Patents

Literature

1534 results about "Belt drive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A belt is a loop of flexible material used to link two or more rotating shafts mechanically, most often parallel. Belts may be used as a source of motion, to transmit power efficiently or to track relative movement. Belts are looped over pulleys and may have a twist between the pulleys, and the shafts need not be parallel.

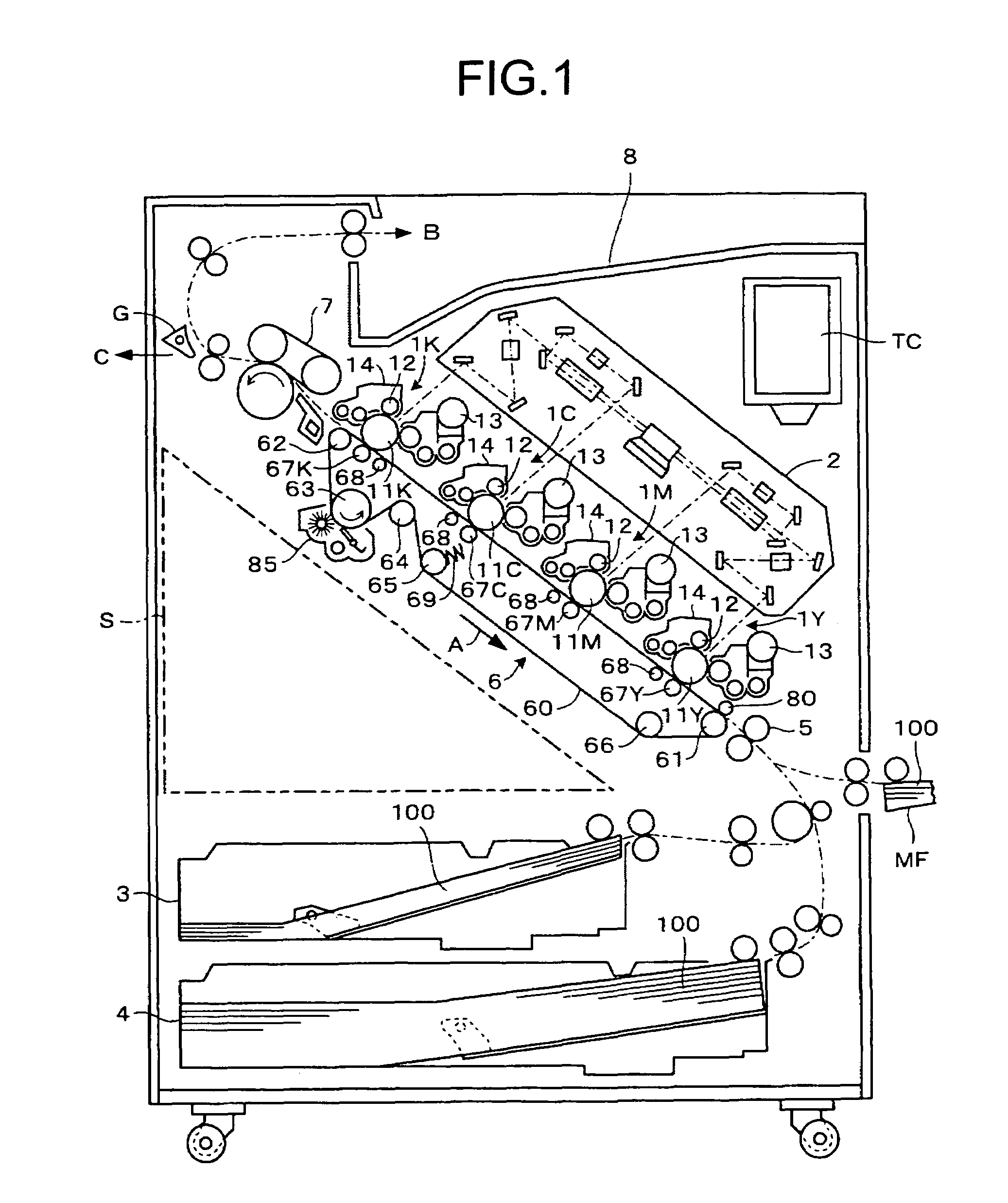

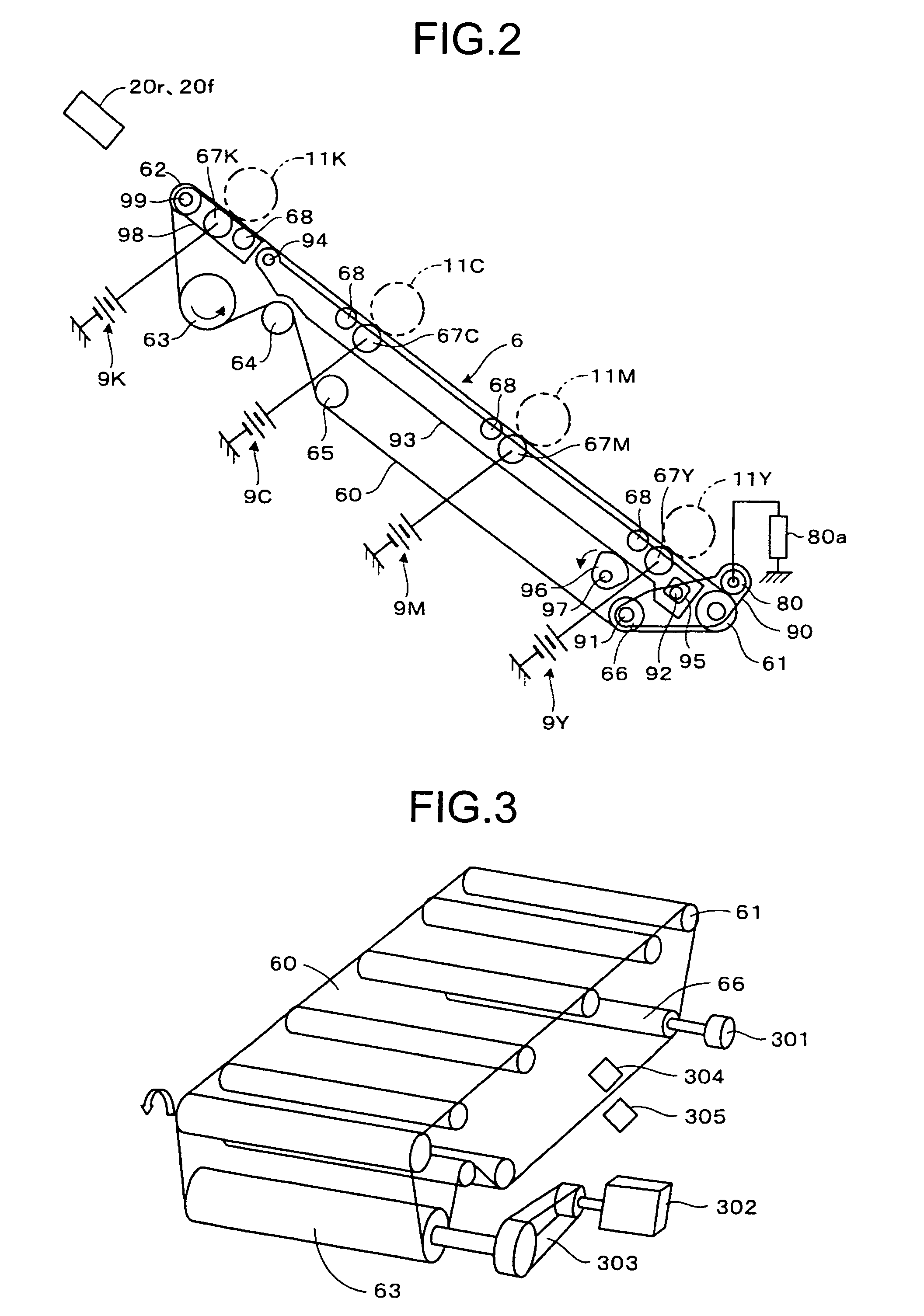

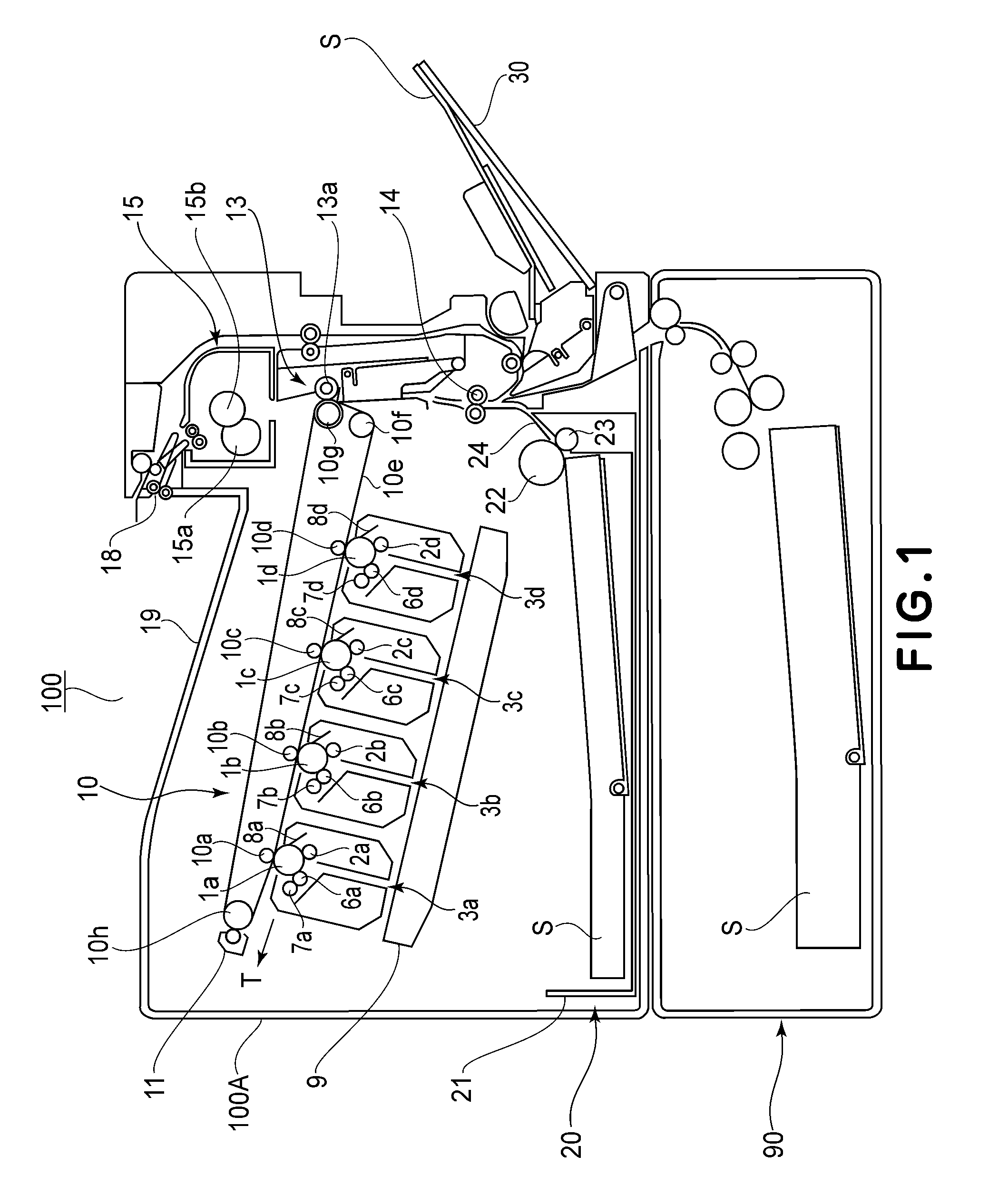

Belt-drive control device, color-shift detecting method, color-shift detecting device, and image forming apparatus

A mark detecting unit detects a mark that is a reference position of an endless belt. An angular-displacement-error detecting unit detects an angular displacement error of an encoder caused by thickness fluctuation of the endless belt. A first calculating unit calculates a phase and a maximum amplitude to the mark. A second calculating unit calculates correction data according to a distance from the mark on the endless belt. A belt-drive control device controls a belt driving unit by adding the correction data to a preset control target value to stabilize speed fluctuation of the endless belt due to the thickness fluctuation.

Owner:RICOH KK

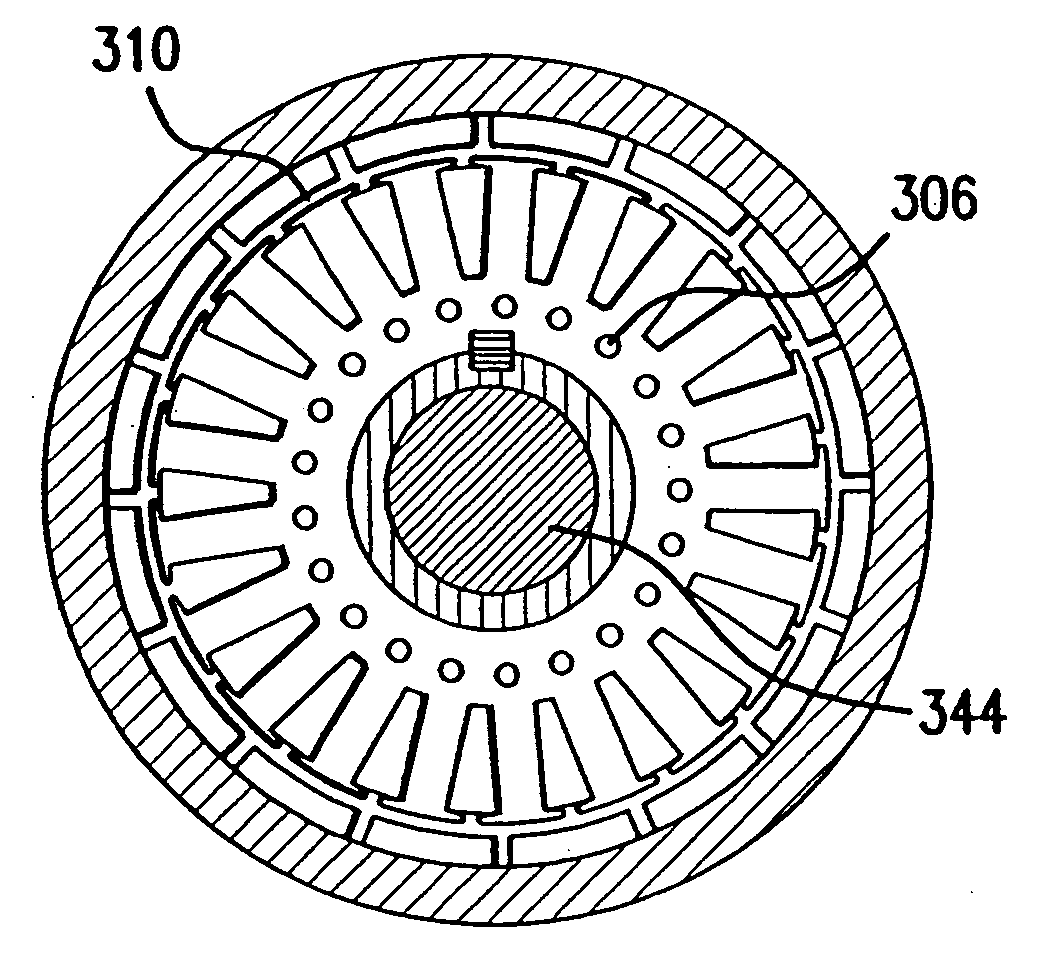

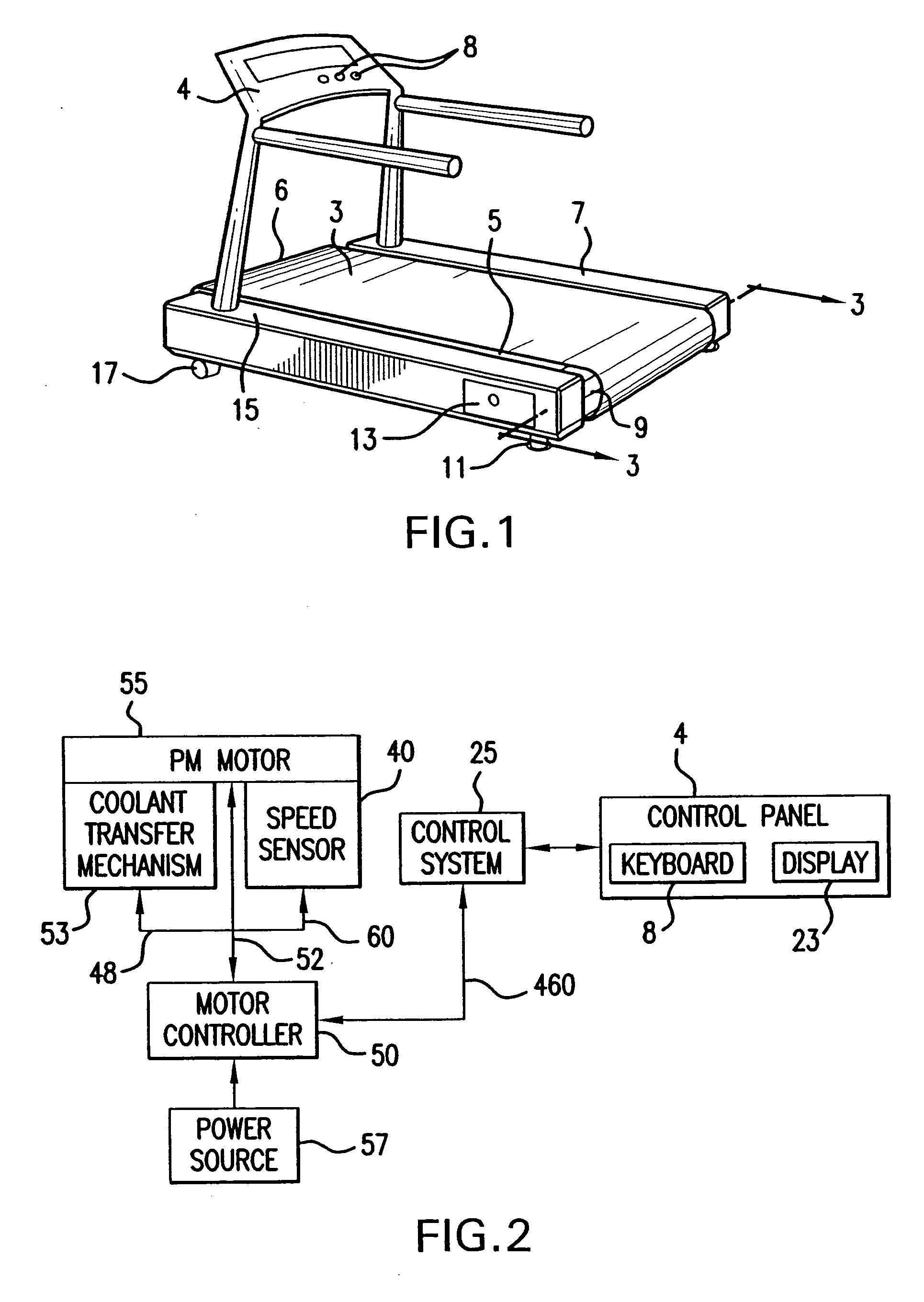

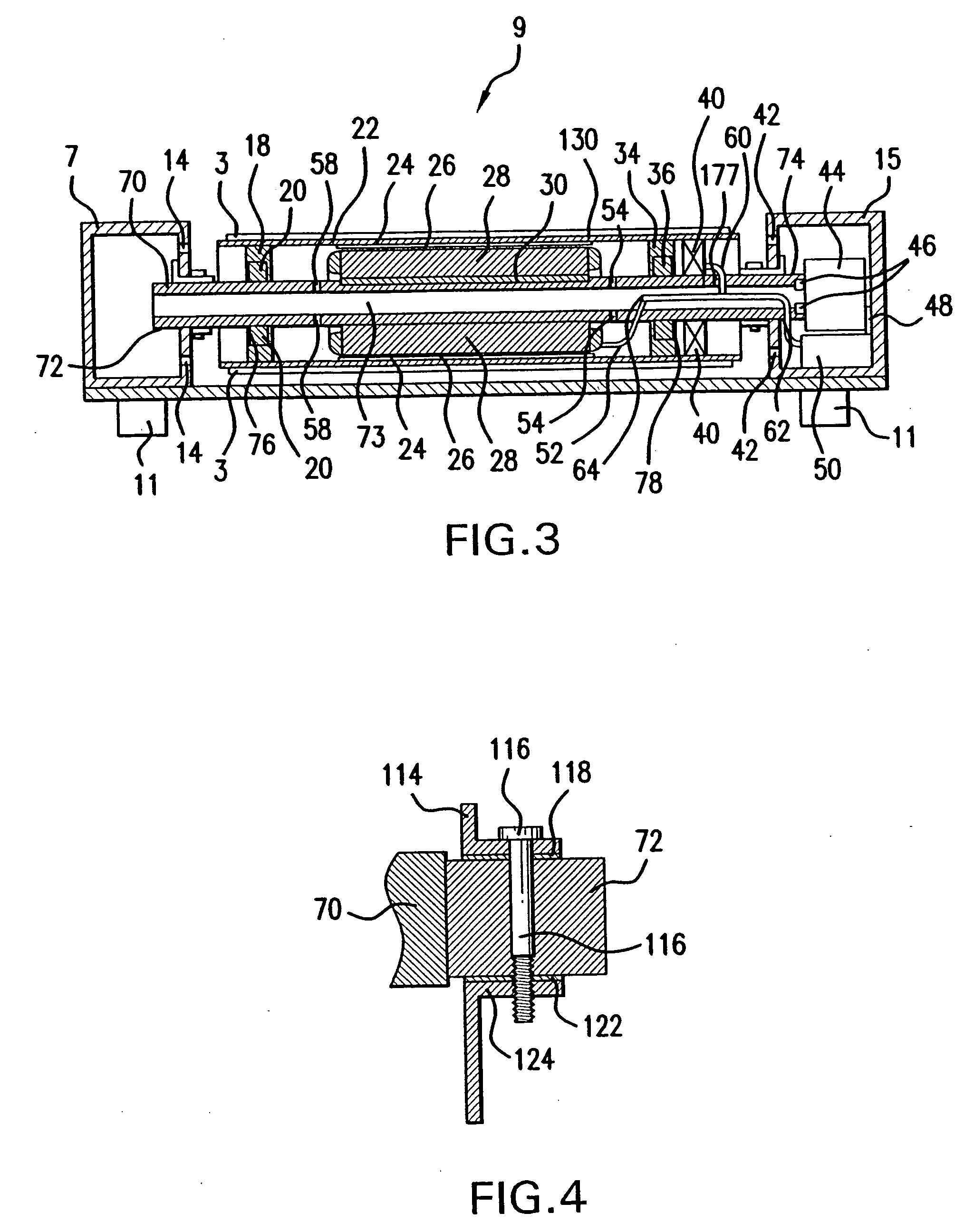

Belt drive system with outer rotor motor

InactiveUS20060232147A1Small sizeImprove power densityVector control systemsMechanical energy handlingCooling effectCoolant channel

An outer rotor motor comprises a tubular shaft for maximum motor cooling effect. Coolant may flow through coolant channels of the shaft and the motor in various configurations to carry away the heat. A thermally conductive component may be inserted into the hollow shaft under the stator section to optimize the airflow and cooling. Physical construction of the motor and control algorithms may further enhance motor performance with appropriate sensors. A compact, smooth, and cool operating motor may thus be achieved for applications such as treadmills or other belt drive systems.

Owner:AEC MOTIONSTAR

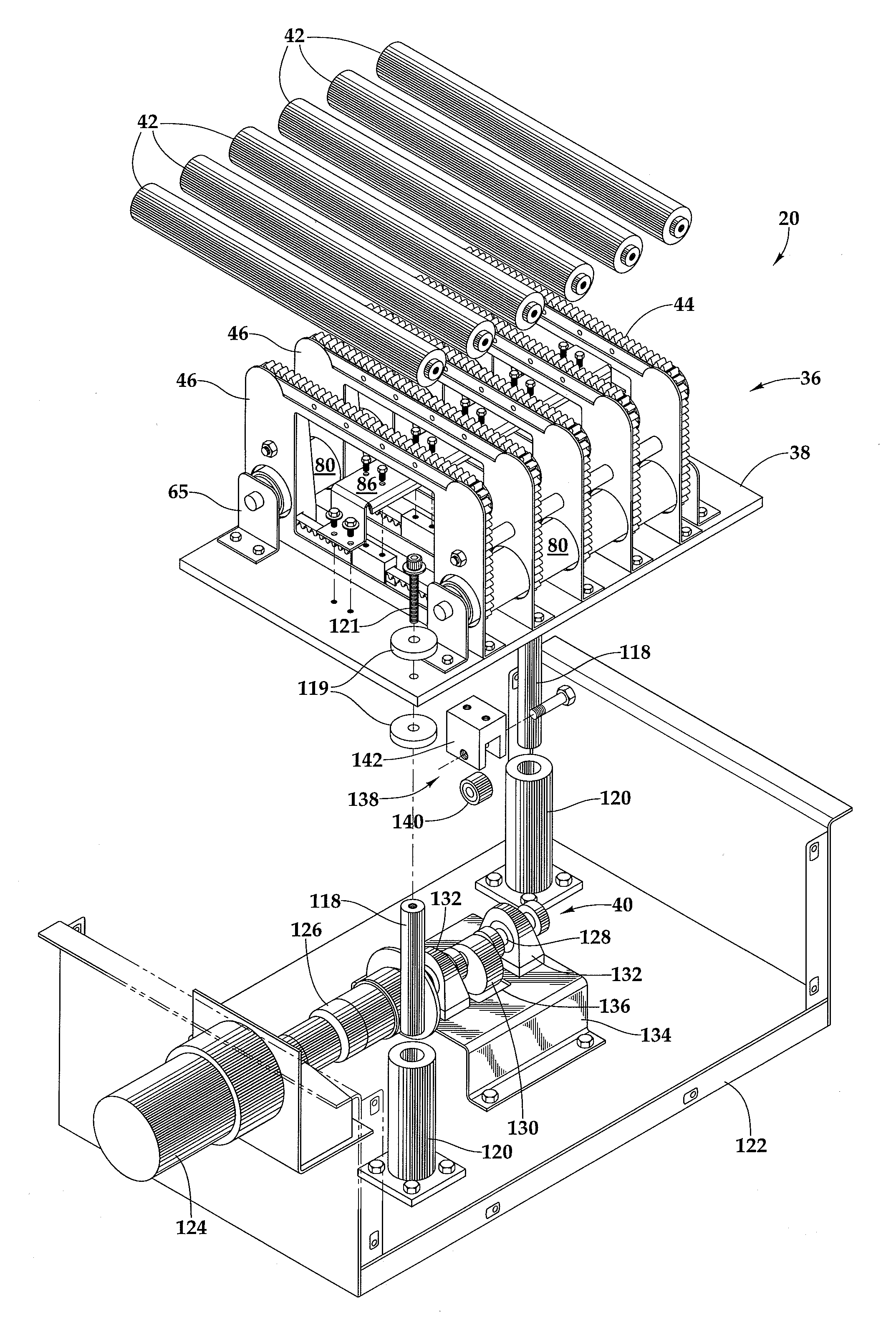

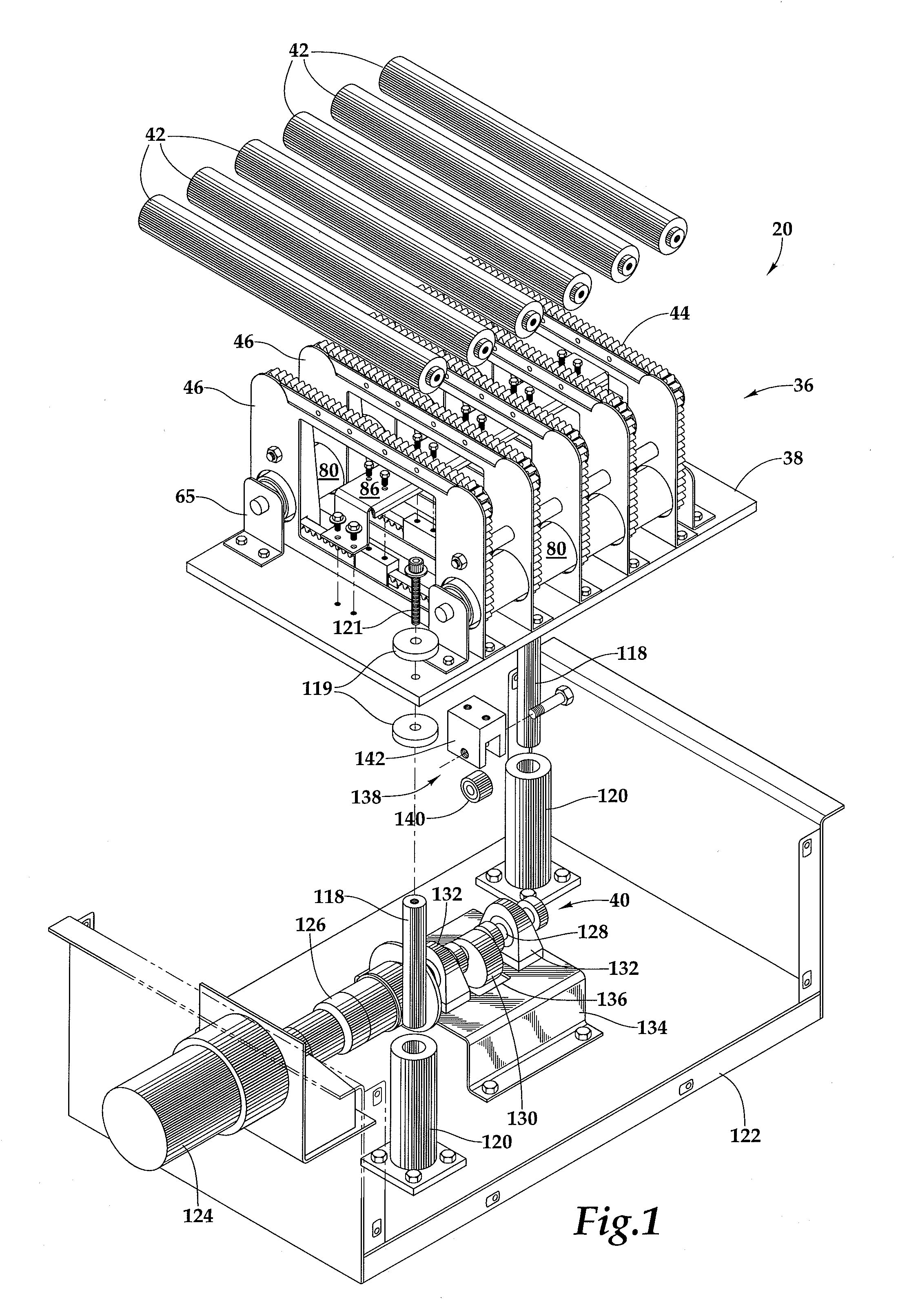

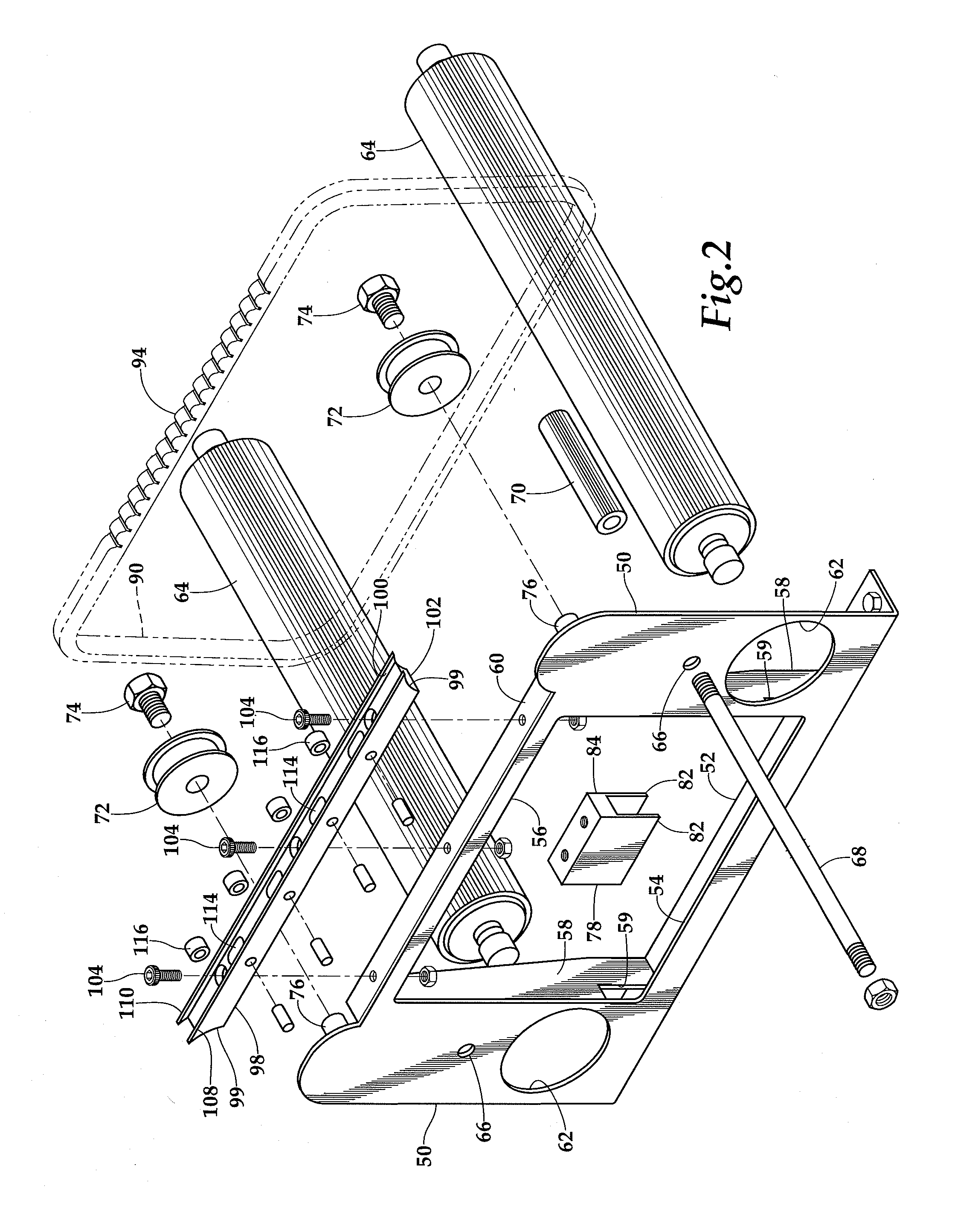

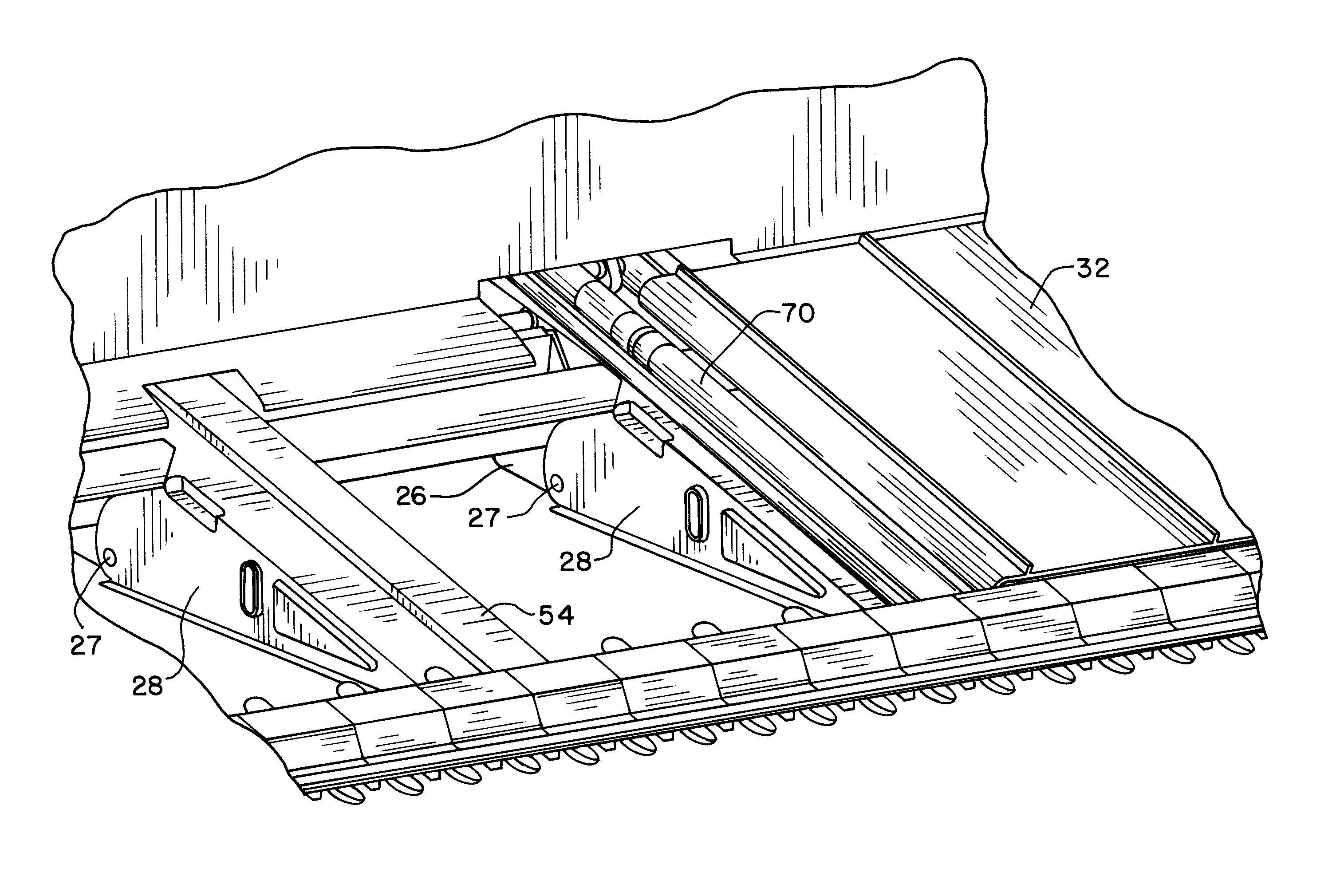

90 degree cross transfer conveyor

A transverse belt drive assembly has multiple belt drive frames spaced in a first direction and positioned between the rollers of a main conveyor which advances articles in the first direction. The belt drive frames support looped toothed belts which are advanced in a second direction perpendicular to the first direction. The belt drive frames are mounted to a platform which is driven on demand by an actuator to raise the belt drive frames to extend up above the roller surfaces of the main conveyor rollers causing the belts to engage articles carried on the conveyor rollers, lifting and advancing the articles in the first direction to transfer them off the conveyor rollers. Each belt has a body with converging walls and is received within a channel within a converging side wall track mounted to a belt drive frame. Rotatable bearings are mounted beneath each channel to support the belt.

