Patents

Literature

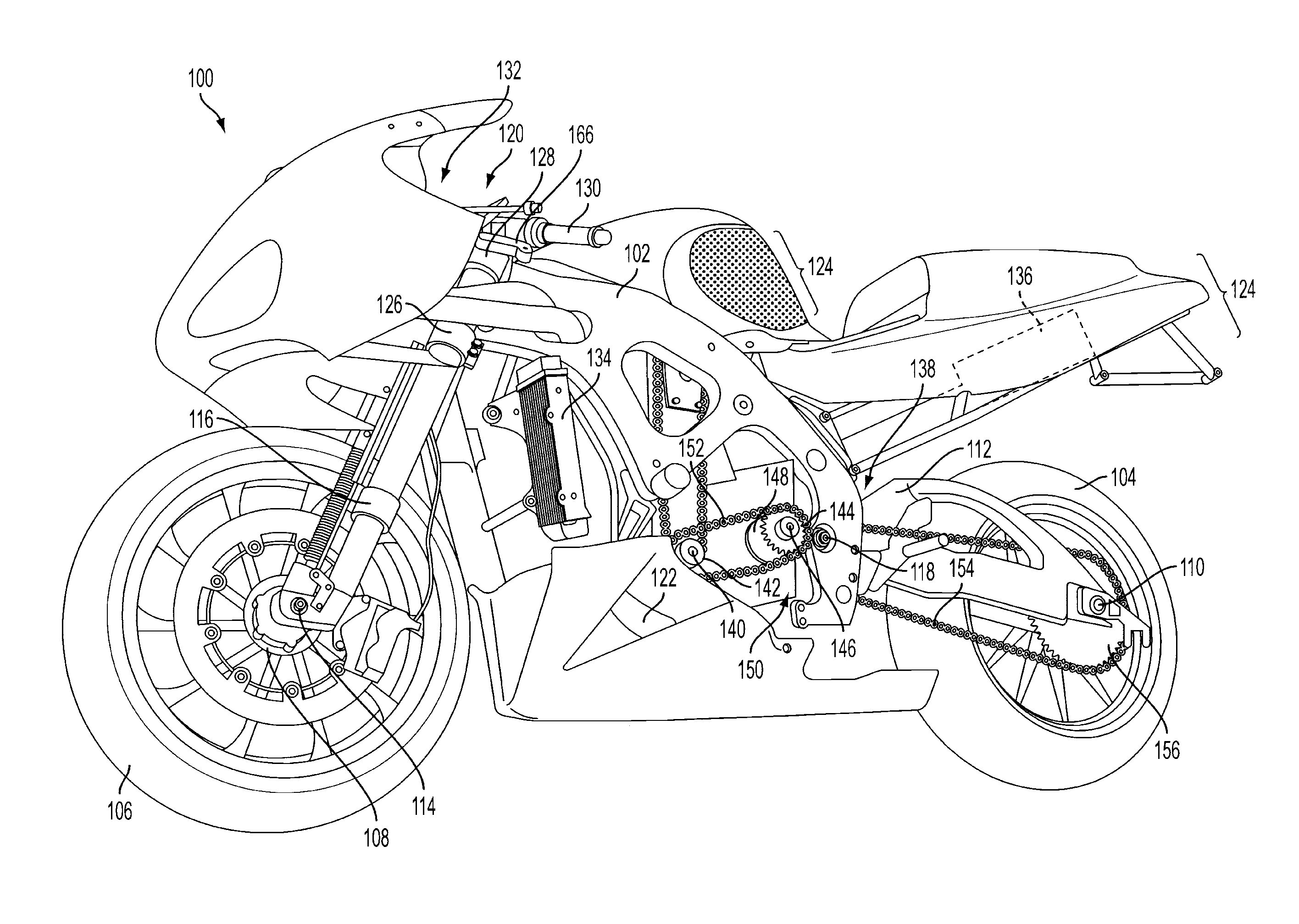

334 results about "Jackshaft" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A jackshaft, also called a countershaft, is a common mechanical design component used to transfer or synchronize rotational force in a machine. A jackshaft is often just a short stub with supporting bearings on the ends and two pulleys, gears, or cranks attached to it. In general, a jackshaft is any shaft that is used as an intermediary transmitting power from a driving shaft to a driven shaft.

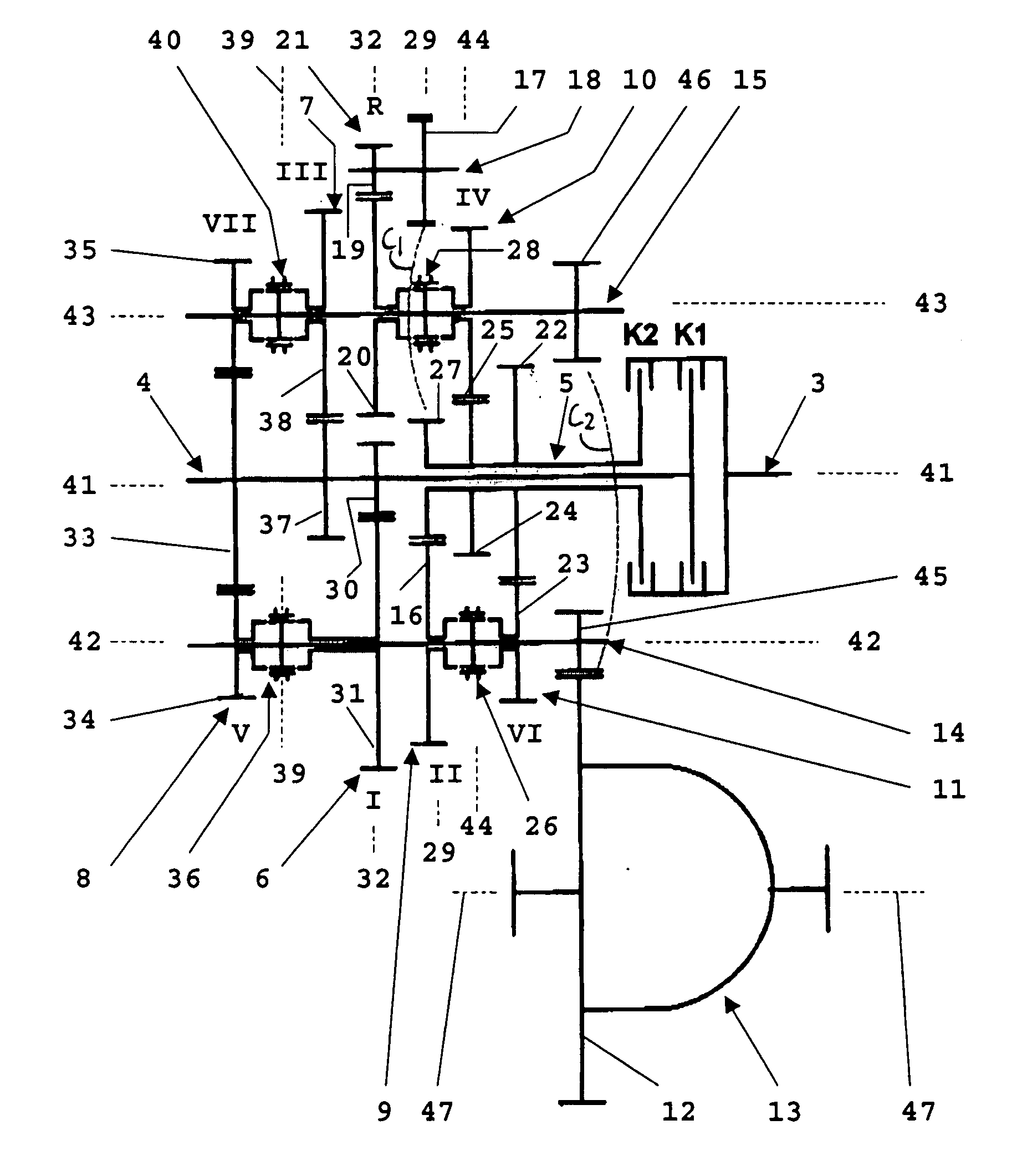

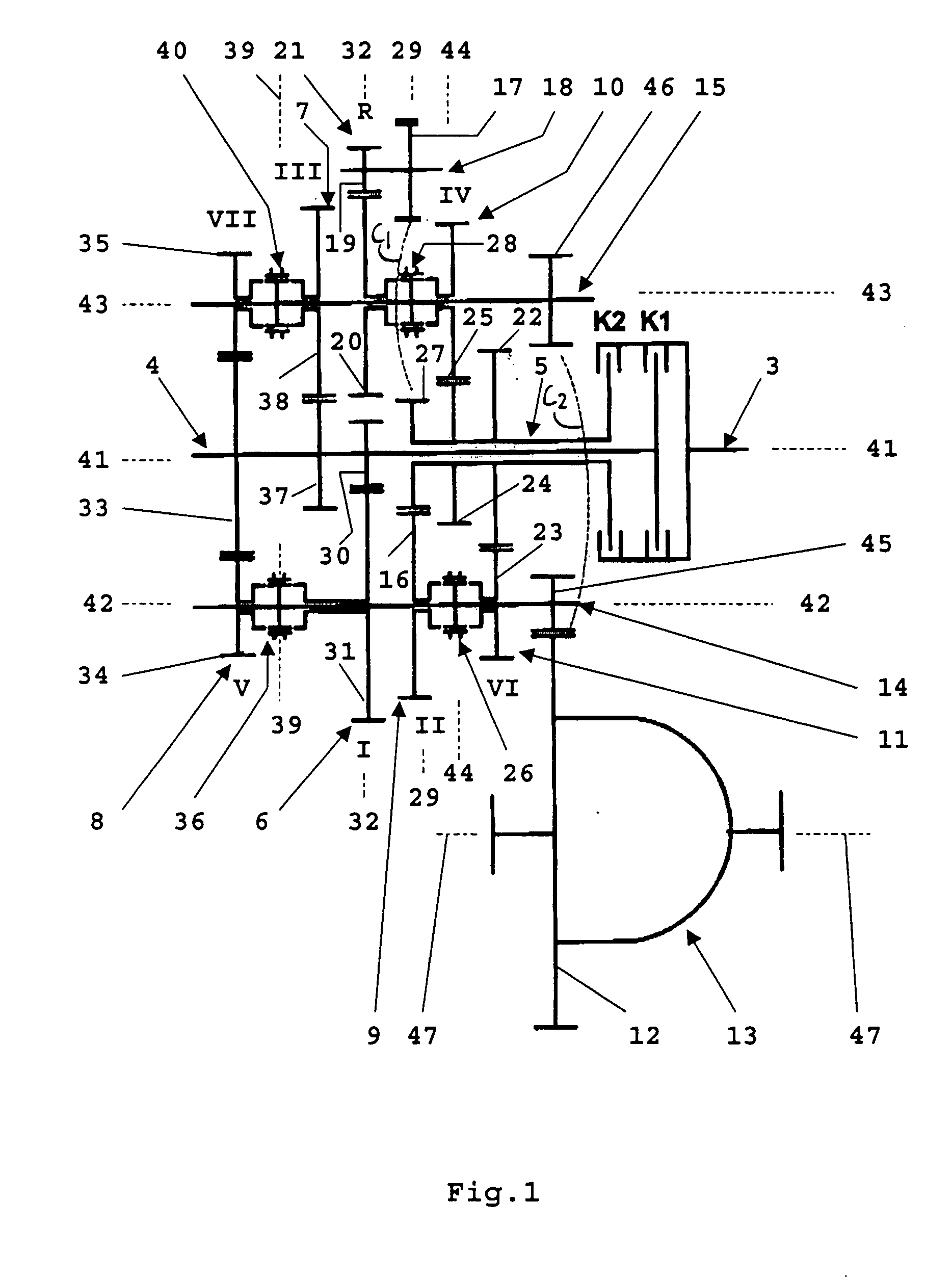

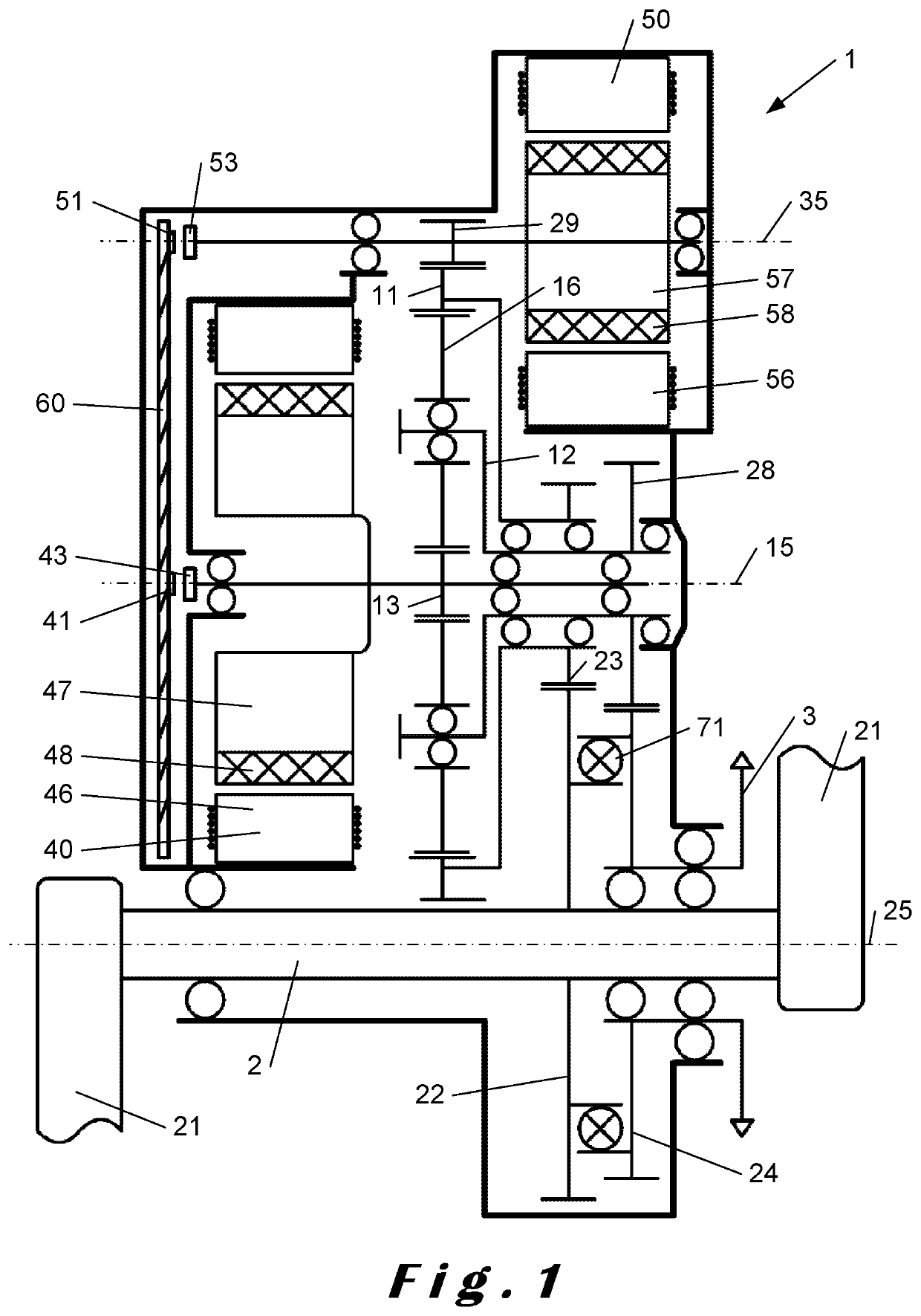

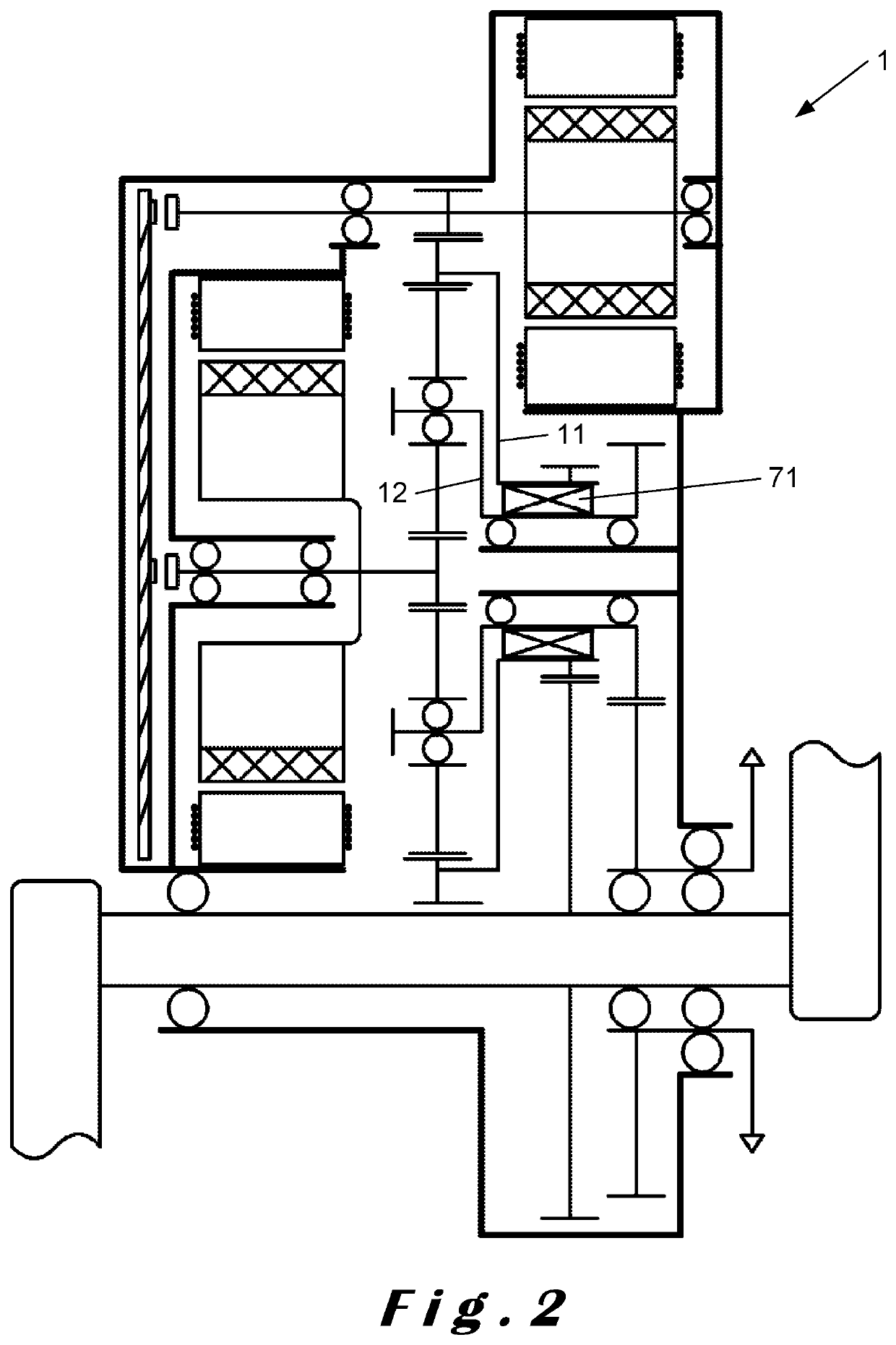

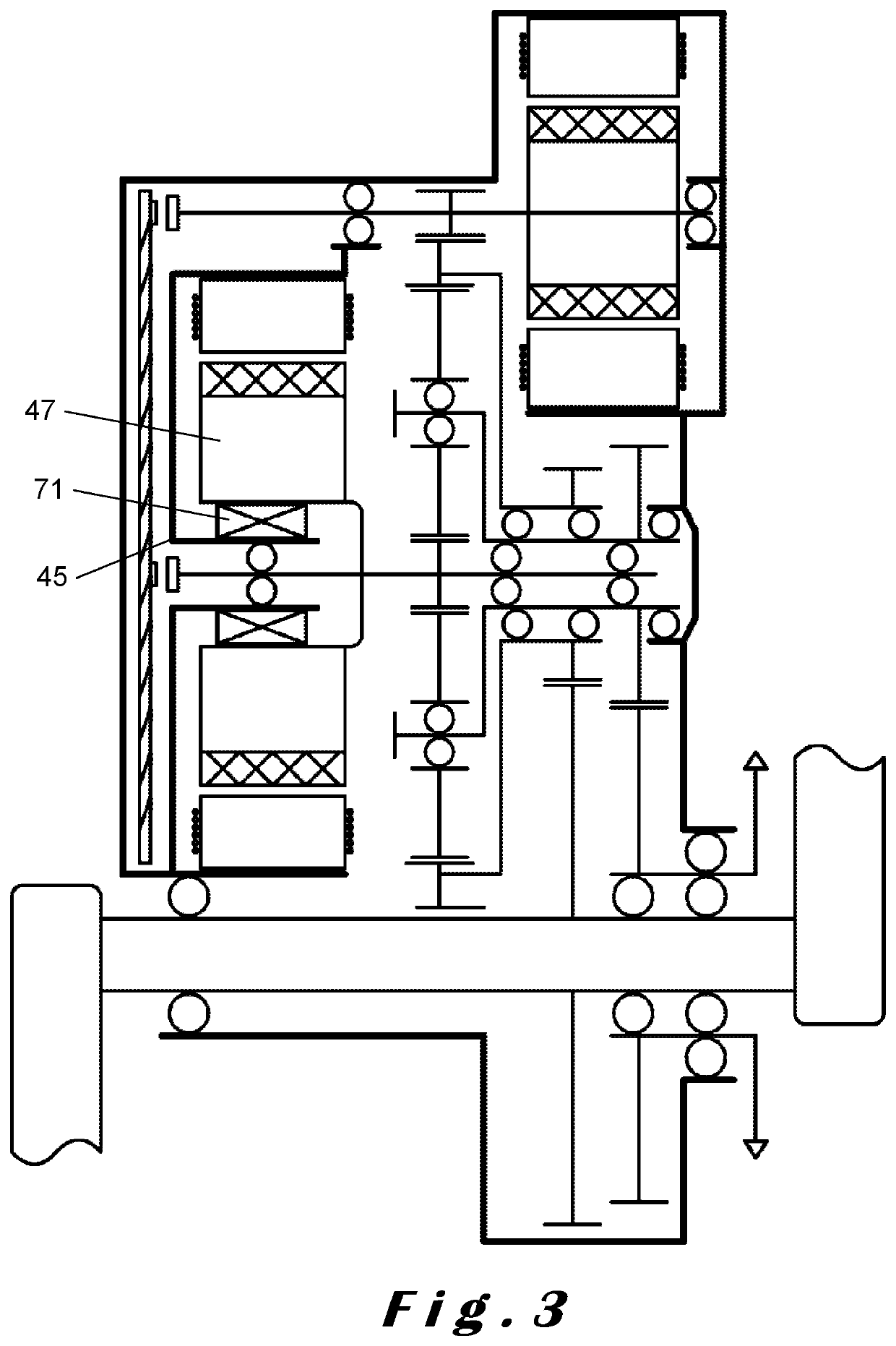

Double clutch transmission

InactiveUS7225696B2Short arrangementCompact designToothed gearingsTransmission elementsJackshaftTransverse engine

Owner:DAIMLER AG

Front wheel energy recovery system

InactiveUS20120080249A1Avoid creatingImproves vehicle dynamicAuxillary drivesDigital data processing detailsJackshaftMotor drive

Owner:W MORRISON CONSULTING GRP

Double clutch transmission

InactiveUS20050193848A1Closely arrangedShort arrangementToothed gearingsTransmission elementsJackshaftTransverse engine

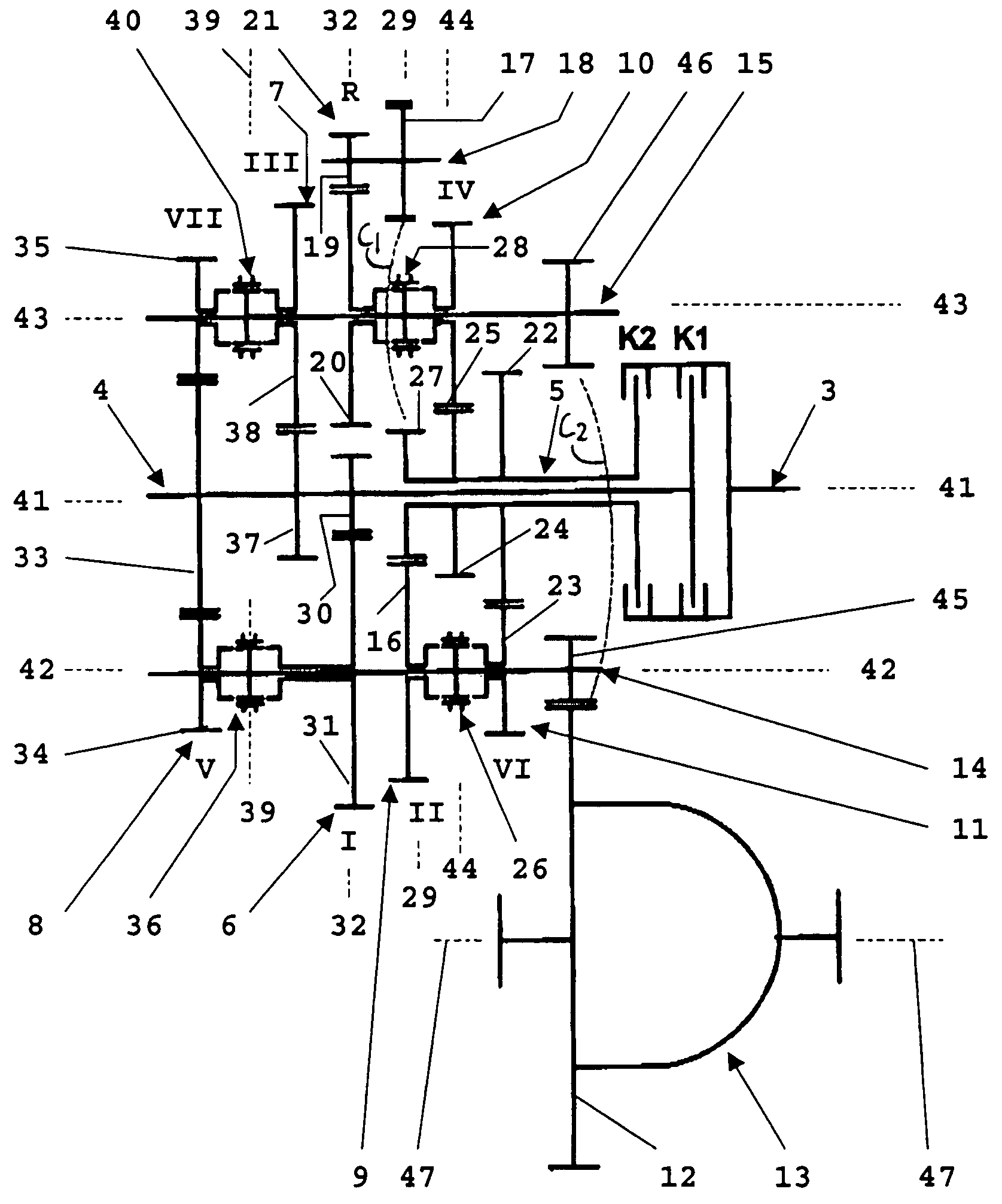

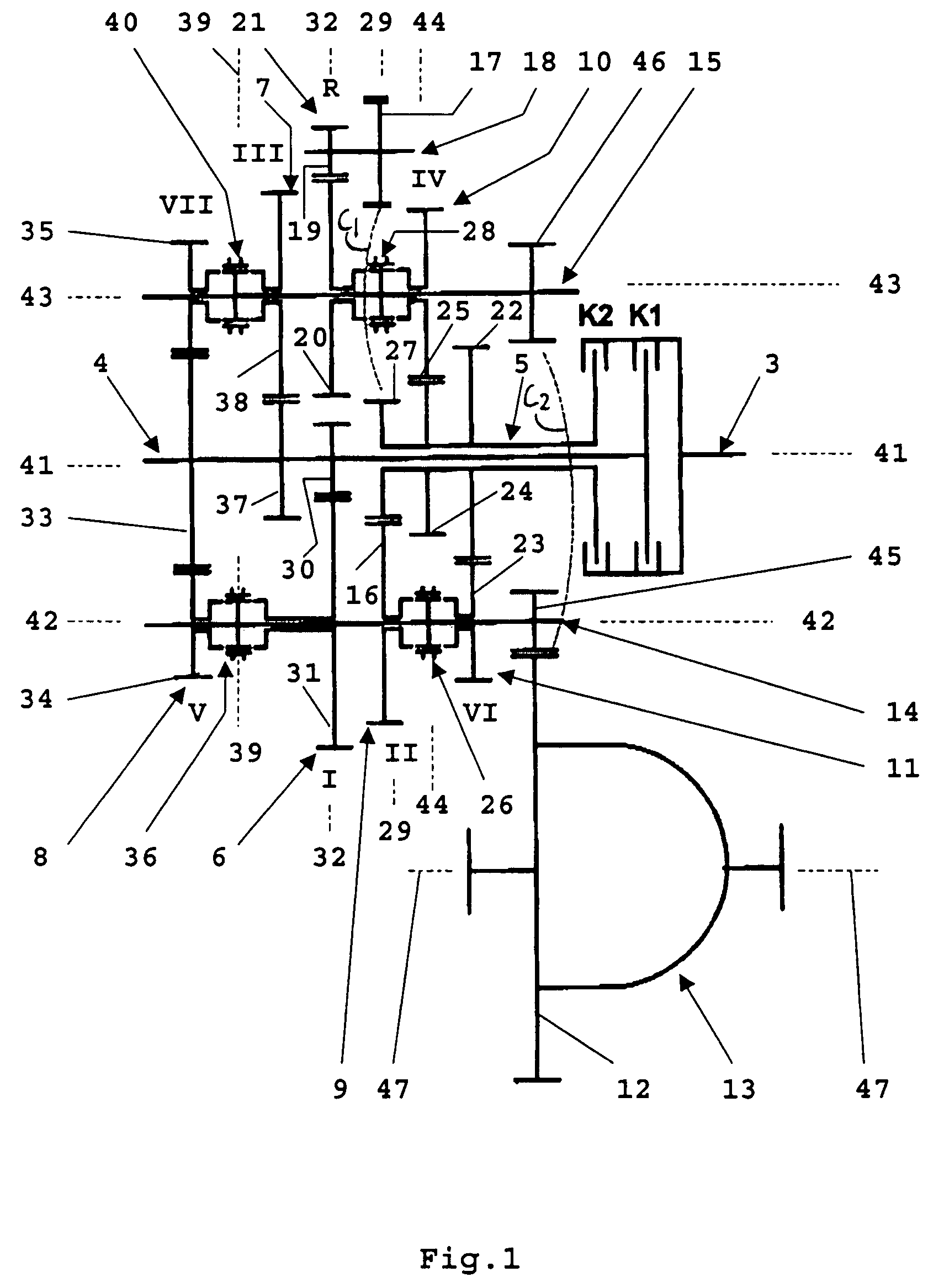

In a double clutch transmission in which an input shaft can be coupled by two load clutches selectively with a central intermediate shaft and a concentric intermediate shaft and each of the intermediate shafts can be operatively connected by gear stages selectively to a first or a second jackshaft arranged in the power output path to a driven vehicle axle, wherein the jackshafts are arranged parallel to the transmission input and intermediate shafts, the intermediate shafts each have at least one gear firmly mounted thereon which forms the input gear for more than one of the gear stages provided for different transmission gear ratios so as to form a compact transmission arrangement, particularly for transverse engine applications.

