intermediate layer (76) that extends to between the inner wrap and the outer wrap along the suction and / or pressure sides.

Owner:SIEMENS ENERGY INC

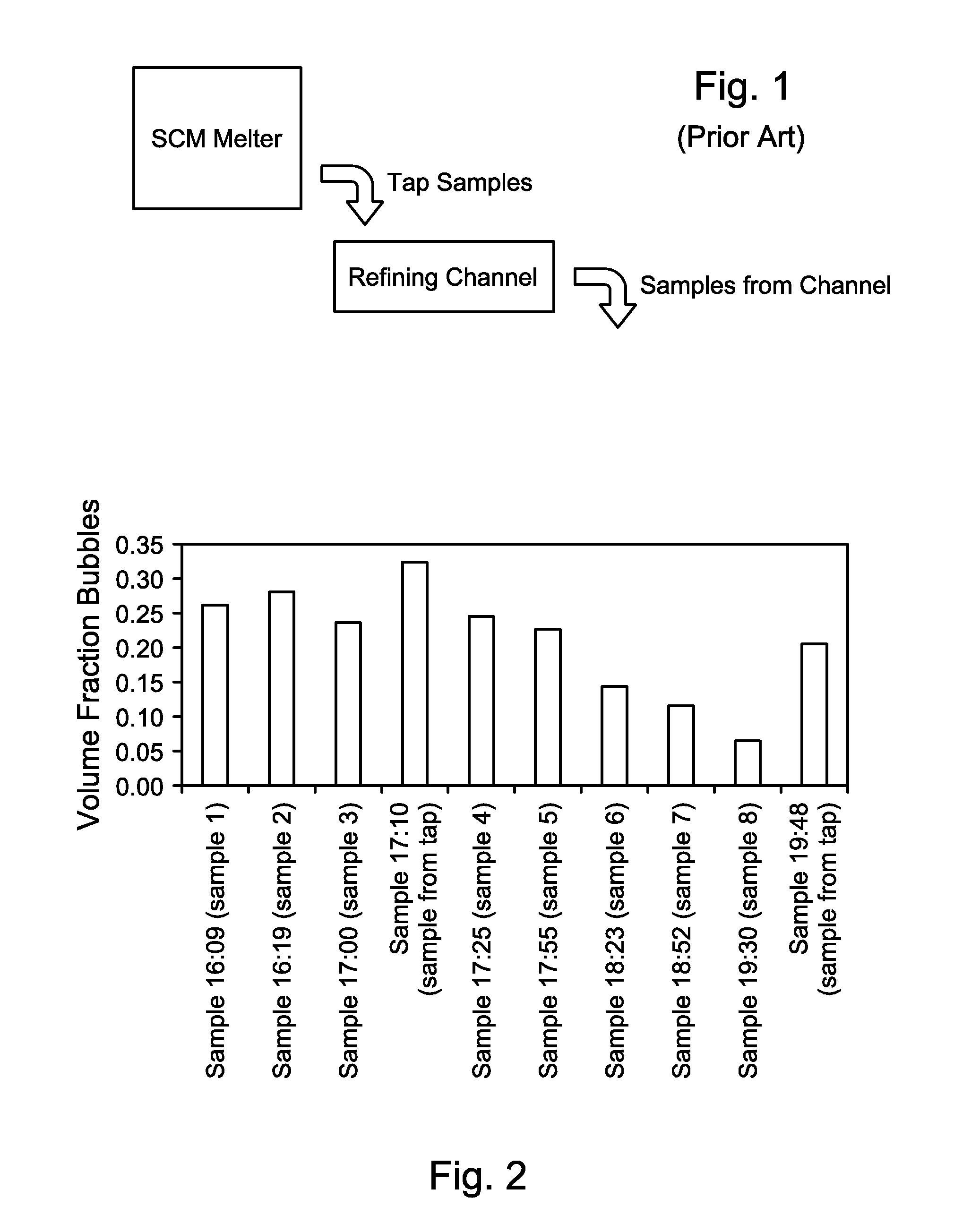

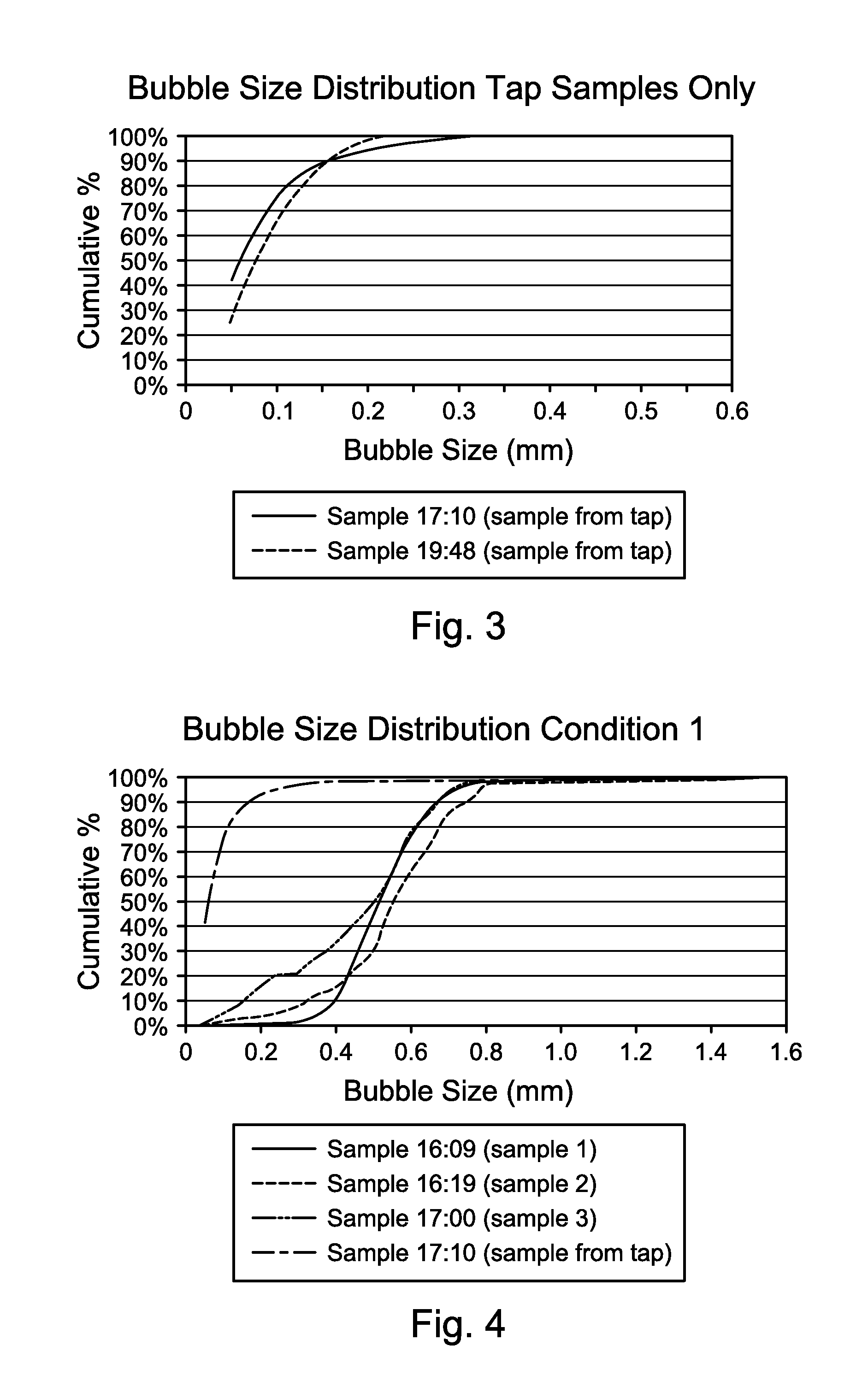

Systems and methods for making foamed glass using submerged combustion

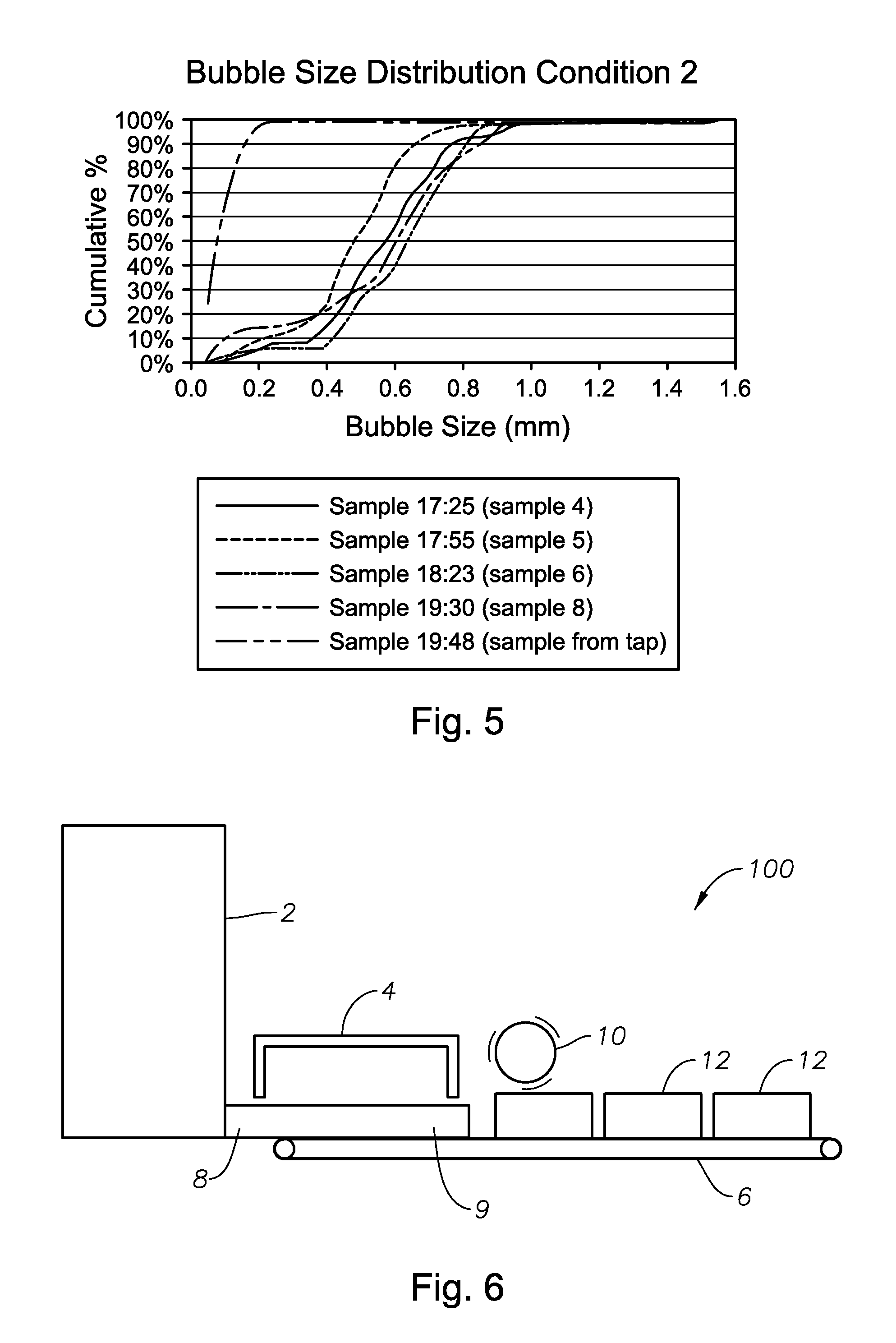

ActiveUS20130086944A1High densityLow densityRibbon machinesGlass furnace apparatusCombustion systemDownstream processing

Submerged combustion systems and methods of use to produce foamed glass. One system includes a submerged combustion melter having an outlet, the melter configured to produce an initial foamy molten glass having a density and comprising bubbles filled primarily with combustion product gases. The initial foamy molten glass is deposited directly onto or into a transport apparatus that transports the initial foamy molten glass to a downstream processing apparatus. An intermediate stage may be included between the melter and the transport apparatus. One intermediate stage is a channel that includes gas injectors. Another intermediate stage is a channel that produces an upper flow of a less dense glass and a relatively more dense glass lower flow. The upper flow may be processed into foamed glass products, while the more dense flow may be processed into dense glass products.