Owner:SKARLUPKA MFG

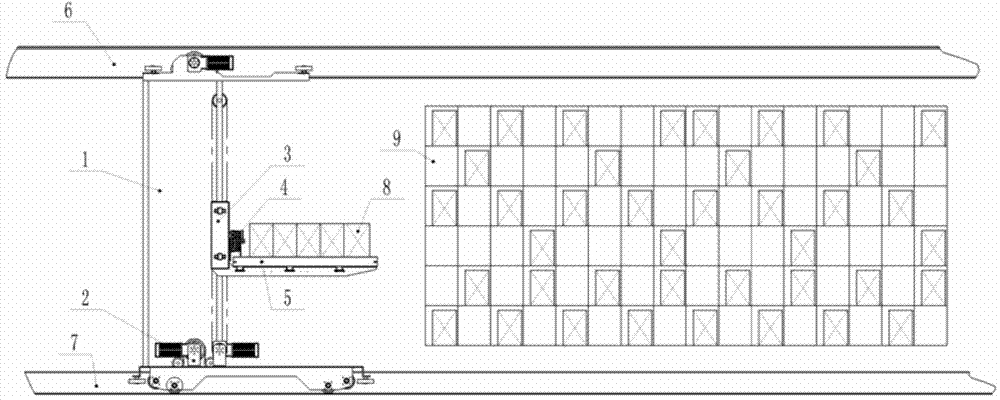

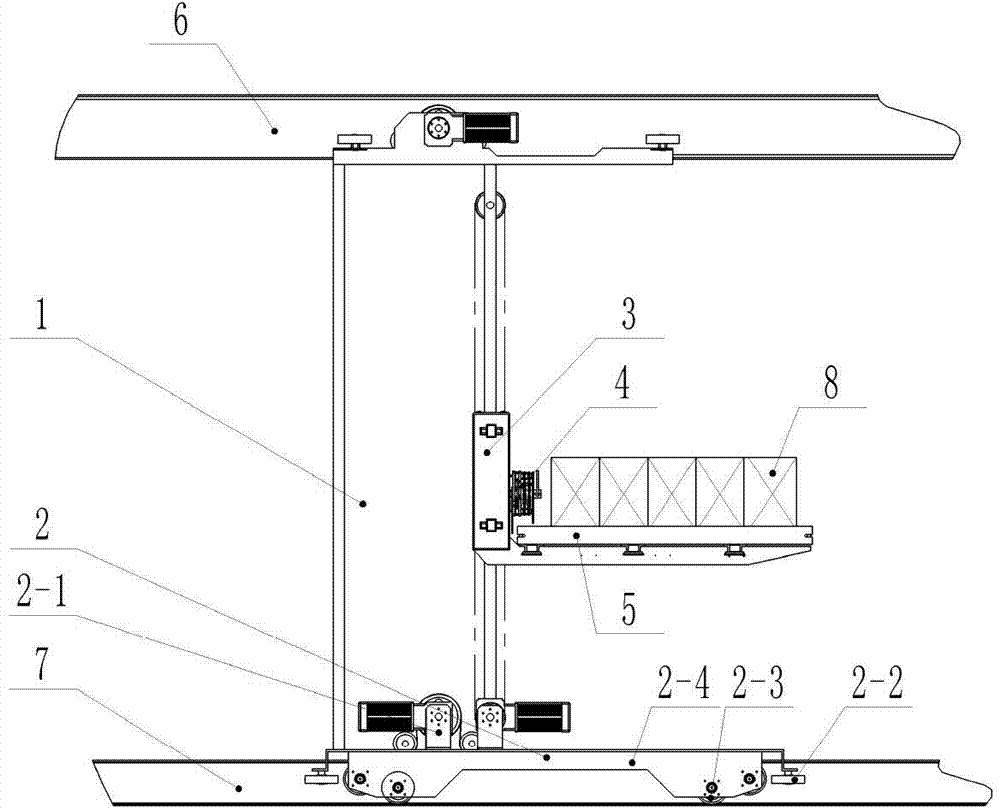

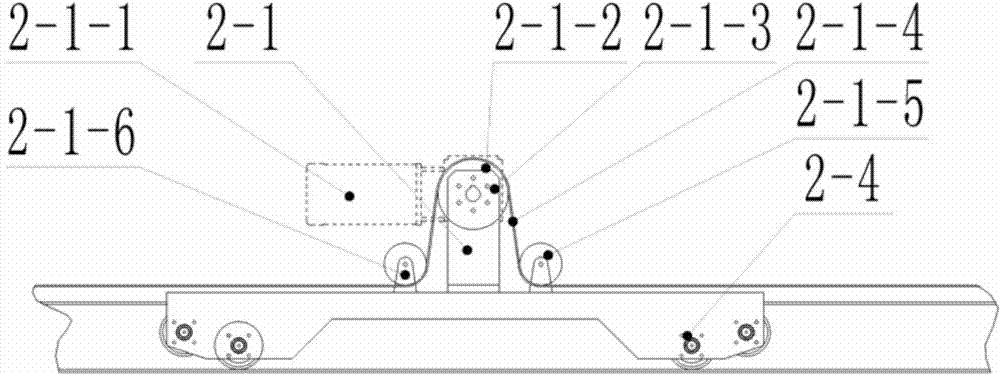

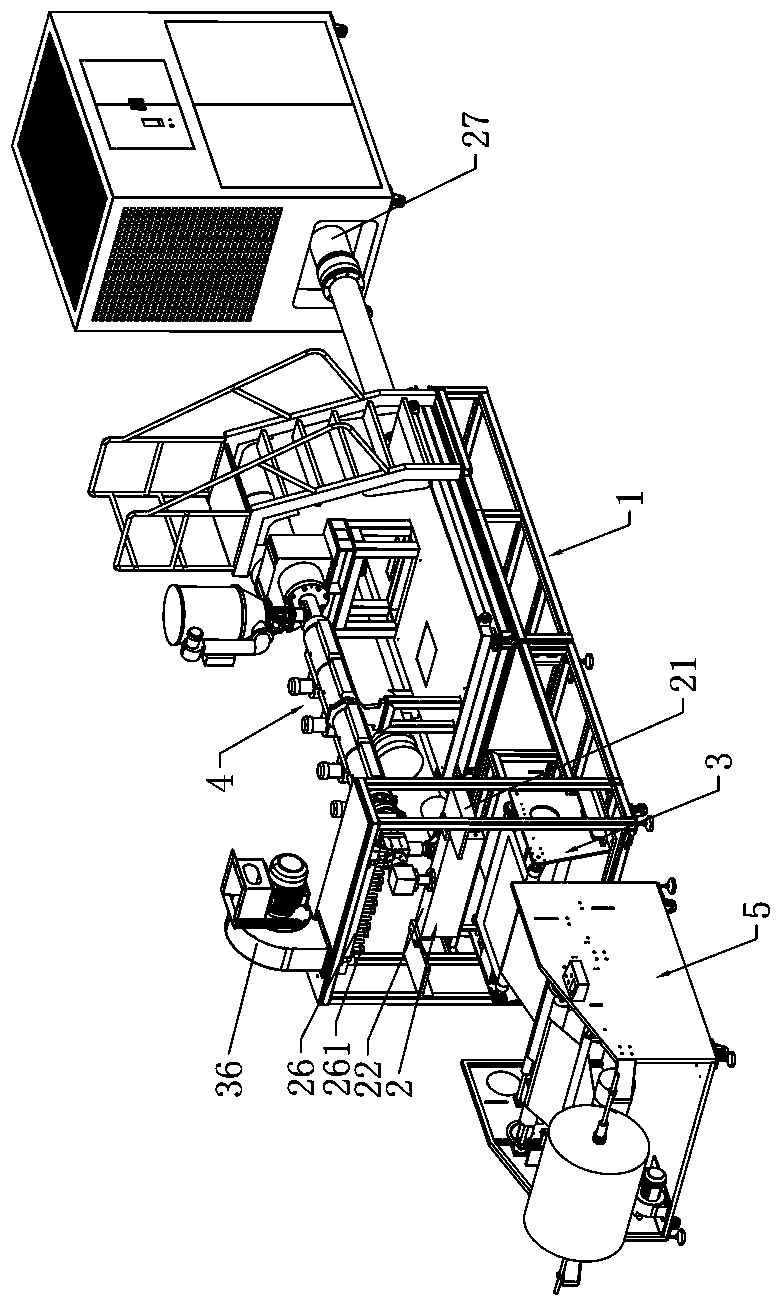

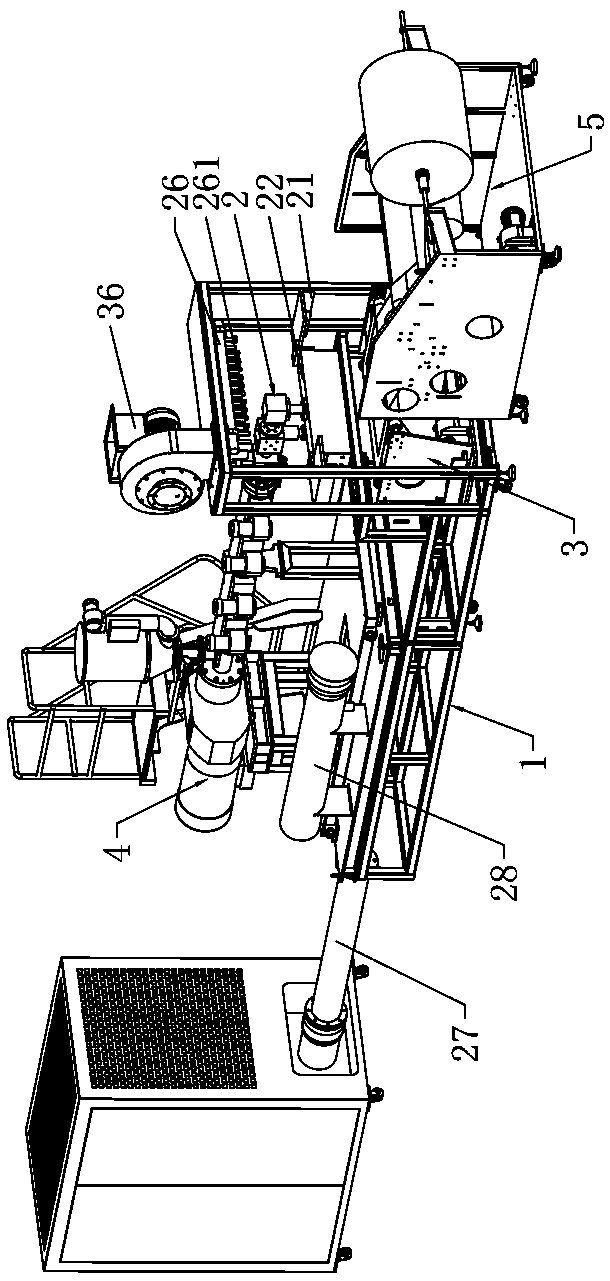

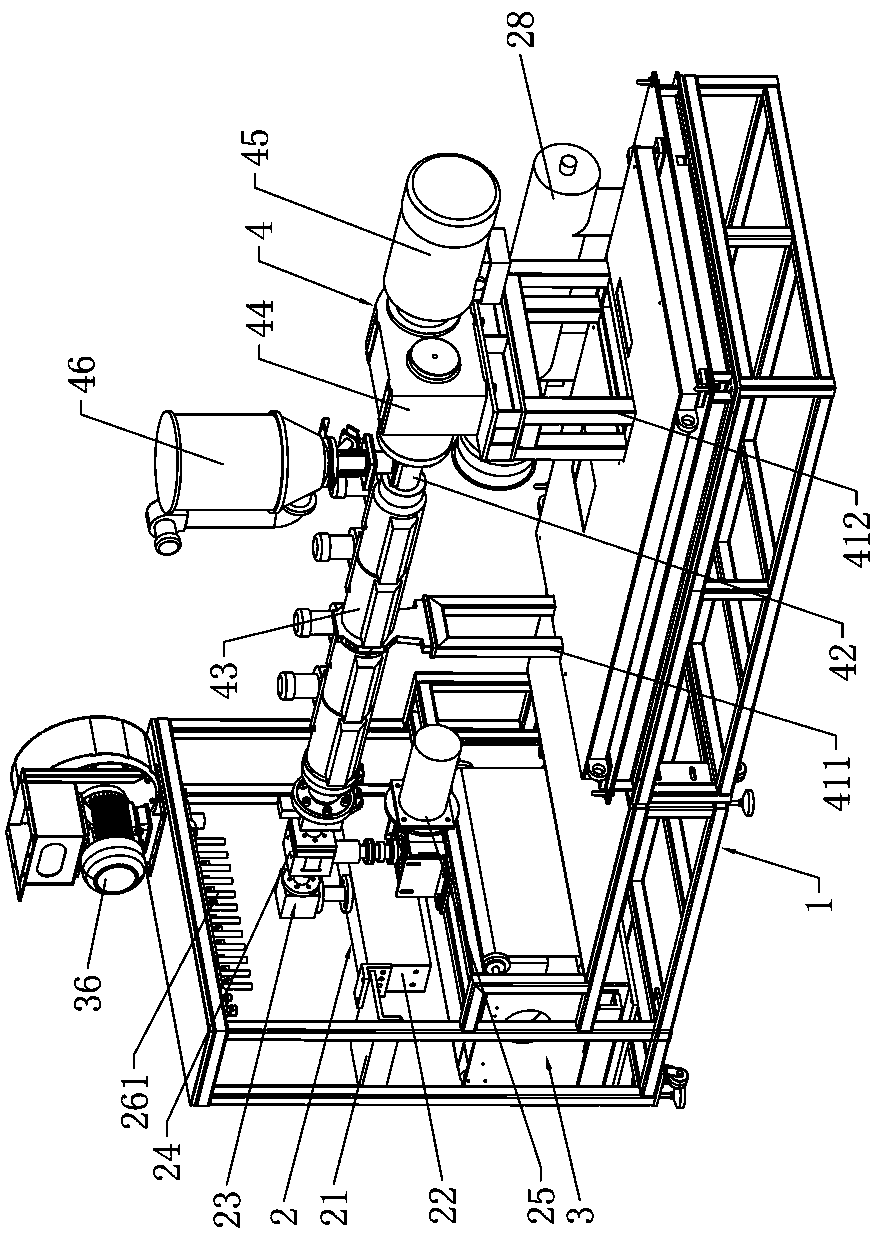

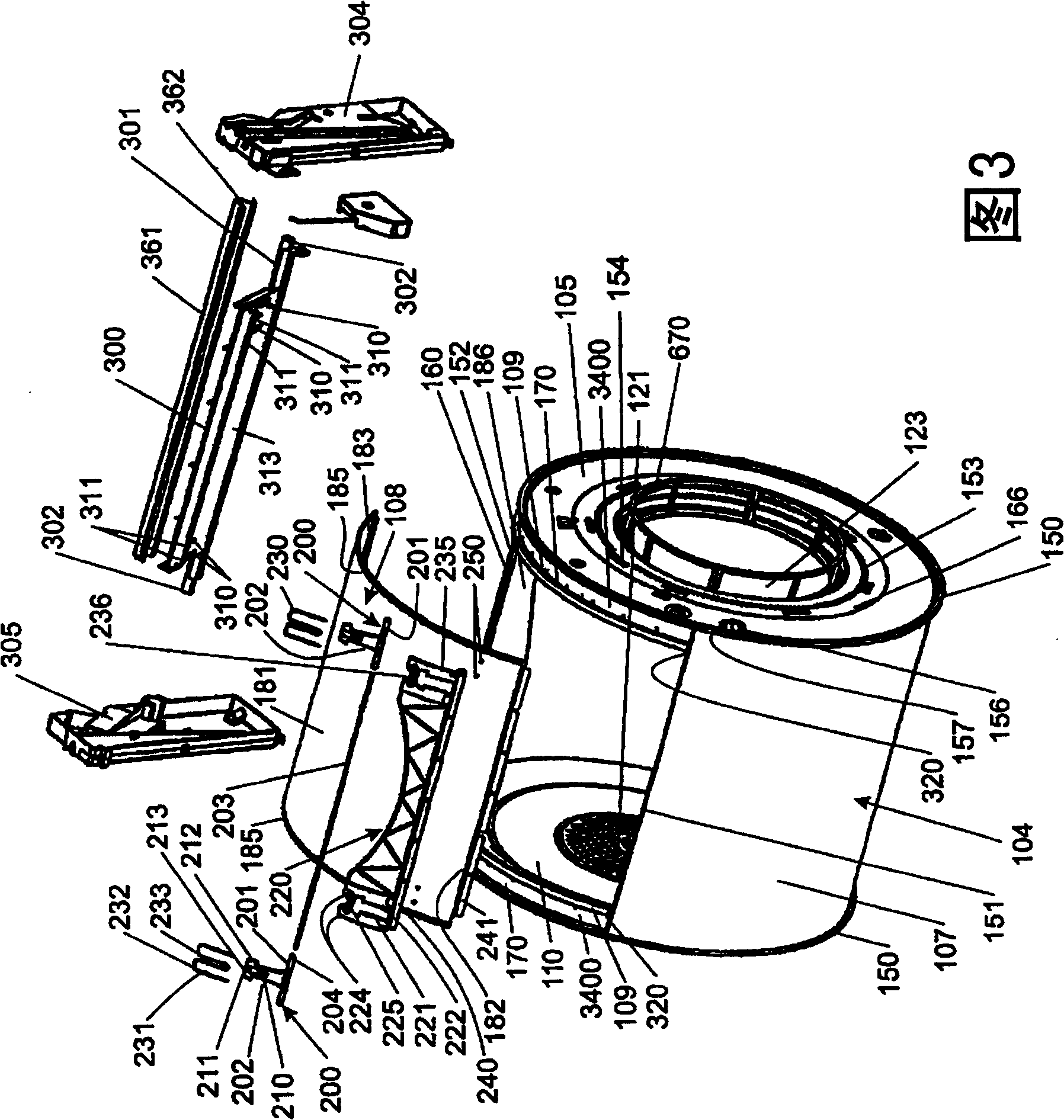

High-speed stacking machine for light material boxes

ActiveCN103879704AHigh positioning accuracyFast positioning accuracyStorage devicesMachineTransfer mechanism

The invention relates to a high-speed stacking machine for light material boxes, in particular to a high-speed stacking machine for light material boxes used for intensive storage of an elevated stereoscopic warehouse. The high-speed stacking machine for light material boxes is characterized by comprising a running device, a lifting mechanism driven by a synchronous belt, a telescopic fork claw shifting mechanism and a material box transferring mechanism, wherein the running device is composed of an upper set of synchronous belt driving mechanism and a lower set of synchronous belt driving mechanism, the running device and the lifting mechanism are arranged on a running framework, and the telescopic fork claw shifting mechanism and the material box transferring mechanism are fixed on a lifting platform of the lifting mechanism. A traditional stacking machine can only transfer one material box every time and is low in efficiency, and a fork of the traditionally stacking machine is large and heavy due to the fact that the material boxes need to be lifted and the gravity of the material boxes needs to be overcome through the commodity taking method. Compared with the traditional stacking machine, the high-speed stacking machine for light material boxes has the advantages of being high in operation speed, high in positioning accuracy, stable in operation, small in noise, high in efficiency, small in size and the like.

Owner:BLUESWORD INTELLIGENT TECH CO LTD

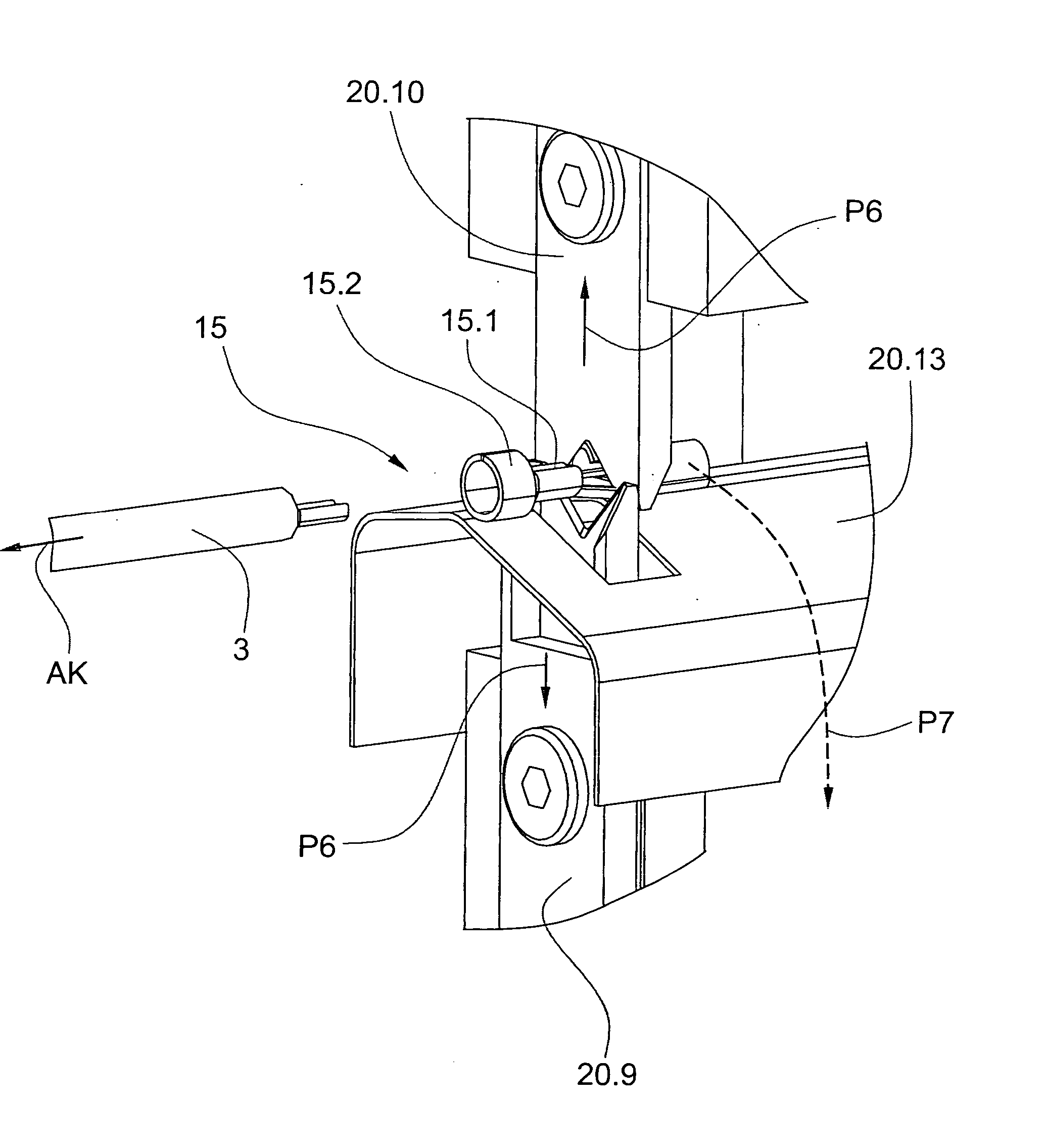

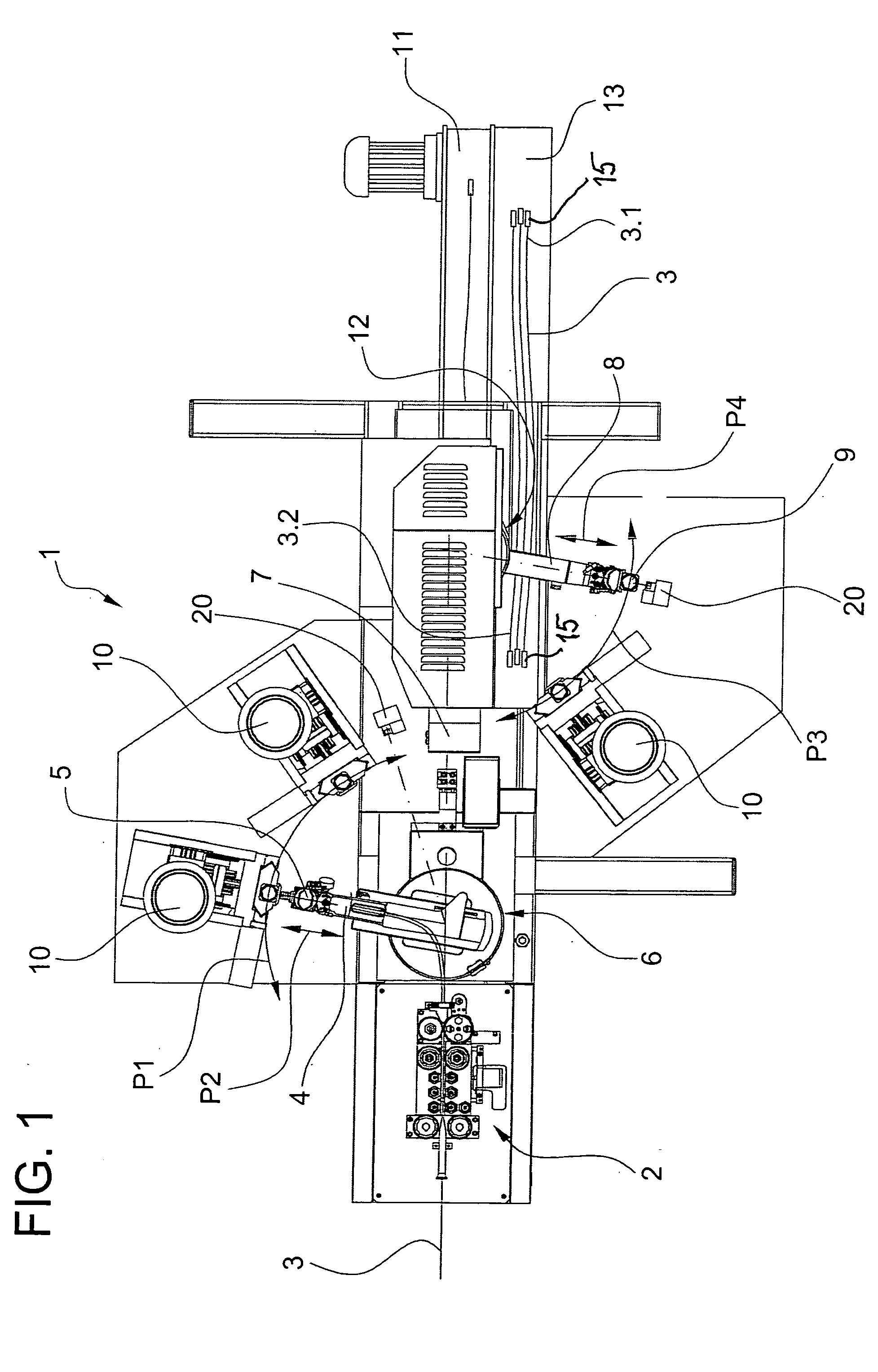

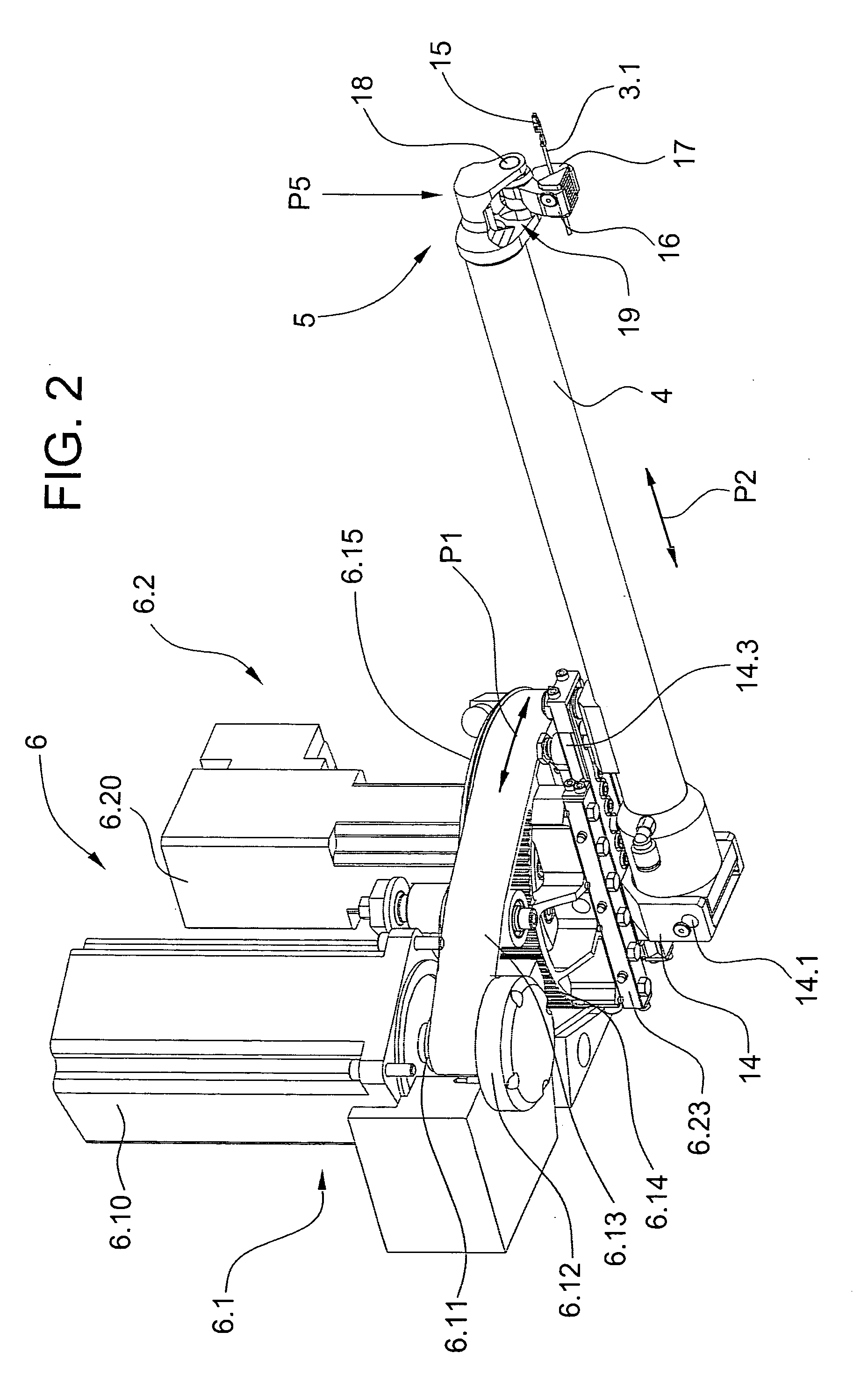

Inspection apparatus and method for wire-processing machine

InactiveUS20050050722A1Avoid disadvantagesEasy to set upContact member manufacturingElectrically conductive connectionsLinear motionEngineering

A wire-processing apparatus has a belt drive that guides a wire to a first swivel arm with a first gripper. The leading end of the wire is fed to processing stations by setting the first swivel arm into a swivel motion and / or a linear motion. The lagging end of the wire is fed to the processing stations by setting a second swivel arm with a second gripper into a swivel motion and / or a linear motion. A holder is used to inspect the wire end connection, or the crimp connection, produced in the automated wire-processing operation, wherein the linear movement of the grippers is also used for the automated inspection of the wire end connection.

Owner:KOMAX HOLDING

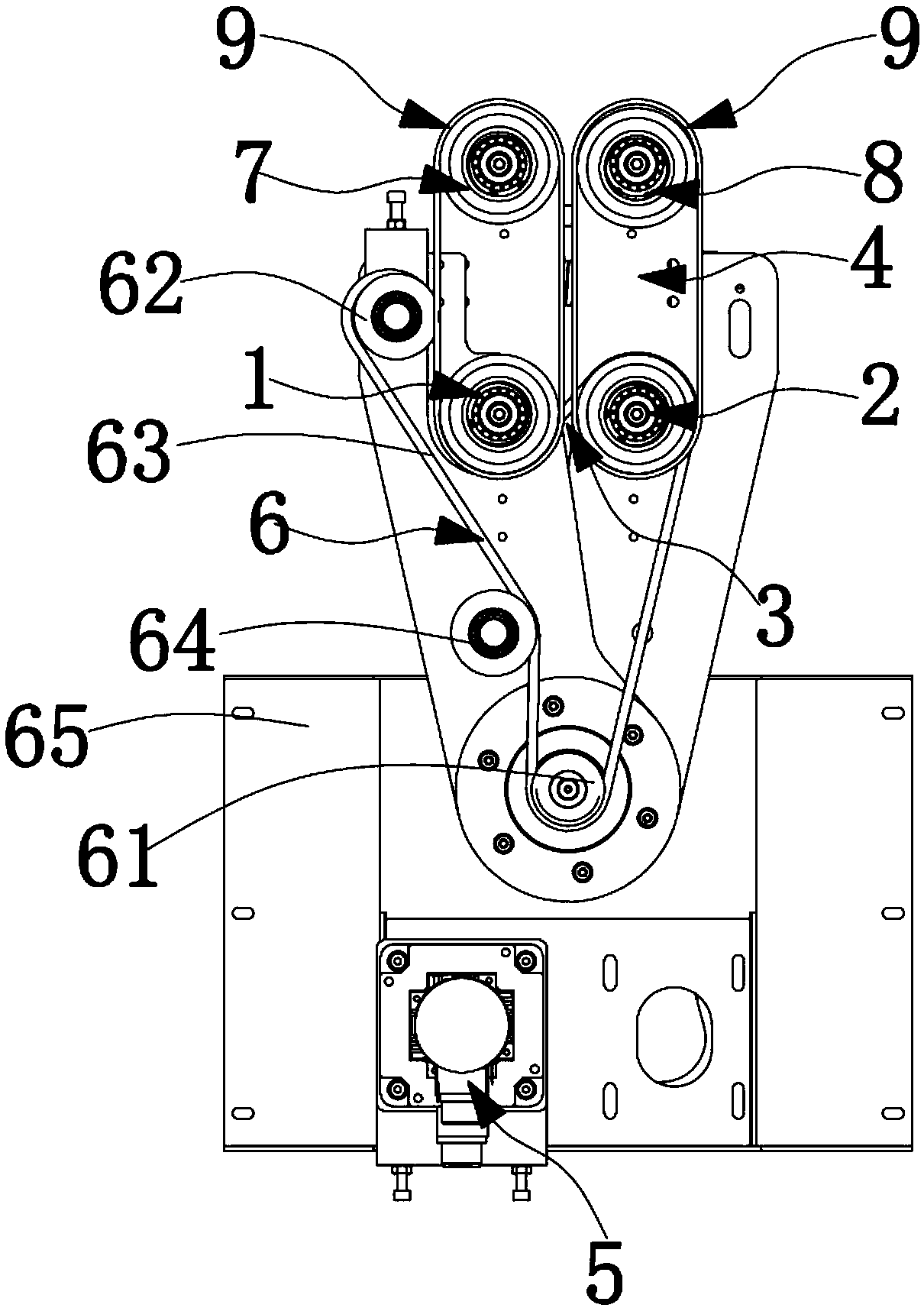

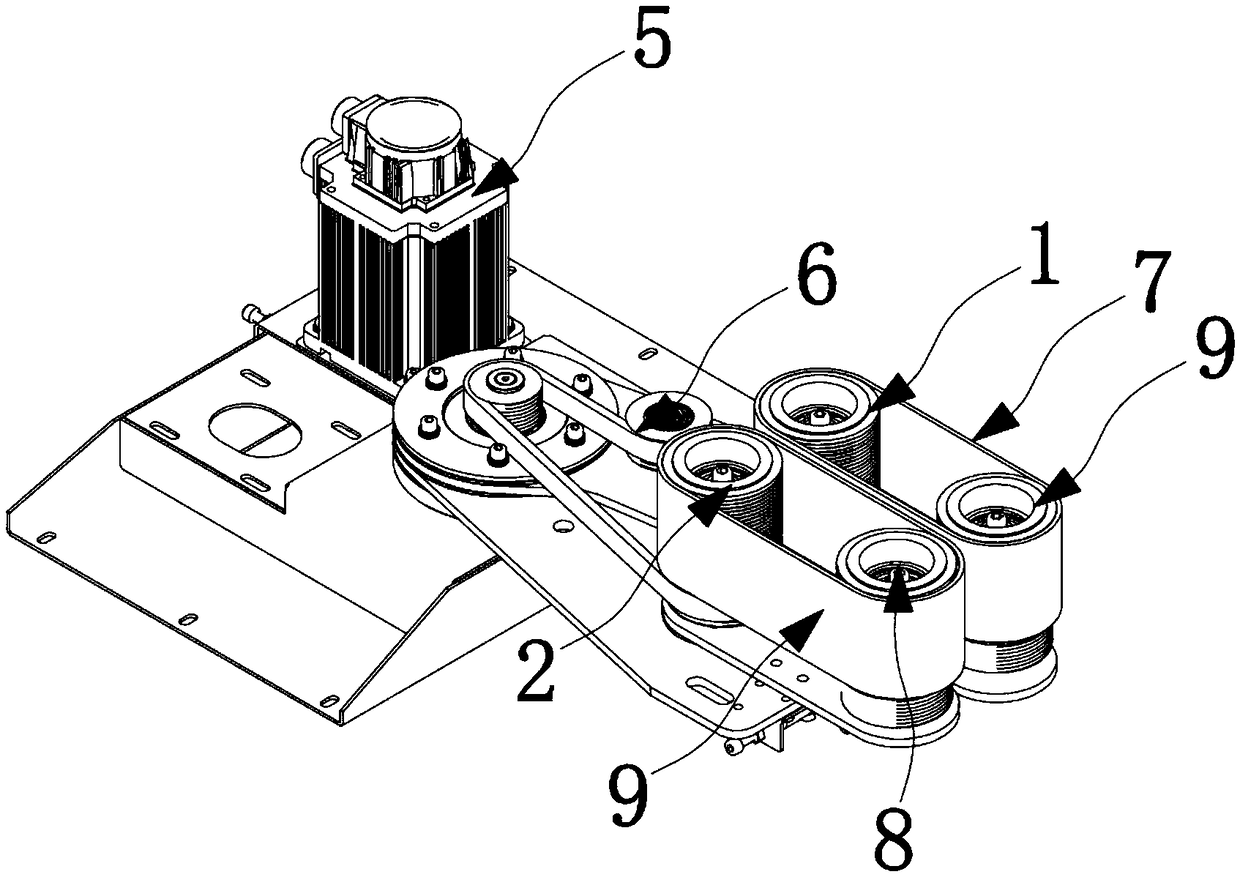

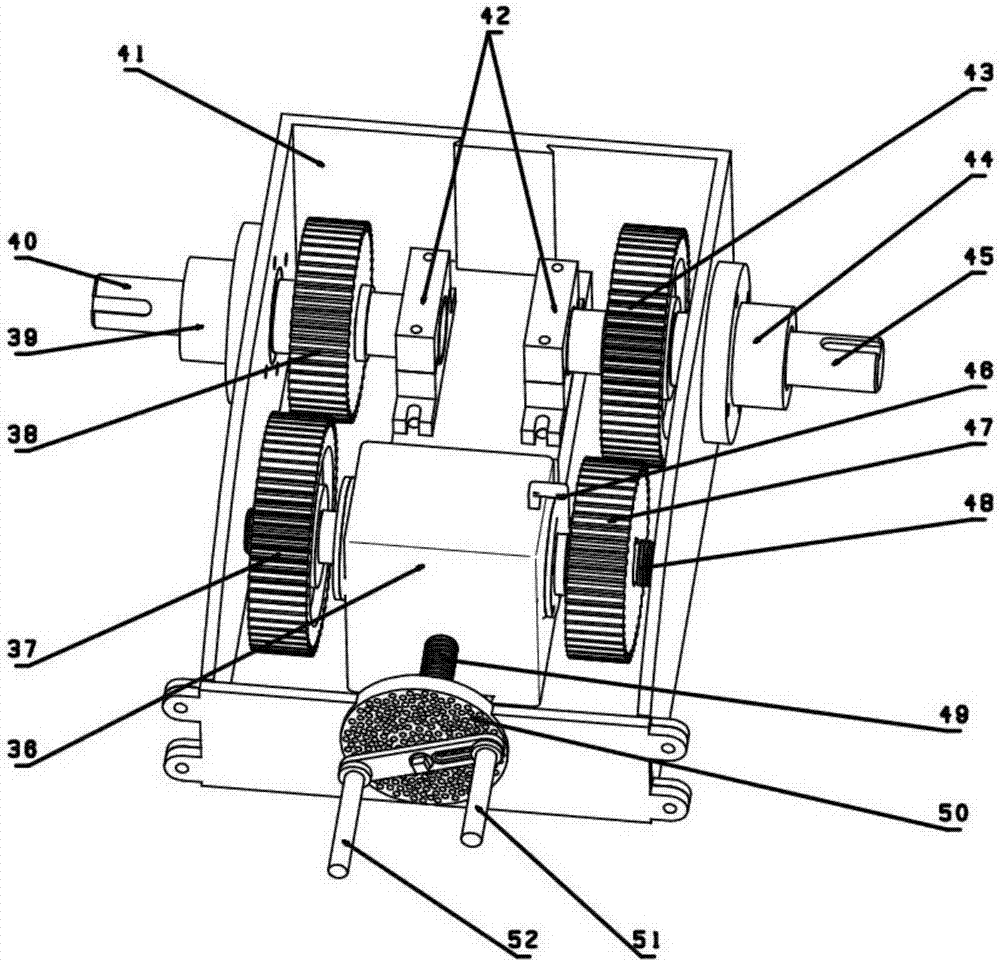

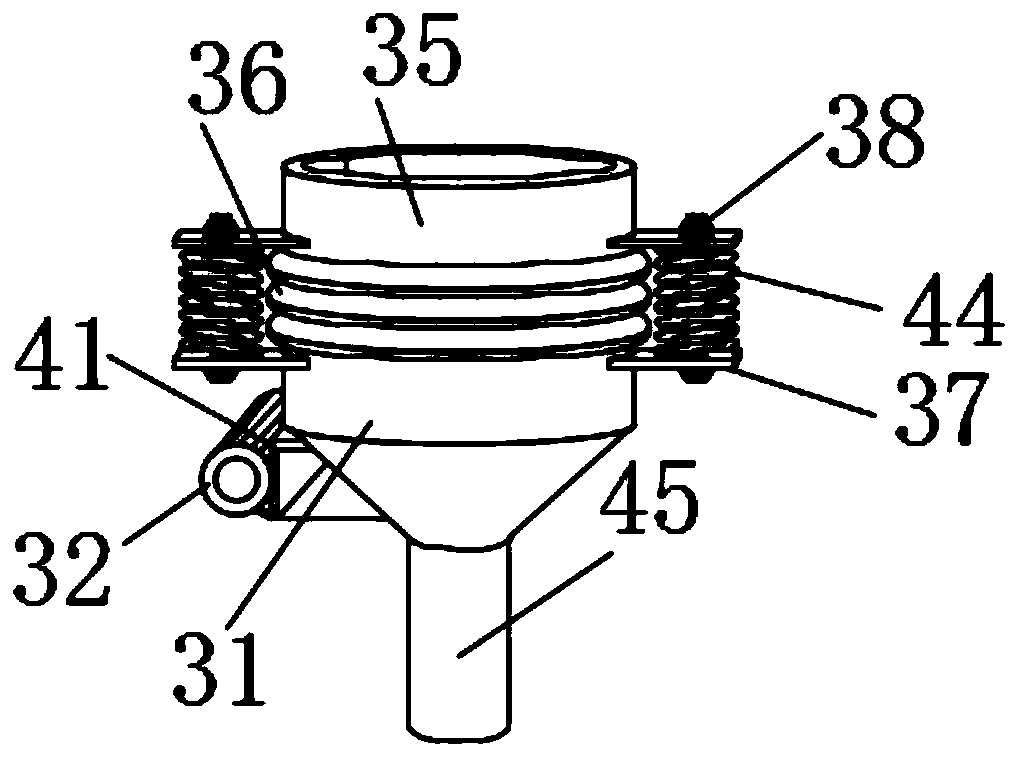

Friction drive device, cross-belt sorting machine and cross-belt sorting system

PendingCN109335568AReduce repair and replacement costsReduce energy consumptionConveyorsControl devices for conveyorsMotor driveDrive wheel

The invention discloses a friction drive device, a cross-belt sorting machine and a cross-belt sorting system. The friction drive device comprises at least one pair of drive wheels keeping a micro-clearance and provided with parallel axes, wherein the two drive wheels can be rotatably arranged on an installation plate and are driven by one same motor so as to self-rotate; and the self-rotation directions of the two drive wheels are opposite. The friction drive device with the scheme is ingenious in design and simple in structure; through arranging a special belt driving mechanism, one motor drives the two drive wheels to rotate, so that compared with an existing friction drive structure, one motor is omitted, the equipment cost is greatly reduced, meanwhile, the energy consumption of the single motor is low compared with the operation energy consumption of two motors, and meanwhile, a transmission mechanism is low in maintenance and replacement cost.