Owner:DAIMLER AG

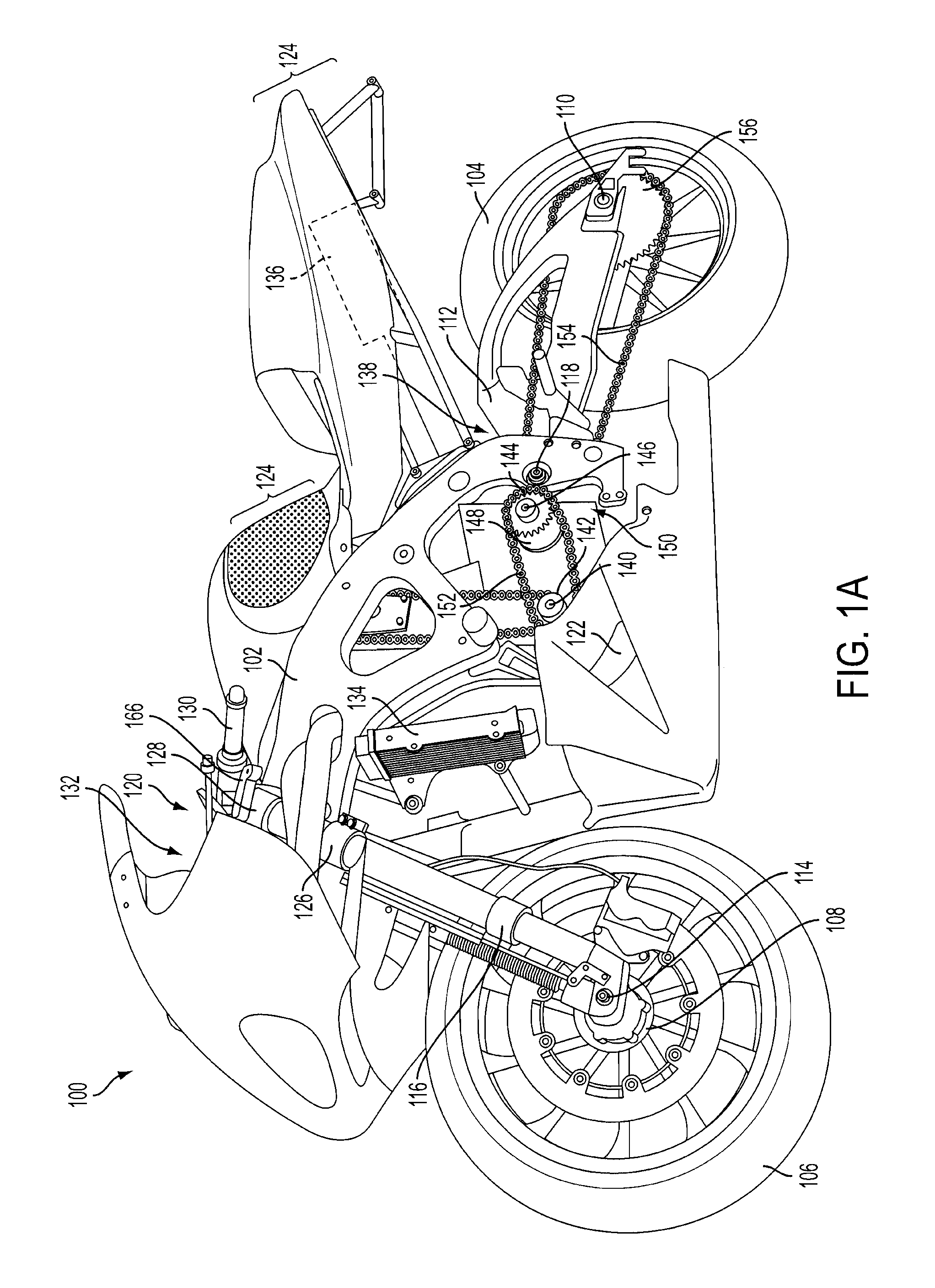

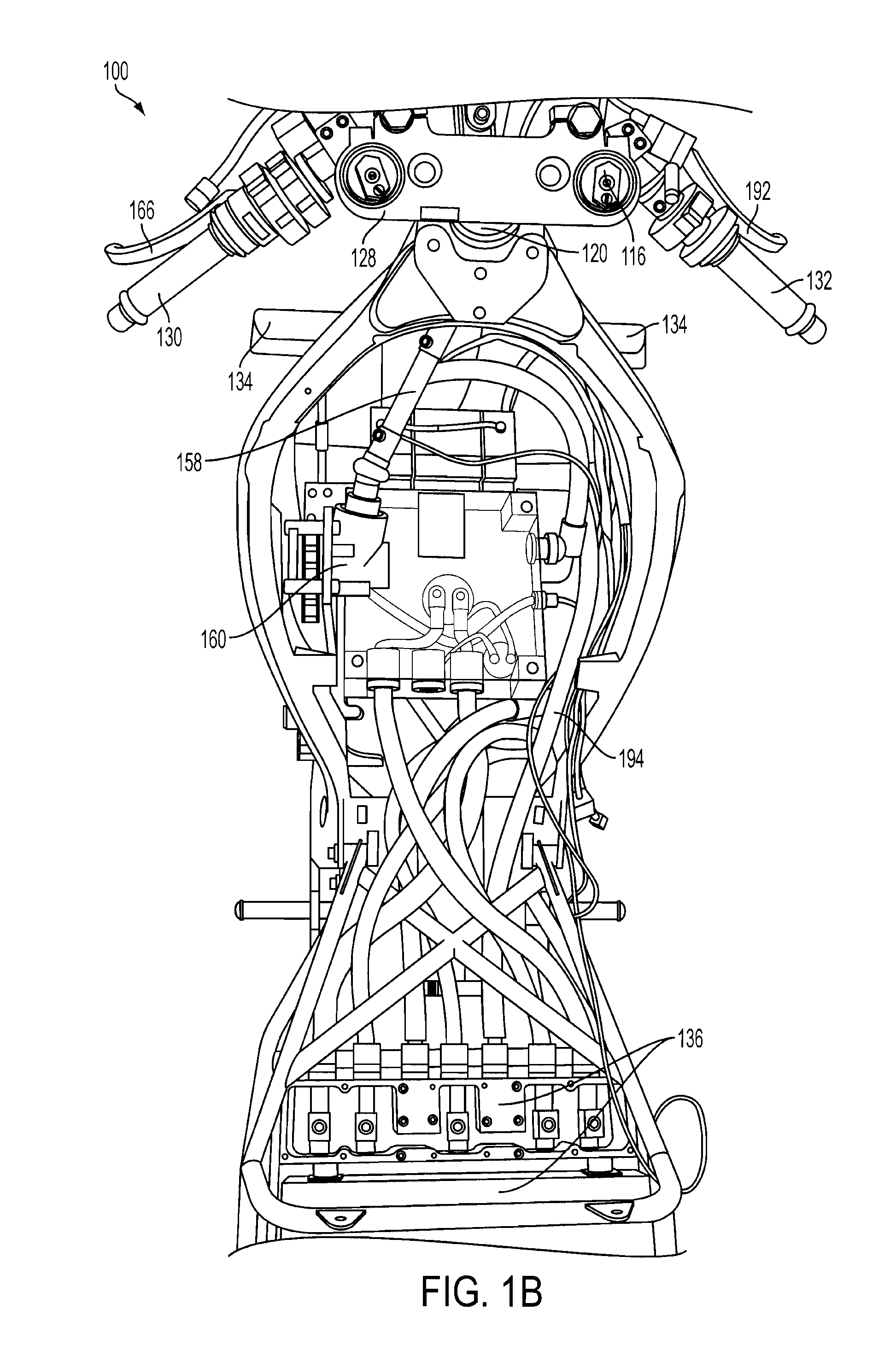

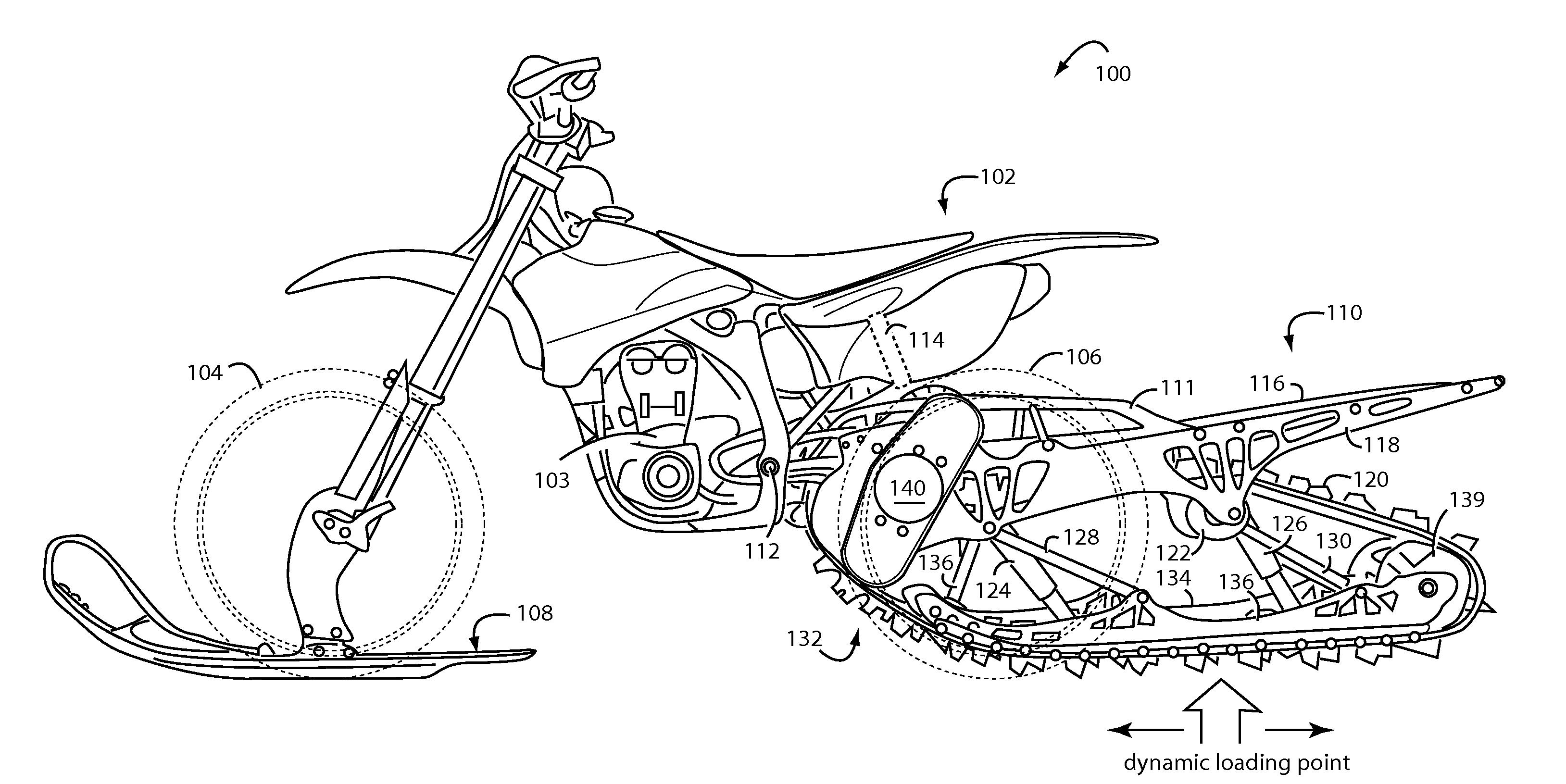

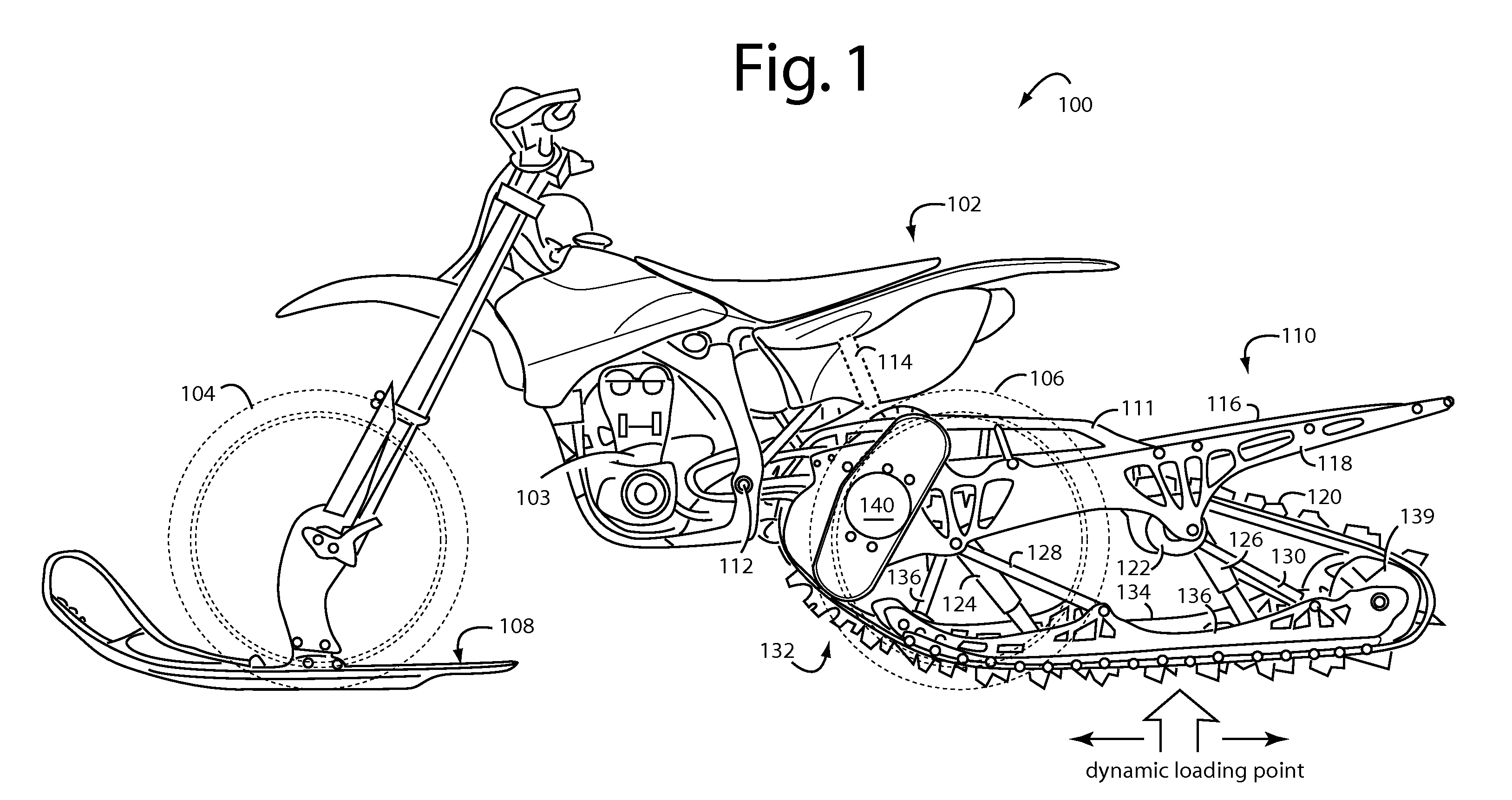

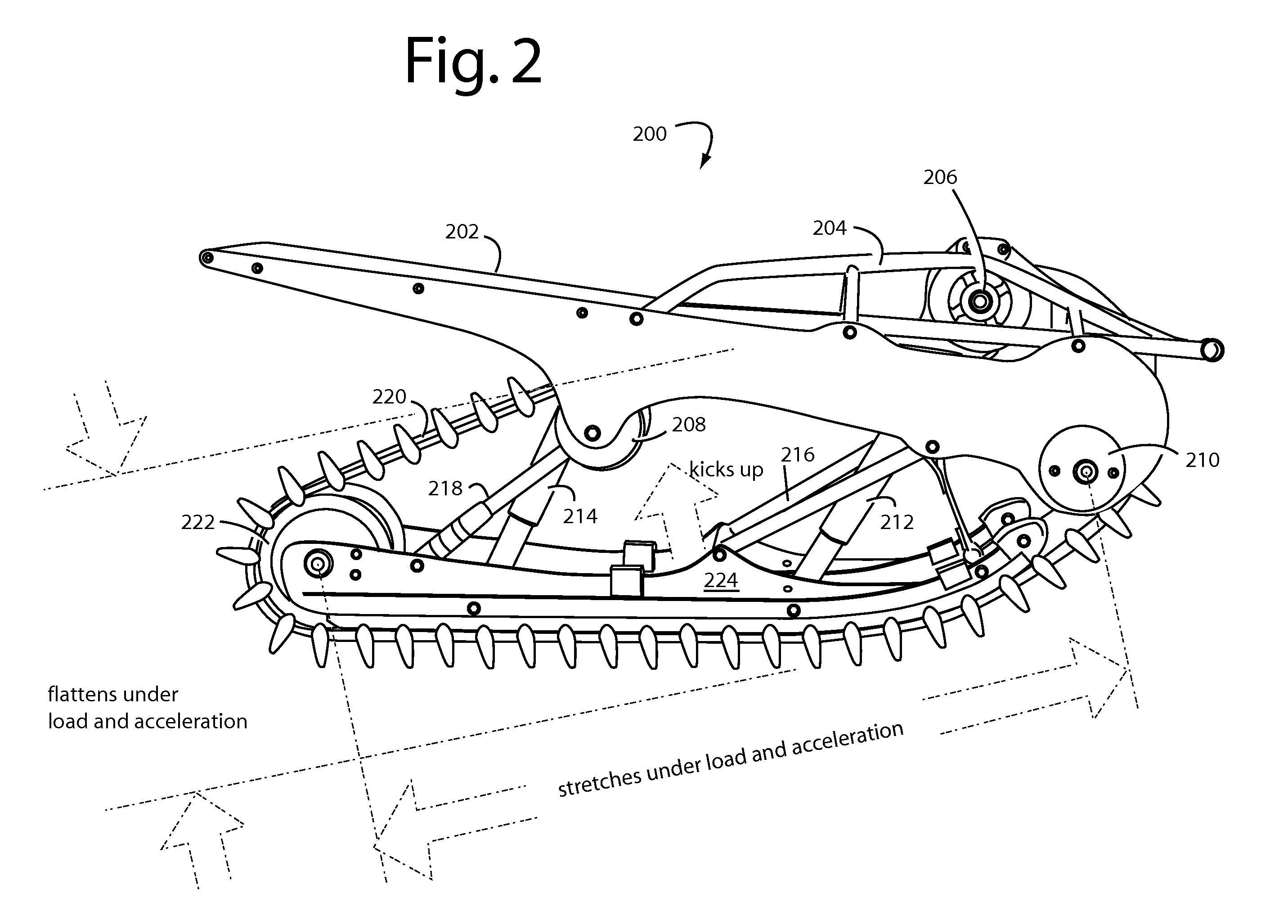

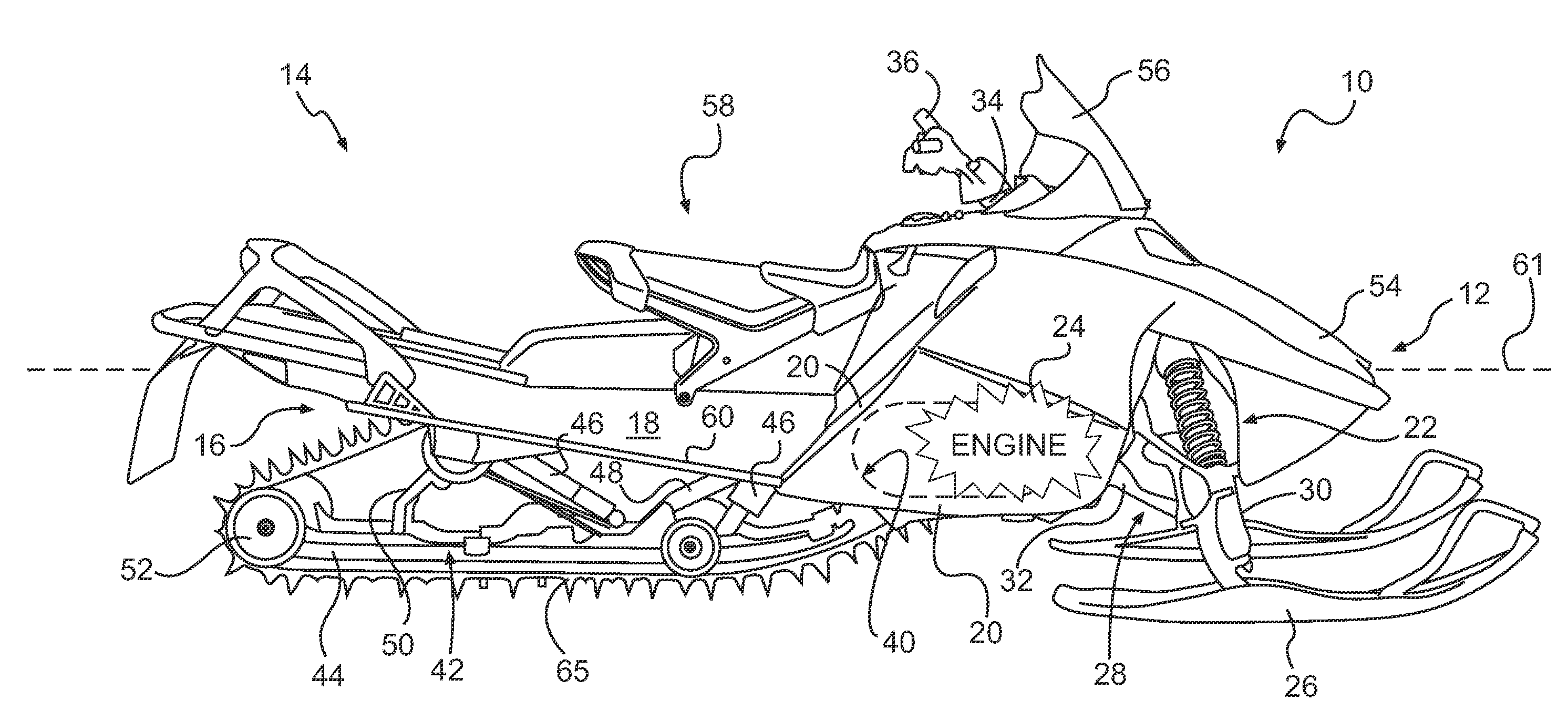

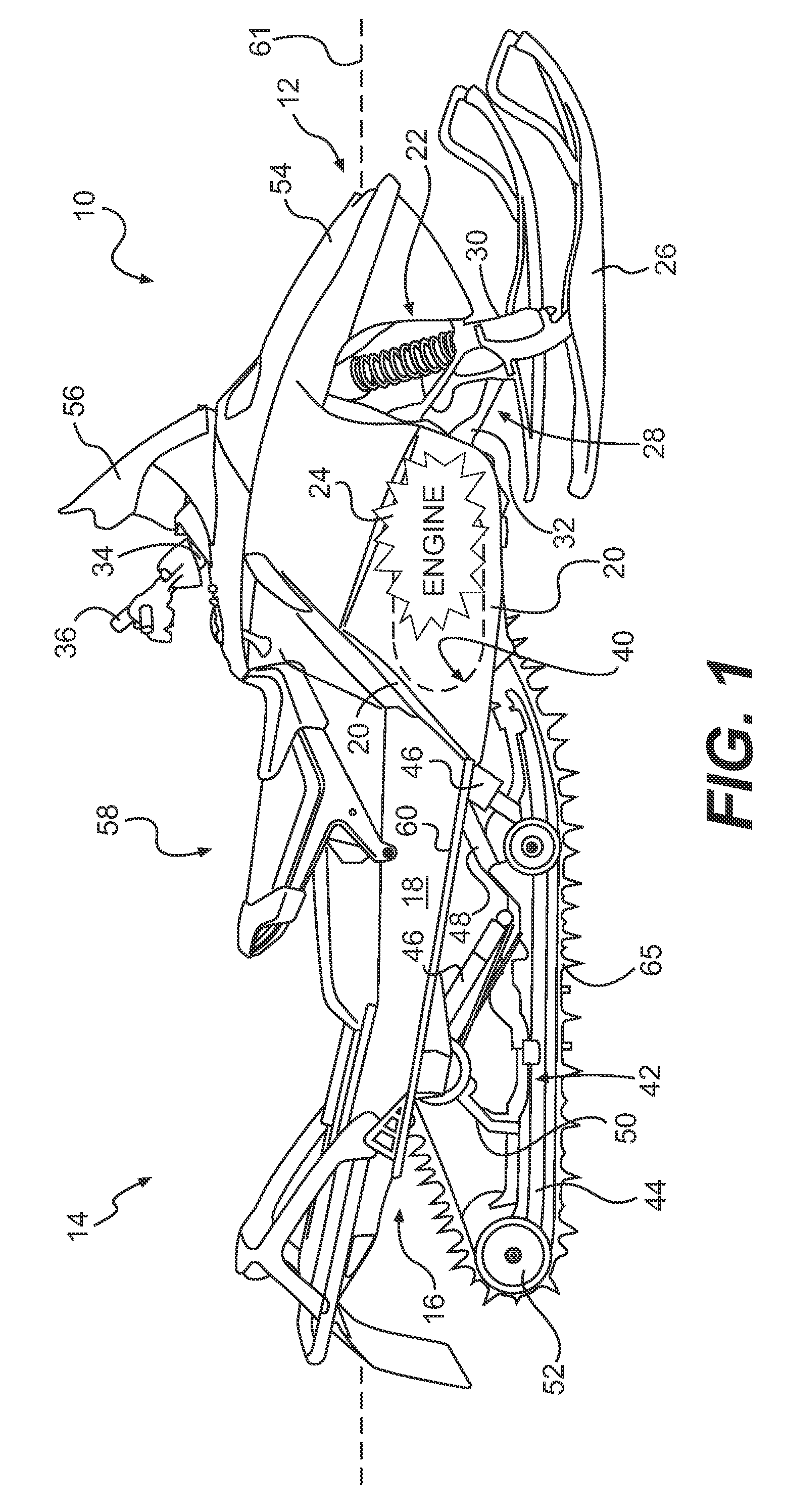

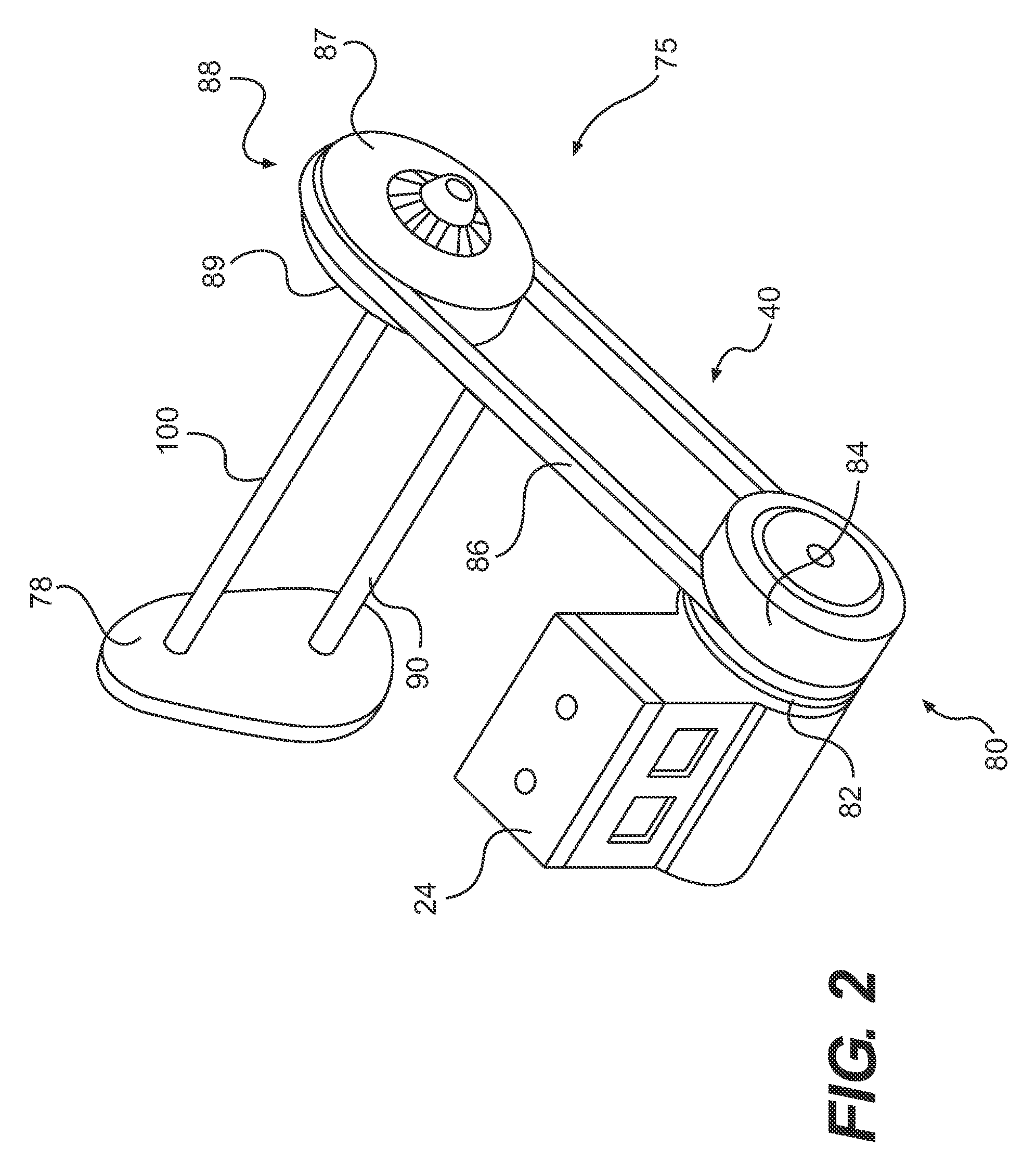

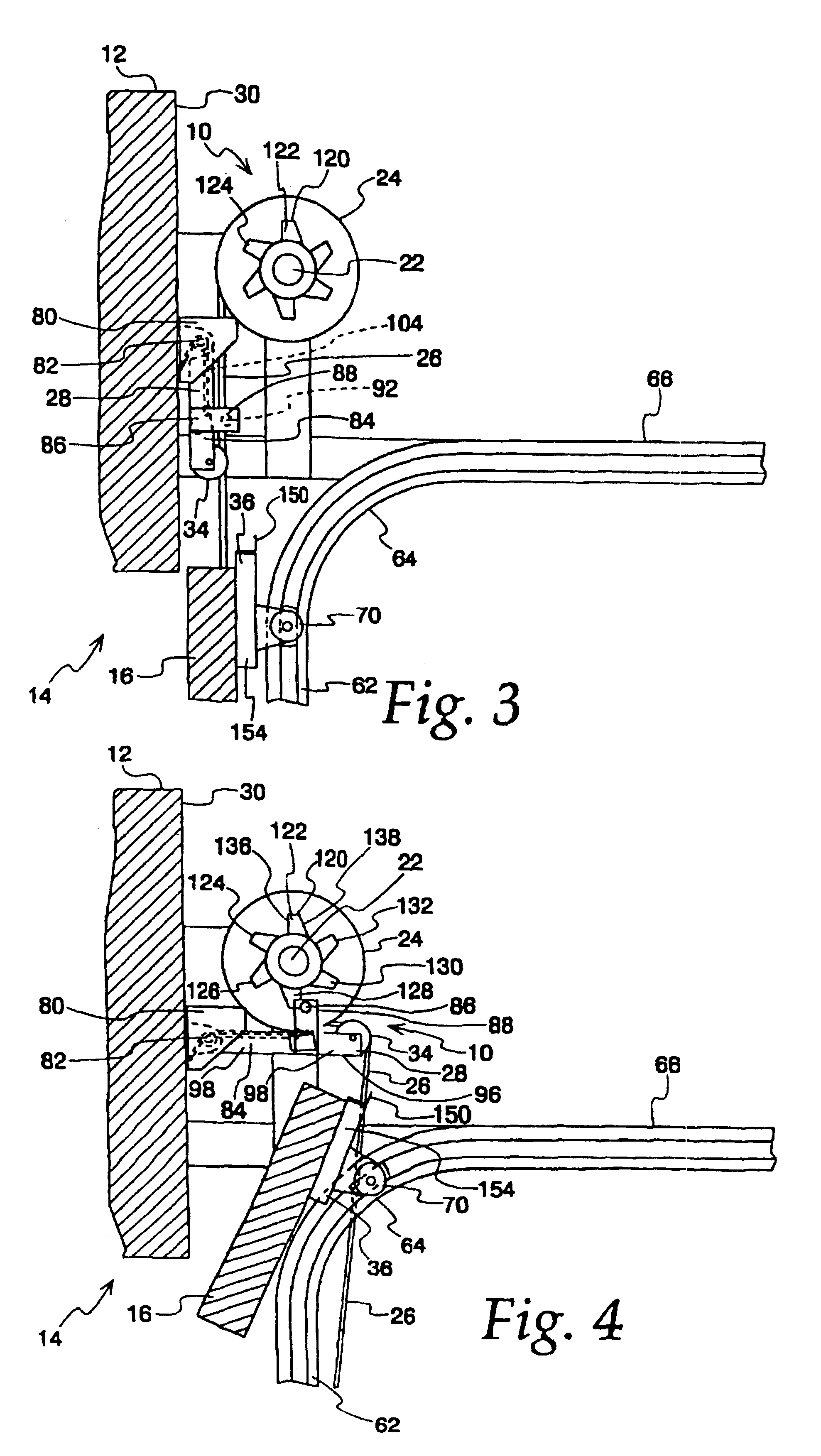

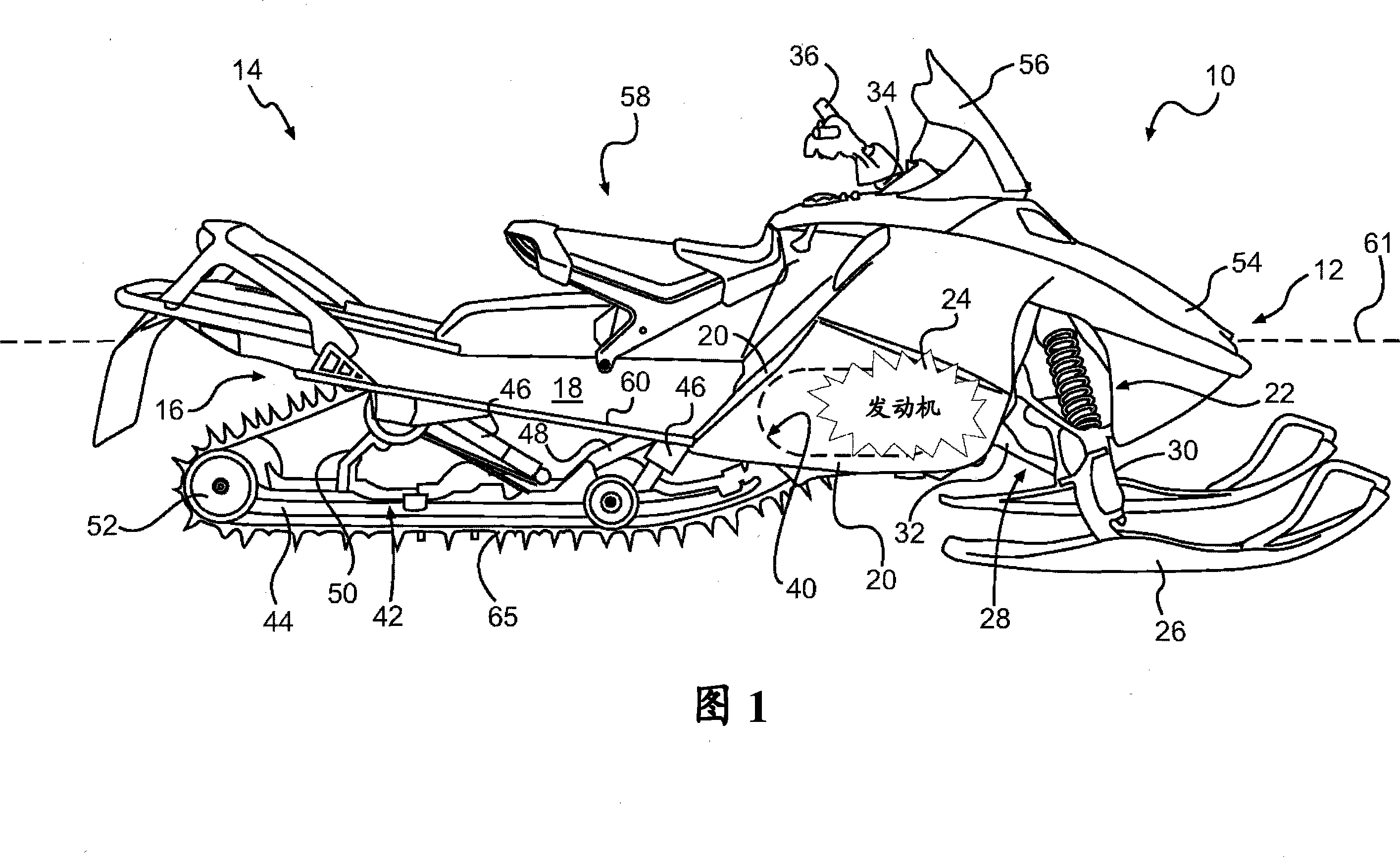

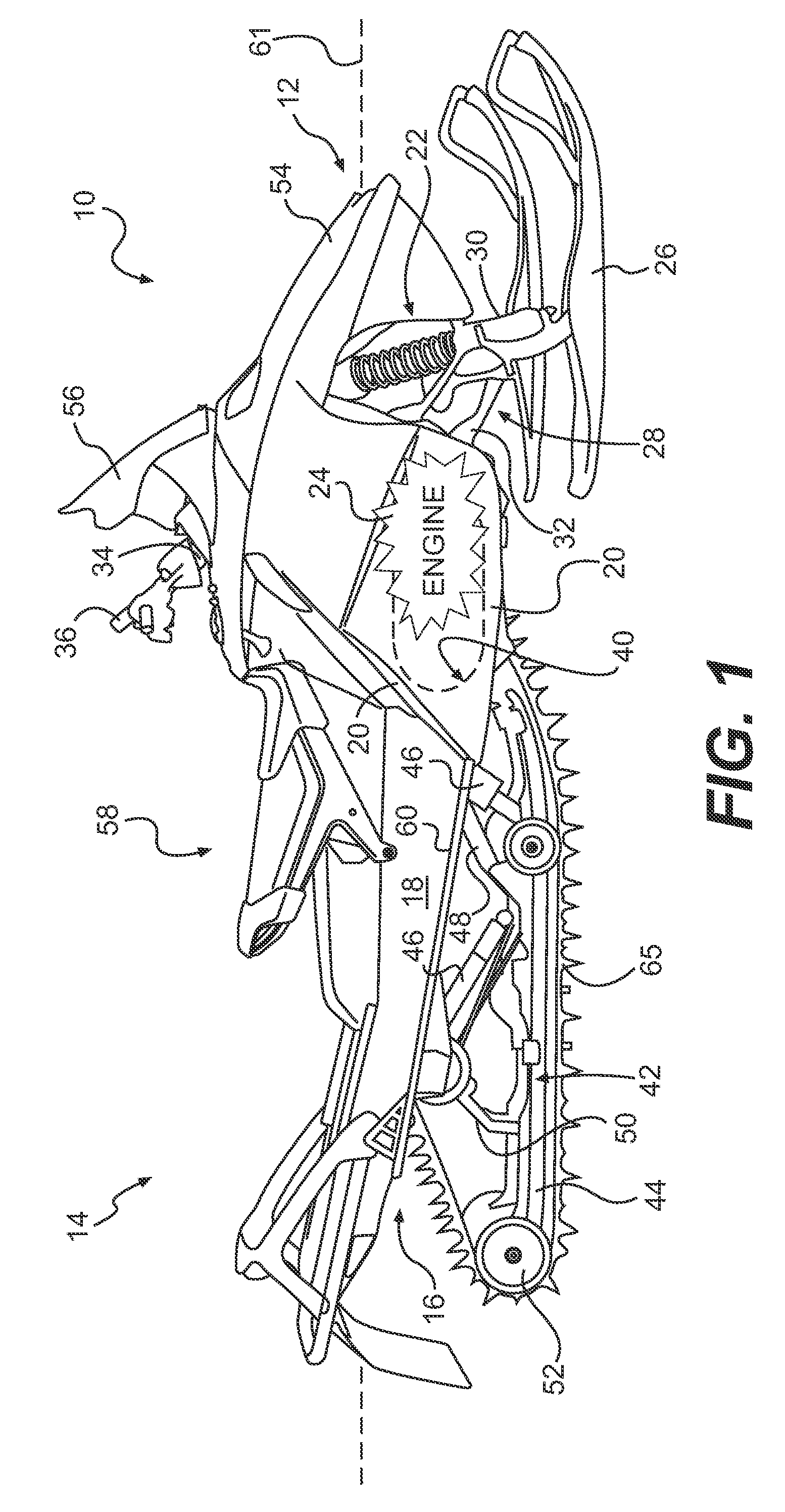

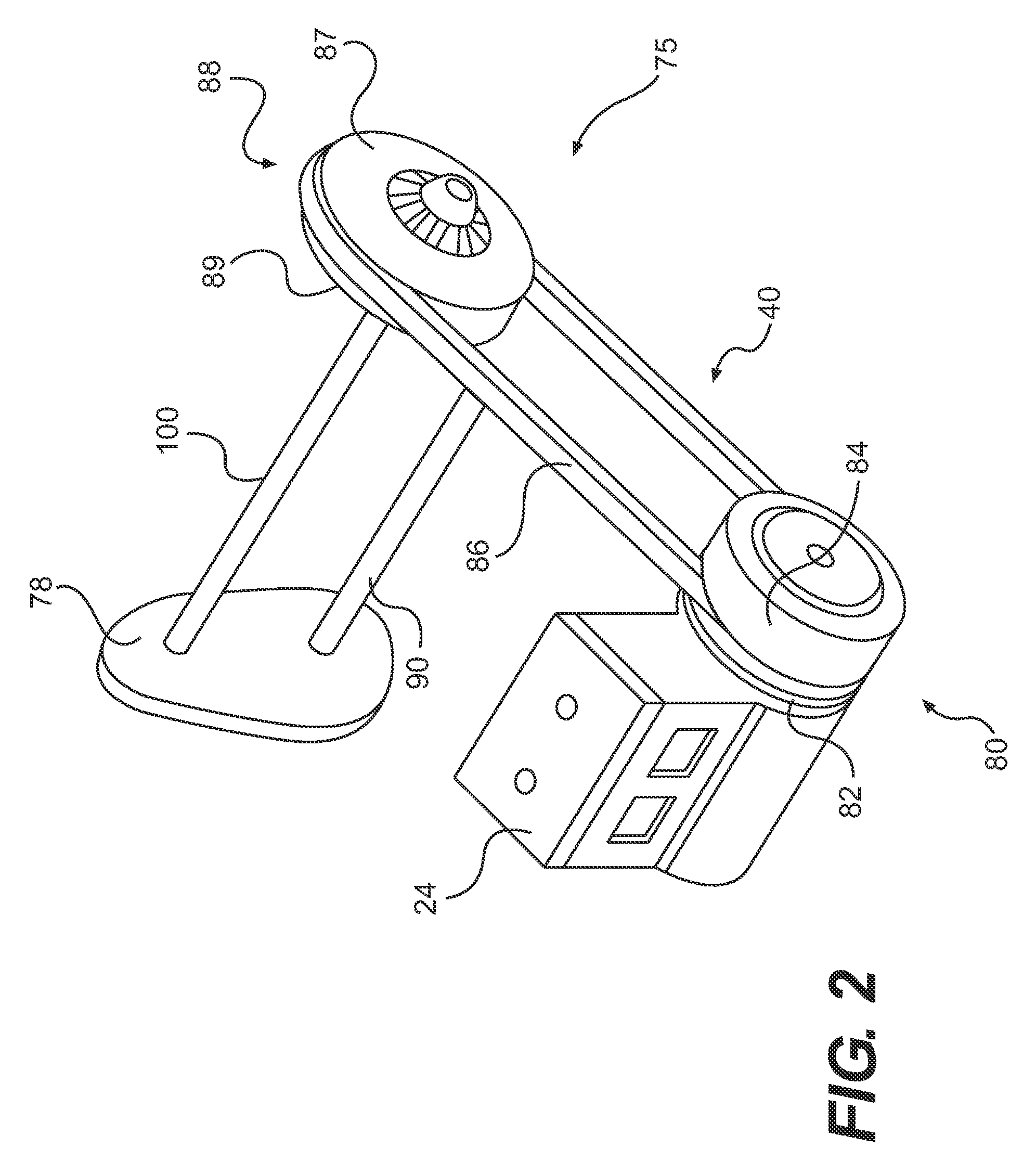

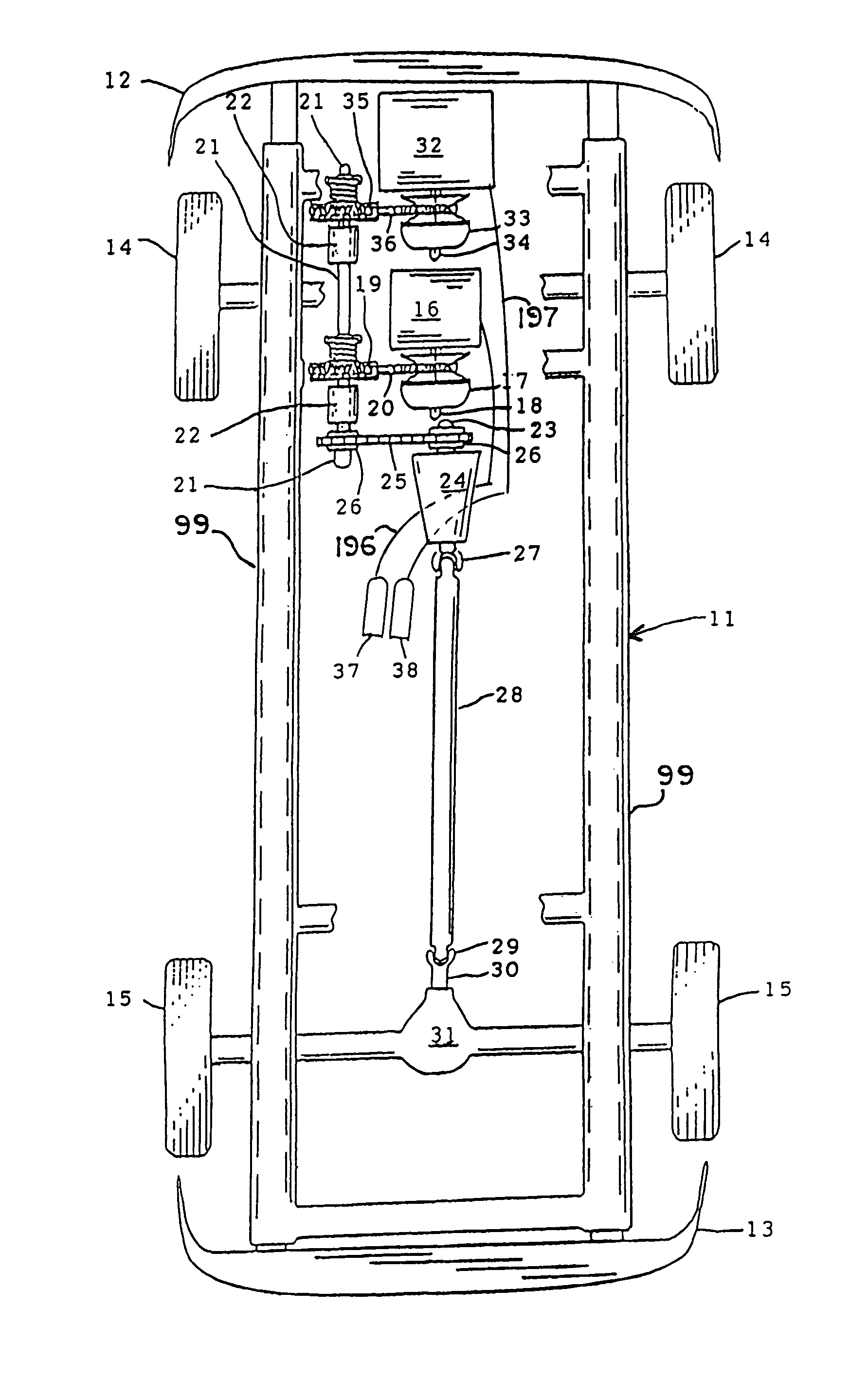

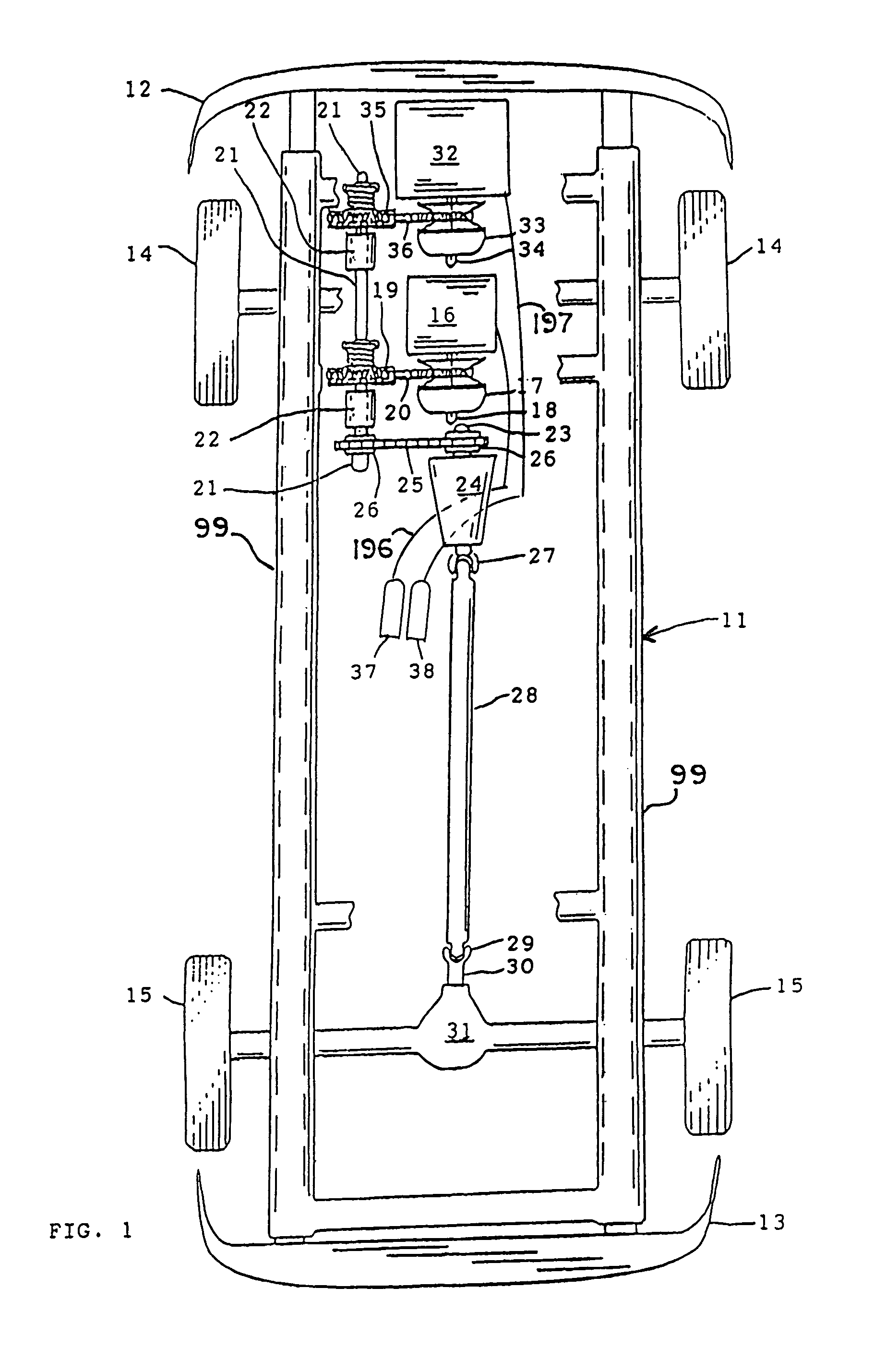

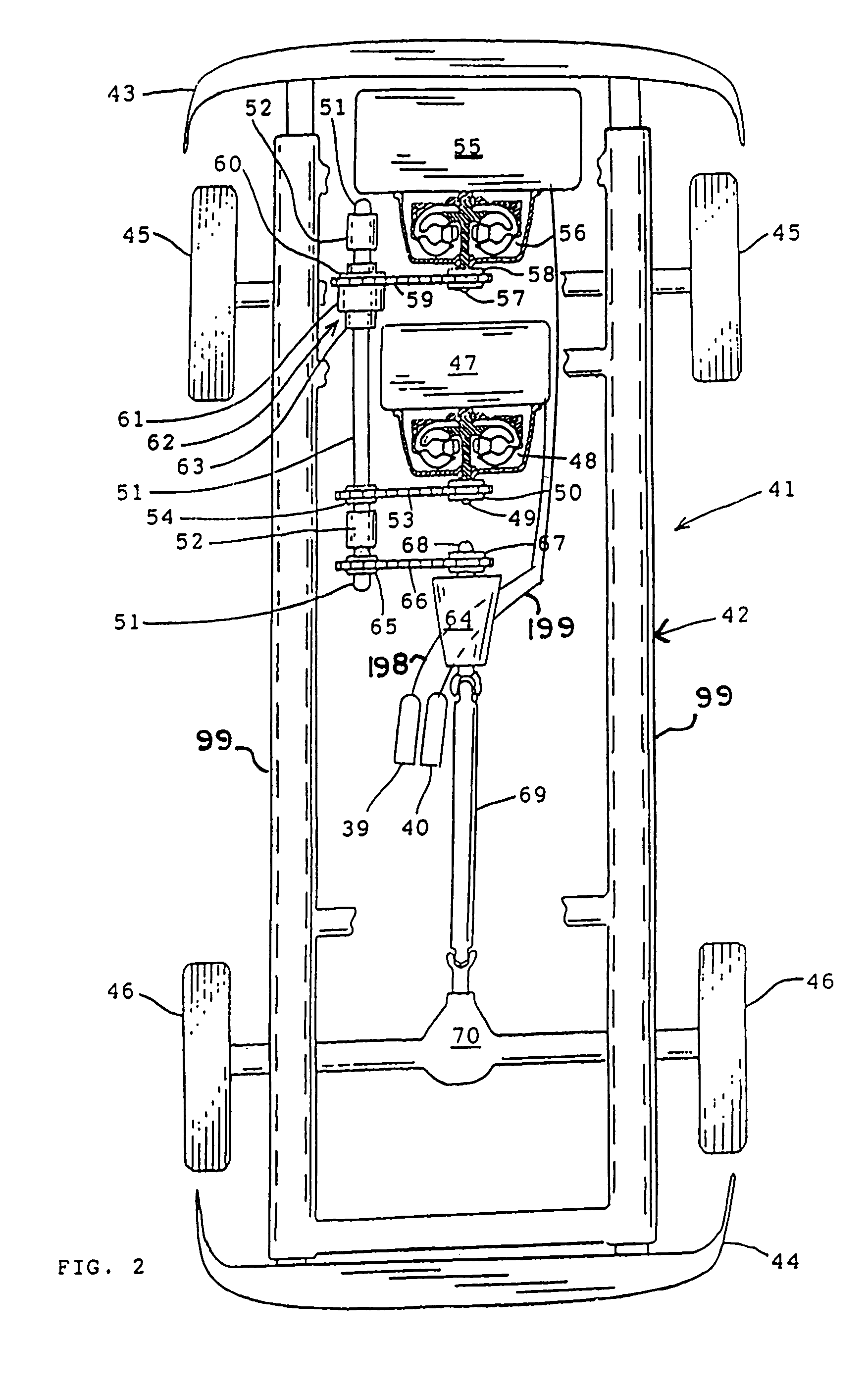

Snow bike conversion system

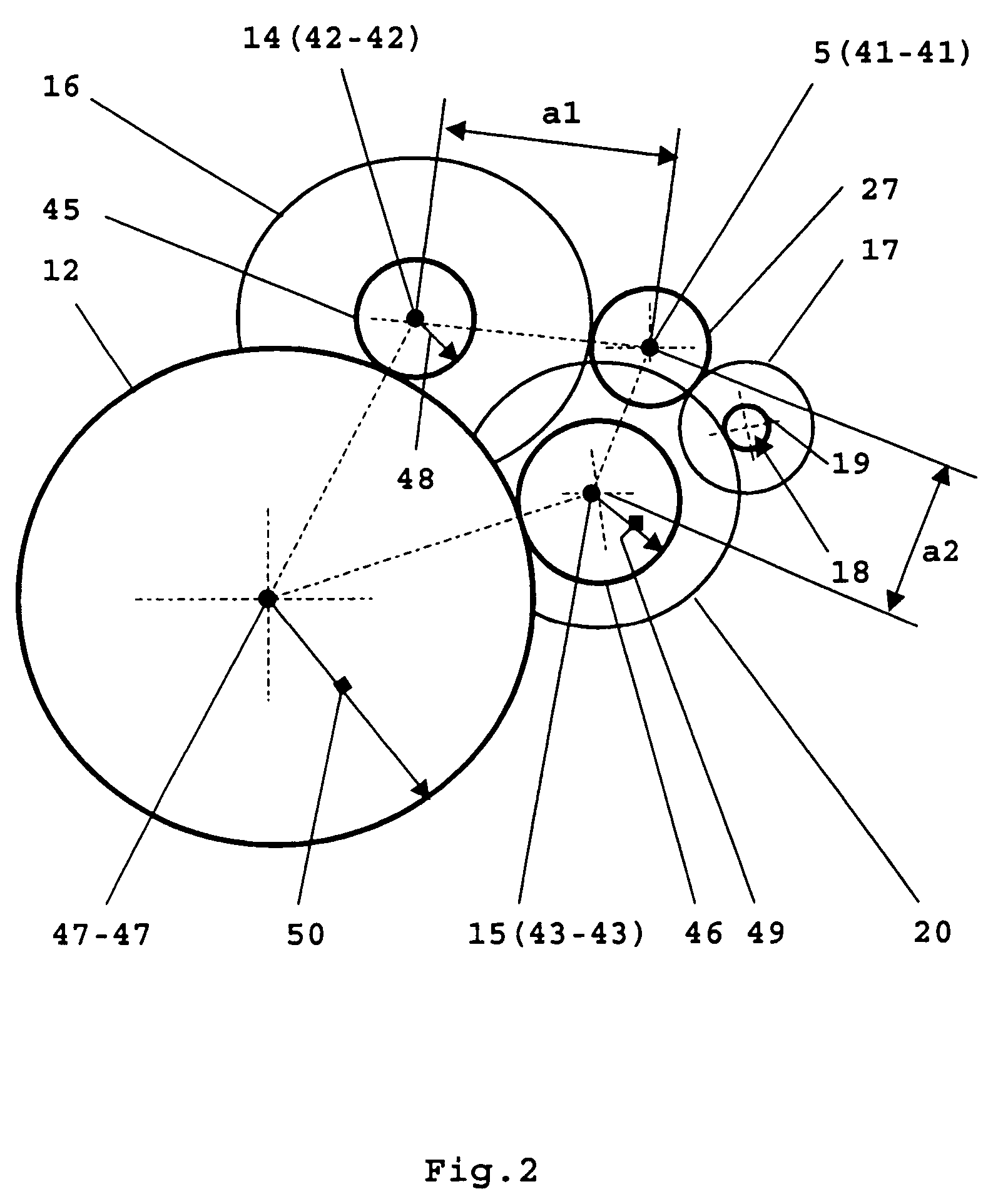

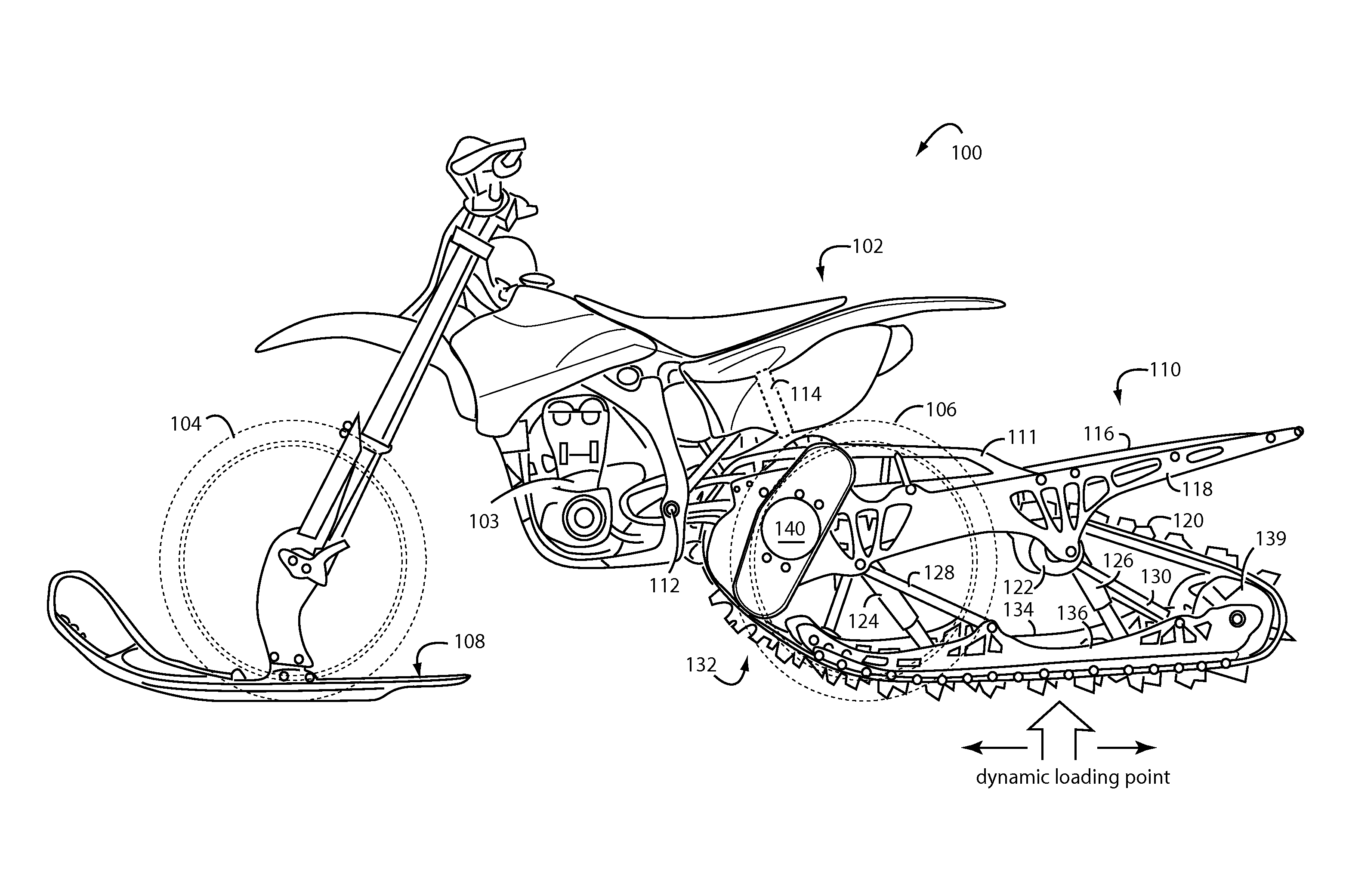

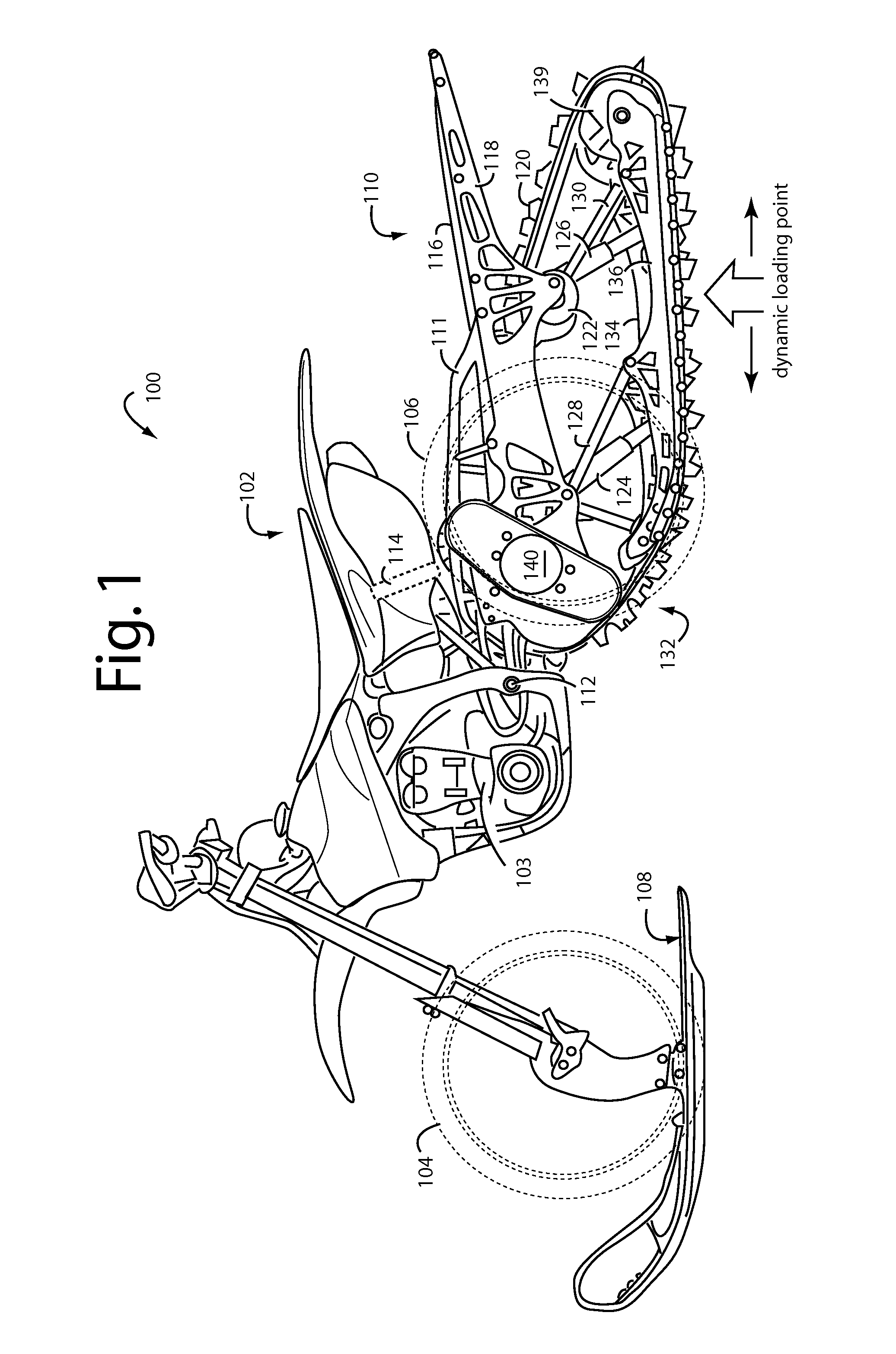

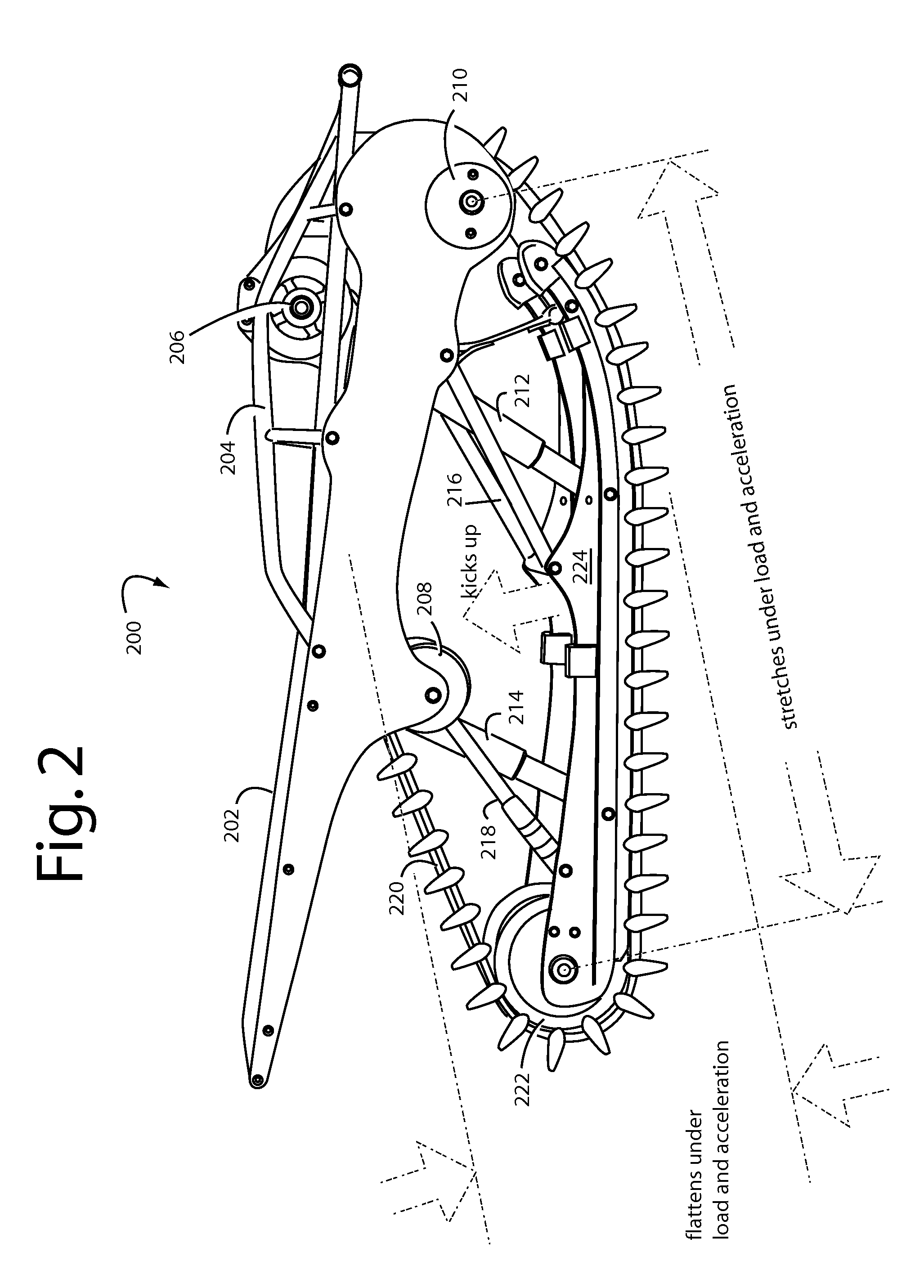

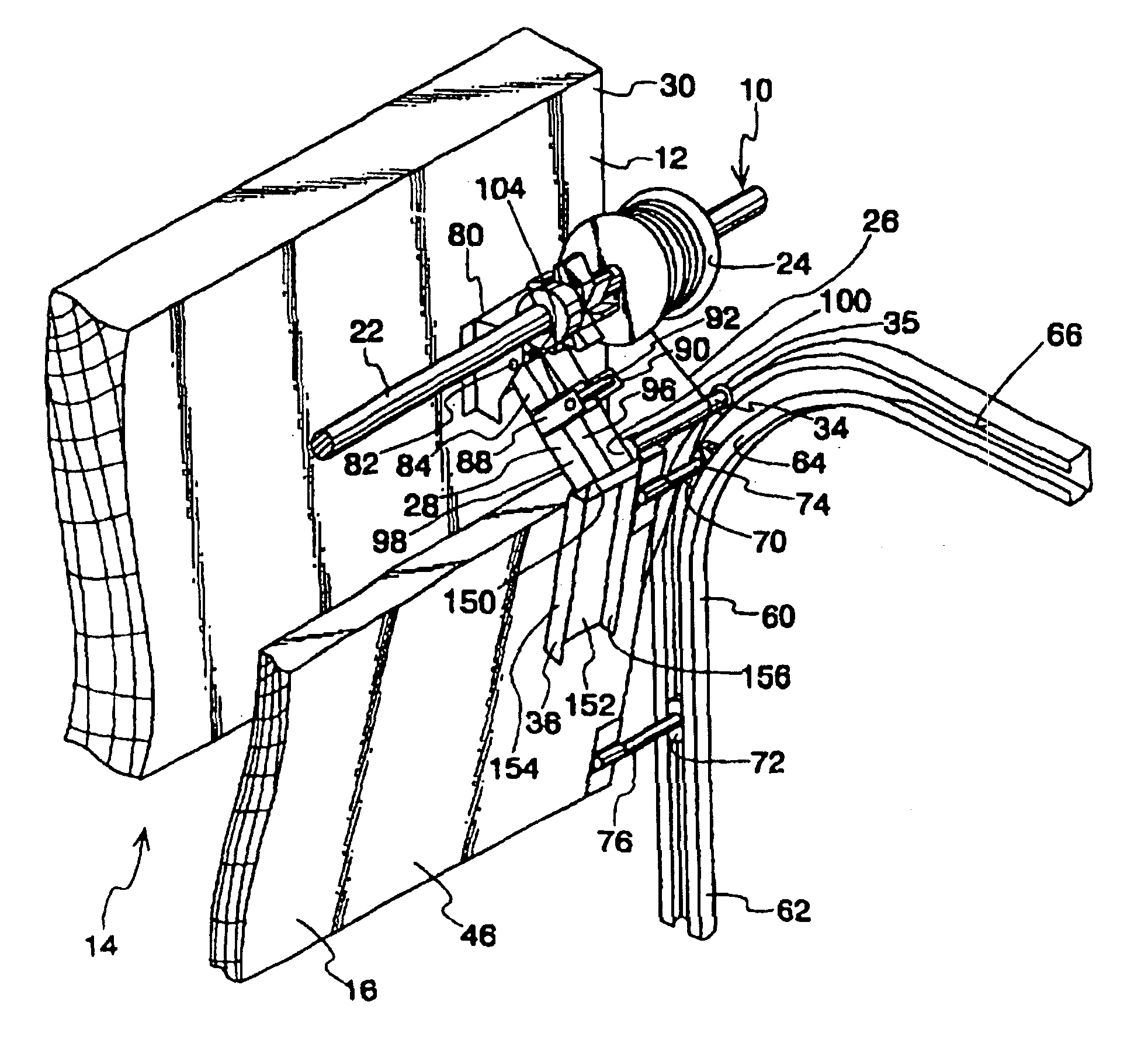

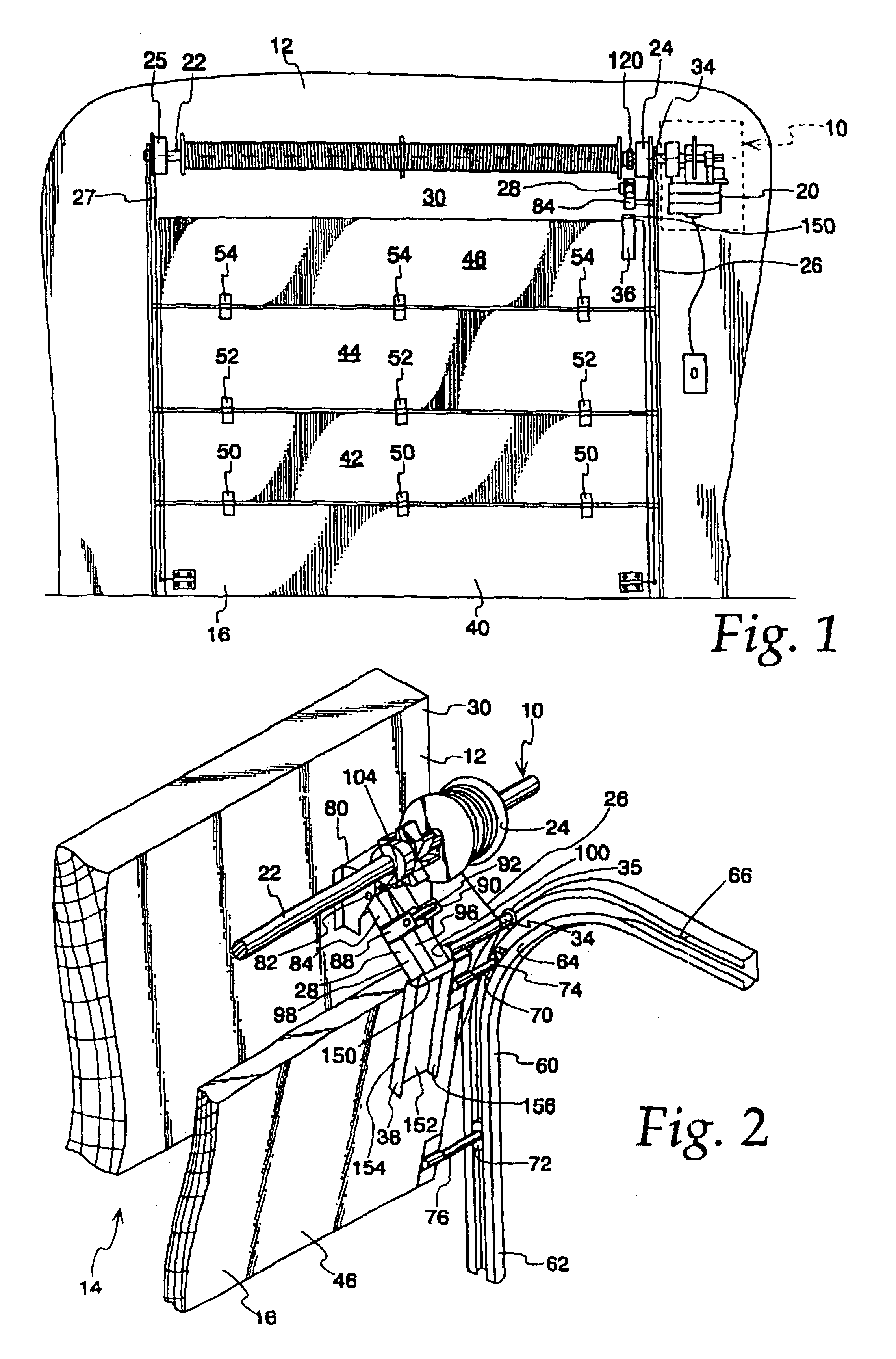

A snow bike system includes a motorcycle converted for use in the snow with a rear suspension and belt track system. The belt track is relatively very wide and driven by a front wheel sprocket through a jackshaft. Matching shocks and struts in the rear suspension independently equalize the pressure applied to the ground. The rear strut is a sliding extension type that causes the front of the sliders to kick up when fully compressed during