Patents

Literature

388 results about "Downstream processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Downstream processing refers to the recovery and the purification of biosynthetic products, particularly pharmaceuticals, from natural sources such as animal or plant tissue or fermentation broth, including the recycling of salvageable components and the proper treatment and disposal of waste. It is an essential step in the manufacture of pharmaceuticals such as antibiotics, hormones (e.g. insulin and humans growth hormone), antibodies (e.g. infliximab and abciximab) and vaccines; antibodies and enzymes used in diagnostics; industrial enzymes; and natural fragrance and flavor compounds. Downstream processing is usually considered a specialized field in biochemical engineering, itself a specialization within chemical engineering, though many of the key technologies were developed by chemists and biologists for laboratory-scale separation of biological products.

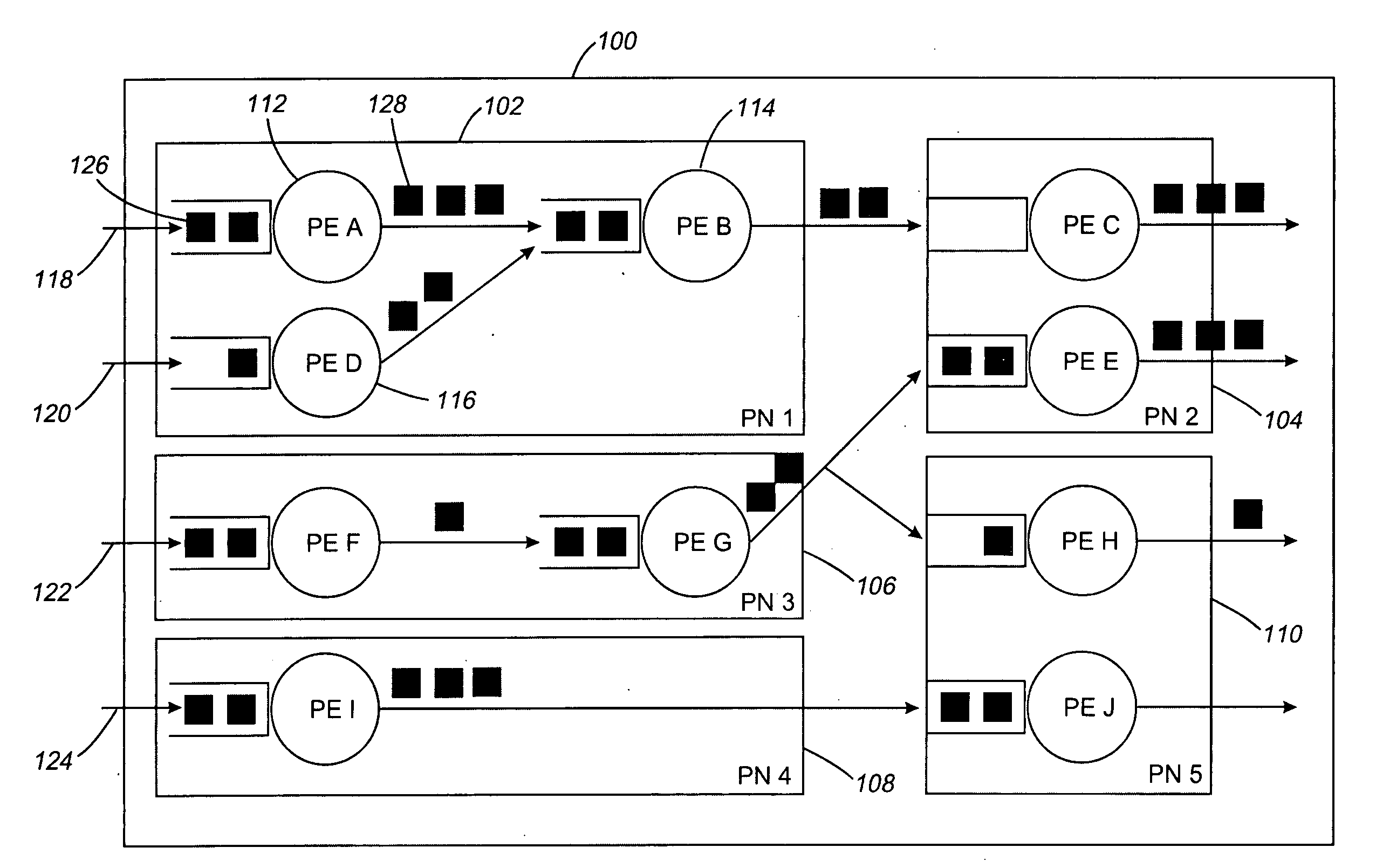

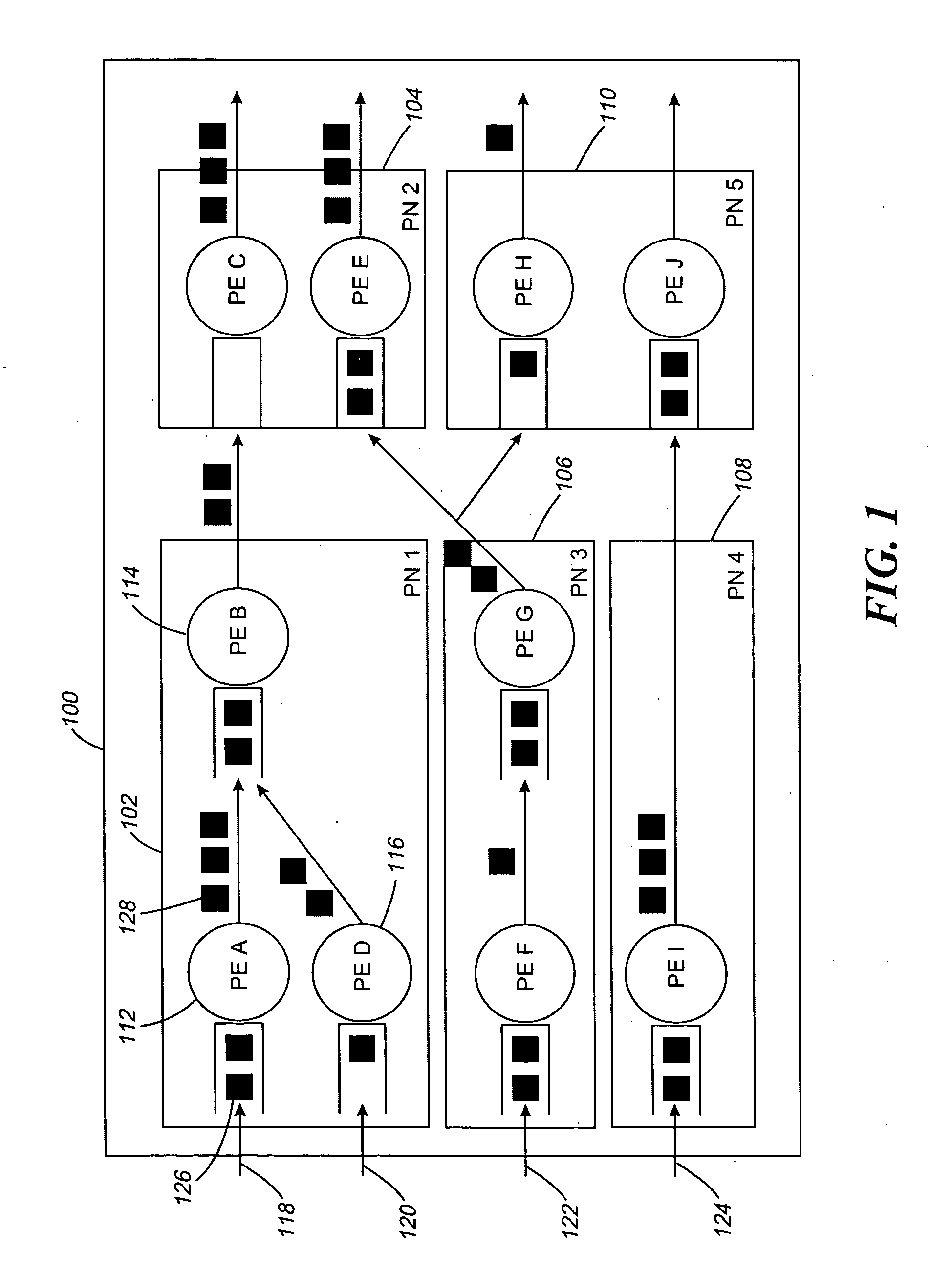

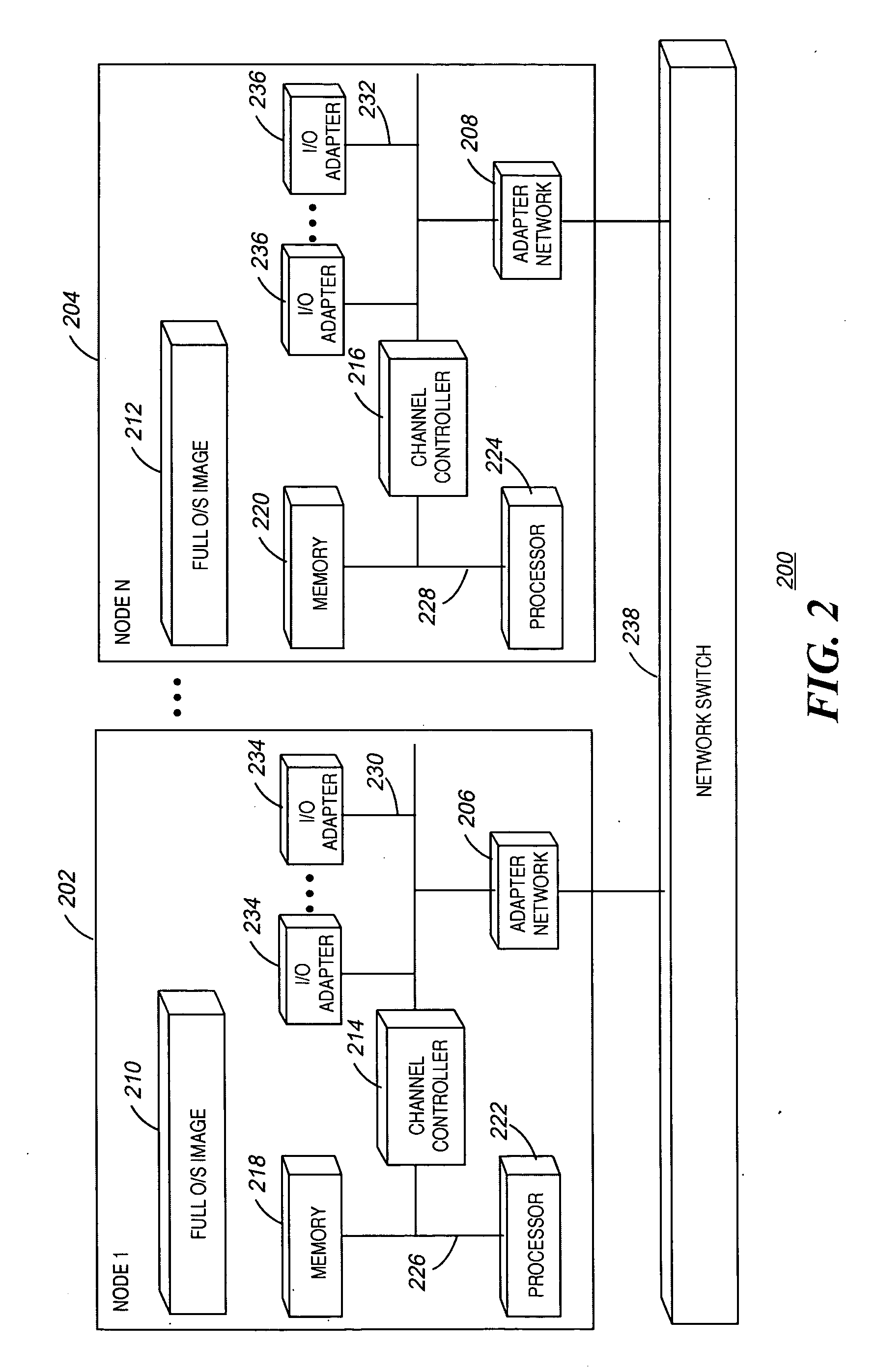

Dynamic stabilization for a stream processing system

InactiveUS7613848B2Function maximizationMaintain stabilityError preventionFrequency-division multiplex detailsDownstream processingProcessing element

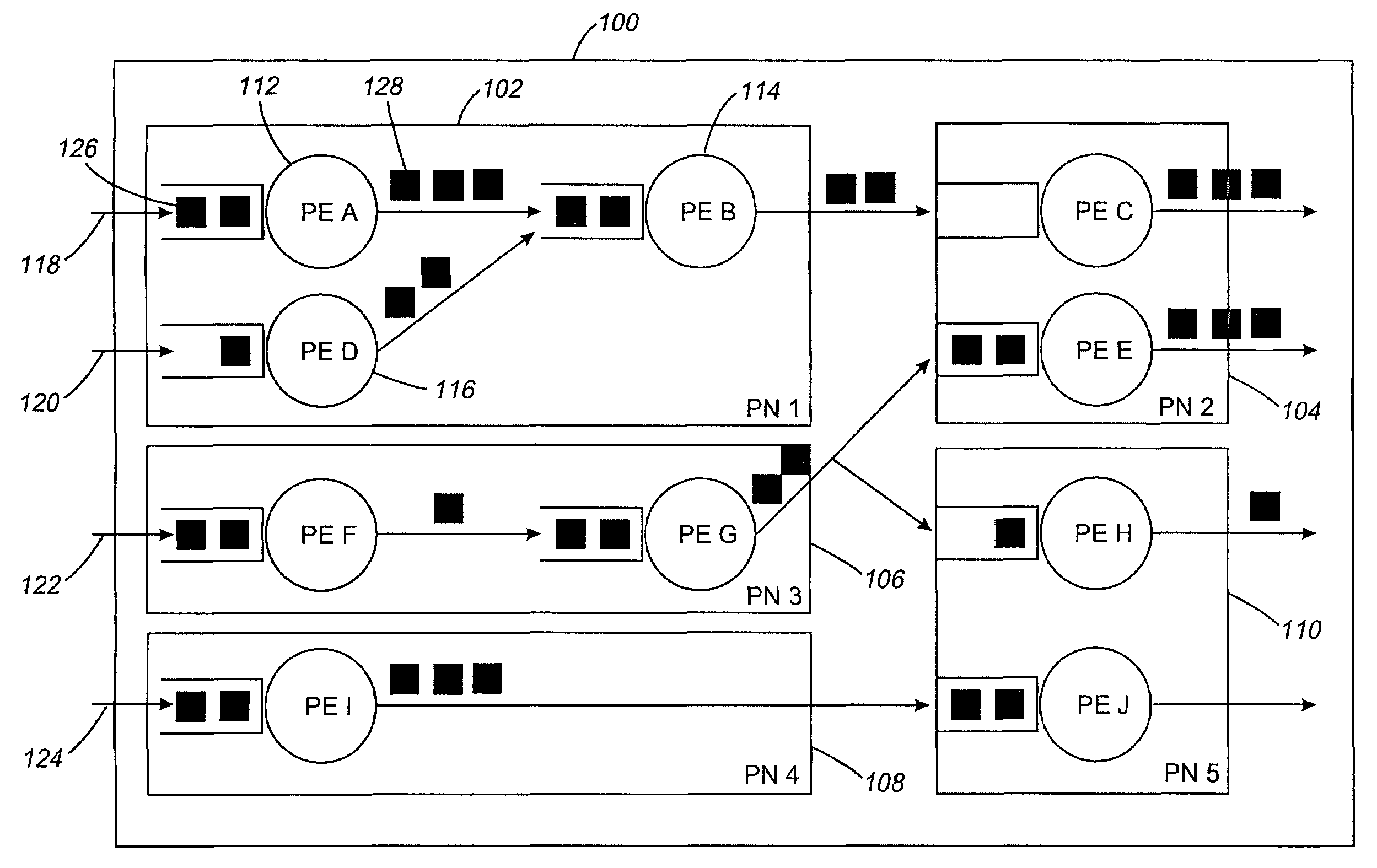

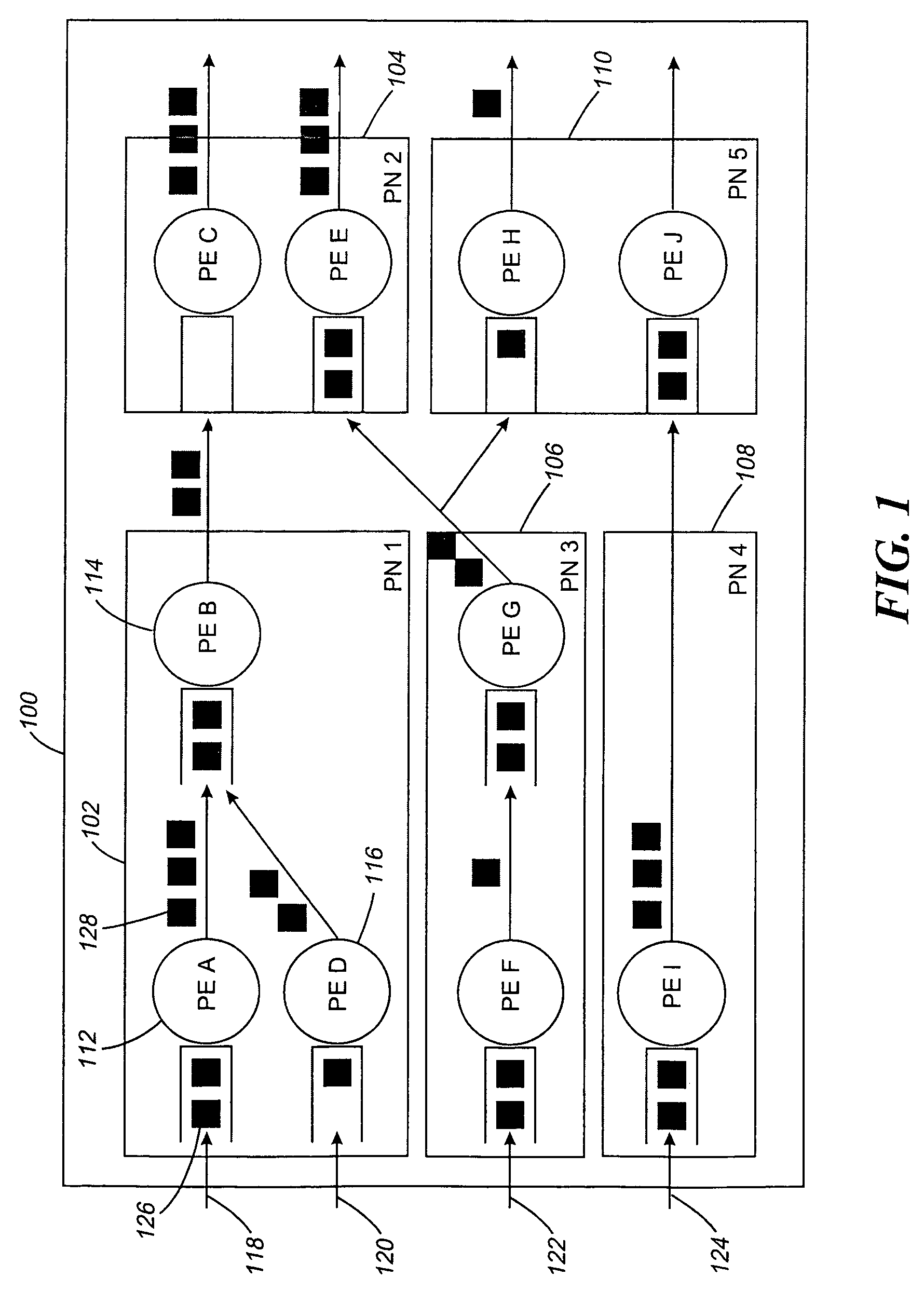

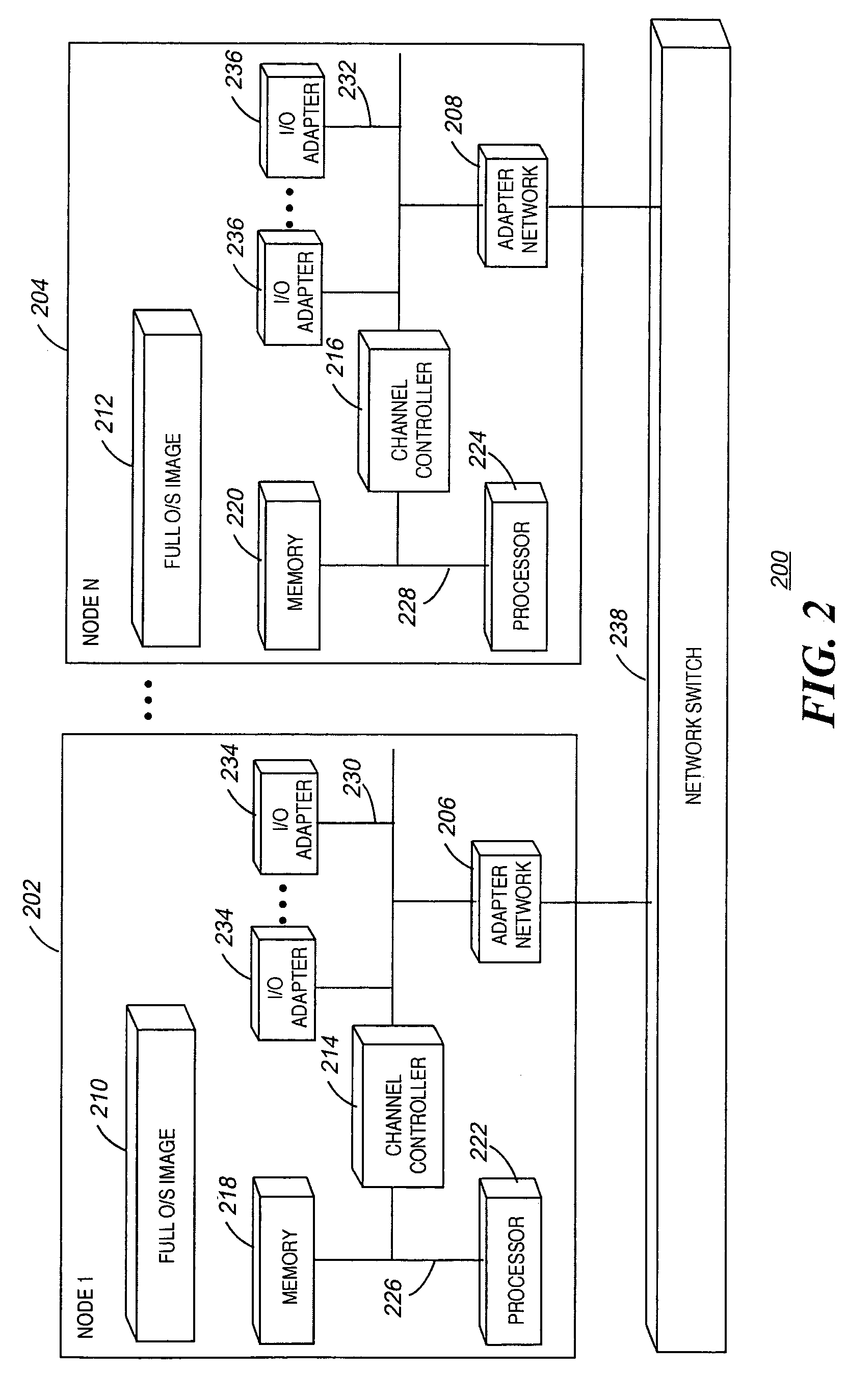

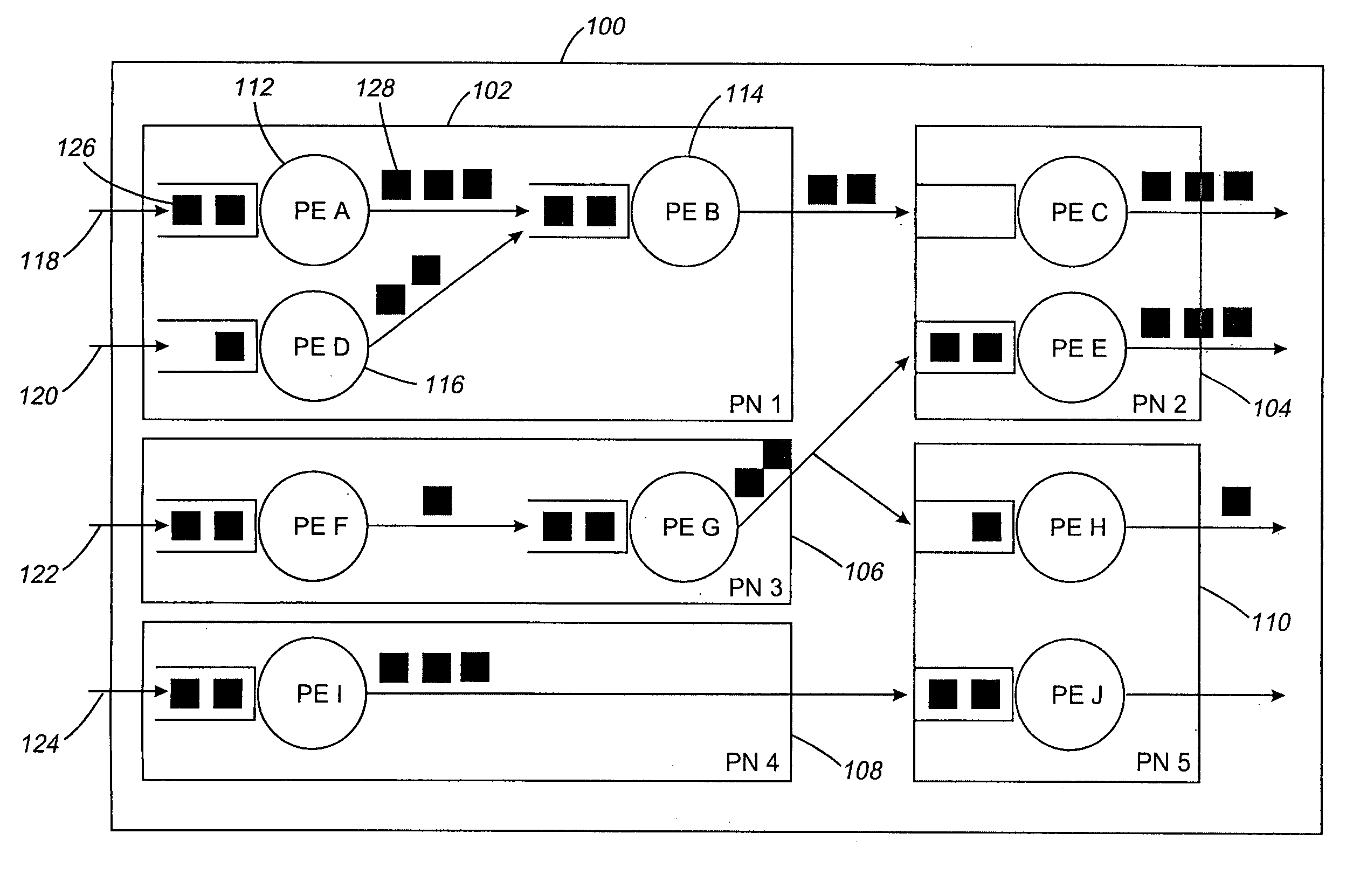

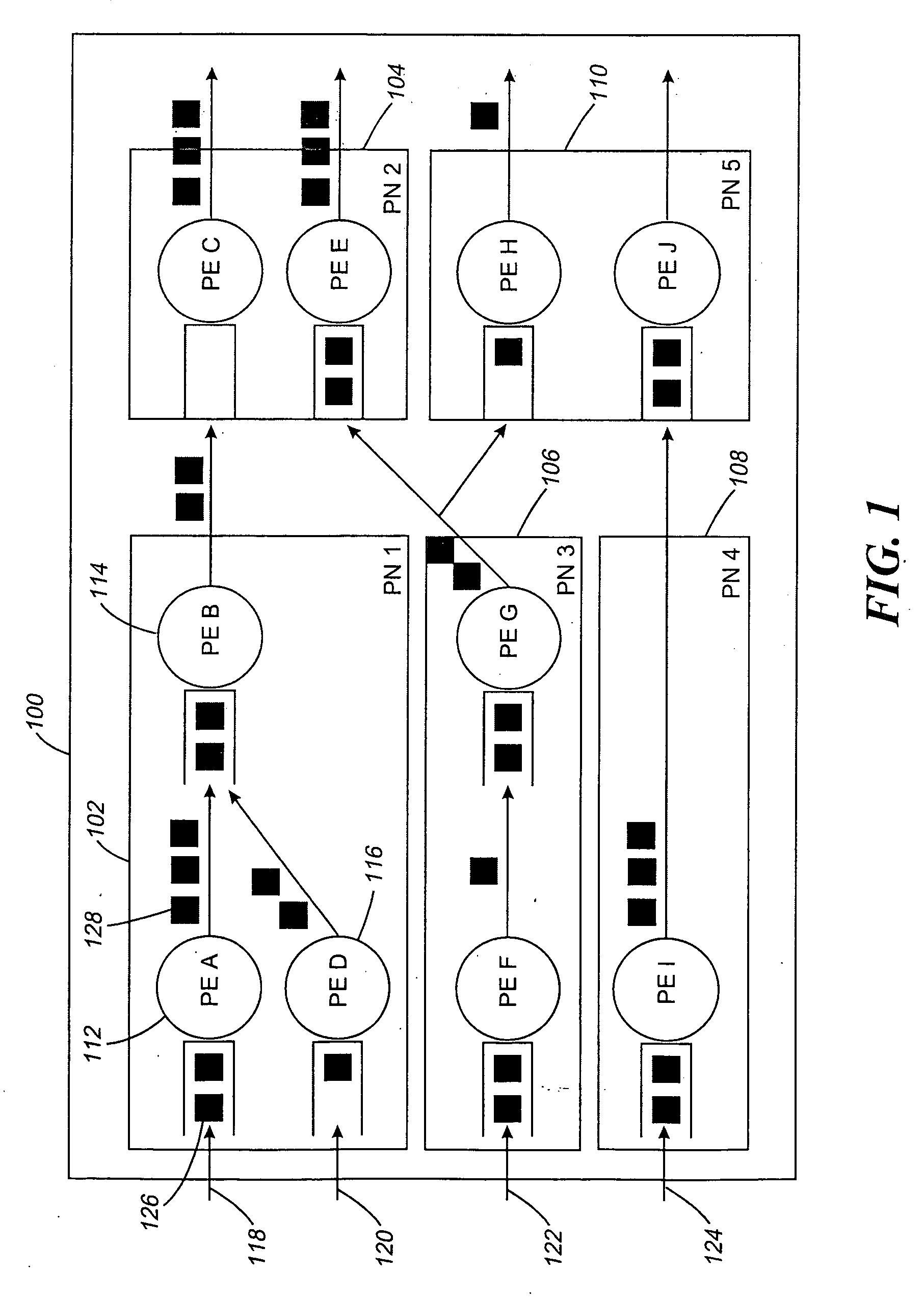

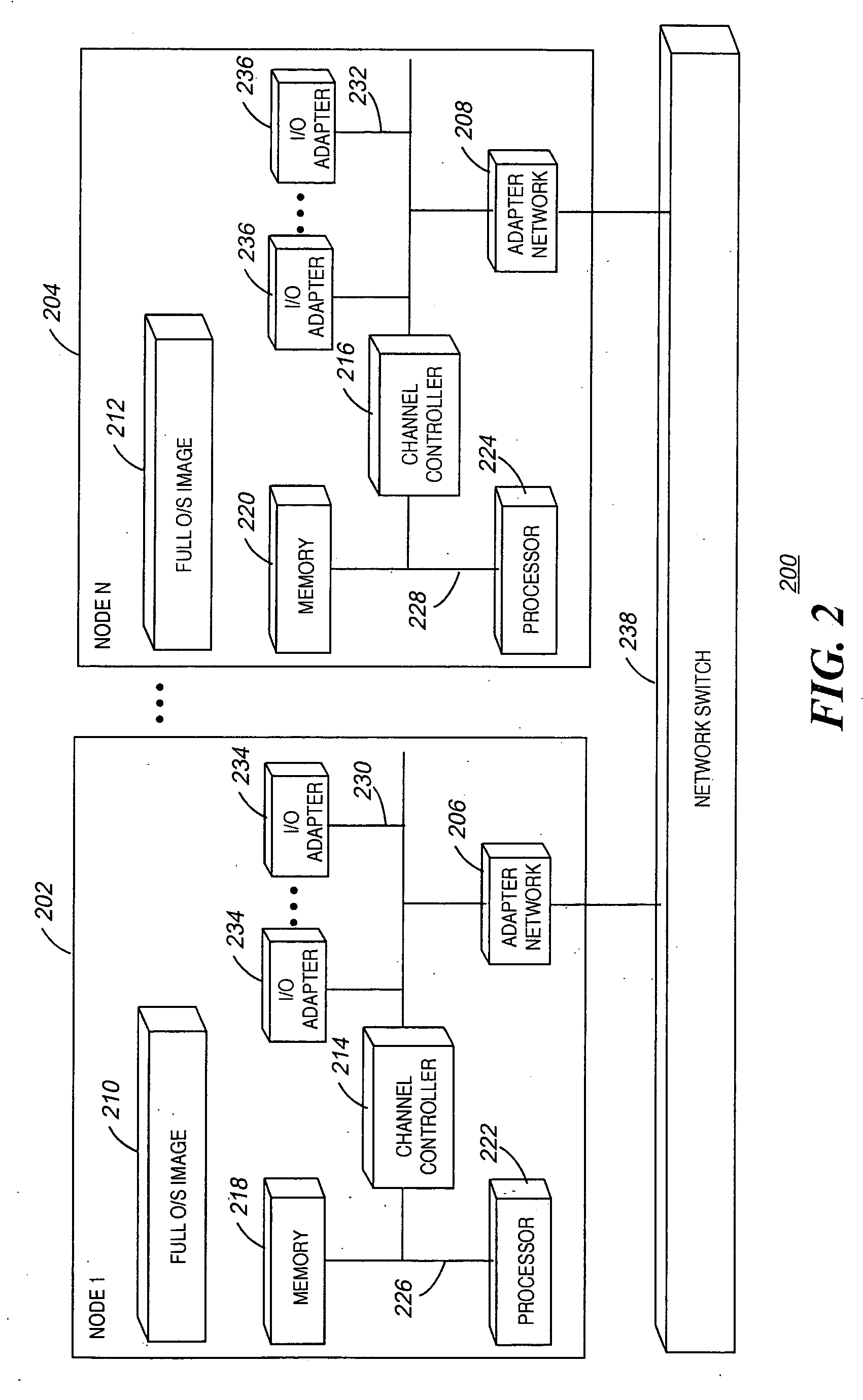

Disclosed are a method, upstream processing node, and computer readable medium for dynamically stabilizing a stream processing system. The method includes receiving at least one computing resource allocation target. The method further includes determining that an input data flow rate of at least one upstream processing element varies. The computing resource is dynamically allocated to the upstream processing element in response to the input rate of the upstream processing element varying. Data flow is dynamically controlled between the upstream processing element and at least one downstream processing element.

Owner:IBM CORP

Dynamic stabilization for a stream processing system

InactiveUS20080005392A1Maximize objective functionMaintain stabilityTransmissionInput/output processes for data processingDownstream processingProcessing element

Disclosed are a method, upstream processing node, and computer readable medium for dynamically stabilizing a stream processing system. The method includes receiving at least one computing resource allocation target. The further includes determining that an input data flow rate of at least one upstream processing element varies. The computing resource is dynamically allocated to the upstream processing element in response to the input rate of the upstream processing element varying. Data flow is dynamically controlled between the upstream processing element and at least one downstream processing element.

