Patents

Literature

5458results about "Rollers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

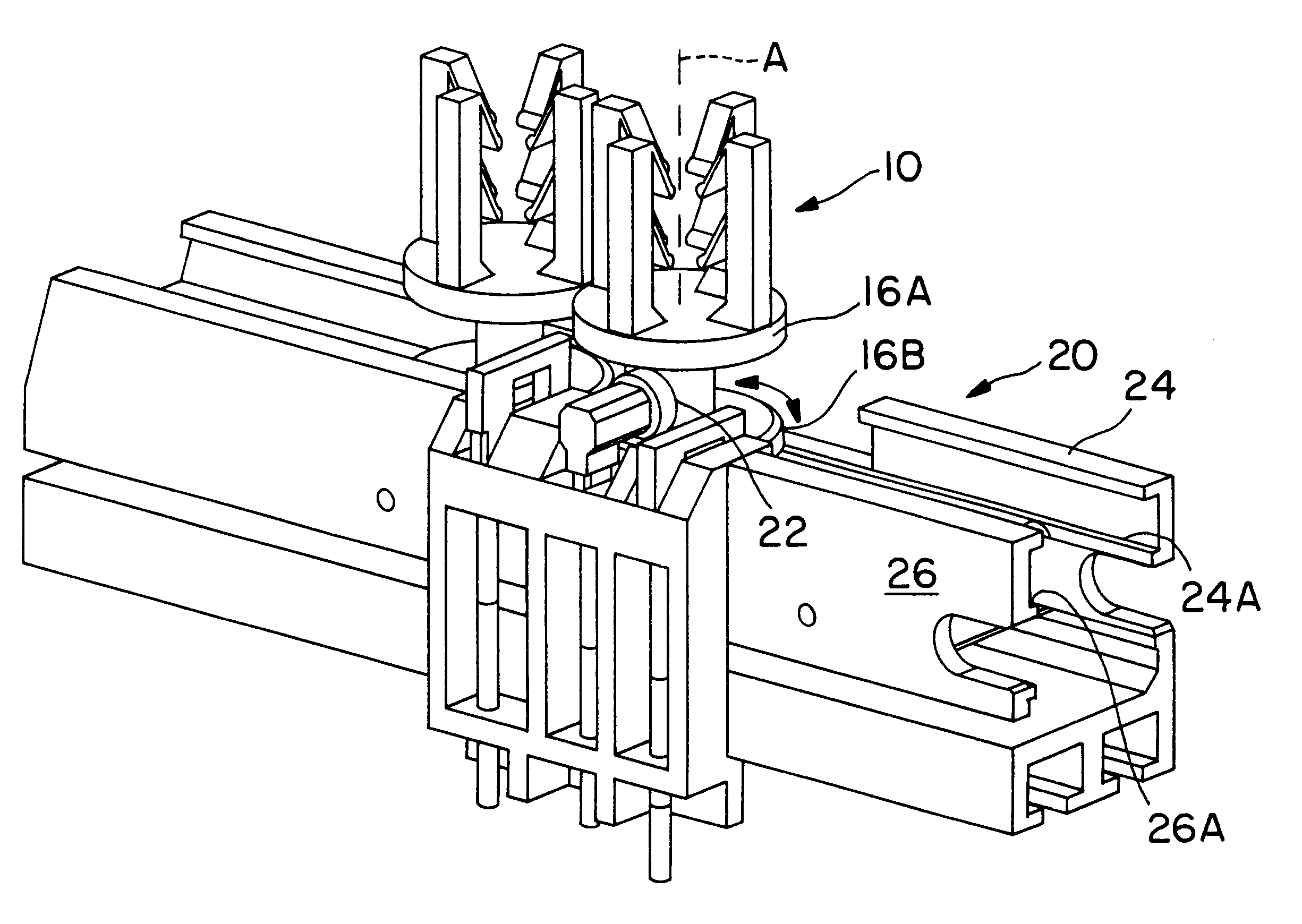

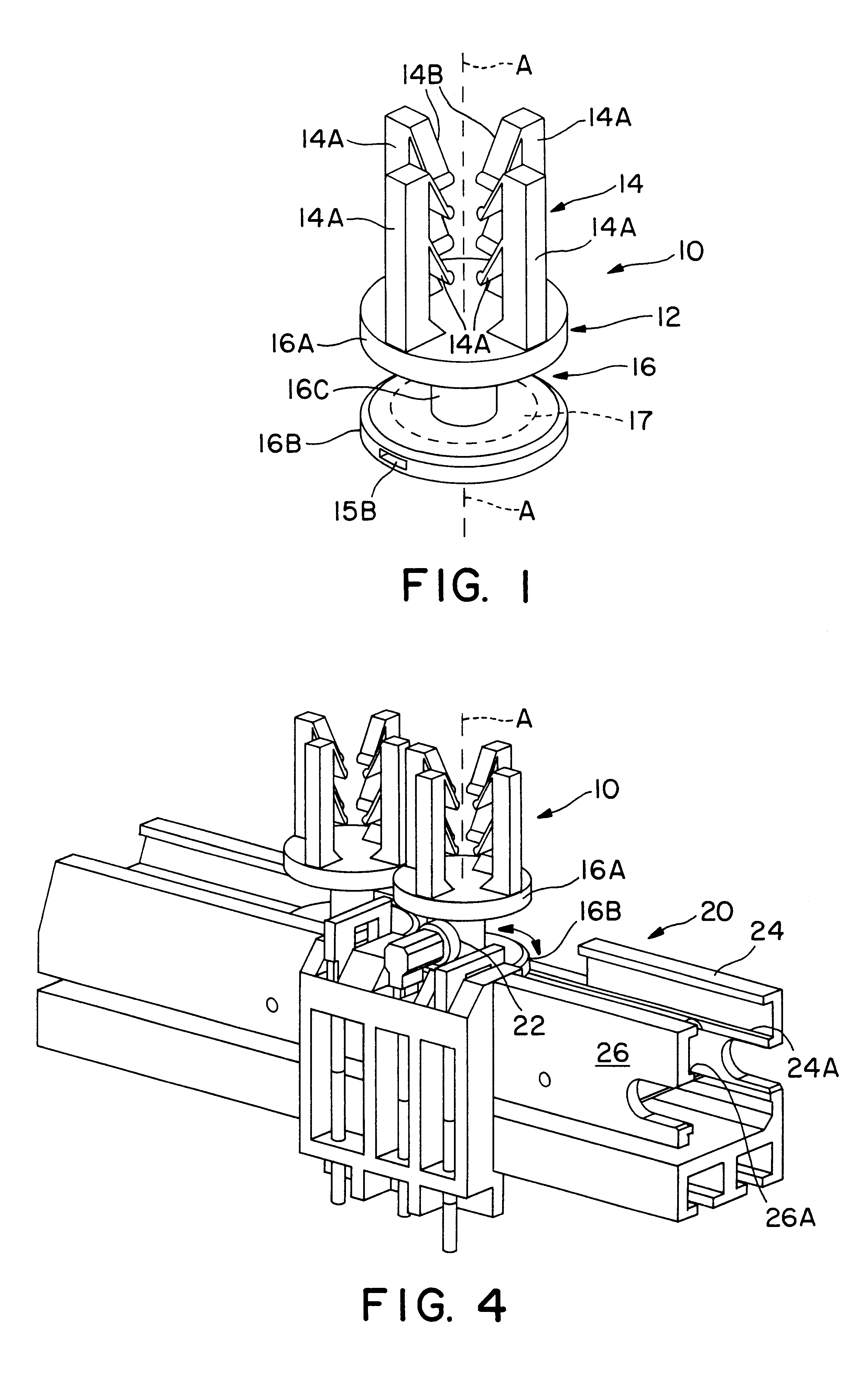

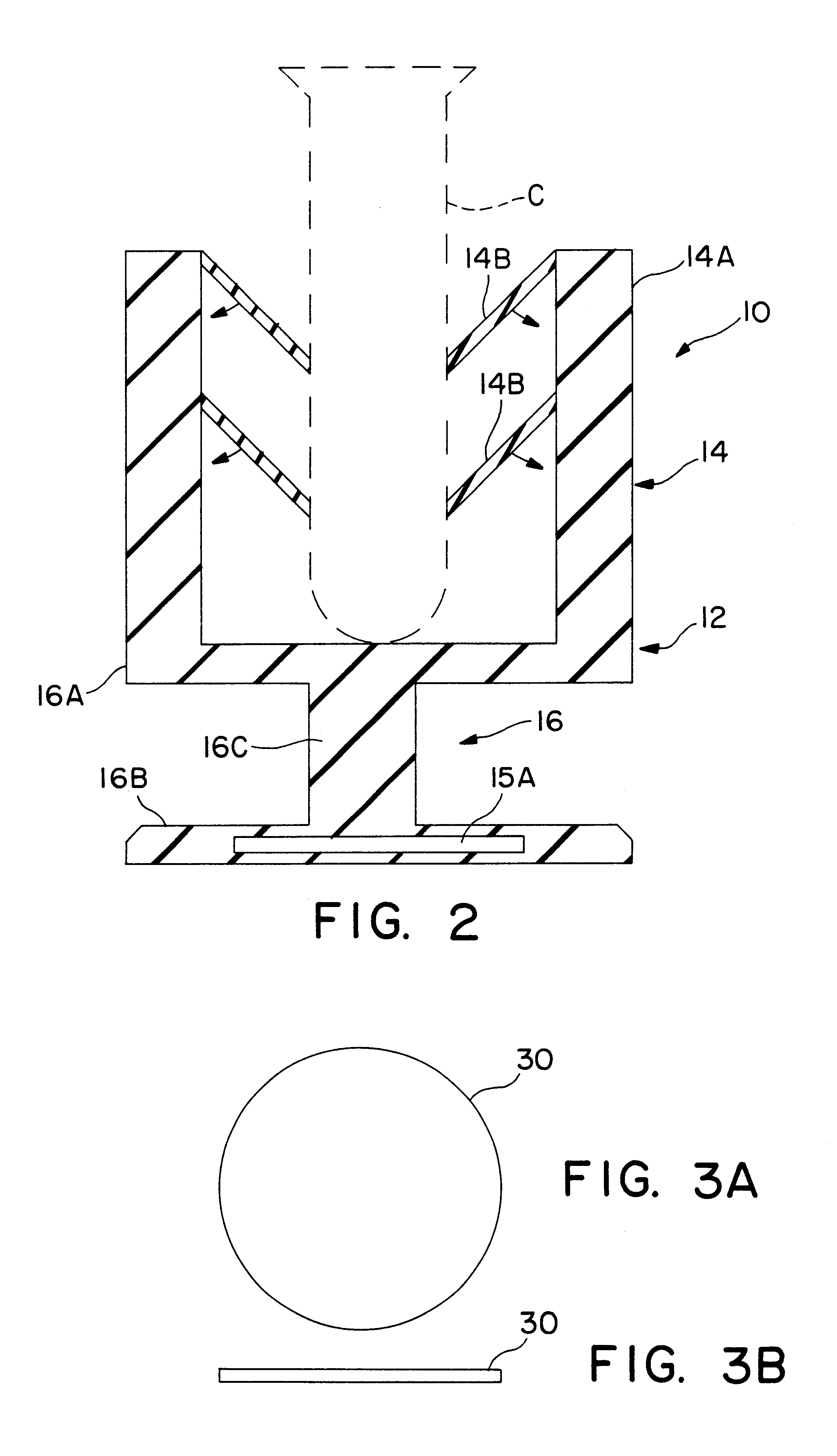

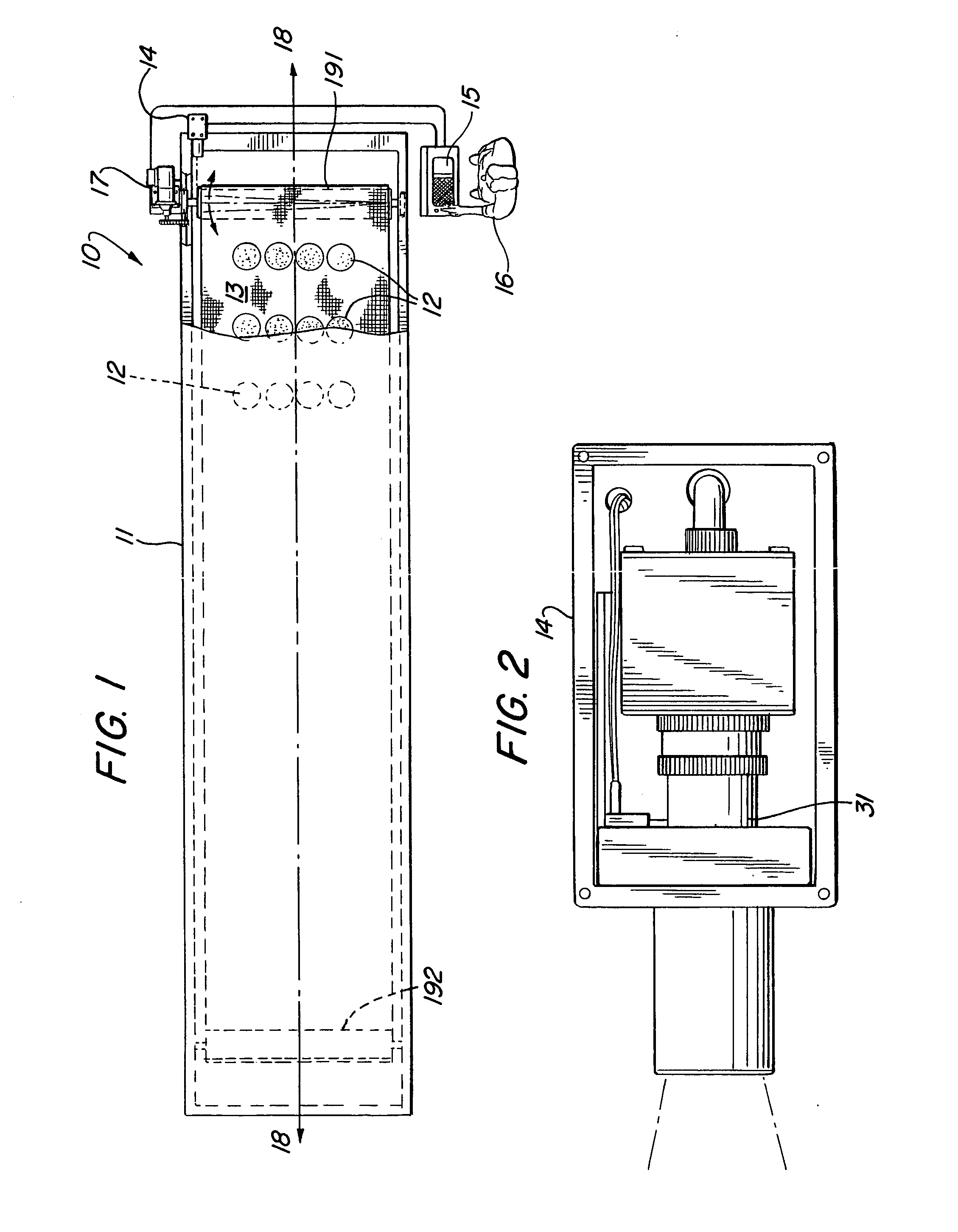

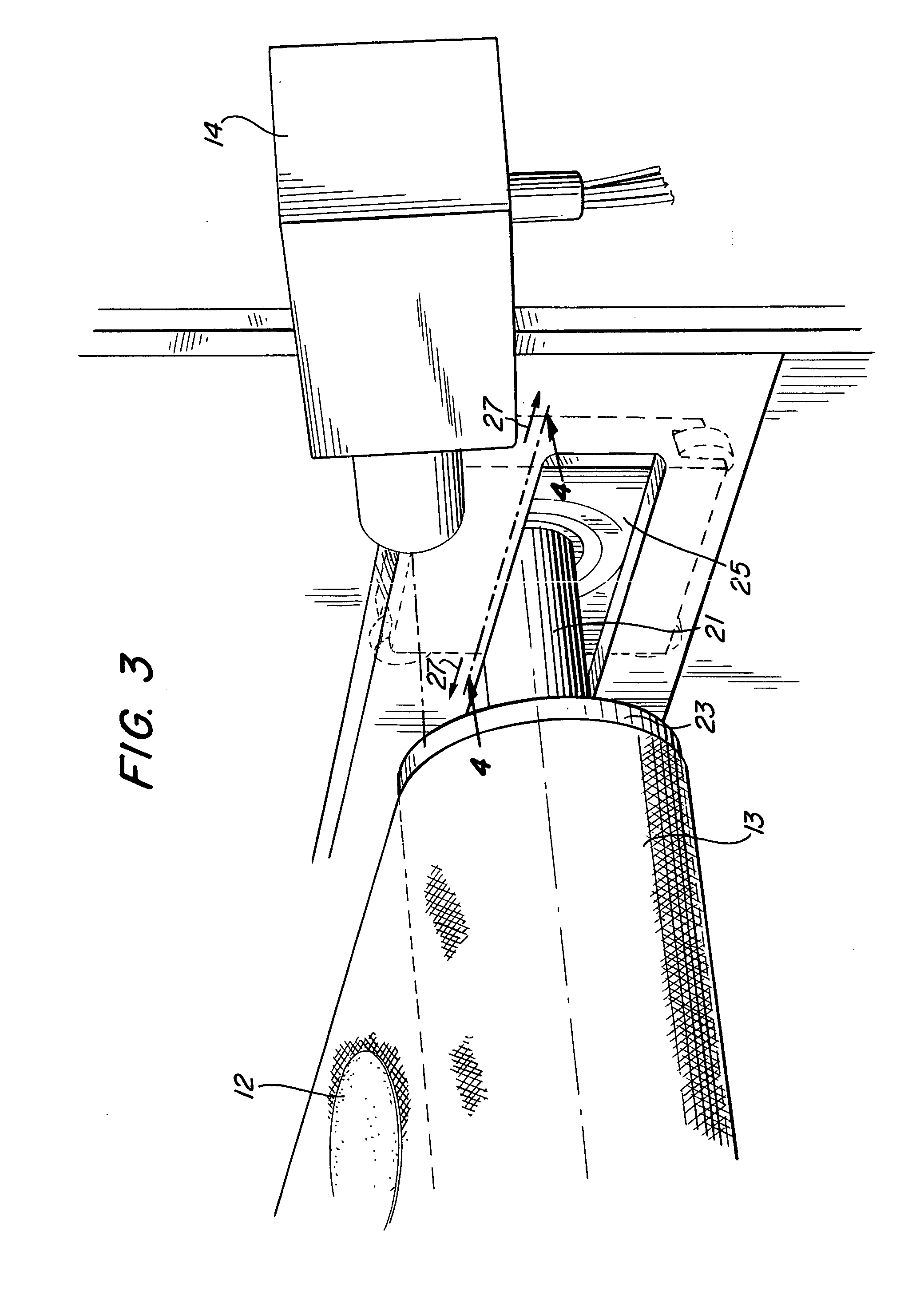

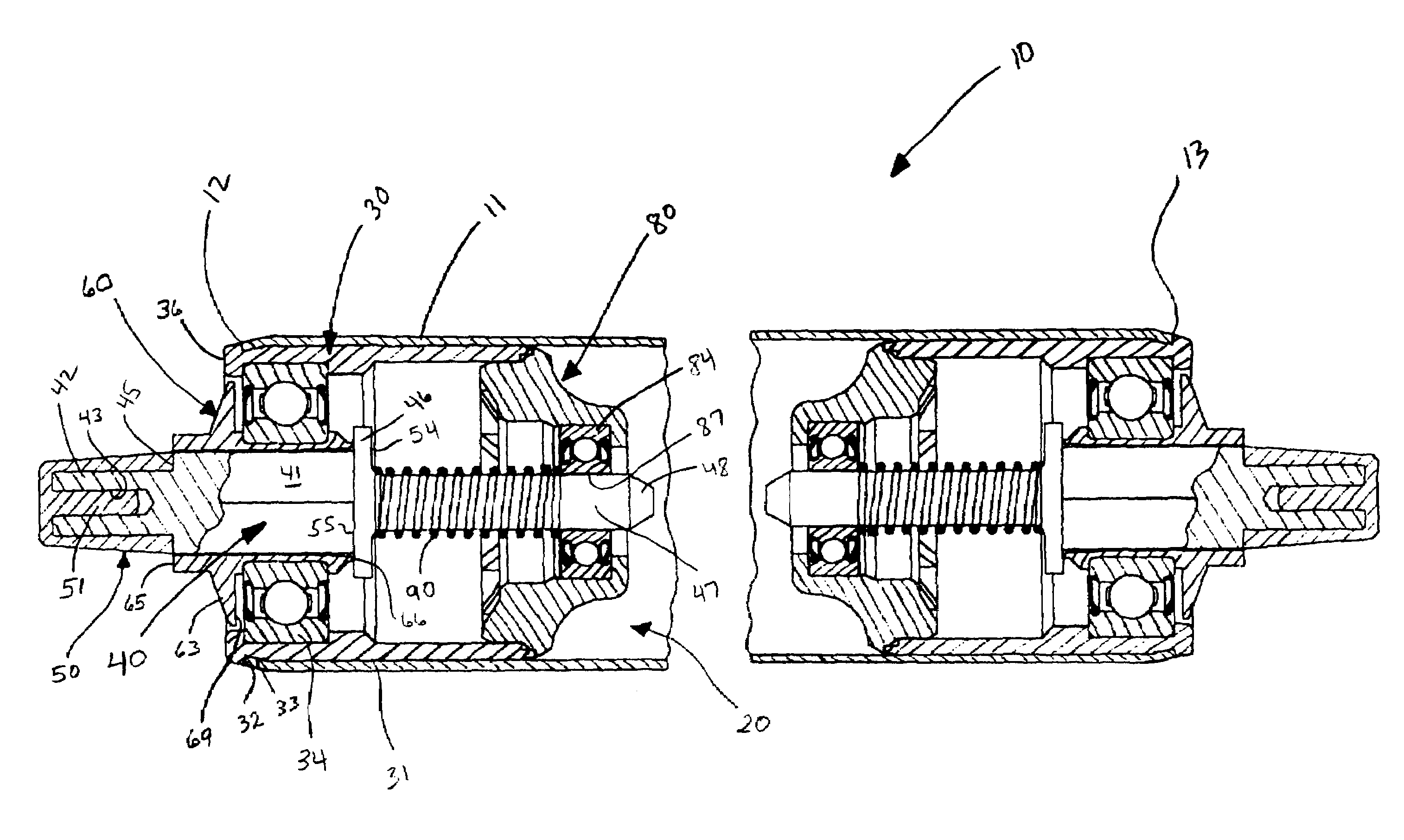

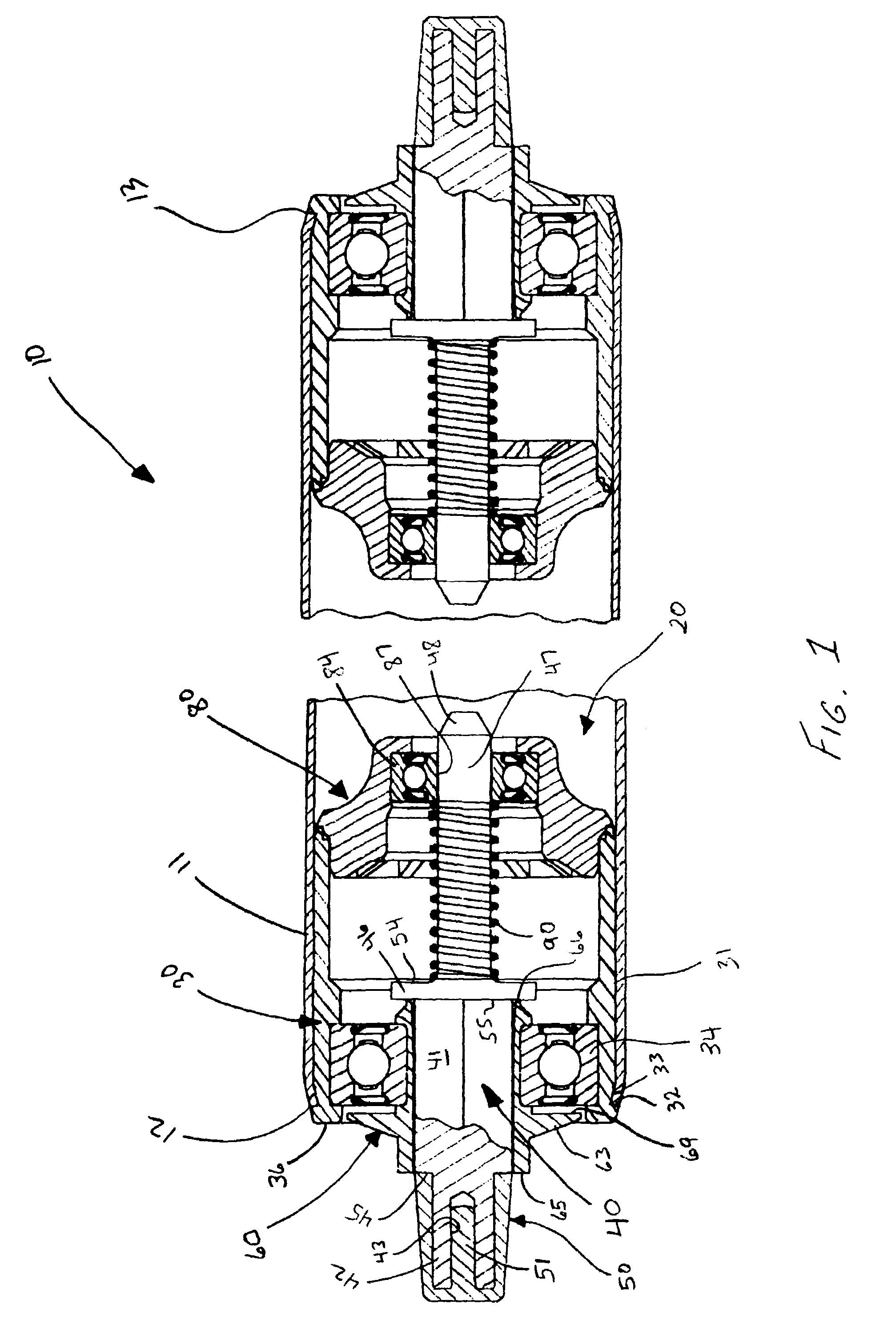

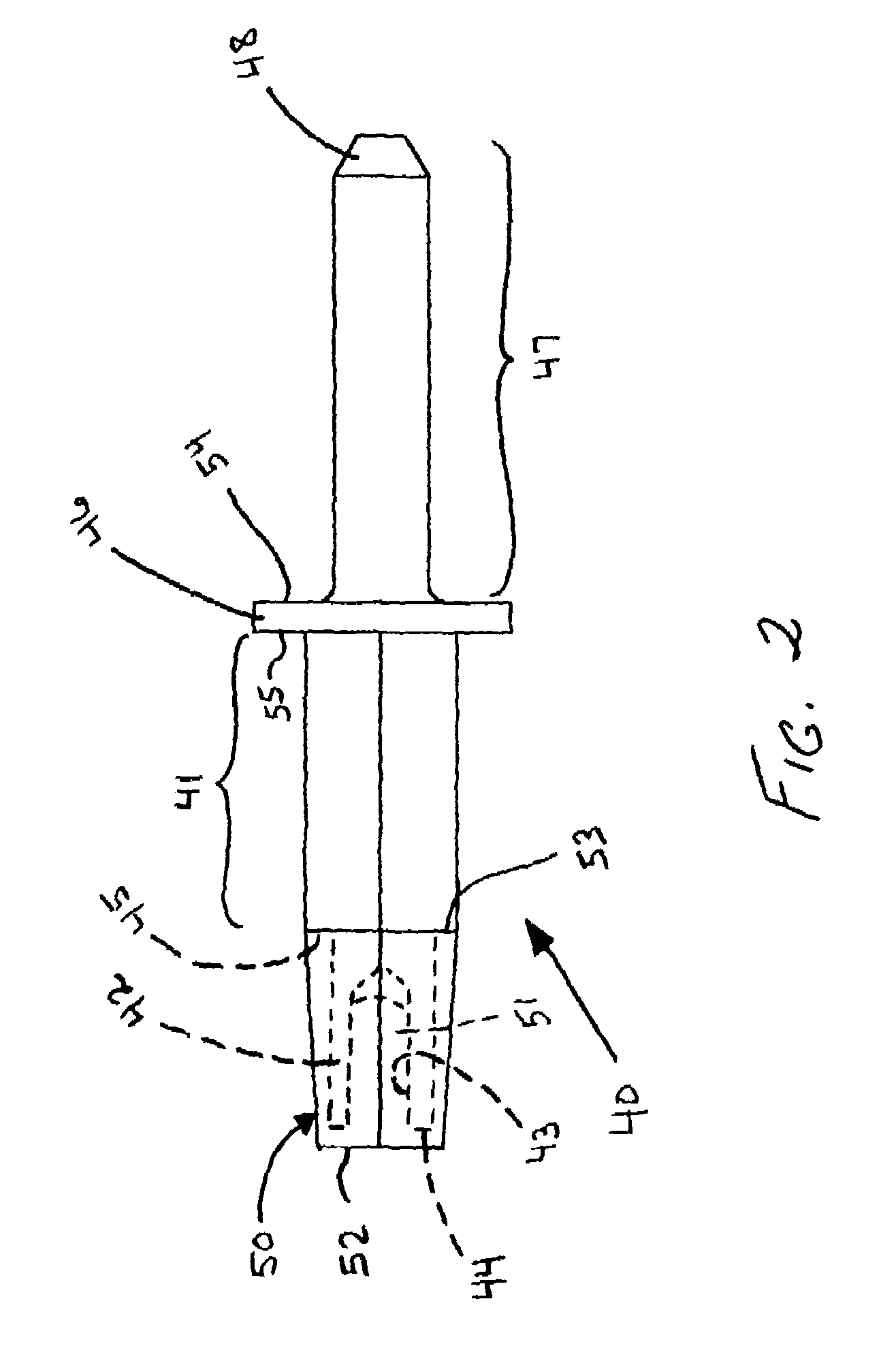

Specimen carrier for automated transport system and method and apparatus for identifying same

A specimen carrier comprises a unitary structure for receiving and retaining a specimen container in an upright orientation. Such unitary structure is defined by a pedestal having upper and lower platforms connected by a stem. Extending upwardly from the upper platform is a plurality of rigid members which support a plurality of opposing flexible fingers adapted to engage and press upon the side wall of a specimen container received by the carrier. Preferably, the specimen carrier of the invention has a chamber formed therein for housing a pre-programmed, programmable or otherwise radio-frequency (RF) identification tag in the form of an RF transponder. Upon being energized by a suitable RF field provided by an RF reader antenna or sensor positioned adjacent the carrier's intended path of movement, the tag transmits a unique identification code, such code being received by the antenna or sensor and decoded by the reader.

Owner:COULTER INTERNATIONAL CORPORATION

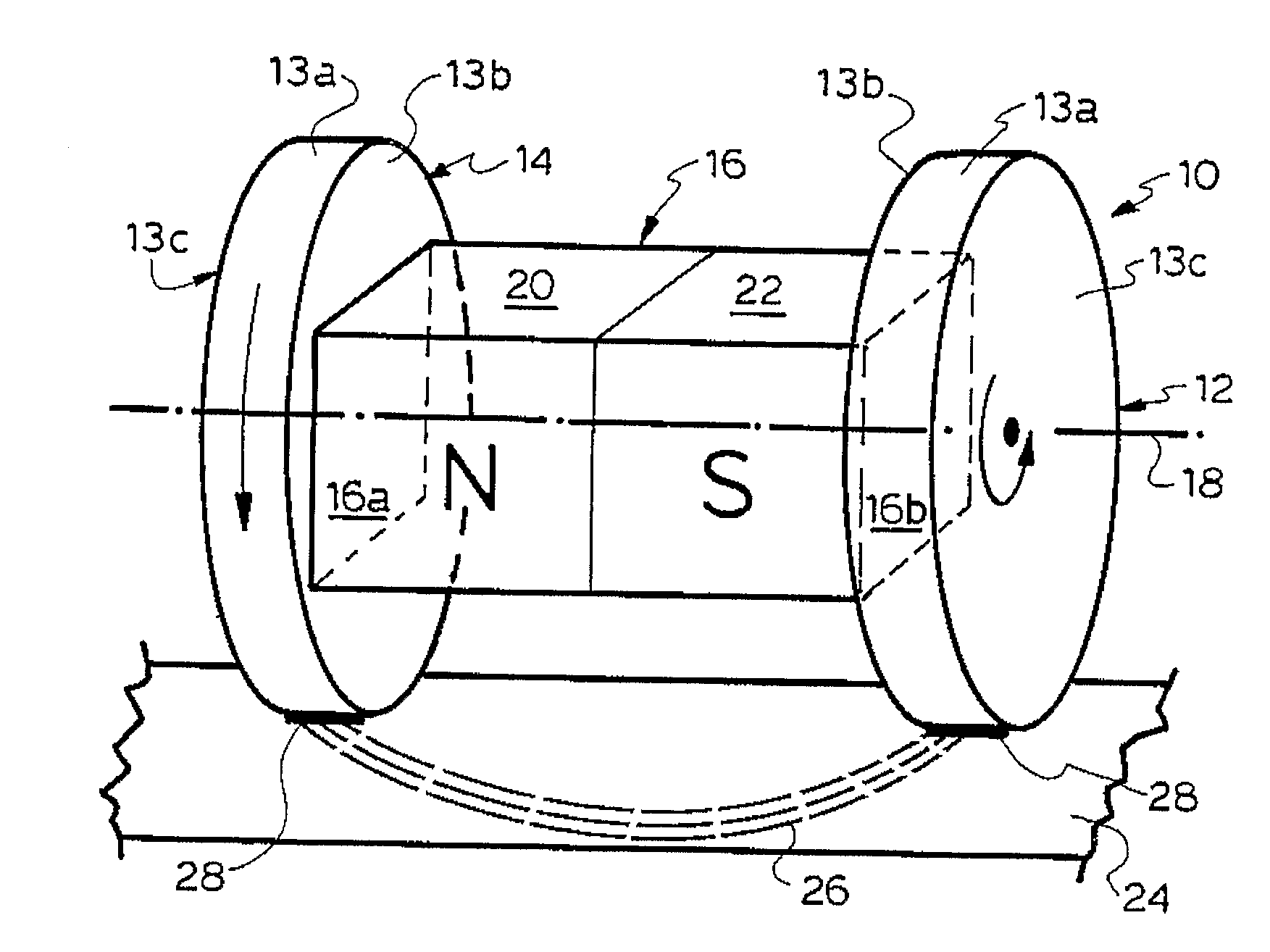

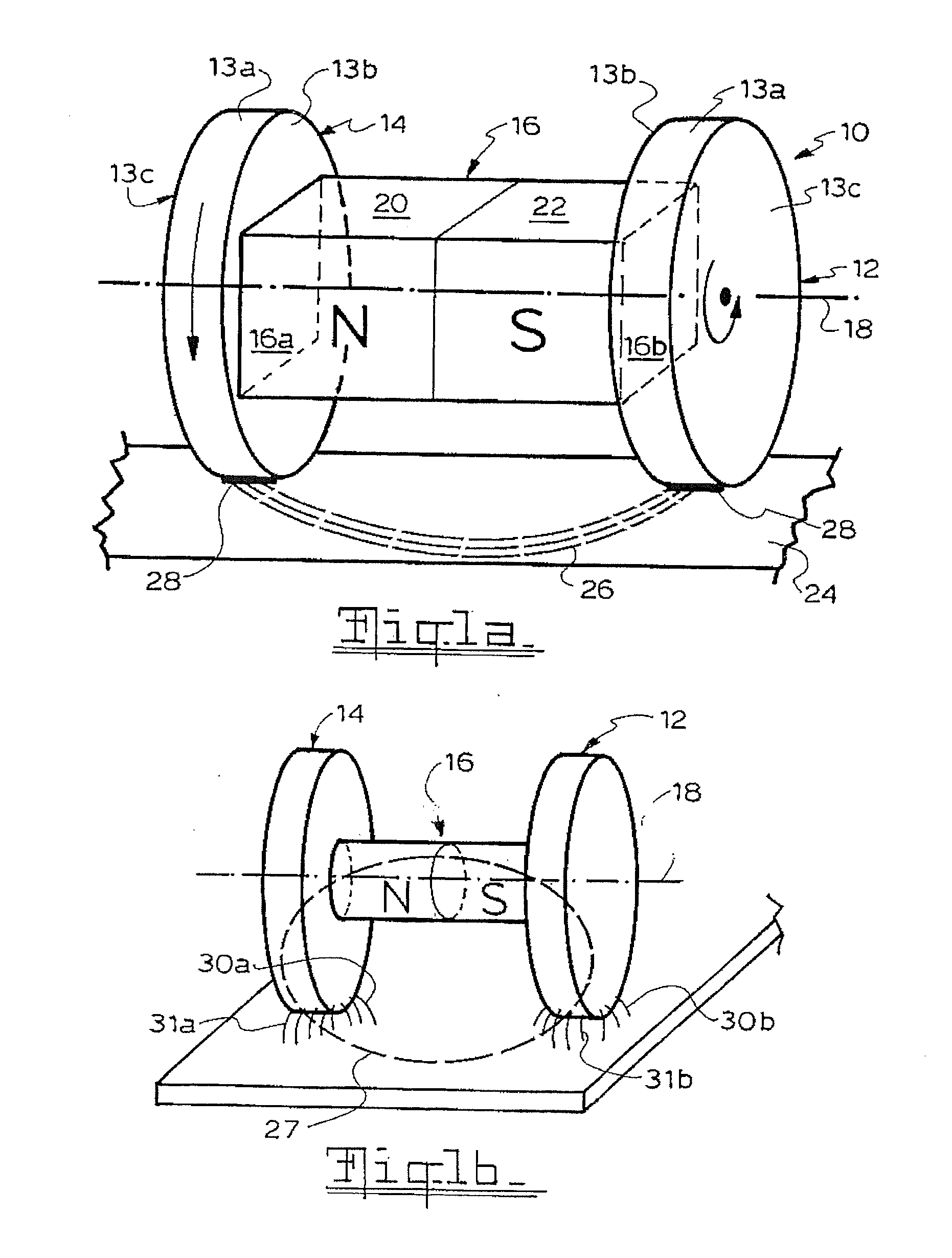

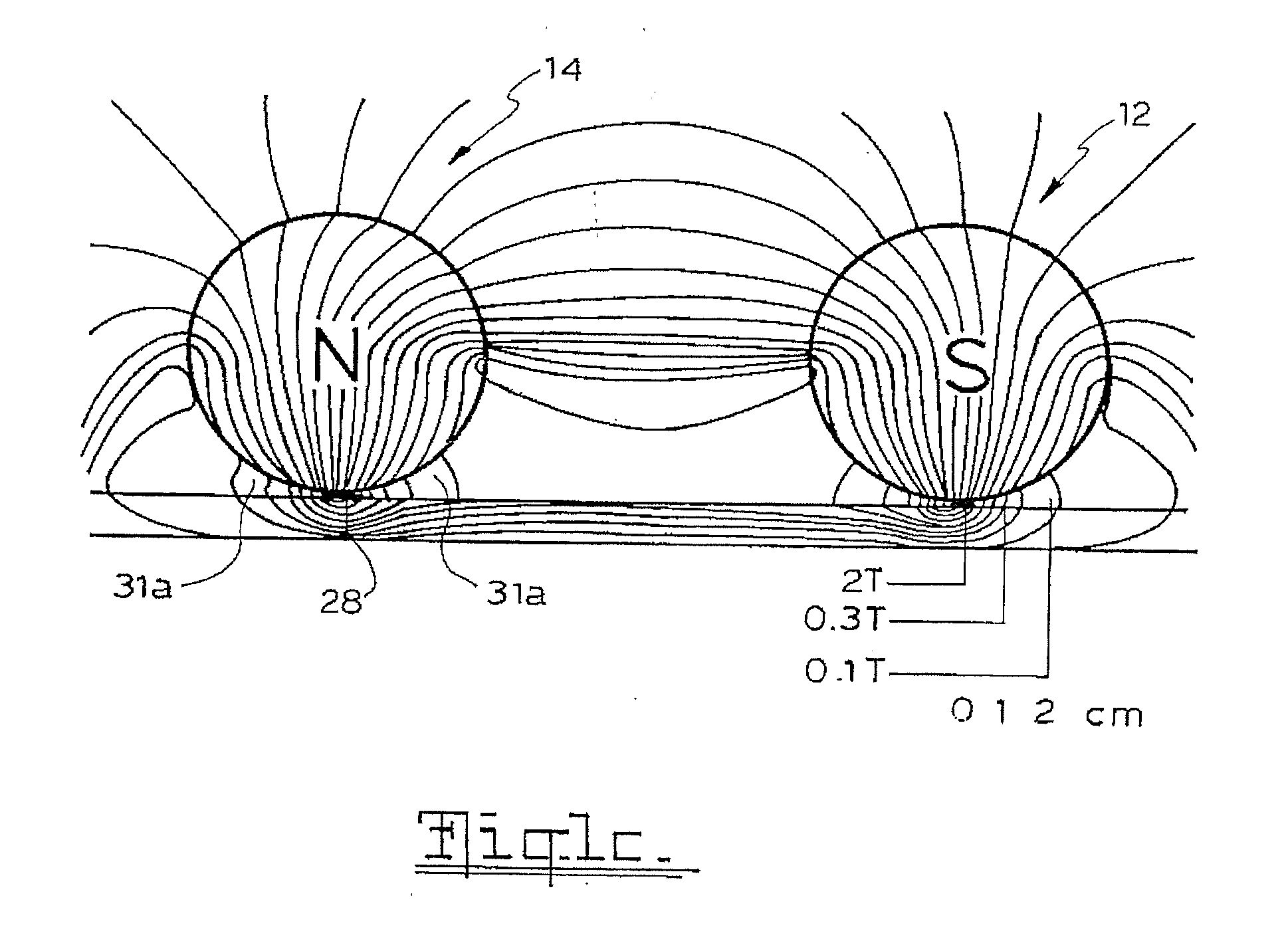

Magnetic wheel

InactiveUS20090078484A1Improve traction efficiencyRestrict movementSki bindingsRailway vehiclesMagnetic polesMagnetic flux

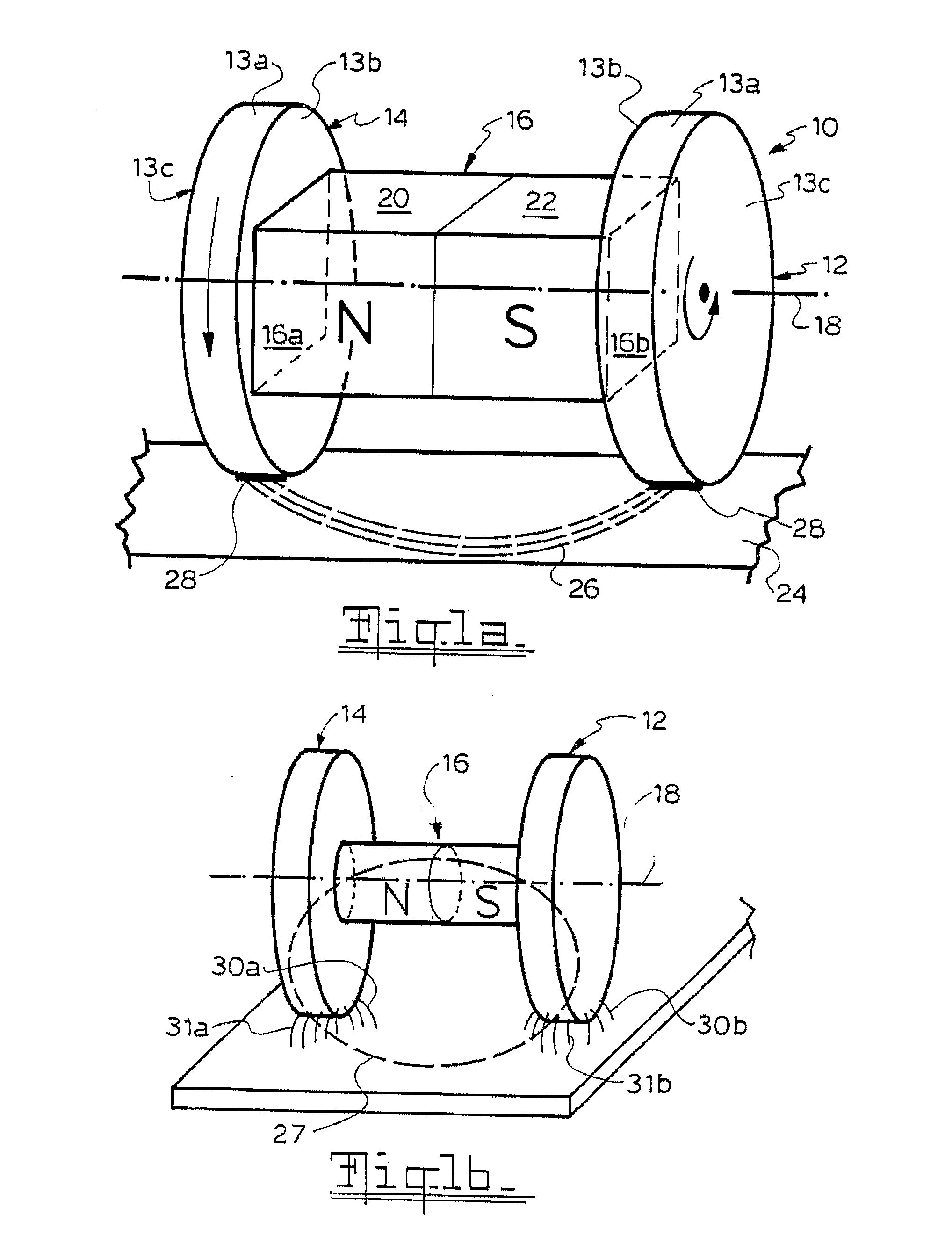

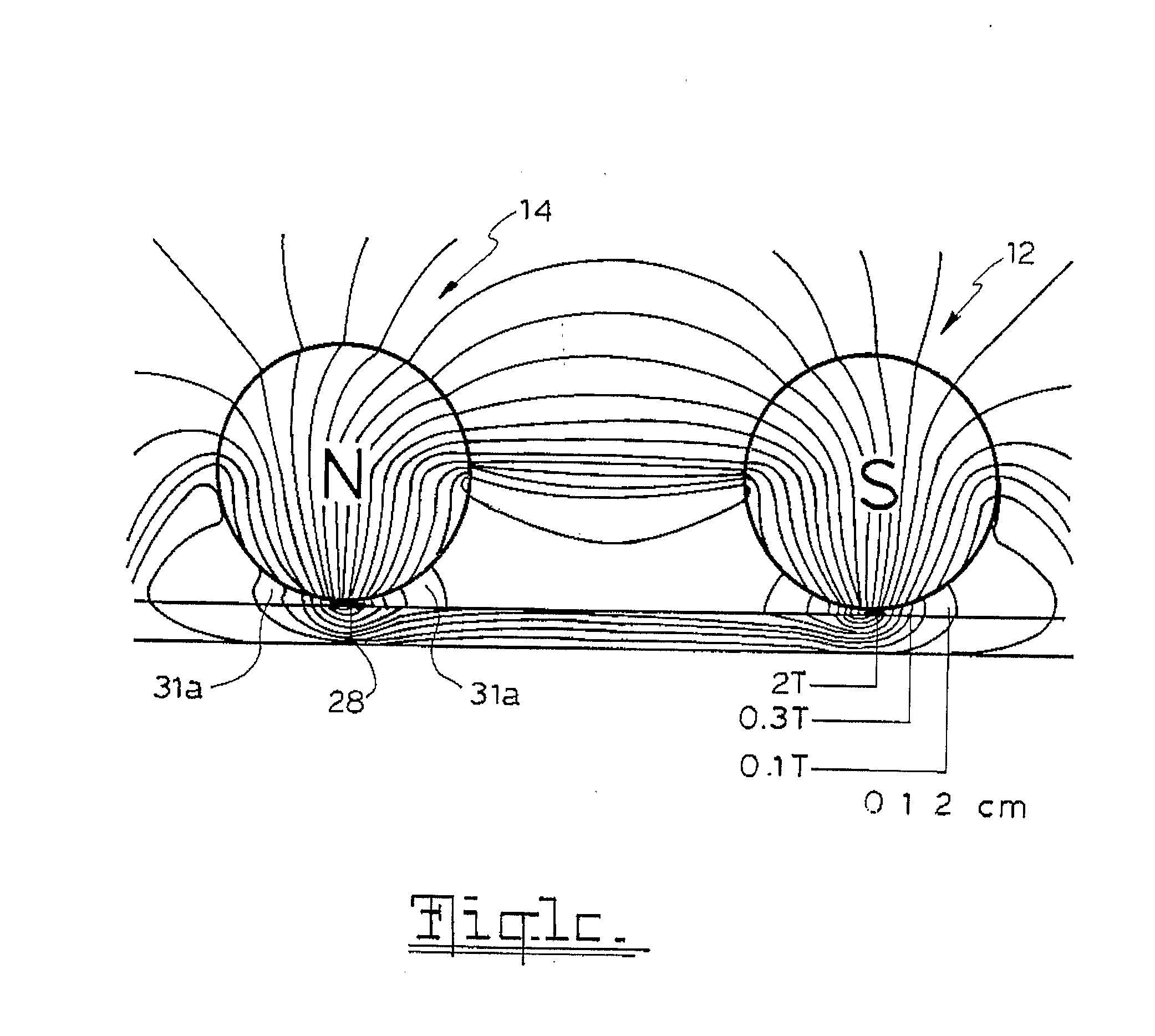

Magnetic circuit that has (a) a source of magnetic flux which includes an electromagnet or one or more permanent magnets, (b) at least two oppositely polarisable pole extension bodies associated with the magnetic flux source, the bodies being disc, wheel, roller or similarly shaped with an outer circumferential surface and held rotatable about respective axes of rotation, and (c) a ferromagnetic counter body which is arranged to cooperate with the pole extension bodies such as to provide an external flux path for the magnetic flux when in magnetic proximity or contact with the circumferential surface of the pole extension bodies, which is characterised in that the magnetic flux source is held stationary relative to the rotatable pole extension bodies.