Owner:SUZHOU JINFENG INTERNET OF THINGS TECH CO LTD

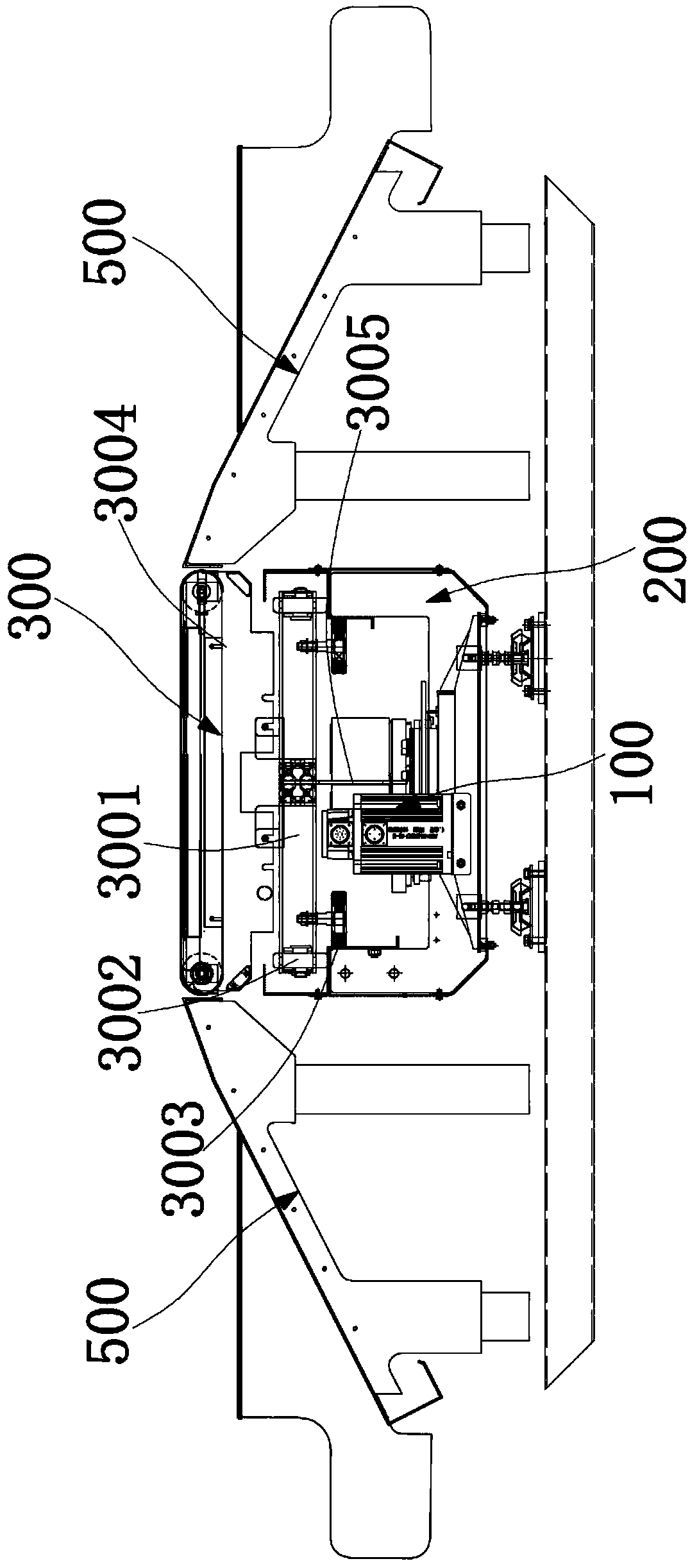

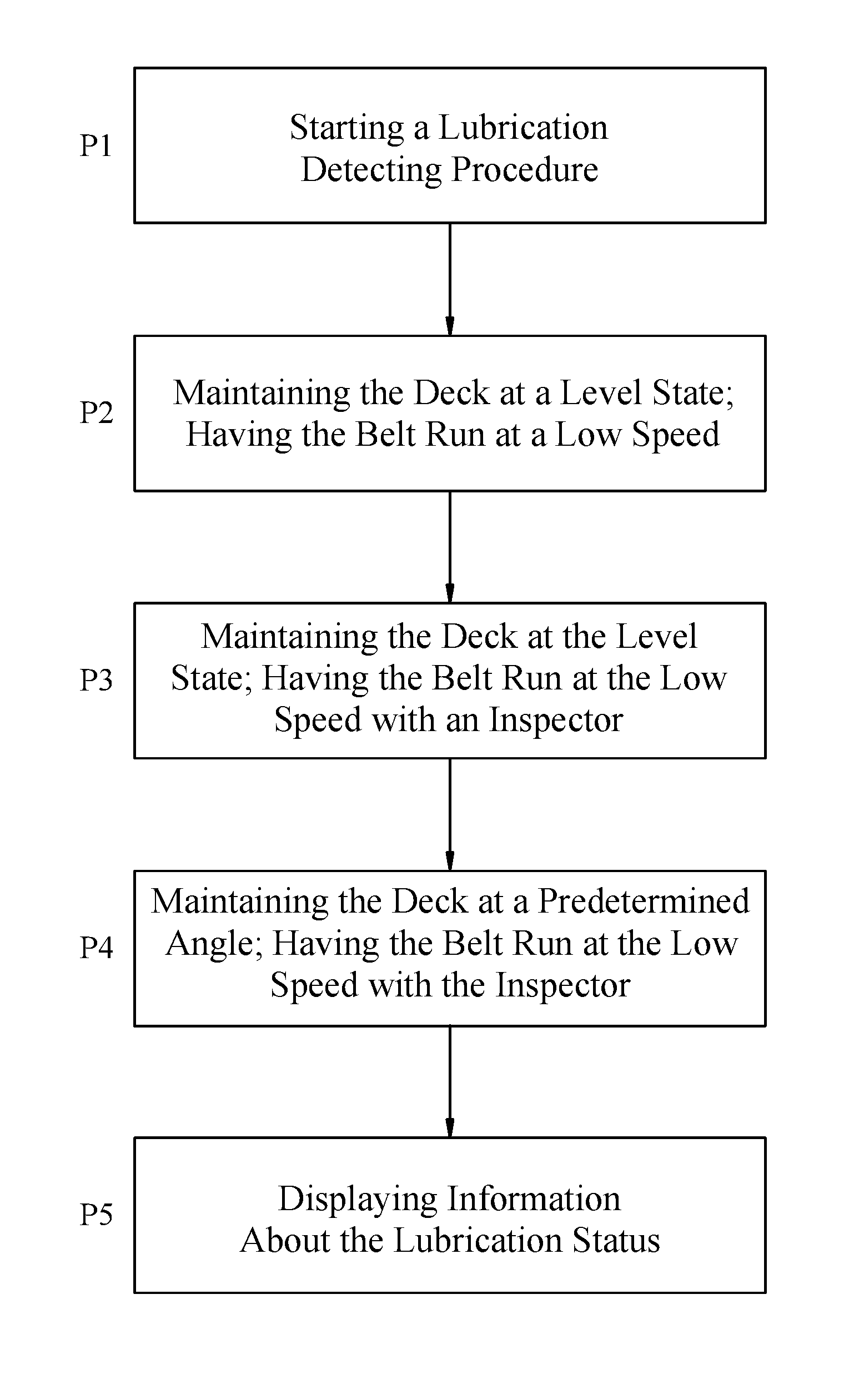

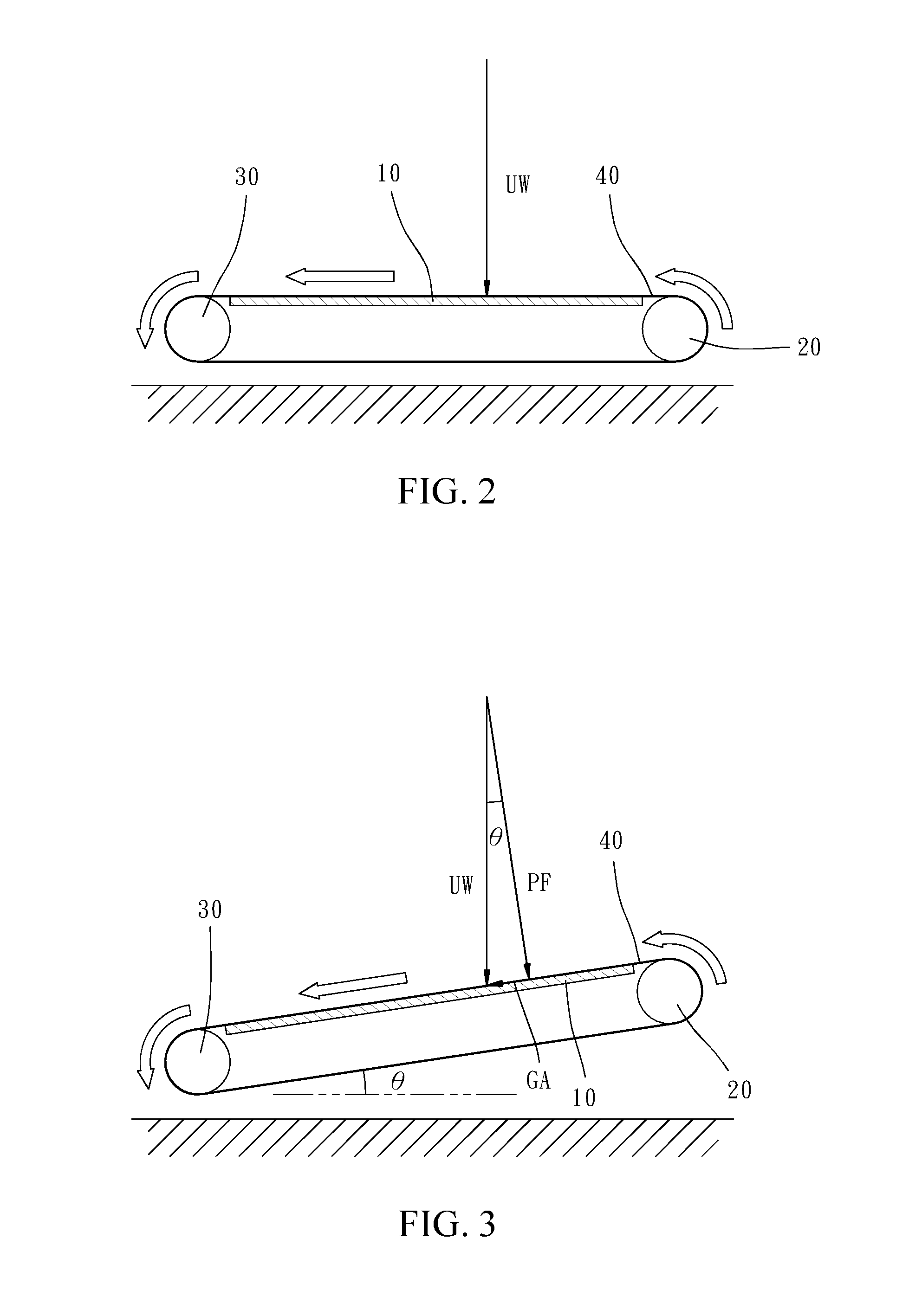

Method of detecting a lubrication status between a deck and a belt of a treadmill

ActiveUS9429511B1Improve reliabilitySimple procedureUsing mechanical meansMovement coordination devicesFrictional coefficientClassical mechanics

The present invention relates to a method of detecting a lubrication status between a deck and a belt of a treadmill. The method includes: starting a lubrication detecting procedure of the treadmill by a user, making the belt driving system drive the belt to run for a period of time without the user on the belt of the treadmill, having the user walk on the belt of the treadmill for a period of time at a level state, having the user walk on the belt of the treadmill for a period of time at a predetermined angle. Thereafter, a central control unit of the treadmill calculates a friction coefficient between the belt and the deck of the treadmill according to measuring results of the procedures, and generating a suggestion of maintenance according to a level of the friction coefficient.

Owner:JOHNSON HEALTH TECH

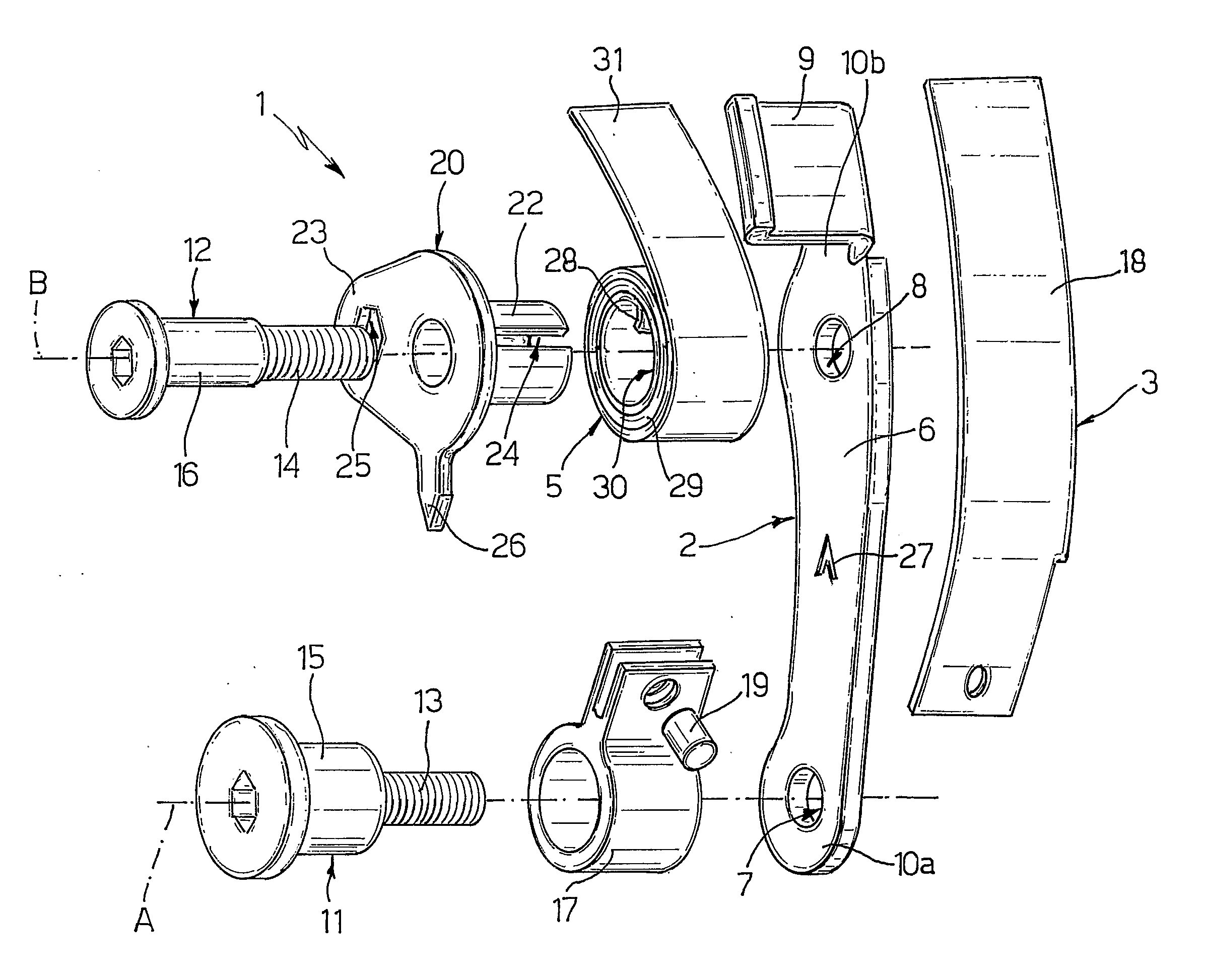

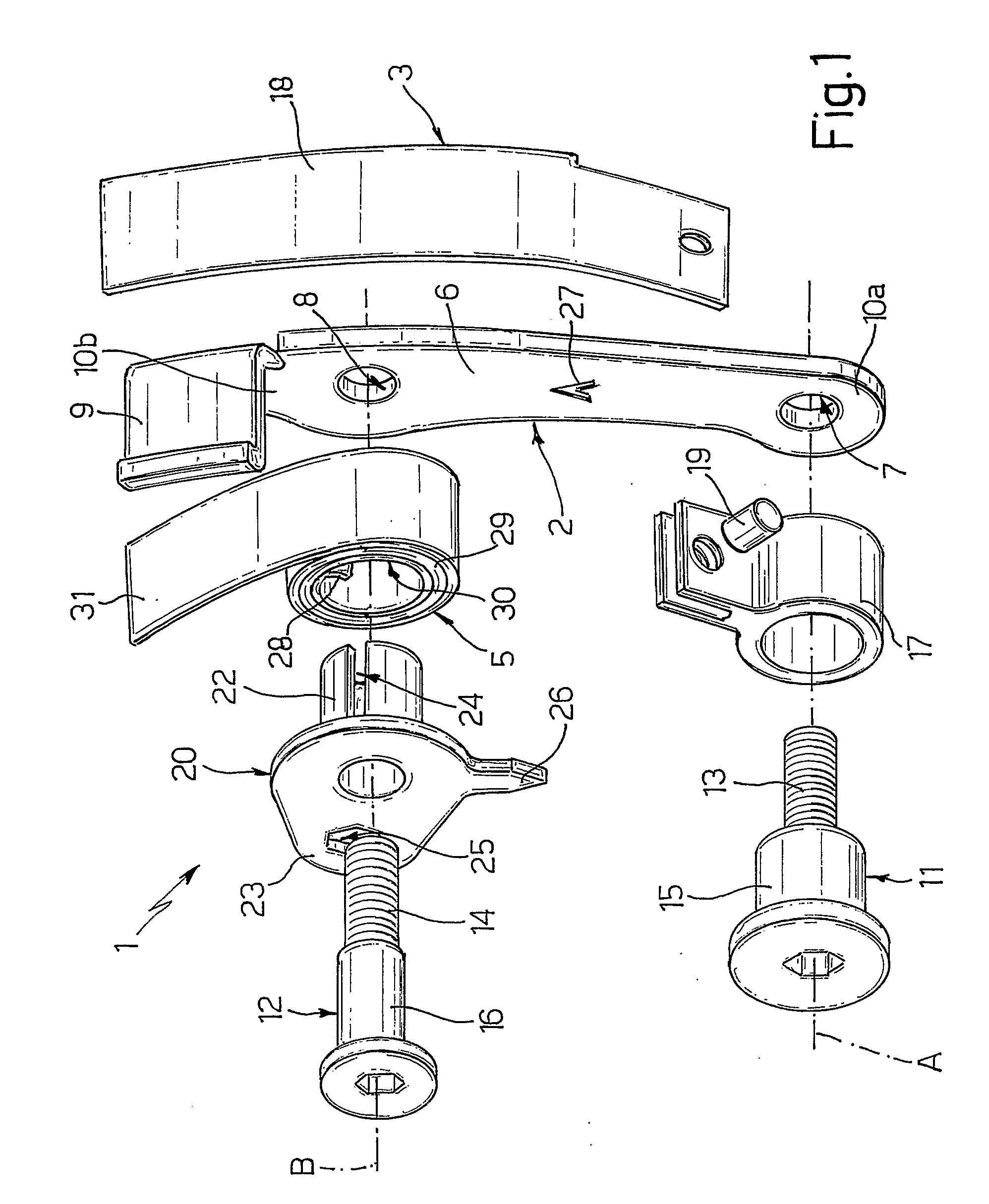

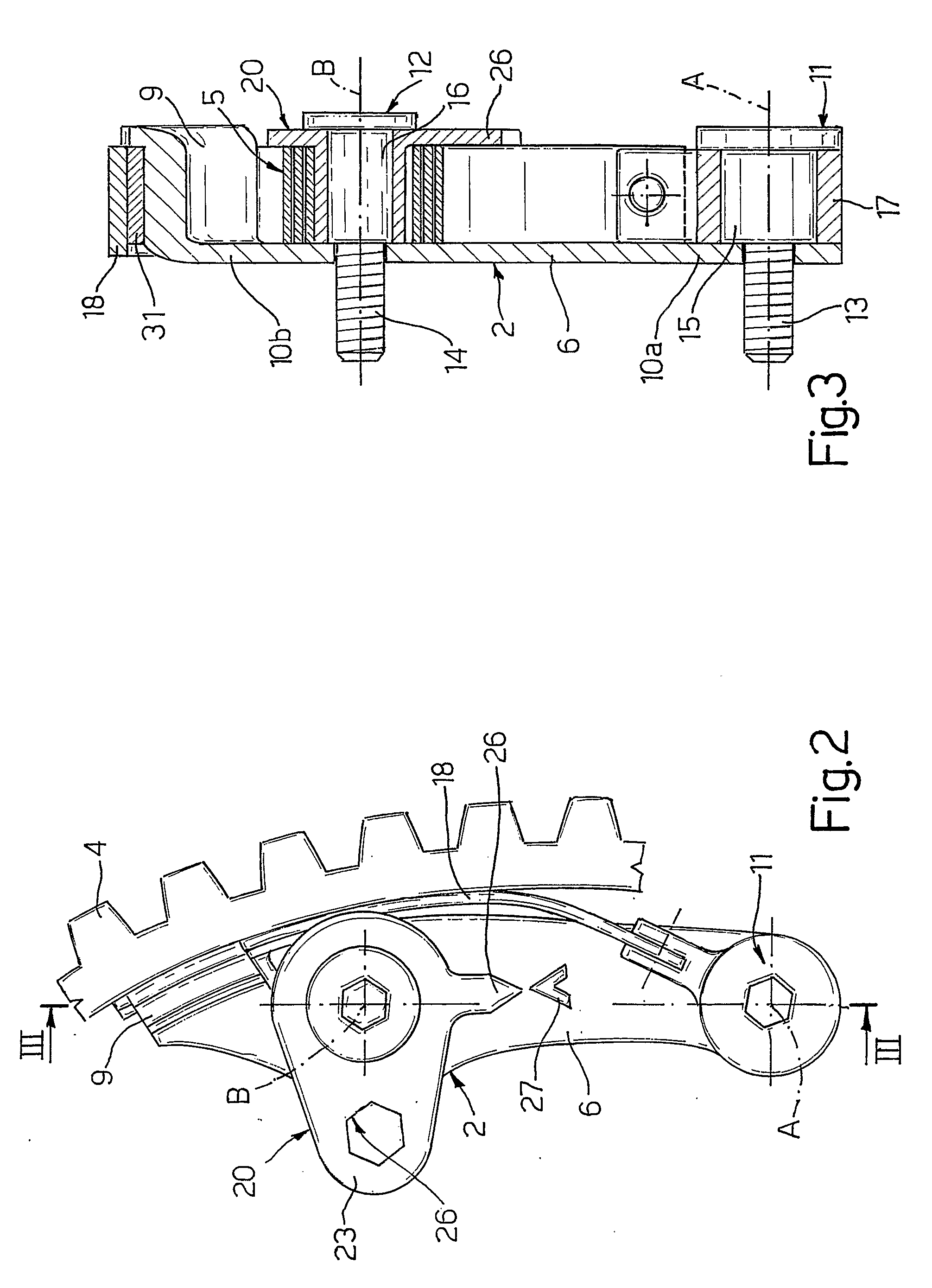

Shoe Tensioner for a Synchronous Belt Drive for Use With Oil

A shoe tensioner for a synchronous belt drive, having a guide member adapted to cooperate with a drive belt and hinged at one end about a first axis; elastic means cooperating with the guide member to tension the belt; and connecting means for connecting the tensioner to a supporting wall. More specifically, the elastic means include a coil spring.

Owner:DAYCO EURO

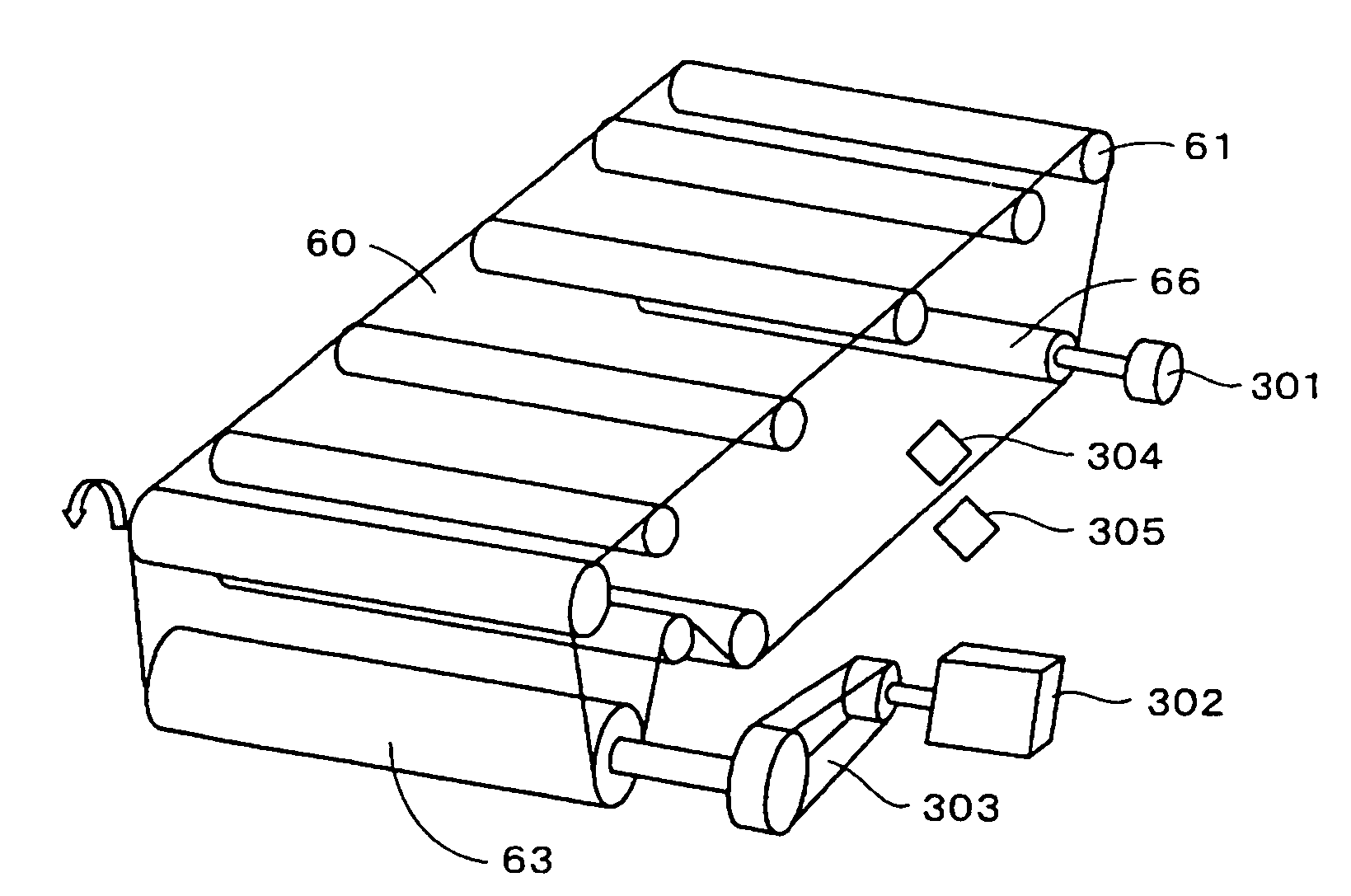

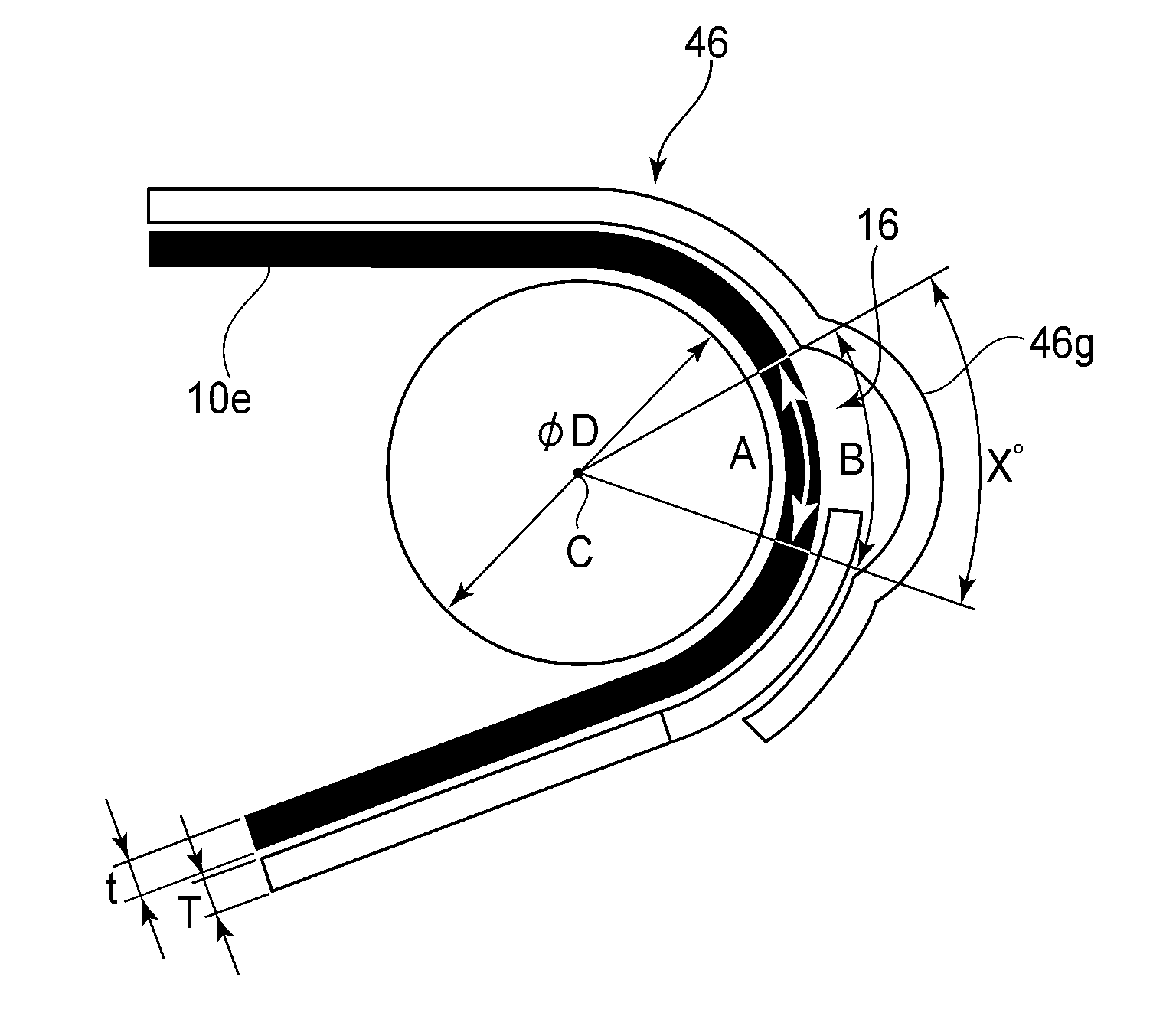

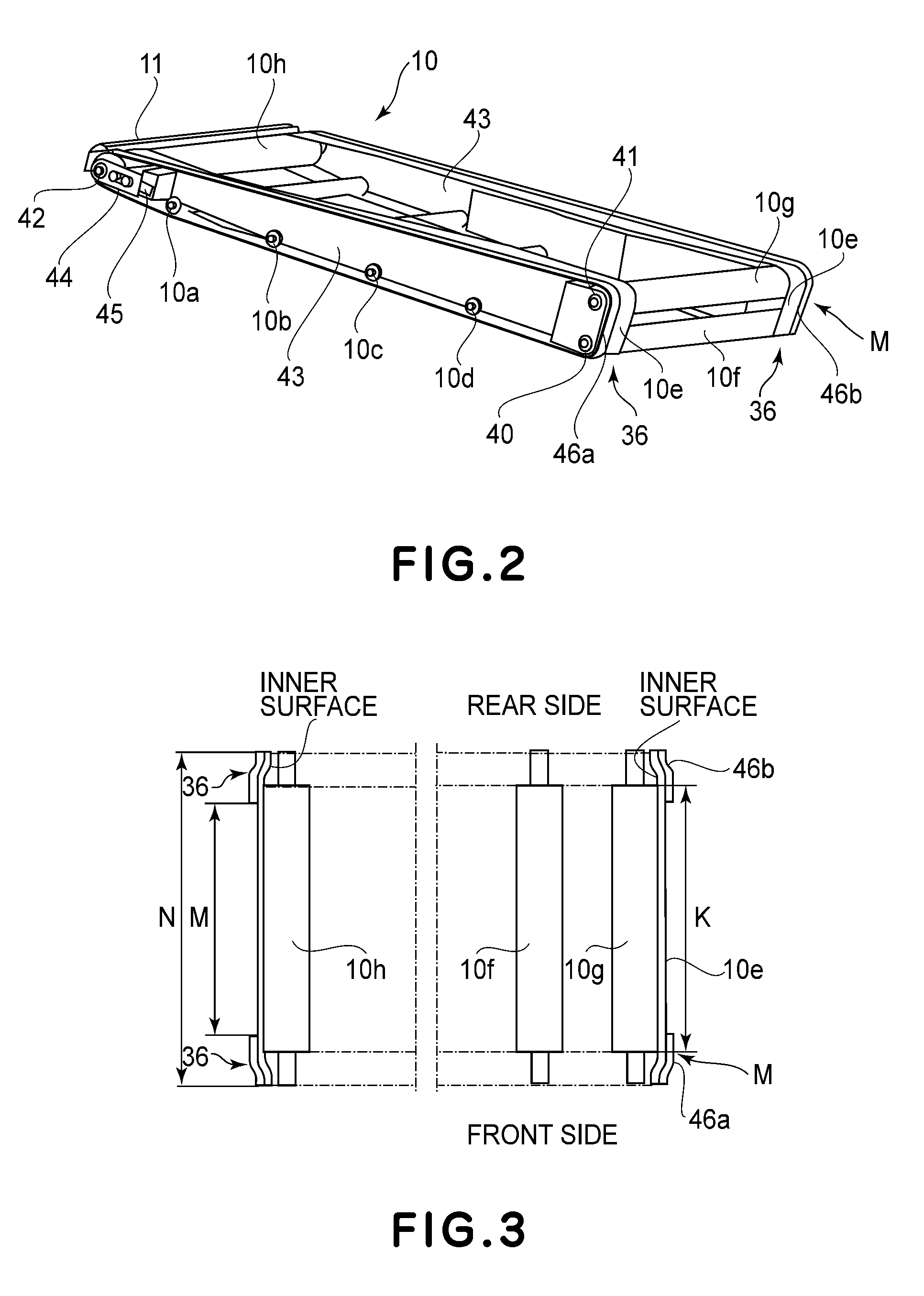

Endless belt, belt driving device and image forming apparatus

An endless belt includes an endless belt body, and a plurality of first tapes each wound around an outer peripheral surface of the belt body. Each of the first tapes has a length shorter than a full circumference of the endless belt, and the first tapes are superposedly applied onto the belt body so that positions of first edges of the first tapes and positions of second edges of the first tapes are different from each other, respectively. A recessed portion is formed in a region between the first edges and the other edges second. In addition, a second tape having a length longer than the length of a full circumference of the endless belt is wound around the first tapes so as to extend along the recessed portion, wherein a winding end edge of the second tape overlaps a winding start edge of the second tape.

