Patents

Literature

2171 results about "Getter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

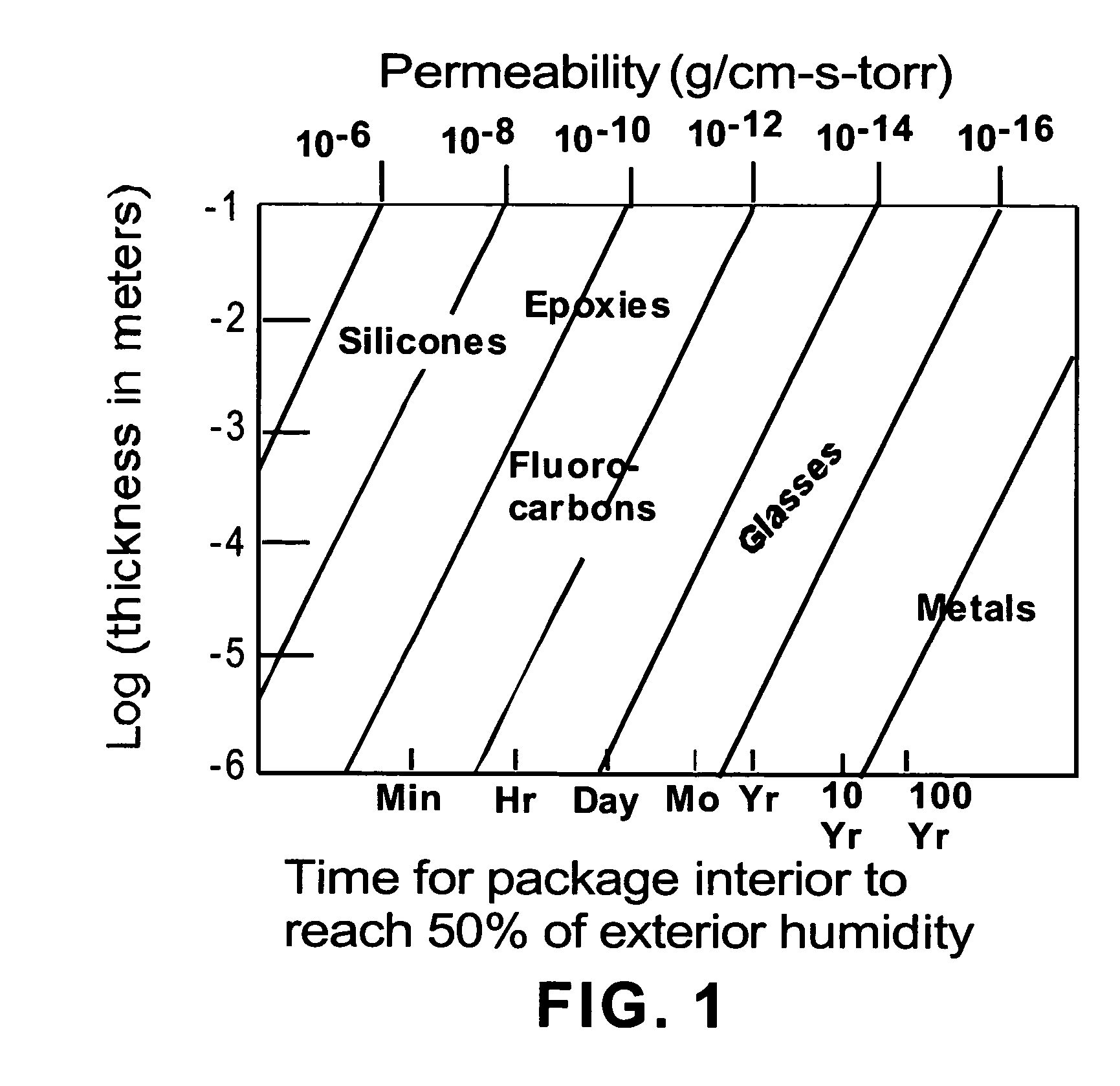

A getter is a deposit of reactive material that is placed inside a vacuum system, for the purpose of completing and maintaining the vacuum. When gas molecules strike the getter material, they combine with it chemically or by absorption. Thus the getter removes small amounts of gas from the evacuated space.

Metal nitride carbide deposition by ALD

InactiveUS7410666B2Material nanotechnologySemiconductor/solid-state device detailsHydrogen halideCorrosive chemical

Owner:ASM INTERNATIONAL

Metal nitride deposition by ALD with reduction pulse

The present methods provide tools for growing conformal metal thin films, including metal nitride, metal carbide and metal nitride carbide thin films. In particular, methods are provided for growing such films from aggressive chemicals. The amount of corrosive chemical compounds, such as hydrogen halides, is reduced during the deposition of transition metal, transition metal carbide, transition metal nitride and transition metal nitride carbide thin films on various surfaces, such as metals and oxides. Getter compounds protect surfaces sensitive to hydrogen halides and ammonium halides, such as aluminum, copper, silicon oxide and the layers being deposited, against corrosion. Nanolaminate structures incorporating metallic thin films, and methods for forming the same, are also disclosed.

Owner:ASM INTERNATIONAL

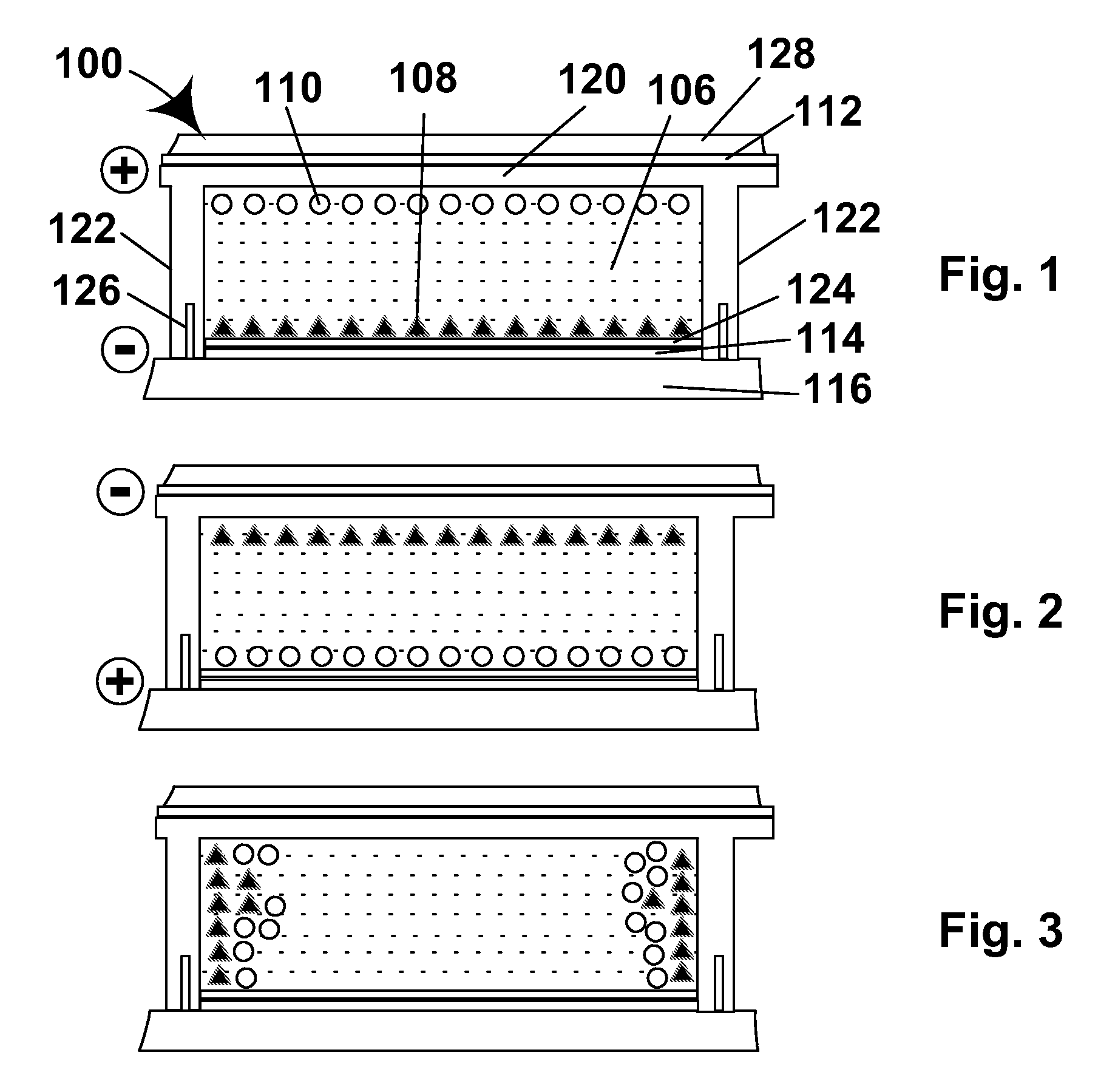

Electrophoretic displays using gaseous fluids

ActiveUS7230751B2Reduce transmissionStatic indicating devicesNon-linear opticsVariable thicknessVitrification

Various improvements are provided in gas-based electrophoretic displays, including (a) the use of water getters to remove water from the gas; (b) the use of electron accepting or donating gases; (c) the use of electrophoretic polymer particles having high glass transition temperatures; (d) lateral movement of electrophoretic particles within the display; and (e) the use of variable thickness coatings on electrodes to provide for gray scale.

Owner:E INK CORPORATION

Polycrystalline group iii metal nitride with getter and method of making

ActiveUS20100151194A1Simple and cost-effective to manufactureCost-effectiveConductive materialRecord information storageNitrogenNitride

A gettered polycrystalline group III metal nitride is formed by heating a group III metal with an added getter in a nitrogen-containing gas. Most of the residual oxygen in the gettered polycrystalline nitride is chemically bound by the getter. The gettered polycrystalline group III metal nitride is useful as a raw material for ammonothermal growth of bulk group III nitride crystals.

Owner:SLT TECH

Encapsulation of organic electronic devices using adsorbent loaded adhesives

InactiveUS20030143423A1Effective and easy-to-applyImprove abilitiesDischarge tube luminescnet screensElectroluminescent light sourcesDesiccantSorbent

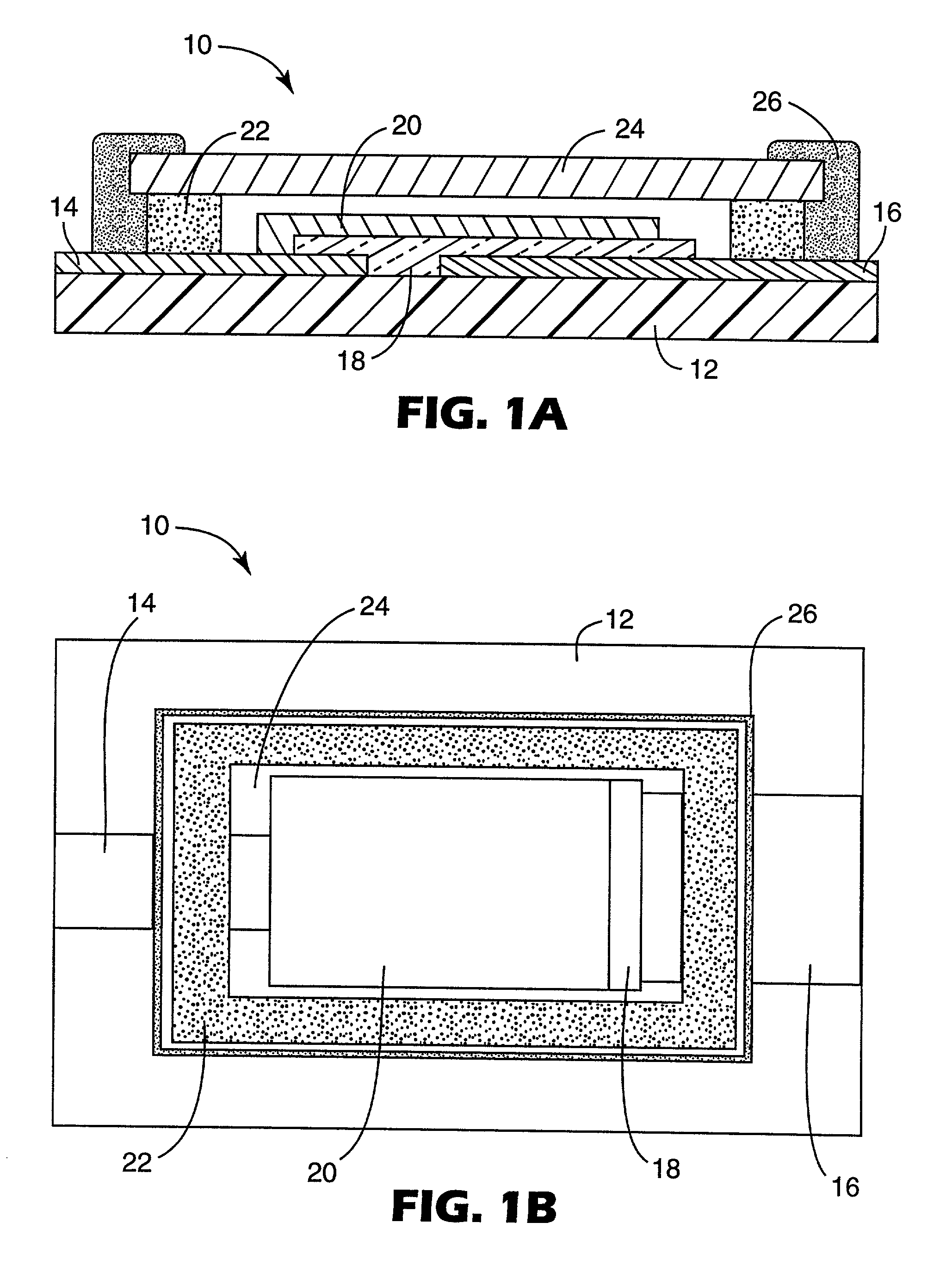

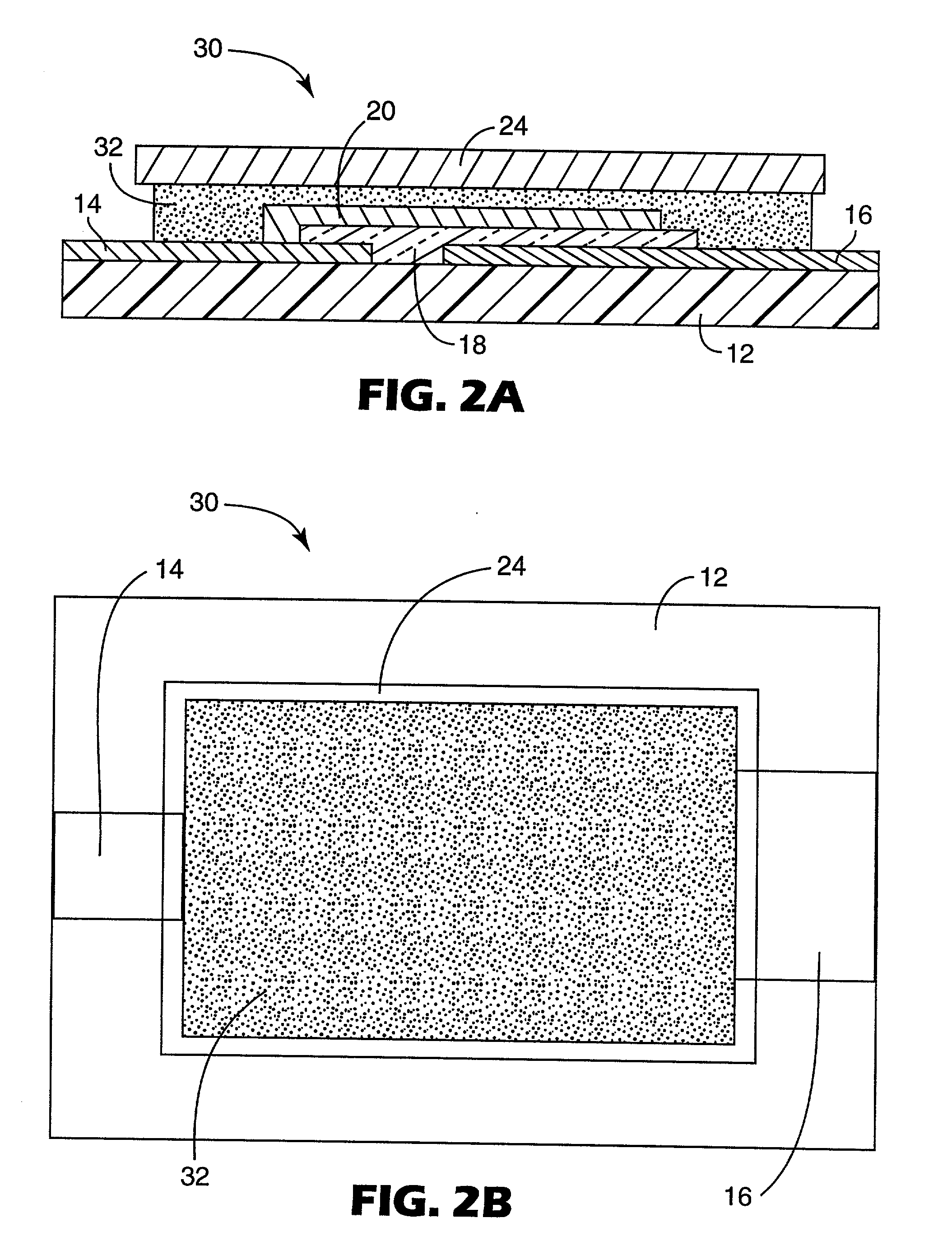

Disclosed herein are organic electronic devices that are encapsulated at least in part by adsorbent-loaded transfer adhesives. The adsorbent material may be a dessicant and / or a getterer. The adsorbent-loaded transfer adhesive may form a gasket around the periphery of the device, or may cover the entire device and its periphery. An encapsulating lid covers the device.

Owner:3M INNOVATIVE PROPERTIES CO

Novel magnetic tunnel junction (MTJ) to reduce spin transfer magnetization switching current

ActiveUS20080179699A1Reduce magnetic “ dead layer ”Magnetic-field-controlled resistorsSolid-state devicesLayer interfaceSpins

Owner:TAIWAN SEMICON MFG CO LTD

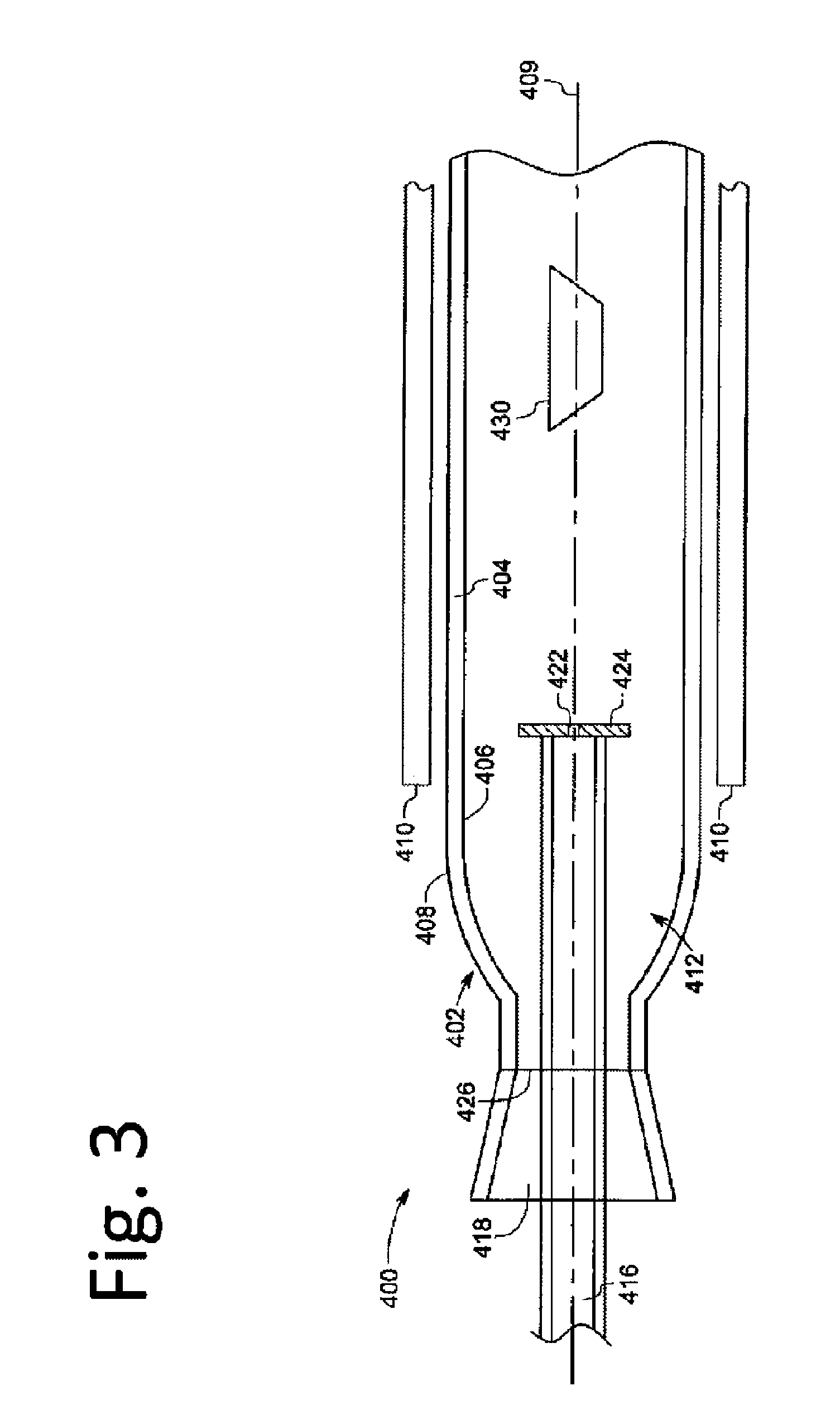

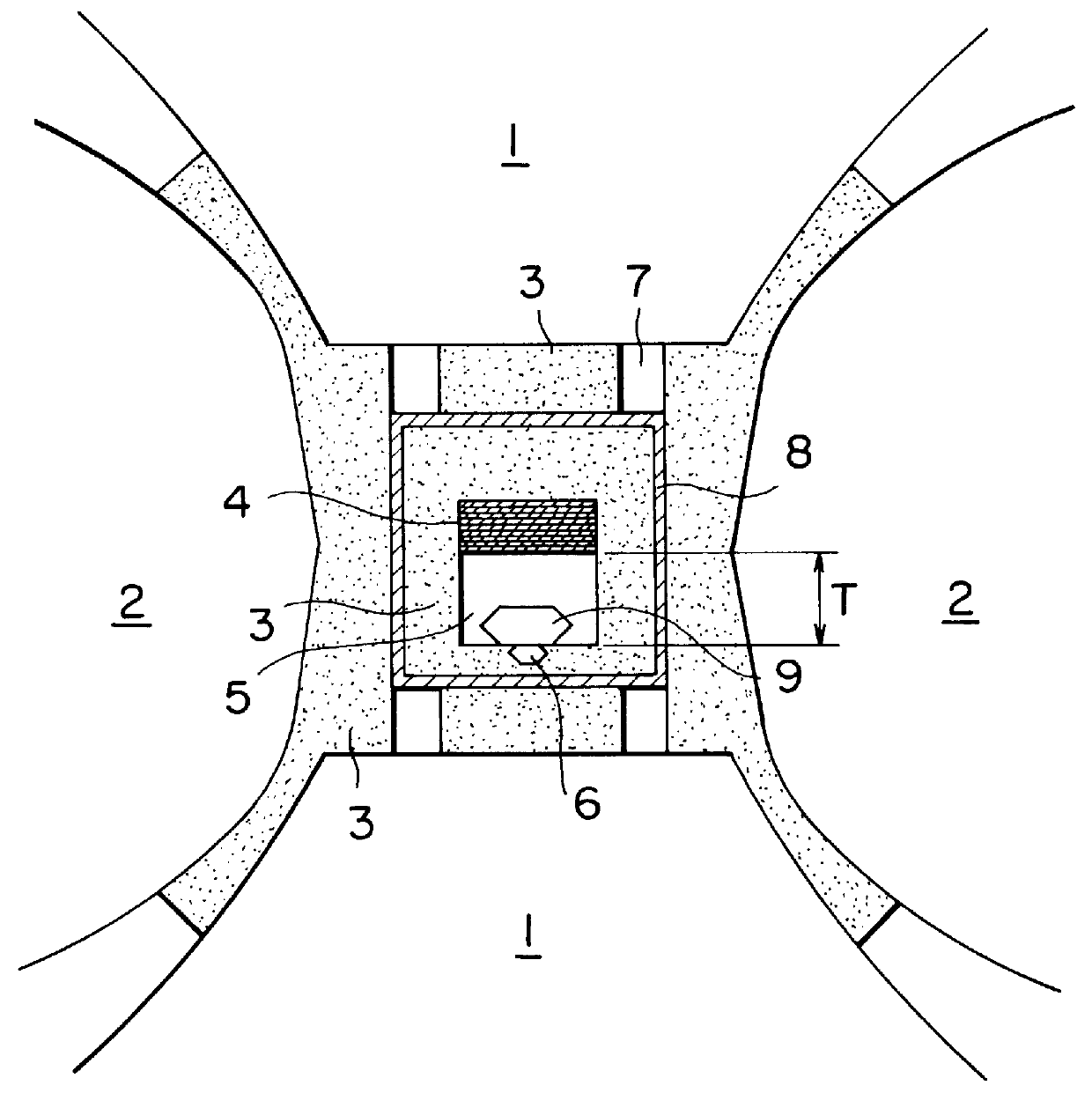

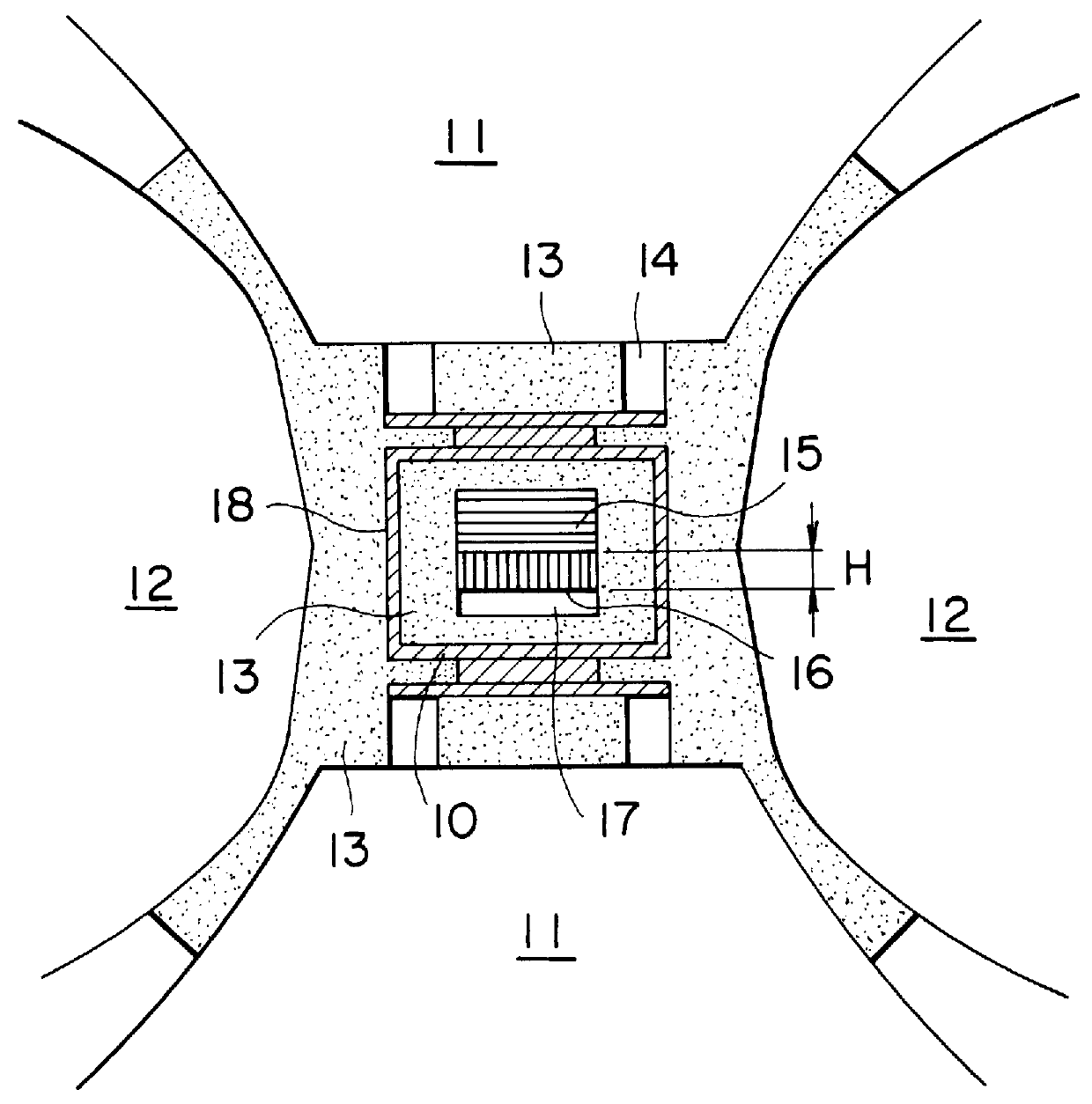

Sensor package arrangement

InactiveUS6040625AEasy to installMinimizing chance for outgassingSemiconductor/solid-state device detailsSolid-state devicesCapacitanceElectrical connection

A highly sensitive silicon micro-machined sensor package is provided for use in a micro-g environment that can also resist high shock in excess of 5000 g. The sensor is provided to measure acceleration in cooperation with associated electronics which are required to have electrical contact with sensor elements. The sensor is sealed in a high vacuum environment, and is arranged and designed to be free of temperature induced stress to the sensor. The sensor die package assembly comprises a silicon micro-machined sensor die, a ceramic package, two contact springs, a shorting clip, solder preform, a metal lid and a getter foil for ensuring a good vacuum for an extended period. The sensor die comprises a moving mass with eight supporting flexures on both sides of the proof mass. The proof mass's movement is protected on both sides by a top and a bottom cap. Acceleration applied to the package and the die causes the proof mass to move vertically in relation with the adjacent caps. The changes in distance between the proof mass and the caps in turn generate a change in an electrical signal which corresponds to the capacitance changes between the gaps. The sensor die package arrangement provides that the sensor die be secured within an evacuated ceramic case. Electrical connections made between external contacts of the case and contacts of the sensor die within the case are made through conductive springs, thereby minimizing materials in the interior of the case which would outgass in the vacuum environment.