Owner:MAGSWITCH TECH WORLDWIDE PTY LTD

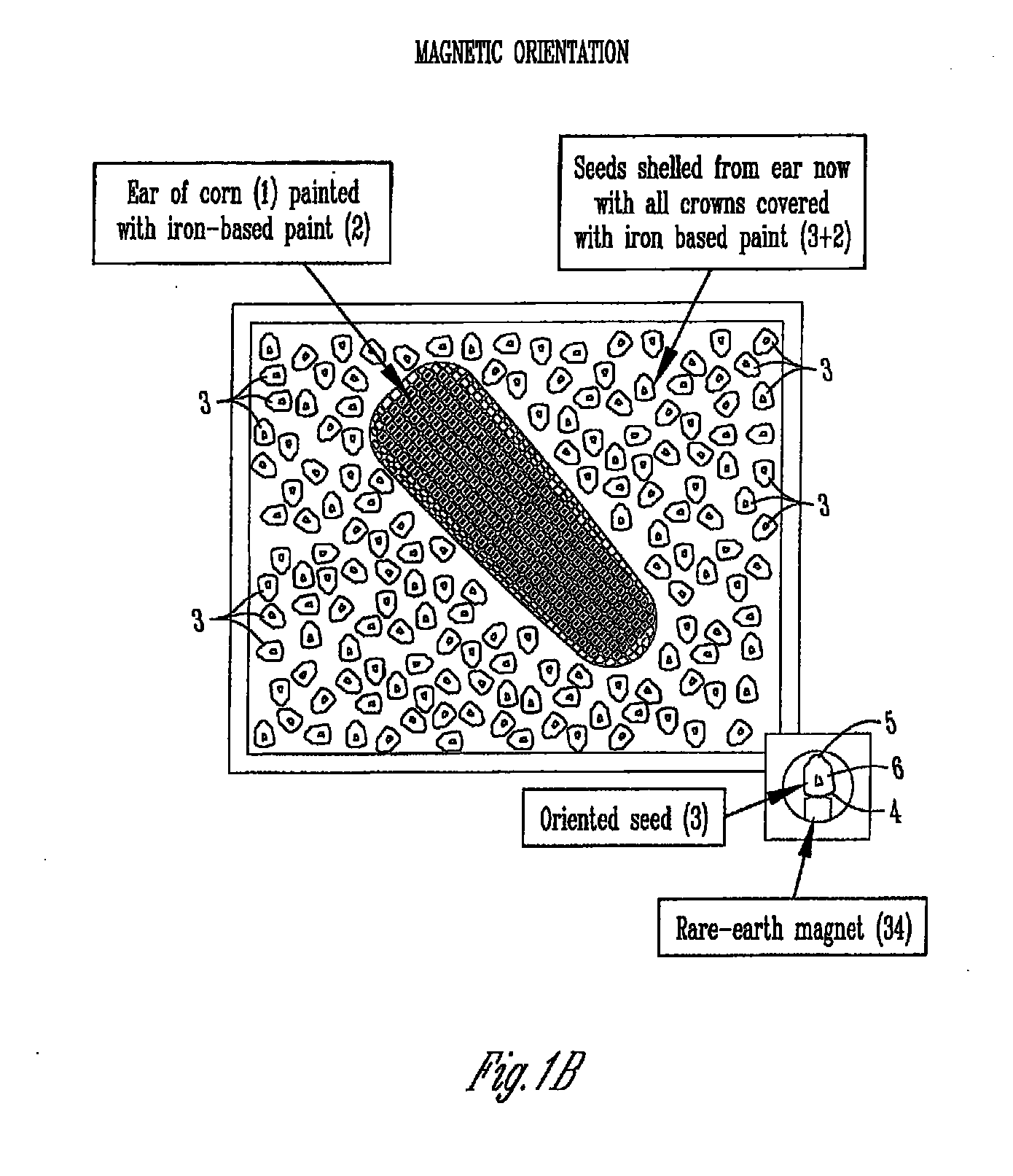

Apparatus, method and system for handling, positioning, and/or automatically orienting objects

InactiveUS20080131254A1Avoid small quantitiesMaximum flexibilityWithdrawing sample devicesPreparing sample for investigationEngineeringComputer vision

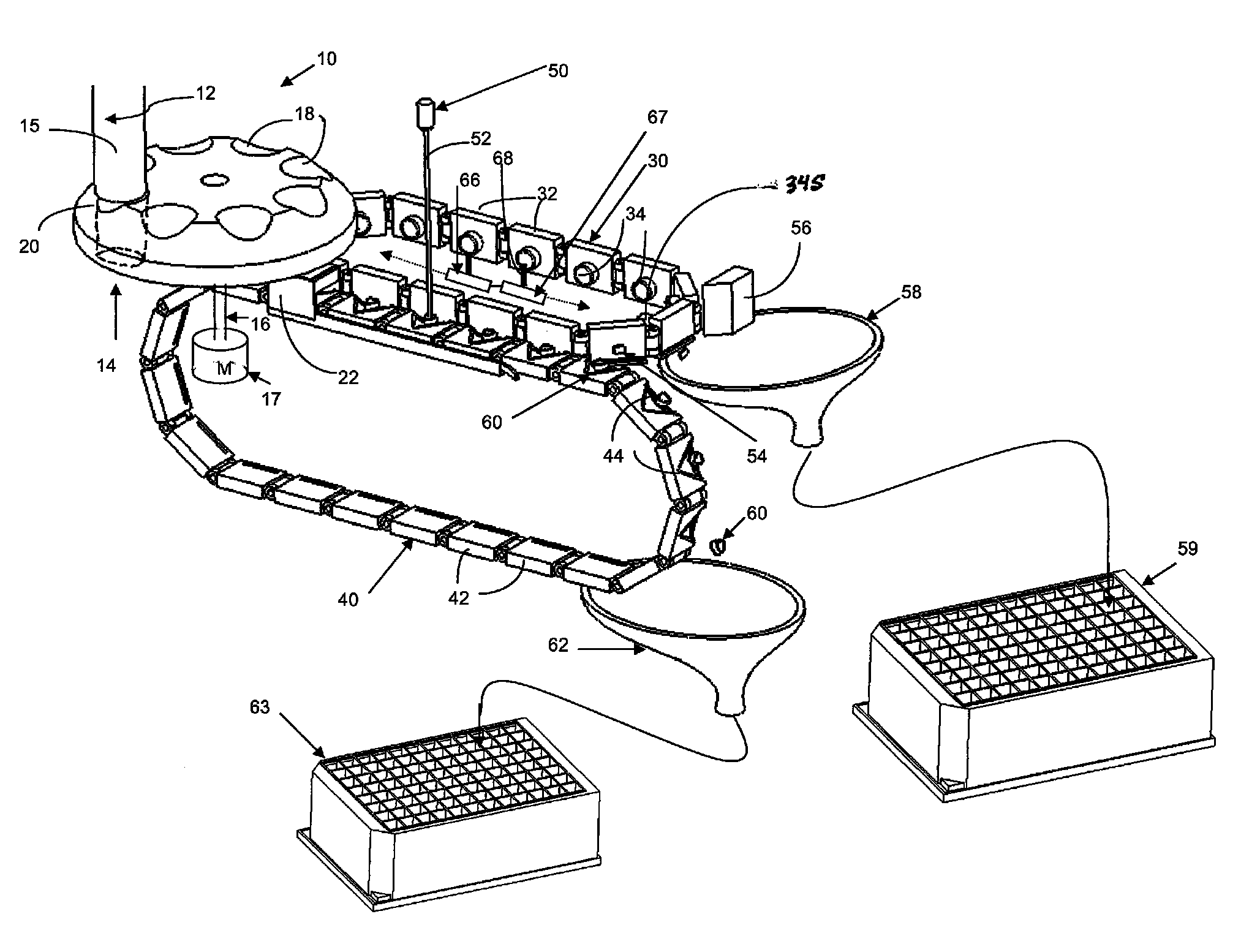

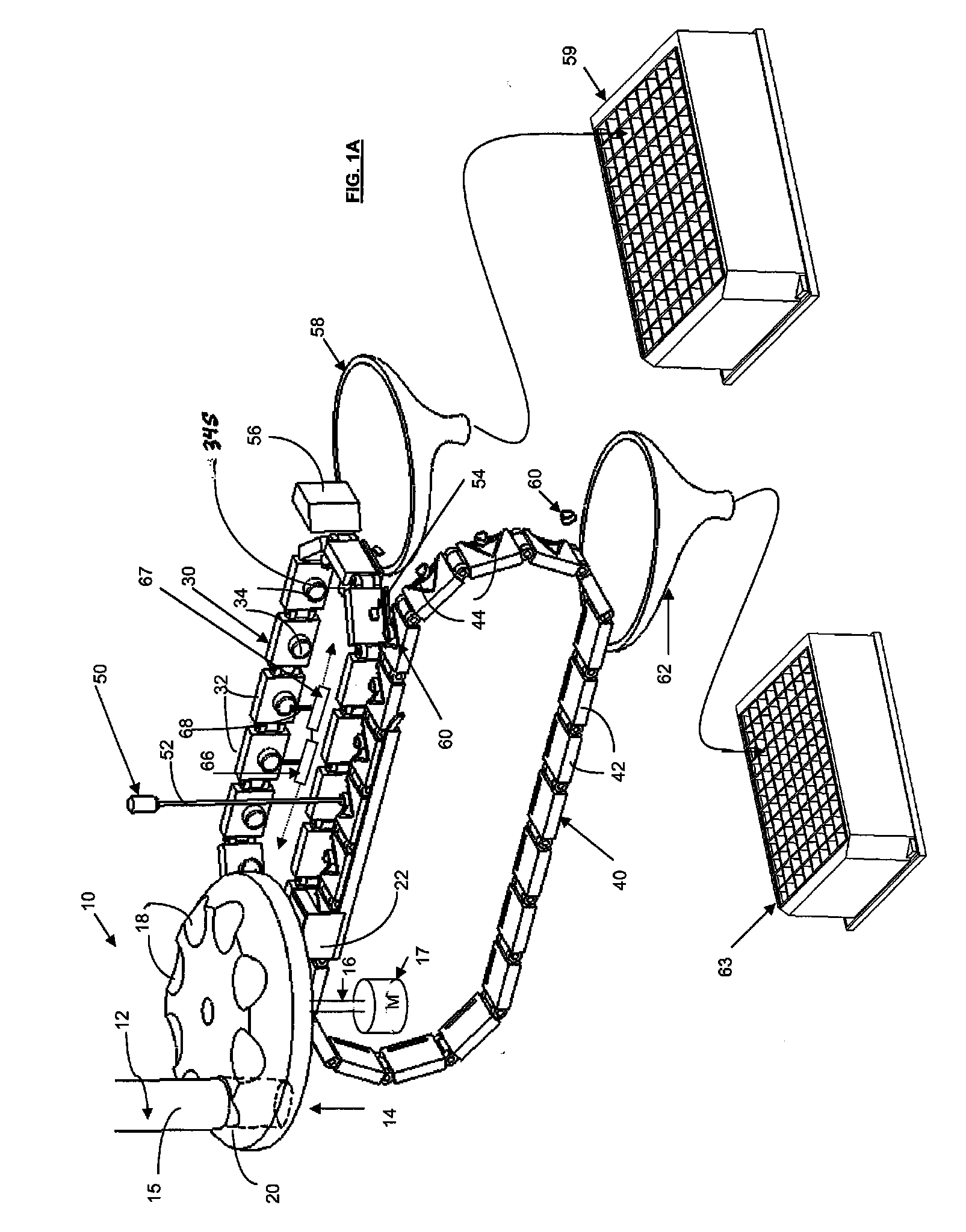

A method and apparatus for automatic positioning and / or orientation of an object. The method includes applying a substance or component to an object, or takes advantage of a substance or component already on or associated with an object. The substance or component has a characteristic that can be utilized to automatically attract the substance or component. That characteristic is used to position, move, and / or orient the object automatically, without requiring manual handling. The object can then be further processed or handled. In one embodiment, the substance or component is a magnetically active substance or component. The attraction can be actuated by a magnet.

Owner:PIONEER HI BRED INT INC

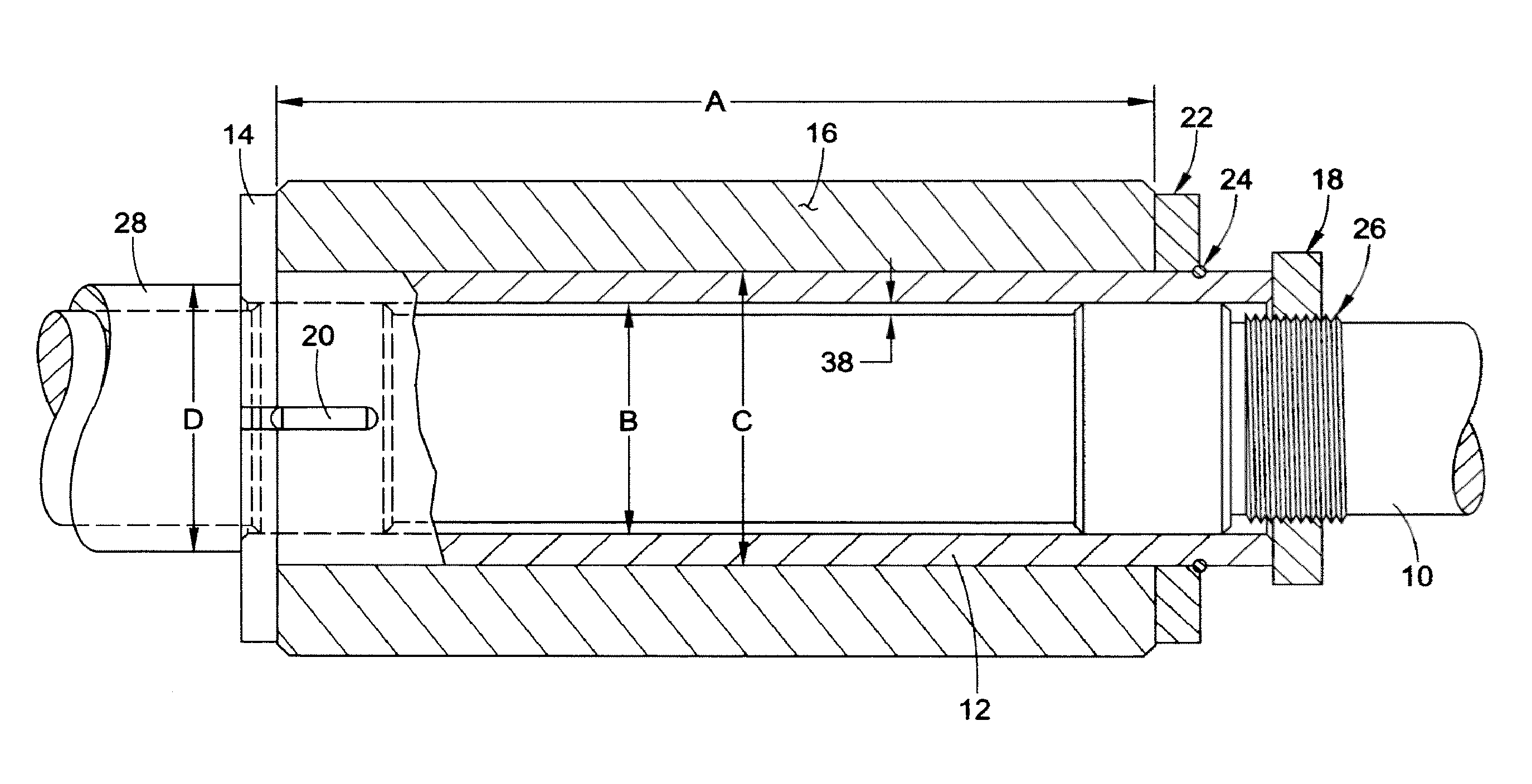

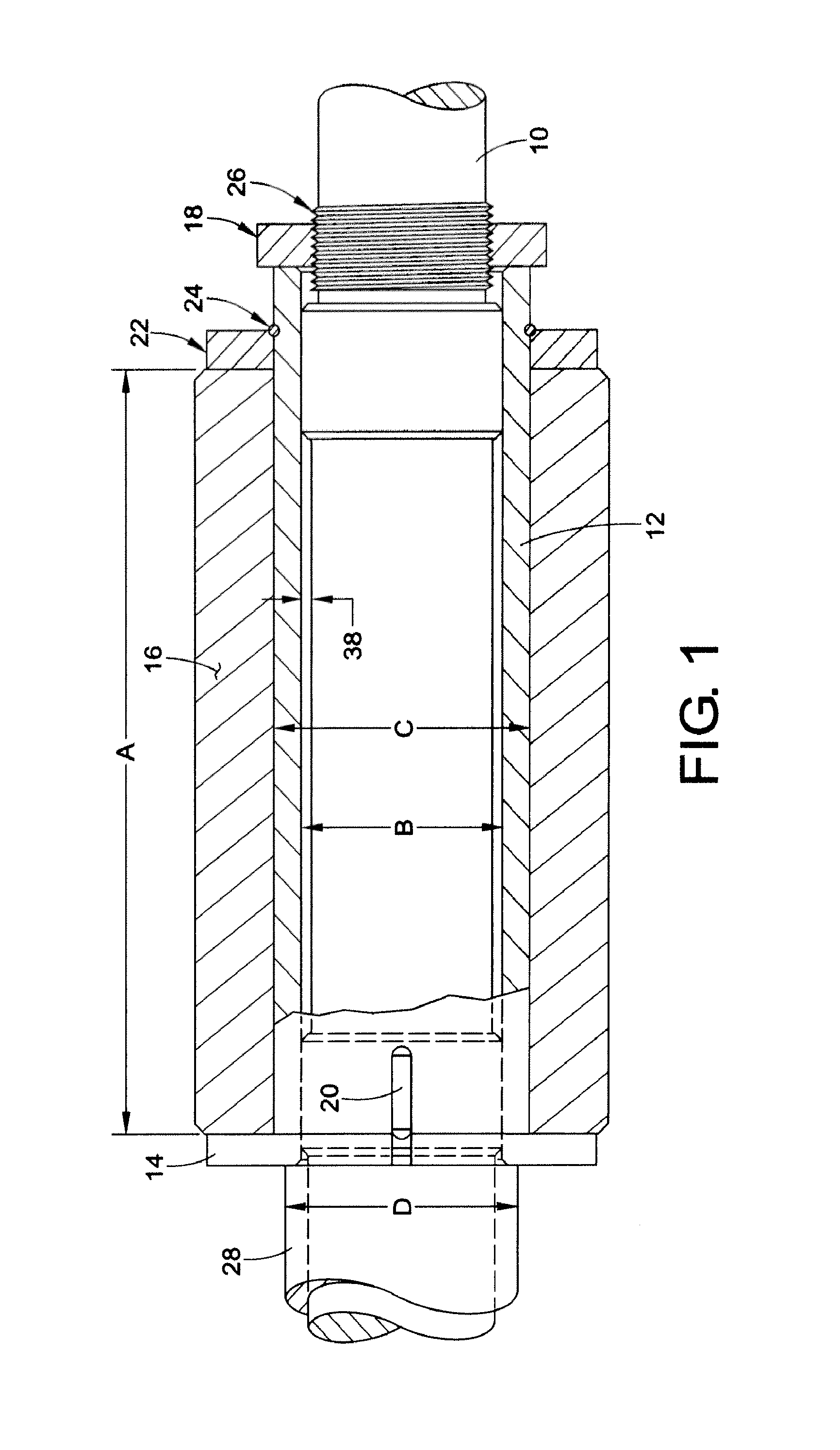

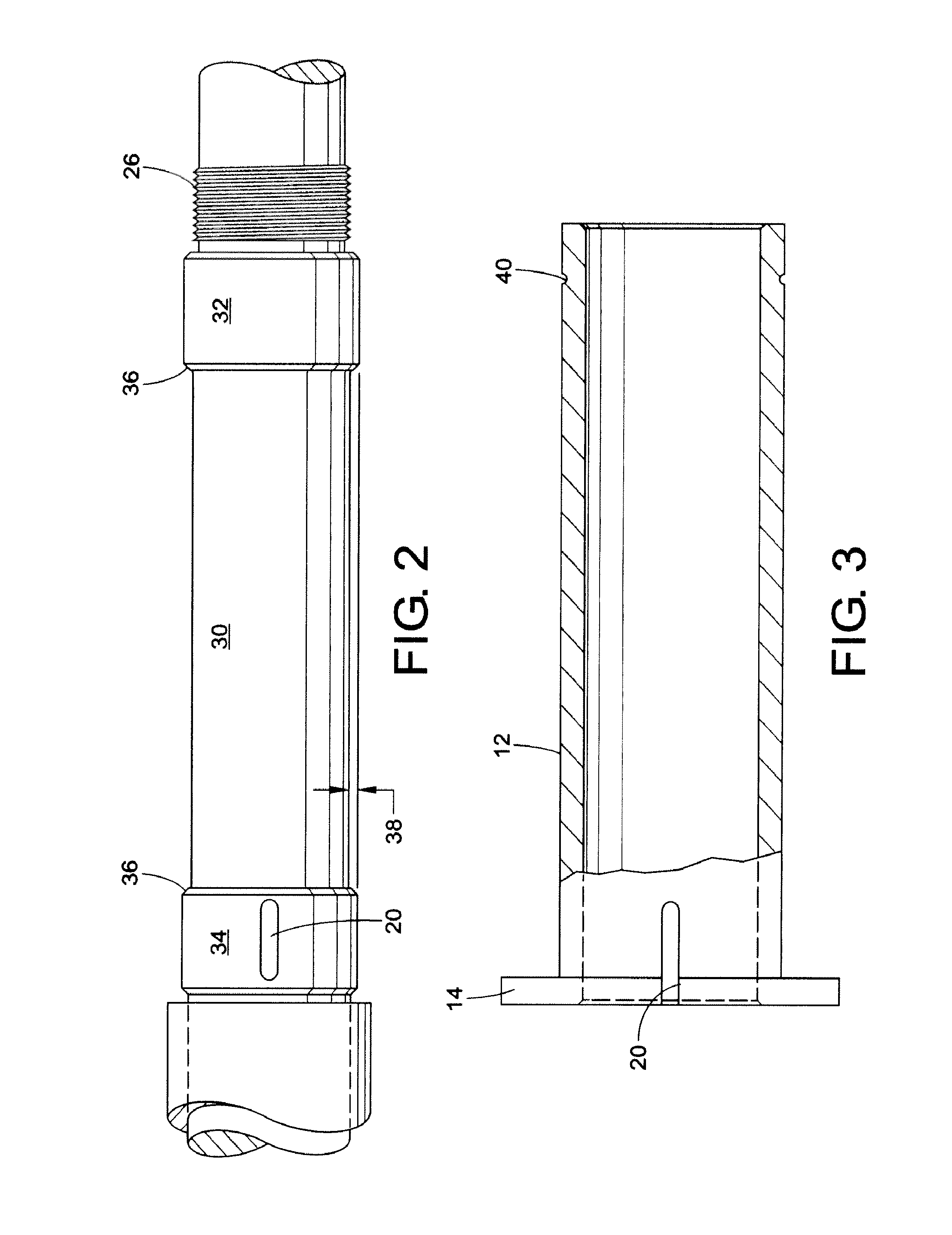

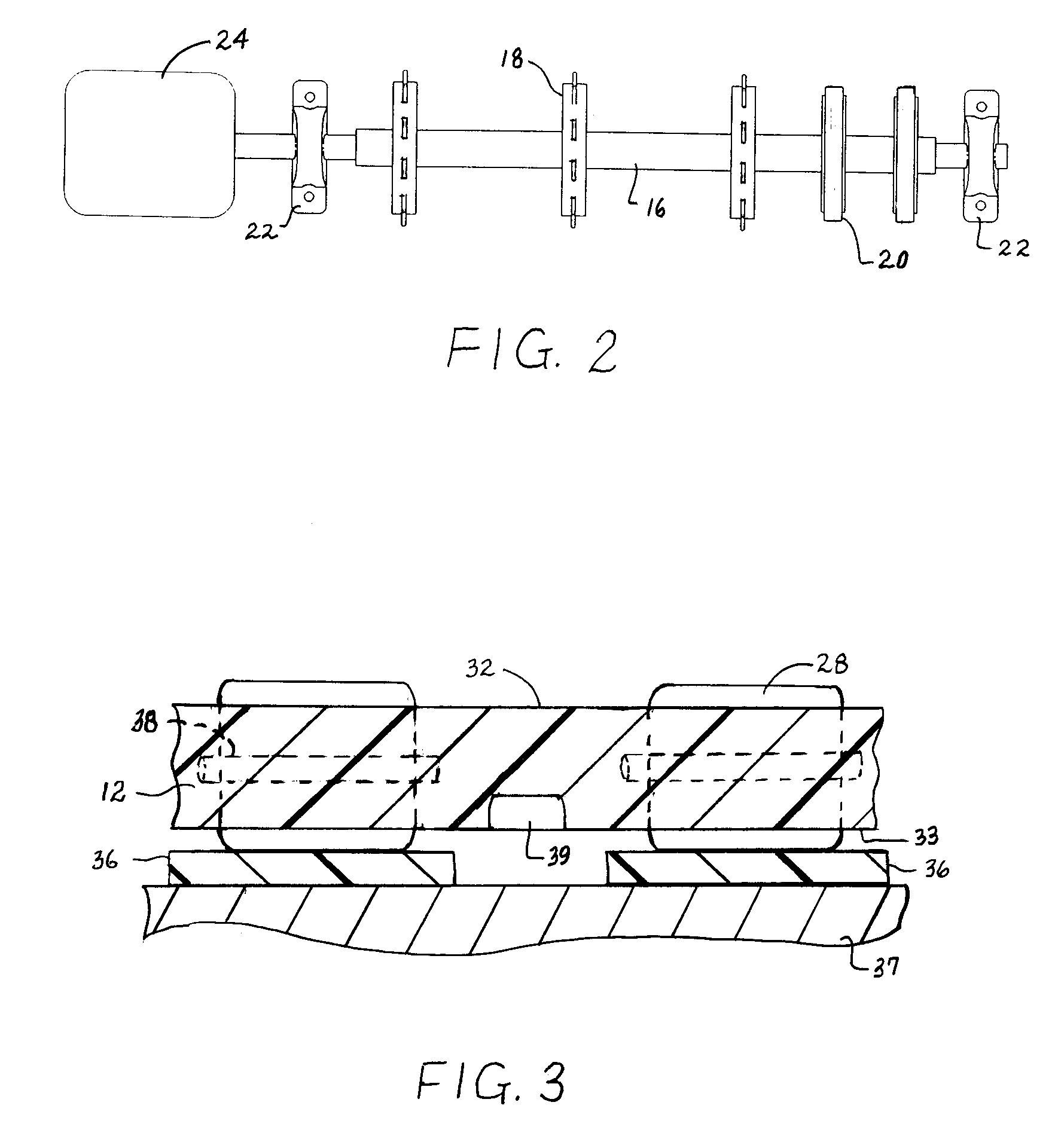

Quick change conveyor roll sleeve assembly and method

InactiveUS8915830B2Hot-dipping/immersion processesElectrolysis componentsEngineeringMechanical engineering

A quick change conveyor roll assembly for metal or glass processing comprising an inner roll shaft having a rigid and elongated cylindrical surface supported and rotationally driven by an associate rotor mean. At least one removable spool having a cylindrical body with a first diameter, a hollow interior therethrough and a collar rigidly adapted at a first end, the collar having a second diameter whereby the second diameter is greater than the first diameter. At least one removable and replaceable insulated roll sleeve being slidably mounted over at least a portion of said removable spool and abutting said collar, the insulated roll sleeve including at least one layer of an insulation material and a securing means operably adjustable to hold said roll sleeve about said removable spool at a second end in a predetermined location on said inner roll shaft.

Owner:PYROTECK INC

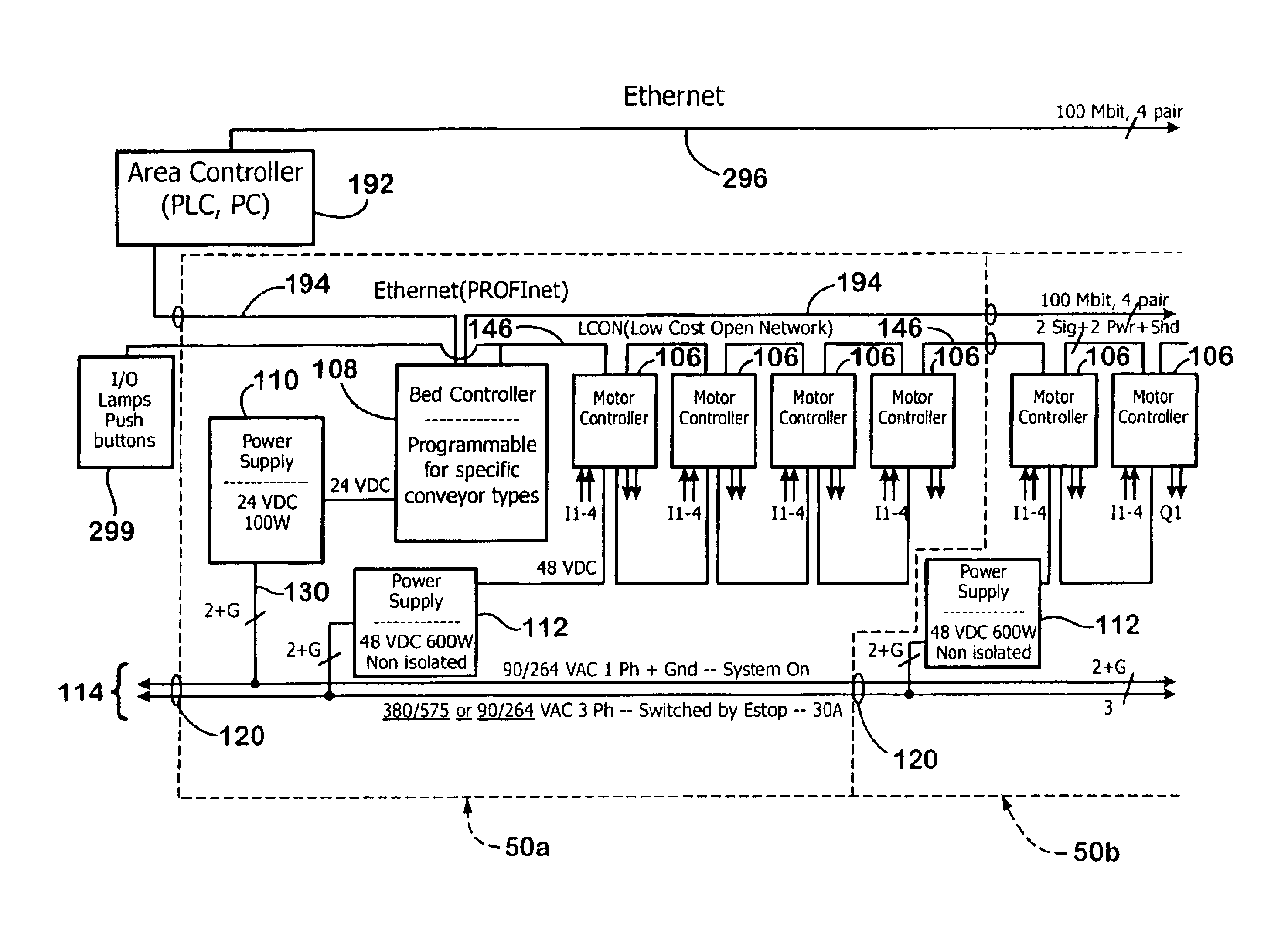

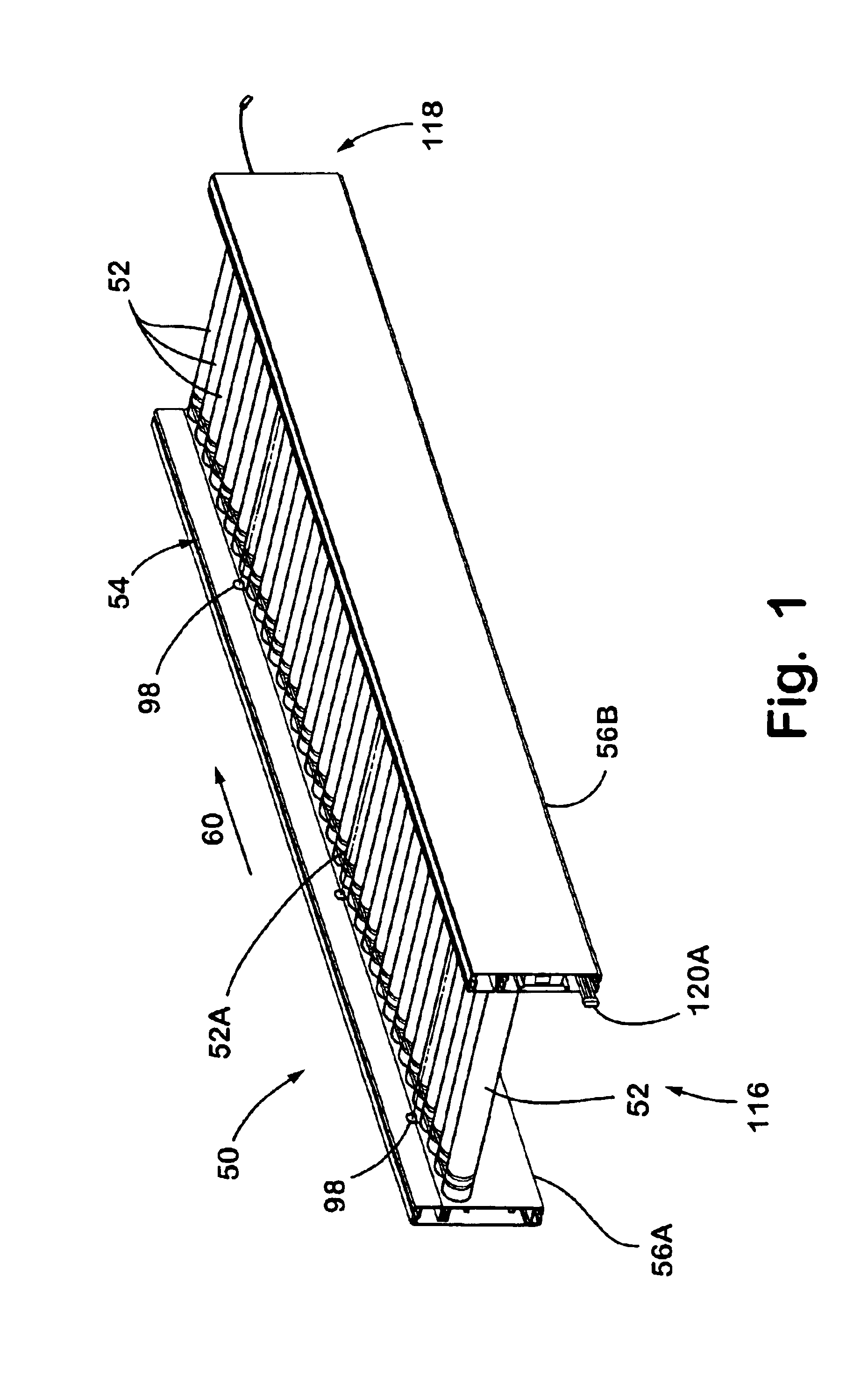

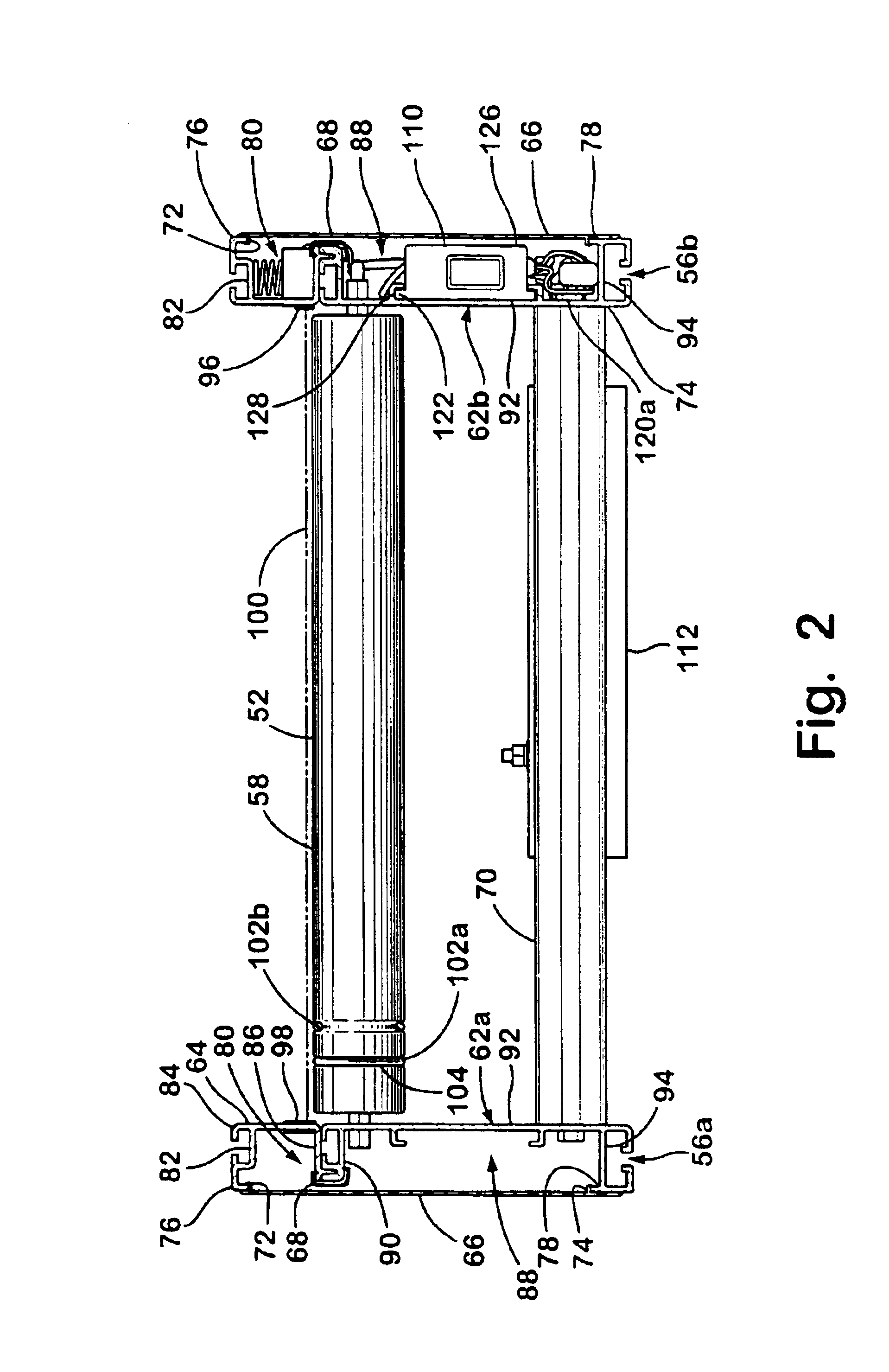

Integrated conveyor bed

InactiveUS7035714B2Simplifies installation and operation and maintenanceEasy to installDigital data processing detailsControl devices for conveyorsControl theoryElectric motor

A conveyor system, and method of controlling the conveyor system, includes providing a conveying surface, at least one motor propelling the conveying surface and a plurality of lower-level controllers. At least one of the lower-level controllers adapted to control the at least one motor. An upper-level controller is provided in communication with the plurality of lower-level controllers. The upper-level controller is adapted to send communications to the lower-level controllers for controlling the at least one motor. A communications bus is provided that carries the communications between the upper-level controller and the lower-level controllers. The upper-level controller is adapted to automatically assign each lower-level controller a unique communications address. The unique communications address enables the upper-level controller to send messages over the communications bus to individual ones of the lower-level controllers.

