Patents

Literature

2364results about "Microstructural devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Susceptor

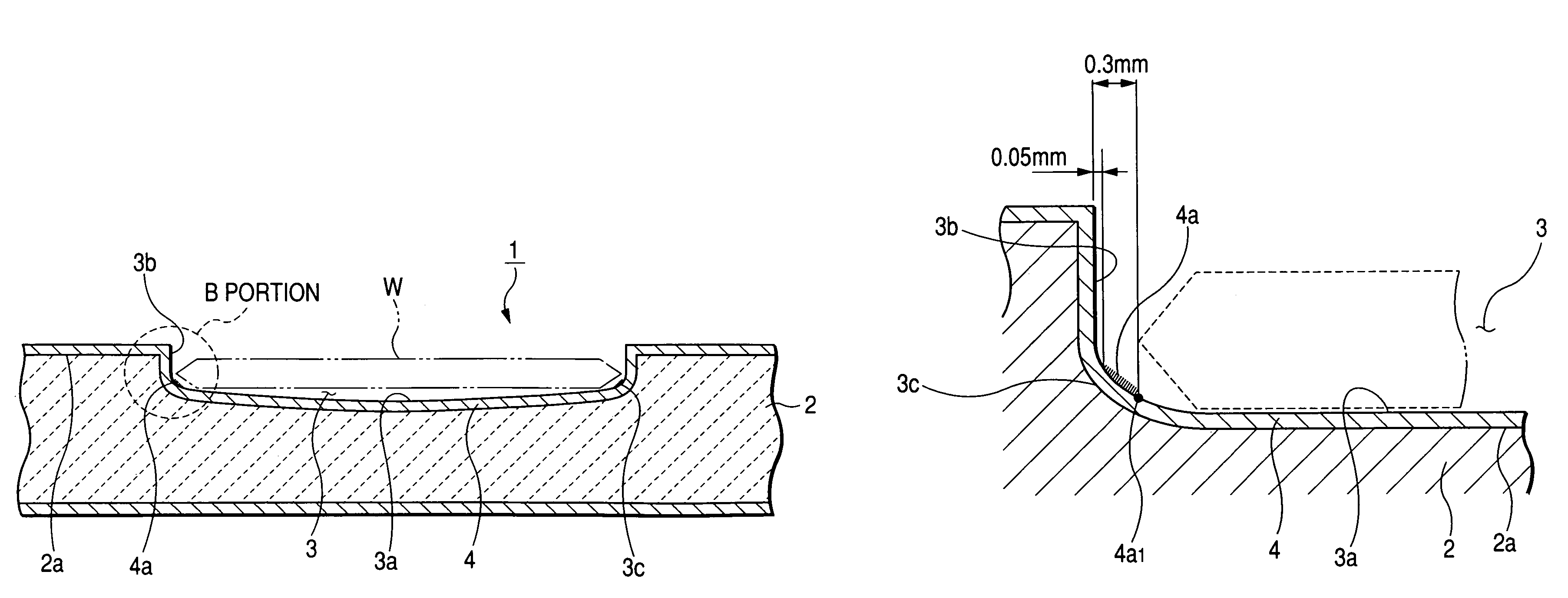

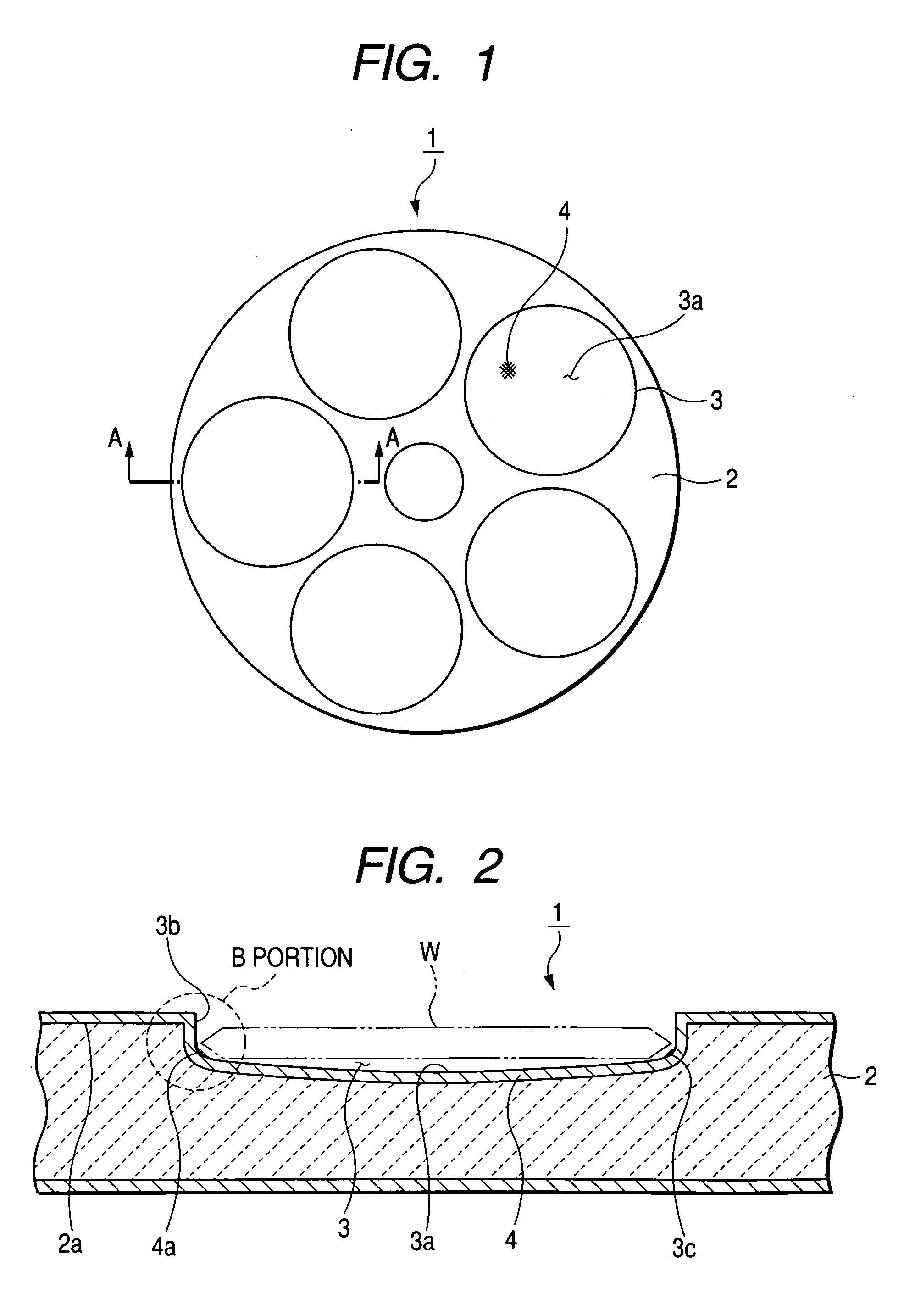

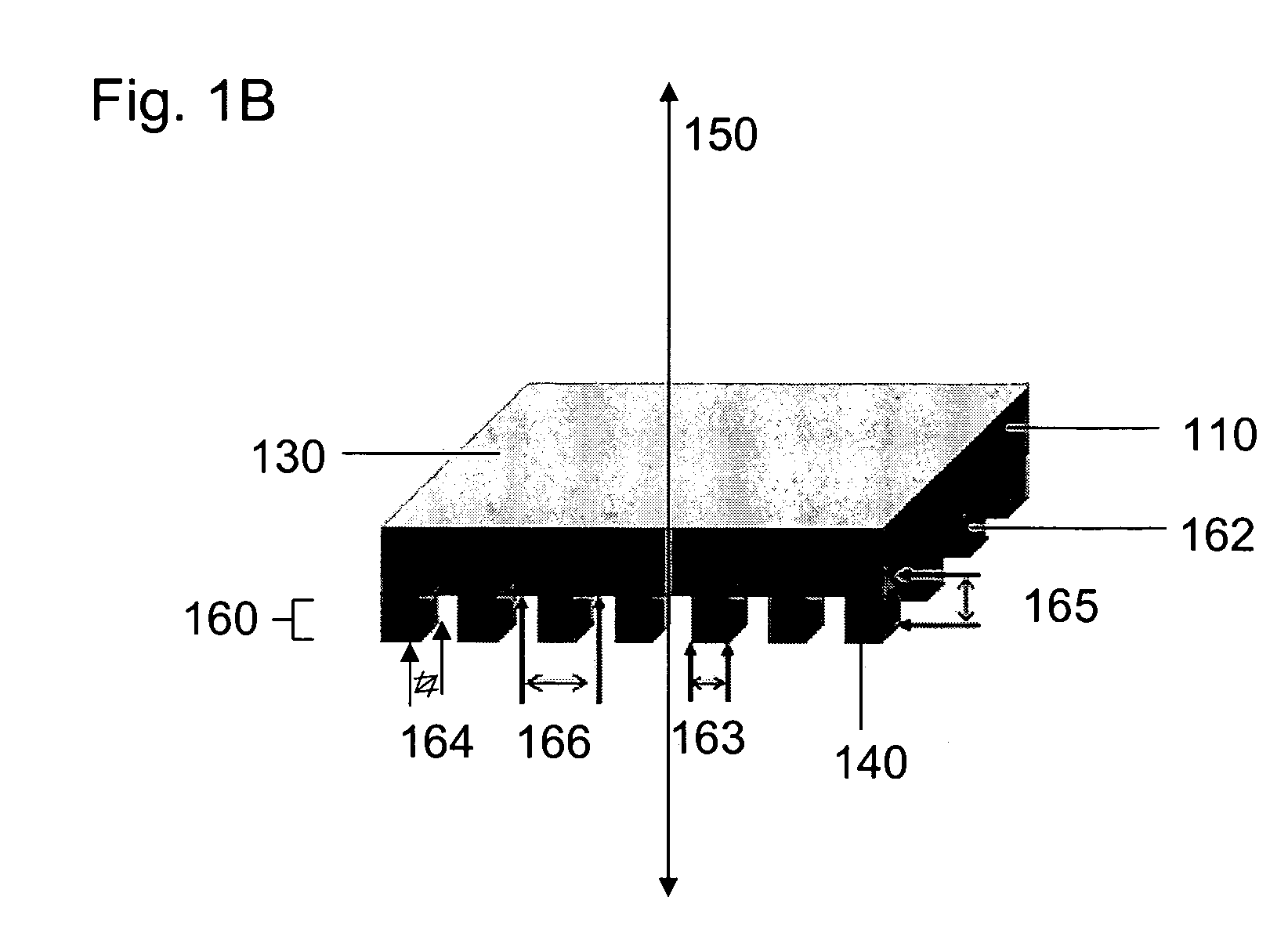

ActiveUS7393418B2Stably holdUnified performanceLiquid surface applicatorsDiffusion/dopingSusceptorSurface roughness

A susceptor at least a surface thereof being coated with SiC, includes a recess where an wafer is mounted, the recess having an round portion disposed on a lower portion of an outer circumferential portion of the recess, a ring-shaped SiC crystal growth surface portion provided within the round portion in a range of 0.05 mm or more and 0.3 mm or less defined from an outer circumference vertical portion of the recess and a contact portion, where the susceptor contacts with the wafer on the recess, having a surface roughness Ra in a range of 0.5 μm or more and 3 μm or less.

Owner:COORSTEK INC

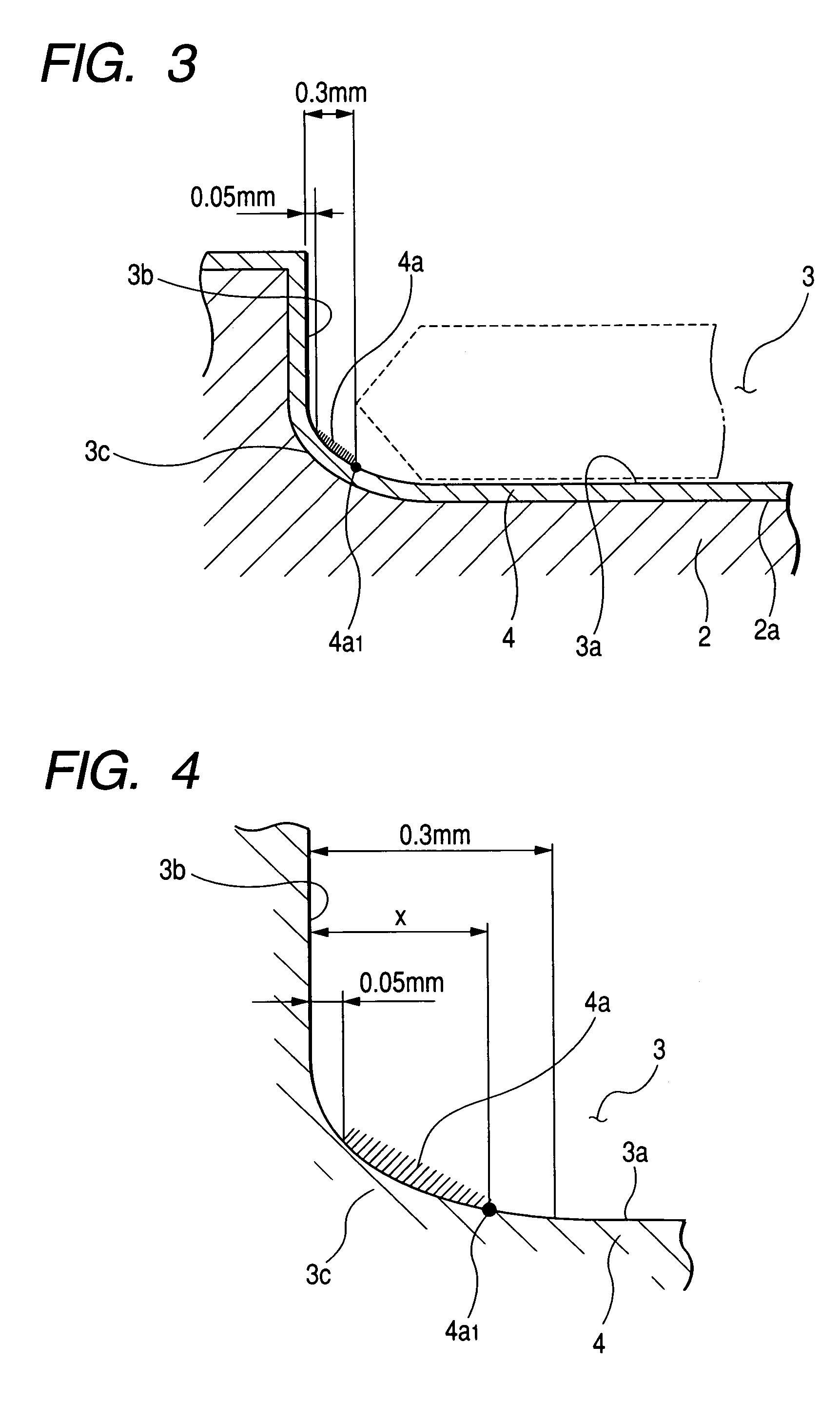

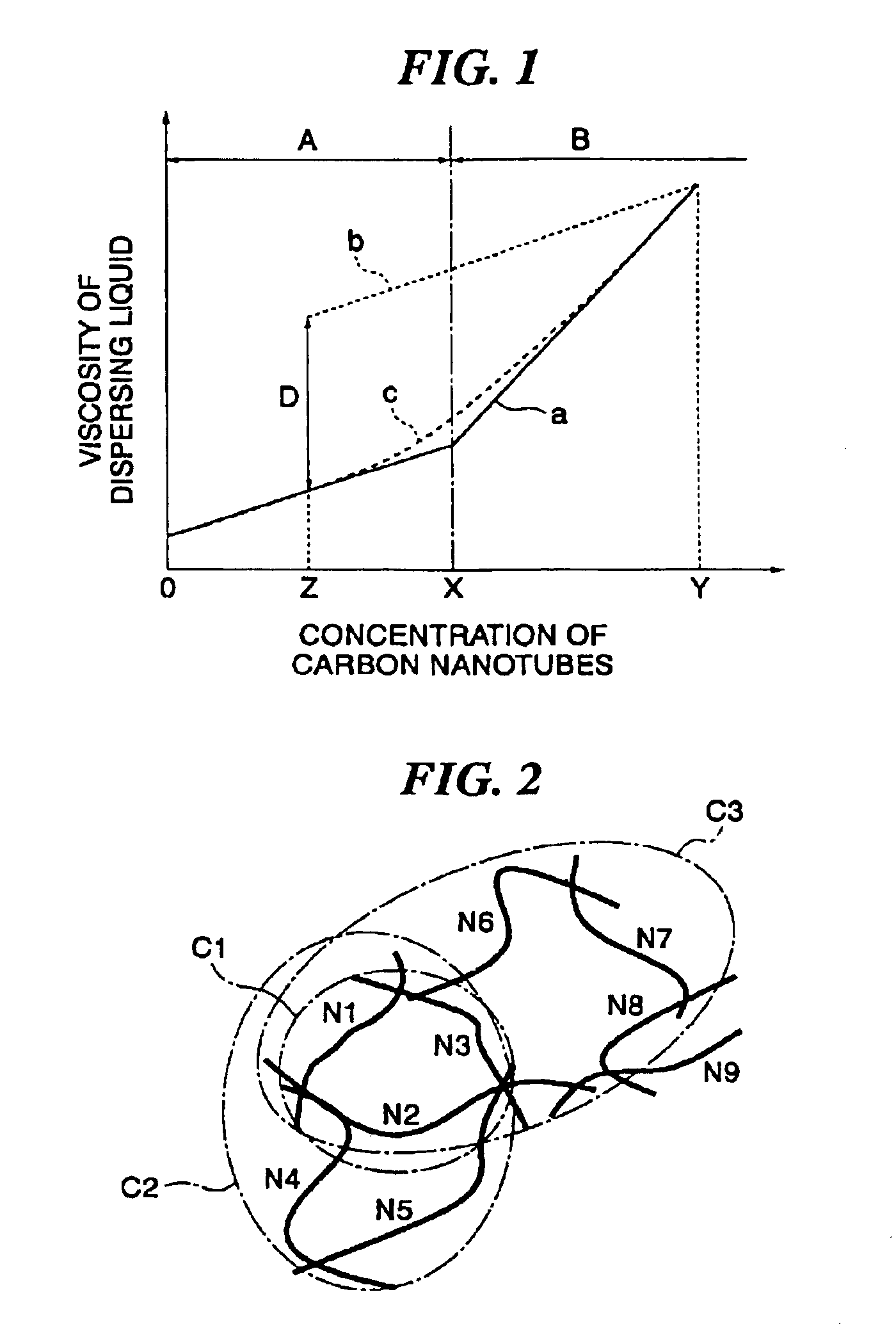

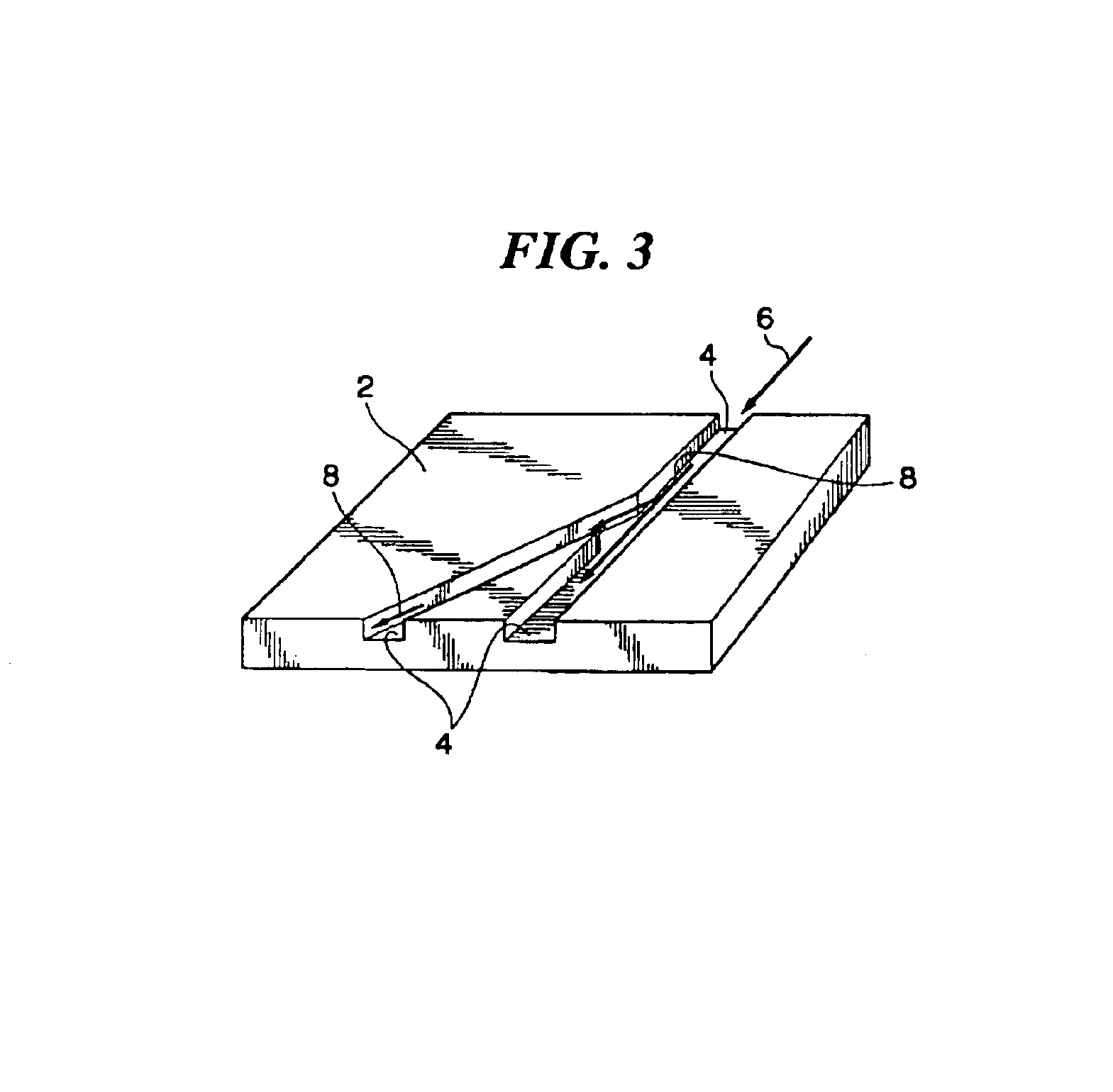

Carbon nanotube structures, carbon nanotube devices using the same and method for manufacturing carbon nanotube structures

InactiveUS6921575B2Easy to manufactureMaterial nanotechnologyCarbon compoundsElectricityCarbon nanotube

Carbon nanotube structures are provided, in which the networks with a desired area and volume, where the carbon nanotubes are electrically or magnetically connected, are formed and the method for easily manufacturing the carbon nanotube structures with less carbon nanotube structures. Carbon nanotube devices are also provided, to which the useful carbon nanotube structures mentioned above are applied. A method for manufacturing carbon nanotube structures includes the steps of applying carbon nanotubes to a low-viscosity dispersion medium to obtain a high-viscosity dispersing liquid which includes carbon nanotubes, and forming a network of the carbon nanotubes having electrical and / or magnetic connections therebetween by removing the low-viscosity dispersion medium from the high-viscosity dispersed liquid.

Owner:FUJIFILM BUSINESS INNOVATION CORP

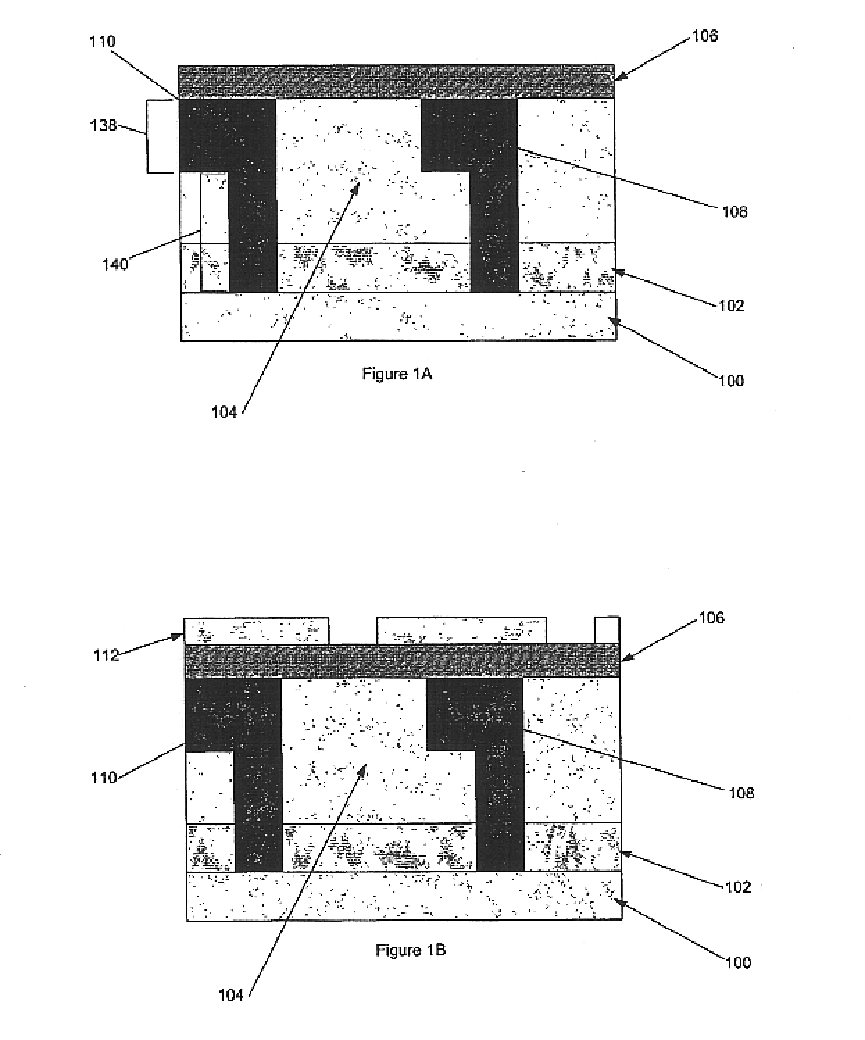

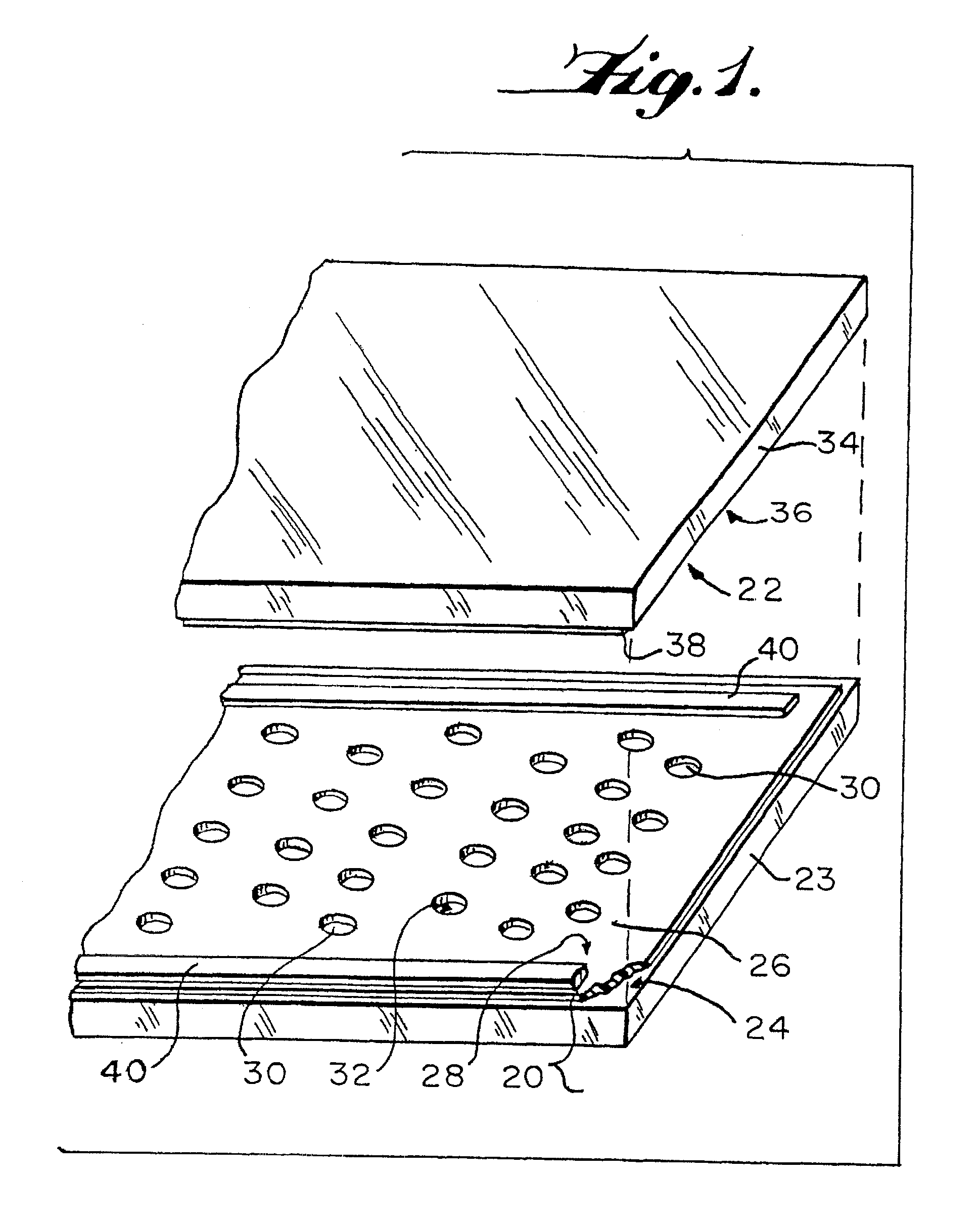

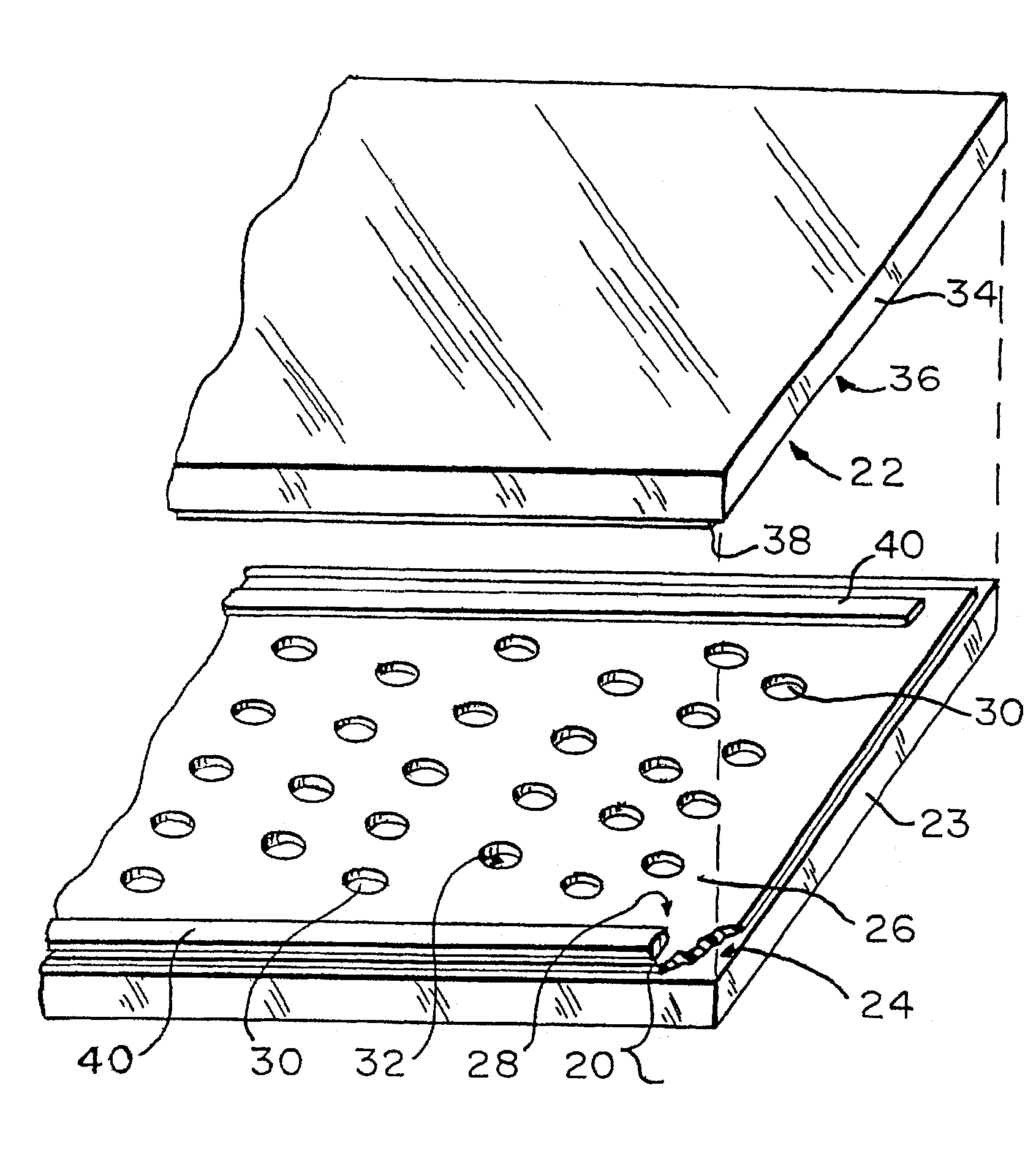

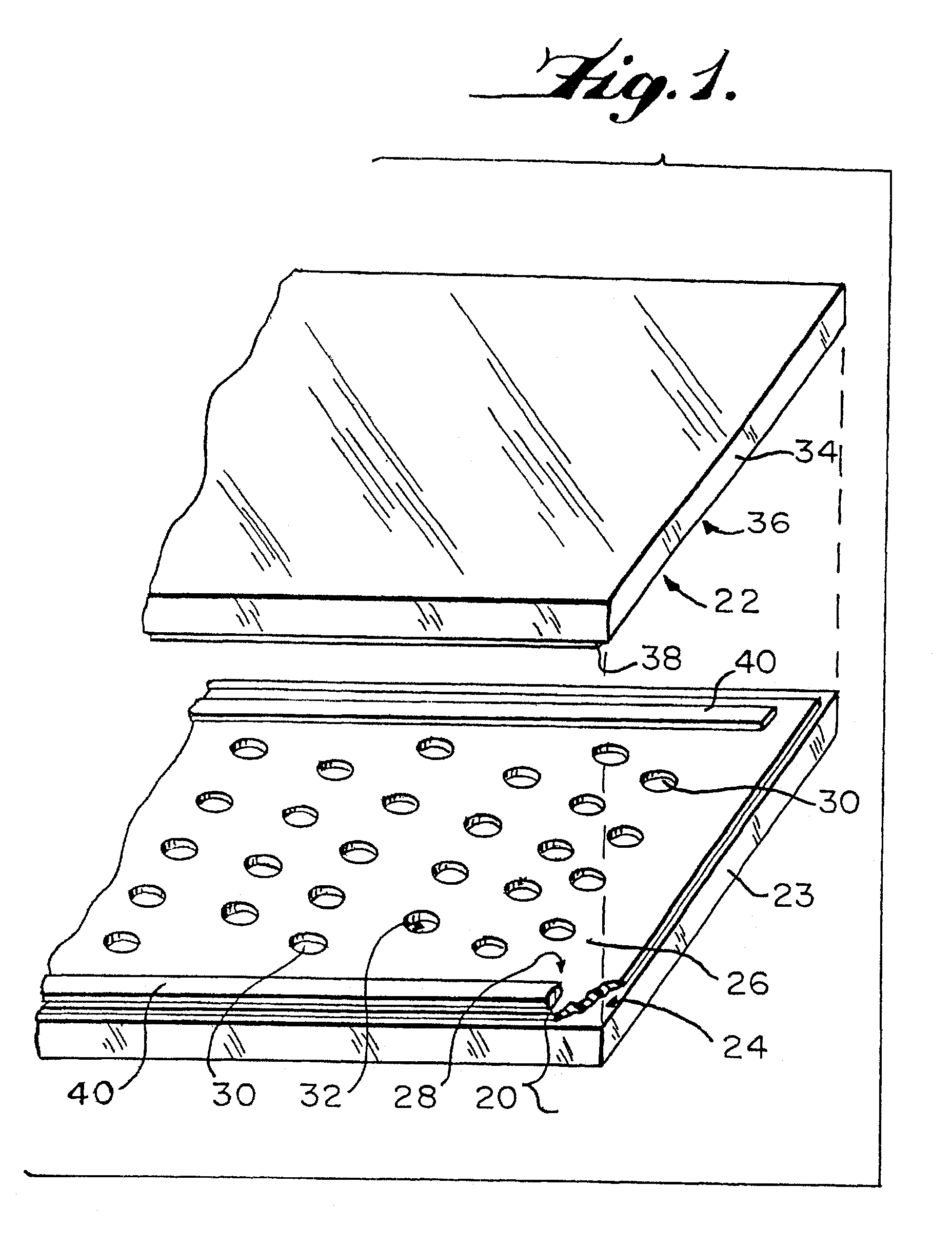

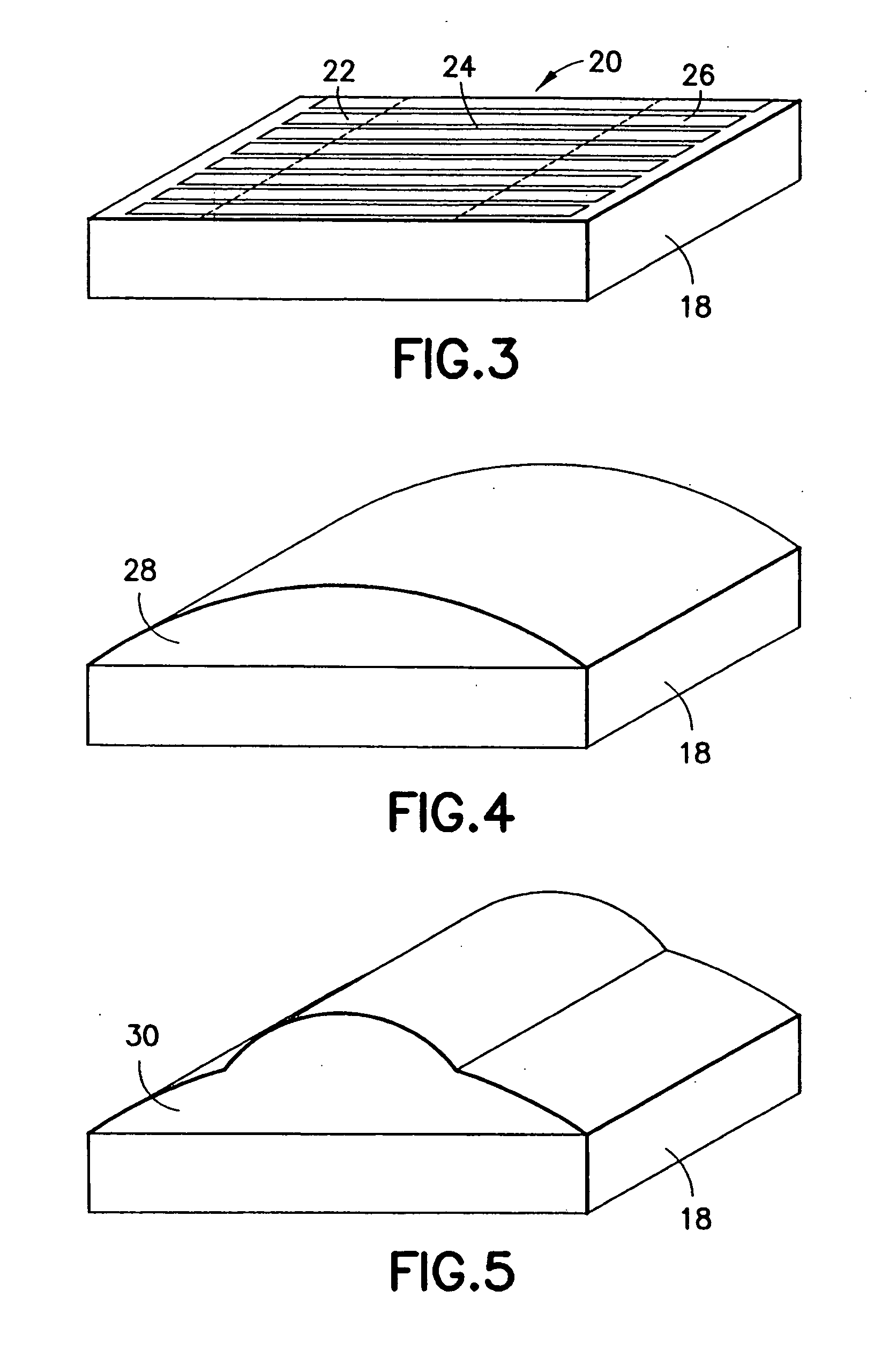

Methods and devices for fabricating three-dimensional nanoscale structures

ActiveUS7704684B2Convenient ArrangementEfficiently patternMaterial nanotechnologyNanostructure manufactureEngineeringElectromagnetic radiation