Owner:I O SENSORS

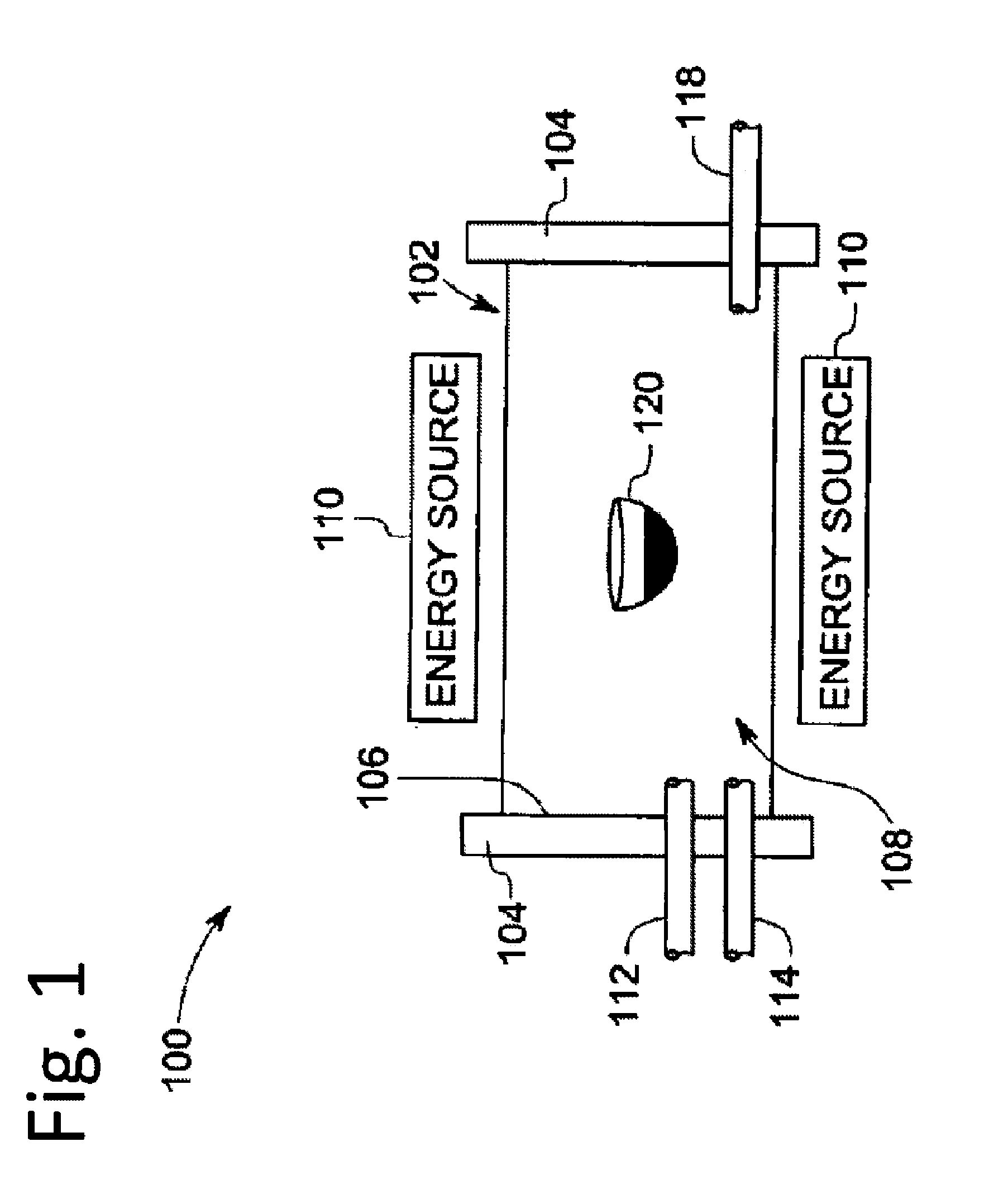

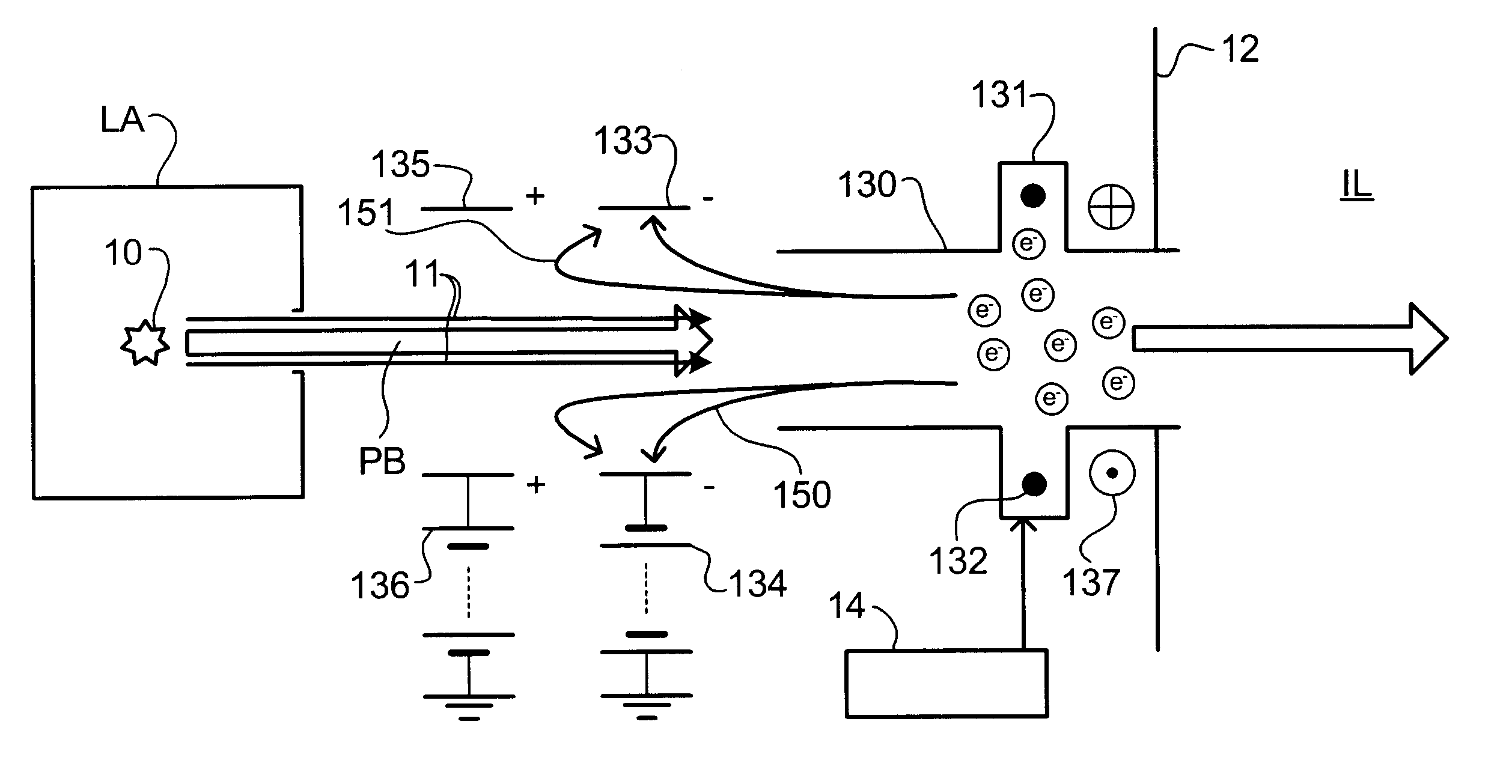

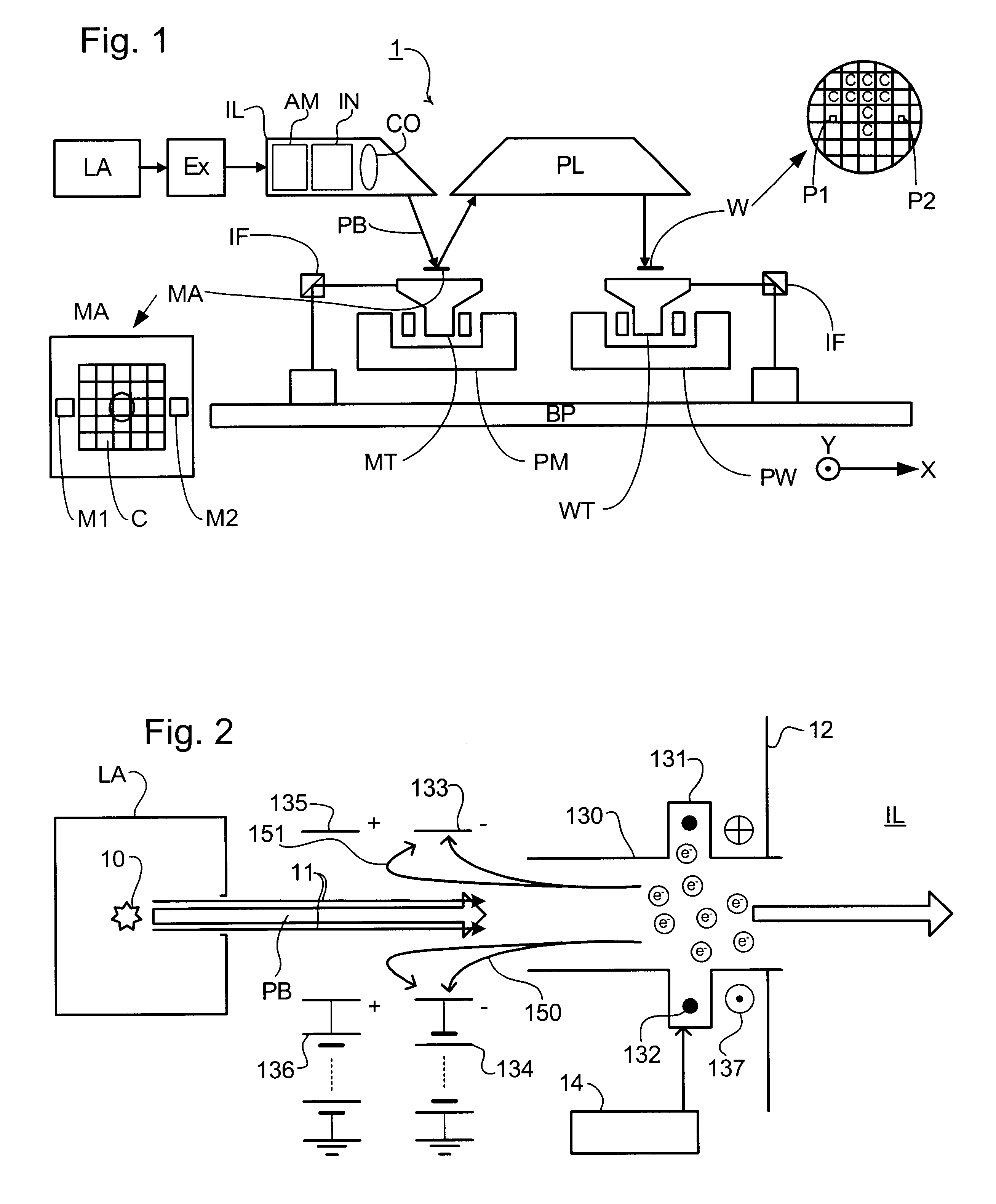

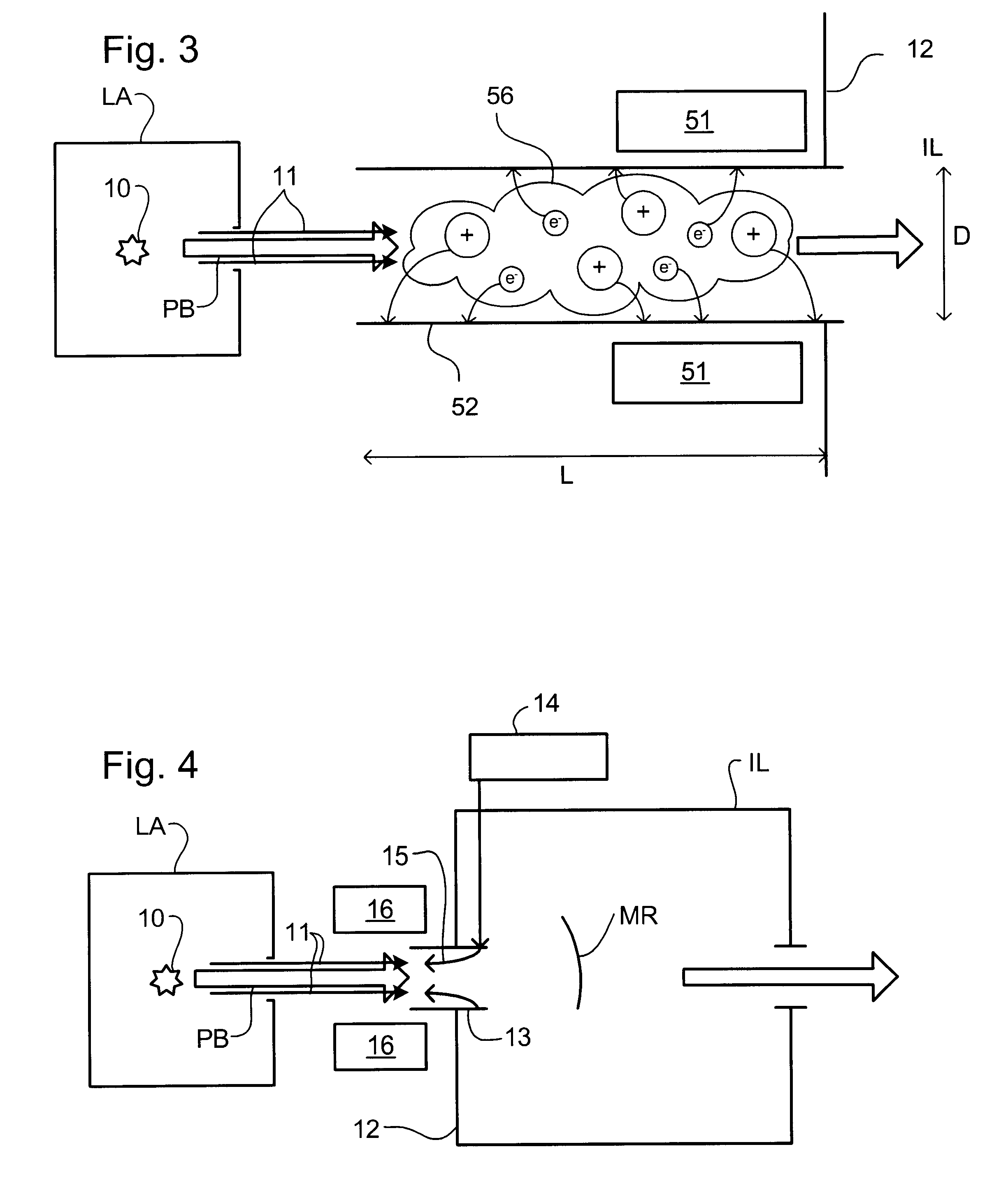

Lithographic projection apparatus, device manufacturing method, and device manufactured thereby

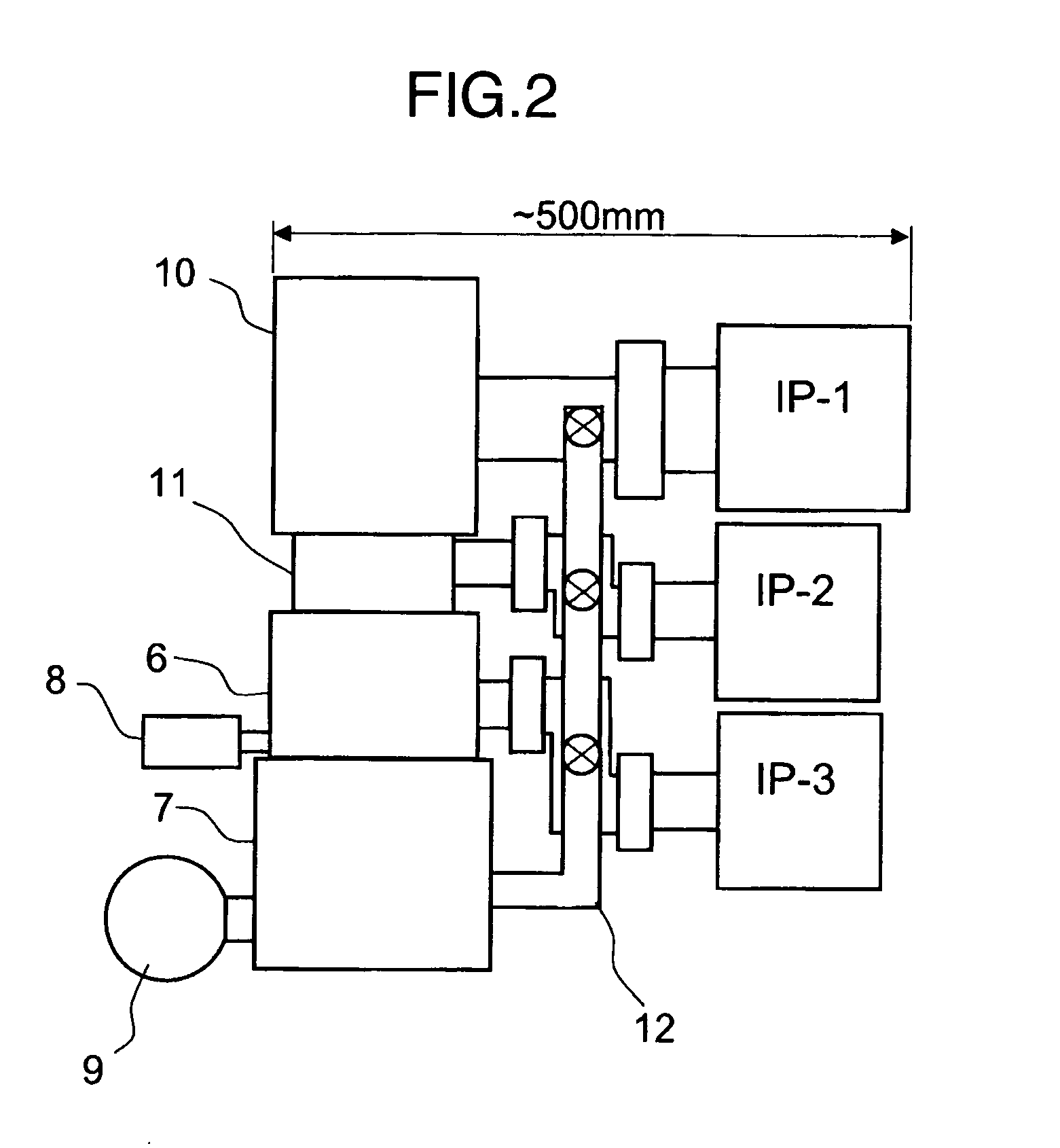

InactiveUS6614505B2Good removal effectImprove the ionization effectInvestigating moving sheetsSemiconductor/solid-state device manufacturingIonizationGas supply

Contaminant particles travelling with a projection beam in a lithographic projection apparatus are ionized. A purge gas may be attracted towards getter plates provided upstream of the purge gas supply. A magnetic field traps electrons generated by the ionizer to improve the ionization of the purge gas. The contaminant particles can be ionized by generating a plasma in a tube having a greater length than width.

Owner:ASML NETHERLANDS BV

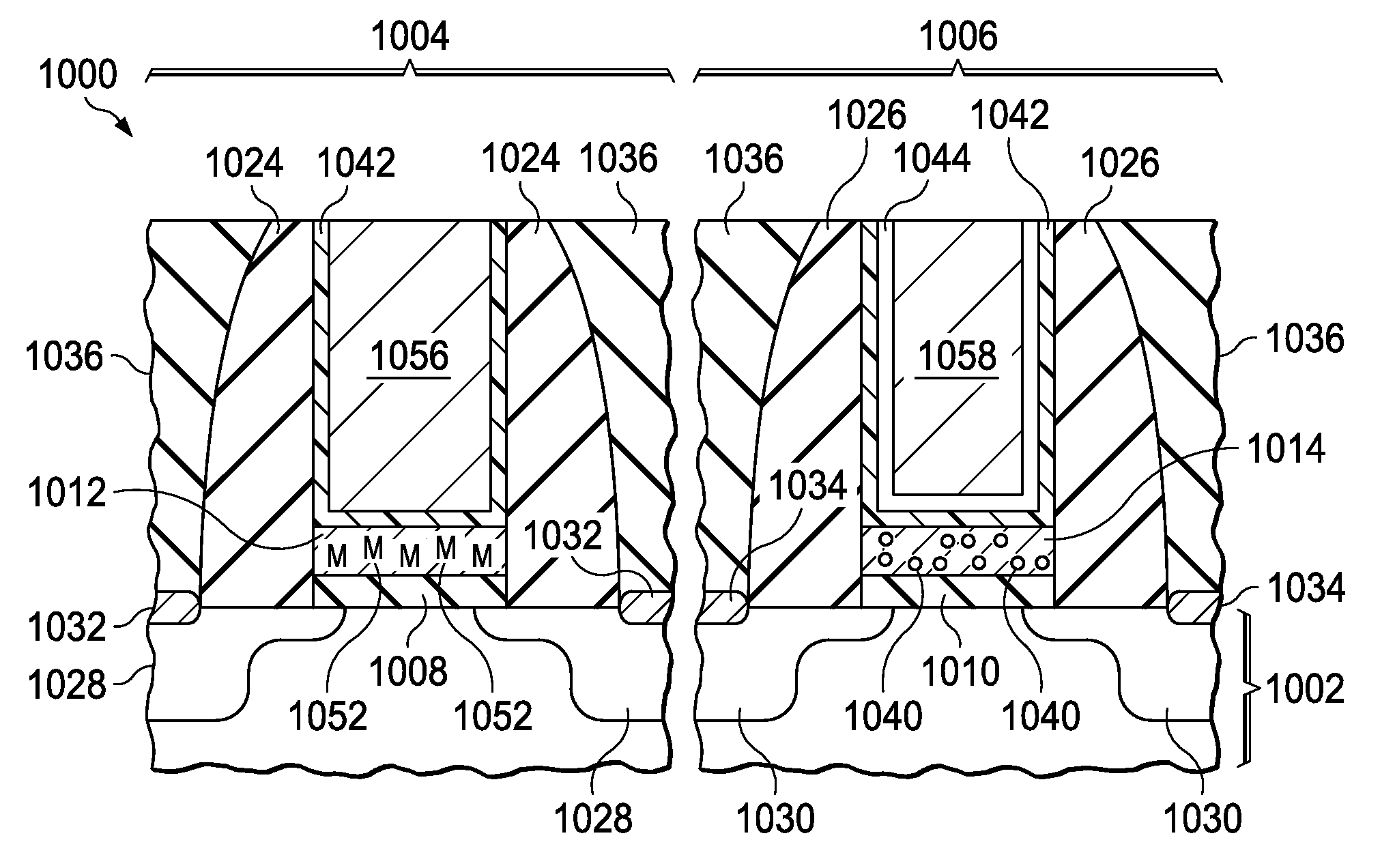

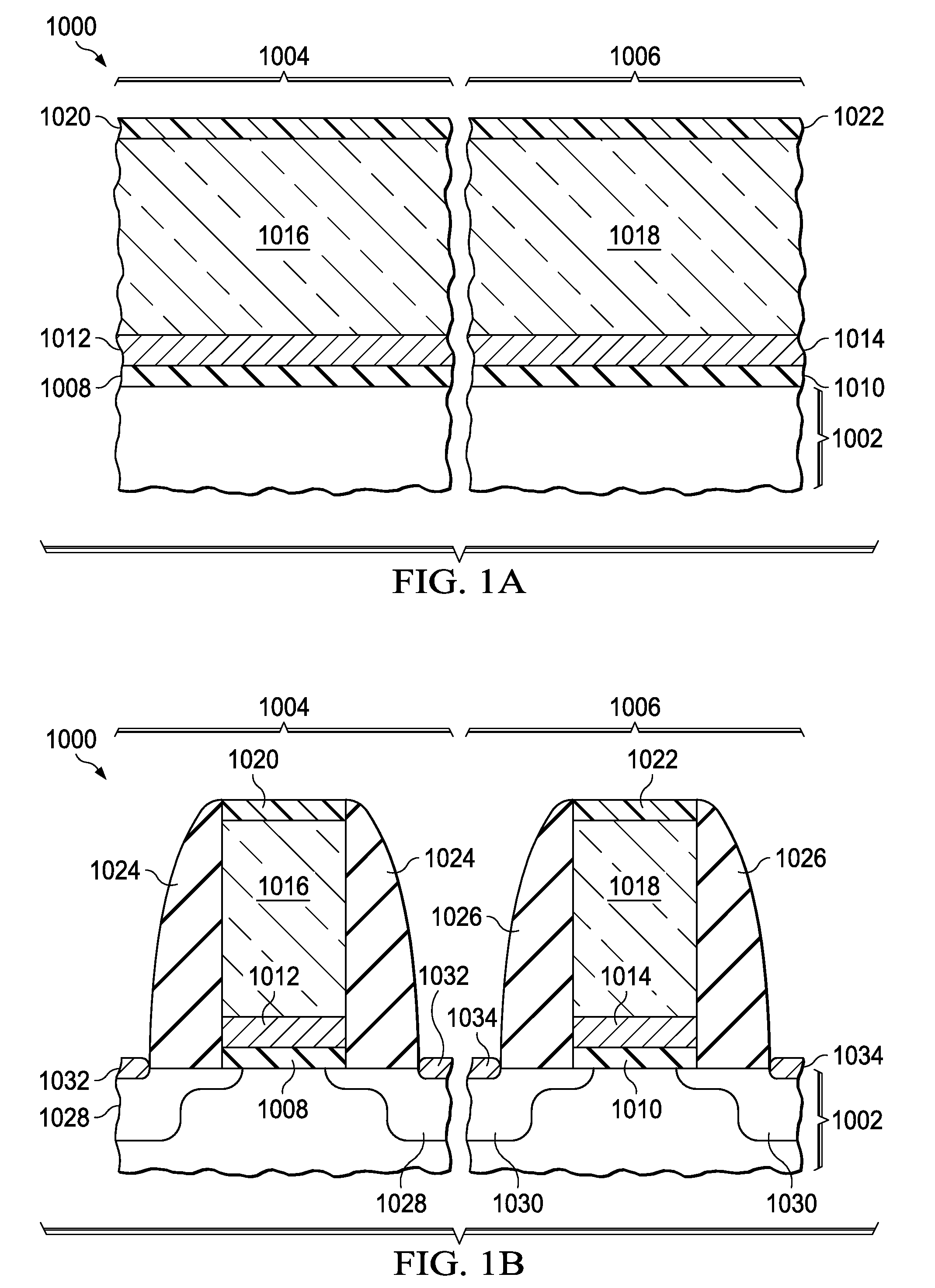

Structure and method for metal gate stack oxygen concentration control using an oxygen diffusion barrier layer and a sacrificial oxygen gettering layer

ActiveUS20100127336A1Increase their effective work functionTransistorSemiconductor/solid-state device manufacturingWork functionDiffusion barrier

A process is disclosed of forming metal replacement gates for NMOS and PMOS transistors with oxygen in the PMOS metal gates and metal atom enrichment in the NMOS gates such that the PMOS gates have effective work functions above 4.85 eV and the NMOS gates have effective work functions below 4.25 eV. Metal work function layers in both the NMOS and PMOS gates are oxidized to increase their effective work functions to the desired PMOS range. An oxygen diffusion blocking layer is formed over the PMOS gate and an oxygen getter is formed over the NMOS gates. A getter anneal extracts the oxygen from the NMOS work function layers and adds metal atom enrichment to the NMOS work function layers, reducing their effective work functions to the desired NMOS range. Processes and materials for the metal work function layers, the oxidation process and oxygen gettering are disclosed.

Owner:TEXAS INSTR INC

Protected organic electronic device structures incorporating pressure sensitive adhesive and desiccant

InactiveUS6998648B2Effective protectionEasy to optimizeSemiconductor/solid-state device detailsSolid-state devicesDesiccantEngineering

Owner:UNIVERSAL DISPLAY

Method for encapsulating electronic devices and a sealing assembly for the electronic devices

InactiveUS20060283546A1Reduce device thicknessSimplify the packaging processFinal product manufactureSemiconductor/solid-state device detailsEngineeringBiological activation

A method for sealing an electronic device includes providing an electronic device on a substrate, providing a lid, activating a getter material in an environment substantially free of contaminants, applying a sealing material to at least a portion of the lid, and attaching the substrate and the lid in an inert environment. The time elapsed between activating the getter material and attaching the substrate and the lid is less than 20 minutes. A sealing assembly for an electronic device includes an activation tool for activating a getter material, a dispensing tool for dispensing a sealing material, and an encapsulation tool for sealing the electronic device. The sealing assembly is in an environment substantially free of contaminants.

Owner:EI DU PONT DE NEMOURS & CO

Electronic devices and a method for encapsulating electronic devices

InactiveUS20060284556A1Discharge tube luminescnet screensElectroluminescent light sourcesAmbient pressureTorr

An electronic device can include a substrate, a lid, a getter material adhered to at least a portion of at least one surface of the electronic device, wherein the portion of the surface will be an interior surface of the electronic device, and a sealing material adhered to at least a portion of the substrate and a portion of the lid. The sealing material includes a spacer material. A method for sealing the electronic device includes includes attaching the substrate and the lid in an inert atmosphere under an absolute pressure of less than 760 torr wherein the sealing material contacts both the substrate and the lid, and raising the pressure on the exterior of the device to ambient pressure.

Owner:EI DU PONT DE NEMOURS & CO +1

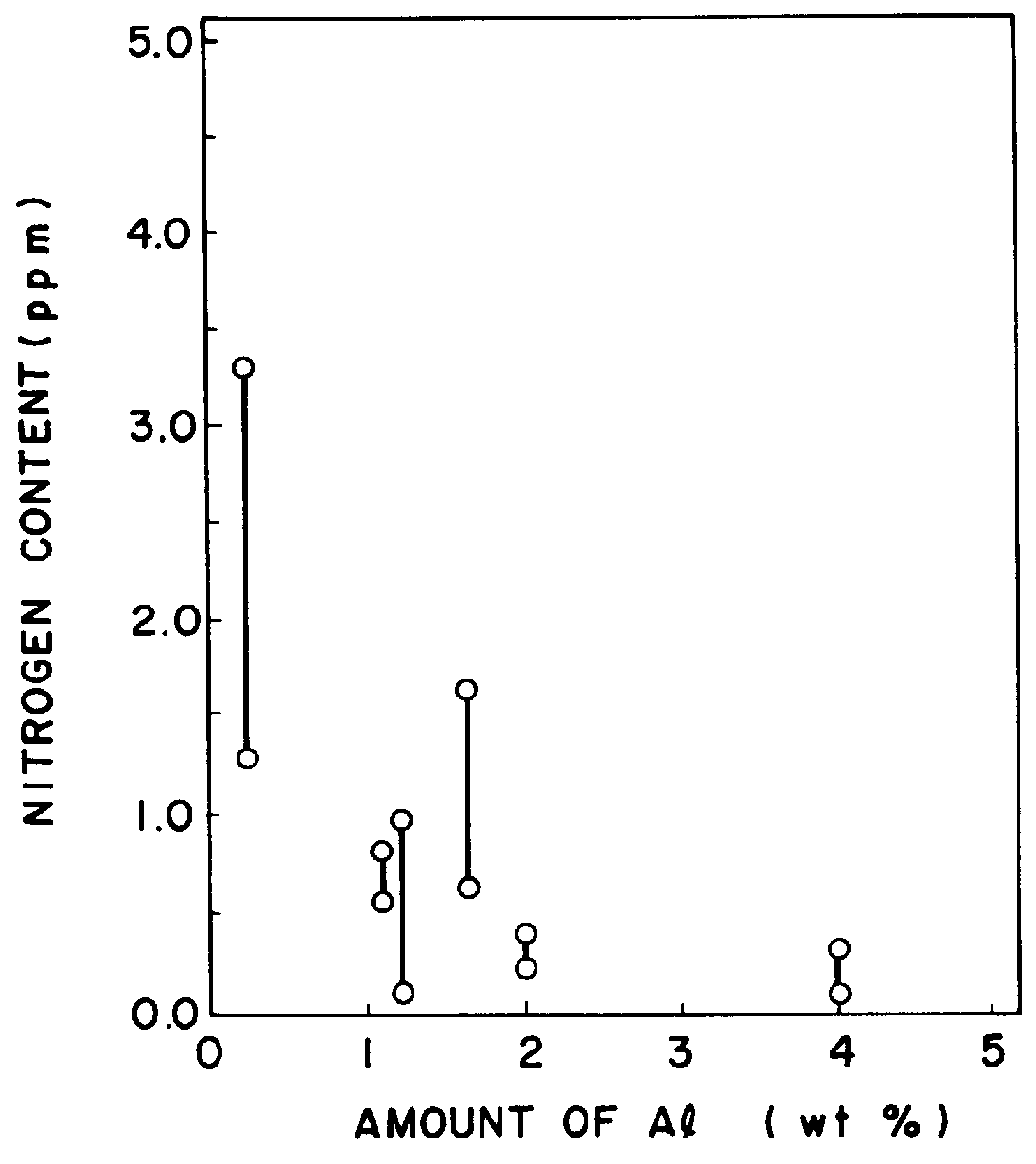

Process for the synthesis of diamond

InactiveUS6129900ALess inclusionReduce the impactUltra-high pressure processesUltra high pressureDiamond crystal

PCT No. PCT / JP92 / 00149 Sec. 371 Date Oct. 14, 1992 Sec. 102(e) Date Oct. 14, 1992 PCT Filed Feb. 14, 1992 PCT Pub. No. WO92 / 14542 PCT Pub. Date Sep. 3, 1992A colorless and transparent, substantially inclusion-free diamond crystal which can be applied to decorative uses and optical parts is synthesized by a process using a temperature gradient method in an ultra-high pressure apparatus. This process comprises using, as a solvent for the growth of the crystal, at least one metal selected from the group consisting of Fe, Co, Ni, Mn and Cr (at least two metals in the case of containing Fe) and as a nitrogen getter for the removal of nitrogen in the solvent, at least one metal selected from the group consisting of Al, Ti, Zr, Hf, V, Nb and Ta in a proportion of 0.5 to 7% by weight (at most 2% by weight when using only Al) to the solvent metal.

Owner:SUMITOMO ELECTRIC IND LTD

Nanometer multiple-layer composite thermal insulation material and preparation method thereof

ActiveCN101799099AEasy to useInhibition of high temperature radiative heat transferThermal insulationPipe protection by thermal insulationAdhesiveMetal foil

The invention discloses a nanometer multiple-layer composite thermal insulation material and a preparation method thereof. The nanometer multiple-layer thermal insulation composite material is formed by alternatively overlapping an infrared reflecting screen and a spacer; the ratio of total layer amounts n of the infrared reflecting screens and the spacers to the total thickness of the nanometer multiple-layer composite thermal insulation material is 0.5-4; the infrared reflecting screen is a metal foil or a metal plated foil; the spacer is a thermostability nanometer porous aerogel composite thermal insulation material; the infrared reflecting screen and the spacer are combined by being adhered with thermostability adhesives or in puncturing connection by thermostability sewing threads. The invention also comprises the preparation method of the nanometer multiple-layer composite thermal insulation material. The nanometer multiple-layer composite thermal insulation material of the invention has low density, favorable mechanical property and favorable high-temperature thermal insulation property, lowers requirements on the vacuum degree by a VIP plate when being used as vacuum thermal insulation plate core materials, does not need getter and can satisfy harsh high-efficiency thermal insulation using requirements on materials by aviation, aerospace and civil fields. The method of the invention can prepare thermal insulation material members with large size and complex shape.

