Patents

Literature

1378 results about "Increase pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

To increase water pressure, decide if you need to only increase pressure at one faucet, fix a broad yet recent low pressure problem, or address a history of low pressure. The exact solution will vary depending on the issue you're dealing with.

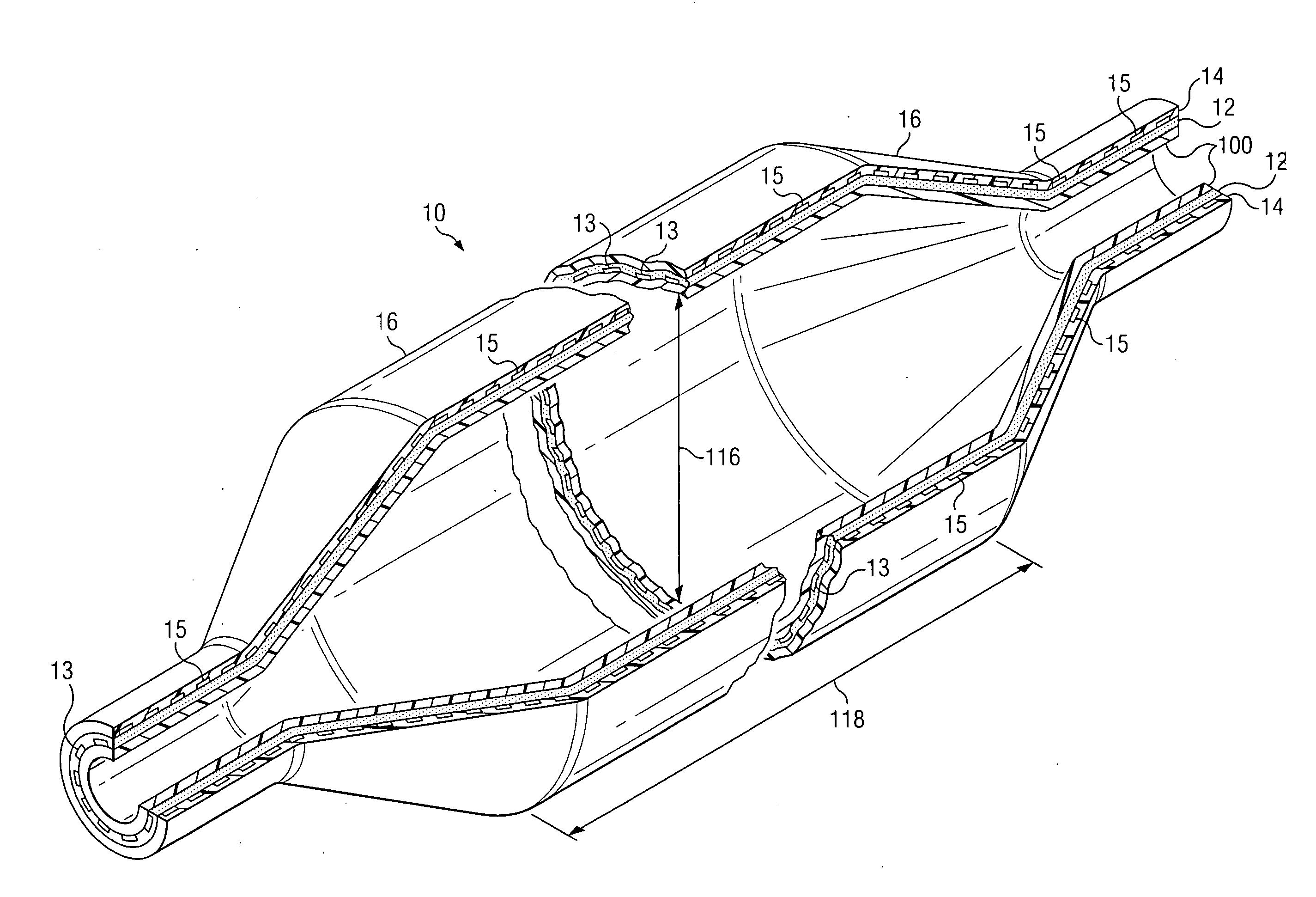

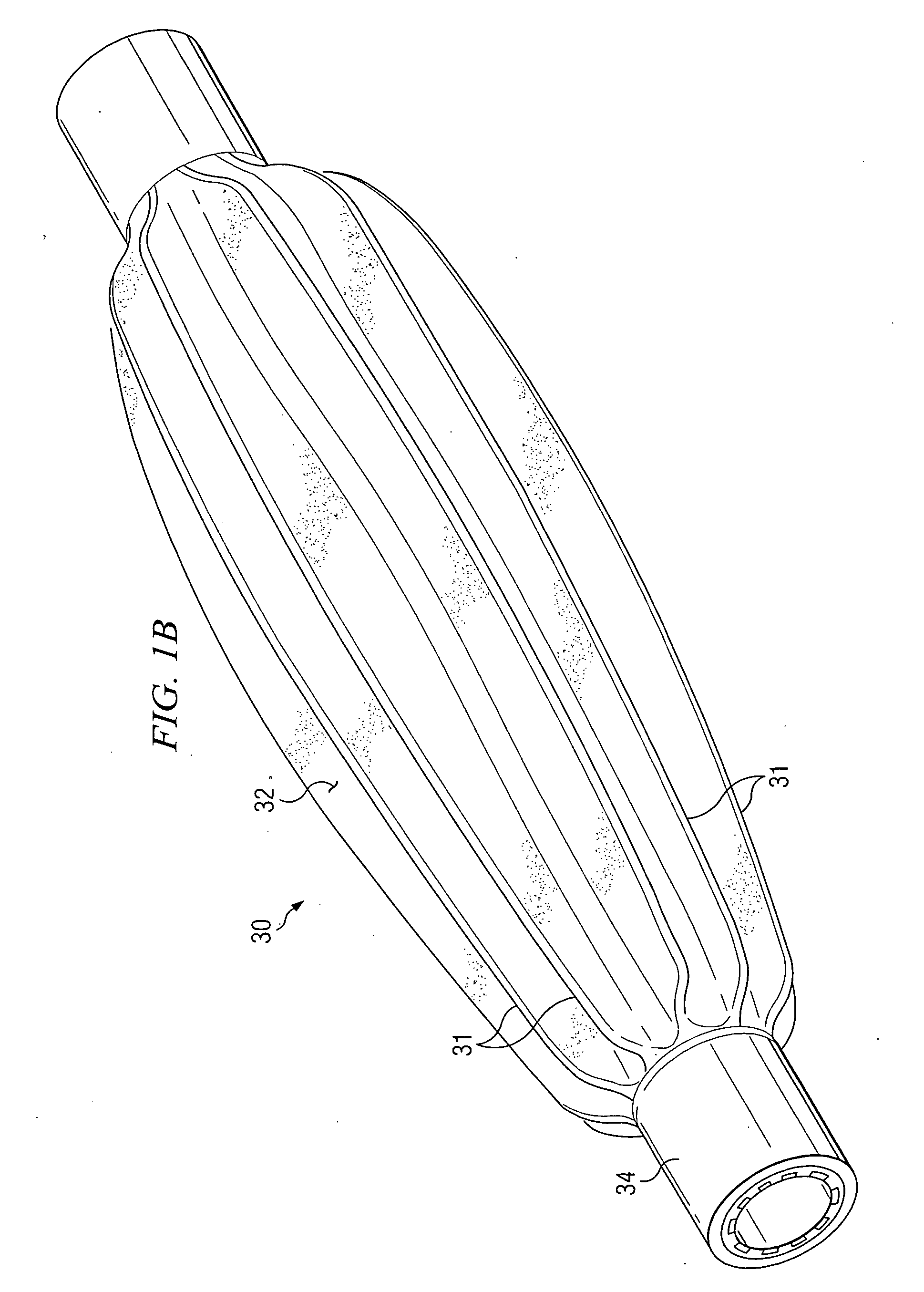

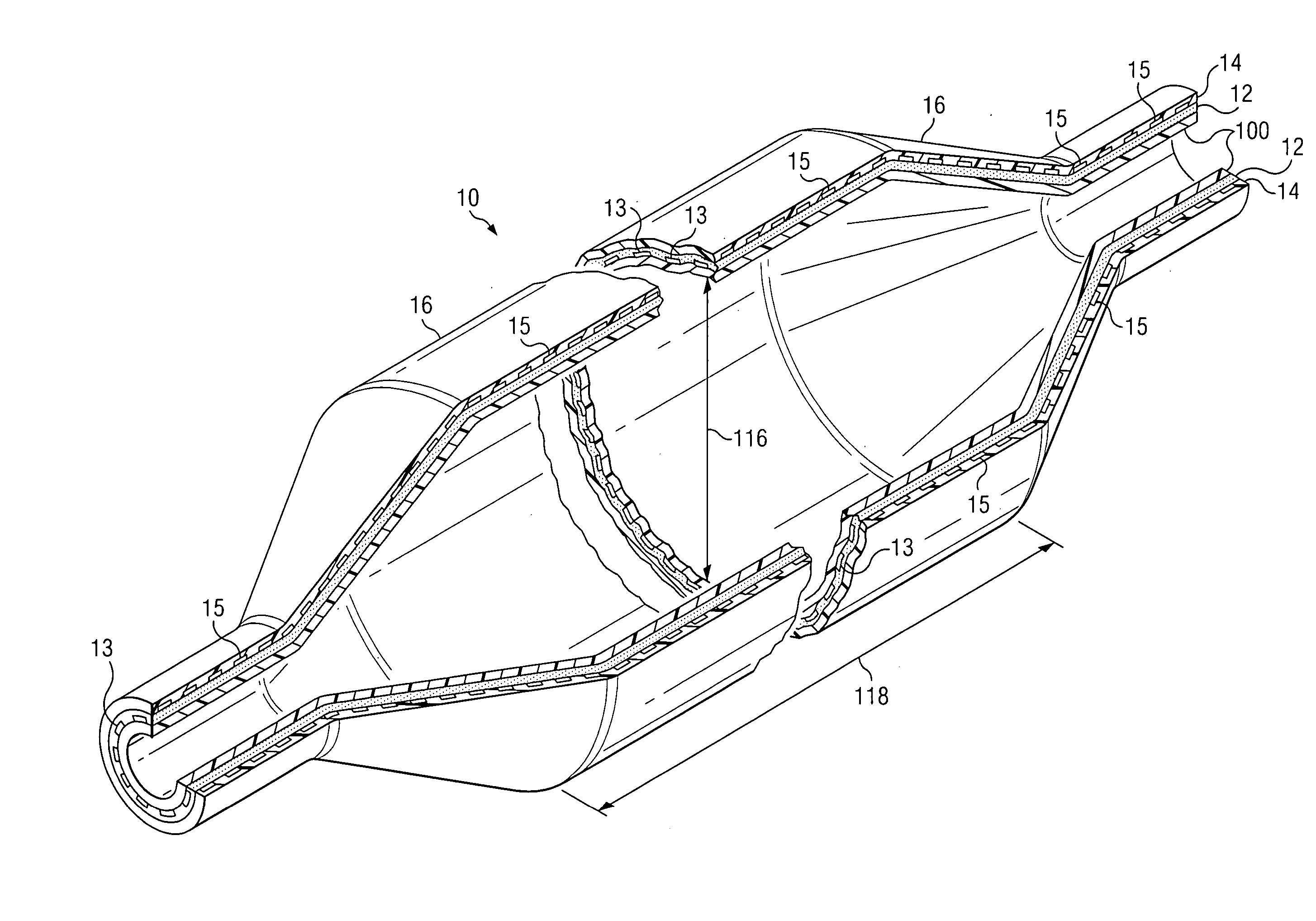

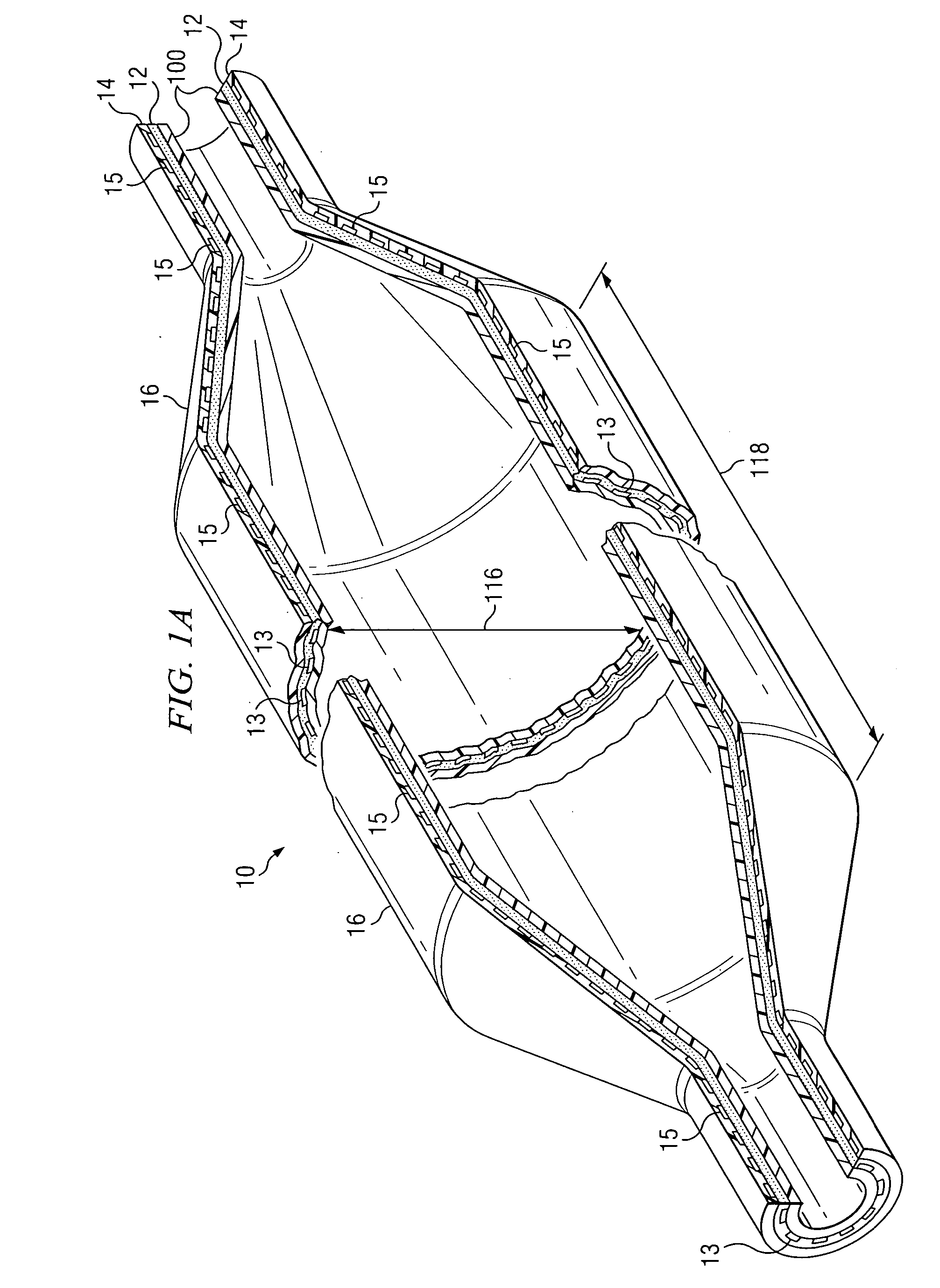

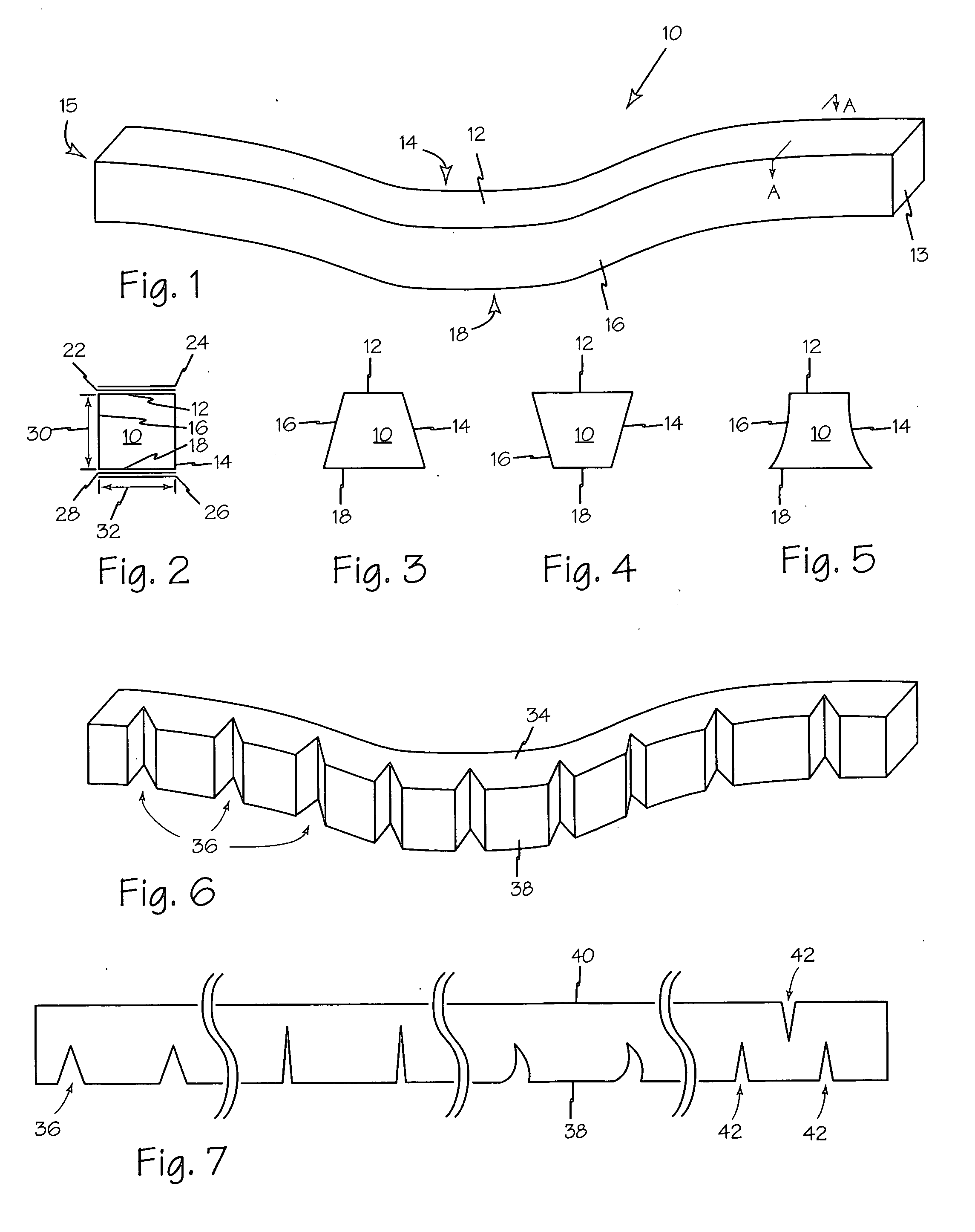

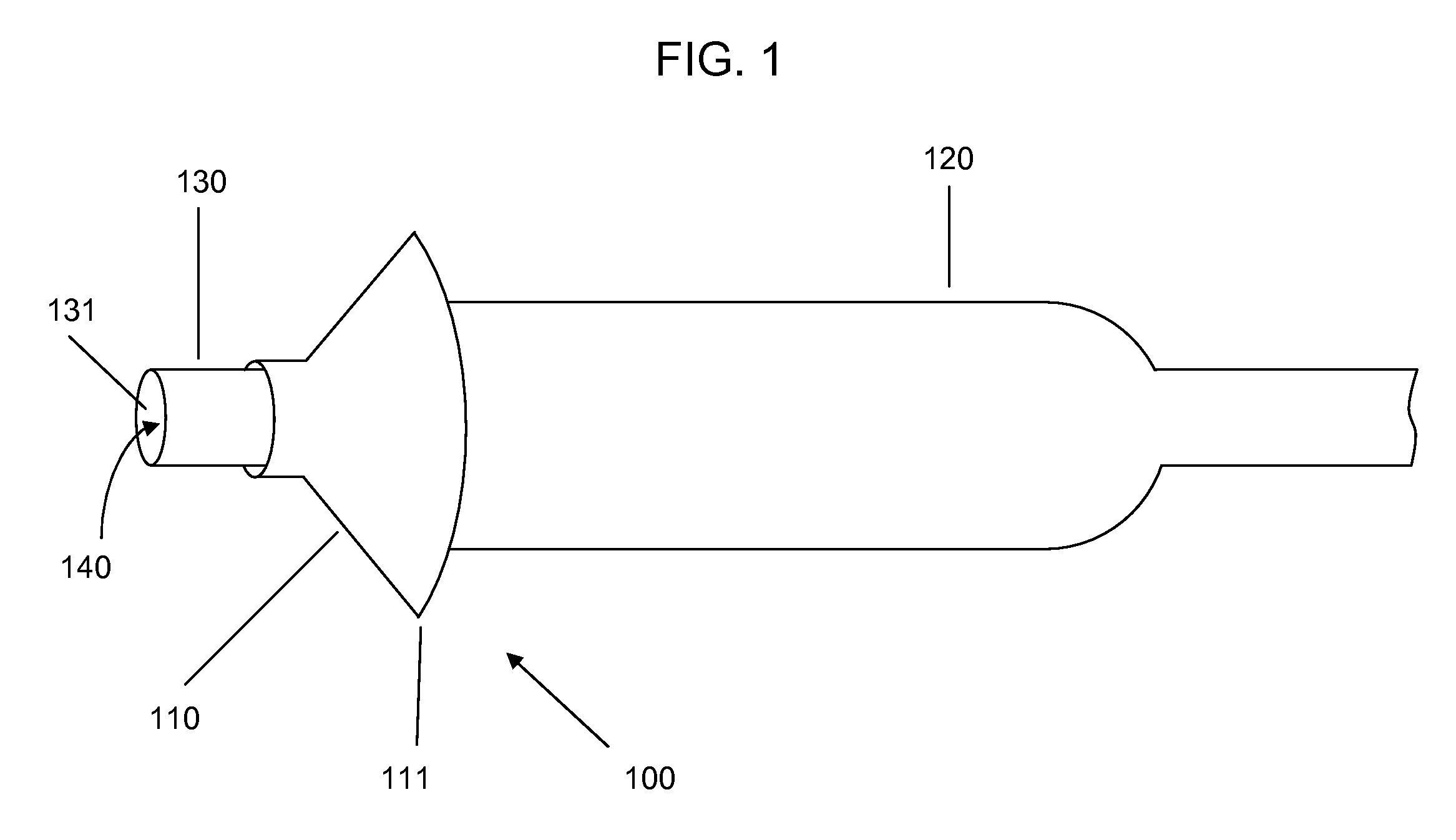

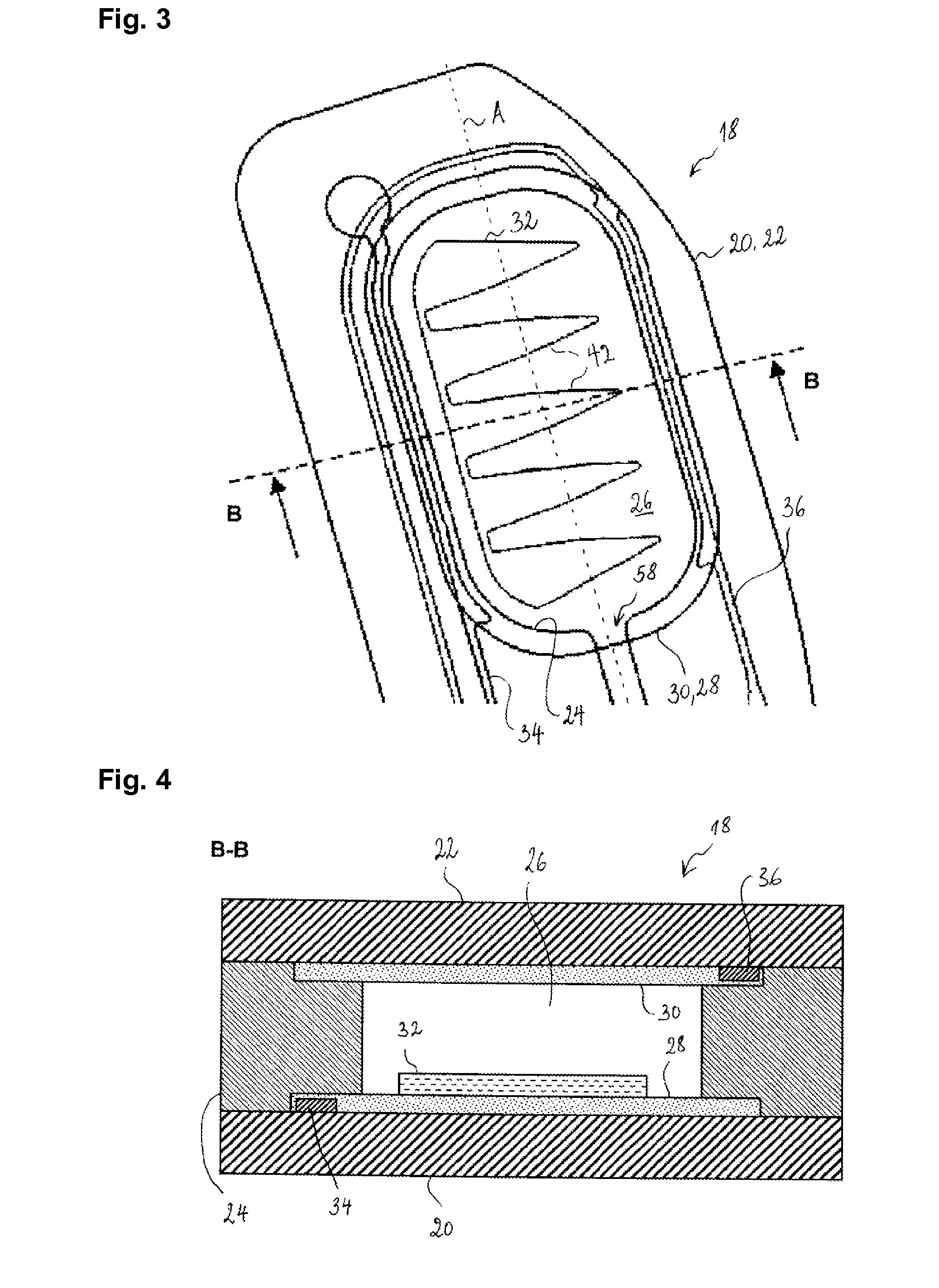

Non-compliant medical balloon having an integral woven fabric layer

A non-compliant medical balloon may be changed from a deflated state to an inflated state by increasing pressure within the balloon. The non-compliant medical balloon is composed of a woven fabric layer composed of at least two woven fabric fibers forming an angle. The angle remains substantially unchanged when the balloon changes from a deflated state to an inflated state.

Owner:BARD PERIPHERAL VASCULAR

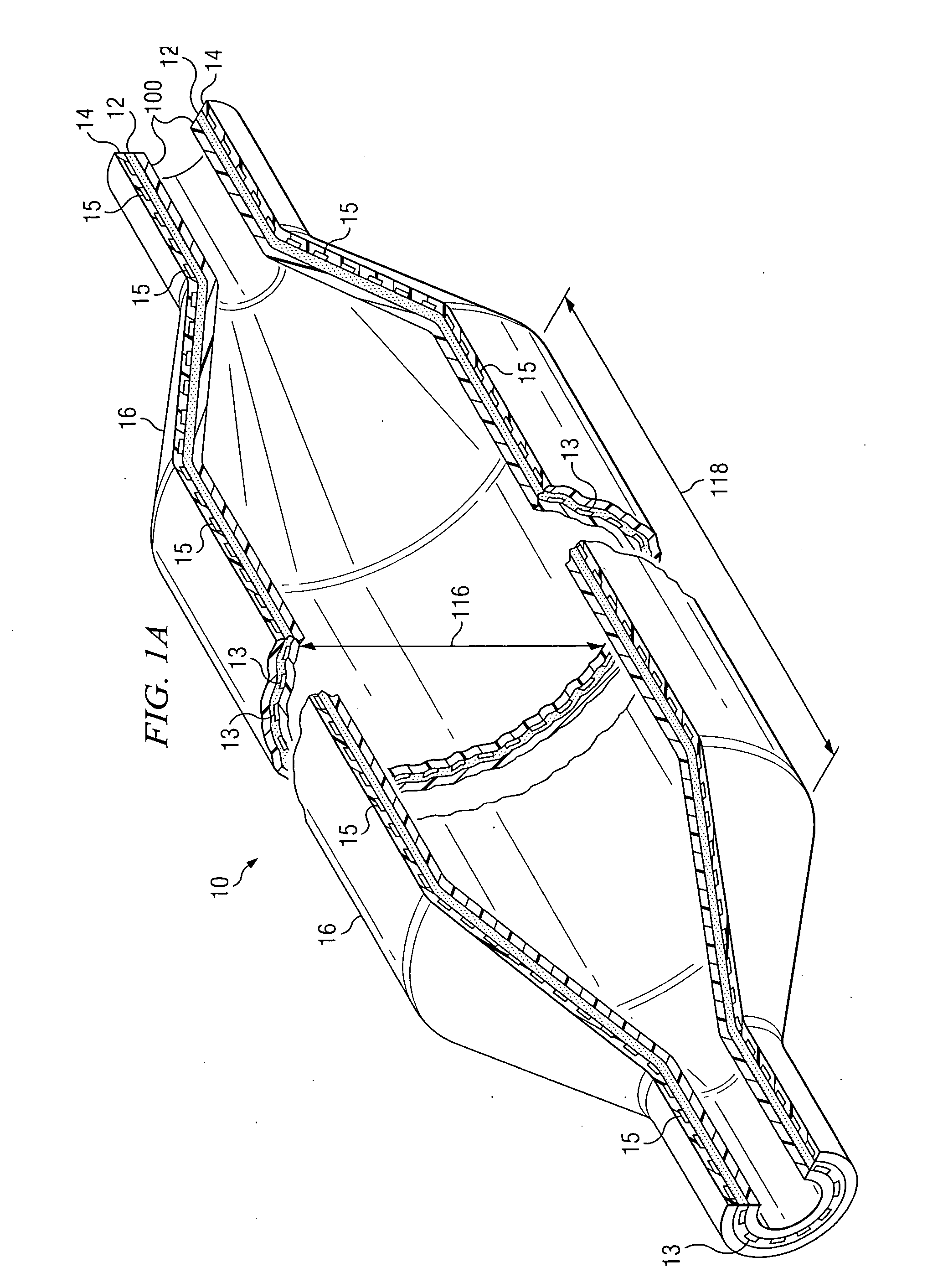

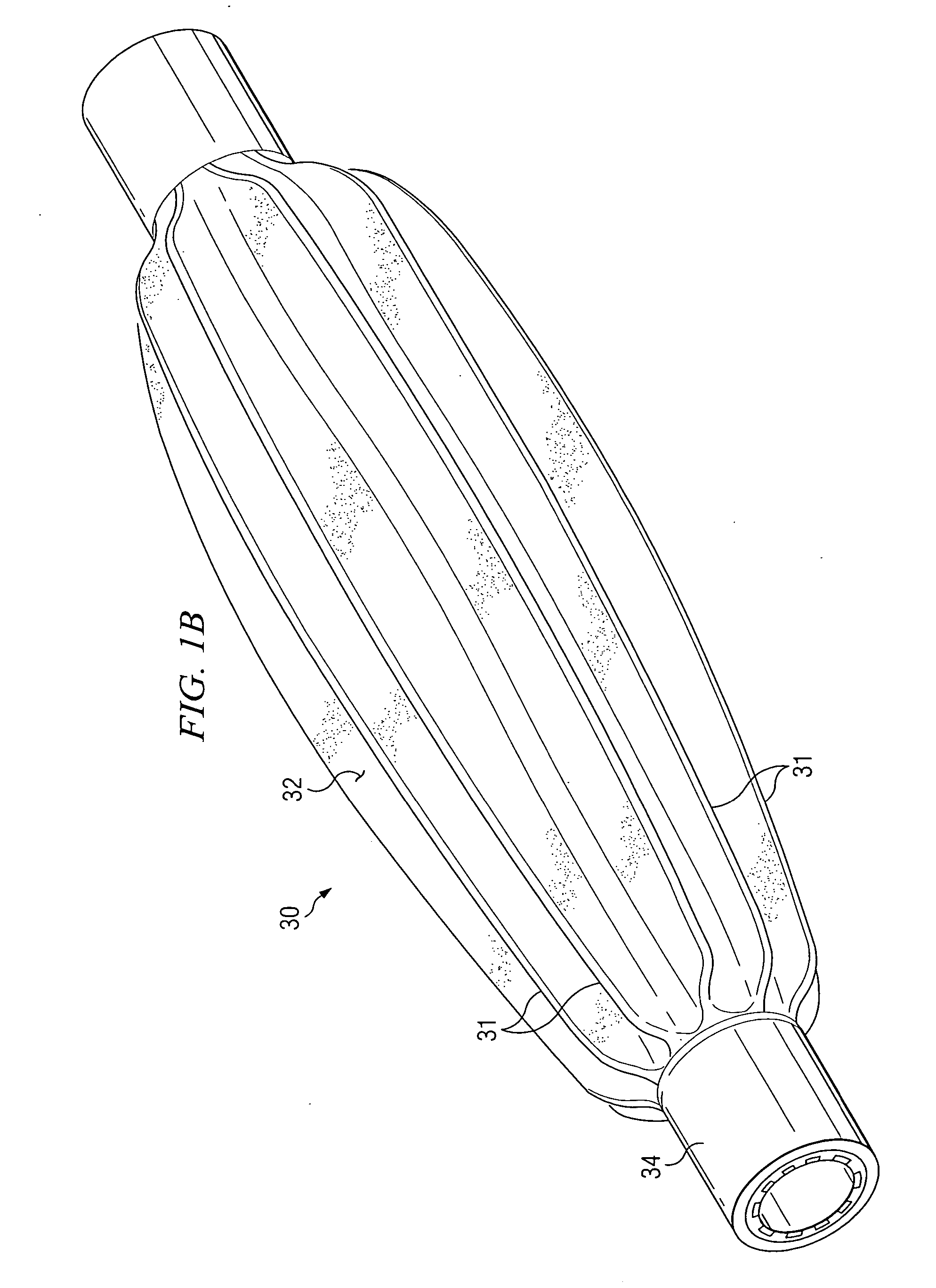

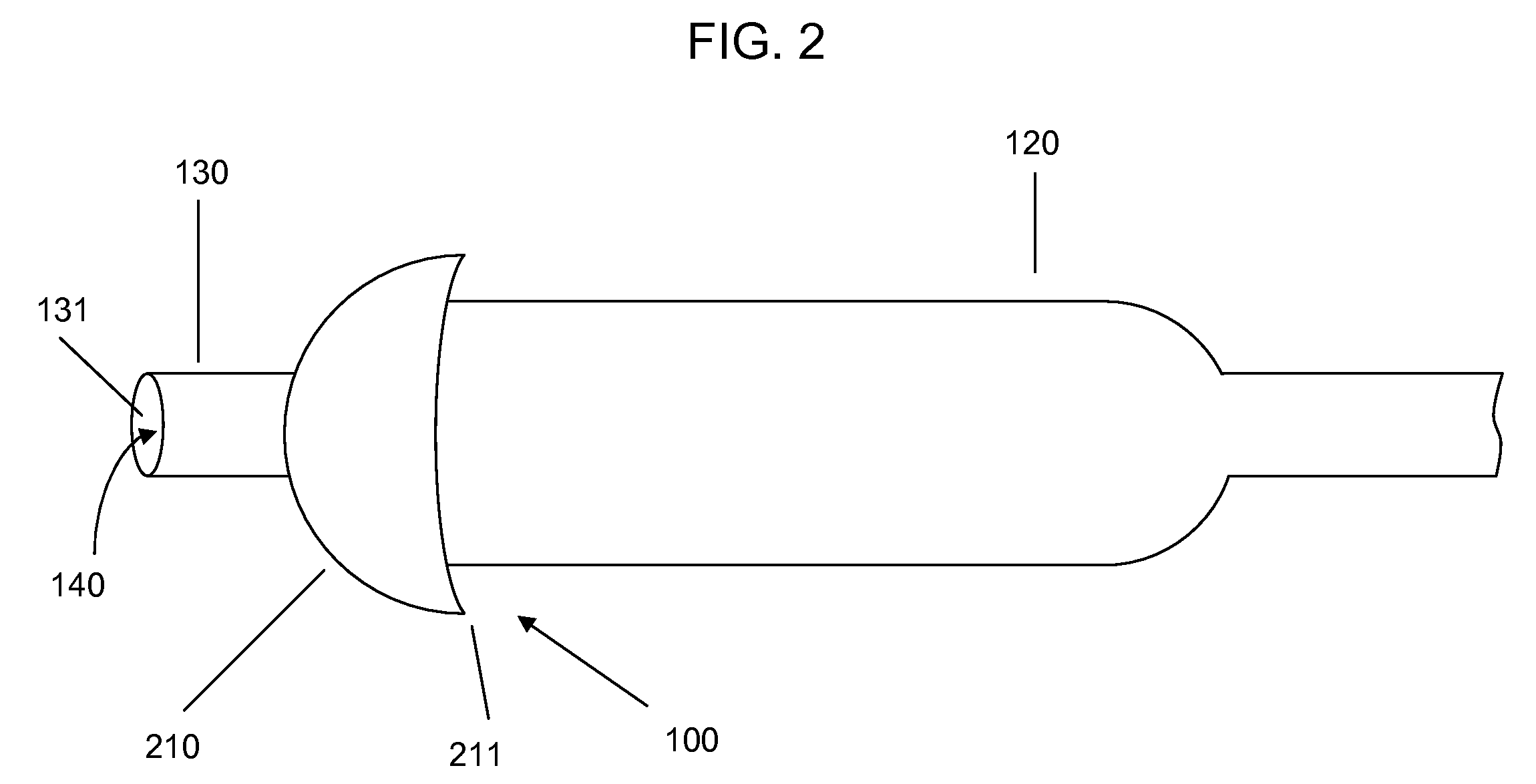

Non-compliant medical balloon having an integral non-woven fabric layer

A non-compliant medical balloon may be changed from a deflated state to an inflated state by increasing pressure within the balloon. The non-compliant medical balloon is composed of a matted fabric layer composed of at least two matted fabric fibers forming an angle. The angle remains substantially unchanged when the balloon changes from a deflated state to an inflated state..