Owner:CANON KK

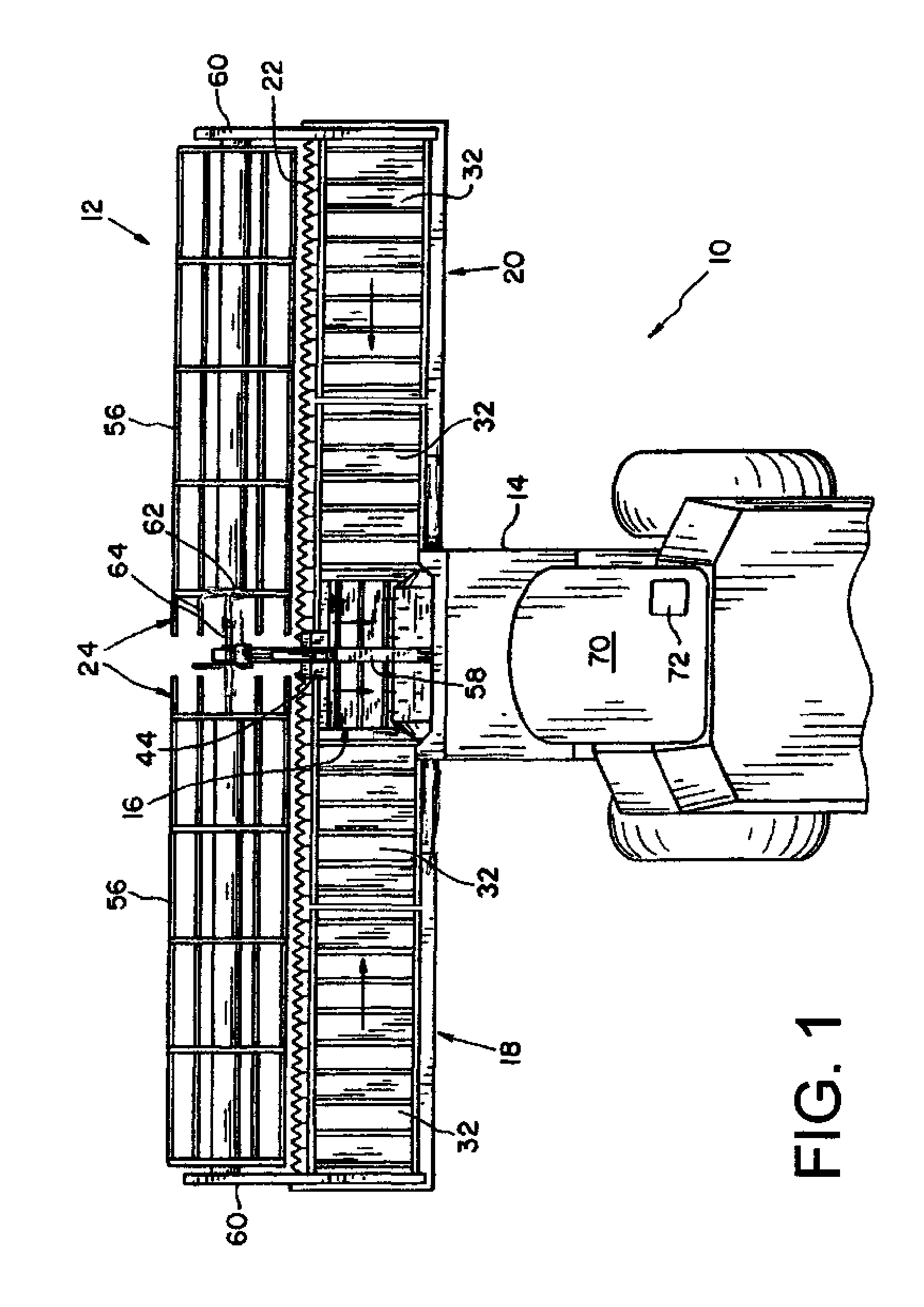

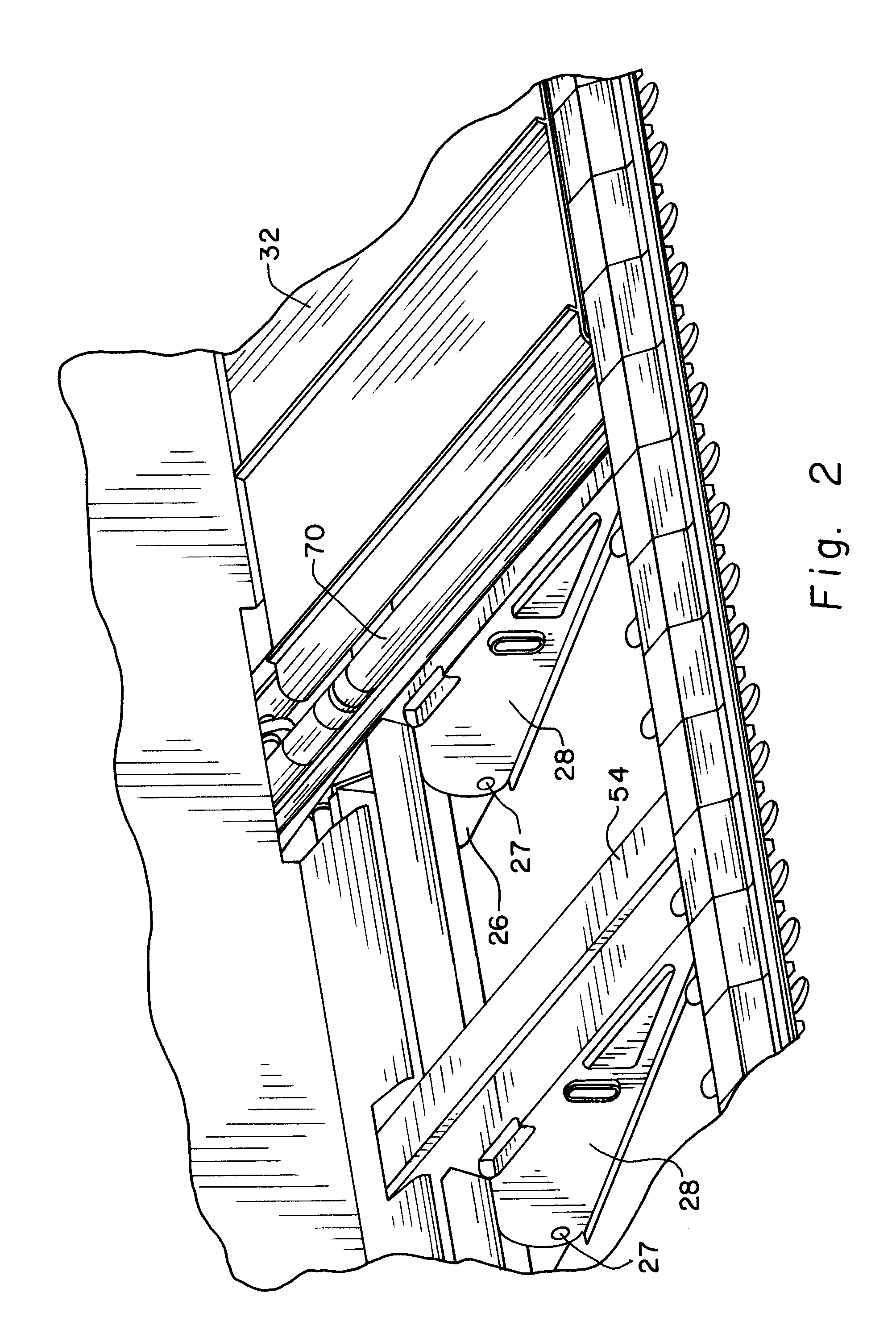

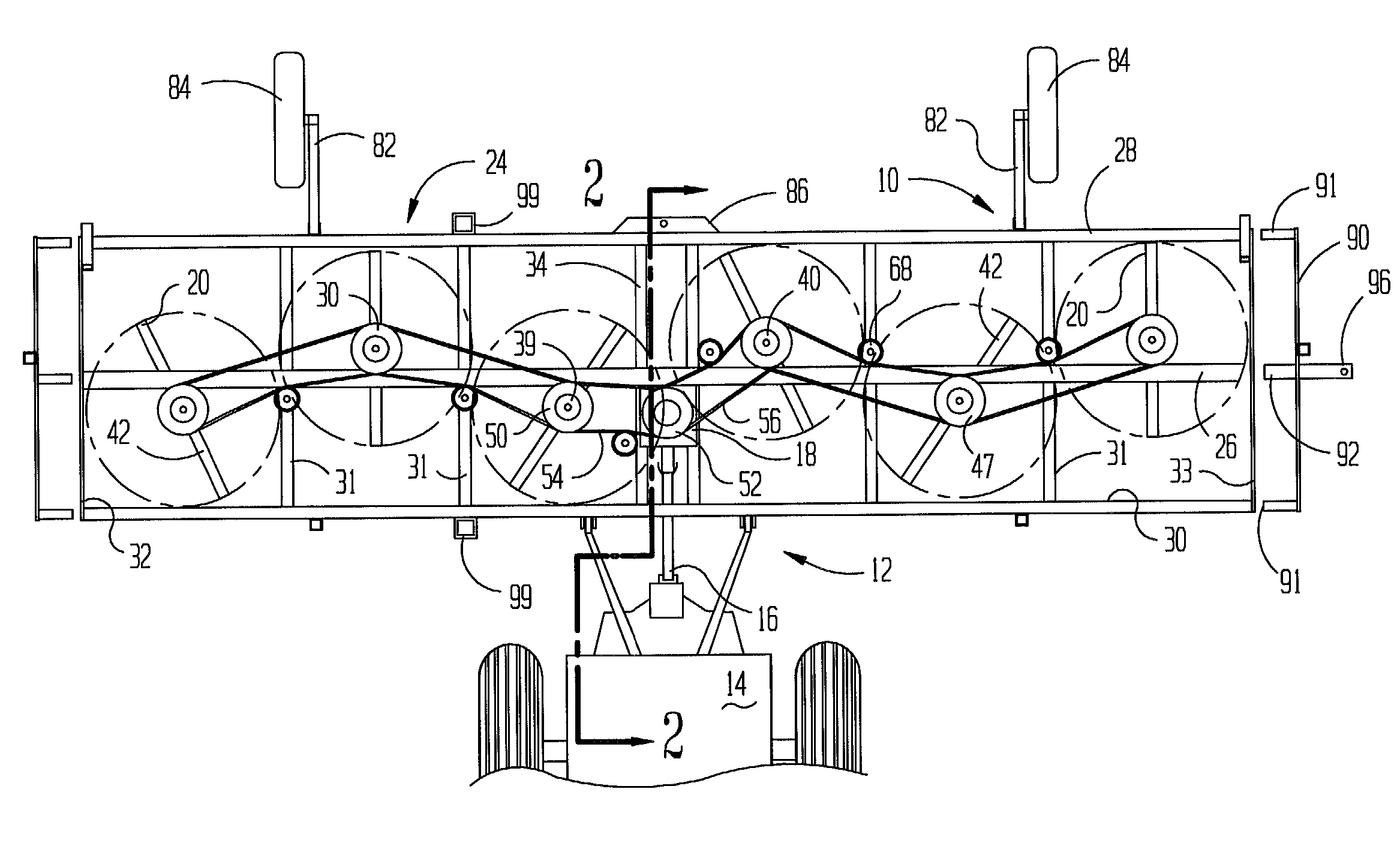

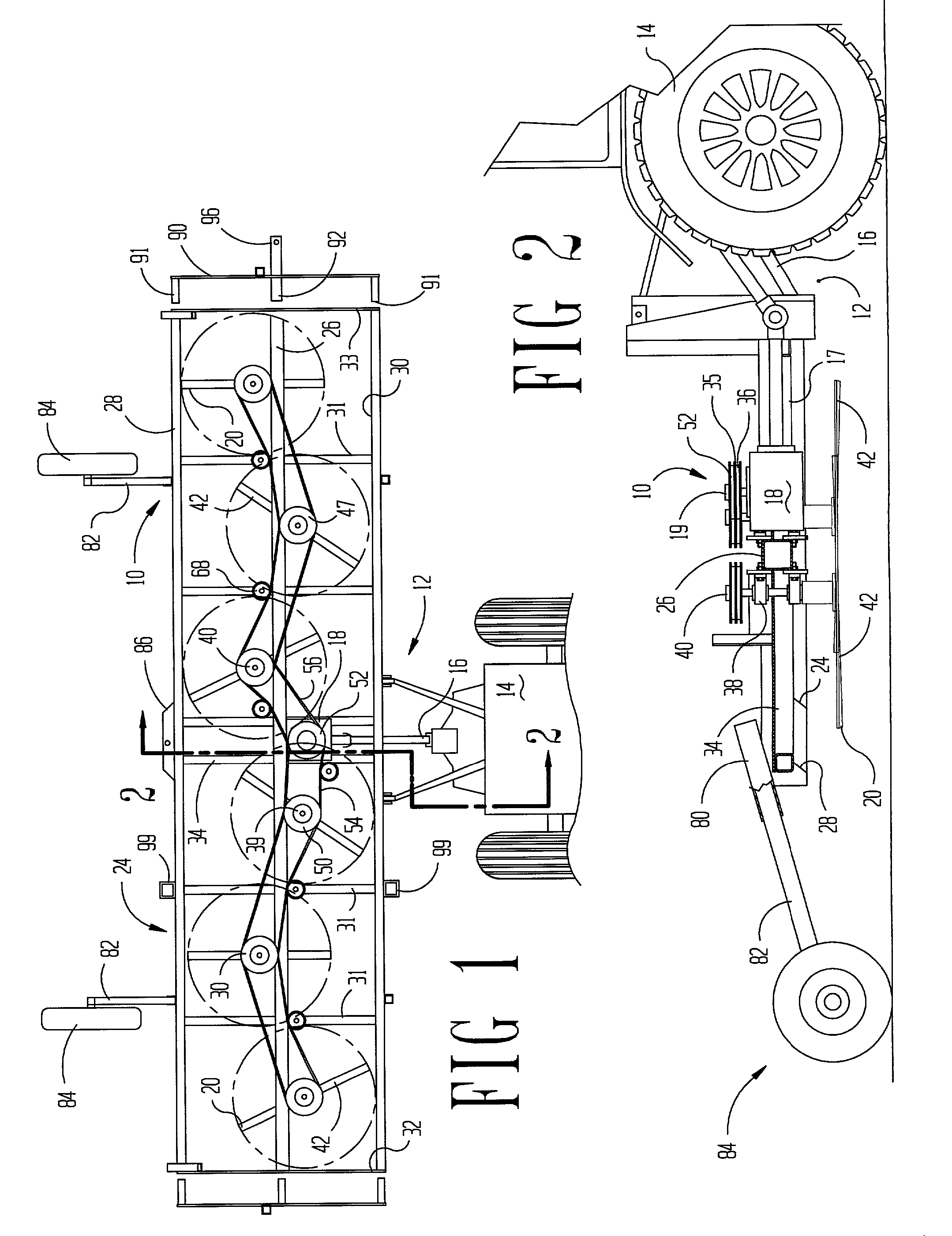

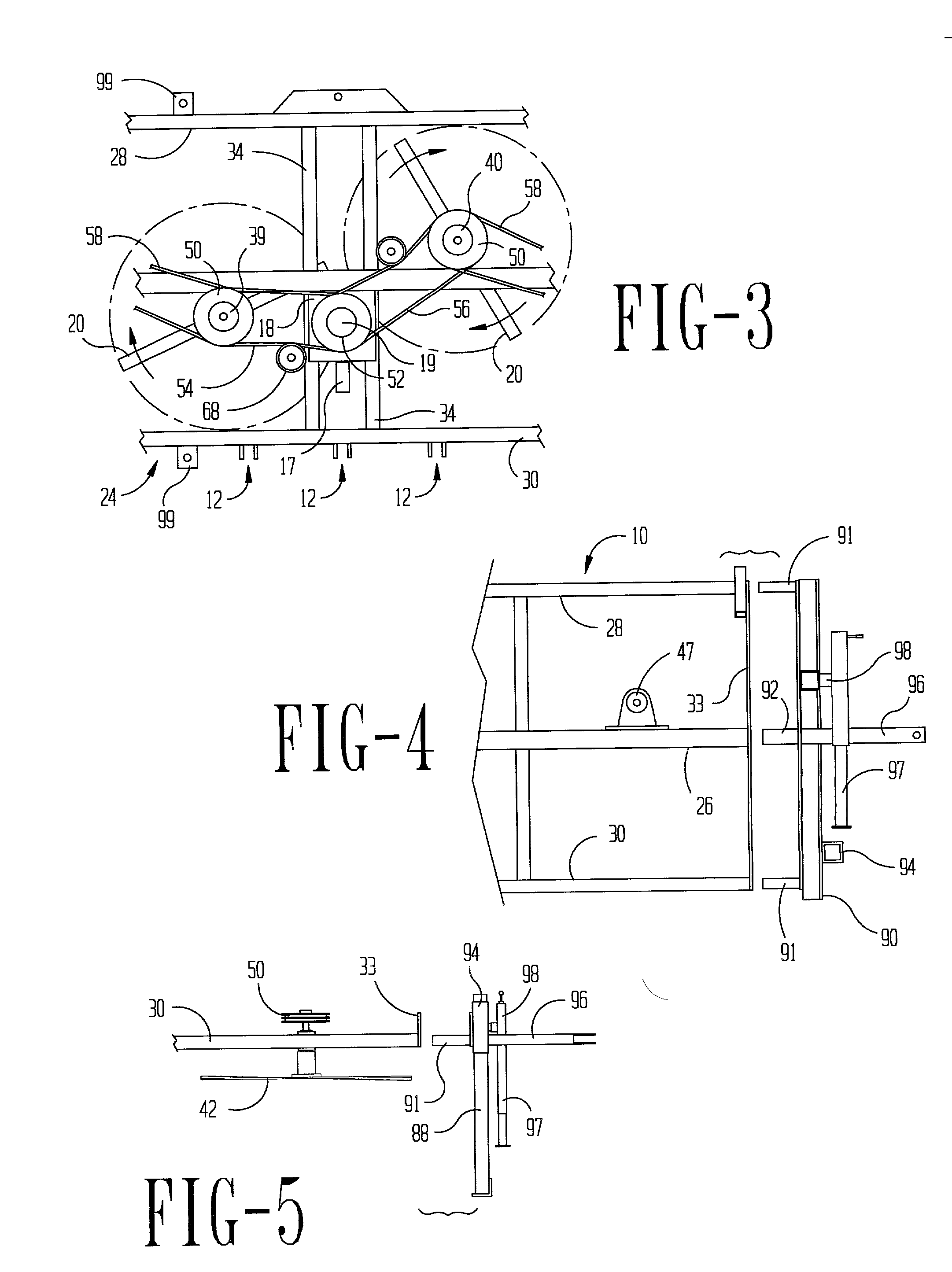

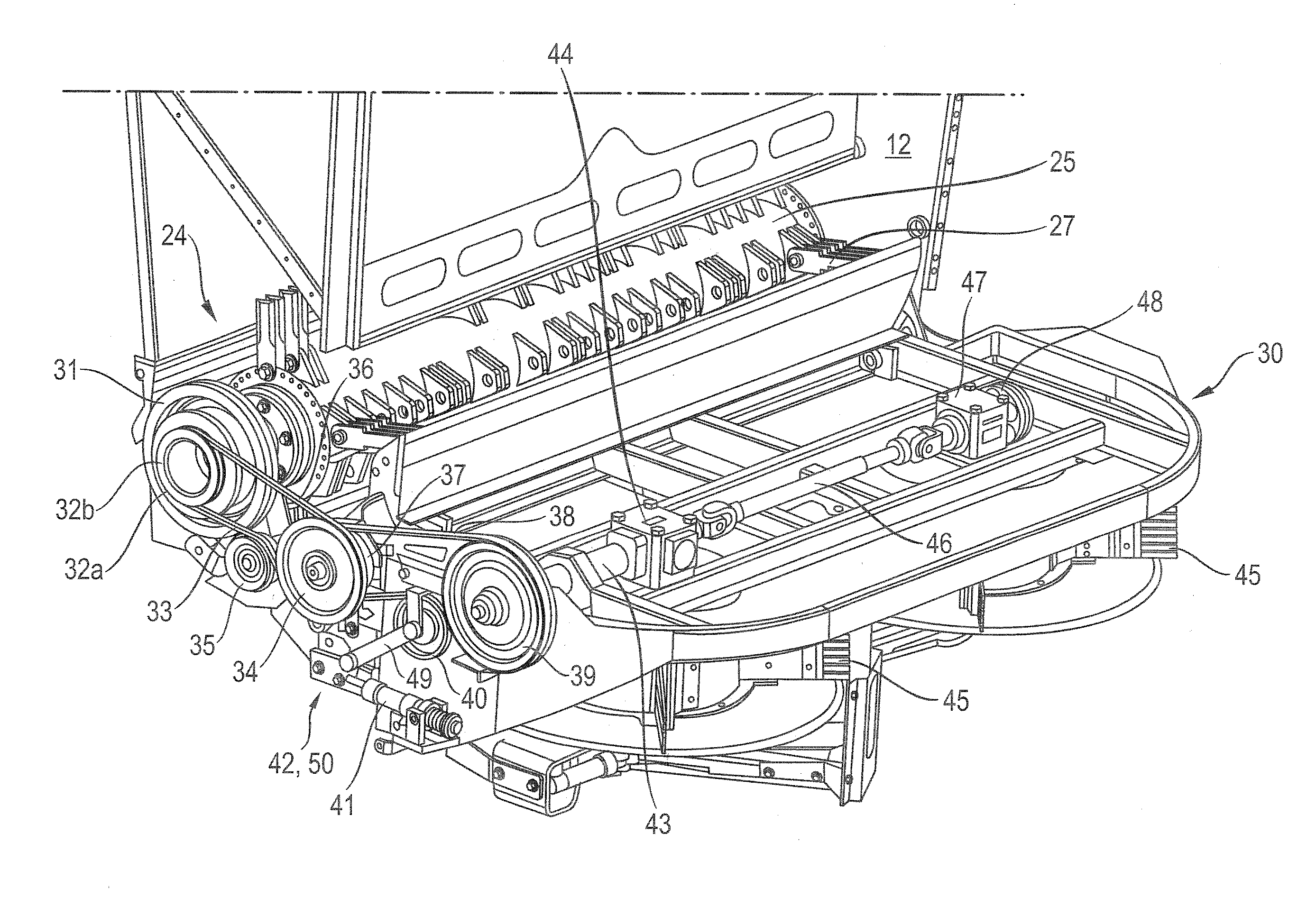

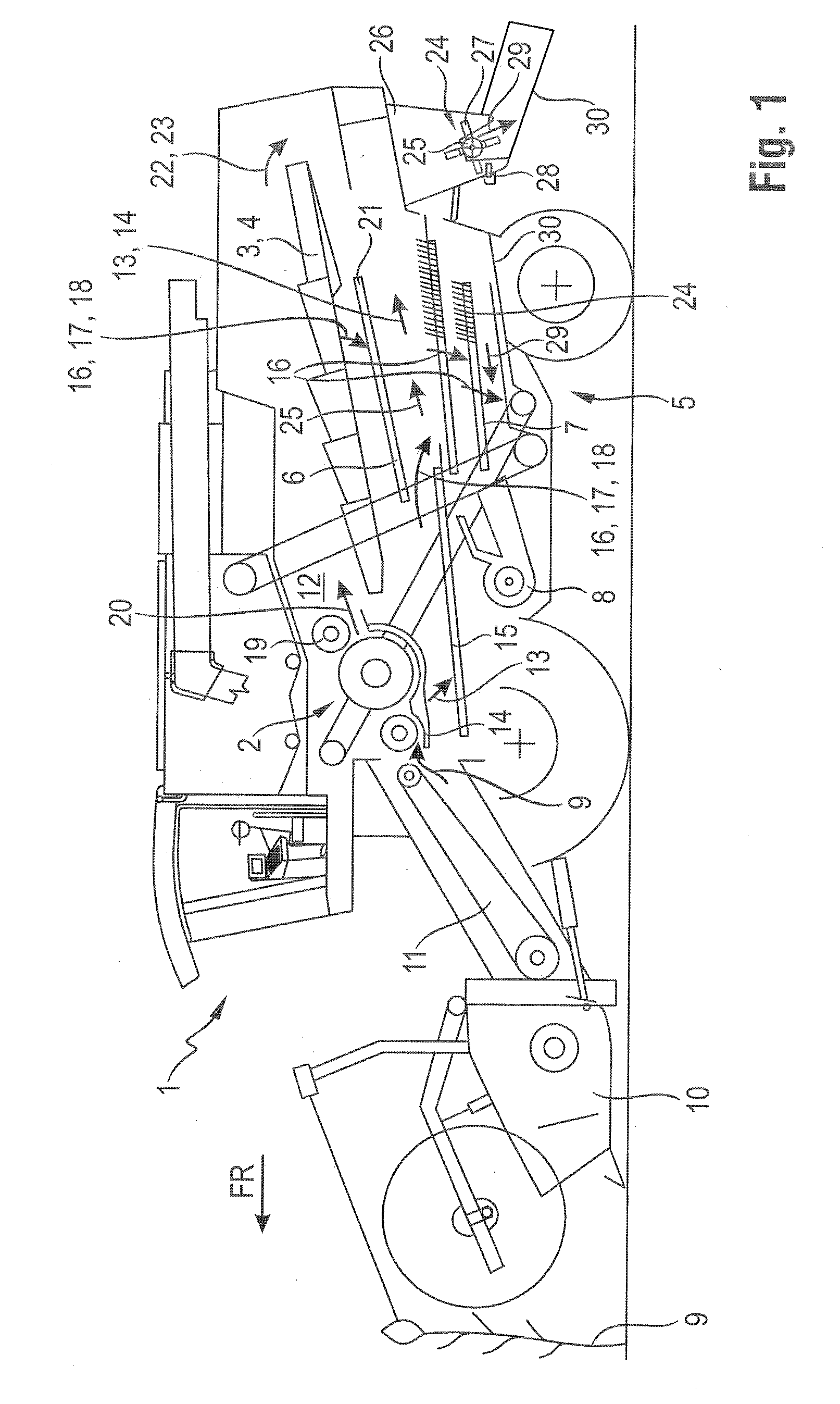

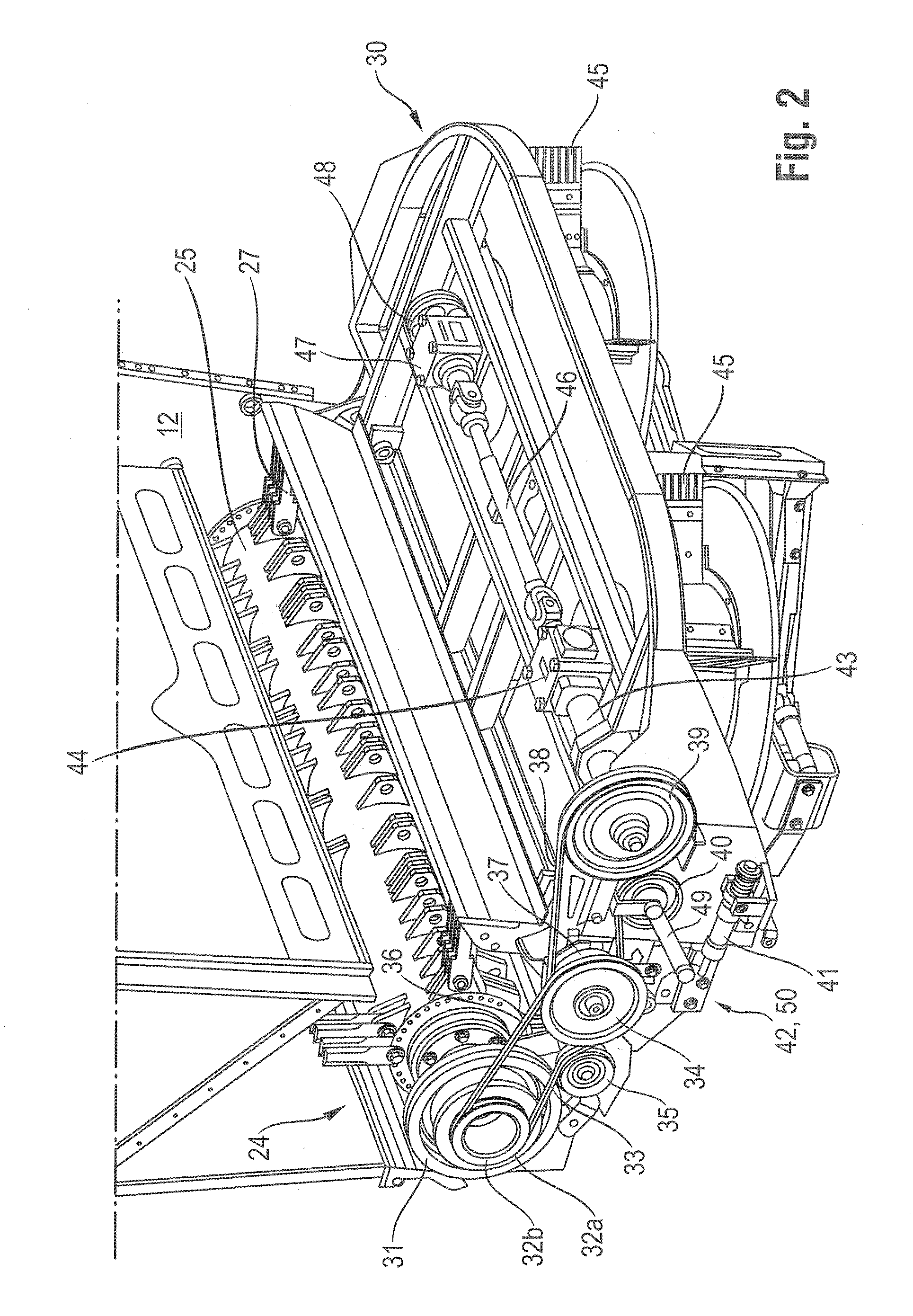

Flexible draper belt drive for an agricultural harvesting machine

ActiveUS20120042617A1Alleviate diagonal stressReduce stressMowersAgricultural engineeringAgricultural science

An agricultural harvesting machine including a flexible cutterbar and associated draper belts for carrying cut agricultural material to a center location. The belts are guided by a drive rollers and idler rollers. The idler roller for each belt is pivotable about an axis generally at 90 degrees to the axis of the belt and the drive roller for each belt is translatable axially to minimize diagonal stresses caused by flexing of the elongated endless belt.

Owner:DEERE & CO

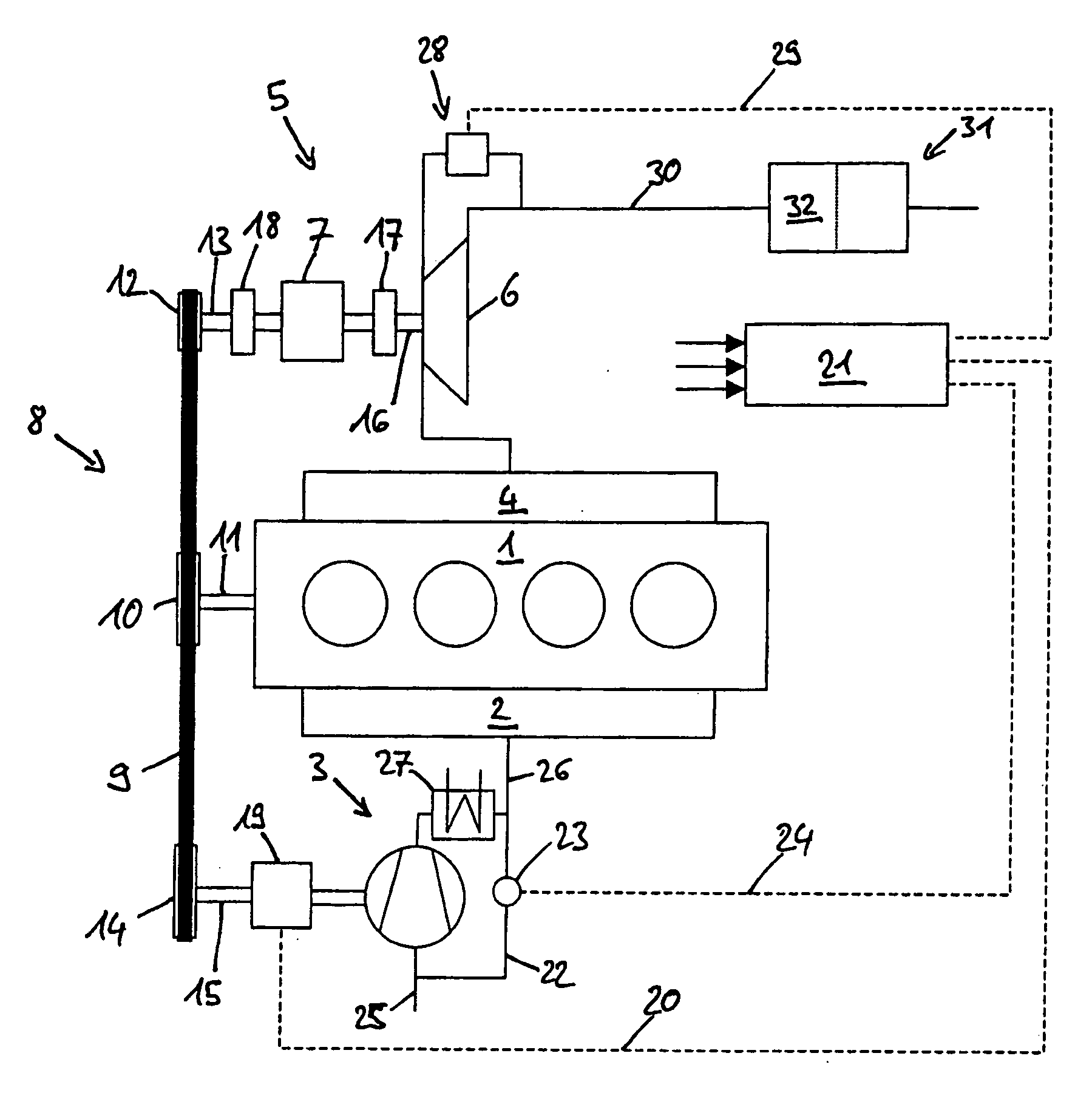

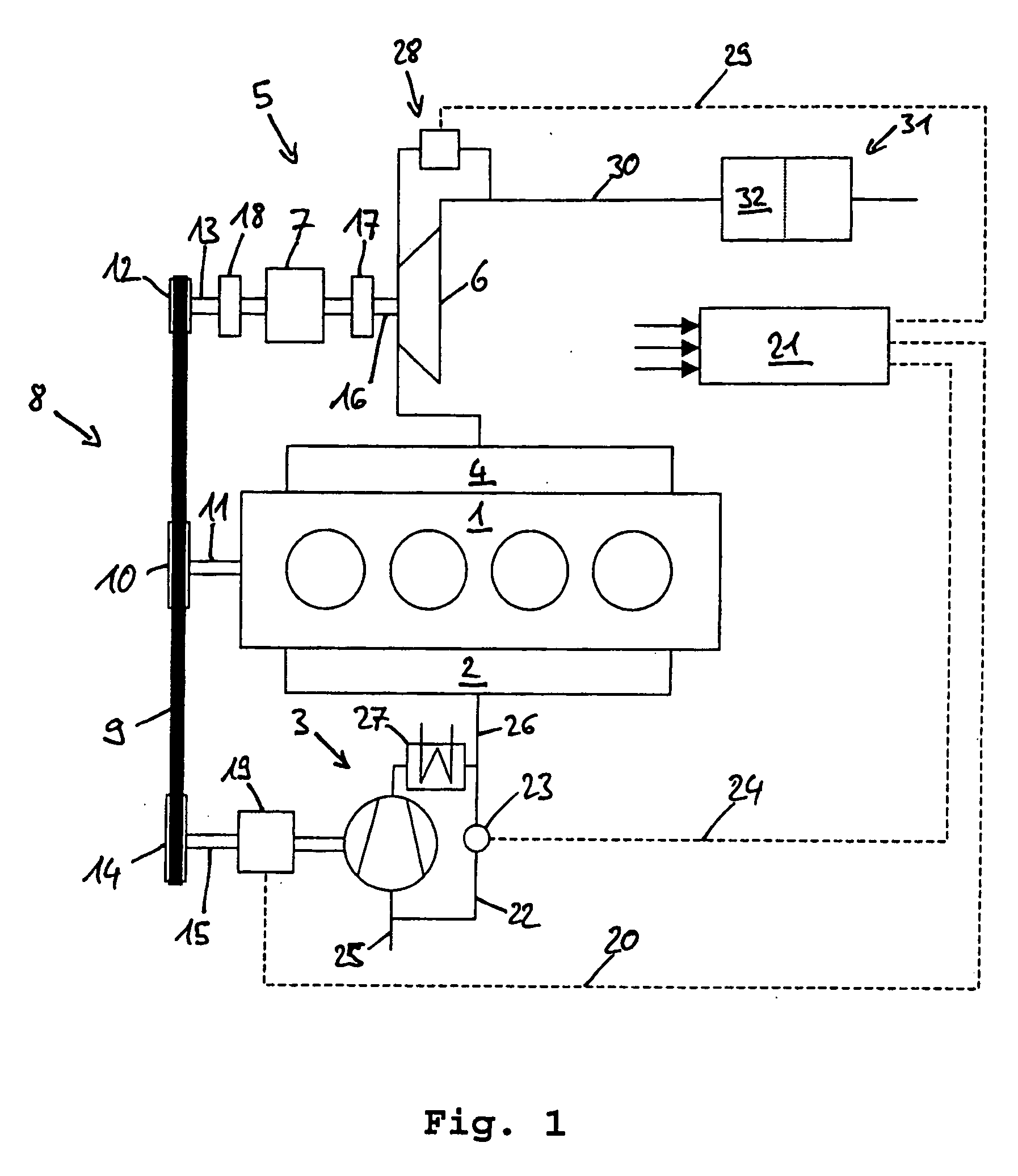

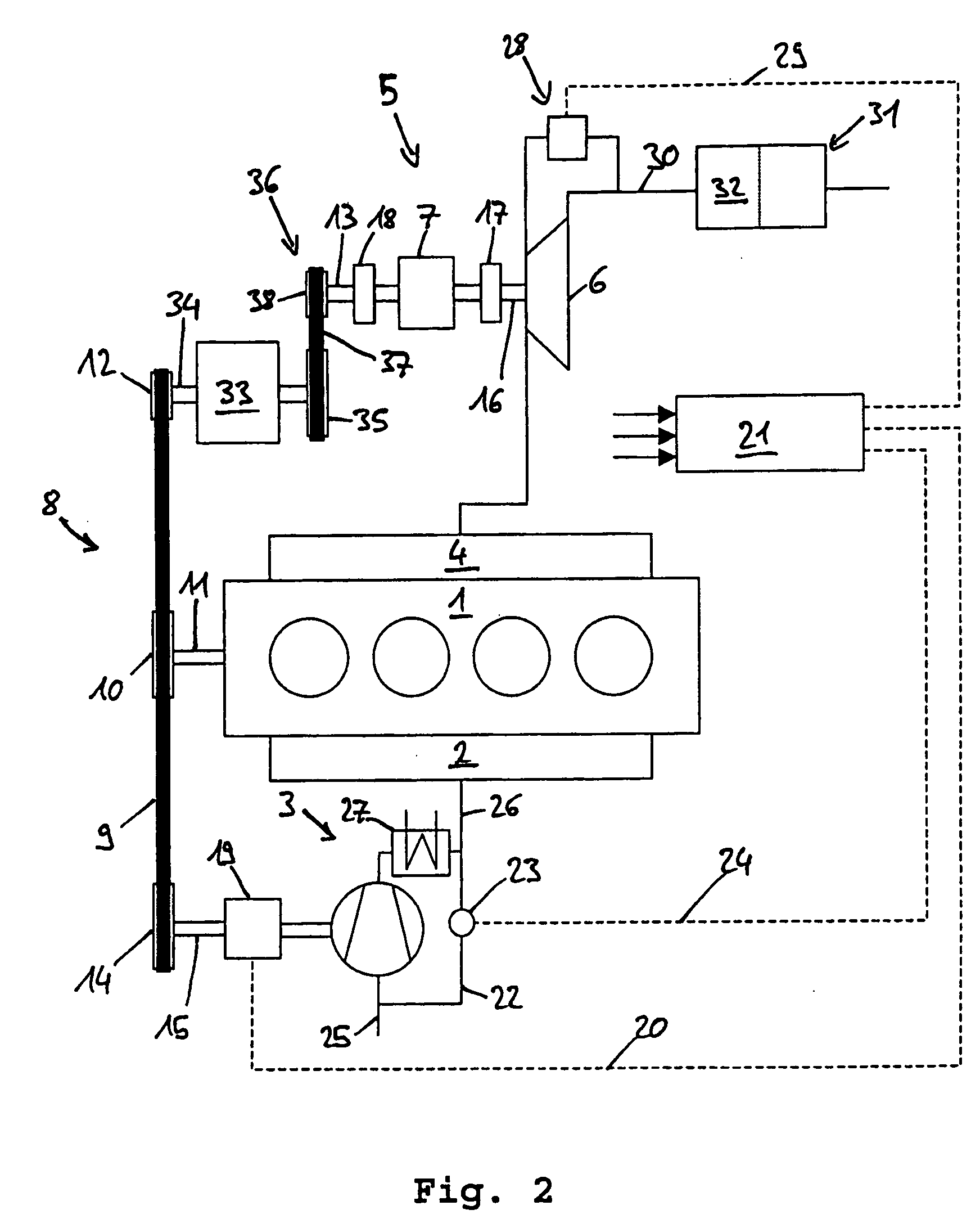

Internal combustion engine comprising a mechanical charger and a turbo-compound

InactiveUS20060254565A1Heating fastLower exhaust gas temperatureInternal combustion piston enginesSteam accumulatorsGear driveDrive shaft

In an internal combustion engine comprising a mechanical charger in the form of a positive displacement compressor connected to the engine intake duct for supplying compressed air to the engine and a turbo-compound including an exhaust gas turbine connected to the engine exhaust duct for converting energy remaining in the exhaust gas to power, the exhaust gas turbine being connected to the engine via a reduction gear drive, the mechanical charger and the turbo-compound are coupled to the engine by a common belt drive including a first belt pulley mounted on the crankshaft of the engine, a second belt pulley mounted on the shaft of the reduction gear drive, and a third belt pulley mounted on the shaft of the mechanical charger.