Owner:JOHNS MANVILLE CORP

Ceramic matrix composite airfoil trailing edge arrangement

Owner:SIEMENS ENERGY INC

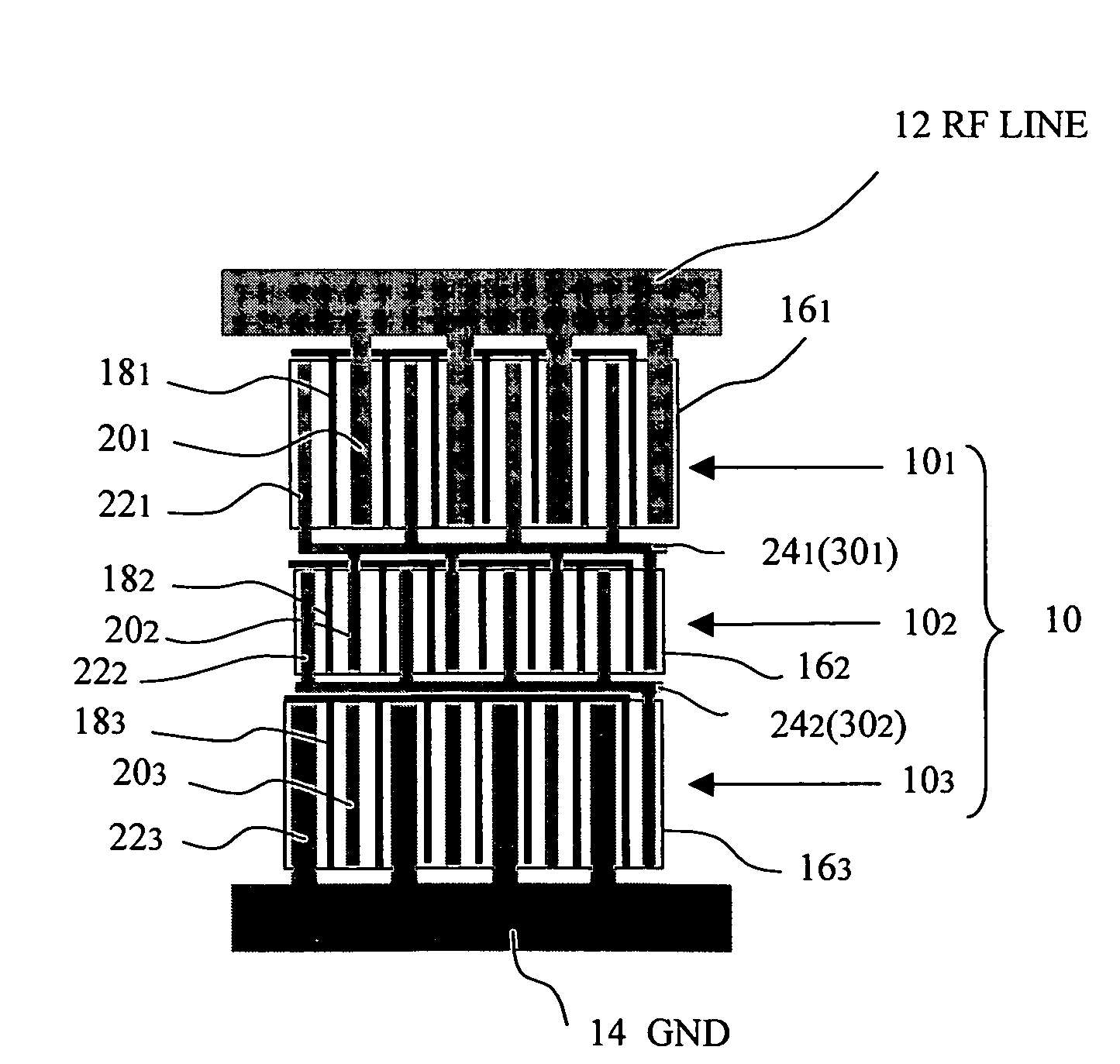

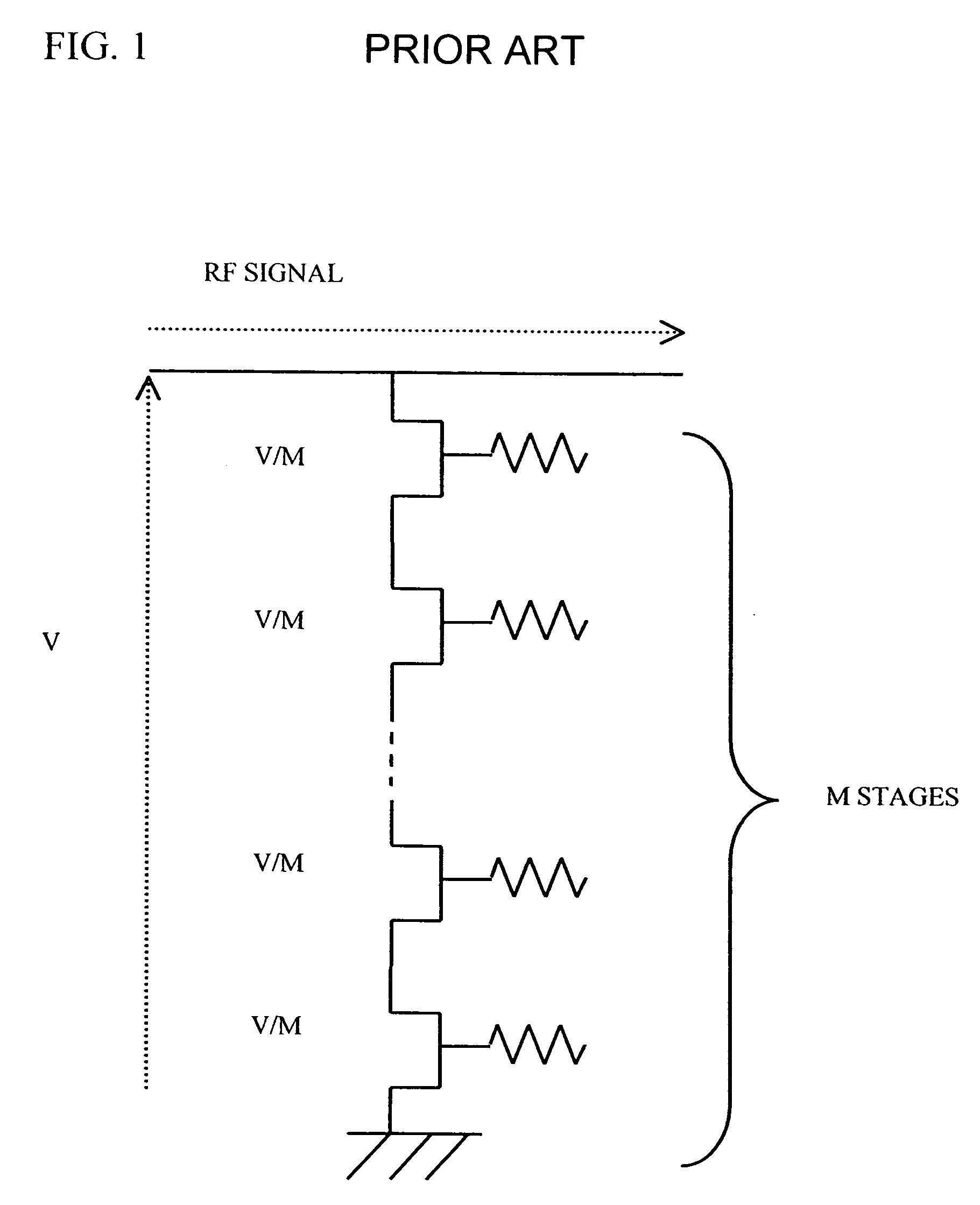

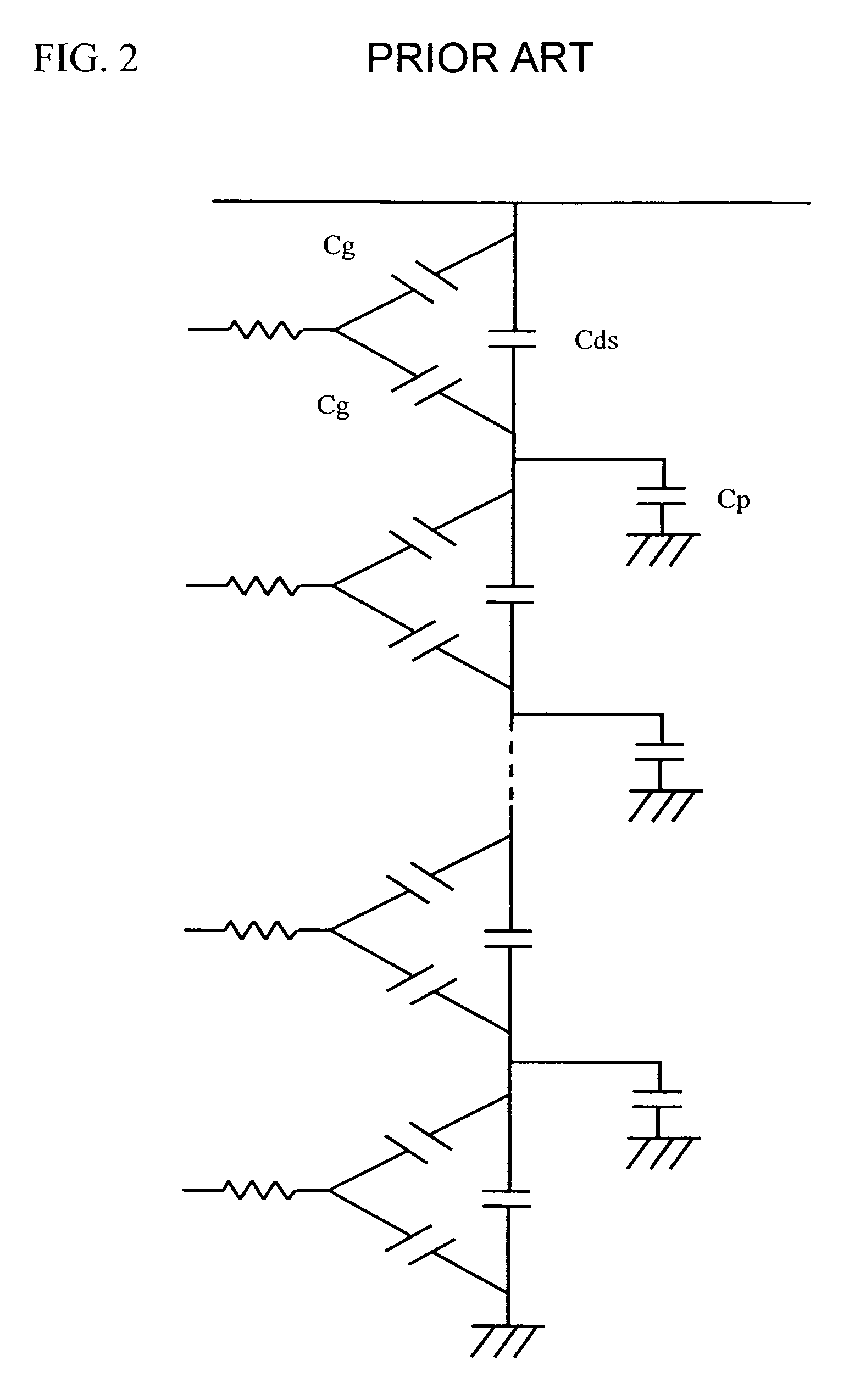

Radio frequency switch

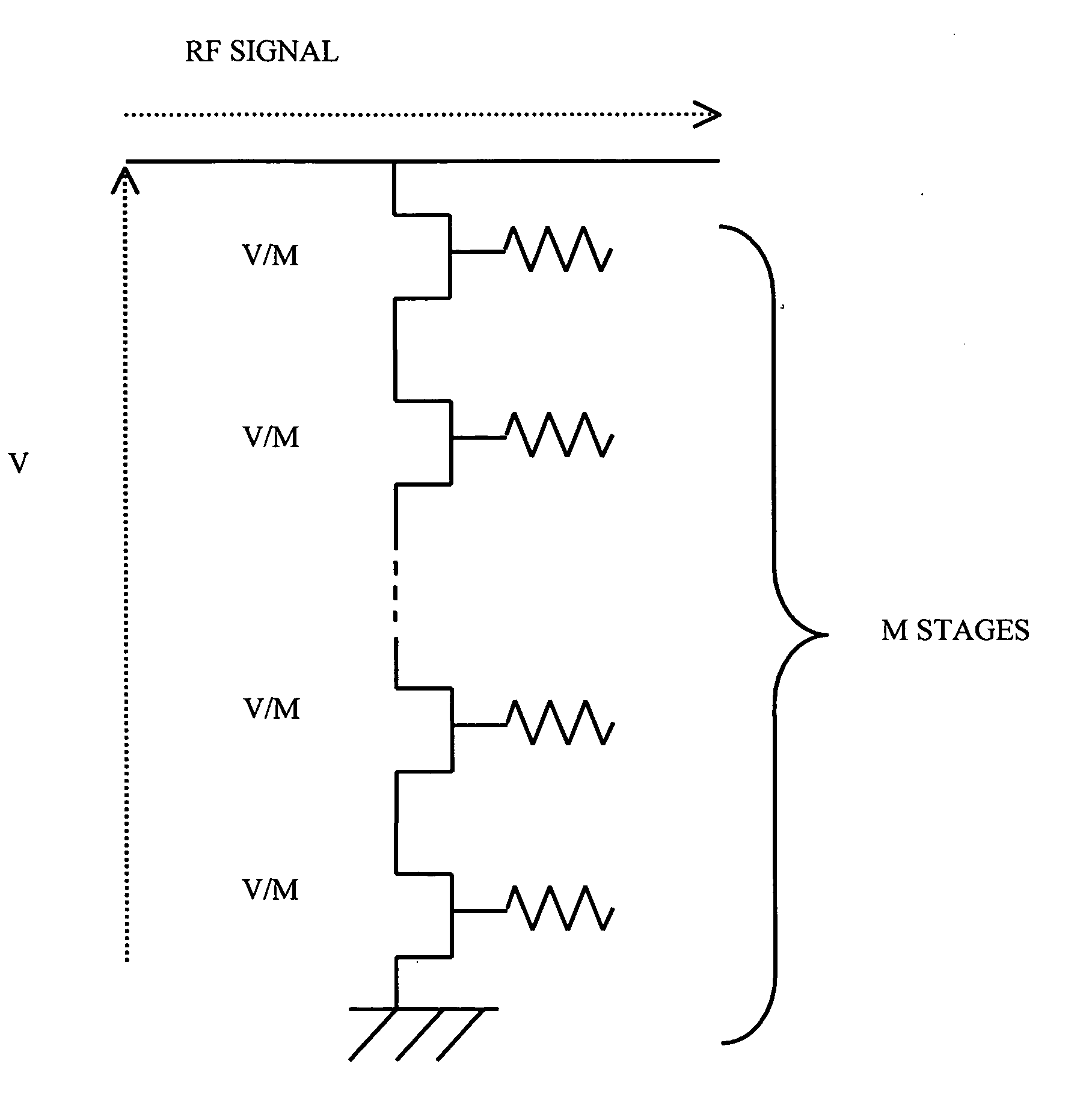

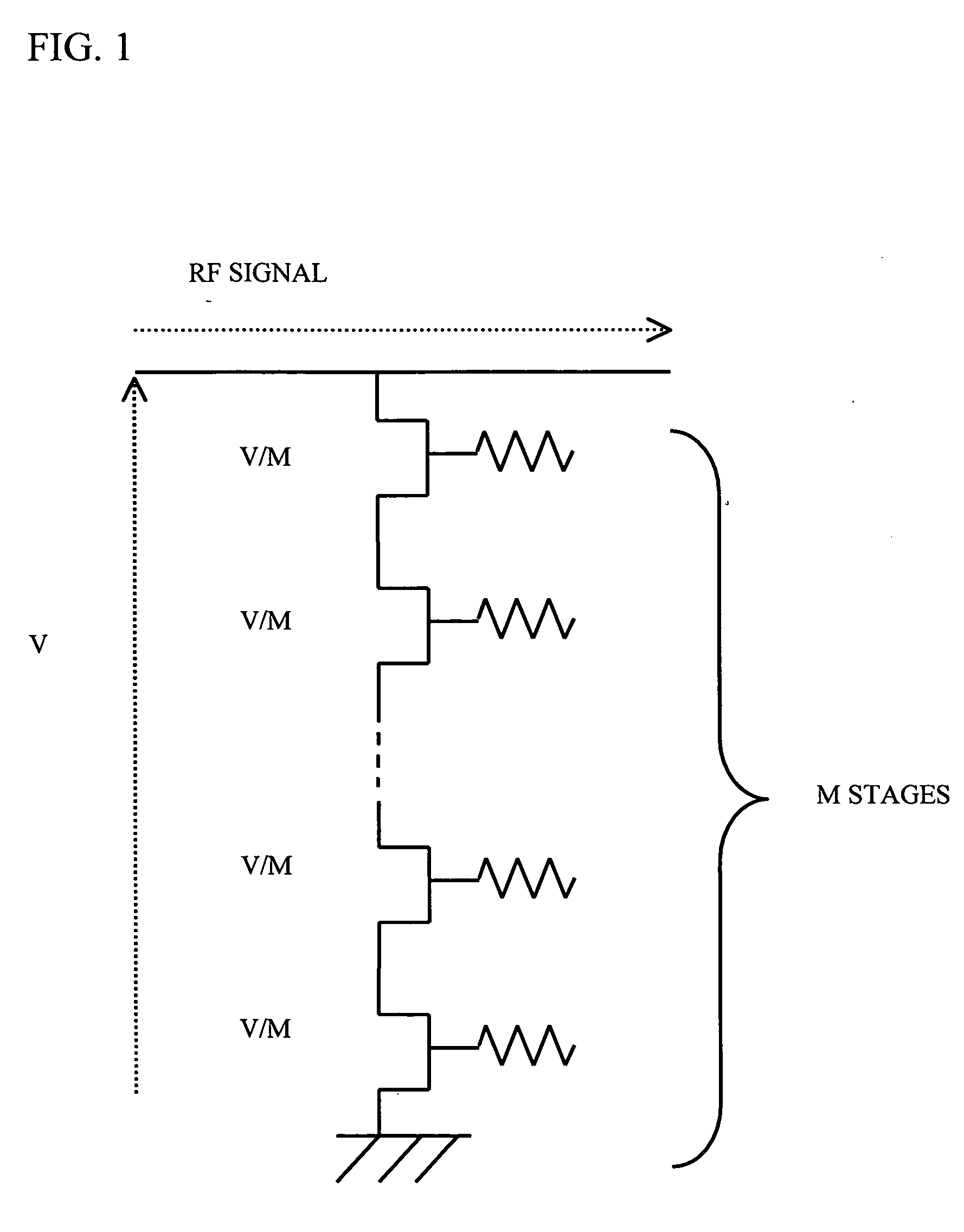

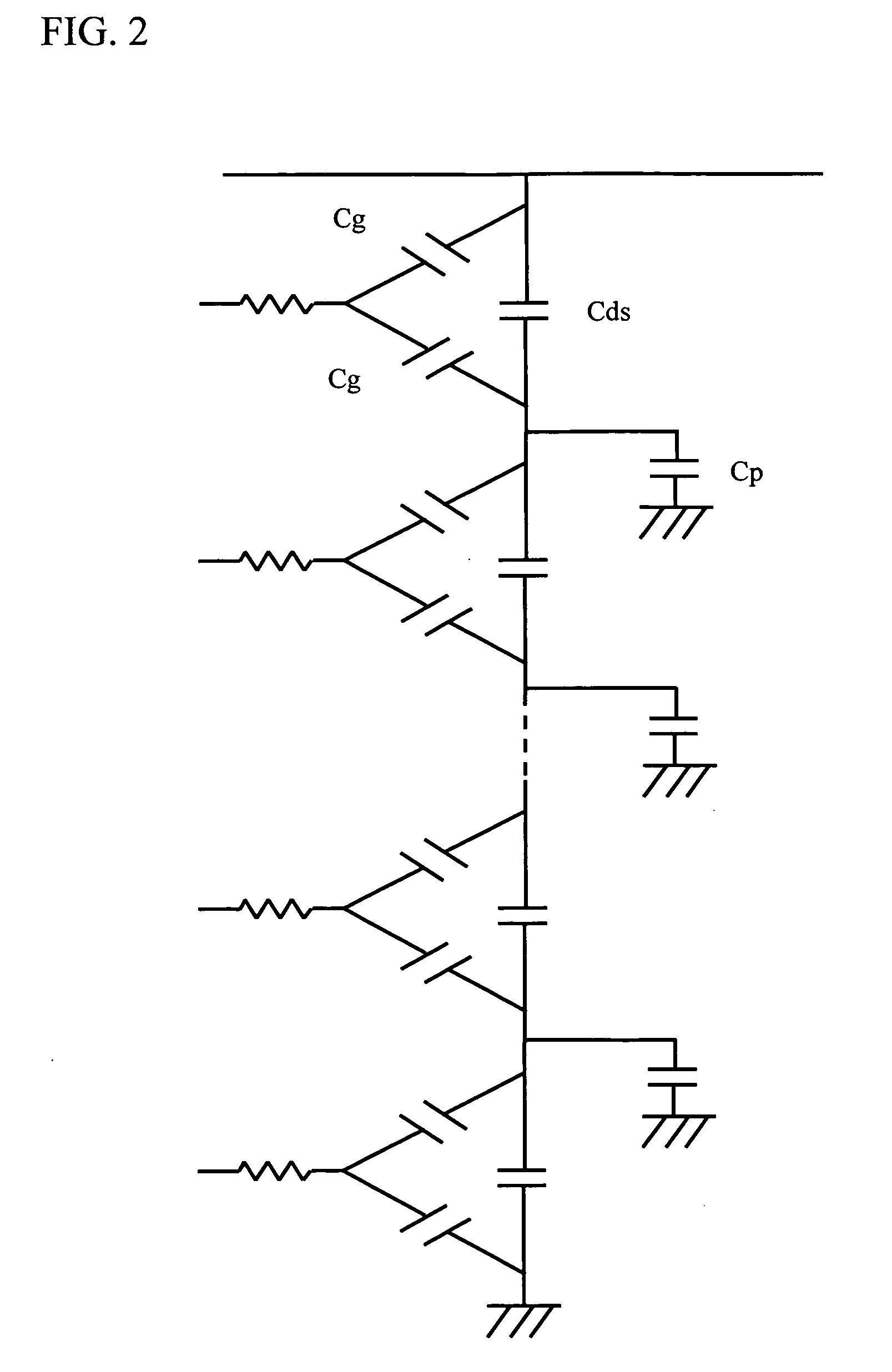

InactiveUS20060160520A1Low costHandling power is easilyTransistorSemiconductor/solid-state device detailsParasitic capacitanceRadio frequency signal

A switch that selectively changes radio frequency signals includes at least three FETs, which are connected in series. The source electrodes or drain electrodes arranged at an intermediate stage have a width narrower than that of the source electrodes or the drain electrodes arranged at the initial and final stages. It is thus possible to lower the parasitic capacitance to ground at the intermediate stage and to thereby realize the switch having a high handling power.

Owner:SUMITOMO ELECTRIC DEVICE INNOVATIONS

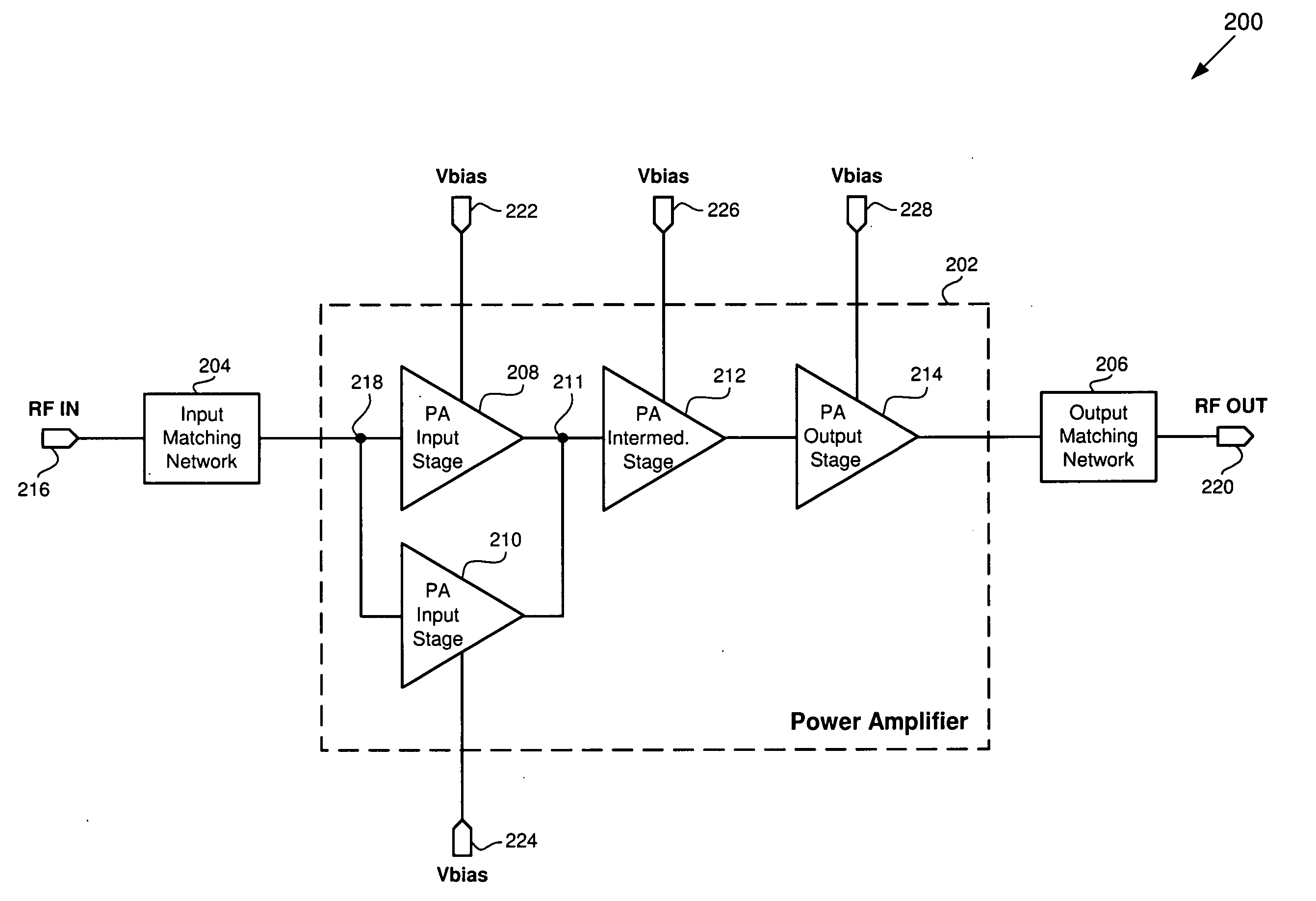

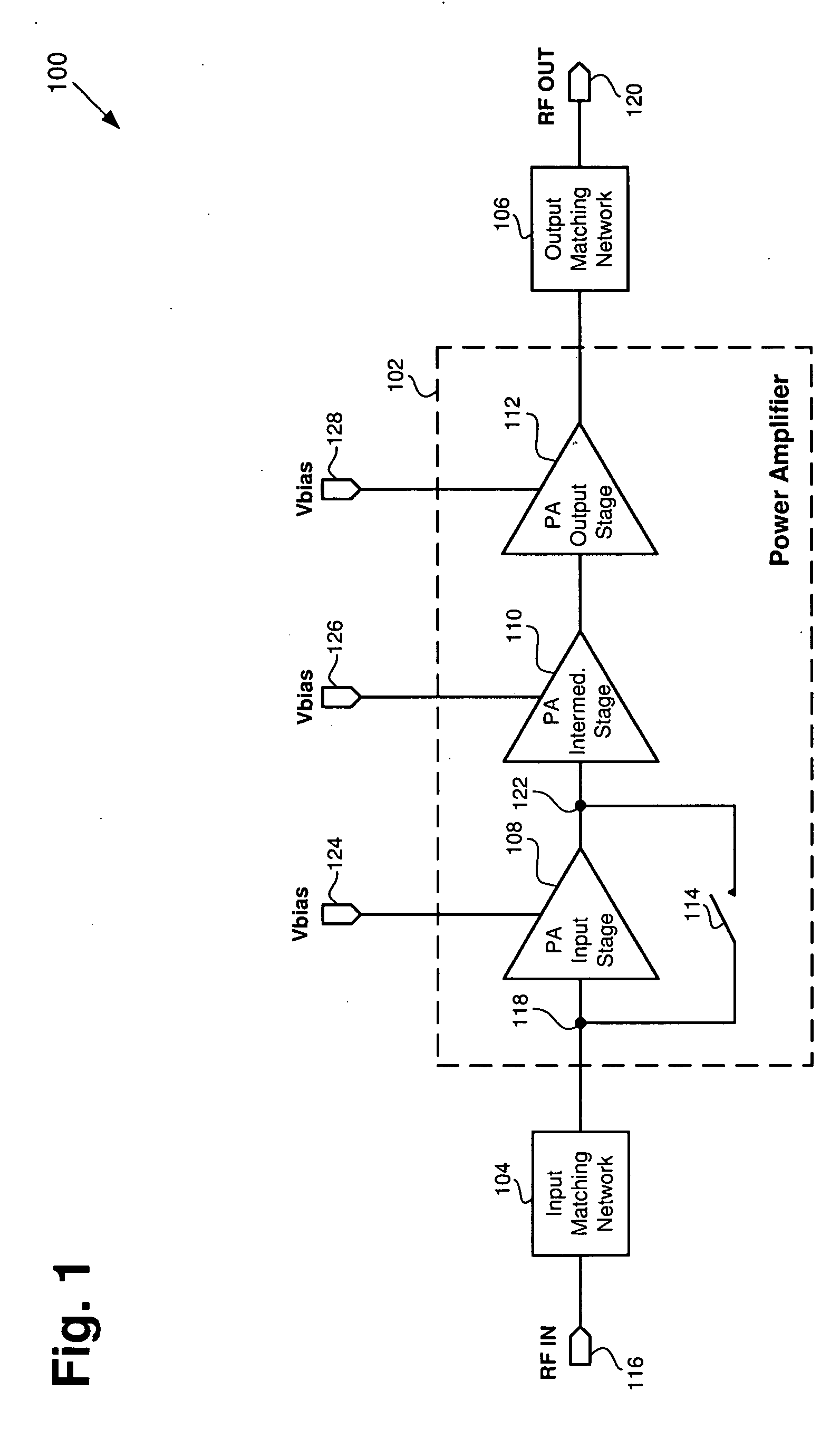

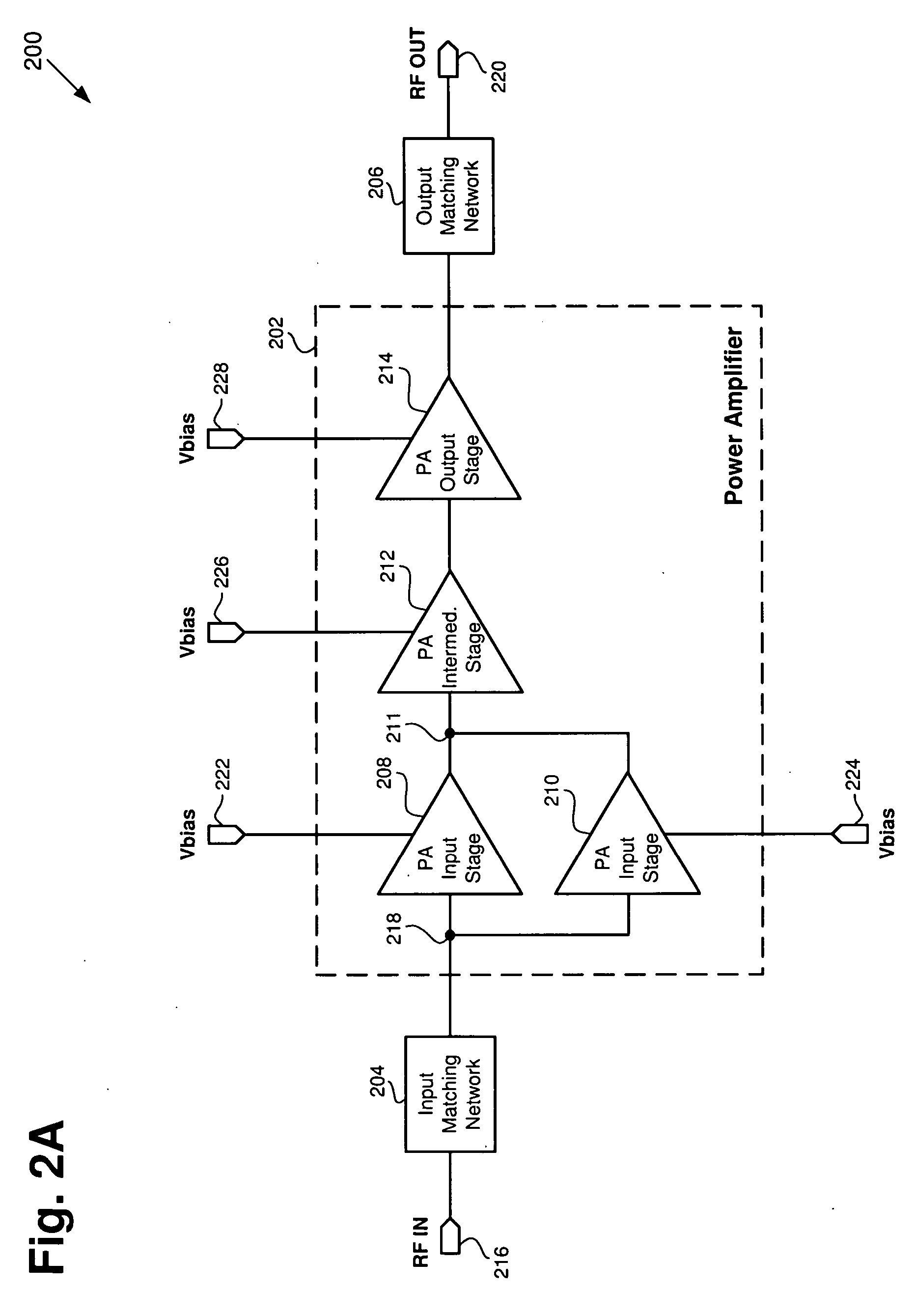

Dual mode power amplifier

A power amplifier is configured to operate in a first gain mode and a second gain mode. A first power amplifier input stage has an input and an output. A second power amplifier input stage has an input and an output, where the output of the second power amplifier input stage is coupled to the output of the first power amplifier input stage. The first input stage is turned on in response to a first bias voltage in the first gain mode and the second input stage is turned on in response to a second bias voltage in the second gain mode. Alternatively, a first input stage and an intermediate stage can be switched off by turning off their respective bias voltages, and a second input stage can be switched on by turning on its respective bias voltage; the intermediate stage and the second input stage sharing a common output.