Owner:BARD PERIPHERAL VASCULAR

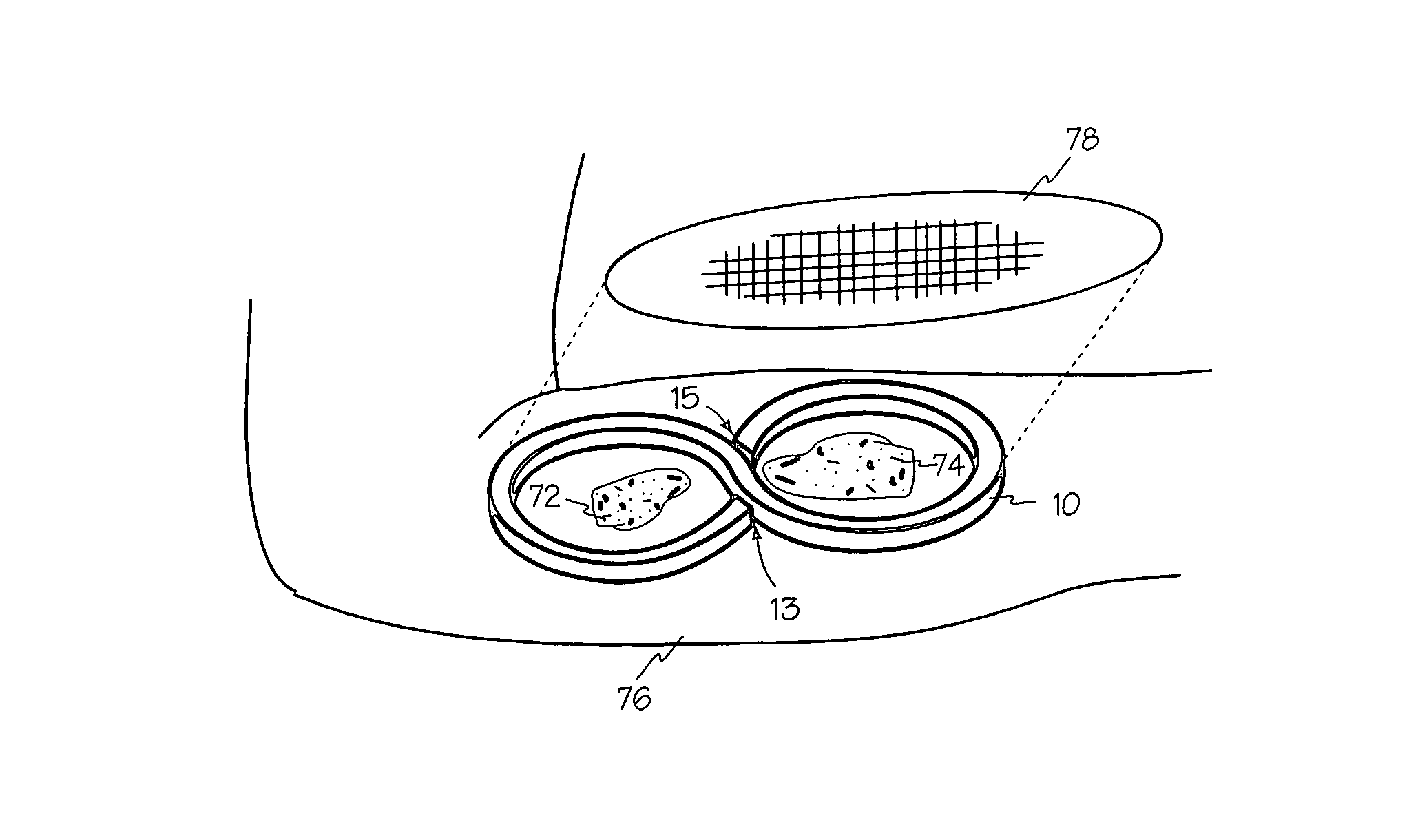

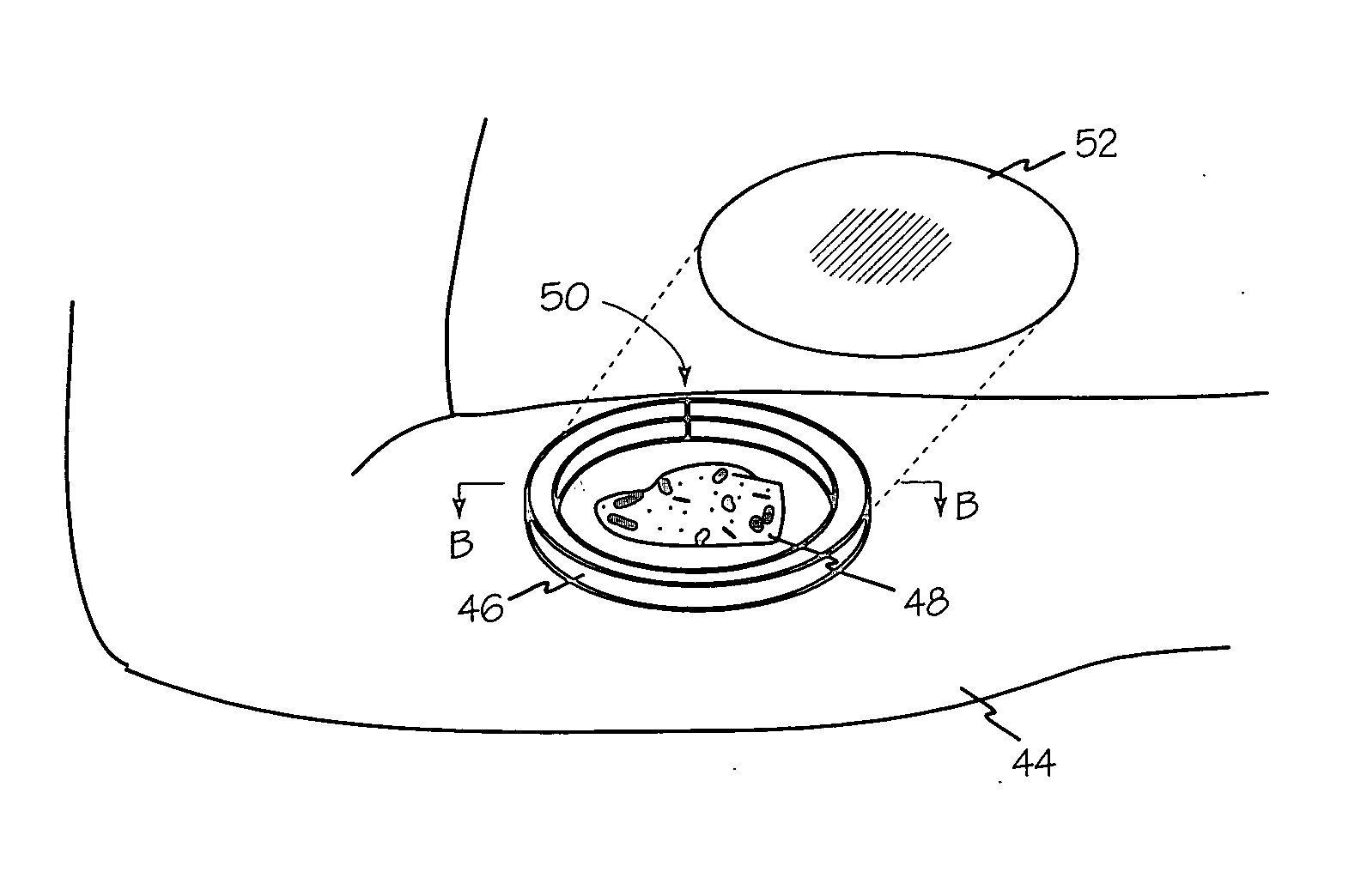

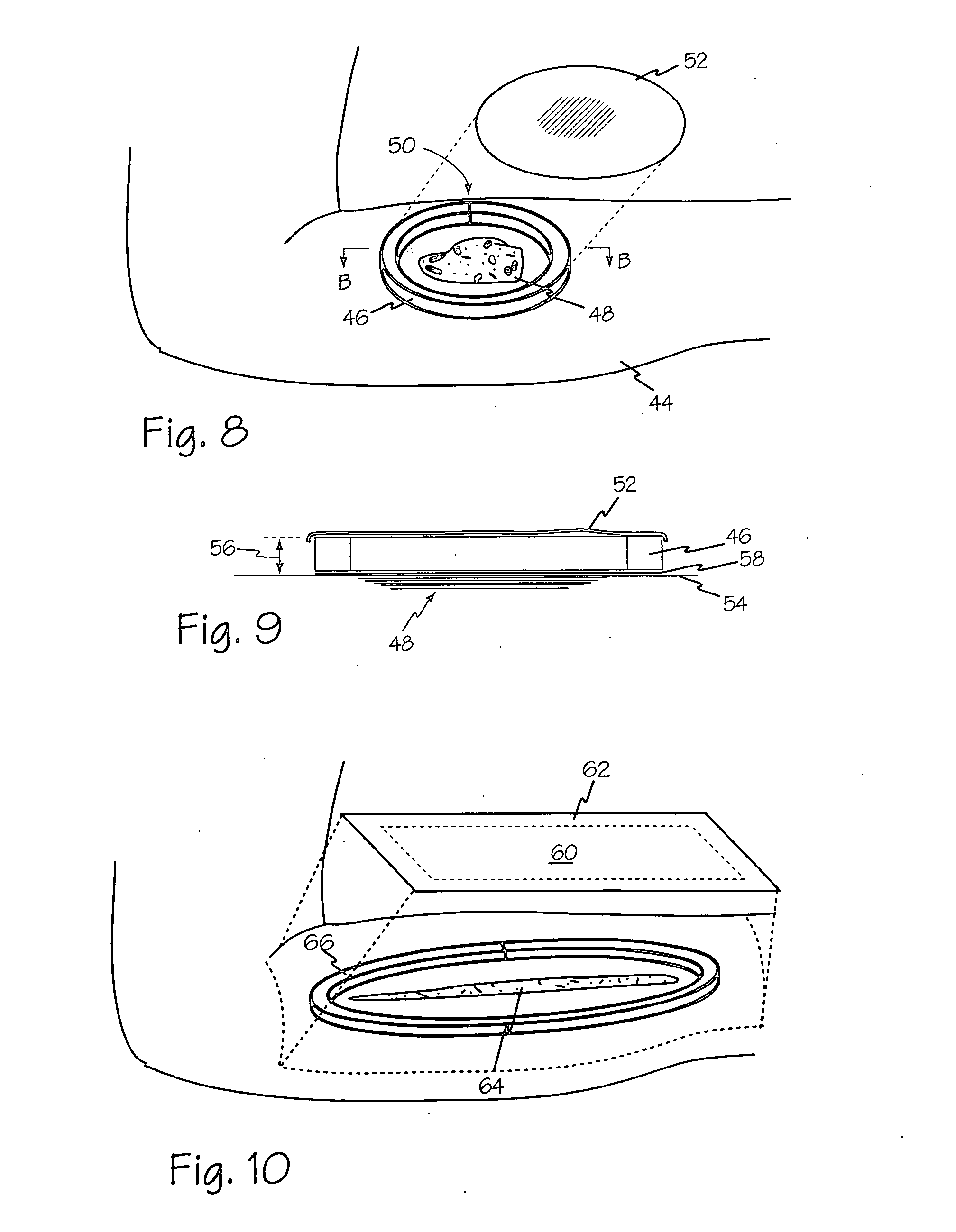

Wound shield for exudate management

A wound shield for exudate management may include a conformable frame to circumscribe a wound. The conformable frame may be formed of material for absorbing wound exudate. Exudate absorbing material may also be one of two or more layers of material forming the conformable frame. The layers may be arranged to keep the exudate absorbing layer at some selected distance from a patients skin. Any suitable dressing may be secured over the conformable frame providing separation between the wound and the dressing. The wound frame may provide pressure relief around a wound or pressure sore to permit healing. The conformable frame may be wrapped, in a spiral, around a wound providing an increasing pressure relief by increasing distance from the wound. A conformable frame may be composed of one or more layers of any suitable material and may include adhesive on one or more surfaces to secure the frame to the wound site and or to secure the dressing to the conformable frame. One layer of the two or more layers of material forming the conformable frame may be a wicking or conduit material that draws exudate from the wound and transports the exudate to any suitable media for exudate storage. The exudate storage may be one or more layers of a dressing covering the wound site, or it may be a removable reservoir.

Owner:AALNEX

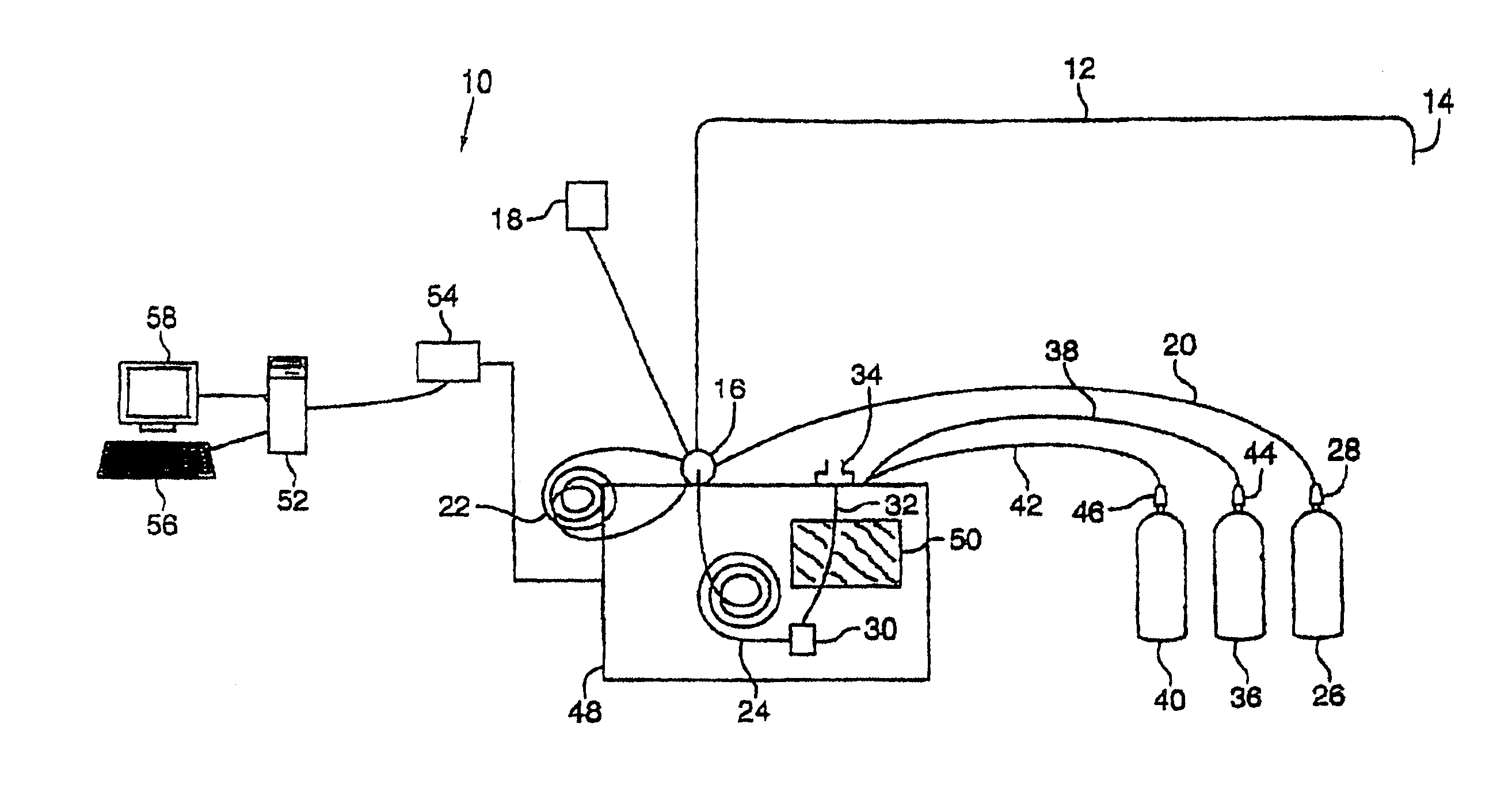

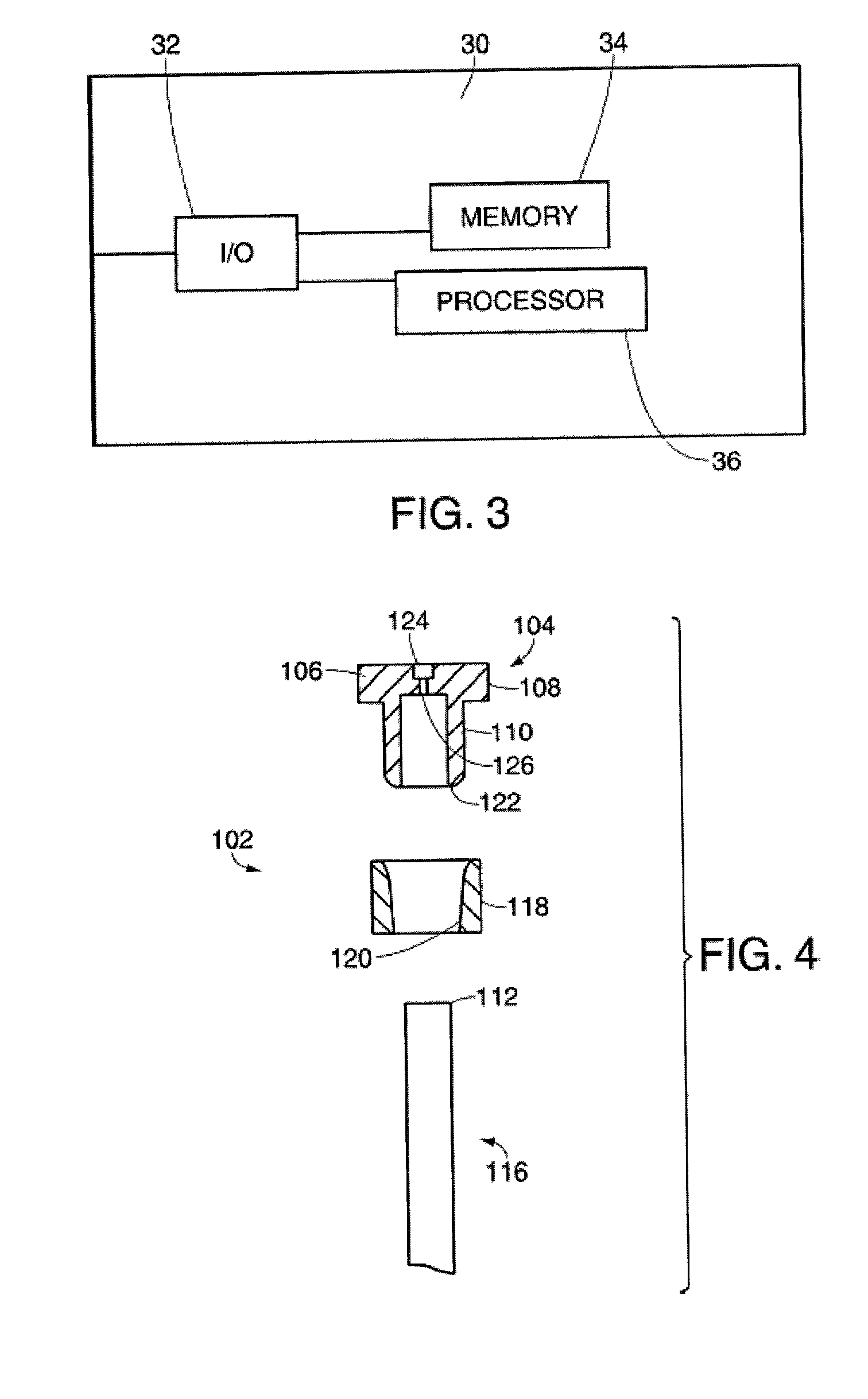

Method and apparatus for sample analysis

InactiveUS6865926B2Easy to operateAnalysing fluids using sonic/ultrasonic/infrasonic wavesComponent separationParticulatesGas analysis

Methods and systems for analyzing samples, such as gas samples, are described. One method comprises providing a gas sample, increasing pressure applied to the gas sample to compress the sample to a smaller volume and provide a pneumatically focused gas sample, and analyzing the pneumatically focused gas sample using any of a variety of analytical techniques. Also disclosed are systems for gas analysis, including systems for analysis of pneumatically focused, and thereby concentrated, gas samples and for analysis of particulate matter in gas samples. Analytical systems constructed within personal computer cases also are disclosed.