The present invention provides methods and devices for fabricating 3D structures and patterns of 3D structures on substrate surfaces, including symmetrical and asymmetrical patterns of 3D structures. Methods of the present invention provide a means of fabricating 3D structures having accurately selected physical dimensions, including lateral and vertical dimensions ranging from 10s of nanometers to 1000s of nanometers. In one aspect, methods are provided using a mask element comprising a conformable, elastomeric phase mask capable of establishing conformal contact with a radiation sensitive material undergoing photoprocessing. In another aspect, the temporal and / or spatial coherence of electromagnetic radiation using for photoprocessing is selected to fabricate complex structures having nanoscale features that do not extend entirely through the thickness of the structure fabricated.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

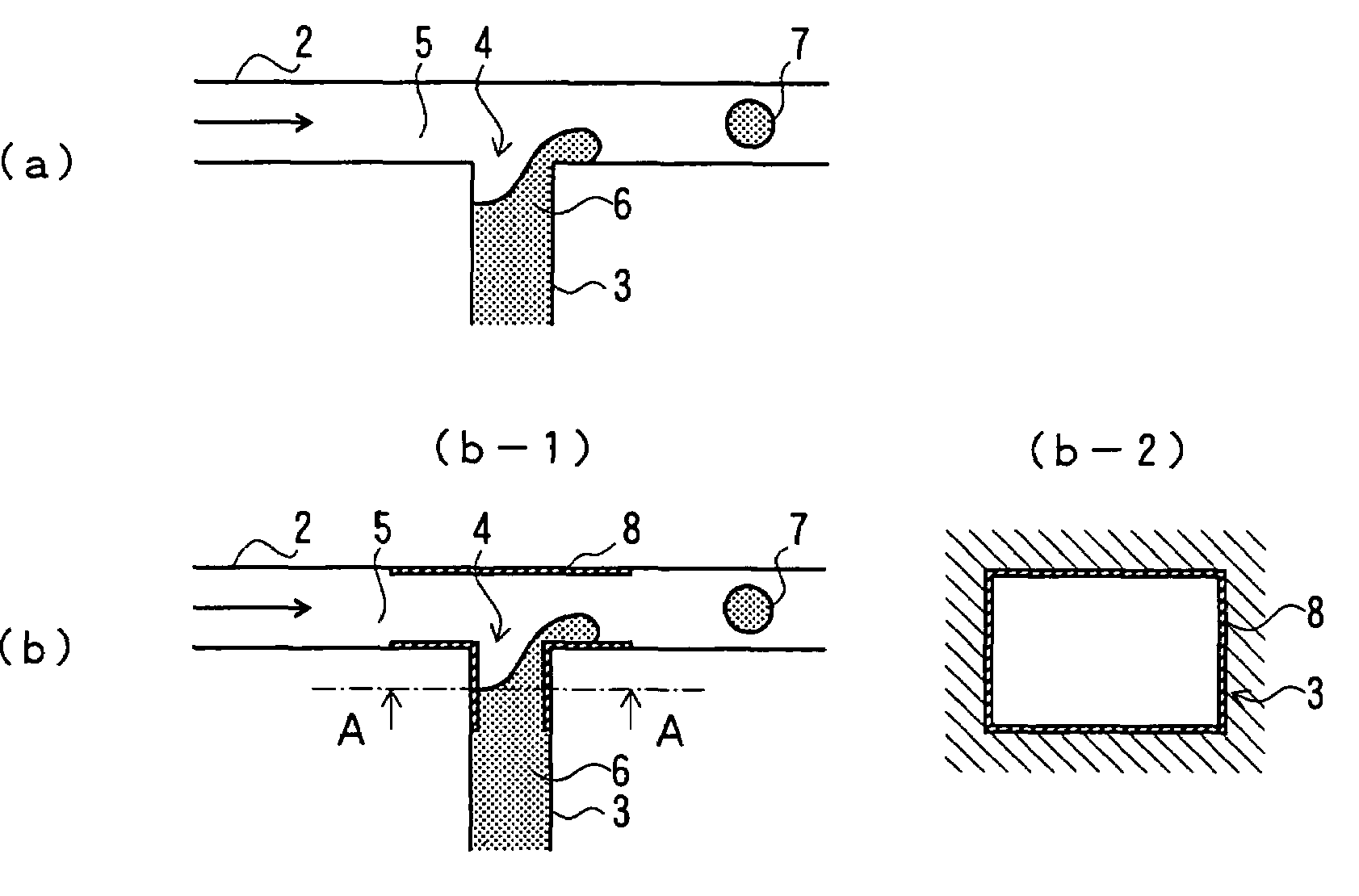

Process for producing emulsion and microcapsules and apparatus therefor

InactiveUS7268167B2Rapid productionSimple wayFlow mixersMixing methodsEmulsionMechanical engineering

Owner:JAPAN SCI & TECH CORP

Wafer-to-wafer transfer of microstructures using break-away tethers

InactiveUS6142358AReduce tensionSemiconductor/solid-state device detailsWelding/cutting auxillary devicesOptoelectronicsMicrostructure

Break-away tethers to secure electronic, mechanical, optical, or other microstructures, during release from one substrate and transfer to another. Microstructures are fabricated with integrated tethers attaching them to a first substrate. The structures are undercut by etching and contacted and bonded to a second substrate. First and second substrates are separated, breaking the tethers.

Owner:RGT UNIV OF CALIFORNIA

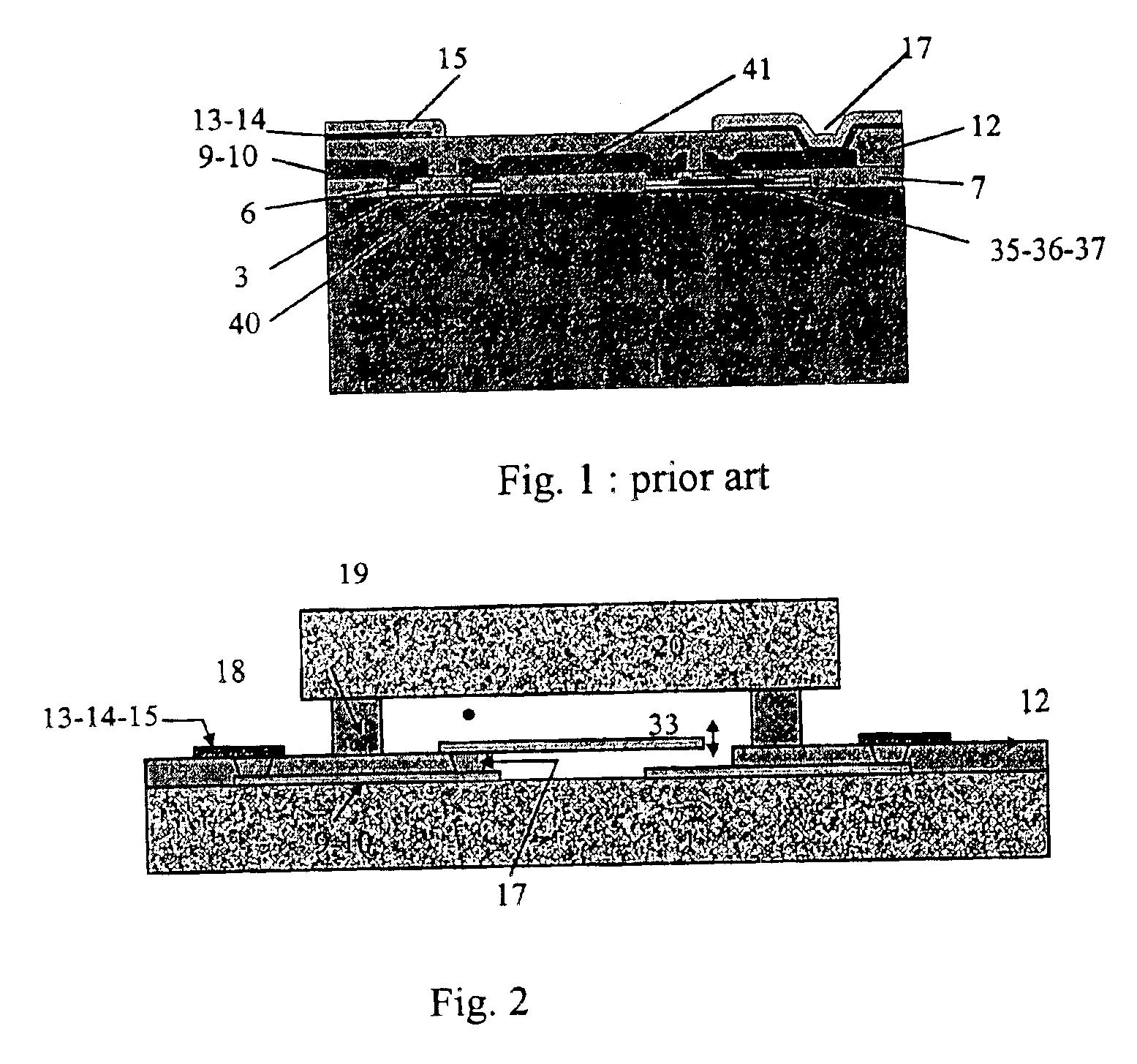

Air gap interconnect method

InactiveUS6861332B2Semiconductor/solid-state device detailsSolid-state devicesElectronic structureEngineering

A low-k dielectric sacrificial material is formed within a microelectronic structure covered with a layer defining an exhaust vent. At an appropriate time, the underlying sacrificial material is decomposed and exhausted away through the exhaust vent. Residue from the exhausted sacrificial material accumulates at the vent location during exhaustion until the vent is substantially occluded. As a result, an air gap is created having desirable characteristics as a dielectric.

Owner:INTEL CORP

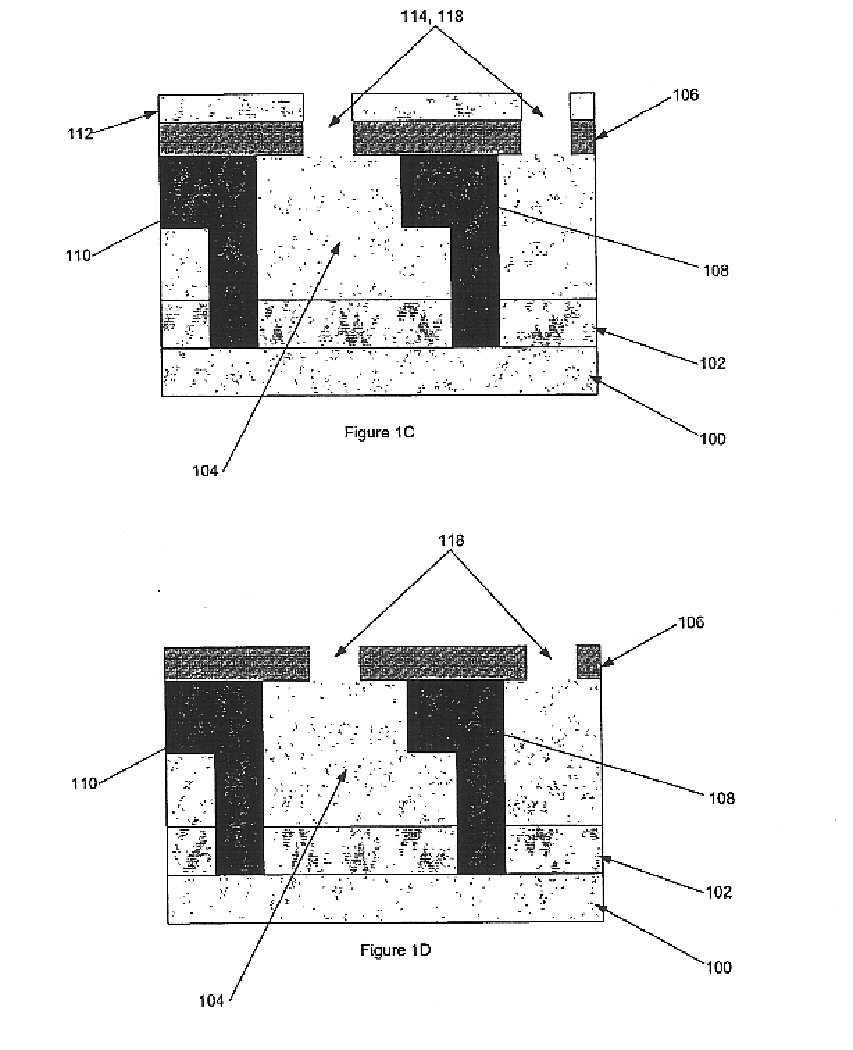

Method and system for fabrication of integrated tunable/switchable passive microwave and millimeter wave modules

InactiveUS6876056B2Electrostatic/electro-adhesion relaysSolid-state devicesMetal interconnectMicrowave

An interconnect module and a method of manufacturing the same is described comprising: a substrate, an interconnect section formed on the substrate, and a variable passive device section formed on the substrate located laterally adjacent to the interconnect section. The interconnect section has at least two metal interconnect layers separated by a dielectric layer and the variable passive device has at least one moveable element. The moveable element is formed from a metal layer which is formed from the same material and at the same time as one of the two interconnect layers. The moveable element is formed on the dielectric layer and is released by local removal of the dielectric layer. Additional interconnect layers and intermediate dielectric layers may be added.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW)

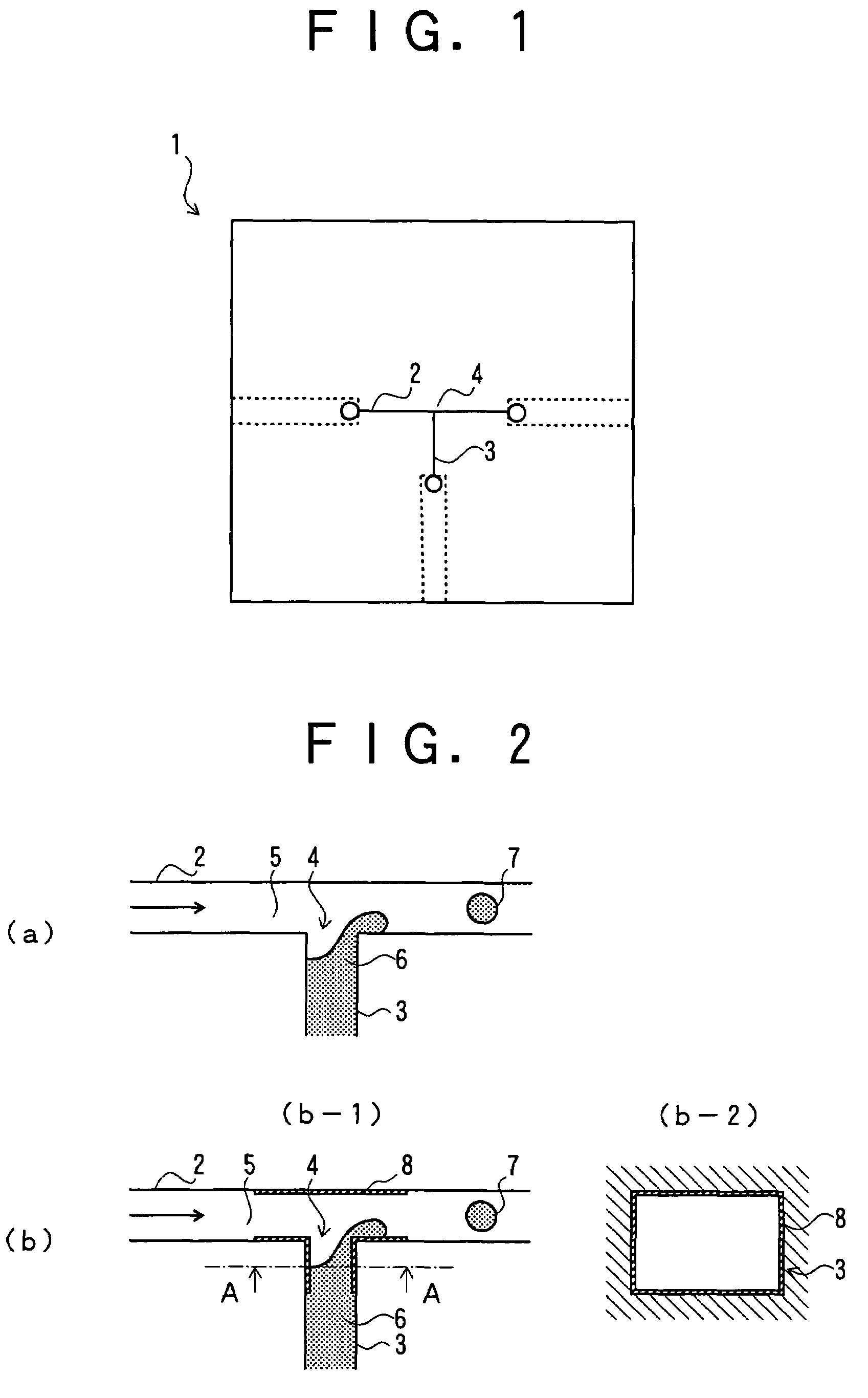

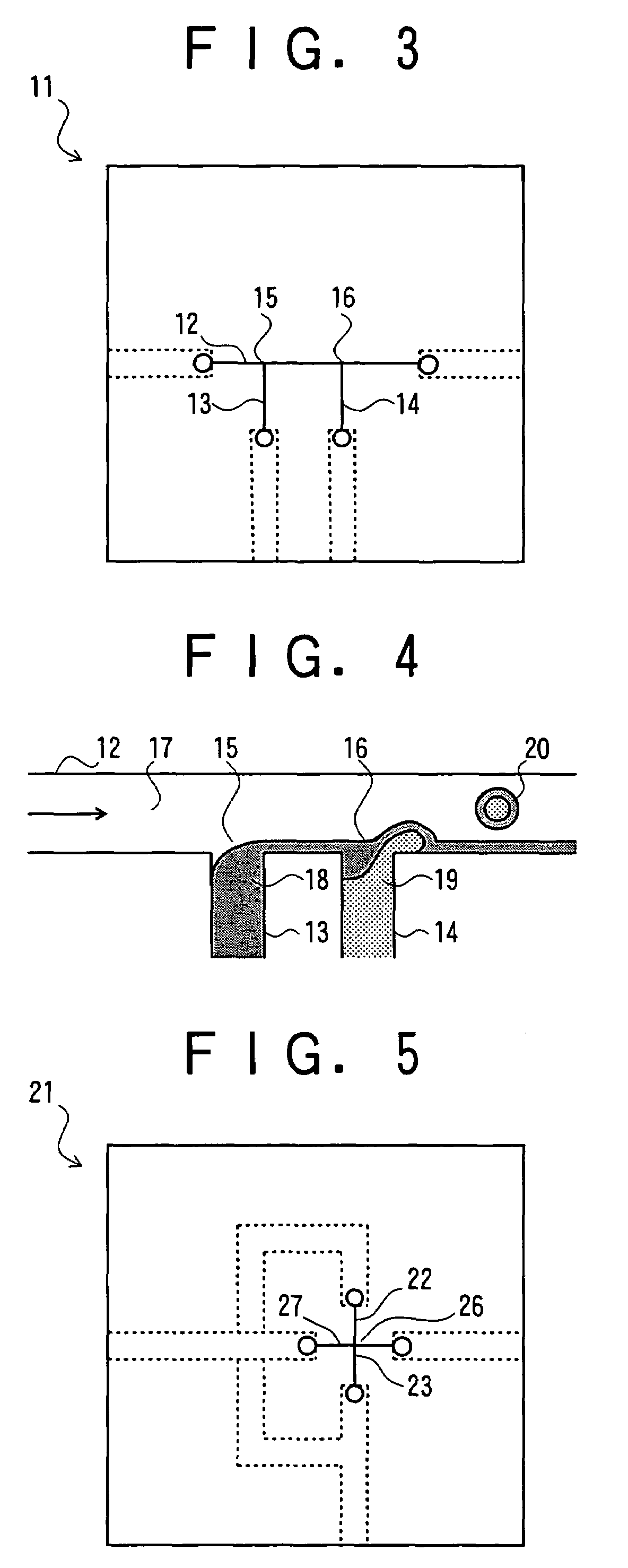

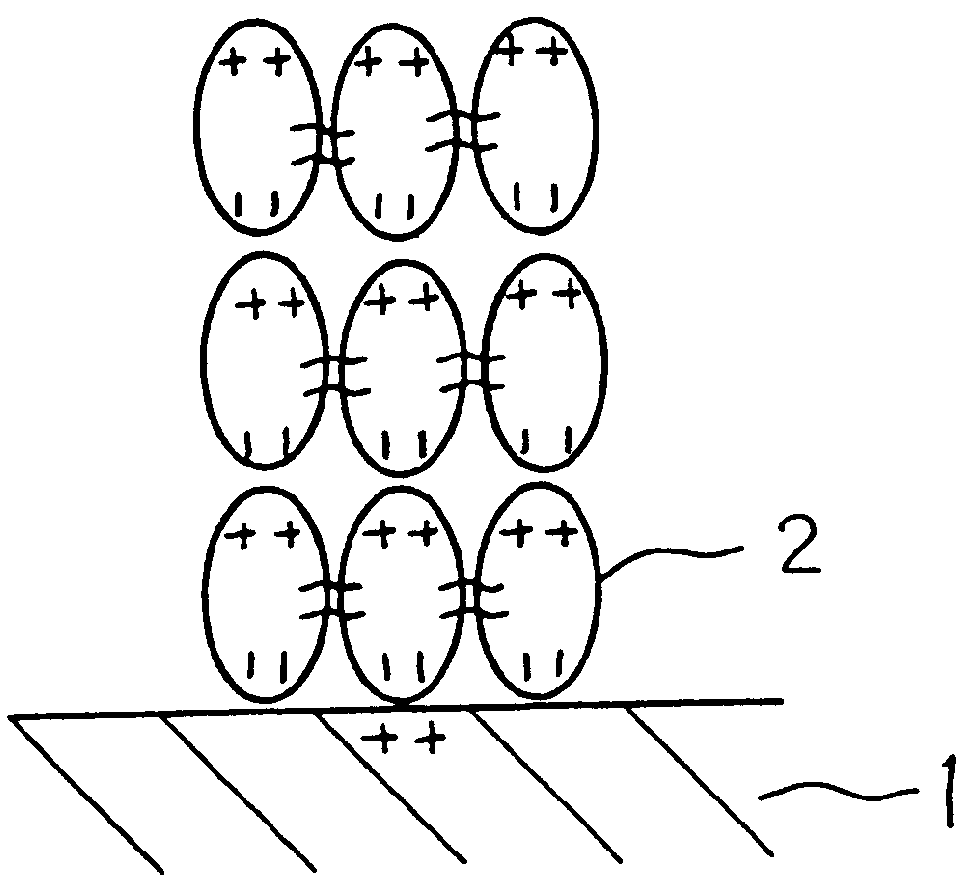

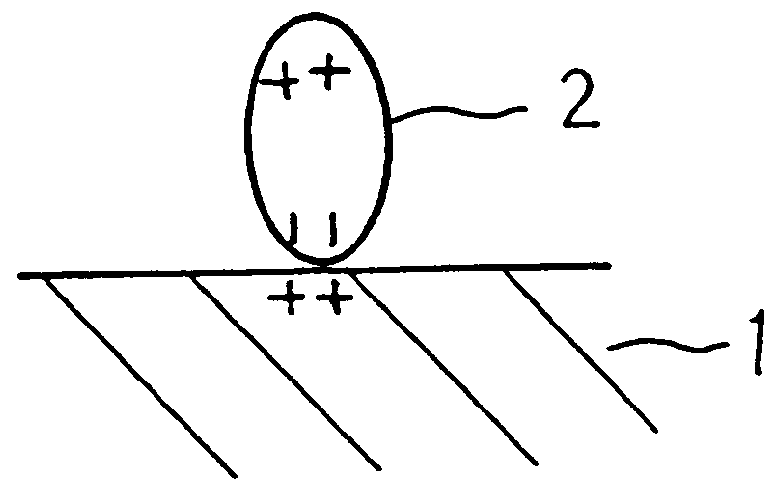

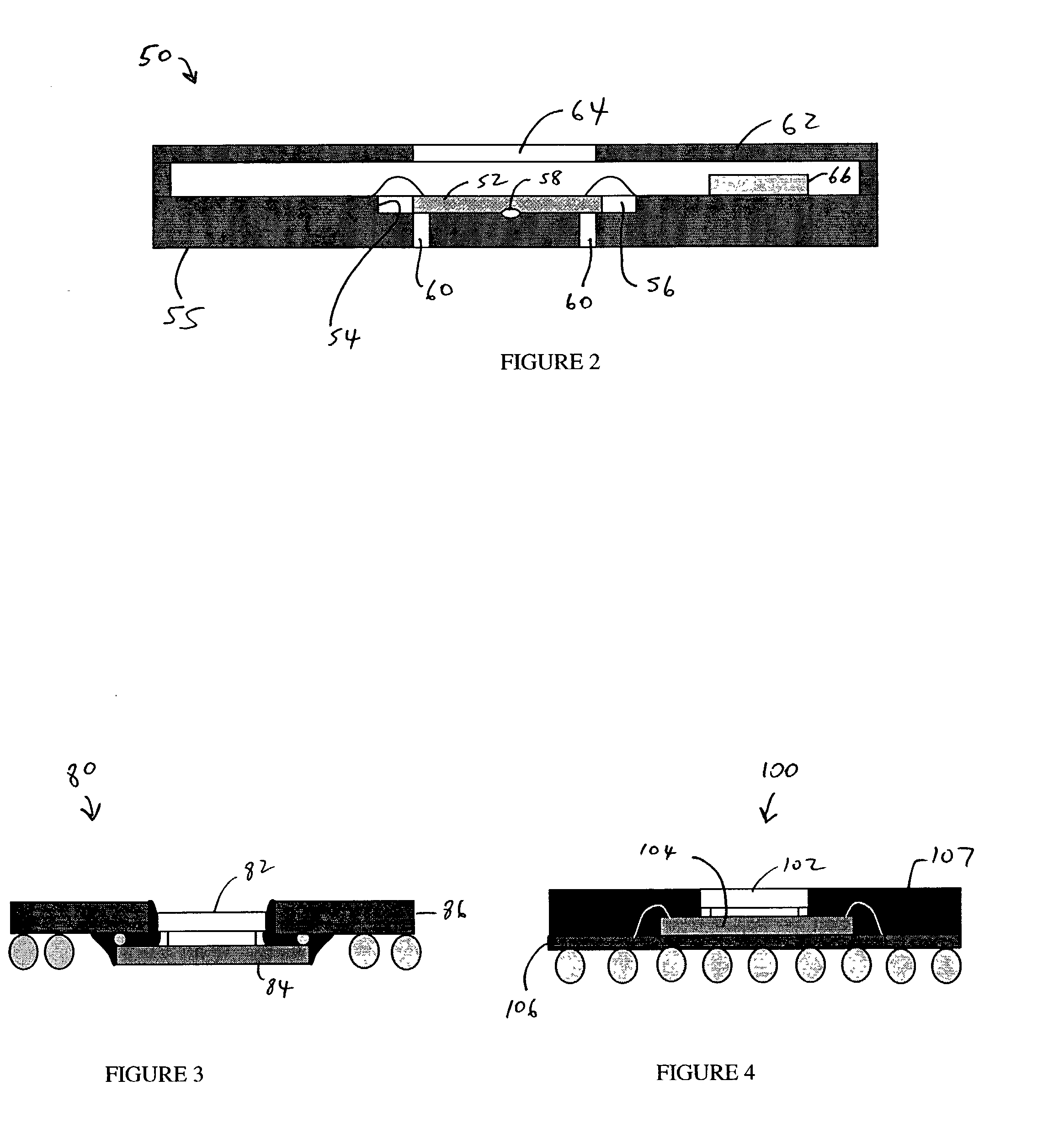

Crystallization control method for organic compound and crystallization control solid-state component employed therefor

InactiveUS6123769APolycrystalline material growthFrom normal temperature solutionsValence electronBiopolymer

A method which can control crystallization of a biopolymer such as protein is provided. A silicon crystal (15) whose valence electrons are controlled to be capable of controlling the concentration of holes or electrons of the surface part in response to the environment of a buffer solution (14) containing the biopolymer such as protein is brought into contact with the solution (14), for getting a crystal of the biopolymer deposited on the surface of the silicon crystal (15). Crystallization is controlled by an electrical state which is generated by the controlled valence electrons on the surface of the silicon crystal (15).