Owner:DAIMLER AG

Topper and shredder

An agricultural implement attached to a farm tractor by a three point hitch is used to cut the top of mature cotton stalks, or shred harvested crops or mow turn rows. Knives are mounted on the bottom of vertical shafts which are rotated by belt driven pulleys. The pulleys are driven from a right angle gear box which is driven from the power take off of the tractor. The knives are staggered along either side of a beam traverse to the direction of travel, so that the knives cannot strike other knives as they mow over-lapping swaths.

Owner:HEARD MARTIN PERRY

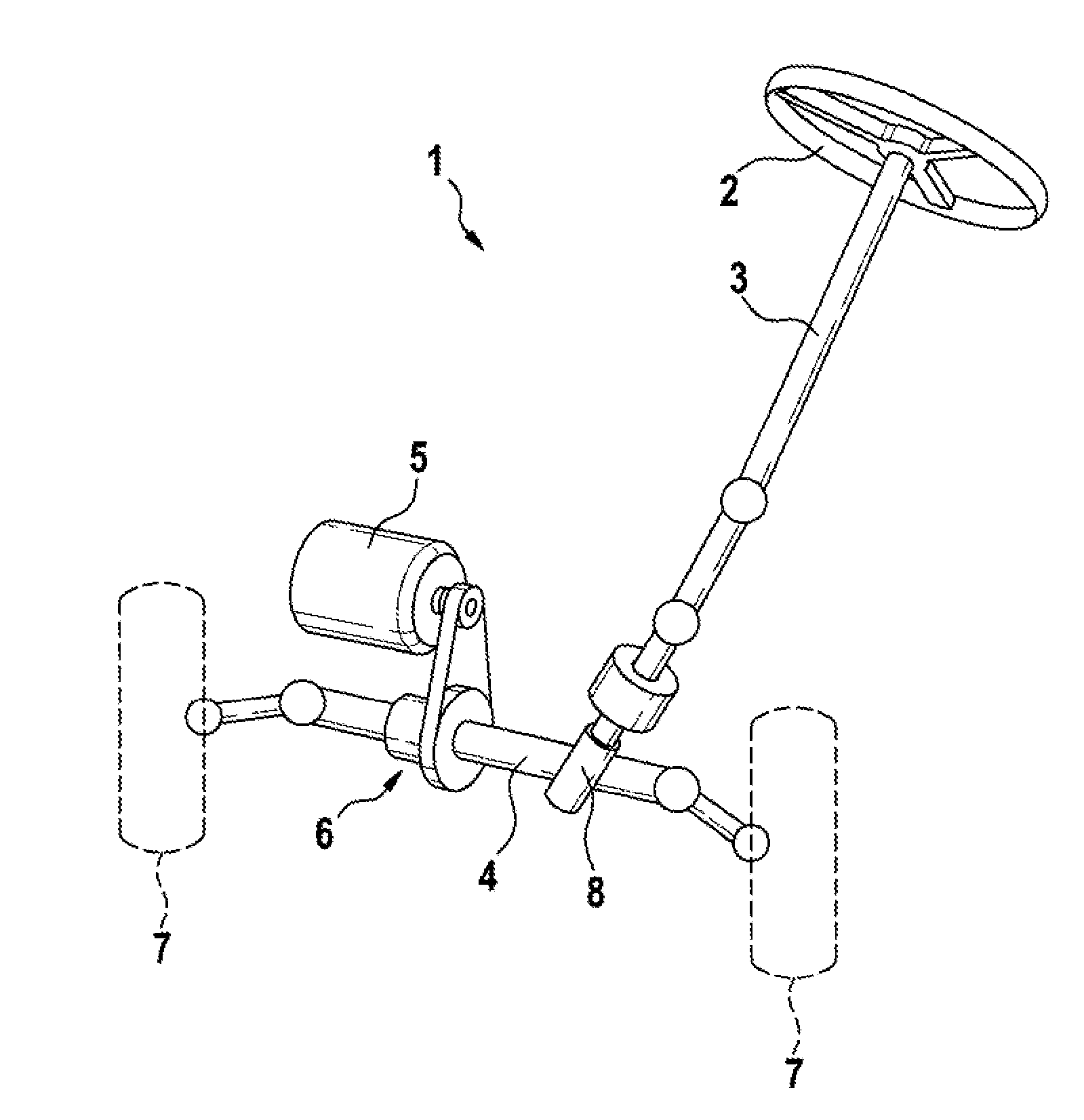

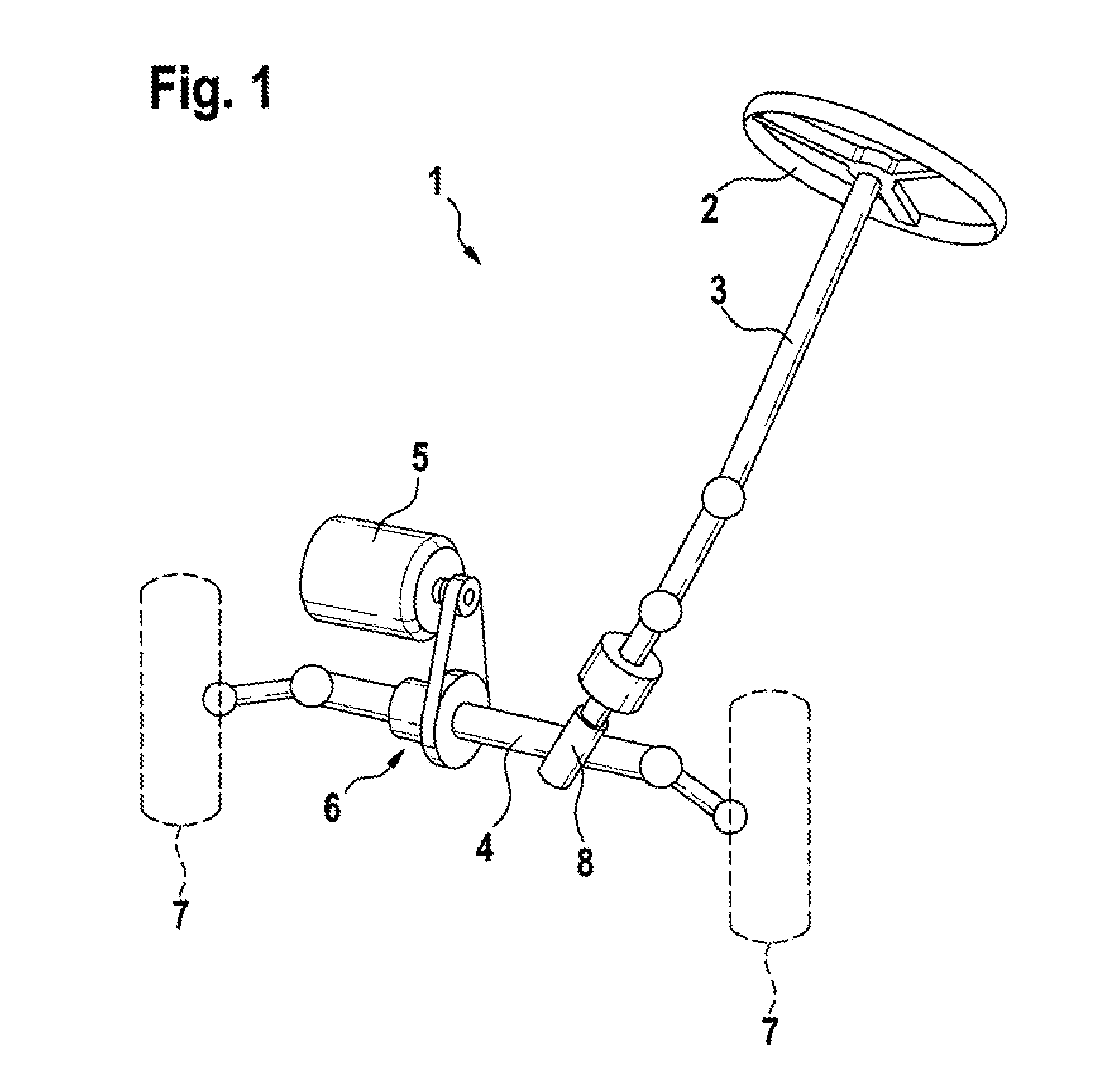

Steering drive for a motor vehicle

ActiveUS20110290581A1Reduce eddy current lossReduces detent torqueMagnetic circuitElectrical steeringSteering wheelSteering column

A steering drive for a motor vehicle comprising a steering wheel, a steering column, on which the steering wheel is disposed, a connecting rod, which interacts with the steering column to deflect the wheels of the motor vehicle, an electric motor, which is provided for boosting the steering thrust, as well as a belt drive, the electric motor interacting with the connecting rod via the belt drive. Said electric motor comprises a stator having twelve stator teeth as well as a rotor having ten rotor poles, the rotor poles being spaced apart from each other by an air gap and embodied as sinus poles.

Owner:ROBERT BOSCH GMBH

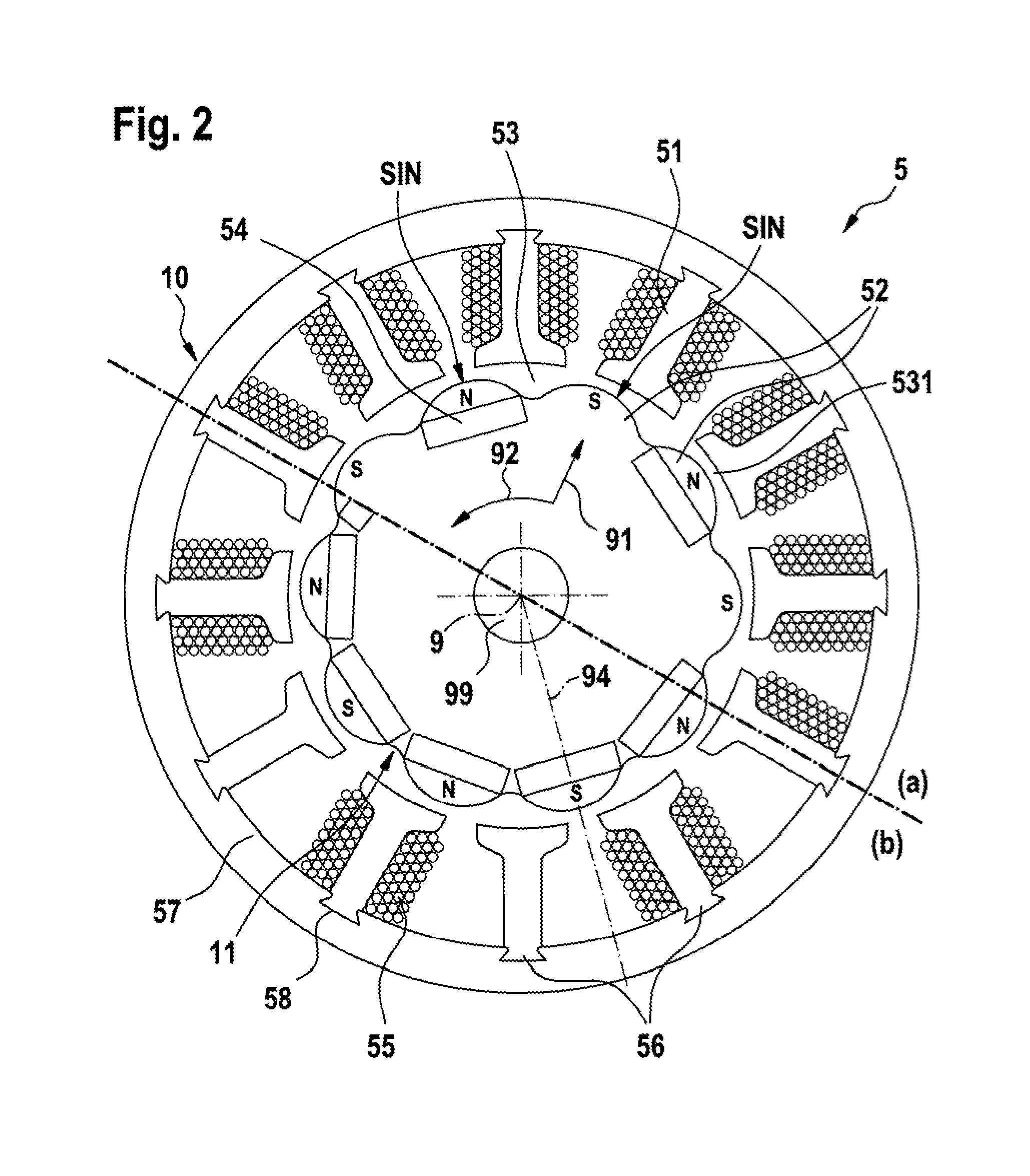

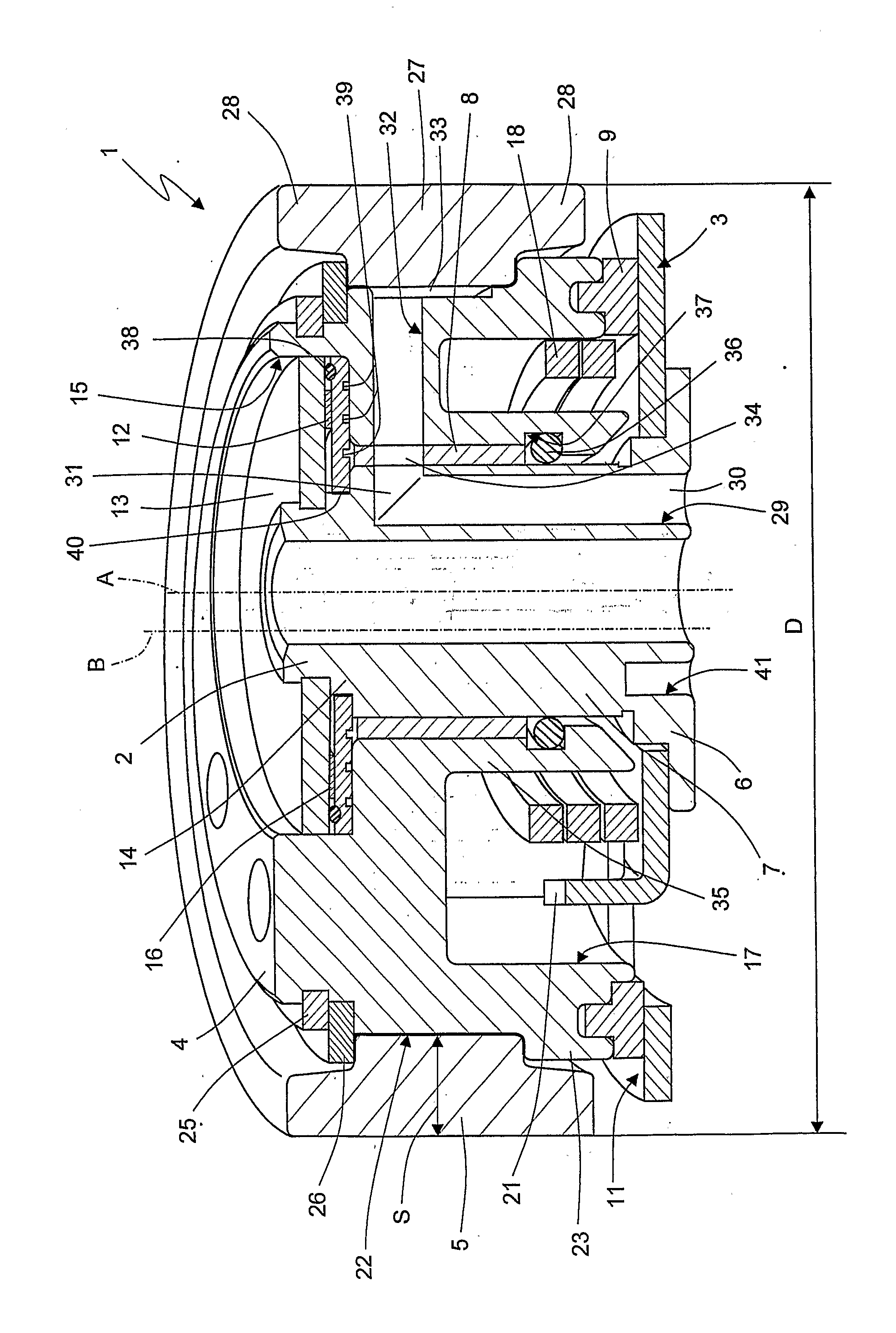

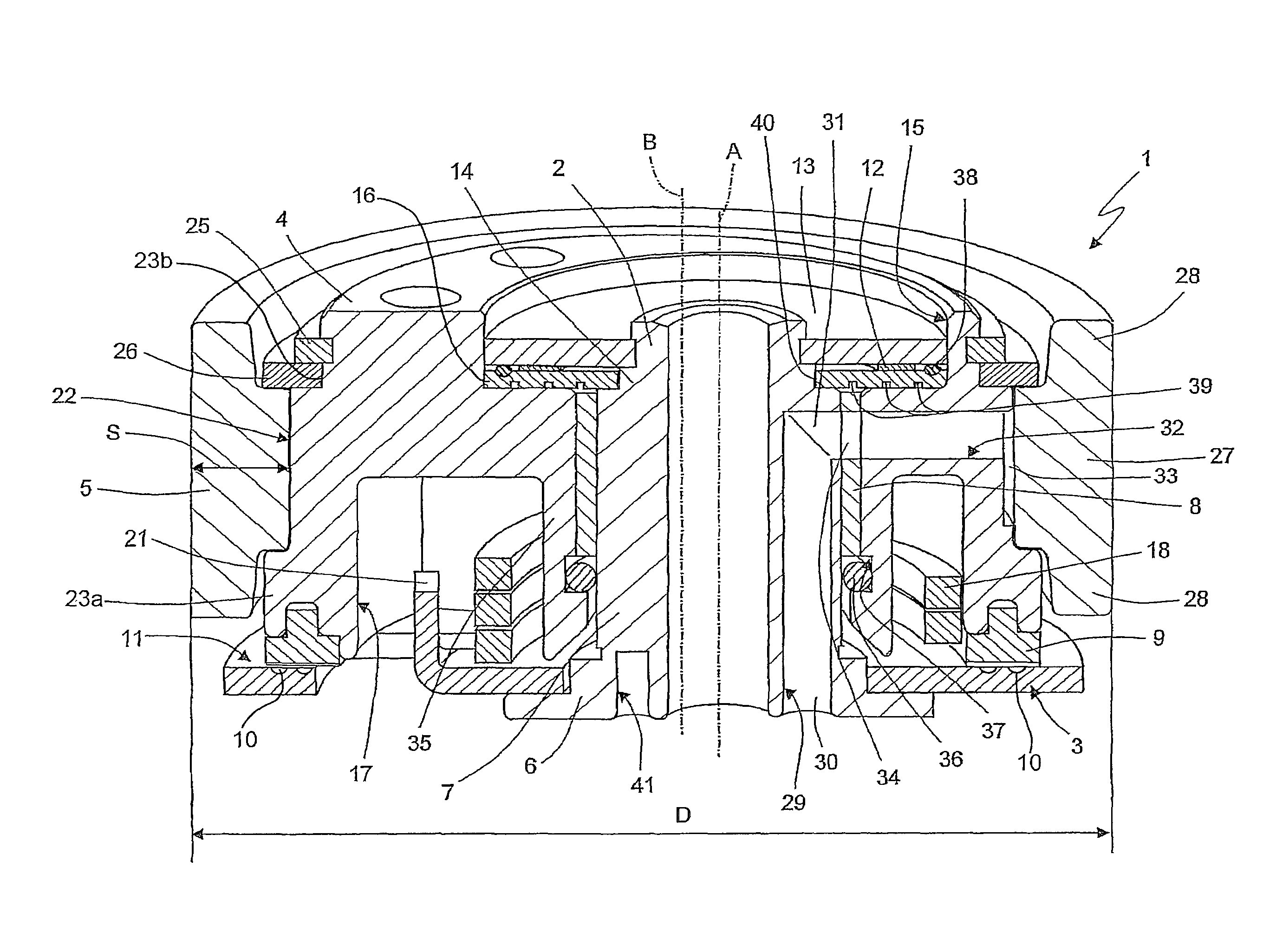

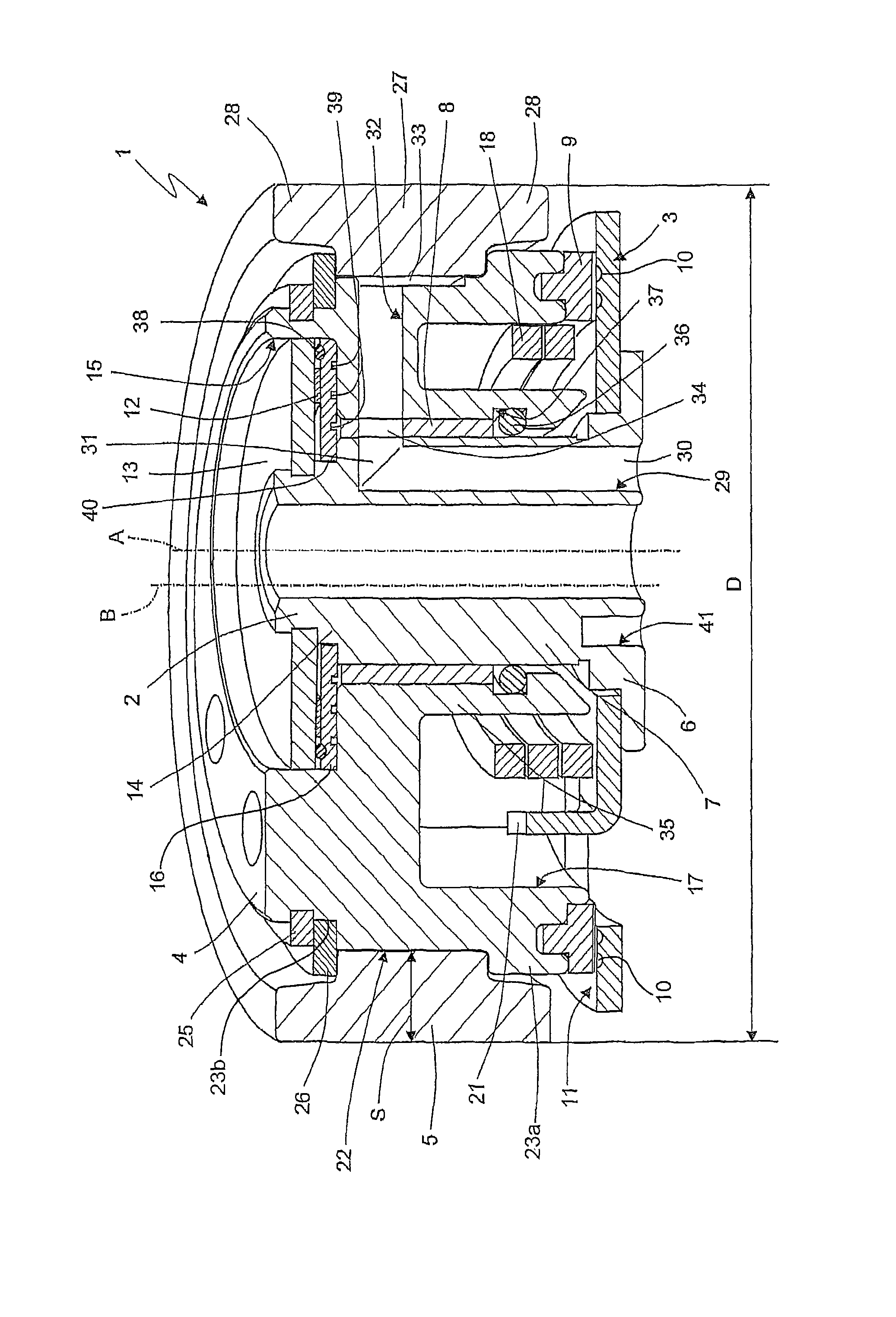

Pulley tensioner for an oil wet belt drive

A tensioner (1) for a belt drive comprises a base(2, 3) defining an axis (A), a mobile element (4) hinged onto axis (A) and defining a guiding surface (22), an elastic helical element (18) having a square or rectangular cross section for actuating the mobile element (4) and an idle pulley (5) surrounding the guiding surface (22). The tensioner (1) further comprises a journal bearing (4, 29, 32, 33) for supporting the pulley (5) on the guiding surface (22).

Owner:DAYCO EURO

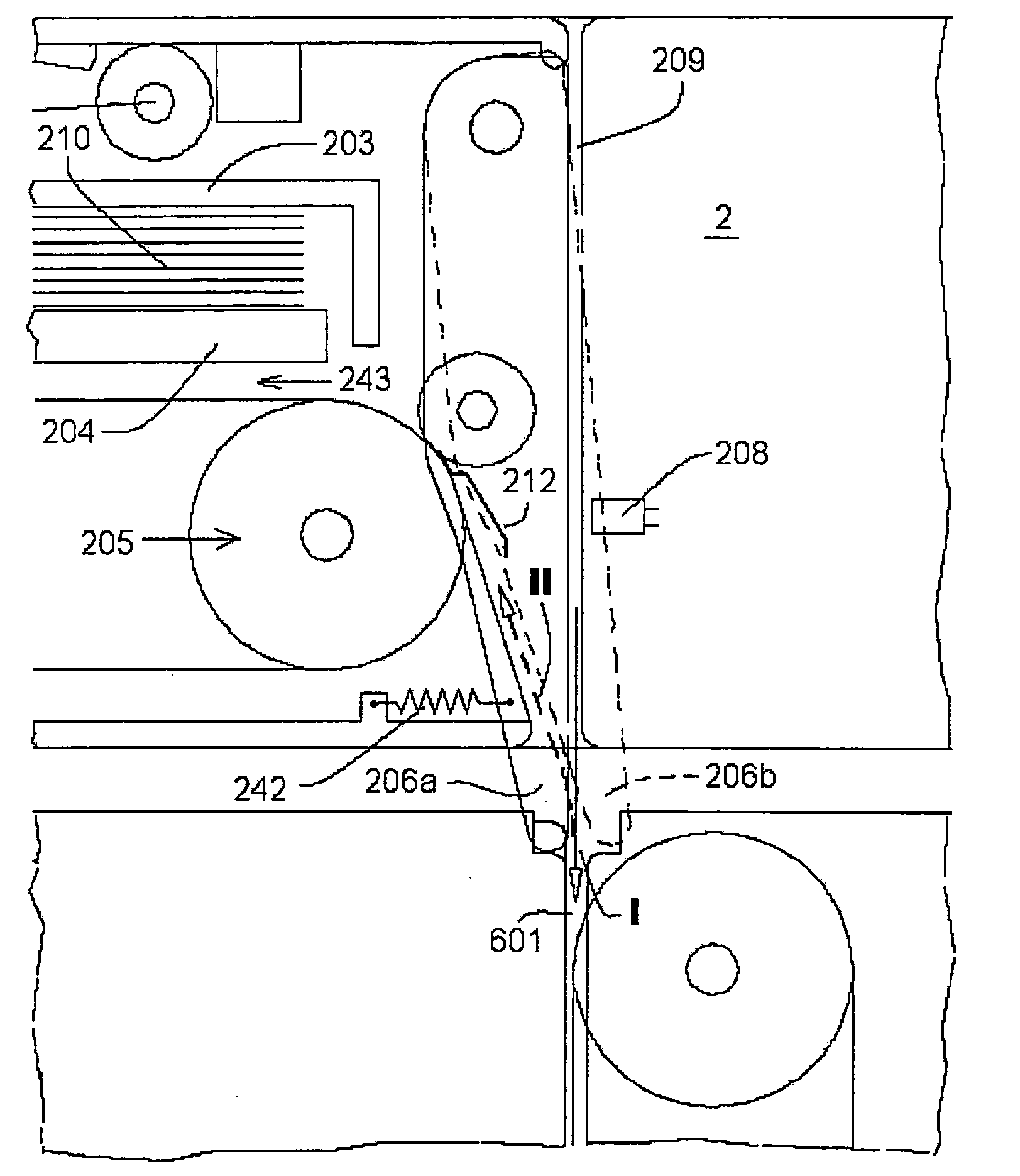

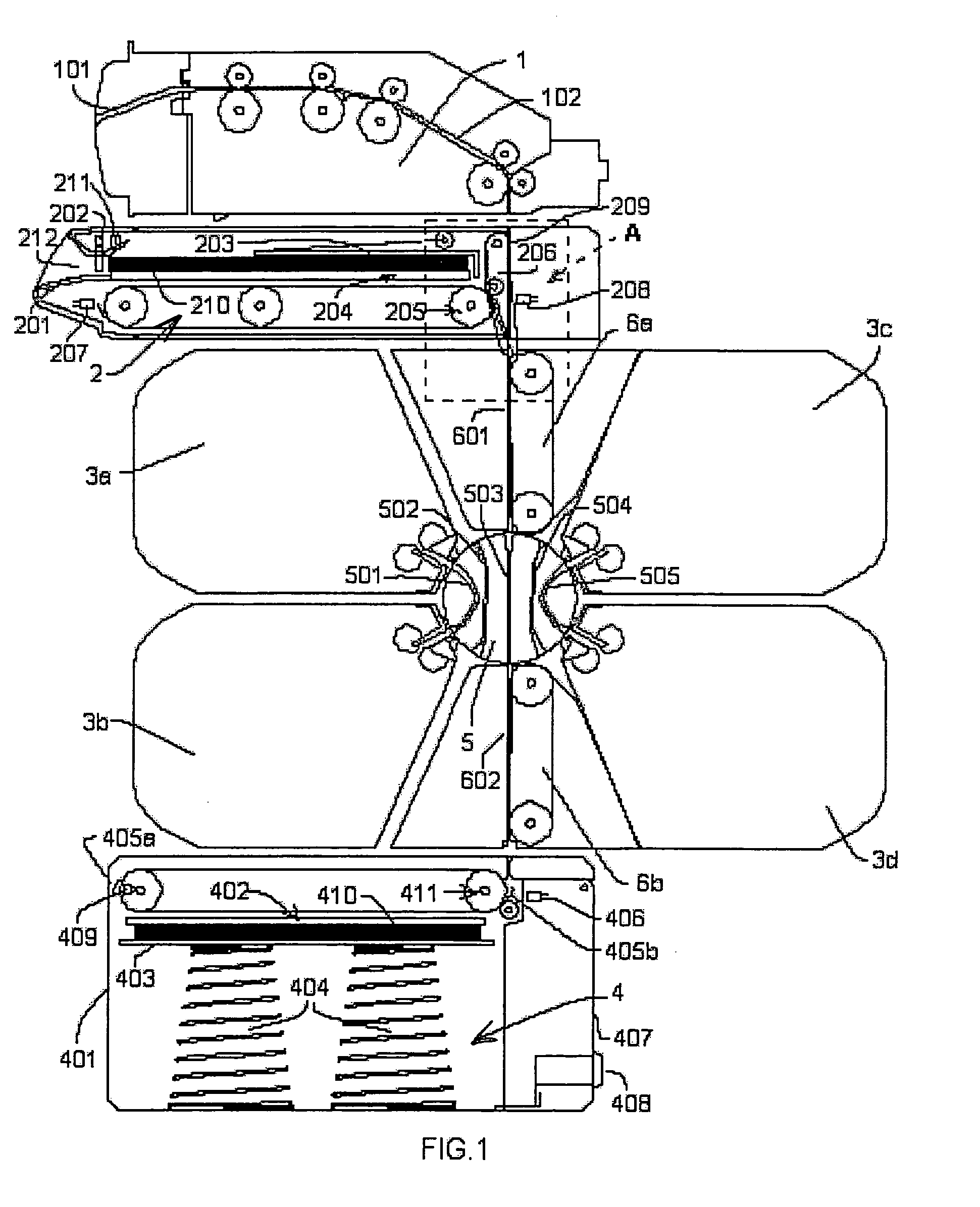

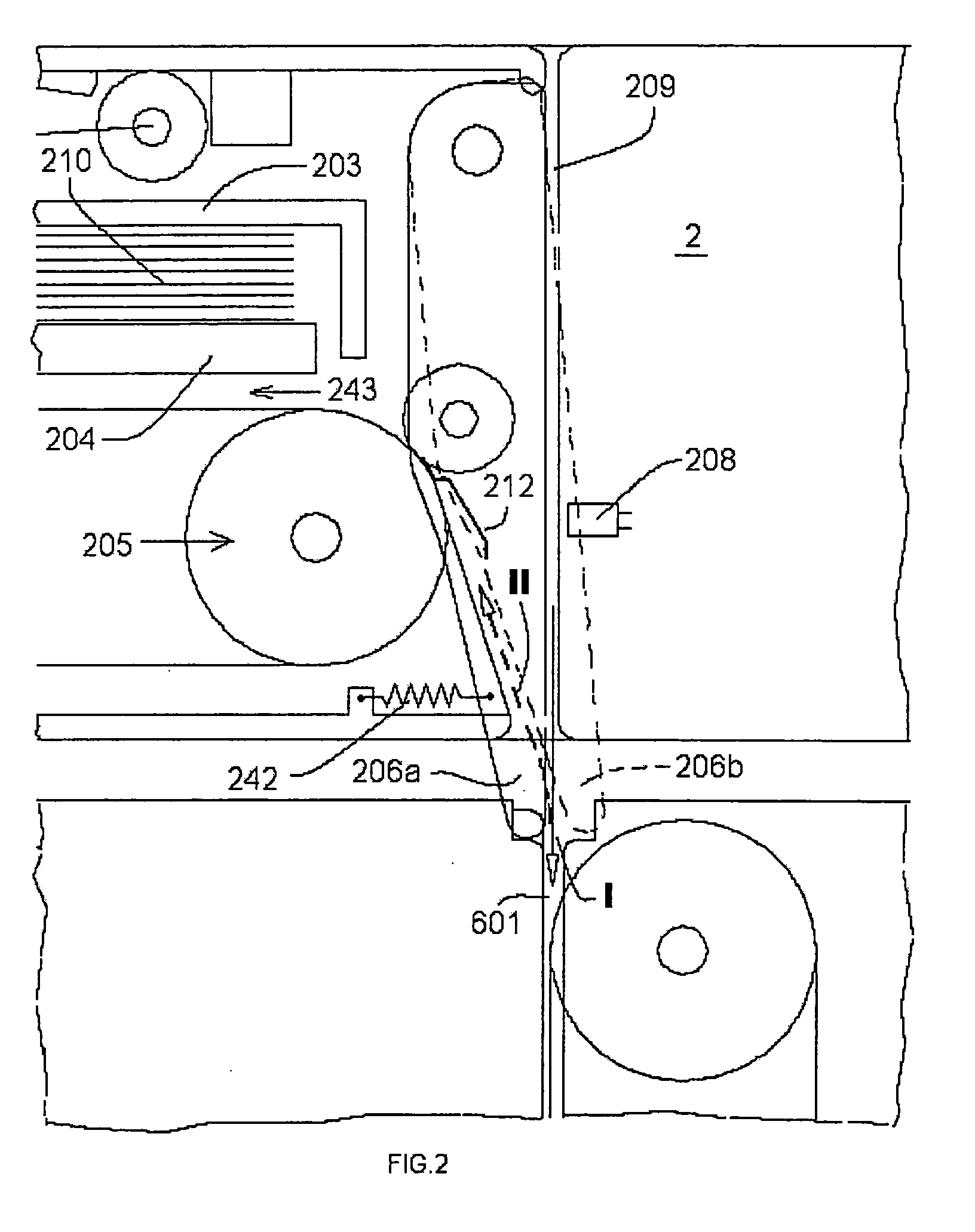

Energy-efficient compact device for dispensing and accumulating banknotes

ActiveUS20090171499A1Reliable captureReduce impactPaper-money testing devicesDigital data processing detailsMicrocontrollerLeading edge

The invention relates to an apparatus for accumulating and dispensing bank notes of various length, width and condition without appreciable deformation of current note and displacement of previously stacked notes, preferably having a device connected in series to verify genuineness of bank notes inserted. Apparatus comprises a lockable removable box with a note transfer, stacker and dispensing mechanism. A note transfer mechanism comprises a belt drive with at least one spring claw for gripping note leading edge. Stacker mechanism comprises two reversible frames with longitudinal revolving panels on their side segments. Dispensing mechanism comprises spring loaded roll pallet with outlet gate. A note is pulled into apparatus by means of gripper under the belt translation. The notes stack or bundle is formed due to reversible motion of frames with corresponding side panels revolving. At the dispenser embodiment the bundle of notes slides out due to cooperative motion of driving belt and roll pallet. Belt and frames drivers are operated by microcontroller. Proposed apparatus is characterized by a simple and therefore economical compact flat construction, multi-purposing using, low energy consumption and high rapidity of action.