Owner:IBM CORP

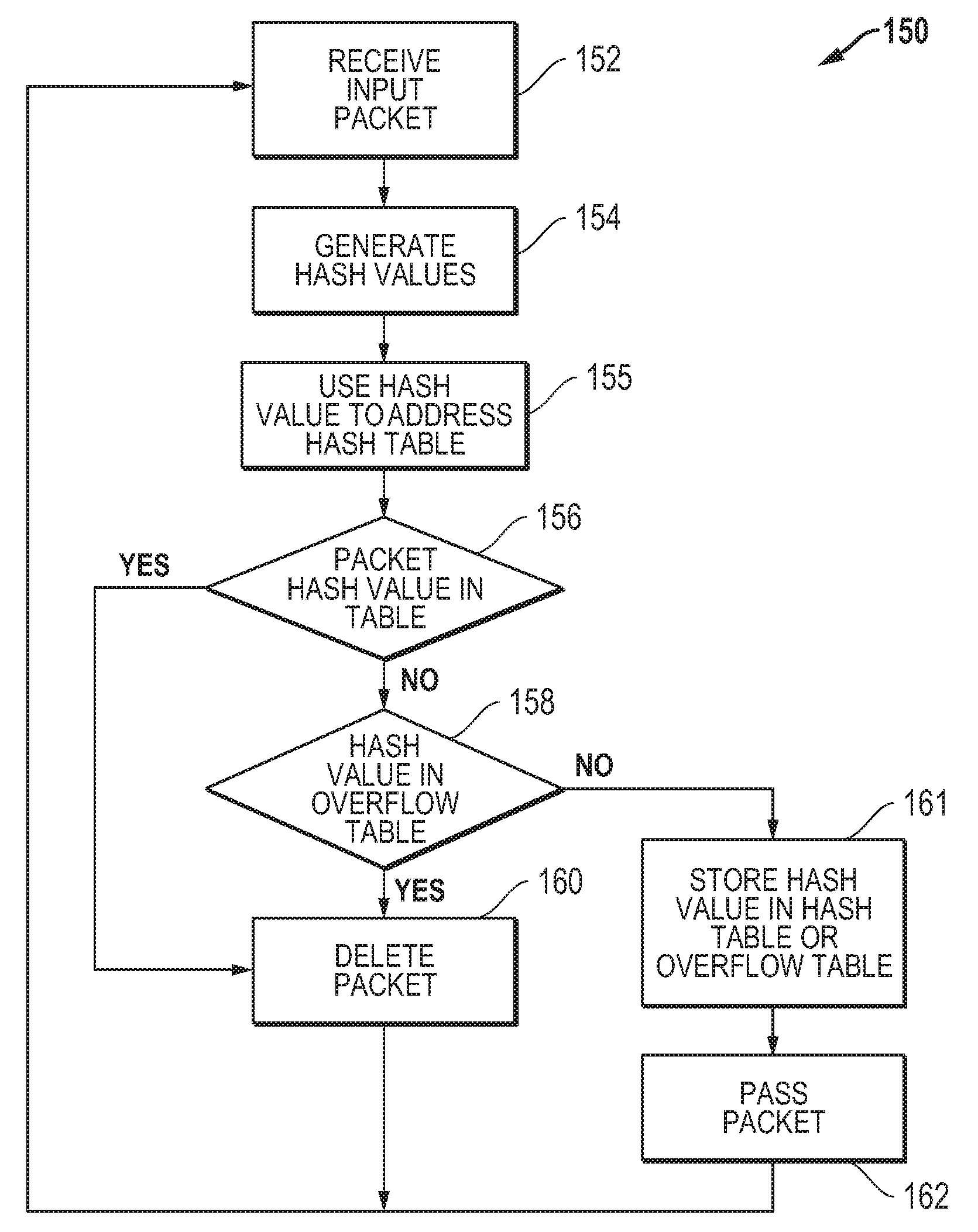

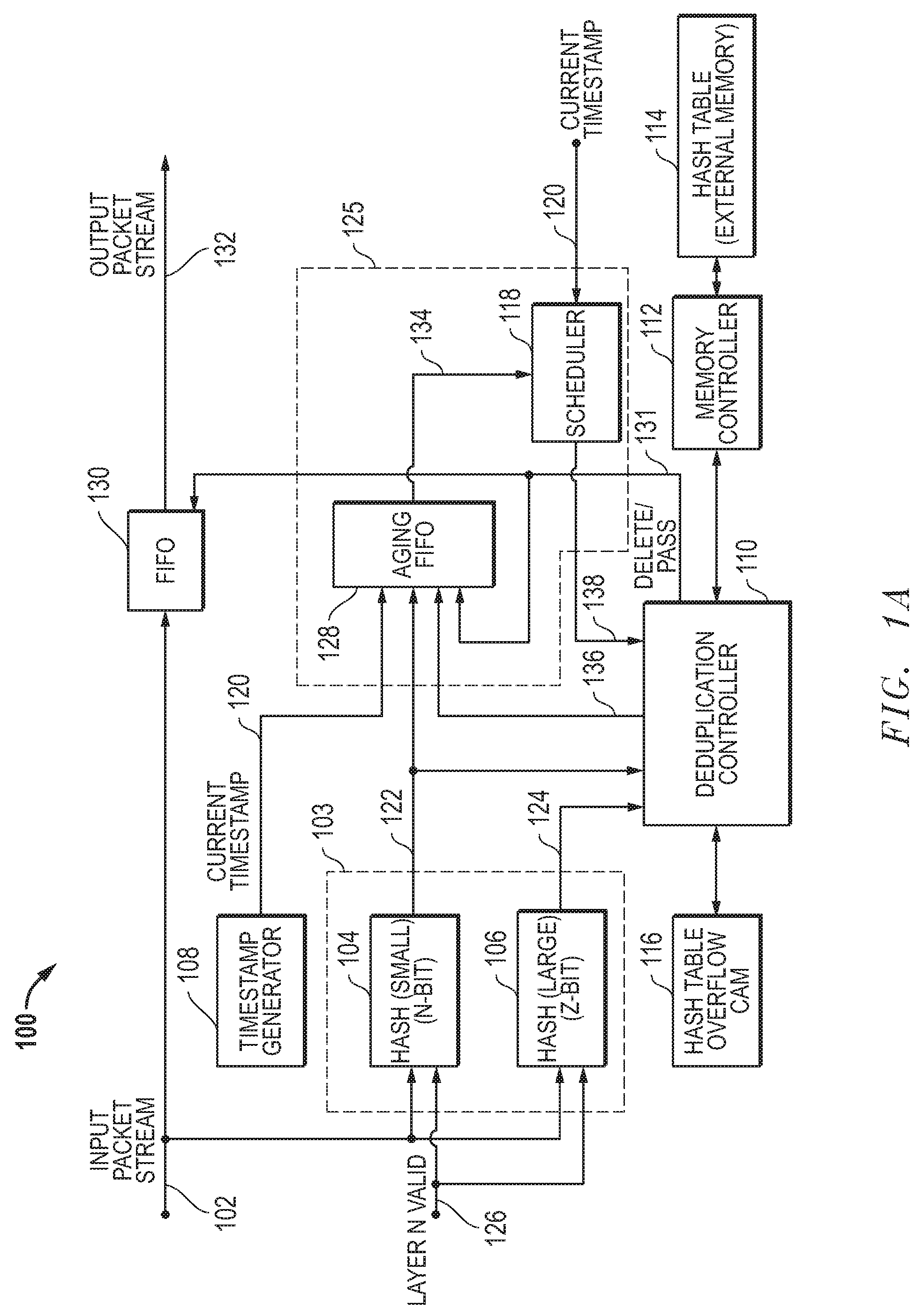

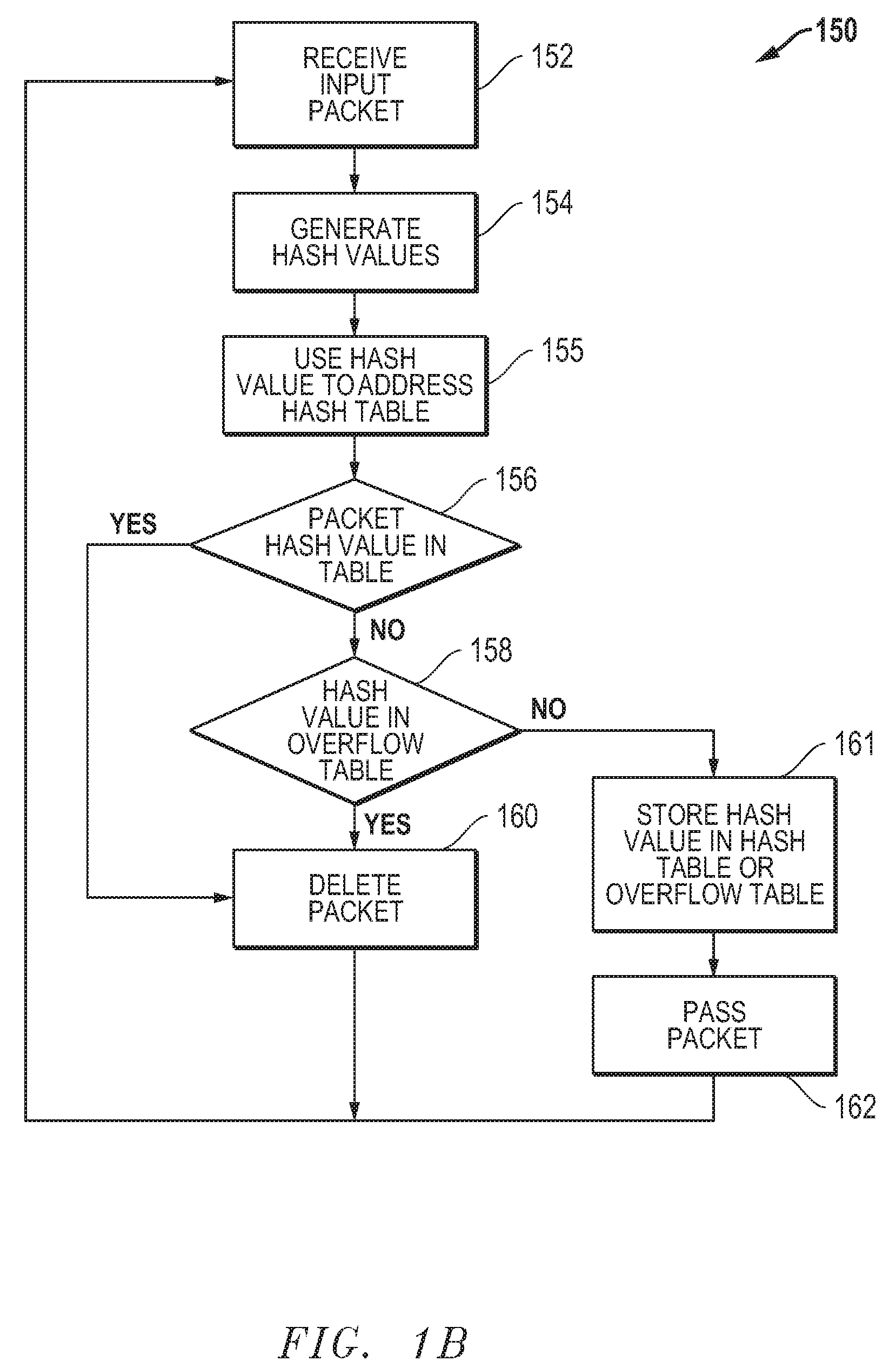

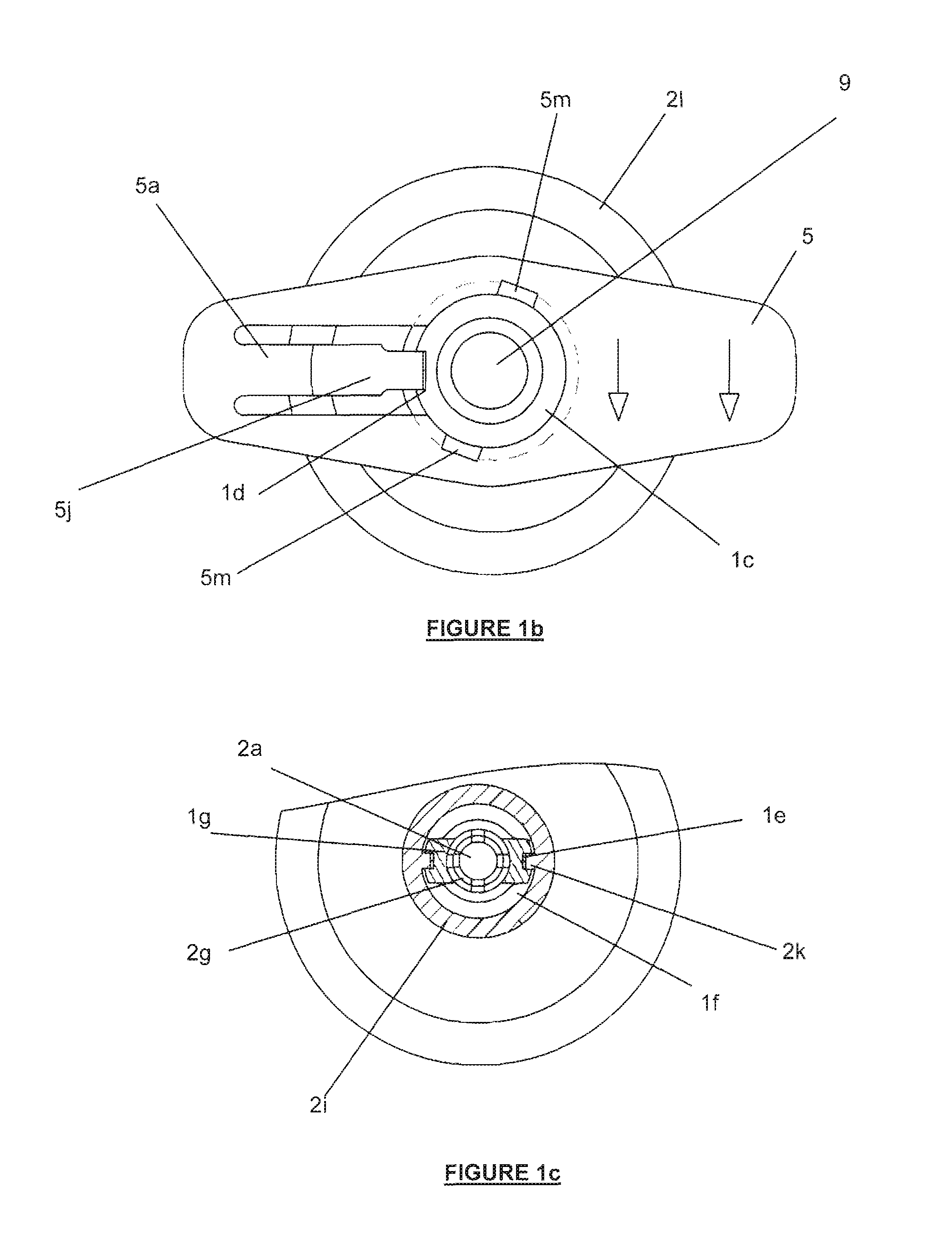

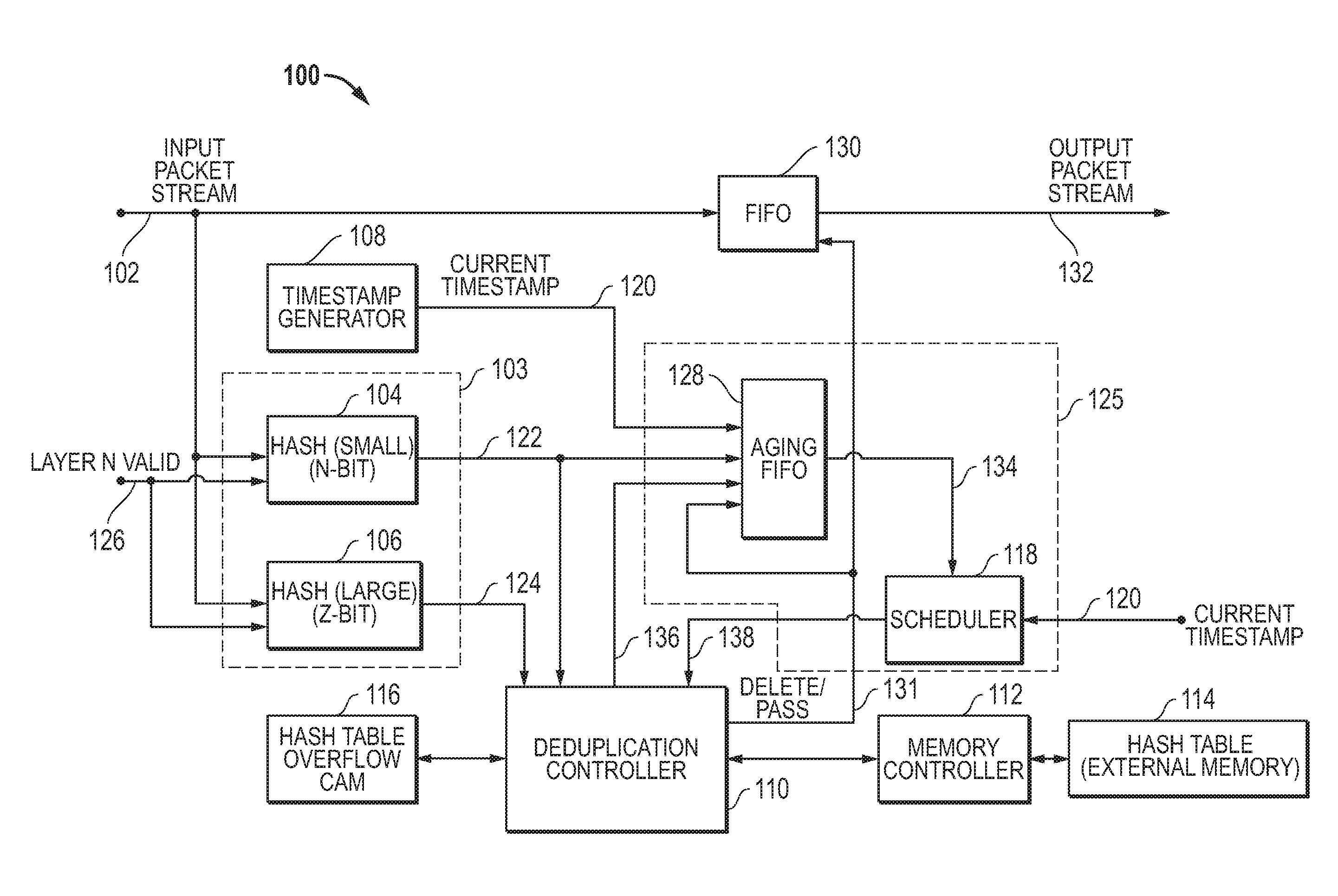

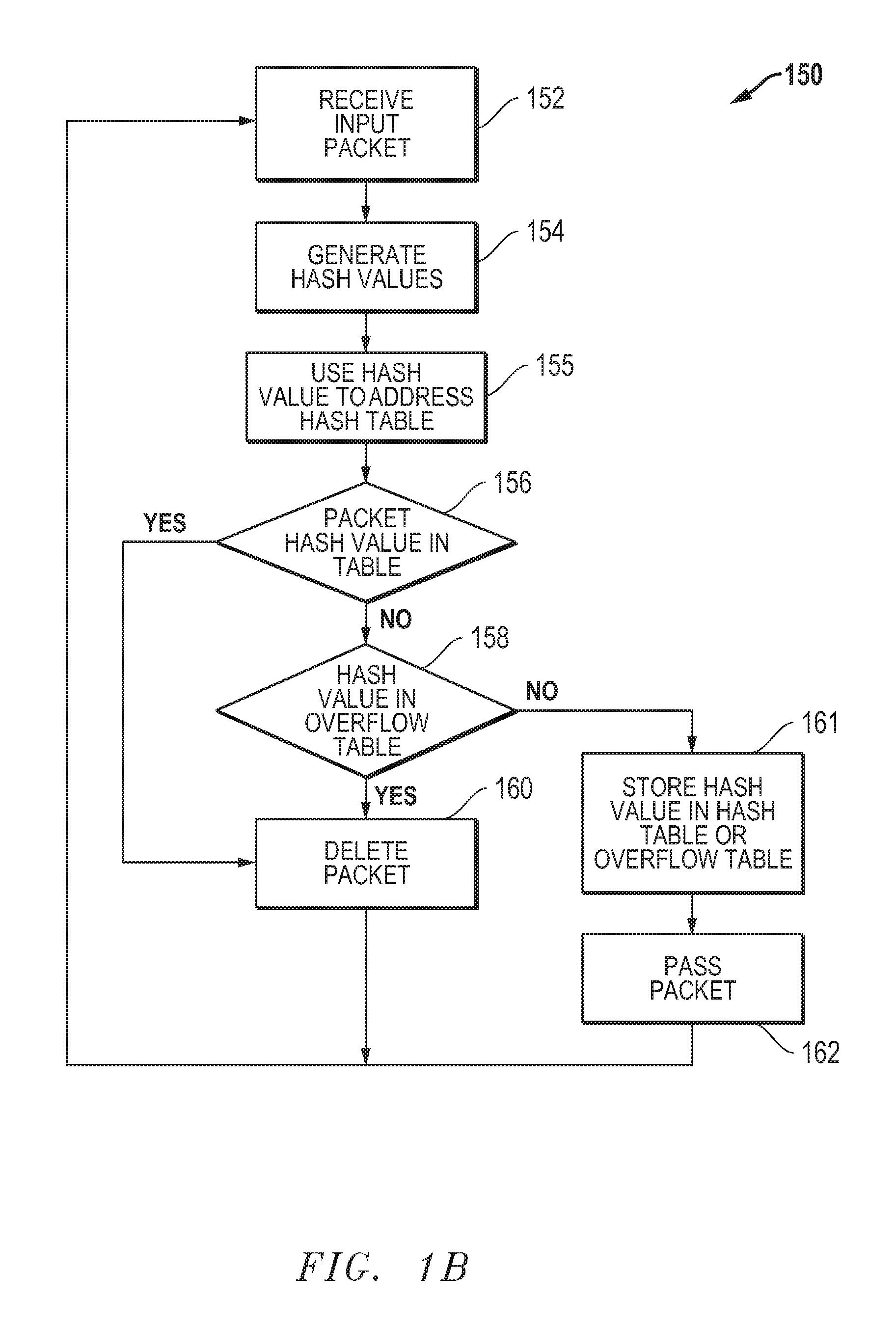

Systems and methods for in-line removal of duplicate network packets

Systems and methods are disclosed for in-line removal of duplicate network packets in network packet streams operating at high speeds (e.g., 1-10 Gbps and above). A hash generator applies at least one hash algorithm to incoming packets to form one or more different hash values. The packet deduplication systems and methods then use the one or more hash values for each incoming packet to identify data stored for previously received backs and use the identified data to determine if incoming packets are duplicate packets. Duplicate packets are then removed from the output packet stream thereby reducing duplicate packets for downstream processing. A deduplication window can further be utilized to limit the amount of data stored for previous packets based upon one or more parameters, such as an amount of time that has passed and / or a number of packets for which data has been stored. These parameters can also be selected, configured and / or adjusted to achieve desired operational objectives.

Owner:KEYSIGHT TECH SINGAPORE (SALES) PTE LTD +1

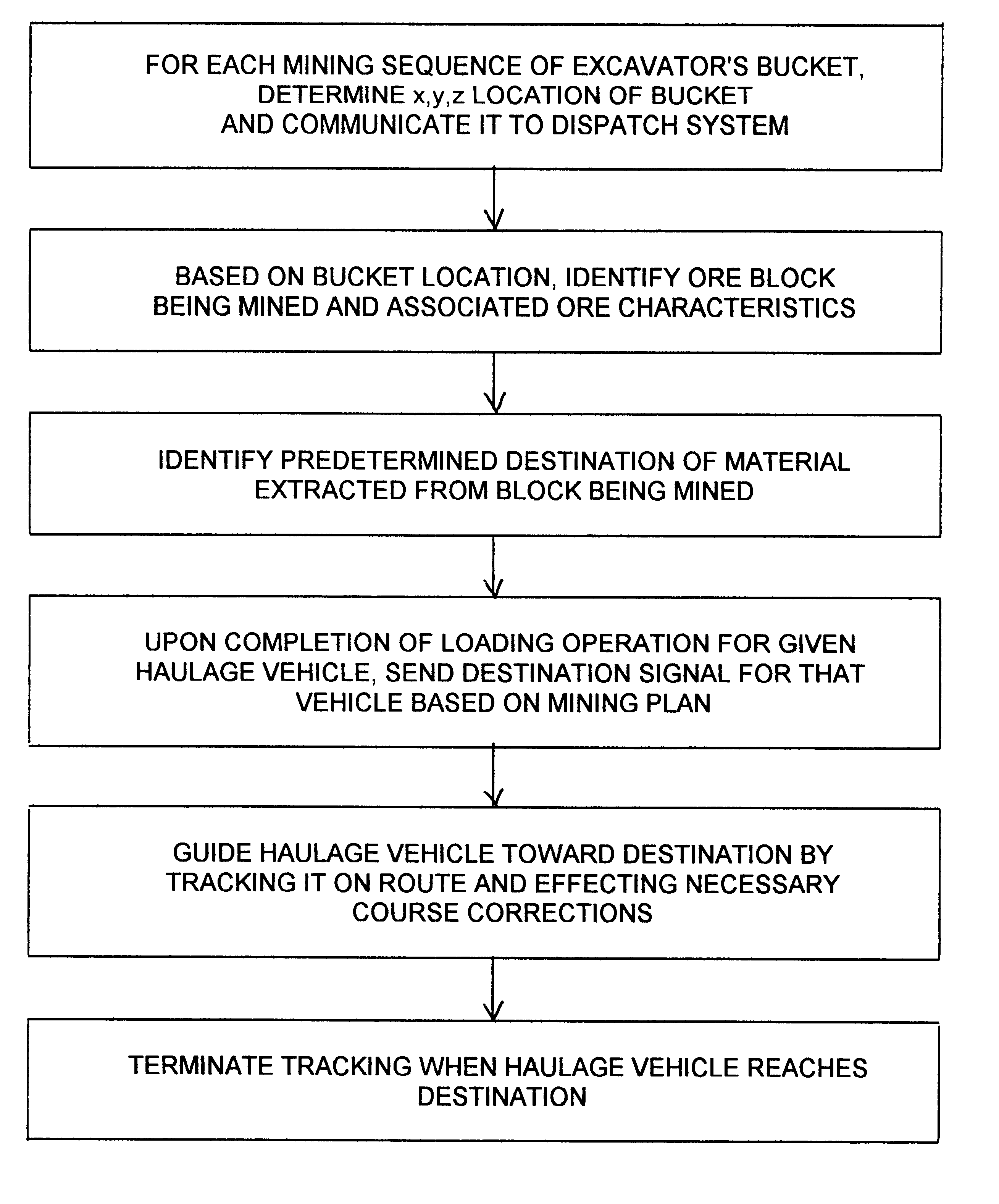

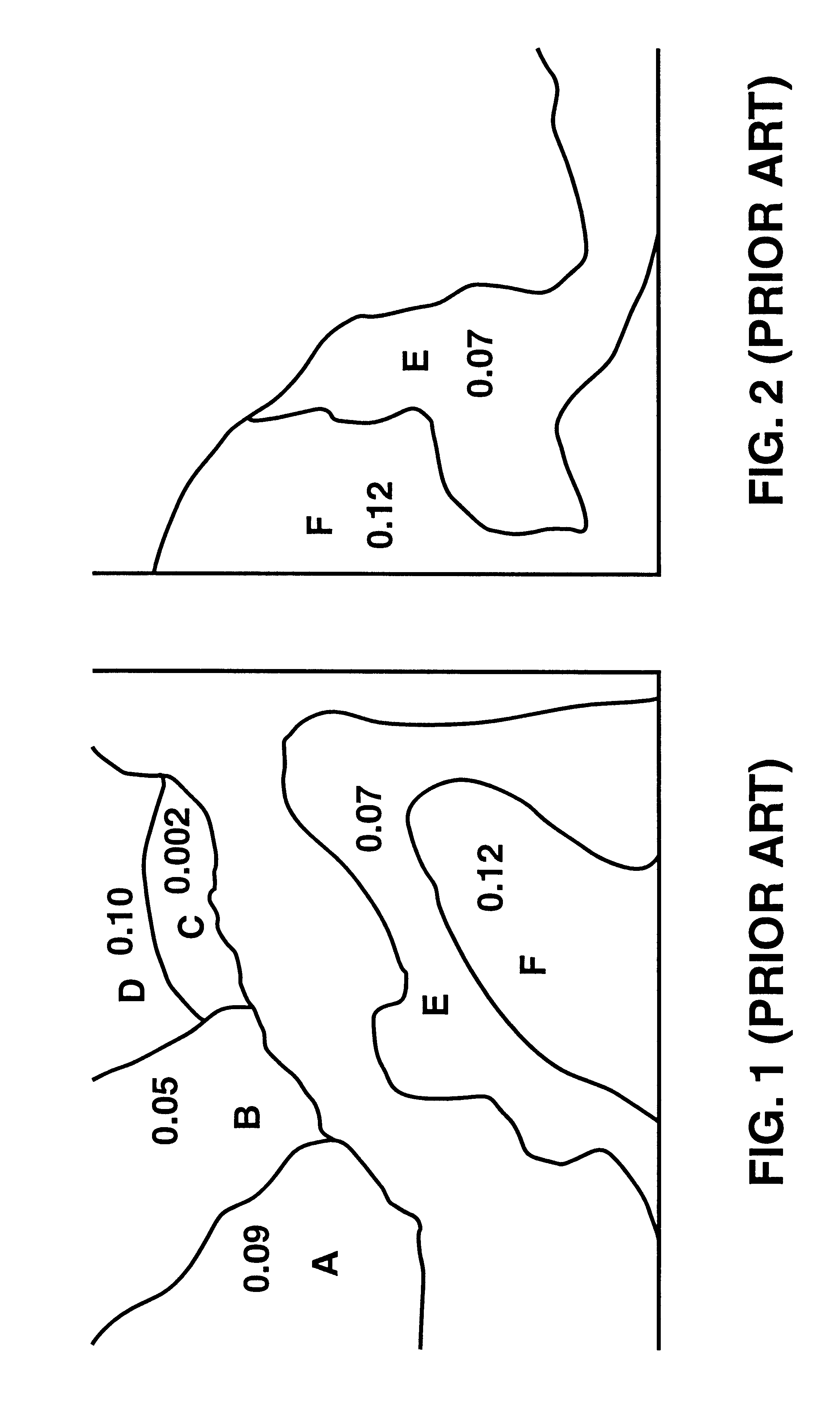

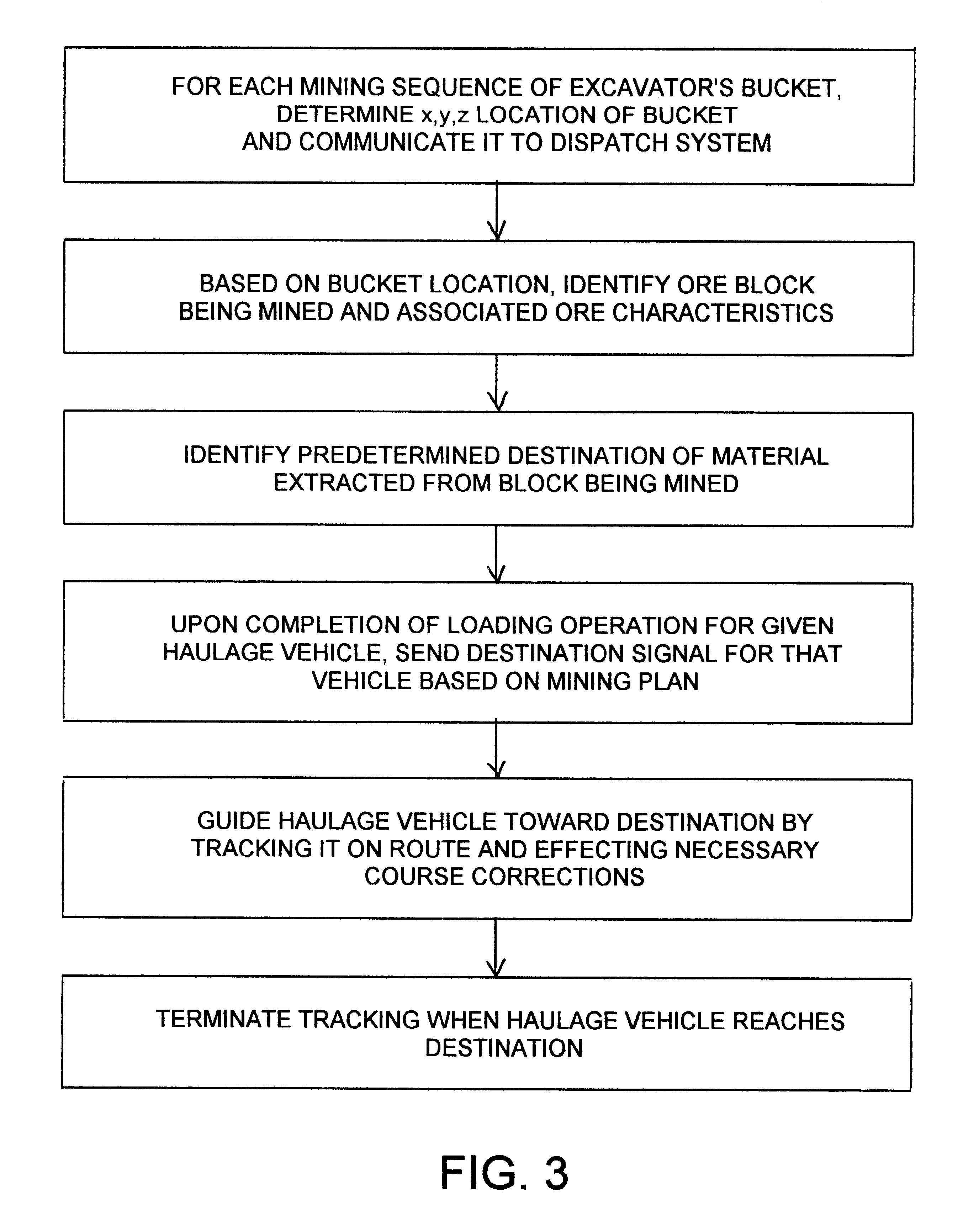

Autonomous-dispatch system linked to mine development plan

InactiveUS6351697B1Analogue computers for trafficRoad vehicles traffic controlDownstream processingEngineering

An autonomous dispatch system links positioning-system units mounted on mining and haulage equipment to a computerized mine development plan for ascertaining the origin of mined material and directing its disposition according to a predetermined downstream-processing plan. A destination signal is automatically communicated to the haulage vehicle, which is then autonomously guided to the correct destination and tracked until the load is released after arrival. If the haulage vehicle is manually operated, the destination signal and the vehicle's progress toward it are preferably also displayed on a monitor for the operator's information and use. The system may further include hardware for blocking the release of a load from the haulage vehicle until and unless the vehicle has reached the prescribed destination.

Owner:MODULAR MINING SYSTEMS

Maximal flow scheduling for a stream processing system

InactiveUS20070299980A1Maximize objective functionMaintain stabilityMultiple digital computer combinationsTransmissionDownstream processingProcessing element

Disclosed is a method, upstream processing node, and computer readable medium for processing data packets. The method includes receiving an allocation for at least one computing resource. At least one data packet at one or more upstream processing elements in an upstream processing node is received. The method also includes determining if at least one output queue of the upstream processing elements includes available space for processing of the data packet. The data packet is processed in response to the output queue including available space to form a resulting data packet. The method further includes determining that an input queue of at least one downstream processing element of a plurality of downstream processing elements includes available space for receiving the resulting data packet In response to the determining, the resulting data packet is transmitted from the upstream processing element to the downstream processing element.

Owner:IBM CORP

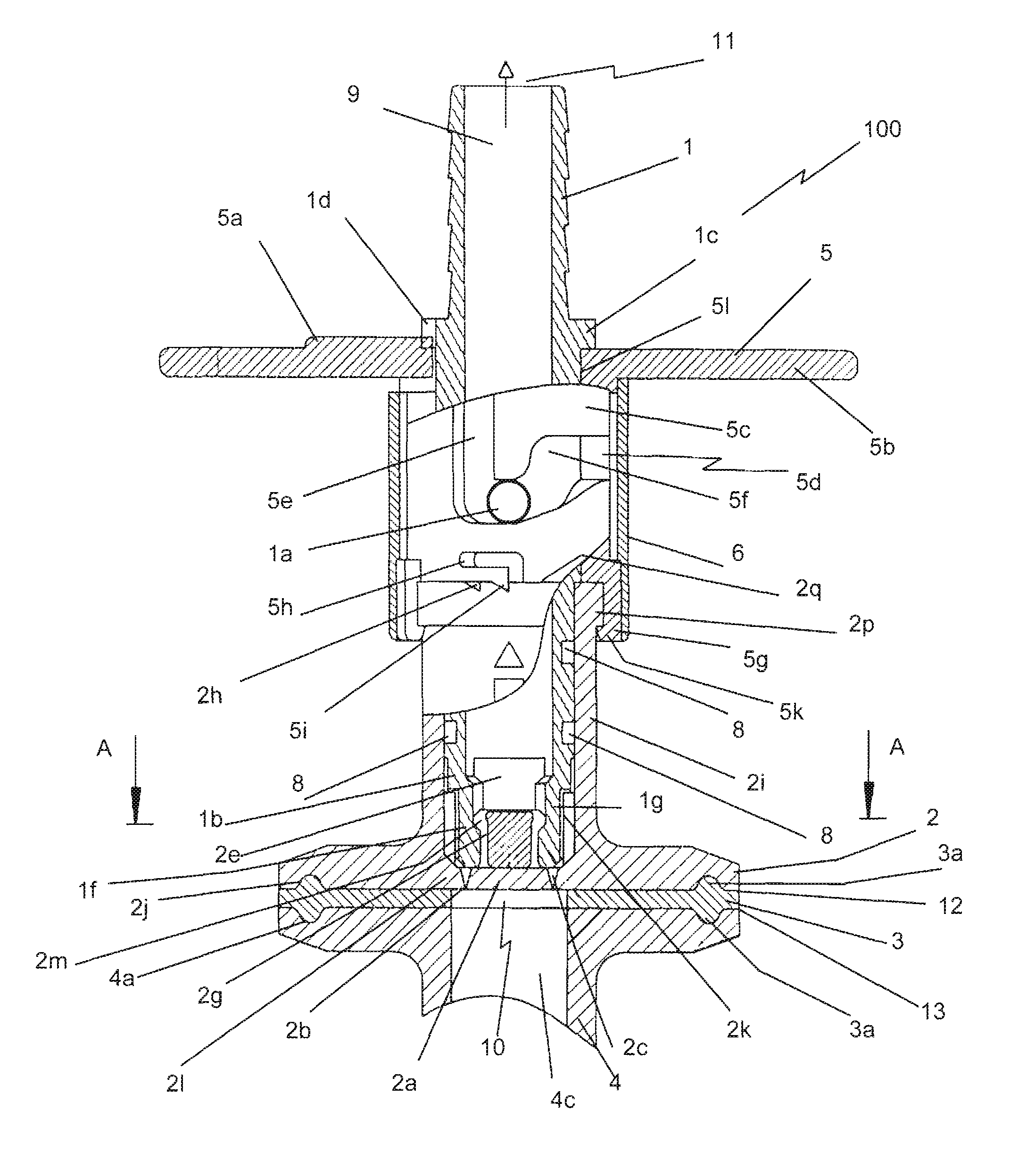

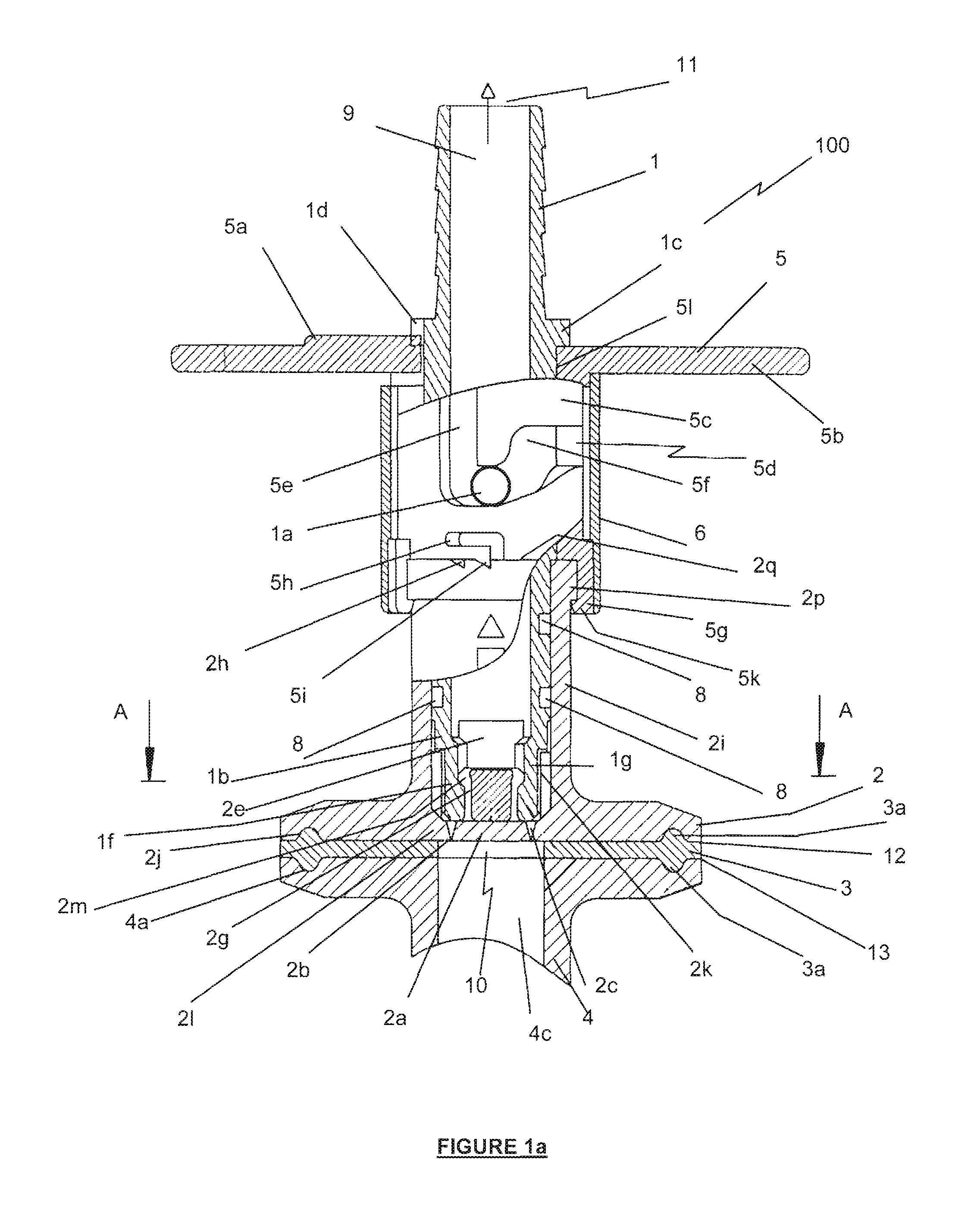

Valve

InactiveUS7350535B2Undesired movement is also preventedCompromising sterilityCheck valvesEqualizing valvesDownstream processingActuator

A valve apparatus (100) for use in sterile fluid transfer or isolator systems has open entry (10) and exit (11) sides and a passageway (9) for fluid between the entry (10) and the exit (11) sides. The entry side (10) is connectable to an opening (4c) of a vessel or pipe (4) and the exit side (11) is connectable to downstream processing by means such as tubing, a vessel or a pipe. The entry side (10) includes a rupturable seal (2a) blocking the open entry side (10). Valve (100) also includes an actuator (5) attached to a piston (1) which moves within the valve (100), the piston being connected to the seal so that on movement of the piston, the seal is torn free from the entry side thereby allowing fluid gain entry to the valve (100) and to pass along the passageway (9) between the open entry (10) and exit (11) sides to downstream processing.

Owner:G A APOLLO

Hydrogenation of biochemical derived 1,3 -propanediol

InactiveUS7098368B2Organic compound preparationOxygen compounds purification/separationDownstream processingHydrogenation process

The invention discloses a hydrogenation process for removing impurities and controlling acid for use in downstream processing of biochemically-derived 1,3-propanediol. Preferably, the biochemically-derived 1,3-propanediol, before the contacting, has an initial color and, after the contracting, has a color that is lower than the initial color.

Owner:EI DU PONT DE NEMOURS & CO

Systems and methods for in-line removal of duplicate network packets

Systems and methods are disclosed for in-line removal of duplicate network packets in network packet streams operating at high speeds (e.g., 1-10 Gbps and above). A hash generator applies at least one hash algorithm to incoming packets to form one or more different hash values. The packet deduplication systems and methods then use the one or more hash values for each incoming packet to identify data stored for previously received backs and use the identified data to determine if incoming packets are duplicate packets. Duplicate packets are then removed from the output packet stream thereby reducing duplicate packets for downstream processing. A deduplication window can further be utilized to limit the amount of data stored for previous packets based upon one or more parameters, such as an amount of time that has passed and / or a number of packets for which data has been stored. These parameters can also be selected, configured and / or adjusted to achieve desired operational objectives.