Owner:PORTLAND STATE UNIV

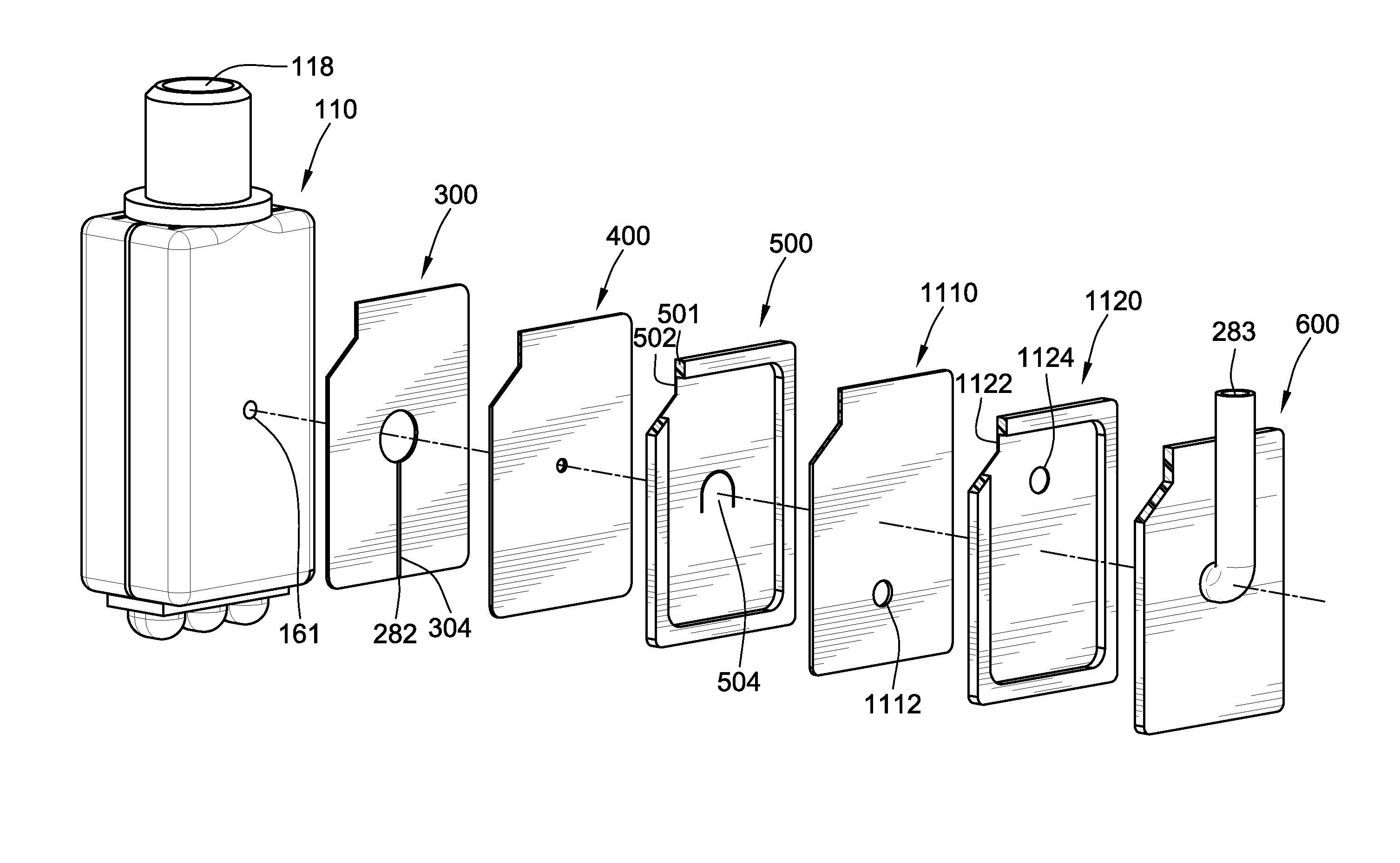

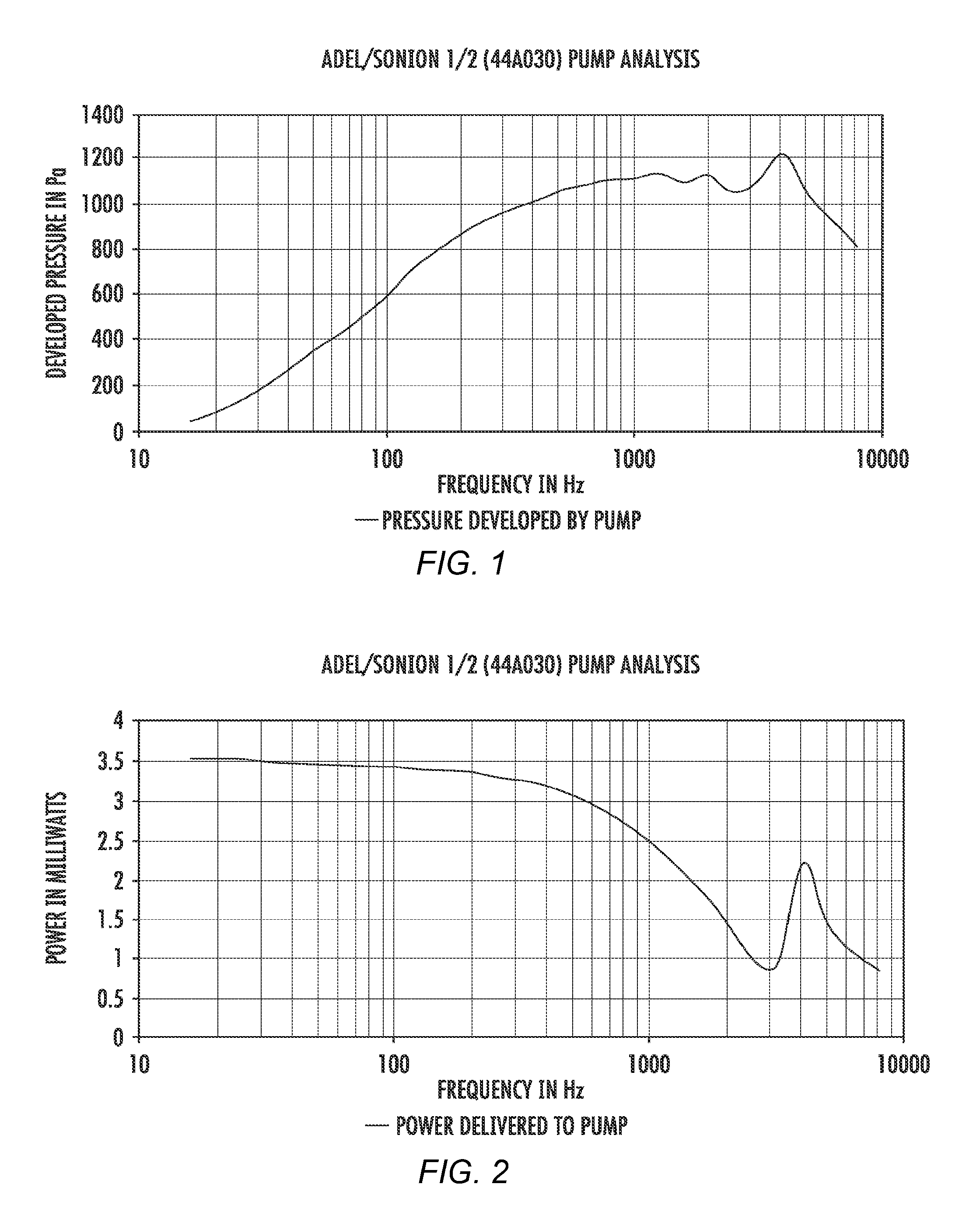

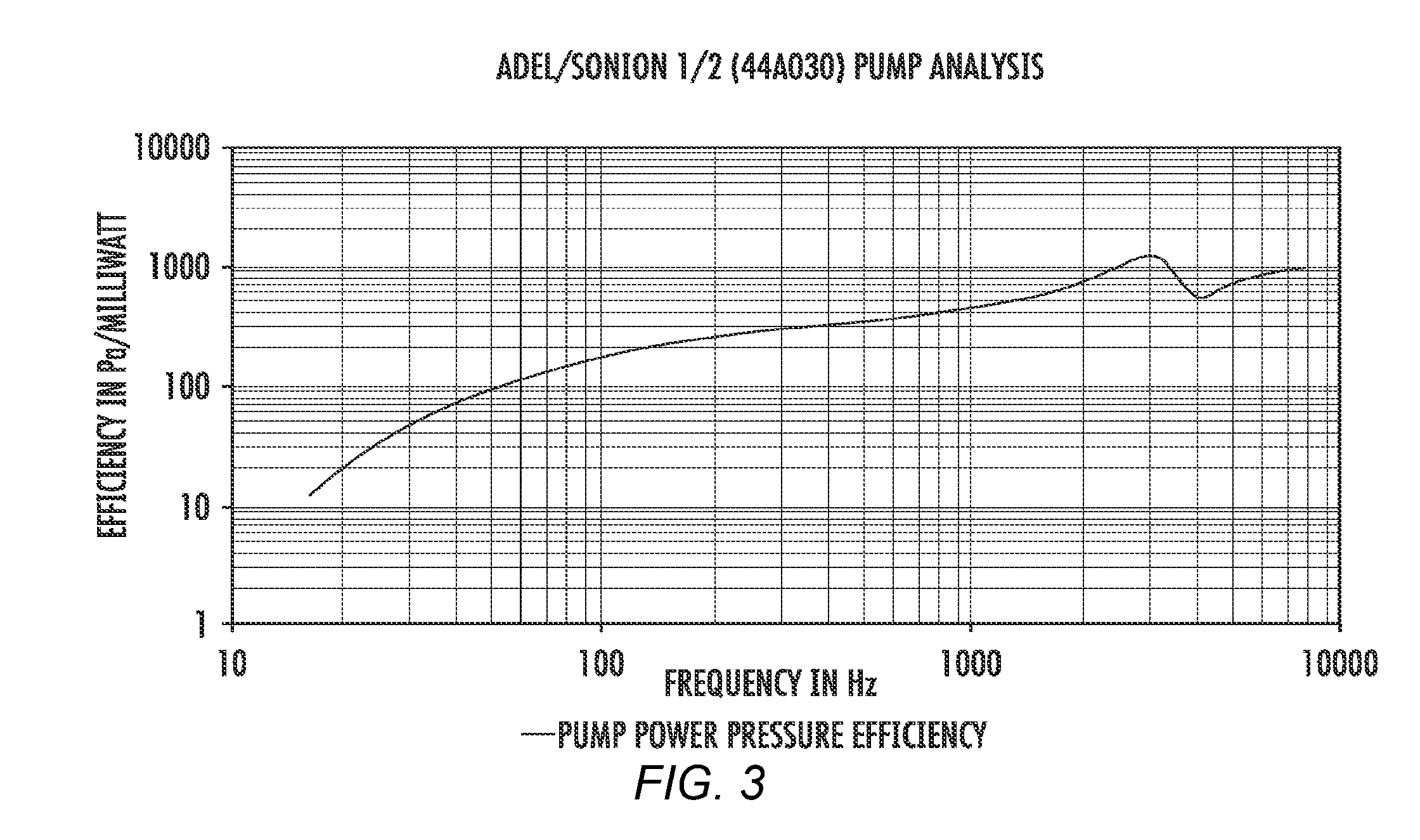

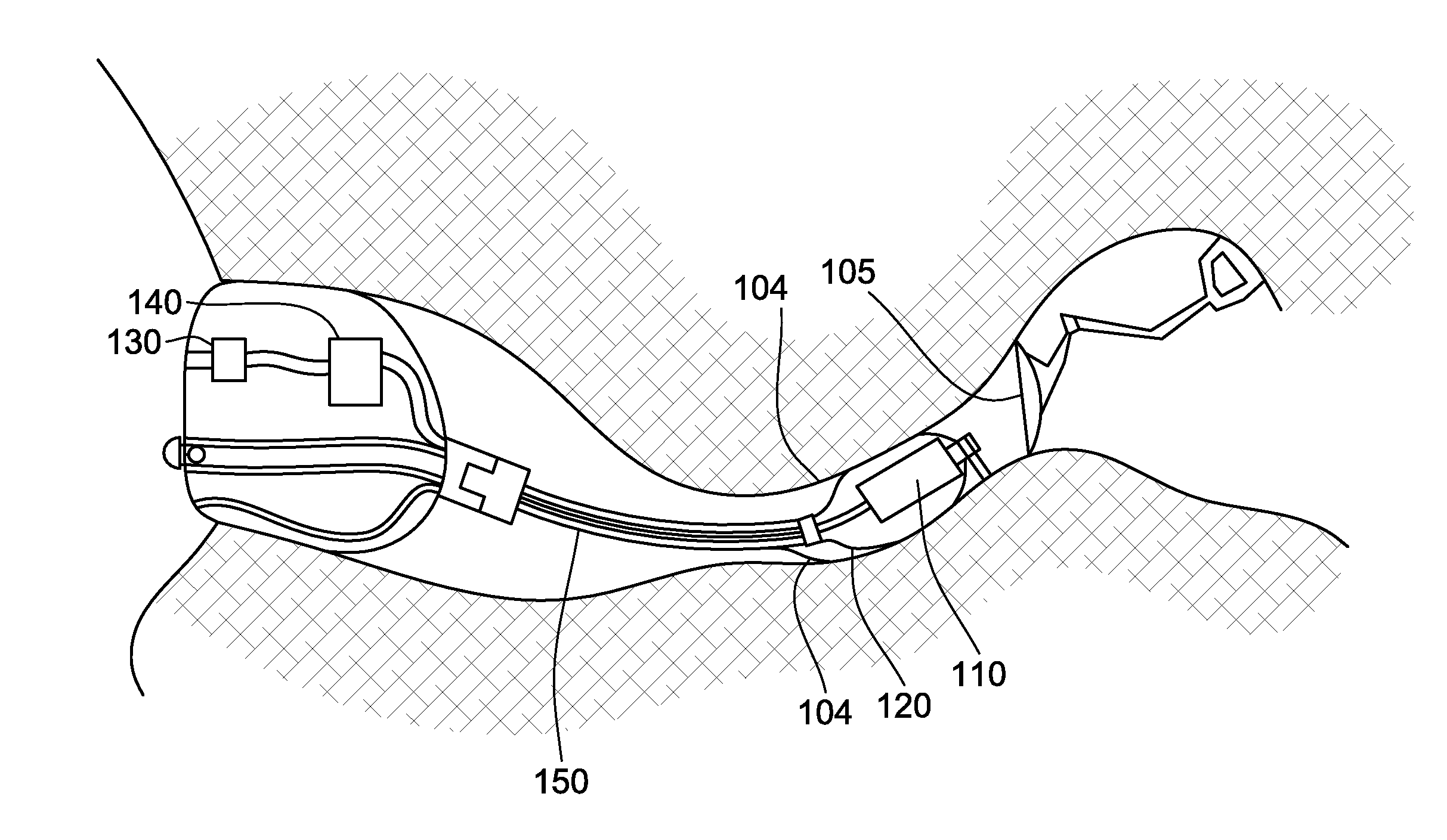

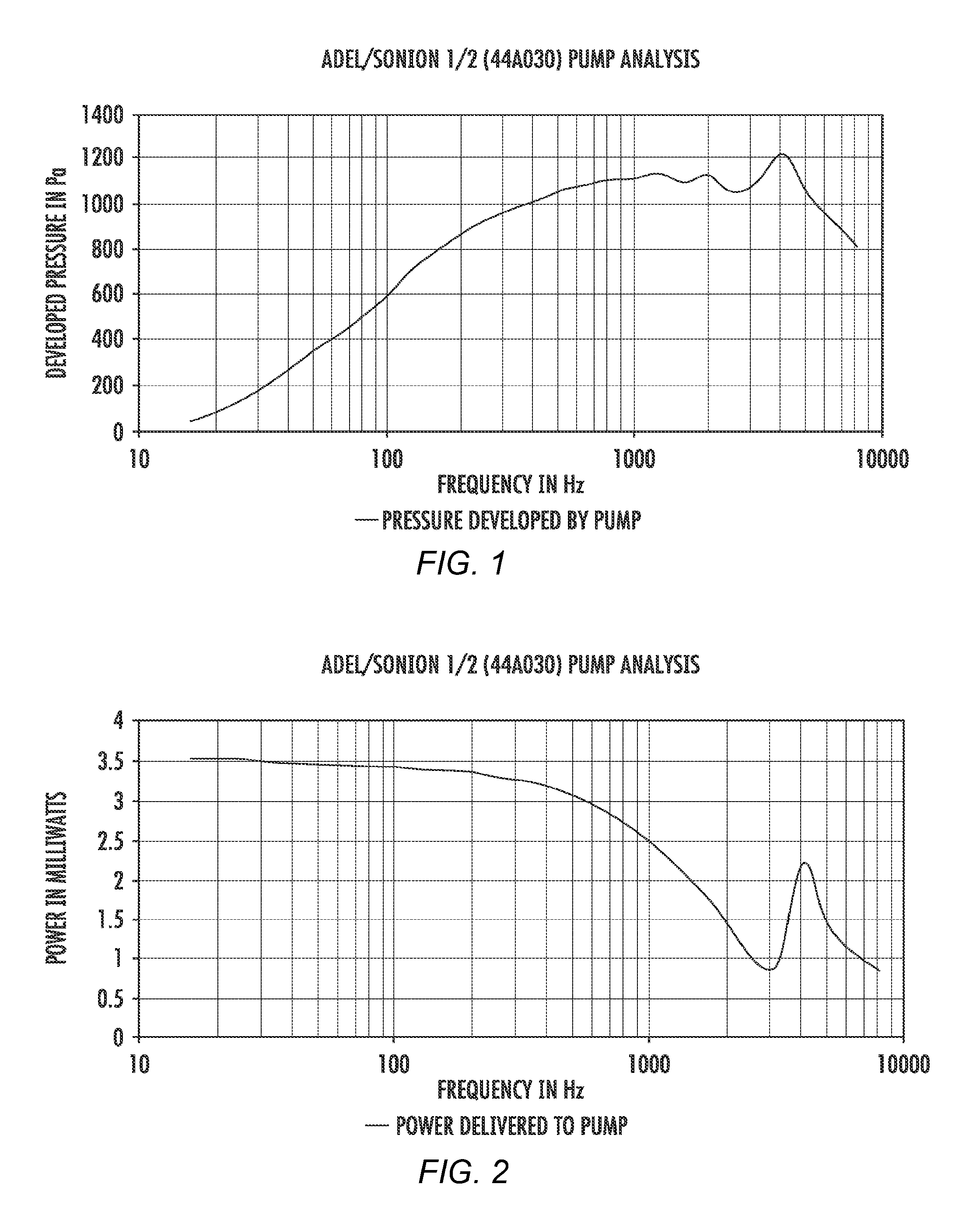

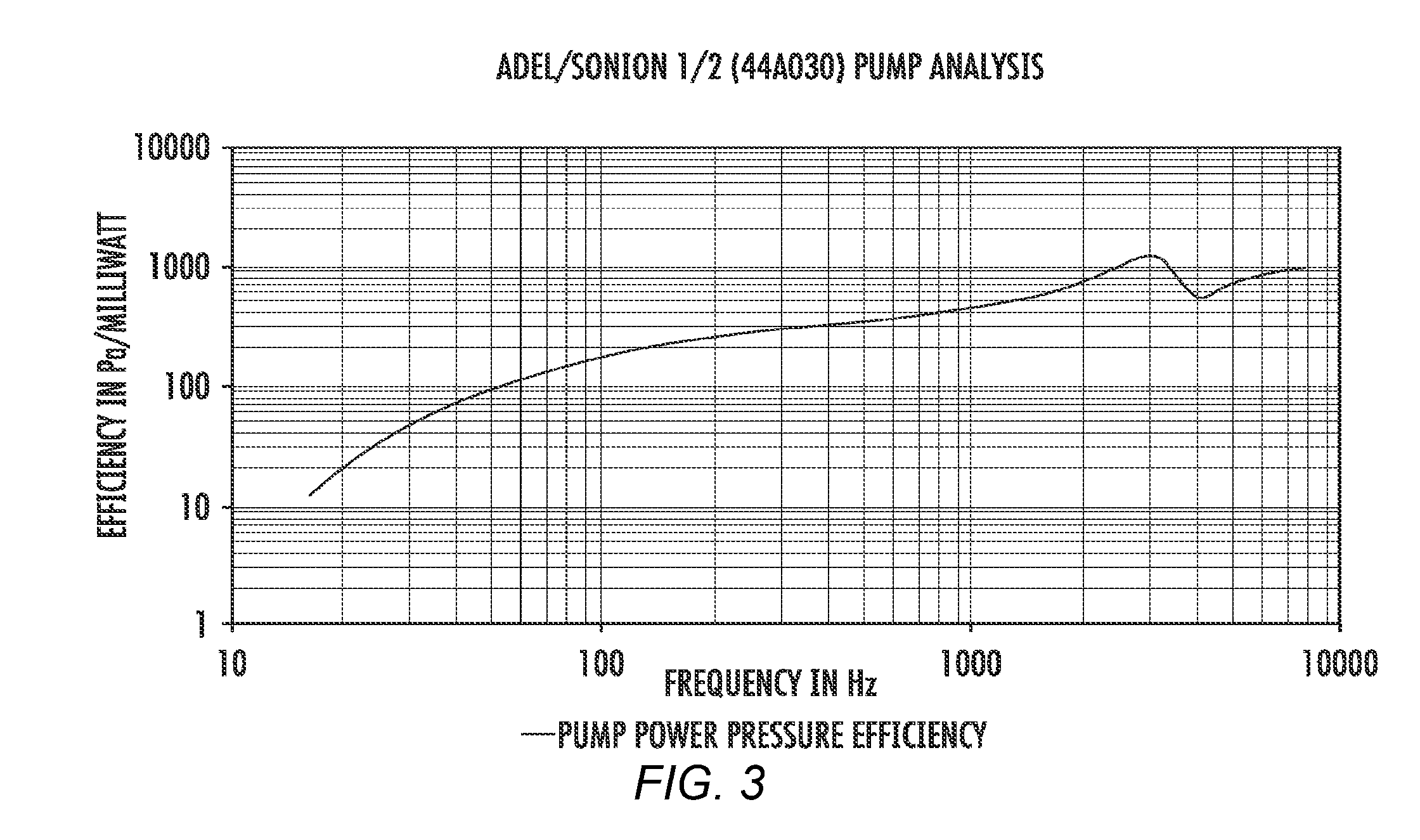

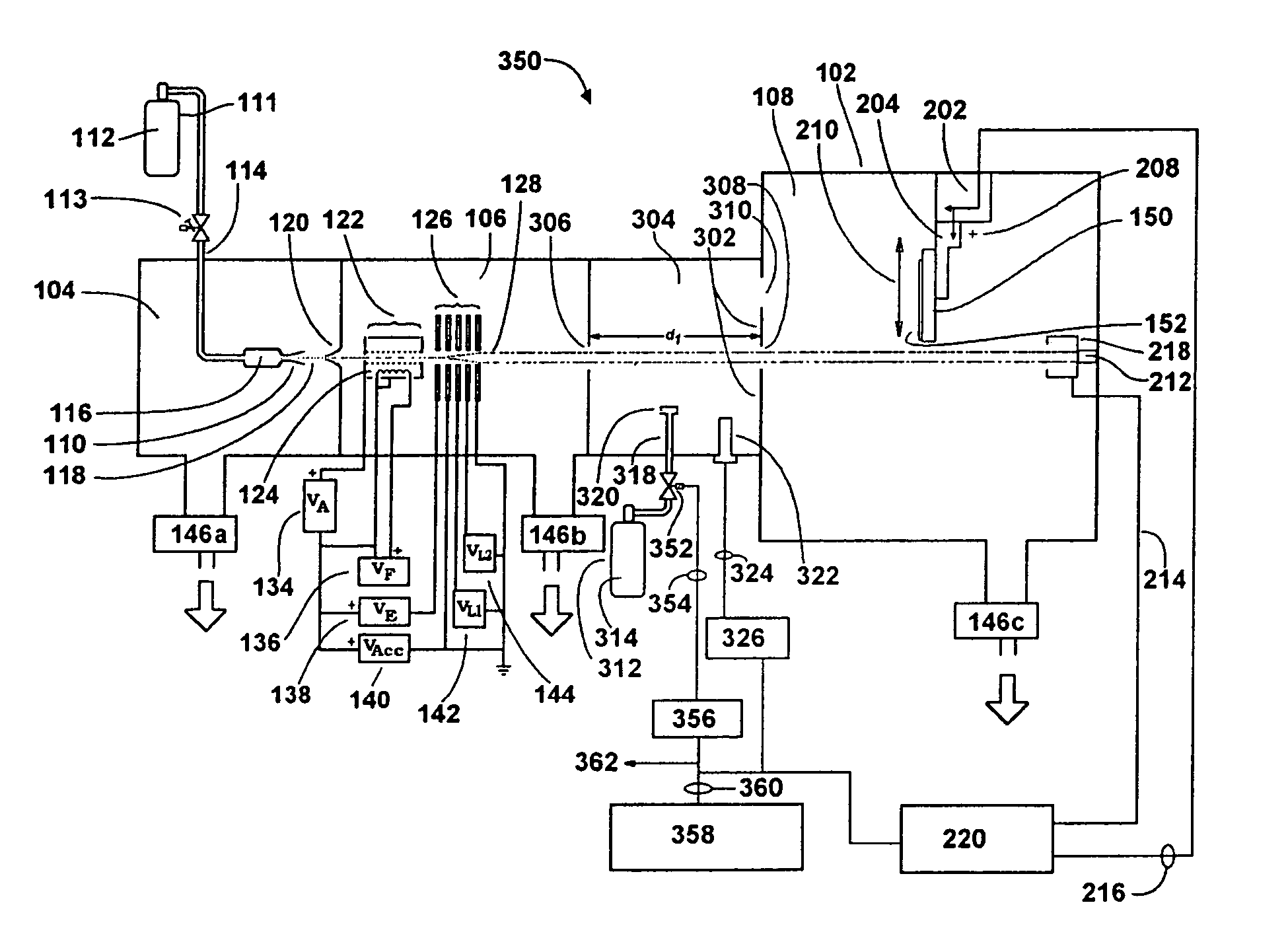

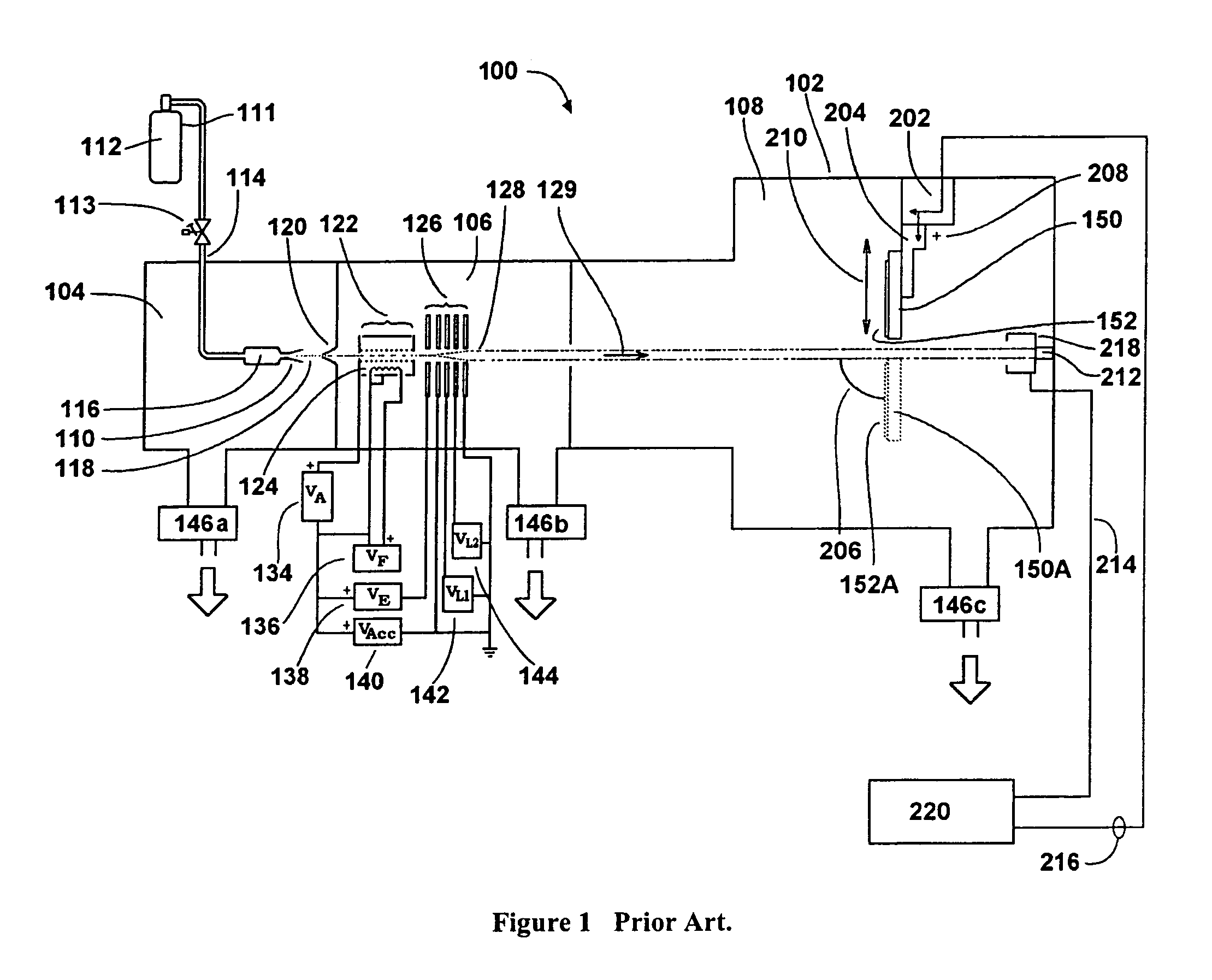

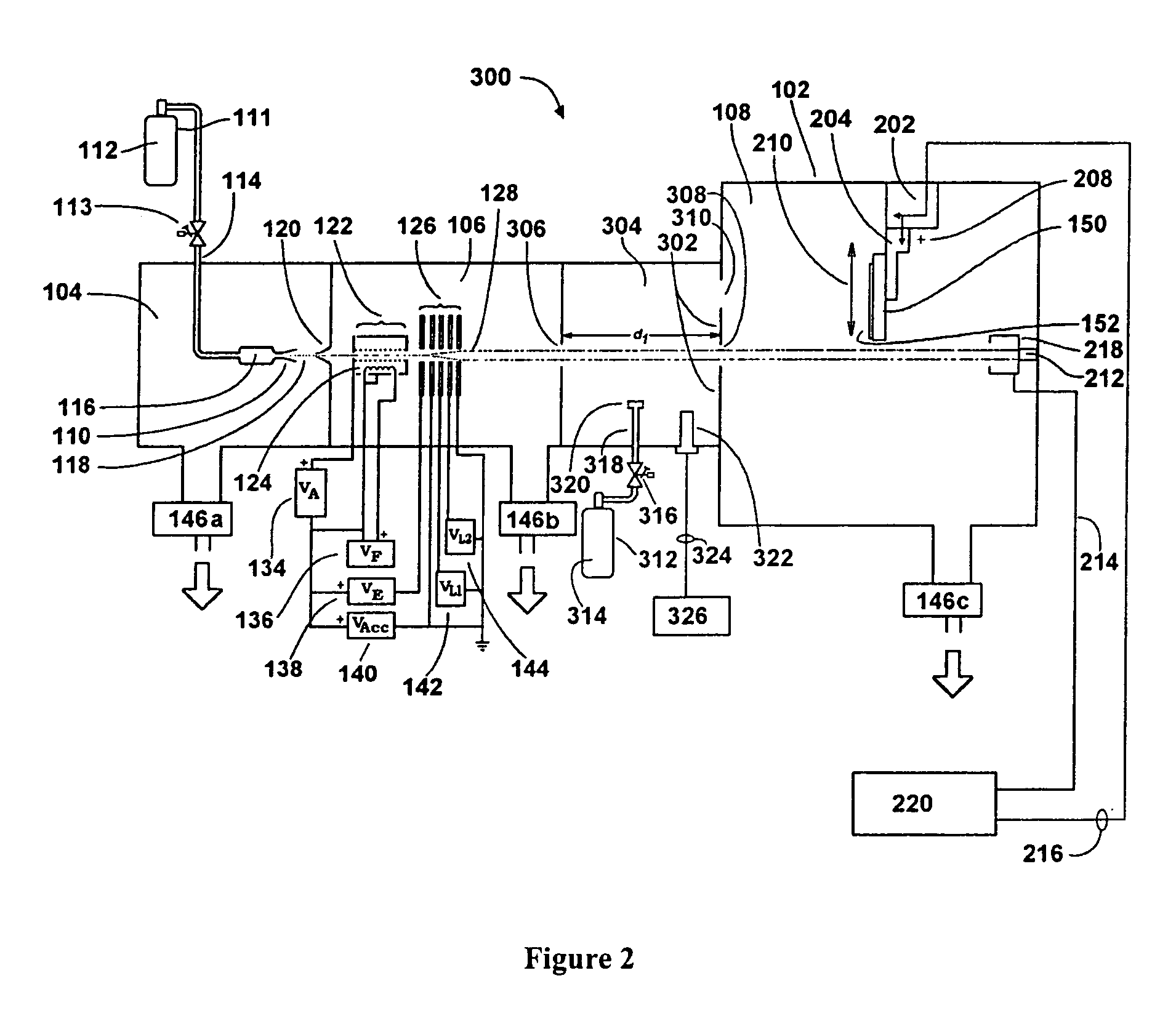

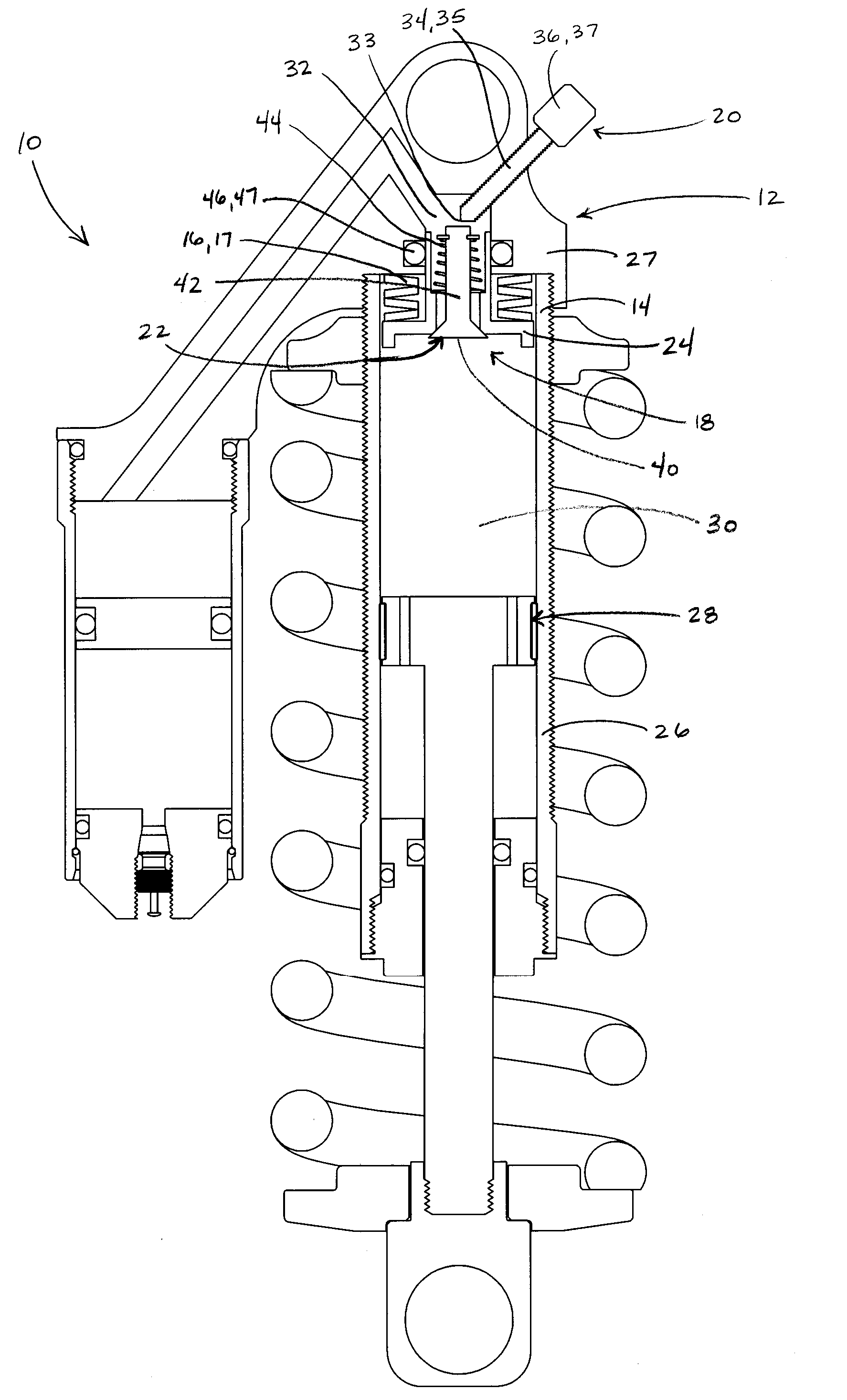

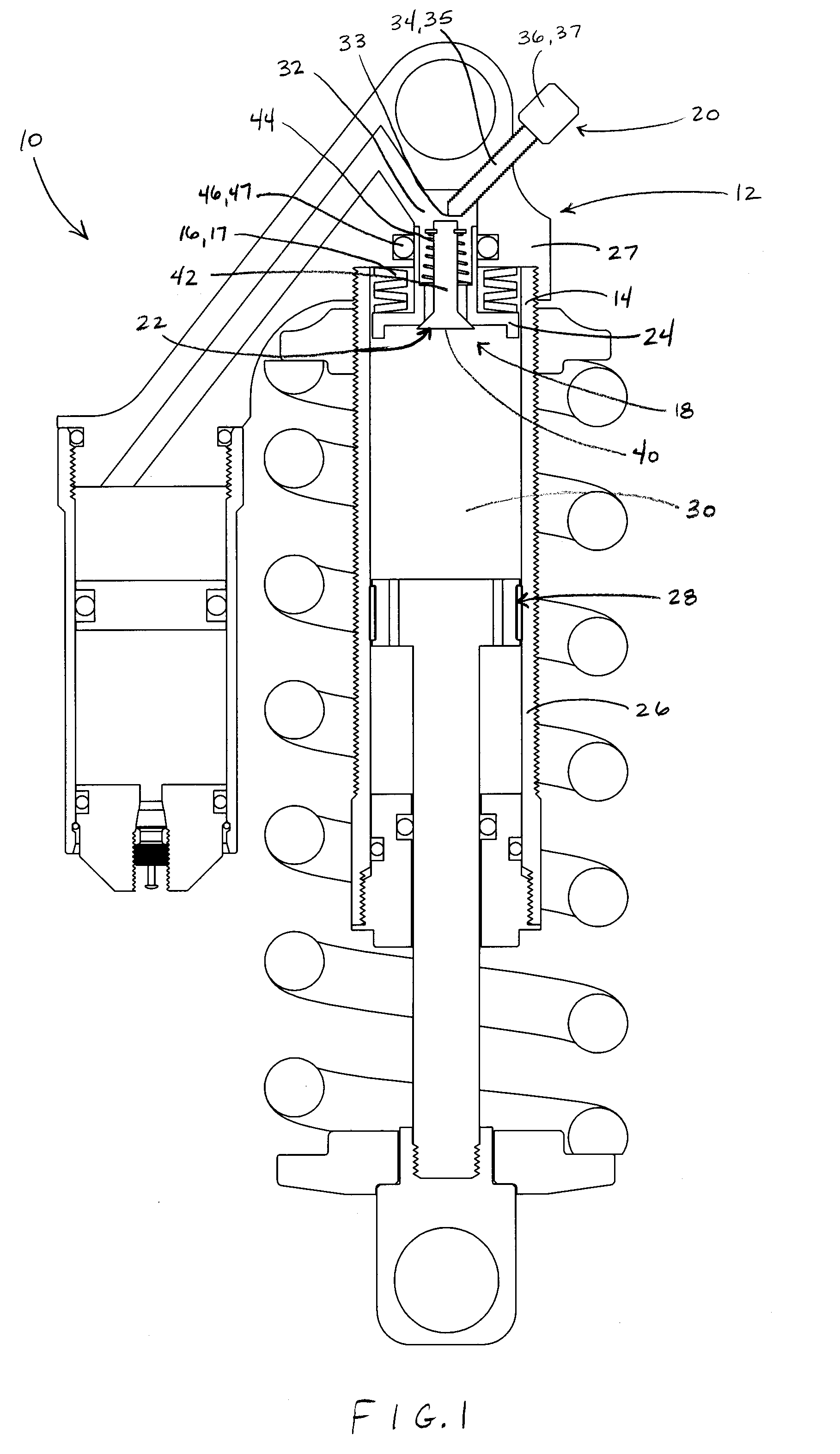

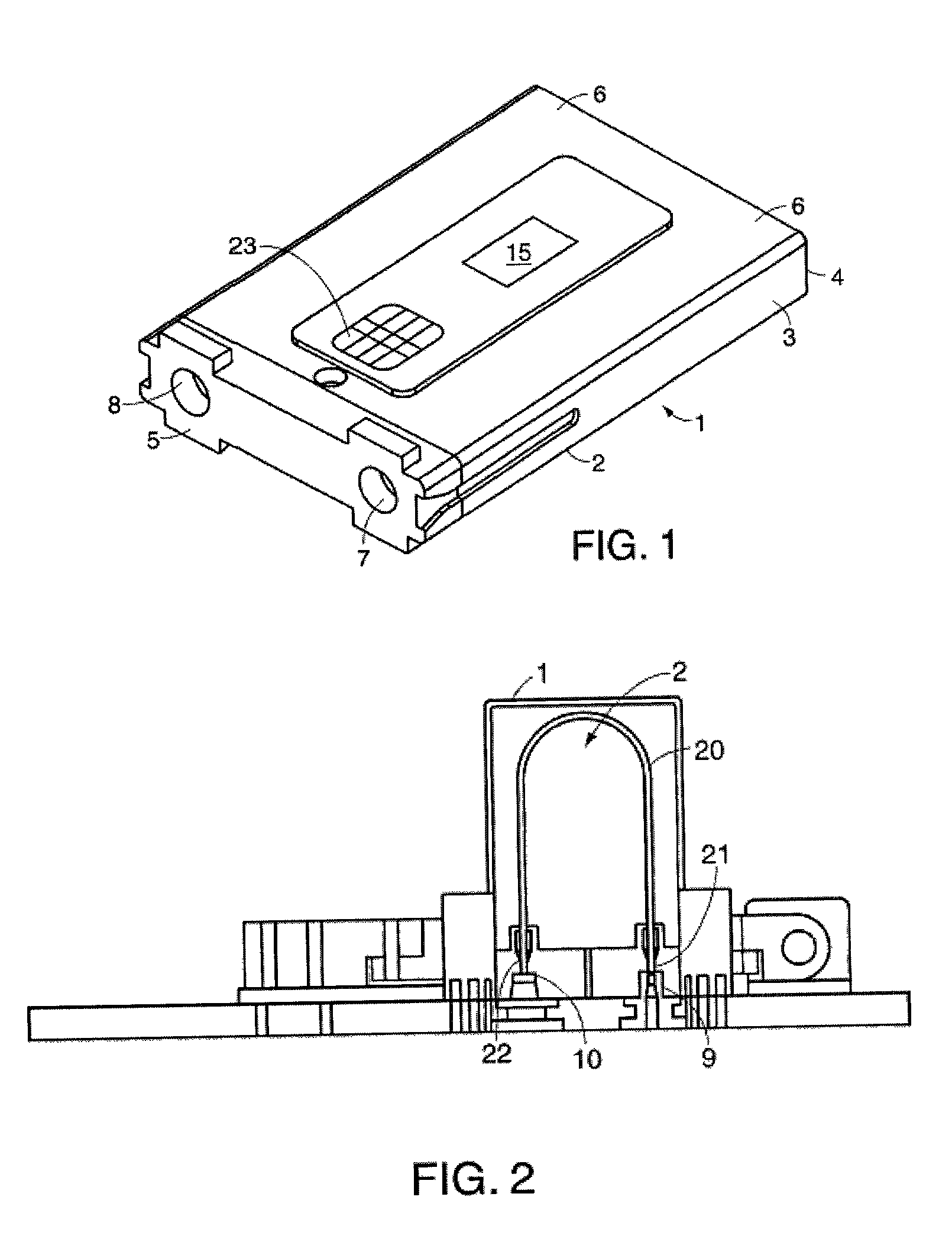

Receiver module for inflating a membrane in an ear device

A receiver module configured to be seated within an ear canal and optimized for simultaneously inflating an inflatable membrane while generating acoustic waves transmitted to a user. The inflatable membrane can be used to secure the receiver module within the bony portion of the ear canal of the user. A multi-layer valve system and method of assembly are disclosed for a valve system to harvest static pressure from acoustic waves generated within the receiver and direct the increased pressure toward the inflatable membrane to inflate the membrane. The multi-layer valve system can be used to prevent a back flow of air and thereby maintain a static pressure differential between ambient air drawn in through an air ingress port and air forced into the inflatable membrane through an air egress port.

Owner:SONION NEDERLAND

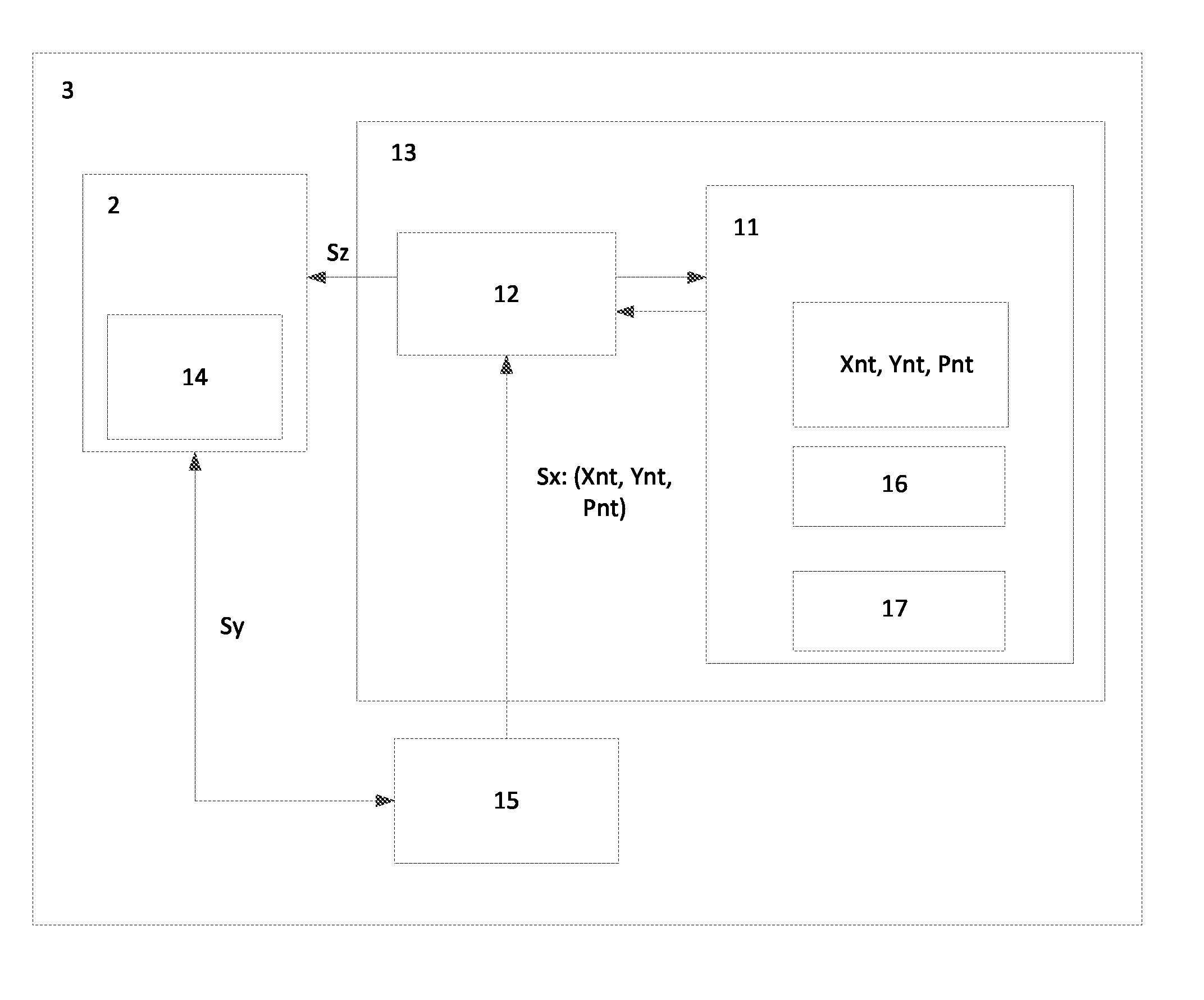

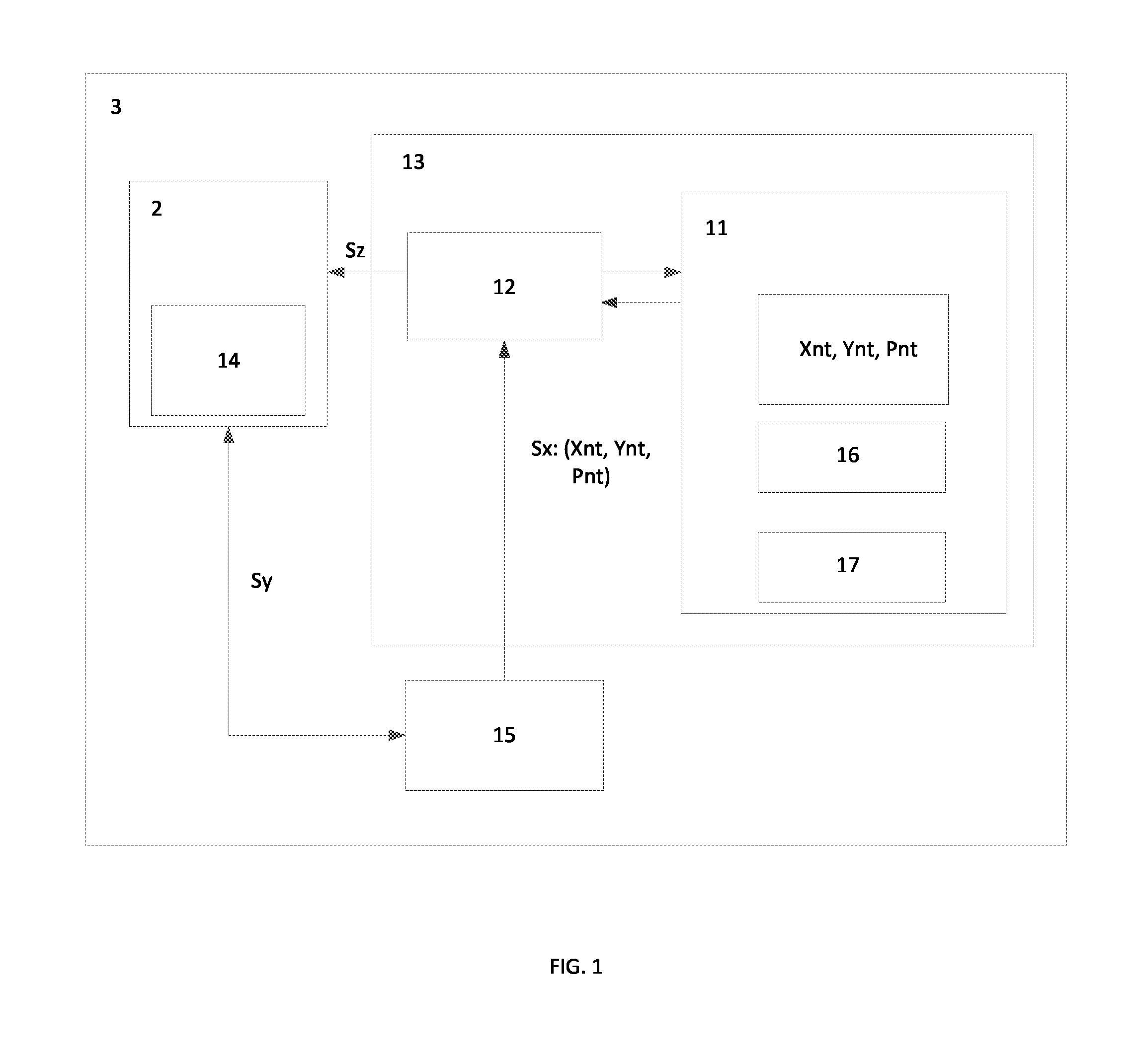

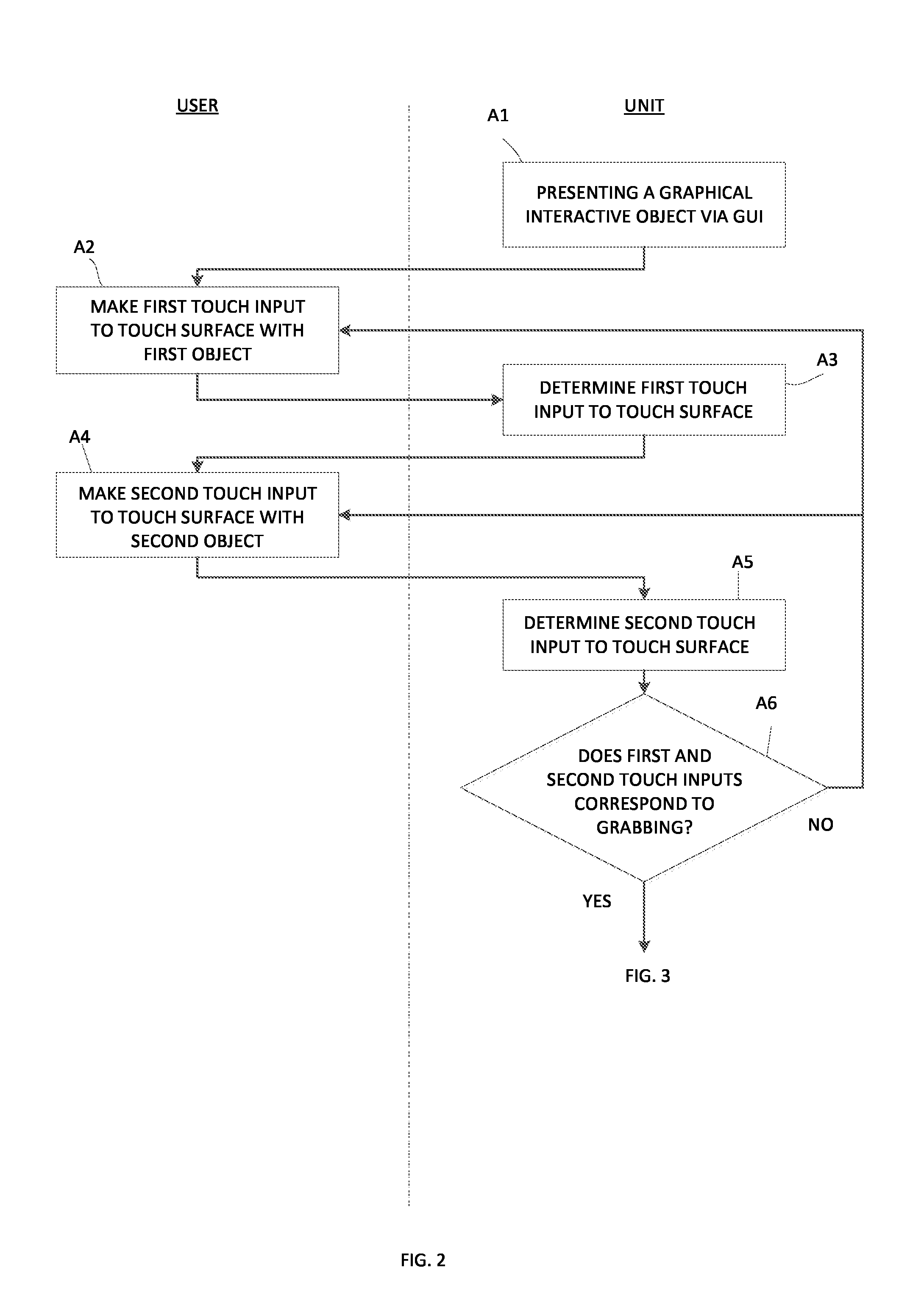

Interpretation of pressure based gesture

InactiveUS20140237408A1Clean appearanceSimplify playbackInput/output processes for data processingGraphicsTouch Senses

The invention relates to a method, a gesture interpretation unit and a touch sensing device, wherein the first and second positions are in a relation to a graphical interactive object corresponding to a grabbing input; and while continuous contact of the first and second objects with the touch surface is maintained: determining from the touch input data if movement of at least one of the first and second touch inputs has occurred, and if movement has occurred, moving the graphical interactive object in accordance with the determined movement; determining from the touch input data if an increased pressure compared to a threshold of at least one of the first and second touch inputs has occurred, and if an increased pressure has occurred, processing the graphical interactive object in response to the determined increased pressure.

Owner:FLATFROG LAB

Receiver module for inflating a membrane in an ear device

A receiver module configured to be seated within an ear canal and optimized for simultaneously inflating an inflatable membrane while generating acoustic waves transmitted to a user. The inflatable membrane can be used to secure the receiver module within the bony portion of the ear canal of the user. A multi-layer valve system and method of assembly are disclosed for a valve system to harvest static pressure from acoustic waves generated within the receiver and direct the increased pressure toward the inflatable membrane to inflate the membrane. The multi-layer valve system can be used to prevent a back flow of air and thereby maintain a static pressure differential between ambient air drawn in through an air ingress port and air forced into the inflatable membrane through an air egress port.

Owner:SONION NEDERLAND

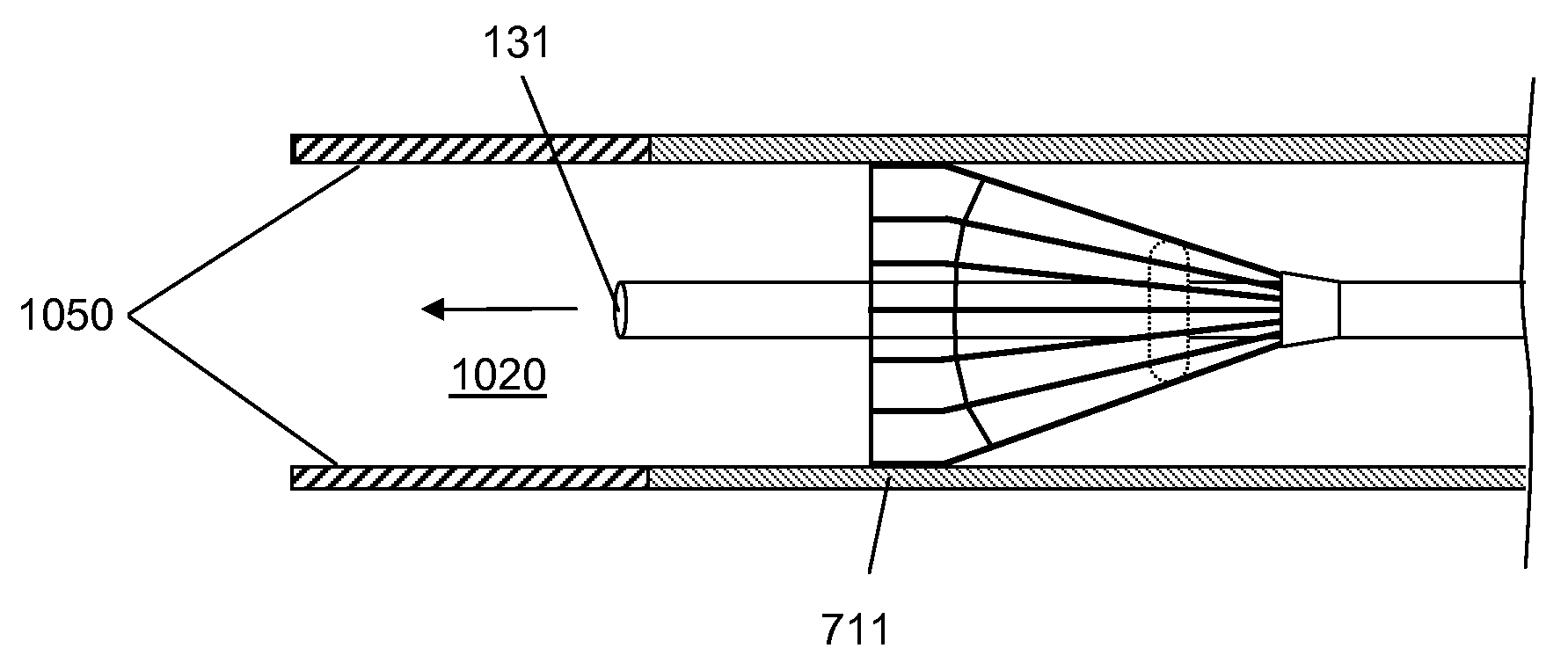

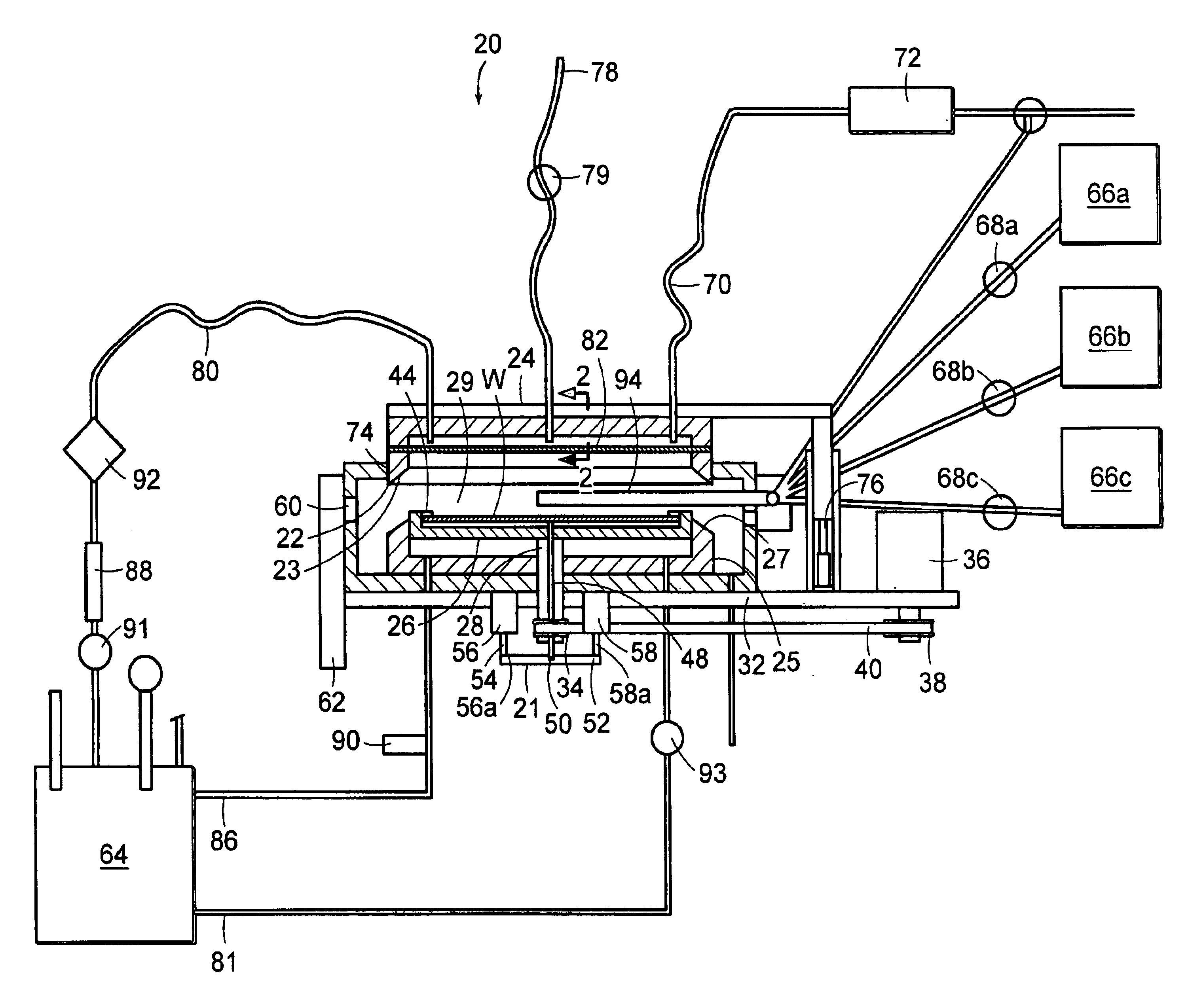

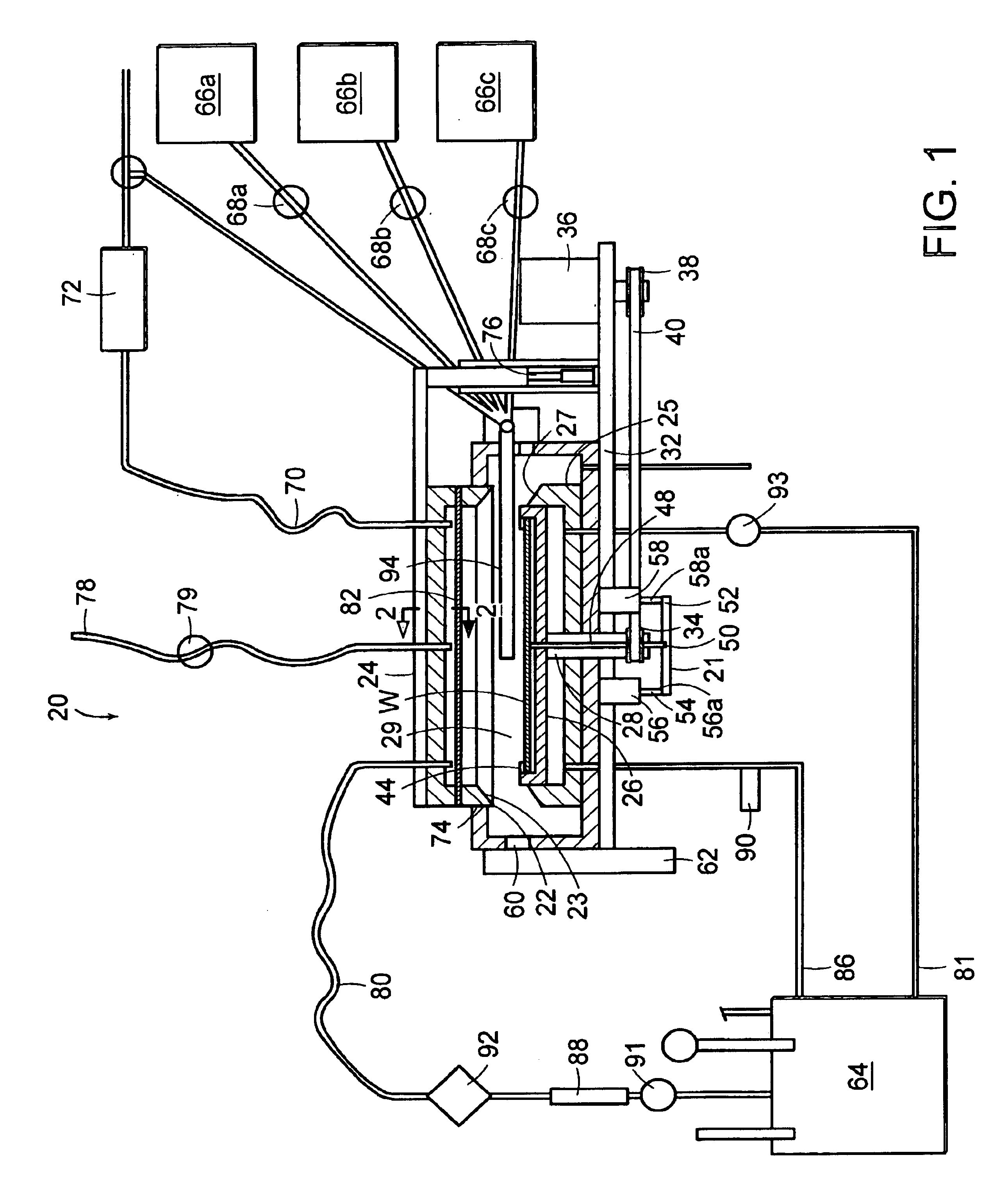

Method and apparatus for improved processing with a gas-cluster ion beam

ActiveUS7060989B2Smoothing capabilityImprove etching effectMaterial analysis by optical meansIon beam tubesGas cluster ion beamLight beam

Apparatus and methods for improving processing of workpieces with gas-cluster ion beams and modifying the gas-cluster ion energy distribution in the GCIB. In a reduced-pressure environment, generating an energetic gas-cluster ion beam and subjecting the beam to increased pressure region.

Owner:TEL EPION

Wound shield for exudate management

InactiveUS20070161937A1Inexpensive and yet effective materialDesirable lengthCannulasPlastersAdhesiveWound.exudate

A wound shield for exudate management may include a conformable frame to circumscribe a wound. The conformable frame may be formed of material for absorbing wound exudate. Exudate absorbing material may also be one of two or more layers of material forming the conformable frame. The layers may be arranged to keep the exudate absorbing layer at some selected distance from a patients skin. Any suitable dressing may be secured over the conformable frame providing separation between the wound and the dressing. The wound frame may provide pressure relief around a wound or pressure sore to permit healing. The conformable frame may be wrapped, in a spiral, around a wound providing an increasing pressure relief by increasing distance from the wound. A conformable frame may be composed of one or more layers of any suitable material and may include adhesive on one or more surfaces to secure the frame to the wound site and or to secure the dressing to the conformable frame. One layer of the two or more layers of material forming the conformable frame may be a wicking or conduit material that draws exudate from the wound and transports the exudate to any suitable media for exudate storage. The exudate storage may be one or more layers of a dressing covering the wound site, or it may be a removable reservoir.