Owner:CRANE CANADA

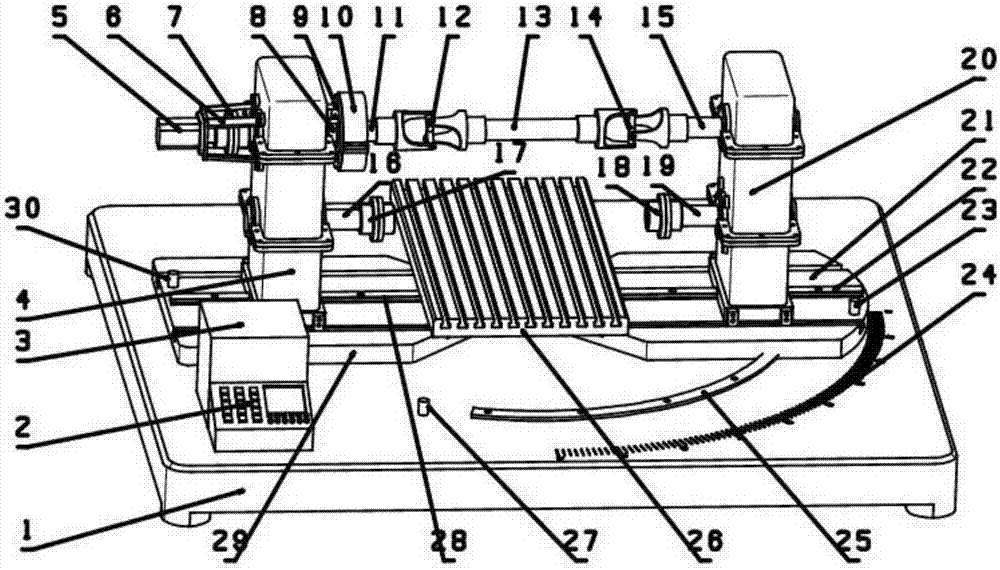

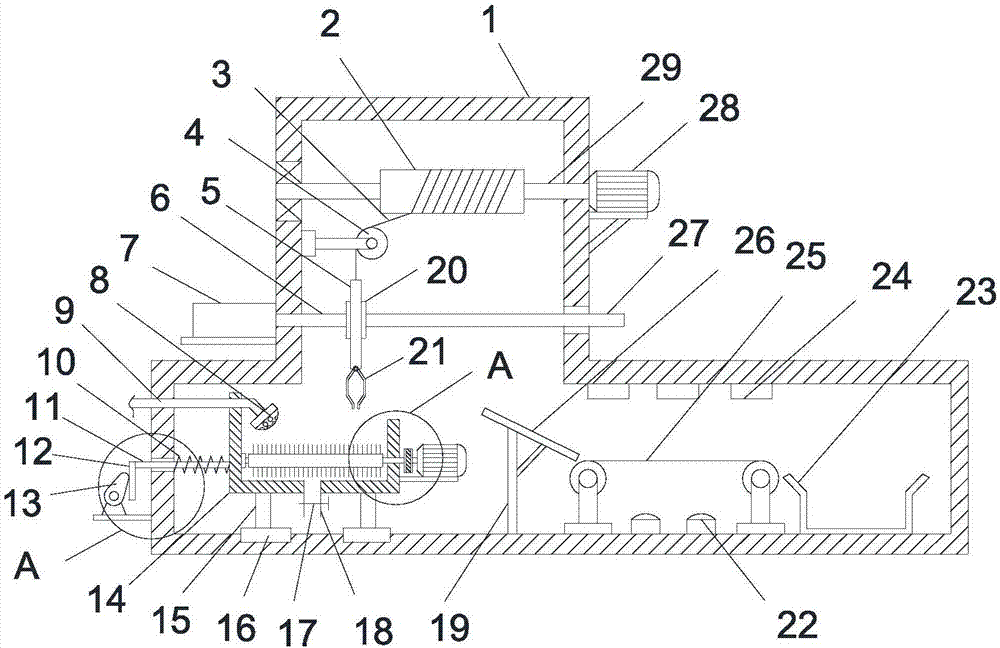

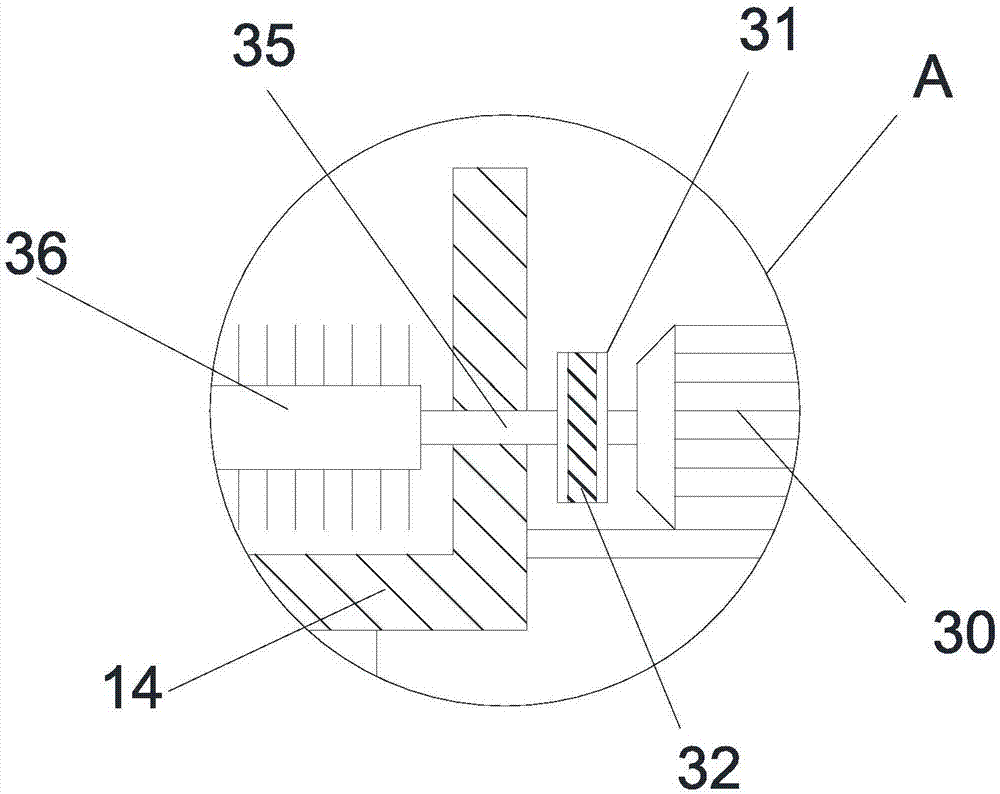

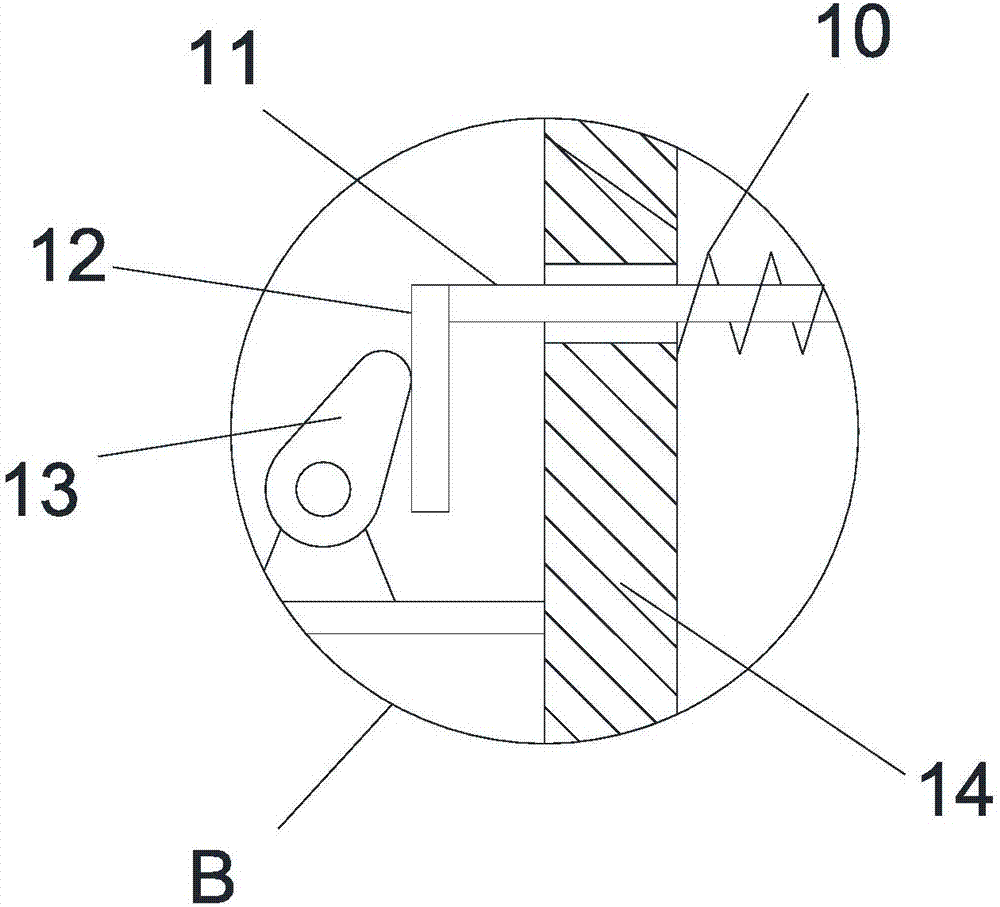

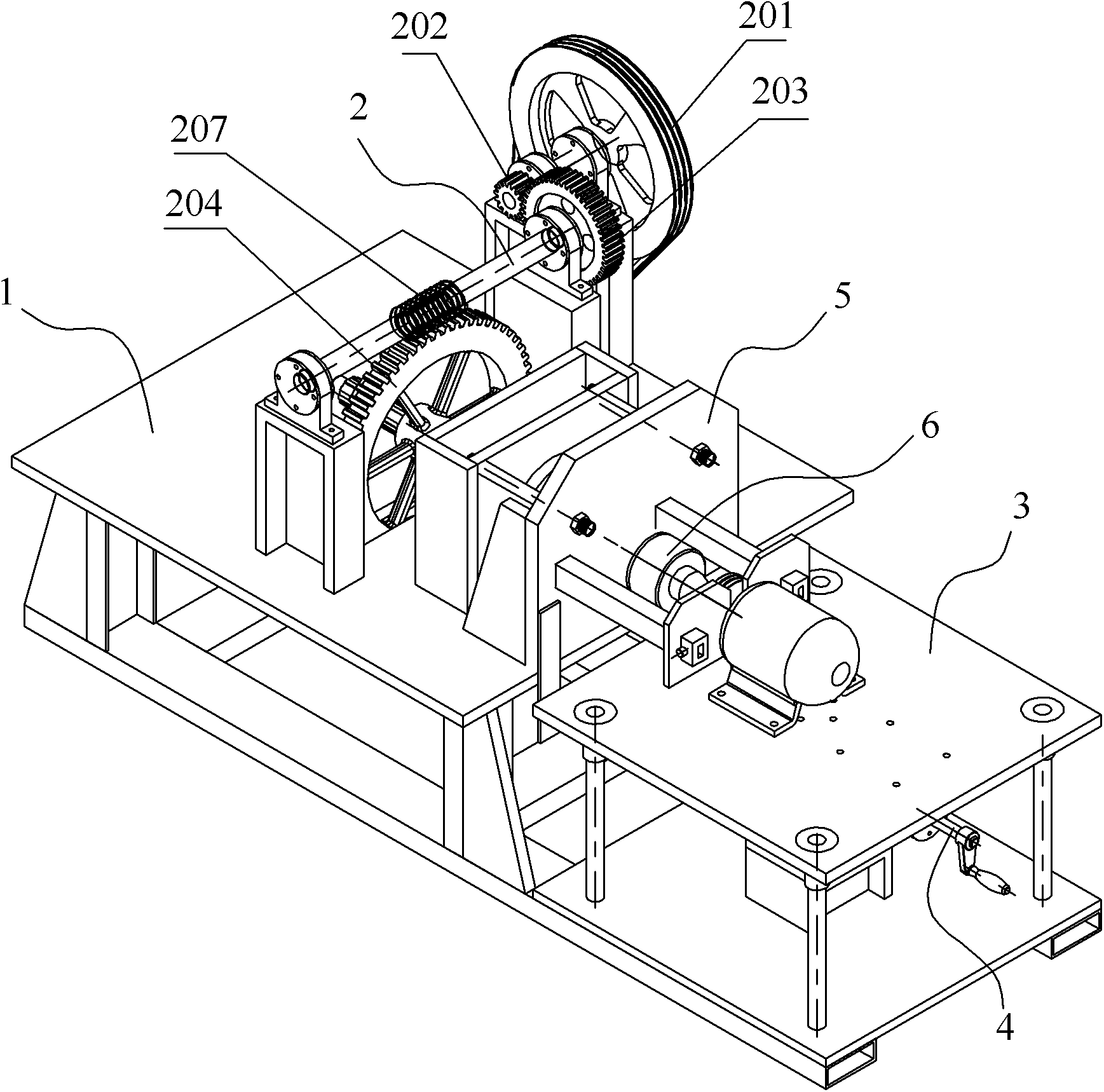

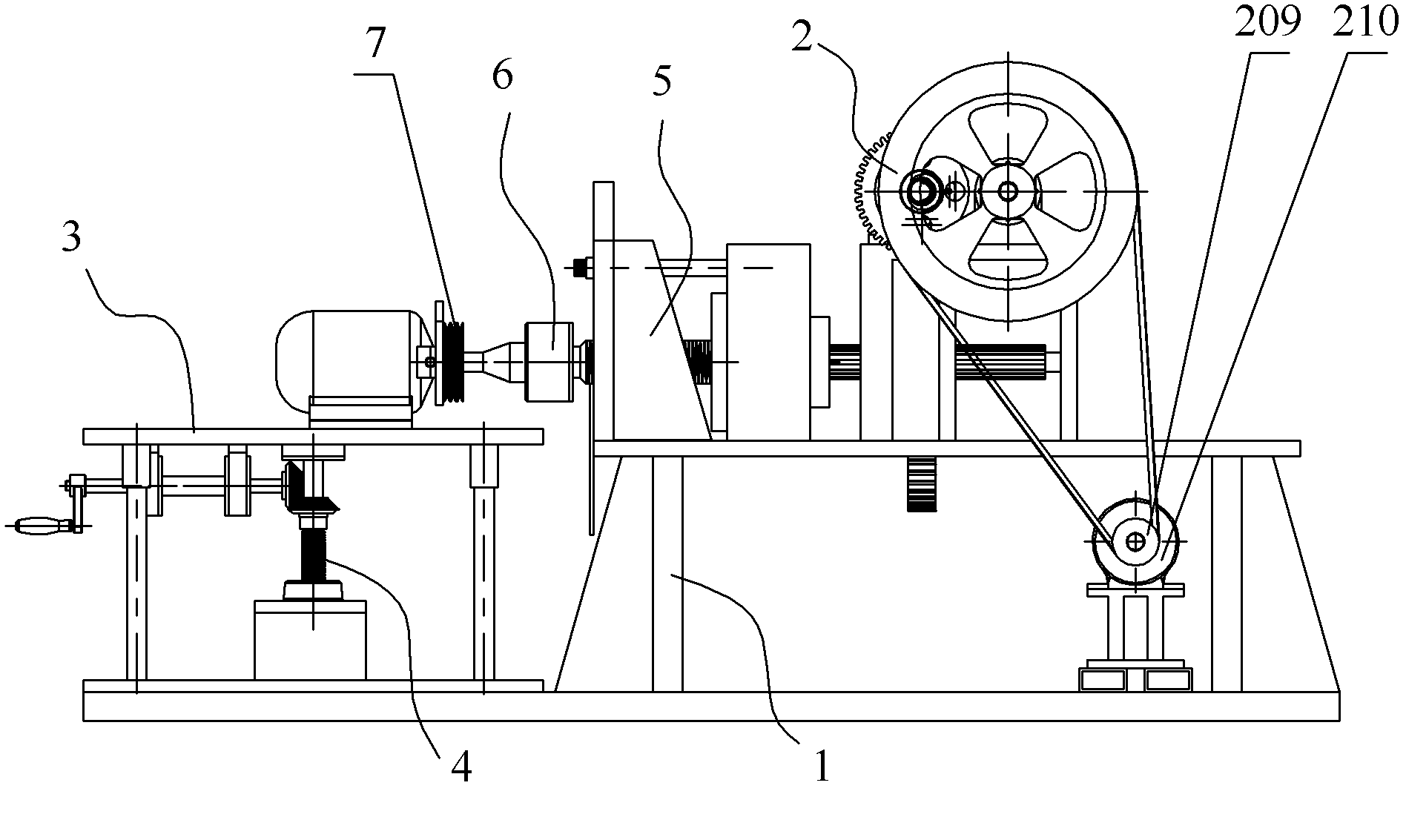

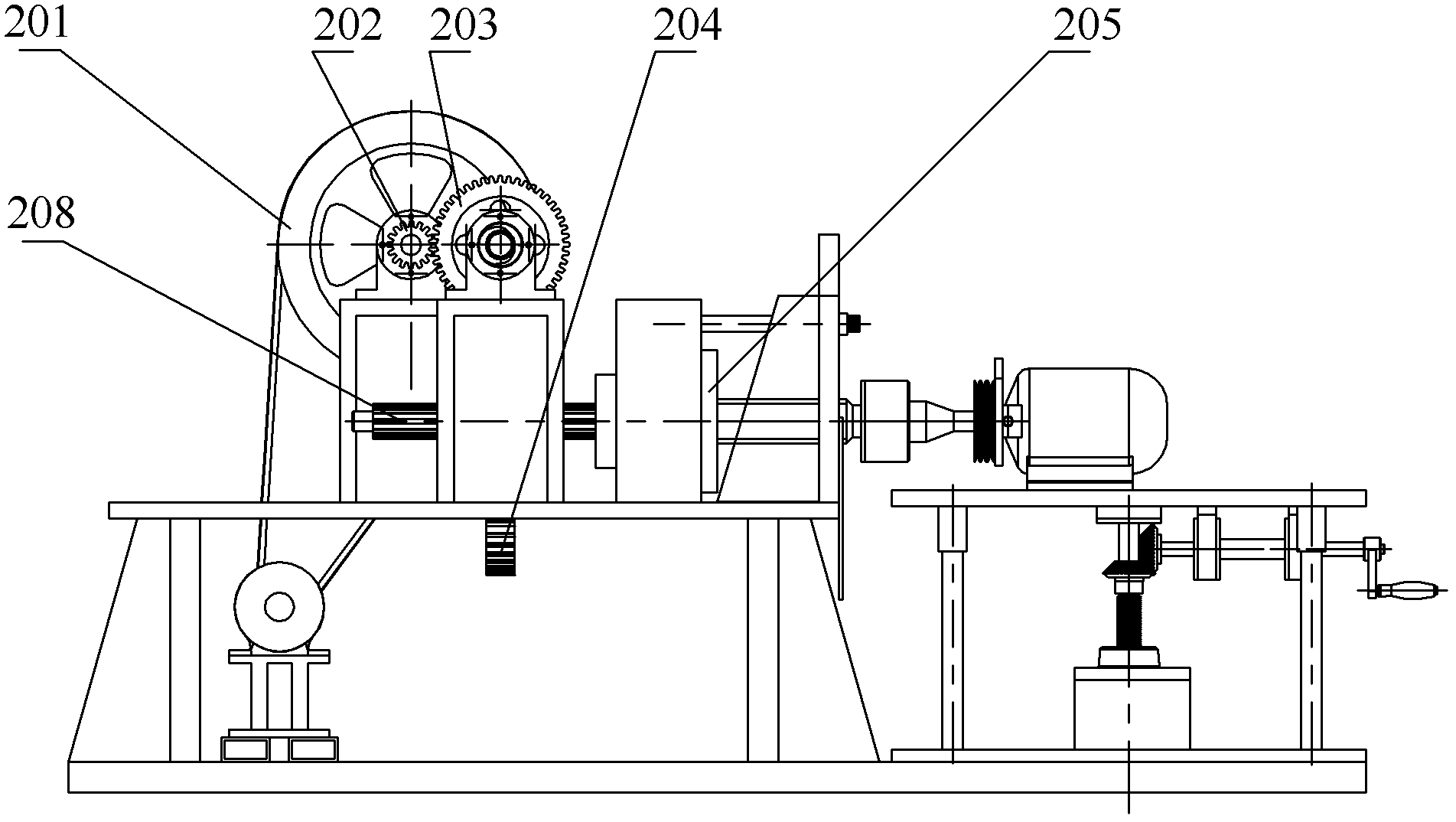

Modular closed-type multifunctional mechanical drive testing stand

PendingCN107421735ARealize data detectionRestricted use efficiencyMachine gearing/transmission testingCouplingElectric machine

The invention discloses a modular closed-type multifunctional mechanical drive testing stand. The modular closed-type multifunctional mechanical drive testing stand comprises a base, an operation panel, a processor, vertical type decelerators, a servo motor, a motor supporting frame, a motor coupling, a gear shaft system, a loader mounting rack, a loader, a connection shaft system, universal couplings, a connection optical axis, a coupling set, a rotating disc, linear slide rails, a calibrated scale, an annular guide rail, an installing plate, stopping blocks, a fixed disc and a test module, and the test module comprises a coupling test module, a parallel-axis cylindrical gear test module, a concurrent-axis bevel gear module, and a belt drive test module which can satisfy test requirements of the couplings, parallel-axis spur gears, concurrent-axis bevel gears, and belt drive. According to the testing stand, the whole transmission system forms a mechanical power flow closed loop, the servo motor merely needs to guarantee the loss power, and the power consumption of the servo motor can be greatly reduced.

Owner:QINGDAO UNIV OF SCI & TECH

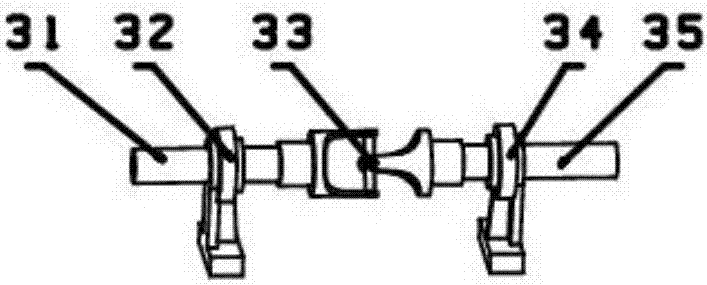

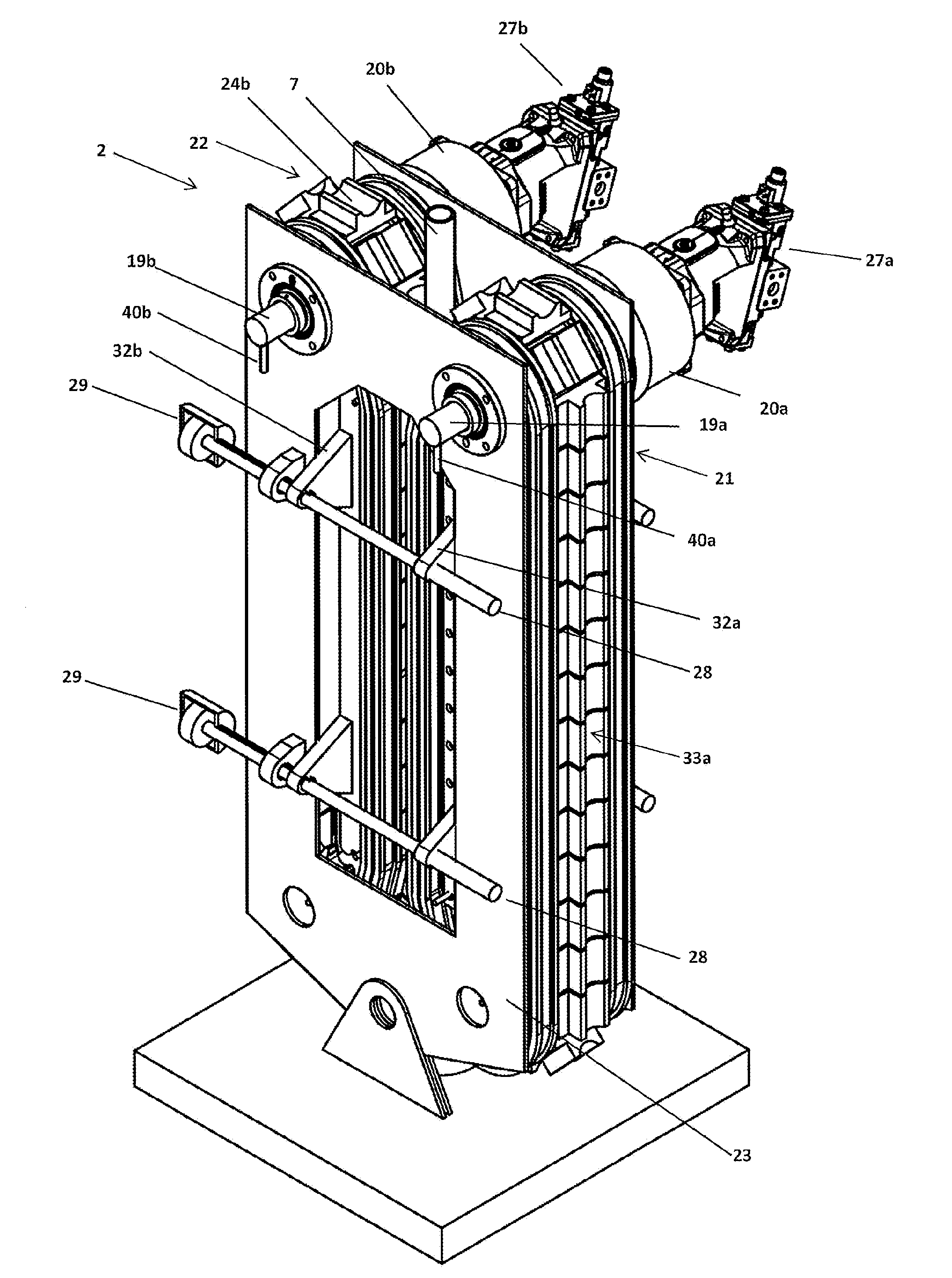

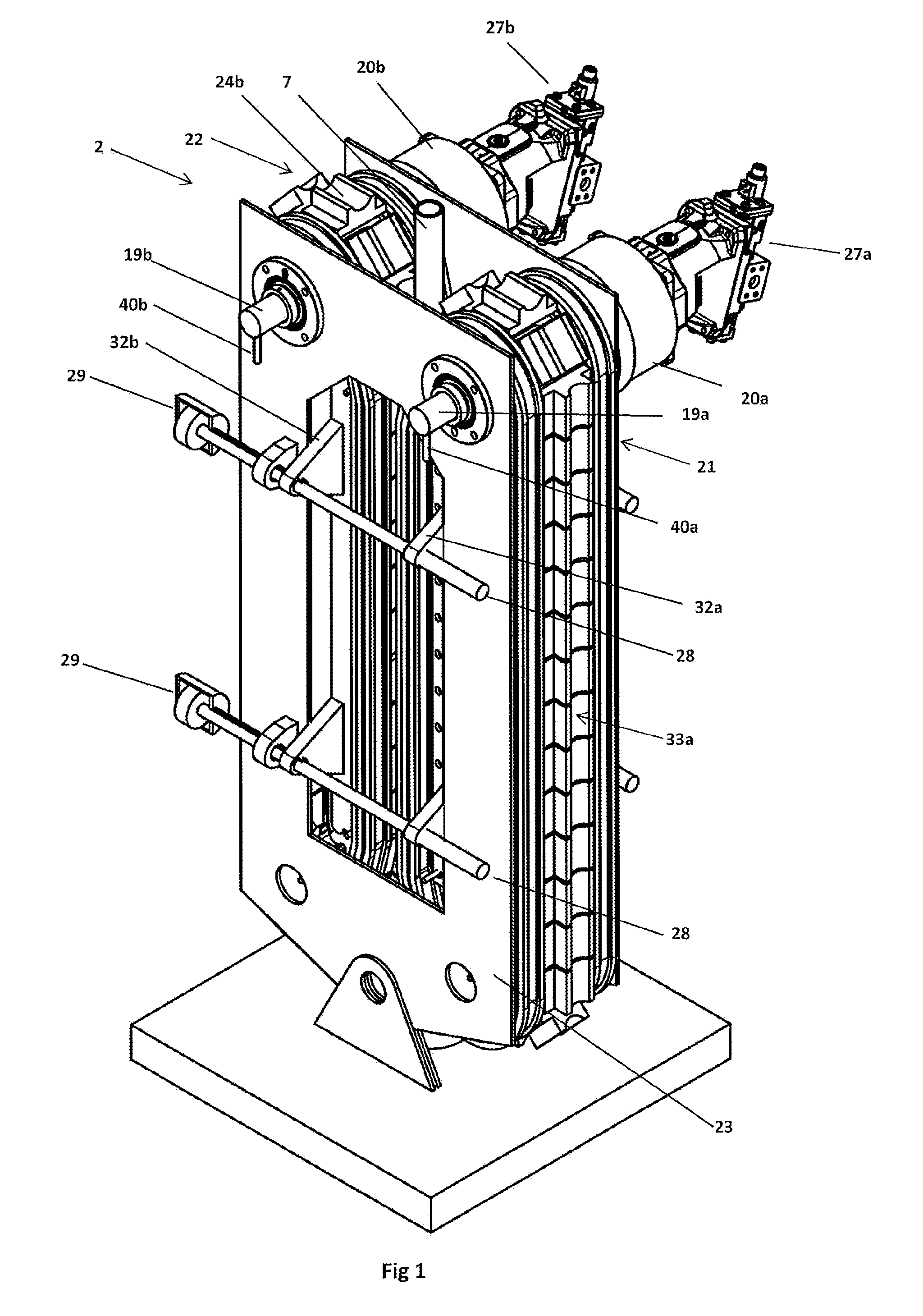

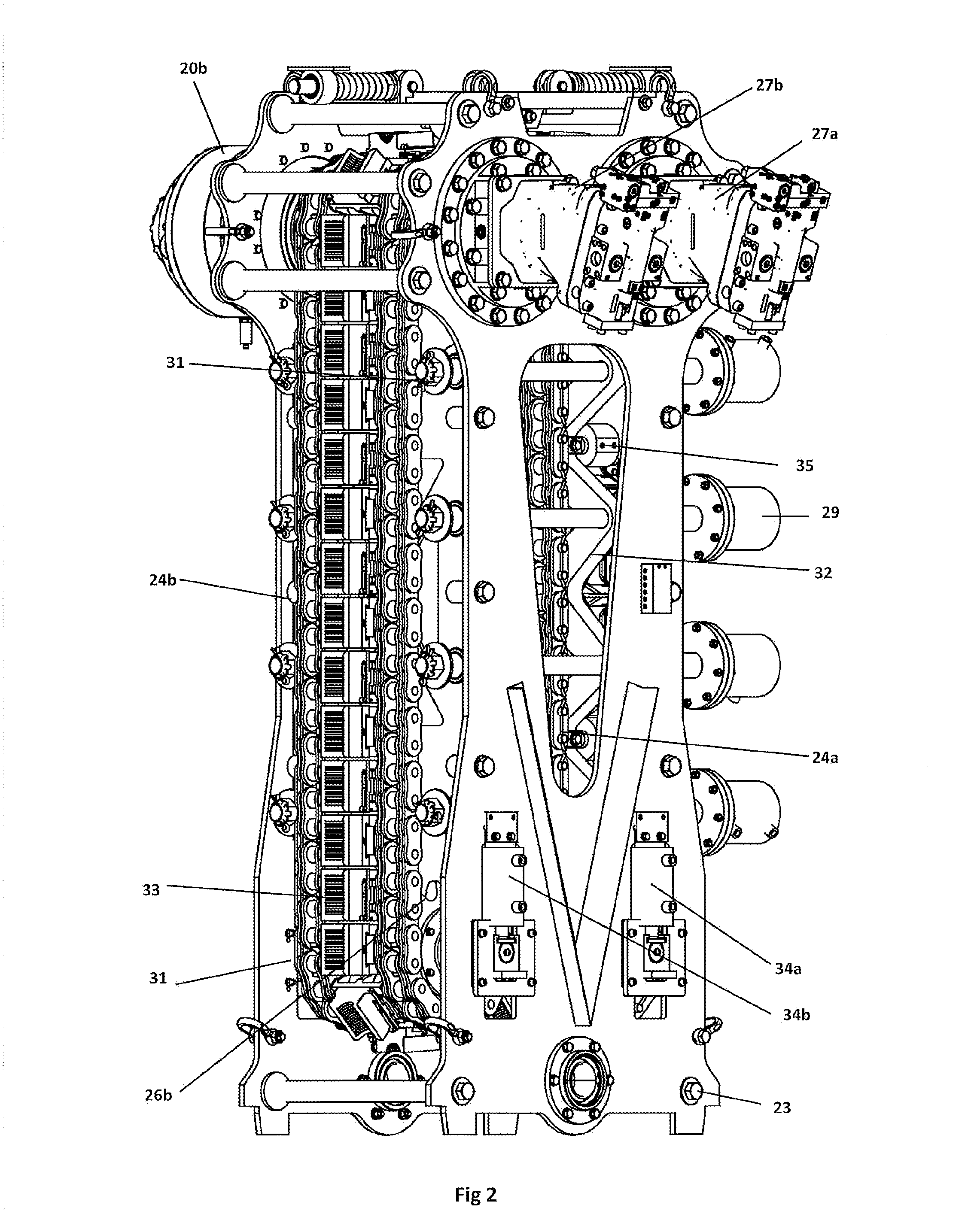

Injector head chain synchronization device

The invention relates to an injector head (2) comprising; a pair of oppositely located, cooperatively movable, segmented continuous belt drive chains (21; 22), said each belt drive chain (21, 22) running over a respective pair of drive sprockets (25a, 25b) and tension sprockets (26a, 26b), wherein a tubing receiving section (7′) is defined between the belt drive chains (21, 22). The tubing receiving section (7′) having a tubing section centerline (46) extending through the center of the tubing receiving section (7′). The injector head (2) having an injector centerline (45) extending through the centerline of the injector head (2), said injector centerline (45) and said tubing section centerline (46) being substantially aligned in the longitudinal direction in an initial position, a pair of elongate counter-force members (32a, 32b) is positioned at each side of the tubing receiving section (7′). The injector head (2) has at least one actuator (35) adapted to move at least one of said elongate counter-force elongate member (32a, 32b) in order to bring the tubing section centerline (46) out of alignment with said injector centerline (45).

Owner:STIMLINE

Pulley tensioner for an oil wet belt drive

A tensioner (1) for a belt drive comprises a base(2, 3) defining an axis (A), a mobile element (4) hinged onto axis (A) and defining a guiding surface (22), an elastic helical element (18) having a square or rectangular cross section for actuating the mobile element (4) and an idle pulley (5) surrounding the guiding surface (22). The tensioner (1) further comprises a journal bearing (4, 29, 32, 33) for supporting the pulley (5) on the guiding surface (22).