Owner:SUMITOMO METAL IND LTD

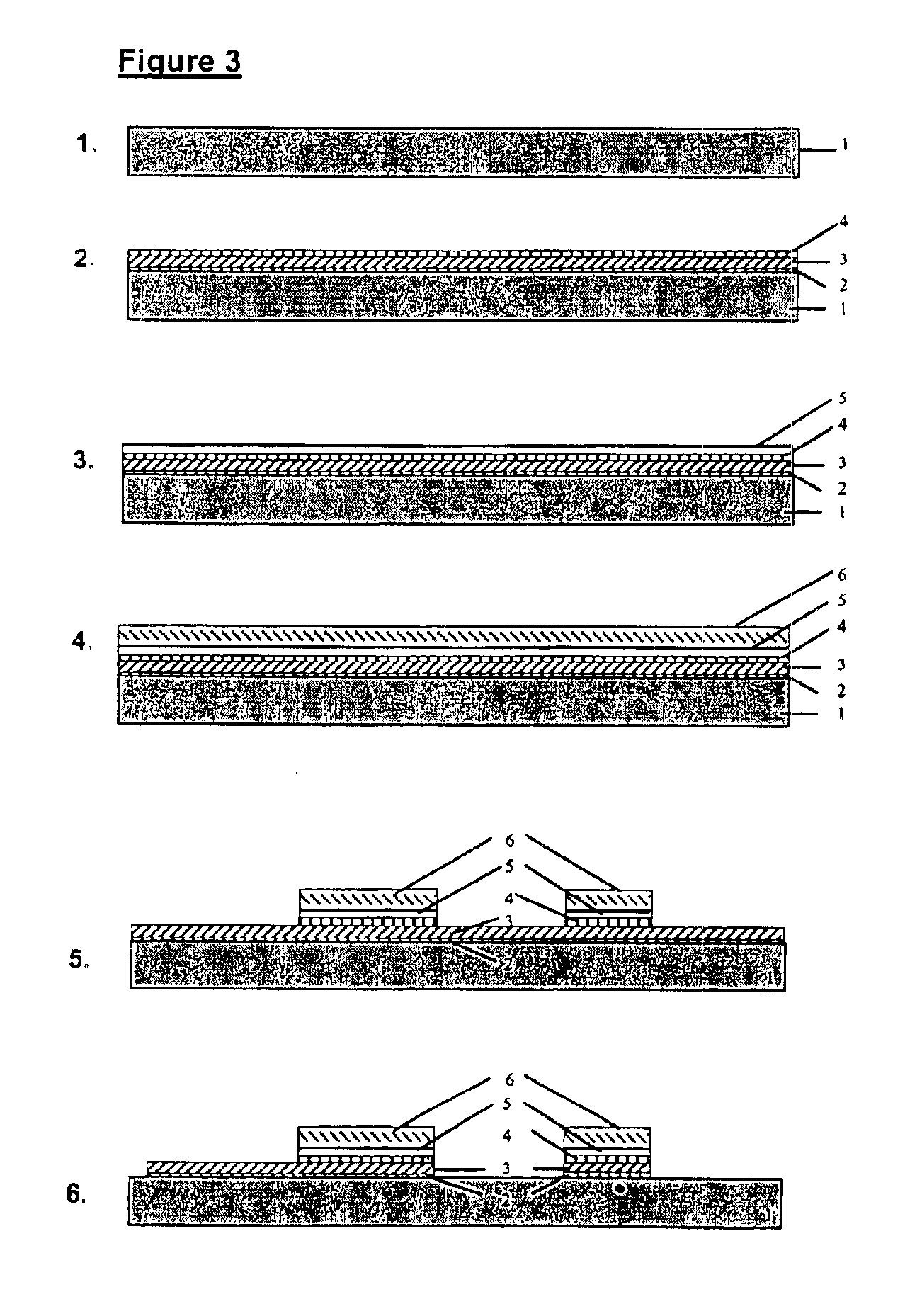

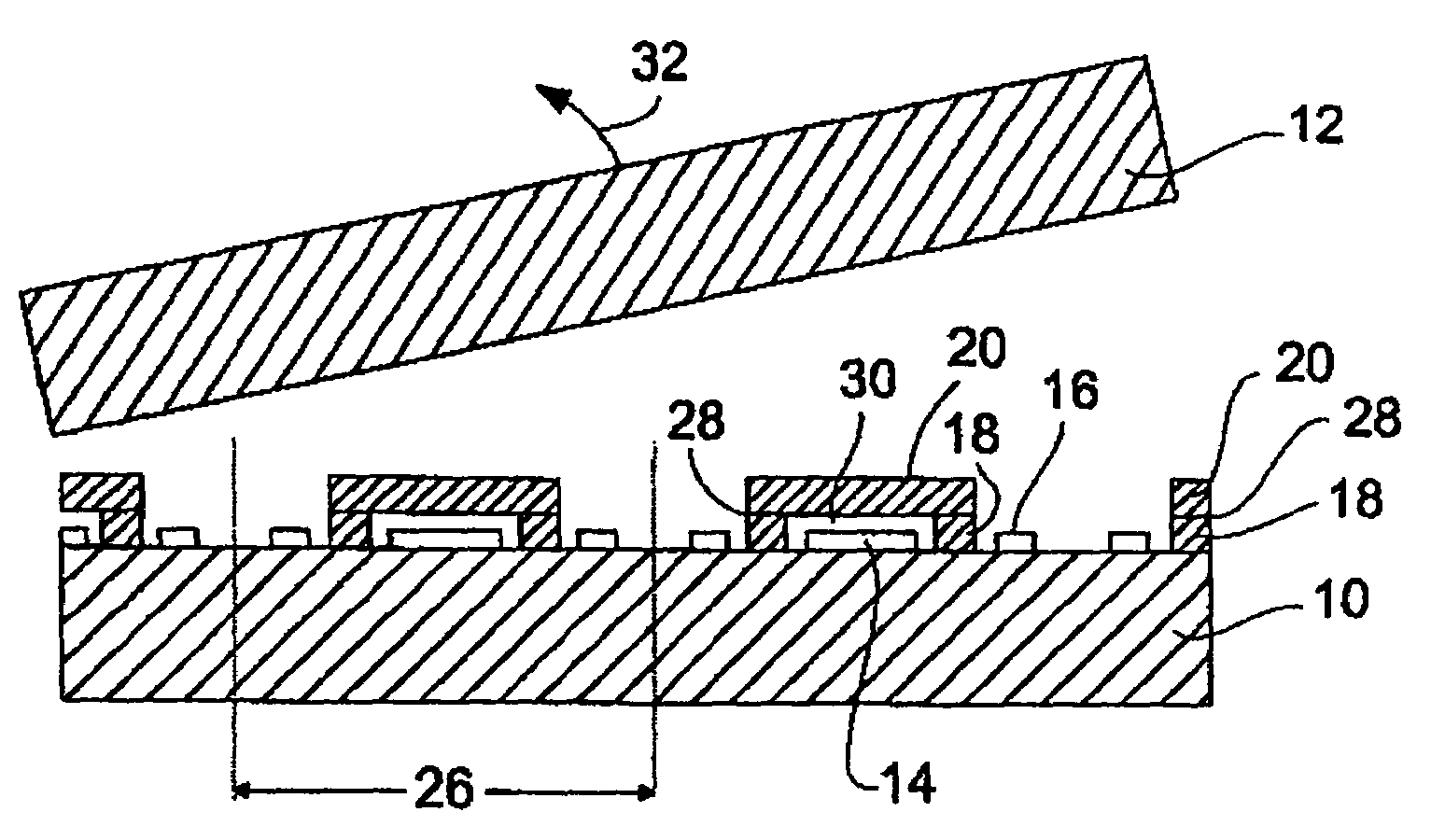

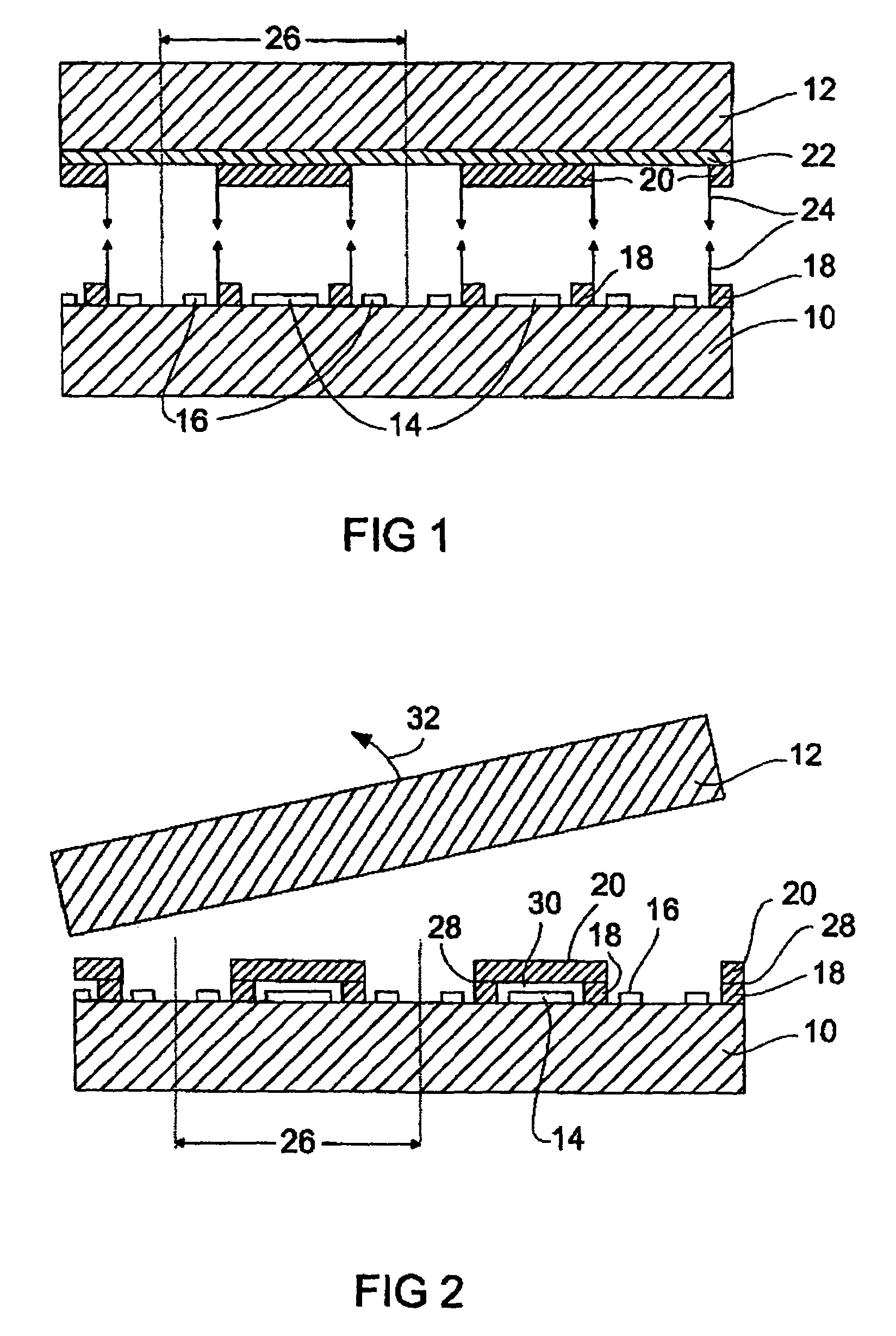

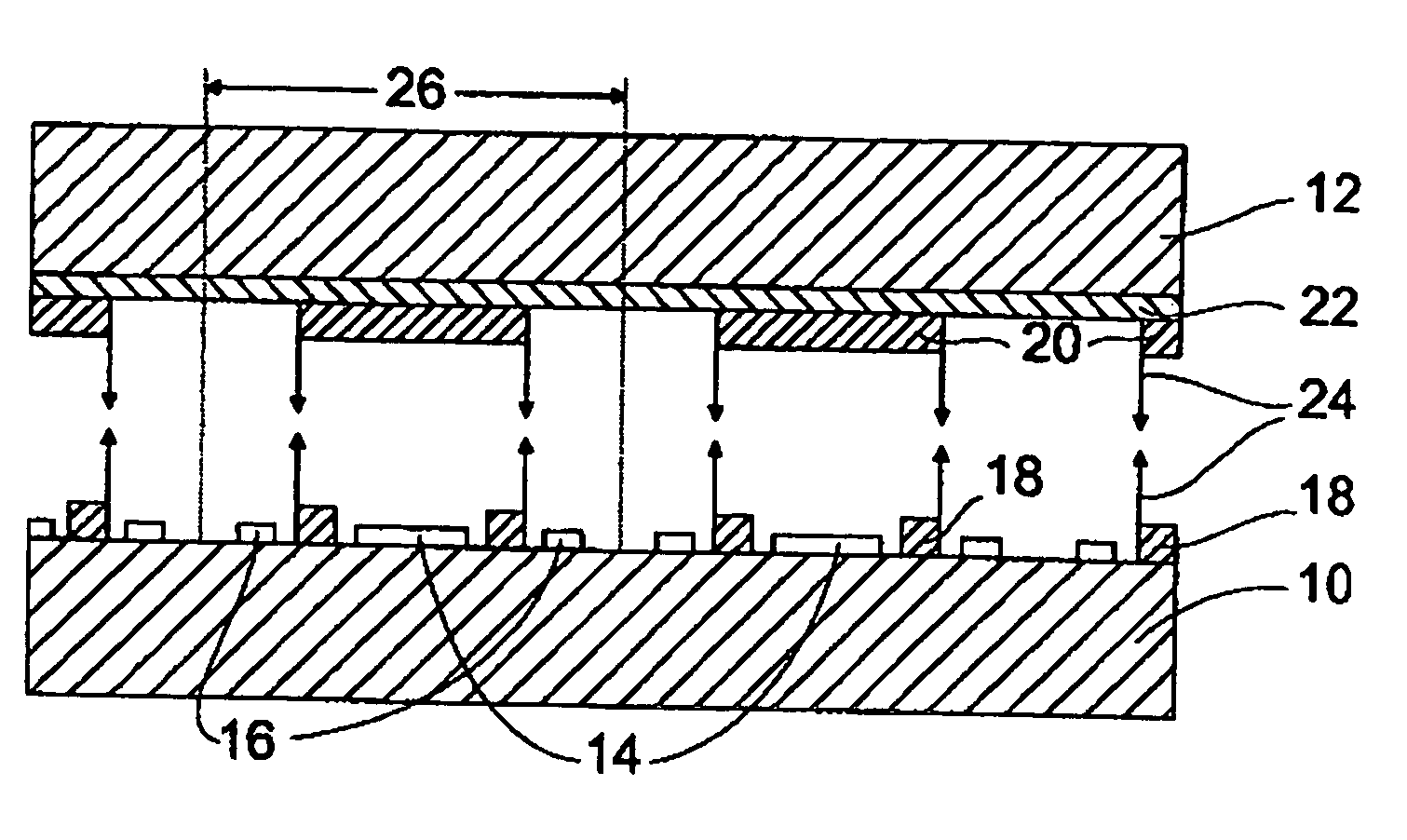

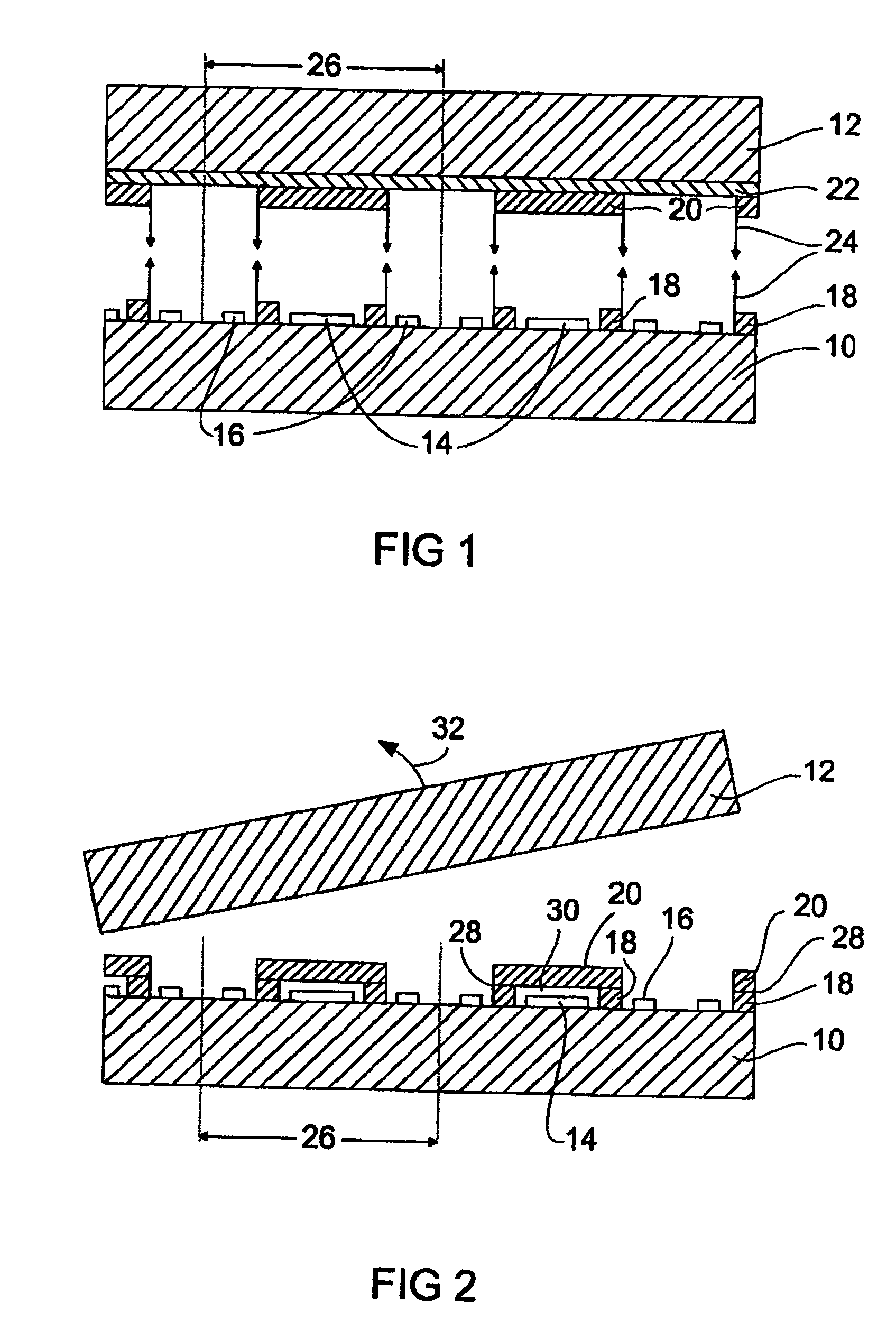

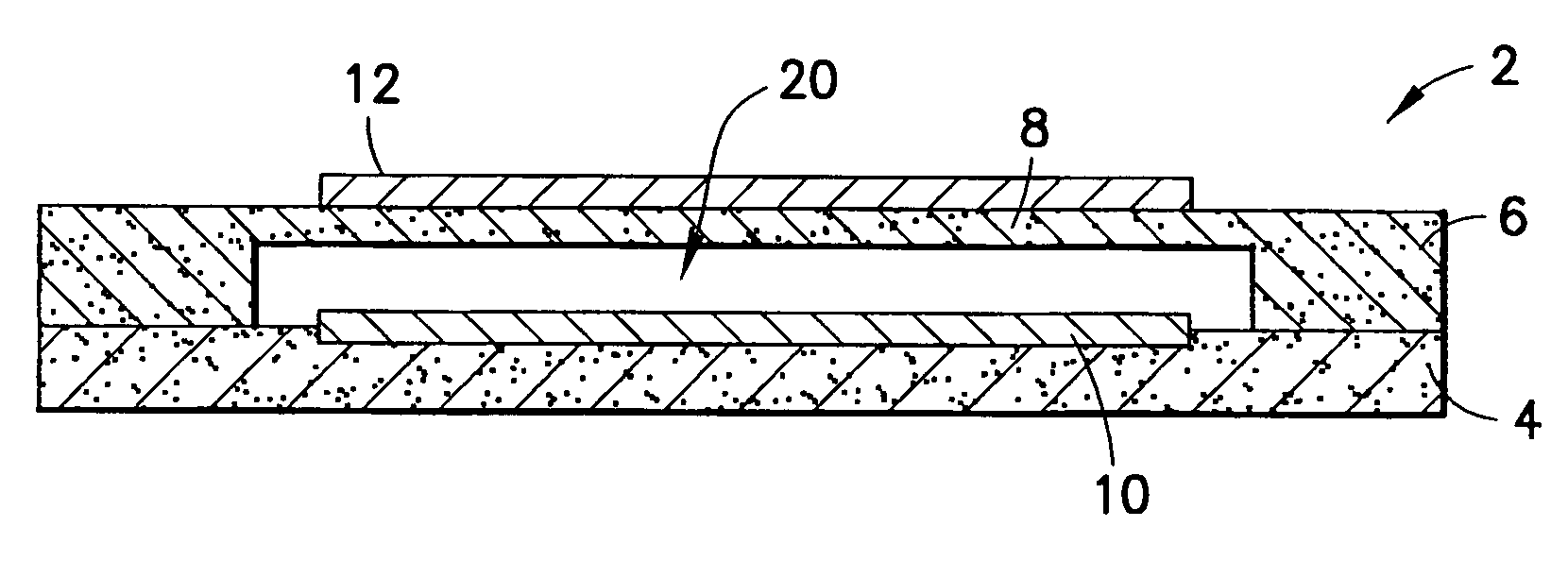

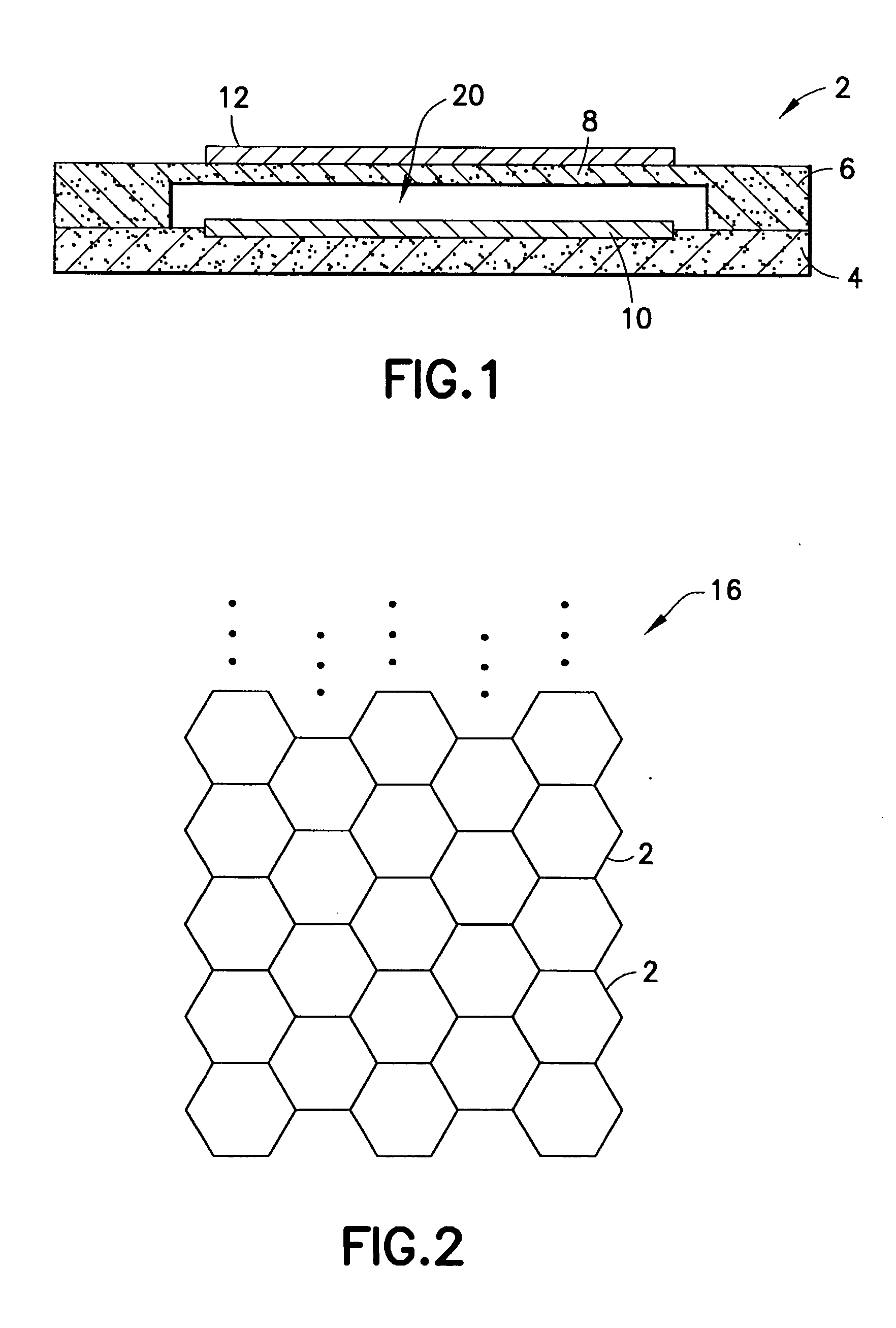

Method for producing a cover, method for producing a packaged device

In a method for producing a cover for a region of a substrate, first a frame structure is produced in the region of the substrate, and then a cap structure is attached to the frame structure so that the region under the cap structure is covered. Thus, sensitive devices may be protected easily and at low cost from external influences and particularly from a casting material for casting the entire packaged device, which results when a diced chip is cast.

Owner:CHEMTRON RES

Method for producing a cover, method for producing a packaged device

In a method for producing a cover for a region of a substrate, first a frame structure is produced in the region of the substrate, and then a cap structure is attached to the frame structure so that the region under the cap structure is covered. Thus, sensitive devices may be protected easily and at low cost from external influences and particularly from a casting material for casting the entire packaged device, which results when a diced chip is cast.

Owner:CHEMTRON RES

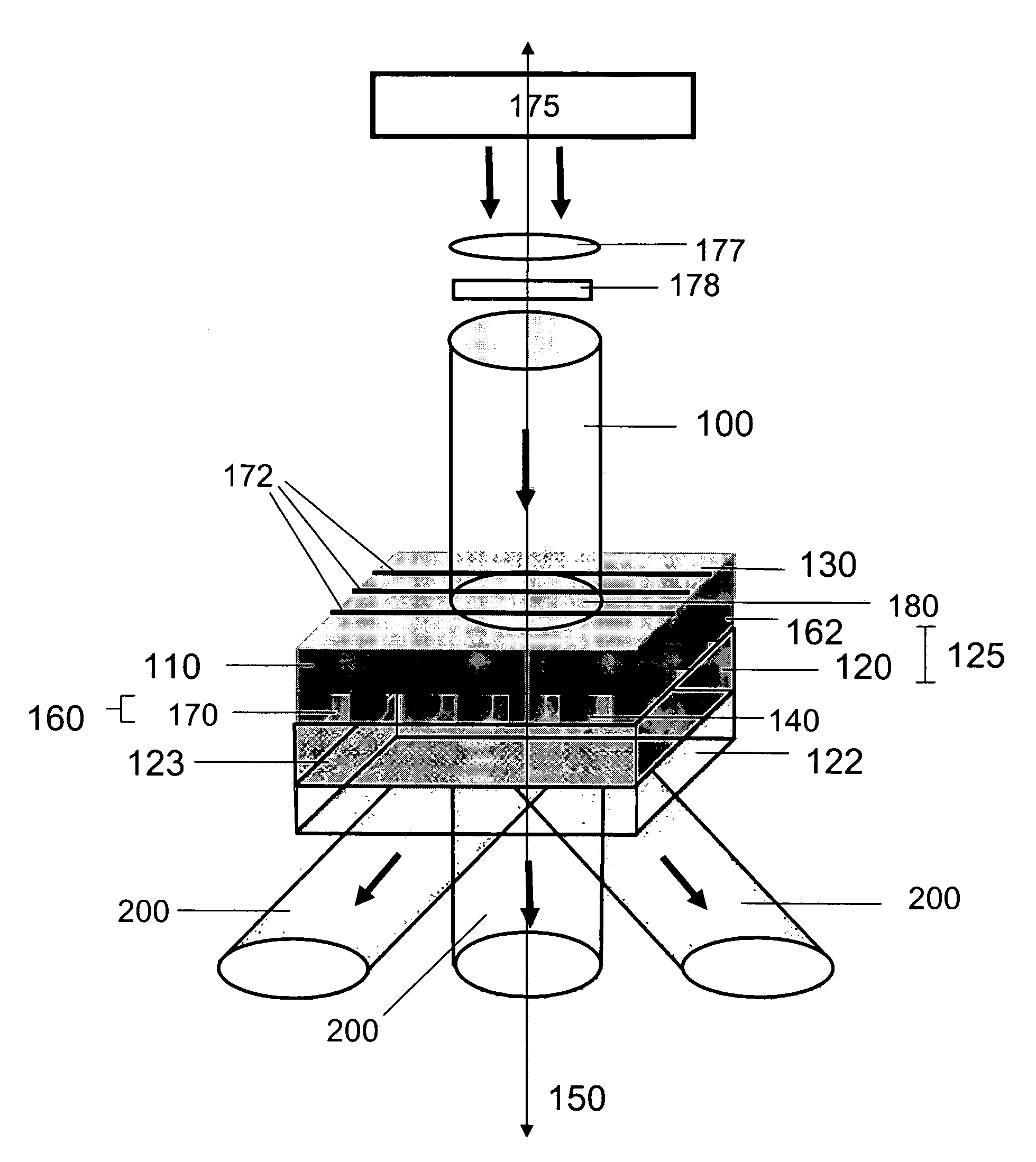

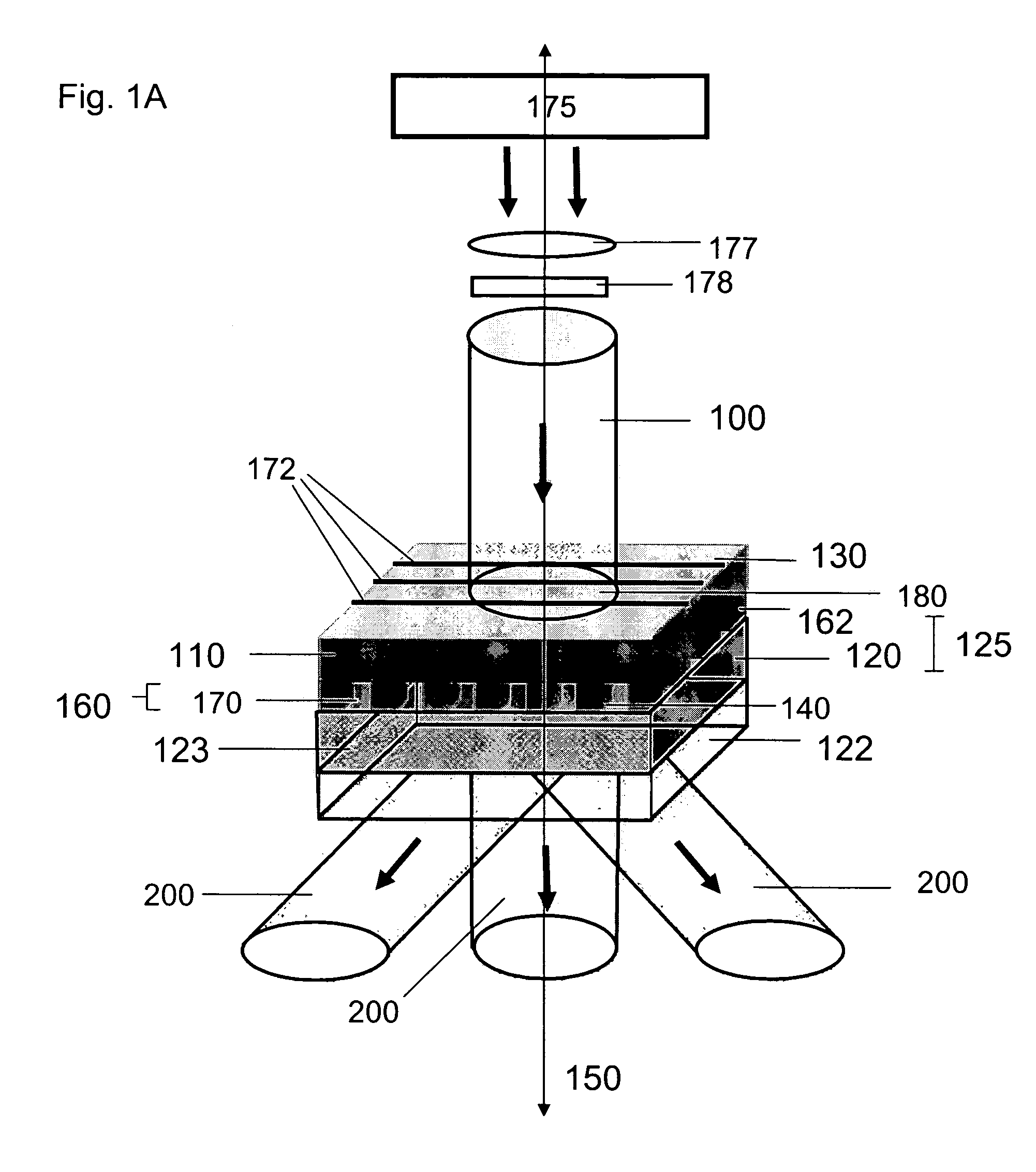

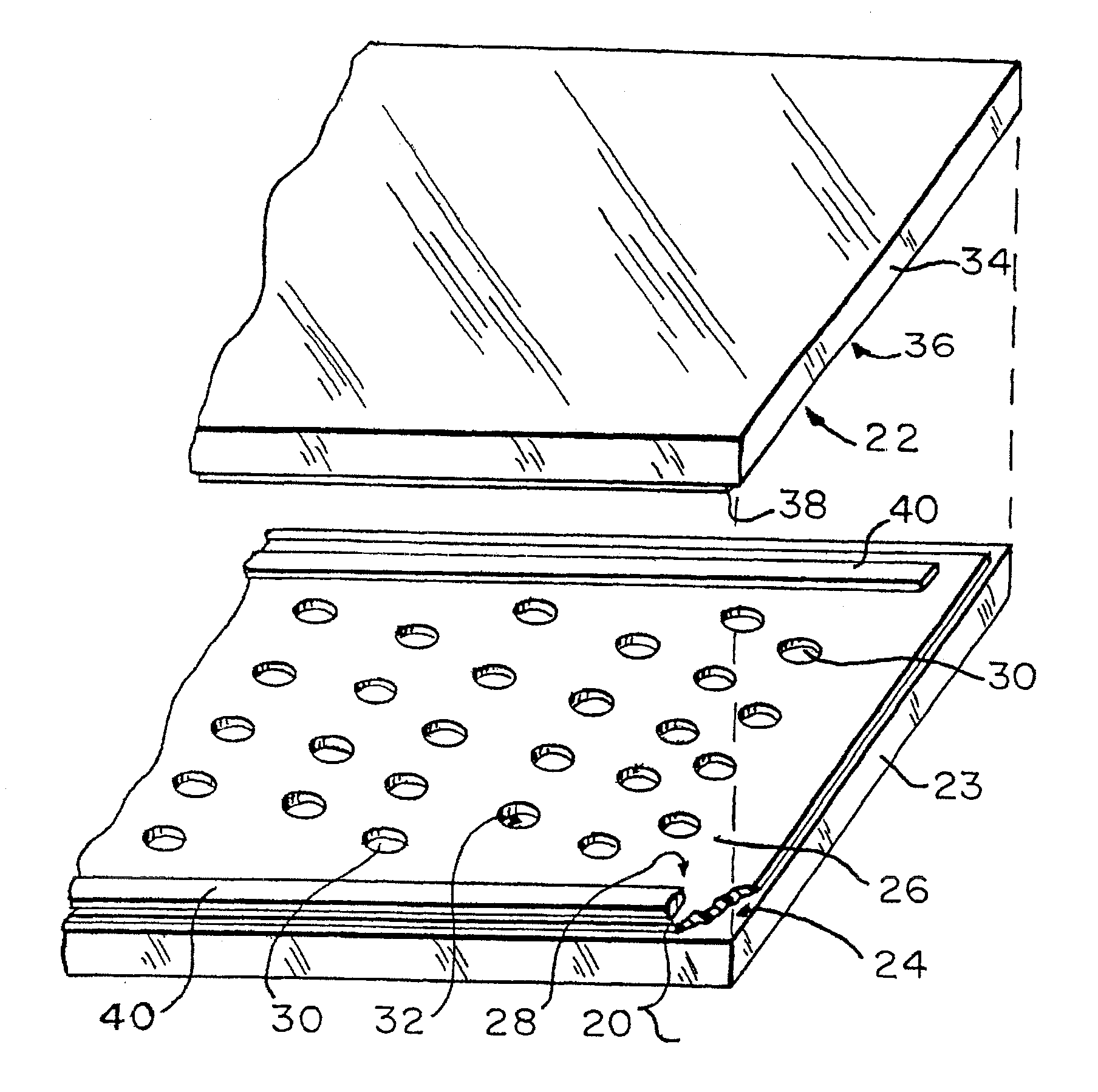

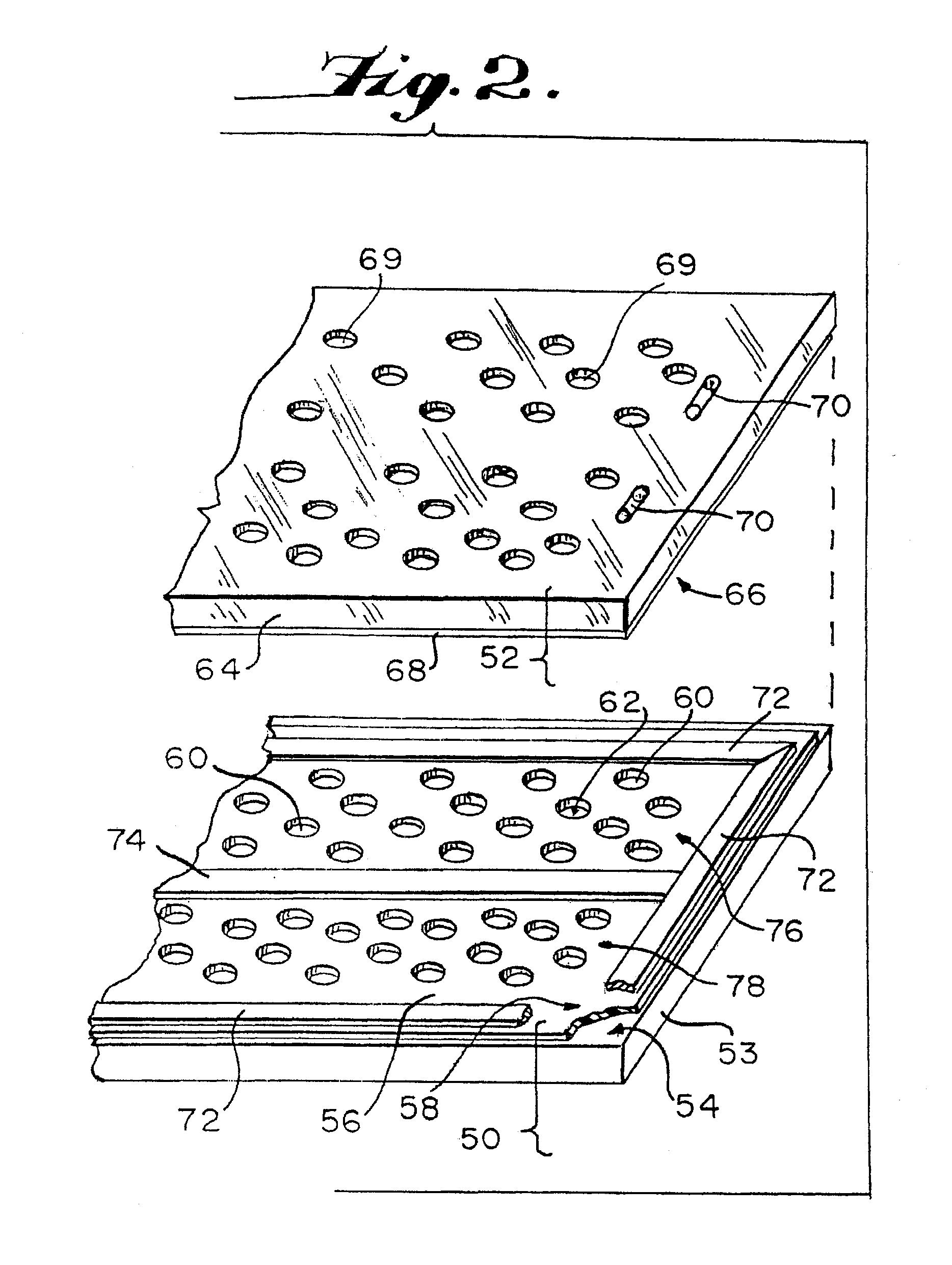

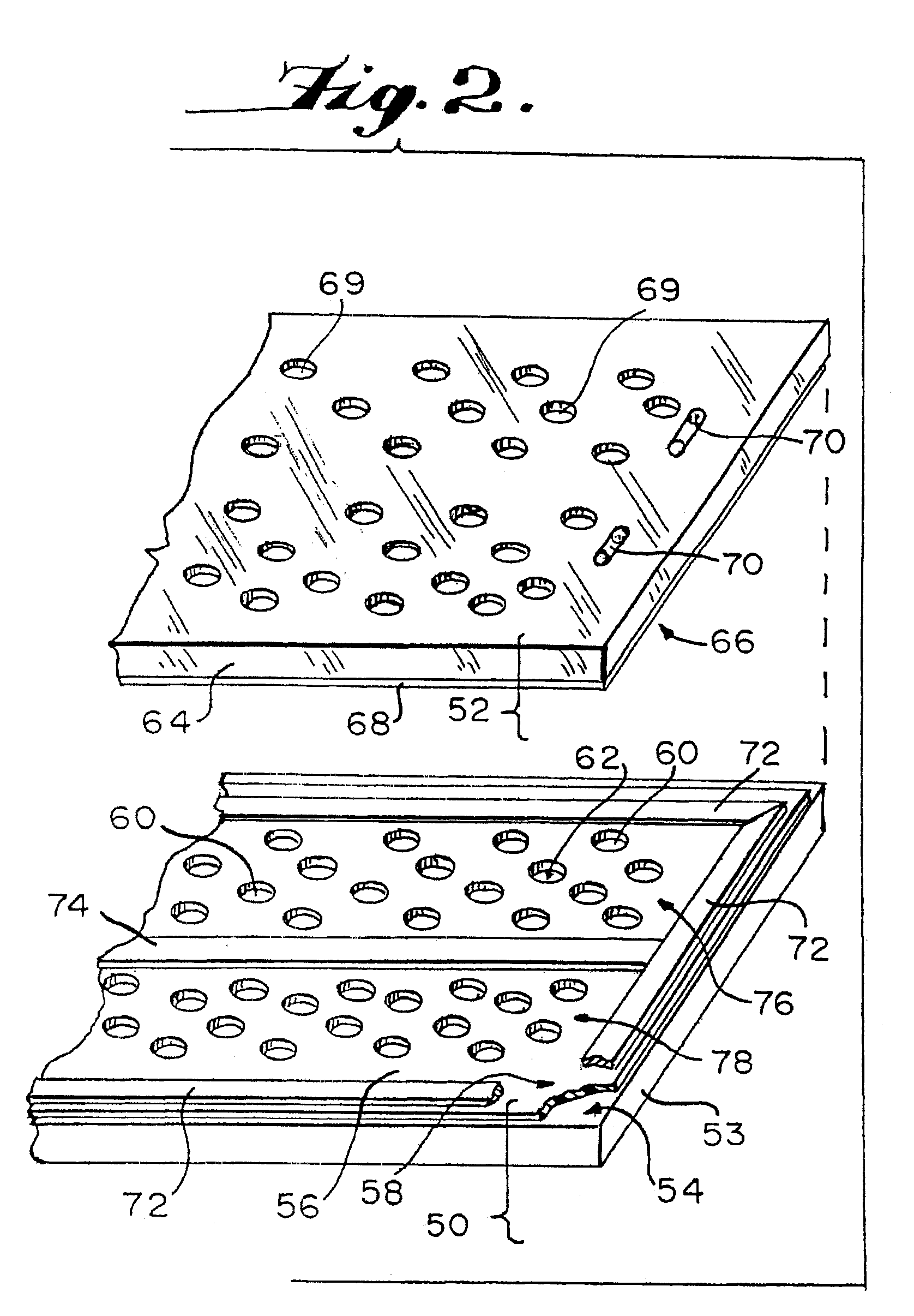

Methods and devices for fabricating three-dimensional nanoscale structures

ActiveUS20060286488A1Simple optical arrangementConvenient ArrangementMaterial nanotechnologyNanostructure manufactureEngineeringElectromagnetic radiation

The present invention provides methods and devices for fabricating 3D structures and patterns of 3D structures on substrate surfaces, including symmetrical and asymmetrical patterns of 3D structures. Methods of the present invention provide a means of fabricating 3D structures having accurately selected physical dimensions, including lateral and vertical dimensions ranging from 10 s of nanometers to 1000 s of nanometers. In one aspect, methods are provided using a mask element comprising a conformable, elastomeric phase mask capable of establishing conformal contact with a radiation sensitive material undergoing photoprocessing. In another aspect, the temporal and / or spatial coherence of electromagnetic radiation using for photoprocessing is selected to fabricate complex structures having nanoscale features that do not extend entirely through the thickness of the structure fabricated.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