Owner:KEYSIGHT TECH SINGAPORE (SALES) PTE LTD +1

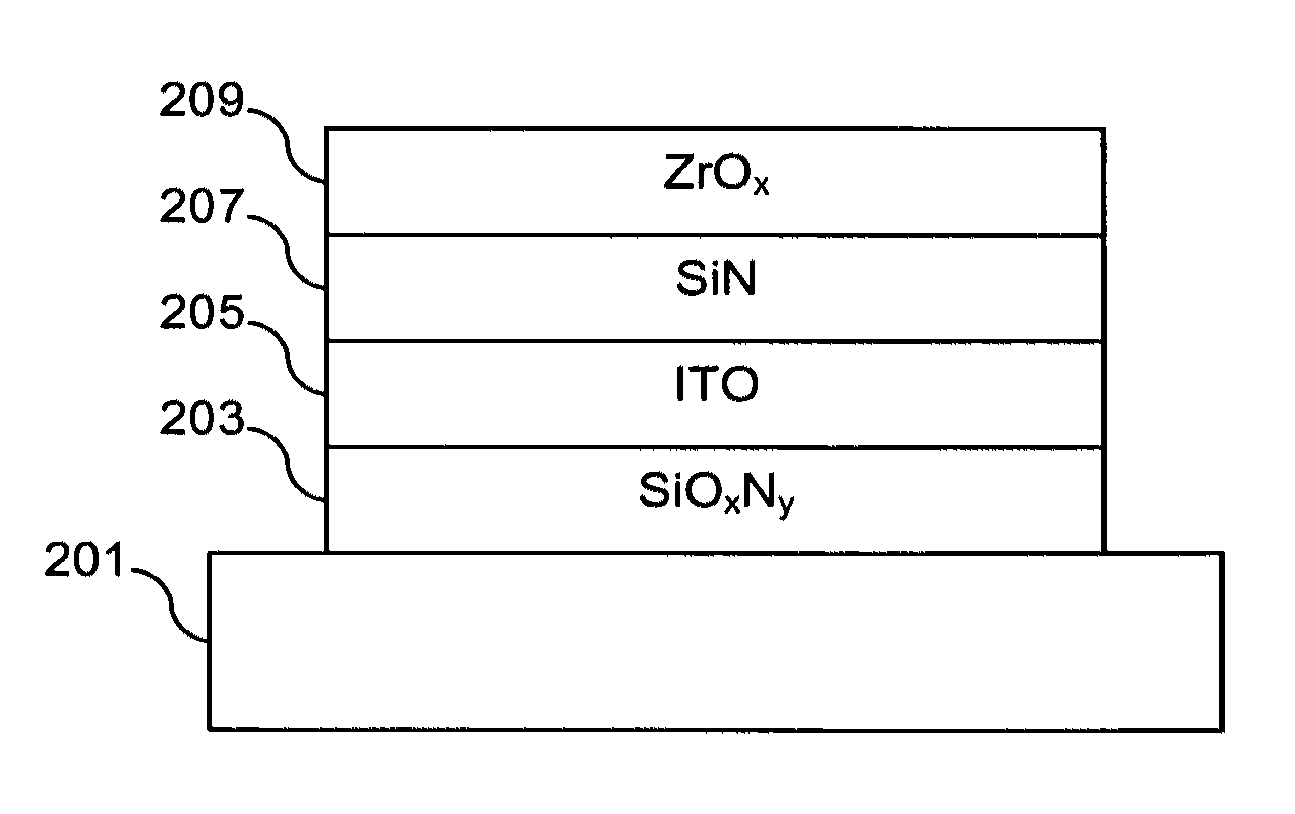

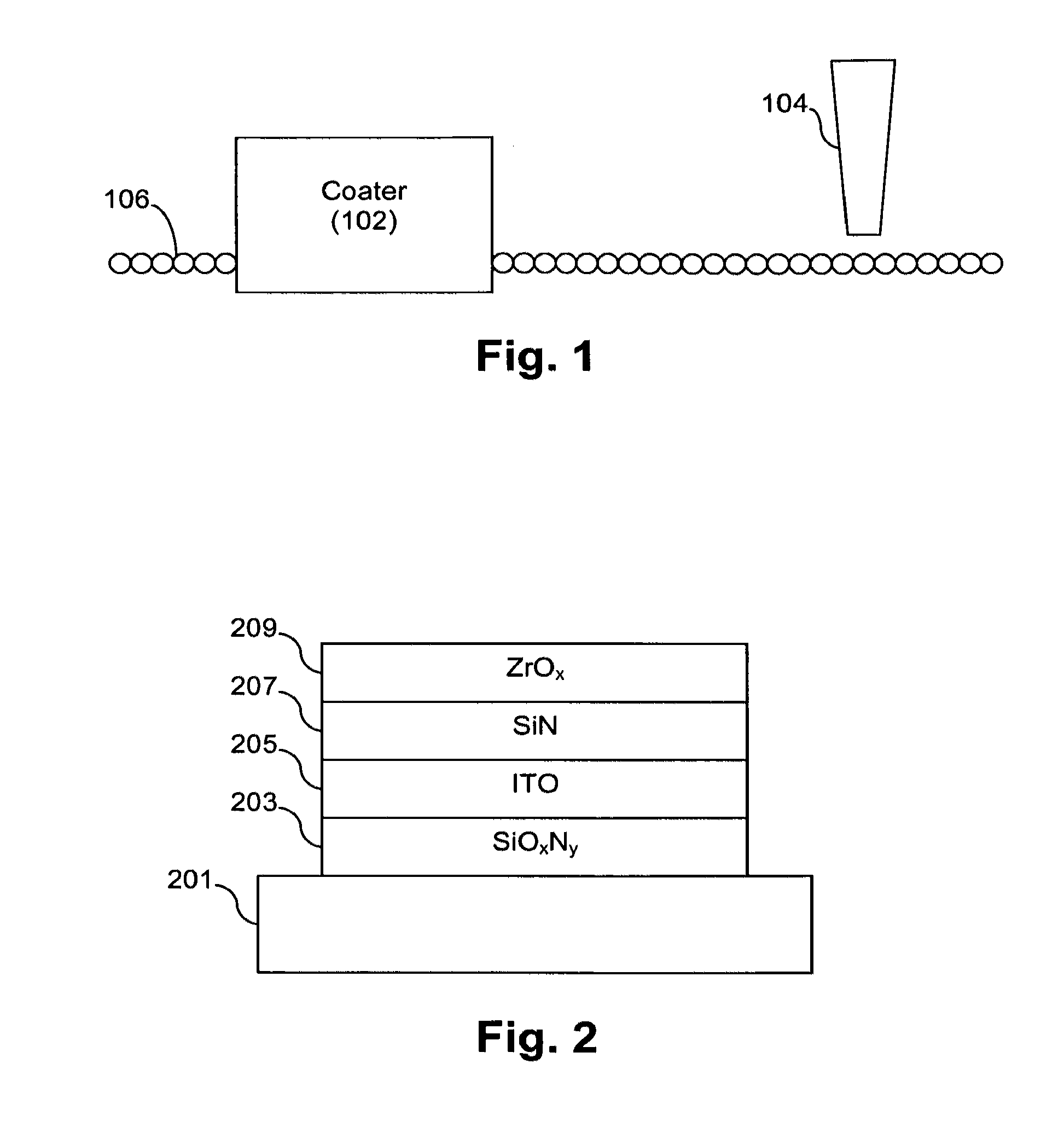

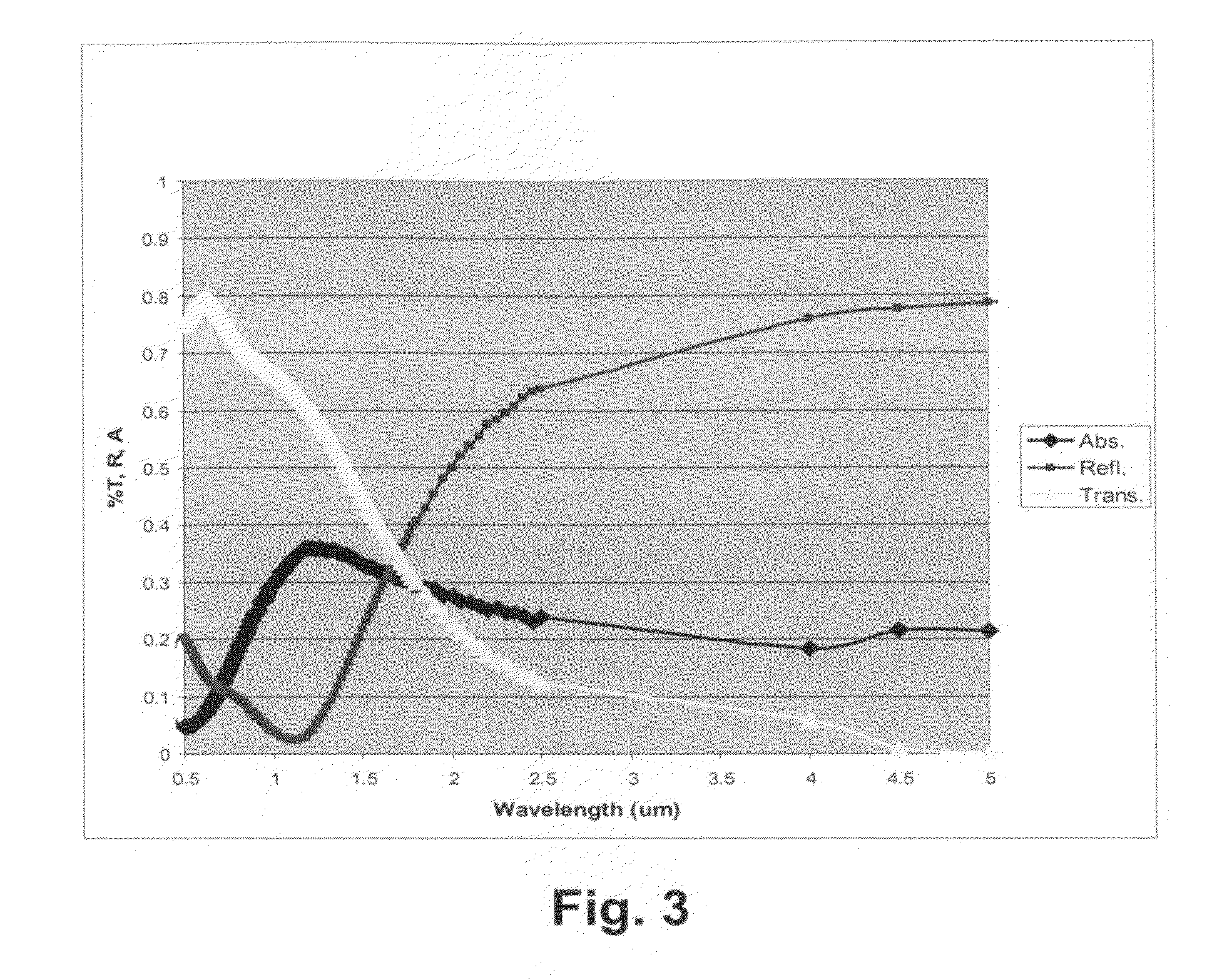

System and/or method for heat treating conductive coatings using wavelength-tuned infrared radiation

ActiveUS20120048722A1Reduce the impactSimple technologyMuffle furnacesVacuum evaporation coatingDownstream processingConductive coating

Certain example embodiments relate to systems and / or methods for preferentially and selectively heat treating conductive coatings such as ITO using specifically tuned near infrared-short wave infrared (NIR-SWIR) radiation. In certain example embodiments, the coating is preferentially heated, thereby improving its properties while at the underlying substrate is kept at low temperatures. Such techniques are advantageous for applications on glass and / or other substrates, e.g., where elevated substrate temperatures can lead to stress changes that adversely effect downstream processing (such as, for example, cutting, grinding, etc.) and may sometimes even result in substrate breakage or deformation. Selective heating of the coating may in certain example embodiments be obtained by using IR emitters with peak outputs over spectral wavelengths where the conductive coating (or the conductive layer(s) in the conductive coating) is significantly absorbing but where the substrate has reduced or minimal absorption.

Owner:GUARDIAN GLASS LLC

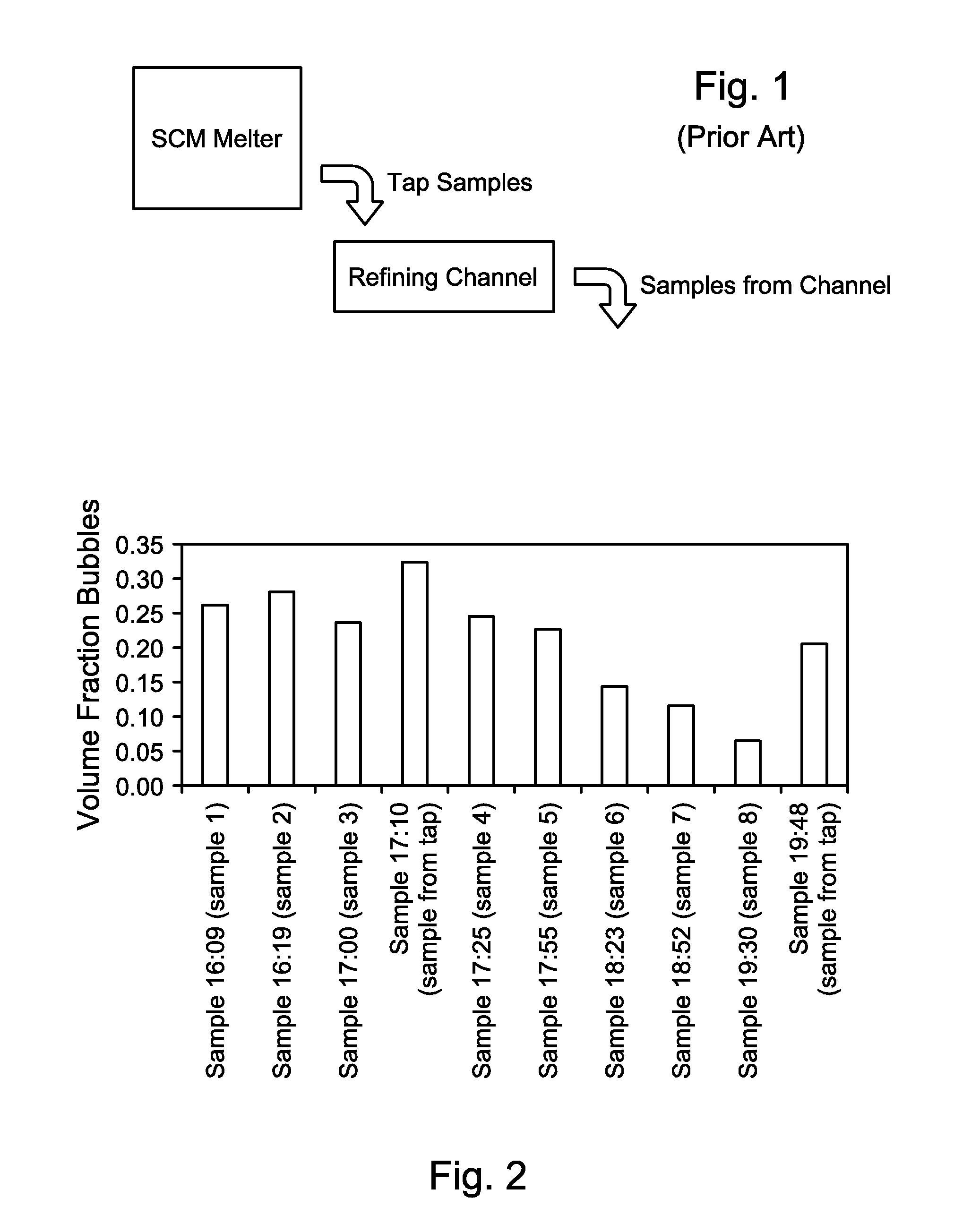

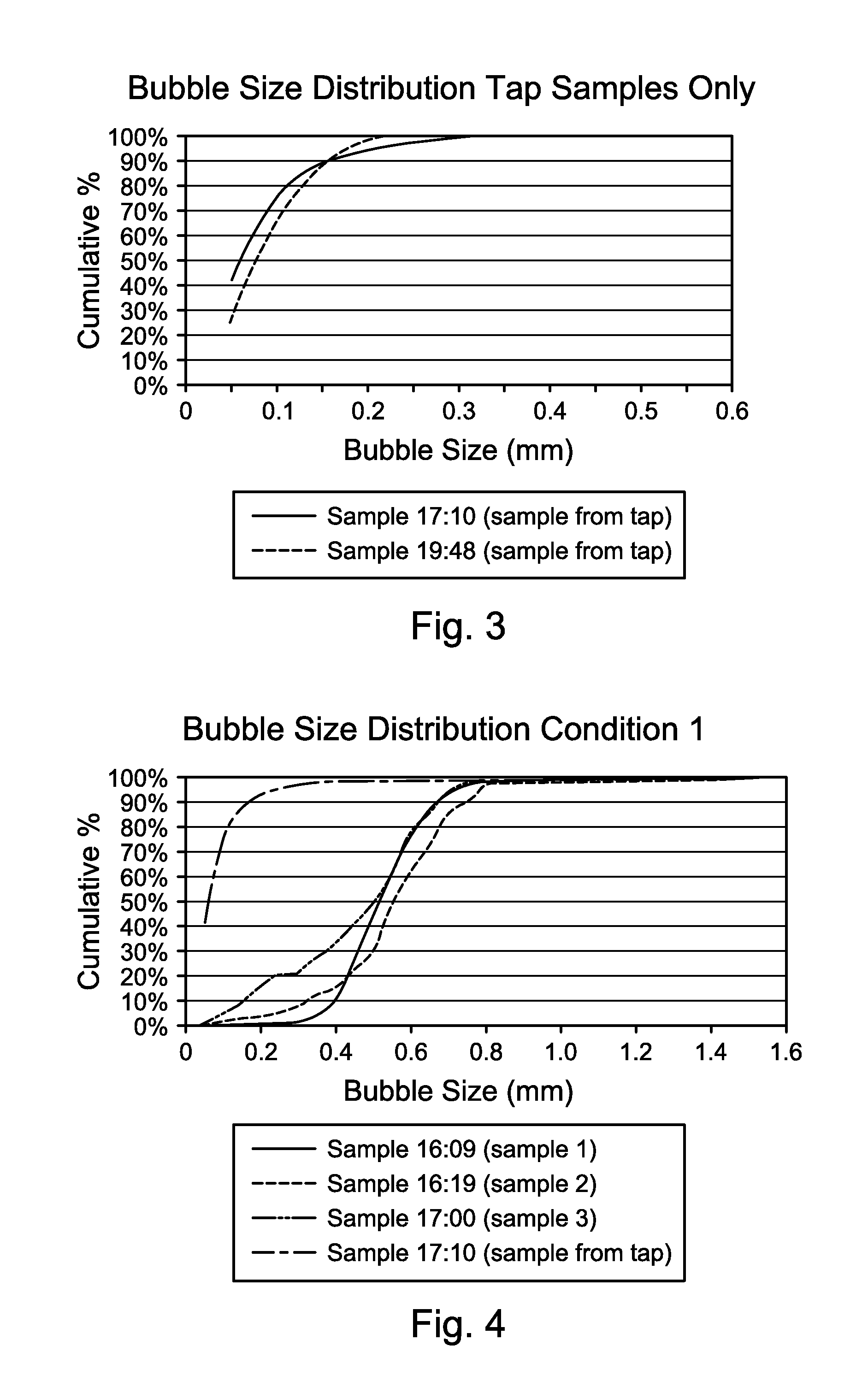

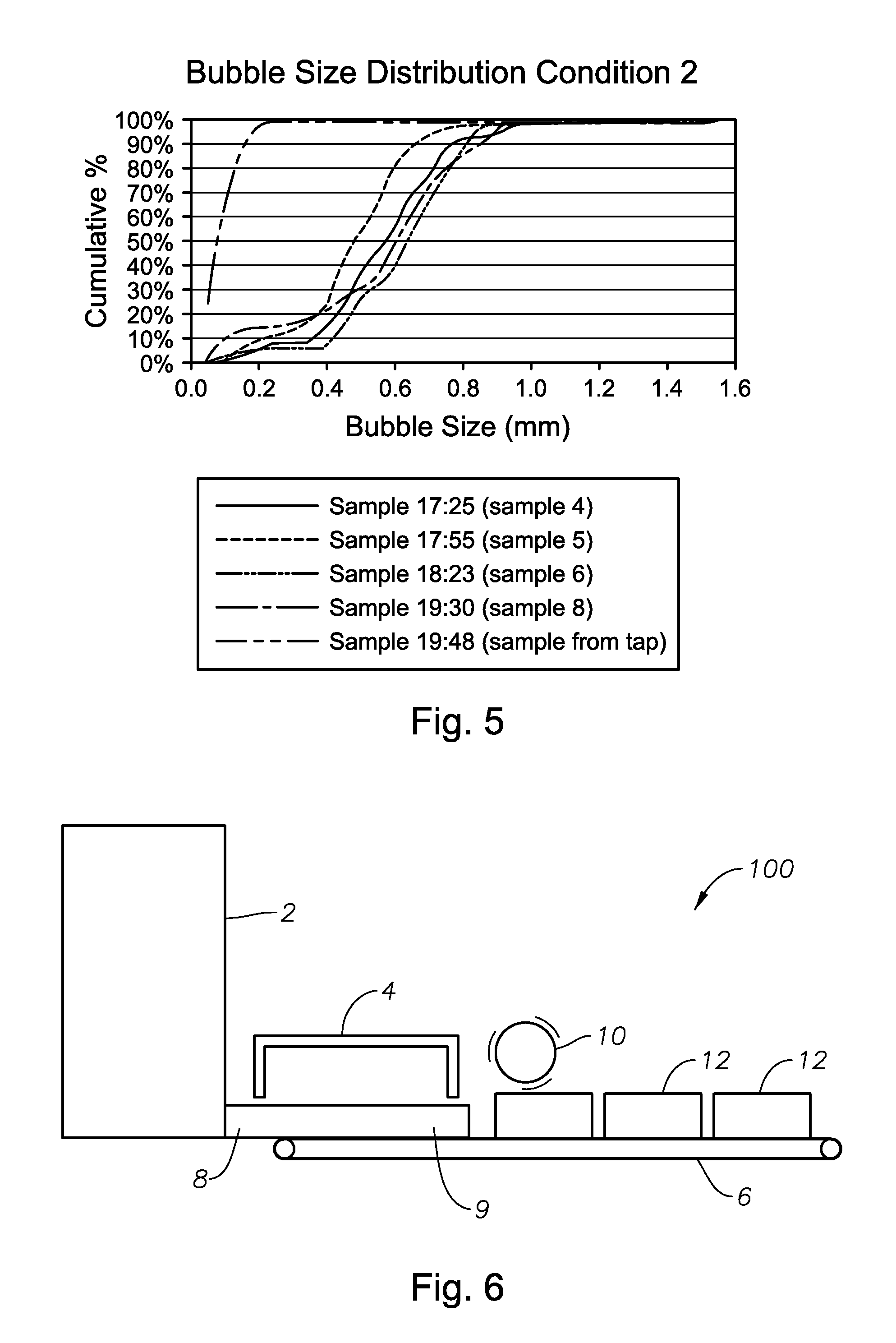

Systems and methods for making foamed glass using submerged combustion

ActiveUS20130086944A1High densityLow densityRibbon machinesGlass furnace apparatusCombustion systemDownstream processing

Submerged combustion systems and methods of use to produce foamed glass. One system includes a submerged combustion melter having an outlet, the melter configured to produce an initial foamy molten glass having a density and comprising bubbles filled primarily with combustion product gases. The initial foamy molten glass is deposited directly onto or into a transport apparatus that transports the initial foamy molten glass to a downstream processing apparatus. An intermediate stage may be included between the melter and the transport apparatus. One intermediate stage is a channel that includes gas injectors. Another intermediate stage is a channel that produces an upper flow of a less dense glass and a relatively more dense glass lower flow. The upper flow may be processed into foamed glass products, while the more dense flow may be processed into dense glass products.

Owner:JOHNS MANVILLE CORP

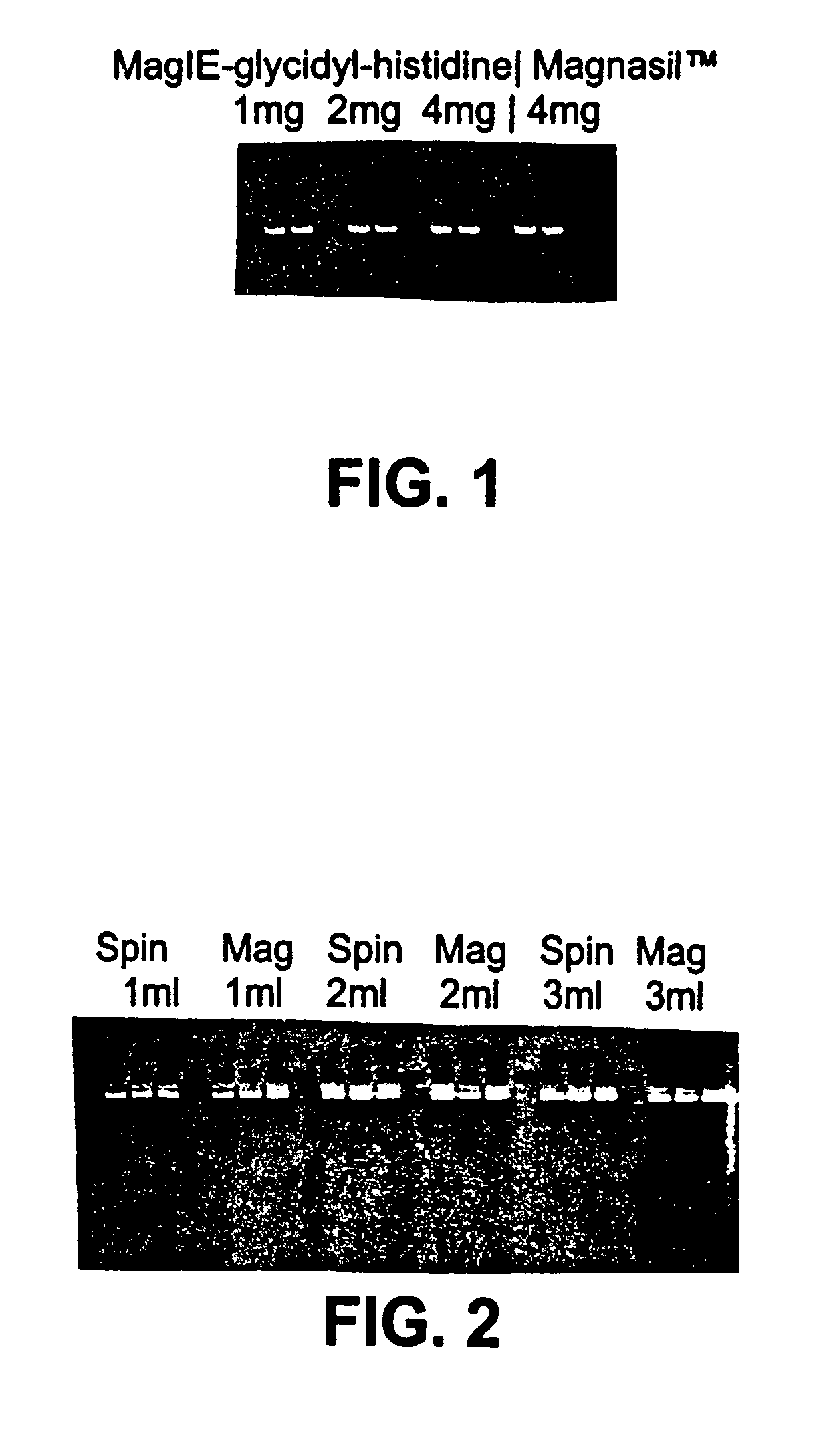

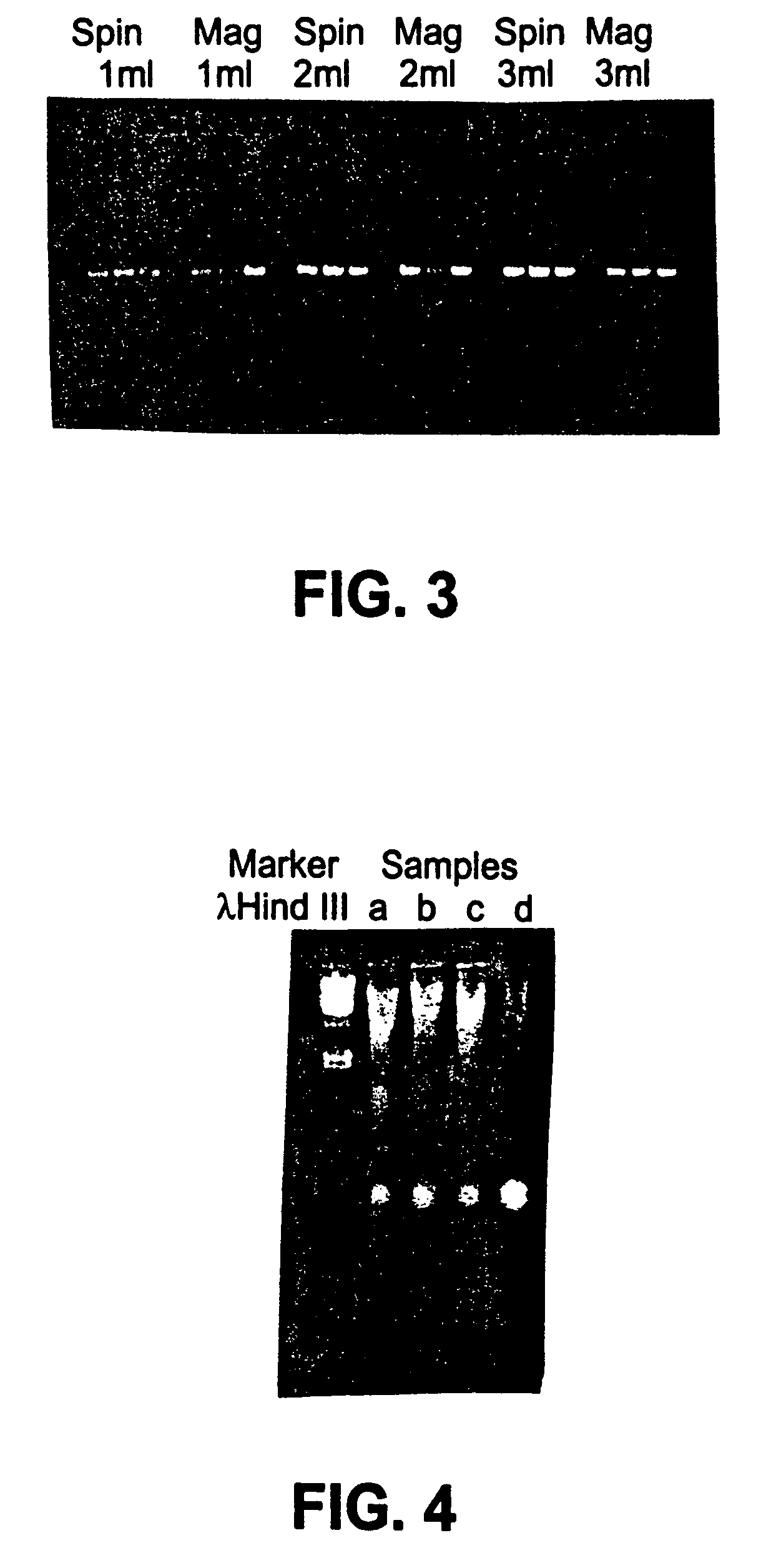

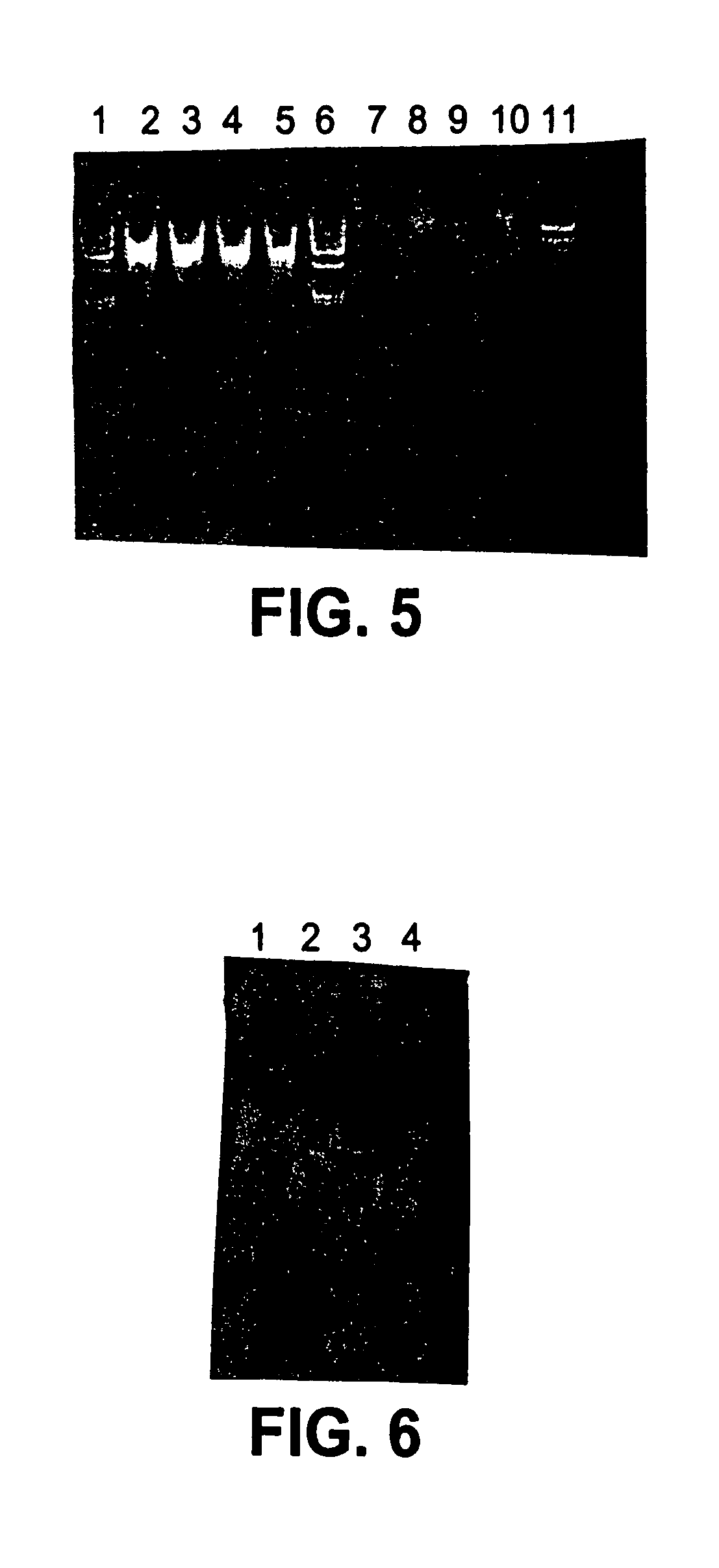

Cell concentration and lysate clearance using paramagnetic particles

InactiveUS7078224B1Bioreactor/fermenter combinationsBiological substance pretreatmentsPresent methodDownstream processing

Methods are disclosed for using paramagnetic particles to concentrate or harvest cells. Methods are also disclosed for clearing a solution of disrupted biological material, such as a lysate of cells or a homogenate of mammalian tissue. Methods are also disclosed for using paramagnetic particles to isolate target nucleic acids, such as RNA or DNA, from a solution cleared of disrupted biological material using the same type or a different type of paramagnetic particle. Kits are also disclosed for use with the various methods of the present invention. Nucleic acids isolated according to the present methods and using the present kits are suitable for immediate use in downstream processing, without further purification.

Owner:PROMEGA CORP

Conversion of solid state source output to virtual source

InactiveUS20070138978A1Optical radiation measurementLight source combinationsDownstream processingOptical processing

A light fixture converts source light from one or more solid state light emitting elements to a virtual light source output. An optical element receives and diffuses light from the solid state emitters to form a processed light for the virtual source output. The optical element forms light that is relatively uniform, for example having a substantially Lambertian distribution and / or having a maximum-to-minimum intensity ratio of 2 to 1 or less over the optical area of the virtual source. In the examples, the diffuse optical processing element comprises a cavity having at least one diffusely reflective surface, and the emitting elements supply light into the cavity at locations that result in reflection and diffusion before emission through an aperture of the cavity. The aperture or a downstream processing element appears as the virtual source of the processed light from the cavity.