Owner:DEMATIC

Conveyor system load transfer devices

Conveyor systems for storage and movement of goods on pallets and slip sheets. The transfer structures enable slip sheet mounted loads to be transferred to a roller conveyor by providing structures that cooperate with wide platen forks of a lift truck. The structures provide roller contact between a portion of the underside of the slip sheet at all times. In other areas there is alternatively contact between a lift truck platen or additional rollers that cooperate in a manner making it possible to move the slip sheet mounted load from the lift truck to an adjacent conveyor system.

Owner:CREATIVE STORAGE SYST

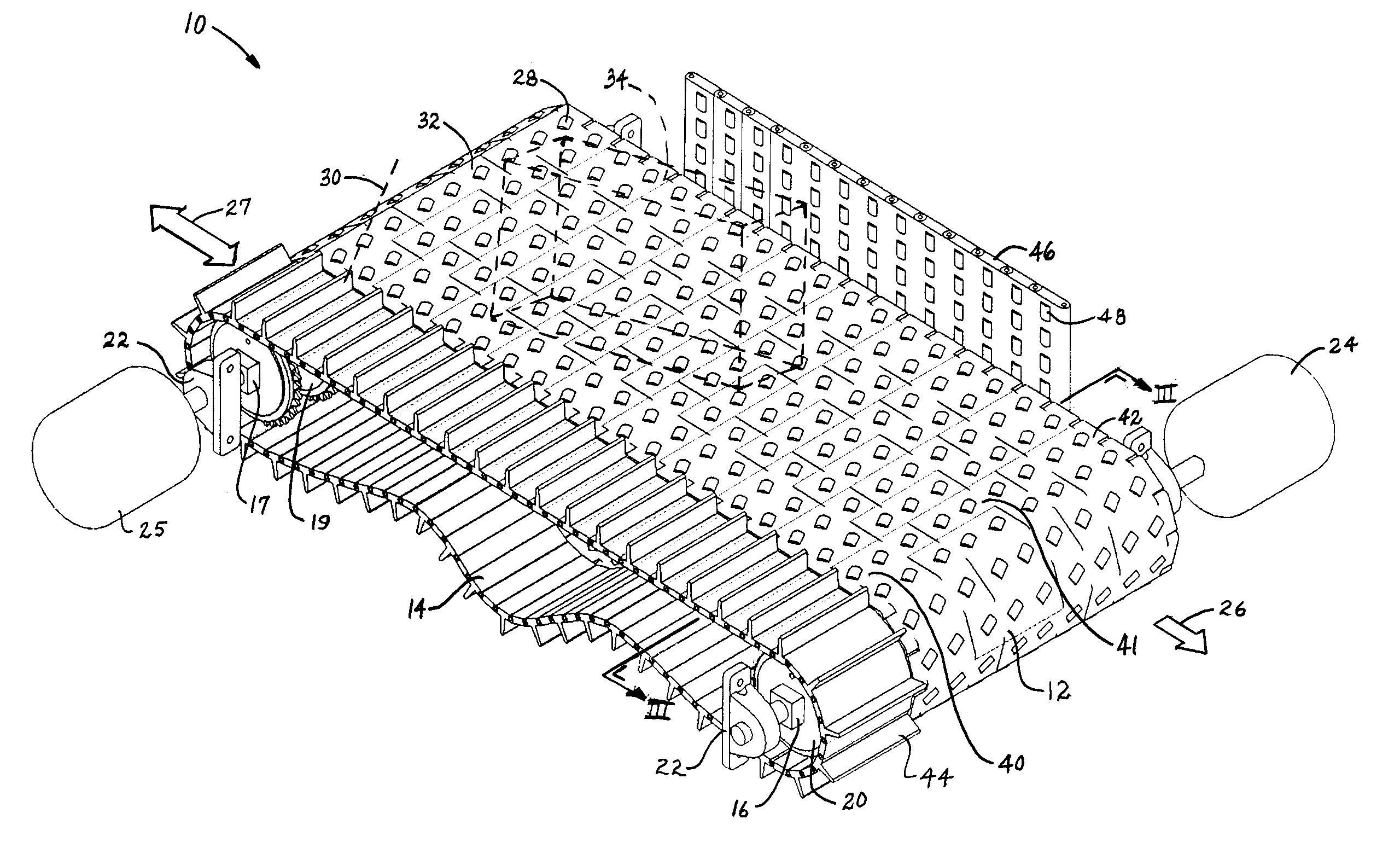

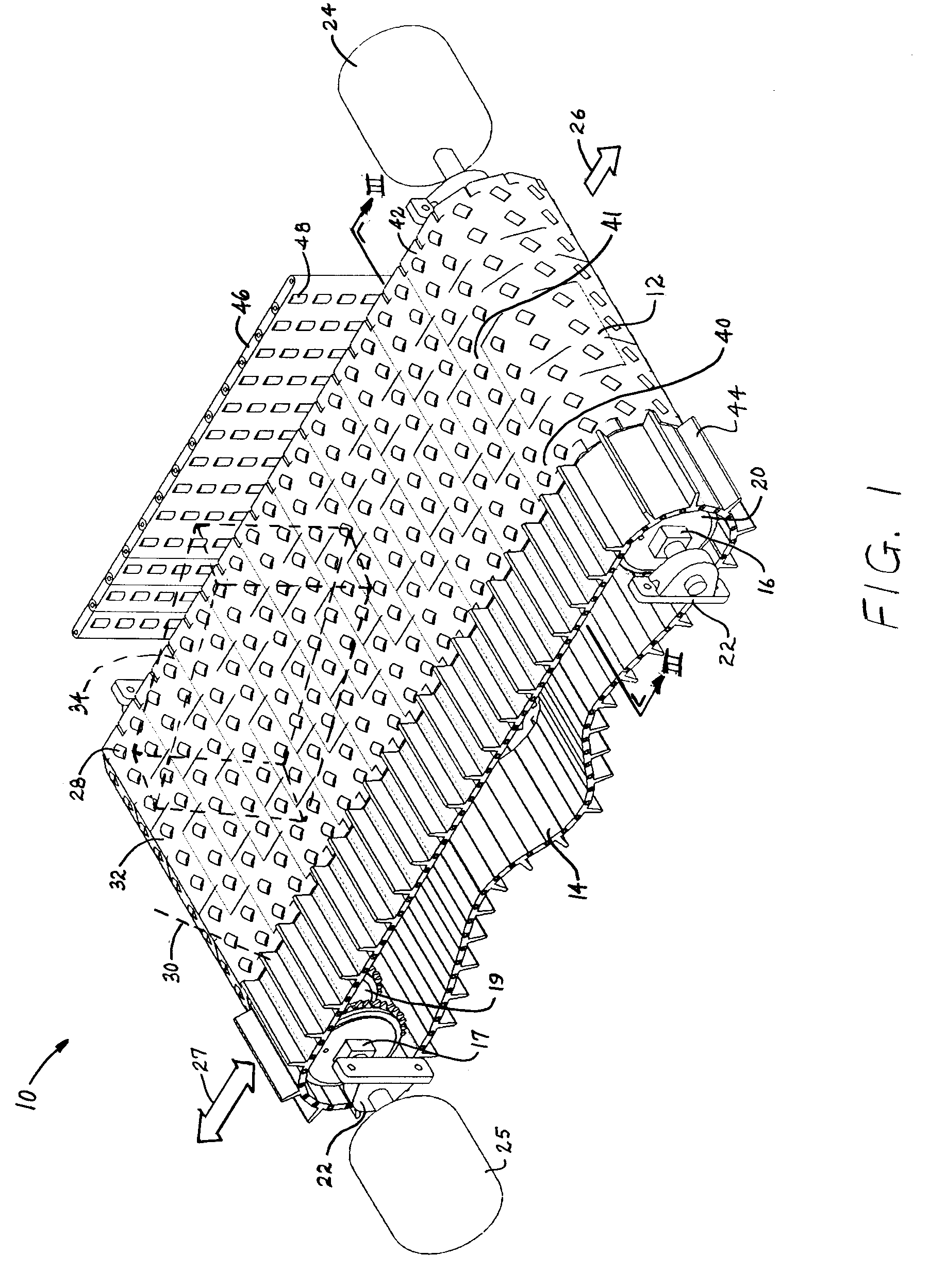

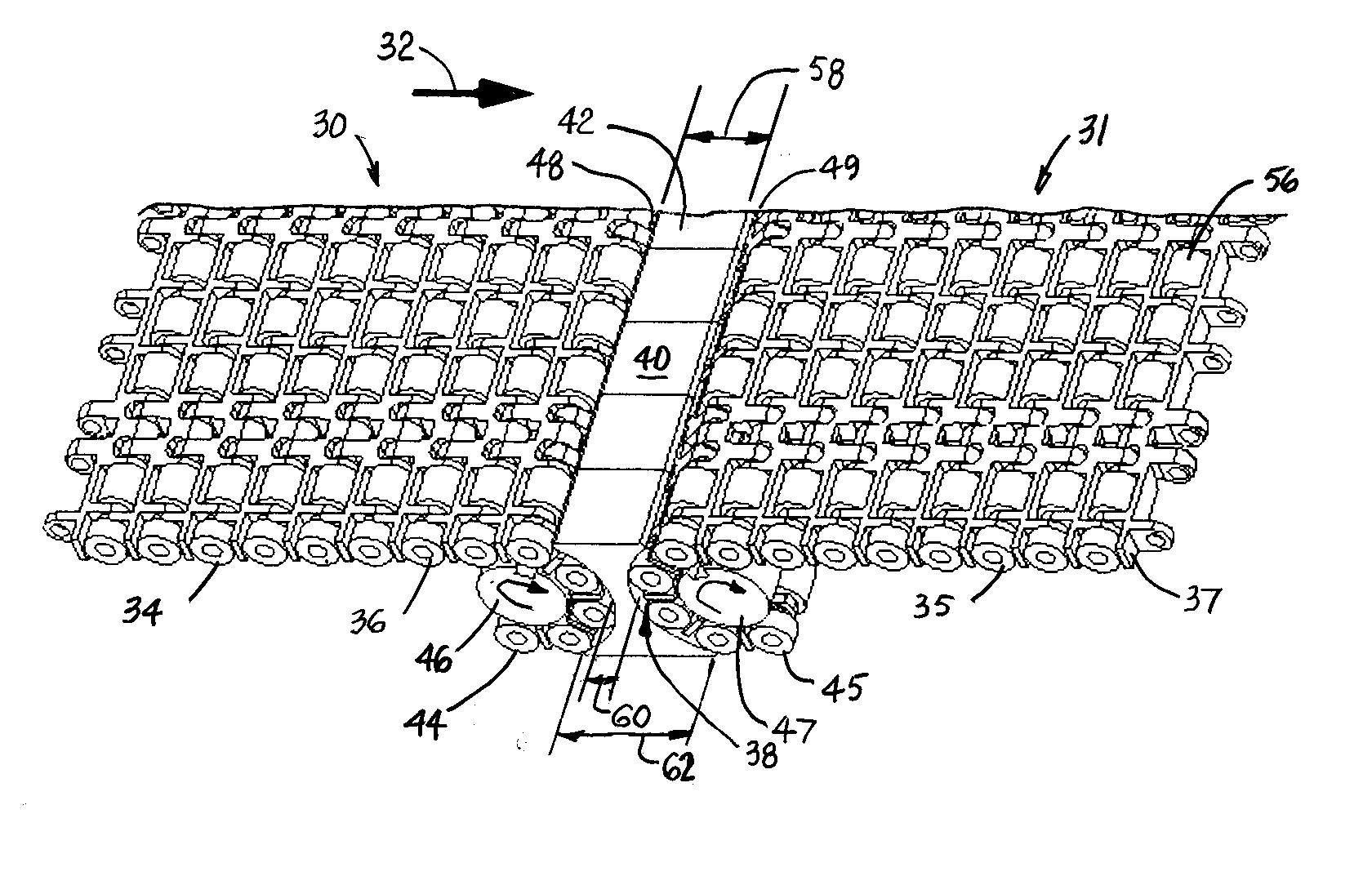

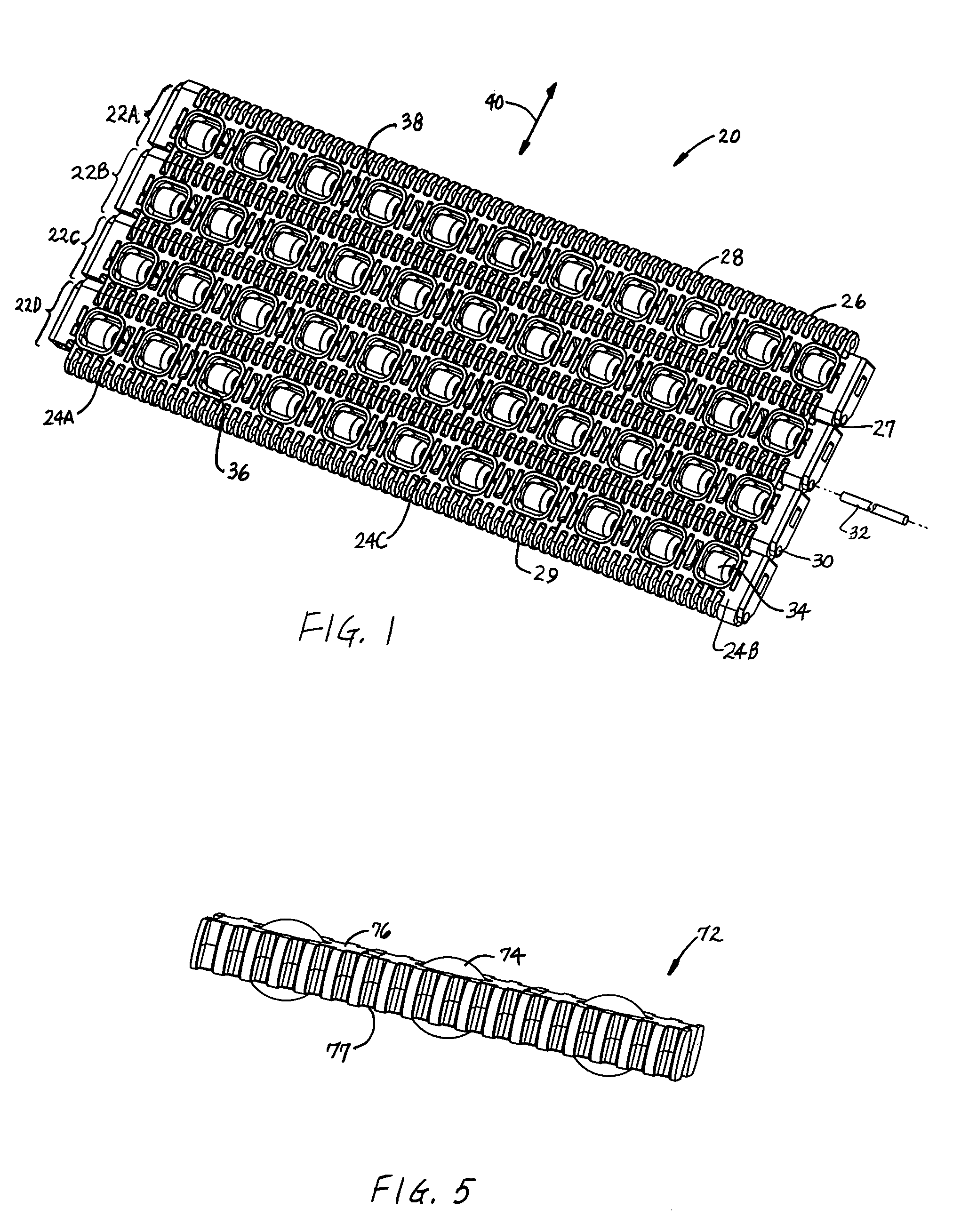

Article-orienting conveyor

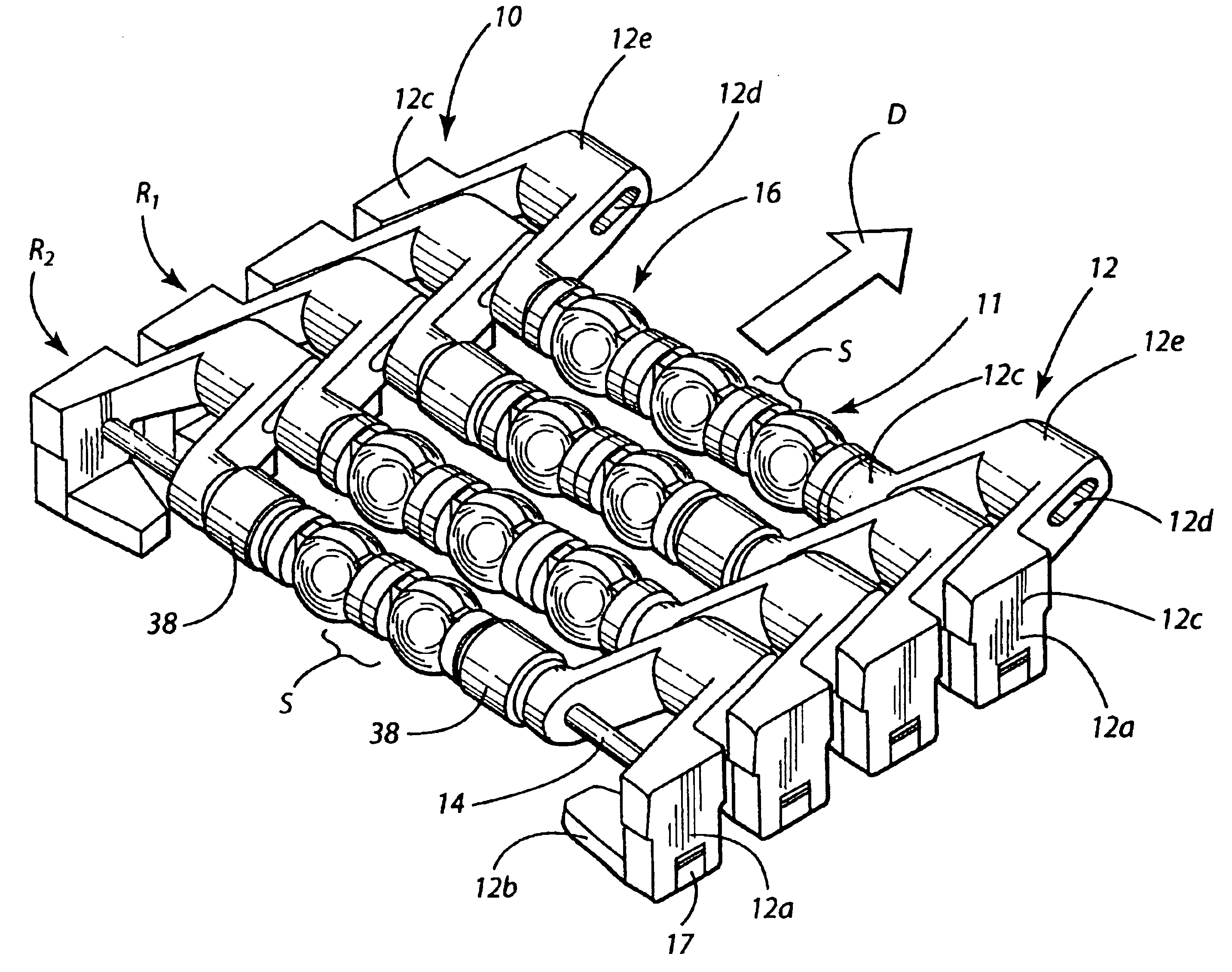

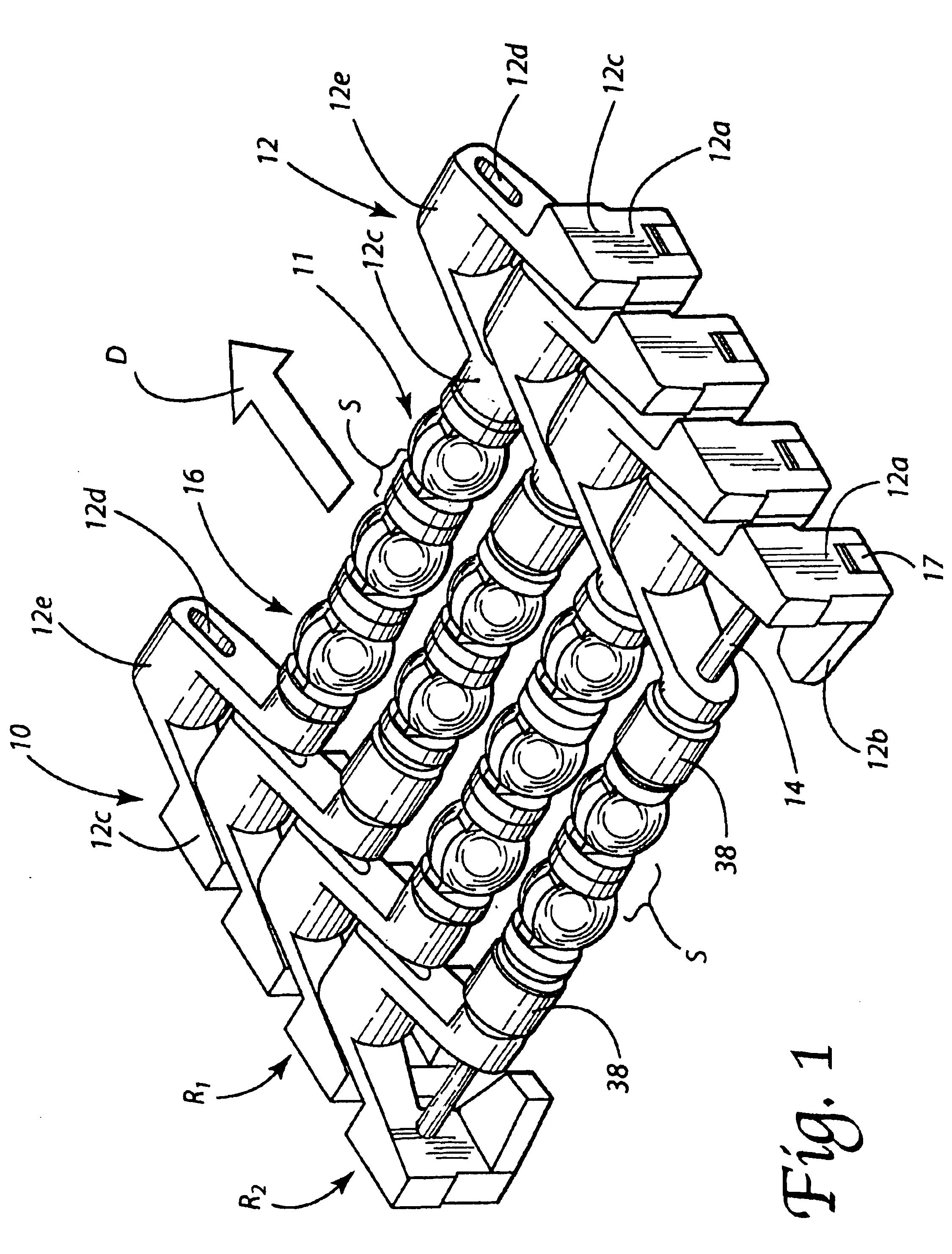

A conveyor for orienting and registering articles in a preferred orientation and position for accurate downstream processing. The conveyor includes a conveyor belt running in a conveyance direction next to an orientation belt running parallel in an opposite direction or more slowly in the same direction. The orientation belt has upstanding structure, such as flights, or a high-friction surface. The conveyor belt includes article-supporting rollers on a top side. The rollers are arranged to rotate about axes oblique to the conveyance direction. The rollers also extend below the bottom side of the belt and are rotated by dynamic contact with bearing surfaces supporting the belt as it advances in the conveying direction. The rotating rollers direct conveyed articles toward a side rail. If a portion of a conveyed article extends past the side edge of the conveyor belt into the path of the orientation belt, the obstructions or high-friction surface of the slower- or oppositely-moving orientation belt strikes the conveyed articles and cause them to rotate clockwise toward an alignment of the article in the conveyance direction and into registration against the side rail at the downstream end of the conveyor. In other versions of the article-orienting conveyor, the orientation belt is replaced by a row of posts or a rotating paddle wheel that strikes conveyed articles extending past the side edge of the conveyor belt.

Owner:LAITRAM LLC

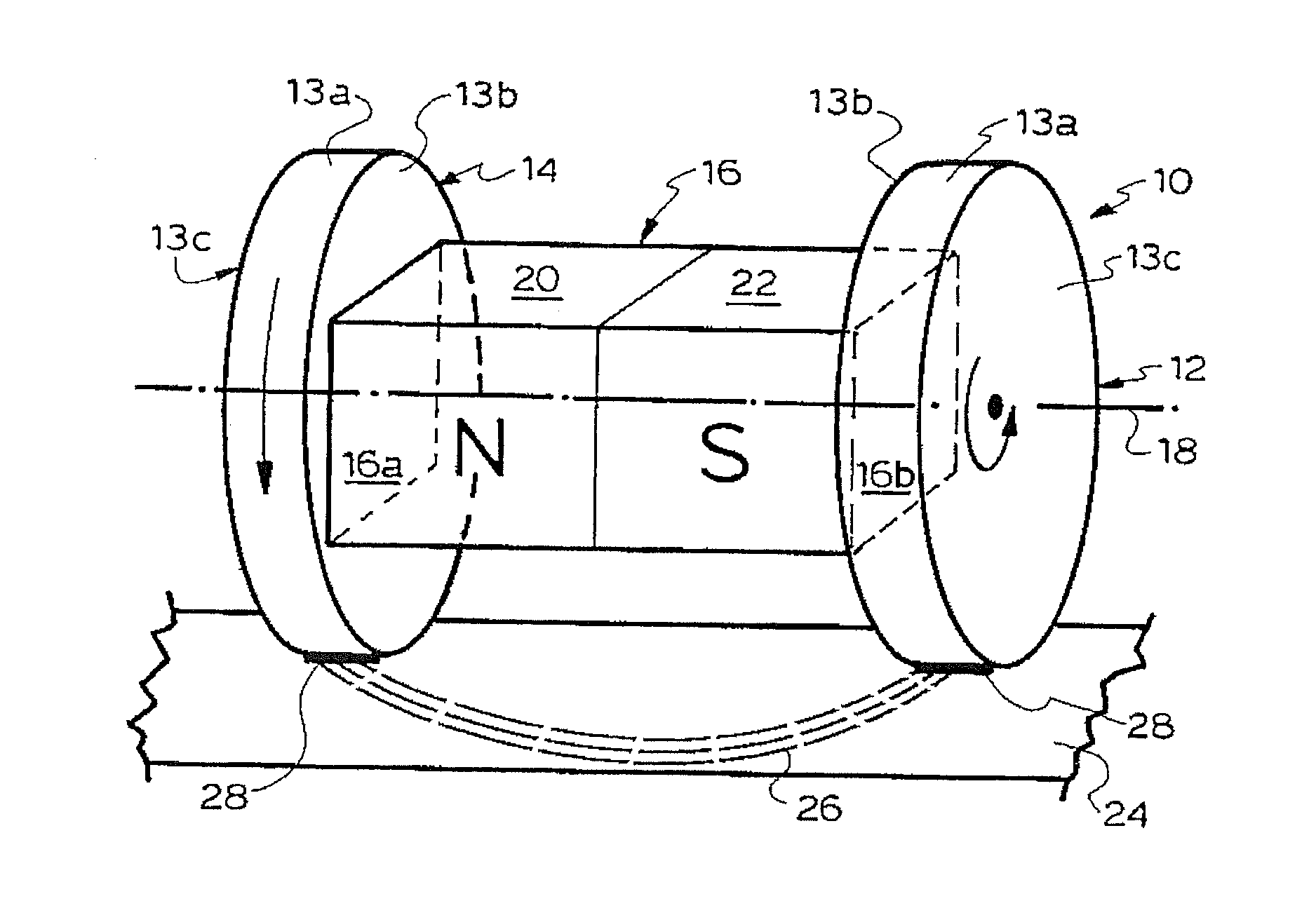

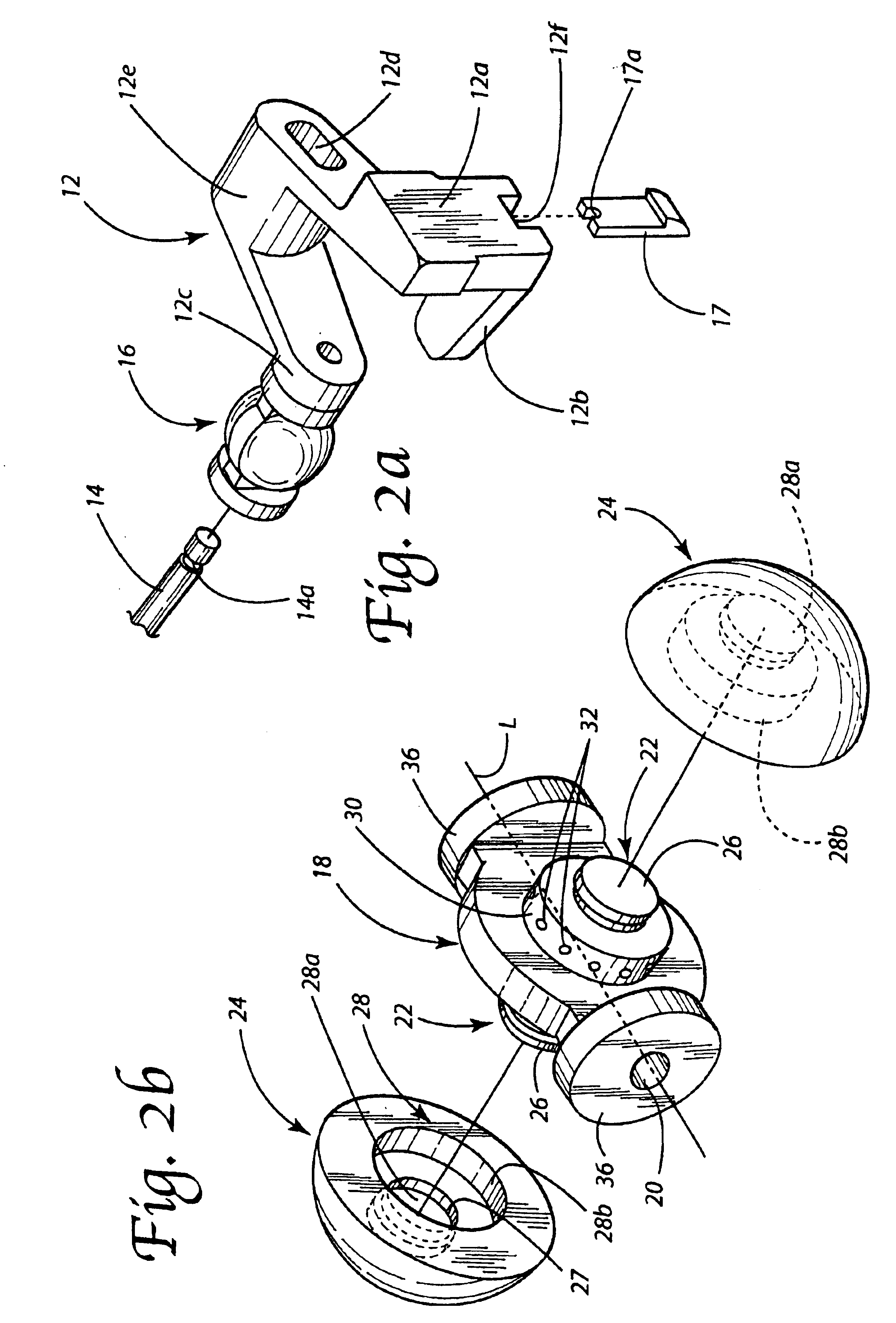

Magnetic wheel

ActiveUS20120200380A1Good flexibilityReducing inertia momentsRailway vehiclesPermanent magnetsMagnetic fluxElectromagnet

Magnetic circuit that has (a) a source of magnetic flux which includes an electromagnet or one or more permanent magnets, (b) at least two oppositely polarisable pole extension bodies associated with the magnetic flux source, the bodies being disc, wheel, roller or similarly shaped with an outer circumferential surface and held rotatable about respective axes of rotation, and (c) a ferromagnetic counter body which is arranged to cooperate with the pole extension bodies such as to provide an external flux path for the magnetic flux when in magnetic proximity or contact with the circumferential surface of the pole extension bodies, which is characterised in that the magnetic flux source is held stationary relative to the rotatable pole extension bodies.

Owner:MAGSWITCH TECH WORLDWIDE PTY LTD

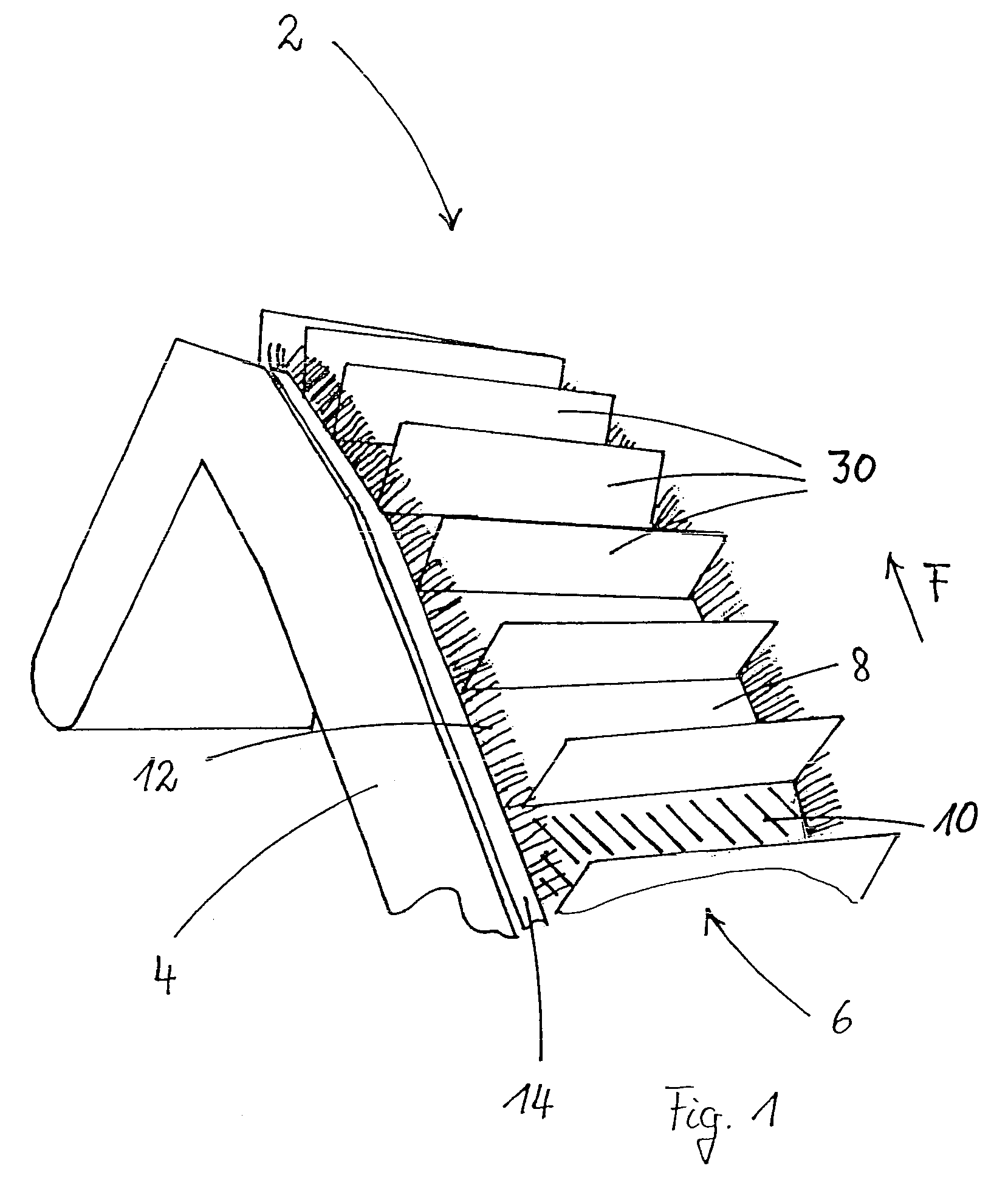

Conveying device for bulk material

ActiveUS7182202B2Risk of damage being done is reducedReduce material wearConveyorsRollersBraced frameSupport surface

A conveying device has a support frame and a conveying member with at least two driven conveying belts that circulate in parallel to one another and with a conveying fabric having at least one support surface and being arranged between the at least two conveying belts. The at least two conveying belts have inner sides facing one another; the inner sides have recesses. The conveying fabric has lateral edges inserted into the recesses. Support parts are attached in an overlapping area or an abutting area where the lateral edges of the conveying fabric and the at least two conveying belts overlap or abut one another. The support parts project upwardly past a plane of the support surface.