acceleration or climbing uphill. Increased weight on the rear track is shifted forward to keep the front ski down. The jackshaft provides both disc braking and moves the motorcycle engine drive power outboard to accommodate the wider belt track. A tubular subframe and tunnel rigidly mounts to the motorcycle's original rear swing arm pivots and shock mounts.

Owner:POLARIS IND INC

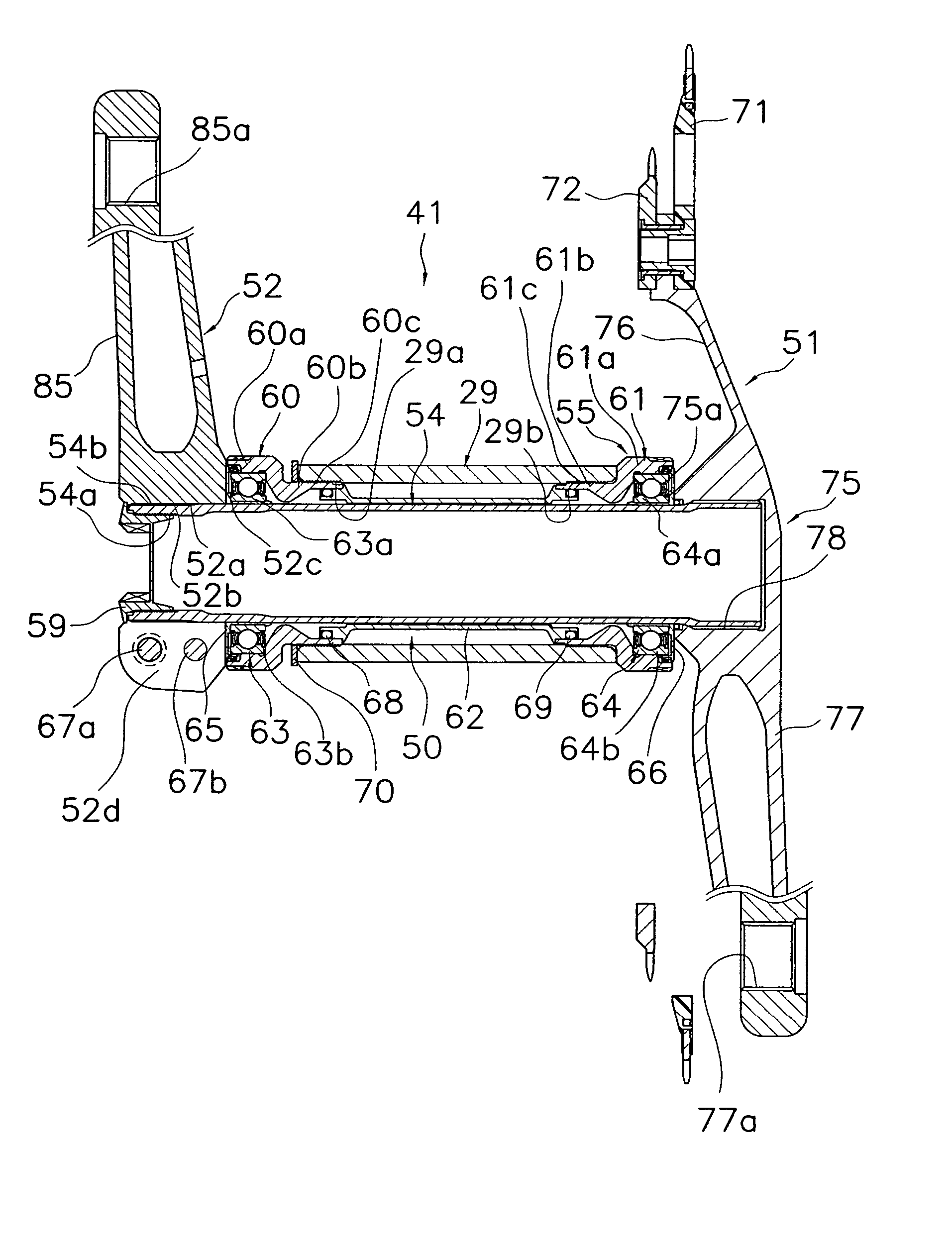

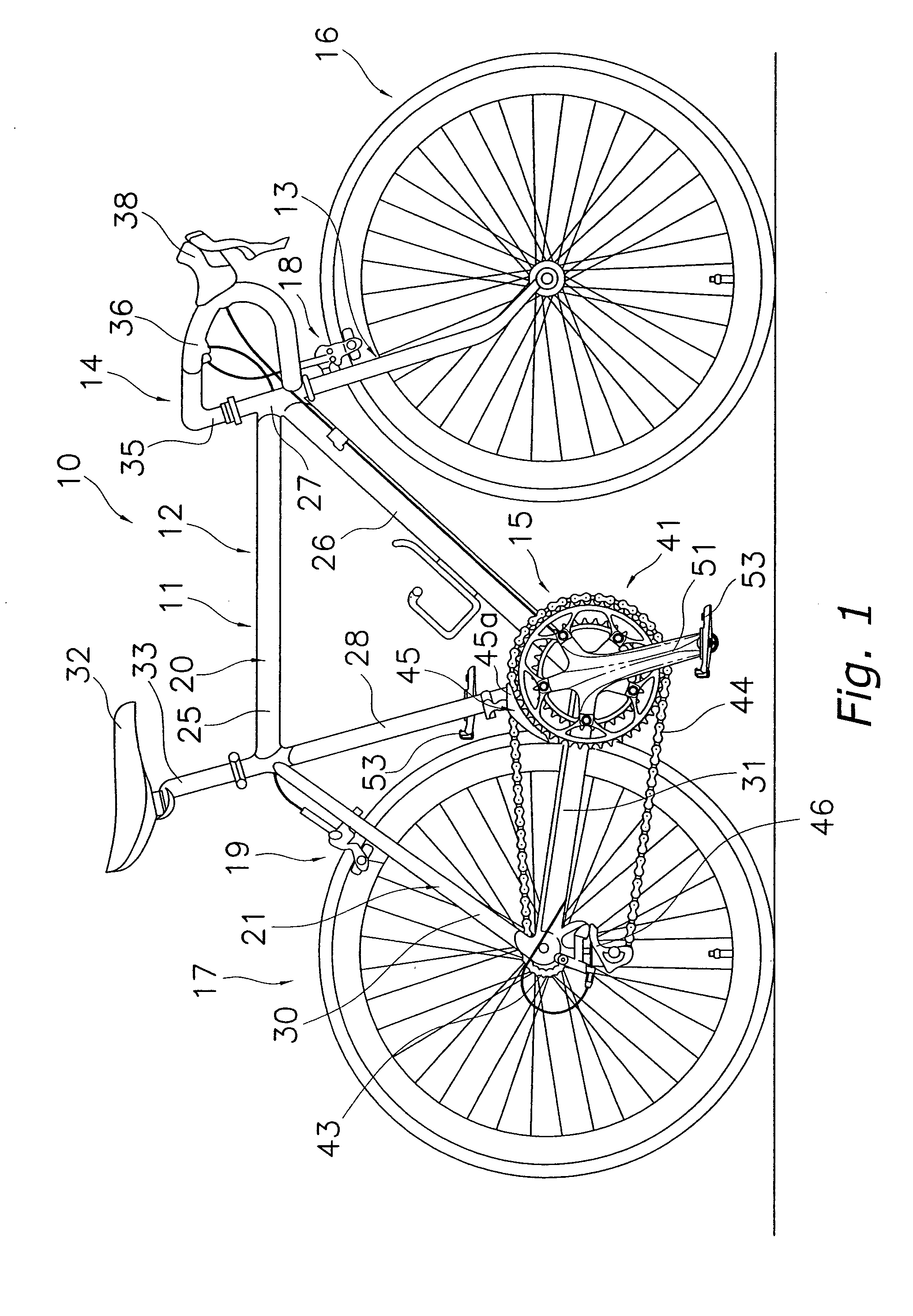

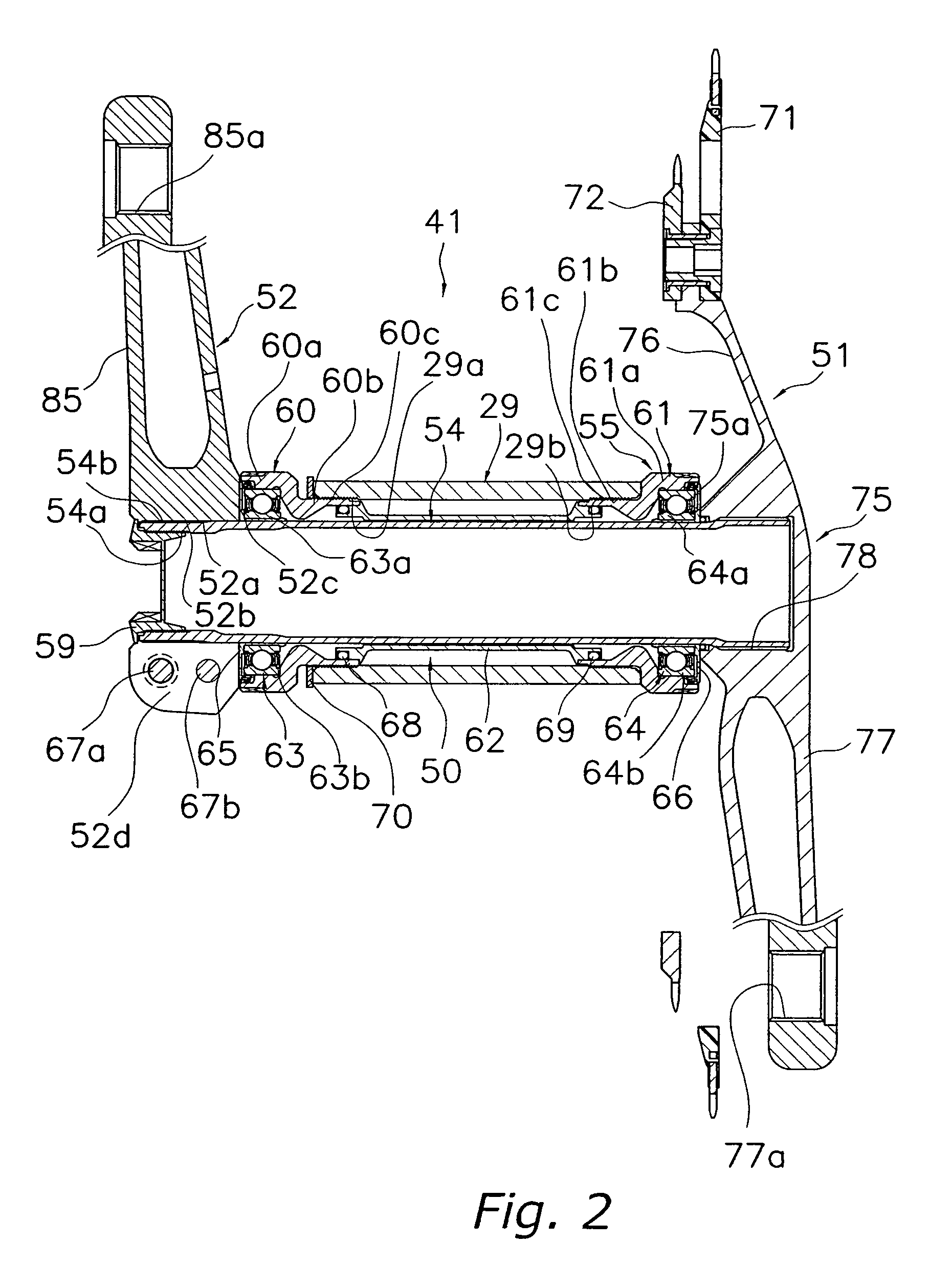

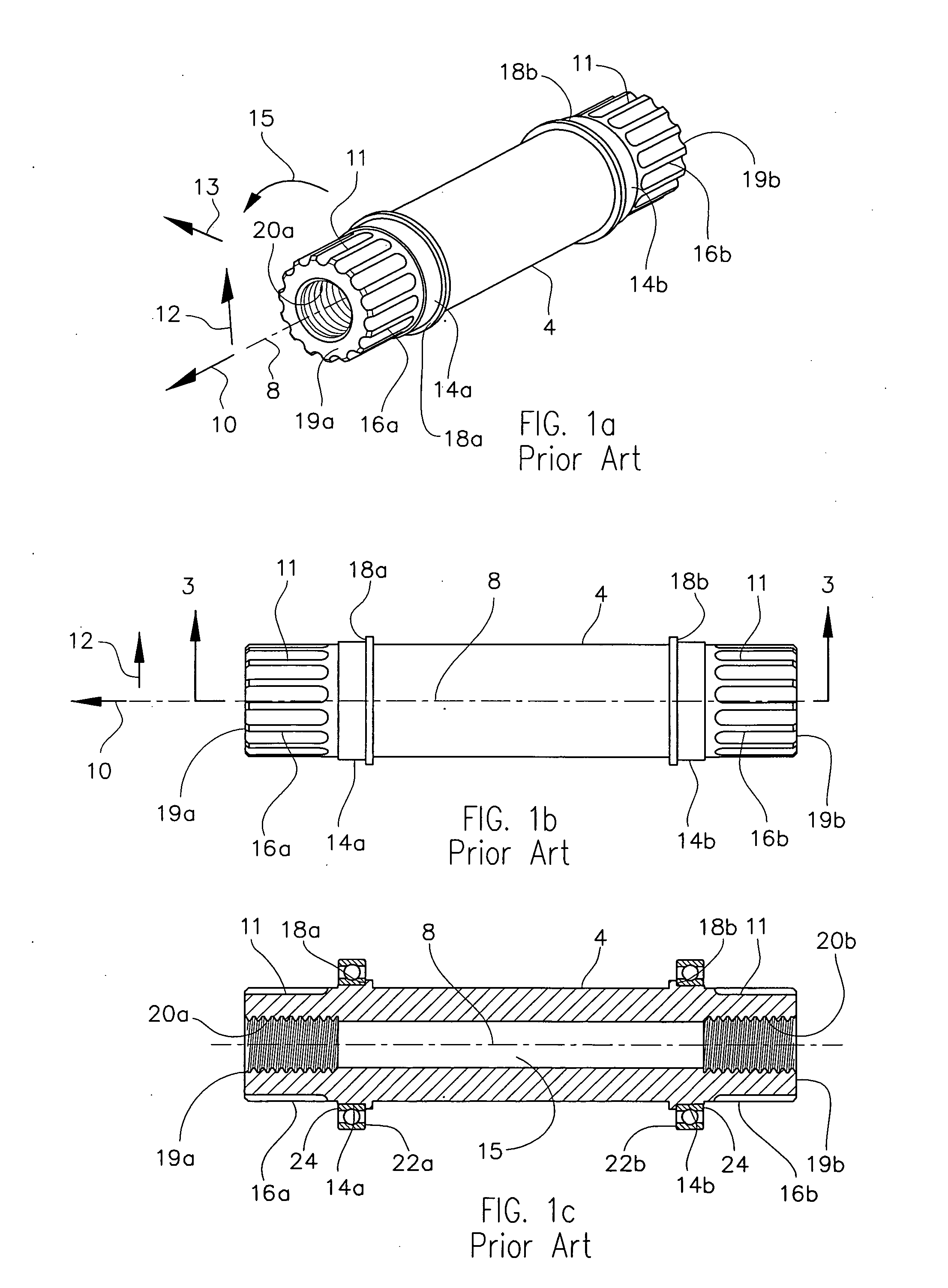

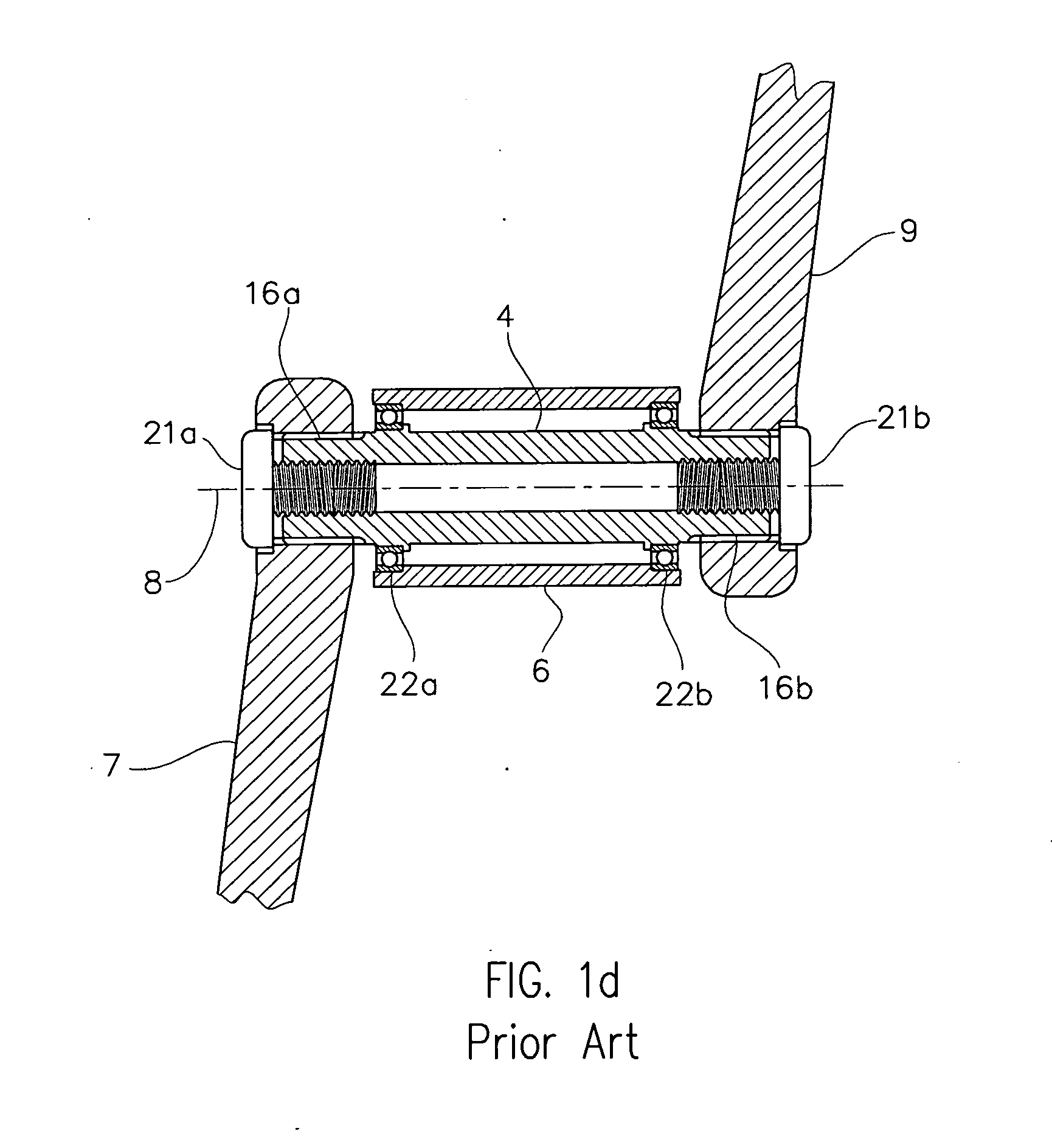

Bicycle crank axle bearing assembly

A bicycle crank axle bearing assembly includes a pair of first and second axle support members, a pair of first and second bearings and a lock nut. The first and second axle support members include first and second mounting sections with first and second male screw parts that are configured and arranged to be non-rotatably coupled to a hanger part of a bicycle frame, and first and second bearing retaining sections in which the first and second bearings are retained to rotatably support a crank axle. The lock nut is disposed at least one of the first and second male screw parts of the first and second axle support members to retain an axial position of the at least one of the first and second support members with respect to the hanger part.