Owner:ADVANCED OPTICAL TECH

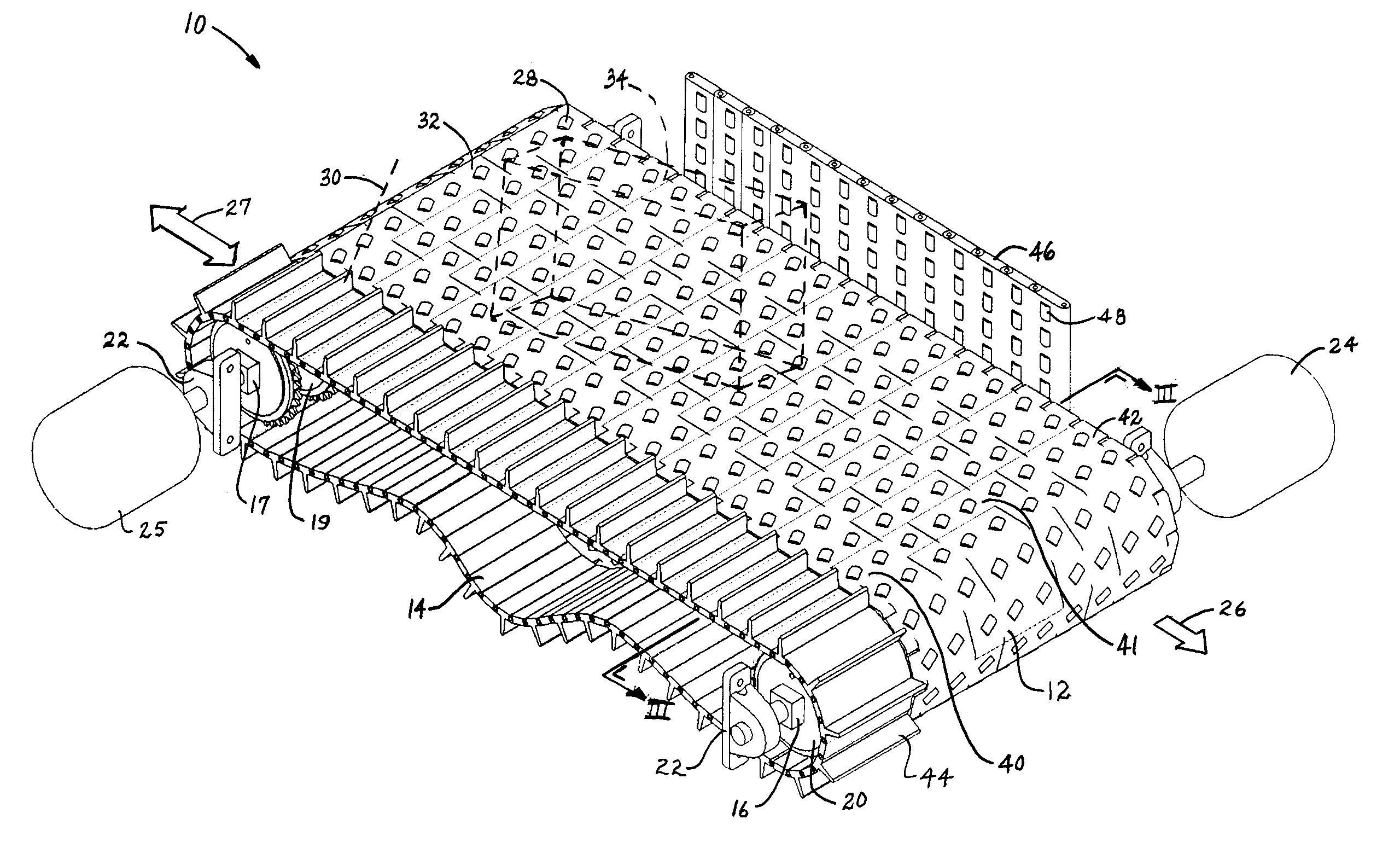

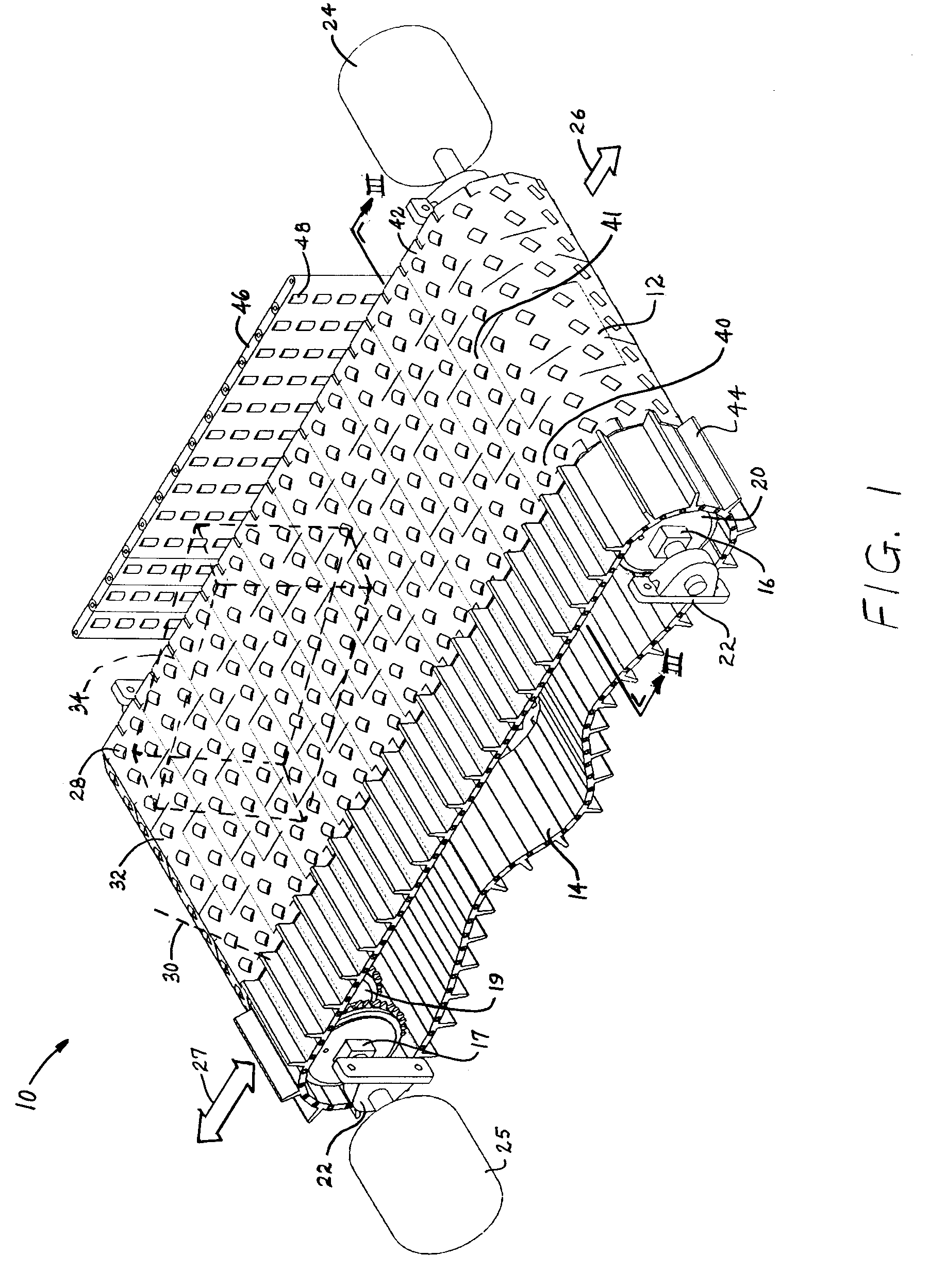

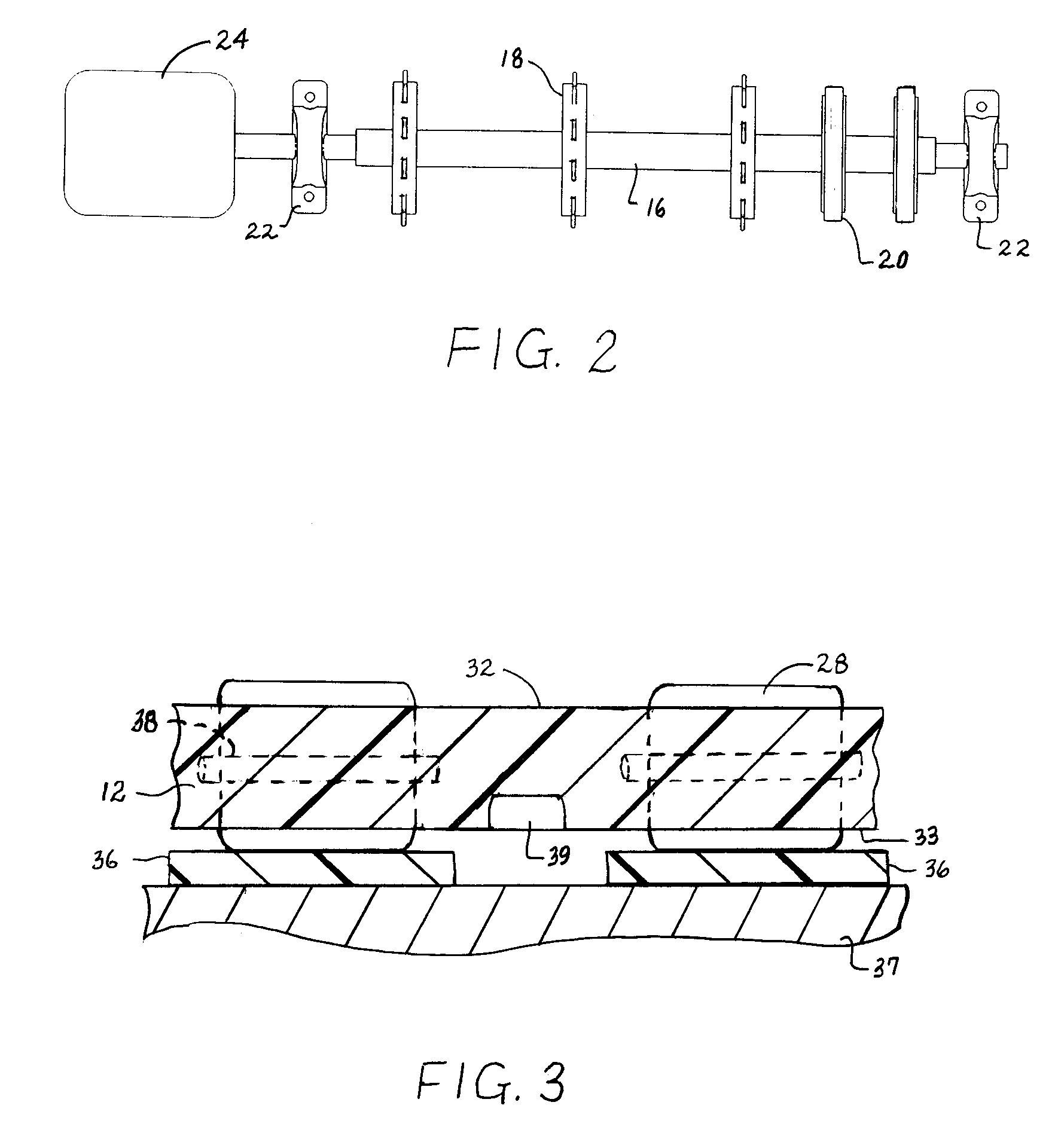

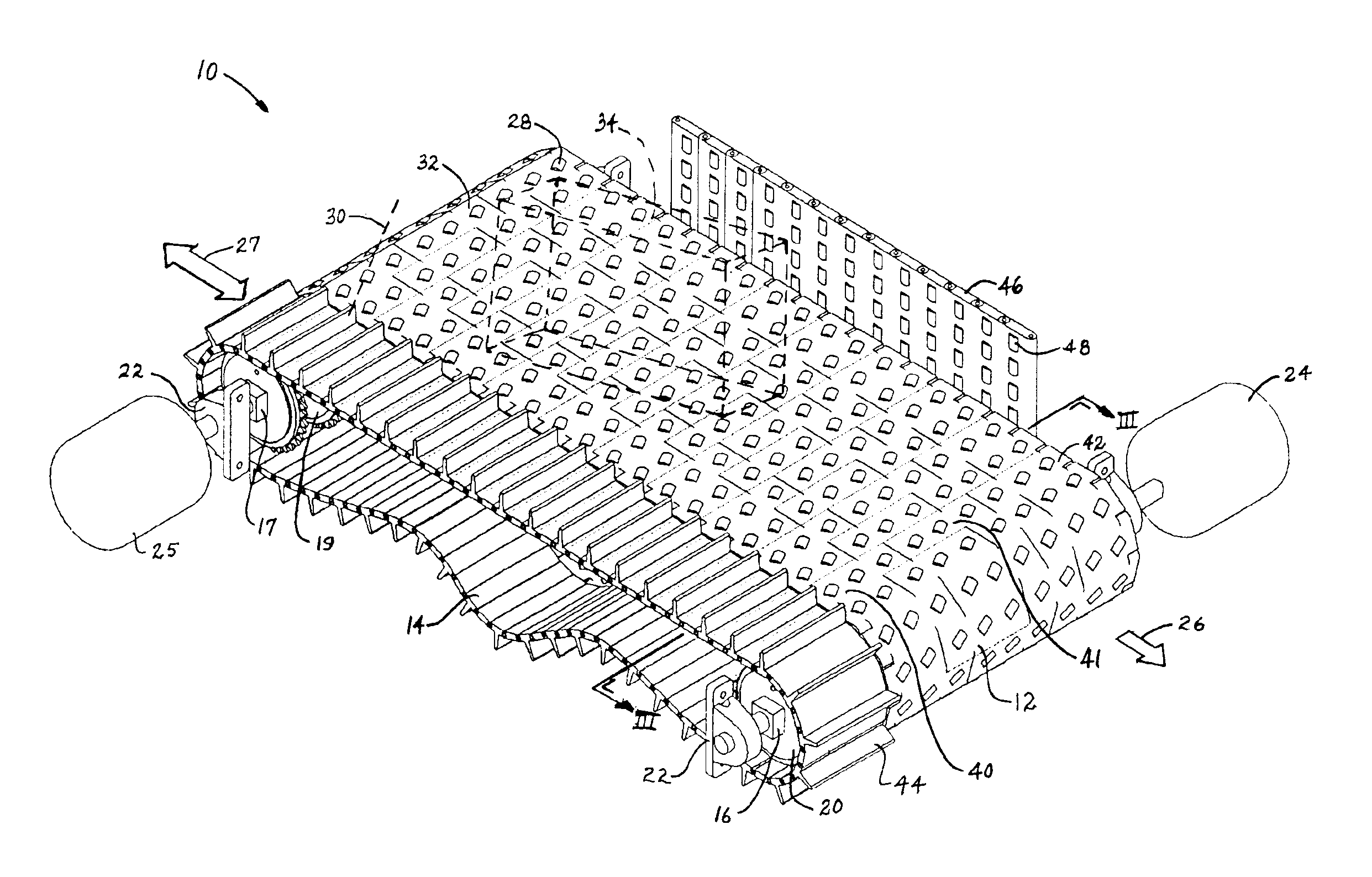

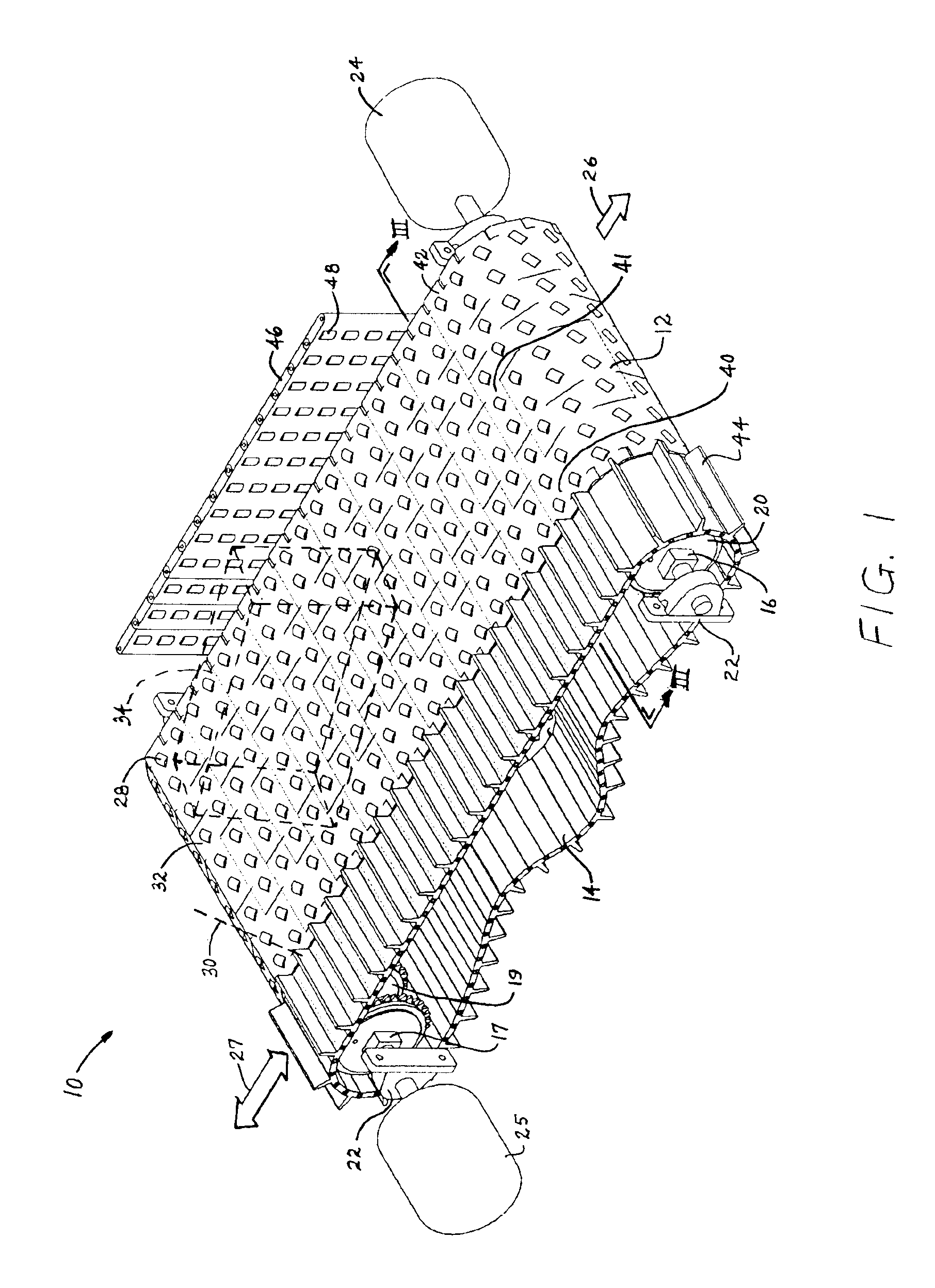

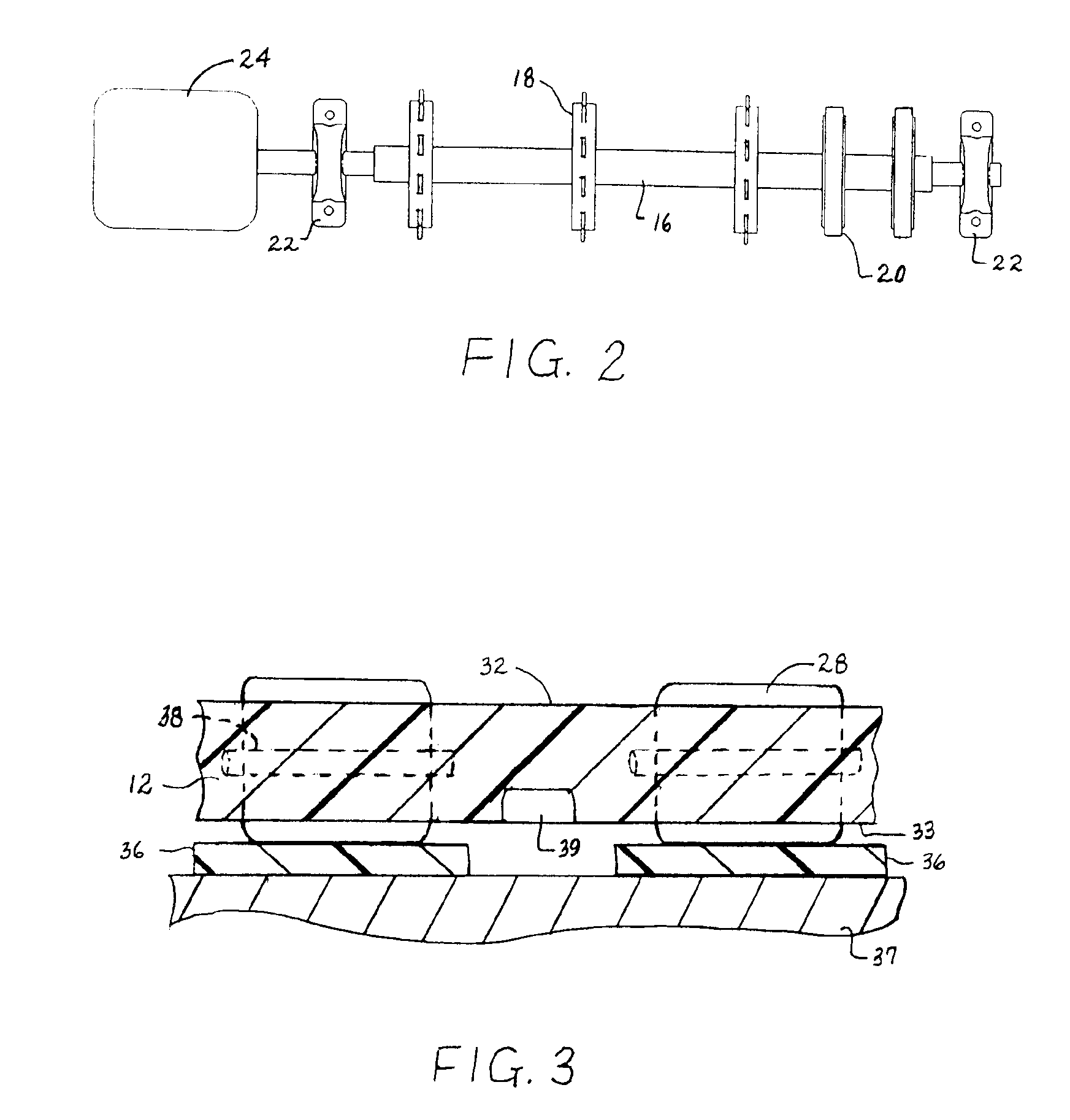

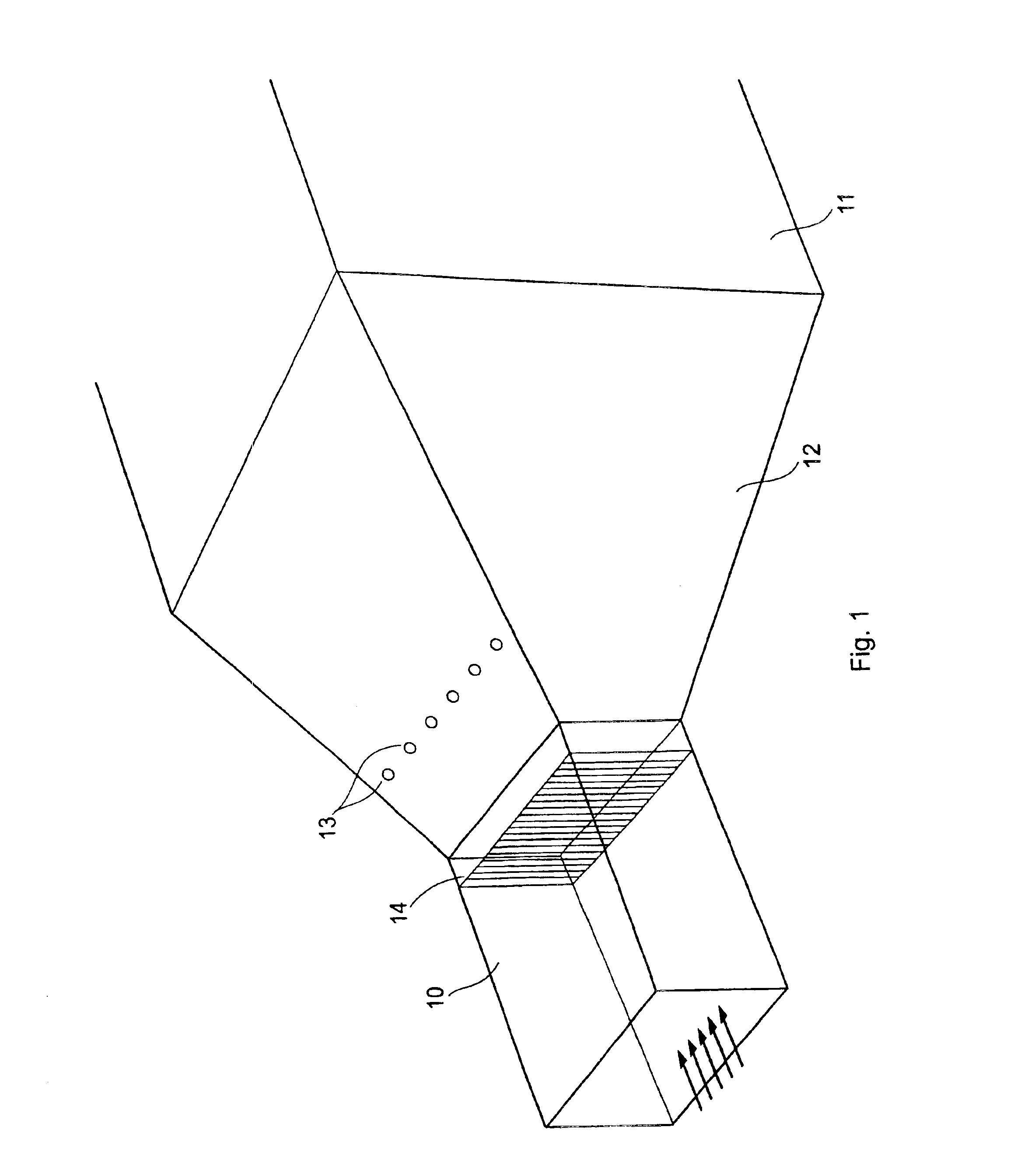

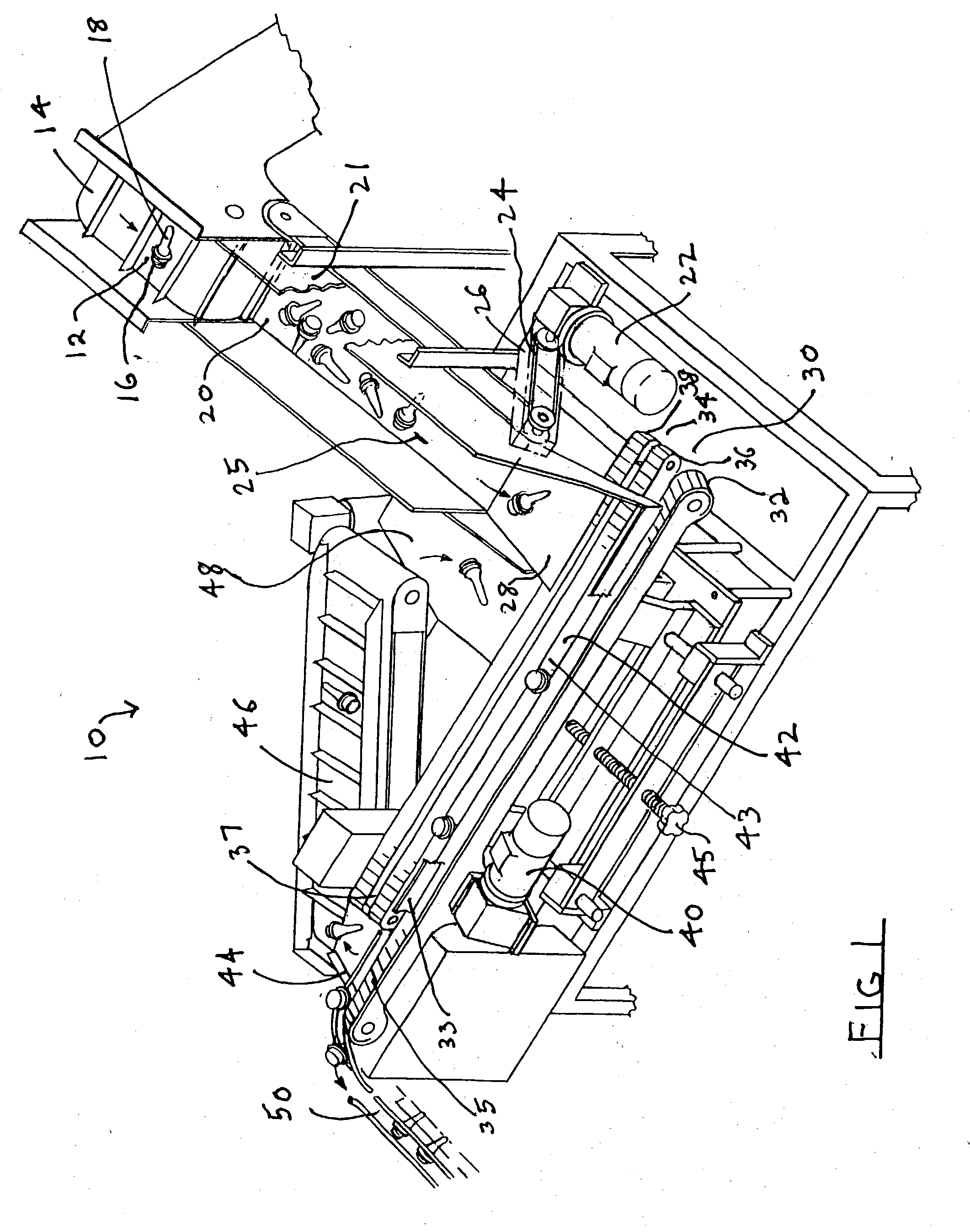

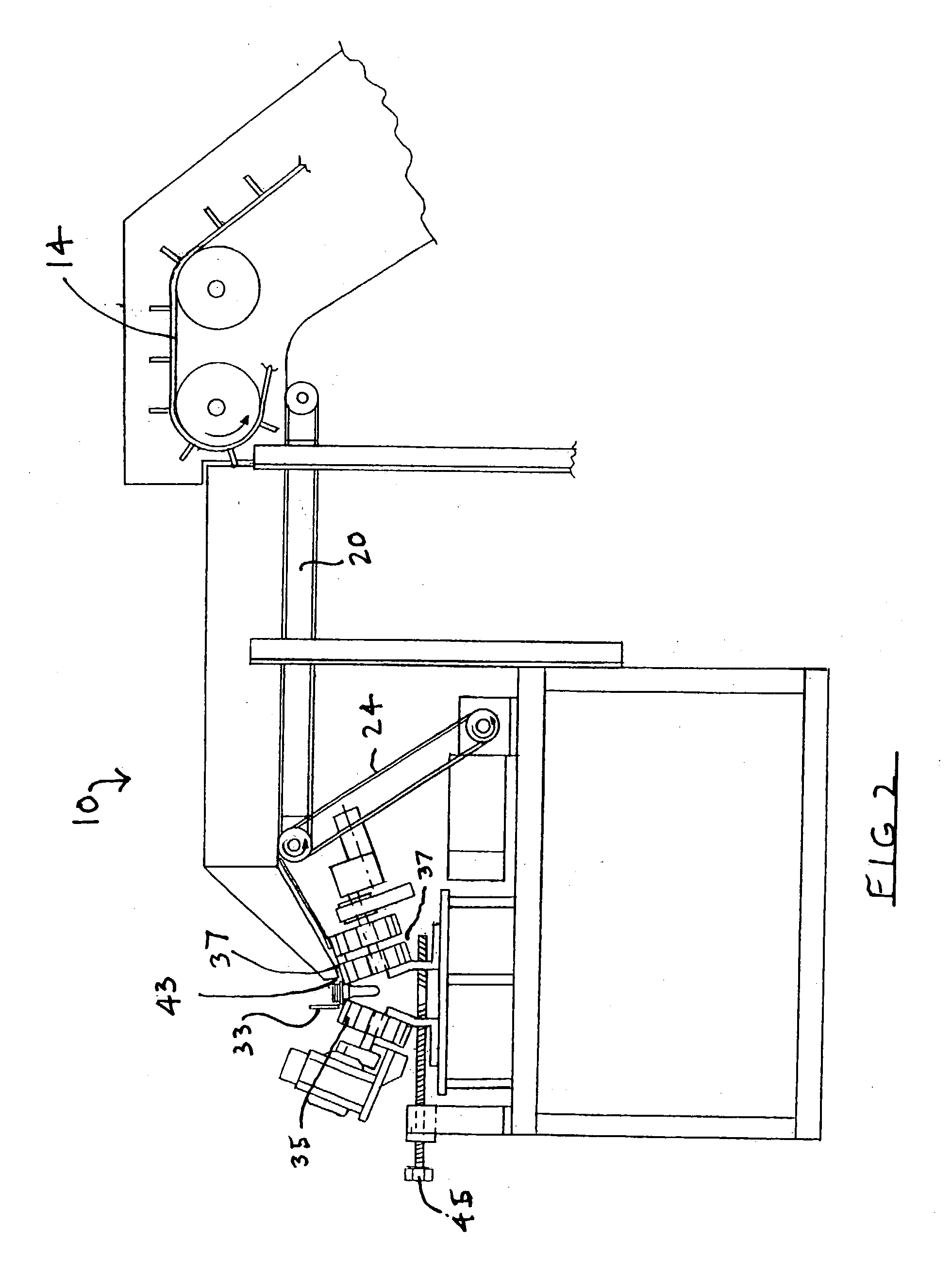

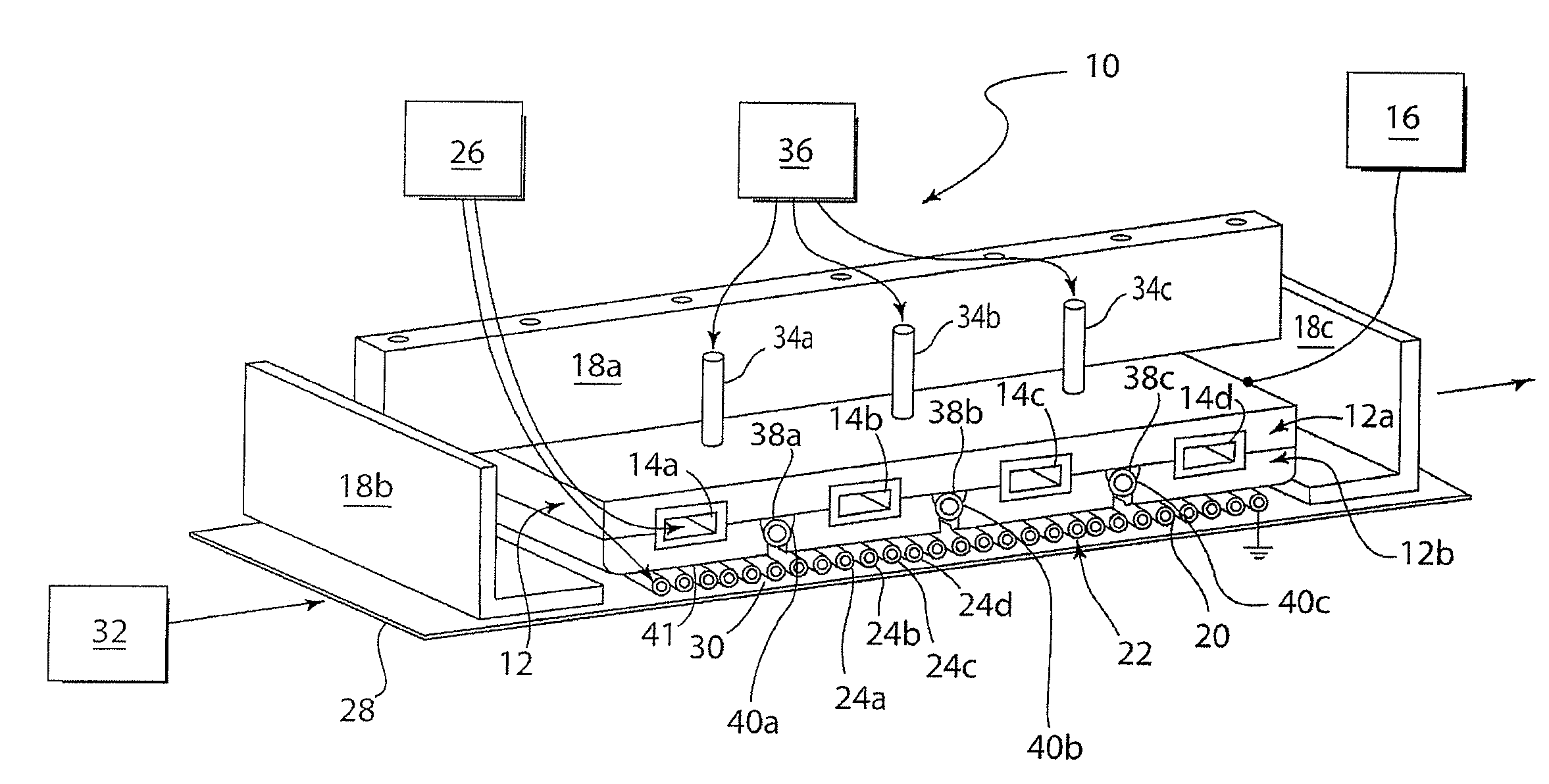

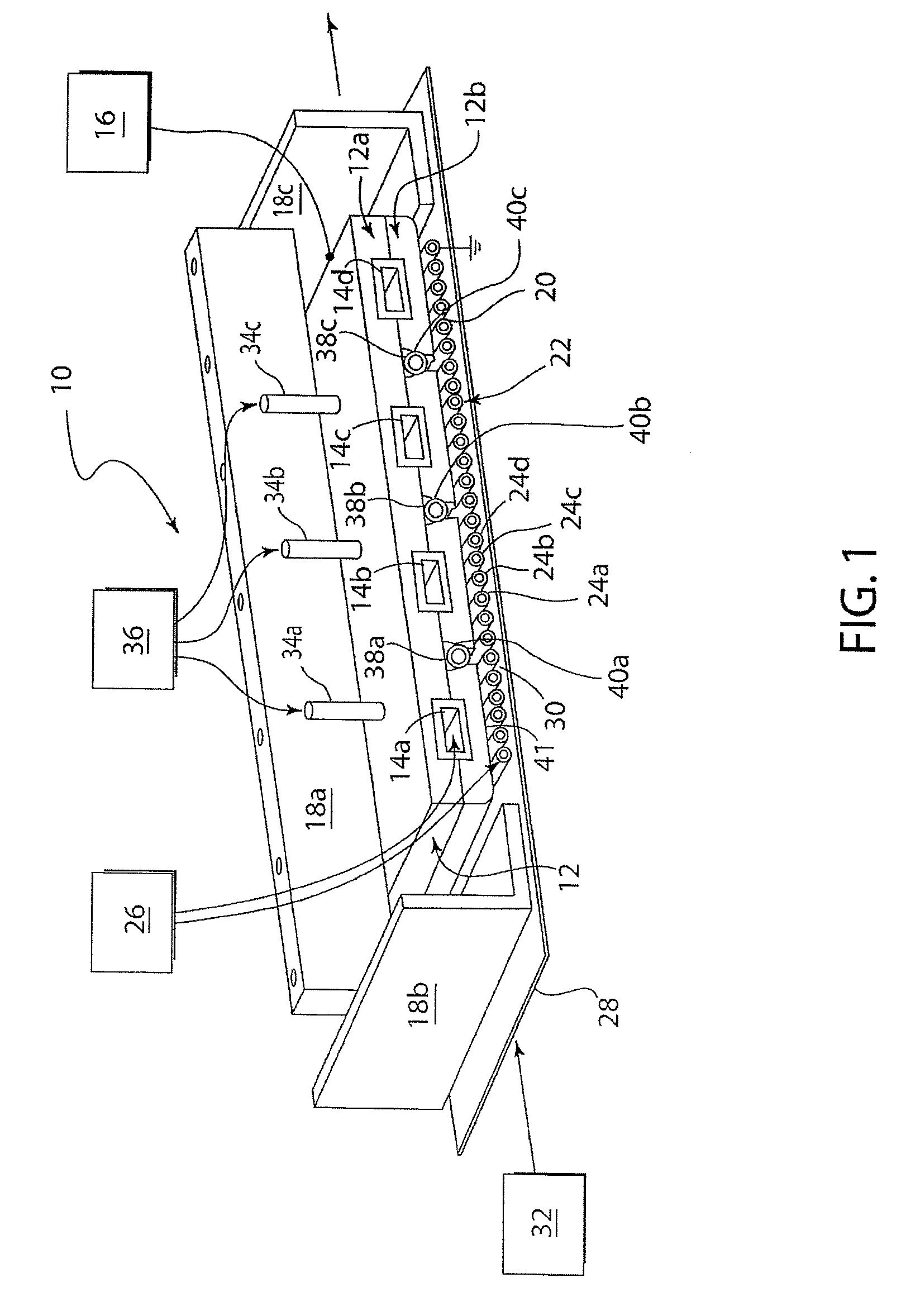

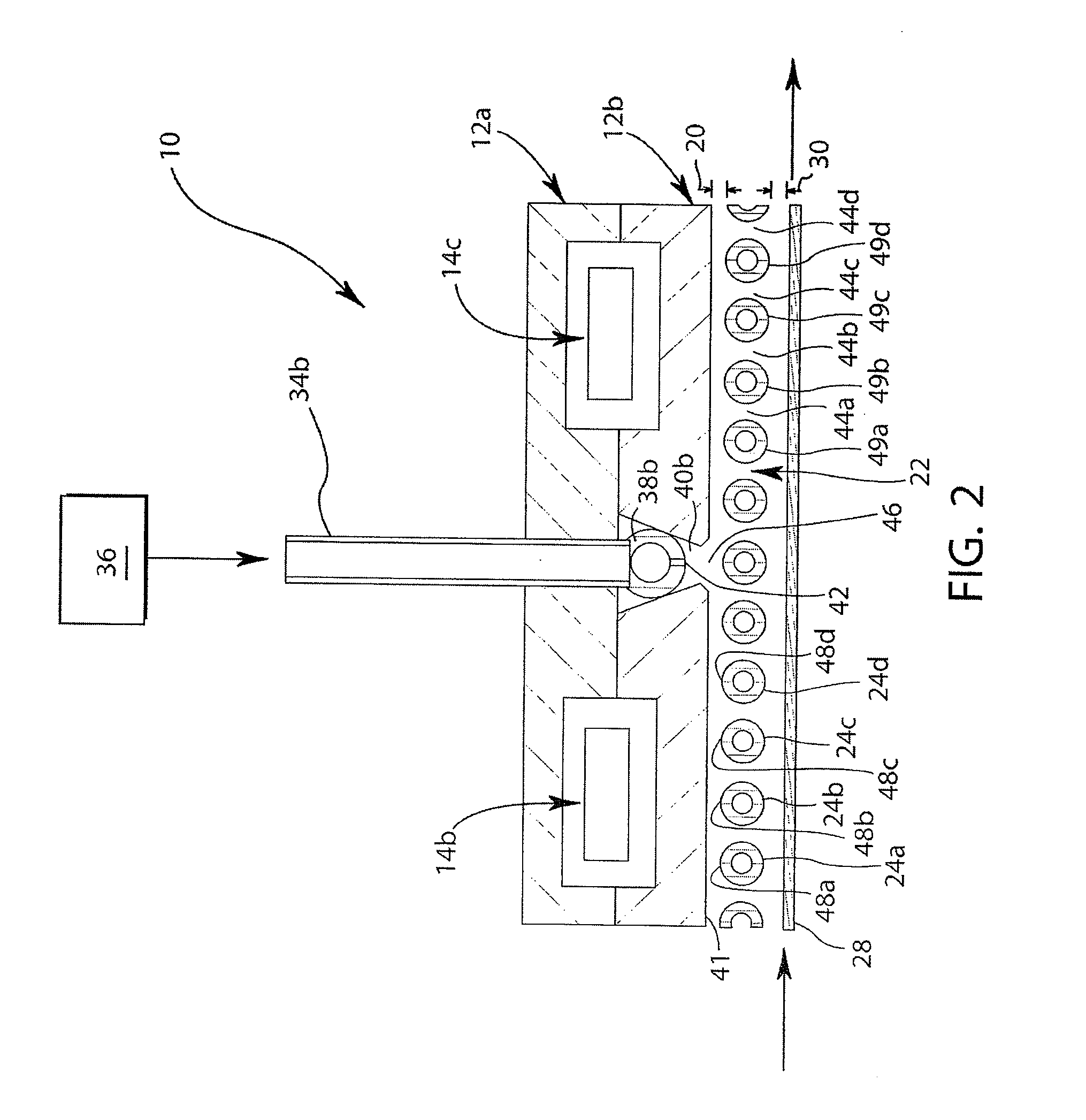

Article-orienting conveyor

A conveyor for orienting and registering articles in a preferred orientation and position for accurate downstream processing. The conveyor includes a conveyor belt running in a conveyance direction next to an orientation belt running parallel in an opposite direction or more slowly in the same direction. The orientation belt has upstanding structure, such as flights, or a high-friction surface. The conveyor belt includes article-supporting rollers on a top side. The rollers are arranged to rotate about axes oblique to the conveyance direction. The rollers also extend below the bottom side of the belt and are rotated by dynamic contact with bearing surfaces supporting the belt as it advances in the conveying direction. The rotating rollers direct conveyed articles toward a side rail. If a portion of a conveyed article extends past the side edge of the conveyor belt into the path of the orientation belt, the obstructions or high-friction surface of the slower- or oppositely-moving orientation belt strikes the conveyed articles and cause them to rotate clockwise toward an alignment of the article in the conveyance direction and into registration against the side rail at the downstream end of the conveyor. In other versions of the article-orienting conveyor, the orientation belt is replaced by a row of posts or a rotating paddle wheel that strikes conveyed articles extending past the side edge of the conveyor belt.

Owner:LAITRAM LLC

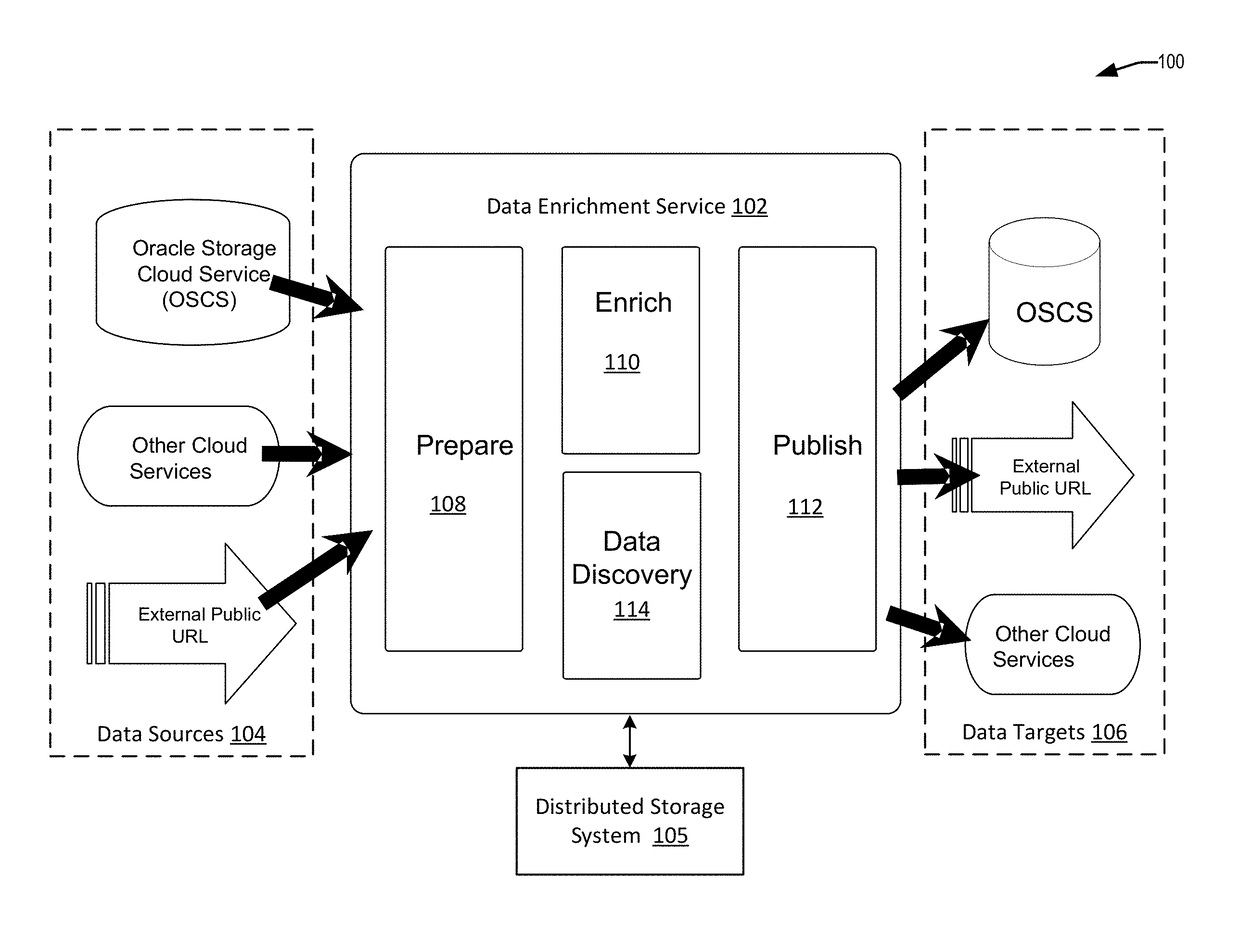

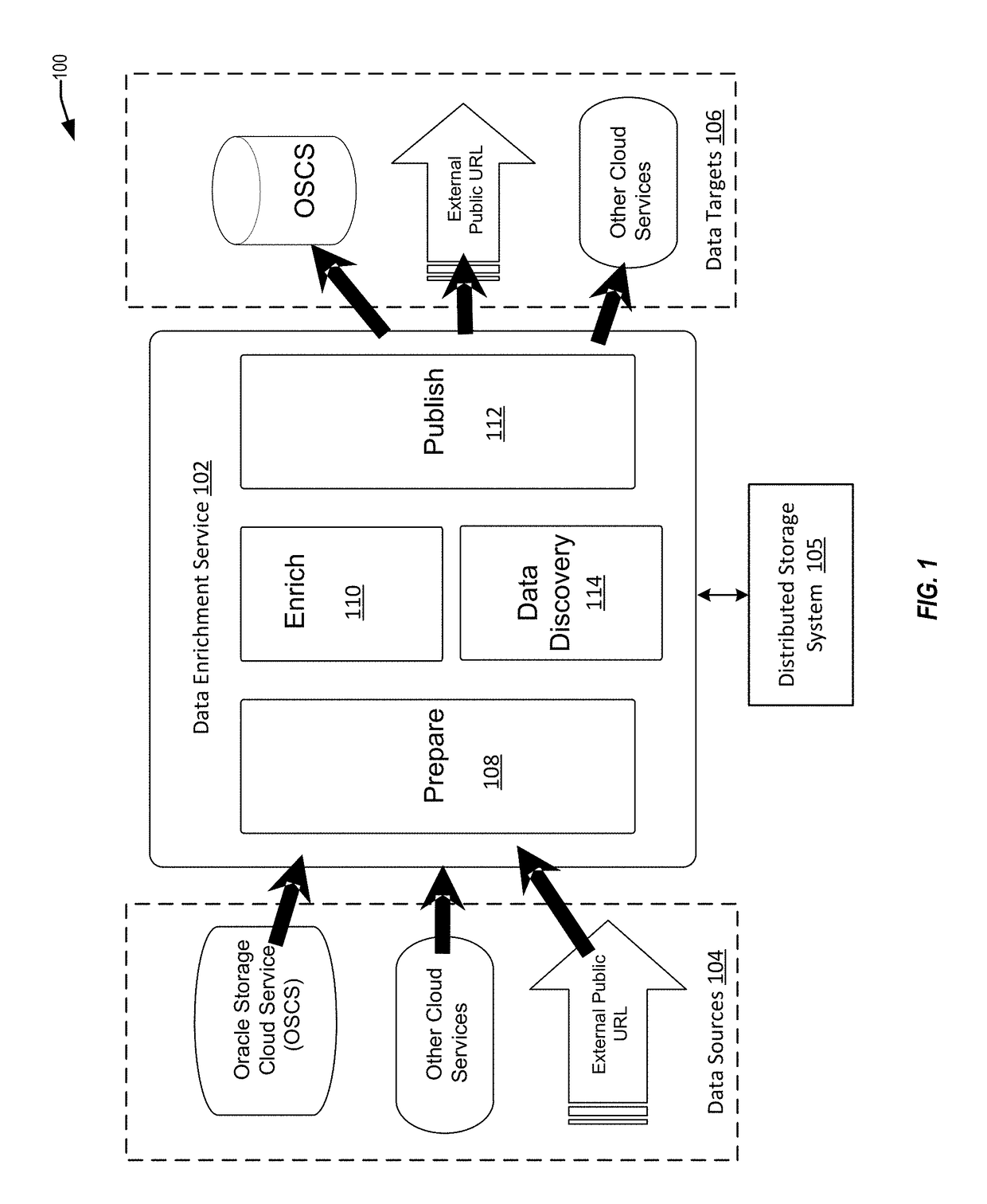

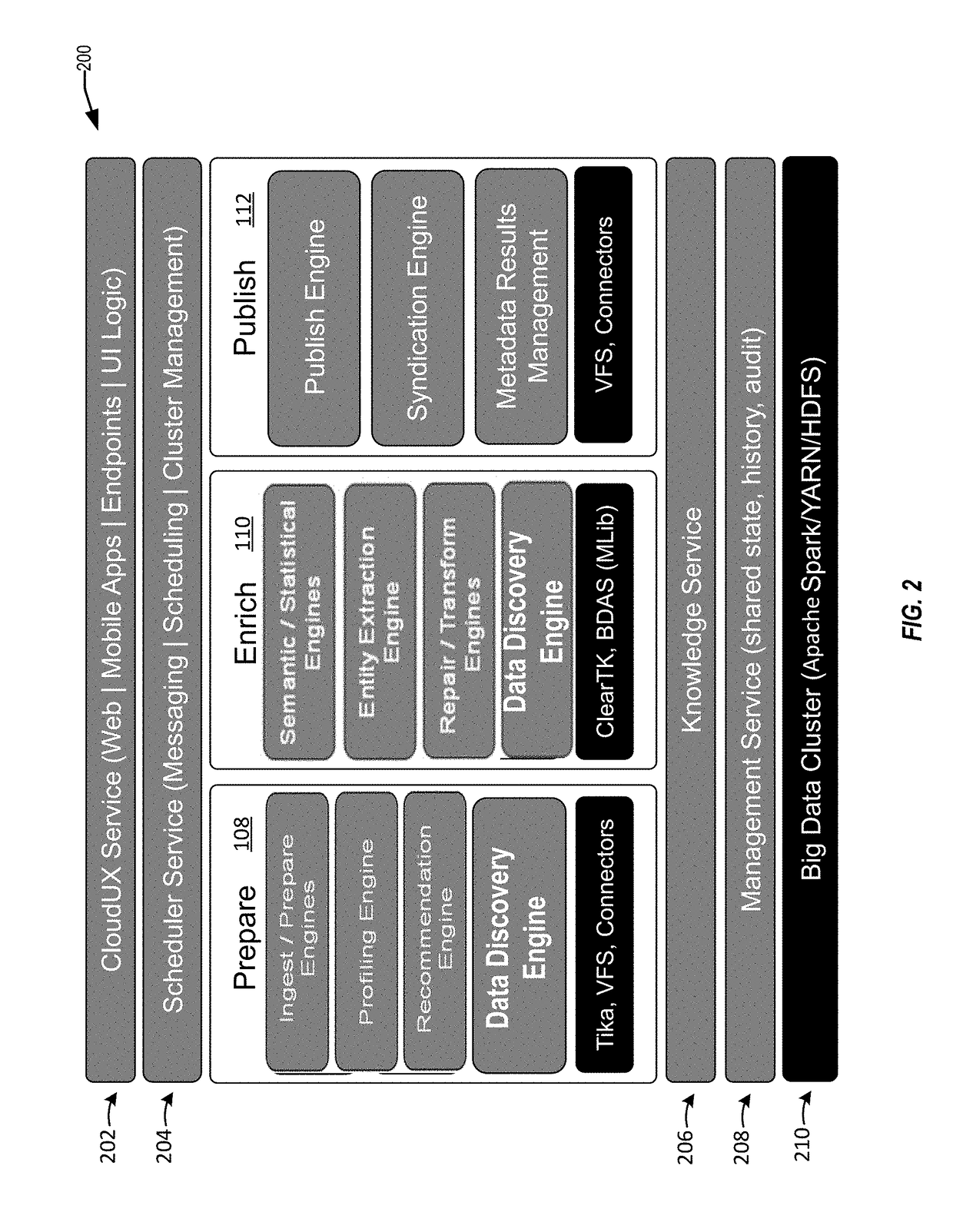

Techniques for dataset similarity discovery

ActiveUS20180074786A1Shorten the timeReduce the amount requiredDatabase management systemsComparison of digital valuesPattern recognitionData set

The present disclosure relates to techniques for analysis of data from multiple different data sources to determine similarity amongst the datasets. Determining a similarity between datasets may be useful for downstream processing of those datasets for different uses. A graphical interface may be provided to display detailed results including: a similarity prediction, data similarity prediction, column order similarity prediction, document type similarity prediction, prediction of overlapping or related columns, orphaned column prediction (e.g., a left orphaned column or a right orphaned column). Detecting similarities may be useful for leveraging prior data transformations generated for the datasets that are analyzed.