Owner:GRIMME LANDMASCHINENFABRIK GMBH & CO KG

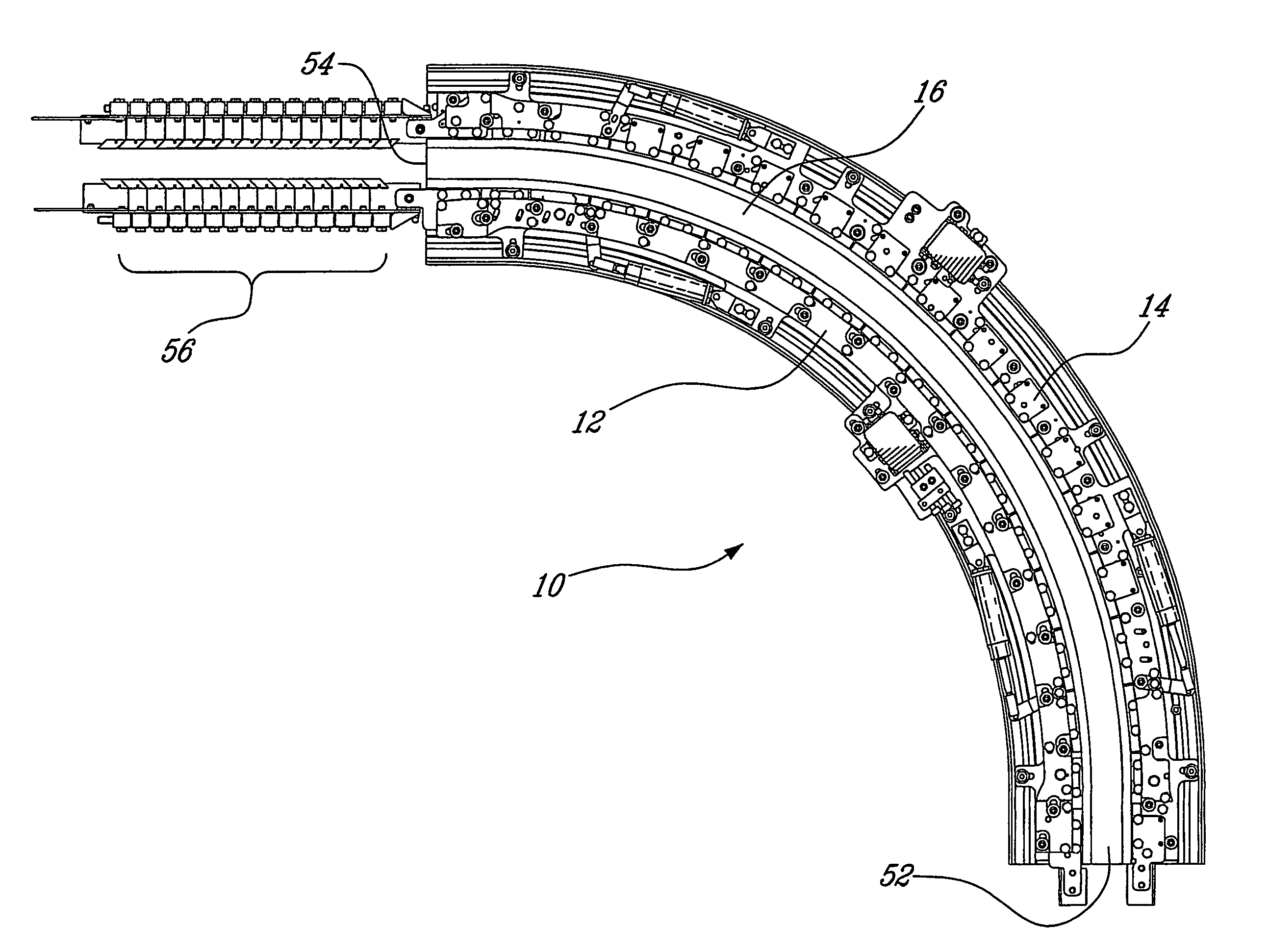

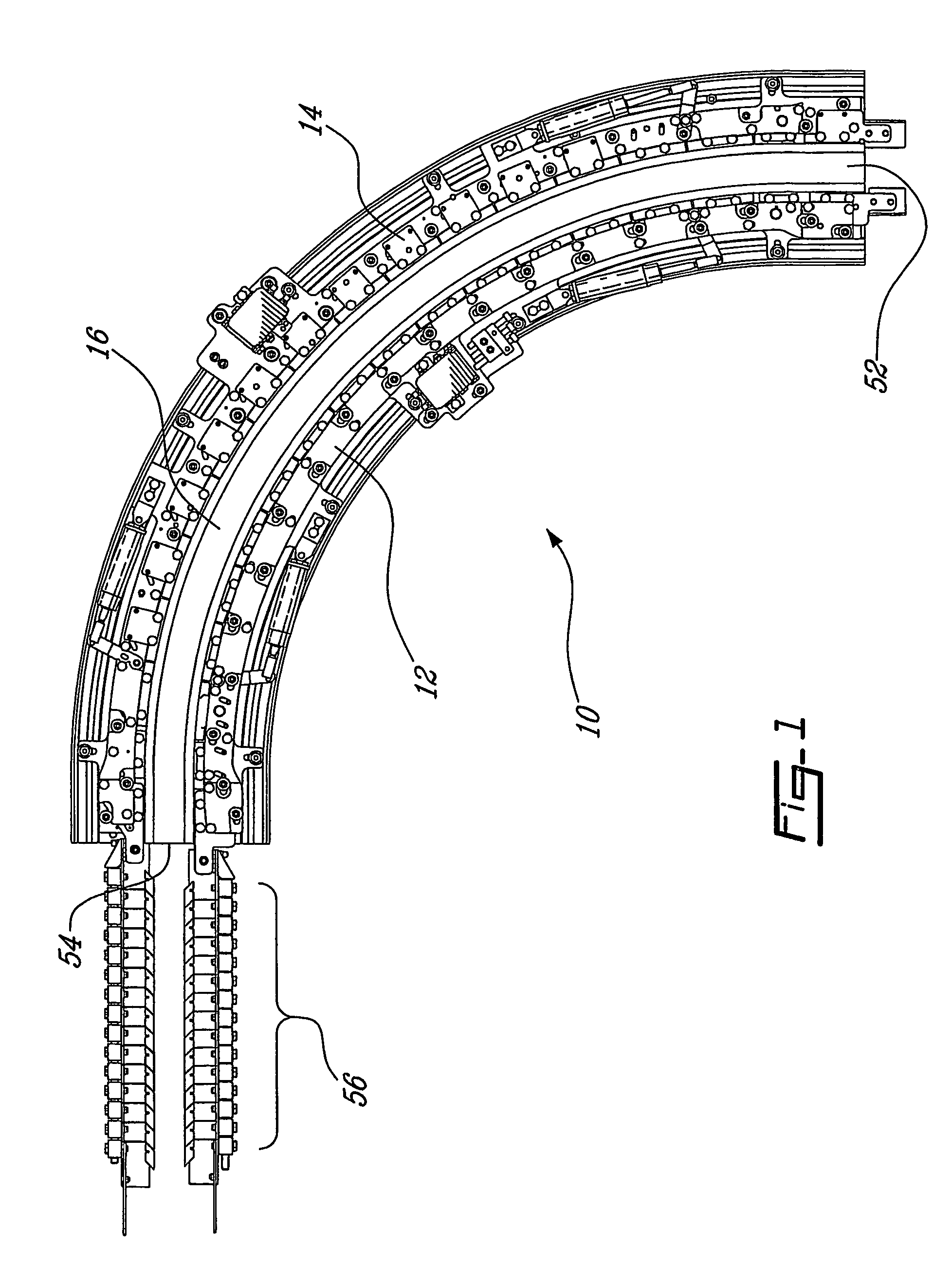

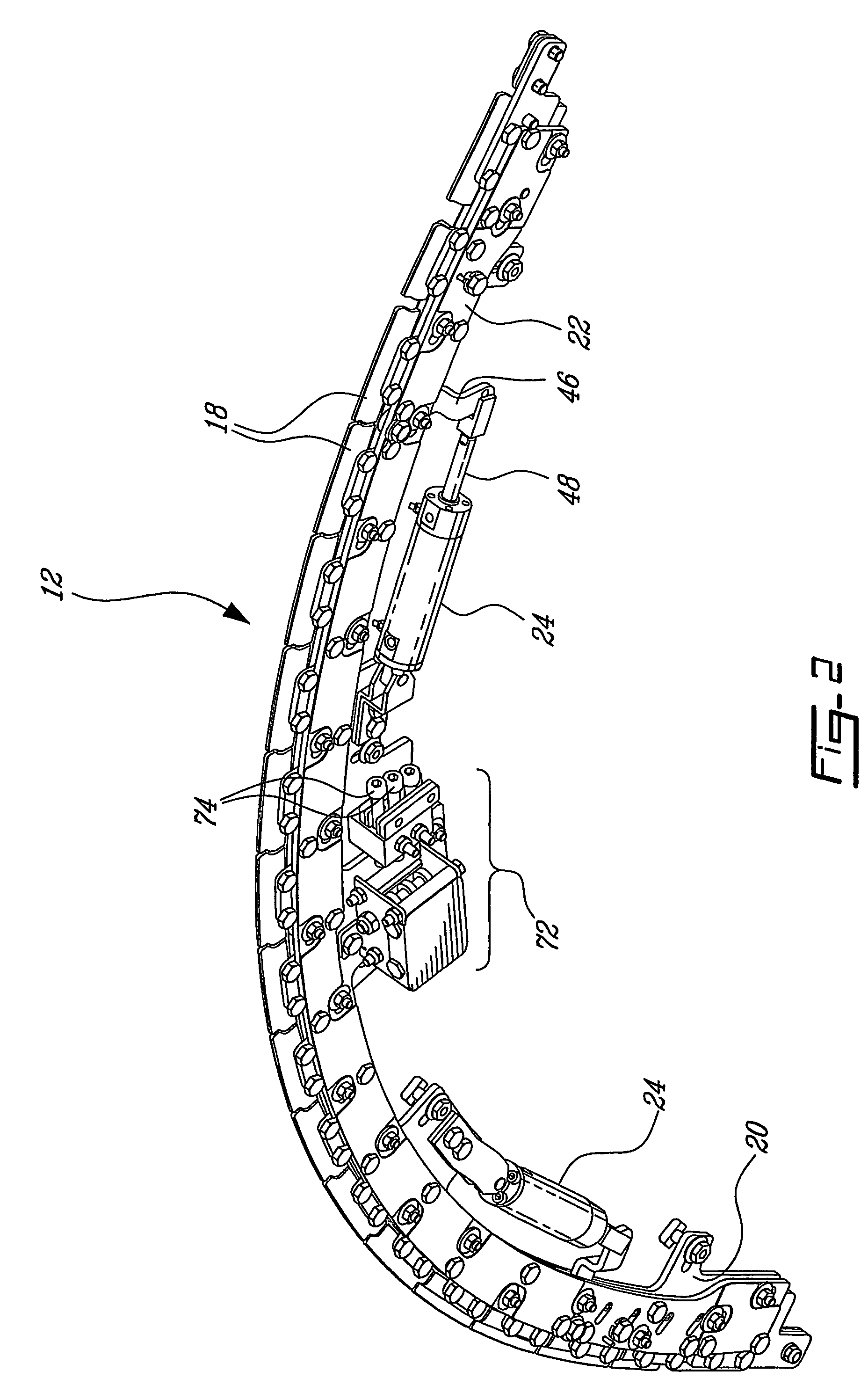

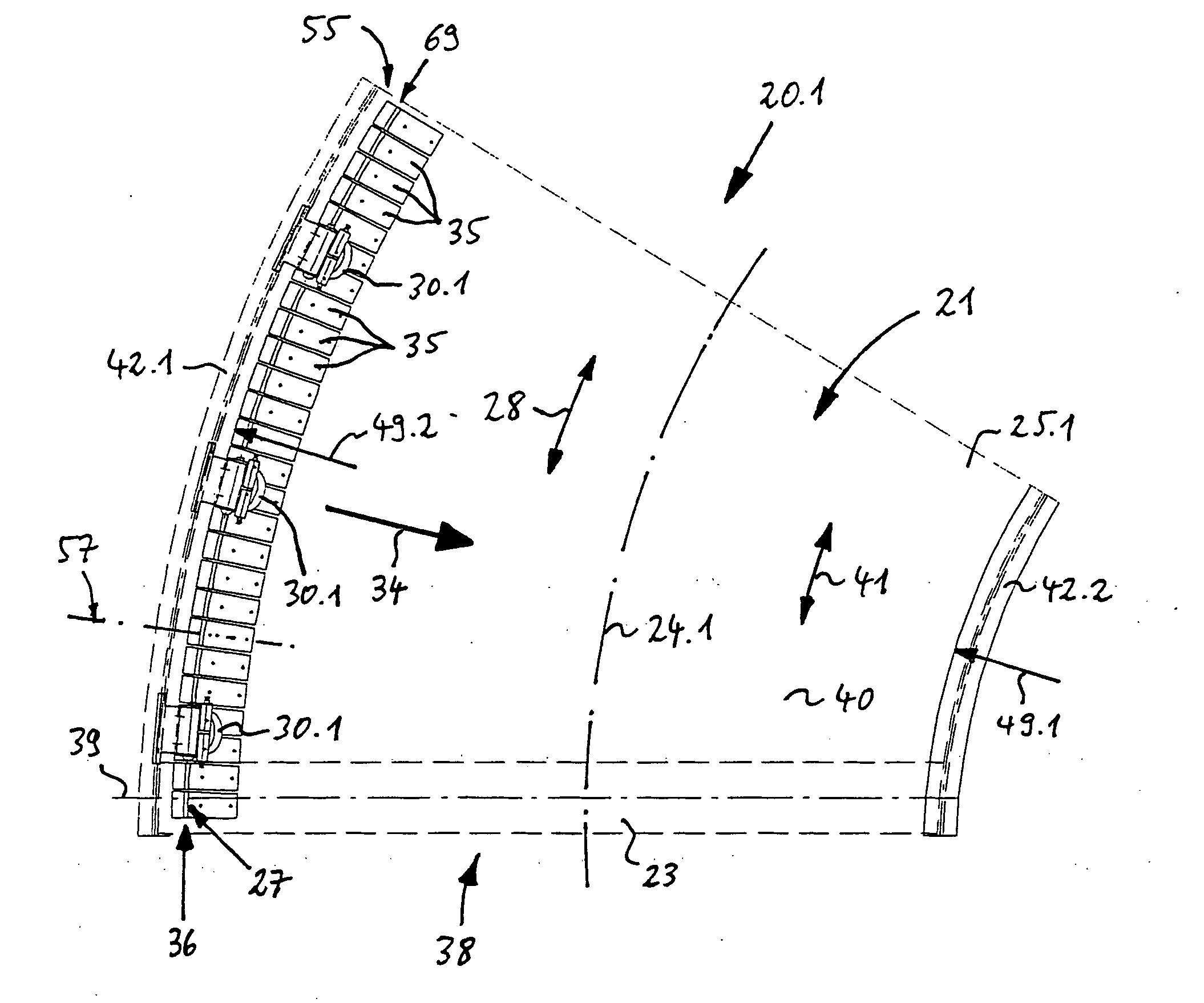

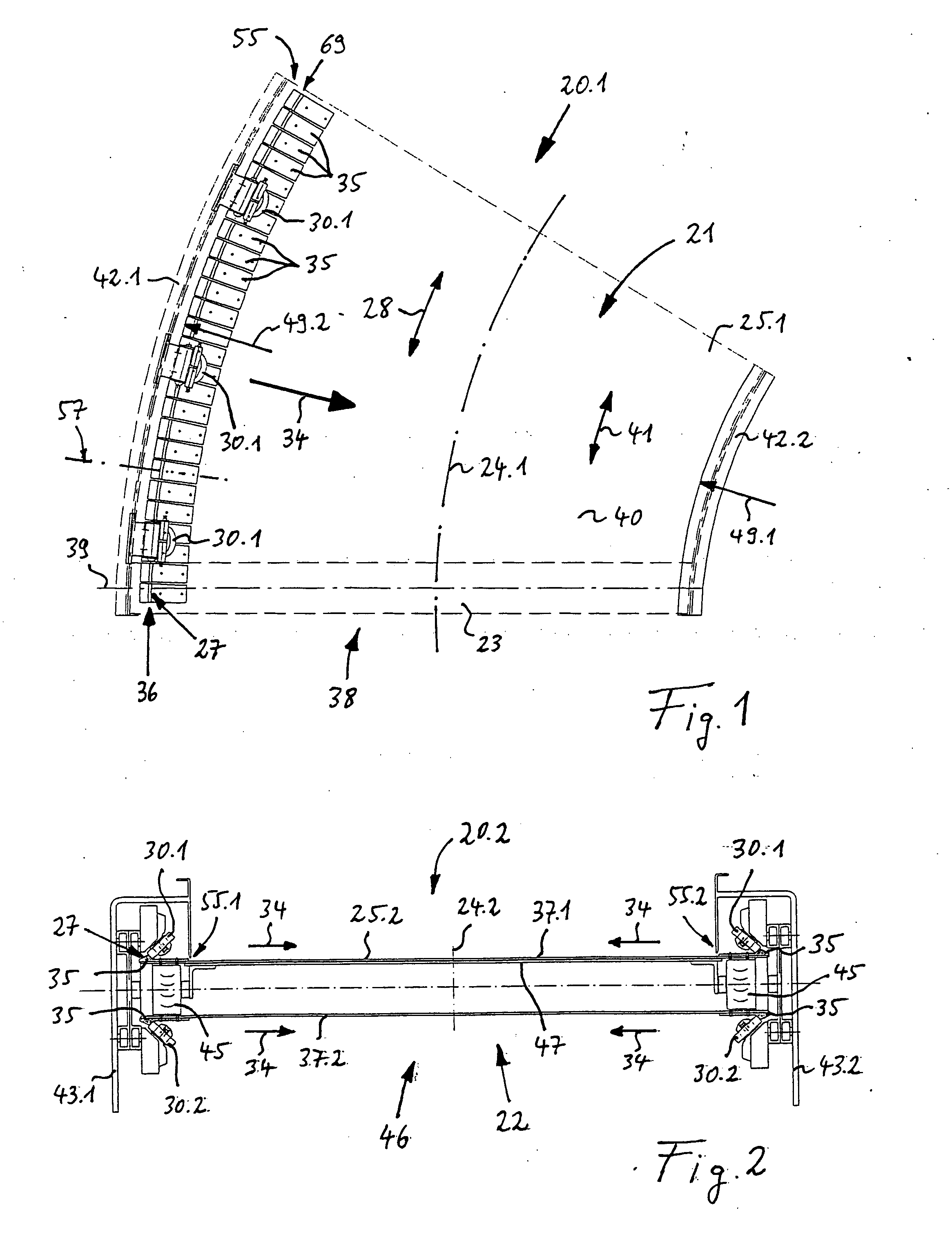

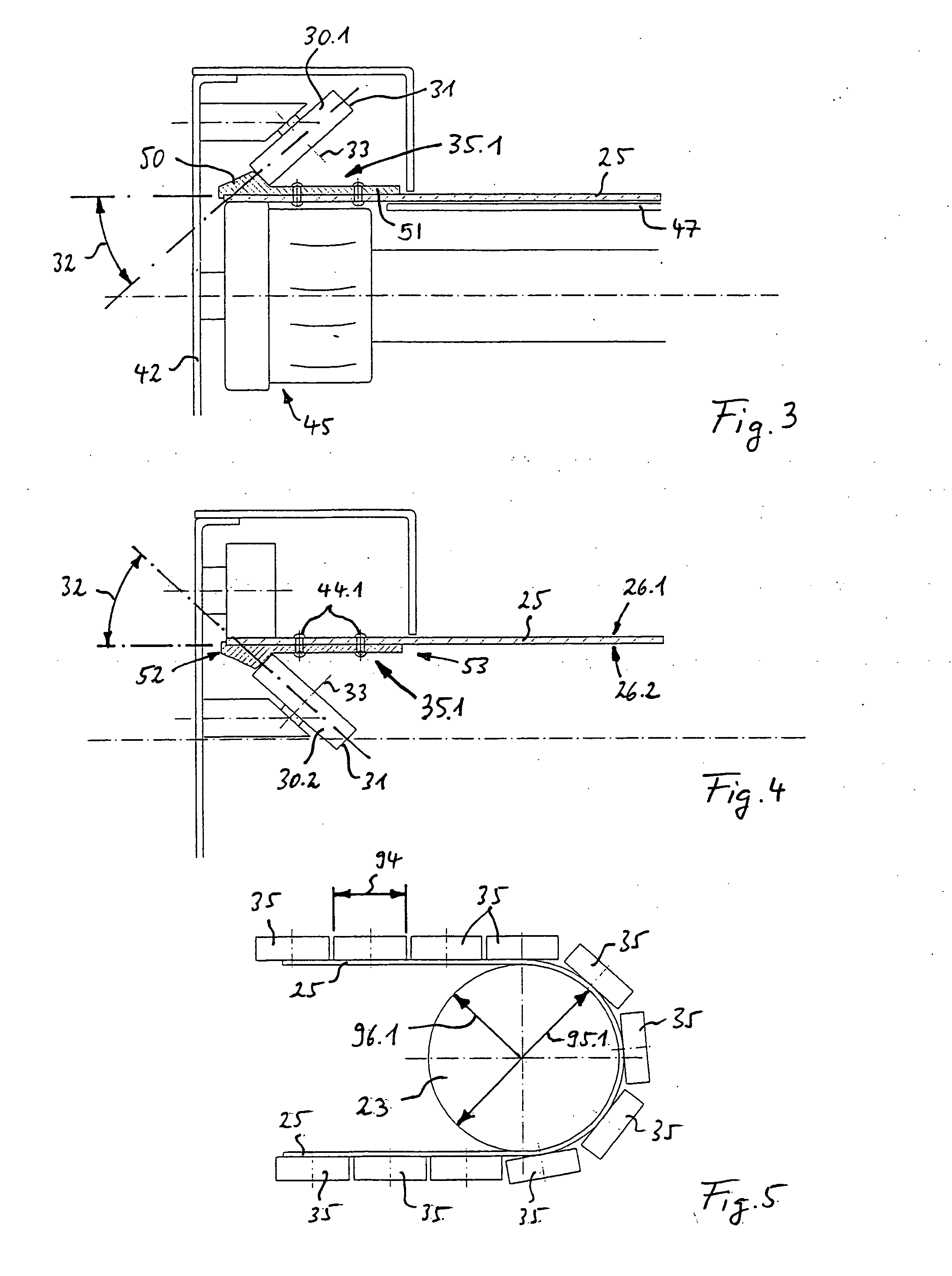

Adjustable curved guideway for a conveyor and method for realising same

Owner:GEBO CERMEX CANADA

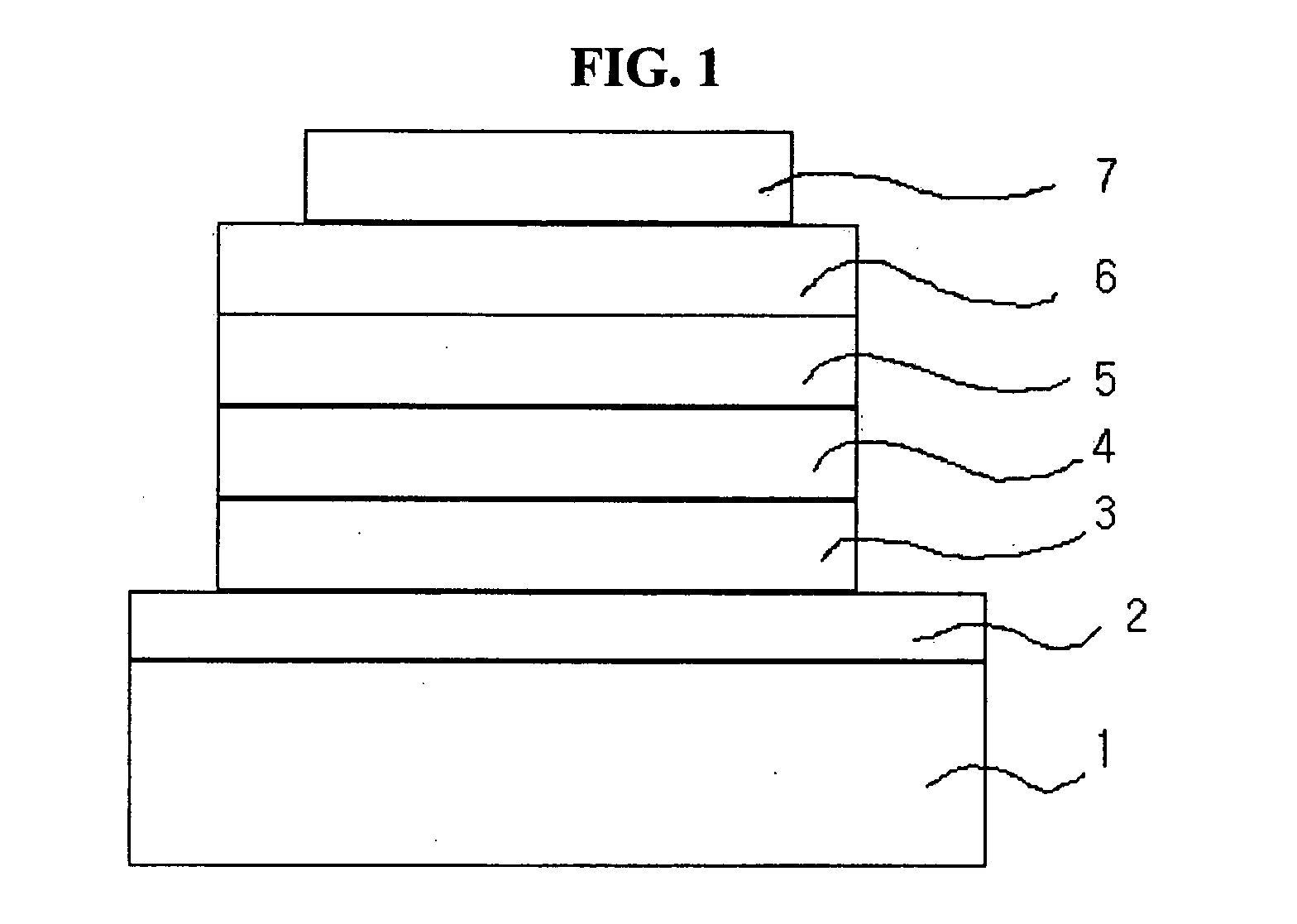

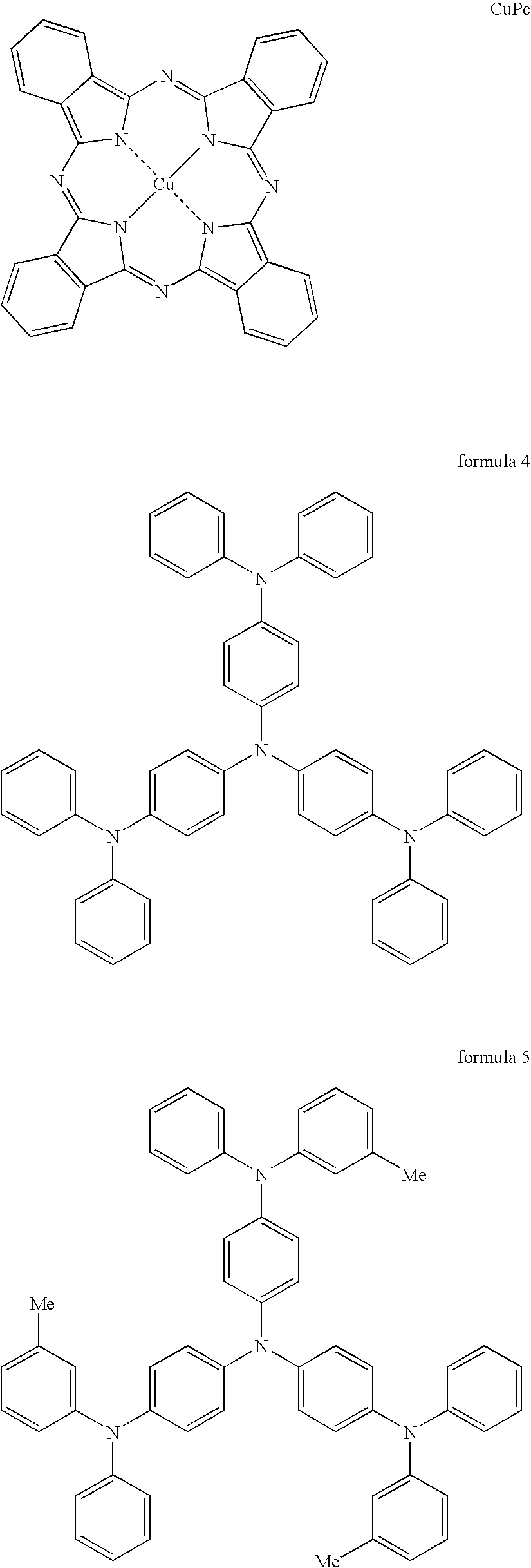

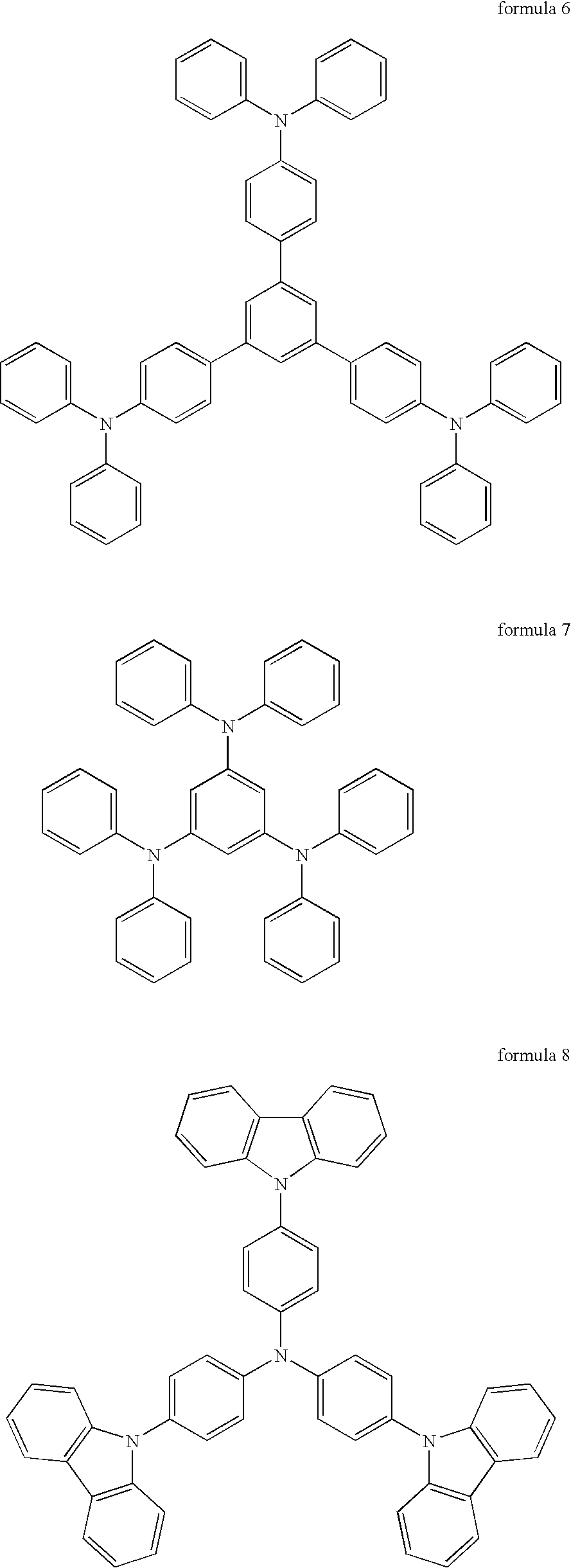

Materials for injecting or transporting holes and organic electroluminescence devices using the same

ActiveUS20050225235A1Solve low luminous efficiencyExtend the lifespanConveyorsOrganic chemistryOrganic light emitting deviceOrganic electroluminescence

The present invention relates to a novel compound that can significantly improve the lifespan, efficiency and thermal stability of an organic light emitting device, and to an organic electroluminescence device or light emitting device comprising the compound in an organic compound layer is also disclosed.

Owner:LG CHEM LTD

Conveyor transfer system with floating transfer platform

A conveyor transfer system and a transfer platform for transferring articles from an upstream conveyor to a downstream conveyor across a gap. The transfer platform fits in the gap between two conveyors arranged end to end. At least one of the conveyors includes a conveyor belt that reverses direction around a reversing element at the gap. The transfer platform floats in the gap supported by the conveyor belt or its reversing element without a direct connection to the conveyor frame.