Owner:NAT UNIV OF DEFENSE TECH

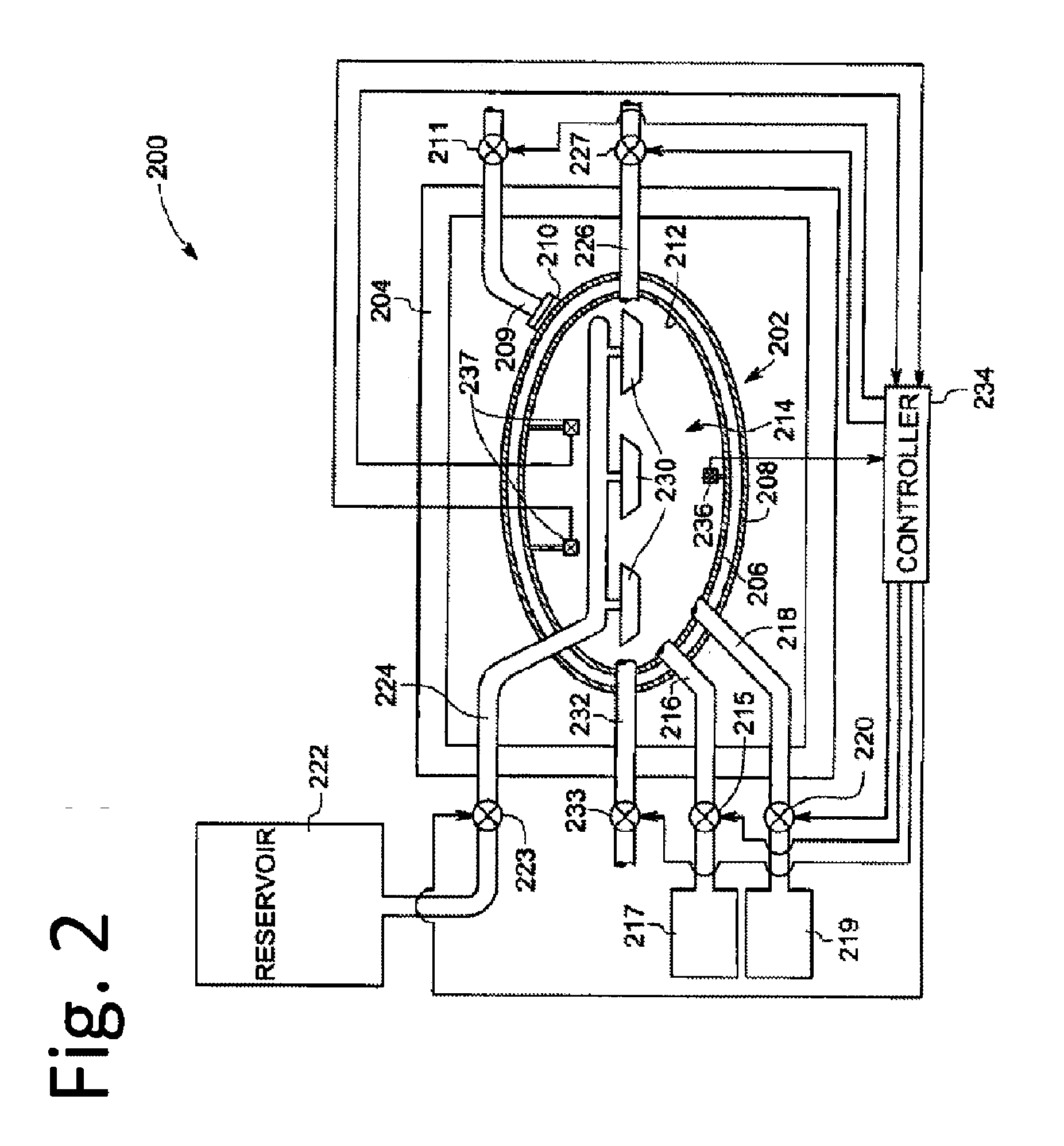

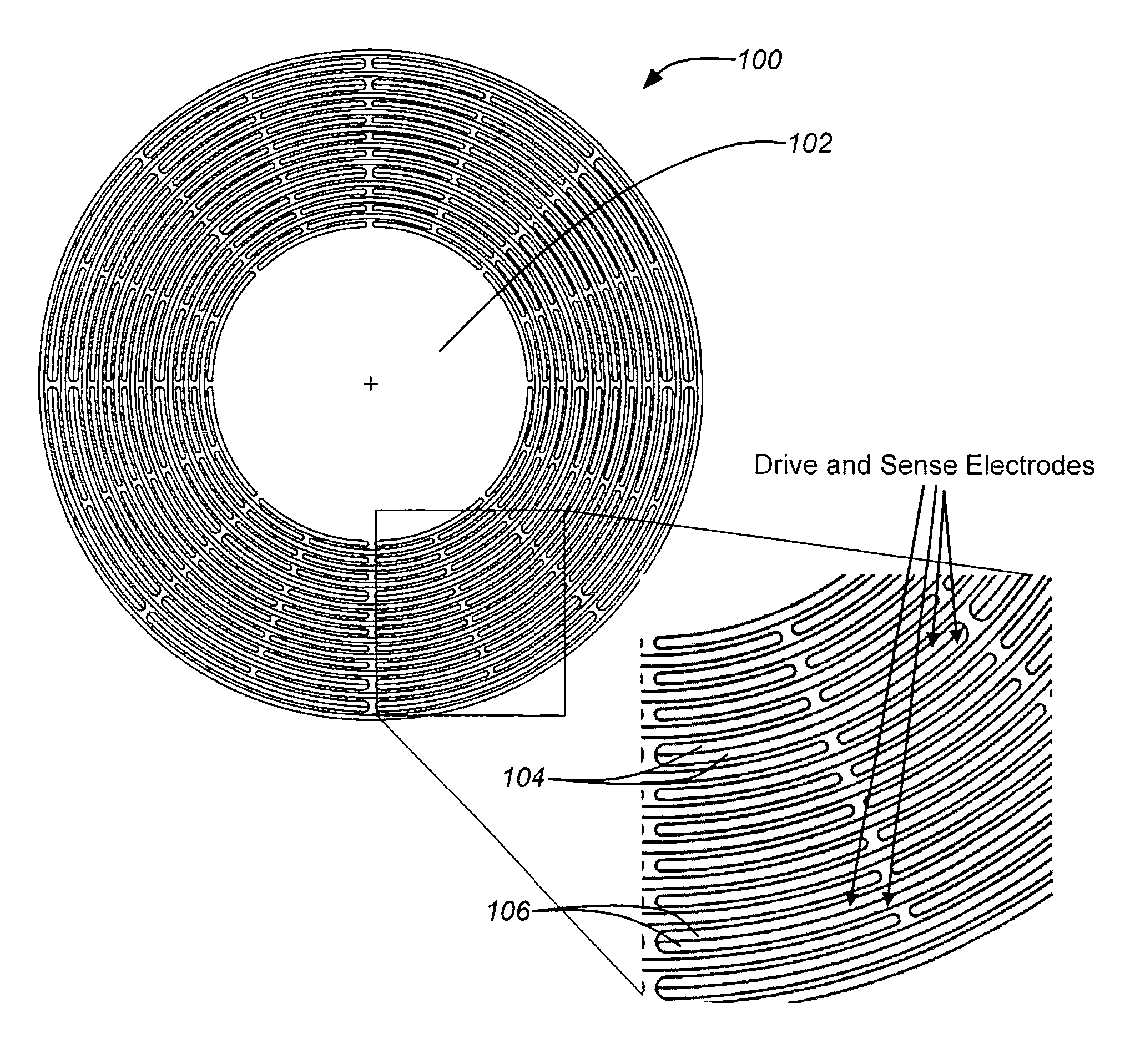

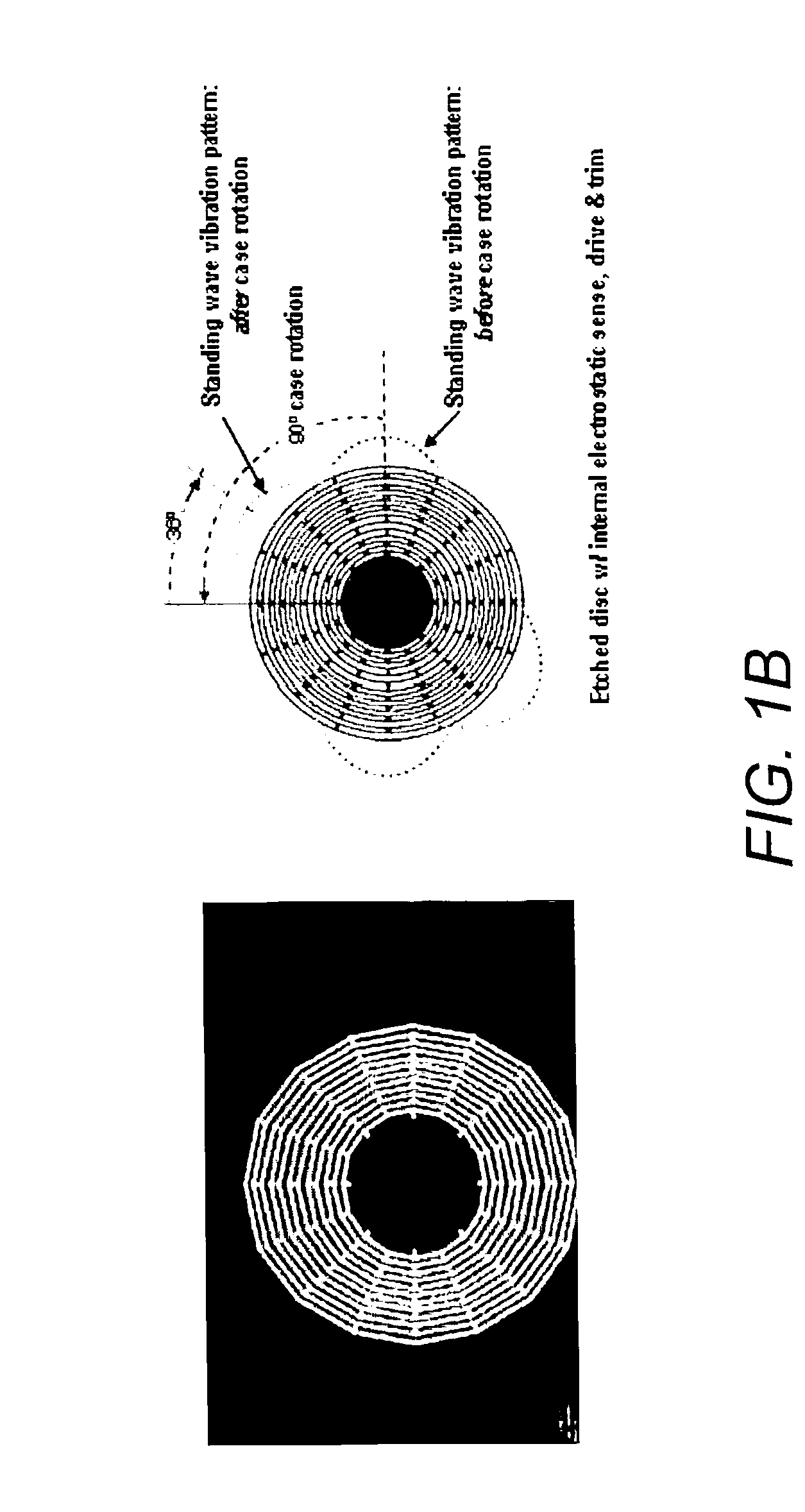

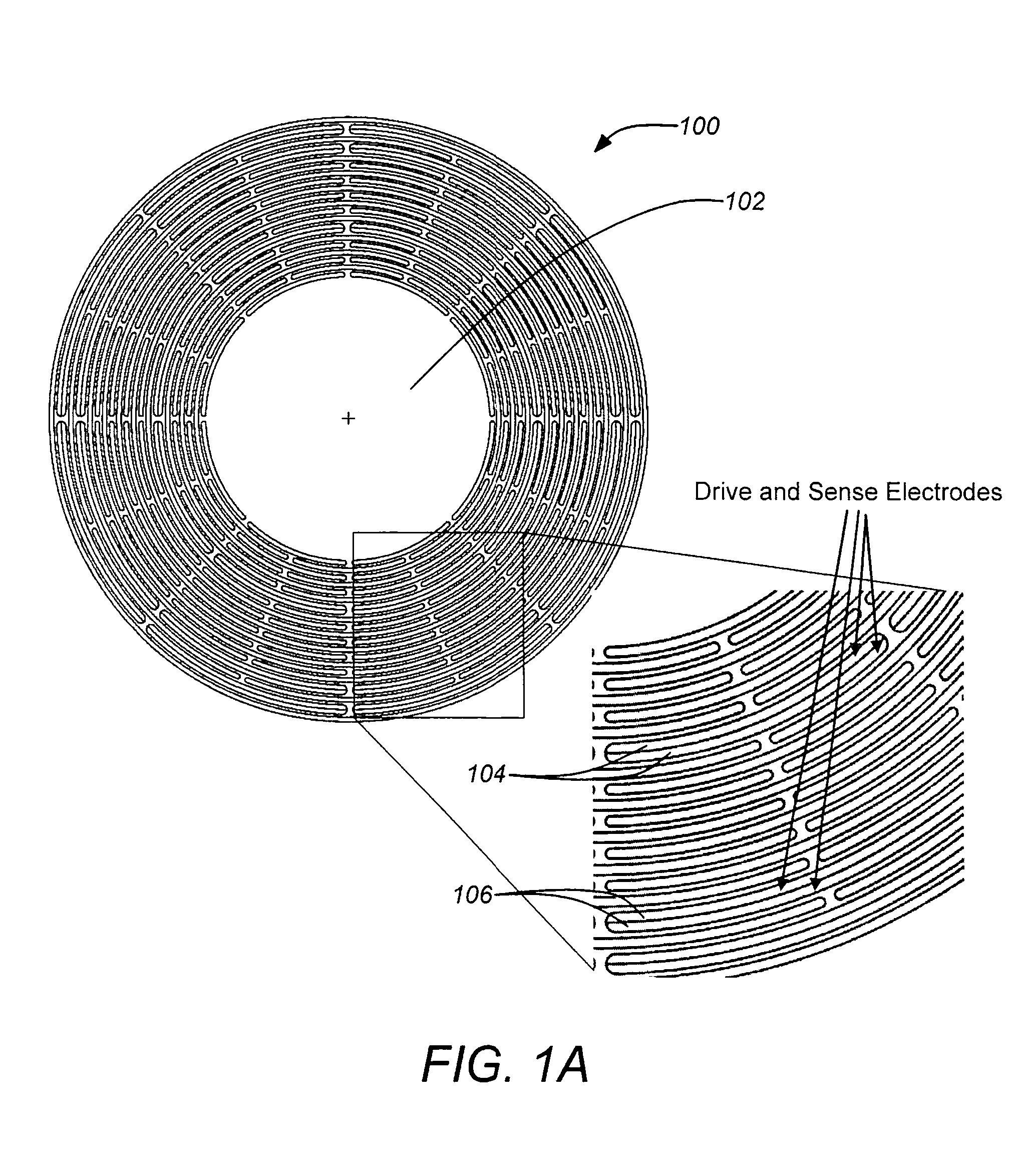

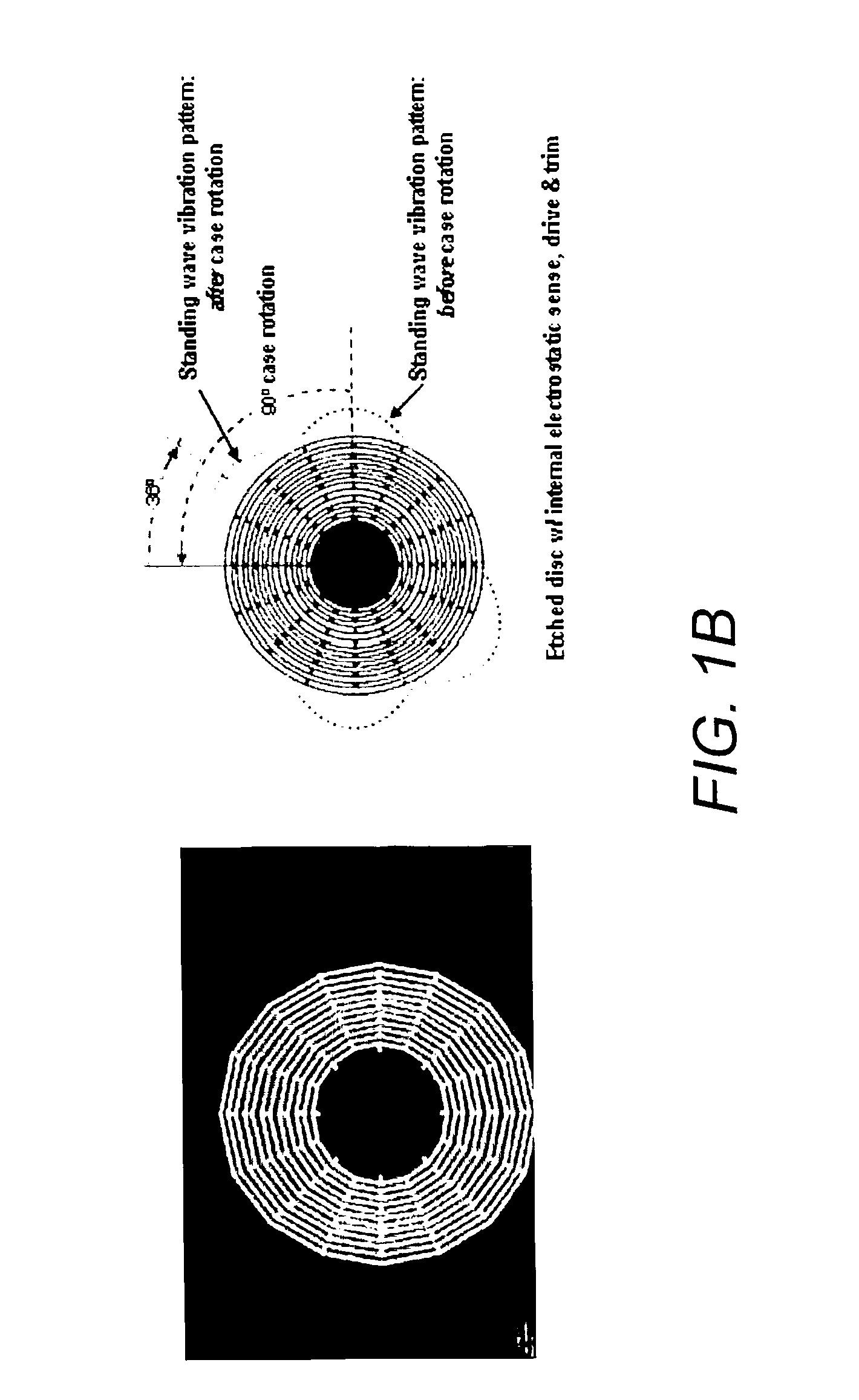

Disc resonator gyroscopes

ActiveUS20070017287A1Low anchor lossHigh QAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsCapacitanceCircular disc

Embodiments of the present invention are directed to apparatuses and methods of making a micromachined resonator gyroscope, e.g. a disc resonator gyro (DRG), including one or more of the following novel features. Embodiments of the invention may comprise a triple-wafer stack gyroscope with an all fused quartz (or all silicon) construction for an electrical baseplate, resonator and vacuum cap. This can yield superior thermal stability over prior art designs. A typical resonator embodiment may include a centrally anchored disc with high aspect-ratio in-plane electrostatic drive and sense electrodes to create large capacitance. A silicon sacrificial layer may be employed for attaching a quartz resonator wafer to a quartz handle wafer for high aspect-ratio etching. In addition, embodiments of the invention may comprise a low thermal stress, wafer-level vacuum packaged gyroscope with on-chip getter. An ultra-thin conductive layer deposited on the quartz resonator may also be utilized for high Q.

Owner:THE BOEING CO

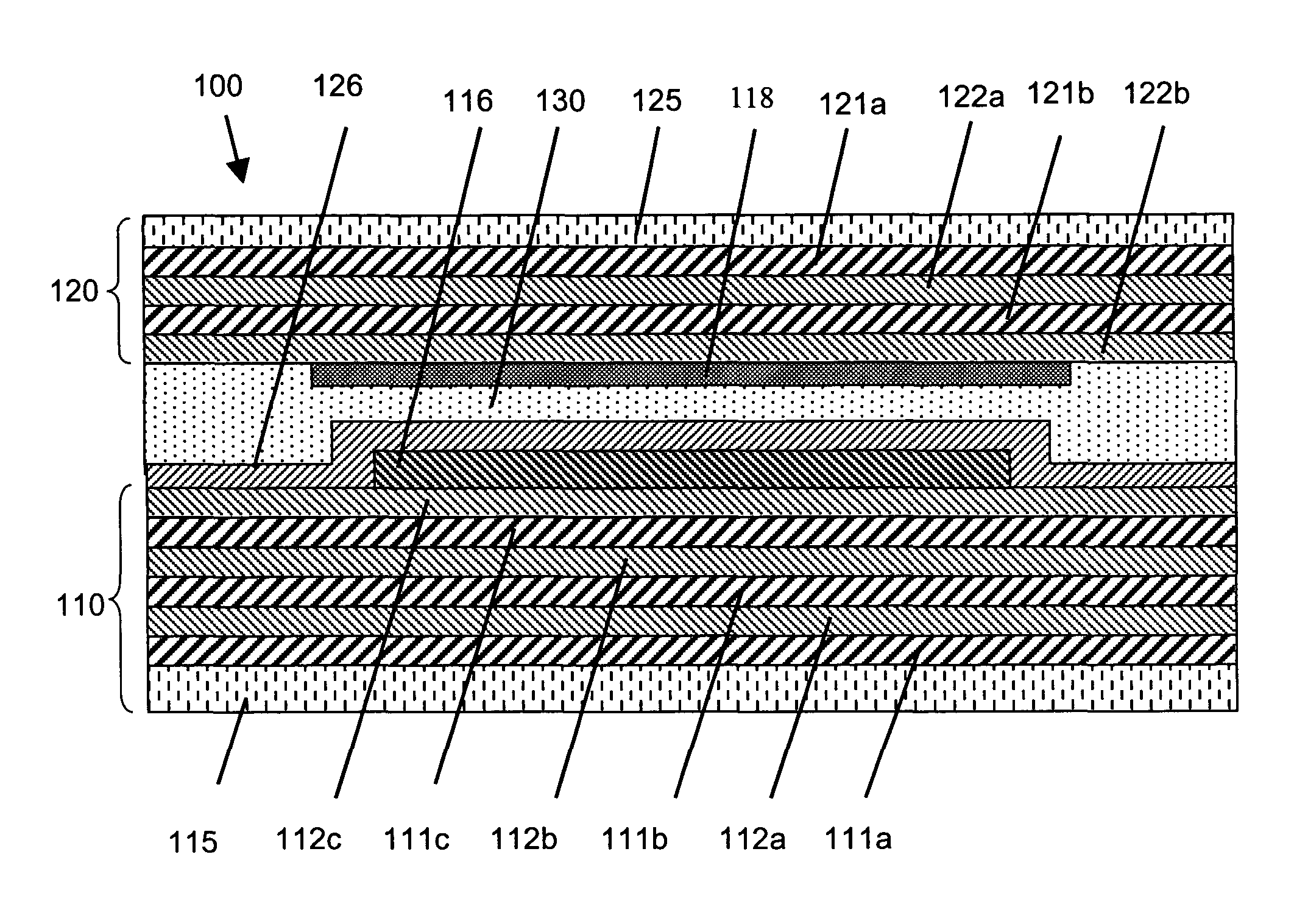

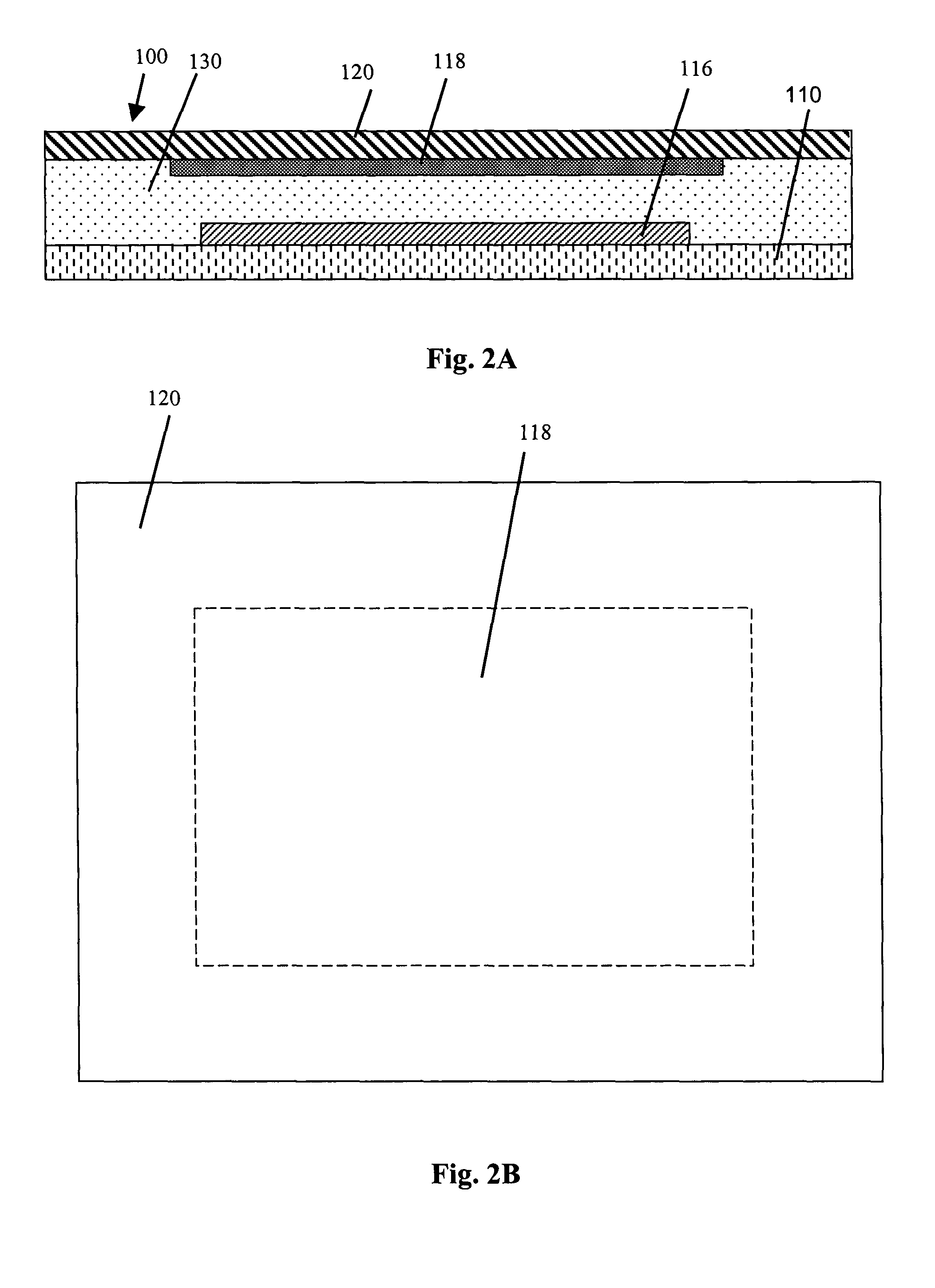

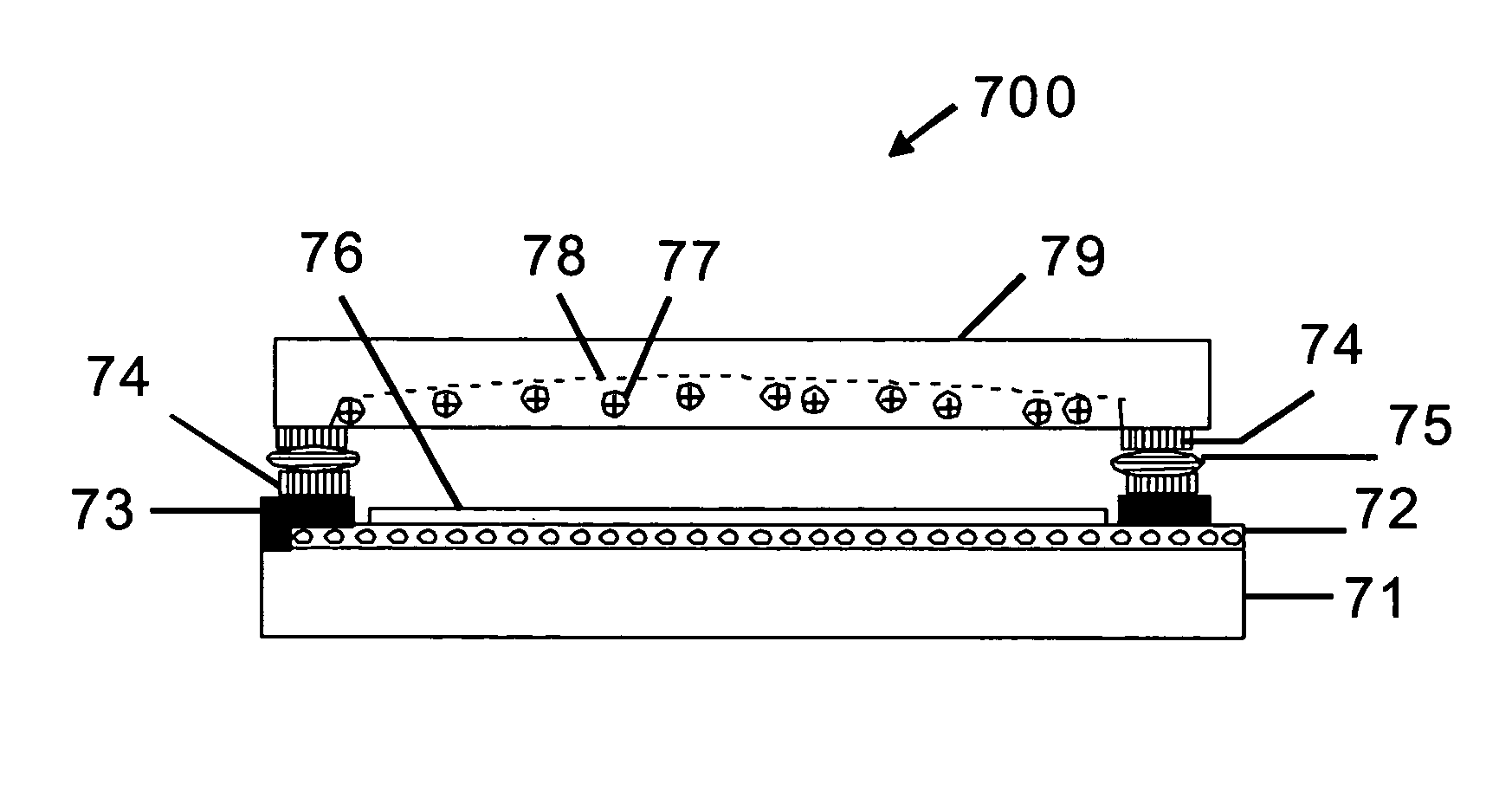

Patterned oxygen and moisture absorber for organic optoelectronic device structures

InactiveUS6888307B2Component is quite sensitiveProvide protectionDischarge tube luminescnet screensElectroluminescent light sourcesWater vaporOxygen

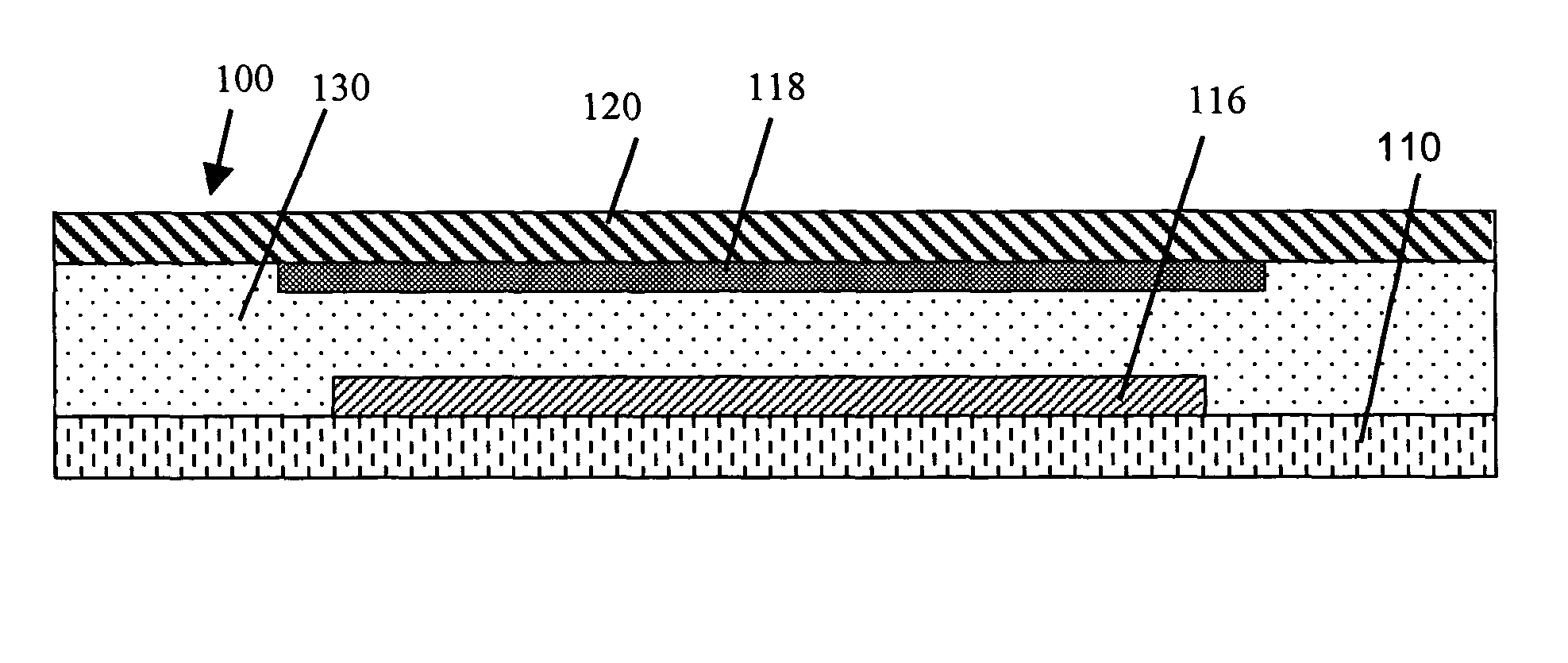

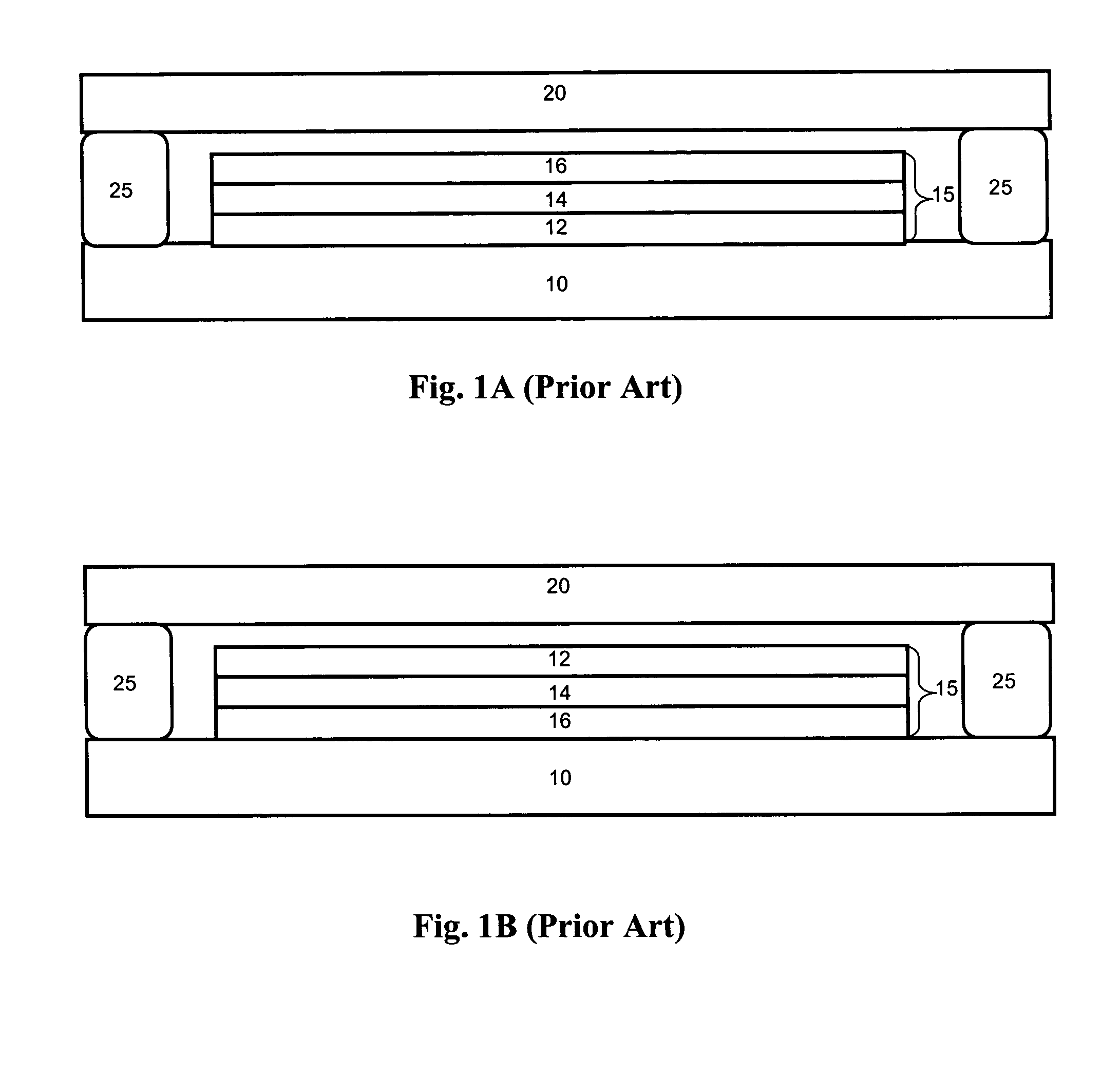

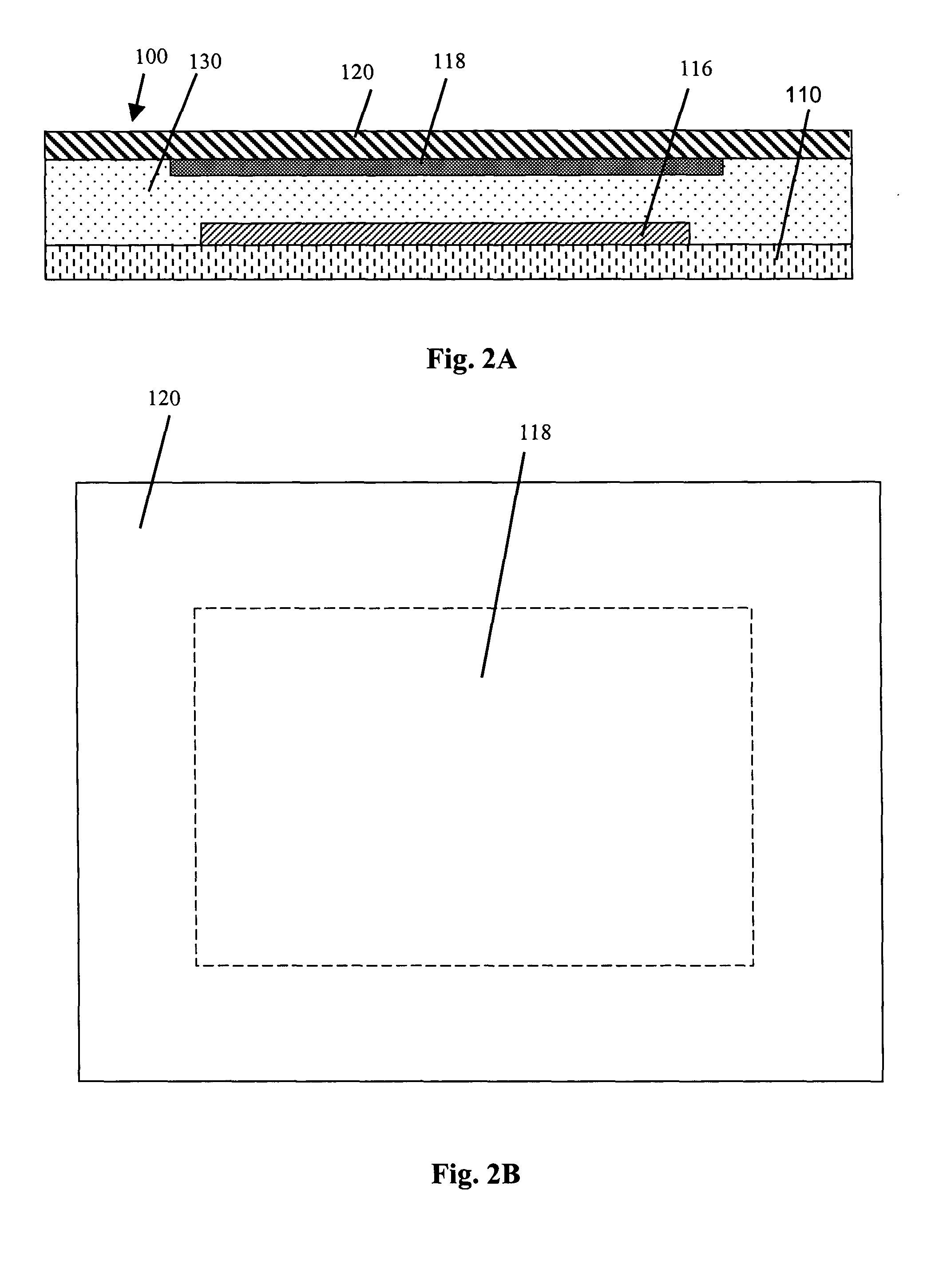

An OLED device structure and a method of making the same. The OLED device structure comprises (a) a substrate, (b) an OLED display area comprising one or more active pixels disposed over the substrate, wherein each of the one or more active pixels comprises an anode region, a cathode region and a light-emitting region, (c) a cover over the OLED display area, wherein the cover permits transmission of light from the one or more active pixels and an outer environment, and wherein the cover and the substrate cooperate to restrict transmission of oxygen and water vapor from the outer environment to the OLED display area, and (d) a patterned getter layer disposed between the substrate and the cover, wherein the patterned getter layer is configured so as to substantially avoid obstructing the transmission of light from the one or more pixels. Also disclosed are a flexible OLED device and an organic optoelectronic device structures having related configurations.