Owner:ORACLE INT CORP

Article-orienting conveyor

A conveyor for orienting and registering articles in a preferred orientation and position for accurate downstream processing. The conveyor includes a conveyor belt running in a conveyance direction next to an orientation belt running parallel in an opposite direction or more slowly in the same direction. The orientation belt has upstanding structure, such as flights, or a high-friction surface. The conveyor belt includes article-supporting rollers on a top side. The rollers are arranged to rotate about axes oblique to the conveyance direction. The rollers also extend below the bottom side of the belt and are rotated by dynamic contact with bearing surfaces supporting the belt as it advances in the conveying direction. The rotating rollers direct conveyed articles toward a side rail. If a portion of a conveyed article extends past the side edge of the conveyor belt into the path of the orientation belt, the obstructions or high-friction surface of the slower- or oppositely-moving orientation belt strikes the conveyed articles and cause them to rotate clockwise toward an alignment of the article in the conveyance direction and into registration against the side rail at the downstream end of the conveyor. In other versions of the article-orienting conveyor, the orientation belt is replaced by a row of posts or a rotating paddle wheel that strikes conveyed articles extending past the side edge of the conveyor belt.

Owner:LAITRAM LLC

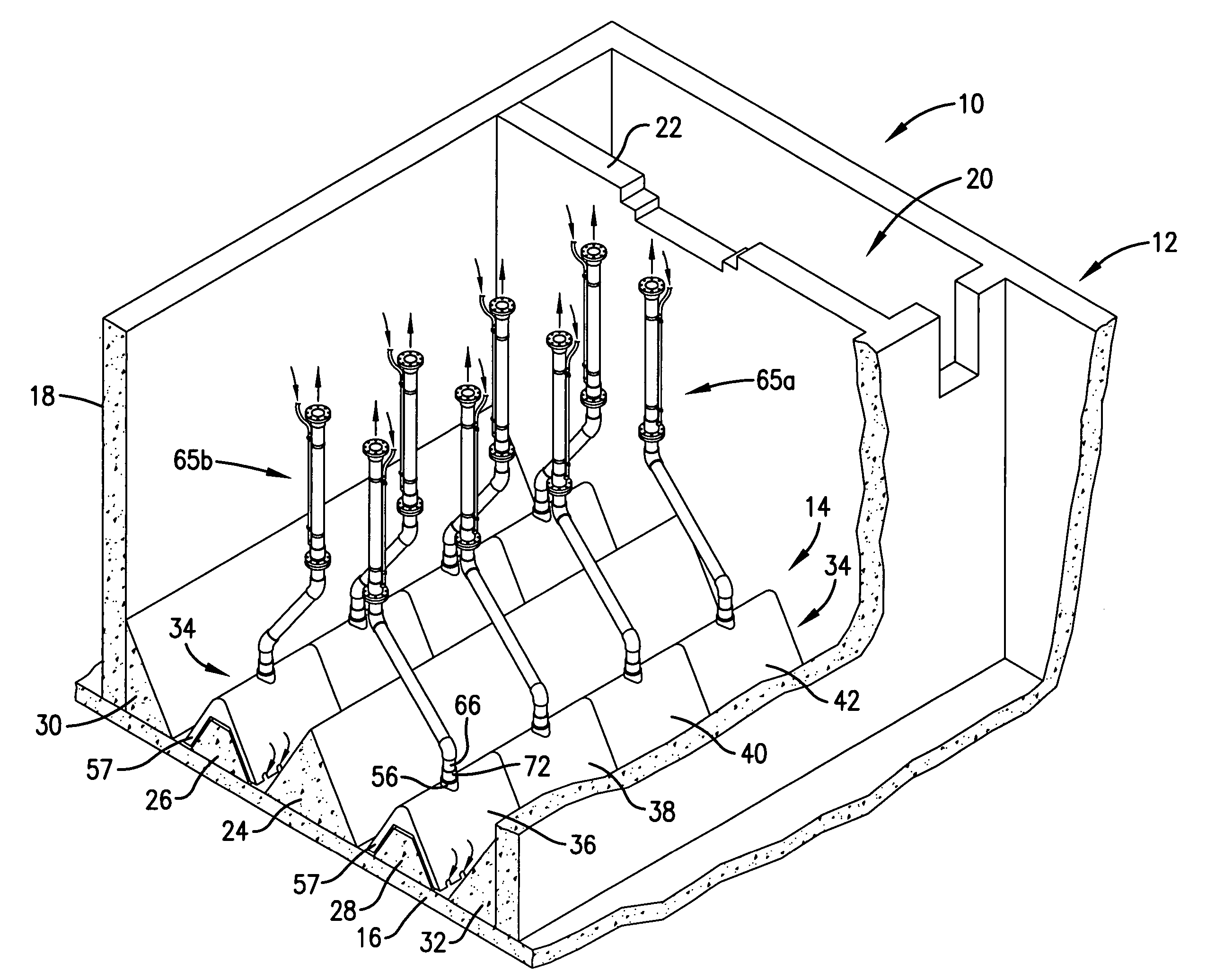

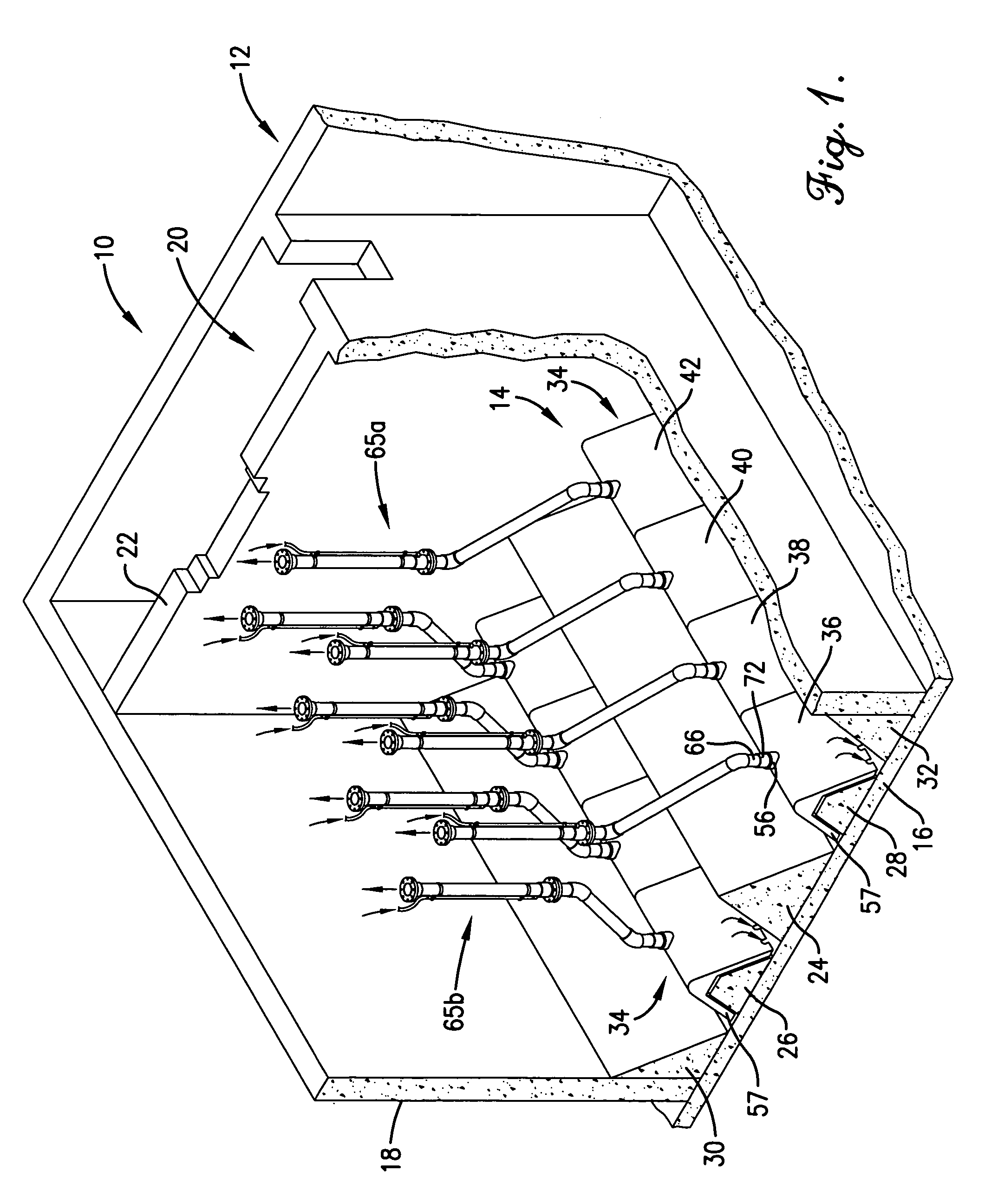

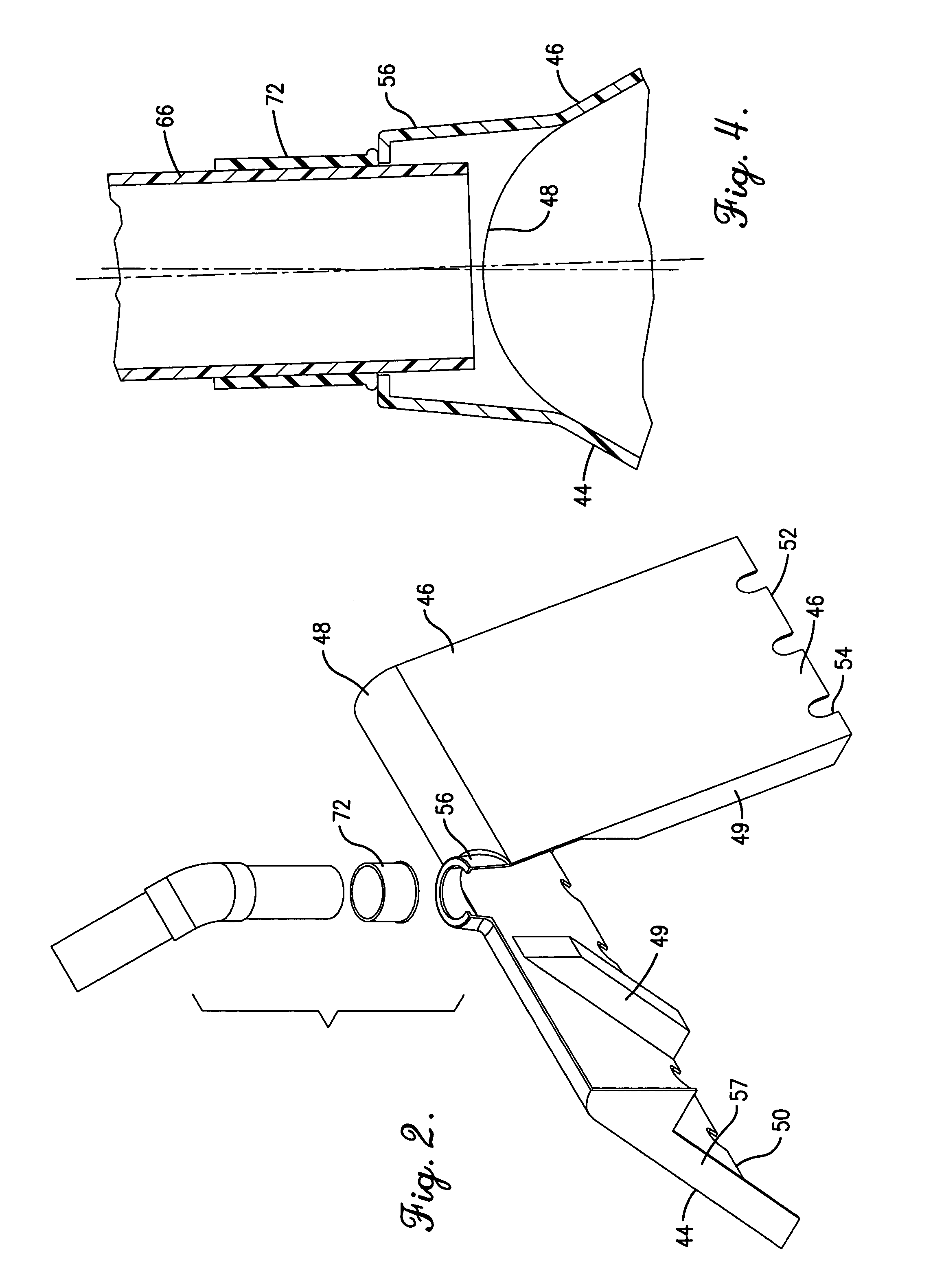

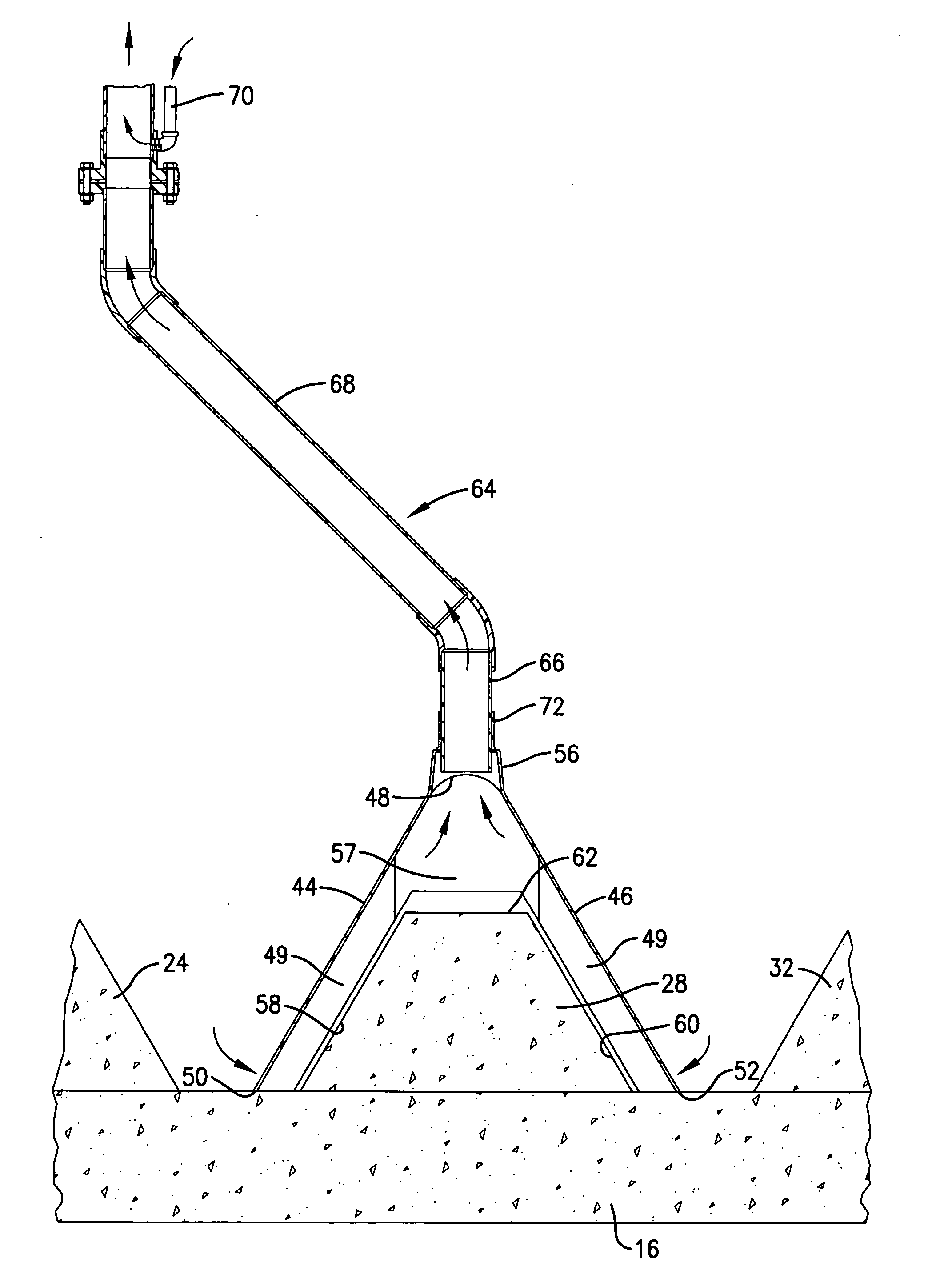

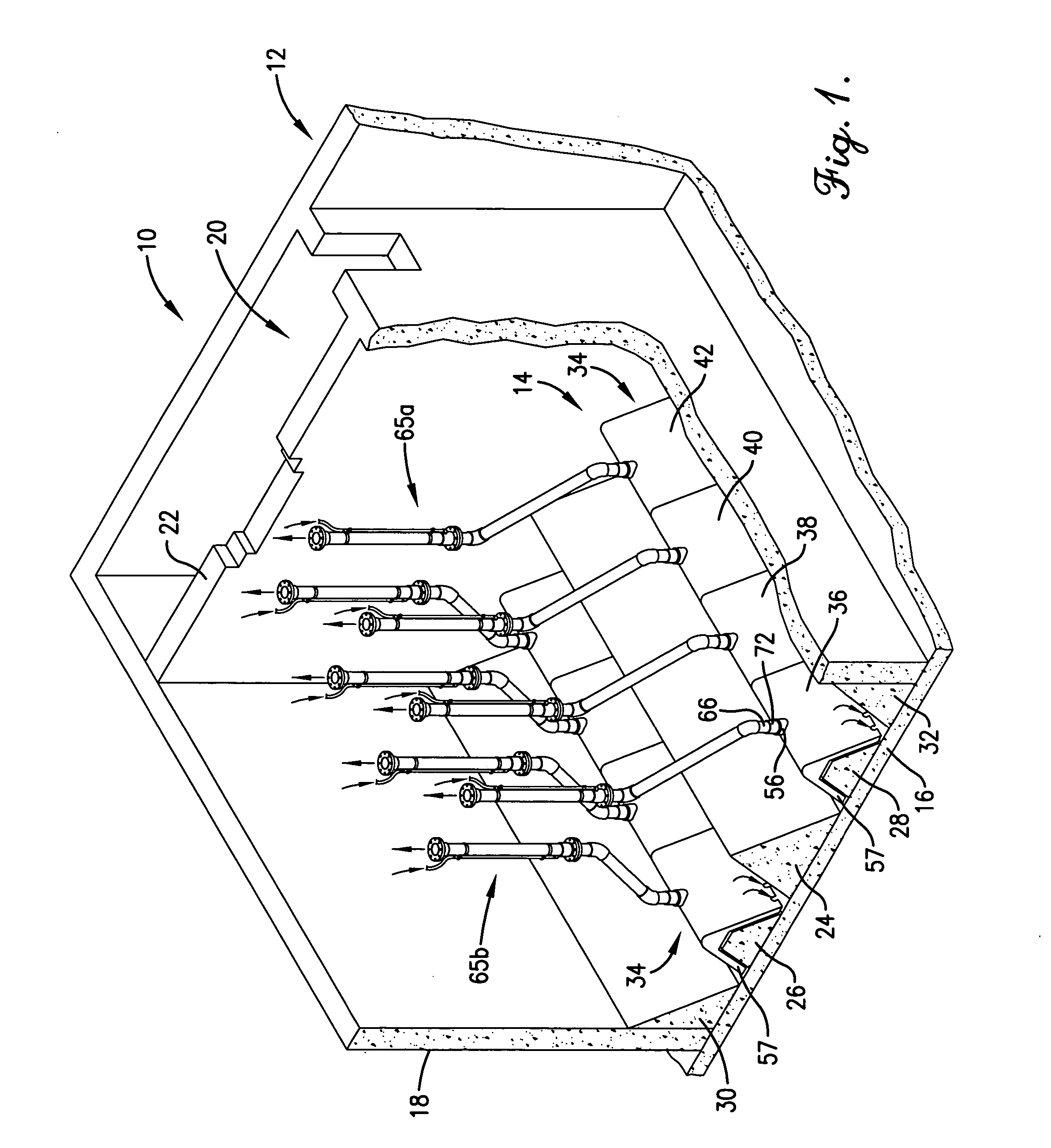

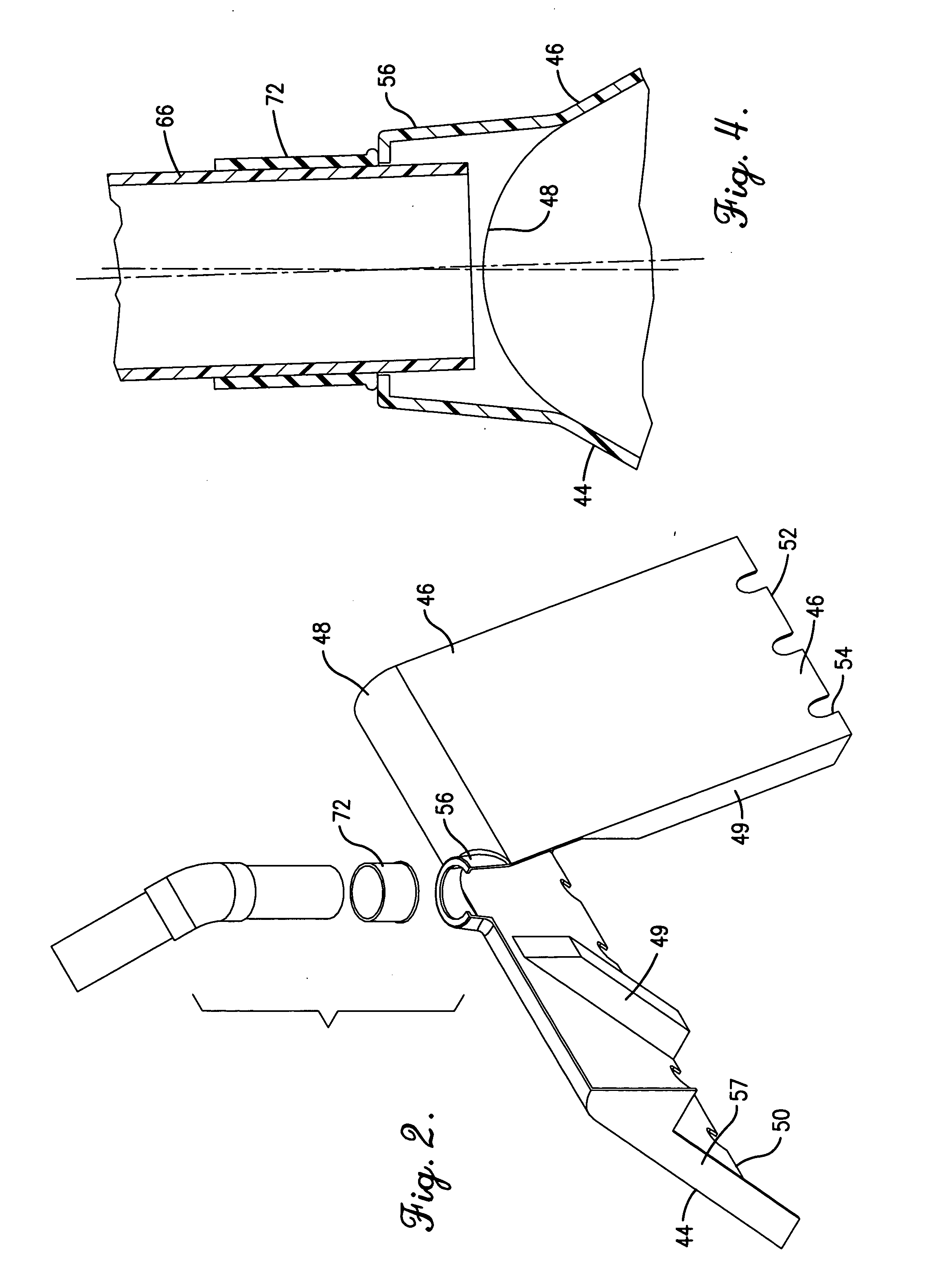

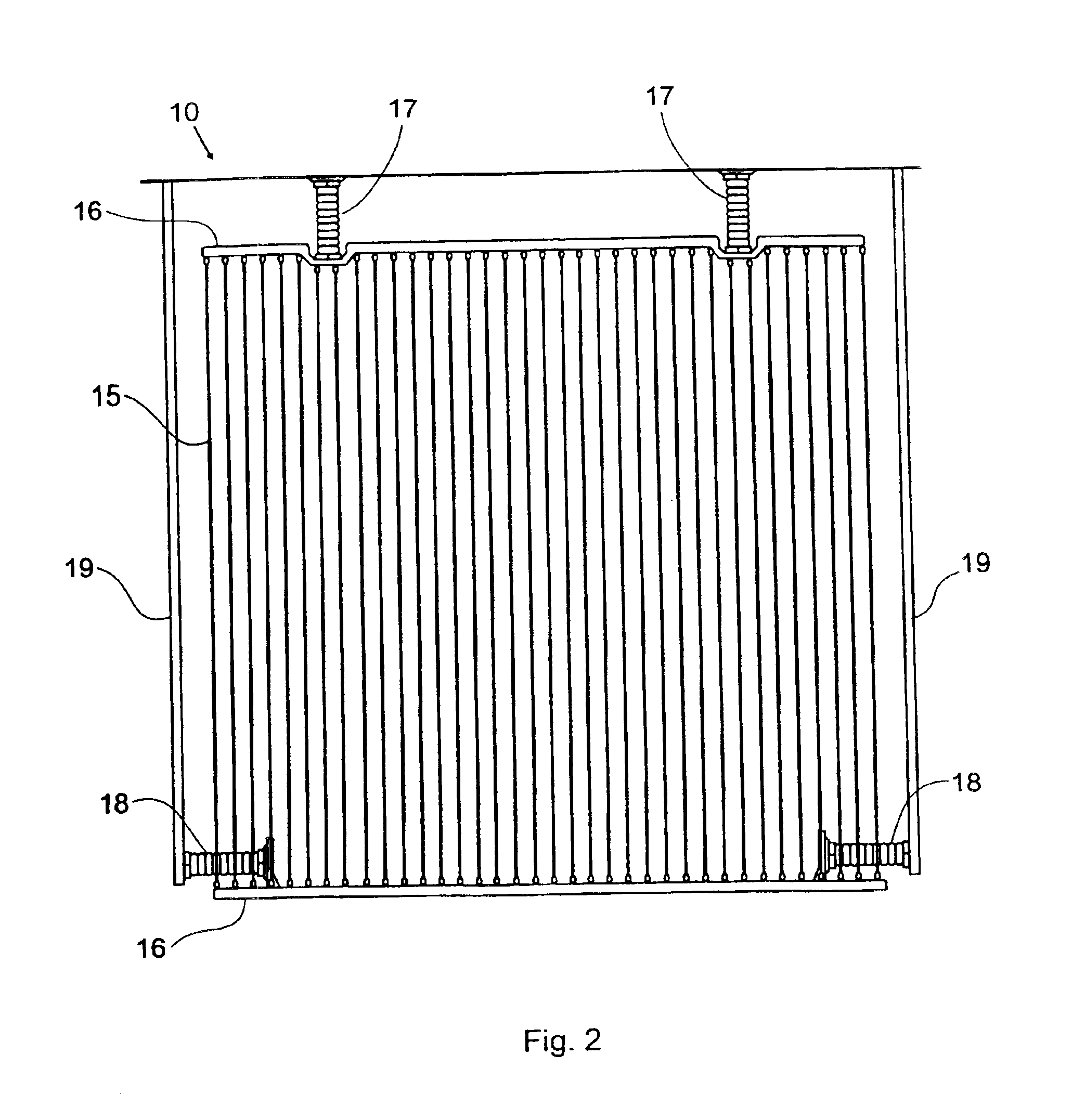

Sedimentation removal assembly for flow-through sedimentary tank

ActiveUS7284670B2Settling tanks feed/dischargeWater/sewage treatmentDownstream processingEngineering

Solids removal assemblies (14) adapted for use in flow-through or batch-type sedimentation tanks (12) are provided which increase the efficiency of solids removal and eliminate physical scraping devices common with such sedimentation tanks. The preferred removal assemblies (14) include an elongated hood (34) disposed over a cooperating and complementally configured fill structure (26,28), which fills the majority of the internal volume of the hood (34). The hood (34) includes converging sidewalls (44, 46) having lower most inlet openings (54) and spaced, tubular outlets (56) adjacent the apex thereof. Outlet pipes (64) are operably coupled with each of the hood outlets (56) for suction withdrawal of waste water-solids suspensions which are then conveyed for downstream processing. The hood (34) and fill structure (26, 28) cooperatively define restricted flow paths for the waste water-solids suspensions, and assist in the creation of relatively high velocity movement of the suspensions to prevent bridging or clogging by collective solids adjacent the bottom of the tanks (12).

Owner:AERO MOD

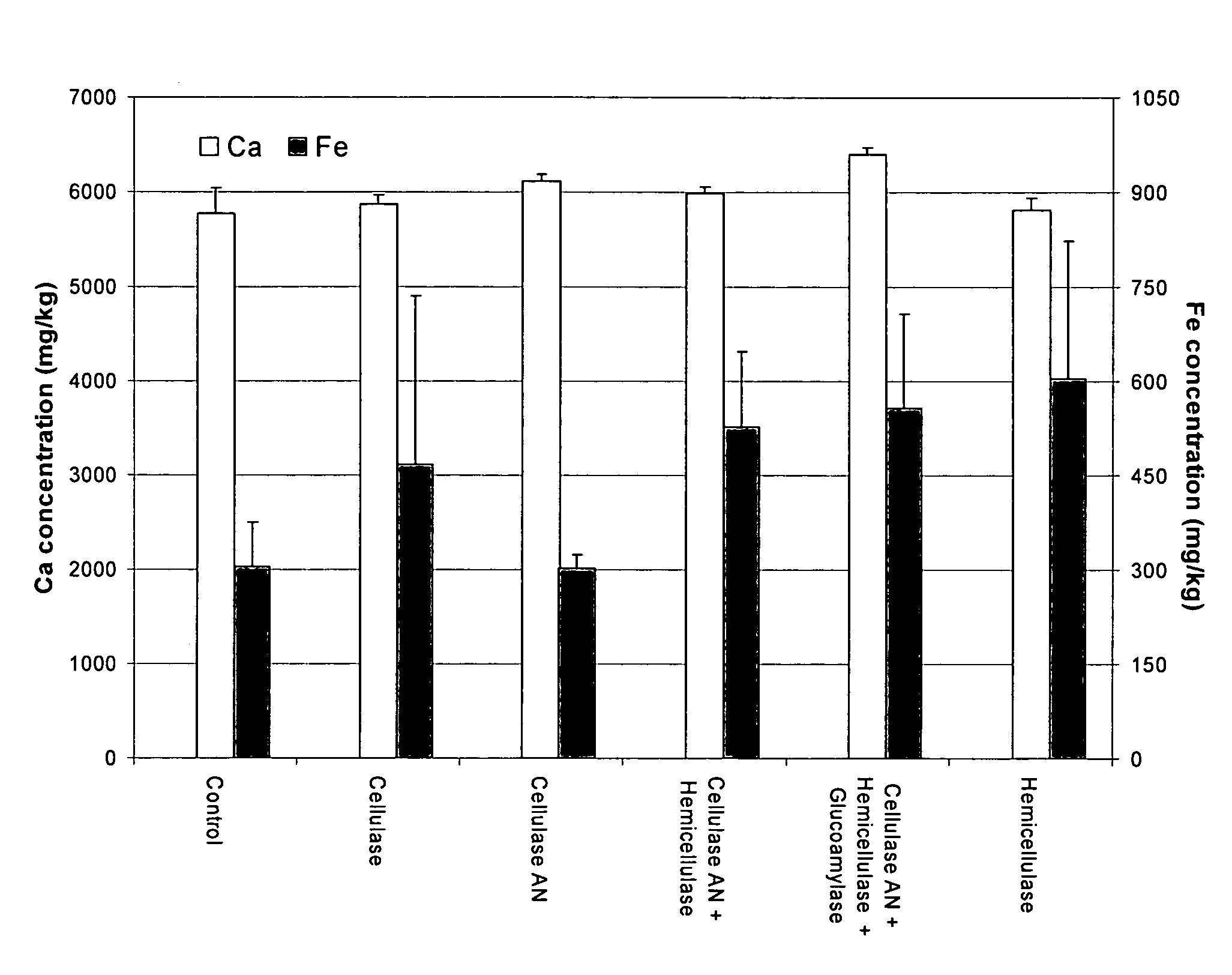

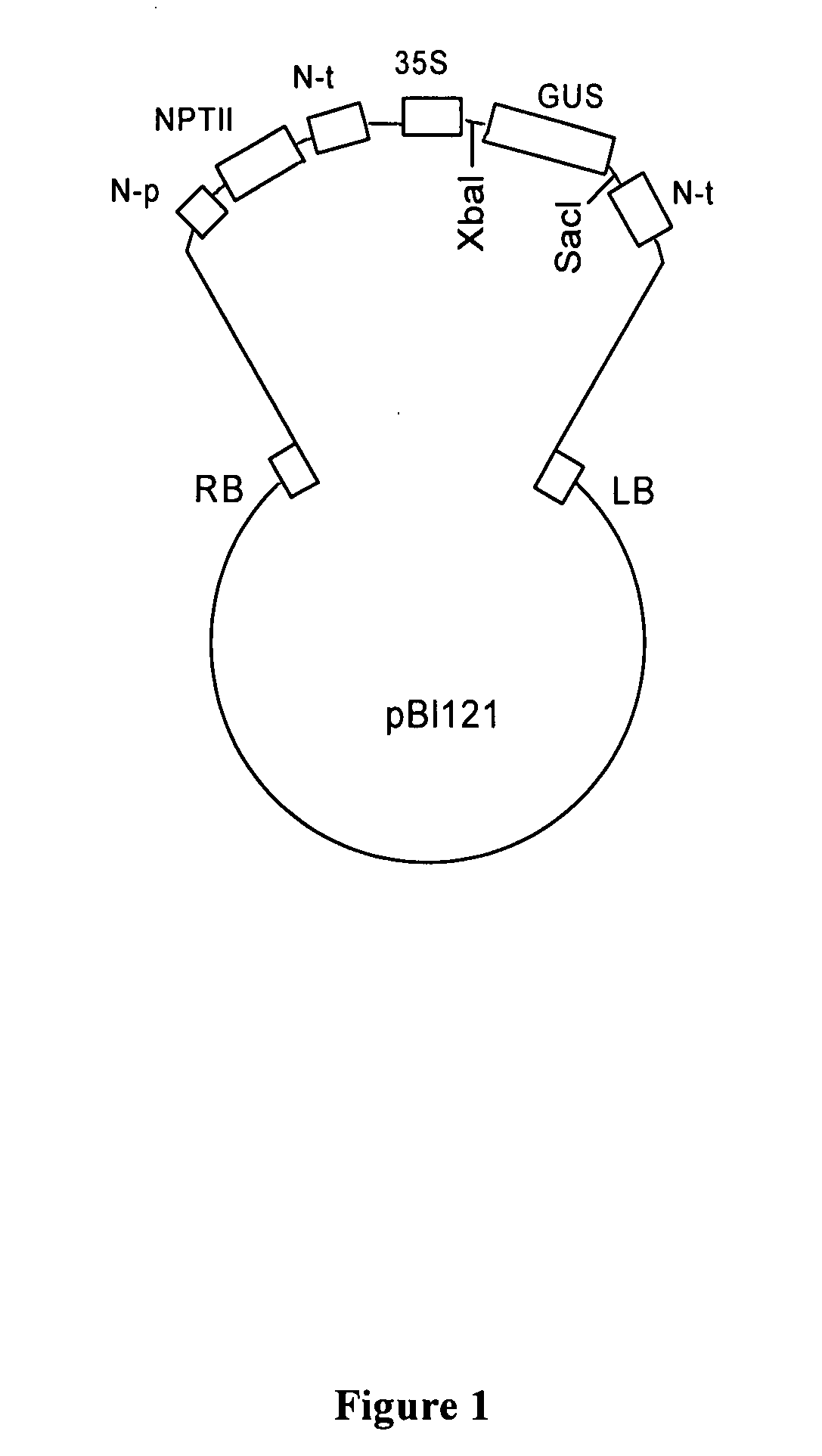

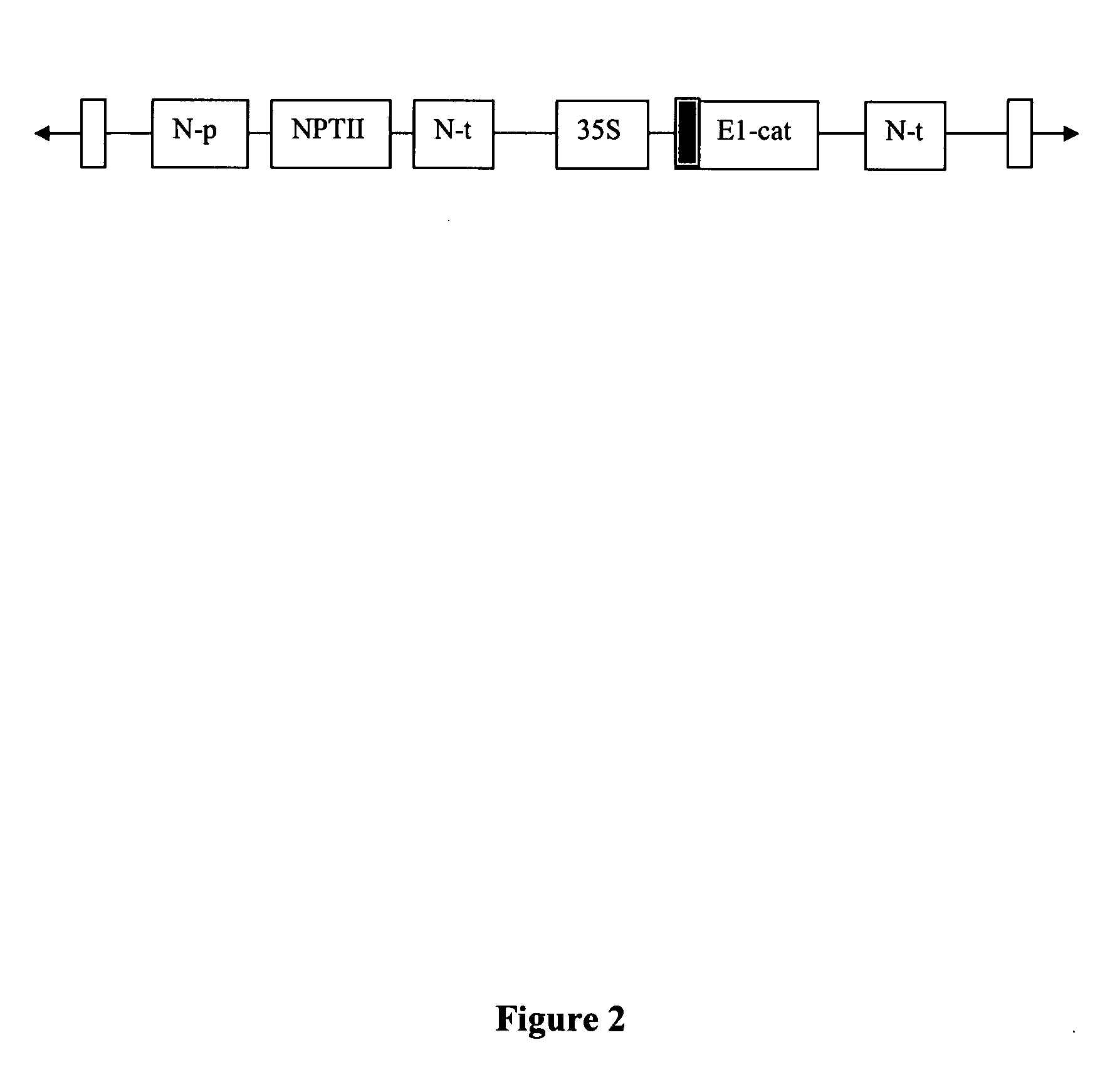

Energy crops for improved biofuel feedstocks

InactiveUS20070250961A1Low costIncrease productionBryophytesSugar derivativesDownstream processingBiofuel feedstock

The present invention is directed to improved systems and methods for reducing costs and increasing yields of cellulosic ethanol. In particular, the present invention provides plants genetically transformed for increased biomass, expression of lignocellulolytic enzymes, and simplification of harvesting and downstream processing. Also provided are methods for using these transgenic plants in the production of clean, marketable feedstocks for production of renewable fuels and chemicals and in other applications including phytoremediation.