Owner:LAITRAM LLC

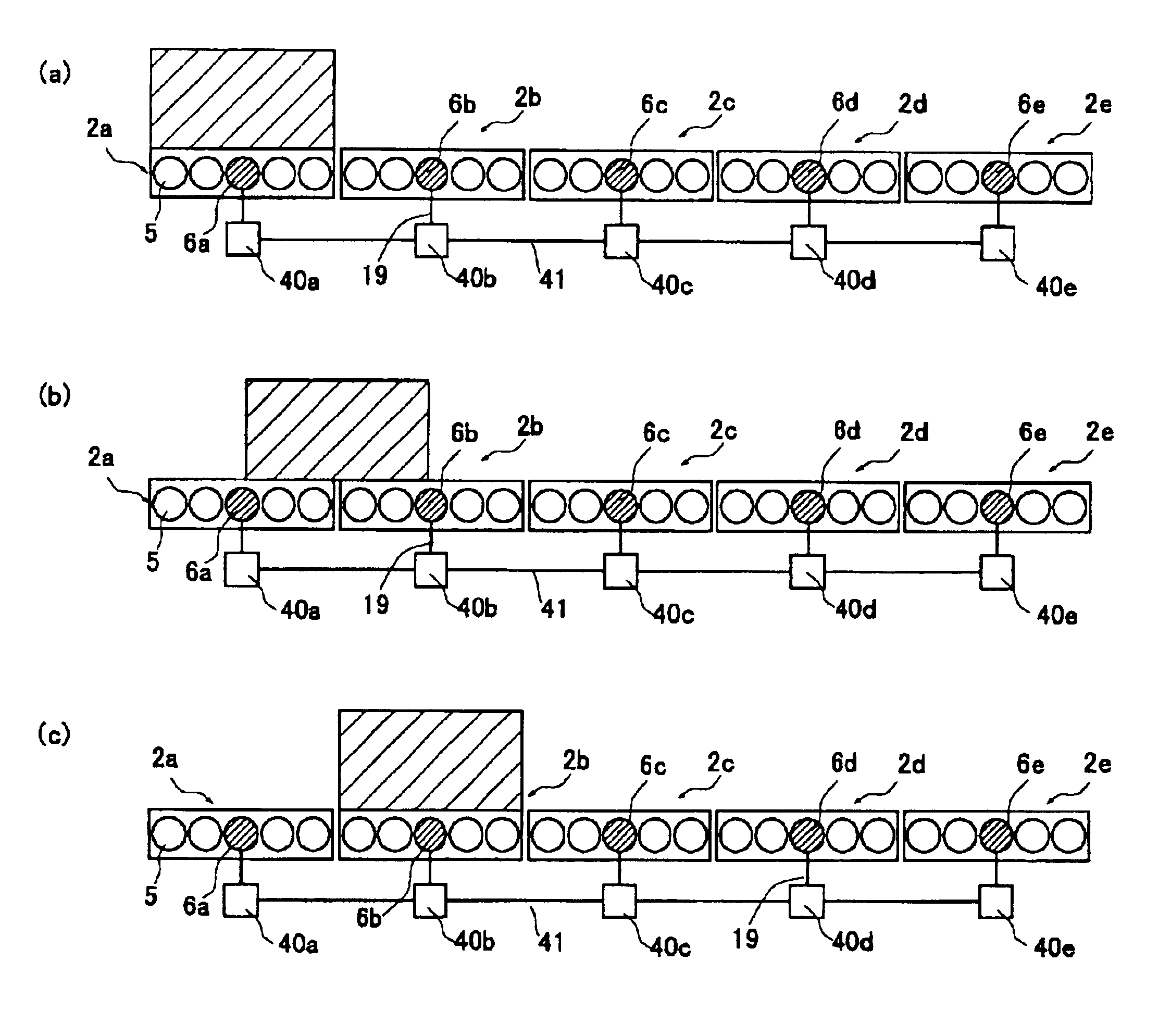

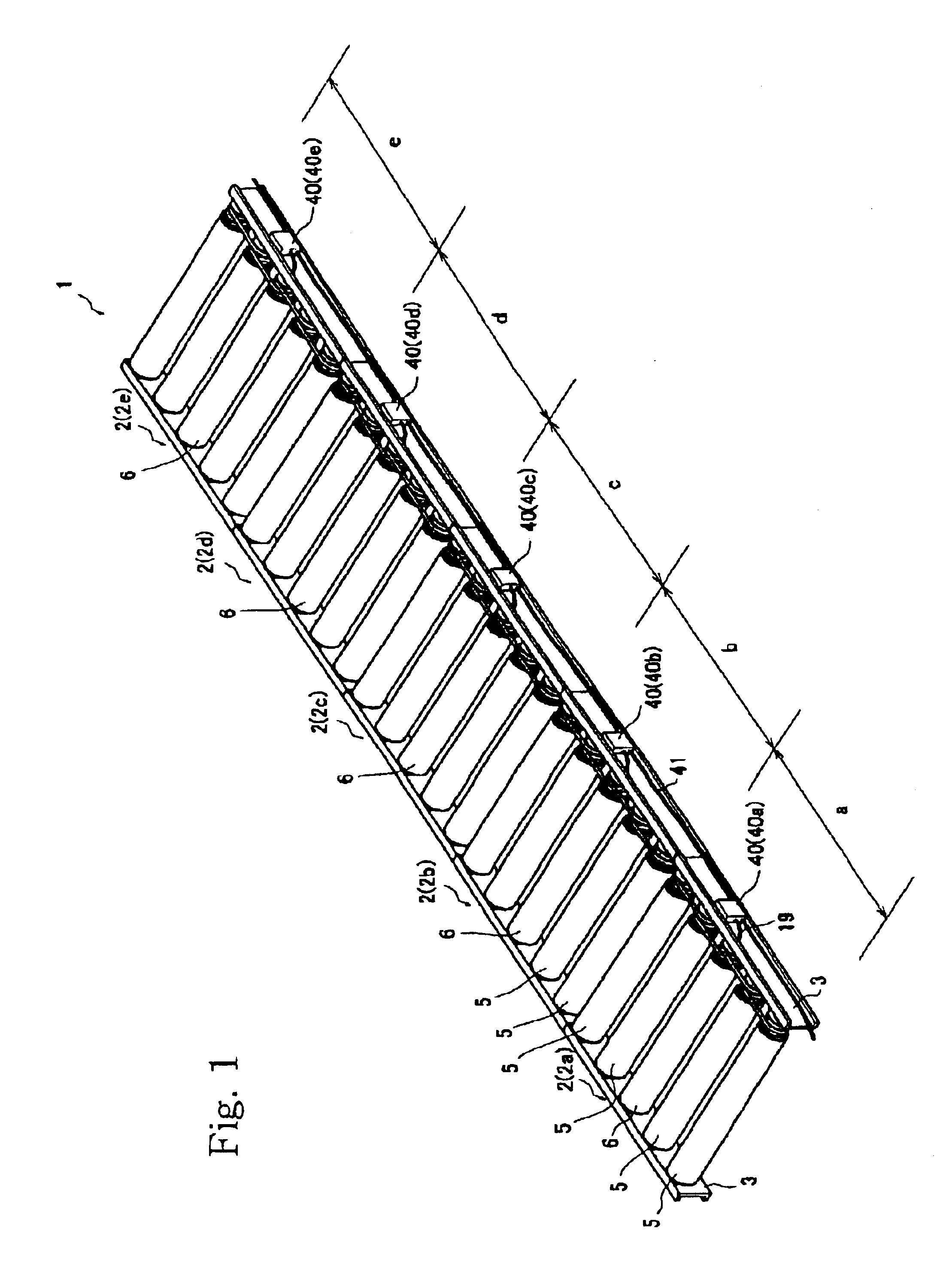

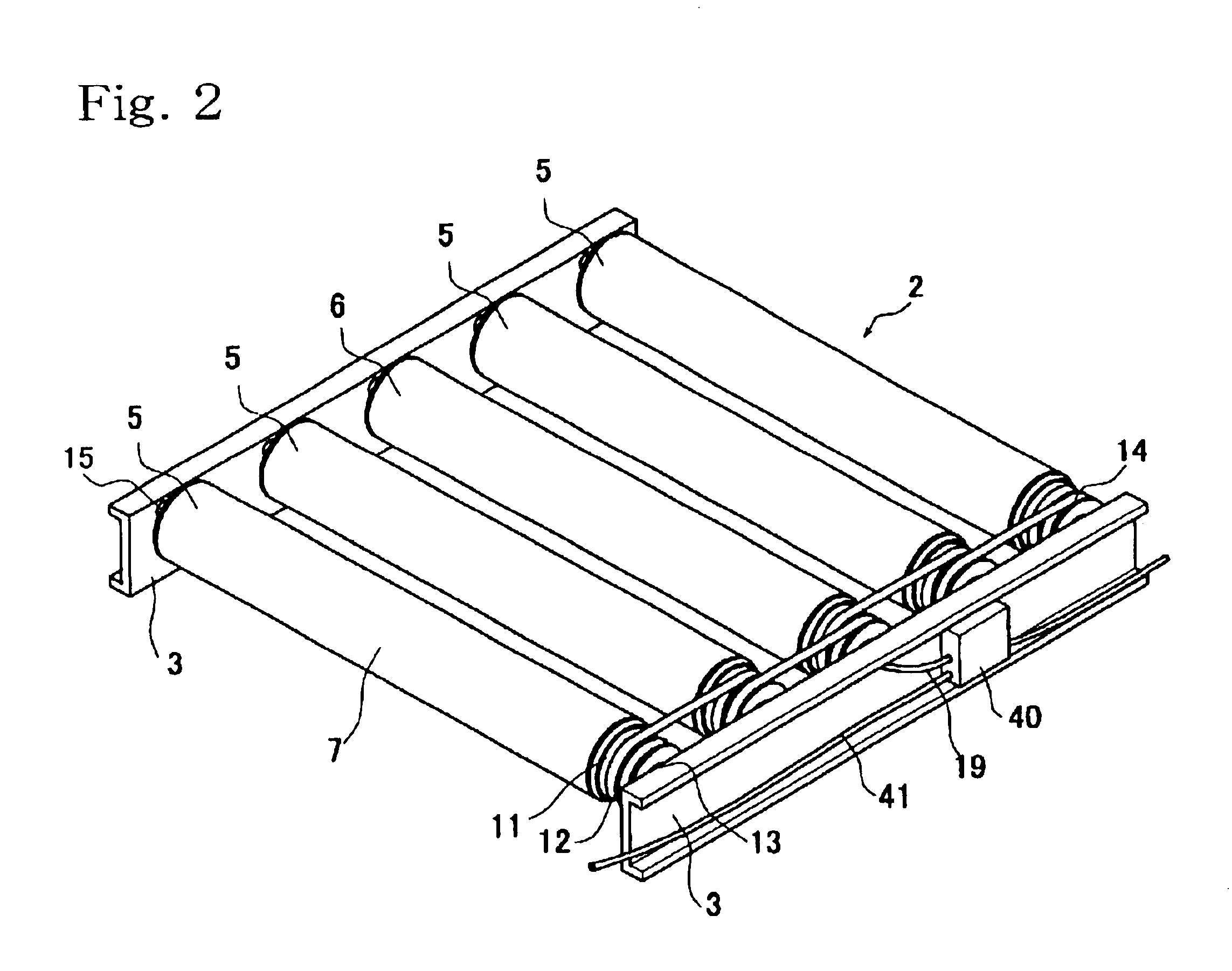

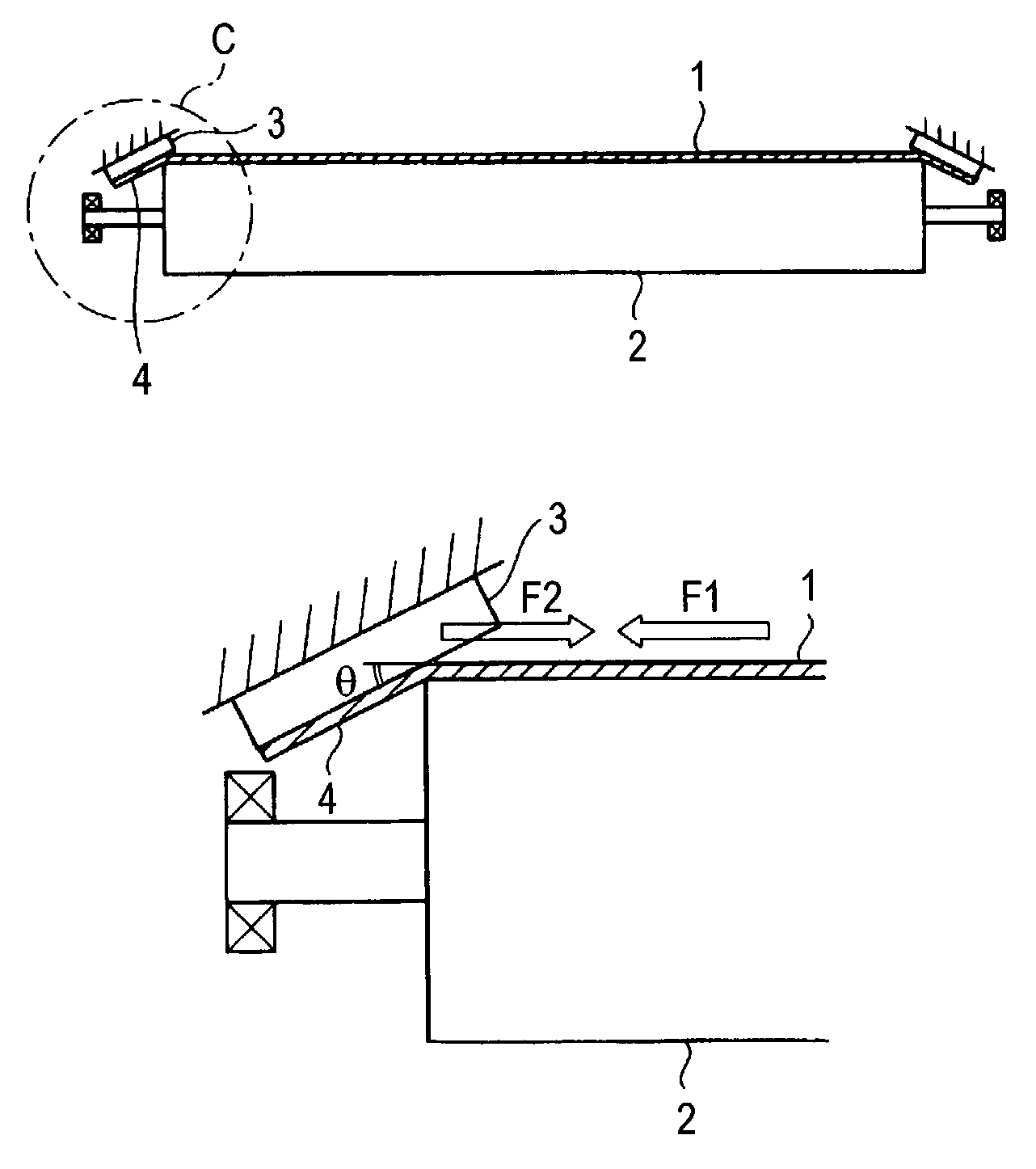

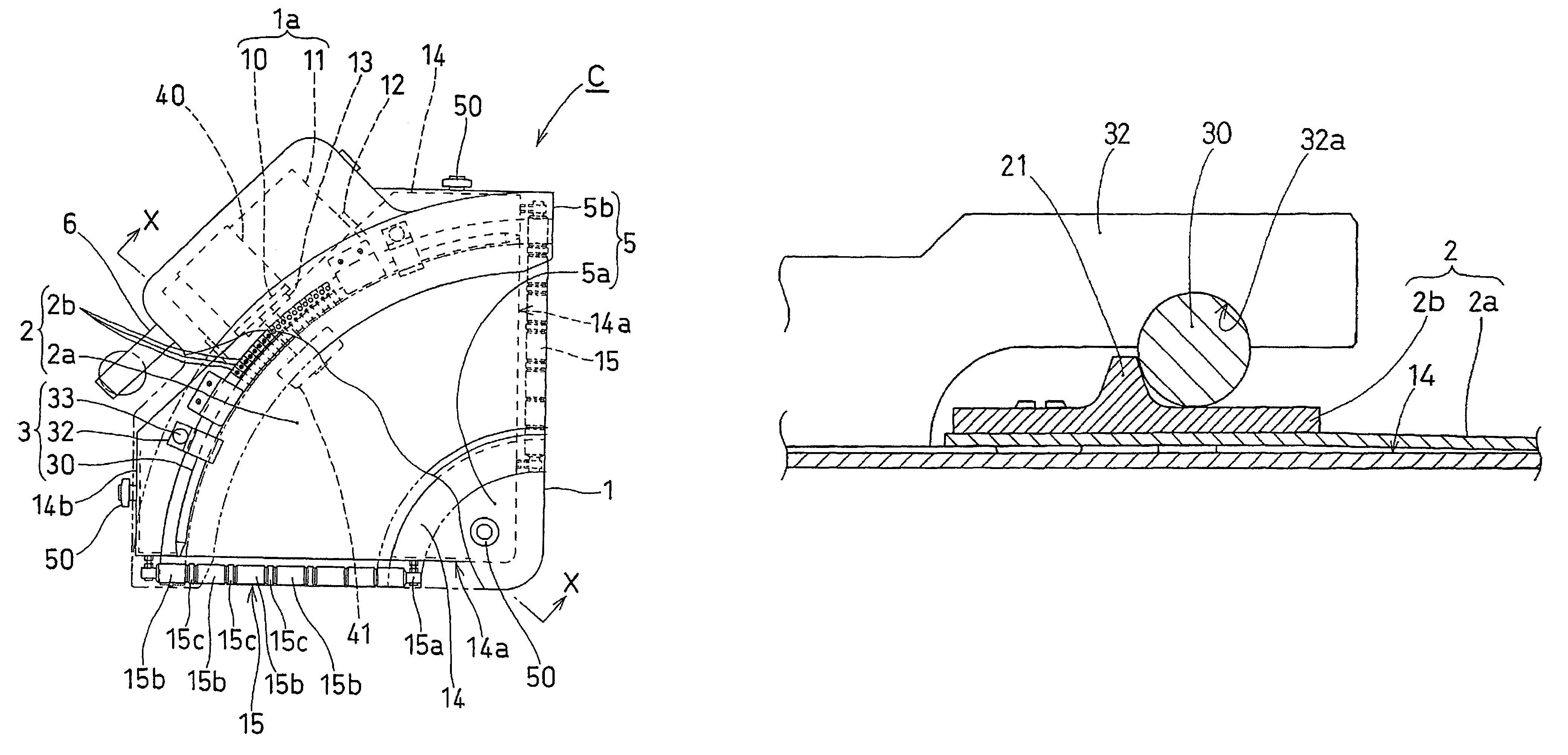

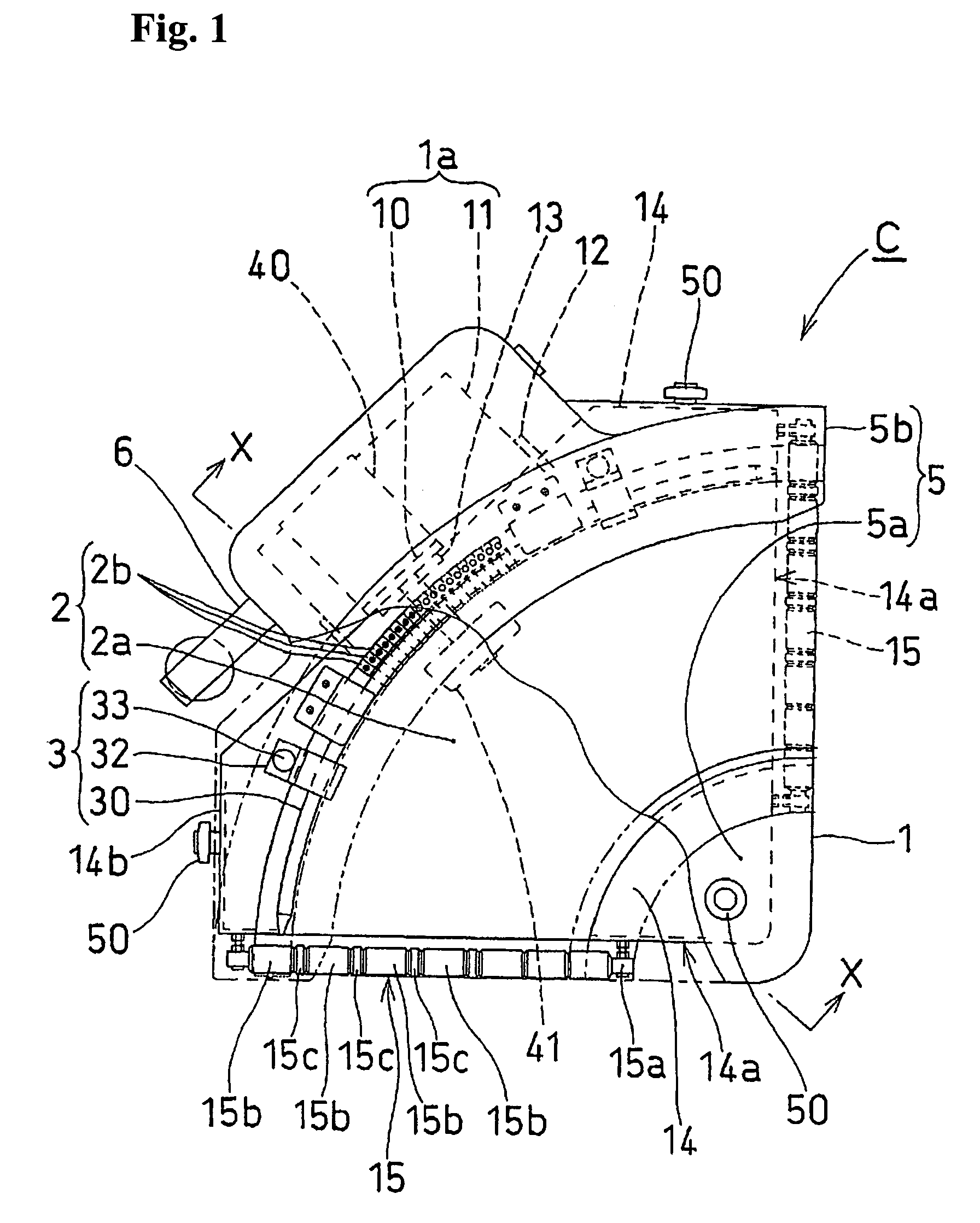

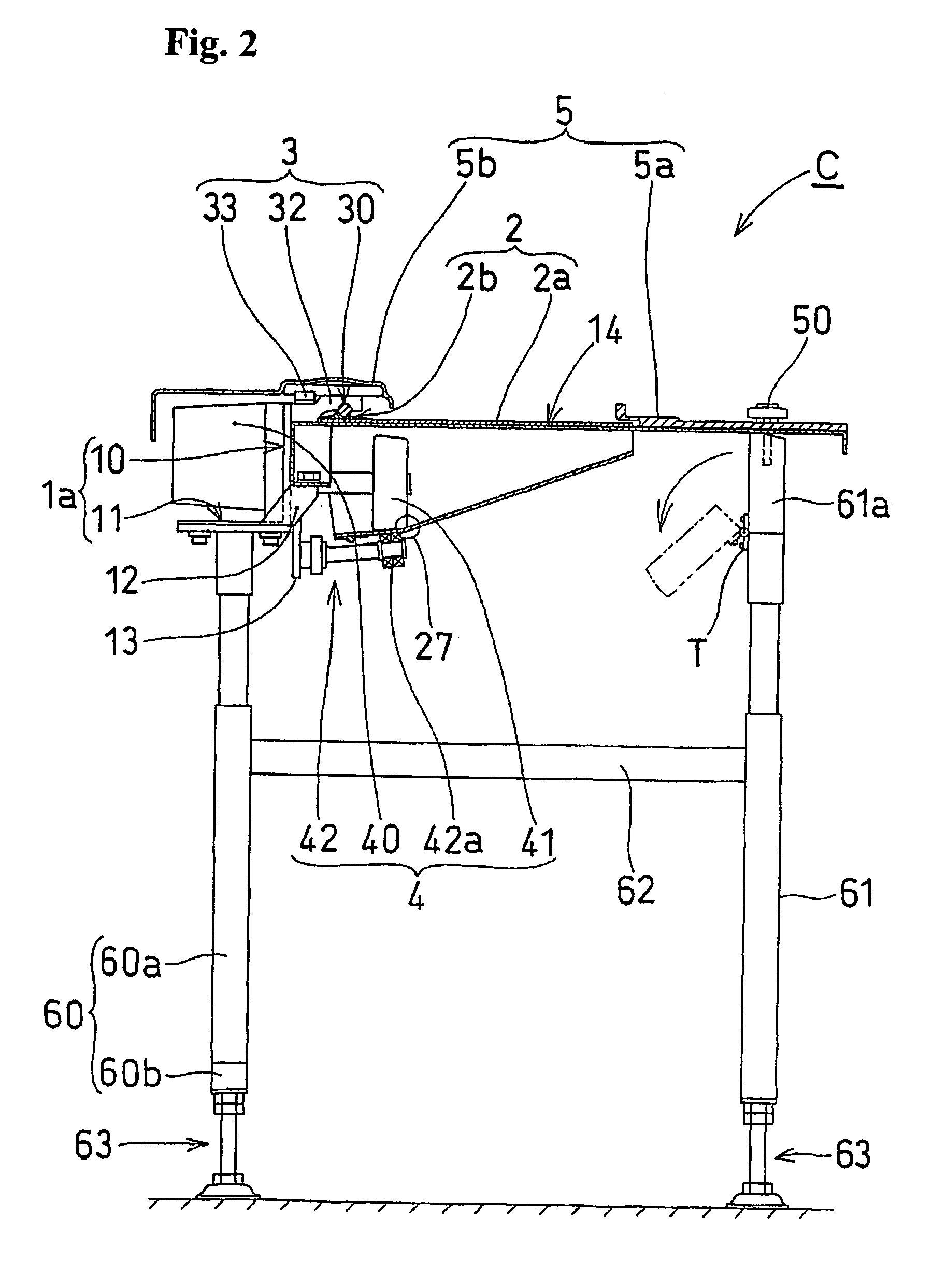

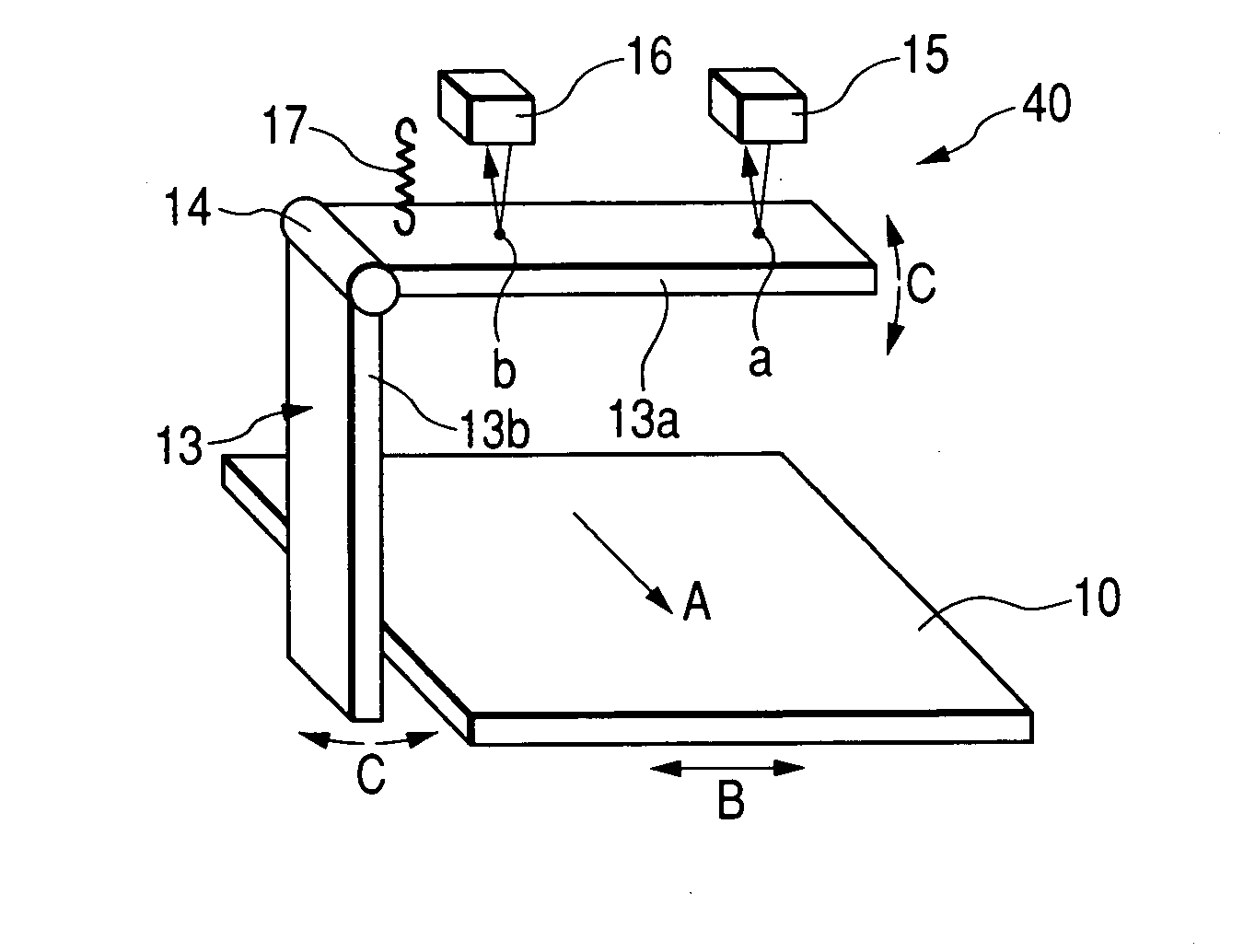

Conveying apparatus

InactiveUS6820736B2Simple structureEasy to assembleConveyorsControl devices for conveyorsMotor controlElectric motor

A conveying apparatus (1) is composed of several conveying modules (2) each having a controller (40) for control of a motorized roller (6) having a motor (16) incorporated in it. A motor-controlling section (45) installed in the controller (40) operates to sense an article being transported on and along the module (2). An article-state detector (48) included in the motor-controlling section (45) compares the actual number (Pr) of signal pulses indicating the number of rotations of the motor (16) with a standard number (P) of such pulses, when judging whether the article is or is not on the module, without aid of any conventional and discrete prior art sensors.

Owner:ITO DENKI KK

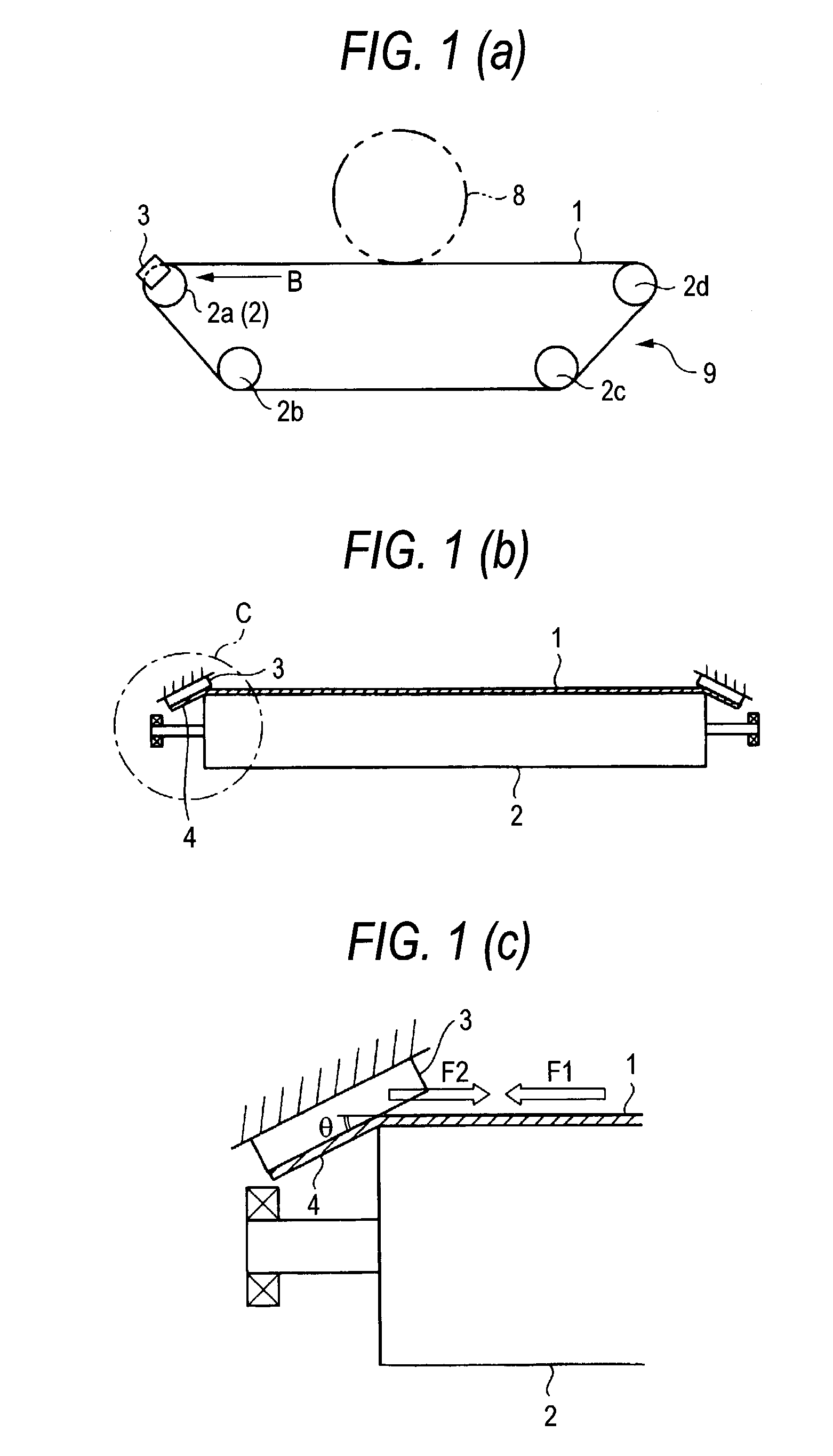

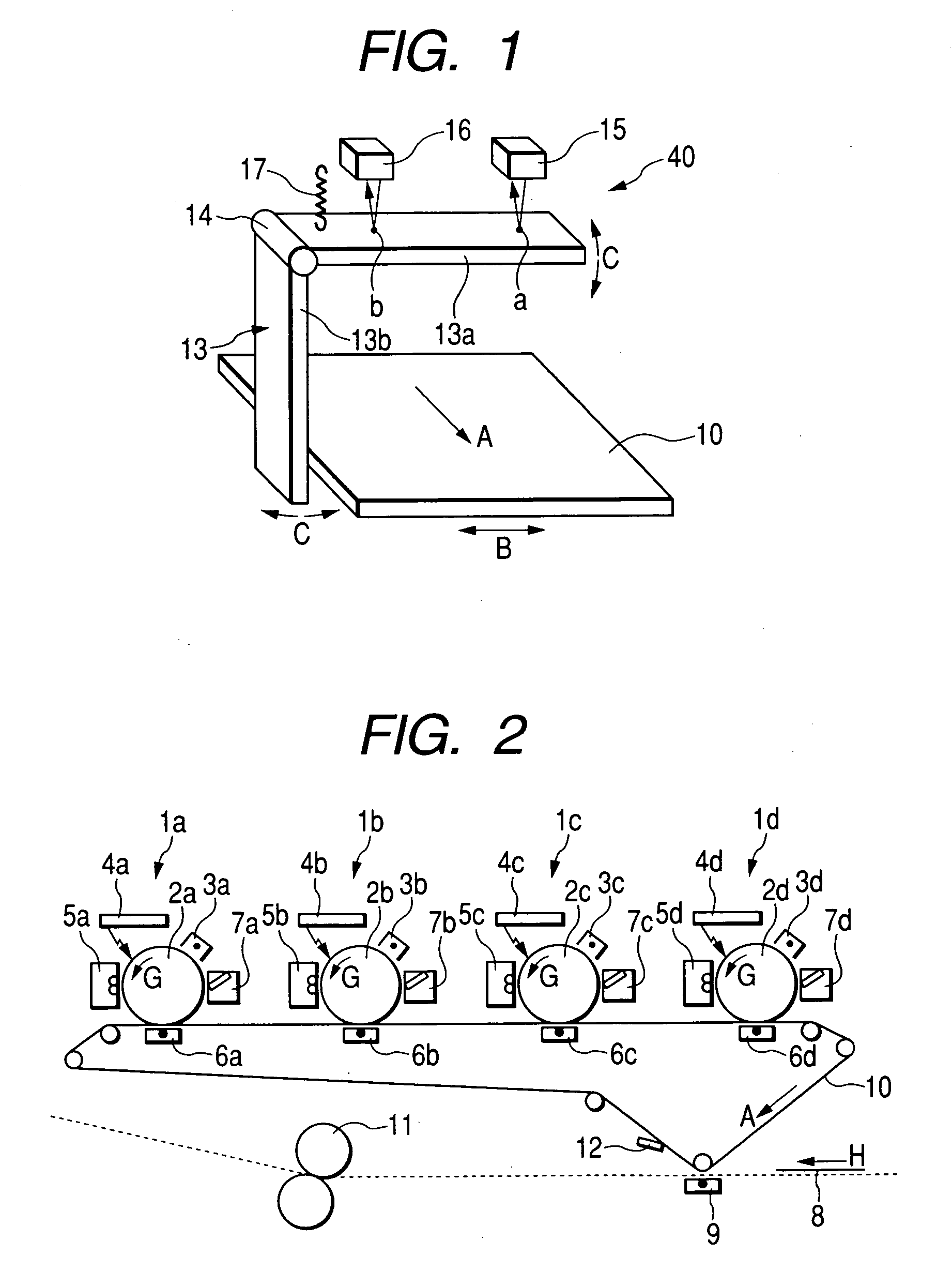

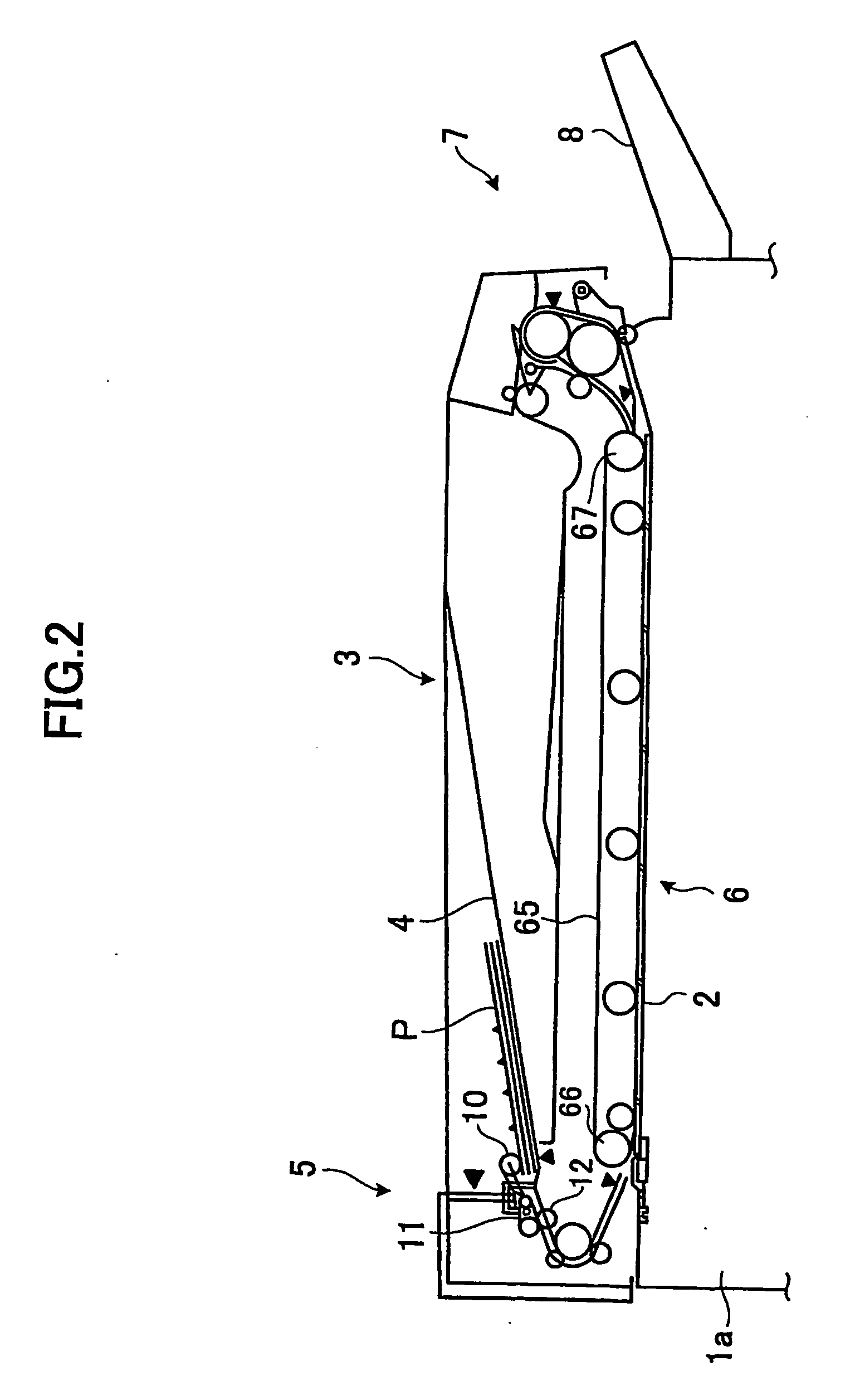

Belt transporting device and image forming apparatus using the same

InactiveUS6970674B2Easy constructionAvoid damageGearingElectrographic process apparatusComputer printingEngineering

A belt transporting device for circulatingly transporting an endless belt, which is in use with an image forming apparatus, such as copying machine or a printer. The belt transporting device includes a plurality of tension rolls, an endless belt laid on the tension rolls, the endless belt having a belt-end edge part protruding from an end of one of the tension roll and a guide member provided in the vicinity of the endless belt. The guide member comes in contact with the belt-end edge part so as to bend the belt-end edge part in a tapering-off direction. The guide member regulates the shape of the belt-end edge part so that a rotary peripheral length of the belt-end edge part becomes smaller than that of an area where a rear side of the endless belt is in contact with the tension roll.

Owner:FUJIFILM BUSINESS INNOVATION CORP

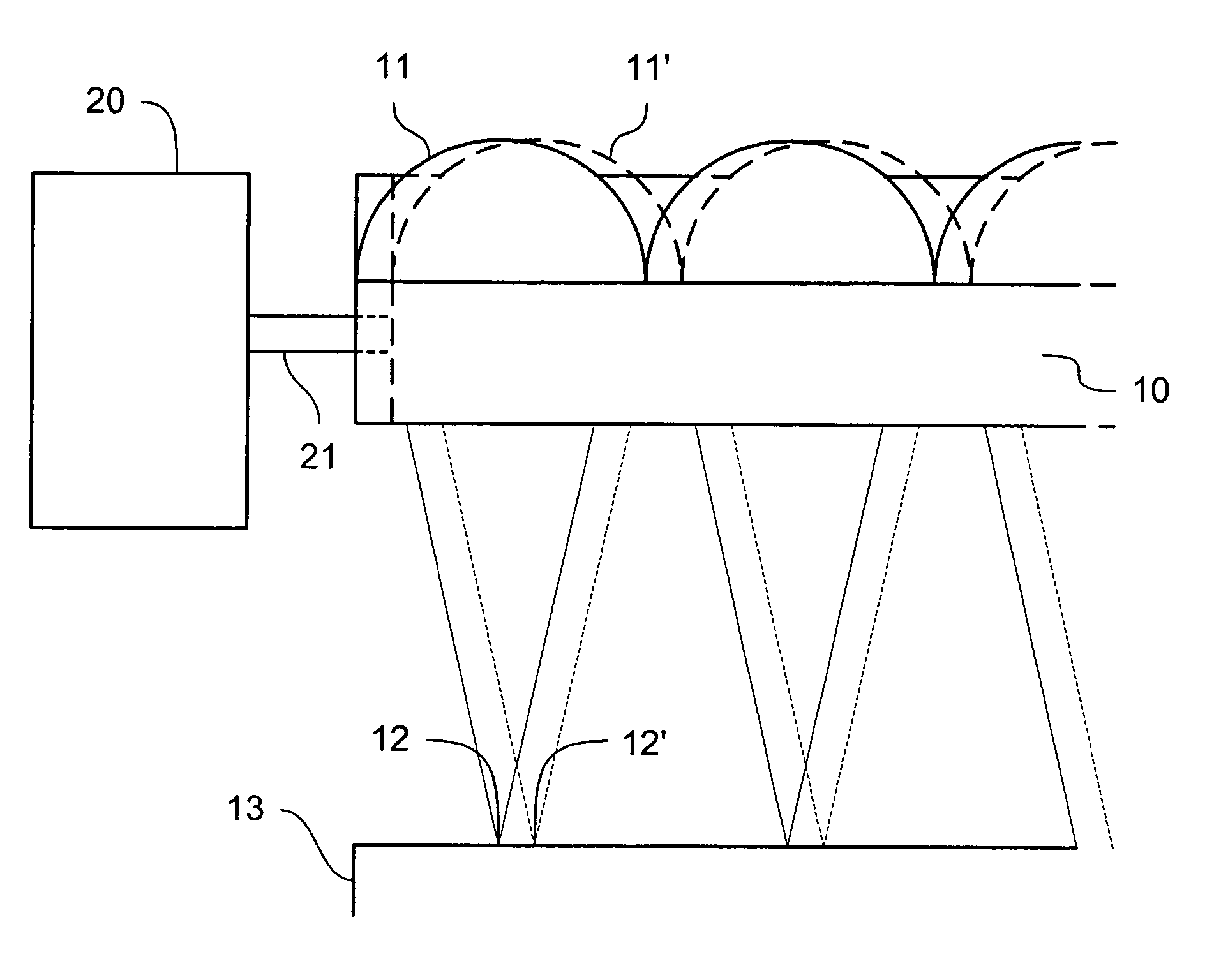

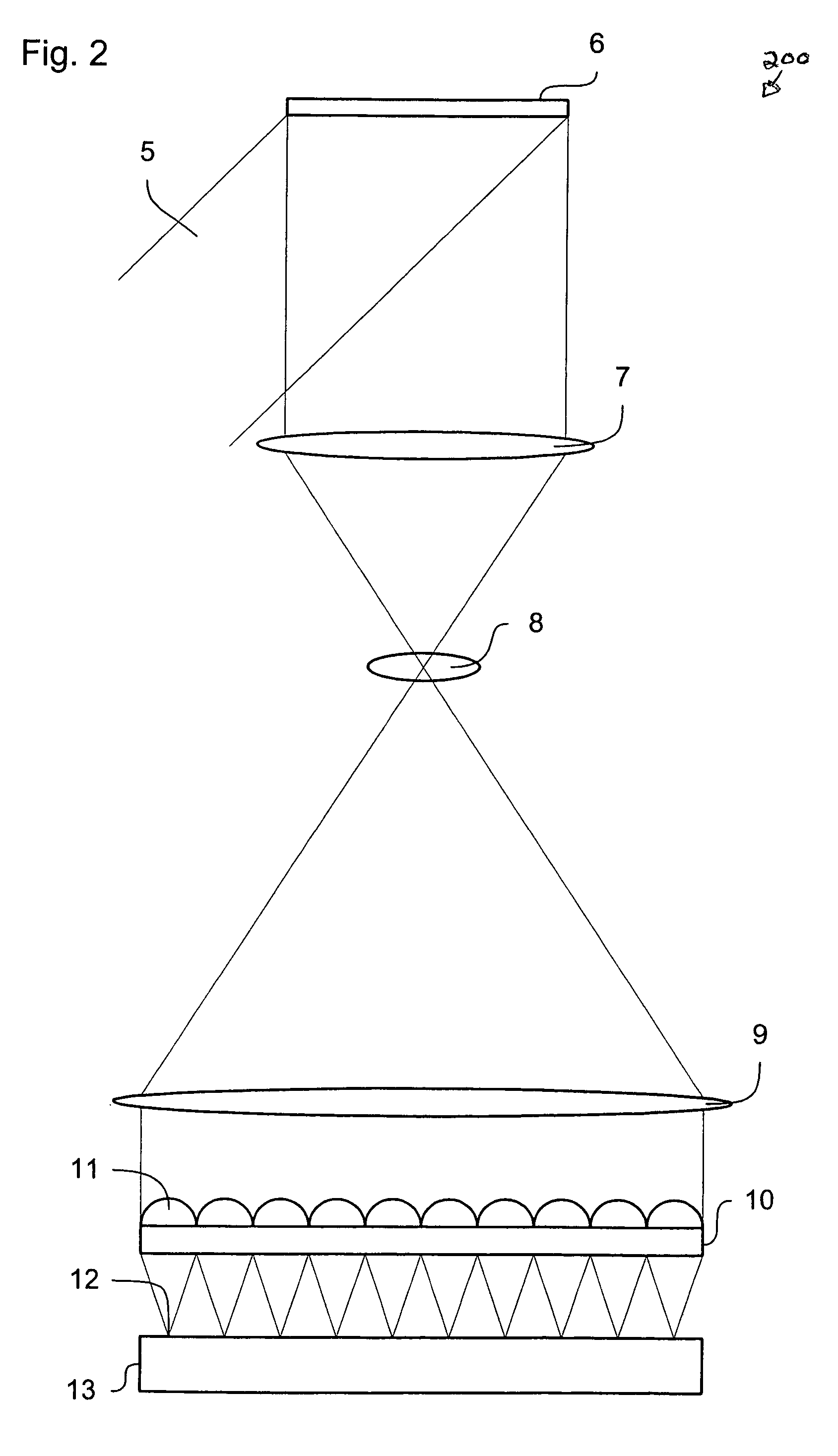

Lithographic apparatus and device manufacturing method

ActiveUS7081947B2Precise positioningEnhance the imageShaft and bearingsSemiconductor/solid-state device manufacturingLight beamOptics

Owner:ASML NETHERLANDS BV

Beaded conveyor belt

The beads of a beaded conveyor belt for a curve conveyor are constituted by a number of bead constituting bodies (2b) that are disposed over the entire periphery of the outer surface along the outer peripheral edge of a belt main body (2a) and that are narrow in the direction of the length of the belt. Further, the beads of a beaded conveyor belt for a liner conveyor are constituted by a number of bead constituting bodies (7b) that are disposed over the entire periphery of the outer surface along opposite side edge of a belt main body (7a) and that are narrow in the direction of the length of the belt. The conveyor belt is installed taut between straight type end rollers (15), and the width of the bead constituting bodies (2b, 7b) lengthwise of the belt is set at about 20–60% of the diameter of the straight type end rollers (15). Even when the conveyor belt is installed taut between small-diameter end rollers, long-term use is possible.

Owner:NITTA CORP

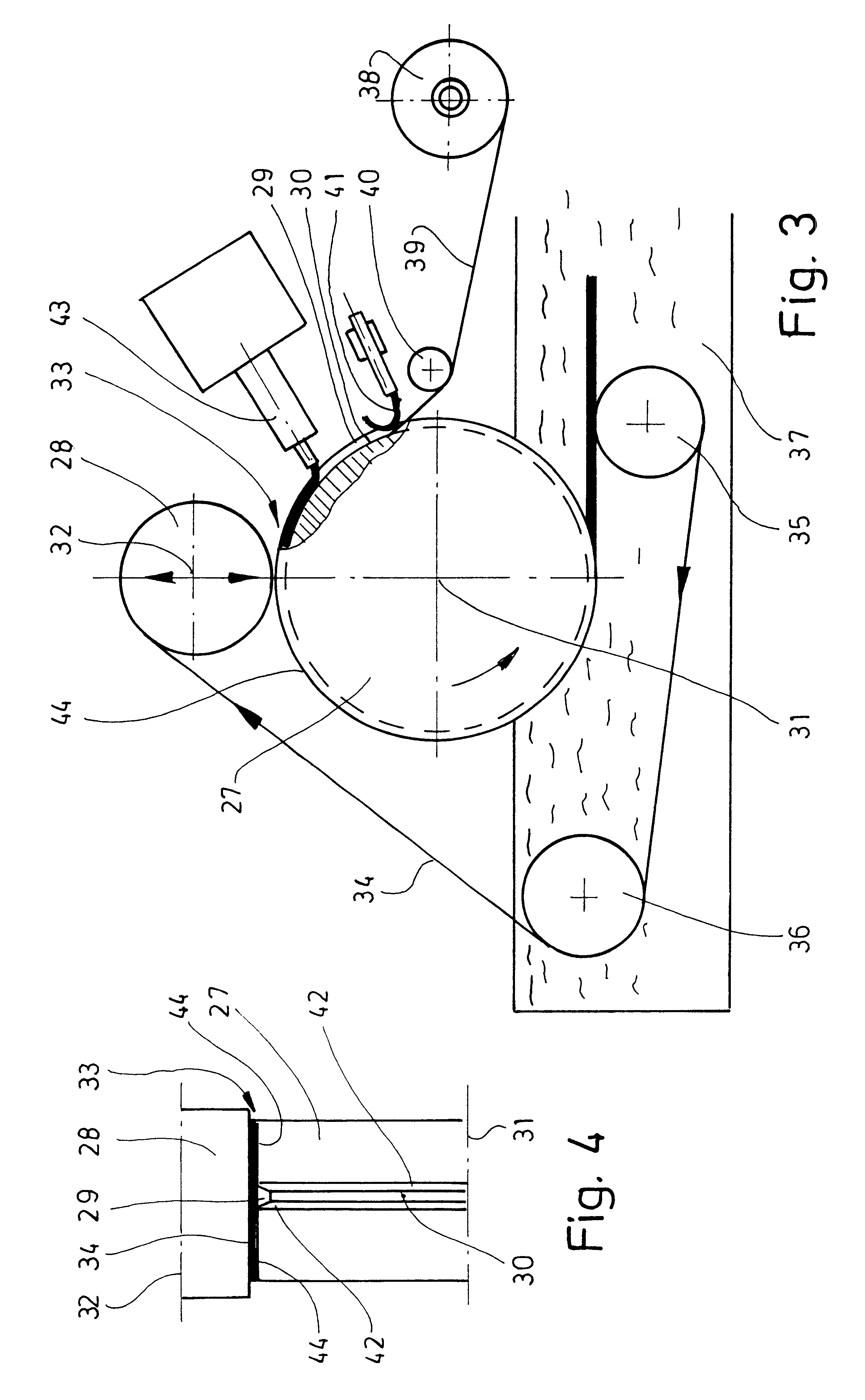

Belt band conveyor having separate guide shoes

InactiveUS20050082146A1Small deflectionSpeed up the cycleConveyorsRollersEngineeringMechanical engineering

The invention relates to a belt band conveyor such as a curved belt conveyor having an endless transport belt that is guided over deflection rollers. There is a guide element that projects beyond the belt plane wherein this guide element can be handled separately before it is attached to the transport belt. This guide element moves along as the transport belt moves, and on whose guide surfaces, which extend in the transport direction of the transport belt has running surfaces that are inclined relative to the belt plane roll off from rotating guide rollers as the transport belt moves. Thus, lateral forces that occur crosswise to the transport direction of the transport belt can be compensated. A plurality of separate guide shoes are attached to the transport belt, forming a guide strip for the guide rollers that extends in the transport direction, circulates, and is divided into multiple parts.

Owner:INTERROLL HLDG

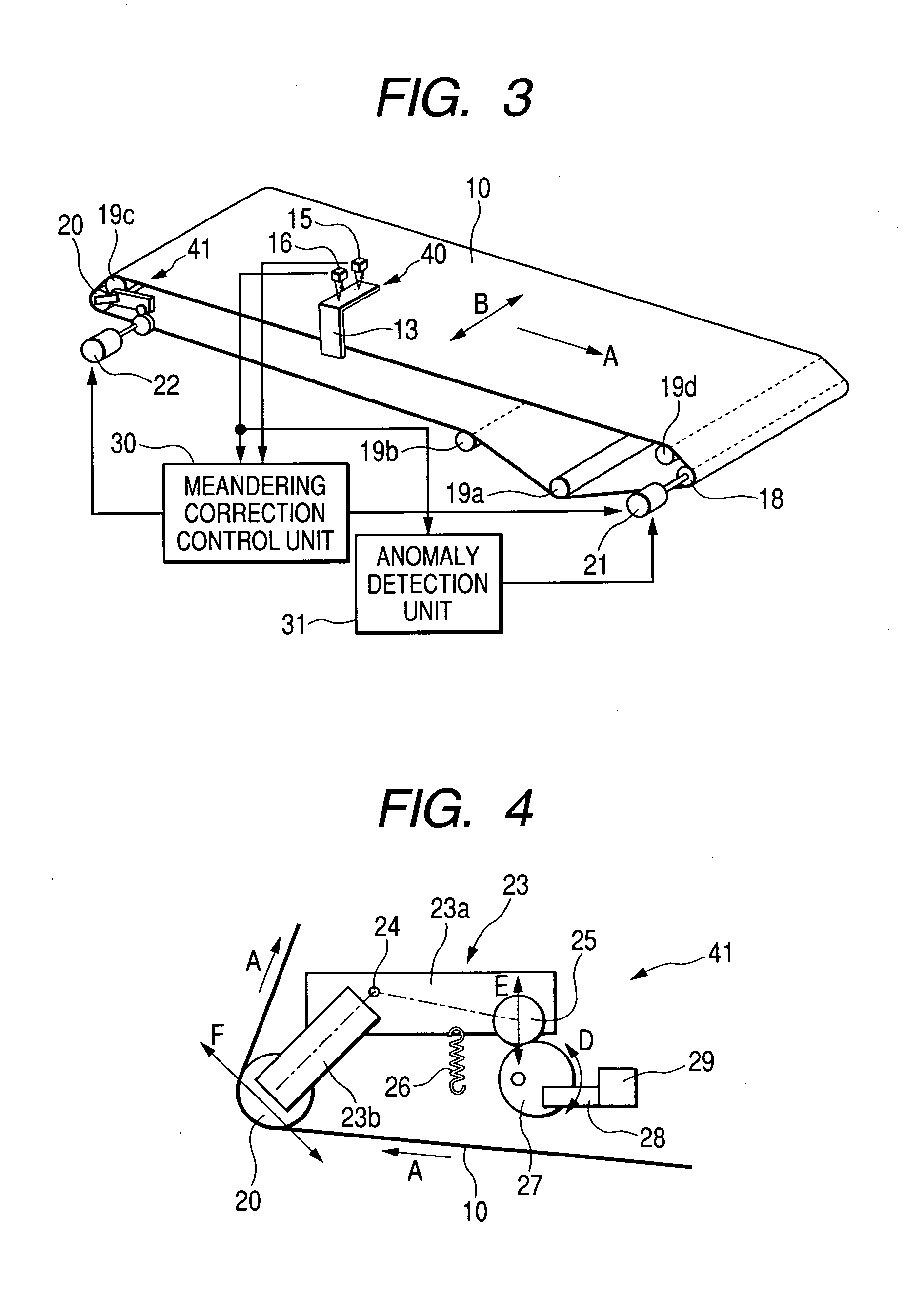

Belt conveyor and image forming apparatus using the same

InactiveUS20060289280A1Improve accuracyImprove picture qualityElectrographic process apparatusRollersImage formationBelt conveyor

A belt conveyor includes: an endless belt that is looped over a plurality of rollers, the plurality of rollers including a drive roller and a meandering correction roller; a drive unit that rotates the drive roller to drive the endless belt; a meandering correction unit that adjusts an inclination of the meandering correction roller to correct meandering of the endless belt in a width direction thereof; a plurality of position detection units that detect positions of the endless belt in the width direction thereof and output detection signals; and a meandering correction control unit that selectively uses the detection signals from the plurality of detection units to control the meandering correction unit.