Owner:DAYCO EURO

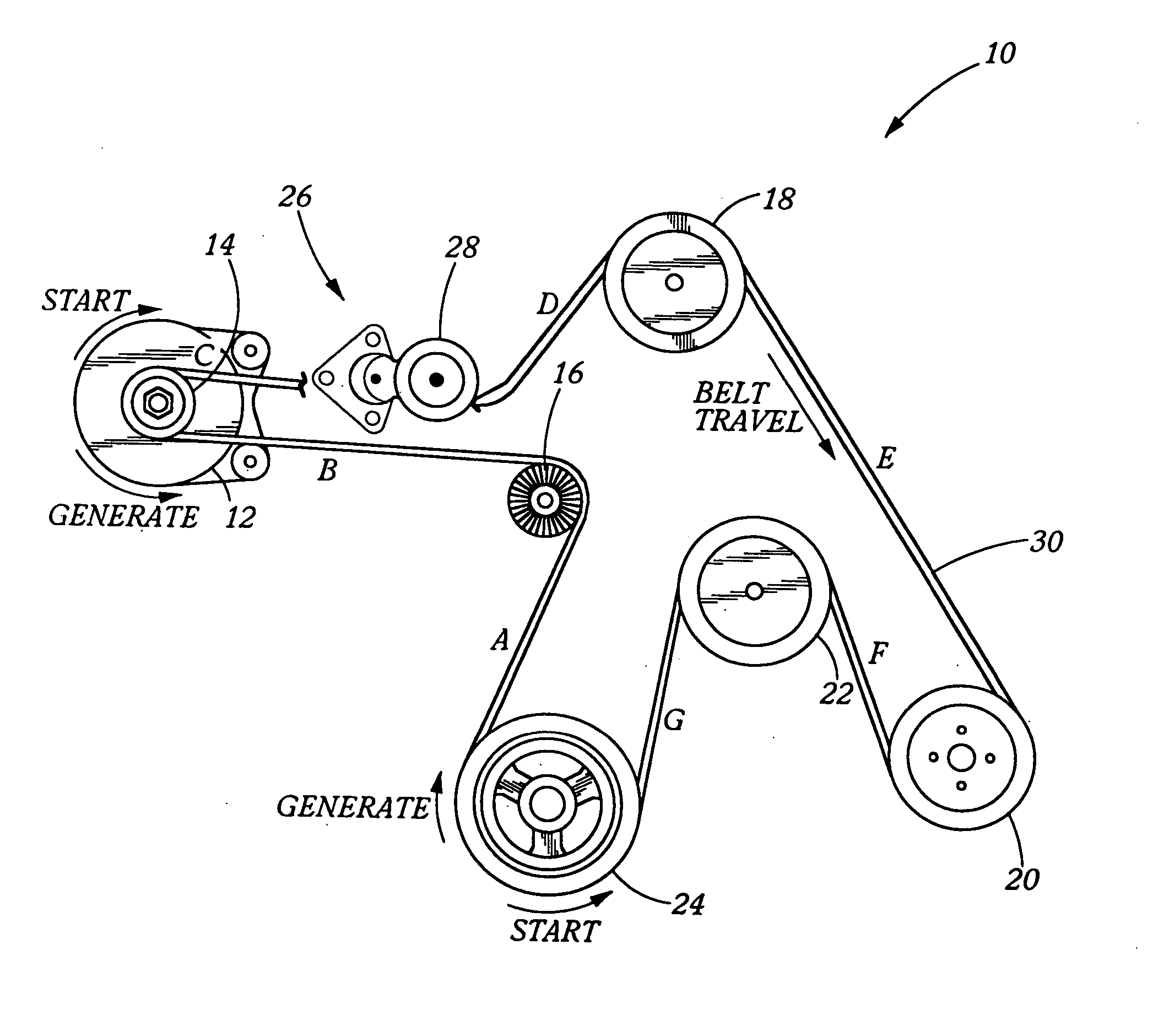

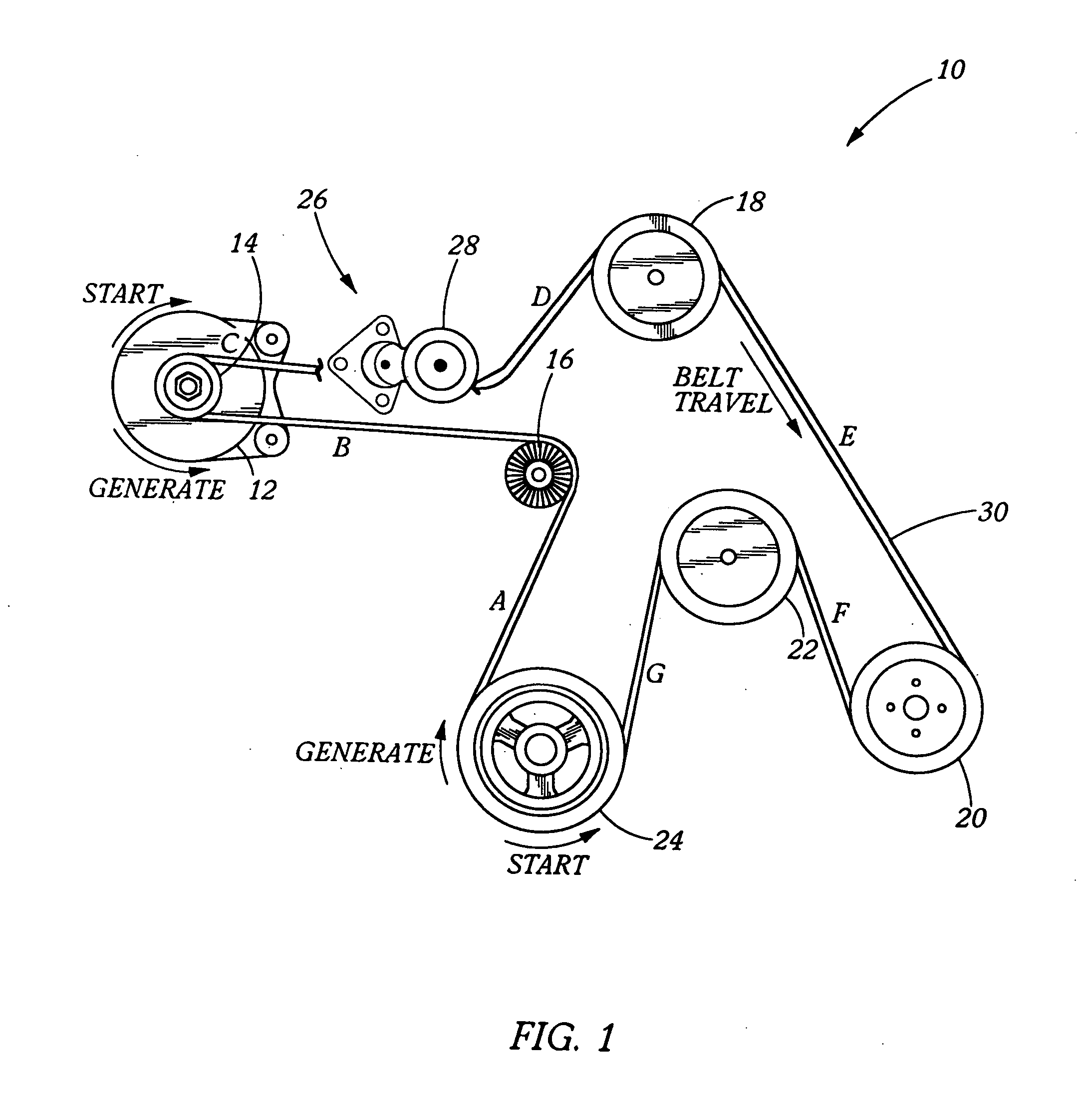

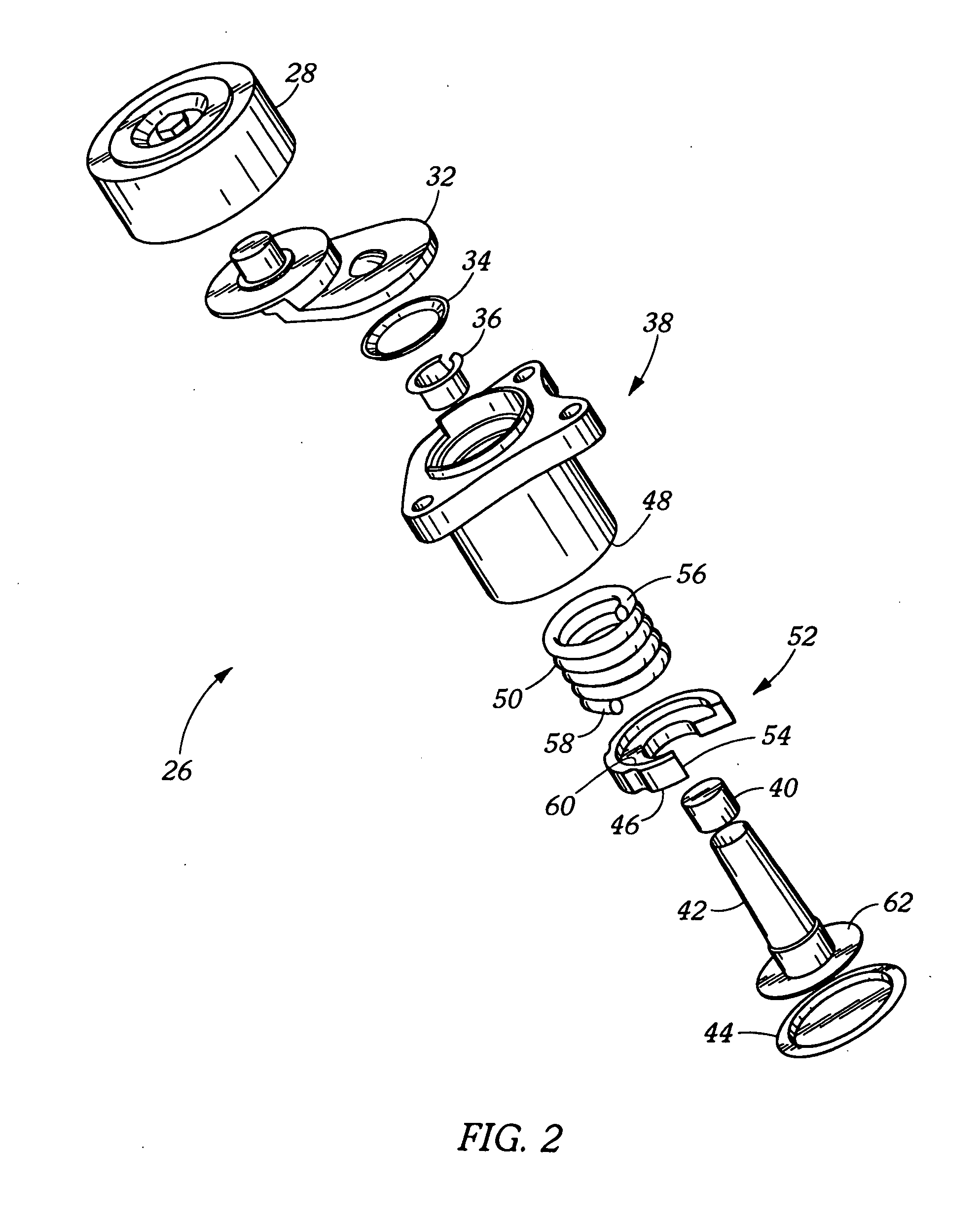

Damped accessory drive system including a motor/generator

InactiveUS20060249118A1Improve performanceGood choiceValve drivesGearingInternal combustion engineControl theory

The invention is an improved internal combustion engine having a crankshaft, an accessory, a motor / generator, and a belt-drive system. The belt drive systems includes a crankshaft pulley, an accessory pulley, a motor / generator pulley, a belt tensioner, a belt tensioner pulley, and a power transmission belt trained about the crankshaft pulley, the accessory pulley, the motor / generator pulley, and the belt tensioner pulley. The belt tensioner pulley contacts the belt at a start-slack-side span. It is improved by the tensioner being asymmetrically biased in a direction tending to cause the power transmission belt to be under tension.

Owner:THE GATES CORP

New full-automatic melt-blown fabric processing equipment

PendingCN111575902ARealize production and processing operationsHigh degree of automationArtificial thread manufacturing machinesUltrasonic/sonic fibre treatmentSpinningElectric machinery

The invention discloses new full-automatic melt-blown fabric processing equipment. An automatic spinning assembly, a bearing and conveying-out assembly located under the automatic spinning assembly, acollosol barrel assembly located on the rear end side of the automatic spinning assembly and an automatic winding assembly located on the front end side of the bearing and conveying-out assembly arearranged on a fixed mounting rack. The collosol barrel assembly comprises a barrel support, a speed reducer support, an extrusion barrel, a collosol heater, a screw drive speed reducer, a screw drivemotor, an extrusion screw and a feeding hopper. The automatic spinning assembly comprises a spinneret plate support, a melt-blow spinneret plate, a melt feed pipeline, a melt metering pump, a meteringpump drive motor, a spinning air supply pipe, an air blower and an air heater. The bearing and conveying-out assembly comprises drive roller mounting plates, conveying belt drive rollers, a conveyingbelt drive motor and a bearing conveying belt. Through the above structural design, melt-blown fabric production and processing work can be achieved automatically and efficiently, and the new full-automatic melt-blown fabric processing equipment has the advantages of being novel in structural design and high in automation degree.

Owner:广东弘为智能装备科技有限公司

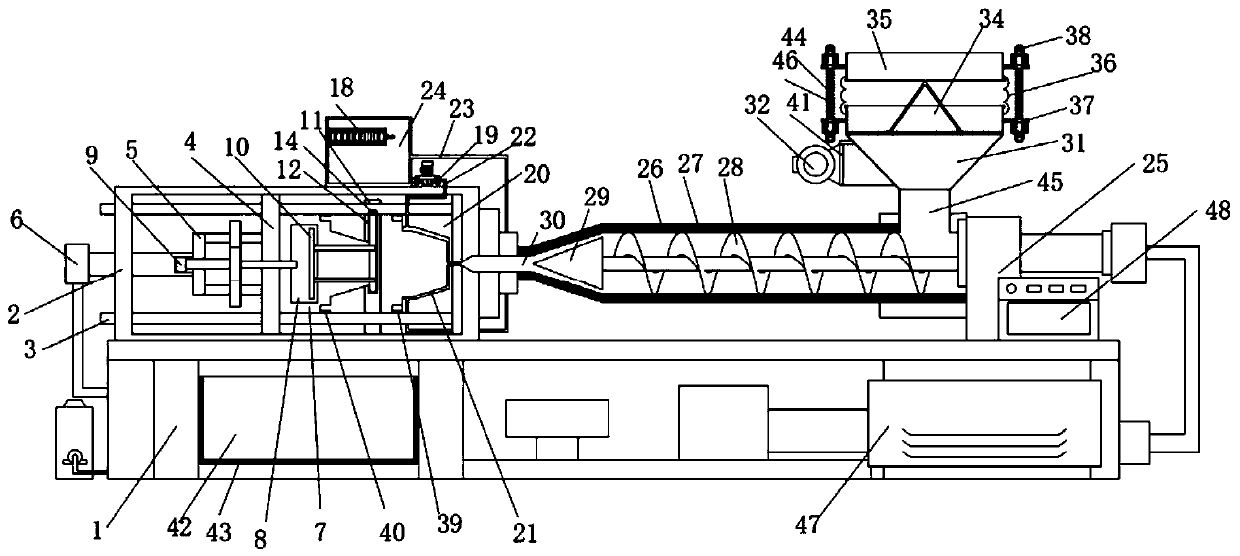

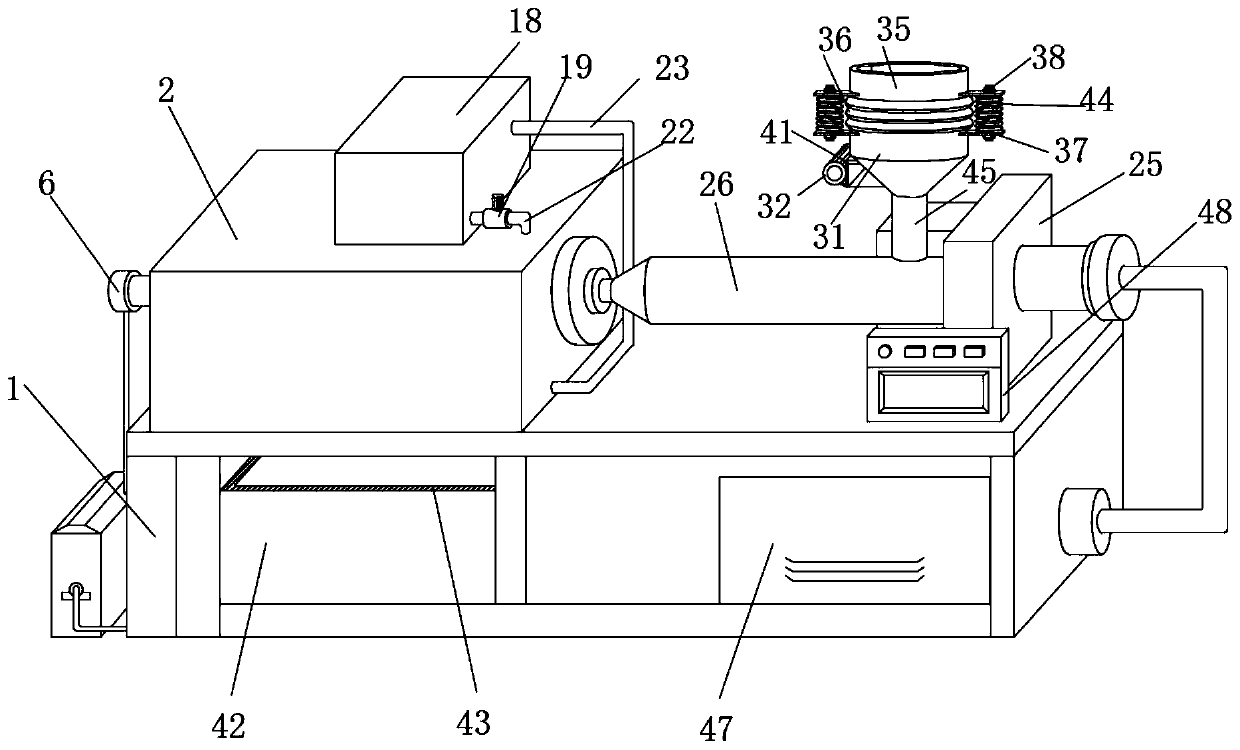

Intelligent horizontal injection press for plastic basin processing

InactiveCN110861255AInto the uniformReduce noiseDomestic articlesHollow articlesReciprocating motionInjection molding machine

The invention discloses an intelligent horizonal injection press for plastic basin processing, and relates to the field of horizonal injection presses. The intelligent horizonal injection press for plastic basin processing comprises a base, wherein a tank is arranged on one side of the top part of the base; guide rods are arranged at the top end and the bottom end in the tank; a guide block movably connected with the guide rods is arranged in the tank; a moving die is arranged on one side of the guide block; a hydraulic rod extending to the inner part of the tank is connected to the middle ofone side of the tank in a penetrating way; a first push rod is connected to one side of the hydraulic rod in the tank; one side, far away from the hydraulic rod, of the first push rod is connected with the guide block; and a guide slot is formed in the moving die. According to the intelligent horizonal injection press for plastic basin processing provided by the invention, a support frame is arranged on two sides of the moving die in the tank, a scraper blade is movably connected into the support frame and is connected with a driving belt, and the driving belt drives the scraper blade to movein a reciprocating way so as to scrape redundant materials in a finished product plastic basin when materials are injection-molded and the moving die is retracted, so that the redundant materials of the plastic basin have no need to be treated subsequently.

Owner:衡阳市鸿康纸塑容器包装有限公司

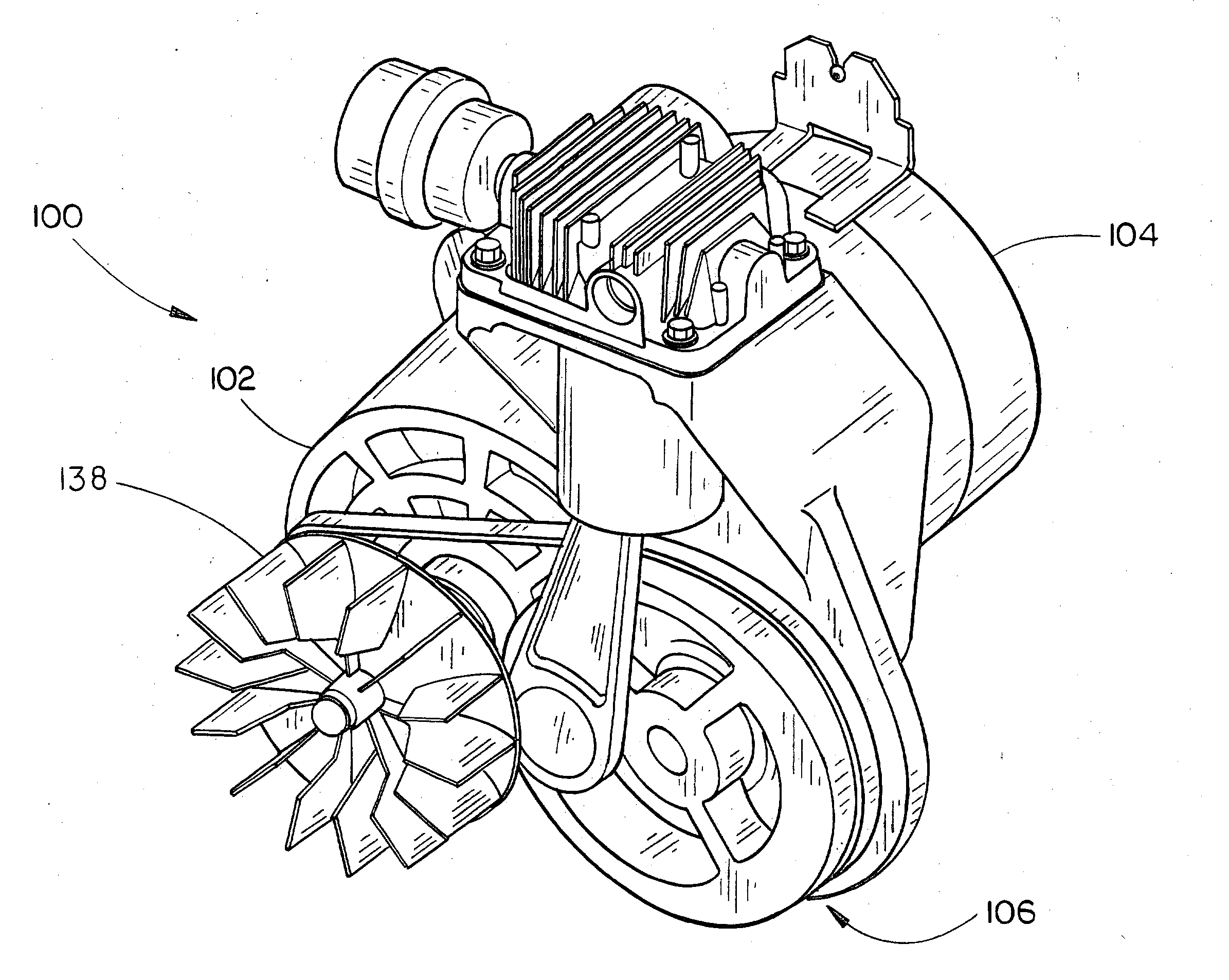

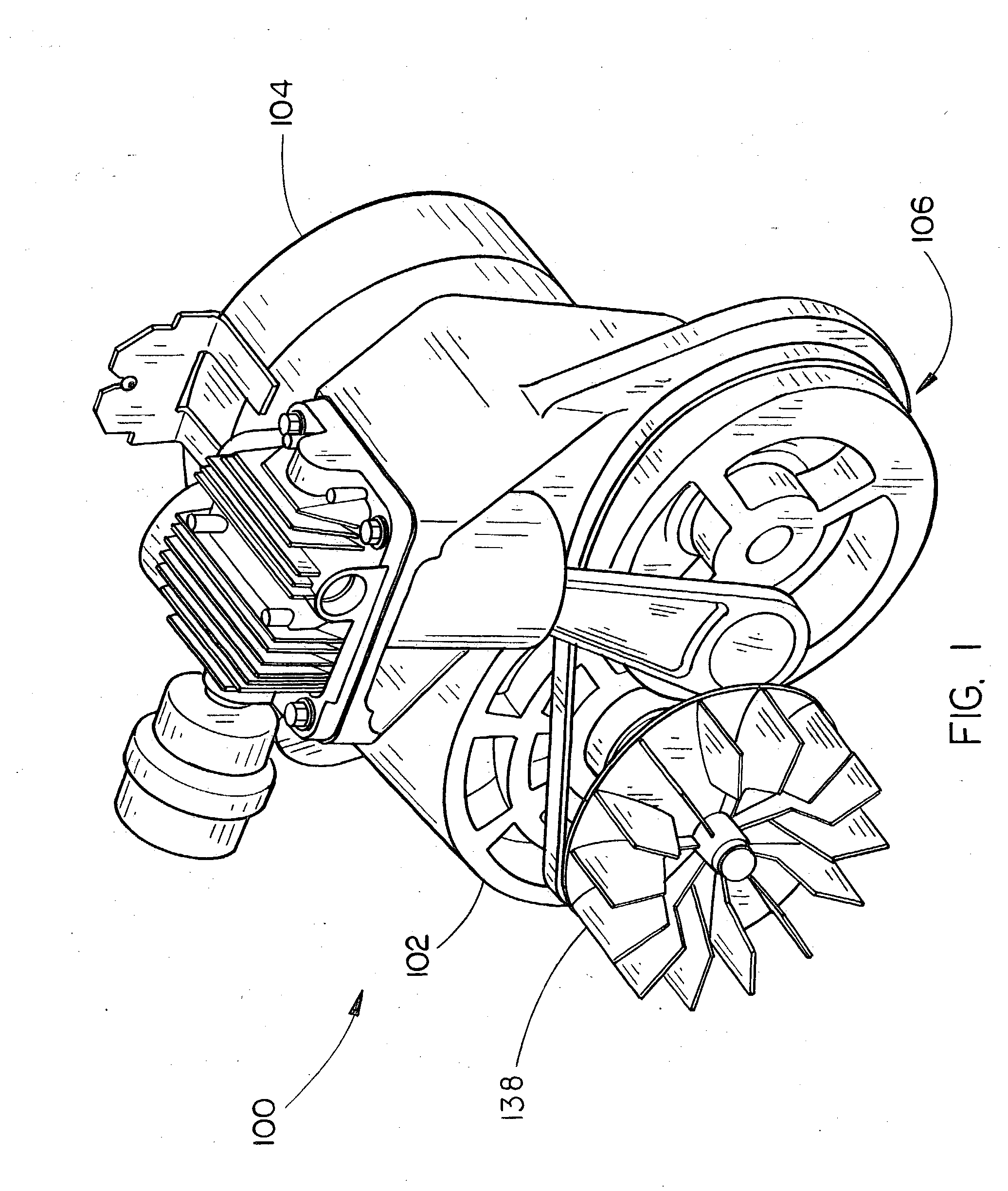

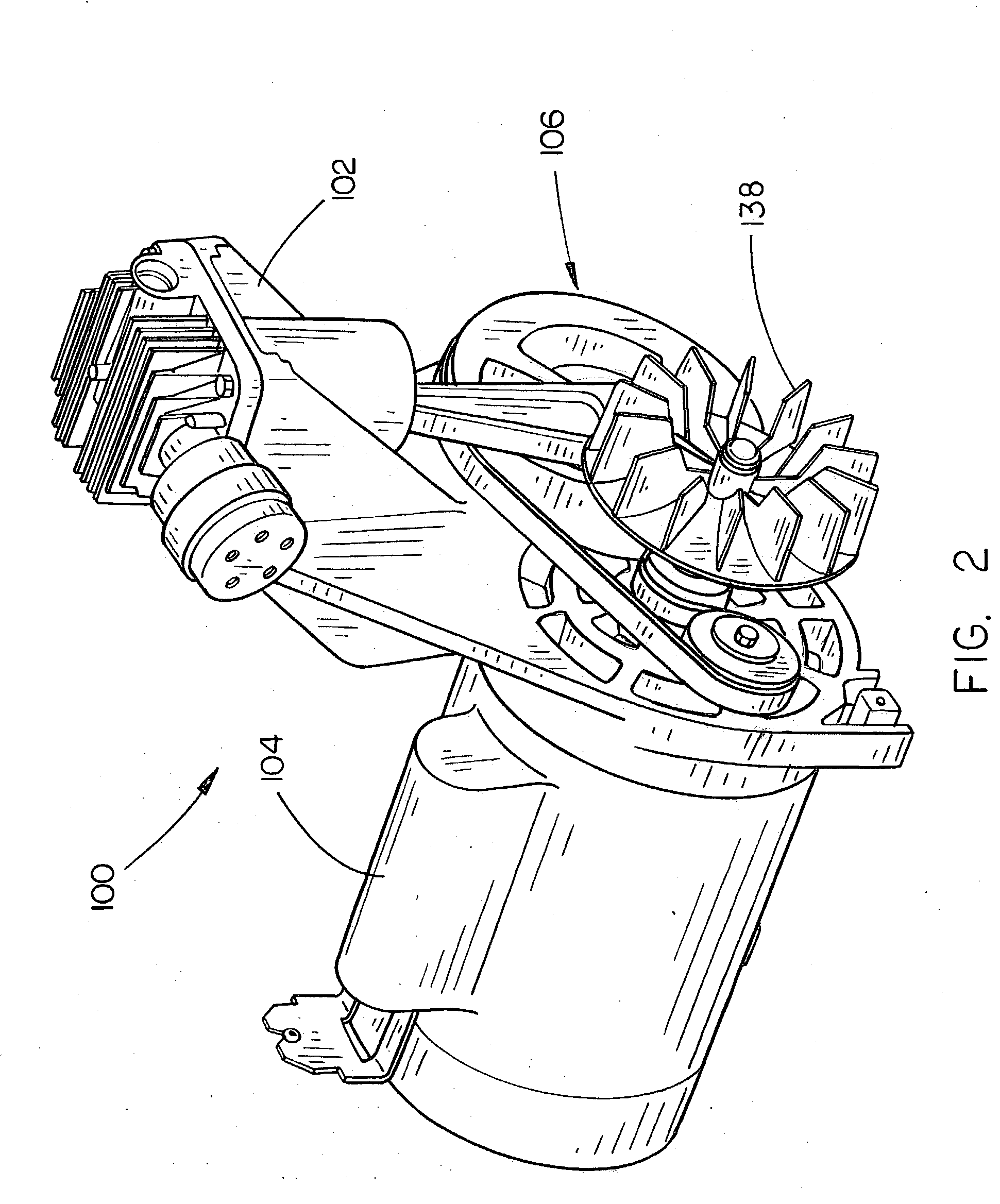

Compressor assembly having counter rotating motor and compressor shafts

ActiveUS20060078438A1Eliminate torsional vibrationPiston pumpsPositive-displacement liquid enginesMoment of inertiaTorsional vibration

A compressor assembly includes a compressor coupled to a motor via a belt drive. The belt drive provides a speed reduction between the motor and compressor and causes the compressor shaft to rotate in the direction opposite that of the motor shaft. The relative values of the mass moments of inertia about the axes of rotation of the rotating motor and compressor shafts are engineered to be inversely proportional to the relative shaft speeds, allowing the mass moments of inertia to be balanced to at least substantially eliminate torsional vibration.

Owner:BLACK & DECKER INC

Washing and disinfecting device for medical instruments

InactiveCN107349446AAchieve rotationAchieve cleaningCleaning using toolsCleaning using liquidsReciprocating motionDrive shaft

The invention discloses a washing and disinfecting device for medical instruments. The washing and disinfecting device comprises an operation chamber, wherein a rotary shaft is arranged in the operation chamber in a horizontal-rotation manner; a cylinder is arranged on the outer wall of the left side of the operation chamber; a sliding sleeve is internally and vertically provided with a longitudinal sliding rod in a sliding manner; a washing groove is fixedly arranged on supporting legs in a horizontal manner; a cam driven by a driving device is arranged at the left side of the operation chamber; a driving shaft and a driven shaft, which are parallel, are arranged at the bottom part of the washing groove in a horizontal-rotation manner; the driving shaft and the driven shaft are respectively provided with a first washing roll and a second washing roll; and the right side of a guiding inclined plate is provided with a conveying belt driven by a drive mechanism, and the right end of the guiding inclined plate is positioned at the left end part of the conveying belt. The washing and disinfecting device disclosed by the invention has the advantages that the structure is ingenious and the design is reasonable; and the medical instruments in the washing groove can be rotatably washed by the first washing roll and the second washing roll, and by rotation of a cam, left-right reciprocating movement of the washing groove is realized, the effects of rotation and horizontal washing of the first washing roll and the second washing roll for the washing groove are realized, so that the washing effect is better and the efficiency is higher.

Owner:ZHENGZHOU UNIV

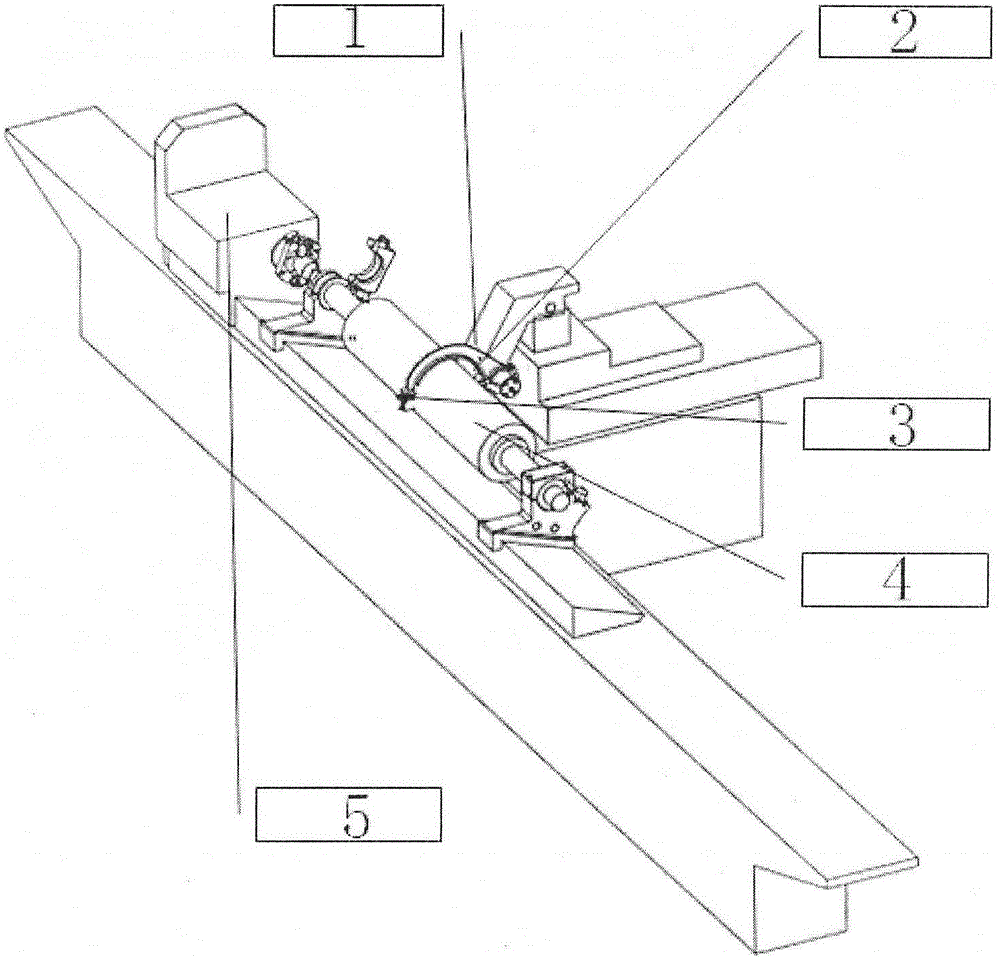

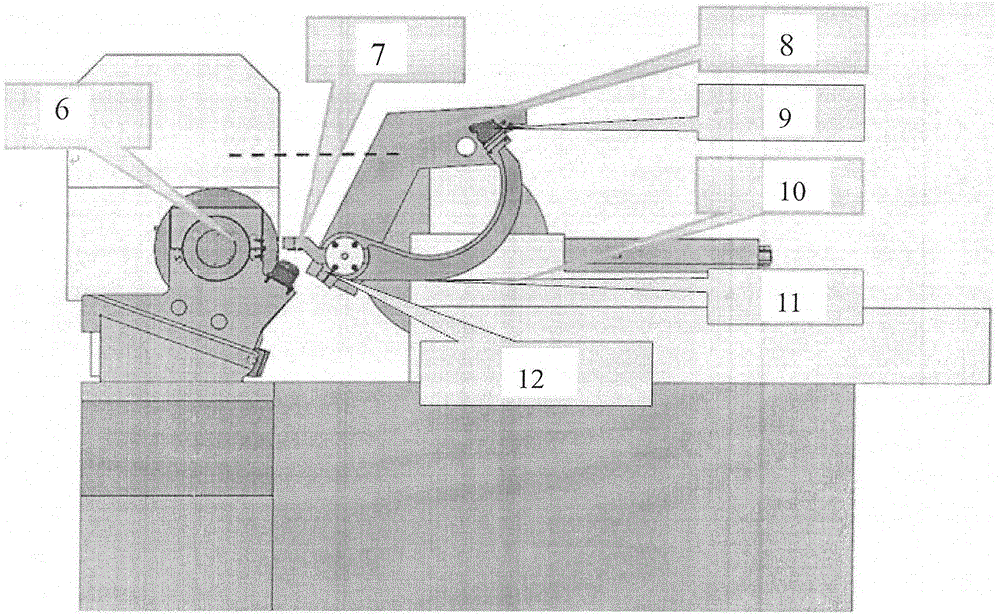

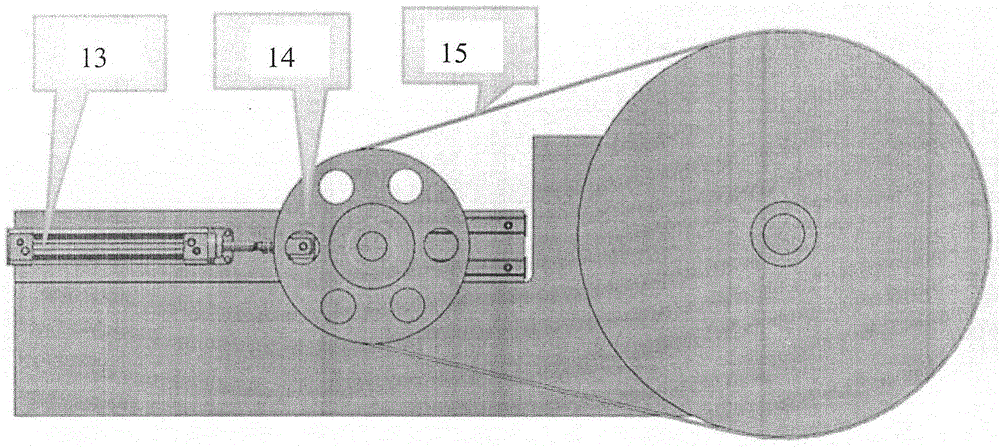

Turning, grinding and polishing all-in-one machine device for rubber roller

InactiveCN105690095AChange contact angleChange contact positionOther manufacturing equipments/toolsDrive wheelEngineering

The invention provides a turning, grinding and polishing all-in-one machine device for a rubber roller. By the adoption of the turning, grinding and polishing all-in-one machine device for the rubber roller, turning, grinding through a grinding wheel and polishing through an abrasive belt can be achieved at the same time. According to the turning, grinding and polishing all-in-one machine device for the rubber roller, a turning machine, a grinding machine and a polishing device for the rubber roller are highly integrated, and new functions are additionally achieved based on the grinding machine special for the rubber roller. A power machine head used for making a workpiece rotate is installed at one end of a machine body, and a machine tail is installed at the other end of the machine body; a spindle is arranged on the machine head; one end of the spindle is connected with a chuck, and the other end of the spindle is connected with a power device; a center used for fixing the workpiece is arranged on the machine tail, and the spindle of the machine head and the center of the machine tail are located on the same center line; a measurement device is installed on the upper surface of the machine body; and an annular abrasive belt driving and tensioning device is installed on a workbench. A whole annular abrasive belt can rotate around the axis of a driving wheel, so that the contact angle between the abrasive belt and the workpiece is changed, and accordingly the position, making contact with the workpiece, of the abrasive belt is changed, and different machining requirements are met.