Owner:SKYWORKS SOLUTIONS INC

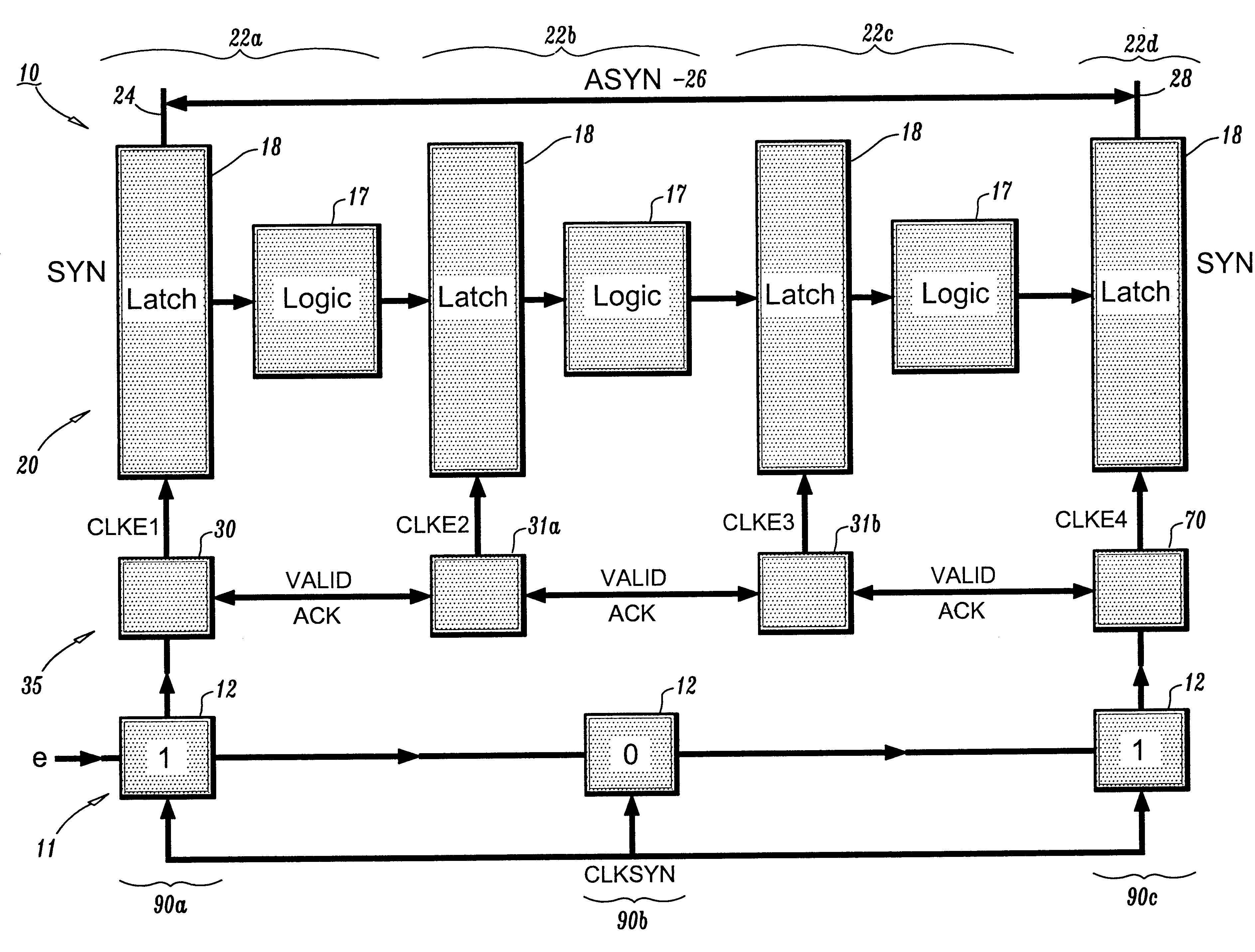

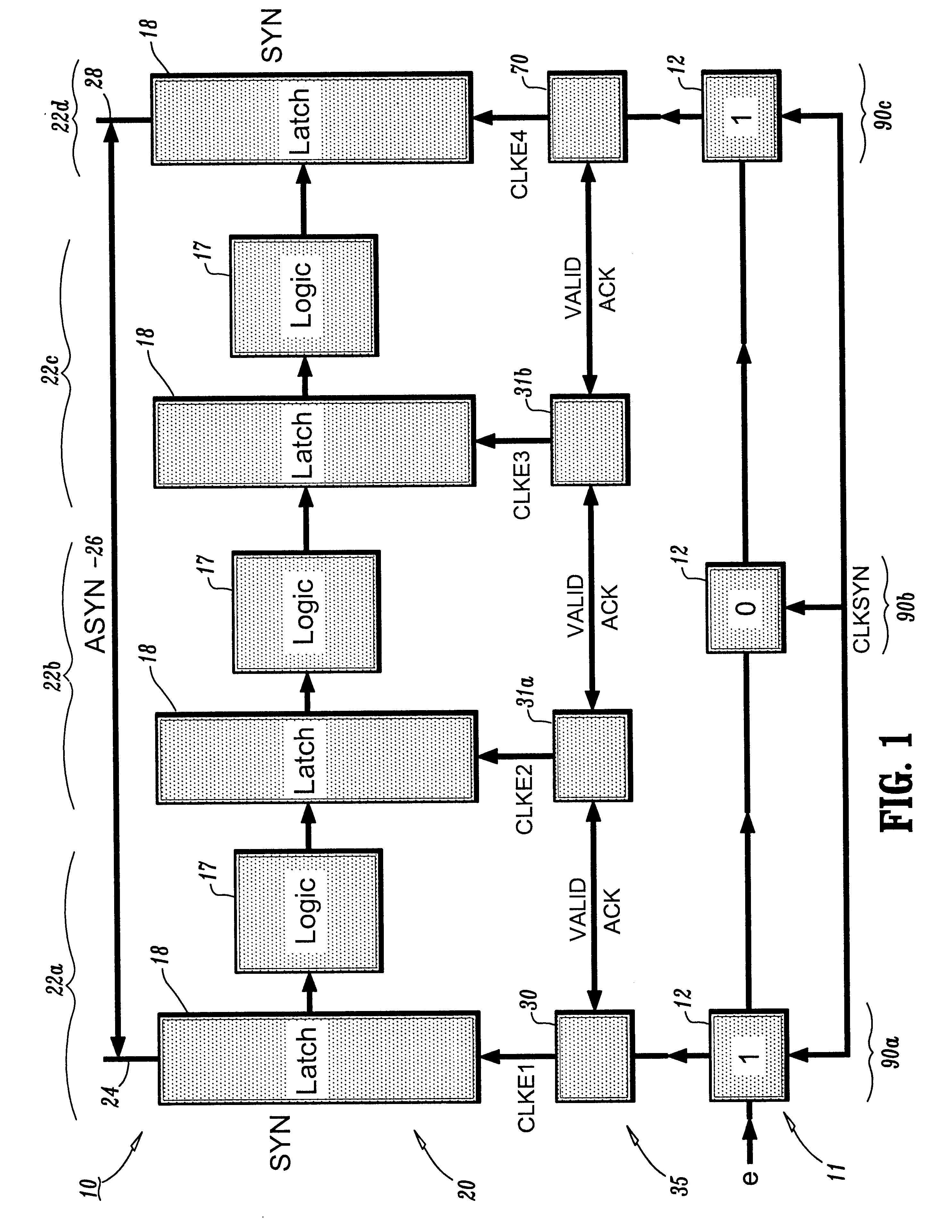

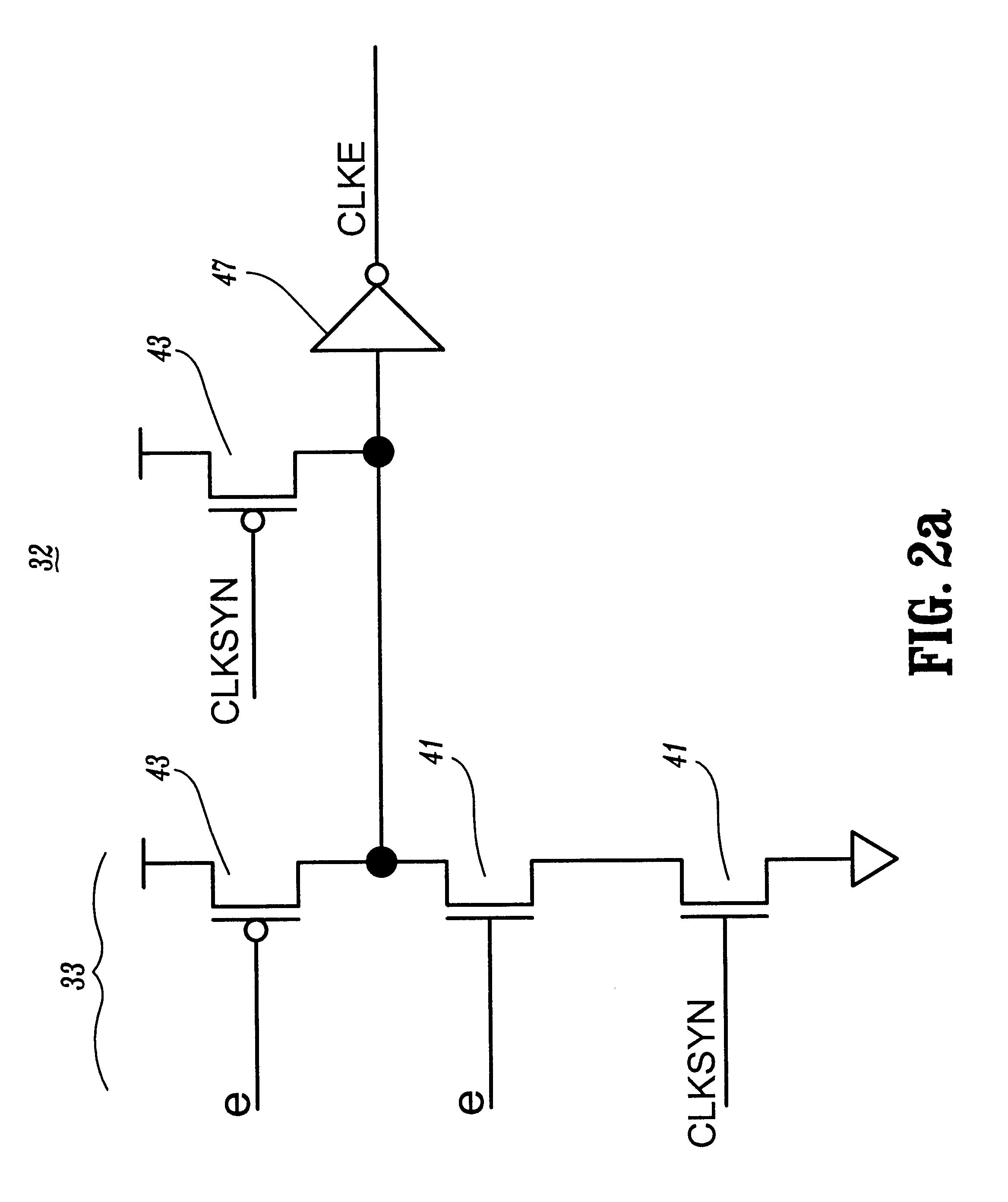

Synchronous to asynchronous to synchronous interface

InactiveUS6848060B2Concurrent instruction executionGenerating/distributing signalsIntermediate stageData transmission

An interface between synchronous and asynchronous data transfer includes a plurality of stages coupled to each other to form a pipeline for data transfer. The plurality of stages include a first stage which performs synchronous to asynchronous data transfer, at least one intermediate stage which performs asynchronous to asynchronous data transfer and a last stage which performs asynchronous to synchronous data transfer. A synchronous clock path propagates a timing signal across the plurality of stages to enable the first and last stages to perform operations when the timing signal is present at that stage.

Owner:IBM CORP

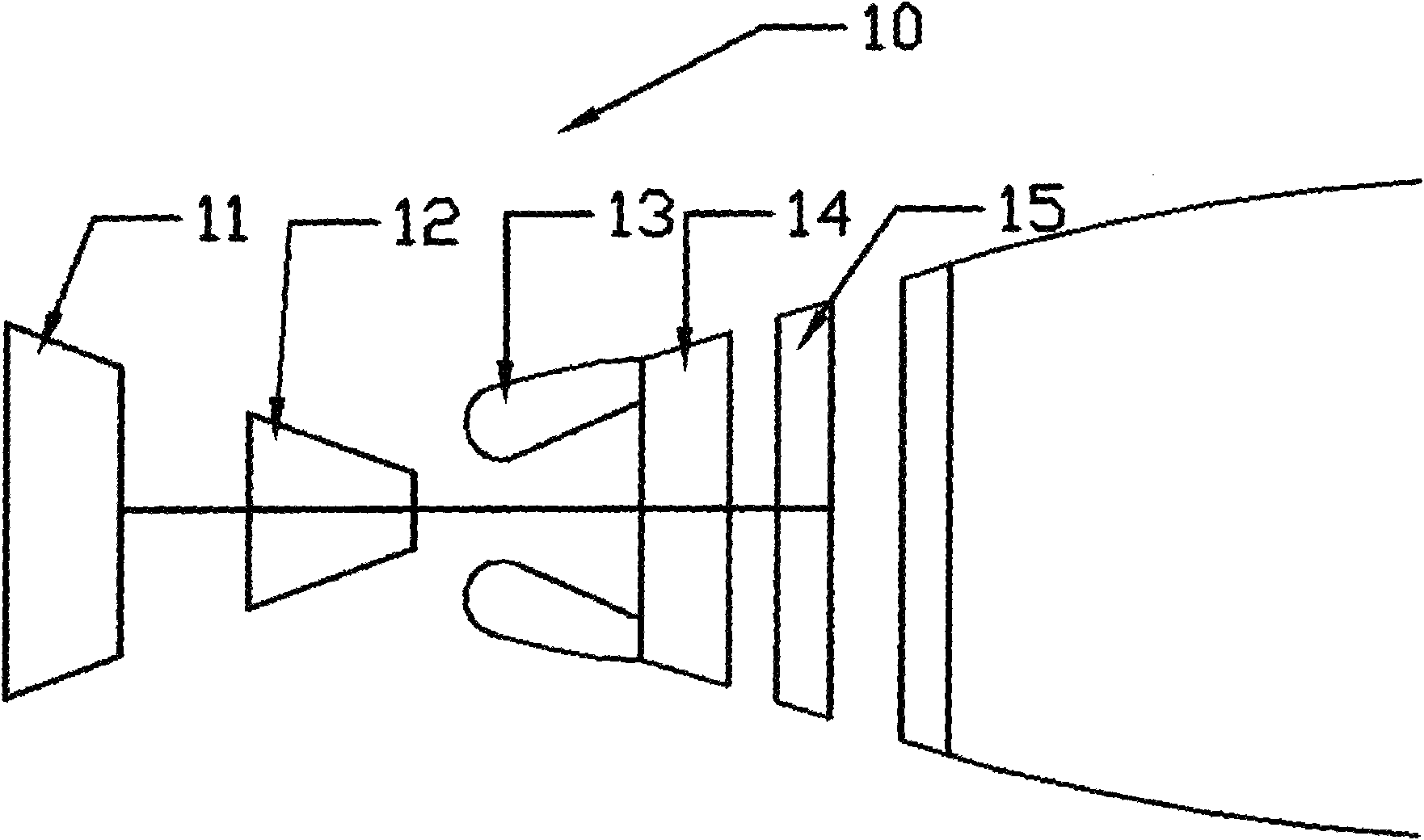

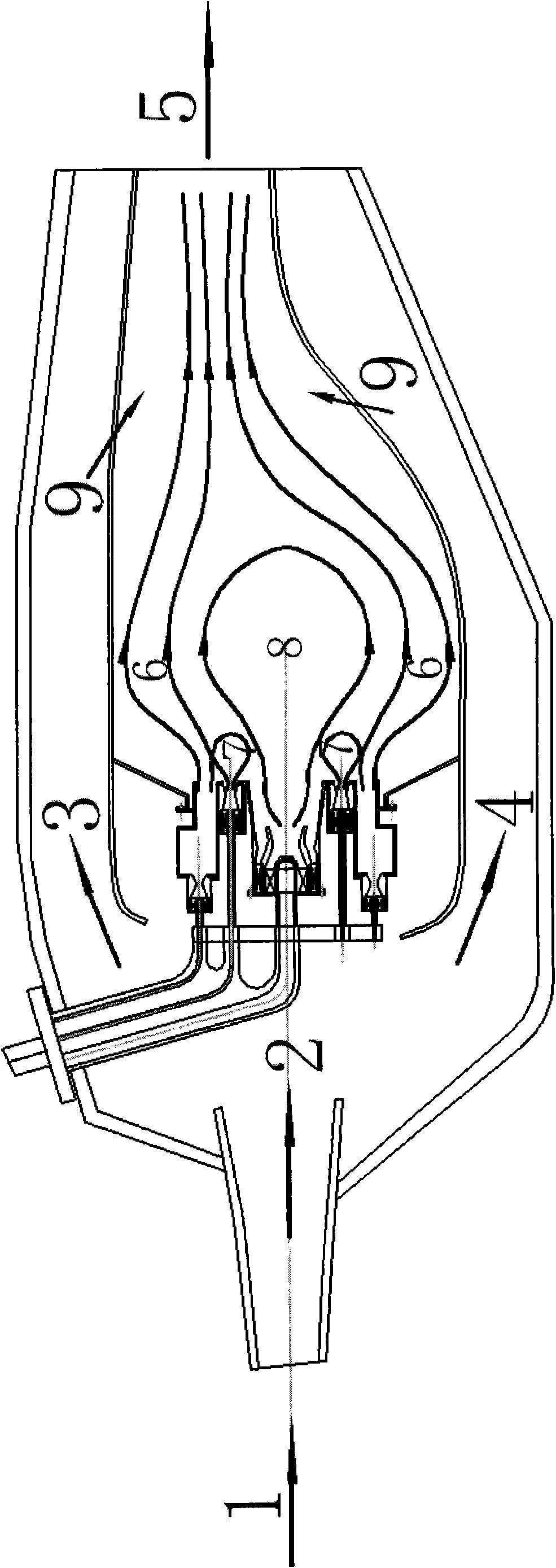

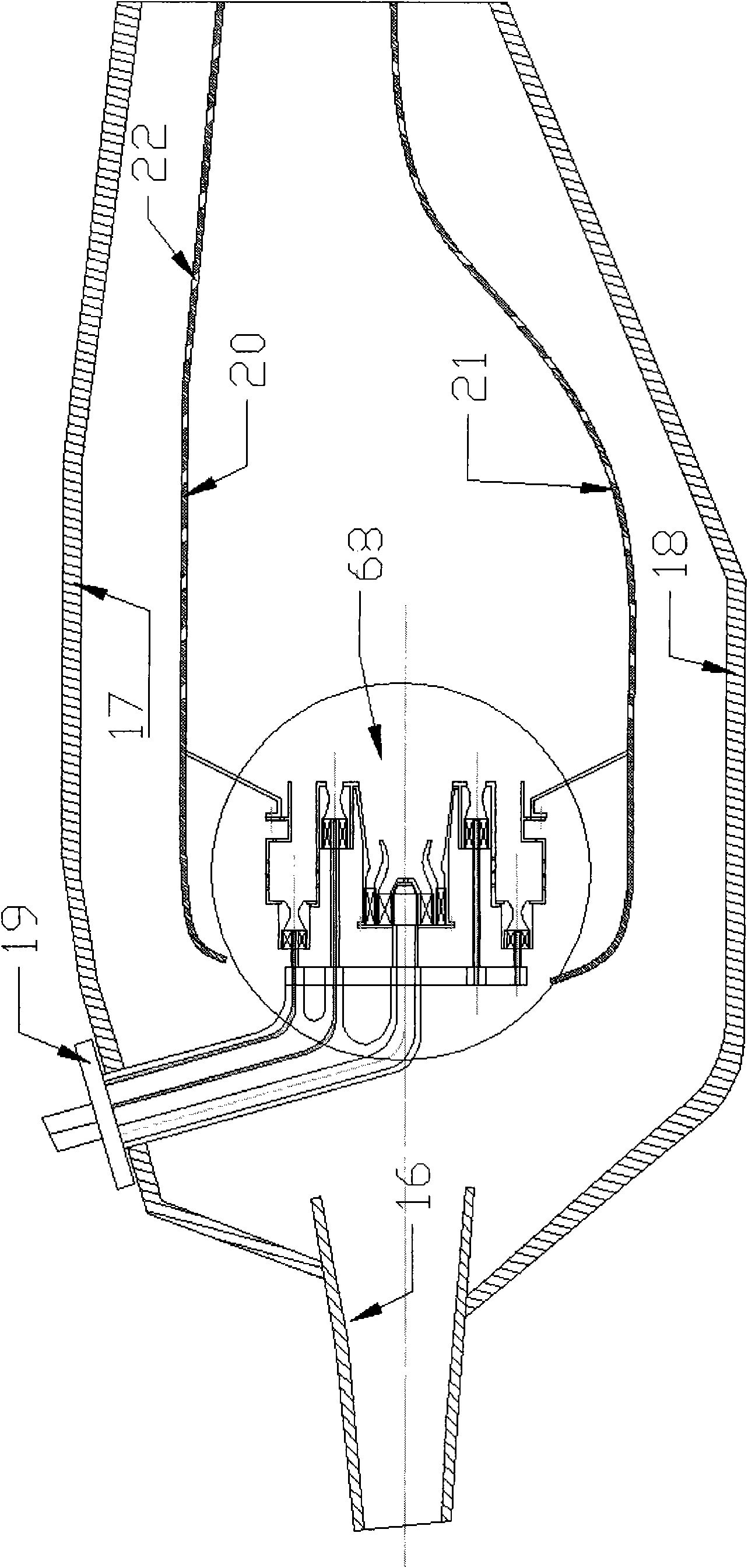

Circumferentially graded low-pollution combustion chamber with multiple middle spiral-flow flame stabilizing stages

InactiveCN102032598AImprove combustion stabilityIncrease the intermediate flame levelContinuous combustion chamberCombustion chamberLow speed

The invention discloses a circumferentially graded low-pollution combustion chamber with multiple middle spiral-flow flame stabilizing stages. The combustion chamber has a single annular cavity structure; a low-pollution combustion organization mode in which air grading is matched with fuel oil grading is adopted; all fuel gas is supplied by a duty stage, a middle stage and a main combustion stage; and fuel oil grading supply proportion is controlled accurately according to the operating condition of an engine and the requirement on stable low-pollution combustion. The duty stage has a combined structure in which two-stage axial spiral flow is matched with a venturi tube, and a formed low-speed reflux region can support stable combustion of the combustion chamber; the middle stage has a combined structure in which a plurality of single-stage axial spiral flow circumferentially and uniformly distributed on the same circumference in the same axial cross section are matched with the venturi tube, and a formed middle flame stabilizing stage combustion region is used for intensifying and stabilizing flame in the main combustion stage; and the main combustion stage has a combined structure in which a plurality of single-stage axial spiral flow circumferentially and uniformly distributed on the same circumference in the same axial cross section are matched with the venturi tube, so that an oil and gas mixed poor-oil premixing and pre-evaporation combustion mode is intensified and the emission of pollutants is further reduced greatly.