Owner:EDENSPACE SYST CORP

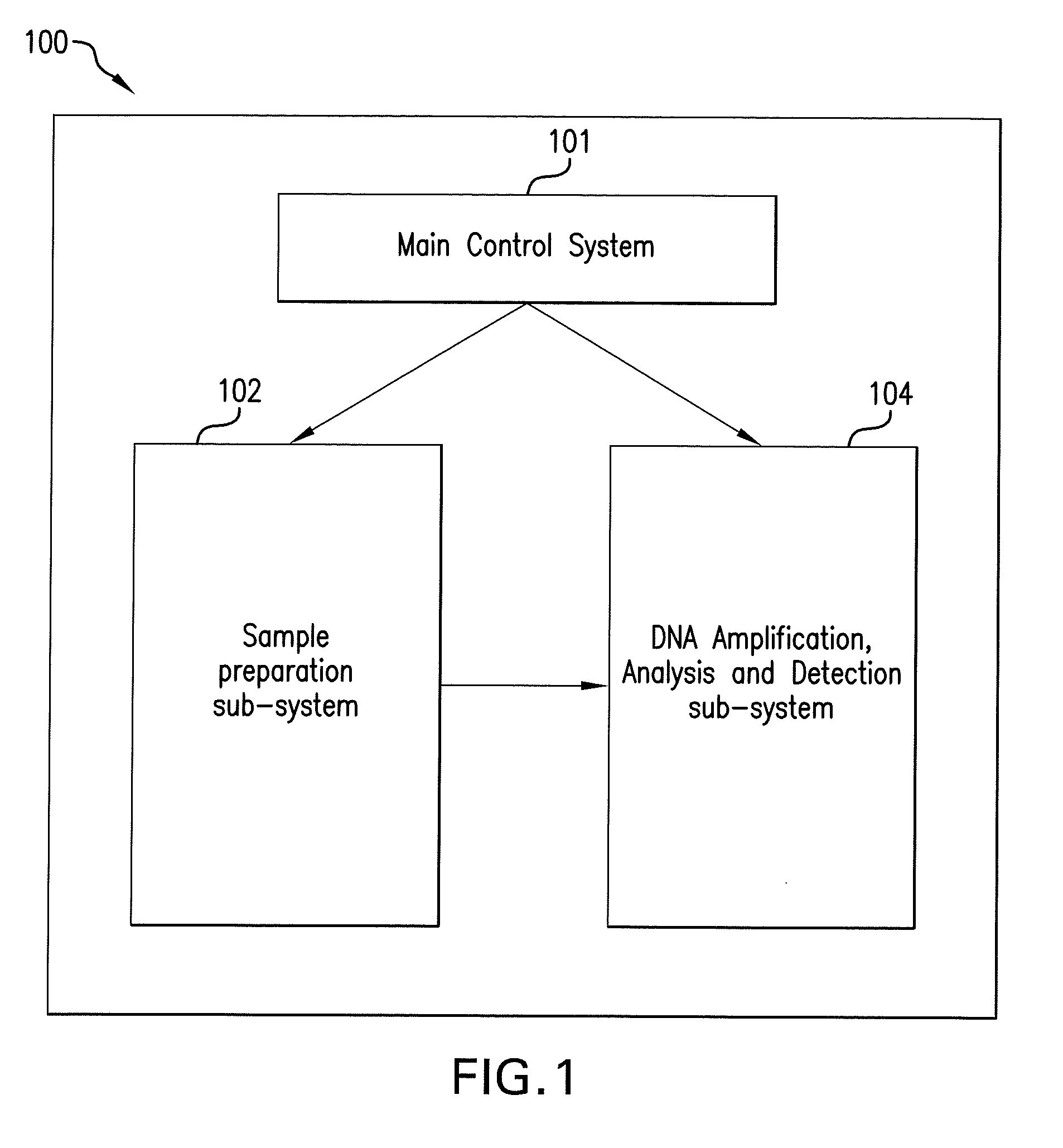

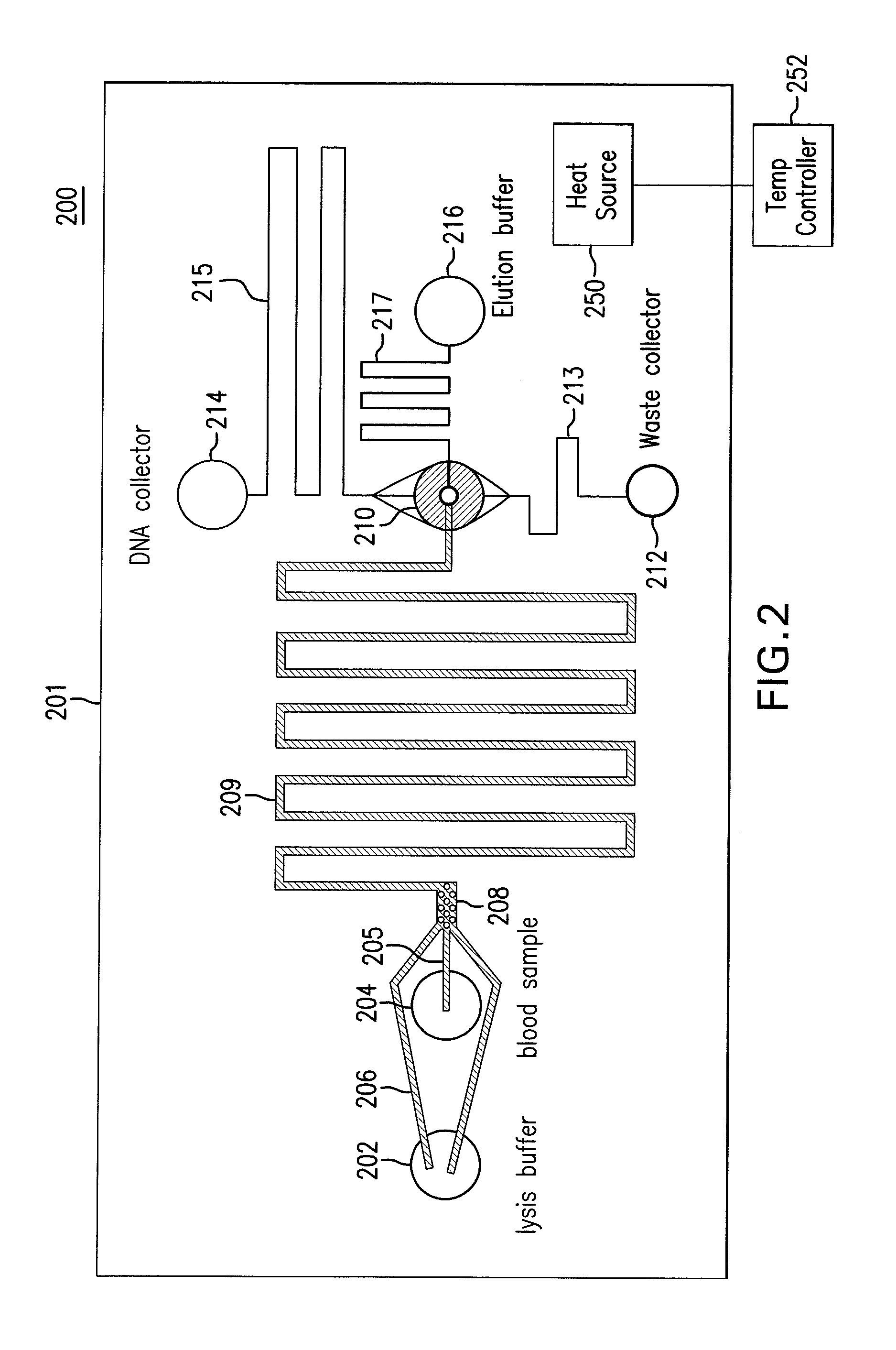

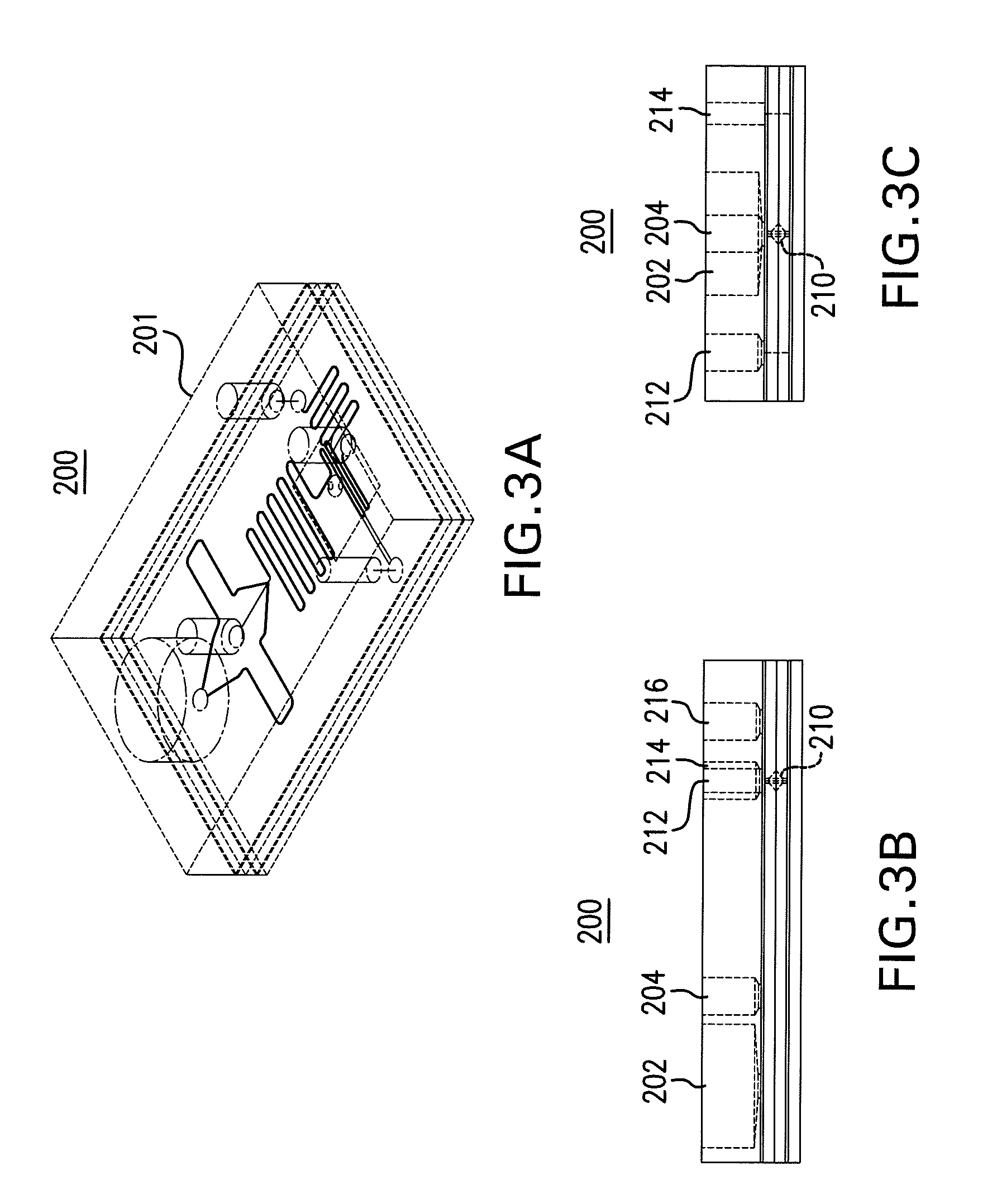

Methods and Systems for Microfluidic DNA Sample Preparation

InactiveUS20100021910A1Easy to disassembleBioreactor/fermenter combinationsHeating or cooling apparatusDownstream processingMicrofluidics

The present invention relates to methods and systems for microfluidic DNA sample preparation. More specifically, embodiments of the present invention relate to methods and systems for the isolation of DNA from patient samples on a microfluidic device and use of the DNA for downstream processing, such as performing amplification reactions and thermal melt analysis on the microfluidic device.

Owner:CANON US LIFE SCIENCES INC

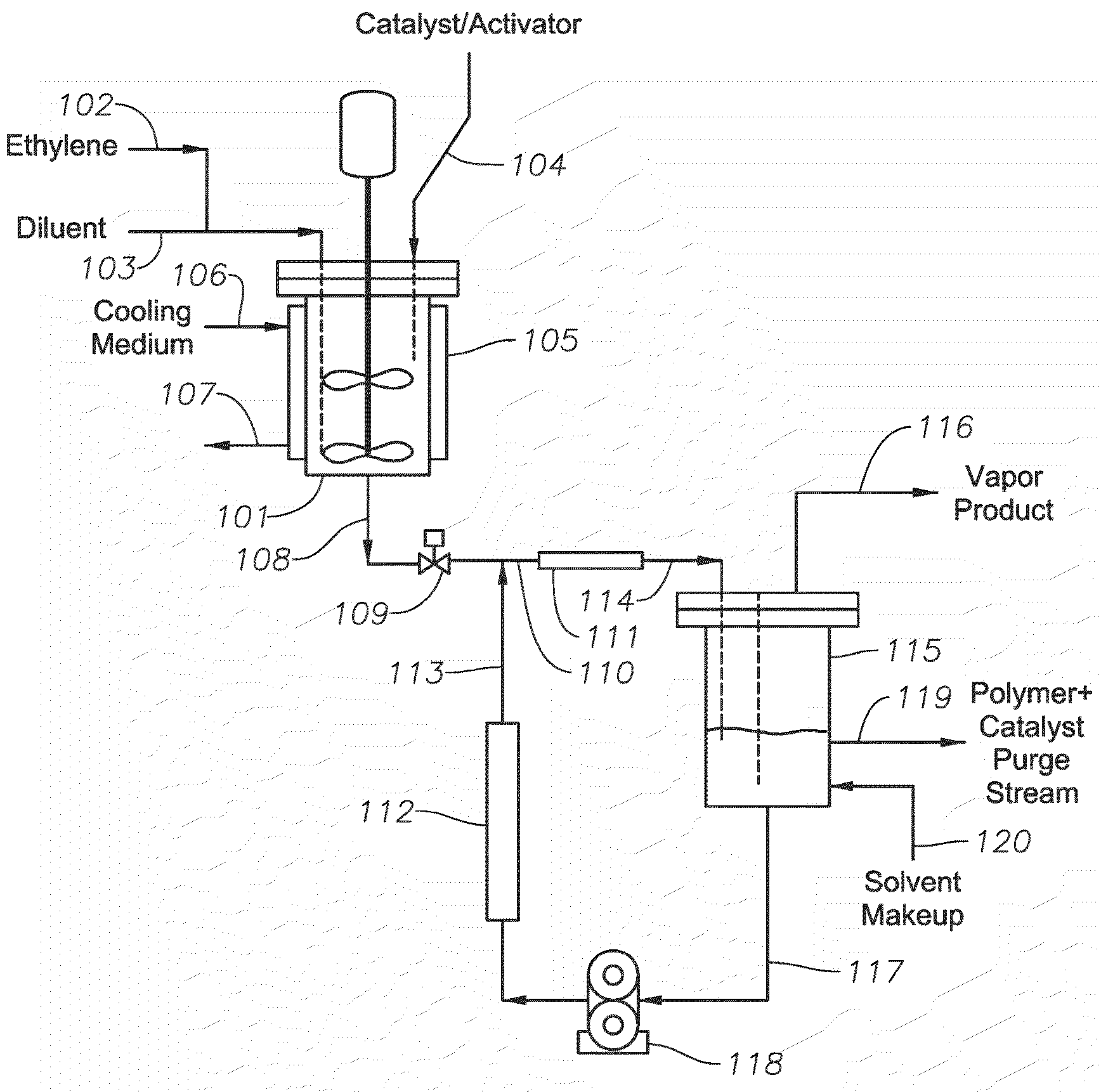

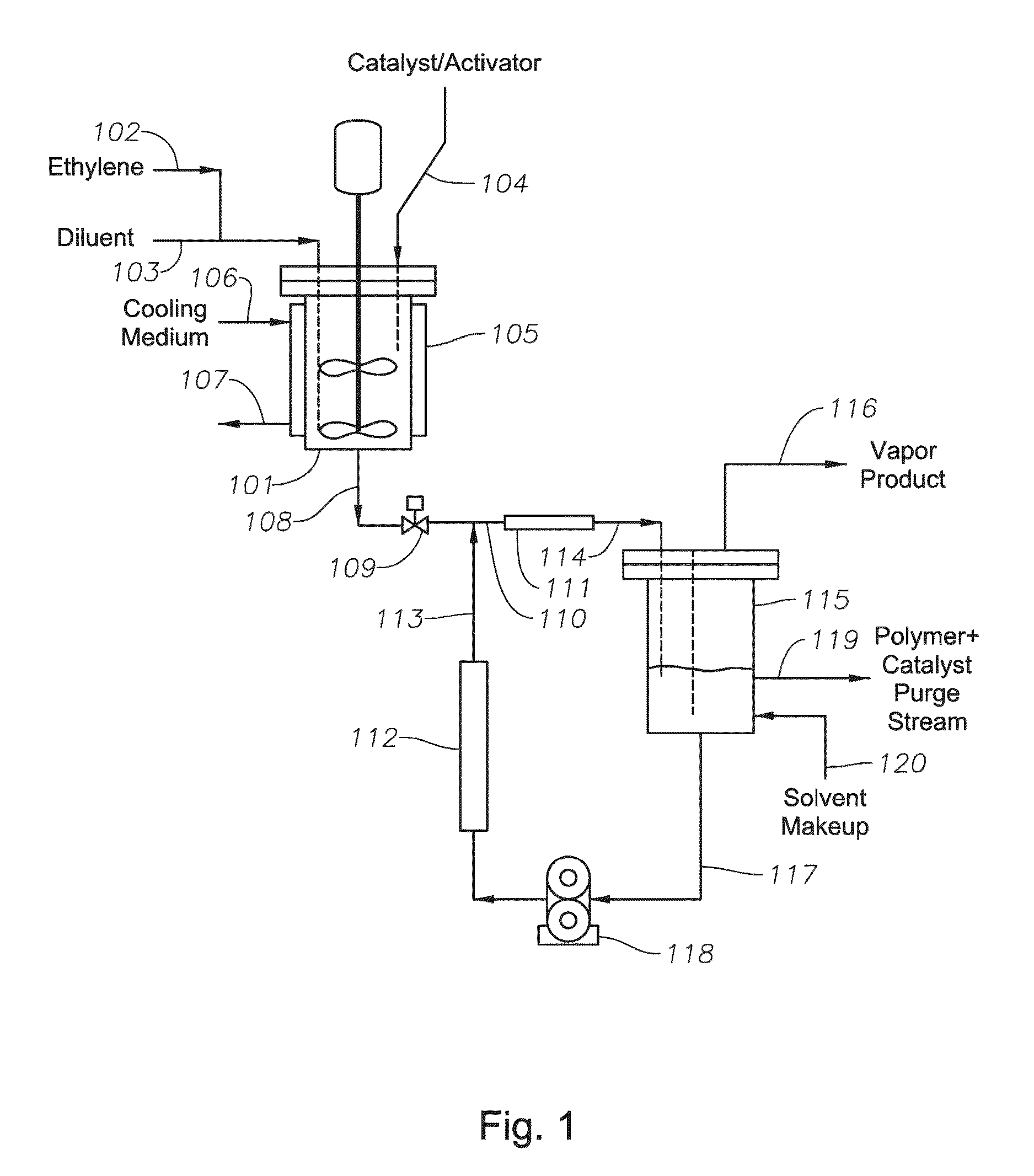

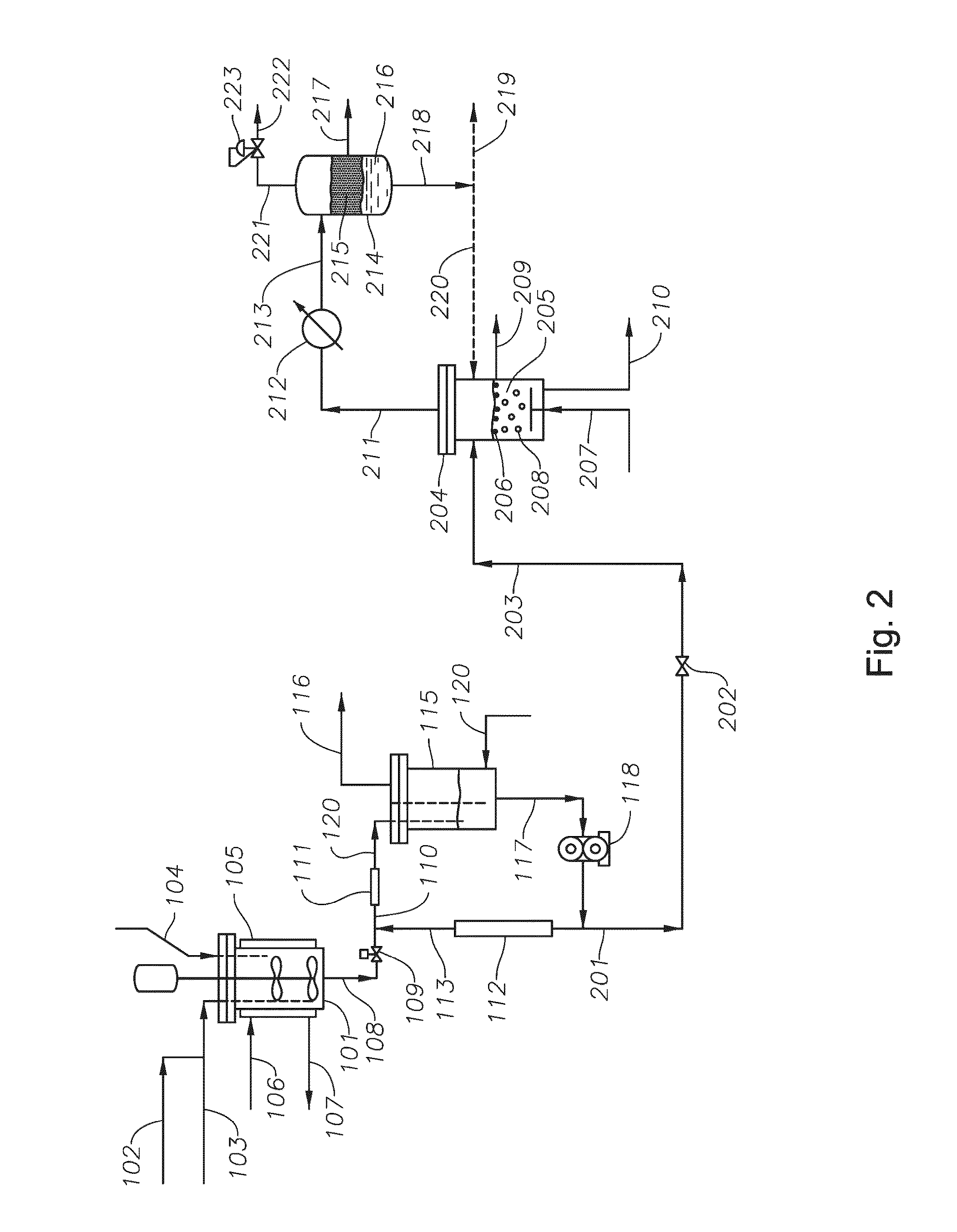

System and method for selective trimerization

ActiveUS8658750B2Distillation purification/separationMolecular sieve catalystsReactor systemDownstream processing

Disclosed herein is a method for separating from the reactor effluent of an olefin oligomerization procedure those catalyst materials and polymeric by-products which can cause difficulties in the downstream processing of such effluent. Polymer by-products and catalyst in the effluent are separated from reaction products by flash vaporization utilizing an in-situ hot solvent which is contacted with the effluent and serves as the heating medium to promote this flash vaporization step. Subsequent processing of a liquid portion of the effluent which is left after flash vaporization involves recovery of catalyst and polymeric by-products therefrom in a steam stripping vessel. Also disclosed is a multiple reactor system which can be used for continuous trimerization of ethylene to 1-hexene while at the same time washing polymeric by-products from one of the reactors in the series using a wash oil solvent.

Owner:EXXONMOBIL CHEM PAT INC

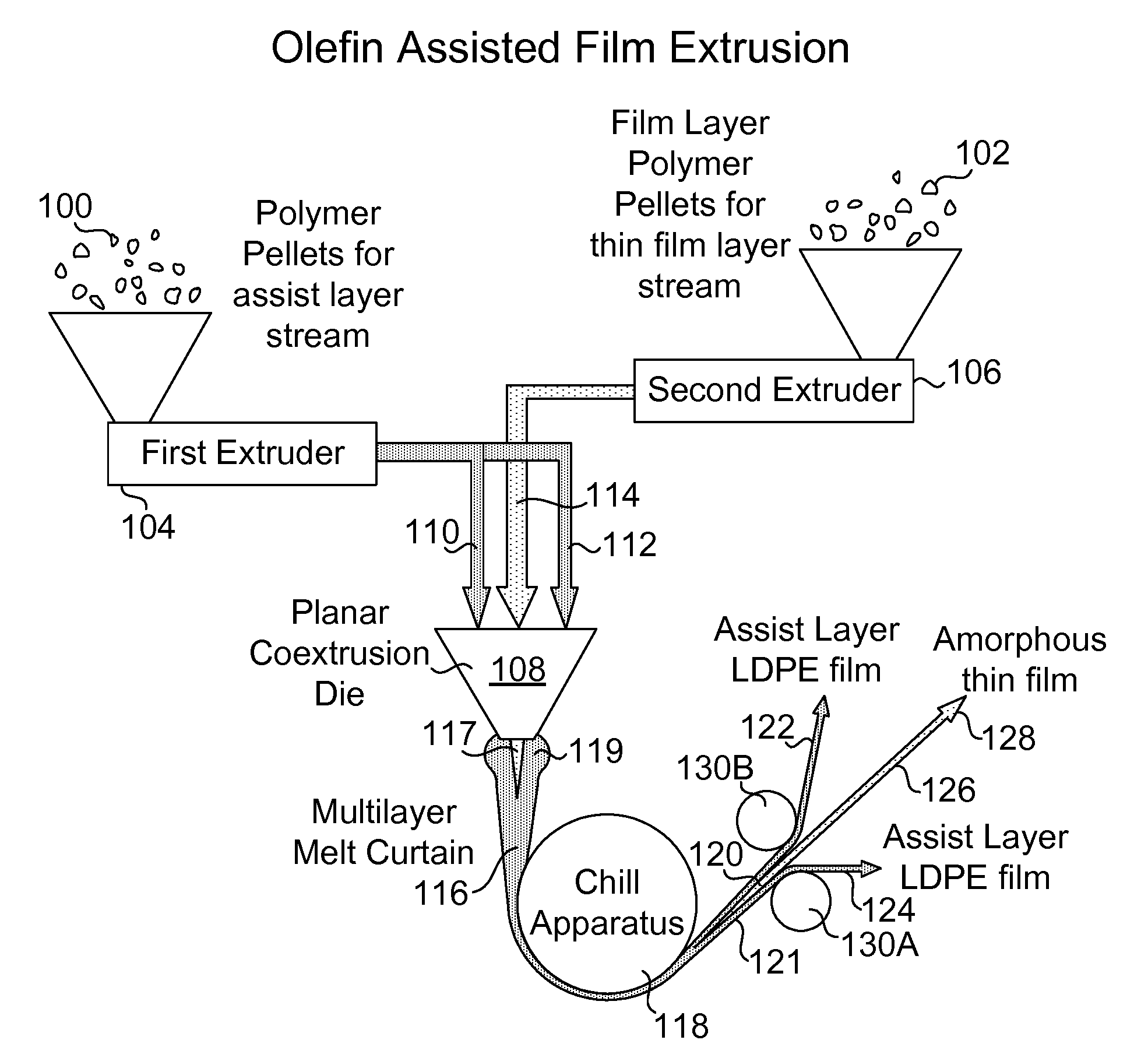

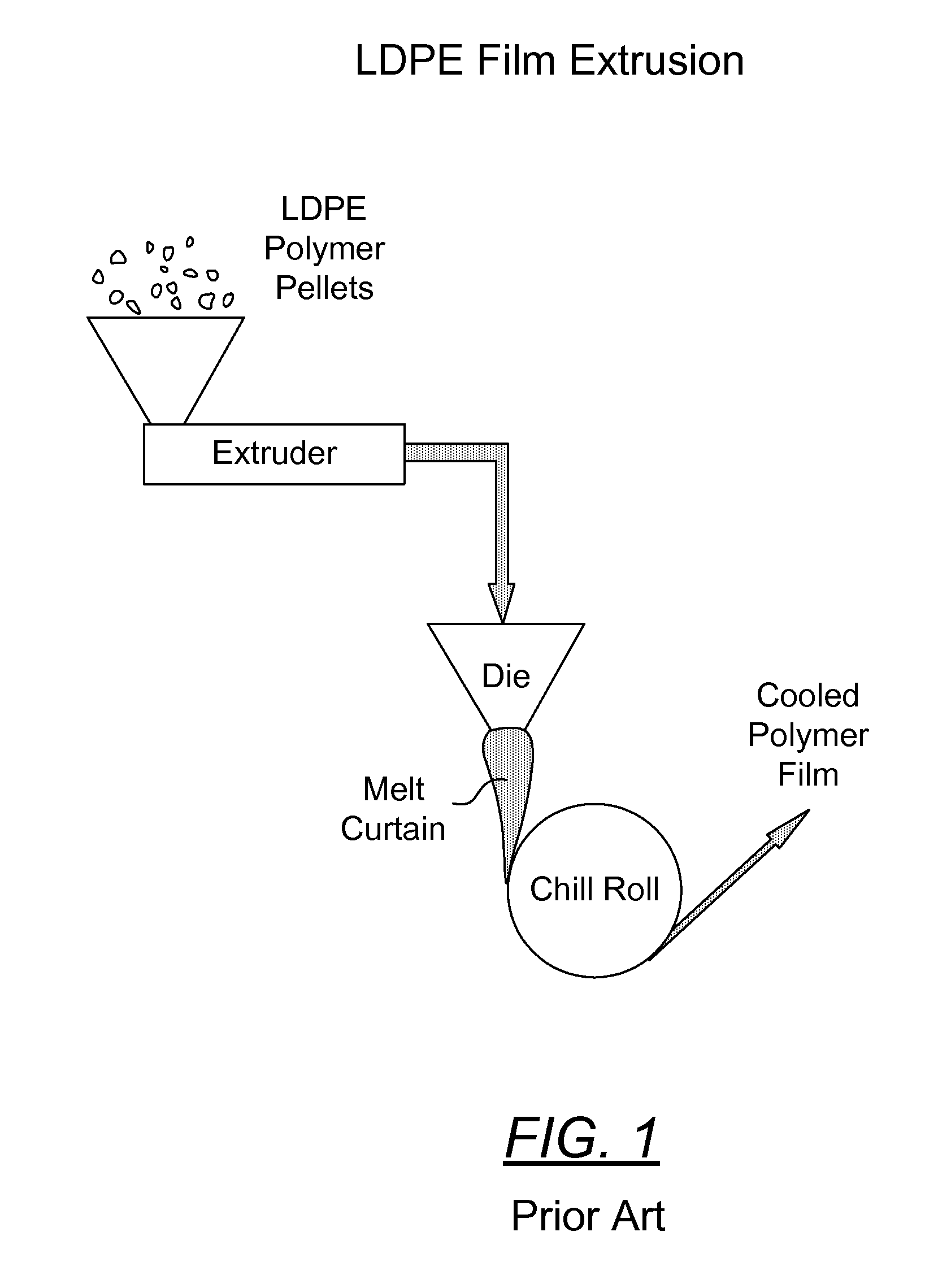

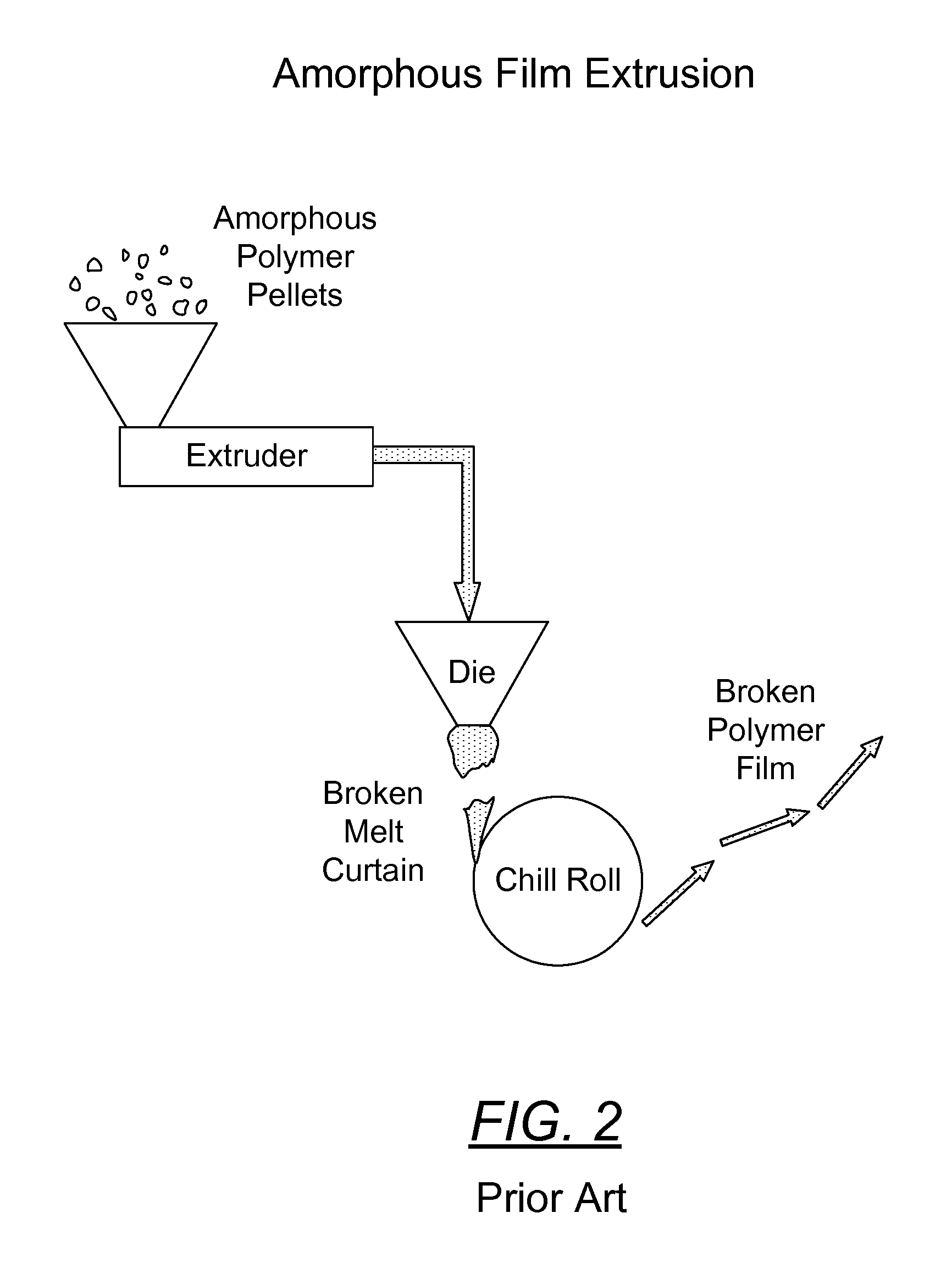

Process For Manufacturing Free Standing Thermoplastic Polymeric Films

InactiveUS20090288764A1Uniform thicknessReduce thicknessLamination ancillary operationsLayered product treatmentCross-linkDownstream processing

This invention discloses a novel process for manufacturing very thin freestanding polymeric films with the steps of supplying a molten film layer stream and a molten assist layer stream by a first extruder and second extruder; intimately contacting the film layer stream and the assist layer stream in coplanar fashion; extruding the film layer stream and the assist layer stream through a planar coextrusion die lip; stretching the multilayer melt curtain; cooling the multilayer film; delaminating the assist layer or layers from the film layer; and transporting the film layer to downstream processing operations. This process allows manufacturing of very thin freestanding films made from amorphous polymers, highly filled films made from amorphous, semi crystalline, or crystalline polymers, chemically cross linked films, and films with diffused addenda that would normally cause undesirable reactions in an extrusion environment.

Owner:TRIPARTISAN TECH

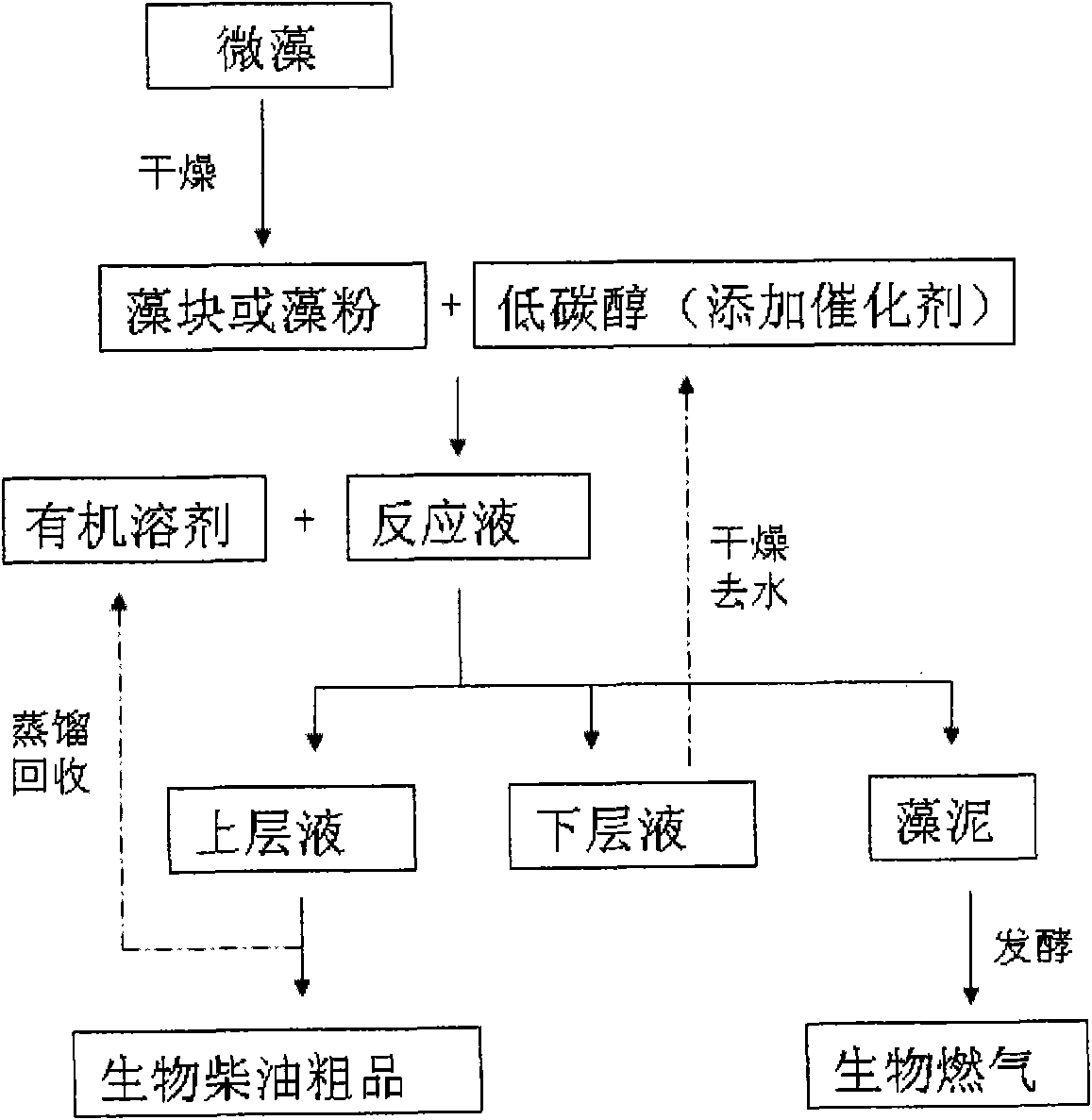

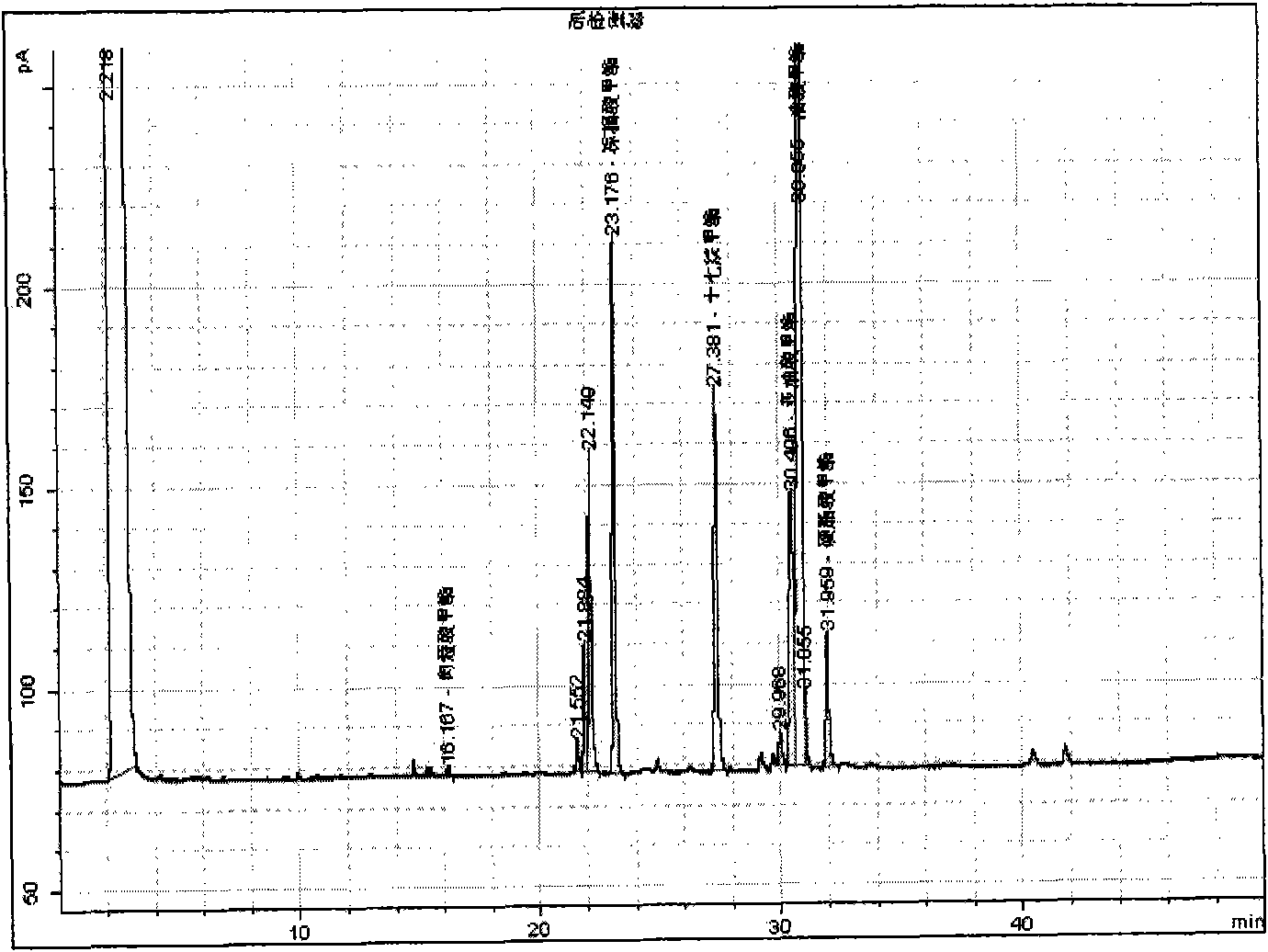

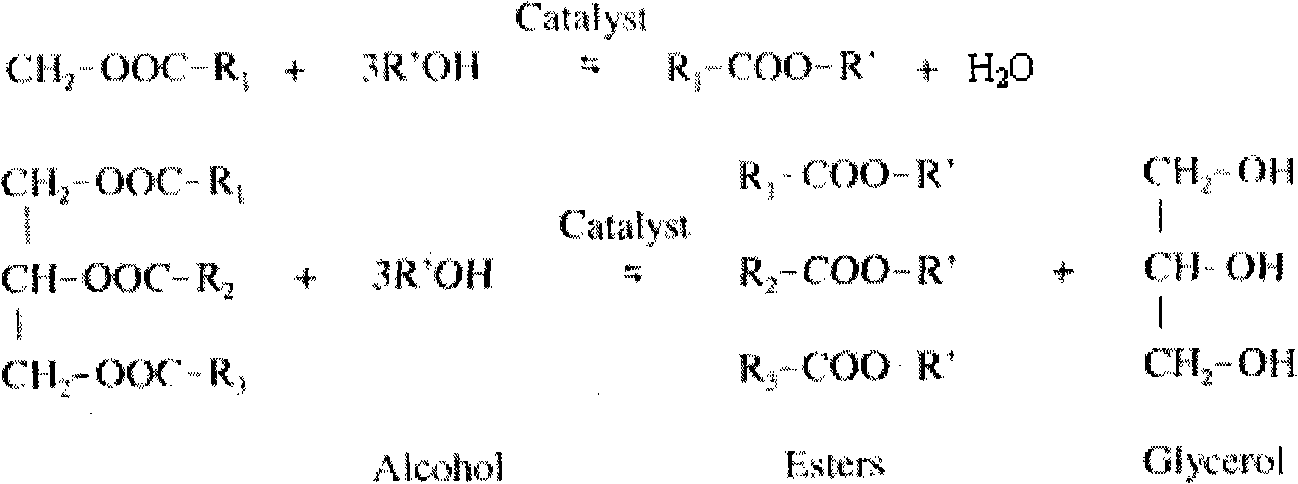

Biomass energy prepared by one-step method of microalgae

ActiveCN101580857AWon't happenRelieve pressurePreparation by ester-hydroxy reactionBiofuelsDownstream processingBiodiesel

The invention provides a method for preparing biodiesel from microalgae. The method comprises the following steps of: a. changing collected microalgae from the wet algae into algae block or algae powder; b. mixing a catalyst into low-carbon alcohol, directly adding the algae block or the algae powder obtained by the step a, and carrying out ester exchange reaction to prepare the biodiesel; c. after the reaction is stopped, adding an organic solvent for extracting reaction solution which is divided into organic solvent phase used for extraction, low-carbon alcohol water-adding phase and algae mud; and d. after the extraction is completed, collecting the organic solvent phase used for extraction, removing the organic solvent by distillation, and obtaining oily liquid, namely crude products of the biodiesel. After preparing the biodiesel, the steps that the low-carbon alcohol water-adding phase is used circularly after dewatered by a solid drying agent, and the produced algae mud is used for producing biogas by biological fermentation are added. The invention completes the oil extraction of microalgae and biodiesel production by one step, simplifies the technique steps and equipment, saves cost; the sulphuric acid and low-carbon alcohol used for production can be recovered, then dewatered by drying, then utilized repeatedly, the cost is reduced, the final product is neutral, does not need washing and reduces the downstream processing pressure; and simultaneously, chlorophyll is mainly concentrated in the low-carbon alcohol, reduces the interference of the chlorophyll to the color of the product and does not need the step of decoloring.