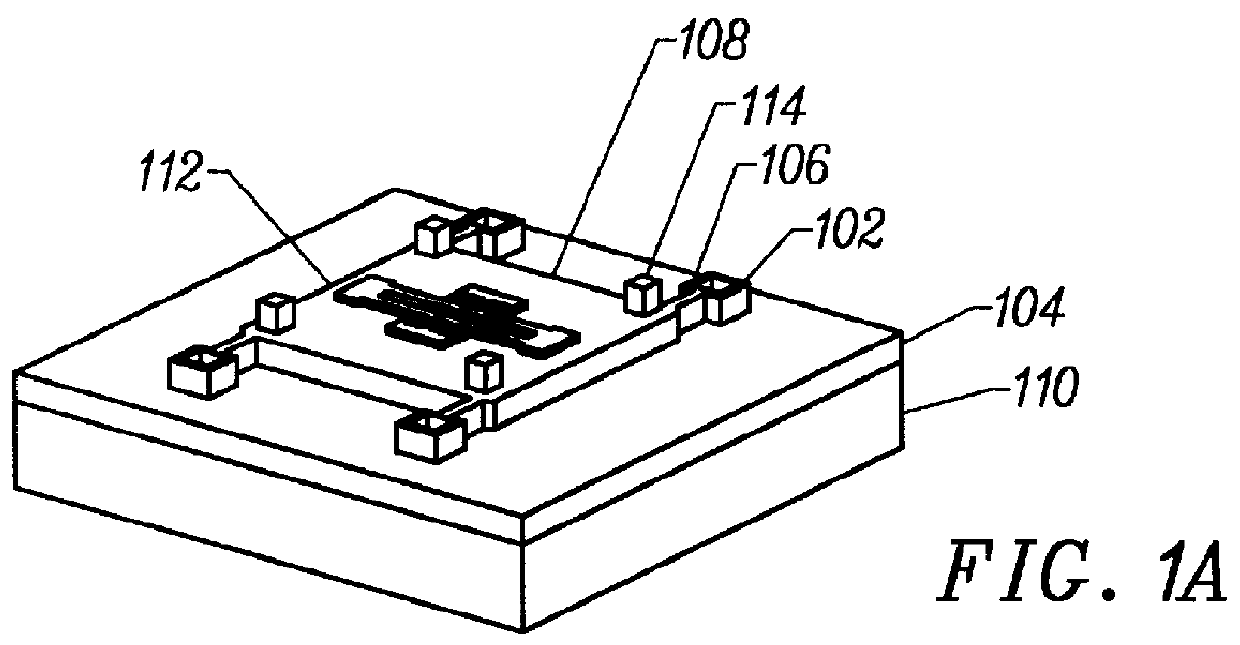

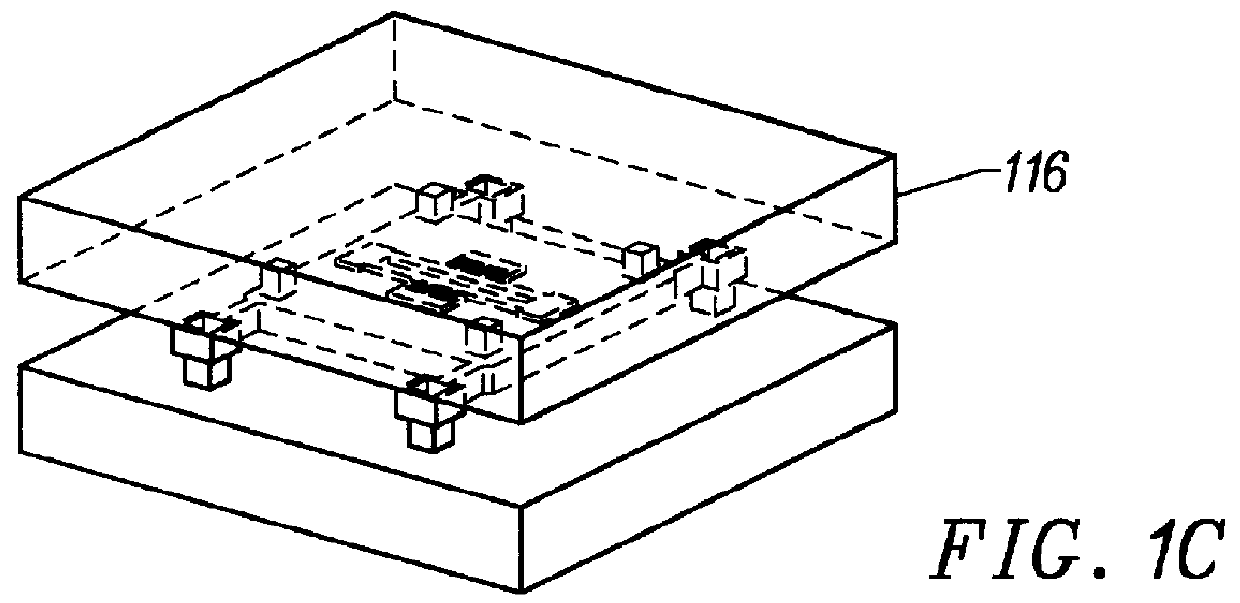

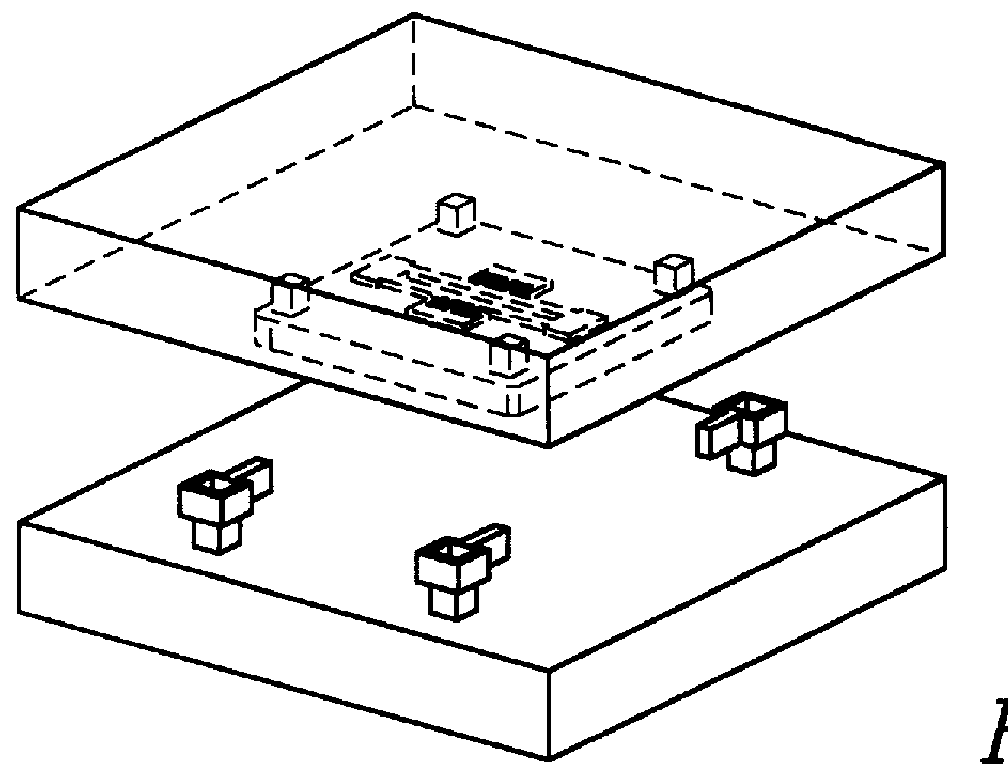

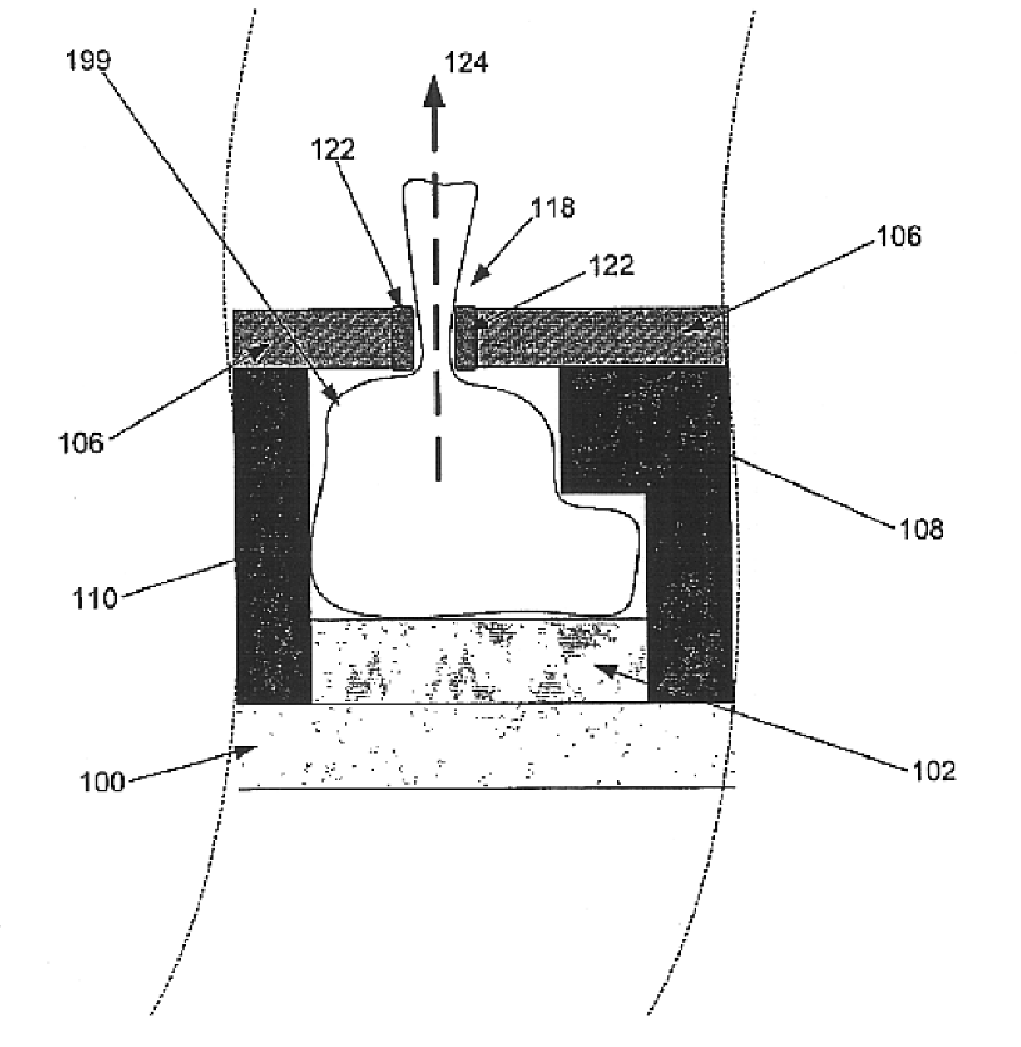

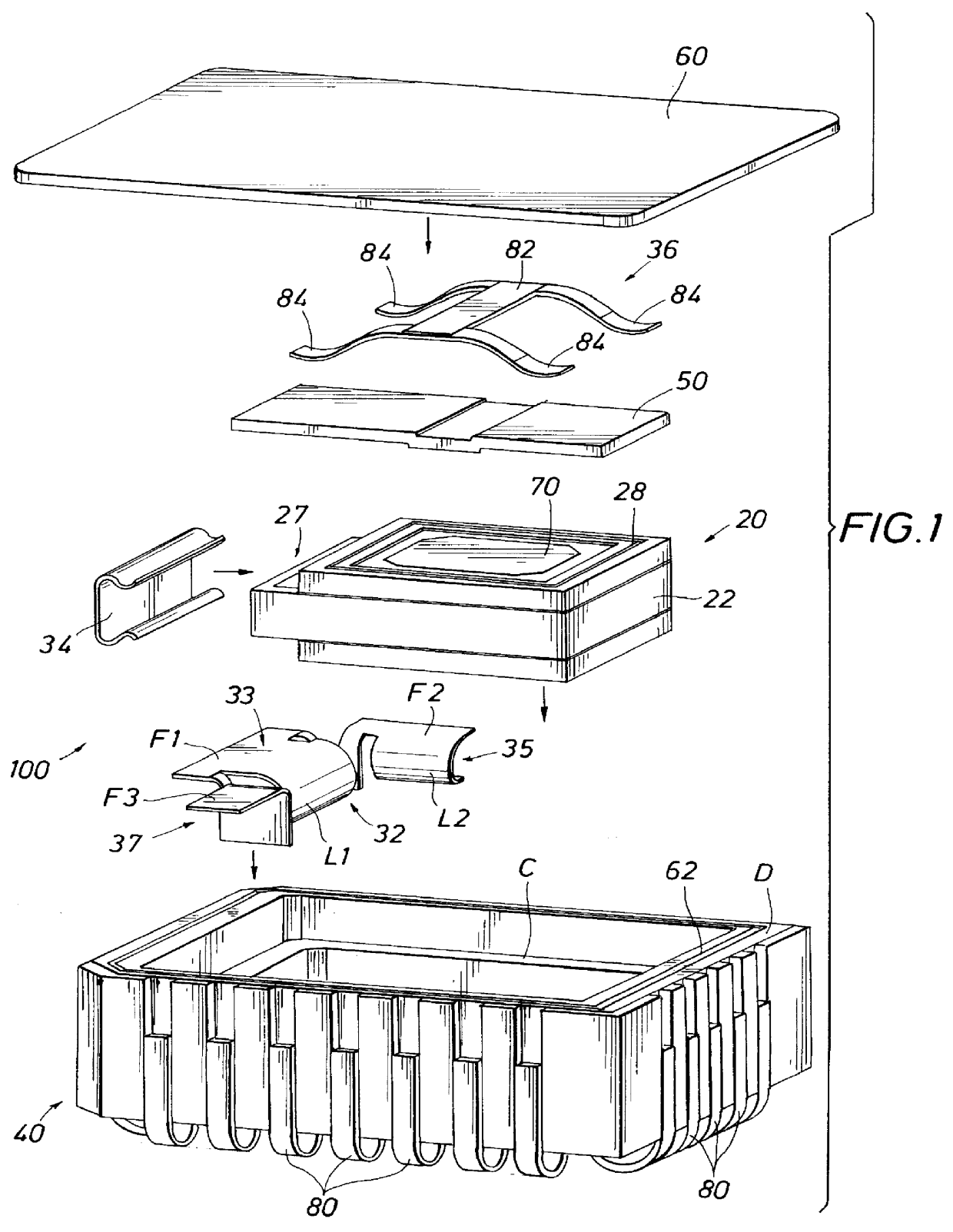

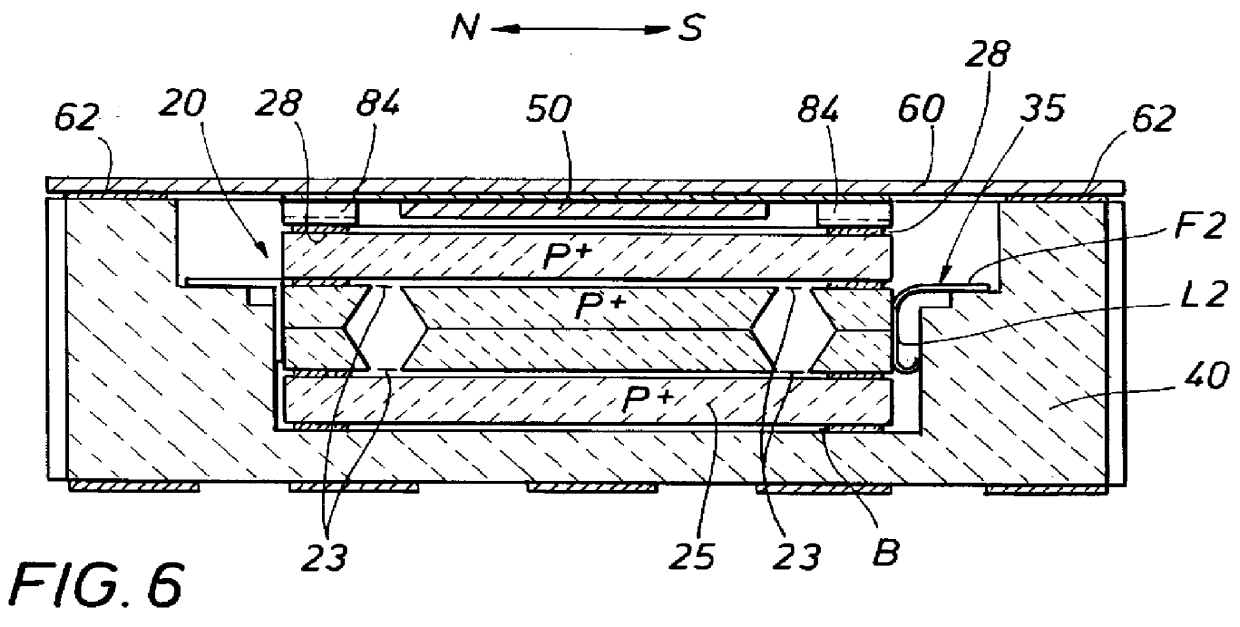

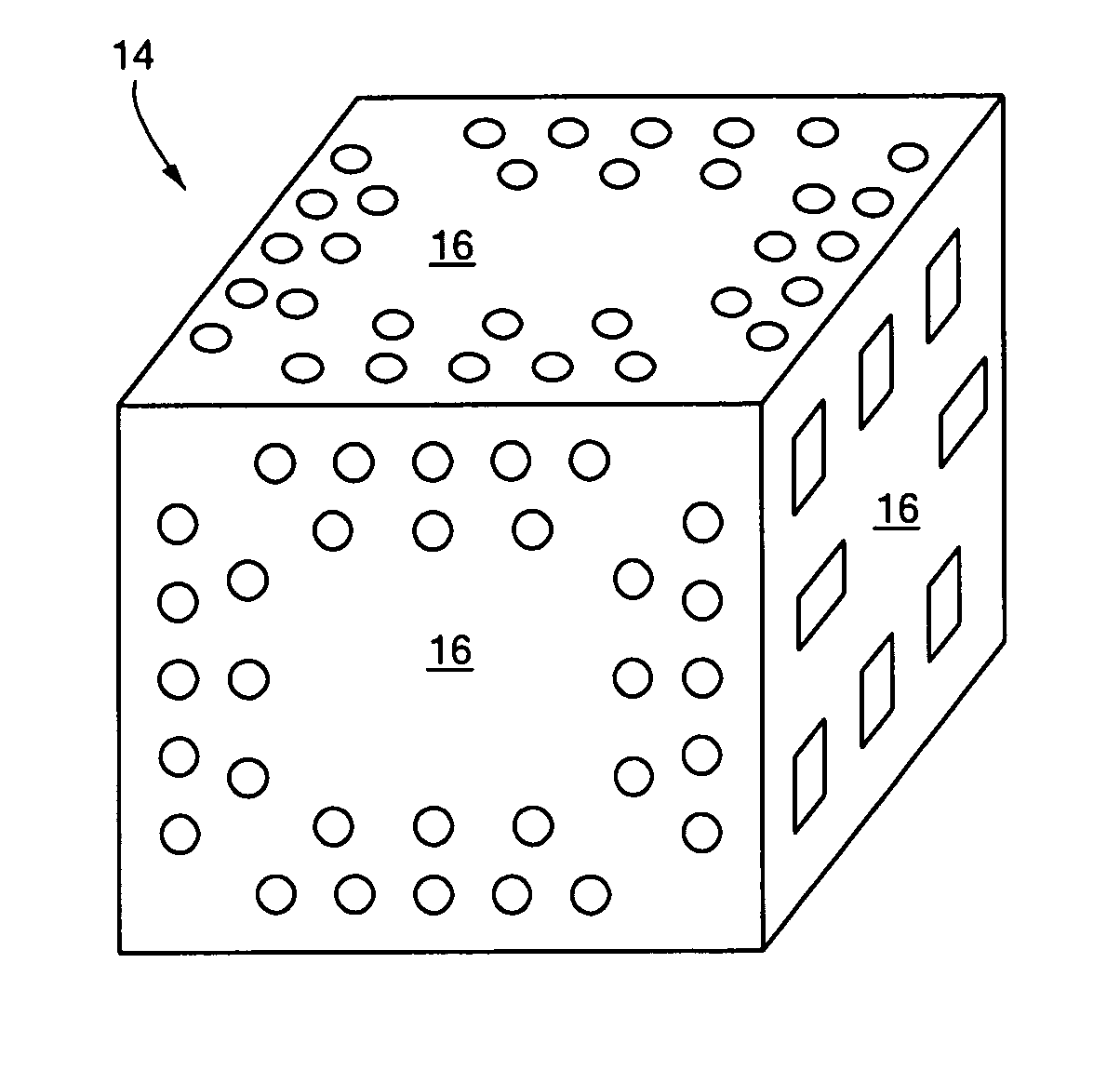

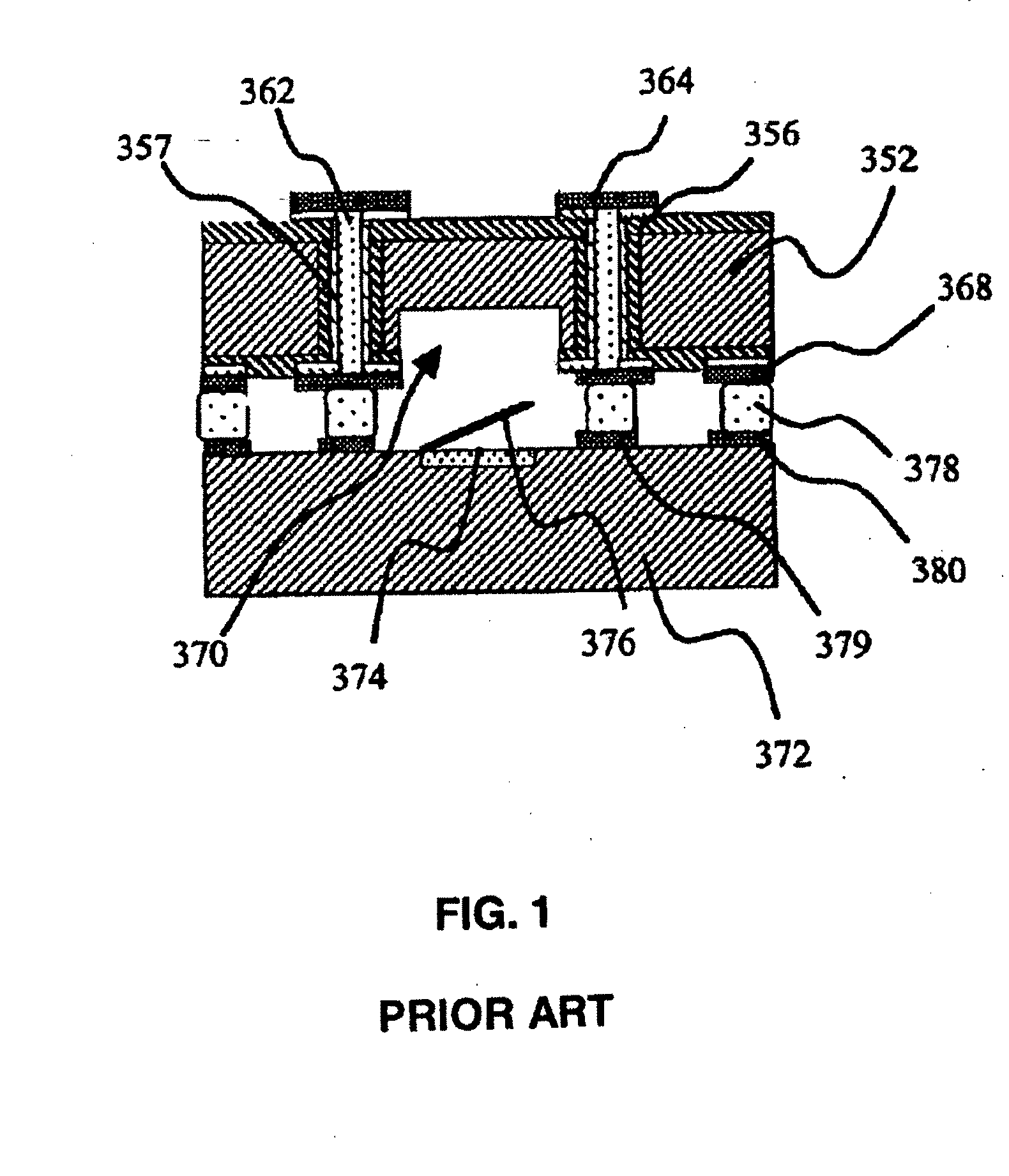

Sensor package arrangement

InactiveUS6040625AEasy to installMinimizing chance for outgassingSemiconductor/solid-state device detailsSolid-state devicesCapacitanceElectrical connection

A highly sensitive silicon micro-machined sensor package is provided for use in a micro-g environment that can also resist high shock in excess of 5000 g. The sensor is provided to measure acceleration in cooperation with associated electronics which are required to have electrical contact with sensor elements. The sensor is sealed in a high vacuum environment, and is arranged and designed to be free of temperature induced stress to the sensor. The sensor die package assembly comprises a silicon micro-machined sensor die, a ceramic package, two contact springs, a shorting clip, solder preform, a metal lid and a getter foil for ensuring a good vacuum for an extended period. The sensor die comprises a moving mass with eight supporting flexures on both sides of the proof mass. The proof mass's movement is protected on both sides by a top and a bottom cap. Acceleration applied to the package and the die causes the proof mass to move vertically in relation with the adjacent caps. The changes in distance between the proof mass and the caps in turn generate a change in an electrical signal which corresponds to the capacitance changes between the gaps. The sensor die package arrangement provides that the sensor die be secured within an evacuated ceramic case. Electrical connections made between external contacts of the case and contacts of the sensor die within the case are made through conductive springs, thereby minimizing materials in the interior of the case which would outgass in the vacuum environment.

Owner:I O SENSORS

Method and device for detecting the presence of a single target nucleic acid in a sample

InactiveUS20080160525A1Quickly and inexpensively detectBioreactor/fermenter combinationsBiological substance pretreatmentsBiologyReagent

Owner:APPL BIOSYSTEMS INC +1

Method and device for detecting the presence of target nucleic acids in a sample, and microfluidic device for use in such methods

InactiveUS20080153091A1Quickly and inexpensively detectBioreactor/fermenter combinationsBiological substance pretreatmentsAdditive ingredientBioinformatics

A method comprising loading sample into at least two sample chambers, subjecting the sample portions in each sample chamber to at least a first amplification step, and determining whether each sample portion contains at least one molecule of a target nucleic acid. If a sample portion contains at least a single molecule of the target nucleic acid, it would attain a detectable concentration of the target nucleic acid after a single round of amplification. Also, a method for detecting whether at least one molecule of a first target nucleic acid is present in a first sample and detecting whether at least one molecule of a second target nucleic acid is present in a second sample. Also, a microfluidic device comprising sample chambers comprising respective ingredients which will react with respective target nucleic acids if contacted with the target nucleic acids and subjected to a round of amplification.

Owner:APPL BIOSYSTEMS INC +1

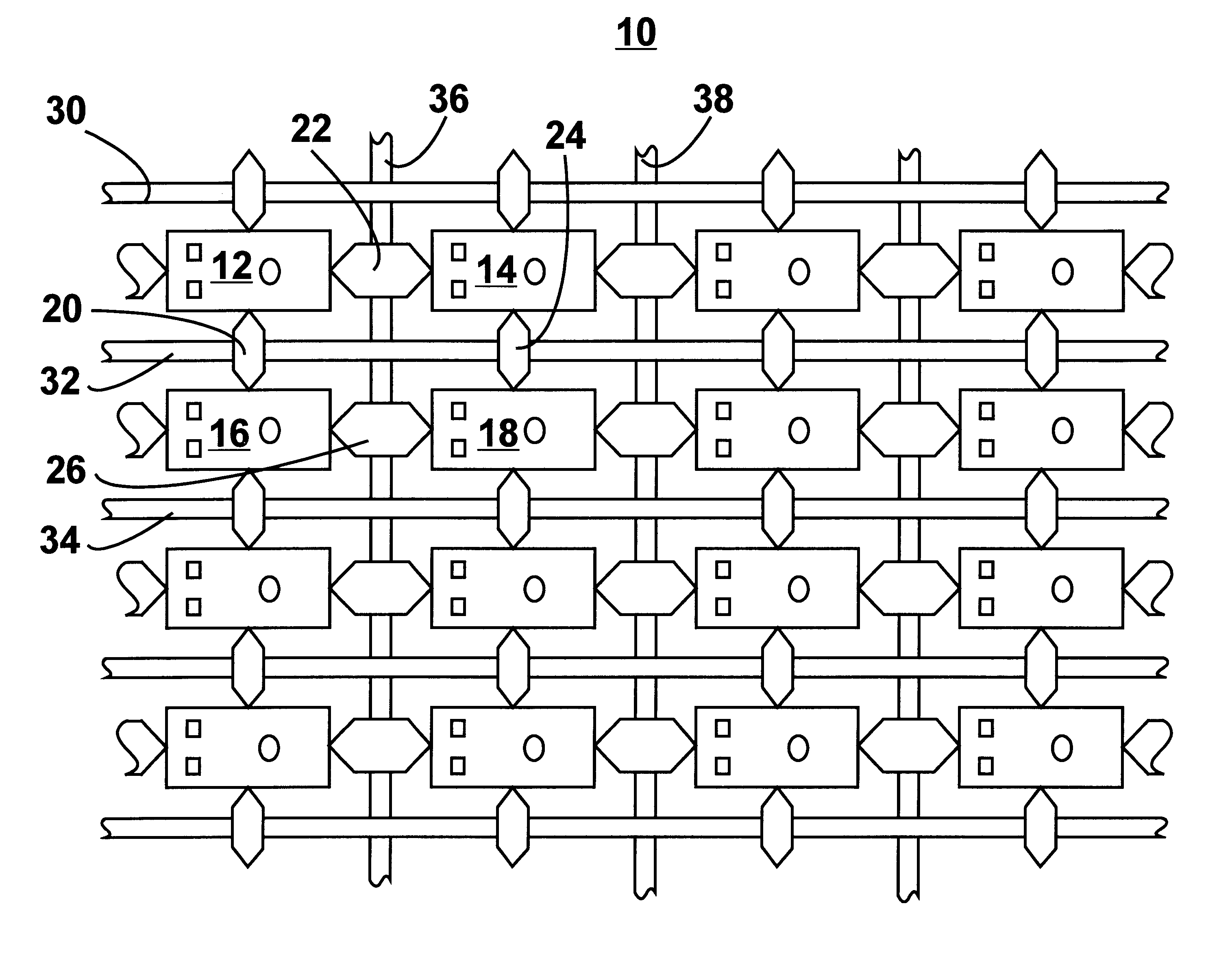

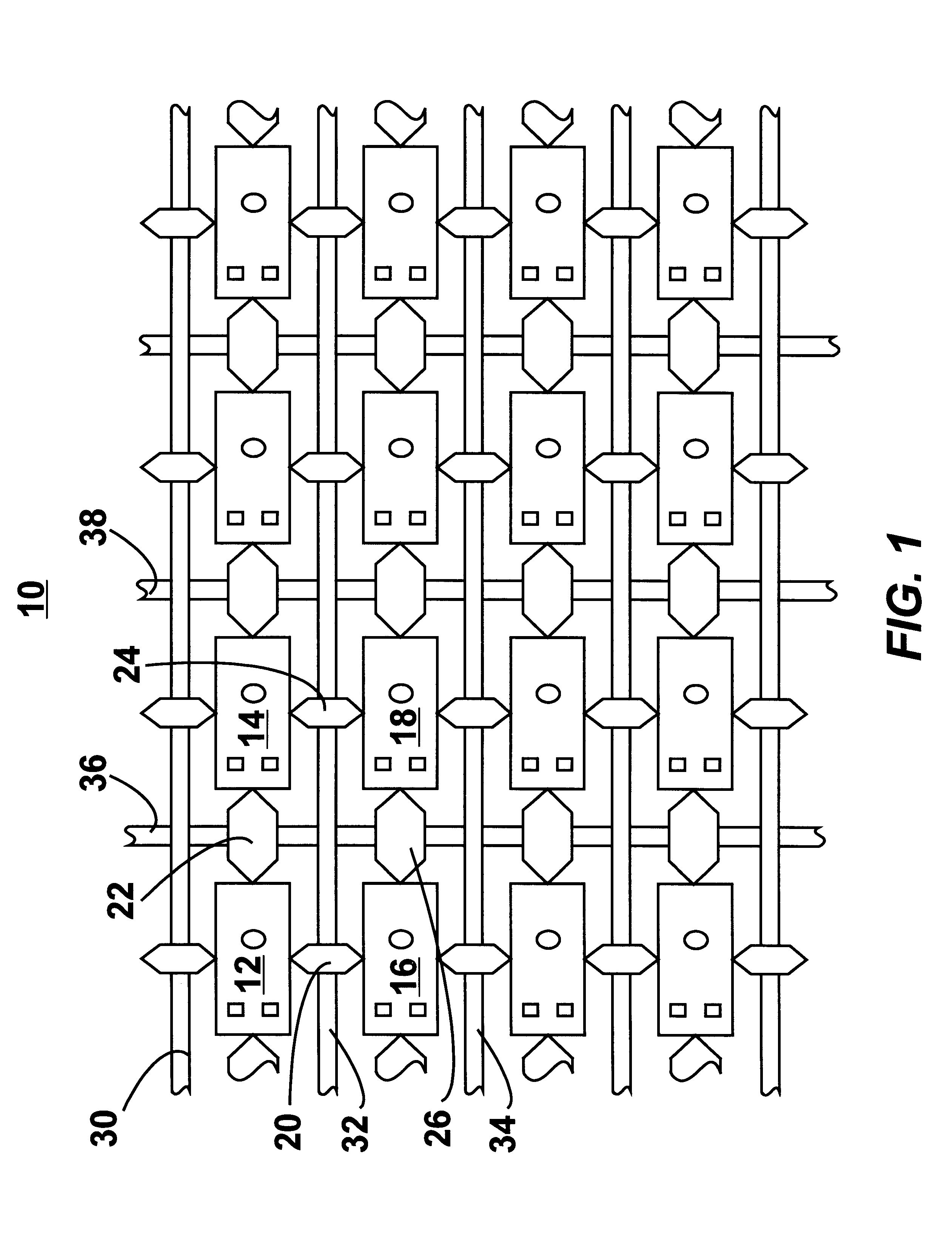

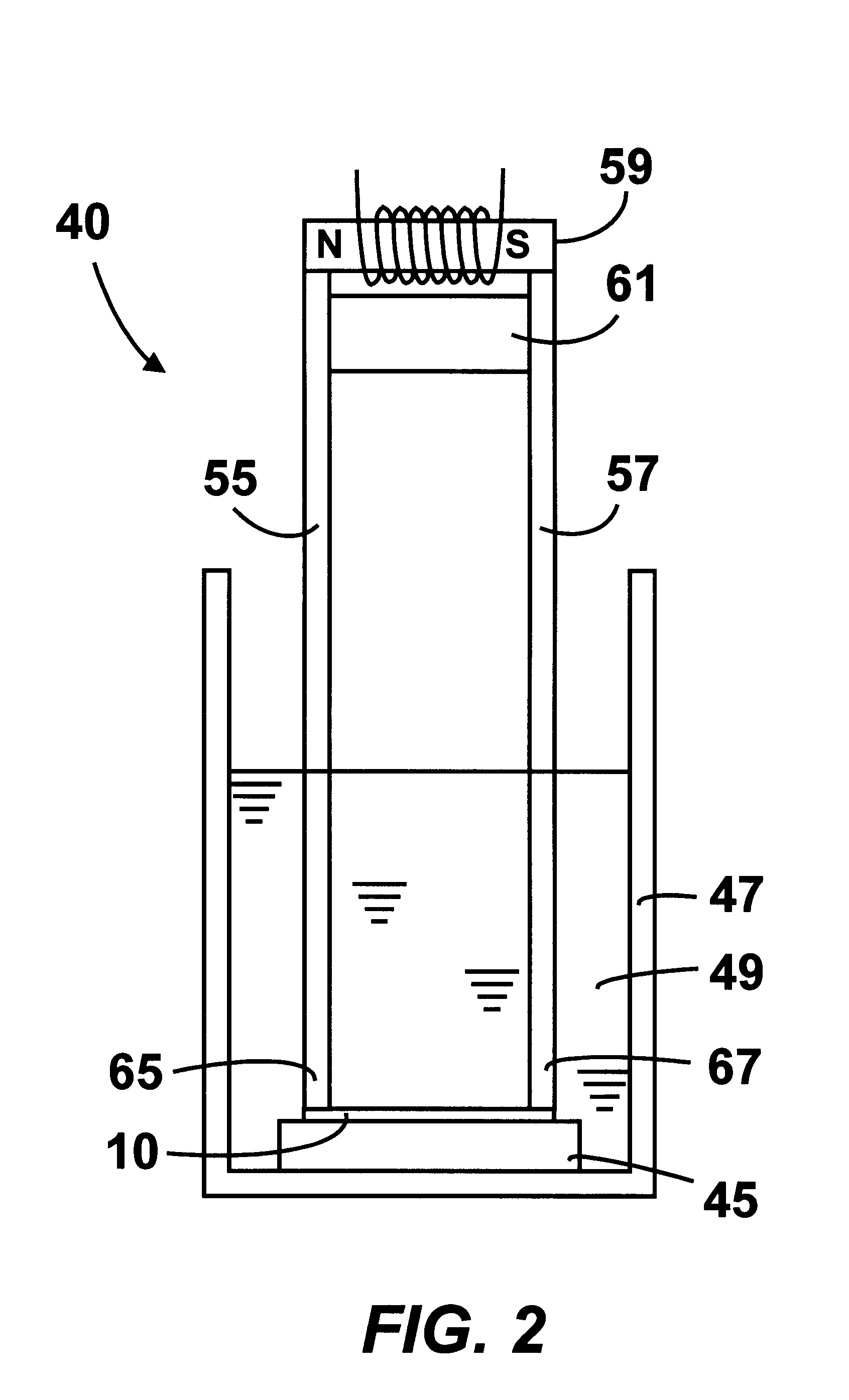

Method and tool for handling micro-mechanical structures

InactiveUS6255721B1High tensile strengthEasy to moveTransistorSemiconductor/solid-state device detailsMicro devicesEngineering

A method of forming and handling an array of micro-devices such as thin film devices that enables simultaneous mass handling and processing of these thin film devices. A plurality of micro-devices and links are simultaneously formed on a wafer, with the links interconnecting the micro-devices for maintaining a unitary array structure. A matrix of magnetic strips is then formed to impart added overall tensile strength to the array. The magnetic strips are secured to the links and form a planar support grid therewith. The array of micro-devices is then released from the wafer and lifted therefrom by means of a magnetic pick-up tool. Using the pick-up tool, the array is transferred onto a magnetic chuck which securely retains the array. Conductive wires are bonded to a row of micro-devices which are then separated from the array into individual micro-devices.