Owner:BEIHANG UNIV

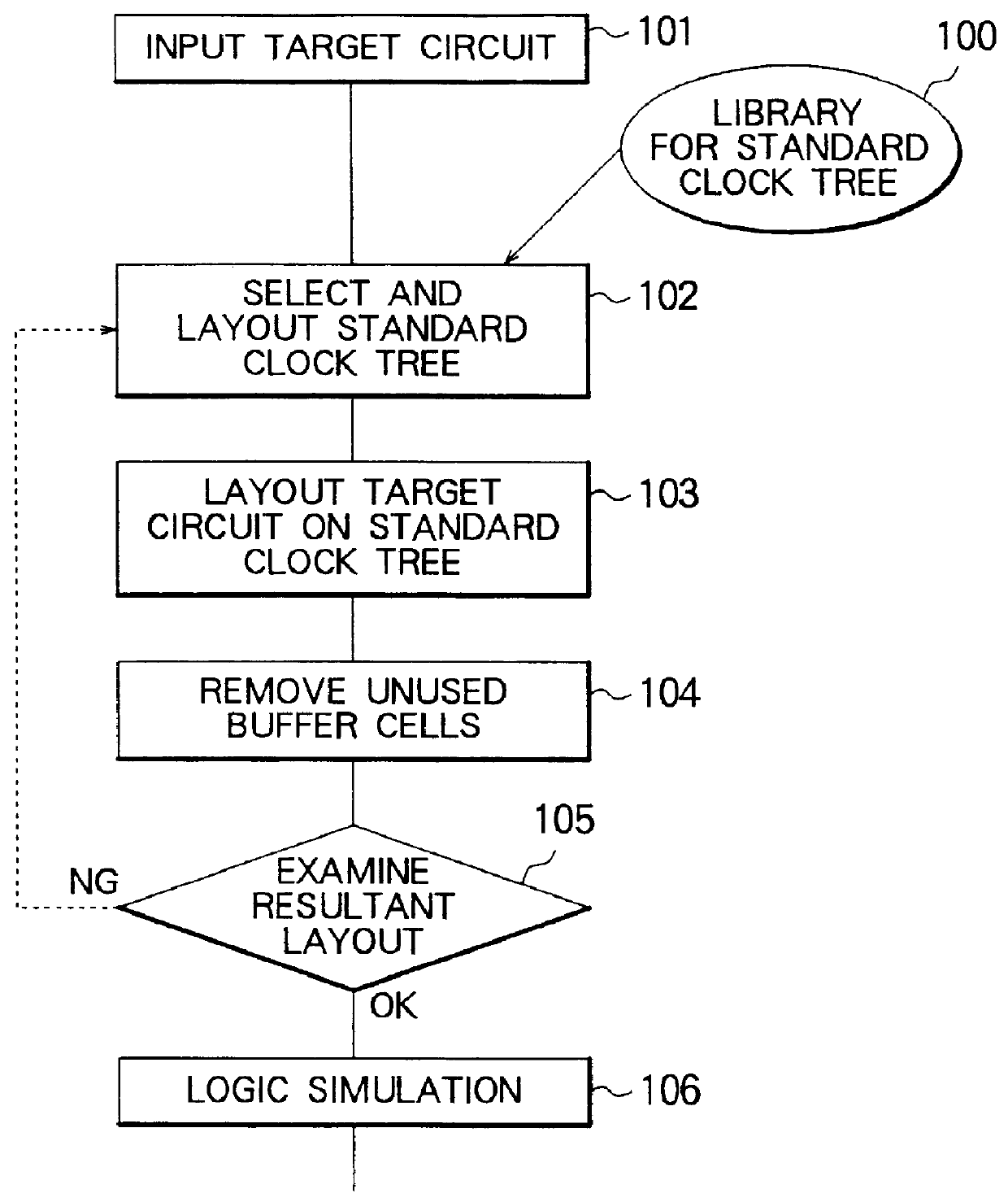

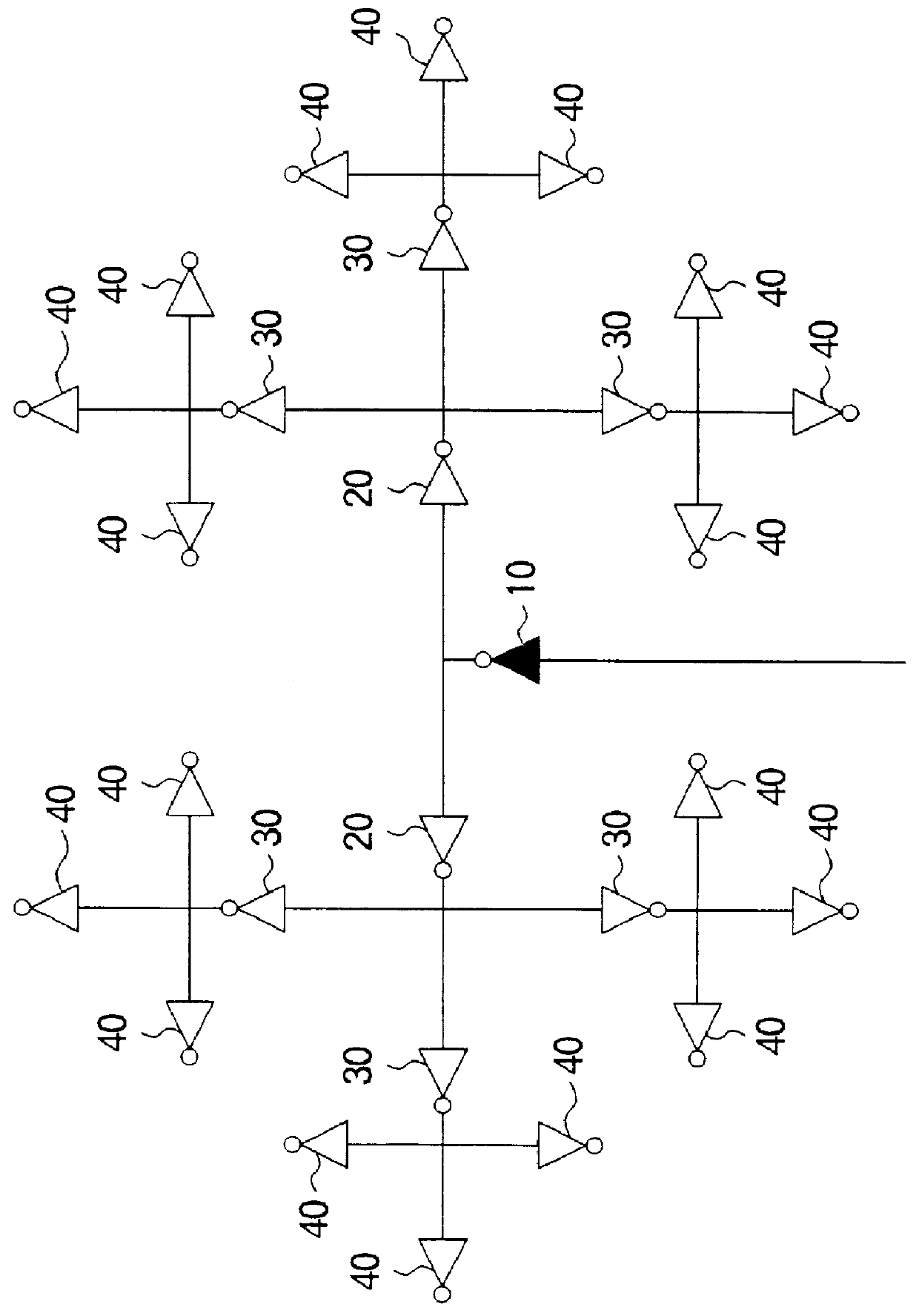

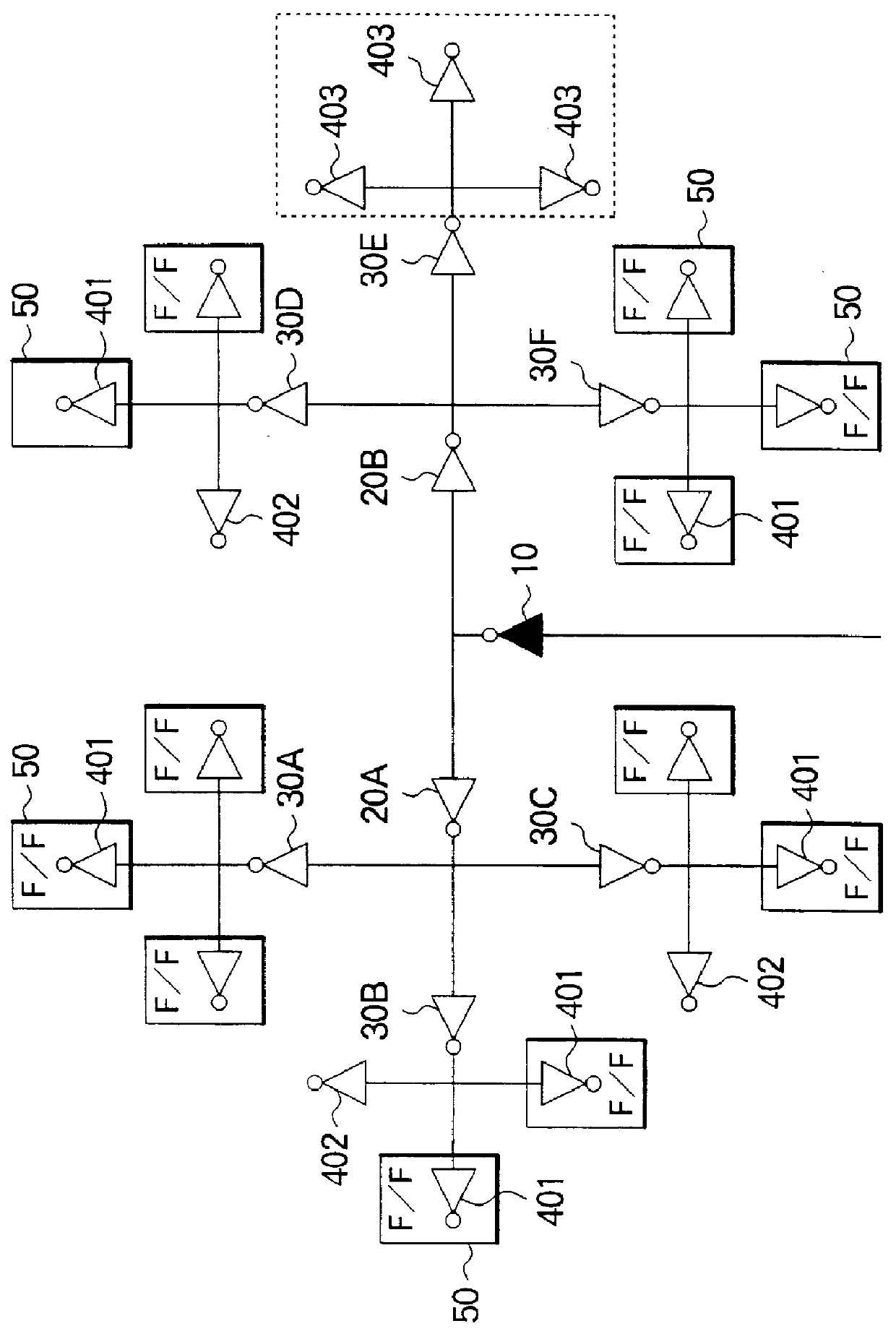

Layout method for a clock tree in a semiconductor device

InactiveUS6053950ASolid-state devicesSemiconductor/solid-state device manufacturingWrite bufferClock tree

A clock signal distribution circuit has a clock tree configuration. In the layout of the clock tree, a standard clock tree is prepared having a route buffer, a plurality of intermediate stage buffer cells and a plurality of last stage buffer cells connected in a hierarchical configuration. All of the clock lines have an equal length. If there are no set of flip-flops ina target integrated circuit corresponding to a set of last stage buffer cells, the set of last stage buffer cells are removed as a whole provided there is not other last stage buffer cells connected to a flip-flop.

Owner:NEC ELECTRONICS CORP

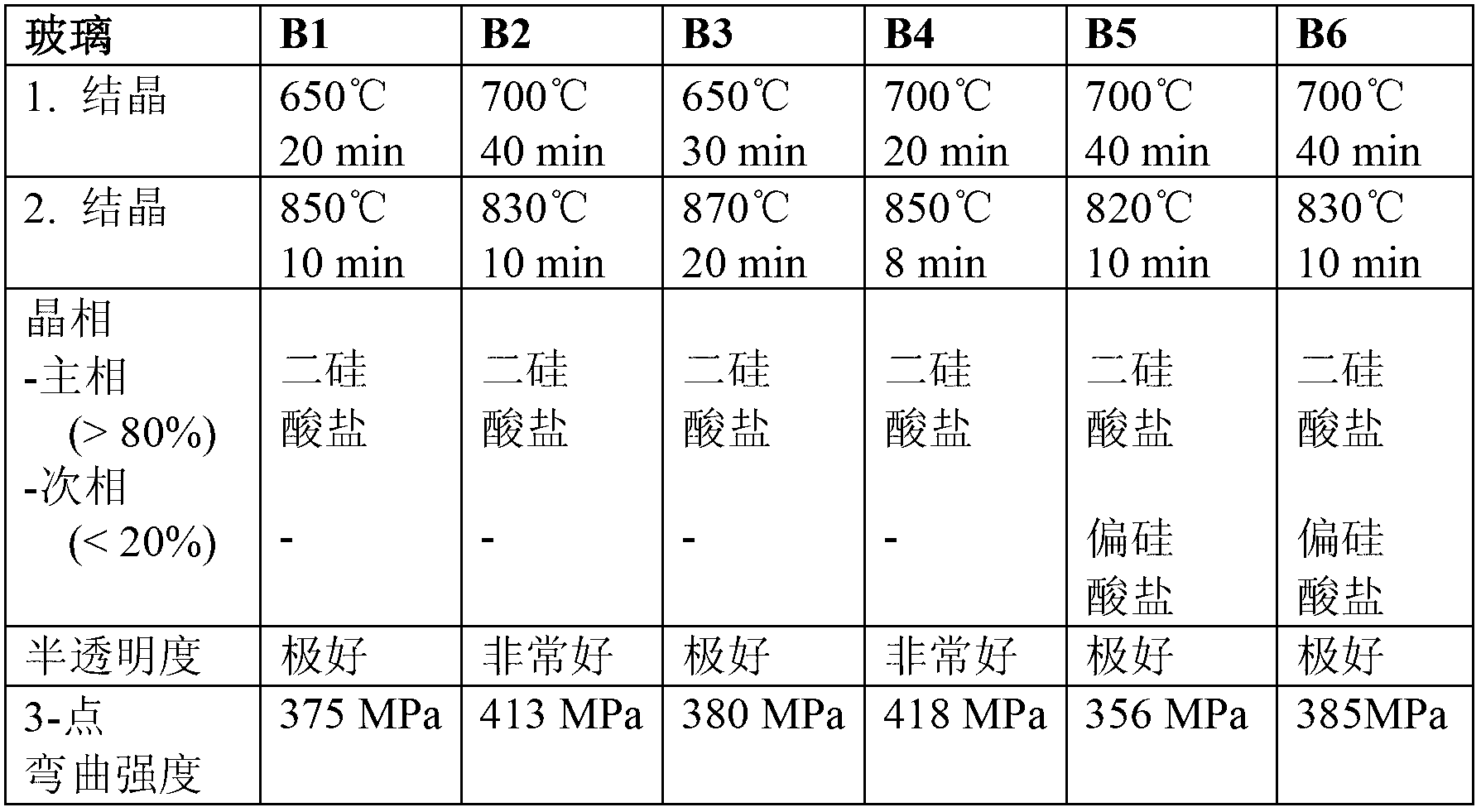

Lithium disilicate glass ceramics, method for the production thereof and use thereof

ActiveCN102741186AEasy to processHigh strengthTooth crownsArtificial teethHigh intensityIntermediate stage

The invention relates to glass ceramics on the basis of the lithium disilicate system, which can be easily mechanically machined in an intermediate stage of the crystallization and which represent high-strength, highly translucent and chemically stable glass ceramics after complete crystallization. Furthermore, the invention relates to a method for producing said glass ceramics. The glass ceramics according to the invention are used as dental material.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV +2

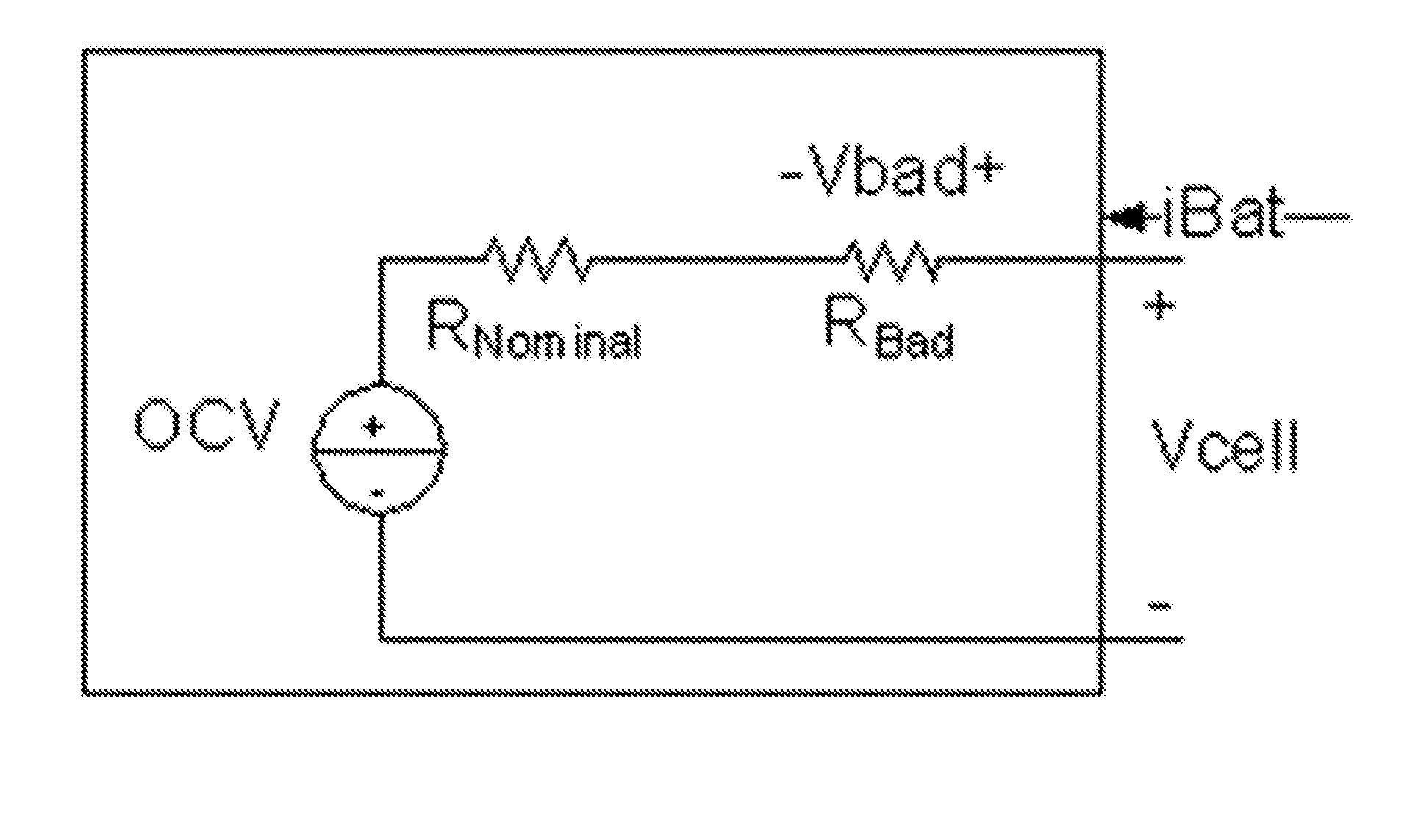

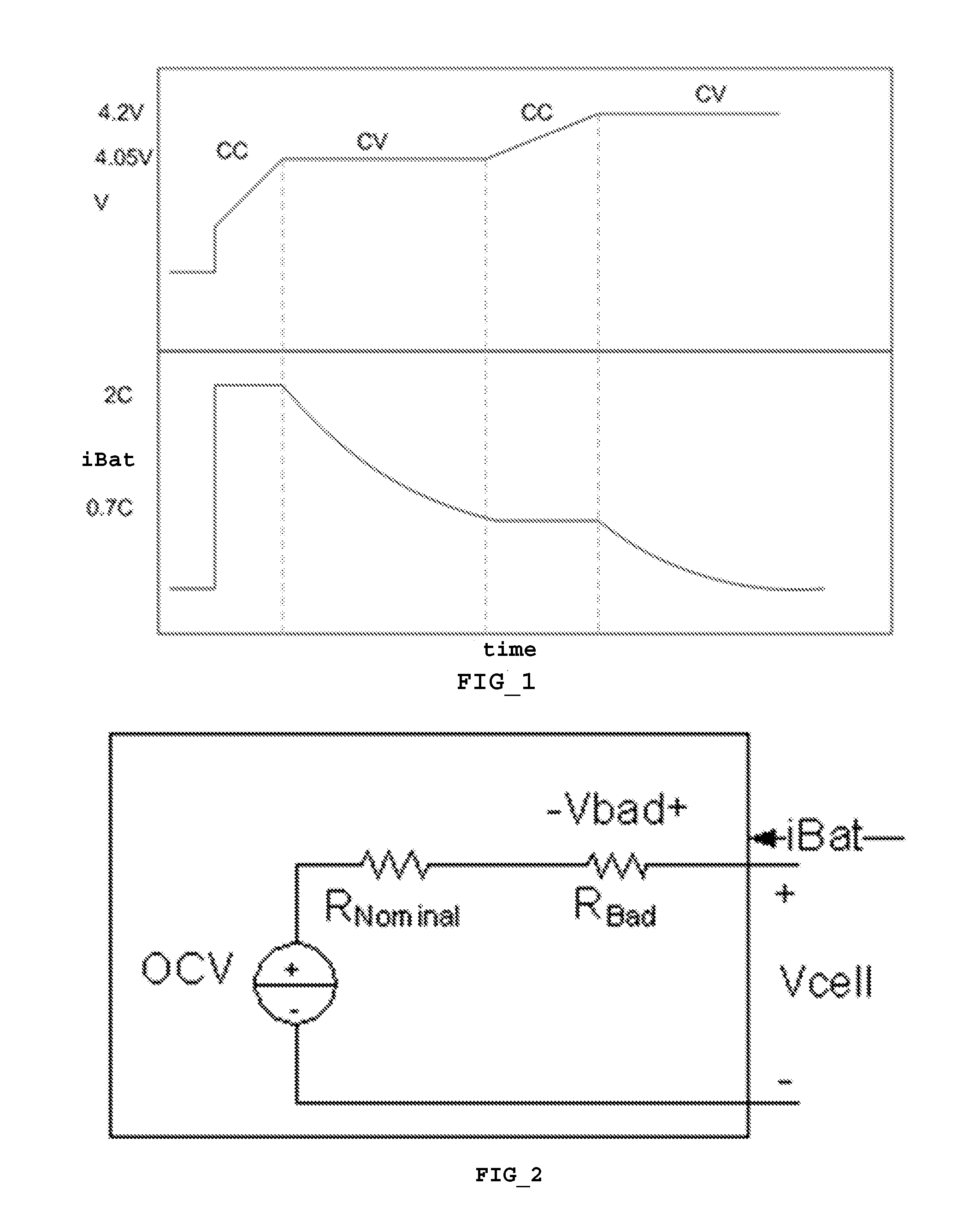

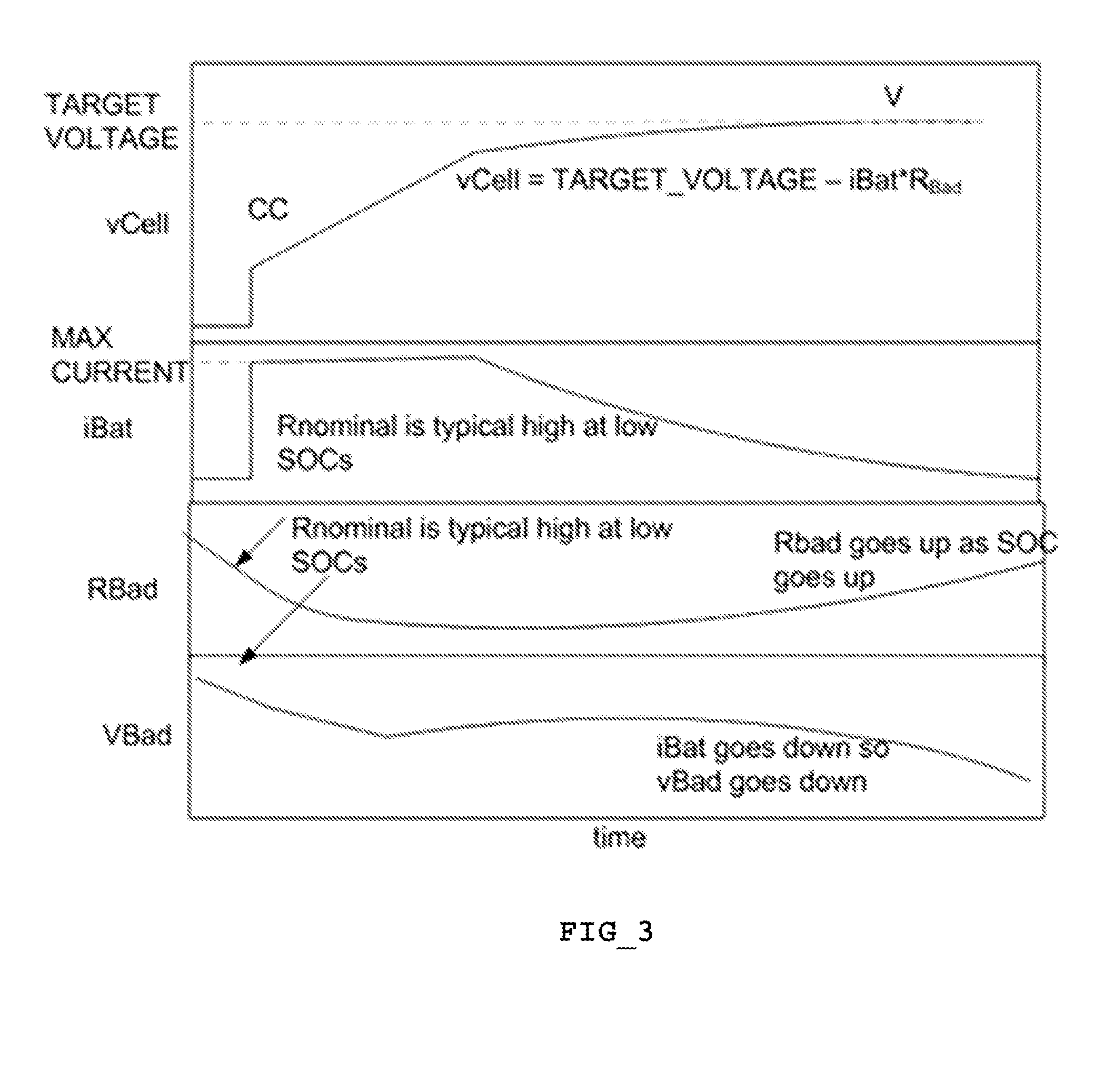

Fast charging of battery using adjustable voltage control

ActiveUS20110012563A1Shorten charging timeReducing/eliminating impactSecondary cells charging/dischargingElectric powerFast chargingEngineering

A battery cell charger for rapidly charging a lithium ion battery cell (or string of series-parallel connected cells) having a maximum battery cell voltage the battery cell charging system including: a circuit for charging the battery cell using an adjustable voltage charging-profile to apply a charging voltage and a charging current to the battery cell wherein the adjustable voltage charging-profile includes: a first charging stage with a constant first stage charging current and an increasing battery cell voltage with the first stage charging current provided until the first stage charging voltage is about equal to a first stage complete voltage less than the maximum battery cell voltage; one or more intermediate charging stages, each intermediate stage selected from the group consisting of one or more of an intermediate constant voltage stage that provides a decreasing charging current, an intermediate constant current stage that produces an increasing battery cell voltage, and combinations thereof; and a final charging stage with a constant final stage charging voltage about equal to an intermediate stage complete voltage and a decreasing final stage charging current with the final stage charging voltage provided until the final stage charging current reaches a desired charge complete level.