Owner:SHIMANO INC

Snow bike conversion system

A snow bike system includes a motorcycle converted for use in the snow with a rear suspension and belt track system. The belt track is relatively very wide and driven by a front wheel sprocket through a jackshaft. Matching shocks and struts in the rear suspension independently equalize the pressure applied to the ground. The rear strut is a sliding extension type that causes the front of the sliders to kick up when fully compressed during acceleration or climbing uphill. Increased weight on the rear track is shifted forward to keep the front ski down. The jackshaft provides both disc braking and moves the motorcycle engine drive power outboard to accommodate the wider belt track. A tubular subframe and tunnel rigidly mounts to the motorcycle's original rear swing arm pivots and shock mounts.

Owner:POLARIS IND INC

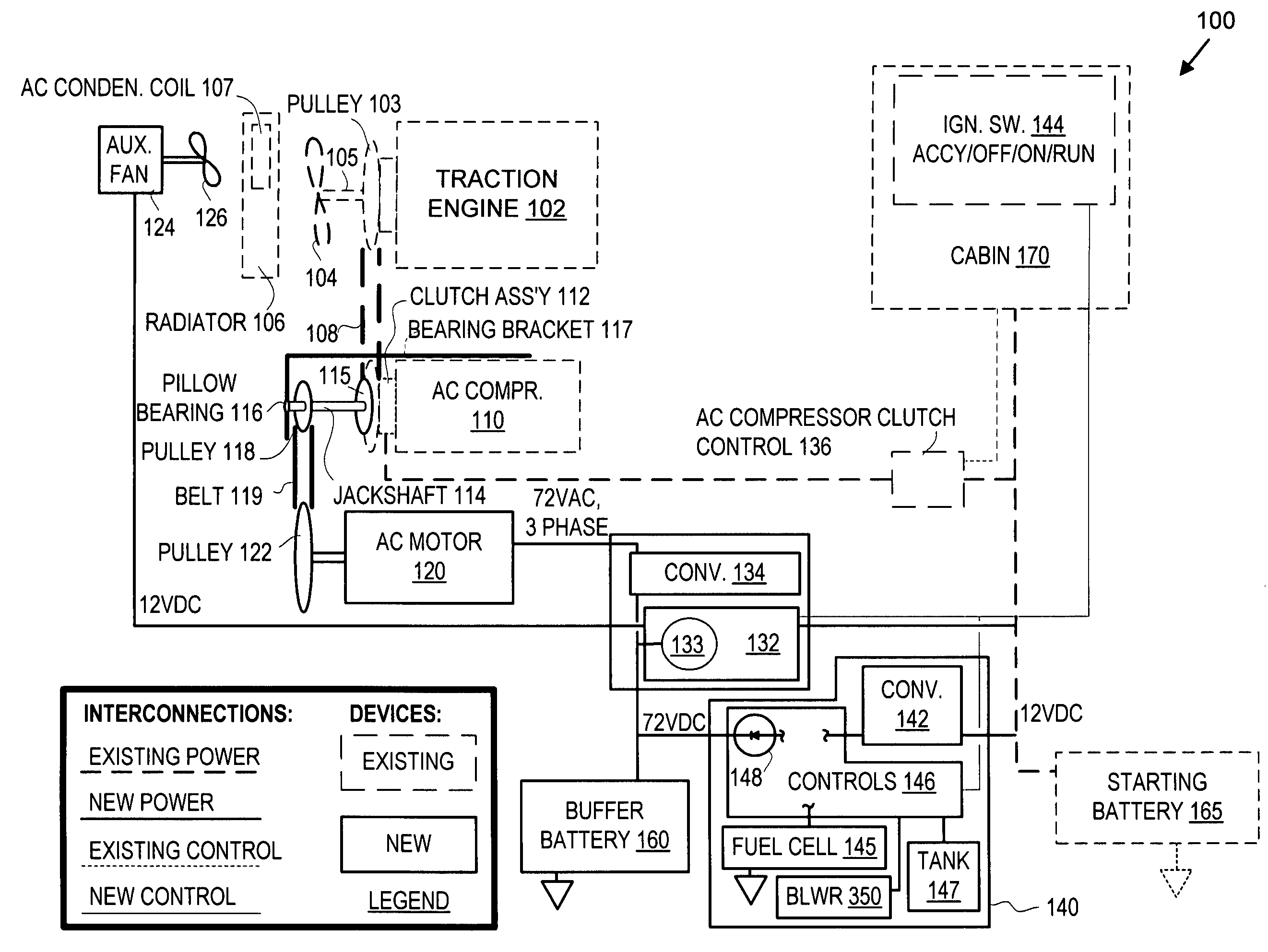

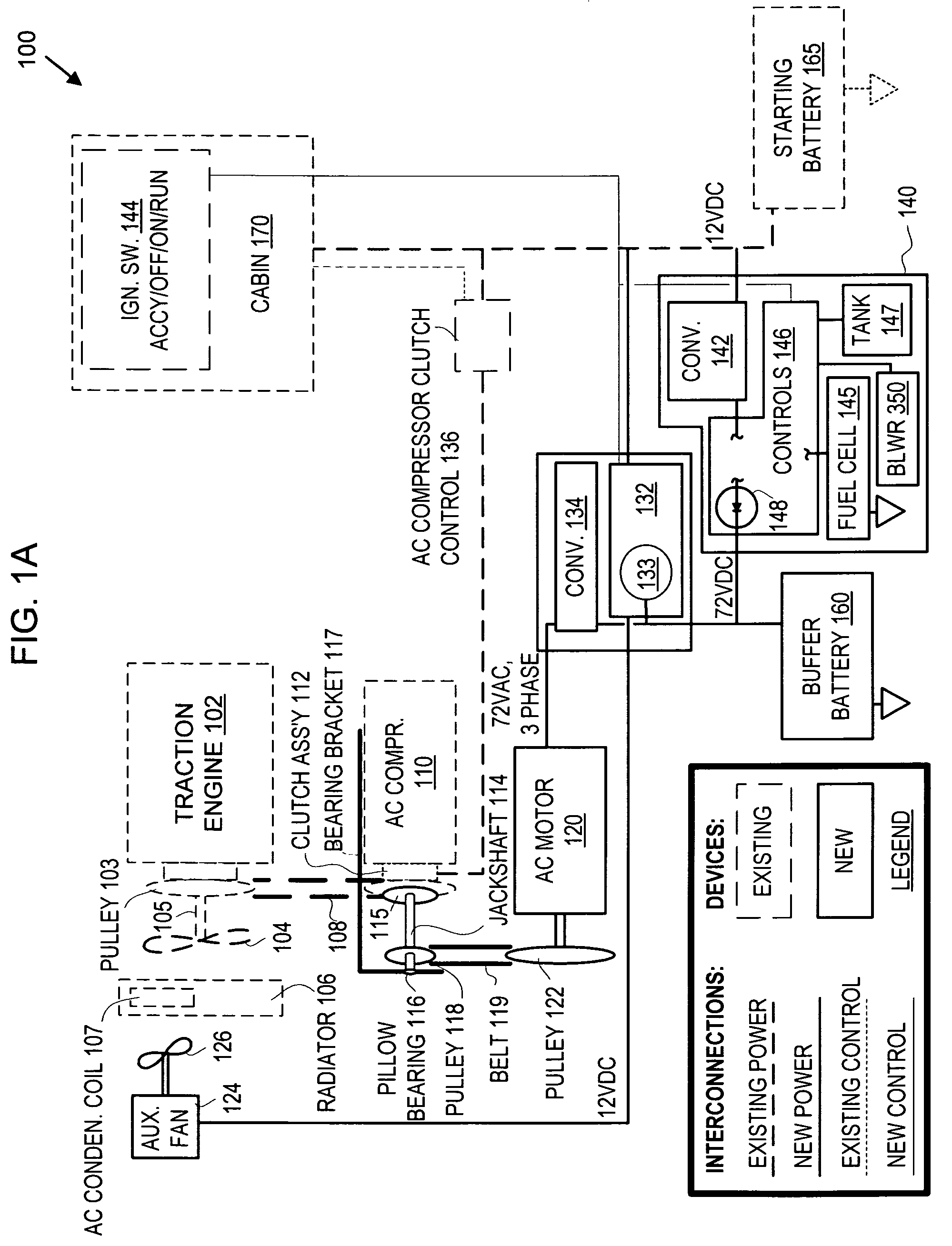

Method and auxiliary system for operating a comfort subsystem for a vehicle

ActiveUS7543454B2Improve abilitiesAir-treating devicesCompression machines with non-reversible cycleJackshaftDrive shaft

According to one form of the invention, an auxiliary system is provided for supplying air conditioning to the cabin of a truck. The system includes an air conditioning compressor having a jackshaft mounted on a hub of the compressor. The system further includes an electric motor connected to the jackshaft by a belt for the motor, wherein the electric motor has a drive shaft and a pulley rigidly secured thereon, i.e., with no clutch and with no provision for slippage of the pulley relative to the drive shaft. The jackshaft has a pulley thereon for the electric motor drive. An end of the jackshaft that is not proximate to the compressor is rotatably held by a bearing and a bearing bracket in order to increase capability of the jackshaft to withstand side loading.

Owner:ENGLAND ANTHONY +1

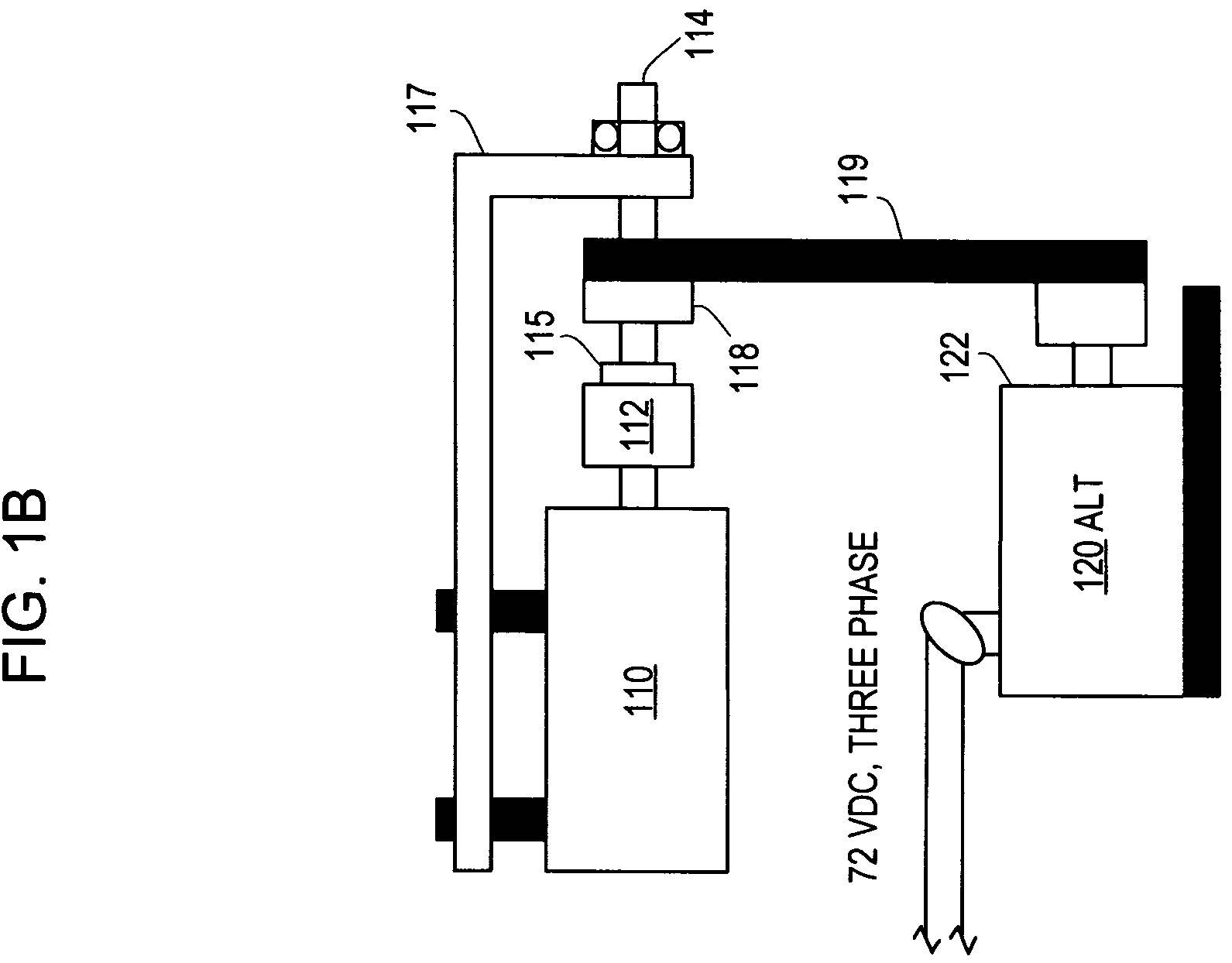

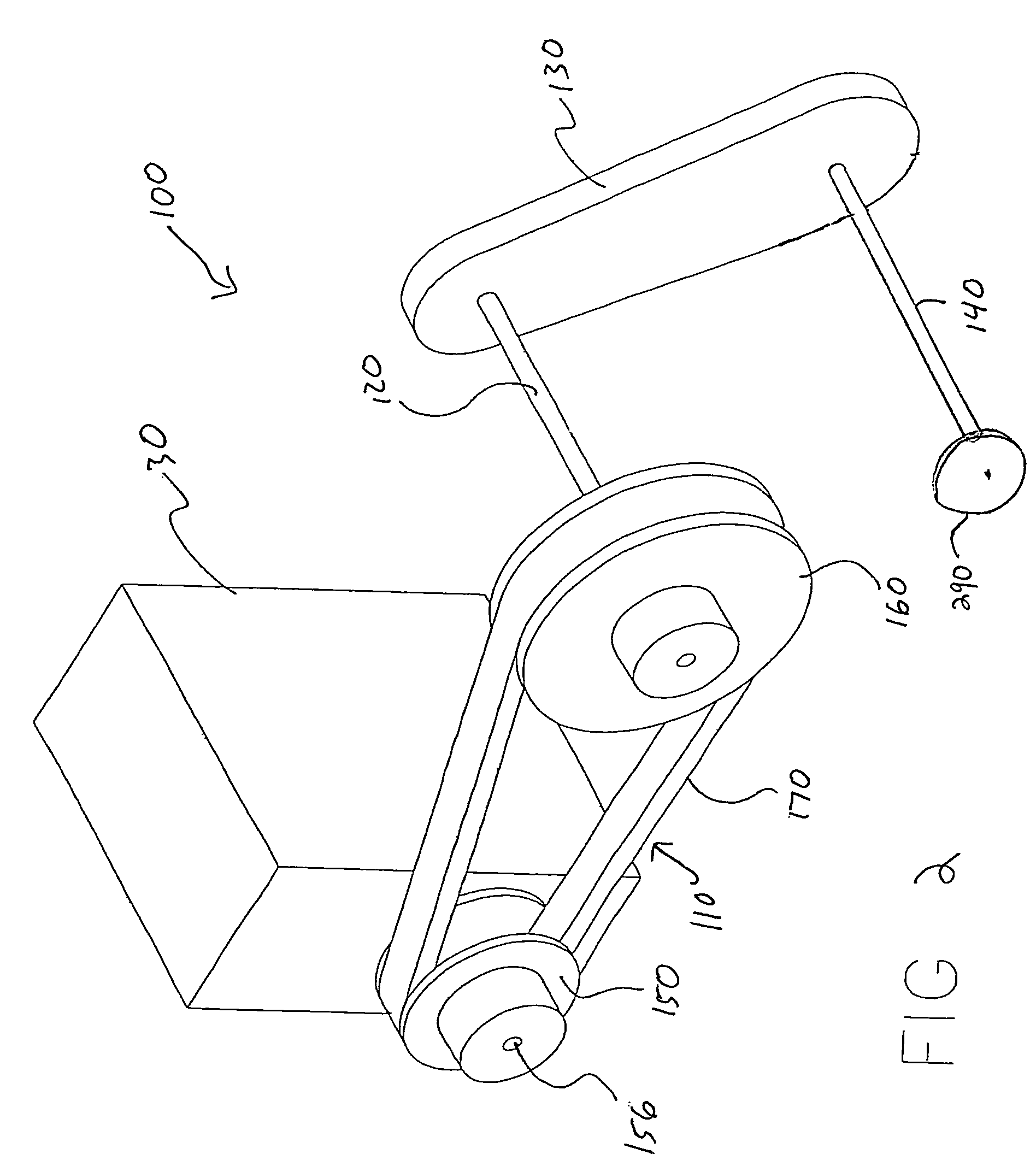

Vehicle with multiple engines coupled to a transmission via a jackshaft

InactiveUS20090288899A1Reduce operating costsMaximize fuel economyElectric propulsion mountingGas pressure propulsion mountingJackshaftMobile vehicle

A motor vehicle is provided with a power train having primary and auxiliary internal combustion engines which selectively feed power to a jackshaft. The power accumulated in the jackshaft is conveyed to a speed change transmission. Fuel economy is achieved by utilizing only one engine when lesser power is needed by the vehicle.

Owner:BELLOSO GREGORIO M

Speed reducer for use in yaw drive apparatus for wind power generation apparatus, and yaw drive method and apparatus for wind power generation apparatus using the speed reducer

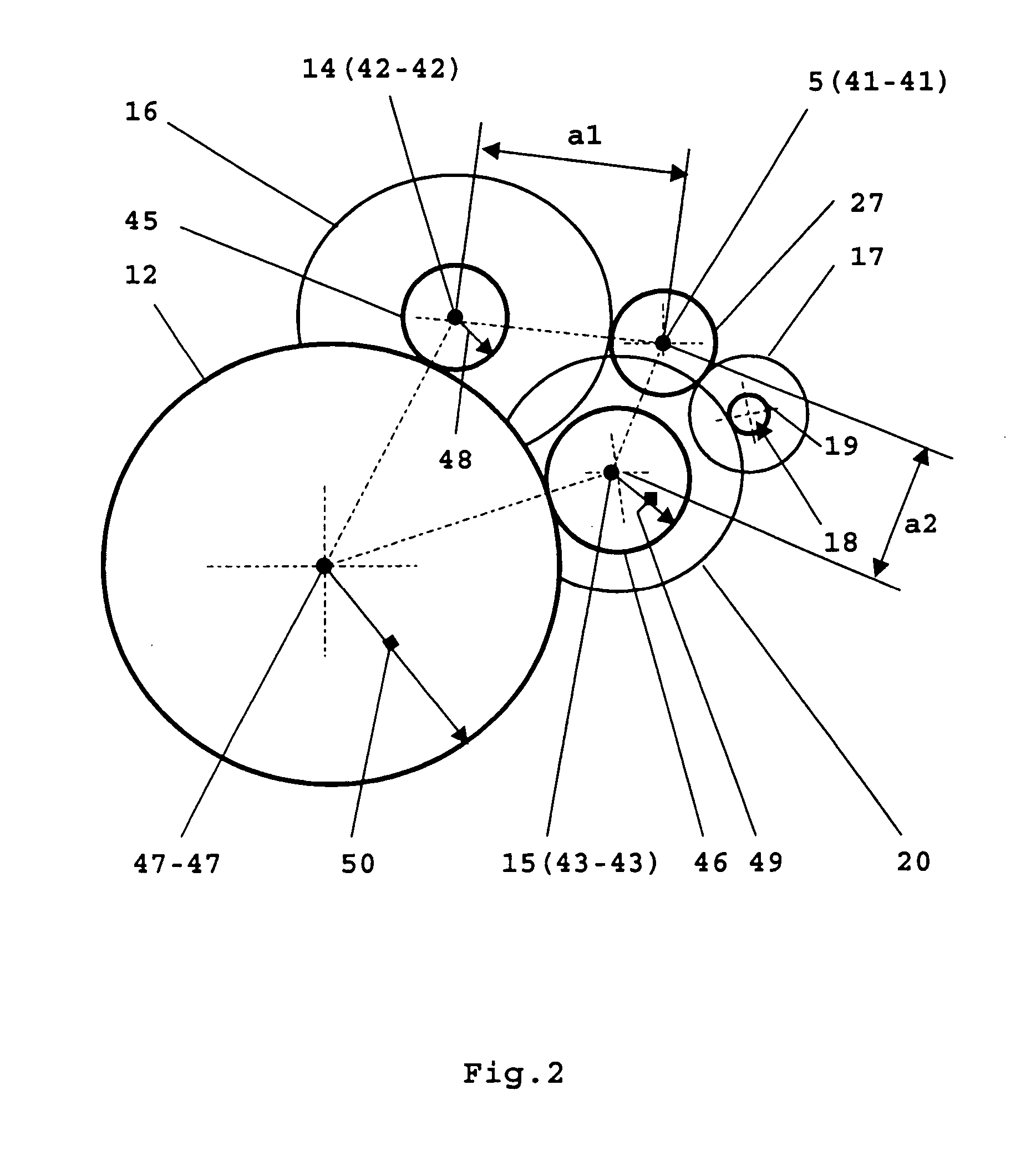

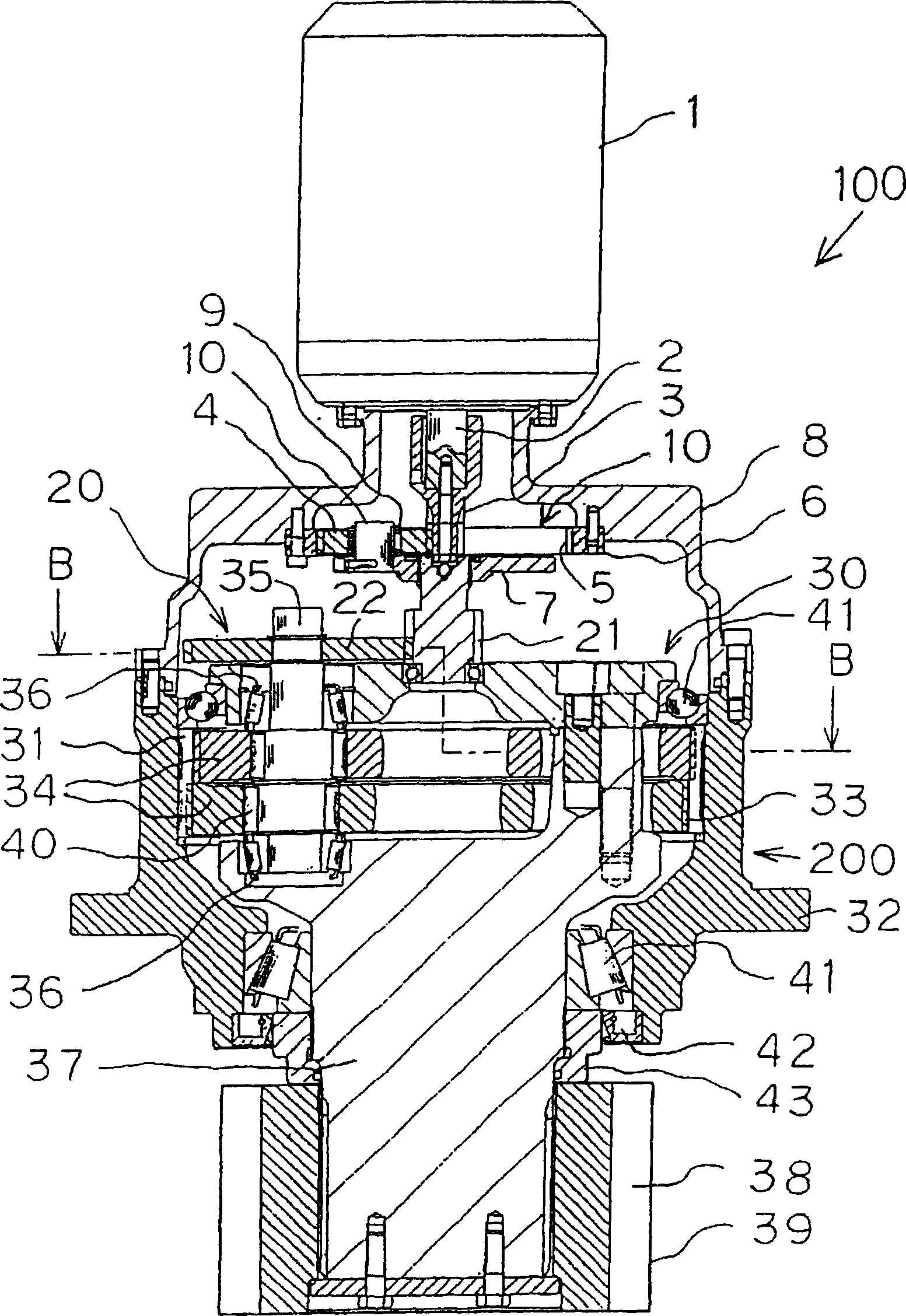

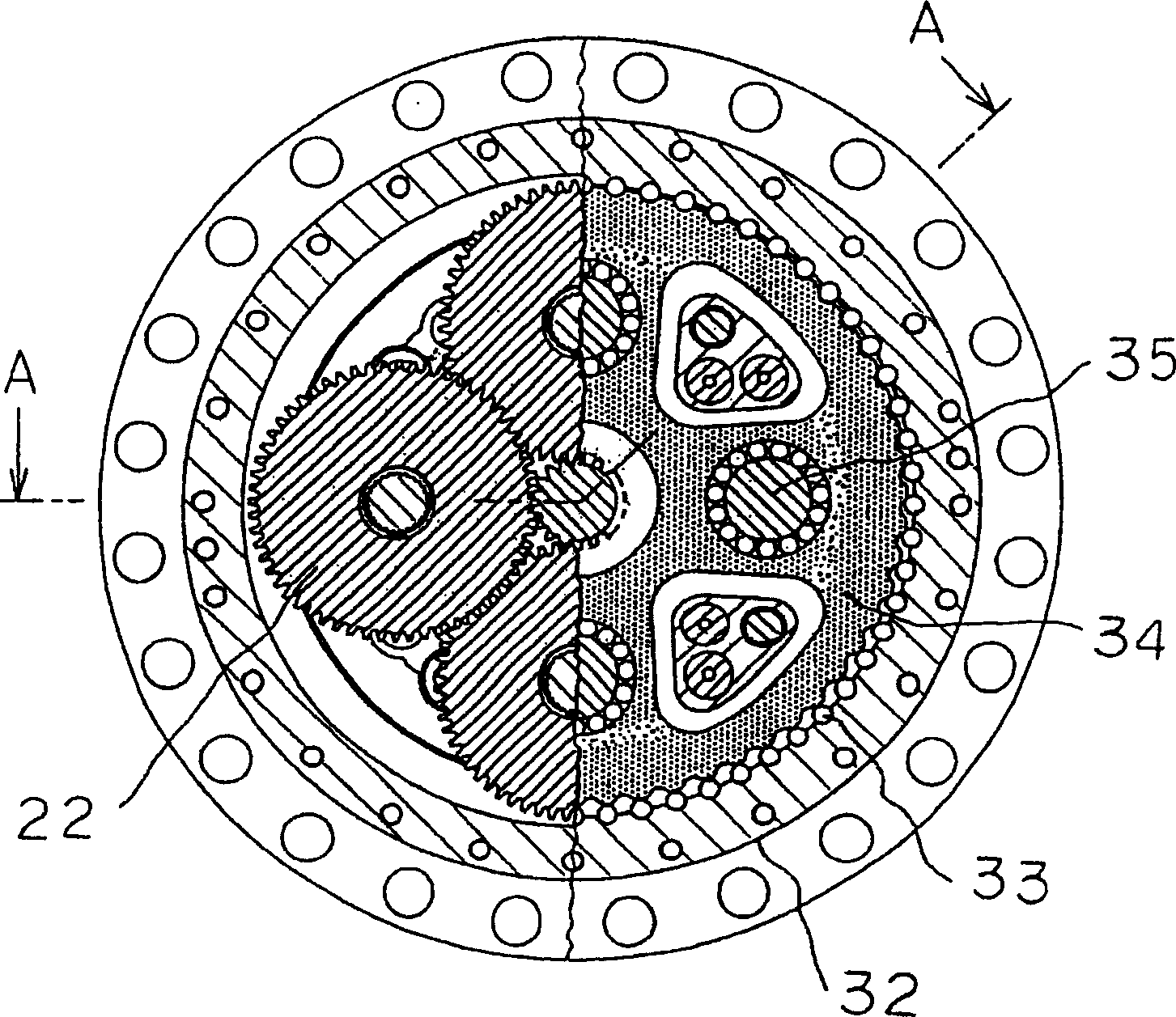

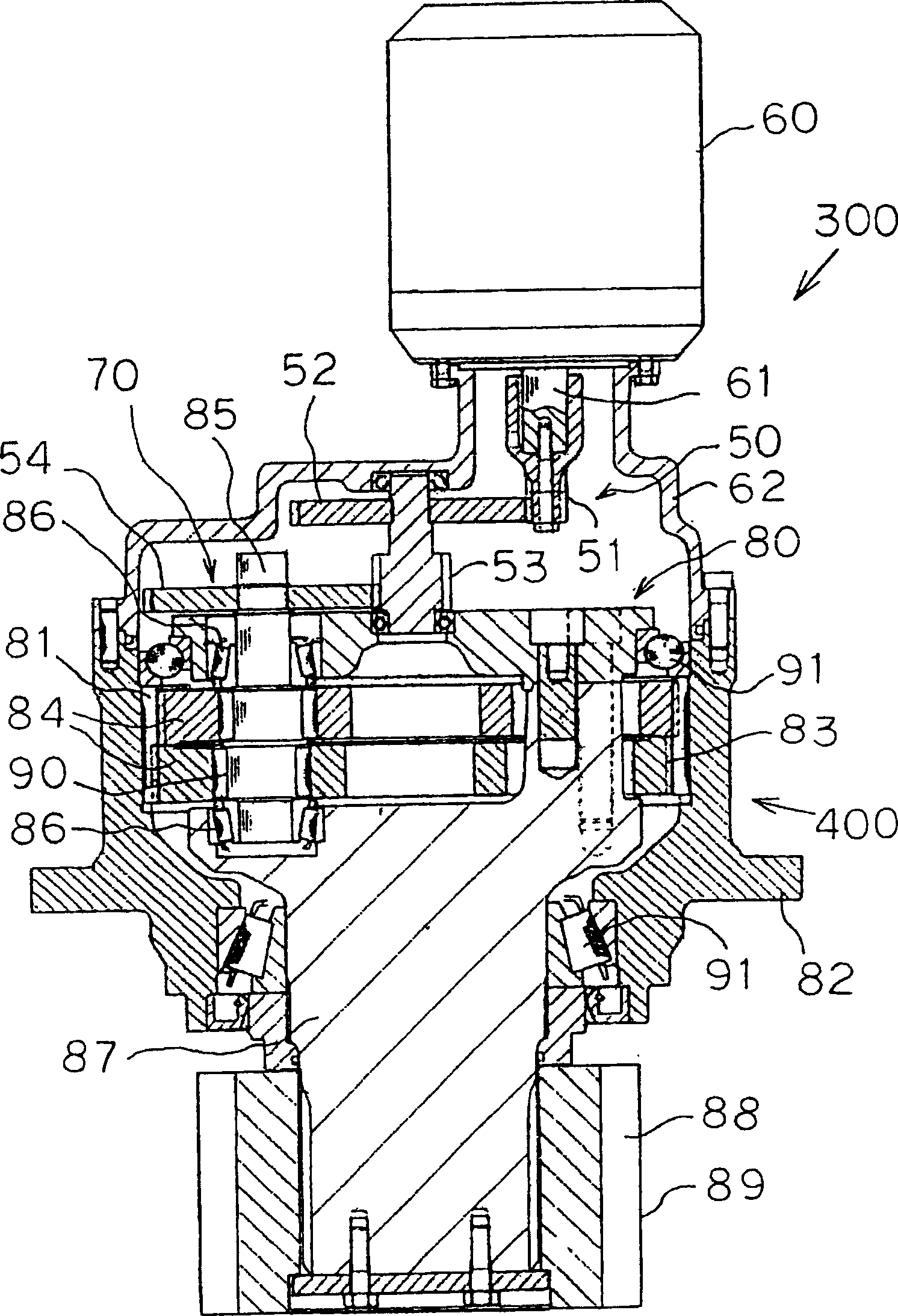

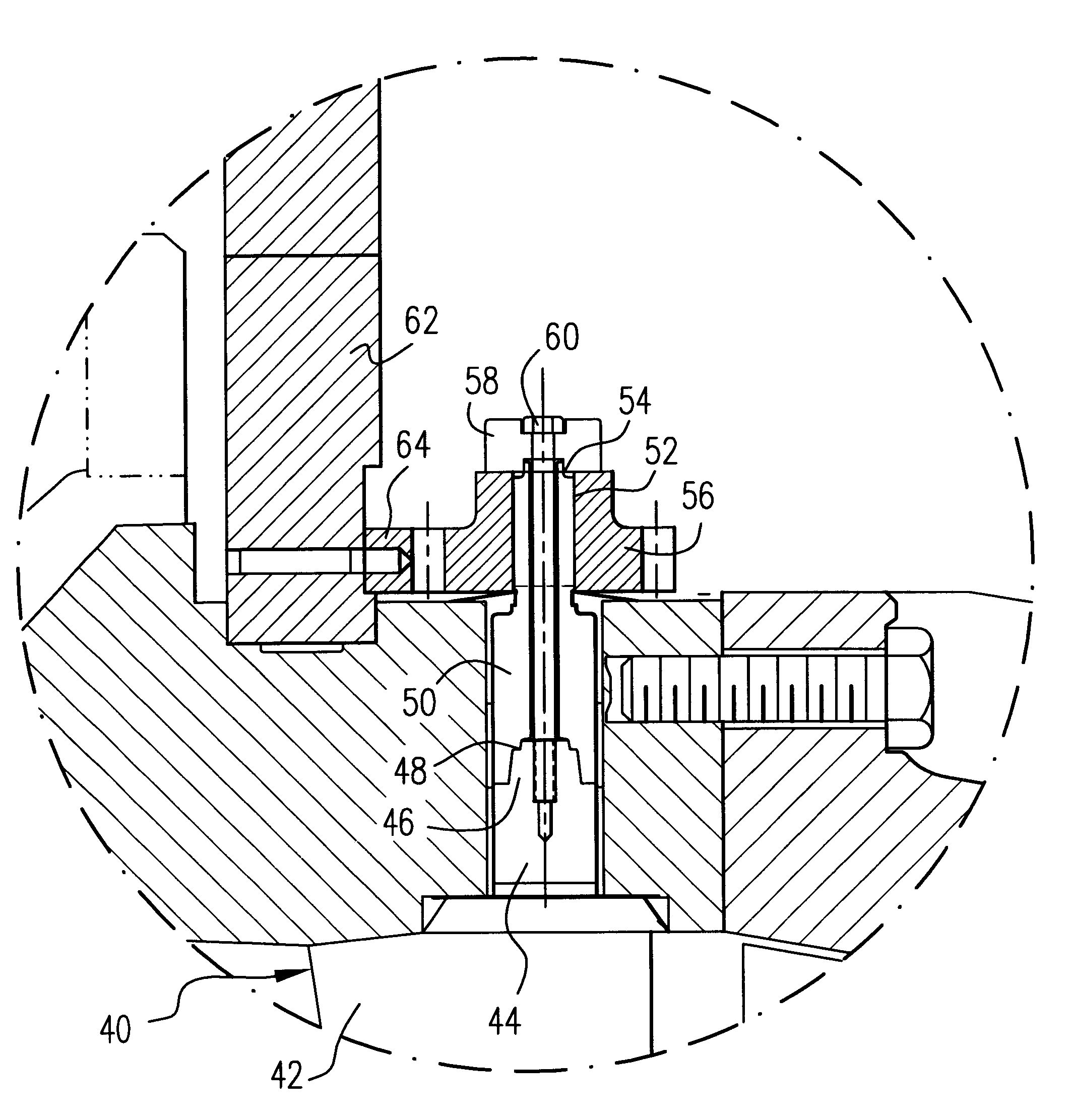

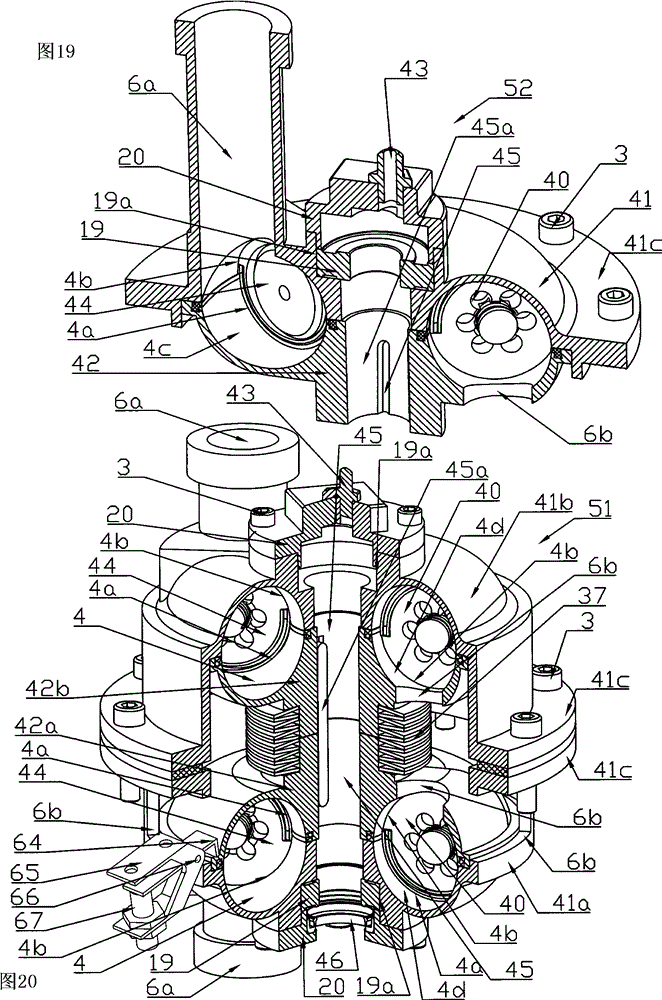

InactiveCN1836104AImprove efficiencyShorten the axial lengthWind motor controlToothed gearingsReduction driveThree stage

A speed reducer and a yaw drive apparatus for a wind power generation apparatus, where the speed reducer has high efficiency and a short axial length, and suitable for the yaw drive apparatus. The speed reducer has three stages for speed reduction. The total reduction gear ratio of a first stage speed reducing portion (10) and a second stage speed reducing portion (20) is set at 1 / 6 to 1 / 60, and a third stage speed reducing portion (30) is constructed from an eccentric oscillating-type speed reducing mechanism having an internal-geared gear body (32), external gears (34), crankshafts (35), and a carrier (37). The reduction gear ratio of the eccentric oscillating-type speed reducing mechanism is set at 1 / 50 to 1 / 140, and the total reduction gear ratio of the speed reducer is set at 1 / 1000 to 1 / 3000. A yaw drive method and the yaw drive apparatus can reduce noise, and the yaw drive apparatus is inexpensive and reduced in size.