Owner:WESTERN DIGITAL TECH INC

Miniature MEMS condenser microphone packages and fabrication method thereof

ActiveUS20100183181A1Piezoelectric/electrostrictive microphonesLine/current collector detailsAcoustic absorptionMems microphone

MEMS microphone packages and fabrication methods thereof are disclosed. A MEMS microphone package includes a cavity that houses a MEMS sensing element, an IC chip and other passive elements supported by a common substrate. The cavity is formed by a top cover member, a housing wall surrounds and supports the top cover member and the common substrate supports the housing wall. A conductive casing encloses and surrounds the cavity, and is electrically connected to a common analog ground lead on a PCB board. The top cover member and the housing wall are non-conductive. And the conductive casing is not connected directly to the ground leads of the package. An acoustic absorption layer is sandwiched between the conductive casing and the cavity which is formed by the top cover member, the housing wall and the substrate.

Owner:NEOMEMS TECH INC WUXI CHINA

Focusing micromachined ultrasonic transducer arrays and related methods of manufacture

InactiveUS20050075572A1Improvement of contrast resolutionUltrasonic/sonic/infrasonic diagnosticsPiezoelectric/electrostrictive transducersContrast resolutionLight beam

A micromachined ultrasonic transducer array that focuses in the elevation direction. A curved lens is used to narrow the beam width in the elevation direction so that contrast resolution is improved and clinically relevant. Alternatively, a curved probe is formed by bending a micromachined substrate to have a predetermined curvature. The invention is further directed to methods of manufacturing such transducers.

Owner:GENERAL ELECTRIC CO

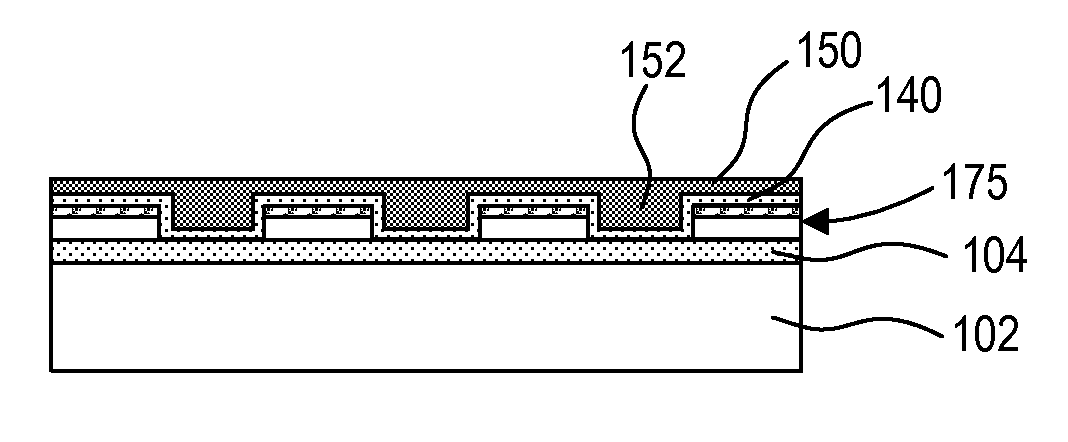

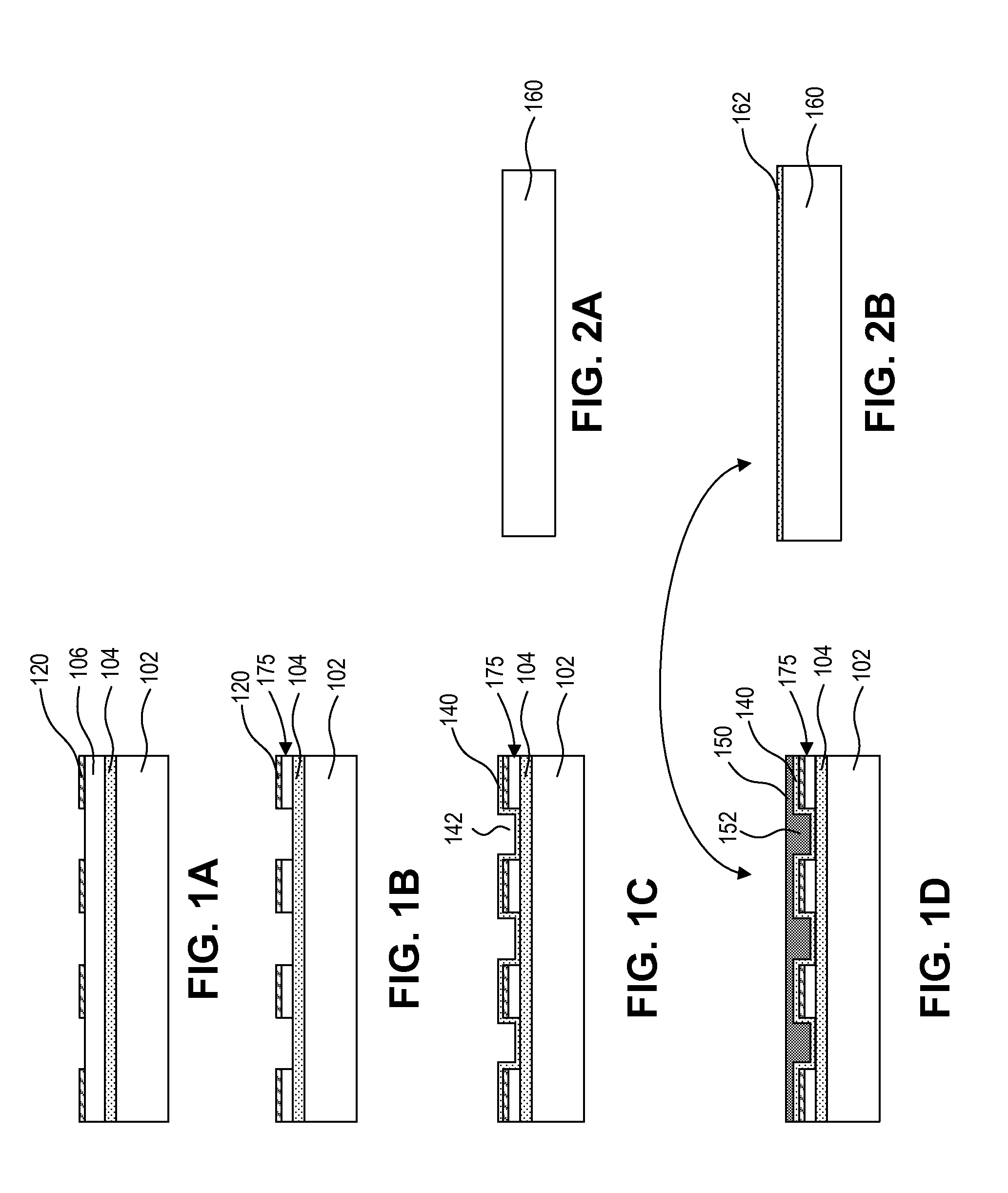

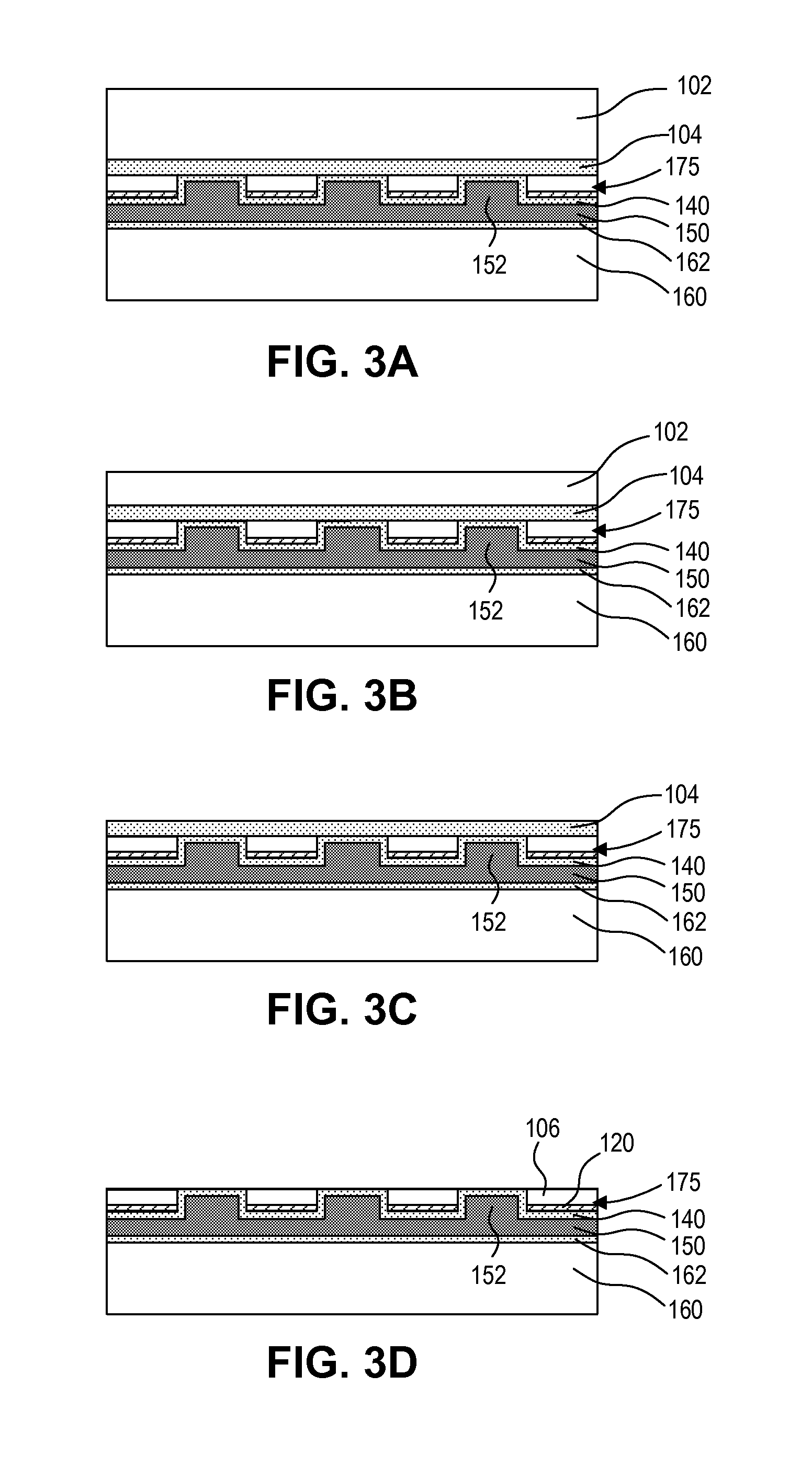

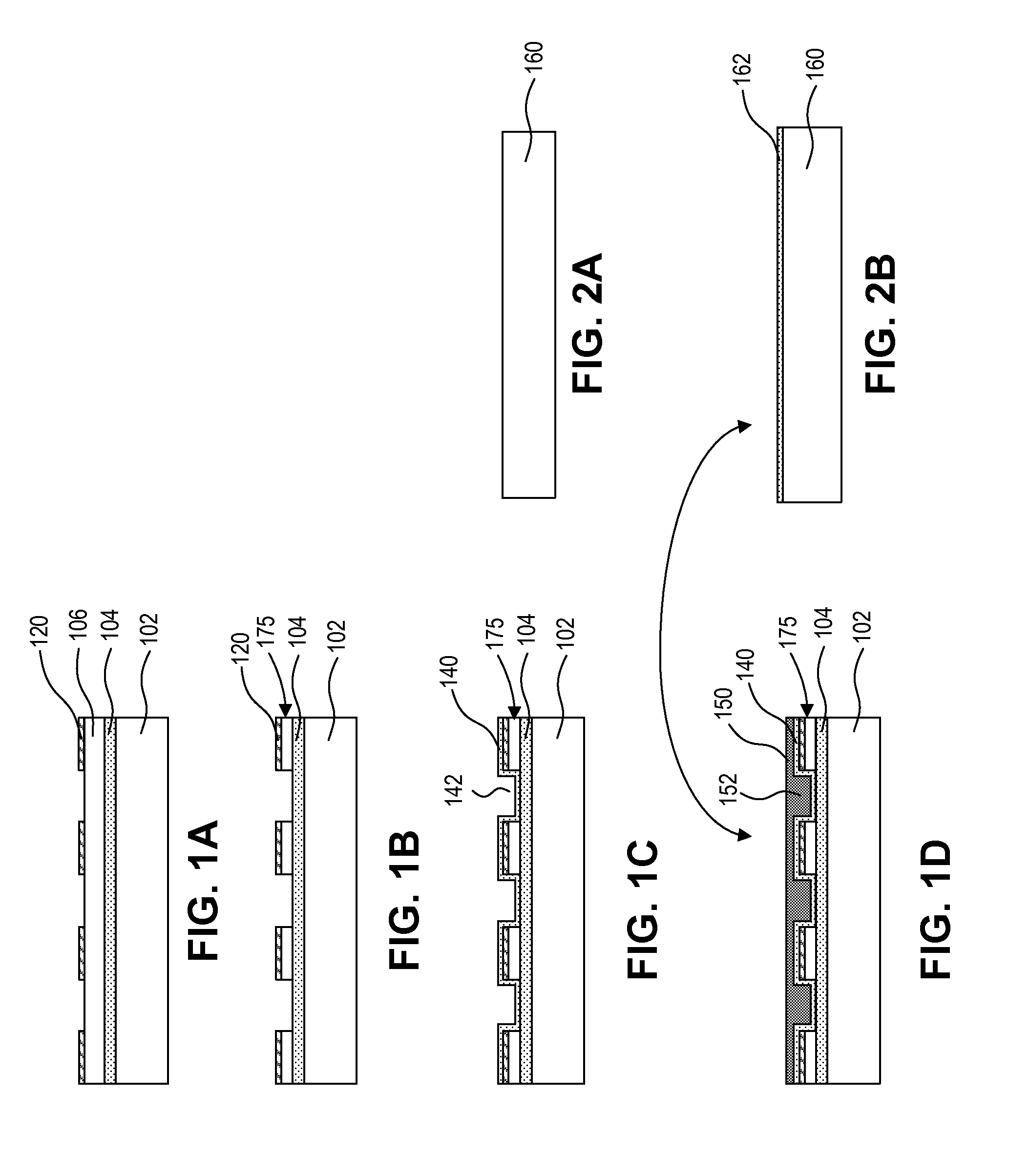

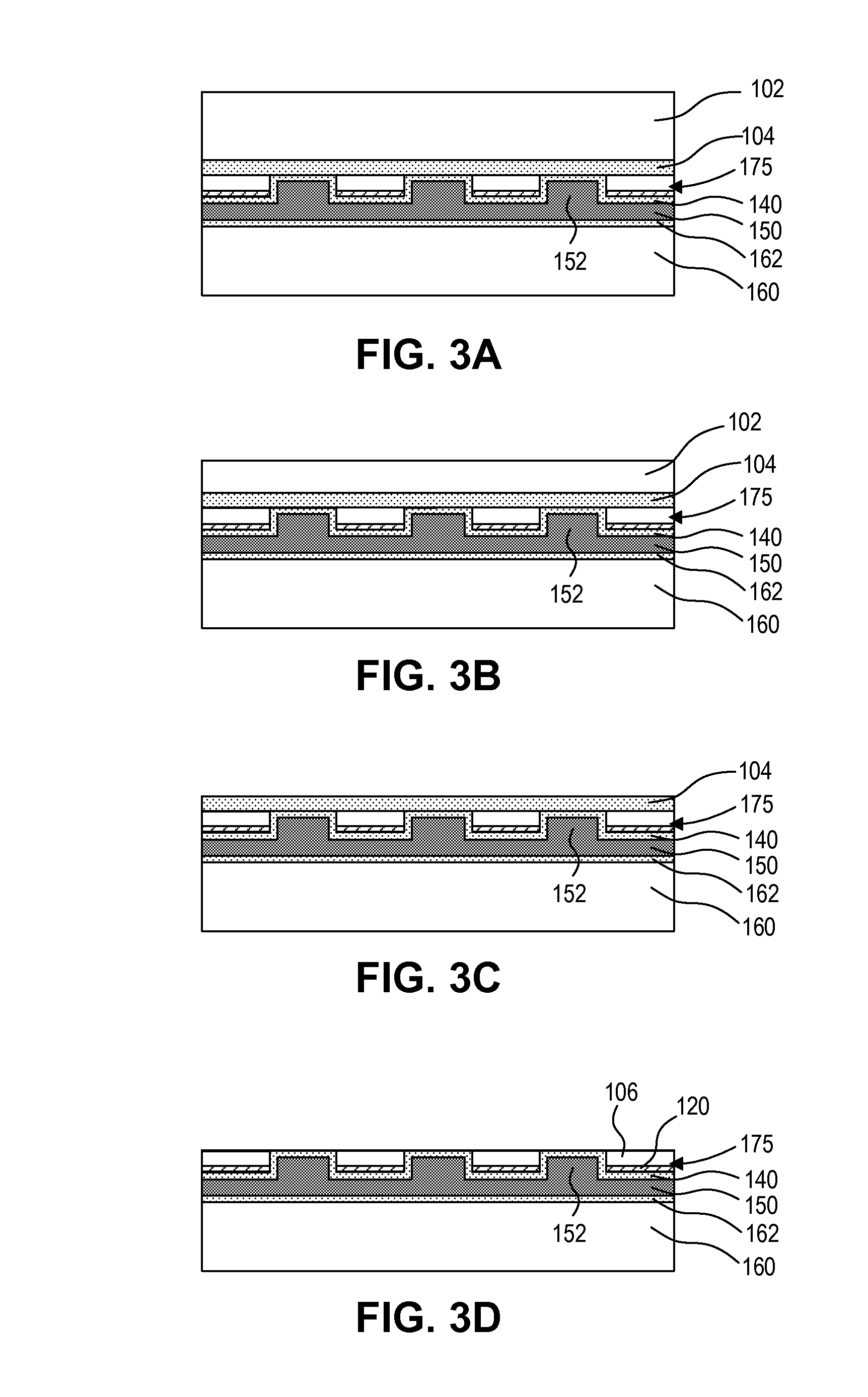

Stabilization structure including sacrificial release layer and staging cavity

ActiveUS20140159065A1Solid-state devicesSemiconductor/solid-state device manufacturingMicro devicesBiomedical engineering

Owner:APPLE INC

Microsystem packaging and associated methods

InactiveUS20040046248A1Semiconductor/solid-state device detailsSolid-state devicesEngineeringMechanical engineering

Methods and apparatus are provided for sealing and reducing warpage in a microsystem device. The microsystem device is assembled with a substrate and packaged.

Owner:CORNING INC

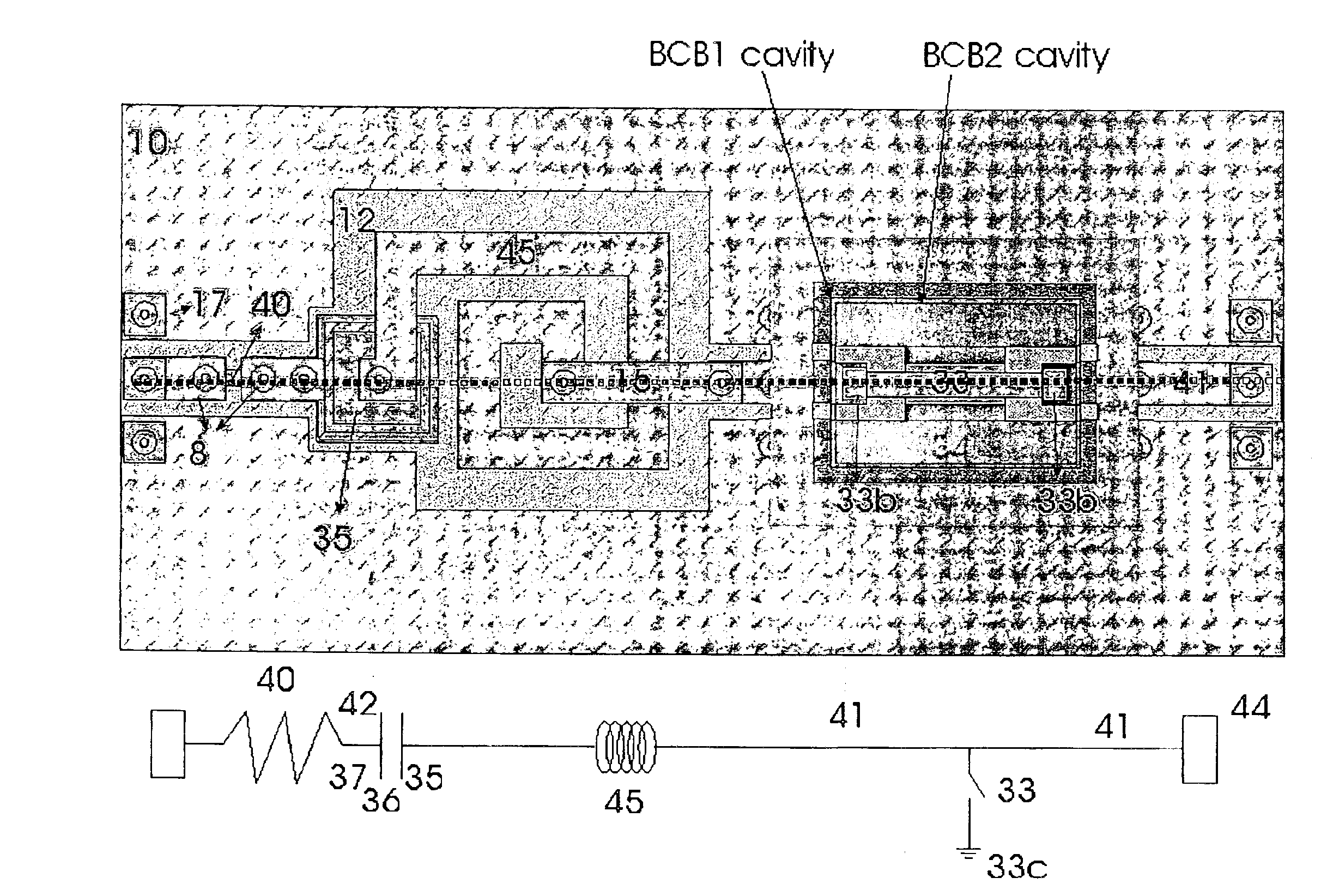

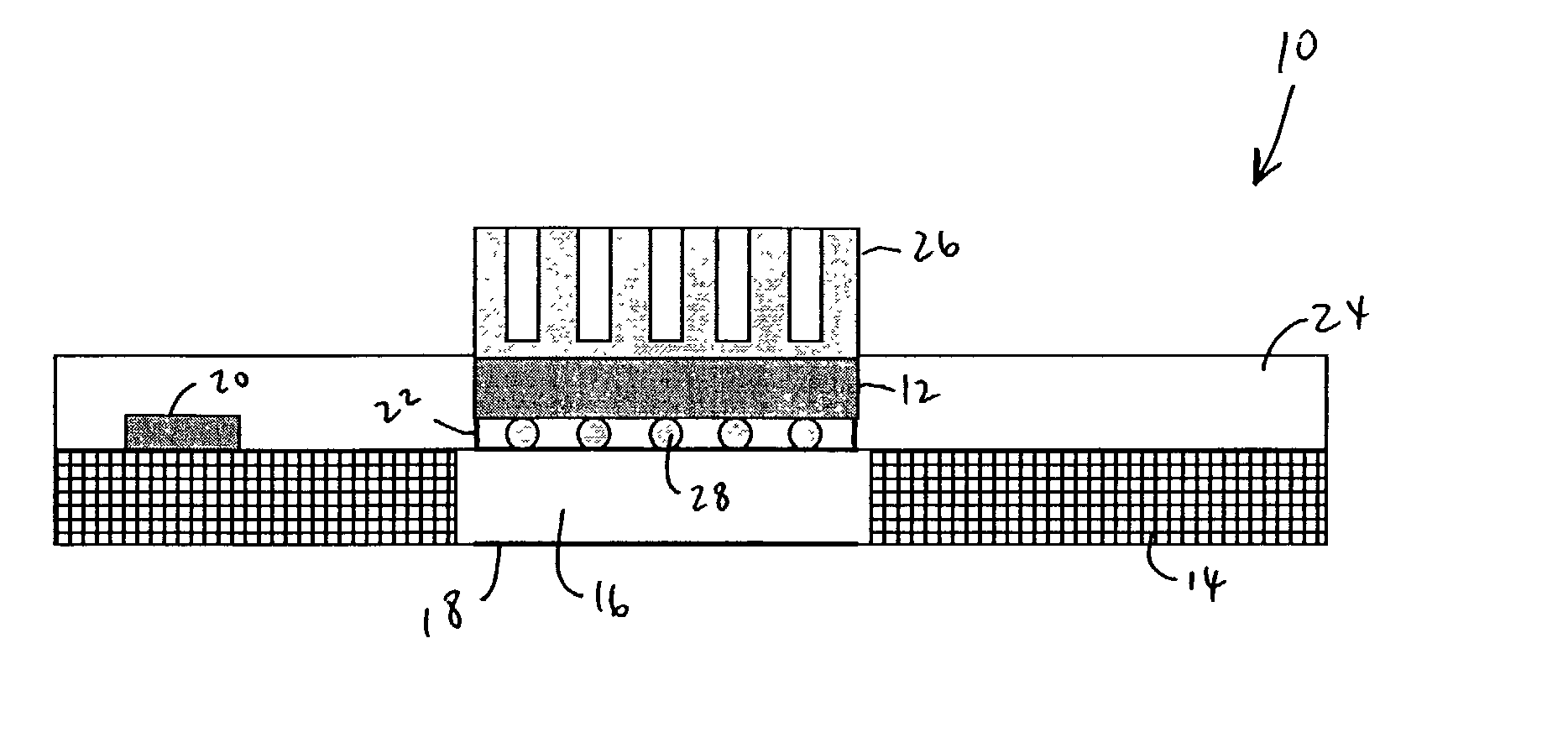

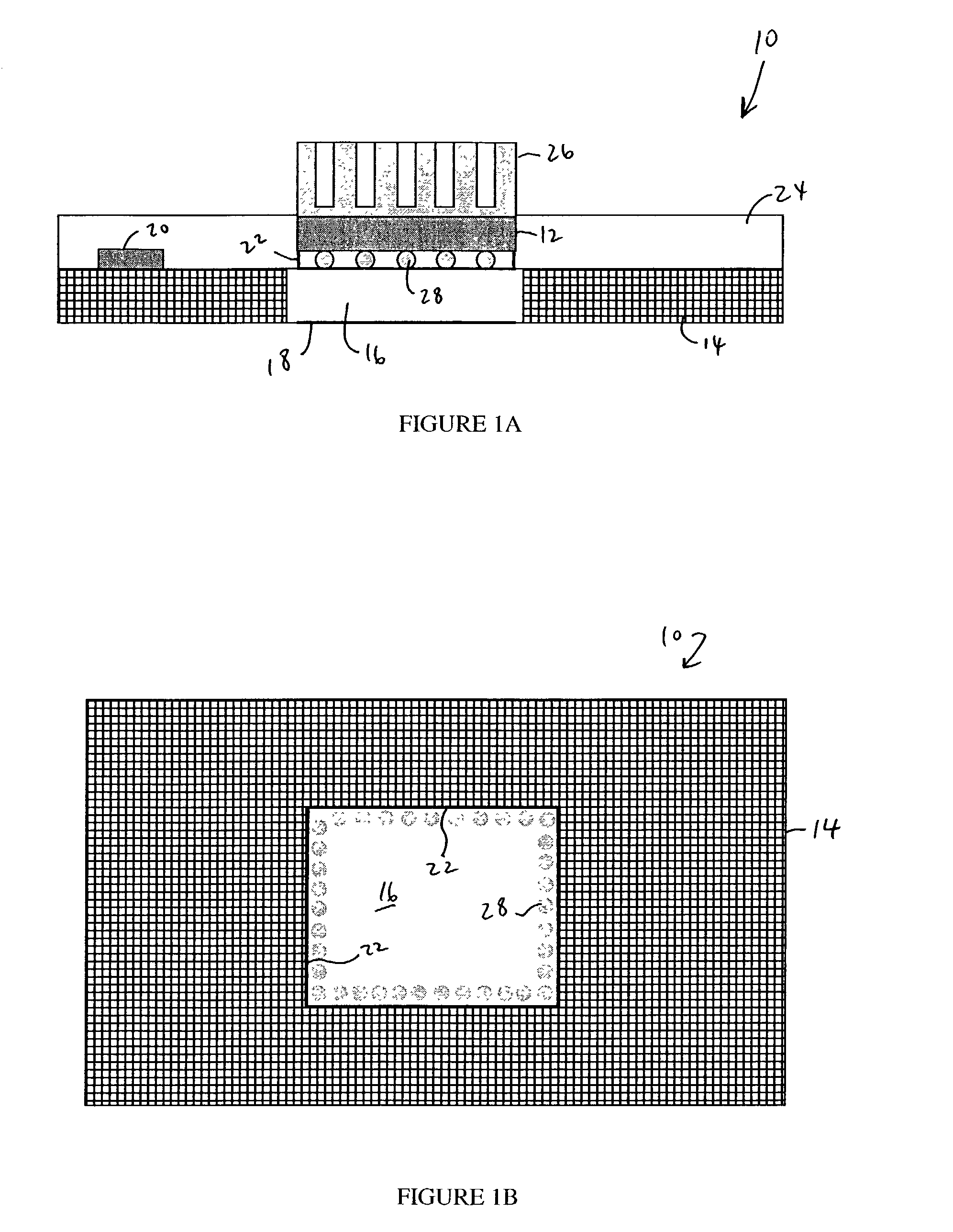

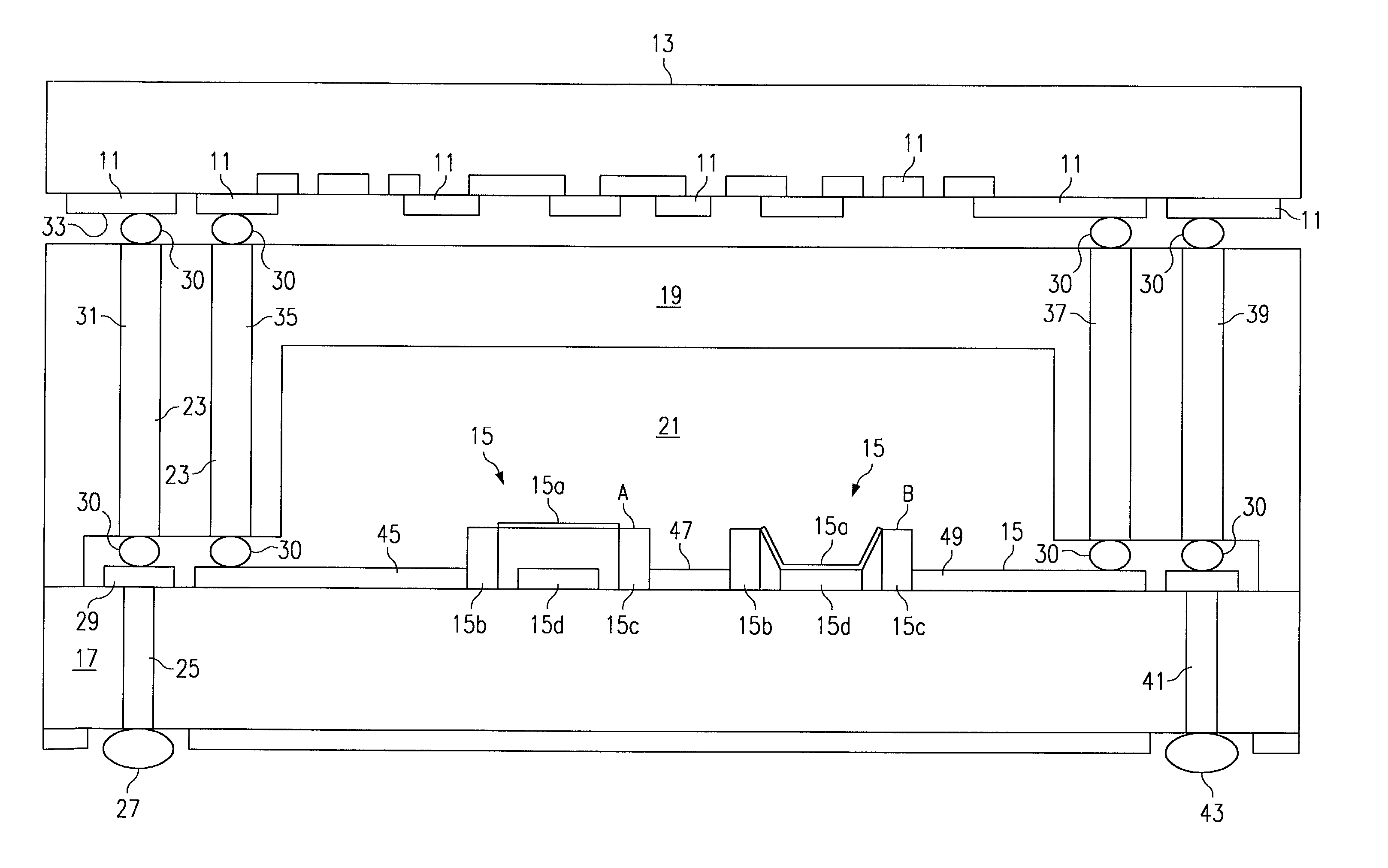

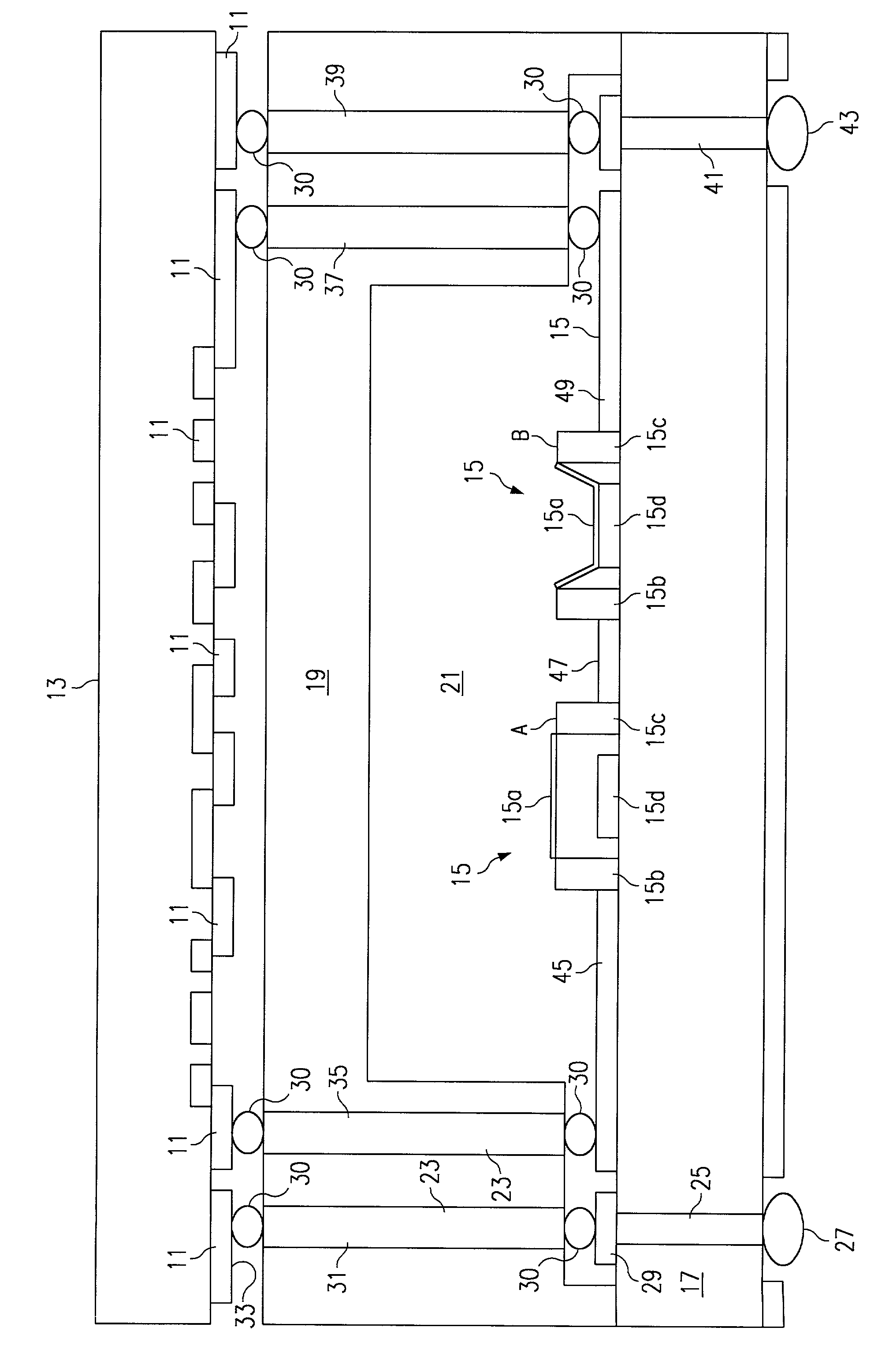

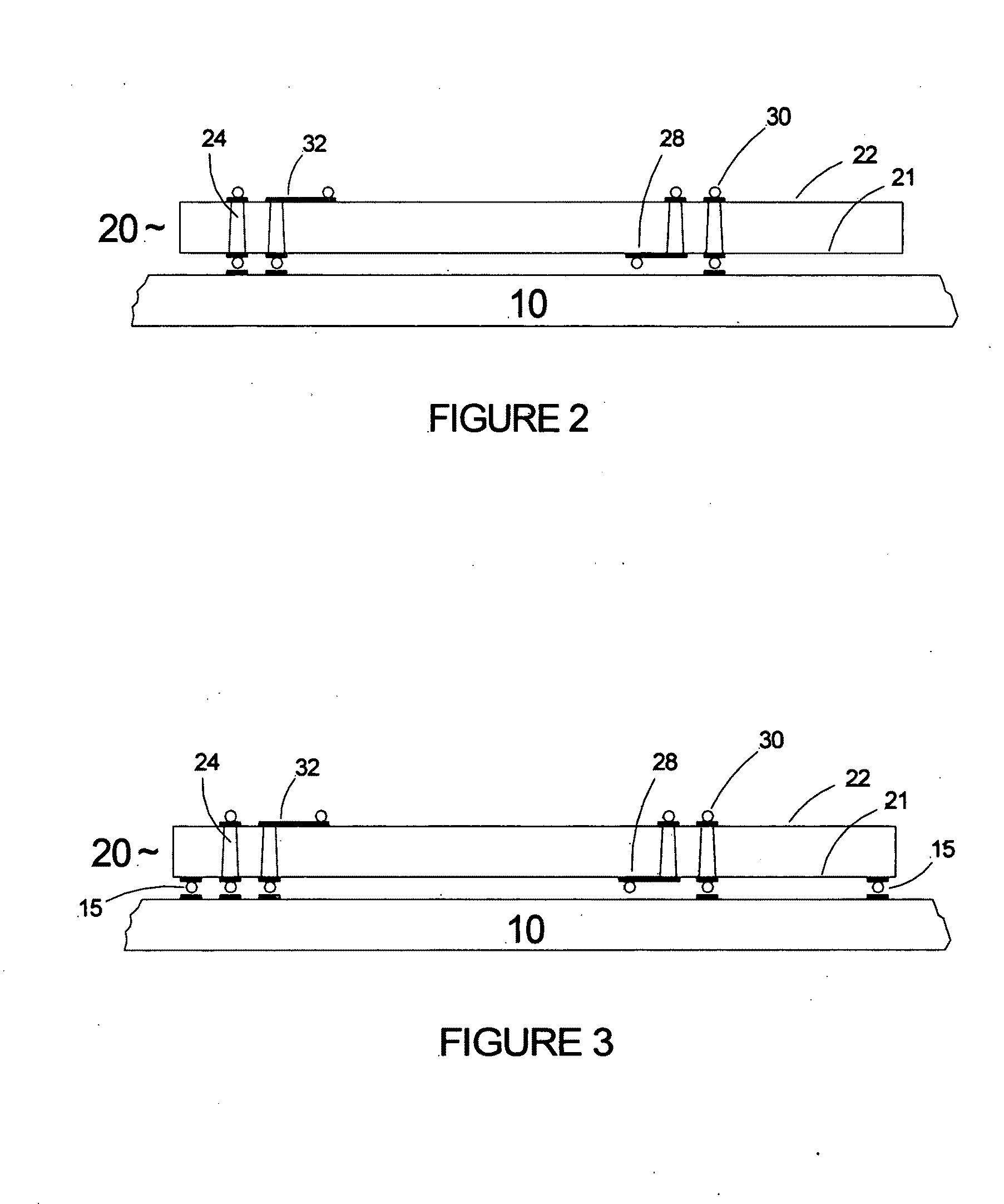

Wafer level interconnection

InactiveUS20030001251A1Television system detailsPiezoelectric/electrostriction/magnetostriction machinesDielectricElectrical conductor

RF MicroElectroMechanical Systems (MEMs) circuitry(15) on a first high resistivity substrate (17)is combined with circuitry (11) onsecond low-resisitivity substrate (13) by overlapping the first high resisitivity substrate (17)and MEMs circuitry (15) with the low resisitivity substrate(13) and circuitry (11) with the MEMs circuitry (15)facing the second circuitry (11). A dielectric lid (19) is placed over the MEMs circuitry (15)and between the first substrate (17)and second substrate (13)with an inert gas in a gap (21)over the MEMs circuitry (15). Interconnecting conductors (25,31,35,37,39,41) extend perpendicular and through the high resistivity substrate (17)and through the dielectric lid (19) to make electrical connection with the low resisitivity substrate (13).