Owner:UNIVERSAL DISPLAY

Protected organic electronic device structures incorporating pressure sensitive adhesive and desiccant

InactiveUS20050045900A1Effective protectionEasy to optimizeSolid-state devicesSemiconductor/solid-state device manufacturingDesiccantGetter

Organic electronic device structures are provided, which comprise: (a) a first portion comprising a substrate and an organic electronic device region (e.g., an OLED region) disposed over the substrate; (b) a second portion comprising a cover and a getter region; and (c) a radiation-curable, pressure-sensitive adhesive layer disposed between the first and second portions and adhering the first and second portions to one another. The adhesive layer is disposed over the entire organic electronic device region and over at least a portion of the substrate. Other aspects of the present invention are directed to methods of making the above structures.

Owner:UNIVERSAL DISPLAY

Disc resonator gyroscopes

ActiveUS7581443B2Low anchor lossHigh QAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsCapacitanceGyroscope

Embodiments of the present invention are directed to apparatuses and methods of making a micromachined resonator gyroscope, e.g. a disc resonator gyro (DRG), including one or more of the following novel features. Embodiments of the invention may comprise a triple-wafer stack gyroscope with an all fused quartz (or all silicon) construction for an electrical baseplate, resonator and vacuum cap. This can yield superior thermal stability over prior art designs. A typical resonator embodiment may include a centrally anchored disc with high aspect-ratio in-plane electrostatic drive and sense electrodes to create large capacitance. A silicon sacrificial layer may be employed for attaching a quartz resonator wafer to a quartz handle wafer for high aspect-ratio etching. In addition, embodiments of the invention may comprise a low thermal stress, wafer-level vacuum packaged gyroscope with on-chip getter. An ultra-thin conductive layer deposited on the quartz resonator may also be utilized for high Q.

Owner:THE BOEING CO

Charged particle beam apparatus

InactiveUS20060231773A1Improve efficiencyEasy maintenanceBeam/ray focussing/reflecting arrangementsBeam/ray deflecting arrangementsGetterFree space

A small-sized charged particle beam apparatus capable of maintaining high vacuum even during emission of an electron beam is provided. A nonevaporative getter pump is placed upstream of differential pumping of an electron optical system of the charged particle beam apparatus, and a minimum number of ion pumps are placed downstream, so that both the pumps are used in combination. Further, by mounting a detachable coil on an electron gun part, the inside of a column can be maintained under high vacuum with a degree of vacuum in the order of 10−8 Pa.

Owner:HITACHI HIGH-TECH CORP

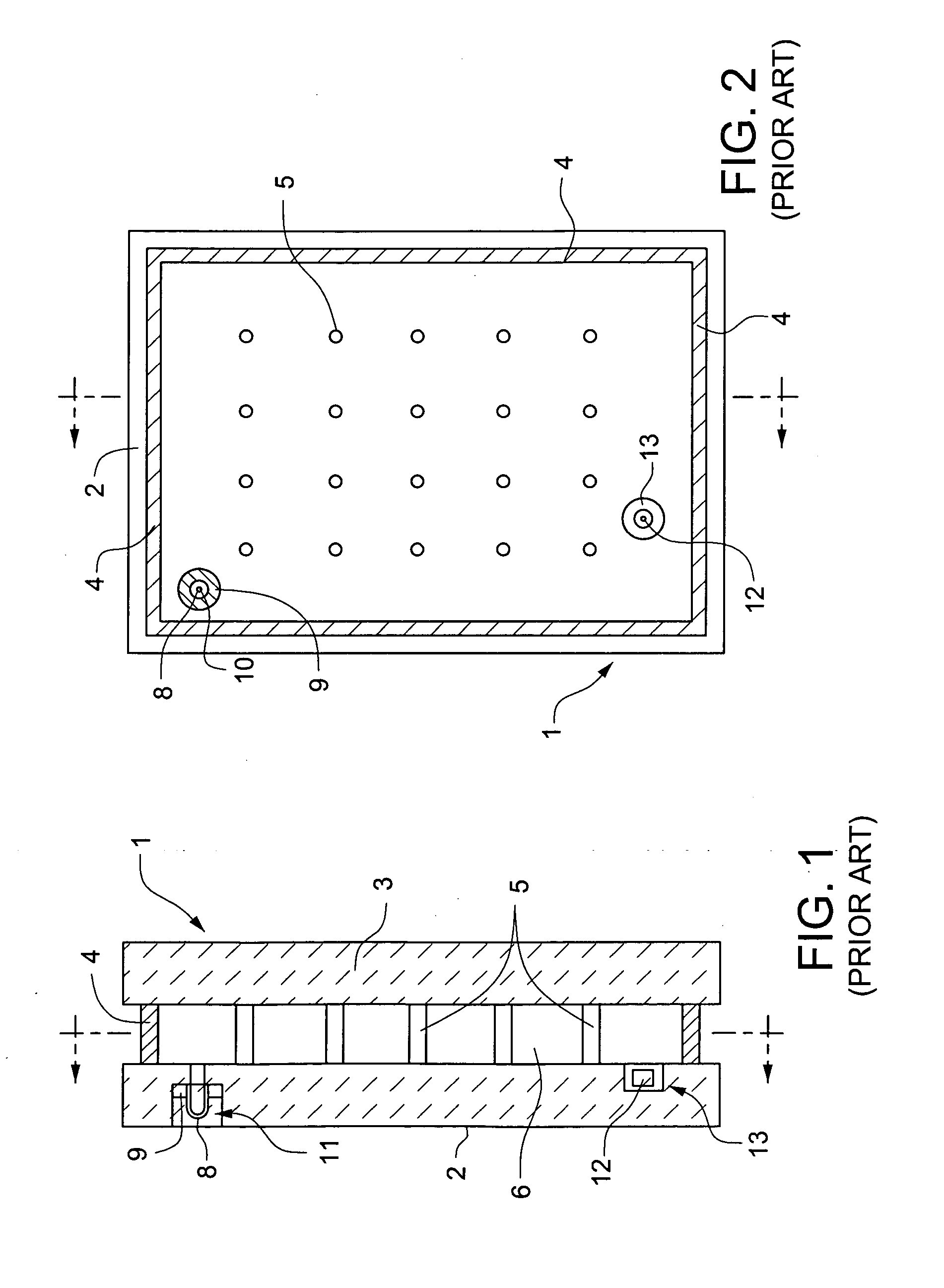

Vacuum insulating glass unit with large pump-out port, and/or method of making the same

ActiveUS20090155500A1Increase the diameterSimple technologyGlass furnace apparatusClimate change adaptationEngineeringGetter

Certain example embodiments of this invention relate to vacuum insulating glass (VIG) units, and / or methods of making the same. More particularly, certain example embodiments relate to VIG units having large pump-out ports, and / or methods of making the same. In certain example embodiments, a vacuum insulating glass (VIG) unit is provided. First and second spaced-apart glass substrates are provided, and a gap is provided between the spaced-apart substrates. A pump-out port has a size (e.g., diameter) of at least about 30 mm. A cover seals the pump-out port. A getter is in communication with the gap. The pump-out port is sealed using the cover, in making the vacuum insulating glass unit, via a sealing material provided proximate to the cover and / or proximate to the pump-out port.

Owner:GUARDIAN GLASS LLC

Method for scavenging mercury

Owner:RGT UNIV OF CALIFORNIA

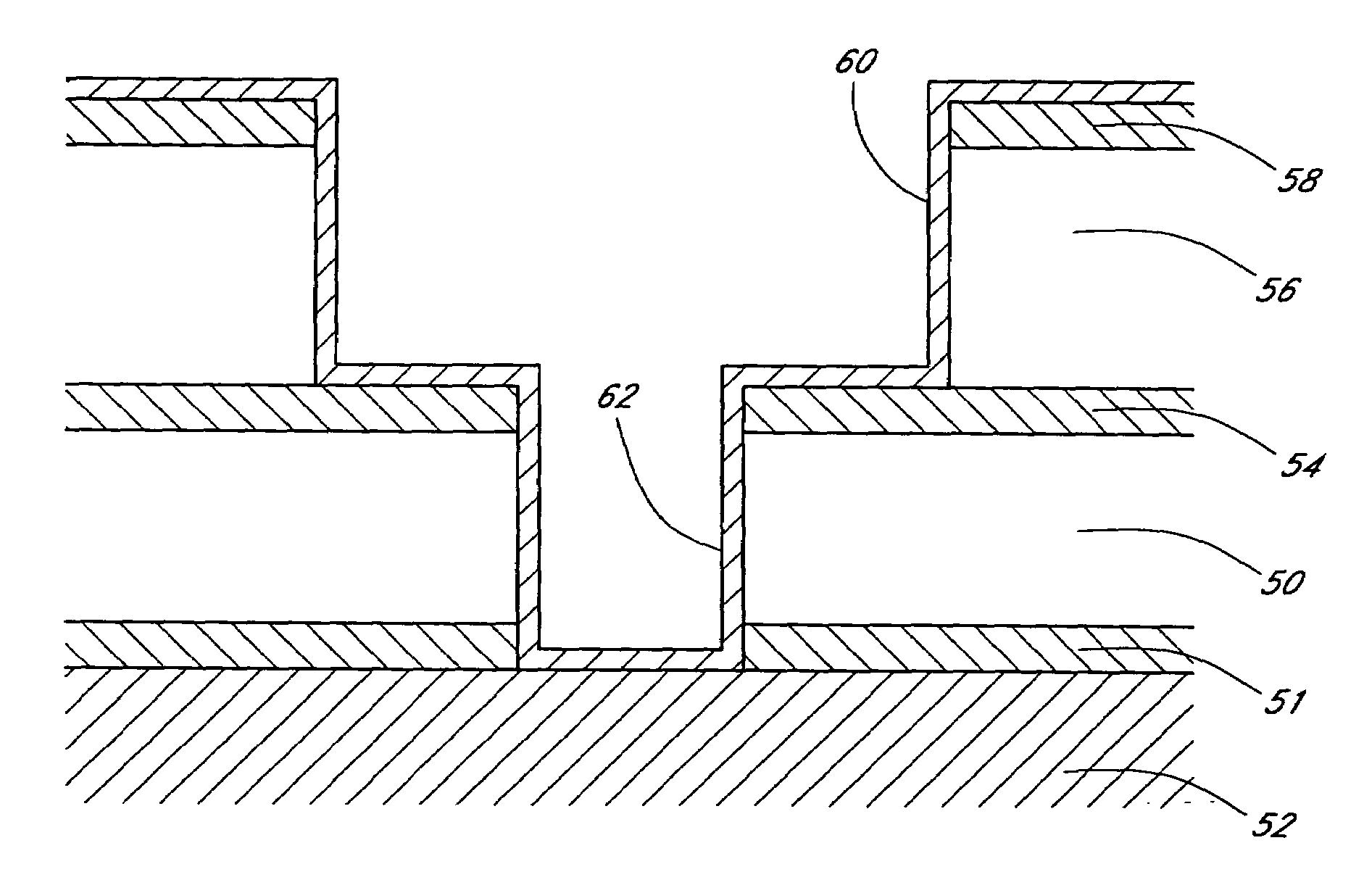

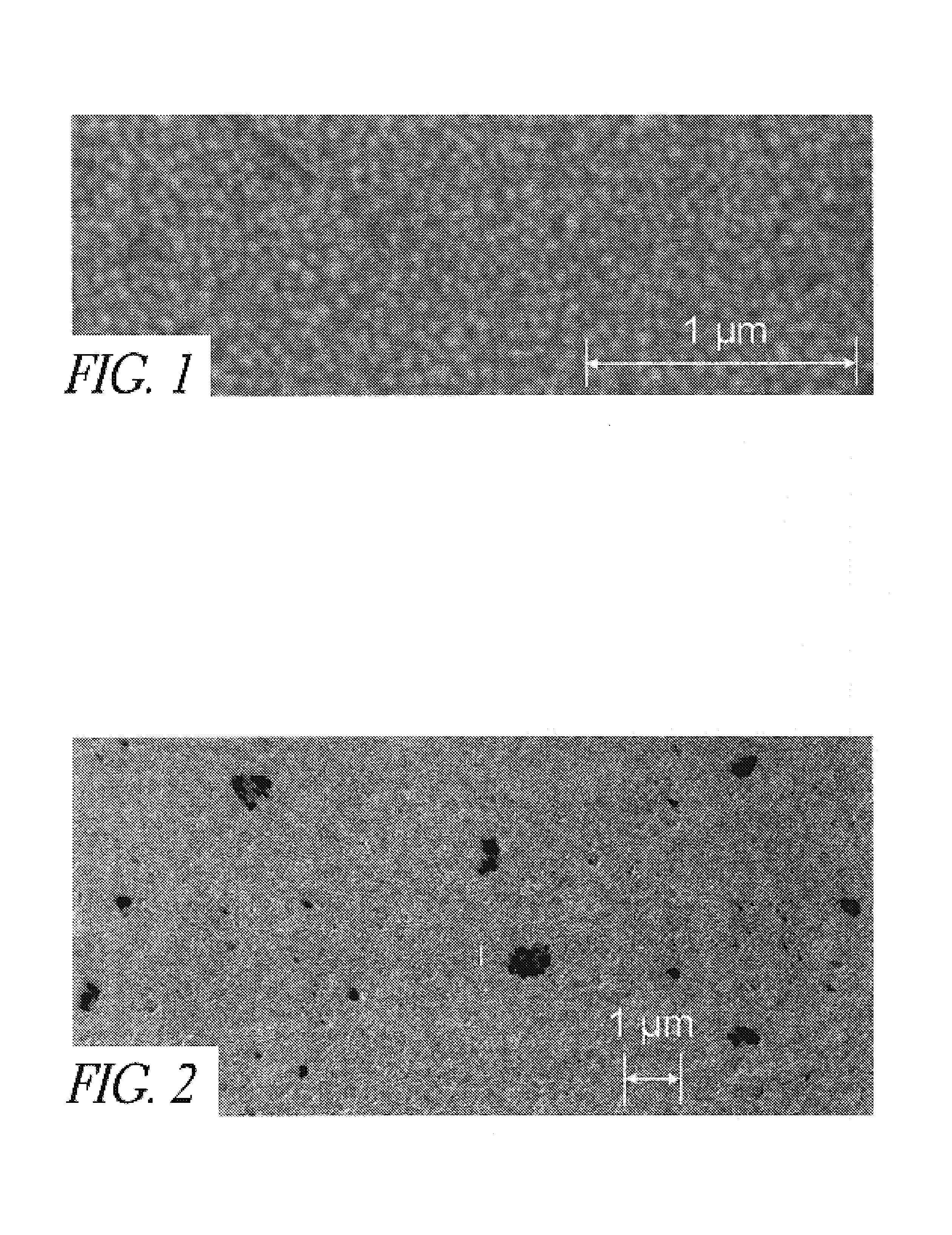

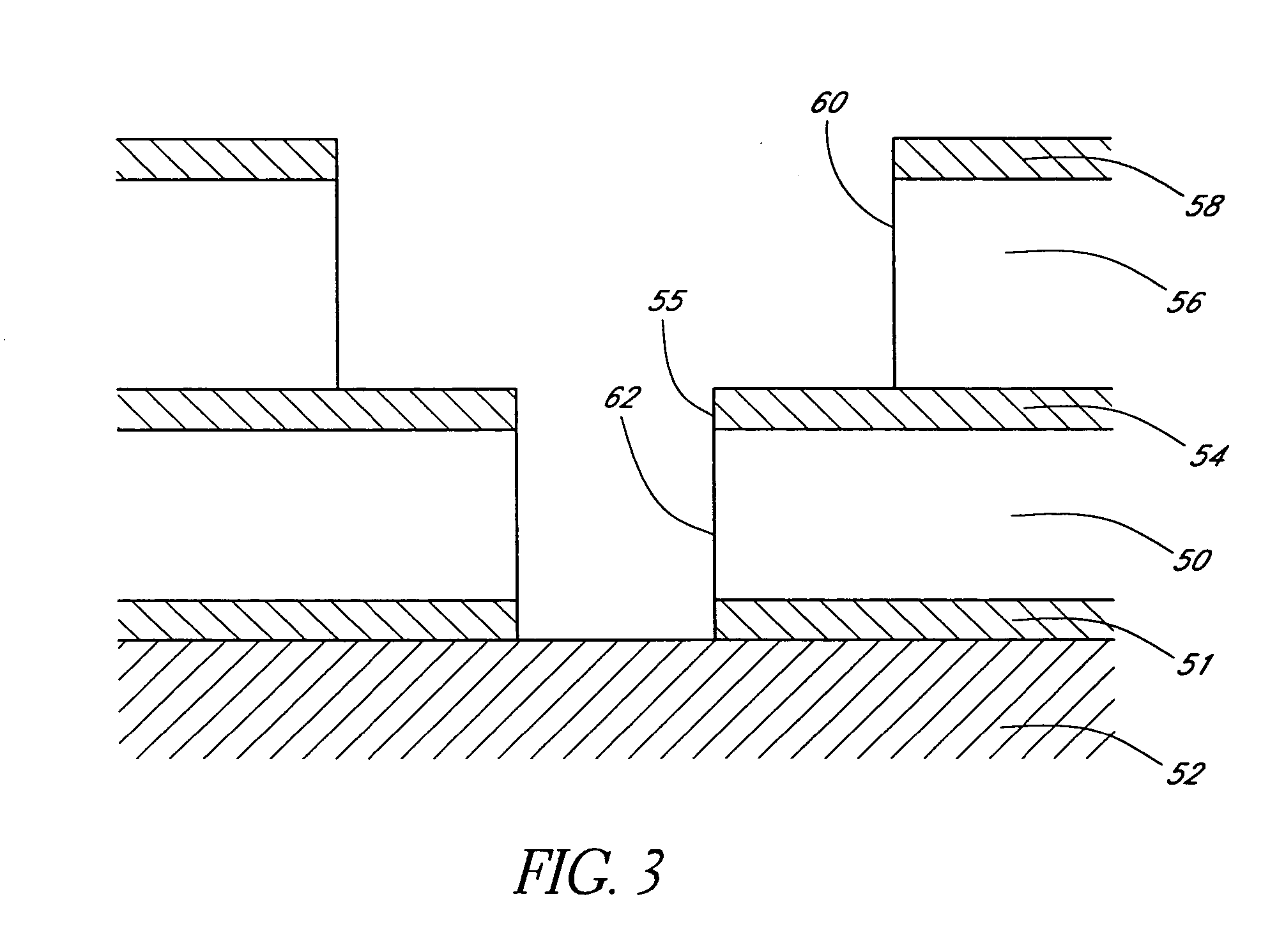

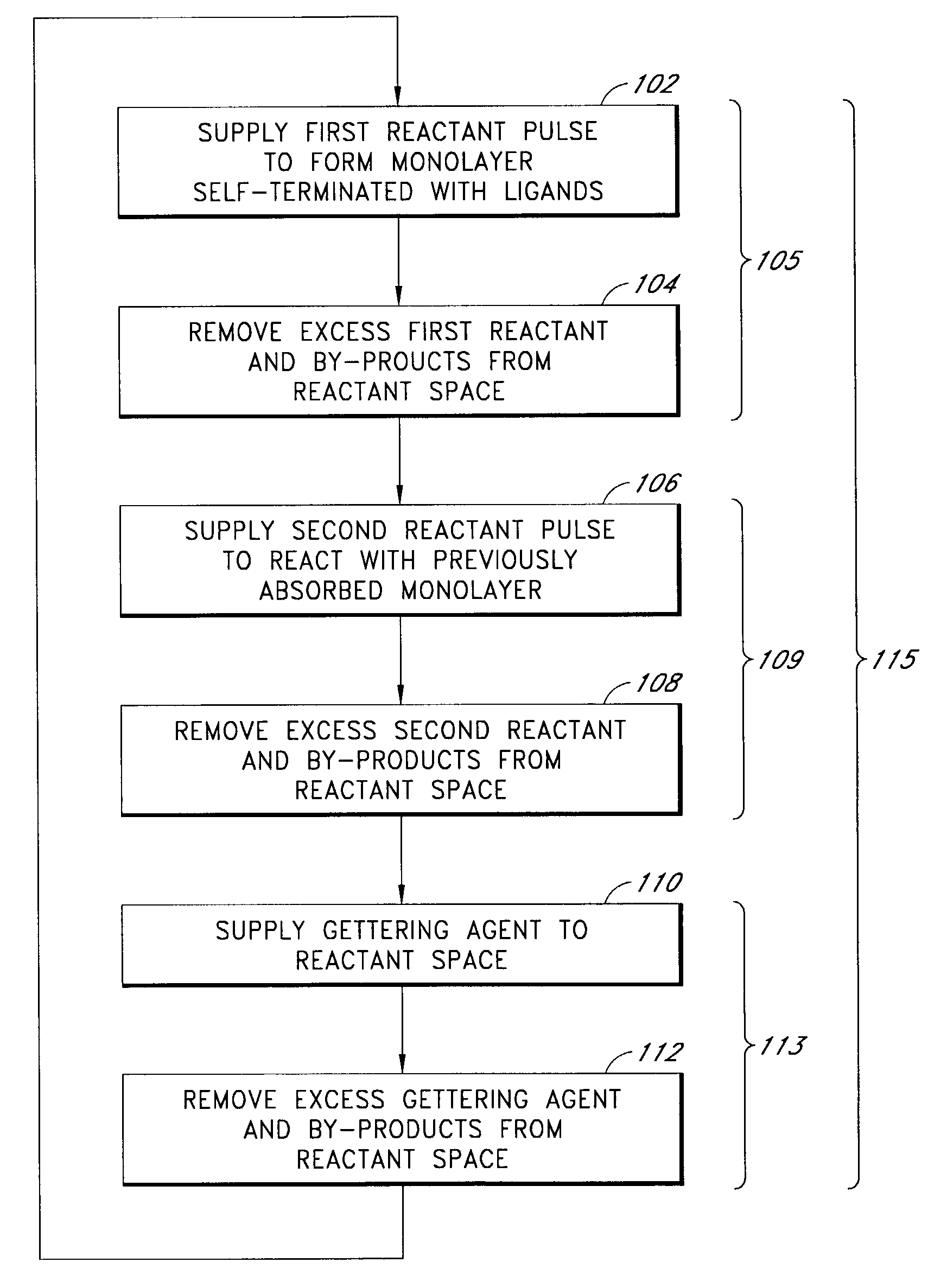

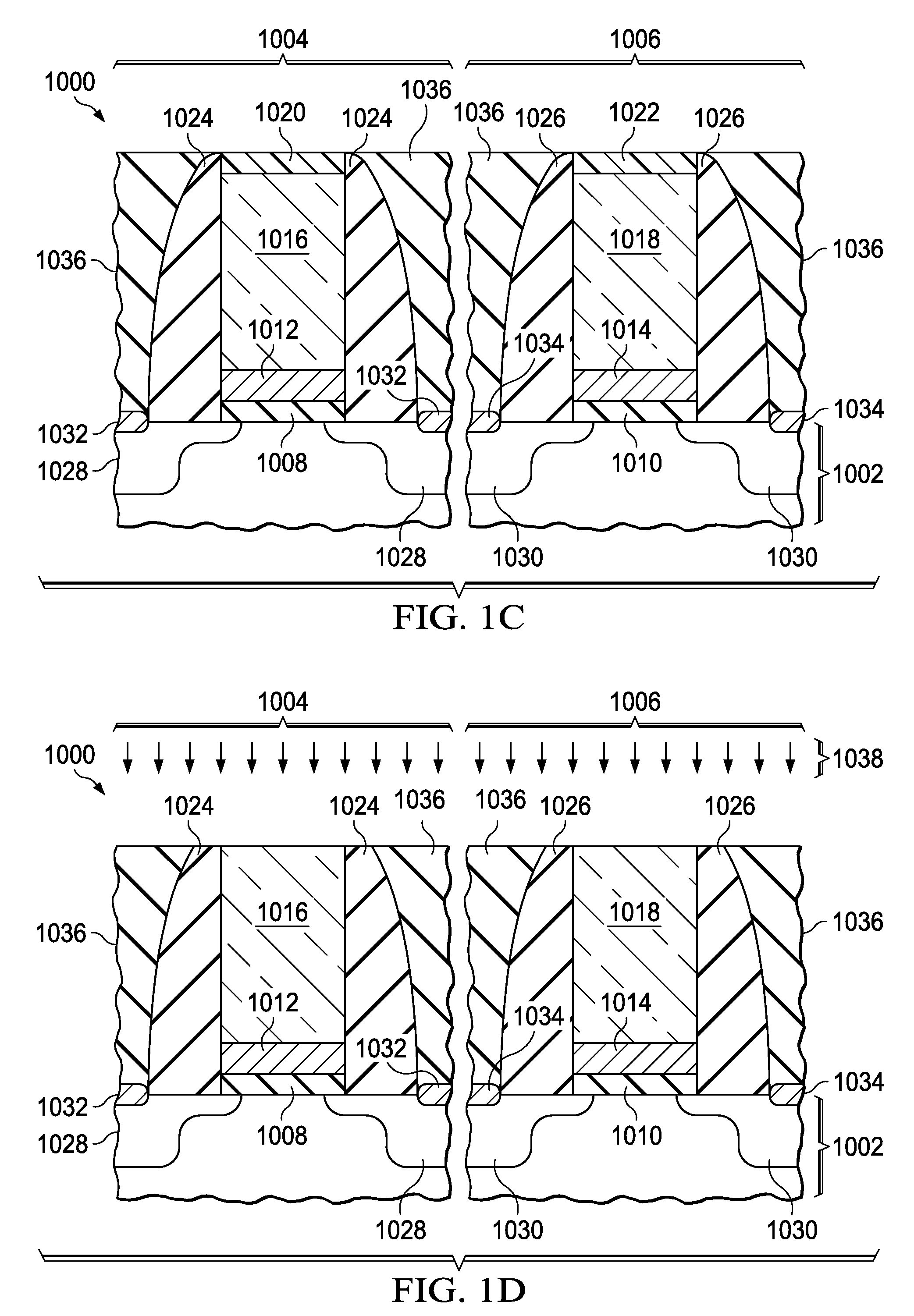

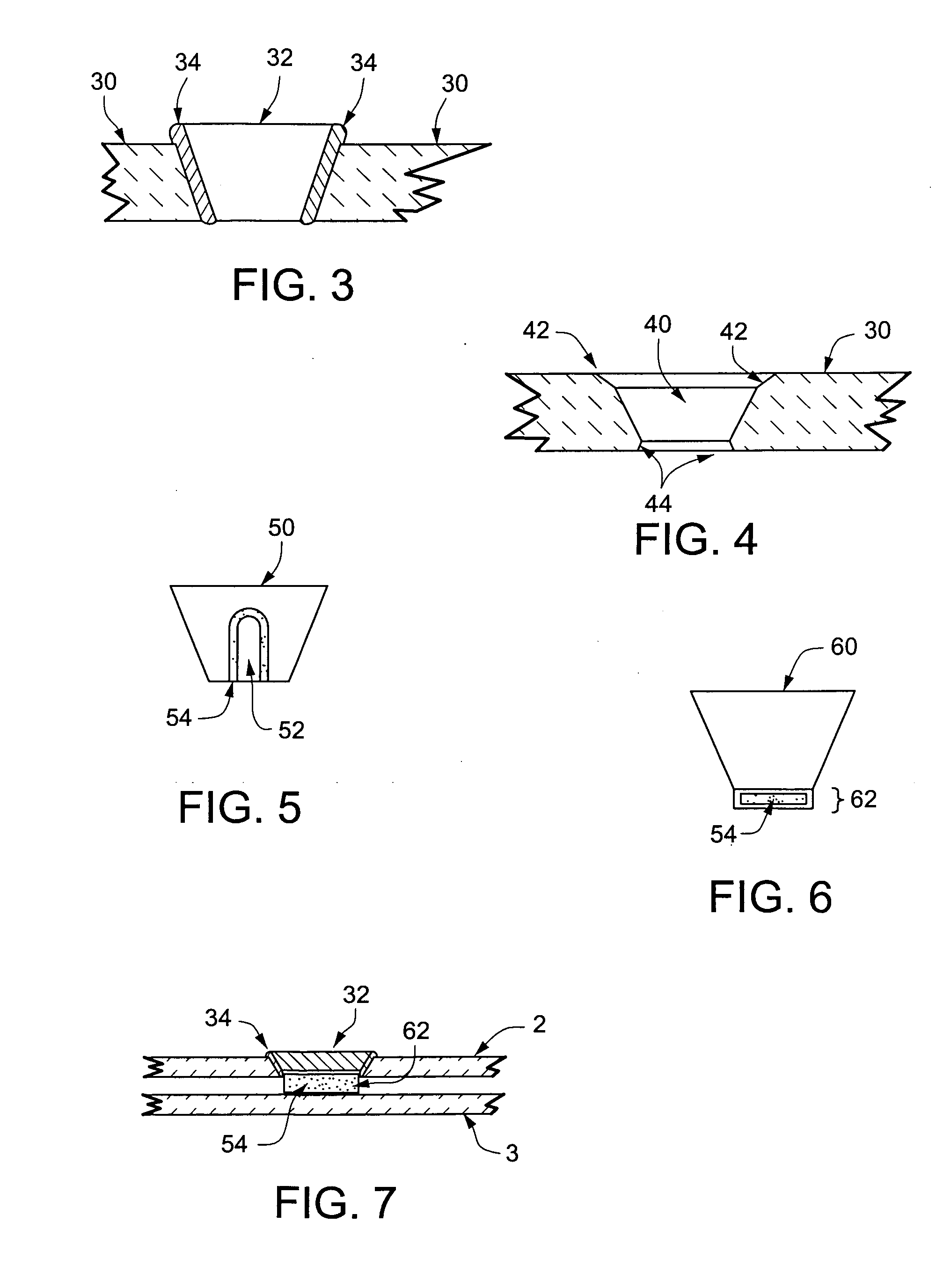

Method for depositing nanolaminate thin films on sensitive surfaces

InactiveUS20050106877A1Polycrystalline material growthSemiconductor/solid-state device manufacturingHydrogen halideCorrosive chemical

The present method provides tools for growing conformal metal nitride, metal carbide and metal thin films, and nanolaminate structures incorporating these films, from aggressive chemicals. The amount of corrosive chemical compounds, such as hydrogen halides, is reduced during the deposition of transition metal, transition metal carbide and transition metal nitride thin films on various surfaces, such as metals and oxides. Getter compounds protect surfaces sensitive to hydrogen halides and ammonium halides, such as aluminum, copper, silicon oxide and the layers being deposited, against corrosion. Nanolaminate structures (20) incorporating metal nitrides, such as titanium nitride (30) and tungsten nitride (40), and metal carbides, and methods for forming the same, are also disclosed.