Owner:TESLA INC

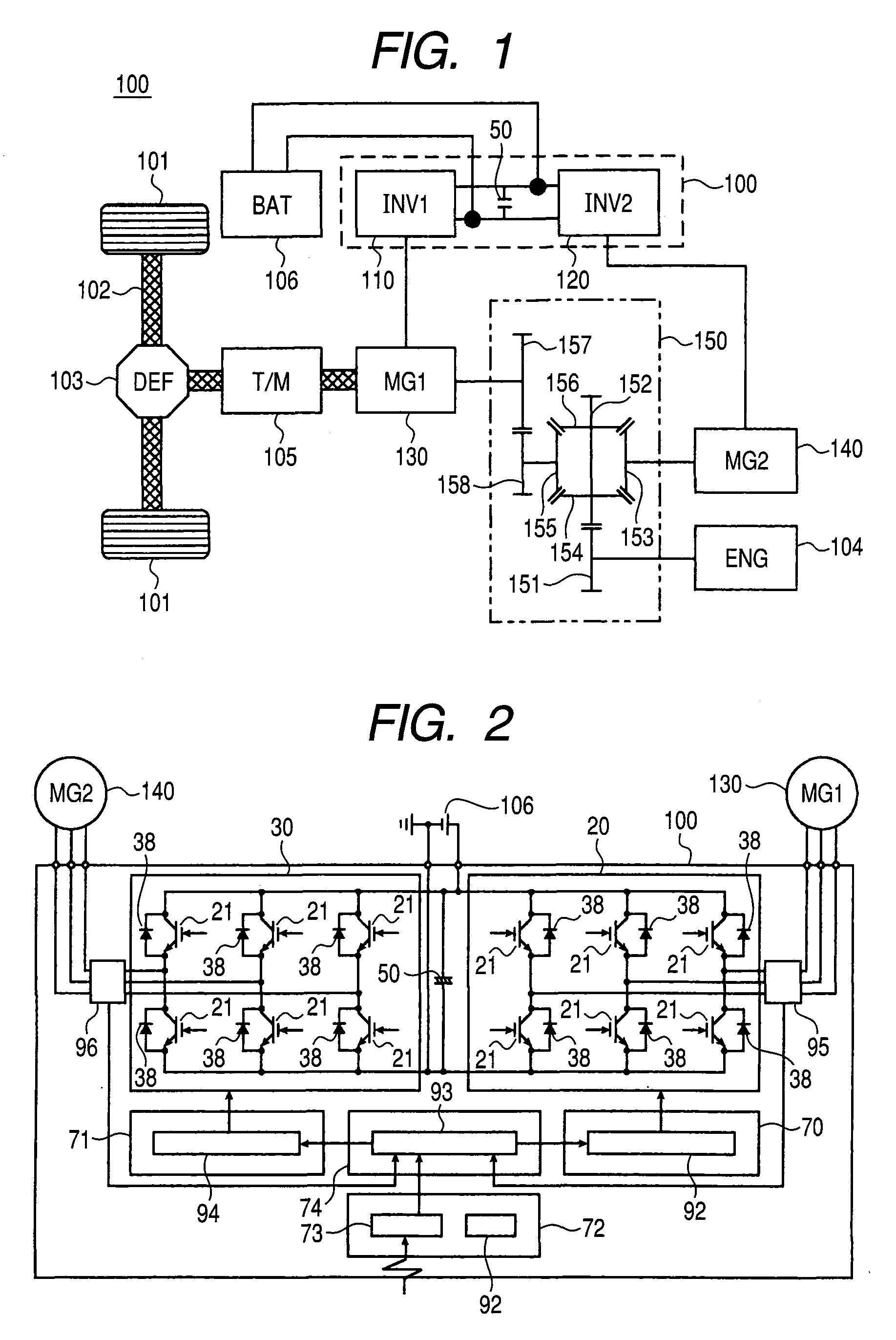

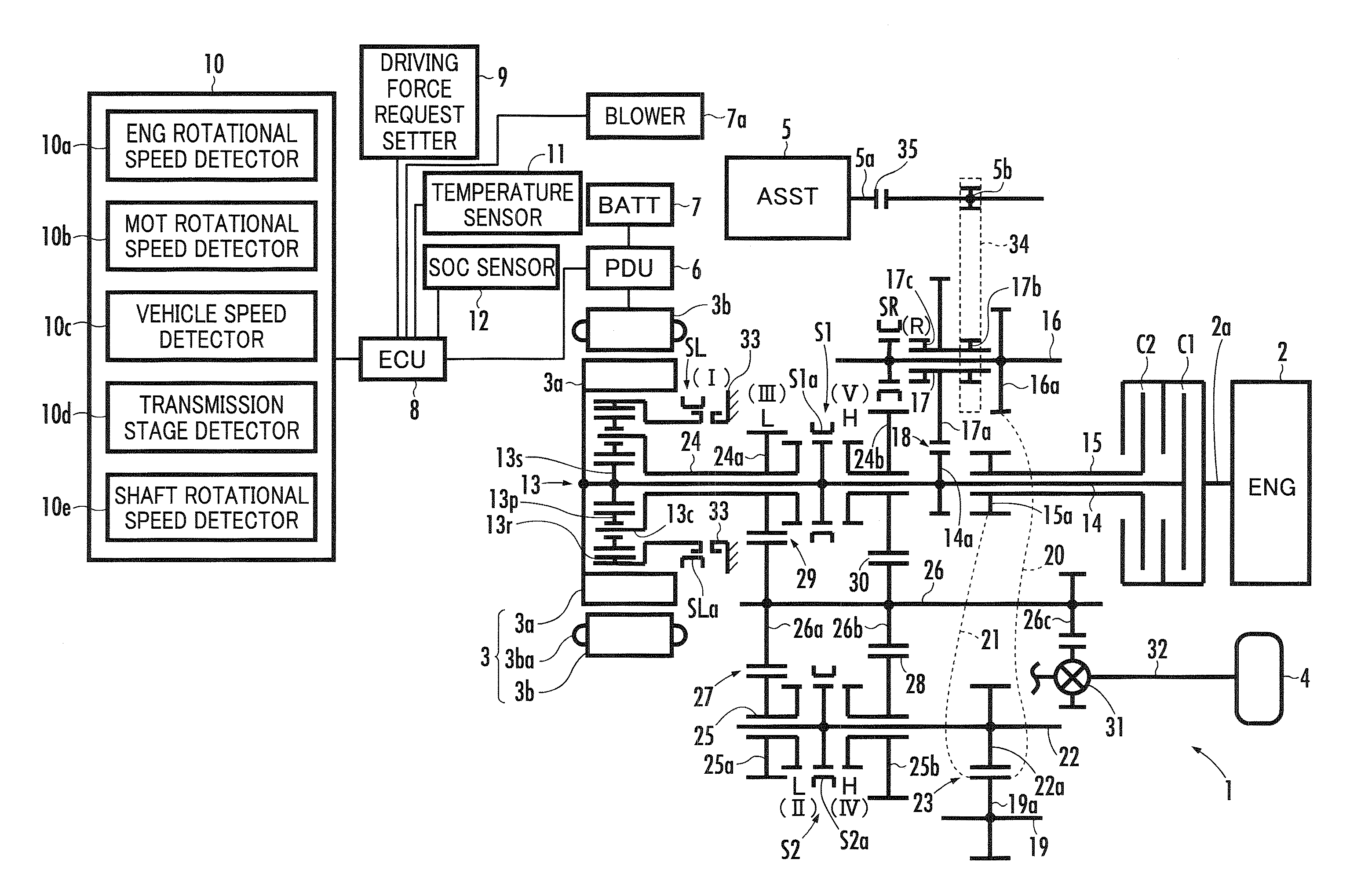

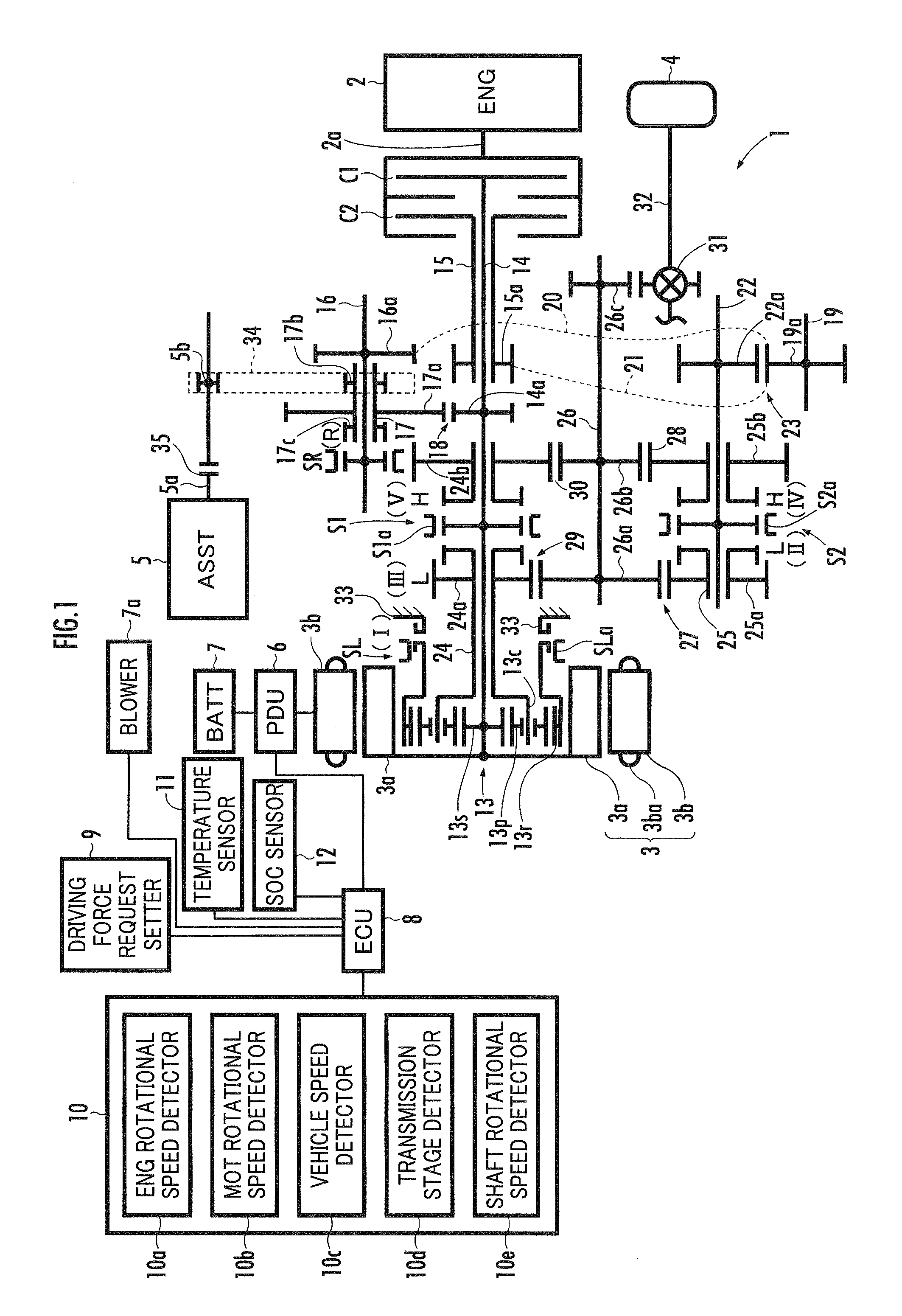

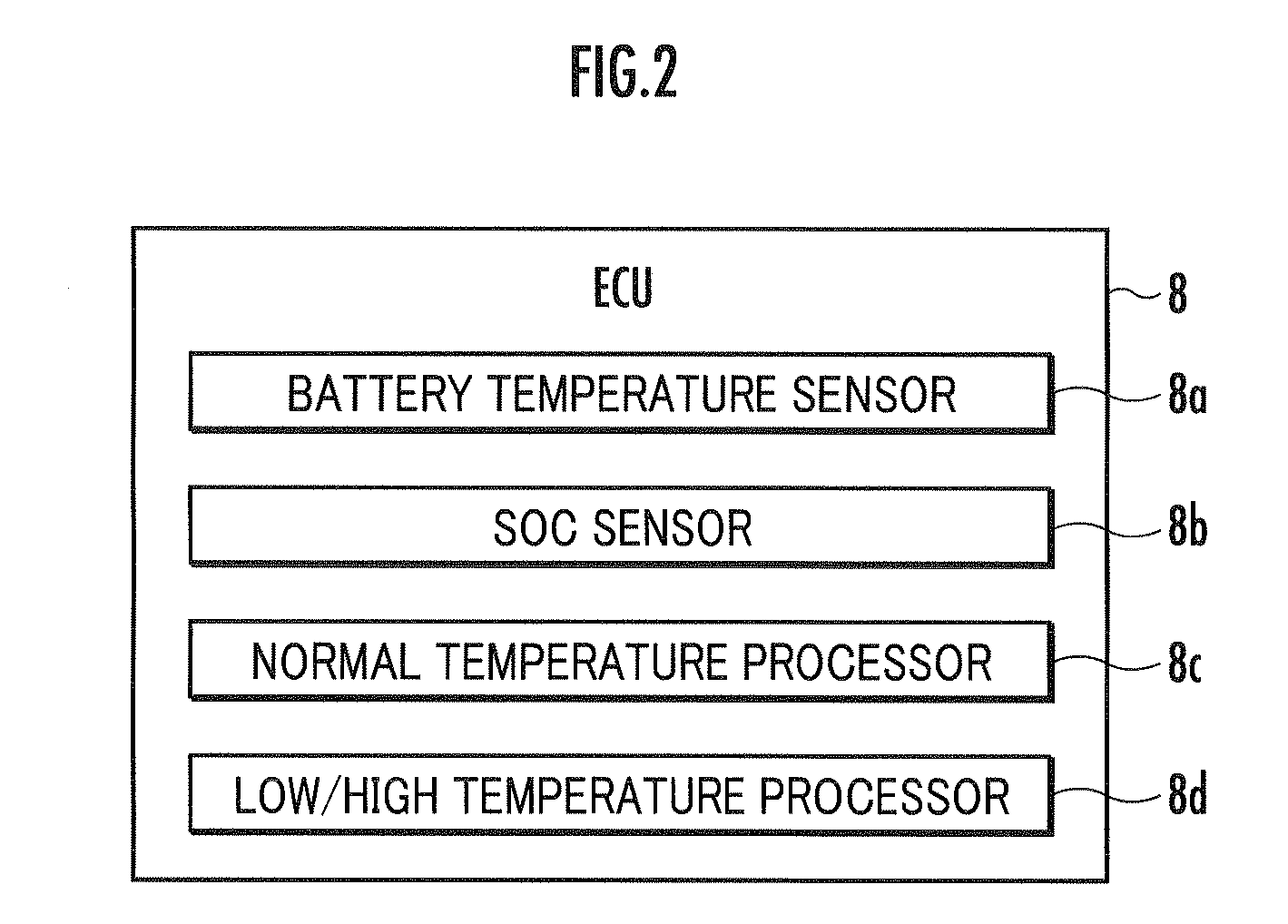

Hybrid vehicle

ActiveUS20120245781A1Increase delayImprove gear shifting responsivenessAuxillary drivesElectric devicesDrive wheelIntermediate stage

A transmission has a first transmission group which is capable of transmitting motive power from an electric motor and / or an engine to driven wheels and which is provided with a plurality of transmission stages having different transmission ratios and a second transmission group capable of transmitting motive power from the engine to the driven wheels. If the temperature of a battery detected by a temperature sensor is below a first predetermined temperature or a second predetermined temperature or higher, then an ECU sets the transmission stage of the first transmission group at an intermediate stage and carries out control so as to travel at an intermediate stage of the second transmission group which is adjacent to the intermediate stage of the first transmission group.

Owner:HONDA MOTOR CO LTD

Saline-alkali soil improvement method

ActiveCN103922846ANo pollutionHigh activityFertilising methodsFertilizer mixturesAlkali soilGreen manure

The invention discloses a saline-alkali soil improvement method. The saline-alkali soil improvement method comprises the following steps: a step I of leveling and cultivating, wherein the saline-alkali soil is firstly leveled and then deeply cultivated by 40 centimeters by virtue of deep-ploughing machinery; after being diluted by 100 times with water, green manure nutrient liquor brewed by a three-in-one leavening agent is used for irrigation; a step II of applying fertilizer and cultivating, wherein aeolian sandy soil easily obtained locally is uniformly scattered on the surface of primarily leveled and cultivated soil; a step III of preparing rectangular pieces of land in a field and planting, wherein planting ridge rectangular pieces of land in the field are designed and manufactured; a step IV of subsequently governing, wherein measures of not using fertilizers and substances which are not chemically synthesized in early-stage, middle-stage and later-stage filed management processes after the plants are planted, not watering and uninterruptedly irrigating the green manure nutrient liquor are taken. The saline-alkali soil improvement method disclosed by the invention can be used for strengthening soil fertility, and changing physical and chemical properties and microbial activity of the soil.