Owner:RAYTHEON CO

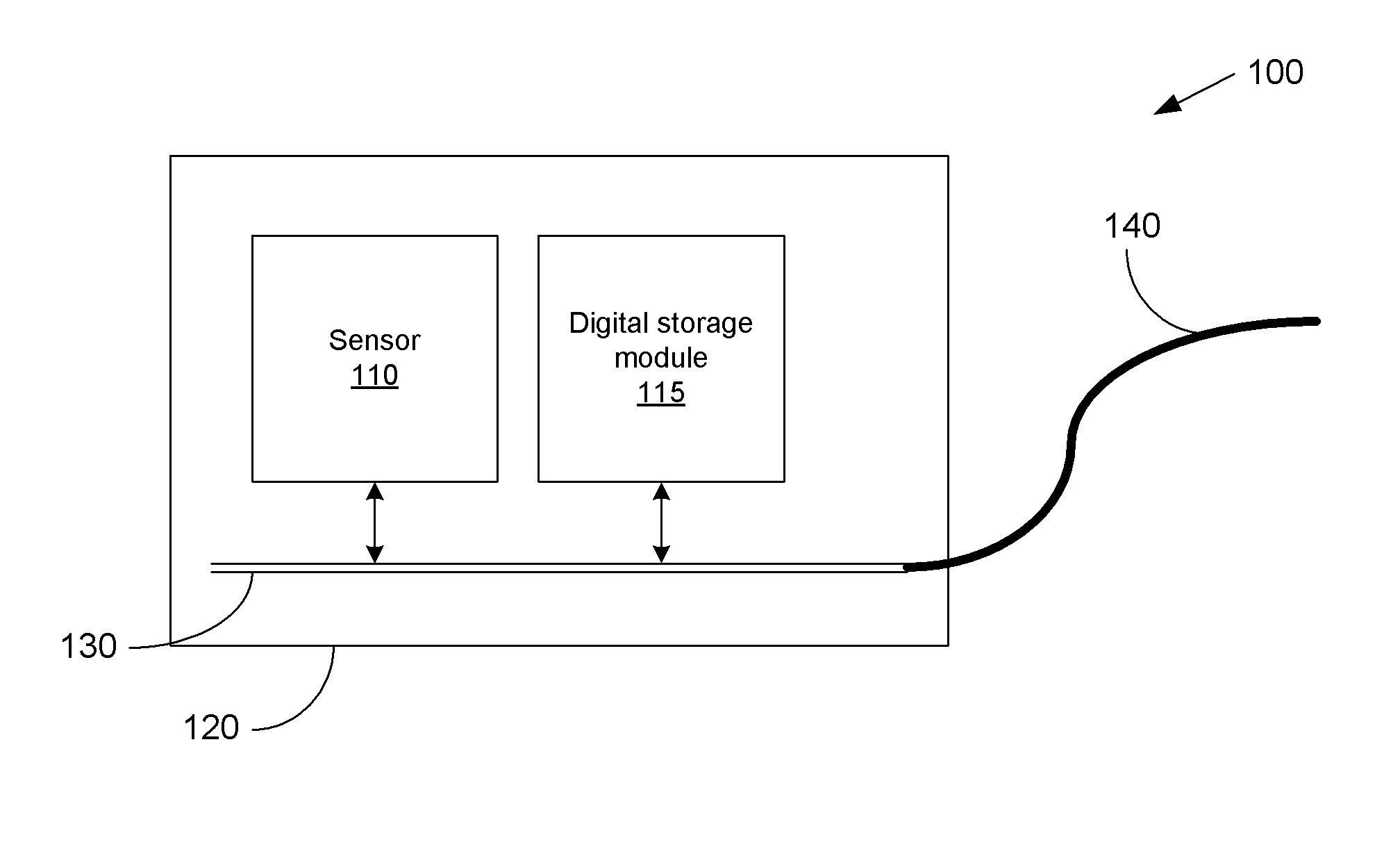

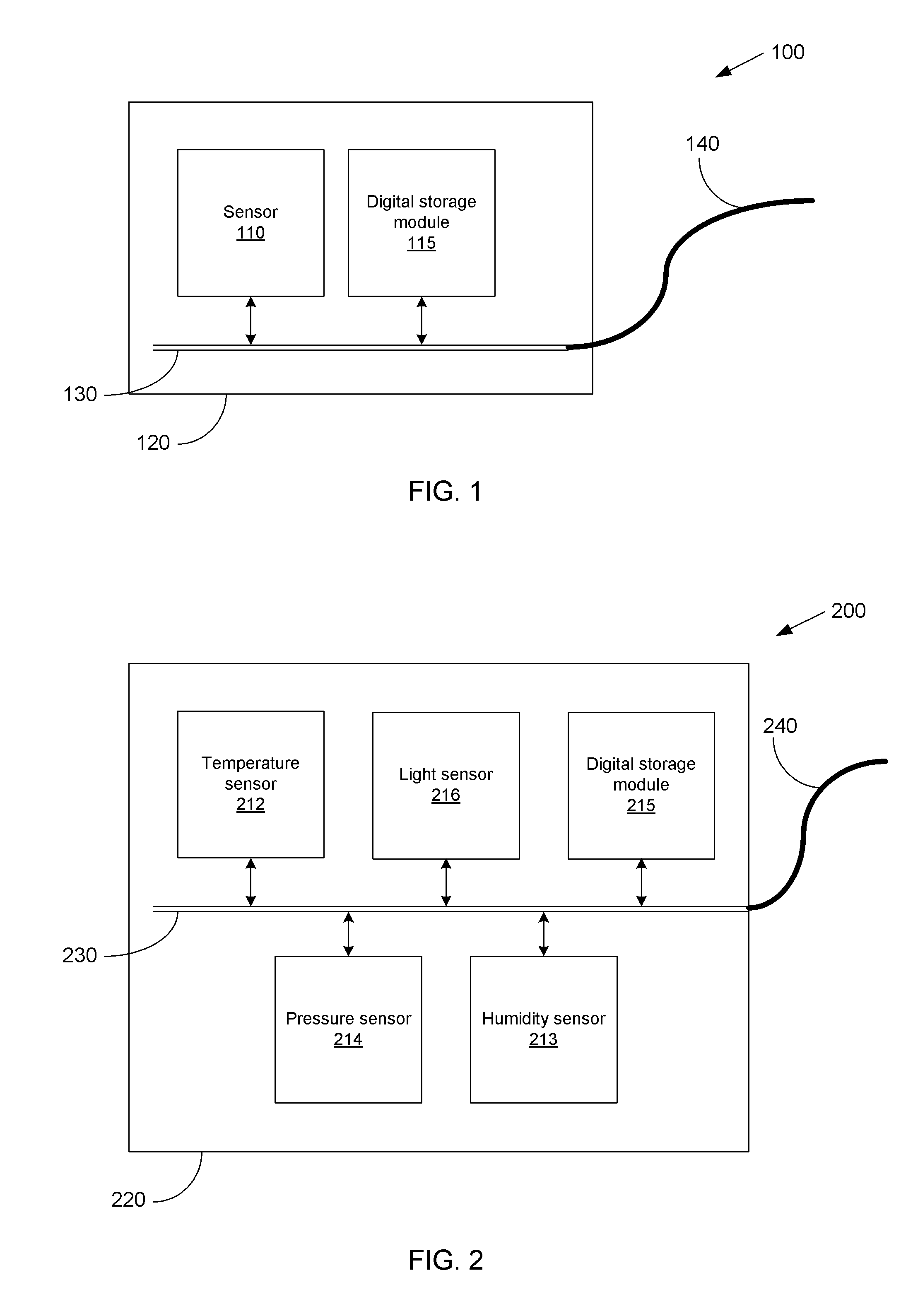

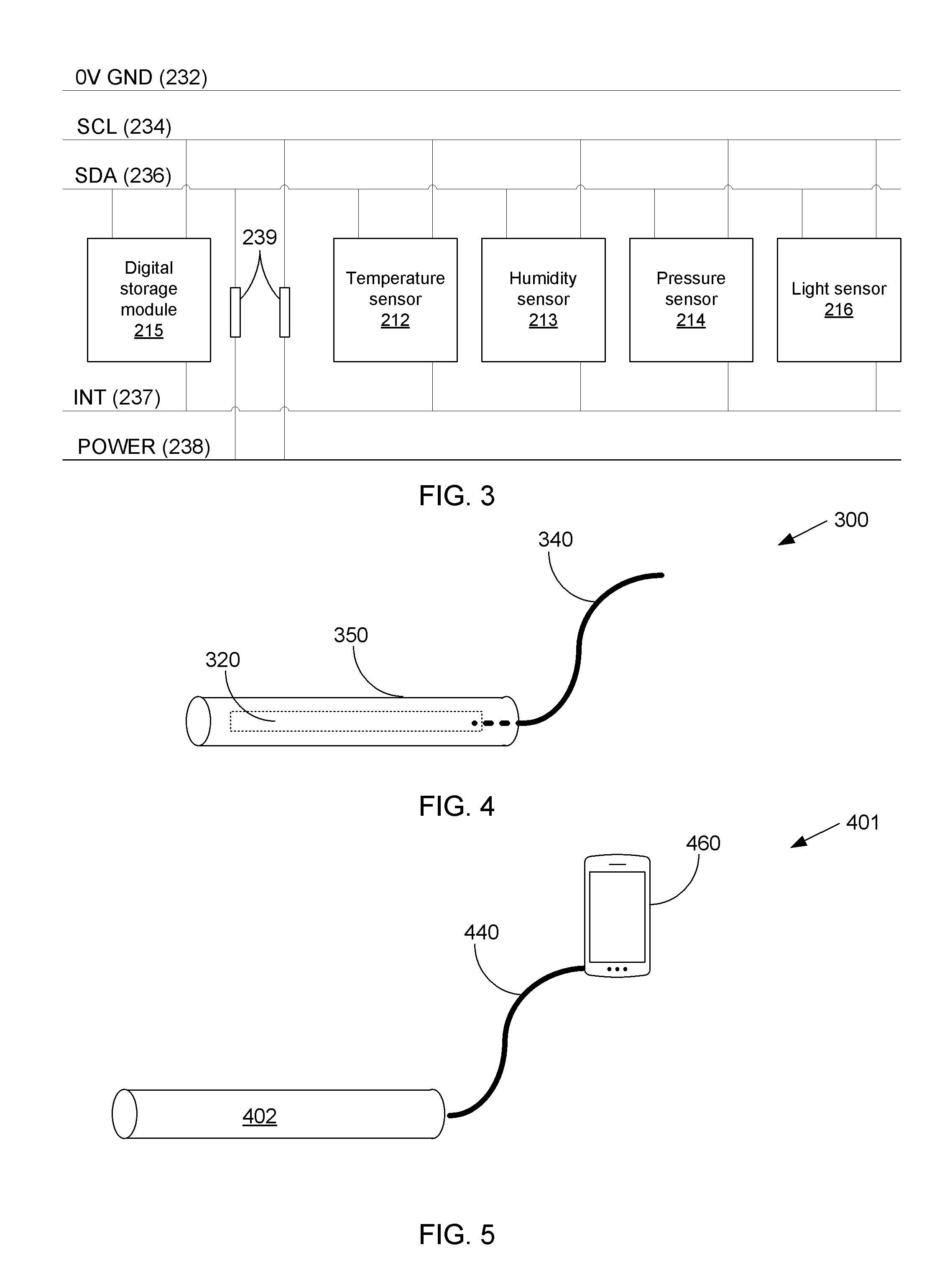

Sensor probe and related systems and methods

ActiveUS20150151960A1Television system detailsTelemetry/telecontrol selection arrangementsTelecommunicationsDigital storage

The invention provides a sensor probe which has: one or more microelectromechanical systems (MEMS) sensors configured to sense one or more parameters and a communication bus in electrical communication therewith. The one or more sensors and communication bus are disposed on a substrate. The sensor probe includes a digital storage module in which a unique probe identifier is stored and which is in electrical communication with the communication bus. The probe includes, a cable, a first end of which is in electrical communication with the communication bus and a second end of which is in electrical communication with a remote monitoring unit. The cable is configured to provide electrical power received from the remote monitoring unit to the one or more sensors, via the communication bus, and to communicate data received from the one or more sensors, via the communication bus, to the remote monitoring unit.

Owner:MCCLELAND BARRY JOHN +1

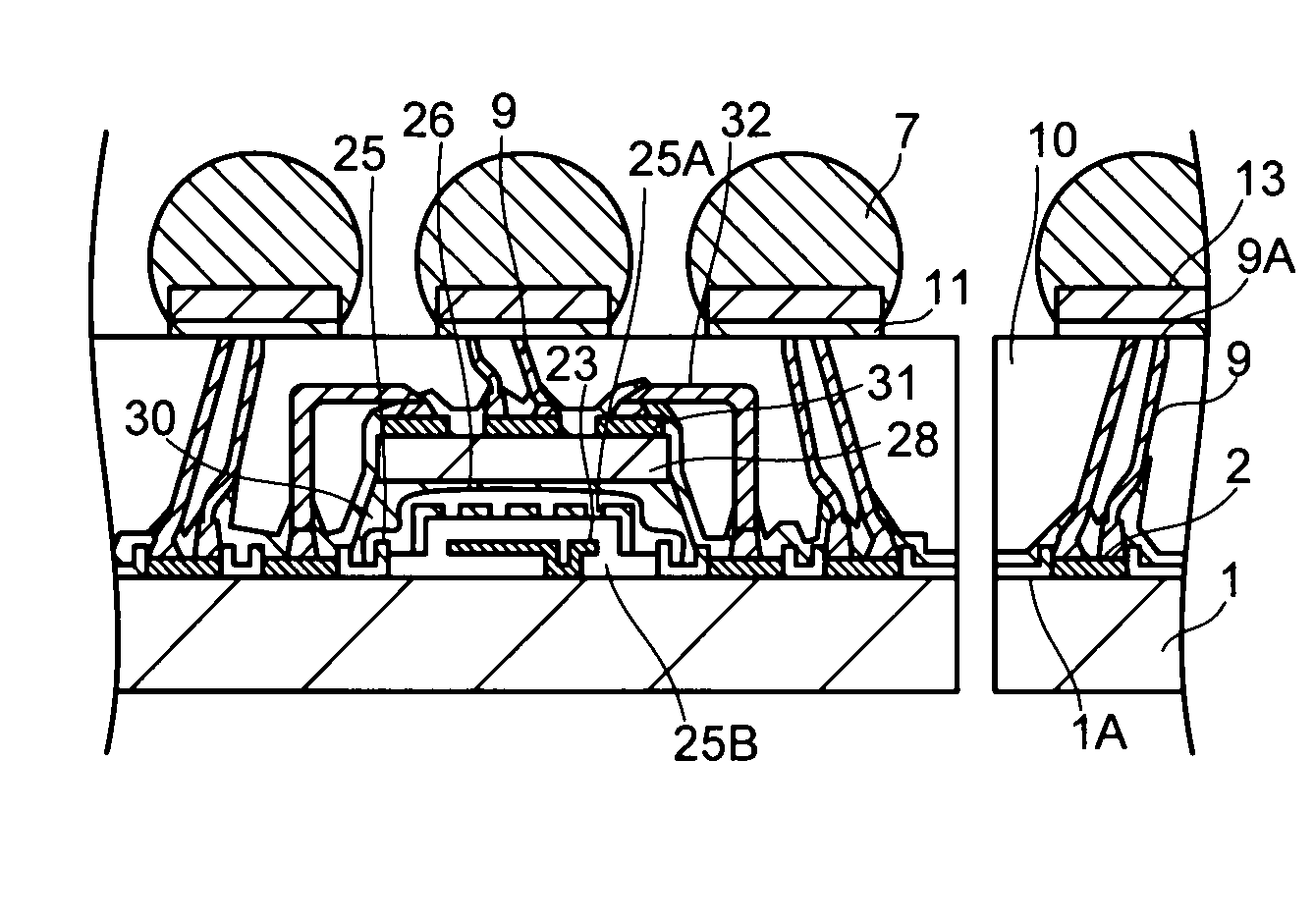

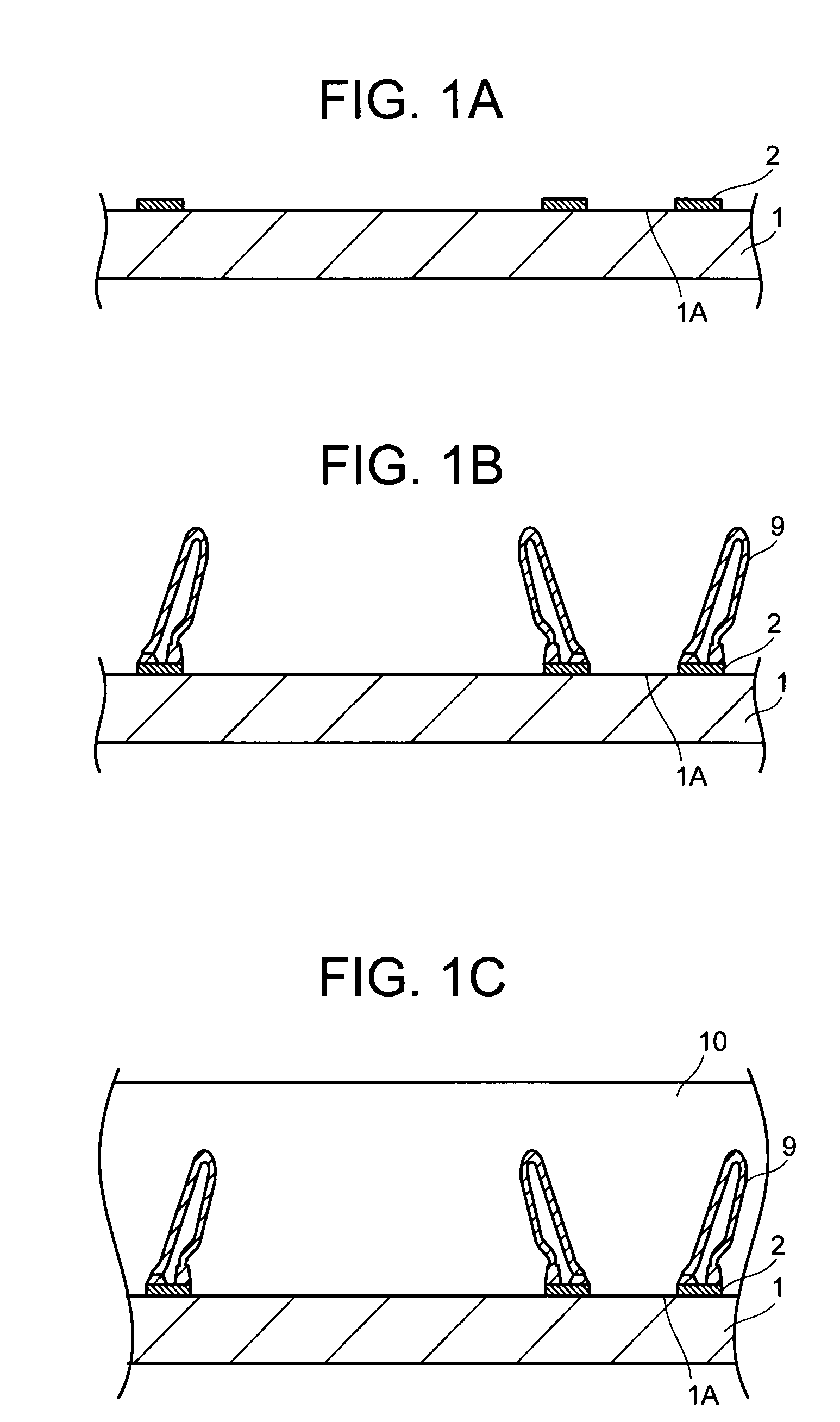

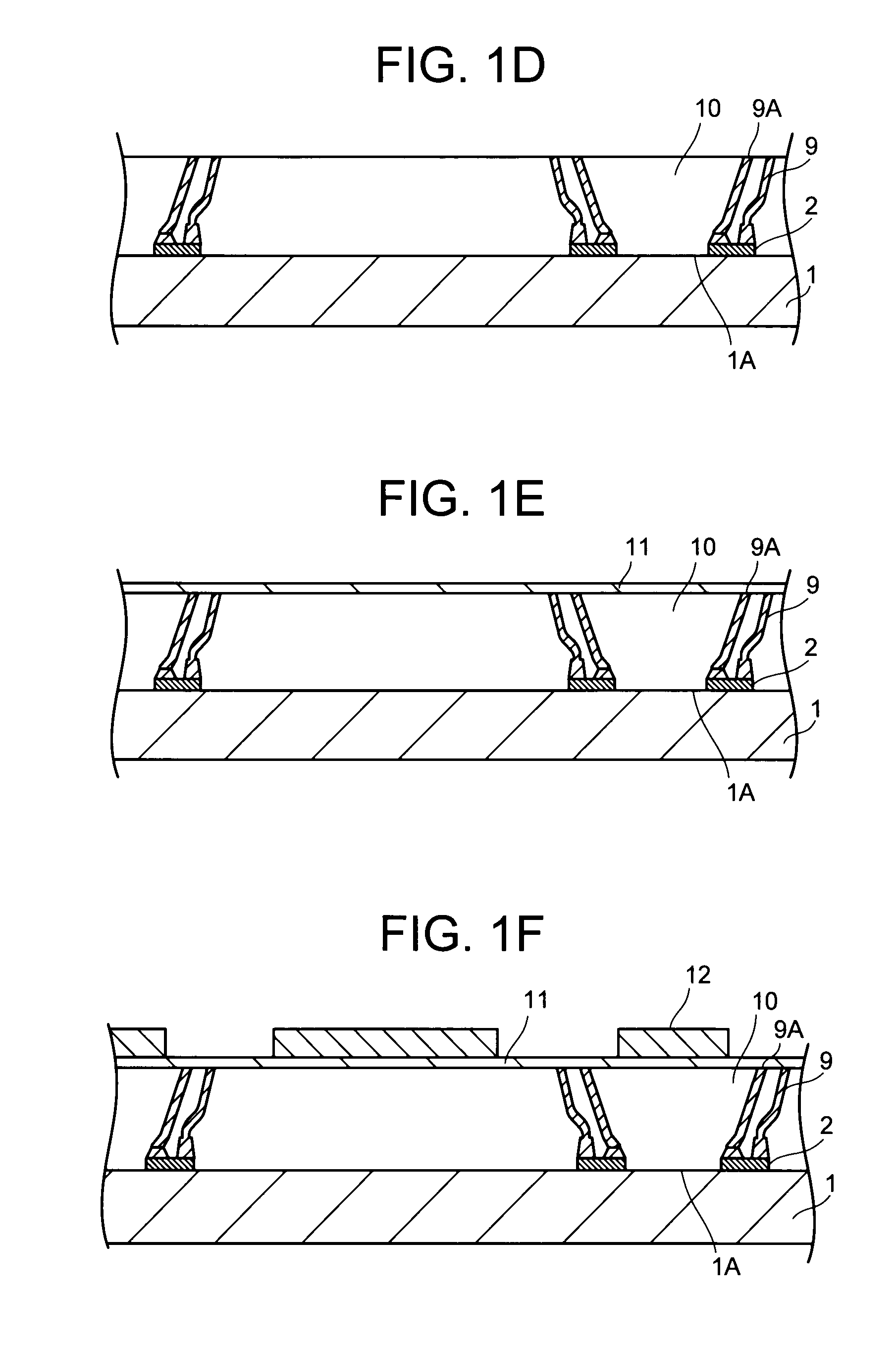

Method for manufacturing an electronic component package and electronic component package

InactiveUS20090085205A1Semiconductor/solid-state device detailsSolid-state devicesElectronic componentElectrode

A manufacturing method of an electronic component package, includes: forming electrode pads on a main surface of a first electronic component; forming first bonding wires shaped in loop so as to be electrically connected with the electrode pads and elongated upward from the electrode pads and such that both ends of the first bonding wires are on the electrode pad, respectively; forming a resin layer over the main surface of the first electronic component so as to embed the first bonding wires; removing the resin layer so as to expose ends of the first bonding wires from the resin layer and removing the end of each of the first bonding wires so that two wires are elongated from on each of the electrode pads; and forming a metallic layer on the surface of the resin layer after removing so that the first bonding wires are electrically connected with the metallic layer.