Owner:RICOH KK

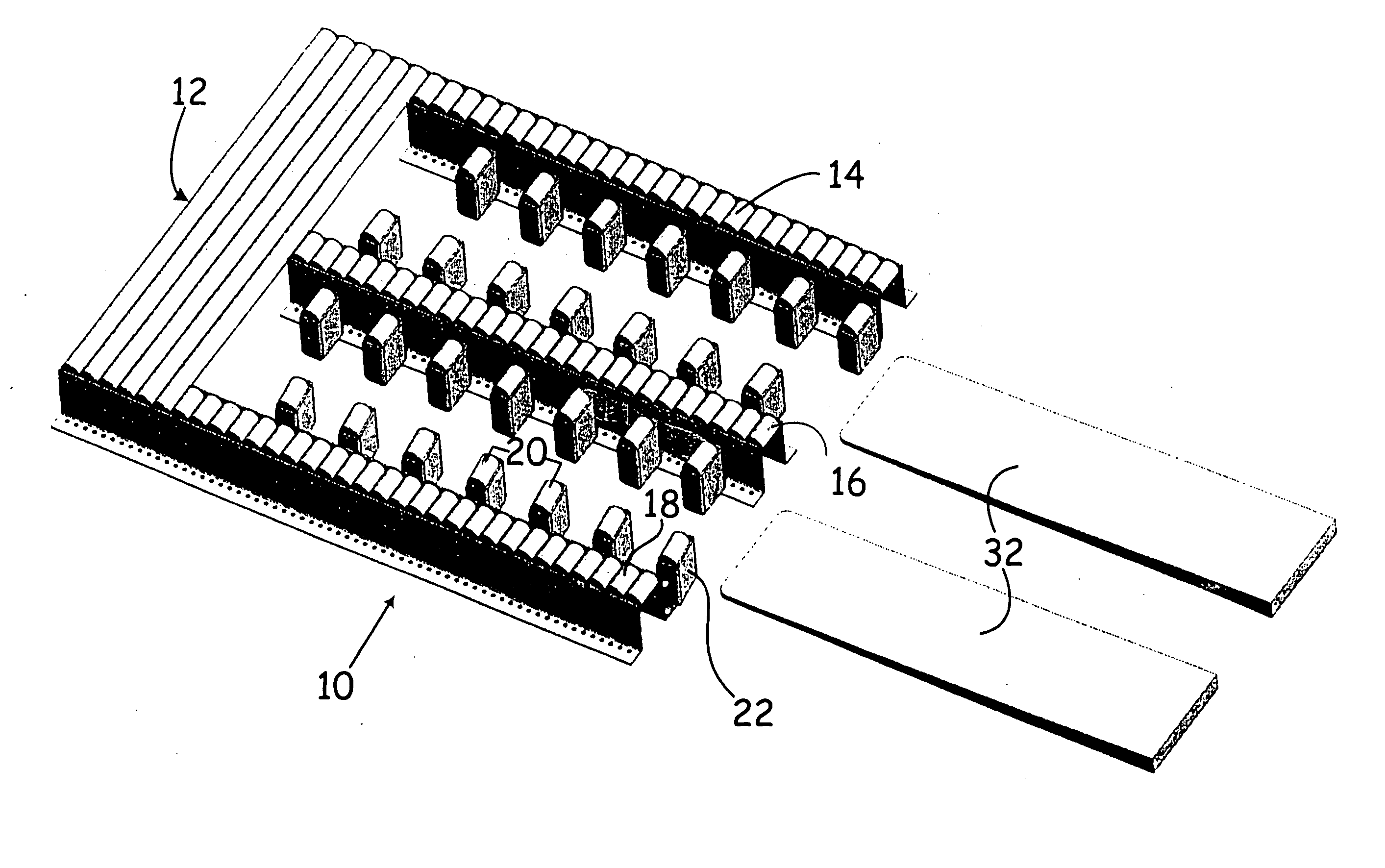

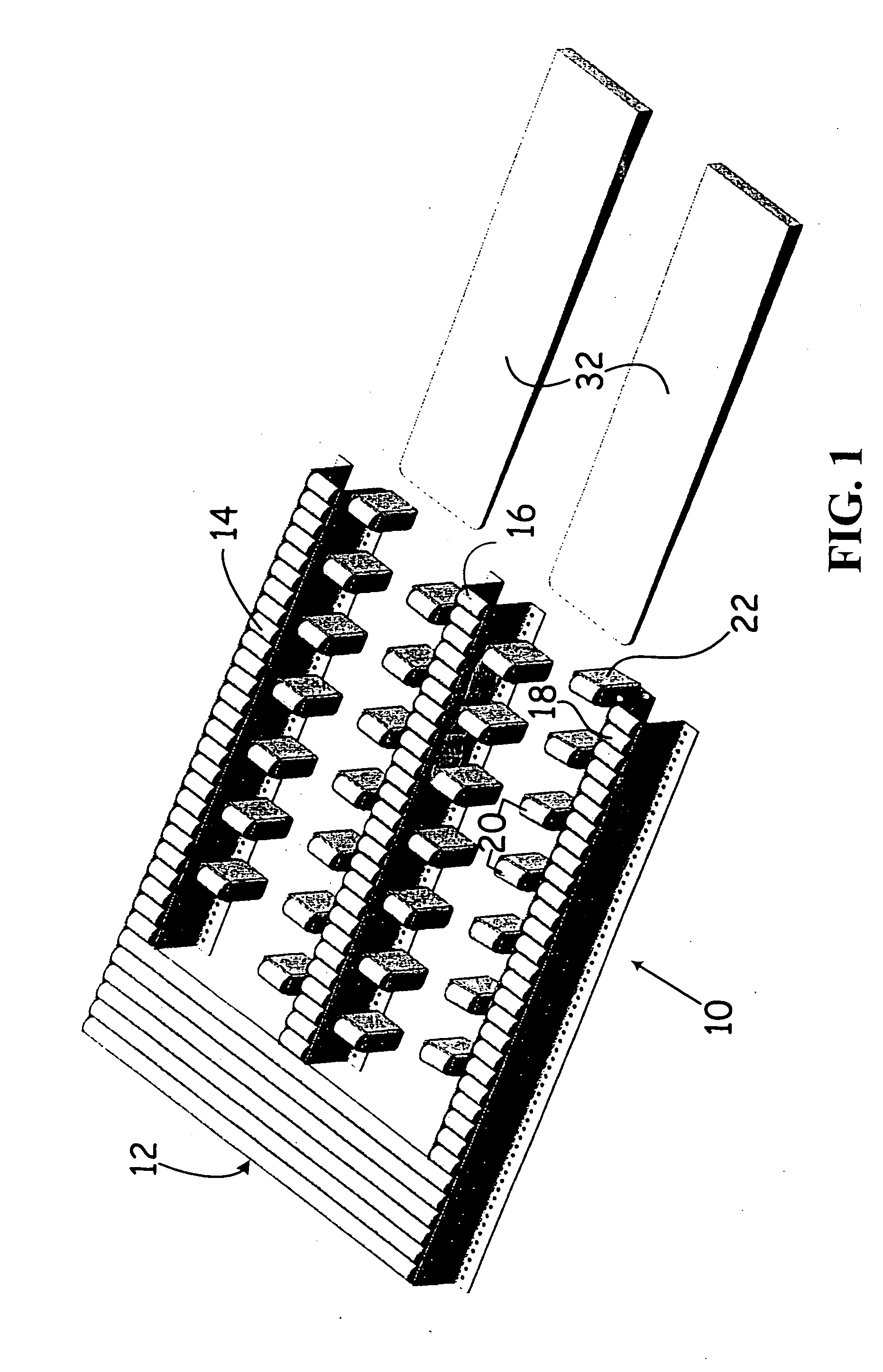

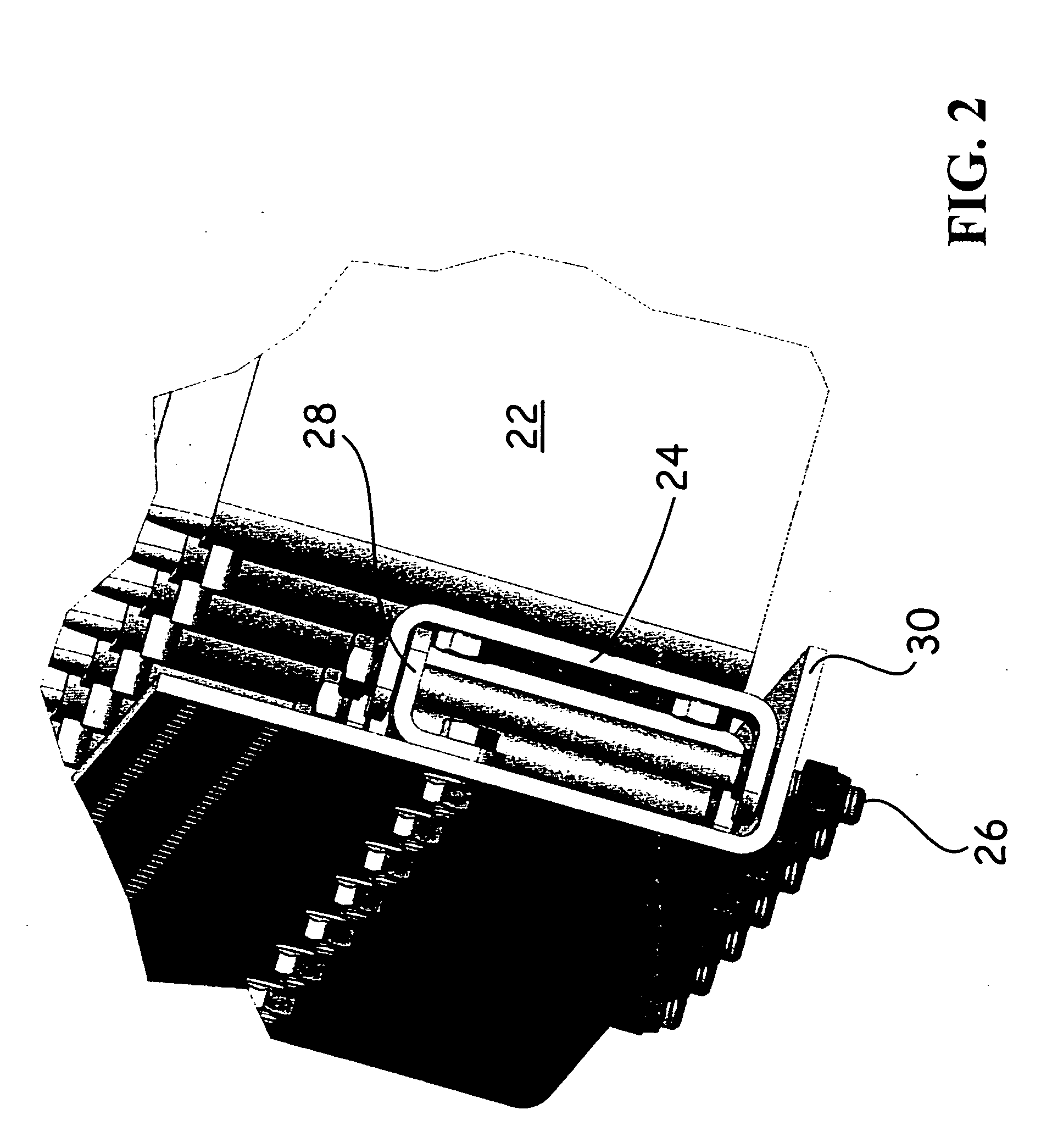

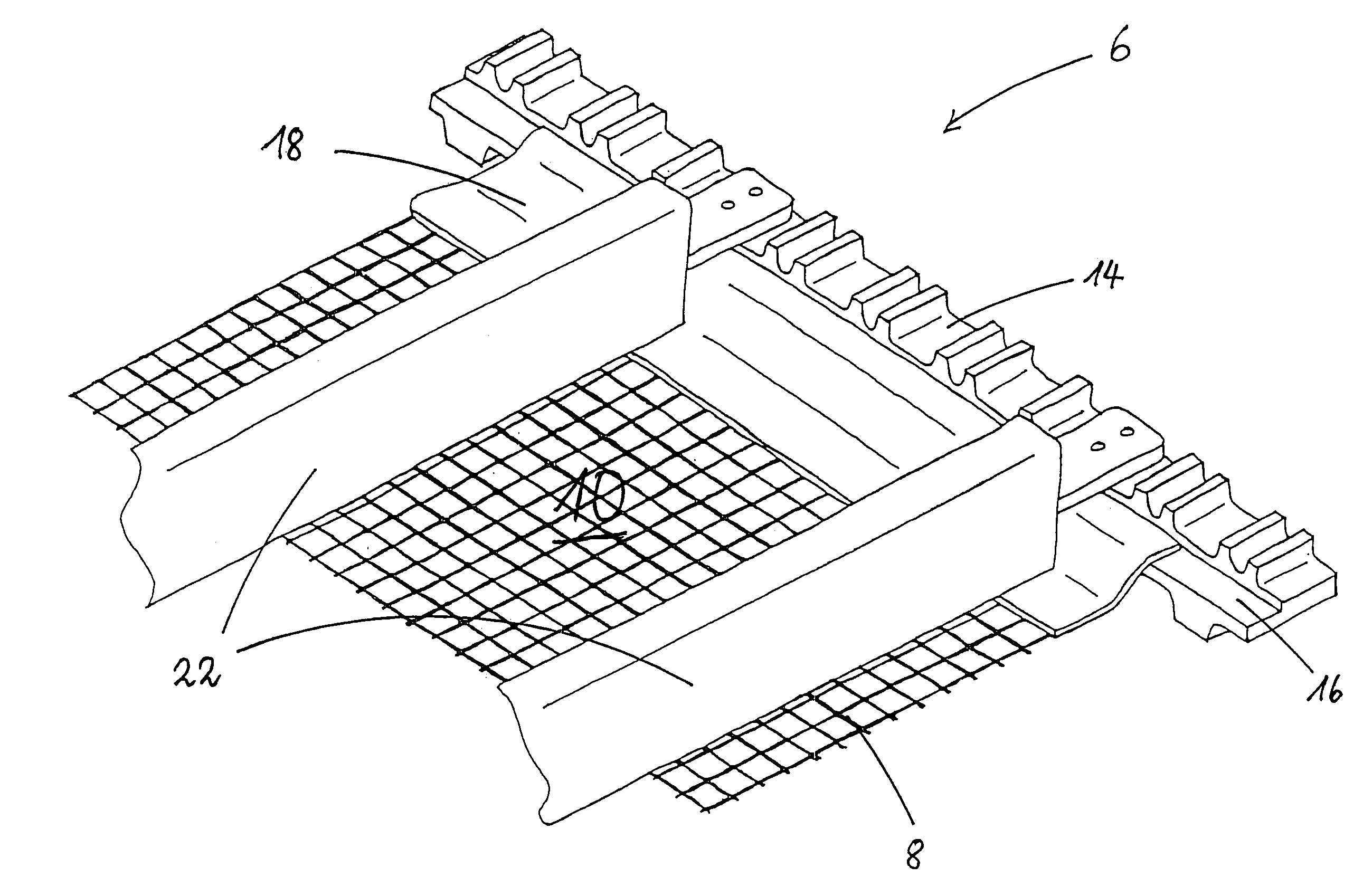

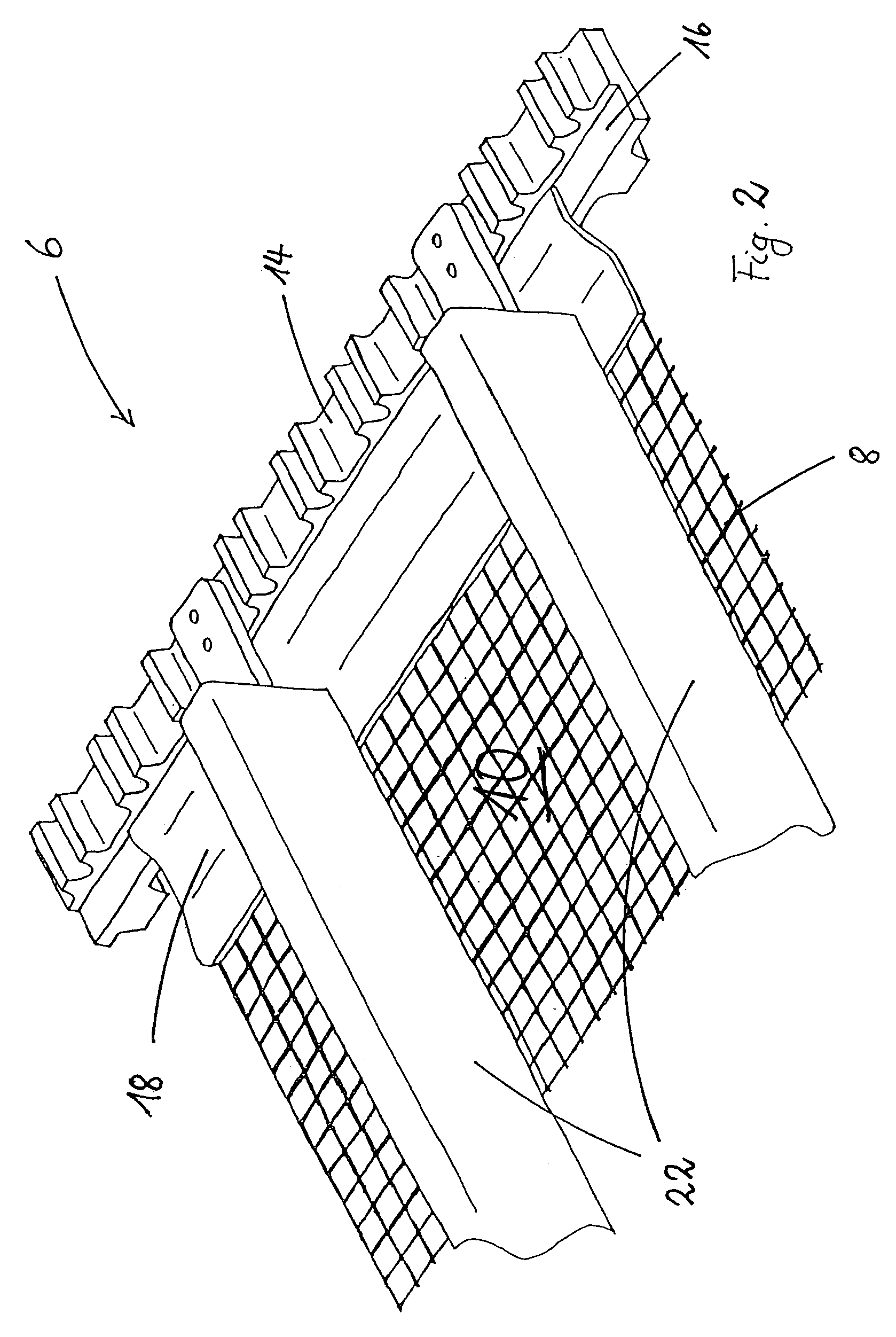

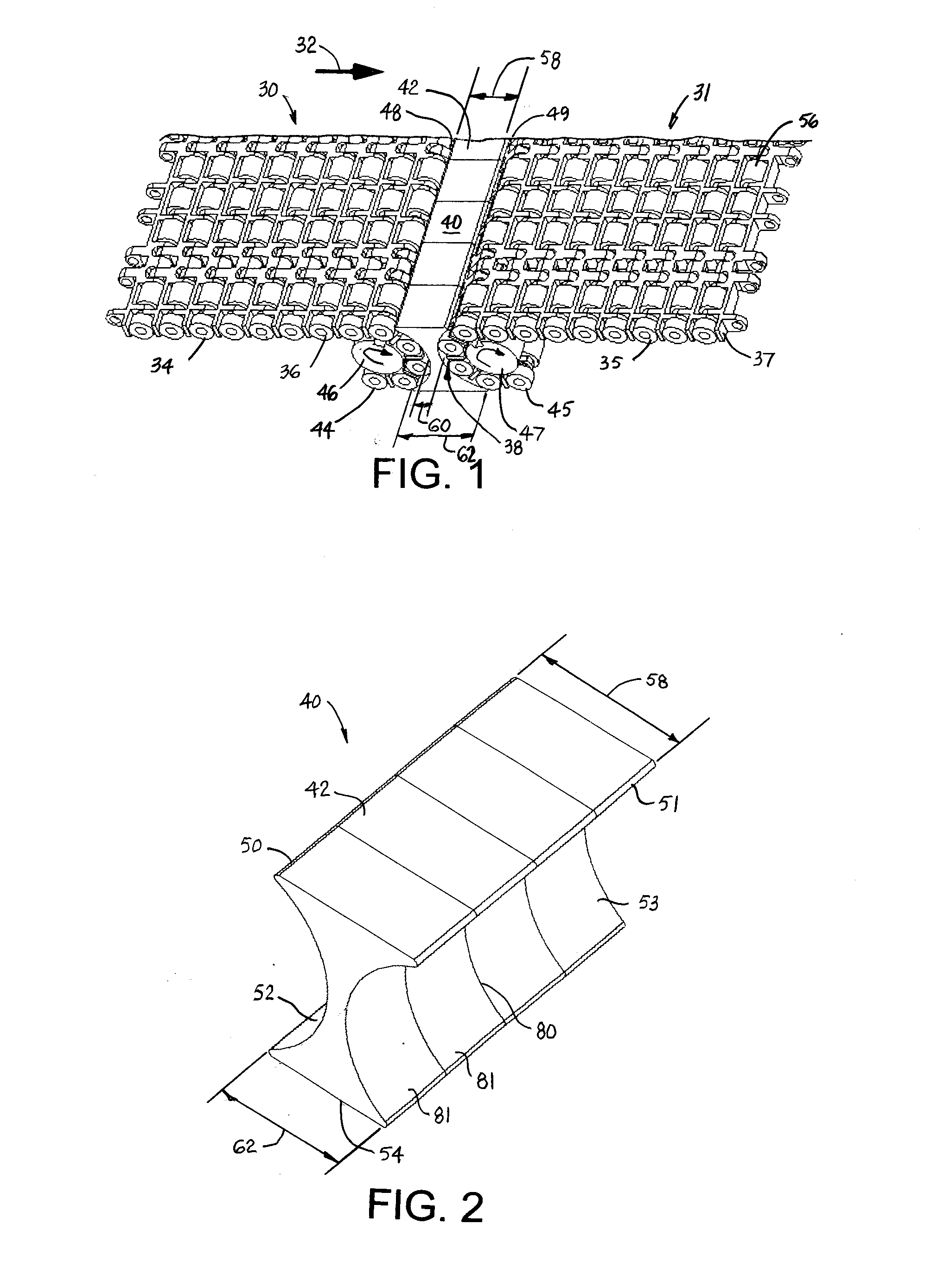

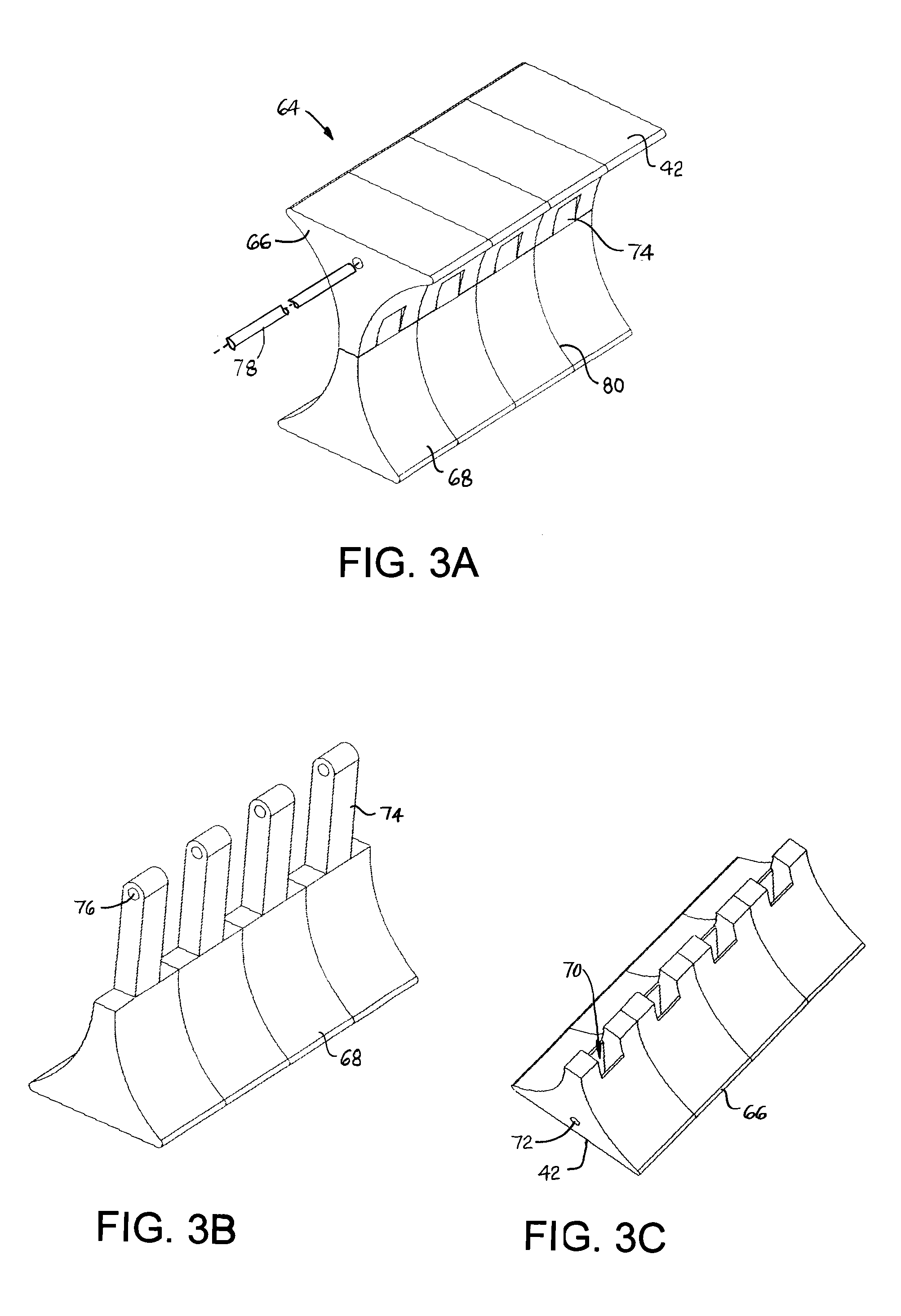

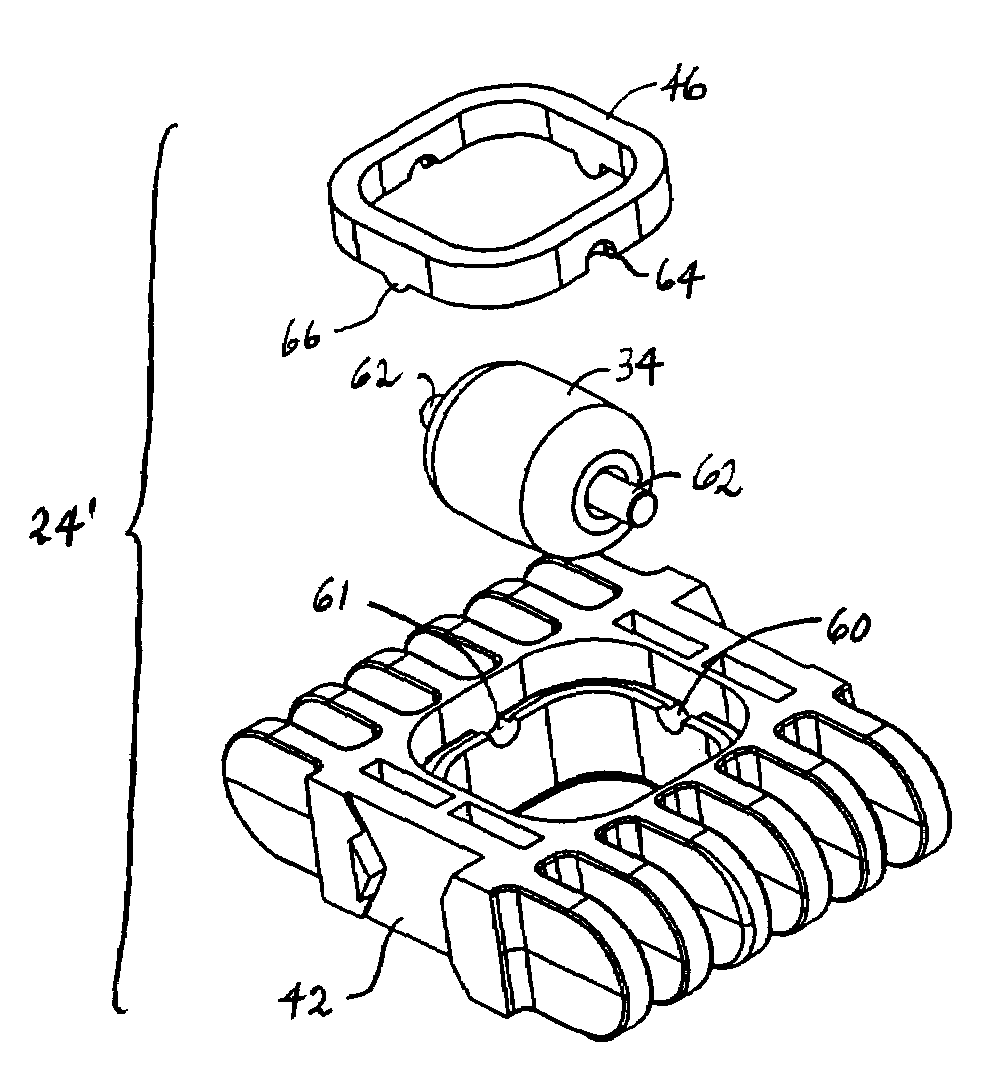

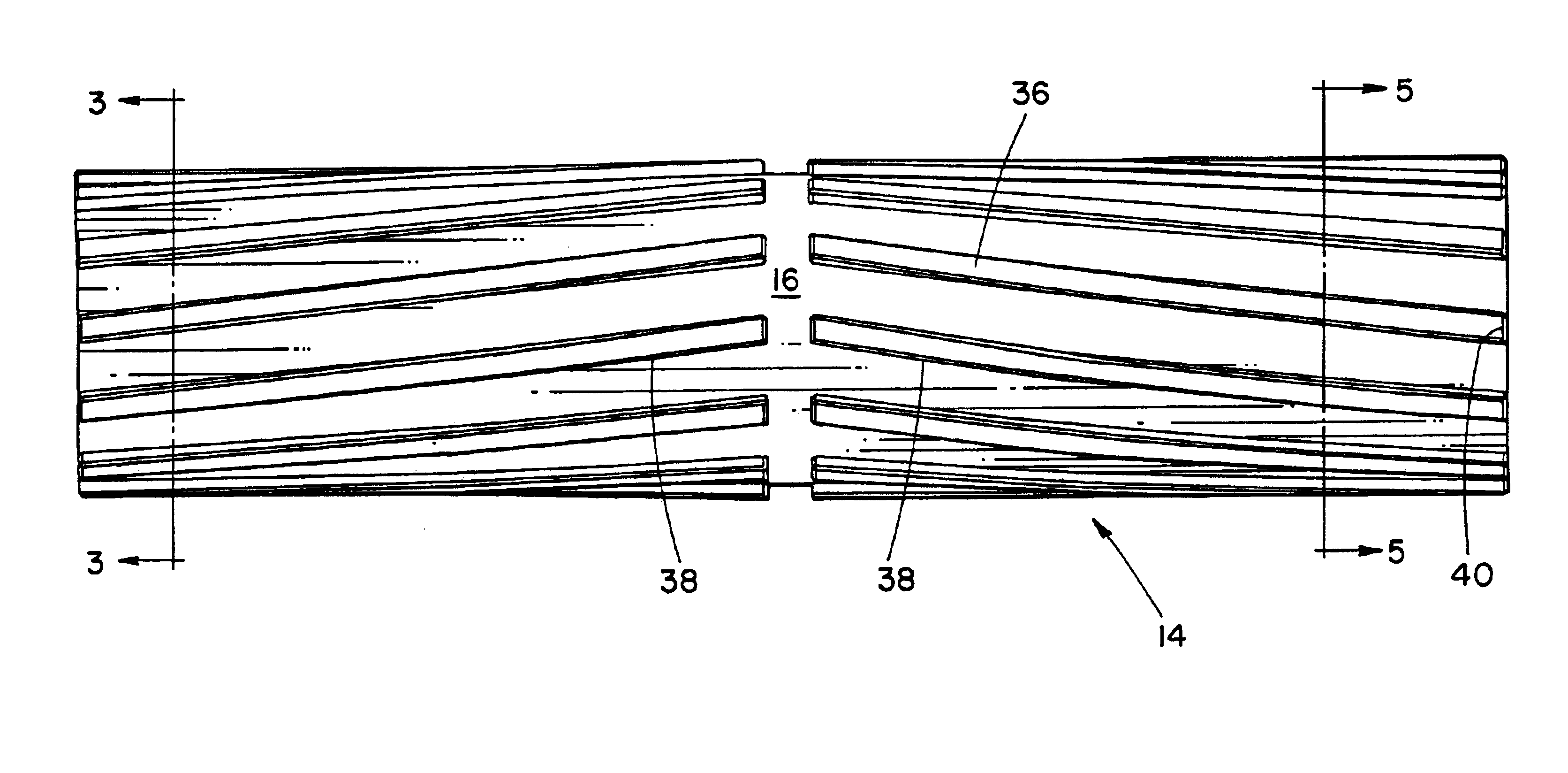

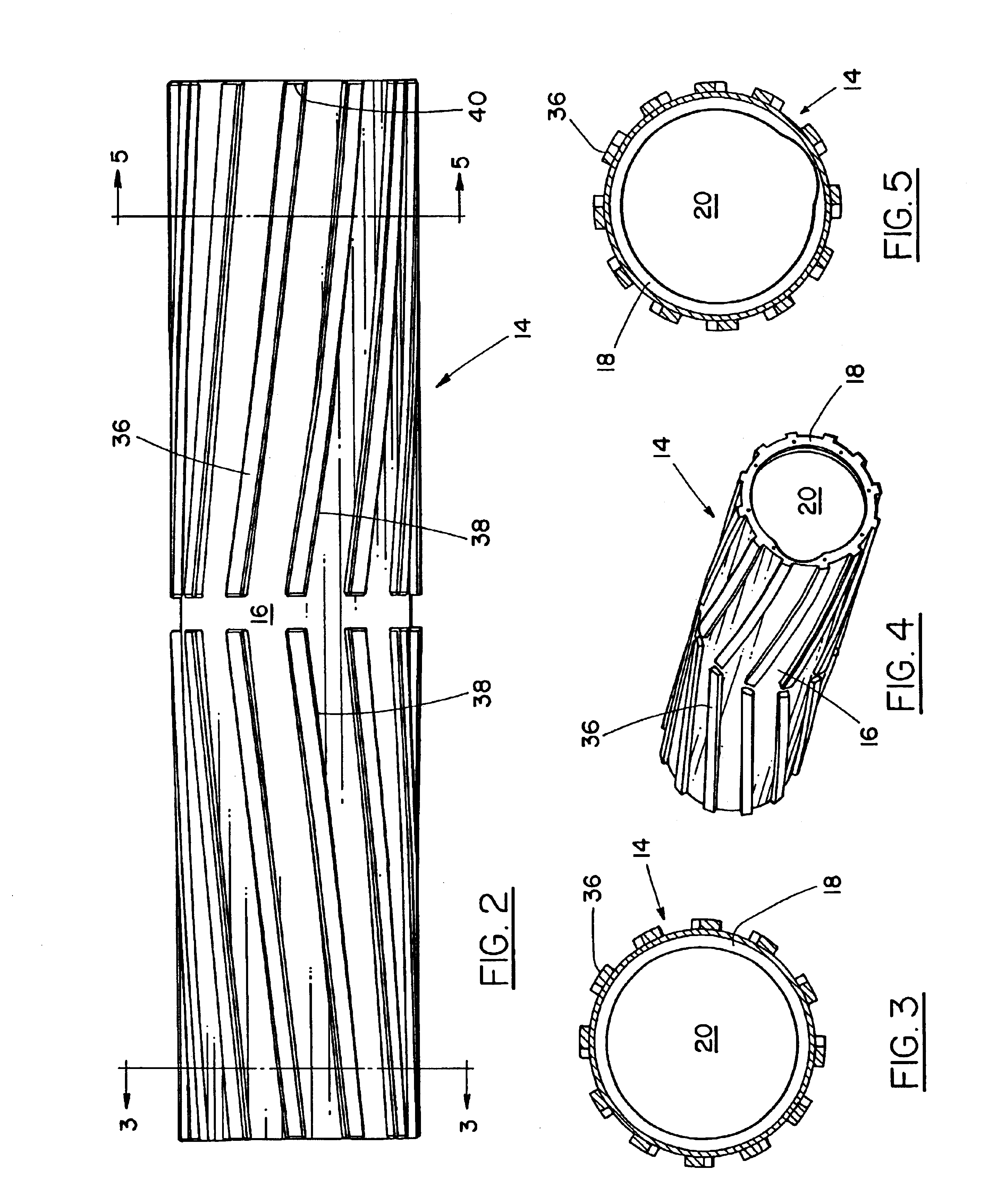

Conveyor belt modules with embedded rollers retained in the modules and associated method

A plastic conveyor belt module with embedded rollers retained in the module and a method for making such a module. The module includes a module body forming a cavity, a roller in the cavity, and a retainer received in the cavity to hold the roller rotatably in place. A salient portion of the roller extends outward from the cavity through the retainer past an outer surface of the module. The retainer is attached to the module body by ultrasonic welding, epoxy- or solvent-bonding, spin welding, electromagnetic welding, staking, screwing, or locking.