Owner:AALNEX

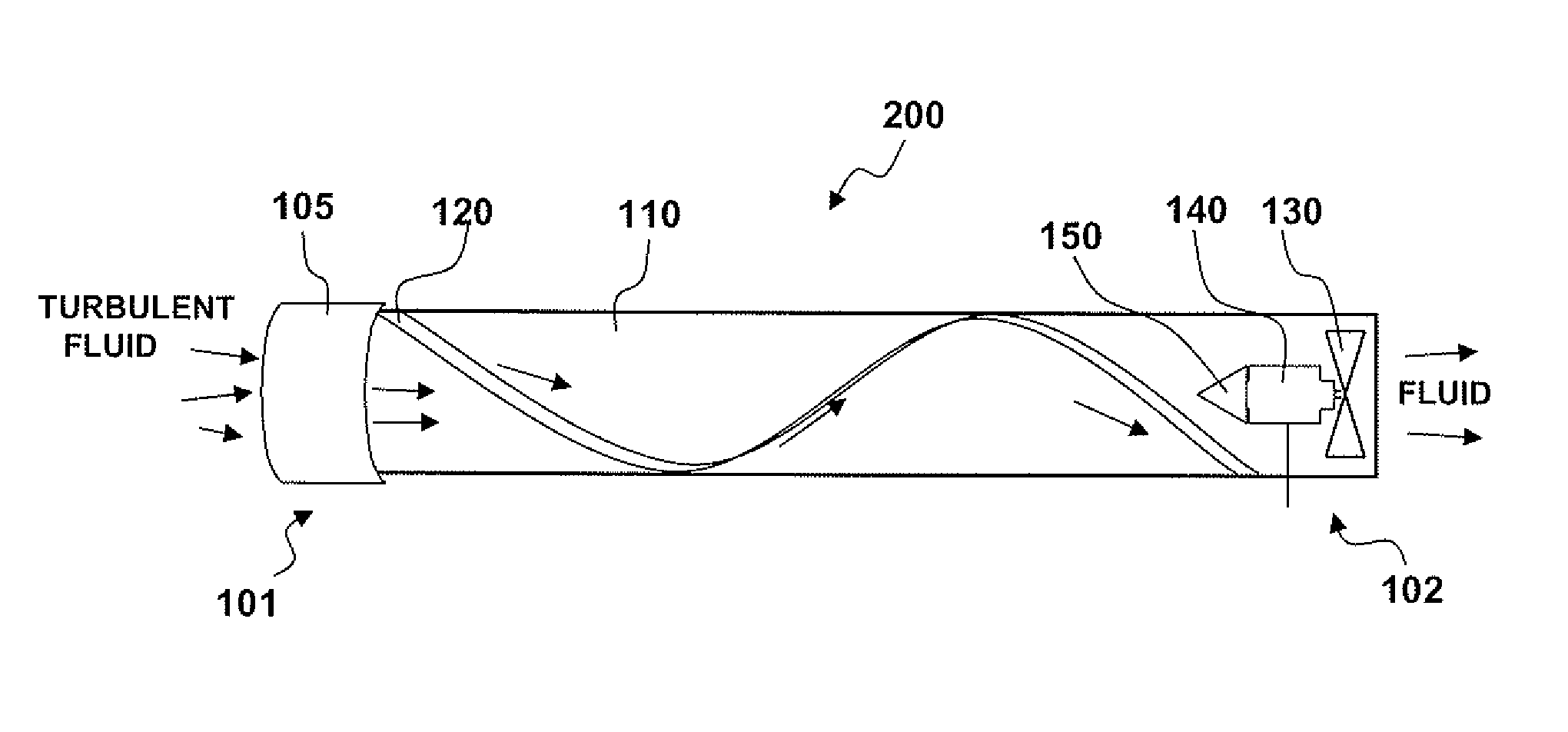

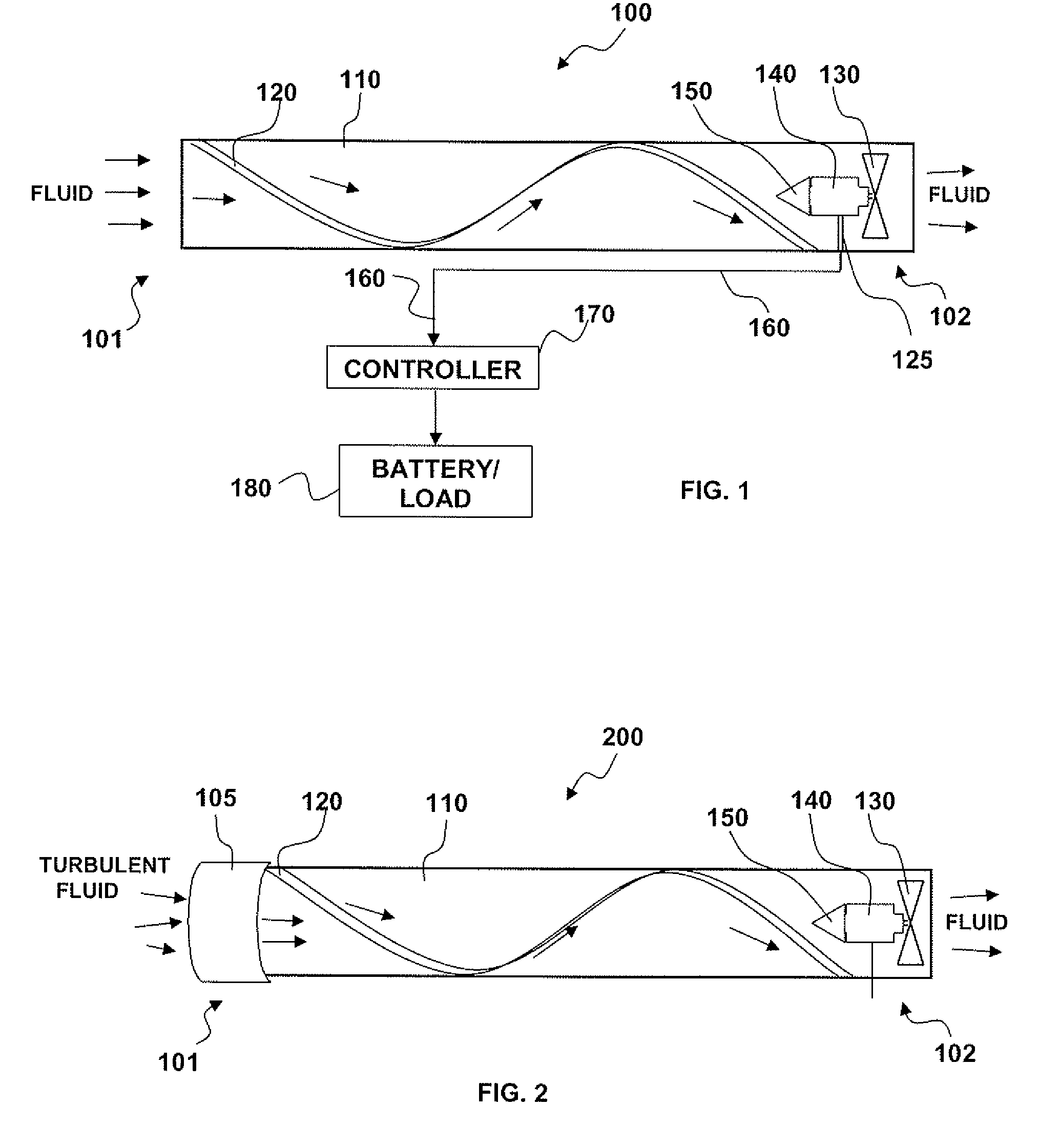

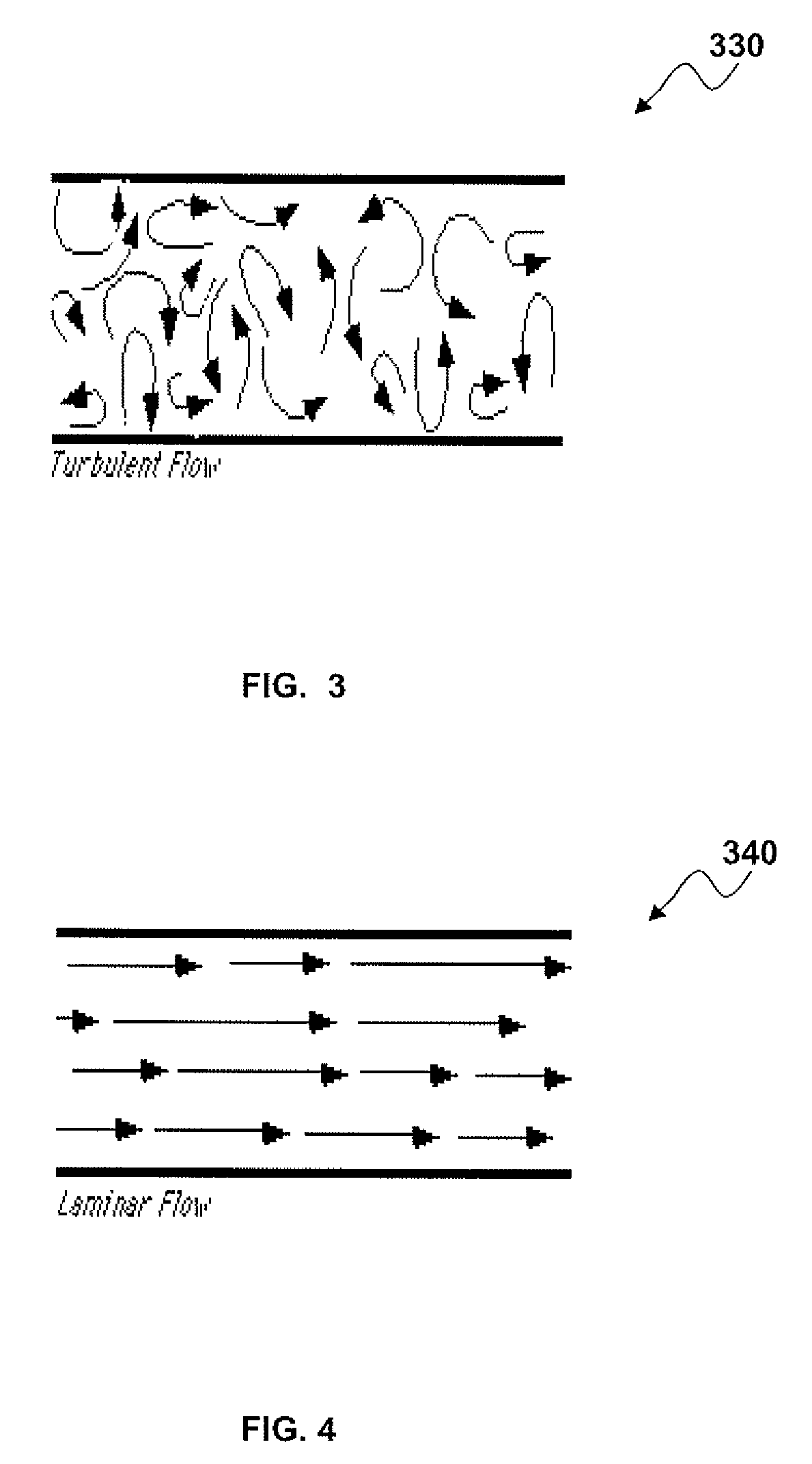

Fluid driven electric power generation system

ActiveUS20080238105A1Scalable in sizeGood effectWind motor controlWind motor supports/mountsAlternatorHelical blade

A tubular housing includes at least one fixed helical vane formed onto the inner surfaces of the tubular housing in a spiral and adapted to direct fluid into a spiraled flow and focus fluid onto a fan blade assembly associated with an alternator system and located within the tubular housing before a system exhaust. A generator cone can be mounted near the center and front of the fan blade assembly facing fluid passing through the tubular housing. As fluid passes over the generator cone it experiences compression between the generator cone and housing resulting in increased pressure and velocity of the fluid, thereby increasing rotational speed of the generator blades and generator as the compressed, spiraled fluid passes through the blades and exits the tubular housing. The system can be used for fixed or mobile applications in water, wind and manually induced air flow.

Owner:MDL ENTERPRISES

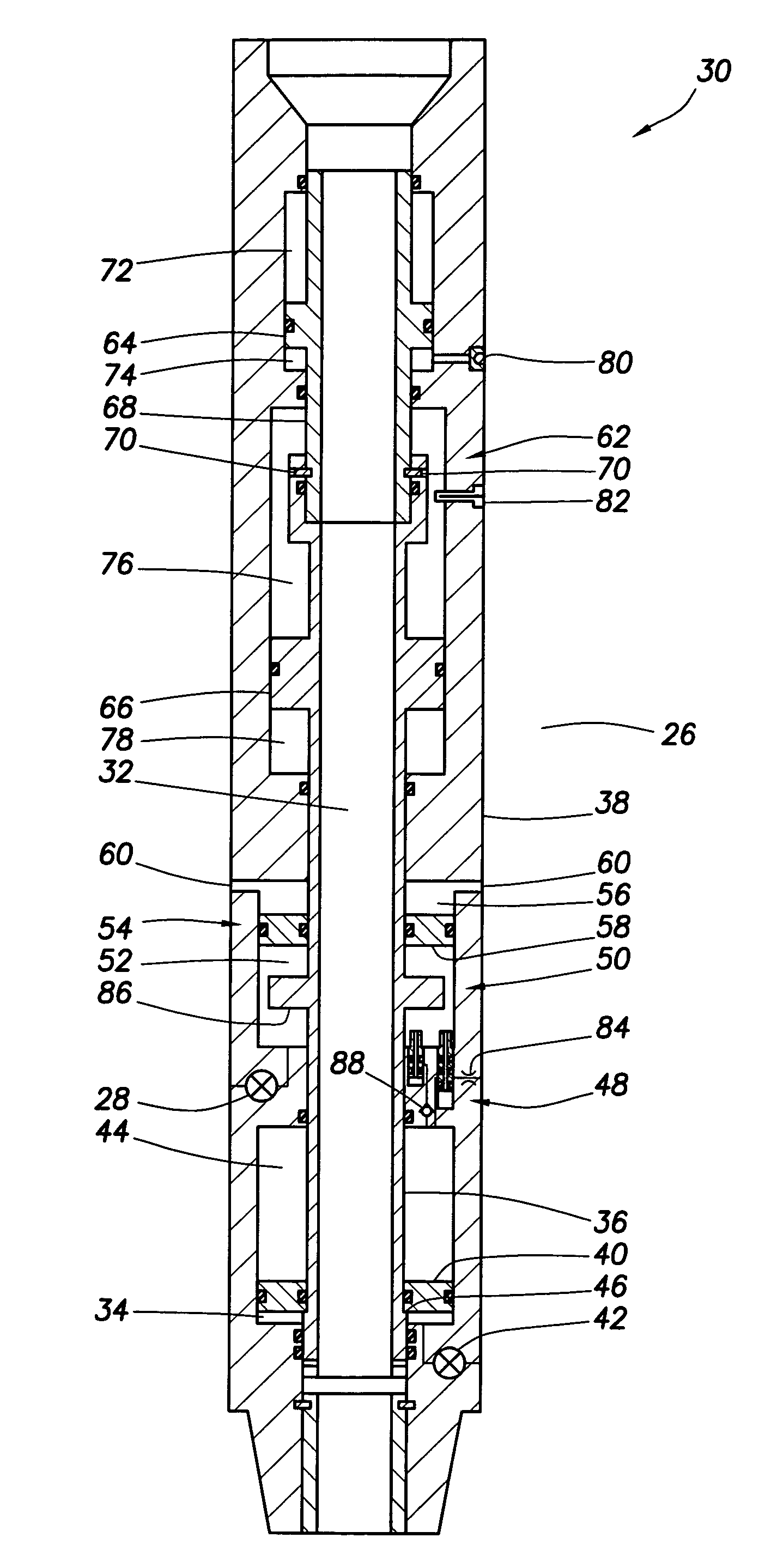

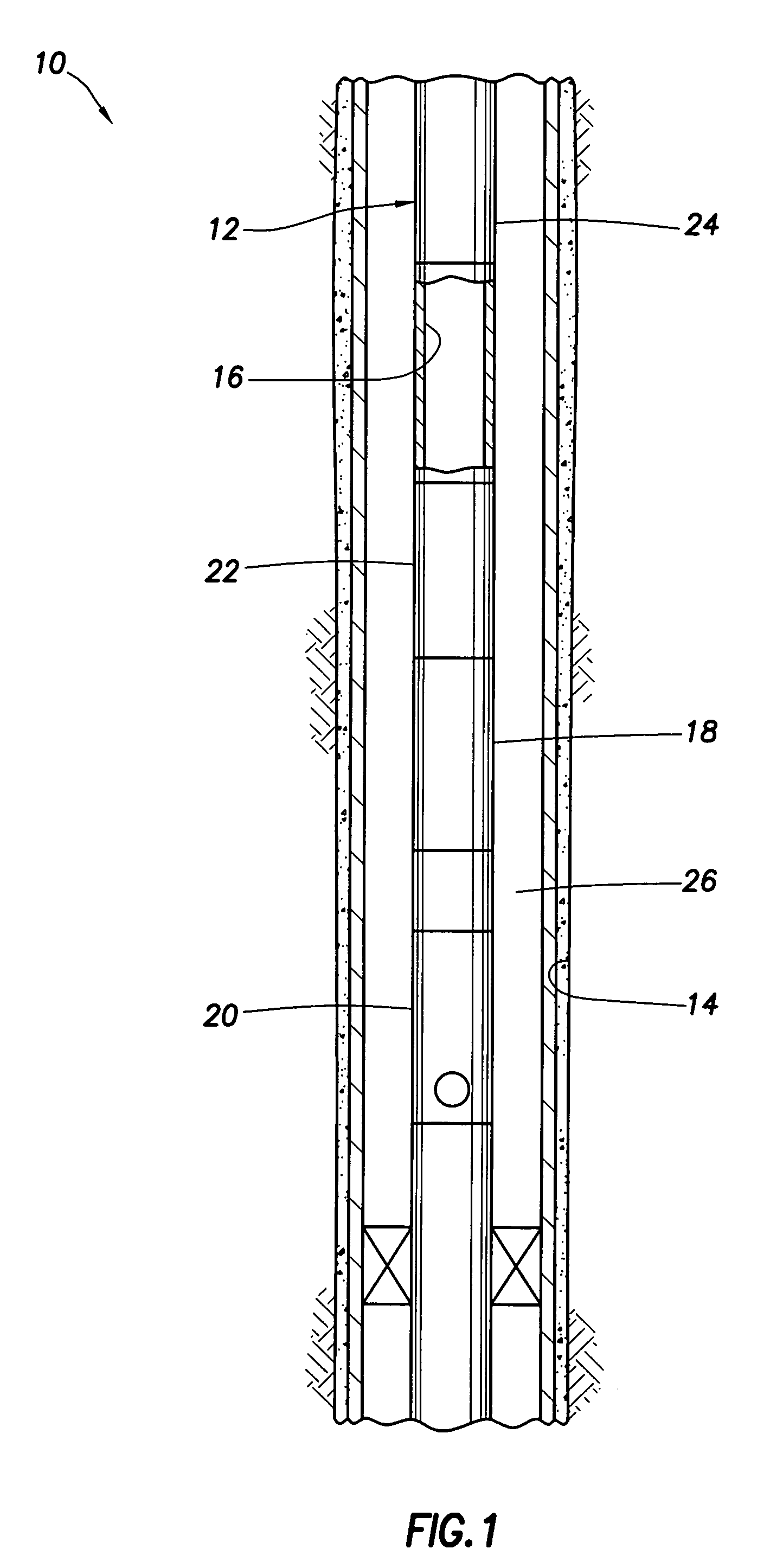

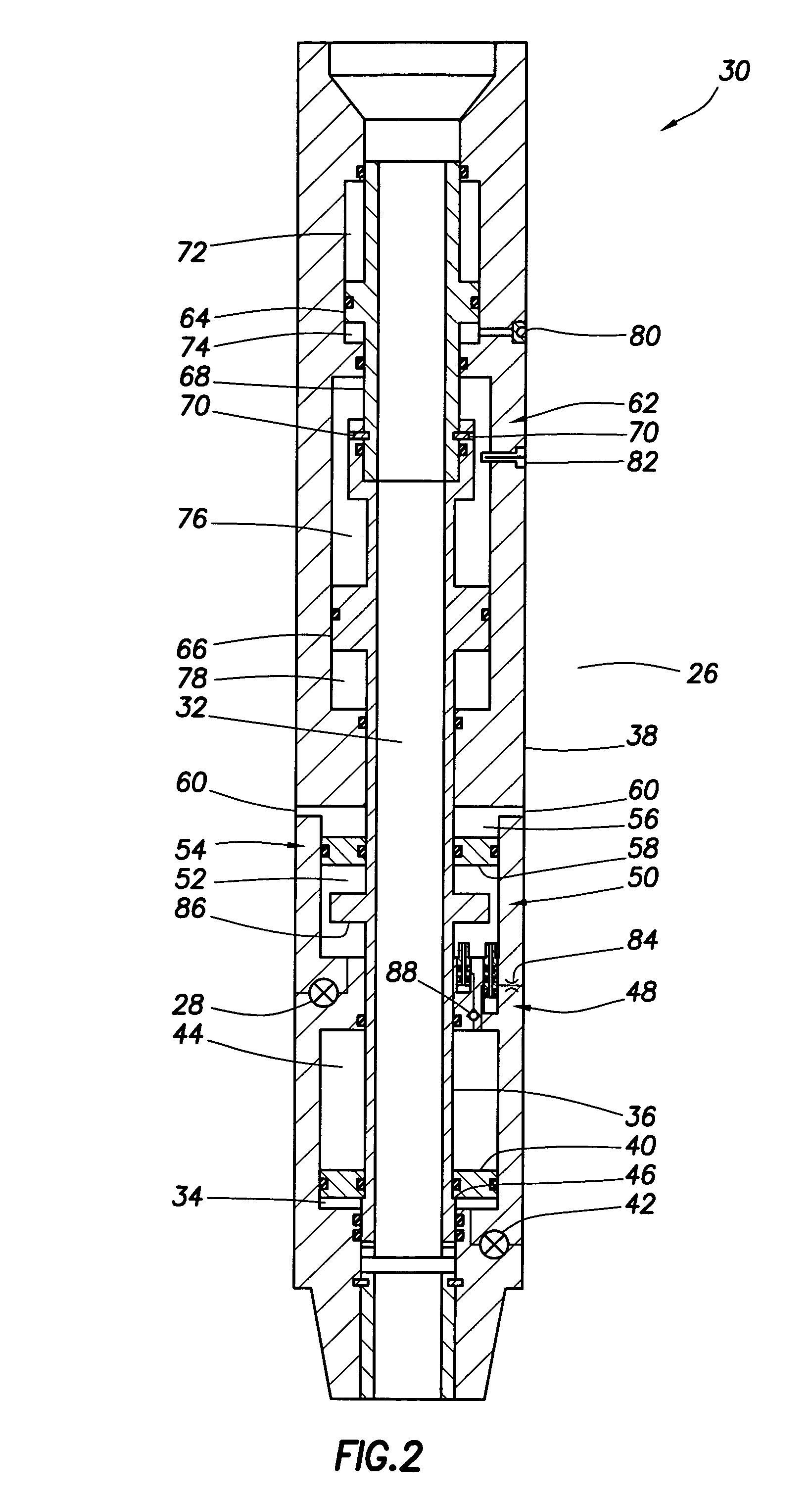

Single phase fluid sampler systems and associated methods

InactiveUS7197923B1Increase pressureIncrease pressure in pressure sourceBorehole/well accessoriesSample chamberIncrease pressure

A single phase fluid sampler system and associated methods. A fluid sampling method includes the steps of: receiving a fluid sample into a sample chamber of a fluid sampler; pressurizing the fluid sample using a pressure source; and increasing pressure in the pressure source while the pressure source is in the well, thereby applying increased pressure to the fluid sample in the sample chamber. Another method includes the step of applying pressure to the well to thereby increase pressure in the pressure source, and to thereby increase pressure on the fluid sample. A fluid sampler system includes a fluid sampler with a sample chamber, a pressure source for pressurizing the sample chamber, and a device which operates to increase pressure in the pressure source while the fluid sampler is in the well.

Owner:HALLIBURTON ENERGY SERVICES INC

Lockout mechanism for a suspension system

ActiveUS20050104320A1Wheel based transmissionFrictional rollers based transmissionEngineeringDischarge pressure

A suspension system that includes a simplified lockout mechanism and an adjustable blow-off mechanism. The system includes a valve mechanism and a valve actuating assembly, a valve mechanism housing and a resilient member disposed between the valve mechanism and the valve mechanism housing. The valve mechanism is slidably mounted along the valve mechanism housing and it separates a first chamber from a second chamber. The valve actuating assembly operates the valve mechanism between open and closed positions. The resilient member is configured to be deformable by the valve mechanism as the valve mechanism is slidably displaced by an increasing pressure in the first fluid chamber. The sliding valve mechanism is configured to collide against the valve actuating assembly when a blow-off pressure is reached in the first fluid chamber switching the valve mechanism from the closed position to the open position.

Owner:SRAM CORPORATION

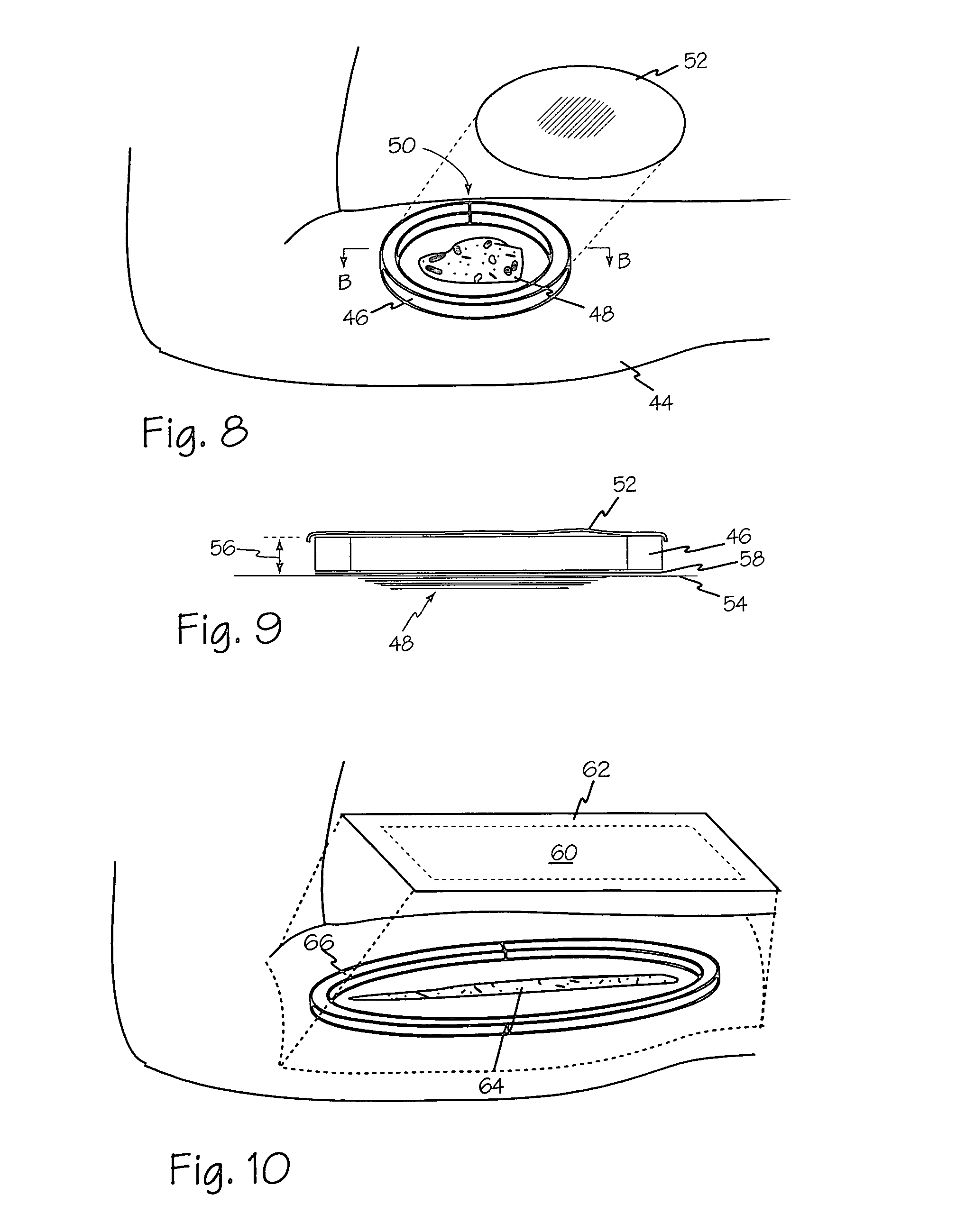

Medical device for vessel compatibility during high pressure infusion

The invention provides devices that can be used to deliver a therapeutic agent to a treatment site within the vessel of a patient at increased pressure, while limiting the contact with and pressure placed on the vessel walls. Devices according to the invention include an expandable structure arranged around and on a tube having a lumen. The expandable structure may include a sealing ring that makes contact with the interior surface of a vessel to prevent or decrease fluid flow during delivery of a therapeutic agent. This allows delivery of a therapeutic agent with decreased risk of injury to the treatment site. The invention also provides for large lumen diameters, preventing shearing stress on therapeutic agents such as cell slurries.