Owner:NABLESCO CORP

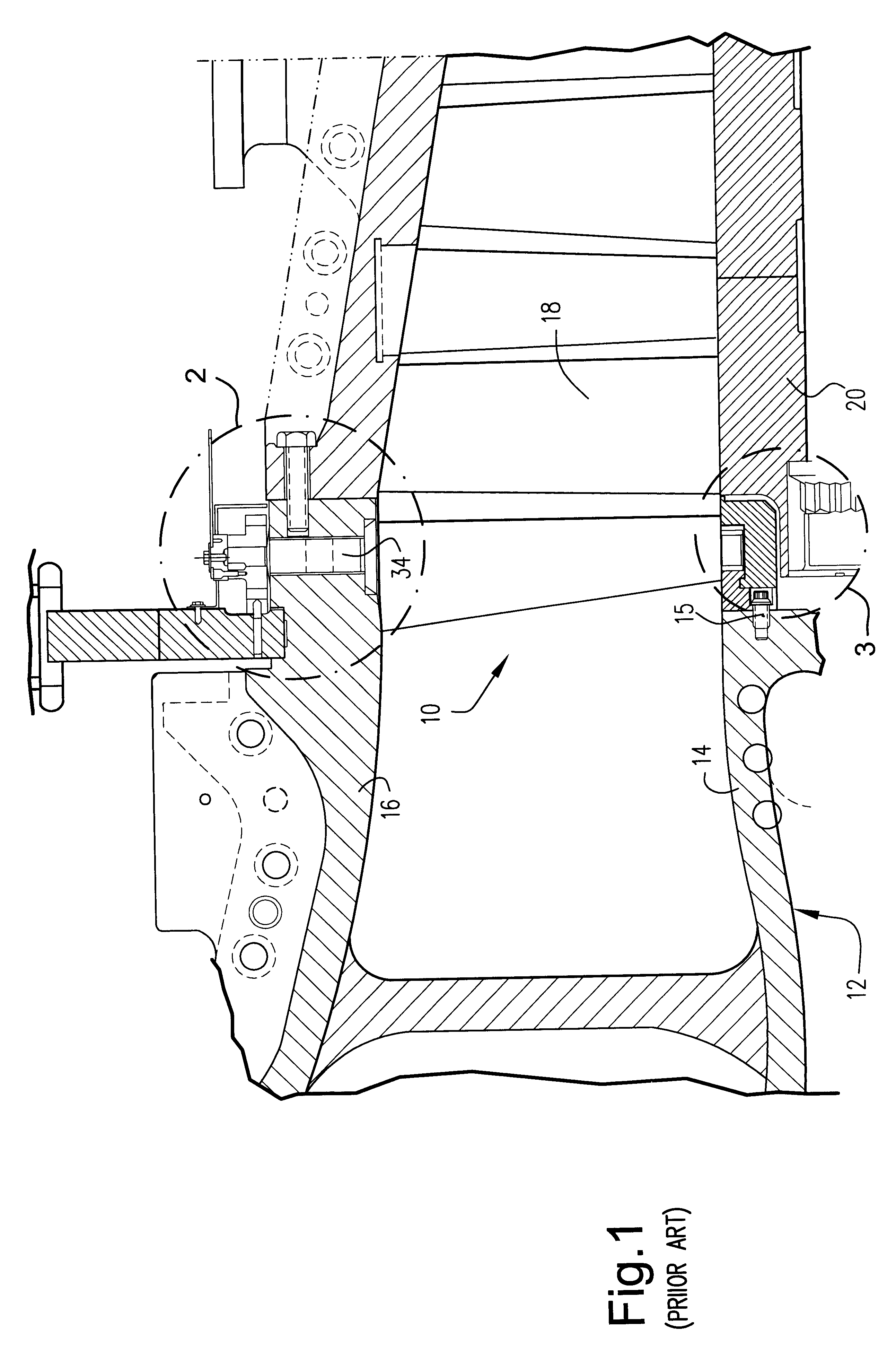

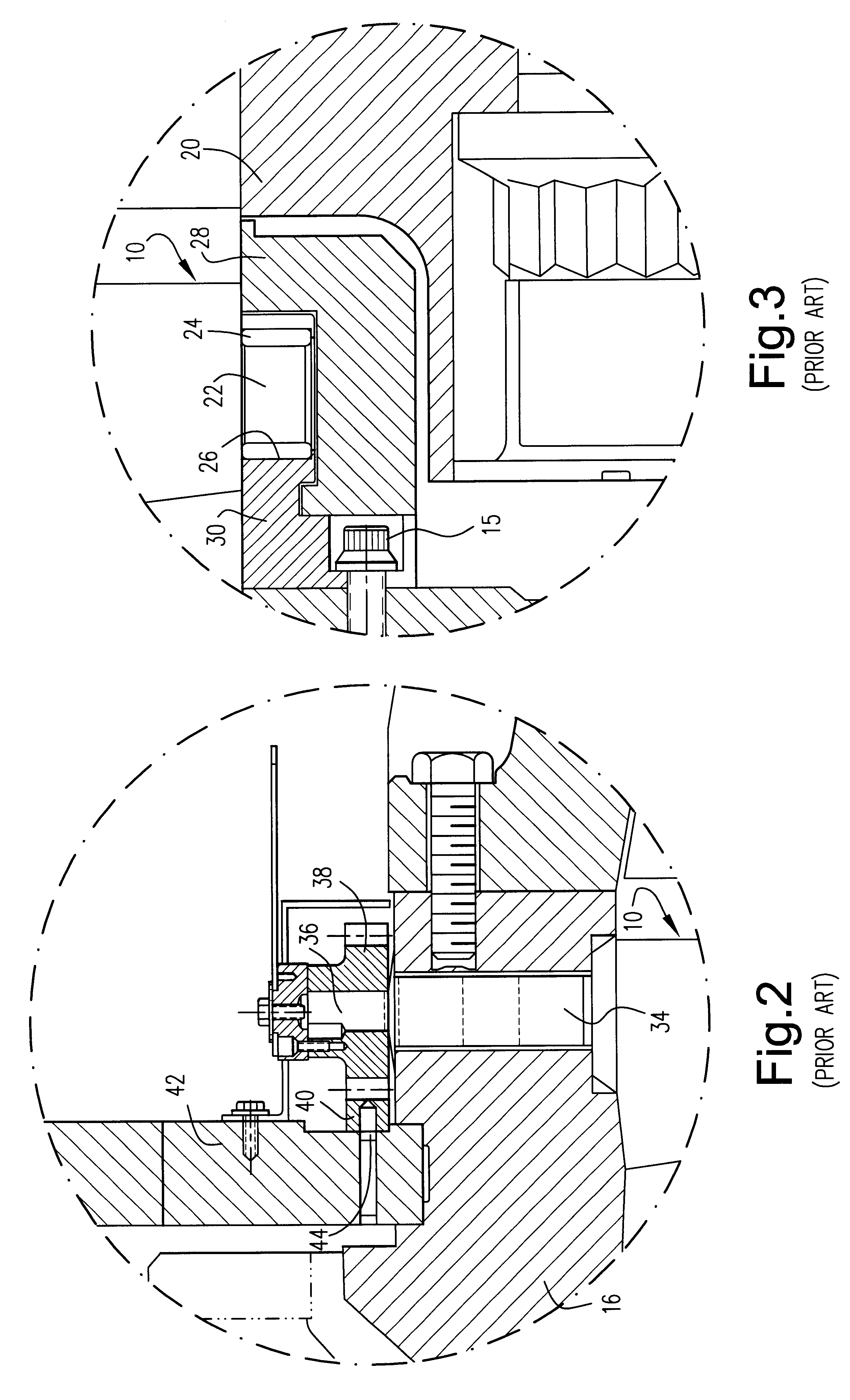

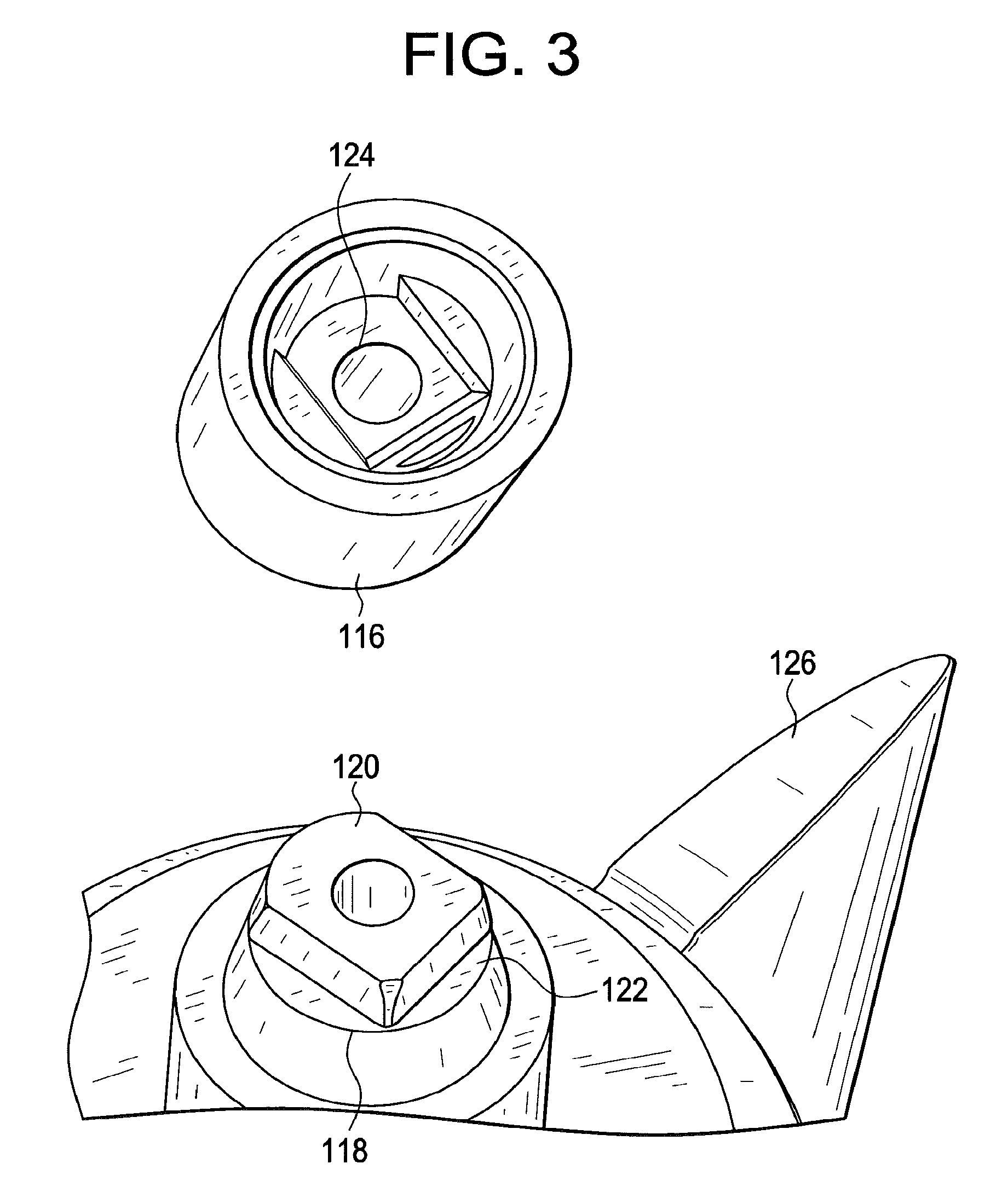

Replaceable variable stator vane for gas turbines

A method of replacing an inlet guide vane from a lower inlet casing of a compressor, the lower inlet casing adapted to be secured to an upper inlet casing at a horizontal joint, and after removal of the upper half of the inlet casing but with a rotor of the compressor remaining in place, wherein the inlet guide vane is supported between radially inner and outer walls of the lower inlet casing, and further wherein the inlet guide vane is formed with an integral stem that extends radially through the outer wall and supports a drive gear on its outer end that engages an annular gear rack, the method including a) removing the gear on the radially outer end of the integral stem of the inlet guide vane; b) shearing the inlet guide vane into two cut portions; c) removing the cut portions from inside the lower inlet casing; and d) replacing the inlet guide vane by a modified inlet guide vane having a two-piece stem assembly that enables installation without removal of the rotor. A new inlet guide vane assembly is provided for replacing the vane. The new assembly includes a vane having a cylindrical stub at a radially inner end thereof and a relatively short integral stem at a radially outer end thereof; a jack shaft adapted for connection at a radially inner end thereof to a radially outer end of the integral stem such that torque applied to the jack shaft is transmitted to the vane, a radially outer end of the jack shaft adapted to receive a drive gear. An outer stem piece is seated on the jack shaft and welded to the drive gear to complete a torque transmission path from the drive gear to complete a torque transmission path from the drive gear to the vane.

Owner:GENERAL ELECTRIC CO

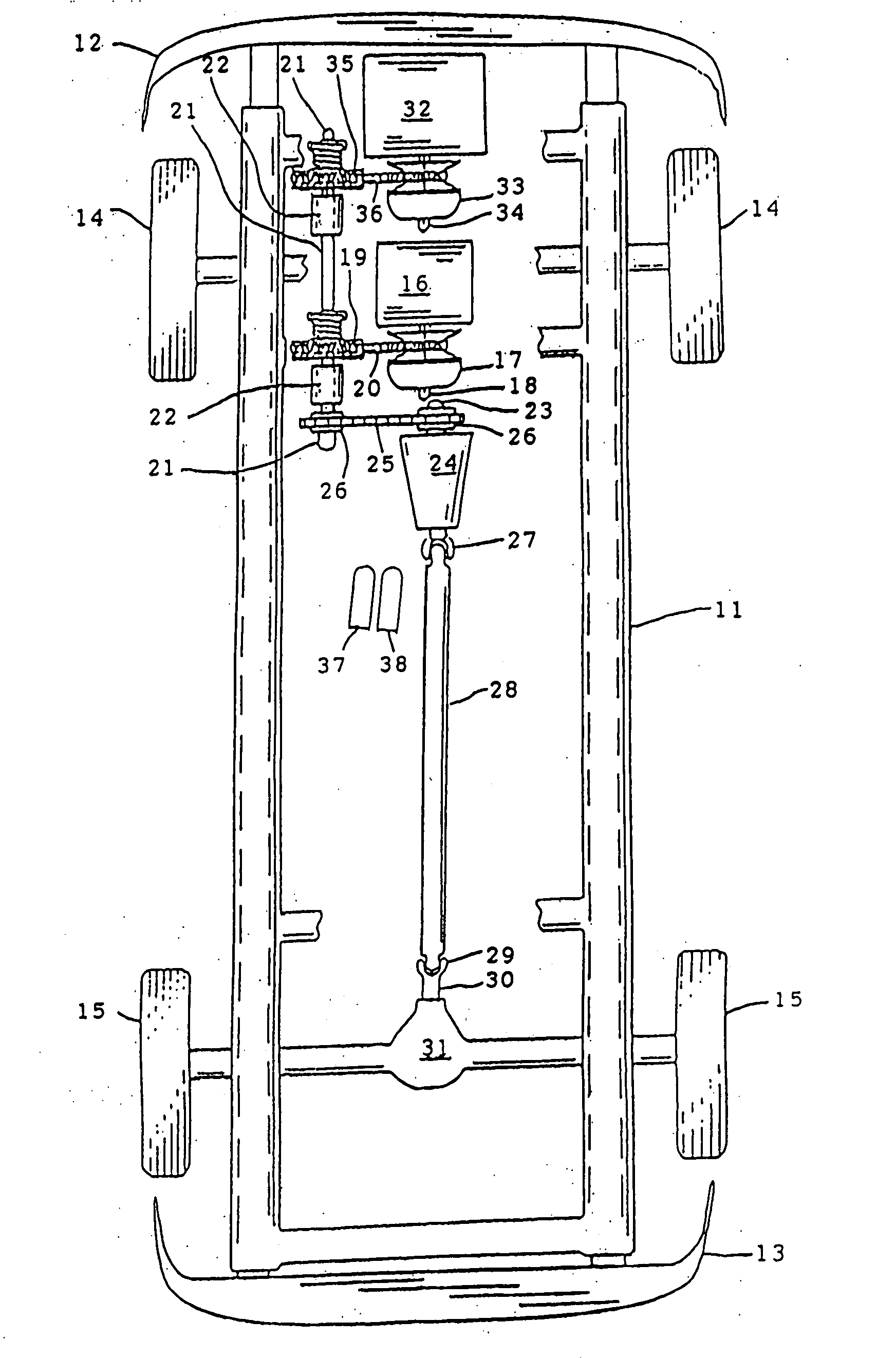

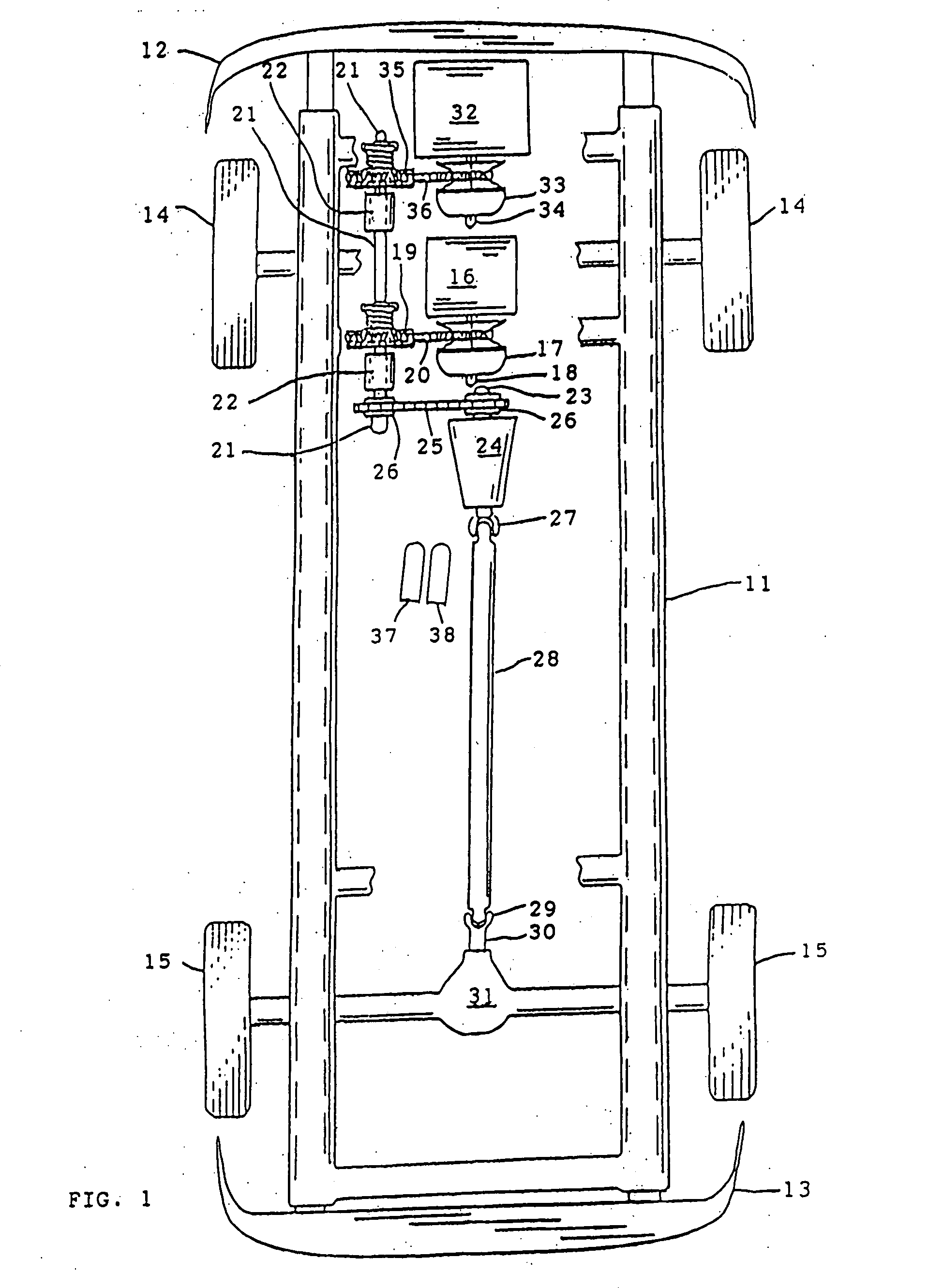

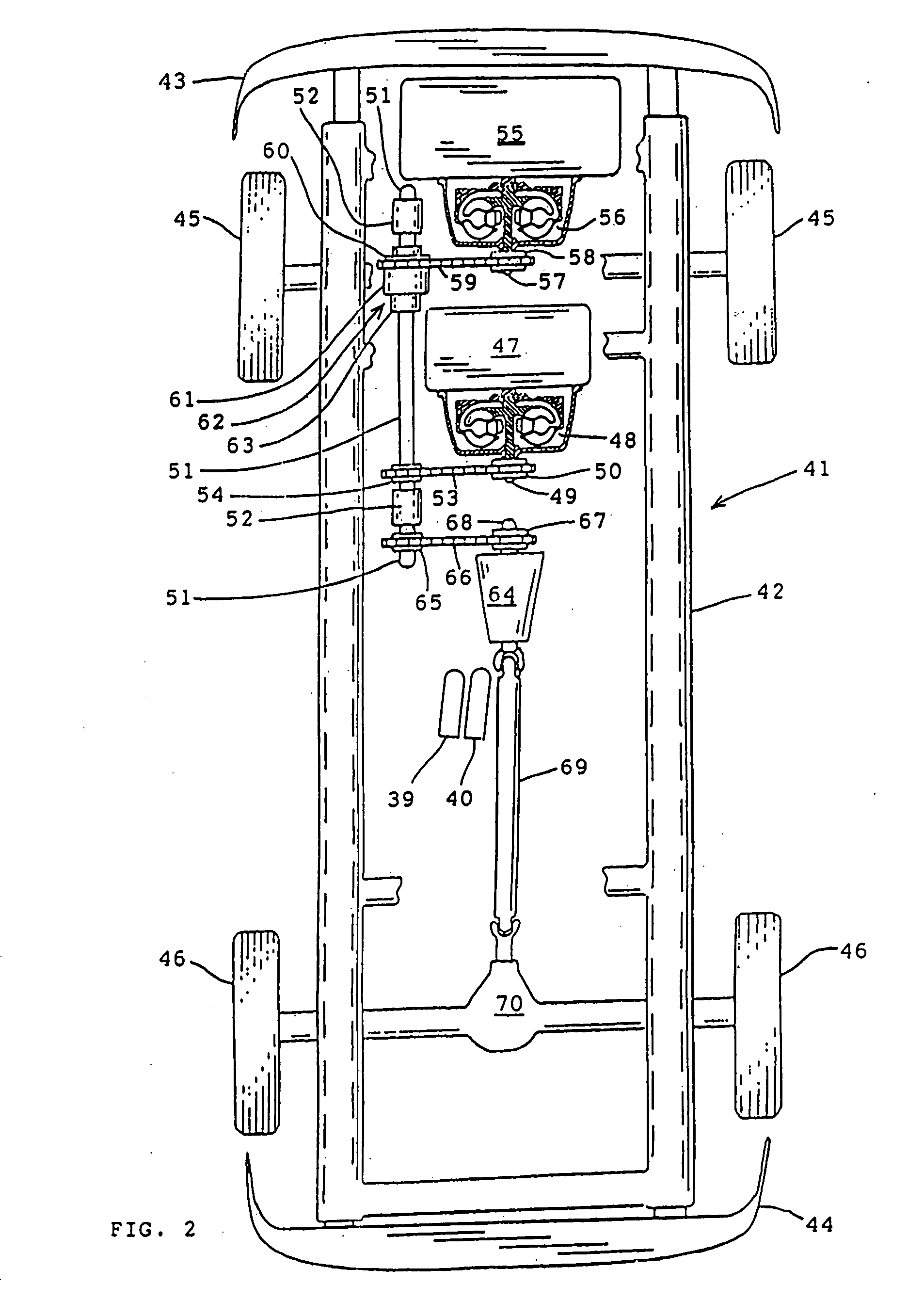

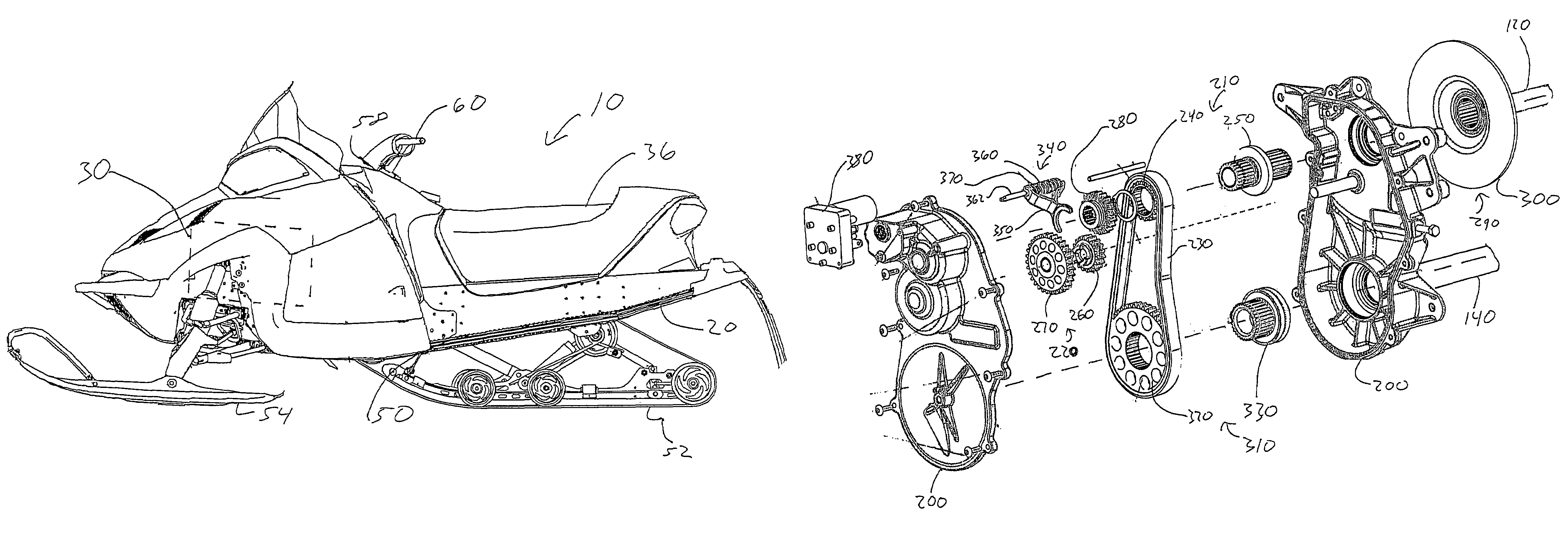

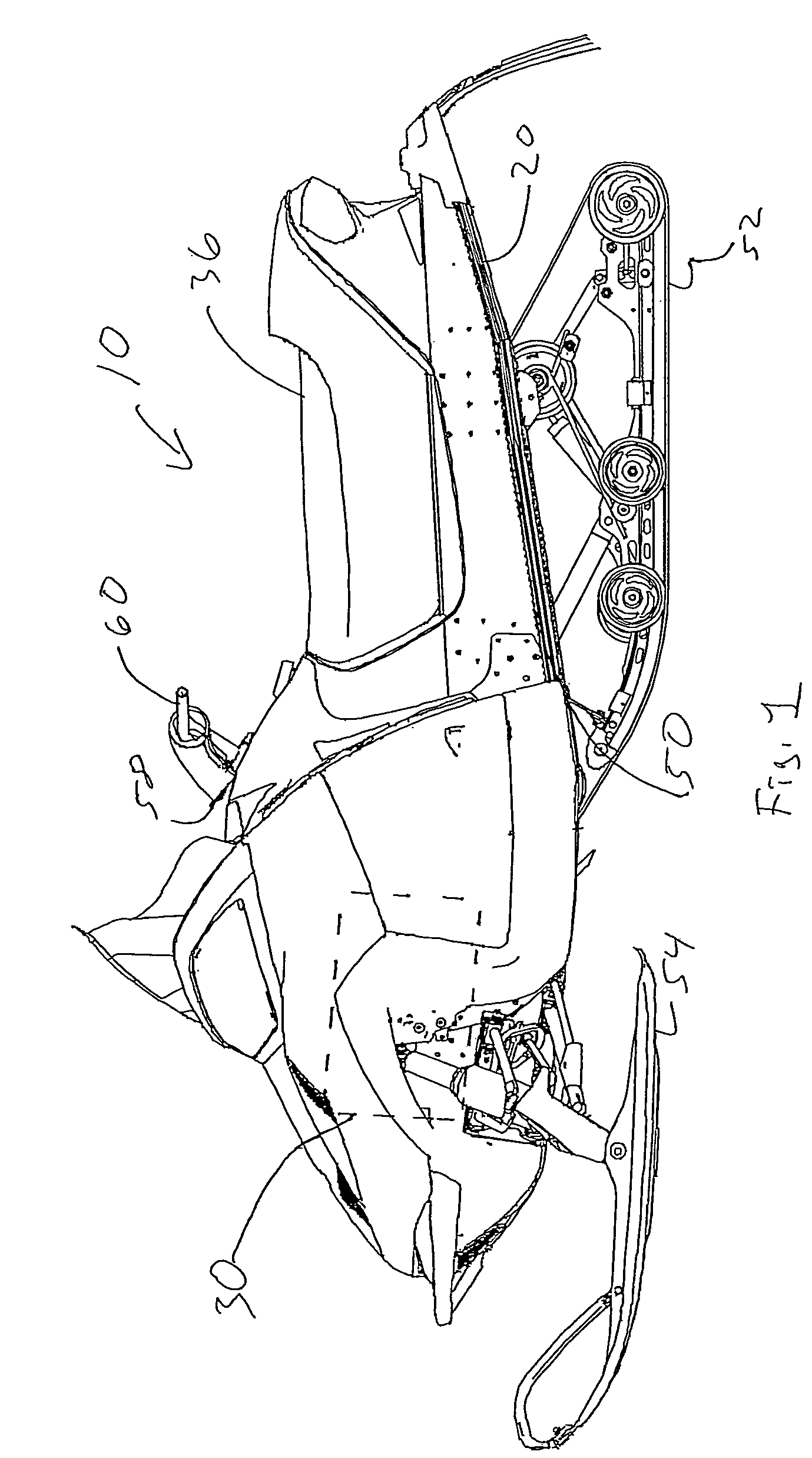

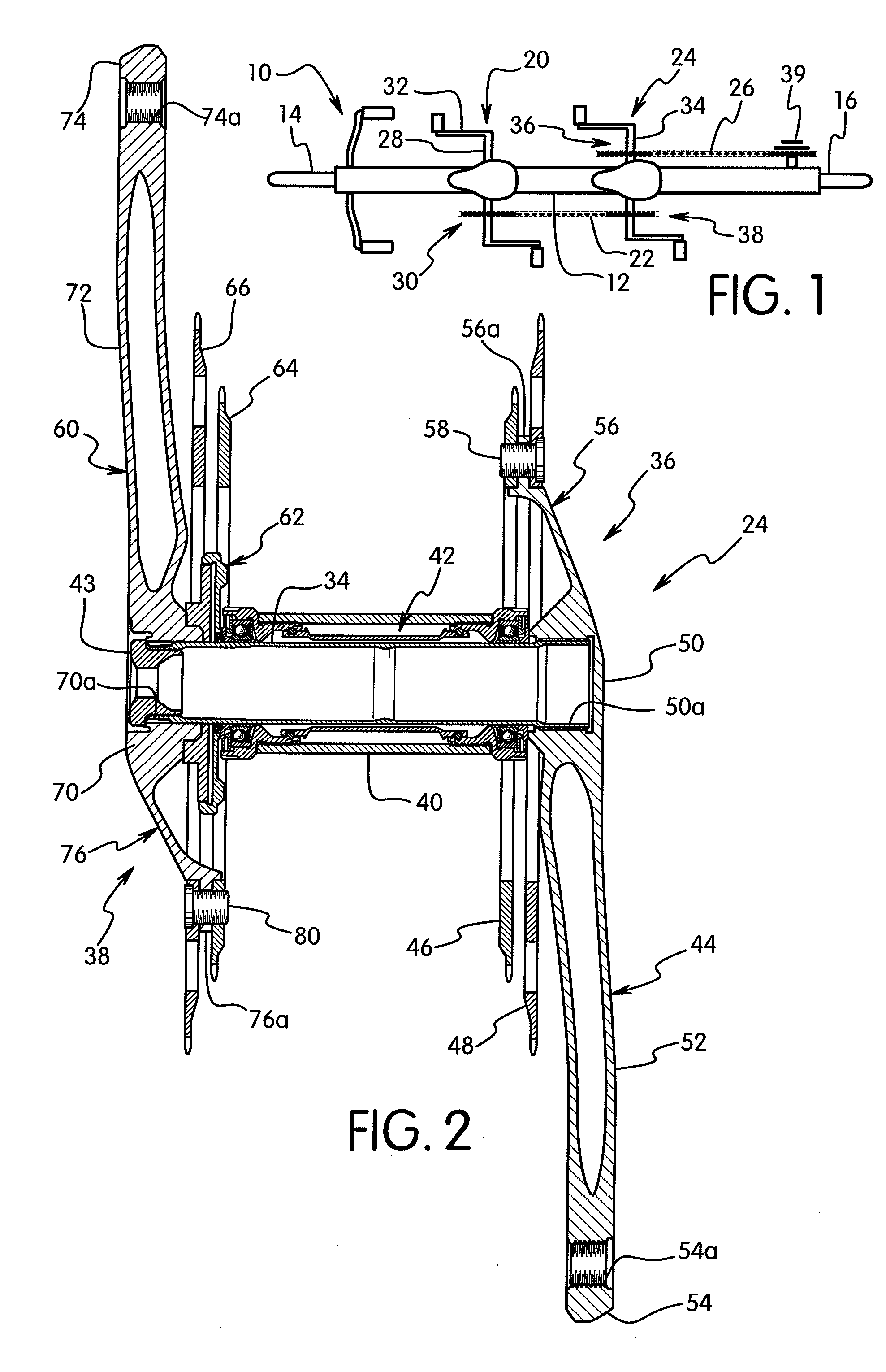

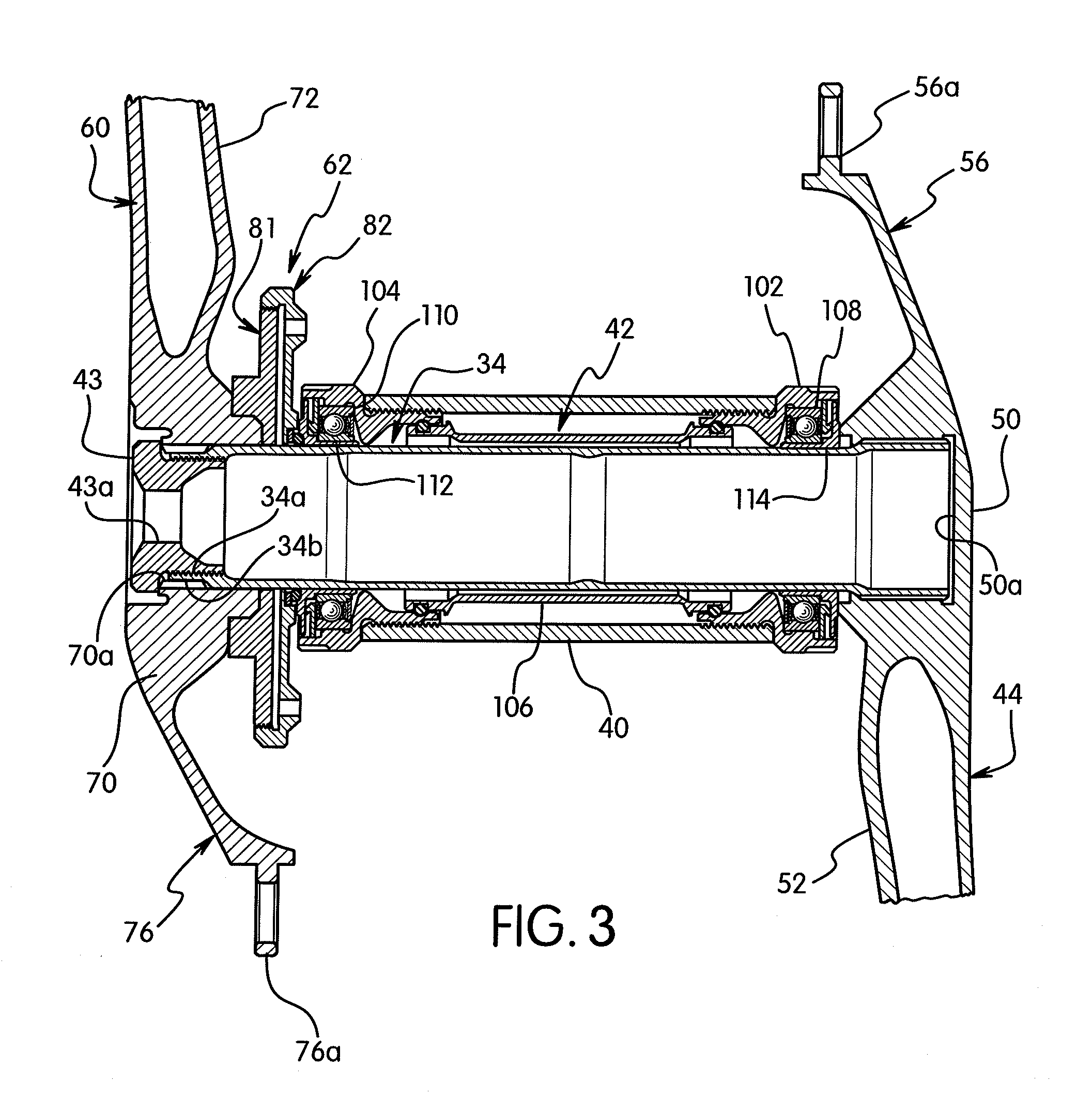

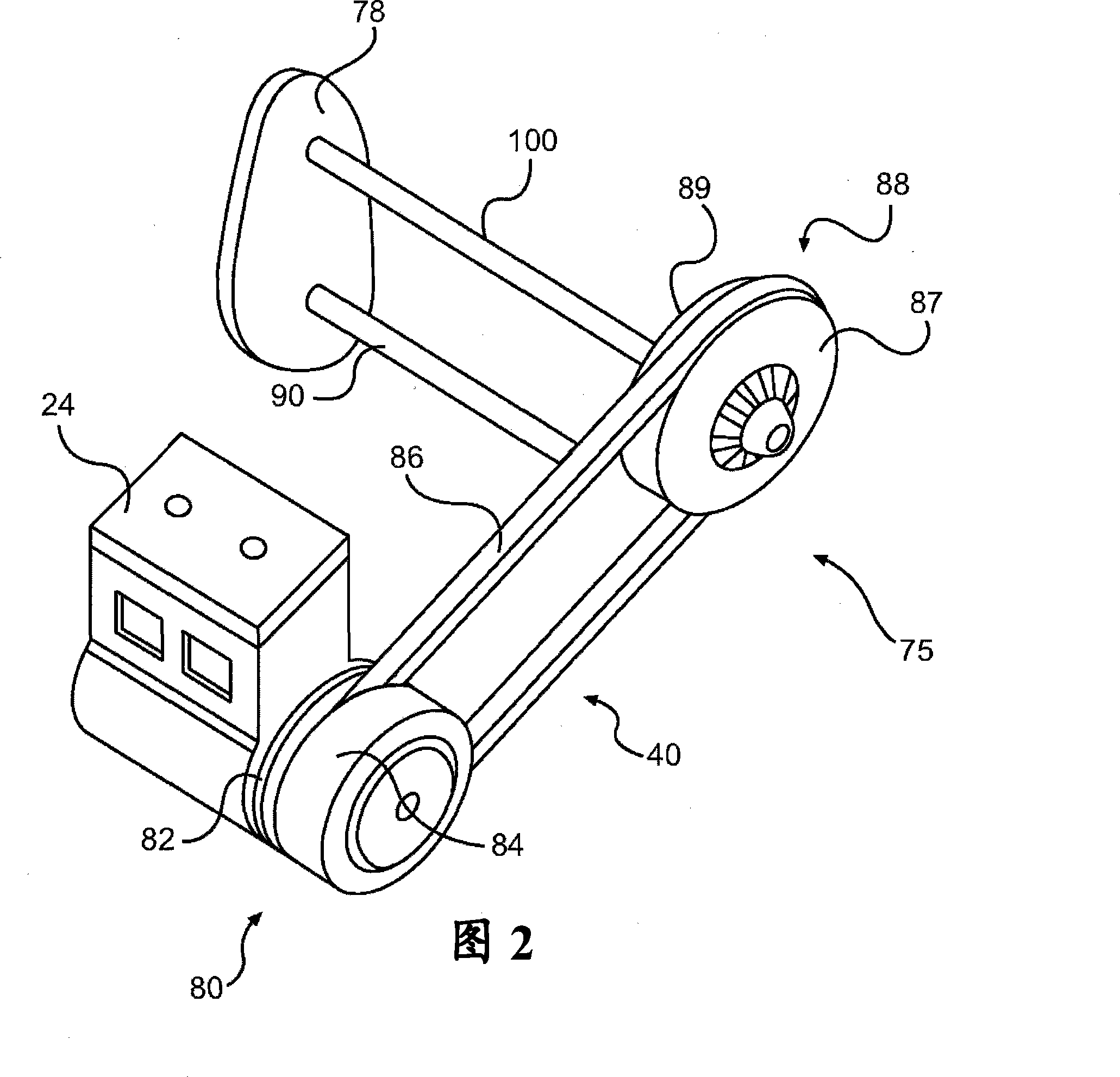

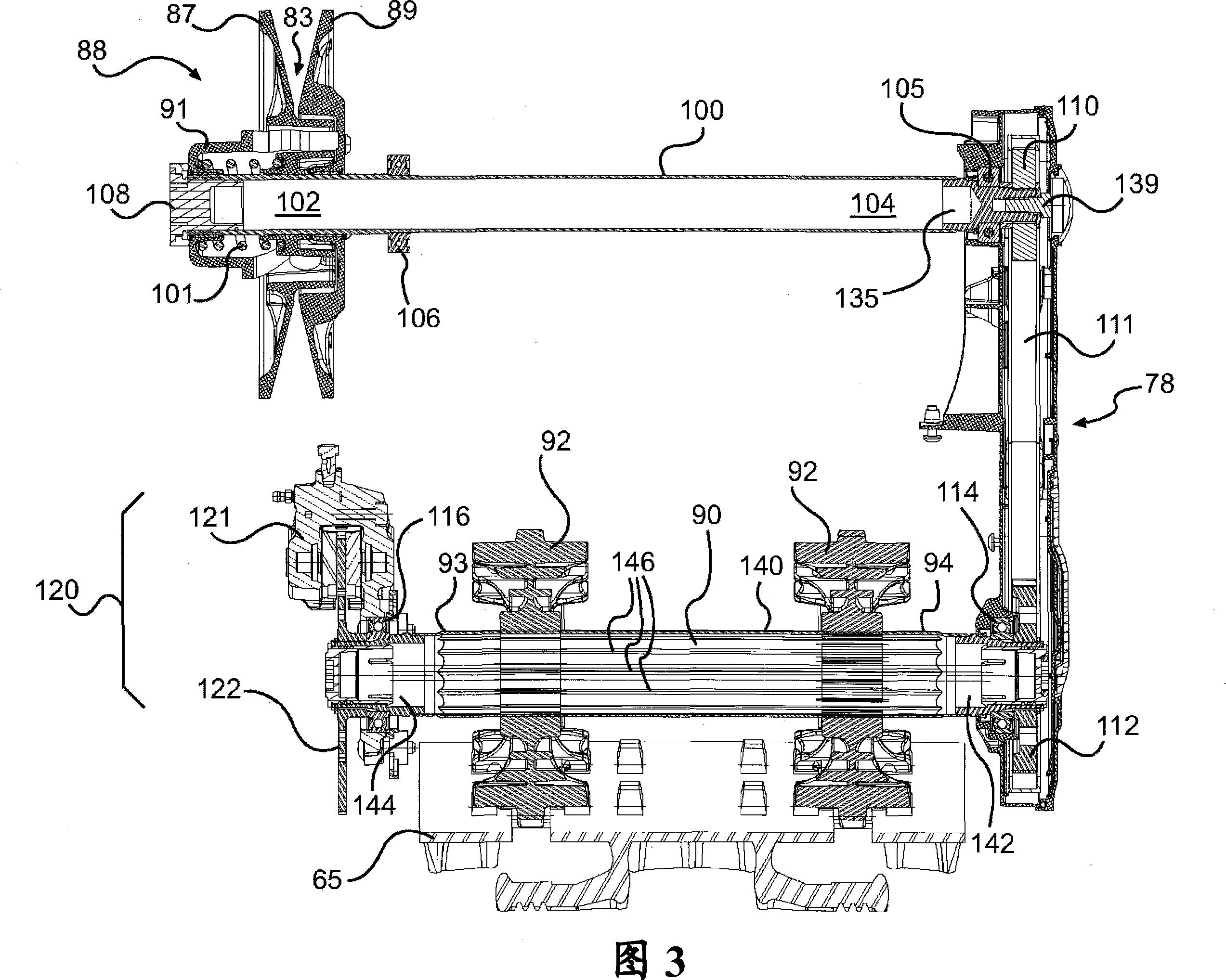

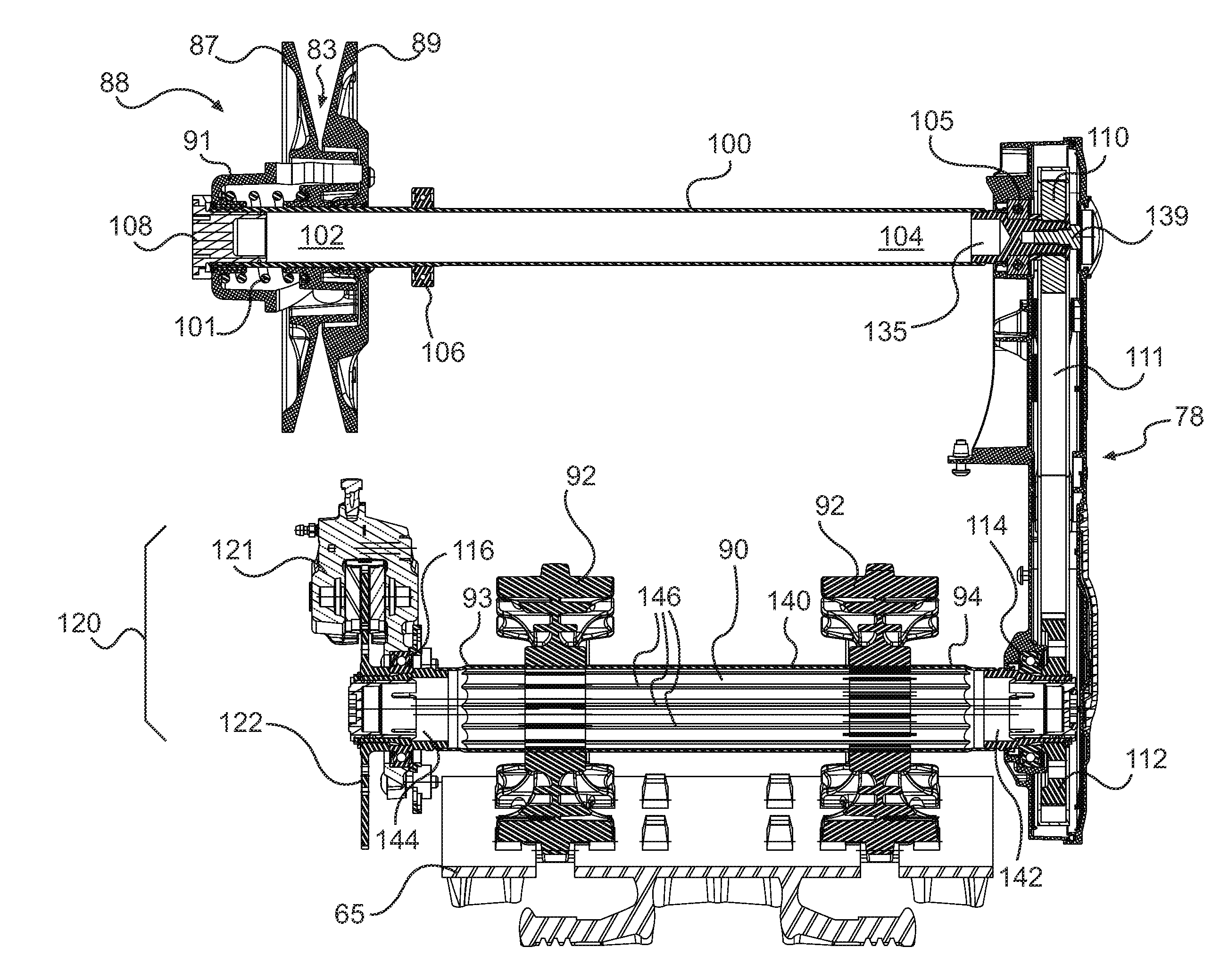

Snowmobile with improved drive train

A snowmobile is disclosed having improved drive train including a continuously variable transmission (CVT) having a drive belt looped around a driving pulley and a driven pulley, and a transversely arranged jackshaft wherein the driven pulley is connected directly onto the outer surface of one end of the jackshaft. The transverse jackshaft is preferably made from a thin-walled hollow tube and the driven pulley is preferably press fitted thereon. A method of assembling a snowmobile drive train is also disclosed.