Owner:SUZHOU HONGSUN ELECTROMECHANICAL TECH CO LTD

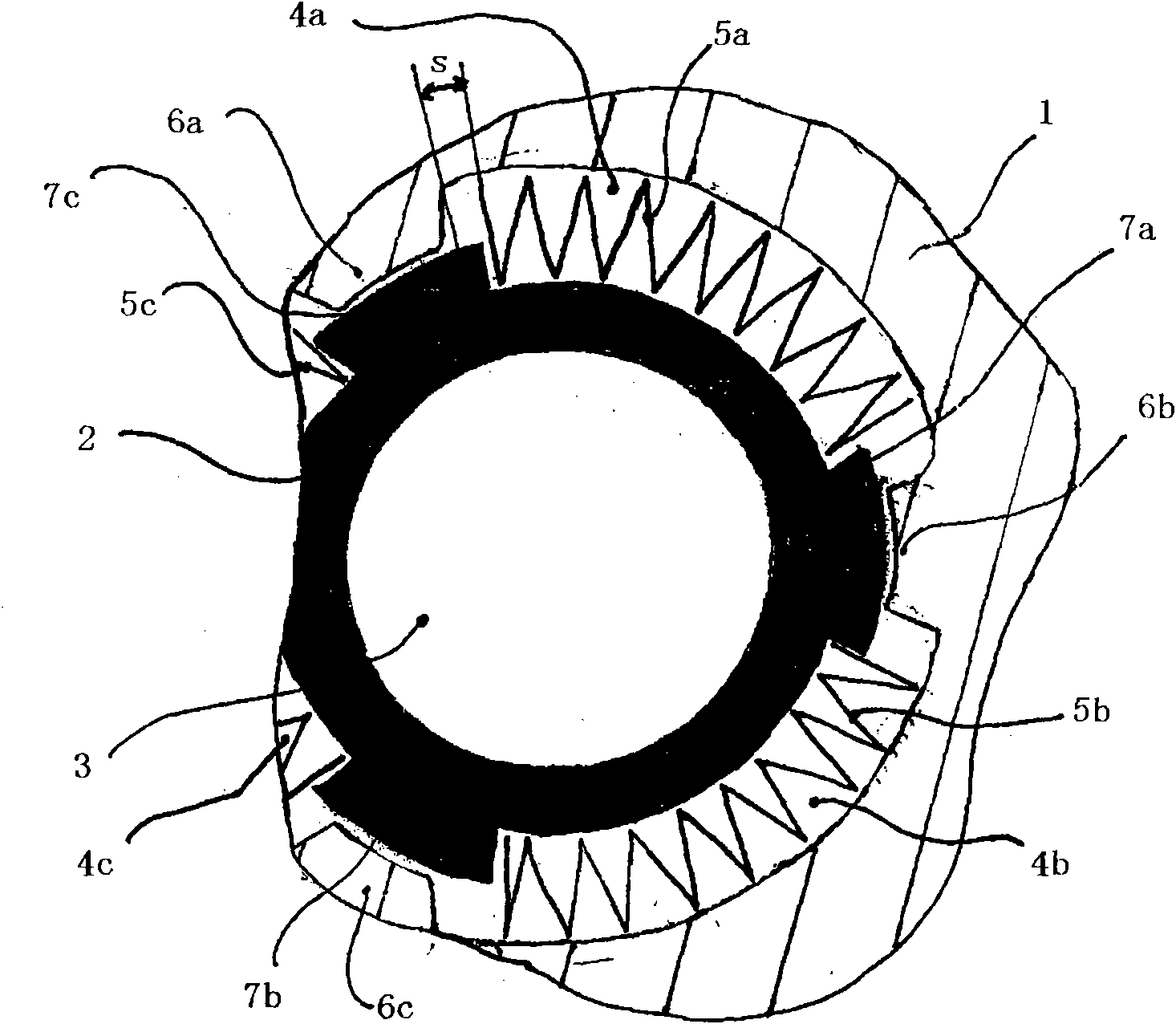

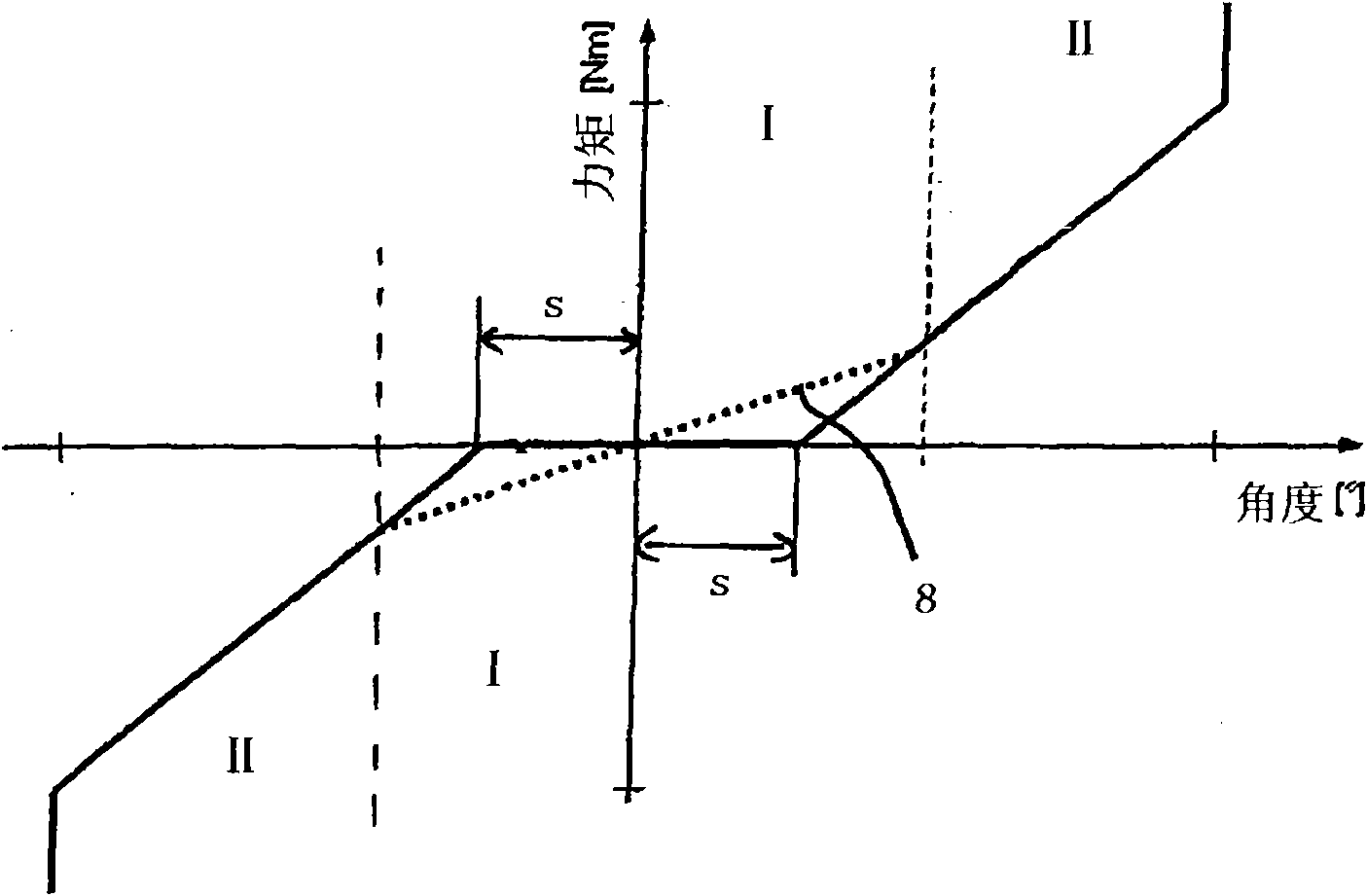

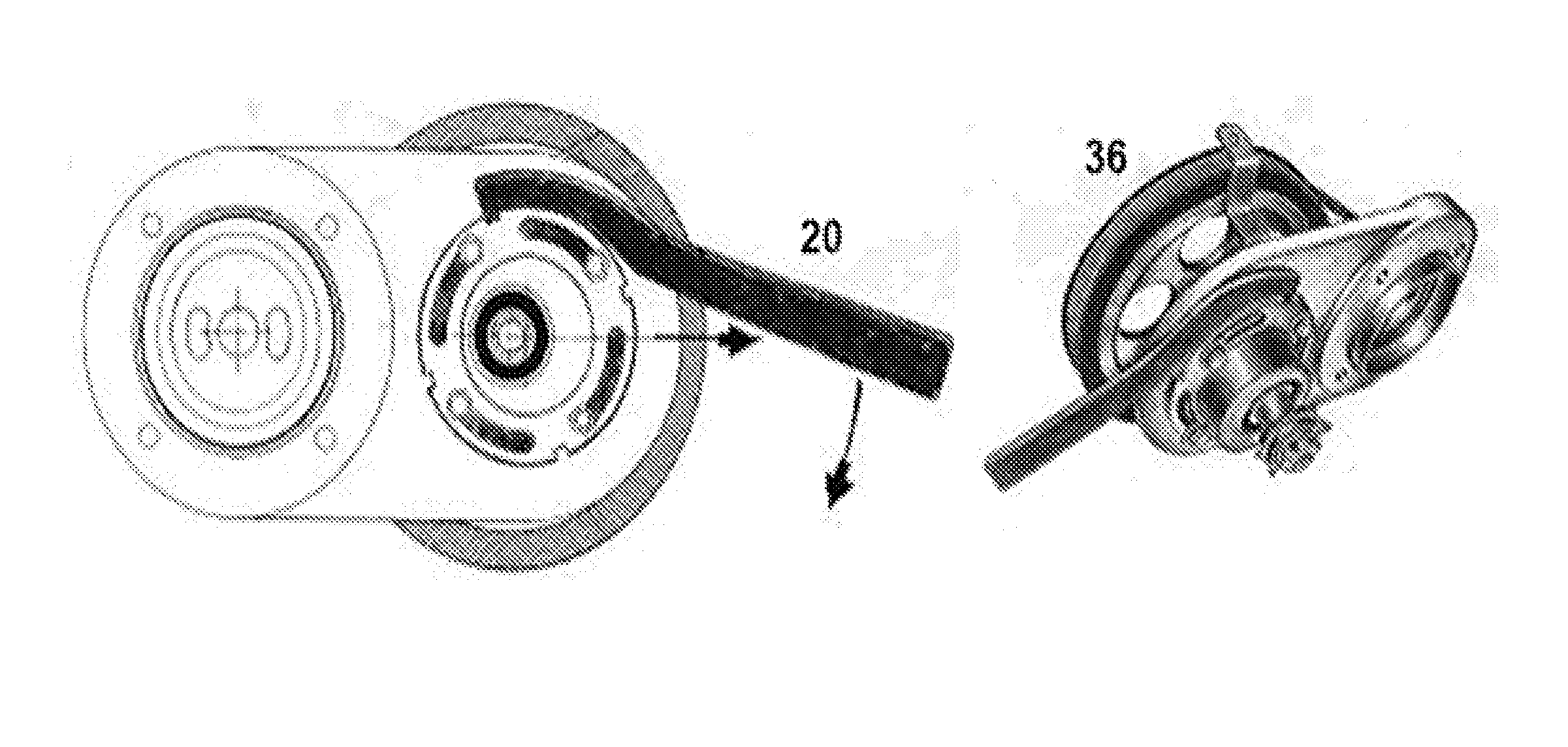

Device for driving a generator by a belt drive of an internal combustion engine

InactiveCN101915298AEasy to assembleReduce self-resonance speedPortable liftingMachines/enginesInternal combustion engineElectric generator

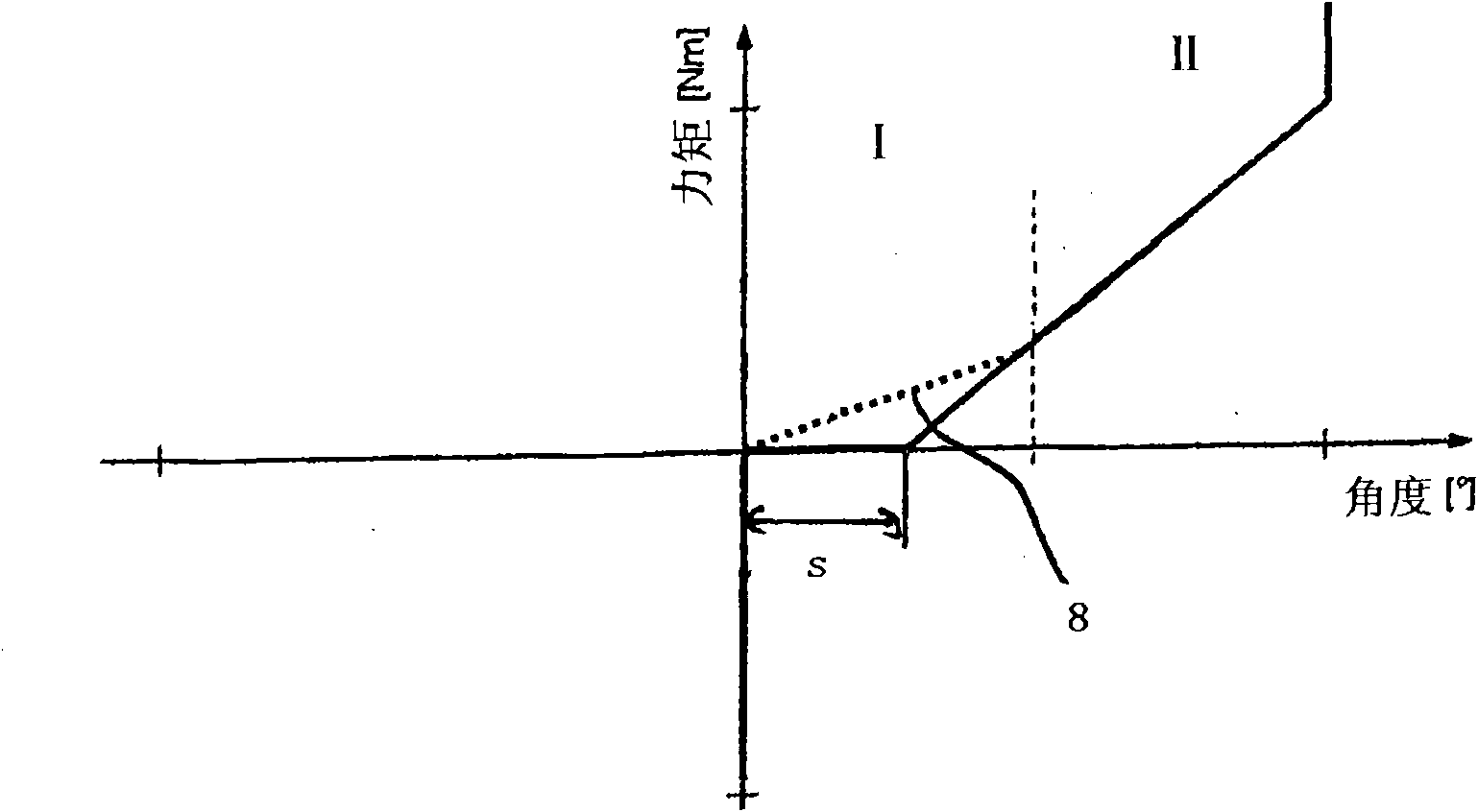

A device for connecting a generator to a belt drive of an internal combustion engine is provided, which includes a belt pulley (1) that is guided so that it can rotate relative to a hub (2) set on a shaft (3). At least one spring element is arranged between the belt pulley (1) and the hub (2) and connects the belt pulley (1) and the hub (2) to each other elastically for transferring rotational motion and here sets a relative rotation between the belt pulley (1) and the hub (2) corresponding to an effective torsional stiffness. The at least one spring element is placed with a defined movement play (s) with respect to the belt pulley (1) and / or the hub (2), in order to allow relative rotation through the movement play (s) in a first region (I) with a low torsional stiffness, while, in a second region (II), a high torsional stiffness can be generated by the at least one spring element.

Owner:SCHAEFFLER TECH AG & CO KG

Mining motor belt pulley automatic disassembly press machine

The invention relates to a mining motor belt pulley automatic disassembly press machine which is mainly composed of a rack, a main drive mechanism, a lifting working table, a working table lifting mechanism, a clamping wheel support, a rapid change type ejector component and the like. The main drive mechanism comprises four drive pairs of a belt drive pair, a gear drive pair, a worm gear drive pair and a screw drive pair. A main drive spline screw shaft can positively or reversely rotate around the X axis and move in the left or right direction of the X axis, so that the rapid change type ejector component which is installed at the right end of the main drive spline screw shaft moves in the left or right direction of the X axis along with the main drive spline screw shaft, and then the goals of ejecting a belt pulley to be disassembled and restoring a machine tool are achieved. By the development of the mining motor belt pulley automatic disassembly press machine, the motor belt pulley can be automatically disassembled, labor intensity is relieved, the efficiency for maintaining a motor is improved, and the mining motor belt pulley automatic disassembly press machine is especially suitable for industrial enterprises where the working environment is poor and the maintenance amount of the motor is large. The development achievement can fill the gap of the non-ferrous industry of China in the field.

Owner:LIUZHOU VOCATIONAL & TECHN COLLEGE

Combine harvester comprising a chopping mechanism

A combine harvester has a chopping mechanism and a spreading mechanism. The spreading mechanism is disposed downstream of the chopping mechanism, mechanically driven by a drive train and includes at least two rotors. The drive train of the spreading mechanism has a belt drive engageable by a clutch and configured to drive a first transmission stage via an output shaft, at least one second transmission stage drivably connected to the first transmission stage by a shaft and a braking device. The first and second transmission stages each have an output shaft for driving one or each of the rotors.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

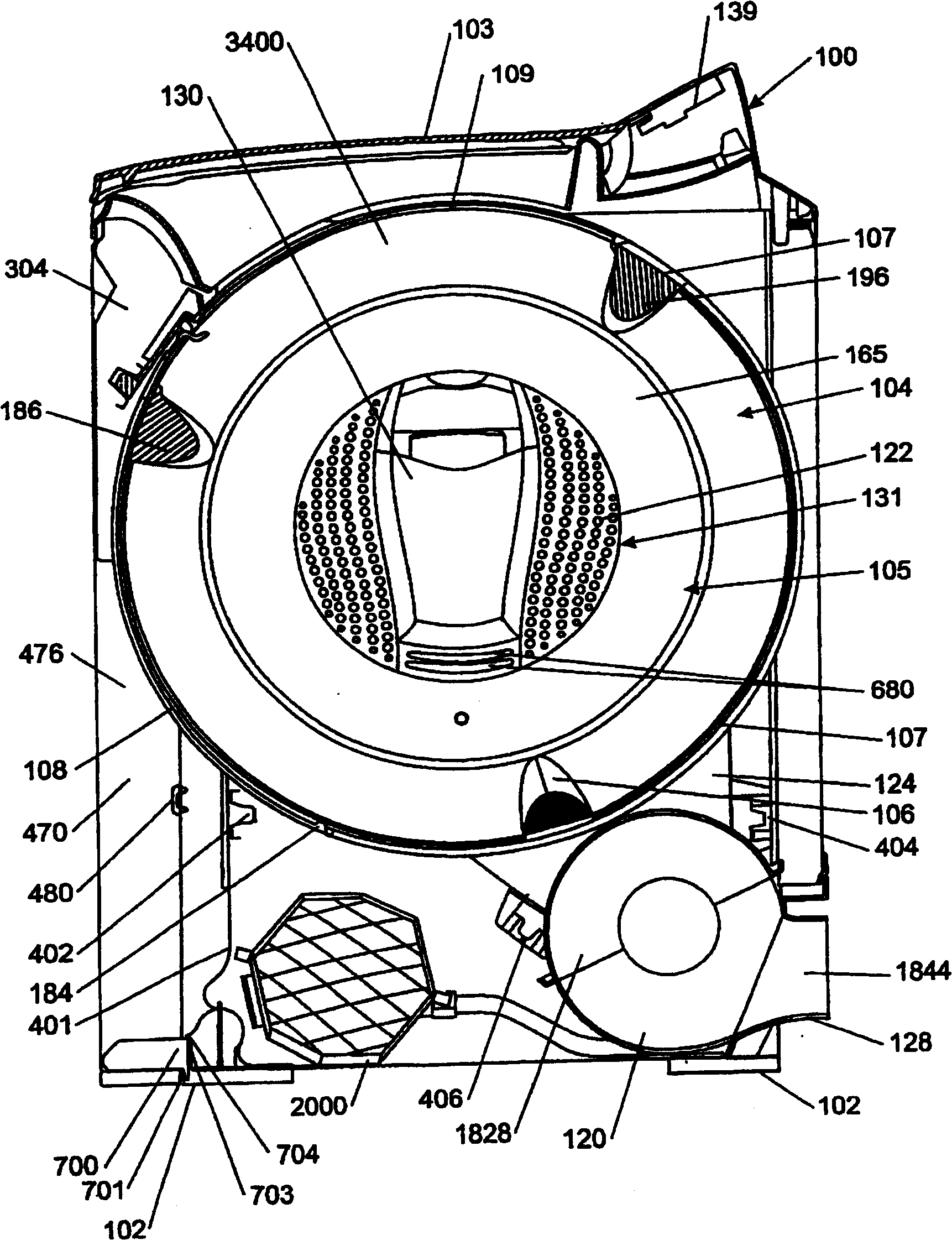

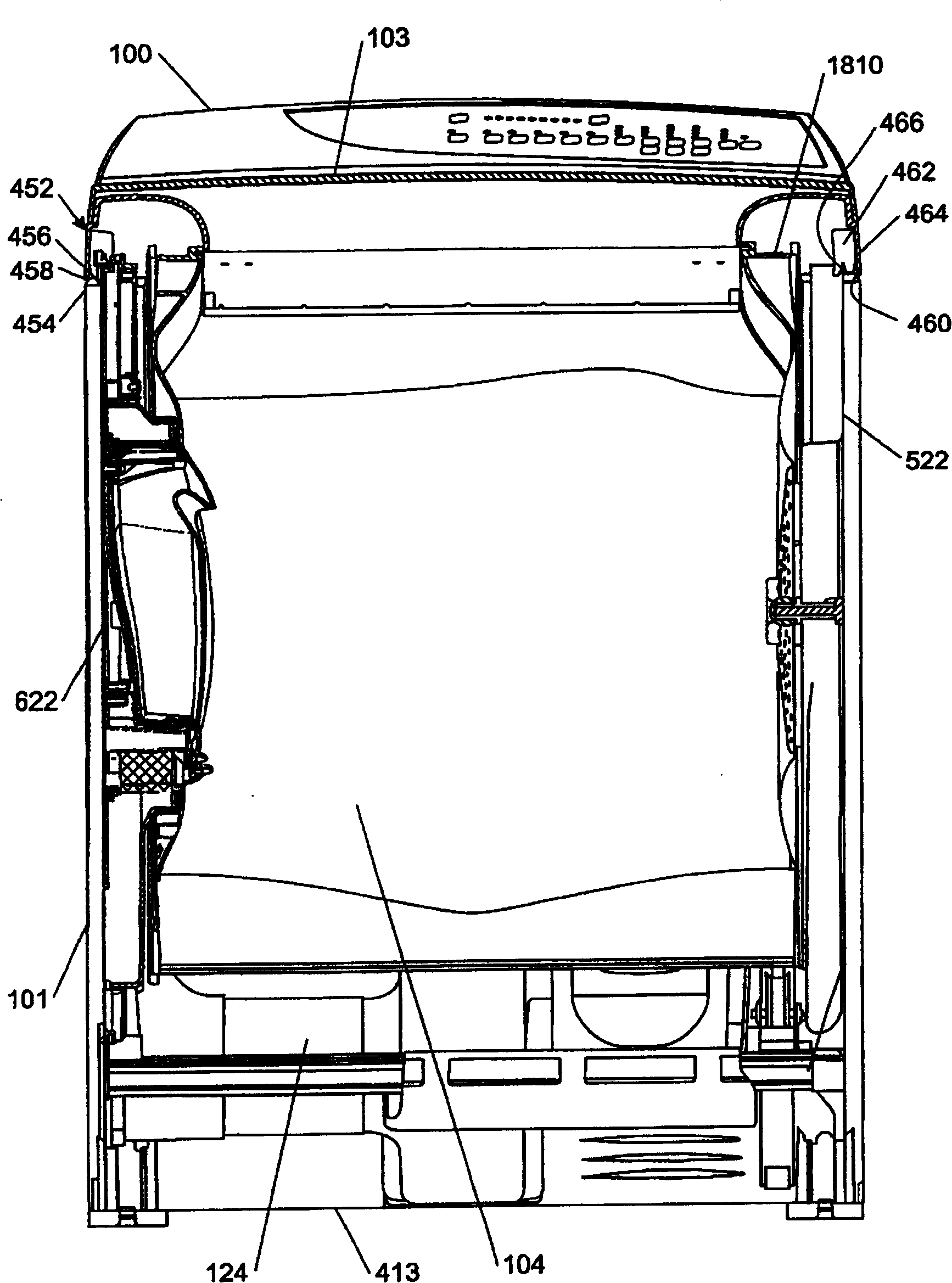

Laundry machine

InactiveCN101302701AGearing controlControl devices for washing apparatusLaundry washing machineElectric machinery

A laundry machine with a rotating drum containing clothing, the rotating drum is rotatablely supported in the machine and comprises a cylindrical wall and a couple of ends. A drum hatch comprises part of the wall; a motor connected to the rotating drum via a belt drives rotation of the rotating drum; a hatch engaging member is actuated to connect the drum hatch to the machine. A controller is connected to operation of the motor, to operate a dryer. The laundry machine comprises the following steps of 1) an opening operation in which the drum hatch is grabbed by the hatch engaging member and the drum is rotated to expose an opening; 2) a closing operation in which the drum is rotated to re-close the opening with the drum hatch; and 3) a drying operation.

Owner:FISHER & PAYKEL APPLIANCES LTD

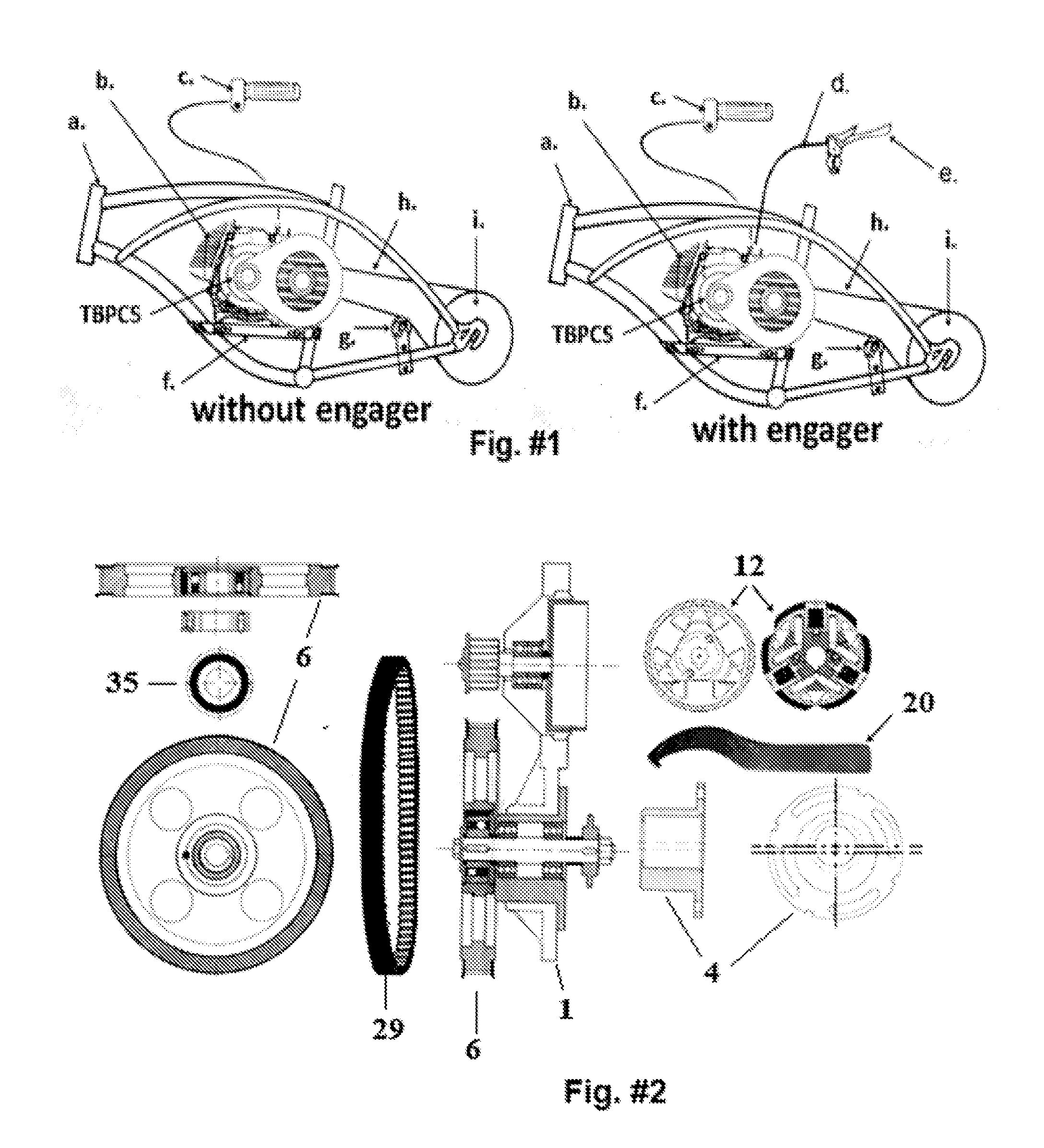

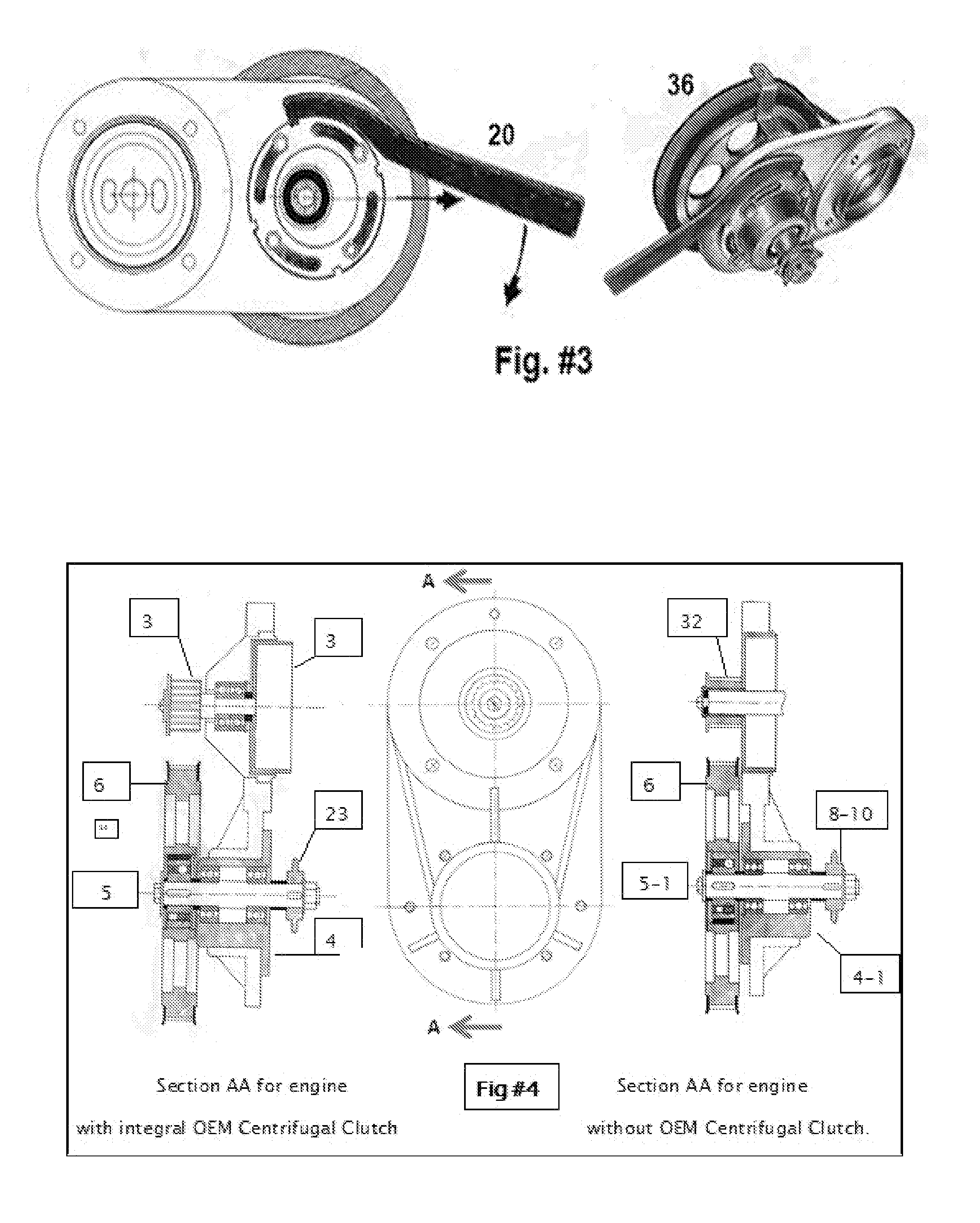

Centrifugal clutch timing belt power transmission control system for a small gasoline engine

A T belt power control system is disclosed to consist of a centrifugal clutch integral bell drum, or in the case of a straight shaft engine such as a Honda GXH50 a non integral bell drum, a T belt drive pulley affixed to a bell drum, an automotive type timing belt, a driven pulley cylindrical cam lock assembly consisting of a larger driven pulley with a one-way bearing for speed reduction and torque enhancement, a non concentric cylindrical housing and an output jackshaft with or without an engine power engaging system to a primary drive sprocket for chain operation. The T Belt tension is secured and maintained by rotating the cam lock assembly with a spanner wrench and then held tight by four bolts. If the T belt power control system is made without an engager system the power is transmitted as soon as the centrifugal clutch latches with the bell drum. If with an engager system the engagement and disengagement of engine power is done by an integral engager remotely controlled by steel cable and hand lever. A motorized vehicle is disclosed as consisting of a standard bicycle frame or modified bicycle frame, a tricycle frame, a go-cart frame, and a paddle wheel boat frame all with the T belt power control system of present invention installed on a gasoline four cycle engine.

Owner:GRUBE DONALD BARTON

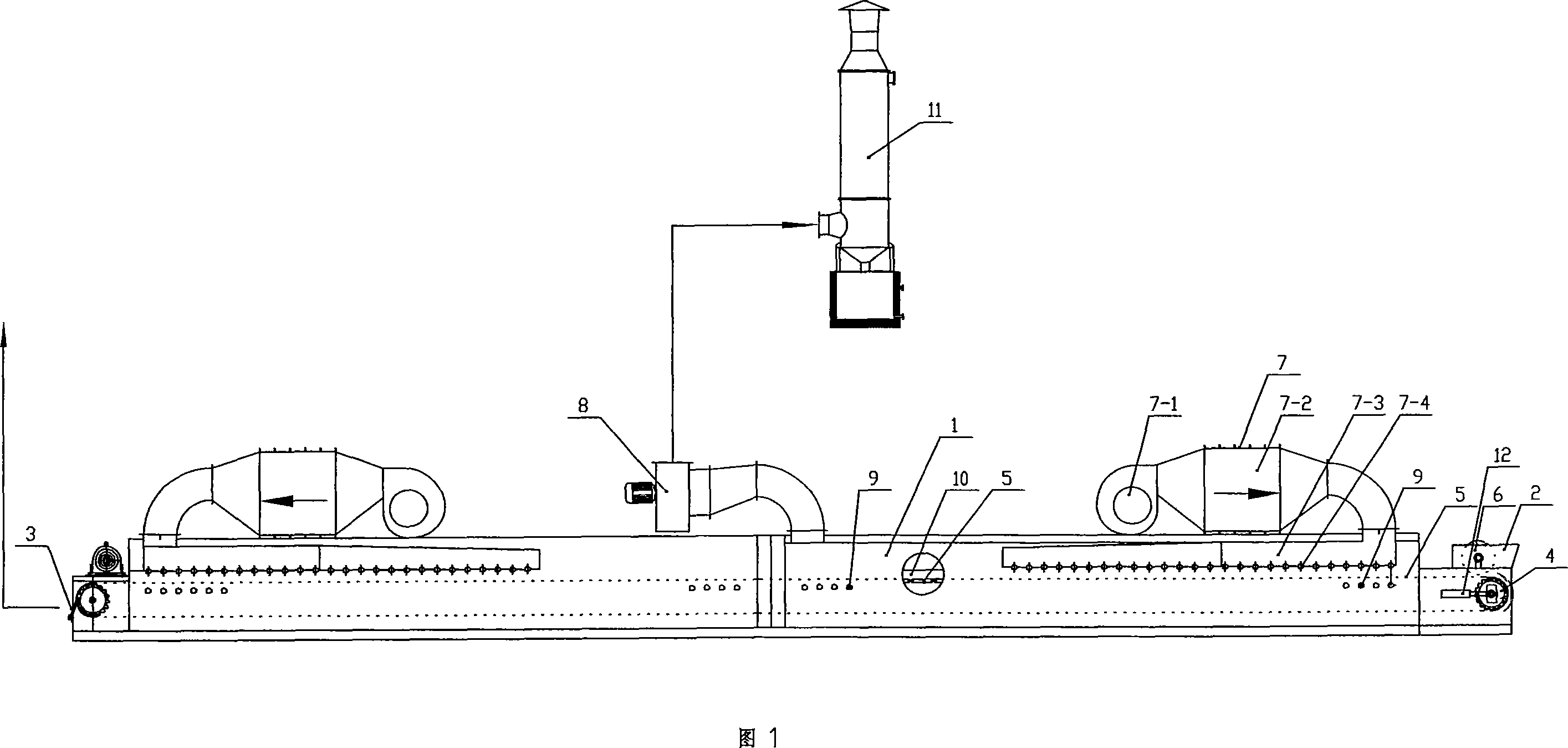

Steel belt type dryer

InactiveCN101105363ASolve deviationEasy to storeDrying machines with progressive movementsDrive wheelEngineering

The invention relates to a mechanical device, in particular to a steel belt type dryer. The steel belt type dryer has a drying passage, a feed port and a discharge port are respectively equipped at two ends of the drying passage, a conveyer belt driven by a driving wheel is equipped in the drying passage, the conveyer belt is a stainless steel belt, a baffle is respectively equipped at two sides of the conveyer belt, a feeding mechanism is equipped at the feed port, and the feeding mechanism is a feeding press roller made from rubber or silicone rubber. A gas heating device and a dehumidifying blower are connected on the drying passage. The invention can be used for drying viscous, paste-like materials with nanometer degree of fineness. The invention has the advantages of sufficient drying, and high drying efficiency.

Owner:查晓峰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com