Owner:LAITRAM LLC

High endurance high capacity ball transfer unit

Owner:ROLLER BEARING OF AMERICA

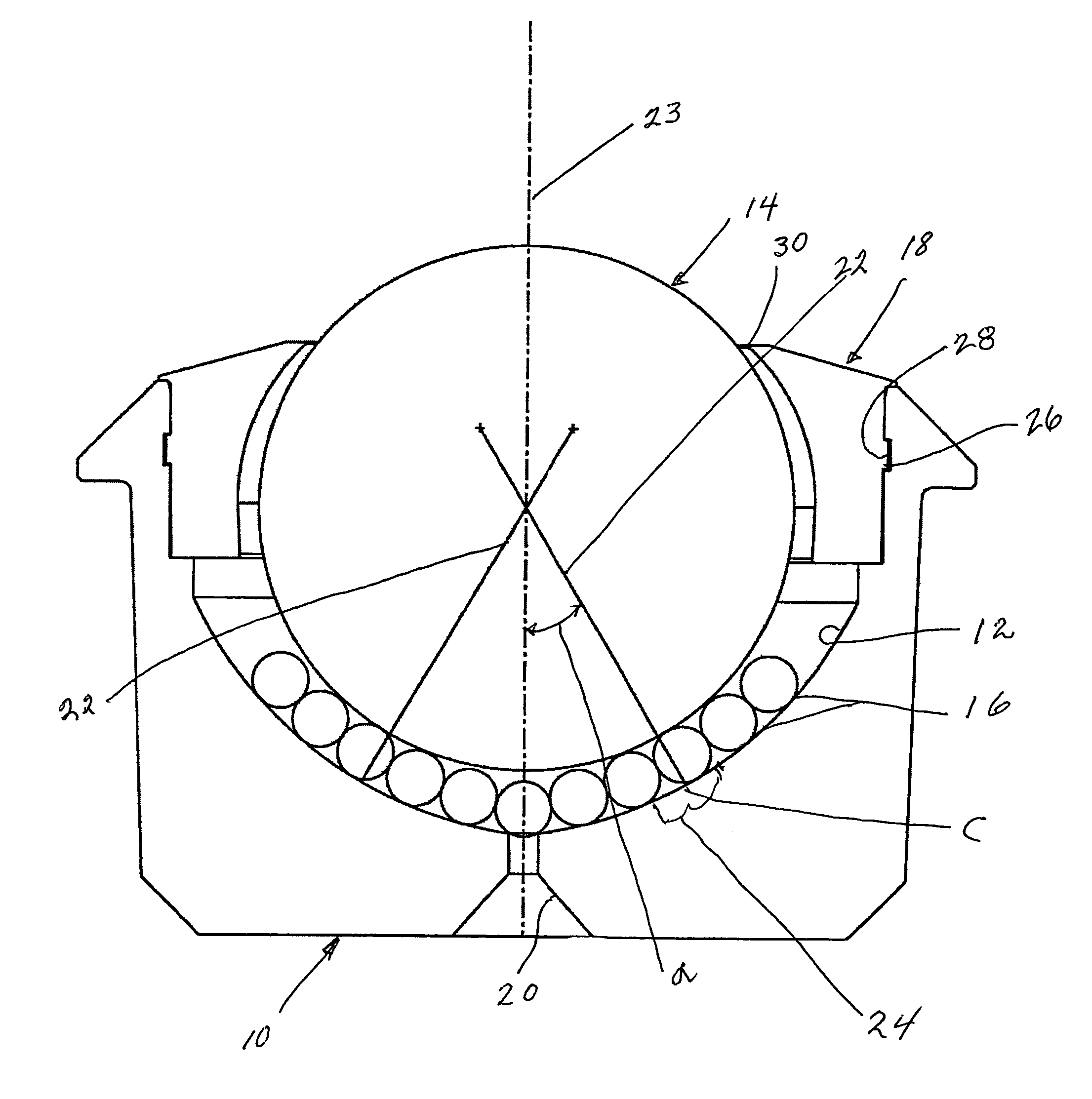

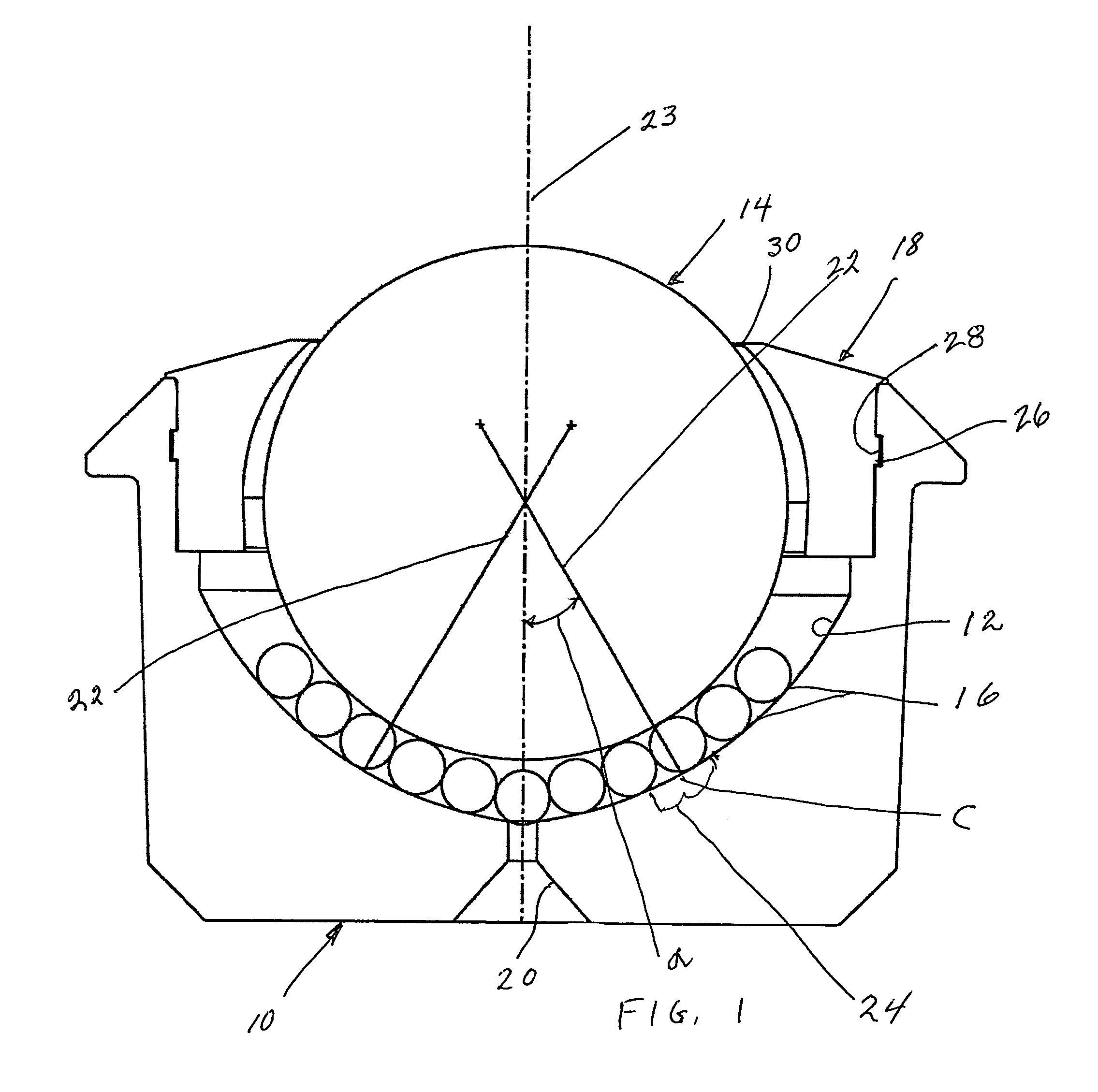

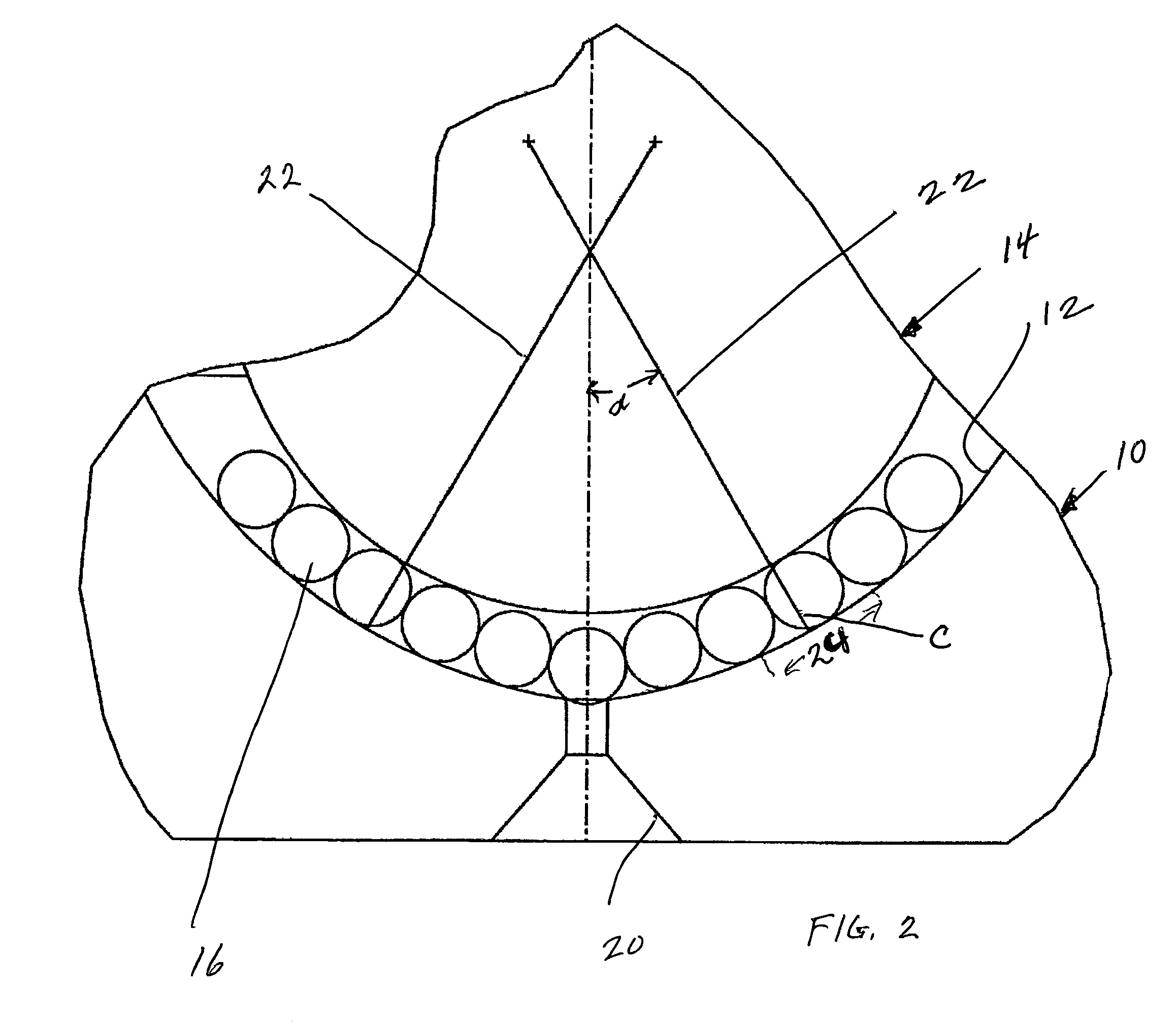

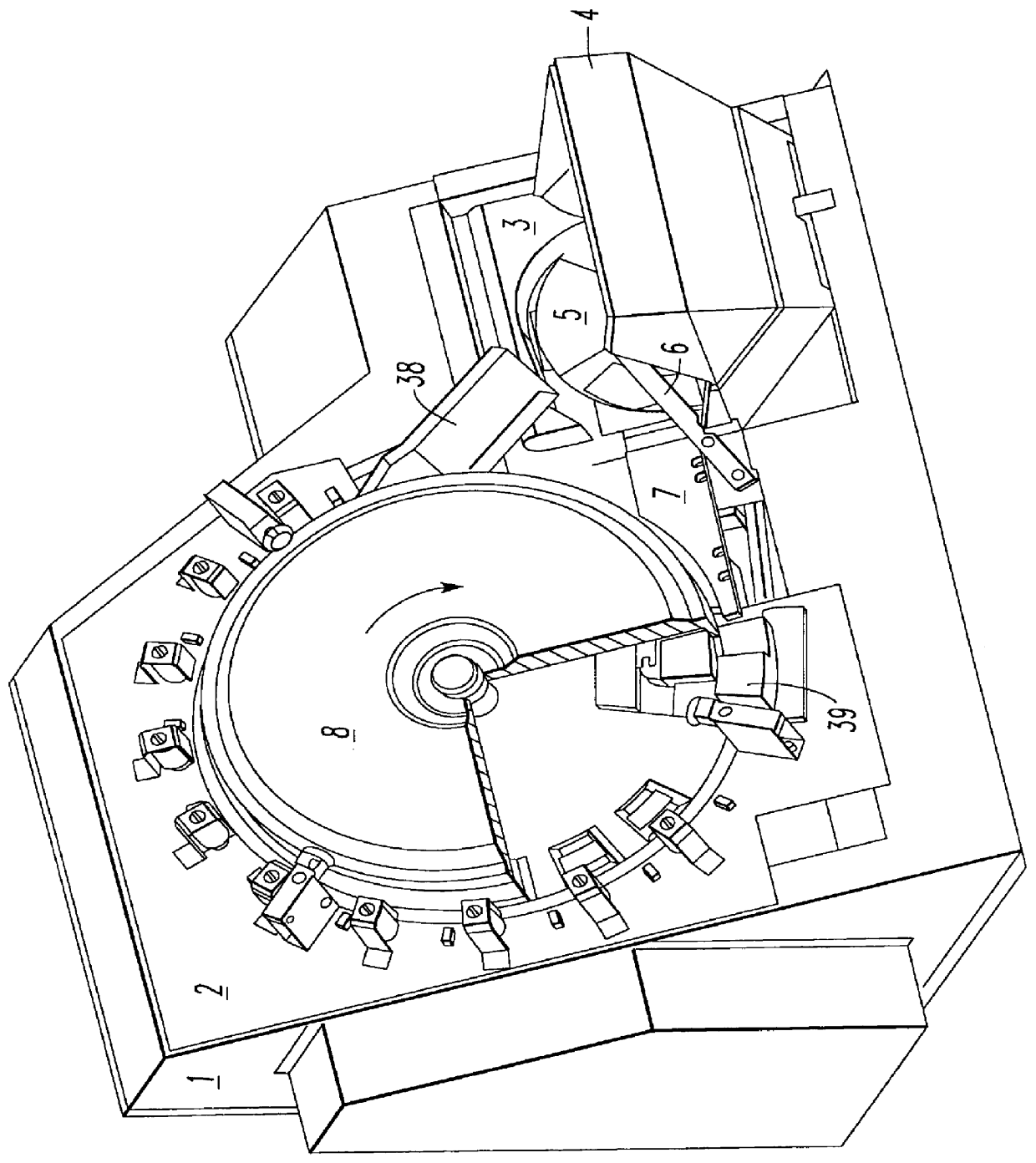

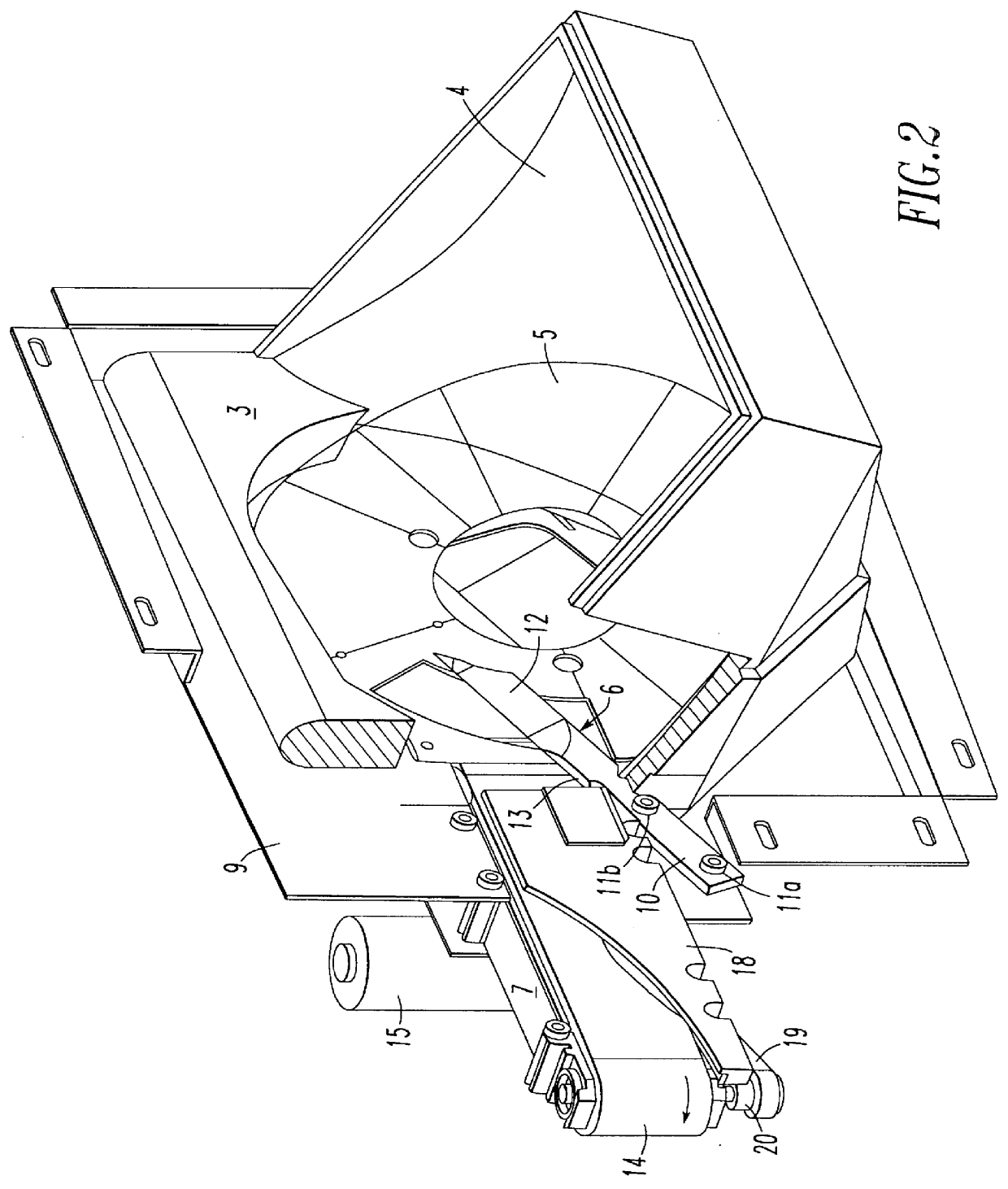

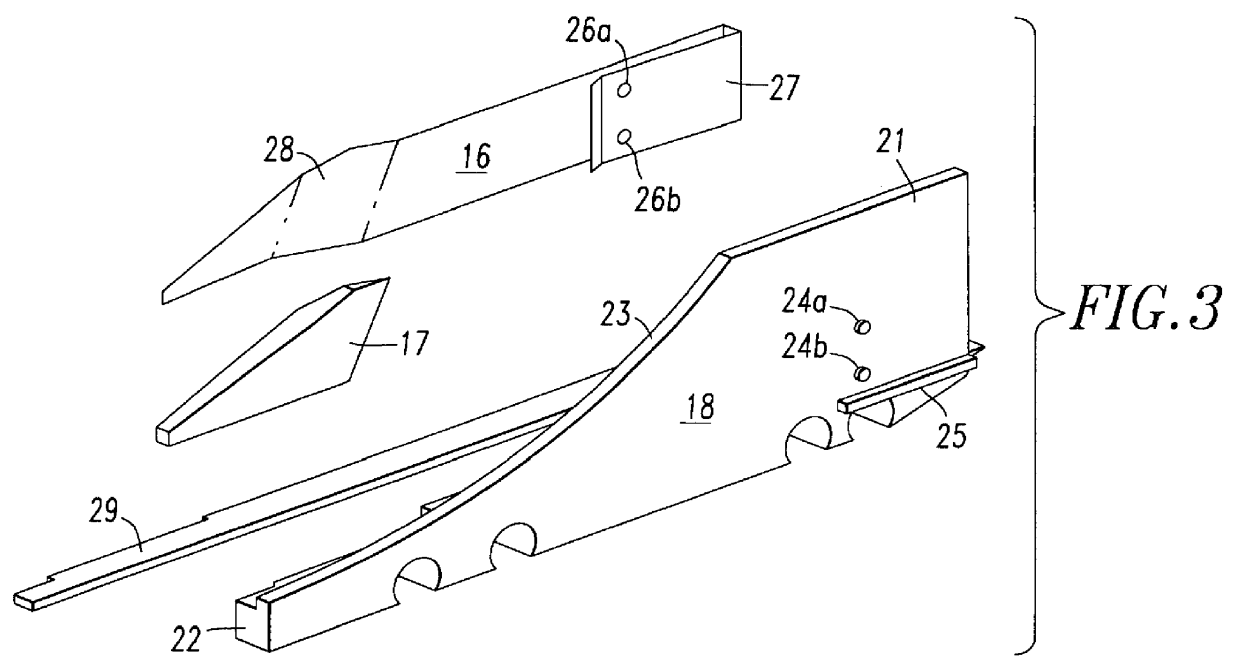

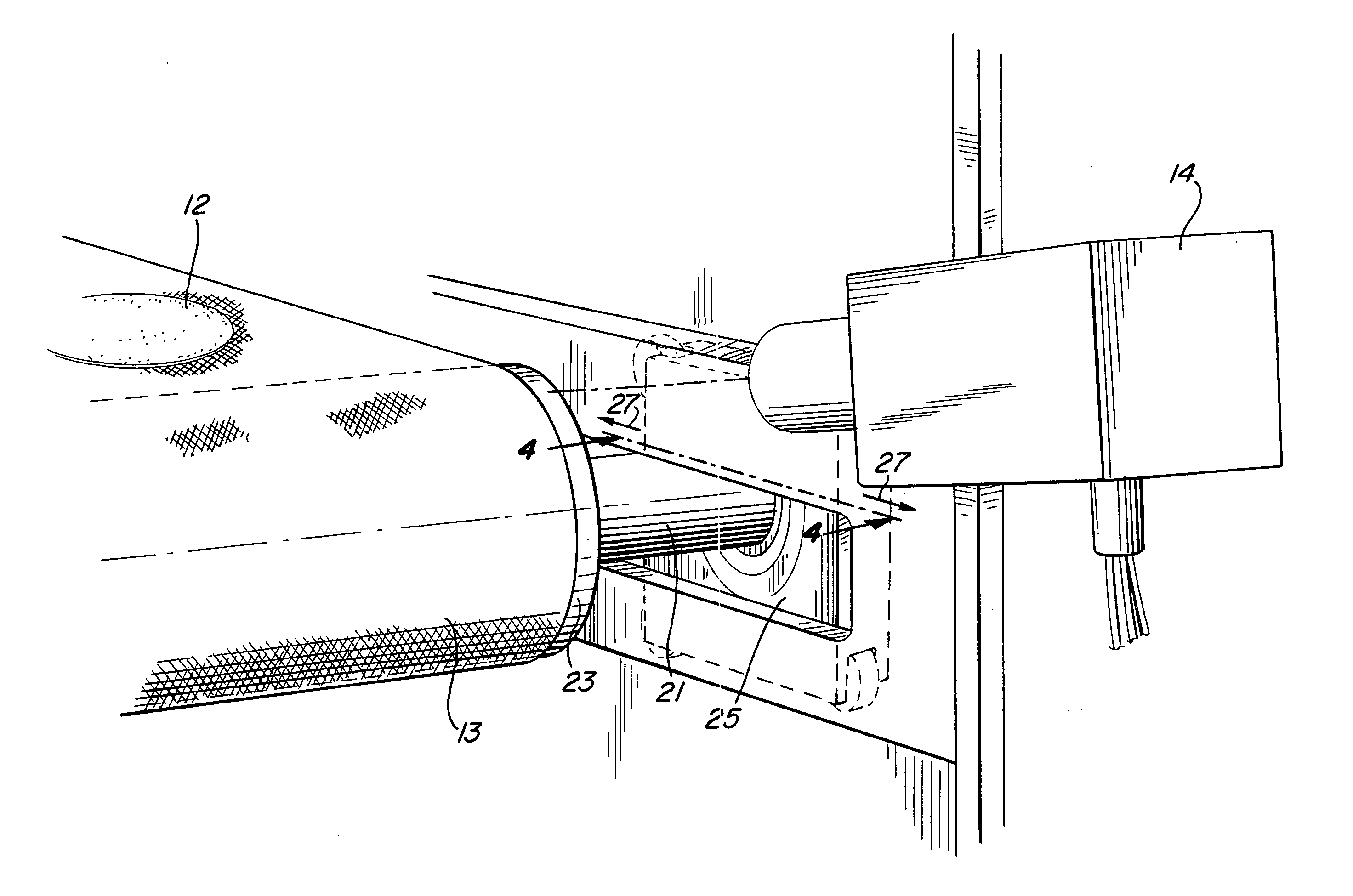

Coin counting and sorting machine

InactiveUS6030284ASimplify the viewing processConveyorsCoin countersEngineeringMechanical engineering

PCT No. PCT / SE96 / 01030 Sec. 371 Date Jun. 8, 1998 Sec. 102(e) Date Jun. 8, 1998 PCT Filed Aug. 21, 1996 PCT Pub. No. WO97 / 07485 PCT Pub. Date Feb. 27, 1997A coin counting and sorting machine has a coin lifting device with an open bowl for receiving and forwarding an unsorted mass of coins, a sorting device for sorting coins being supplied thereto, and a coin transferring device for transferring the coins from the coin lifting device to the coin sorting device while establishing an order among the coins suitable for sorting and counting. The coin transferring device is provided with a first and a second element between which a transportation channel for the coins is disposed, wherein the first element is movable with respect to the second element so as to effect the transferring of the coins, and with a resilient device arranged with the transportation channel for pressing the coins against the first, movable element with a locally increased coin transferring speed as a result.

Owner:SCAN COIN

Oven conveyor alignment system apparatus and method

An oven conveyor alignment system for maintaining a conveyor belt centered on its supporting rollers is disclosed. The system comprises a camera that generates an image of alignment and stores it as a digital pixel representation. Thus, the system is able to take advantage of new improvements in digital camera resolution. The image information is used by interactive software that is able to transmit an electrical signal to a tension adjustment assembly.

Owner:CASA HERRARA

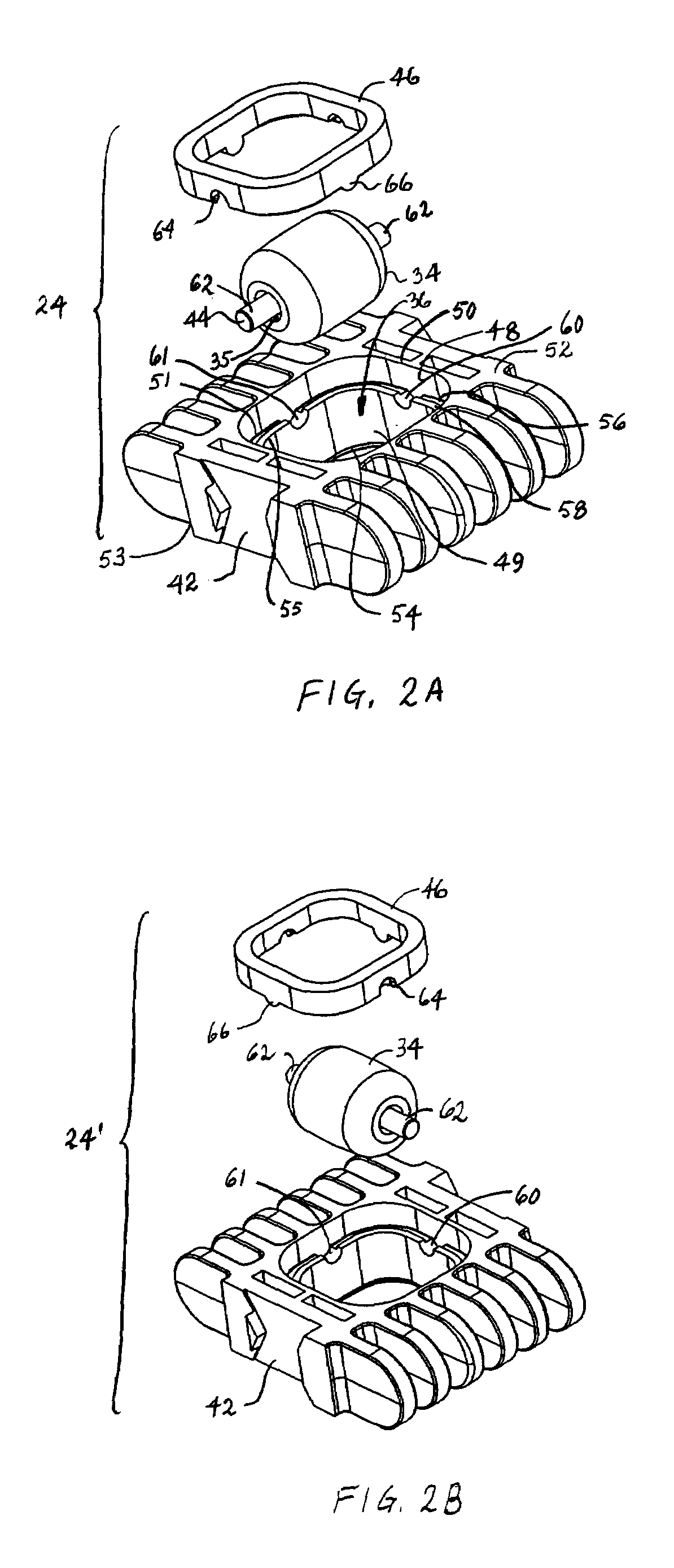

Modular link conveyor chain with rotatable article engaging assemblies

Disclosed is a conveyor chain including modular links interconnected by an elongated transverse connector rotatably supporting article engaging assemblies including rotatably mounted caps. In one embodiment, the caps are provided with a generally spherical outer surface and are mounted for rotation about an axis generally transverse to a longitudinal axis of the connector. This arrangement thus allows for article conveyance with low backline pressure while facilitating the smooth and efficient diversion of an article in a direction generally transverse to the direction of chain movement through engagement with the caps. The chain may be of fixed length, or alternatively may be adapted to undergo side-flexing movement to negotiate curves or bends when driven in an endless path over a support structure forming part of a conveyor system, as well as longitudinal expansion and compression. One or more spacers may laterally offset the article engaging assemblies on alternating connectors forming the chain.

Owner:SPAN TECH

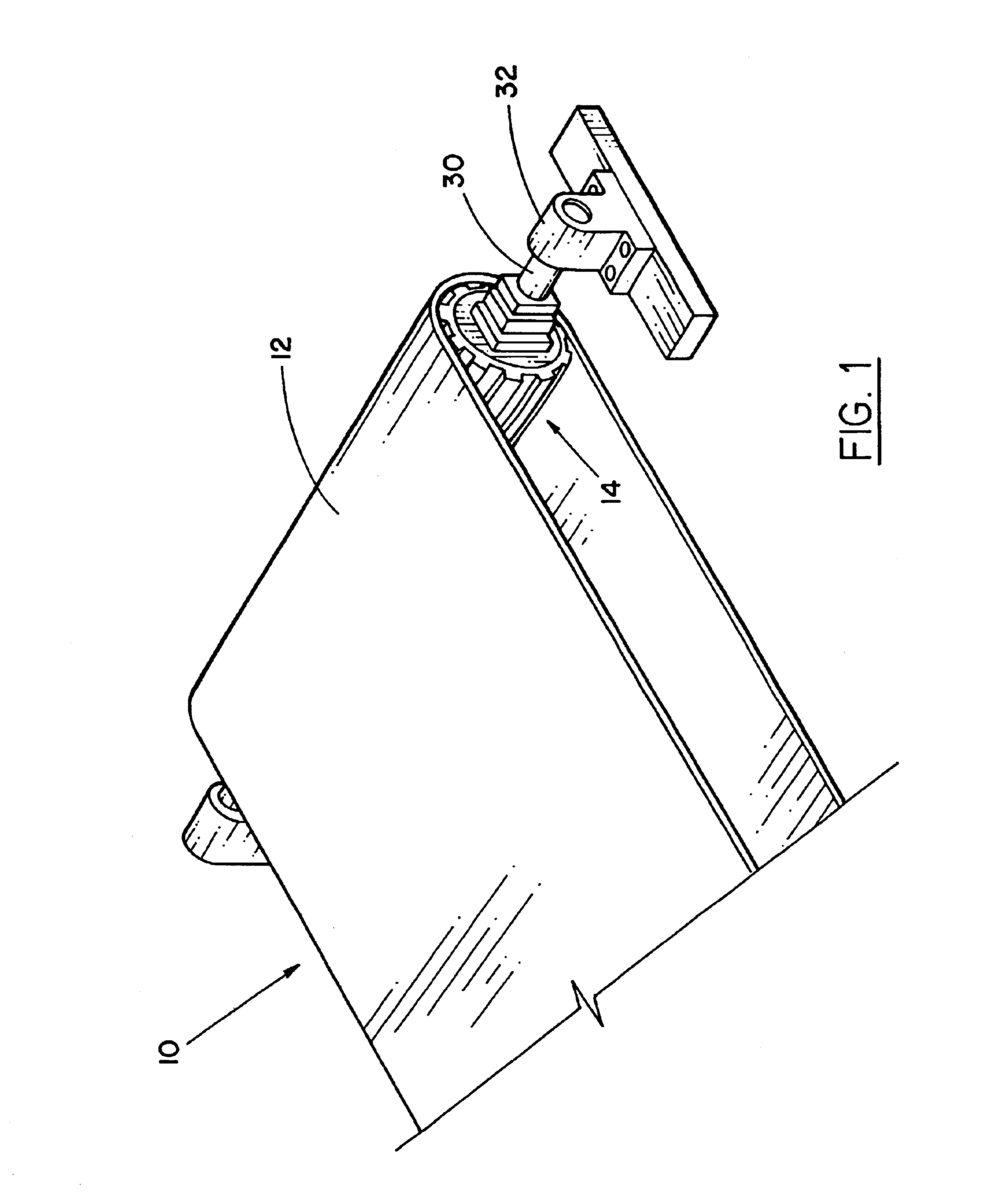

Self-cleaning conveyor roller

A self cleaning conveyor roller for supporting a conveyor media carrying contaminant materials. The conveyor roller consists of a drum defining a support surface, having a generally cylindrical shape, and being adapted to be supported for rotation, for supporting a conveyor media. The conveyor roller has a plurality of abutments on the support surface, raised above the support surface, and defining a series of spaced apart conveyor media support ridges lying on a circular configuration, concentric with the drum. The abutments are arranged in generally chevron shapes, around the drum. During rotation of the conveyor roller the abutments cause any debris or contaminants between the roller and the conveyor media to be guided out of the conveyor system. Also disclosed is a method of cleaning a conveyor roller.

Owner:VAN DER GRAAF

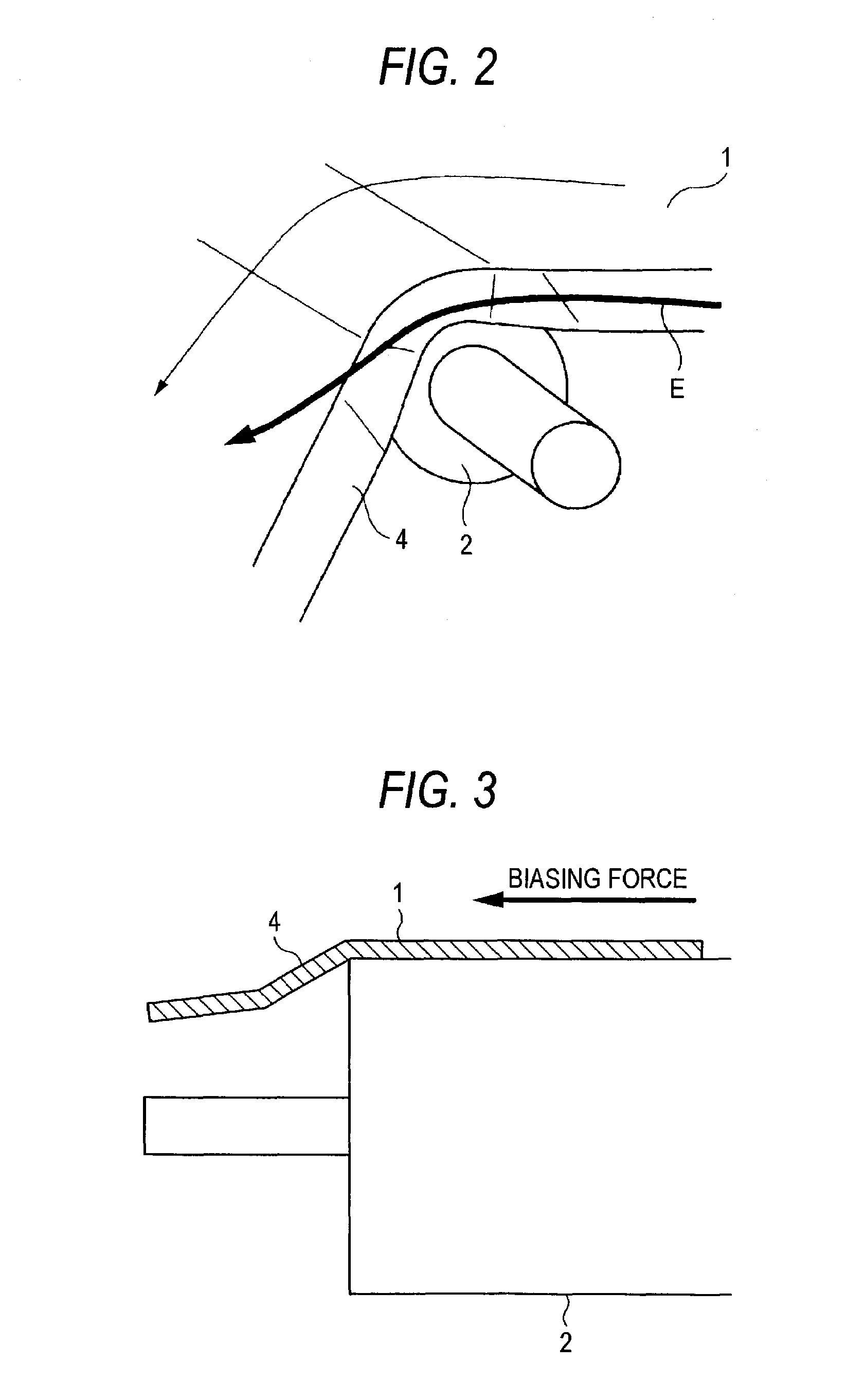

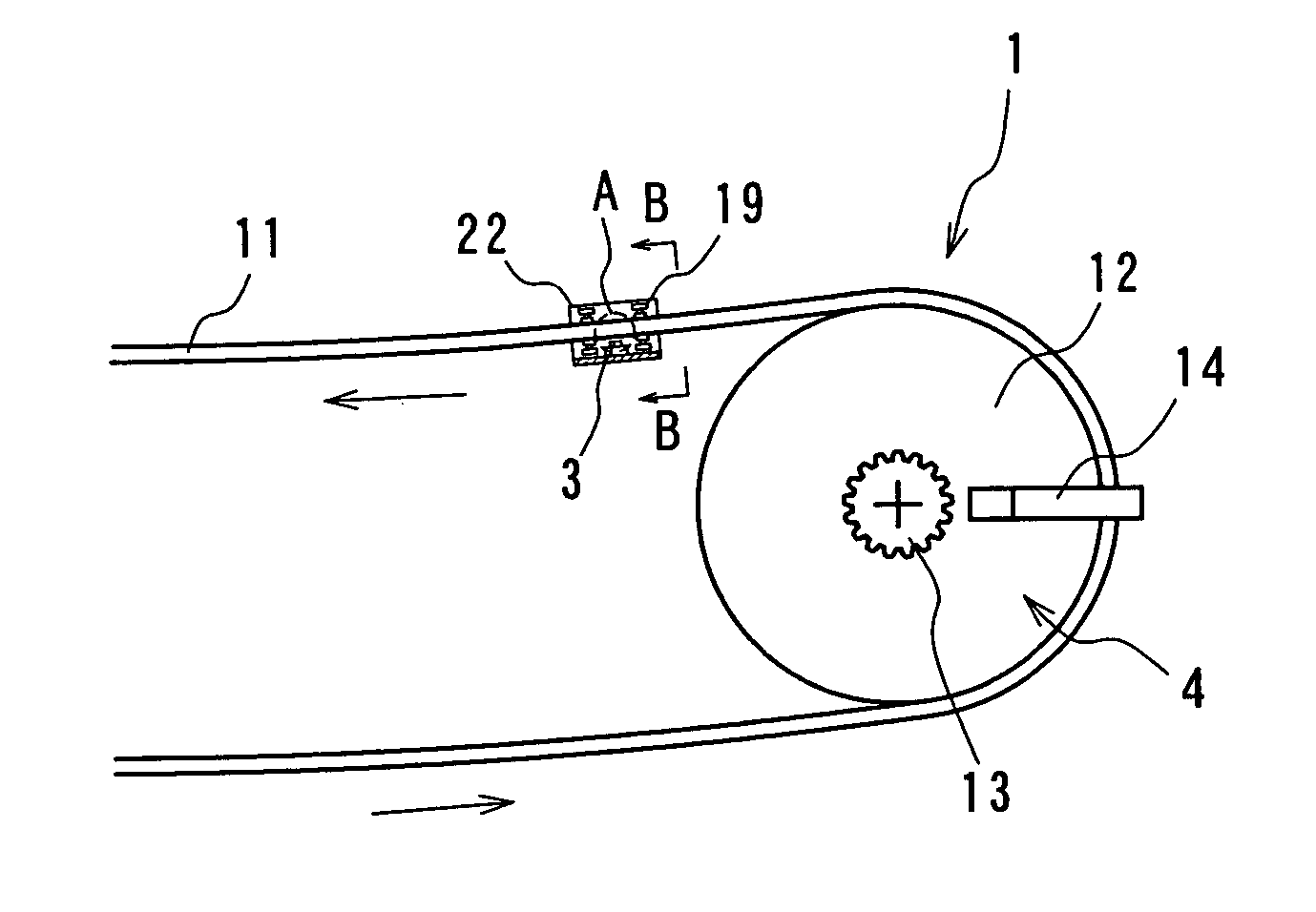

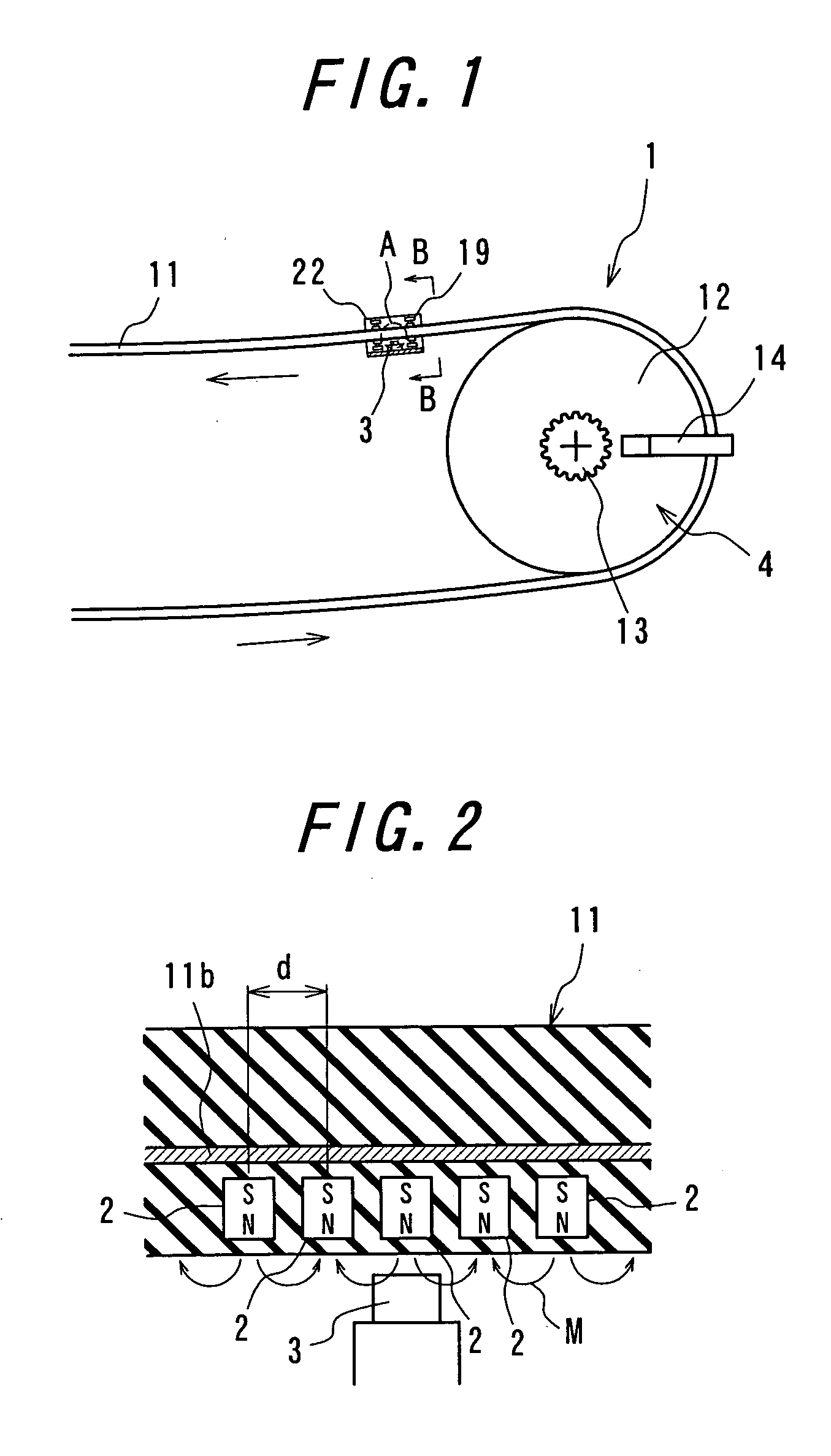

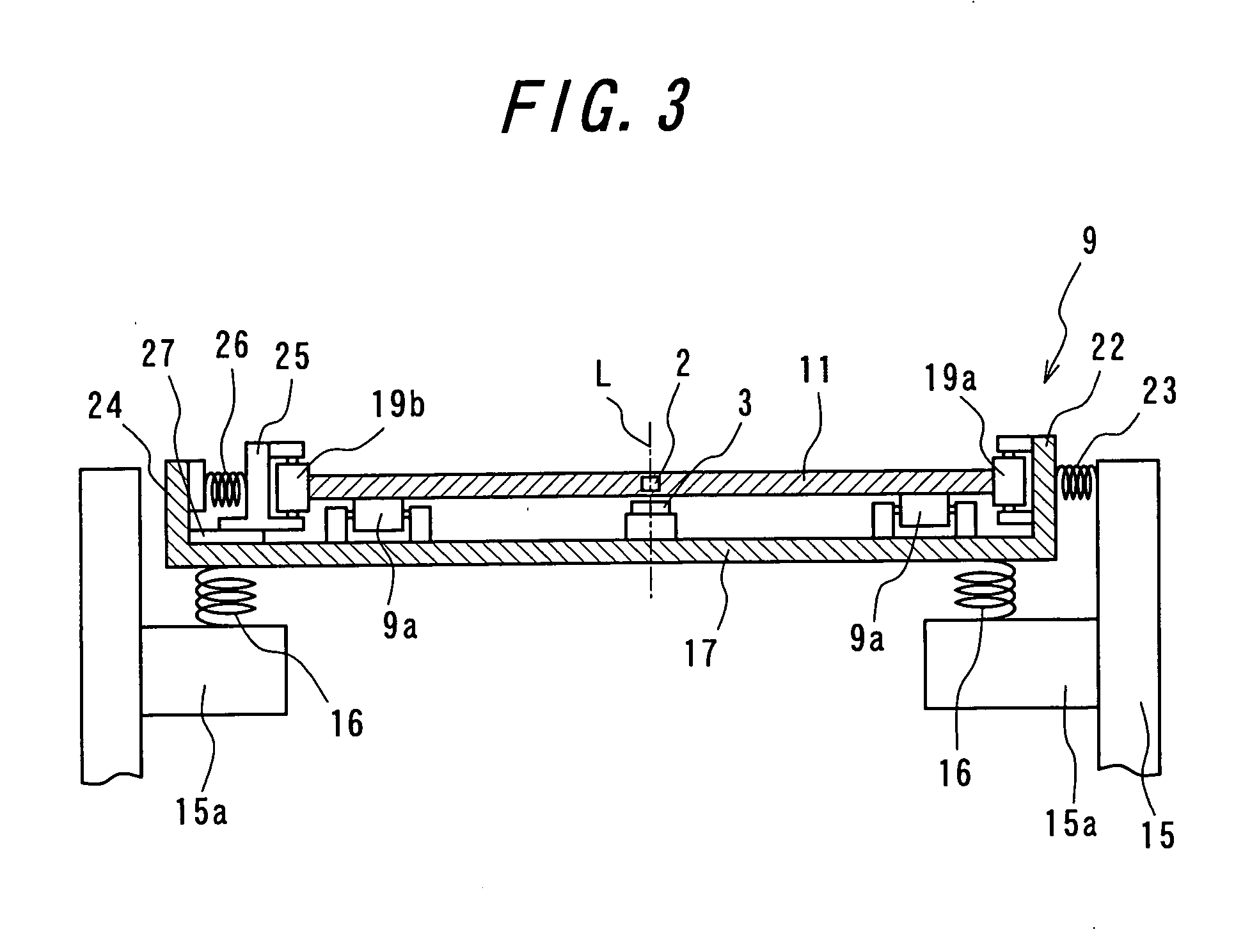

Method and device for measuring conveyor belt elongation, method and device for measuring conveyor belt wear extent, method and device for measuring conveyor belt temperature, rubber magnet sheet, and method of producing rubber magnet sheet

ActiveUS20060219528A1Magnetically stableEnhanced magnetic forceConveyorsThermometers using electric/magnetic elementsConveyor beltInternal temperature

Methods and devices for measuring elongation, wear, and internal temperature of a conveyor belt to catch signs of conveyor belt failure such as breakage by detecting a magnetic field from a magnetic body by using a magnesium sensor, as well as a rubber magnet sheet as a magnetic body and a method of producing the sheet, the rubber magnet sheet being able to be used while it is embedded in the conveyor belt. To measure elongation of a running conveyor belt (11), a magnetic field of a magnetic body (2) embedded in the belt (11) is detected by a magnetism sensor (3) fixed to the earth, and elongation of the belt (11) is calculated from temporal variation of the detected magnetic field.