Owner:BOMBARDIER RECREATIONAL PROD INC

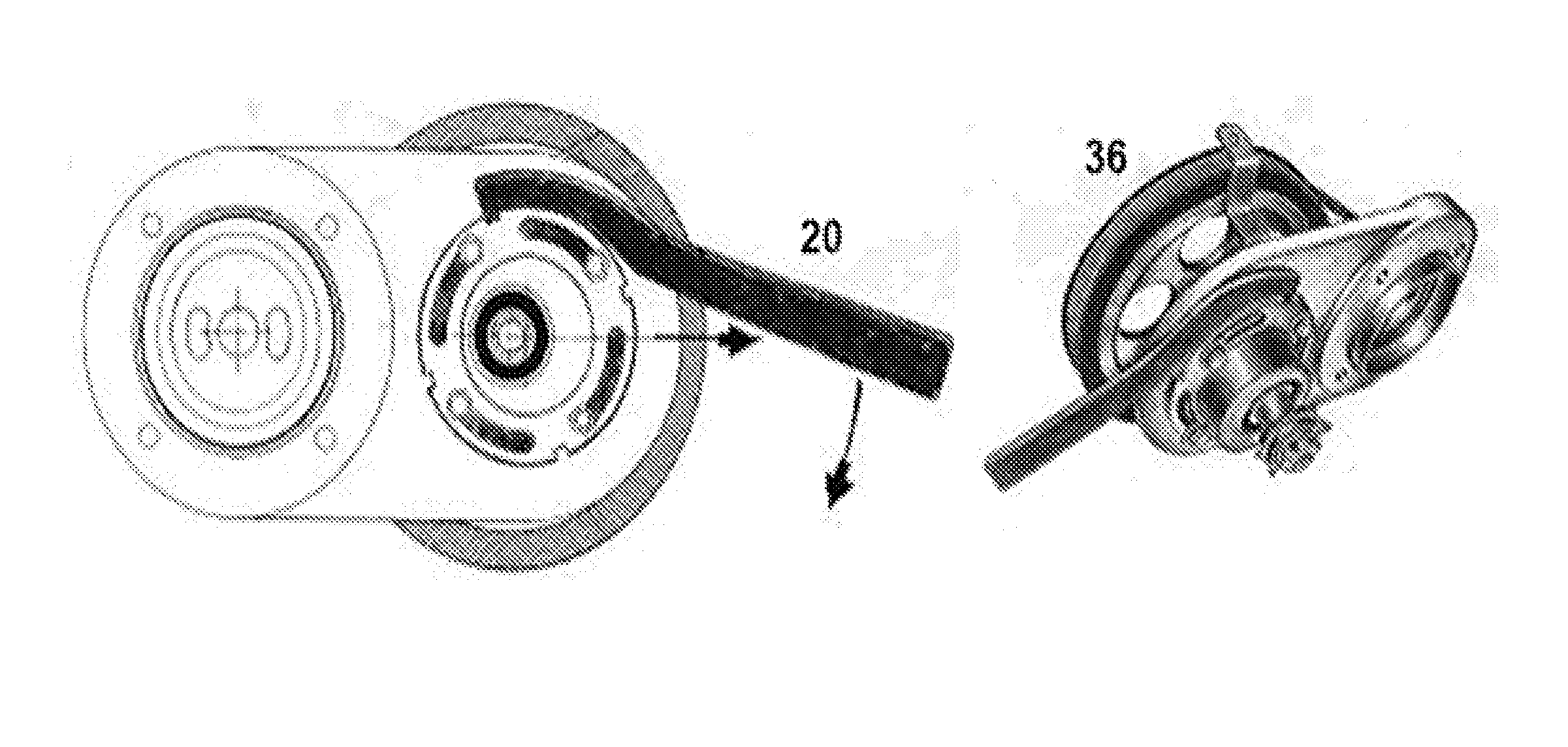

Shifting gear system and method

Embodiments of the invention facilitate shifting by reducing forces on certain shifting components and includes a snowmobile comprising a chassis, an engine supported by the chassis, a drive train operatively connected to the engine, the drive train comprising a reverse sprocket assembly functionally coupled to an upper sprocket assembly, a jackshaft rotatable within the upper sprocket assembly, and a pinion operatively connected to the jackshaft and selectively positionable axially along the jackshaft to a first position that engages the upper sprocket assembly to translate the snowmobile in a forward direction or to a second position that engages the reverse sprocket assembly to translate the snowmobile in a reverse direction.

Owner:POLARIS IND INC

Bicycle crank assembly

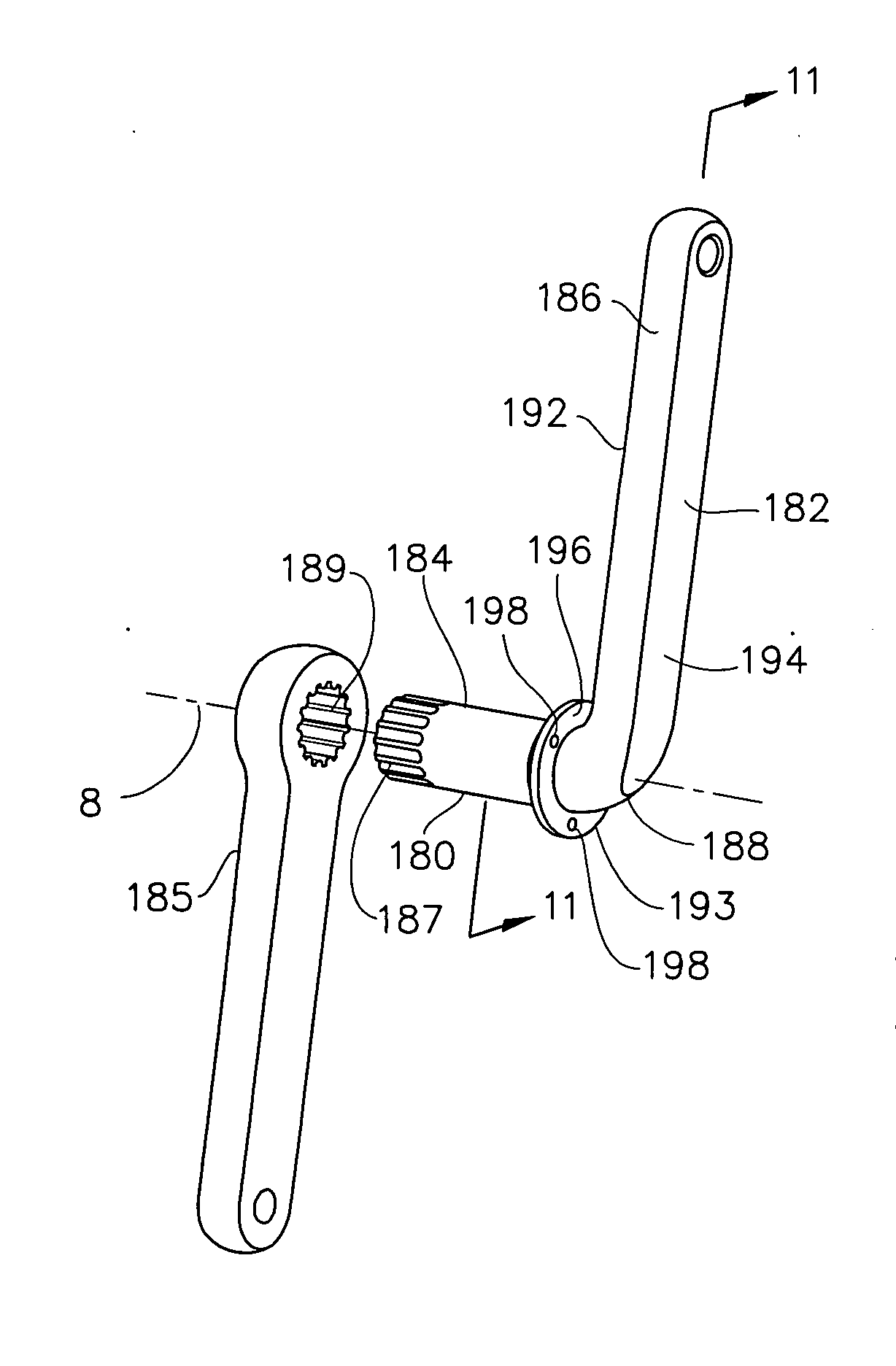

InactiveUS20100326233A1Easy to getImprove performanceMechanical apparatusVehicle cranksJackshaftCrank

An improved bicycle crankshaft assembly, including a crank axle with an axial axial axis, a first axle end, and a second axle end axially opposed to the first axle end; a first crank arm connected to the crank axle at a first crank arm interface adjacent the first axle end; a second crank arm connected to the crank axle at a second crank arm interface axially spaced from the first crank arm interface; a first bearing surrounding said crank axle adjacent said first axle end for rotation of said crank axle about said axial axis; a second bearing surrounding the crank axle and axially spaced from the first bearing. The crank axle includes reinforcement fibers for structural reinforcement of the crank axle and the crank axle is an integral crank axle that extends through the first bearing and the second bearing.

Owner:SCHLANGER RAPHAEL

Bicycle crank assembly

A bicycle crank assembly is provided with a crank arm and an axial gap adjustment device. The crank arm has a crank axle mounting part, an extension part extending from the crank axle mounting part, a pedal attachment part provided on a radial outer end of the extension part and a sprocket attachment part. The axial gap adjustment device includes an adjustment adapter and an adjustment member. The adjustment adapter has a crank arm engagement structure that non-rotatably engages the crank arm, a first crank axle opening, and a first screw part. The adjustment member has a second crank axle opening, and a second screw part threadedly engaged with the first screw part to selectively position the adjustment member relative to the adjustment adapter.

Owner:SHIMANO INC

Jack shaft garage door operator

InactiveUSRE40001E1Reduce tensionPrevent upward movementBuilding braking devicesMan-operated mechanismJackshaftEngineering

A jack shaft garage door operator for opening and closing a movable garage door has a drive containing an electric motor. A rotatable jack shaft is connected to the drive unit to be driven thereby. A pull-up cable drum is connected to and driven by the jack shaft. A pull-up cable extends from the drum about which it is wound and connects to a bottom part of the garage door to raise the door. A pivoting arm is mounted near the jack shaft and provides tension to the cable. A shaft lock hub mounted on the jack shaft is engaged and locked by the arm if the tension in the cable drops. A stop is mounted on the garage door for engagement by the movable arm in the event that the door is opened without the cable being drawn in the cable drum.

Owner:THE CHAMBERLAIN GRP INC

Compressional deformation strengthened flexible hollow half axle and fabrication process thereof

InactiveCN101348055AReduce driving noiseReduce vibrationAxle unitsManufacturing technologyMetallic materials

The invention belongs to the field of automobile manufacturing, relating to a jackshaft part in an automobile power transmission system and the manufacturing technology thereof. The process adopts hyposteel bars of normalized condition as the raw stock, and heats the bar raw stock to 900 DEG C for extrusion molding. The entire extrusion molding process comprises the following extrusion technology: forward extrusion molding technology, overall backward extrusion molding technology, long-hole extrusion molding technology, drawing-down extrusion molding technology and diameter extension extrusion technology; wherein, the number of the working steps of the extrusion technique required in the extrusion molding procedures of the jackshaft parts with different structures and dimensions is different; the temperature of the metal material reduces from 900 DEG C to 100 DEG C; the extrusion workpiece, the shape and dimension of which is similar to that of jackshaft part finished product, is obtained, and the part is manufactured after mechanical cutting processing procedure, alignment and inspection procedures. After the entire extrusion molding is finished, the bending strength, shear strength and impact ductility of the extrusion workpiece are superior to the mechanical performance index of a test bar of the same material which is subject to hardening and tempering as well as heat treatment, and the tensile strength is similar to the test bar of the same material which is subject to hardening and tempering as well as heat treatment; the elastic torsion angle of the hollow jackshaft is larger than 120 degrees.

Owner:邓晓光

Snowmobile with improved drive train

A snowmobile is disclosed having improved drive train including a continuously variable transmission (CVT) having a drive belt looped around a driving pulley and a driven pulley, and a transversely arranged jackshaft wherein the driven pulley is connected directly onto the outer surface of one end of the jackshaft. The transverse jackshaft is preferably made from a thin-walled hollow tube and thedriven pulley is preferably press fitted thereon. A method of assembling a snowmobile drive train is also disclosed.

Owner:BOMBARDIER RECREATIONAL PROD INC

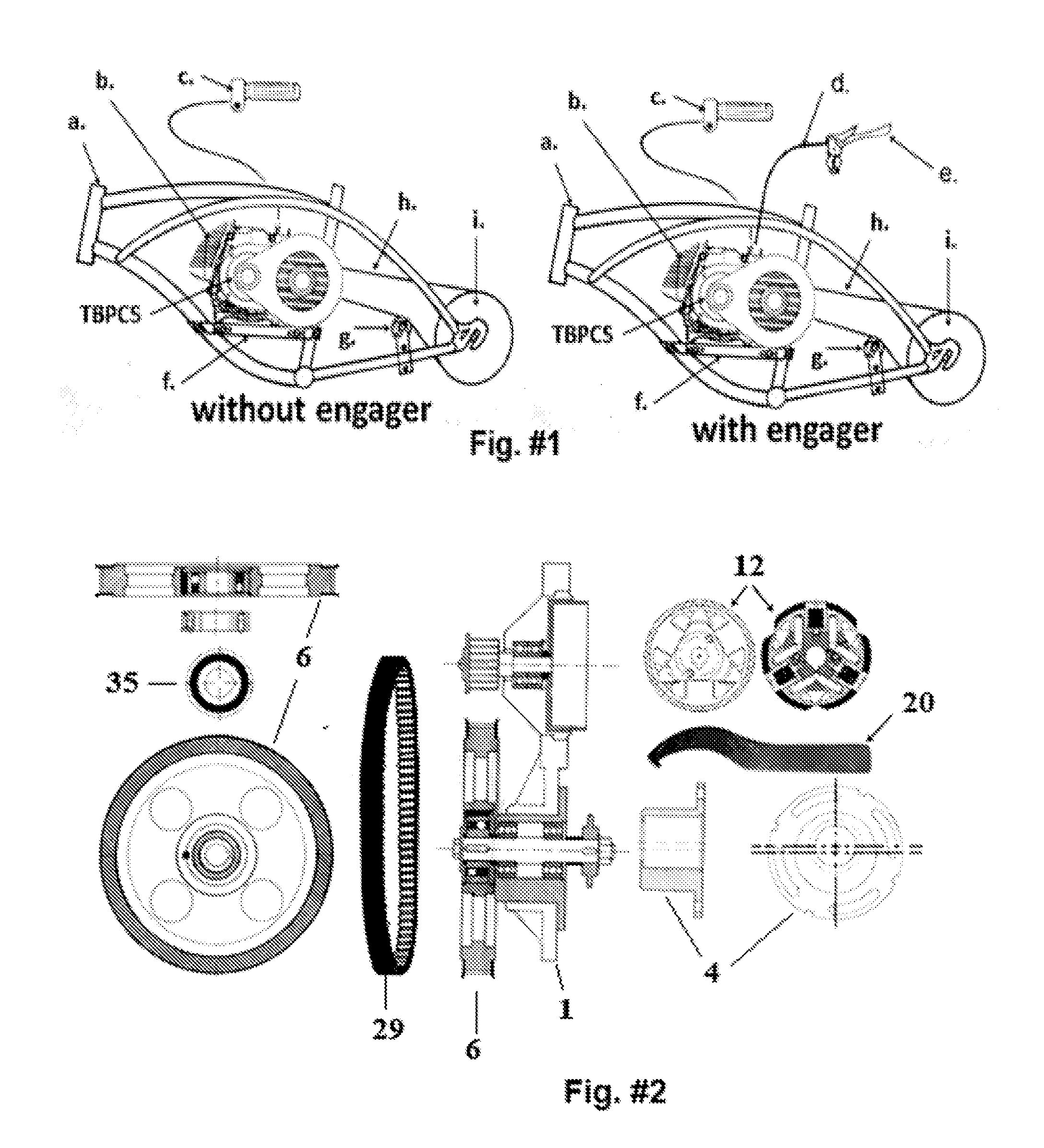

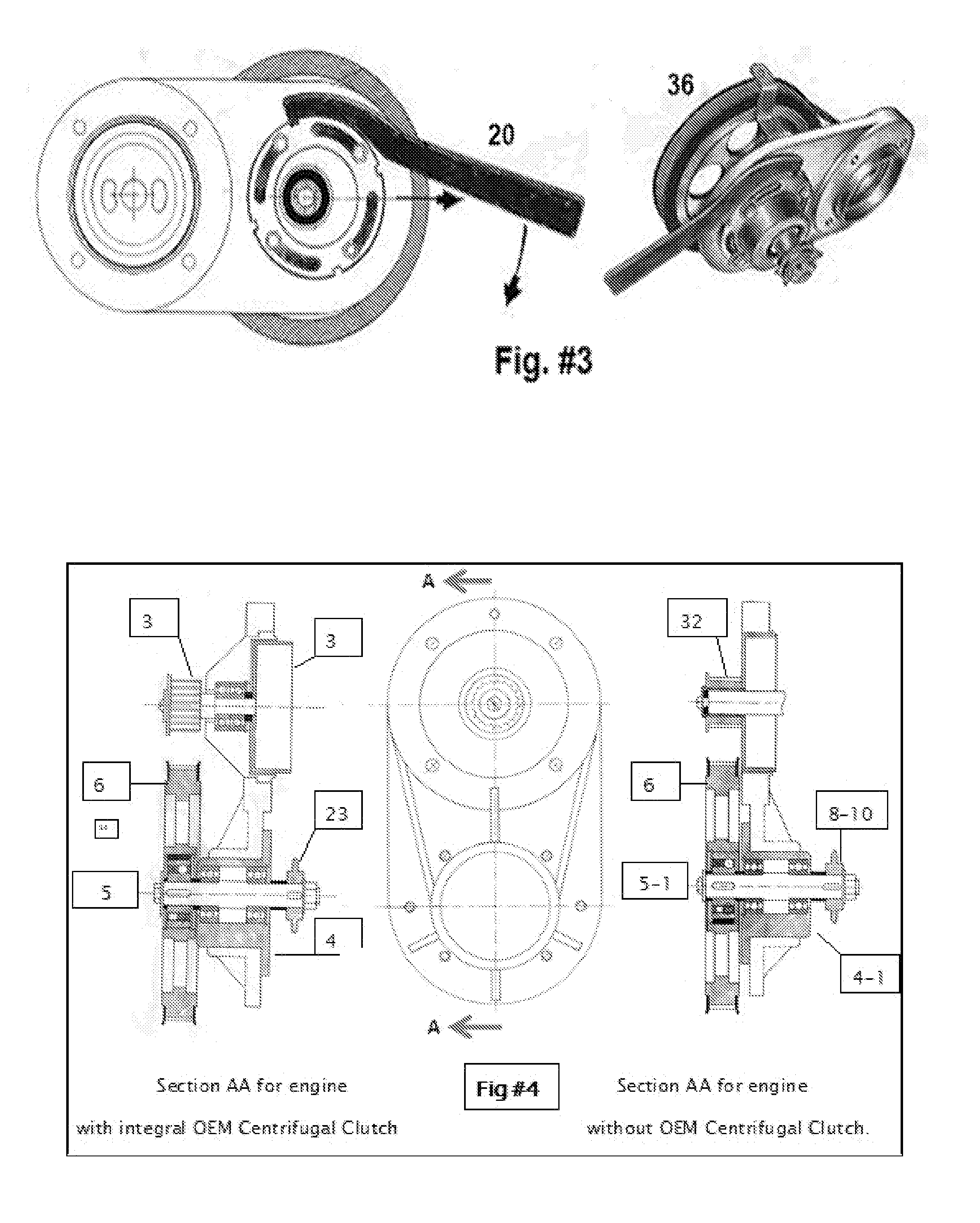

Centrifugal clutch timing belt power transmission control system for a small gasoline engine

A T belt power control system is disclosed to consist of a centrifugal clutch integral bell drum, or in the case of a straight shaft engine such as a Honda GXH50 a non integral bell drum, a T belt drive pulley affixed to a bell drum, an automotive type timing belt, a driven pulley cylindrical cam lock assembly consisting of a larger driven pulley with a one-way bearing for speed reduction and torque enhancement, a non concentric cylindrical housing and an output jackshaft with or without an engine power engaging system to a primary drive sprocket for chain operation. The T Belt tension is secured and maintained by rotating the cam lock assembly with a spanner wrench and then held tight by four bolts. If the T belt power control system is made without an engager system the power is transmitted as soon as the centrifugal clutch latches with the bell drum. If with an engager system the engagement and disengagement of engine power is done by an integral engager remotely controlled by steel cable and hand lever. A motorized vehicle is disclosed as consisting of a standard bicycle frame or modified bicycle frame, a tricycle frame, a go-cart frame, and a paddle wheel boat frame all with the T belt power control system of present invention installed on a gasoline four cycle engine.

Owner:GRUBE DONALD BARTON

Snowmobile with improved drive train

A snowmobile is disclosed having improved drive train including a continuously variable transmission (CVT) having a drive belt looped around a driving pulley and a driven pulley, and a transversely arranged jackshaft wherein the driven pulley is connected directly onto the outer surface of one end of the jackshaft. The transverse jackshaft is preferably made from a thin-walled hollow tube and the driven pulley is preferably press fitted thereon. A method of assembling a snowmobile drive train is also disclosed.

Owner:BOMBARDIER RECREATIONAL PROD INC

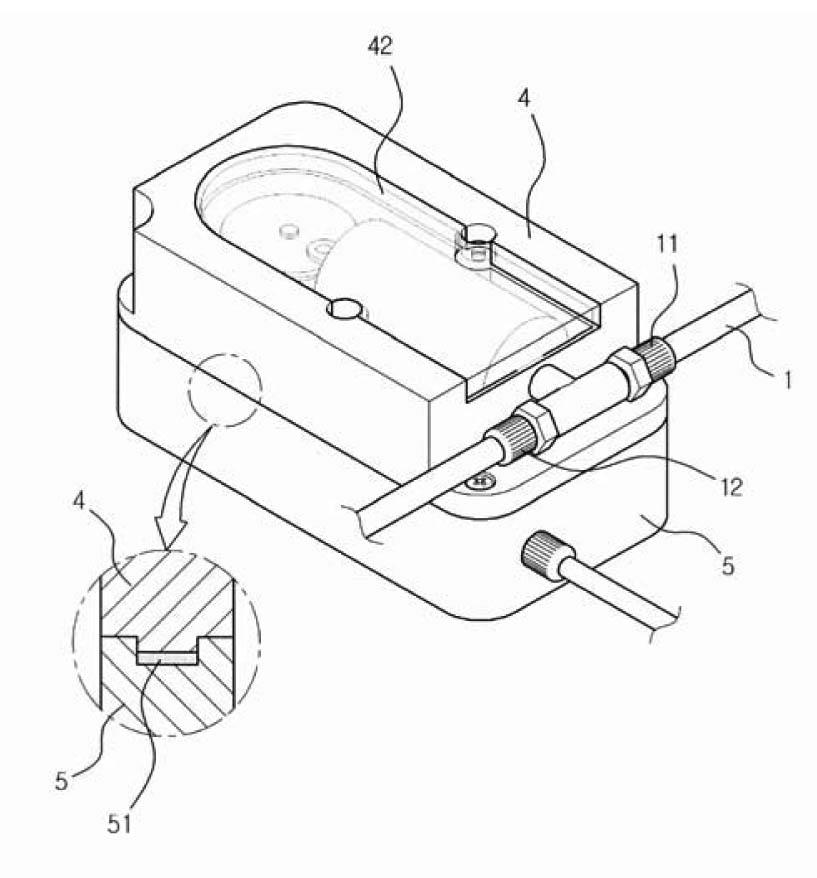

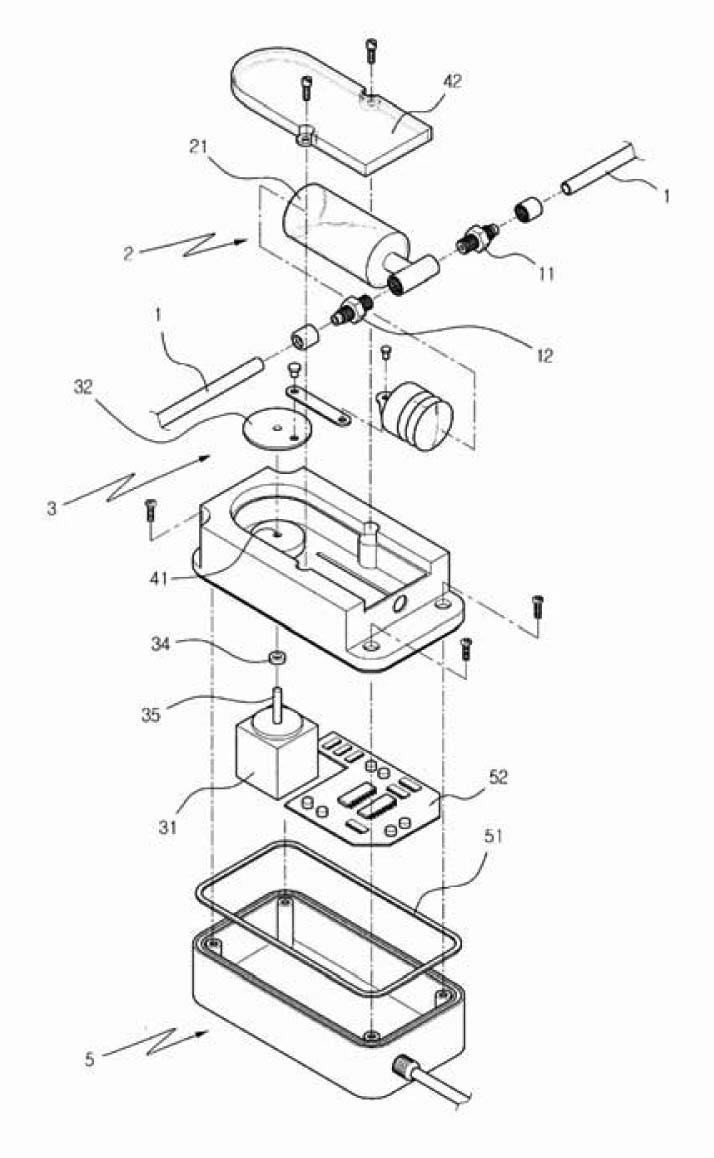

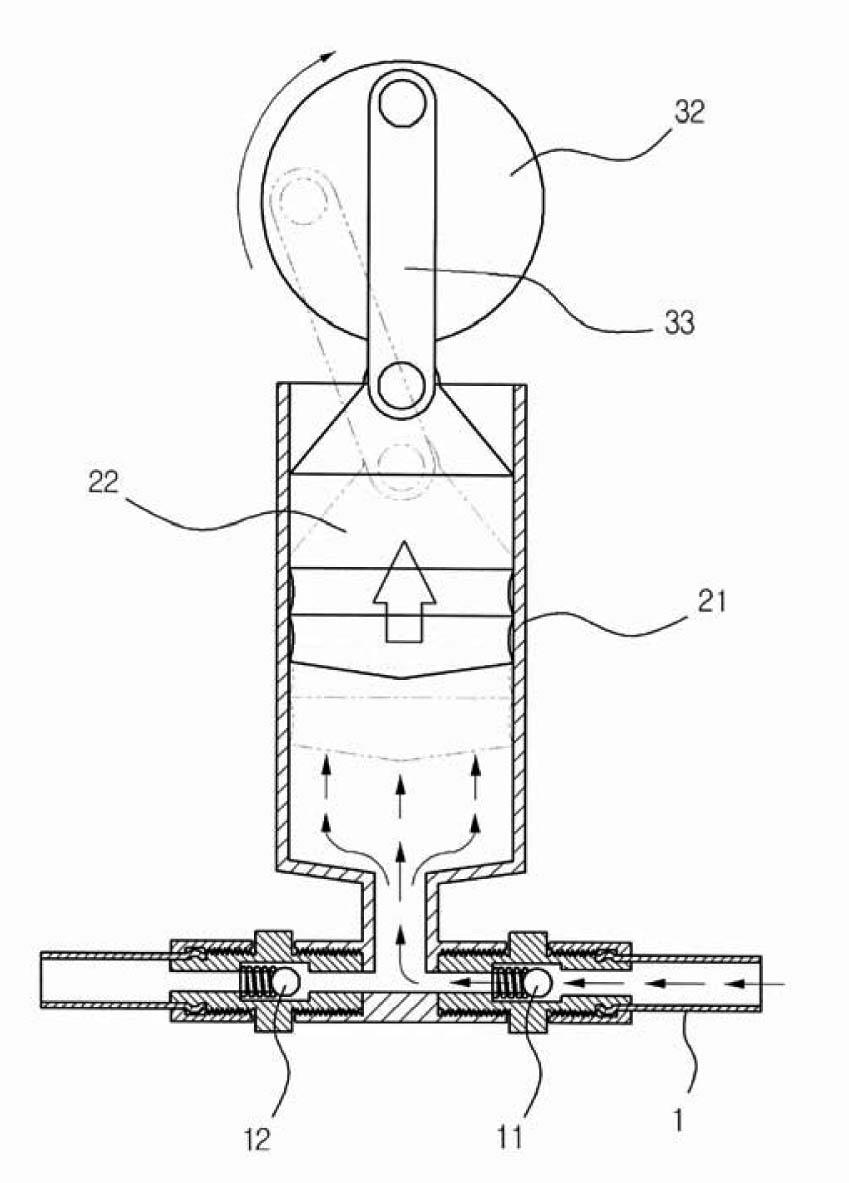

Condensate drain pump for an air conditioner

InactiveCN102099635ANoise minimizationComfortable atmospherePositive displacement pump componentsCondensate preventionJackshaftLow speed

The present invention is a condensate drain pump for an air conditioner, comprising a condensate discharge hose including two check valves which are formed in neighboring places, respectively and are extended to a storage tank where generated condensate is stored and a place where the condensate is discharged, so that inhaled condensate can be discharged via a check valve if a piston moves toward only a direction to which the condensate is discharged in the middle between the storage tank and the place, and the inhaled condensate cannot be discharged to the storage tank by the check valve; a pumping device including a cylinder having one opened end and the other end connected to a position between said two check valves, and the piston inserted from an open position of the cylinder for executing reciprocating motions while maintaining water tightness; and a driving device including a crank axis rotated by a low speed motor, and a connecting rod having one end connected to the crank axis and the other end connected to the piston for converting rotation movements of the low speed motor into rectilinear reciprocating movements of the piston.

Owner:申春赫

Vehicle with multiple engines coupled to a transmission via a jackshaft

InactiveUS8561744B1Reduce operating costsMaximize fuel economyElectric propulsion mountingPropulsion using engine-driven generatorsJackshaftCombustion

A motor vehicle is provided with a power train having primary and auxiliary internal combustion engines which selectively feed power to a jackshaft. The power accumulated in the jackshaft is conveyed to a speed change transmission. Fuel economy is achieved by utilizing only one engine when lesser power is needed by the vehicle.

Owner:BELLOSO GREGORIO M

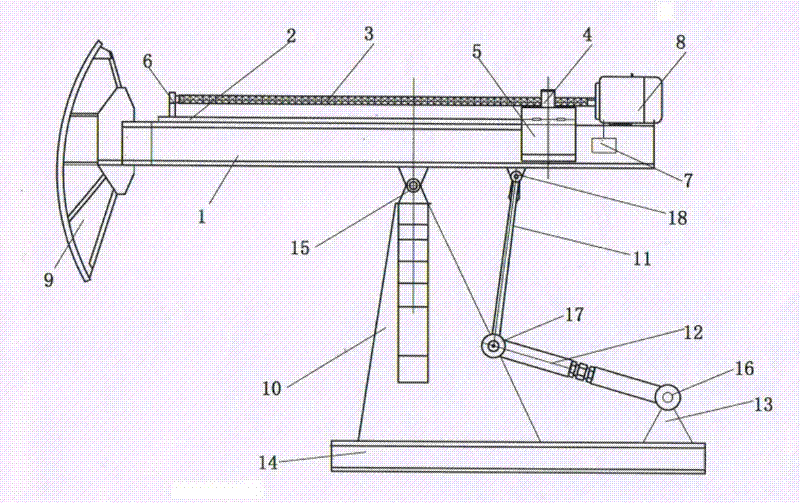

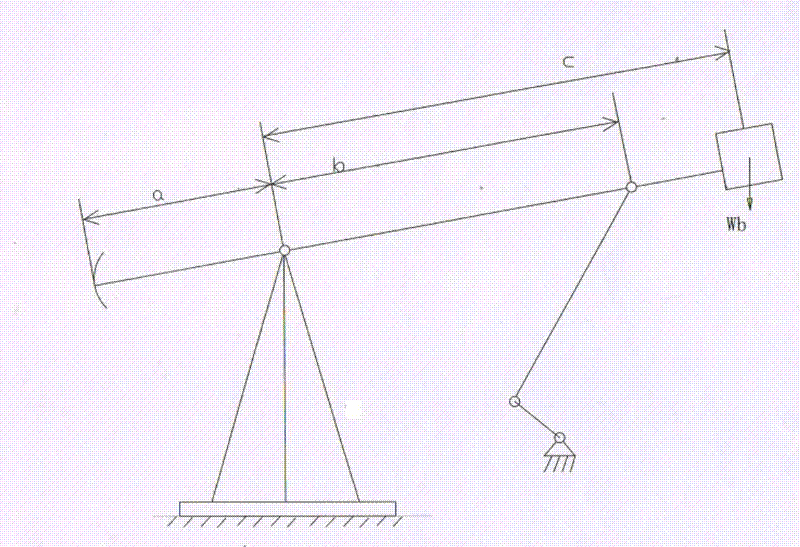

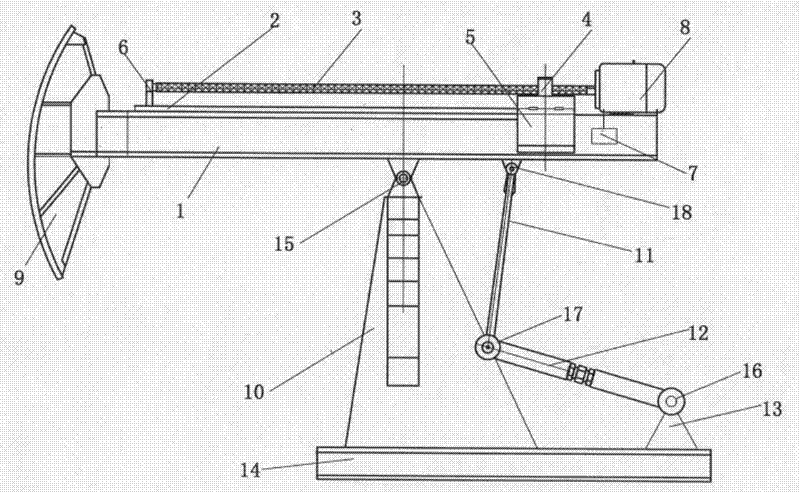

Mobile counterweight type pumping unit

InactiveCN102678089ASimple structureSave energyFlexible member pumpsFluid removalJackshaftBalancing machine

A mobile counterweight type pumping unit comprises a counterweight type balancing mechanism, a triangular support, a crank and connecting rod mechanism and frame. The counterweight type balancing mechanism comprises a walking beam, two slideways, a reciprocating screw rod, two counterweight blocks, a variable frequency motor and a horsehead. The variable frequency motor is fixed on the right of the upper end face of the walking beam and is connected to the right end of the reciprocating screw rod. The left end of the reciprocating screw rod is supported on the left of the upper end face of the walking beam through a screw rod bearing. The slideways are fixed on two sides of the walking beam. A nut is fitted on the reciprocating screw rod. Two identical counterweights are fixed onto the nut and are slidably fitted with the slideways respectively. A balancing block is fixed at the right end of the walking beam. The upper end of the triangular support is connected with the walking beam through a triangular support shaft. The upper end of a connecting rod is connected with the walking beam through an upper shaft. The lower end of a crank is connected with a shaft seat through a crankshaft. The lower end of the triangular support and the shaft seat are fixed onto the frame respectively. By replacing an original balancing block and a reducer with the counterweights and adding the balancing block onto the walking beam, the mobile counterweight type pumping unit is simple in structure and energy-saving.