Owner:ASM INTERNATIONAL

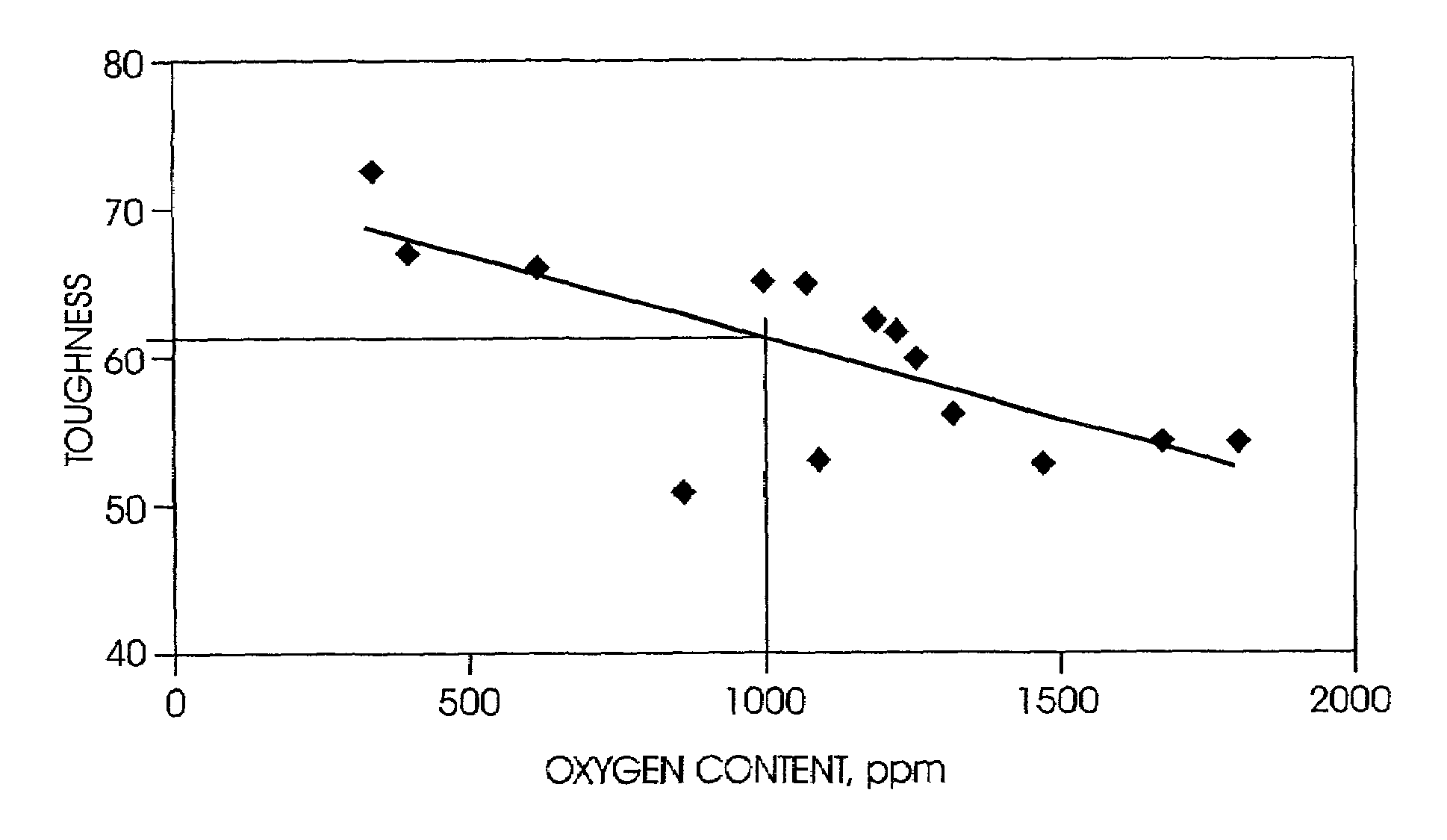

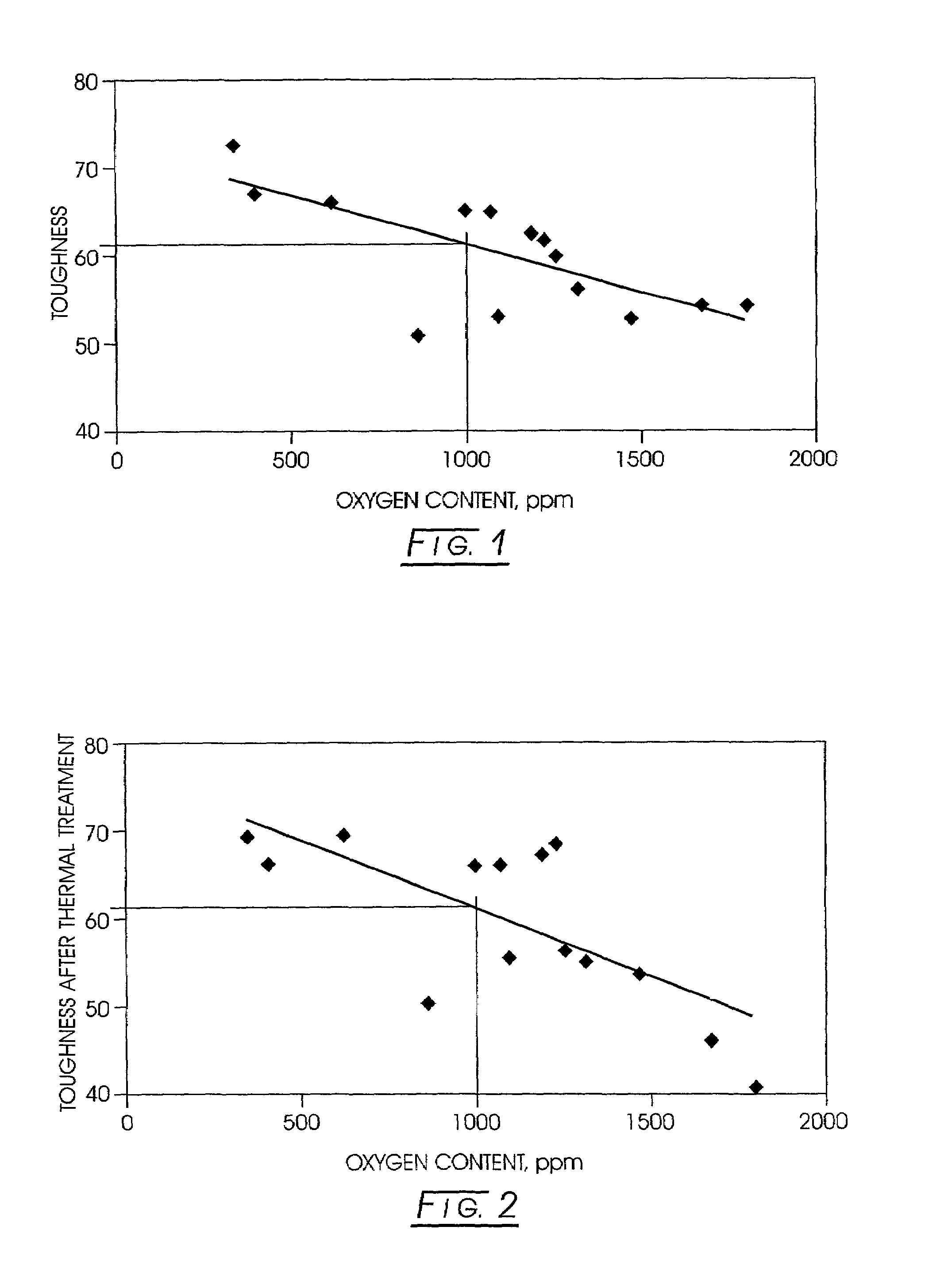

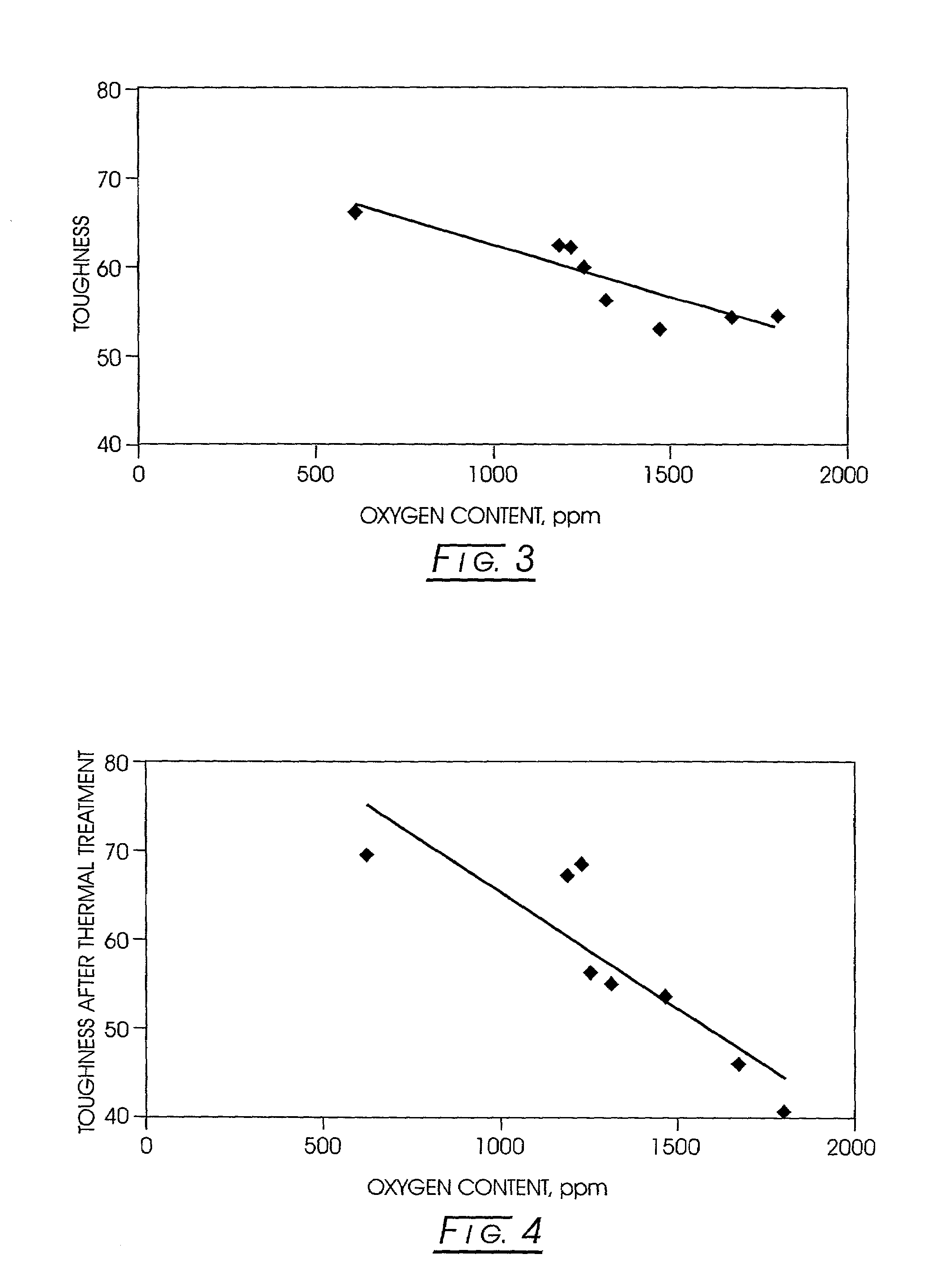

Low oxygen cubic boron nitride and its production

InactiveUS7001577B2Increased toughness indexImprove toughnessFrom gel statePolycrystalline material growthBoron nitrideHigh pressure

A method for improving the toughness of a CBN product made by a high temperature / high pressure (HP / HT) process commences by forming a blend of an oxygen getter and CBN product-forming feedstock. The blend is subjected to a CBN high temperature / high pressure (HP / HT) process for forming a CBN product. The amount of oxygen getter in the blend is sufficient to improve the toughness of the CBN product. The resulting CBN product desirably has an oxygen content of less than about 300 ppm. Oxygen getters include Al, Si, and Ti. The HP / HT process is conducted in the absence or presence of catalytic materials.

Owner:DIAMOND INNOVATIONS INC

Field emission display

InactiveUS6172456B1Reduce in quantityIncrease in costGas filling substance selectionDischarge tube luminescnet screensField emission displayDisplay device

A flat-panel field emission display comprises a luminescent faceplate, a rigid backplate, and an interposed or sandwiched emitter or cathode plate. A positioning spacer or connector ridge is formed on the rear surface of the faceplate to space the cathode plate a fixed distance behind the faceplate. A peripheral seal is formed between the faceplate and the backplate. The faceplate, backplate, and peripheral seal define an evacuated internal space which contains the cathode plate. The backplate is spaced behind the cathode plate to create a rearward vacuum space in which a getter is located.

Owner:MICRON TECH INC

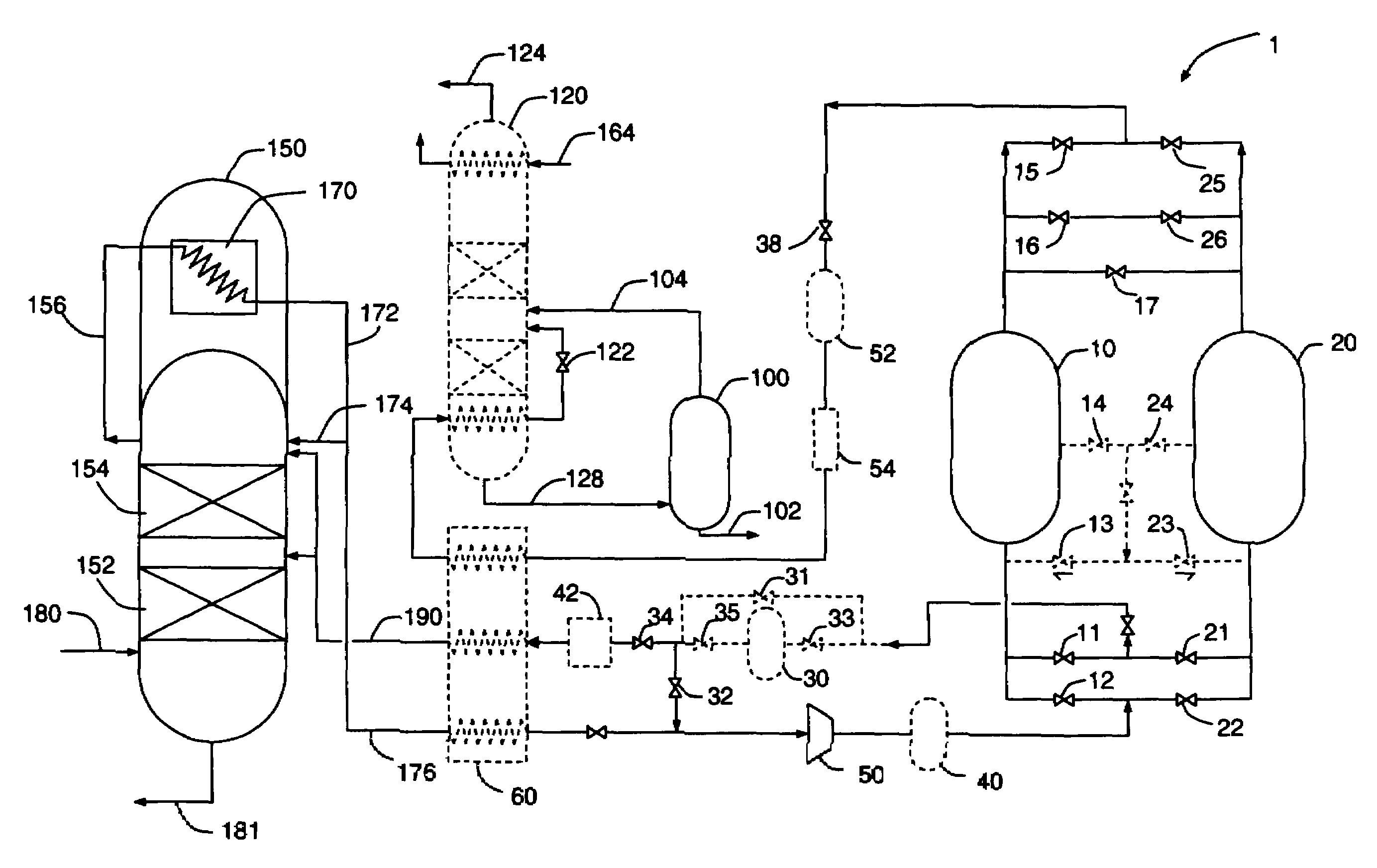

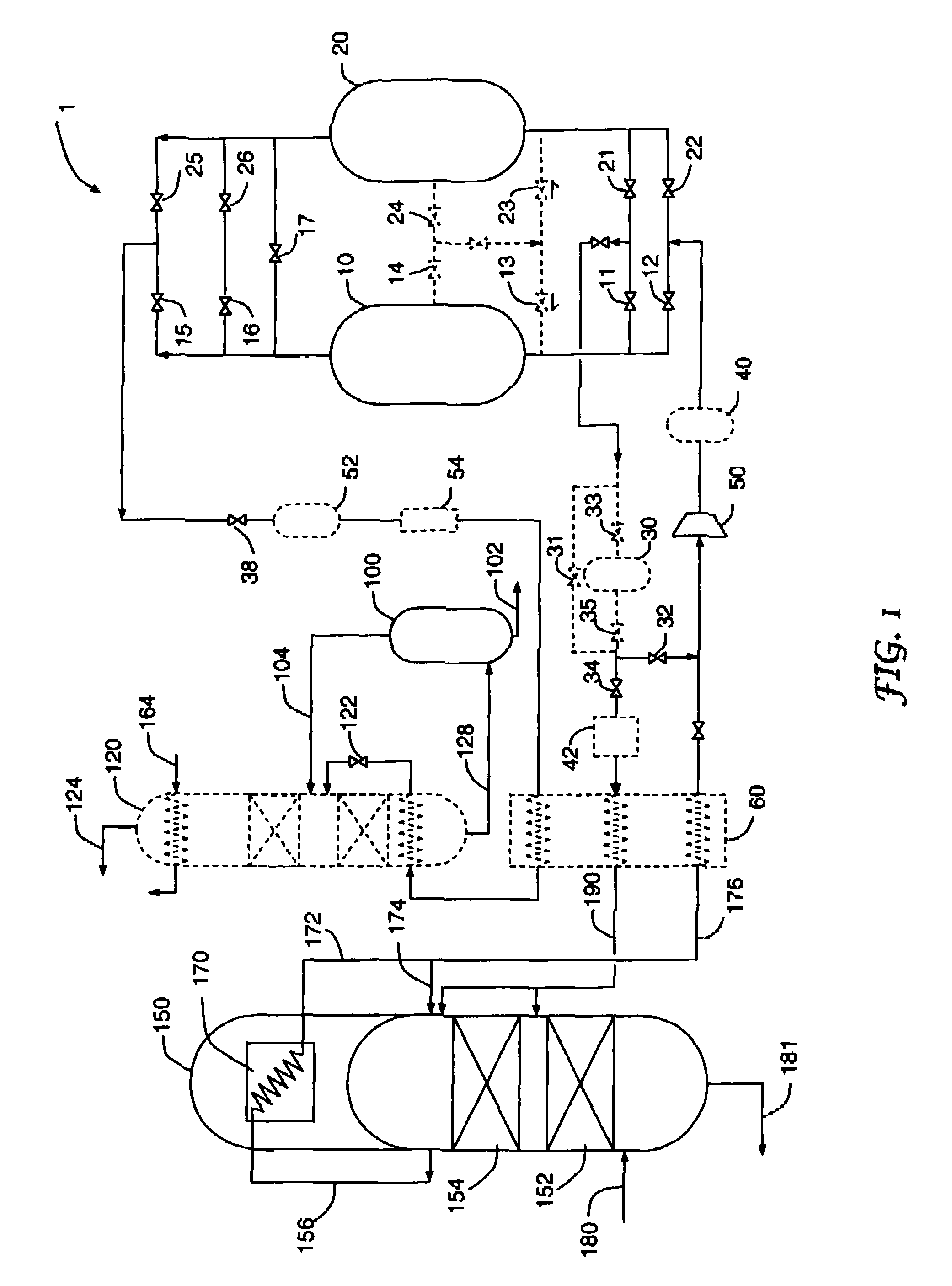

Combined cryogenic distillation and PSA for argon production

ActiveUS7501009B2Improvements in the refining of crude argonSpeed up the processSolidificationLiquefactionParticulatesFiltration

A method and apparatus for producing high purity argon by combined cryogenic distillation and adsorption technologies is disclosed. Crude argon from a distillation column or a so-called argon column is passed to a system of adsorption vessels for further purification. Depressurization gas from adsorption is introduced back, in a controlled manner, to the distillation column and / or a compressor or other means for increasing pressure. Particulate filtration and getter purification may optionally be used.

Owner:AIR PROD & CHEM INC

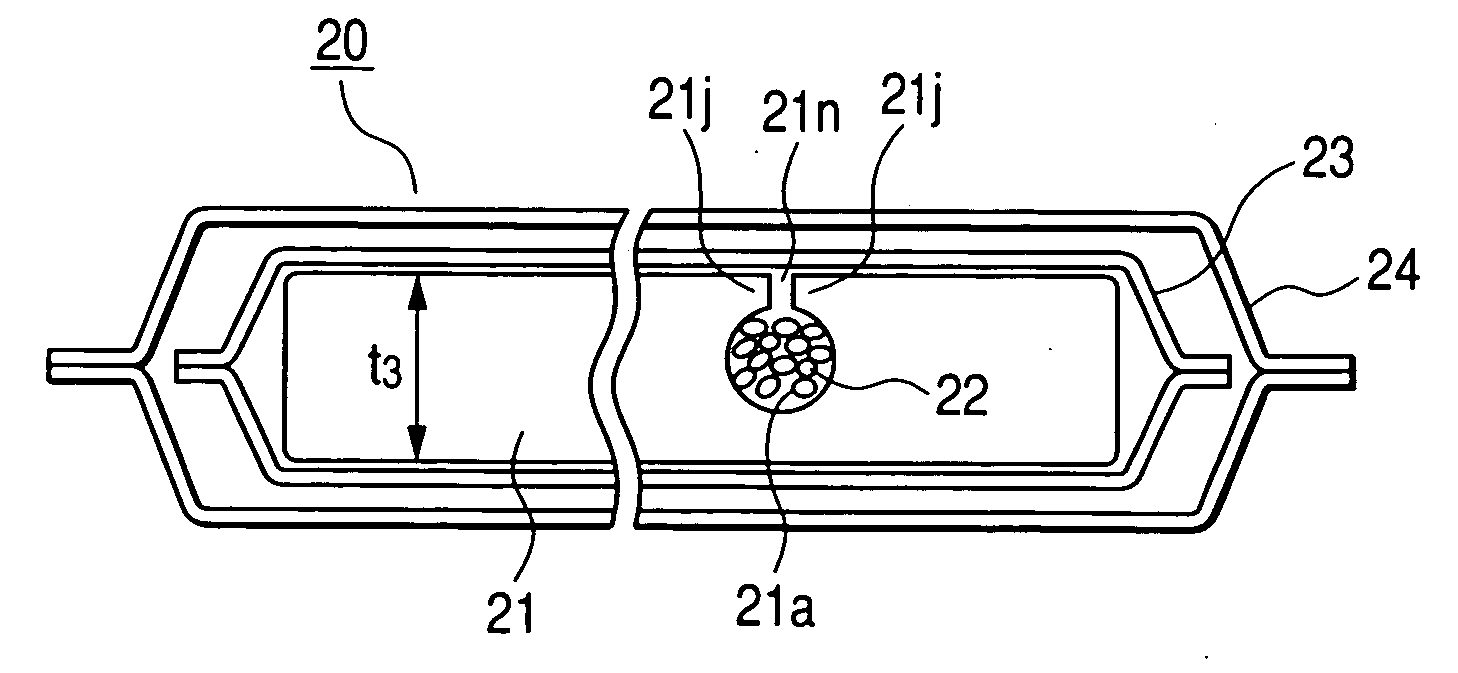

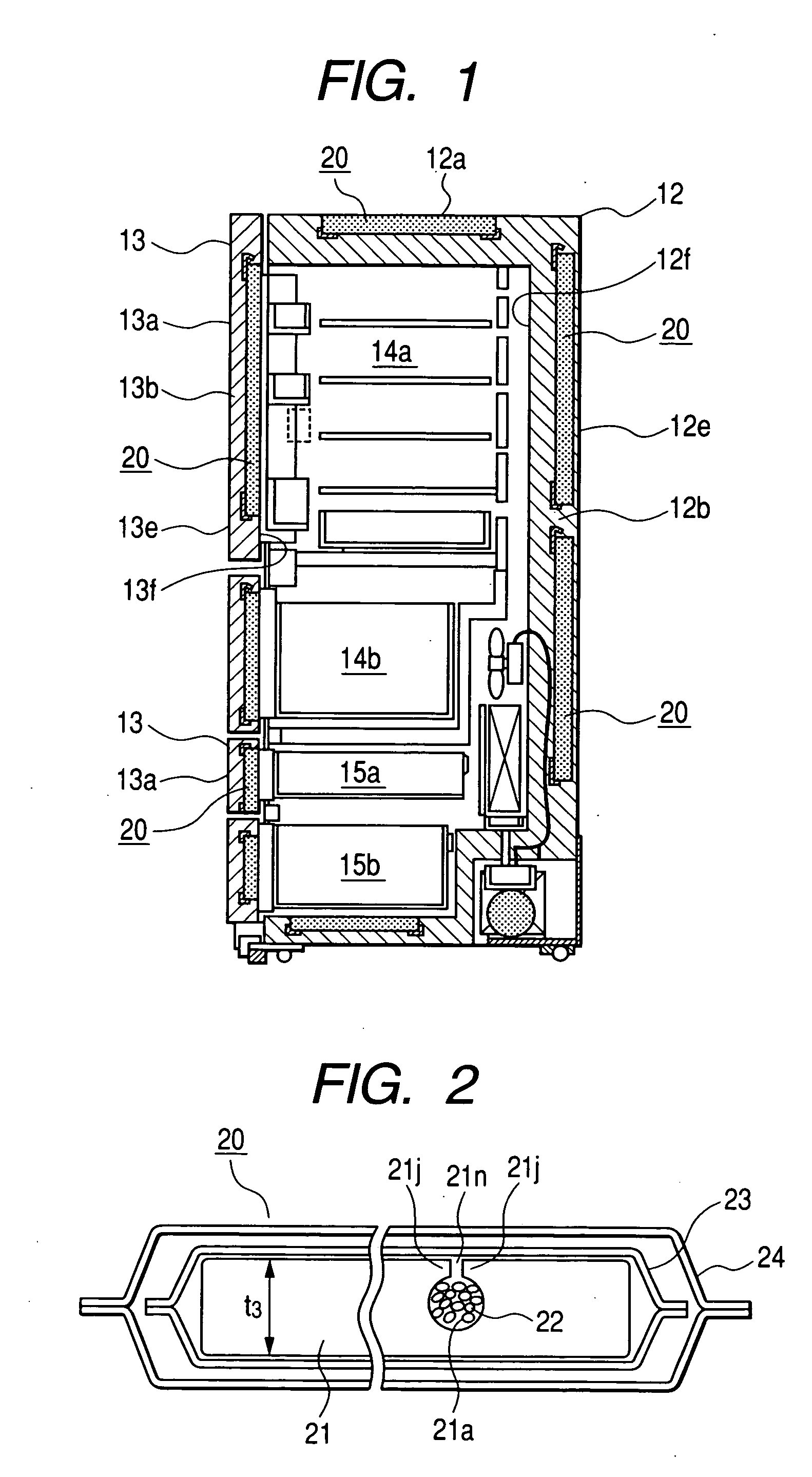

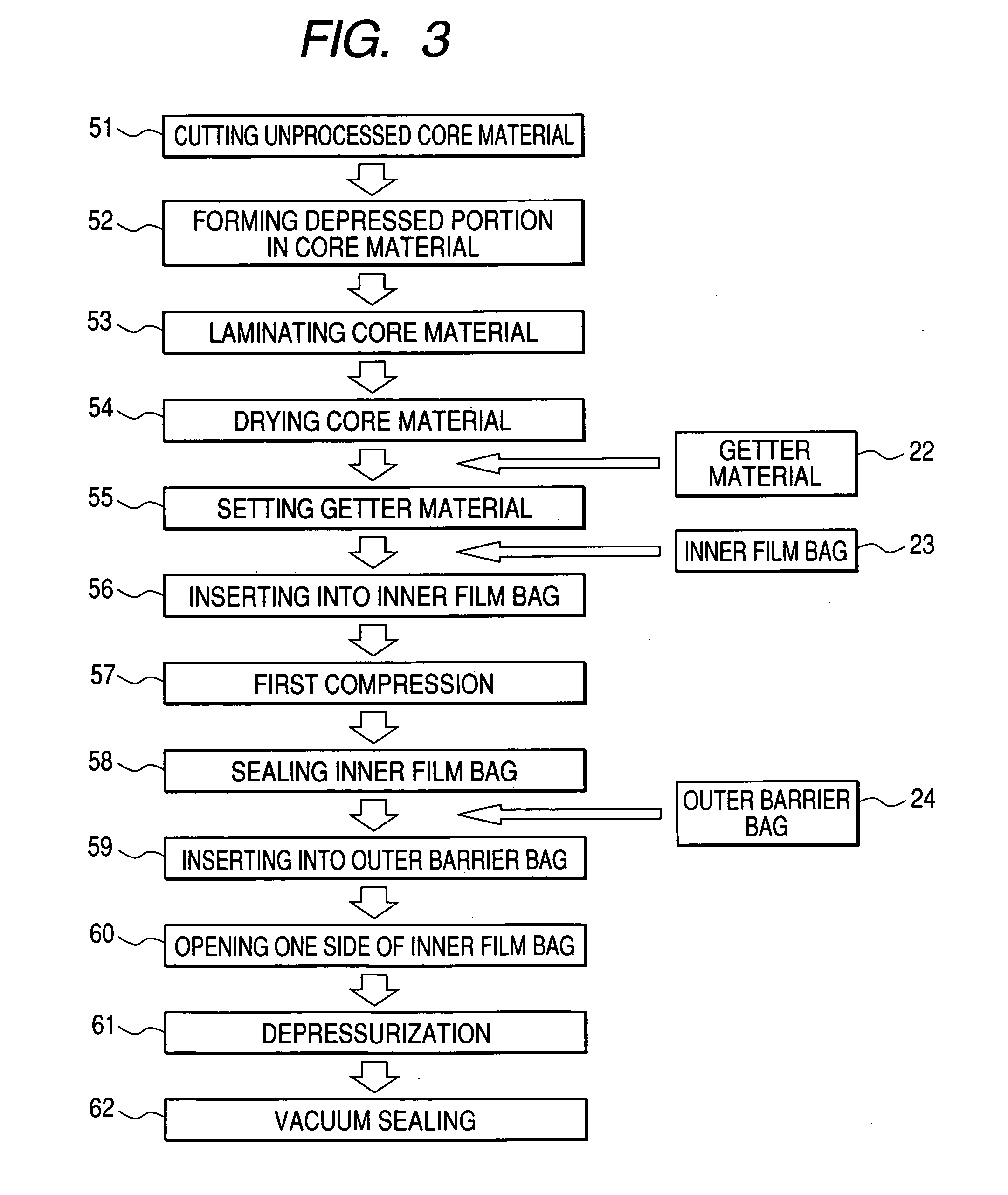

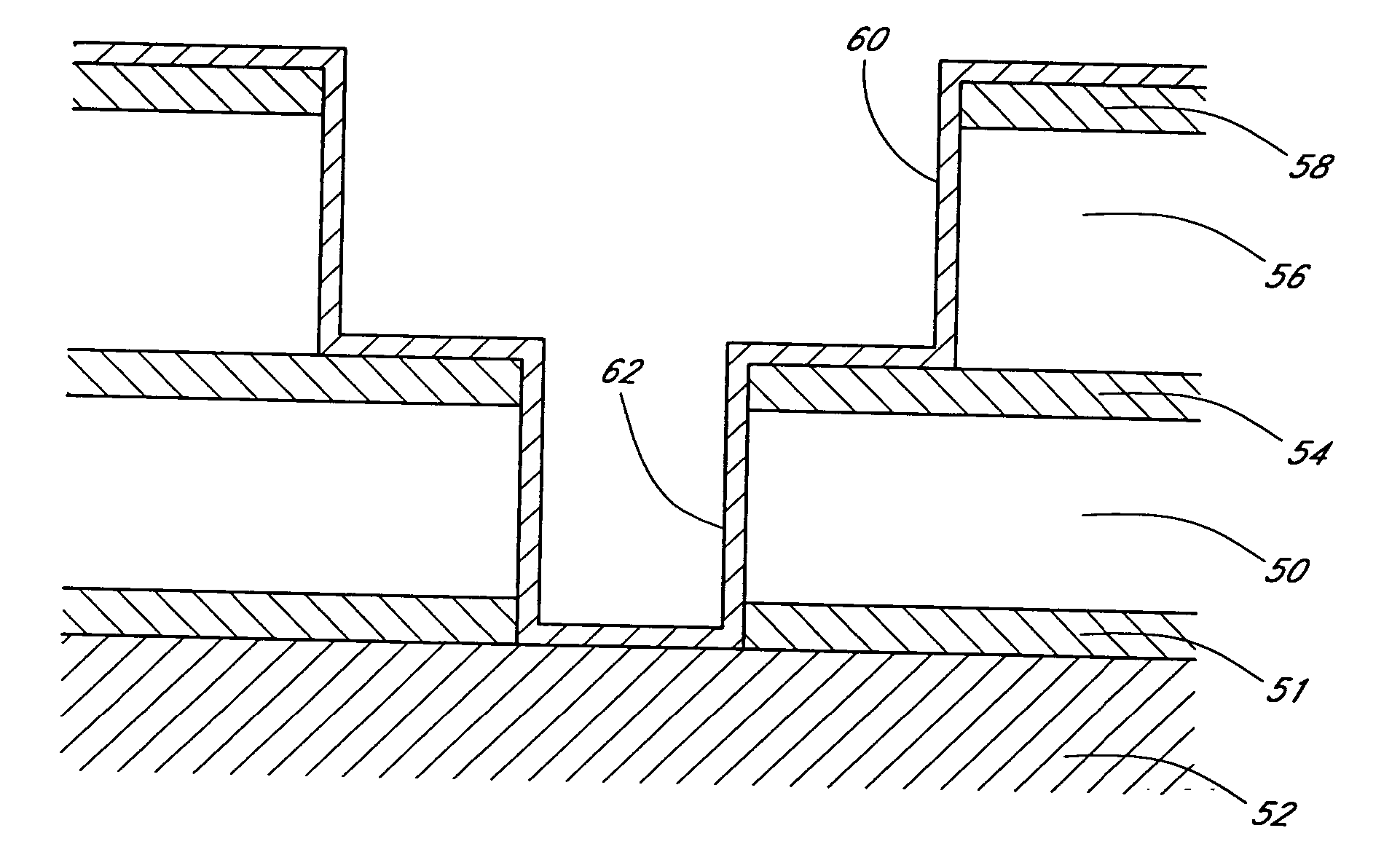

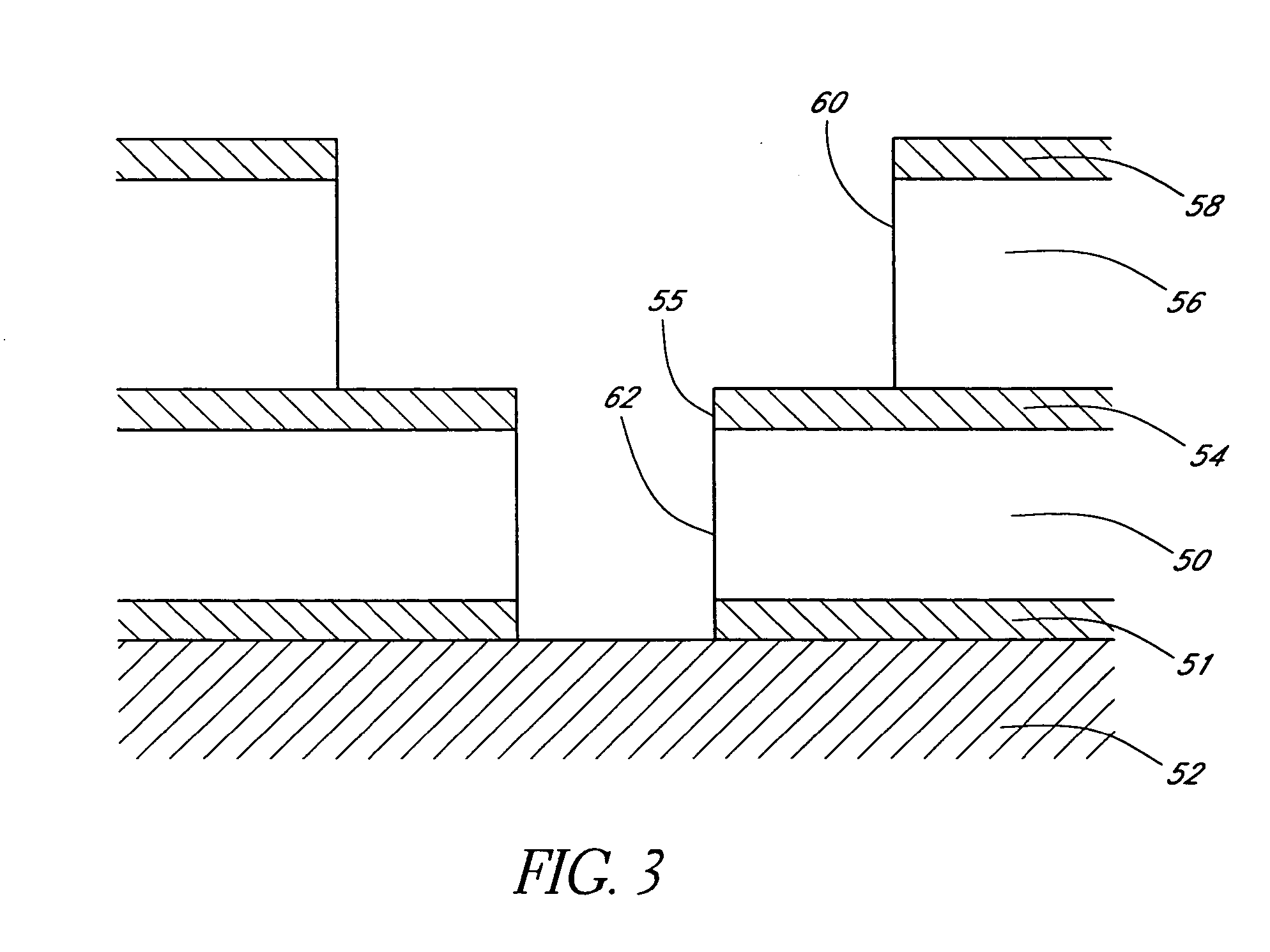

Vacuum insulation panel, refrigerator incorporating the same, and method for producing the same

InactiveUS20060076863A1Increased processing flexibilityHigh adsorption rateThermal insulationLayered productsAir cycleEngineering

The invention provides a vacuum insulation panel to which moisture and gas do not easily adsorb while it is being processed or being in storage in an unfinished state. The vacuum insulation panel includes a core provided with air circulation, a getter material which adsorbs moisture and gas from the core, an inner film bag which accommodates the core and the getter material, and an outer barrier bag which accommodates the inner film bag. The getter material is filled in an incision provided on the surface of the core. To prevent the getter material from getting out of the incision, the opening of the incision is narrowed by evacuating air from the interior of the inner film bag and, concurrently, compressing the inner film bag and the core.