Owner:赵光

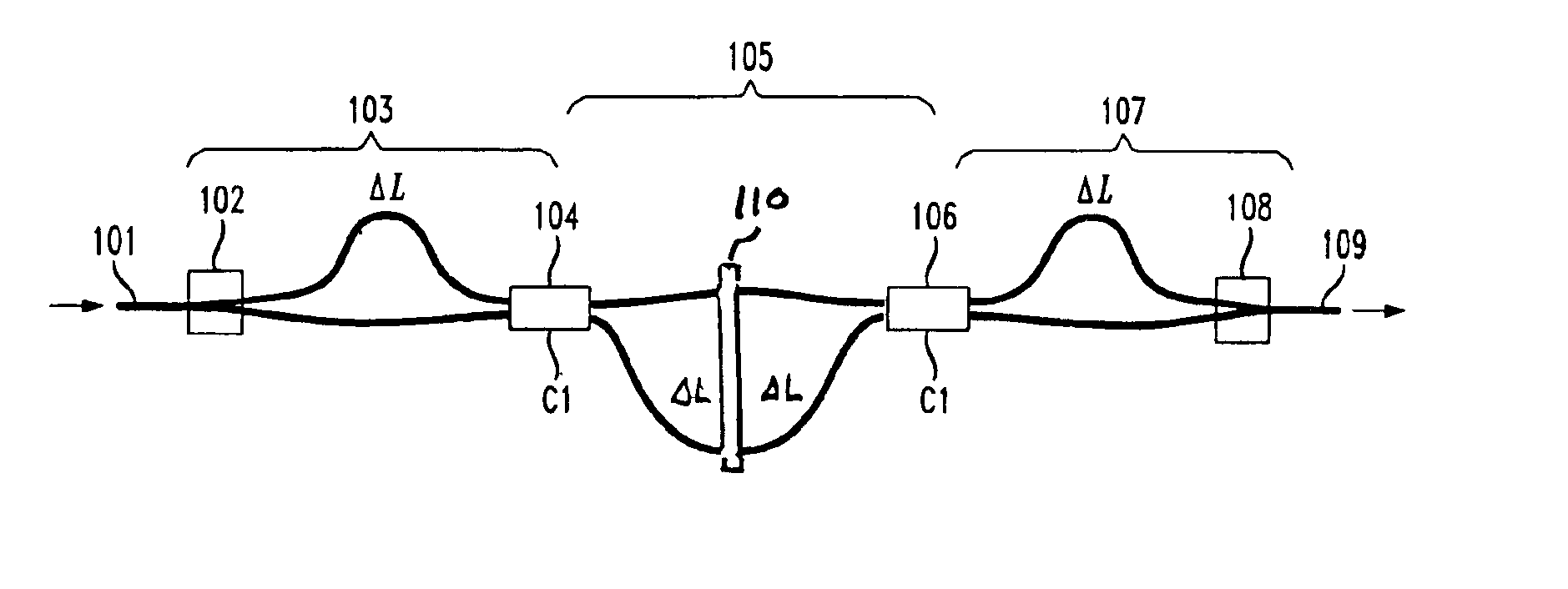

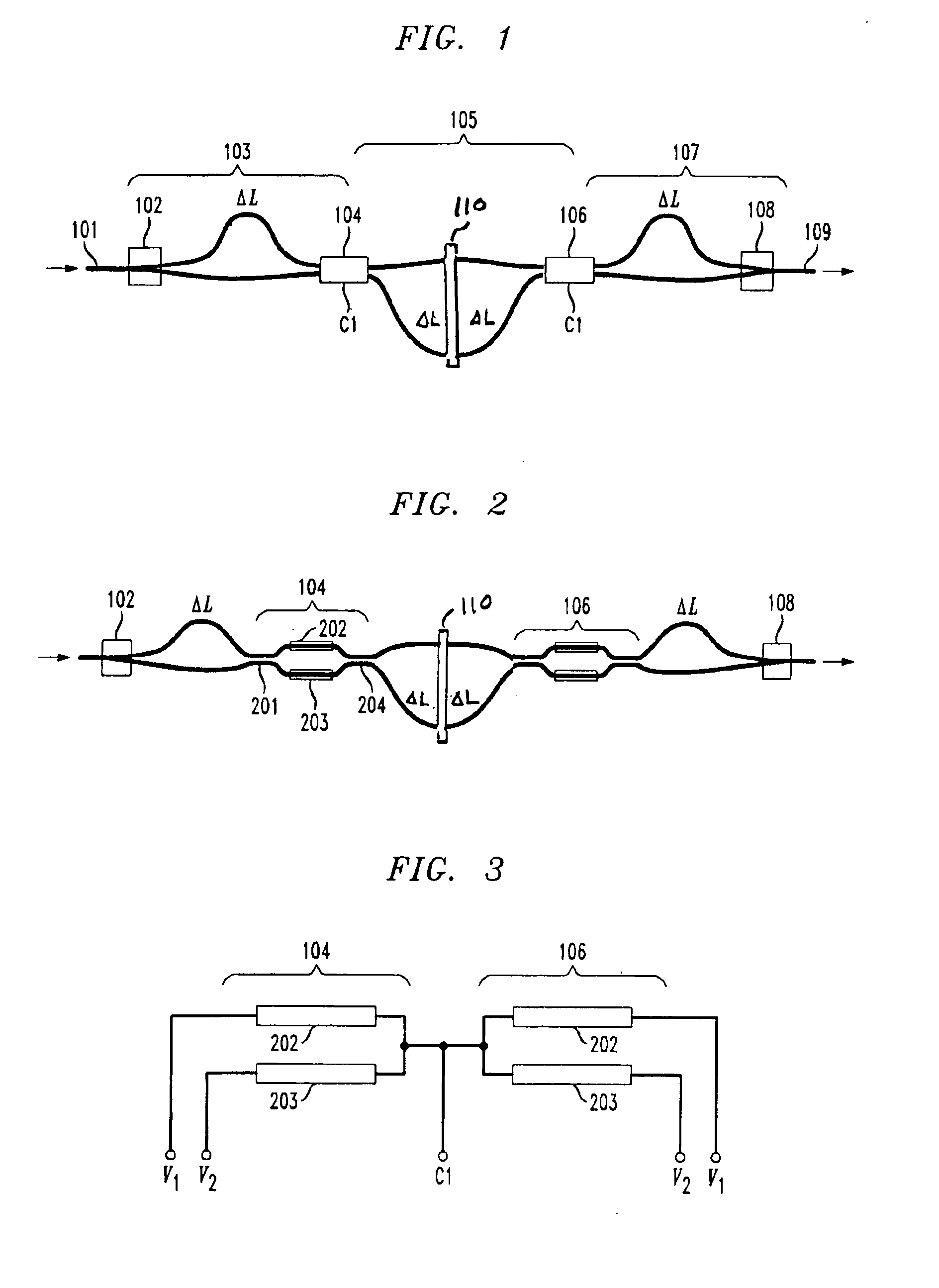

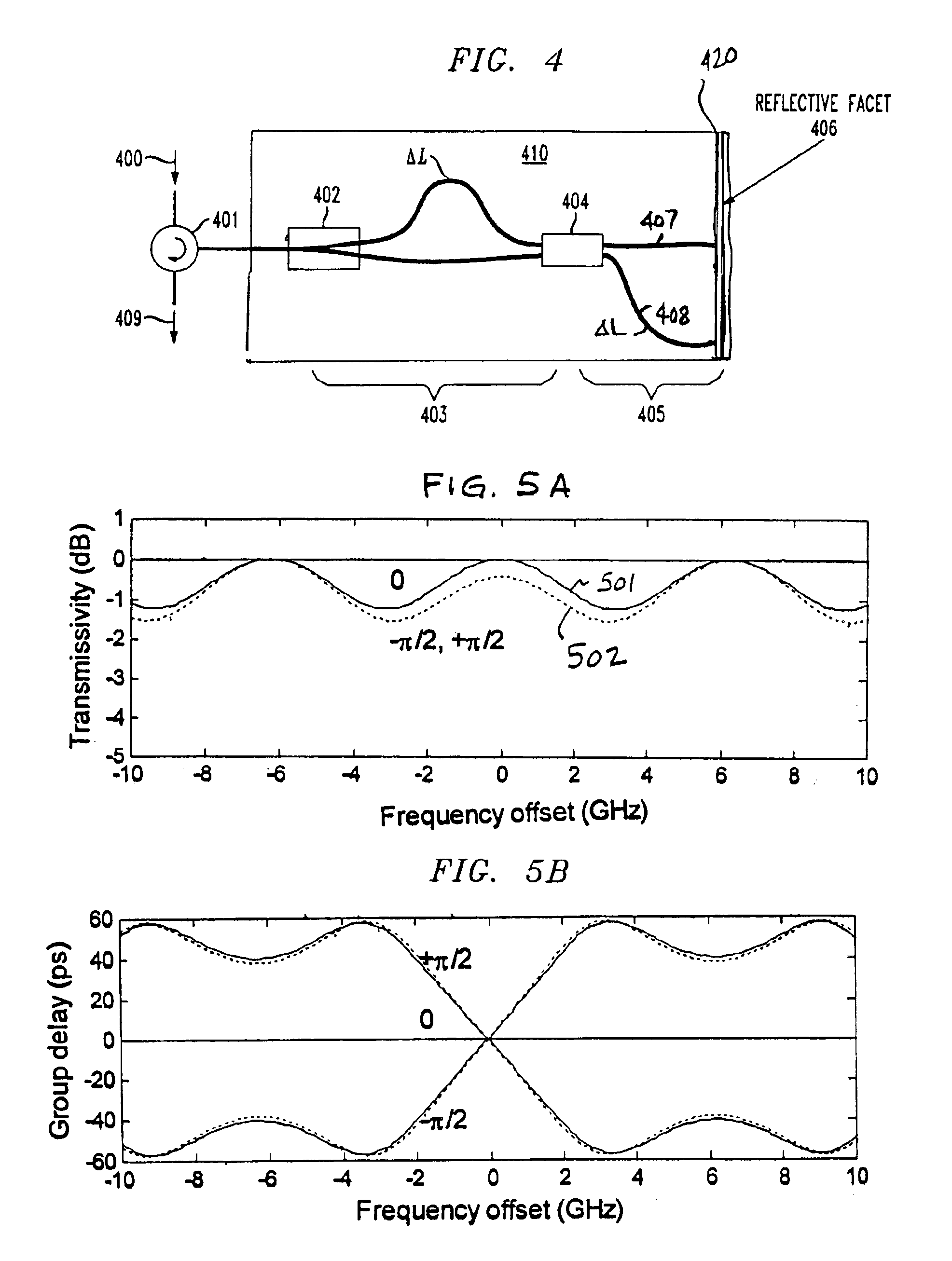

Tunable dispersion compensator

InactiveUS6961492B2Low powerSimple to fabricateCoupling light guidesElectromagnetic transmissionPath lengthThree stage

A method and apparatus for implementing a colorless polarization independent Mach-Zehnder-interferometer (MZI)-based tunable dispersion compensator (TDC) that has only three MZI stages (two in a reflective MZI-TDC) and two adjustable couplers which are responsive to one control voltage, making it compact, low power, and simple to fabricate, test, and operate. Polarization independence is obtained by using a half-wave plate positioned across the midpoints of the two path lengths of middle stage MZI of the three stage MZI-TDC and by using a quarter-wave plate in front of a reflective facet of the reflective MZI-TDC. A cascaded MZI-TDC arrangement with also only a single control is formed by cascading two MZI-TDC arrangements and driving all adjustable couplers with the same control signal.

Owner:ALCATEL-LUCENT USA INC +1

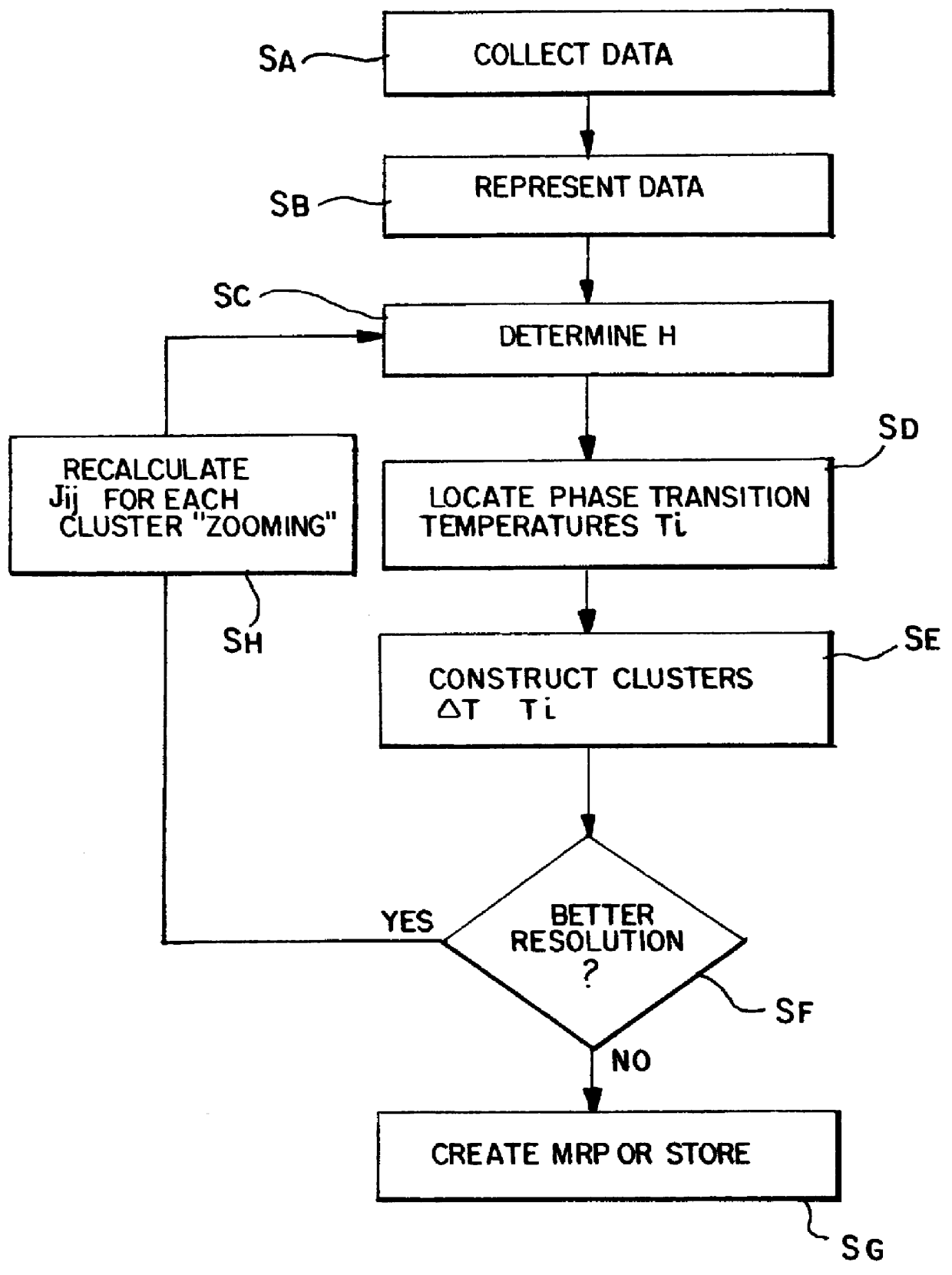

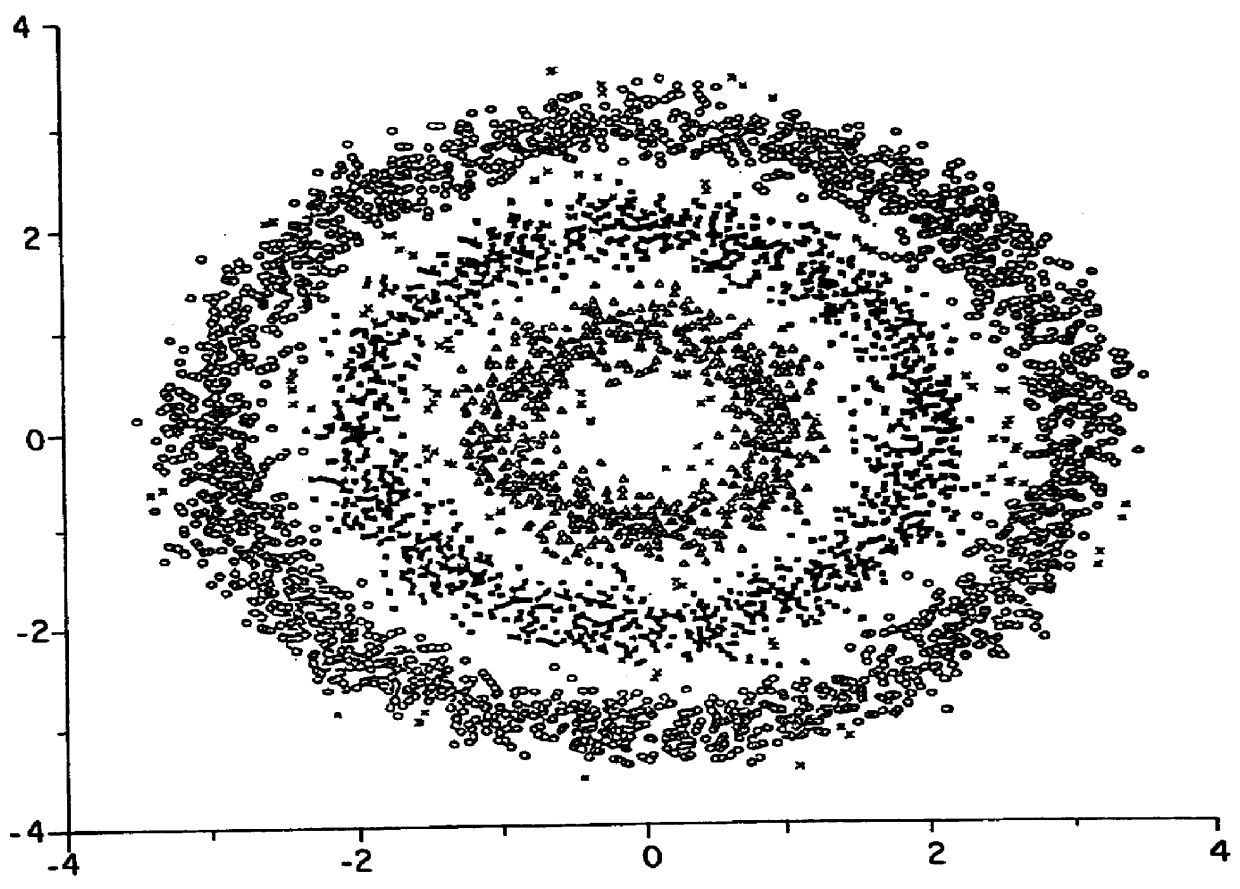

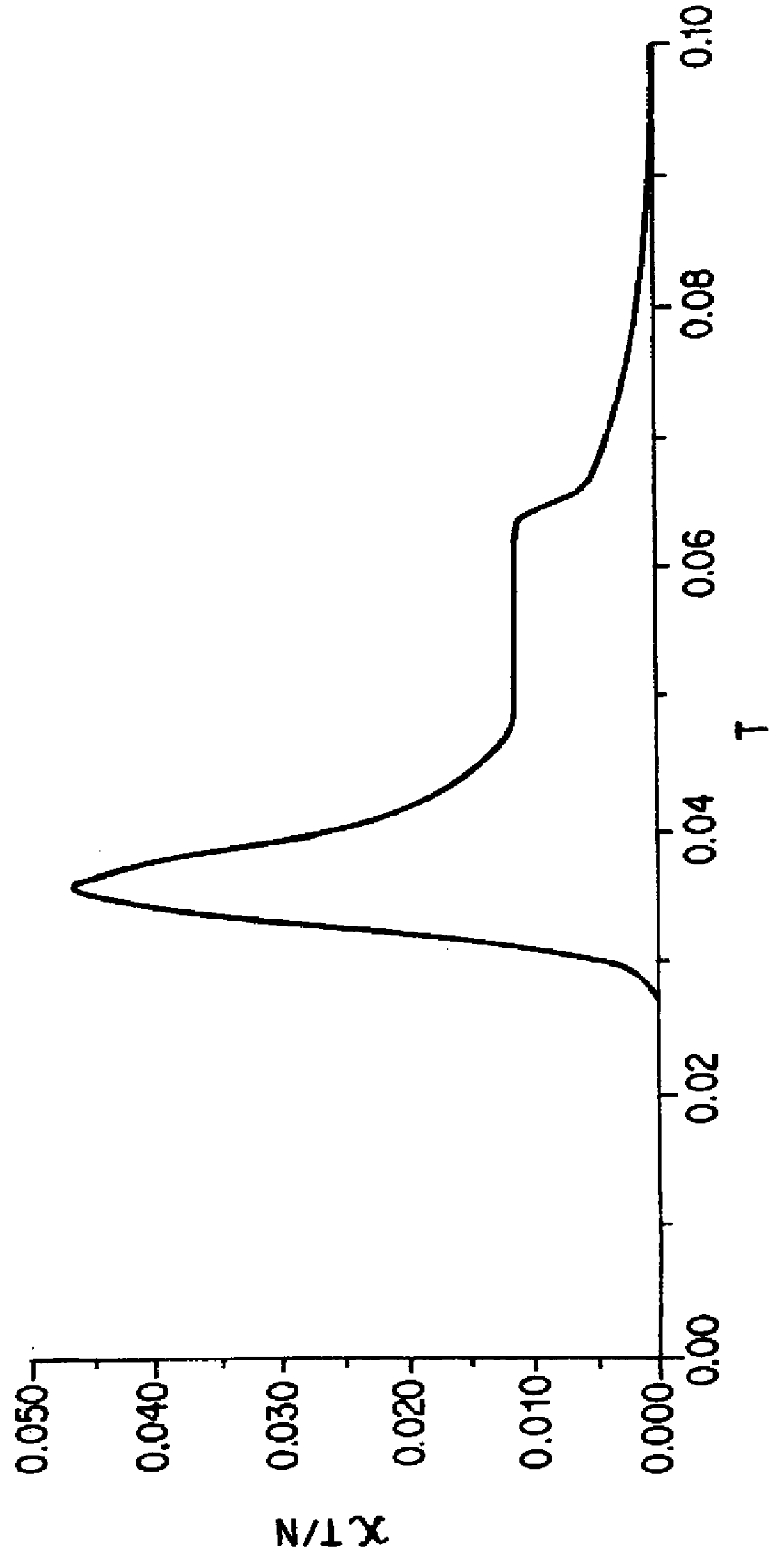

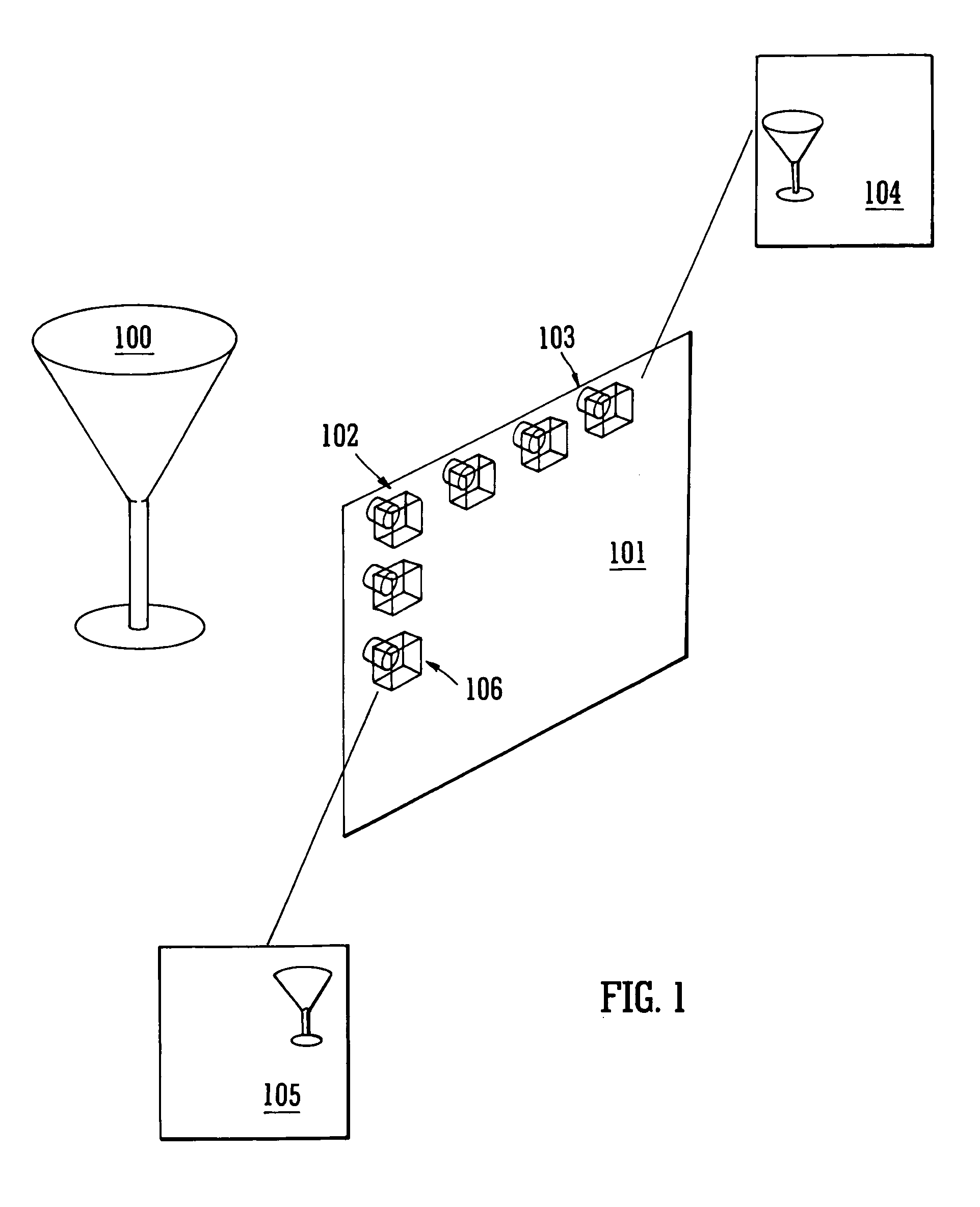

Method and apparatus for clustering data

InactiveUS6021383AImprove efficiencyImprove performanceNuclear monitoringHardware monitoringClustered dataData set

A method and apparatus for partitioning a data set for clustering, based on the physical properties of an inhomogeneous ferromagnet. No assumption is made regarding the underlying distribution of the data. A Potts spin is assigned to each data point and an interaction between neighboring points is introduced, whose strength is a decreasing function of the distance between the neighbors. This magnetic system exhibits three phases. At very low temperatures it is completely ordered; i.e. all spins are aligned. At very high temperatures the system does not exhibit any ordering and in an intermediate regime clusters of relatively strongly coupled spins become ordered, whereas different clusters remain uncorrelated. This intermediate phase is identified by a jump in the order parameters. The spin-spin correlation function is used to partition the spins and the corresponding data points into clusters.