Owner:樊红海

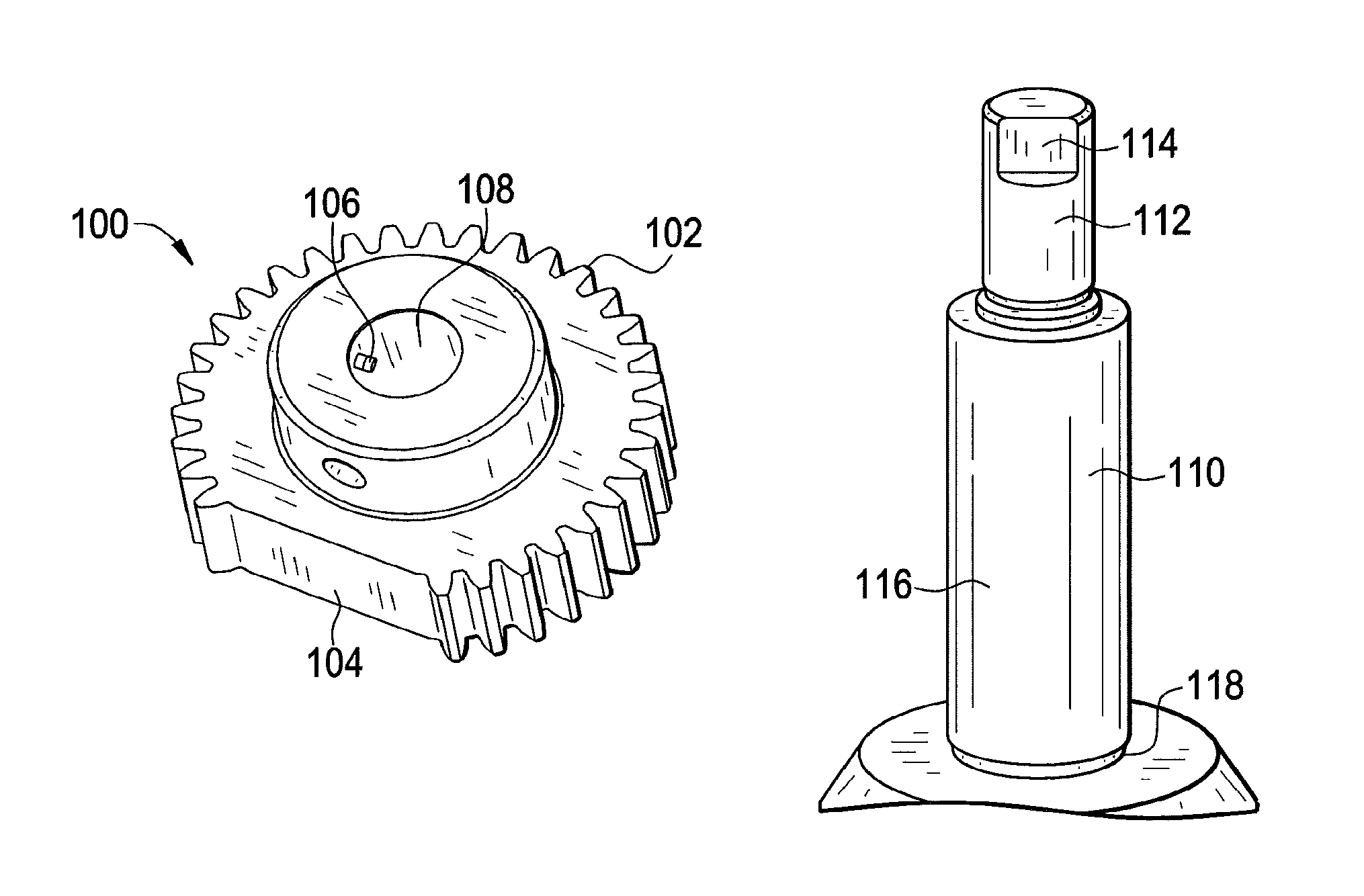

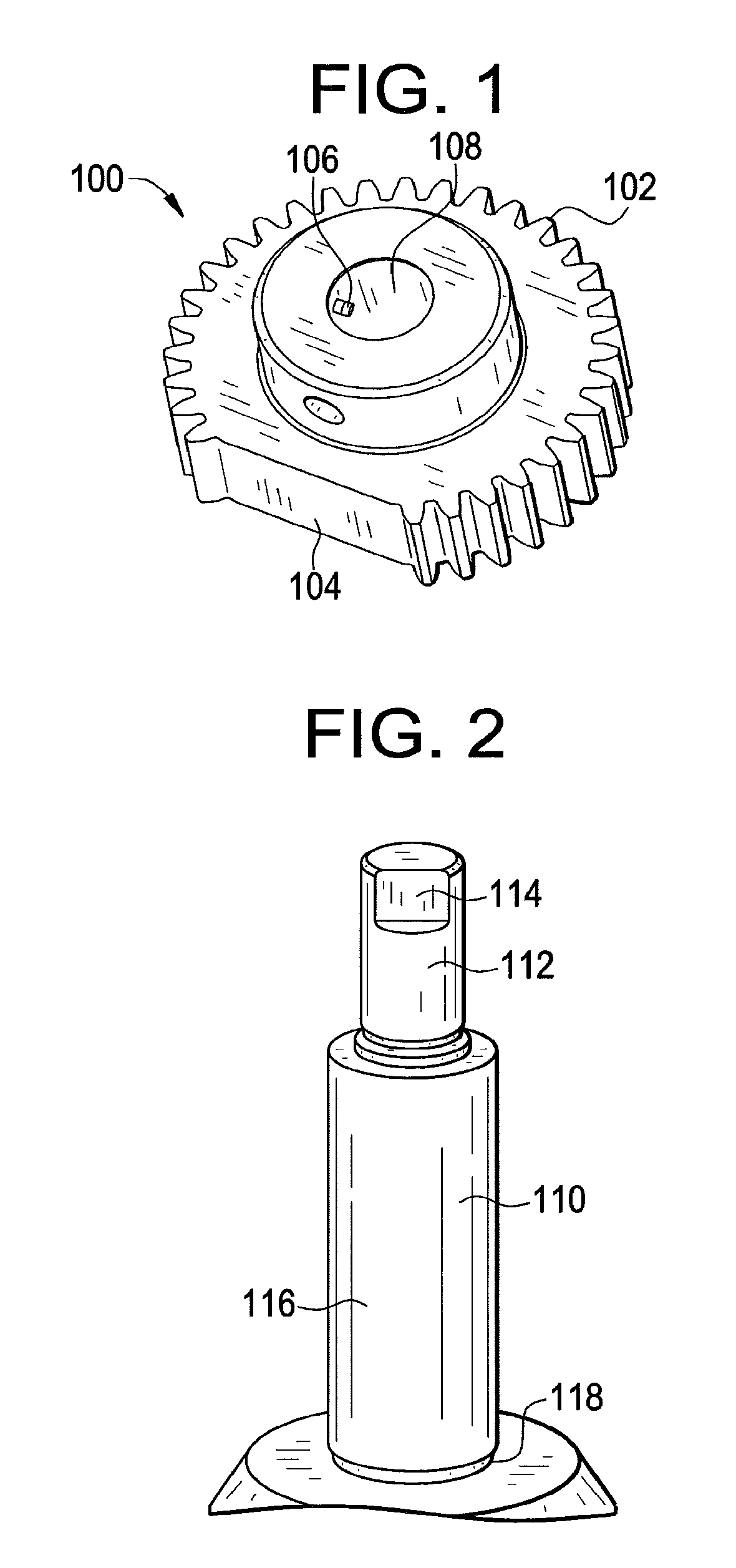

Features to properly orient inlet guide vanes

Several physical features on an inlet guide vane (IGV) ensure proper orientation of the IGV within a compressor during assembly. A gear with several teeth removed results in a flat surface on the gear which inhibits the gear from rotating on the rack of the compressor inlet casing. An orientation pin is located in the internal bore of the gear. The cylindrical IGV spindle has a portion formed as a flat surface and the orientation pin engages this flat surface. These features are applicable to both a one-piece IGV where the jackshaft is integrated with the IGV stem and a two-piece IGV in which the jackshaft is separate from the IGV stem. A feature applicable to a two-piece IGV is a shaped boss on the IGV stem that allows the jackshaft to be located on the IGV stem in only one orientation.

Owner:GE INFRASTRUCTURE TECH INT LLC

Power train

ActiveUS20200198727A1Easy to manufactureSmall sizeWheel based transmissionRider propulsionRotational axisJackshaft

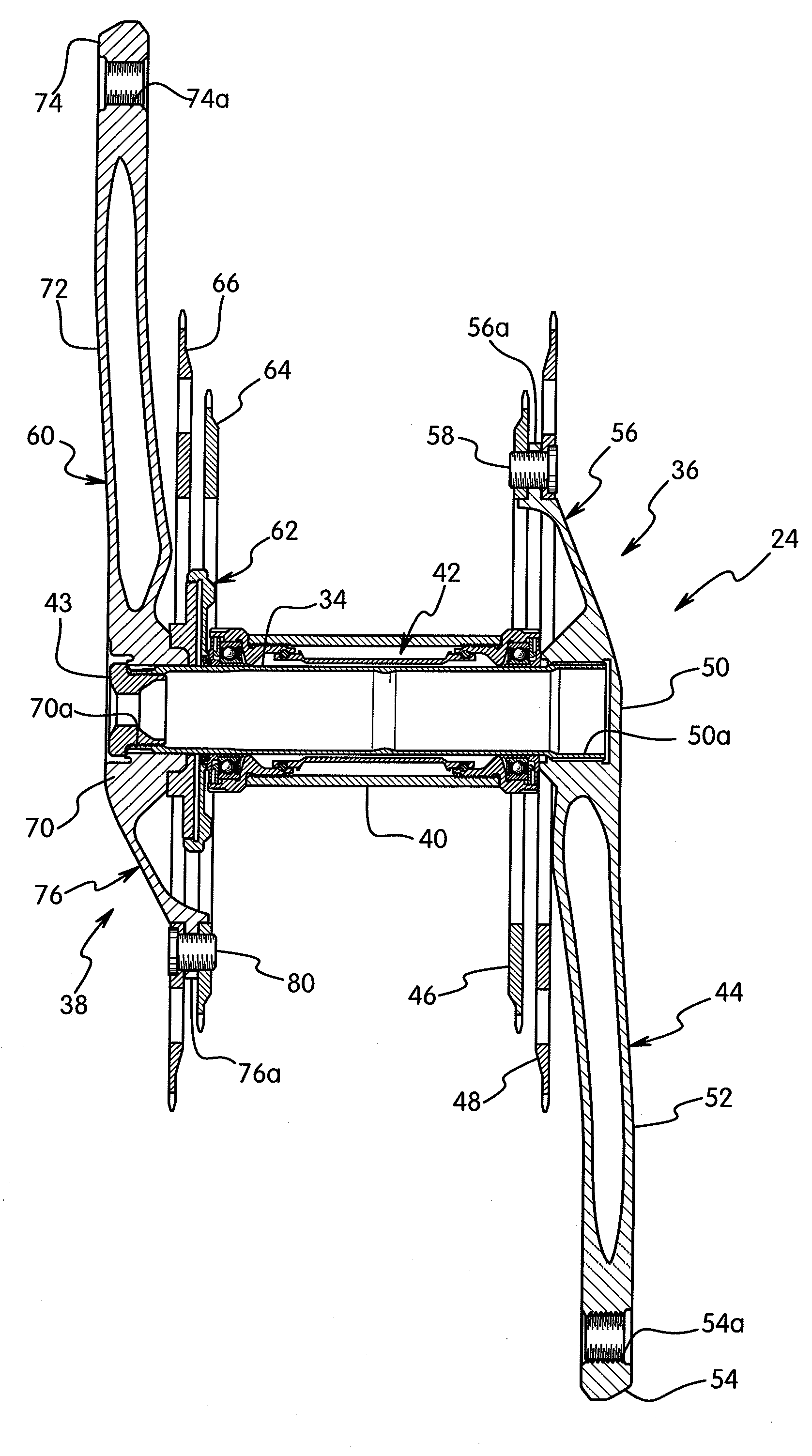

A powertrain for a pedal vehicle includes a crank axle and an output sprocket rotating around a first rotation axis. The coupling between the crank axle and the output sprocket goes through an epicyclic gear system that includes a ring gear, a planet carrier, and a sun gear (13) which rotate around a second rotation axis that is spatially offset from the first rotation axis.

Owner:E2 DRIVES

Powershift gearbox for construction machines, especially for a tractor backhoe loader and a telescopic handler

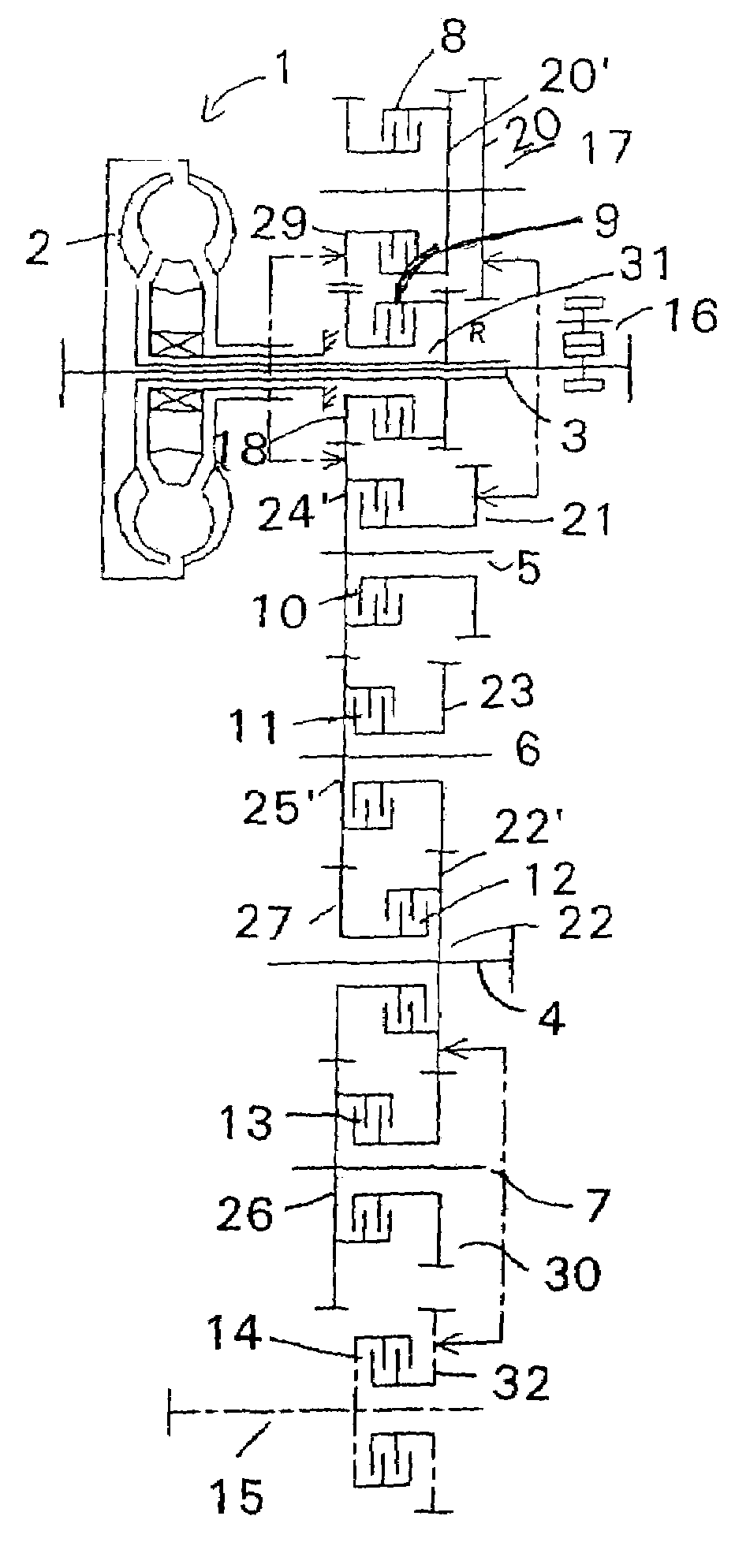

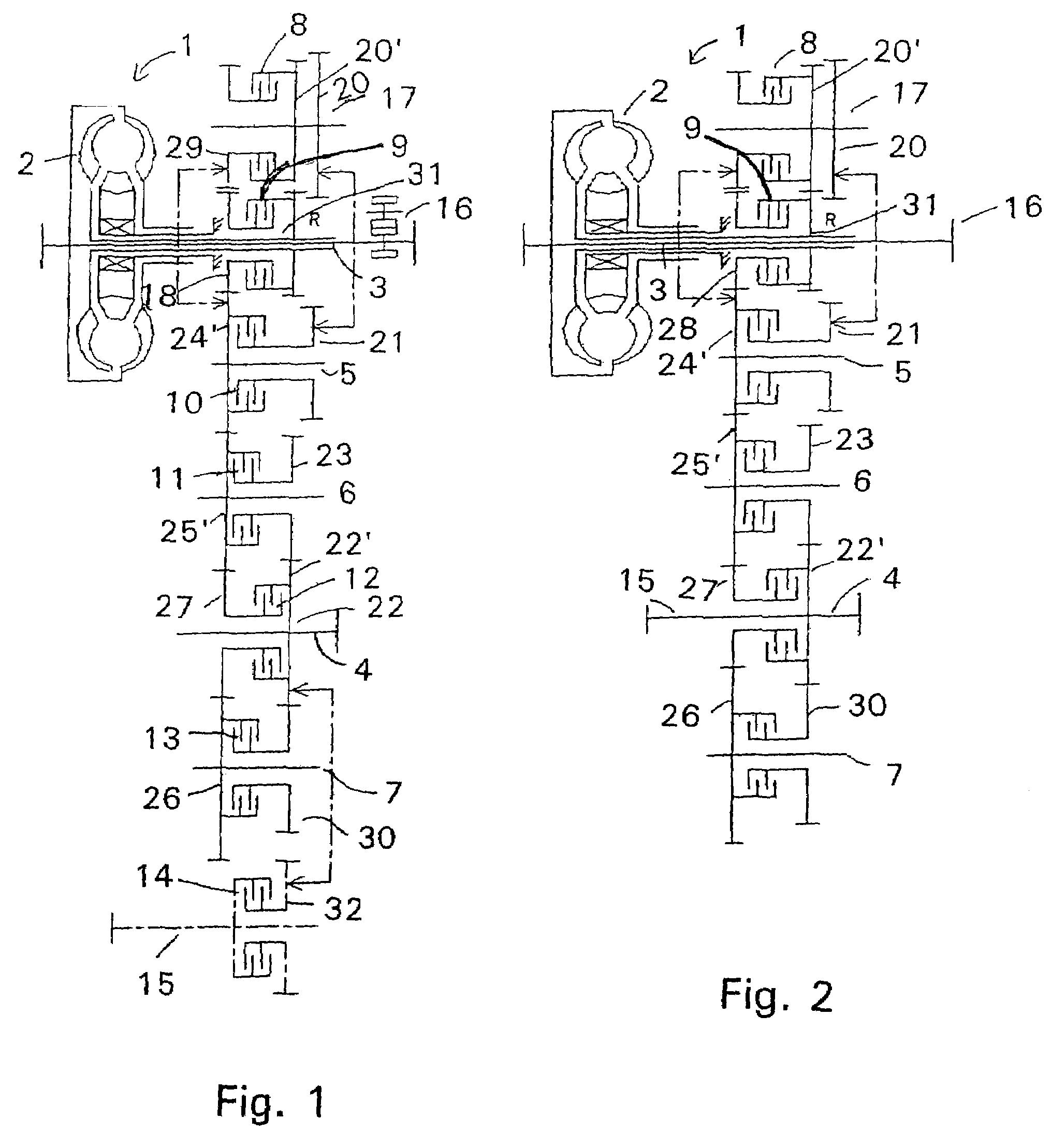

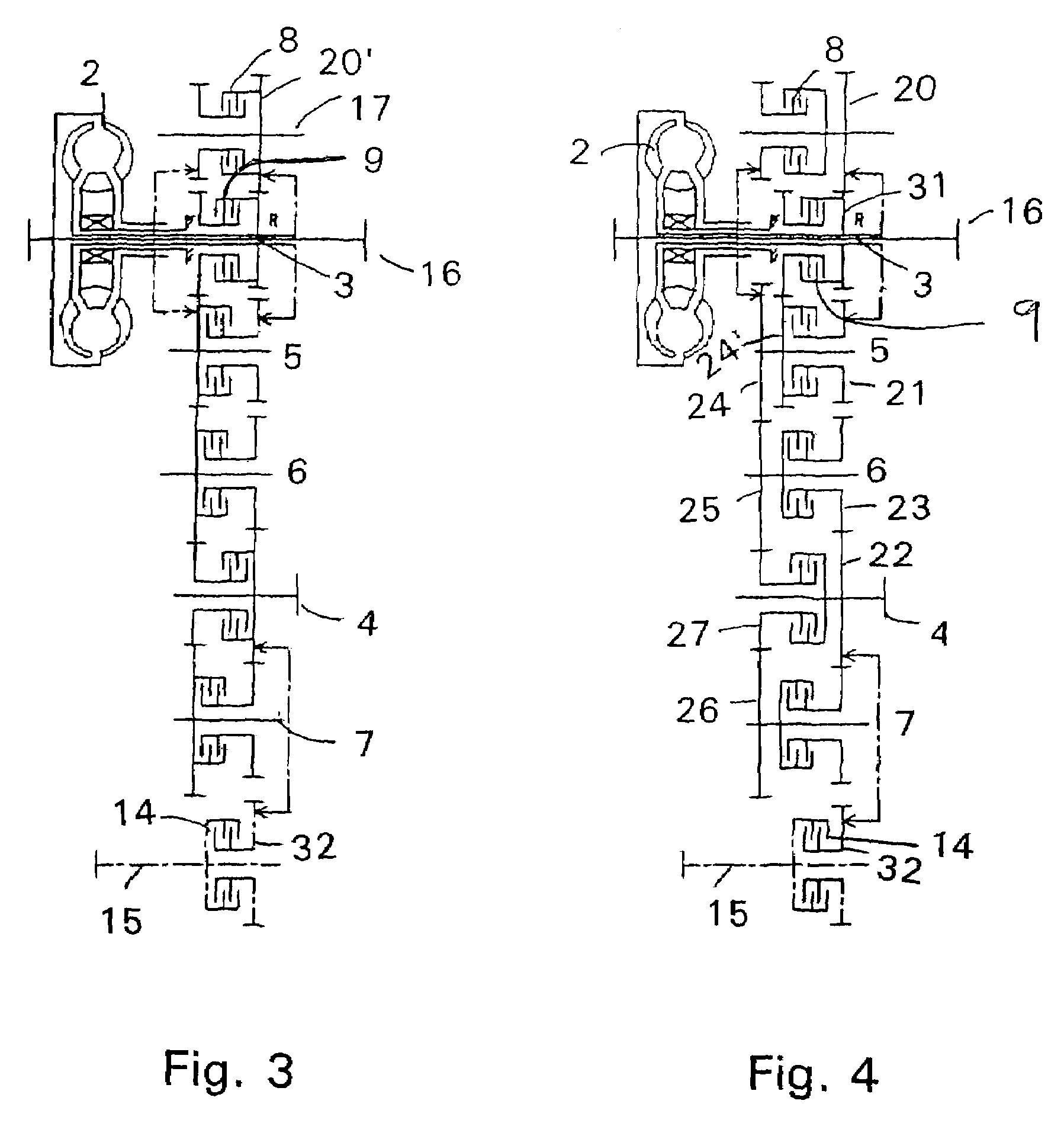

A multi-geared high-low clutch for construction machines and telescopic handlers, with a torque converter, a drive shaft, an output shaft and several jack shafts, with distributed idlers on the shafts, fixed wheels and shift clutches, which form several reduction gear units for the gearshift and direction circuit, containing six forward gears and three reverse gears, whereby output shaft is also used as a jack shaft for a gear, with which the corresponding jack shaft of forward gear unit and the corresponding jack shaft of a further forward gear unit engages with drive shaft. Both jack shafts can be rotated around drive shaft, where corresponding jack shafts of the gears, applied to drive shaft, are arranged one behind the other on a side of the drive shaft and where the corresponding jack shafts of the further gears, can currently be rotated around the next jack shaft.

Owner:ZF FRIEDRICHSHAFEN AG

Medium voltage circuit breaker arrangement

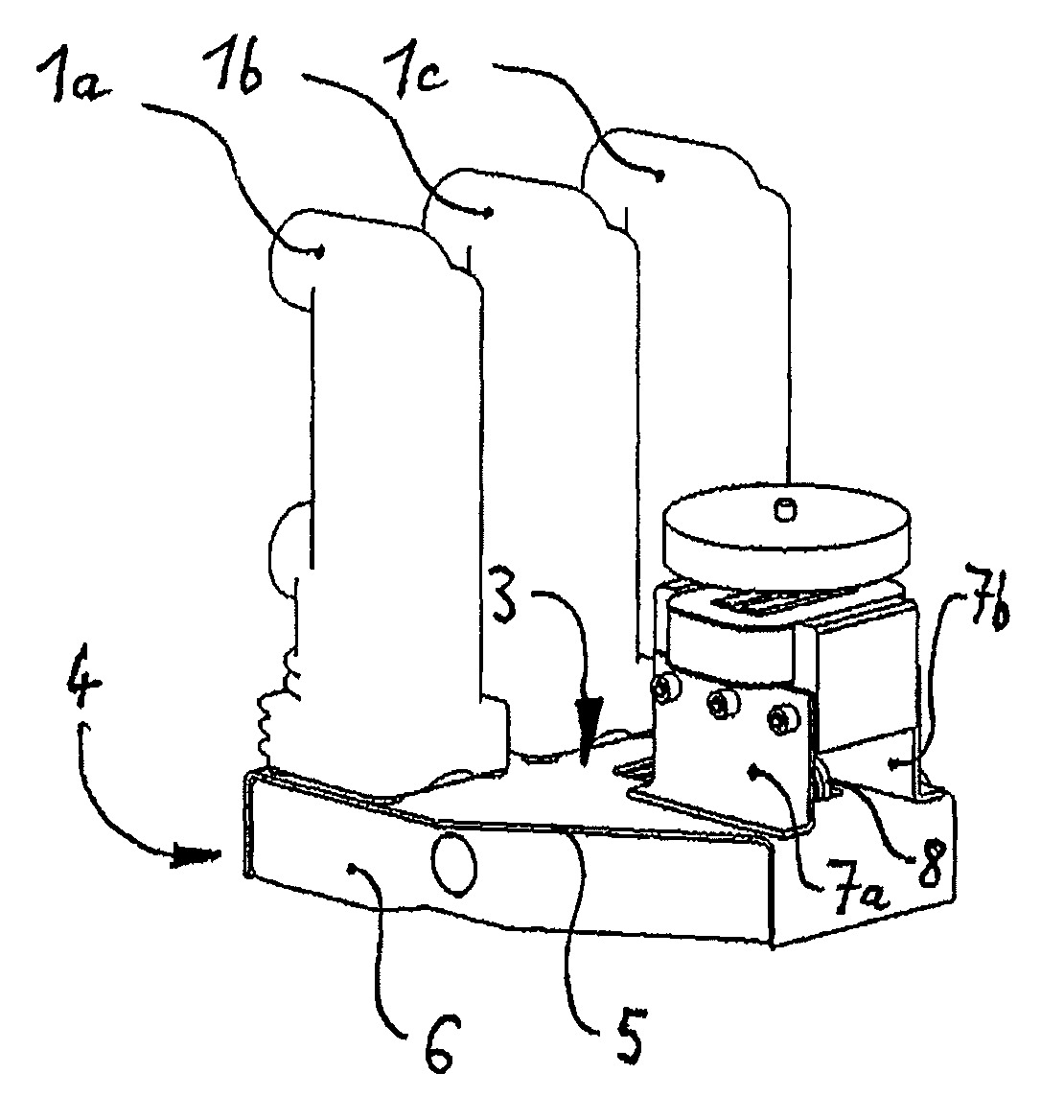

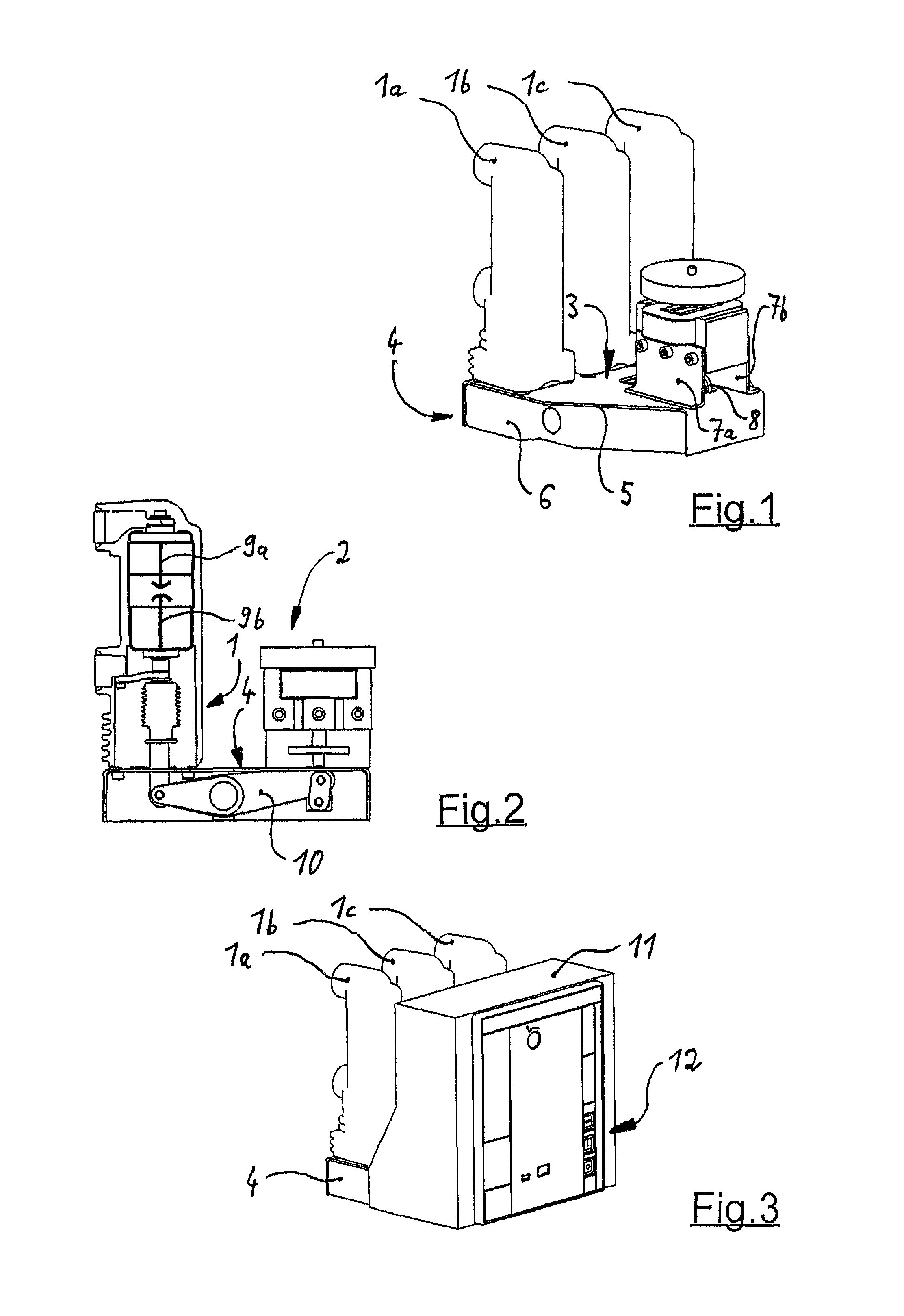

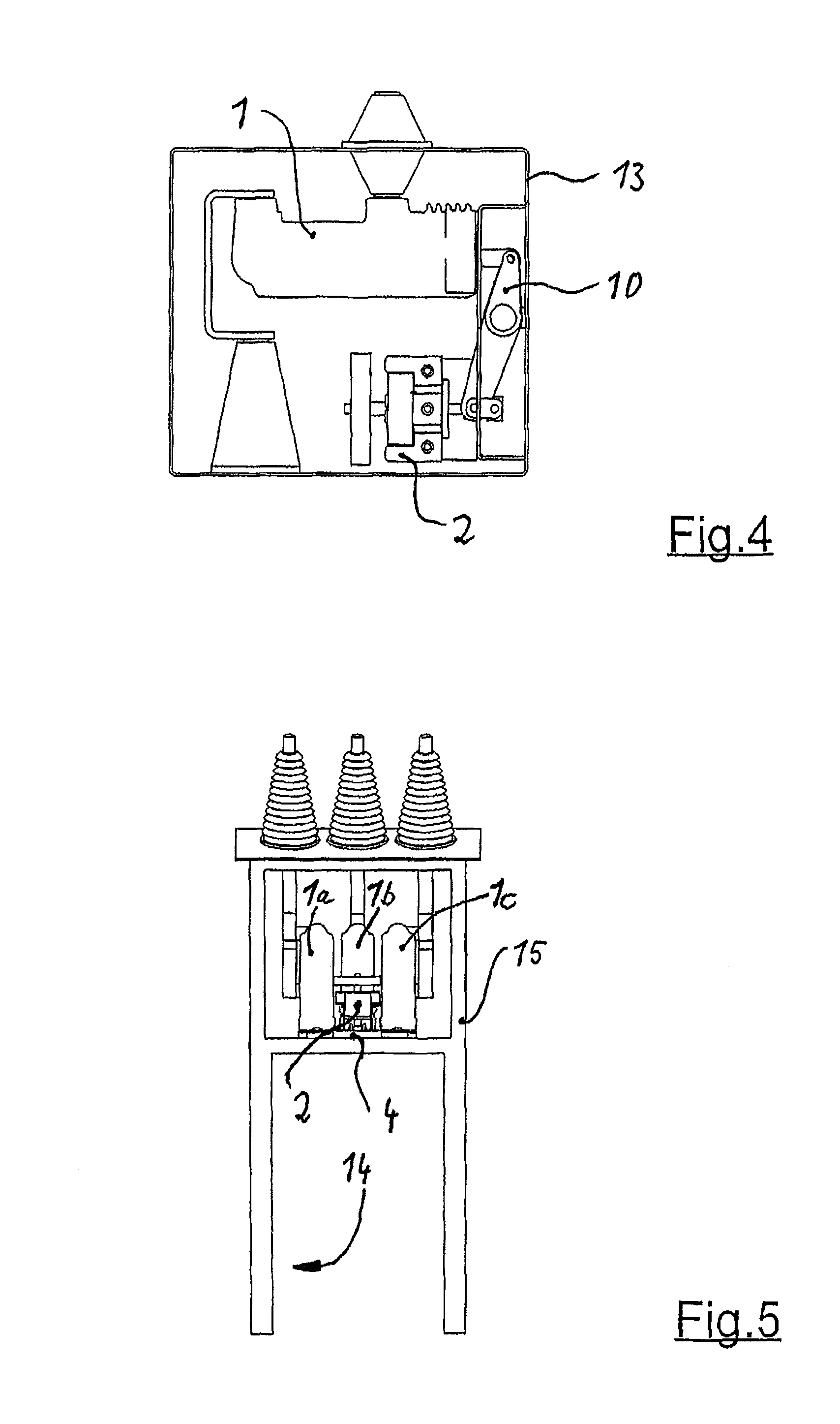

InactiveUS8629366B2Easy to assembleHigh-tension/heavy-dress switchesContacts enclosures/screensJackshaftStructural engineering

Exemplary embodiments are directed to a medium voltage circuit breaker arrangement that includes at least one pole part housing for accommodating a pair of coaxially arranged electrical contacts, wherein one electrical contact of the pair of electrical contacts is axially movable via a jackshaft arrangement which is accommodated in a recasted sheet metal housing, and driven by an actuator unit. The sheet metal housing forms a suspension construction for the at least one pole part housing and the jackshaft arrangement and the corresponding actuator unit forming a module. An additional housing part is provided for covering at least the actuator unit of the module in order to define the outer geometrical dimensions of the circuit breaker arrangement.