Owner:ENN SCI & TECH DEV

Sedimentation removal assembly for flow-through sedimentary tank

ActiveUS20060091072A1Settling tanks feed/dischargeWater/sewage treatmentDownstream processingWastewater

Solids removal assemblies (14) adapted for use in flow-through or batch-type sedimentation tanks (12) are provided which increase the efficiency of solids removal and eliminate physical scraping devices common with such sedimentation tanks. The preferred removal assemblies (14) include an elongated hood (34) disposed over a cooperating and complementally configured fill structure (26,28), which fills the majority of the internal volume of the hood (34). The hood (34) includes converging sidewalls (44, 46) having lower most inlet openings (54) and spaced, tubular outlets (56) adjacent the apex thereof. Outlet pipes (64) are operably coupled with each of the hood outlets (56) for suction withdrawal of waste water-solids suspensions which are then conveyed for downstream processing. The hood (34) and fill structure (26, 28) cooperatively define restricted flow paths for the waste water-solids suspensions, and assist in the creation of relatively high velocity movement of the suspensions to prevent bridging or clogging by collective solids adjacent the bottom of the tanks (12).

Owner:AERO MOD

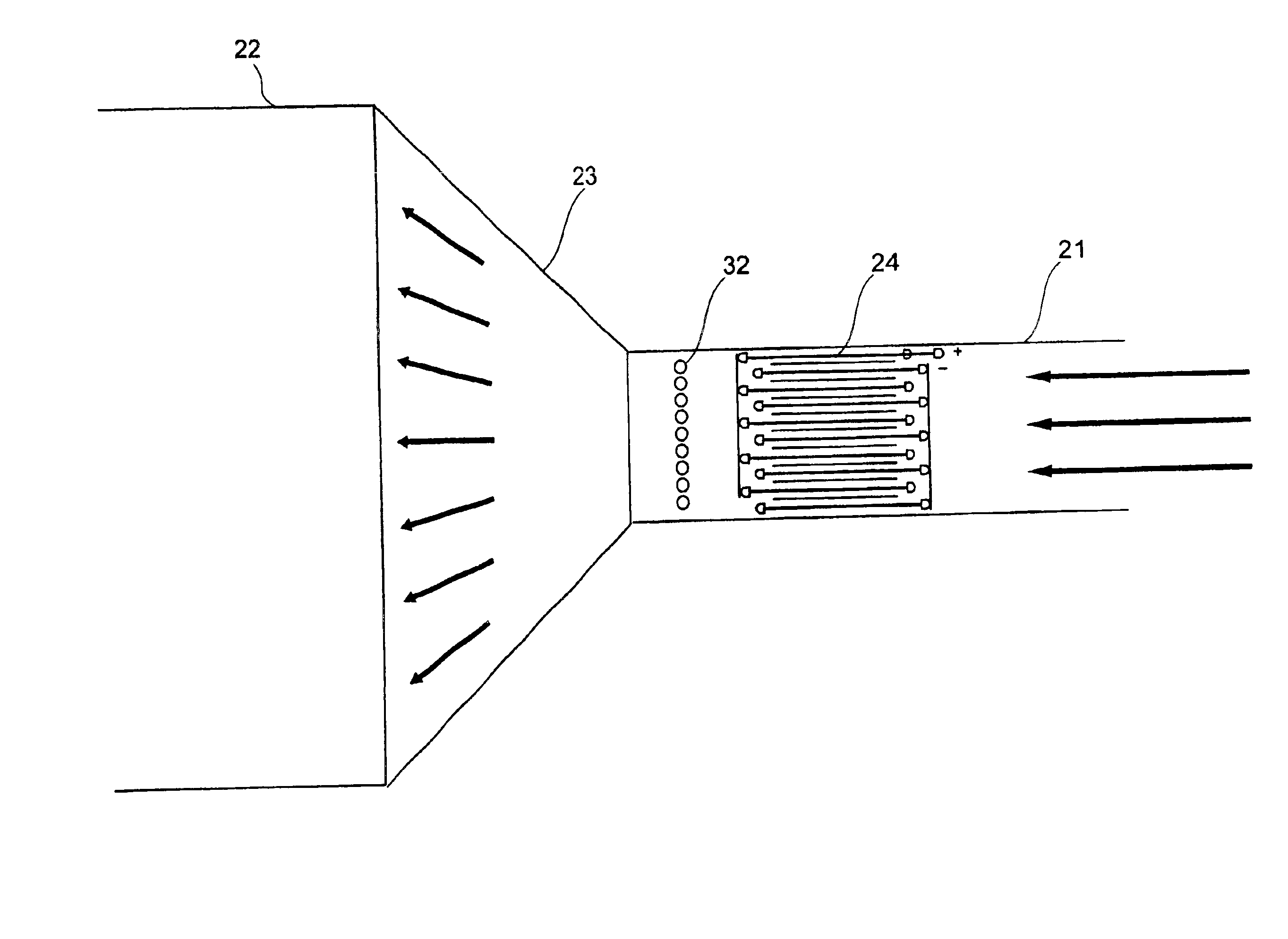

Method and apparatus for particle agglomeration

InactiveUS6872238B1Well mixedImprove adhesionElectrostatic separation housingAuxillary pretreatmentDownstream processingEngineering

Fine particles of dust and other pollutants in gas streams are agglomerated to form larger particles which are more easily filtered in downstream processing. In one embodiment, particles in successive portions of the gas stream are charged with opposite polarity, and the gas stream is introduced into an Evasé portion (12) to slow it down. Particles of different sizes have differential deceleration and therefore mix generally in the direction of flow, leading to agglomeration of oppositely-charged particles. In another embodiment, a gas stream is divided into substreams in respective parallel passages, and the particles in adjacent passages are charged to opposite polarity. Deflectors at the downstream end of the passages cause substreams of particles of opposite polarity to mix, with resultant agglomeration of oppositely charged particles.

Owner:HANSOM ENVIRONMENTAL PROD

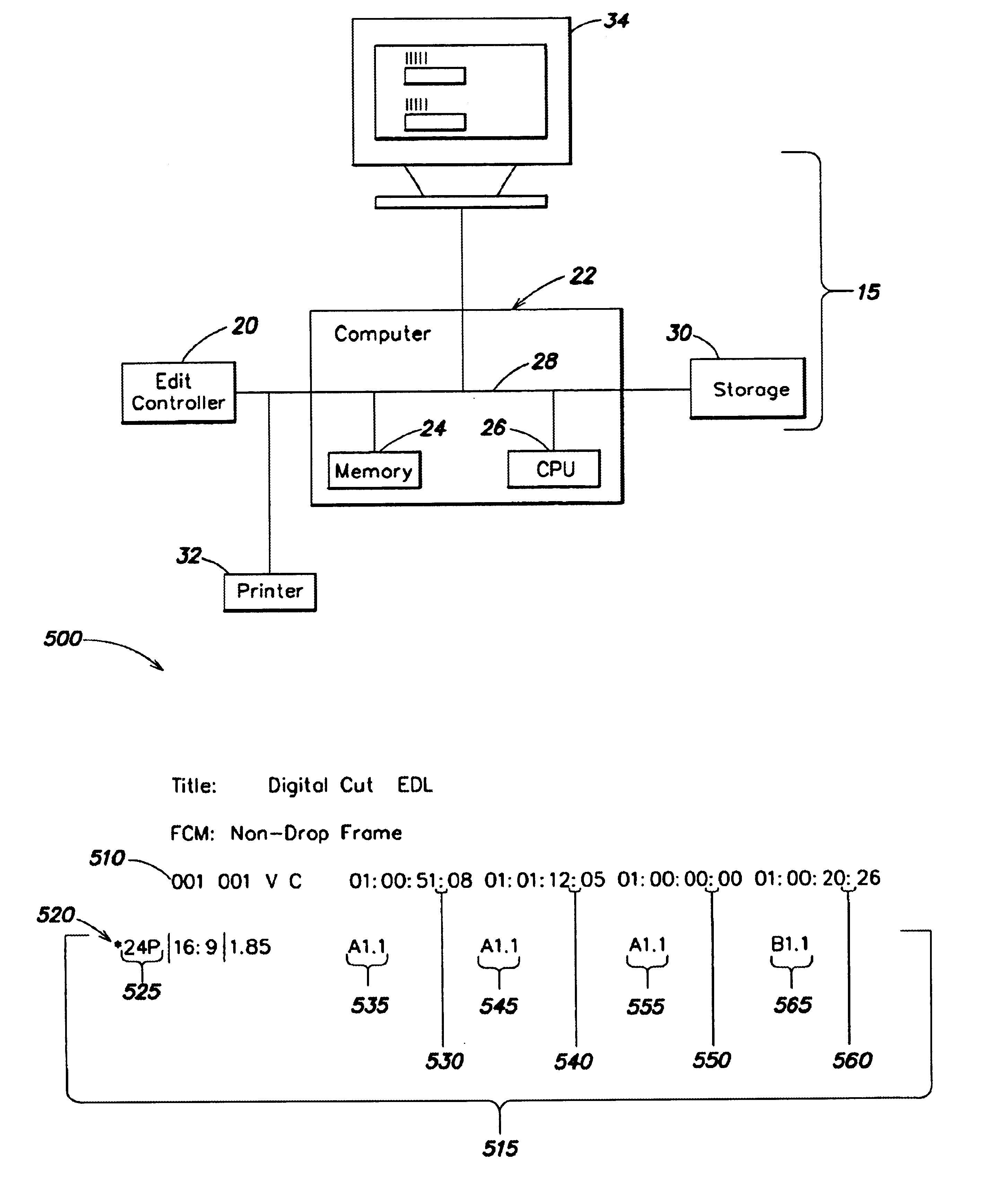

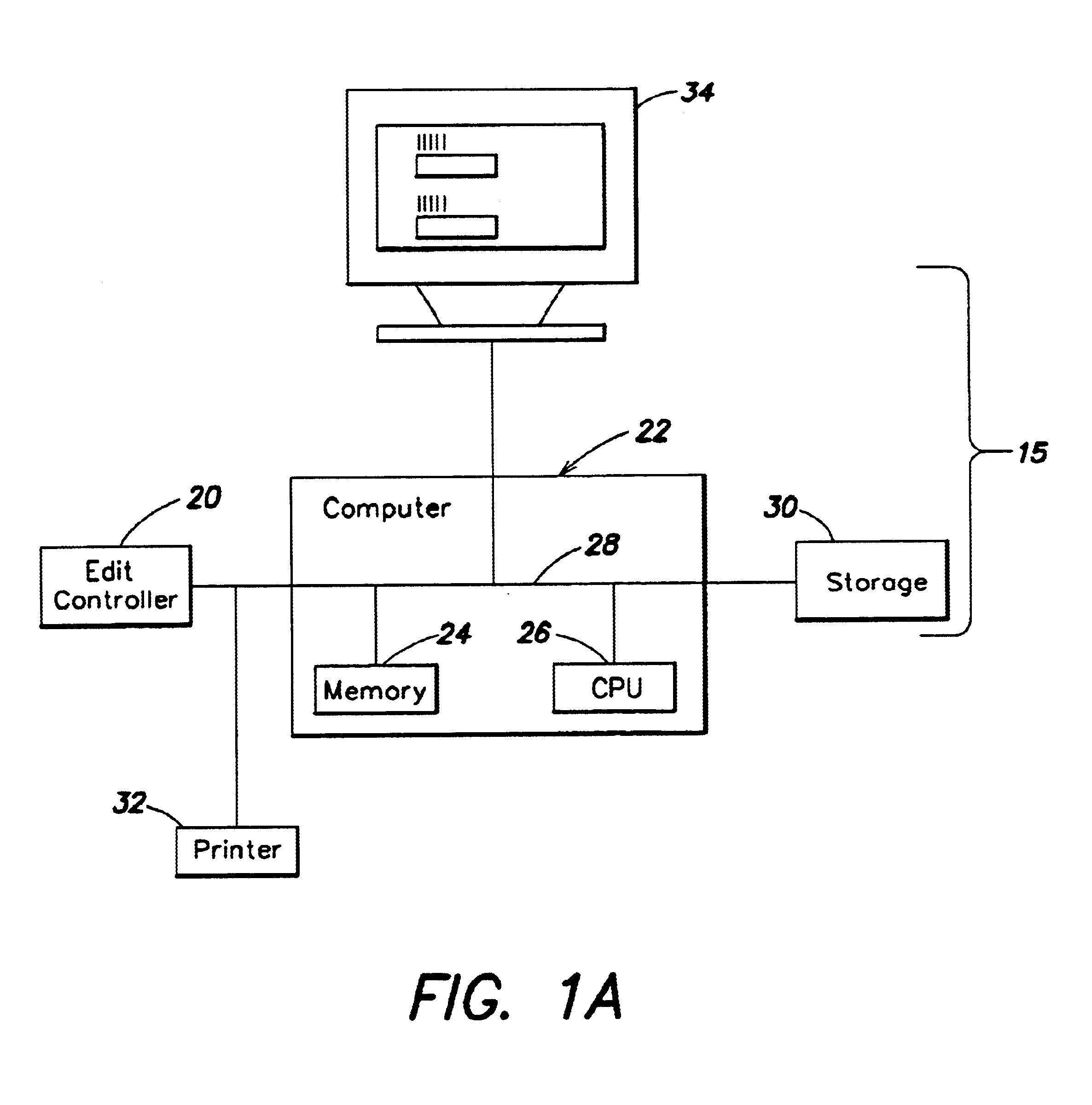

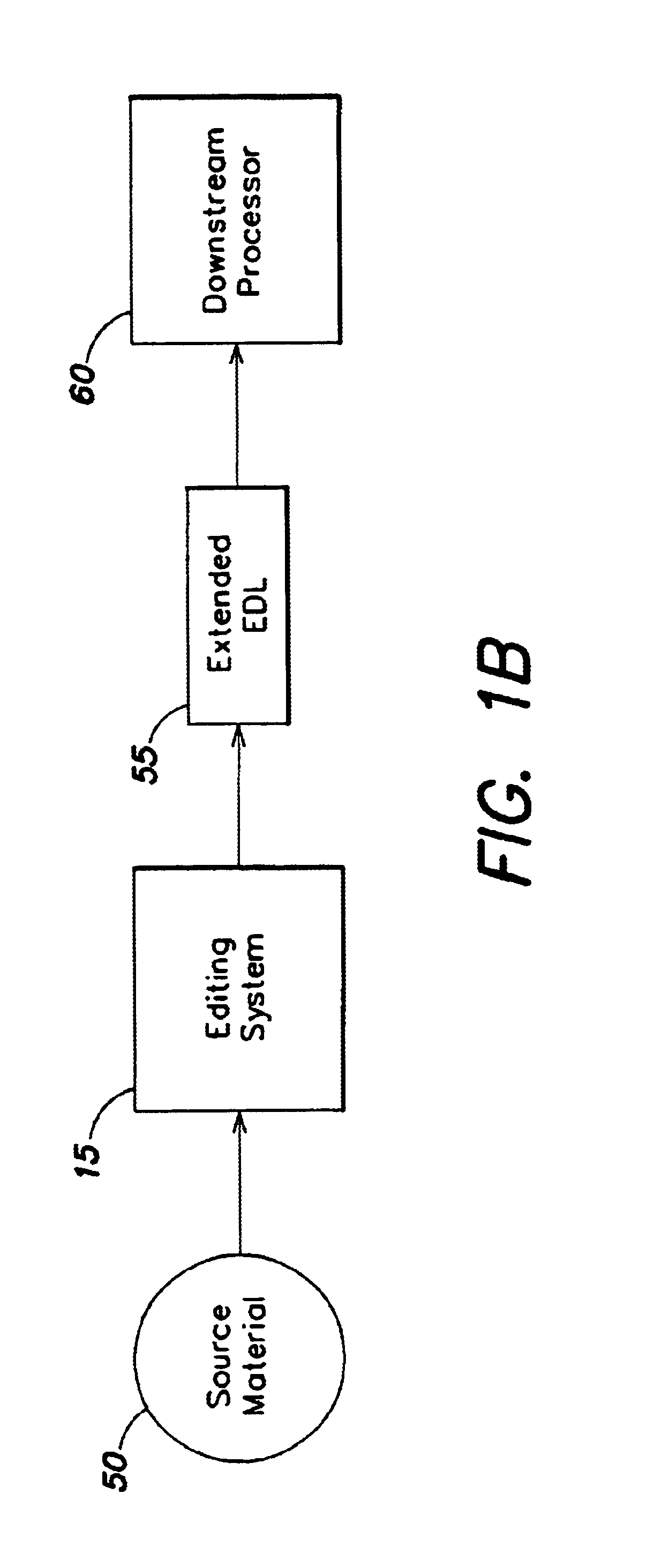

Edit decision list for identifying the pull down phase of a video signal

InactiveUS6871003B1Easy to optimizeFacilitate the processTelevision system detailsElectronic editing analogue information signalsRecording durationDownstream processing

The invention provides an editing system for editing and combining media material into a resulting media composition. The media may be film or video based material, and also may include audio material. The video may adhere to either NTSC or PAL timing. In response to editing instructions, an Edit Decision List (EDL) is produced that specifies the material that makes up the edited composition, and the order of presentation of this material in the output composition. The EDL specifies the input clips that are taken from the source material using source timecode and similarly defines the output order again according to a new time code, the record time code. The editing system produces an extended EDL that facilitates the downstream processing (after the editing has been completed) for post production tasks requiring the need to know accurately where edit points occur.

Owner:AVID TECHNOLOGY

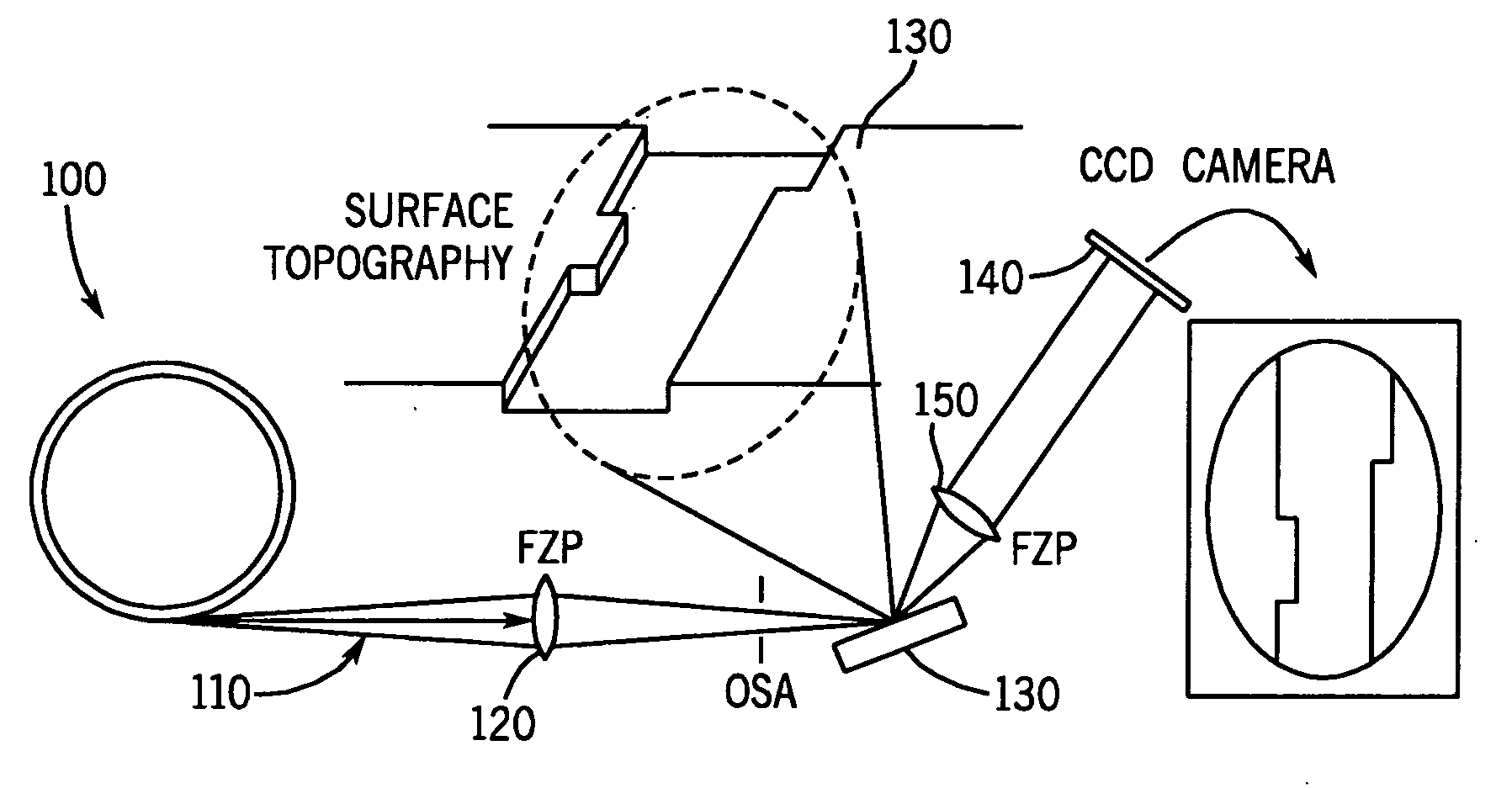

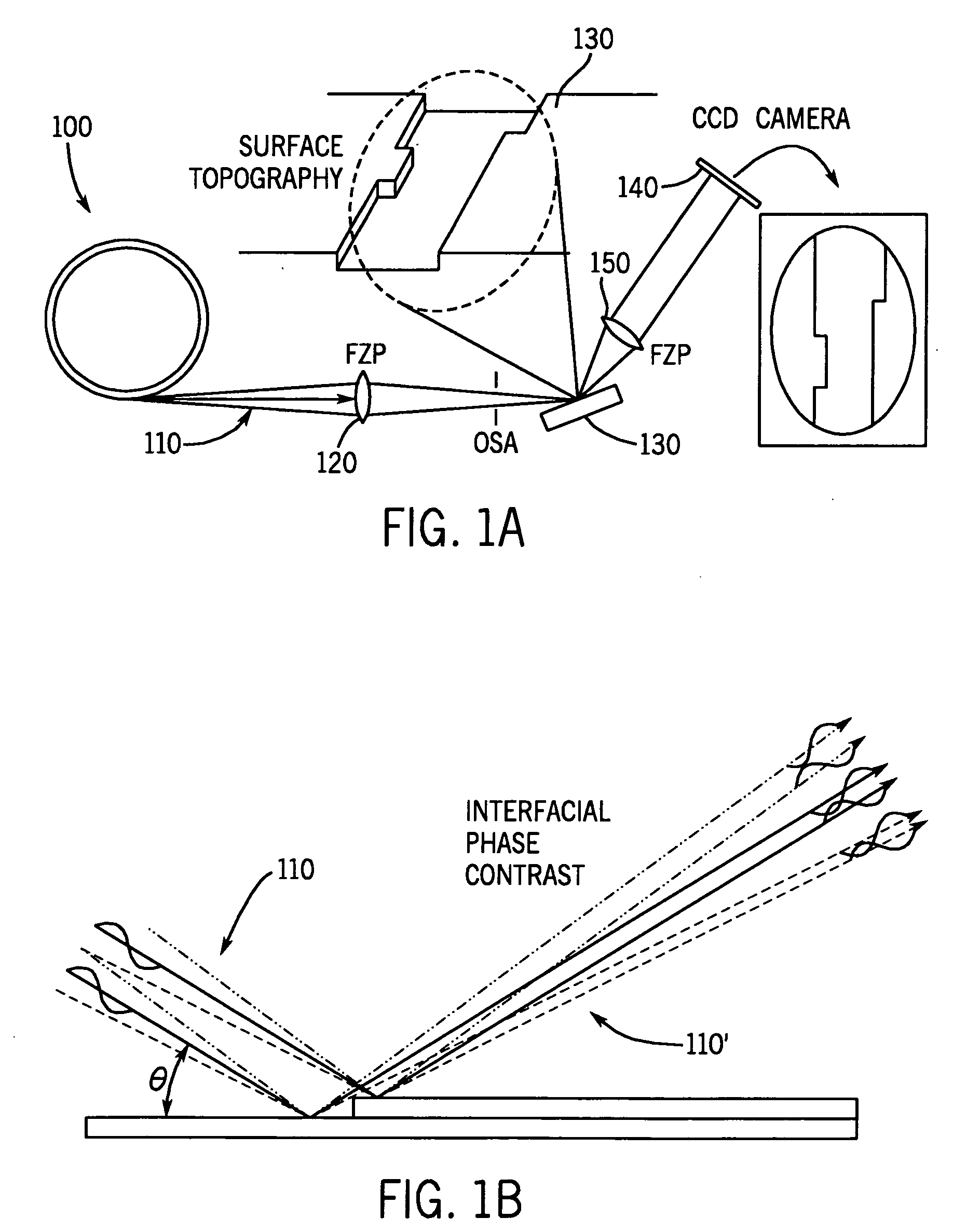

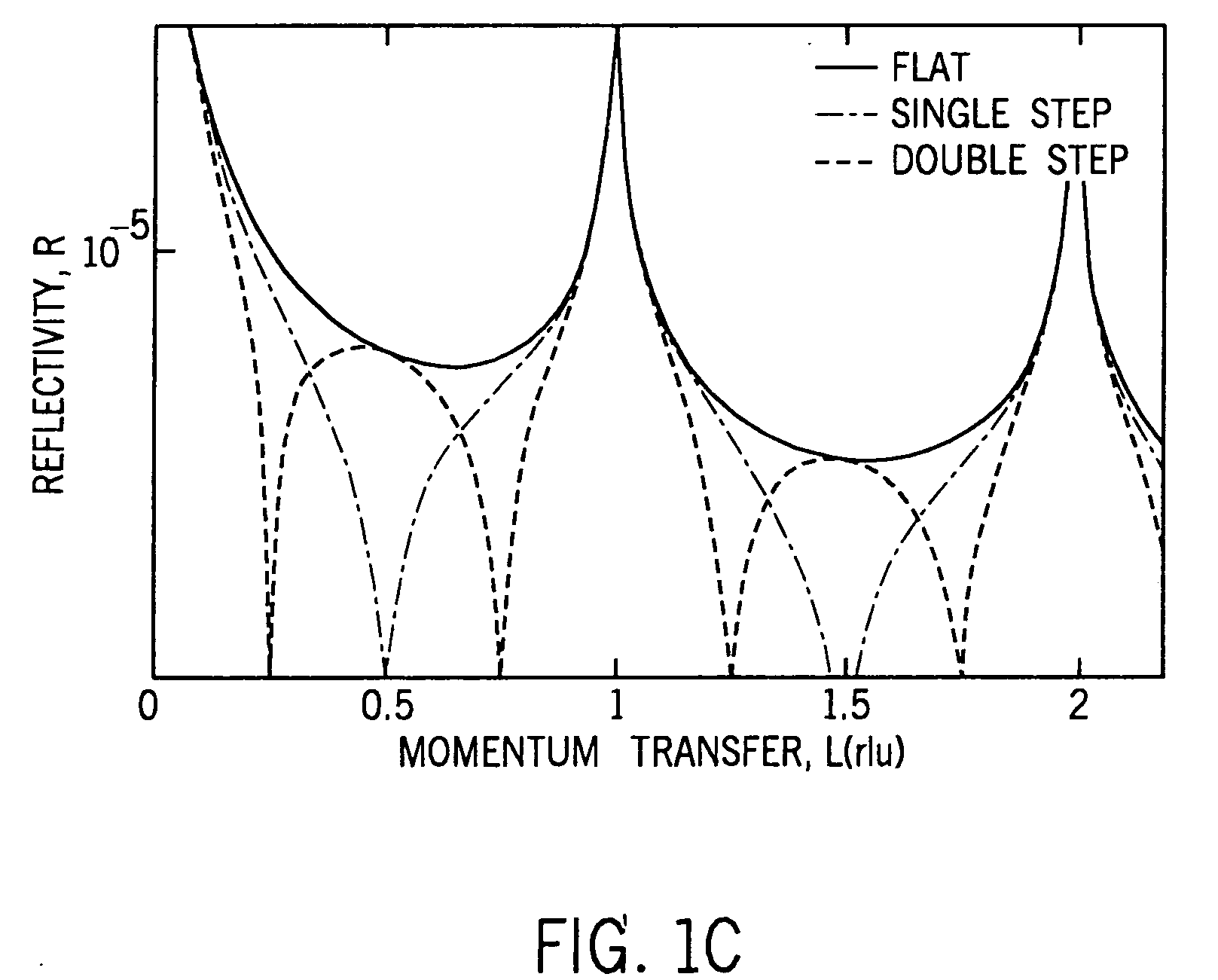

Surface topography with X-ray reflection phase-contrast microscopy

A system and method for monitoring a surface or interfacial area. The system and method includes an intense X-ray beam directed to a surface or interface at a low angle to achieve specular reflection with phase contrast associated with an event, such as changing topography, chemistry or magnetic state being detected by a CCD. Upstream or downstream processing can be carried out with the X-ray phase contrast system.

Owner:UCHICAGO ARGONNE LLC

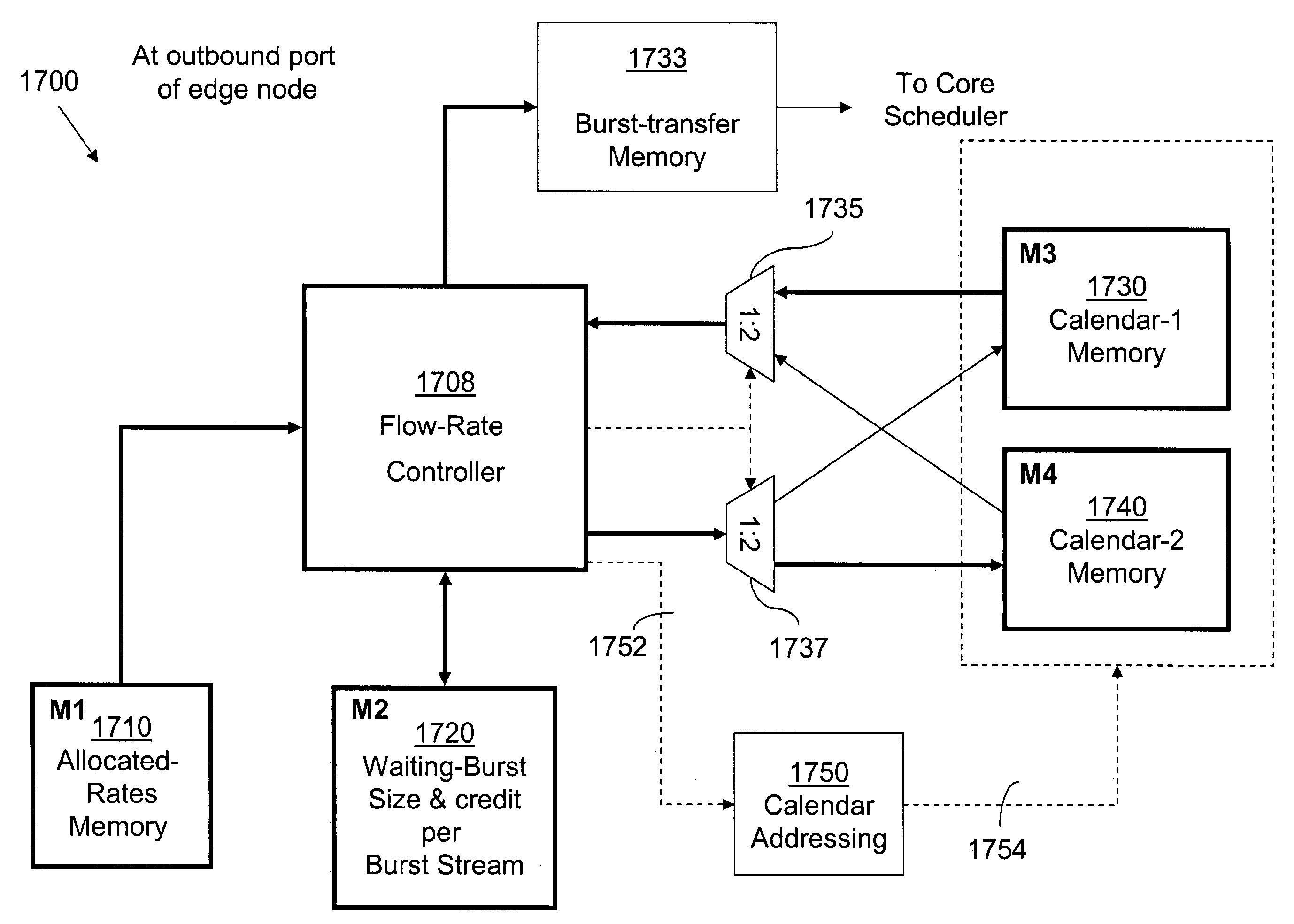

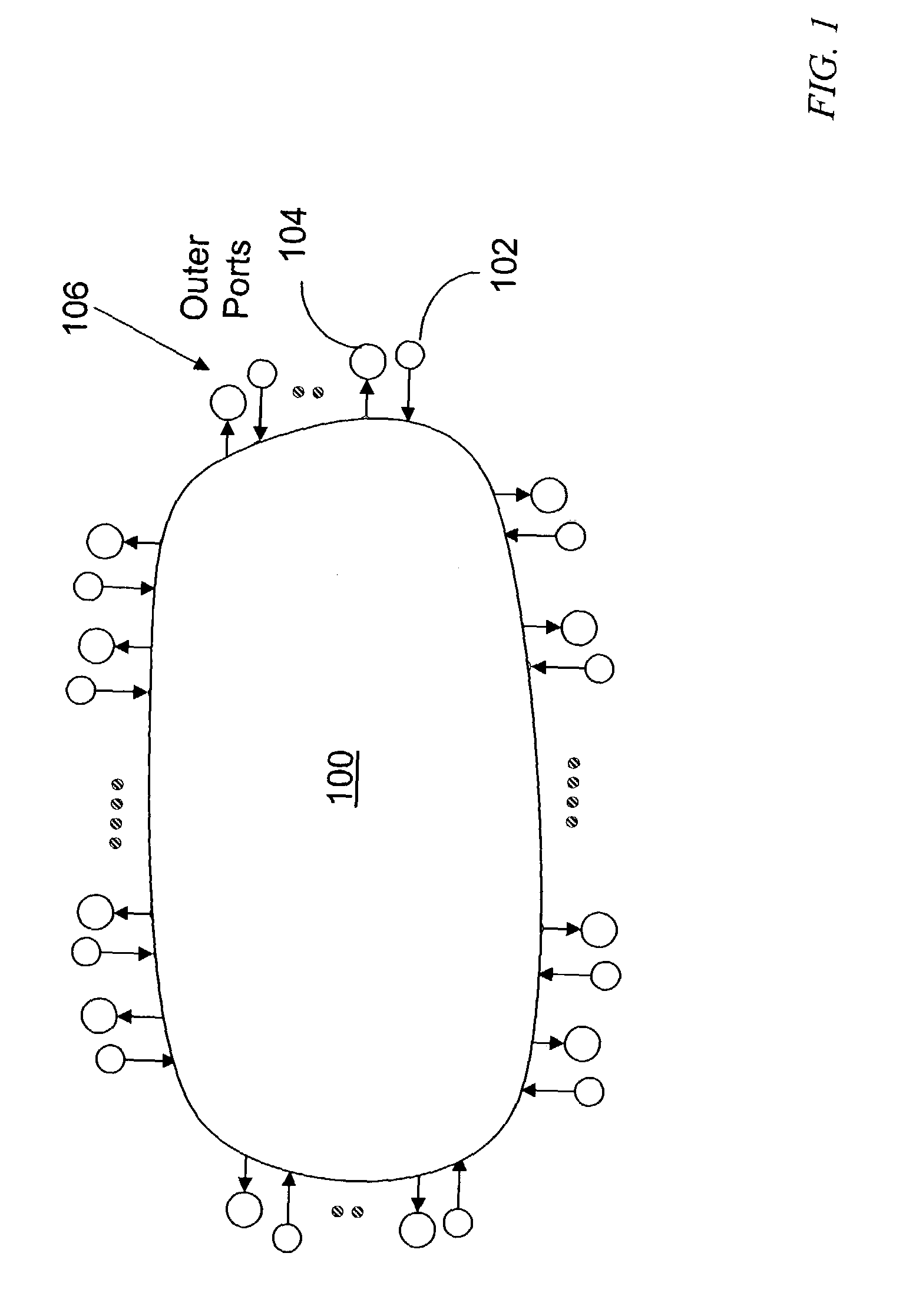

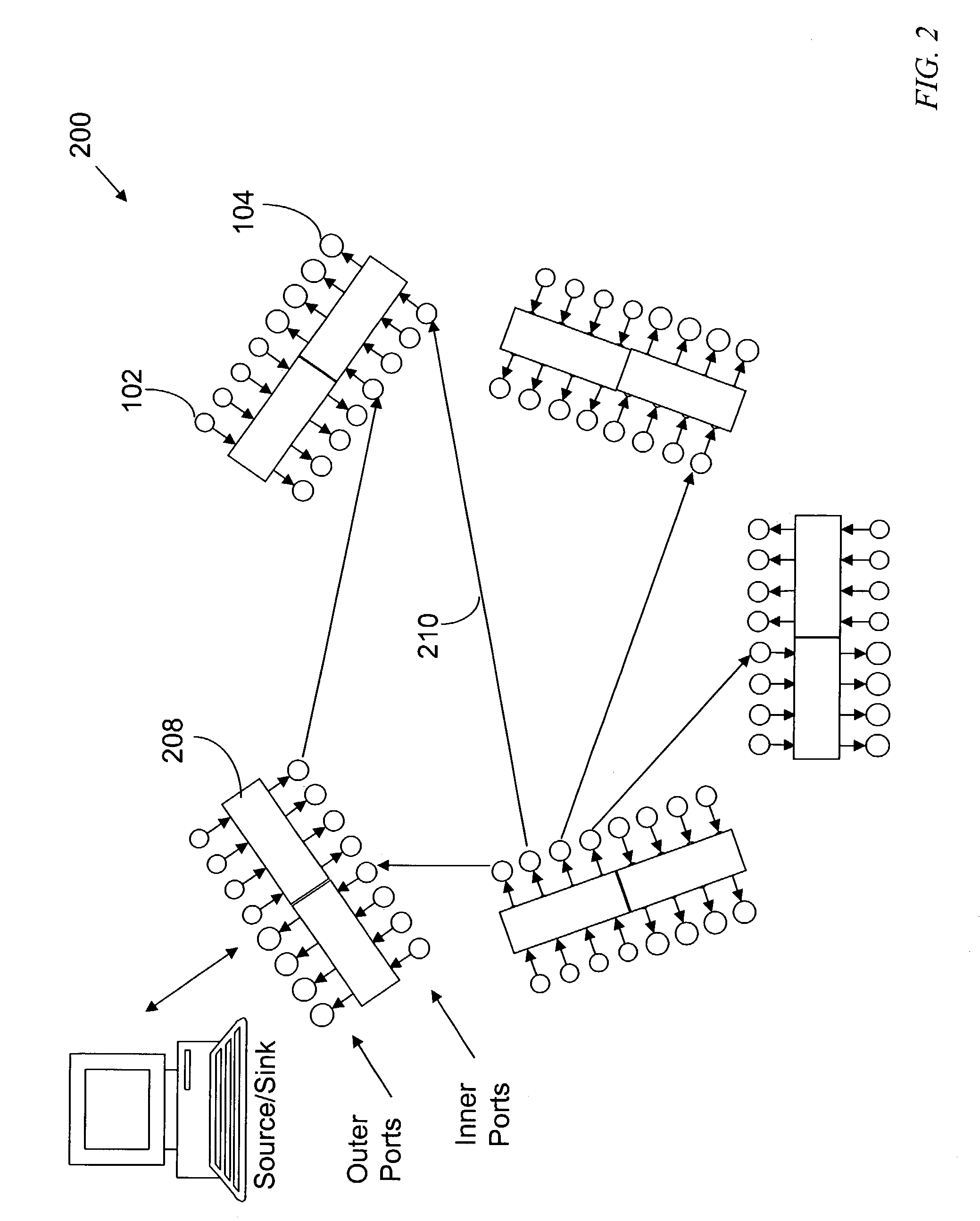

Regulating data-burst transfer

InactiveUS7369491B1Multiplex system selection arrangementsError preventionQuality of serviceDownstream processing

The invention discloses methods and apparatus for regulating the transfer of data bursts across a data network comprising electronic edge nodes interconnected by fast-switching optical core nodes. To facilitate switching at an electronic edge node, data bursts are organized into data segments of equal size. A data segment may include null data in addition to information bits. The null data are removed at the output of an edge node and the information data is collated into bursts, each carrying only information bits in addition to a header necessary for downstream processing. To ensure loss-free transfer of bursts from the edge to the core, burst transfer permits are generated at controllers of the optical core and sent to respective edge nodes based on flow-rate-allocation requests. Null-padding is not visible outside the edge nodes and only the information content is subject to transfer rate regulation to ensure high efficiency and high service quality.