Owner:YEDA RES & DEV CO LTD

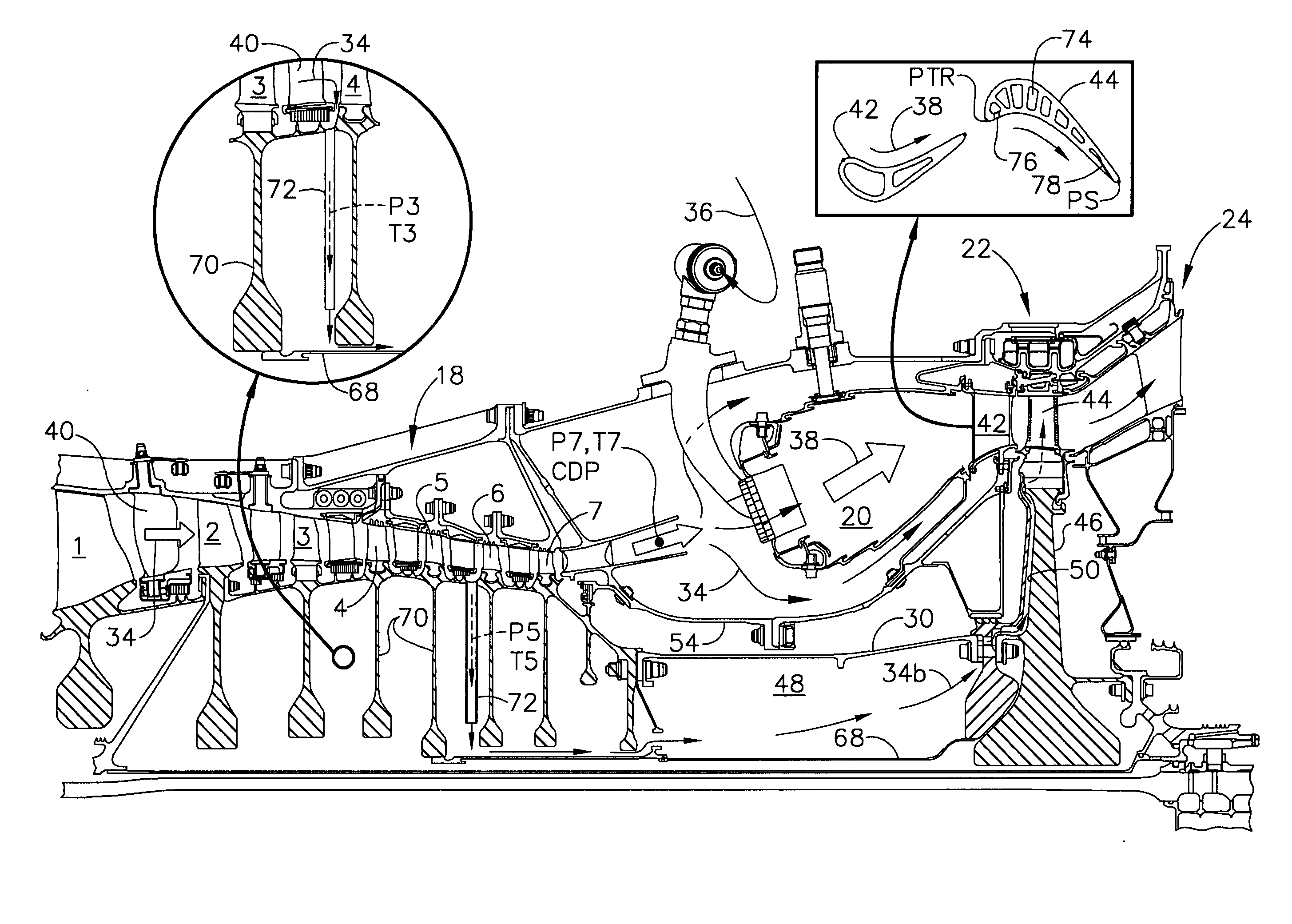

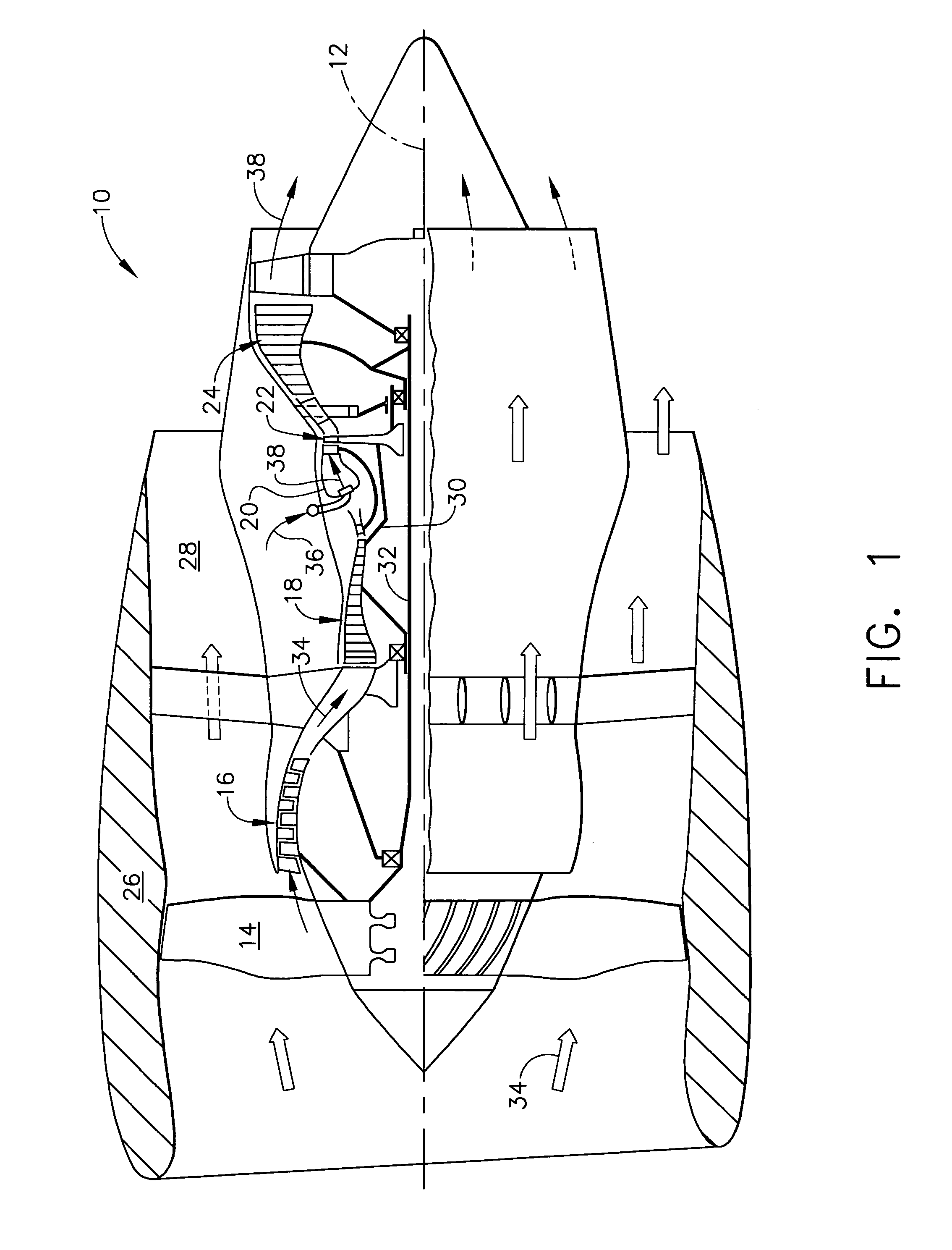

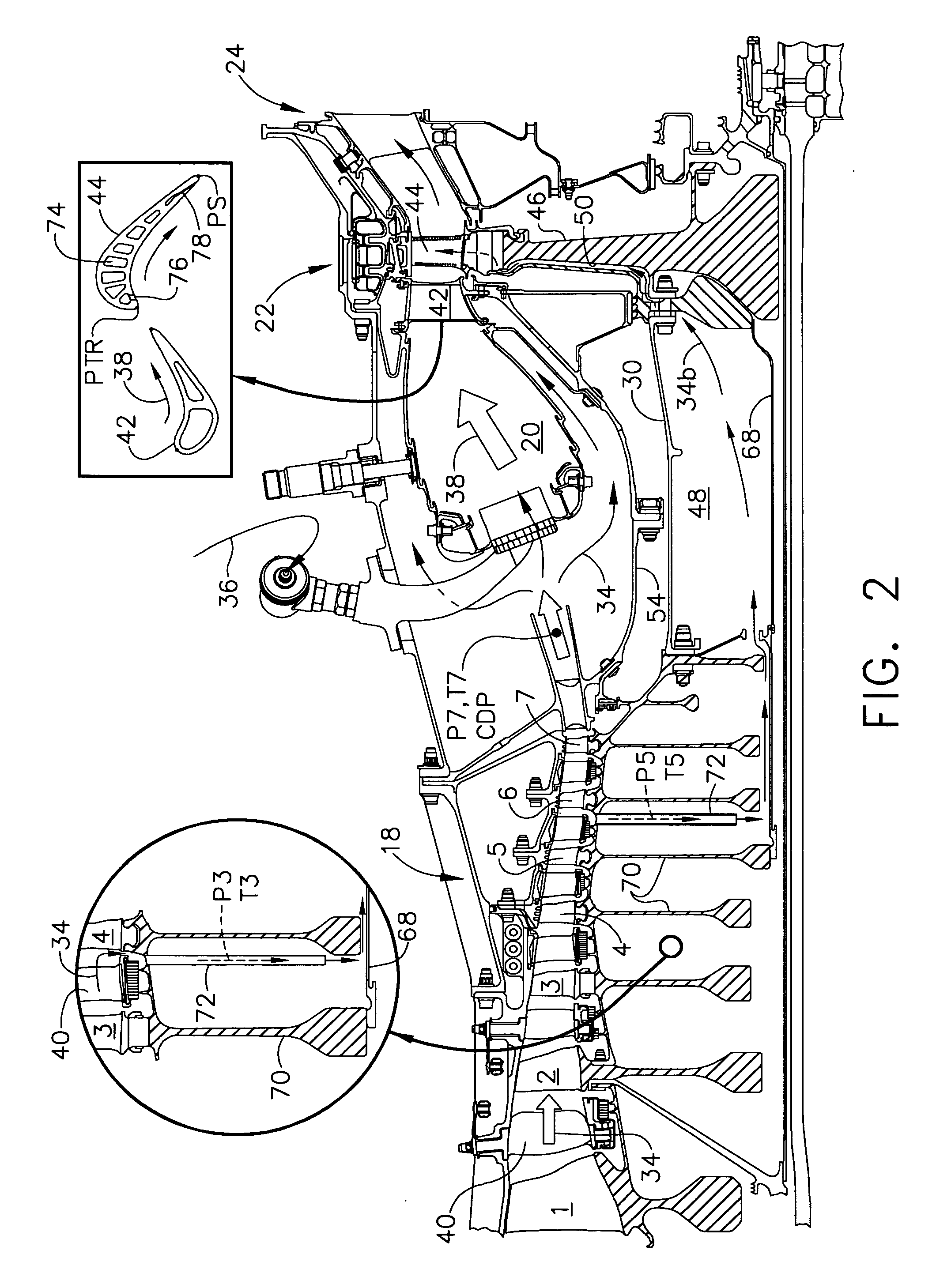

Interstage cooled turbine engine

A gas turbine engine includes a compressor, combustor, and high pressure (HP) turbine operatively joined together. An interstage cooling circuit is joined in flow communication from an intermediate stage of the compressor to a forward face of an HP disk supporting a row of turbine blades for channeling interstage bleed cooling air thereto.

Owner:GENERAL ELECTRIC CO

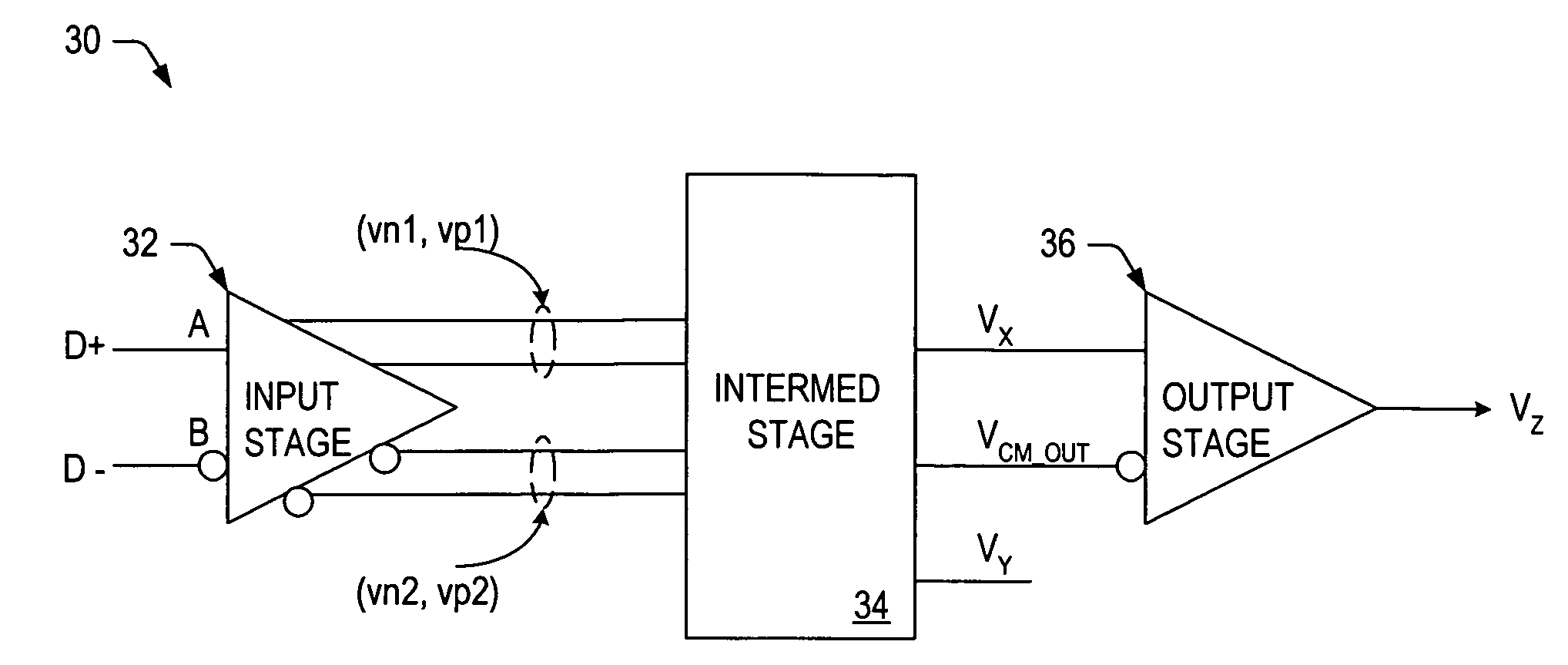

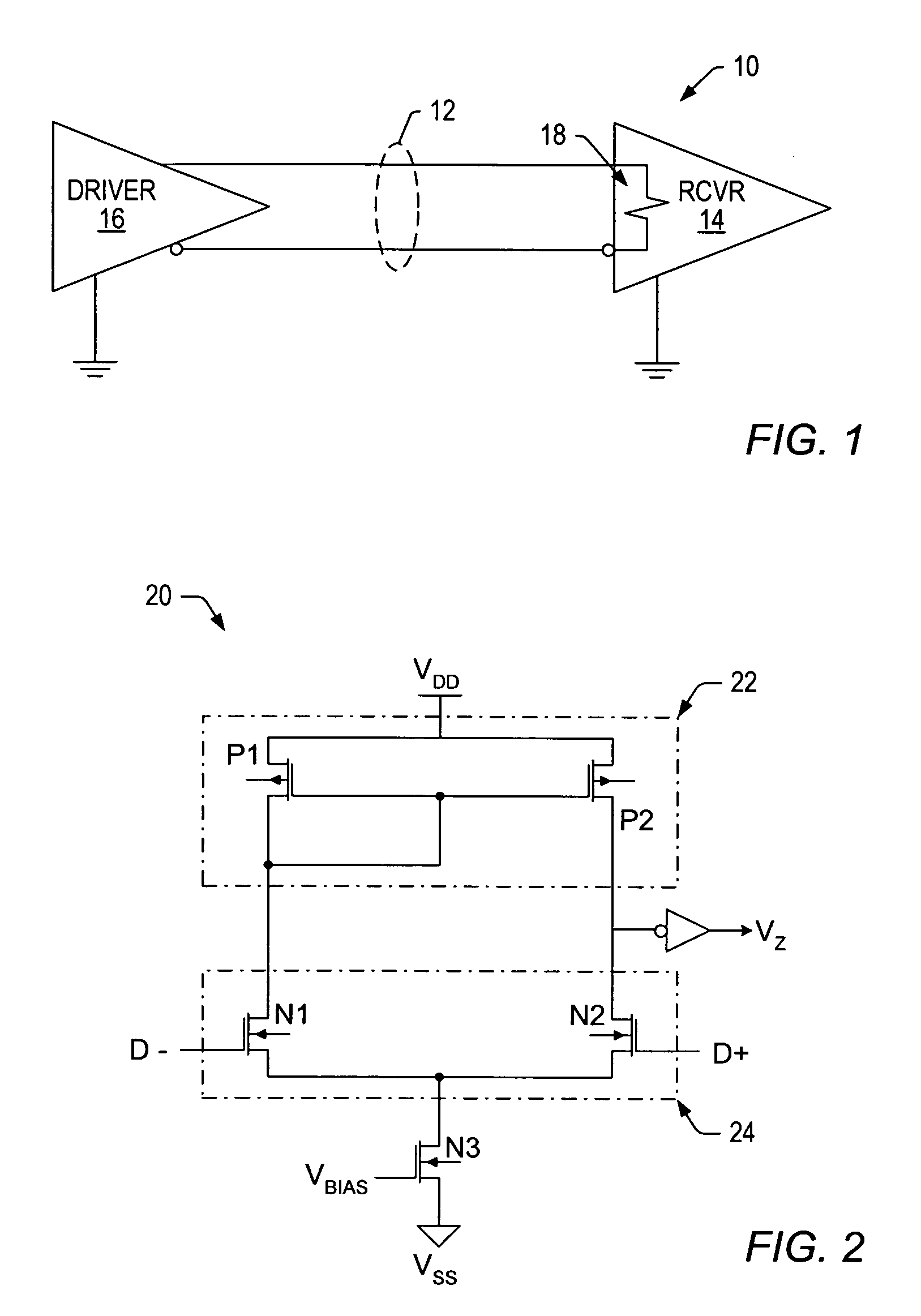

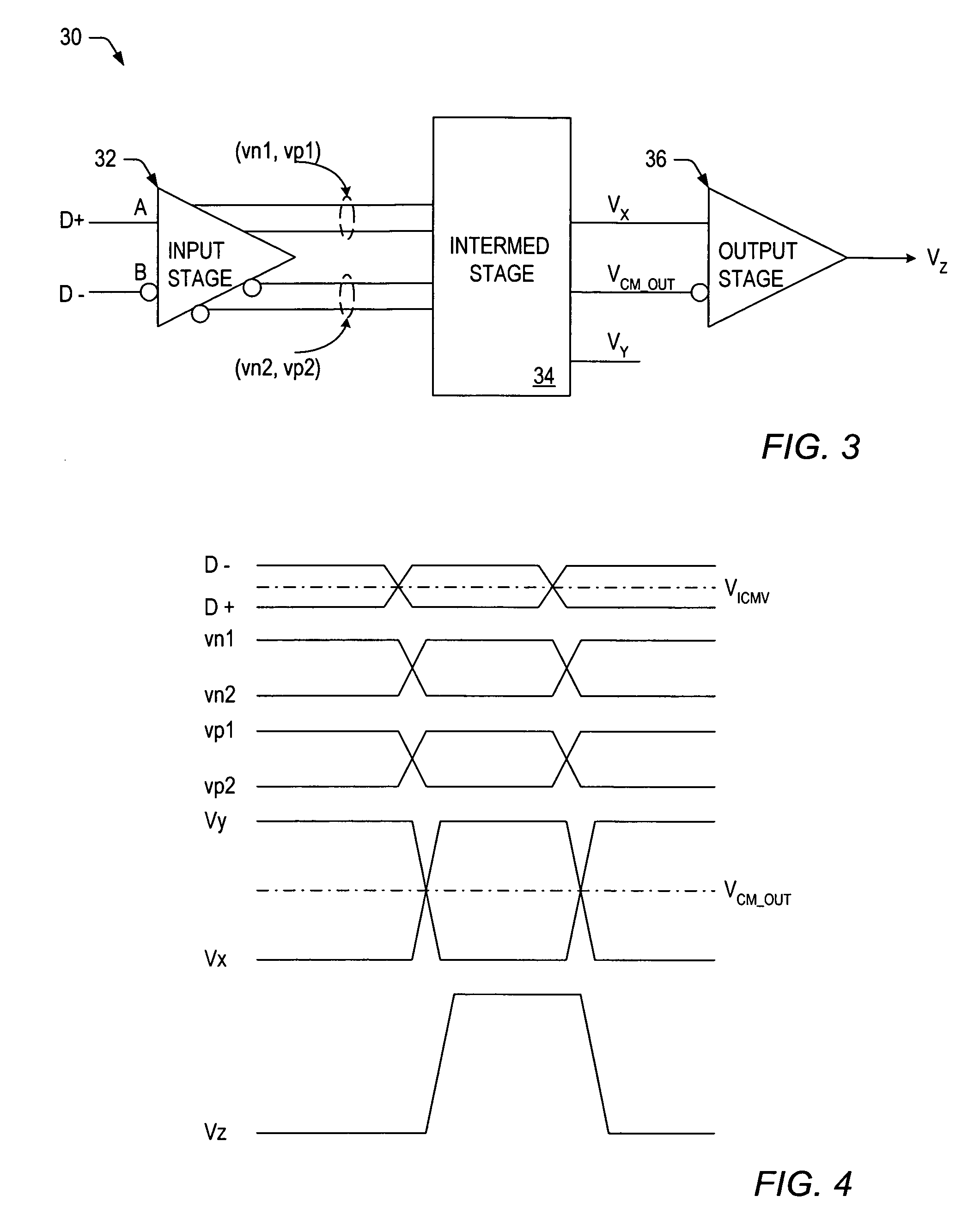

Differential receiver with wide input common mode range and low duty cycle distortion

ActiveUS7400173B1Avoid excessive duty cycle distortionIncrease working frequencyLogic circuits characterised by logic functionLogic circuit coupling/interface arrangementsDifferential signalingDuty cycle distortion

A transmission system, circuit and method are provided herein for converting differential signals into low duty cycle distortion, single-ended signals that are insensitive to variations in PVT and input common mode voltage. In one embodiment, the signal translation circuit includes an input stage for receiving a pair of differential input signals and producing one or more differential output signals; an intermediate stage for combining the one or more differential output signals into a pair of complementary signals from which a common mode voltage is detected; and an output stage for generating a single-ended output signal that switches from a first value to an opposite value when one of the complementary signals is substantially equal to the common mode voltage.