Owner:ABB TECH AG

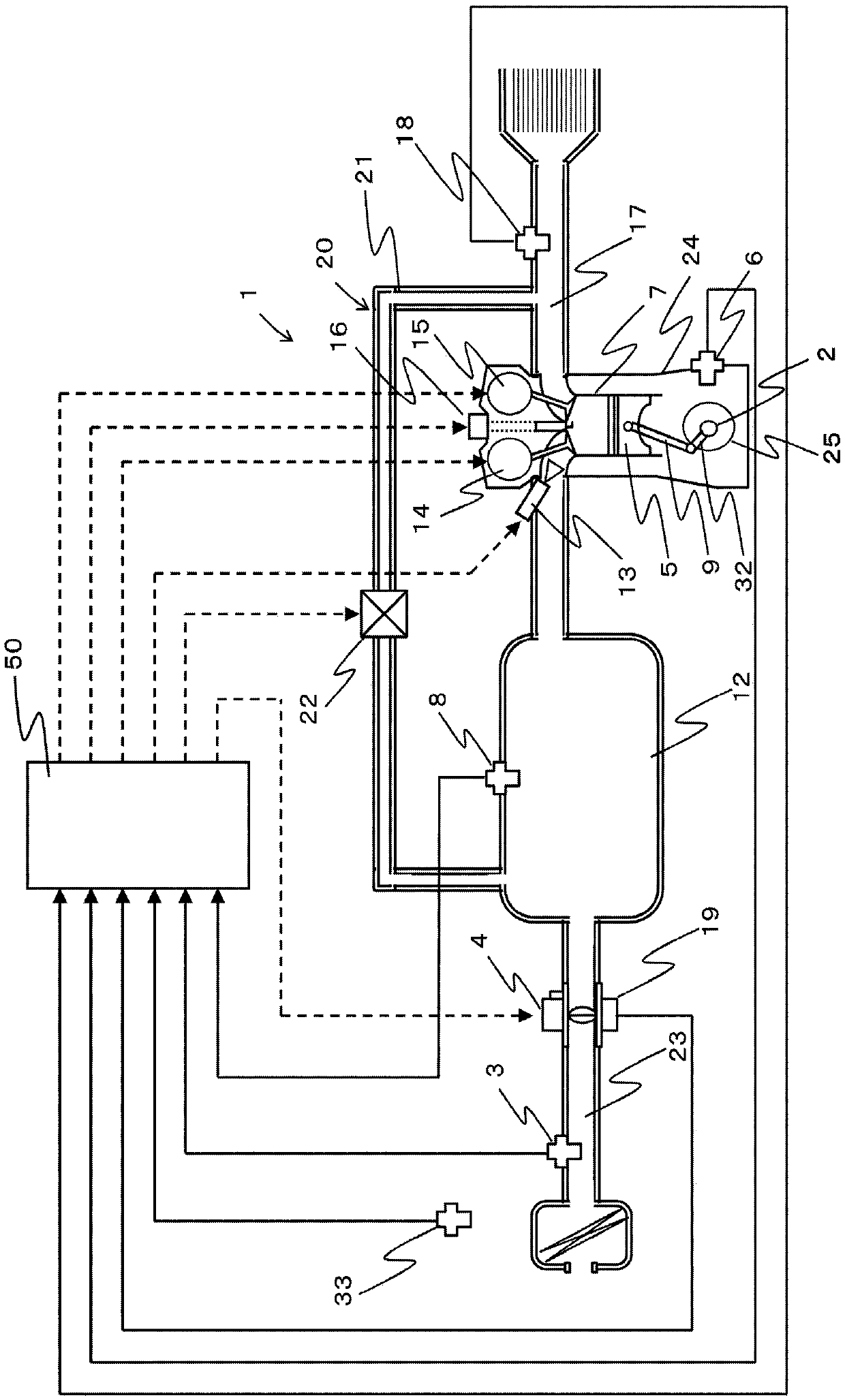

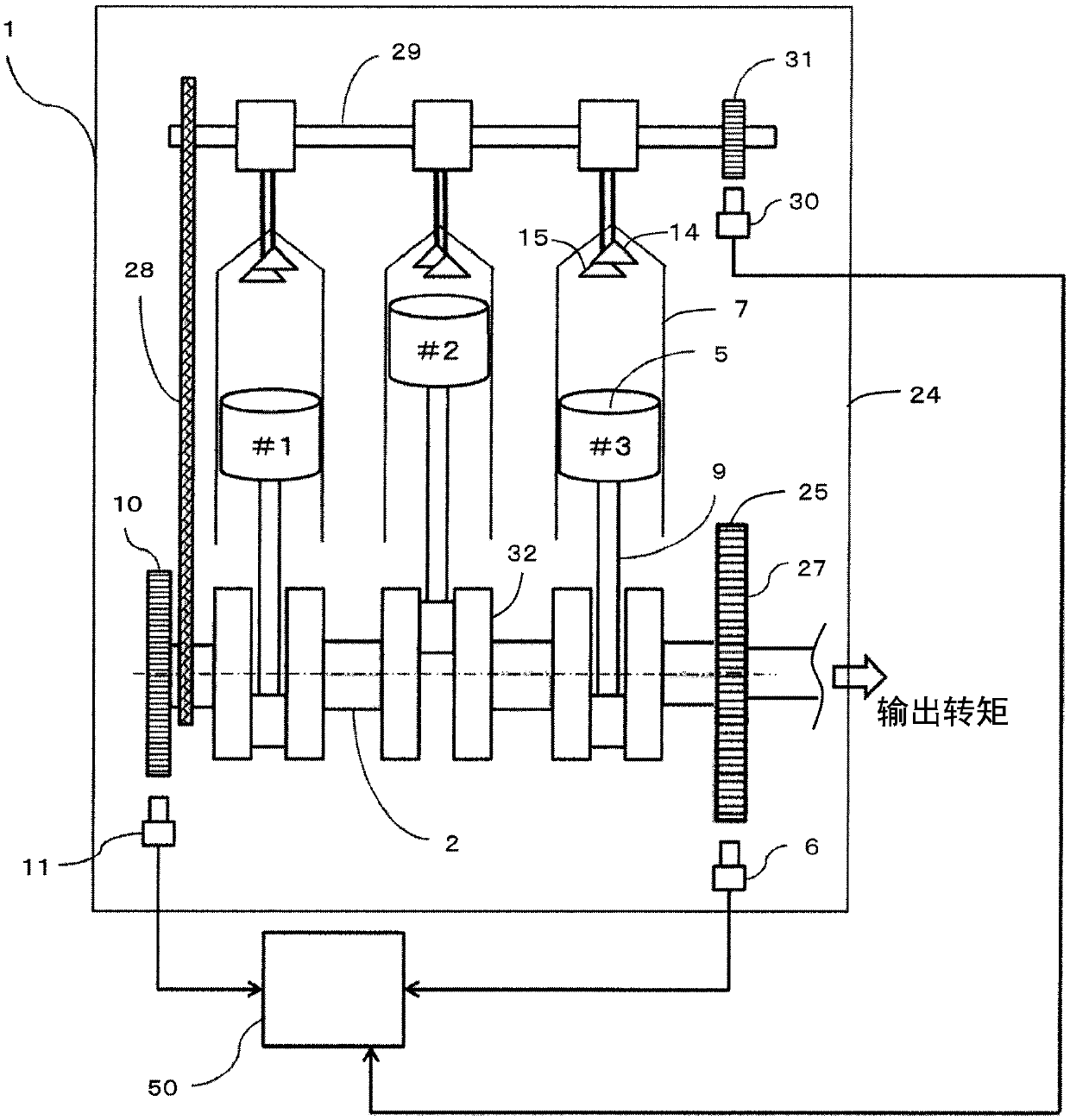

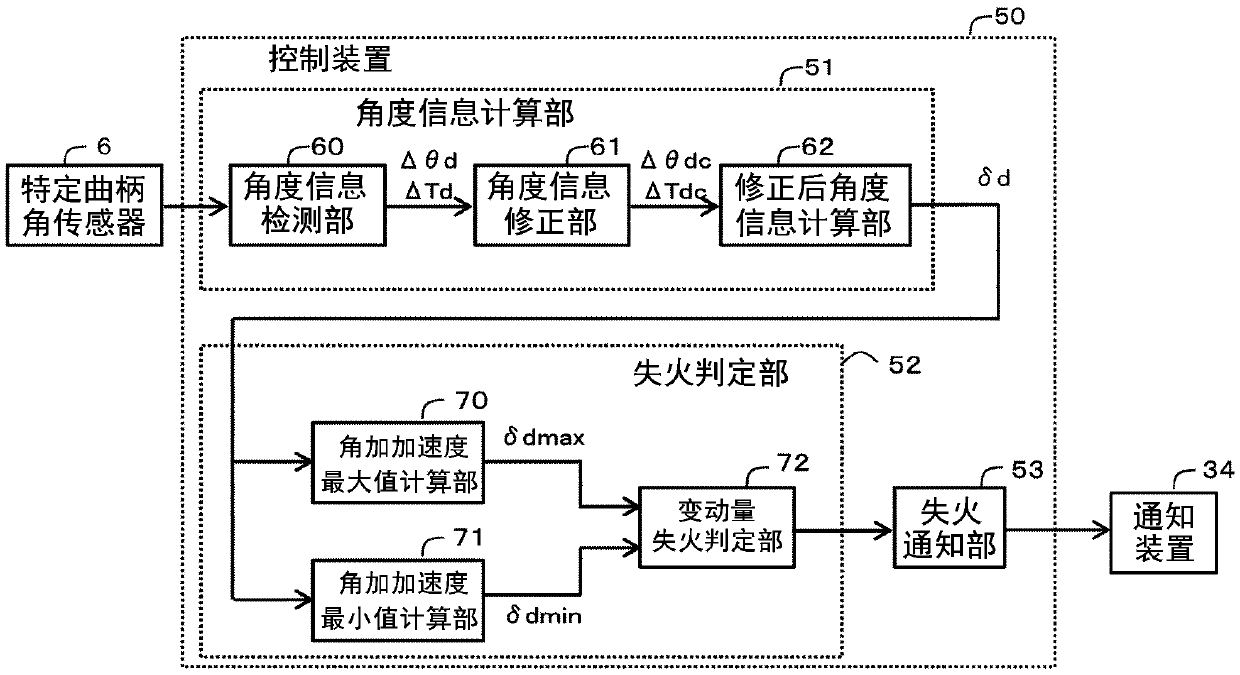

Controller and control method for internal combustion engine

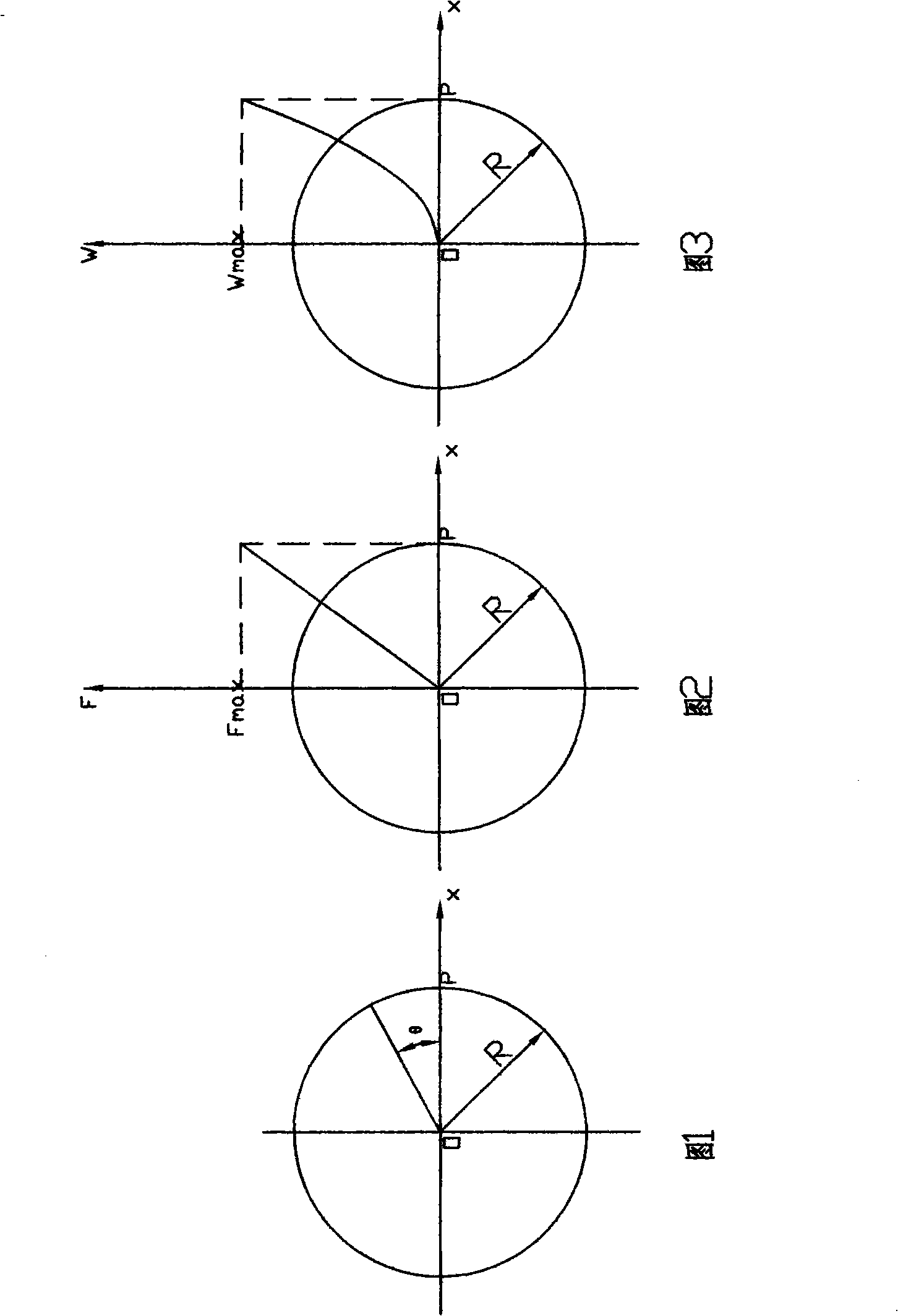

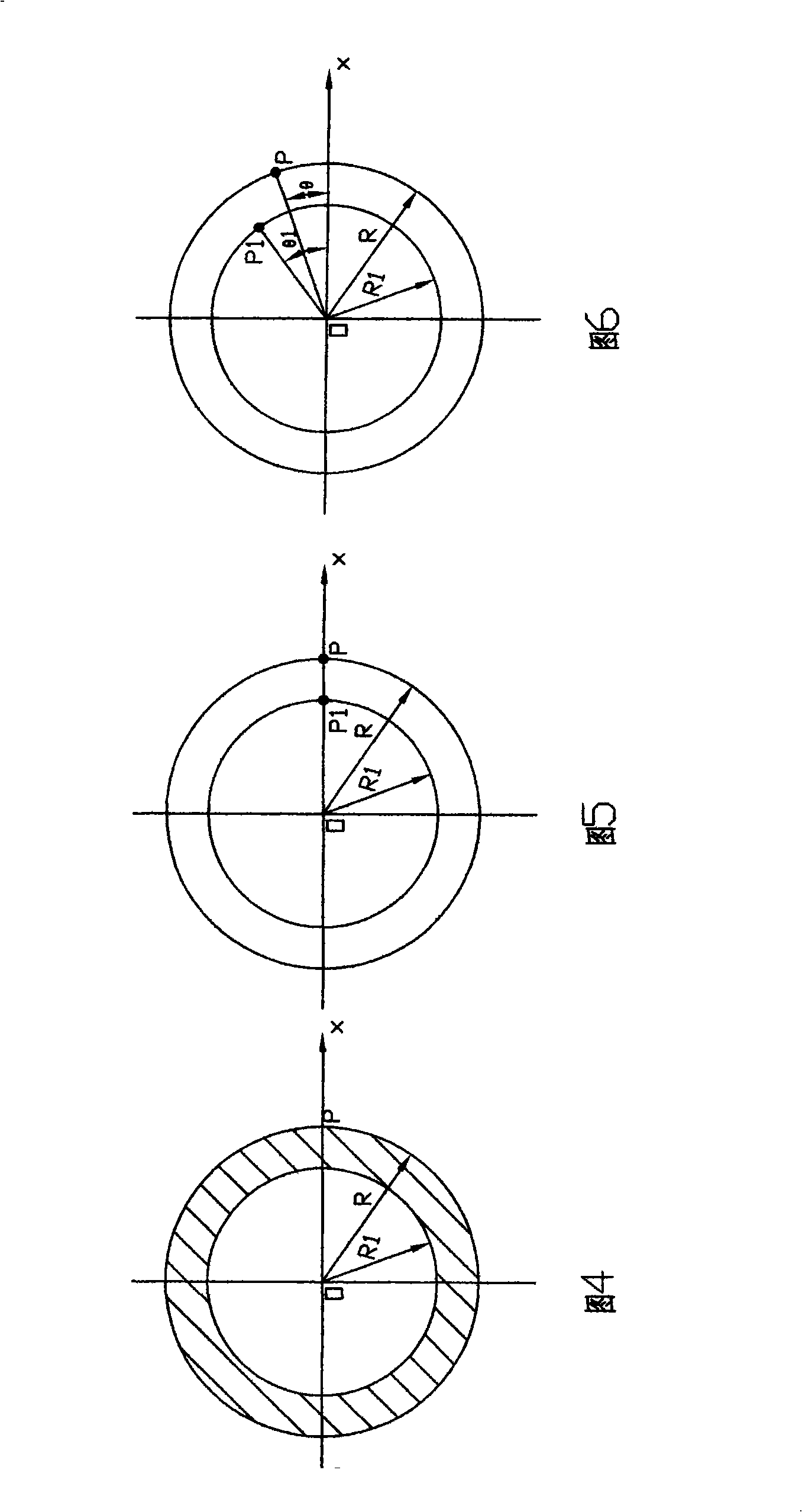

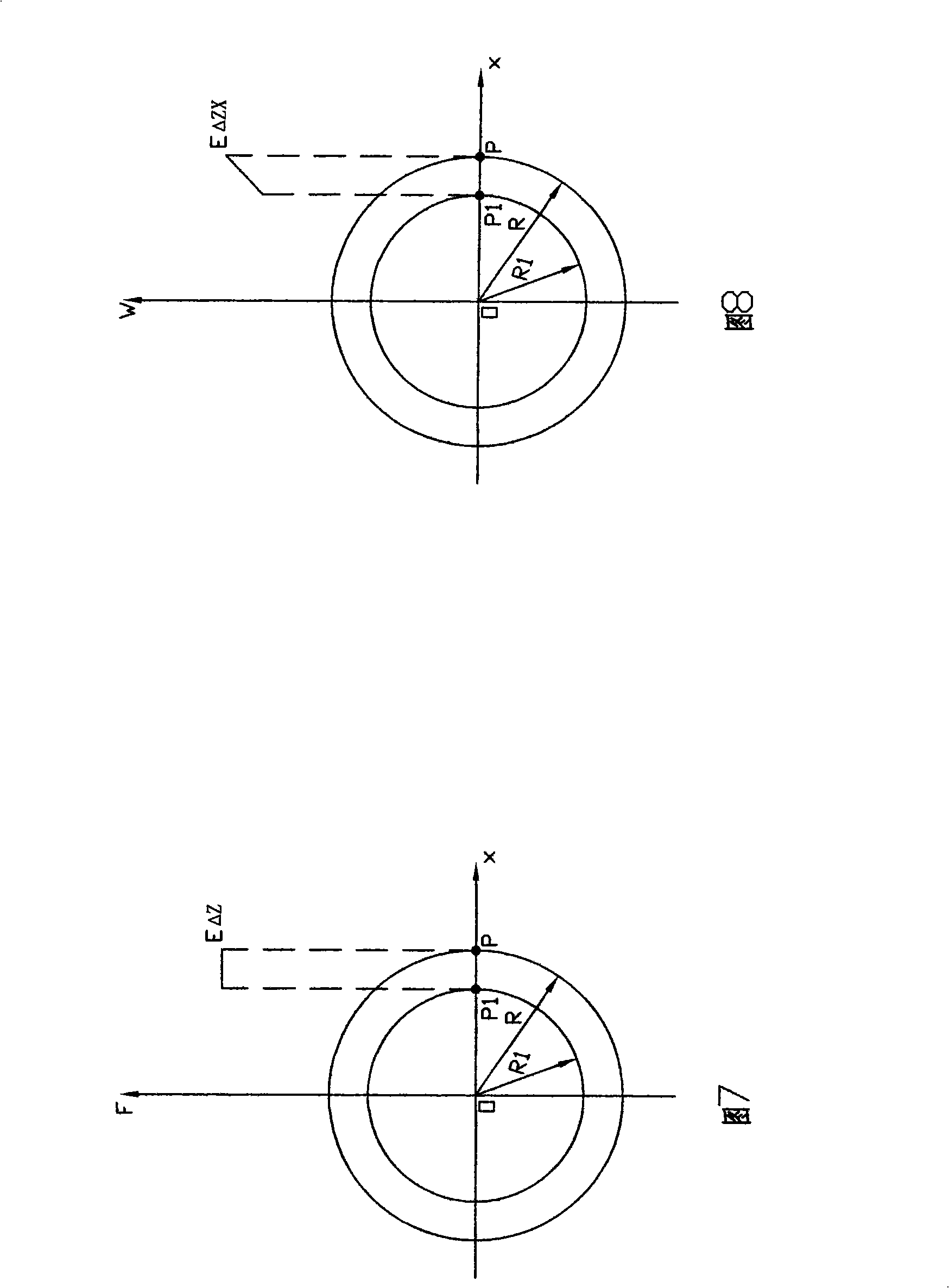

ActiveCN109899160ANot susceptible to vibrations from multiple stroke cyclesHigh precision misfire detectionInternal-combustion engine testingElectrical controlCombustionTime changes

To provide a controller and a control method for an internal combustion engine capable of detecting misfire with good accuracy by simple calculation, even when a vibration in a period of about severalstrokes occurs in the crankshaft. A controller 50 and a control method for an internal combustion engine detects crank angle [theta d] based on an output signal of the specific crank angle sensor 6,and calculates a crank angle speed [omega d], a crank angle acceleration [alpha d], and a crank angle jerk [delta d] which is a time change rate of the crank angle acceleration [alpha d]; calculates afluctuation amount [delta delta d] of the crank angle jerk [delta d] in a determination period which is set corresponding to a one combustion stroke based on the crank angle jerk [delta d]; and determines a presence / absence of misfire in the one combustion stroke based on the fluctuation amount [delta delta d] of the crank angle jerk.

Owner:MITSUBISHI ELECTRIC CORP

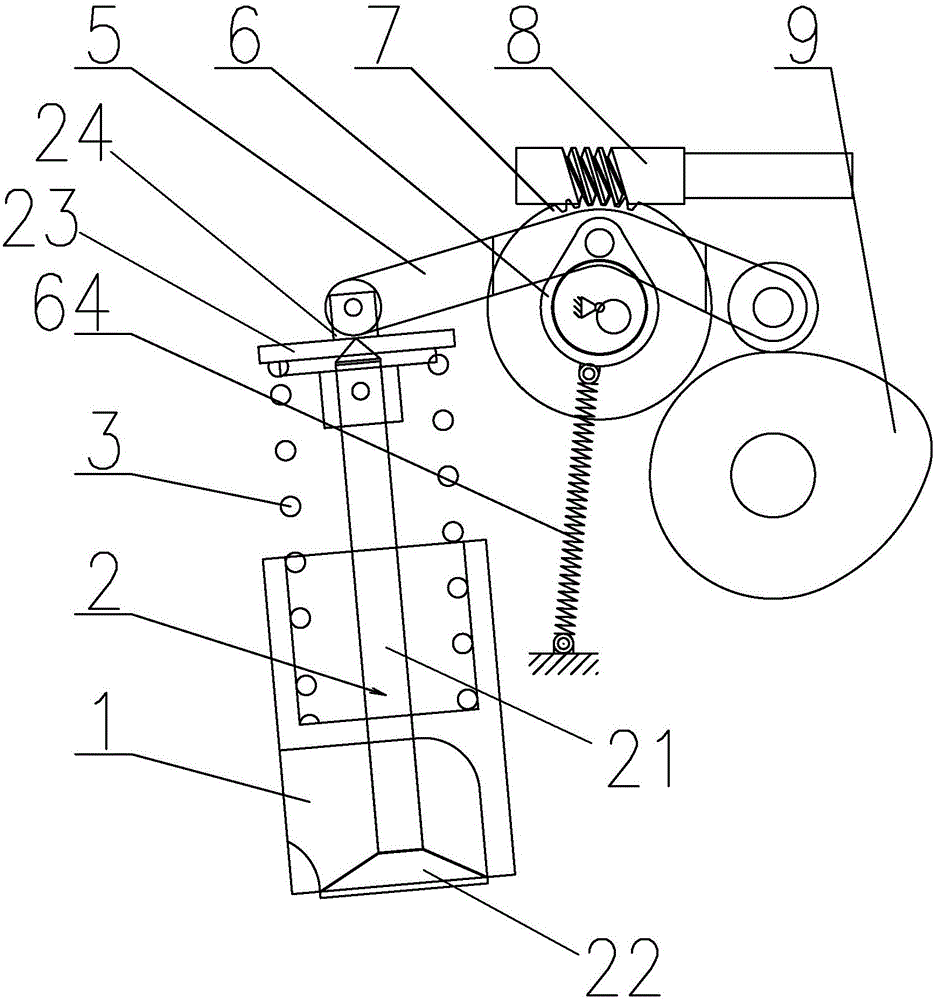

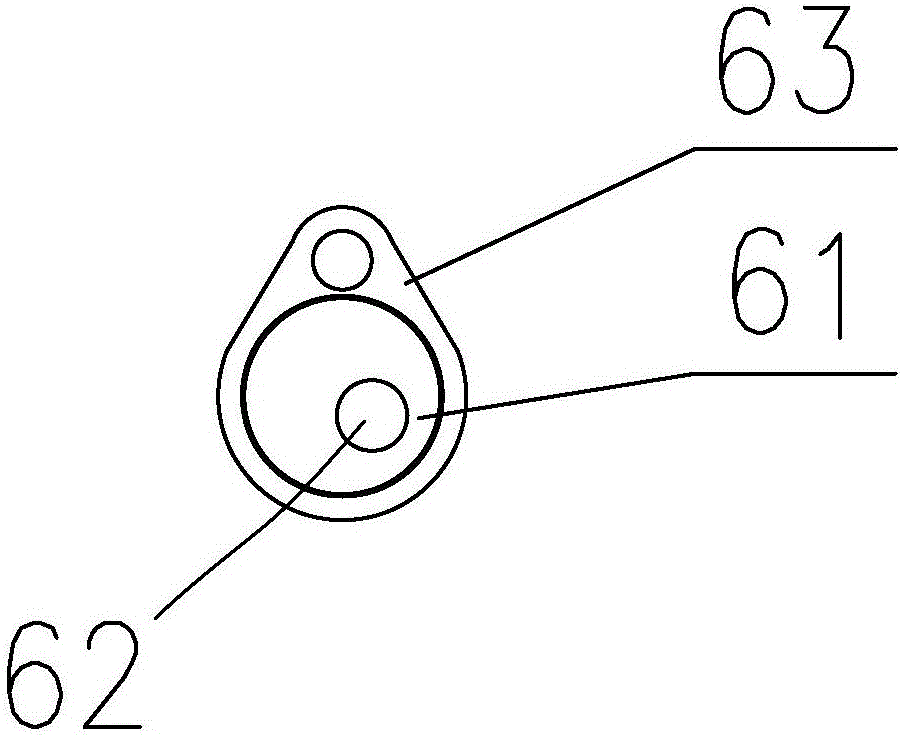

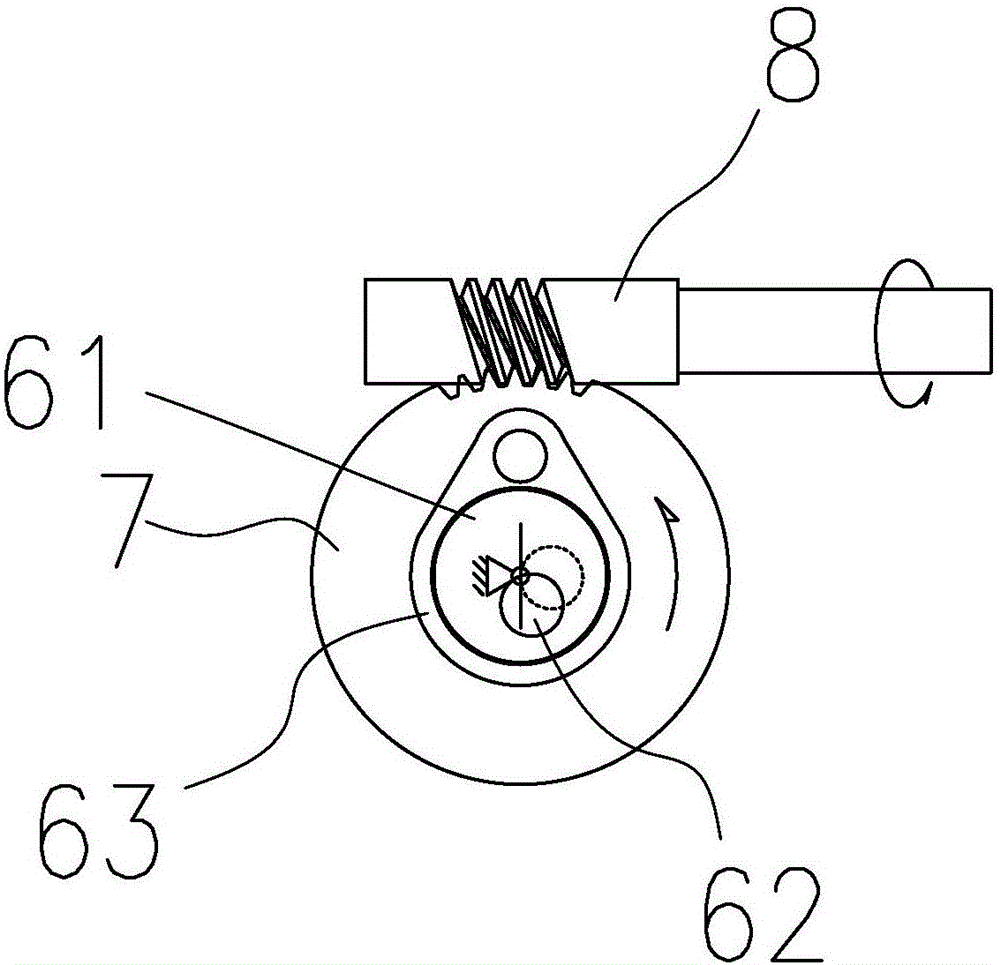

Stepless valve rocker mechanism with variable lift and corresponding valve device

The invention discloses a stepless valve rocker mechanism with a variable lift and a corresponding valve device. A rocker mechanism is used for being in linkage matching with a valve rod of the valve device to control the size of a valve channel of the valve device and comprises a crank connecting rod component, a crankshaft position regulation component, a valve rocker and a rocker drive component; the crank connecting rod component is composed of a crank, a crankshaft, a connecting rod and a connecting rod reset spring; the crank is an eccentric wheel; an eccentric hole of the crank is connected to the crankshaft; the position of the crankshaft is in stepless regulation by the crankshaft position regulation component; the connecting rod is an eccentric sleeve and sleeves the outer part of the eccentric wheel; one end of the connecting rod reset spring is connected with the connecting rod; the other end of the connecting rod reset spring is connected to a fixed point; the valve rocker is a lever with an eccentric part of the connecting rod as the middle fulcrum; the left end of the valve rocker is hinged to the upper end of the valve rod; and the right end of the valve rocker is in driving matching with the rocker drive component. According to the stepless valve rocker mechanism, under the conditions that the lift of an overhead cam and the phase relationship between the opportunity of opening and closing the valve and a piston crank are invariable, the lift of the valve can be regulated in a stepless manner.

Owner:苏立群

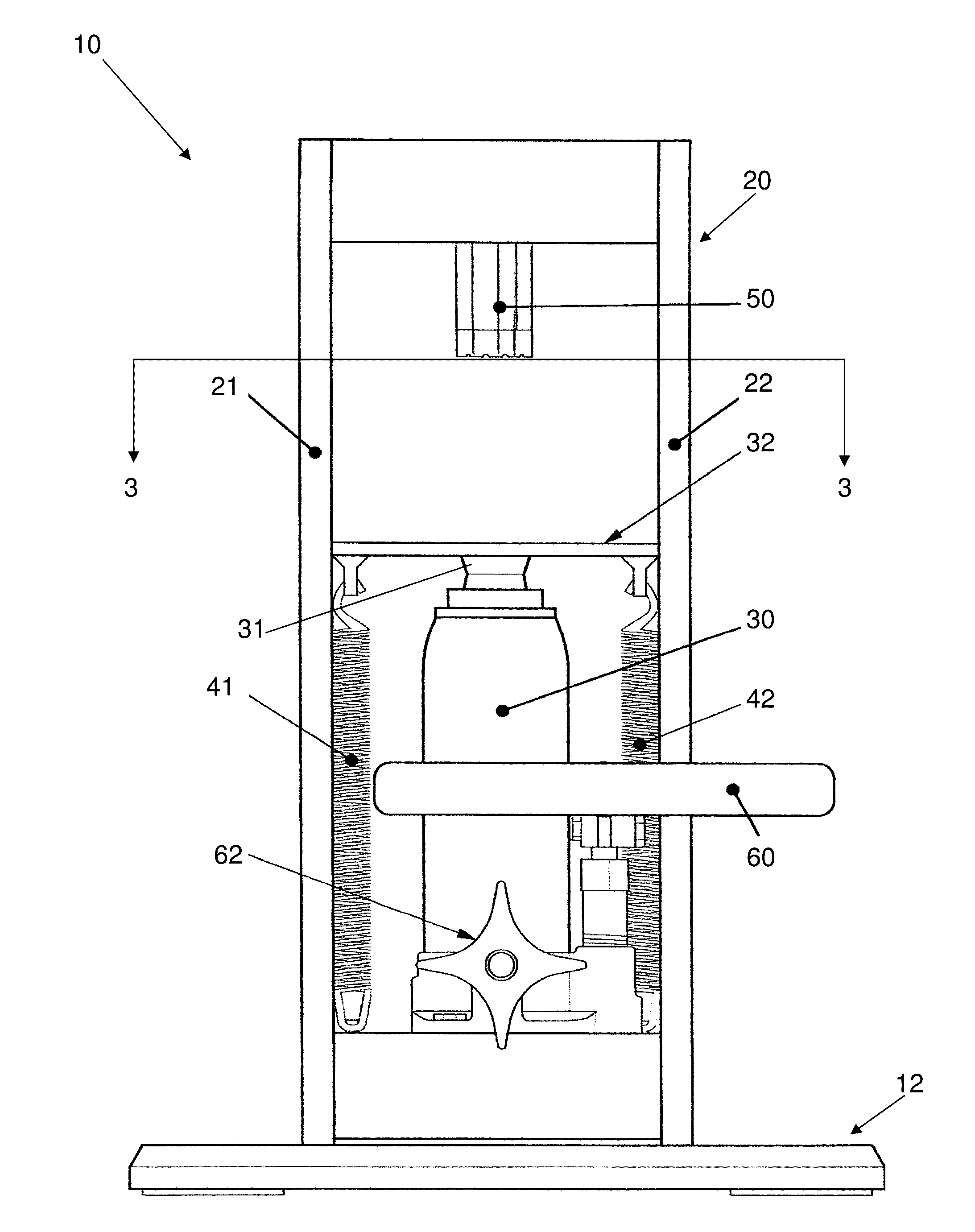

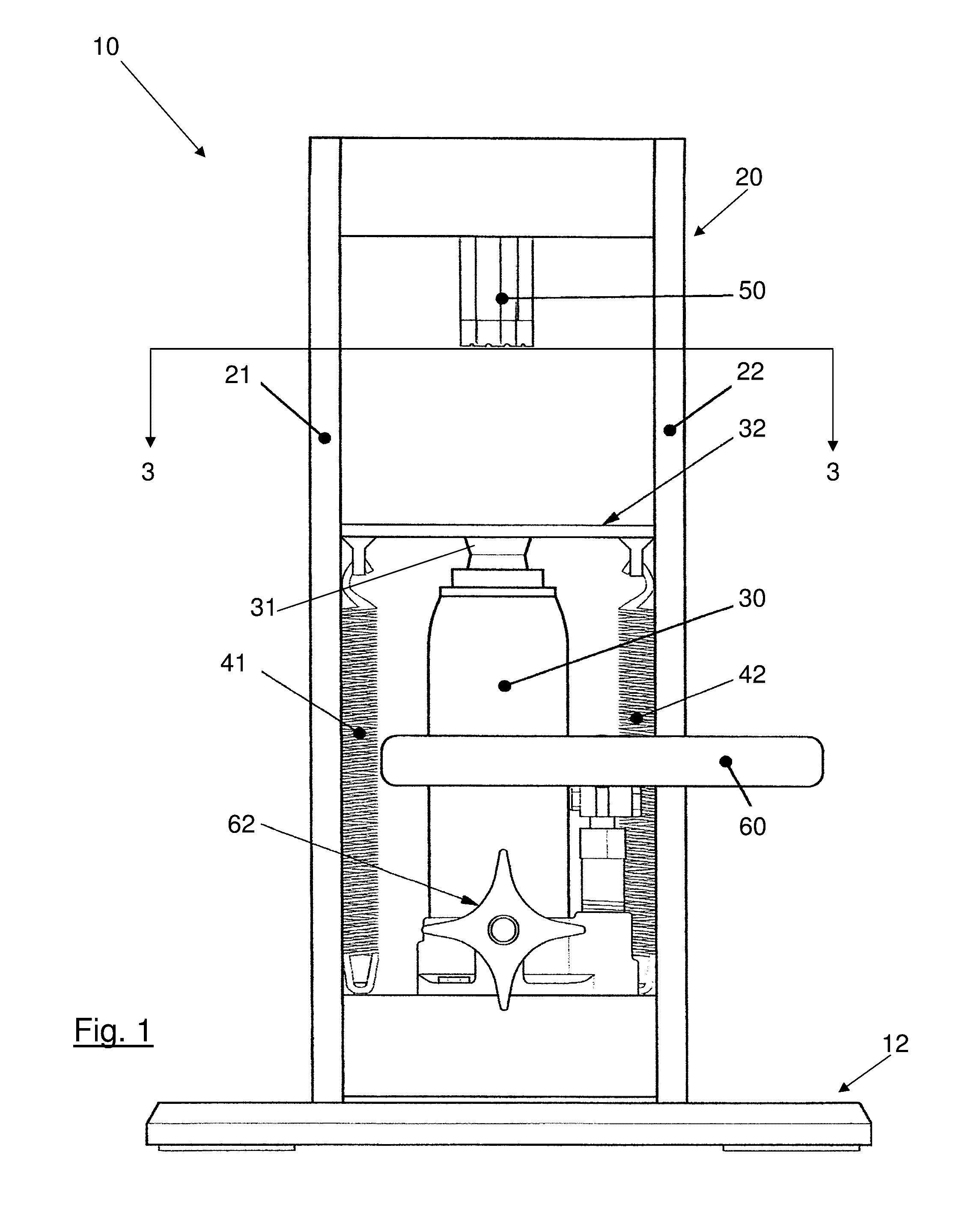

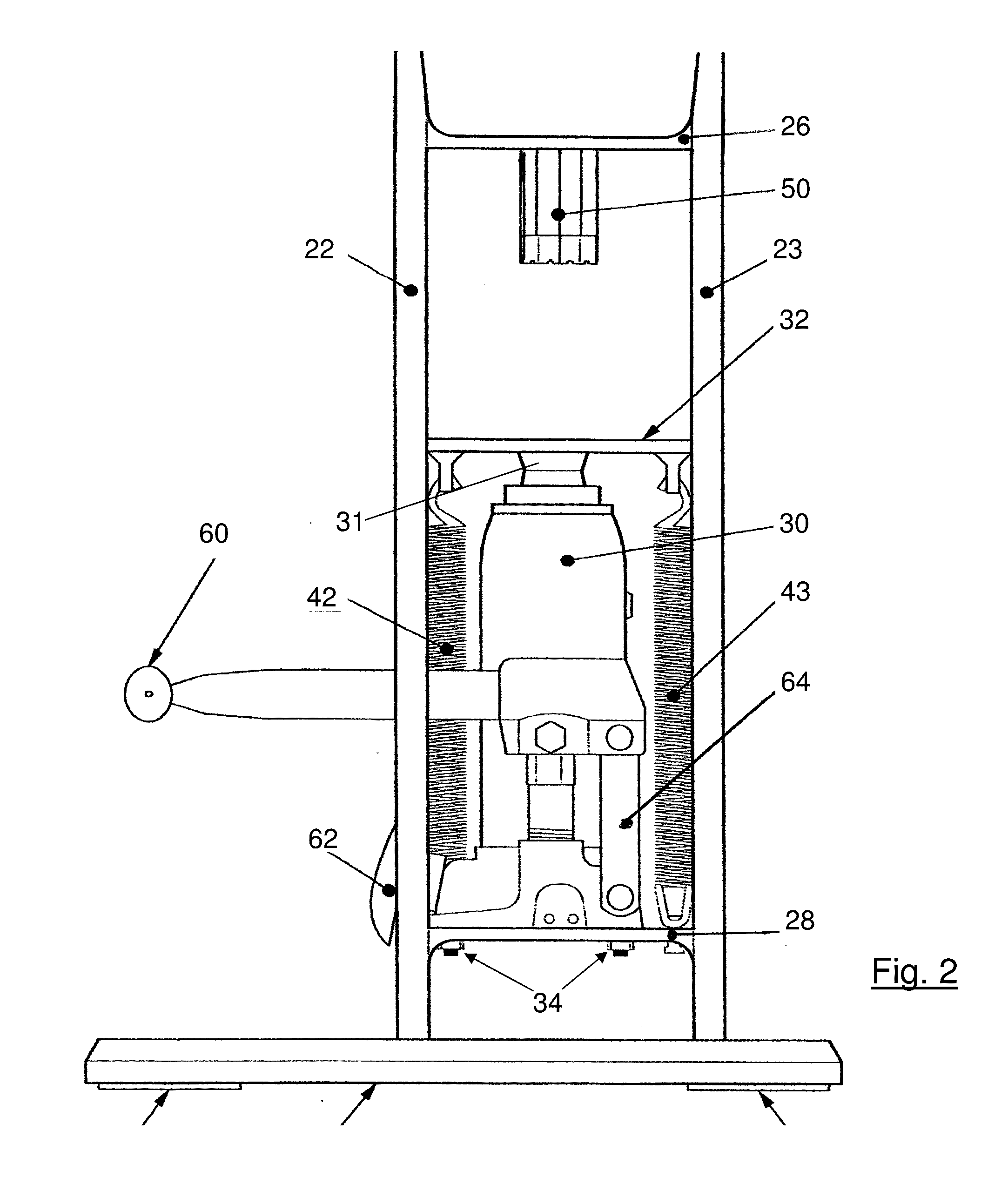

Nut cracker with mechanical advantage

InactiveUS20160316974A1Light weightEasy to useKitchen equipmentHuskingJackshaftMechanical advantage device

A nut cracking device with a frame comprising elongated, parallel members that surround a mechanical advantage device, such as a hydraulic jack. Top and bottom channel members are mounted at opposite ends of the frame members to separate the frame members and form a rigid frame structure. An anvil with texture to reduce slipping and increase pressure is mounted to the top member and extends toward the jack, on which a table is mounted. A nut may be placed on the table. Upon displacement of the jack's shaft, the table moves toward the anvil and any nut on the table is clamped, and ultimately fractured, between the table and the anvil. A hand-grippable knob permits manual bypass of a valve to permit the table to be pulled away from the anvil by springs mounted to the table.

Owner:NUTDEMANDER LLC

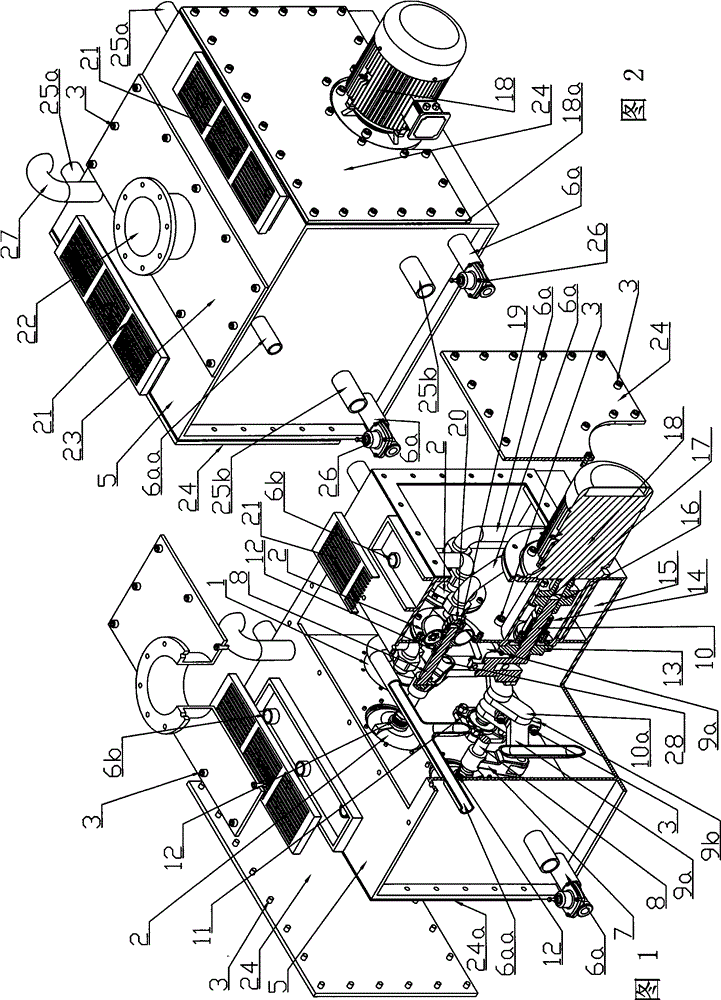

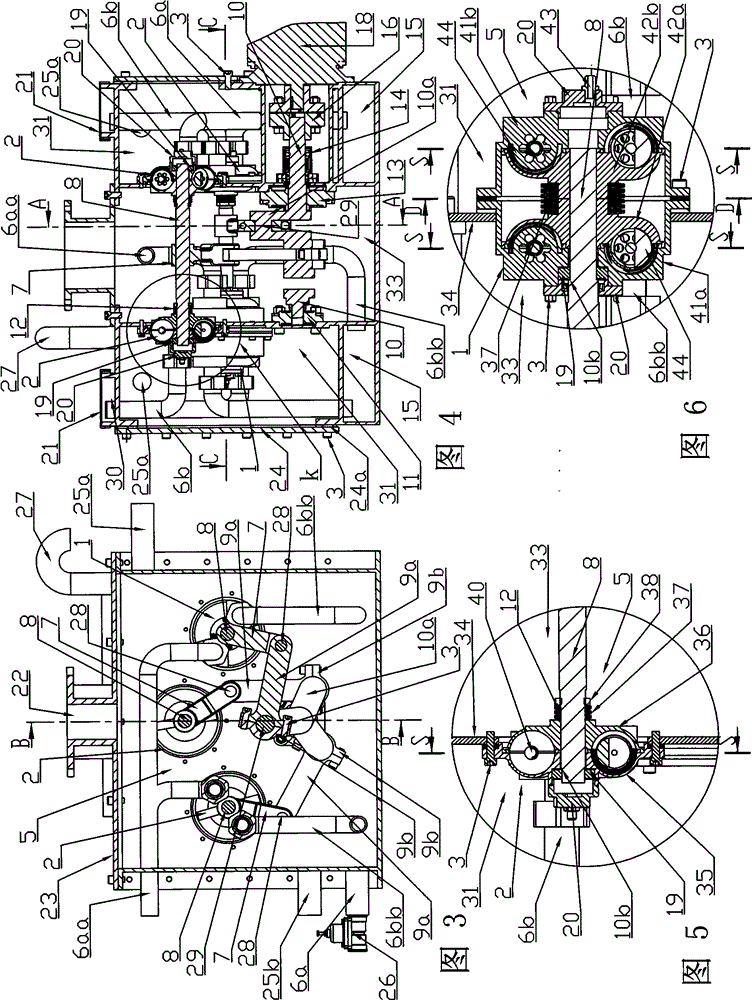

Tray piston swing pressure fluid feeding machine driven by crank-link mechanism

InactiveCN104948453AExtend your lifeReduce machining accuracyOscillating piston pumpsOscillating piston liquid enginesJackshaftPrime mover

A tray piston type rocking fluid pressure-feeder driven by a crank connecting rod mechanism comprises a support housing (5), a plurality of tray piston type rocking execution devices (2), a fluid inlet and outlet passage system, a cooling system, and a driving force generation system. The fluid inlet and outlet passage system comprises a fluid passage (6, 6a, 6b), a pipe orifice and a valve. The fluid passage (6, 6a, 6b) is in communication with a working chamber (4c). The cooling system is a mechanism for forced cooling and / or natural heat dissipation of components of the fluid pressure-feeder. The support housing (5) is provided with n (n≥1) tray piston type rocking execution devices (2), rotating centerlines of rocking trays (36) of the n tray piston type rocking execution devices (2) are distributed on the same circumferential diameter around the rotating center of a driving crankshaft (10), and the rotating centerlines of the rocking trays (36) are perpendicular to a plane of a support wallboard (34). A system for mechanically driving pistons to act on a fluid load comprises a prime motor and a crank rocker mechanism. The reciprocating rocking range of an angular travel of rocking piston plates (40) is approximately 0 to 150 degrees, and the fluid pressure-feeder is applied to driving the pistons to pressure-feed a fluid for pumping work; and the pressure-fed fluid is gas or liquid.

Owner:天津市石化通用机械研究所有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com