Owner:HITACHI APPLIANCES INC

Metal nitride carbide deposition by ALD

InactiveUS20060078679A1Material nanotechnologySemiconductor/solid-state device detailsHydrogen halideCorrosive chemical

Owner:ASM INTERNATIONAL

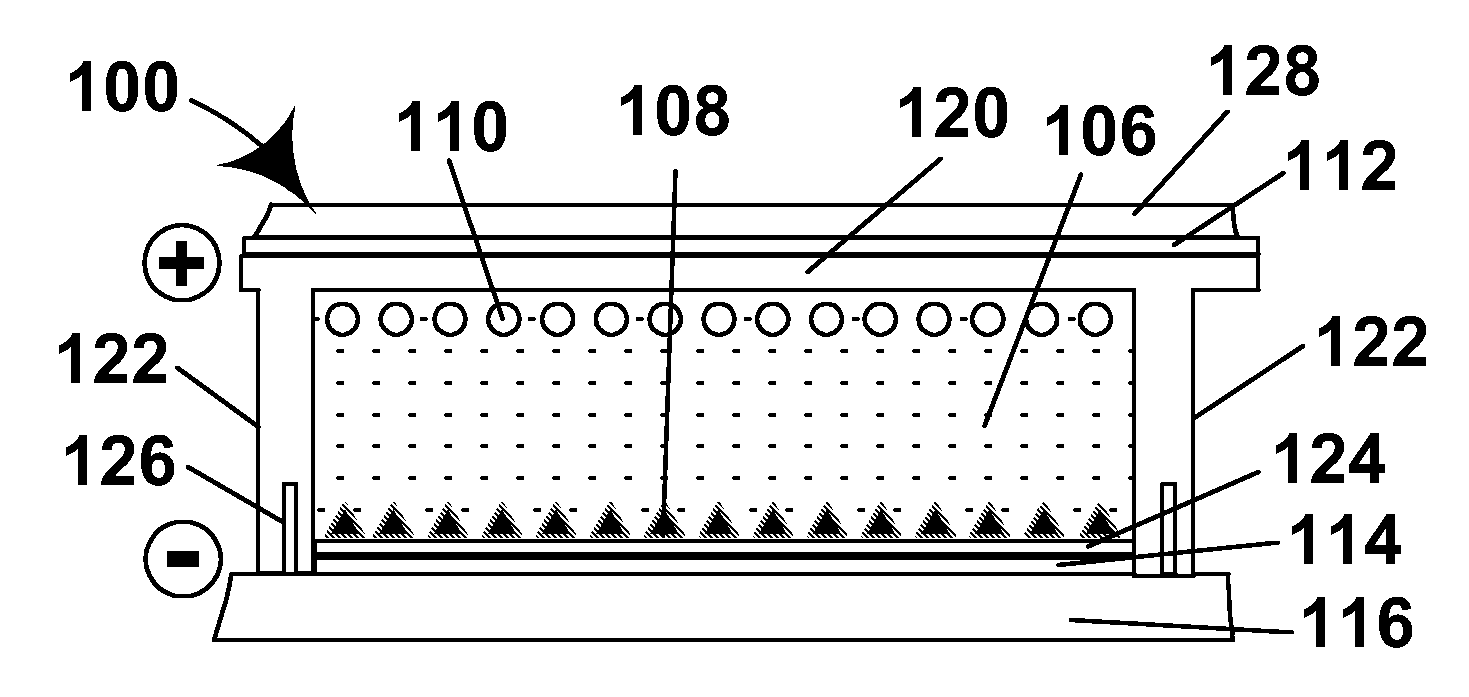

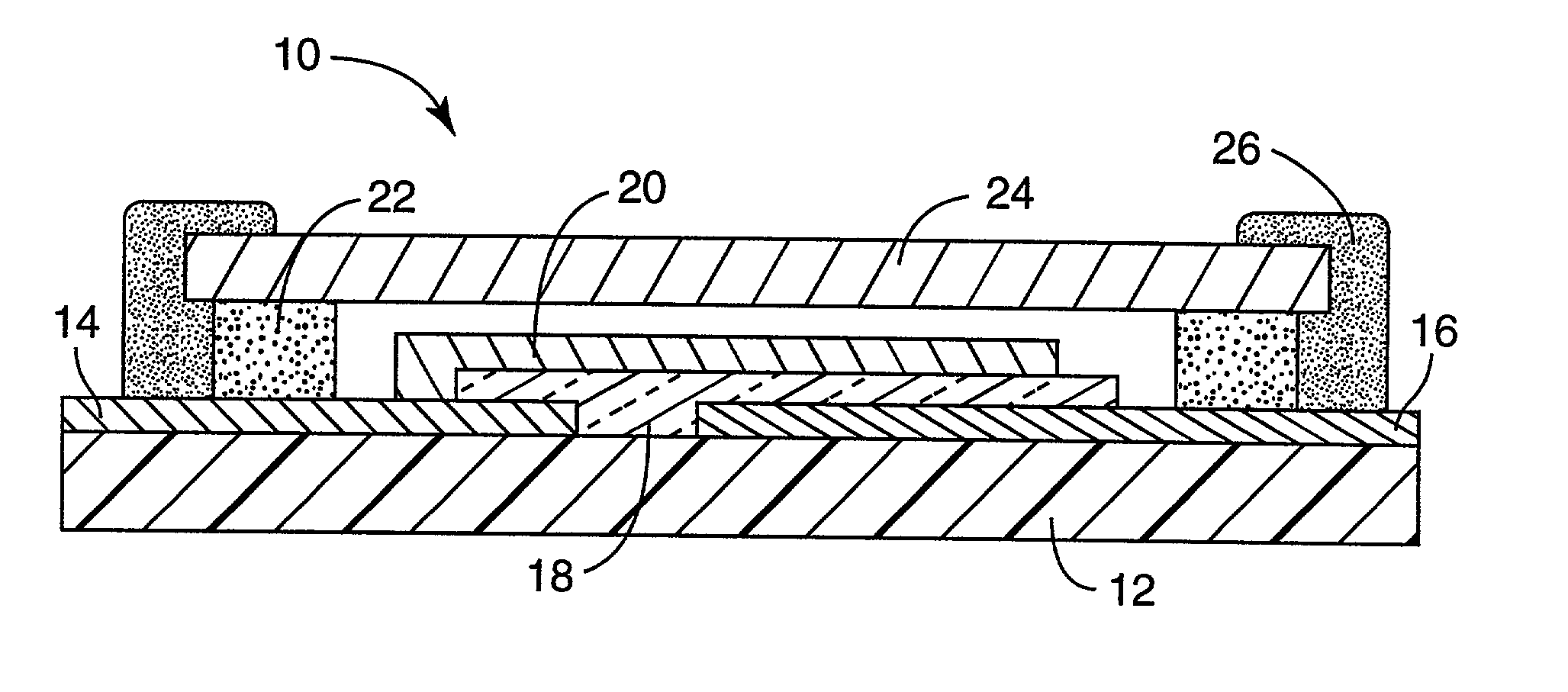

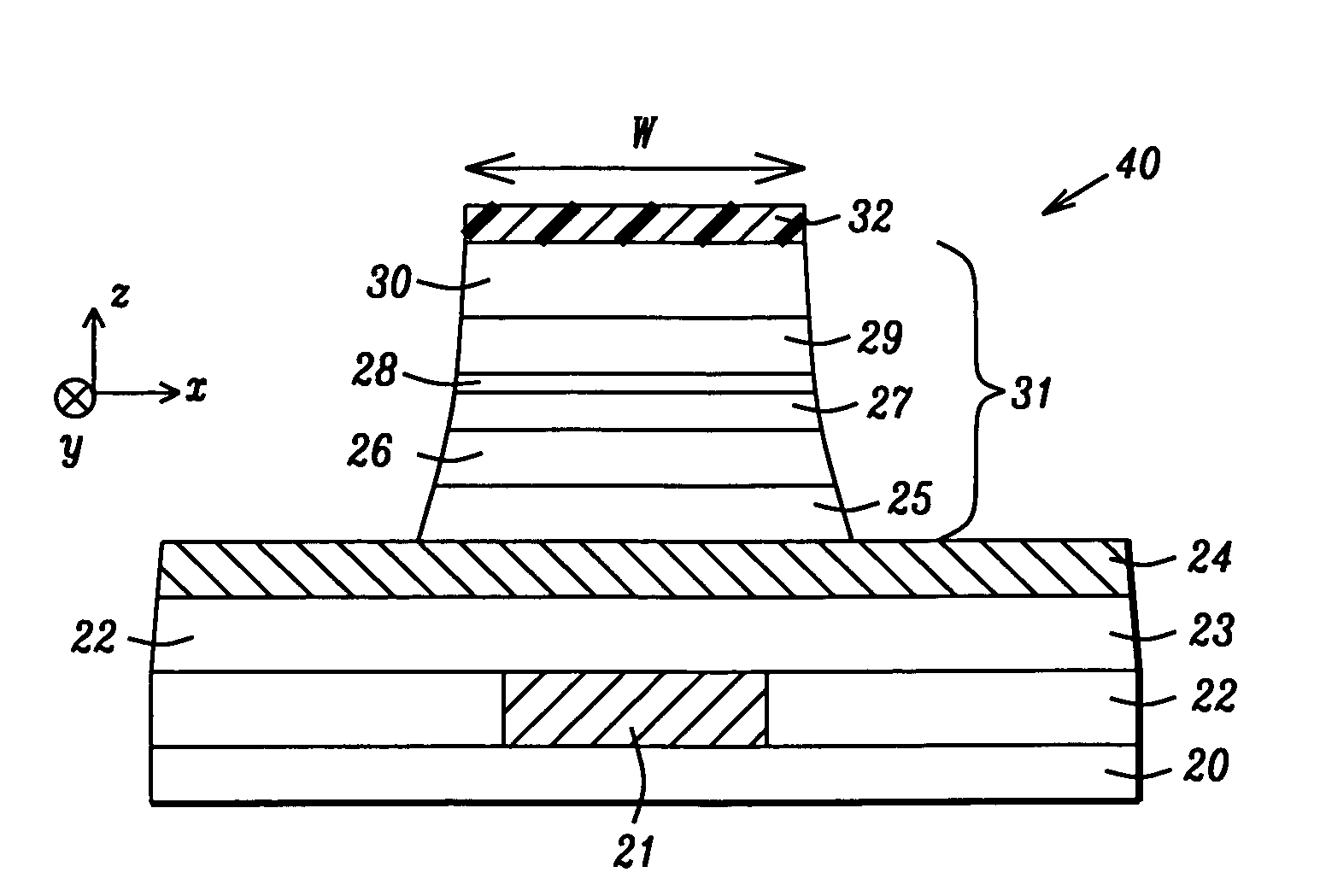

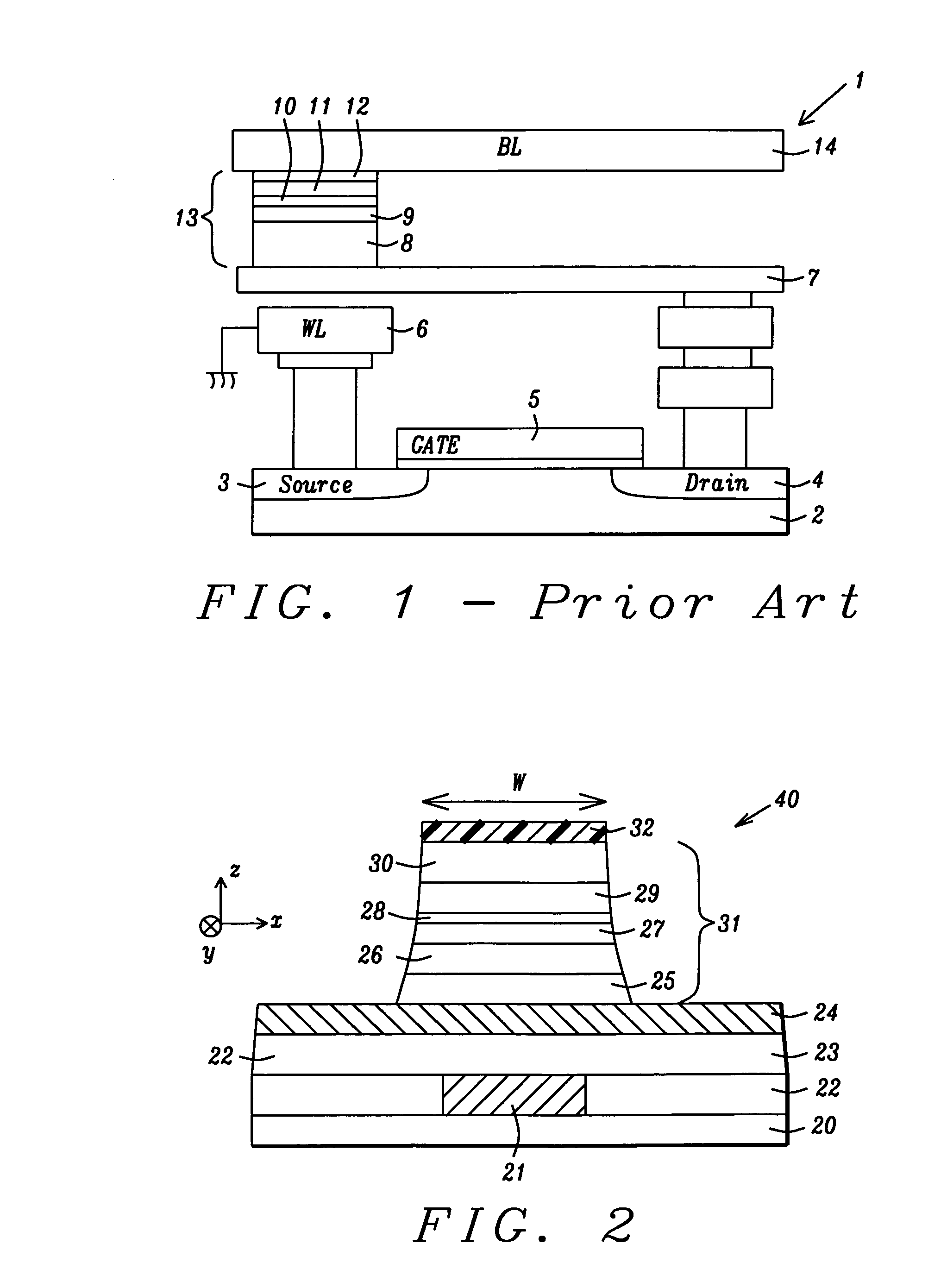

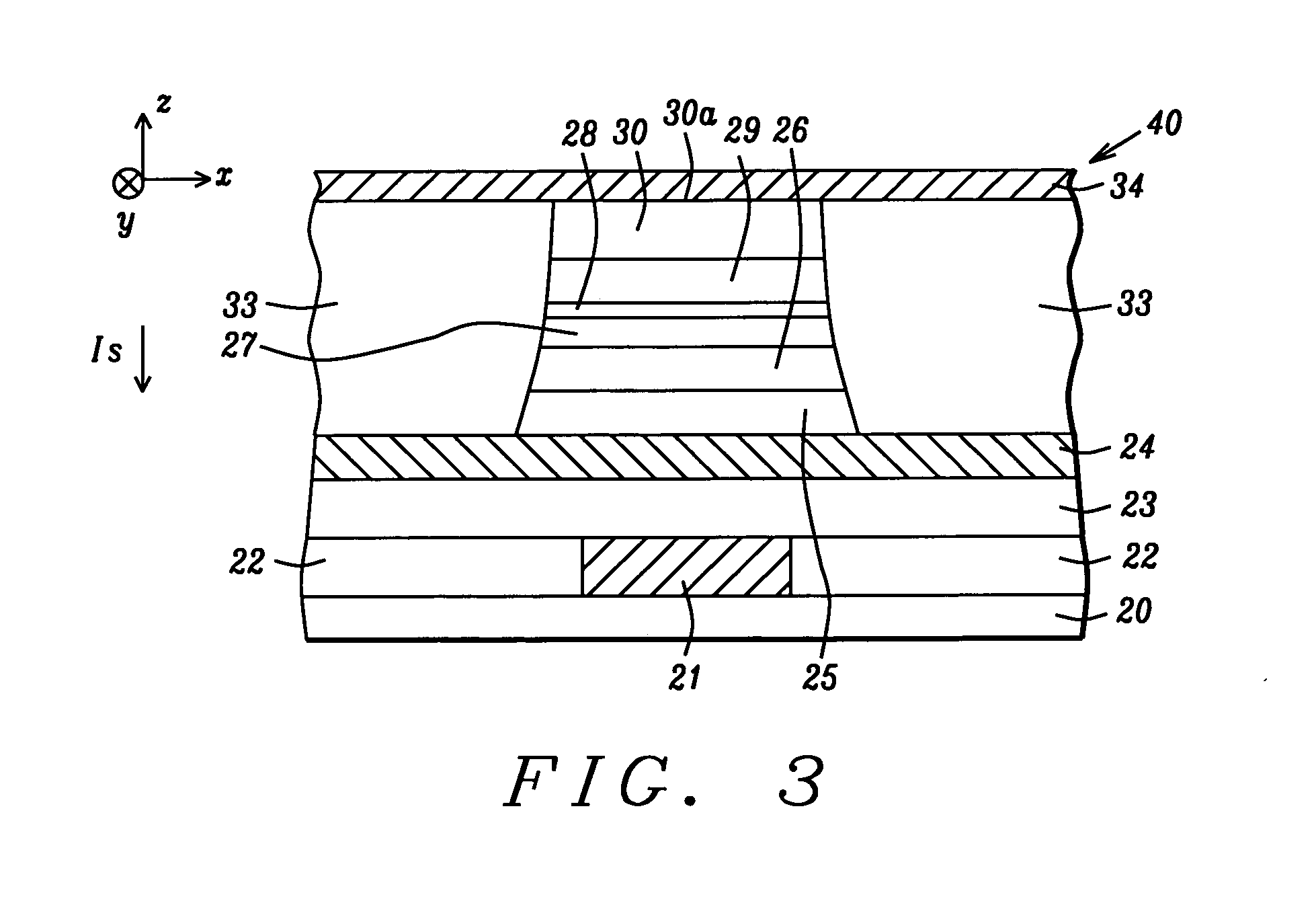

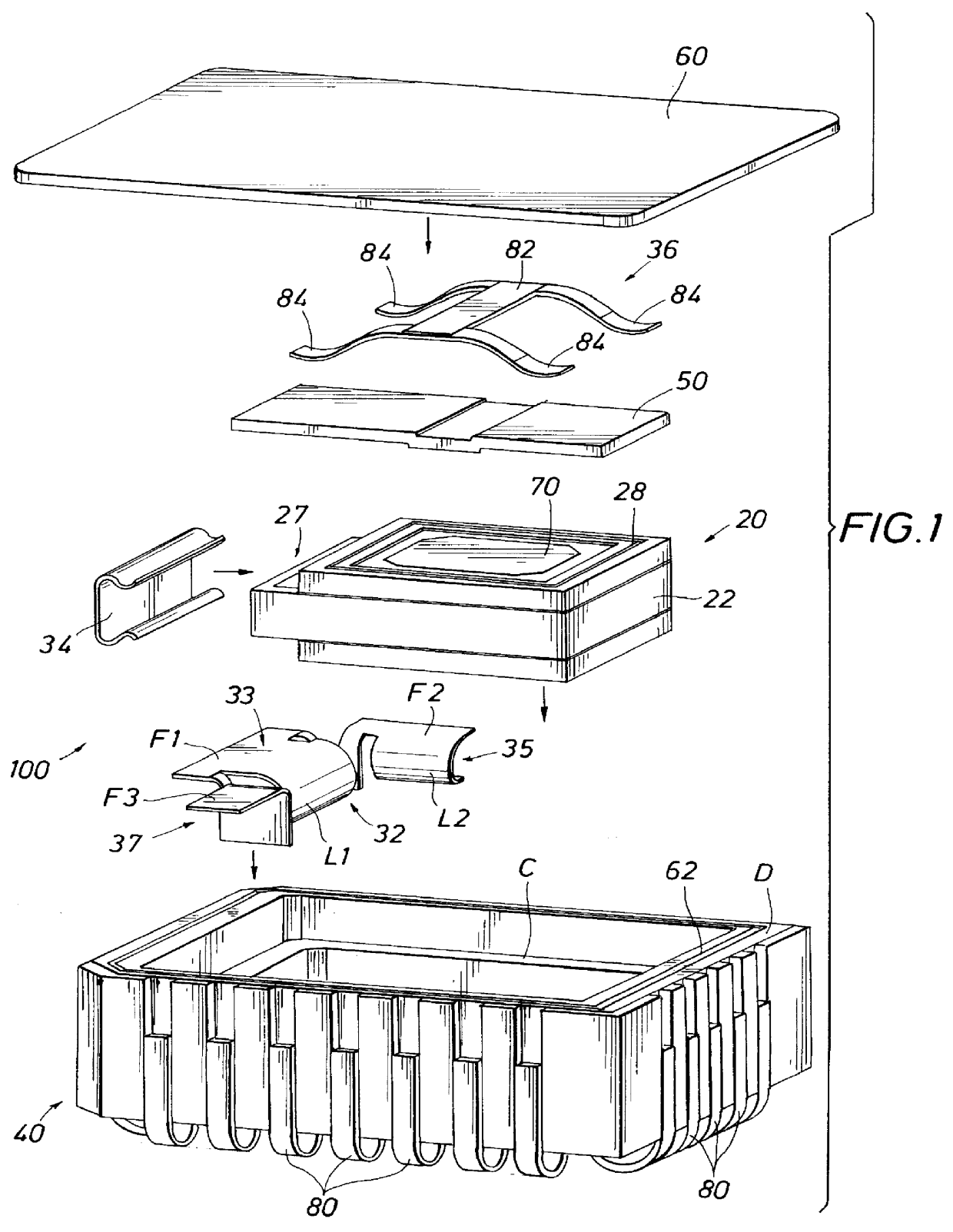

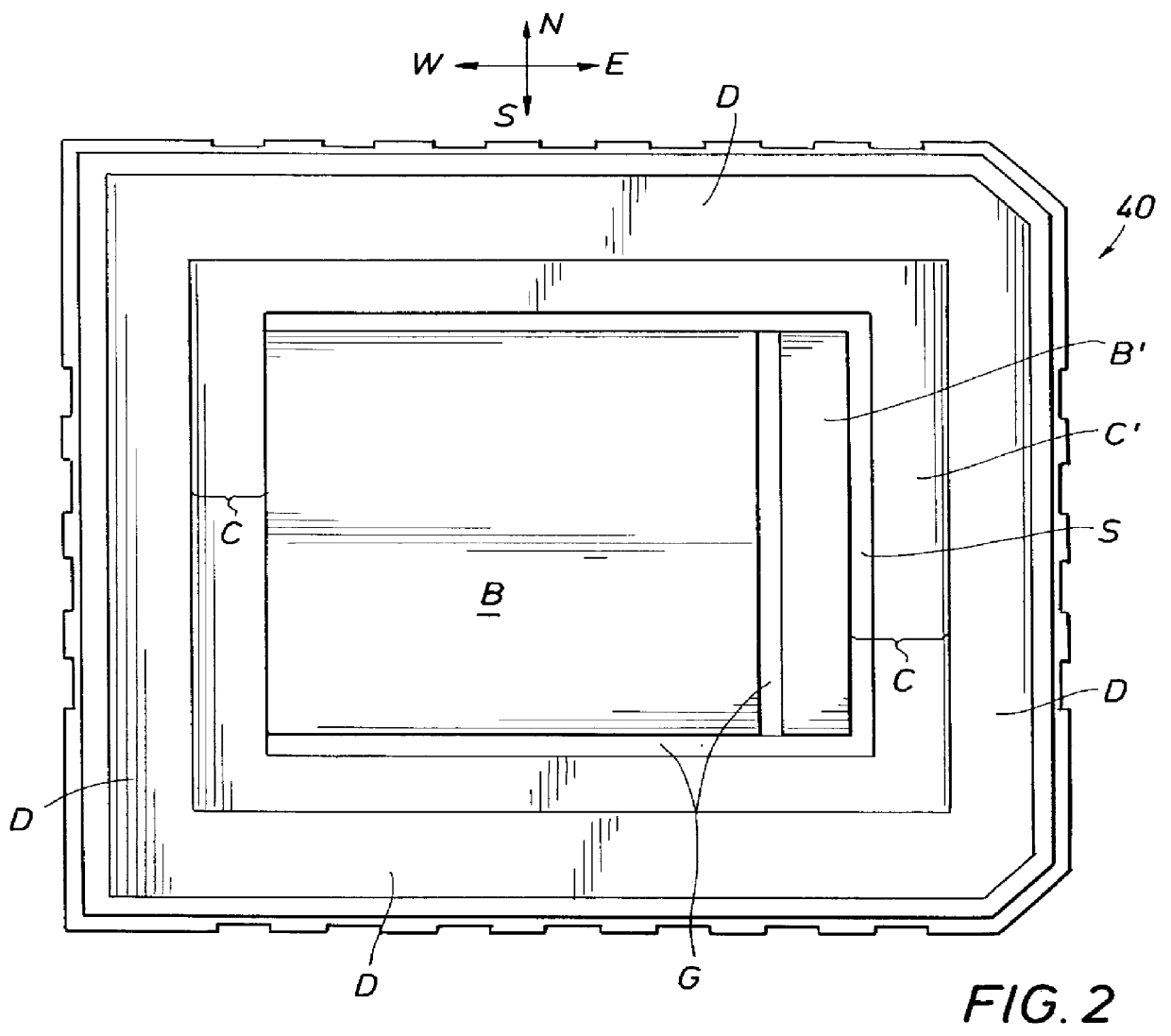

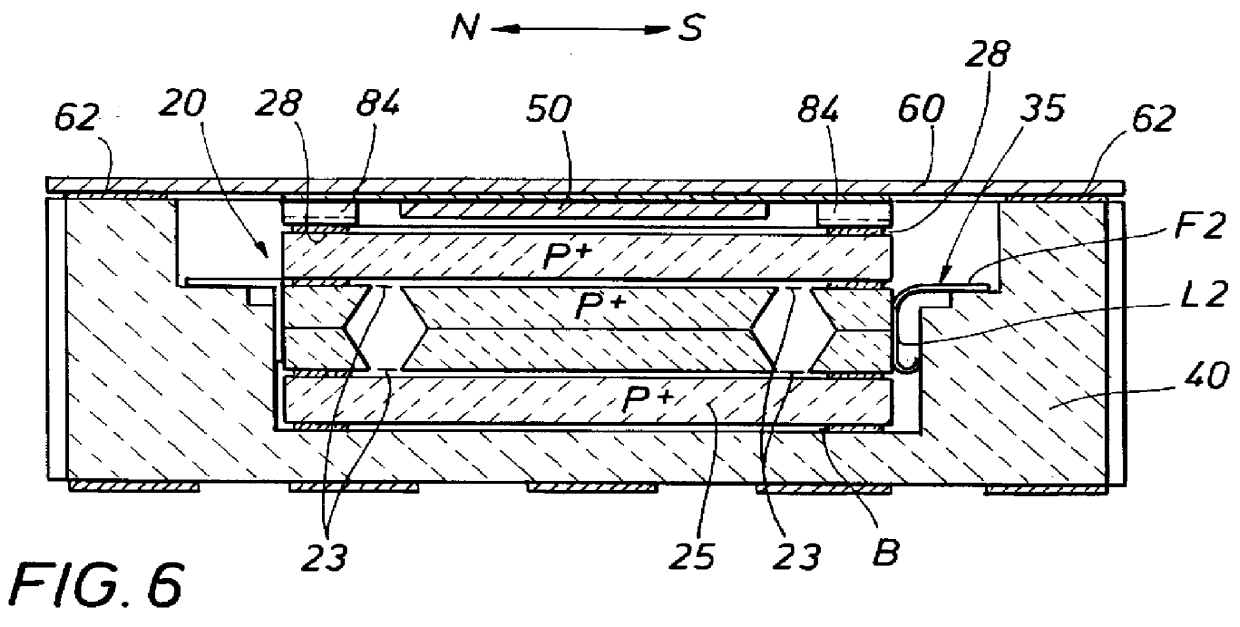

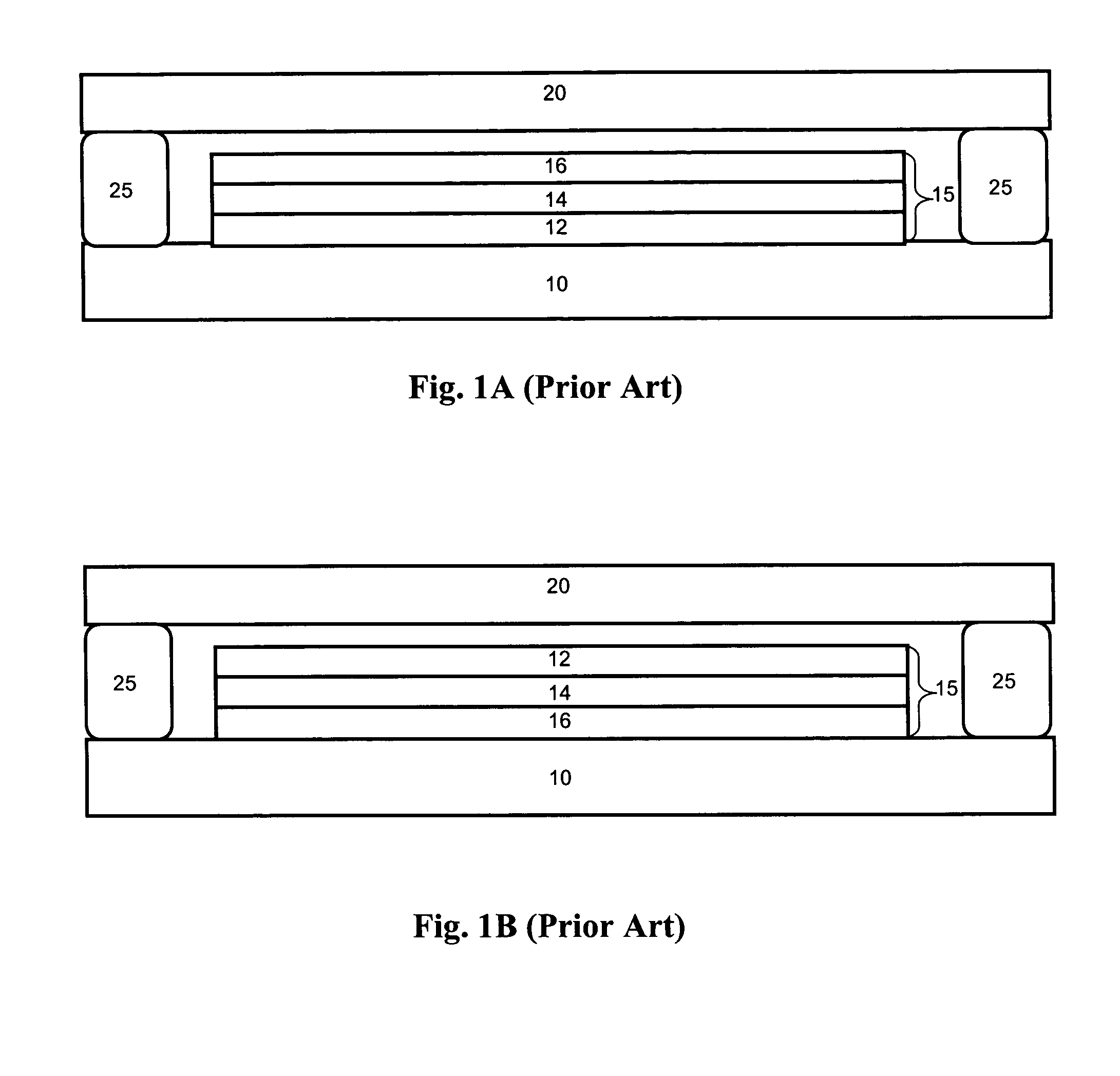

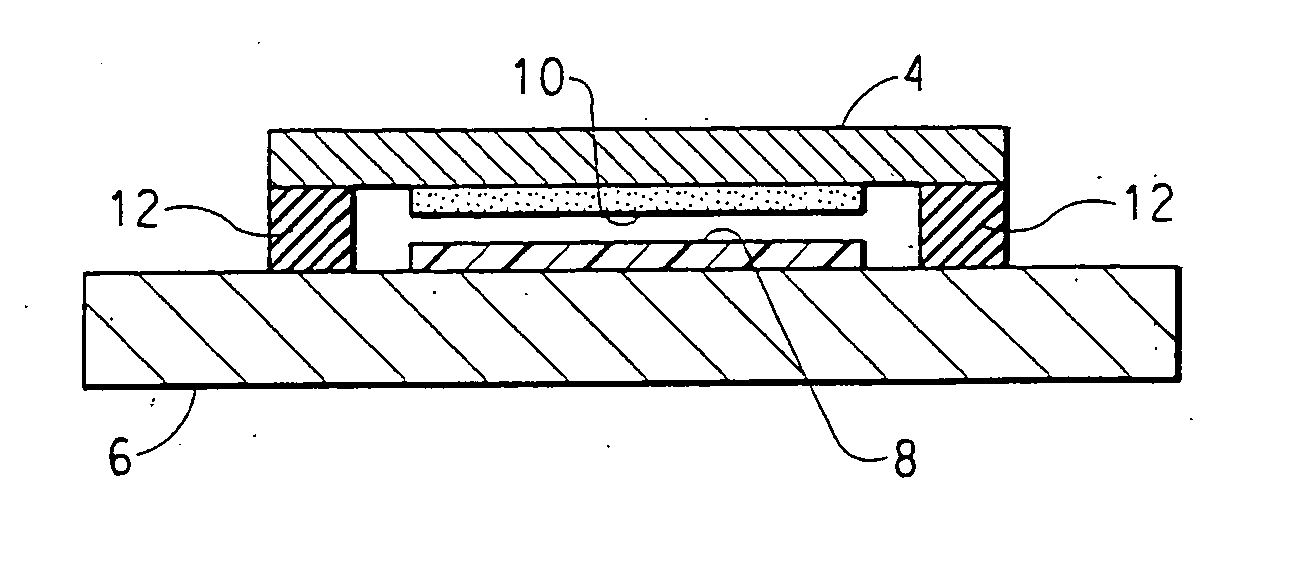

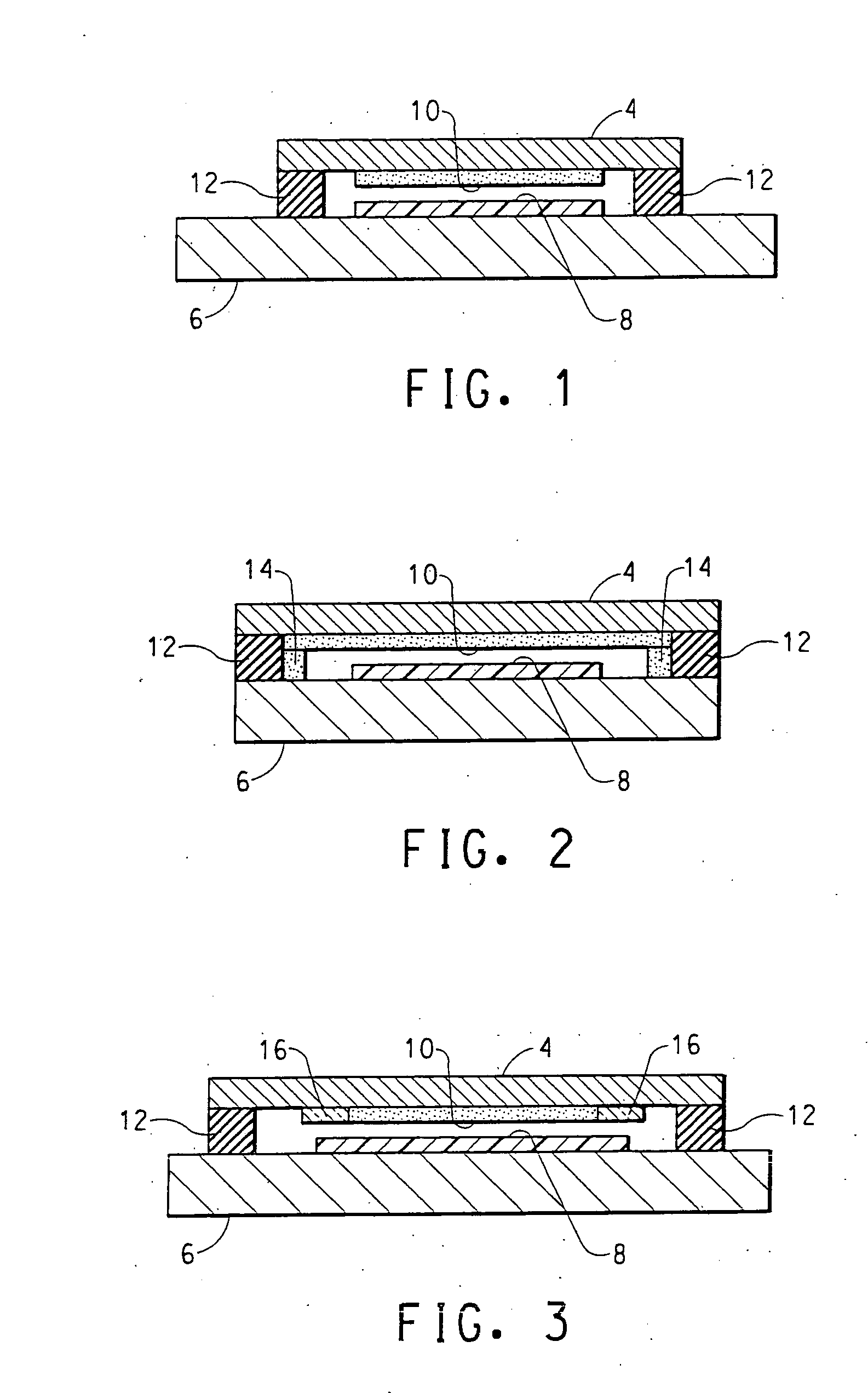

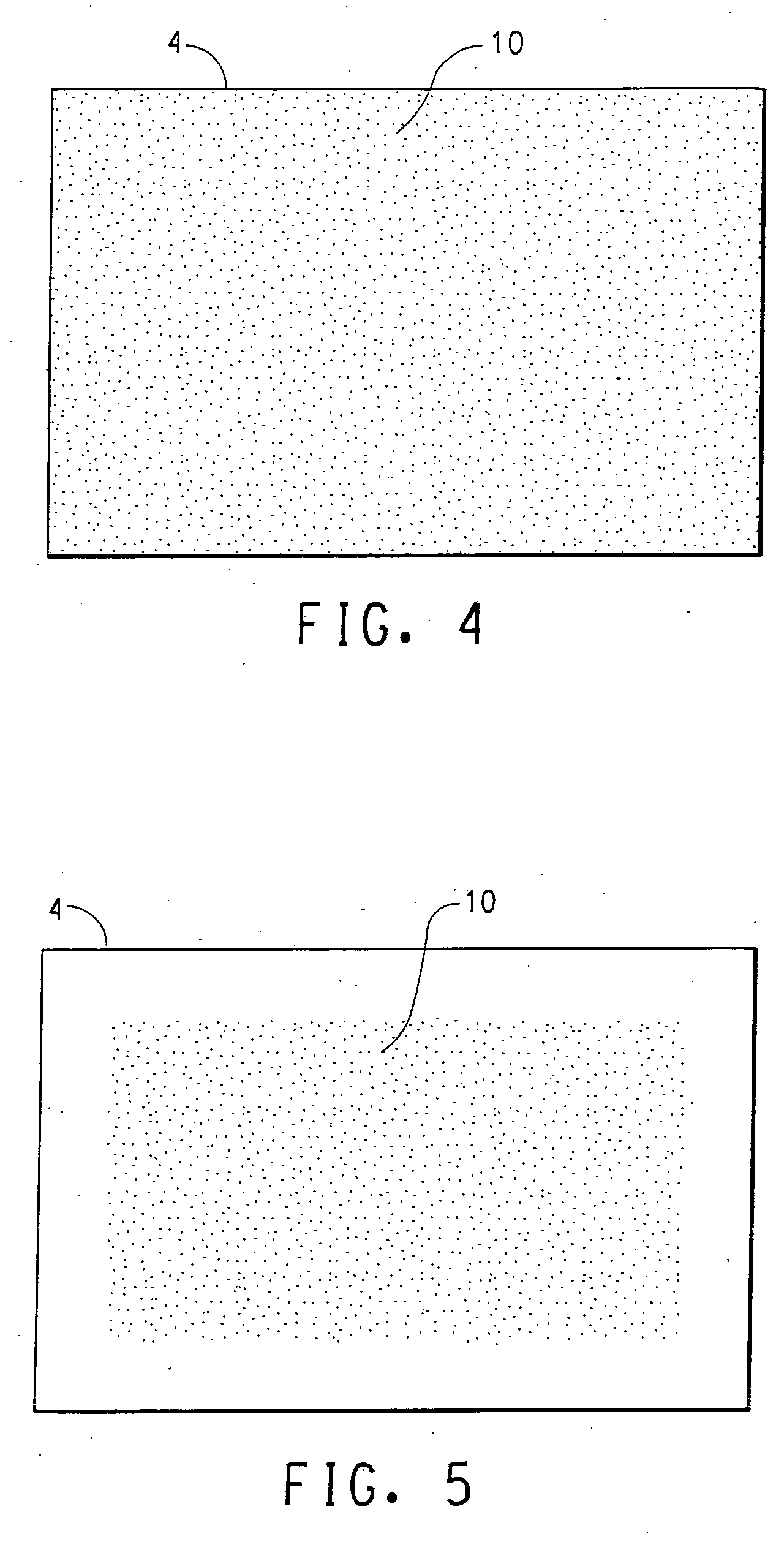

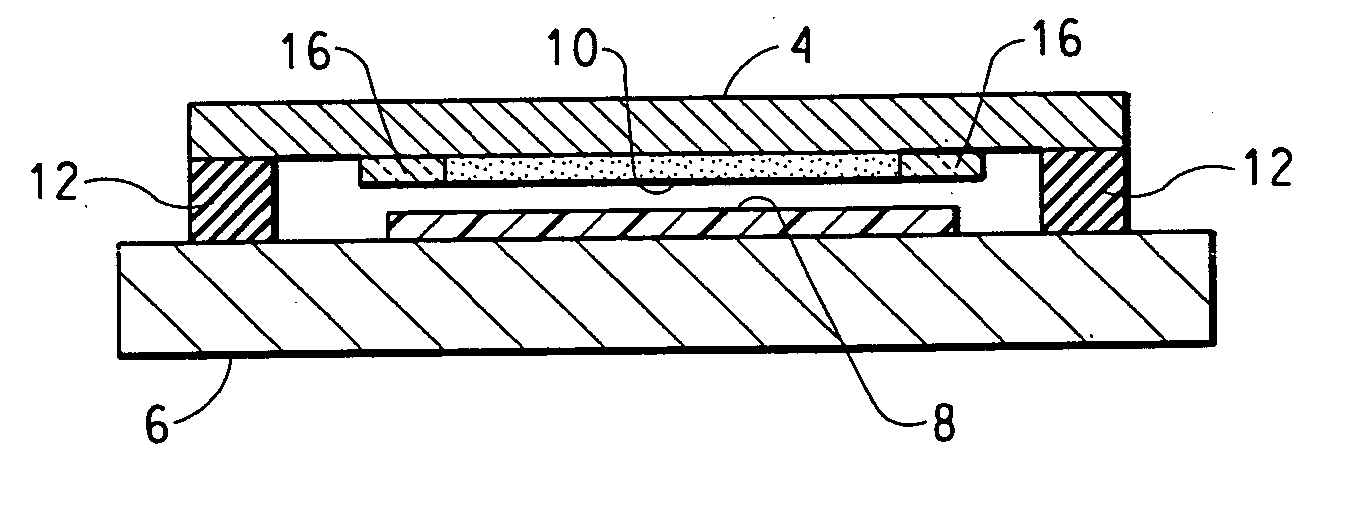

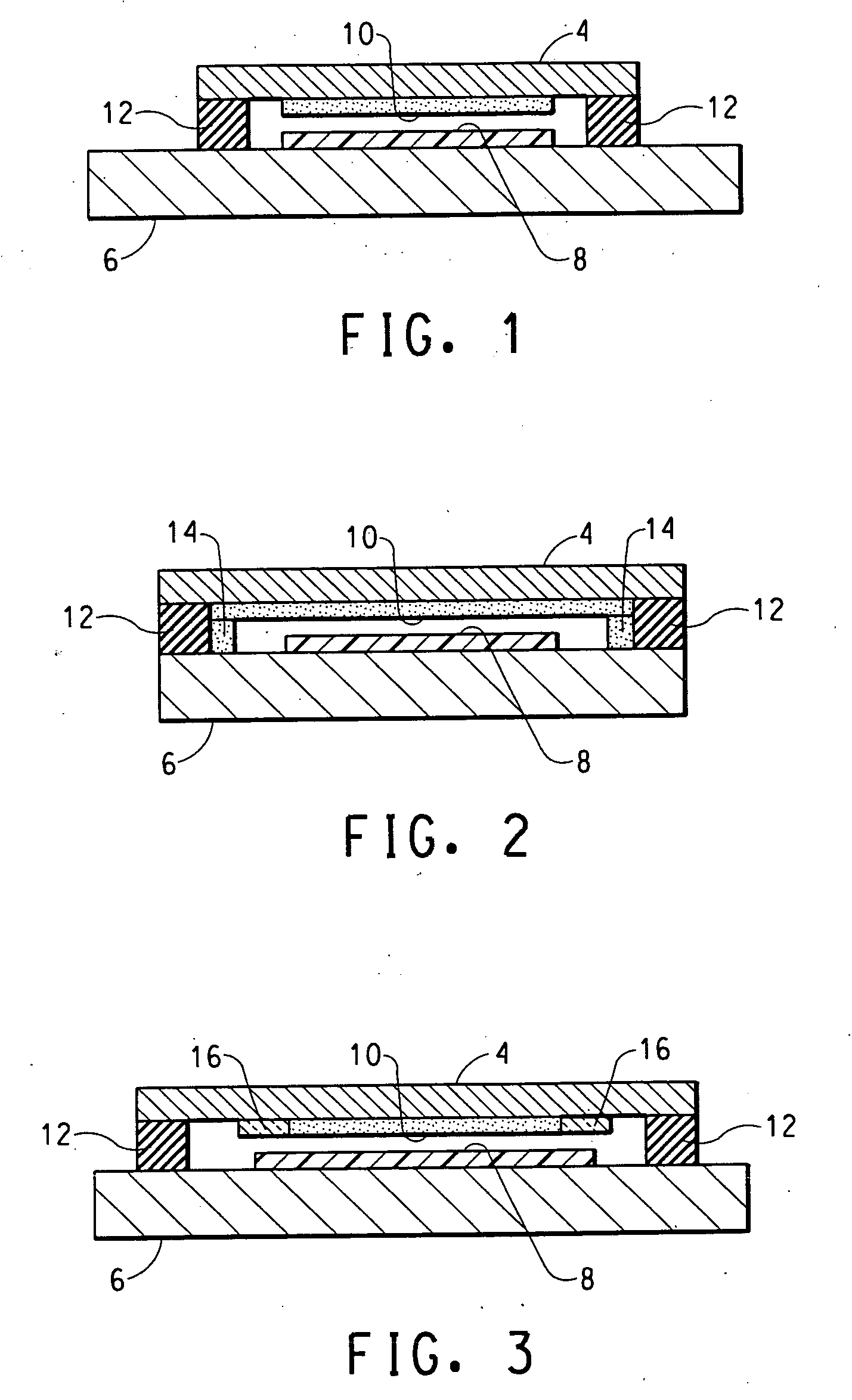

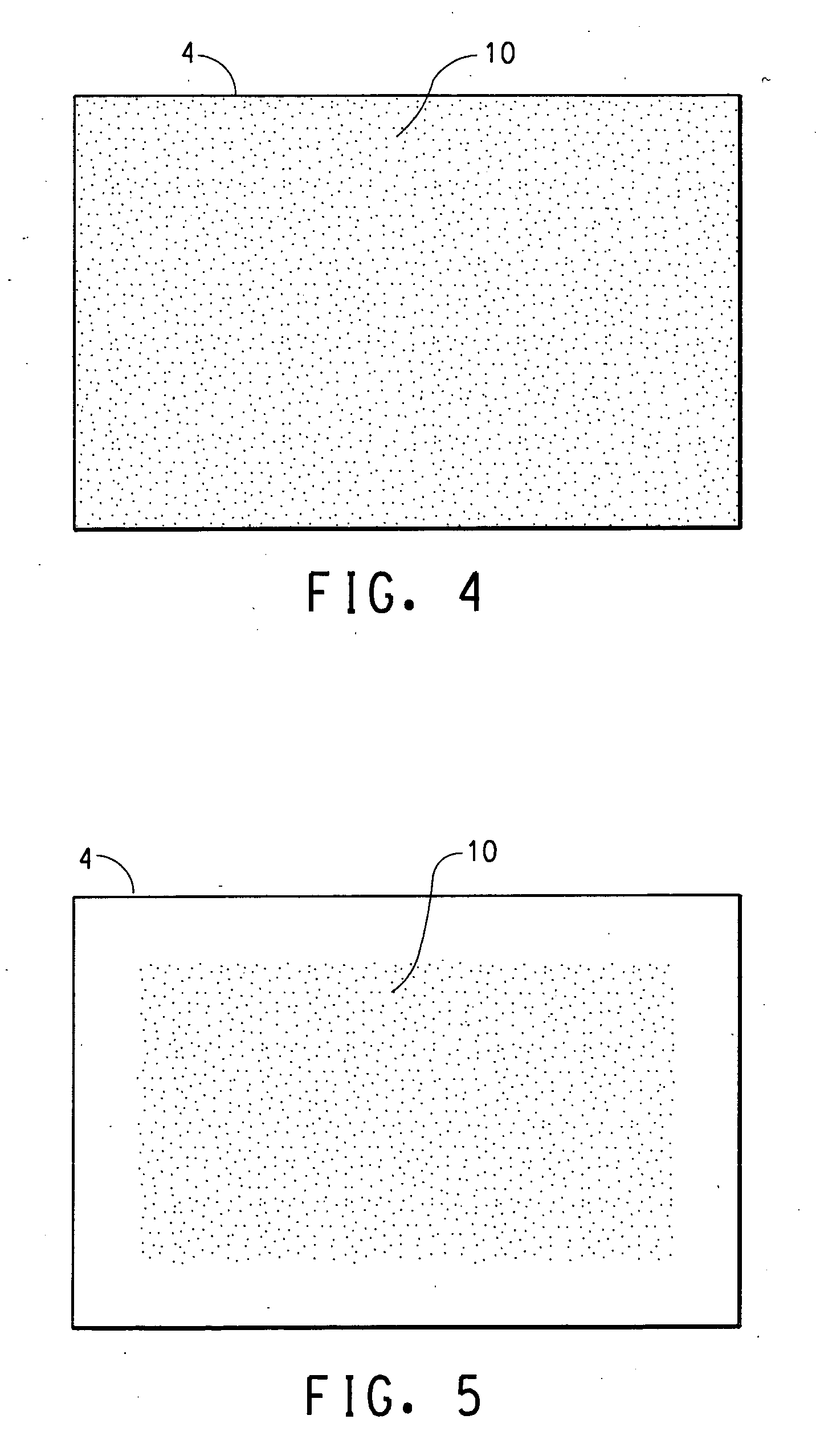

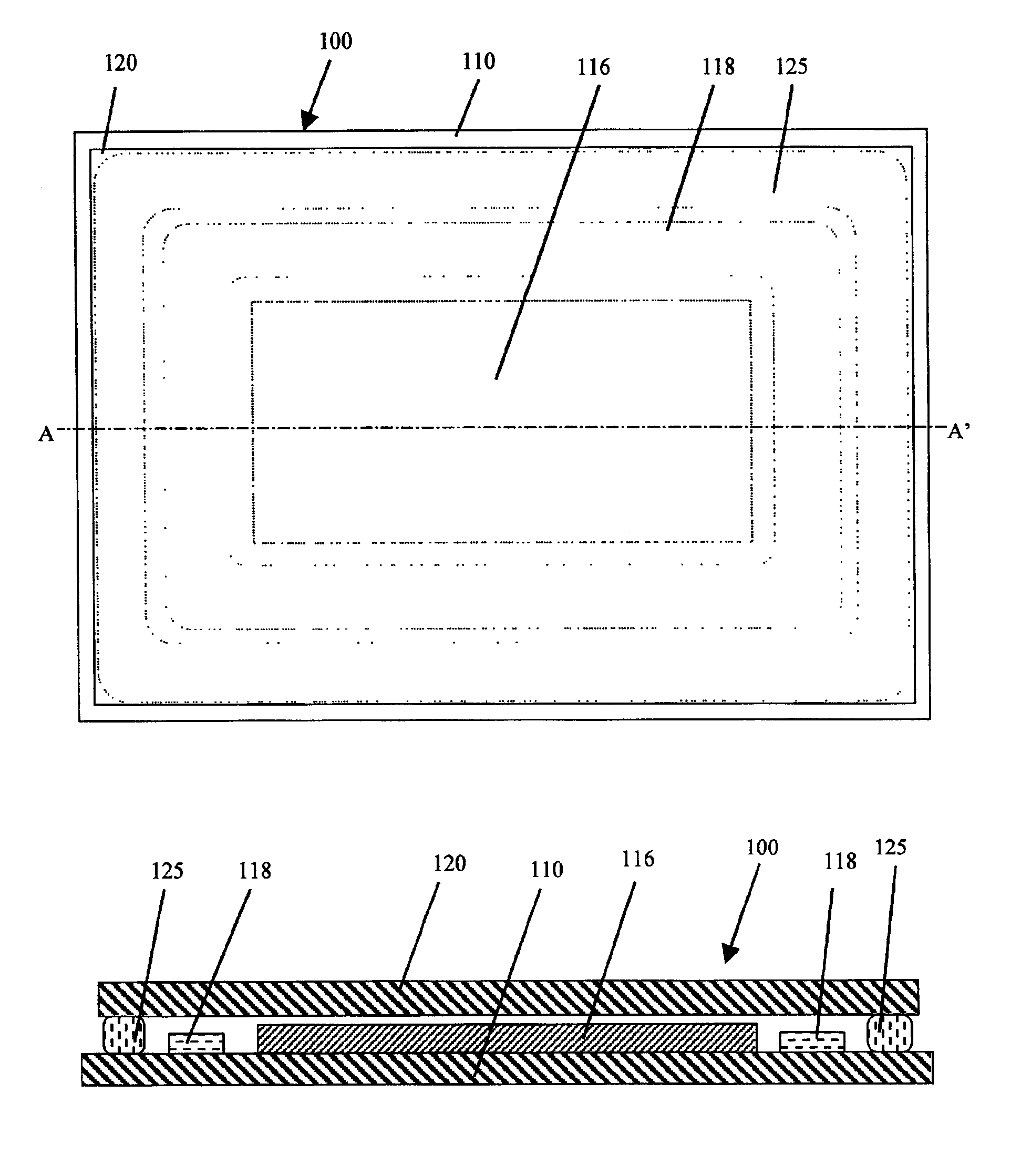

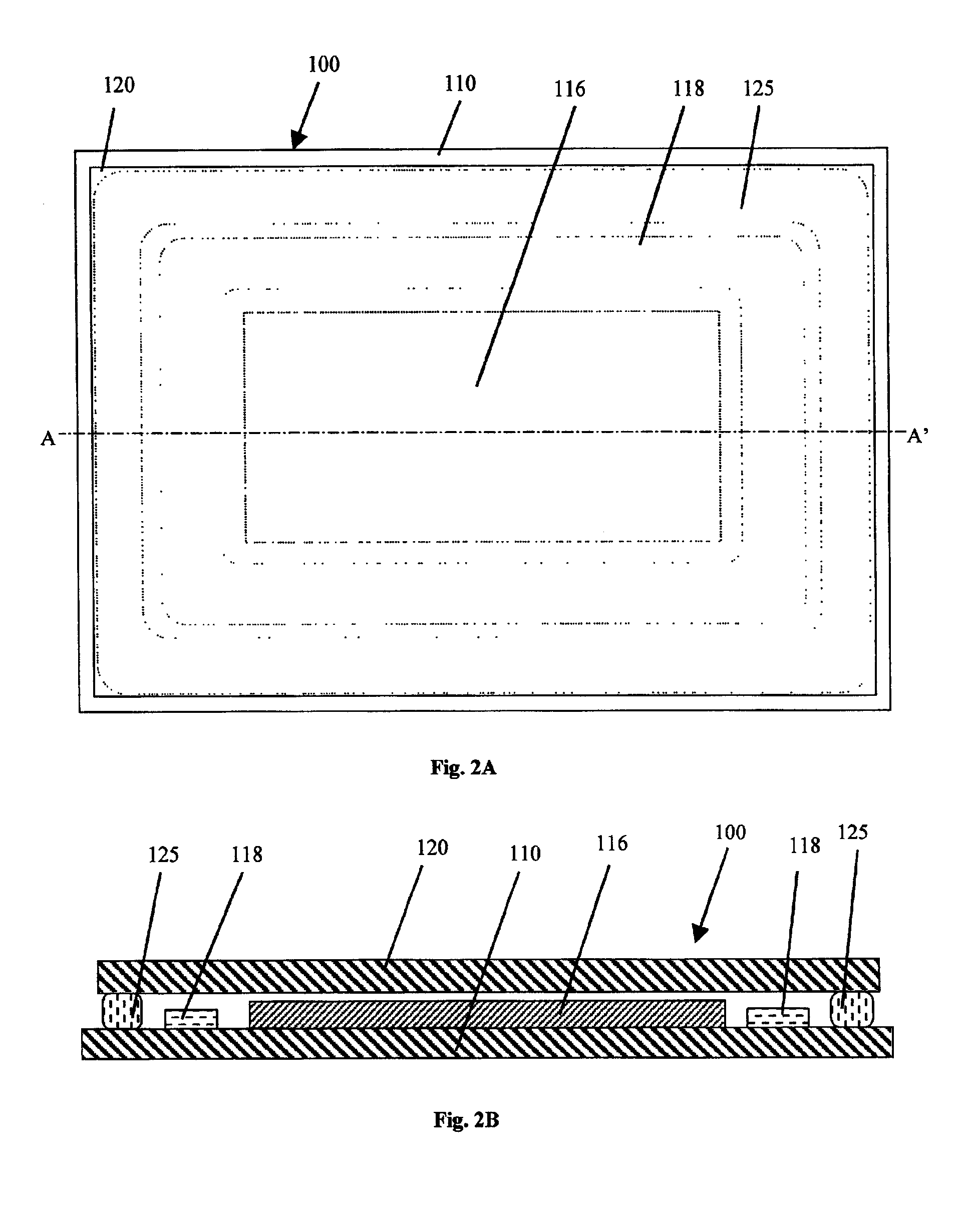

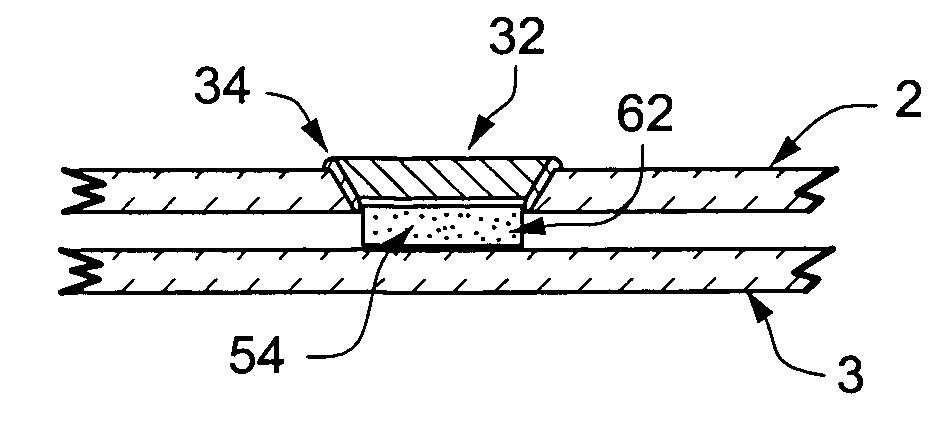

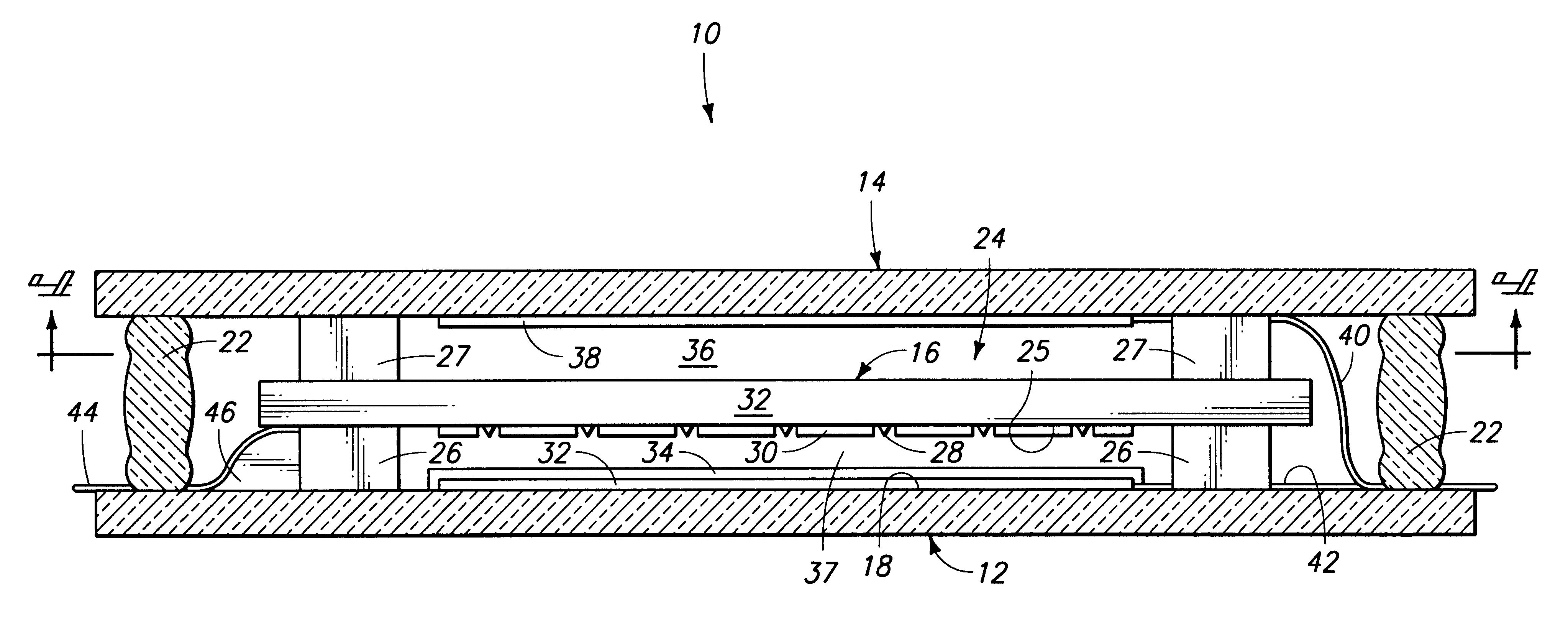

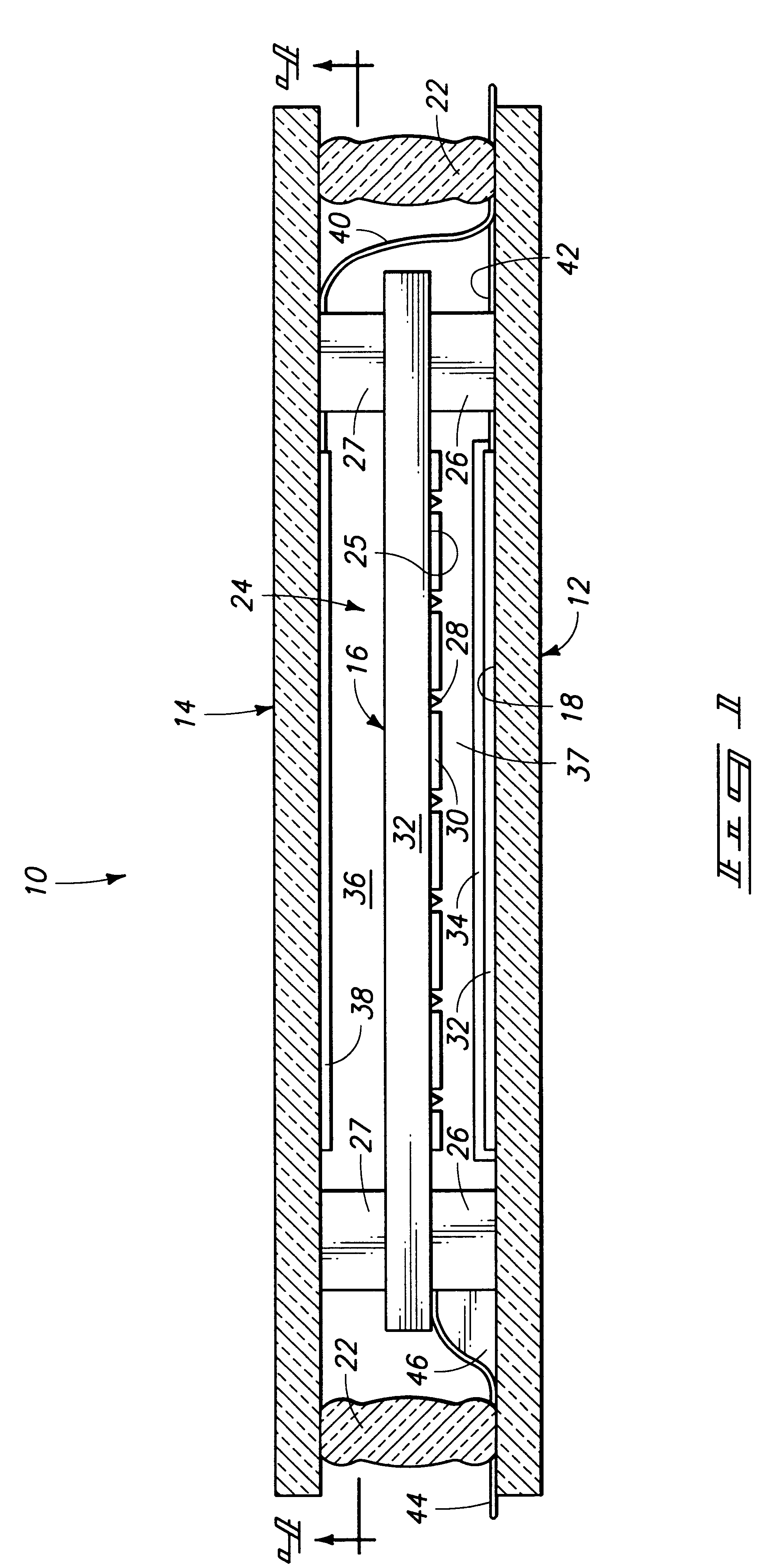

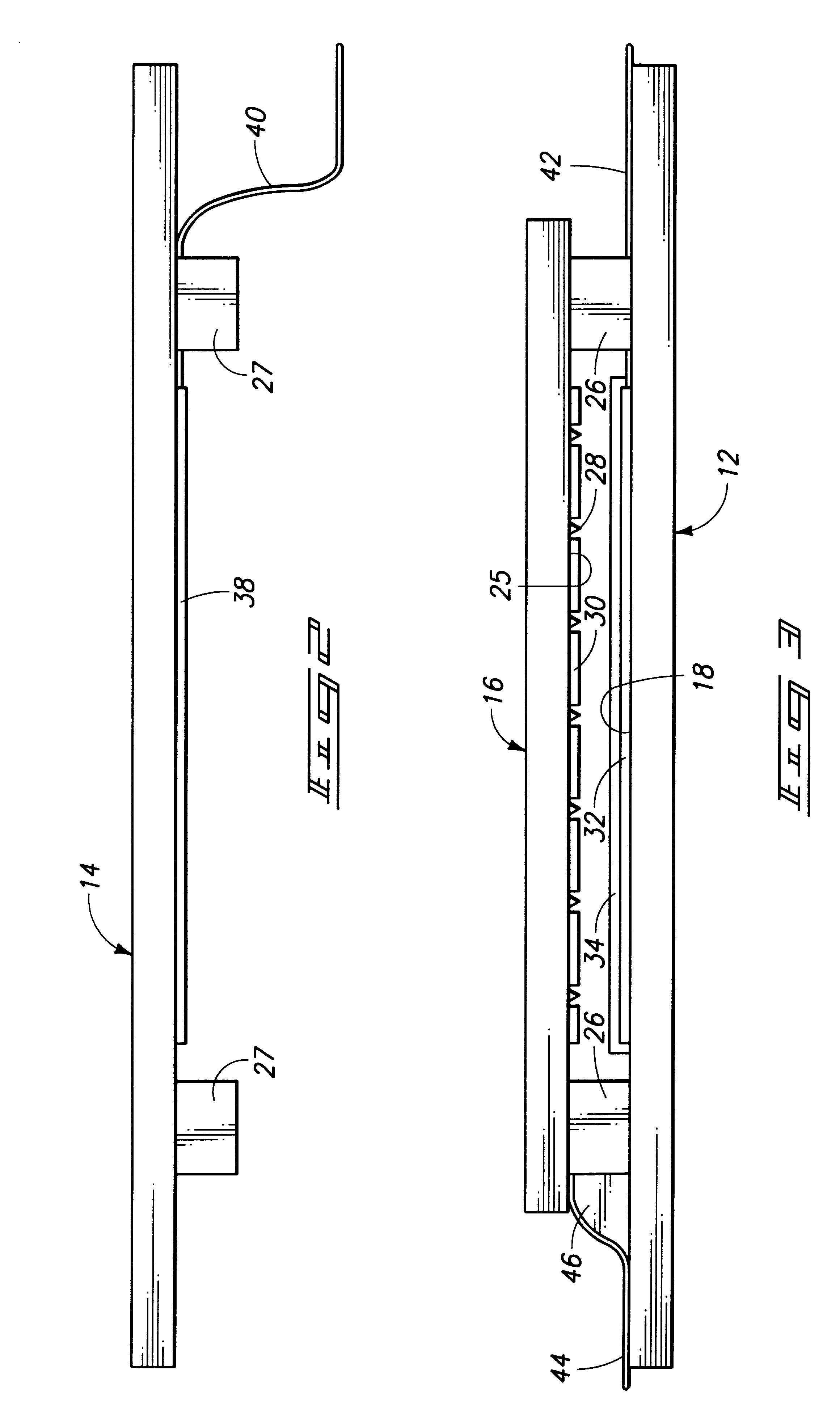

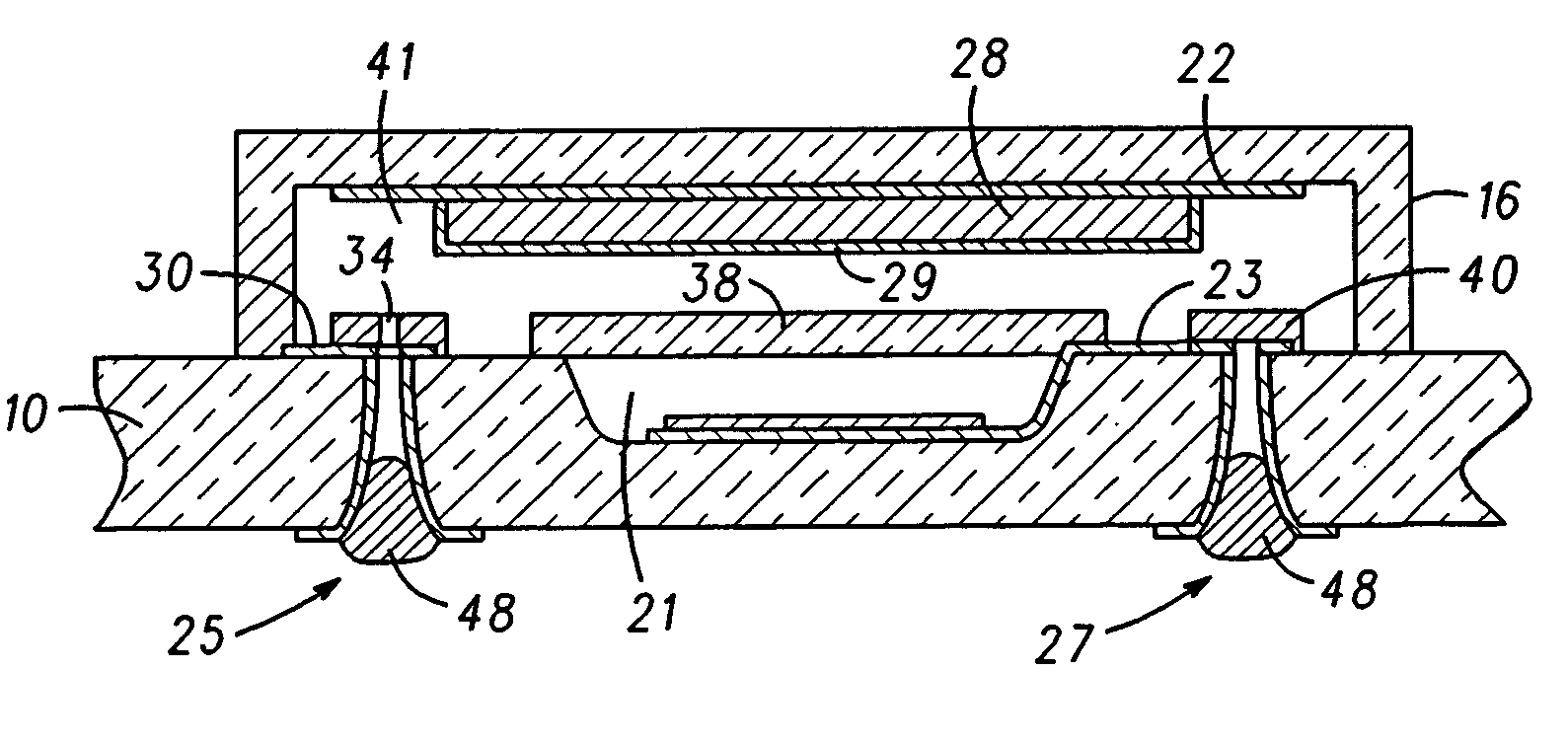

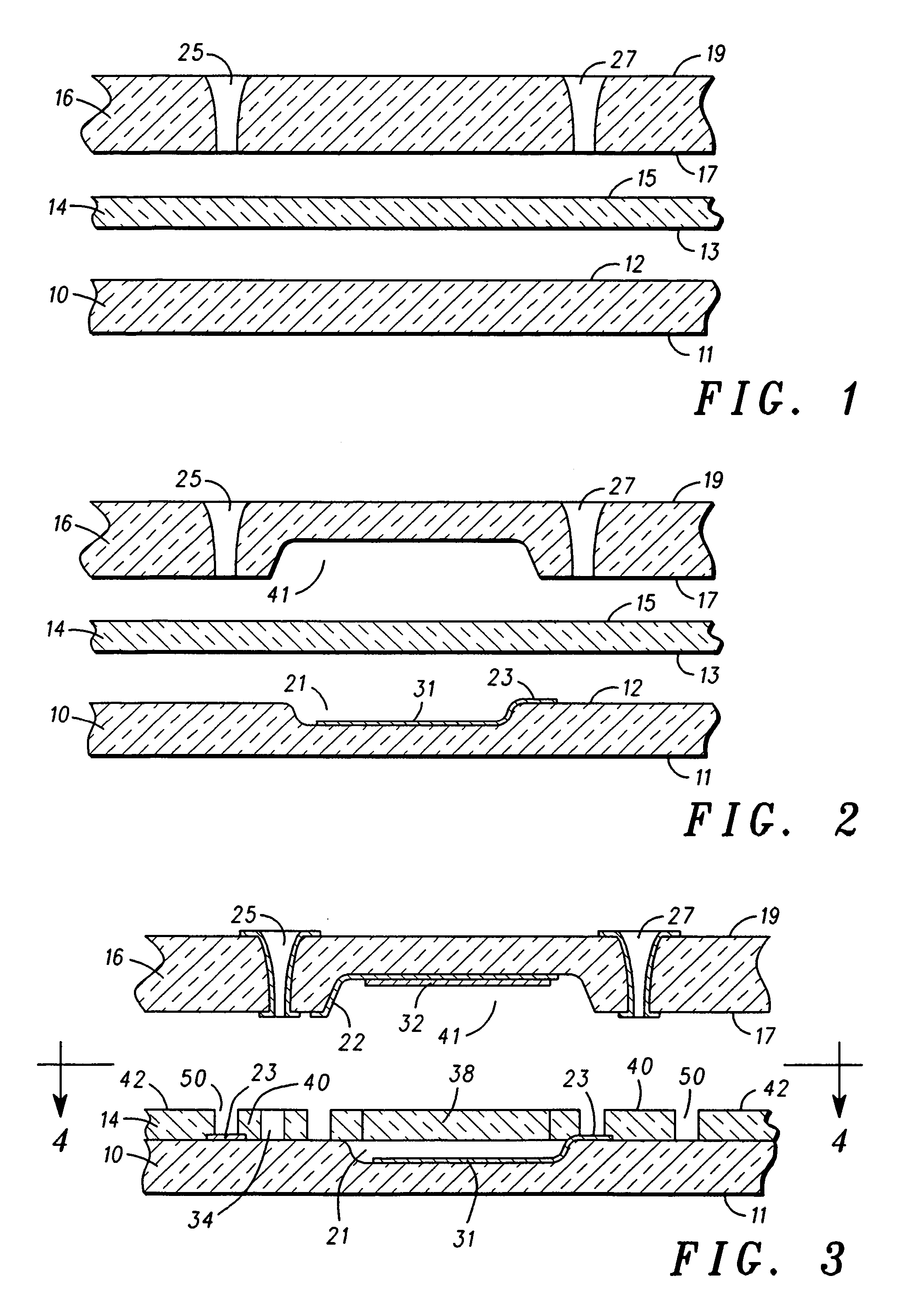

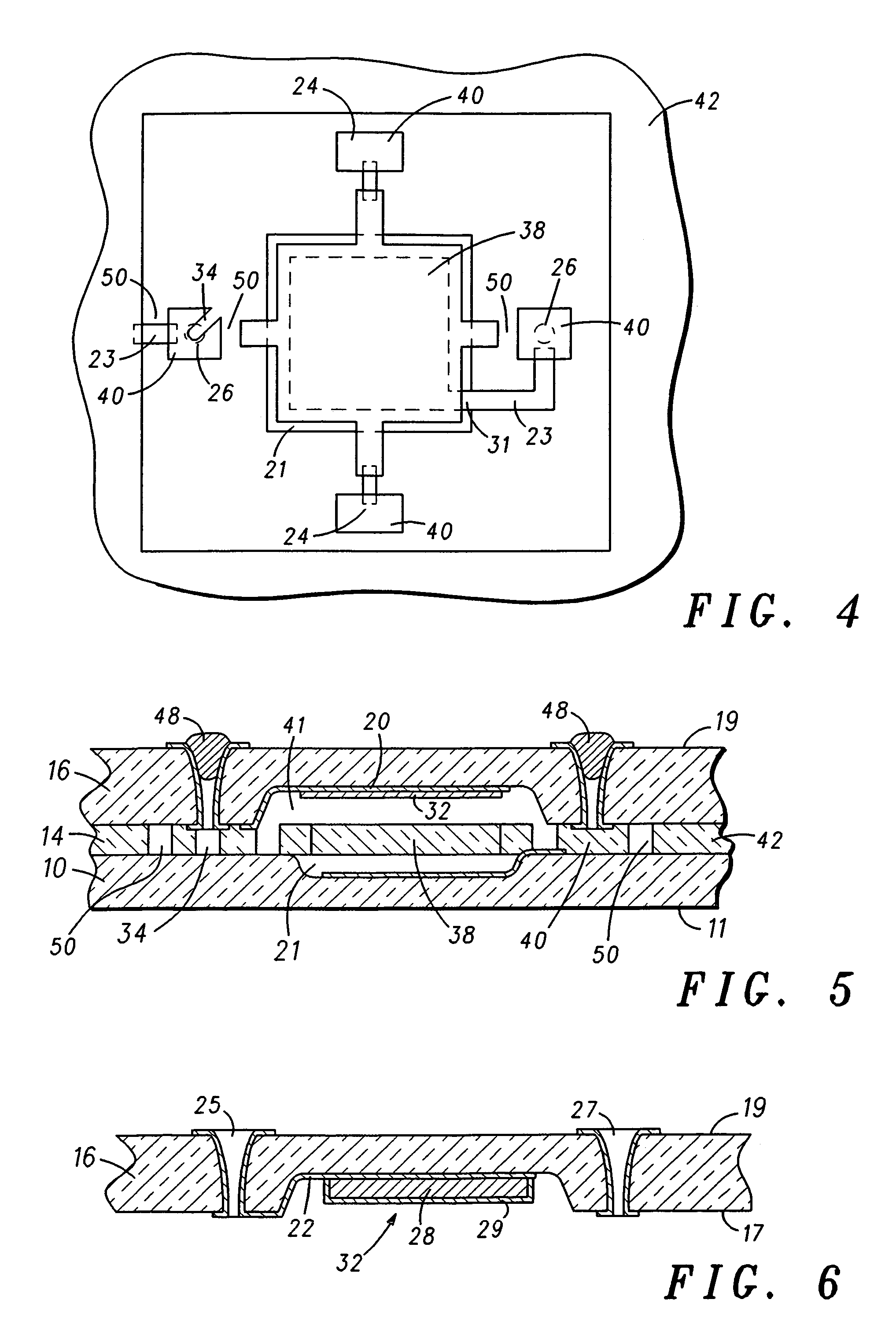

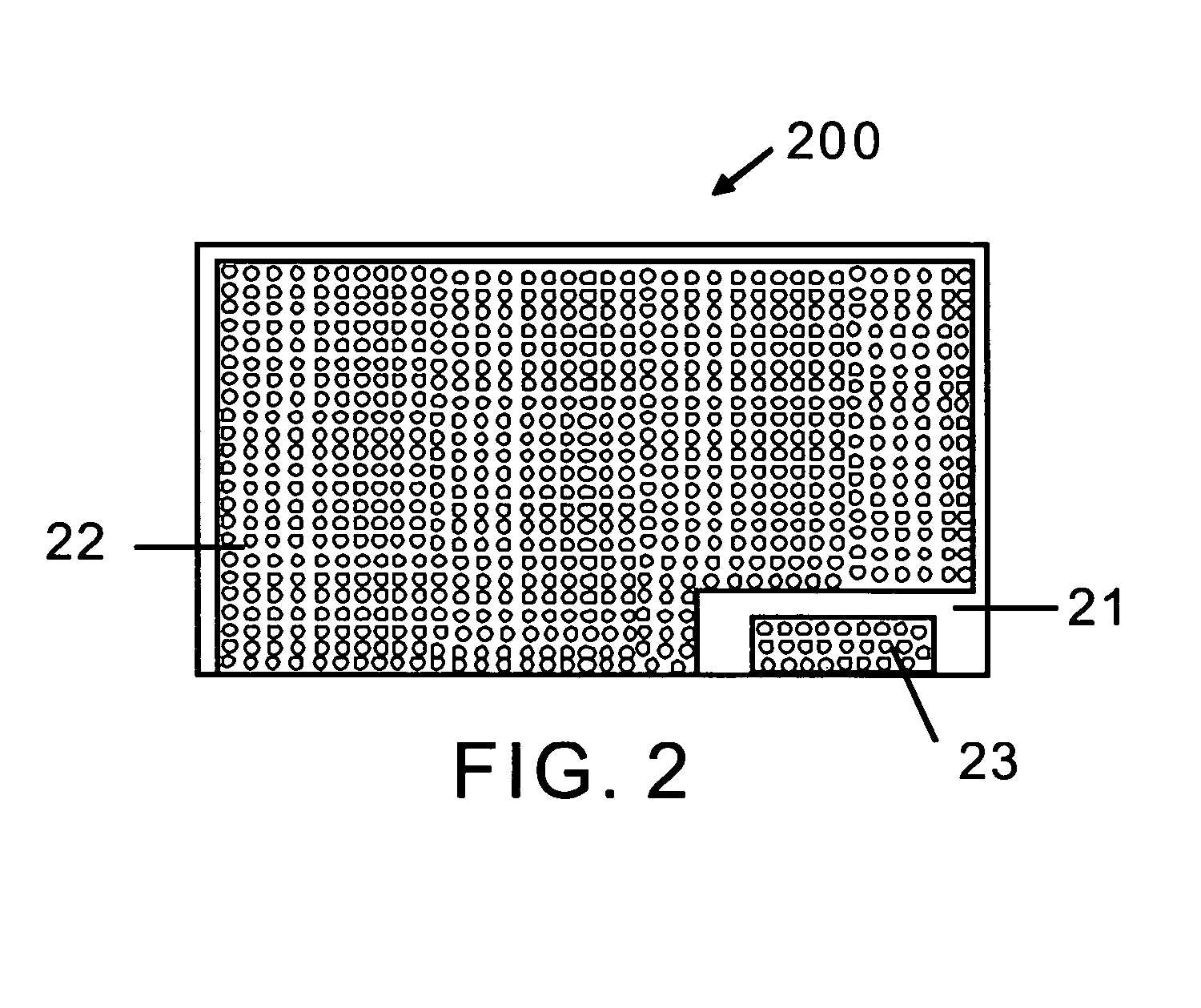

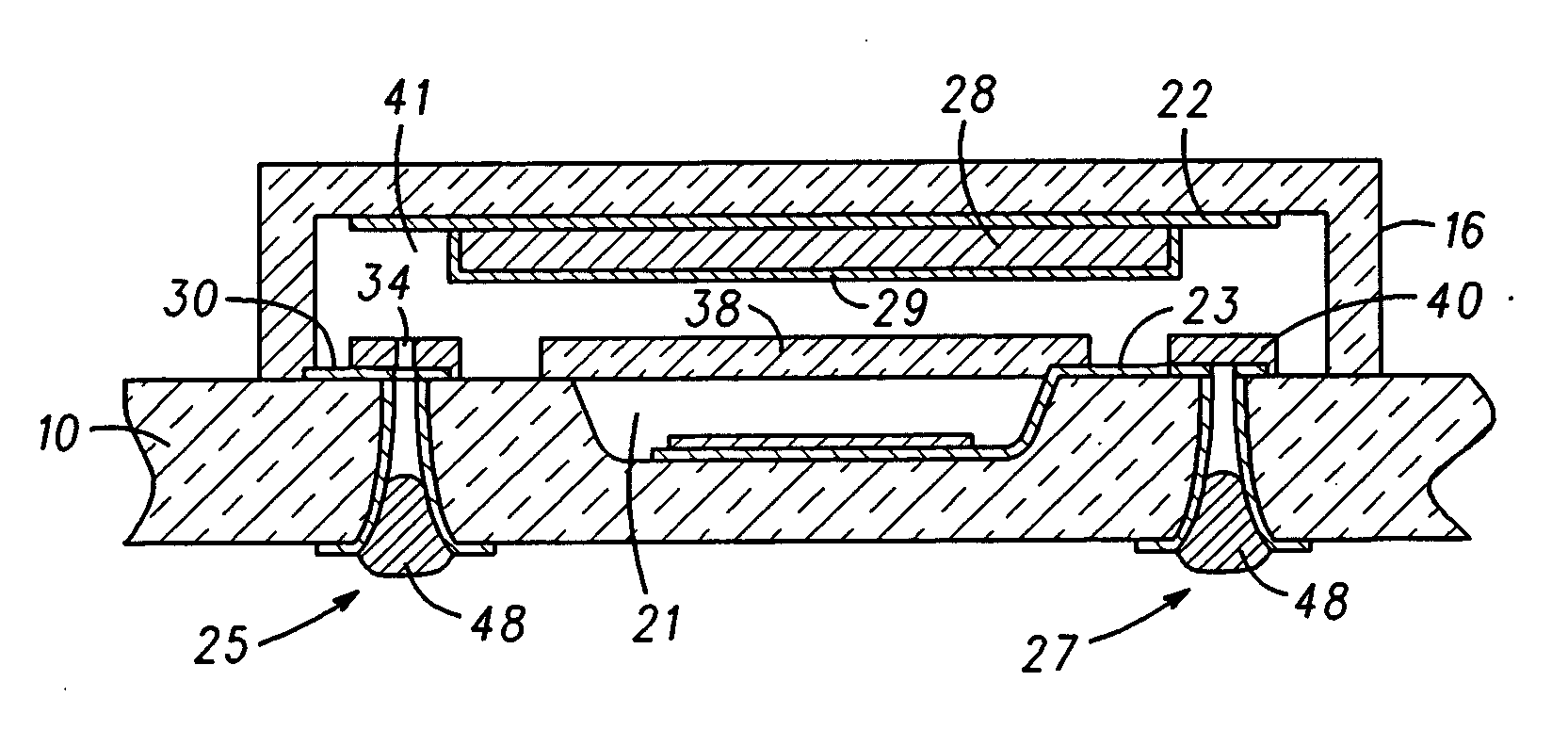

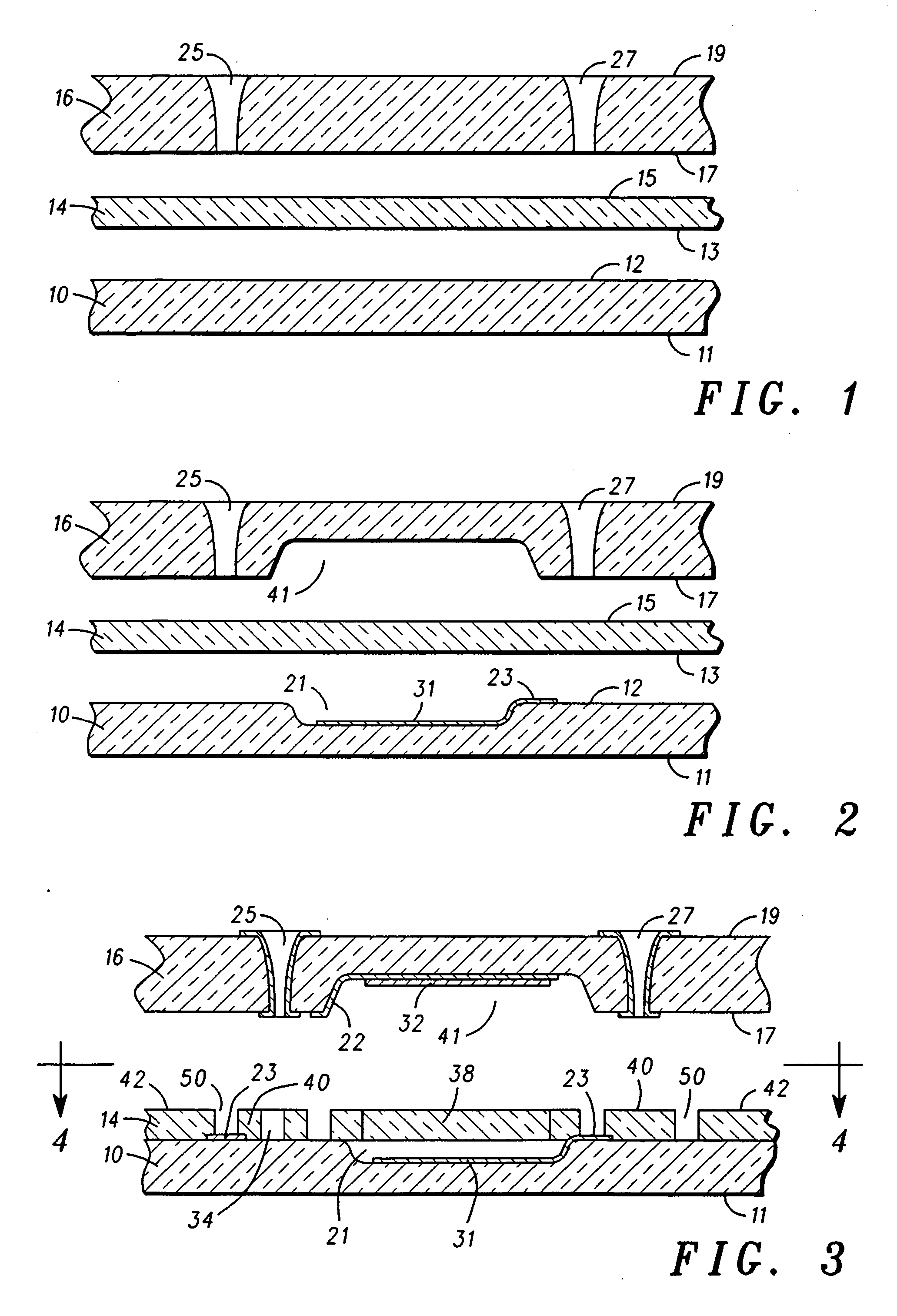

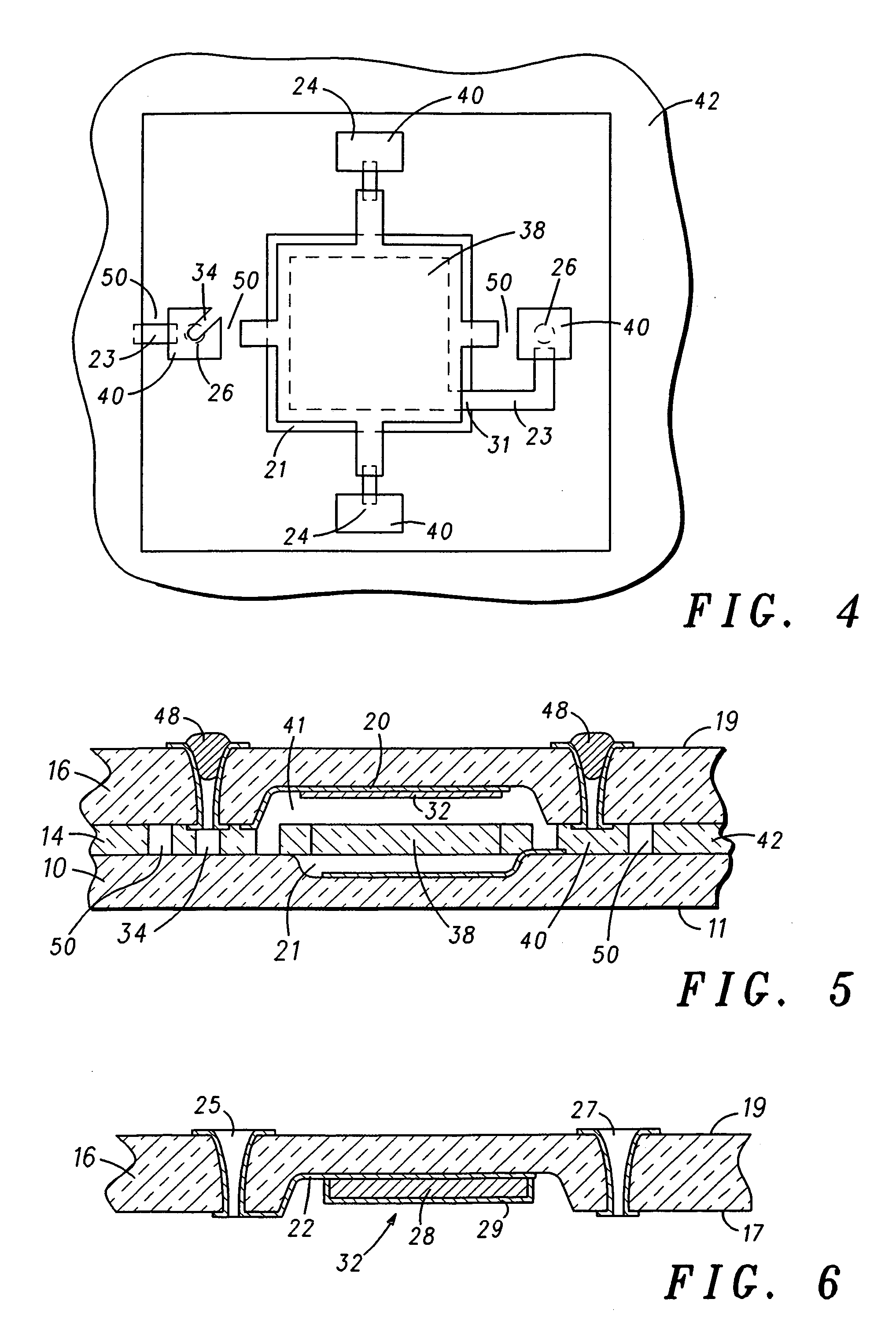

Hermetically sealed microdevice with getter shield