Owner:BOSTON SCI SCIMED INC

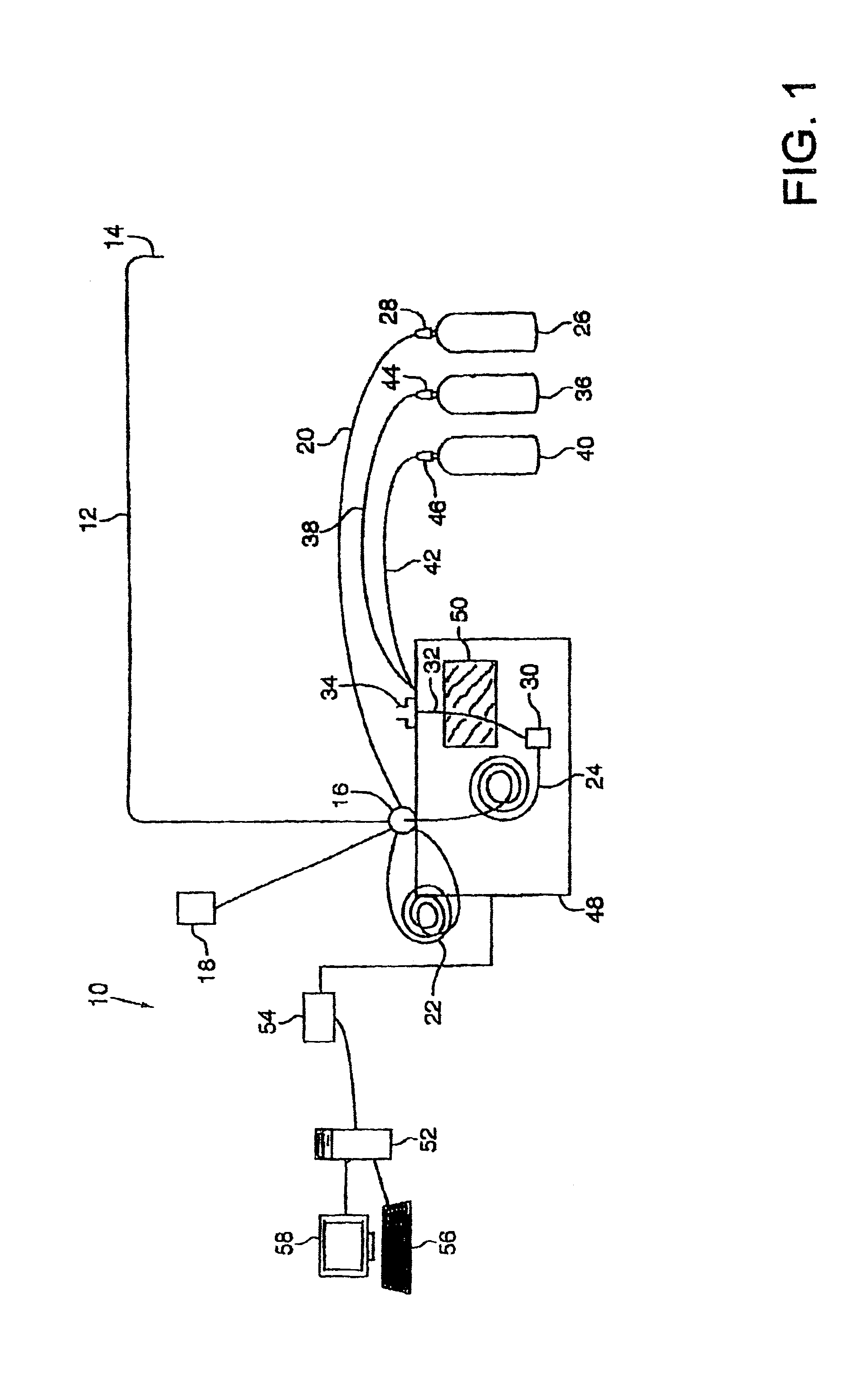

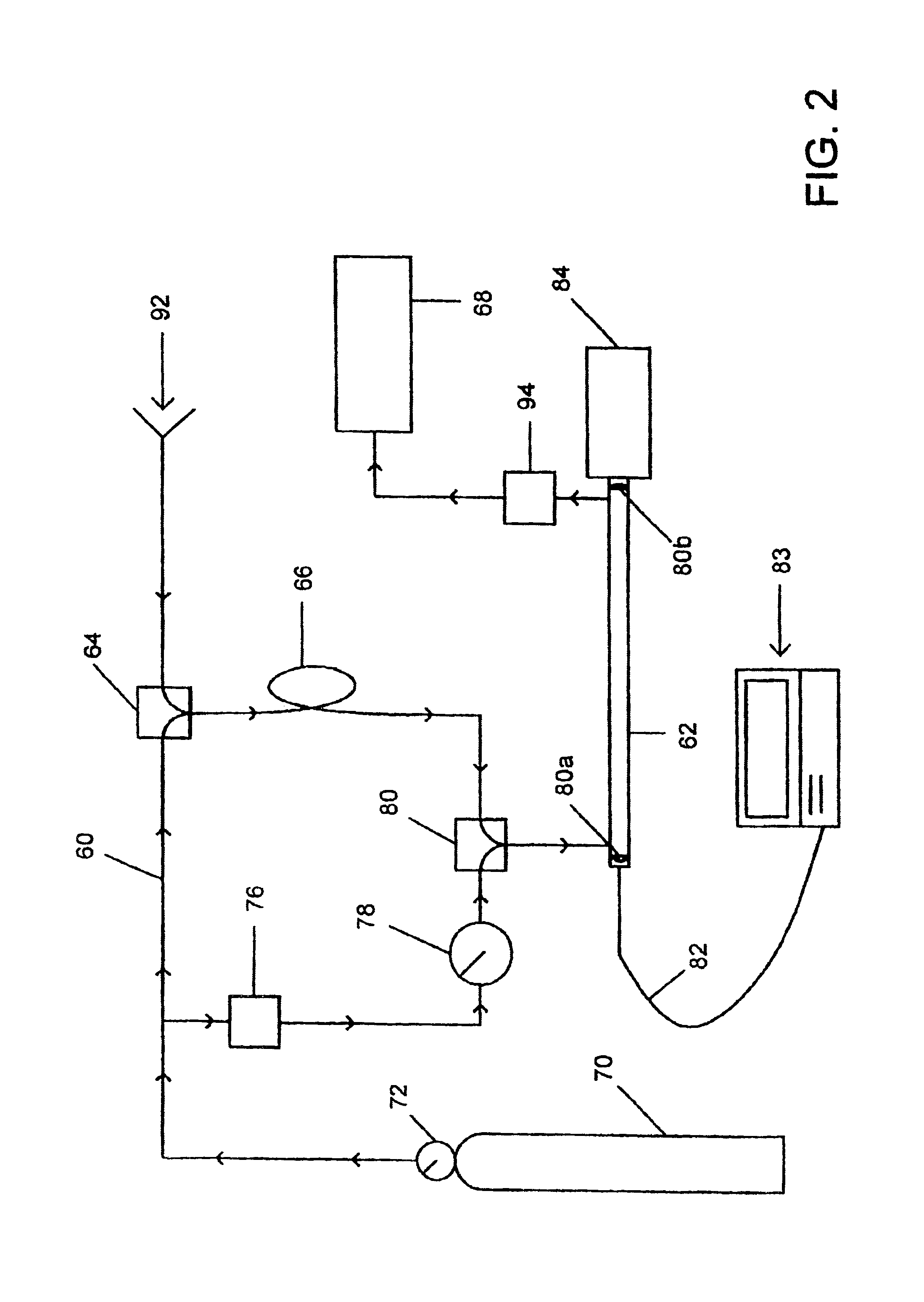

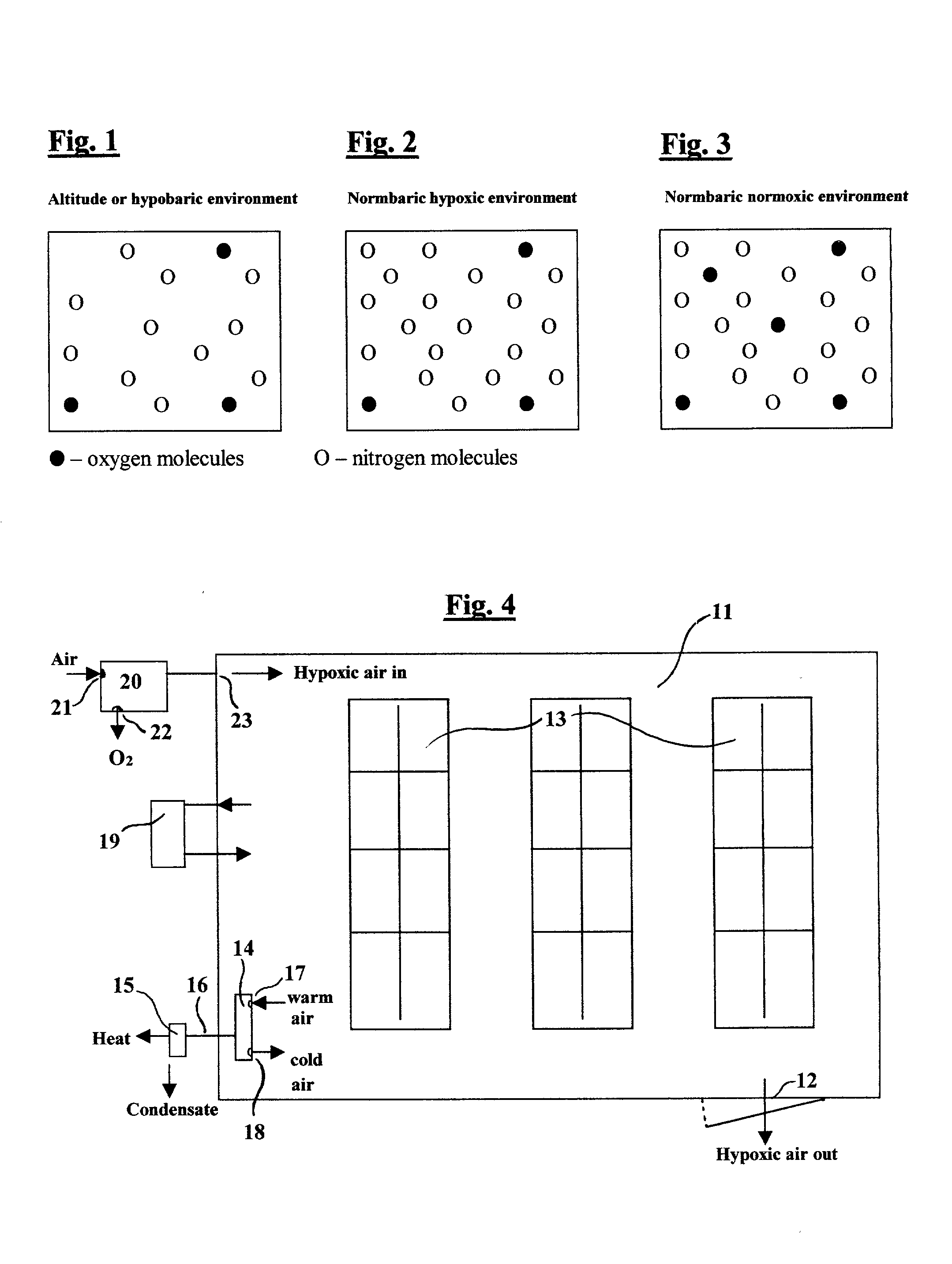

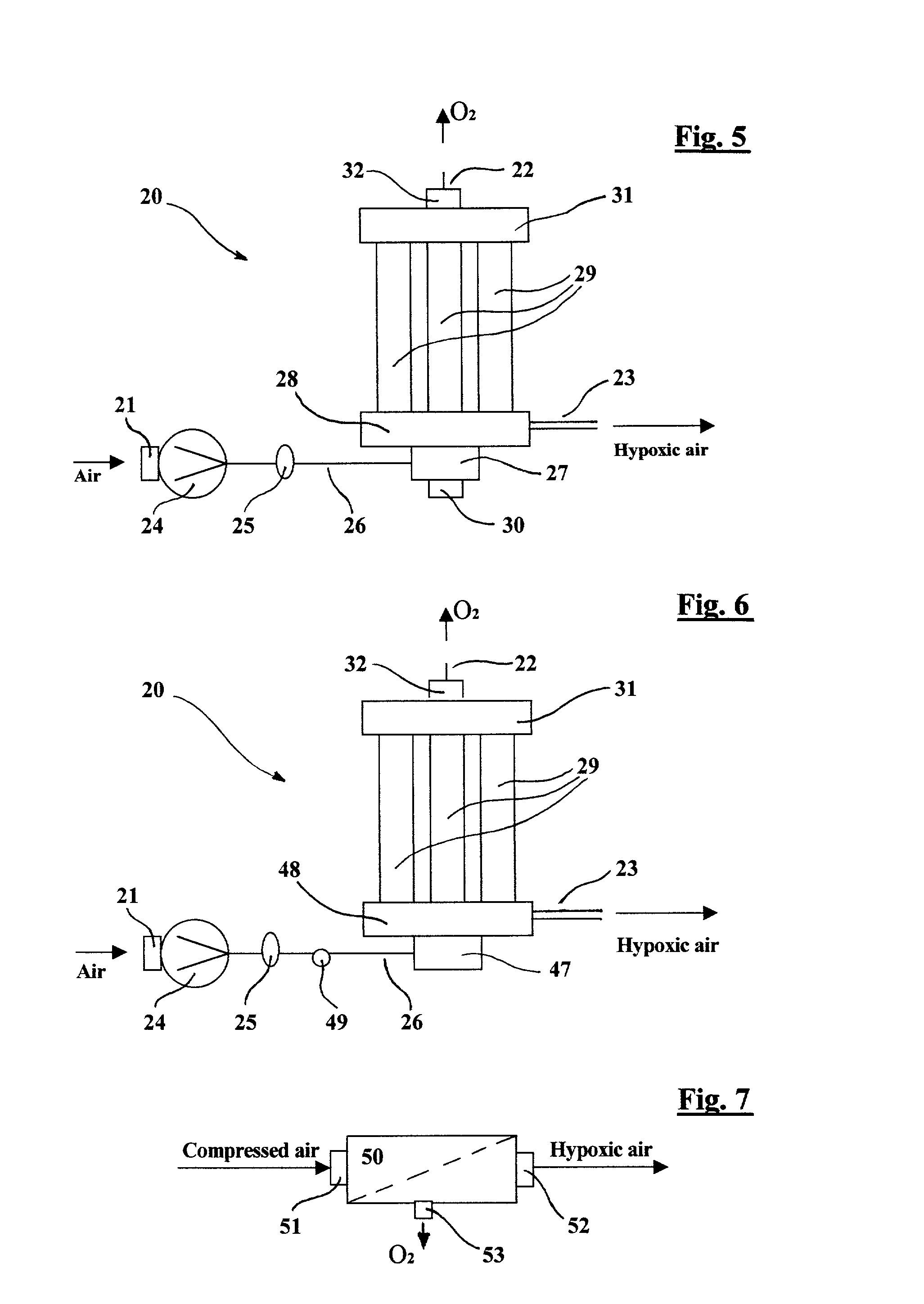

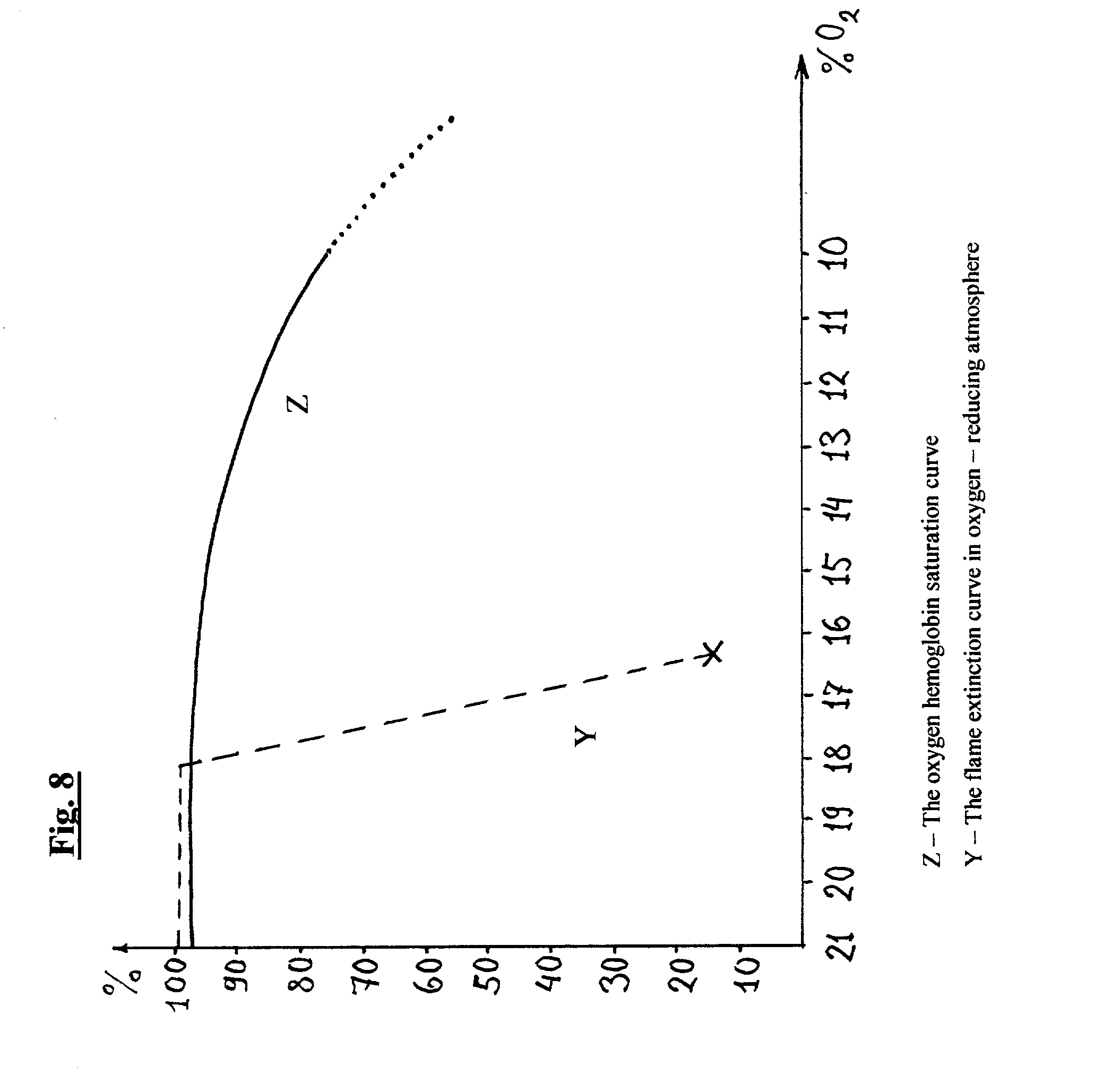

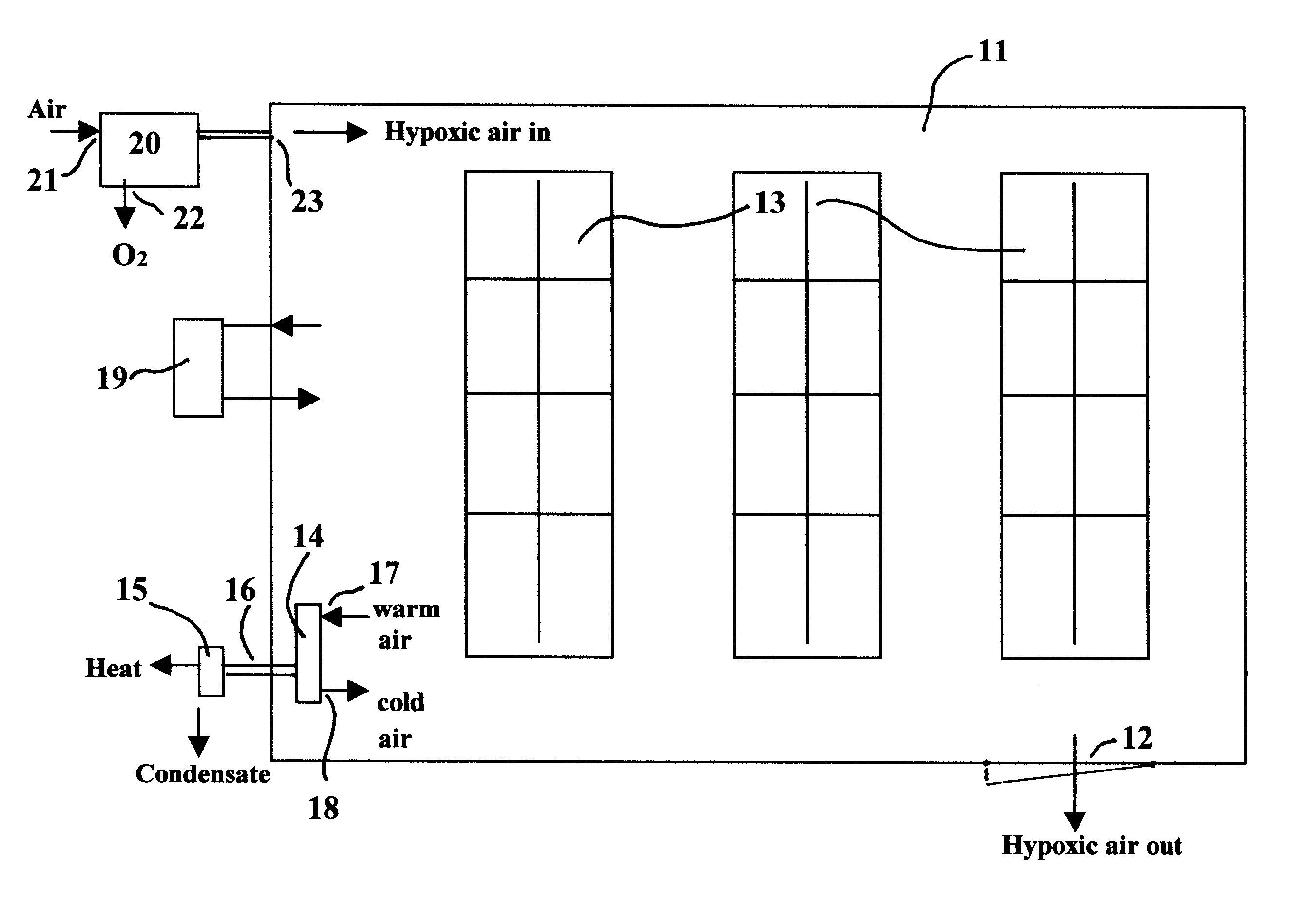

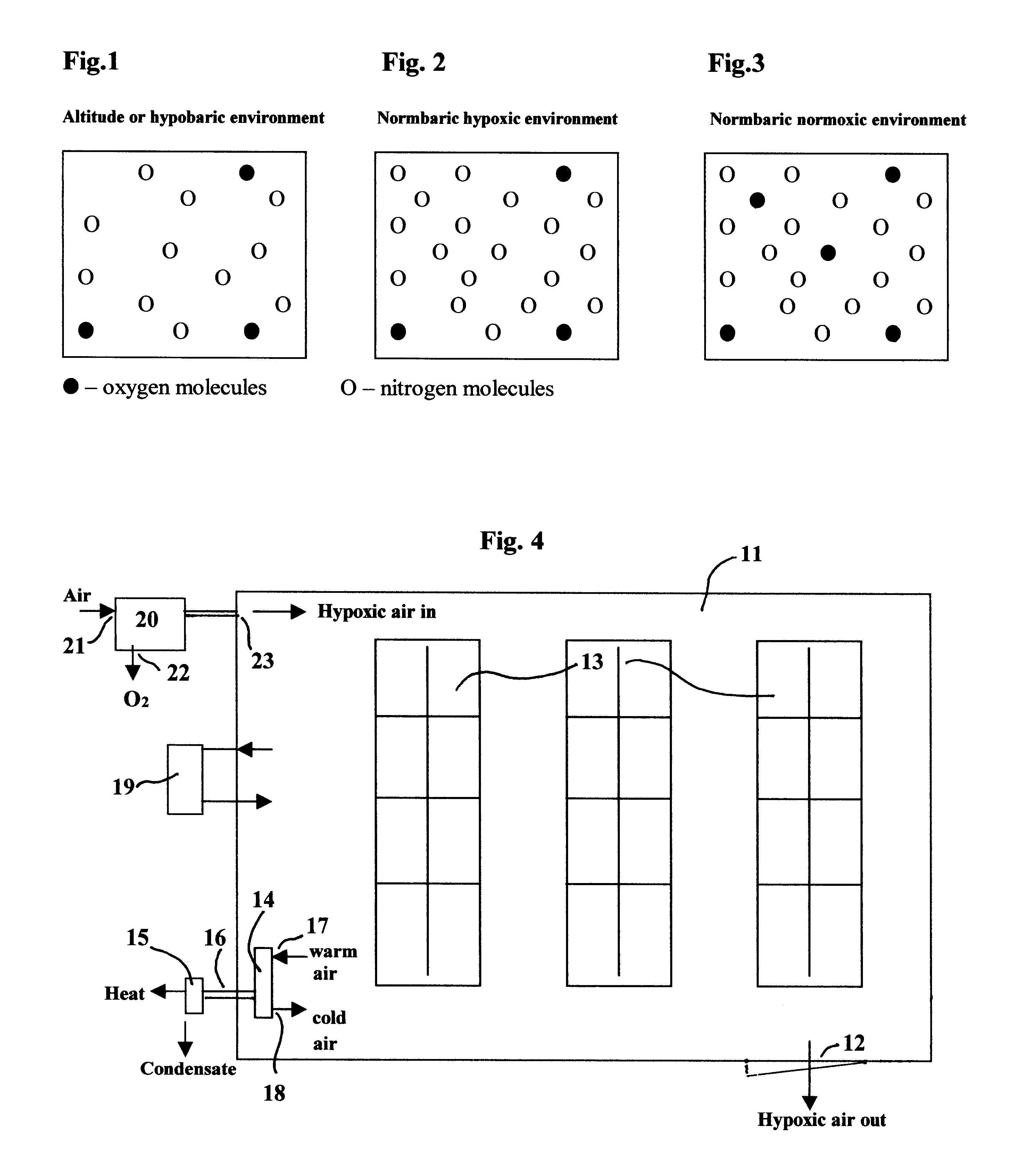

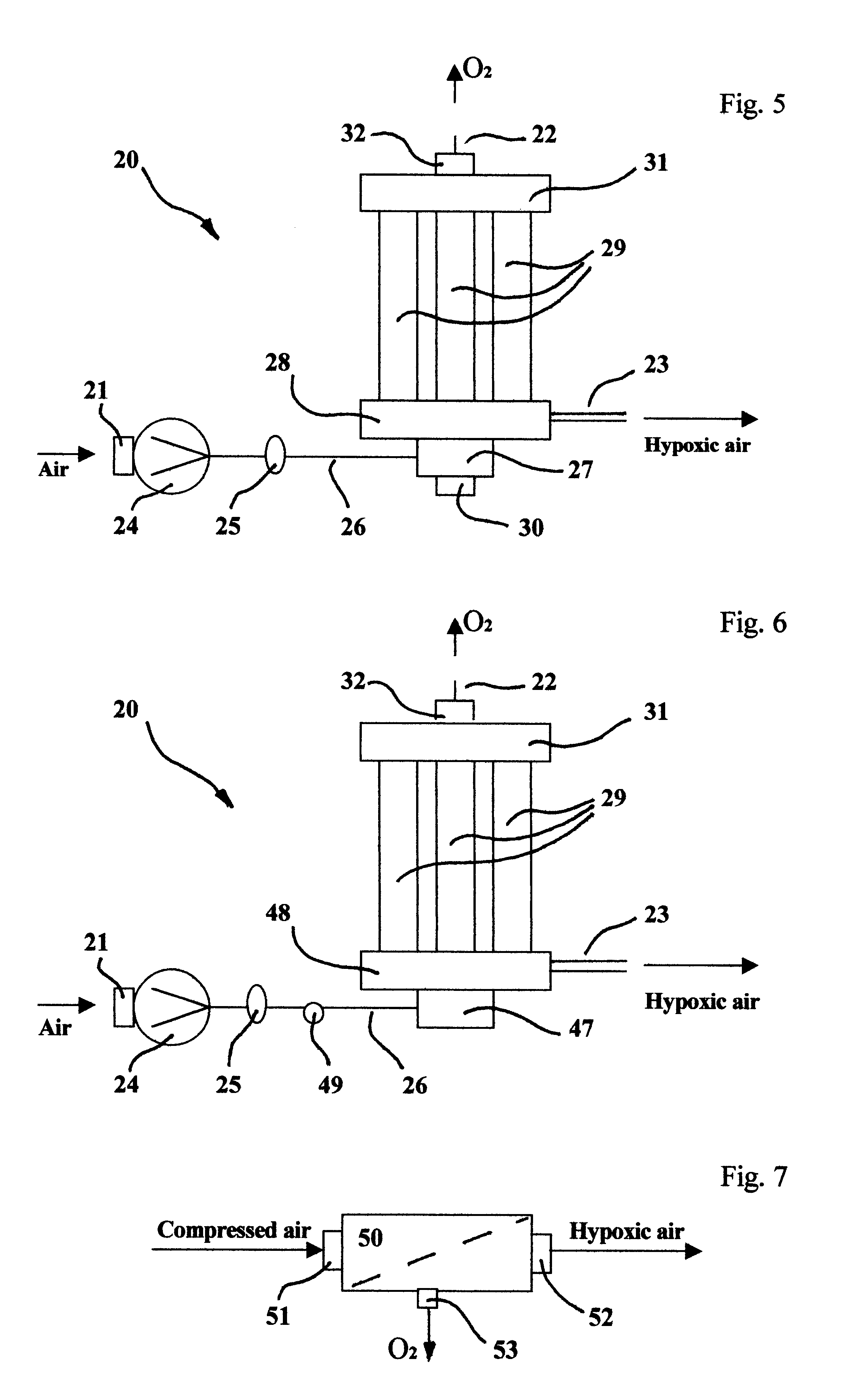

Hypoxic fire prevention and fire suppression systems and breathable fire extinguishing compositions for human occupied environments

Fire prevention and suppression systems and breathable fire-extinguishing compositions are provided for rooms, houses and buildings, transportation tunnels and vehicles, underground and underwater facilities, marine vessels, aircraft, space stations and vehicles, military installations and vehicles, and other human occupied objects and facilities. The system provides a low-oxygen (hypoxic) fire-preventive atmosphere at standard atmospheric or slightly increased pressure. The system employs an oxygen-extraction apparatus supplying oxygen-depleted air inside a human-occupied area or storing it in a high-pressure container for use in case of fire. A breathable fire-extinguishing composition, being mostly a mixture of nitrogen and oxygen and having oxygen content ranging from 12% to 17% for fire-preventive environments. The fire-suppression system is provided having fire-extinguishing composition with oxygen concentration under 16%, so when released it creates a breathable fire-suppressive atmosphere having oxygen content from 10 to 16%. A technology for automatically maintaining a breathable fire-preventive composition on board a human-occupied hermetic object is provided.

Owner:FIREPASS CORP

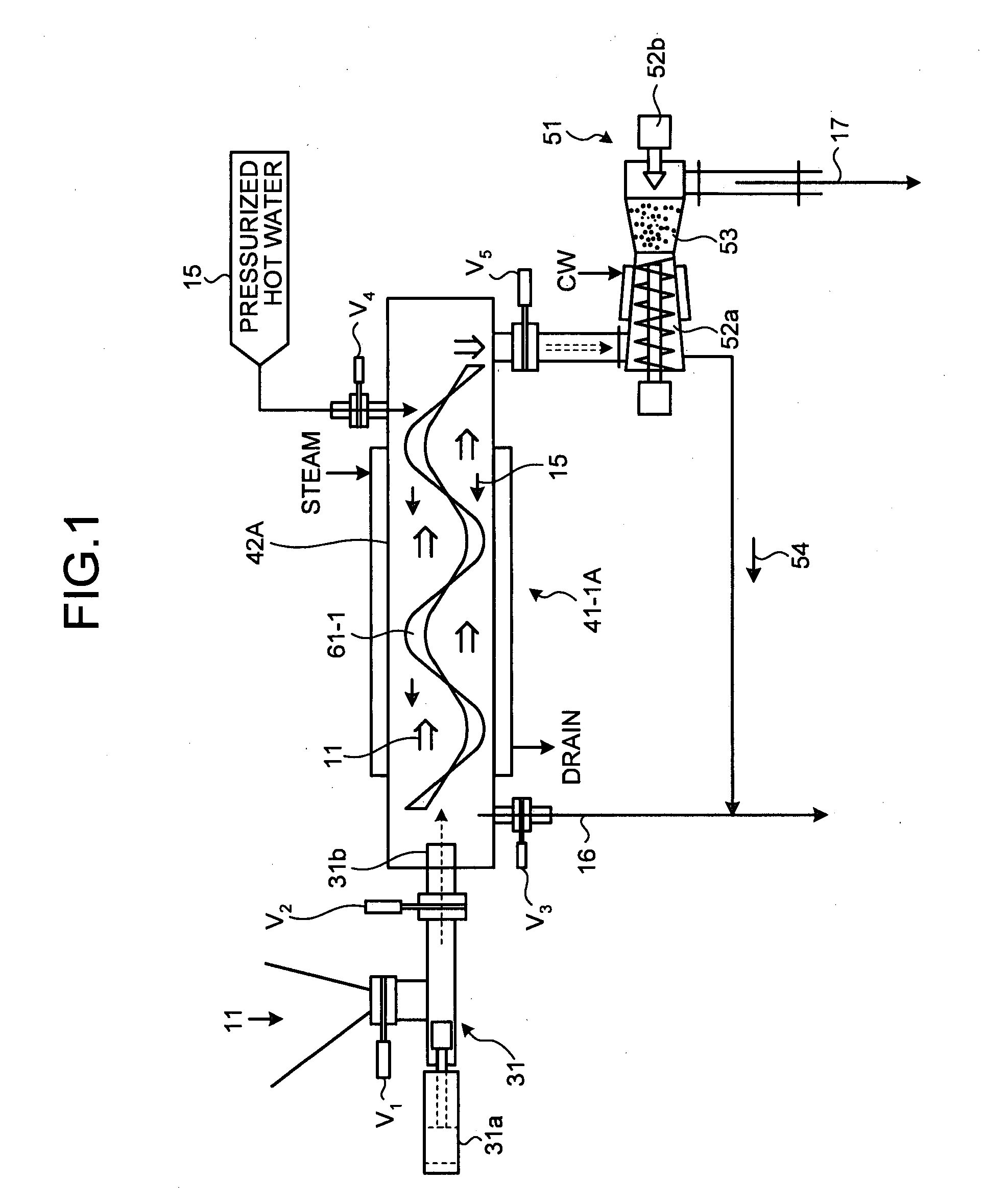

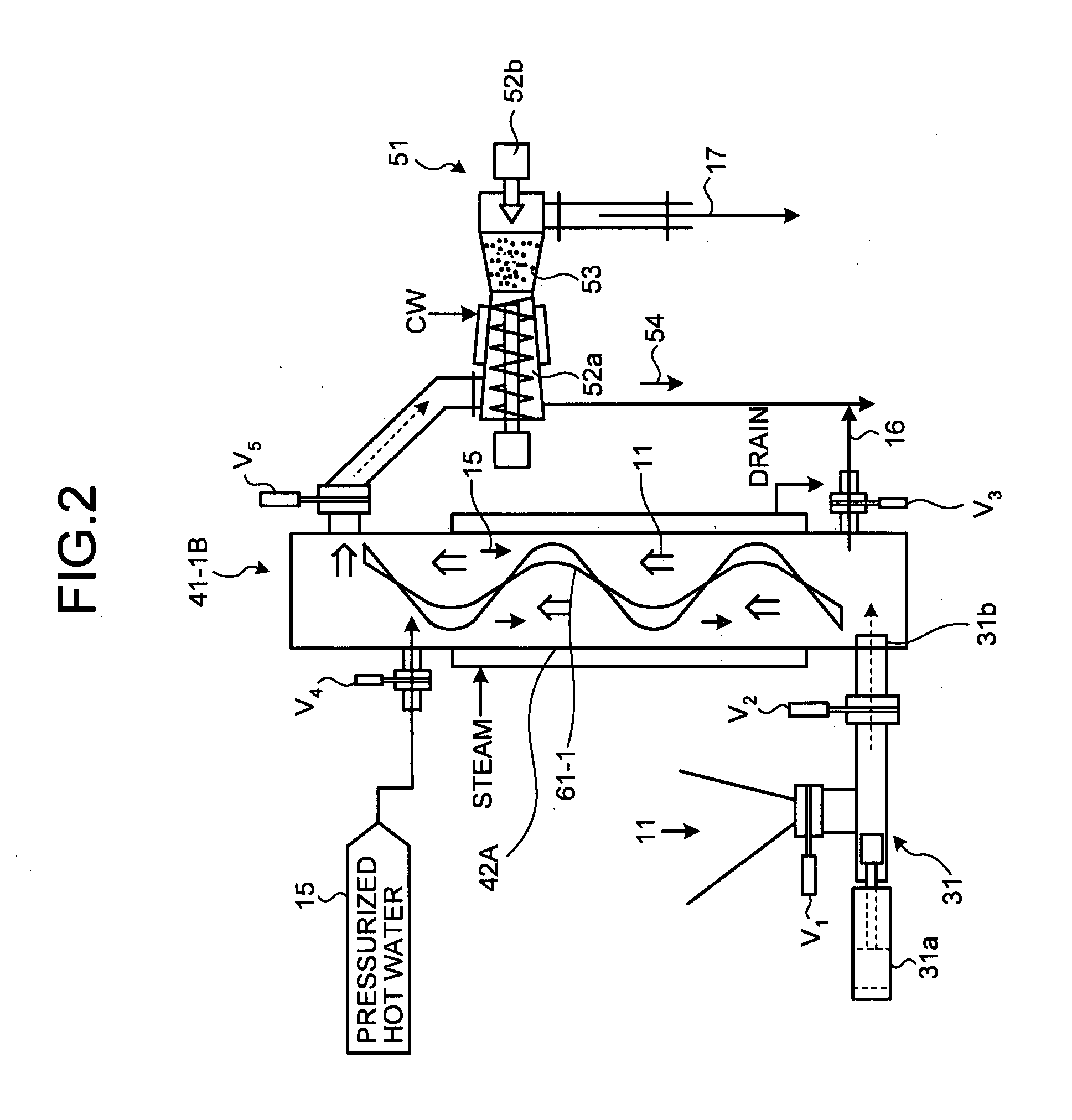

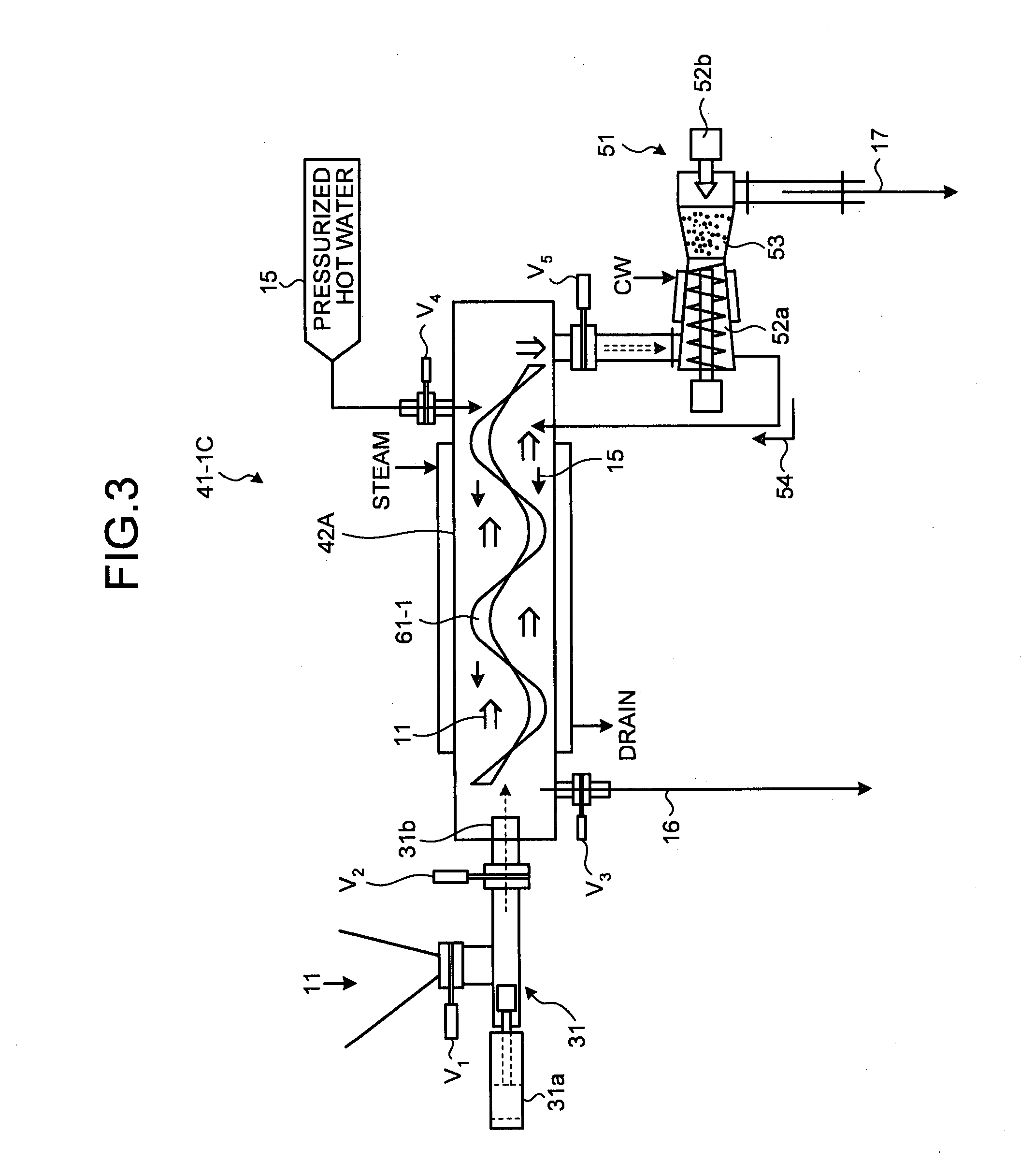

Biomass hydrothermal decomposition apparatus, method thereof, and organic material production system using biomass material

ActiveUS20100184176A1Efficiently saccharifyingEfficient productionBioreactor/fermenter combinationsBiological substance pretreatmentsDecompositionEngineering

A biomass hydrothermal decomposition apparatus includes, a biomass feeder (31) that feeds biomass material (11) under normal pressure to under increased pressure, a hydrothermal decomposition device (42A) that allows the fed biomass material (11) to be gradually moved inside a device main body (42A) from either end thereof in a consolidated condition, and also allows hot compressed water (15) to be fed from an other end of a feed section for the biomass material into the main body (42A), so as to cause the biomass material (11) and the hot compressed water (15) to countercurrently contact with each other and undergo hydrothermal decomposition, and that elutes a lignin component and a hemicellulose component into the hot compressed water, so as to separate the lignin component and the hemicellulose component from the biomass material (11); and a biomass discharger (51) that discharges, from the side where the hot compressed water is fed into the device main body, a biomass solid residue (17) under increased pressure to under normal pressure.

Owner:MITSUBISHI HITACHI POWER SYSTEMS ENVIRONMENTAL SOLUTIONS LTD

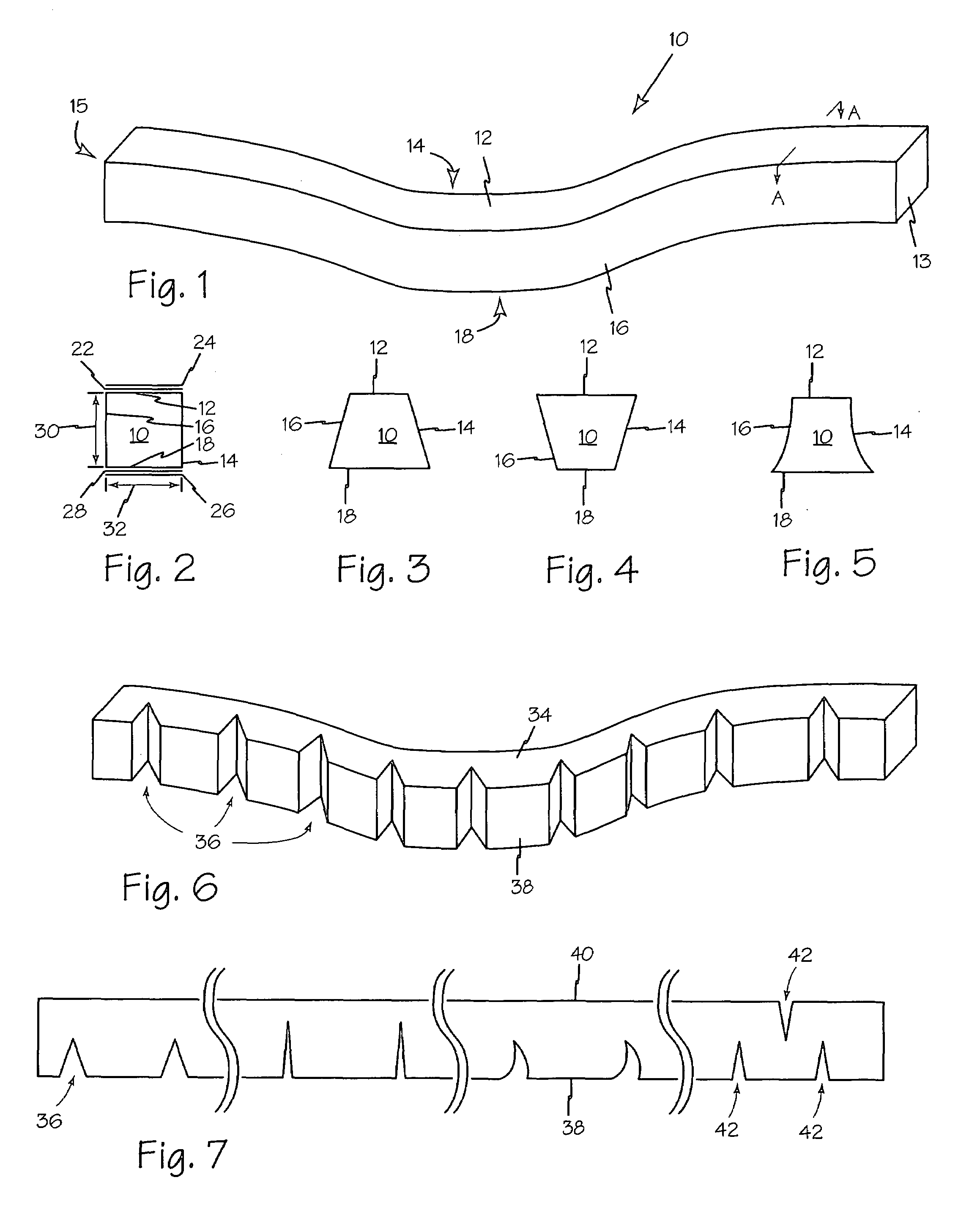

Multi-walled gelastic material

The present invention is directed to a gelastic cushion. The gelastic cushion is made from a conventional gelastic composition. The gelastic cushion has a structure having a first wall that defines an opening area and buckles when a force is applied to the first wall. When the first wall buckles a predetermined amount, a second wall, interconnected to the first wall, also buckles. The second wall decreases the chance that the first wall bottoms out. Bottoming out increases the pressure on the patient (a.k.a., the force) overlying the gelastic cushion. That increased pressure is undesirable.

Owner:STRYKER CORP

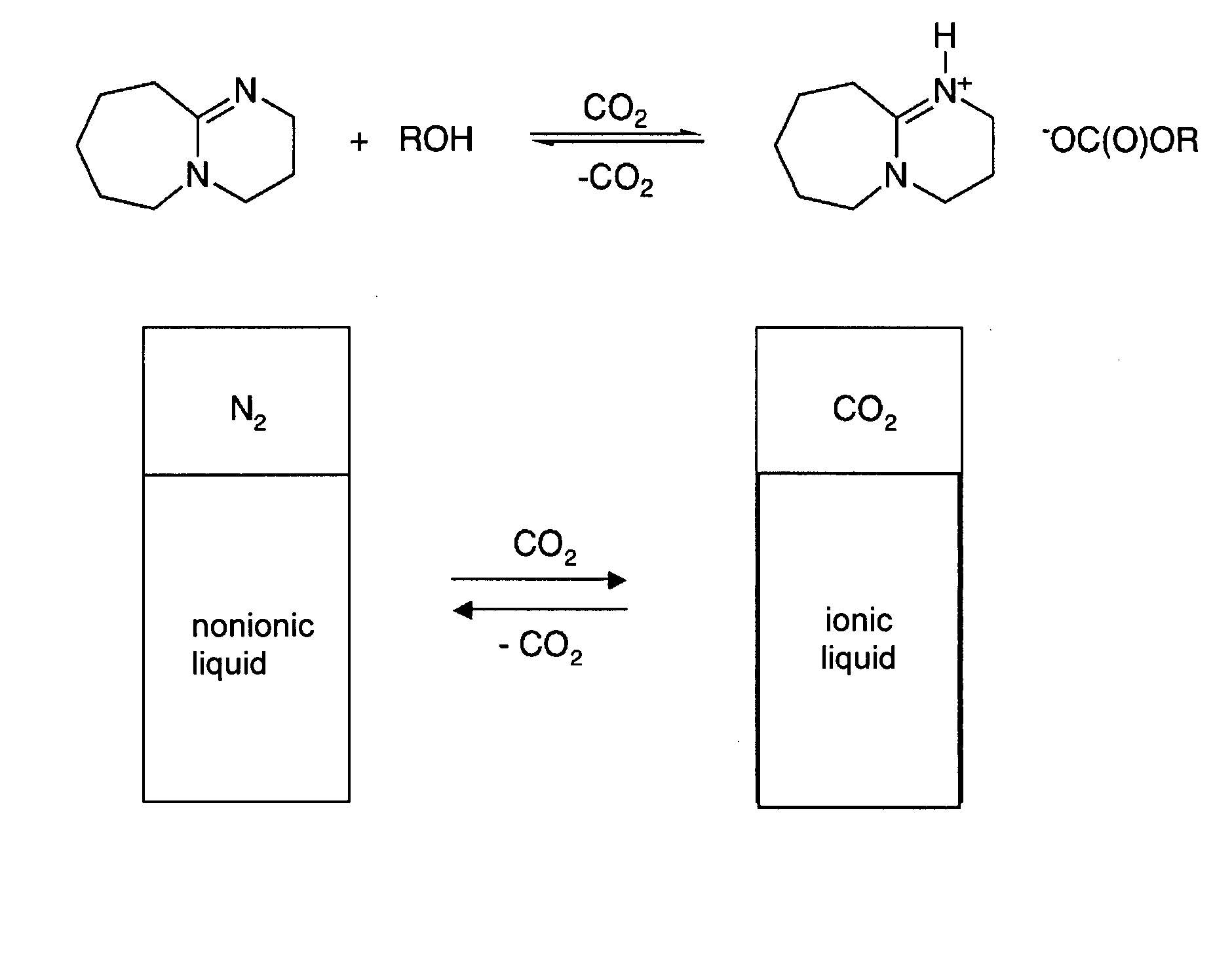

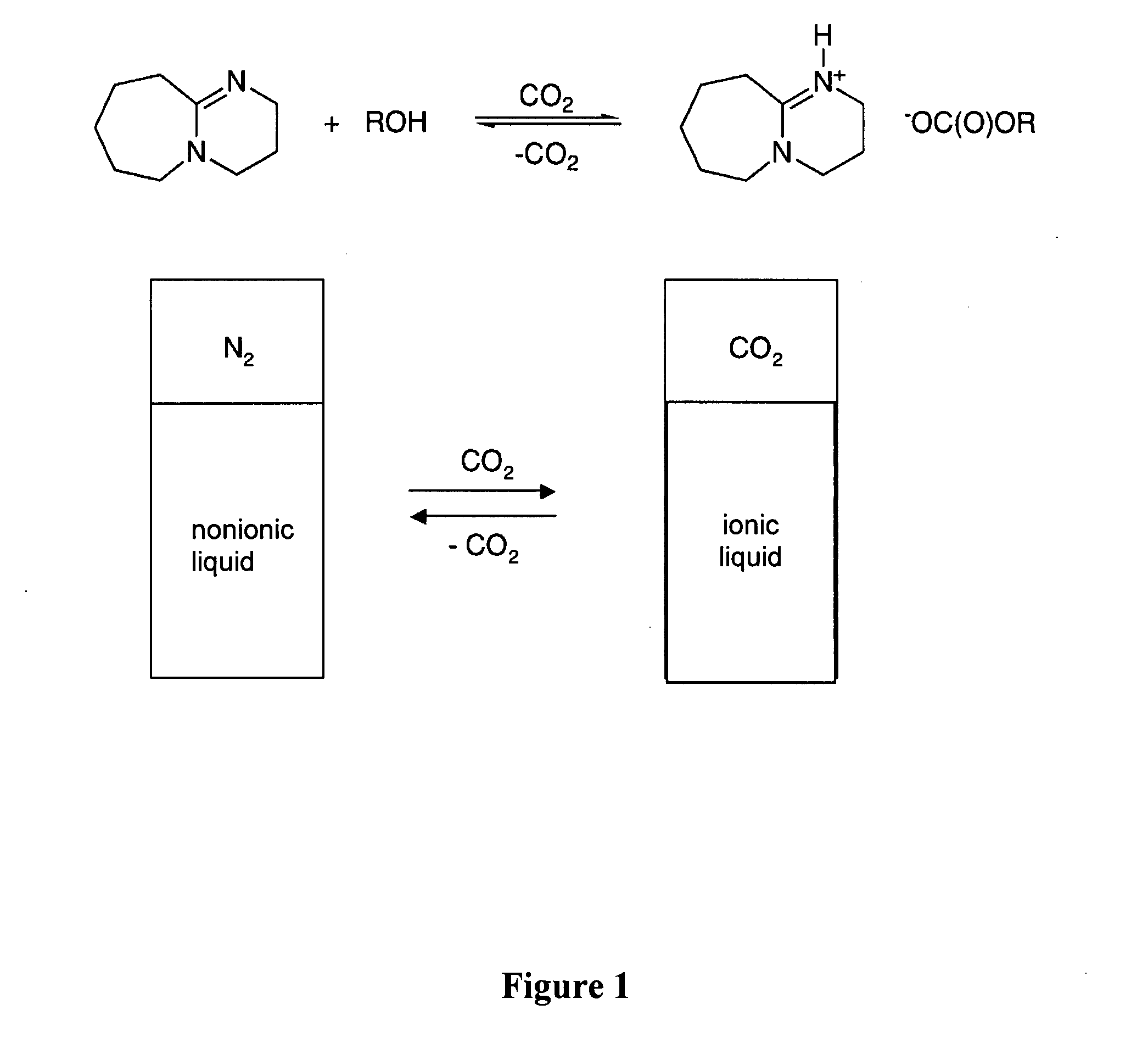

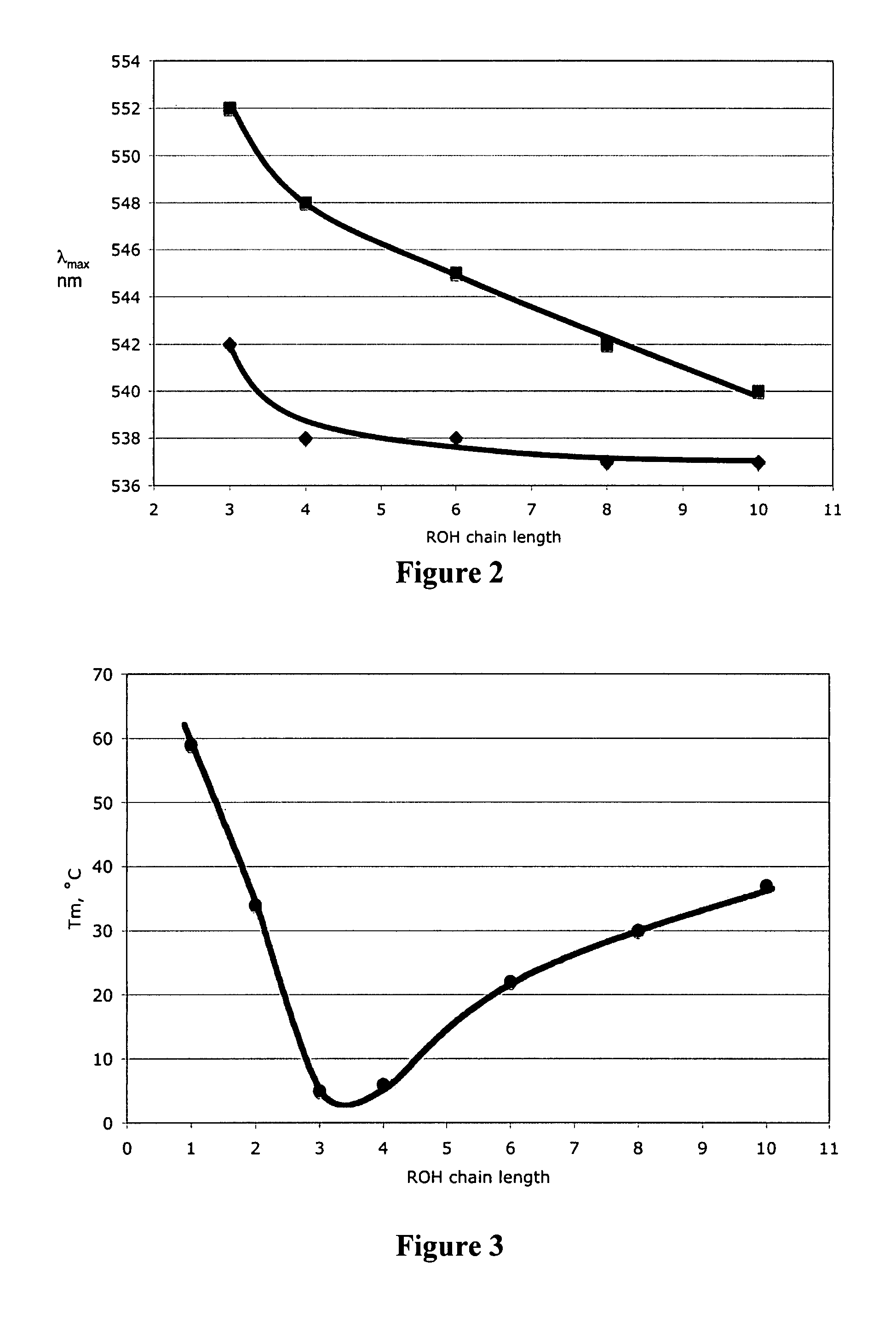

Switchable solvents and methods of use thereof

InactiveUS20080058549A1Low viscosityOrganic compounds purification/separation/stabilisationSolvent extractionAlcoholNon ionic

A solvent that reversibly converts from a nonionic liquid mixture to an ionic liquid upon contact with a selected trigger, e.g., contact with CO2, is described. In preferred embodiments, the ionic solvent is readily converted back to the nonionic liquid mixture. The nonionic liquid mixture includes an amidine or guanidine or both, and water, alcohol, or a combination thereof. Single component amine solvents that reversibly convert between ionic and non-ionic states are also described. Some embodiments require increased pressure to convert; others convert at 1 atmosphere.