Owner:TAIWAN SEMICON MFG CO LTD

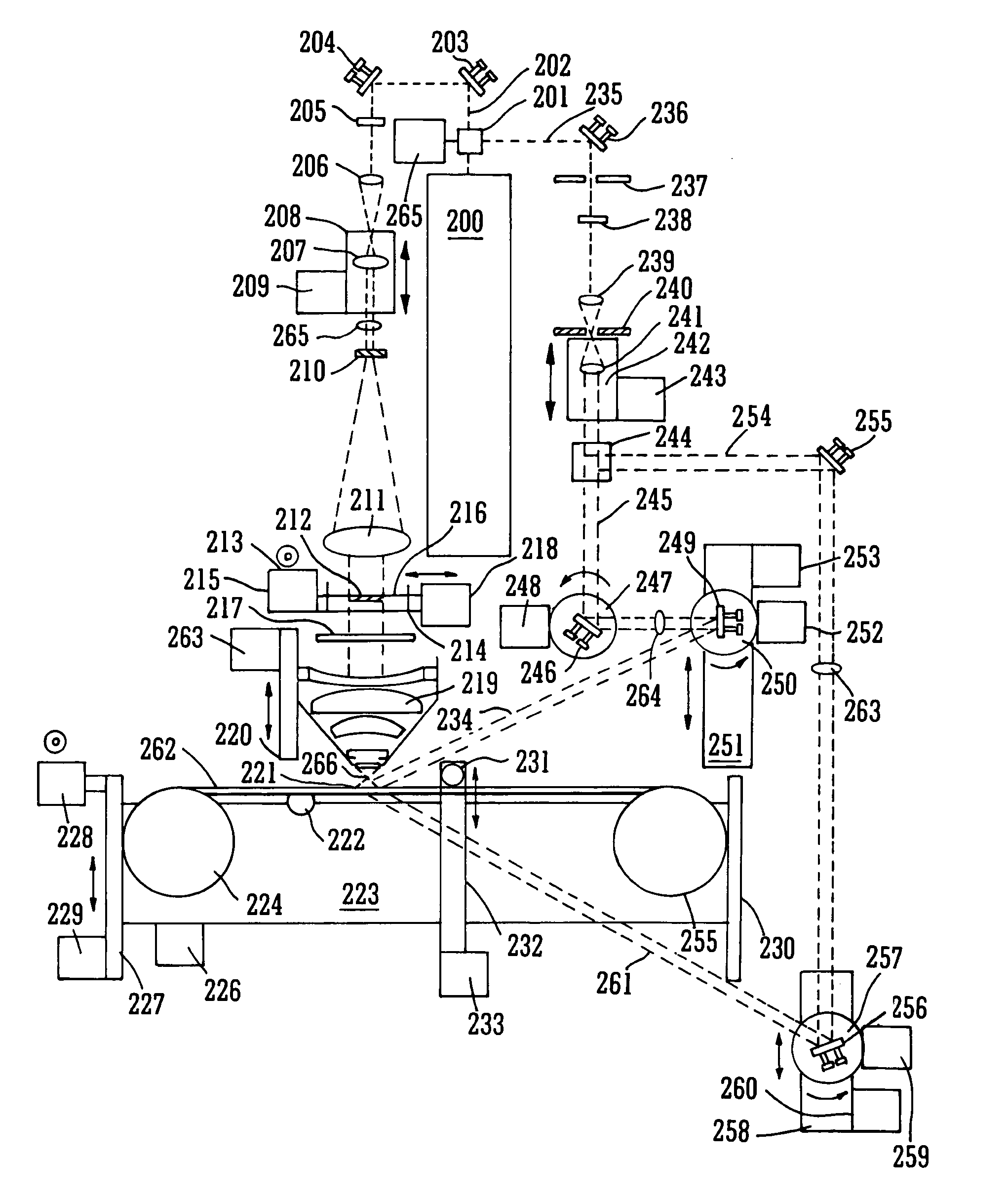

Holographic printer

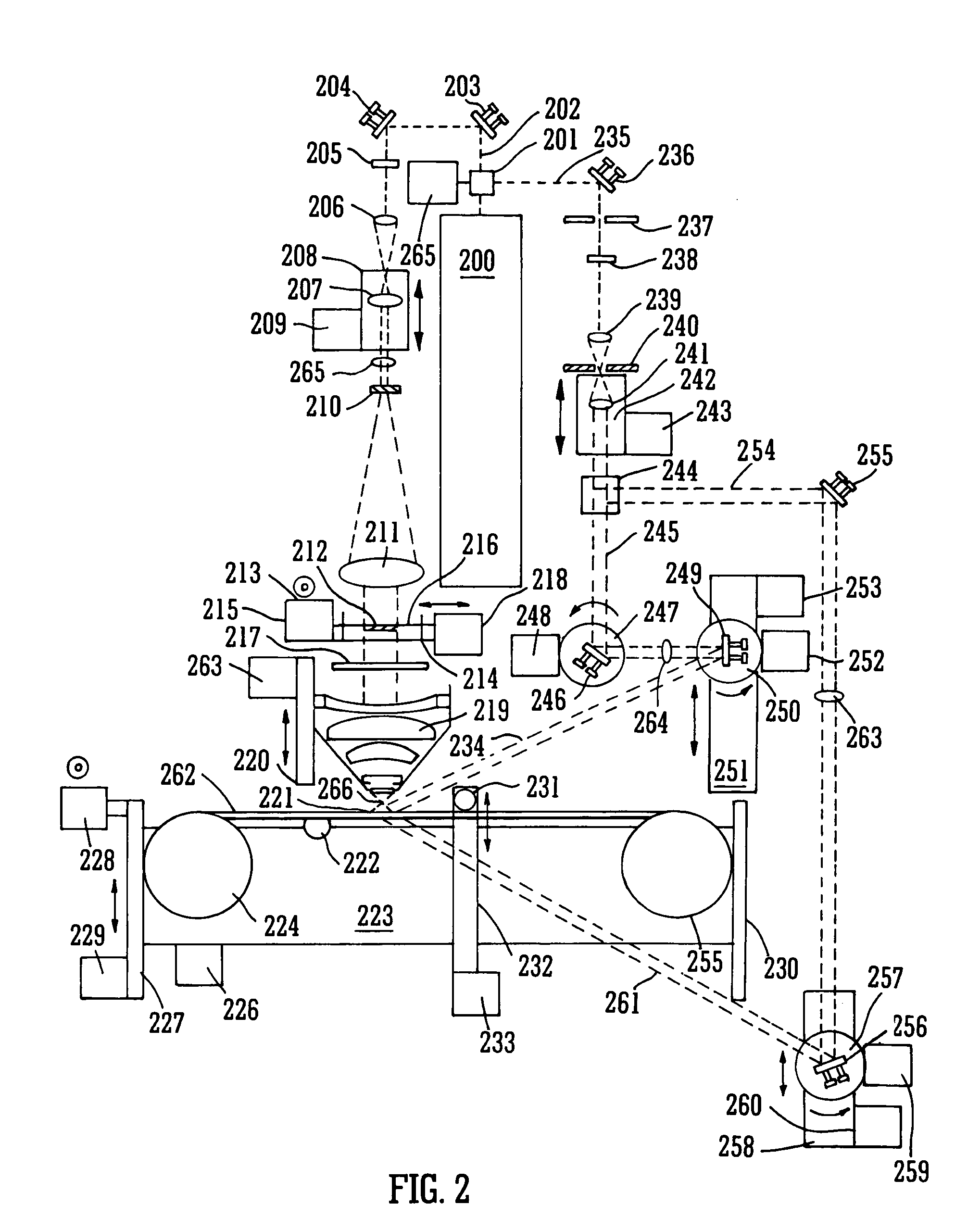

InactiveUS7009742B2Increase printing speedGuaranteed uptimeHolographic light sources/light beam propertiesHolographic optical componentsCamera imageDigital data

Owner:XYZ IMAGING

Radio frequency switch

InactiveUS7561853B2Improve powerLow costTransistorSemiconductor/solid-state device detailsRadio frequency signalParasitic capacitance

A switch that selectively changes radio frequency signals includes at least three FETs, which are connected in series. The source electrodes or drain electrodes arranged at an intermediate stage have a width narrower than that of the source electrodes or the drain electrodes arranged at the initial and final stages. It is thus possible to lower the parasitic capacitance to ground at the intermediate stage and to thereby realize the switch having a high handling power.

Owner:SUMITOMO ELECTRIC DEVICE INNOVATIONS

Power converter

ActiveUS7830689B2Avoid excessive volumeIncrease productionConversion constructional detailsSolid-state devicesIntermediate stageSemiconductor

First and second bases and composing a coolant path structure are arranged at the middle stage of the power converter, and semiconductor modules and a capacitor are arranged on both surfaces of the coolant path structure. Furthermore, through-holes are formed in the first and second bases, and cables of DC and AC circuits are laid via the through-holes.

Owner:HITACHI ASTEMO LTD

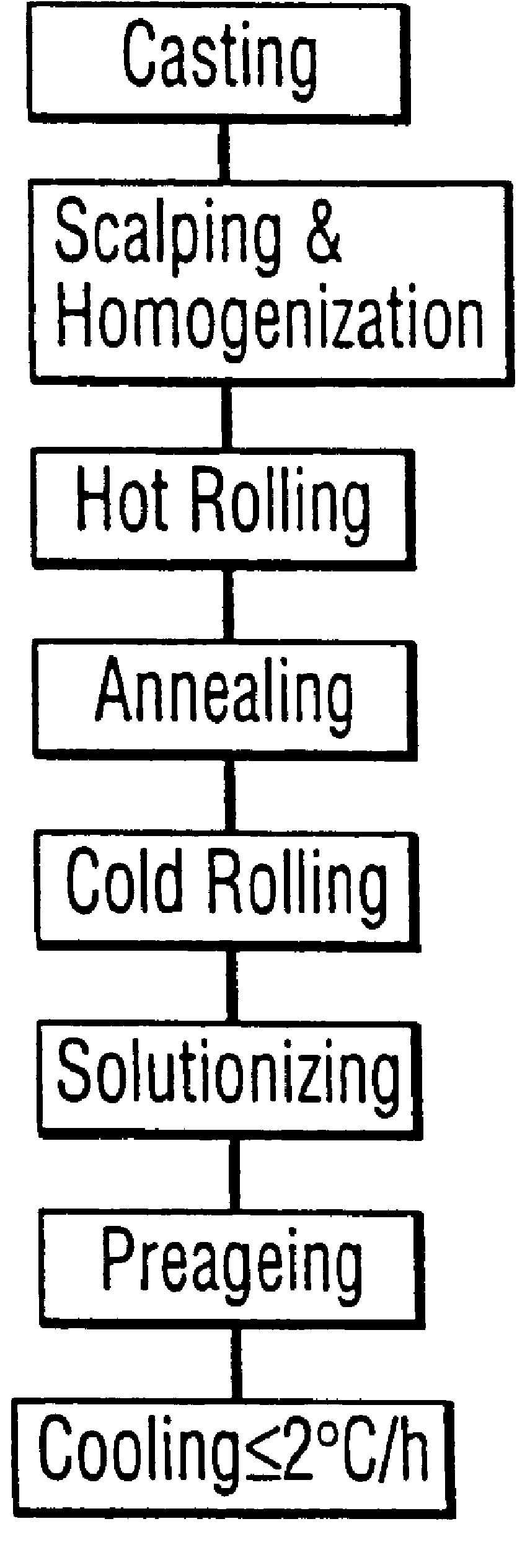

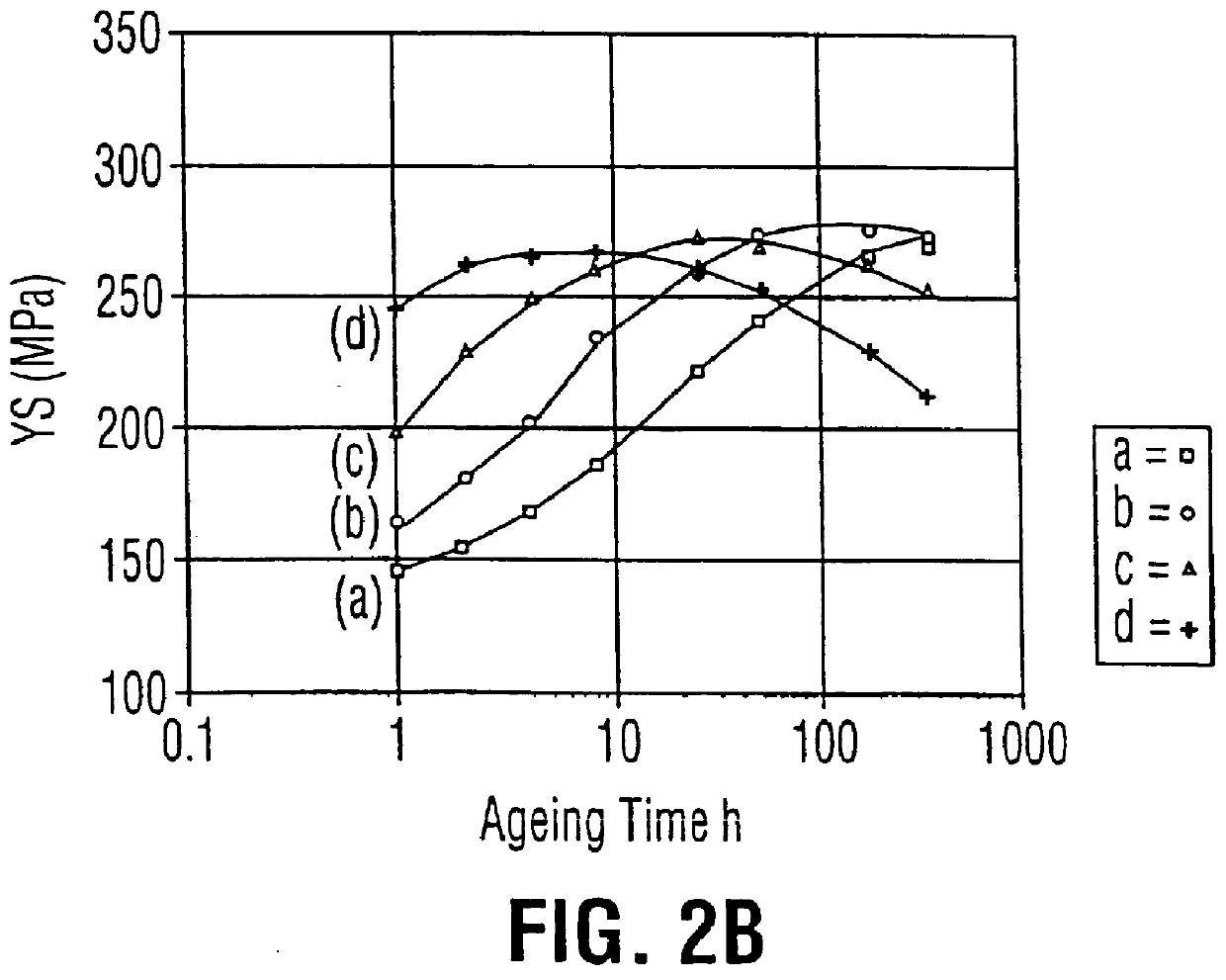

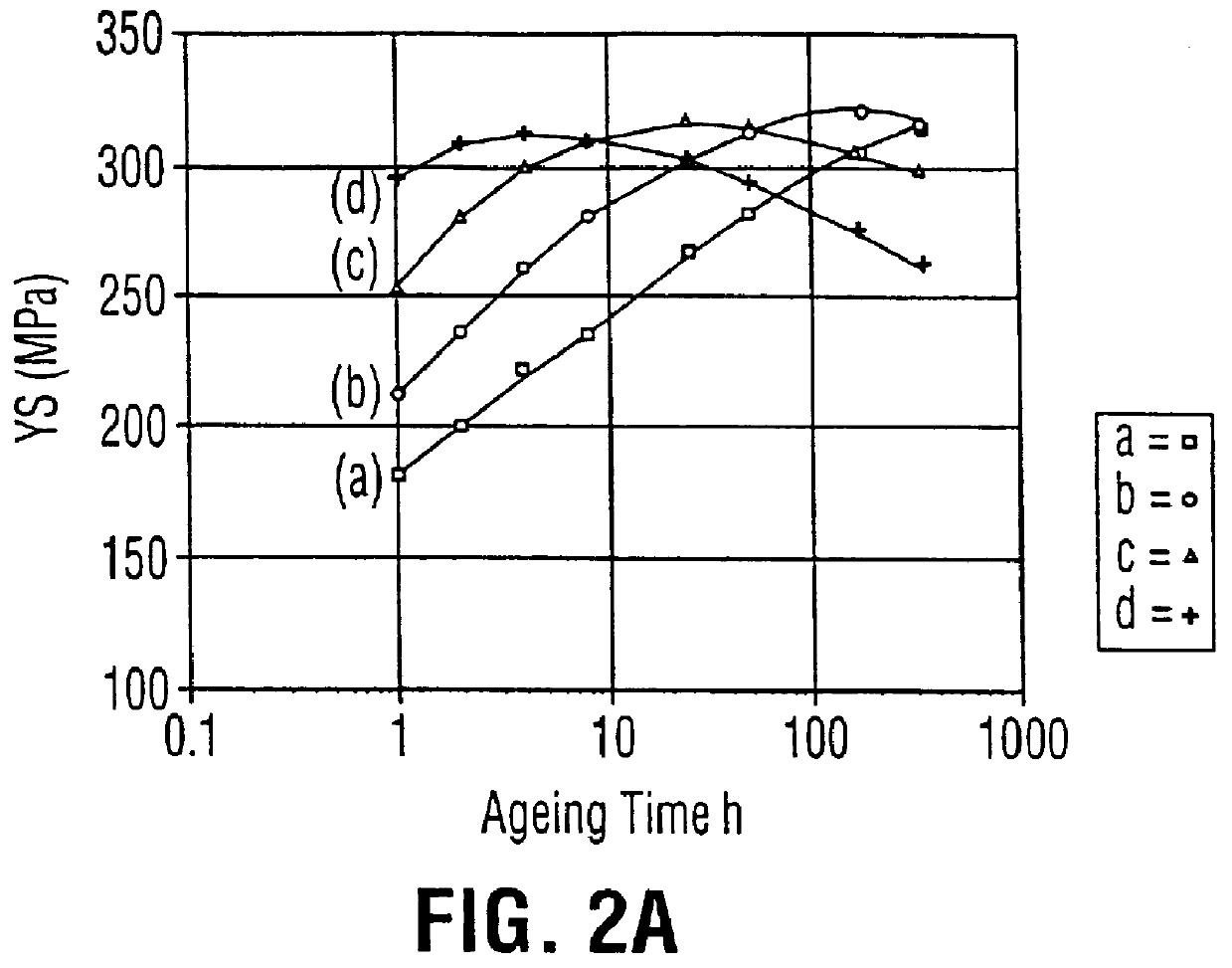

Process of producing aluminum alloy sheet exhibiting reduced roping effects

A process of producing an aluminum alloy sheet product suitable for forming into automotive parts and exhibiting reduced roping effects. The process involves producing an aluminum alloy sheet product by direct chill casting an aluminum alloy to form a cast ingot, homogenizing the ingot, hot rolling the ingot to form and intermediate gauge product, cold rolling the intermediate gauge product to form a product of final gauge, and subjecting the final gauge product to a solutionizing treatment by heating the product to a solutionizing temperature, followed by a pre-aging step involving cooling the product to a coiling temperature above 50 DEG C., coiling the cooled product at the coiling temperature, and cooling the coiled final gauge product from the coiling temperature above 50 DEG C. to ambient temperature at a rate less than about 10 DEG C. per hour to improve T8X temper characteristics of the product. Additionally, a batch anneal step is carried out on the intermediate gauge product or at an intermediate stage of the cold rolling to reduce or eliminate roping tendencies of the alloy sheet product. To maintain a high T8X response, the alloy used in the process has the following composition: 0.4 to 1.1% by weight magnesium; 0.3 to 1.4% by weight silicon; 0 to 1.0% by weight copper; 0 to 0.4% by weight iron; 0 to 0.15% by weight manganese; 0 to 0.15% weight naturally-occurring impurities (collective total); and the balance aluminum. The invention also relates to a sheet alloy product exhibiting reduced roping effects produced by the indicated process.

Owner:NOVELIS INC

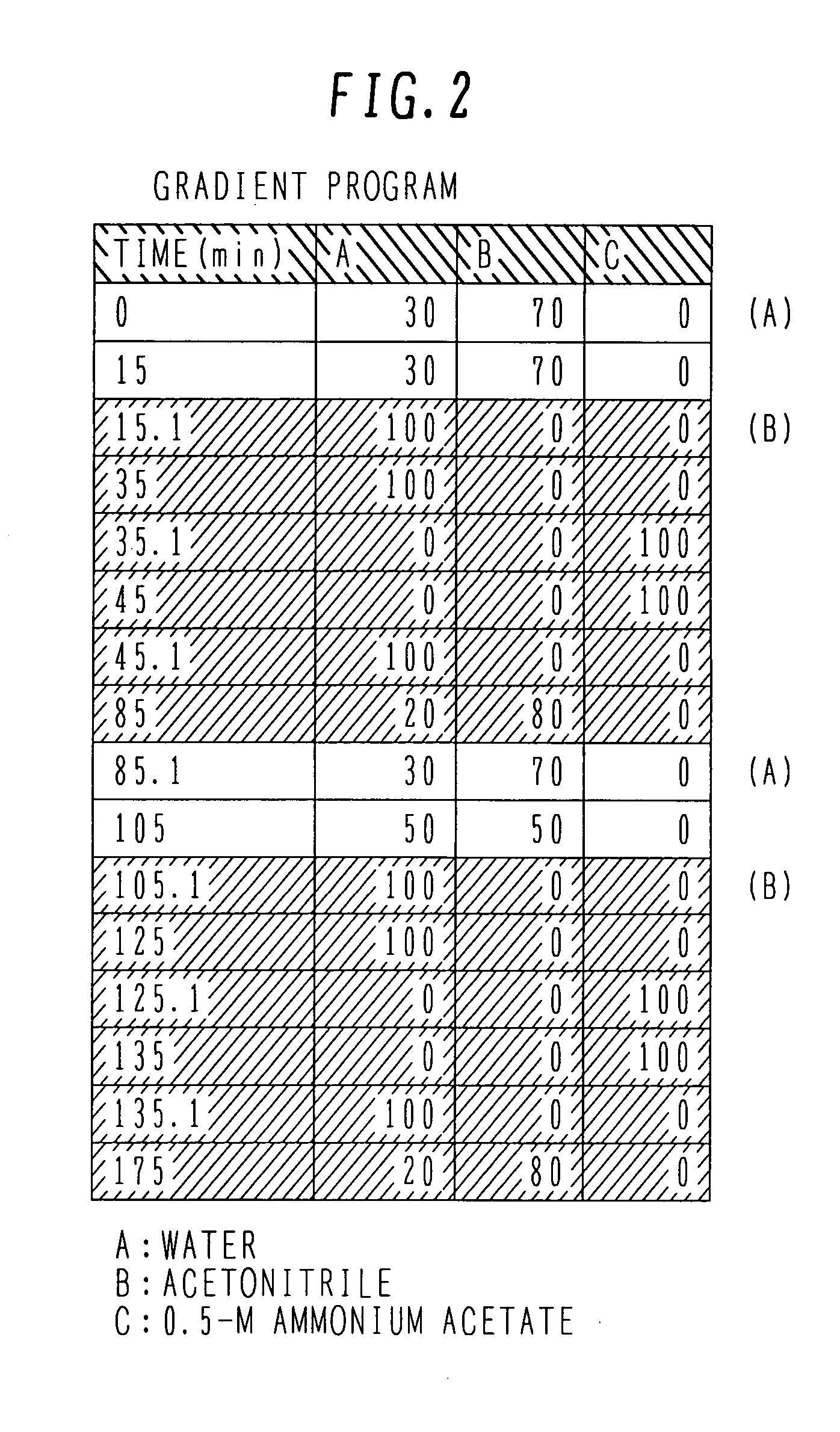

Three-dimensional liquid chromatography

InactiveUS20070199874A1Easy to separateIon-exchange process apparatusAnalysis using chemical indicatorsIntermediate stageMixed states

In a liquid chromatography apparatus, a separation column of intermediate stage is additionally connected between a separation column of first stage and a separation column of second stage. Preferably, a switching unit and a liquid feed unit for mixing and feeding a plurality of solutions are added to improve a separation capability. A three-dimensional liquid chromatography apparatus capable of avoiding the “solution interference” can be realized. Even a complex sample containing a hydrophilic component and a hydrophobic component in a mixed state can be separated and analyzed satisfactorily on-line.

Owner:HITACHI HIGH-TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com