InactiveUS7204737B2Vessels or leading-in conductors manufactureMicrostructural devicesElectrical connectionGetter

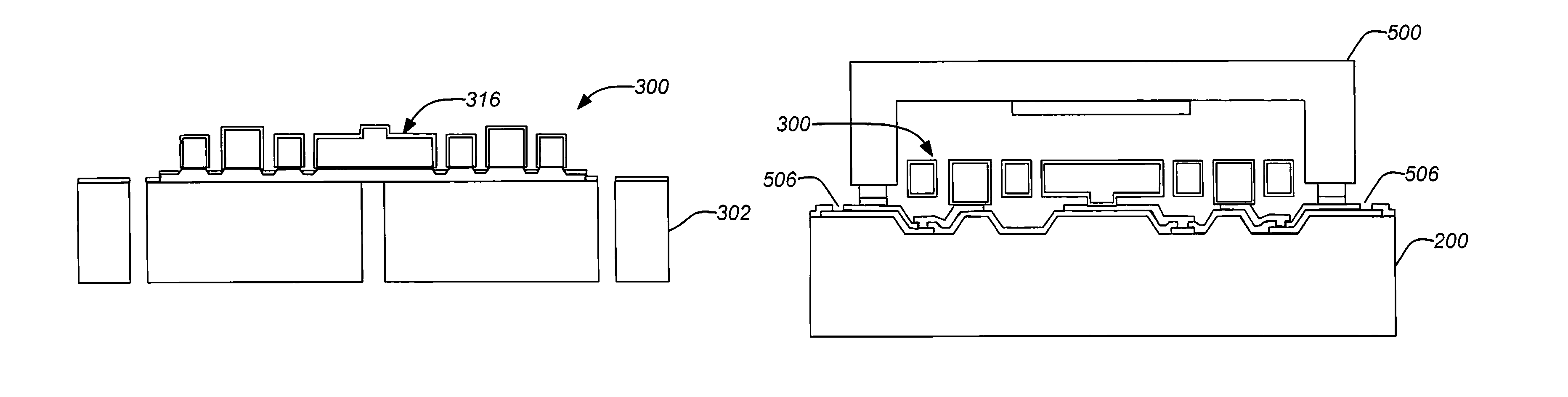

A microdevice that comprises a device microstructure (38) and vent channel (34) in a wafer (14) that is sandwiched between a substrate (10) and a cap (16). The cap (16) and substrate (10) have recesses (41, 21) around the microstructure (22) to define a cavity. A vent (25) is connected to the vent channel (34) and subsequently to the cavity. The vent (25) is used to evacuate and seal the microstructure (38) in the cavity. A getter layer (32) can be used to maintain the cavity vacuum. An electrical connection can be provided through the vent (25), vent channel (34) and cavity to the getter (32) to electrically ground the getter layer (32).

Owner:TEMIC AUTOMOTIVE OF NORTH AMERICA

Metal seal packaging for organic light emitting diode device

InactiveUS7202602B2Suppress permeation of moistureImprove life performanceDischarge tube luminescnet screensElectroluminescent light sourcesDesiccantLight-emitting diode

A metal sealed organic light emitting diode device comprising a lid, containing a recessed portion to accommodate large quantity of getter / dessicant, a band of metal stack at the perimeter over which is laid a band of low temperature melting solder alloy, pre-tinned subsequently, and a substrate. The substrate containing organic light emitting diode at the central area with a band of metal stack at the perimeter. The lid and the substrate are placed together in substantial alignment such that the pre-tinned low melting solder band of the lid contacts the metal stack of the substrate and thermally sealed in a controlled atmosphere. Multiples of substrates are sealed with a single lid containing multiplicity of recessed portions with multi-segmented metal stack and pre-tinned solder band to derive a large area device.

Owner:ORGANIC LIGHTING TECH

Hermetically sealed microdevice with getter sheild

InactiveUS20060063462A1Vessels or leading-in conductors manufactureMicrostructural devicesElectrical connectionEngineering

A microdevice that comprises a device microstructure (38) and vent channel (34) in a wafer (14) that is sandwiched between a substrate (10) and a cap (16). The cap (16) and substrate (10) have recesses (41, 21) around the microstructure (22) to define a cavity. A vent (25) is connected to the vent channel (34) and subsequently to the cavity. The vent (25) is used to evacuate and seal the microstructure (38) in the cavity. A getter layer (32) can be used to maintain the cavity vacuum. An electrical connection can be provided through the vent (25), vent channel (34) and cavity to the getter (32) to electrically ground the getter layer (32).

Owner:TEMIC AUTOMOTIVE OF NORTH AMERICA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com