Owner:GEORGIA TECH RES CORP +1

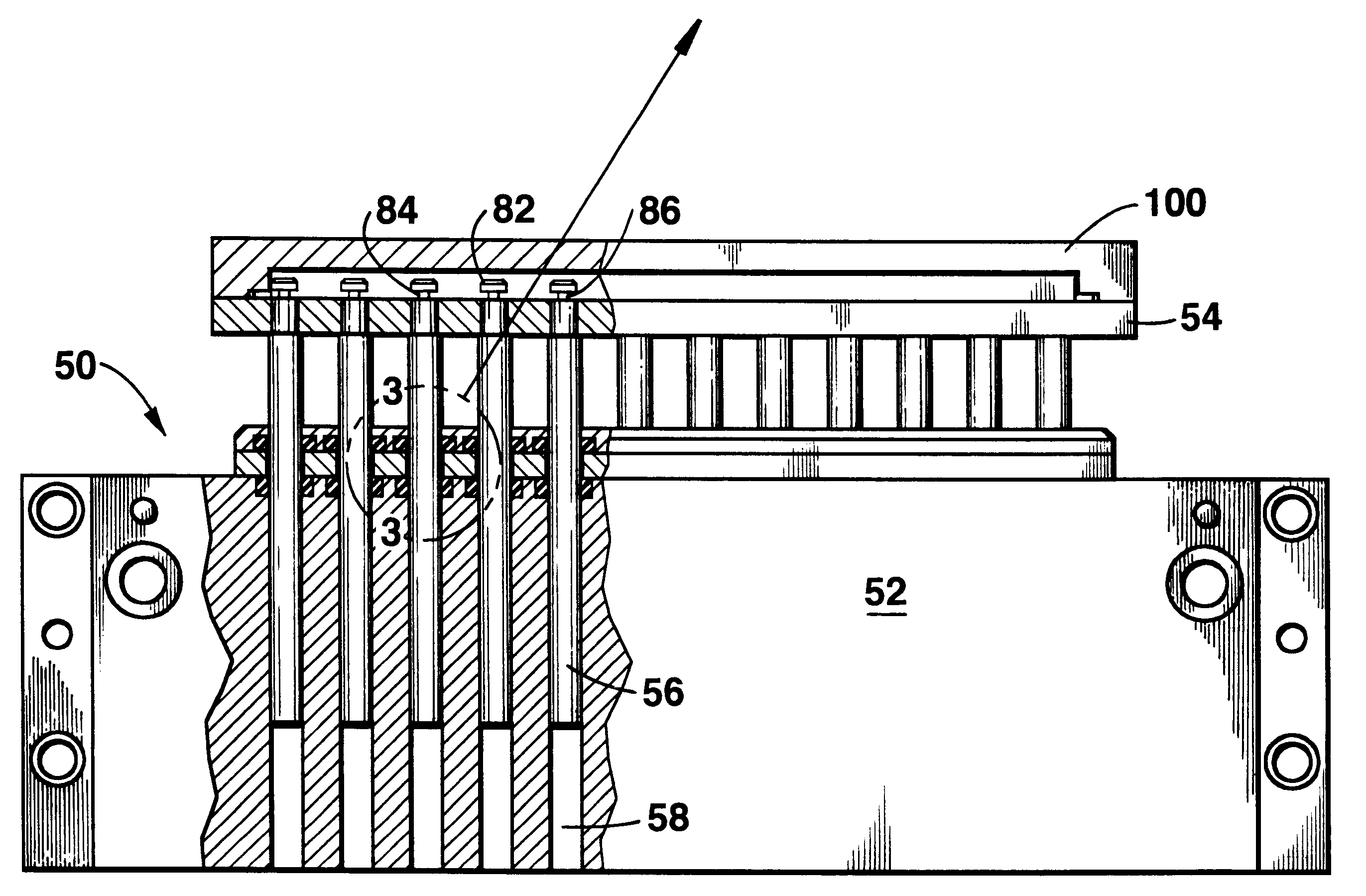

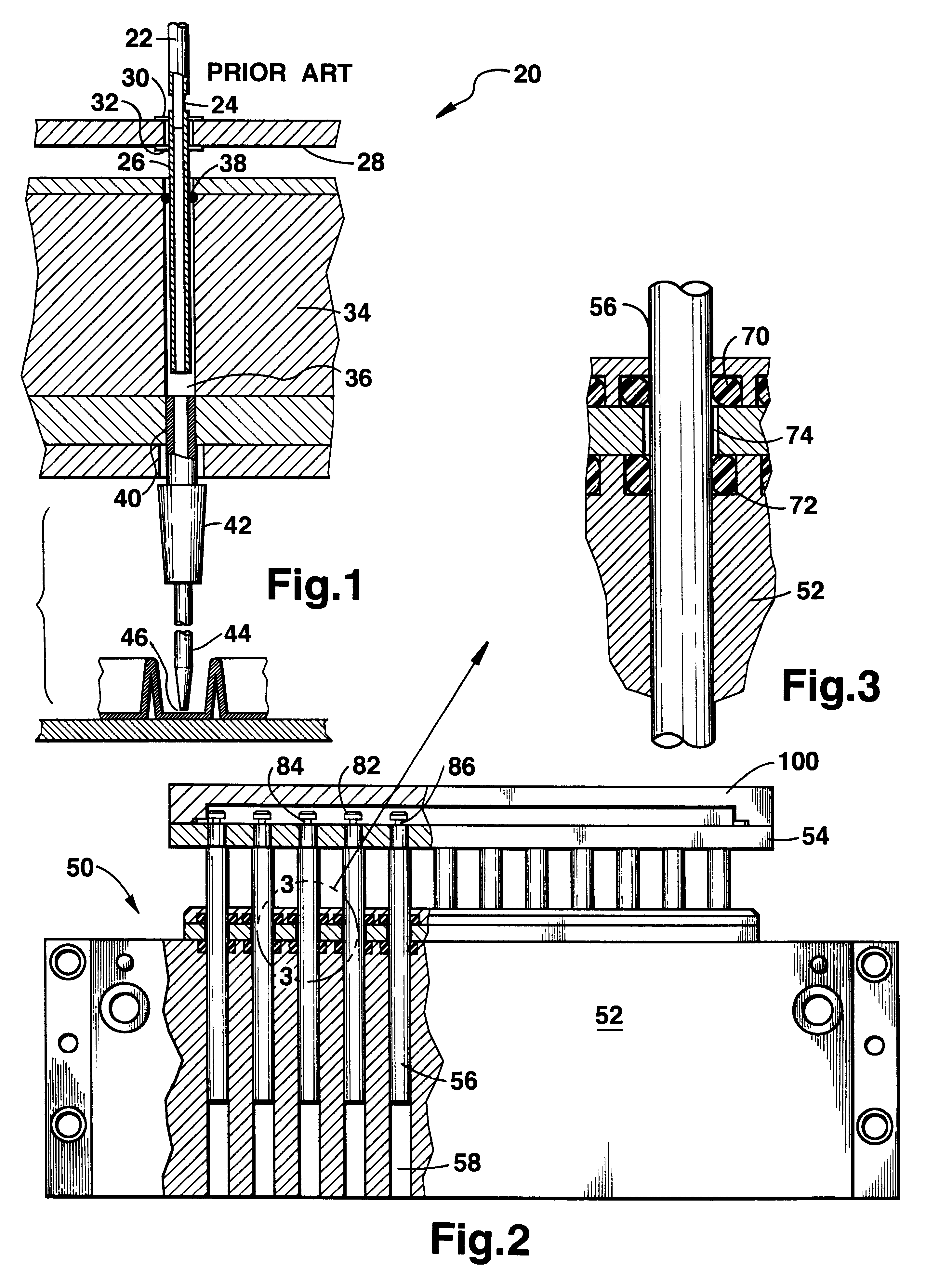

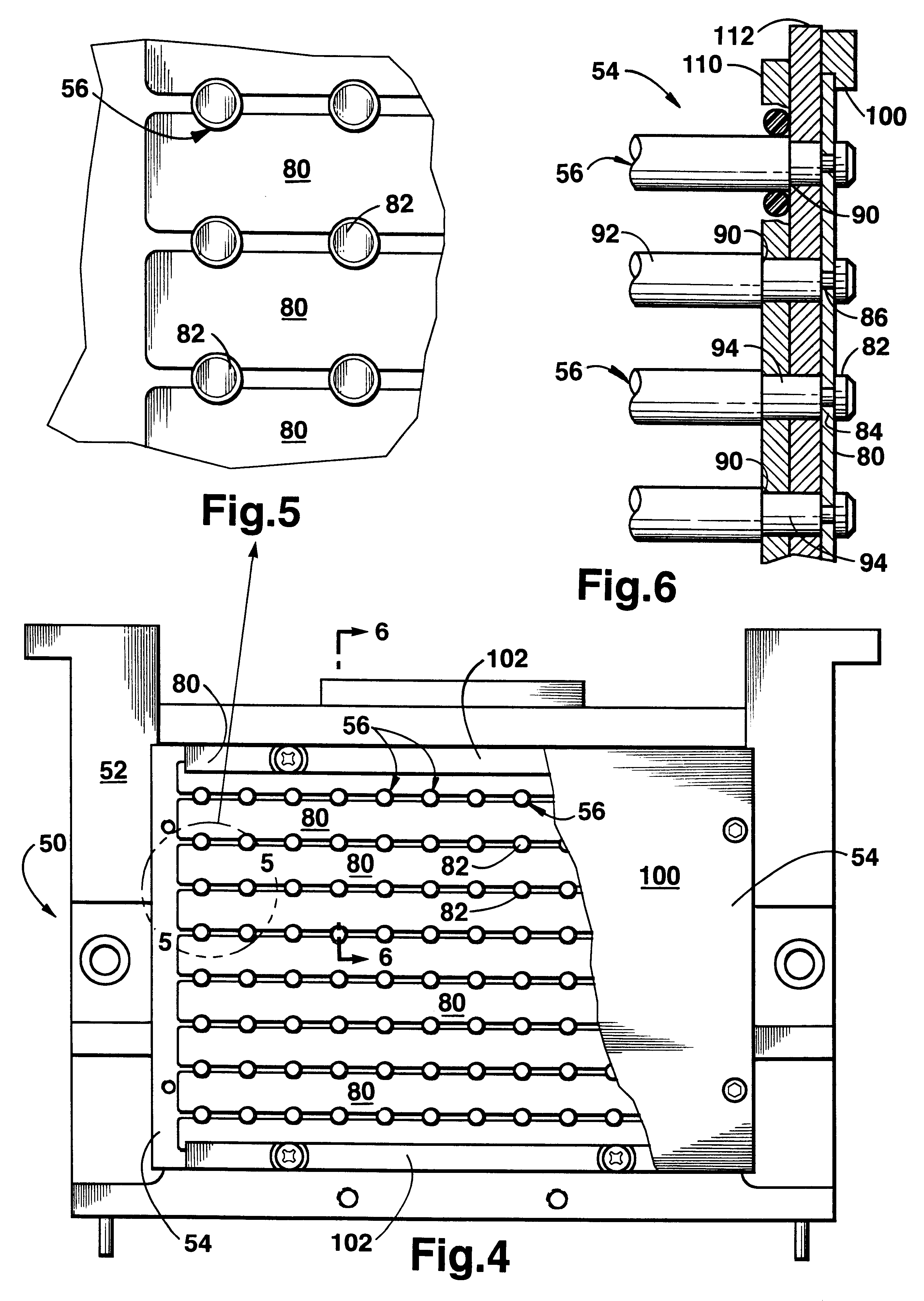

Pipette dispensing block

InactiveUS6258324B1Improve sealingResilient and long lastingWithdrawing sample devicesBurettes/pipettesPipettePressure difference

A pipette dispensing block has an improved piston seal and lift plate engagement / disengagement means. In a pipette dispensing block where a piston is used to create a pressure differential to aspirate or extract and dispense or eject fluid material, the maintenance of a vacuum or increased pressure is enhanced by a pair of O-ring seals engaging the piston. A reservoir separates the O-rings and is filled with a low vapor pressure lubricant such as silicone oil or grease. The lubricant is maintained in the reservoir by the O-rings and serves to enhance the vacuum seal while maintaining the O-rings in a pliable and resilient manner. The heads of the pistons are engraved or grooved to leave a circular central pillar surrounded above and below by the piston head and a lower intermediate piston pillar section. The individual pistons are arranged in straight rows so that a slat may slip through opposite pairs of opposing piston pillars thereby entrapping the pistons and preventing them from sliding past the lift plate as the lift plate is lifted upwardly. Shoulders present on the pistons below the lift plate serve to allow the lift plate to push the pistons into the cylindrical chambers of the head block so that a pipette dispenser is provided. The lift plate or portions thereof are then trapped between the slats and the piston shoulders, coupling the pistons to the lift plate. Upward and downward control is thereby established and maintained by the lift plate on the pistons.

Owner:SS8 NETWORKS

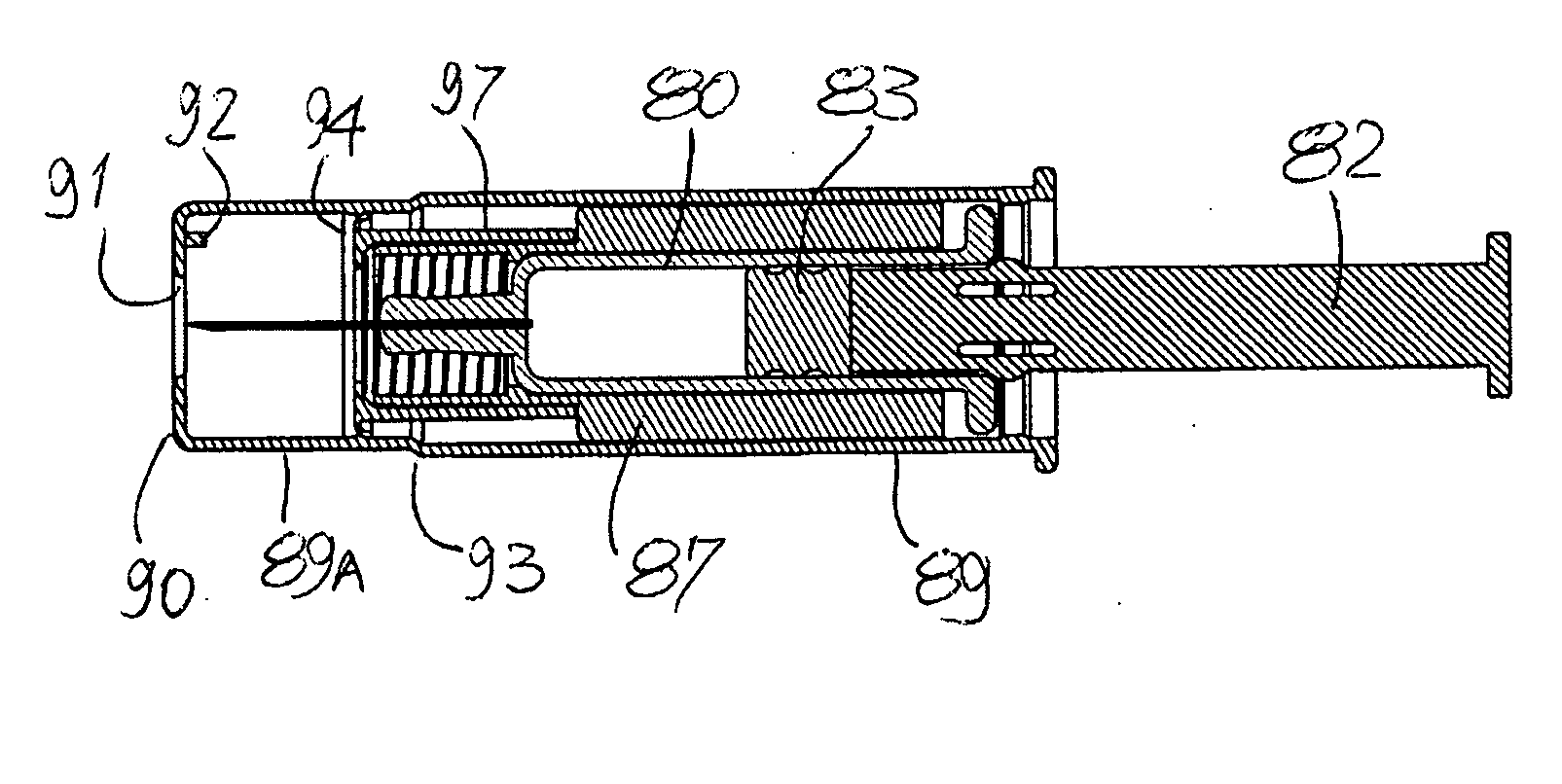

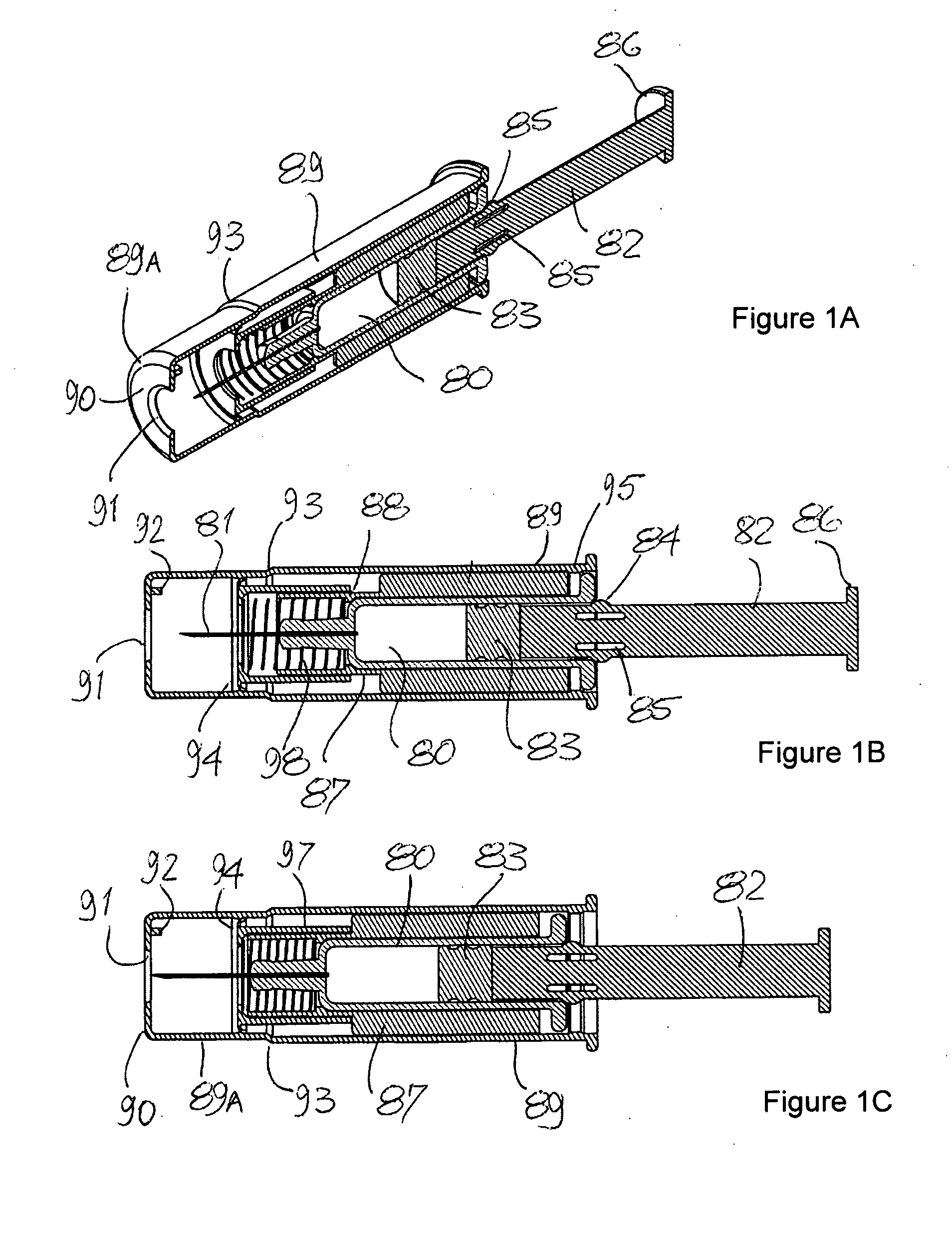

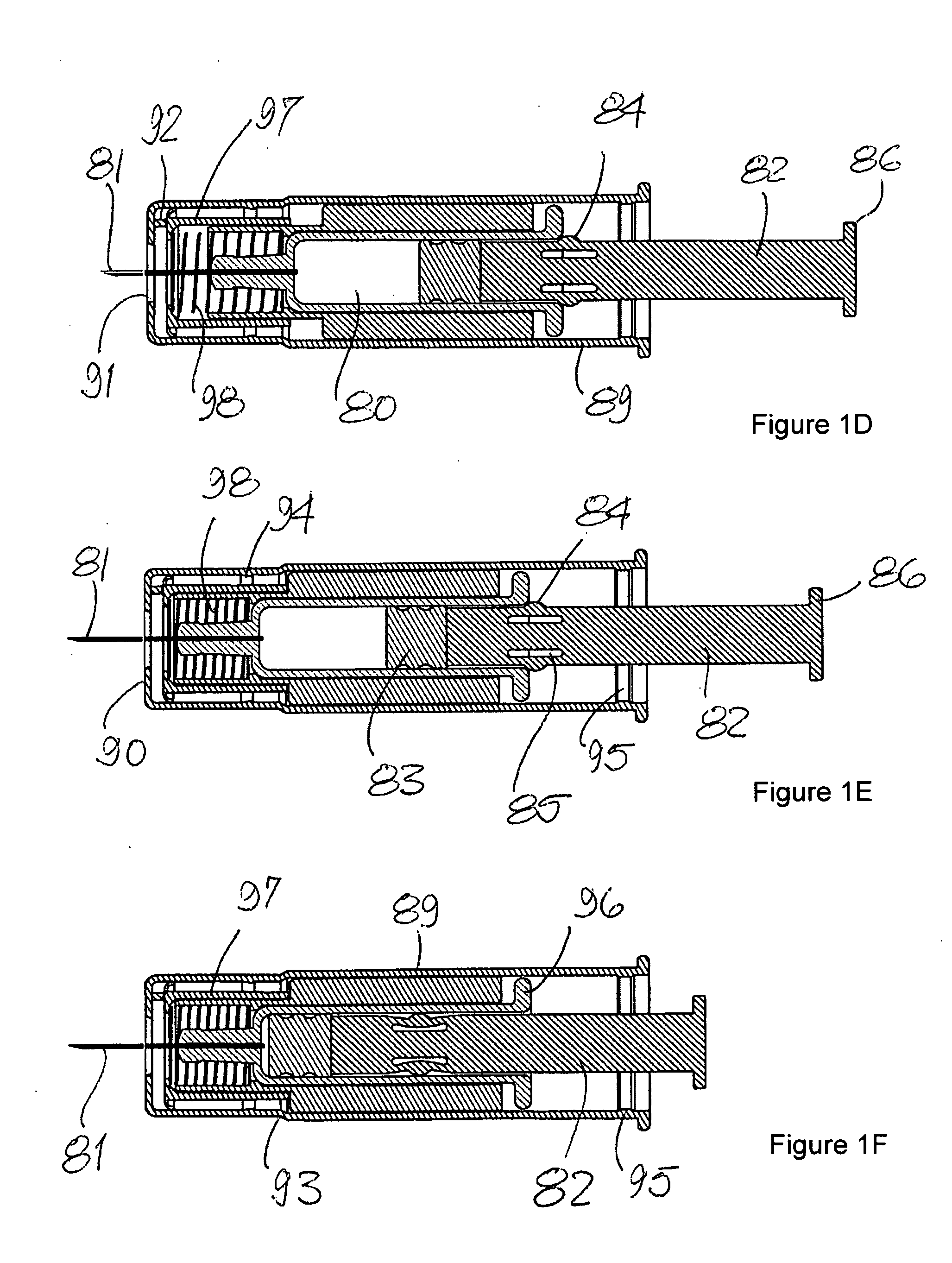

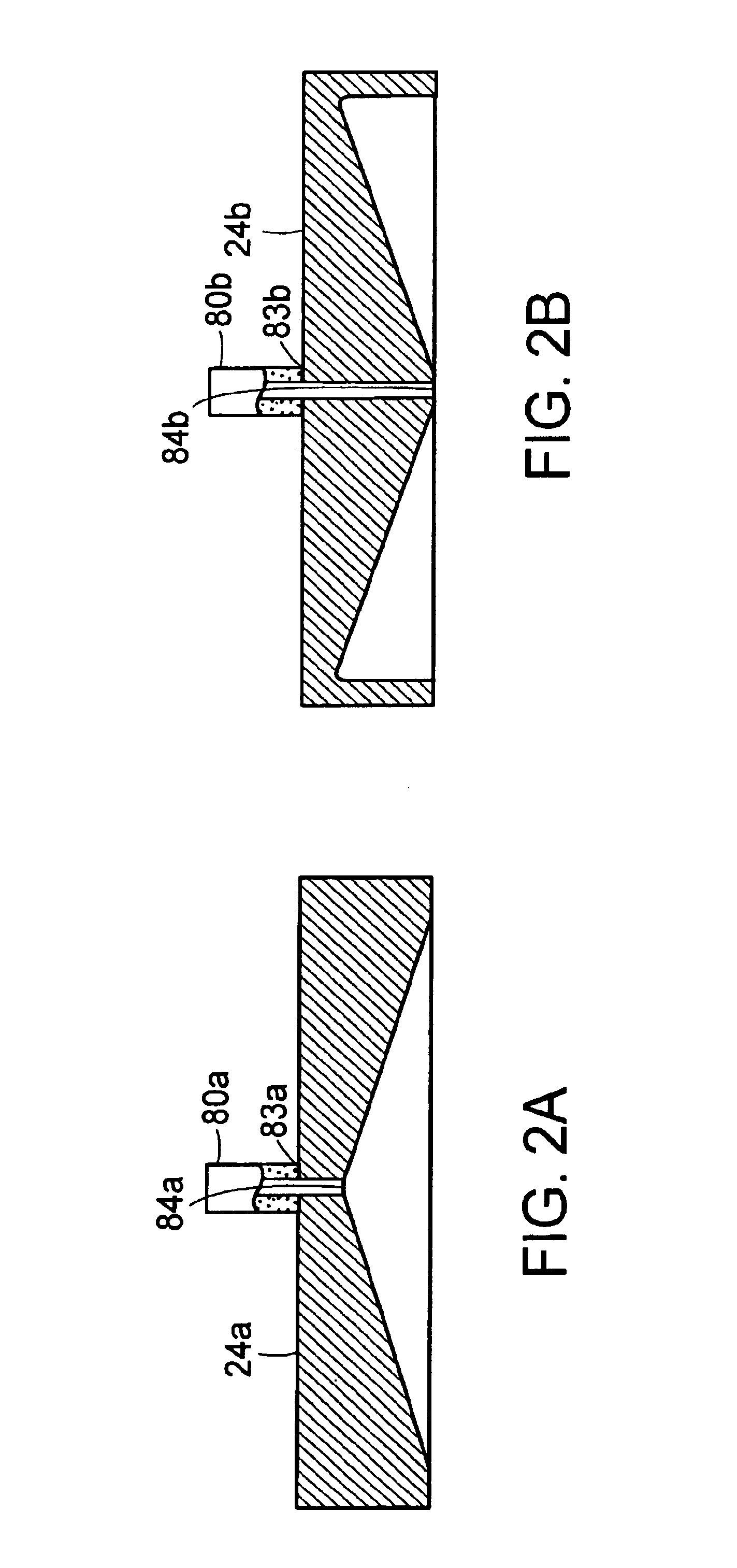

Medical Injector

InactiveUS20090204076A1Accurate sortingInfusion syringesInfusion needlesBiomedical engineeringPlunger

A medical injector has a syringe body 80 with a needle 81 secured at the forward end thereof and a plunger 82 projecting from the rearward end. The plunger 82 is arranged to drive a piston 83 forwardly into the syringe body 80 to dispense medicament through the needle. A safety device for the syringe includes a sleeve 89 slidably mounted on the syringe and spring loaded to a forward position where the sleeve 89 covers the projecting needle 81. An outwardly directed protuberance 84 is disposed partway along the length of the plunger 82 and engageable with the syringe body 80. The protuberance 84 is resiliently movable inwardly of the plunger 82 and defines a stop position for the plunger, subsequent increased pressure on the plunger 82 then allowing the plunger to move forwardly to dispense medicament. The protuberance 84 allows proper sequencing of the injector such that the needle 81 may penetrate a patient before medicament is dispensed.

Owner:LIVERSIDGE BARRY PETER

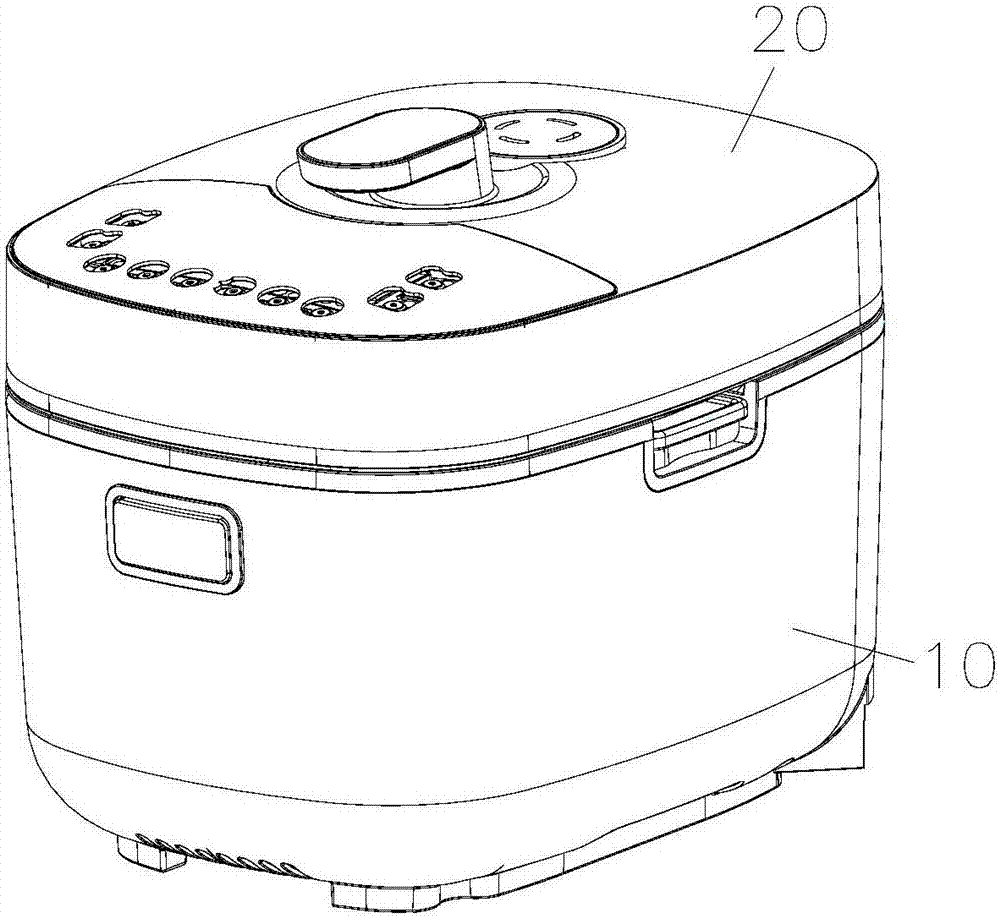

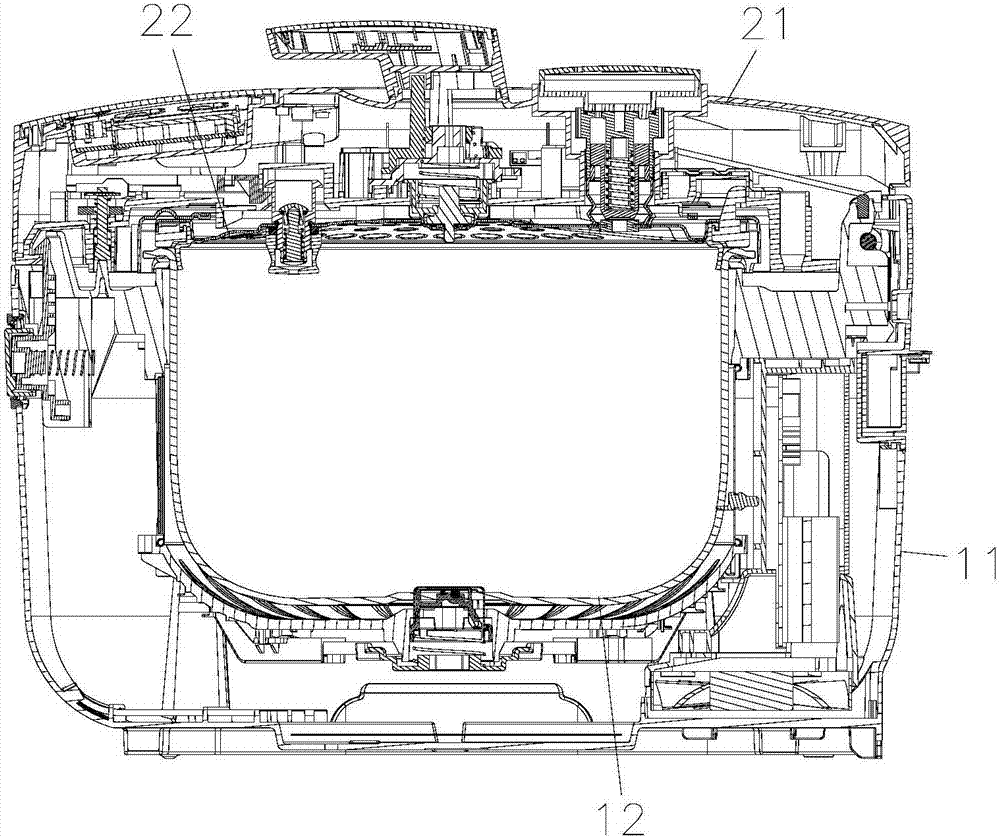

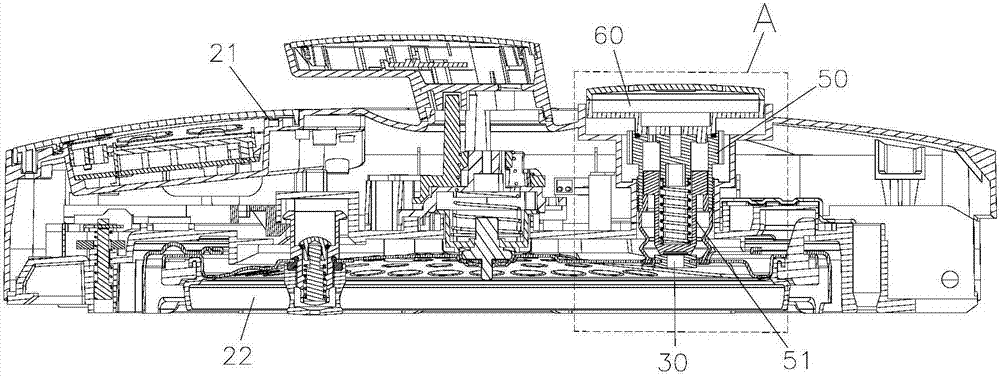

Electric pressure cooker

ActiveCN107019423ASolve the problems of long cooking time and cumbersome operation steps for flavor enhancement and juice collectionEasy to operatePressure-cookersFood processingCooked foodCooker

The invention discloses an electric pressure cooker, which comprises a cooker body, a cooker cover, a pressure limiting valve and a driving mechanism for driving the pressure limiting valve, wherein the cooker body comprises an outer pot and an inner pot which is arranged in the outer pot; the inner pot is used for accommodating cooked foods and a heating piece, which is used for heating the inner pot, is arranged in the outer pot; the cooker cover is arranged on the cooker body; an exhaust mechanism, which communicates with the interior of the inner pot, is arranged on the cooker cover, and diameter of the exhaust passage is within a range from 3.3mm to 30mm; the pressure limiting valve is movably arranged at the upper side of the exhaust passage so as to open or seal the exhaust passage; the inner pot is heated by the heating piece and the pressure limiting valve, which is driven by virtue of the driving mechanism, is used for sealing the exhaust passage so as to increase pressure in the inner pot and to keep the pressure in the inner pot at a rated pressure when the electric pressure cooker is under a boosting mode; and the inner pot is heated by the heating piece and the pressure limiting valve, which is driven by virtue of the driving mechanism, is used for opening the exhaust passage so as to release the cooking pressure in the inner pot when the electric pressure cooker is under a buck mode. With the application of the technical scheme provided by the invention, problems in the prior art that an electric pressure cooker are long in cooking duration and complex in operating steps of flavoring and thickening are solved.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

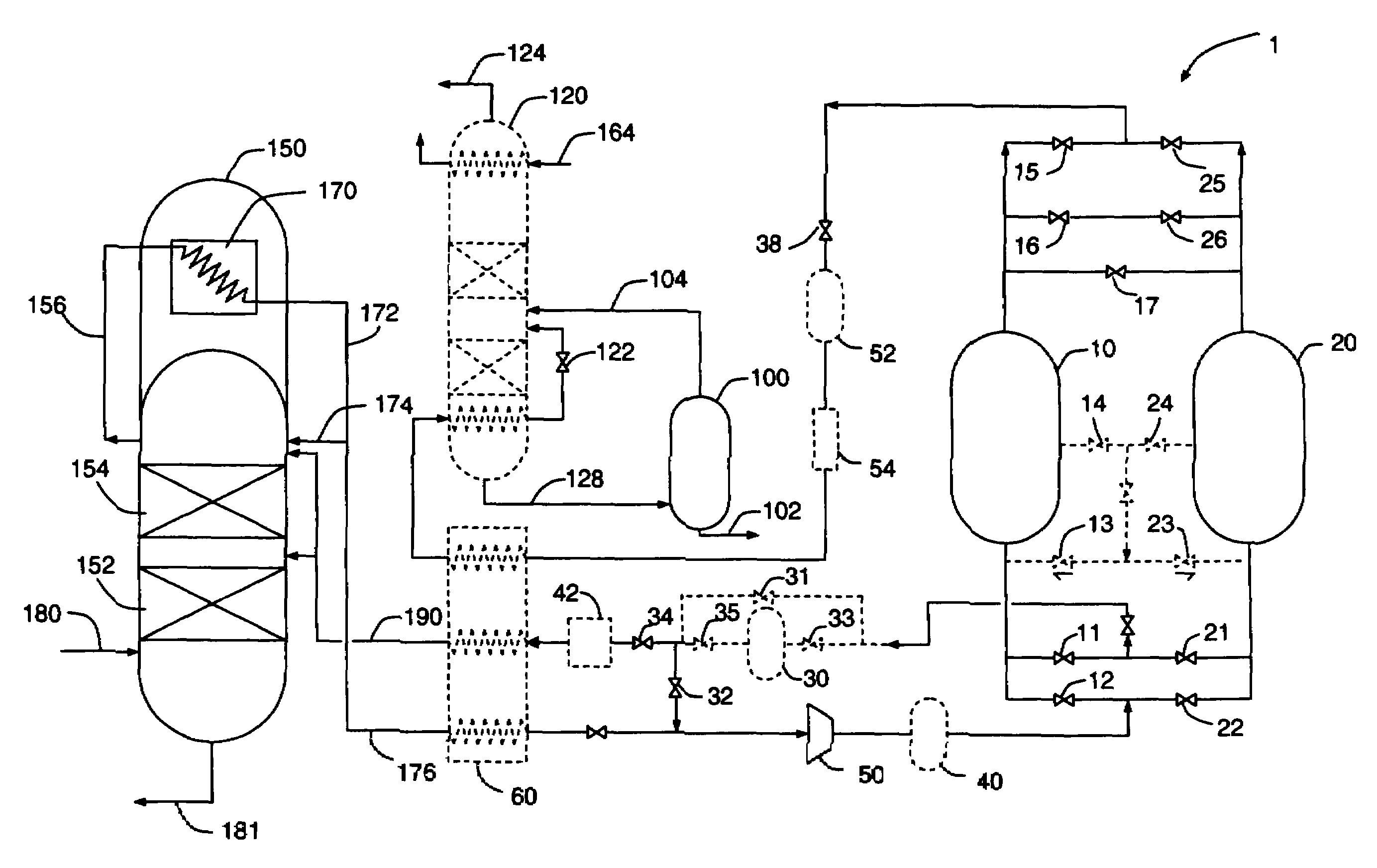

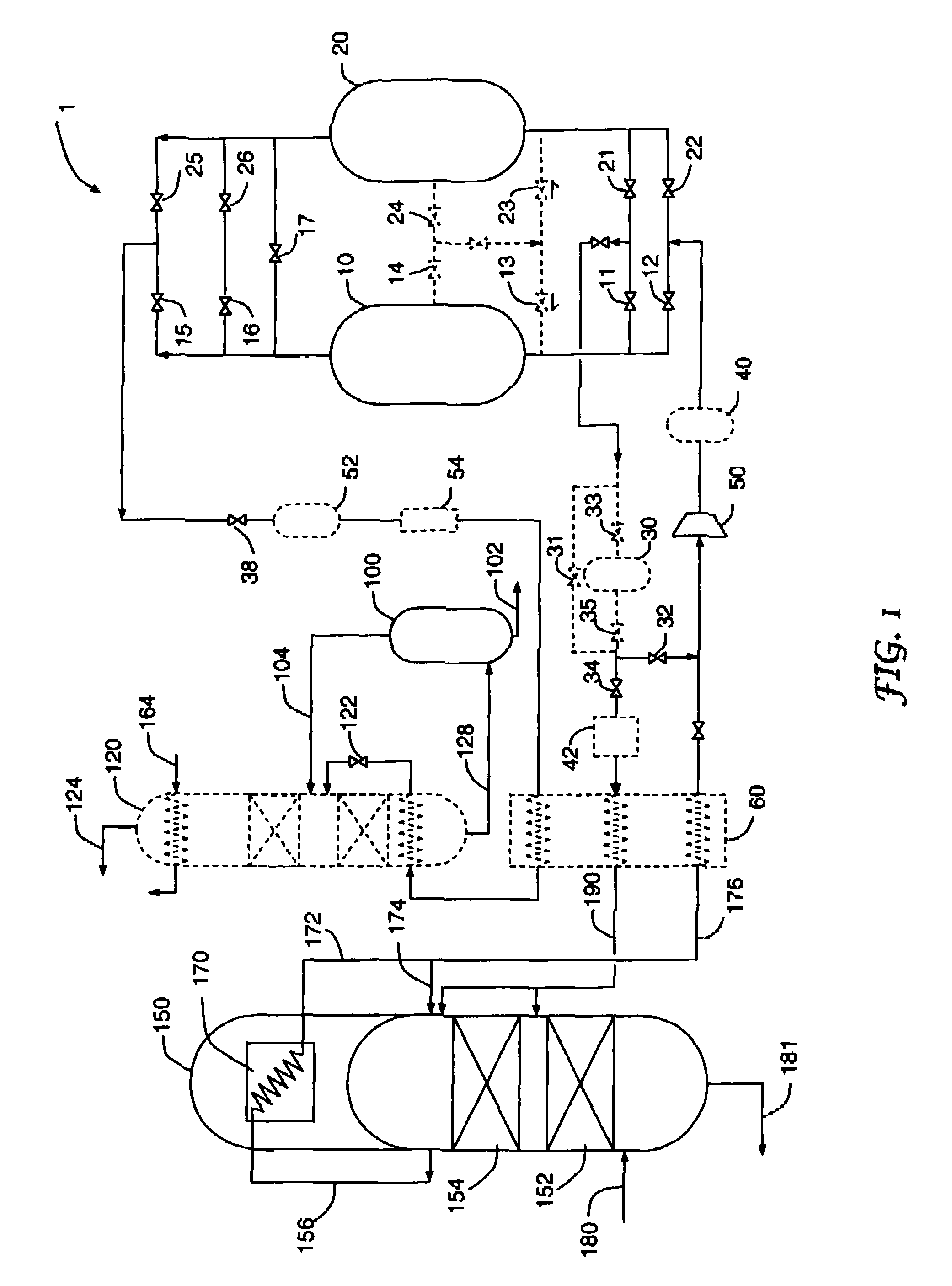

Combined cryogenic distillation and PSA for argon production

ActiveUS7501009B2Improvements in the refining of crude argonSpeed up the processSolidificationLiquefactionParticulatesFiltration

A method and apparatus for producing high purity argon by combined cryogenic distillation and adsorption technologies is disclosed. Crude argon from a distillation column or a so-called argon column is passed to a system of adsorption vessels for further purification. Depressurization gas from adsorption is introduced back, in a controlled manner, to the distillation column and / or a compressor or other means for increasing pressure. Particulate filtration and getter purification may optionally be used.