Owner:KK TOSHIBA

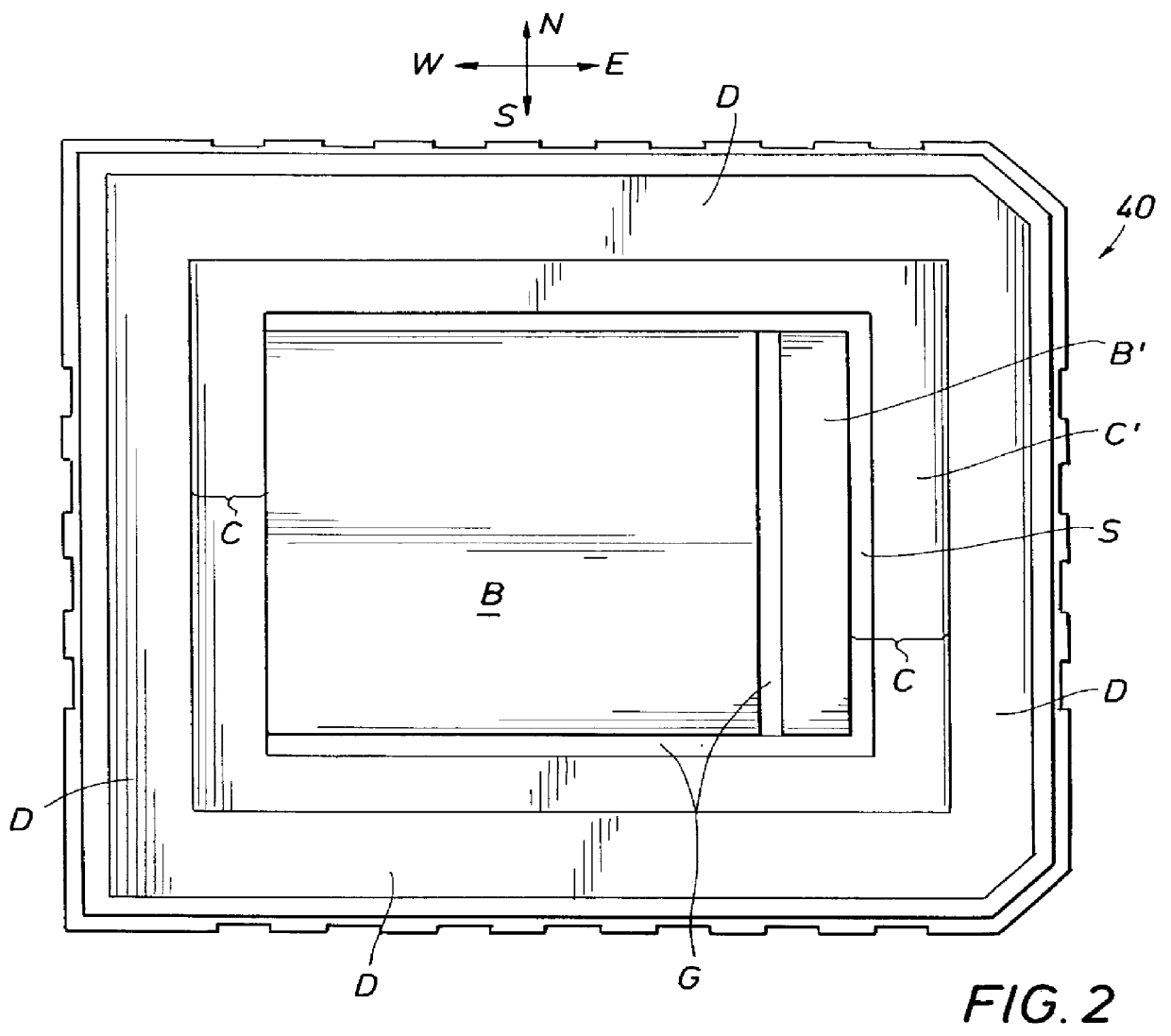

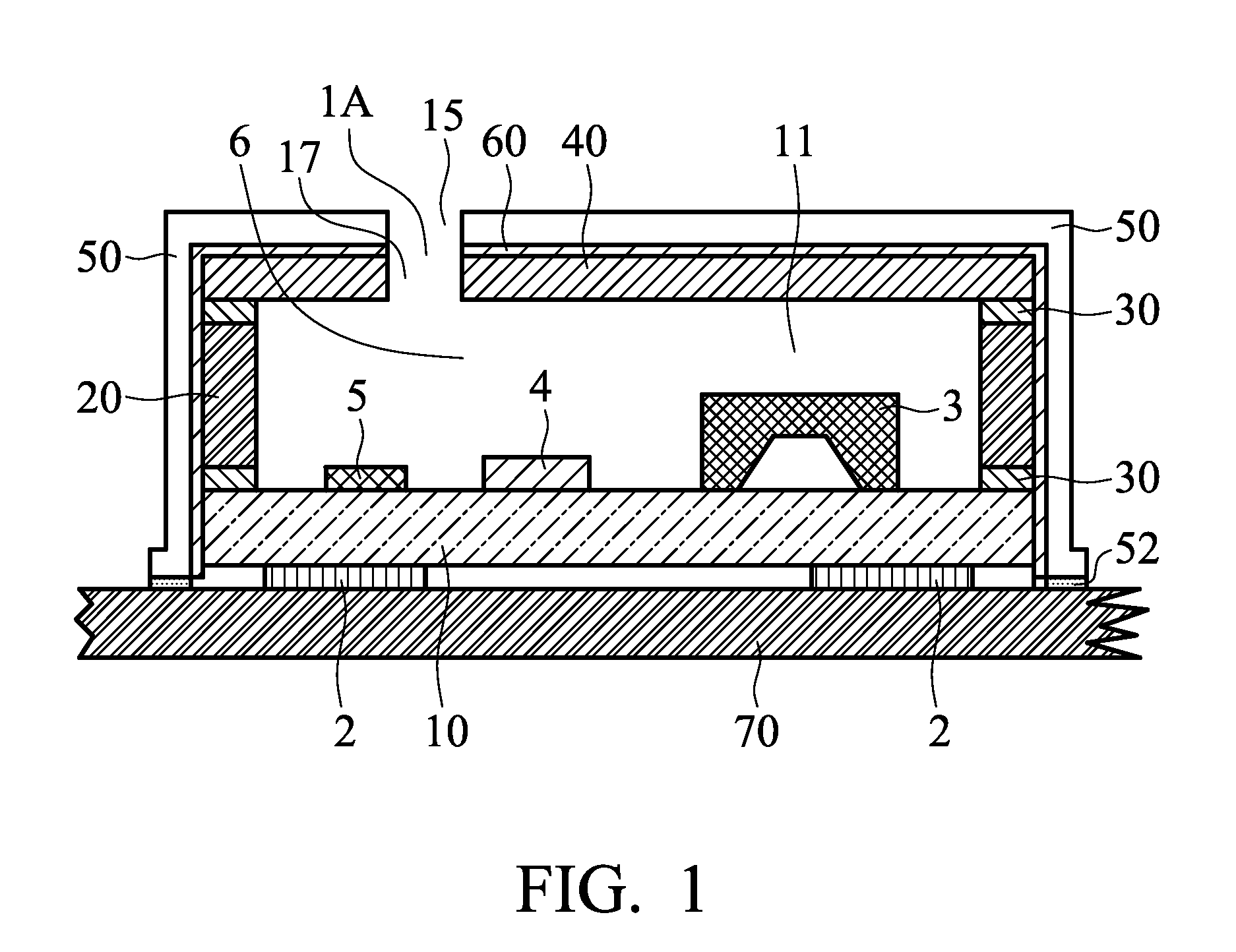

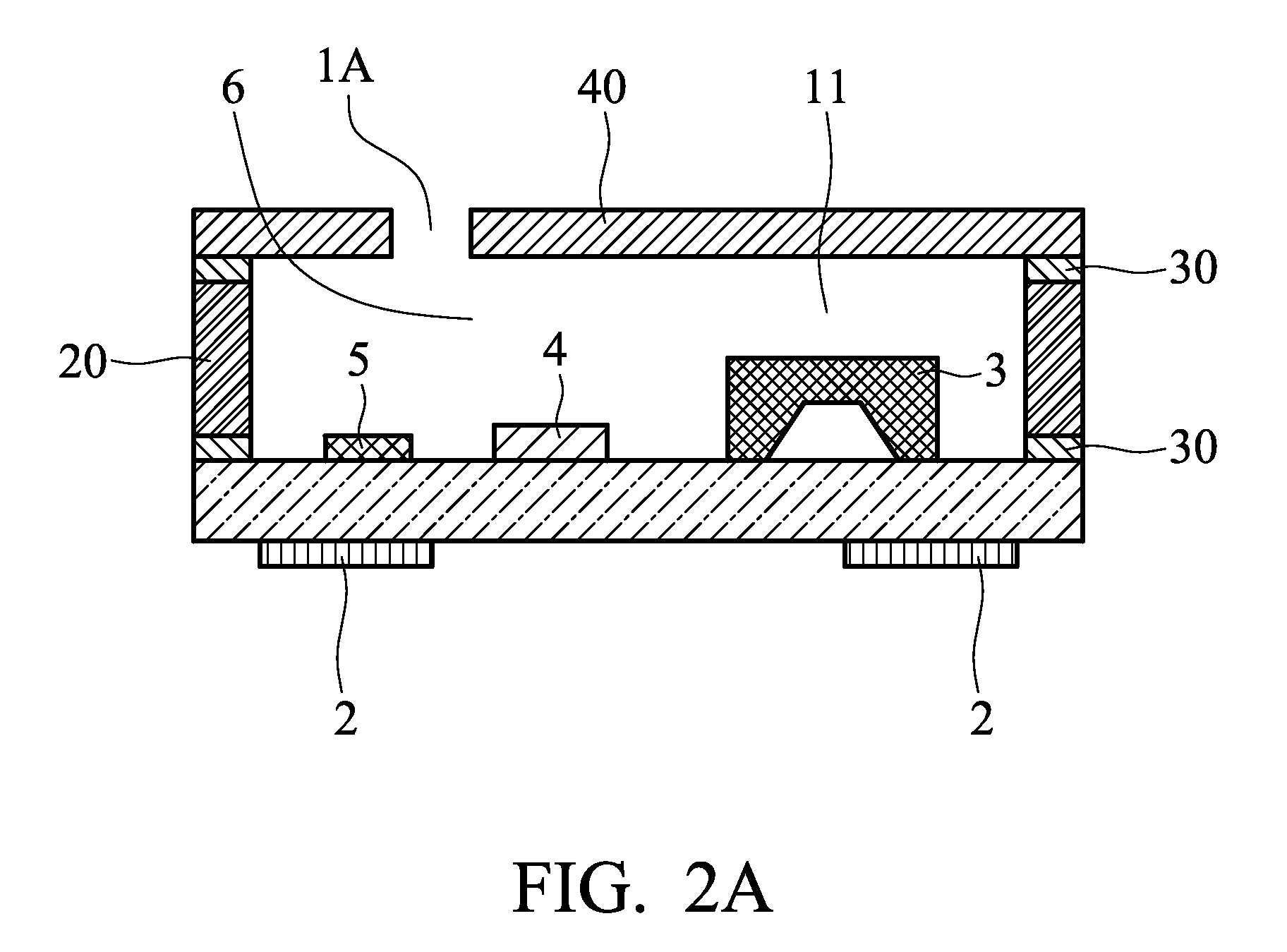

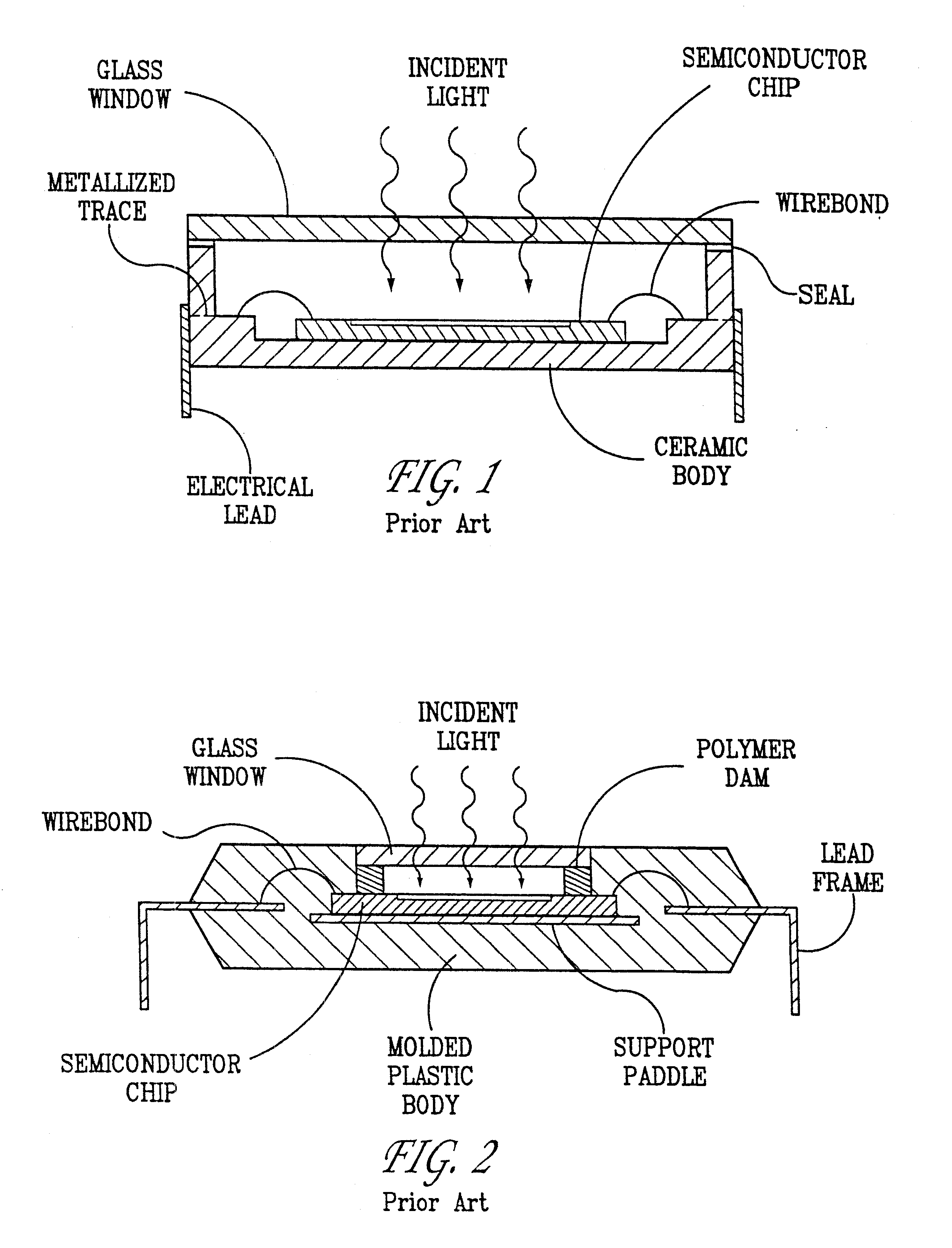

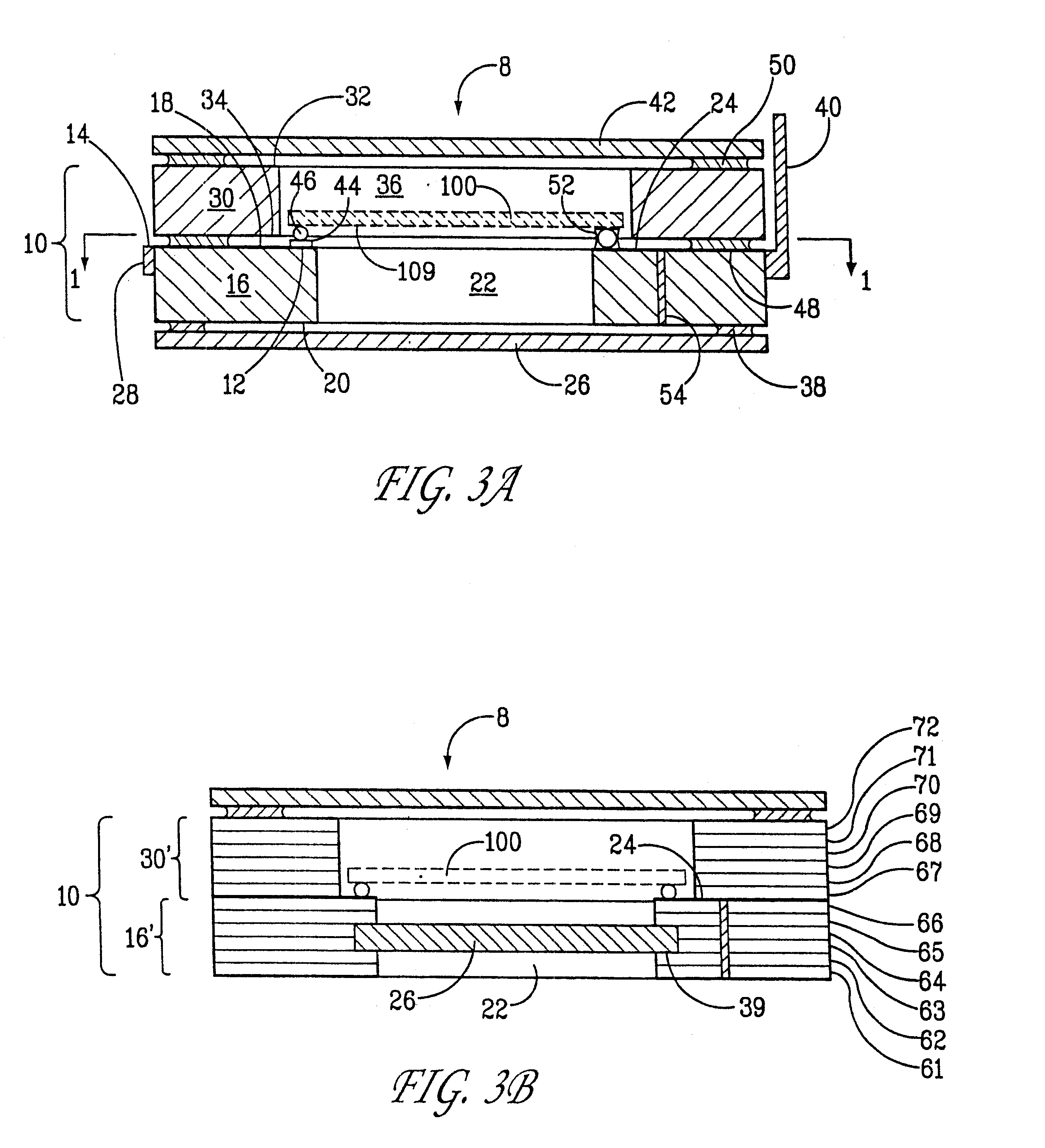

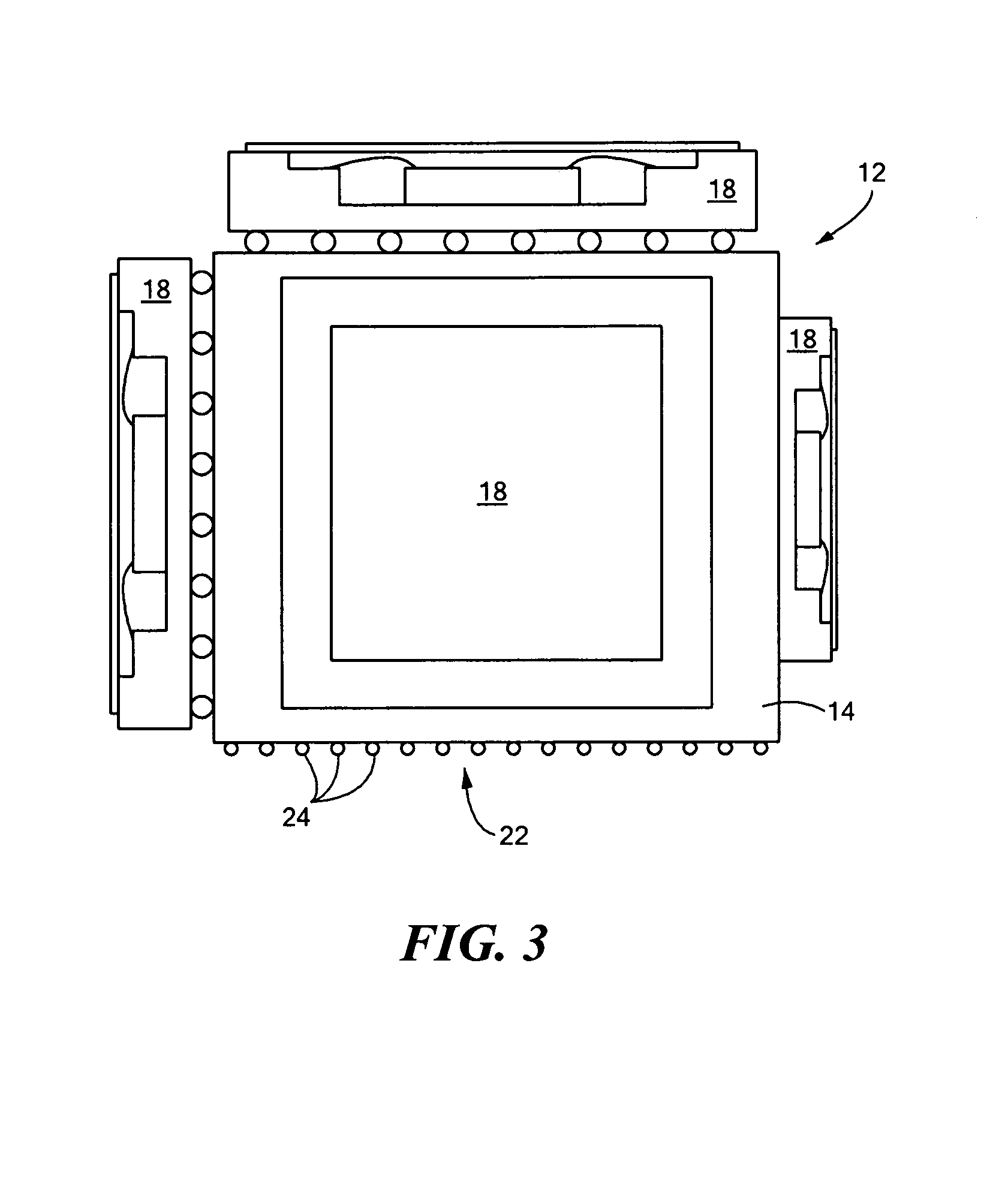

Bi-level multilayered microelectronic device package with an integral window

InactiveUS6495895B1Reduce pollutionMinimize timePrinted circuit detailsSemiconductor/solid-state device detailsHermetic sealLead bonding

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

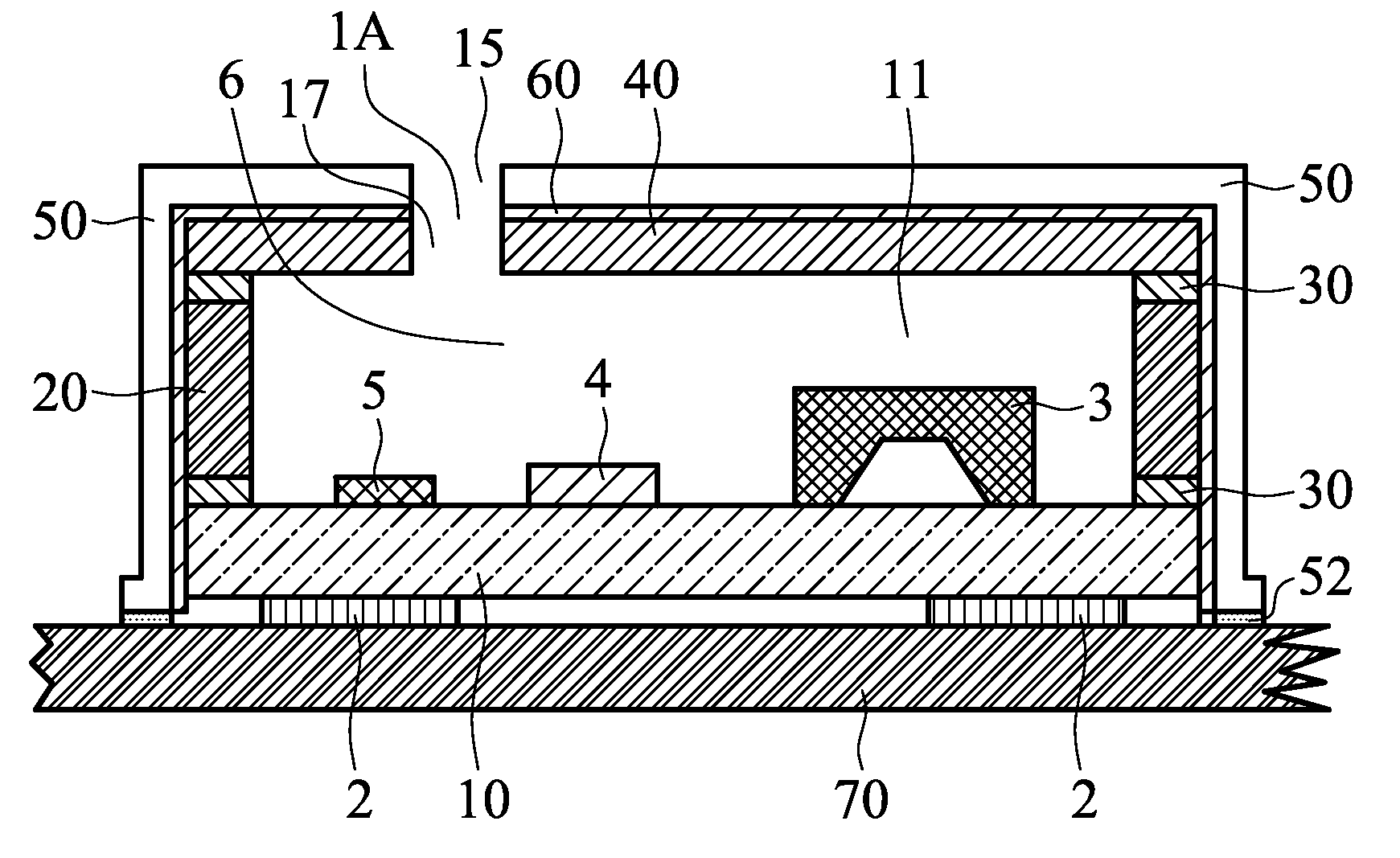

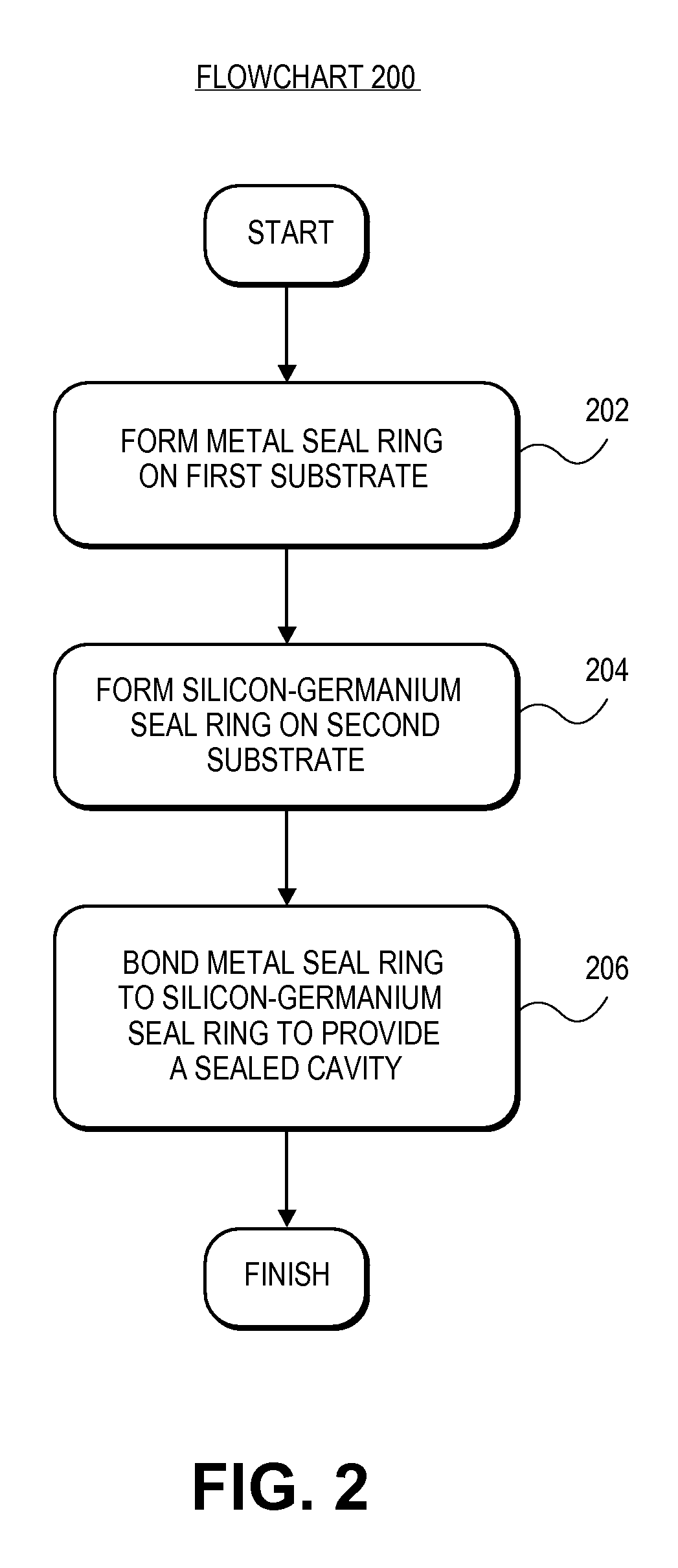

Encapsulated MEMS device and method to form the same

ActiveUS8349635B1Fluid pressure measurement by electric/magnetic elementsSemiconductor/solid-state device manufacturingEngineeringMetal

An encapsulated MEMS device and a method to form an encapsulated MEMS device are described. An apparatus includes a first substrate having a silicon-germanium seal ring disposed thereon and a second substrate having a metal seal ring disposed thereon. The metal seal ring is aligned with and bonded to the silicon-germanium seal ring to provide a sealed cavity. A MEMS device is housed in the sealed cavity. A method includes forming a silicon-germanium seal ring on a first substrate and forming a metal seal ring on a second substrate. The metal seal ring is bonded to the silicon-germanium seal ring to provide a sealed cavity that houses a MEMS device.

Owner:SEMICON MFG INT (SHANGHAI) CORP

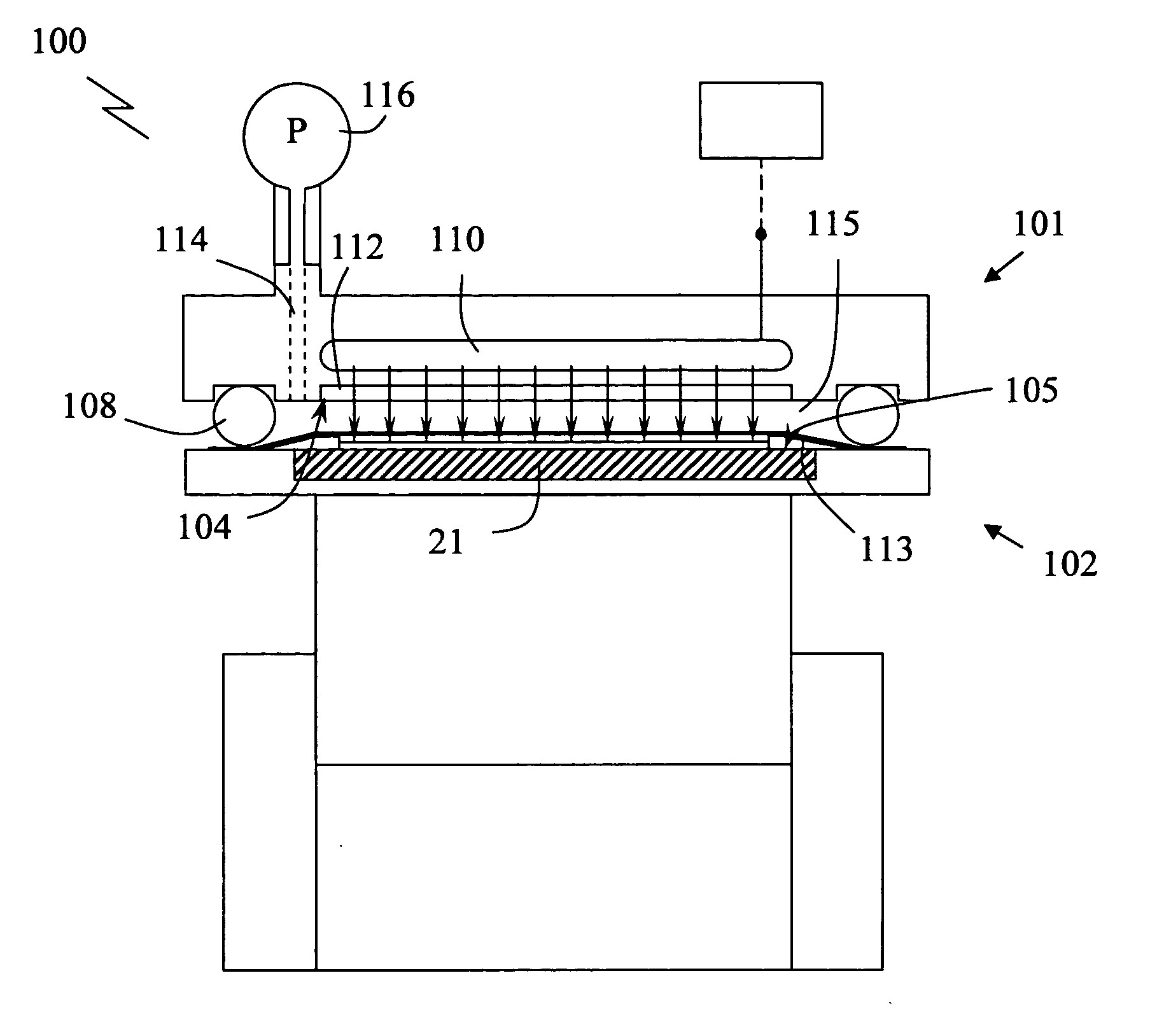

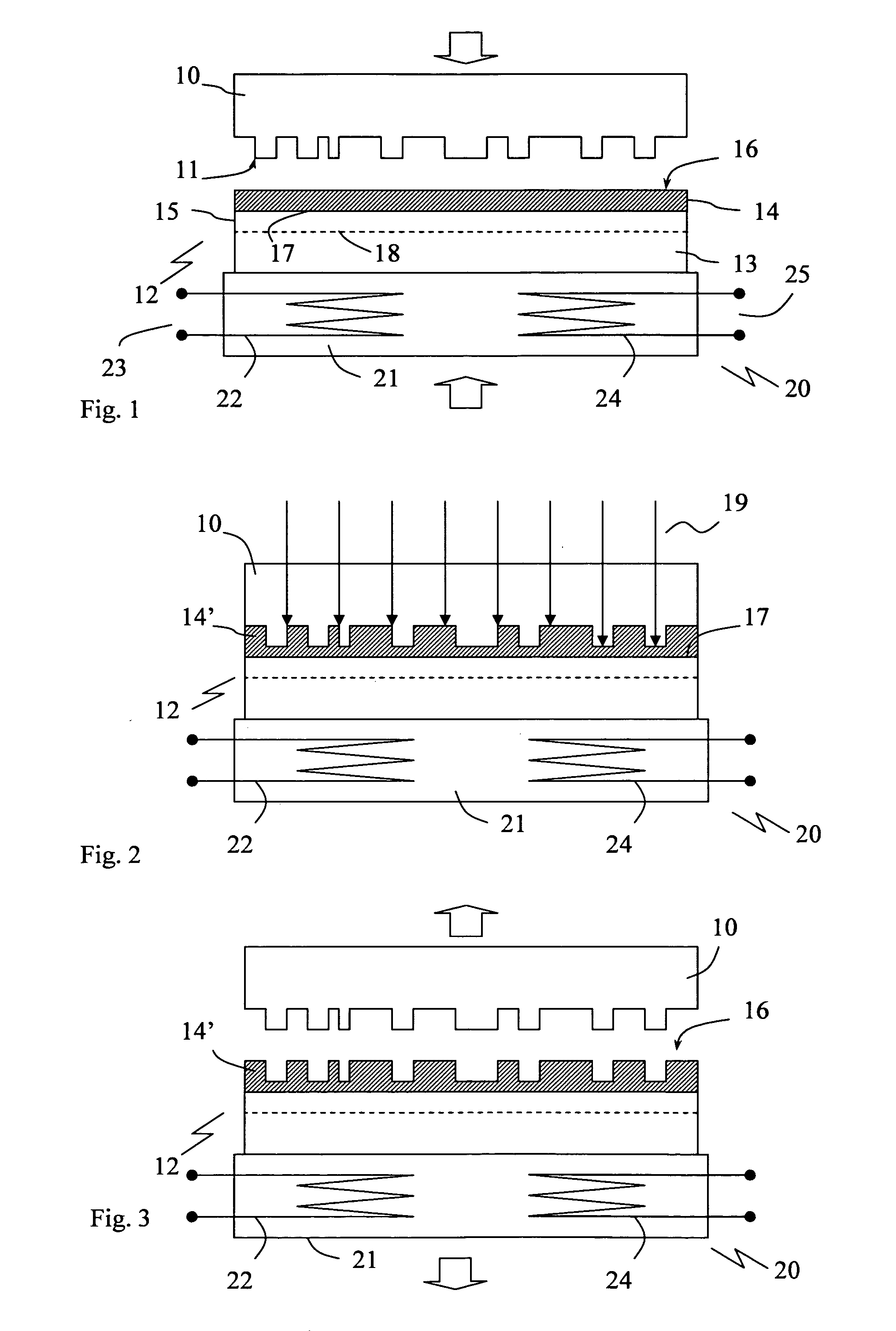

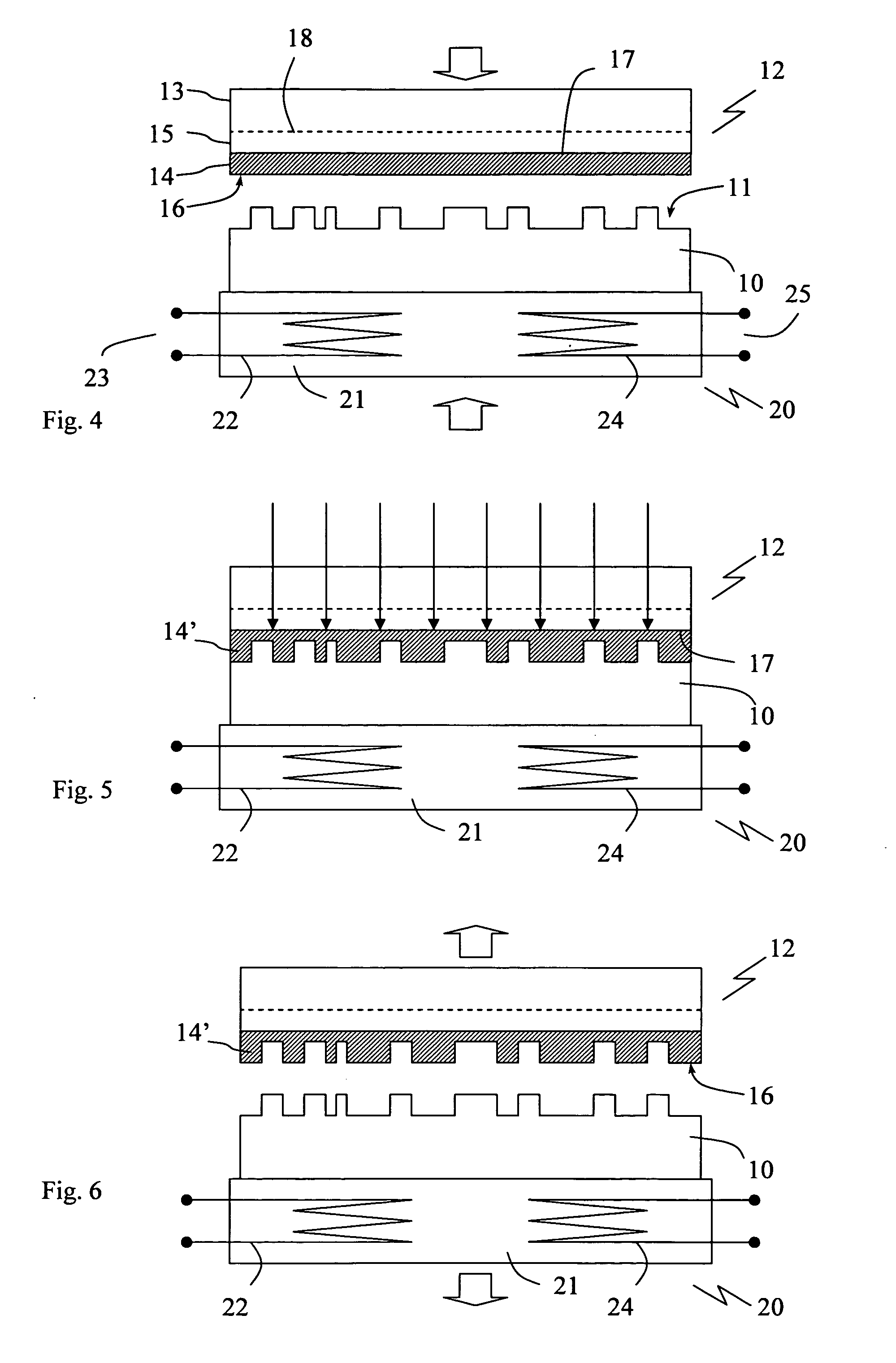

Device and method for lithography

InactiveUS20050274693A1Cost-effective and more versatileAdded fabricationDecorative surface effectsNanoinformaticsSurface layerFluid layer

Apparatus and method for transferring a pattern from a template (10) having a structured surface to a substrate (12) carrying a surface layer of a radiation polymerisable fluid (14). The apparatus comprises a first main part (101) and a second main part (102) having opposing surfaces (104;105), means for adjusting a spacing (115) between said main parts, support means (106) for supporting said template and substrate in mutual parallel engagement in said spacing with said structured surface facing said surface layer, a radiation source (110) devised to emit radiation into said spacing. A cavity (115) has a first wall comprising a flexible membrane (113) devised to engage said template or substrate, and means (114;116) are provided for applying an adjustable overpressure to a medium present in said cavity, whereby an even distribution of force is obtained over the whole of the contact surface between the substrate and the template. The apparatus further includes a heater device having a surface facing said spacing, for heating either fluid layer (14).

Owner:OBDUCAT AB SE

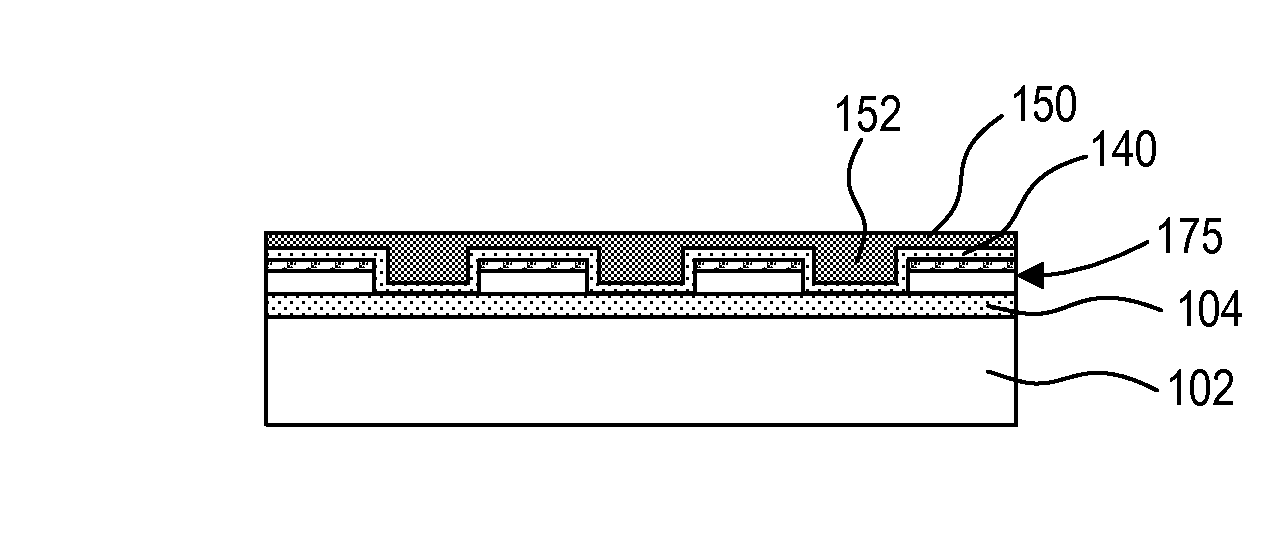

Stabilization structure including sacrificial release layer and staging cavity

ActiveUS9166114B2Solid-state devicesSemiconductor/solid-state device manufacturingMicro devicesBiomedical engineering

Owner:APPLE INC

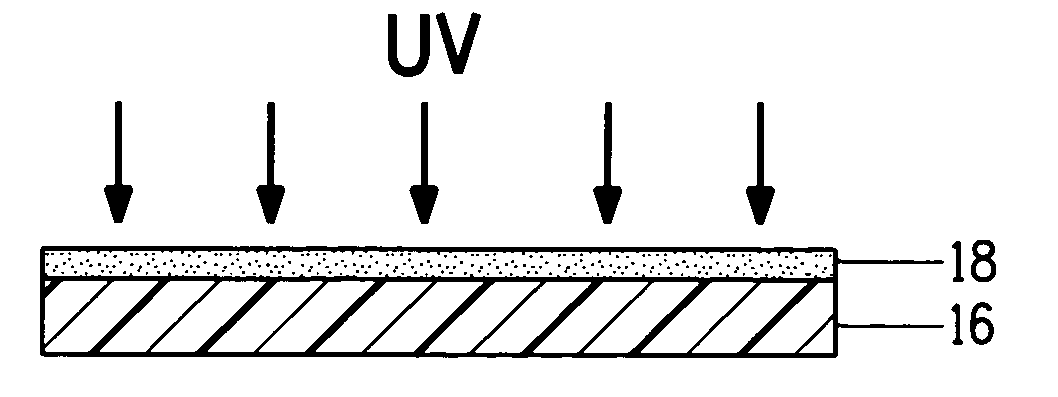

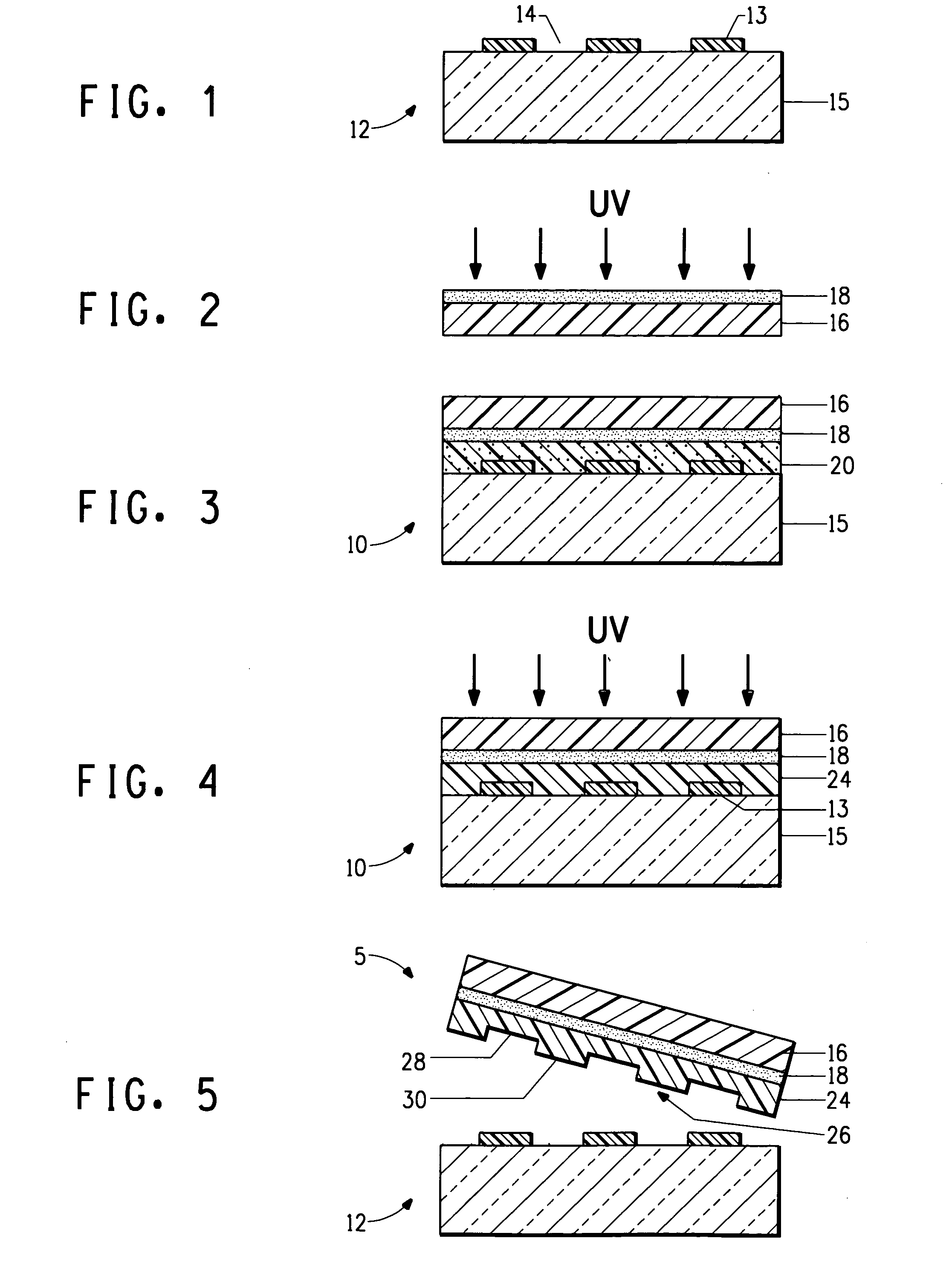

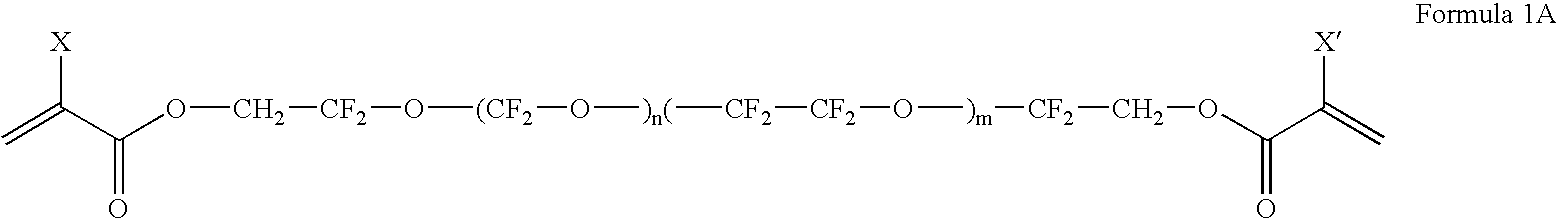

Printing form precursor and process for preparing a stamp from the precursor

The invention pertains to a printing form precursor and a method for preparing a stamp from the precursor for use in soft lithographic applications. The printing form precursor includes a composition layer of a fluorinated compound capable of polymerization upon exposure to actinic radiation and a flexible support transparent to the actinic radiation adjacent the composition layer.