Owner:BRIDGESTONE CORP

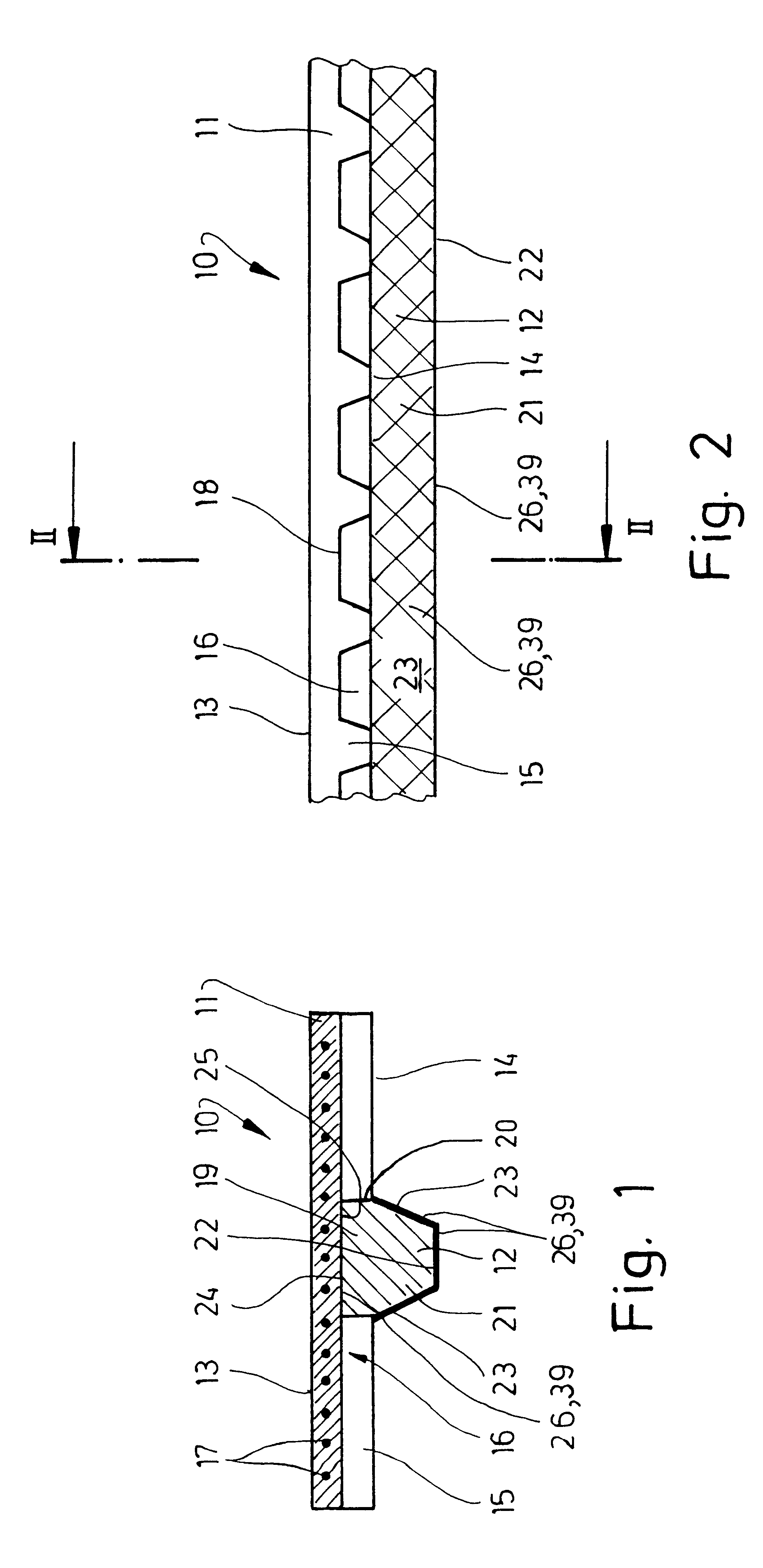

Belt, especially conveyer belt and method for manufacturing same

InactiveUS6561344B1Reduce noiseReduce the valueConveyorsDriving beltsTransmission beltStructural engineering

Conveyer belts (10) are deflected many times along a conveying path of the objects to be conveyed. It has been shown that unpleasant squeaking noises are generated in the region of this deflection between the guide means (12) of the conveyer belt (10) and guide rollers or guide drums.The invention is based on the knowledge that the squeaking noises are caused by the relatively high friction value of the material of the conveyer belt (10). The design according to the invention therefore proposes that at least the outer side of the guide means (12) of the conveyer belt (10) is provided with a coating (26) made from a material with a lower frictional value. As a result, it has been shown that undesirable squeaking noices can be effectively avoided.

Owner:NORDDEUTSCHE SEEKABELWERKE AG

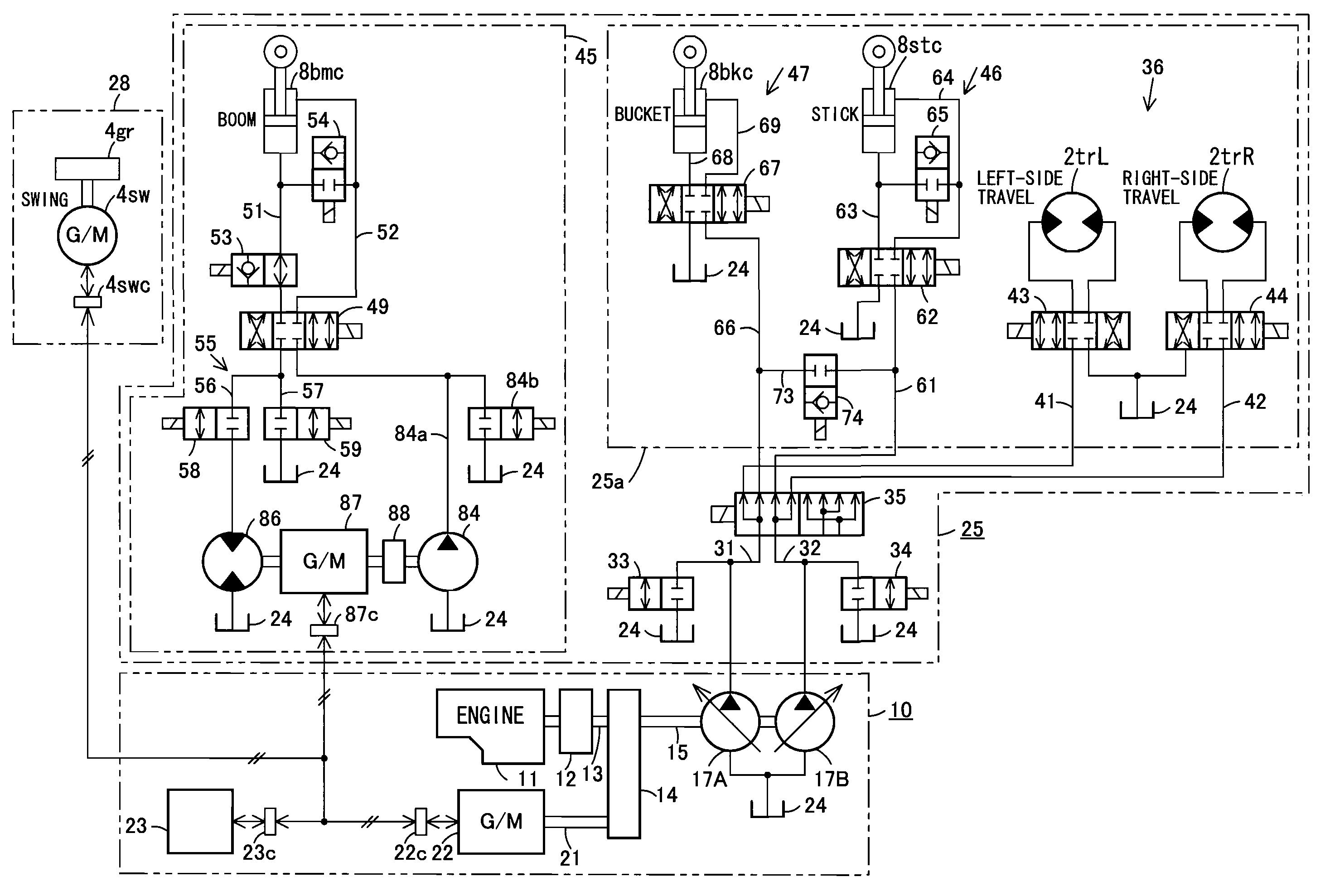

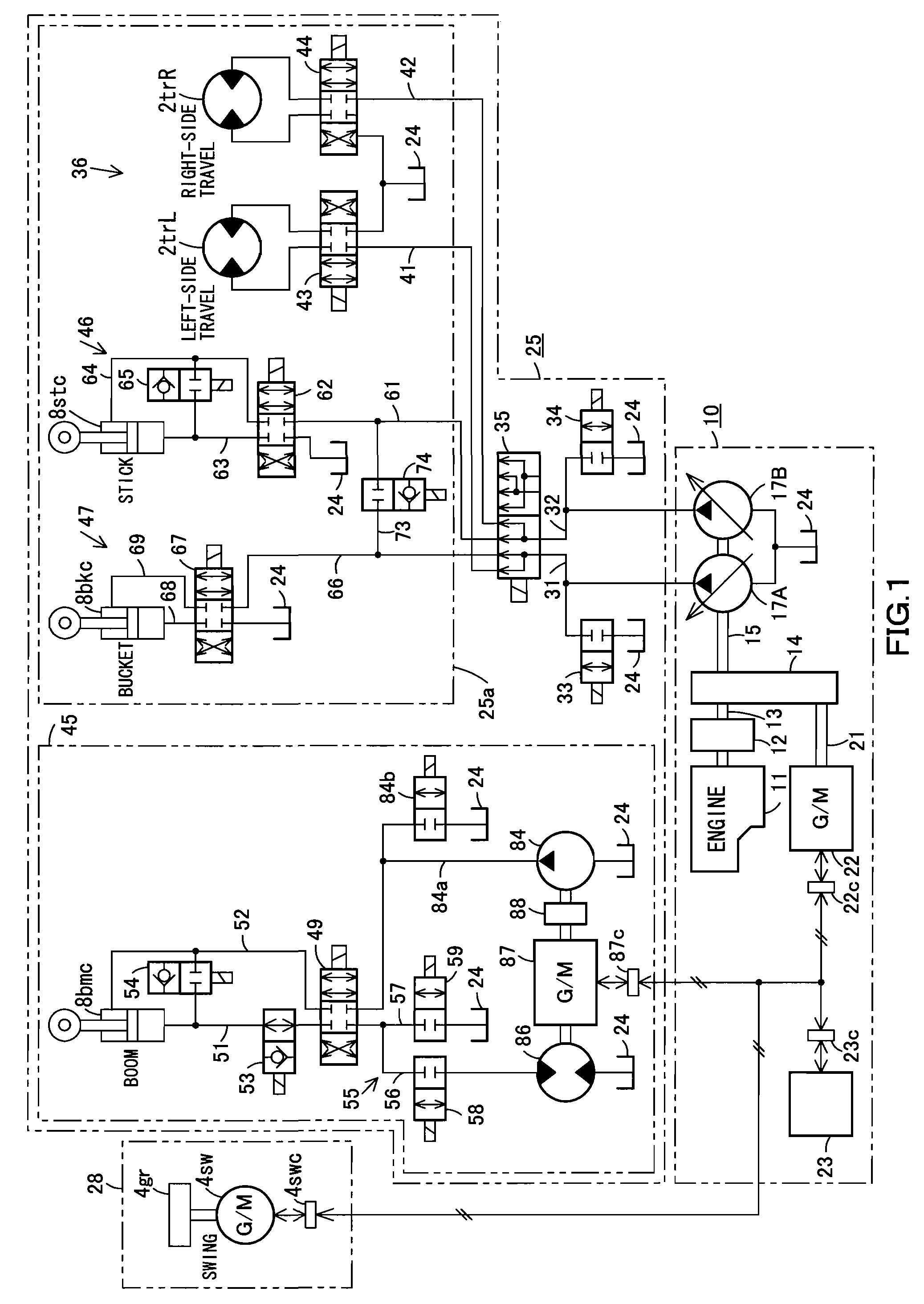

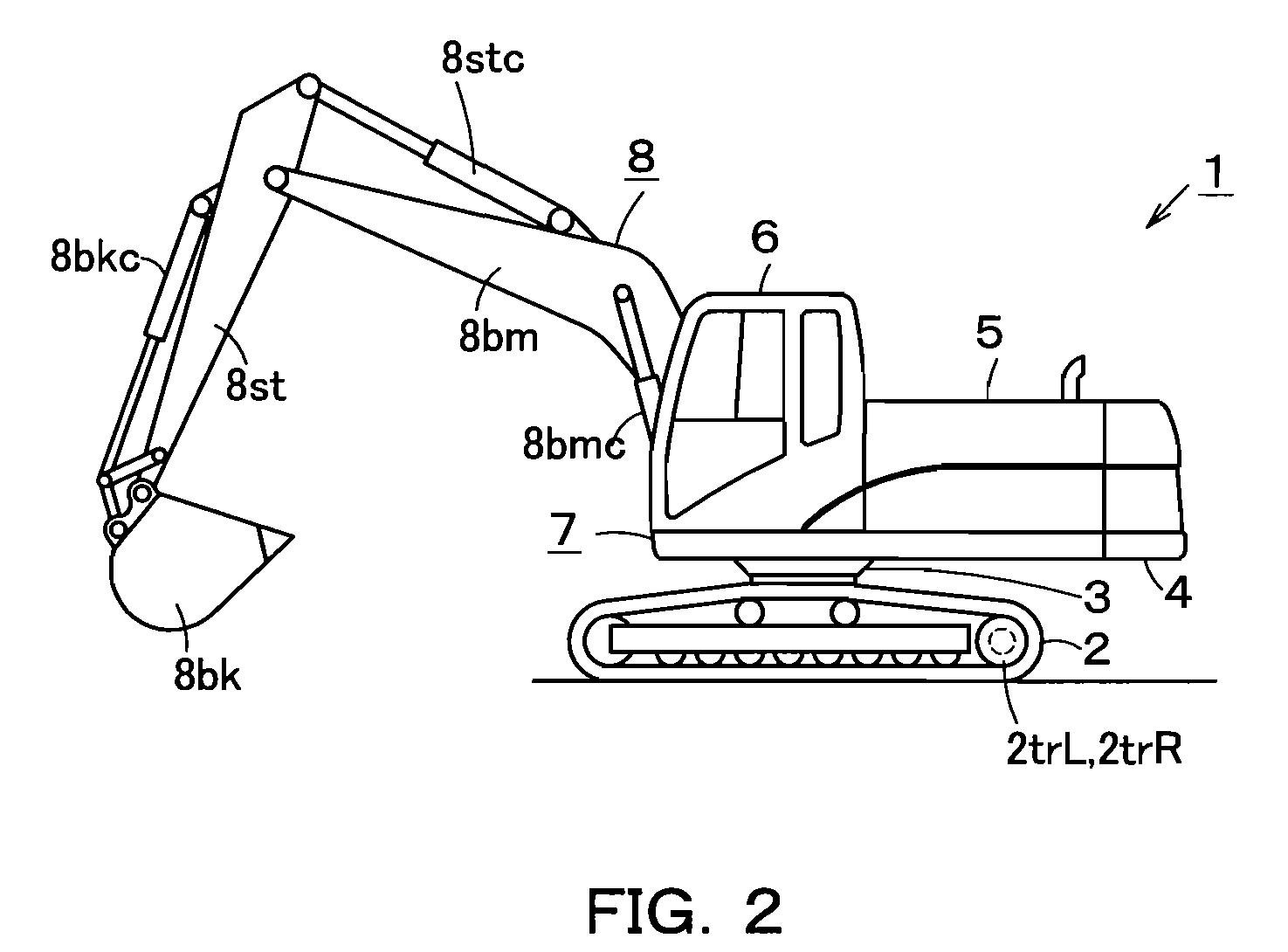

Work machine

InactiveUS20090077837A1Increasing flow rate proportionAvoid it happening againServomotorsServometer circuitsEngineeringEnergy recovery

A boom control circuit for controlling hydraulic fluid fed to a boom cylinder is provided separately and independently from a travel / stick / bucket control circuit, which serves to control hydraulic fluid fed to travel motors, a stick cylinder, and a bucket cylinder. The boom control circuit includes a boom pump, an energy recovery motor disposed in a return passage through which return fluid from the boom cylinder 8bmc passes, and a boom motor generator connected to the energy recovery motor. The aforementioned boom pump is connected through a clutch to the boom motor generator. The invention is capable of providing a work machine of which a boom control circuit is adapted to function independently so that the flow rate required by the boom control circuit can be easily ensured.

Owner:CATEPILLAR SARL

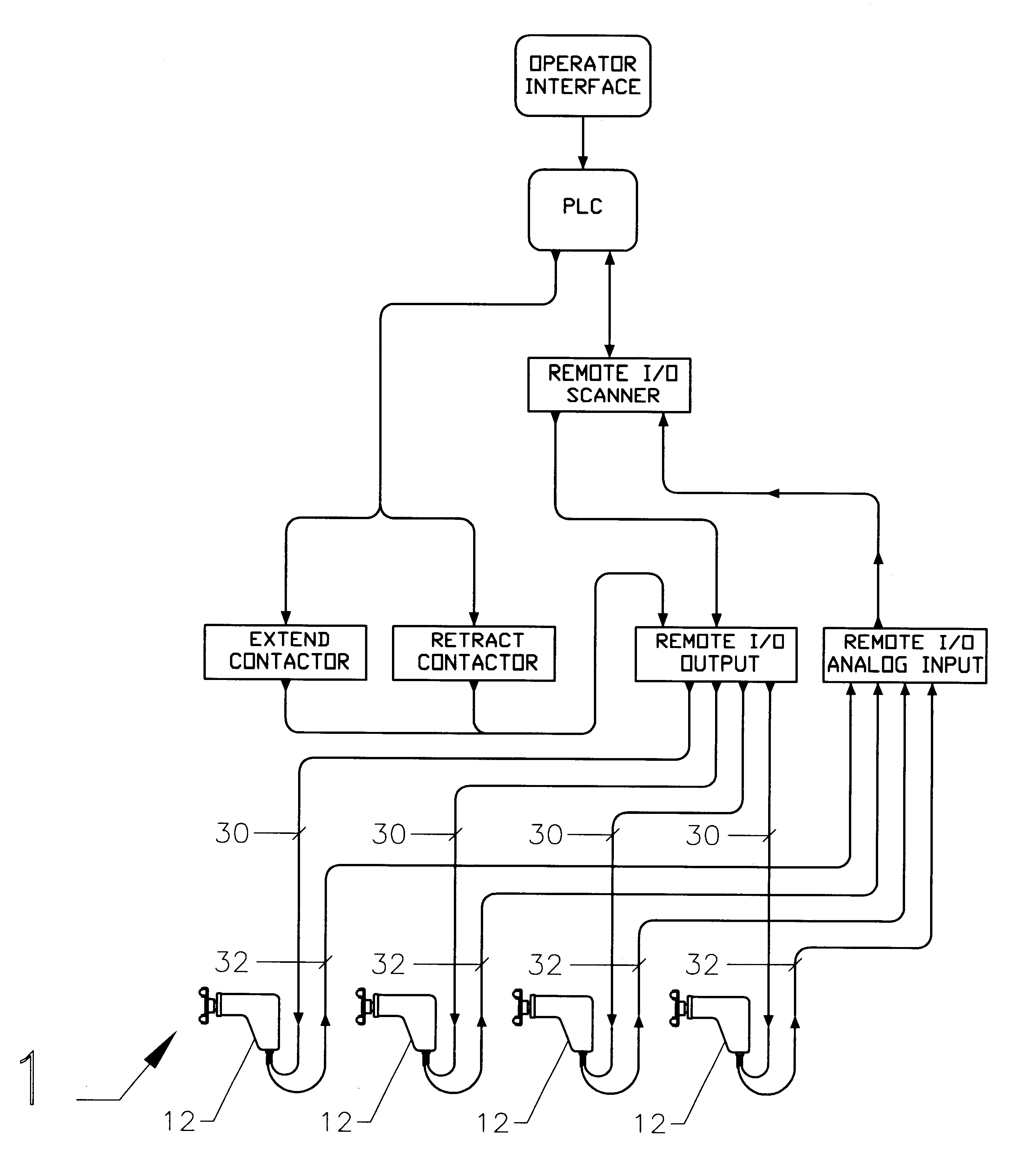

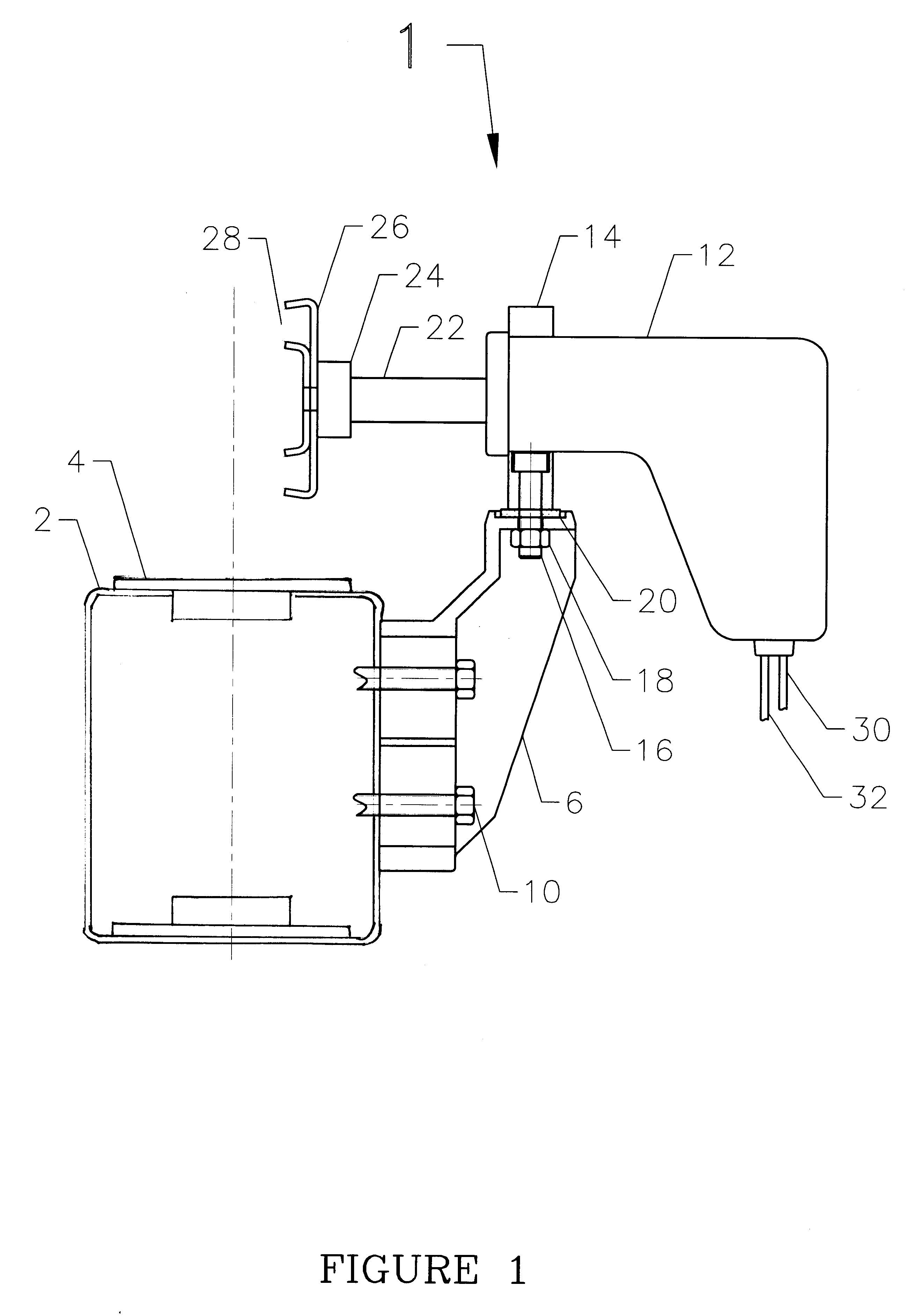

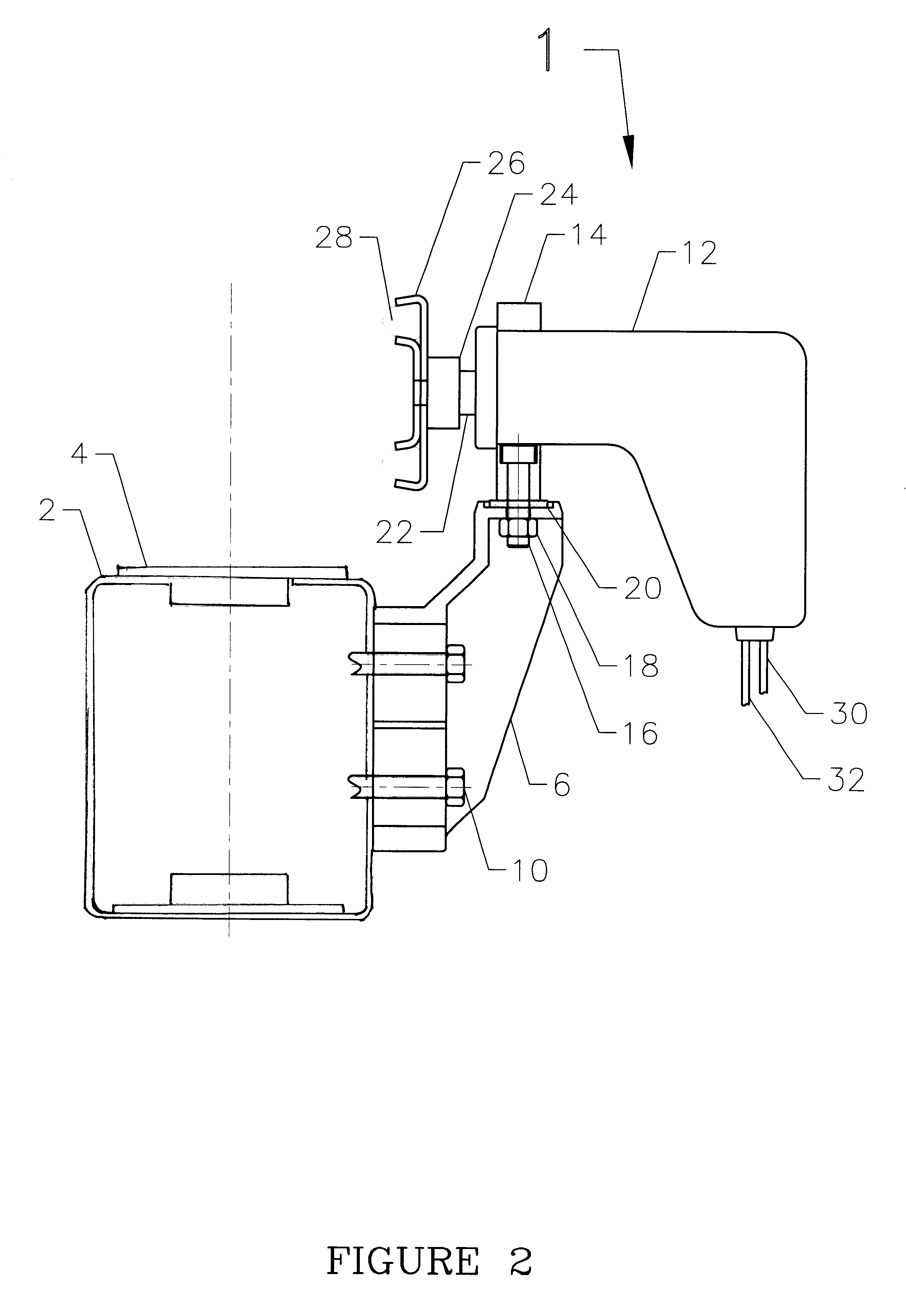

Remotely adjustable railing support posts for conveyor lines and method of operation thereof

An adjustable railing support system has a conveyor and a railing extending along each side of the conveyor. The conveyor is used to transport containers of various sizes and shapes in different runs. For each size and shape of container, the support posts must be adjusted and the actuators are connected to a programmable logic controller that is operable and connected to sequentially adjust the support posts relative to the conveyor until all of the support posts have been adjusted as required to transport container of one particular size and shape. The controller has a memory so that the precise location of the support posts for a particular product line can be stored. When switching from one known product line to another, the adjustments can be made automatically from the memory of the controller.

Owner:DIAGEO CANADA

Conveyor roller assembly, conveyor roller insert and axle for conveyor roller

Owner:SST CONVEYOR COMPONENTS INC

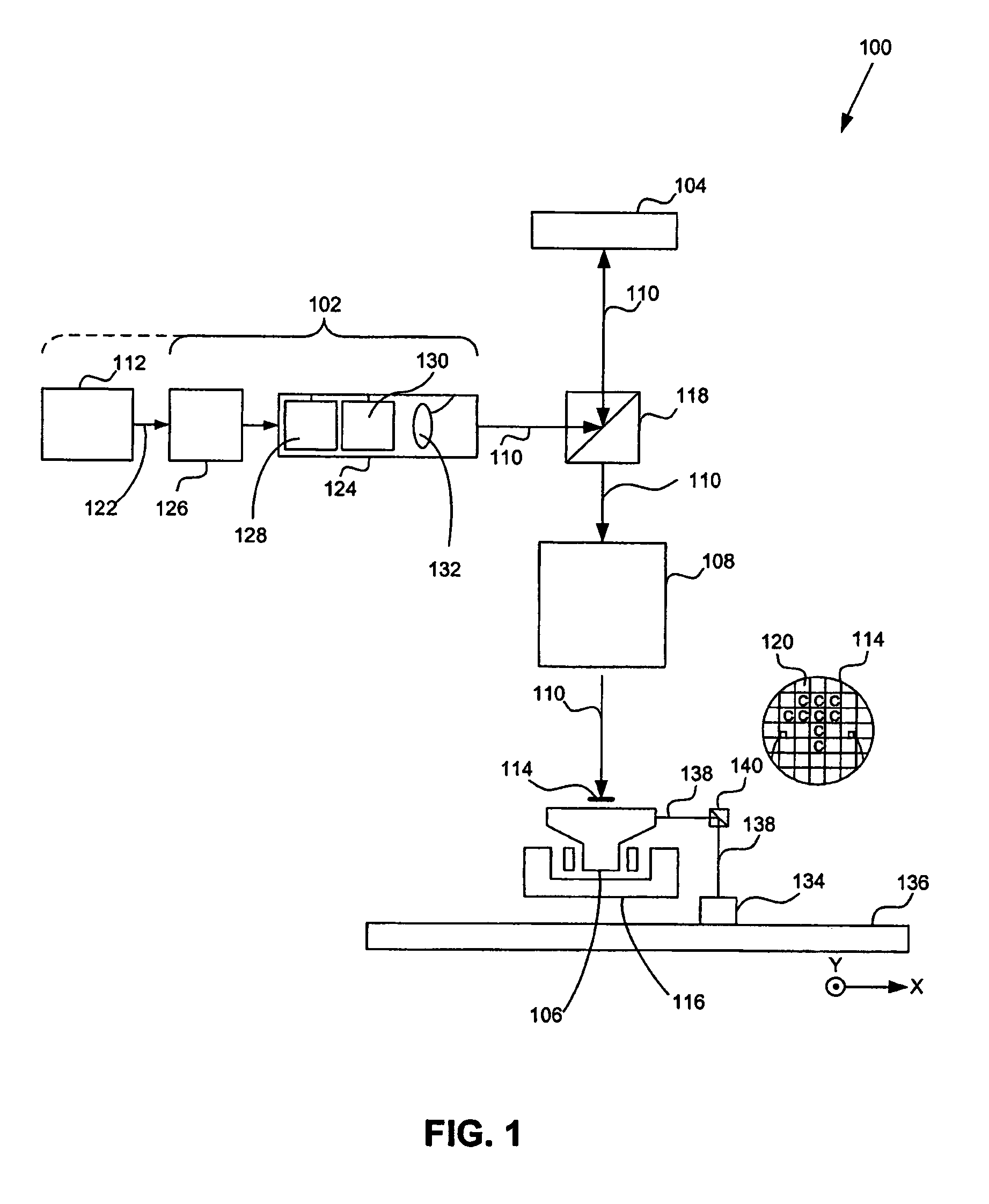

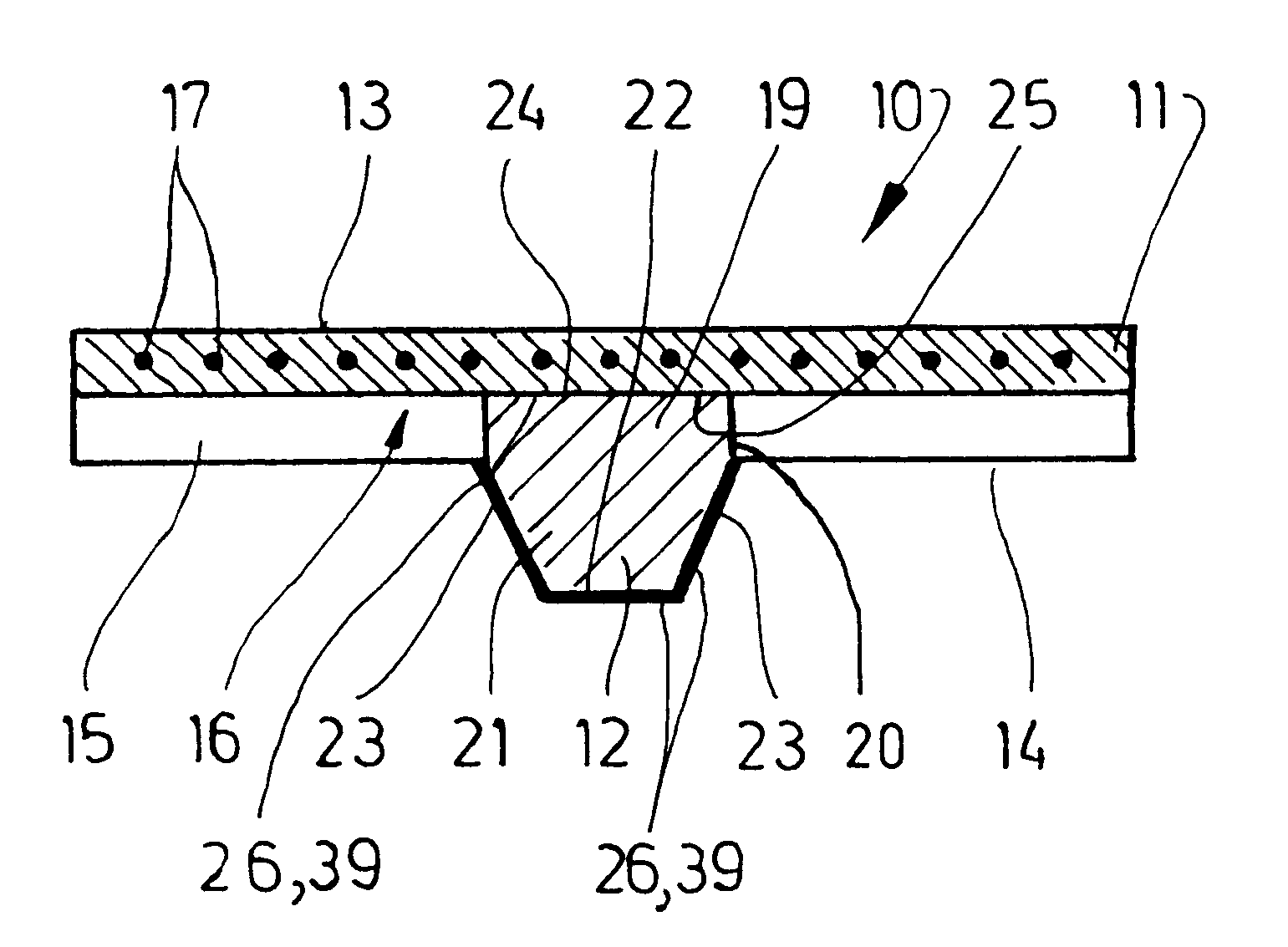

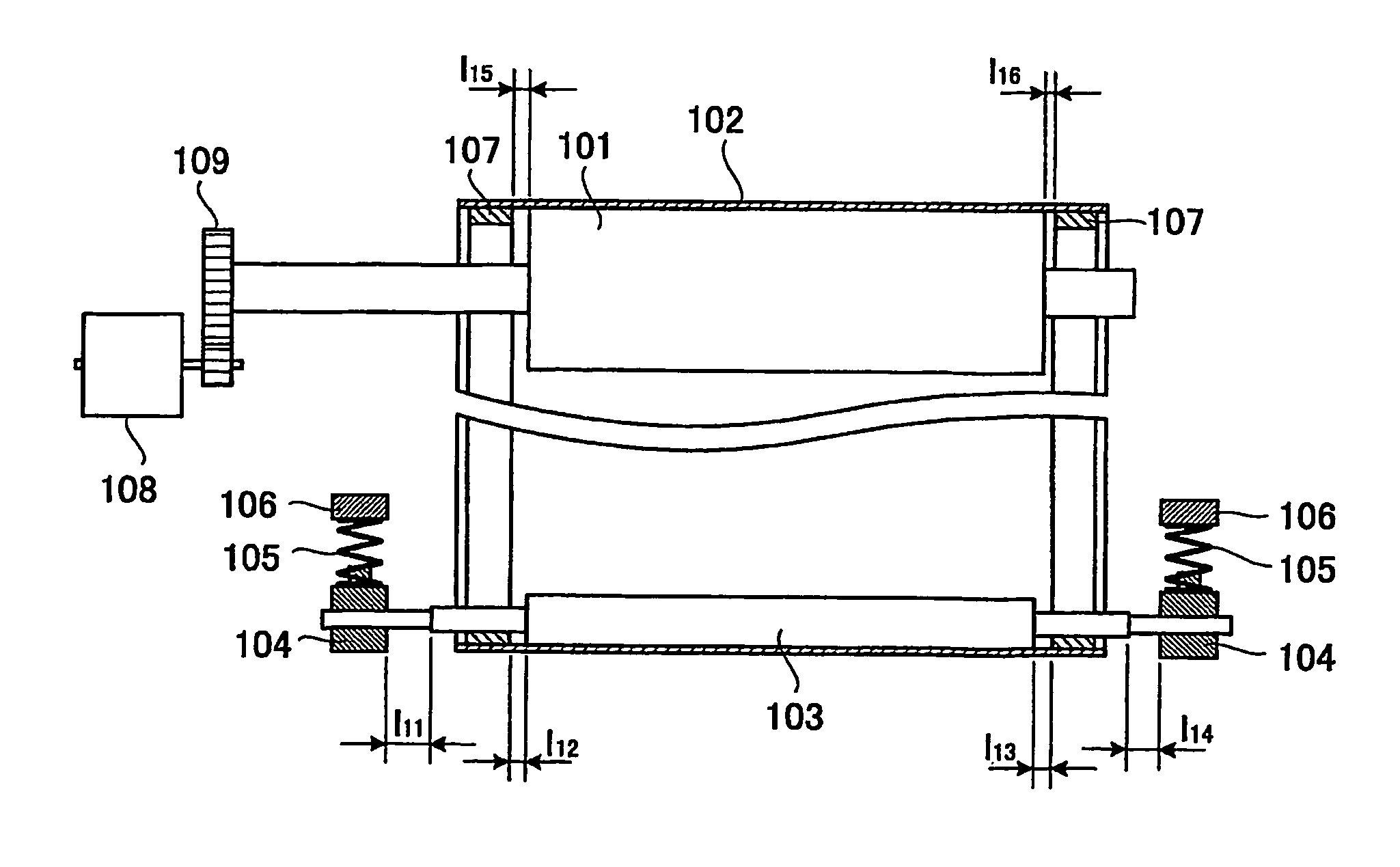

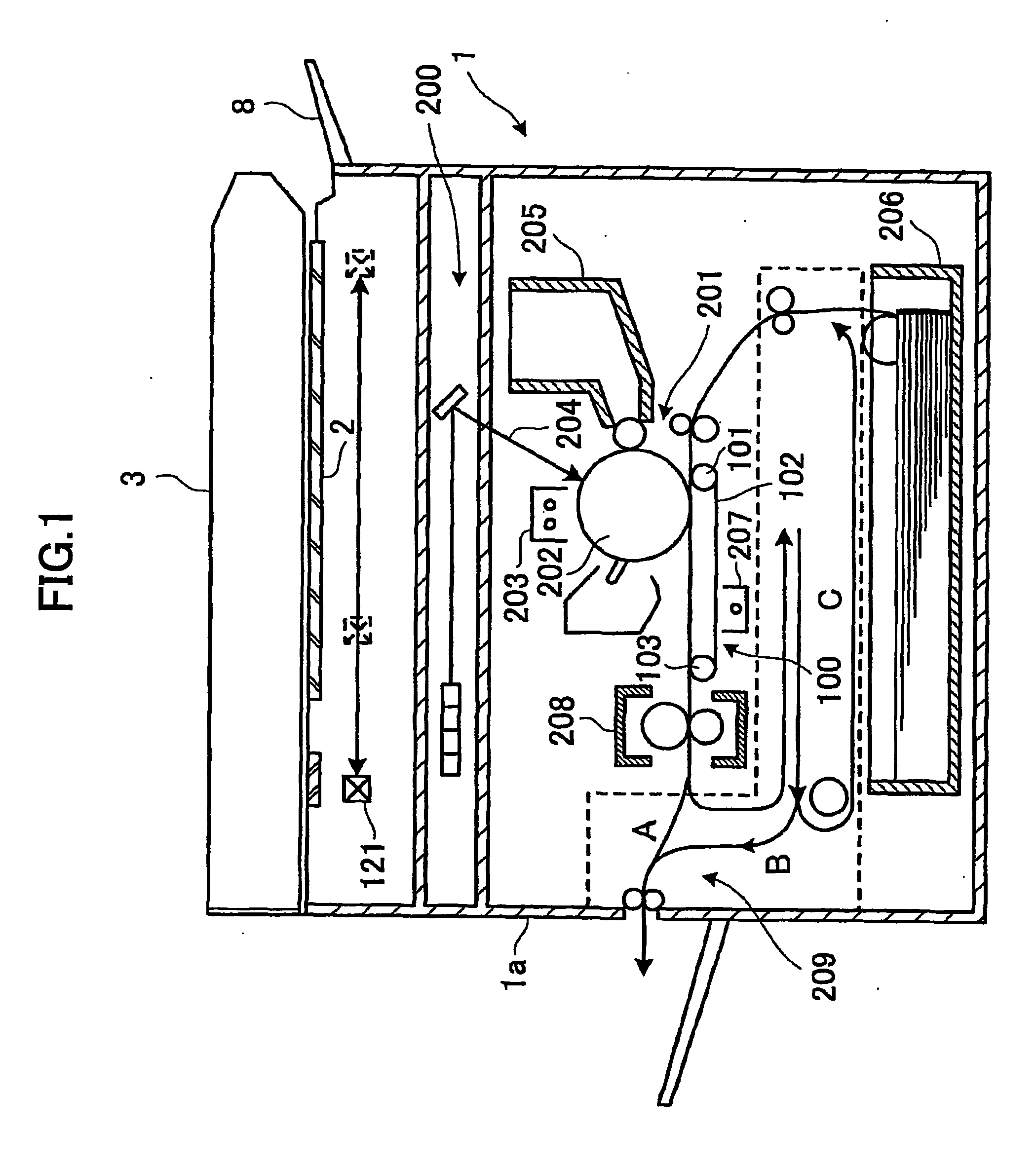

Belt conveyance apparatus and image forming apparatus using such a belt conveyance apparatus

ActiveUS20060233578A1Accurate deflectionControl deflectionConveyorsElectrographic process apparatusEngineeringMechanical engineering

In an intermediate transfer part (100), a bead 107 is formed on an inner side of an intermediate transfer belt (102), which is rotated by an intermediate transfer belt drive roller (101). Driven roller bearings (104a, 104b) support an intermediate transfer belt driven roller (103). The intermediate transfer belt driven roller (103) is movable in a thrust direction. Ends of the intermediate transfer belt driven roller (101) and the intermediate transfer belt driven roller (103) interfere with a bead (107) so as to restrict a deflection of the intermediate transfer belt in the thrust direction. The intermediate transfer belt driven roller (103) is movable in the thrust direction against a deflection of the intermediate transfer belt (102).

Owner:RICOH KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com