Owner:AIR PROD & CHEM INC

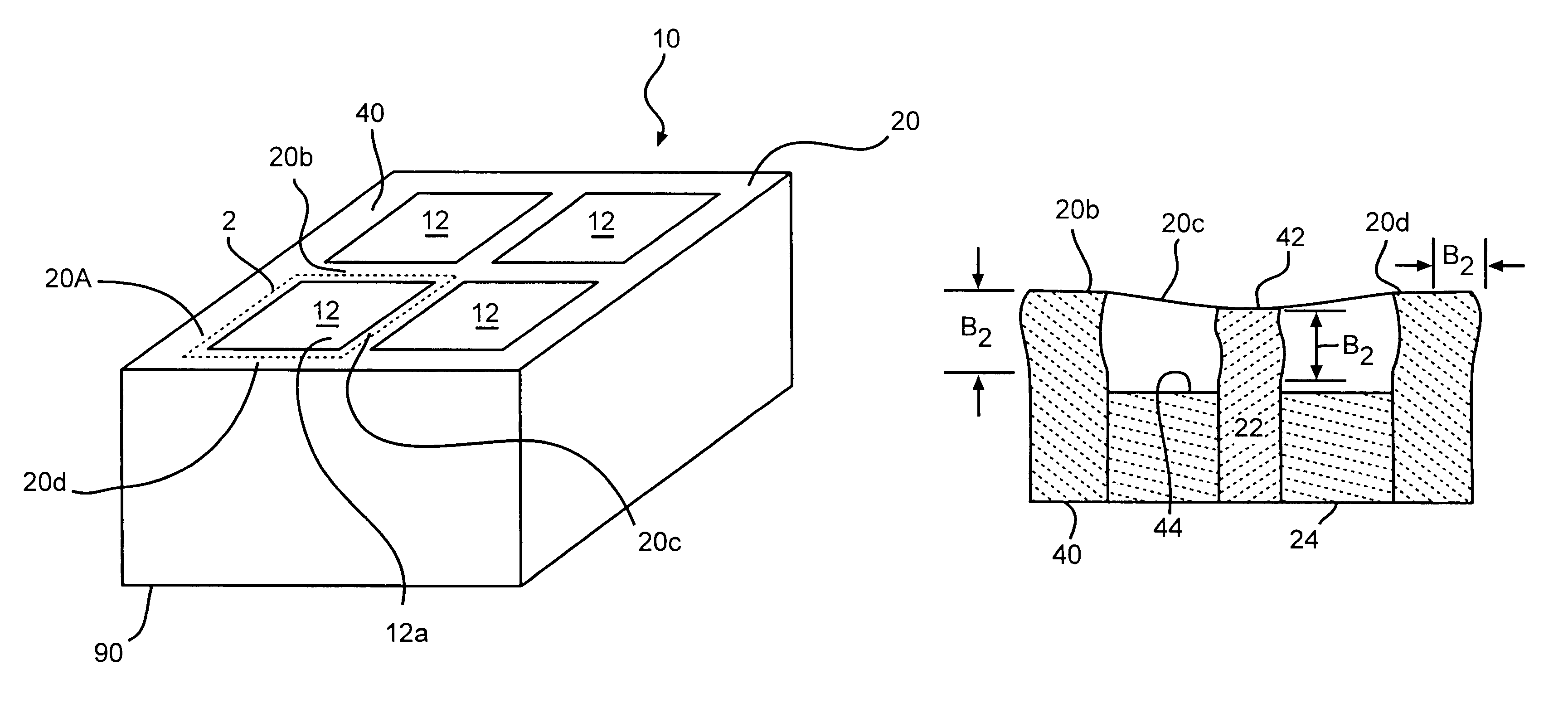

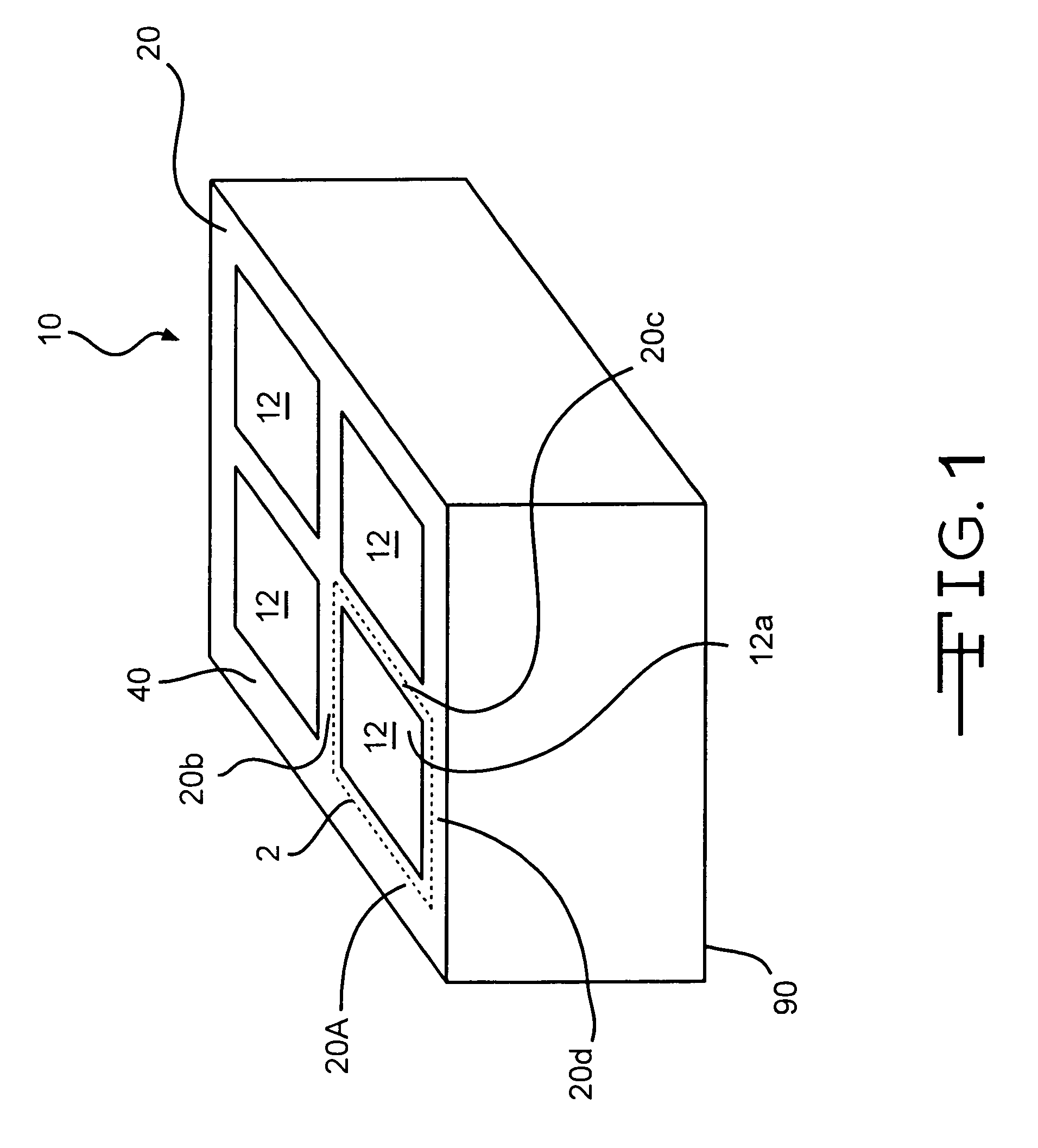

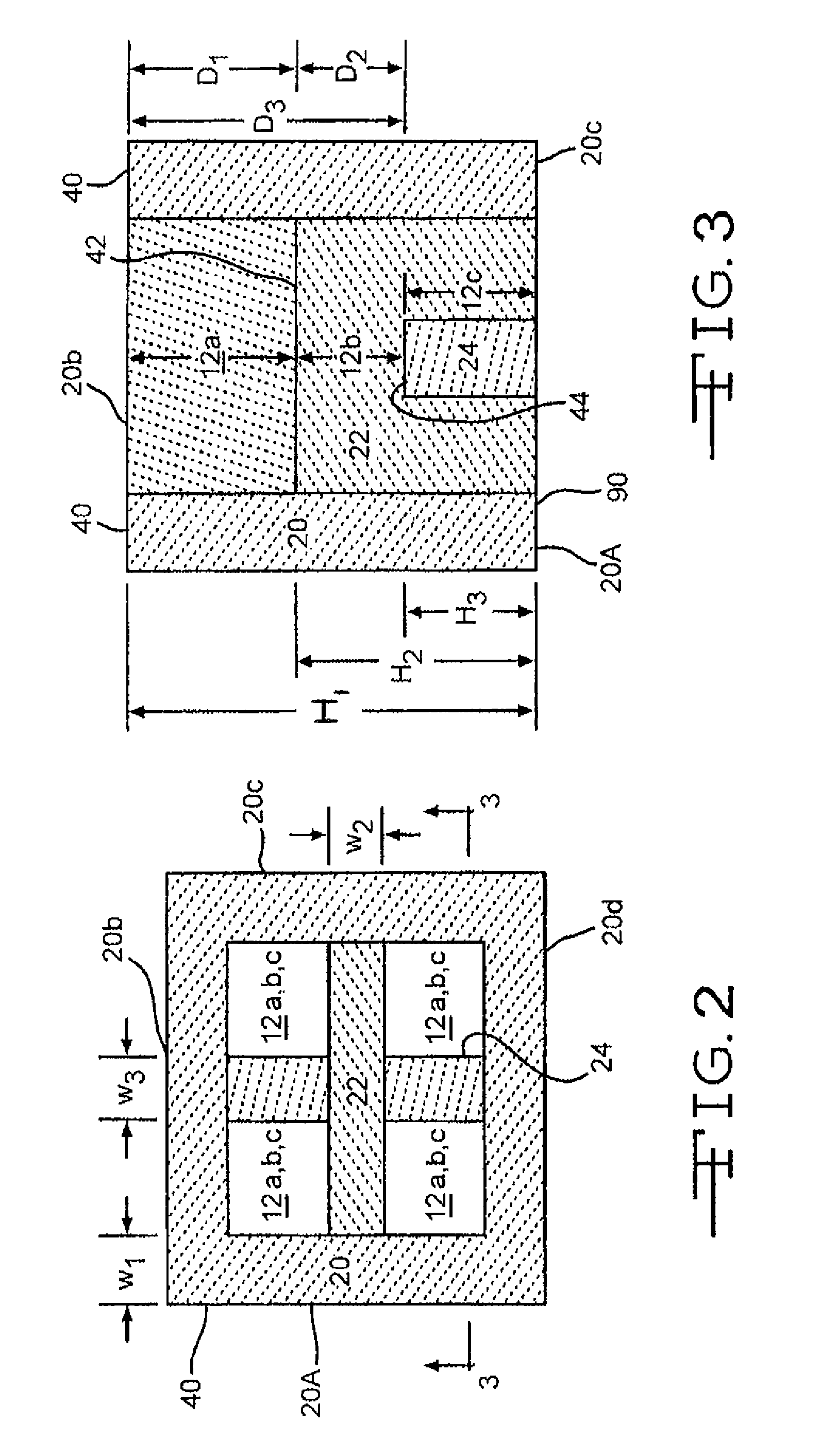

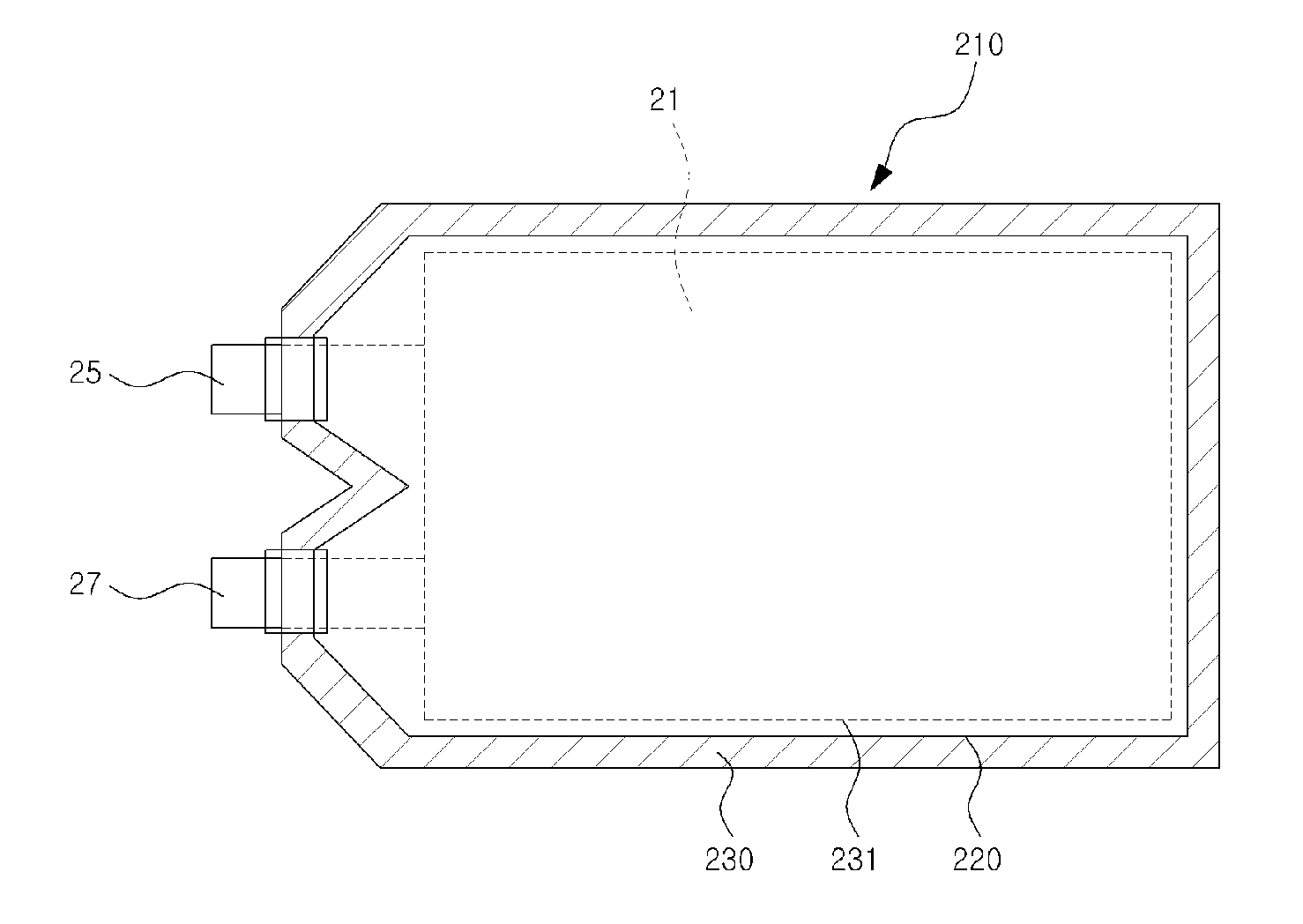

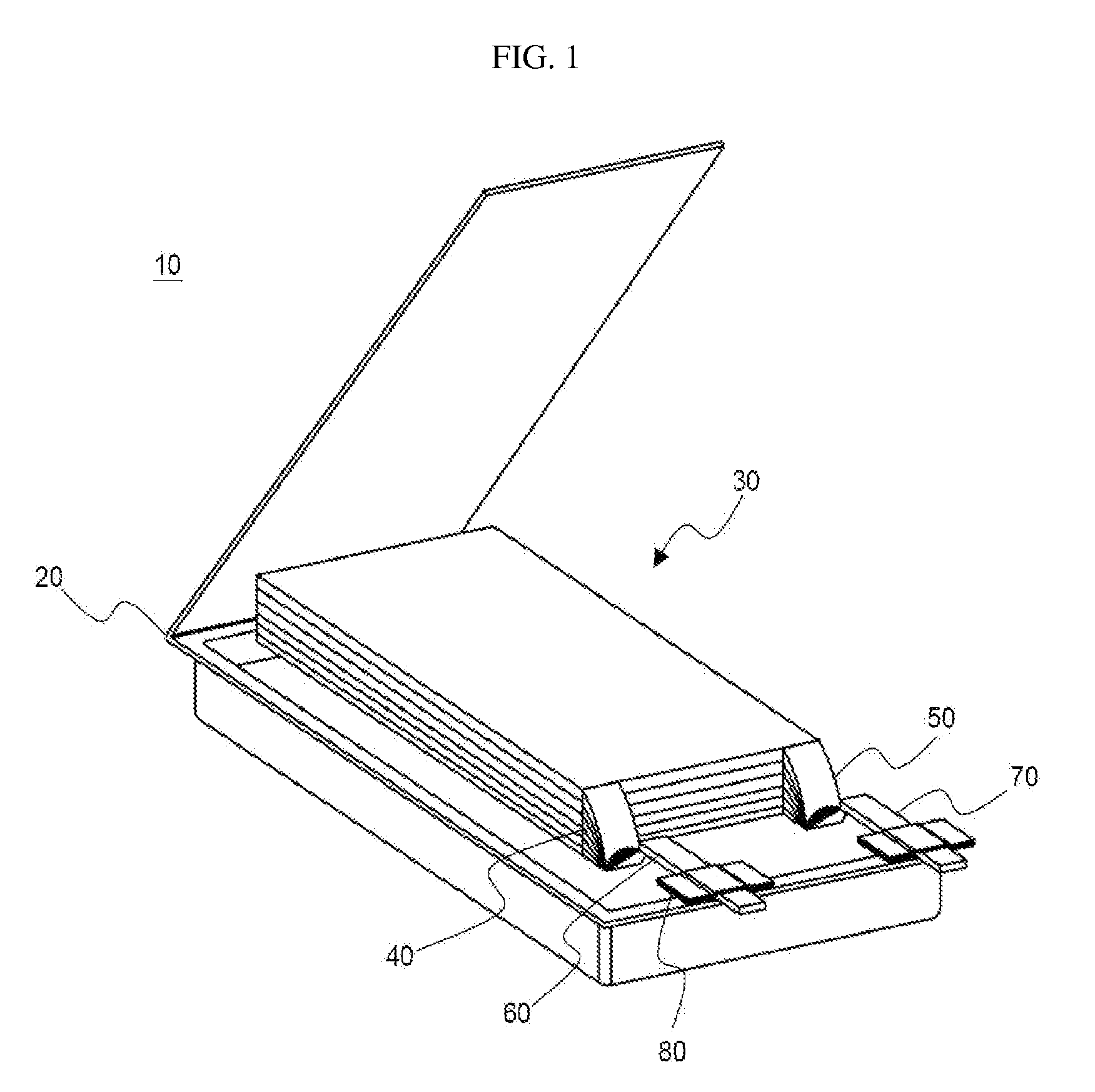

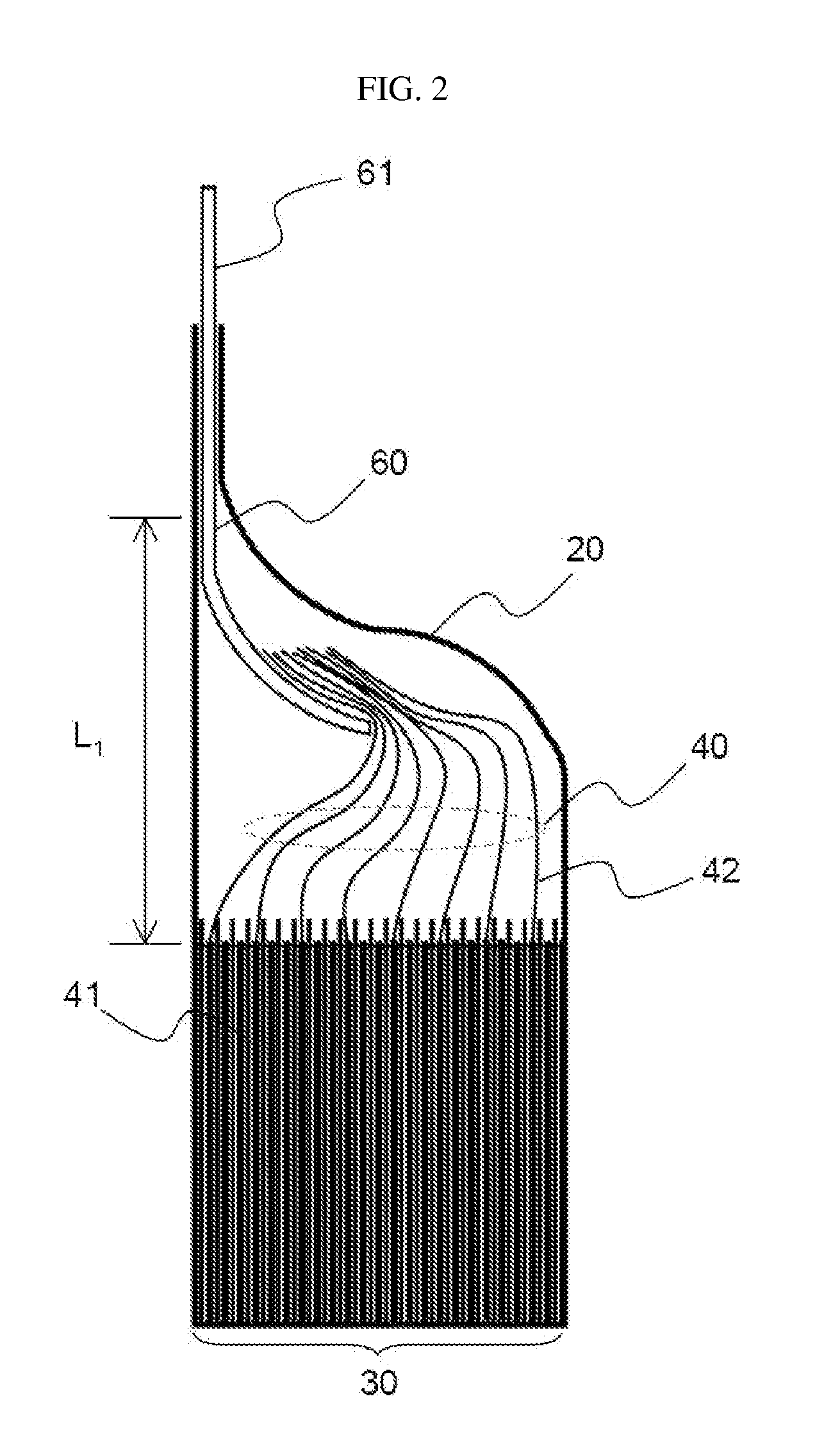

Pouch type case and battery pack including the same

ActiveUS20110274955A1Reduce dead spaceMaximize space utilizationPrimary cell to battery groupingFinal product manufactureEngineeringBattery capacity

The present invention relates to a pouch type case having trimming portions formed on both sides or four corners thereof and a battery pack including the same. The trimming portions are formed on the corners of the pouch type case such that the trimming portions are indented toward an electrode assembly accommodating part to reduce a unit area so as to increase pressure applied to unit cells when a battery pack is assembled, thereby facilitating assembling of the battery pack and increasing cell capacity per unit area. Furthermore, the unit cells can be fixed in the battery pack more stably. The pouch type case reduces the unit area so as to include a relatively large number of cells for pressure applied to the cells when the battery pack is assembled to thereby increase the cell capacity.

Owner:LG ENERGY SOLUTION LTD

Apparatus and method for electroless deposition of materials on semiconductor substrates

InactiveUS6913651B2Simple and compact structureReduce manufacturing costLiquid surface applicatorsSpraying apparatusEngineeringElectroless deposition

An apparatus of the invention has a closable chamber that can be sealed and is capable of withstanding an increased pressure and high temperature. The chamber contains a substrate holder that can be rotated around a vertical axis, and an edge-grip mechanism inside the substrate holder. The deposition chamber has several inlet ports for the supply of various process liquids, such as deposition solutions, DI water for rinsing, etc., and a port for the supply of a gas under pressure. The apparatus is also provided with reservoirs and tanks for processing liquids and gases, as well as with a solution heater and a control system for controlling temperature and pressure in the chamber. The heater can be located outside the working chamber or built into the substrate holder, or both heaters can be used simultaneously. Uniform deposition is achieved by carrying out the deposition process under pressure and under temperature slightly below the boiling point of the solution. The solution can be supplied from above via a shower head formed in the cover, or through the bottom of the chamber. Rinsing or other auxiliary solutions are supplied via a radially moveable chemical dispensing arm that can be arranged above the substrate parallel thereto.

Owner:LAM RES CORP

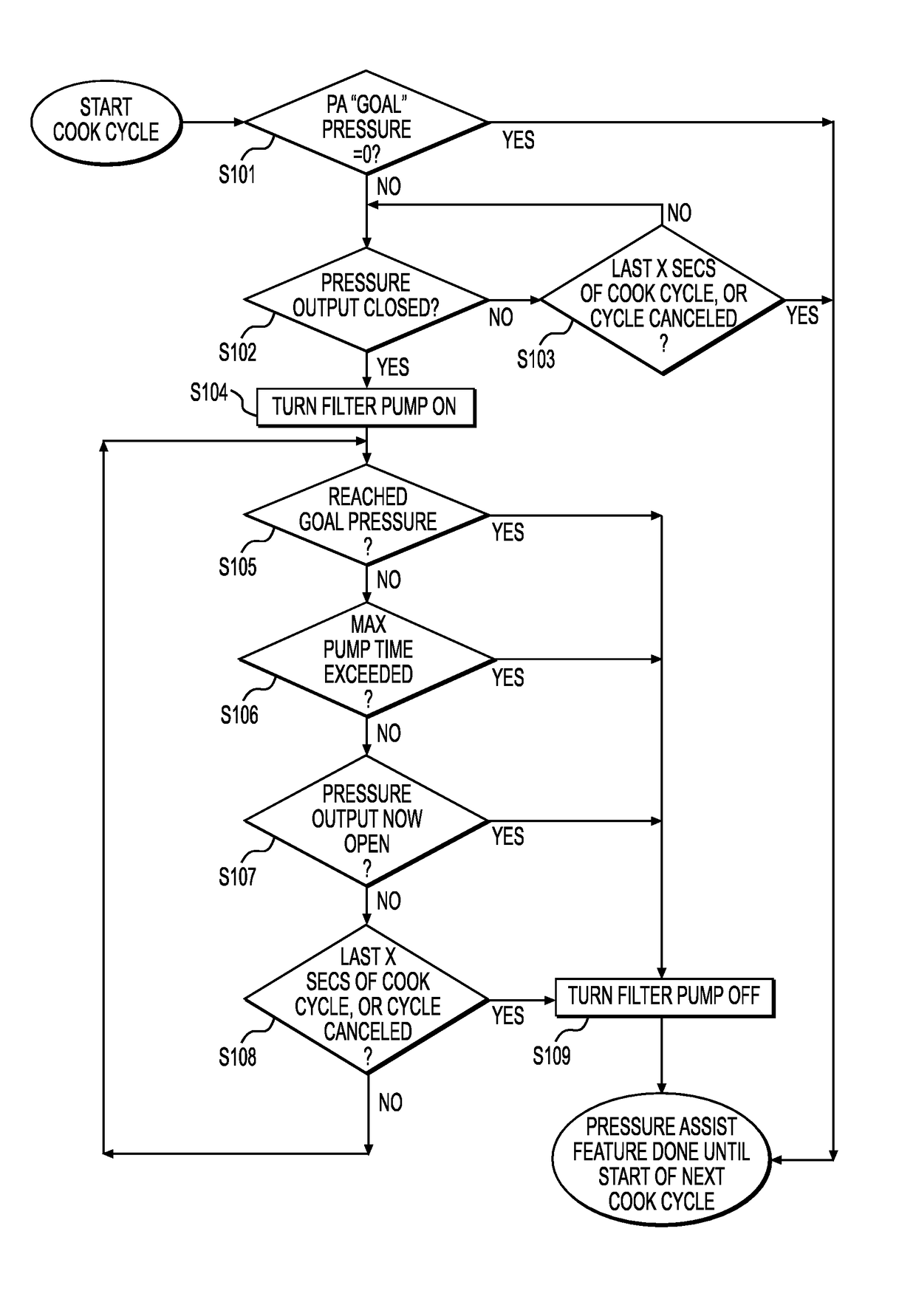

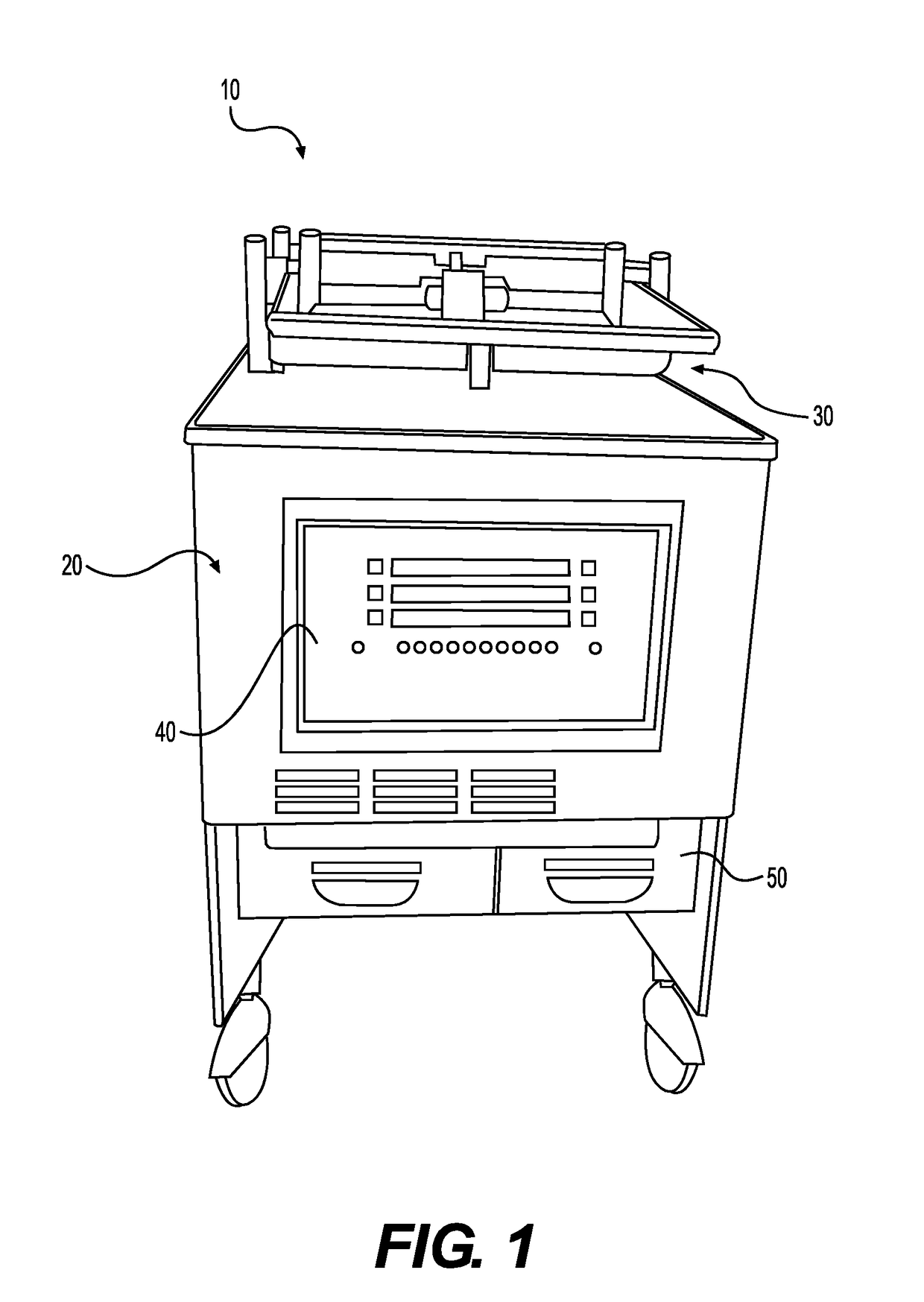

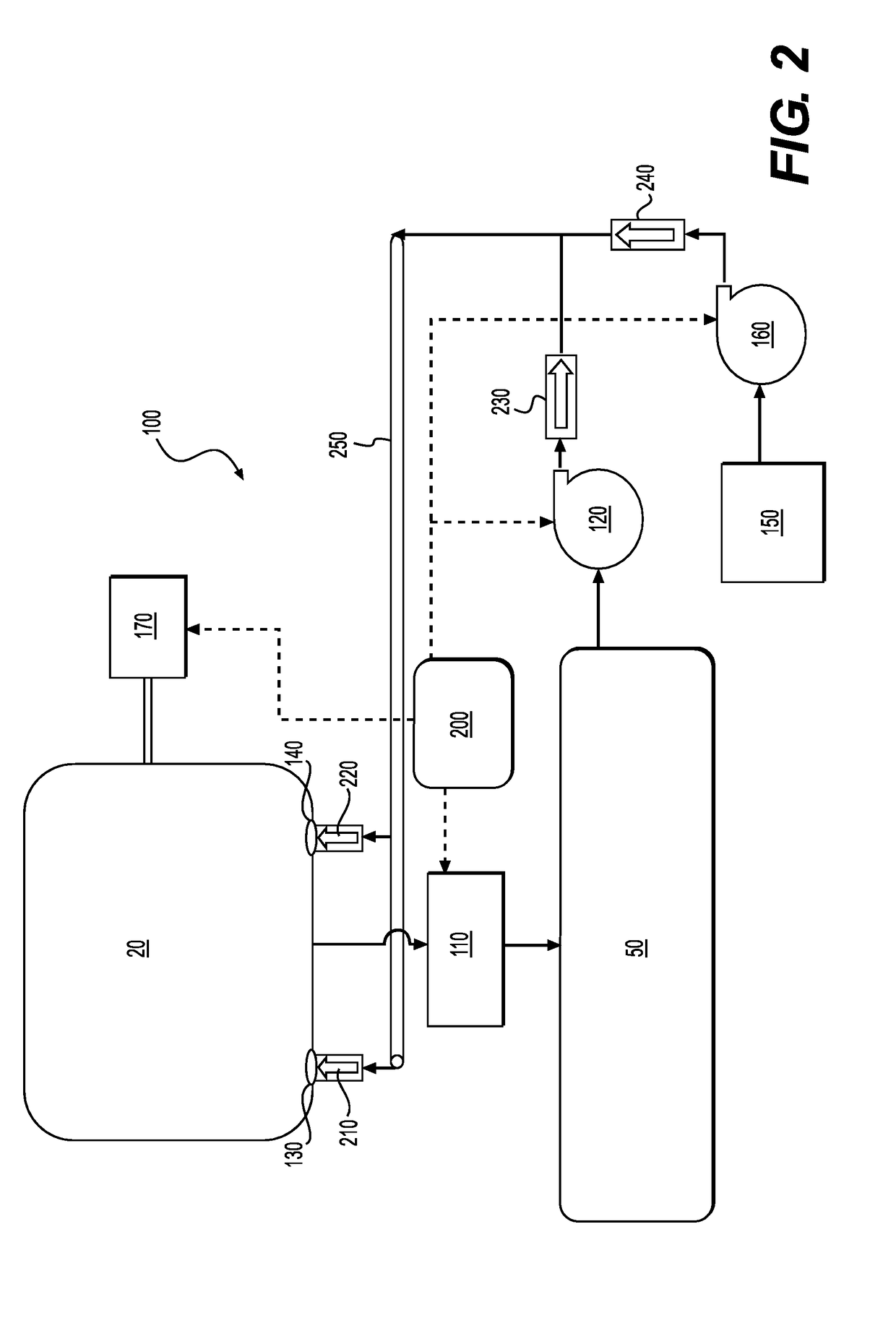

Pressure assist feature for pressure fryer

Methods and systems disclosed herein may be methods for rapidly increasing pressure in a pressure fryer cooking vessel during a cooking cycle. Such methods and systems may comprise determining whether a pressure output in the cooking vessel is closed. Such methods and system may also include determining a pressure of the cooking vessel, comparing the pressure of the cooking vessel to a predetermined optimal pressure to determine whether the pressure of the cooking vessel is less than the optimal pressure, and activating a filter pump configured to supply air from a drain pan into the cooking vessel in response to determining that the pressure output is closed and the pressure of the cooking vessel is less than the optimal pressure. Such methods and systems may further include deactivating the filter pump when the pressure within the cooking vessel is equal to or greater than the optimal pressure.

Owner:HENNY PENNY CORP

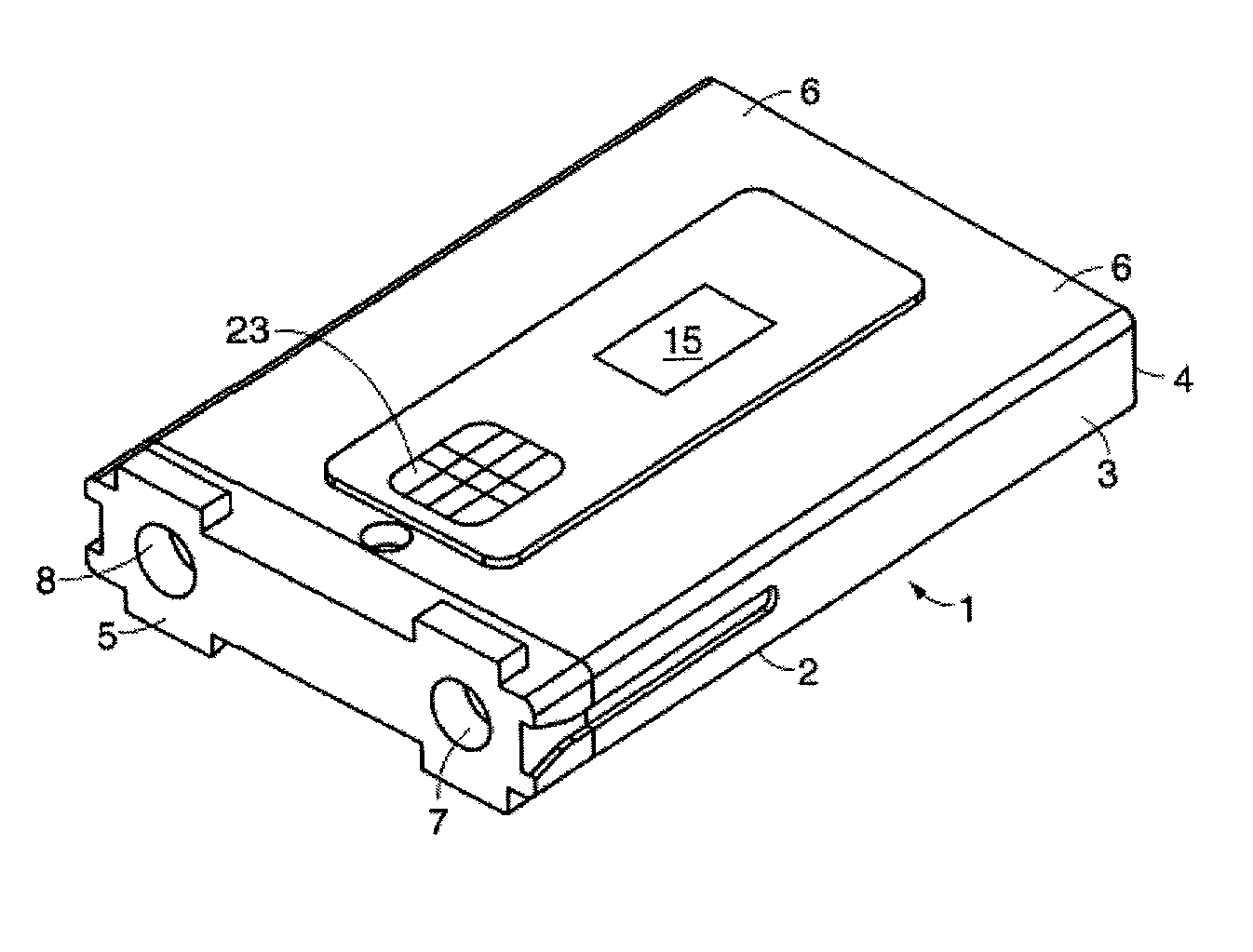

Fluid Separate conduit cartridge

InactiveUS20020155033A1Increase pressurePrevent movementSemi-permeable membranesFixed microstructural devicesCatheterBiomedical engineering

A fluid separation conduit cartridge comprising a fluid separation conduit is disclosed. In certain embodiments the fluid separation conduit is potted to provide operation at increased pressures. In other embodiments, the fluid separation conduit cartridge has one or more memory units. The memory units are operative to store data such as, for example, cartridge usage and test results.