Owner:EI DU PONT DE NEMOURS & CO

Multi-surface mounting member and electronic device

ActiveUS7040922B2Measurement apparatus componentsCoupling device detailsElectricityFlexible circuits

An electrical interconnect apparatus has a mounting member with a plurality of sides. The mounting member is formed from an insulator as a cuboid. Moreover, the mounting member also may be formed from a flexible circuit. Among other things, the plurality of sides includes an interface side. At least two of the plurality of sides are in electrical communication with the interface side.

Owner:ANALOG DEVICES INC

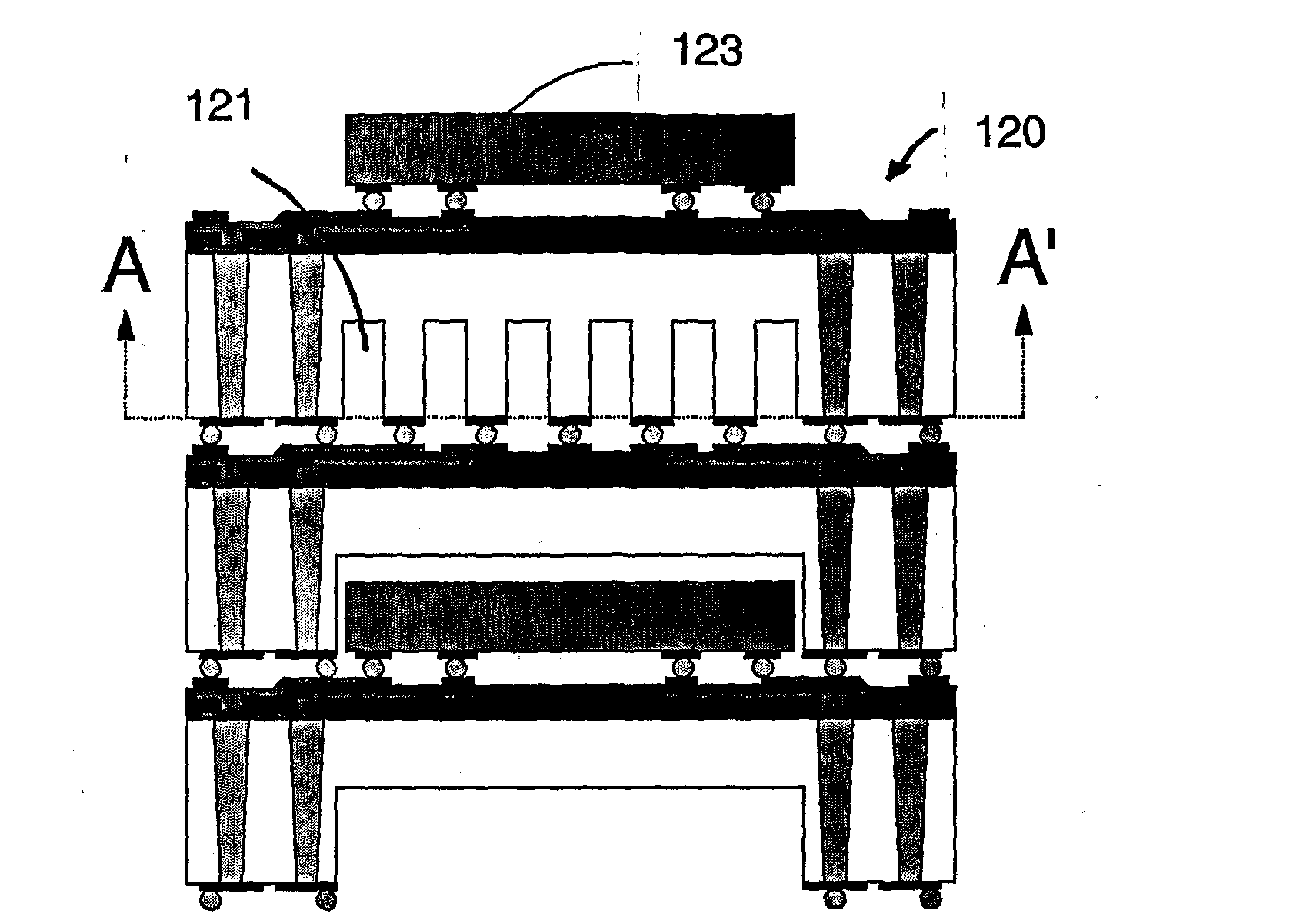

Infinitely Stackable Interconnect Device and Method

ActiveUS20090212407A1Semiconductor/solid-state device detailsSolid-state devicesConductive materialsInterconnection

An infinitely stackable interconnect device and method having the capability for electrical, thermal, optical, and fluidic interconnections to various layers. Through-substrate vias in the interconnect device are filled to enable electrical and thermal connection or optionally hermetically sealed relative to other surfaces to enable fluidic or optical connection. Optionally, optical components may be placed within the via region in order to manipulate optical signals. Redistribution of electrical interconnection is accomplished on both top and bottom surfaces of the substrate of the interconnect chip. The method for fabricating the interconnect device includes the steps of: forming, insulating, and at least partially filling vias with conductive material; connecting vias to conductive traces on a top surface of the interconnect chip; connecting vias to conductive traces on a bottom surface of the interconnect chip; providing bump regions for electrical and mechanical interconnection to a subsequent interconnect device; and forming recessed regions to accommodate a subsequent die in a stack. The method simultaneously accomplishes interconnection and packaging of multiple semiconductor die to form a stack.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

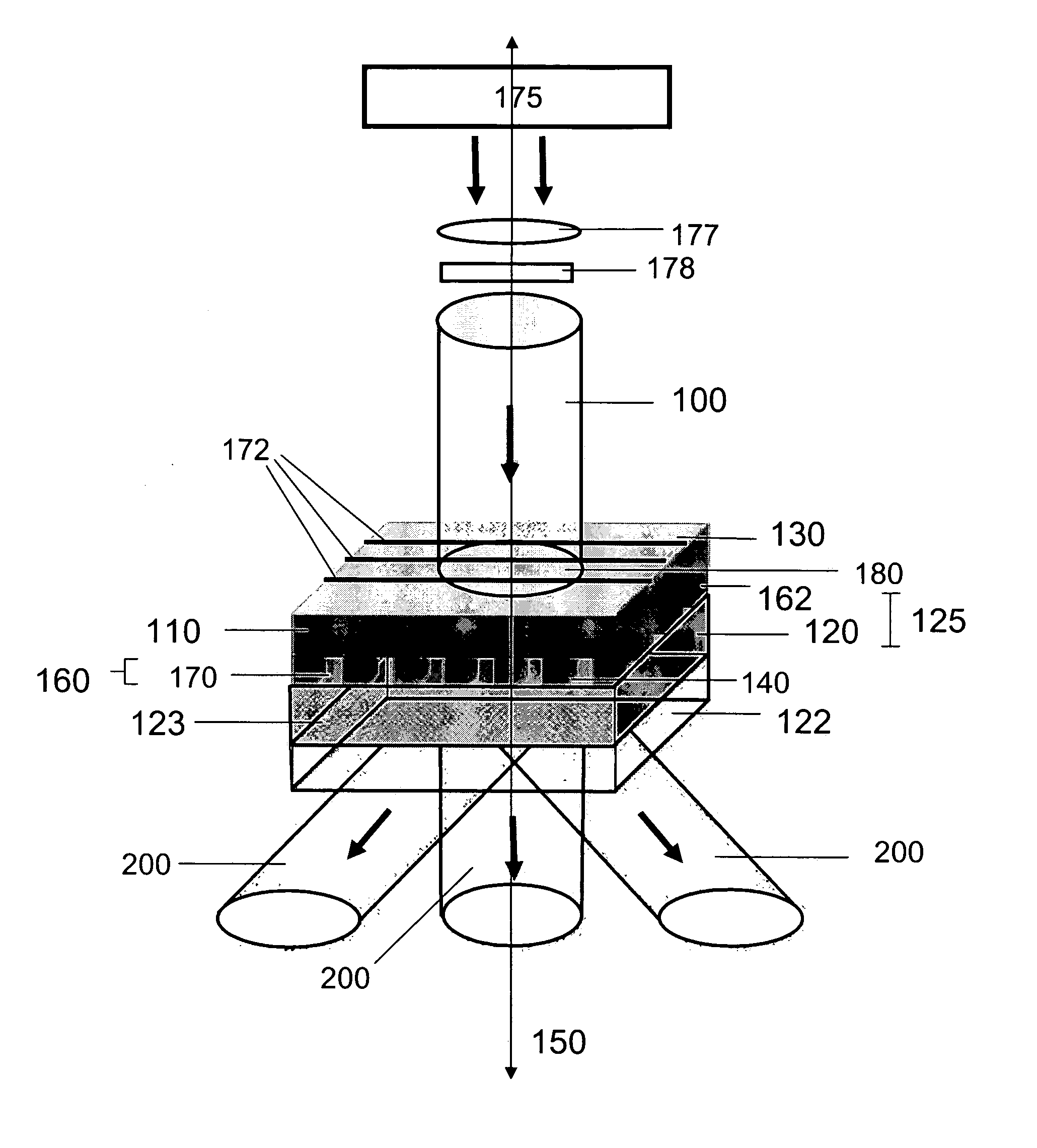

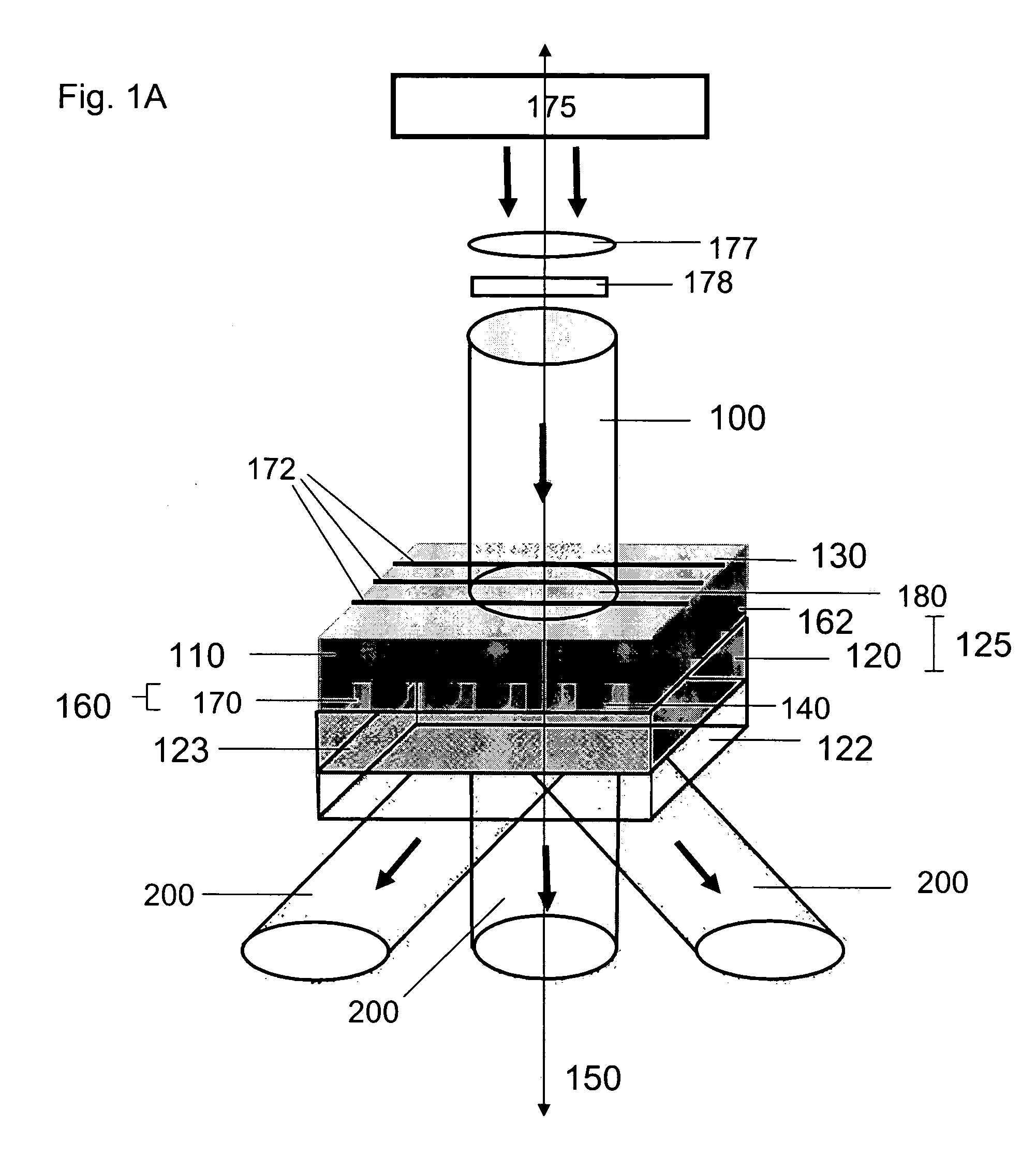

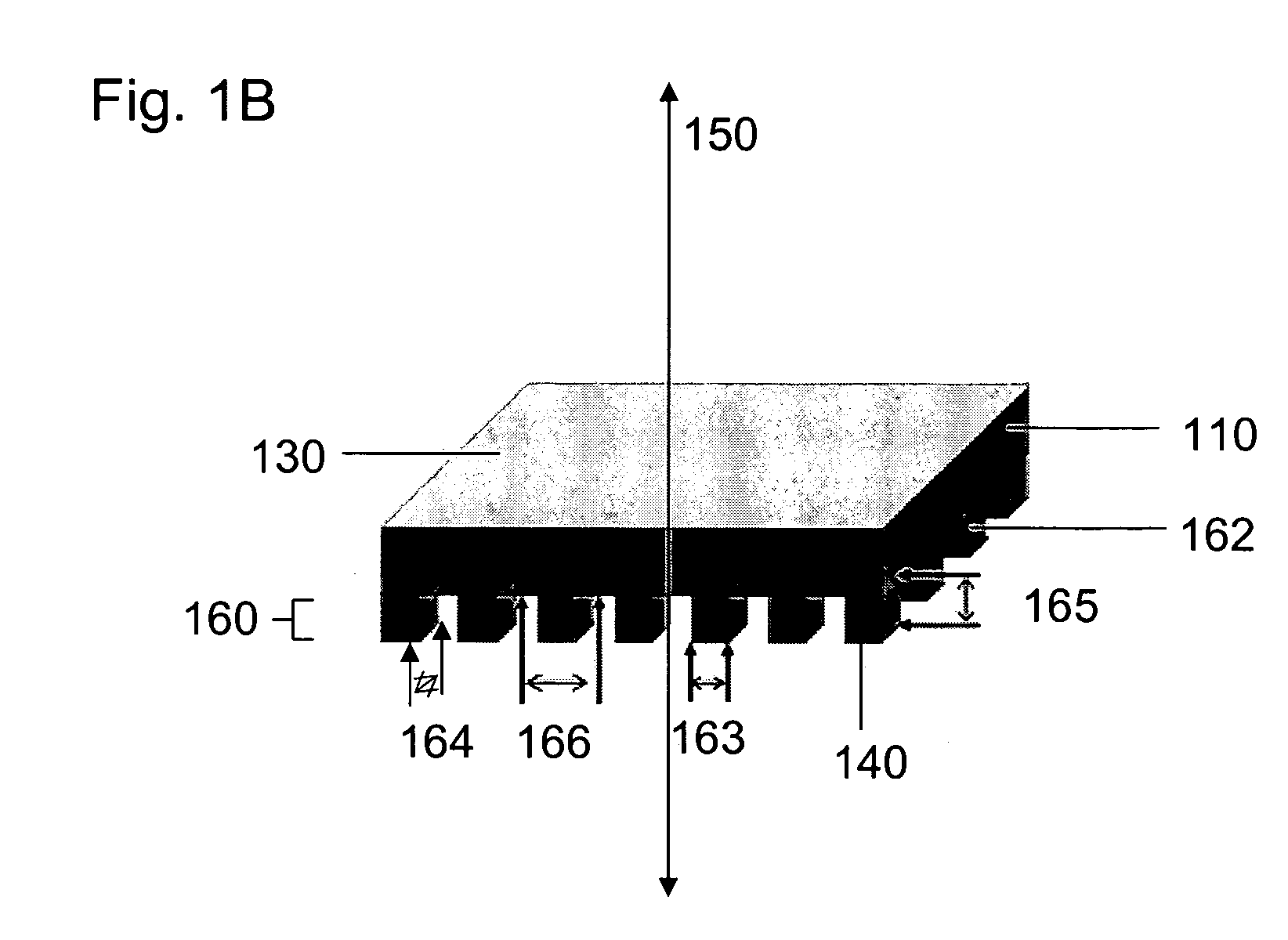

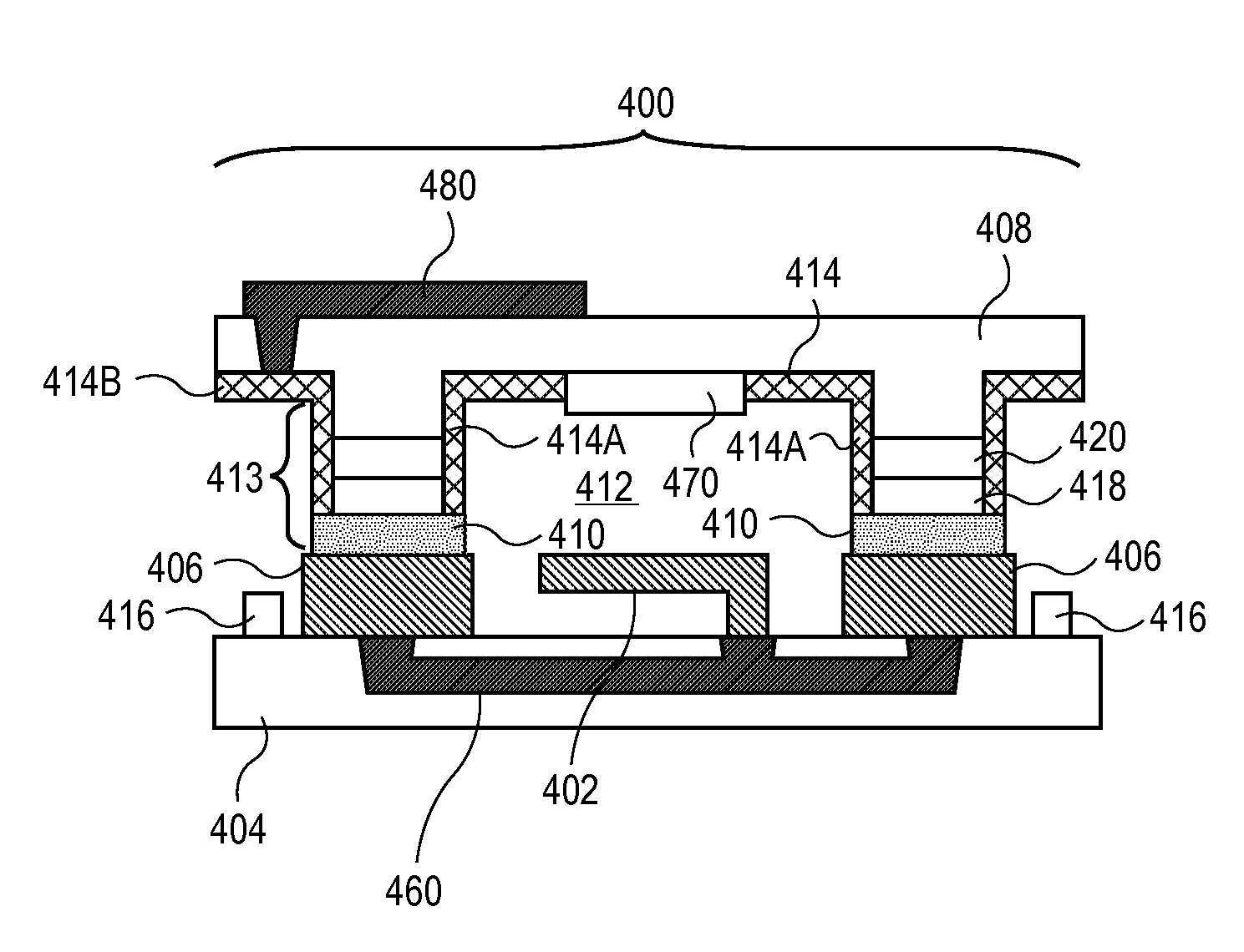

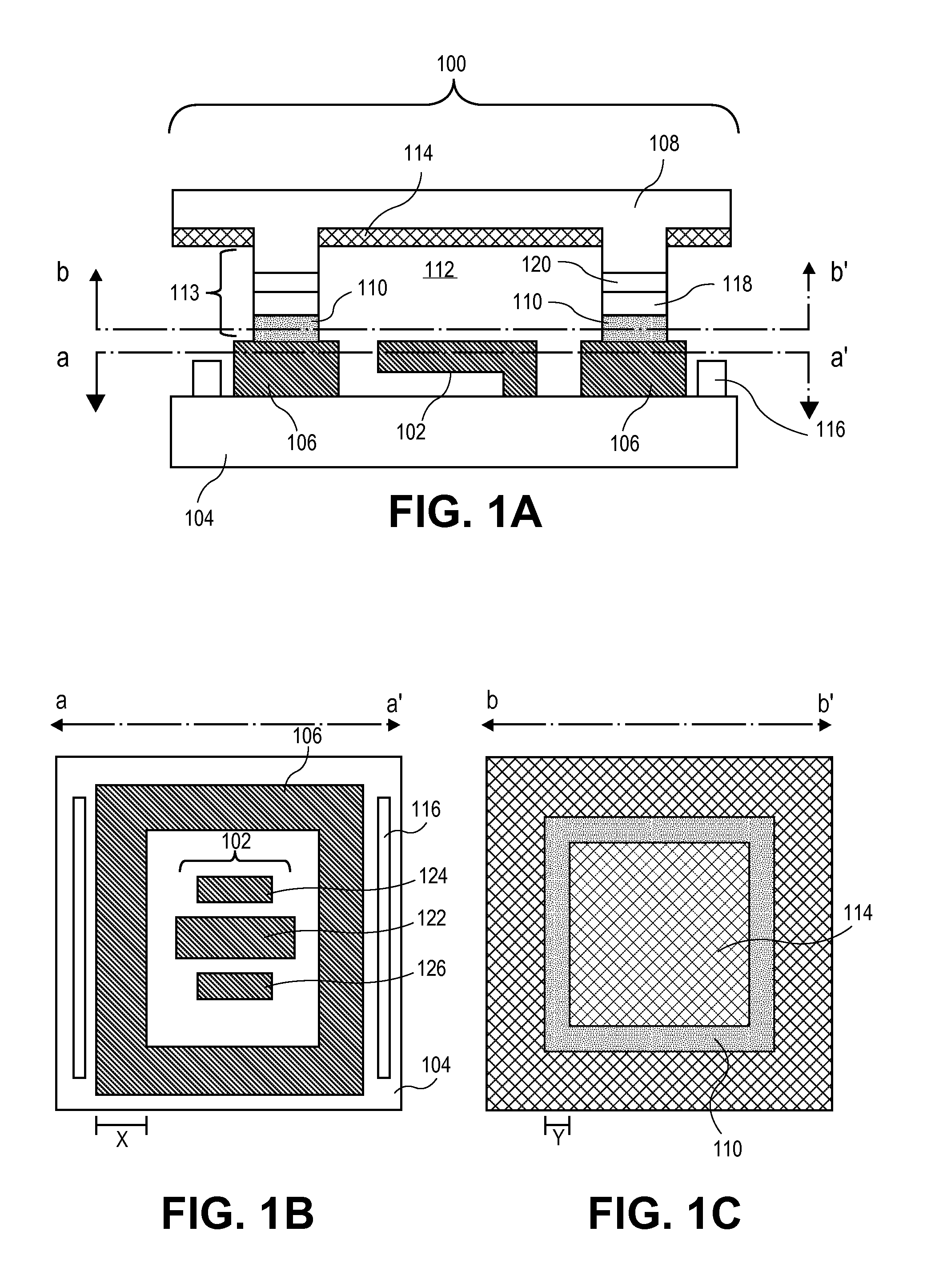

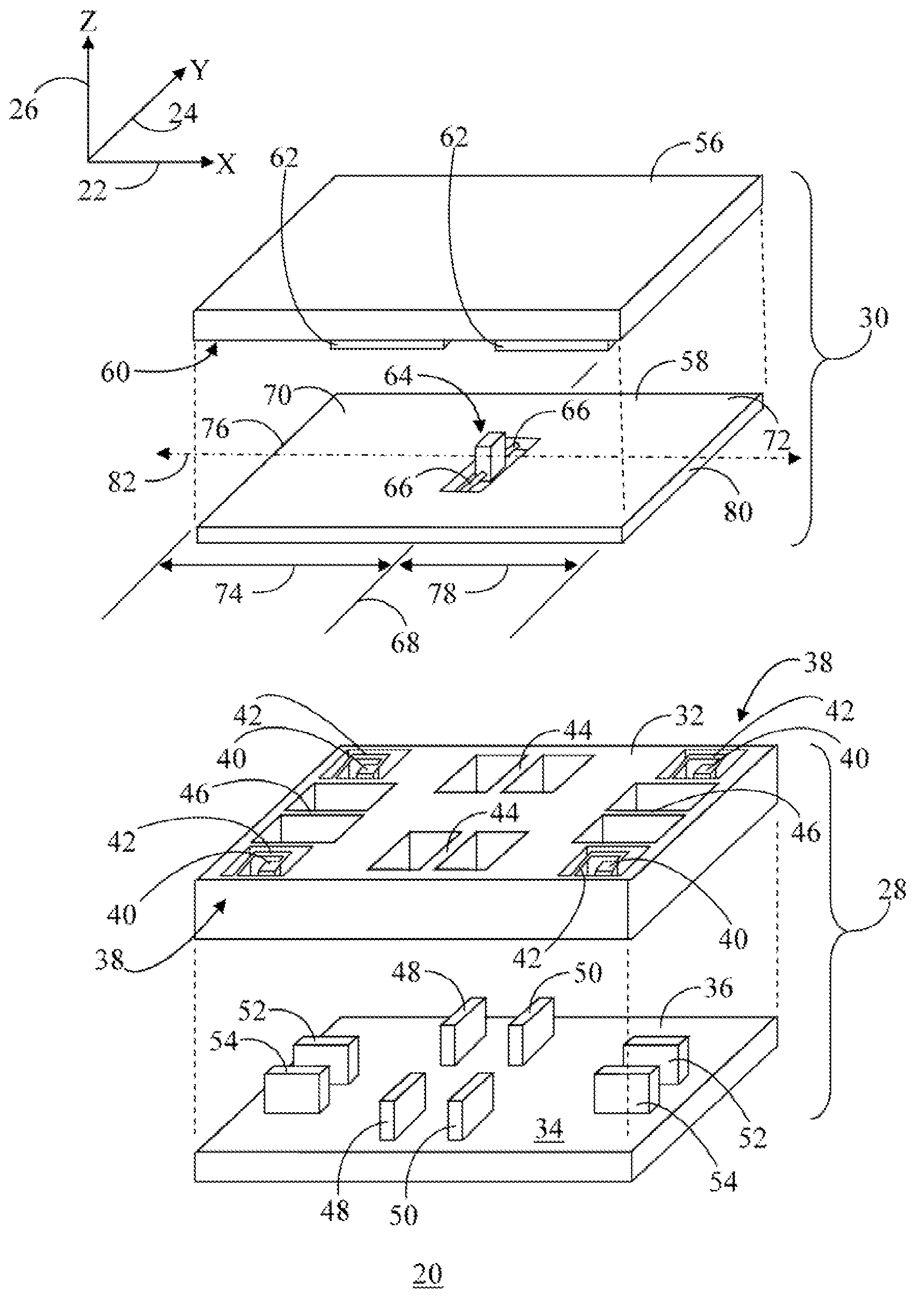

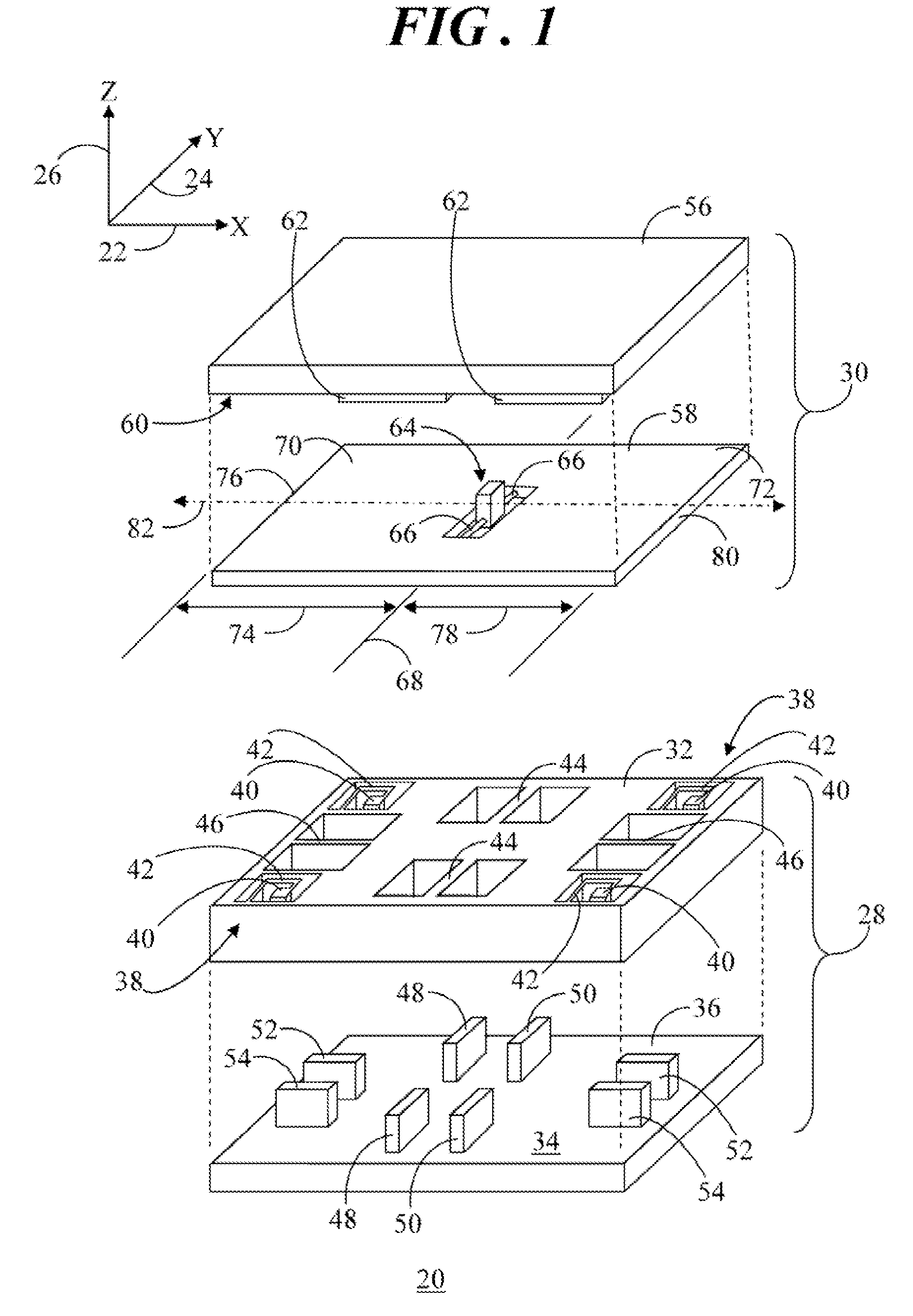

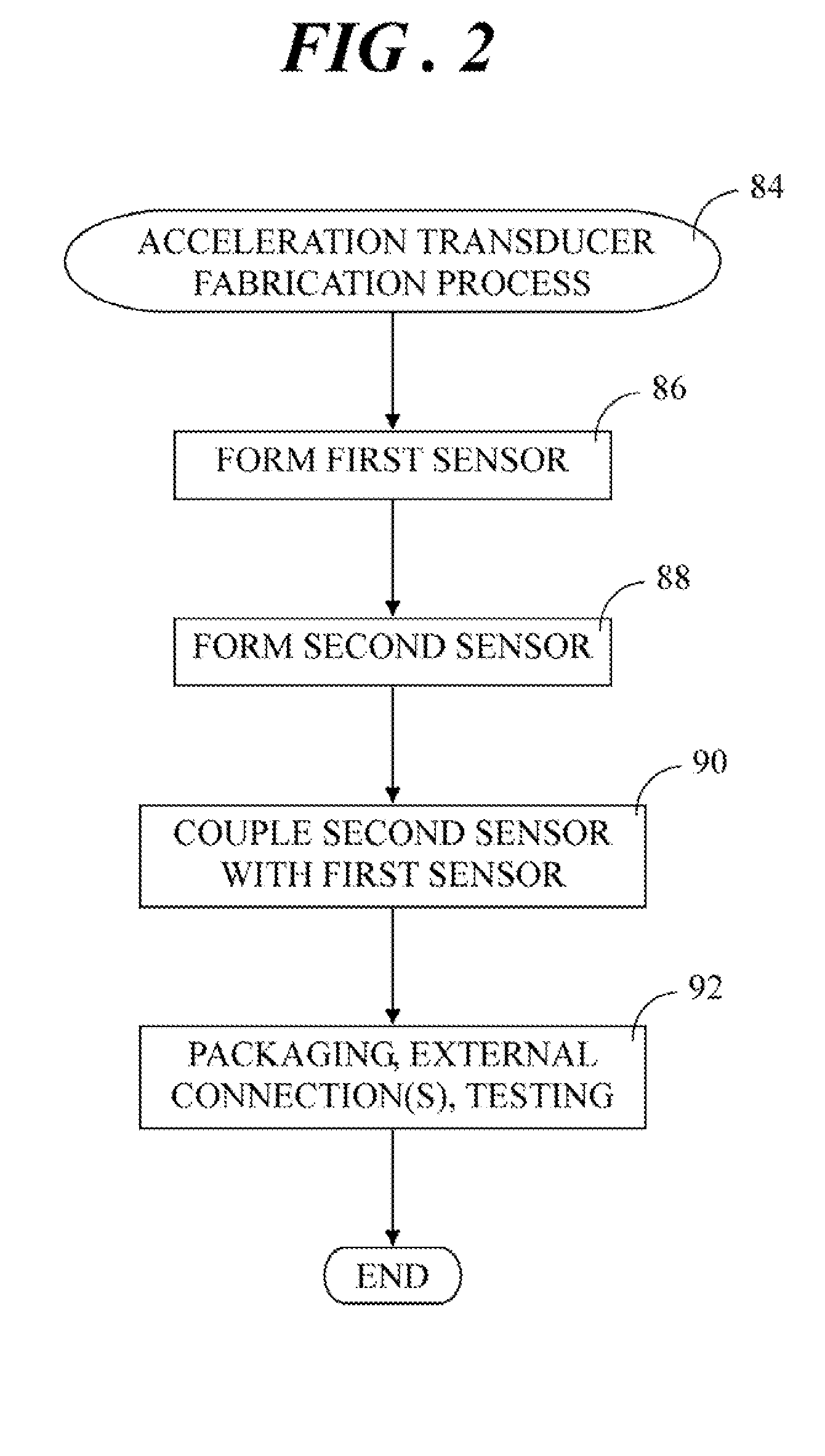

Vertically integrated MEMS sensor device with multi-stimulus sensing

InactiveUS20100242603A1Printed circuit assemblingSpeed/acceleration/shock instrument detailsEngineeringMems sensors

A microelectromechanical systems (MEMS) sensor device (184) includes a sensor portion (180) and a sensor portion (182) that are coupled together to form a vertically integrated configuration having a hermetically sealed chamber (270). The sensor portions (180, 182) can be formed utilizing different micromachining techniques, and are subsequently coupled utilizing a wafer bonding technique to form the sensor device (184). The sensor portion (180) includes one or more sensors (186, 188), and the sensor portion (182) includes one or more sensors (236, 238). The sensors (186, 188) are located inside the chamber (270) facing the sensors (236, 238) also located inside the chamber (270). The sensors (186, 188, 236, 238) are configured to sense different physical stimuli, such as motion, pressure, and magnetic field.

Owner:NORTH STAR INNOVATIONS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com