Owner:RPX CLEARINGHOUSE

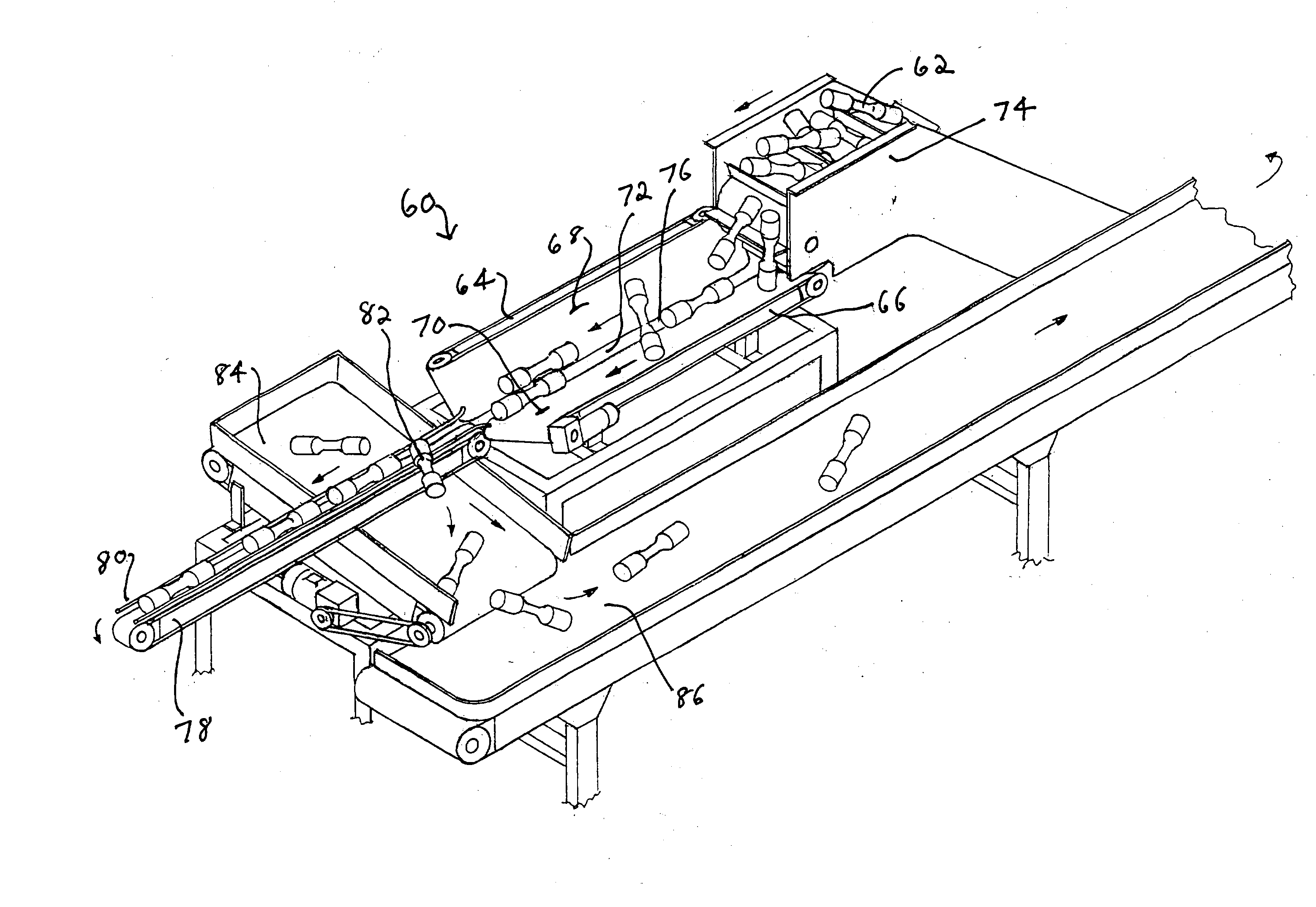

Orienting and feeding apparatus and method for manufacturing line

Apparatus and methods for rapidly orienting and feeding generally cylindrical, elongated objects having a maximum transverse diameter Y. First and second conveying belts are provided having input and output ends for cooperatively conveying such objects toward a downstream processing line. The belts are mounted so that their respective conveying surfaces are movable in a common parallel direction. The facing edges of the conveying surfaces of these belts are spaced from one another to define a uniform gap between them of a dimension less than Y. The conveying surfaces are upwardly sloped away from the gap, to define a zone converging downwardly in the direction of the gap. Object input means deposit the initially unoriented elongated objects at the input ends of the conveying belts. The belts are moved in a common direction, but at different speeds. The elongated objects are rotated by contact with the differentially speeding belts as they descend into the converging zone and become supported at the gap and conveyed by riding on the edges of the moving belts which border the gap. The objects as they descend become oriented in positions of gravitationally maximum stability relative to the mode of support, these positions being characteristic for the objects. Object output means at the ends of the belts receive the oriented objects and direct them toward the downstream processing line.

Owner:NORWALT DESIGN

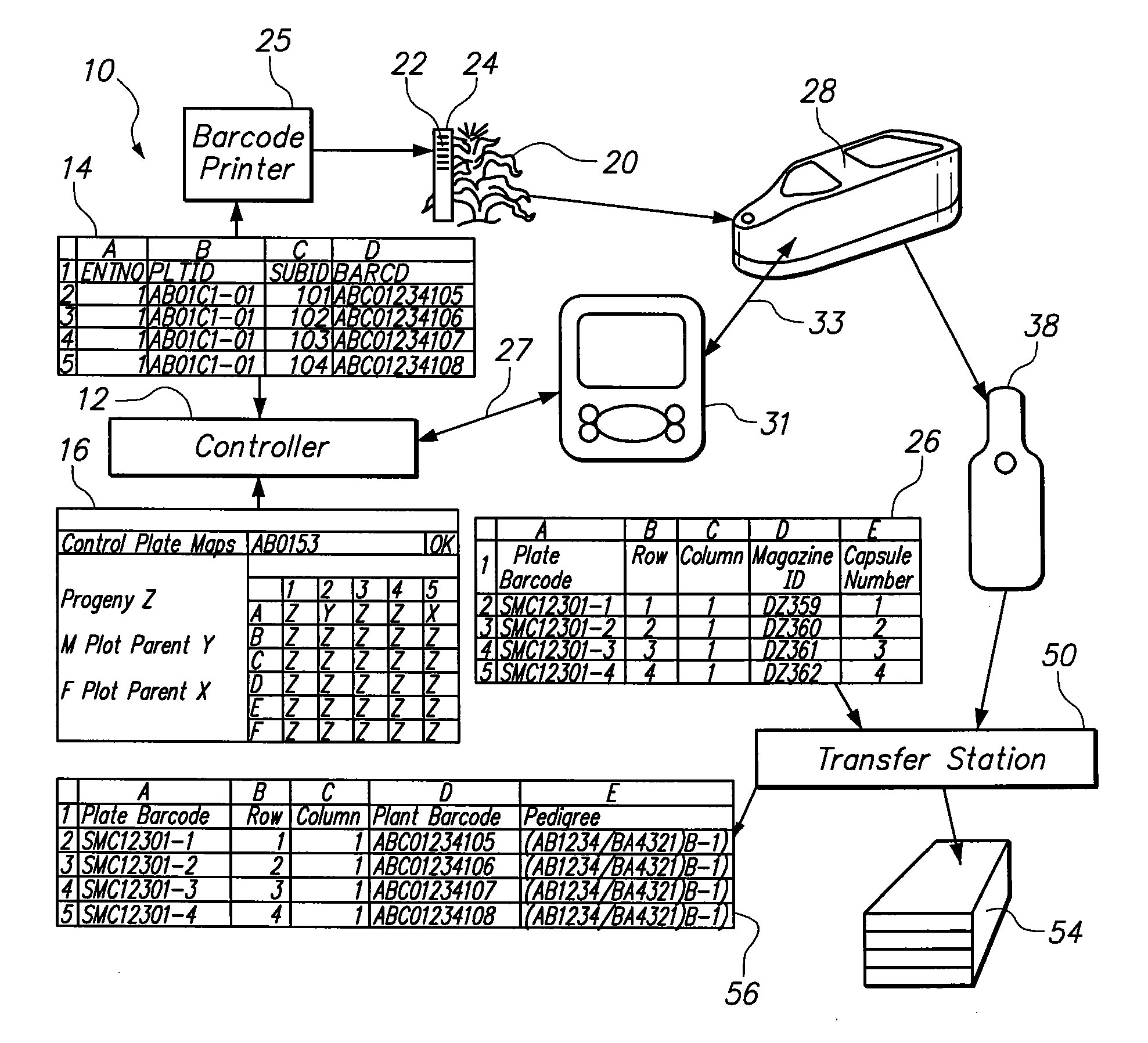

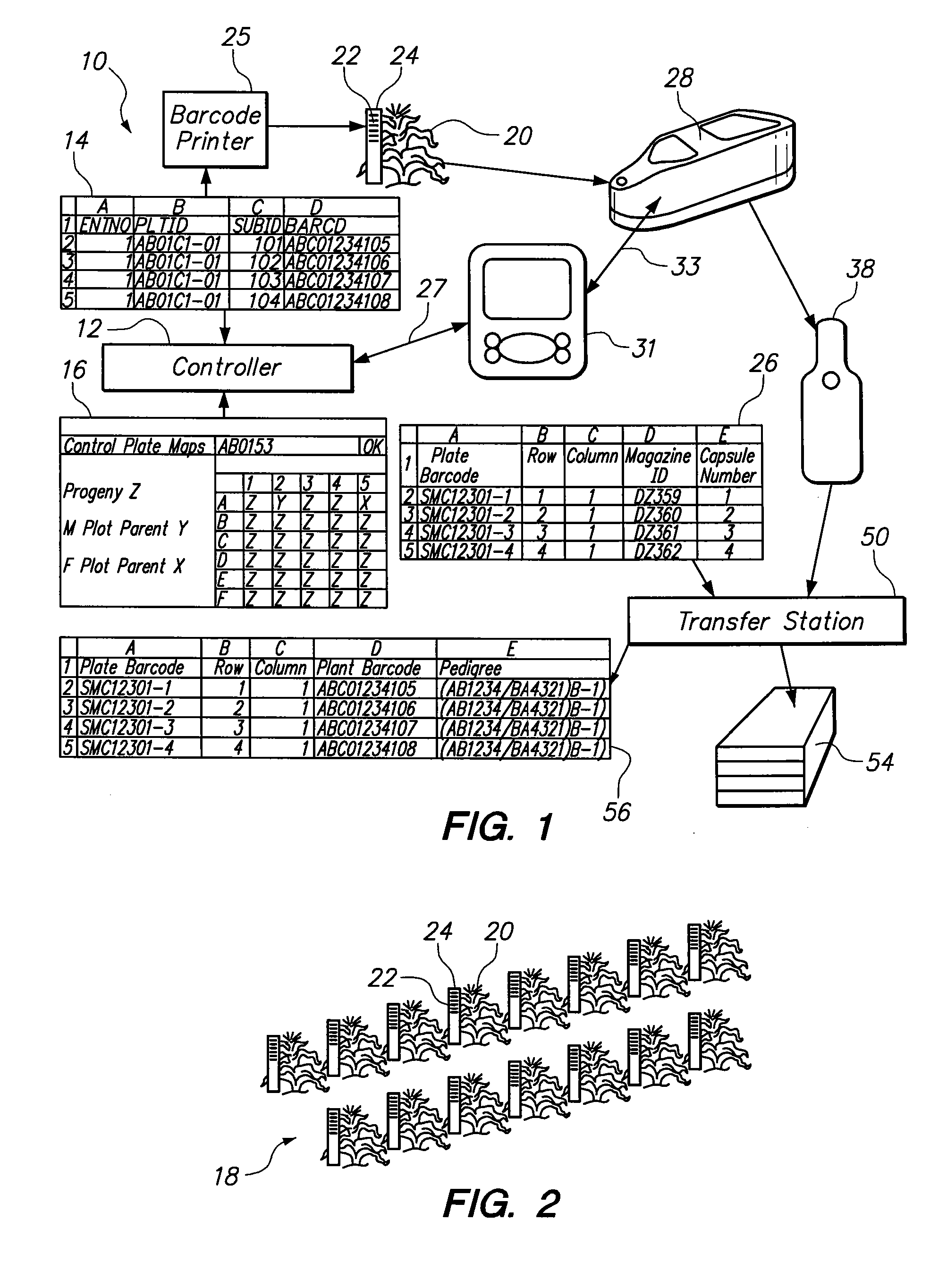

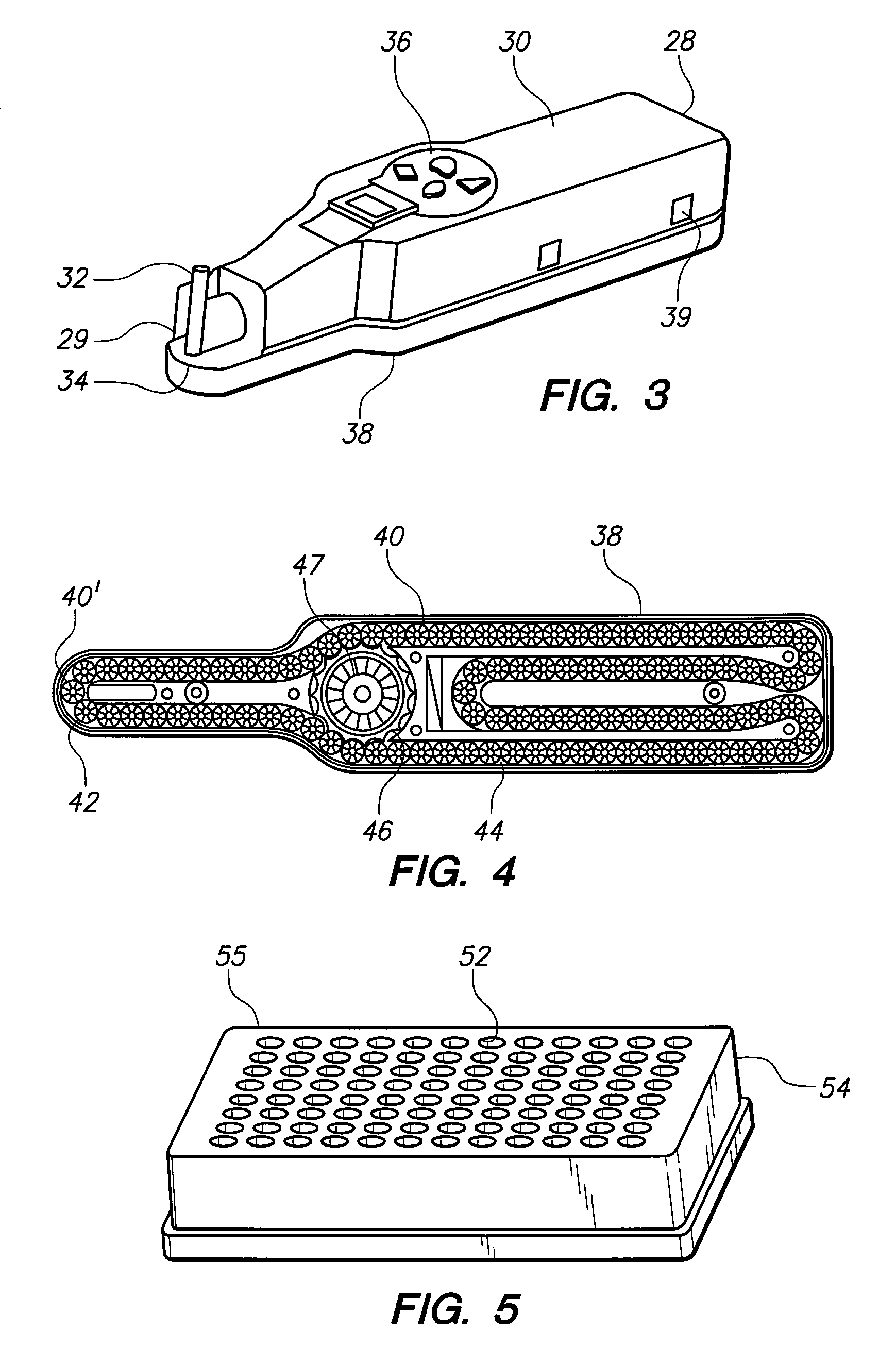

System for sampling and tracking plant material

ActiveUS20090042180A1Easy to prepareBioreactor/fermenter combinationsBiological substance pretreatmentsDownstream processingPlant Sources

A system and method for processing, i.e., sampling and tracking, plant material requires the ability to identify each plant in a plurality of plants. Initially, samples are taken from selected plants and are collected in respective storage locations in a magazine. During sampling, the identity of the plant source for each plant sample is stored. Further, the identity of each storage location receiving a plant sample is stored. Subsequently, the samples are transferred from the storage locations and are placed in respective wells of a receiving member for further downstream processing. Again, the identity of each well receiving a plant sample is stored. As a result, a plant sample in a well can be traced back to its plant source.

Owner:SYNGENTA PARTICIPATIONS AG

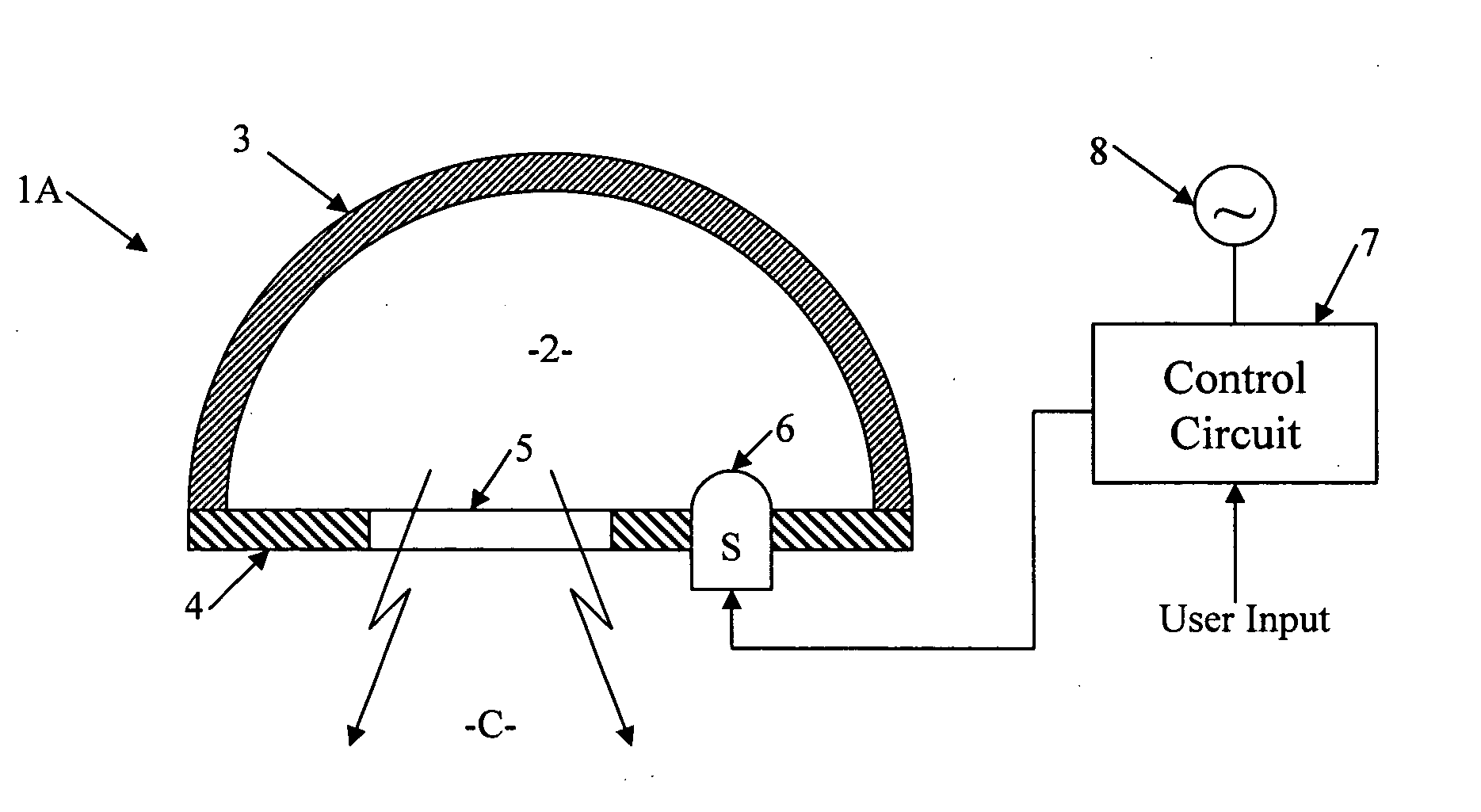

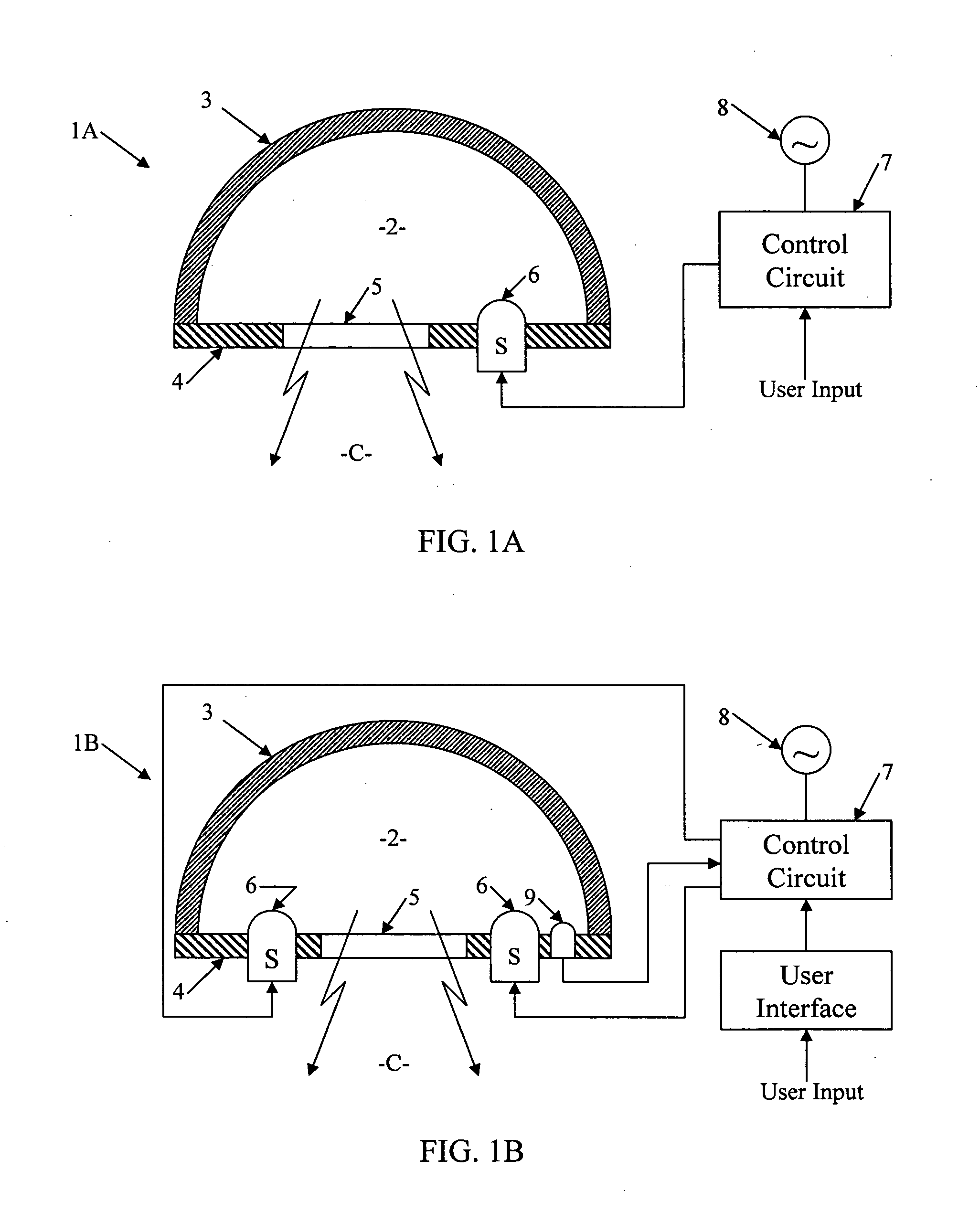

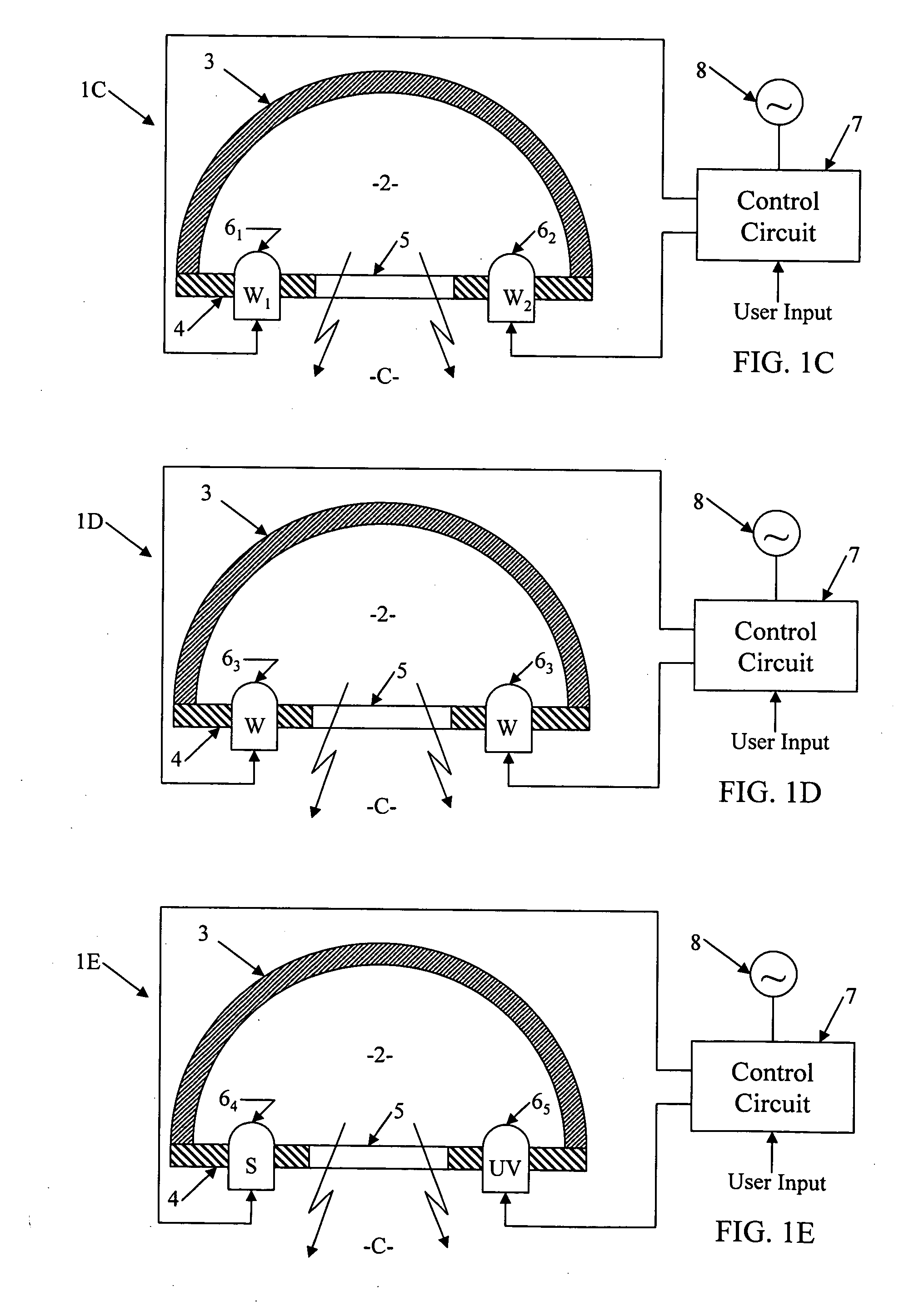

Large area, atmospheric pressure plasma for downstream processing

InactiveUS20090200948A1Uniform surface treatmentPromote resultsElectric discharge tubesElectric arc lampsEtchingDownstream processing

An arcless, atmospheric-pressure plasma generating apparatus capable of producing a large-area, temperature-controlled, stable discharge at power densities between about 0.1 W / cm3 and about 200 W / cm3, while having an operating gas temperature of less than 50° C., for processing materials outside of the discharge, is described. The apparatus produces active chemical species, including gaseous metastables and radicals which may be used for polymerization (either free radical-induced or through dehydrogenation-based polymerization), surface cleaning and modification, etching, adhesion promotion, and sterilization, as examples. The invention may include either a cooled rf-driven electrode or a cooled ground electrode, or two cooled electrodes, wherein active components of the plasma may be directed out of the plasma and onto an external workpiece without simultaneously exposing a material to the electrical influence or ionic components of the plasma.

Owner:APJET INC

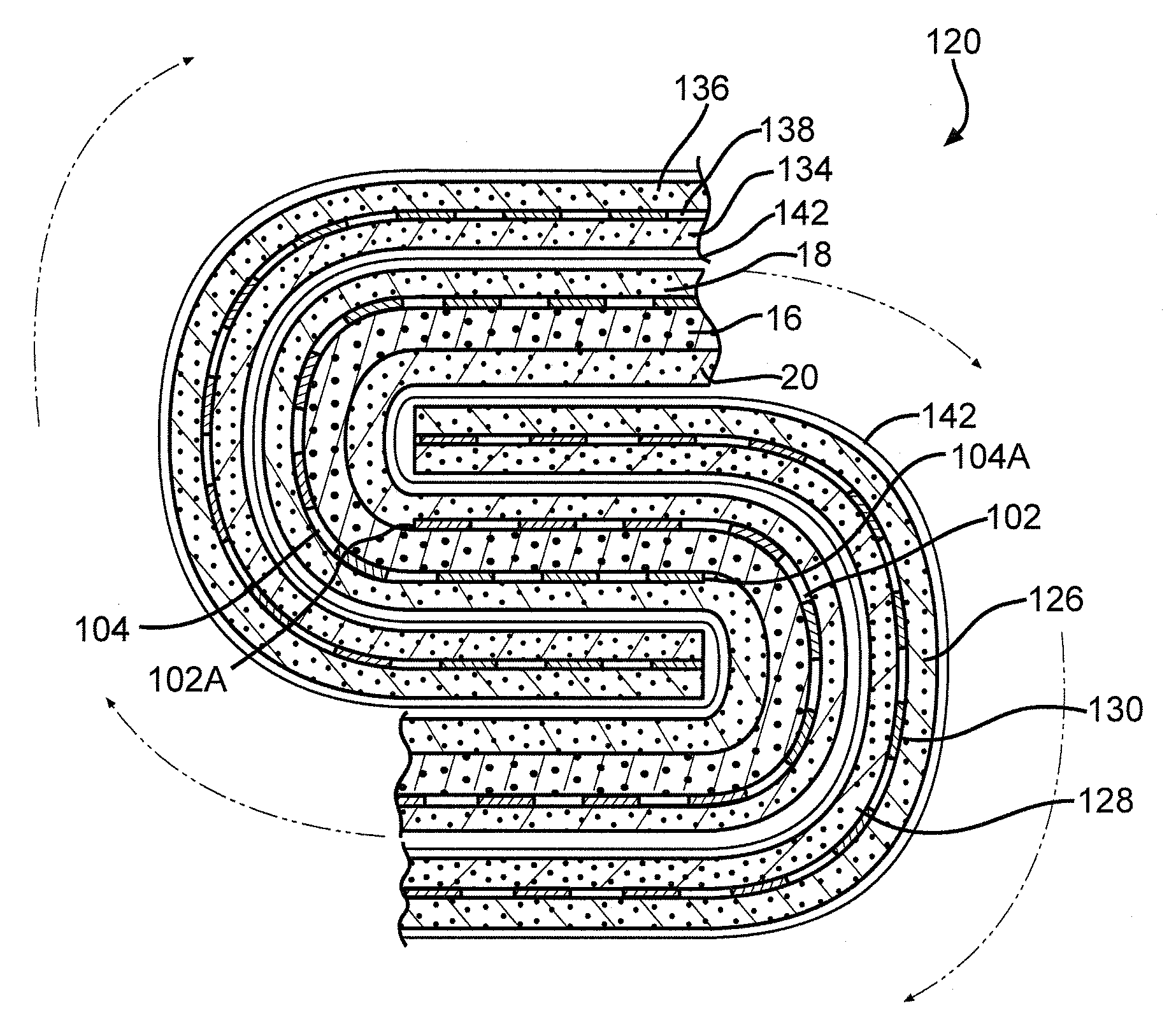

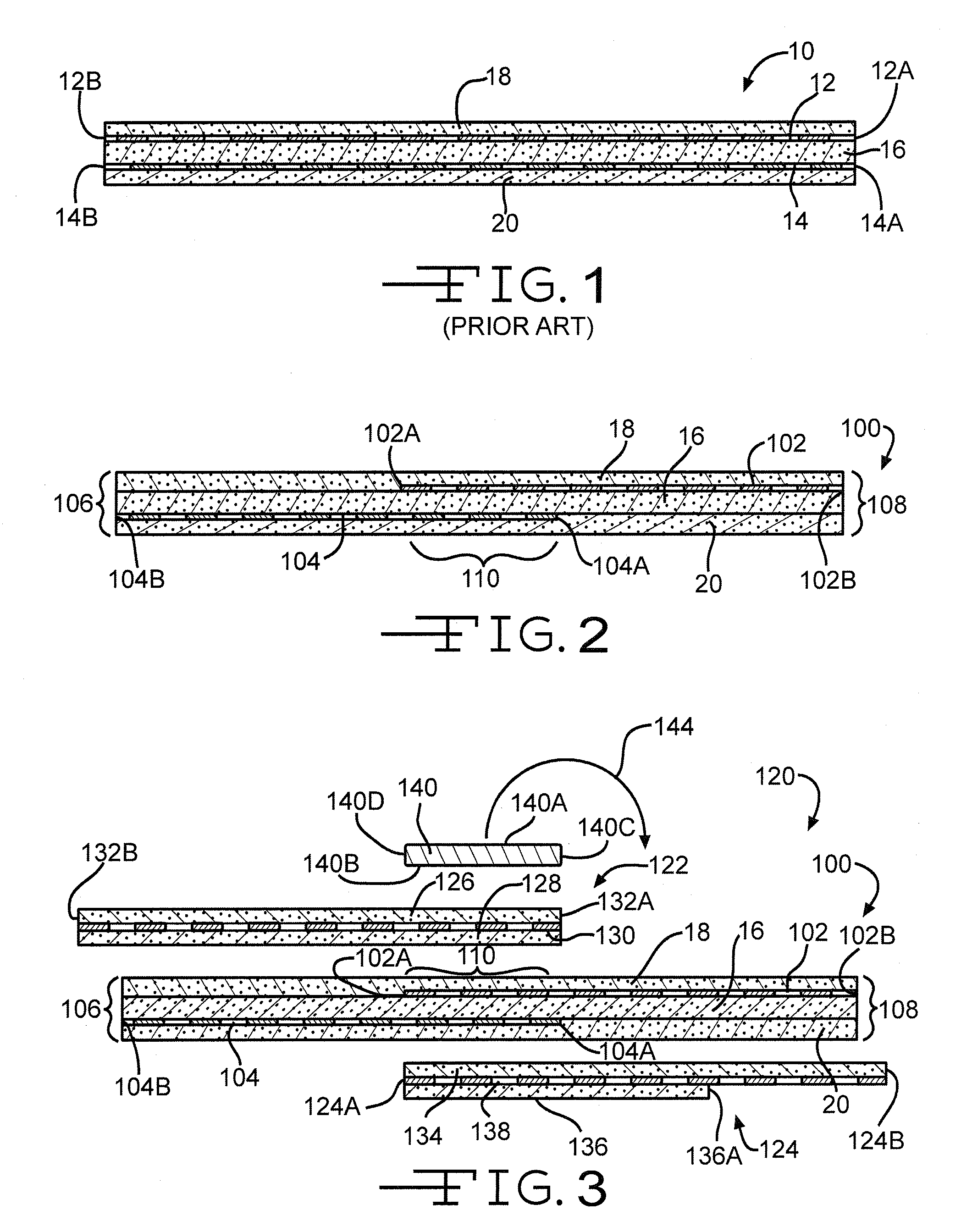

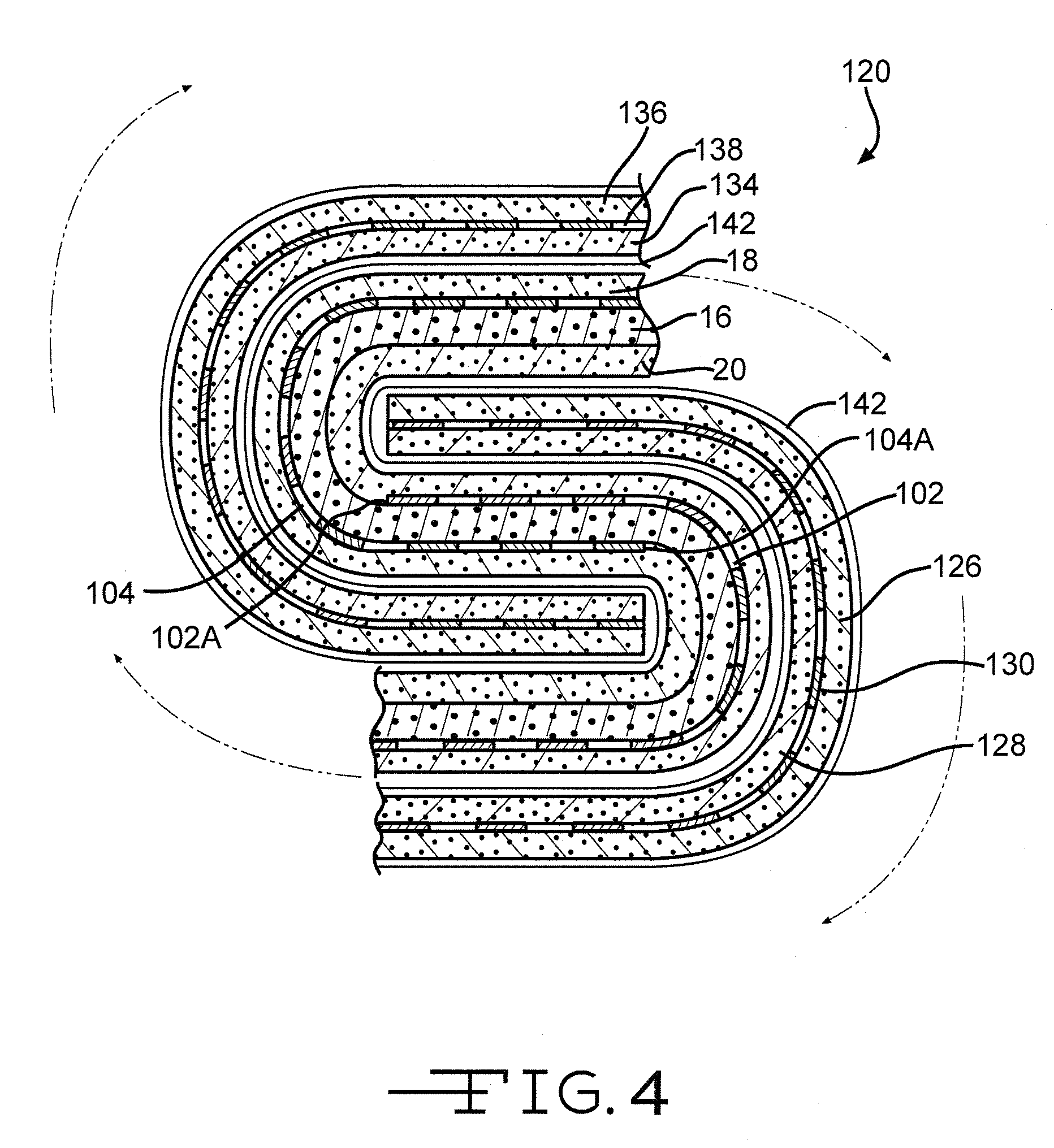

Sandwich Cathode Electrochemical Cell With Wound Electrode Assembly

InactiveUS20070059599A1Amenable for downstream processingImprove reliabilitySilver accumulatorsFinal product manufactureDownstream processingEngineering

A new design for a cathode having a configuration of: SVO / first current collector / CFx / second current collector / SVO is described. The two cathode current collectors are vertically aligned one on top of the other in a middle region or zone of the cathode. This coincides to where a winding mandrel will be positioned to form a wound electrode assembly with an anode. The overlapping region of the two current collectors helps balance the expansion forces of the exemplary SVO and CFx active material layers. This, in turn, helps maintain a planar cathode that is more amenable to downstream processing. The use of two current collectors on opposite sides of an intermediate cathode active material also provides for enhanced reliability when cathodes are wound from the center as they lend structural integrity to outer portions of the wind.

Owner:WILSON GREATBATCH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com