Owner:PROTASIS CORP

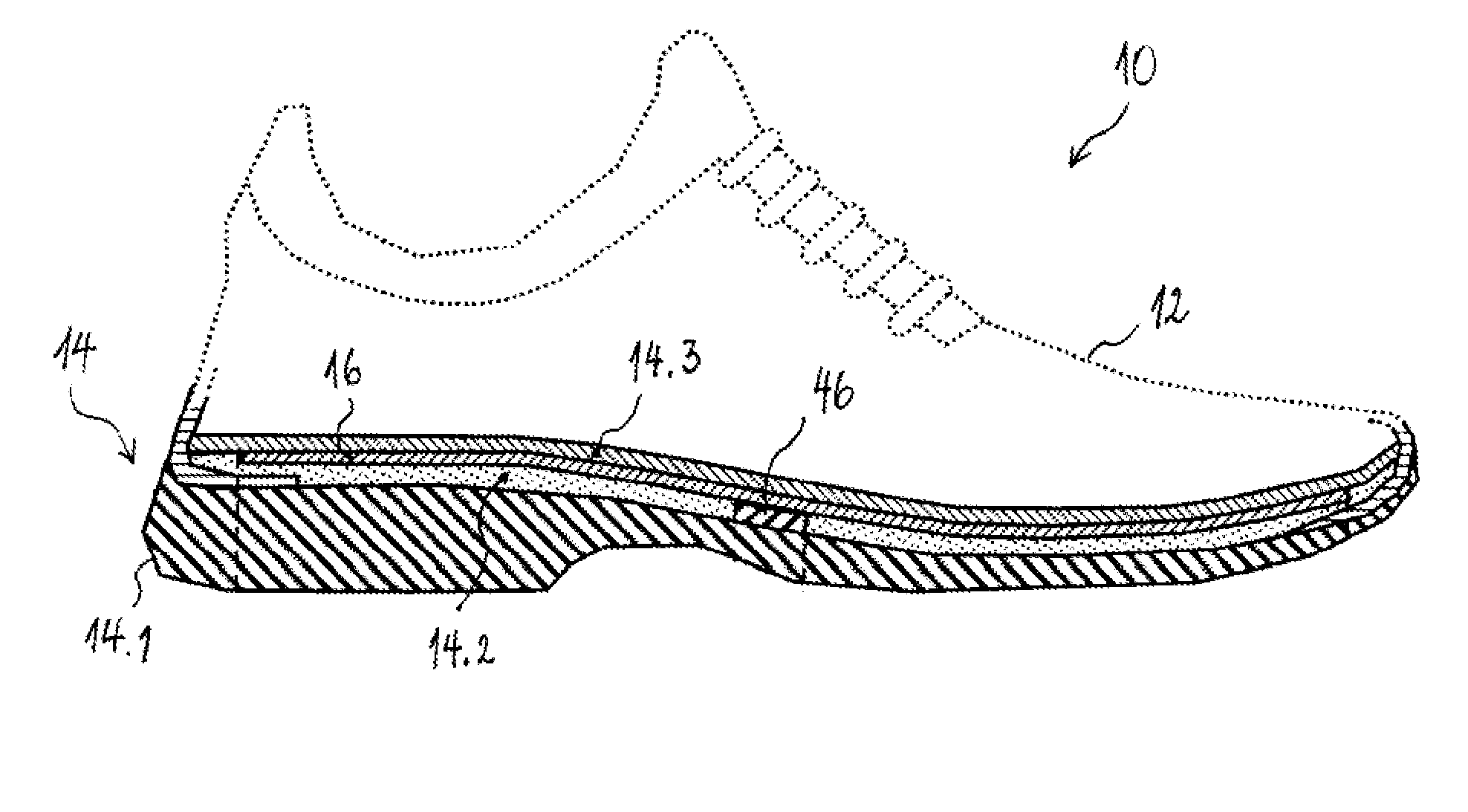

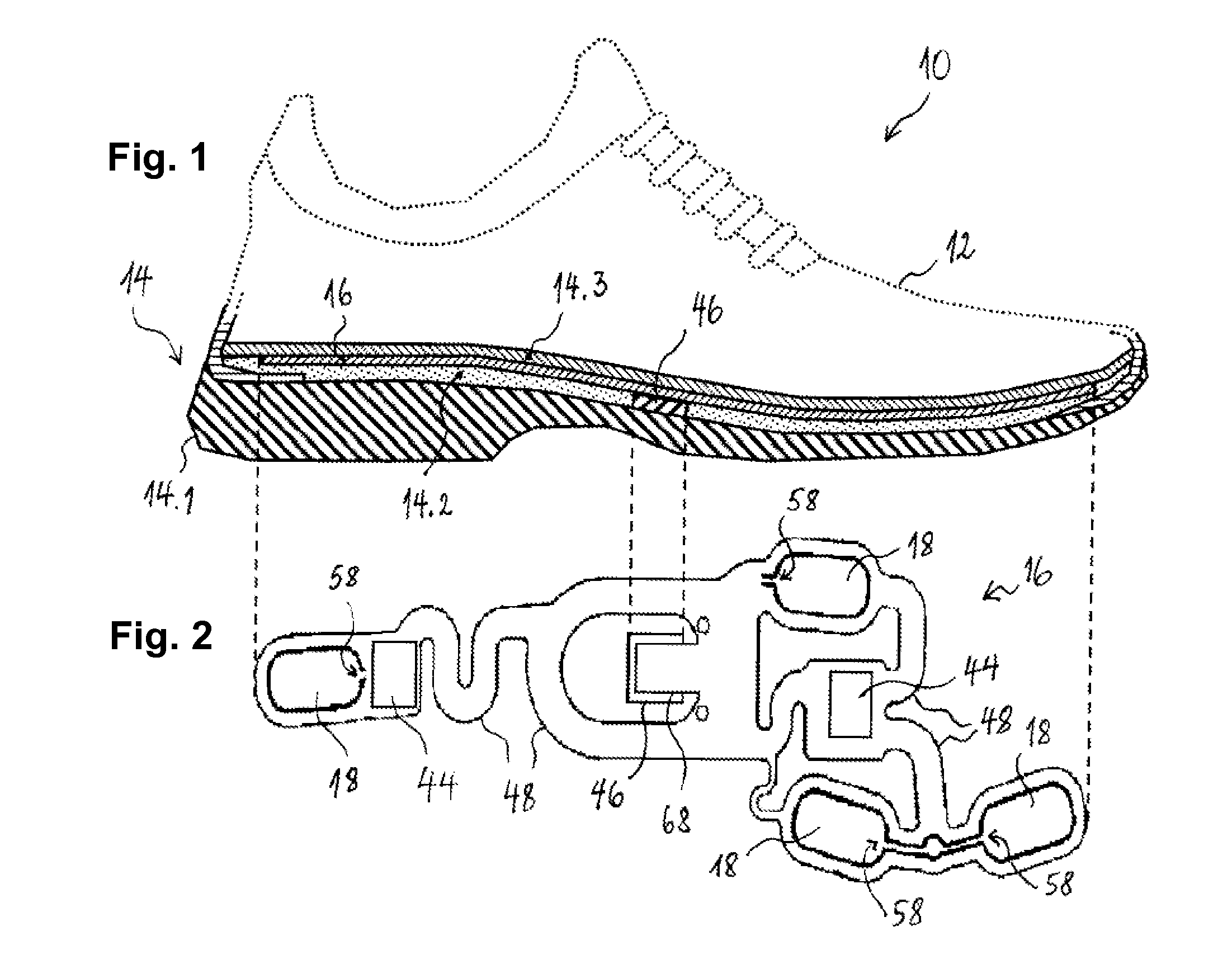

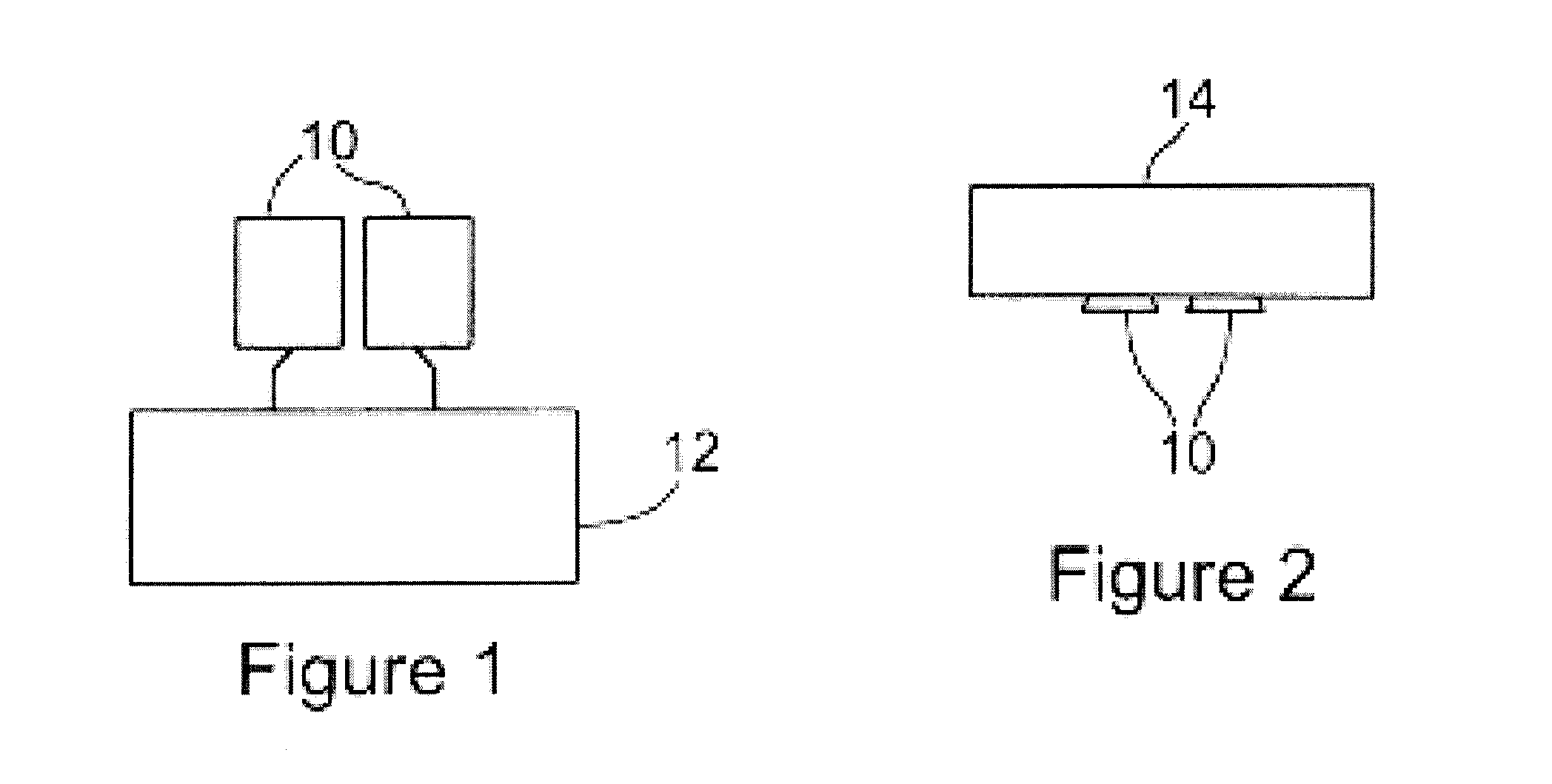

Footwear article with pressure sensor

InactiveUS20140033572A1Flexible adjustmentDifferent sizeSolesForce measurementElectricityEngineering

An article of footwear including a pressure sensor arranged in the sole structure, where the sensor includes elongated pressure-sensing cells, each of which has an axis of main extension, each cell having a first and a second carrier film, which are attached to one another by a spacer film having an elongated opening oriented along the axis of main extension, as well as a first and a second electrode on the first and the second carrier film, respectively, where the electrodes are arranged in facing relationship with each other, so that a contact area between them increases with increasing pressure, and an electrically insulating layer is arranged within the opening having a shape such that it locally prevents direct contact between the electrodes where the insulating layer is present and enables the direct contact where it is absent, where the shape is constant or repetitionary along the axis of main extension of the cell.

Owner:IEE INT ELECTRONICS & ENG SA

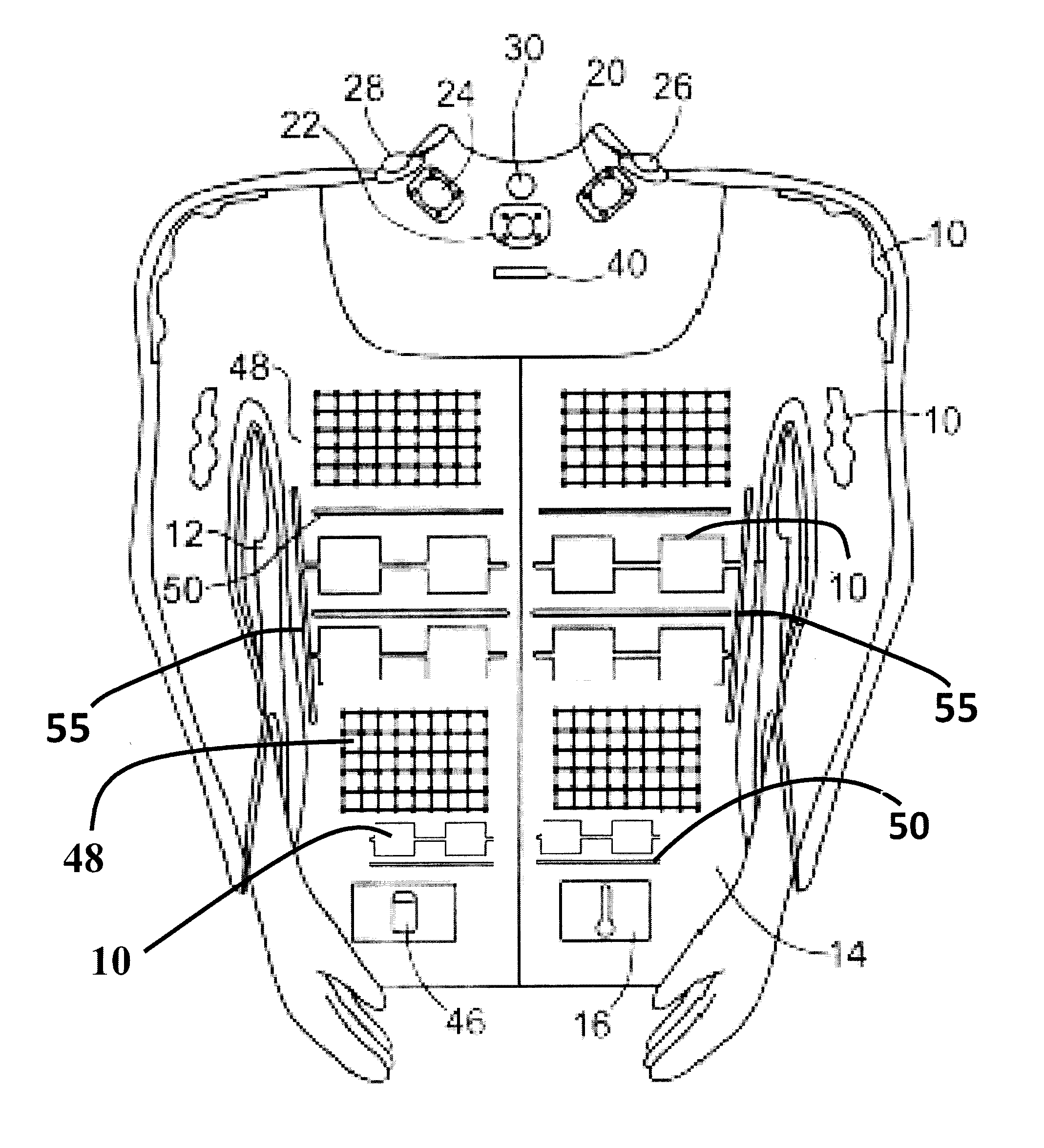

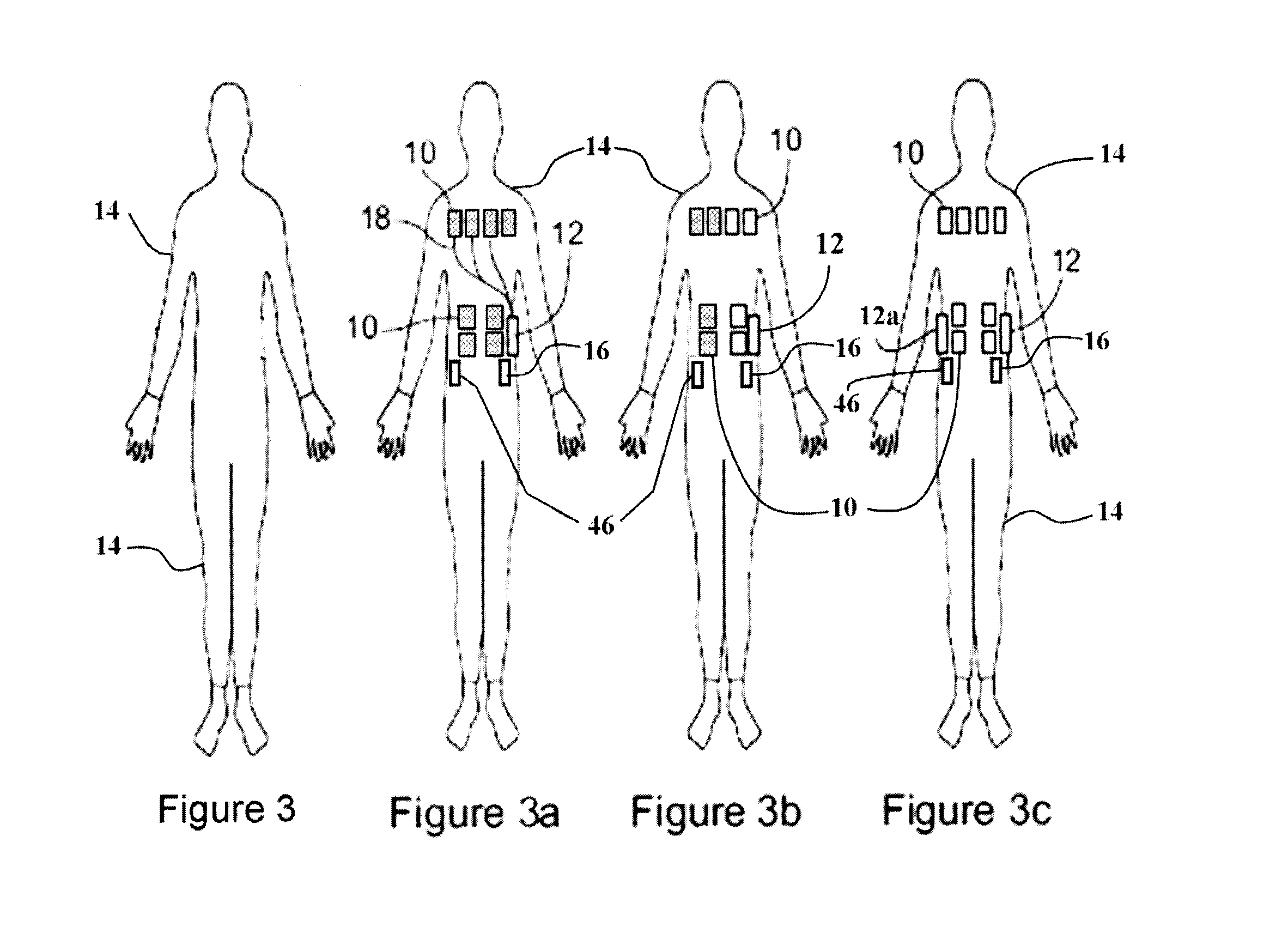

Wearable devices, systems, methods and architectures for sensory stimulation and manipulation and physiological data acquisition

ActiveUS20160317383A1Accurate placementPneumatic massageAcoustic sensorsHuman bodyPhysical Stimulation

A garment with prepositioned, definite sensory stimulating devices attached. These sensory stimulating devices include, but are not limited to, electrical stimulation, audio and physical stimulation such as localised force generation, compression, constriction, vibration, and surround sound. Predetermined and defined actuators allow the wearer to receive tissue, nerve and / or muscle stimulation and / or contraction so that the stimulation is precise as determined by its ability to conform to the scientific methodology of repeatability, reproducibility and reliability; this being due to consistency of actuator positioning in one or multiple locals on the human body. A personal surround sound can also be integrated to the garment to ensure the wearer is always in the optimal position relative the speakers. These actuators can be force generators within the garment for the wearer to feel impact or apparatus or electrodes included in the garment to locally constrict and increase pressure on the wearer.

Owner:IFTECH INVENTING FUTURE TECH

Hypoxic fire prevention and fire suppression systems for computer rooms and other human occupied facilities

Fire prevention and suppression system is provided for human occupied computer rooms and other industrial and public facilities. The equipment of the system provides low-oxygen environments with climate control and at normal atmospheric or slightly increased pressure. The system employs an oxygen-extraction apparatus, which supplies oxygen-depleted air inside an enclosed area communicating with the device. A fire-extinguishing composition is provided for continuous use in human occupied environments, being mostly a mixture of nitrogen and oxygen having oxygen content ranging from 12% to 18%.

Owner:FIREPASS CORP

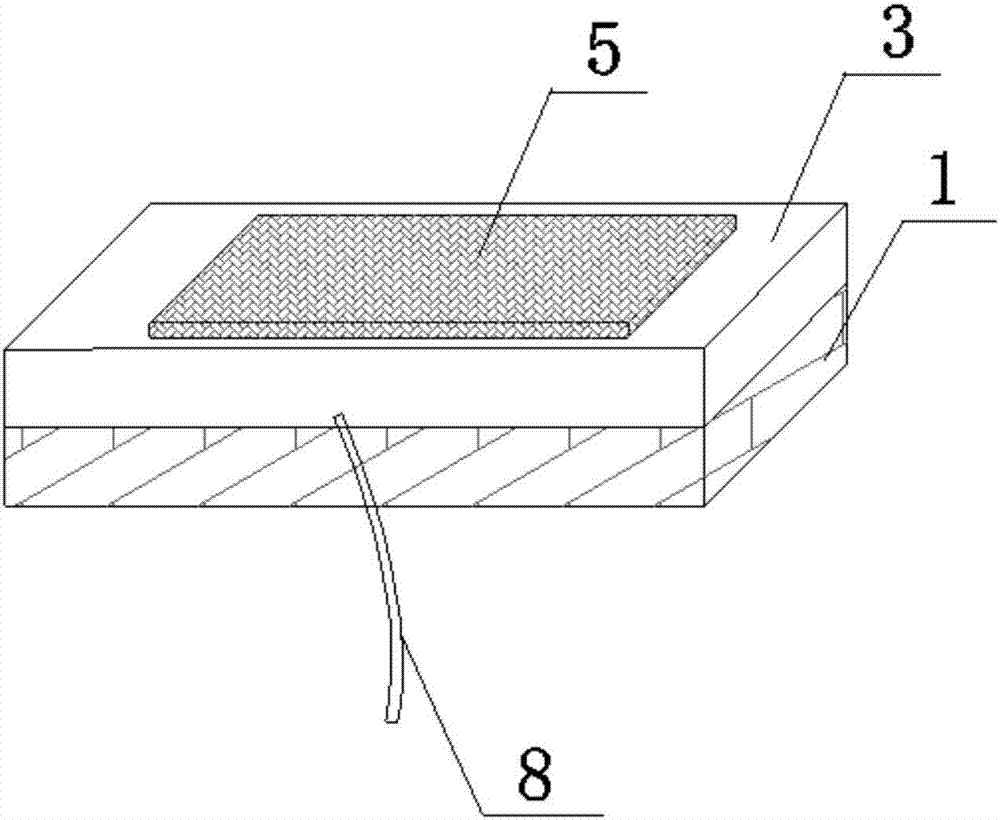

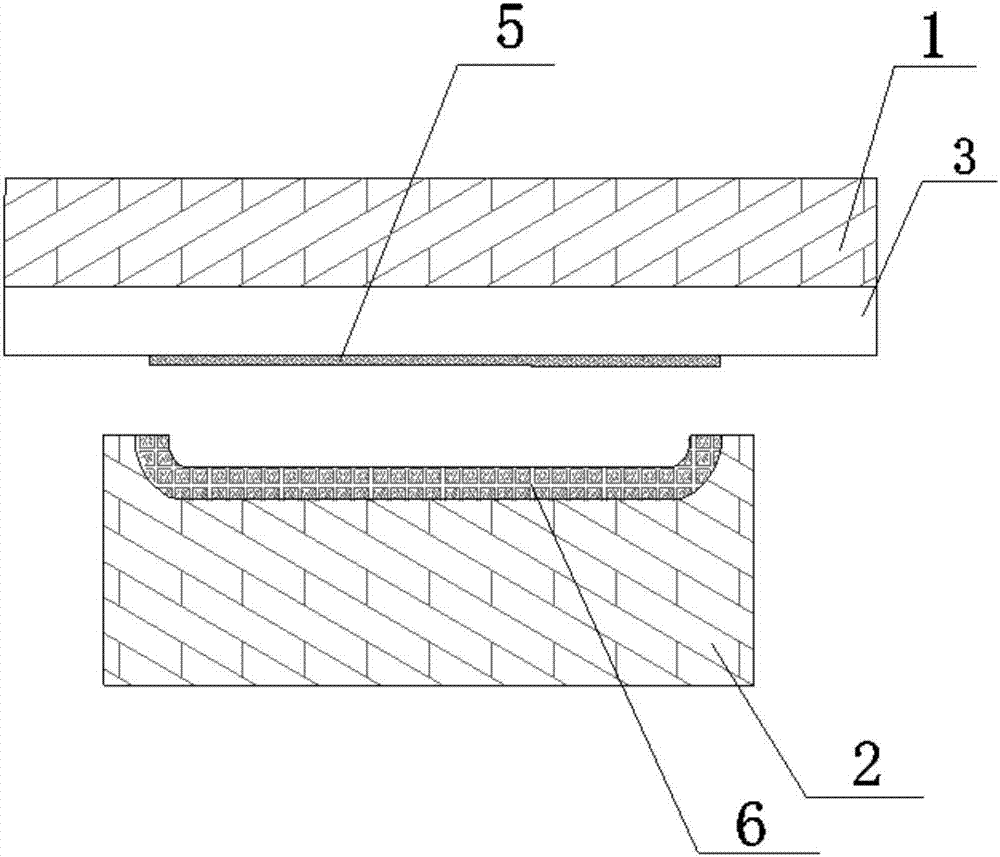

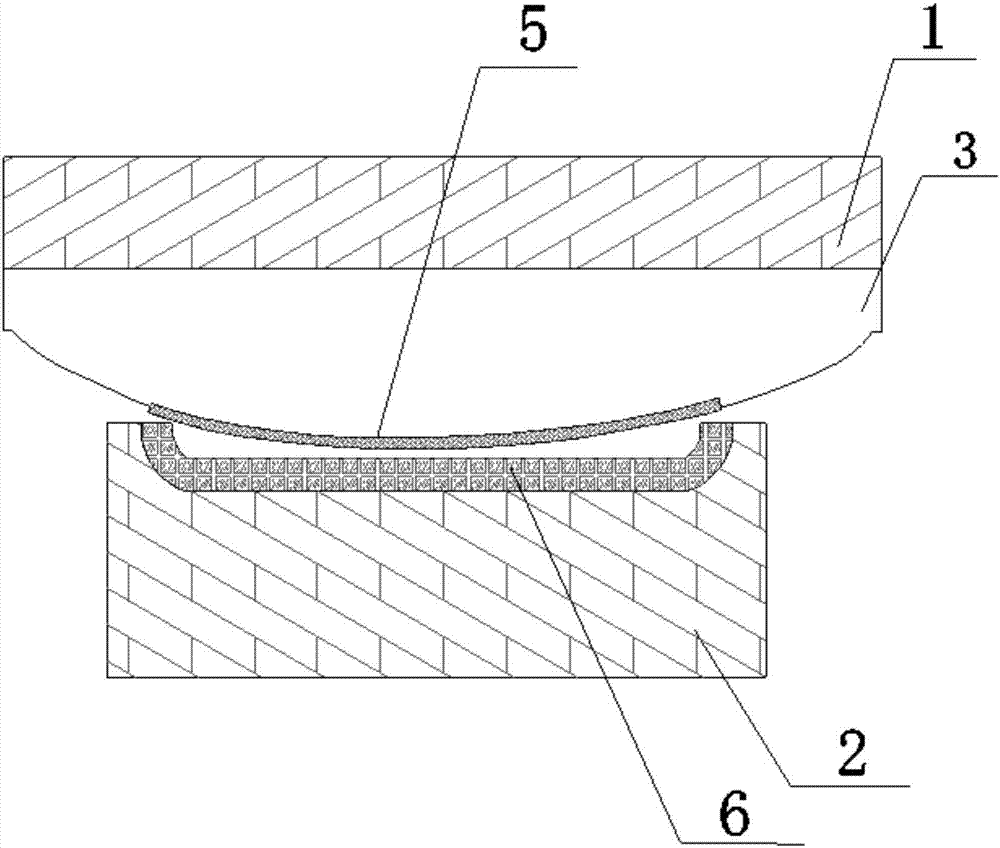

Airbag laminating device and method for curved glass on touch screen

ActiveCN107020785AOptimize the force structureIncrease pressureLaminationLamination apparatusEngineeringAirbag deployment

The invention discloses an airbag laminating device and method for curved glass on a touch screen. The airbag laminating device comprises a support plate and a fixture platform located below the support plate, wherein the fixture platform is used for positioning the curved glass; a main airbag is arranged on one side of the support plate close to the fixture platform; an auxiliary airbag is arranged at a position inside the main airbag corresponding to a bent part of the curved glass; the auxiliary airbag is used for tightly laminating a flexible film to the bent part of the curved glass. The airbag laminating device improves a stress structure of the bent part of the curved glass during lamination by arranging the auxiliary airbag corresponding to the bent part of the curved glass in the main airbag, and increases pressure of the bent part during lamination, so that the flexible film is further laminated to the bent part of the curved glass under compression effect of the auxiliary airbag, thereby eliminating the lamination bubbles of the flexible film and the curved glass, increasing the lamination quality and reducing yield loss.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

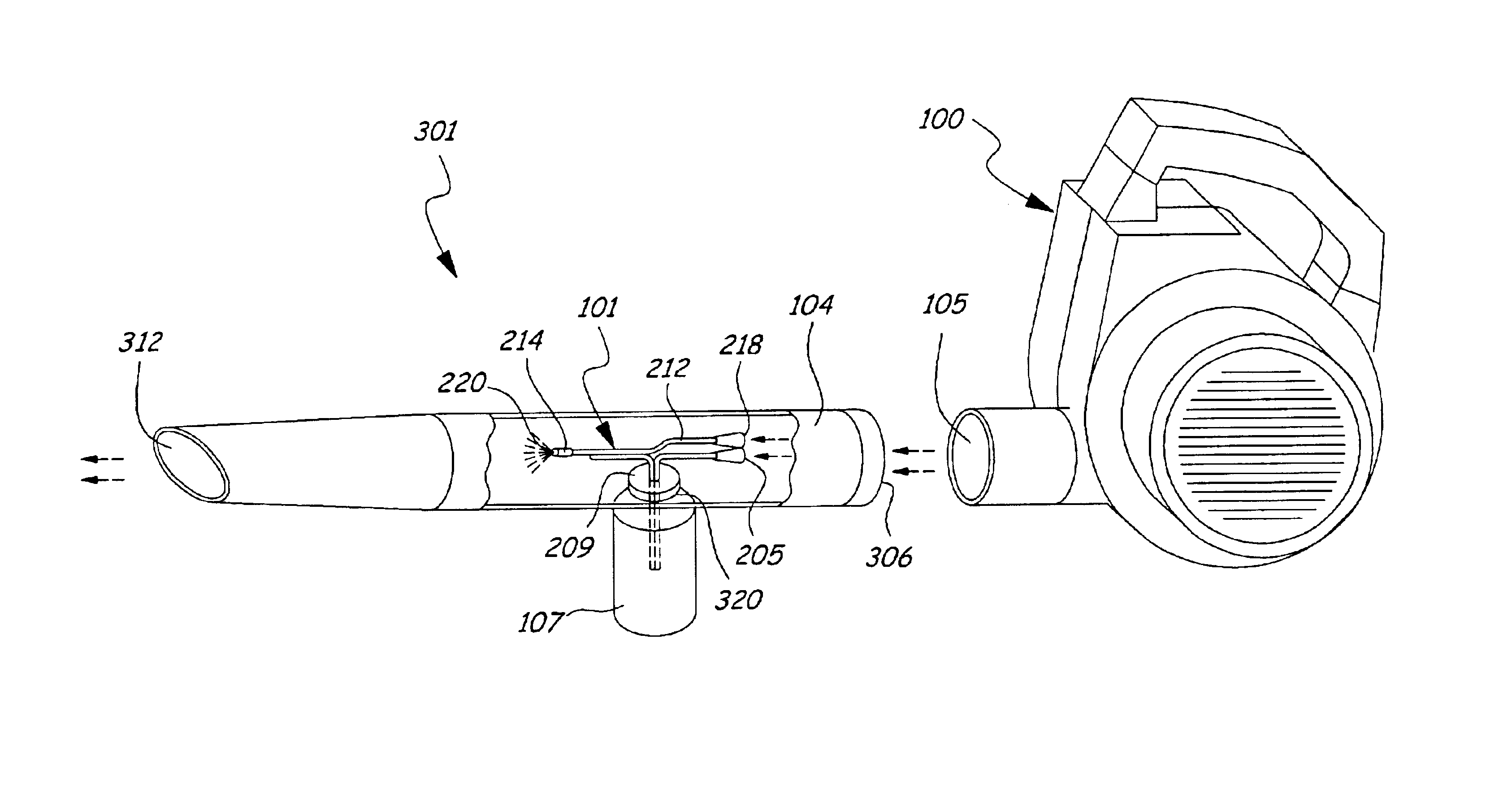

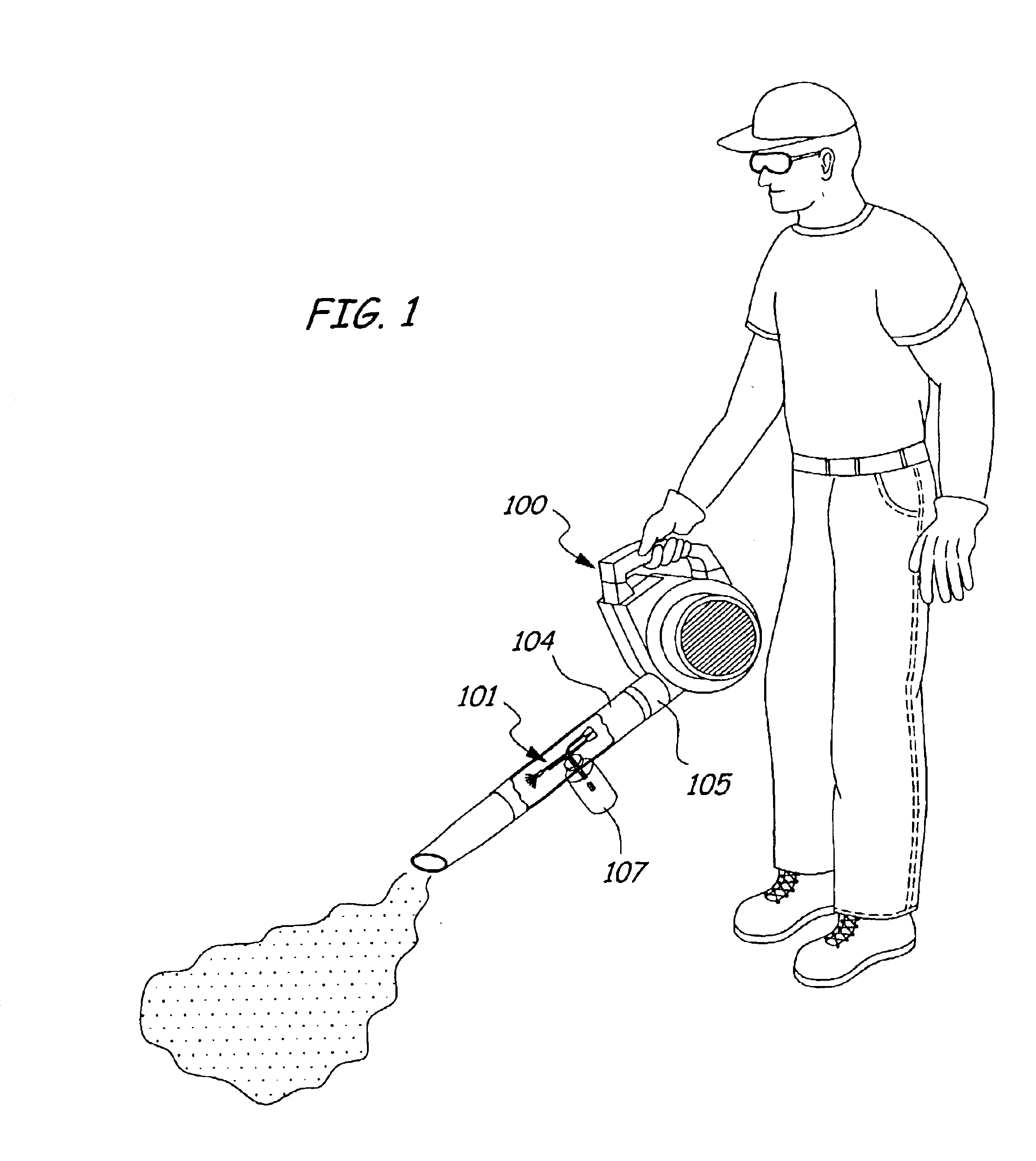

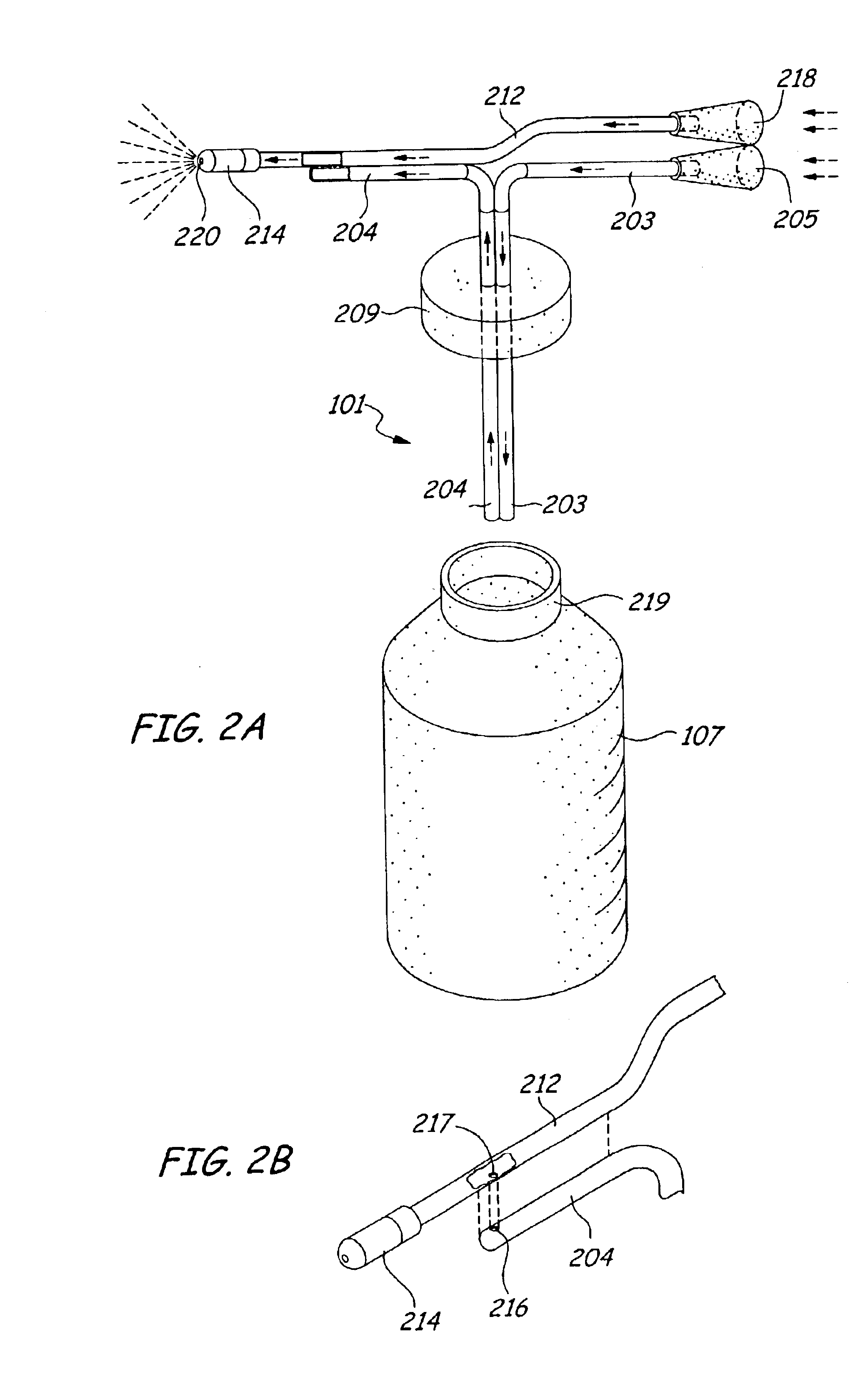

Apparatus for adapting air blower to perform liquid dispersal and related method

An apparatus for adapting a blower system to the dispersing of liquid material is partially housed within an extension tube of a portable blower and includes a pressurizing tub with an inlet for accepting airflow discharged by the blower. The pressurizing tube discharges into a liquid container thus increasing pressure within the container. An extraction tube exits the container and meets a Venturi tube that also accepts airflow discharge by the blower. A vacuum is created in the extraction tube through first and second apertures that allow fluid communication between the Venturi tube and the extraction tube. The vacuum created in the extraction tube extracts liquid from the liquid container and the liquid is drawn out of the extraction tube through the Venturi hole into the Venturi tube mixing with air flowing there through and discharging into airflow by-passing the spray adapter apparatus.

Owner:CLARK LACEY BOOTH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com